Patents

Literature

198results about How to "Good recoatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermo-setting acrylic-acid emulsion, its preparing method and paint containing same

This invention discloses a thermoset crylic acid latex and its preparation method and a corrosion resistant bottom coat containing such latex and used in the Al fins of the heat converter of air conditioners, in which, said latex includes a crylic acid kind monomers, an ionic vinyl monomers, an ethene monomers, a vinyl silane coupler, a crosslink monomers, a surface active agent and an initiator to be got by seed latex and semi-continuous drop technology. Said bottom coat includes said thermoset crylic acid latex, water-base coating resin, water-base cross-linker, booster solvent, neutralization agent, a water-base adhesive force accelerant, a catalyst and water.

Owner:GUANGZHOU HUMAN CHEM

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint and preparation method thereof

InactiveCN103242718ASolve the problem of pollution flashoverImprove hydrophobicityCoatingsPolymer sciencePolymer chemistry

The invention discloses titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint which comprises the following components in parts by weight: 30-50 parts of fluorocarbon resin, 10-30 parts of filler, 1-10 parts of pigment, 3.5-10 parts of curing agent, 2-10 parts of coupling agent, 0.03-3 parts of assistant, 35-45 parts of solvent and 0.001-0.1 part of drying agent. The invention also discloses a preparation method of the fluorocarbon resin paint. The static contact angle theta of the fluorocarbon resin paint can be up to 118 degrees; and the fluorocarbon resin paint has favorable hydrophobicity and hydrophobic migration performance and high pollution flashover preventing performance, thus ensuring that the physical / chemical properties and electric properties of a prepared coating can meet pollution flashover preventing conditions. The invention is used for insulator pollution flashover prevention, and solves the problem of insulator pollution flashover of a high-voltage transmission line.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Organosilicon concrete protective agent and preparation method

The invention discloses an organosilicon concrete protective agent and a preparation method. The organosilicon concrete protective agent comprises the main compositions in percent by volume: 50-60% of an alkyl alkoxy silane, 5-10% of terminal-substituted polydimethylsiloxane, 3-5% of an emulsifier, 0.05-1% of a catalyst, 5-10% of a solvent and 20-30% of water. The protective agent is prepared by uniformly mixing the alkyl alkoxy silane, terminal-substituted polydimethylsiloxane and the emulsifier in the organic solvent at room temperature, then adding the catalyst to perform a uniform reaction, then dropwise adding the completely-reacted oil phase system into deionized water, and performing high-speed shearing for obtaining a paste. The preparation method is simple, the coating operation is simple, the cost is low, when the concrete surface is coated with the organosilicon concrete protective agent, a layer of a hydrophobic film is formed along the aperture inner walls of concrete, so that freeze-thaw cycle, chloride ion erosion and the like can be prevented, and the organosilicon concrete protective agent is applicable to facilities such as highways, bridges, tunnels, seaport wharfs, airports and the like, and is applicable to industrialized production.

Owner:XIAMEN NORNS TECH

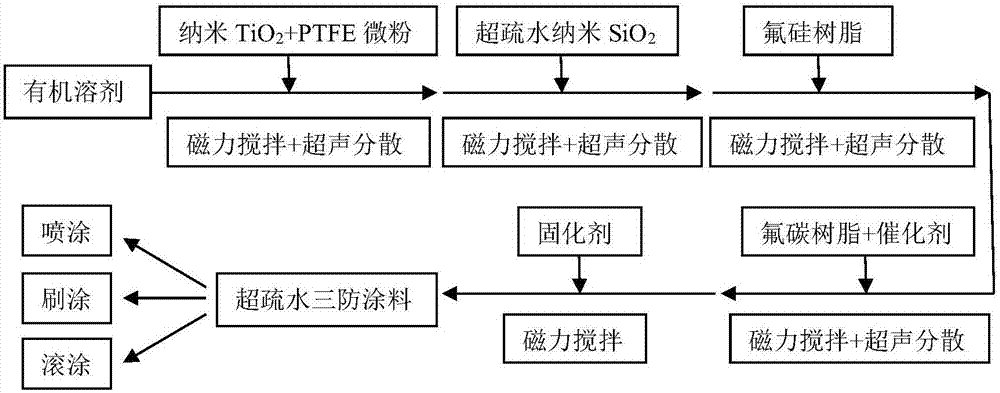

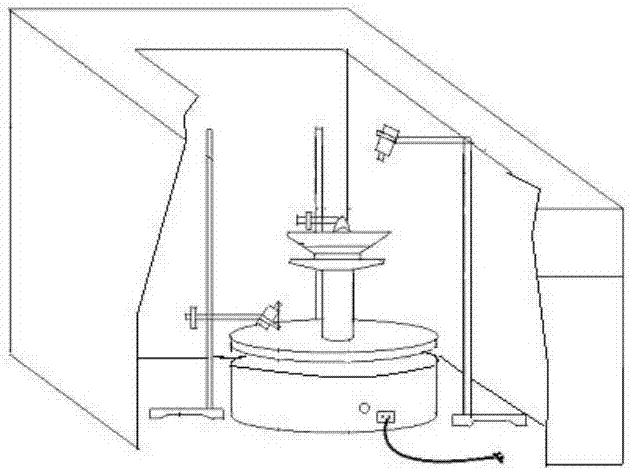

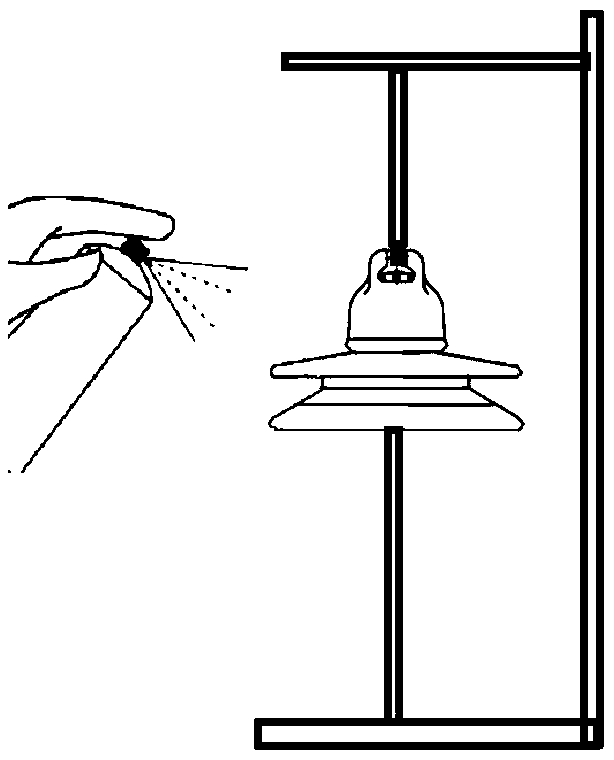

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

Shipping ballast cabin coating composition

ActiveCN101134867AImprove water resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyAdhesion force

The present invention is one kind of paint composition for ship ballast tank and belongs to the field of paint chemical technology. The paint composition with special liquid petroleum resin modified epoxy resin has excellent performance, including high water tolerance, high corrosion resistance, excellent flexibility, great adhesion force and high leaching resistance. It consists of special liquid petroleum resin 5-30 %, epoxy resin-1 10-40 %, epoxy resin-2 10-40 %, titanium white powder 18-30 %, talcum powder 10-40 %, antisagging agent 0.5-1.5 %, anti-setting agent 0.5-2 %, xylene 2-10 %, and curing agent 15-39 %, where, the special liquid petroleum resin is liquid petroleum resin with hydroxyl group content as high as 1.0-10.0.

Owner:中山大桥化工集团有限公司

Water epoxy floor coating, preparation method and construction method thereof

InactiveCN101565584ASafe and environmentally friendlyNo burningEmulsion paintsEpoxy resin coatingsOrganic solventEmulsion

The invention discloses a water epoxy floor coating which is a double-component emulsion coating comprising a component A and a component B, wherein the component A comprises water, a water epoxy curing agent, an addition agent, a filler and paint; and the component B comprises liquid epoxy resin, a reactive diluent and an environmentally-friendly type organic solvent; and the proportion of the component A to the component B is 10:3. The water epoxy floor coating has the advantages of the avoidance of the environmental pollution and the harm to the health of the human body, strong ventilation property, suitability for moist base planes and satisfaction of environmentally-friendly requirements and can be widely applied to the field of the industrial floor coating.

Owner:KOATWAY SHANGHAI CHEM IND CO LTD

Water-based colourful building coating and preparation method thereof

InactiveCN104212288AImprove stabilityGood storage stabilityMulticolor effect coatingsWater basedEmulsion

The invention discloses water-based colourful building coating. The water-based colourful building coating is formed by mixing the following components in percentage by mass: 5-20% of water-based colour paste, 60-70% of colour chip system and 30-40% of emulsion binder. A preparation method of the water-based colourful building coating comprises the following steps: preparing basic paint, matching colour, preparing a protection glue system, preparing a colour chip system, preparing an emulsion binder, and adding the colour chip system into the prepared emulsion binder, thus the stable water-based colourful building coating is formed. The water-based colourful building coating has the advantages that the protection glue system and cellulose in the basic paint interact with each other, so that produced gel is firmly wrapped on the surface of the basic paint of each colour, and surface activity of negative ions provides negative charges to form stable colour chips in various colours; the water-based colourful building coating can improve colour chip stability and storage stability, can prevent precipitation, colour bleeding and muddy water of the water-based colourful particles, is moulded by spraying in one step, good in recoatability, realistic in natural marble imitating effect and simple to maintain, has certain elasticity and can be used for making up micro cracks of a wall body.

Owner:SHANDONG QINHENG TECH

Preparation method of polyacrylate levelling agent active matters for powdery paints

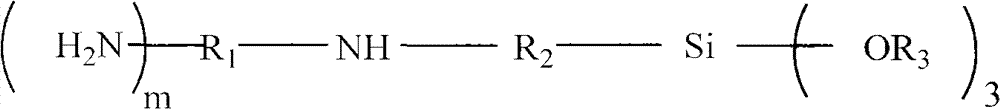

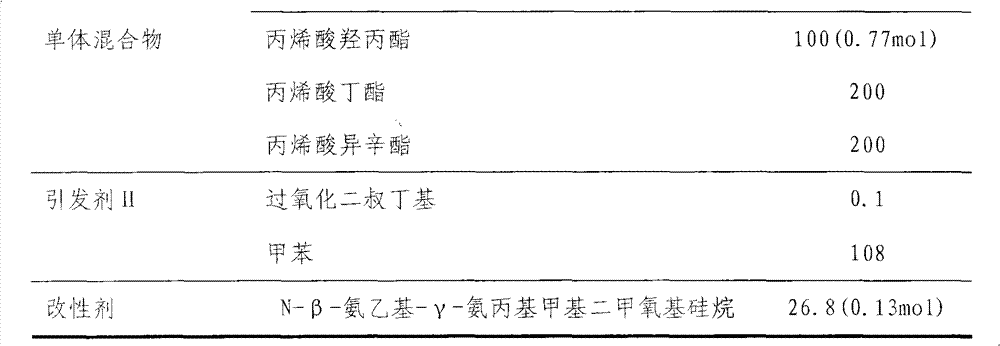

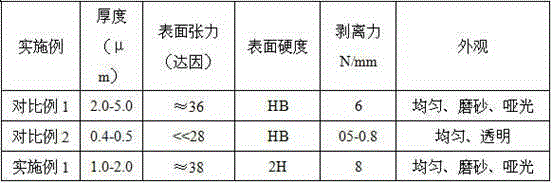

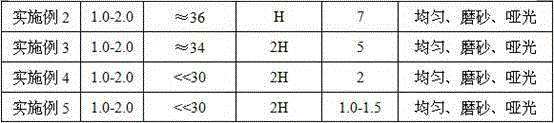

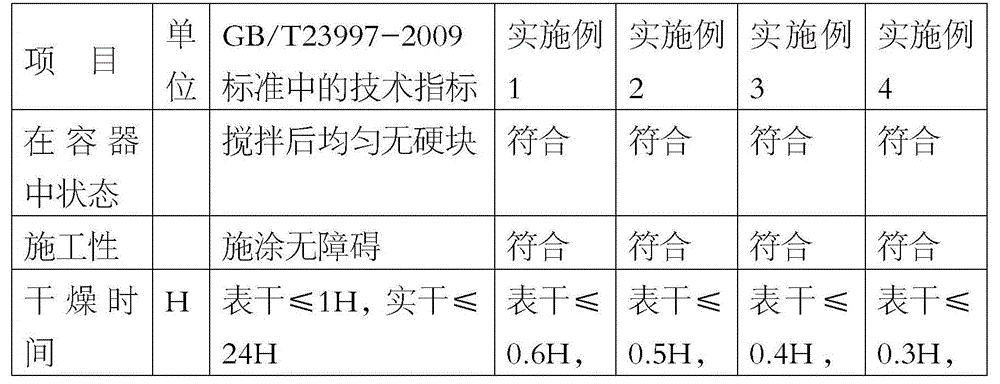

The invention, relating to the field of paint auxiliary agents, particularly relates to a preparation method of polyacrylate levelling agent active matters for powdery paints, comprising the following steps: polymerization of at least a hydroxy acrylate monomer and at least an acrylate monomer which contains no hydroxy and is not reacted with hydroxyl; and modification with an amino siloxane coupling agent. According to the invention, the levelling agent active matters disclosed herein are solid after being processed by fumed silica adsorption or polyester maternal dispersion, and can be directly applied in powdery paints for improving the adhesive force and appearance of the powdery paints; especially in the process of changing color, a small amount of previous colored powder can be uniformly dispersed to prevent the formation of variegated points or variegated pots in later color painting, the significant anti-interference effect is achieved, thus the color change of the powdery paints is greatly simplified; thus according to the levelling agent prepared by using the active matters, the adhesive force of the powdery paints on glass, metal and other substrates can be obviously improved.

Owner:六安科瑞达新型材料有限公司

Matt release film

ActiveCN105348946ASolve technical problems caused by residuesHigh residual adhesionCoatingsPolymer scienceAcrylic resin

The invention relates to a matt release film. The matt release film comprises a base film and a matt release coating layer arranged at one side of the base film; and the matt release coating layer is formed by coating a fluorine-containing thermosetting coating, and the coating comprises fluorine series resin, acrylic resin, aldehyde ketone resin, a curing agent system, an assistant, a delustering agent and a mixed solvent. The matt release film has the advantages of low surface tension, good adhesiveness and overcoatability, excellent heat and solvent resistance, and high residual adhesion rate and excellent matt effect after peeling when the matt release film is used in the field of electron manufacturing.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

High-sinking-resistance transparent primer and preparation method thereof

The invention relates to a high-sinking-resistance transparent primer and a preparation method thereof. The high-sinking-resistance transparent primer is particularly suitable for application on a wood substrate and especially suitable for application on a substrate with deeper wood-grain guide tubes. The primer is prepared from a main paint, a curing agent and a diluter in a mass ratio of 1:0.5:(0.3-1):0.5:0.7. The main paint is prepared from the following raw materials in parts by mass: 55-70 parts of small-oil-length alkyd resin, 5-15 parts of castor oil modified alkyd resin, 3-10 parts of zinc stearate, 0-30 parts of talcum powder, 0.5-1 part of anti-settling agent, 0.3-1 part of defoamer, 0.2-0.5 part of leveling agent, 0.1-0.5 part of wetting and dispersing agent, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The primer can be well combined with the substrate after being applied, and has excellent properties in the aspect of wood grain / guide tube filling. After the primer is placed for a long time, the paint film of the finish paint can not shrink, and can not generate the phenomenon of sinking.

Owner:SKSHU PAINT

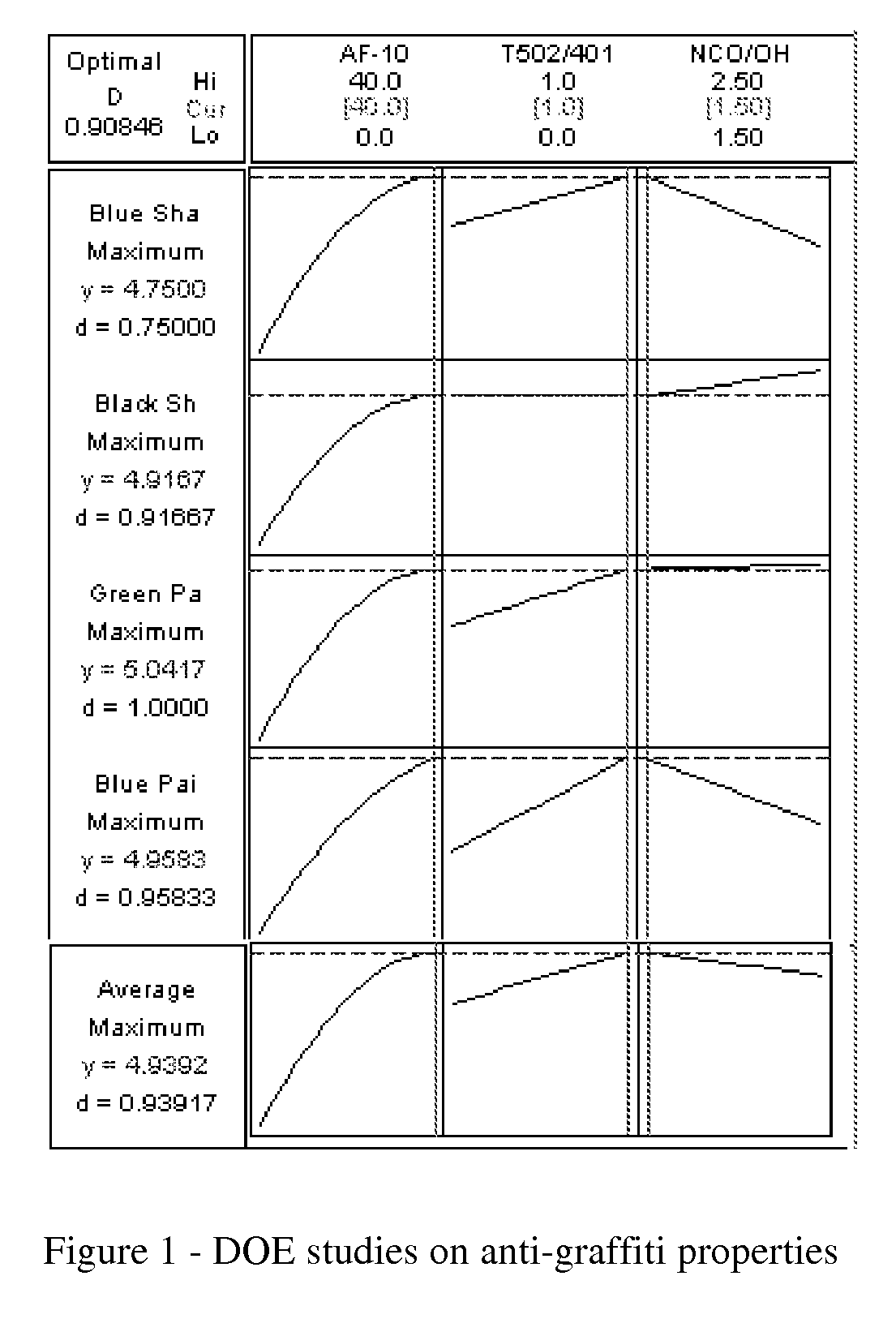

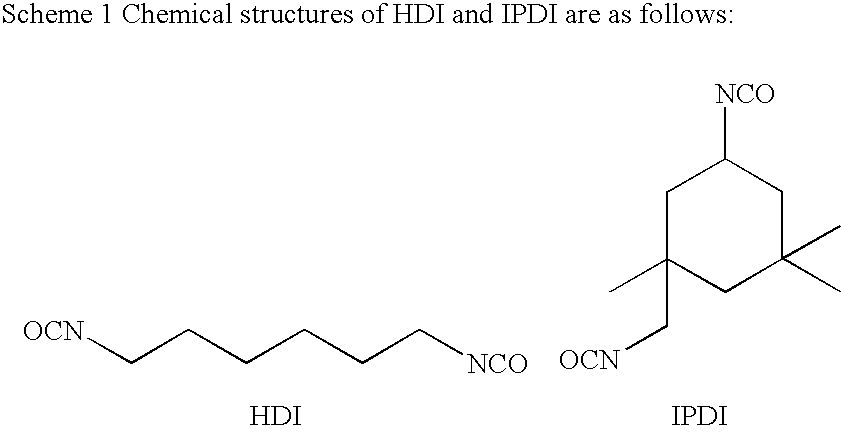

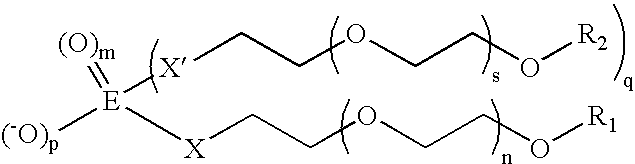

Two component waterborne polyurethane coatings for Anti-graffiti application

ActiveUS20090054570A1Impart propertyGood recoatabilityPolyurea/polyurethane coatingsPolymer sciencePolyol

Two component (2K) waterborne polyurethane coating compositions which when cured achieve excellent anti-graffiti properties at low VOC level (below 100 g / L) are disclosed. The composition comprises (A) a fluorinated polyol and optionally a non-fluorinated polyol; and (B), a blend of polyisocyanates comprising a hydrophilically modified trimer of hexamethylene diisocyanate (HDT) and a hydrophilic ally modified trimer of isophorone diisocyanate (IPDT). The glass transition temperature of the ambient cured coatings, crosslinked network structure, and fluorine content at the surface enable excellent anti-graffiti properties. The waterborn coatings of the invention have excellent recoatability and exceptional chemical resistance.

Owner:RHODIA OPERATIONS SAS +1

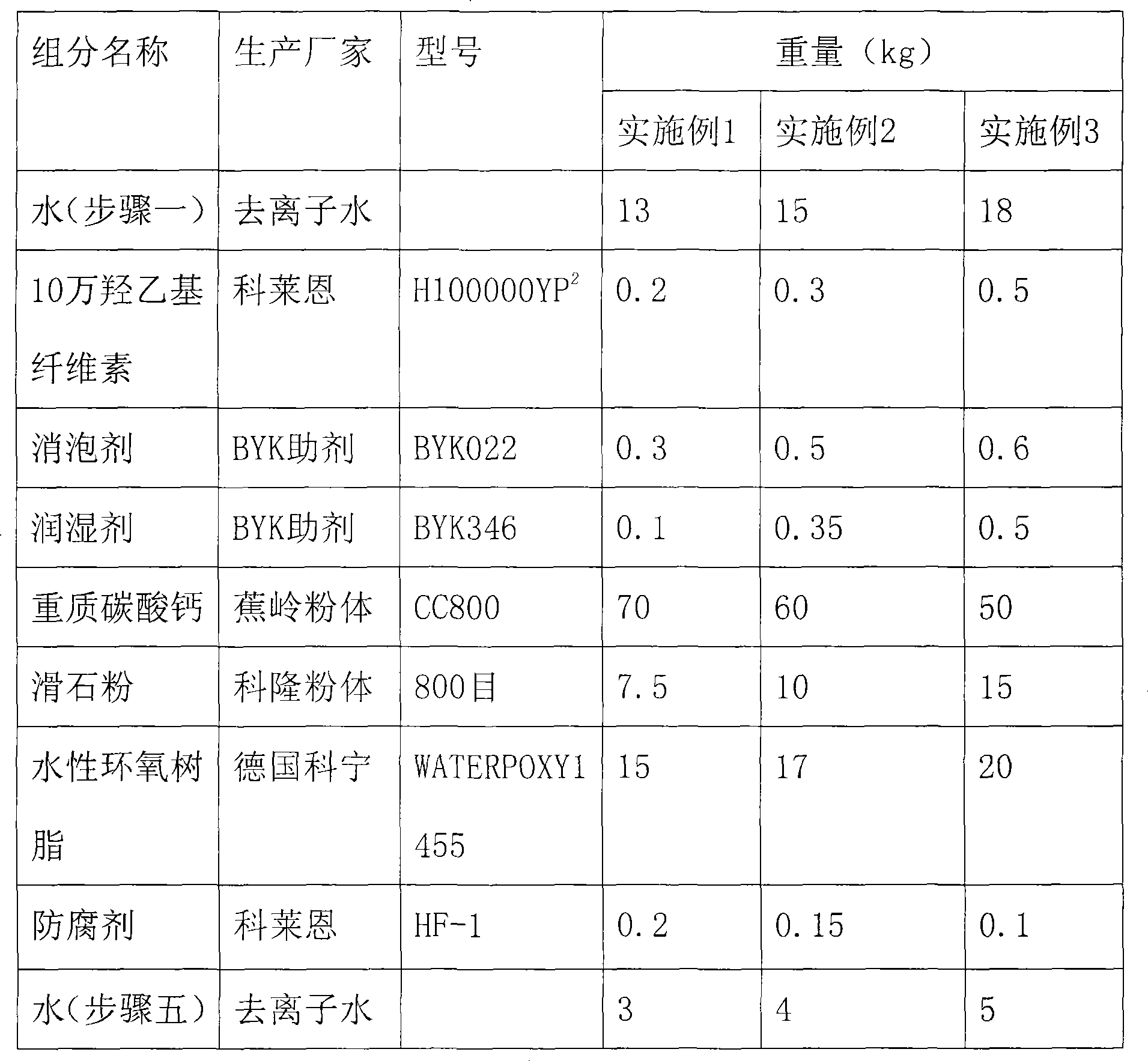

Aqueous epoxy putty, and preparation and use method thereof

The invention relates to an aqueous epoxy putty and a preparation method thereof. The preparation method comprises the following steps: 1. 13 to 18 weight portions of water is added with 0.2 to 0.5 weight portion of thickening agent under the stirring at the speed of 500 to 800 revolutions / minutes, is stirred and is fully dissolved; 2. 0.3 to 0.6 weight portion of a defoaming agent and 0.1 to 0.5 weight portion of wetting agent are sequentially added into the mixture and are evenly stirred; 3. 50 to 70 weight portions of powdered whiting and 7.5 to 15 weight portions of talcum powder are added into the mixture; under the rotational speed of 500 to 800 revolutions / minute, all composition are mixed; and if water is too little to stir the compositions evenly, 3 to 5 weight portions of an aqueous epoxy resin is added into the mixture, is stirred for 5 to 8 minutes till the fineness is between 30 and 40 microns at the rotational speed of 1,200 to1,500 revolutions / minute; 4. at the middle rotational speed, the residual amount of the aqueous epoxy resin is fully replenished to 15 to 20 weight portions totally and is evenly stirred; and 5. the mixture is continuously added with 0.1 to 0.2 weight portion of antiseptic and 3 to 5 weight portions of water, is stirred for 7 to 19 minutes at low speed, and is filtered to obtain the aqueous epoxy putty. According to weight ratio of 6 to 4, an aqueous epoxy curing agent and water are mixed to obtain a special matched curing agent; and according to weight ratio of 20 to 1, the aqueous epoxy putty and the curing agent are mixed for use. The aqueous epoxy putty can solve the problem that oily paint dissolves a polystyrene plate due to the fact that an aqueous epoxy primer is leaked to paint or the thickness of the painted primer does not meet the requirement, and can well decorate and protect a coating layer.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Scratch resistance water-borne wood coating

InactiveCN102816512AImprove scratch resistanceImprove drynessPolyurea/polyurethane coatingsPolyurethane dispersionWax

The invention provides a scratch resistance water-borne wood coating which comprises, by weight, 80.0-86.0% of acrylic modified polyurethane emulsion, 3.0-5.0% of film formation auxiliaries, 0.3-0.5% of antifoaming agent, 3.0-11.0% of deionized water, 0.1-0.3% of wetting agent, 0.1-0.3% of aralkyl modified polymethyl alkyl silicon solution with mass percentage as 48-52%, 3.0-5.0% of wax emulsion, 0.3-0.5% of thickener and 0.1-0.2% of preservative. The acrylic modified polyurethane emulsion is formed by copolymerizing acrylics monomers, acrylic acid and waterborne polyurethane dispersoid, and the solid mass percentage is 30-40%. The scratch resistance water-borne wood coating has the advantages that water is used as a solvent, the coating is environment-friendly and energy-saving and good in dryness and anti-adhesion; the coating is good in scratch resistance and firm in film; and construction is simple, maintenance is easy, and recoatability is good.

Owner:浙江博星化工涂料有限公司

Super-scratch-resistant unsaturated polyester matte transparent finish paint

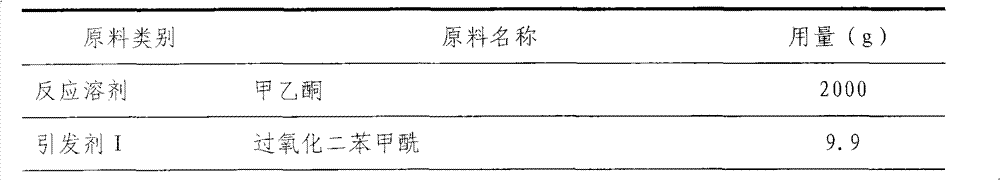

InactiveCN103254745AImprove scratch resistanceImprove fullnessPolyester coatingsPolyesterUnsaturated polyester

The invention discloses the field of decoration and coating of wooden office furniture and particularly relates to a super-scratch-resistant unsaturated polyester matte transparent finish paint which can meet the curing of a normal-temperature environment condition and can finish through spraying construction; and a coating film has an excellent wear resistance. The super-scratch-resistant unsaturated polyester matte transparent finish paint is formed by mixing a main paint, an initiator and an accelerant; and the weight proportion is that the main paint to the initiator to the accelerant is 100: 1.6: 1.8. According to the super-scratch-resistant unsaturated polyester matte transparent finish paint disclosed by the invention, the scratch-resistant problem of a UPE unsaturated polyester wood transparent matte coating is completely solved; the finish paint is treated by a certain construction process and then can be directly sprayed on the surface of wooden furniture; the scratch resistance is excellent, and the flexibility and the fullness are good; and finish paint can be used for coating protection on the surface of the wooden furniture, has a good mechanical performance and is simple to operate; and an environment-friendly and excellent-performance air-drying transparent matte coating is provided.

Owner:SKSHU PAINT

Coating Composition

ActiveUS20090293768A1Maintain good propertiesIncrease resistanceGroup 4/14 element organic compoundsFibre treatmentPolymer scienceOrganometallic catalysis

A coating composition which is excellent in crack resistance, alkali resistance and solvent resistance while having a high hardness and which is excellent in recoatability, anti-graffiti property, and removability of graffiti is provided. The coating composition according to the present invention comprises as the essential components, (a) a liquid organosiloxane compound which is a mixture of (a-1) a liquid organosiloxane compound having an alkoxy group content of 20 to 60% by mass and (a-2) a liquid organosiloxane compound having an alkoxy group content of 5% by mass or more and less than 20% by mass, in which an (a-1) / (a-2) mass ratio is 10 / 90 to 60 / 40, (b) an organometallic catalyst, (c) at least one compound selected from among alkoxy group-containing organosilane compounds having a primary or secondary amino group, amino-modified silicone oils, and amino group-containing organosiloxane compounds, and (d) at least one compound selected from among compounds having two or more glycidyl groups in one molecule, glycidyl group-containing silane compounds and glycidyl group-containing silicone oligomers.

Owner:DYFLEX CORP

Polyurethane heat reflection ship hull coating

InactiveCN101550314ASolve the problem of external corrosion protectionWith heat reflection functionAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesion forceAcrylic resin

The invention discloses polyurethane heat reflection ship hull coating, and relates to double-component acrylic polyurethane weathering heat reflection ship hull coating which can reach the film thickness requirements by generally applying one to two topcoat in coating. The film forming matters of the polyurethane heat reflection ship hull coating includes aliphatic polyurethane resin and acrylic resin, which are simultaneously added with weathering pigments and fillers and heat reflection materials so that various mechanical physical performances and weathering performances of the coating are greatly improved. The coating is double-component acrylic polyurethane corrosion protective coating, including acrylic resin, polyurethane resin, plasticizers, heat reflection material, pigments and fillers, imported dispersants, anti-sedimentation agents, and the like; and the weight ratio of A component and B component is 8:1. The coating has very excellent aging resistant performance, hard coating film, high glossiness and strong adhesion force, can achieve good external corrosion prevention effect, and is widely used in steel structures, pipelines, storage tanks, tank cars and equipment in the industries such as the chemical engineering, the machinery, the ship, the metallurgy and the like as the surface corrosion prevention coating.

Owner:上海海悦涂料有限公司

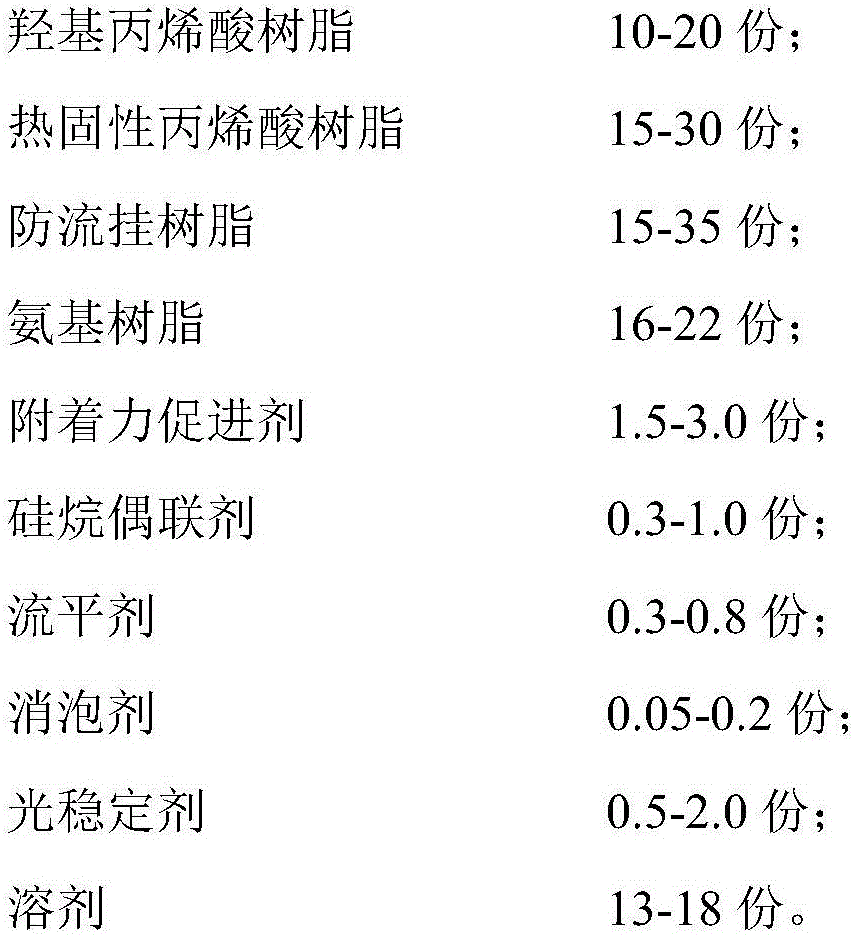

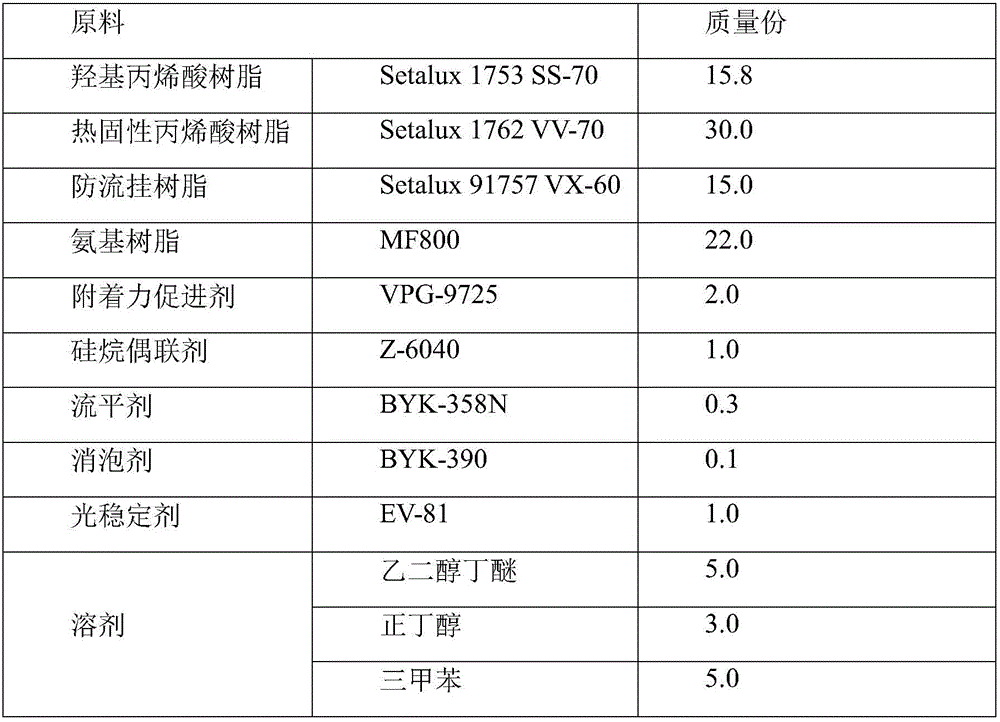

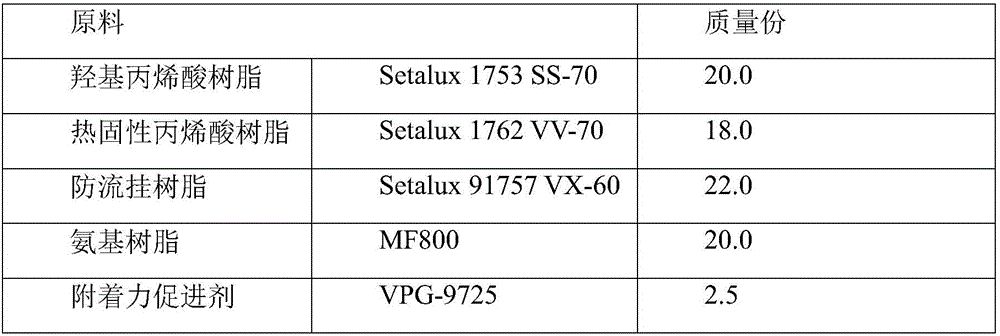

Aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating and preparation method thereof

The invention relates to an aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating, wherein the aluminum alloy wheel finishing varnish is prepared from the following components in parts by weight: 10-20 parts of hydroxyl acrylic resin, 15-30 parts of thermosetting acrylic resin, 15-35 parts of anti-sagging resin, 16-22 parts of amino resin, 1.5-3.0 parts of an adhesion promoter, 0.3-1.0 part of a silane coupling agent, 0.3-0.8 part of a leveling agent, 0.05-0.2 part of a defoaming agent, 0.5-2.0 parts of a light stabilizer, and 13-18 parts of a solvent. The invention also provides a preparation method for the aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating. The aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating has the relatively large advantages in salt fog resistance, water resistance, recoatability and the like, and has excellent re-coating adhesive force and good weather resistance.

Owner:广东四方威凯新材料有限公司

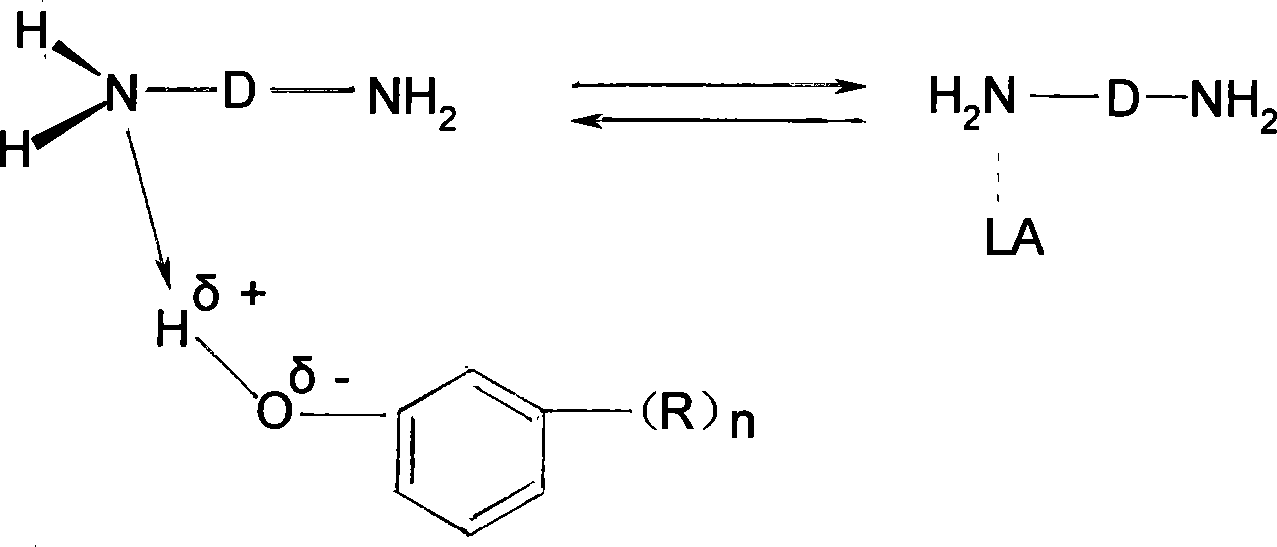

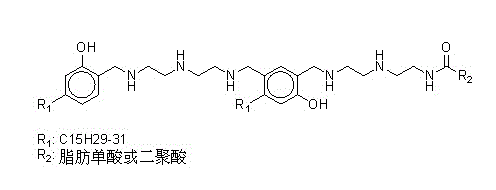

Cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and preparation method of cashew phenolic aldehyde amide epoxy hardener

ActiveCN102977670AComponent ratio scienceImprove reaction efficiencyOrganic compound preparationCarboxylic acid amides preparationFeeding orderDiethylenetriamine

The invention discloses a cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and a preparation method of the cashew phenolic aldehyde amide epoxy hardener. The cashew phenolic aldehyde amide epoxy hardener is composed of, by weight, one part of diethylenetriamine, 2.5-3 parts of dimer acids or fat single acids, 2.8-3.2 parts of anacardol, one part of the diethylenetriamine, and 0.9-1.2 parts of 96%-purity paraformaldehyde. Raw material composition, and the best matching and the feeding order of each material are optimized through a large number of experiments, and each component matching is scientific and reasonable. The method of mannich addition after amidation is utilized, the whole process is strong in operability, cost is low, production periods are short, productivity is high, the prepared cashew phenolic aldehyde amide epoxy hardener can be general in four seasons, drying is rapid, operation periods are short, anti-corrosion performance is good, and water-proof performance is excellent. The cashew phenolic aldehyde amide epoxy hardener can be widely used in the fields of pipe and storage tank storage corrosion prevention, adhesion agents, metallic top coats, chip heavy corrosion prevention and the like.

Owner:江苏三木化工股份有限公司

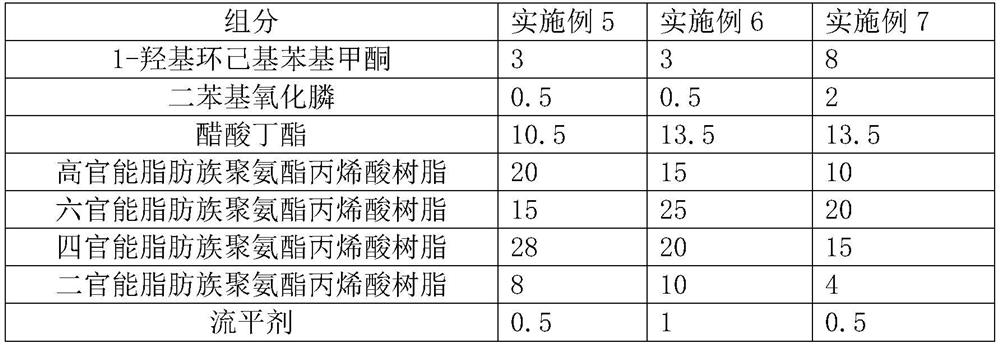

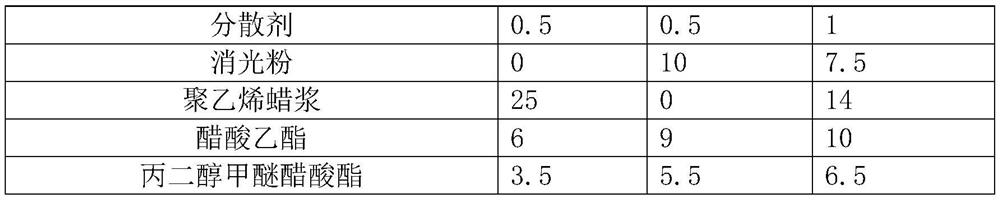

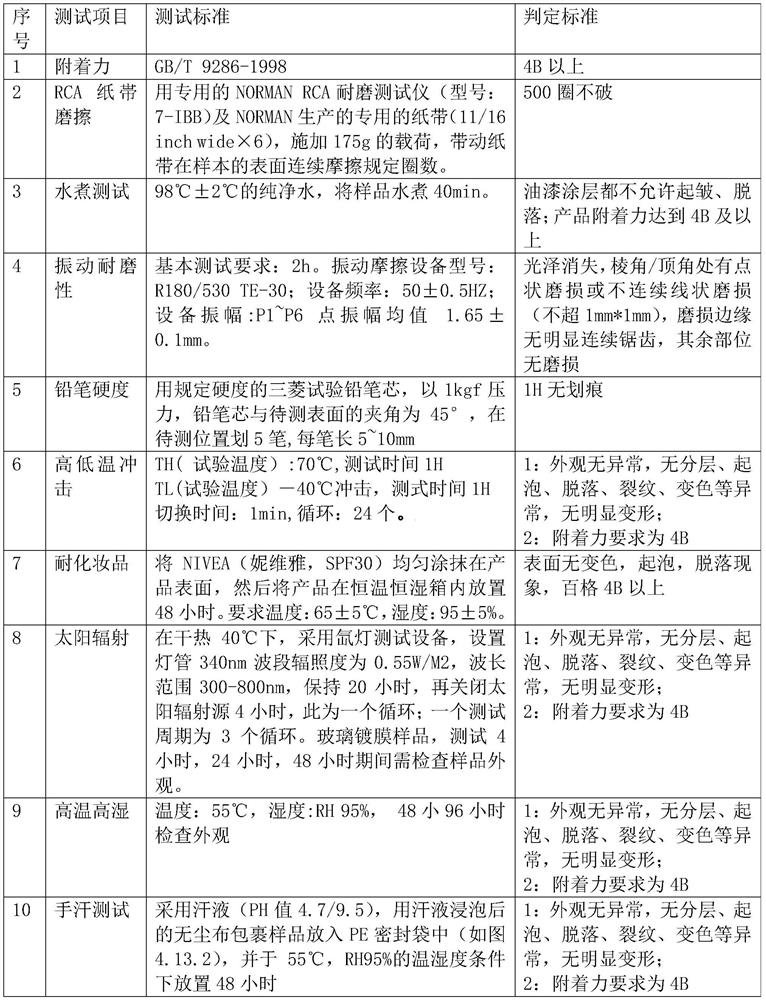

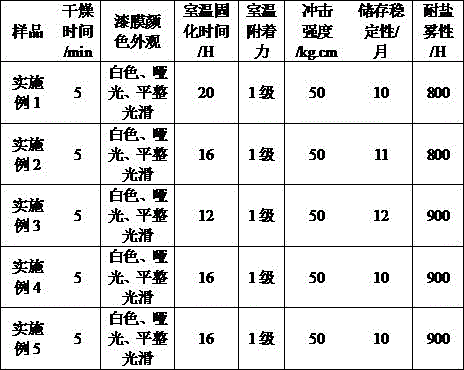

Vibration wear-resistant coating and preparation method and spraying process thereof

ActiveCN112538293AInhibit sheddingSolve the phenomenon of uncertain performance such as sheddingPretreated surfacesPolyurea/polyurethane coatingsCellulosePolymer science

The invention provides a vibration wear-resistant coating and a preparation method and a spraying process thereof. The vibration wear-resistant coating comprises PU type primer and UV photocurable finish coating. The PU type primer is prepared from 40-50 parts of thermoplastic acrylic resin, 10-20 parts of hydroxy acrylic resin, 1-3 parts of cellulose acetate butyrate, 1-2 parts of adhesion promoter, 2-4 parts of auxiliaries, 15-25 parts of pigment filler and 20-30 parts of mixed solvent; and the UV photocurable finish coating comprises the following components in parts by weight: 10-20 partsof high-functionality polyurethane acrylate, 15-25 parts of six-functionality polyurethane acrylate, 15-28 parts of four-functionality polyurethane acrylate, 4-10 parts of two-functionality polyurethane acrylate, 0.5-1 part of a dispersing agent, 0.5-1 part of a leveling agent, 0-10 parts of extinction powder, 0-25 parts of wax liquor, 0-10 parts of a photoinitiator and 20-30 parts of a mixed solvent. When the vibration wear-resistant coating is applied to a mobile phone (plastic material) frame or a mobile phone side key, the vibration wear resistance and durability of the product can be improved, and a coating film can be prevented from falling off after long-time use.

Owner:东莞市贝特利新材料有限公司

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Method for improving surface tension and recoatability of organosilicone synthetic leather coating

InactiveCN109722917ARetain wear-resistantRetain scratch resistantTextiles and paperDouble bondChemistry

The invention discloses a method for improving the surface tension and recoatability of an organosilicone synthetic leather coating. Through the coordination addition reaction of a silicon hydrogen bond and a double bond, a polarity polyurethane chain segment with a terminal sealed by the double bond is introduced into an organosilicone synthetic leather coating material, the surface tension and recoatability of the organosilicone synthetic leather coating are improved, the technical problems that a monotonous organosilicone synthetic leather coating is poor in adhesion to base cloth, after-finishing wet smoothness and recoatability due to the low surface energy is effectively solved, and the method has the feasibility of changing the product aesthetics effect and special effect. In addition, the prepared modified organosilicone coating has the advantage of keeping the wear resistance, scratching resistance, cold resistance, water resistance and the like of the organosilicone coating,does not contain any organic solvent, has the outstanding green and environment-friendly characteristics, and can be widely applied to the industries of leather, synthetic leather, textiles, plastic,rubber, building material, coating and the like.

Owner:SICHUAN UNIV

Imitating metal fluorocarbon coatings using aluminium powder slurry after surface treatment

InactiveCN101397434AExcellent pinking and discolorationSolve the phenomenon of blackening and powder loss due to insufficient alkali resistanceInorganic pigment treatmentCoatingsSlurrySolvent

A pseudo-metallic fluorocarbon paint adopts polymer or inorganic substance-coated aluminum paste, solving the problems of darkening and peeling caused by insufficiency of alkali resistance of untreated aluminum powder paste used in the prior art. The pseudo-metallic fluorocarbon paint comprises composition I including hydroxyl fluorocarbon resin, the polymer or inorganic substance-coated aluminum paste, wetting and dispersing agent, cellulose acetate butyrate, anti-settling sagging agent and solvent; and composition II, hexamethylene diisocyanate (HDI) trimer, wherein, the proportion of composition I to composition II is 16-19:1. The pseudo-metallic fluorocarbon paint prepared by using such compositions including polymer or inorganic substance-coated aluminum paste, in such a proportion, has the advantages of extraordinary alkali and color-changing resistance, so in alkaline environment, aluminum powder erosion changes seldom occur. When being applied to building walls for coating protection, the paint has excellent color retention performance.

Owner:SKSHU PAINT

Scratch resistant polyurethane woodenware glossy black finish paint

ActiveCN103937402AStrong molecular structureGood flexibilityPolyurea/polyurethane coatingsLacquerAcrylic resin

The invention relates to a preparation method of a scratch resistant polyurethane woodenware glossy black finish paint. The finish paint is composed of a resin paint component A and a curing agent component B; wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic resin, aldehyde-ketone resin, carbon black color paste, a chelating leveling agent, an antifoaming agent, an anti-settling agent, and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The prepared finish paint has the advantages of high hardness, low viscosity, and good leveling property. The finish paint can form a membrane at a time, the membrane is thick, and no sag is generated. The paint has high gloss and a transparent crystal appearance like a black jade. The paint membrane is like a crystal, is thick and smooth, gives people a high quality sense, has a decoration effect like a mirror, and creates a fresh, grace, concise, and tranquil space. A refreshing unique feeling is created by the finished paint which is accord with the modern aesthetics, so the finish paint is welcomed by market and customers. The finish paint can be used to decorate and protect the surfaces of woodenware, metal products, and plastic products.

Owner:UNION FOSHAN CHEM +1

Novolac epoxy resin radiation protective paint and preparation method thereof

InactiveCN105694677AHigh transparencyHigh hardnessFireproof paintsAntifouling/underwater paintsEpoxyTemperature resistance

The invention provides a phenolic epoxy resin radiation protection coating, which comprises the following raw materials in parts by weight: 20-30 parts of phenolic epoxy resin, 10-15 parts of expanded graphite, 5-10 parts of carbon nanotubes, 1-30 parts of titanium dioxide 5 parts, 0.5-3 parts of hydroxypropyl methylcellulose, 8-14 parts of glass powder, 5-10 parts of talc powder, 8-12 parts of kaolin powder, 5-10 parts of perlite, 10-15 parts of wollastonite powder , 1-5 parts of dicyclopentenyloxyethyl acrylate and 20-30 parts of water. The present invention also provides a preparation method of the above-mentioned phenolic epoxy resin radiation protection coating. The components in the above-mentioned phenolic epoxy resin radiation-proof coating provided by the present invention cooperate with each other and complement each other, so that the coating has excellent anti-corrosion, radiation protection, antibacterial, flame-retardant, and anti-corrosion properties under the premise of maintaining good adhesion. High temperature, anti-cracking, anti-corrosion, resistance to alternating cold and heat, storage stability and other characteristics.

Owner:HUANGHE S & T COLLEGE

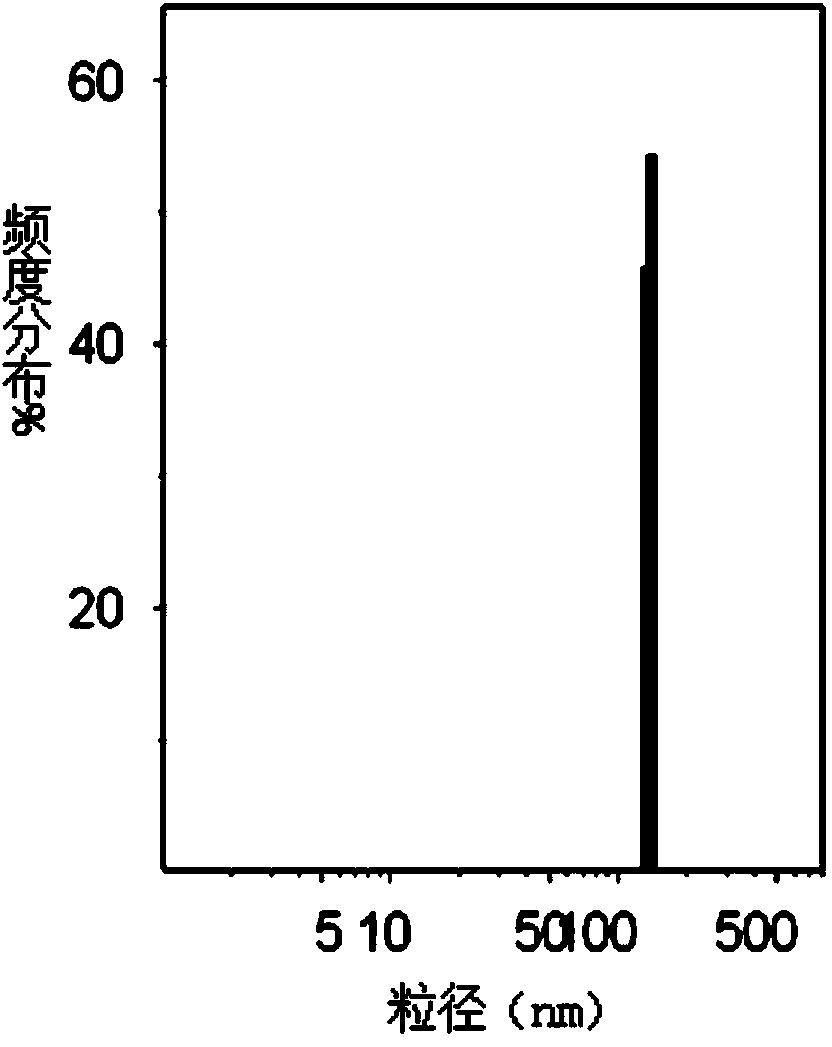

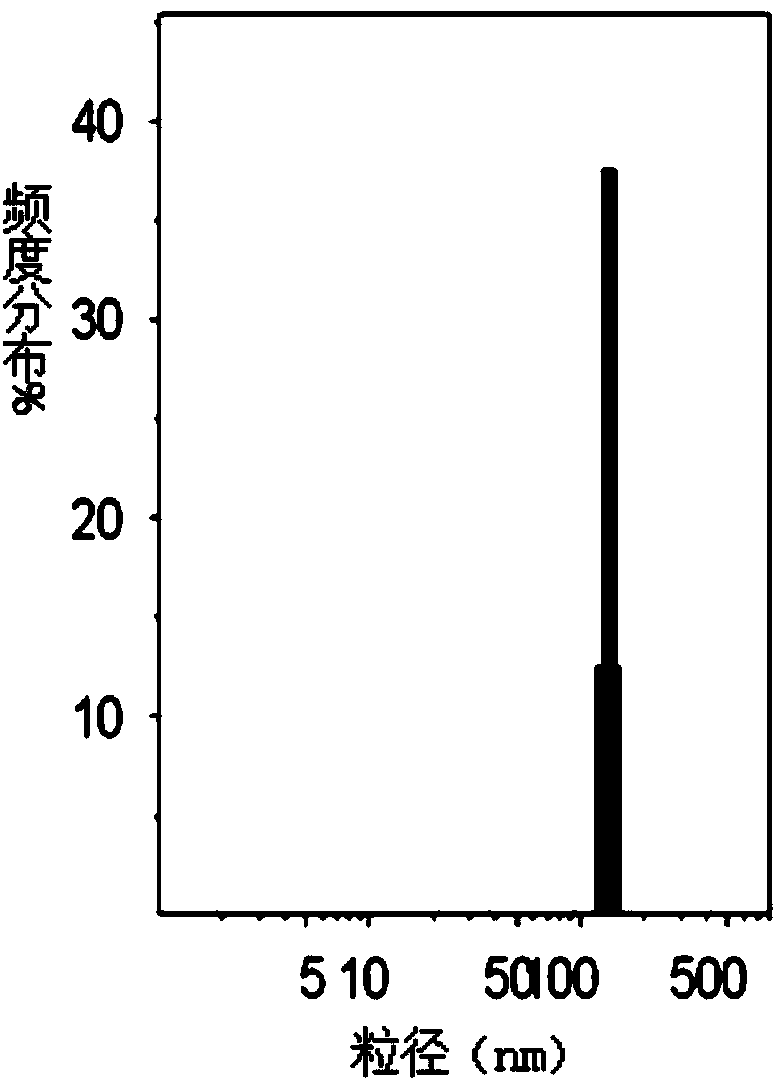

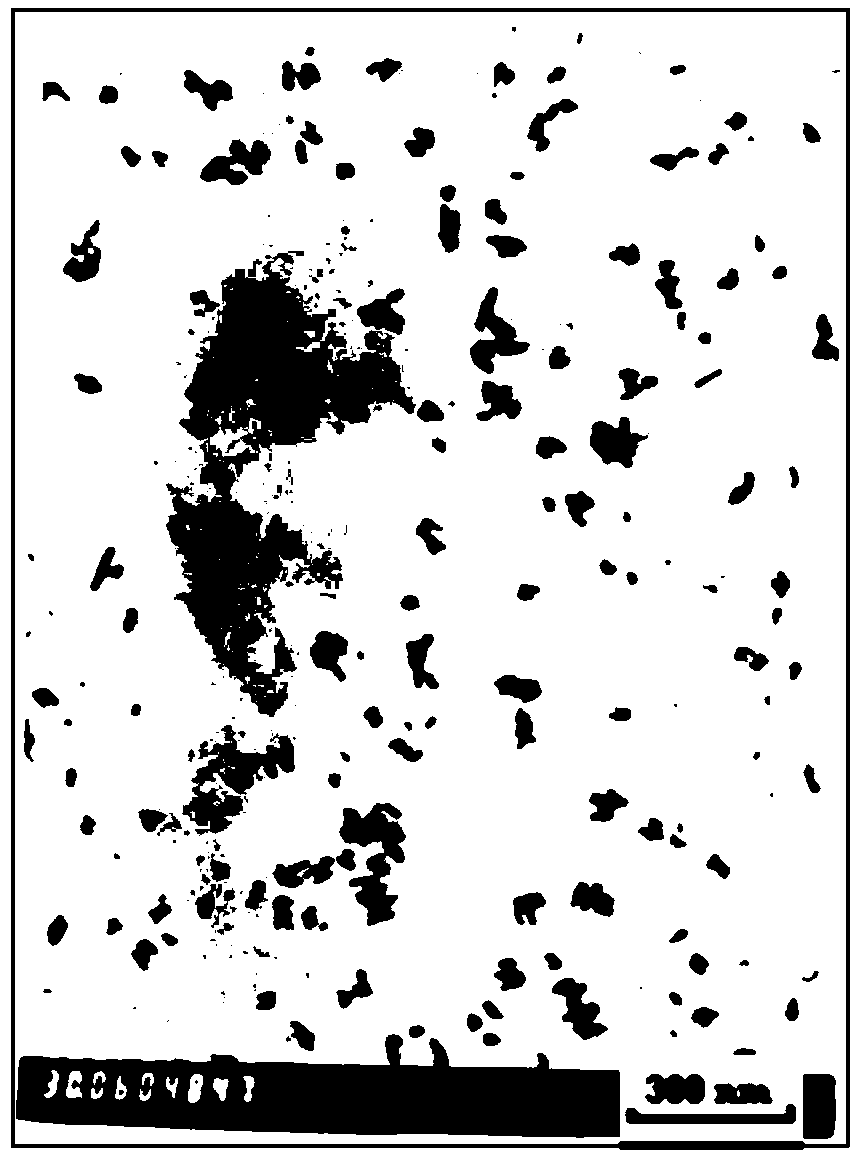

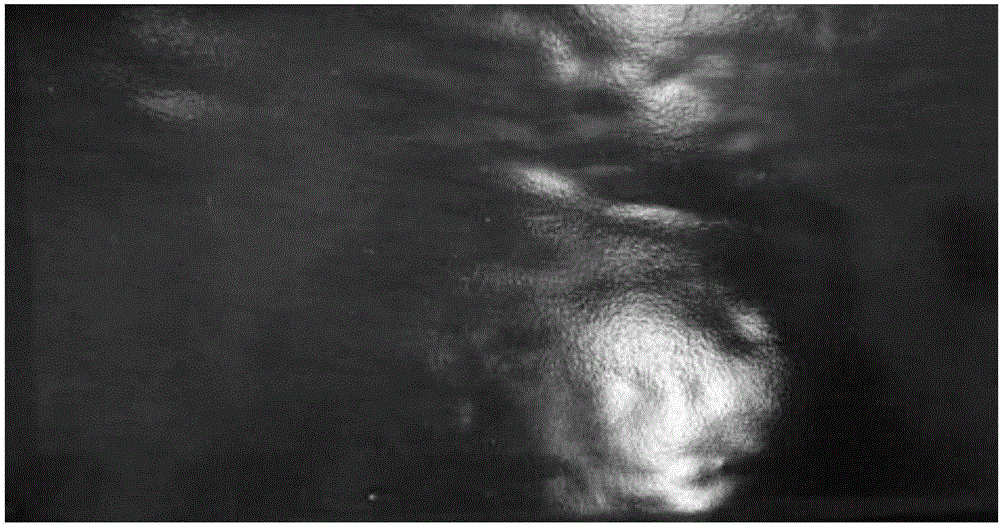

Preparation method of fouling resistant coating for highway barrier

ActiveCN103555174AImprove adhesionImprove self-cleaning and anti-fouling propertiesPolyurea/polyurethane coatingsPhosphateSlurry

The invention belongs to the field of fine chemical coatings, and discloses a preparation method of a fouling resistant coating for a highway barrier. The method comprises the following steps of: firstly preparing a phosphate-group-containing hydroxyl acrylic acid water dispersion, then preparing nanometer TiO2 dispersion slurry which is stable in performance, and finally preparing an ingredient A by dispersing and grinding the nanometer TiO2 dispersion slurry, the phosphate-group-containing hydroxyl acrylic acid water dispersion, an ultraviolet absorber, a solvent, a pigment filler and other auxiliaries in proportions. The coating for the highway barrier prepared from the ingredient A and an aliphatic isocyanate curing agent (ingredient B) can be easily coated thick; the coated film has the characteristics of good weather resistance, strong fouling resistance, and excellent corrosion resistance; the shortcomings that coating equipment needs to be fixed, a barrier plate needs to be repaired, the field maintenance is difficult, and the decoration performance is poor in the traditional coating construction for the highway are avoided; and therefore the coating can be widely applied to the highway barrier facilities of barrier plates, upright posts, bolts and the like, and also can be widely applied to the protection of large-sized construction machinery and other outdoor steel structures.

Owner:浙江纳宝莱化工科技有限公司

Micro powder reinforced polyurethane-based high-strength waterproof heat preservation and decoration integrated material and preparation method thereof

InactiveCN106431087AImprove performanceRealize the utilization of solid wastePolyurea/polyurethane coatingsSlurryUltimate tensile strength

The invention relates to a micro powder reinforced polyurethane-based high-strength waterproof heat preservation and decoration integrated material and a preparation method thereof. According to the material, polyurethane is adopted as matrix resin, a large number of micro powder particles and multiple compounding agents are added, grinding is carried out, foaming is controlled, and the closed-cell material is prepared. Coatings or rolls or plates or blocks can be manufactured by means of brushing or spraying or pouring. The material can be manufactured to be red, yellow, blue, black, white and other colors by adjusting a coloring agent. The material has the comprehensive advantages of being efficient, waterproof, good in heat preservation performance and decoration effect, high in strength, good in corrosion resistance, resistant to inflaming and the like. The coatings are tightly bonded with a substrate, and the surface is smooth. The material has good toughness as the rolls and can be used for waterproofness and heat preservation of newly-built or existing buildings, tunnels, underground facilities and the like. The material serves as the plates, sand particles can be bonded to the surface of damp-dry slurry to obtain various building plates with a stone grain decoration effect. The material is extremely low in cost and has good market prospects.

Owner:SOUTHEAST UNIV +1

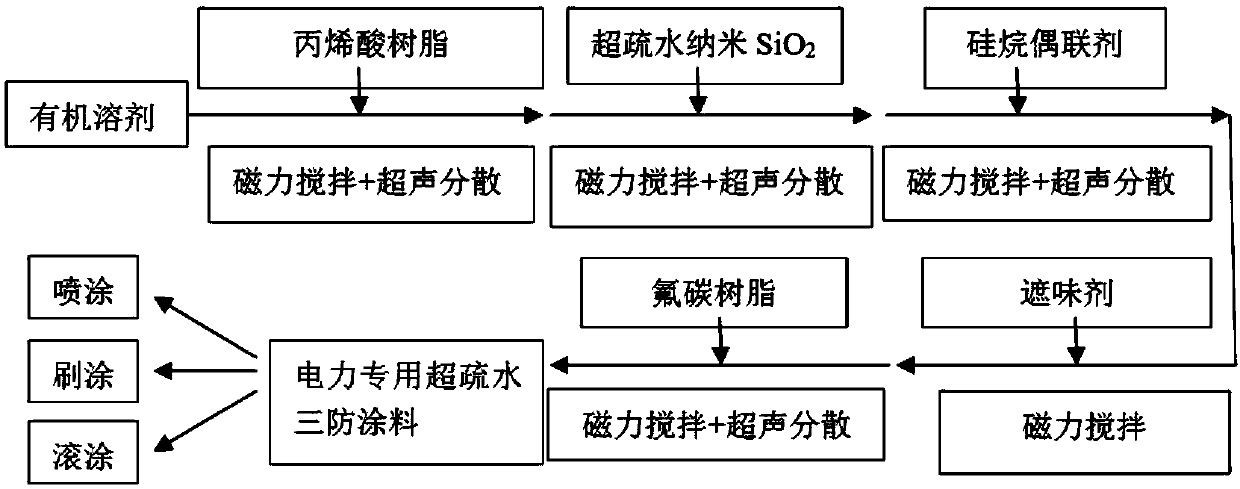

Room-temperature-curing super-hydrophobic coating specially used for electricity, and preparation and use methods of same

ActiveCN109554036AImprove performanceImprove insulation performanceAntifouling/underwater paintsPaints with biocidesElectricityOrganic solvent

The invention discloses a room-temperature-curing super-hydrophobic coating specially used for electricity, and preparation and use methods of same. The coating includes, by mass, 50%-63% of an organic solvent, 10%-20% of hydrophobic nanoparticles, 1%-2% of a silane coupling agent, 10%-25% of fluorocarbon resin, 7%-20% of acrylic resin, and 0.5-1% of an odor-covering agent. The components are stepwise stirred and mixed and then are ultrasonically dispersed uniformly to make the coating. The use method of the coating includes fill-packaging the coating and directly spray-coating surface of facilities therewith, wherein the thickness of the coating layer only need to avoid sagging phenomenon, and curing the coating for 30 min to 2 h according to the thickness at room temperature. The super-hydrophobic coating is simple in preparation method and low in cost, is convenient to use, has super-hydrophobicity and weather resistance, has insulation performance, and has wide application prospect.

Owner:昆明理工大电力工程技术有限公司

Imitation metal fluorocarbon paint

The imitation metal fluorocarbon paint includes component A containing fluorocarbon resin (53%), metal pigment paste, wetting dispersing agent, cellulose acetate-butyrate, colour paste, antisettling sagging agent and solvent and component B containing hexamethylene diisocyanate tripolymer. Their mixing ratio is A:B=10-14:1, according to the above-mentioned mixing ratio, the imitation metal fluorocarbon paint can be made up. It possesses the following advantages: 1. it can be solidified and film-formed at normal temp.; 2. it can be directly spray-coated on the surface of external wall of cement building; 3. its construction is simple, its cost is 1 / 5 of that of baked aluminium curtain wall; and 4. said paint not only can be used for decorative protection of wall body but also can be used in the fields of steel and iron structure, wooden product and plastics.

Owner:大连振邦氟涂料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com