Patents

Literature

2230 results about "Paraformaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraformaldehyde (PFA) is the smallest polyoxymethylene, the polymerization product of formaldehyde with a typical degree of polymerization of 8–100 units. Paraformaldehyde commonly has a slight odor of formaldehyde due to decomposition. Paraformaldehyde is a poly-acetal.

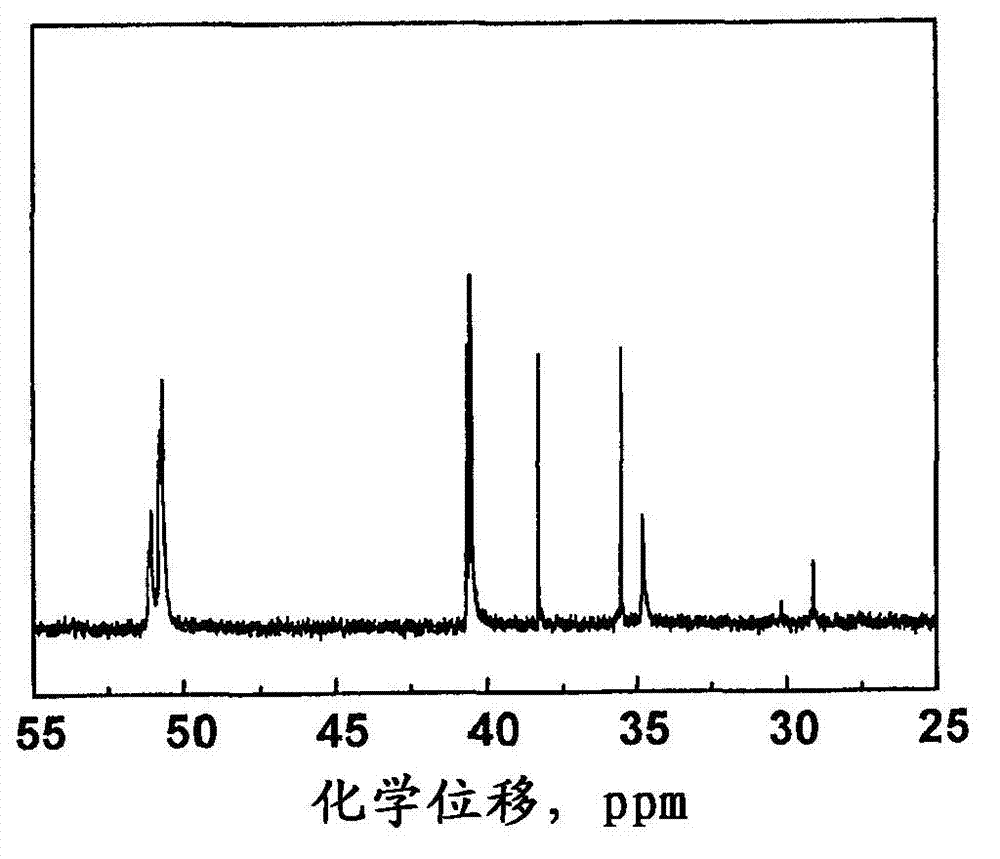

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Catalytic synthesis method for polyoxymethylene dimethyl ethers (PODE) by molecular sieves

ActiveCN102040491AStrong acidHigh yieldOrganic chemistryOrganic compound preparationSynthesis methodsReaction temperature

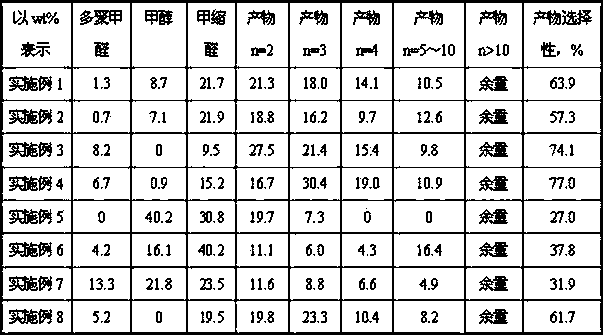

The invention relates to a catalytic synthesis method for polyoxymethylene dimethyl ethers (PODE) by molecular sieves, mainly solving the problem of relatively high cost in the conventional method which adopts trioxymethylene as a raw material. In the method, methanol, methylal and paraformaldehyde are adopted as raw materials based on the mass ratio of (0-10): (0-10):1, the raw materials contactwith a catalyst to react and generate PODE, wherein the dosages of the methanol and the methylal can not be zero at the same time; the reaction temperature is 70-200 DEG C; the reaction pressure is 0.1-6MPa; and the adopted catalyst is selected from at least one of beta zeolite, X zeolite, Y zeolite, ZSM-5 molecular sieve, MCM-22, MCM-56, UZM-8 or SAPO-34 molecular sieve. The technical scheme adopted by the invention solves the above problem preferably, thus being applicable to industrialized production of the PODE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dibenzoxazine containing oxazole ring and preparation method thereof

InactiveCN102250117ASimple preparation processLow equipment requirementsLiquid crystal compositionsOrganic chemistrySolventOrtho-aminophenol

The invention relates to a dibenzoxazine containing an oxazole ring and a preparation method thereof. The preparation method comprises the following two steps of: 1: mixing ortho-aminophenol hydrochloride and para-hydroxybenzoic acid, adding polyphosphoric acid as a solvent, reacting at 60-180 DEG C for 24-60 hours, and washing by using deionized water, filtering and drying to obtain diphenol containing an oxazole ring structure; and 2: mixing the diphenol containing the oxazole ring structure, phenylamine and paraformaldehyde, reacting at 80-110 DEG C for 40-80 minutes, then filtering and precipitating, washing 4-8 times by using alkali liquor, and then washing, filtering and drying to obtain the product. The dibenzoxazine disclosed by the invention has the advantages of very good mechanical property because the high temperature resistant oxazole ring structure is introduced to a benzoxazine molecule structure, dielectric constant of only 1.6-2.3, simple process, lower equipment requirement and suitability for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

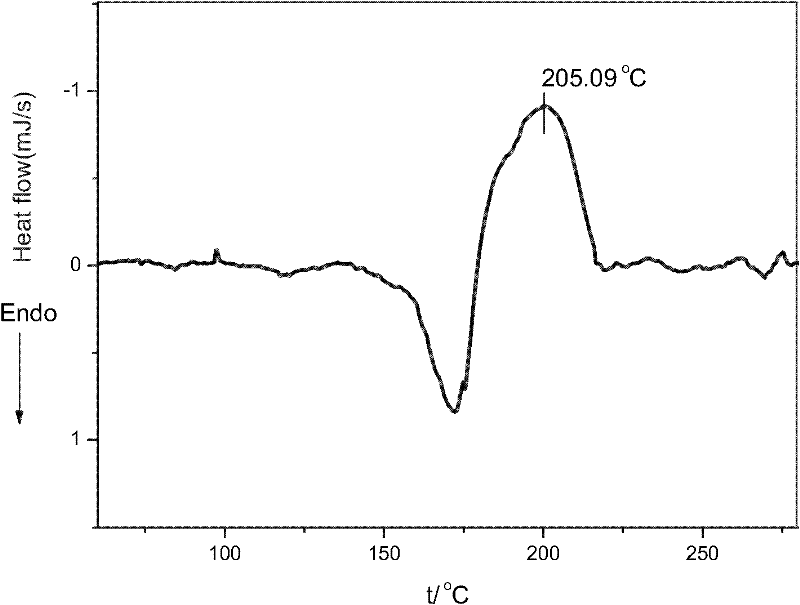

Benzoxazine colophony based on renewable resources, its composition and preparing method thereof

The invention relates to a kind of benzoxazine colophony whose materials come from renewable resources, its composition and preparing method. This kind of benzoxazine colophony is prepared with phenols stemmed from the renewable resources, such as eugenol, guaiacol and cardanol, and diamine stemmed from the renewable resources such as decamethylene diamine, and cavaform or triformol or formaldehyde liquid. The relevant composition is prepared with this kind of benzoxazine colophony and other heat-convertibleresin. The benzoxazine and its composition can be used in many fields such as coatings, thermosetting plastics, matrix colophony of composite materials and so on.

Owner:BEIJING UNIV OF CHEM TECH

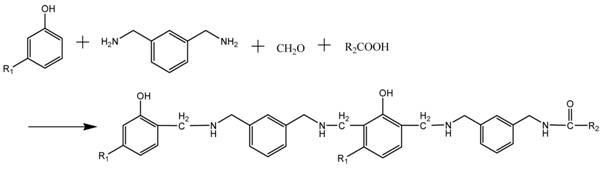

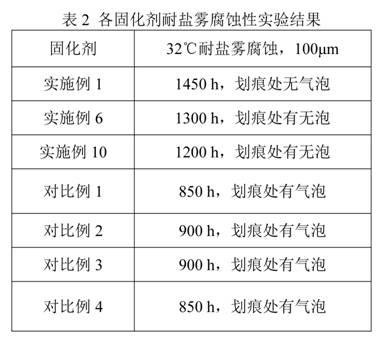

Alkylphenol modified phenolic amide curing agent and preparation method thereof

ActiveCN102633991AStrong resistance to salt spray corrosionHigh impact strengthOrganic compound preparationCarboxylic acid amides preparationAlkylphenolPerylene derivatives

The invention discloses an alkylphenol modified phenolic amide curing agent and a preparation method thereof. The alkylphenol modified phenolic amide curing agent comprises the raw components including phenol or phenol derivatives, methanal or paraformaldehyde, polyamine and fatty acid or fatty acid polymer. The preparation method comprises the following steps of: uniformly mixing the fatty acid or the fatty acid polymer and the polyamine, heating the mixture, cooling the mixture, adding the phenol or the phenol derivatives in the mixture, uniformly mixing the methanal or the paraformaldehyde with the mixture, heating the new mixture, and performing dehydration on the new mixture to obtain the product; or the preparation method comprises the following steps of: uniformly mixing the phenol or the phenol derivatives, the polyamine and the methanal or the paraformaldehyde, heating the mixture, adding the fatty acid or the fatty acid polymer into the mixture, heating the new mixture, and performing the dehydration on the new mixture to obtain the product. The curing agent disclosed by the invention is very strong in salt spray corrosion resistance, is superior to polyamide curing agent and curing agent products of modified phenolic aldehyde amide resin and mixtures of the modified phenolic aldehyde amide resin, and has good impact strength and flexibility as well as excellent water tolerance.

Owner:CARDOLITE CHEM ZHUHAI

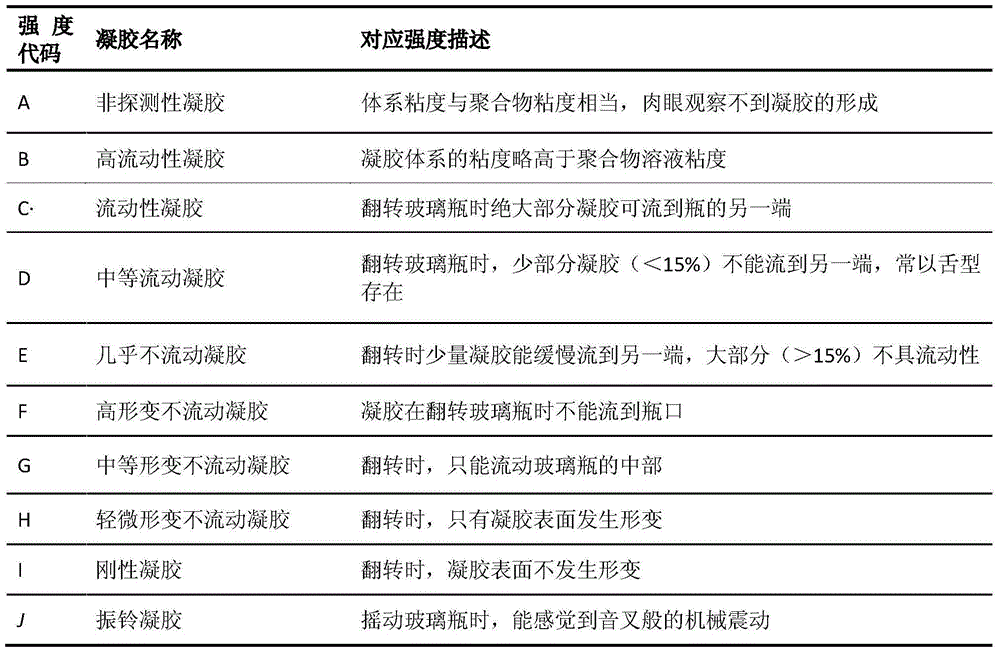

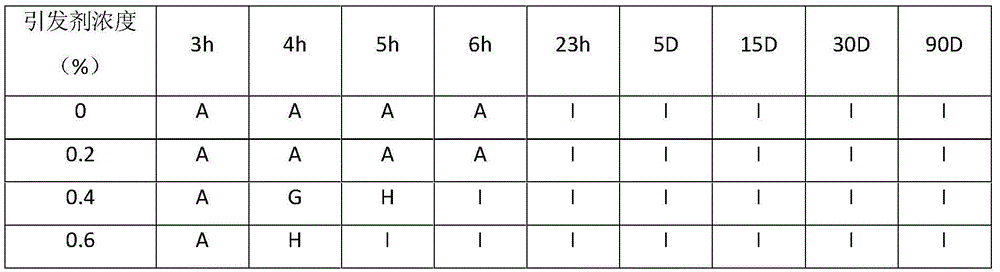

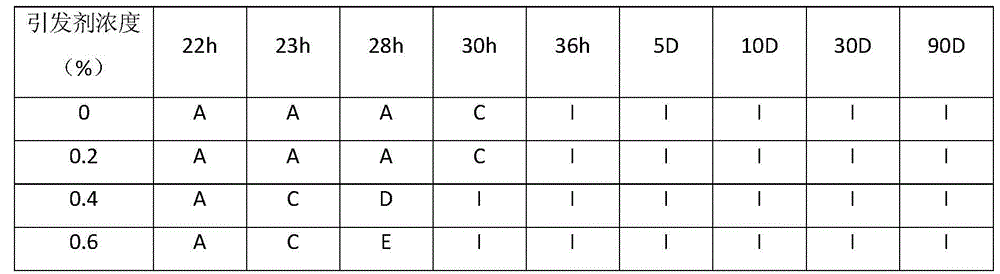

Temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel

The invention discloses temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel which mainly consists of, by mass, main agent 4%-6%, cross-linking agent 1%-2% and the balance saline water. The main agent consists of a monomer A and a monomer B, wherein the monomer A is acrylamide, and the monomer B is ester matter. The cross-linking agent is one of or a mixture of two or more formaldehyde, phenolic resin, resorcinol, hexamethylene tetramine, paraformaldehyde and polyethyleneimine. The temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel spontaneously produces cross-linking polymerization under the condition of high temperature, an initiator is not added, the gelling time can be controlled to be 2 hours to 28 hours at the temperature of 120 DEG C, the water plugging gel can be directly prepared by high-salinity water, the gelling strength can be up to the visual inspection code level I, and synaeresis does not occur after 90 days. The temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel is low in initial viscosity, has the advantages of being few in components, good in instant solubility and pumping injection performance, high plugging strength, good in thermohaline stability, low in cost and the like and has wide application prospect on the aspect of high-temperature high-salinity oil reservoir profile control water plugging.

Owner:成都西南石大石油工程技术有限公司

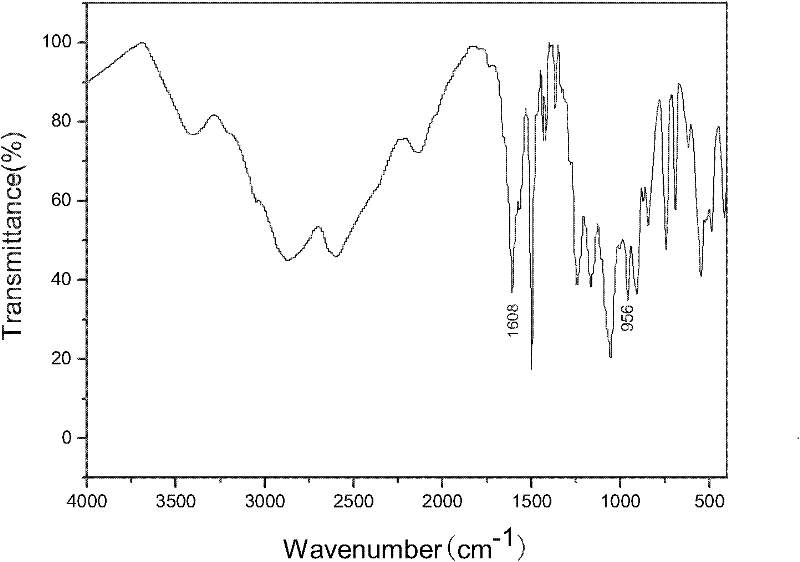

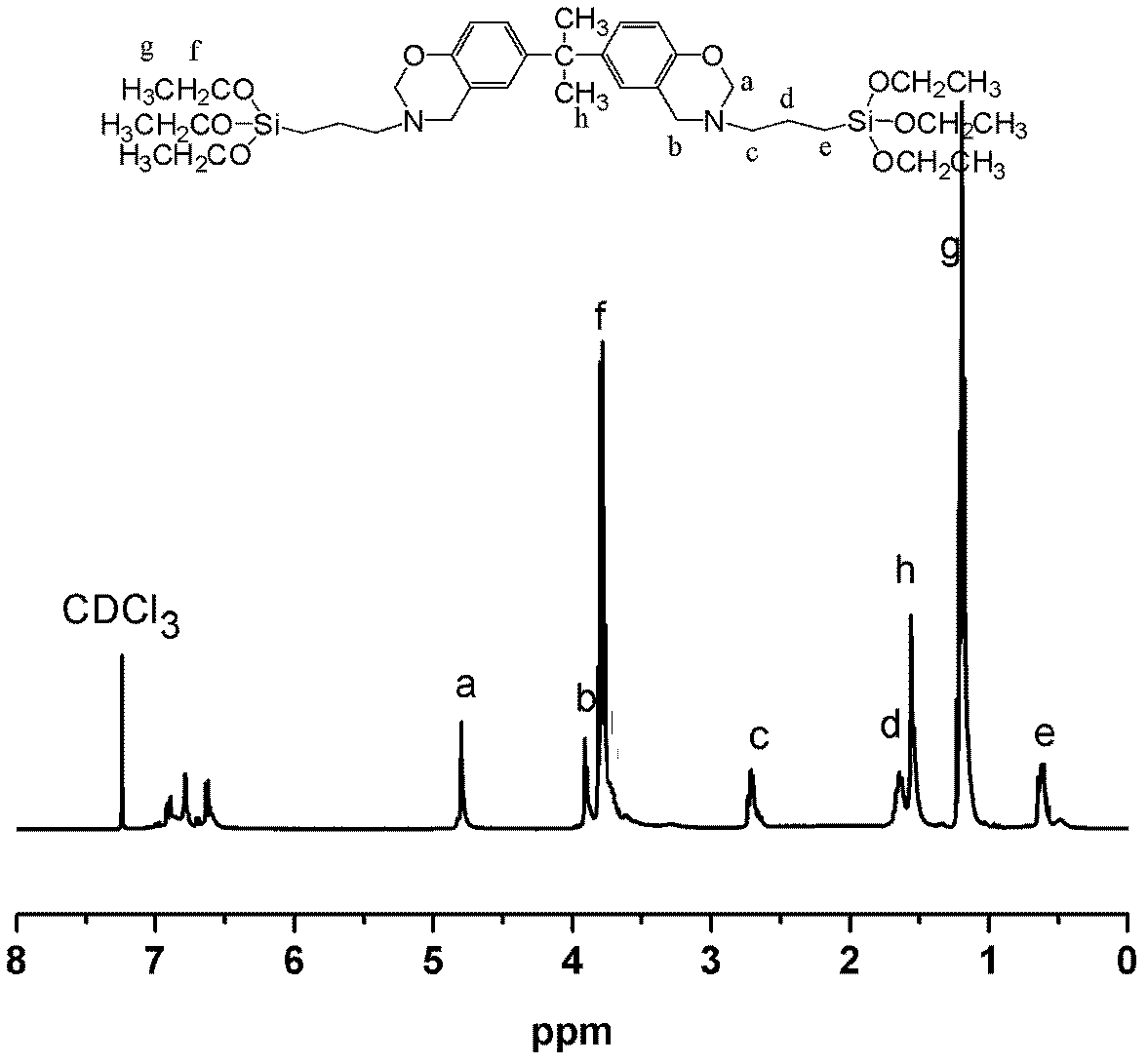

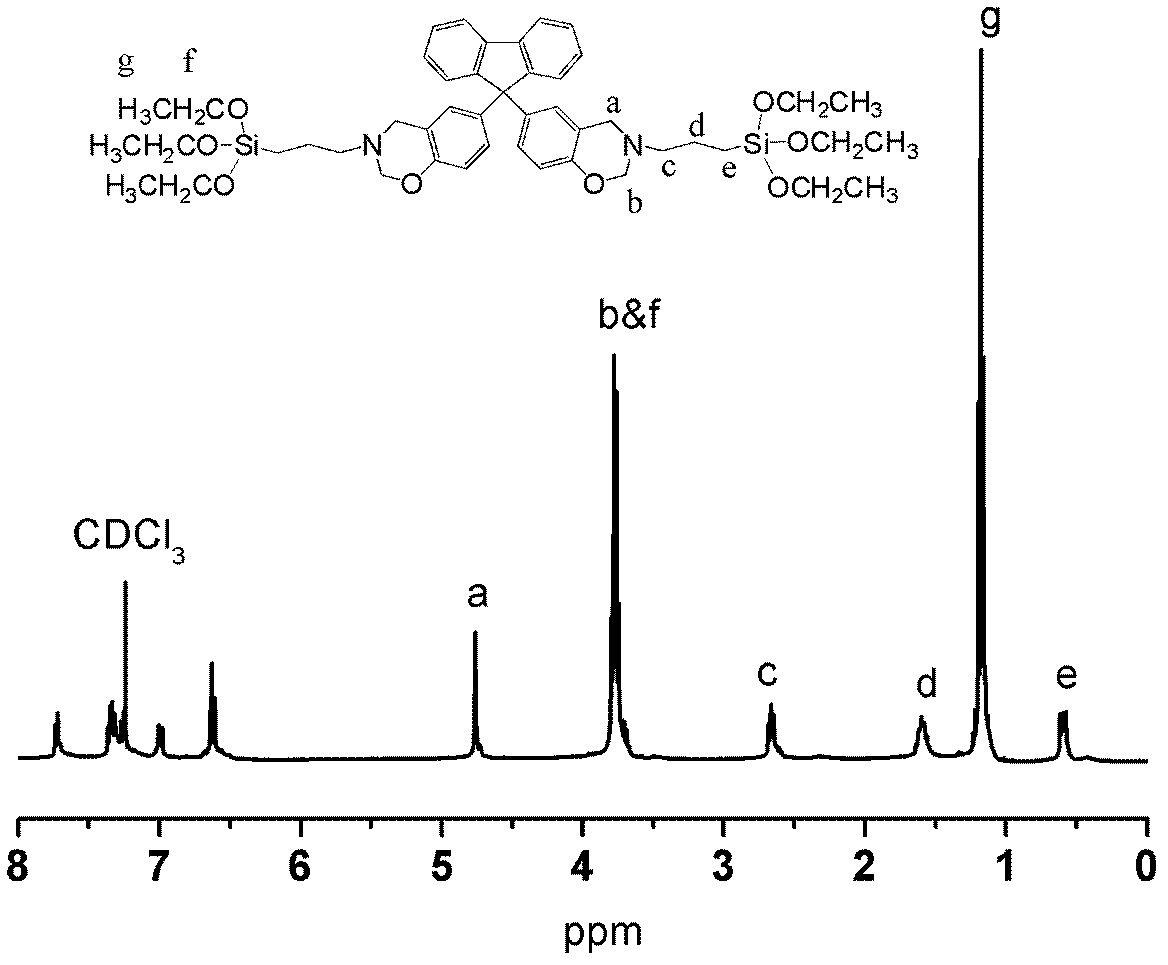

Benzoxazine monomer, benzoxazine precursor and low-dielectric benzoxazine resin

InactiveCN102584884AEasy to introduceEasy to processGroup 4/14 element organic compoundsCoatingsDielectricSolvent

The invention discloses a silicon-based benzoxazine monomer, a silicon-based benzoxazine precursor and low-dielectric silicon-based benzoxazine resin. An oily solvent, paraformaldehyde and an amino silane coupling agent are subjected to heating reflux reaction, so as to obtain the silicon-based benzoxazine monomer. The silicon-based benzoxazine monomer, an aqueous solvent and a catalytic agent are subjected to hydrolysis reaction, so as to obtain the silicon-based benzoxazine precursor. The silicon-based benzoxazine monomer or the silicon-based benzoxazine precursor is heated and cured gradually so as to prepare low-dielectric silicon-based benzoxazine resin. The low-dielectric silicon-based benzoxazine resin achieves low dielectric constant and high heat resistance; a great number of flexible cells are brought in molecular chains, so that the low-dielectric silicon-based benzoxazine resin achieves better toughness; and the low-dielectric silicon-based benzoxazine resin is a material with more excellent processing characteristics, mechanical properties, electric properties and heat resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

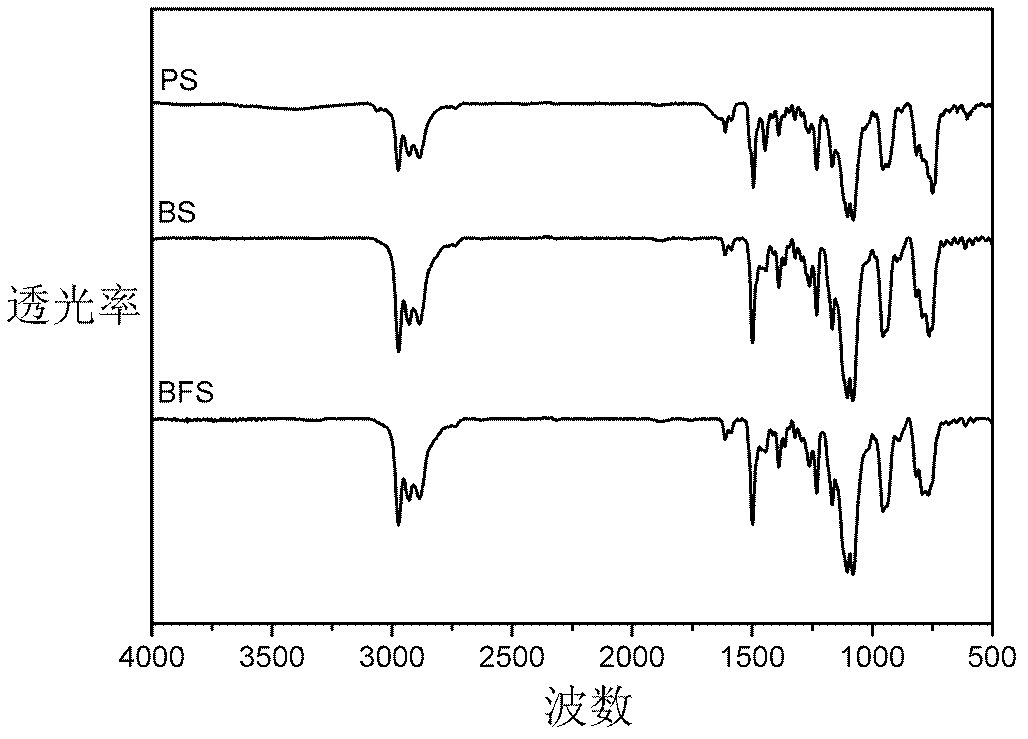

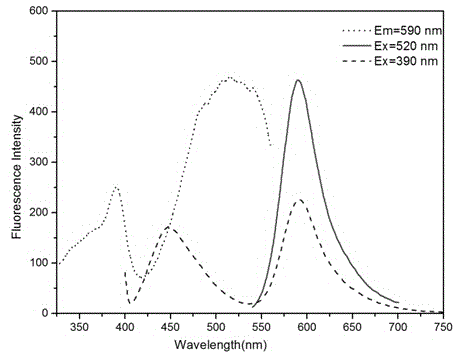

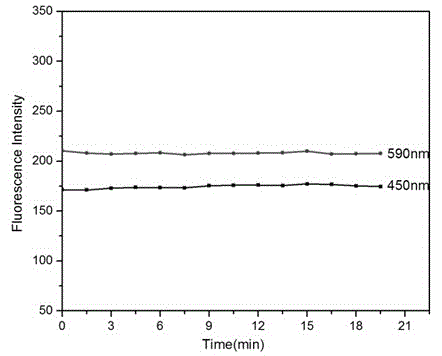

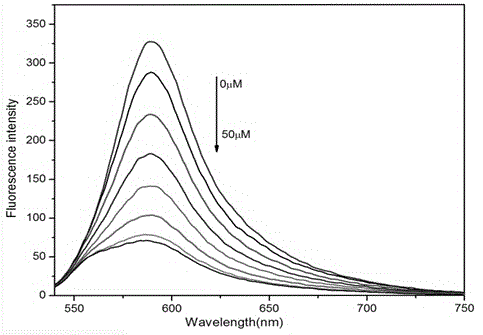

Visible and reversible ratiometric fluorescent probe as well as preparation method and application thereof

InactiveCN105038766ARealize qualitative and quantitative detectionGood linear relationshipOrganic chemistryFluorescence/phosphorescenceFluorescenceHand held

The invention discloses a visible and reversible fluorescent probe which comprises a cyanine fluorescent group and a benzothiazole group, and the general formula of the probe is shown in the description. The preparation method of the reversible fluorescent probe comprises the following steps: (1) dropwise adding phosphorus oxychloride into salicylaldehyde and paraformaldehyde for reaction, so as to obtain a product 1; (2) enabling the product 1 and hexamethylene-tetramine to react, so as to obtain a product 2; (3) enabling the product 2 and 2-aminobenzenethiol to react at the room temperature, so as to obtain a product 3; (4) enabling the product 3 and a compound 4 to react, so as to obtain the visible and reversible fluorescent probe. According to the ratiometric fluorescent probe provided by the invention, obvious color variation can be found out under natural light or an ultra-violet lamp, and the qualitative detection of sulfur dioxide gas can be implemented under natural light or a hand-held ultra-violet lamp, so that the operation is simple, high convenience and quickness are achieved, and the effect is remarkable; the fluorescent probe can effectively prevent interference from other impurities in samples, and is excellent in selectivity; in addition, the cumbersome pre-processing process of samples is avoided, so that the detection efficiency is high.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

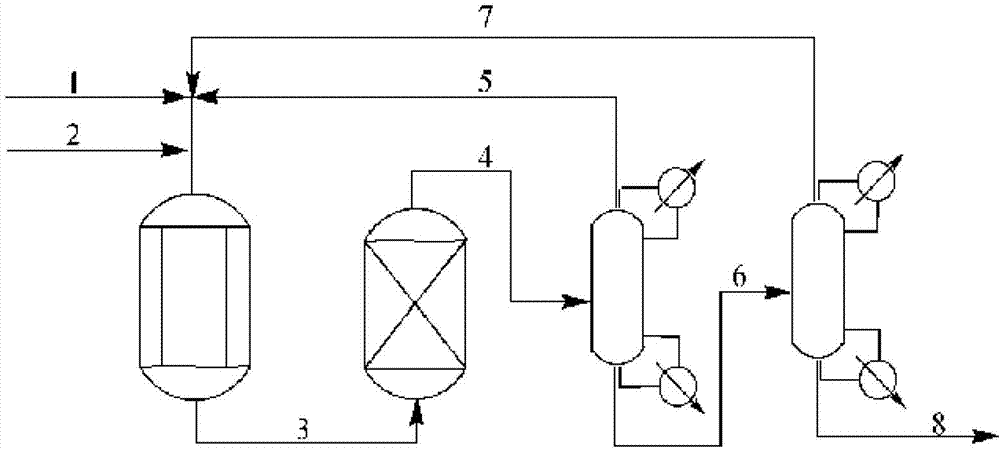

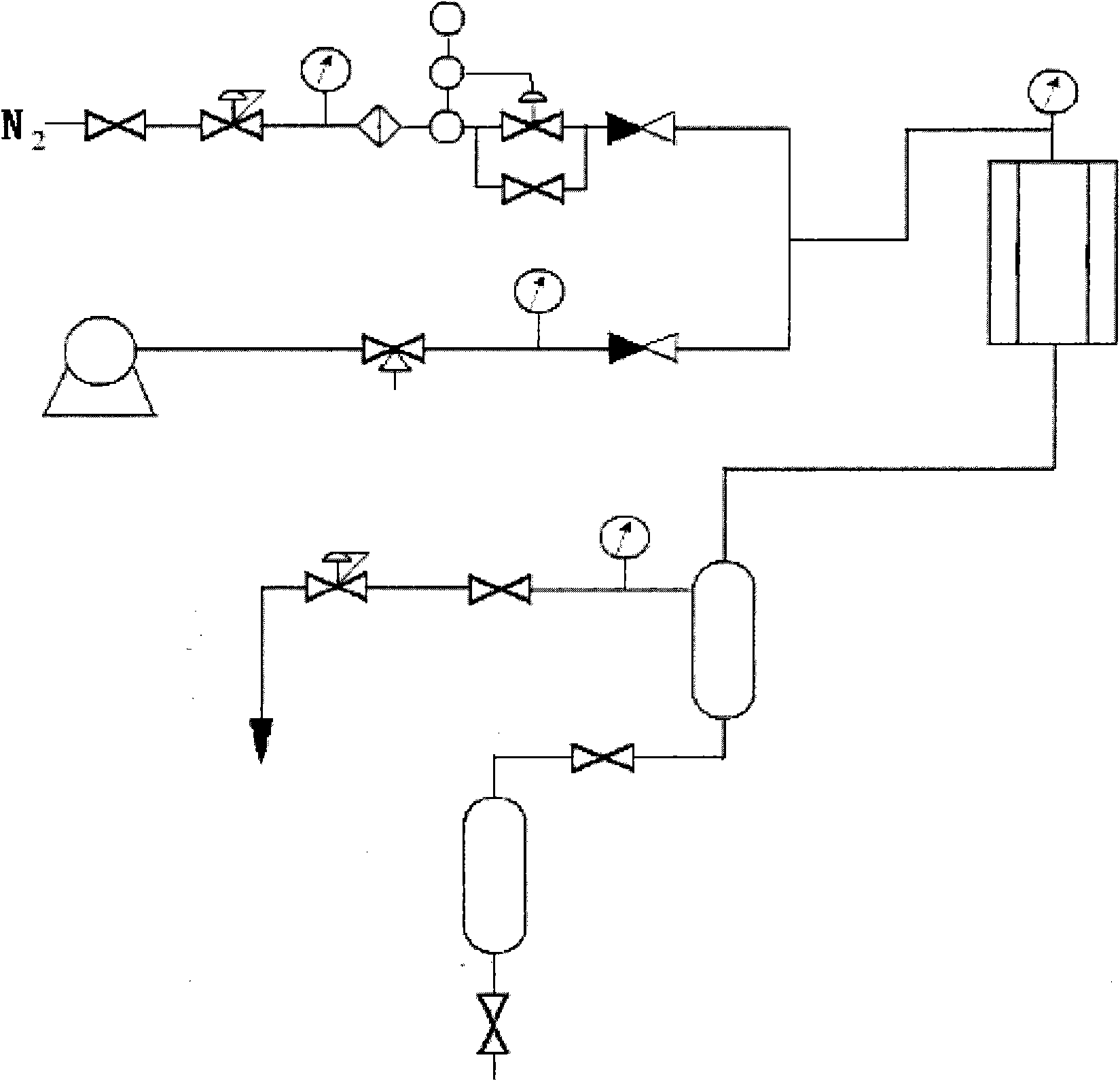

Combined process for preparing poly methoxy-dimethyl ether

InactiveCN103360224AEasy to separateEasy to use equipmentOrganic chemistryOrganic compound preparationSolid acidDimethoxymethane

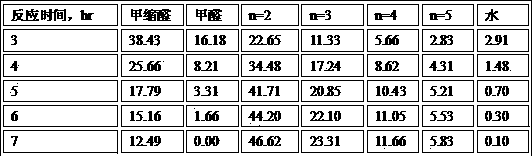

The invention relates to a combined process for preparing poly methoxy-dimethyl ether. According to the method, methylal and paraformaldehyde are used as reactants and a solid acid is used as a catalyst. The combined process comprises the following steps of feeding raw materials: adding the solid acid catalyst and solid paraformaldehyde in a reactor, then adding methylal in the reactor and stirring the above materials uniformly; meting and reacting: heating the reactor slowly and reacting for 2-6 hours by keeping a temperature within 100-200 DEG C and a pressure between 0.1 MPa and 2 MPa; dehydrating the reaction liquid: pumping the reaction liquid into a film separation and dehydration device at a flow velocity of 5-15 L / hr so as to remove water in a reaction mixture and send the water to the reactor; and circulating the reaction materials: circulating the reaction materials between the reactor and the film separation and dehydration device, dehydrating while reacting, and taking a sample for analysis every one hour until methylal is completely reacted. By the combined process, water generated during the reaction process is removed continuously, thereby allowing paraformaldehyde to be reacted completely and benefiting the separation of reaction products. The process is simple in use of apparatuses, reasonable in process flow and suitable for large-scale popularization.

Owner:DONGYING RUNCHENG CARBON MATERIAL TECH +1

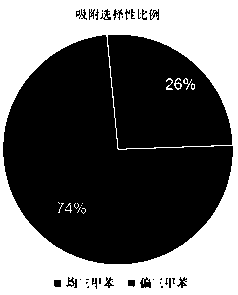

Synthetic method for polyoxymethylene dimethyl ether

ActiveCN103880614AEvenly distributedHigh adsorption potentialOrganic chemistryOrganic compound preparationActivated carbonReaction temperature

The invention relates to a synthetic method for polyoxymethylene dimethyl ether, and mainly overcomes the problem of relatively high cost in a conventional method for synthesizing polyoxymethylene dimethyl ether by using trioxymethylene as a raw material. The synthetic method takes use of methanol, methylal and paraformaldehyde as raw materials, wherein a mass ratio of methanol to methylal to paraformaldehyde is 0-10 : 0-10 : 1; and the usage amount of methanol and methylal is not zero at the same time; and the raw materials are contacted with a catalyst under a reaction pressure of 0.2-6 MPa to produce polyoxymethylene dimethyl ether (CH3O(CH2O)nCH3), wherein the used catalyst is selected from activated carbon. By adopting the above technical solution, the problem is overcome relatively well; and the synthetic method can be used for industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of modified phenolic resin with high boron content

Production of modified phenolic resin of high-boron content is carried out by reacting boric acid with carbolic acid to generate boric acid ester by two-step method, reacting boric acid ester with paraformaldehyde to obtain final product. It is simple, controllable and quantitative, has higher boron content, excellent thermal, mechanical, friction and anti-corrosive performances. It can be used for high-temperature brake friction material, anti-corrosive materials and special thermal-insulating material.

Owner:TONGJI UNIV

High-temperature-resistant and high-salinity-resistant water-plugging profile control agent, and preparation method and application thereof

ActiveCN102533233ABreak usabilityBreak the limitationsFluid removalDrilling compositionBenzaldehydeCyclodextrin

The invention relates to a high-temperature-resistant and high-salinity-resistant water-plugging profile control agent, and a preparation method and application thereof. The water-plugging profile control agent comprises polyacrylamide, a composite crosslinking agent, cyclodextrin, metaphenylene diamine and deoxidant, wherein the composite crosslinking agent consists of aldehyde, phenol and aluminum citrate; the aldehyde is one or the combination of benzaldehyde and paraformaldehyde; and the phenol is one or more of phenol, resorcinol and hydroquinone. The water-plugging profile control agent can resist the temperature of 120 DEG C, can be directly prepared by using water with mineralization degree of 150,000 mg / L, and has high crosslinking performance and long-term stability. The preparation method for the water-plugging profile control agent is simple, convenient to operate, and easy to control, and water-plugging profile control agent has a good plugging effect, and construction can be performed after the water-plugging profile control agent is directly prepared on site.

Owner:PETROCHINA CO LTD

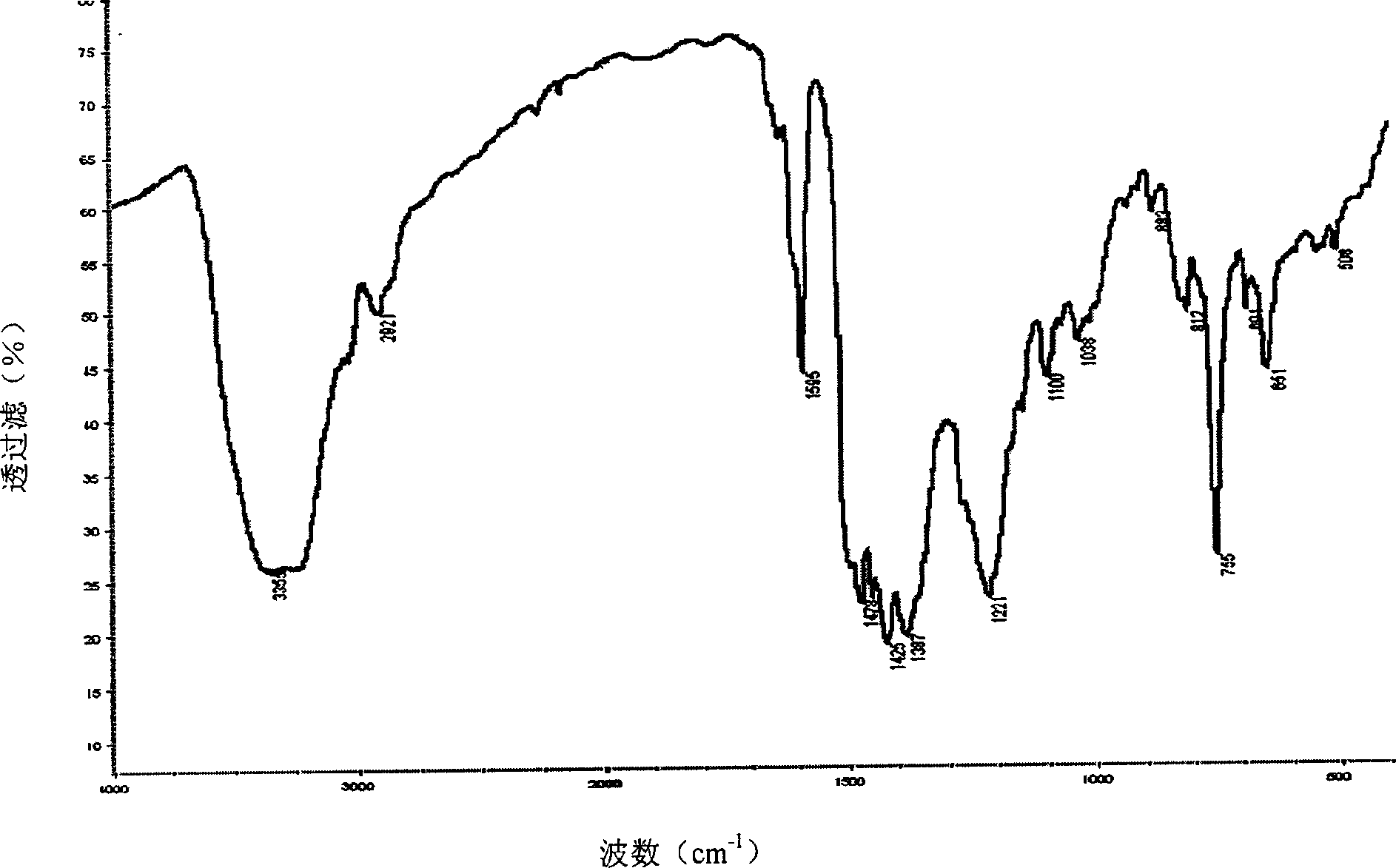

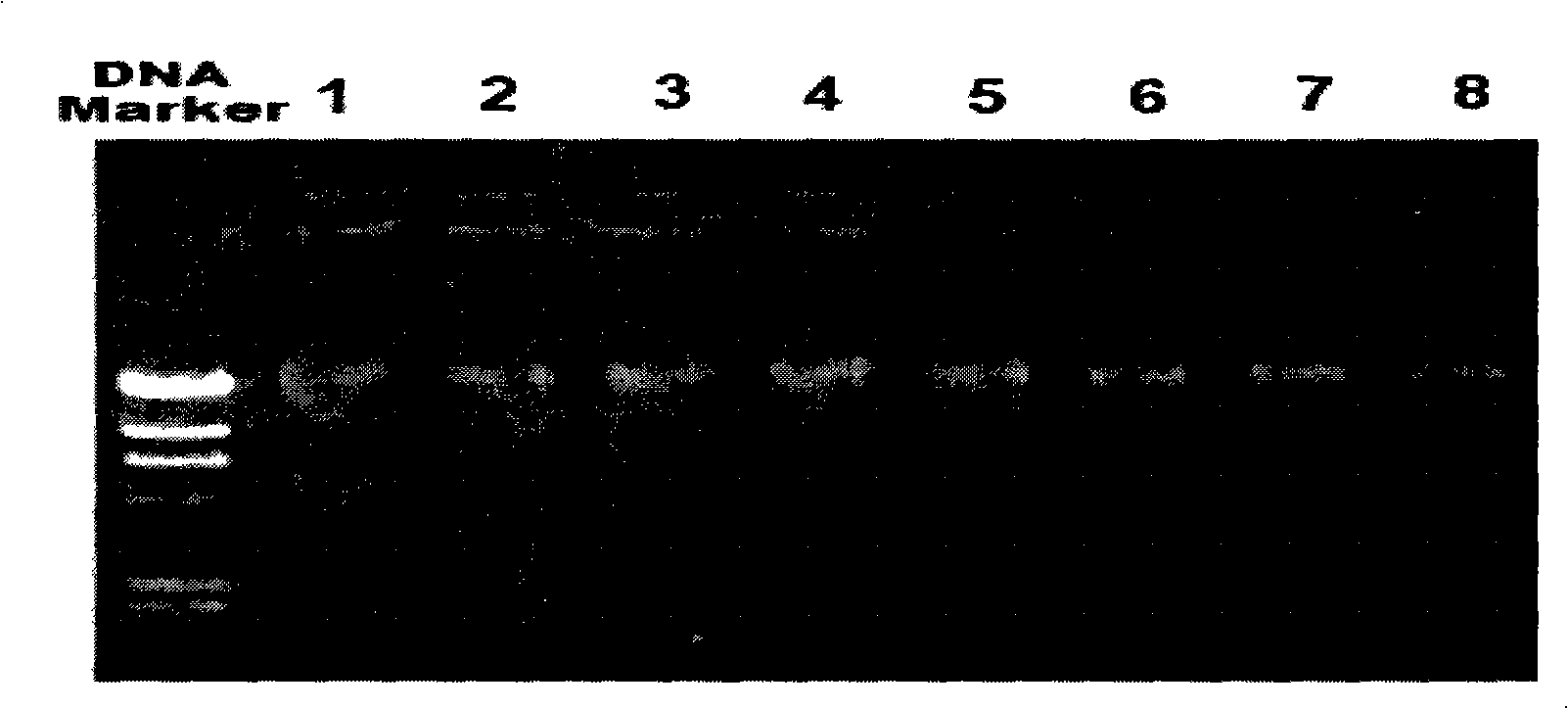

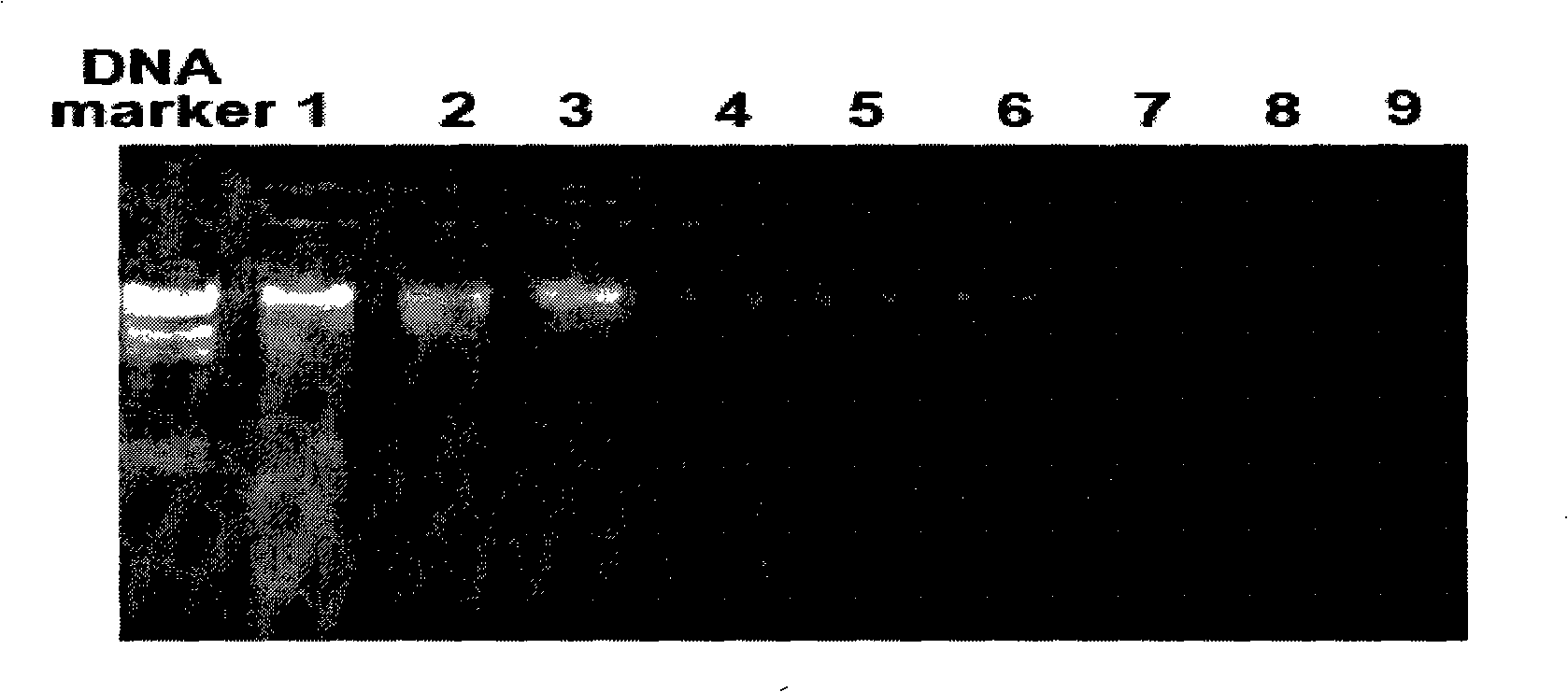

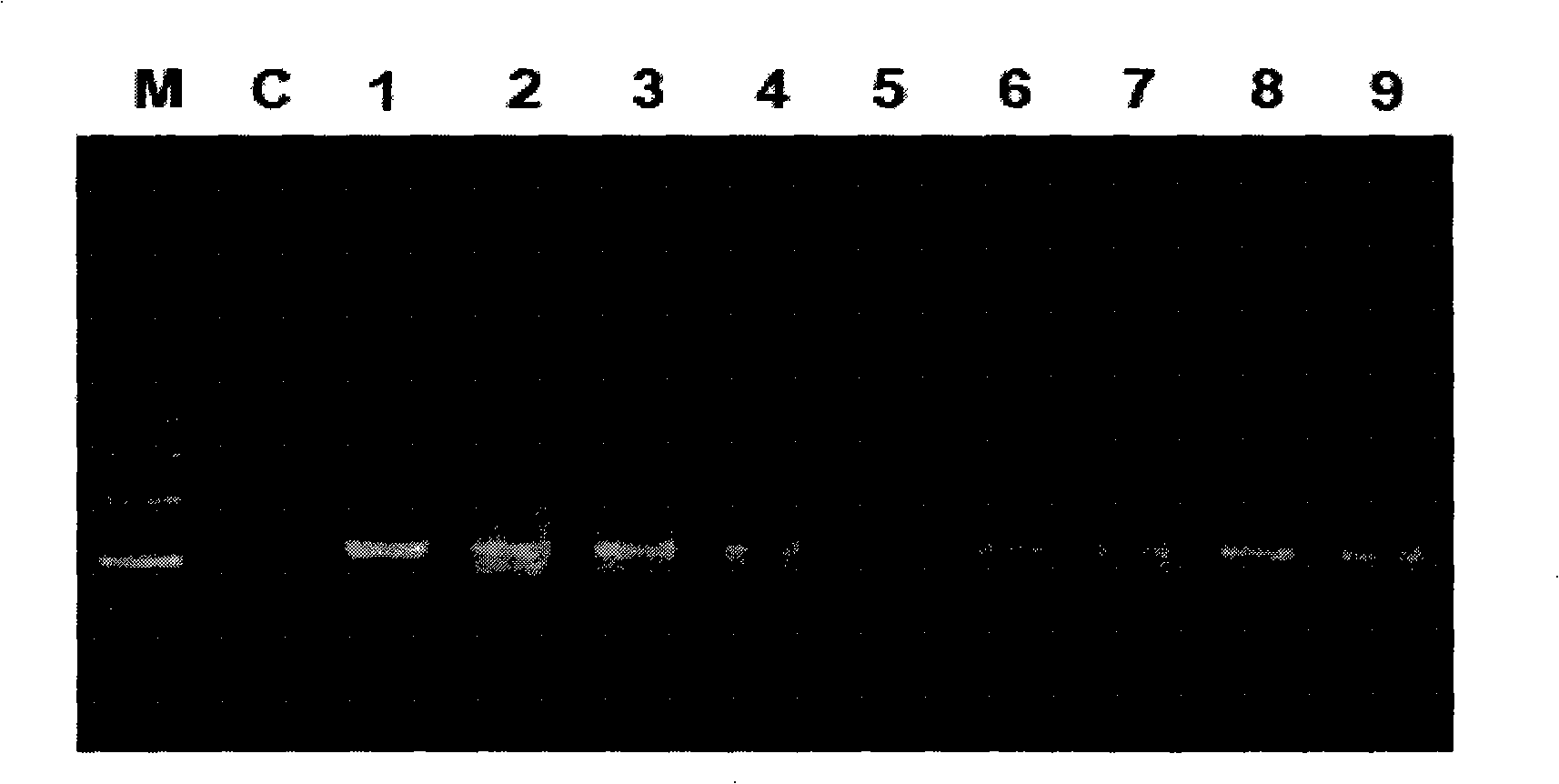

Process for abstracting total DNA of swine waste sample

The invention relates to the microbiology and molecular biology technical field, in particular to a method for extracting pig manure sample total DNA. The method mainly comprises manure sample pretreatment and sample total DNA extraction. Moreover, the method comprises the following steps that: collected fresh manure sample or frozen manure sample is taken as a material; the pretreatment of the manure sample is carried out by means of a PBS buffer solution, a paraformaldehyde solution and anhydrous alcohol so as to obtain manure sample bacteria suspension; and a CTAB solution and beta-mercaptoethanol, etc. are used to carry out cell fragmentation, thereby releasing DNA. The method has the characteristics of simple operation, quickness, high efficiency and ideal repeatability and economical efficiency, etc.; moreover, the extracted DNA has high concentration, purity and yield, and can be directly used in subsequent molecular biology experimental researches such as PCR amplification without purification.

Owner:SICHUAN UNIV

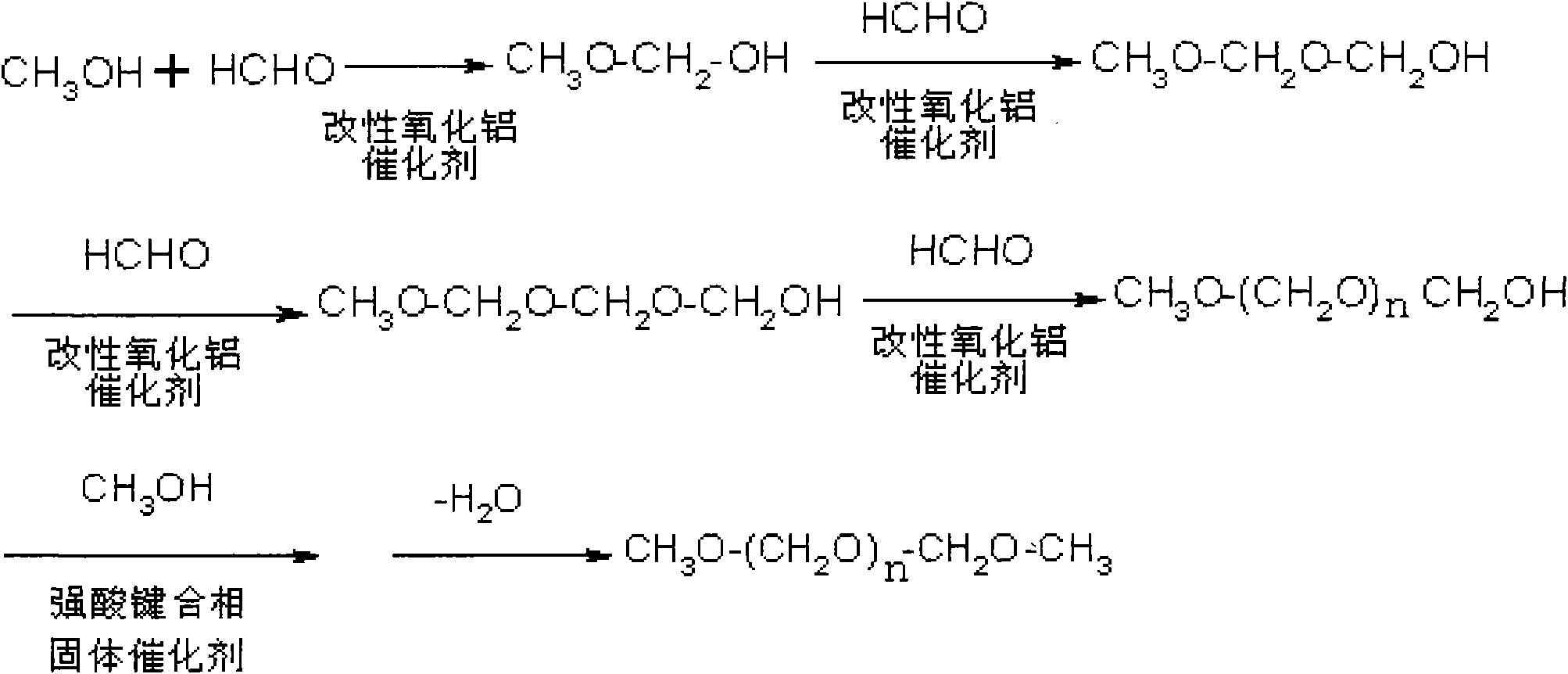

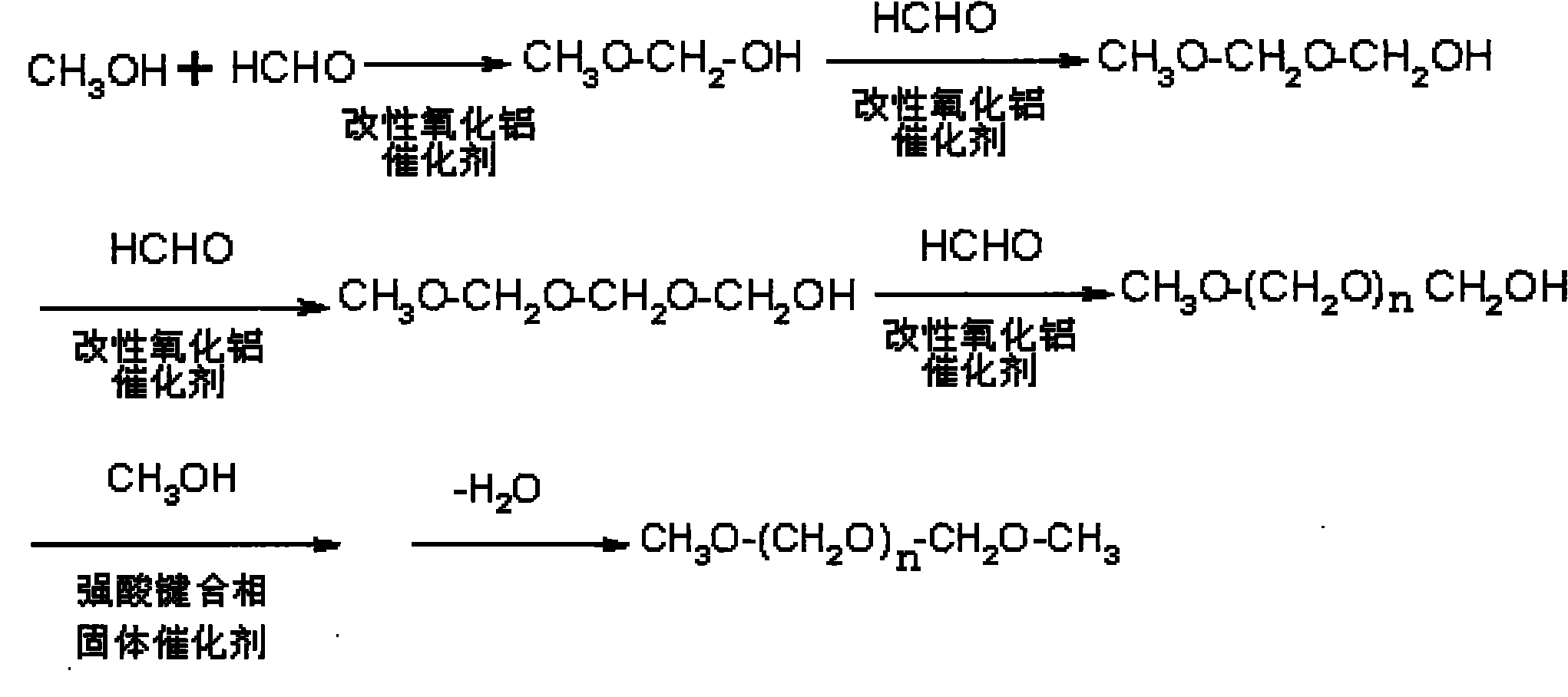

Method for synthesizing polyoxymethylene dimethyl ethers

ActiveCN101898943AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationSynthesis methodsStrong acids

The invention relates to a method for synthesizing polyoxymethylene dimethyl ethers, comprising the following steps: step one, generating hemiacetal by methanol and excessive methanal or paraformaldehyde with low polymerization degree under the existence of a modified alumina catalyst, reacting the hemiacetal with methanal to generate hemiacetal with one more carbon, and successively continuing the above steps to generate poly-hemiacetal with more carbon atoms; and step two, generating the polyoxymethylene dimethyl ethers by the poly-hemiacetal mixture under the existence of methanol and an organic strong acid bonded phase solid catalyst. The invention can achieve the technical targets of improving raw material conversion rate, product selectivity, target product yield and economical efficiency by the two steps of reaction process, adjusts the space velocity by a fixed bed continuous reactor and combines with a catalyst to control the polymerization degree. The synthesis method in the invention has mild reaction conditions and easy control.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

A method for immunofluorescence staining of suspension cells

InactiveCN102288471AGood dyeing resultPreparing sample for investigationImmunofluorescenceFluorescent staining

The invention relates to an immunofluorescence staining method for suspension cells. The immunofluorescence staining method for the suspension cells is characterized by comprising the following steps of: collecting cells into a centrifuge tube; performing 800-gram centrifugation to collect the cells; respectively adding paraformaldehyde to fix, Triton-X100 to pass through and 1 percent bovine serum albumin (BSA) to close; adding a primary antibody and a secondary antibody sequentially to incubate; washing by an 800-gram centrifugation method after the operation of each step; performing diamino phenyl indole (DAPI) staining; and dripping on a glass slide and closing the glass slide to observe. The immunofluorescence staining method for the suspension cells has the advantages that: the immunofluorescence staining process is performed in the centrifuge tube, so the problems that the suspension cells grow on the glass slide difficultly and drop off easily in the test process are solved; the staining result is good; and the method is suitable for the suspension cells and cells which are adhered to the wall difficultly.

Owner:RENJI HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

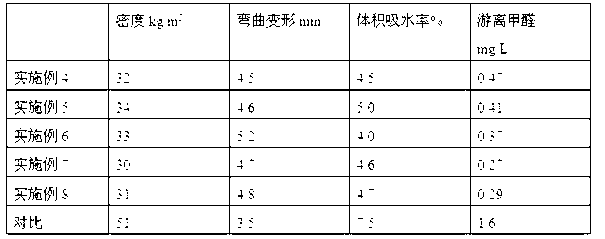

Preparation method of flame-retardant melamine hard foam

The invention belongs to the technical field of macromolecular foam materials, and in particular relates to a preparation method of flame-retardant melamine hard foam. The method comprises the steps of performing reaction on melamine and paraformaldehyde according to a mole ratio of 1:(1.5 to 3.5), melamine and a modifier I according to a mass ratio of 1:(0.1 to 0.6) and alcohol serving as a solvent under a water bath of 75 DEG C till the materials are clarified and transparent, adding a modifier II and melamine into resin according to a mass ratio of (0.05 to 0.2):1, continuously performing reaction for 0.5-2 hours, removing the solvent, and adjusting the solid content by water to 85-92 percent to obtain a foam prepolymer. The flame-retardant melamine hard foam prepared by the preparation method disclosed by the invention has the advantages of high compressive strength, high closing rate, excellent flame retardancy and the like, cannot enable powder to fall off and can be applied to the air conditioner air pipe, laminboard and external wall heat preservation material markets.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

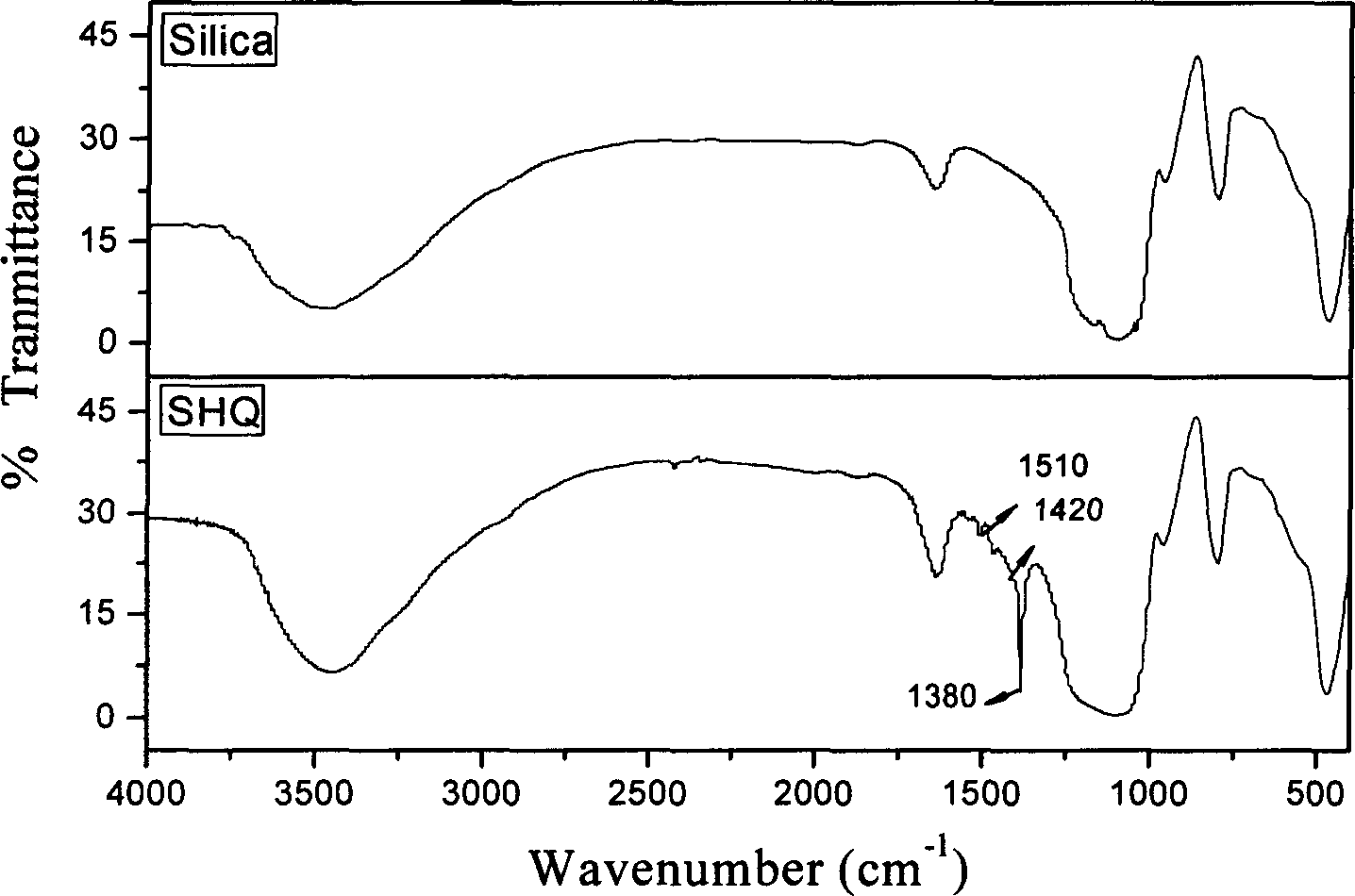

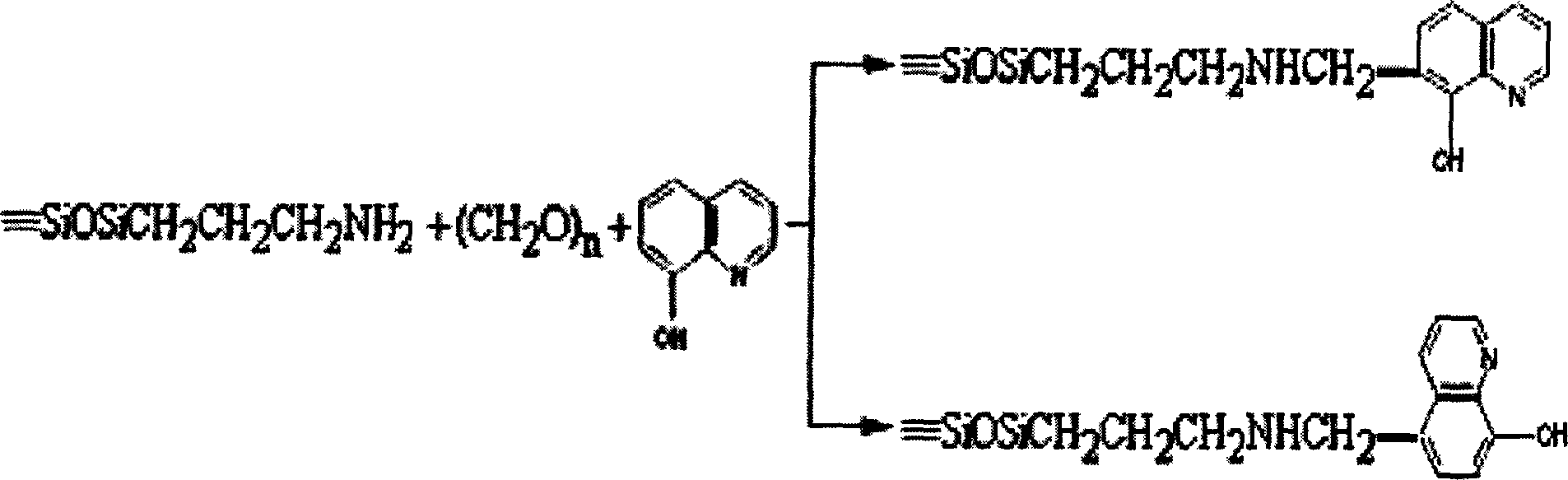

8-hydroxy quinoline type chelated resin and its synthesis

InactiveCN1772386AImprove rigidityImprove the coordination effectComplex ion-exchangersIndustrial waste waterQuinoline

The 8-hydroxy quinoline type chelated resin has 8-hydroxy quinoline fixed onto macroporous silica gel through silanizing reagent and paraformaldehyde as spacer arm and bonding amount of 120-542 umol / g. Its synthesis process includes the steps of: pre-treating macroporous silica gel; introducing spacer arm; fixing ligand and acid washing to set via drying intermediate product II, washing with alcohol and drying for several times, washing with hydrochloric acid, and washing with deionized water to neutral so as to obtain yellow chelated resin. The resin has simple synthesis process, mild reaction condition, short synthesis time, easy control, high synthesis efficiency, low cost, high rigidity and high metal ion complexing capacity, and may be used in on-line enriching analysis of trace metal, enriching recovery of noble metals, purifying industrial waste water, etc.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O

InactiveUS20080009635A1Improve reaction speedReduce yieldOrganic chemistryHydrocarbon solventsAcetic acid

A one-pot industrial process for preparing 1,2,3,9-tetrahydro-9-methyl-3-[(2-methyl-1H-imidazole-1-yl)methyl]-4H-carbazol-4-one of Formula-(I) from 1,2,3,9-tetrahydro-9-methyl-4H-carbazol-4-one of Formula-(IV) involves reaction of Formula (IV) with HNR1R2 salt and paraformaldehyde, where R1,R2 are independently alkyl groups or together forms a cyclic alkyl group, in a solvent system of acetic acid and hydrocarbon solvent to form a crude mixture of intermediate compounds of Formula (III) and (VIII), which is converted to ondansetron (Formula (I)) without isolation by reaction with 2methyimidazole in a suitable solvent system in the same pot.

Owner:IPCA LAB LTD

Catalyst for synthesizing acrylic acid (ester) by taking formaldehyde and acetic acid as raw materials and preparation method thereof

ActiveCN103611522AReduce typesReduce contentMolecular sieve catalystsOrganic compound preparationPositive pressureReaction temperature

The invention provides a catalyst for synthesizing acrylic acid (ester) by taking formaldehyde and acetic acid as raw materials and a preparation method thereof. The method is characterized by comprising the following steps: 1, selecting one or more than one oxide of cesium (Cs), barium (Ba), strontium (Sr), magnesium (Mg), antimony (Sb) and bismuth (Bi) according to the fact that the selected oxide accounts for 2% to 30% of total mass of a carrier, and selecting one or more than one oxide of vanadium (V), phosphorus (P) and molybdenum (Mo) as an auxiliary agent according to the fact that the selected oxide accounts for 0.1% to 20% of total mass of the carrier; 2, selecting gamma-Al2O3, SiO2 or a molecular sieve as the carrier of the catalyst; and 3, depolymerizing paraformaldehyde in methanol, ethanol, isopropyl alcohol and the like by using sodium hydroxide or potassium hydroxide, adding the depolymerization solution of the paraformaldehyde into the acetic acid according to the acid-aldehyde molar ratio being 2-6, evenly mixing the mixture and then directly pumping the mixture into a reaction kettle through a sample injection pump; and performing catalytic synthesis at a reaction temperature within 200 DEG C to 400 DEG C and under the micro-positive pressure by using a fixed bed reaction device for synthesizing the acrylic acid (ester). The two target products, namely, the acrylic acid and the corresponding ester, are contained in the synthesized catalyst under a proper condition, wherein the total yield of the acrylic acid (ester) can reach more than 35%; and the by-product is less in variety and low in content. The catalyst is low in cost and environment-friendly by taking the formaldehyde and the acetic acid as the raw materials. The catalyst applied to an acrylic acid (ester) synthesis technology is simple in process and easy to industrialize.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

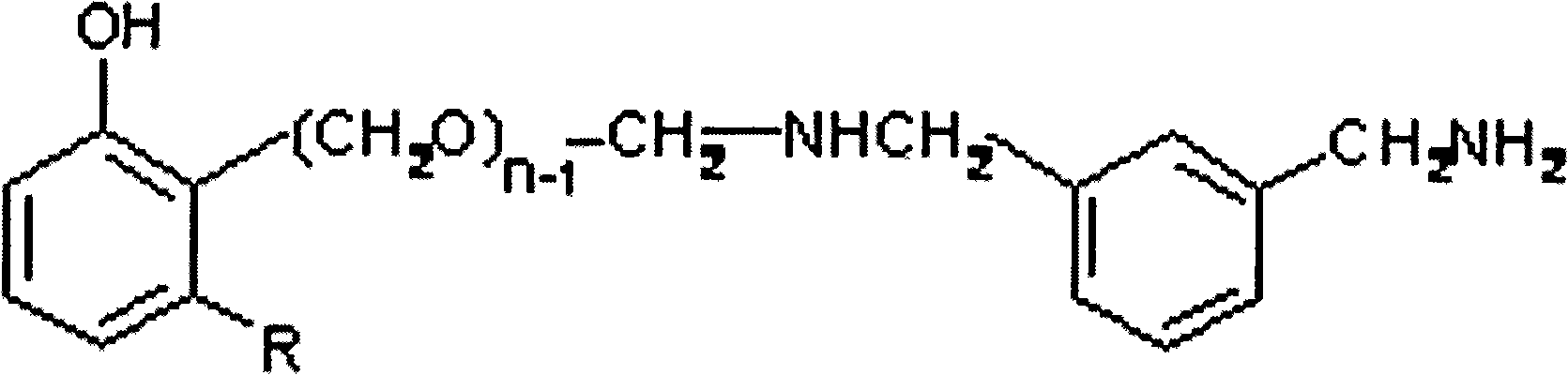

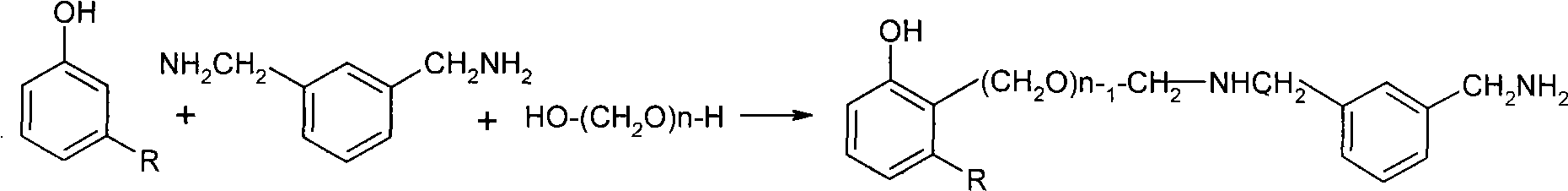

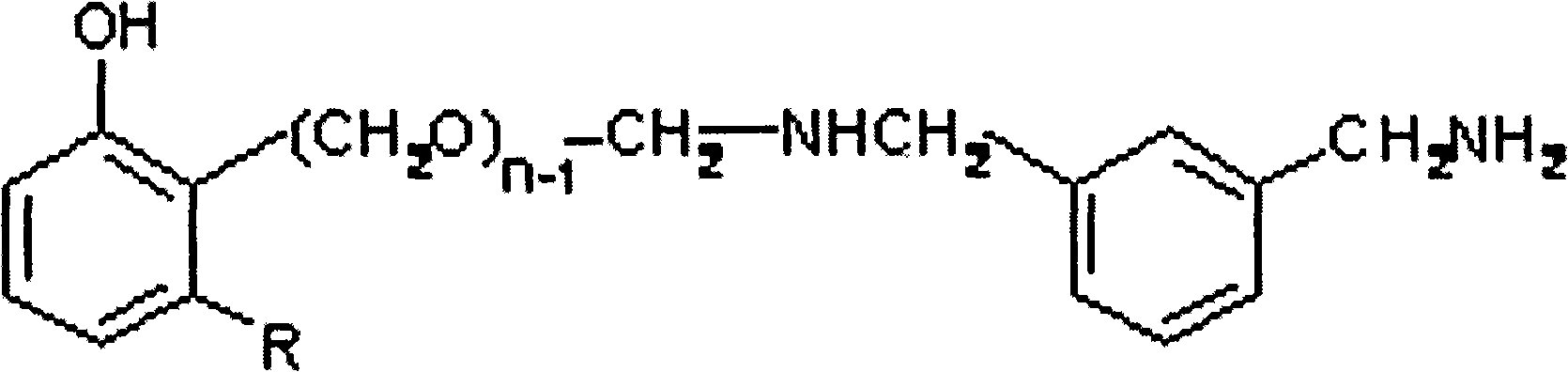

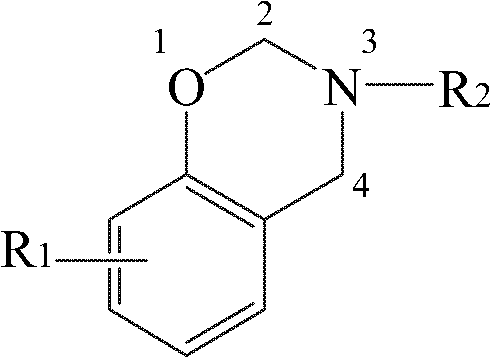

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

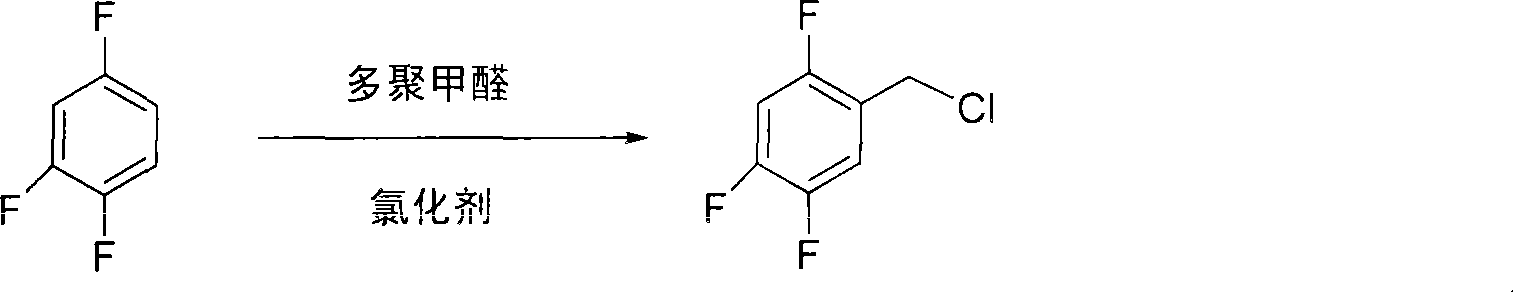

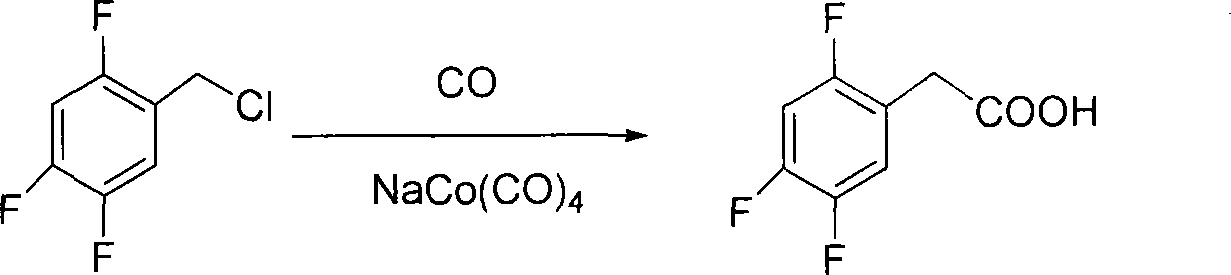

Method for preparing 2,4,5 trifluorobenzene acetic acid

ActiveCN101092345ALow priceFew reaction stepsCarboxylic preparation from carbon monoxide reactionAcetic acidPtru catalyst

This invention provides a method for preparing 2, 4, 5-trifluorophenylacetic acid. The method comprises: (1) reacting 1,2,4-trifluorobenzene and chlorinating agent in paraformaldehyde to obtain 2,4,5-trifluorobenzyl chloride; (2) performing carbonylation reaction with CO in the presence of catalyst to obtain 2,4,5-trifluorophenylacetic acid. The catalyst is alkali cobalt tetracarbonyl. The method has such advantages as few reaction procedures, and mild reaction conditions, and is suitable for industrial production of 2, 4, 5-trifluorophenylacetic acid.

Owner:ZHEJIANG YONGTAI TECH CO LTD

Cardanol modified phenolic aldehyde foam and preparation method thereof

The invention discloses cardanol modified phenolic aldehyde foam and a preparation method of the cardanol modified phenolic aldehyde foam. The cardanol modified phenolic aldehyde foam is prepared by the following materials in parts by weight: 100 parts of a cardanol modified phenolic aldehyde resin, 4-7 parts of a surfactant, 6-10 parts of a foaming agent and 15-20 parts of a curing agent, wherein the cardanol modified phenolic aldehyde resin is a phenolic aldehyde resin obtained by performing a first step of reaction on cardanol and liquid formaldehyde under a basic catalyst condition, then, adding phenol and paraformaldehyde, and performing a second step of reaction under the basic catalyst condition, and at last, adding a hydroxymethylurea resin to react. According to the preparation method, on the basis of not affecting the heat conductivity coefficient and high fire resistance of the phenolic aldehyde foam, the density, water absorption and free formaldehyde of phenolic aldehyde foam plastic are reduced by the cardanol, the tenacity of phenolic foam is improved, and meanwhile, renewable plant resources are adequately used. The cardanol modified phenolic aldehyde foam can be used as a building heat-insulation, heat-preservation and fire-proof material, and is a product with good market prospect.

Owner:北京傲德新材料科技有限公司

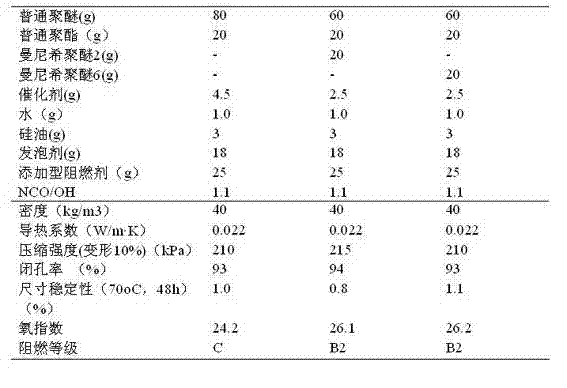

Preparation method and applications of reaction type Mannich polyether polyol with permanent flame retardant effect

The invention provides a preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect. The preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect comprises the following steps: reacting paraformaldehyde or formaldehyde solution with diethanol amine to obtain 3-ethoxyl-1,3-oxazolidine reaction liquid, and then carrying out reduced pressure distillation to obtain the product 3-ethoxyl-1,3-oxazolidine; reacting aromatic phenol compounds or / and melamine compounds with 3-ethoxyl-1,3-oxazolidine to obtain Mannich base as intermediate; and carrying out polymerization reaction between the intermediate Mannich base and epoxy compound to obtain crude product of reaction type Mannich polyether polyol with permanent flame retardant effect, then carrying out reduced pressure distillation to remove impurities with low boiling points, and thus obtaining finished product. The reaction type Mannich polyether polyol simultaneously has the high stability and thermal stability of rigid polyurethane foam and the flame resistance of phenolic foam, is applied to foaming rigid polyurethane foam, and has wide application prospect.

Owner:JIANGSU YOKE TECH

Macrocyclic and cage-like molecules based on biphenylarene and derivatives of macrocyclic and cage-like molecules as well as synthetic methods and applications of macrocyclic and cage-like molecules and derivatives

ActiveCN110642684AAchieving Modular SynthesisEasy to take offIon-exchanger regenerationOrganic chemistry methodsPorphyrinPhenyl group

The invention discloses macrocyclic and cage-like molecules based on biphenylarene and derivatives of the macrocyclic and cage-like molecules as well as synthetic methods and applications of the macrocyclic and cage-like molecules and the derivatives. A series of novel macrocycles are obtained mainly by performing a reaction on bis(2,4-dialkoxyphenyl)arenes (naphthalene, anthracene, pyrene, porphyrin and the like) or tris(2,4-dialkoxyphenyl)arenes (benzene, sym-tribenzobenzene) and paraformaldehyde under the catalysis of a Lewis acid in high yield. In addition, perhydroxybiphenylarenes (quaterphenyl trimer, naphthalene dimer and the like) can be obtained by performing demethylation, a plurality of water-soluble derivatives can be obtained by performing further modification, and the derivatives show good bonding ability to guest molecules (viologen and the like); and moreover, functional groups introduced into the framework make the biphenylarene have excellent adsorption and separationability and photophysical properties. The compounds, derivatives and methods provided by the invention have the following advantages: raw materials of the biphenylarene are commercially available, the synthesis is simple and convenient, the yield is high, and the modification is convenient, so that the compounds and the derivatives have broad application prospects in gas adsorption and separation, performance improvement of light-emitting materials, and adsorption of water-soluble toxic substances.

Owner:TIANJIN NORMAL UNIVERSITY

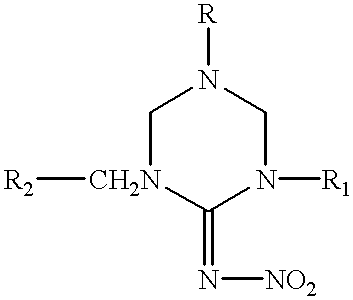

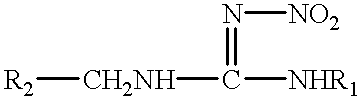

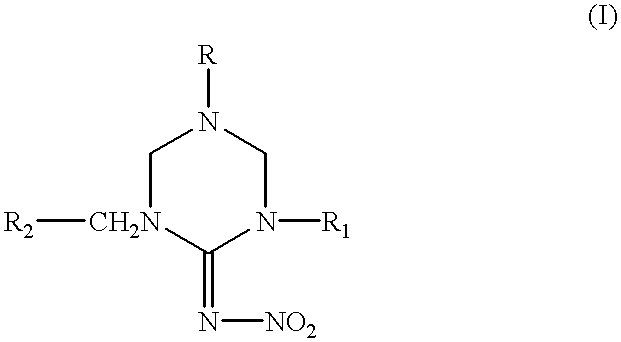

Hexahydrotriazine compounds and insecticides

InactiveUS20010046994A1Easy to prepareHigh insecticidal activityBiocideOrganic chemistryParaformaldehydeAvicide

Owner:KANESHO

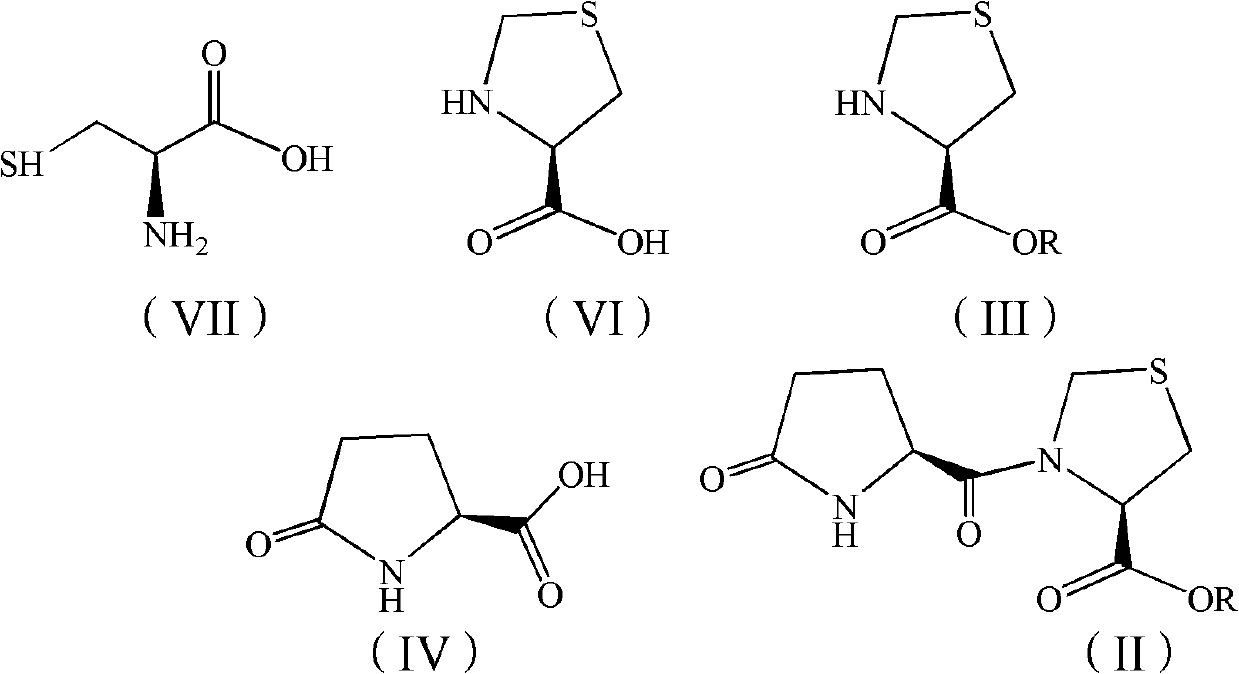

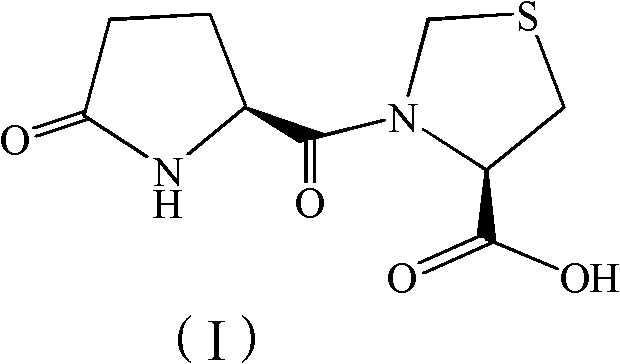

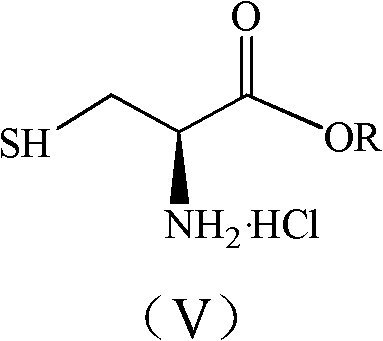

Synthesis method of pidotimod

InactiveCN102167727AThe synthesis process is simple and safeEasy to operatePeptidesSynthesis methodsThiazolidine carboxylate

The invention discloses a synthesis method of pidotimod. The synthesis method comprises the following steps: reacting L-cysteine with paraformaldehyde or formaldehyde to generate L-thiazolidine-4-carboxylic acid, performing esterification to generate L-thiazolidine-4-carboxylate, or reacting L-cysteine ester hydrochloride with paraformaldehyde or formaldehyde to generate L-thiazolidine-4-carboxylate; and then carrying out condensation reaction on L-thiazolidine-4-carboxylate and L-pyroglutamic acid to generate (4R)-3-[[(2S)-5-oxo-2-pyrrolidinyl]carbonyl]-4-thiazolidine carboxylate, and then synthesizing pidotimod through hydrolysis reaction. Compared with the prior art, the technology in the invention is simple, is easy to operate, has high product yield and low production cost, is environmentally friendly and is suitable for industrial production.

Owner:ZHEJIANG KINGLYUAN PHARMA

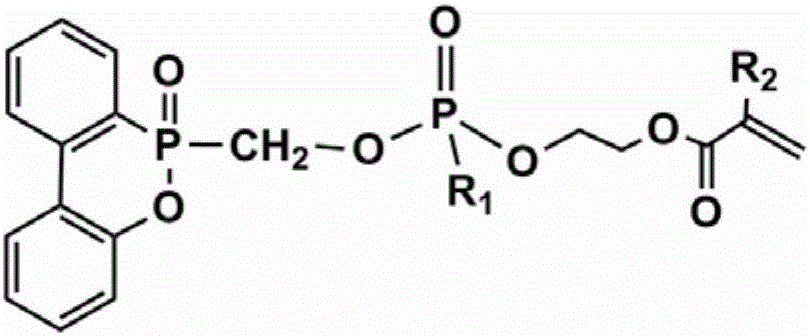

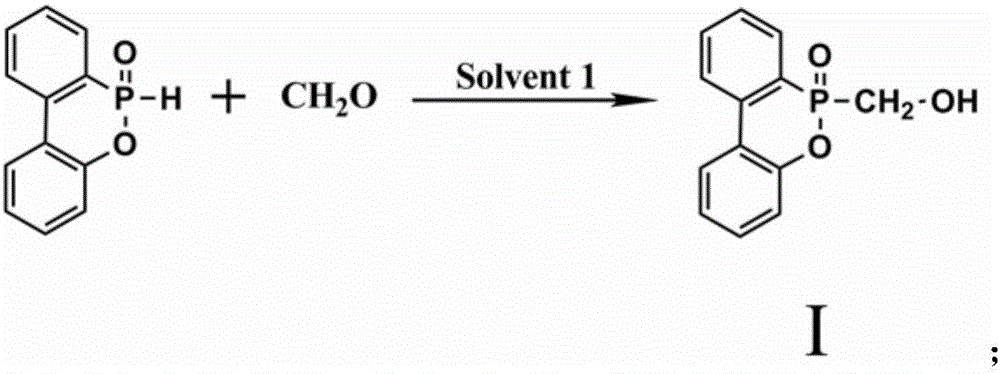

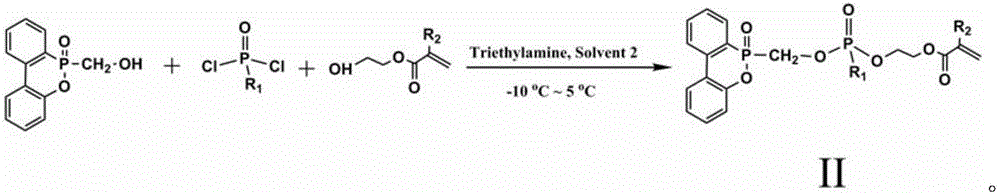

DOPO-based flame retardant, and preparation method thereof

ActiveCN106243385AHigh molecular weightImprove flame retardant performanceGroup 5/15 element organic compoundsGas phaseResin matrix

The invention discloses a DOPO-based flame retardant, and a preparation method thereof. According to the preparation method, 9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide and paraformaldehyde are taken as raw materials, and a precursor I is synthesized via substitution reaction; active hydroxide radicals of the precursor I, phenyl dichlorophosphate, and hydroxyethyl acrylate are subjected to substitution / esterification reaction so as to prepare a flame retardant which is high in phosphorus content and possesses active double bonds; and the flame retardant is added into an unsaturated polyester resin matrix so as to obtain a flame-retardant unsaturated polyester resin composite material. According to the DOPO-based flame retardant, flame resistance of the unsaturated polyester resin matrix is improved via a gas phase and a condensed phase, problems of conventional additive flame retardants that compatibility with polymer matrix is poor, migration is easily caused, and flame retardant efficiency is low are solved. When the DOPO-based flame retardant is applied to inflaming retarding of unsaturated polyester resin, material vertical flame rating is capable of reaching V-0 grade at a relatively low adding amount, and flame resistance is excellent. The DOPO-based flame retardant is high in purity and yield, and aftertreatment is simple.

Owner:SOUTH CHINA UNIV OF TECH

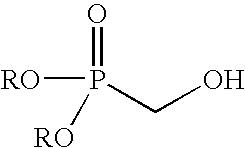

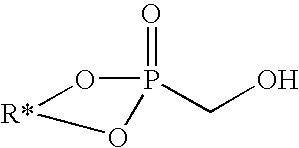

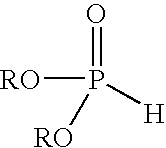

Method of making hydroxymethylphosphonate, polyurethane foam-forming compositions, polyurethane foam and articles made therefrom

ActiveUS20100160468A1Reduce acidityHigh purityPhosphorus organic compoundsHindered amine light stabilizersNitrogen

A method of making hydroxymethylphosphonate comprising heating paraformaldehyde in a solvent to a desired reaction temperature, wherein the solvent is present in at least an amount necessary to solvate or suspend the paraformaldehyde; adding at least one alkyl phosphite to the heated paraformaldehyde, to provide hydroxymethylphosphonate, the alkyl phosphite being added to the heated paraformaldehyde at a rate which will avoid or inhibit the production of a significant exotherm and resulting high / significant level of acid by-product(s), there being present in the reaction medium at least one hindered amine catalyst in which the nitrogen in the amine is directly bound to a secondary and / or tertiary carbon of an organic group; and, optionally, following the completion of the addition, heating the reaction mixture to an elevated temperature.

Owner:ICL IP AMERICA INC

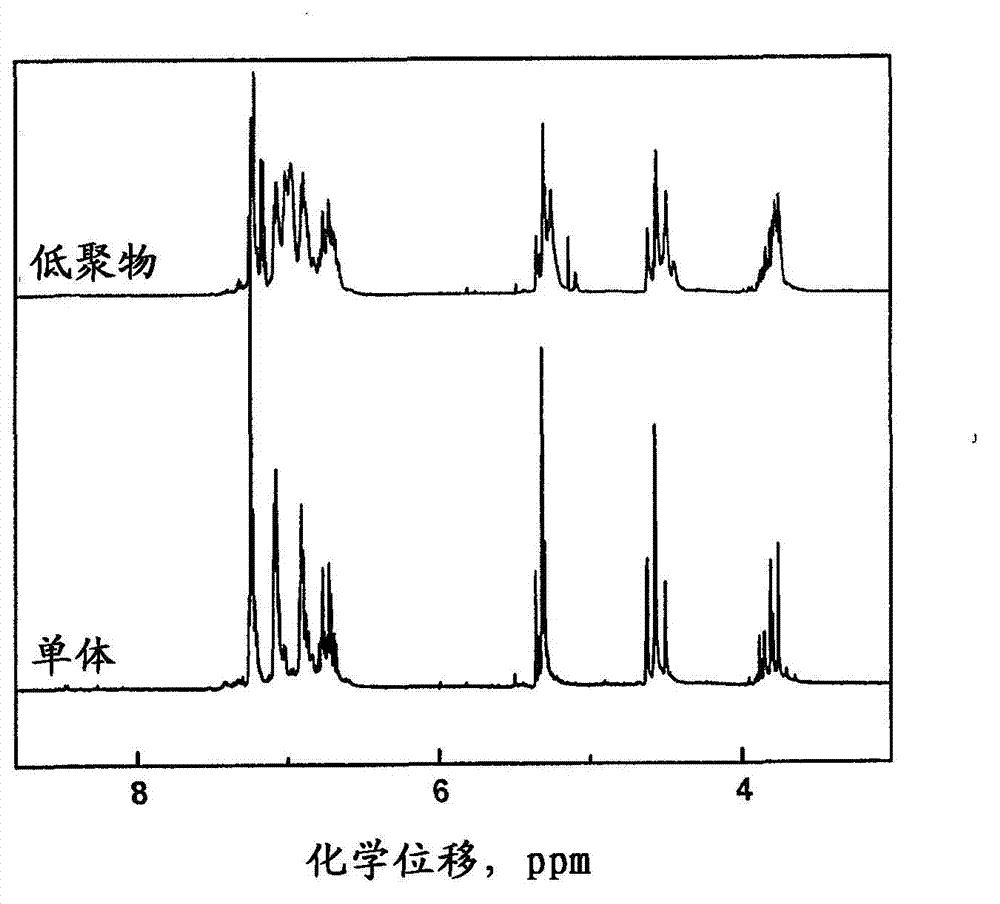

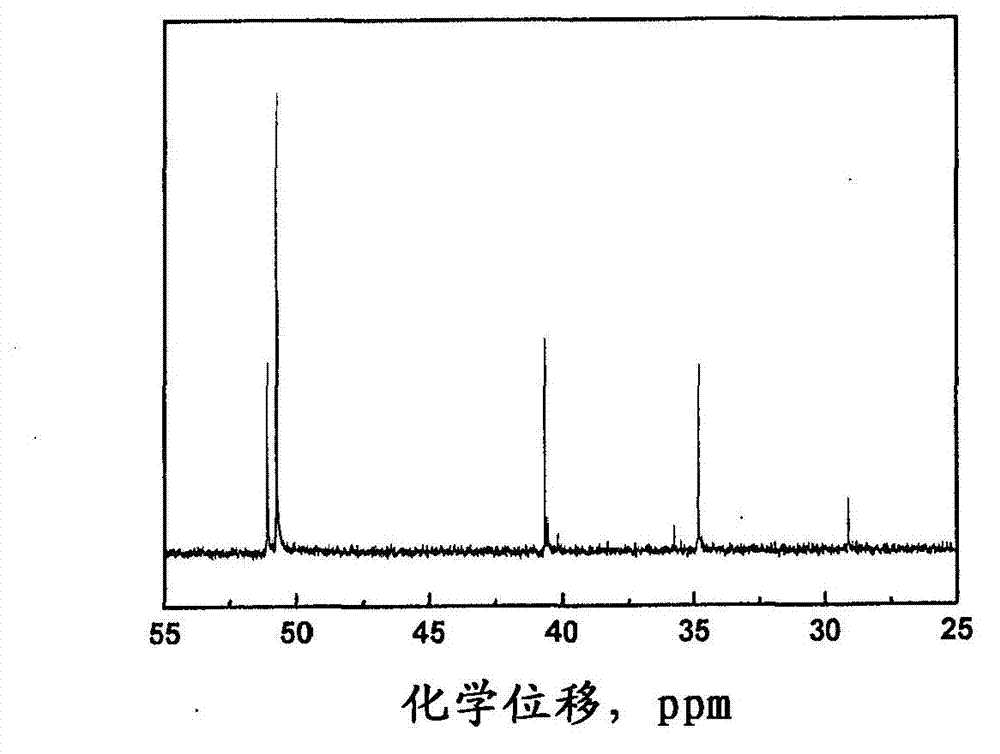

Main-chain benzoxazine oligomer compositions, and method for the preparation thereof

Disclosed are benzoxazine compositions where oxazine rings are part of the polymer main-chain. The benzoxazine oligomers are prepared by the reaction of a bisphenol and an aldehyde, such as formaldehyde or paraformaldehyde, with one or more diamines or polyamines, and optionally with one or more monofunctional amines or monofunctional phenols. Also disclosed are benzoxazine monomers prepared from a bisphenol, an aldehyde, such as formaldehyde or paraformaldehyde, and a monofunctional amine, which benzoxazine monomers may be optionally used as reactive diluents. Further disclosed are benzoxazine monomers are prepared from a diamine, and aldehyde, such as formaldehyde or paraformaldehyde, and a monofunctional phenol, which benzoxazine monomers may also be optionally used as reactive diluents.

Owner:MOMENTIVE SPECIALTY CHEM RES BELGIUM +1

Process method for preparing polyoxymethylene dimethyl ethers

ActiveCN105566077AAvoid cloggingAchieve dehydrationOrganic compound preparationCarbonyl compound separation/purificationCyclic processLiquid water

The invention discloses a process method for preparing polyoxymethylene dimethyl ethers. The method includes the steps that formaldehyde gas is cooled to 100 DEG C and below, so that vapor is removed; dehydrated gas formaldehyde is directly absorbed by a mixture of polyoxymethylene dimethyl ethers DMM1-2 and polyoxymethylene dimethyl ethers DMM6-10 of different degrees of polymerization, then a reaction is conducted, polyoxymethylene dimethyl ethers DMM 3-5 are prepared, and DMM1-2 and DMM 6-10 with the DMM 3-5 separated continuously serve as raw materials and are recycled. According to the method, formaldehyde gas generated by methanol oxidation is cooled to 100 DEG C and below, vapor is condensed into liquid water, the purpose of dehydration is achieved, and due to the fact that water in the formaldehyde is removed before being absorbed by reactant, and the situations that a polycondensation reaction occurs and device is blocked by paraformaldehyde generated by formaldehyde polycondensation are avoided; the mixture of the DMM1-2 and DMM6-10 also participates in a polymerization reaction and a depropagation reaction in the cyclic process and is finally converted to the polyoxymethylene dimethyl ethers DMM3-5 of the target degree of polymerization. The method is simple in process and easy to operate, the speed for generating the DMM3-5 is high, the conversion rate of the DMM3-5 is high, and energy consumption and equipment investment are lowered.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O](https://images-eureka.patsnap.com/patent_img/8248cb64-9651-4786-8c08-49e307ca69de/US20080009635A1-20080110-C00001.png)

![One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O](https://images-eureka.patsnap.com/patent_img/8248cb64-9651-4786-8c08-49e307ca69de/US20080009635A1-20080110-C00002.png)

![One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O](https://images-eureka.patsnap.com/patent_img/8248cb64-9651-4786-8c08-49e307ca69de/US20080009635A1-20080110-C00003.png)