Patents

Literature

940 results about "Reaction type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The main four types of reactions are direct combination, analysis reaction, single displacement, and double displacement. If you're asked the five main types of reactions, it is these four and then either acid-base or redox (depending who you ask). Keep in mind, a specific chemical reaction may fall into more than one category.

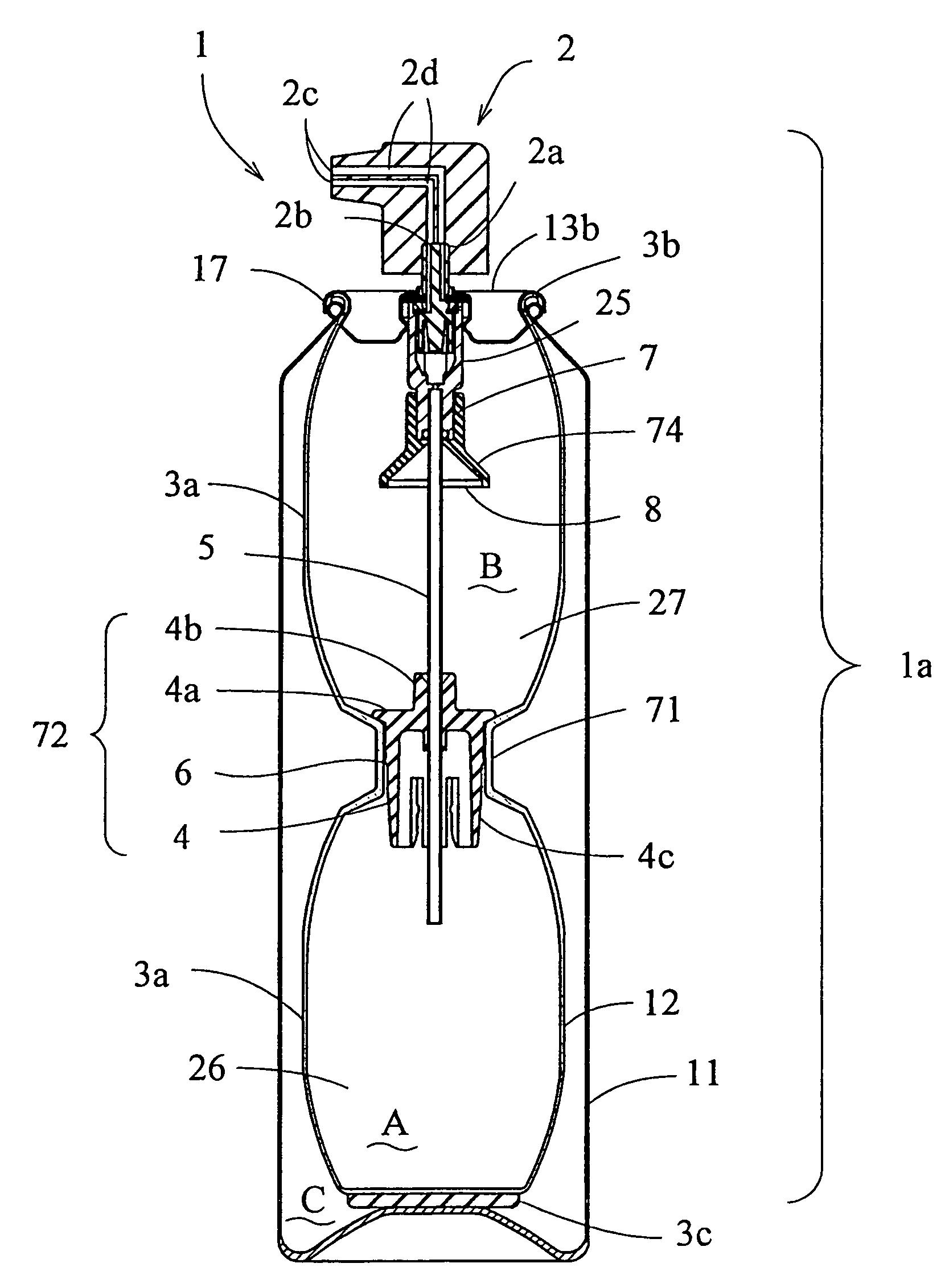

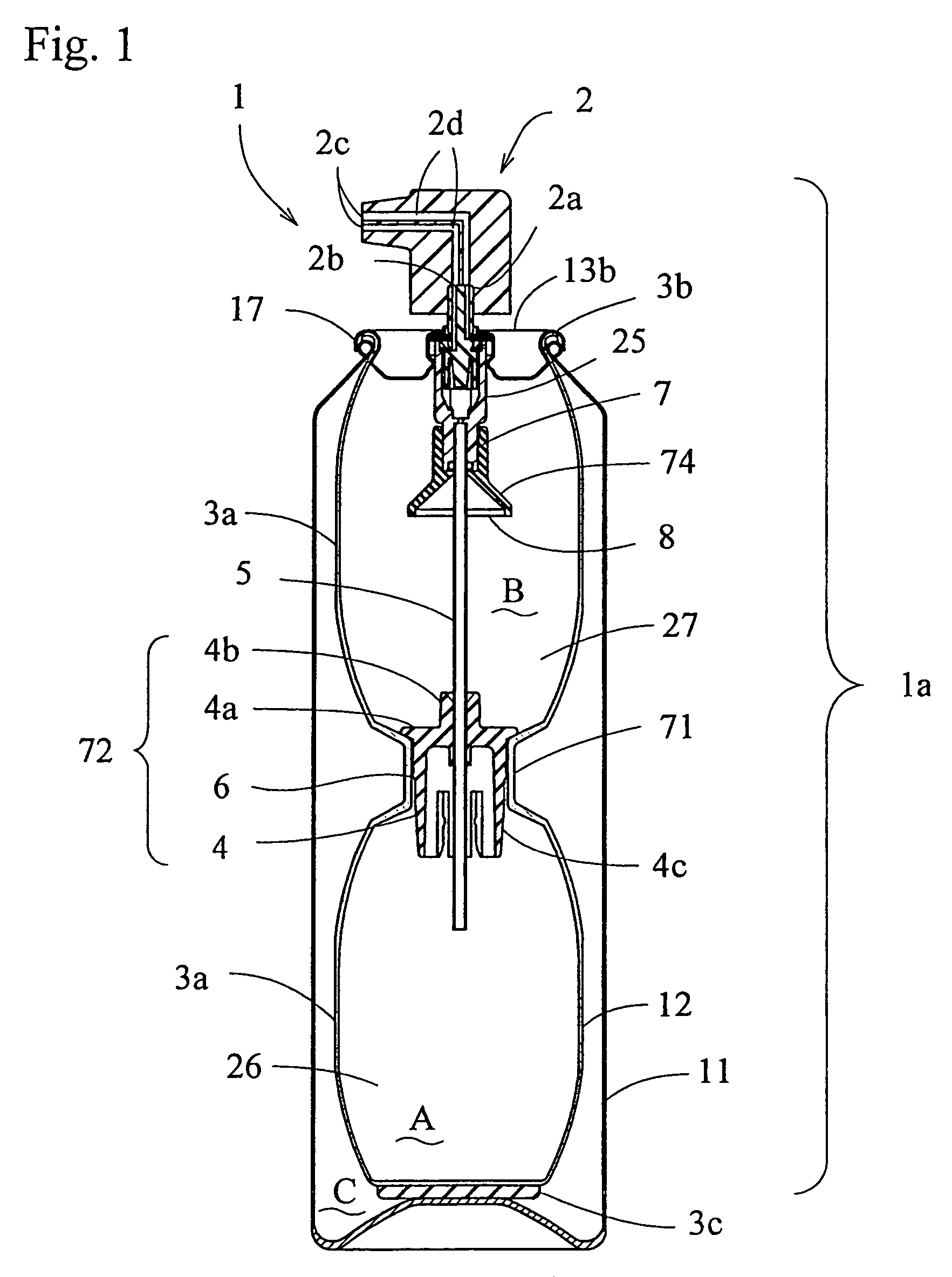

Container for discharging plural contents, a dispenser using the container, and a process for producing the dispenser

InactiveUS7455195B2Easy to splitIncrease charging rateLiquid transferring devicesSingle-unit apparatusHair dyesVitamin Preparations

An aerosol container 190a provided with an outer container 11, a collapsible inner bag 12 inserted in the outer container, and a valve 13. The inner bag 12 comprises an upper and lower chamber 27, 26 and the chambers are divided at a constriction part formed in the middle of the inner bag by a partitioning member 72. The valve 13 has communicating holes that communicates valve 13 with the upper chamber 27 and the lower chamber 26 through a dip tube 28. An inner bag type aerosol product may be obtained by charging different kind of contents A and B into the container. Two-liquid reaction type agents, such as hair dye. enzyme hair dye, hair dress agent or setting agent for hair, reduction of inflammation pain killer, anti-heat flushes, coolants, pack agents, cleansing agents, shaving foams, moisturizers, antipersipirants. vitamin preparations, emollients and etc. may be preferably used for the combination of the contents for aerosol product.

Owner:DAIZO

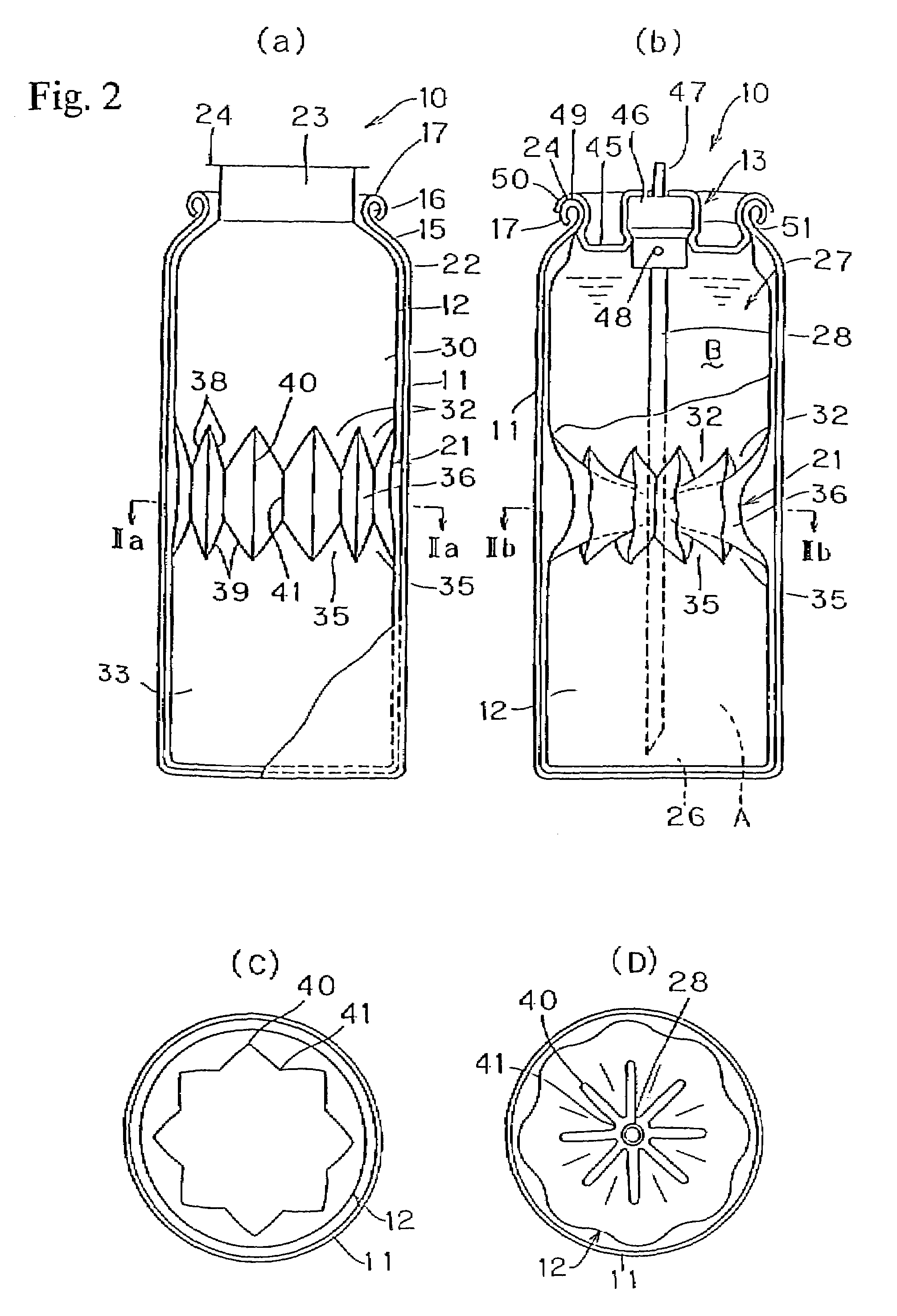

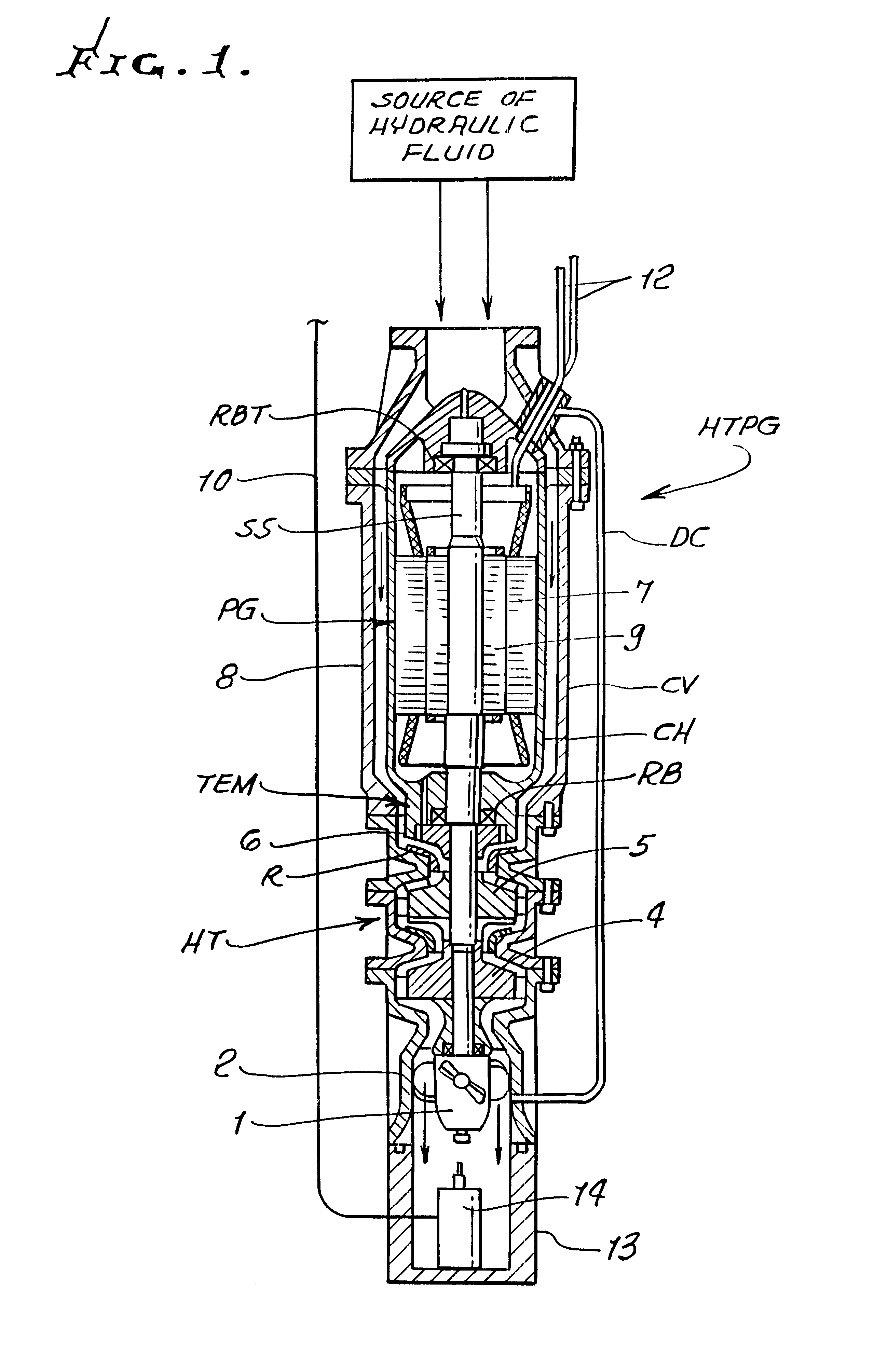

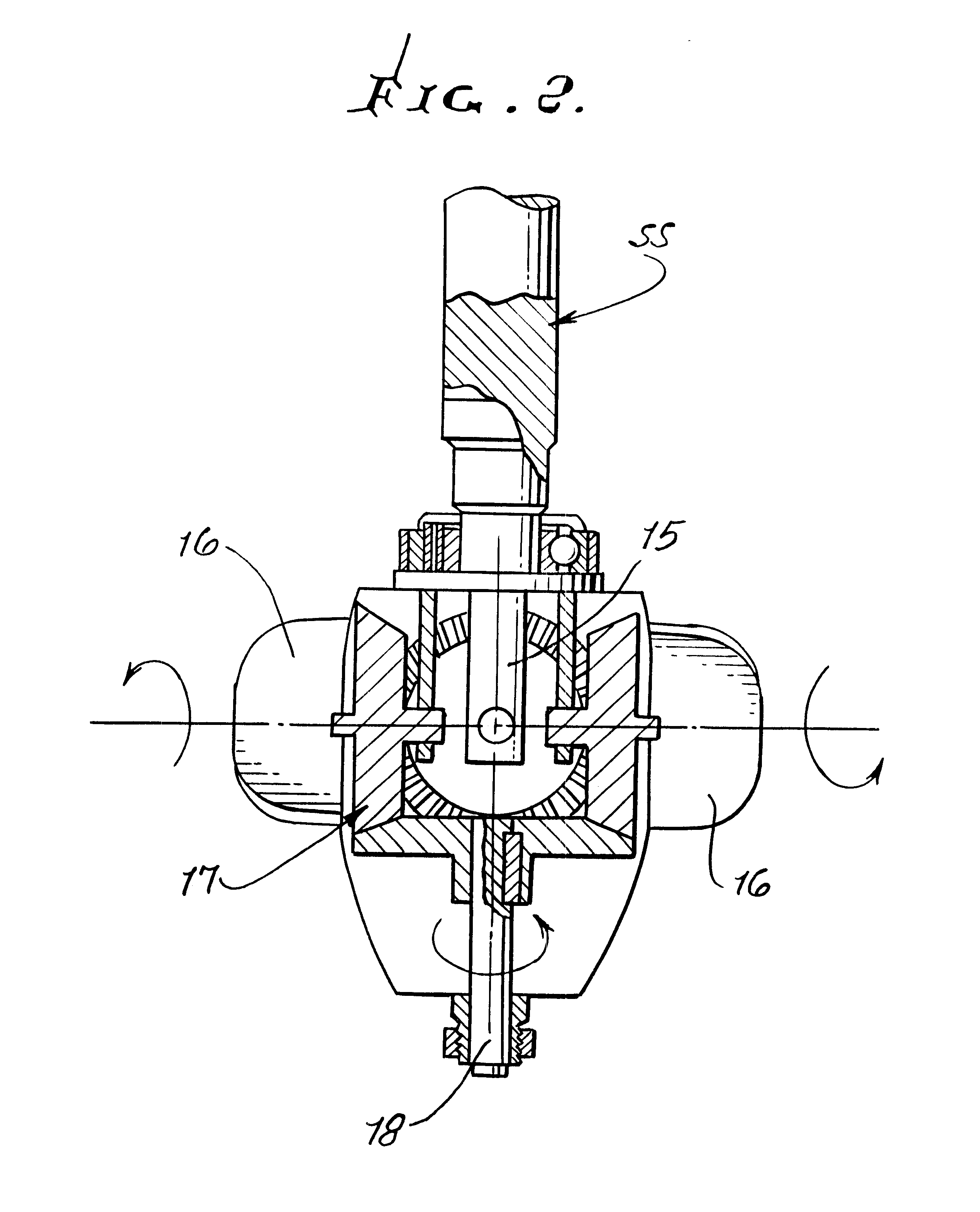

Dual type multiple stage, hydraulic turbine power generator including reaction type turbine with adjustable blades

InactiveUS6441508B1Maximize efficiencyConstant speedGas turbine plantsReaction enginesEngineeringHydraulic fluid

A hydraulic turbine power generator mounted on a single shaft wherein the hydraulic turbine means includes a plurality of reaction type turbine stages arranged to be in combination, rotatably responsive to the hydraulic fluid coupled to the turbines. One of the turbine stages having axial turbine runner means mounted to the single shaft and having a plurality of adjustable blades for permitting the pitch of the blades to be adjusted for controlling the effective operative fluid head to cause the shaft to rotate at a preselected speed and including means for adjusting the pitch of the adjustable blades. The turbine stages can be a Francis type turbine and a Kaplan type turbine. The hydraulic turbine power generator can be oriented in an upward direction to cause the fluid flow to travel upwardly through the turbine stages and function as a two phase turbine expander resulting in the separation of the liquid phase from the gas / vapor stage.

Owner:ELLIOTT CO

Low-VOC scratch-resistant modified polypropylene composite material and preparation method thereof

InactiveCN101787159AImprove adsorption capacityFully dispersedMolecular sievePolypropylene composites

The invention belongs to the field of modified polypropylene composite material, and relates to a low-VOC scratch-resistant modified polypropylene composite material which is applicable to manufacturing automobile interior trim parts, and comprises the components based on the parts by weight: 60-90 parts of polypropylene, 5-20 parts of toughening agent, 5-20 parts of mineral filler, 0.1-4 parts of odor adsorbent, 5-15 parts of wear-resistant agent / scratch-resistant agent and 0.1-3 parts of auxiliary agent, wherein the odor adsorbent is a mixture of three selected from clay, bentonite, porous silicon dioxide, activated aluminium oxide or molecular sieve; and the wear-resistant agent / scratch-resistant agent is one or a mixture of two in polytetrafluoroethylene micro powder or reaction-type polyorganosiloxane. The modified polypropylene composite material not only has better impact-resistant performance and strength, but also has excellent scratch-resistant performance and low-VOC diffusion characteristic; and the needed raw materials have wide source and can be conveniently and easily obtained.

Owner:SUZHOU SUNWAY POLYMER

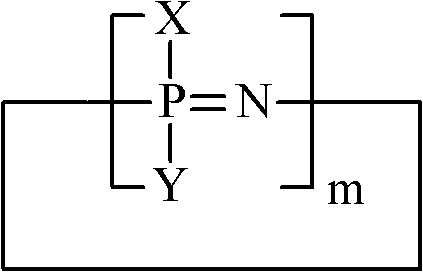

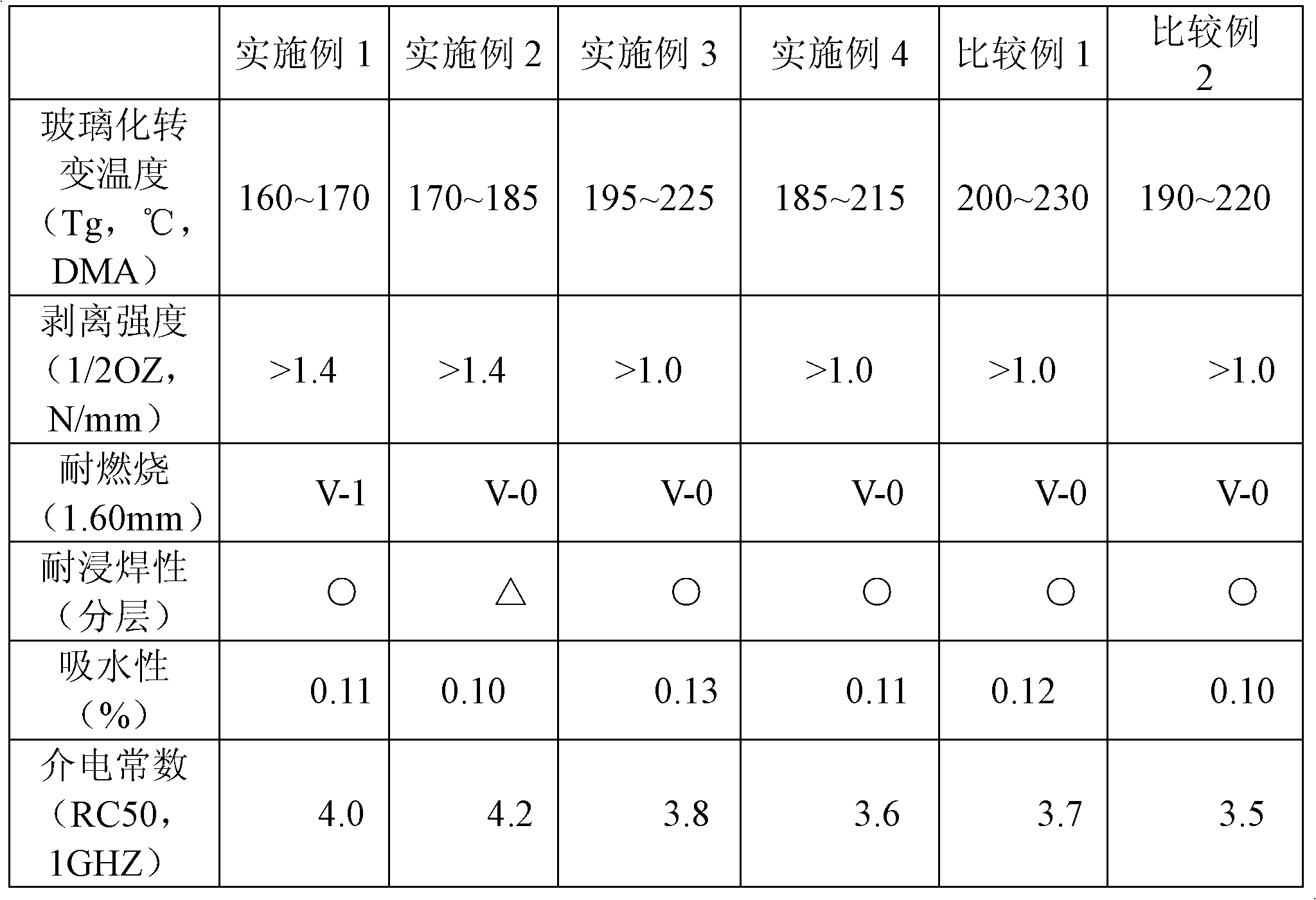

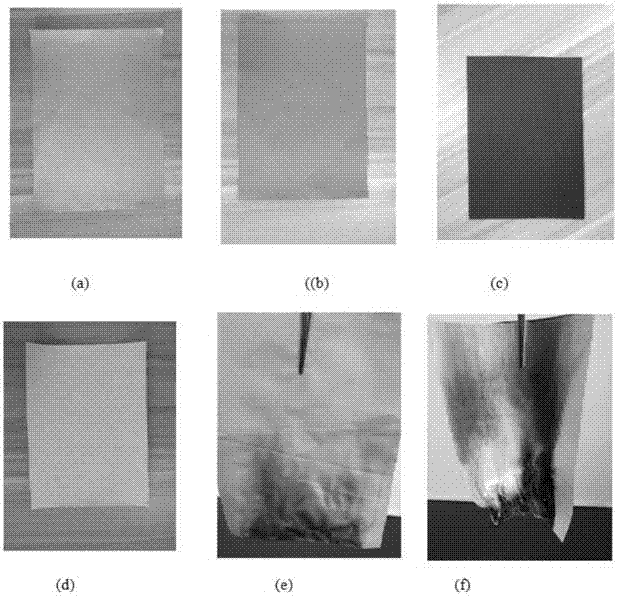

Halogen-free resin composition and method for preparing copper-clad plate from the halogen-free resin composition

ActiveCN102977551ASmall dielectric lossImprove electrical performanceSynthetic resin layered productsLaminationDielectric lossHeat resistance

The invention discloses a halogen-free resin composition and a method for preparing a copper-clad plate from the halogen-free resin composition. Based on the total weight part of solid ingredients of the halogen-free resin composition, the halogen-free resin composition comprises, by weight, 5 to 50 parts of reaction-type allylphenoxycyclotriphosphazene or vinylphenoxycyclotriphosphazene, 15 to 85 parts of a thermosetting resin, 1 to 35 parts of a crosslinking curing agent, 0 to 5 parts of a crosslinking curing accelerator and 0 to 100 parts of a filling material. Through introduction of reaction-type allylphenoxycyclotriphosphazene or vinylphenoxycyclotriphosphazene having very low water absorbency into the thermosetting resin, the halogen-free resin composition can satisfy halogen-free flame-retardation requirements, improve system electrical properties, and realize non-halogenation of a high-frequency high-speed substrate material. The copper-clad plate prepared from the halogen-free resin composition satisfies halogen-free requirements, has excellent heat resistance and moisture resistance and has a low dielectric loss.

Owner:GUANGDONG SHENGYI SCI TECH

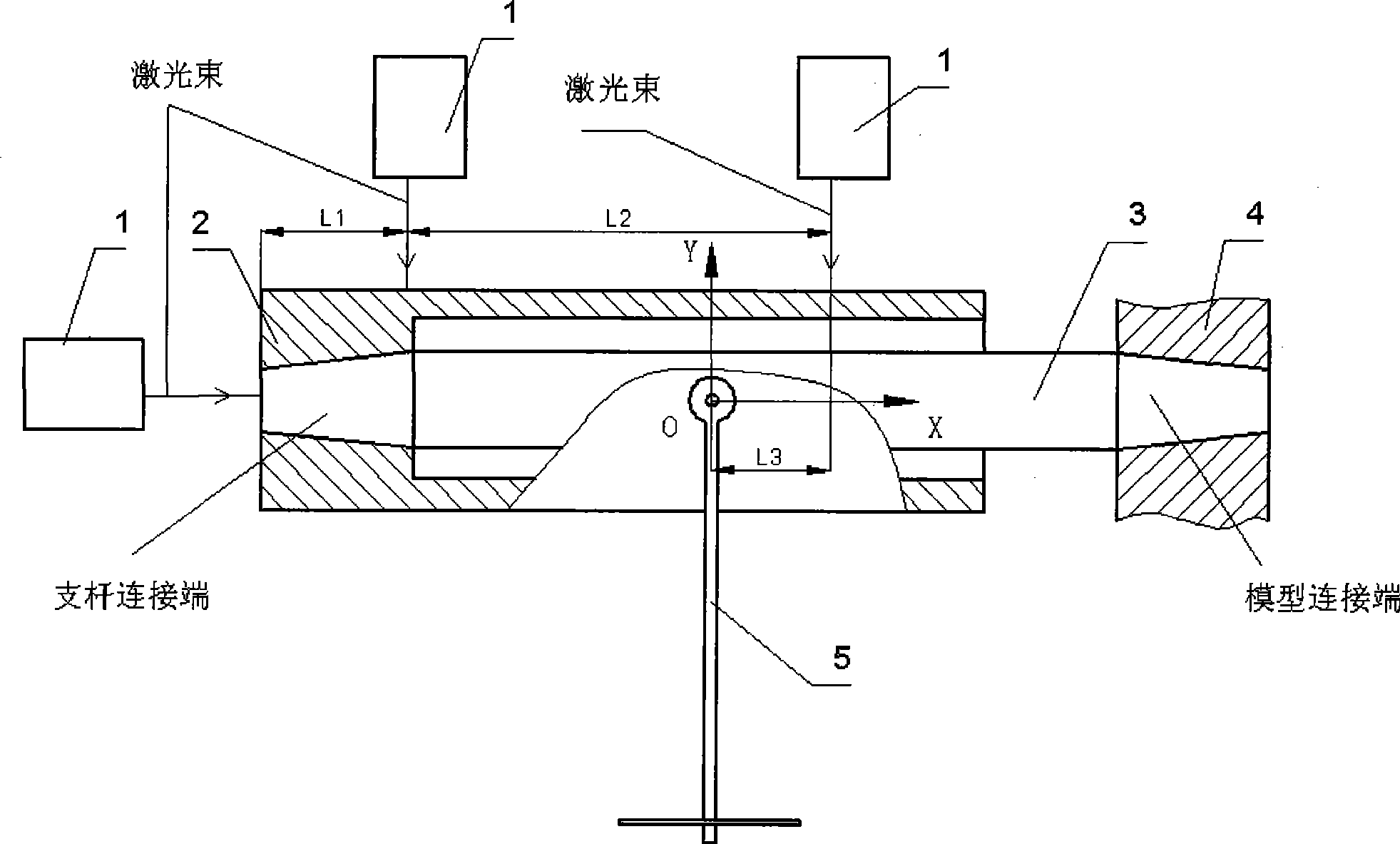

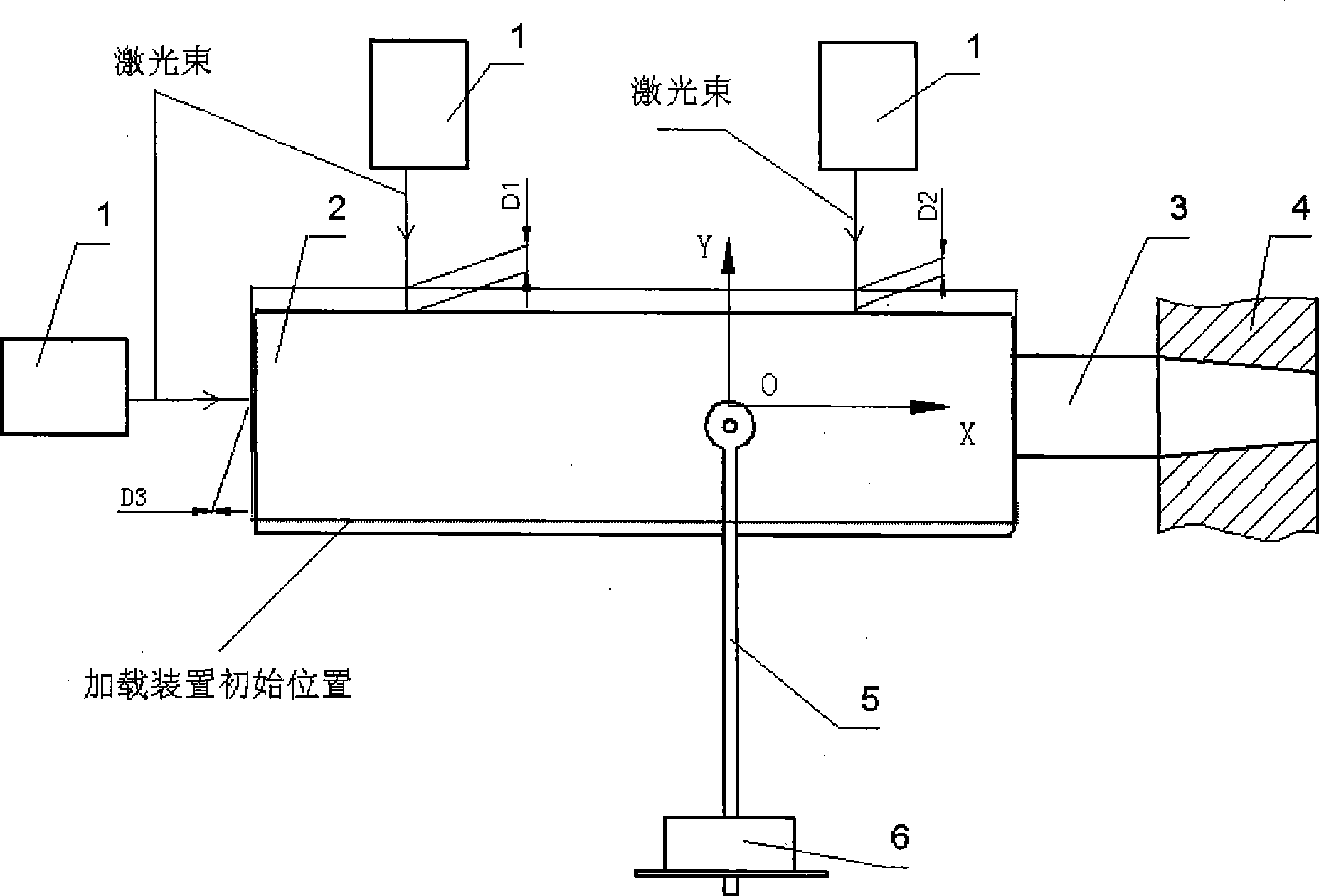

Support reaction type wind-tunnel balance shafting static calibration method

ActiveCN101419118ASimplify static calibration deviceSimple calculationAerodynamic testingGaussian eliminationEngineering

The invention relates to a method for statically calibrating a body axial system of a bearing reaction wind tunnel balance, wherein a loading device is arranged on a connecting end of a supporting rod of the wind tunnel balance, and the displacement of the loading device of the wind tunnel balance is measured through a laser displacement sensor which is arranged on a rigid support; after the wind tunnel balance is loaded, the reading of the laser displacement sensor is acquired, and the displacement of the loading device of the wind tunnel balance and the displacement of various loading points are calculated; the load exerted is subjected to translation and synthesized on an origin of a coordinate system of a body axle, and the bearing reaction generated on the wind tunnel balance by a base on the origin of the coordinate system of the body axle is solved and taken as the load of the body axial system of the wind tunnel balance; and a static calibration formula of the wind tunnel balances is solved through the least square method and the Gaussian elimination method by combination of the increment of outputted voltage signals before and after loading of all the wind tunnel balances and the loads of body axial systems. The static calibration method can simplify a static calibration device of the wind tunnel balance, not only does not need to use a complex offset-type or single-vector motion mechanism but also does not need to be limited by the performance of a reference balance, and is simple to calculate due to fixed position of the body axial system of the wind tunnel balance compared with the displacement method of a measuring and loading device.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

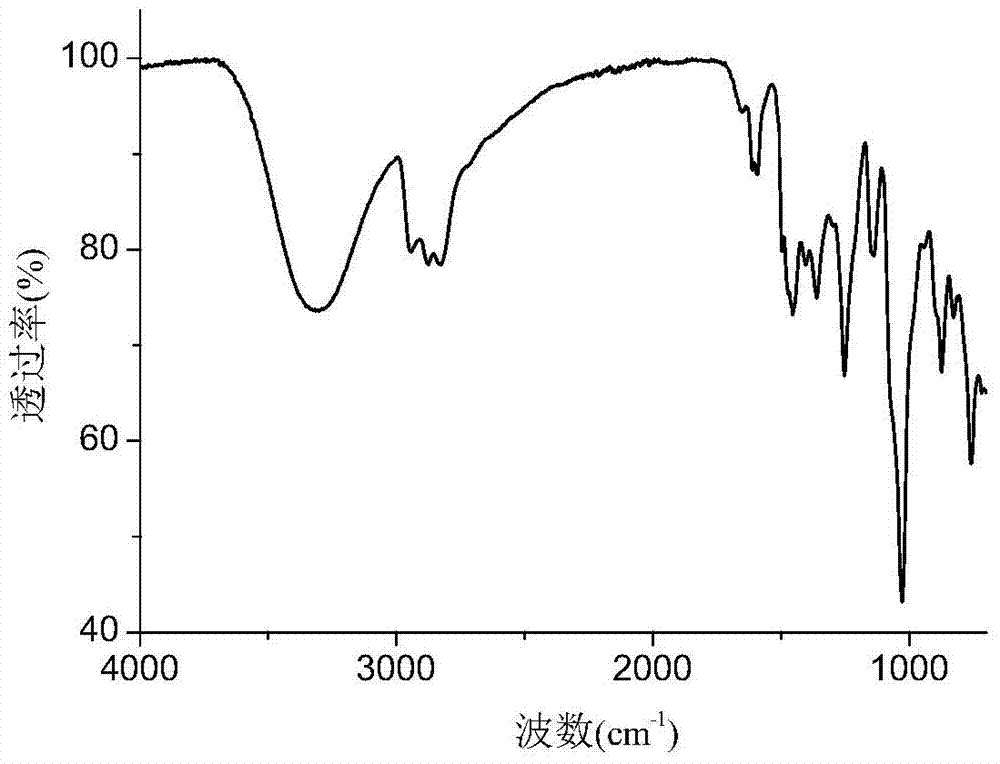

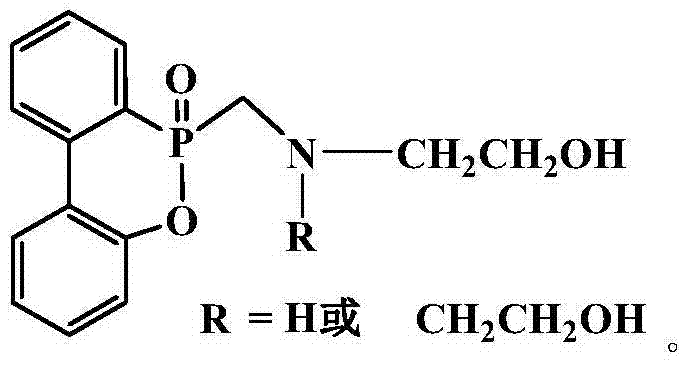

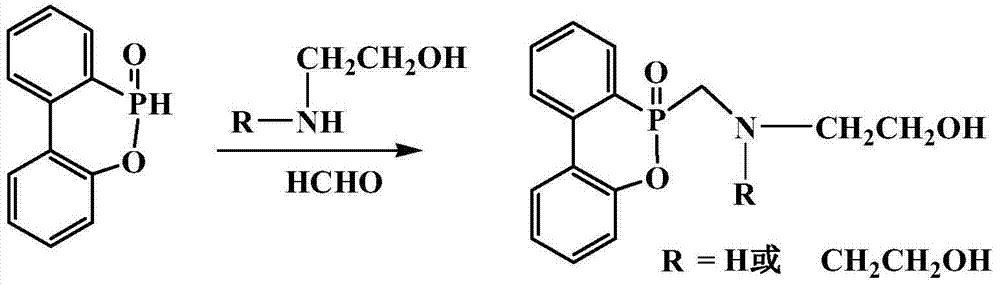

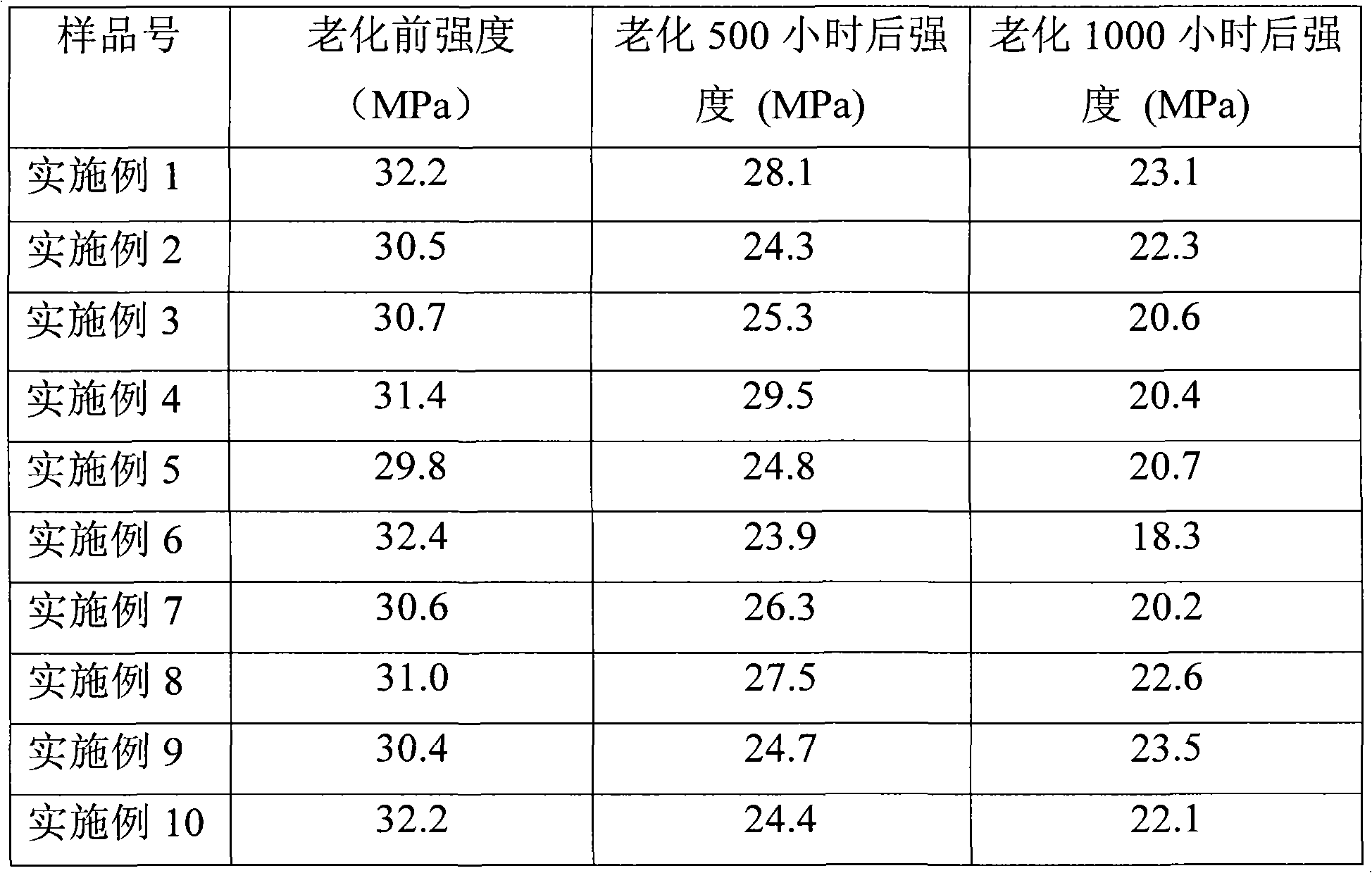

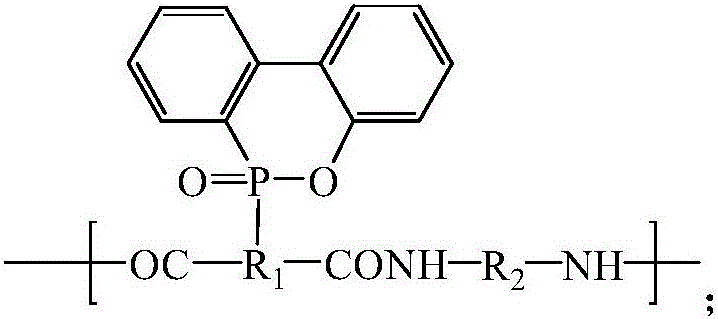

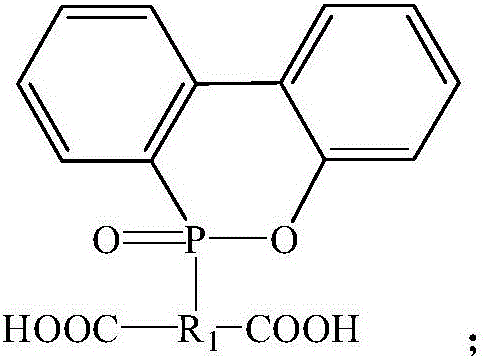

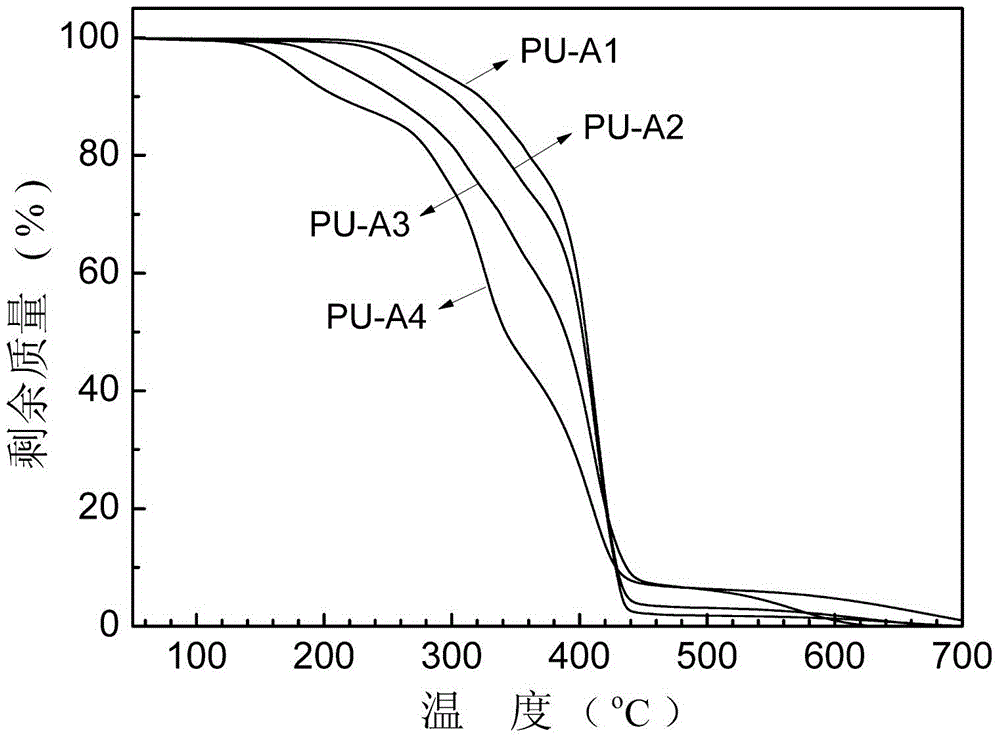

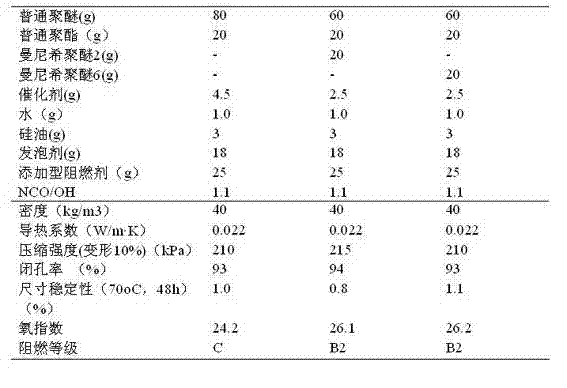

Halogen-free reaction type flame retardant for polyurethane foam as well as preparation method and application thereof

ActiveCN103694434AGood storage stabilityGood compatibilityGroup 5/15 element organic compoundsMannich reactionOxygen

The invention provides a halogen-free reaction type flame retardant for polyurethane foam as well as a preparation method and an application thereof. The halogen-free reaction type flame retardant is prepared through a Mannich reaction of 9,10-dihdro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), alcohol amine and formaldehyde; the structural formula of the halogen-free reaction type flame retardant is as shown in the specification; the alcohol amine and the formaldehyde are introduced to the DOPO flame retardant structure through a DODO reaction; the cost of the flame retardant is reduced; the synthesized halogen-free reaction type flame retardant contains active hydroxyl, flame retardant nitrogen and phosphorus, and primary amine or tertiary amine and has relatively high reaction activity; as rigid benzene rings are applied to the flame retardant type polyurethane foam, the flame retardant type polyurethane foam has relatively high flame retardance, the strength and the flame retardance durability of the flame retardant type polyurethane foam are improved, and the oxygen index can reach 23-28%. The flame retardant type polyurethane foam has wide application prospect in buildings, heat preservation fields and certain special occasions.

Owner:徐州市洛克尔化工科技有限公司

High fused mass strength polypropylene containing long branched chain structure and preparing method thereof

The invention relates to a high fused mass strength polypropylene contained long-chain branch and the preparation method thereof. The high fused mass strength polypropylene resin is prepared by polypropylene grafted object, amine or alcohols compound as well as antioxidant and heat stabilizer, etc. The invention adopts a melting and continuously extrusion method with a reaction-type double screw extruder to prepare the high fused mass strength polypropylene, and uses supercritical carbon dioxide to assist the extrusion, which can lower the extrusion temperature, reduce the degradation of polymer and meanwhile greatly strengthen the pervasion of molecule, so as to further promote the reaction. In the reaction process, as chain extender, amine and alcohols compound react with special functional group of polypropylene grafted object, link linearity polypropylene molecular chain, consequently produce novel polypropylene that each grafted point includes two long-chain branch structures and of which the melt flow rate is adjustable. The novel polypropylene is characterized by non-gelatin and strain hardening. The product shows great advantages over a plurality of aspects like color, mechanical property and workability, therefore, the product is suitable for application areas of blowing, thermo-forming, blown film, extrusion and coating, etc.

Owner:ZHEJIANG UNIV

Preparation method of nanometer in situ composite reaction type organic silicone modified cationic water-based polyurethane and product thereof

InactiveCN102199274AGood dispersionImprove wear resistanceFibre treatmentDyeing processCompound organicWater based

The invention relates to a preparation method of nanometer in situ composite reaction type organic silicone modified cationic water-based polyurethane and a product thereof. The preparation method comprises the following steps: preparing raw materials of basic monomers, modified monomers and adjuvants; carrying out dewatering pretreatment on mixed polyether glycol; and carrying out pre-polymerization, chain extension, blocking, quaternization and emulsification. So the nanometer in situ composite reaction type organic silicone modified cationic water-based polyurethane is obtained. The method is easy to implement and control, and the nanometer in situ composite reaction type organic silicone modified cationic water-based polyurethane prepared by the method is in a microemulsion state, has a small and uniform emulsion particle size and a good dispersion, and combines merits of organic silicone, polyurethane and inorganic nanometer materials. So the polyurethane prepared in the invention, which can be used to improve the color fastness and pilling resistance of various dyed textiles, allows the textiles to have certain stain resistance, and soft feel of the textiles not to be damaged. Thereby the polyurethane has the advantages of good application performance, wide range of use, safety and environmental protection, and convenient usage.

Owner:清河羊绒产业技术研究院

Halogen-free flame-retardant electromagnetic shielding material and preparation method and application thereof

ActiveCN108003771APlay a role in wetting and dispersingGood flame retardant synergistic effectFireproof paintsMagnetic/electric field screeningElectricityHalogen

The invention discloses a halogen-free flame-retardant electromagnetic shielding material. The halogen-free flame-retardant electromagnetic shielding material comprises an electricity conducting powder material, a halogen-free flame retardant powder material, a liquid flame retardant, a flame-retardant synergist, a reaction type phosphorus-containing flame retardant containing active groups, a charring agent, a wetting agent, a dispersing agent and a thickening agent. When all the compositions are baked at a high temperature, a whole is formed through adhesion and crosslinking of a flame-retardant polymer binder and a flame-retardant cross-linking agent, and an excellent flame-retardant effect and an electromagnetic shielding function are achieved. When the application is achieved in a coating mode, the flame-retardant polymer binder and the flame-retardant cross-linking agent are bonded and crosslinked with the reaction type phosphorus-containing flame retardant containing the activegroups and the charring agent under the action of high-temperature baking, various flame-retardant compositions and the electricity conducting powder material are bonded with a substrate, the bondingstrength between the coating and the substrate is very high, an excellent in-situ charring capacity is achieved, the flame-retardant performance of a condensed phase is excellent, and the halogen-freeflame-retardant electromagnetic shielding material has good electromagnetic shielding performance.

Owner:HANGZHOU XIANGJUN TEXTILE FLAME RETARDANT TECH

Adsorption absorption reaction type formaldehyde eliminating agent

An adsorption-absorption reaction type formaldehyde removing agent is composed of adsorption-absorption agent (activated carbon, alumina, diatomite, polyamide or water) for adsorbing and absorbing the formaldehyde from indoor air, and reactant (sodium sulfite and ammonium salt or hydroxy amine hydrochloride) for reacting on adsorbed and absorbed formaldehyde to become non-toxic, no-odor and non-pollution substance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nano polyacrylate emulsion for water-based wood coating and method for preparing same

ActiveCN101638451AImprove mechanical propertiesLiquid surface applicatorsEmulsion paintsEpoxyWater based

The invention provides a nano polyacrylate emulsion for a water-based wood coating and a method for preparing the same. In the method, a plurality of functional monomers are used in the design of a core-shell structure and a molecular branch chain interpenetrating network of the emulsion particles; the aim of the invention can be achieved by the polymerization technology under a condition of a reaction type emulsifier, simultaneously beta-cyclohexyl-epoxy-ethyl-ethoxy silane is used for making the coating film crosslinked in a drying process, the mechanical property of the coating prepared bythe method is greatly improved compared with the coating of the water-based polyacrylate emulsion which does not use the beta-cyclohexyl-epoxy-ethyl-ethoxy silane, the shock resistance of the coatingis over 45kg.cm, the hardness of the coating reaches H or above class, and the waterproof property of the coating reaches 240 hours.

Owner:上海展辰涂料有限公司 +1

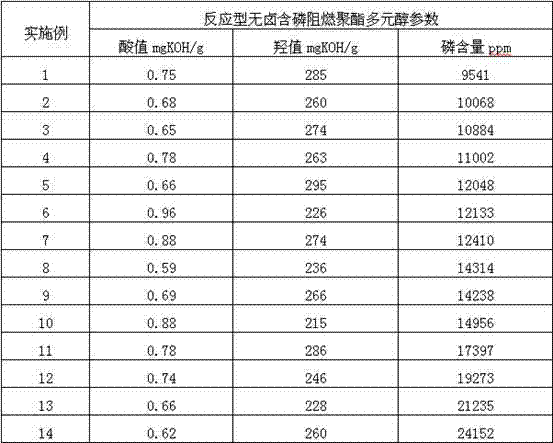

Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

The invention discloses a preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol. The preparation method is characterized by comprising following steps: taking binary acid, dihydric alcohol, halogen-free phosphorous copolymer fire retardant and catalyst to be put into a reaction kettle, stirring and warming up, filling nitrogen to empty, reacting for 2 to 8h when the temperature reaches 125 to 155 DEG C, then warming up to 180 DEG C, vacuumizing to ensure the air pressure to be 100 to 5000 Pa, controlling reaction temperature to be 180 to 245 DEG C, after reacting for 2 to 4h, sampling at an interval of 10 to 40 min to test acid value, stopping heating when the acid value is reduced below 2 mgKOH / g, and stirring for cooling so as to obtain the reaction type halogen-free phosphorous flame retardant polyester polyol. The reaction type halogen-free phosphorous flame retardant polyester polyol is applied to synthesis of rigid or soft polyurethane foamed plastic, and the prepared polyurethane foamed plastic has excellent flame retardant property, and the limit oxygen index can be up to more than 32%.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Preparation of single-component fire retardation polyurethane foam sealant

InactiveCN103923294AImprove flame retardant performanceIncrease elasticityOther chemical processesPolyesterSealant

The present invention relates to a preparation method of a single-component fire retardation polyurethane foam sealant. According to the present invention, the single-component fire retardation polyurethane foam sealant is prepared by adopting the following raw materials: a fire retardation polyester polyol, a fire retardation polyether polyol, a polyester polyol, a polyether polyol, a fire retardation agent, a foam stabilizer, a catalyst, and a foaming agent; the preparation method is characterized in that the reaction type fire retardation agent containing chlorine, bromine, phosphorus, nitrogen and other fire retardation elements and the addition-type fire retardation agent are concurrently adopted, and the fire retardation performance and the use performance of the foams are improved by optimizing the ratio of various raw materials; and the single-component fire retardation polyurethane foams prepared through the preparation method have high oxygen index and low smoke density.

Owner:上海联合气雾制品灌装有限公司

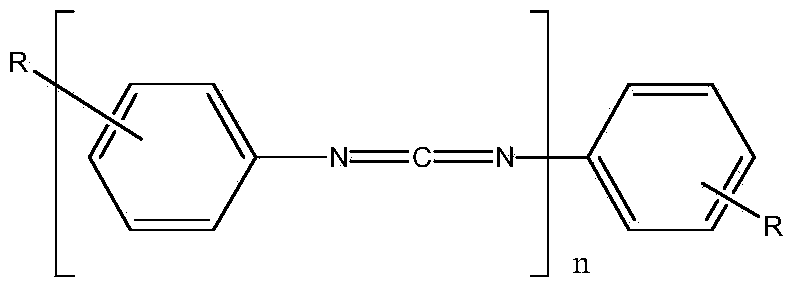

Preparation method of polyether material, polyether film and preparation method thereof

ActiveCN103627150AImprove stabilityEfficient responseSynthetic resin layered productsPhotovoltaic energy generationPolymer scienceHydrolysis

The invention relates to a preparation method of a polyether material, a polyether film and a preparation method thereof, belonging to the technical field of a polyether film for a backboard film of a solar battery. In order to solve the problem of bad flame retardance and humidity resistance of the existing polyether film, the invention provides a polyether film which comprises a surface layer I, a core layer and a surface layer II, wherein the core layer comprises a polyether chip and a master batch polyether chip, and the core layer also comprises a modified highly humidity-resistant flame-retardant polyether material which is prepared by the following steps: in the presence of a catalyst, performing an esterification reaction between pure terephthalic acid and dihydric alcohol; after the reaction, performing a pre-condensation polymerization reaction; when the intrinsic viscosity reaches 0.20-0.30g / dl, adding a reaction type phosphorus-based flame retardant, increasing the vacuum degree, and performing a condensation polymerization reaction; when the intrinsic viscosity reaches 0.50-0.65g / dl, adding a chain extender ADR and an anti-hydrolysis agent aromatic polycarbodiimide for a copolymerization reaction. Meanwhile, the polyether film has the advantages of high flame retardance and high humidity resistance.

Owner:浙江南洋科技有限公司

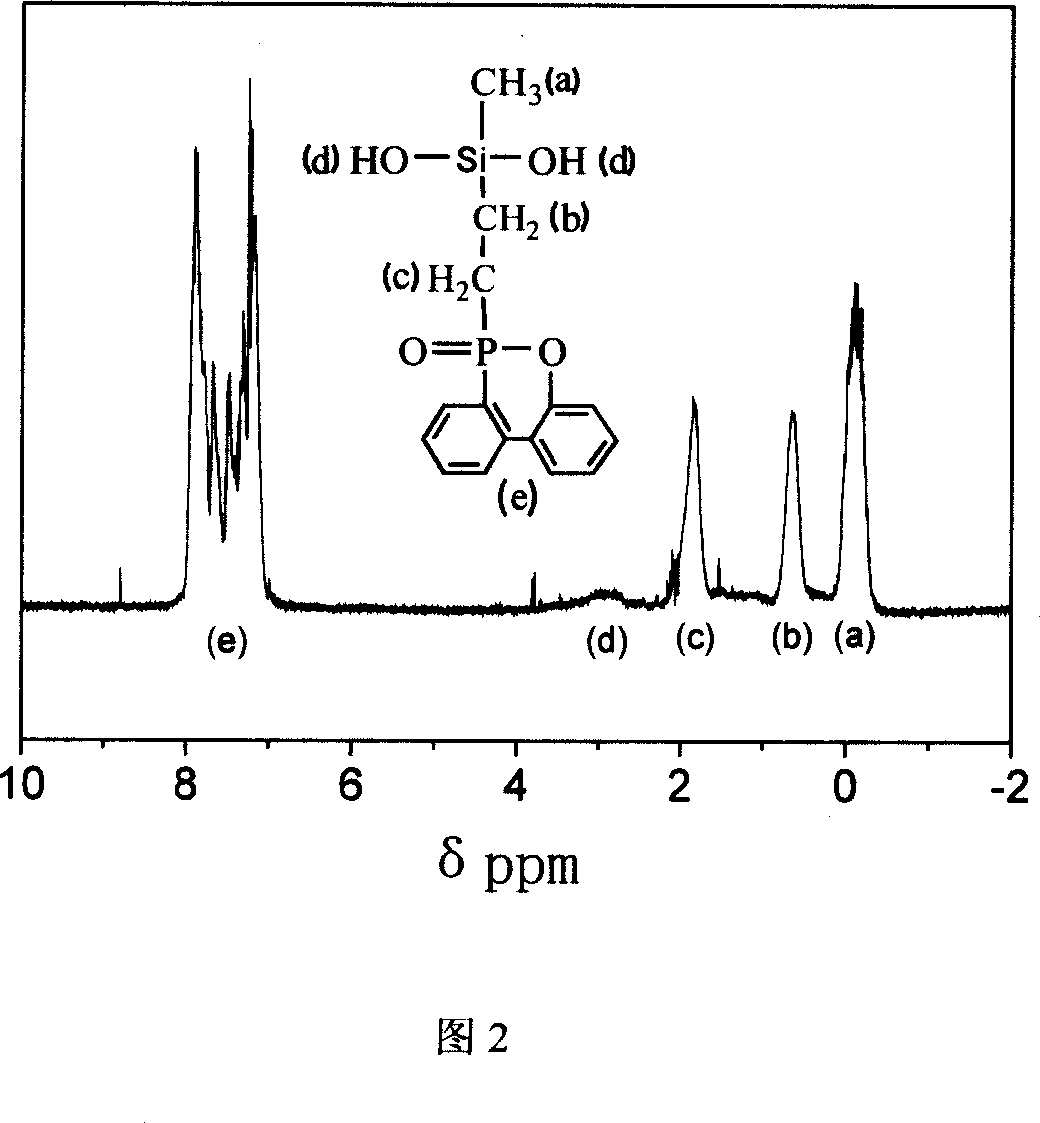

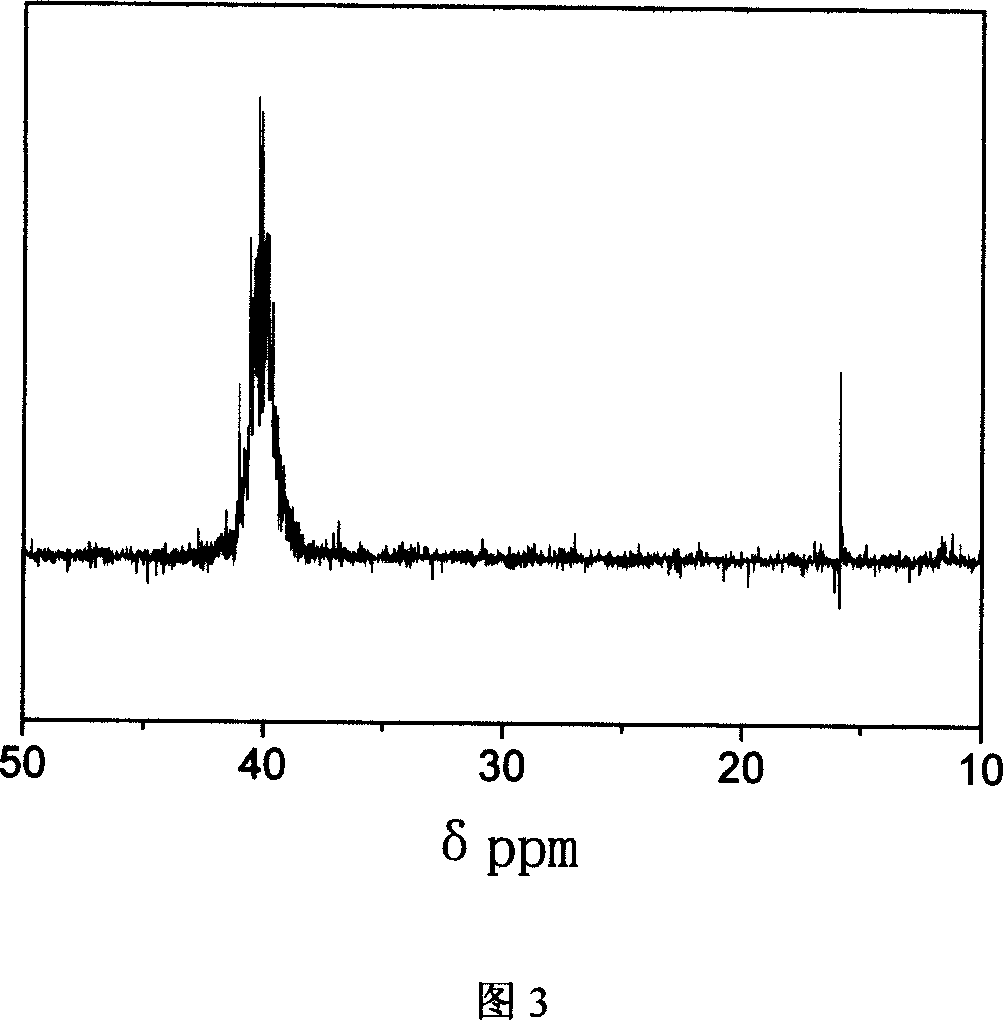

Organic silicon compound containing phosphorus and its preparing method

The present invention discloses one kind of organosilicon compound containing phosphorus and its preparation process, and the compound contains two fire-retarding elements, Si and P, and hydroxyl groups and may be used as the reaction type fire-retarding intermediate. The materials 9, 10-dihydro-9-oxo-10-phosphaphenanthryl-10-oxide (DOPO) and siloxane containing C-C double bond are heated to produce addition reaction, and water and catalyst are then added to hydrolyze alkoxy radical to prepare the organosilicon compound containing phosphorus and hydroxyl groups. The organosilicon compound containing phosphorus and hydroxyl groups is superior to DOPO in that it contains several functional groups and thus may be polycondensated with other substance to prepare macromolecular fire retardant.

Owner:CHANGZHOU BAYI CABLE

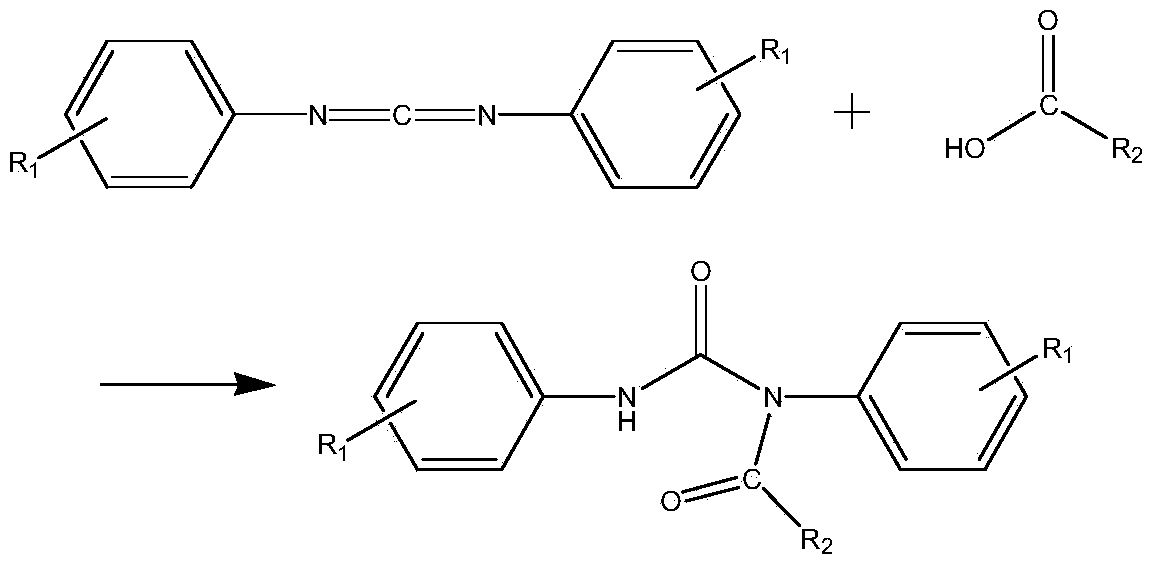

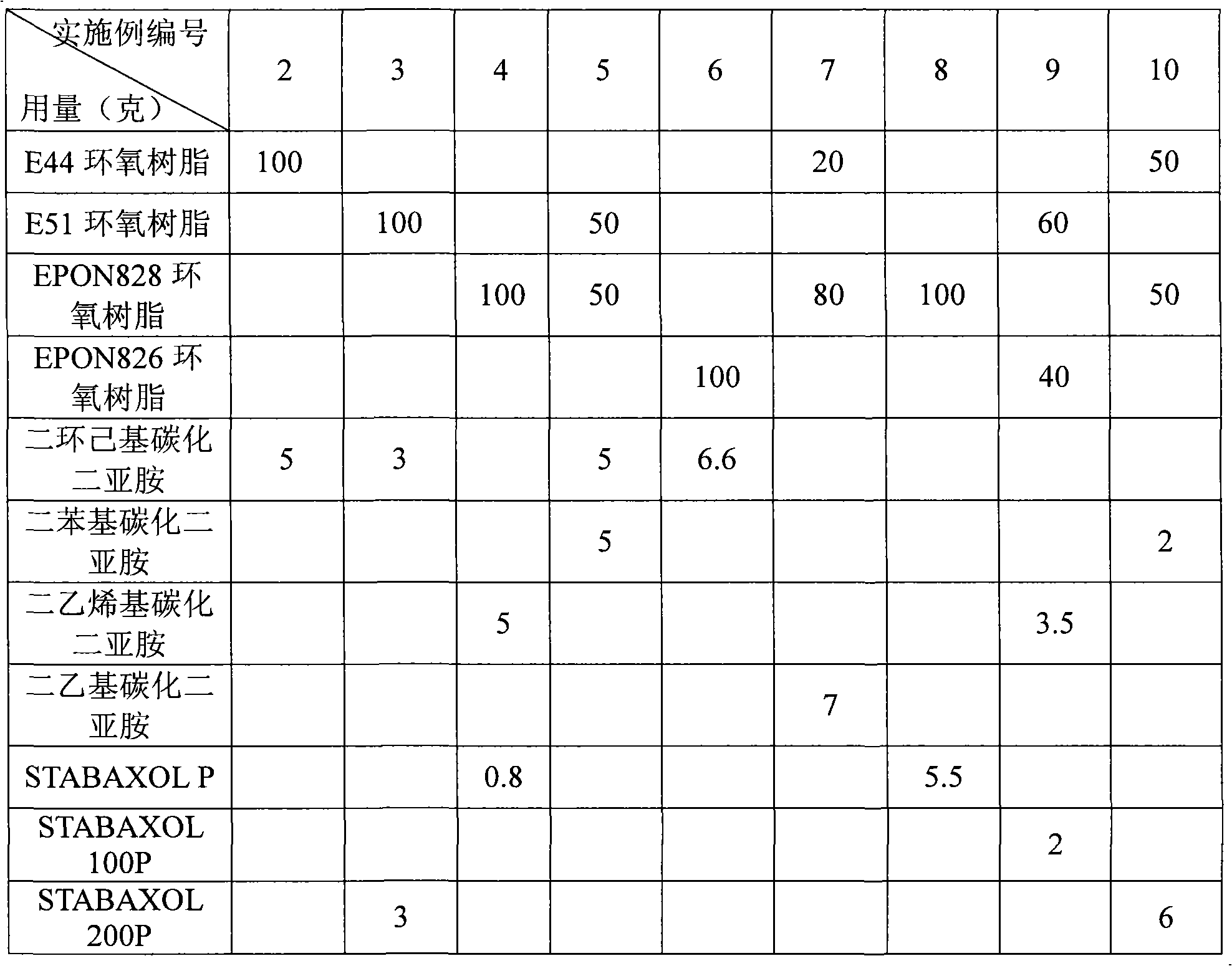

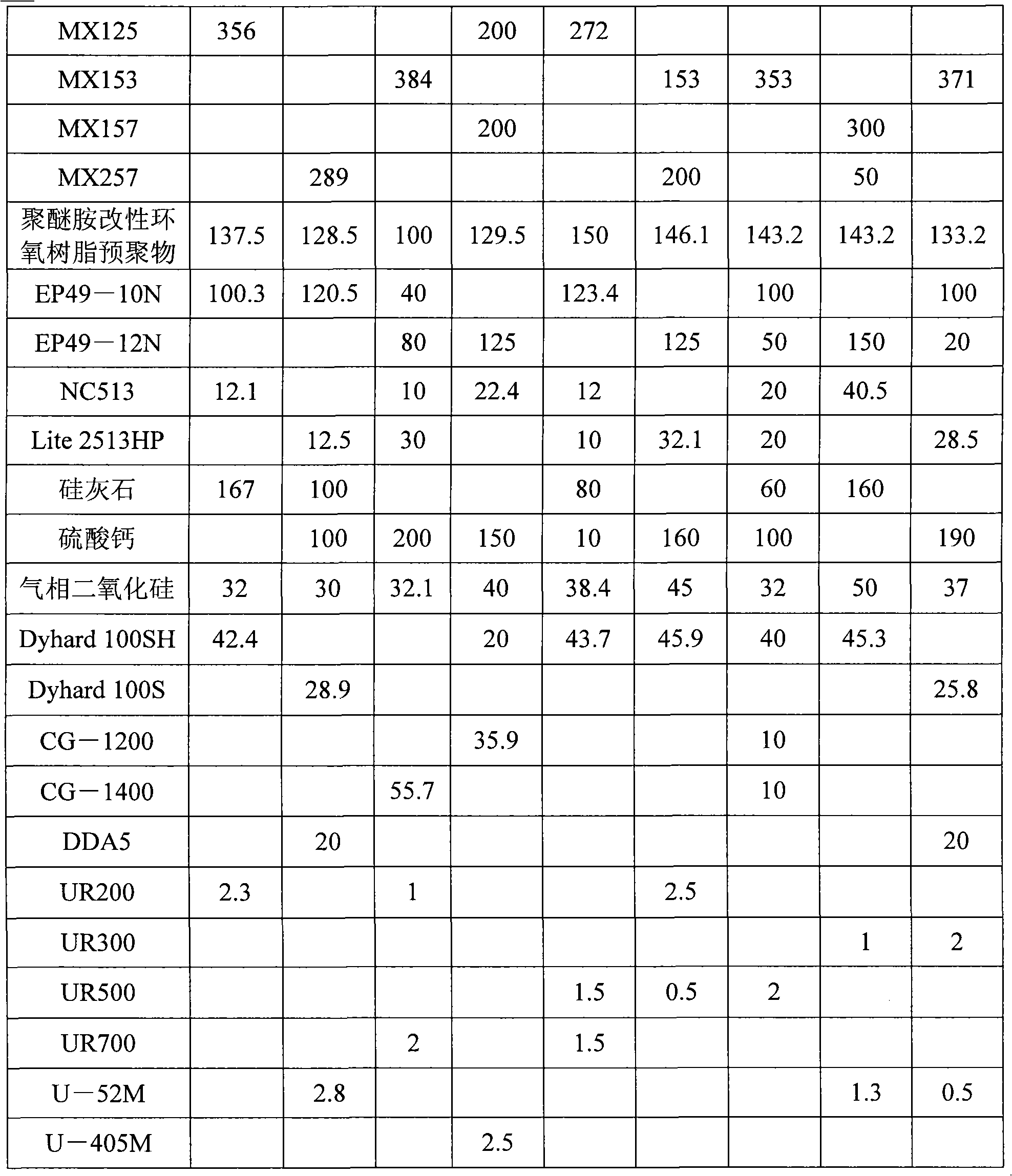

Adhesive composition with single-component epoxy structure

InactiveCN102911631AGood moisture and heat aging resistanceIncreased shear strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyDiluent

The invention relates to an adhesive composition with a single-component epoxy structure. The adhesive composition comprises at least one unmodified epoxy resin, a toughness modified epoxy resin, a polyether amine modified epoxy prepolymer, a damp and heat ageing resistant additive comprising a carbodiimide structure, a curing agent, an optional curing accelerator, an optional phosphating modified epoxy resin, and one or more of other optional components as follows: a filling, a monofunctional epoxy reaction type diluent, a thixotropic agent and a mixture thereof.

Owner:HENKEL CORP

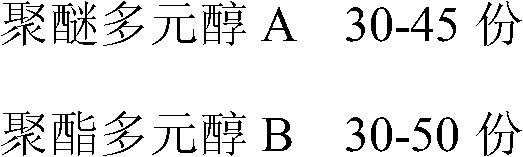

Spraying and wind leaking stoppage polyurethane combined polyether for coal mine as well as preparation and use methods thereof

InactiveCN102585139AReduce dosageFine cellsUnderground chambersTunnel liningHigh resistanceChemical synthesis

The invention belongs to the field of chemical synthesis and in particular relates to a spraying and wind leaking stoppage polyurethane combined polyether for a coal mine as well as preparation and use methods thereof. According to the invention, the polyether is prepared through formulation regulation by using HCFC (hydrochlorofluorocarbon)-365mfa and / or HCFC-245fa as foaming agents, is free of fluorine and is environment-friendly; because the boiling point of HCFC-245fa is low, prepared foam is good in size stability; a reaction type amine catalyst with low VOC (volatile organic compound) and low smell is applied, thus the problem of irritative smell is solved; and the foam prepared by using a fire retardant is good in fire retardant property, and an antistatic agent is added so as to improve the problem of high resistance on the surface of polyurethane foam.

Owner:SHANGHAI DONGDA POLYURETHANE

High-water-resistance acrylate emulsion and preparation method thereof

The invention provides a high-water-resistance acrylate emulsion. The emulsion comprises the following raw materials in percentage by weight: 20%-25% of styrene, 15%-20% of butyl acrylate, 3%-5% of methyl methacrylate, 1%-3% of acrylic acid, 1%-2% of organic silicon monomer, 1%-2% of mixed emulsifying agent, 0.5% of sodium bicarbonate, 0.5% of initiator and the balance of water. According to the invention, in the emulsion polymerization process, a reaction type emulsifying agent is adopted to carry out a polymerization reaction, and the emulsifying agent is polymerized to a large molecule chain in the polymerization process, thereby reducing the transfer of the emulsifying agent in a paint film, reducing the water adsorption rate of the paint film and improving water resistance; through adopting a nucleus-shell polymerization process, a shell polymerization part is subjected to copolymerization modification with organic silicon, so that a hydrophobic structure is formed on the surface of a latex particle, thereby improving the water resistance after film formation finally; and through the synergistic effect of the two methods, the water resistance of the prepared emulsion is greatly improved and the prepared emulsion can be widely applied to production and preparation of paints for inner and outer walls.

Owner:GANSU JINDUN CHEM

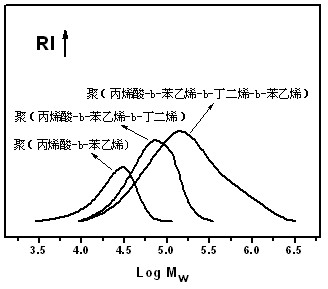

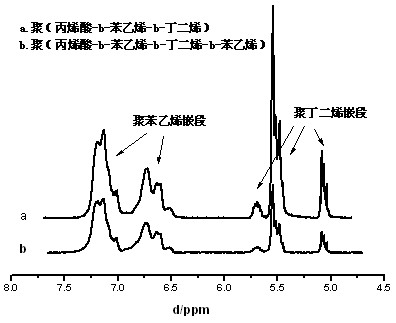

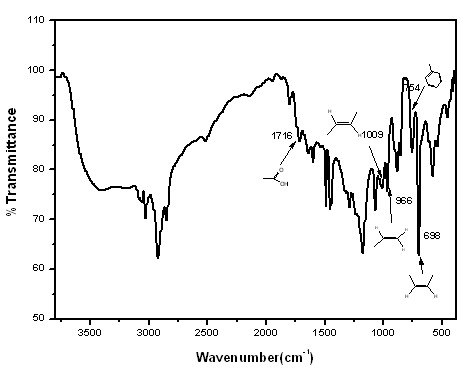

Poly-((methyl) crylic acid-b-styrene-b-butadiene-b-styrene) segmented copolymer latex and preparation method thereof

The invention discloses a poly-((methyl) crylic acid-b-styrene-b-butadiene-b-styrene) segmented copolymer latex and a preparation method thereof. An amphiphilic macromolecule reversible addition fracture chain transfer reagent adopted by the latex not only serves as a chain transfer reagent but also serves as a reaction type emulsifier. Stable poly-((methyl) crylic acid-b-styrene-b-butadiene-b-styrene) segmented copolymer latex is directly obtained through emulsion polymerization reaction. The preparation method is simple, environment-friendly and energy-saving in process, and the poly-((methyl) crylic acid-b-styrene-b-butadiene-b-styrene) segmented copolymer latex product has broad application prospects in the fields of modified asphalt, adhesives, polymer toughening modification and thelike.

Owner:ZHEJIANG UNIV

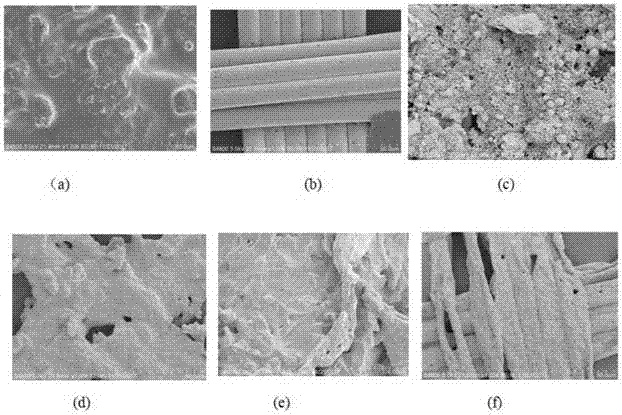

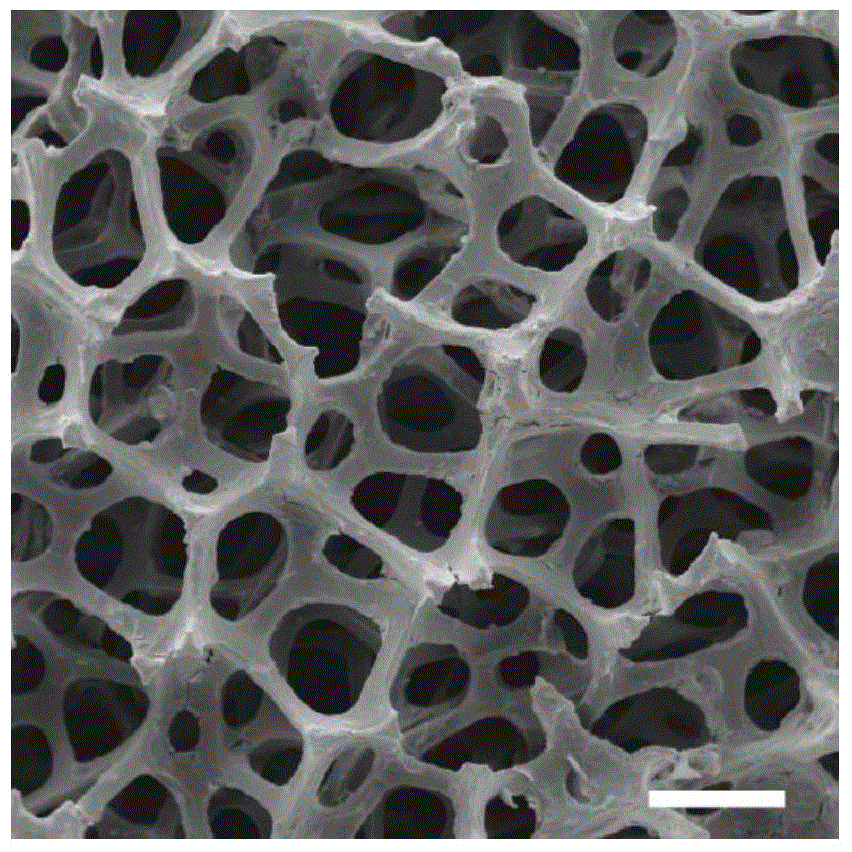

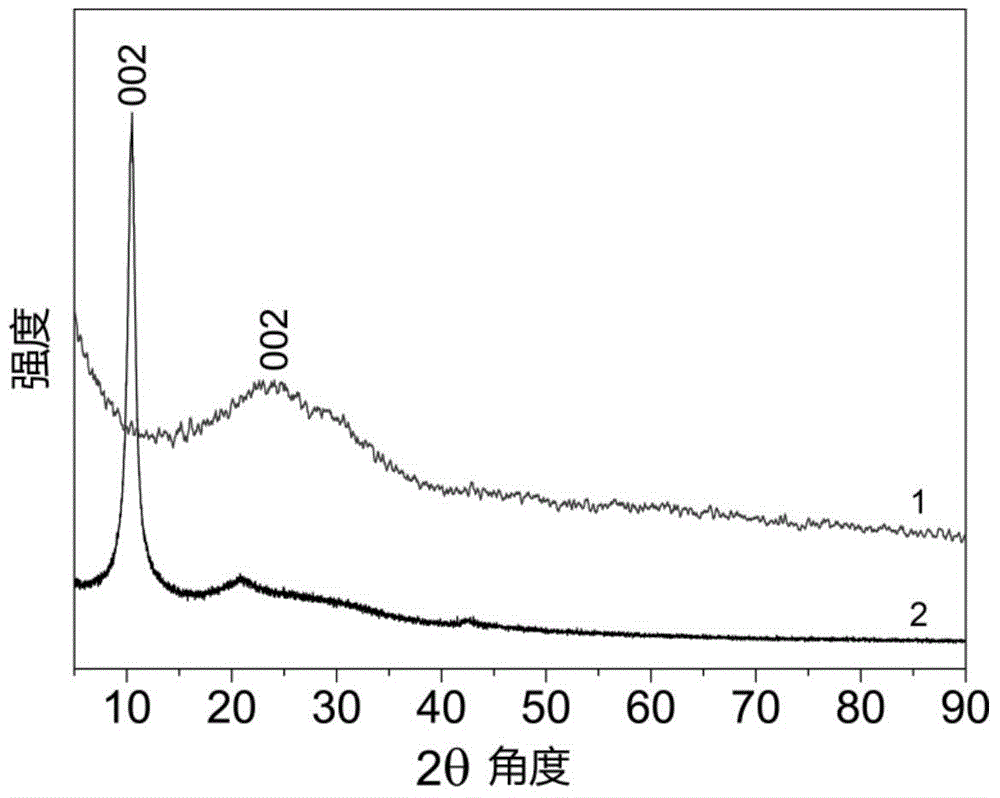

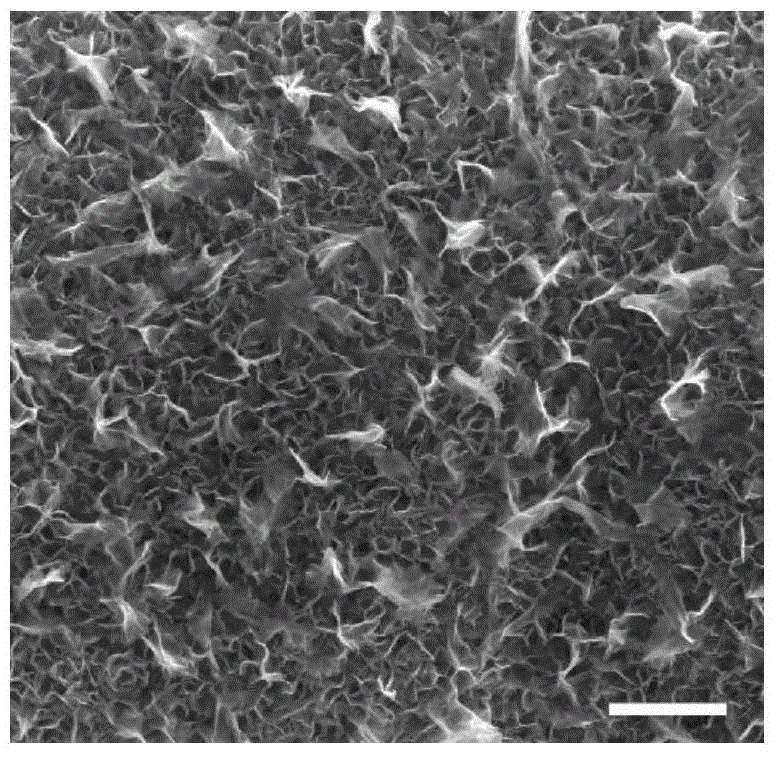

Method for preparing directly soaking reaction type foamed nickel-graphene three-dimensional porous electrode

ActiveCN104600238AImprove reaction speed and product characteristicsPromotes spontaneous growthElectrode manufacturing processesLiquid/solution decomposition chemical coatingReaction rateReaction temperature

The invention discloses a method for preparing a directly soaking reaction type foamed nickel-graphene three-dimensional porous electrode. The method comprises the following steps: cleaning foamed nickel by adopting glacial acetic acid, acetone and ethanol sequentially; cleaning the foamed nickel by using deionized water, airing and standing; preparing graphene oxide aqueous solution with the mass concentration of 0.5-5mg / mL, directly soaking the foamed nickel into the solution, standing, and reacting to form the foamed nickel-graphene product of a three-dimensional porous structure, wherein the reaction temperature is controlled to be 30-80 DEG C in the soaking process, and the soaking time is 2-6 hours. According to the method, the reduction reaction can be rapidly finished by virtue of a simple and easily controlled soaking process only, direct deposited growth of graphene on the surface of the substrate is realized based on a substrate-enhanced effect of the foamed nickel, the product with the three-dimensional porous structure and high specific surface area is formed, the overall reaction rate is correspondingly and greatly improved, and the method is particularly suitable for large-scale production purposes.

Owner:HUAZHONG UNIV OF SCI & TECH

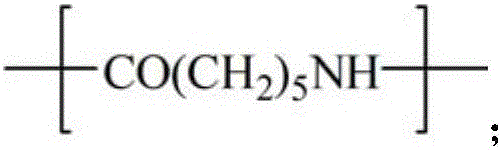

Flame-retarded polyamide 6 and preparation method thereof

The invention relates to flame-retarded polyamide 6 and a preparation method thereof. The preparation method comprises the steps of firstly obtaining flame retardant salt through reaction between a DOPO-based reaction type phosphorus-based flame retardant and diamine; then adding an addition type phosphorus-based flame retardant, the flame retardant salt and other components during a process of polymerizing caprolactam into polyamide 6 so as to prepare the flame-retarded polyamide 6, wherein a molecular chain of the flame-retarded polyamide 6 is formed by a polyamide chain segment and a DOPO-based reaction type phosphorus-based flame retardant chain segment; the content of phosphorus in the molecular chain is 0.4 to 0.8 percent by weight; and the molecular chain contains 3 to 9 percent by weight of the addition type phosphorus-based flame retardant. The flame-retarded polyamide 6 prepared through the invention has the limit oxygen index being larger than 29 percent, the tensile strength ranging from 55 to 69MPa, the elongation at break ranging from 40 to 110 percent, can become gears, bearings, automobile parts and other products through injection molding and other methods, and can also be prepared into polyamide 6 fiber so as to be further processed to be textile, military fabrics, equipment and the like.

Owner:DONGHUA UNIV

Acrylic ester pressure-sensitive adhesive with high permanent adhesion performance at 80 DEG C and preparation method thereof

InactiveCN106520033AIncrease stickinessPaste tightlyMacromolecular adhesive additivesEster polymer adhesivesFunctional monomerPolymer science

The invention relates to an acrylic ester pressure-sensitive adhesive with the high permanent adhesion performance at 80 DEG C. The acrylic ester pressure-sensitive adhesive is prepared from, by weight, 55-90 parts of acrylic ester soft monomers, 5-25 parts of acrylic ester hard monomers, 0.5-15 parts of reaction-type functional monomers, 0.2-3 parts of an initiating agent, 5-30 parts of tackifying resin, 0.5-5 parts of a curing agent and 60-200 parts of a solvent. The acrylic ester pressure-sensitive adhesive is prepared through the processes that the acrylic ester soft monomers, the acrylic ester hard monomers, the reaction-type functional monomers and part of the initiating agent are dissolved, the total concentration of the monomers is controlled to be not lower than 60 wt%, the weight of the initiating agent accounts for 0.04%-0.1% of the total weight of the monomers, and heating reflux is conducted for 3-6 h; the remaining initiating agent is dropwise added, reacting continues for 0.5-2 h after dropwise adding, diluting and reacting are conducted step by step, and the obtained material is uniformly mixed with the tackifying resin and the curing agent. According to the pressure-sensitive adhesive prepared through the method, the performance is excellent, and a permanent adhesion performance test shows that displacement is not generated after the pressure-sensitive adhesive exists for 48 h at 80 DEG C.

Owner:WUXI HAITE NEW MATERIAL RES INST +1

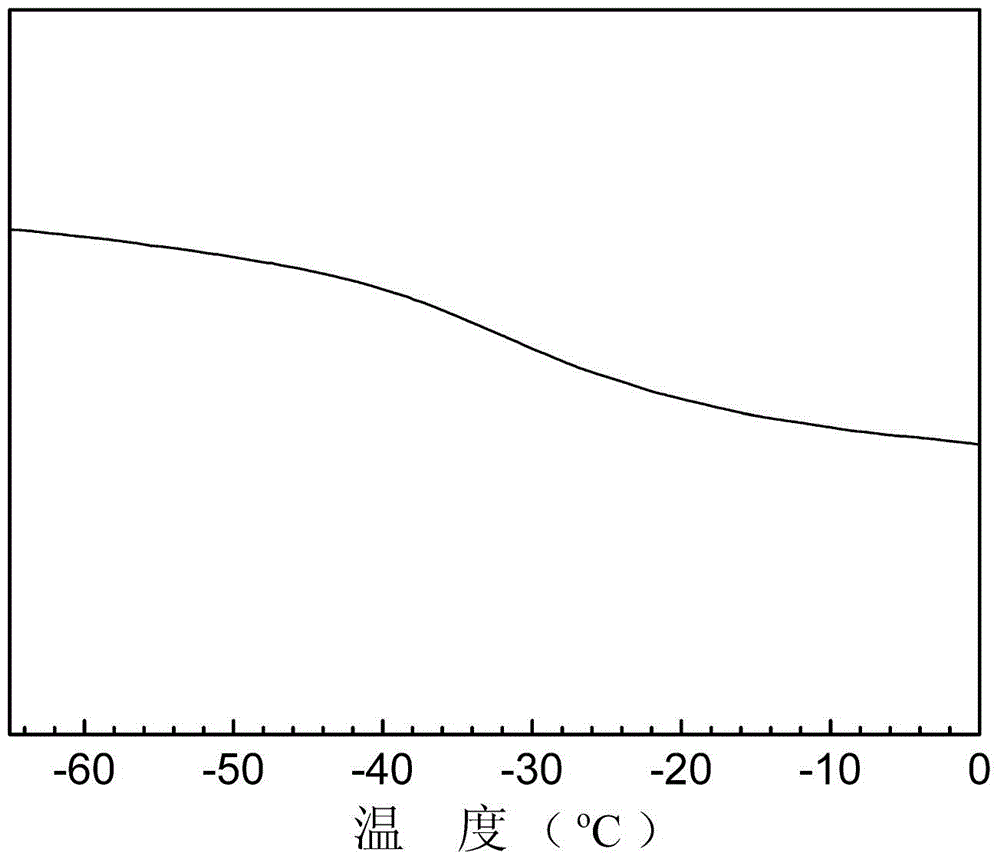

Bi-component reaction-type flame-retardant waterborne polyurethane and preparation method thereof

The invention discloses bi-component reaction-type flame-retardant waterborne polyurethane and a preparation method thereof. Although the present single-component waterborne polyurethane has convenient construction, multiple performances of the present single-component waterborne polyurethane such as water resistance, solvent resistance, chemicals resistance, abrasion resistance, hardness and the like cannot reach the requirement of the performance of the solvent-type polyurethane. The bi-component reaction-type flame-retardant waterborne polyurethane consists of a component A and a component B, wherein the mass ratio of the components A and B is 5 to 15:1, the component A is obtained by dispersing prepolymer which is synthesized by non-flame-retardant polyalcohol, flame-retardant polyalcohol, diisocyanate, hydrophilic chain extender and catalyst into neutralizer water solution, and the component B is of hydrophilia polyisocyanates curing cross-linking agent. The polyisocyanates is used as the cross-linking agent for crosslink and curing, so the crosslink density of the waterborne polyurethane is greatly improved, and the performance of the water borne polyurethane can be equaled to that of the solvent polyurethane coat.

Owner:传化智联股份有限公司 +2

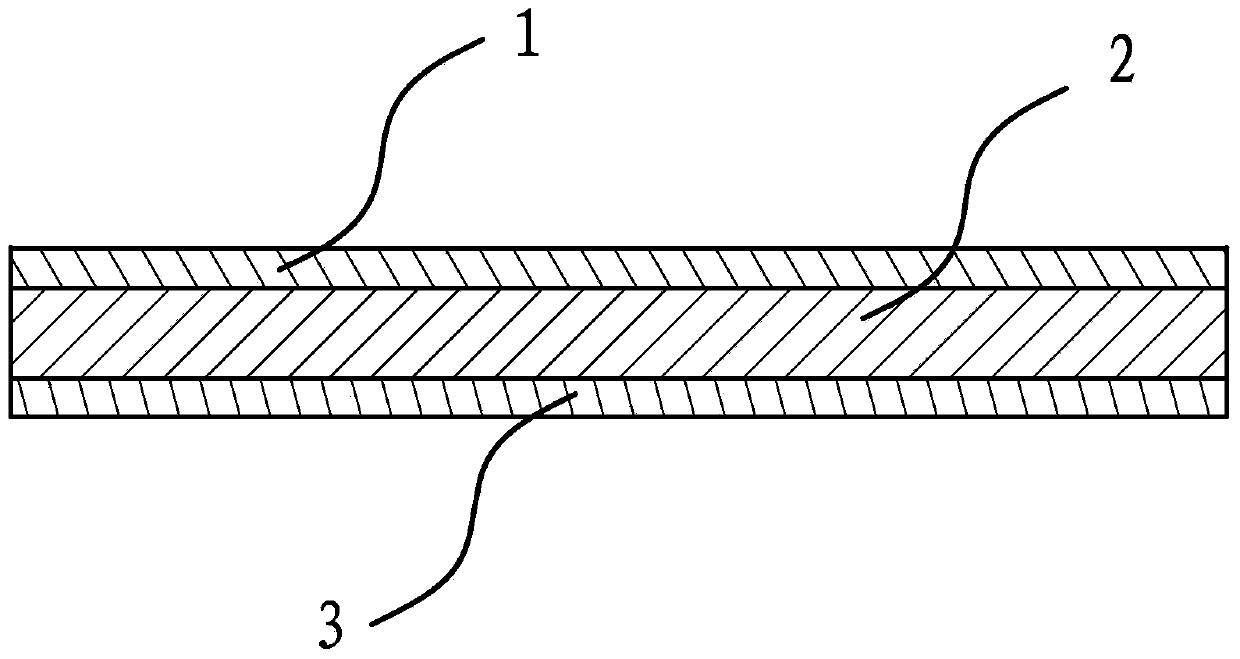

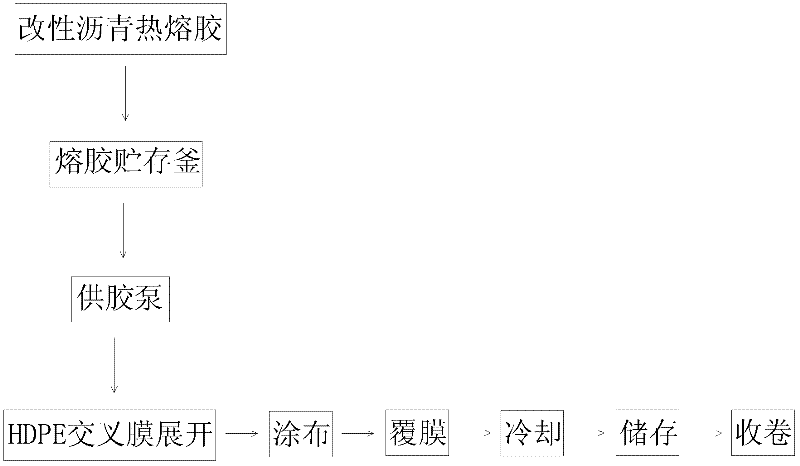

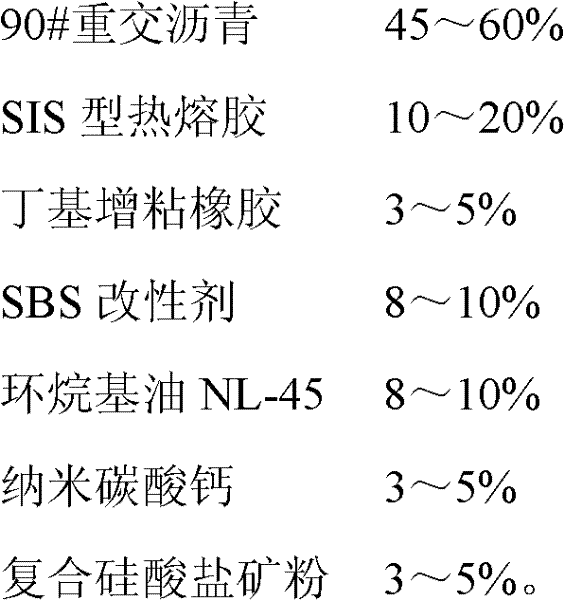

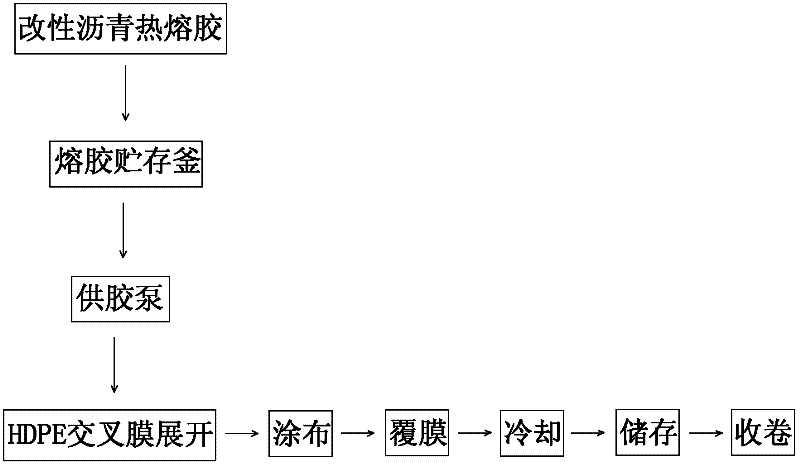

Reaction-type high-strength laminated film waterproof roll

InactiveCN102604553ASolve the problem of poor UV and weather resistanceNot easy to ageNon-macromolecular adhesive additivesUnderground chambersCross-linkAging resistance

The invention discloses a reaction-type high-strength laminated film waterproof roll which comprises a layer of high-strength cross laminated film (HDPE, high-density polyethylene) with thickness of 0.10-0.14mm and a layer of modified asphalt super glue which can react with cast-in-place concrete and is solidified together with the cast-in-place concrete. The waterproof roll can be chemically cross-linked and physically blended with concrete; under the effect of a coagent, a bonding layer can be continuously and permanently bonded with a base layer processing agent or the concrete poured on the bonding layer so as to completely prevent water from permeating into a clearance between the waterproof roll and the structure and form a skin-type net-shaped integer together with the base surface. Since the high-strength cross laminated film of special material HDPE has good tensile strength, breaking elongation rate and anti-puncture capability, the self-adhered waterproof roll of the high-strength cross film has the advantages of relatively good tensile strength, breaking elongation rate, anti-puncture capability and aging resistance.

Owner:KESHUN WATERPROOF TECH CO LTD

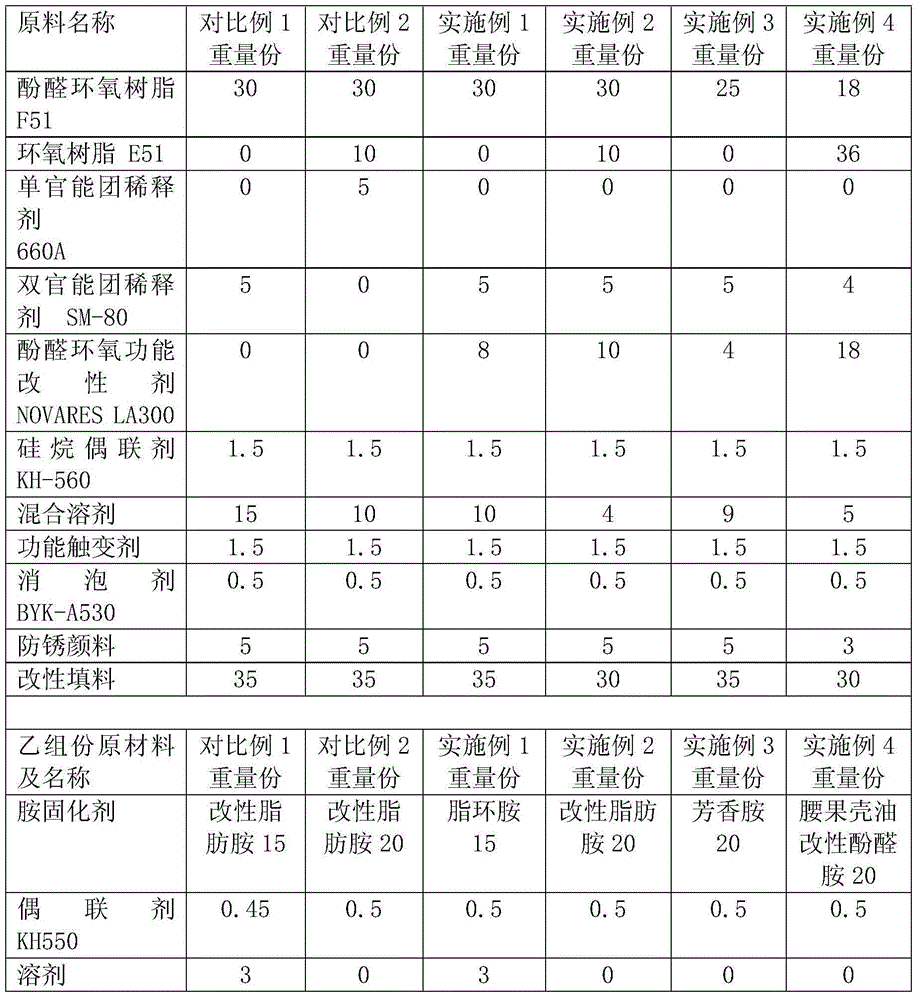

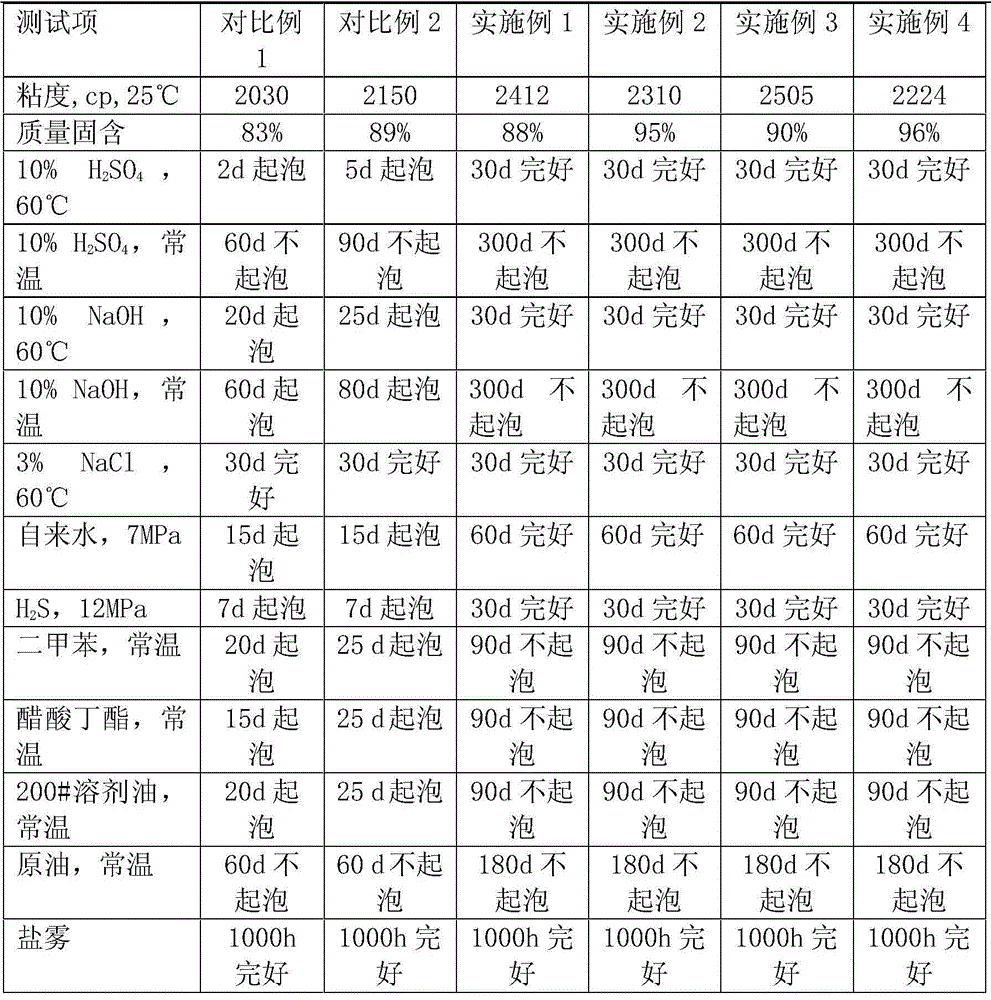

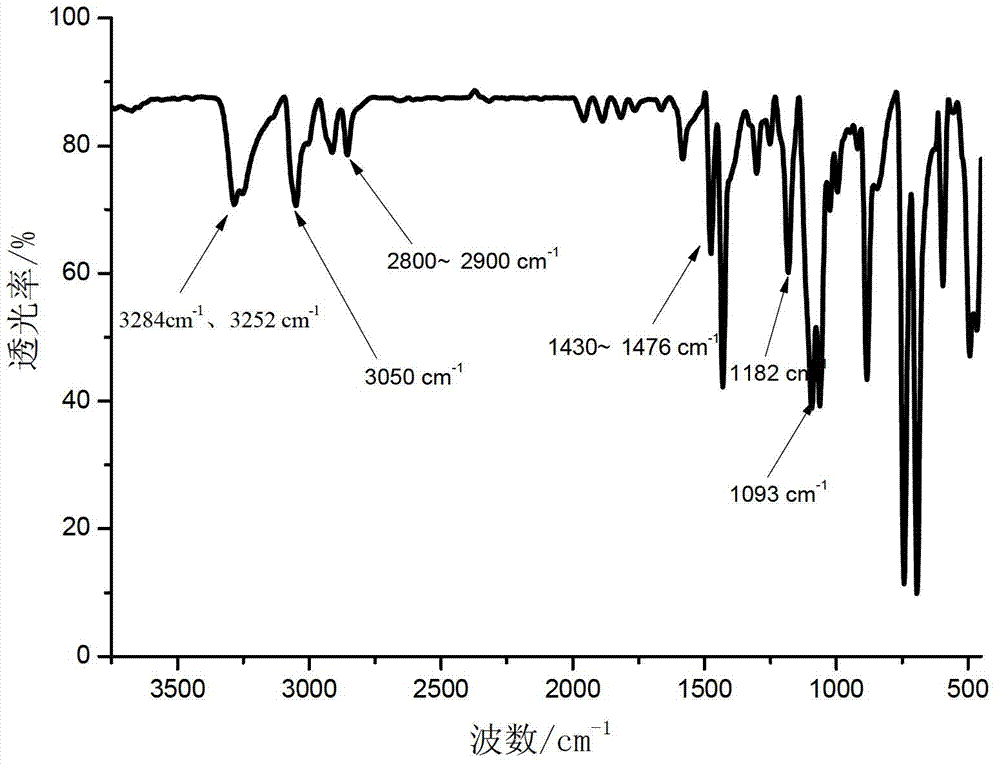

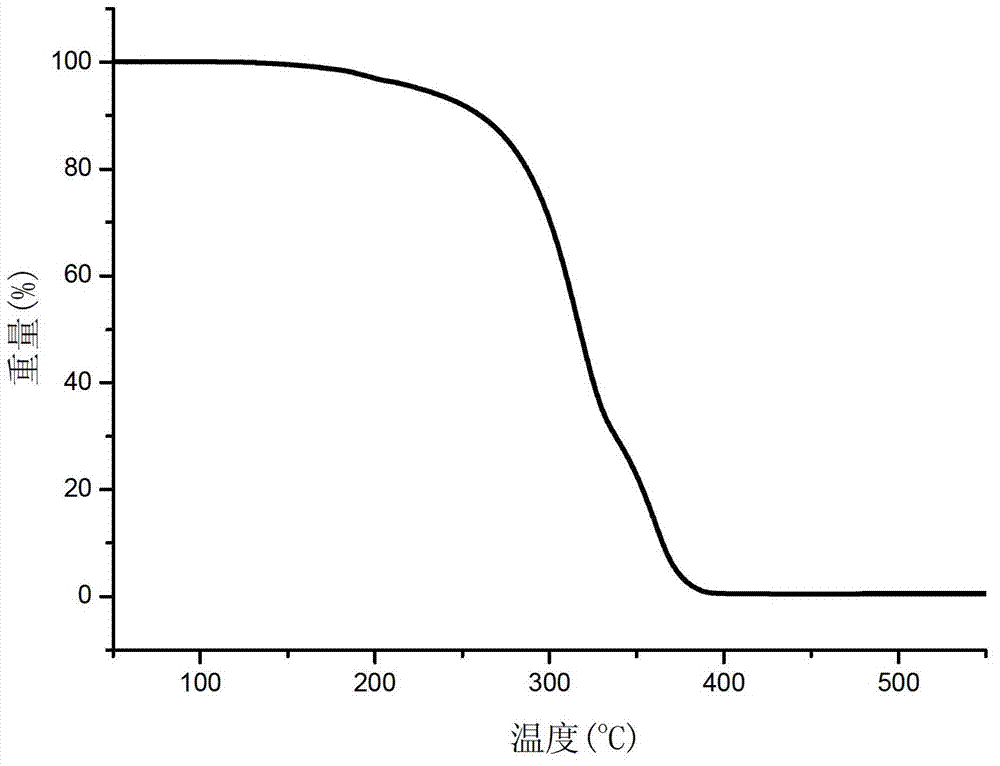

Phenol aldehyde epoxy paint with chemical medium resistance and preparation method thereof

ActiveCN104087124AIncreased resistance to chemical mediaImprove toleranceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention discloses phenol aldehyde epoxy paint with lasting electrical conductivity and a preparation method thereof, and belongs to the paint field. The phenol aldehyde epoxy paint comprises a component A and a component B, wherein the component A consists of the following components in percentage by mass of 20-60% of epoxy resin, 3-20% of phenol aldehyde epoxy functional modifier, 3-15% of reaction type epoxy diluents, 4-25% of solvent, 0.1-1% of anti-foaming agent, 2-10% of rust-proof pigment, 0.1-2% of coupling agent, 0.5-3% of functional thixotropic agent, 25-67% of modifying filler; the component B consists of the following components in percentage by mass of 97-99.5% of amine curing agents, 0-20% of solvent, 0.5-3% of coupling agent. Mass solids of the phenol aldehyde epoxy paint disclosed by the invention are over 95%, so that solid content is high; moreover, the rust-proof pigment is partly added for being used as rust-proof paint, and therefore, the phenol aldehyde epoxy paint has relatively good fog mist resistance and seawater resistance, satisfies interior-exterior anticorrosive coating, and the like of the conventional ship industry and the chemical plant, has relatively high performance for resisting chemical media such as acid-base, and the like, and particularly has thermal acid-base resistance.

Owner:XIAMEN SUNRUI SHIP COATING

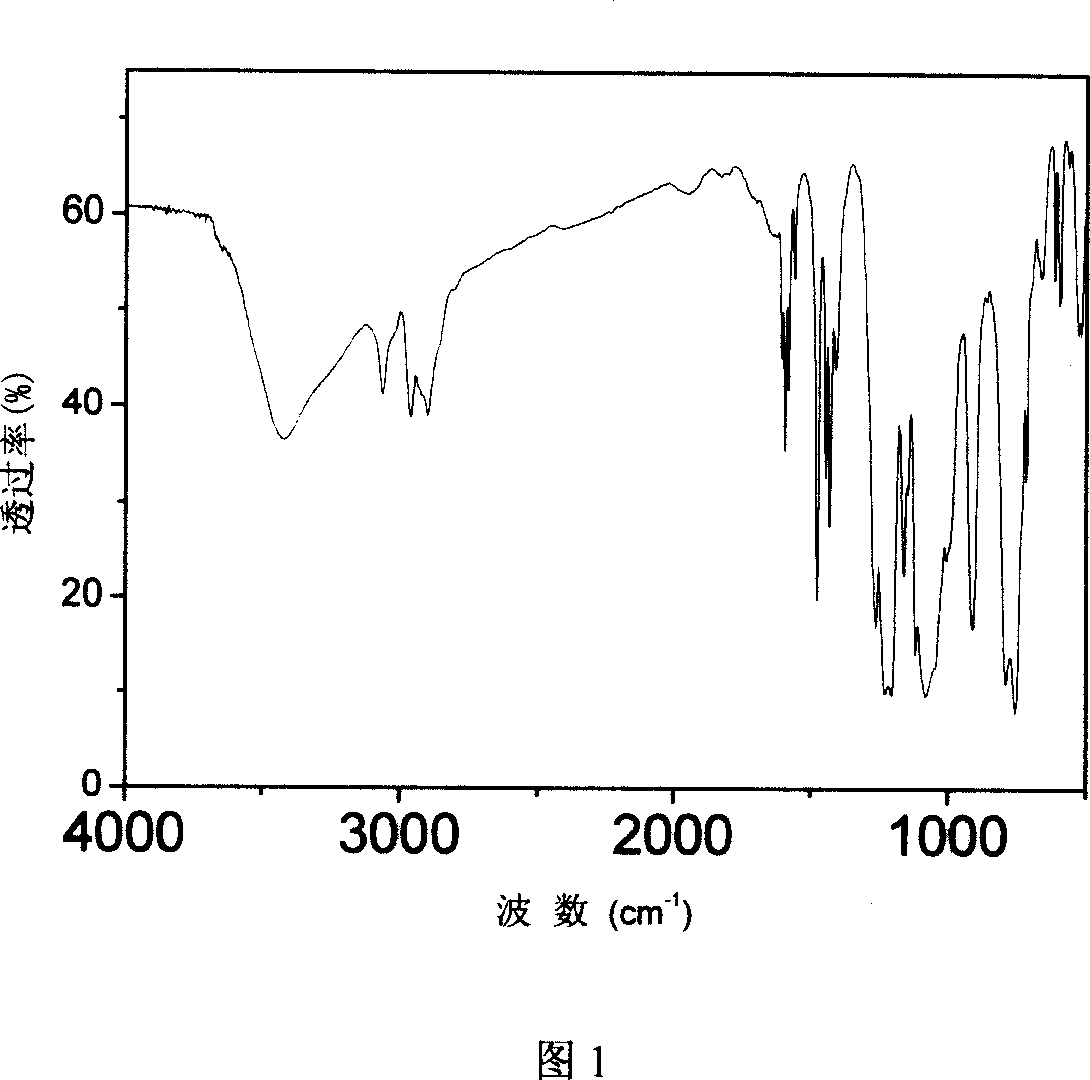

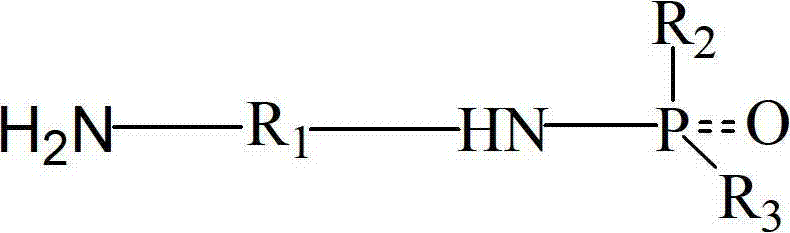

Reaction type phosphorus-nitrogen fire retardant and synthesizing method thereof

InactiveCN102757580ASimple preparation processNo complicated post-processingNon-macromolecular adhesive additivesGroup 5/15 element organic compoundsFiberChemical Linkage

The invention discloses a reaction type phosphorus-nitrogen fire retardant and a synthesizing method of the reaction type phosphorus-nitrogen fire retardant. The synthesizing method comprises the following steps: adding a diamido compound into a reaction container containing solvents, adding an acid-binding agent, then adding phosphorus chlorine compound or phosphorus oxychloride compound, stirring uniformly, adjusting the temperature to 50 DEG C-90 DEG C, and reacting for 5-15h at constant temperature; filtering, washing a filter cake with water repeatedly and filtering or dissolving the filter cake with a strong-polarity solvent, and drying to obtain the reaction type phosphorus-nitrogen fire retardant. According to the reaction type phosphorus-nitrogen fire retardant and the synthesizing method of the fire retardant, the synthesizing method is simple, is free of complicated aftertreatment and is easy to implement; and the reaction type phosphorus-nitrogen fire retardant is high in thermal stability, active amido functional groups contained in molecules of the fire retardant have chemical bonding with polymer or polymer raw materials, so that the reaction type phosphorus-nitrogen fiber retardant can be mixed with substrate materials, and can be applied to polymers with various substrate materials.

Owner:GUANGDONG JUSHI CHEM CO LTD +1

Solvent type polyurethane structure adhesive and preparation method thereof

InactiveCN104893644ADouble curing effectPlay the effect of curing cross-linkingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyurethane adhesive

The invention discloses a method for preparing a solvent type polyurethane structure adhesive. The method is characterized in that an isocyanate solidifying agent sealed by a sealing agent and a polyurethane prepolymer at the sealed end of hydroxyl group are mixed to obtain a polyurethane adhesive, or the polyurethane prepolymer sealed by the sealing agent and a trihydroxy compound are mixed, or the polyurethane prepolymer sealed by the sealing agent and the isocyanate solidifying agent sealed by the sealing agent are mixed to be added into an adsorbing filling material to obtain the polyurethane adhesive. When in use, the adhesive is heated and unsealed to obtain the isocyanate solidifying agent or polyurethane prepolymer containing NCO, and reacts with polyurethane prepolymer or the trihydroxy compound to obtain cross-linked and cured polyurethane. The adhesive can be stably stored at the room temperature, can be heated to obtain reaction type bi-component when in construction, and is different from the conventional bi-component solvent type polyurethane which wastes time in the processes of metering, mixing and the like, the construction process is simple, the performance adjustment of the single component polyurethane system is realized, and the unsealed unsealing agent cannot overflow.

Owner:UNIV OF SCI & TECH OF CHINA

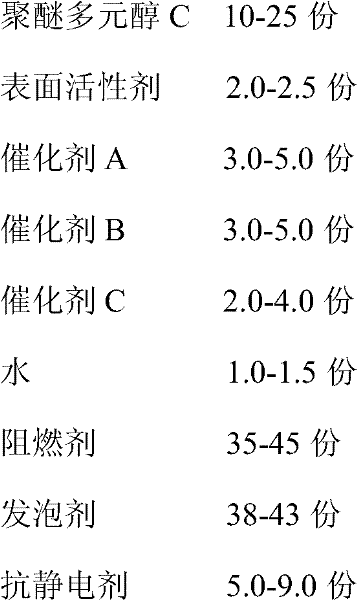

Environment-friendly flame-retardant polyurethane wood-imitation material

The invention belongs to the field of chemical synthesis, and in particular relates to an environment-friendly flame-retardant polyurethane wood-imitation material, which is characterized by comprising a component A and a component B, wherein the component A consists of polyether polyalcohol, a foam stabilizer, a catalyst, a foaming agent and a flame retardant; and the component B is polymethylene polyphenyl polyisocyanate. A method for preparing the environment-friendly flame-retardant polyurethane wood-imitation material comprises the following steps of: mixing and stirring the component A and the component B, injecting the components into a constant-temperature die at the temperature of between 40 and 50 DEG C, reacting and curing for 10 to 13 minutes to obtain the environment-friendly flame-retardant polyurethane wood-imitation material. The invention has the advantages that due to the adoption of the reaction type catalyst, the generation of volatile gas is prevented, and the harm to the health of human bodies is reduced greatly; water is used as the single foaming agent instead of the conventional hydrochlorofluorocarbon (HCFC)-141B foaming agent, so that the consumption of an ozone layer is reduced effectively; and demolding can be performed after 10 to 13 minutes during production, so that the production efficiency is improved greatly.

Owner:SHANGHAI DONGDA POLYURETHANE

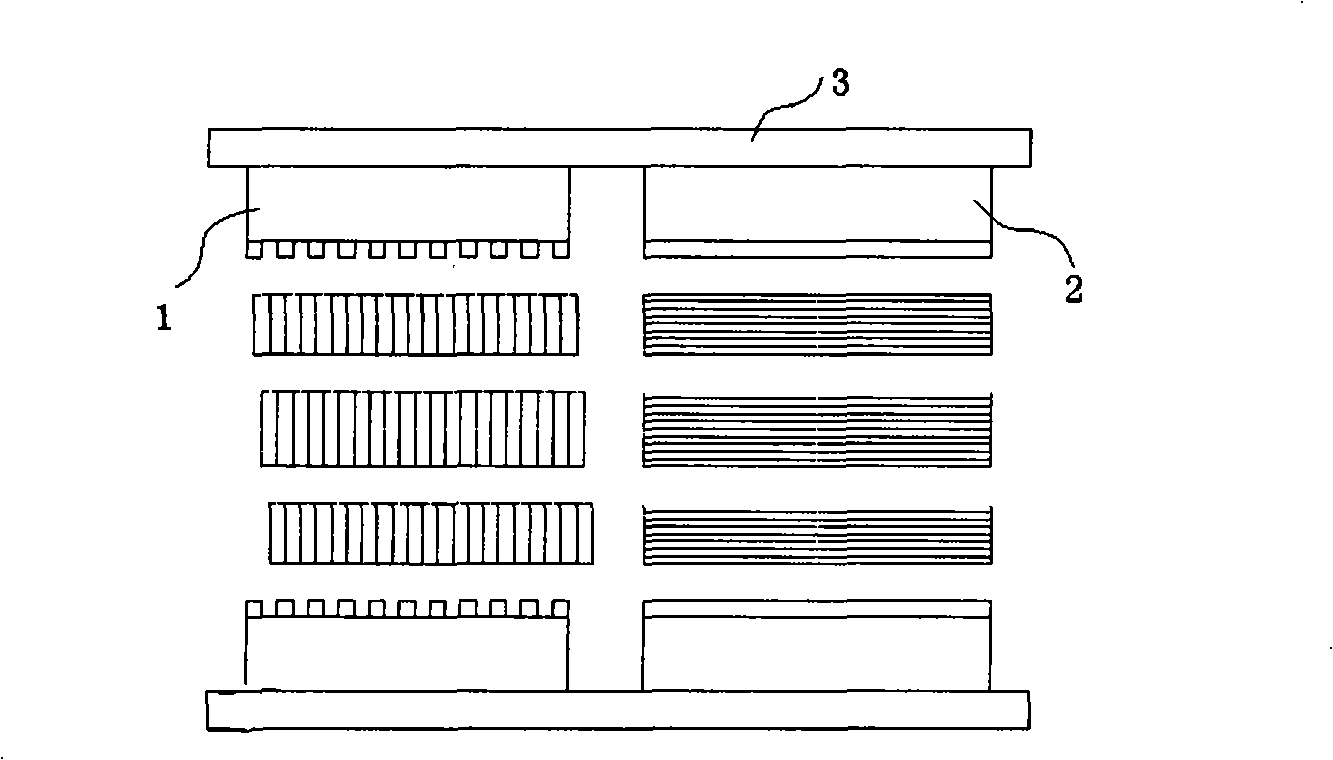

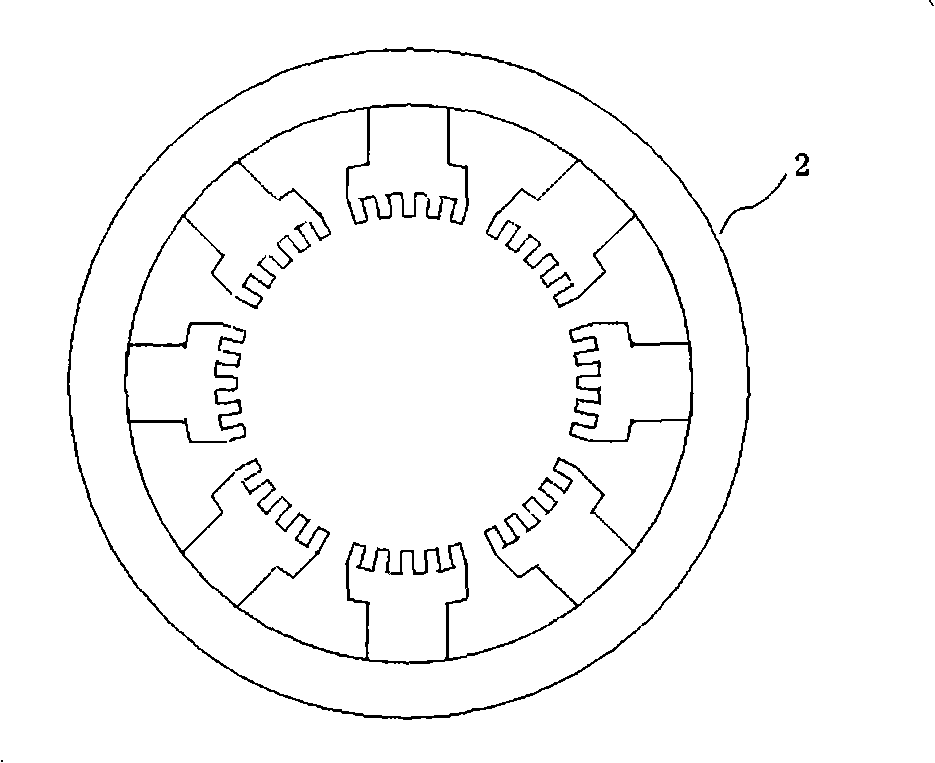

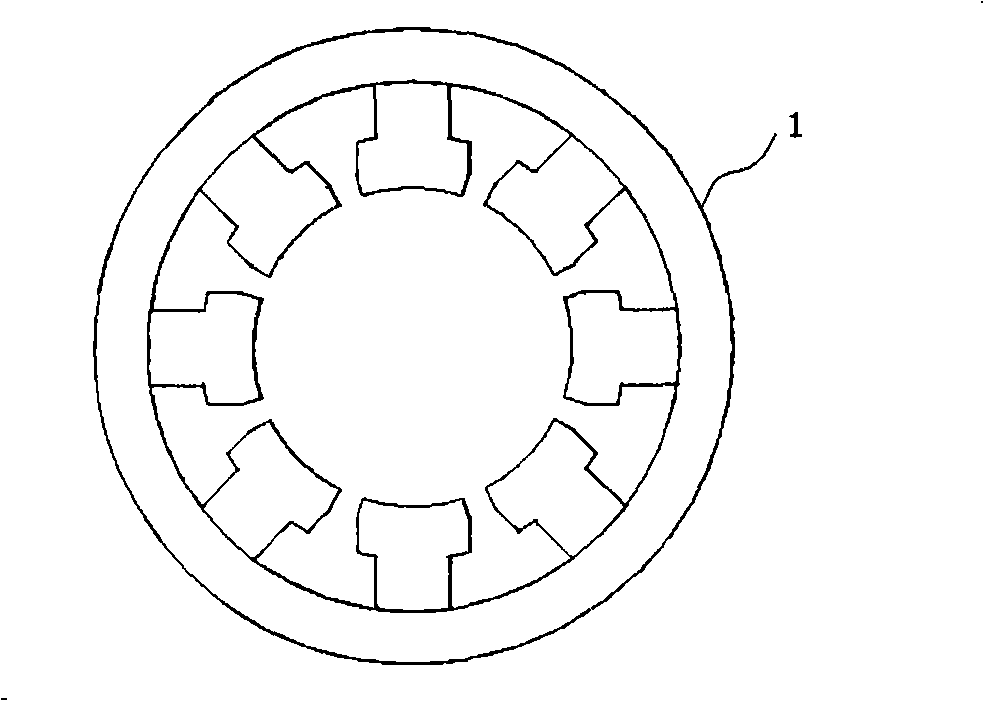

Dual radial directions magnetic field reaction type straight-line rotating stepper motor

InactiveCN101355290ASimple structureSimple processing technologyPropulsion systemsElectric machineMagnetic poles

The invention relates to a biradial magnetic field reactive linear rotary stepping motor. The two sections of magnetic poles of a stator of the stepping motor generate an axial magnetic field and a radial magnetic field which are intersected. A magnetic path of a rotor has two space radial magnetic flux paths so that the rotor structure is greatly simplified and the lamination structure is used, thereby increasing the magnetic conductivity of the rotor and reducing the magnetic reluctance of the magnetic path and the volume of the motor. The stepping motor not only can move linearly but also rotate and do spiral motion. Compared with the reluctance linear stepper motor, the biradial magnetic field reactive linear rotary stepping motor has a simple structure and simple processing technique due to the absence of a permanent magnet, simply needs a unipolar drive power supply in the control aspect, and has a simple control circuit, low total cost and high reliability.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

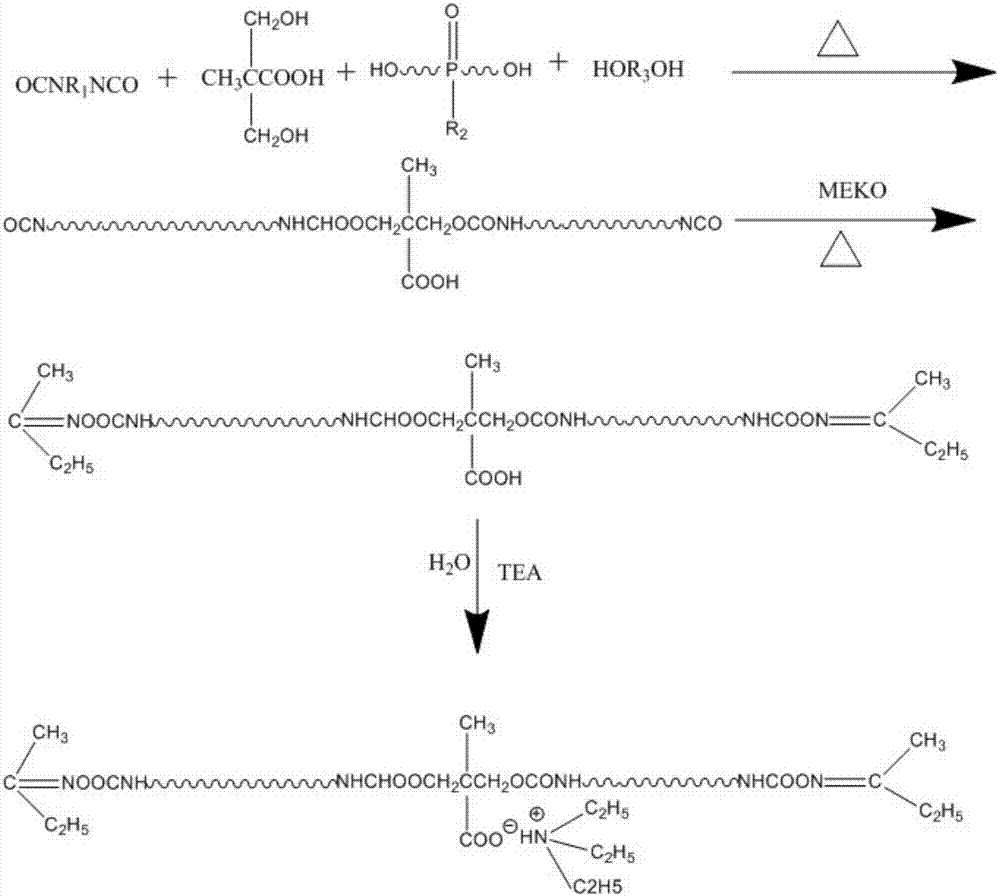

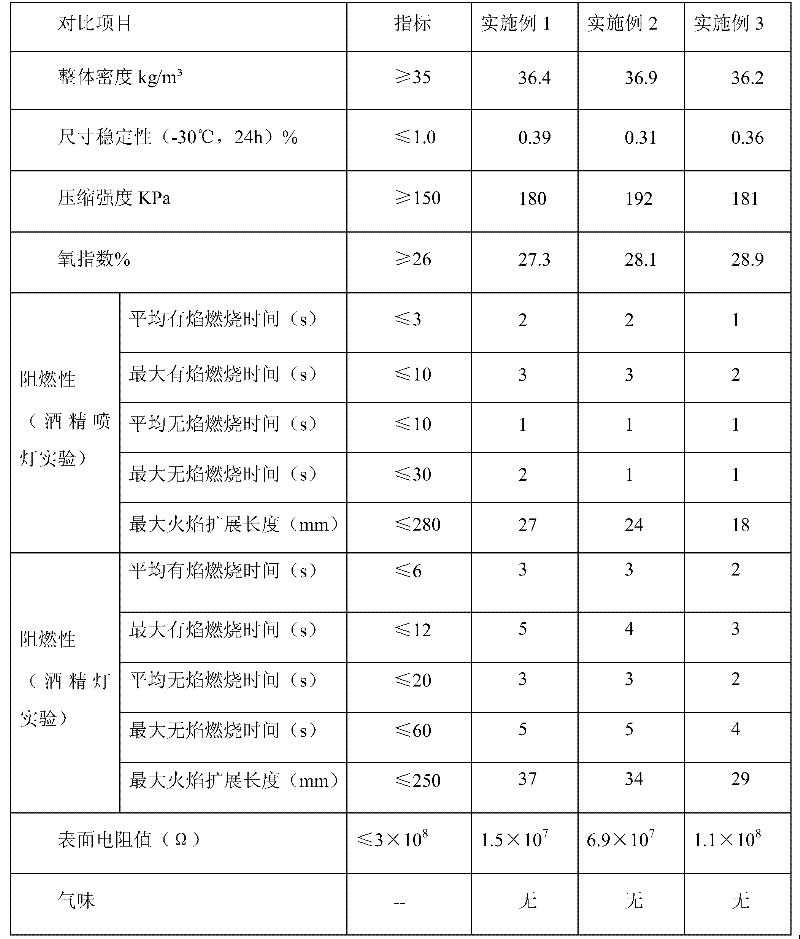

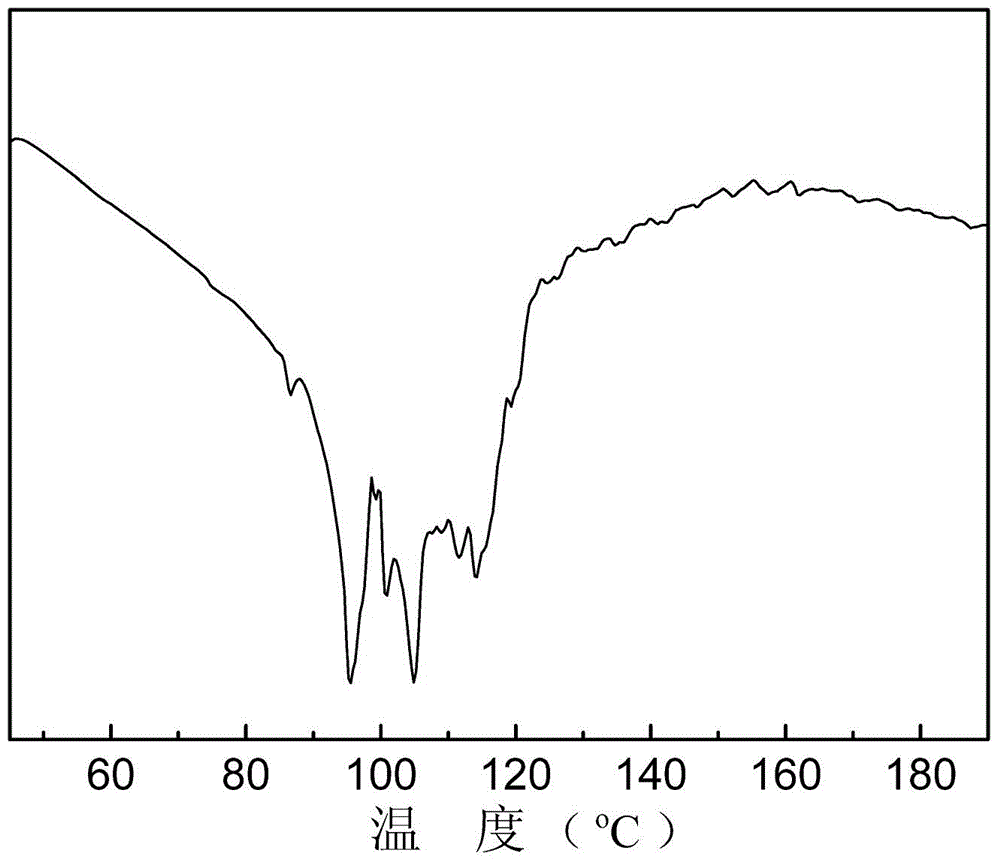

Preparation method and applications of reaction type Mannich polyether polyol with permanent flame retardant effect

The invention provides a preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect. The preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect comprises the following steps: reacting paraformaldehyde or formaldehyde solution with diethanol amine to obtain 3-ethoxyl-1,3-oxazolidine reaction liquid, and then carrying out reduced pressure distillation to obtain the product 3-ethoxyl-1,3-oxazolidine; reacting aromatic phenol compounds or / and melamine compounds with 3-ethoxyl-1,3-oxazolidine to obtain Mannich base as intermediate; and carrying out polymerization reaction between the intermediate Mannich base and epoxy compound to obtain crude product of reaction type Mannich polyether polyol with permanent flame retardant effect, then carrying out reduced pressure distillation to remove impurities with low boiling points, and thus obtaining finished product. The reaction type Mannich polyether polyol simultaneously has the high stability and thermal stability of rigid polyurethane foam and the flame resistance of phenolic foam, is applied to foaming rigid polyurethane foam, and has wide application prospect.

Owner:JIANGSU YOKE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com