Patents

Literature

1154results about How to "Green" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

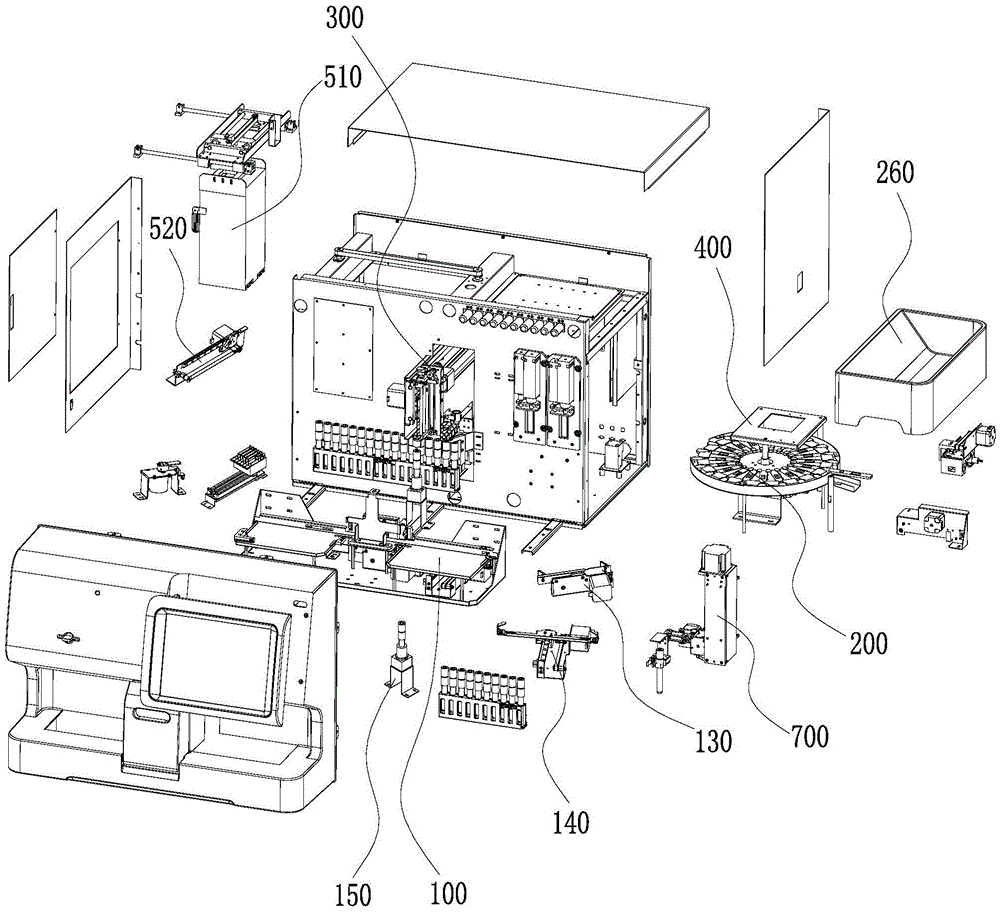

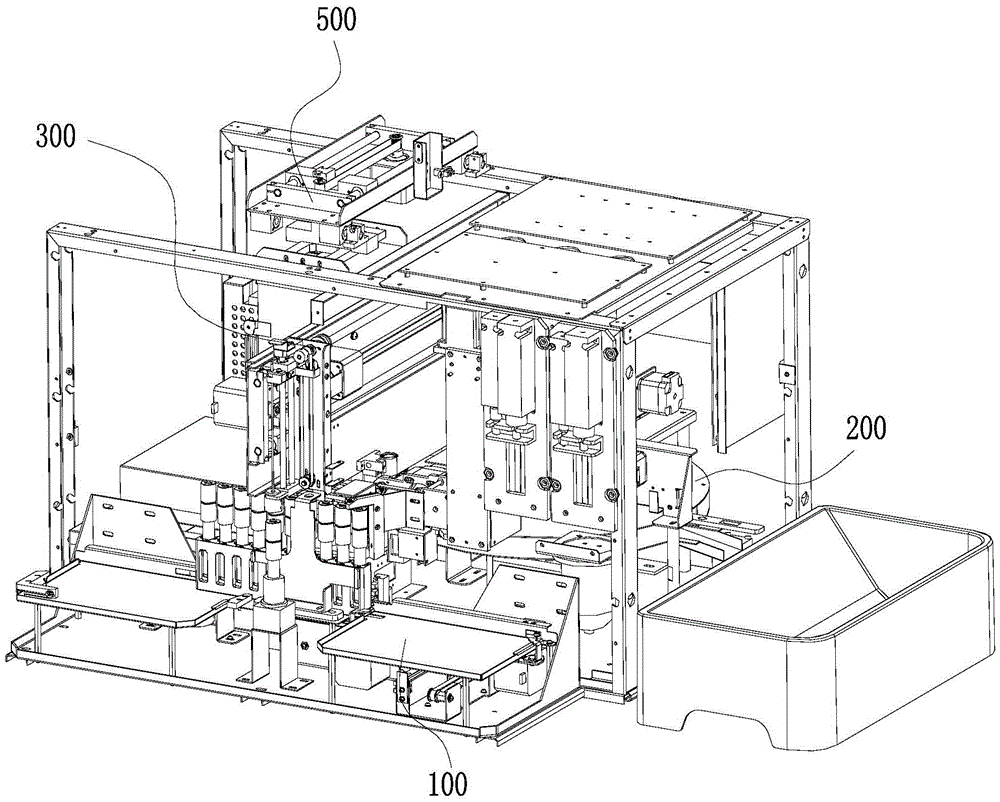

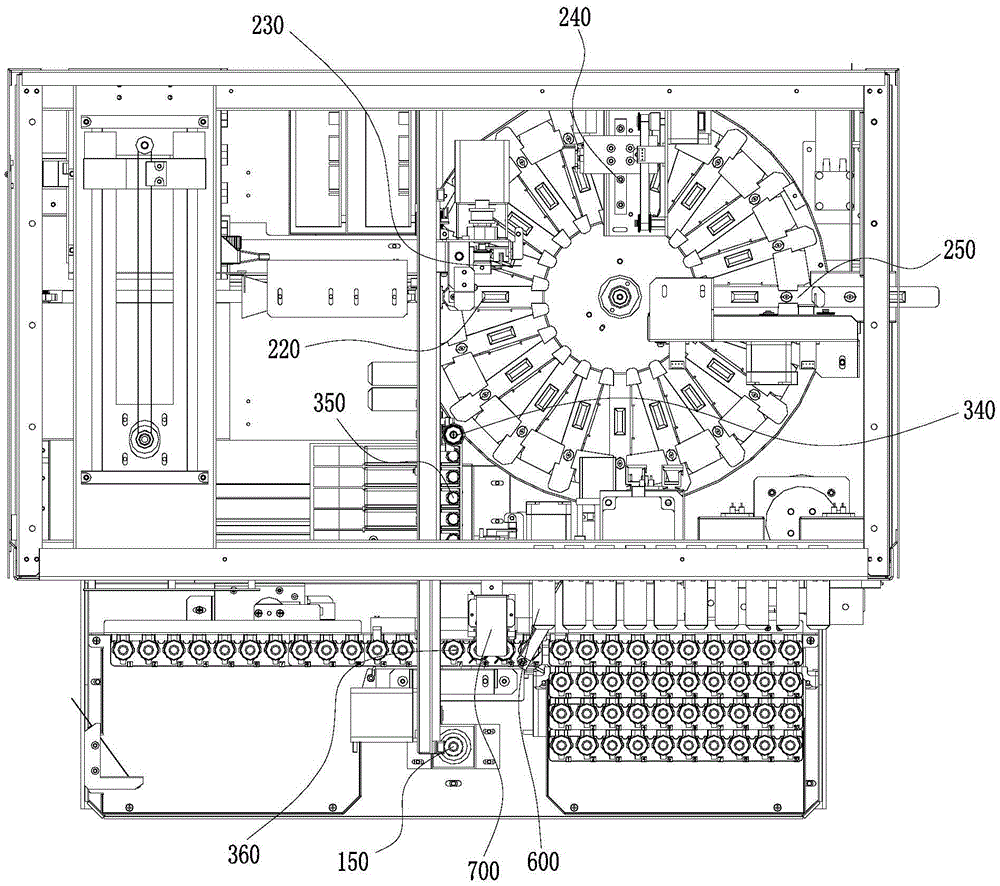

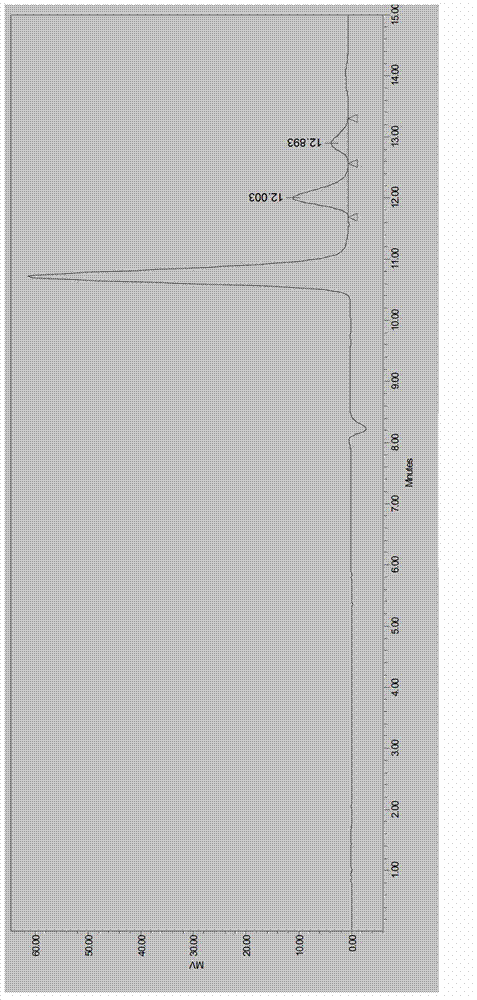

Full-automatic fluorescent quantitative immunity analyzer and detection method

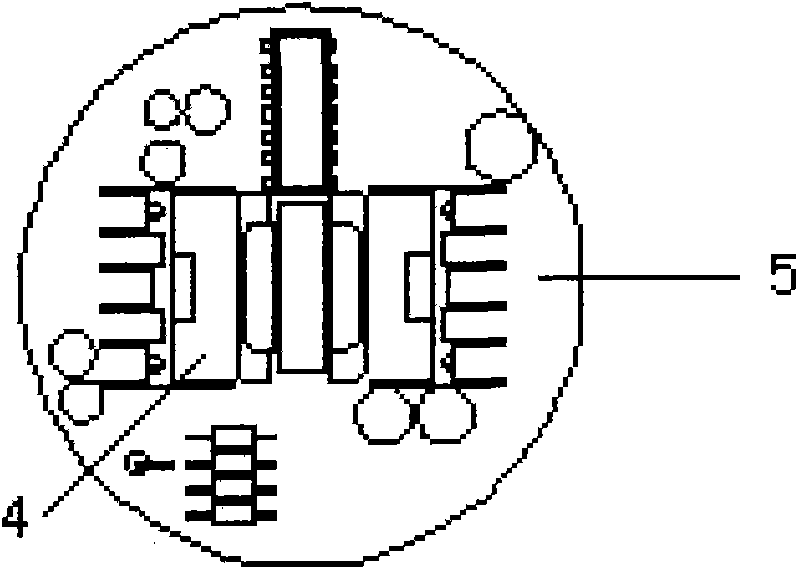

ActiveCN105572407AProcessing supportRealize fully automated detection and analysisMaterial analysisFluorescenceData acquisition

The invention relates to a full-automatic fluorescent quantitative immunity analyzer and a method, and belongs to the technical field of detection. The full-automatic fluorescent quantitative immunity analyzer comprises a sample feeding device, a hatching device, a sampling device, a data acquisition device, a reagent card device and a system control module; the purpose of automatic quantitative immunity analysis is achieved through organic combination of all the devices and modules and mutual cooperation of all elements. According to the fluorescent quantitative immunity detection method, the full-automatic fluorescent quantitative immunity analyzer is adopted, therefore, full-automatic instrumental analysis is achieved, the detection efficiency is improved, and the professional requirement on an operator is lowered.

Owner:GUANGZHOU WONDFO BIOTECH

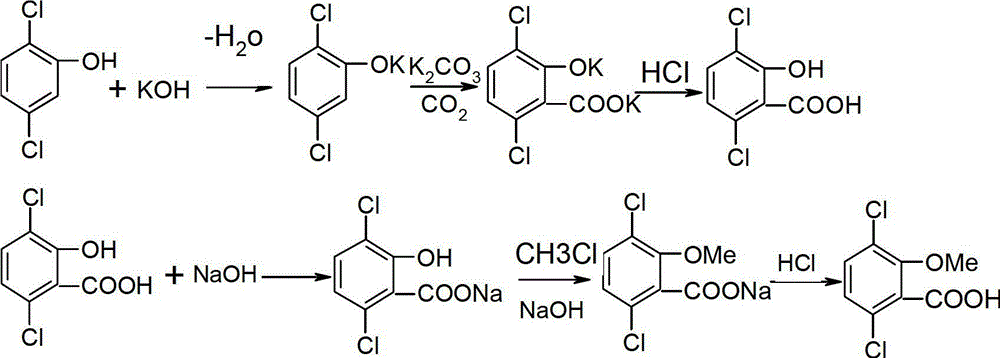

Synthetic process of herbicide dicamba

ActiveCN102942474AImprove one-way yieldImprove quality and efficiencyOrganic compound preparationCarboxylic compound preparationMethoxylaricinolic acidFixed bed

The invention relates to a preparation method of herbicide dicamba. The preparation method includes: (1) liquid potassium hydroxide and 2, 5-dichlorophenol are reacted according to molar ratio of 0.95:1-1:1 to obtain 2, 5-dichlorophenol potassium; (2) at the presence of anhydrous potassium carbonate and catalyst, the 2, 5-dichlorophenol potassium obtained in the step (1) is reacted with CO2 to generate 3, 6-dichlorosalicylic acid, pressure of CO2 is controlled to be 4-6MPa, reaction temperature ranges from 100 DEG C to 160 DEG C, and molar ratio of anhydrous potassium carbonate and 2, 5-dichlorophenol potassium is 1-2:1; and (3) in alkaline condition, at the temperature of 70-100 DEG C, the 3, 6-dichlorosalicylic acid obtained in the step (2) and chloromethane are reacted under the action of the catalyst through a tube fixed-bed reactor according to molar ratio 1:1-3.5, saponification and acidification are performed to obtain 3, 6-dichloro-2-methoxysalicylic acid, namely the dicamba. The process is high in reaction yield, simple in reaction condition, good in product quality, small in three wastes and low in energy consumption.

Owner:JIANGSU YOUJIA CHEM +2

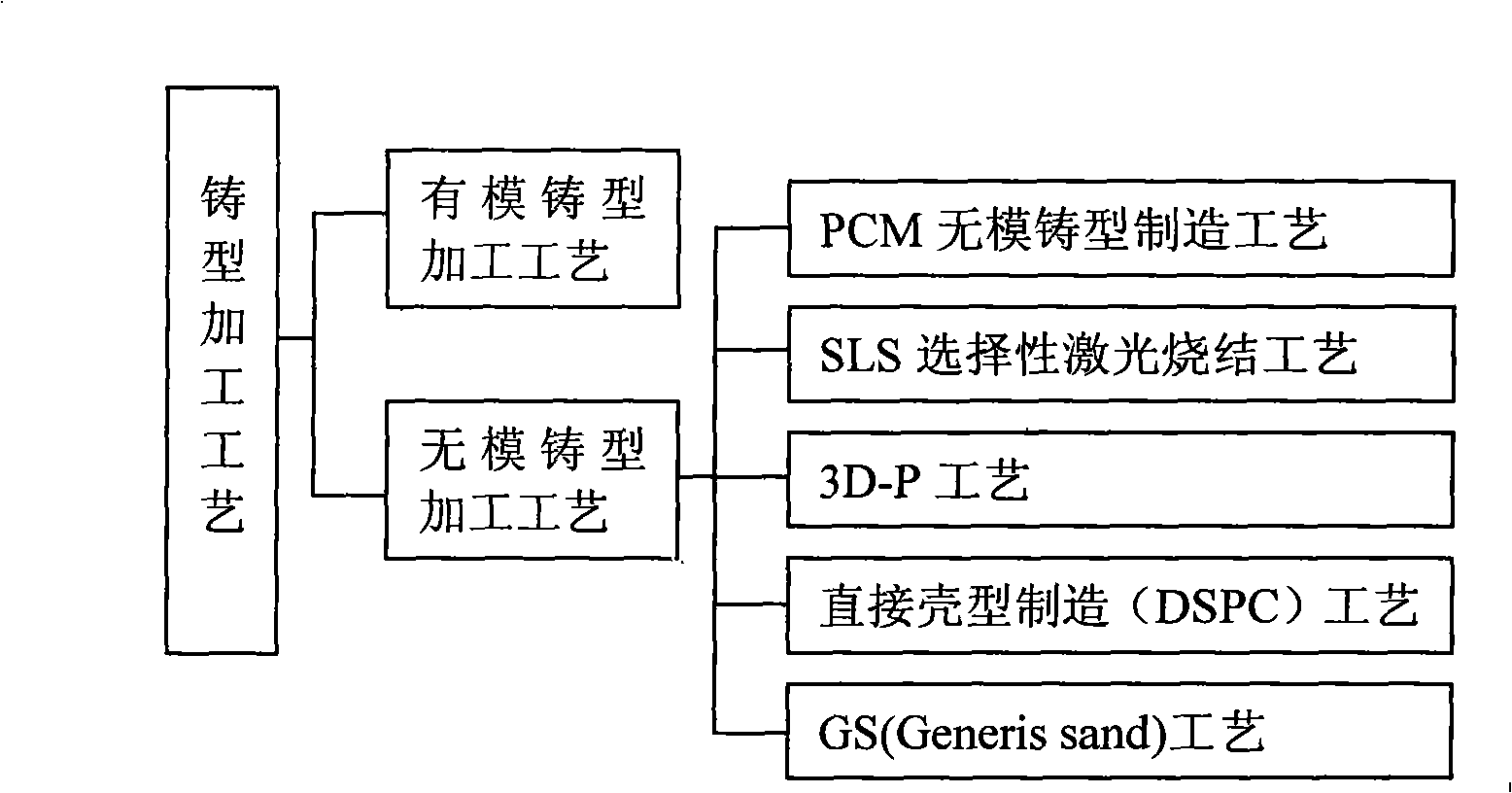

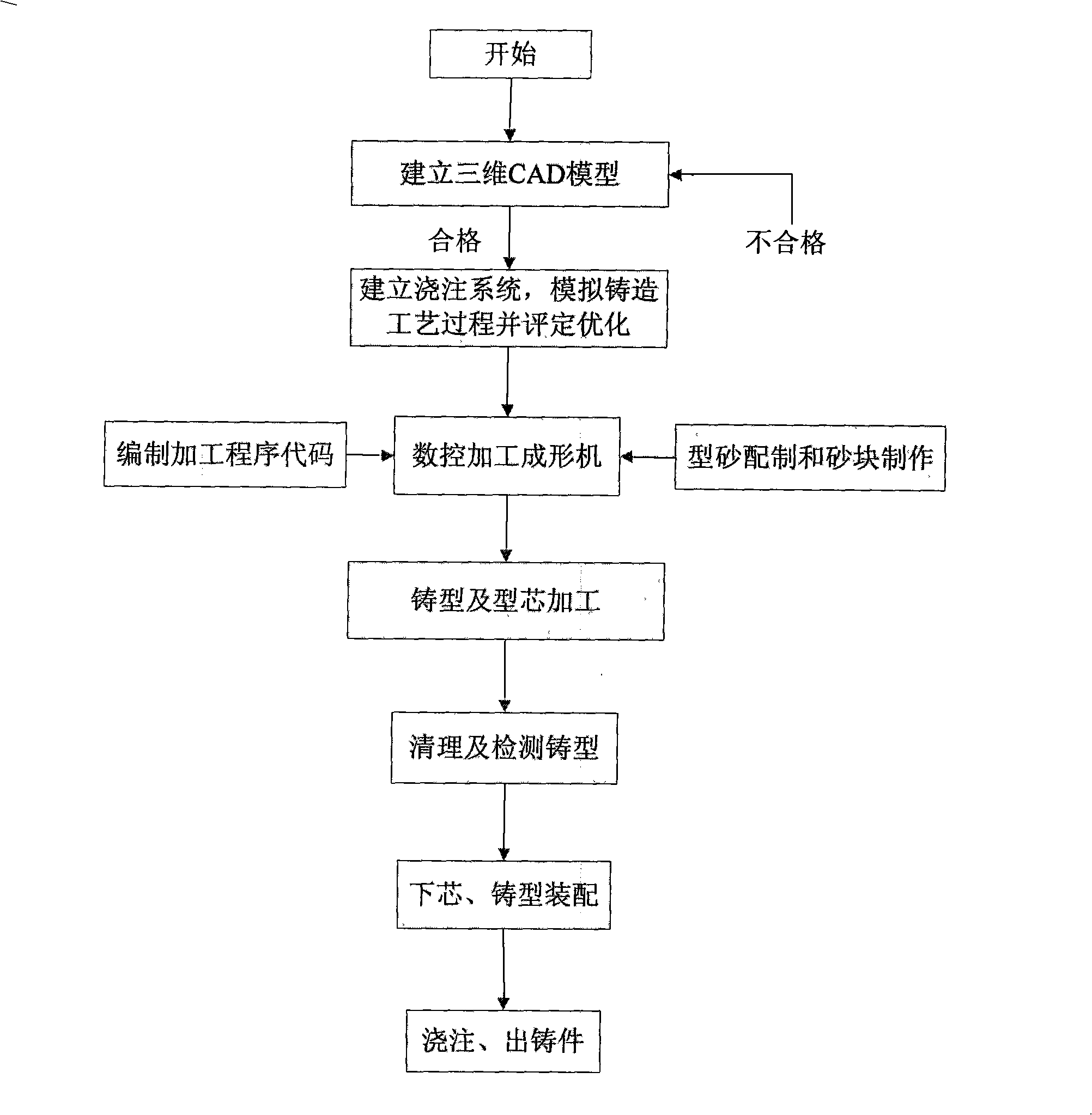

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

BIM-based assembly building forward deepening design method

PendingCN108763710AFast agingReduce forward and reverse iterationsGeometric CADDesign optimisation/simulationDesign cycleData information

A BIM-based assembly building forward deepening design method is provided. The method comprises the following steps: determining design parameters of an assembly building according to design requirements of construction engineering, structural engineering, HVAC engineering, and electromechanical engineering, and generating an editable geometry and data information model; performing assembly component disassembling on the geometry and data information model generated in the deepening design software, and checking component parameters, so that the component size and weight meet the requirementsfor production, transportation, and installation; performing modeling on the protruding bar, the component bracing, the formwork, and the protective frame of the assembly component, and performing dynamic collision inspection on the installation of the assembly component; performing new collision inspection, and performing non-extension rib modeling of the component after there is no collision conflict; automatically generating an assembly building construction drawing and a component drawing by using a BIM drawing output module, and generating a component production material list; and finally, deriving a deeply designed BIM model to assist the mold design. According to the method provided by the present invention, the design cycle is shortened, and coordination of various professions is facilitated.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

Internal wall putty and production process thereof

The invention belongs to the technical field of building materials, and particularly relates to an internal wall putty which comprises the following components in parts by weight: 150-300 parts of white cement, 500-900 parts of calcium carbonate powder, 10-50 parts of grey desert soil, 1-8 parts of cellulose ether, 7-30 parts of polymer latex powder, 1-10 parts of water repellent, 0.05-3 parts of starch ether and 0.5-7 parts of wood fiber. Compared with the prior art, the internal wall putty has the advantages that 107 glue water or 801 glue water is not used, thus formaldehyde is not contained, the environment is protected; and pregelatinized starch is not used, and the water repellent is added, thus the internal wall putty has the function of preventing water and moisture. In addition, with the white cement and the calcium carbonate powder as the strength basis and the grey desert soil as an auxiliary strength material, the strength of the internal wall putty is ensured; due to the synergistic effect of the cellulose ether and the starch ether, the water-retaining property and the application property of the internal wall putty are ensured; and because the polymer latex powder is added, the flexibility of the internal wall putty and the adhesion of the polymer latex powder and the wall are improved.

Owner:黄明杰

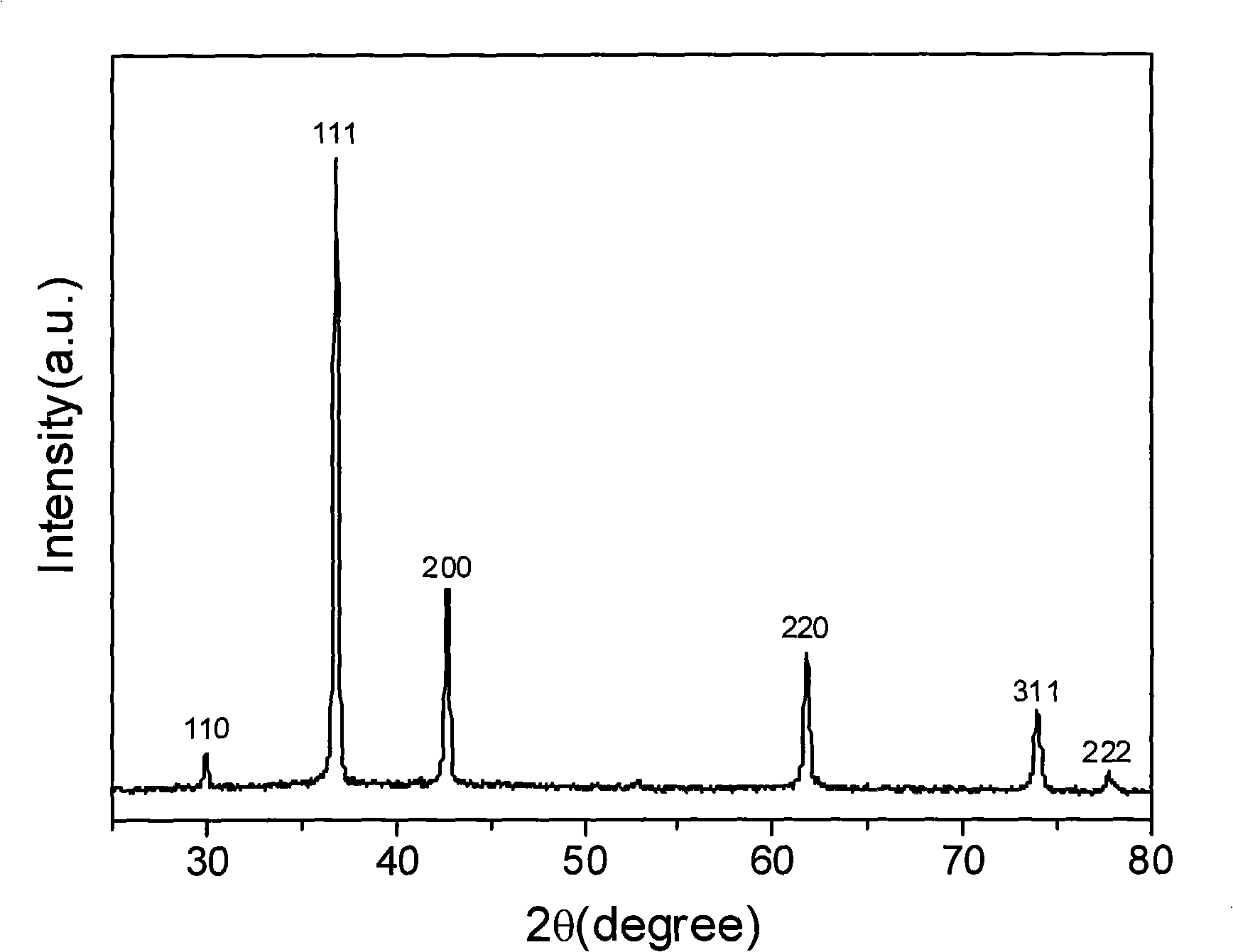

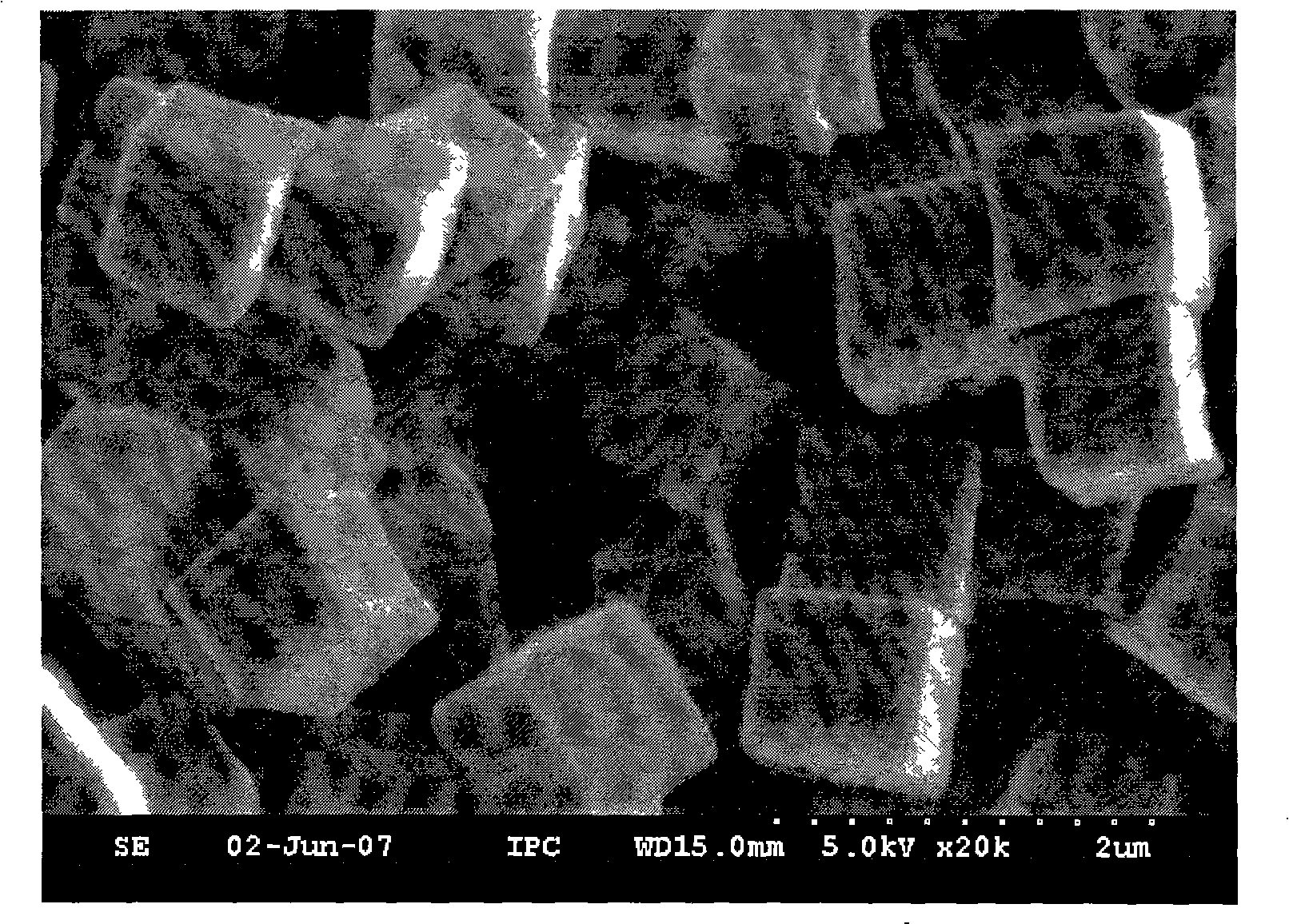

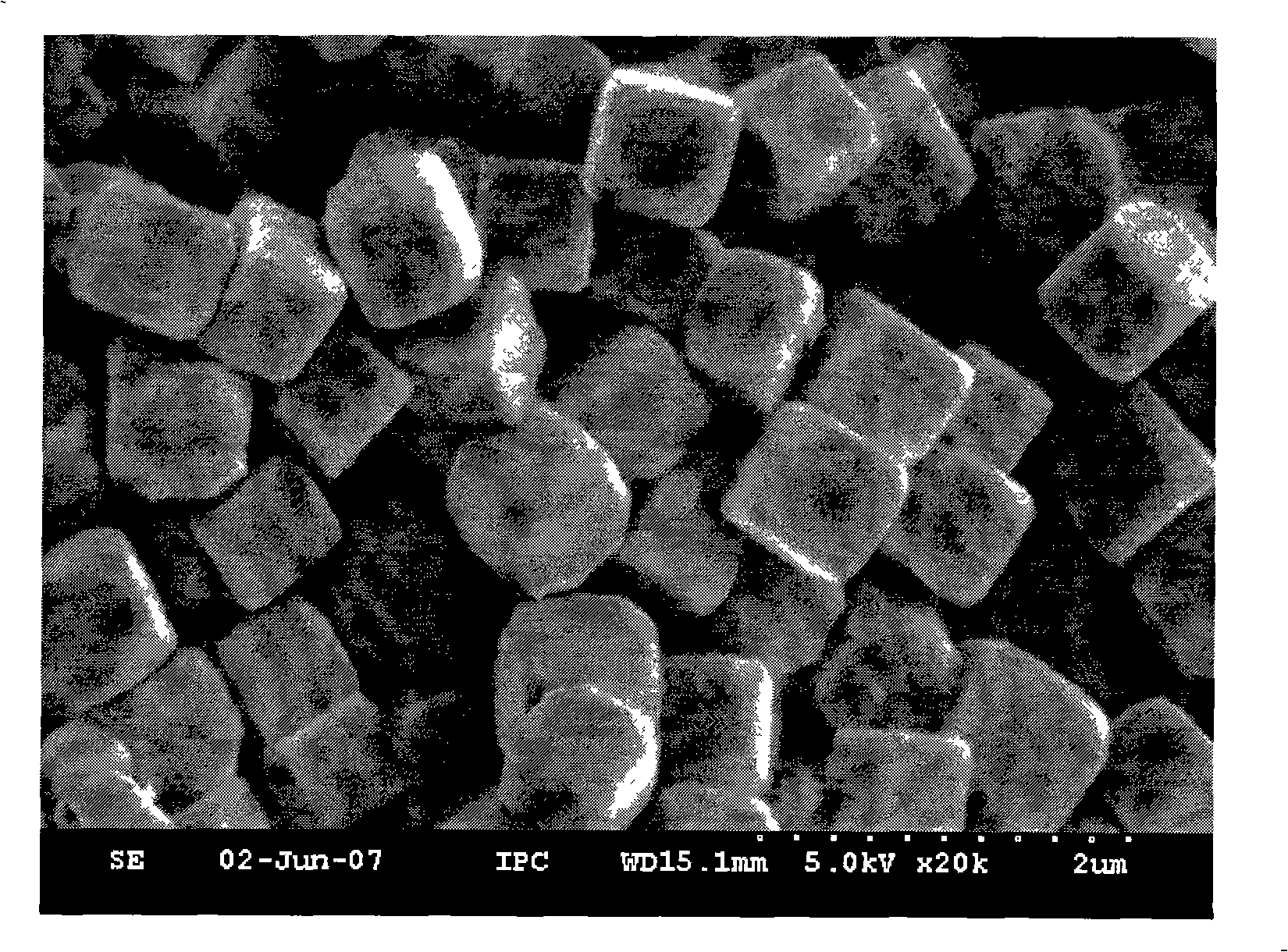

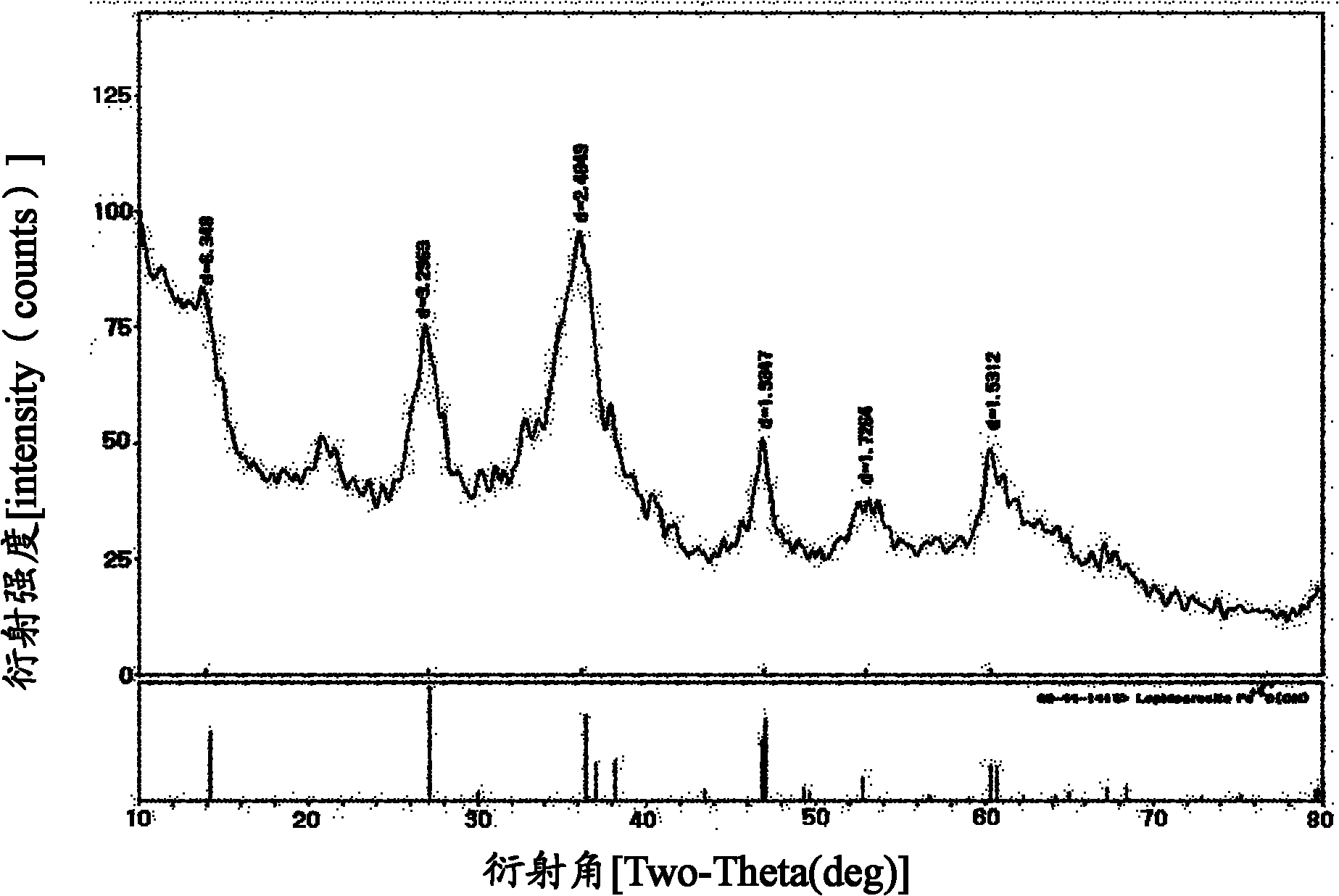

Preparation of polyhedral cuprous oxide nano particle

The invention provides a method for preparing polyhedral cuprous oxide nanometer granules. The method adopts a chemical solution method to prepare polyhedral cuprous oxide nanometer granules comprising cubes, chamfered cubes, cubic octahedrons, chamfered octahedrons or octahedral series. The method comprises the following concrete steps: copper salt is dissolved in water and stirred at a temperature between 50 and 60 DEG C; polyvinyl pyrrolidone, strong base solution and ascorbic acid solution are orderly added, stirred at a constant temperature between 50 and 60 DEG C and kept for 1 to 3 hours; after the reaction is over, the centrifugation is carried out; and a large amount of the deionized water is used for washing, and the cuprous oxide nanometer granules can be obtained after vacuum drying. By regulating the adding amount of the polyvinyl pyrrolidone, the polyhedral cuprous oxide nanometer granules comprising the cubes, the chamfered cubes, the cubic octahedrons, the chamfered octahedrons or the octahedral series are obtained. The method has the advantages of moderate condition, simple operation, low cost, high yield, controllable shape, and so on.

Owner:BEIHANG UNIV

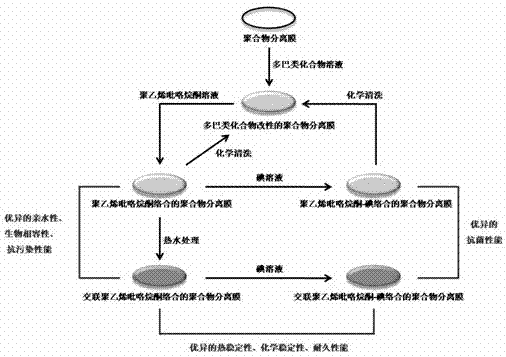

Surface modification method for polymer separation membrane

ActiveCN103041721AModification equipment is simpleShorten the production cycleSemi-permeable membranesPolymer scienceAgglutination

The invention discloses a surface modification method for a polymer separation membrane. Under the water solution condition, a dopa compound is easily oxidized by dissolved oxygen in water to generate auto-agglutination-composite reaction in order to generate a firmly attached dopa compound composite layer on the surface of the polymer separation membrane; the dopa compound composite layer contains rich catechol radicals which can form the multi-point hydrogen bonding effect with lactam radicals in polyvinylpyrrolidone, and the polyvinylpyrrolidone is firmly complexed on the surface of the separation membrane; and the polymer separation membrane immobilized with povidone-iodine on the surface can be prepared through the complexation between the polyvinylpyrrolidone and iodine. The method has simple technique, and is suitable for the polymer separation membranes with different materials and shapes; and the modified polymer separation membrane has excellent hydrophily, blood compatibility, contamination resistance and bacterial resistance, so that the important significance is given to improve the comprehensive performance of the polymer separation membrane.

Owner:ZHEJIANG UNIV

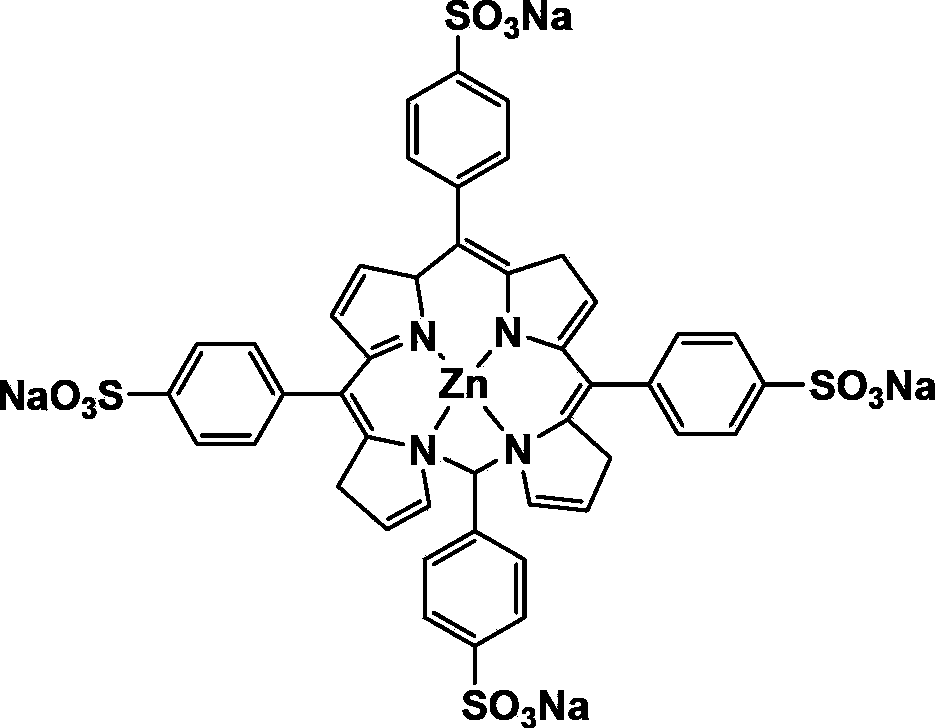

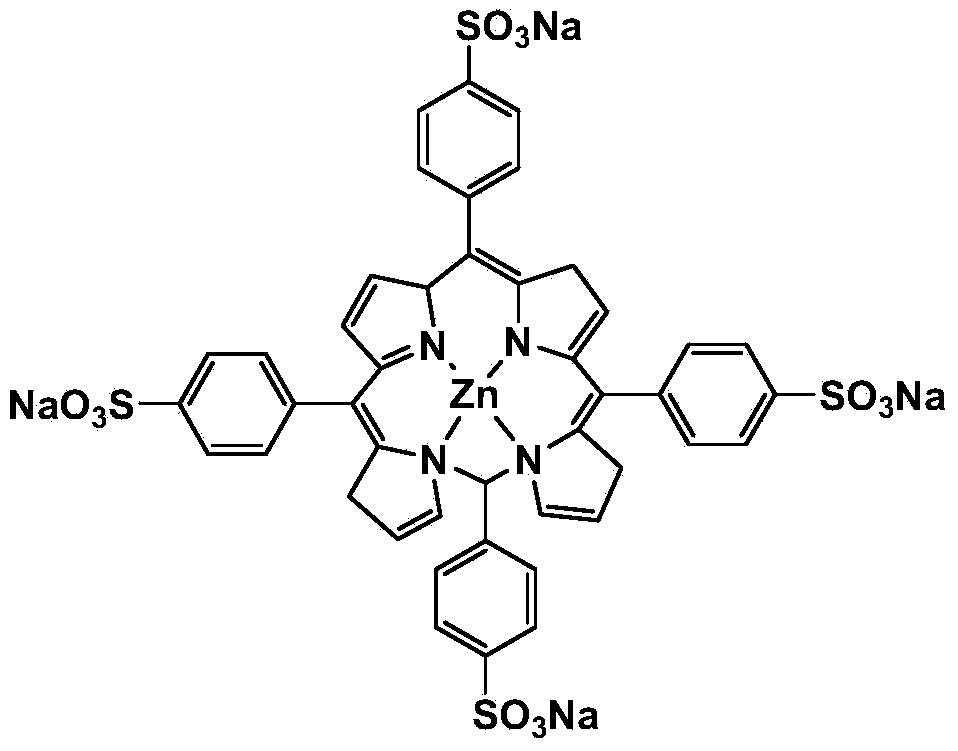

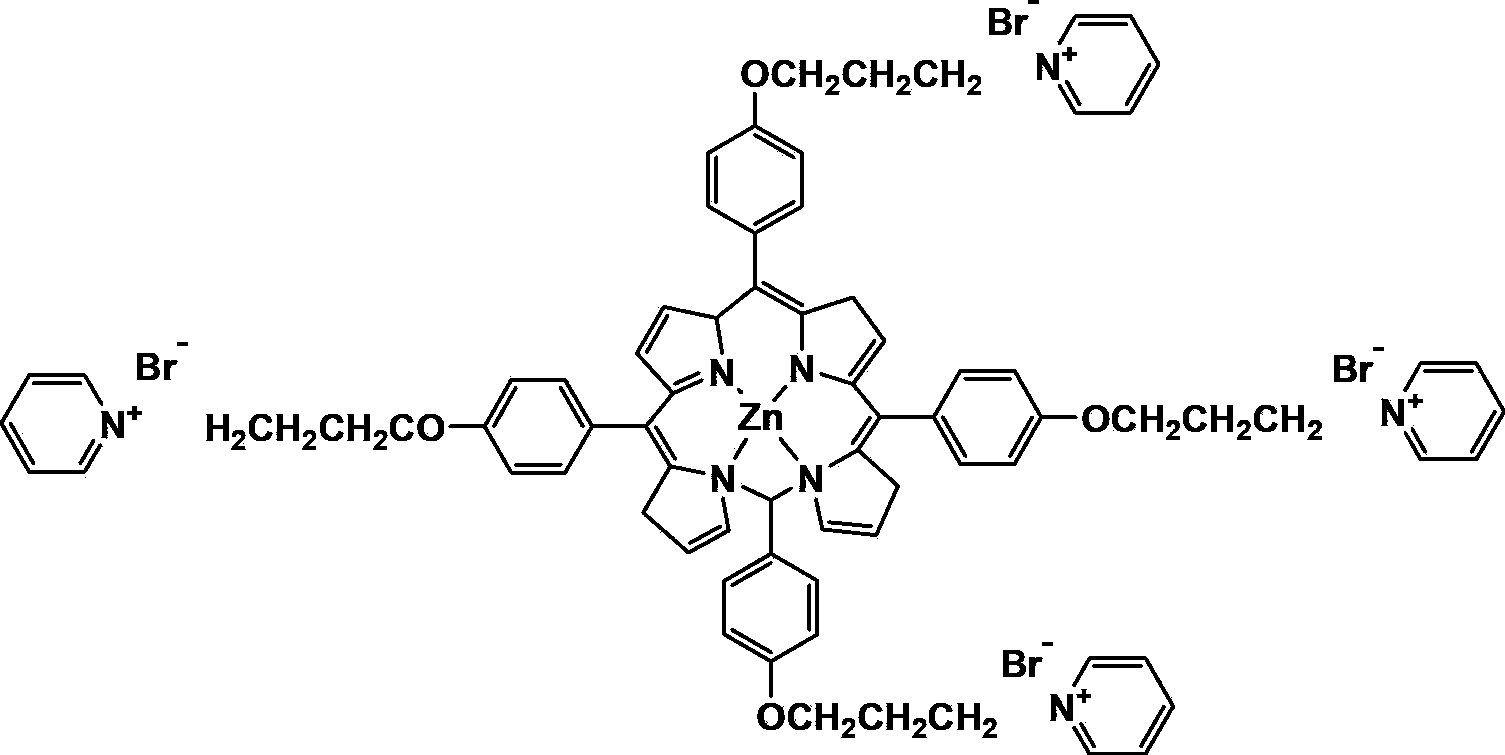

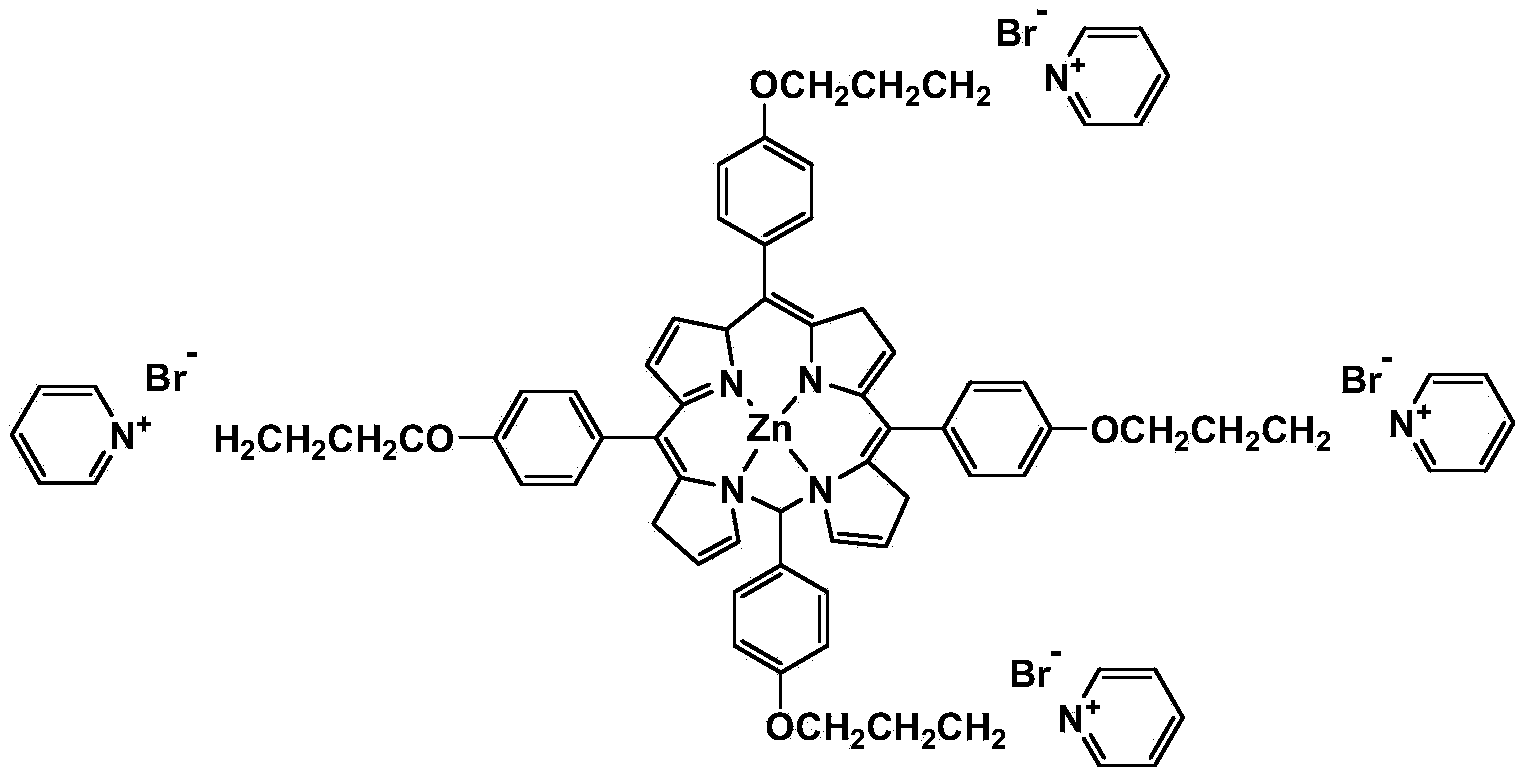

Use of water-soluble tetra sodium sulfonate phenyl porphyrin metal complex in microcontact printing

ActiveCN102964910BReduce usageSoluble in waterInksLiquid/solution decomposition chemical coatingSolubilityMicrocontact printing

The invention discloses a method for applying a water-soluble tetra sodium sulfonate phenyl porphyrin metal complex to microcontact printing. The method comprises the following specific steps of: 1) substrate carboxylation; 2) preparation of 5,10,15,20-tetra sodium sulfonate phenyl zinc porphyrin water solution; 3) microcontact printing; and 4) chemical plating. The method has the beneficial effects that 1. the obtained pattern is exquisite and fine and a new thought is provided for the microcontact printing industry; and 2. as a printing agent, the 5,10,15,20-tetra sodium sulfonate phenyl zinc porphyrin water solution has water solubility, can reduce use of organic solvents, has the advantages of environment-friendliness, low cost and stability and has great potential in industrial application.

Owner:南通博亿峰都新材料科技有限公司

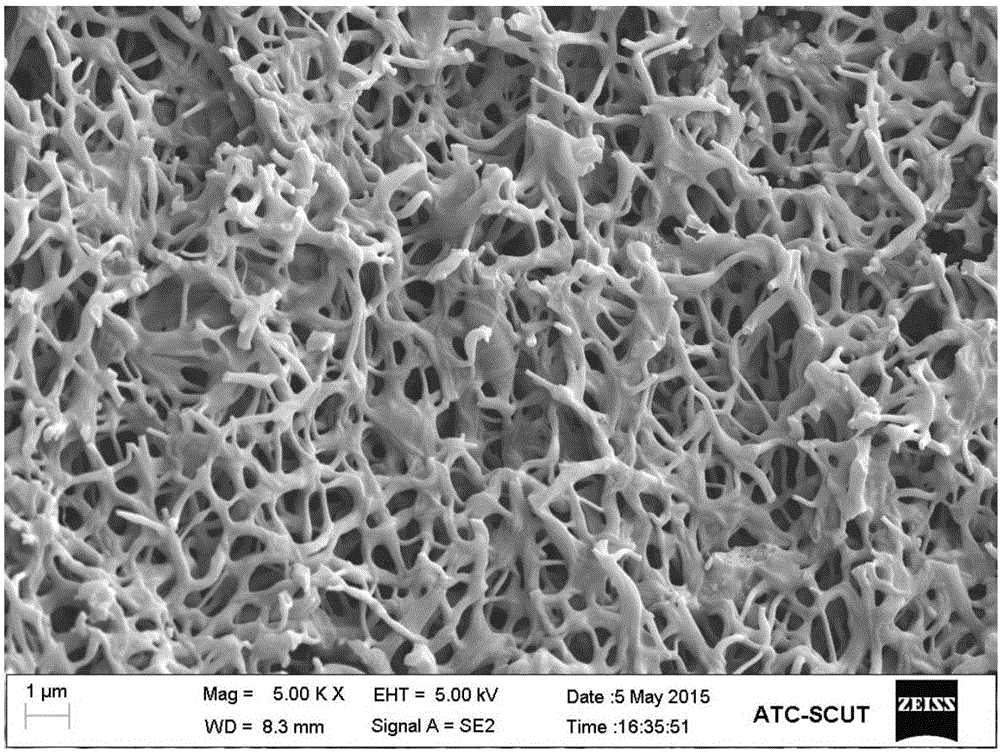

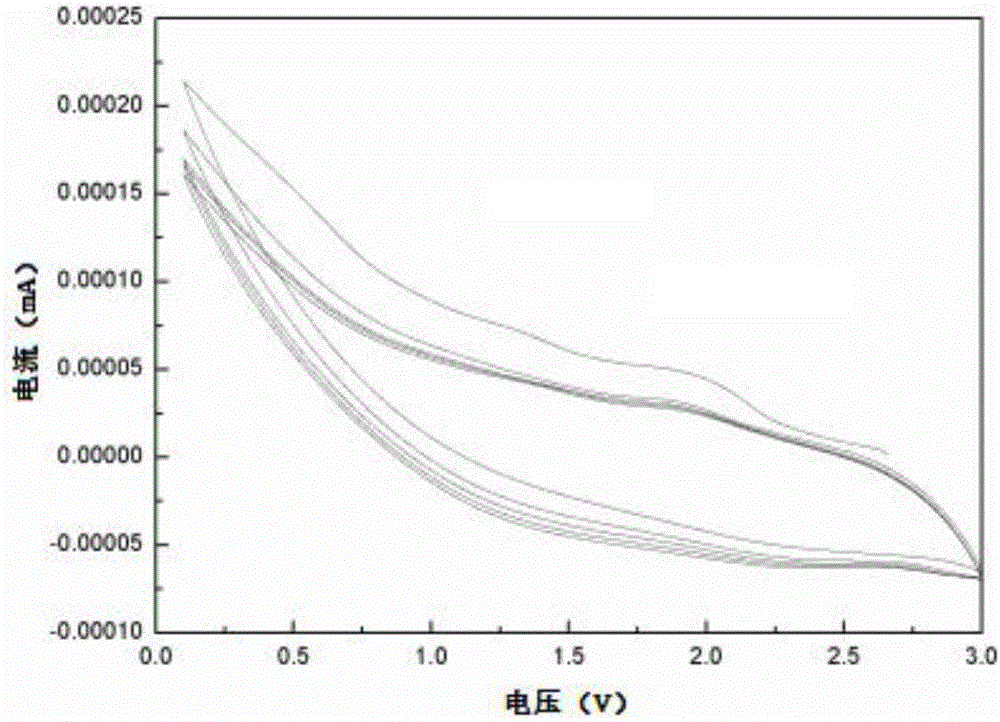

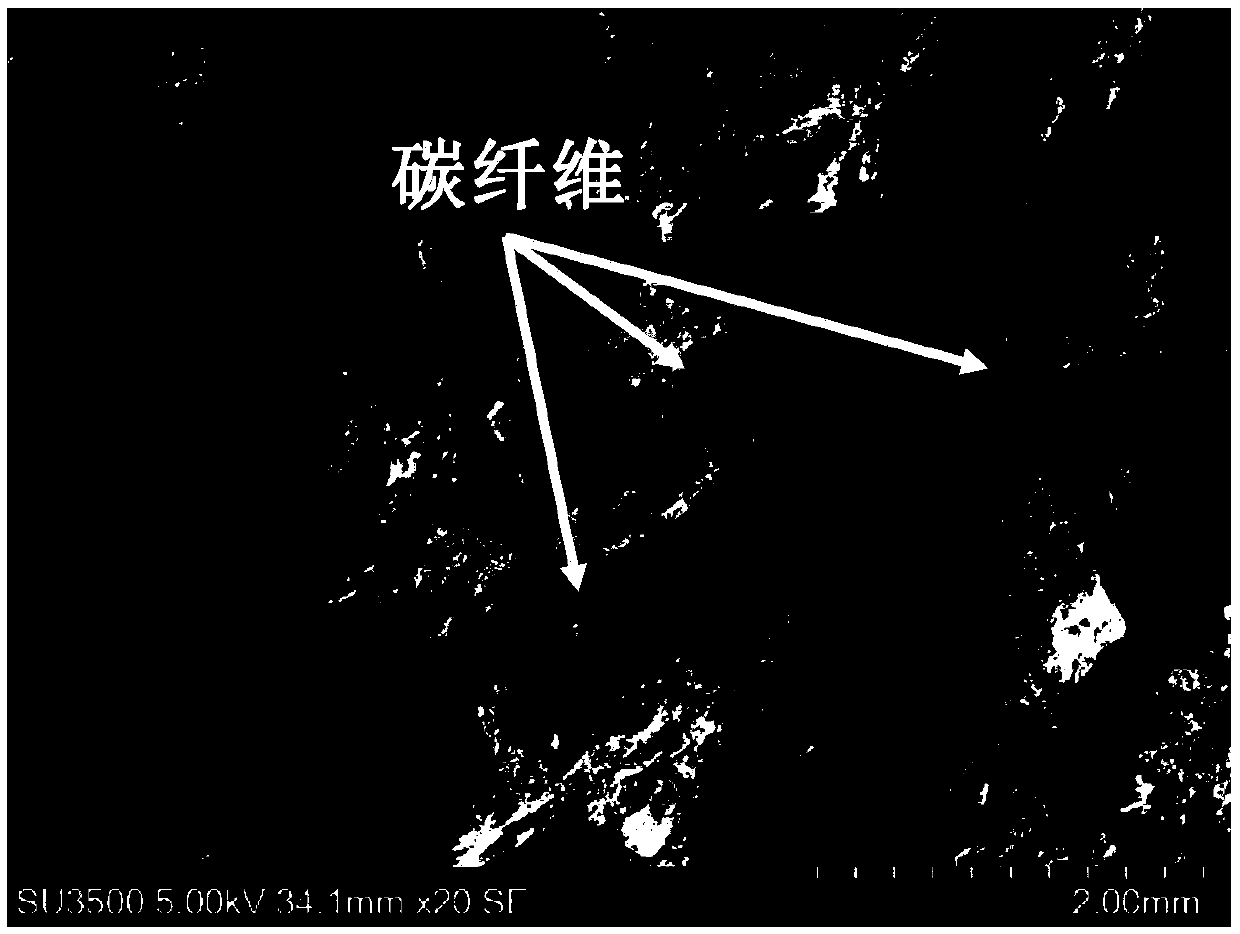

Alkali lignin-based electrostatic spinning carbon fiber and preparation method and application thereof

InactiveCN105862173AWide range of sourcesGreenCell electrodesFibre chemical featuresAir atmosphereN dimethylformamide

The invention belongs to the technical field of the biomass material processing and discloses an alkali lignin-based electrostatic spinning carbon fiber and a preparation method and application thereof. The preparation method comprises the steps of dissolving alkali lignin and polyacrylonitrile in N, N-dimethylformamide to obtain a uniform lignin / polyacrylonitrile solution; then performing electrostatic spinning to obtain a lignin-based nanofiber membrane; heating the membrane in carbonization equipment to 200-280 DEG C; pre-oxidizing for 2-8h in an air atmosphere, heating to 600-900 DEG C, carbonizing in nitrogen gas or argon gas atmosphere and grinding to obtain the alkali lignin-based electrostatic spinning carbon fiber. According to the method, alkali lignin and polyacrylonitrile are used as carbon sources of carbon materials, and the method has the advantages of environment friendliness and low preparation cost; and the carbon fiber can replace graphite to be used as the positive electrode material of a lithium battery.

Owner:SOUTH CHINA UNIV OF TECH

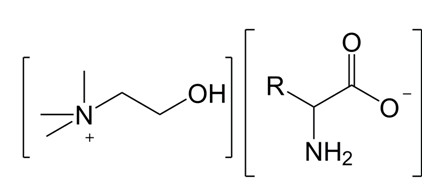

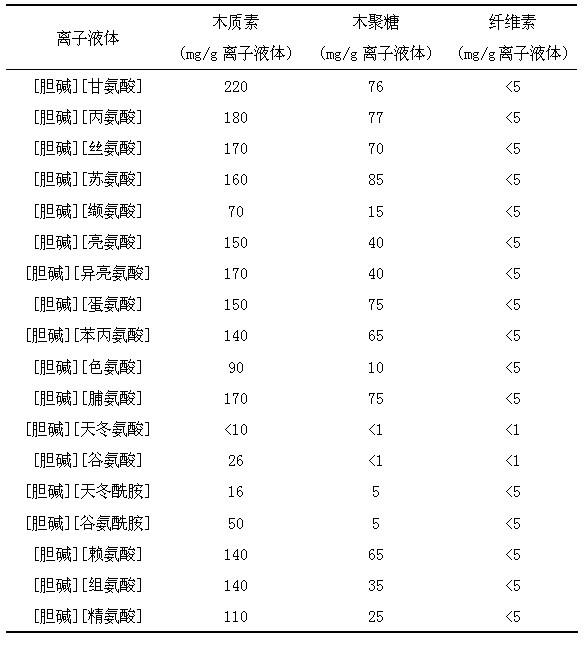

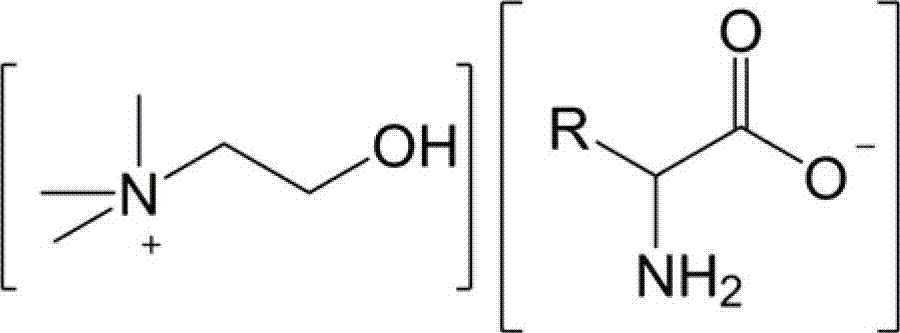

Method for increasing enzymolysis efficiency of rice straws through choline and amino acid ionic liquid pretreatment

InactiveCN102533907ARealize comprehensive utilizationOvercome the disadvantage of waste of resources (waste of hemicellulose components)FermentationBulk chemical productionCellulaseXylanase

The invention discloses a method for increasing enzymolysis efficiency of rice straws through choline and amino acid ionic liquid pretreatment, which comprises the following steps: firstly, performing pretreatment on the rice straws at certain temperature for a certain period of time by taking choline and amino acid ionic liquid as a solvent; then filtering and separating to obtain residues; drying the residues to obtain the pretreated rice straws. The residues of the rice straws are used as substrates, and enzymolysis is performed on the substrates by utilizing cellulase and xylanase to finally obtain sugar liquor taking glucose and xylose as main components. The method for increasing the enzymolysis efficiency of the rice straws through the choline and amino acid ionic liquid pretreatment not only is capable of effectively increasing the enzymolysis efficiency of the rice straws and increasing the yield of reducing sugar (the glucose and the xylose) which can be fermented, but also is capable of overcoming the defects that a traditional ionic liquid pretreatment process environment is not friendly and the like.

Owner:SOUTH CHINA UNIV OF TECH

Use of water-soluble zinc porphyrin complex in microcontact printing

ActiveCN102964909BReduce usageSoluble in waterInksLiquid/solution decomposition chemical coatingMicrocontact printingChemical plating

Owner:西安方舟包装工业有限公司

Method for pretreating lignocellulose by using renewable ionic liquid aqueous solution

The invention discloses a method for pretreating lignocellulose by using a renewable ionic liquid aqueous solution, including the steps of: (1) taking a choline and amino acid ionic liquid aqueous solution as a pretreatment solvent, mixing lignocellulose and the pretreatment solvent under the protection of nitrogen, stirring at 50-120 DEG C, cooling to room temperature, filtering, washing residue, and drying to obtain the pretreated lignocellulose; and (2) weighing the pretreated lignocelluloses, adding a citrate buffer, adding cellulase, reacting for 3-12 h with 150-250 r / min at 40-60 DEG C to obtain sugar liquid mainly including glucose and xylose. The pretreatment process not only can effectively enhance the efficiency of enzymatic hydrolysis of lignocelluloses, and improve the yield of fermentable reducing sugar, but also has the advantages of environmental protection, renewability, low viscosity, easy operation, low cost, and low power consumption.

Owner:SOUTH CHINA UNIV OF TECH

High-conductivity hydrographene conductive ink as well as preparation method and composition thereof

The invention relates to high-conductivity hydrographene conductive ink as well as a preparation method and a composition thereof. The composition of the high-conductivity hydrographene conductive inkis prepared from the following components in parts by mass: 20 to 30 parts of a conductive unit, 15 to 30 parts of a coupling agent, 0.1 to 20 parts of an adjuvant and 50 to 100 parts of water. By the adoption of the composition and the preparation method which are provided by the invention, the sheet resistivity of the prepared high-conductivity hydrographene conductive ink is less than or equalto 20 ohms / square, and the conductive unit content is less than or equal to 30 percent, and the high-conductivity hydrographene conductive ink has the advantages of low conductive unit content, highmechanical property and high conductivity. Meanwhile, water is used as a solvent, so that the high-conductivity hydrographene conductive ink has outstanding environmental protection and safety characteristics of greenness, environmental friendliness, non-toxicity, harmlessness, incombustibility, non-explosivity and the like.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

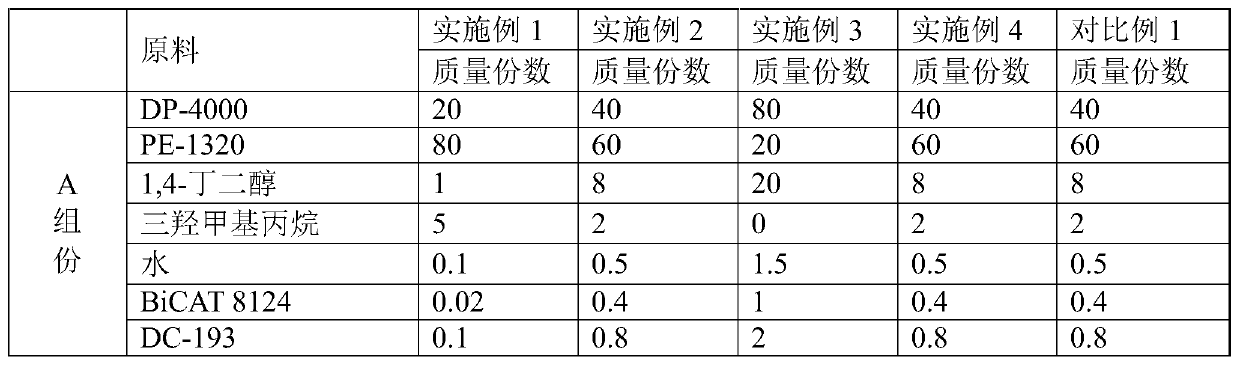

Solvent-free polyurethane resin for synthetic leather, preparation method thereof and application thereof in aqueous/solvent-free polyurethane synthetic leather

The invention provides a solvent-free polyurethane resin for synthetic leather, a preparation method thereof and an application thereof in aqueous / solvent-free polyurethane synthetic leather. The invention provides the solvent-free polyurethane resin for the synthetic leather, which is prepared by mixing and reacting a component A and a component B according to a mass ratio of 1:2-2:1; wherein thecomponent A comprises polyhydric alcohol, a small molecular chain extender, a cross-linking agent, water, a catalyst and a foam stabilizer; the component B comprises polyhydric alcohol, isocyanate and dimethylolpropionic acid. The solvent-free polyurethane resin for the synthetic leather does not contain any organic solvent, has low energy consumption and high production efficiency, and when thesolvent-free polyurethane resin is used for aqueous / solvent-free polyurethane synthetic leather, the obtained aqueous / solvent-free polyurethane synthetic leather product is environment-friendly, softand plump in hand feeling and high in peeling strength.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

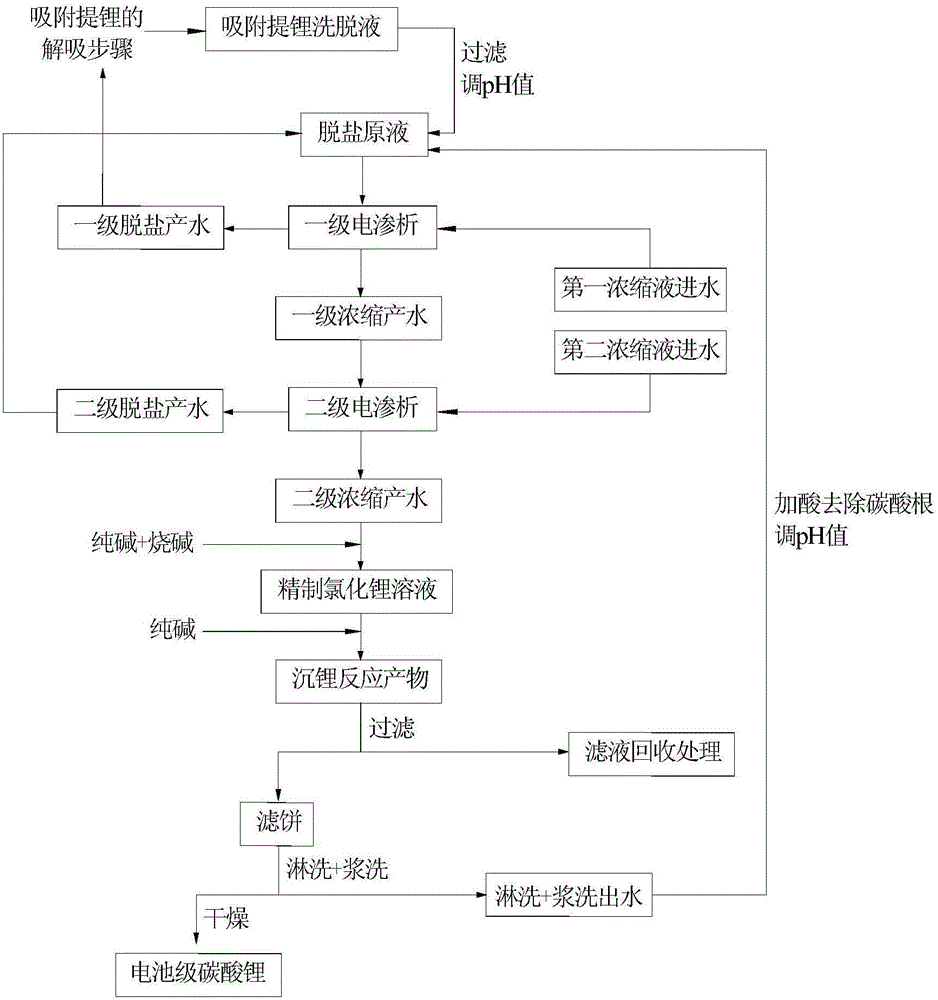

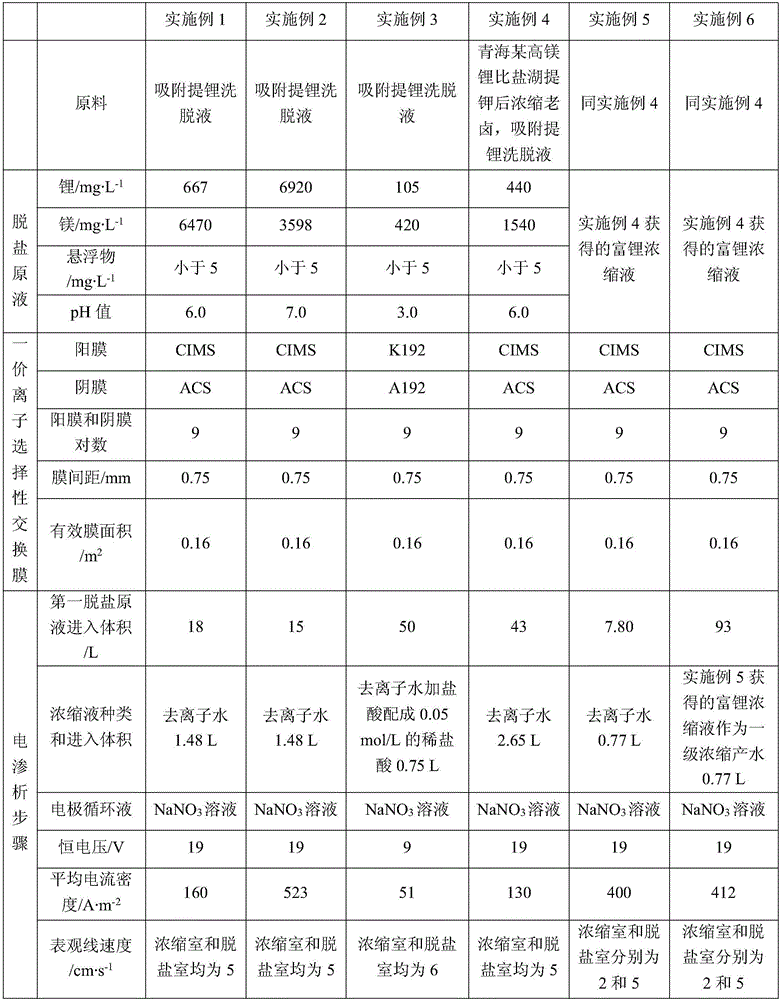

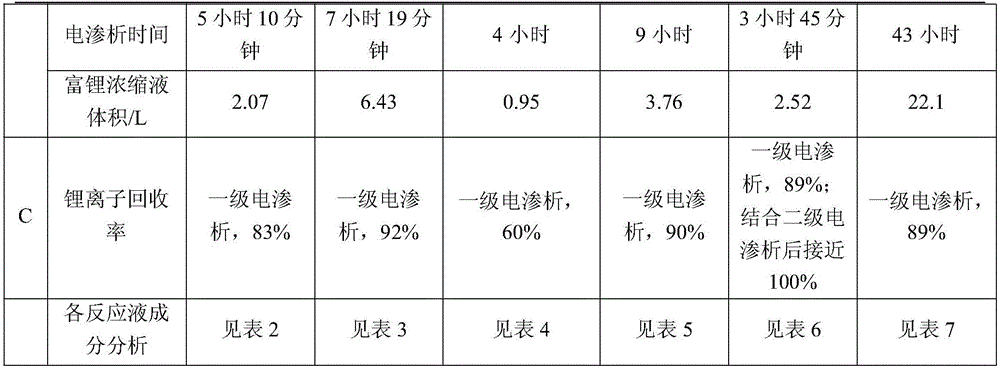

Preparation method of battery-grade lithium carbonate

ActiveCN106186002AEfficient separationShort processGeneral water supply conservationElectrodialysisLithium carbonateMonovalent ions

The invention discloses a preparation method of battery-grade lithium carbonate. The preparation method comprises the following steps: taking a lithium adsorption and desorption eluent as a raw material, performing primary and secondary monovalent ion selective electrodialysis treatment, concentrating and enriching a lithium ion by utilizing the monovalent ion selectivity of a monovalent ion selective cation membrane and a monovalent ion selective anion membrane, and intercepting magnesium ions, sulfate ions and borate ions, thereby realizing efficient separation of lithium and magnesium as well as sulfate and borate ions and other impurity ions and lithium concentration and obtaining a lithium-rich concentrated solution with a lithium content of 10-20 g / L and a ratio of magnesium to lithium of 0.1-1; obtaining the battery-grade lithium carbonate through the steps of deep calcium and magnesium removal, heavy lithium conversion, filtering and washing, drying, cooling and the like. According to the preparation method disclosed by the invention, the preparation process of the battery-grade lithium carbonate is greatly shortened, the process continuity is obviously improved, the cost is reduced, and the bottleneck problem of magnesium removal and concentration by using the salt lake lithium adsorption and desorption eluent with high magnesium-lithium ratio is solved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

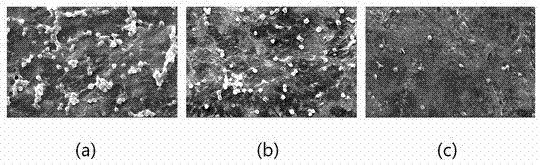

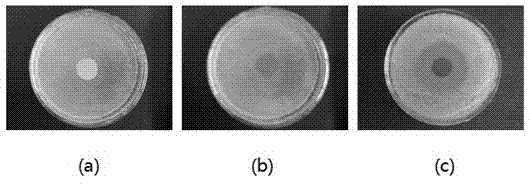

Method for preparing gelatin/nano-silver/chitosan derivative composite film

The invention provides a method for preparing a gelatin / nano-silver / chitosan derivative composite film. The composite film is prepared by the following steps: by taking gelatin as a main raw material, heating to raise the temperature for dissolving gelatin particles, preparing gelatin / nano-silver sol through an in-situ reduction method, and preparing a gelatin / nano-silver film by adopting a self-assembling method in the solution; assembling a chitosan derivative macromolecule on the surface of the gelatin / nano-silver film by further adopting an electrostatic self-assembling method, and thus preparing the gelatin / nano-silver / chitosan derivative antibacterial composite film. The composite film has high biocompatibility and high antibacterial and bactericidal performance and is environment-friendly. Moreover, because the main raw material is gelatin, the composite film is rich in source, low in price, and good in film-forming property and has wide application prospects in aspects such as human skin, medical antibiosis and hemostatic materials. Meanwhile, the composite film is simple in preparation process and low in equipment requirement.

Owner:UNIV OF SCI & TECH BEIJING

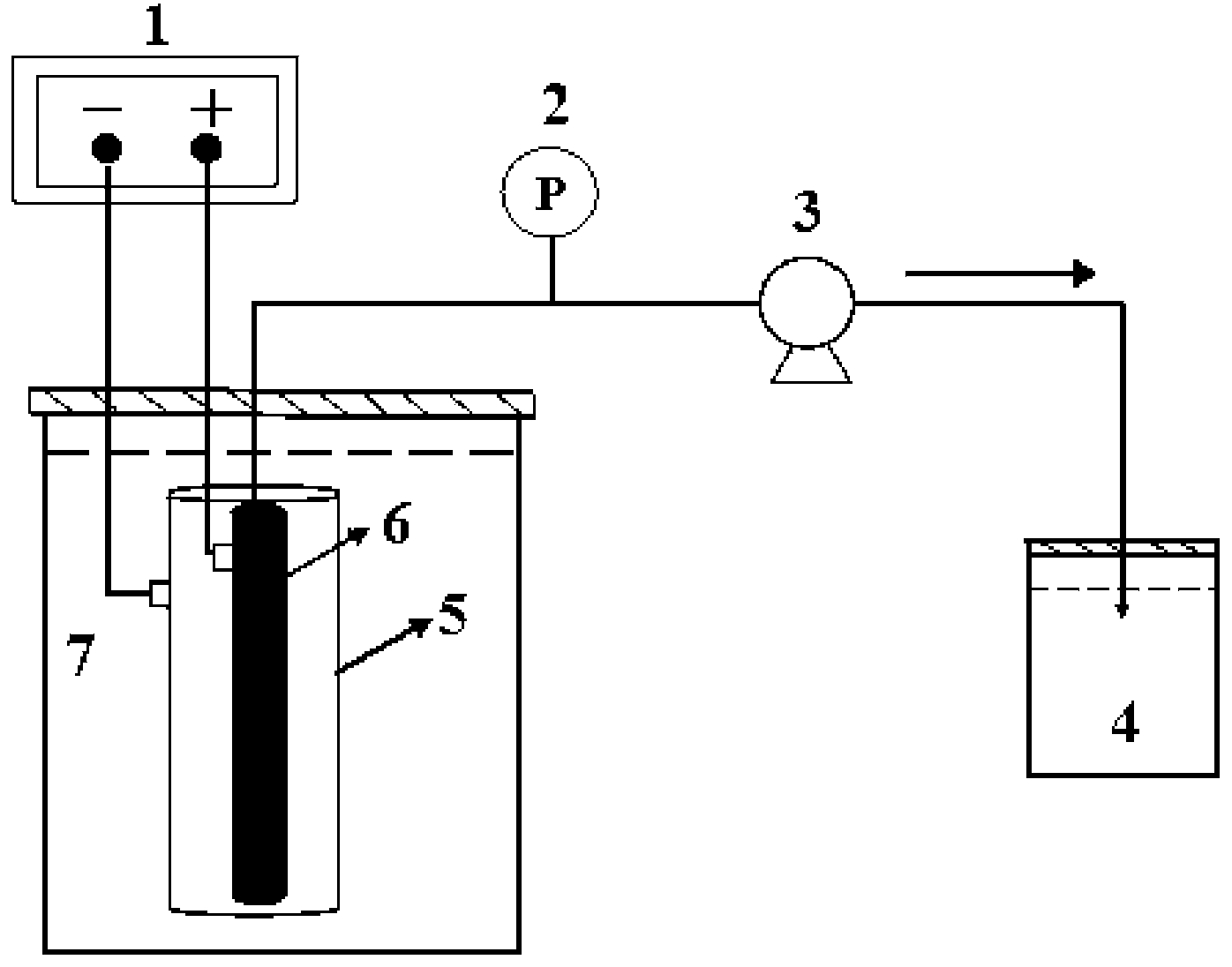

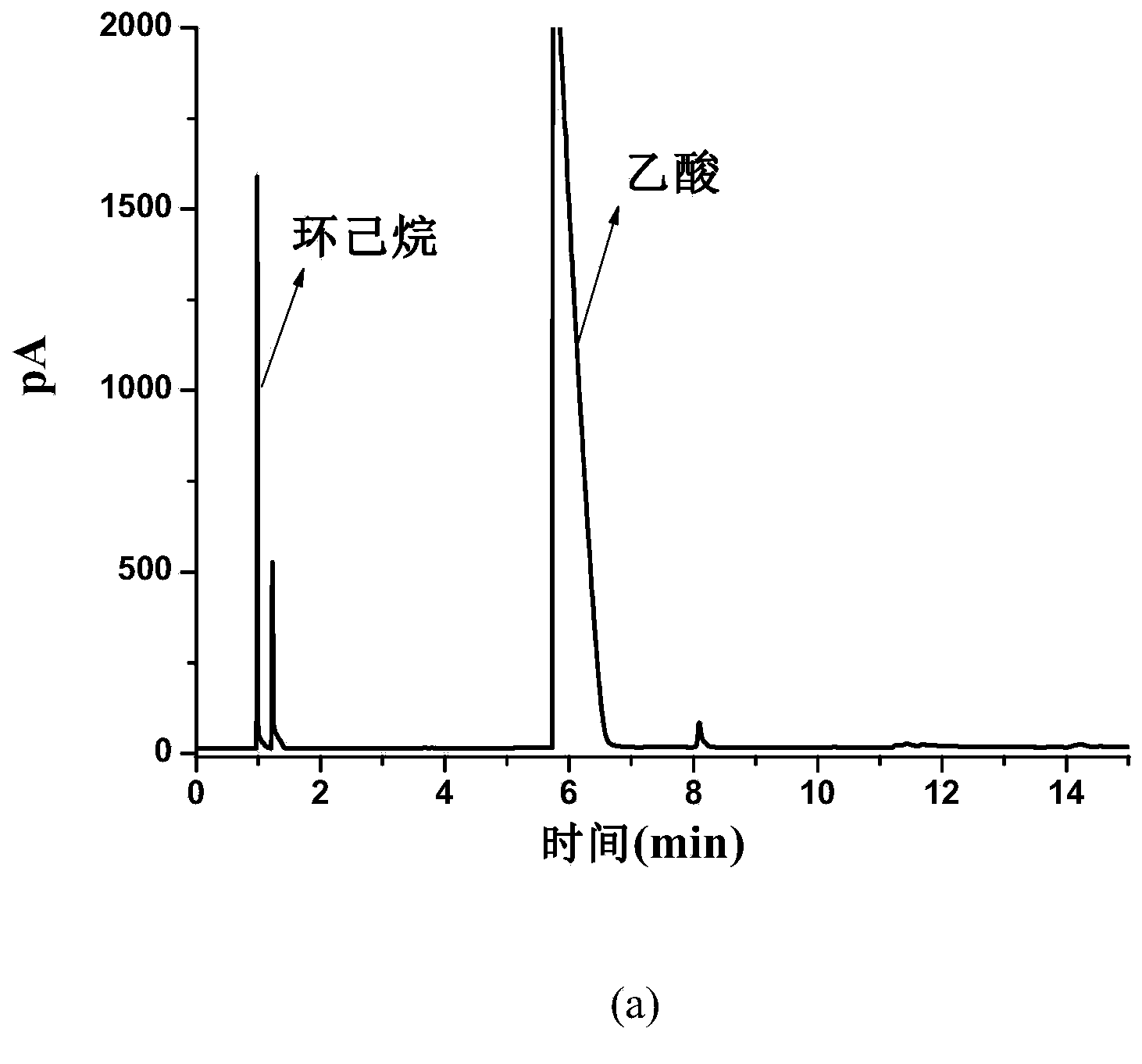

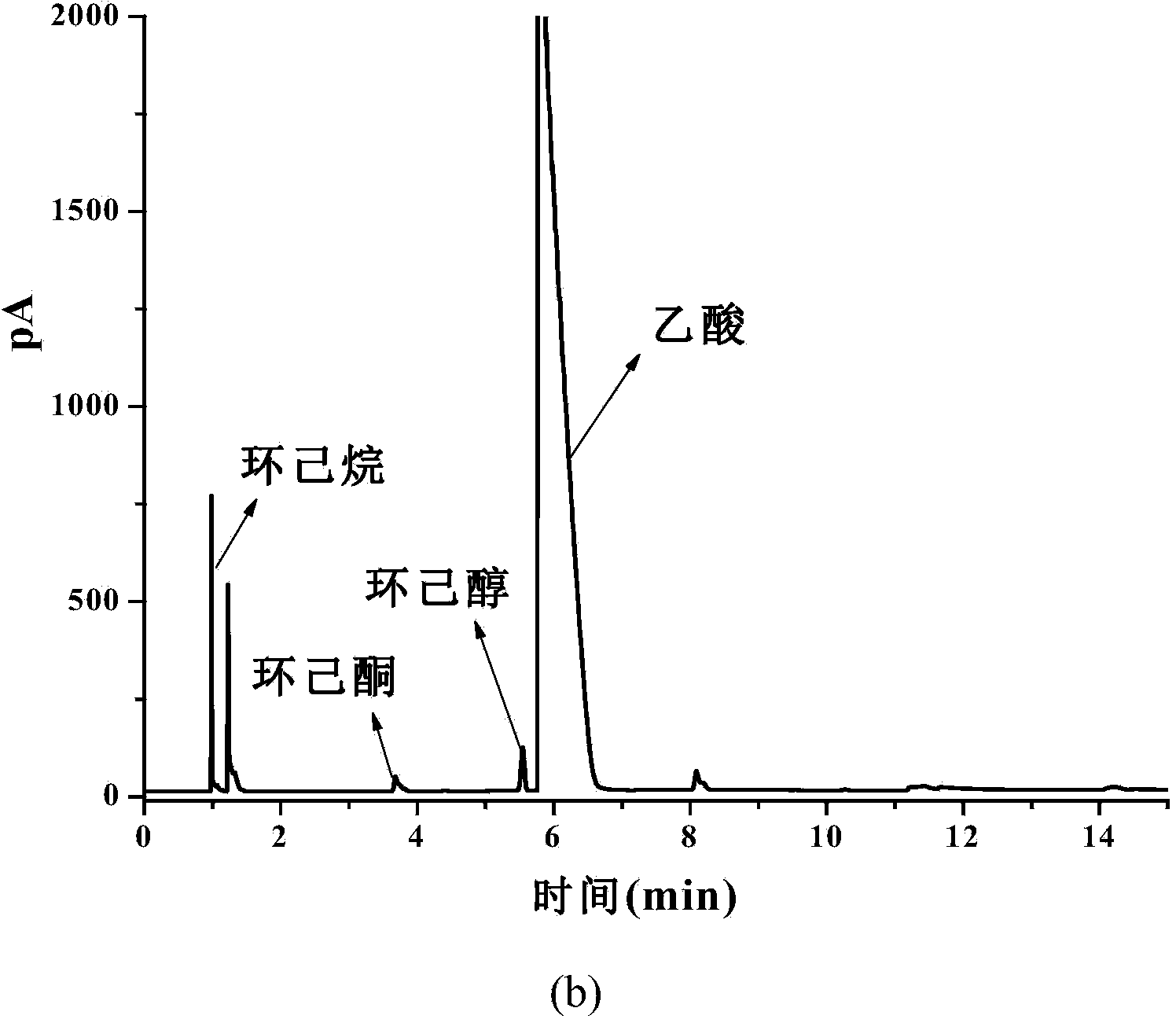

Method for preparing cyclohexanol and cyclohexanone by virtue of electrochemically catalytic oxidation of cyclohexane

InactiveCN104032327AHigh selectivityEasy to operateElectrolysis componentsElectrolytic organic productionAuxiliary electrodePeristaltic pump

The invention discloses a method for preparing cyclohexanol and cyclohexanone by virtue of electrochemically catalytic oxidation of cyclohexane in the technical field of organic electrochemical synthesis. The method comprises the following steps: forming an electrocatalytic membrane reactor by taking a metal oxide loaded porous metal electrocatalytic membrane as an anode and an auxiliary electrode as a cathode; with a mixed water solution of cyclohexane, an organic solvent and electrolyte as a reaction raw material solution, catalytically oxidizing cyclohexane on the surface of the membrane and in a hole by using metal oxide loaded on the membrane to form products, namely cyclohexanol and cyclohexanone under a certain working voltage and current density condition; meanwhile, sucking the products to a permeation side under a certain membrane permeation flux condition by means of negative pressure generated by a peristaltic pump to realize real-time online separation or transfer; then, separating and purifying a membrane permeation solution to finally obtain the products, namely cyclohexanol and cyclohexanone. Compared with the traditional process, the method has the advantages of high efficiency, environment friendliness, high selectivity, simplicity in operation and the like, is suitable for industrial implementation and has wide application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

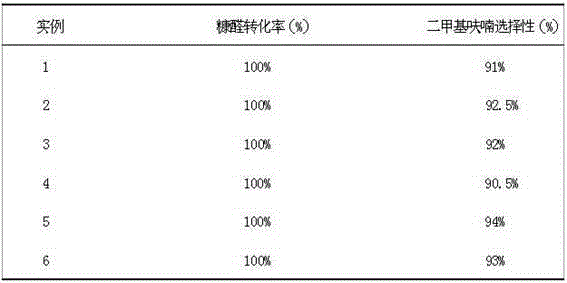

2-methyl furan catalyst and preparation method thereof

InactiveCN104383929AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsFuranAlkaline earth metal

The invention discloses a 2-methyl furan catalyst and a preparation method thereof, and relates to a catalyst and a preparation method thereof. The catalyst comprises active ingredients, such as 30-50 mass percent of CuO, 40-60 mass percent of aluminum oxide or silicon oxide, and aids selected from CaO, BaO, Na2O, K2O, Sr2O and ZnO, wherein the total mass percent of one or two of the aids is 5-10. The 2-methyl furan catalyst is synthesized by virtue of furfural hydrogenation. The preparation method comprises the following steps: dissolving a metal copper salt and an alkali metal or alkaline-earth metal salt in alumina sol or silica sol; enabling the salts to react with a precipitator so as to obtain a precipitate, aging for 1-4 hours after the precipitation is finished, washing, drying, molding and roasting; and finally preparing an oxidation state precursor of the catalyst, wherein an addition mode of reacting a salt solution and the precipitator refers to a positive addition method, a back addition method or a parallel addition method. The component of the catalyst does not contain Cr, and the catalyst is green; and moreover, the catalyst has the high activity and the high selectivity, the furfural conversion rate is 100 percent, and the selectivity of the 2-methyl furan is over 90 percent.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

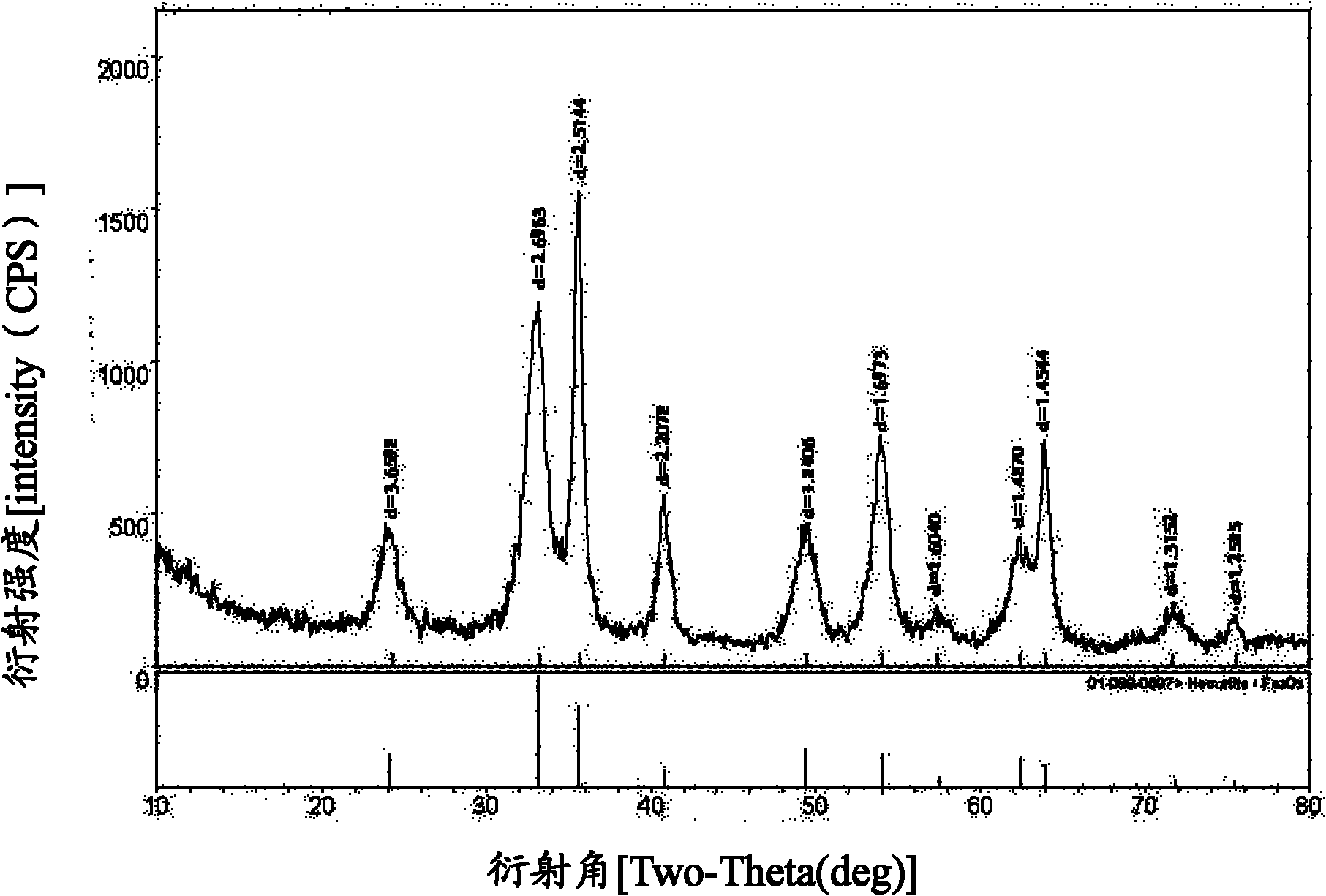

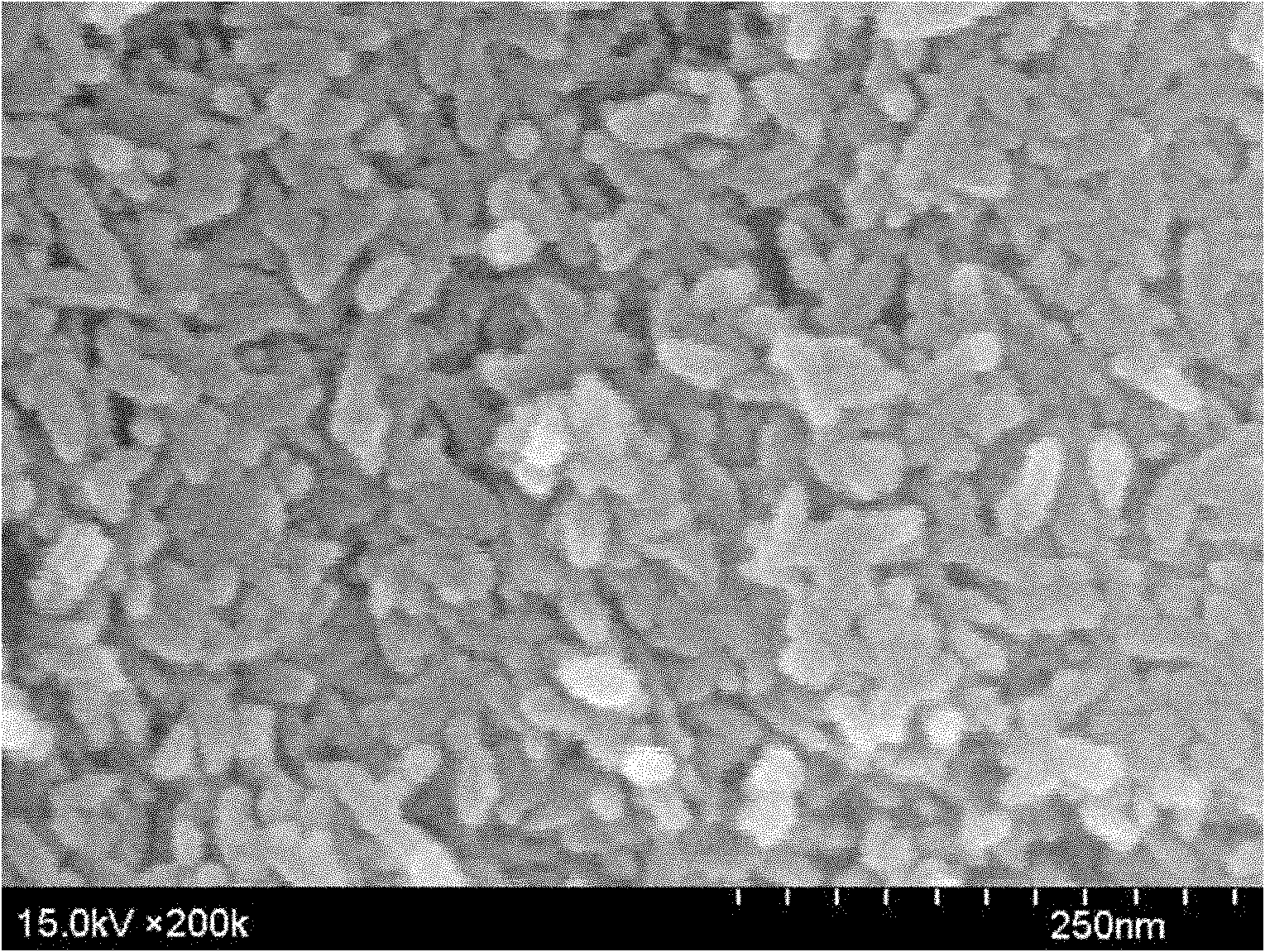

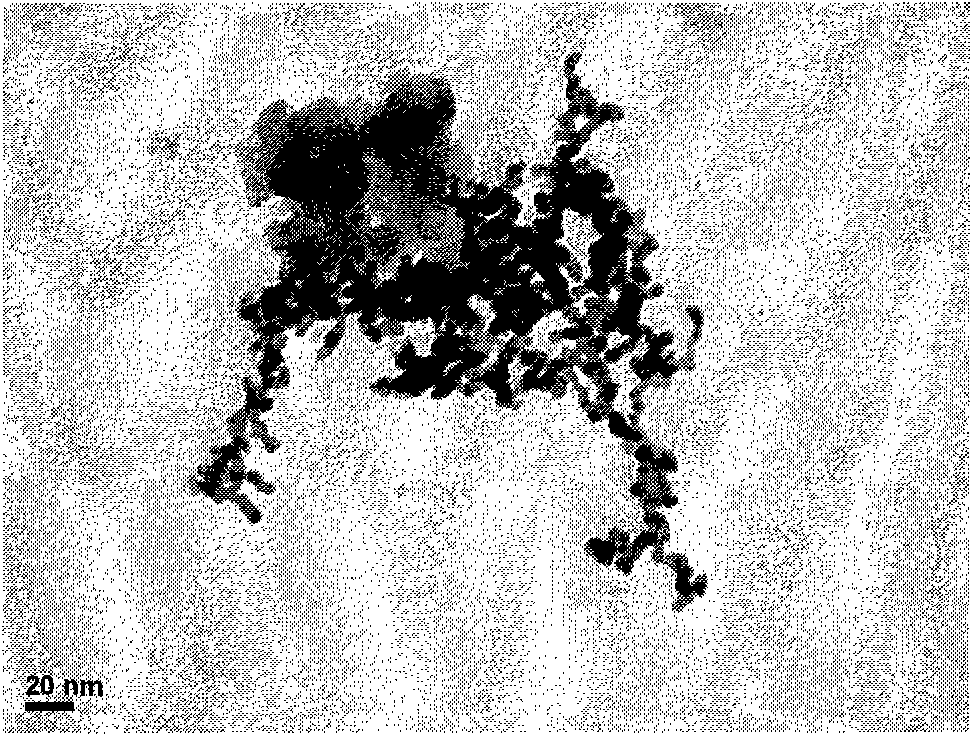

Preparation method of nano iron oxide yellow or nano iron oxide red

InactiveCN102092794AGood crystal formStable performanceNanotechnologyFerric oxidesIonBrown iron oxide

The invention discloses a preparation method of nano iron oxide yellow or nano iron oxide red. The preparation method comprises the following steps: (a) adding a polymerization inhibitor in a ferrite solution with iron ion concentration of 0.05mol / L-1.2mol / L, and dropwise adding a precipitator until the pH value is 3.5-5.0 so as to form a reaction system; (b) continuously reacting for 90-120 minutes to obtain a product after dropwise adding an oxidant in the reaction system; (c) filtering the product obtained from the step (b), washing and drying the obtained filter cake so as to obtain the nano iron oxide yellow; and (d) firing the nano iron oxide yellow obtained from the step (c), cooling the fired nano iron oxide yellow to obtain the nano iron oxide red. By using the method, the particle size of the product can be effectively controlled between 20-100 nanometers, and the nano iron oxide yellow and nano iron oxide red are obtained by subsequent processing; and the method has the characteristics of simple process, small pollution, low energy consumption and short period.

Owner:ZHEJIANG UNIV

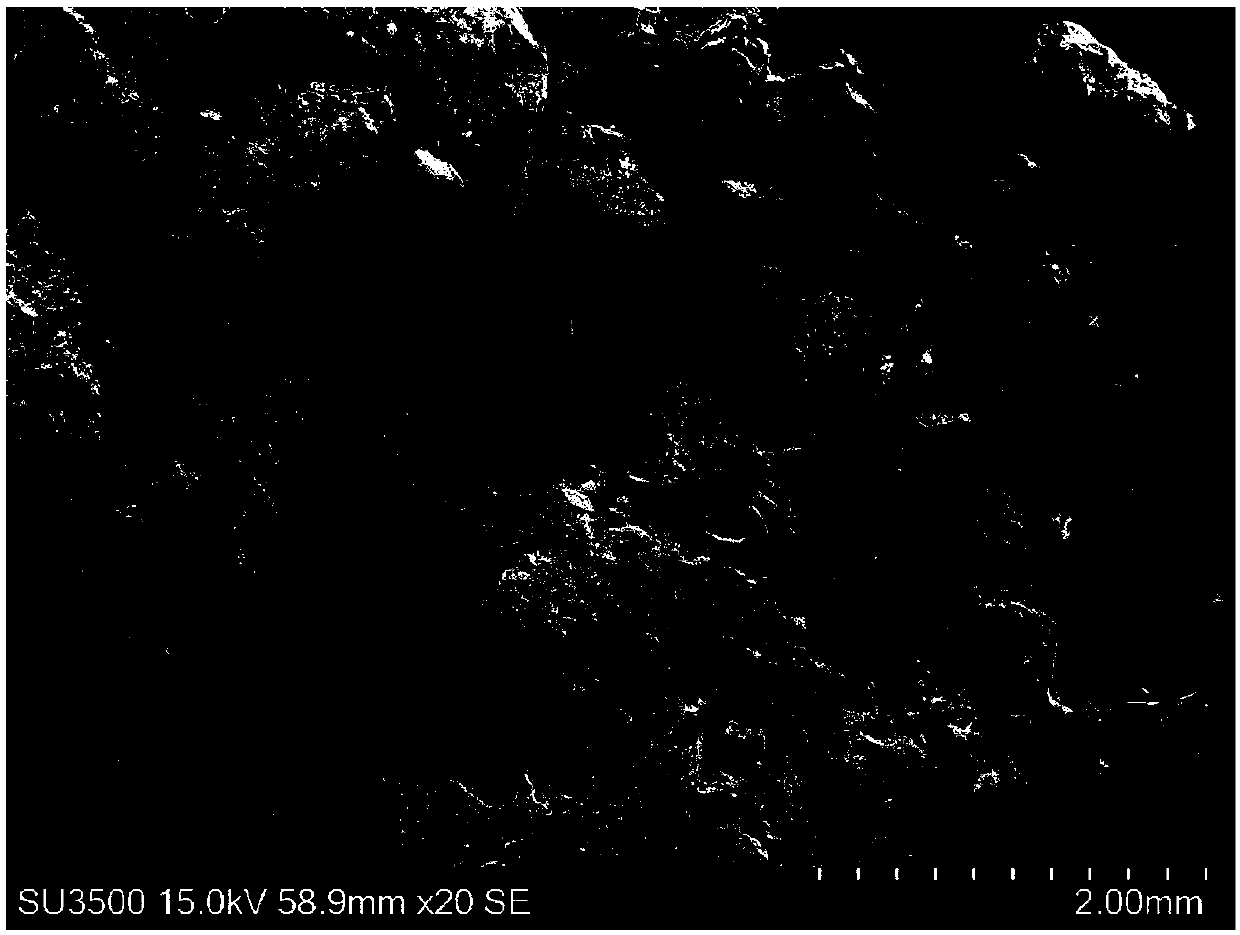

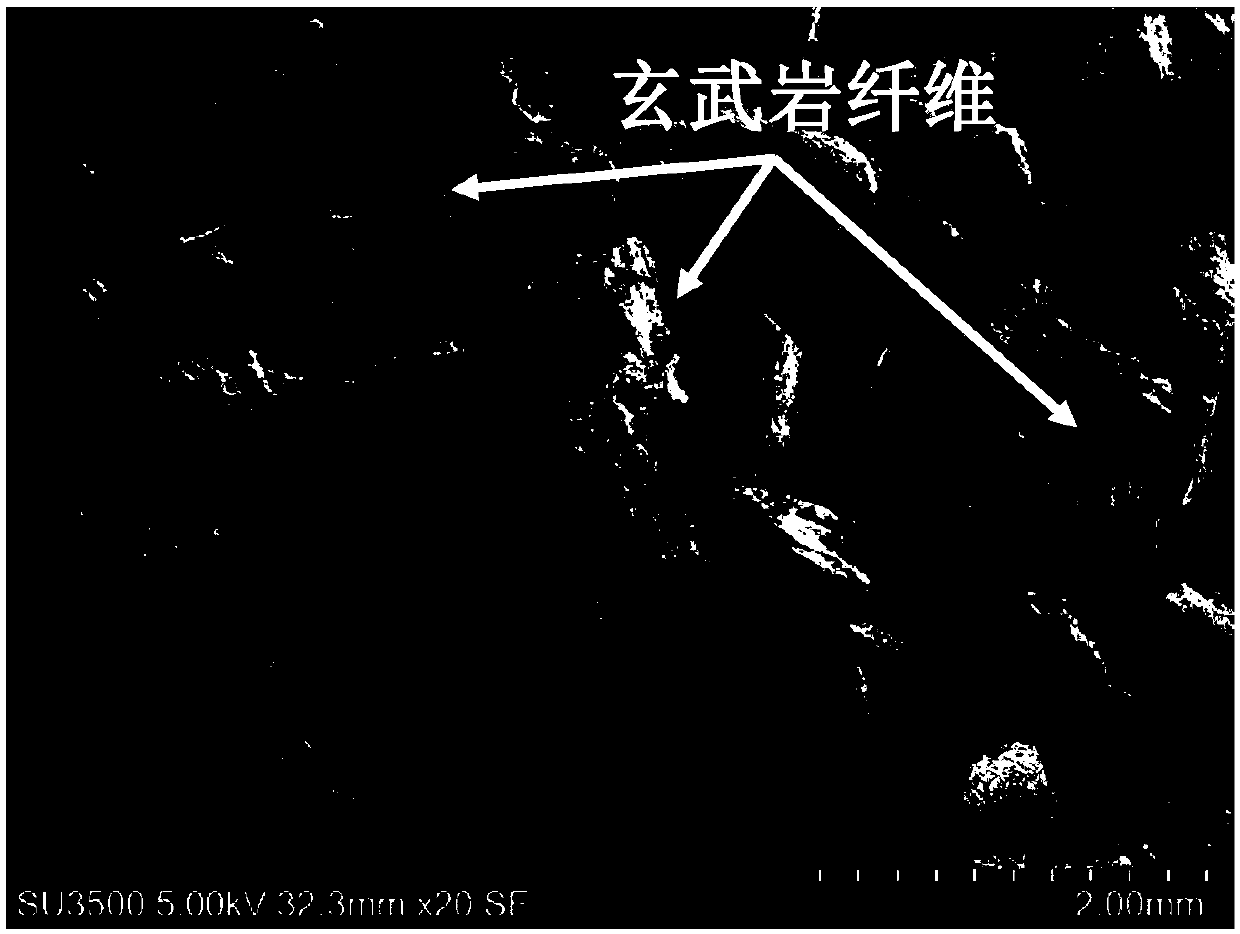

Microbial curing-fiber reinforcement combined sandy soil modification method

ActiveCN109594552AHigh strengthImprove toughnessSoil preservationResidual strengthEngineering structures

The invention discloses a microbial curing-fiber reinforcement combined sandy soil modification method and belongs to the field of geological engineering-microbial interdiscipline. The method comprises the steps as follows: 1) adding a fiber material to sandy soil, adding water, performing uniform stirring, putting the mixture in a mold, and leaving the mixture to stand and drying the mixture after compacting and filling the mold; 2) activating a microbial solution with mineralization; 3) soaking the sandy soil in the activated microbial solution; 4) transferring the treated sandy soil to a maintenance device, and filling the maintenance with a gluing solution for gluing and curing. An MICP technology and a fiber reinforcement technology are combined to modify the sand soil, so that loosesandy soil is cured, the forming strength is improved, meanwhile, brittleness of a sandy soil cured body can be significantly reduced and residual strength and toughness of the sandy soil cured body can be improved due to addition of the fiber, the engineering properties of traditional MICP cured sandy soil are improved as a whole, and the method has great significance in further improving safetyand stability of engineering structures.

Owner:南京南智碳中和研究院有限公司

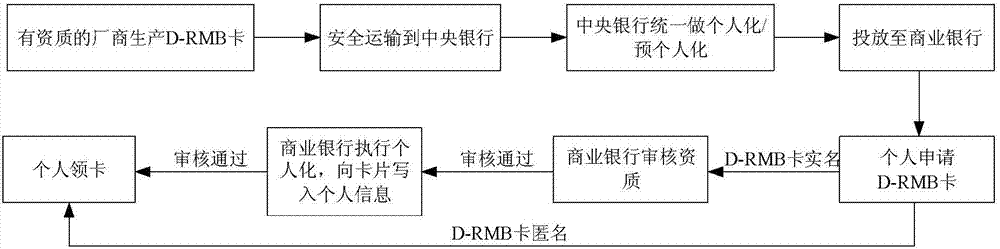

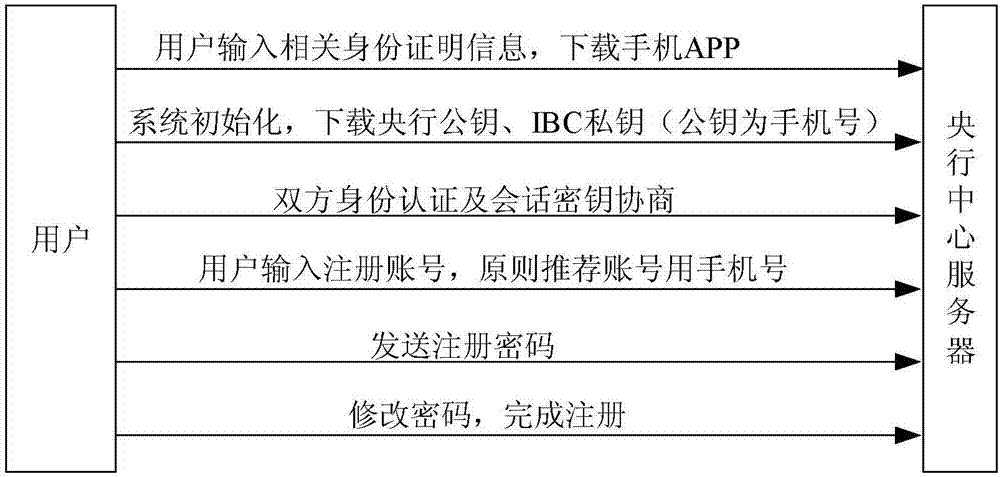

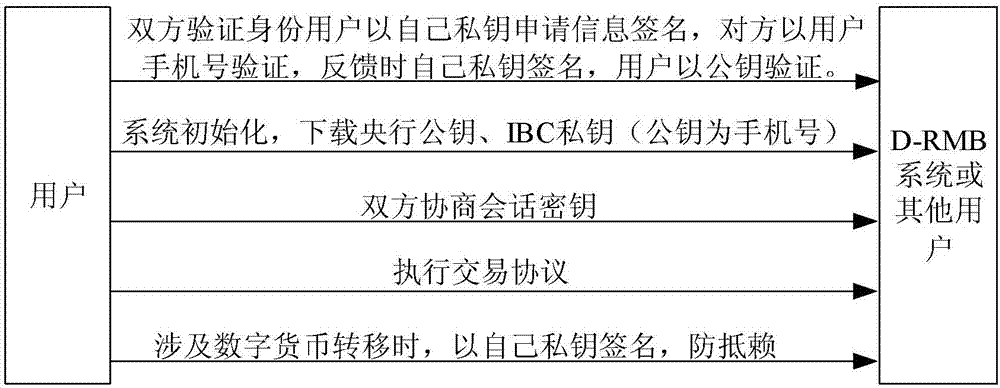

Method and system of paying digital currency

ActiveCN107230055AAvoid portabilityImprove anti-counterfeiting performancePayment protocolsPayment circuitsNear field communicationMonetary Amount

The invention provides a method and a system of paying digital currency. The method and the system solve a variety of deficiencies in the prior art. The method of paying the digital currency of the invention comprises: receiving a payment amount and a receiving side identifier input by an external operation by a payment side terminal device; selecting the digital currency, of which the total amount is equal to the payment amount, in a payment side digital-currency purse by the payment side terminal device; sending the digital currency to a receiving side terminal device, which corresponds to the receiving side identifier, in a near field communication (NFC) manner by the payment side terminal device; sending the digital currency to a commercial bank digital-currency system by the receiving side terminal device through a network; sending the digital currency to a central bank digital-currency system by the commercial bank digital-currency system through the network; and changing owner information of the digital currency from a payment side to a receiving side by the central bank digital-currency system.

Owner:THE PEOPLES BANK OF CHINA DIGITAL CURRENCY INST

Plant fiber-reinforced polypropylene composite material and preparation method thereof, and application of plant fiber-reinforced polypropylene composite material in preparation of automobile components

The invention discloses a plant fiber-reinforced polypropylene composite material and a preparation method thereof, and an application of the plant fiber-reinforced polypropylene composite material in preparation of automobile components. The composite material is prepared from the following raw materials in percentage by weight: 40%-77% of polypropylene, 20%-40% of a plant fiber, 1%-10% of vegetable oil, 1%-10% of a flexibilizer and 0.1%-5% of an assistant, wherein the plant fibers and the vegetable oil are from renewable biomass, and conform to the requirements of low-carbon, environment-friendly and sustained economic development. In addition, a low-density biomass material is capable of further promoting light weight of automobiles, and is of great significance in energy conservation and emission reduction. The plant fiber-reinforced polypropylene composite material for automobiles can be prepared by extrusion once, so that the method is simple, easy to operate and suitable for industrialized production.

Owner:NINGBO HOMELINK ECO ITECH CO LTD

Method for preparing ZrO2 compound ceramic film on surfaces of magnesium and magnesium alloy through microarc oxidization

InactiveCN102345151AImprove corrosion resistanceFast growthAnodisationPlasma electrolytic oxidationMagnesium alloy

The invention discloses a method for preparing a ZrO2 compound ceramic film on surfaces of magnesium and magnesium alloy through microarc oxidization. The method comprises the steps of: based on a zirconium salt system solution as an electrolyte, placing the magnesium or magnesium alloy in the electrolyte to be used as an anode, taking a stainless steel plate as a cathode, controlling the temperature of the electrolyte to be 10-35 DEG C, regulating the pulse frequency to be 300-1000Hz and the duty cycle to be 5-45%, carrying out constant-voltage treatment for 10-30 minutes under the condition that the voltage is 250-300V, then raising the voltage to 400-450V, and carrying out constant-voltage treatment for 20-60 minutes, thereby growing a uniform and compact ZrO2 compound ceramic film in situ on the surface of the magnesium or magnesium alloy. By adopting the method disclosed by the invention, the compact ZrO2 compound ceramic film can be rapidly obtained on the surface of the magnesium alloy. The method has no special requirements for materials, shapes, sizes and the like of the magnesium or magnesium alloy, and has better generality.

Owner:CHANGAN UNIV

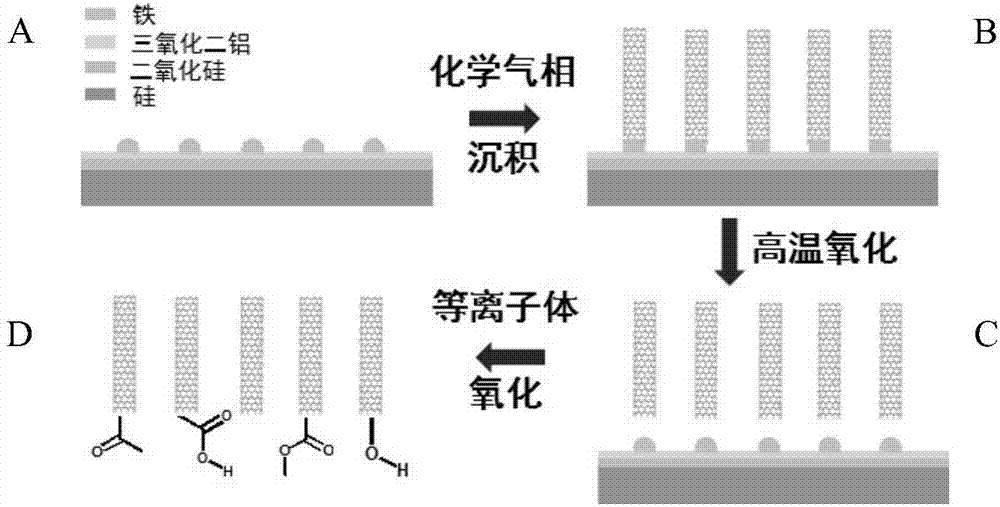

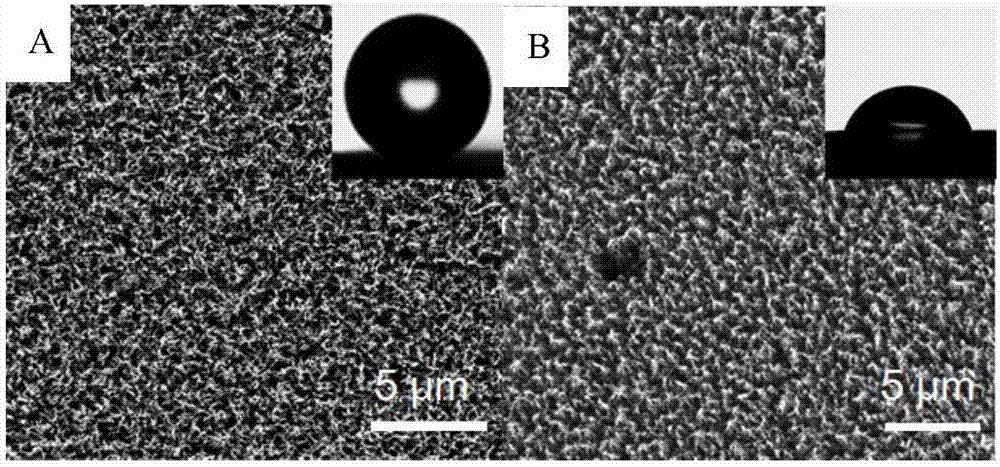

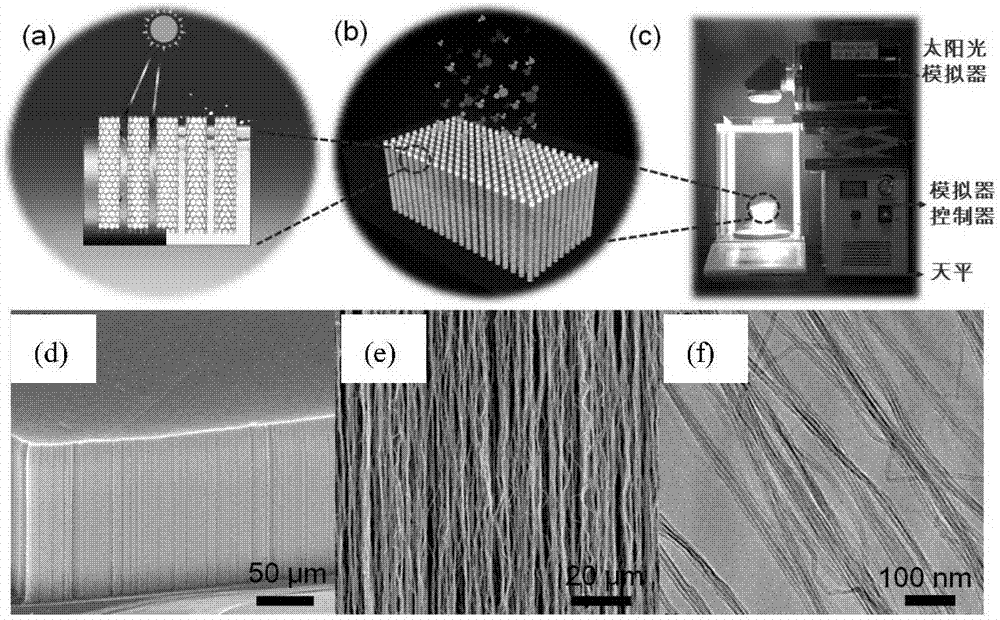

Solar seawater desalination or sewage treatment method based on carbon nano-tube film

ActiveCN107311255AImprove light-to-heat conversion efficiencyFast water purificationGeneral water supply conservationSeawater treatmentCarbon nanotubeChemical vapor deposition

The invention discloses a solar seawater desalination or sewage treatment method based on a carbon nano-tube film. The method comprises the following steps: using a carbon nano-tube vertical array which is directly prepared by adopting a chemical vapor deposition method as a raw material, and carrying out treatment to obtain a carbon nano-tube vertical array film having strong light absorption property and surface hydrophilicity; putting the hydrophilicity carbon nano-tube film on a to-be-treated water surface. Because the carbon nano-tube film can effectively absorb the light and light-thermal conversion can be carried out, so that the water can be quickly evaporated when a water body is heated, and the steam is condensed to obtain purified water. The technology has the characteristics of environmental protection, simple and convenient process, high light-thermal conversion efficiency, high water purification speed, good durability and the like, and has a wide application prospect.

Owner:TSINGHUA UNIV

Feedstuff addictive and its preparing technology and application in process for manufacturing birds flu-preventing feedstuff

The invention discloses a feed addictive with its preparing technology and application in producing feedstuff on anti- bird's flu. By means of inoculating medicinal fungus into all character base material comprised of drug character base material and nutritional base material, adjusting fermentation conditions, it will gain the feed addictive collecting drug character fungus after fermentation spanning some time. This feed addictive can enhance animals' immunity and used to produce feedstuff on anti- bird's flu. The equipment has simple technique, low coat and be green and environmental protection.

Owner:NANJING XIAOZHUANG UNIV

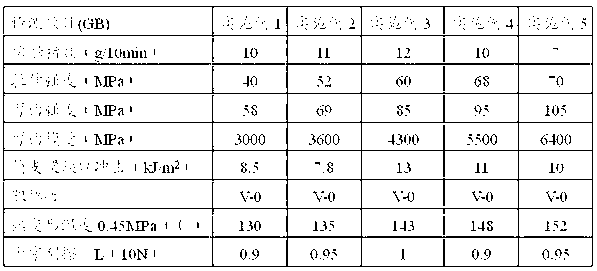

Kitchen flame-retardant and scrapping-resistant polypropylene materials and preparation method of the same

The invention discloses kitchen flame-retardant and scrapping-resistant polypropylene materials, and further discloses a preparation method of the kitchen flame-retardant and scrapping-resistant polypropylene materials. The kitchen flame-retardant and scrapping-resistant polypropylene materials are prepared from the following components: by weight, 29-55.5 parts of polypropylene, 5-20 parts of continuous glass fiber, 5-10 parts of compatilizer, 19-27 parts of compound flame retardant and 1.5-3 parts of scrapping-resistant agent. The kitchen flame-retardant and scrapping-resistant polypropylene materials have the advantages of being flame-retardant, scrapping-resistant, environment-friendly, non-poisonous, free of sucking water, mould-proof, anticorrosion, acid-alkali resistant, anti-aging, heat-resisting, recoverable, capable of conducting injection molding, convenient to process, capable of having different color custom-made according to requirements and being made into different styles and patterns in an injection molding mode according to requirements and the like, simple in production flow, continuous in production process, high in production efficiency and stable in production quality, and satisfies requirements for energy conservation, emission reduction, environmental-friendly residence, comfort and beauty, and are ideal kitchen materials.

Owner:HEFEI GENIUS NEW MATERIALS

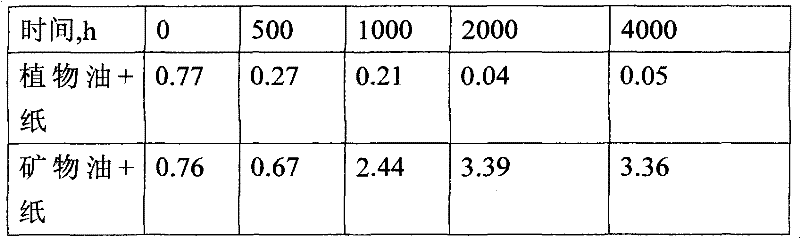

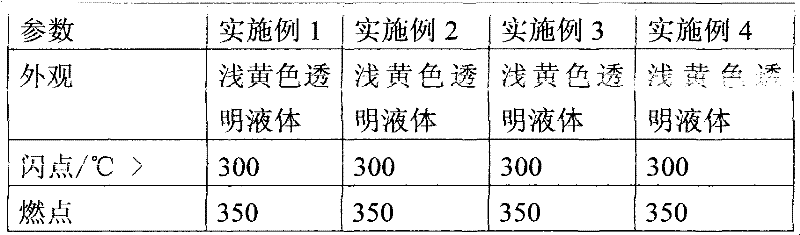

Vegetable insulating oil and preparation method thereof

InactiveCN102543262AGreenLow-carbon and energy-savingLiquid organic insulatorsTransformers/inductances coils/windings/connectionsVegetable oilTransformer

The invention discloses vegetable insulating oil, which is mainly prepared from the following raw materials in percentage by weight: 90 to 95 percent of vegetable oil and 2 to 5 percent of antioxidant. The invention also provides a method for preparing the vegetable insulating oil. The product is a novel vegetable insulating oil, is insulating oil for a transformer, is a high-performance insulating material extracted from renewable plants, and has the characteristics of environment friendliness, safe operation, long service life, high overload capacity, low carbon, energy saving and the like.

Owner:GUANGDONG JOOYN NEW MATERIAL TECH CO LTD

Green and high-yield method for fructus trichosanthis

InactiveCN105379523AIncrease productionImprove securityHorticultureEnvironmentally friendlySoil preparation

A green and high-yield planting method for fructus trichosanthis. The method comprises the steps of: seed treatment; soil preparation; application of base fertilizer; colonization; seedling management; soil and fertilizer management; flowers and fruits protection; harvesting and processing; and overwintering management. Compared with the prior art, according to the reasonable green planting method, not only a yield of fructus trichosanthis is improved greatly, but also the method has advantages of green and environmentally friendly planting, high safety and easy operations, etc. Meanwhile, the planting method for fructus trichosanthis has broad market prospects in application and popularization.

Owner:潜山市传文瓜子有限公司

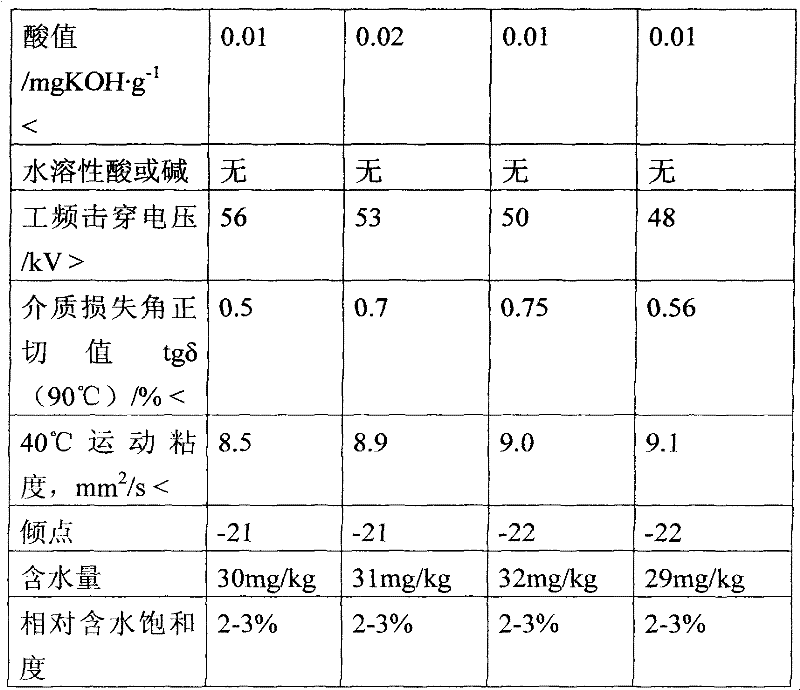

Body automatic sensing LED light

InactiveCN102062315AImprove utility conversion efficiencySolution to short lifePoint-like light sourceElectric circuit arrangementsPhotodetectorTransformer

The invention discloses a body automatic sensing LED light which is invented for solving the problems of high energy consumption, separation of incandescent bulbs and switches and the like in the prior art. The body automatic sensing LED light comprises a light holder, a shell and at least one LED luminous tube; a circuit board is arranged in the shell; an aluminum base plate is connected to the lower side of the circuit board; a circuit assembly is arranged on the circuit board; a pyroelectricity infrared sensor and a photodetector are arranged on the bottom surface of the aluminum base plate; the LED luminous tubes are all arranged on the bottom surface of the aluminum base plate; and a lens is arranged under the pyroelectricity infrared sensor. With the structure, the body automatic sensing LED light is switched in a commercial power 220V lamp holder, a circuit is rectified and filtered by an effective electronic transformer; a sensing signal is combined with the photodetector after being subjected to coupling signal processing, voltage amplification and shaping so as to realize the breakthrough of 90 percent of the commercial power conversion efficiency, large illumination, long service life and static micropower consumption. When the light is turned off when meeting the environment illumination in the day light, the light cannot turn on even if people moves in a light movement area; when no light is emitted at night, people can automatically trigger and turn on the light and the light is turned off in a delay way when people leaves, and the light works in cycles. The invention has the advantages of economical efficiency, practicability, environmental protection and energy conservation.

Owner:侯山春

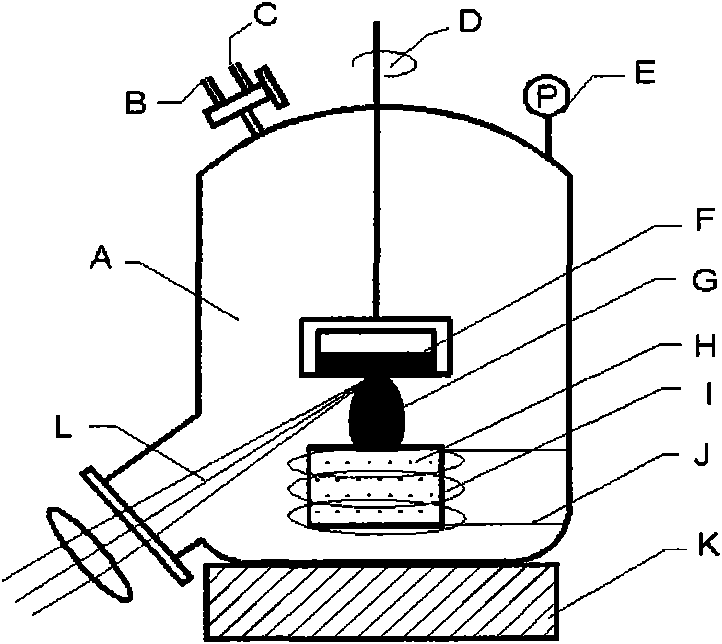

Method for preparing supported nanometer gold catalyst by laser deposition

InactiveCN101574654AEvenly distributedGreenVacuum evaporation coatingSputtering coatingCatalytic reformingFuel cells

The invention discloses a method for preparing a supported nanometer gold catalyst by laser deposition, which comprises the following steps: hanging and fixing metal Au on the middle part of a laser deposition pond; putting a carrier in the laser deposition pond at a position closer to the bottom than the metal Au; heating the carrier to 25-600 DEG C and stirring the carrier so as to ensure that the carrier is in a moving state; under a vacuum condition and the protection of inert gas, focusing pulsed laser onto the surface of the metal Au by a laser so as to excite Au atoms into an atomic beam which is directionally and uniformly deposited on the surface of the carrier; and obtaining the supported nanometer gold catalyst. The preparation method has simple operation and no environmental pollution, and the prepared supported nanometer gold catalyst has higher catalytic activity, selectivity and stability. The supported nanometer gold catalyst can be applied to the fields of fuel-cell catalysts, carbon monoxide oxidation catalysts, catalytic hydrogenation catalysts, catalytic reforming catalysts, and the like and has greater implementation values and important social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com