Preparation method of battery-grade lithium carbonate

A lithium carbonate, battery-grade technology, applied in the field of preparation of battery-grade lithium carbonate, can solve the problems of long adsorption-regeneration time, high cost, low overall efficiency, etc., to avoid high acid-base and water consumption, yield and quality Stable, improved process continuity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

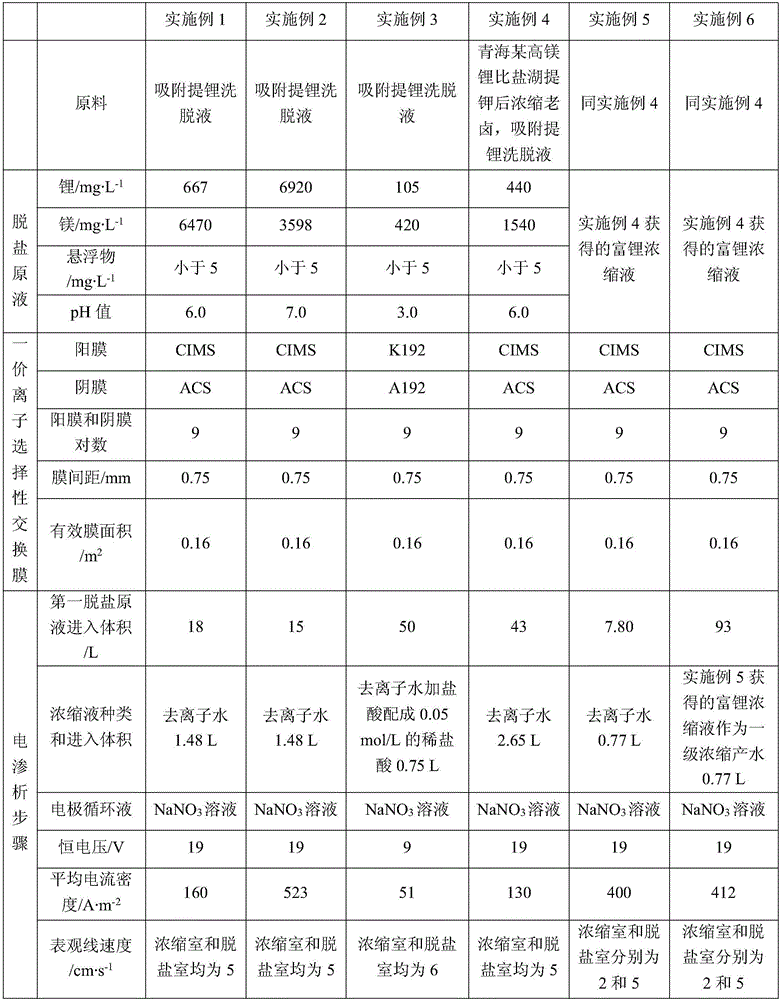

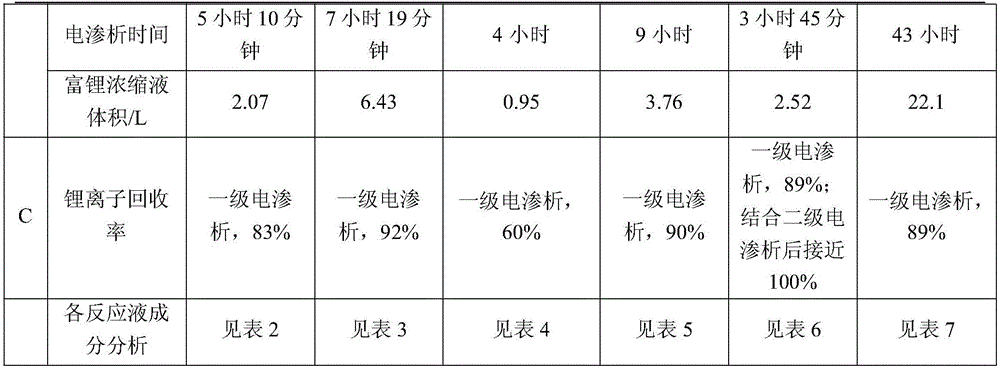

Examples

preparation example Construction

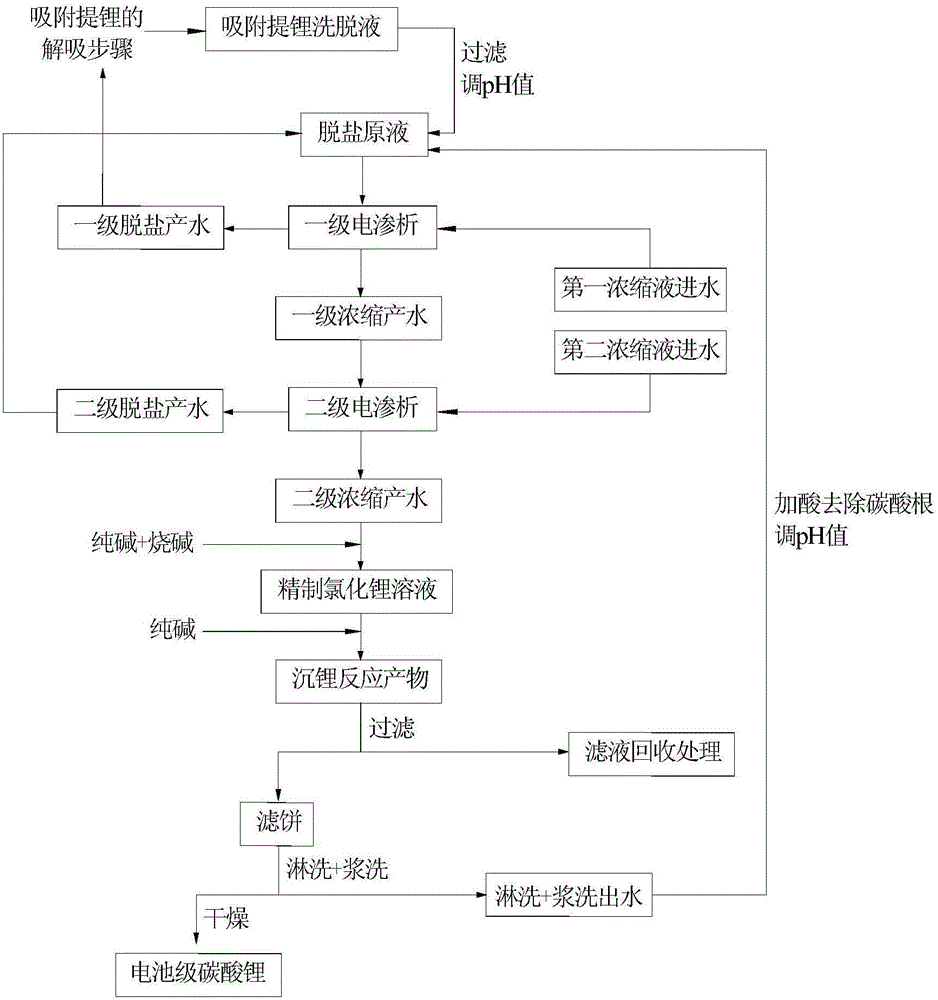

[0042] Such as figure 1 Shown, the invention provides a kind of preparation method of battery grade lithium carbonate, comprises the steps:

[0043] Step 1: Obtaining and preprocessing raw materials.

[0044] The lithium-containing feed liquid used in the present invention is derived from the eluent of adsorption and extraction of lithium, wherein the weight ratio of magnesium to lithium ions is 0.3-20, and the lithium content is 80 mg / L-10000 mg / L. Preferably, the weight ratio of magnesium and lithium ions in the lithium-containing feed solution is controlled to be 0.5-10; the lithium ion content is 100 mg / L-7000 mg / L, which is more effective.

[0045] The solid impurities in the lithium-containing feed solution are removed, so that the suspended solids (SS) content after filtration is not higher than 5 mg / L.

[0046] After the lithium-containing feed solution is pretreated, the pH value is adjusted to 2-8 to obtain the first desalination stock solution. The first desalted...

Embodiment 7

[0091] This embodiment is the process of using the lithium-rich concentrated solution obtained in embodiment 5 or embodiment 6 as a raw material to prepare battery-grade lithium carbonate.

[0092] Add 2.5kg of caustic soda per ton of sodium carbonate, prepare a sufficient amount of 28% soda ash with deionized water under the condition of heating and stirring, and vacuum filter it for later use. At the same time, prepare a sufficient amount of 30% caustic soda solution with deionized water for subsequent use.

[0093] Take 5L of the lithium-rich concentrated solution obtained in Example 6, heat it to 60°C, and add 40mL of the pure lye at a ratio of 7L to 9L per cubic meter under sufficient stirring conditions, and then slowly add 30% caustic soda solution to form the first reaction solution until the pH of the first reaction solution reaches 13.0, and a total of 139 mL of 30% caustic soda solution is consumed.

[0094] After continuing to stir and react for 40min, filter to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com