Patents

Literature

109 results about "Magnesium salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epsom Salt is actually a form of Magnesium. Its compound name is Magnesium Sulfate and looks a lot like salt! Magnesium Sulfate is used to treat all sorts of health issues ranging from strained, sore muscles to mental well-being. It is traditionally used in baths, but can be safely ingested as well.

Inkjet recording method

InactiveUS20140055520A1Achieving fixabilitySuppressing featheringDuplicating/marking methodsInksSolubilityNickel salt

An inkjet recording method which suppresses feathering and color bleeding and is excellent in fixability to a recording medium. The inkjet recording method includes the steps of applying an ink-receiving solution prepared by dissolving in an aqueous solvent at least one metal salt having a water solubility of 0.1 mol / l or more, selected from calcium salts, magnesium salts, nickel salts and zinc salts having a valence of 2 or more, to at least the surface to be printed by using an inkjet ink or the entire surface of a recording medium; and printing on the metal salt adhered part by using the inkjet ink comprising at least a pigment, a resin emulsion and an aqueous solvent containing a surfactant. Further, a phosphorus-containing group having at least one P—O or P═O bond is bound to the surface of the pigment.

Owner:DNP FINE CHEMICALS CO LTD

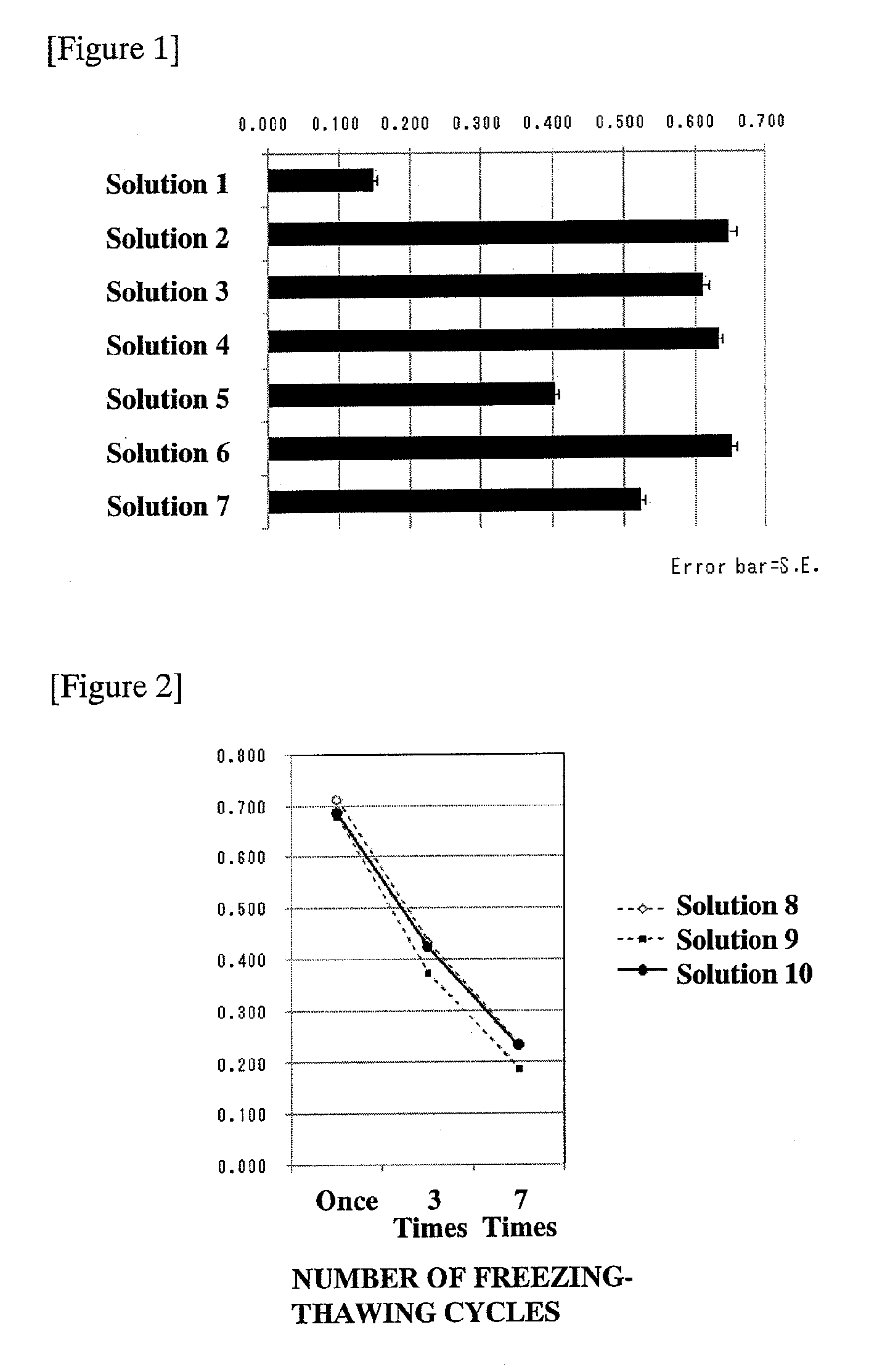

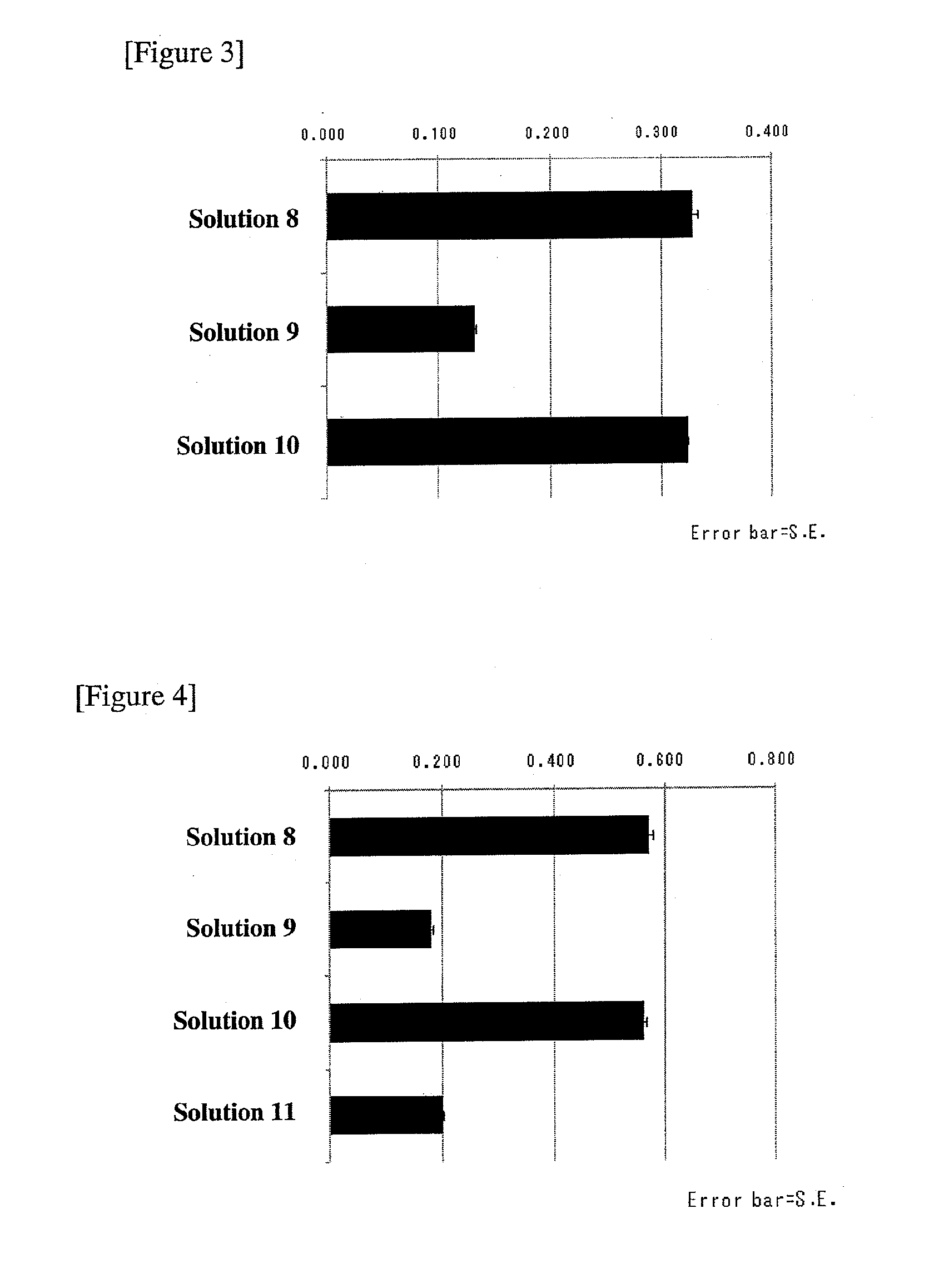

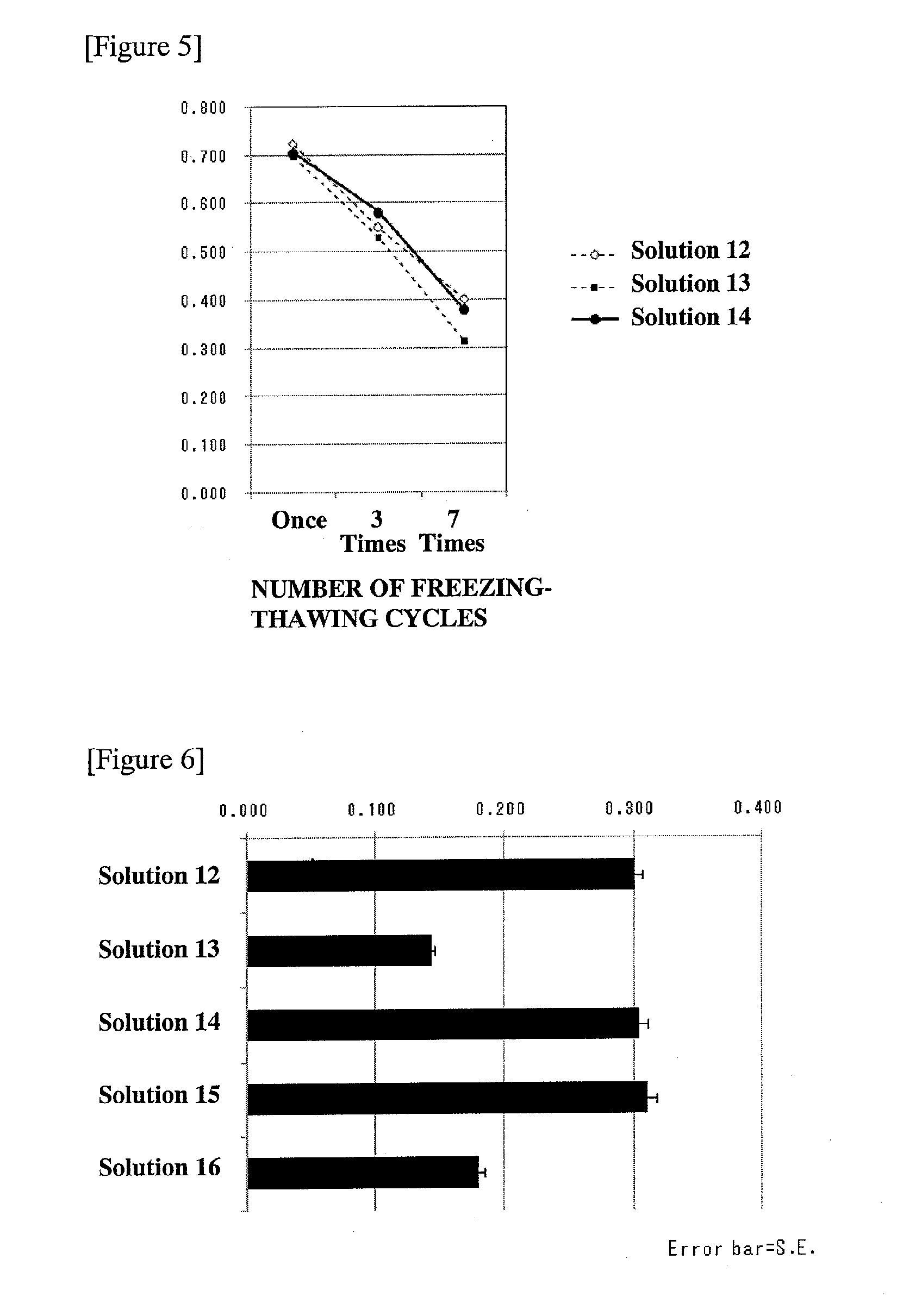

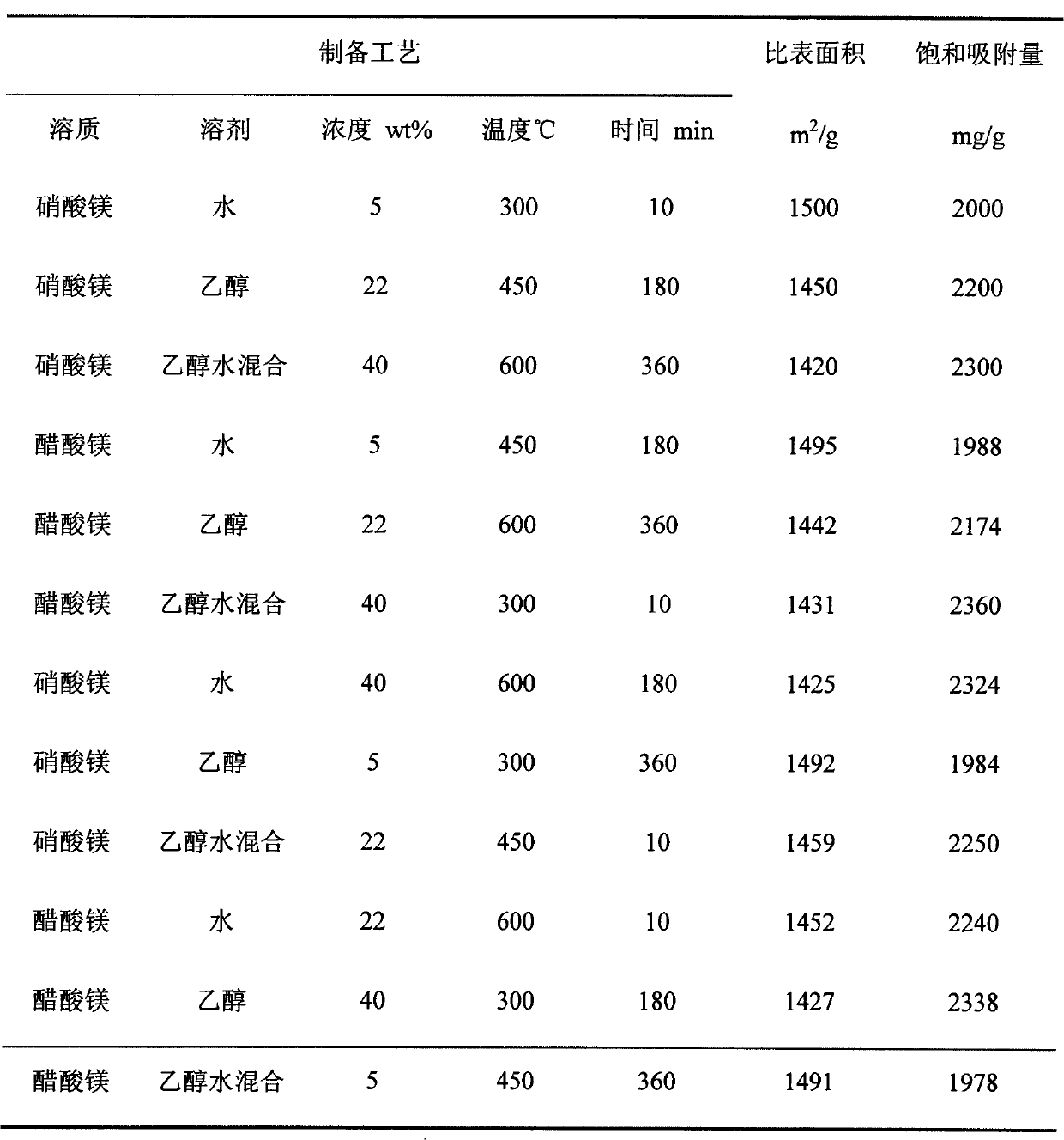

Cell preservation method

InactiveUS20120149108A1High viability rateIncrease chanceAnimal cellsDead animal preservationMagnesium saltsSodium salt

A method for cryopreservation of cells characterized by the use of a solution containing, as essential components, a sodium salt, a potassium salt, a saccharide, a cryoprotectant, and a hydrogencarbonate salt and / or a carbonate salt, the solution further optionally containing a component selected from the group consisting of proteins, magnesium salts, and calcium salts. According to the present invention, a method for cryopreservation of cells capable of maintaining a high viability rate after thawing, and a cryopreservation solution used in the cryopreservation are provided. In addition, by using the method for cryopreservation, the cells can be preserved in a state of maintaining a high viability rate even after thawing, and also maintaining their physiological functions; further, a cell washing step after freezing and thawing is unnecessary, thereby making it very useful in the fundamental researches of cells and the application studies on the medical treatment.

Owner:TAKARA HOLDINGS

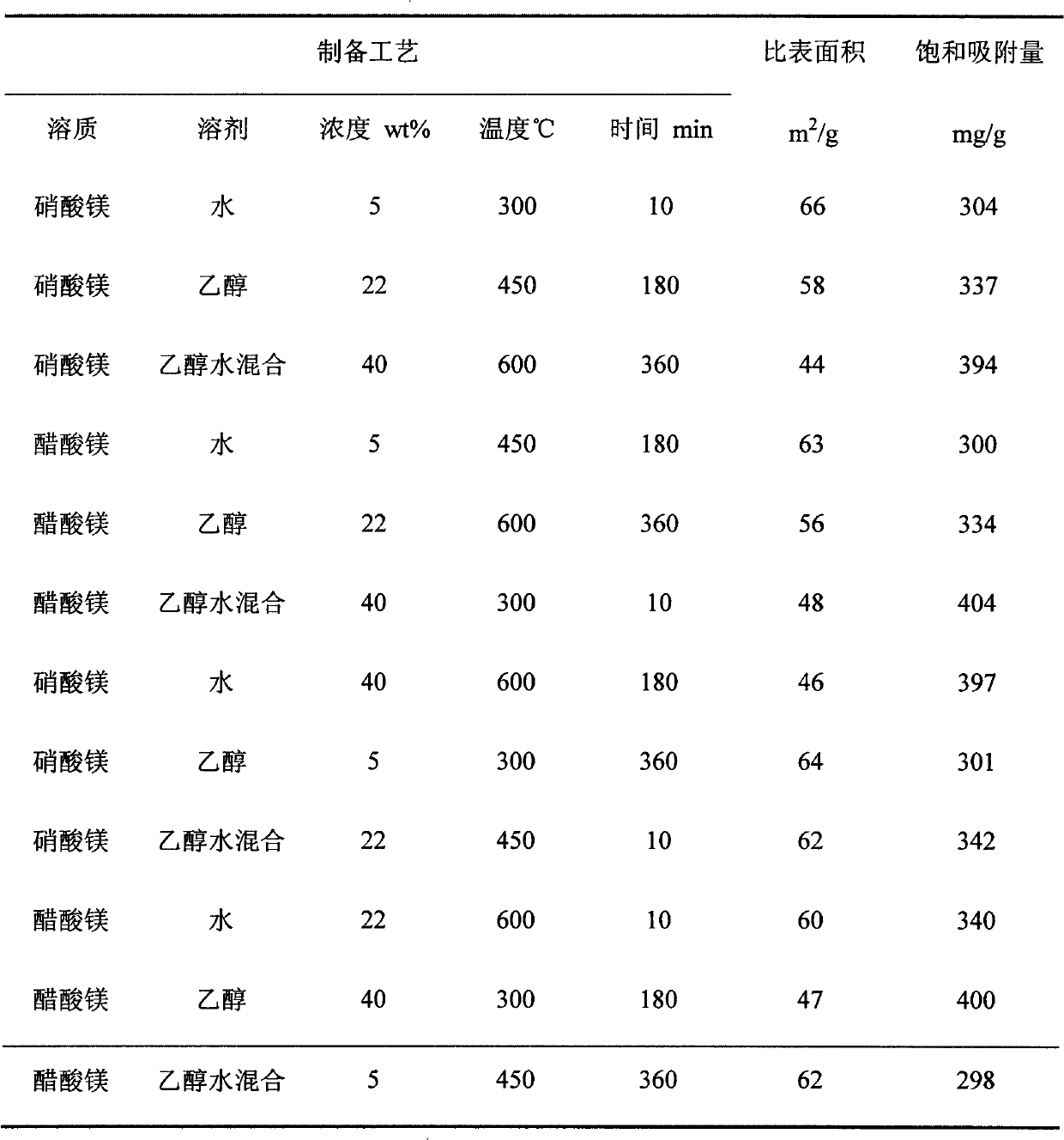

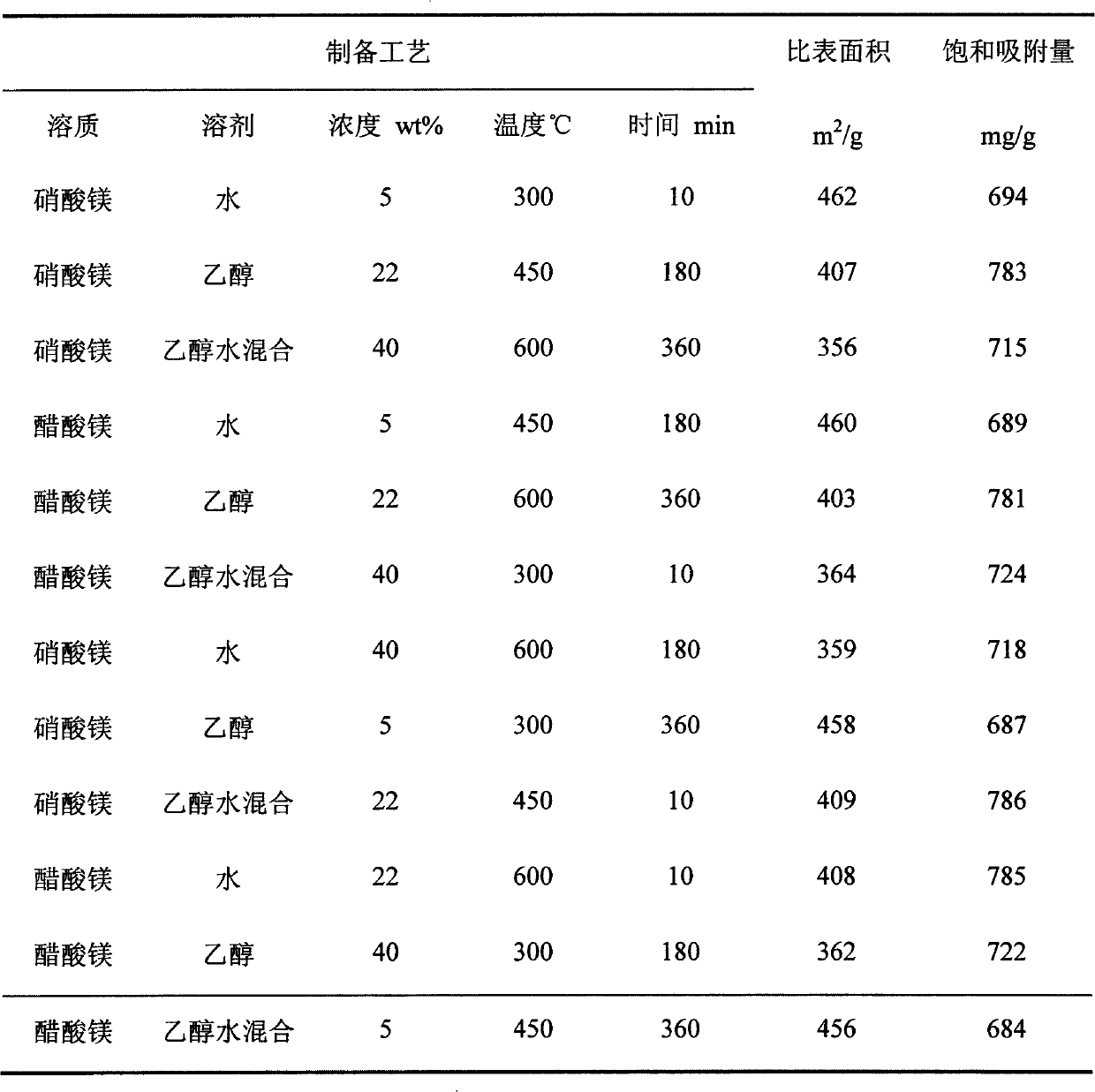

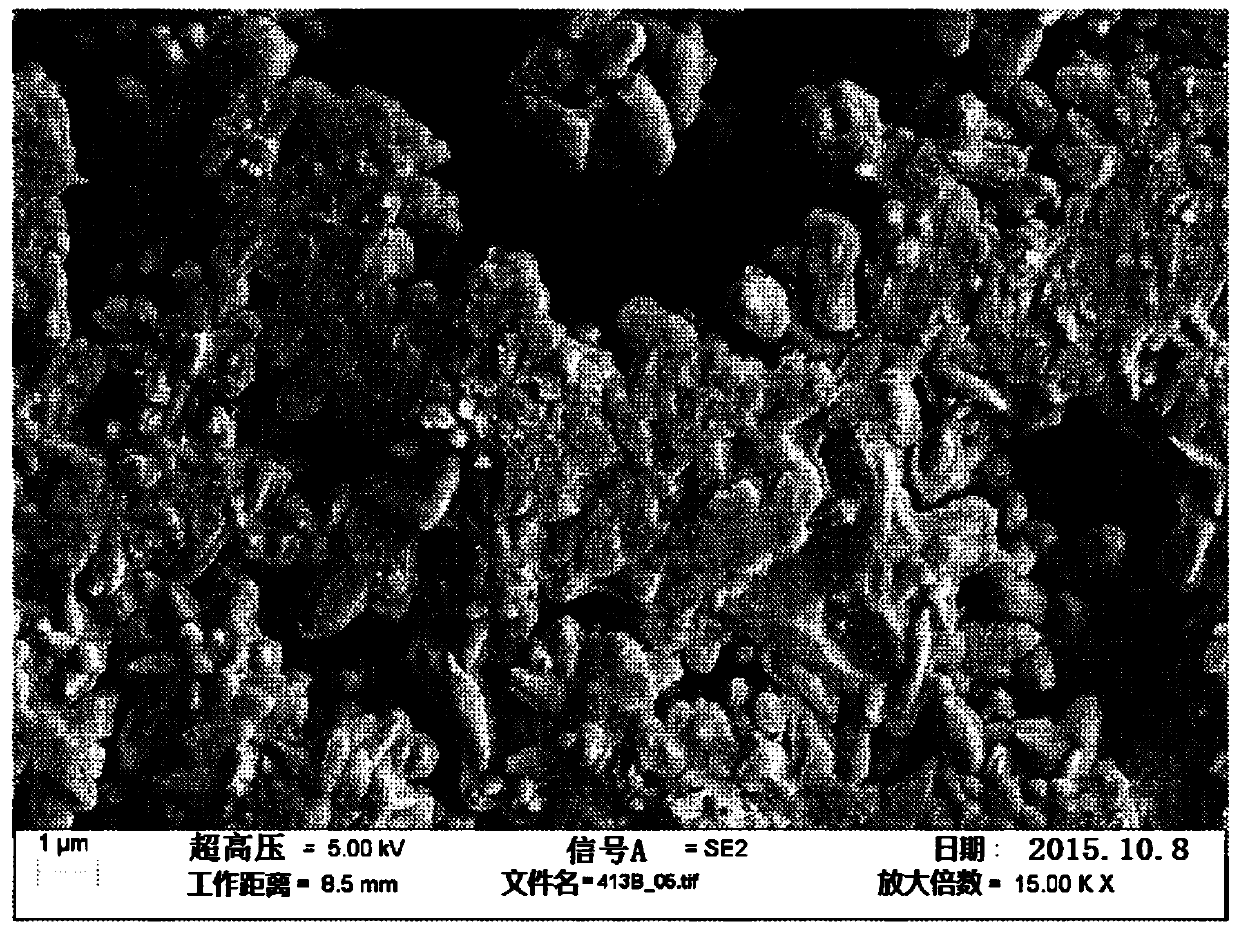

Preparation method of efficient adsorbent porous magnesium oxide

InactiveCN102908979ALow costOther chemical processesAlkali metal oxides/hydroxidesSorbentMagnesium salt

The invention relates to a preparation method of an efficient adsorbent porous magnesium oxide. The method is characterized by loading magnesium salts in ducts and surfaces of porous materials and obtaining the efficient adsorbent porous magnesium oxide through calcining, wherein the used magnesium salts are at least one of magnesium nitrate and magnesium acetate; the solvents of the magnesium salts are at least one of water and ethanol; the used porous materials are at least one of activated carbon, diatomite, silica gel and molecular sieves; the concentration of the magnesium salt solution is 5-40wt%; the calcination temperature is 300-600 DEG C; and the calcination time is 10-360min. The method has the advantages of simple needed equipment, short process flow, high preparation efficiency and low preparation cost. The prepared porous magnesium oxide has the advantages of large specific surface area, strong heavy metal ion adsorption capacity and high saturation adsorption, and has good industrial application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

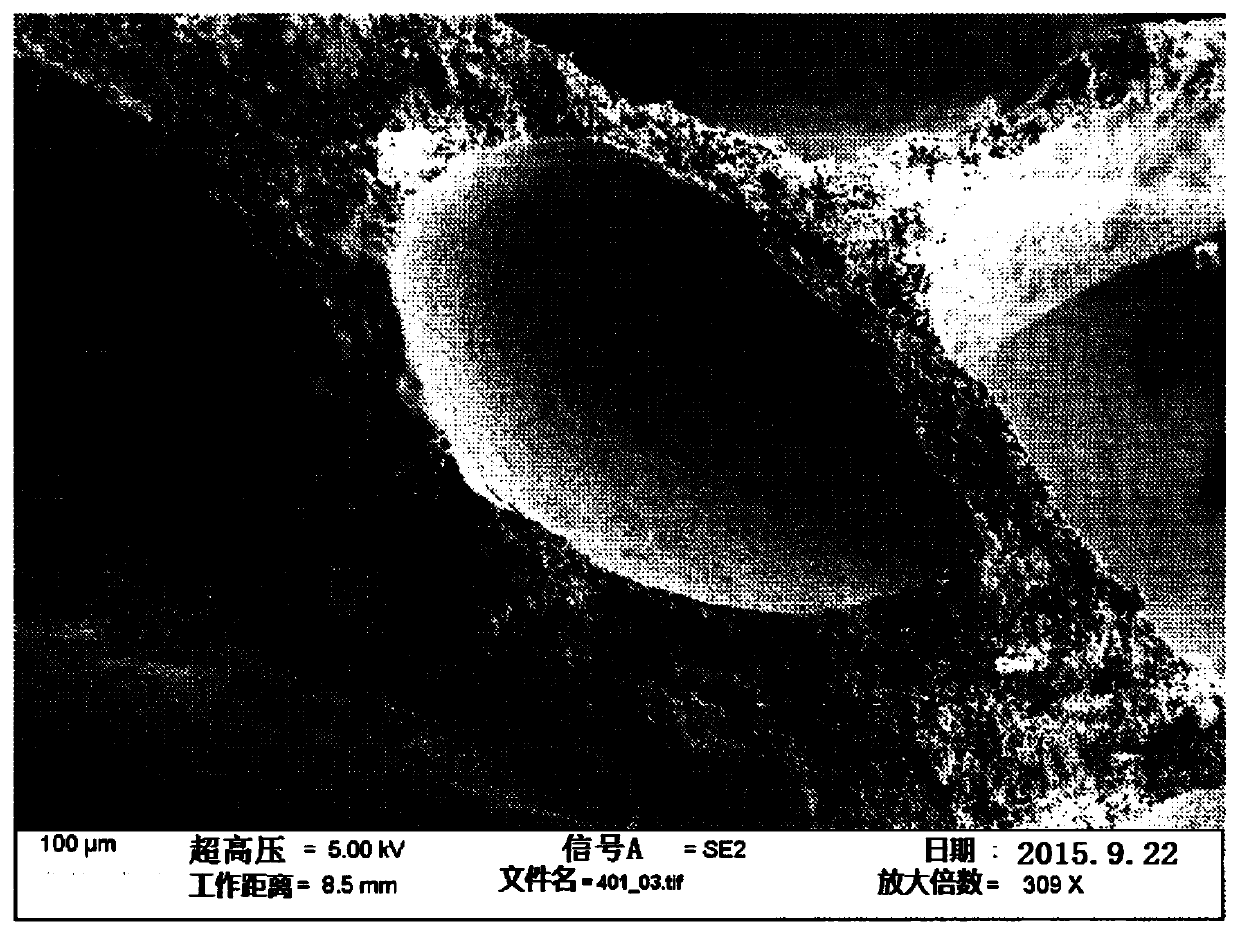

Micro-arc oxidation electrolyte and micro-arc oxidation method for titanium alloys

InactiveCN103911644AGood degreasingNo pollution in the processSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention relates to a micro-arc oxidation electrolyte and micro-arc oxidation method for titanium alloys. The electrolyte comprises phytic acid or phytate, and one or more of electrolytes such as bioactive element containing calcium salts, magnesium salts, zinc salts or organic additives such as tannic acid and hydroxides also can be added. The micro-arc oxidation method comprises the steps of pretreatment, micro-arc oxidation, and post-processing. The micro-arc oxidation electrolyte disclosed by the invention does not contain Cr<6+>, F<-> and PO4<3->, therefore, the electrolyte has no pollution to the environment. A coating prepared according to the micro-arc oxidation method disclosed by the invention is of a typical microporous structure, and has good antimicrobial properties, biological activity, corrosion resistance and wear resistance; the method is easily-obtained in raw materials, and suitable for industrial production.

Owner:JIANGXI SCI & TECH NORMAL UNIV

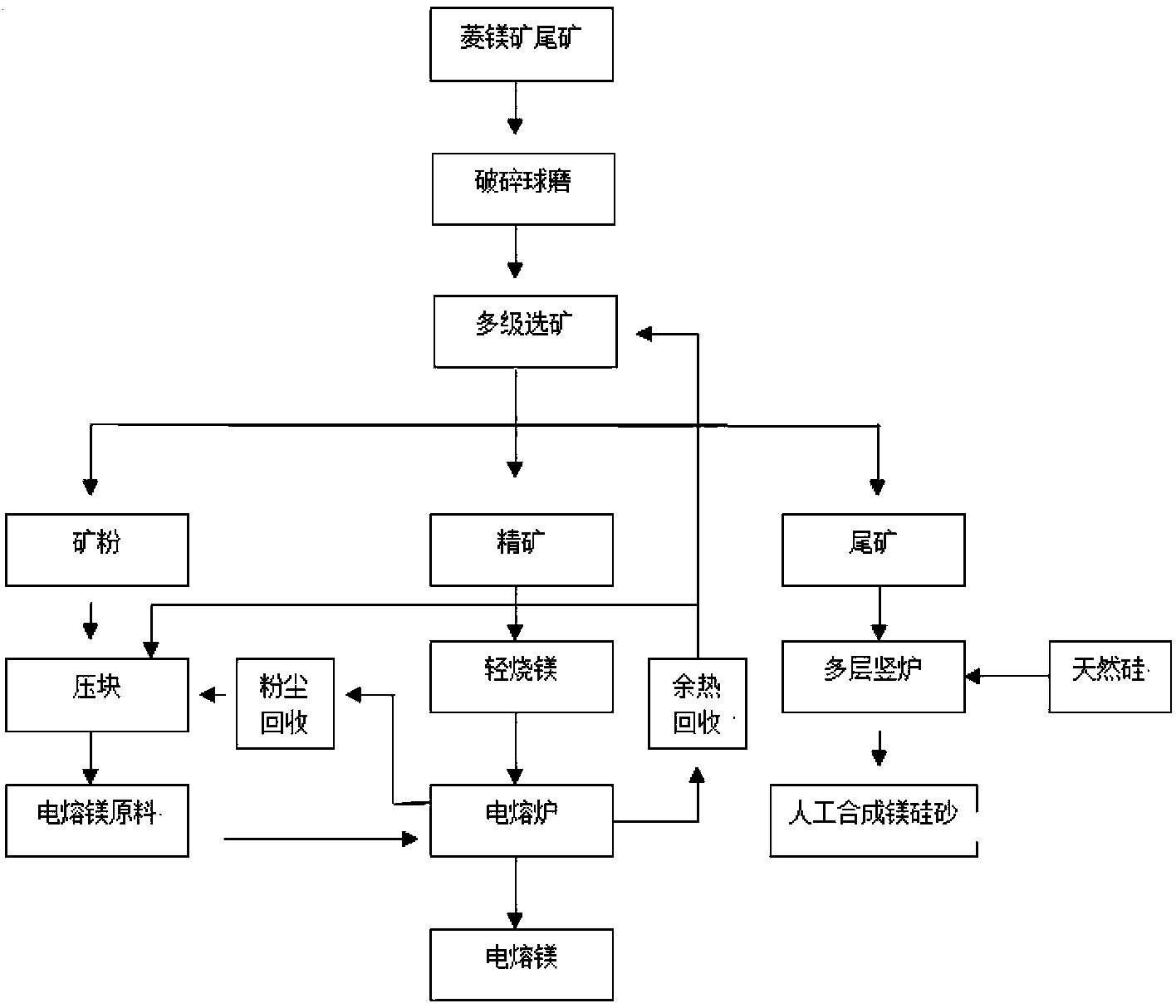

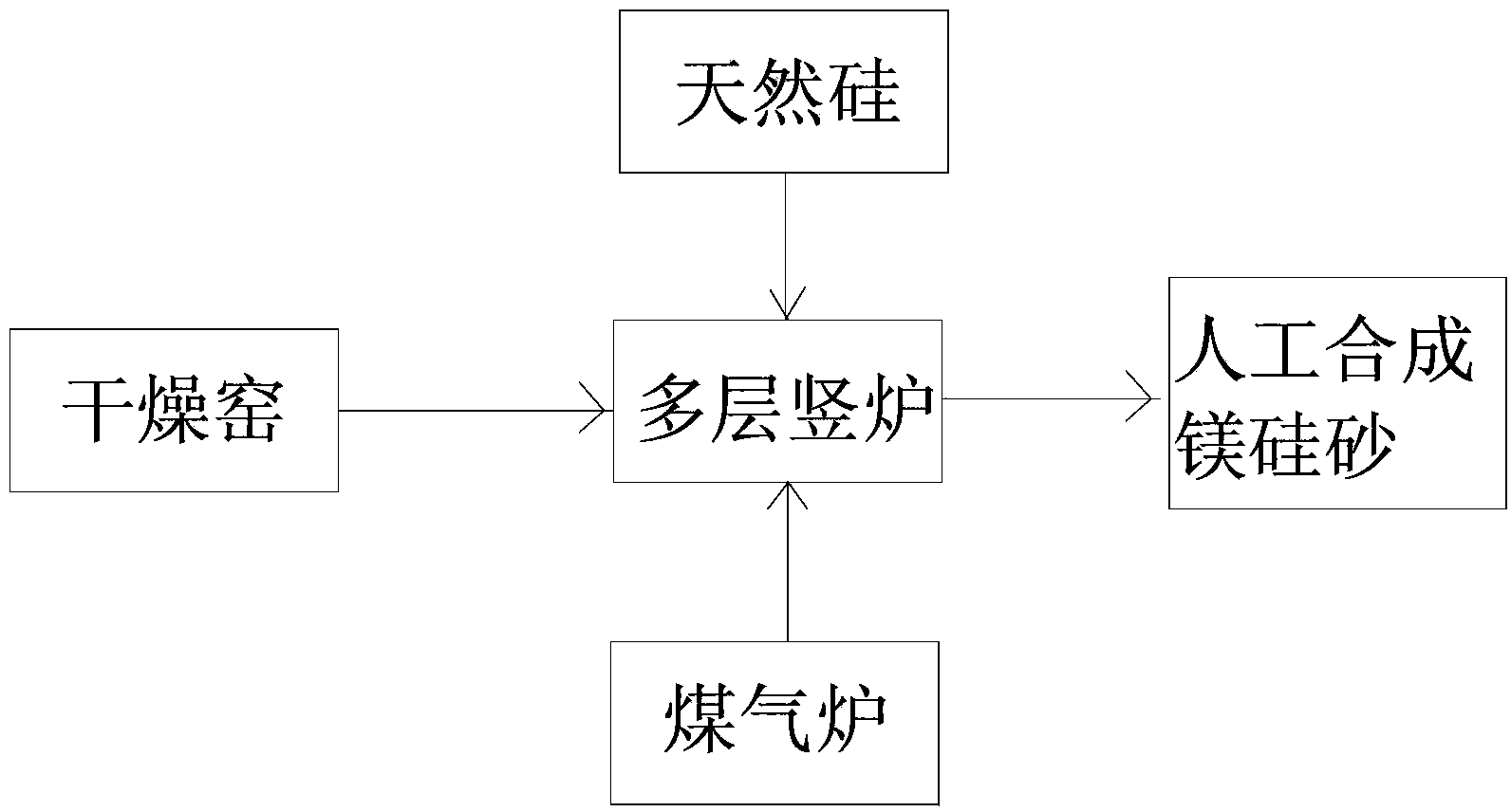

Multi-stage segmental ore-dressing, purifying, and comprehensive utilization method for low-grade magnesite

InactiveCN103406196ATake advantage ofAchieving zero emissionsWaste processingMechanical material recoveryShaft furnaceMagnesium salts

The invention relates to a multi-stage segmental ore-dressing, purifying, and comprehensive utilization method for low-grade magnesite. The method comprises the following steps of: crushing low-grade magnesite, ore grinding, grading, sorting and purifying, light burning of products after ore dressing, high-purity magnesium oxide preparation by magnesium salts converted by useful components after light burning, fused magnesite production, forsterite preparation by tailings, waste heat recovery for ore-dressing heating, and fused magnesite preparation by cake pressing of recovery dust. Compared with the prior art, the method has the beneficial effects of realizing zero release of tailings of magnesite, efficiently utilizing ore resources, saving energy by virtue of the adopted multi-layer shaft furnaces and multi-layer roasting and maximizing the economic benefits; the method has the advantages of simple process, low production cost, high product purity, high yield and no environment pollution.

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

Polyvinylbutyral interlayer sheet with improved adhesion to glass and a process for preparing same

ActiveUS20050234185A1Synthetic resin layered productsGlass/slag layered productsPotassiumMagnesium salts

The present invention is an improved PVB composition comprising an adhesion control agent which is a mixture of potassium and magnesium salts in a ratio of from about 0.05:1 to about 5:1, by weight, potassium salts to magnesium salts. The present invention also describes a method for improved control of adhesion of PVB to glass.

Owner:KURARAY AMERICA INC

Calcium and magnesium salts as squeakiness enhancers in cleansing compositions

Owner:CONOPCO INC D B A UNILEVER

Preparation method for magnetism-containing modified corundum composite material

The invention relates to a preparation method for a magnetism-containing modified corundum composite material. The composite material comprises the following main chemical components (wt): more than 95% of Al2O3 and less than 5% of MgO (Al2O3+MgO>99%); a main phase is a spinel-corundum phase. The preparation method comprises the following steps: taking industrial Al2O3, alpha-Al2O3 and Al(OH)3 as aluminum sources and magnesium salts such as brucite, light-burned MgO, dead burnt magnesite and magnesite as magnesium sources, adding 0.5-5% of alumina sol as a bonding agent or a combustion supporting agent, uniformly mixing through a gap-type or continuous-type ball mill, finely grinding, grading powder through air separation, forming the powder through a process of balling, pressing or the like, finally quickly sintering in a vertical kiln or a rotary kiln at 1,700-1,950 DEG C, crushing, grading, and deironing to obtain the magnetism-containing modified corundum composite material. According to the method, a high-quality refractory material for a liner of a high-temperature kiln is obtained, is low in expansion, high in strength, good in stability in a high-temperature reduction atmosphere and good in alkali resistance and slag corrosion resistance, and is a conventional sintered corundum upgrade product.

Owner:JIANGSU JINGXIN NEW MATERIAL

Inkjet recording method and ink set for inkjet recording

InactiveUS20140132661A1Achieving fixabilityClear imagingPhotosensitive materialsDuplicating/marking methodsNickel saltSolvent

Provided is an inkjet recording method which minimizes blur and achieves excellent fixing to a recoding medium. This inkjet recording method is characterized by adhering a receiving solution (A) to at least areas on a recording medium (R) which are to be printed with an inkjet ink (I) or the whole surface of the medium (R) which is to be printed, said receiving solution (A) being a solution obtained by dissolving (inclusive of dispersing) one or more metal salts (S) selected from among at least divalent, calcium salts, magnesium salts, nickel salts, aluminum salts, boron salts, and zinc salts and one or more resins (B) having hydrophilic groups in an aqueous solvent in such amounts that the concentrations of the metal salts (S) and the resins (B) fall within the range of 0.005 to 2.0 mol / l and within the range of 0.5 to 20 mass % respectively, and then applying the inkjet ink (I) to areas where the metal salts are present in an adhered state to carry out printing. Said inkjet ink (I) is an ink which comprises a pigment (P), an anionic resin emulsion (E), and an aqueous solvent, and in which phosphorus-containing groups each having at least one P—O or P═O bond are bonded to the surface of the pigment (P) or the surface of the anionic resin emulsion (E).

Owner:DNP FINE CHEMICALS CO LTD

Phosphoric acid beverages with calcium to phosphorus ratios of 1:1 or greater and methods of making

Phosphoric acid-based beverages and beverage concentrates supplemented with calcium, phosphorus and optionally magnesium salts. The consumable beverage maintains a calcium / phosphorus ratio of 1:1 or greater. These stabilized phosphoric acid-based beverages have a pH 3.5-5.0 and may be artificially sweetened in addition to sucrose, fructose and other sweeteners and methods of making.

Owner:LEDERMAN STEVEN N +1

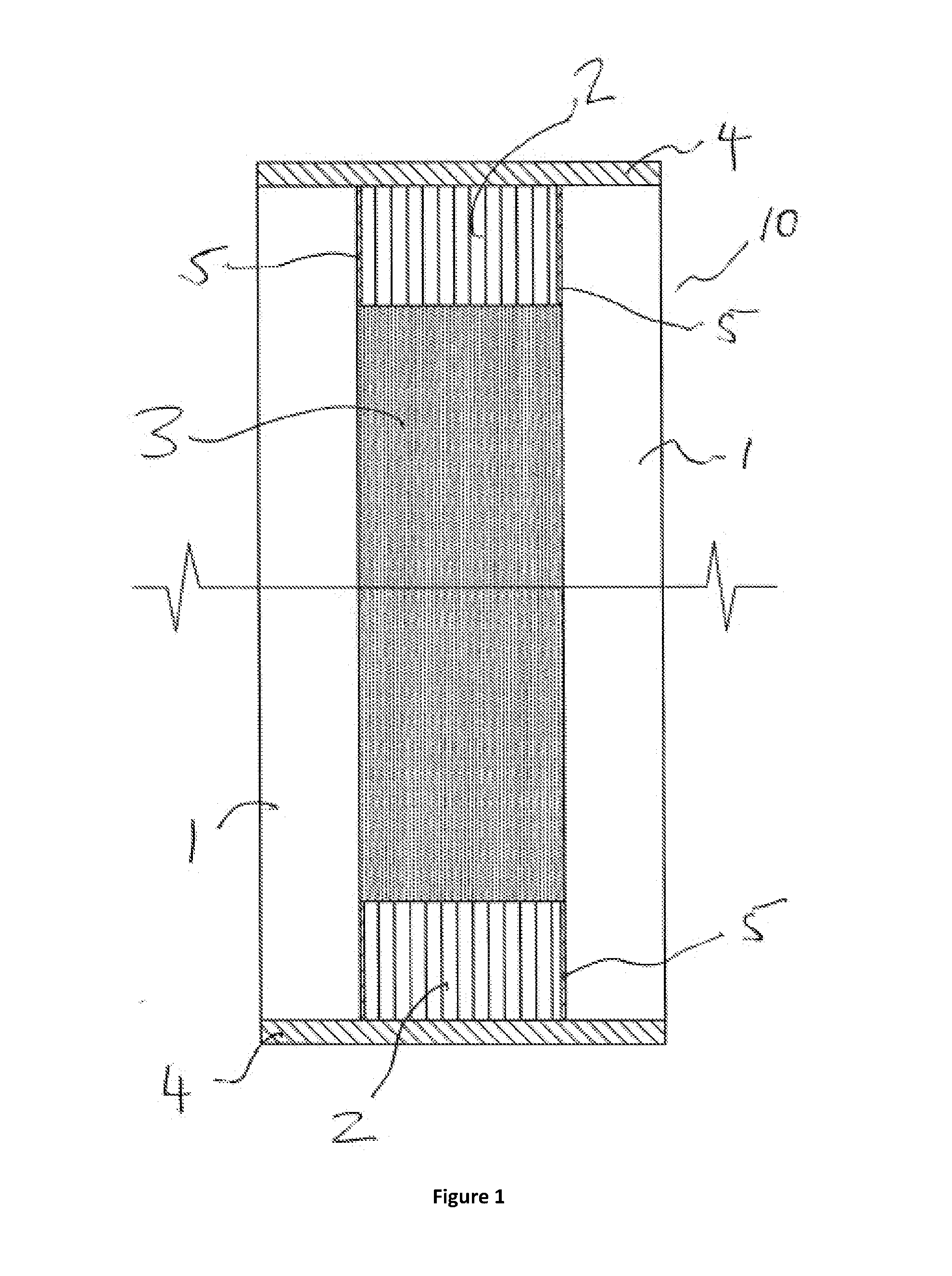

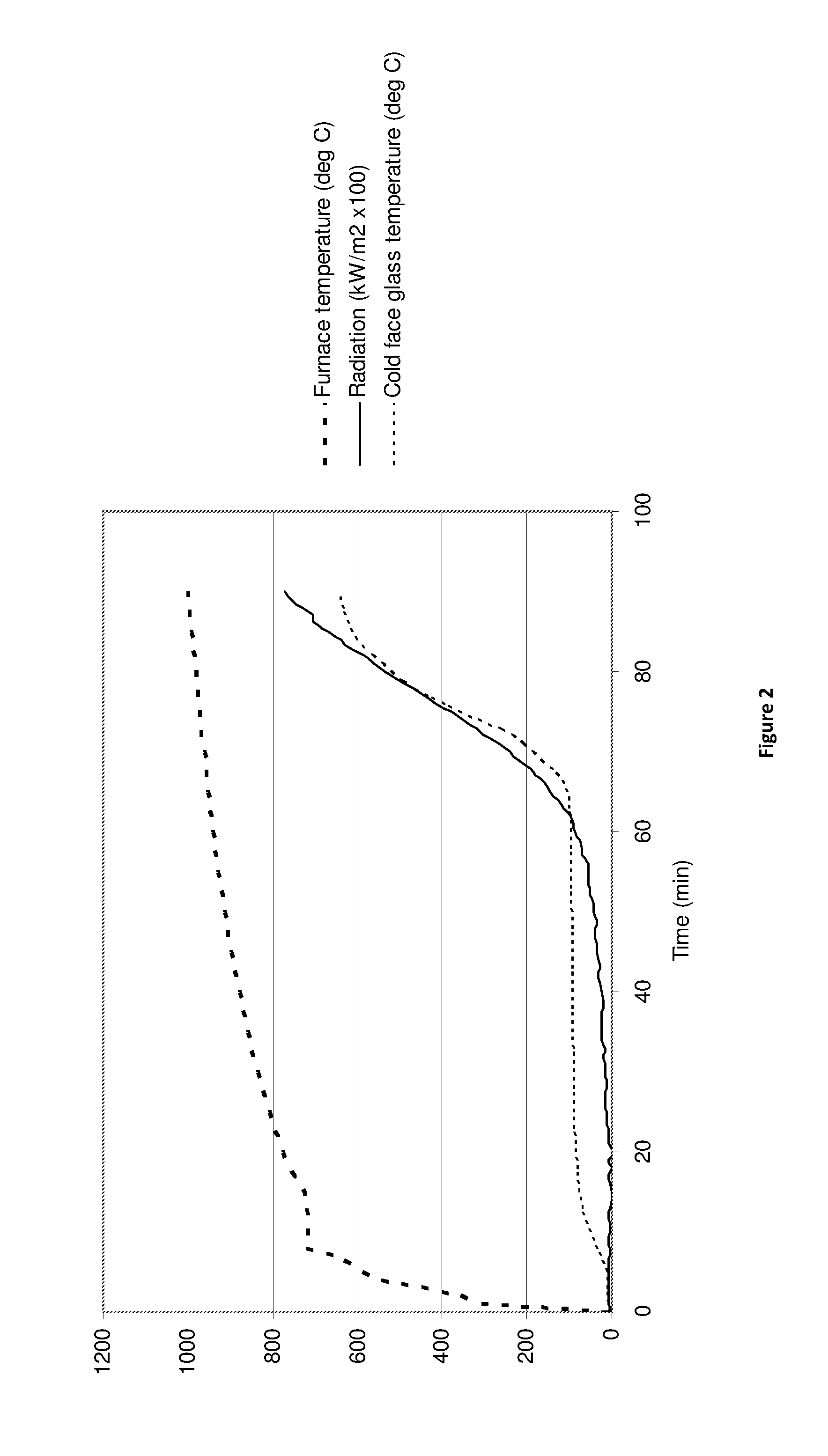

Fire resistant glazing unit

ActiveUS20150000825A1Improve performanceReduce volumeFireproof paintsGlass/slag layered productsMagnesium saltsGlass sheet

The present invention relates to a fire resistant glazing unit (10), and in particular to novel curable gelling compositions which may form a fire-resistant hydrogel interlayer (3) between the glass panes (1) of the glazing unit (10). The gelling compositions of the invention comprise 5-40% w / w of a curable hydrogel-forming component (typically an acidic vinyl monomer such as acrylic acid or its metal salt); 20-60% w / w of one or more salts (e.g. magnesium salts); 40-90% w / w of an aqueous vehicle; and the gelling compositions have an acidic p H between p H 1 and 7. Such gelling compositions, when cured to form a hydrogel interlayer, provide excellent fire-resistant properties and also an excellent radiation barrier in the event of a fire.

Owner:PYROGUARD UK

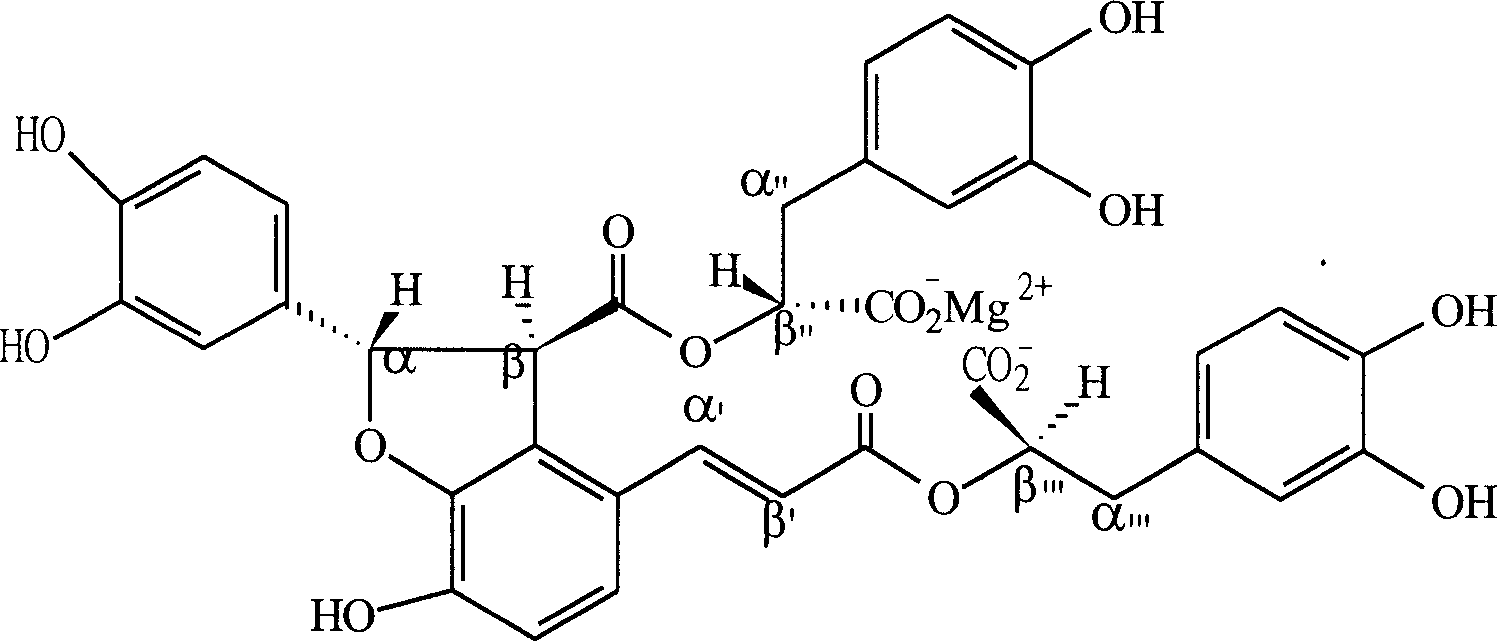

Method for preparing salvianolic acid B magnesate

The invention provides a manufacturing method of red phenolic acid B magnesium salts. Crushes the radix salviae miltiorrhizae, immerses and extracts with alcohol containing water or acetone, condenses, eliminates the sediment. Then uses macropore to absorb resin chromatography, washes them with water, then wash with alcohol. The coarse product is obtained after condensed, then carries on chromatography with polyamide, and washes with water or alcohol. There gets the 90% purity product through condensation, cooling, drying.

Owner:上海天甲生物医药有限公司 +1

Kit and method for determining triglyceride

ActiveCN106399460AMicrobiological testing/measurementBiological material analysisPeroxidaseMagnesium salt

The invention relates to a kit and a method for determining triglyceride. The kit comprises a reagent group 1 and a reagent group 2, wherein the reagent group 1 comprises magnesium salts, triphosadenine, glycerokinase, glycerol lipase oxidase, peroxidase and chromogen; the reagent group 2 comprises lipoprotein lipases and 4-amino-antipyrine, wherein the chromogen is N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3,5-dimethoxyaniline (DAOS) or comprises DAOS. The kit and the method provided by the invention have the advantage that the interference caused by calcium dobesilate and / or etamsylate existing in the sample during the triglyceride detection can be reduced.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI +1

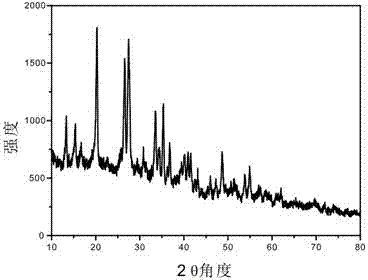

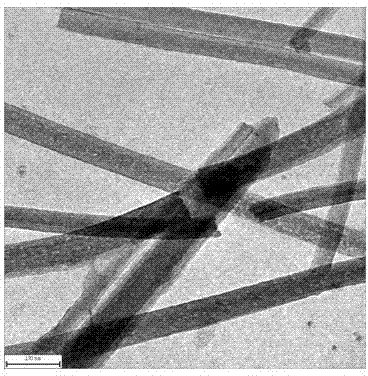

Preparation method of one-dimensional basic magnesium carbonate nano wire and porous magnesium oxide nano wire

InactiveCN102897805AHigh crystallinityHigh purityMaterial nanotechnologyMagnesium carbonatesAir atmosphereNanowire

The invention relates to a preparation method of porous magnesium oxide nano wire, belonging to the technical field of preparation of nano materials. The method comprises steps of sealing a mixed aqueous solution of metal magnesium salts and urea, heating to 90 to 130 DEG C, and reacting for 6 to 24 hours to obtain the one-dimensional basic magnesium carbonate nano wire with a diameter of 50 to 250 nanometers and a length of 10 to 500 micrometers; and then drying the basic magnesium carbonate nano wire, and calcining under an air atmosphere or an inert atmosphere to obtain the one-dimensional porous magnesium oxide nano wire. The method is simple to process and low in production cost, and is very suitable for industrial production.

Owner:ANHUI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

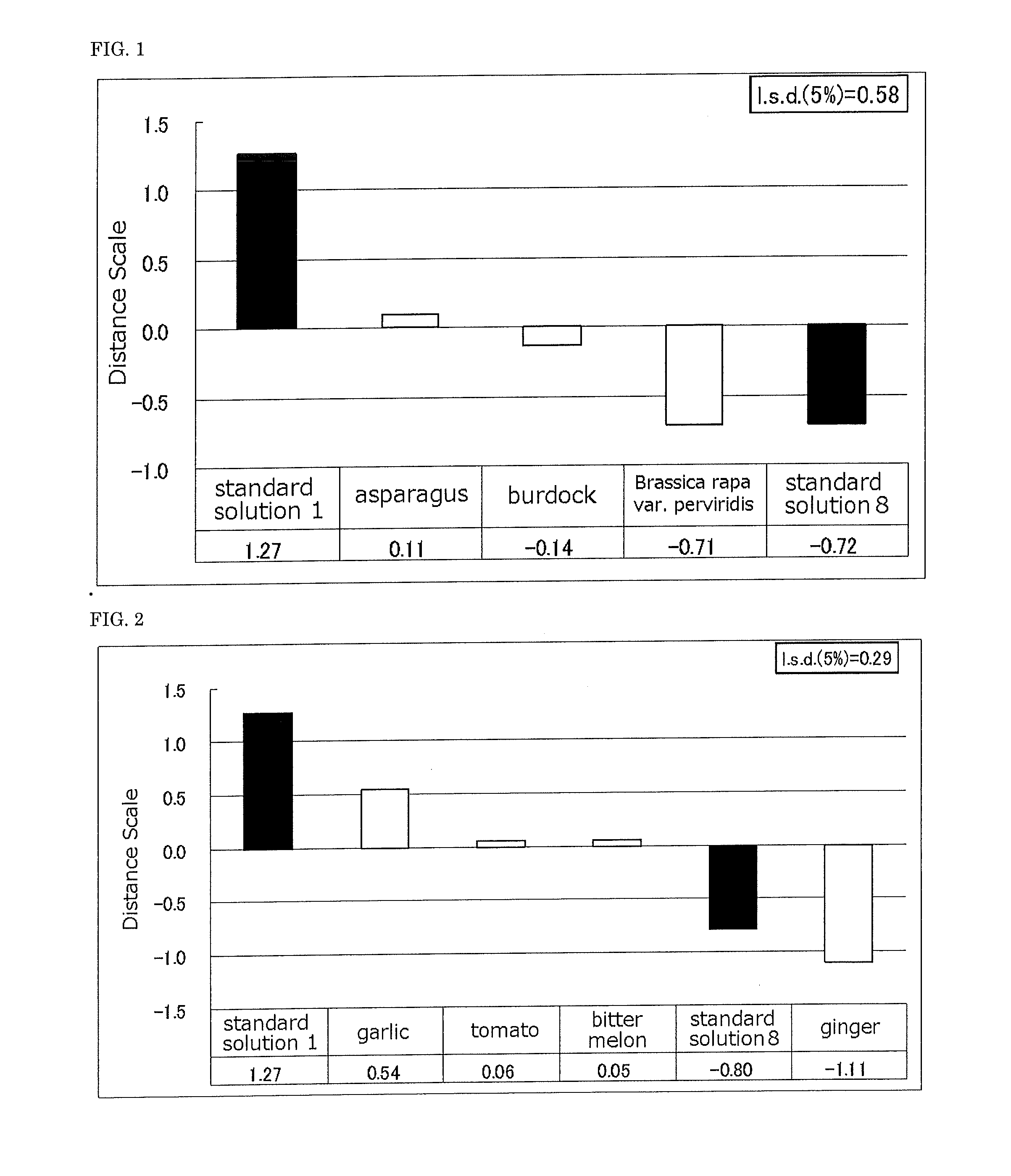

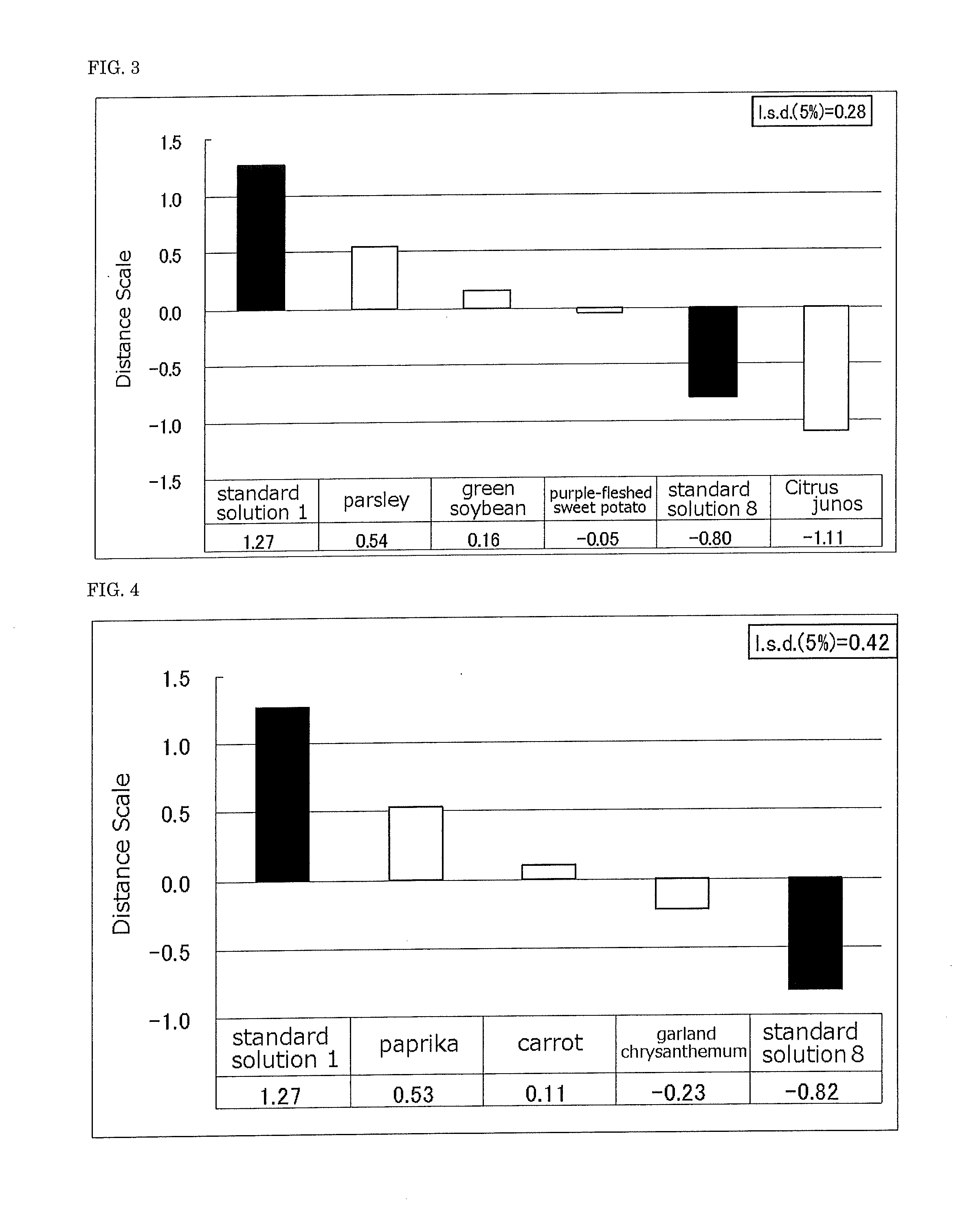

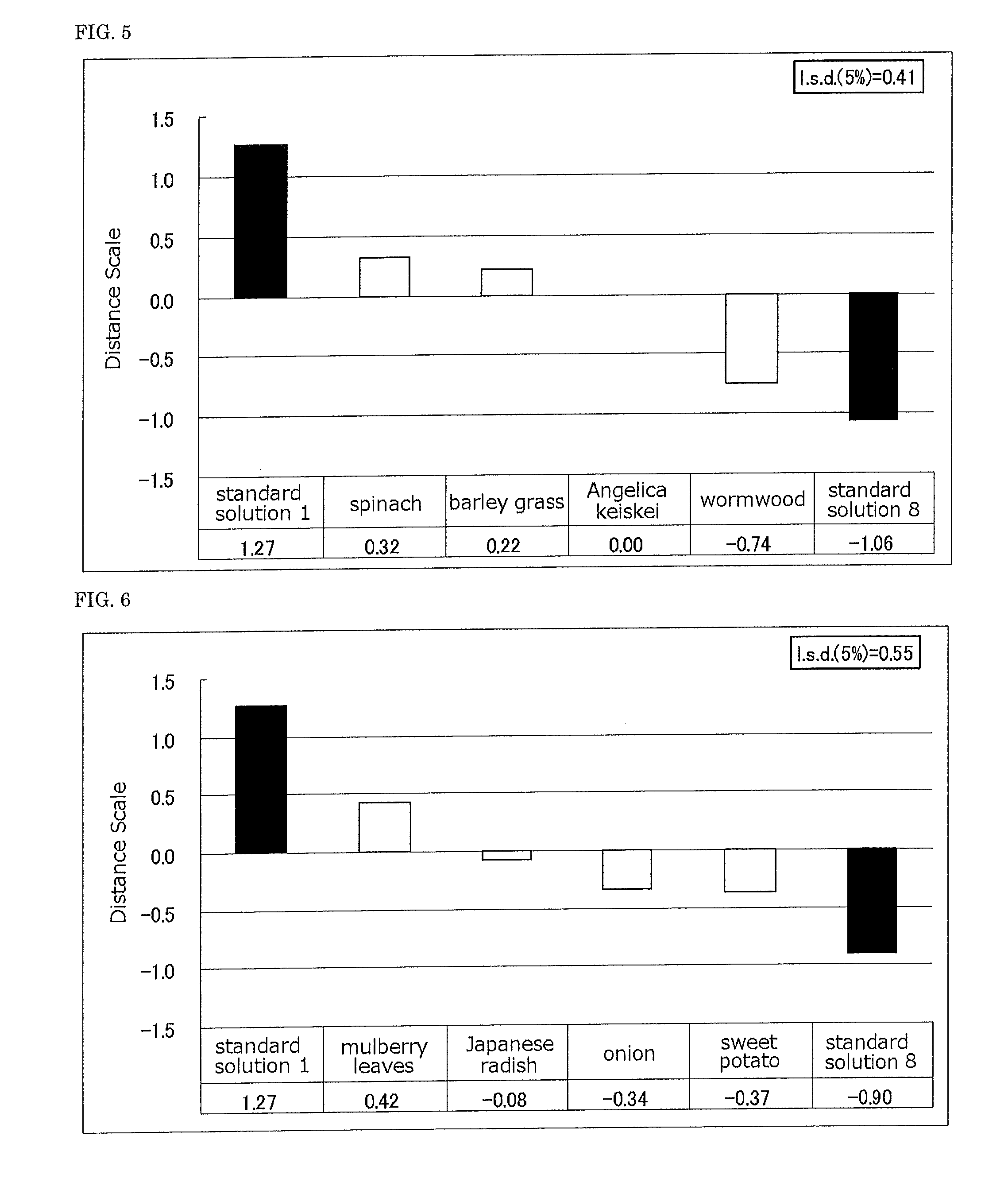

Taste-improving agent and food or drink containing same

ActiveUS20150125589A1Improving and reducing unpleasant bitternessImproving and reducing and astringent taste and taste and tasteFood ingredient as taste affecting agentPhosphatide foodstuff compositionsArgininePotassium

Provided is a taste improver that improves or decreases unpleasant bitterness, astringent taste, harsh taste, bitter taste, or the like that results from potassium salts, magnesium salts, calcium salts, and ammonium salts without adversely affecting savoriness of a food or drink. The taste improver includes a vegetable extract and / or a phospholipid. In the taste improver, the aforementioned vegetable extract includes a vegetable-derived glycoside and / or glycoside aglycone. In the taste improver, the aforementioned phospholipid is phosphatidylcholine, phosphatidylserine, phosphatidylethanolamine, phosphatidylinositol, and / or a lyso form thereof. Arginine is further added to the aforementioned taste improver. Trehalose and / or hydrogenated starch syrup are further added to the taste improver. A manufacturing method of such and an improvement method for the unpleasant bitterness, astringent taste, harsh taste, bitter taste, or the like caused by potassium salts, magnesium salts, calcium salts, and ammonium salts using these taste improvers. A food or drink including these taste improvers.

Owner:NIPPON SUISAN KAISHA LTD

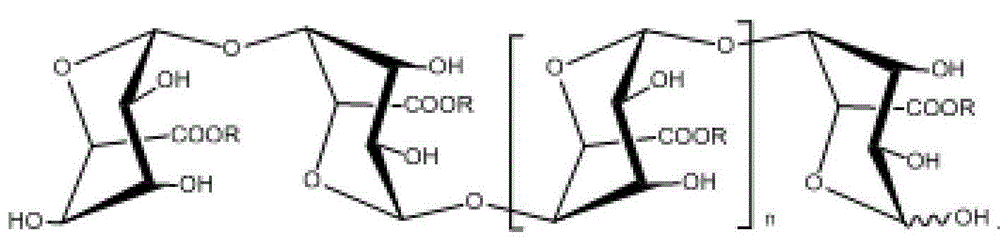

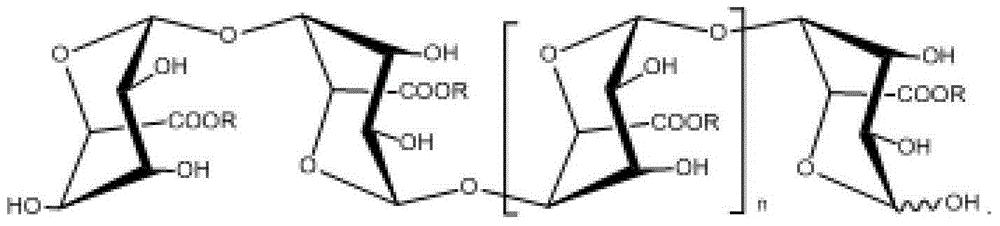

Application of oligoguluronates in preparation of drugs for prevention and treatment of liver damage and various hepatitis, liver fibrosis or cirrhosis

ActiveCN103977021AImprove protectionAbundant resourcesOrganic active ingredientsDigestive systemPotassiumLiver fibrosis

The invention belongs to the field of marine drugs, and in particular relates to an application of oligoguluronates in preparation of drugs for prevention and treatment of liver damage and various hepatitis, liver fibrosis or cirrhosis. The oligoguluronates are used in preparation of the drugs for protection of livers and treatment of various hepatitis, liver fibrosis or cirrhosis; the oligoguluronates adopt algin as a raw material, and oligoguluronic acids with different molecular weights are obtained through a chemical degradation method or a physical degradation or a combination of the two degradation methods; the oligoguluronic acids are neutralized to prepare lithium salts, sodium salts, potassium salts, calcium salts or magnesium salts of the oligoguluronic acids with different molecular weights, wherein a molecular skeleton is a linear oligosaccharide compound formed by connecting L-guluronic acid (G) through alpha-(1,4)-glycosidic bonds. The products are derived from the marine natural product, have many advantages of abundant resources, easy industrialization, safety, effectivity and the like, and have broad development and application prospects in prevention and treatment of liver damage and various hepatitis, liver fibrosis or cirrhosis.

Owner:MARINE BIOMEDICAL RES INST OF QINGDAO CO LTD

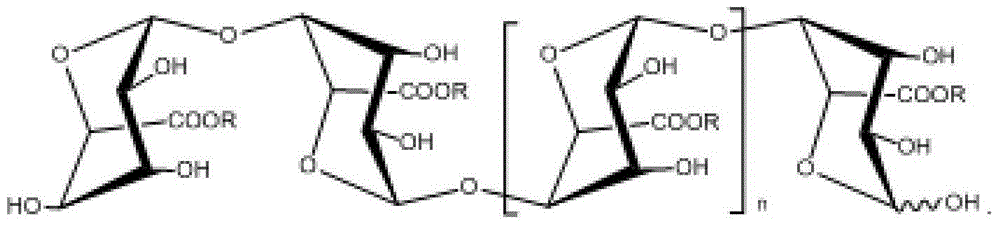

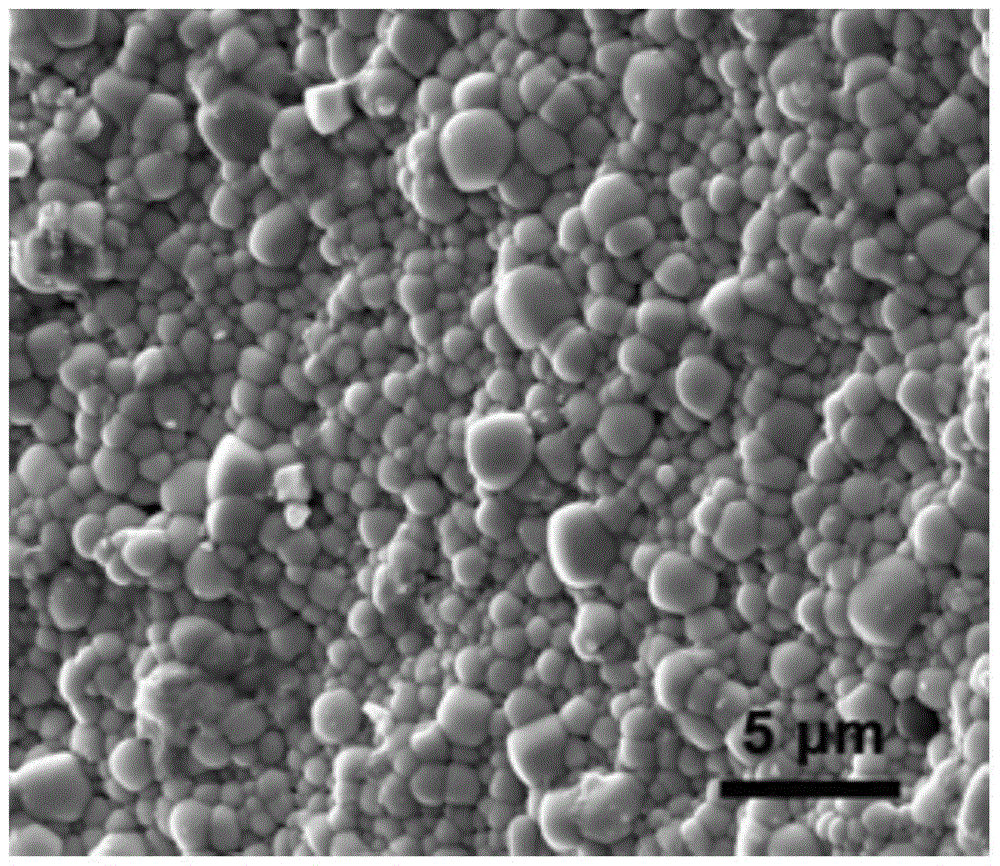

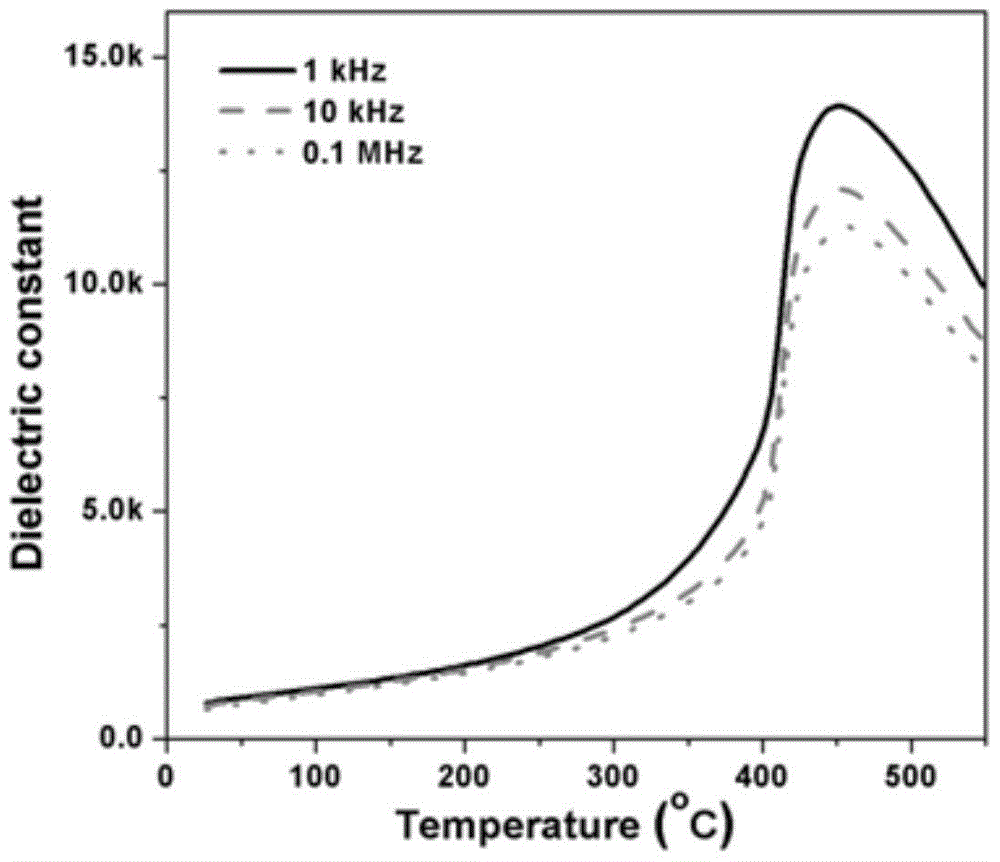

Preparation method of piezoelectric ceramic with high Curie temperature and film thereof

The invention relates to a preparation method of a piezoelectric ceramic with a high Curie temperature and a film thereof. The chemical formula of the prepared piezoelectric ceramic material is (1-x)(BiMg<1 / 2>Ti<1 / 2>O<3>)-x(PbTiO<3>)-yMe, wherein 0.3<=x<=0.45, 0<=y<=0.05, and Me represents a modifying element. Bismuth salts, magnesium salts, lead salts, chromium salts, or / and manganese salts and organic titanium salts are taken as the primary raw materials; through selecting a proper dispersing medium and controlling the solution temperature and concentration and addition sequence, the metal salts form uniform sol through the chelating effect of a stabilizing agent, then the sol is concentrated, dried and calcined to obtain piezoelectric nano powder with a high Curie temperature, and the piezoelectric nano powder is ball-grinded, dried, screened, pressed, and sintered to prepare piezoelectric ceramic with a high Curie temperature. Or through various solution methods such as spin coating, infiltrating, and the like, uniform sol is painted on an inorganic substrate to prepare a film, and then the substrate is dried and annealed to prepare a piezoelectric ceramic film. The prepared piezoelectric ceramic film can be used to prepare various related piezoelectric devices with a work temperature higher than 200 DEG C such as energy converter, sensor, and the like, and has a wide application prospect.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

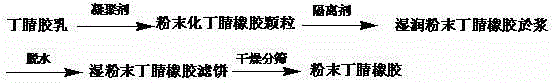

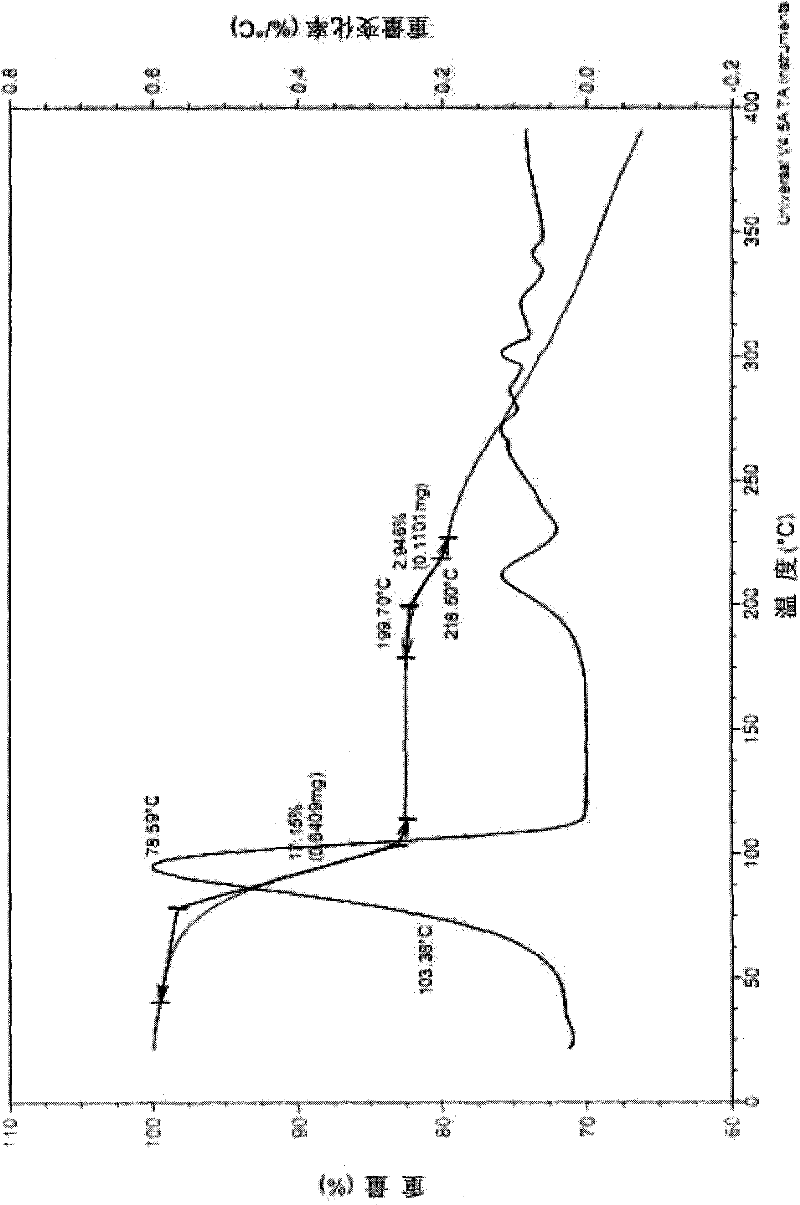

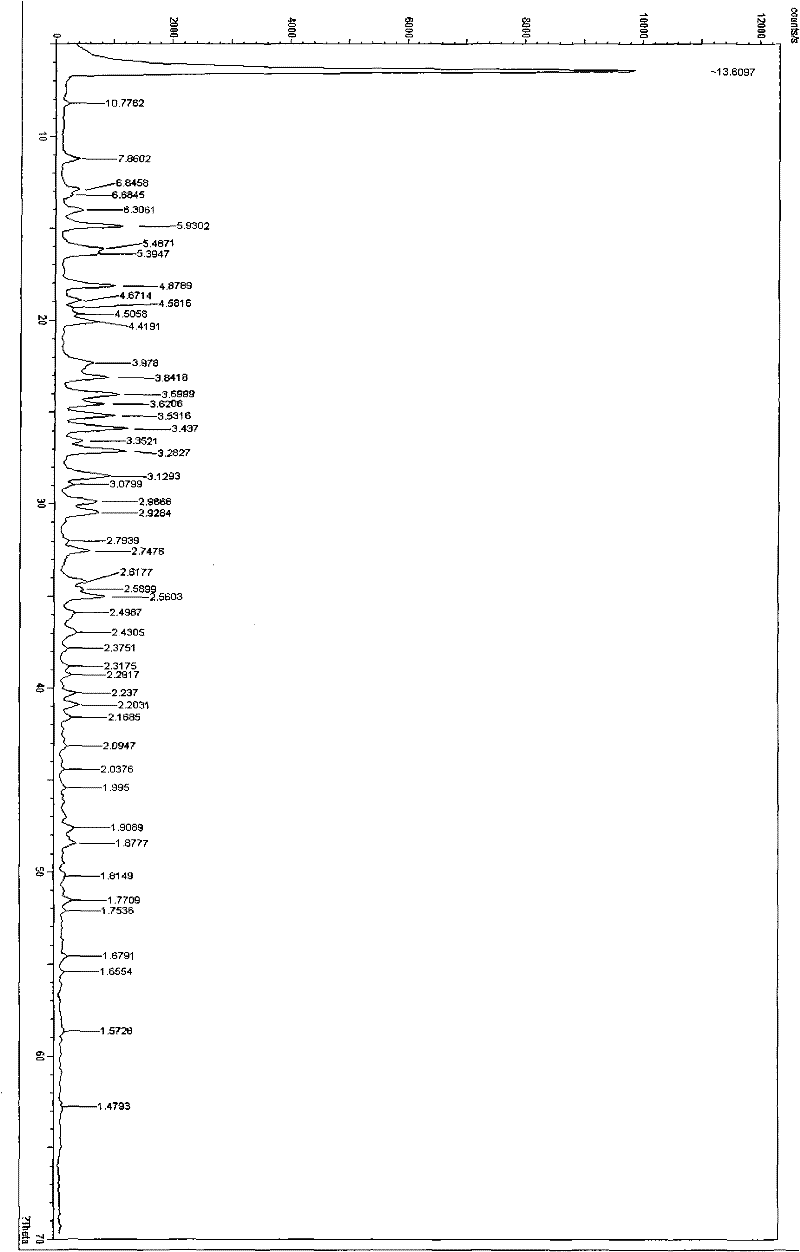

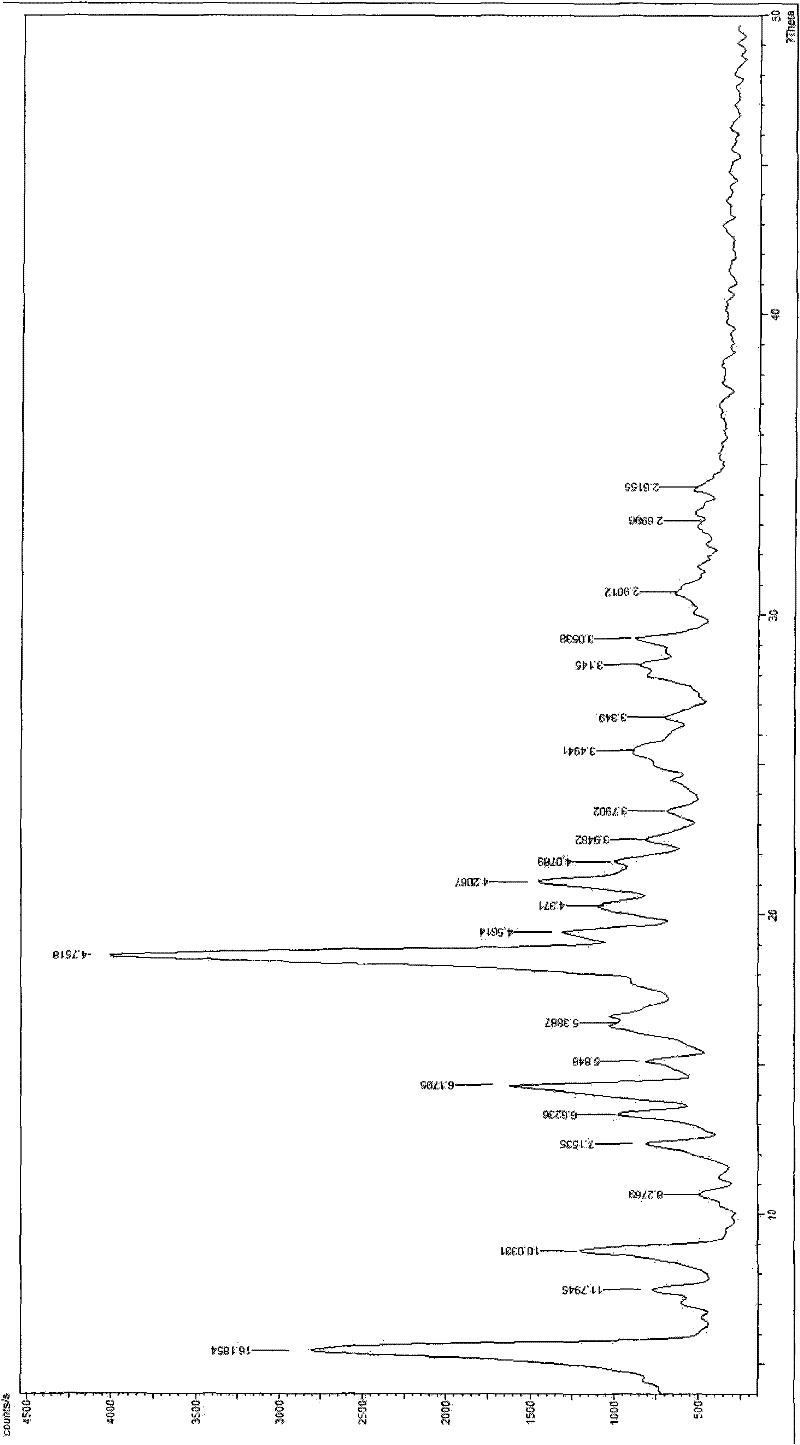

Production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile

The invention relates to a production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile. Firstly, nitrile rubber paste is synthetized, then agglomerated and isolated into powder, and finally dehydrated and dried. In the polymerization reaction stage, potassium carbonate is added as a reaction buffer agent, and diethylhydroxylamine, hydroxylamine sulfate, a mixed solution of potassium hydroxide and soft water are added as a composite terminating agent. In the isolation and powdering stage, WSL and DLTP are added as an antiager, monovalent sodium salts and divalent magnesium salts or monovalent sodium salts and divalent calcium salts are used as a coagulant, and the nitrile rubber paste is agglomerated and isolated into powder at 30-75 DEG C. The production process of the present invention is simple, easy to operate, low in production costs, small in energy consumption, and high in conversion rate which can reach more than 95%. The production method employs a new composite terminating agent, which is stable in mooney and good in termination effect. The powdered acrylonitrile-butadiene rubber is relatively fine, therefore dispersibility is improved during processing. The product is very good in heat resistance and wear resistance, and can meet the application requirements of train high friction brake block.

Owner:HUANGSHAN HUALAN TECH

New S-omeprazole salts

InactiveCN102241668AEasy to processEasy to storeOrganic active ingredientsOrganic chemistryOrganic solventOmeprazole

The invention provides new S-omeprazole salts in special crystal forms, namely an S-omeprazole potassium salt di-ethanol adduct and an S-omeprazole magnesium salt trihydrate. The invention also relates to a method for preparing the S-omeprazole magnesium salt trihydrate with a special crystal form from the S-omeprazole potassium salt di-ethanol adduct. The invention aims to provide a simple method for preparing the S-omeprazole magnesium salt hydrate in the special form by utilizing water, a magnesium source and a cheap organic solvent on the basis of a simple and cheap enantioselectivity oxidation method for preparing new optically pure omeprazole potassium salts.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Lemon flavored nutritional bean curd (tofu) and preparation method thereof

ActiveCN102499294ASave raw materialsFull of nutritionCheese manufactureFood scienceKidney stoneAdditive ingredient

The invention relates to lemon flavored nutritional bean curd (tofu) and a preparation method thereof. The lemon flavored nutritional tofu comprises soybean milk and lemon juice, wherein the weight ratio of the lemon juice and the soybean milk is (1-3):100, and is prepared by the steps of carefully selecting raw materials, pulping, boiling pulp, adding lemon juice, compression moulding, and othersteps. The lemon flavored nutritional tofu has the color and fragrance of lemon, rich nutrient and tender mouthfeel. The preparation method of the lemon flavored nutritional tofu uses fresh lemons directly without addition of other coagulators, only uses the action of lemon self to achieve the coagulating effect of tofu, so as to simplify preparation process, prevents environmental pollution and fully utilize raw materials. The obtained tofu has the fragrance and nutritional ingredients of lemon. The preparation method of the invention does not use calcium salts and magnesium salts, and citrate contained in the lemon juice can inhibit calcium salts crystallization, thereby preventing the formation of renal calculi, even dissolving the calculi formed previously. The lemon flavored nutritional tofu of the invention is suitable for a large range of people.

Owner:陈日光

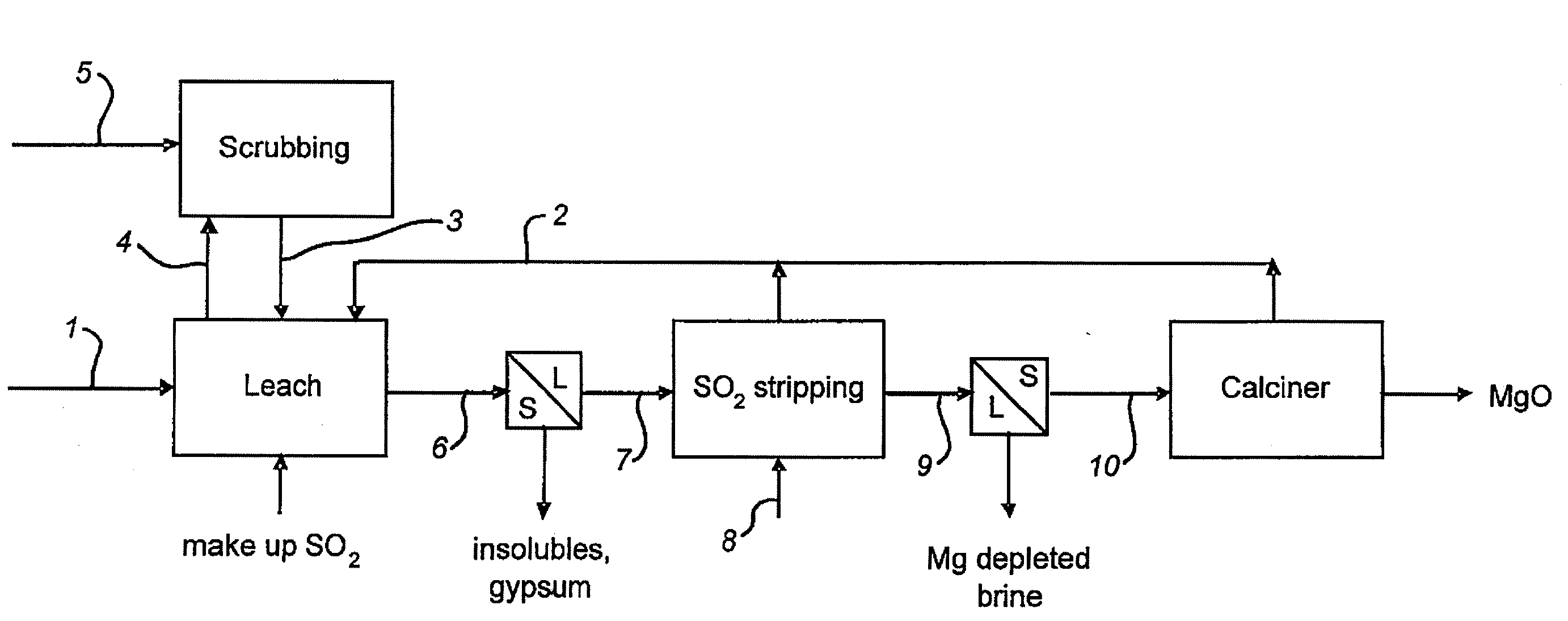

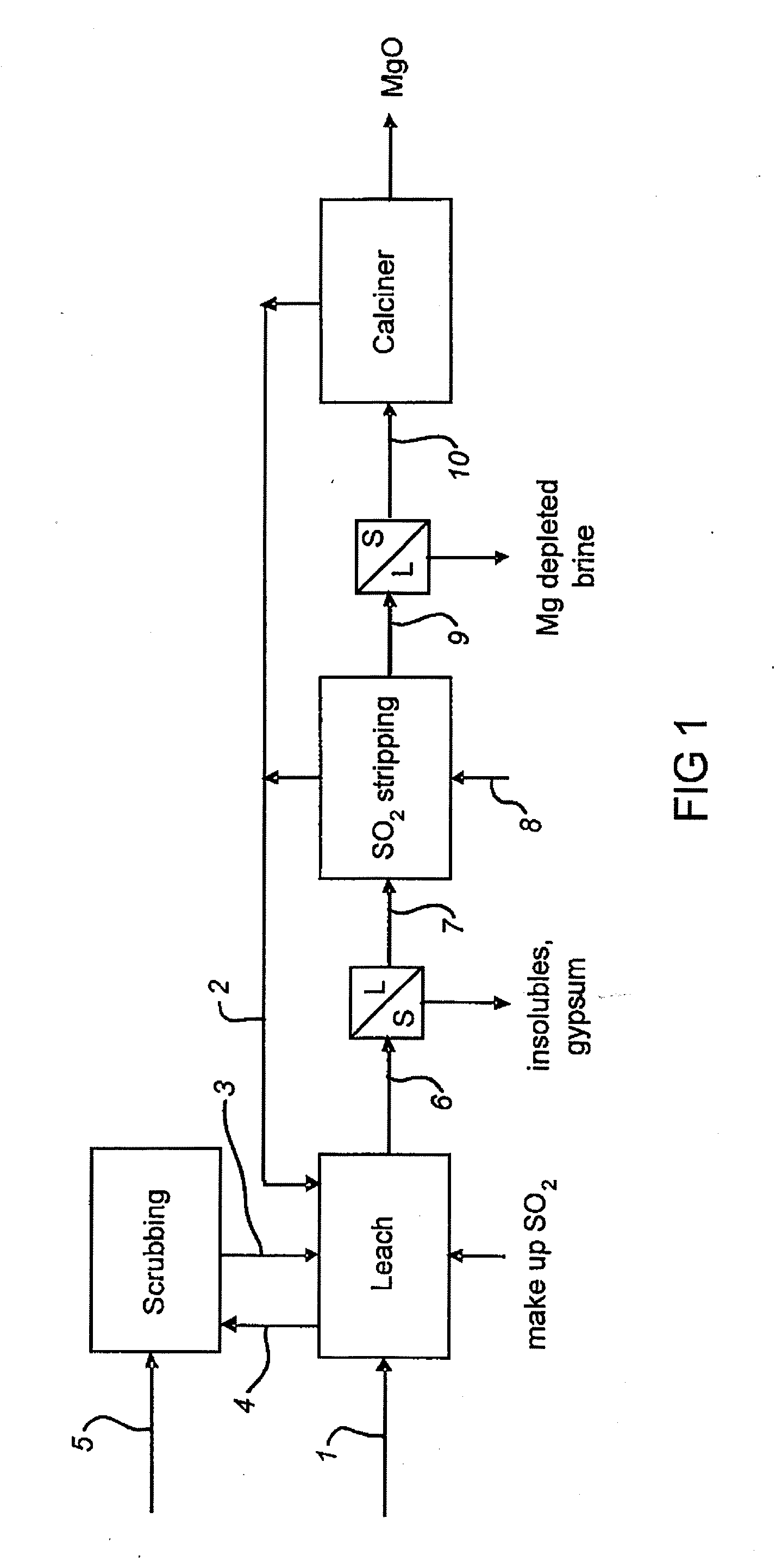

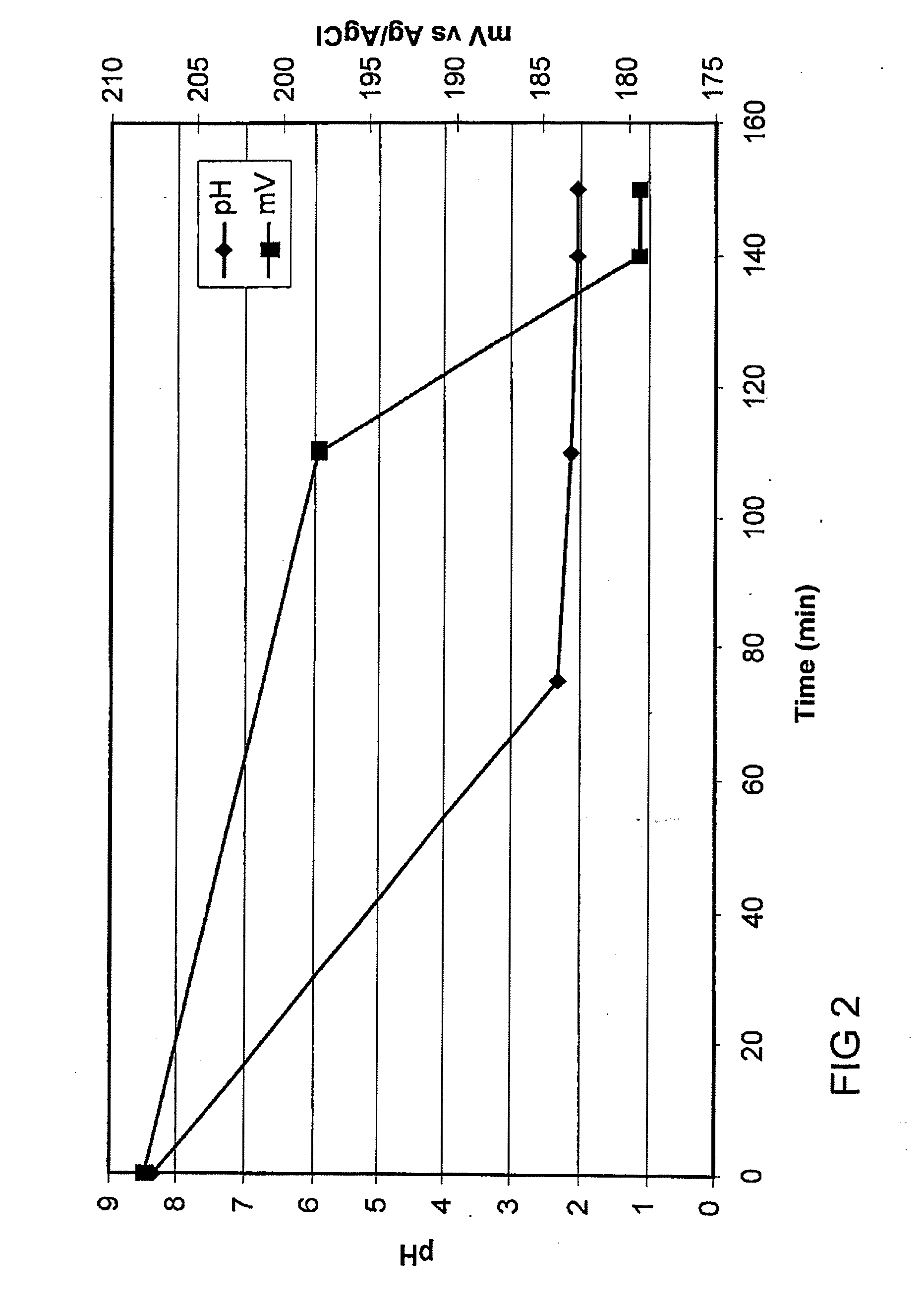

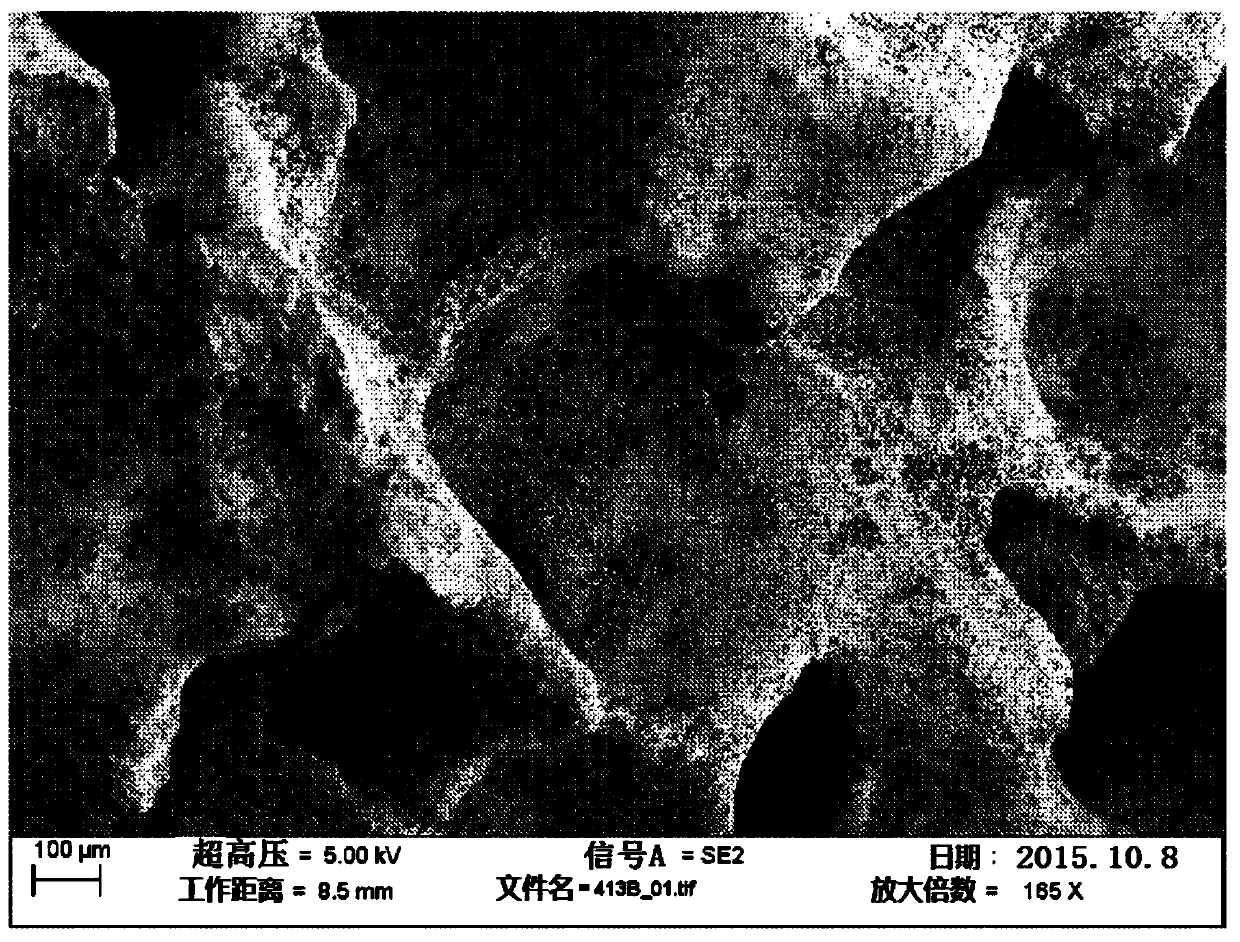

Process for the Production of Magnesium Oxide

InactiveUS20080025892A1Low costEasy to recycleCalcium/strontium/barium compoundsMagnesium sulfitesMagnesium saltPhysical chemistry

A process for the recovery of magnesium oxide from a source containing magnesium salts, said process including the steps of: (a) adding an alkali and sulfur dioxide to the source containing magnesium salts, in a leach step to form a magnesium bi-sulfite containing leachate;(b) separating the insoluble materials from the leachate; (c) stripping excess sulfur dioxide from the leachate and precipitating the magnesium as solid magnesium sulfite hydrate; (d) separating the solid magnesium sulfite hydrate from the magnesium depleted leachate; and (e) calcining the solid magnesium sulfite hydrate and recovering the magnesium as magnesium oxide.

Owner:BHP BILLITON SSM TECH PTY LTD

Mineral additives and production of lightweight composite materials from carbonatable calcium silicate

The invention provides novel aerated composite materials made from a carbonatable calcium silicate composition, and formulations and methods of manufacture and use thereof, in particular, the use of novel additive mineral compositions in the form of magnesium, magnesium salts or magnesium oxides, to improve physical chemical properties of low density concrete materials. The low density, aerated material is comprised of calcium carbonate (CaC03) and silica (Si02), as cured products of carbonatable calcium silicate compositions.

Owner:SOLIDIA TECH

Method for stable and controlled delivery of (-)-hydroxycitric acid

InactiveUS7189416B2Maximum availabilityReduce disassembly stepsPowder deliveryBiocideInitial treatmentPotassium

A method for making the potassium, sodium and other hygroscopic salts of (−)-hydroxycitric acid and mixtures thereof workable by initial treatment with a desiccating agent, such as fumed silicon dioxide. These may be further rendered non-hygroscopic and non-reactive in acidic media via subsequent encasement in hydrophobic and acidophobic polymers. The calcium and magnesium salts of (−)-hydroxycitric acid likewise can be rendered nonreactive in acidic media. The resulting products are suitable for tableting, encapsulation and use in other dry media for weight loss, appetite suppression, improvements in fat metabolism and postprandial lipemia and other pharmaceutical purposes. Further, the products of this invention can be made nonreactive as components of acidic liquid drink mixes and snack bars and can be used in the production of controlled release administration formats.

Owner:NUTRITION RES GRP LTD

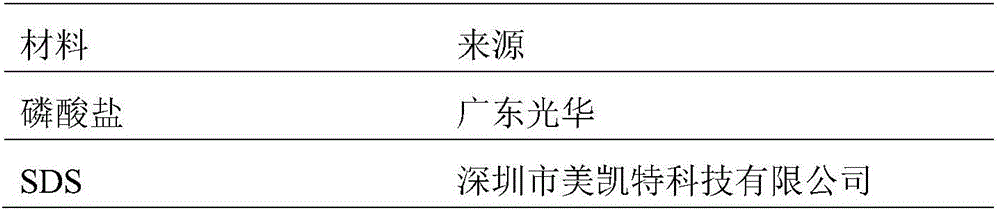

Method for preparing composite ammonia nitrogen remover and application thereof

The present invention provides a preparation method for remover for compound ammonia nitrogen, which is developed aiming at the defects of utilizing the biological method and the aeration stripping method to apply the treatment to the ammonia nitrogen in the sewage that the technological process is long and the removal rate is not high. The preparation method for remover for compound ammonia nitrogen comprises the following steps: first the mixture of the phosphates and the magnesium salts is remixed; wherein the mixing is carried out following the molar ratio ranging from 1.0:1.0 to 1.3:1.0 according to Mg2+:PO42- and the mixture is mixed with the water in a mass ratio of 1:9 so as to be dissolved into the solution, and then the solution containing ferrous acids which the acidity (calculated according to the content of HCl) ranges from 10% to 50%, the content of Fe3+ ranges from 0.05% to 5% and the content of Fe2+ ranges from 8% to 8% in is added in the solution and the homogeneous solution is obtained under the sufficient stirring. A liquid ammonia nitrogen treatment agent prepared according to the present invention has simple manufacturing technique, is beneficial to the transportation and adding, has very strong ability of removing the ammonia nitrogen, is suitable for removing the ammonia nitrogen in the industrial sewage and domestic sewage of various industries, in particular the printing and dyeing, chemical engineering, paper making industries, etc and simultaneously has the auxiliary effect of removing the phosphorus ions in the sewage and lower COD.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Special chemical fertilizer for carrots and preparation method of special chemical fertilizer

InactiveCN104311273APromote growthReduce formationFertilizer mixturesMonopotassium phosphateGreen manure

The invention discloses a special chemical fertilizer for carrots and a preparation method of the special chemical fertilizer. The special chemical fertilizer consists of the following components in parts by mass: 20-23 parts of potassium magnesium salts, 18-22 parts of sainfoin green manure, 16-19 parts of ammonium sulfate, 14-16 parts of hydrated lime in powder, 11-14 parts of potassium chloride, 12-15 parts of indole-3-butyric acid potassium, 9-12 parts of magnesium sulfate, 6-8 parts of prepared chicken manure, 5-9 parts of plant ash, 4-8 parts of azotobacter fertilizers, 3-6 parts of cassia twig powder, 2-5 parts of monopotassium phosphate, 1-3 parts of diguozhuangdiling and 60-70 parts of water. The special chemical fertilizer disclosed by the invention is rich in nutrient, contains organic fertilizers and can be used for effectively promoting the growth of underground root system to thicken a nutrient transport duct of the underground fruits, expand fleshy roots and reduce the formation of acute fleshy roots, so that the fruit type is big and the yield and the mouthfeel are improved.

Owner:胡伟东

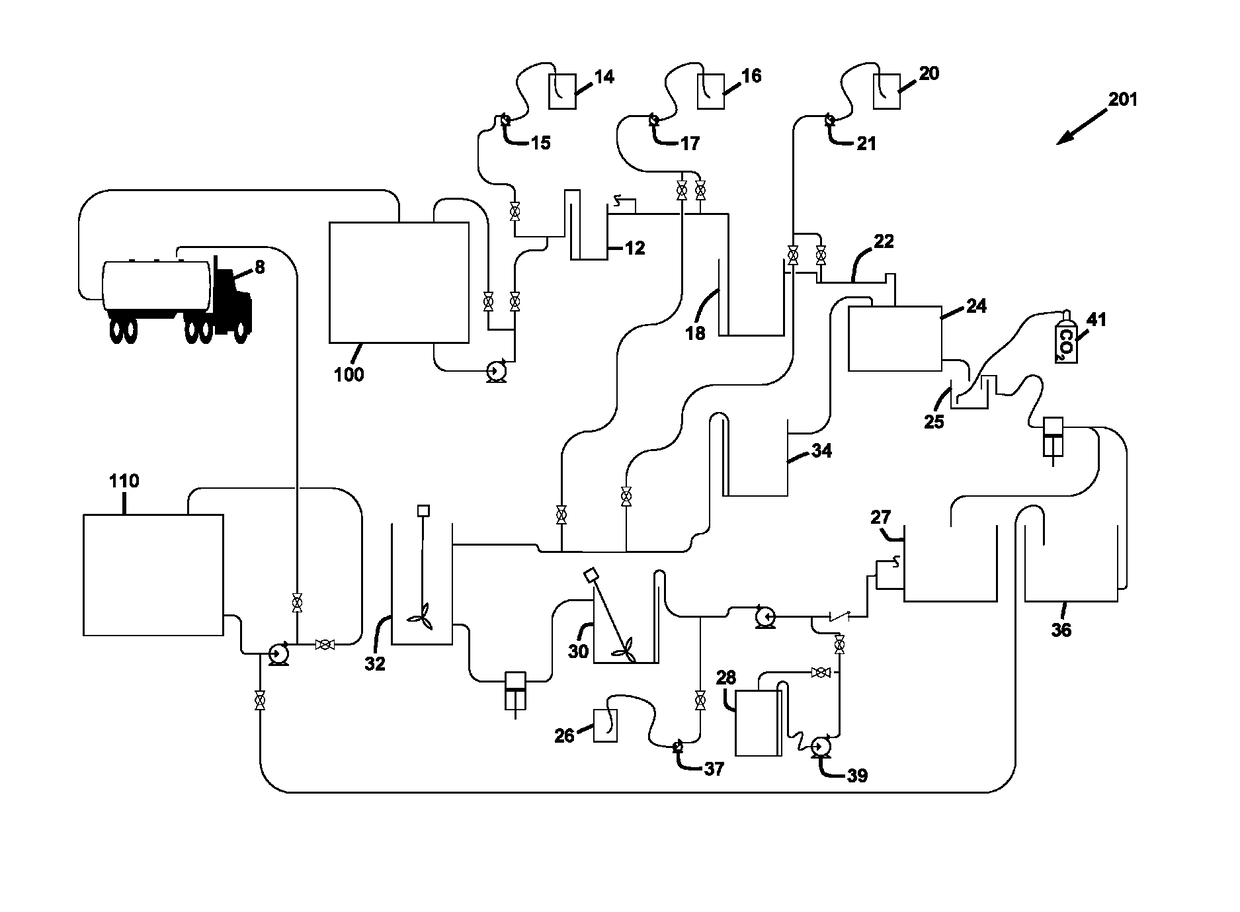

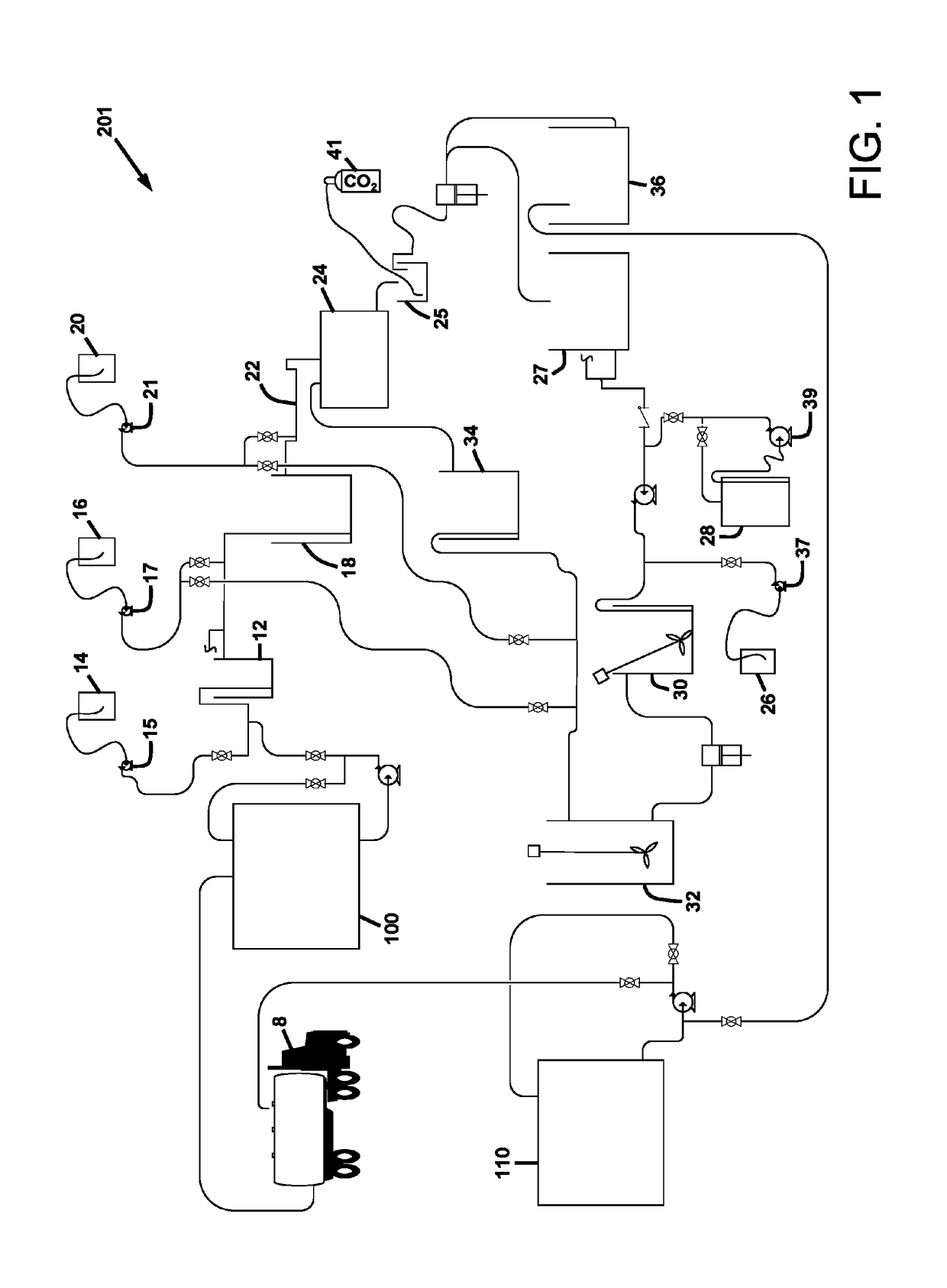

Method for treating fracture water for removal of contaminants at a wellhead

ActiveUS9815716B2Easy to moveWaste water treatment from quariesTreatment involving filtrationIron saltsMagnesium salt

A method and apparatus for removing the barium and strontium salts in water that flows back to the well head after hydrofracturing in gas well drilling. Trace levels of iron salts may also be removed from the waste frac water, followed by removal of the calcium and magnesium salts, where applicable. The barium and strontium salts are precipitated in the inert sulfate form, which renders the resulting solids mass suitable for conventional landfill or on-site disposal, and more significantly, for potential reuse and as an additive to certain well drilling processes. The calcium and magnesium salts are similarly inert and suitable for conventional disposal. The process may be managed to selectively remove barium and strontium salts to desired levels, depending upon the intended reuse or disposition. The apparatus may be provided in a highly compact portable configuration that is transportable by a highway vehicle.

Owner:EAU MIDSTREAM INC

Magnesium salts

A method of making a salt of the formula: Mg[Al(R)4]2, where R represents a compound selected from a de-protonated alcohol or thiol; an amine; or a mixture thereof. The method comprising the steps of; combining a Mg(AlH4)2 precursor with an alcohol, thiol or amine of the general formula R—H to create a reaction liquor containing Mg[Al(R)4]2; and washing the reaction liquor in an organic solvent.

Owner:DYSON TECH LTD

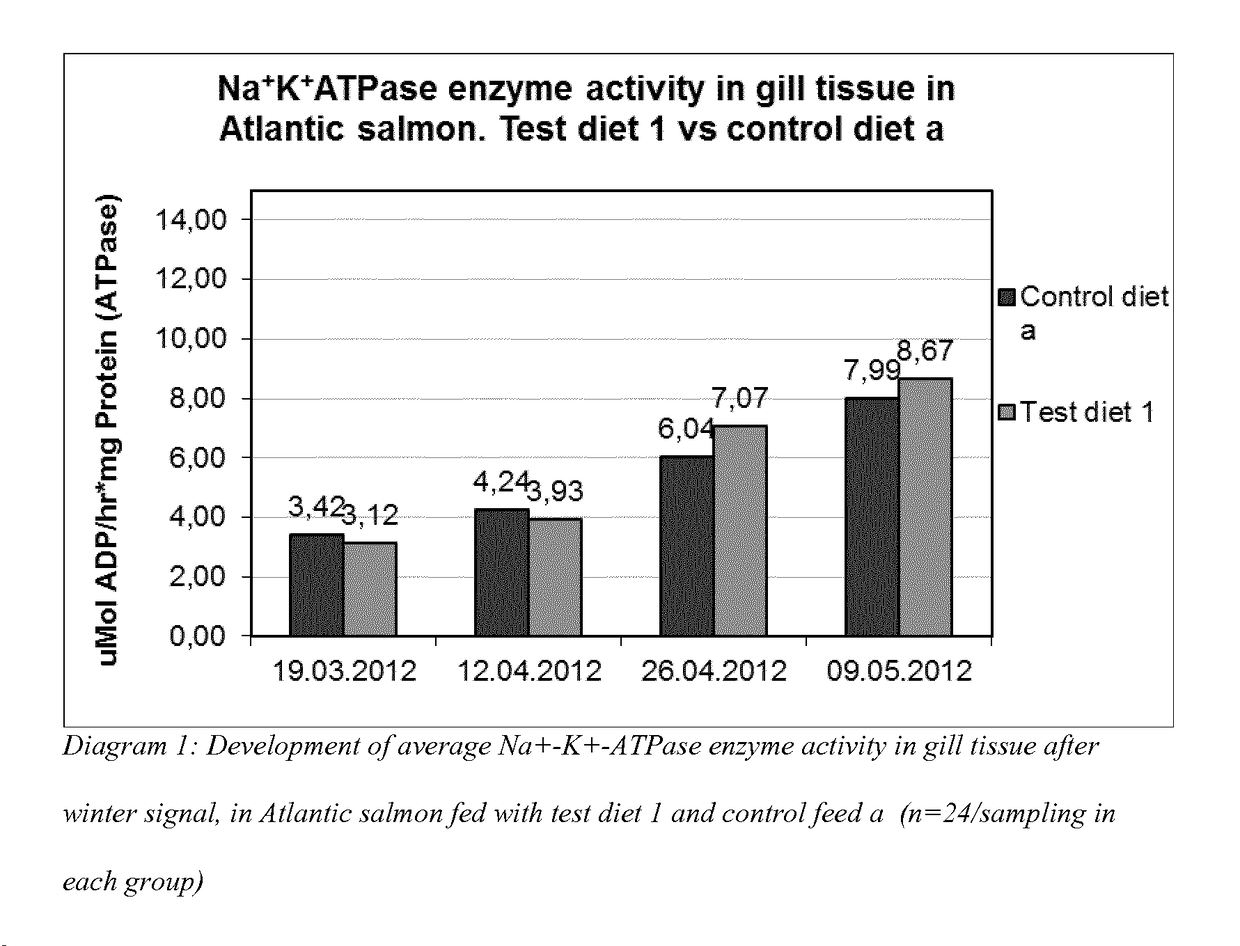

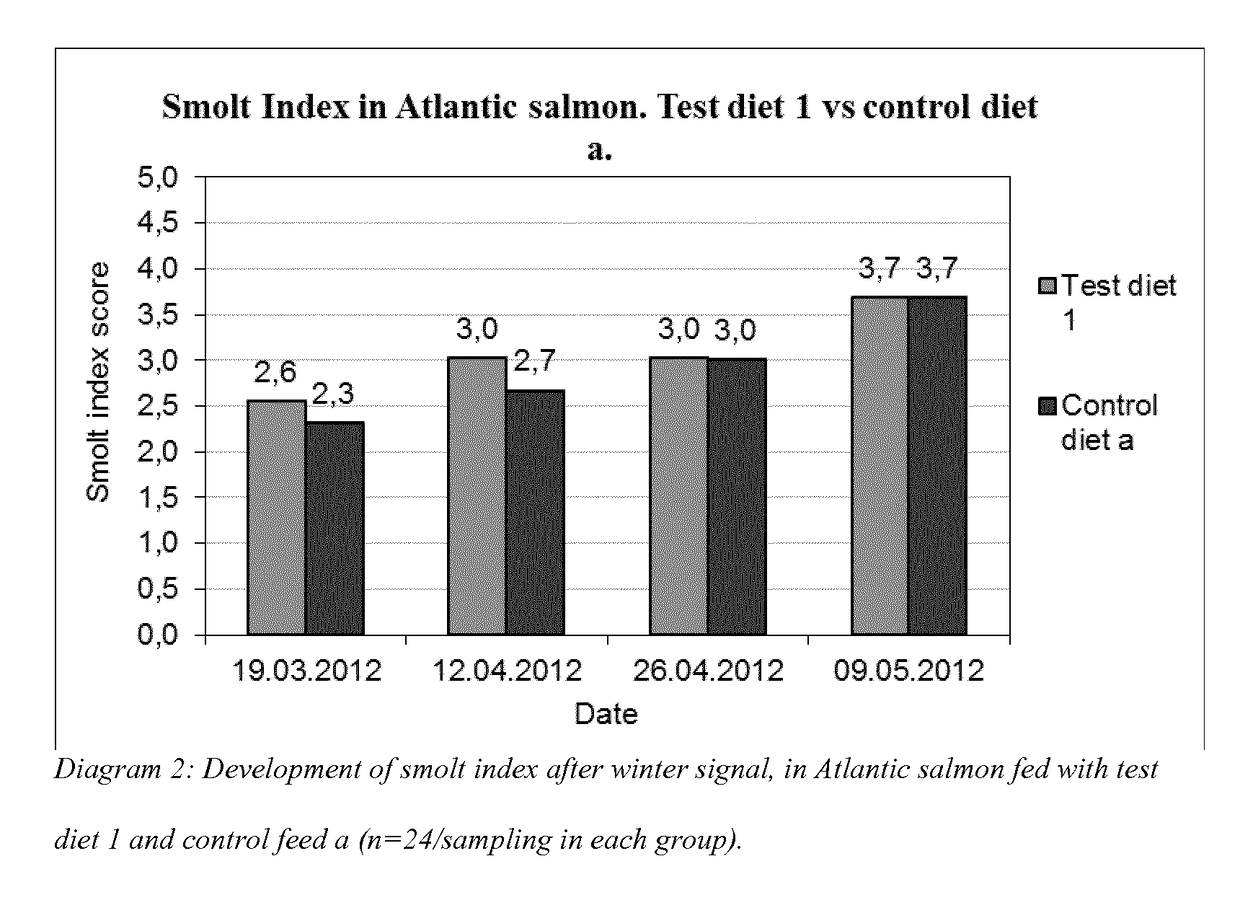

A fish feed and method for smoltification and prevention of desmoltification in Salmonidae, and for prophylaxis and treatment of haemorrhagic smolt syndrome (HSS) in Salmonidae

InactiveUS20170208840A1Eliminates and reduces disadvantageLow rate of growthClimate change adaptationAccessory food factorsMagnesium saltsVitamin

A fish feed useful in a method for smoltification and prevention of desmoltification in Salmonidae, and for prophylaxis and treatment of haemorrhagic smolt syndrome (HSS) in Salmonidae. The feed contains protein, fat, carbohydrates, vitamins, minerals and water, and in addition comprises sodium salts (Na+) from 10-100 g / kg by weight, polyvalent cation receptor modulator (PVCR) from 1-10 g / kg by weight, magnesium salts (Mg2+) from 0.1-100 g / kg by weight, and calcium salts (Ca2+) from 0.1-100 g / kg by weight.

Owner:EURO PHARMA AS

Meat quality ameliorant and preparation method thereof

InactiveCN103202397AEasy to shapeImprove lean meat percentageAnimal feeding stuffLean meatMagnesium salts

The invention belongs to the feed technical field, and particularly relates to a meat quality ameliorant and a preparation method thereof. The meat quality ameliorant is characterized in that the meat quality ameliorant comprises, by weight, 100-150 parts of Vitamin Es, 0.1-0.2 parts of methionines chrome, 0.1-0.2 parts of selenium yeasts, 100-150 parts of natural tea extracts and 1000 parts of carriers (magnesium salts or zeolite powders). The meat quality ameliorant can be used for improving commercial pig body types, increasing lean meat percentages, preventing all kinds of stress reactions, especially for summer heat stress, and improving flesh color and muscle water-holding capacity, and has obvious functions of prolonging fresh meat quality guarantee periods.

Owner:浙江东立绿源科技股份有限公司

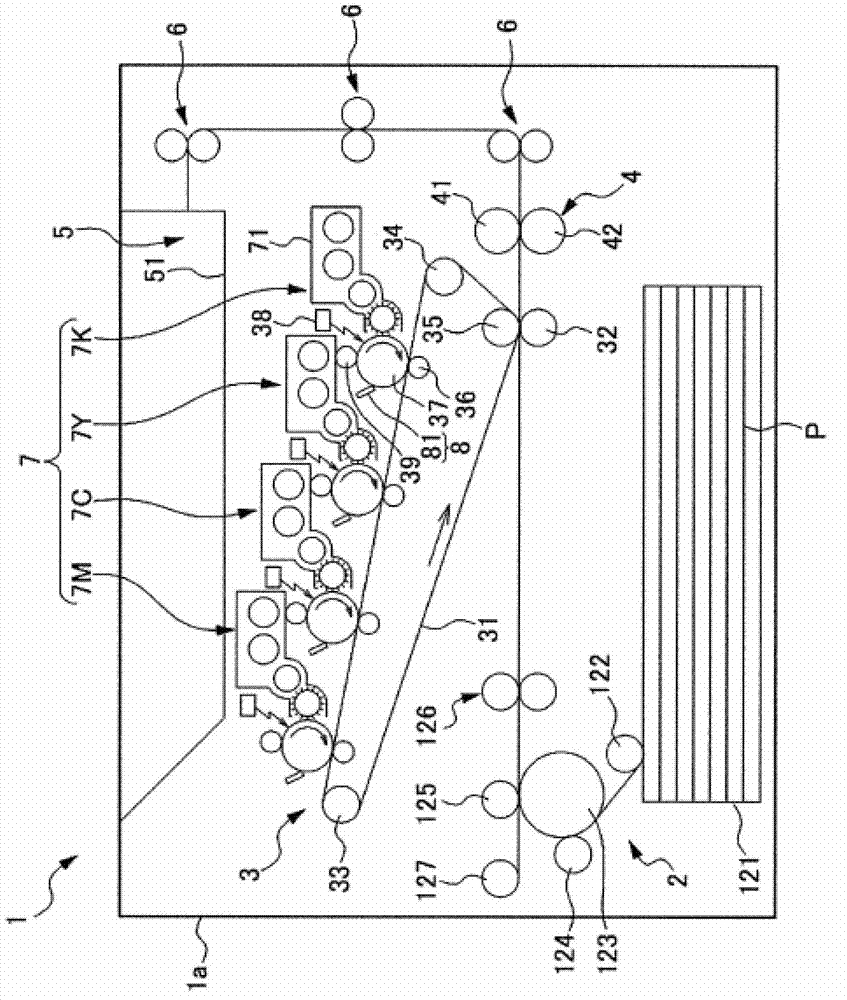

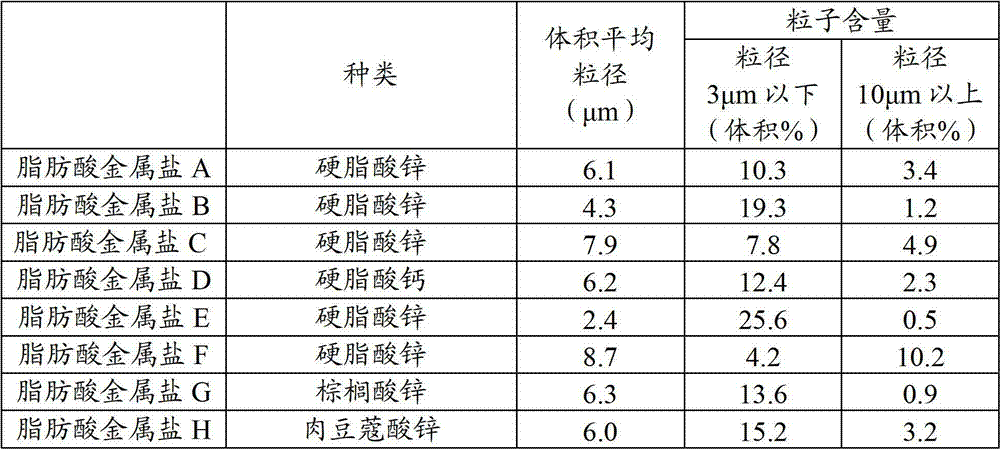

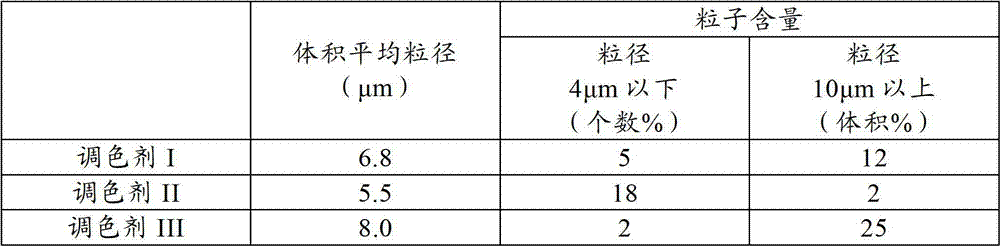

Developer for electrostatic latent image development and image forming method

ActiveCN102902172ASuppression of scatteringDevelopersElectrographic process apparatusLatent imageImage formation

The invention provides a developer for electrostatic latent image development. The developer for electrostatic latent image development including a positively chargeable toner and a fatty acid metal salt is used, in which the fatty acid metal salt is a metal salt selected from the group consisting of zinc, calcium, and magnesium salts of fatty acids of 12 to 20 carbon atoms and has a certain volume average particle diameter and particle size distribution. By using the developer for electrostatic latent image development, toner scattering or generation of image defects such as fog in the resulting images can be reduced.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com