Patents

Literature

421 results about "Magnesium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anhydrous magnesium acetate has the chemical formula Mg(C₂H₃O₂)₂ and in its hydrated form, magnesium acetate tetrahydrate, it has the chemical formula Mg(CH₃COO)₂ • 4H₂O. In this compound magnesium has an oxidation state of 2⁺. Magnesium acetate is the magnesium salt of acetic acid. It is deliquescent and upon heating, it decomposes to form magnesium oxide. Magnesium acetate is commonly used as a source of magnesium in biological reactions.

A liquid-based cell preservation solution

The invention relates to a pathological examination, in particular to a liquid-based cell preservation solution used in cytopathological examination of human cervical mucus, sputum, urine, pleural fluid, tracheal mucus and the like. It is characterized in that it is prepared from alcohols, sodium phosphate buffer, edetate disodium, sodium chloride 0.08%-0.12%, potassium chloride, formaldehyde, dithiothreitol, calcium acetate, magnesium acetate, etc. As a result, it can not only maintain the stability of the cell structure. It can reduce the agglomeration and precipitation of cell mucus and the loss of cell rupture, and can also make cells easy to stain, improve the clarity of cell preparation, facilitate the smooth progress of pathological examination, and the cost is low, which is conducive to popularization and use.

Owner:XIAOGAN CENT HOSPITAL +1

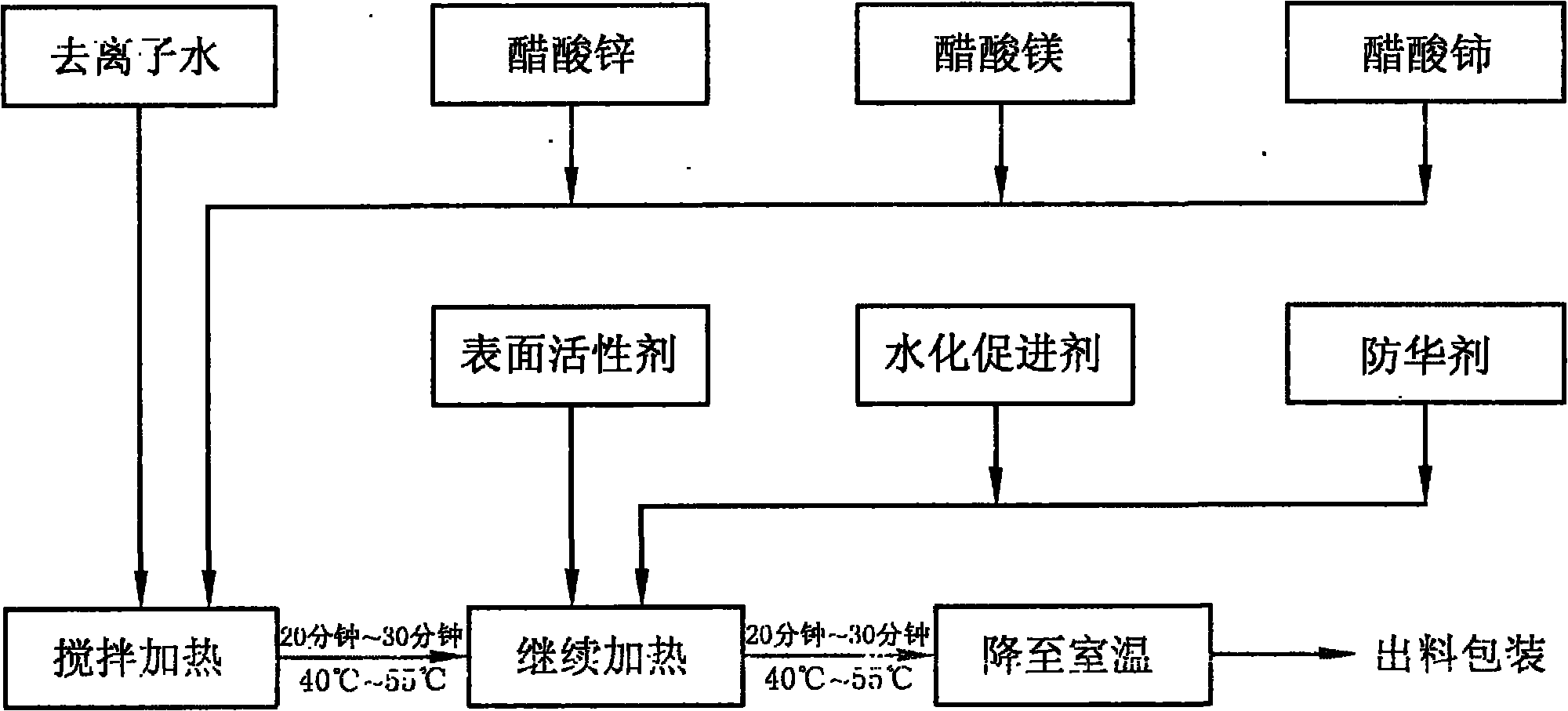

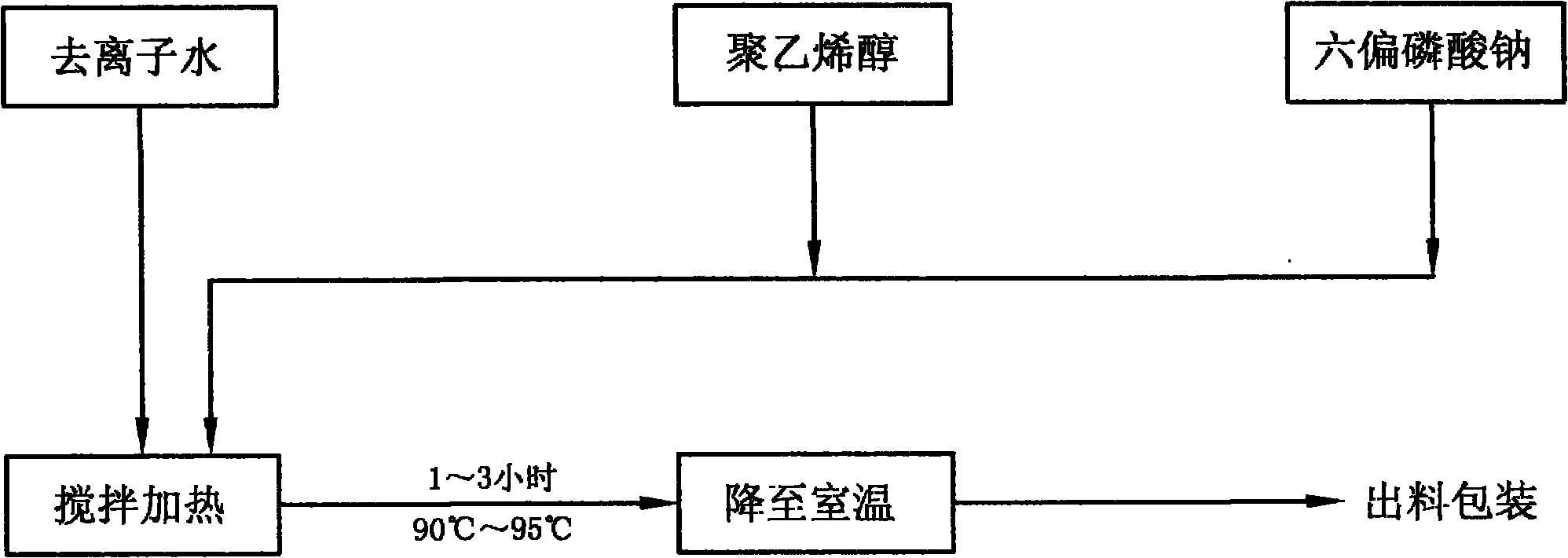

Method for preparing aluminum alloy anodic oxide film sealant

InactiveCN101812713AImprove pass rateImprove protectionSurface reaction electrolytic coatingSODIUM METAPHOSPHATEPolyvinyl alcohol

The invention discloses a method for preparing an aluminum alloy anodic oxide film sealant, which comprises the main processes of adding deionized water, zinc acetate, magnesium acetate, cerium acetate, surfactant, hydration promoter and sublimation preventing agent into a reaction kettle in turn, and mixing, stirring and heating the components to form the sealant. One of the important components of the sealant is sublimation preventing agent which is prepared by mixing the deionized water, polyvinyl alcohol and sodium hexametaphosphate together and then stirring and heating the mixture in the reaction kettle. The raw materials adopted by the preparation method do not contain nickel and fluorine elements, so the sealant is favorable for environmental protection; and the sealant reduces energy consumption during use, and improves the qualification rate of aluminum alloy products.

Owner:李继光

Isothermal amplification kit for detecting SARS-COV-2 and primer probe set

PendingCN111074007AStrong specificityHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationViral nucleic acidBiotin

The invention discloses an isothermal amplification kit for detecting SARS-COV-2 and a primer probe set. The kit comprises (1) inactivated lysate; and (2) an isothermal amplification system: a reaction buffer solution Buffer A, magnesium acetate Buffer B, negative control, nuclease-free water, a primer probe set and RAA enzyme. The lysate is used for rapid inactivation and release of viral nucleicacid, an isothermal amplification technology is utilized for rapidly enriching and amplifying a target area, whether a specific amplified product exists is rapidly determined through combination of aprobe with modification groups and a product with biotin, by a lateral chromatography technology and by use of colloidal gold developing. The kit is simple to operate, professional extraction reagents and detection instruments are not required limitation of detection laboratories and professionals is freed, the kit can perform rapid detection in an instrument-free state outdoors, the whole process only needs 30 min, and reading is very convenient.

Owner:上海世和医学检验实验室有限公司

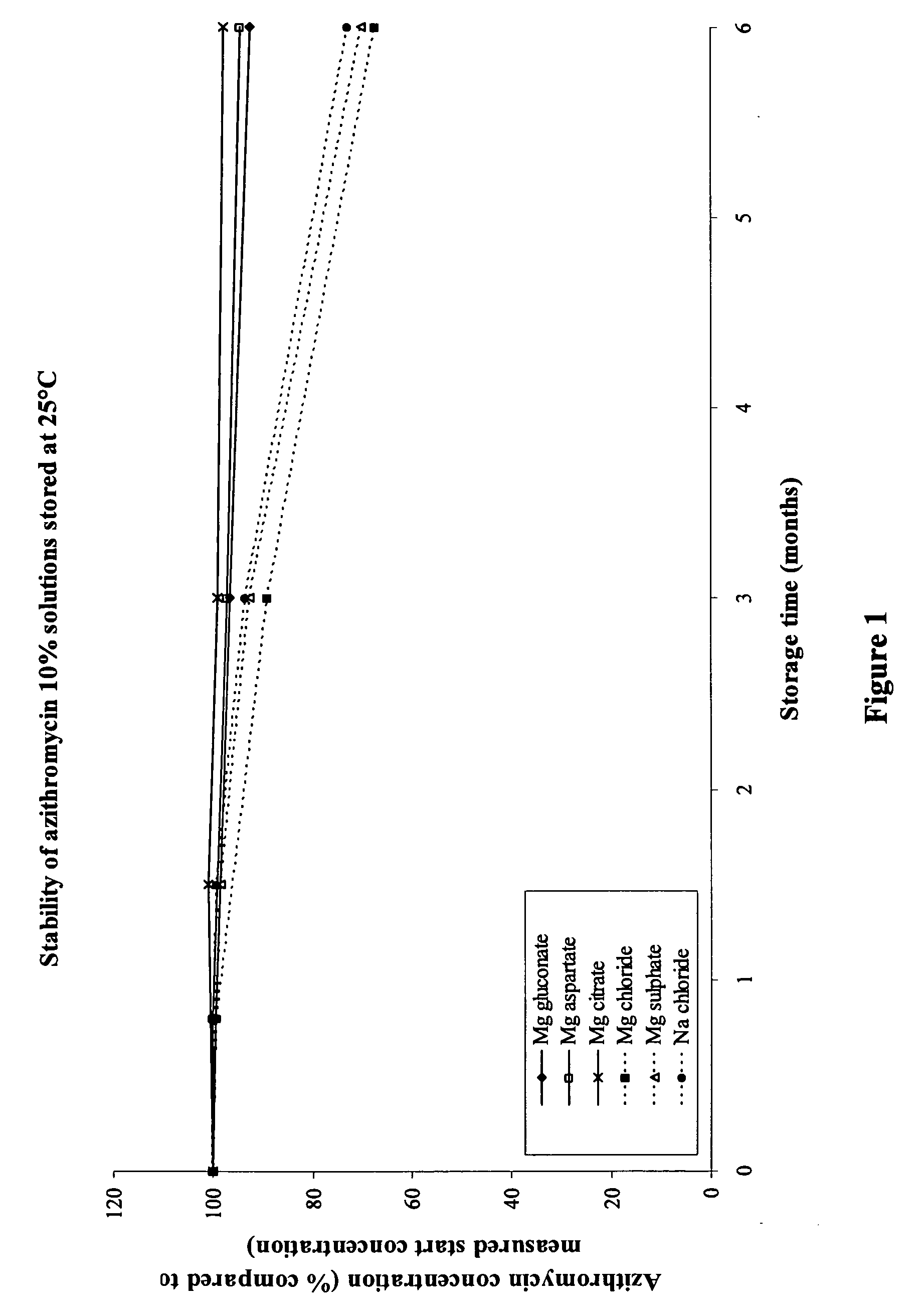

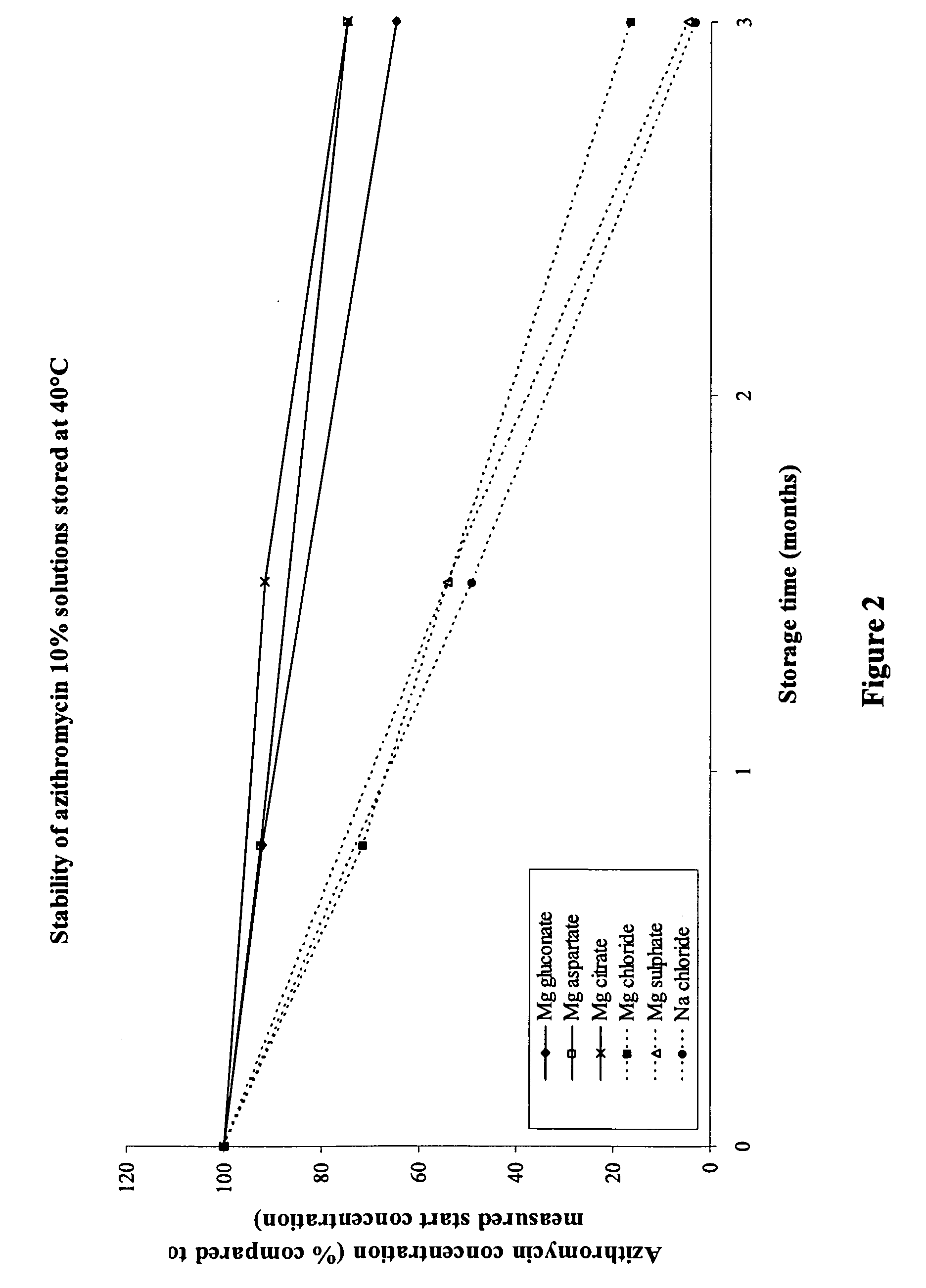

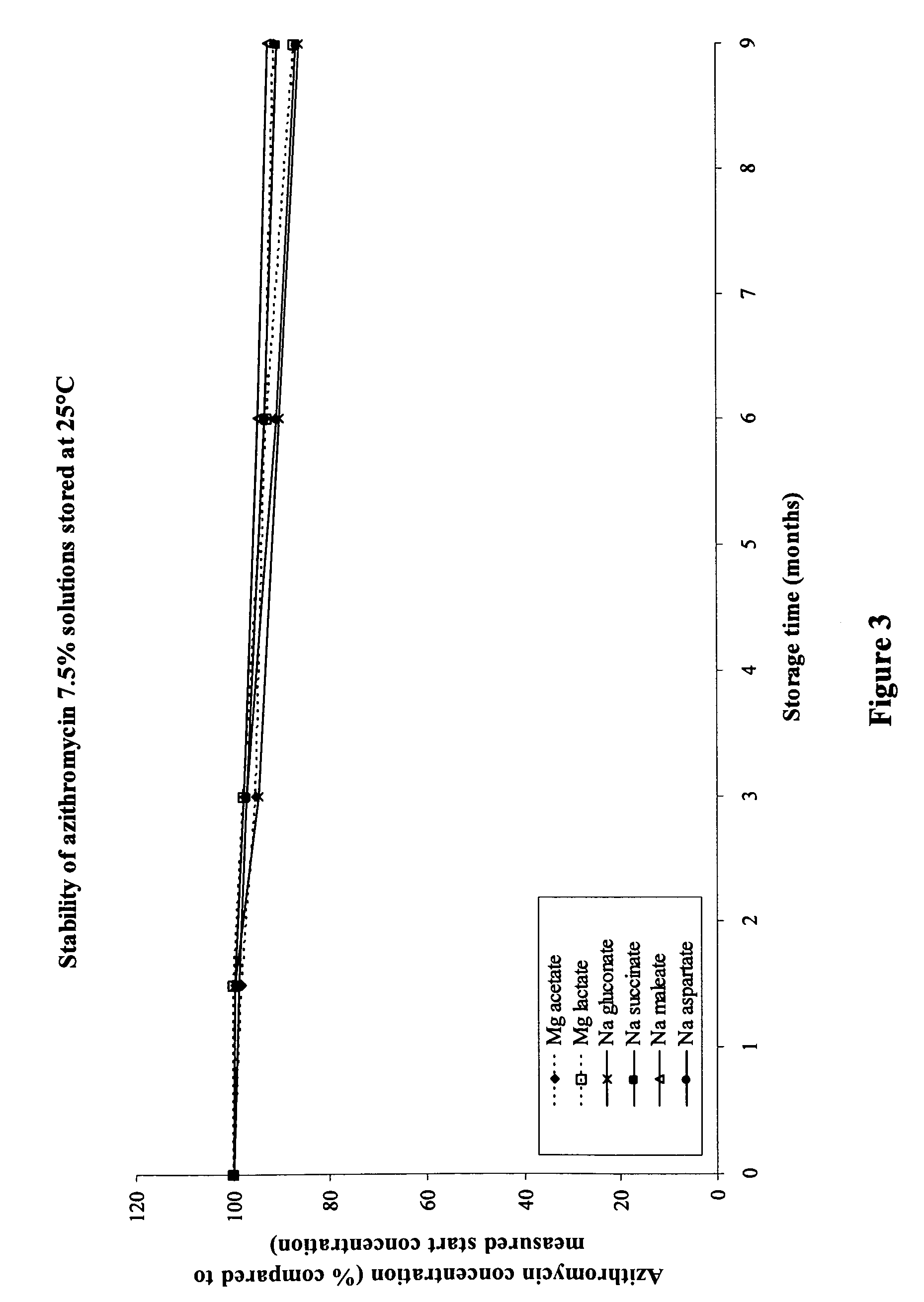

Macrolide compositions having improved taste and stability

InactiveUS20090232744A1Improve stabilityBad tasteBiocideDispersion deliverySodium acetateSodium lactate

The invention provides an aqueous pharmaceutical composition for administration as an aerosol to the respiratory tract, nose or oropharyngeal region comprising (i) a macrolide having a poor taste and poor chemical stability in aqueous solution; (ii) at least one salt selected from the group consisting of sodium gluconate, sodium aspartate, sodium acetate, sodium lactate, sodium succinate, sodium maleate, magnesium gluconate, magnesium aspartate, magnesium citrate, magnesium acetate, magnesium lactate, magnesium succinate, and magnesium maleate; or mixtures thereof and (iii) a taste-masking agent different from said salt; wherein (a) the concentration of said macrolide in the composition is in the range of about 0.25 wt.-% to about 15 wt.-%; (b) the molar ratio of said macrolide:said salt is in the range from about 1:0.5 to about 1:100; (c) the pH of the composition is in the range of about 3 to 9; and (d) the osmolality of the composition is in the range of about 150 mOsmol / kg to about 1500 mOsmol / kg. The invention further provides a method of generating an aerosol, preferably by means of a nebuliser, which uses such an aqueous pharmaceutical composition. The macrolide may be used alone or in combination with other drugs. The composition is suitable to treat inflammatory disorders and / or infections of the respiratory tract. It has an improved taste and stability.

Owner:PARI PHARMA GMBH

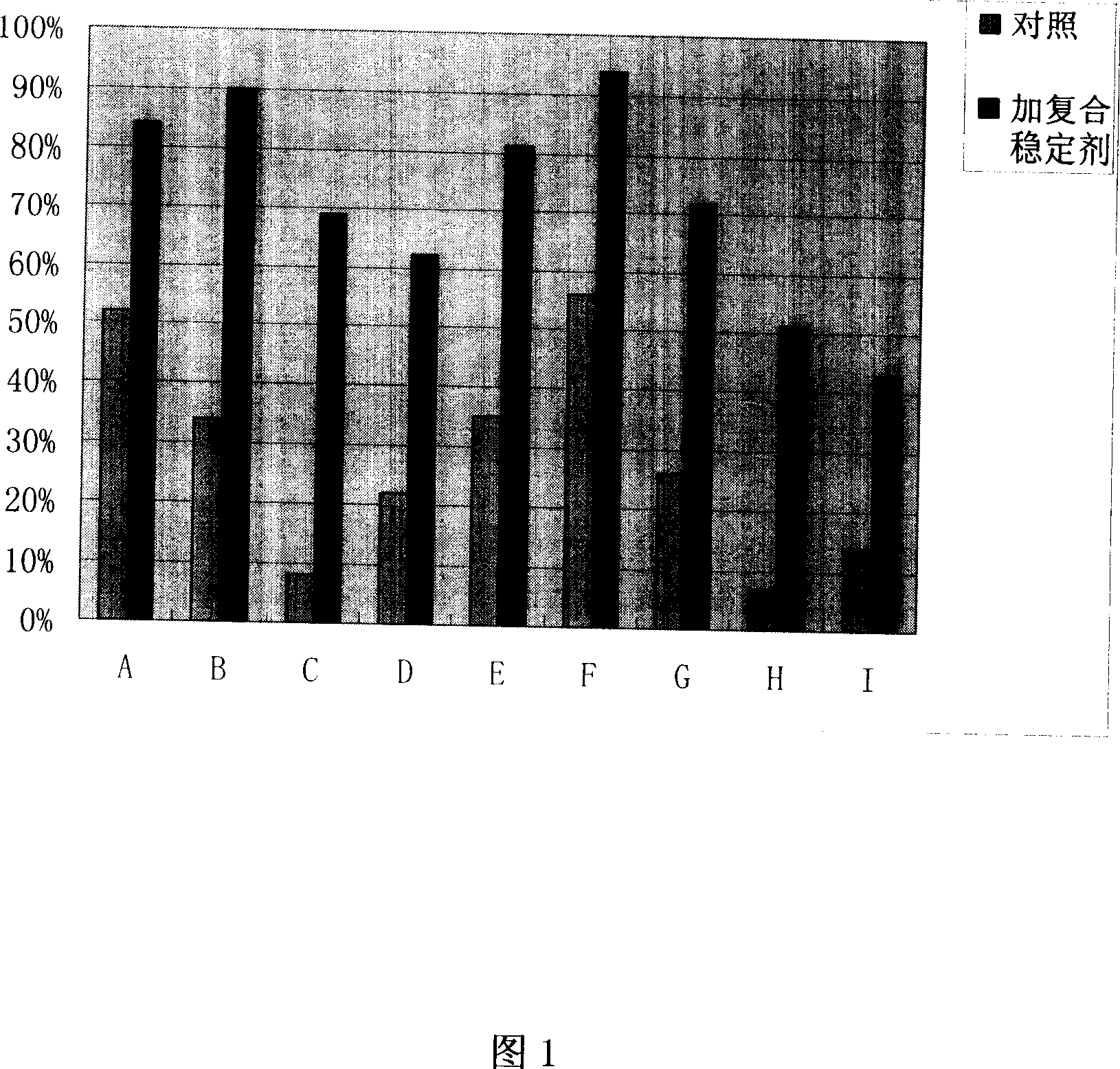

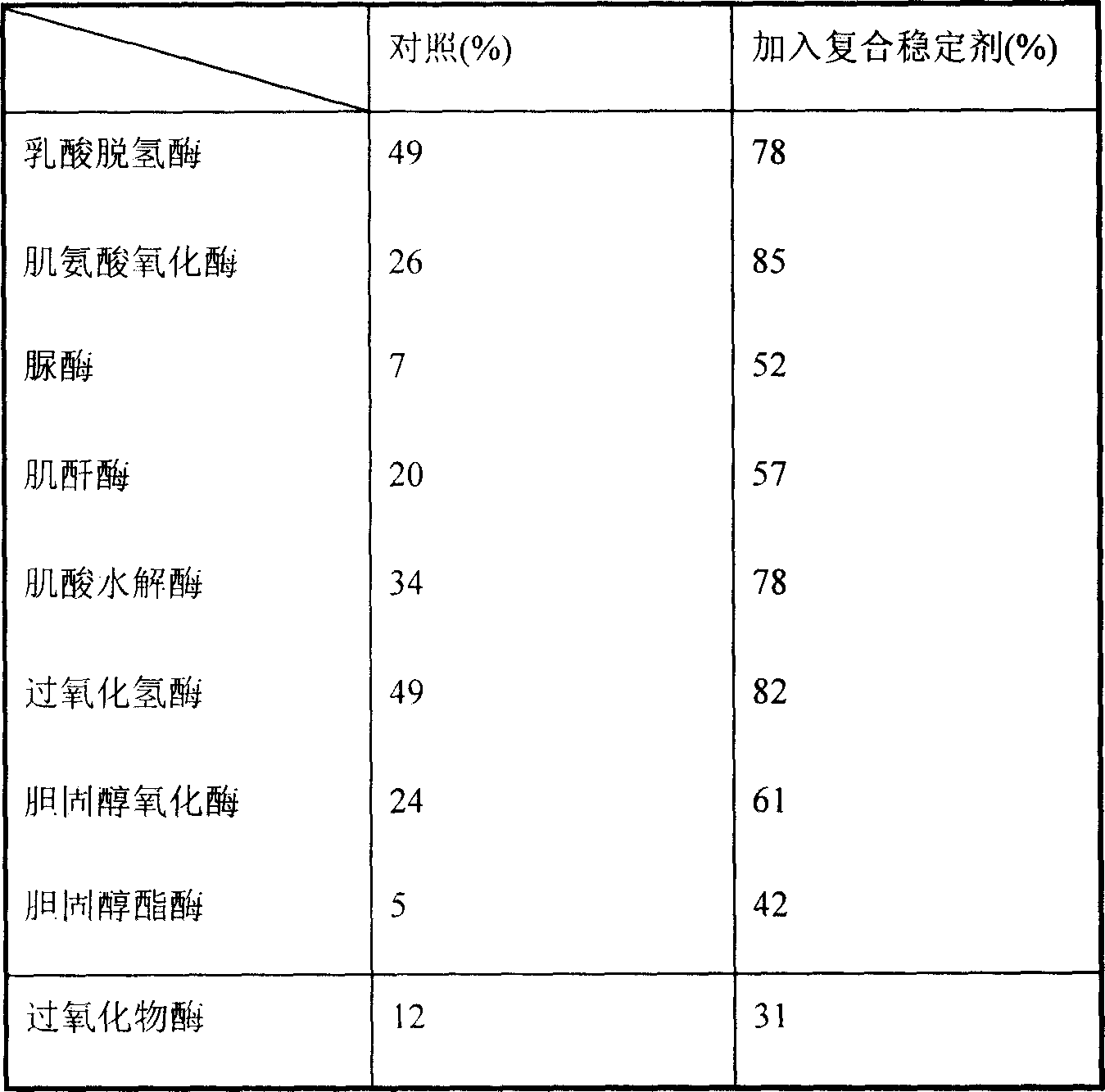

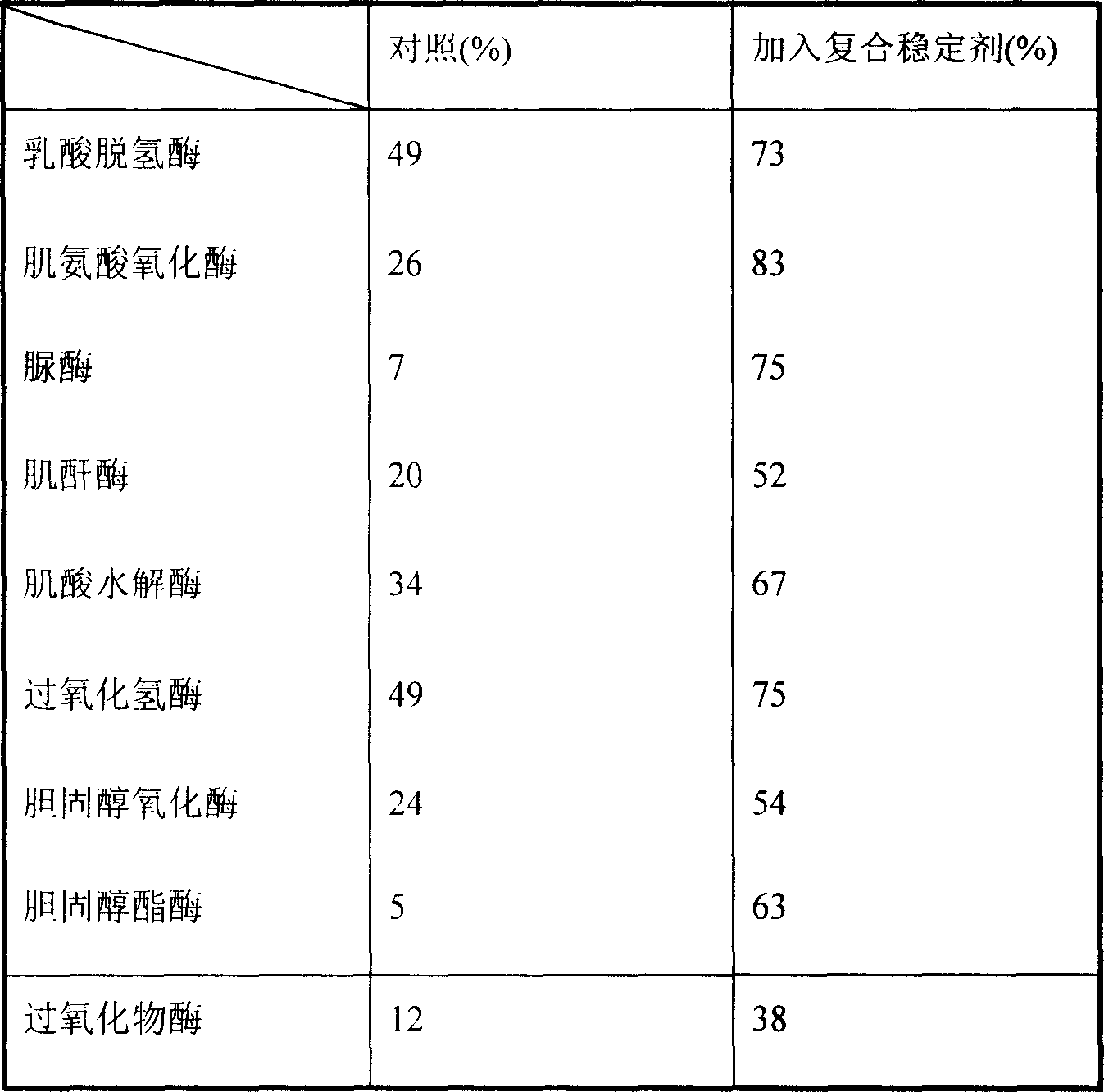

Enzyme combining stabilizer

ActiveCN1986785APlay a role in quality stabilityPeptide/protein ingredientsEnzyme stabilisationLactate dehydrogenaseCreatinine rise

The present invention provides a kind of efficient enzyme combining stabilizer with high stabilizing effect on enzymes for clinical diagnosis reagent. The enzyme combining stabilizer consists of bovine serum albumin, EGTA, 1, 2-dithio threitol, potassium gluconate, sodium chloride, proclin300, magnesium acetate, etc. It has powerful stabilizing effect on lactate dehydrogenase, sarcosie oxidase, urease, creatinine enzyme, creatine hydrolase, etc.

Owner:SHANGHAI FOSUN LONG MARCH MEDICAL SCI CO LTD +1

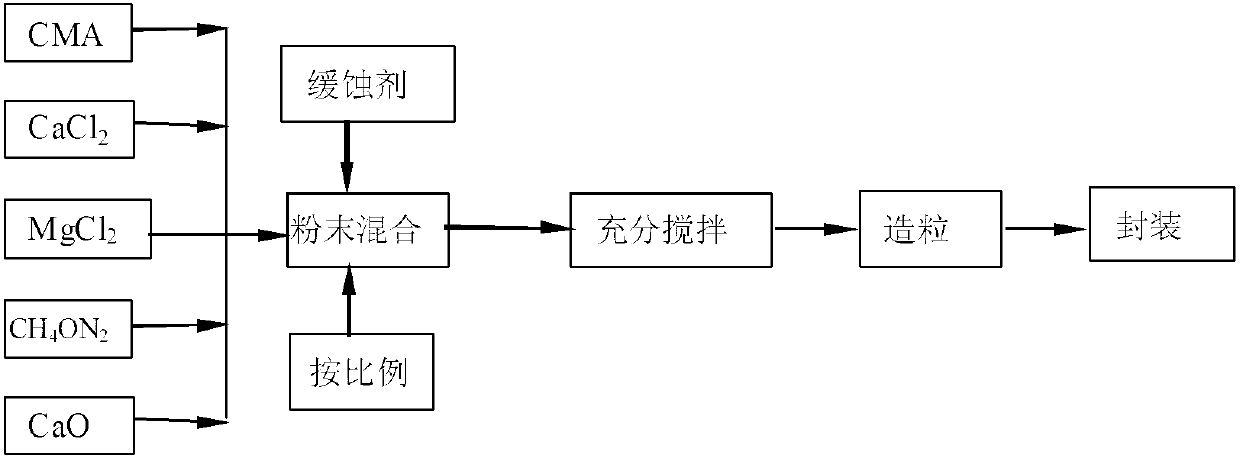

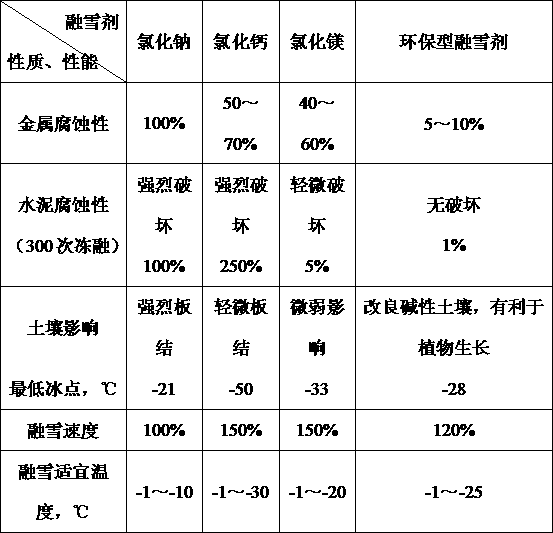

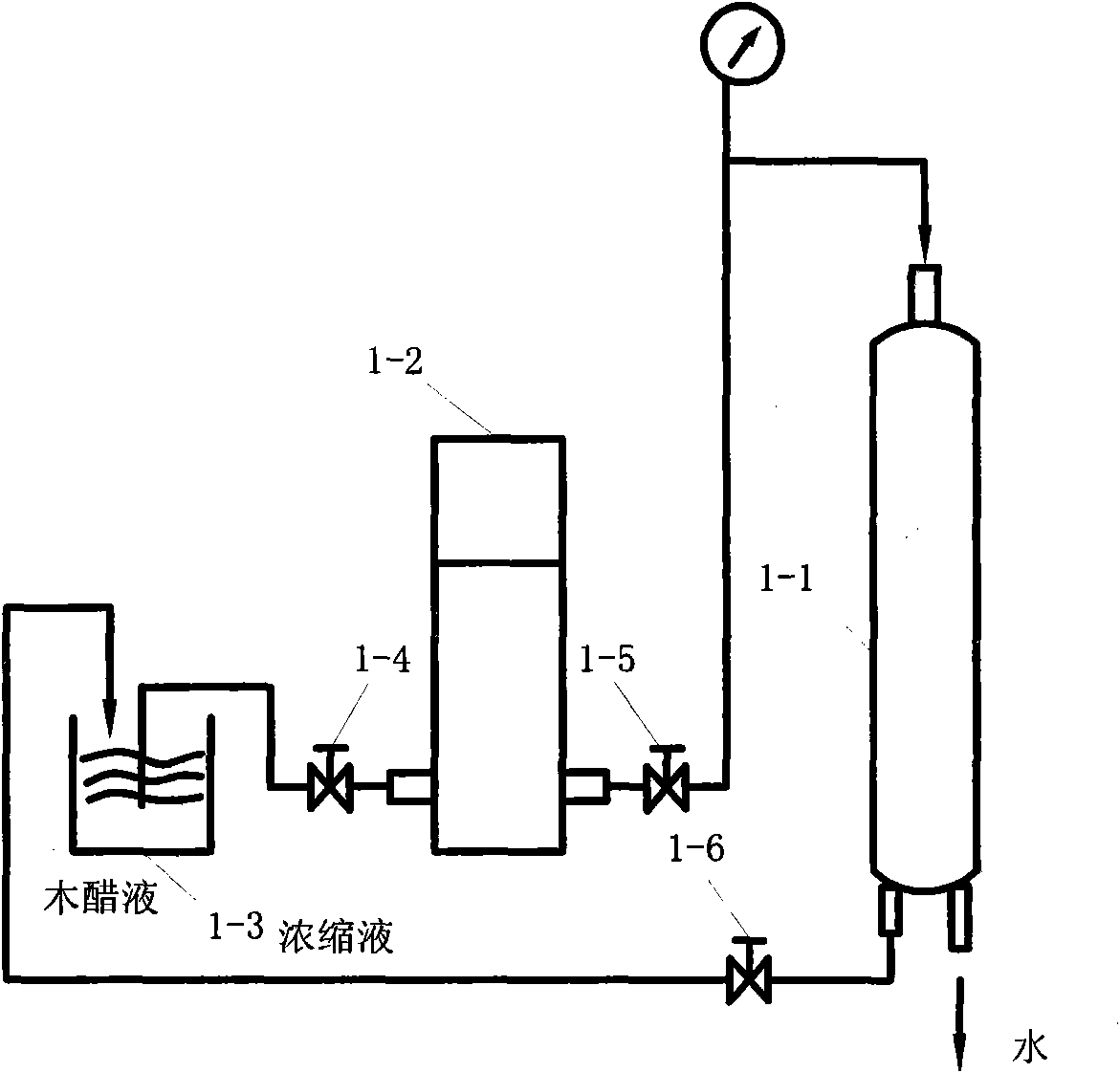

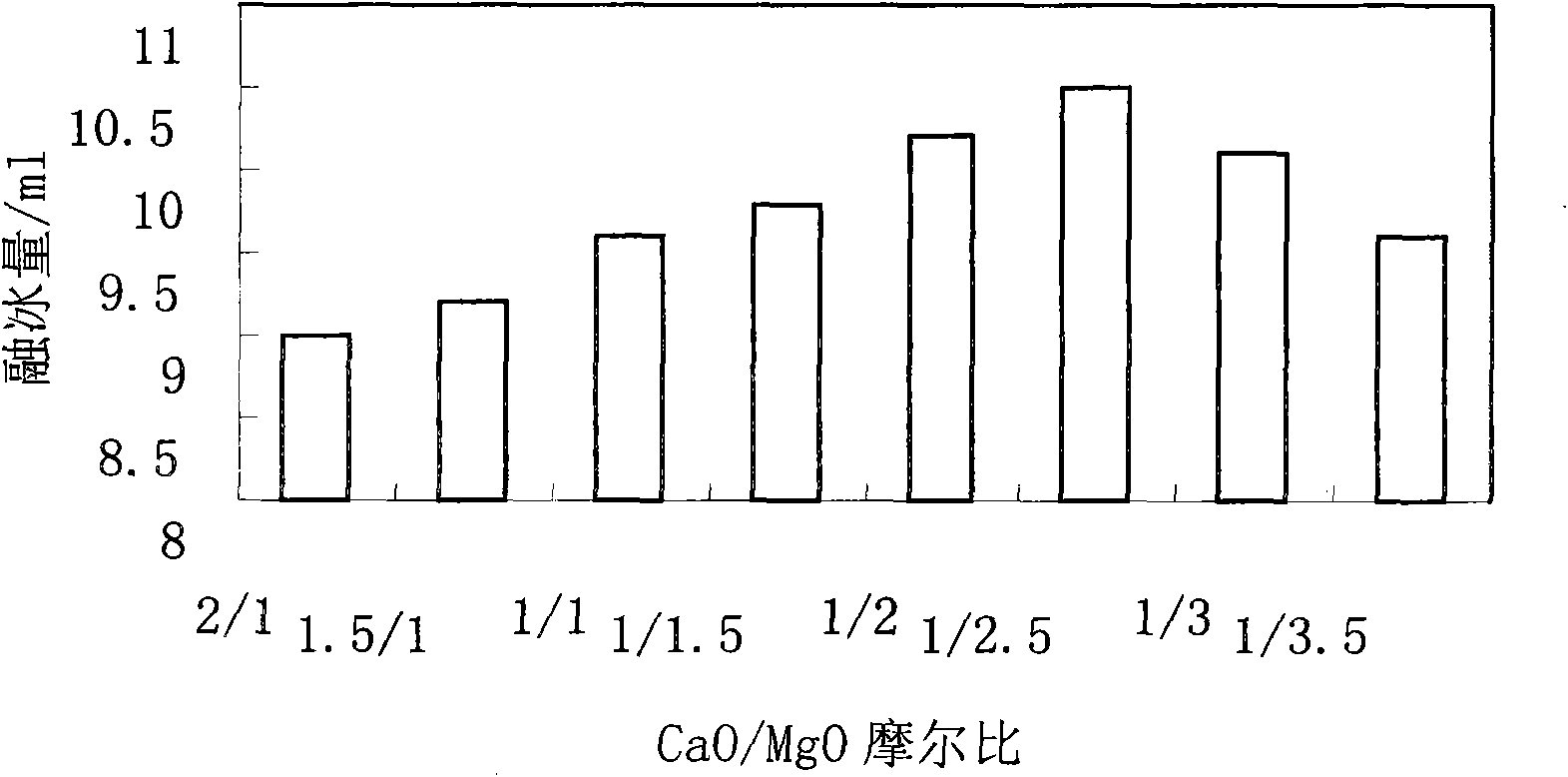

Environment-friendly snow melting agent and preparation method thereof

ActiveCN103342988AReduce manufacturing costSimple production processOther chemical processesSnow meltingEthylic acid

The invention relates to an environment-friendly snow melting agent and a preparation method of the snow melting agent, and belongs to the field of the snow melting agents. The snow melting agent is prepared from acetates and chlorine salts with low corrosivity as the main raw materials by mixing acetates including potassium acetate, magnesium acetate and calcium acetate with calcium chloride and magnesium chloride in a certain proportion, as well as a small quantity of corrosion inhibitor. The common fault that a common inorganic snow melting agent is high in corrosivity is effectively overcome, the cost is reduced, and therefore the snow melting agent is suitable for promotion and application.

Owner:SHENYANG POLYTECHNIC UNIV

Preparation method of nickel cobalt lithium manganate as high voltage lithium battery anode material

InactiveCN103715412ASmall surface areaIncrease charge and discharge voltageCell electrodesNickel saltPotassium hydroxide

The invention relates to a preparation method of nickel cobalt lithium manganate as a high voltage lithium battery anode material. The preparation method comprises the following steps of adding a nickel salt, a cobalt salt and a manganate salt into a reaction kettle, adding a mixed solution of sodium hydroxide or potassium hydroxide and ammonium hydroxide, and reacting to generate nickel cobalt lithium manganate hydroxide precipitate; washing, filter-pressing and drying the precipitate to obtain nickel cobalt manganate hydroxide; carrying out ball milling on the nickel cobalt manganate hydroxide and a lithium salt, and uniformly mixing; sintering a mixed product so as to obtain the nickel cobalt lithium manganate; adding magnesium acetate and zirconium acetate in the deionized water, and preparing a mixed solution; and adding the mixed solution to a water phase system of the nickel cobalt lithium manganate, and drying; and carrying out high-temperature processing on the dried product to obtain a final product. The preparation method provided by the invention has the advantage that the capacity property and the cycling property of the lithium battery anode material can be effectively improved.

Owner:JIANGSU KING LITHIUM CELL

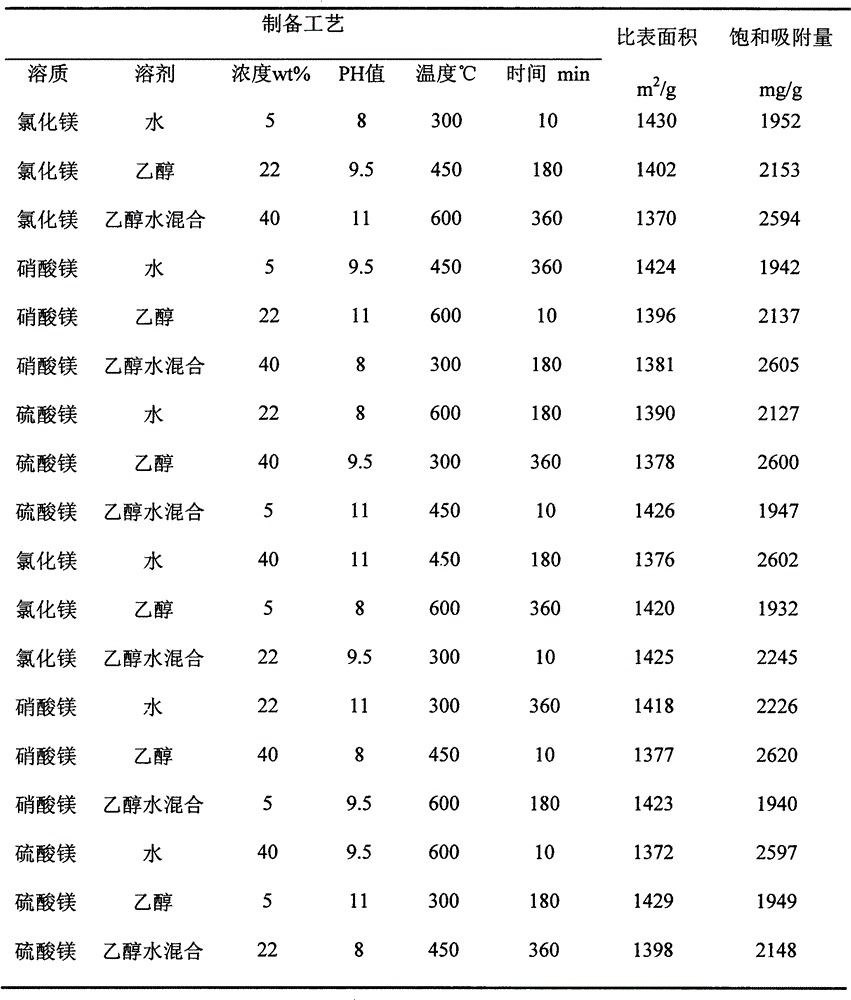

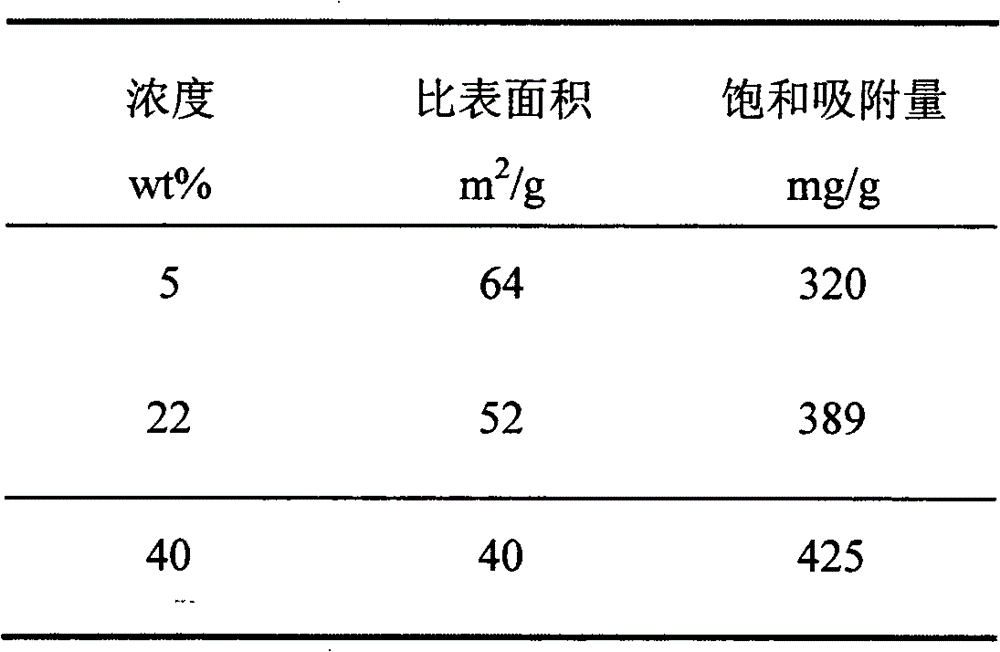

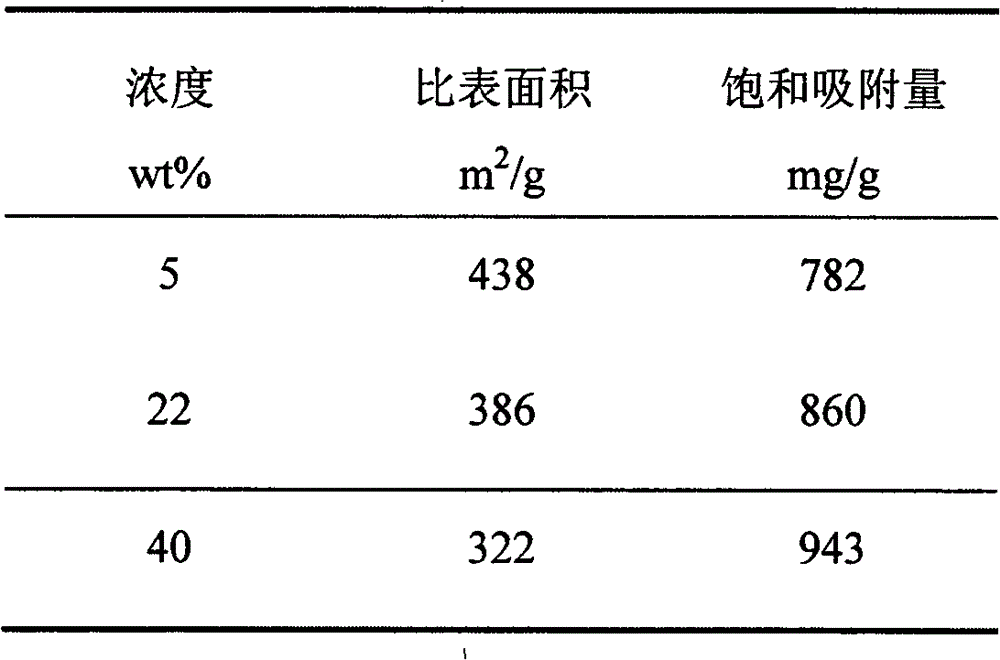

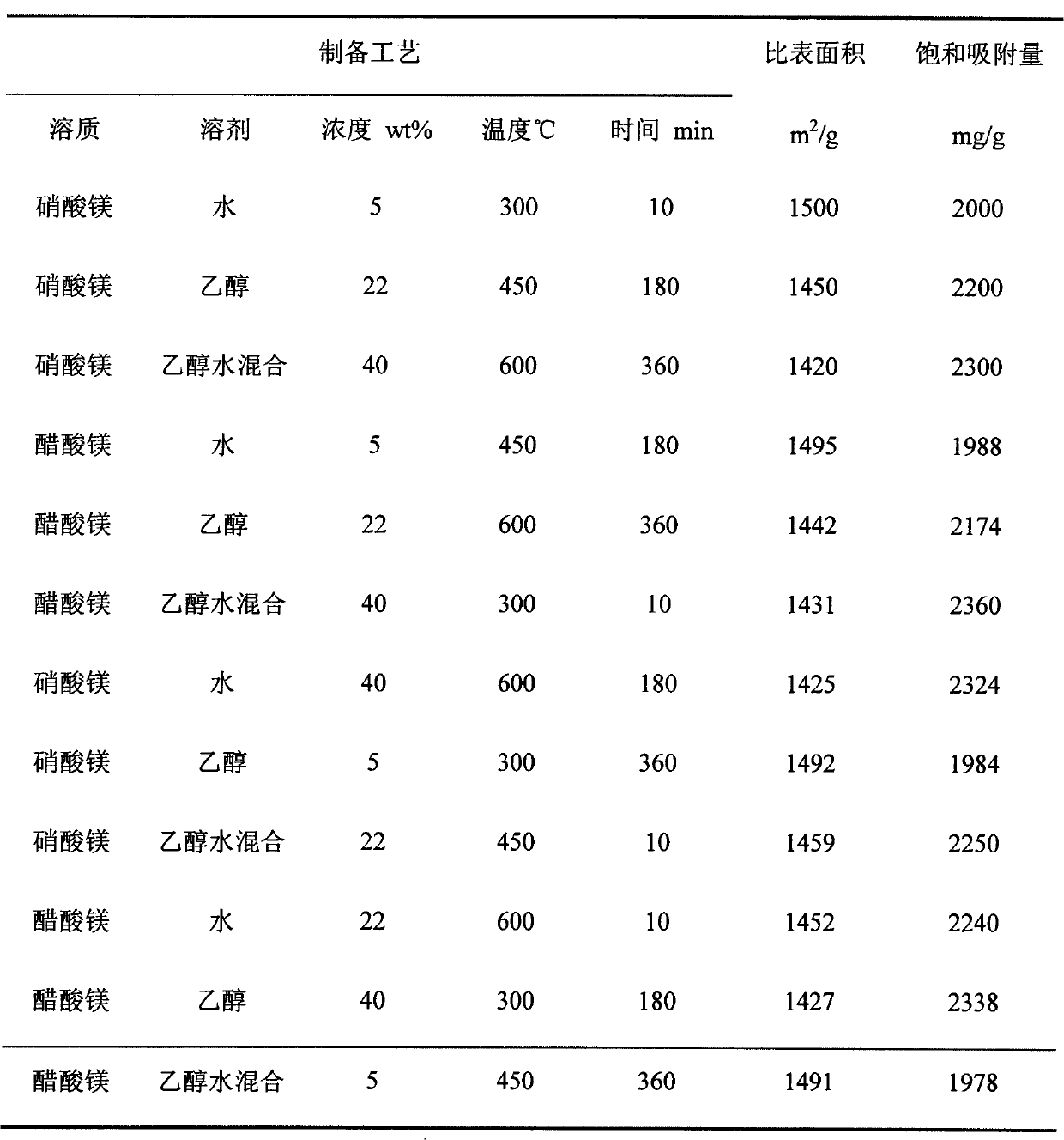

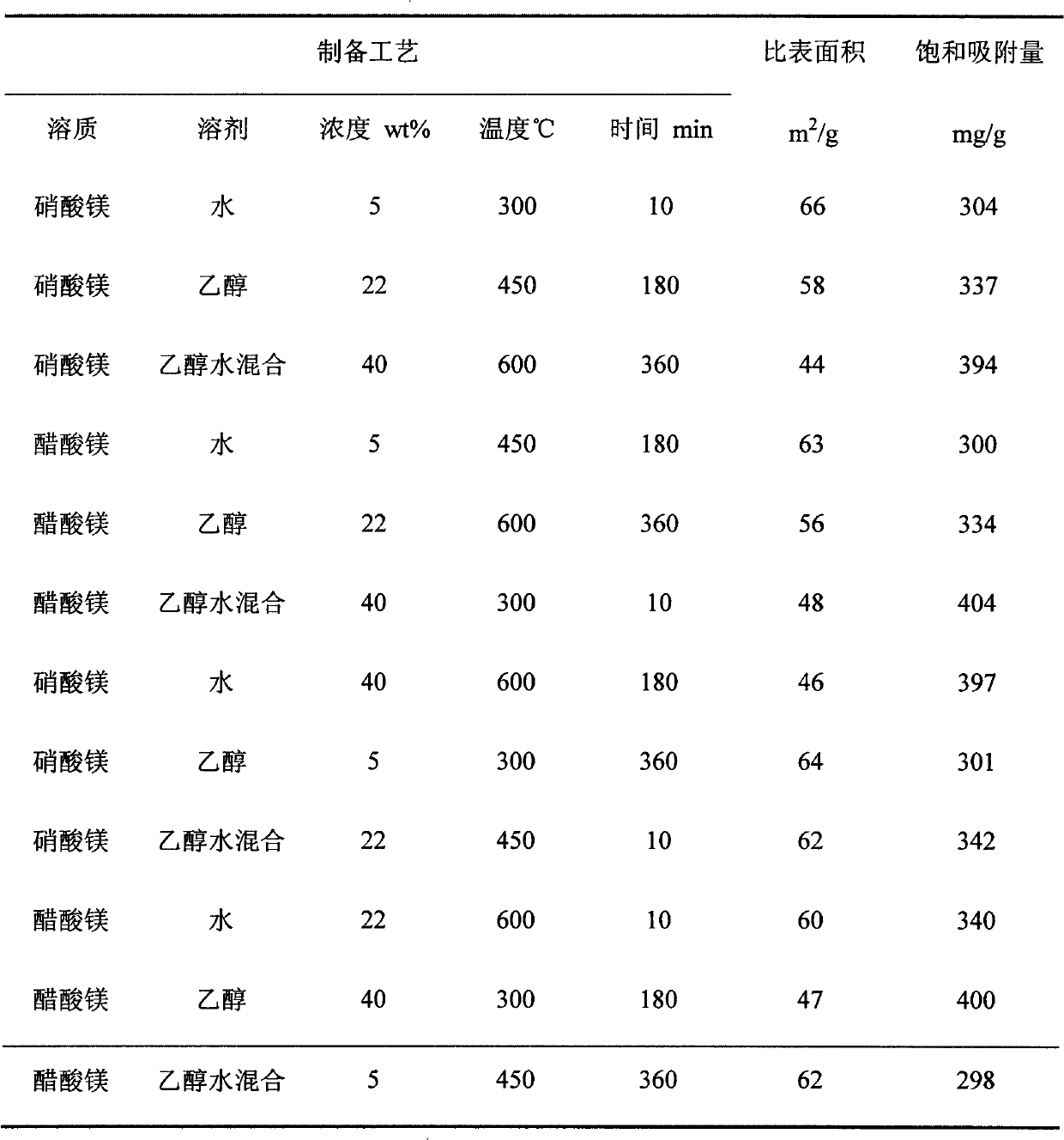

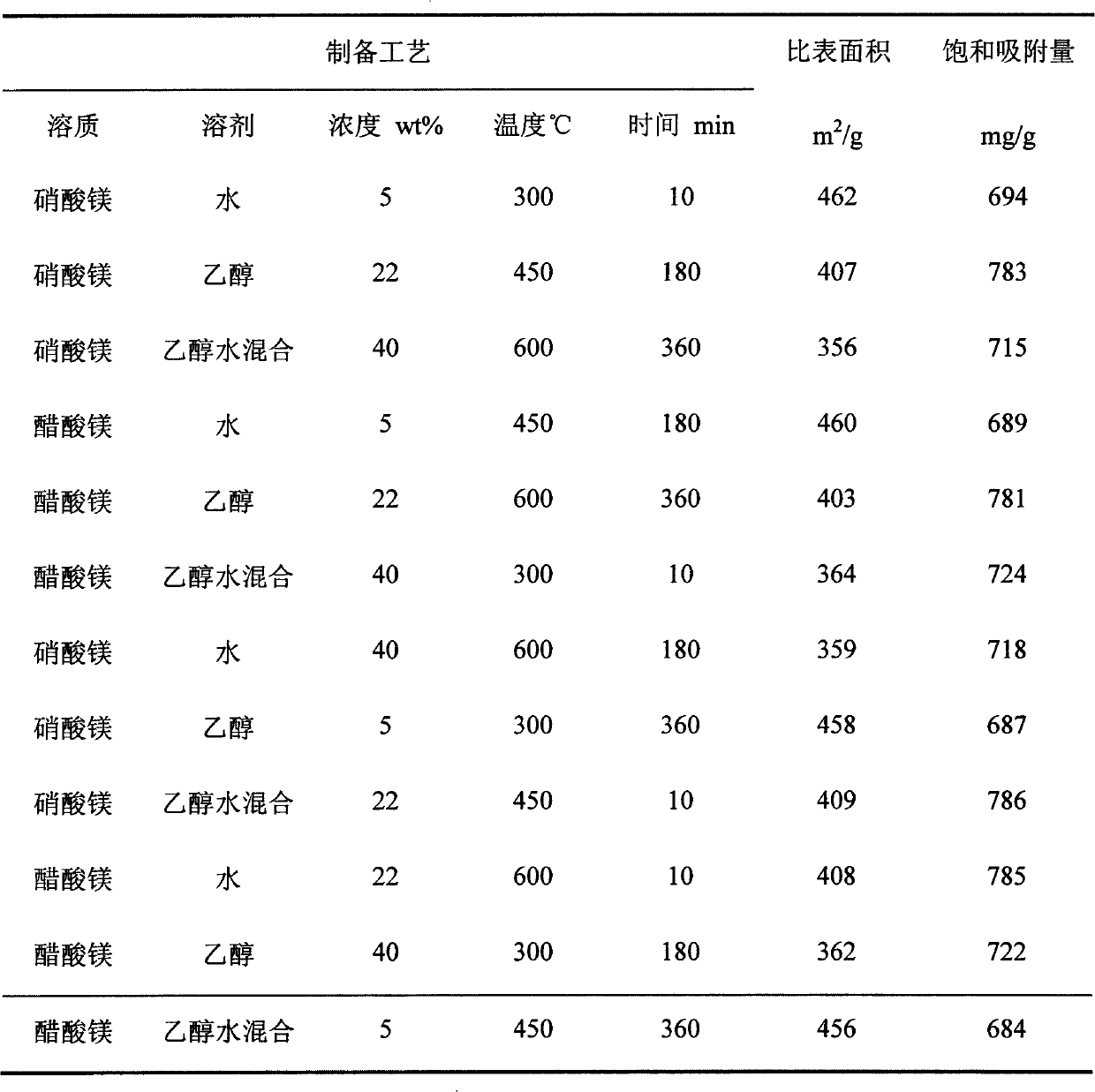

Method for preparing efficient adsorbent through in-situ reaction

InactiveCN102908978AReduce manufacturing costOther chemical processesAlkali metal oxides/hydroxidesMagnesium saltSorbent

The invention relates to a method for preparing an efficient adsorbent through in-situ reaction. The method is characterized by firstly chemically absorbing magnesium ions in ducts and surfaces of porous materials, then adjusting the pH value to 8-11, generating magnesium hydroxide in situ and obtaining the efficient adsorbent porous magnesium oxide through calcining, wherein the adopted magnesium salts are at least one of magnesium chloride, magnesium nitrate, magnesium acetate and magnesium sulfate; the solvents of the magnesium salts are at least one of water and ethanol; the concentration of the magnesium salt solution is 5-40wt%; the calcination temperature is 300-600 DEG C; and the calcination time is 10-360min. The method has the advantages of simple needed equipment, short process flow, high preparation efficiency and low preparation cost. The prepared porous magnesium oxide has the advantages of large specific surface area, strong heavy metal ion adsorption capacity and high saturation adsorption, and has good industrial application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

Preparation method of efficient adsorbent porous magnesium oxide

InactiveCN102908979ALow costOther chemical processesAlkali metal oxides/hydroxidesSorbentMagnesium salt

The invention relates to a preparation method of an efficient adsorbent porous magnesium oxide. The method is characterized by loading magnesium salts in ducts and surfaces of porous materials and obtaining the efficient adsorbent porous magnesium oxide through calcining, wherein the used magnesium salts are at least one of magnesium nitrate and magnesium acetate; the solvents of the magnesium salts are at least one of water and ethanol; the used porous materials are at least one of activated carbon, diatomite, silica gel and molecular sieves; the concentration of the magnesium salt solution is 5-40wt%; the calcination temperature is 300-600 DEG C; and the calcination time is 10-360min. The method has the advantages of simple needed equipment, short process flow, high preparation efficiency and low preparation cost. The prepared porous magnesium oxide has the advantages of large specific surface area, strong heavy metal ion adsorption capacity and high saturation adsorption, and has good industrial application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

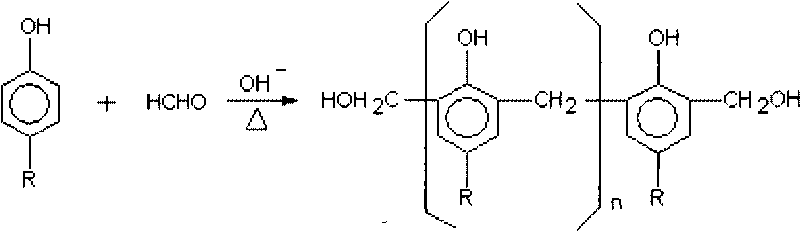

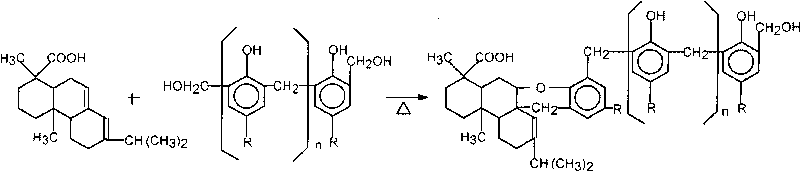

Preparation method of rosin modified phenolic resin

The invention relates to a preparation method of a rosin modified phenolic resin. The method comprises the following three steps of reactions: 1. performing condensation of tert-butylphenol, bisphenol A, tung oil and solid formaldehyde under the action of catalyst magnesium acetate and lime to generate polymer of hydroxymethyl tert-butylphenol; 2. performing an addition reaction with rosin to generate an addition product; and 3. performing esterification of the addition product, pentaerythritol and glycerin under the action of catalyst zinc chloride to generate the rosin modified phenolic resin. The preparation method adopts proper raw material proportioning, reaction temperature, reaction time, catalyst and other technical conditions, thus during the production process, the resin viscosity can be effectively controlled, and the operation is simple and flexible and has good effect. The quality of the product is increased, the oil solubility of resin is good, the oil medium viscosity is high, the normal heptane capacity is 4.5ml / g or more; and the prepared paint film ink has good water resistance and alkali resistance, high hardness, excellent anti-after-binding performance, quick-drying performance, lightness and strong adhesive force. Therefore, the preparation method of the invention is applicable to industrial production.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

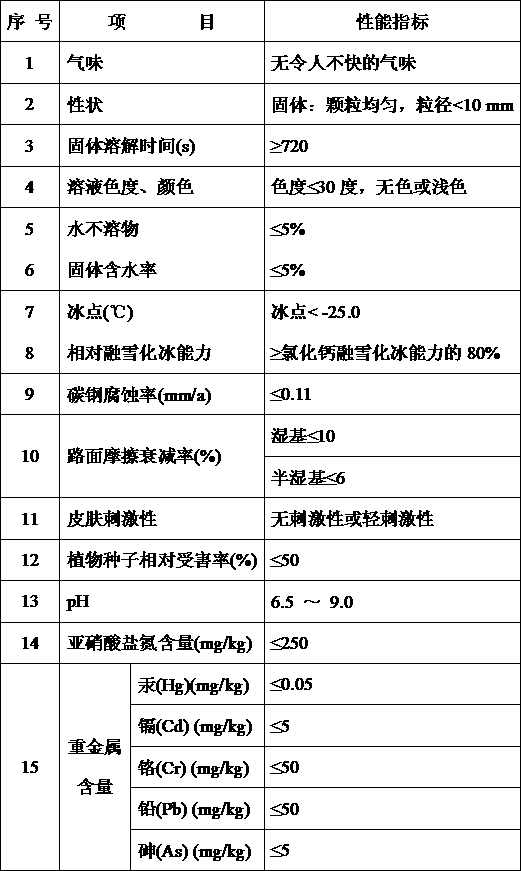

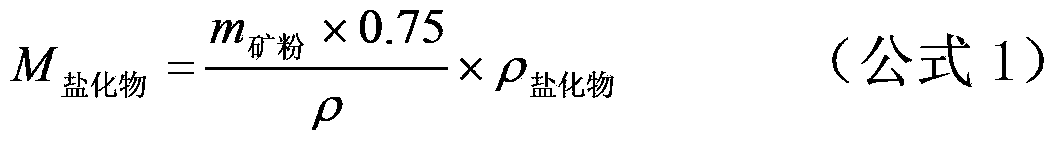

Environment-friendly salt for ice and snow melting and preparation method thereof

InactiveCN103387817ALess corrosiveReduce construction costsOther chemical processesSnow meltingMagnesium acetate

The invention discloses an environment-friendly salt for ice and snow melting and a preparation method thereof. The salt comprises, based on the weight percentage, the following compositions: 40% to 60% of snow-melting agent, 2% to 5% of heat-release agent, 10% to 40% of porous mineral aggregate, 10% to 20% of desiccator and 5% to 20% modifying agent. The method in the invention has simple process, low cost and good snow-melting effect; the snow-melting agent in the salt mainly comprises calcium acetate and magnesium acetate which have very small corrosivity to surrounding environment in comparison with the snow agent such as calcium chloride and sodium chloride used in MAFILON and other salts and can play a good role in environmental protection.

Owner:CHANGAN UNIV

Isothermal nucleic acid amplification reaction reagent and isothermal nucleic acid amplification method

ActiveCN102816756AStrong specificityEfficient amplificationDNA preparationRibonucleosidePolyethylene glycol

The invention discloses an isothermal nucleic acid amplification reaction reagent which comprises Tris buffer solutions, potassium acetate, magnesium acetate, dithiothreitol, polyethylene glycol, adenosine triphosphate (ATP), deoxy-ribonucleoside triphosphate (dNTPs), phosphocreatine, creatine kinase, a primer group, single-strand binding (SSD) protein, colon bacillus helicase RecQ protein, UvsY protein and DNA polymerase. The invention further discloses an isothermal nucleic acid amplification method which includes steps of extracting DNA or performing inverse transcription after DNA extracting, and adding the isothermal nucleic acid amplification reaction reagent and reacting the mixture at a temperature in a range between 25 DEG C and 45 DEG C for 10 minutes to 60 minutes to complete the nucleic acid amplification. Compared with traditional polymerase chain reaction (PCR) technologies and according to the technology, nearly no professional instrument is needed, the operation is simple, technical requirements for operators are low, and the reaction time only needs about half an hour.

Owner:JIANGSU QITIAN GENE BIOTECHNOLOGY CO LTD

Capsule type snow ice melt inhibiting material, preparation method and application thereof

InactiveCN101948260ANo secondary pollutionAchieve energy saving and emission reductionSorbentPolyethylene glycol

The invention provides a capsule type snow ice melt inhibiting material doped into asphalt pavement filling materials in road building or pavement building, a preparation method and application thereof. The capsule type snow ice melt inhibiting material consists of a capsule wall, a capsule core and protection solution, wherein the capsule core is formed by mixing an absorbent with a grain diameter of 30 micrometers and a nanometer bone material, wherein the absorbent is modified by absorbing calcium acetate and magnesium acetate; the mass ratio of capsule wall chitosan or ethyl cellulose to polyethylene glycol is 1:1, the ratio of the mass sum of the modified adsorbent and the bone material to the capsule wall mass is 10:1; the mass ratio of the modified adsorbent to the bone material is 7:3; the mass ratio of the modified adsorbent to the calcium acetate to the magnesium acetate thereof is 2:1:1-2:1.2:0.8; the calcium acetate and the magnesium acetate solution are added into the adsorbent respectively; and the solution is oscillated on an oscillator at room temperature, and is stirred and oscillated continuously, and is filtered after standing; the capsule core is dispersed into the capsule wall solution, and is slowly dripped into the polyethylene glycol solution in stirring to prepare the snow ice melt inhibiting material to be doped into the asphalt pavement filling material after stirring, vacuum filtering, cleaning and drying.

Owner:怀方林

Animal excrement fermented fertilizer and preparation method thereof

InactiveCN103724140AIncrease productionEffective absorptionFertilizer mixturesPotassium persulfateSaccharum

The invention discloses an animal excrement fermented fertilizer and a preparation method thereof. The animal excrement fermented fertilizer is characterized by being prepared from the following raw materials in parts by weight: 75-85 parts of urea, 60-80 parts of potassium dihydrogen phosphate, 65-70 parts of saltpeter, 60-75 parts of potassium persulfate, 20-35 parts of cane sugar, 100-200 parts of rabbit excrement, 100-200 parts of pig excrement, 35-50 parts of plant ash, 2-3 parts of an EM bacterium agent, 15-25 parts of magnesium chloride, 20-30 parts of magnesium acetate, 50-85 parts of calcium nitrate and 10-12 parts of a soil activator. According to the invention, a soil improver comprises a jade composition, which contains a large number of micro elements good for a human body, and is beneficial for the human body; in addition, noxious heavy metal elements in the soil can be effectively absorbed and cured, and accordingly the heavy metal elements absorbed by the crop can be reduced; moreover, the nutrition facts of the rabbit excrement and the pig excrement are mutual complementary, as a result, the fermentation fertilizer combining the rabbit excrement and the pig excrement has more comprehensive, reasonable and uniform fertilizer nutrient compared with a single fermentation fertilizer, and crop absorption law can be better met.

Owner:枞阳县新少圩种粮农民专业合作社

Aluminum alloy nickel-free environment-friendly hole sealing agent

The invention relates to an aluminum alloy nickel-free environment-friendly hole sealing agent. The aluminum alloy nickel-free environment-friendly hole sealing agent is an aqueous solution, and the hole sealing agent further comprises 1-20 g / L of magnesium acetate, 0.01-1 g / L of heterocyclic compound, 5-30 g / L of a complexing agent and 0.01-10 g / L of a pH buffering agent, wherein the heterocyclic compound comprises one or more groups of sulfo groups, mercapto groups and amino groups. The hole sealing agent is simple in process, low in energy consumption, stable in hole sealing and processing effect and excellent in corrosion resistance, the environment protection requirements are met, and especially the excellent performances of hole sealing operation can be maintained after dyeing.

Owner:SHENZHEN QIANHAI AILIYOU TECH CO LTD

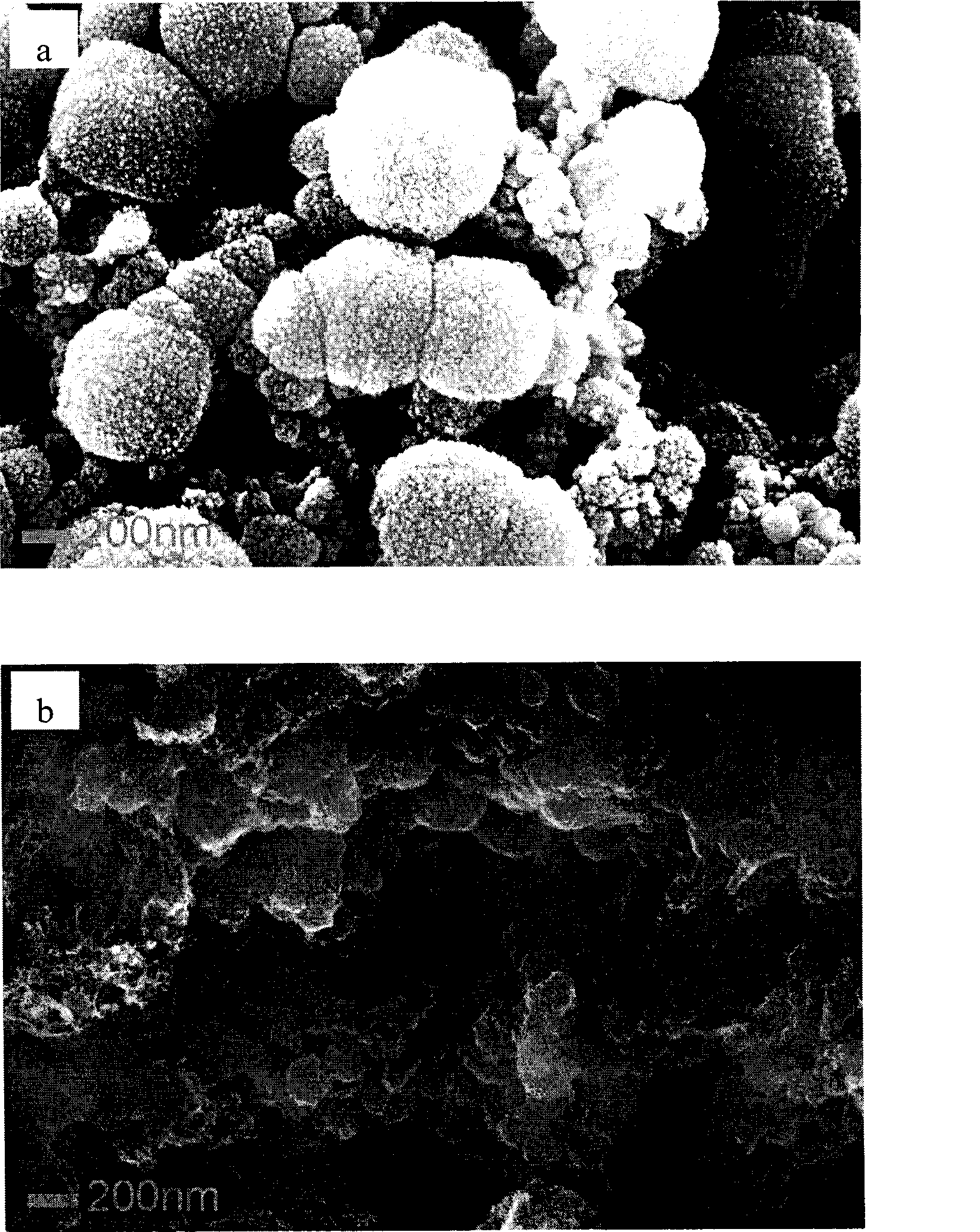

Medical titanium with a trace element slow-release function or titanium alloy implant material as well as preparation method and application of same

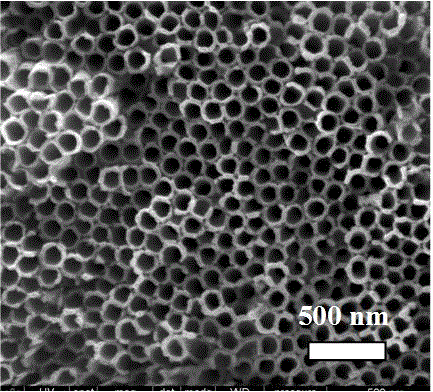

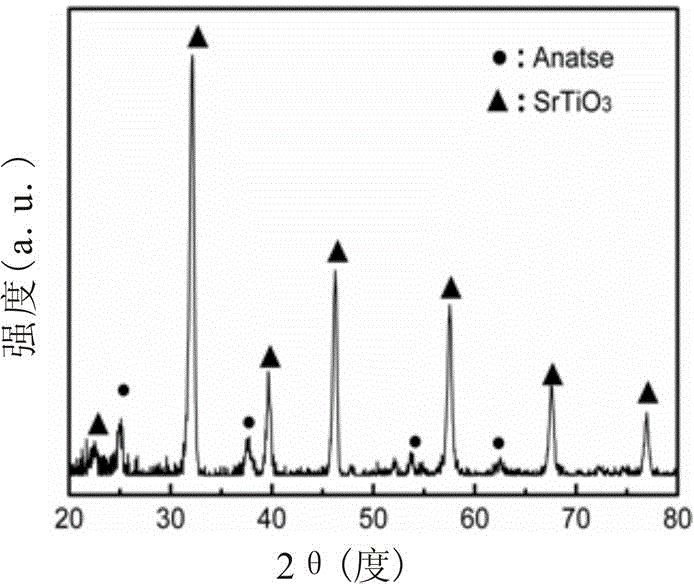

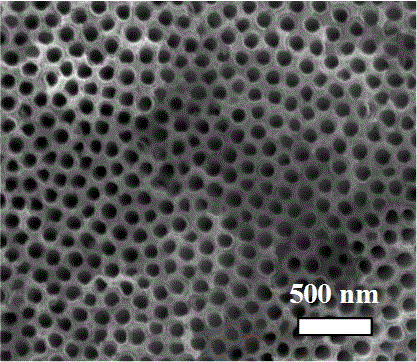

InactiveCN102908661AImprove biological activityIncrease success rateSurface reaction electrolytic coatingSuperimposed coating processElectrolytic agentTitanium metal

The invention relates to medical titanium with a trace element slow-release function or a titanium alloy implant material as well as a preparation method and an application of the medical titanium. The invention adopts the technical scheme that the preparation method comprises the following steps: putting a polished titanium-containing metal sheet into an electrolyte as an anode for anodic oxidation; flushing and drying the titanium-containing metal sheet subjected to anodic oxidation, carrying out heat treatment for 1-3 hours at a temperature of 100-500 DEG C, naturally cooling and ultrasonically cleaning and drying; and putting the dried titanium-containing metal sheet into one of or mixed solution of more than any two strontium hydroxide, strontium acetate, zinc acetate or magnesium acetate, carrying out hydrothermal reaction for 0.5-12 hours in a closed container at a temperature of 100-300 DEG C, naturally cooling, taking out, cleaning and drying, and carrying out heat treatment for 1-3 hours at a temperature of 450-550 DEG C to obtain the medical titanium with the trace element slow-release function or the titanium alloy implant material. The medical titanium or the titanium alloy implant material as well as the preparation method and the application thereof have the beneficial effects that the preparation method is simple and reliable, the loading quantity and the release amount of trace elements of the medical titanium in a nano tube are controllable, the medical titanium and the biological activity on the alloy surface can be better promoted, and the application prospect is good in the medical implant material.

Owner:WUHAN UNIV OF SCI & TECH

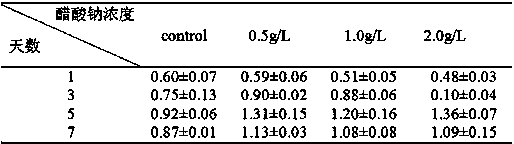

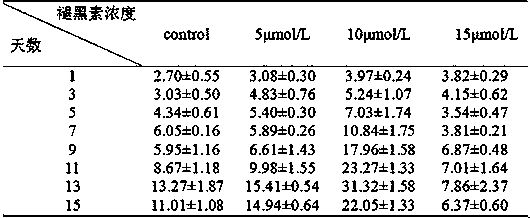

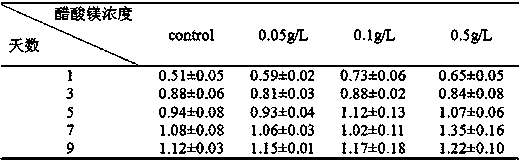

Method for increasing biomass and astaxanthin content of haematococcus pluvialis

InactiveCN108753620AIncrease biomassIncreased astaxanthin contentUnicellular algaeMicroorganism based processesSodium acetateBiology

The invention relates to a method for increasing biomass and astaxanthin content of haematococcus pluvialis, and belongs to the technical field of bioengineering. The method comprises steps as follows: a BBM culture medium with sodium acetate or magnesium acetate added is prepared firstly, after being sterilized, the BBM culture medium is inoculated with the haematococcus pluvialis cultured to theexponential phase until the concentration reaches 2.0*10<5>-2.5*10<5> cells / mL, culturing is performed at the temperature of 24-26 DEG C under the condition of light intensity being 2000-2500 lx, andsampling is performed every other day for biomass measurement; algae cells are collected when the biomass is maximum, diluted by the nitrogen-deficient BBM culture medium with melatonin added until the concentration is 2.0*10<5>-2.5*10<5> cells / mL, culturing is performed at the temperature of 26-28 DEG C under the condition of light intensity being 12000-14000 lx, and sampling is performed everyother day for astaxanthin content measurement. The method is simple and easy to operate, growth cycle of the haematococcus pluvialis can be shortened to a certain degree, and the biomass and the astaxanthin content of the haematococcus pluvialis are increased.

Owner:KUNMING UNIV OF SCI & TECH

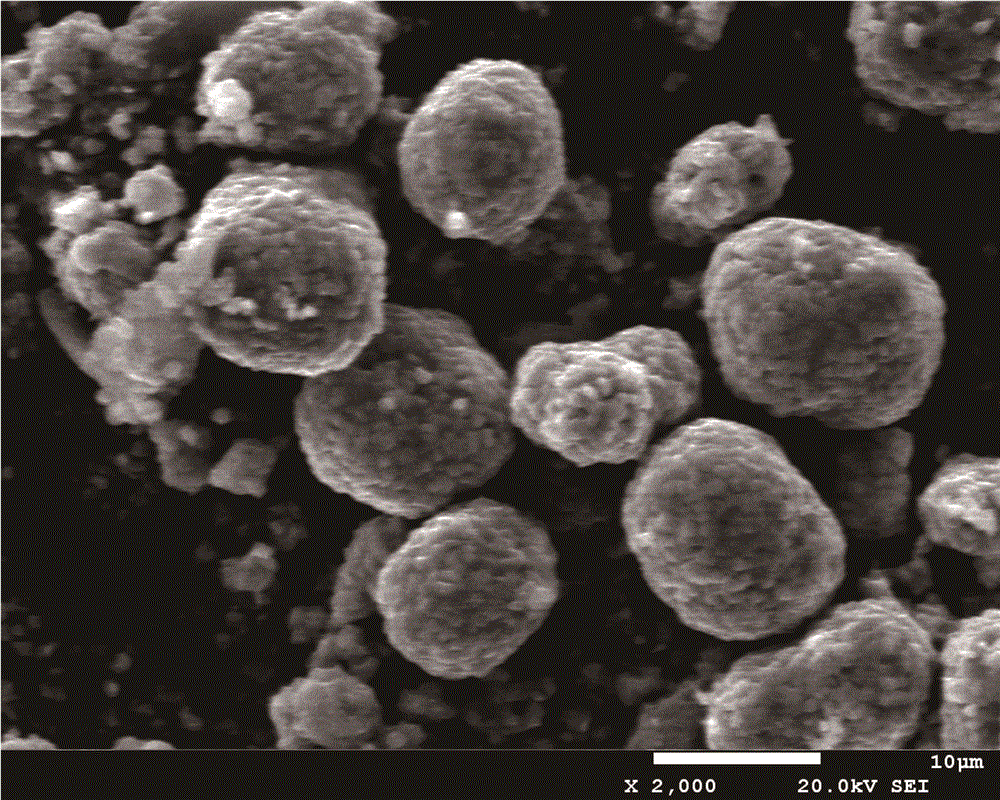

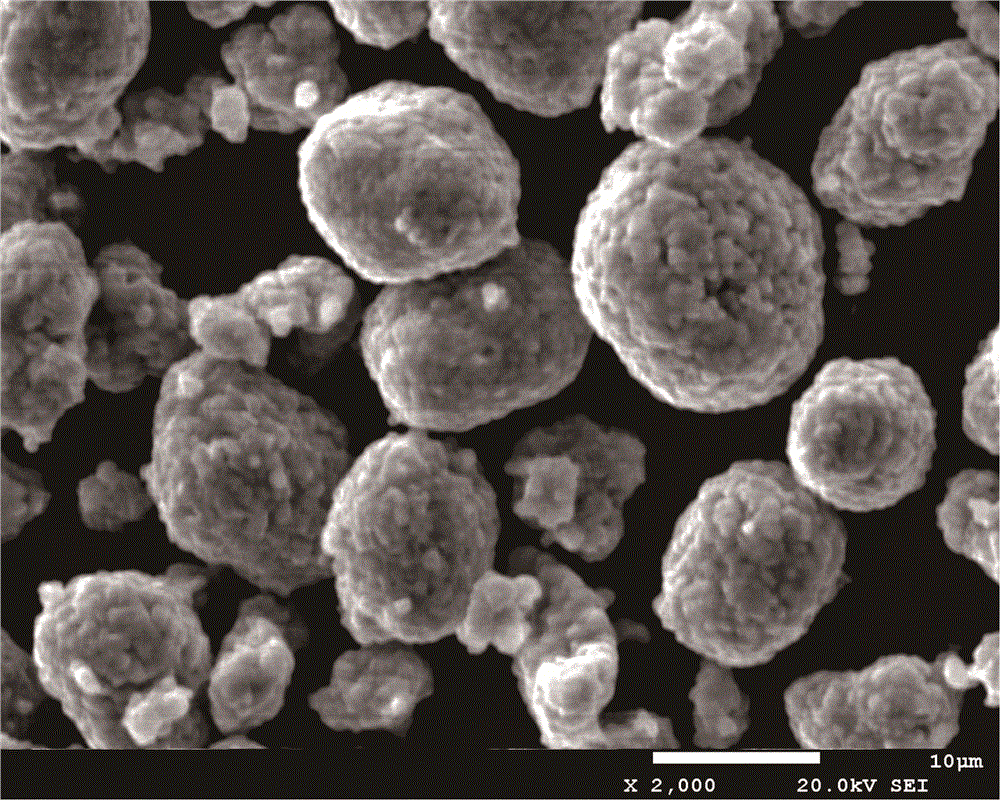

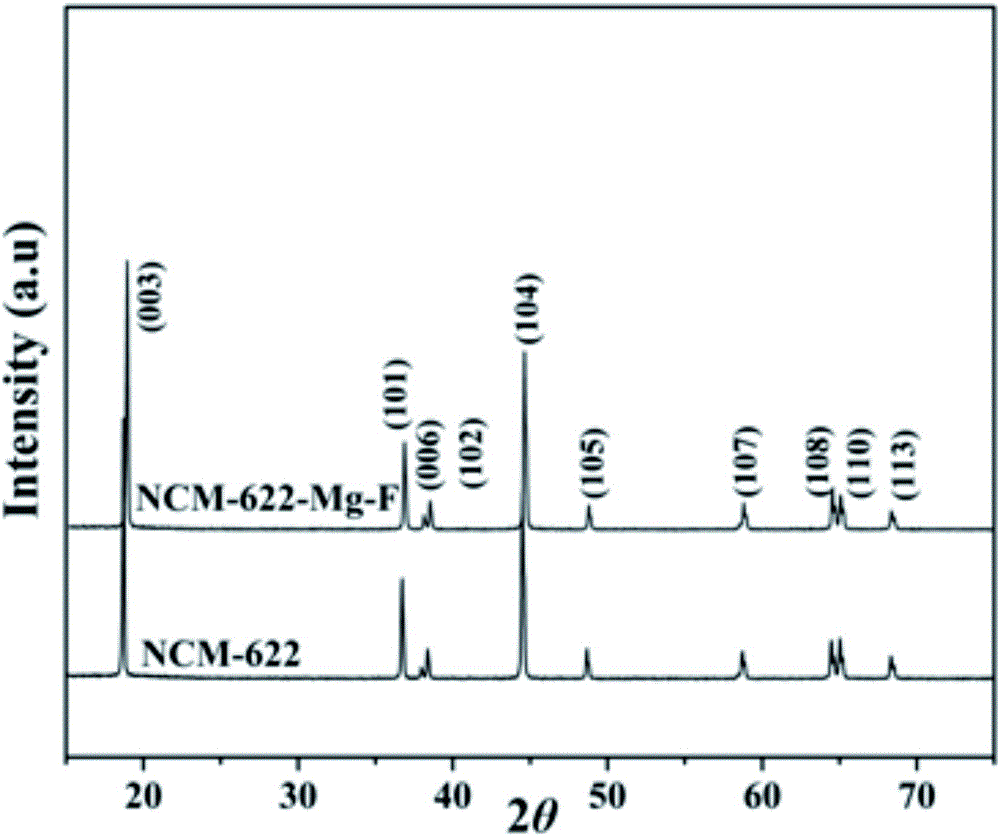

Modified spherical nickel cobalt lithium manganate NCM622 anode material and preparation method thereof

InactiveCN106058238ASimple preparation processReduce manufacturing costCell electrodesSecondary cellsLithium carbonateManganate

The invention discloses a modified spherical nickel cobalt lithium manganate NCM622 anode material. A general formula of the anode material is Li[NiCo0.2Mn0.2]xMg1-xO2-yFy, wherein x is greater than or equal to 0.01 and less than or equal to 0.05, and y is greater than or equal to 0.2 and less than or equal to 0.4. The preparation method includes following steps: (1), preparing a solution; (2), feeding nitrogen into a reaction kettle for 20 min, respectively adding the mixed solution in the step (1), NaOH solution of 1 mol / L in concentration and NH4OH solution of 0.5 mol / L in concentration, and stirring for reaction; (3), subjecting Ni0.6Co0.2Mn0.2(OH)2 precursor, battery-grade lithium carbonate, magnesium acetate and lithium fluoride to ball milling for mixing for 3-4 h; (4), performing solid-phase sintering. The modified anode material is high in stability and safety and excellent in cycling performance and multiple rate performance.

Owner:四川省有色冶金研究院有限公司

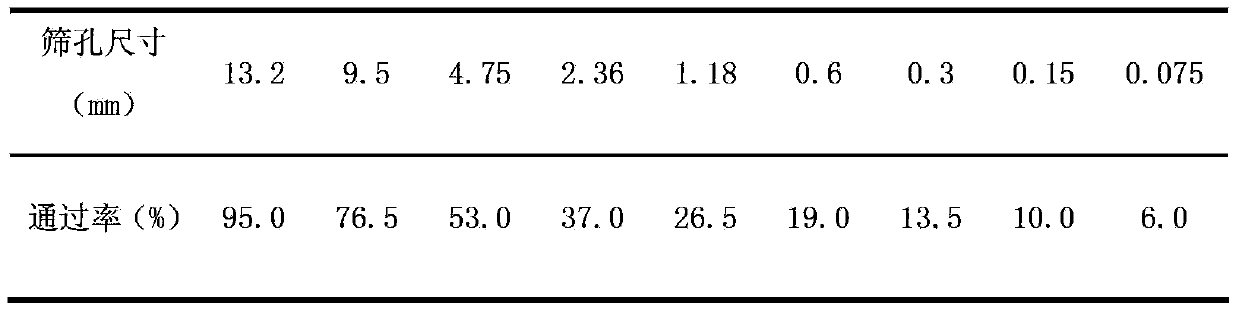

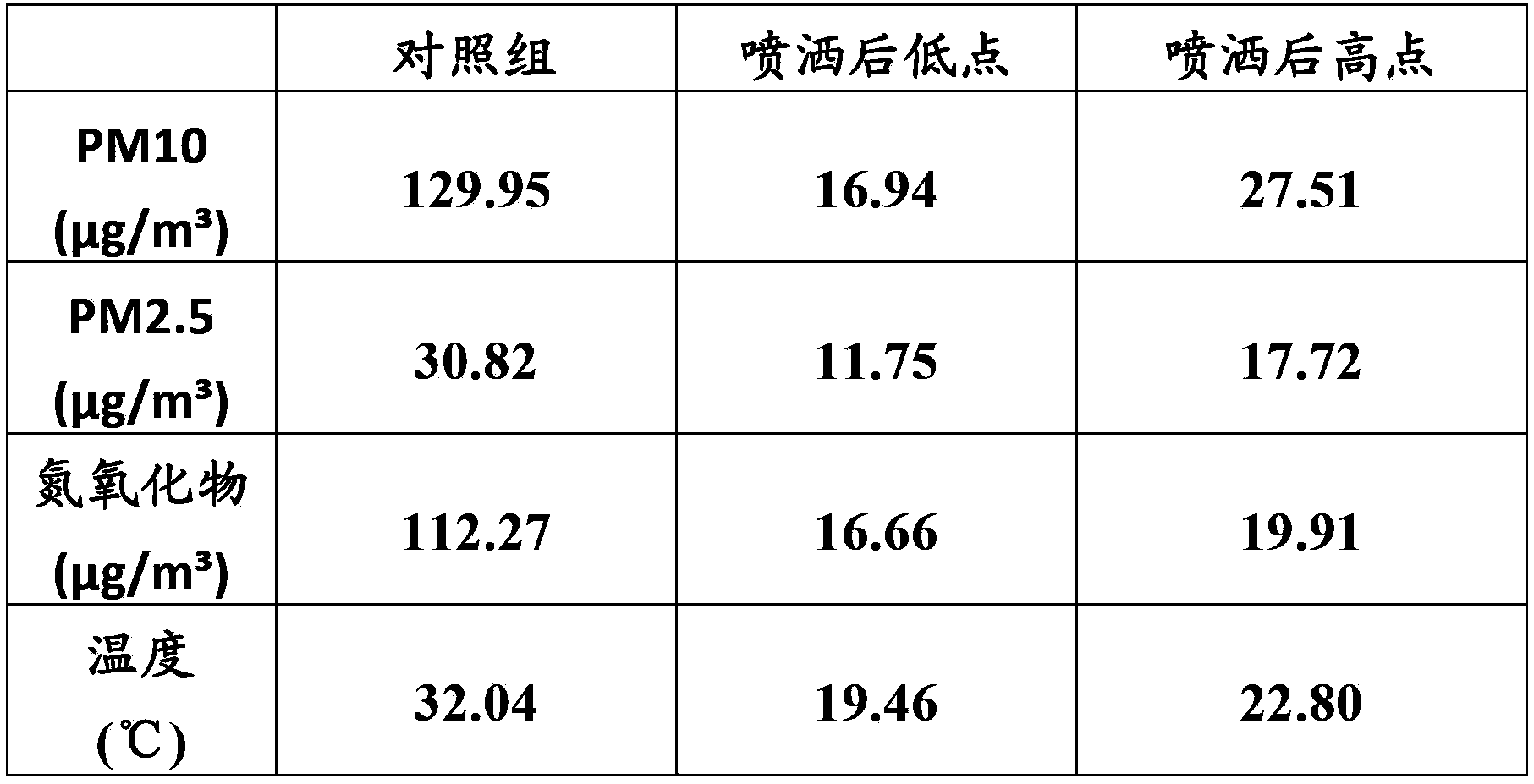

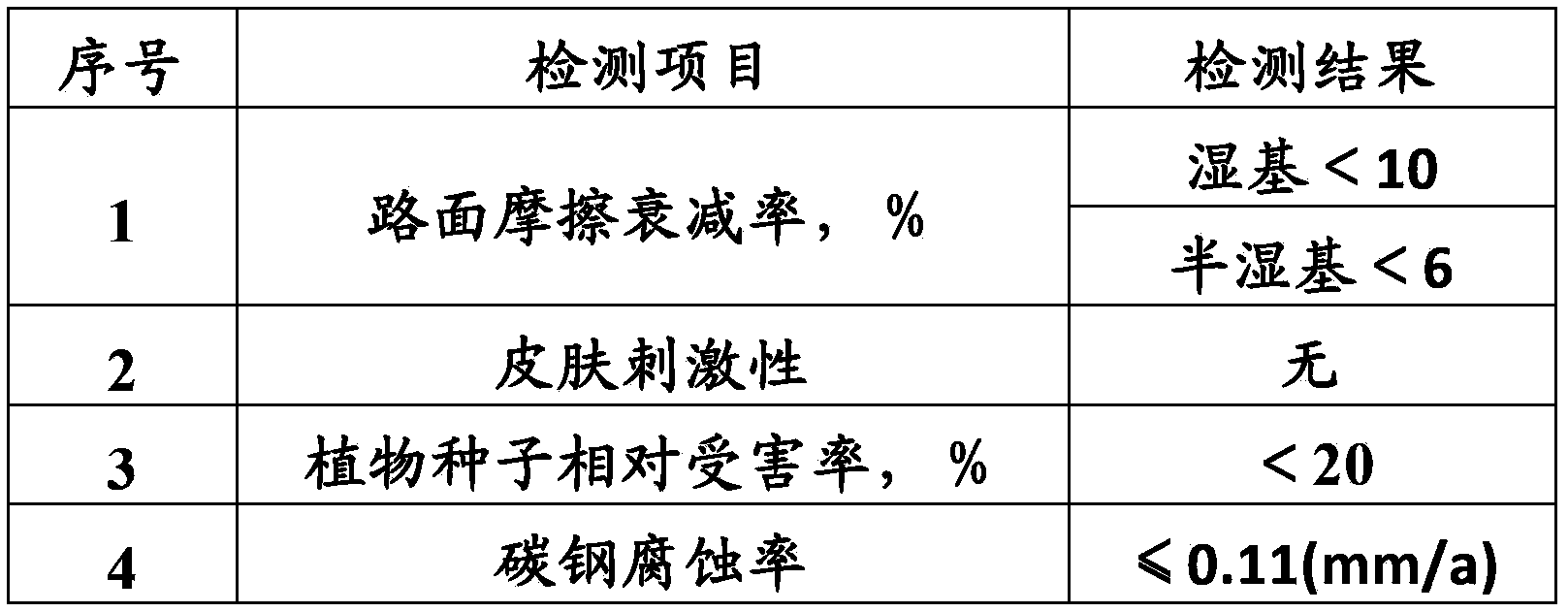

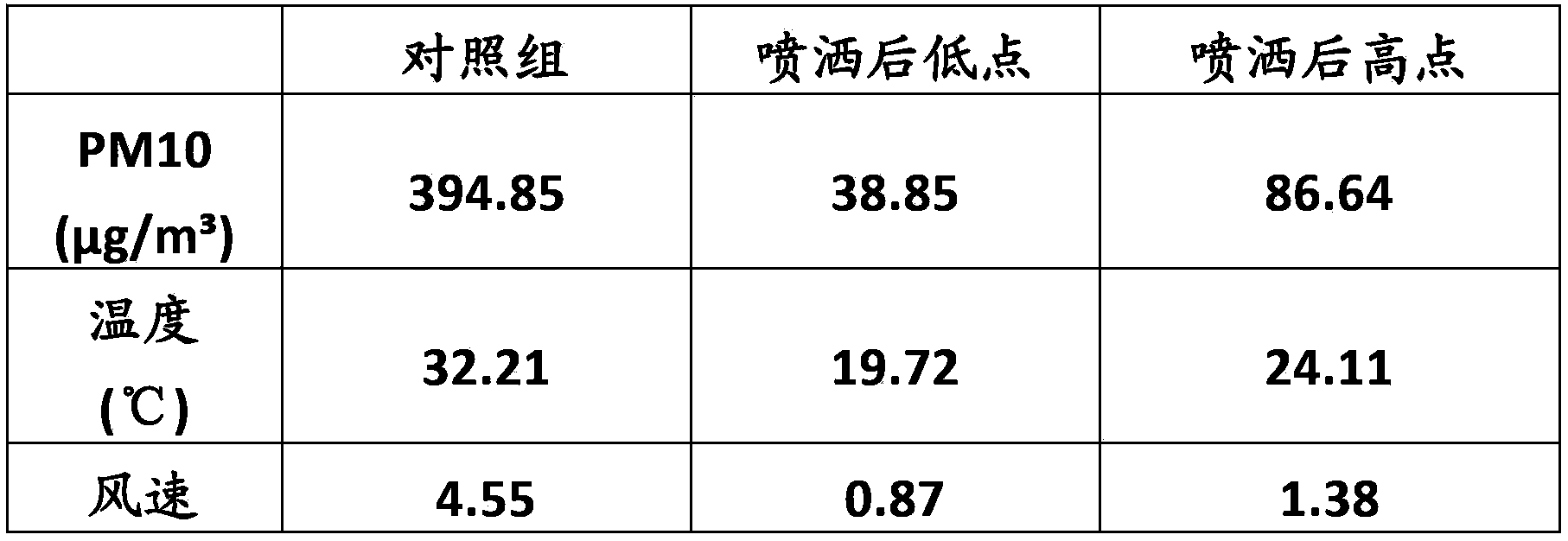

Road dust suppressant for controlling inhalable particles in near-surface air and preparation method

ActiveCN104073222AReduce concentrationWeak corrosiveOther chemical processesDispersed particle separationHazardous substanceAlkylphenol

The invention relates to a road dust suppressant for controlling the inhalable particles in near-surface air and a preparation method thereof. The road dust suppressant comprises the following components in parts by weight: 100-150 parts of calcium magnesium acetate, 0.04-0.2 part of dust suppression aid and 300-1,800 parts of water, wherein the calcium magnesium acetate comprises 0.1-0.9 part of calcium acetate and 0.1-0.9 part of magnesium acetate; and the dust suppression aid is one of surfactants including sodium lauryl sulfate, alkylphenol polyoxyethylene ether TX-10, wetting agent X-405, sodium dodecyl benzene sulfonate, Tween and Span or a mixture of more than one of the surfactants. The road dust suppressant provided by the invention can effectively reduce the inhalable particles and harmful substances such as nitrogen oxides and sulfides on the road, and has the characteristics of environmental friendliness, low corrosion to vehicles and pavement, long-lasting effect and the like.

Owner:北京首创大气环境科技股份有限公司

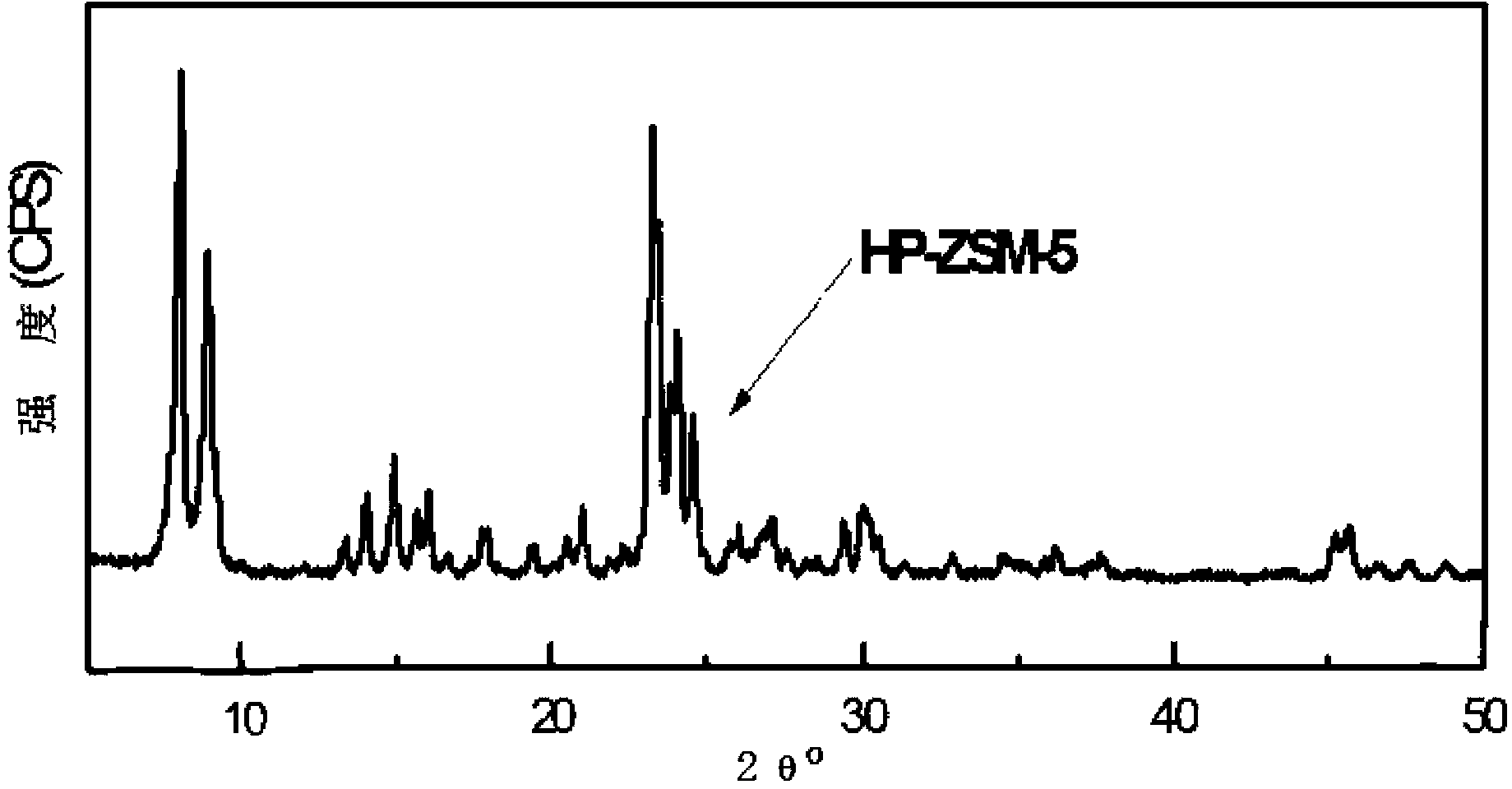

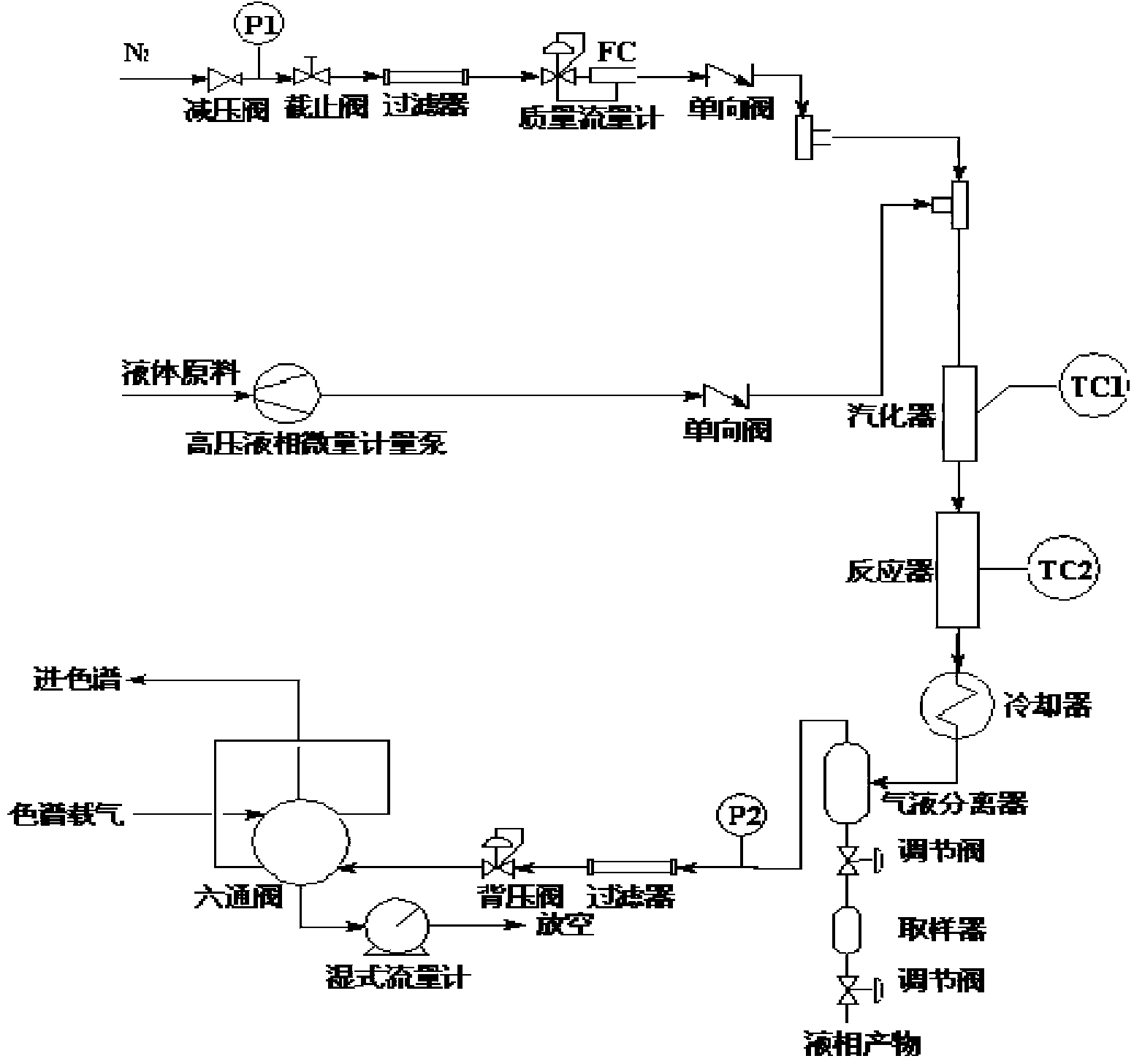

Multilevel porous molecular sieve catalyst as well as preparation method and application thereof

InactiveCN104226357AHigh activityNot easy to coke and generate carbonMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferSilanes

The invention relates to a multilevel porous molecular sieve catalyst as well as a preparation method and application thereof. The preparation method of the multilevel porous molecular sieve catalyst comprises the following steps: adding an organic template agent ethanol solution into an aluminum source, a silicon source and a silane ethanol solution to form gel, performing air drying on the gel to obtain dry gel, adding water and tetrapropylammonium hydroxide into the dry gel to obtain a mixture, putting the mixture into a high-pressure kettle, crystallizing the mixture for 3 days at the temperature of 180 DEG C to obtain a multilevel porous ZSM-5 molecular sieve, uniformly mixing the multilevel porous ZSM-5 molecular sieve with gamma-Al2O3, adding a dilute nitric acid solution, then performing mixed kneading, performing strip extruding for forming, drying and roasting in air so as to obtain a carrier; and soaking the carrier by utilizing a magnesium acetate solution, drying and roasting the carrier to obtain a phenylcarbinol alkylation catalyst. When the prepared catalyst is applied to the phenylcarbinol alkylation reaction, the catalyst has the advantages that coke and carbon are not easily generated, the activity is high, and the product selectivity is high. Compared with other catalysts in the prior art, for the catalyst disclosed by the invention, the activity and the reaction stability are high, and the service life is longer.

Owner:PETROCHINA CO LTD

Preparation method of medium-viscosity cellulose acetate butyrate

The invention discloses a preparation method of medium-viscosity cellulose acetate butyrate. The preparation method comprises the following steps of pulverizing wood pulp; uniformly spraying a mixture of acetic acid and butyric acid into the pulverized wood pulp, and activating for 1h to 6h at the normal temperature; cooling a mixture of acetic anhydride, butyric anhydride, butyric acid and a liquid acid catalyst to minus 5 DEG C to minus 20 DEG C for standby use; slowly throwing the activated wood pulp into the well-cooled mixture, and maintaining the temperature to be less than or equal to 65 DEG C; adding magnesium acetate solution into the reacted system, and adding 200 to 500 parts by weight of acetic acid with the mass percentage of 50 to 70 percent for hydrolysis, wherein the system temperature is controlled at 60 to 70 DEG C, and the hydrolysis time is 2h to 5h; continuing adding magnesium acetate to neutralize the liquid acid catalyst, and adding the material into water for chromatographic solid-liquid separation; washing the separated CAB (cellulose acetate butyrate) solids with water until the acid value is less than 300ppm, and drying the CAB solids to obtain the CBA finished product. Through the method, a method for preparing medium / high-viscosity CAB is developed, and the content of butyryl in CAB is 36 to 40 percent; the power viscosity is 400cps to 1000cps.

Owner:JIANGSU RUICHEN CHEM

Method for uniformly drying lettuce by normal pressure and negative pressure combined microwave spouted bed

InactiveCN102405958AReduce lossesHigh retention rateFruits/vegetable preservation by dehydrationMicrowaveMagnesium acetate

The invention relates to a method for uniformly drying lettuce by a normal pressure and negative pressure combined microwave spouted bed, and belongs to the technical field of fruit and vegetable food processing. The main processes of the method comprises: removing leaves and peels from fresh lettuce, cleaning, cutting into cubes (cutting into sheets), adding a EDTA-Na solution to carry out colorprotection, blanching, adding a magnesium acetate solution and a zinc acetate solution to carry out color protection, and carrying out treatments of microwave spouted drying, packaging and storage. With the present invention, the microwave drying technology is adopted so as to shorten the drying time, reduce the drying energy consumption, and reduce the loss of the chlorophyll in the lettuce during the processing process; the normal pressure spouted bed drying technology and the negative pressure spouted bed drying technology are combined to dry the lettuce, and the material has the circular motion, such that the disadvantage of the nonuniformity of the microwave drying is overcome; the product dried by the microwave spouted drying method has characteristics of good water reabsorbing capacity, high water reabsorbing rate, good crisp taste after water reabsorbing, unique lettuce aroma, high chlorophyll content, good and uniform color.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Liquid-based cell preservation solution

InactiveCN105409925ABrightly dyedLess inflammatory cellsDead animal preservationPotassiumCervical mucus

The present invention relates to pathological examination, especially to a liquid-based cell preservation solution used in pathologically examining cells such as human cervical mucus, sputum, urine, thoracic liquid, and tracheal mucus. The liquid-based cell preservation solution is characterized by being prepared from alcohols, a sodium phosphate buffer solution, disodium ethylenediamine tetraacetate, 0.08-0.12% sodium chloride, potassium chloride, formaldehyde, dithiothreitol, calcium acetate, magnesium acetate and the like. The cell preservation solution cannot only maintain the cell structure stability and reduce the agglomerated precipitation of the cell mucus and the cell breakage loss, but also enables the cells easily to be stained, improves the clarity of the cell sheets, and facilitates smooth performance of the examination work. Moreover, the cell preservation solution is low in cost and easy to promote and use.

Owner:孝感宏翔生物医械技术有限公司

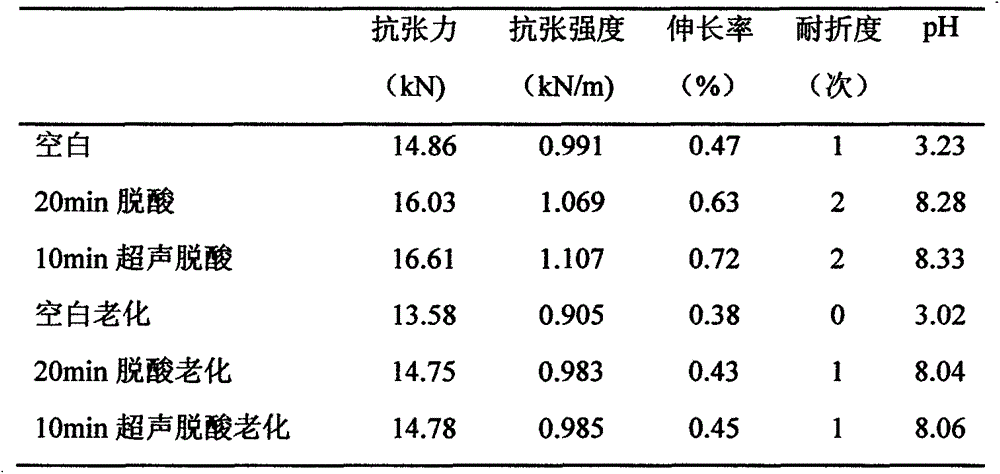

Ultrasound-assisted method for deacidification of paper

InactiveCN103147353AShorten deacidification soaking timeUniform deacidification effectOld paper after-treatmentCalcium hydroxideUltrasonic assisted

The invention discloses a method for deacidification of paper by using an ultrasound-assisted deacidification agent. The method comprises the following steps of: putting paper, especially aged and acidulated paper into an ultrasonic treatment device, and treating the paper by using an aqueous solution of a deacidification agent (such as calcium hydroxide, borax or magnesium acetate and the like), a fatty alcohol solution or a mixed solution of fatty alcohol and water. By adopting the method, the pH value of the paper is controlled in the optimum range of 7.0-8.5; compared with soaking deacidification, the deacidification time is obviously shortened, and the deacidification is uniform; and meanwhile, the strength of the paper is obviously improved, and the mechanical strength of each item is greatly improved, so that the storage life of the paper is favorably prolonged.

Owner:GUANGDONG UNIV OF TECH

Cellulose acetate butyrate mixed ester with high butyryl content, and preparation method thereof

The invention discloses cellulose acetate butyrate mixed ester with high butyryl content, and a preparation method thereof. The cellulose ester is prepared from the following components in parts by weight: 600 parts of wood pulp, 800-1200 parts of butyric acid, 2500-3500 parts of butyric anhydride, 20-40 parts of acetic anhydride, and concentrated sulfuric acid catalyst accounting for 5-10% of total weight parts of wood pulp. The preparation method comprises the following steps: activating, performing esterification reaction, mixing, adding magnesium acetate solution, hydrolyzing, performing chromatography, and then sequentially conventionally filtering, washing and drying to obtain a finished product. According to cellulose acetate butyrate mixed ester with high butyryl content, cellulose acetate butyrate with the butyryl content of 48-53% and acetyl content of less than or equal to 4% can be obtained after the combination according to specific formula and proportion, and the product is stable in performances. The preparation method is simple in steps, the preparation period is short, the preparation conditions are not strict and easily achieved, and especially, the activated solid is fed into a cooling liquid within 2-5min, so that the quality of products can be guaranteed while the fast follow-up reaction is guaranteed.

Owner:JIANGSU RUICHEN CHEM

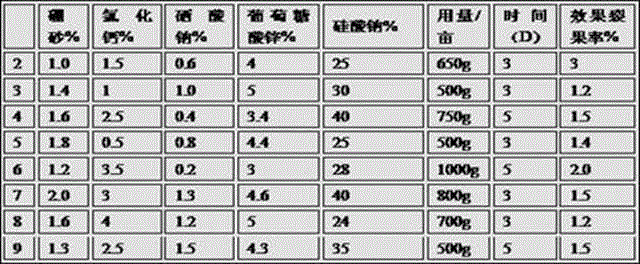

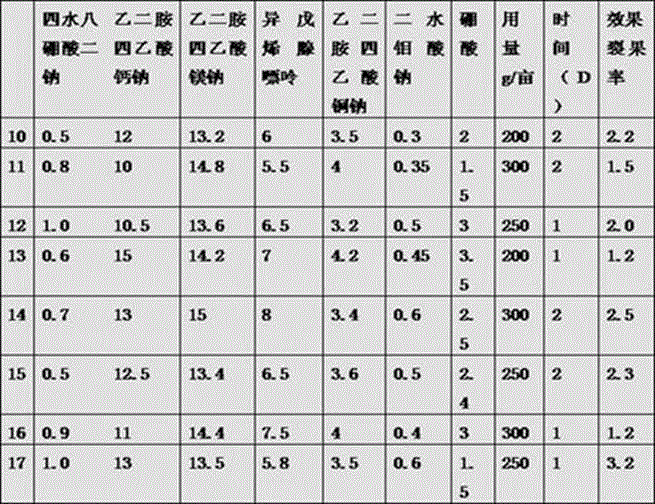

Method for preventing fruit cracking of melons

ActiveCN103329745APrevent fruit crackingImprove qualityHorticulture methodsFertilizer mixturesNucleotideGluconic acid

The invention discloses a method for preventing fruit cracking of melons. The method comprises the following steps of: spraying equal mass solutions of 800-1000 times of nucleotides and 800-1000 times of cytokinins on the melons and leaves per 3-5 days; or spraying anti-cracking agents on the melons per 3-5 days on the basis of 500-1000g / mu, wherein the anti-cracking agents are composed of 1-2 weight parts of sodium borates, 0.5-4 weight parts of CaCl2, 0.2-1.5 weight parts of sodium selenate, 3-5 weight parts of zinc gluconate, 20-40 weight parts of sodium silicate and the balance of water; or spraying the anti-cracking agents on the melons and the leaves per 1-2 days on the basis of 200-300g / mu, wherein the anti-cracking agents are composed of the following components by weight percent: 0.5%-1% of disodium octaborate tetrahydrate, 10%-15% of EDTA (ethylene diamine tetraacetic acid) calcium complex disodium salt, 13%-15% of EDTA magnesium complex disodium salt, 5-8% of isopentennyladenine, 3%-4% of disodium EDTA-copper, 0.3%-0.6% of sodium molybdate dihydrate, 1.5-3.5% of boric acids and the balance of water. According to the method provided by the invention, the fruit cracking is effectively prevented and the yield and quality are both high.

Owner:JIANGSU YANTENG AGRI DEV

Porous carbon and preparation method thereof

InactiveCN101445232AHigh carbon contentLarge specific surface areaOther chemical processesMagnesium saltPorous carbon

The invention discloses a porous carbon and a preparation method thereof. The preparation method of the porous carbon comprises the following steps: 1) 1 part by weight of petroleum residual oil and 3-9 parts by weight or organic magnesium salt are mixed and smashed, and then the temperature is increased to 700-1000 DEG C for carbonization for 1-2 hours, thereby obtaining carbonized products; the pressure of inert gas during the carbonization is 100kPa-105kPa; 2) the acid treatment is carried out on the carbonized products, then the carbonized products are washed until neutral, and the porous carbon is obtained after drying. The porous carbon obtained by the invention has high specific surface area (up to 1183m<2> / g) and good absorption performance; furthermore, the pore size can be regulated and controlled according to the needs of applications. The preparation method has the following advantages: the preparation method does not need to carry out the stabilization and the activation processes, and the operation is simple and easy; magnesium oxide particles generated after the carbonization are easy to remove and can be removed by weak acetic acid, thereby being capable of realizing the recycling of magnesium acetate and reducing the production cost; and the yield of the porous carbon is higher.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing cellulose acetate butyrate

The invention discloses a preparation of cellulose acetate-butyrate, including steps of: crushing cotton pulp paper, activating it with organic acid for 2-24 hours at the temperature of 40-110 DEG C., charging acid anhydride and concentrated sulfuric acid, esterifying them at the temperature of 25-110 DEG C. for 3-24 hours; charging adequate magnesium acetate to neutralize residual concentrated sulfuric acid after esterification, then prcipitate and filter it in ethanol-water solution, and obtaining the cellulose acetate-butyrate after scrubbing and drying. The invention avoids using toxic solutions such as DMF, DMAC as activation solution, and uses organic acid both as solution and reaction reagent, so that damage to environment and human body in production process is reduced tremendously, and processes of production, after-treatment and product separation is simple. The prepared cellulose acetate-butyrate can be used as adjuvant of multiple paint, has properties of improving leveling, outdoor durability and toughness of paint, can be applied in biodegradable plastics and films.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Waterproof noise-reduction multifunctional woven fabric and production method thereof

InactiveCN104652016AImprove spinnabilityImprove spinning qualityWoven fabricsMonocomponent polyesters artificial filamentFiberBenzoyl peroxide

The invention discloses a waterproof noise-reduction multifunctional woven fabric which is formed by weaving warp yarns and weft yarns by an air-jet loom, wherein the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30 to 36 parts of isotatic polypropylene, 10 to 14 parts of polyvinyl chloride, 20 to 24 parts of cowhair, 17 to 19 parts of alpinia fiber, 22 to 26 parts of kenaf fiber, 18 to 23 parts of cotton pulp, 7 to 9 parts of liquid paraffin, 8 to 10 parts of ethyl carbamate, 7 to 11 parts of polytetramethylene glycol, 1.1 to 2.5 parts of benzoyl peroxide, 2.1 to 3.2 parts of chitosan, 0.3 to 0.5 part of magnesium acetate, 2 to 4 parts of shell powder, 1 to 3 parts of rhizoma, 2 to 5 parts of mangnolia officinalis, 85 to 95 parts of 1-butyl-3-methyl imidazole acetate, 95 to 105 parts of 1-allyl-3-methyl imidazole chloride salt, a proper amount of water and 4 to 7 parts of assistant. The woven fabric has the advantages of warmth keeping, ventilation, wear resistance, antibacterial performance and the like.

Owner:章云

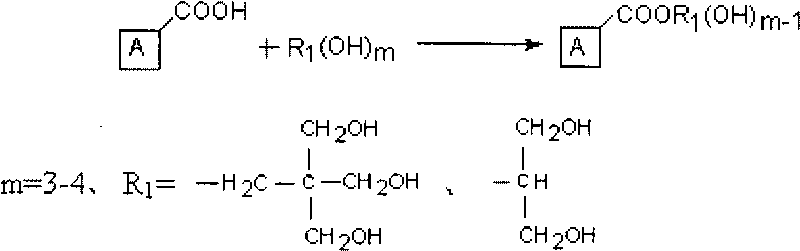

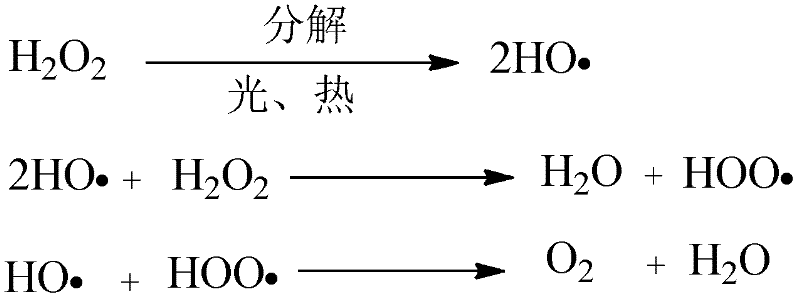

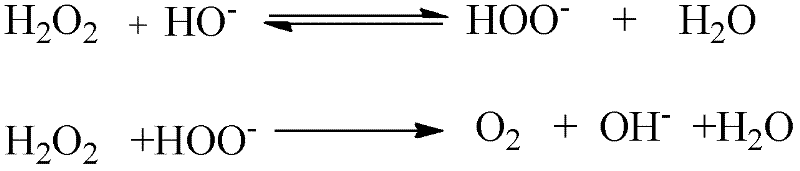

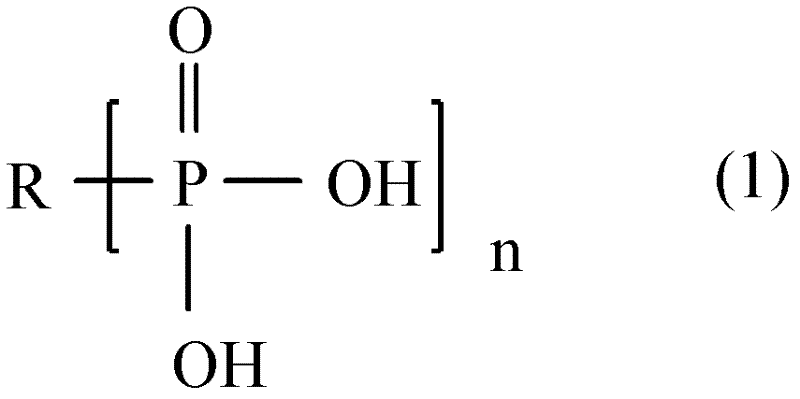

A hydrogen peroxide stabilizer

InactiveCN102295274AAchieve stabilityLow costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMagnesium saltAcid group

The invention discloses a hydrogen peroxide stabilizer, the mass percentage of which is composed of: 15-30% of organic phosphonic acid; 10-15% of magnesium salt; 55-75% of distilled water; the sum of each component is 100%. Magnesium salts include magnesium chloride, magnesium sulfate, magnesium acetate, magnesium nitrate or magnesium perchlorate; the organic phosphonic acid has the structure of general formula (1), wherein R represents a substituent, which is an alkyl group or a heteroatom-substituted alkyl group ; n represents the number of phosphonic acid groups connected to the substituent R, and n=2-5. Under the synergistic action of organic phosphonic acid and magnesium salt, the stabilizer of the invention can effectively realize the stabilization of hydrogen peroxide under strong alkaline conditions.

Owner:TIANJIN YUNSHENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com