Preparation method of rosin modified phenolic resin

A technology for modifying phenolic resin and rosin, which is applied in applications, coatings, inks, etc. It can solve the problems of the internal quality of the resin being affected, the viscosity of the resin being difficult to control, and the unfavorable phenolic condensation reaction, so as to overcome the coking tendency and control the resin The effect of high viscosity and operating elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

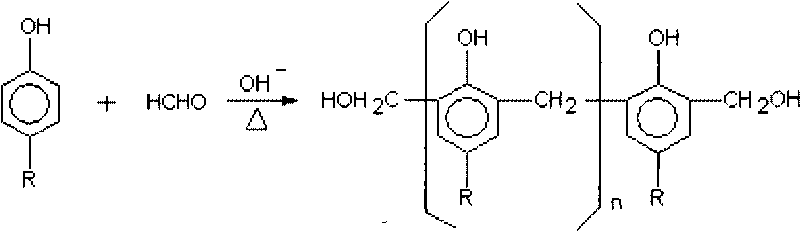

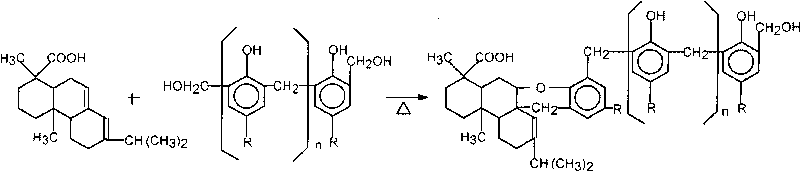

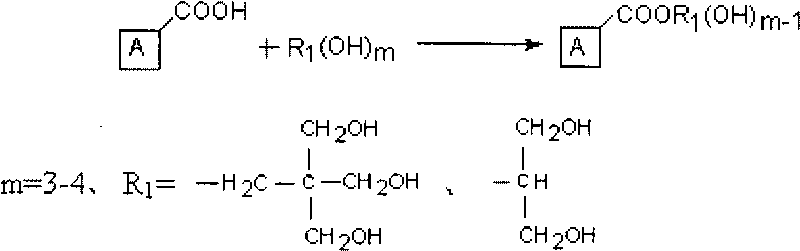

Method used

Image

Examples

Embodiment 1

[0031] (1) In a 6-ton reactor, suck 2500 kg of molten rosin, and at 140°C, put 275 kg of tung oil, 932 kg of p-tert-butylphenol, 22 kg of bisphenol A, and 4.8 kg of catalyst magnesium acetate (Shanghai Pudong Haiguang trace element additive factory), 5.0 kilograms of catalyst lime (produced by Shanghai Youyin Building Materials Co., Ltd.), and 280 kilograms of solid formaldehyde with a concentration of 93% were added at 120° C. of temperature. Under alkaline conditions (pH = 8), p-tert-butylphenol, bisphenol A, tung oil and solid formaldehyde with a concentration of 93% are condensed at 115-118°C under the action of catalyst magnesium acetate and catalyst lime. hour, generate the polymer of hydroxymethyl p-tert-butylphenol;

[0032] (2) After the condensation reaction finishes, heat up, polymer and rosin carry out addition reaction at 220 ℃ for 5 hours and 45 minutes, generate the adduct of the polymer of methylol p-tert-butylphenol and rosin;

[0033](3) Then add 240 kg of p...

Embodiment 2

[0035] (1) In a 6-ton reactor, suck 3,400 kilograms of molten rosin, and at 145° C., drop into 285 kilograms of tung oil, 950 kilograms of p-tert-butylphenol, 25 kilograms of bisphenol A, 5.0 kilograms of catalyst magnesium acetate, and 5.5 kilograms of catalyst lime 480 kg of solid formaldehyde with a concentration of 95% was added at a temperature of 123°C. Under alkaline conditions (pH = 8), p-tert-butylphenol, bisphenol A, tung oil and solid formaldehyde with a concentration of 95% are condensed at 116-118°C under the action of catalyst magnesium acetate and catalyst lime 5.5 hour, generate the polymer of hydroxymethyl p-tert-butylphenol;

[0036] (2) After the condensation reaction finishes, heat up, polymer and rosin carry out addition reaction at 220 ℃ for 5 hours and 30 minutes, generate the adduct of the polymer of methylol p-tert-butylphenol and rosin;

[0037] (3) Then add 310 kg of pentaerythritol and 62 kg of glycerin, stir at 220-225°C for 1 hour, then heat up t...

Embodiment 3

[0039] (1) In a 6-ton reactor, suck 4,000 kilograms of molten rosin, and at 148° C., drop into 290 kilograms of tung oil, 940 kilograms of p-tert-butylphenol, 27 kilograms of bisphenol A, 5.4 kilograms of catalyst magnesium acetate, and 5.8 kilograms of catalyst lime 540 kg of solid formaldehyde with a concentration of 94% was added at a temperature of 124°C. Under alkaline conditions (pH = 8), p-tert-butylphenol, bisphenol A, tung oil and solid formaldehyde with a concentration of 94% are condensed at 115-118°C under the action of catalyst magnesium acetate and catalyst lime 6.5 hour, generate the polymer of hydroxymethyl p-tert-butylphenol;

[0040] (2) After the condensation reaction is completed, the temperature is raised, and the polymer and rosin are subjected to an addition reaction at 220° C. for 5 hours and 20 minutes to generate an adduct of a polymer of methylol p-tert-butylphenol and rosin.

[0041] (3) Then add 350 kg of pentaerythritol and 65 kg of glycerin, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com