Patents

Literature

93455 results about "Aqueous solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aqueous solution is a solution in which the solvent is water. It is mostly shown in chemical equations by appending (aq) to the relevant chemical formula. For example, a solution of table salt, or sodium chloride (NaCl), in water would be represented as Na⁺(aq) + Cl⁻(aq). The word aqueous (comes from aqua) means pertaining to, related to, similar to, or dissolved in, water. As water is an excellent solvent and is also naturally abundant, it is a ubiquitous solvent in chemistry. Aqueous solution is water with a pH of 7.0 where the hydrogen ions (H⁺) and hydroxide ions (OH⁻) are in Arrhenius balance (10⁻⁷).

Drug administration method

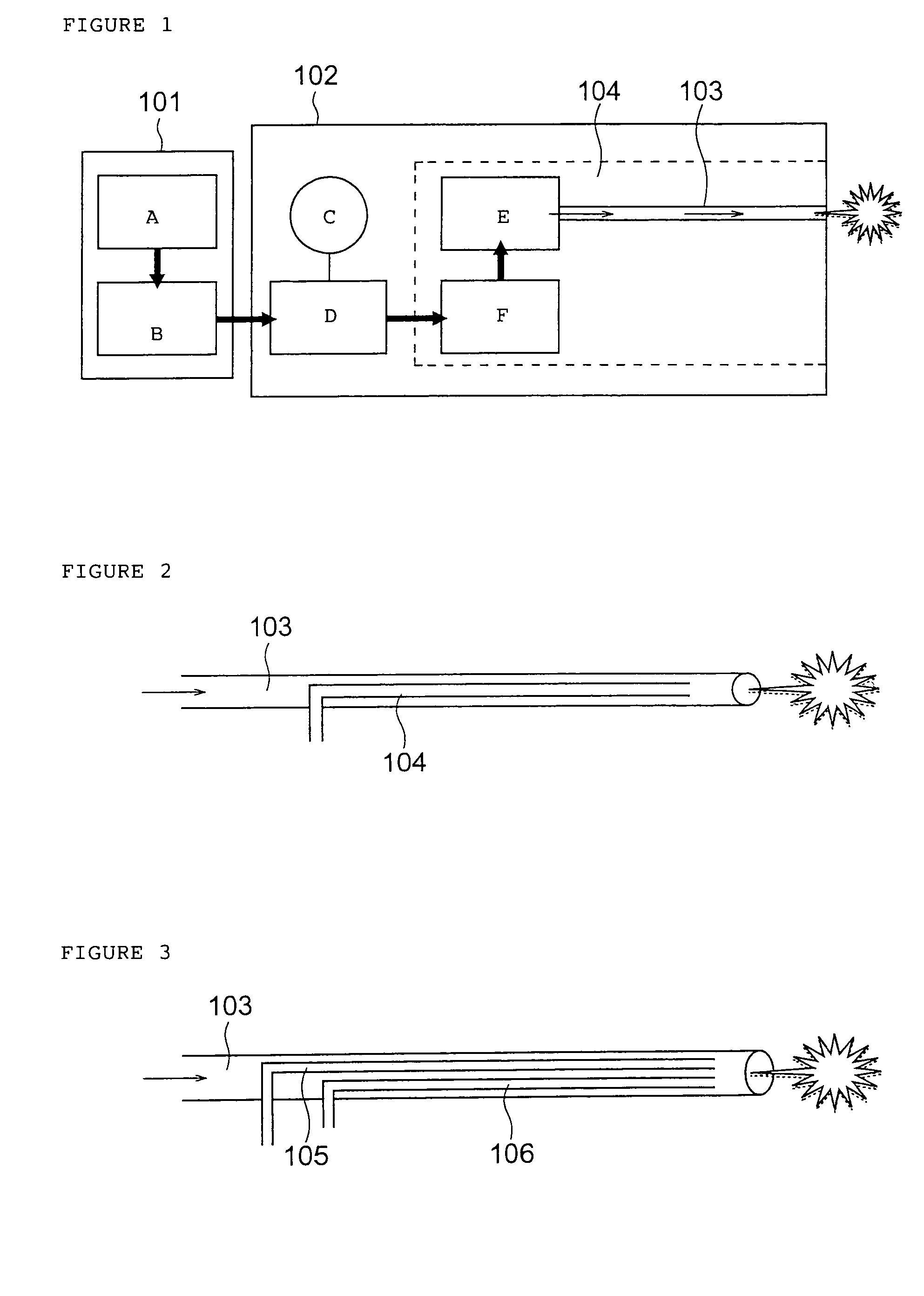

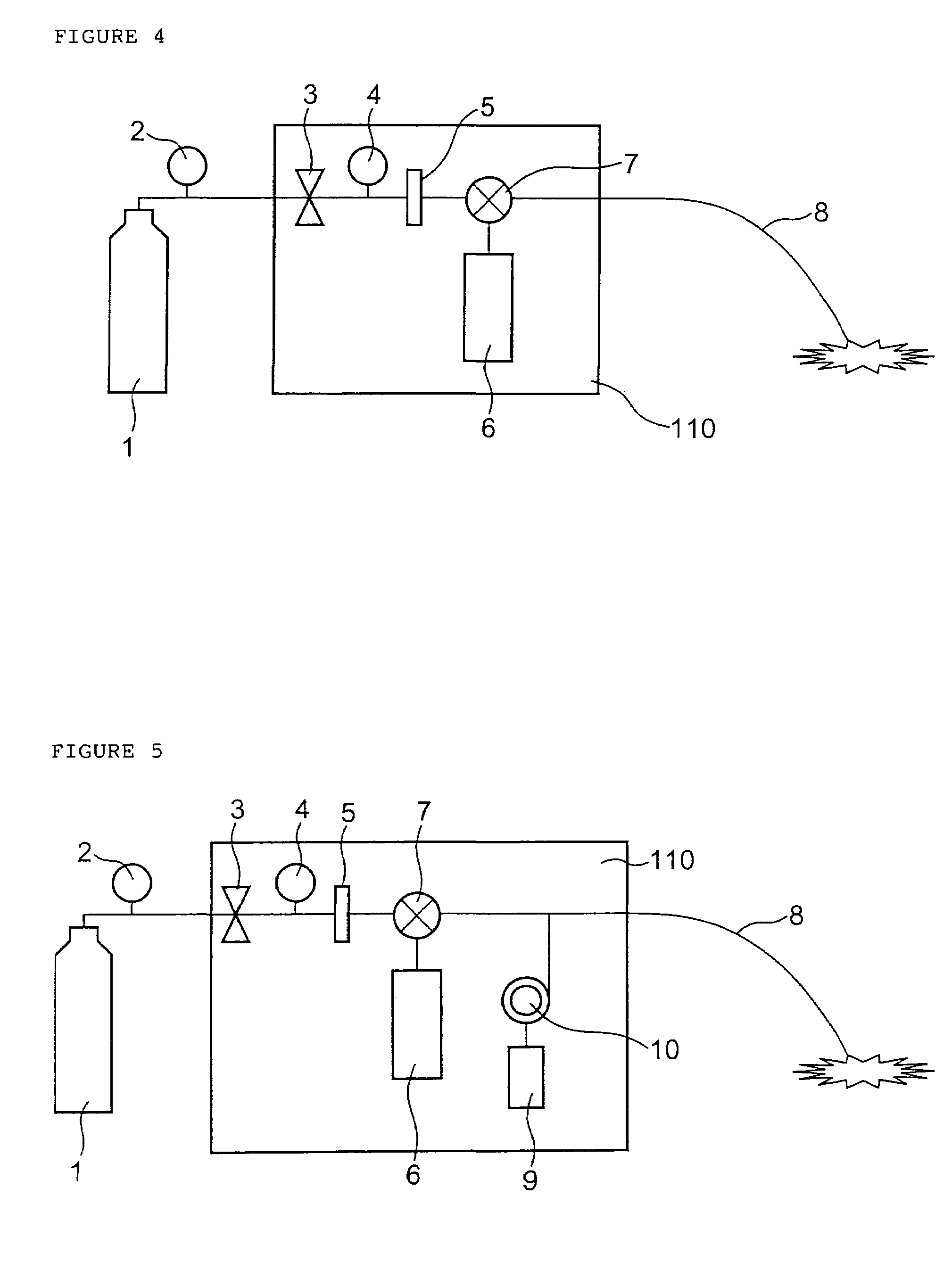

InactiveUS7427607B2Reduce weightPrevention of the adhesion of an organBiocidePowder deliveryBiopolymerDrug administration

A method of administering a drug whereby a fine drug powder can be accurately administered to a target site (in particular, a target site in the body cavity) via fluidization and spraying with a gas by using a micro tube. Concerning the administration mode, in particular, the drug alone or a biopolymer is administered or the biopolymer is employed as a carrier in the above method. More specifically speaking, a method of administering a fine drug powder which comprises finely milling one or more types fine particles of the drug and / or the biopolymer, blending them each other, fluidizing the blend with a gas, then transporting the fluidized matter in a micro tube by the gas stream and spraying the fine drug powder from the tip of the micro tube toward the target site. Further, an administration method which comprises concentrically providing a capillary tube in the micro tube, supplying an aqueous solution of the drug and / or the biopolymer from the capillary tube into the gas stream and then mixing it with other fine particles of the drug and / or the biopolymer under transportation by the gas.

Owner:NEXT21 KK

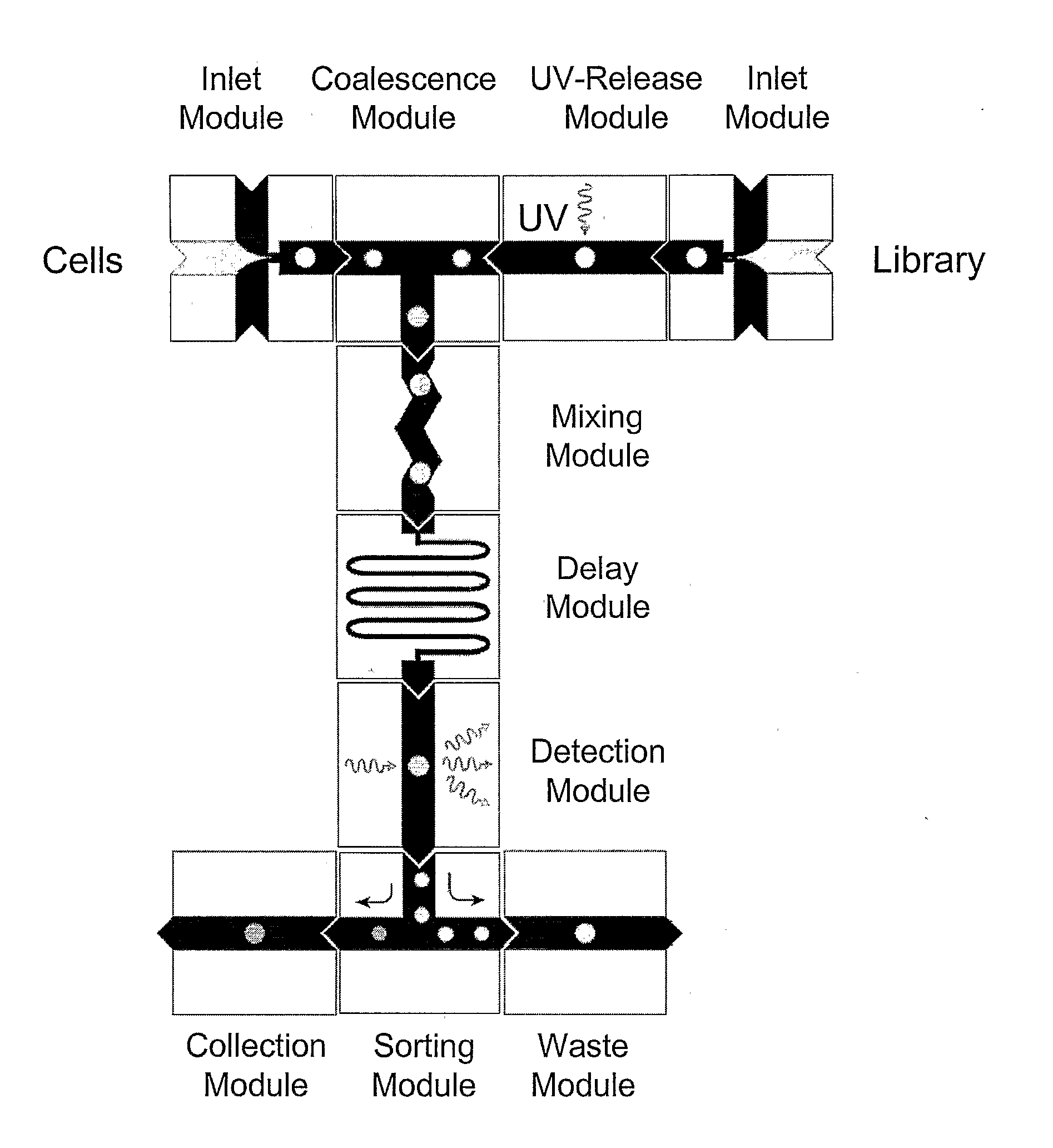

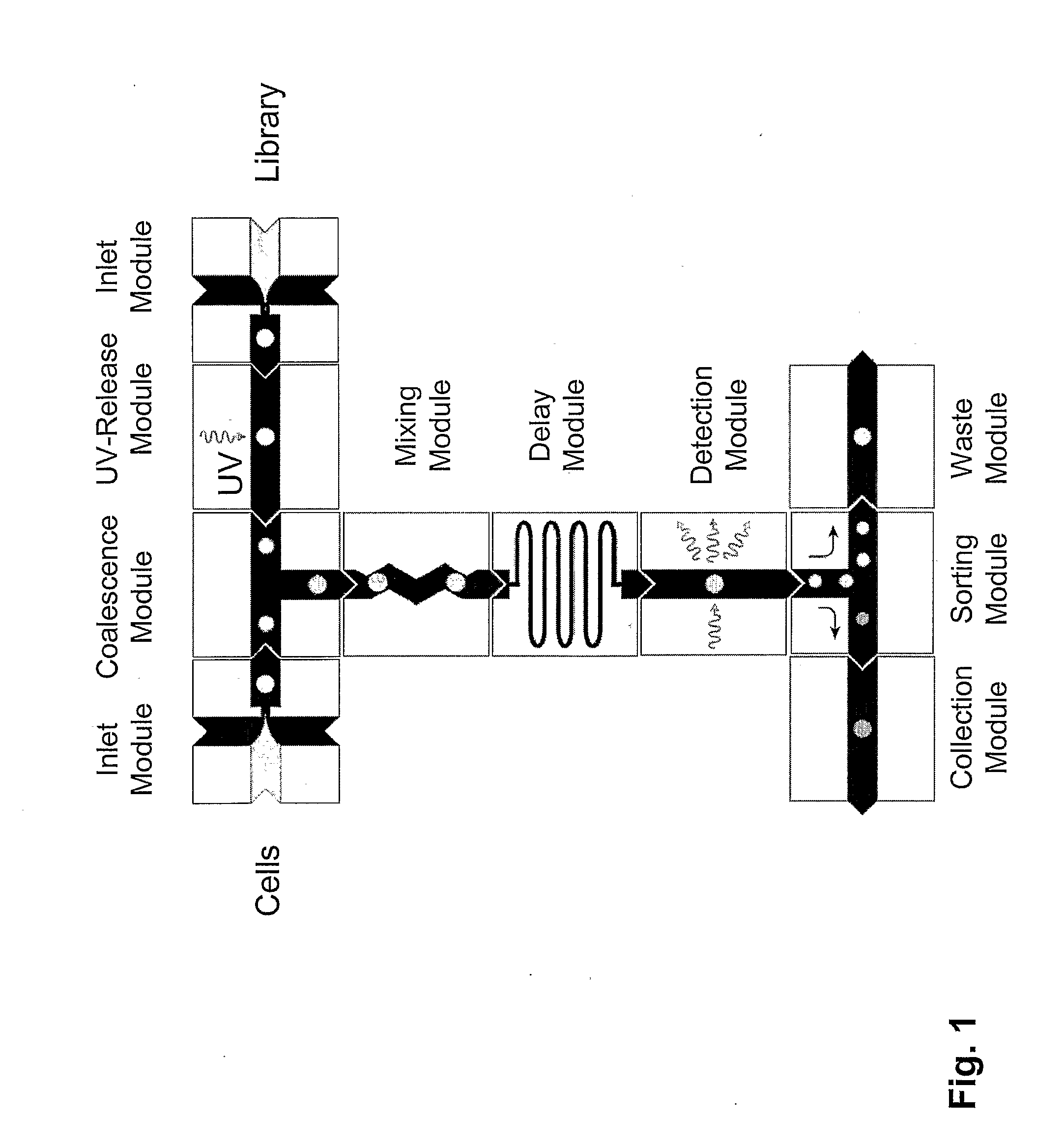

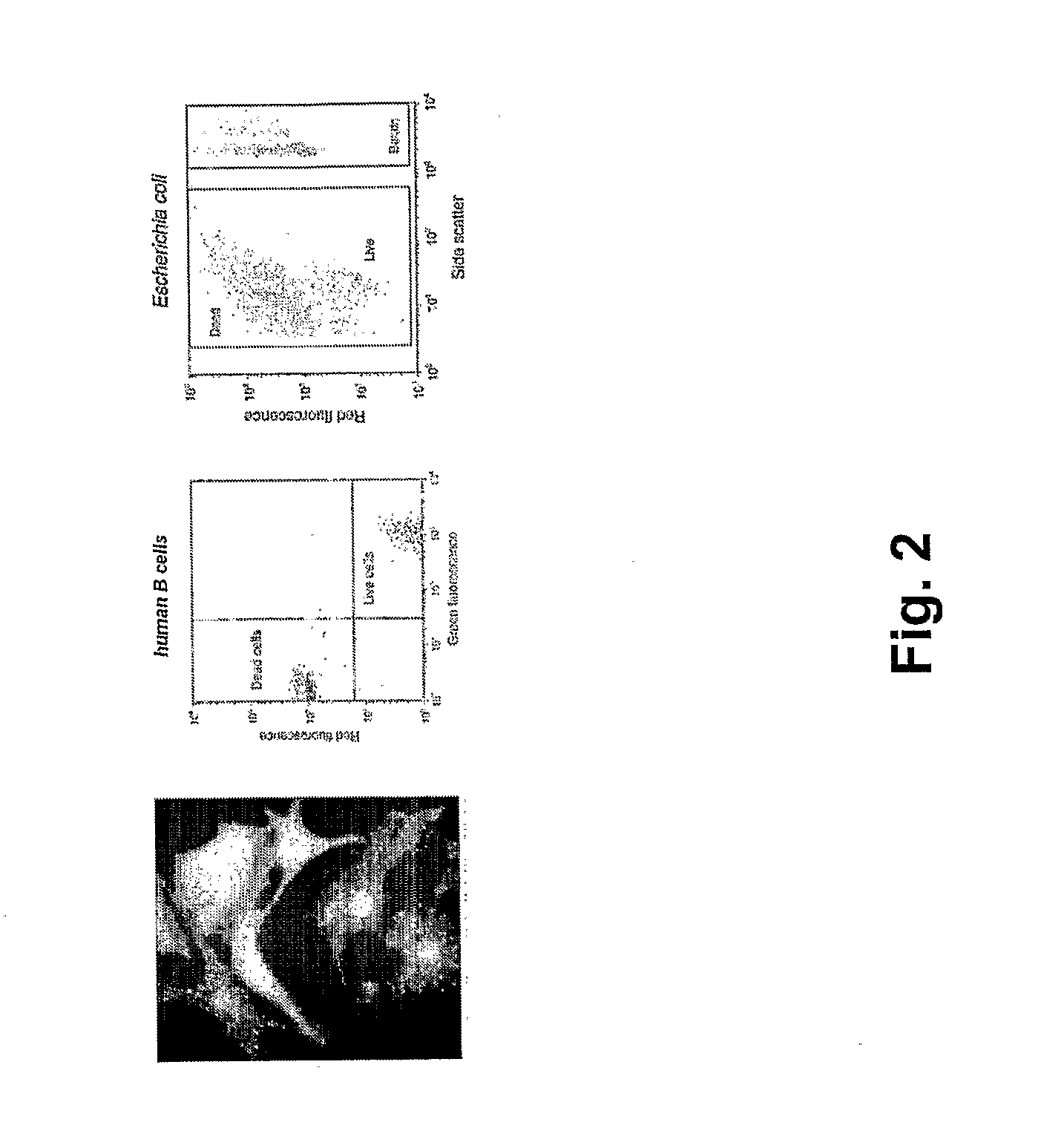

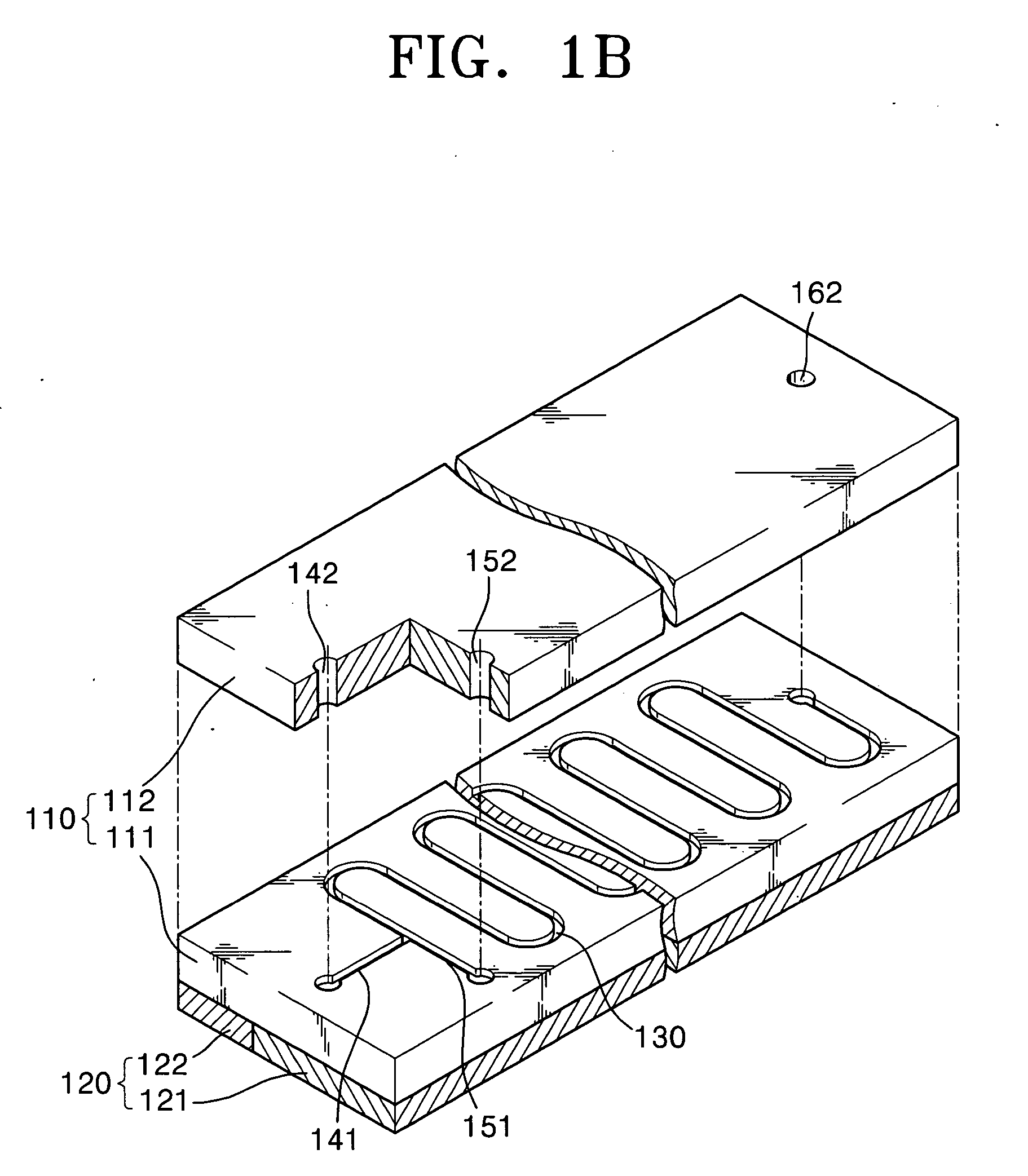

Microfluidic Devices and Methods of Use in The Formation and Control of Nanoreactors

InactiveUS20100137163A1Material nanotechnologyCompound screeningHigh-Throughput Screening AssaysEmulsion

The present invention provides novel microfluidic devices and methods that are useful for performing high-throughput screening assays and combinatorial chemistry. Such methods can include labeling a library of compounds by emulsifying aqueous solutions of the compounds and aqueous solutions of unique liquid labels on a microfluidic device, which includes a plurality of electrically addressable, channel bearing fluidic modules integrally arranged on a microfabricated substrate such that a continuous channel is provided for flow of immiscible fluids, whereby each compound is labeled with a unique liquid label, pooling the labeled emulsions, coalescing the labeled emulsions with emulsions containing a specific cell or enzyme, thereby forming a nanoreactor, screening the nanoreactors for a desirable reaction between the contents of the nanoreactor, and decoding the liquid label, thereby identifying a single compound from a library of compounds.

Owner:BIO RAD LAB INC

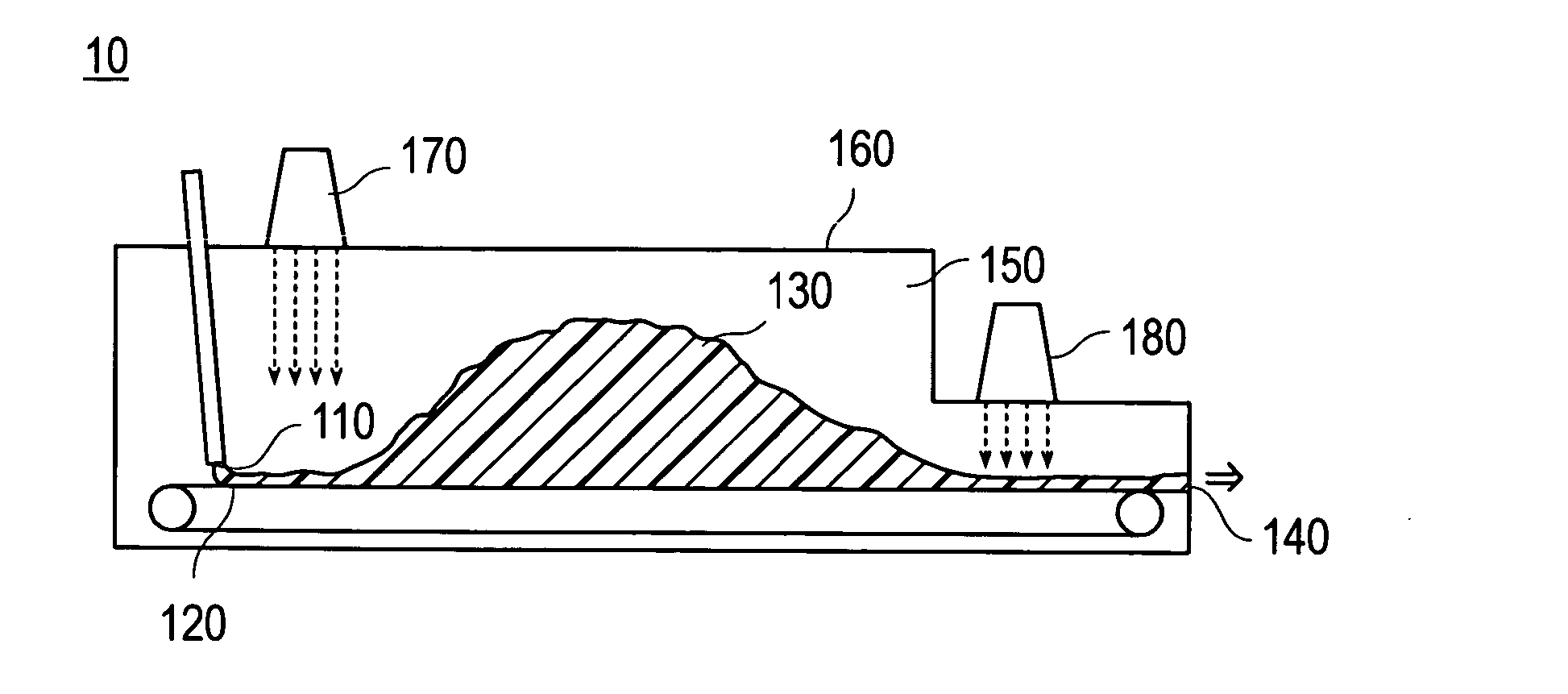

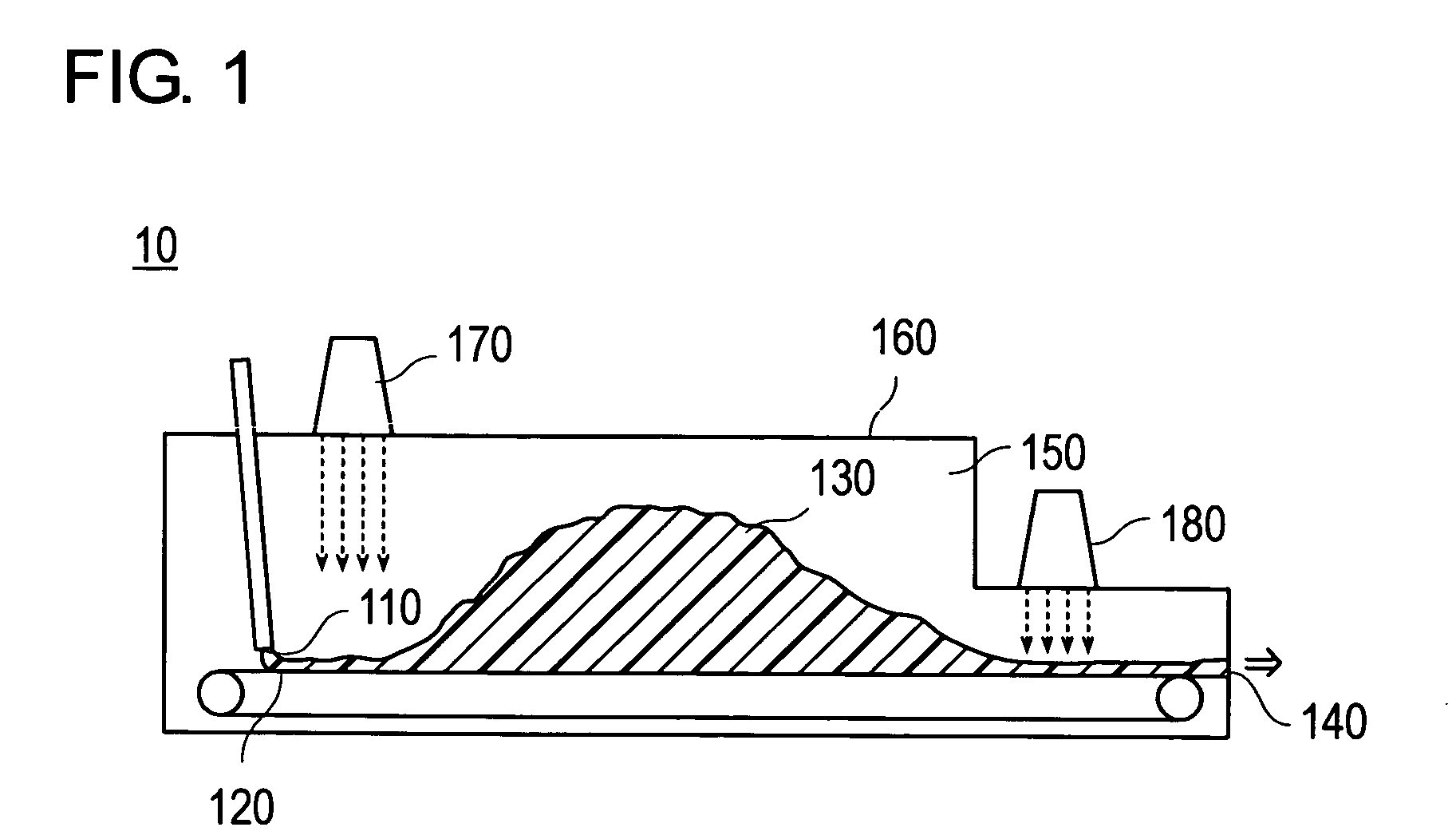

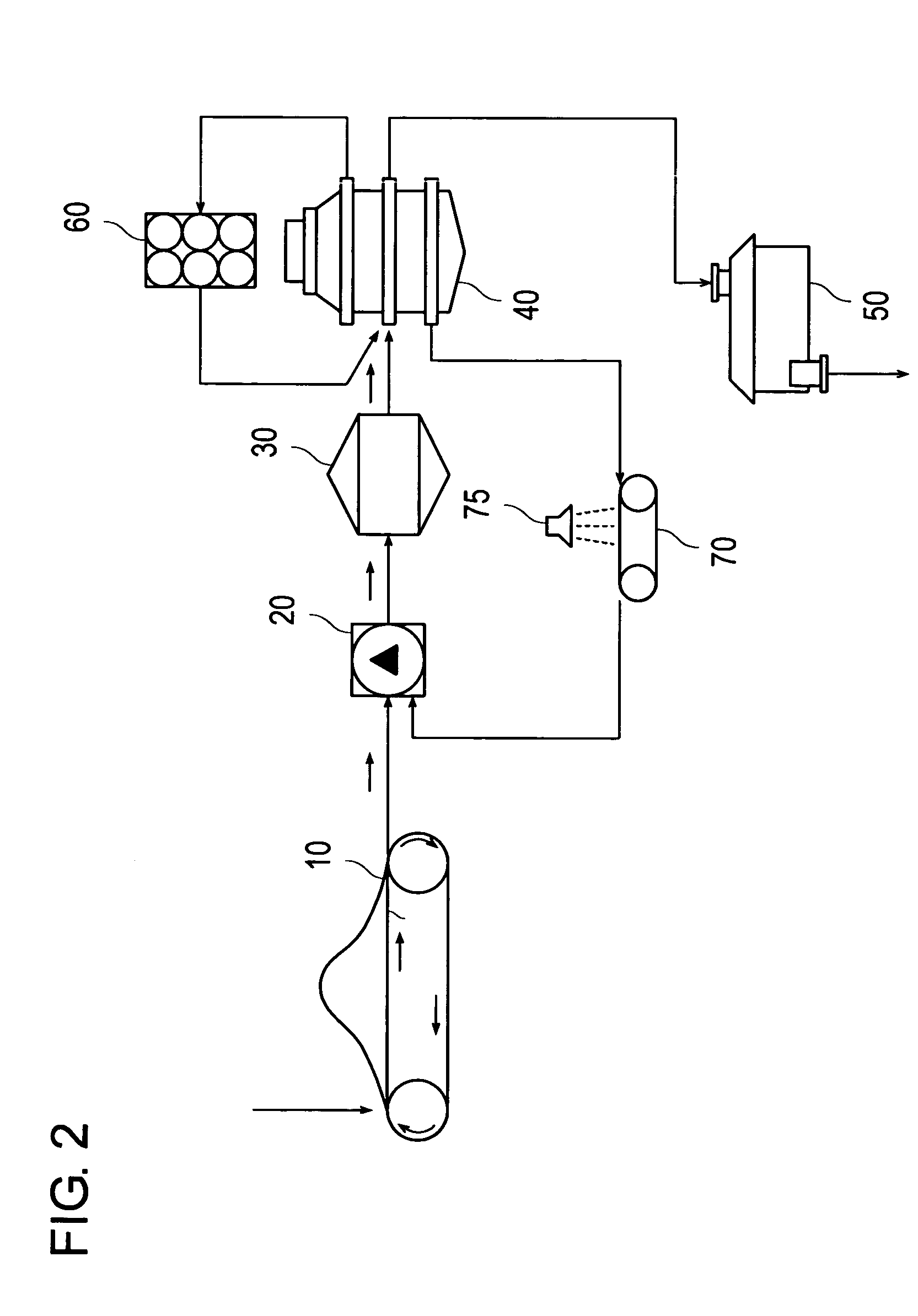

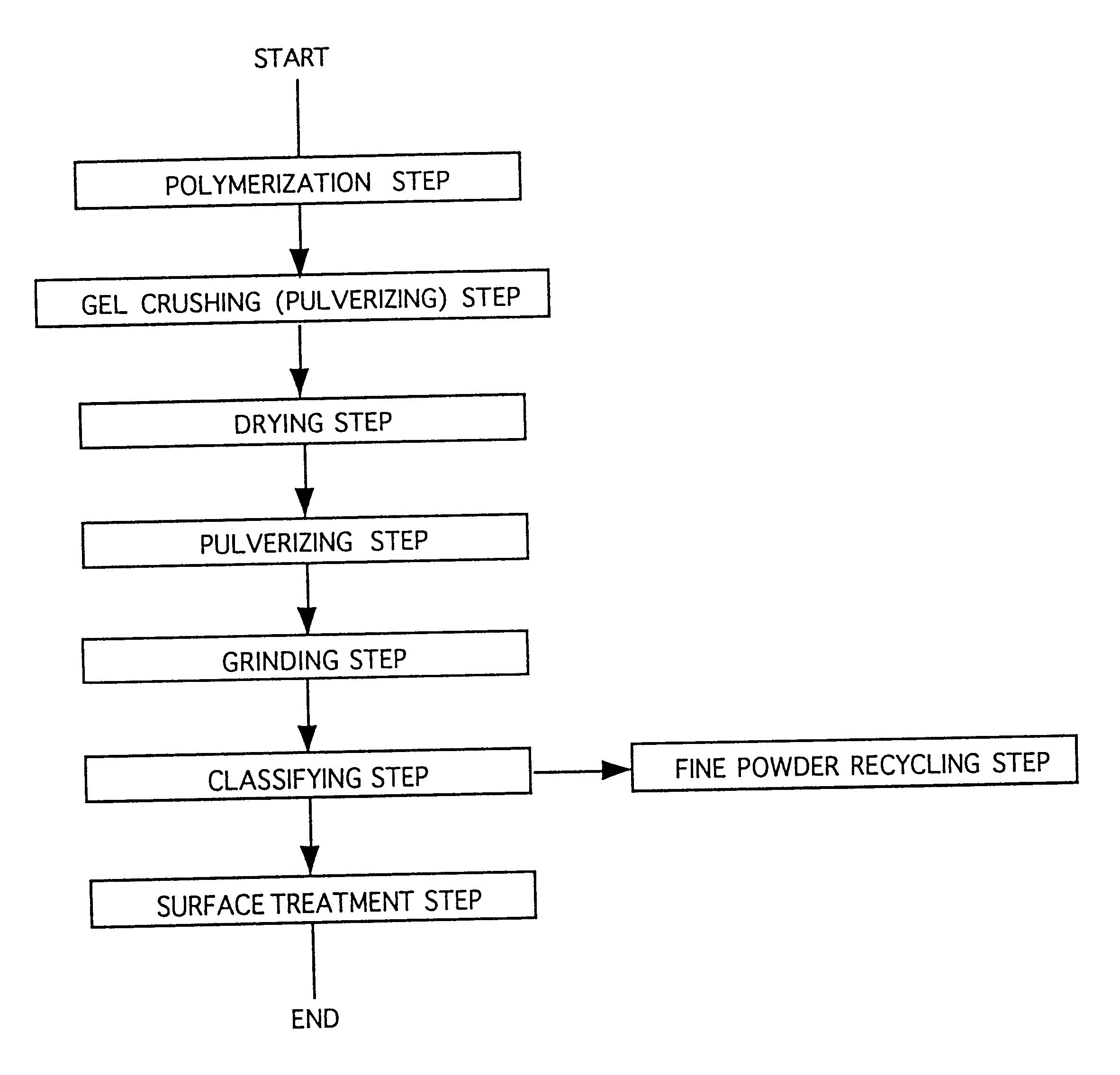

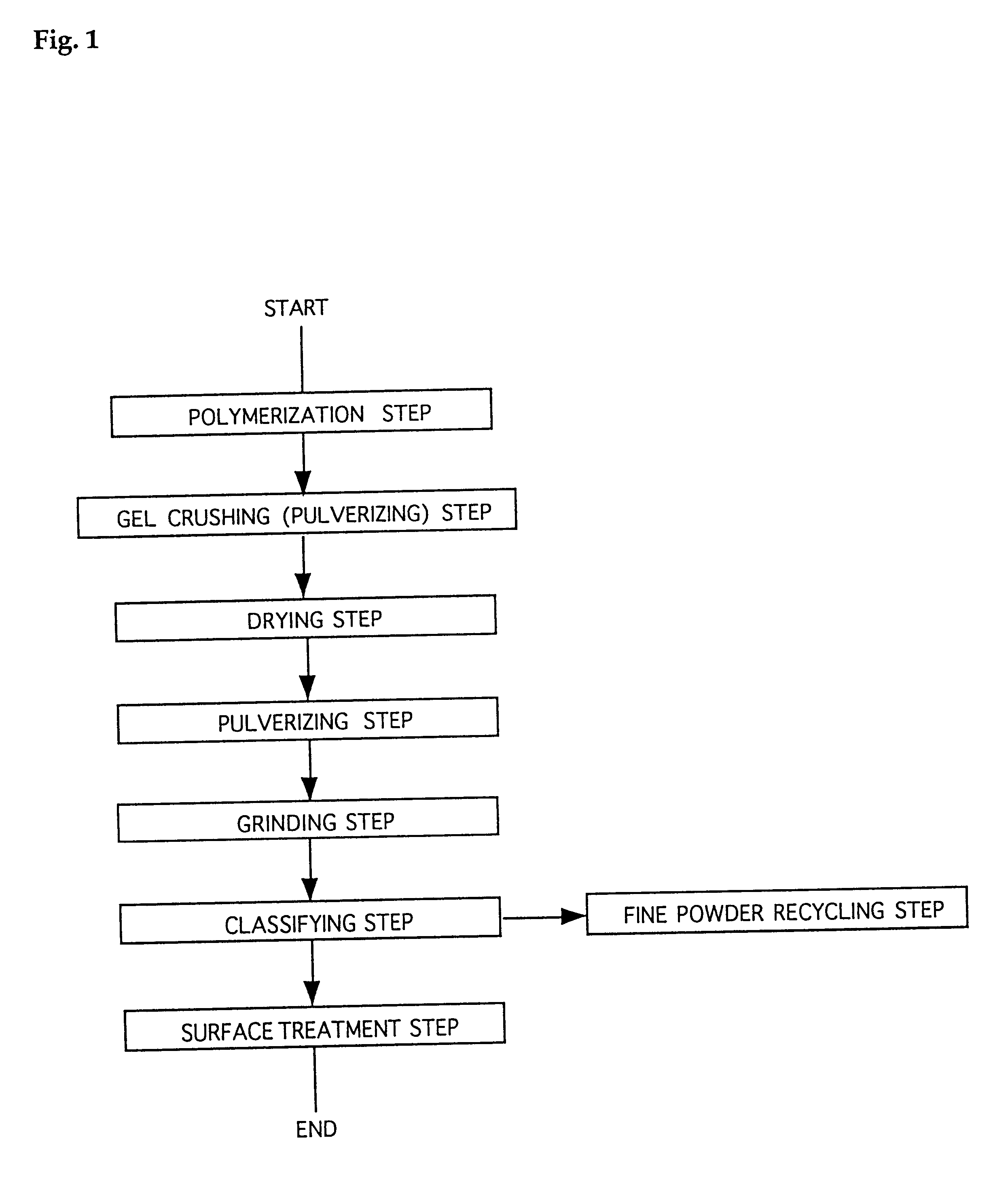

Method for continuous production of water-absorbent resin

The present invention relates to a method for continuous production of a water-absorbent resin by use of an continuous polymerization device having a charge part of a monomer aqueous solution; an endless belt on which the monomer and a hydropolymer formed are conveyed; and a discharge part of the hydropolymer, wherein the continuous polymerization device has side walls and a ceiling, and the space ratio in the device represented by the equation, “space ratio in the device=B / A”, is in the range of 1.2 to 20. In the equation, A is a maximum cross-sectional area (cm2) of the hydropolymer during the polymerization in the width direction of the endless belt, and B is a maximum cross-sectional area (cm2) of the space between the endless belt of the continuous polymerization device and the ceiling of the continuous polymerization device in the width direction of the endless belt.

Owner:NIPPON SHOKUBAI CO LTD

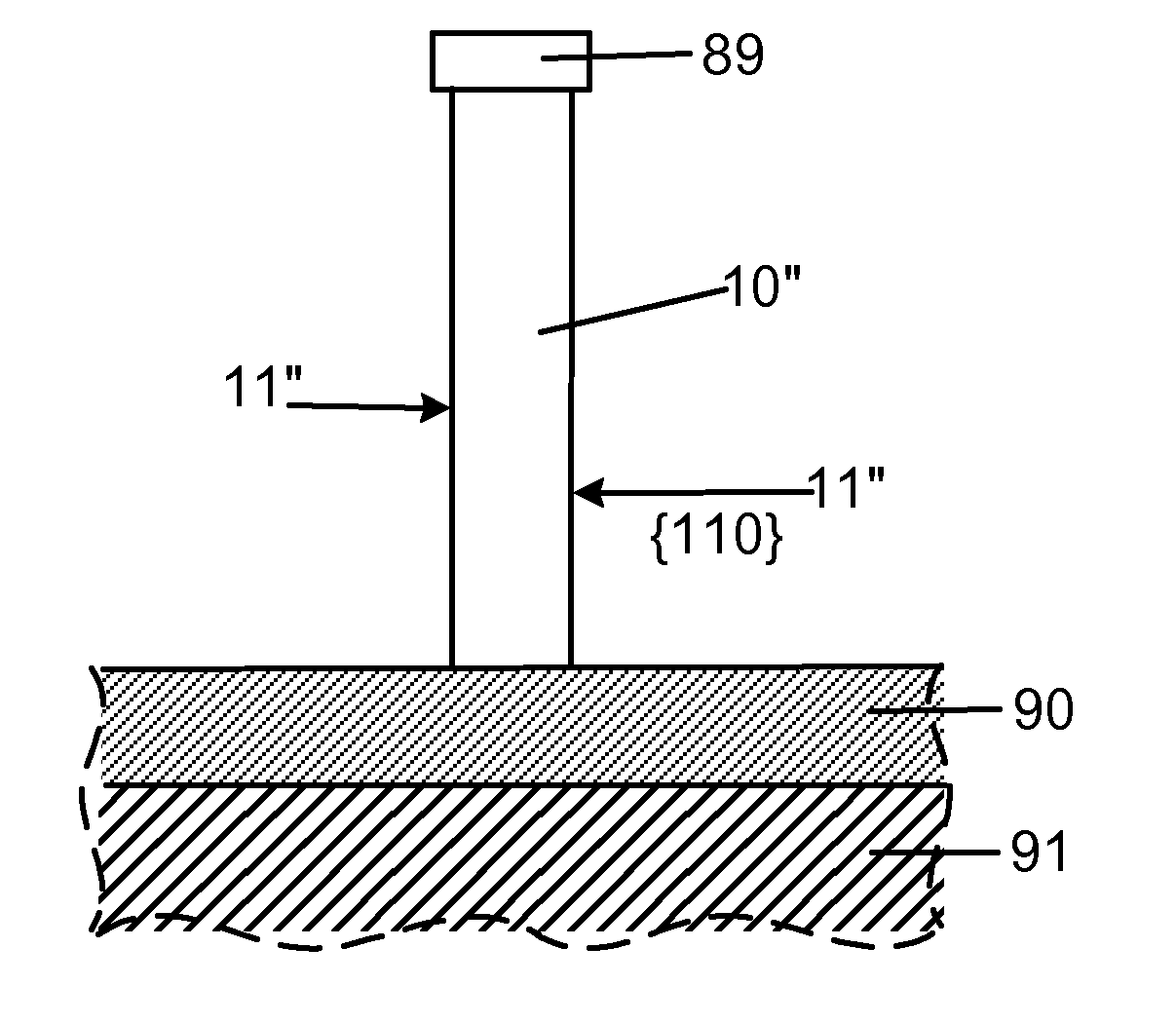

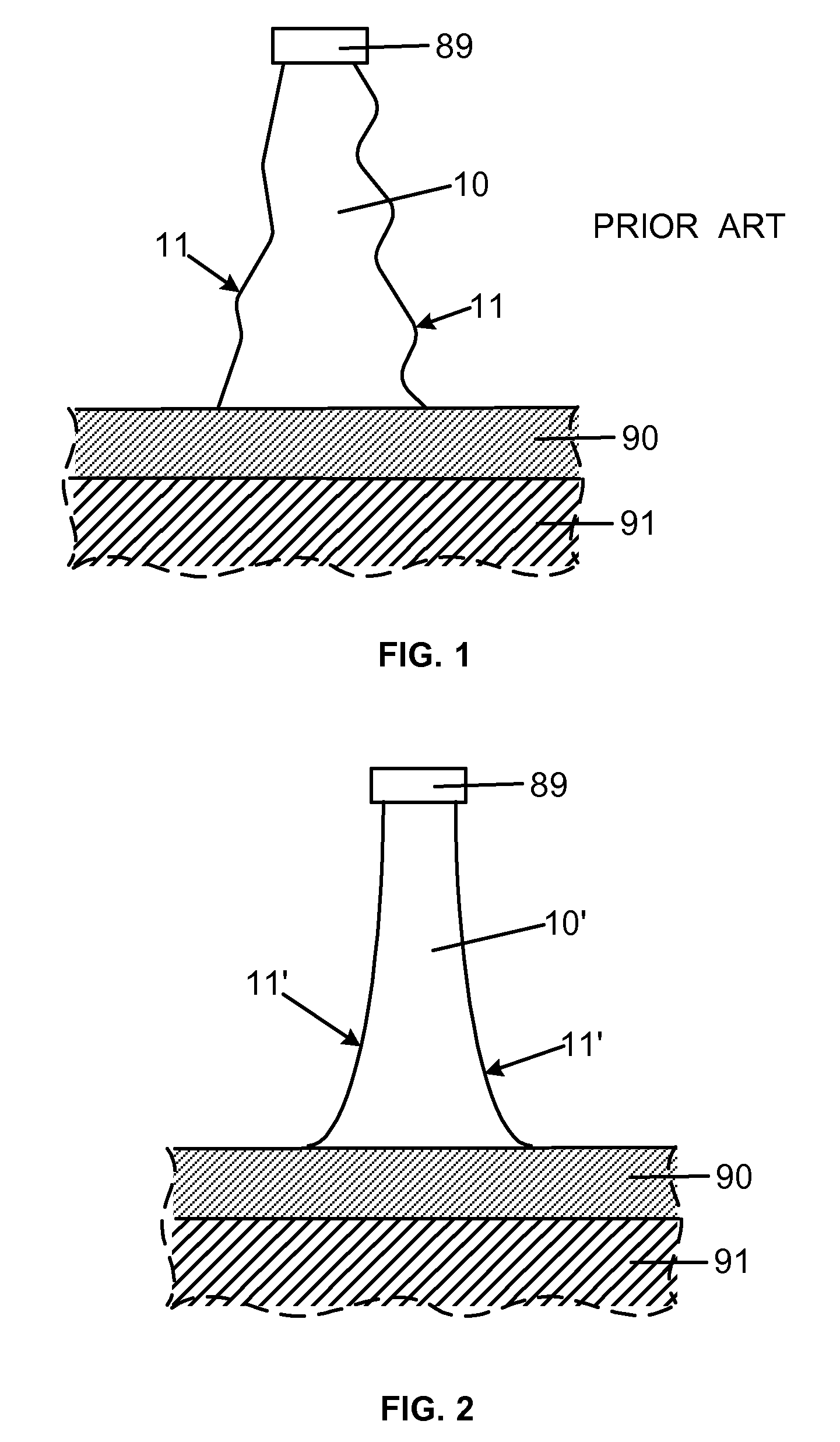

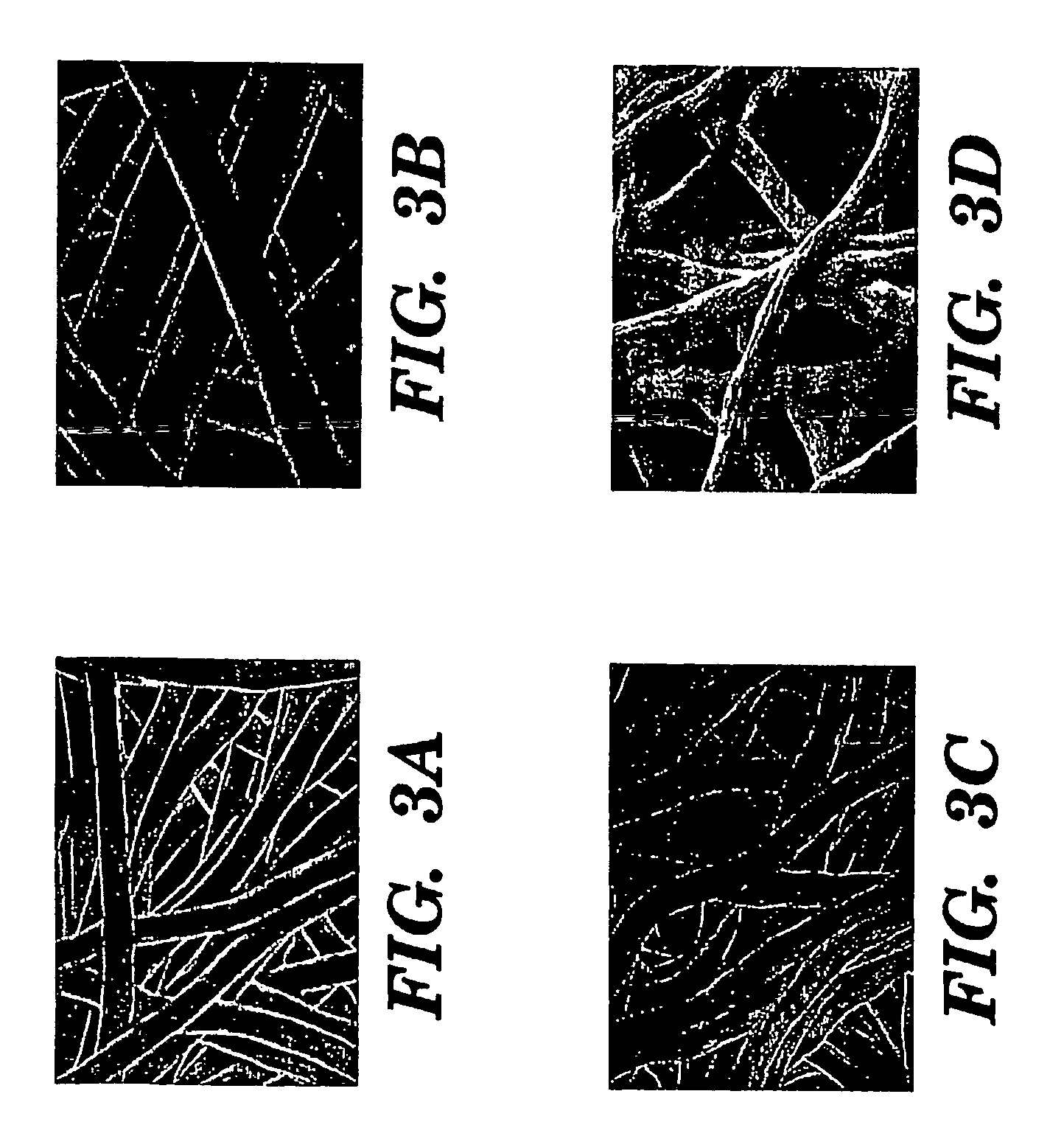

Smooth and vertical semiconductor fin structure

InactiveUS20100048027A1Semiconductor/solid-state device manufacturingSemiconductor devicesSelf limitingCrystal orientation

A method for processing a semiconductor fin structure is disclosed. The method includes thermal annealing a fin structure in an ambient containing an isotope of hydrogen. Following the thermal annealing step, the fin structure is etched in a crystal-orientation dependent, self-limiting, manner. The crystal-orientation dependent etch may be selected to be an aqueous solution containing ammonium hydroxide (NH4OH). The completed fin structure has smooth sidewalls and a uniform thickness profile. The fin structure sidewalls are {110} planes.

Owner:GLOBALFOUNDRIES INC

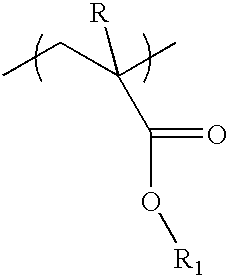

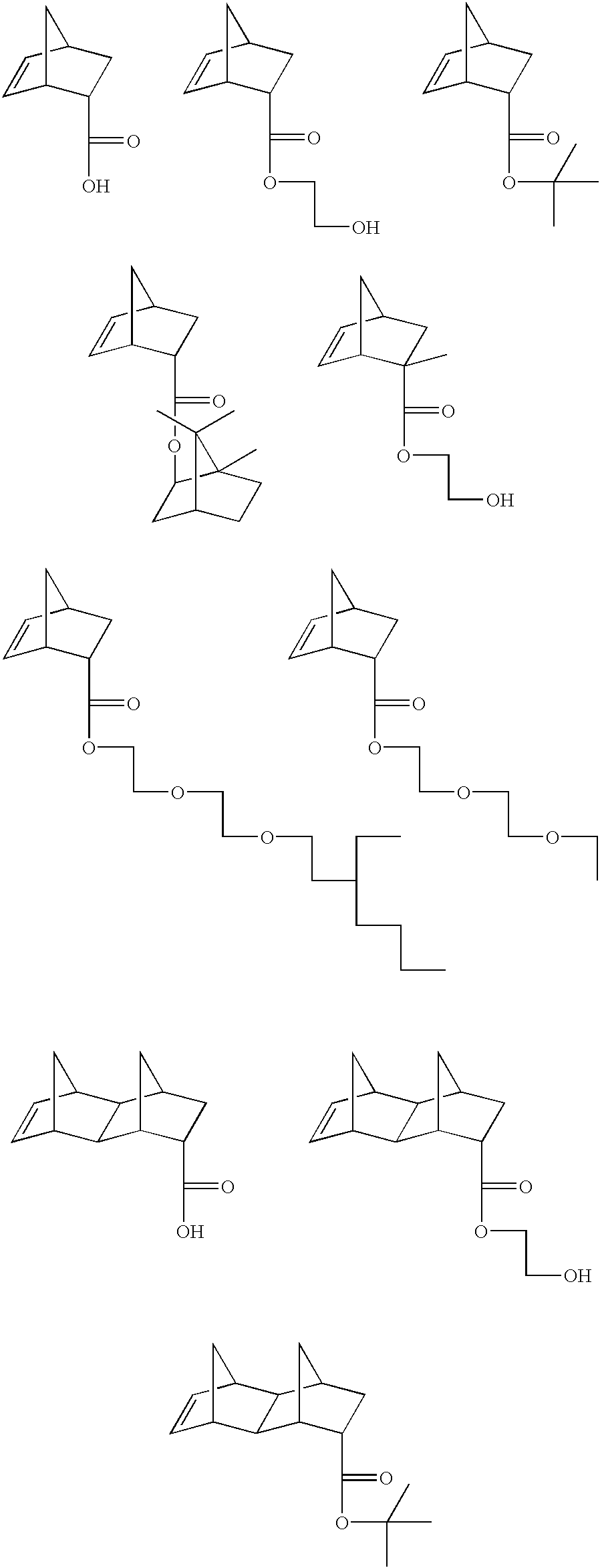

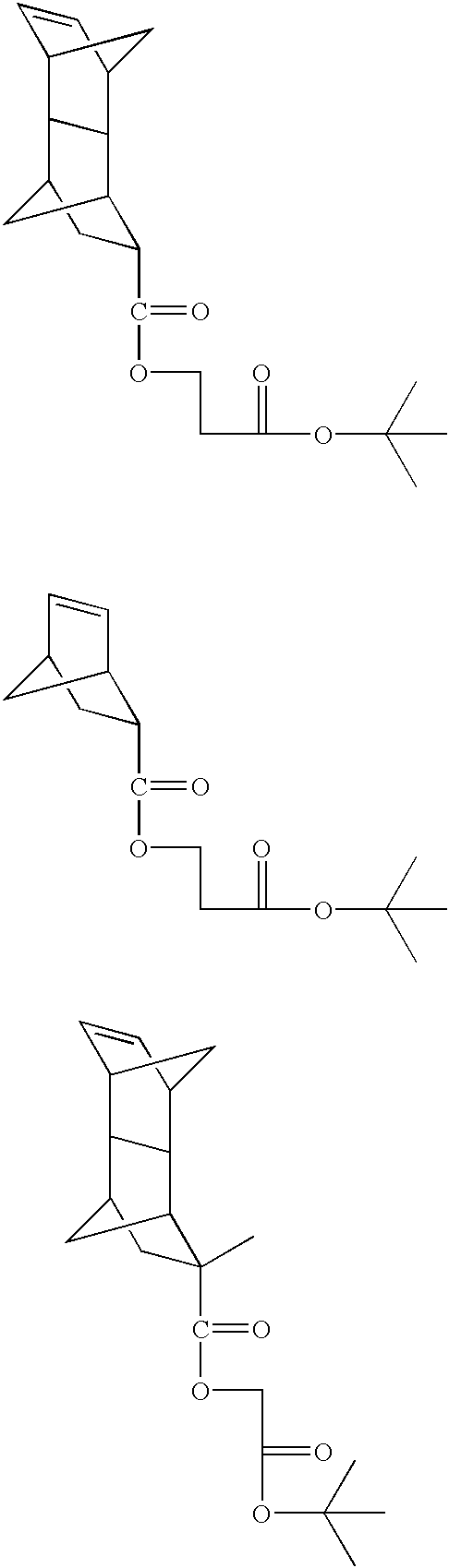

Photoresist composition for deep UV and process thereof

InactiveUS6447980B1Radiation applicationsSemiconductor/solid-state device manufacturingResistSide chain

The present invention relates to a chemically amplified system, which is, sensitive to wavelengths between 300 nm and 100 nm, and comprises a) a polymer that is insoluble an aqueous alkaline solution and comprises at least one acid labile group, b) a compound capable of producing an acid upon radiation. The present invention comprises a polymer that is made from a alicyclic hydrocarbon olefin, an acrylate with a pendant cyclic moeity, and a cyclic anhydride. The present invention also relates to a process for imaging such a photoresist.

Owner:AZ ELECTRONICS MATERIALS USA CORP

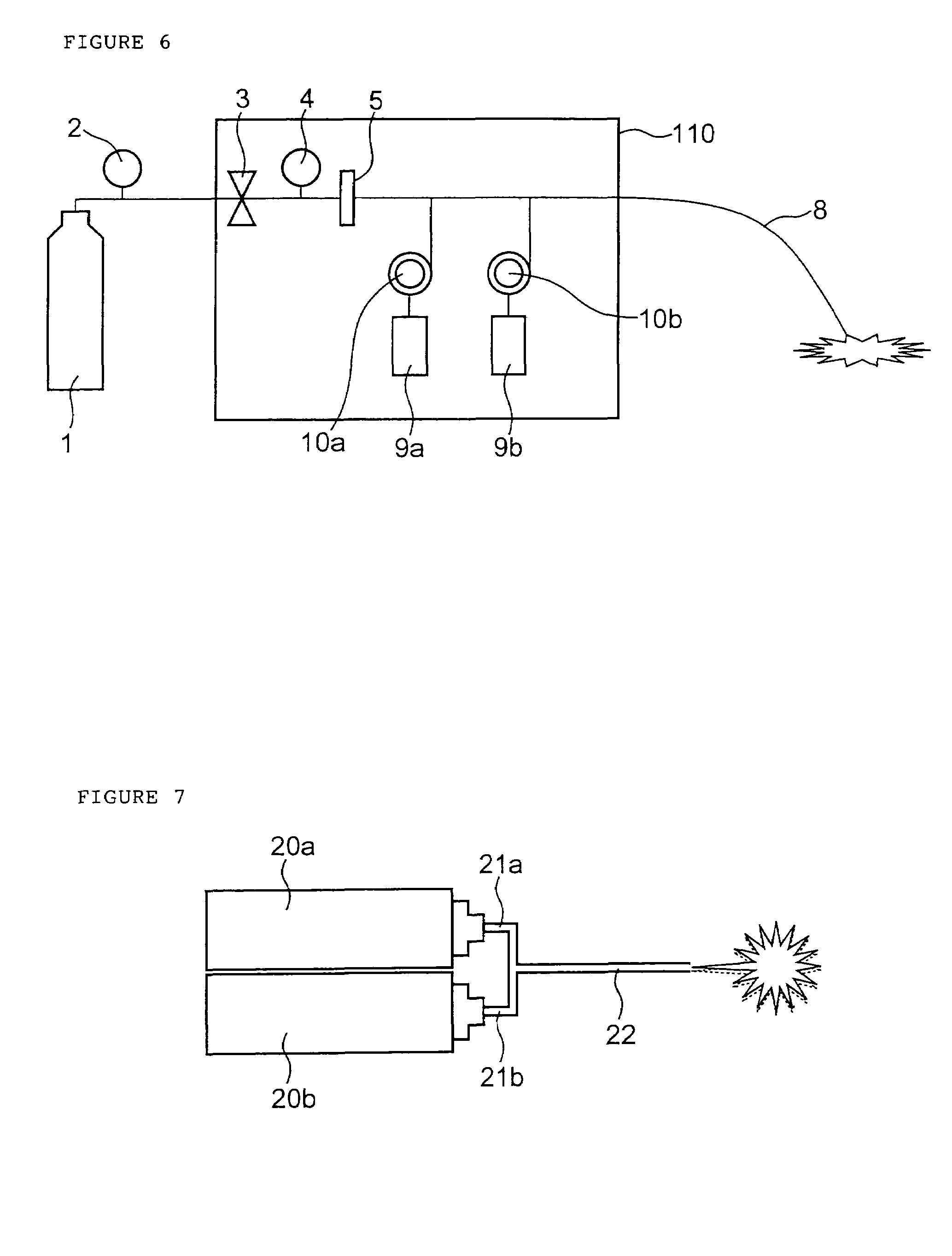

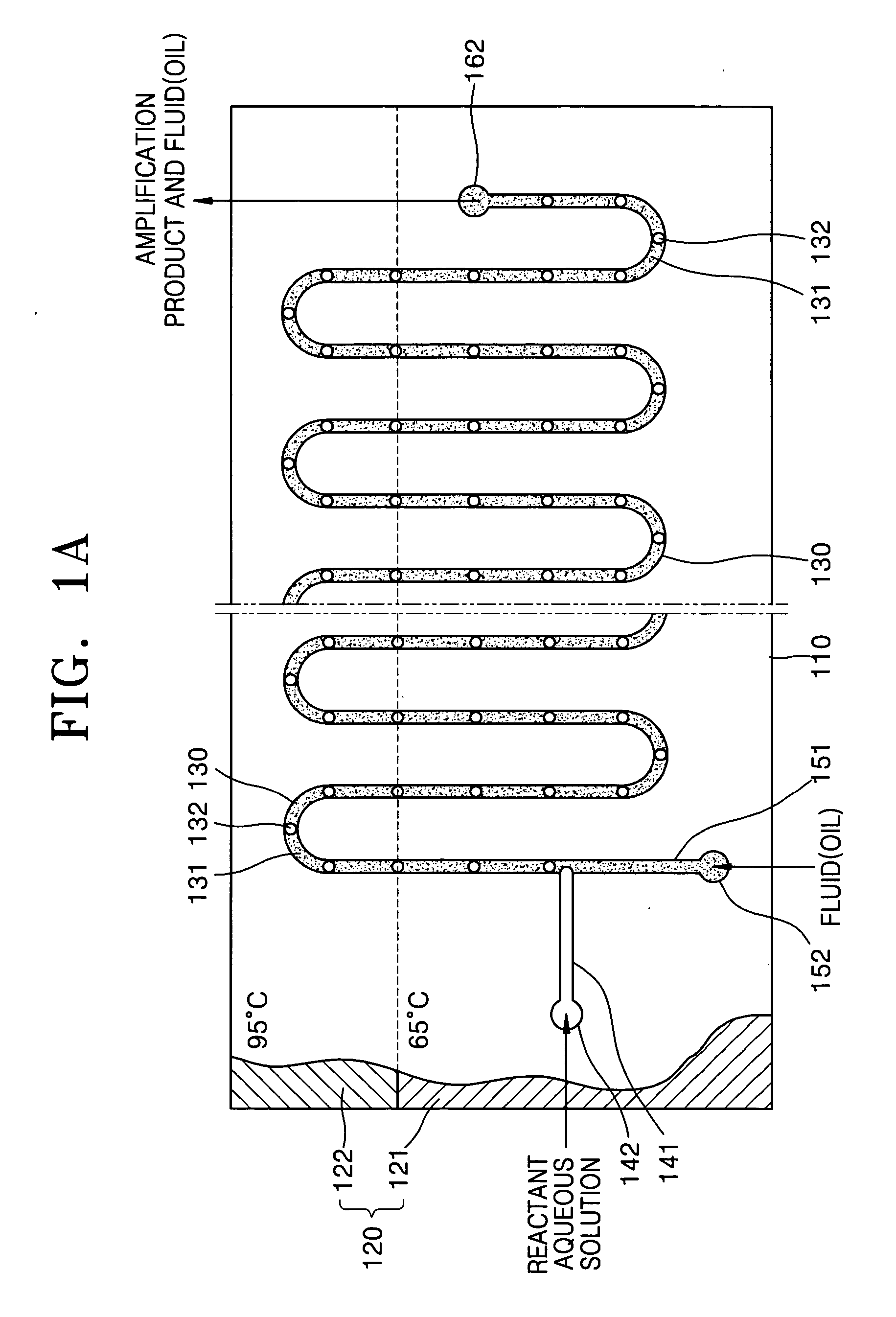

Method and apparatus for amplifying nucleic acids

ActiveUS20050202489A1Bioreactor/fermenter combinationsBiological substance pretreatmentsInlet channelAqueous solution

Provided are a method and apparatus for amplifying nucleic acids. The method includes introducing into a reaction vessel via different inlet channels a reactant aqueous solution containing reactants for nucleic acid amplification and a fluid that is phase-separated from the reactant aqueous solution and does not participate in amplification reaction, creating a plurality of reactant aqueous solution droplets surrounded by the fluid by contacting the reactant aqueous solution with the fluid in the reaction vessel, and amplifying the nucleic acids in the reactant aqueous solution droplets. The apparatus includes a substrate, a reaction vessel formed inside of the substrate, at least one first inlet channel formed inside the substrate, connected to an end of the reaction vessel, and allowing introduction of a reactant aqueous solution containing reactants for nucleic acid amplification into the reaction vessel, a second inlet channel formed inside the substrate, connected to the end of the reaction vessel, and allowing introduction of a fluid that is phase-separated from the reactant aqueous solution and does not participate in amplification reaction into the reaction vessel, and a heating unit installed on the substrate in such a way to thermally contact with the substrate and heating the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

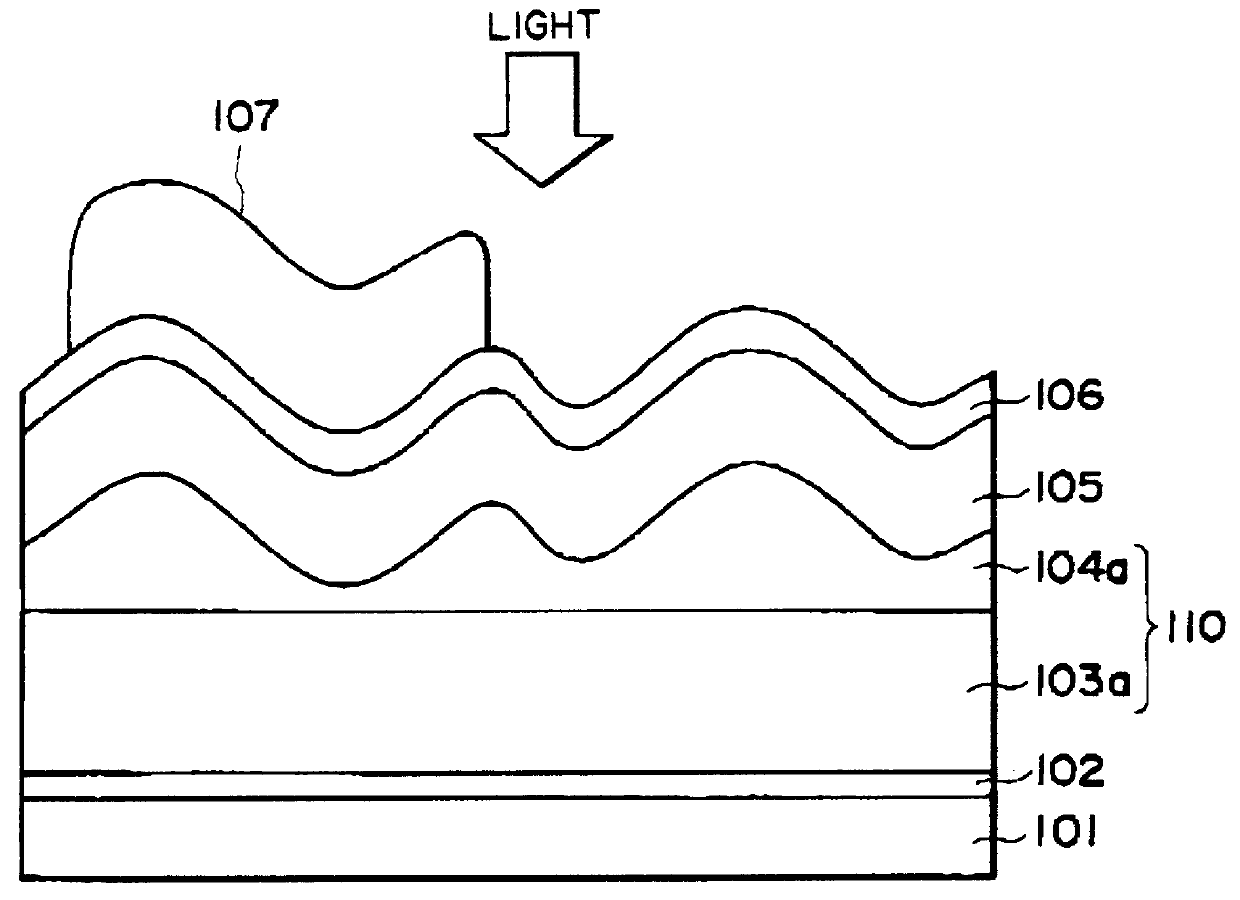

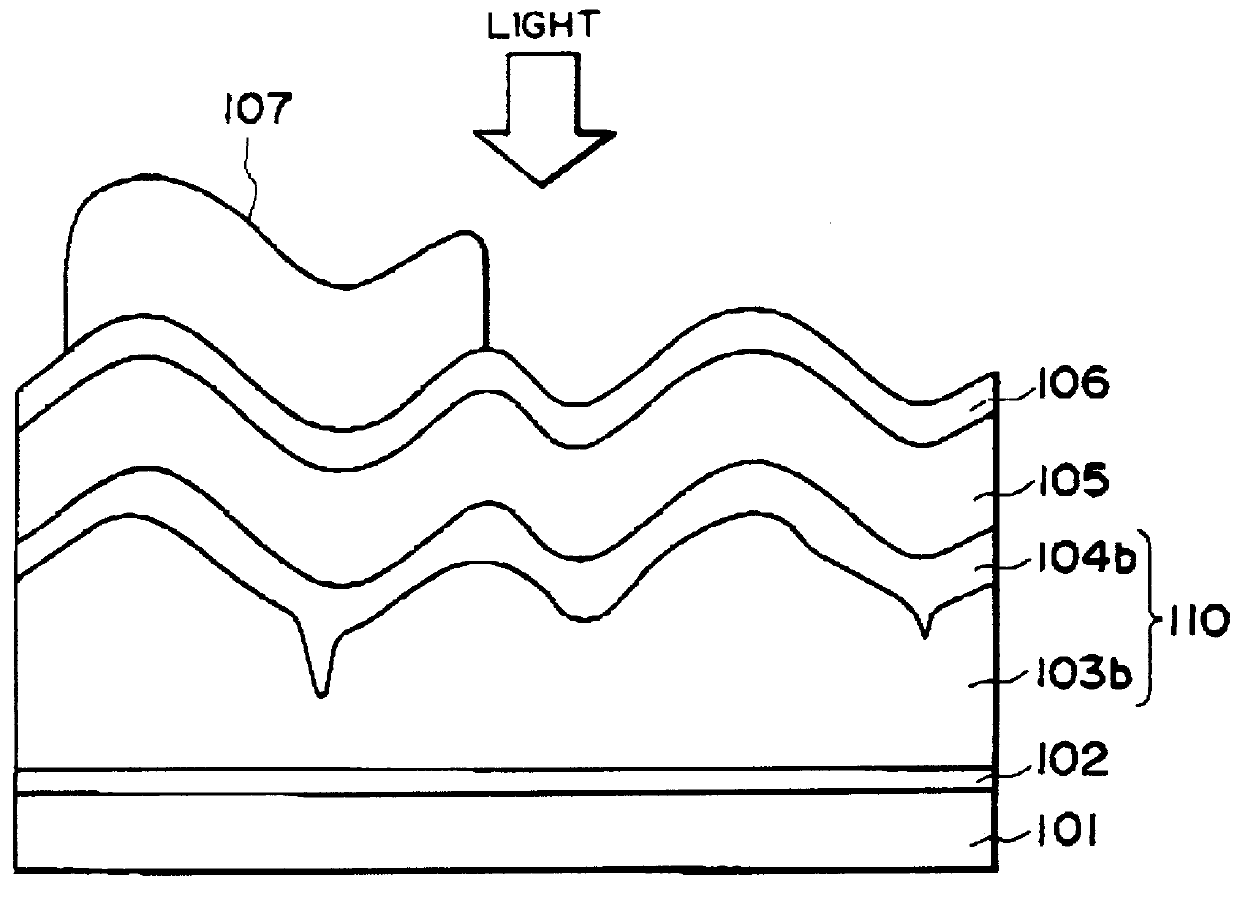

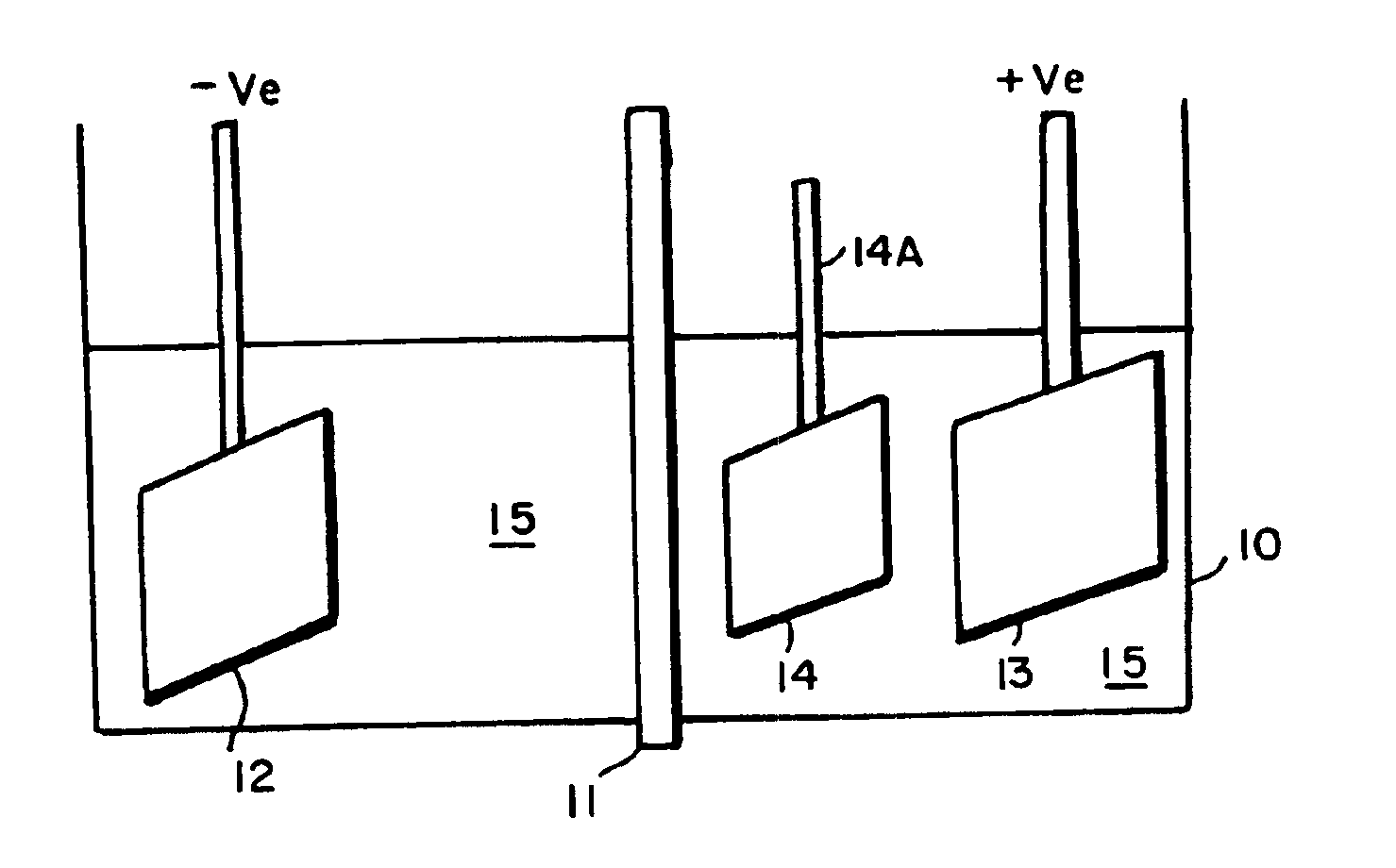

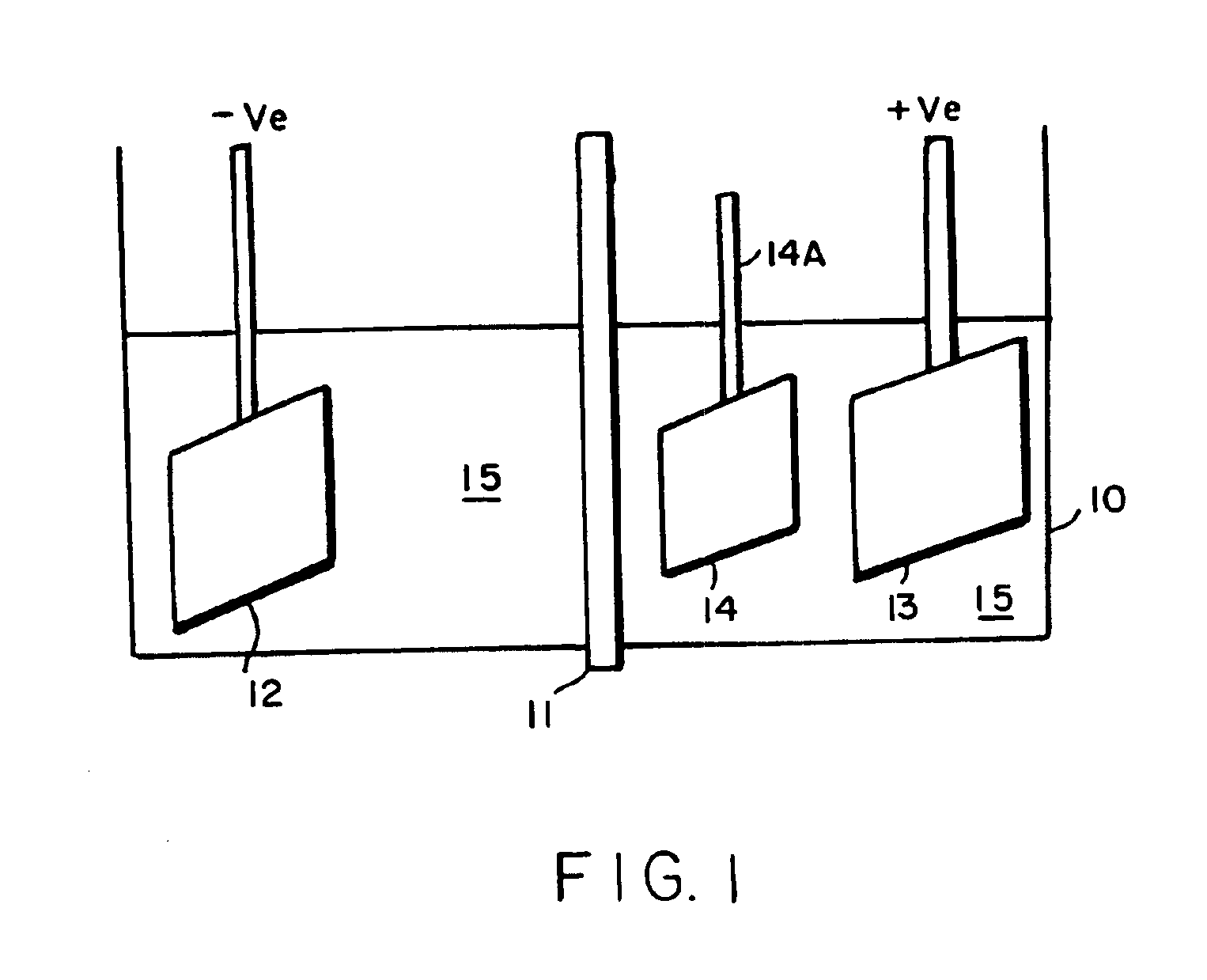

Process for producing photo-electricity generating device

InactiveUS6123824AInhibition of abnormal growthReduce leakage currentElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectricityPower flow

A photo-electricity generating device is produced through the steps of: immersing an electrode and an electroconductive substrate in an aqueous solution comprising nitrate ions and zinc ions, supplying a current passing through a gap between the electrode and the electroconductive substrate to form a first zinc oxide layer on the electroconductive substrate, etching the first zinc oxide layer, and forming a semiconductor layer on the zinc oxide layer. The zinc oxide layer may preferably be formed in two zinc oxide layers under different electrudeposition conditions. In this case, the etching step may preferably be performed between steps for forming these zinc oxide layers. The zinc oxide layer is provided with an unevenness at its surface suitable for constituting a light-confining layer of a resultant photo-electricity generating device.

Owner:CANON KK

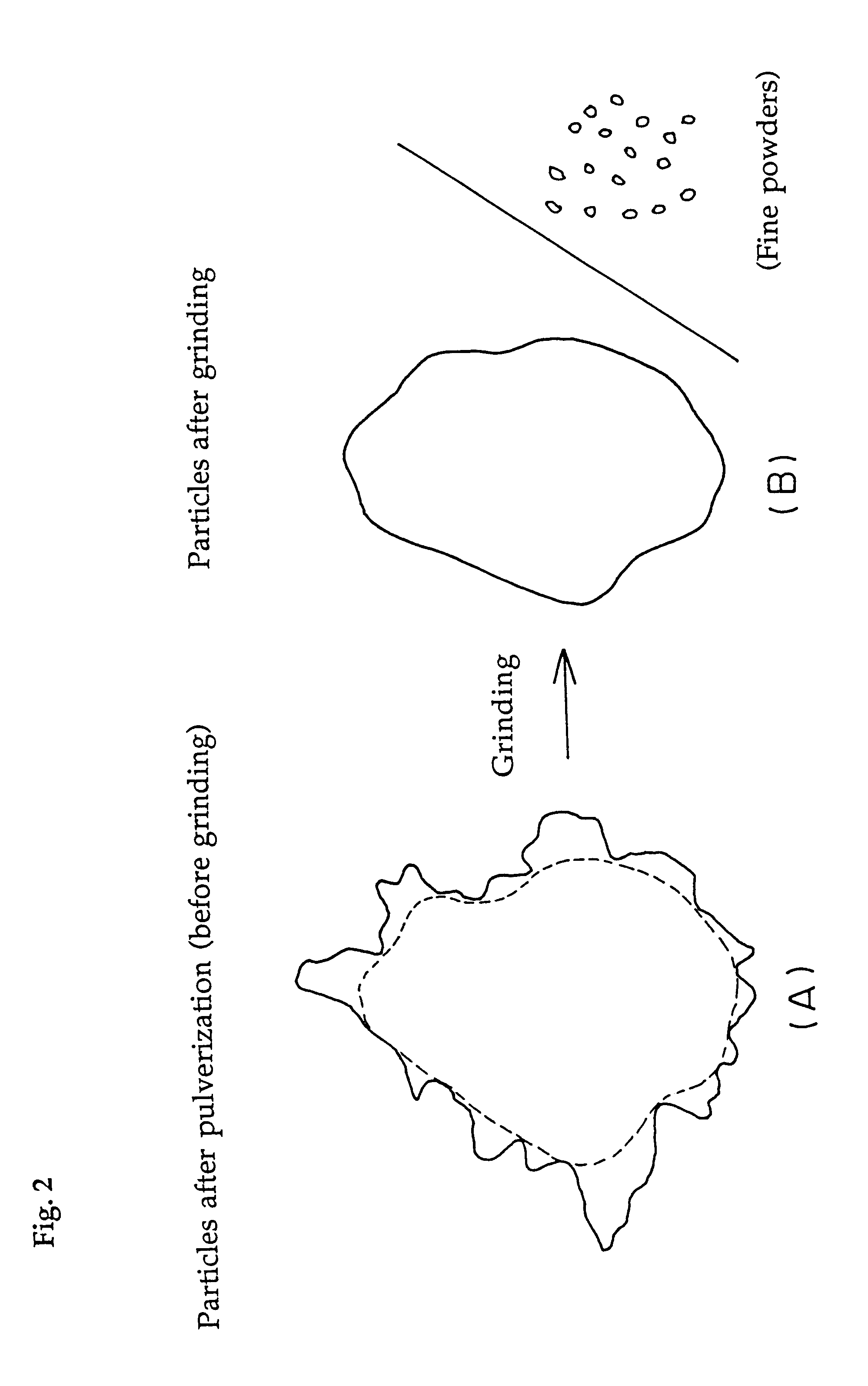

Water-absorbent resin powder and its production process and use

The present invention provides a water-absorbent resin powder and its production process and use, wherein the water-absorbent resin powder has high liquid permeability and high water absorbency. The production process for a water-absorbent resin powder, according to the present invention, comprises the step of obtaining water-absorbent crosslinked polymer particles by an aqueous solution polymerization step, and grinding the resultant crosslinked polymer particles until the bulk density thereof increases to not lower than 0.72 (g / ml). The water-absorbent resin powder is characterized by being arbitrarily pulverized and having a bulk density of not lower than 0.74 (g / ml) and a water absorption capacity of not lower than 20 (g / g) for 0.9 weight % physiological saline under a load of 0.7 psi (4.83 kPa). In addition, the absorbent structure comprises the above water-absorbent resin powder and a fibrous material. The absorbent article comprises an absorbent layer including the above absorbent structure.

Owner:NIPPON SHOKUBAI CO LTD

Photoresist composition for deep UV radiation containing an additive

InactiveUS6723488B2Reduce impactPrevent degradationPhotosensitive materialsElectric discharge tubesUltravioletAqueous solution

Owner:AZ ELECTRONICS MATERIALS USA CORP

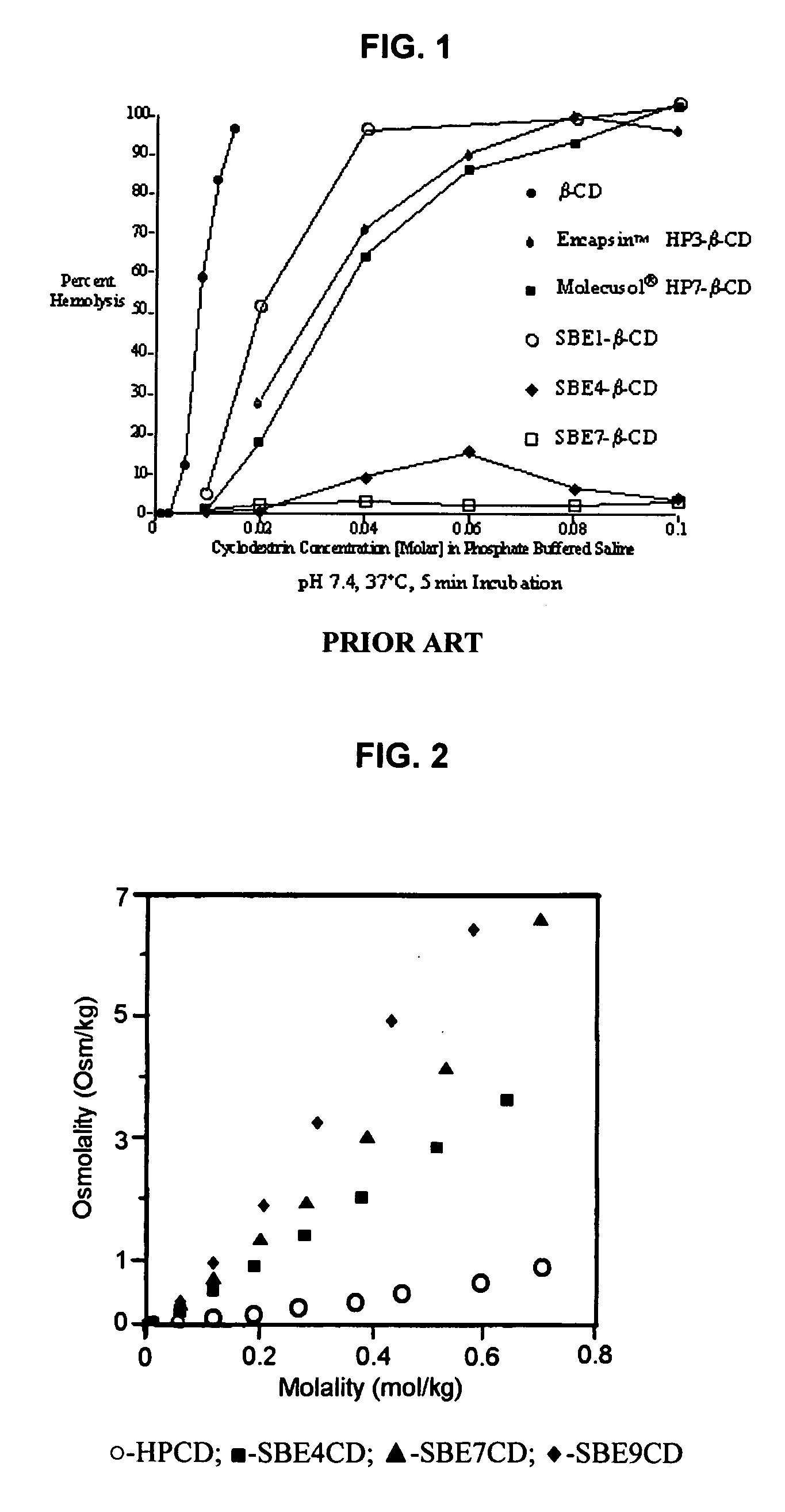

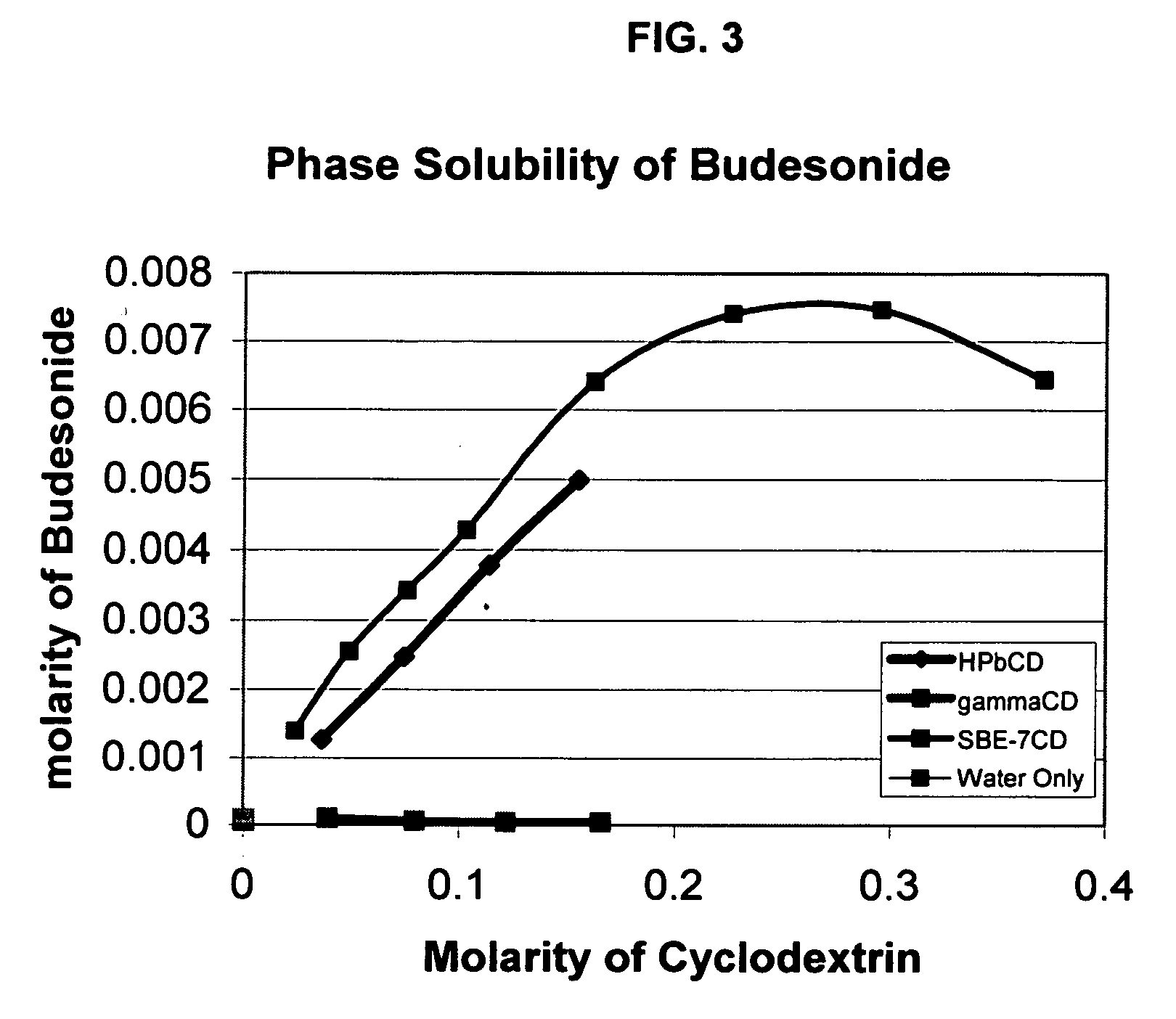

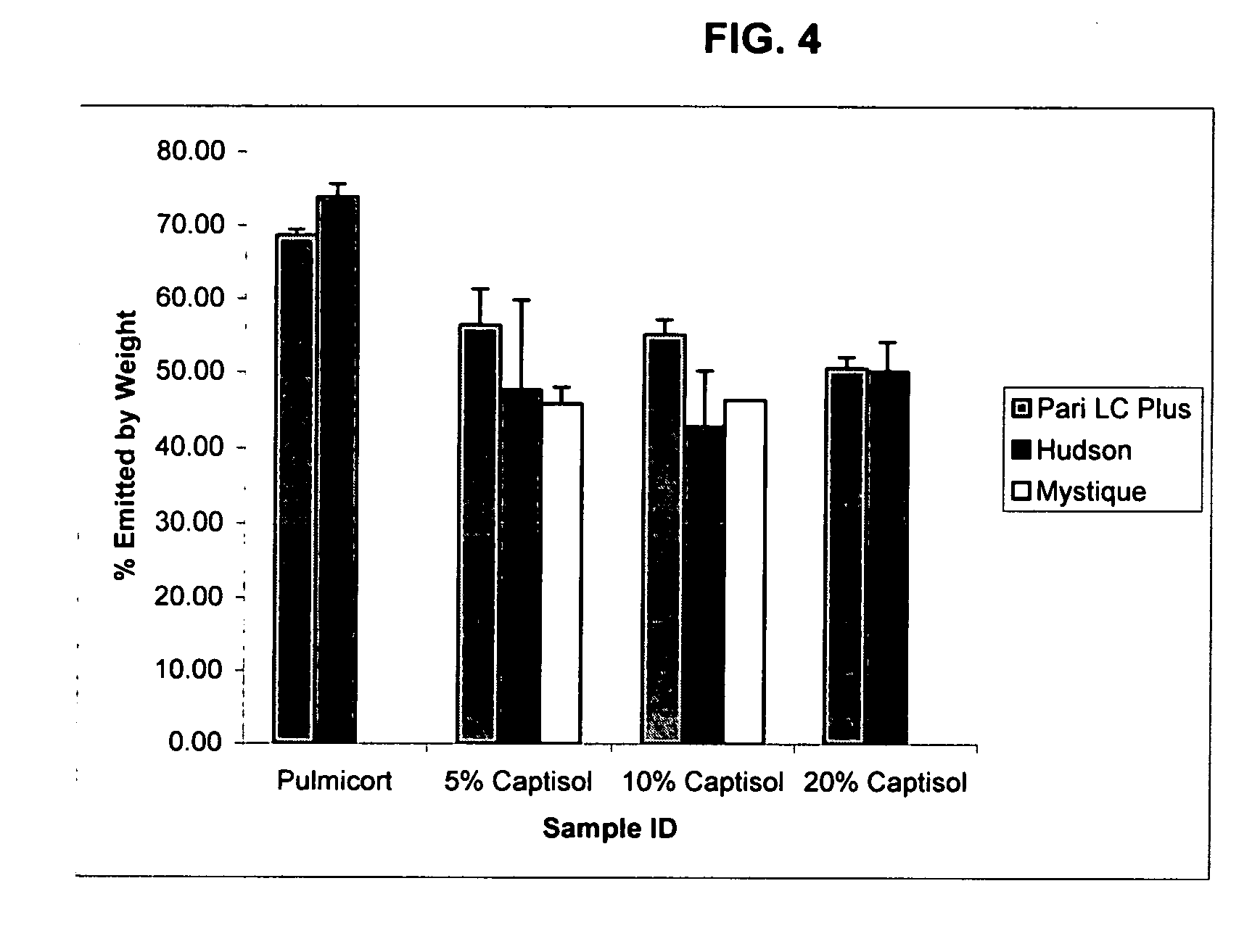

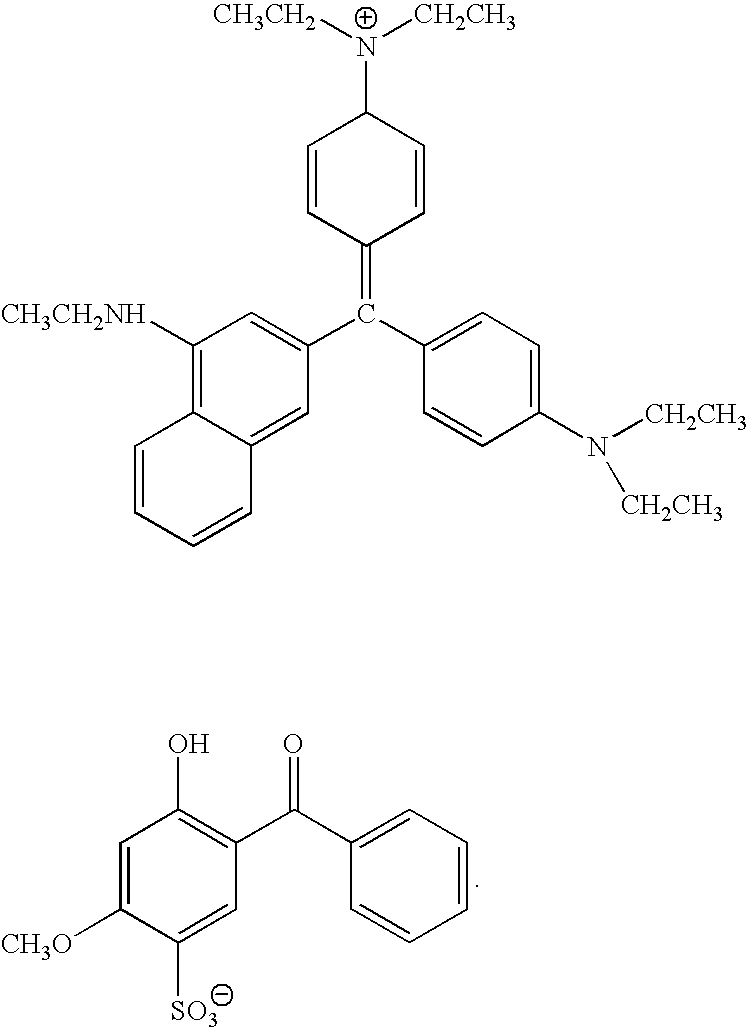

Inhalant formulation containing sulfoalkyl ether cyclodextrin and corticosteroid prepared from a unit dose suspension

InactiveUS20070020196A1Reduce the degradation rateIncrease productivityBiocideDispersion deliveryNebulizerCyclodextrin

An inhalable unit dose liquid formulation containing SAE-CD and corticosteroid is provided. The formulation is adapted for administration to a subject by nebulization with any known nebulizer. The formulation can be included in a kit. The formulation is administered as an aqueous solution or concentrated composition. The formulation is employed in an improved nebulization system for administering corticosteroid by inhalation. SAE-CD present in the formulation significantly enhances the chemical stability of corticosteroid, such as budesonide. A method of administering the formulation by inhalation is provided. The formulation can also be administered by conventional nasal delivery apparatus. The formulation is prepared by mixing SAE-CD, in solid or liquid (dissolved) form, with an inhalable suspension-based unit dose formulation.

Owner:CYDEX PHARMACEUTICALS INC

Water-developable infrared-sensitive printing plate

ActiveUS20050123853A1Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersPendant groupAqueous solution

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. The imageable element can be developed using an aqueous developer solution. Alternatively, the imageable element can be developed on-press by contact with ink and / or fountain solution.

Owner:KODAK POLYCHROME GRAPHICS

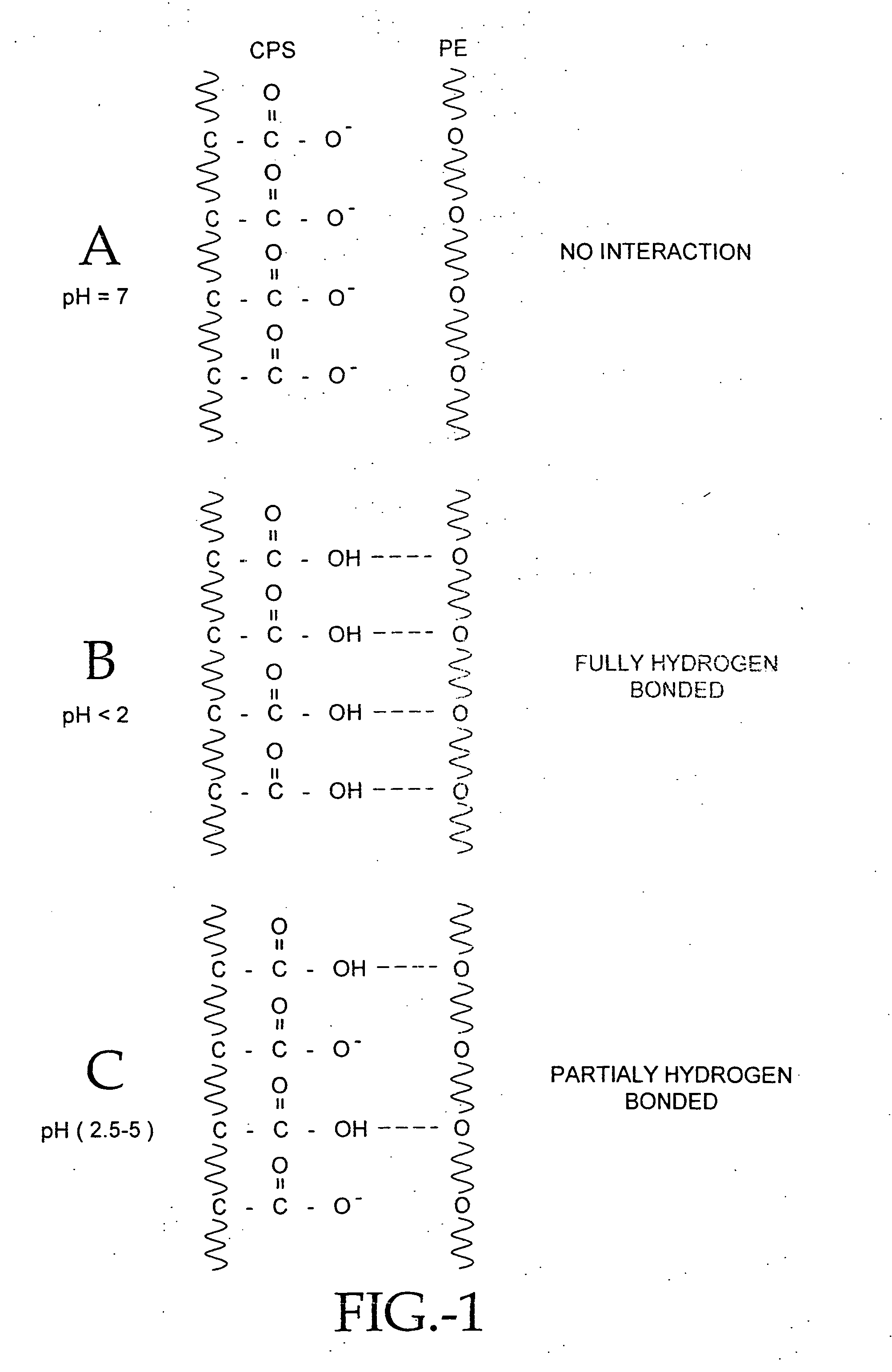

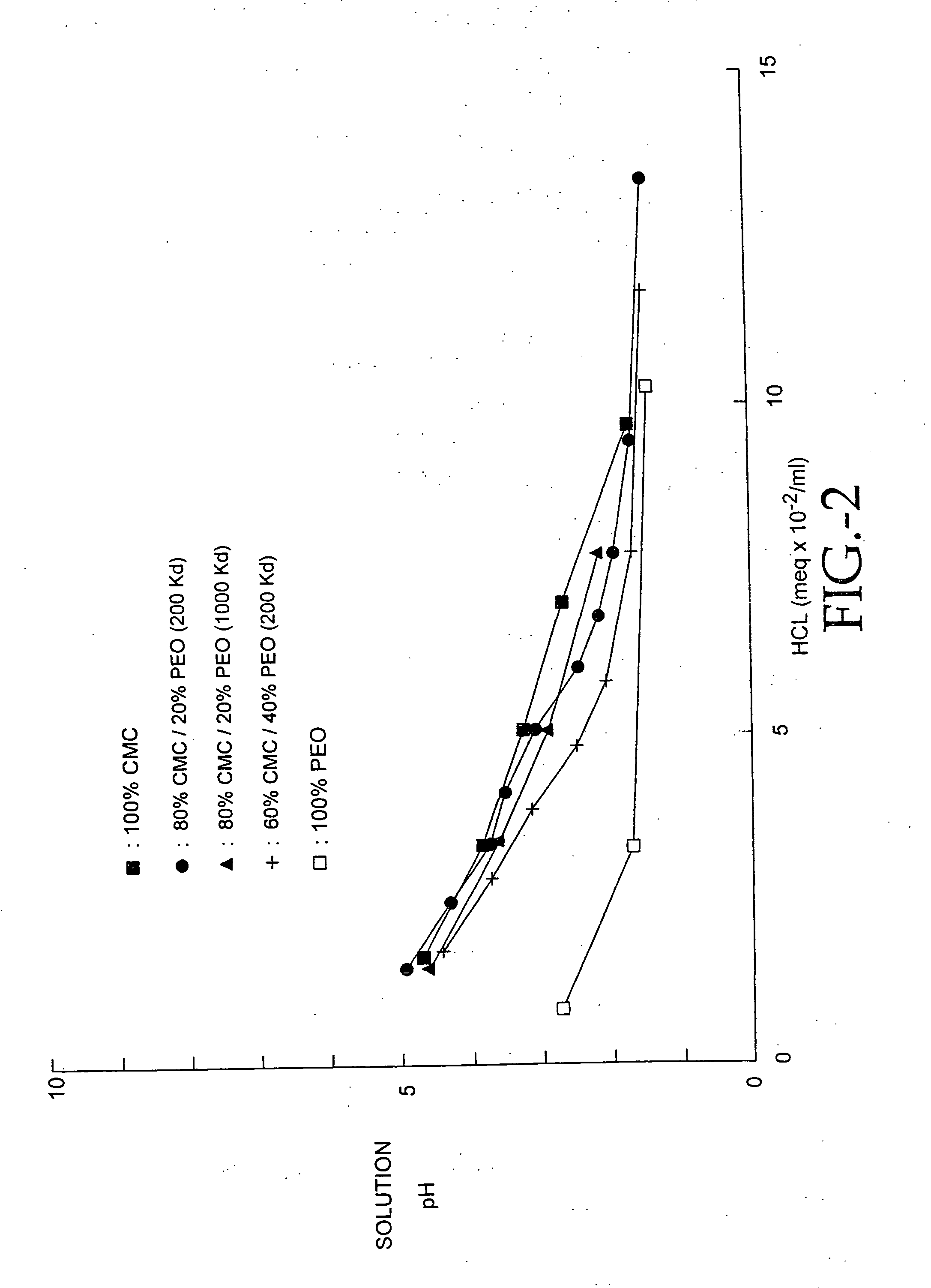

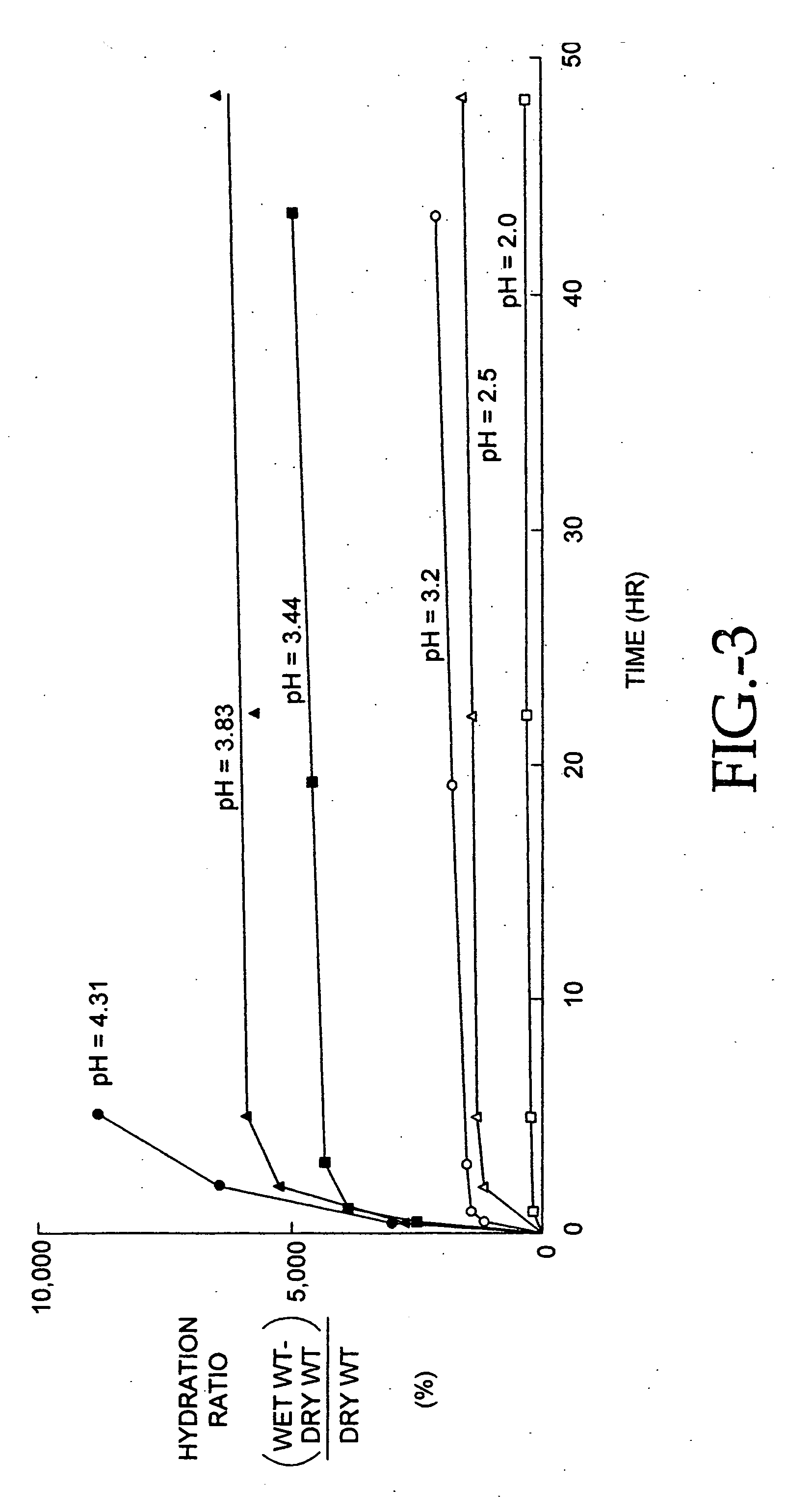

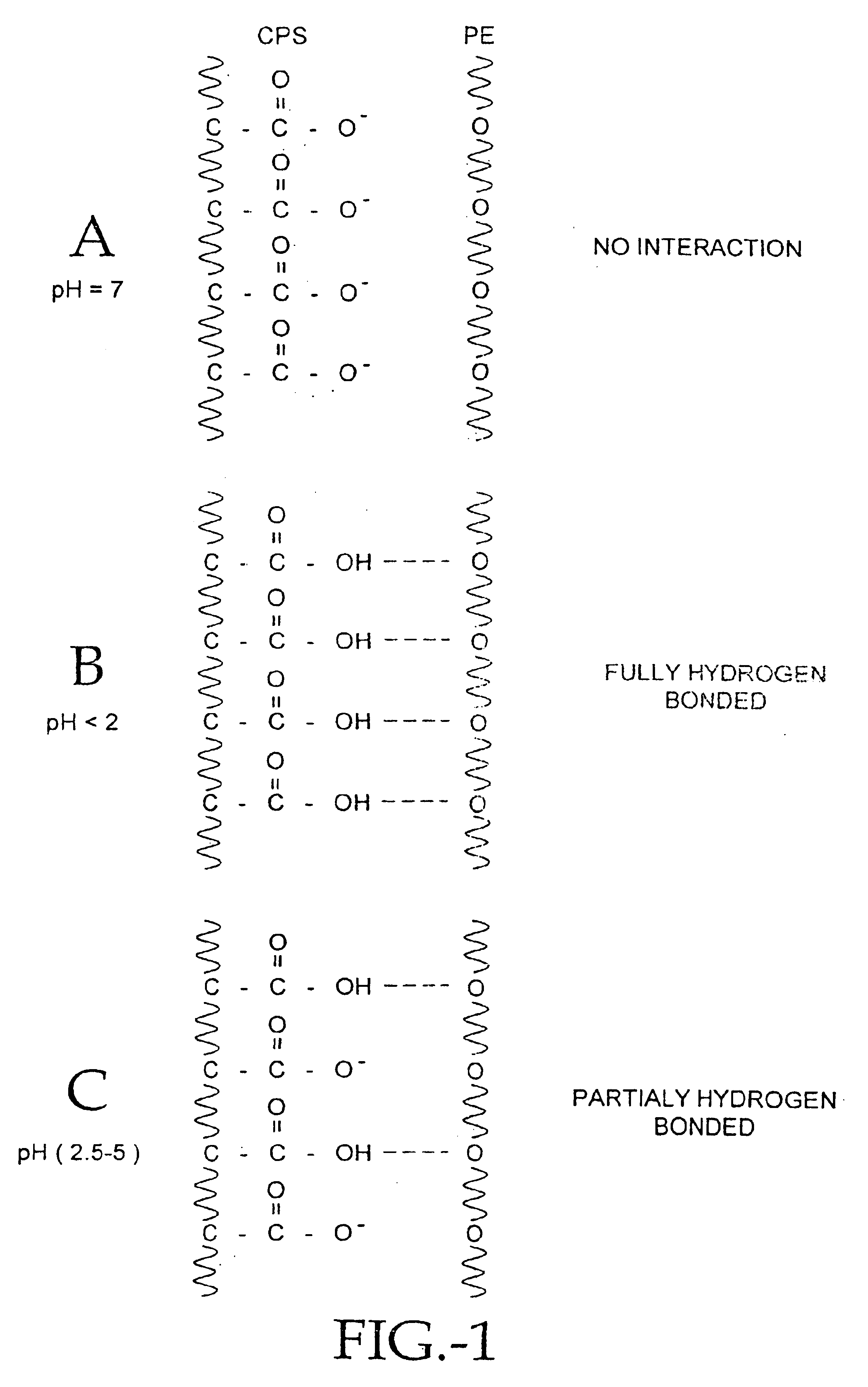

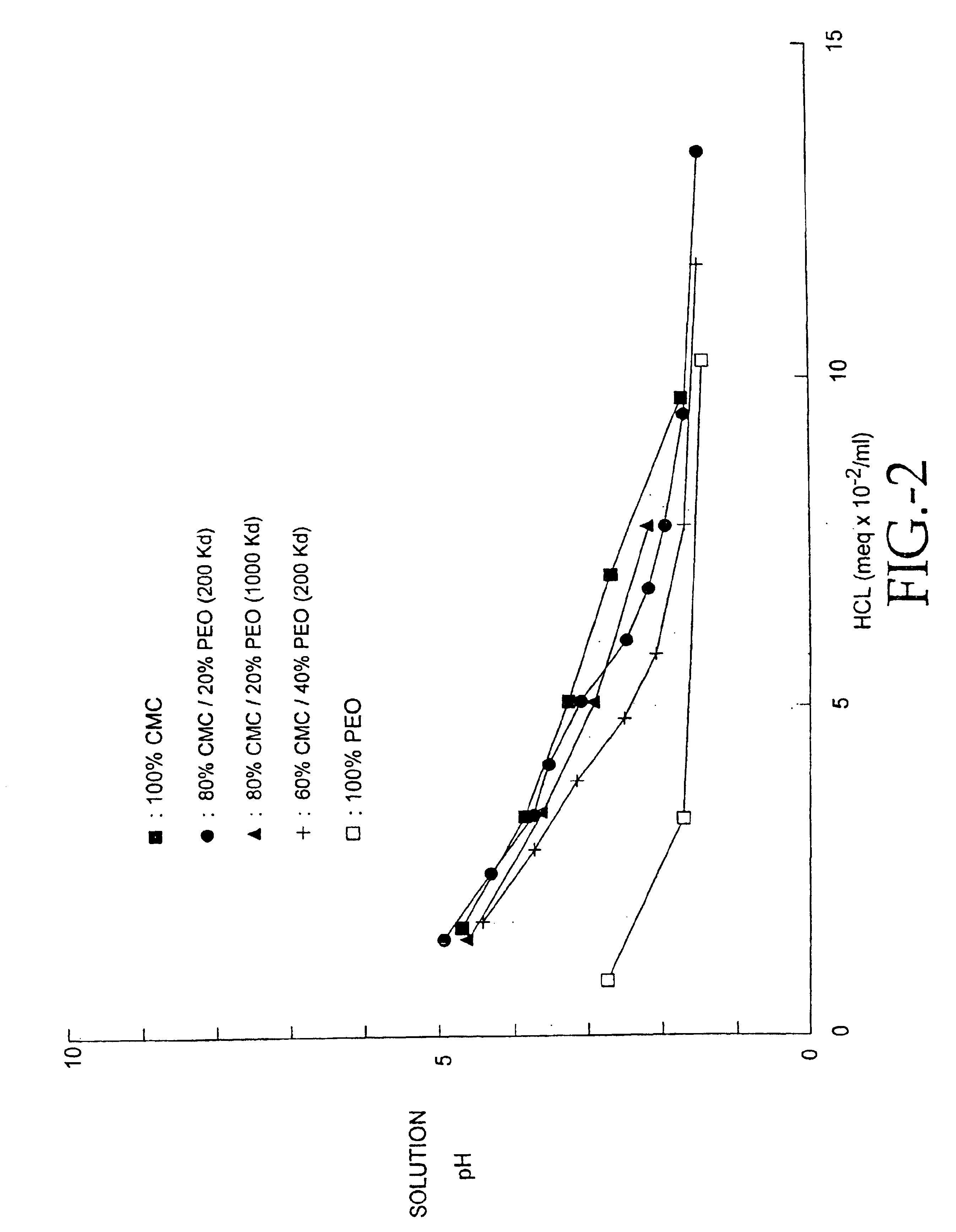

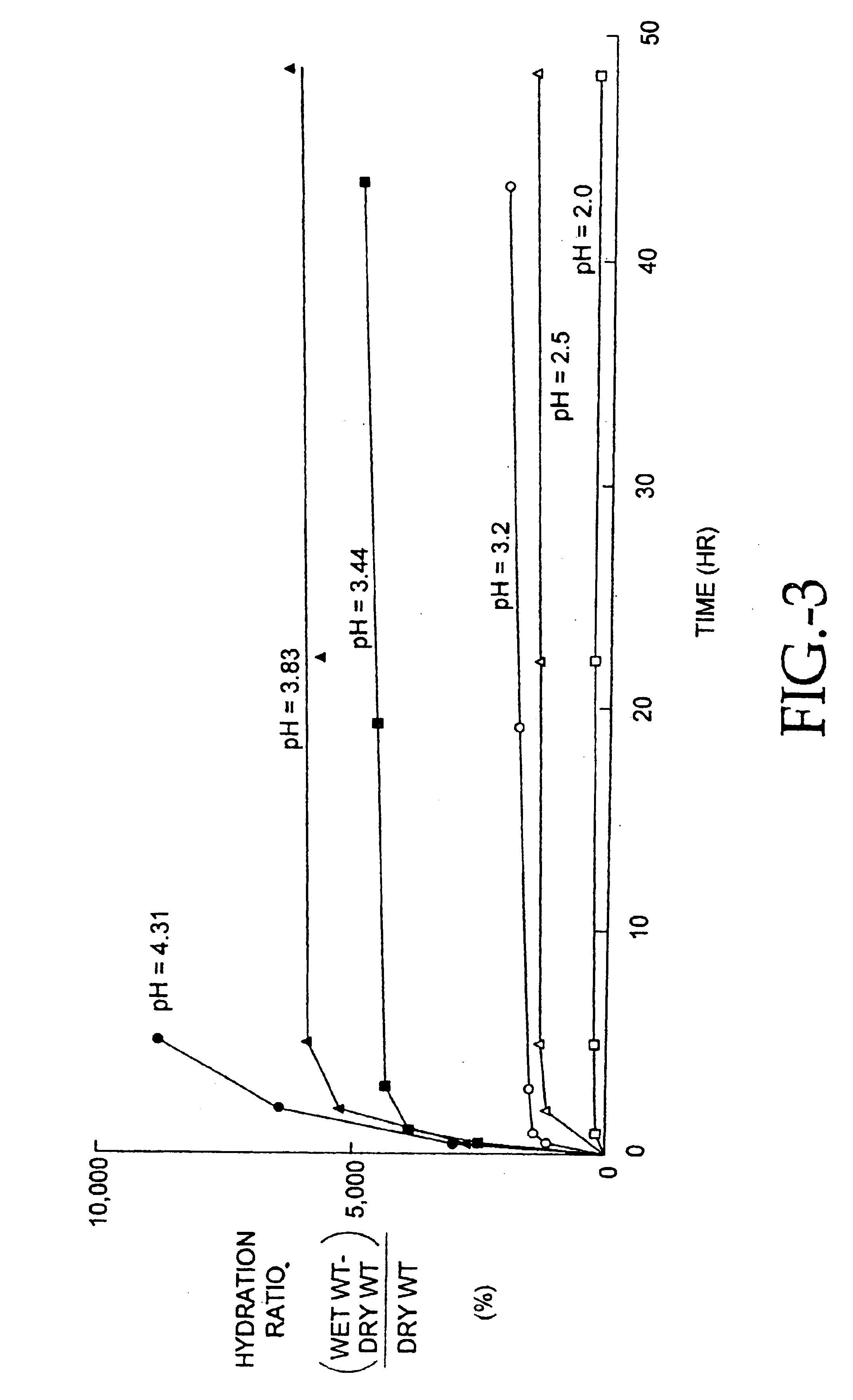

Compositions of polyacids and methods for their use in reducing adhesions

InactiveUS20050074495A1Improve anti-adhesion performancePrevent reformationPowder deliverySurgeryMicrosphereSurgical site

The present invention relates to improved methods for making and using bioadhesive, bioresorbable, anti-adhesion compositions made of inter-macromolecular complexes of carboxyl-containing polysaccharides, polyethers, polyacids, polyalkylene oxides, multivalent cations and / or polycations. The polymers are associated with each other and are then either dried into membranes or sponges or are used as fluids or microspheres. Bioresorbable, bioadhesive, antiadhesion compositions are useful in surgery to prevent the formation and reformation of post-surgical adhesions. The compositions are designed to breakdown in vivo, and thus be removed from the body. Membranes are inserted during surgery either dry or optionally after conditioning in aqueous solutions. The antiadhesion, bioadhesive, bioresorptive, antithrombogenic and physical properties of such membranes and gels can be varied as needed by carefully adjusting the pH and / or cation content of the polymer casting solutions, polyacid composition, the polyalkylene oxide composition, or by conditioning the membranes prior to surgical use. Multi-layered membranes can be made and used to provide further control over the physical and biological properties of antiadhesion membranes. Membranes and gels can be used concurrently. Antiadhesion compositions may also be used to lubricate tissues and / or medical instruments, and / or deliver drugs to the surgical site and release them locally.

Owner:FZIOMED

Passivating solution and surface treatment method for galvanized material

InactiveCN101608306AImprove corrosion resistanceMeet the requirements of the RoHS directiveMetallic material coating processesChromium freeAlcohol

The invention relates to a passivating solution which is aqueous solution containing water-soluble molybdic compound, boric acid, water-soluble organic matter and silica sol, wherein the water-soluble organic matter is a mixture of alcohol and organic carboxylic acid. The invention also provides a surface treatment method for a galvanized material, which comprises the following step: enabling the passivating solution to be in contact with a galvanized material. A galvanized layer can be passivated by the contact between the passivating solution and the galvanized material so as to enable the galvanized material to have excellent corrosion resistance. In addition, the paint composition is chromium free and meets the requirements of a RoHS instruction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Method of making biochips and the biochips resulting therefrom

InactiveUS6174683B1Rapid and simple and cost-effective methodHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsSodium bicarbonateSolid substrate

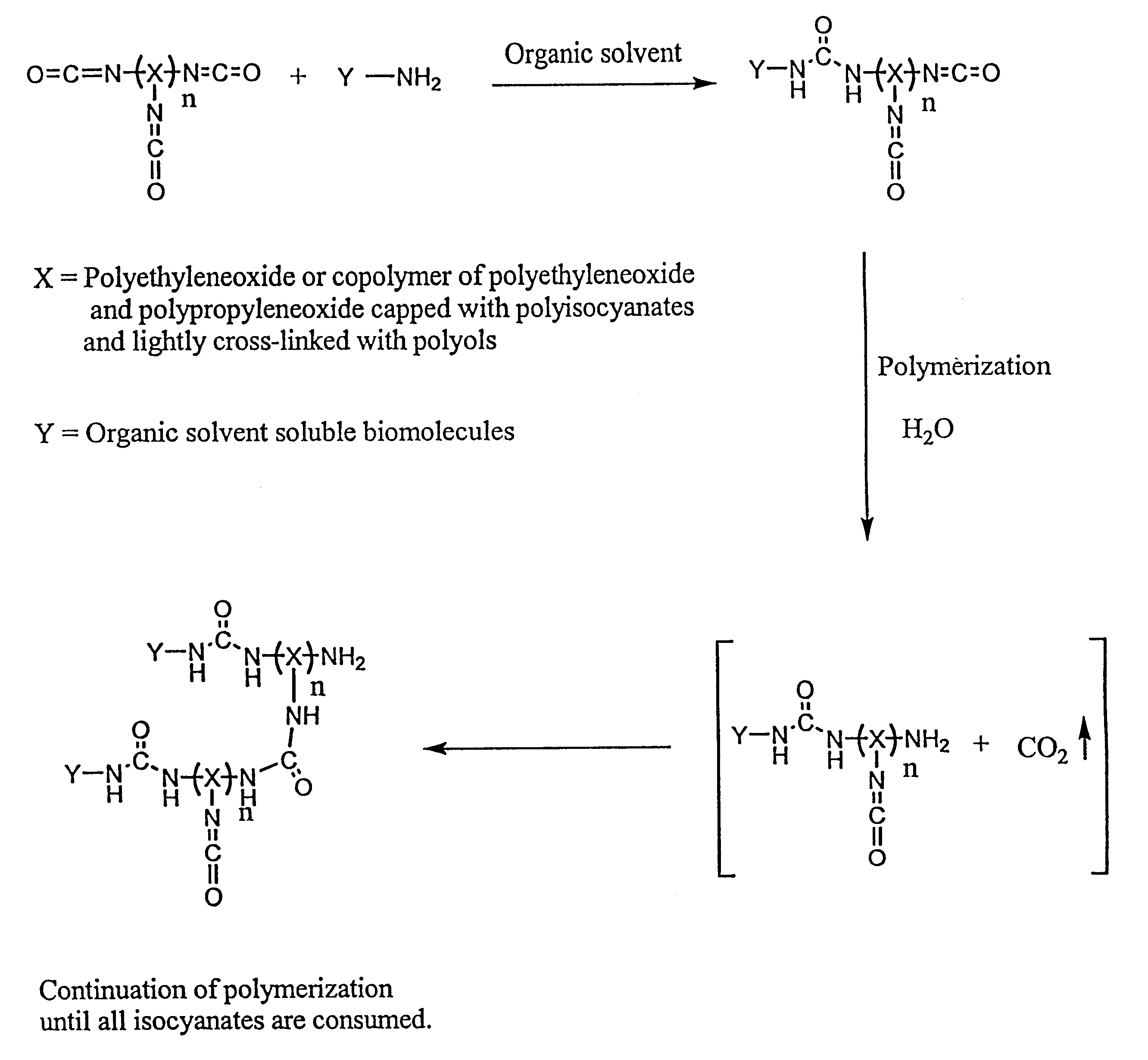

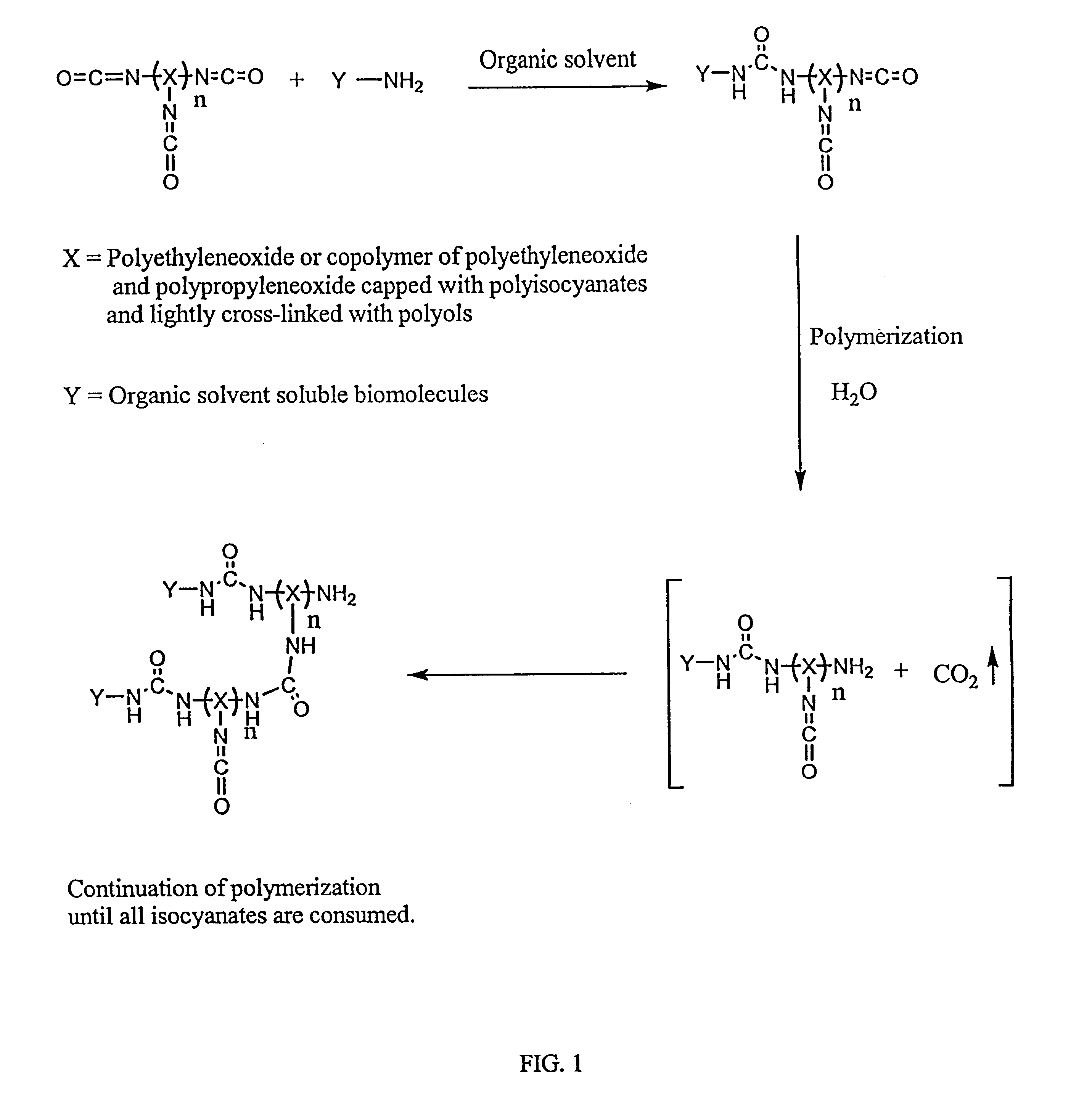

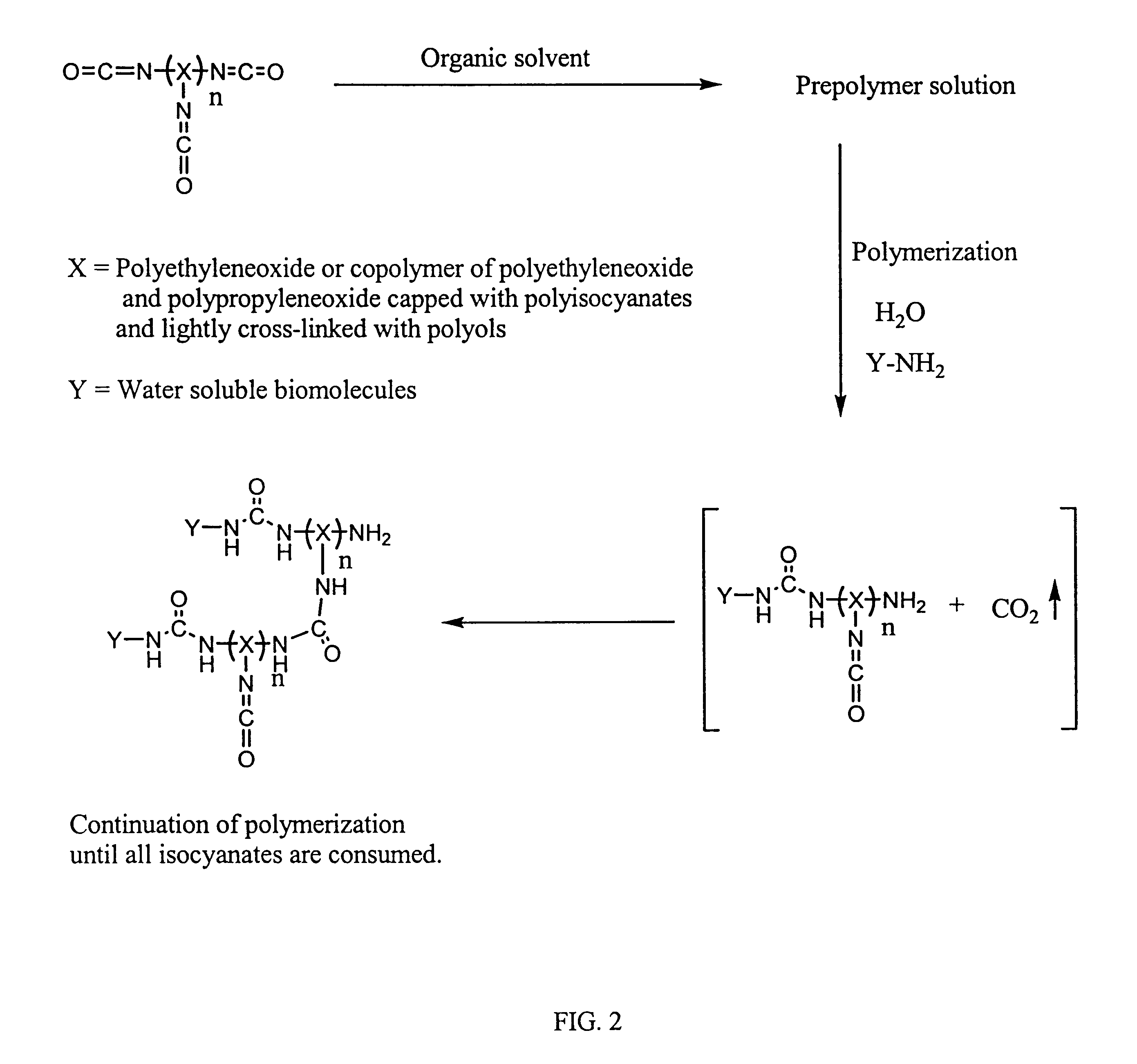

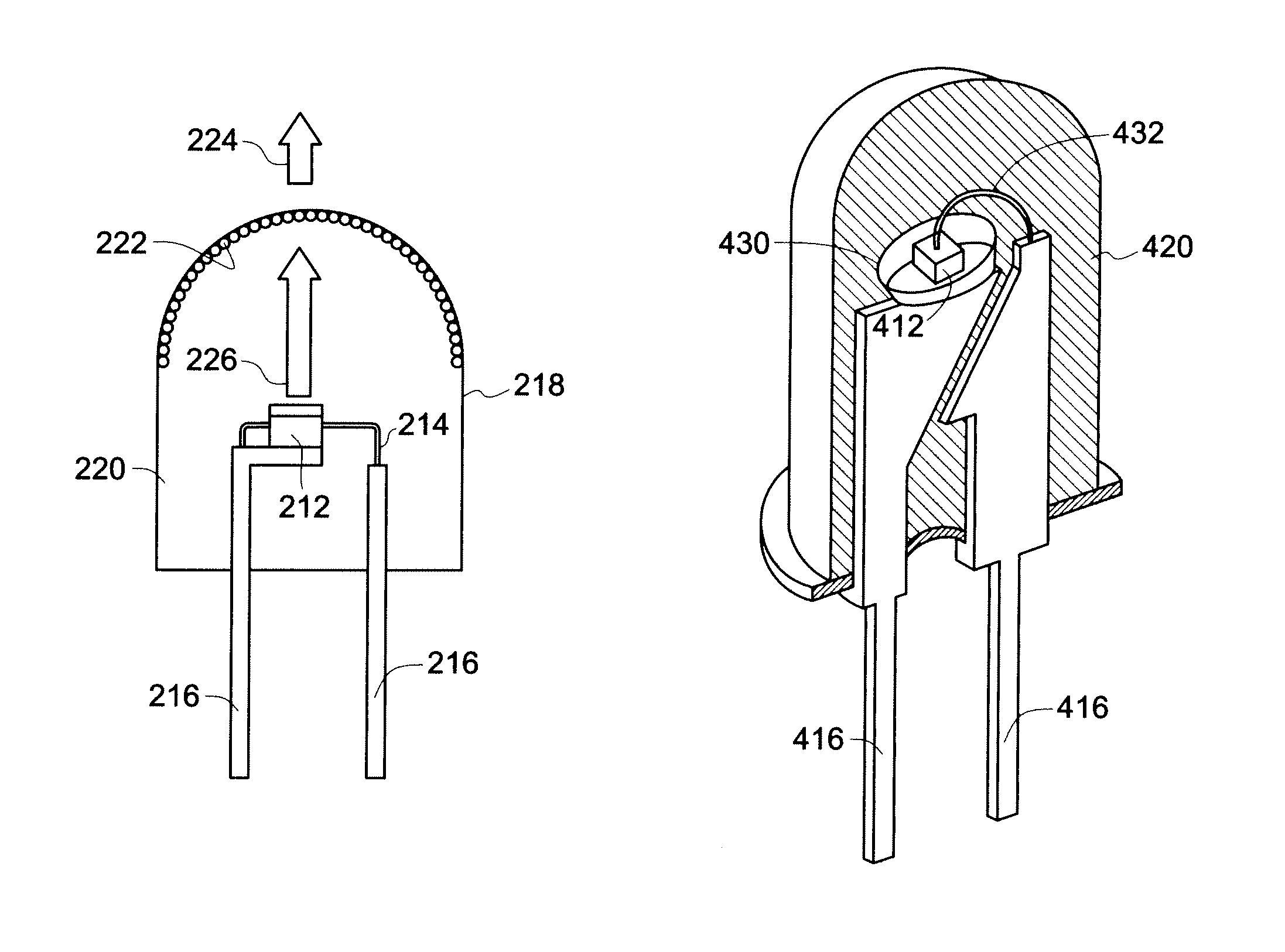

Methods for preparing a biochip are provided herein wherein the biomolecular probe to be used with the biochip is alternatively bound to a hydrogel prepolymer prior to or simultaneously with polymerization of the prepolymer. In particularly preferred embodiments, a polyurethane-based hydrogel prepolymer is derivatized with an organic solvent soluble biomolecule, such as a peptide nucleic acid probe in aprotic, organic solvent. Following derivatization of the prepolymer, an aqueous solution, for example sodium bicarbonate, preferably buffered to a pH of about 7.2 to about 9.5, is added to the derivatized prepolymer solution to initiate polymerization of the hydrogel. Alternatively, a water soluble biomolecule, such as DNA or other oligonucleotide, is prepared in an aqueous solution and added to the polyurethane-based hydrogel prepolymer such that derivatization and polymerization occur, essentially, simultaneously. While the hydrogel is polymerizing, it is microspotted onto a solid substrate, preferably a silanated glass substrate, to which the hydrogel microdroplet becomes covalently bound. Most preferably the hydrogel microdroplets are at least about 30 mum thick, for example about 50 mum to about 100 mum thick. The resulting biochips are particularly useful for gene discovery, gene characterization, functional gene analysis and related studies.

Owner:BIOCEPT INC

Color stable manganese-doped phosphors

ActiveUS8252613B1Solid-state devicesSemiconductor/solid-state device manufacturingParticulatesHydrofluoric acid

A process for preparing color stable Mn+4 doped phosphors includes providing a phosphor of formula I;Ax[MFy]:Mn+4 Iand contacting the phosphor in particulate form with a saturated solution of a composition of formula II in aqueous hydrofluoric acid;Ax[MFy]; IIwhereinA is Li, Na, K, Rb, Cs, NR4 or a combination thereof;M is Si, Ge, Sn, Ti, Zr, Al, Ga, In, Sc, Y, La, Nb, Ta, Bi, Gd, or a combination thereof;R is H, lower alkyl, or a combination thereof;x is the absolute value of the charge of the [MFy] ion; andy is 5, 6 or 7.In particular embodiments, M is Si, Ge, Sn, Ti, Zr, or a combination thereof.A lighting apparatus capable of emitting white light includes a semiconductor light source; and a phosphor composition radiationally coupled to the light source, and which includes a color stable Mn+4 doped phosphor.

Owner:GE LIGHTING SOLUTIONS LLC

Calcium based neutral and bioresorbable bone graft

InactiveUS20030055512A1Improve mechanical propertiesReduce decreaseSurgical adhesivesBone implantSulfateBone implant

An injectable and moldable putty comprising biodegradable calcium-based compounds including calcium sulfate, hydroxyapatite, and tricalcium phosphate is invented. The putty hardens into a solid body when mixed with water, saline, serum, or other neutral aqueous solutions. The hardening time of the putty can be tailored in order to meet the specific requirements of various dental or orthopedic applications. The pH of the putty is neutral during and after mixing. The invented putty may be used as bone graft, bone implant, or implantable drug delivery device.

Owner:BERKELEY ADVANCED BIOMATERIALS

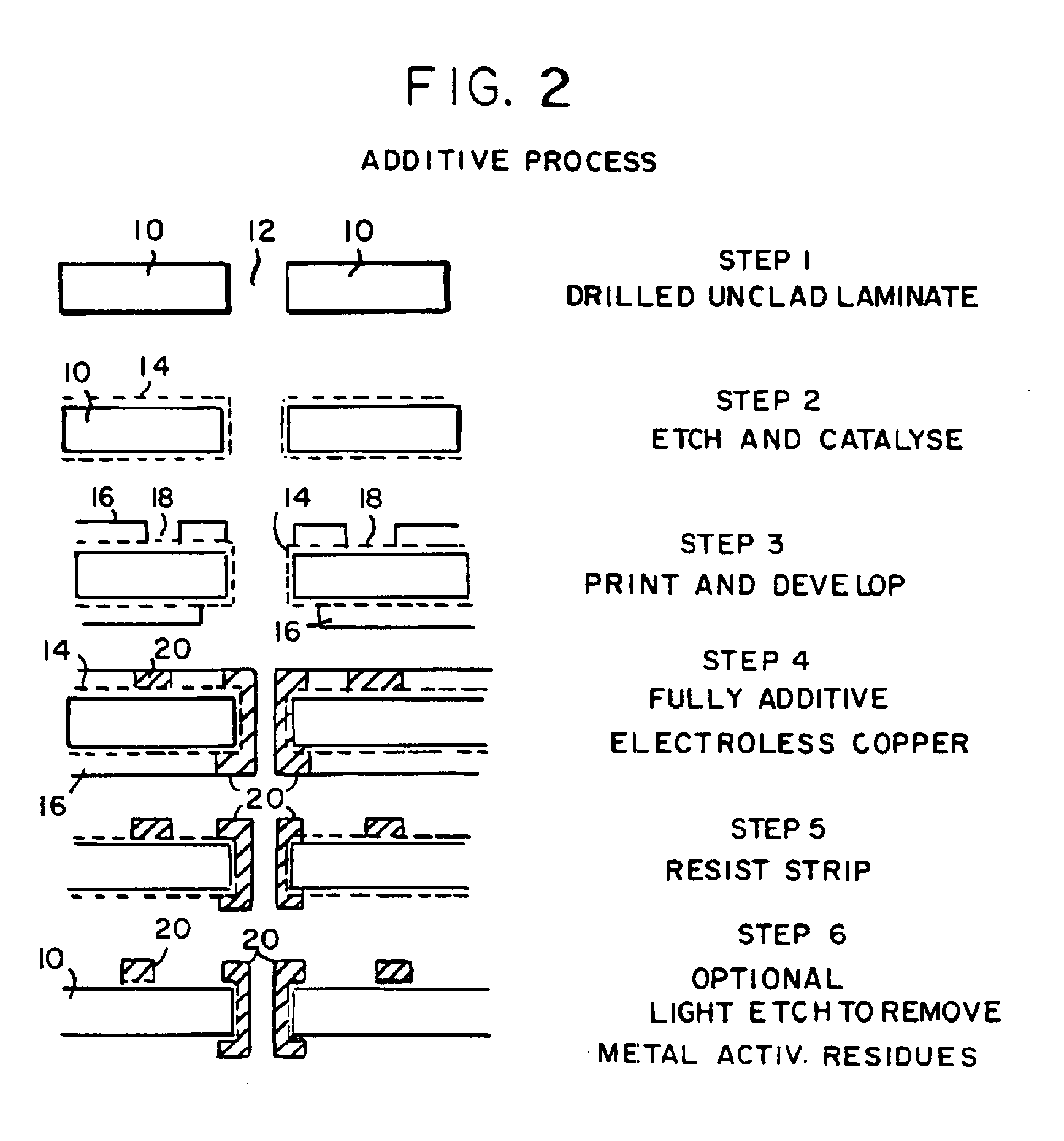

Electroless plating processes

InactiveUS6861097B1Reducing problem encounteredSimple methodPaper/cardboard articlesDecorative surface effectsPolymeric surfaceOxidation state

The invention includes processes for combined polymer surface treatment and metal deposition. Processes of the invention include forming an aqueous solution containing a metal activator, such as an oxidized species of silver, cobalt, ruthenium, cerium, iron, manganese, nickel, rhodium, or vanadium. The activator can be suitably oxidized to a higher oxidation state electrochemically. Exposing a part to be plated (such as an organic resin, e.g. a printed circuit board substrate) to the solution enables reactive hydroxyl species (e.g. hydroxyl radicals) to be generated and to texture the polymer surface. Such texturing facilitates good plated metal adhesion. As part of this contacting process sufficient time is allowed for both surface texturing to take place and for the oxidized metal activator to adsorb onto said part. The part is then contacted with a reducing agent capable of reducing the metal activator to a lower ionic form, or a lower oxidation state. That reduction can result in the formation of metallic catalytic material over the surface of the part. The reduced metal activator can then function to catalyze the electroless deposition of metal such as copper from solution by contacting the part with the plating solution.

Owner:SHIPLEY CO LLC

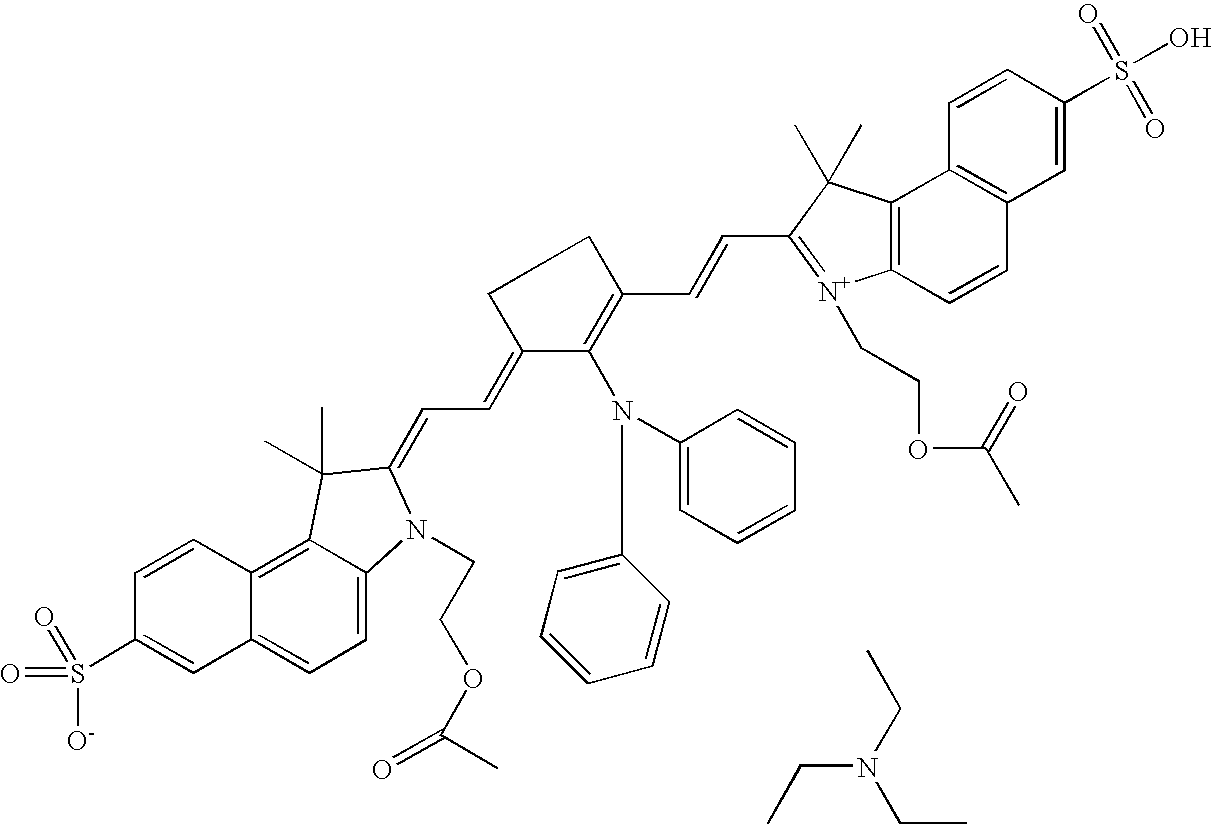

Compositions of polyacids and polyethers and methods for their use in reducing adhesions

InactiveUS6869938B1Improve anti-adhesion performancePrevent reformationBiocideSurgeryMicrosphereThrombogenicity

The present invention relates to improved methods for making and using bioadhesive, bioresorbable, anti-adhesion compositions made of intermacromolecular complexes of carboxyl-containing polysaccharides, polyethers, polyacids, polyalkylene oxides, multivalent cations and / or polycations. The polymers are associated with each other, and are then either dried into membranes or sponges, or are used as fluids or microspheres. Bioresorbable, bioadhesive, anti-adhesion compositions are useful in surgery to prevent the formation and reformation of post-surgical adhesions. The compositions are designed to breakdown in-vivo, and thus be removed from the body. Membranes are inserted during surgery either dry or optionally after conditioning in aqueous solutions. The anti-adhesion, bioadhesive, bioresorptive, antithrombogenic and physical properties of such membranes and gels can be varied as needed by carefully adjusting the pH and / or cation content of the polymer casting solutions, polyacid composition, the polyalkylene oxide composition, or by conditioning the membranes prior to surgical use. Multi-layered membranes can be made and used to provide further control over the physical and biological properties of antiadhesion membranes. Membranes and gels can be used concurrently. Antiadhesion compositions may also be used to lubricate tissues and / or medical instruments, and / or deliver drugs to the surgical site and release them locally.

Owner:FZIOMED

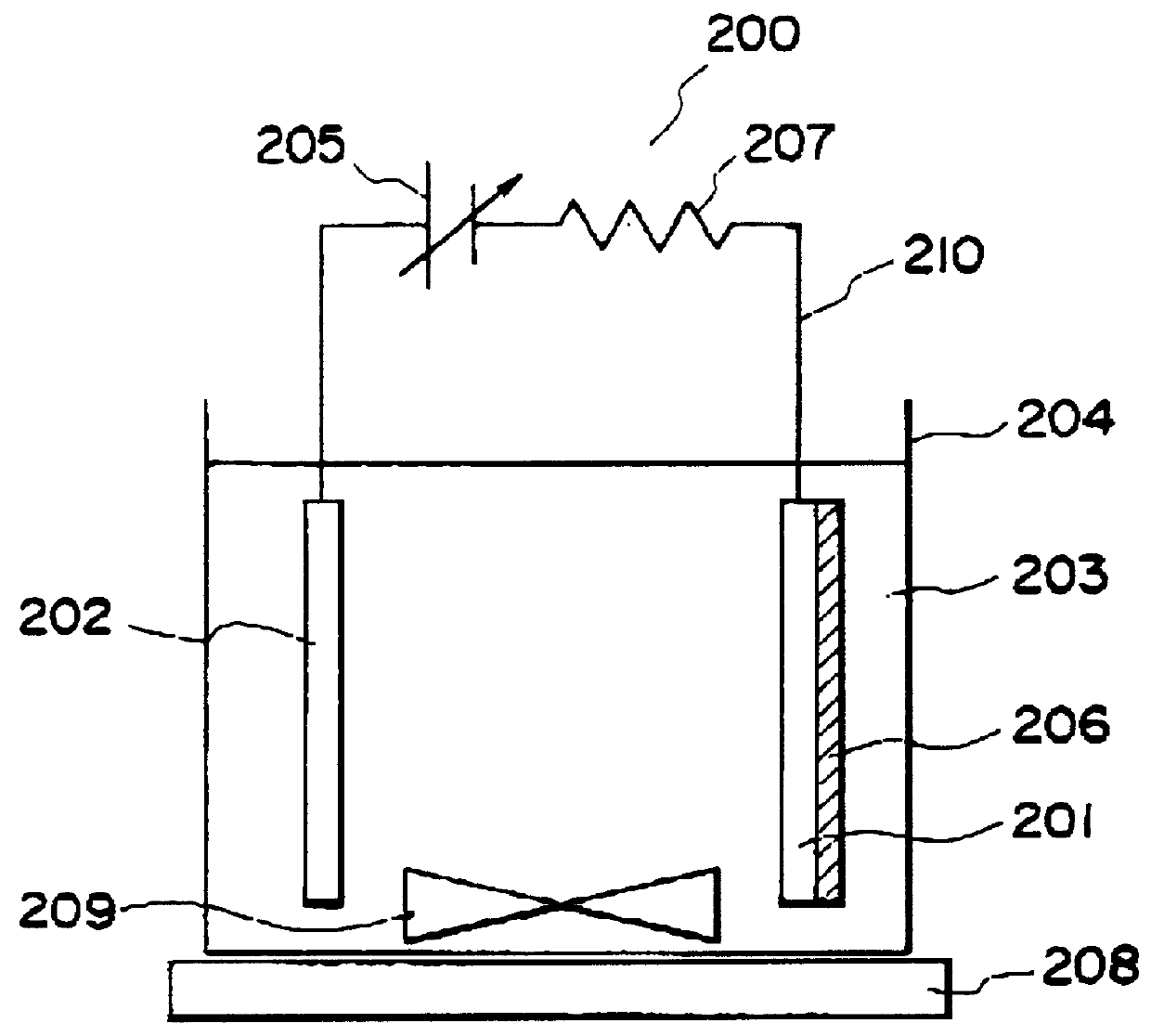

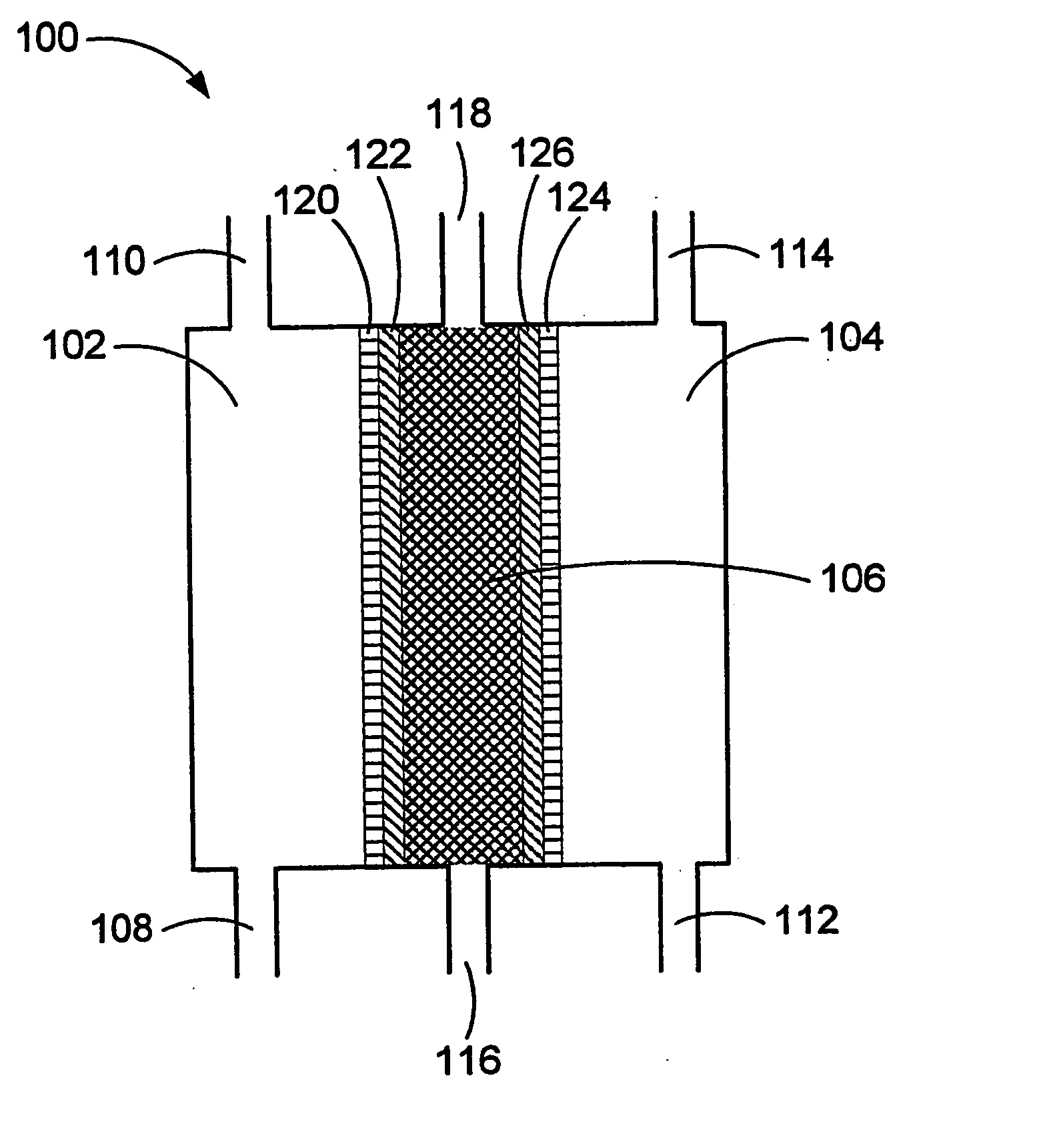

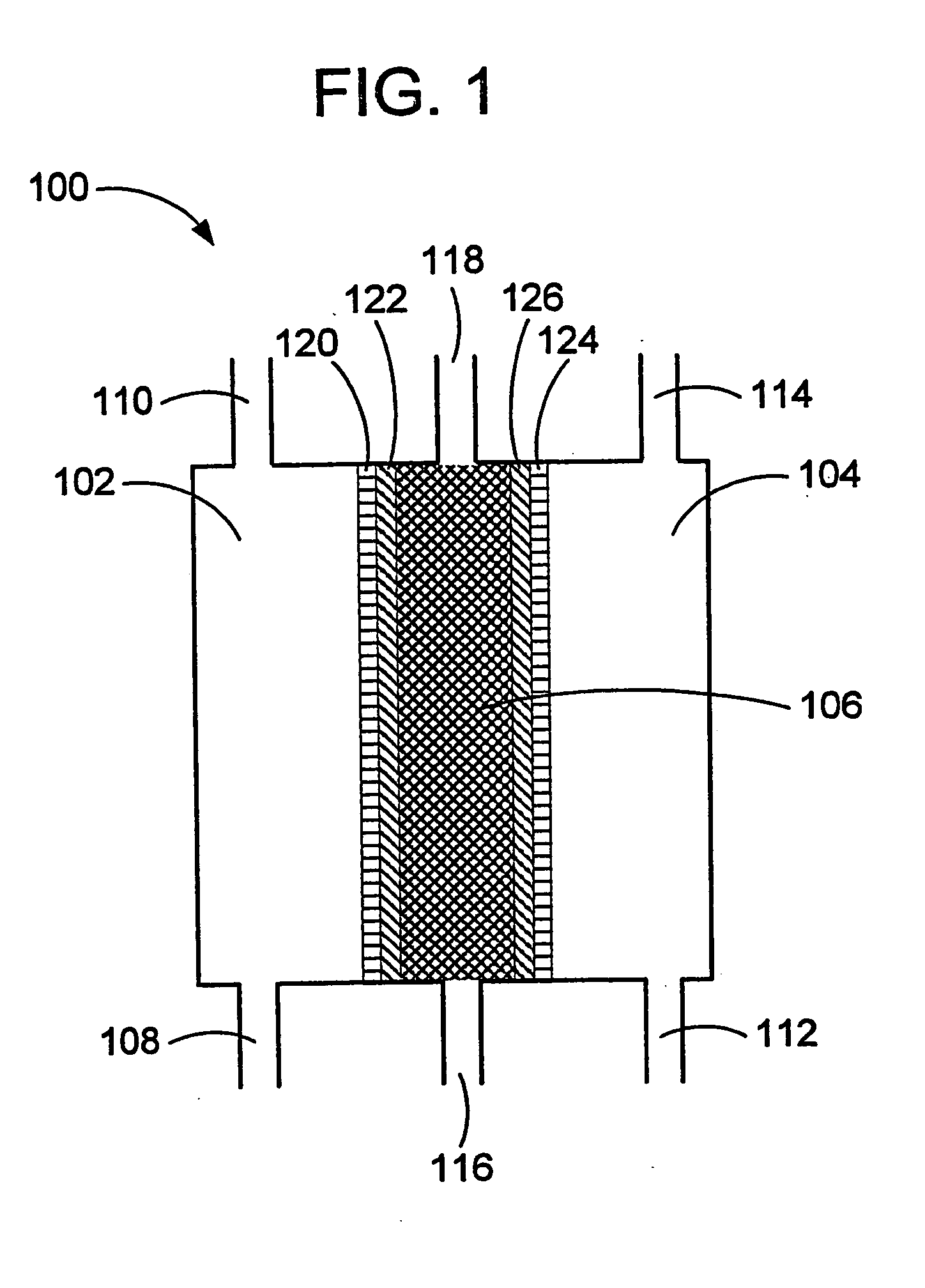

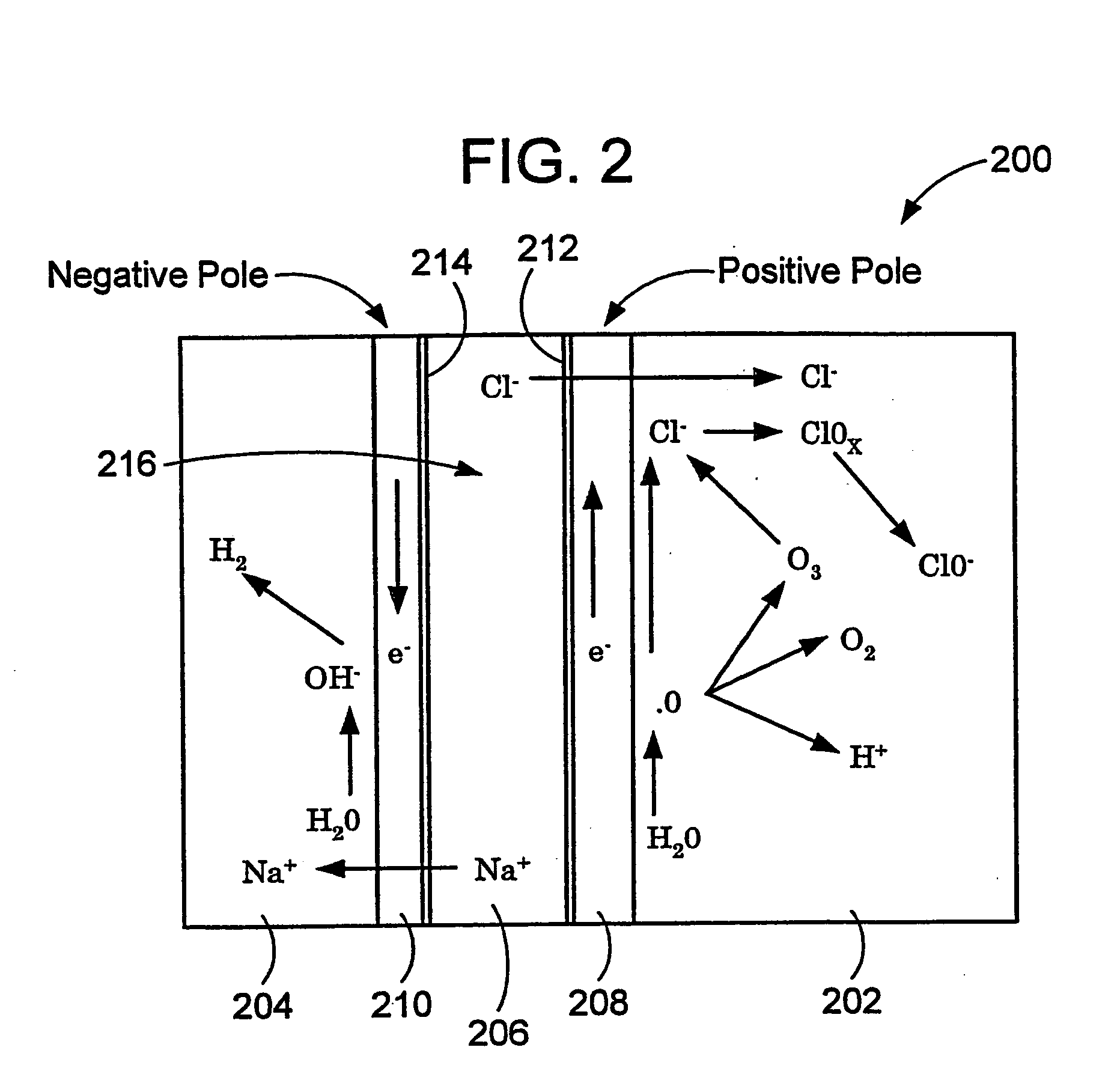

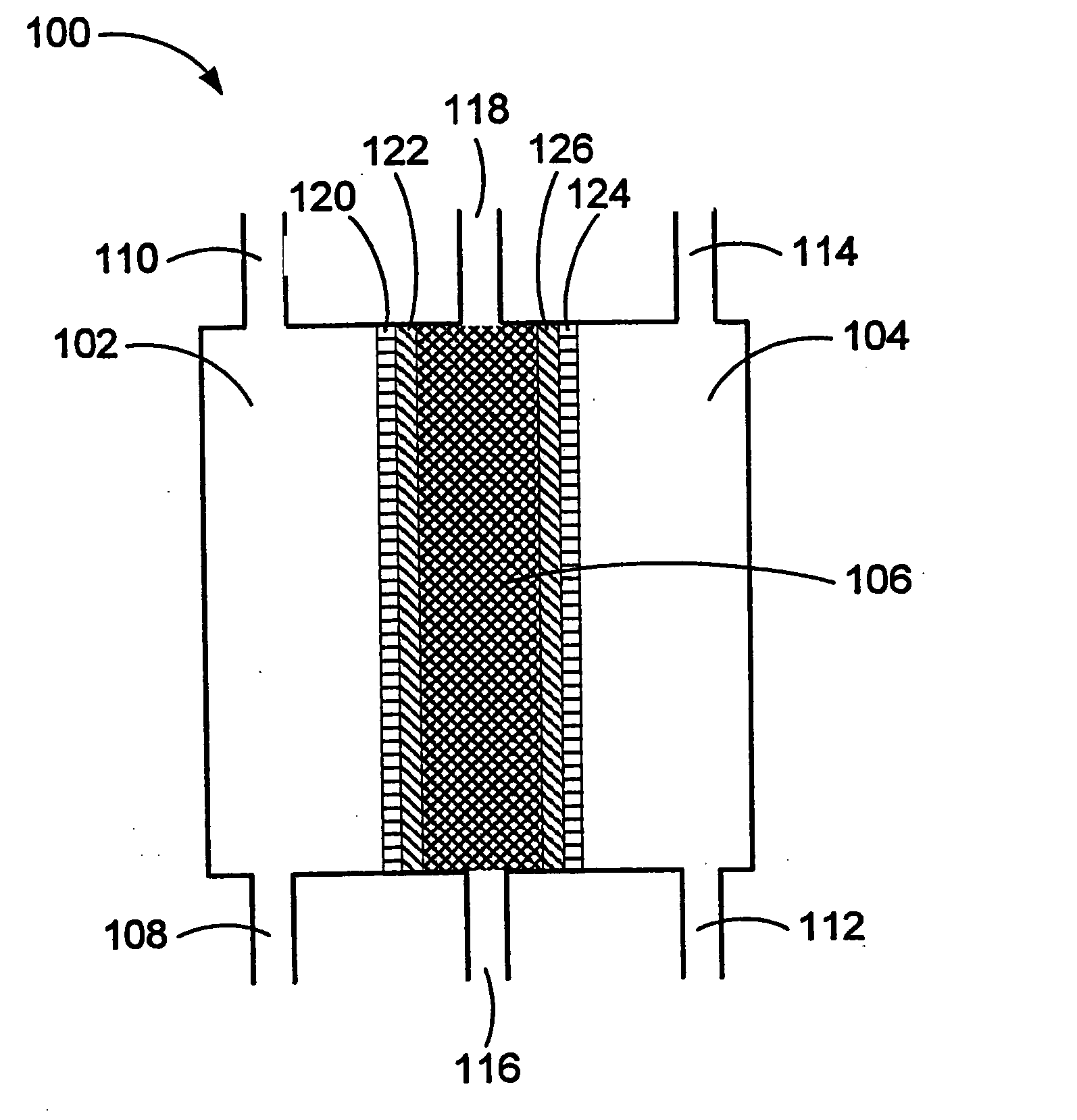

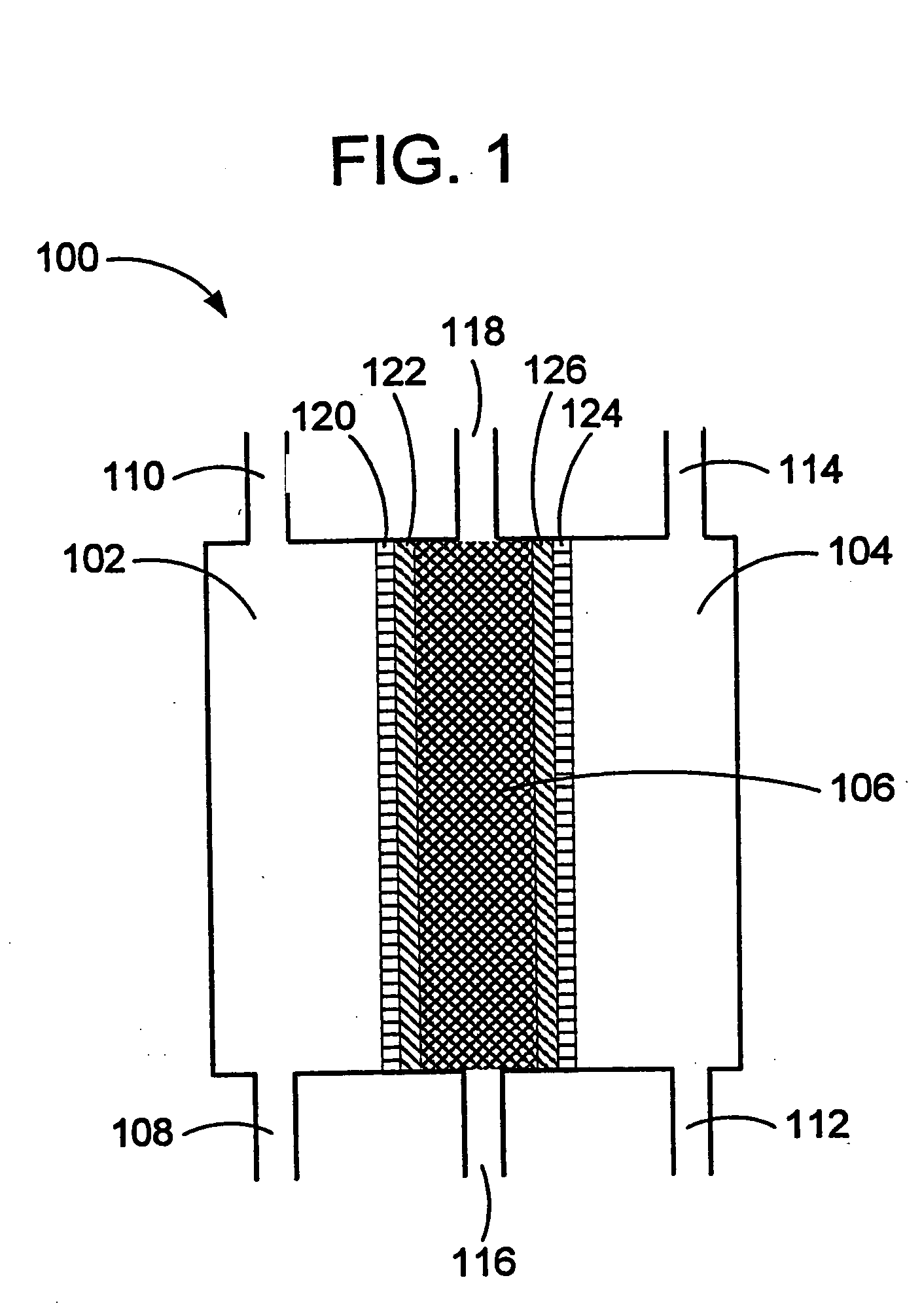

Oxidative reductive potential water solution and process for producing same

An oxidative reduction potential water solution that is stable for at least twenty-four hours. The invention also relates to an ORP water solution comprising anode water and cathode water. Another aspect of the invention is an apparatus for producing an ORP water solution comprising at least two electrolysis cells, wherein each cell comprises an anode chamber, cathode chamber and salt solution chamber located between the anode and cathode chambers, wherein the anode chamber is separated from the salt solution chamber by an anode electrode and a first membrane, and the cathode chamber is separated from the salt solution chamber by a cathode electrode and a second membrane.

Owner:SONOMA PHARMA INC

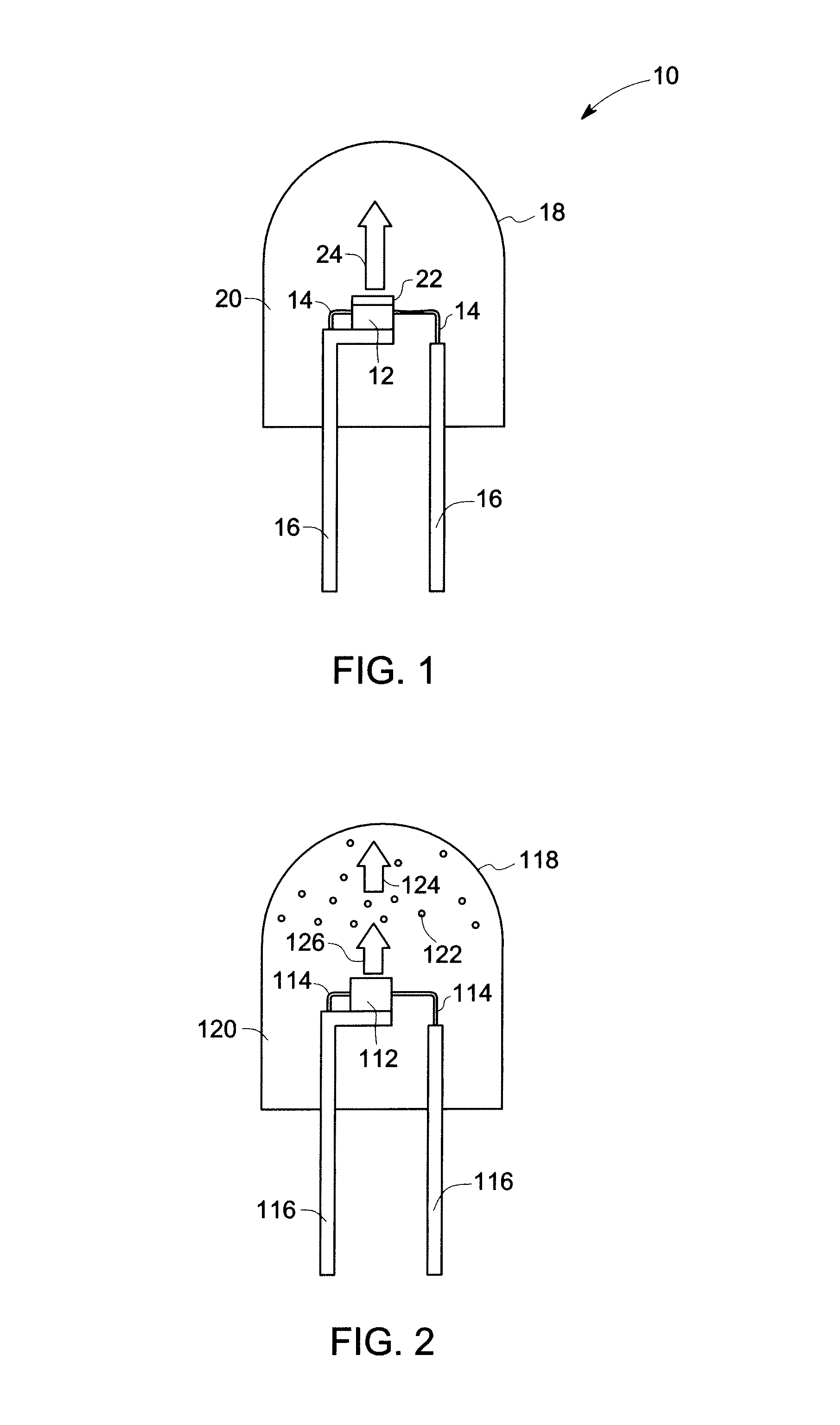

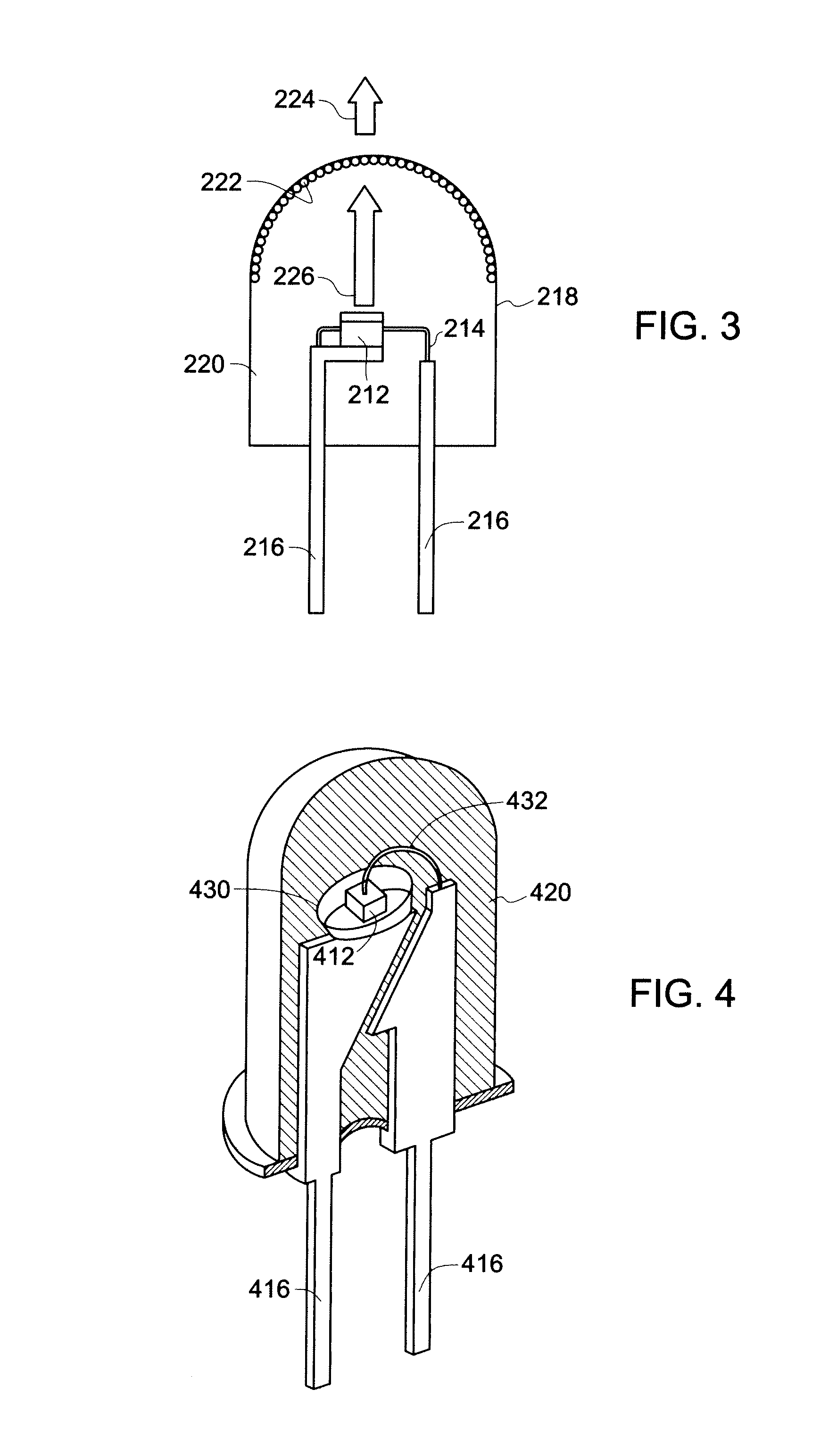

Methods and systems for operating an aerosol generator

InactiveUS20050217666A1Improve security levelImprove delivery efficiencyAntibacterial agentsOrganic active ingredientsDiseaseAmikacin

A method of treating a patient with a pulmonary disease, where the method includes delivering a dose of aerosolized medicament intermittently to a ventilator circuit coupled to the respiratory system of the patient. Also, a method of treating a patient with a pulmonary disease, where the method includes taking the patient off a ventilator, and administering to the patient, a nebulized aerosol comprising from about 100 μg to about 500 mg of a medicament. Additionally, an aerosolized medicament for the treatment of a pulmonary disease, where the medicament includes amikacin mixed with an aqueous solution having an adjusted pH from about 5.5 to about 6.3. The pH is adjusted by adding hydrochloric acid and sodium hydroxide to the aqueous solution.

Owner:NOVARTIS AG

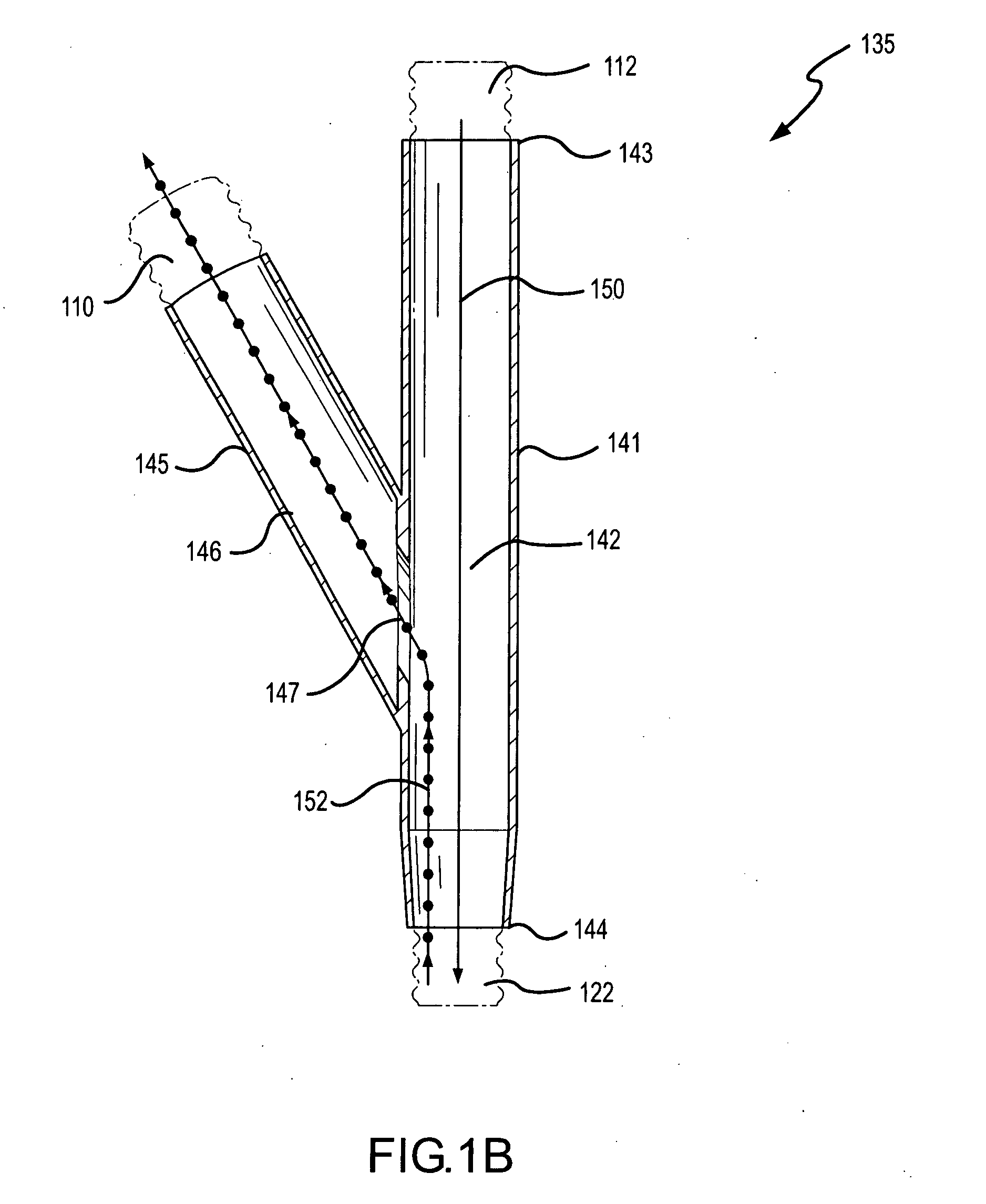

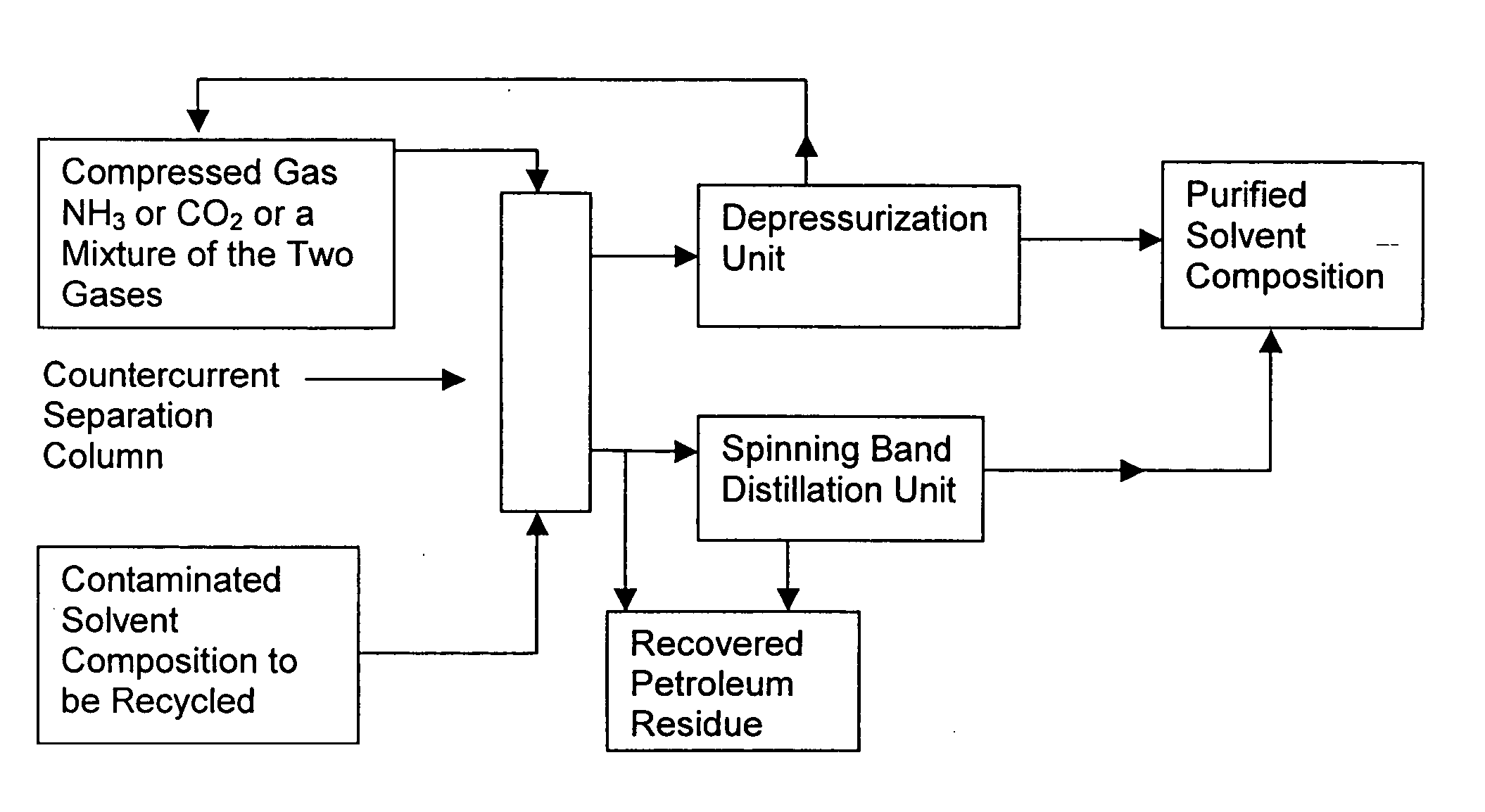

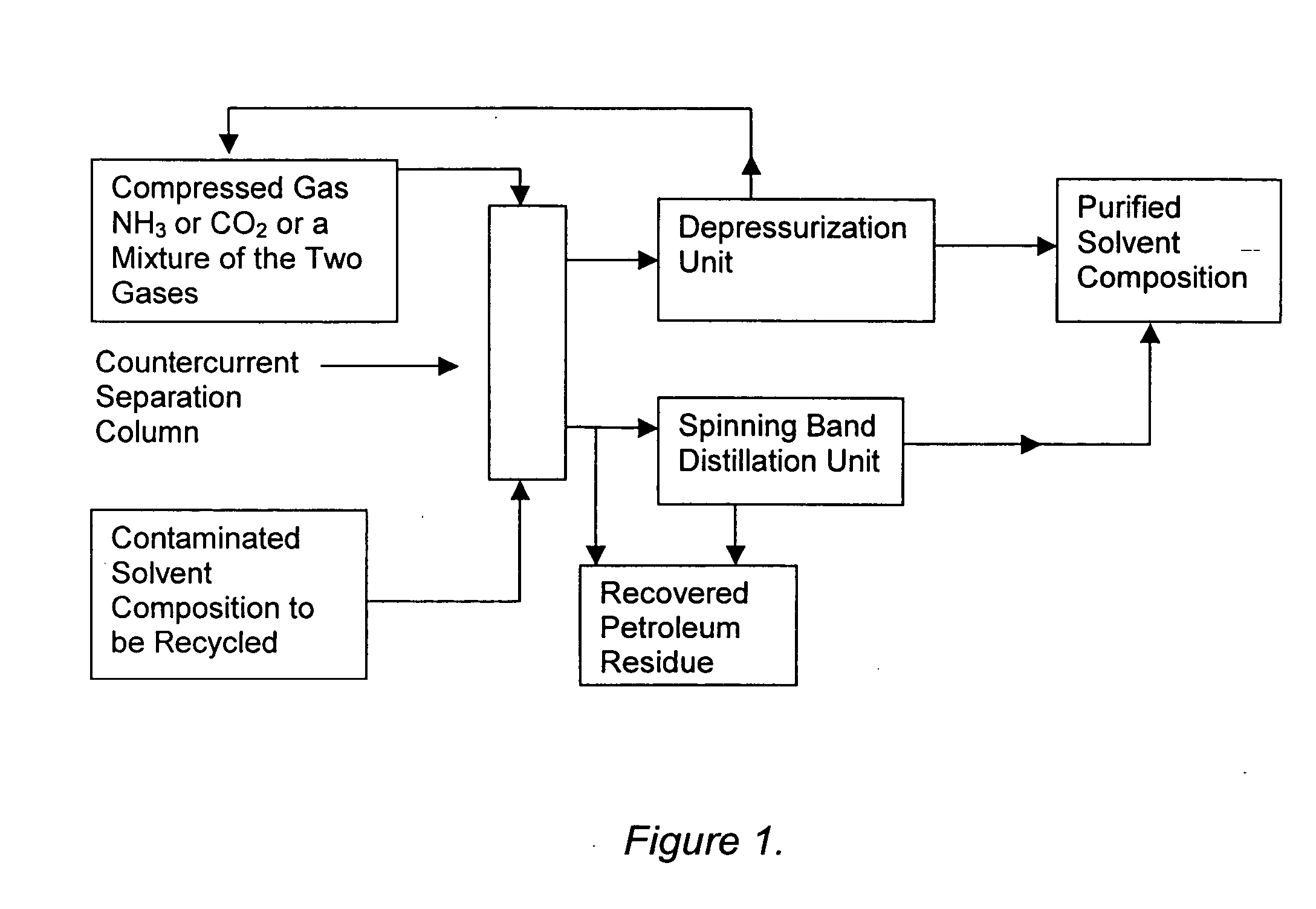

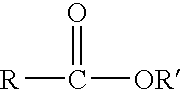

Solvent compositions for removing petroleum residue from a substrate and methods of use thereof

ActiveUS20050197267A1Cationic surface-active compoundsNon-ionic surface-active compoundsSpinning band distillationPetroleum

Water-soluble solvent compositions, including from about 10% to about 60% by weight of an aromatic ester; from about 30% to about 60% by weight of an aliphatic ester; from 0% to about 15% by weight of a co-solvent; from 0% to about 20% of one of a cyclic terpene and a terpenoid; from 0% to about 1% by weight of an odor-masking agent; and from 0% to about 20% by weight of a nonionic surfactant, for removing petroleum residue from a substrate, and methods of use thereof. The composition can further comprise water. The composition also can comprise an aqueous solution. The method for removing petroleum residue from a substrate can further comprise recycling the solvent composition by using a countercurrent separation column charged with compressed ammonia and / or carbon dioxide and a spinning band distillation column to separate the solvent composition from the petroleum residue.

Owner:CRUDE SPILL CLEANING CO INC

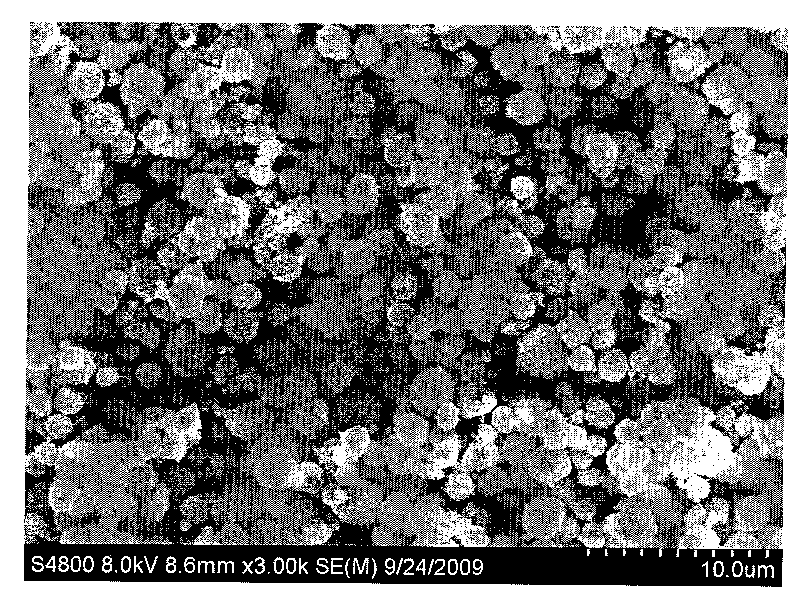

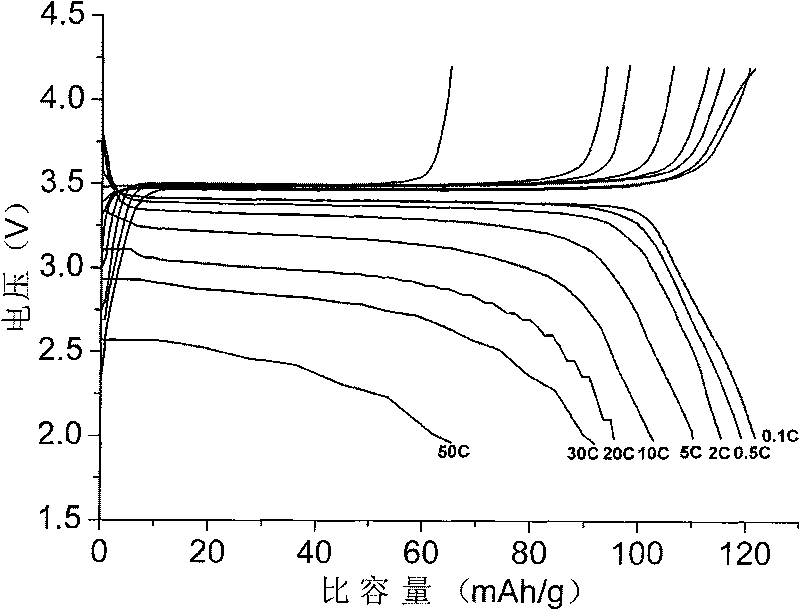

Graphite alkene iron lithium phosphate positive active material, preparing method thereof, and lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material

InactiveCN101752561AImprove conductivityImprove cycle stabilityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

The present invention relates to graphite alkene iron lithium phosphate positive active material, a preparing method thereof, and a lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material. Graphite alkene and iron lithium phosphate are dispersed into water solution to be mixed evenly by stirring and ultra audible sound, then, are dried to obtain iron lithium phosphate material compounded by the graphite alkene and the iron lithium phosphate to be annealed by high temperature, and finally, the graphite alkene modified iron lithium phosphate positive active material is obtained. Compared with traditional carbon coated and conductive polymeric adulteration modified lithium batteries, the lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material has the advantages of high battery capacity, good charging-discharging circulating performance, long life and high circulating stability, and has great utility value.

Owner:宁波艾能锂电材料科技股份有限公司

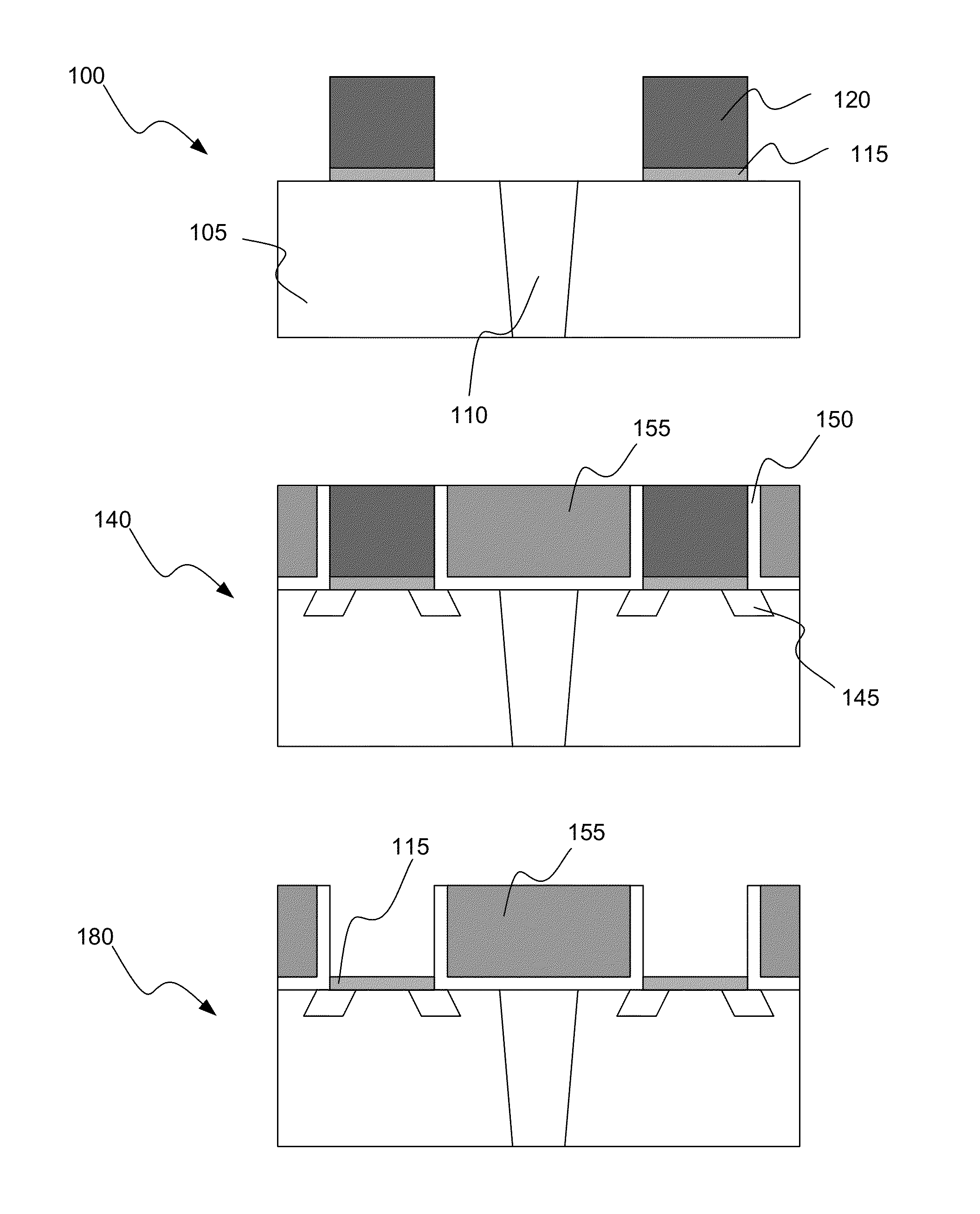

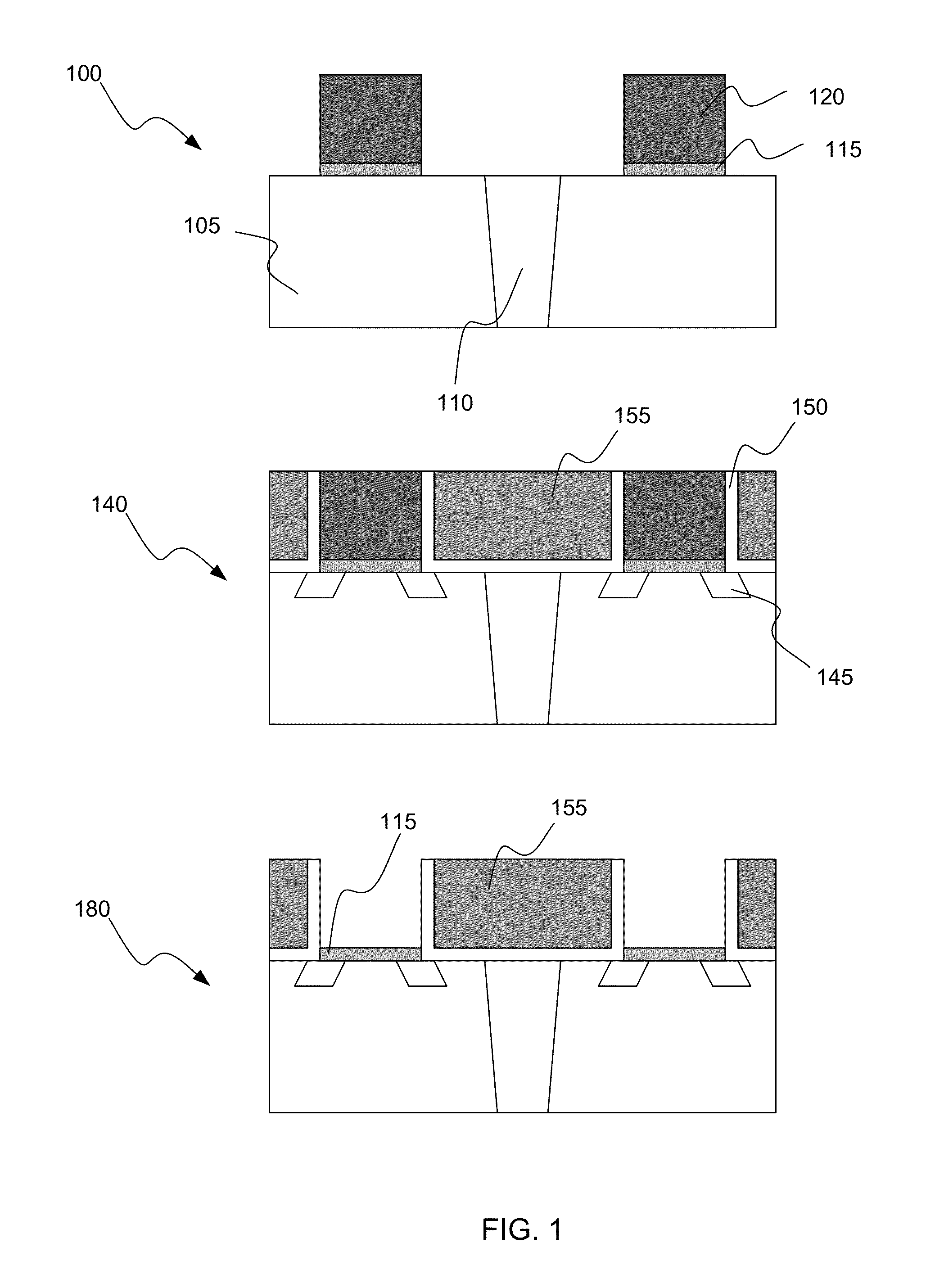

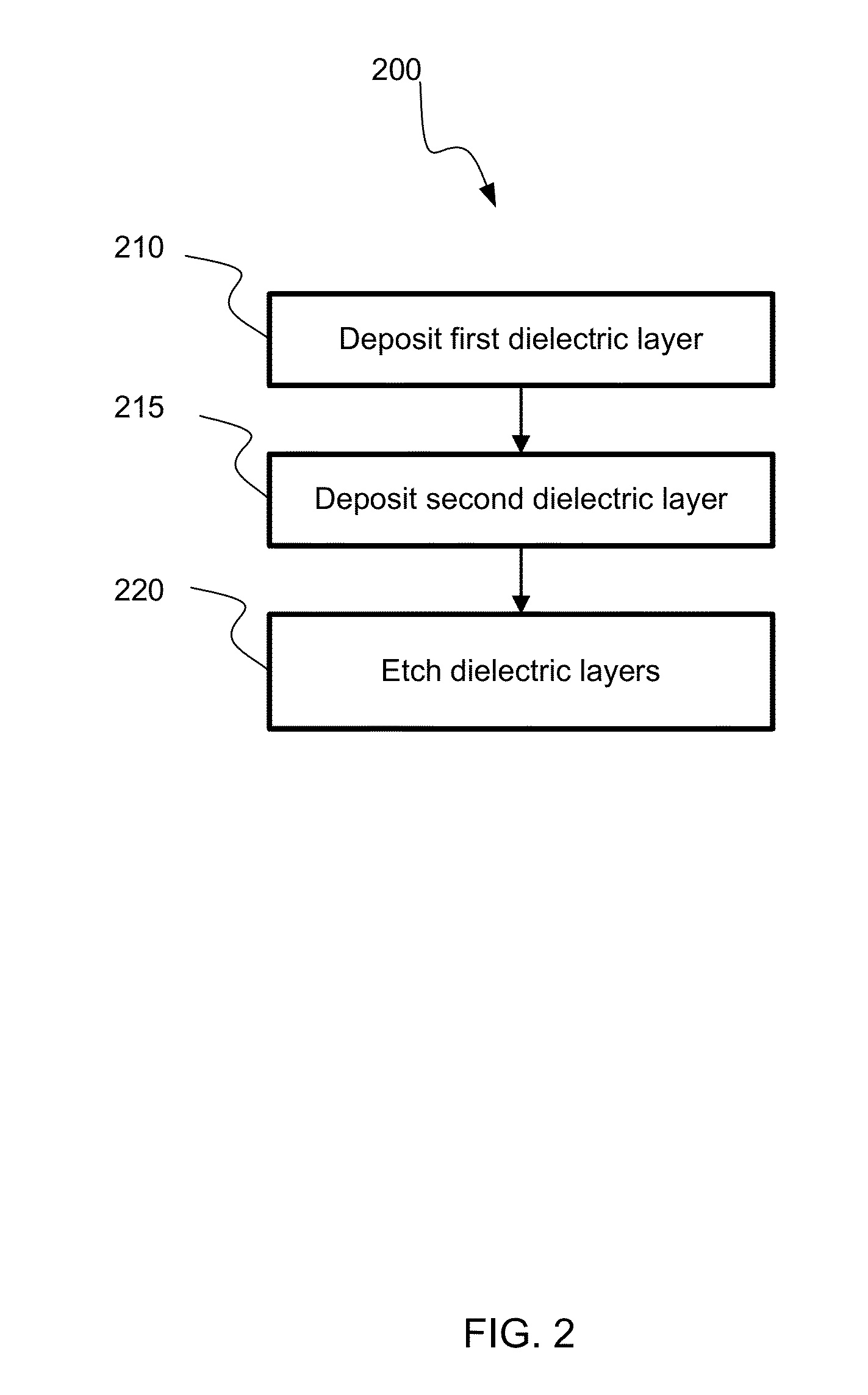

Insensitive dry removal process for semiconductor integration

InactiveUS20130260564A1Improve film qualityDeterioration of film qualitySemiconductor/solid-state device manufacturingSemiconductor devicesAqueous solutionDielectric layer

Methods of depositing and etching dielectric layers from a surface of a semiconductor substrate are disclosed. The methods may include depositing a first dielectric layer having a first wet etch rate in aqueous HF. The methods also may include depositing a second dielectric layer that may be initially flowable following deposition, and the second dielectric layer may have a second wet etch rate in aqueous HF that is higher than the first wet etch rate. The methods may further include etching the first and second dielectric layers with an etchant gas mixture, where the first and second dielectric layers have a ratio of etch rates that is closer to one than the ratio of the second wet etch rate to the first wet etch rate in aqueous HF.

Owner:APPLIED MATERIALS INC

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

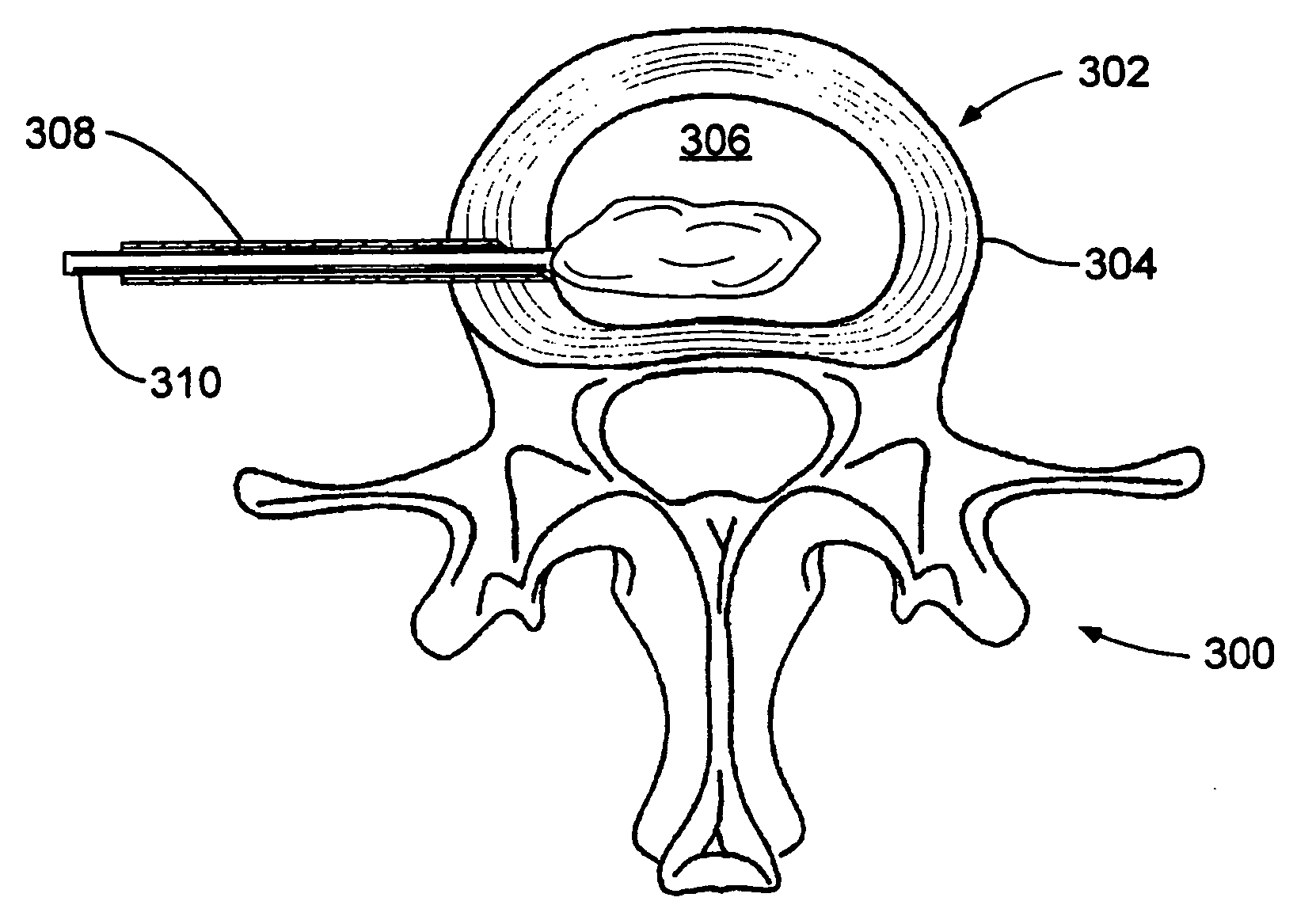

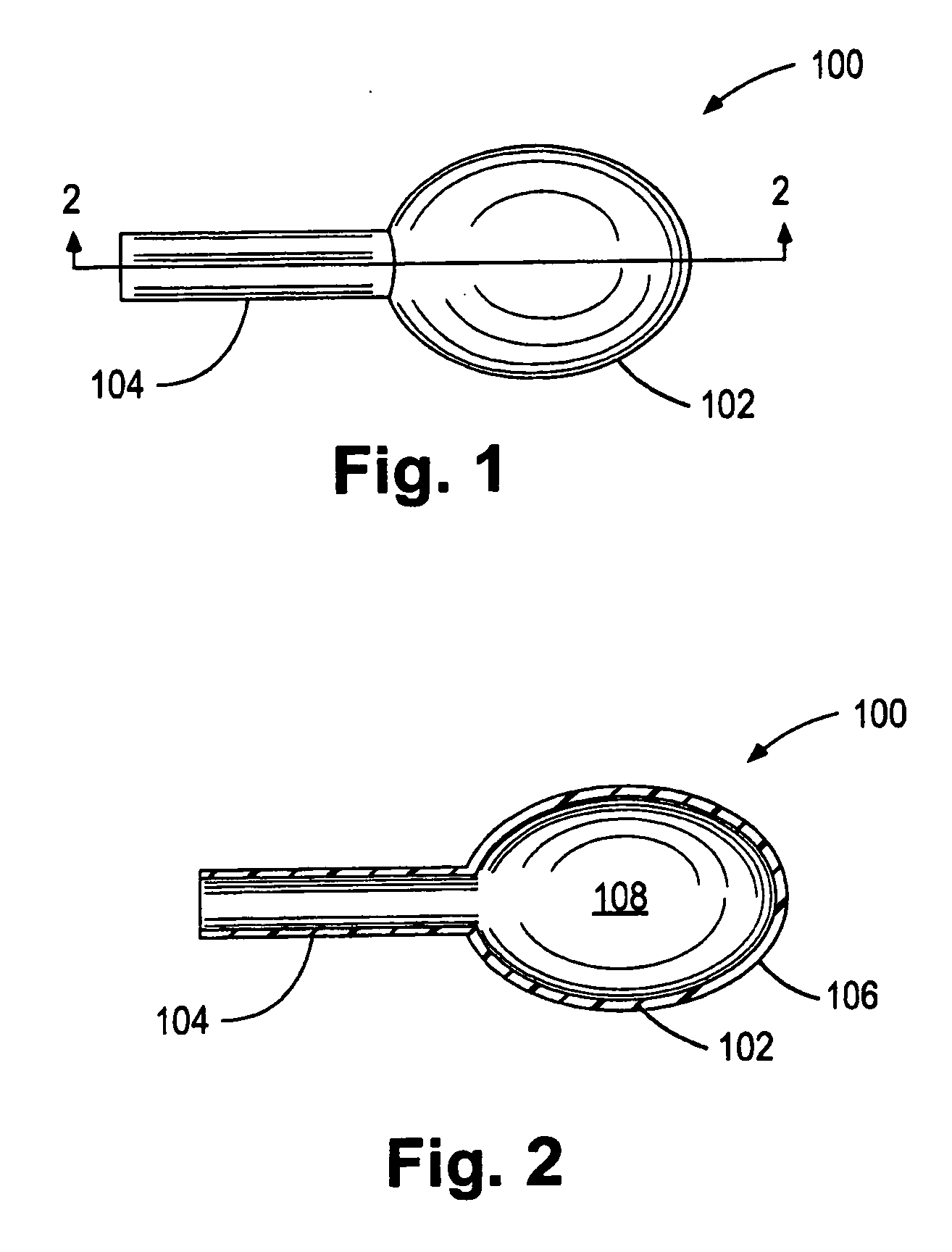

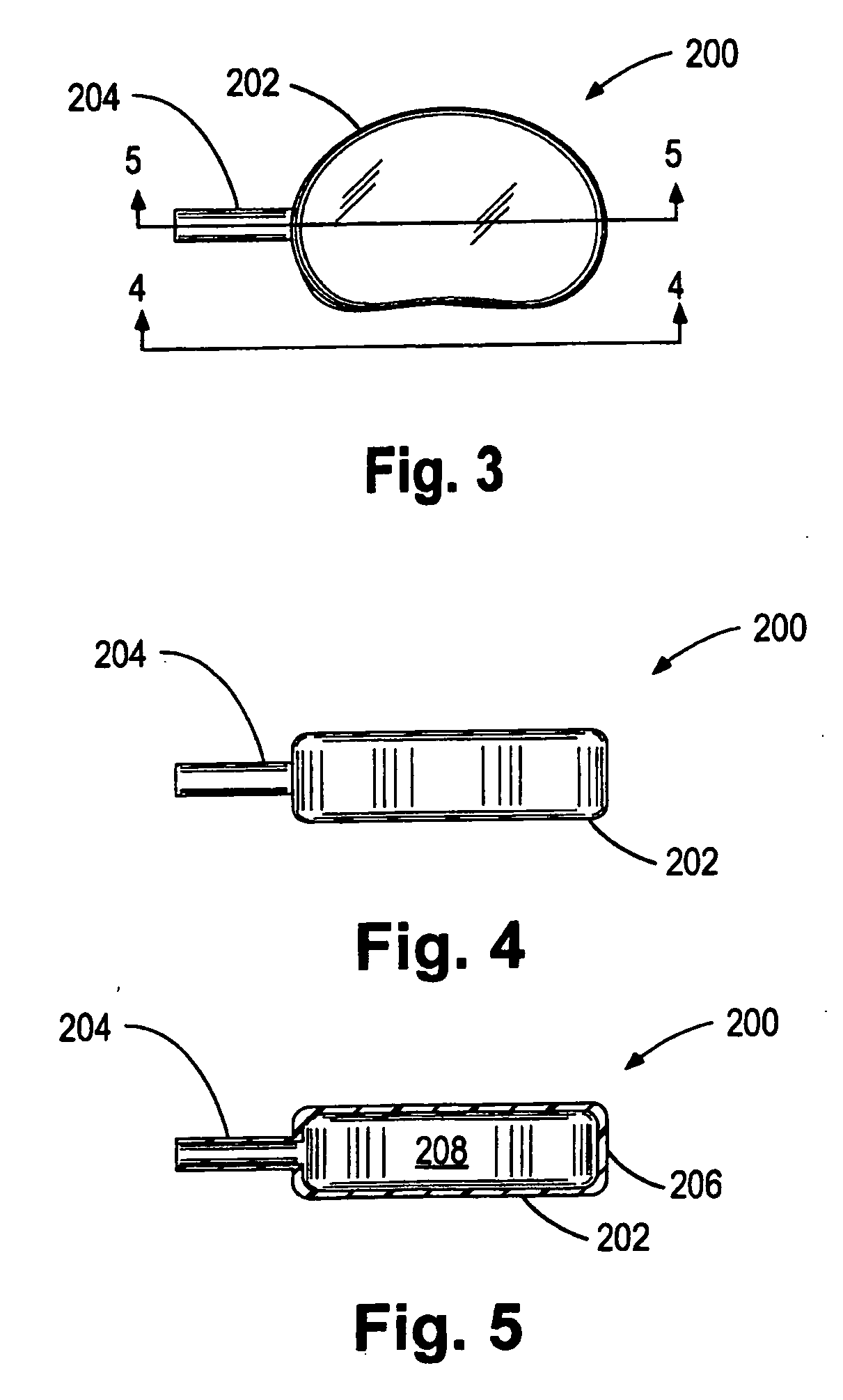

Hydrogel balloon prosthesis for nucleus pulposus

Owner:SYNTHES USA +1

Oxidative reductive potential water solution and methods of using the same

Provided is an oxidative reduction potential (ORP) water solution that is stable for at least twenty-four hours and methods of using the solution. The present invention provides a method of preventing or treating a condition in a patient, which method comprises administering a therapeutically effective amount of the ORP water solution. Additionally provided is a method of treating impaired or damaged tissue, which method comprises contacting the tissue with a therapeutically effective amount of the ORP water solution. Further provided is a method of disinfecting a surface, which method comprises contacting the surface with an anti-infective amount of the ORP water solution.

Owner:SONOMA PHARMA INC

Method for Preparing Flavorful and Aromatic Compounds

InactiveUS20100037903A1Add flavorIncrease aromaTobacco treatmentSolid sorbent liquid separationMaillard reactionPyrazine

The invention provides a method of preparing a purified, pyrazine-containing aqueous composition by mixing a reducing sugar, a base, and an amino acid in water to produce a mixture; heating the mixture for a time and under conditions conducive to Maillard reactions such that a flavorful and aromatic aqueous solution is formed, the aqueous solution comprising a plurality of pyrazines and a first 4-methylimidazole concentration; distilling the aqueous solution to produce an aqueous distillate comprising a plurality of pyrazines and having a second 4-methylimidazole concentration lower than the first 4-methylimidazole concentration; and collecting the aqueous distillate. The invention also includes flavorful and aromatic aqueous compositions formed by this inventive method, as well as tobacco products (e.g., smokable materials, smoking articles, and smokeless tobacco) incorporating the flavorful and aromatic composition.

Owner:R J REYNOLDS TOBACCO COMPANY

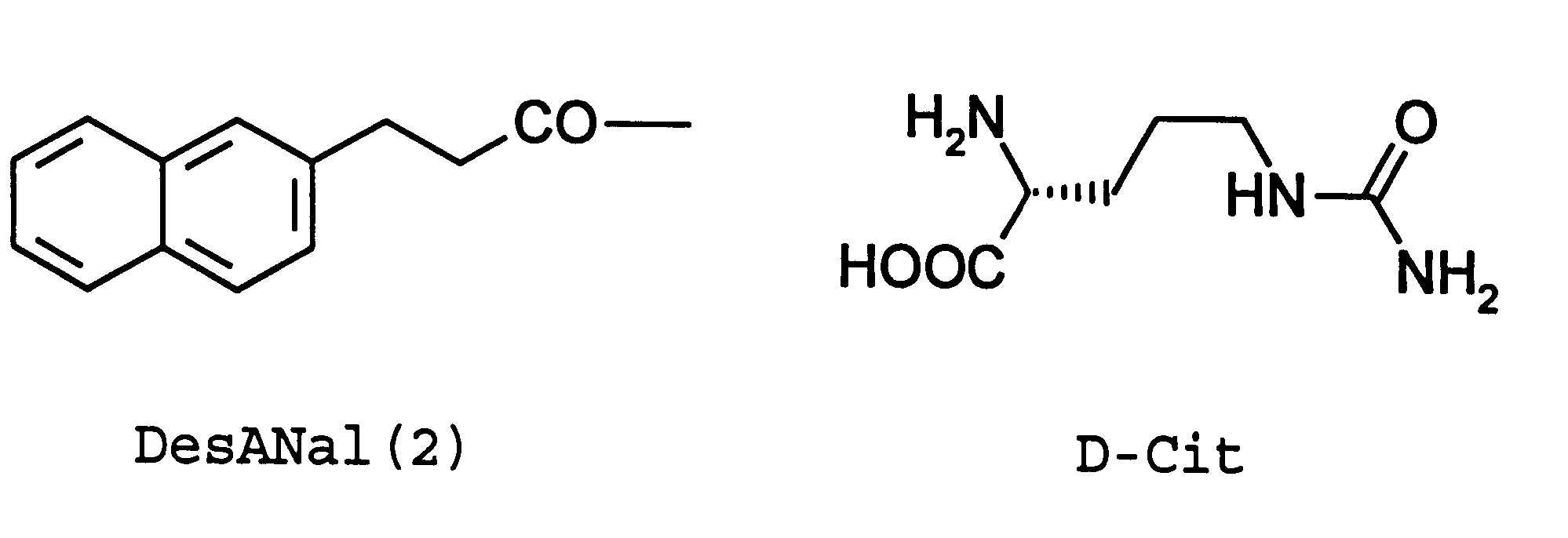

Method of producing morphologically uniform microcapsules and microcapsules produced by this method

InactiveUS6294204B1Readily water-miscibleSpeed up concentrationPowder deliveryBiocidePolymer dissolutionEmulsion

The invention relates to a process for the production of morphologically uniform microcapsules that contain peptides, proteins or other water-soluble biologically active substances as active ingredients as well as microcapsules that are produced according to this process with a degree of concentration of between 3 to 30% by weight and a diameter<=8 mum.According to the invention, biodegradable polymers are dissolved in a halogen-free solvent or solvent mixture, and the buffered active ingredient solution, which has a pH of between 6.0 to 8.0, is dispersed into this solution. Then, an aqueous solution that contains a surface-active substance (W / O / W-emulsion) is added to this W / O-emulsion, and the solvent is removed.The microcapsules that are produced with this process do not show any tendency toward agglomeration. The encapsulation efficiency of the process is approximately 90 to 95%.

Owner:ALRISE BIOSYST

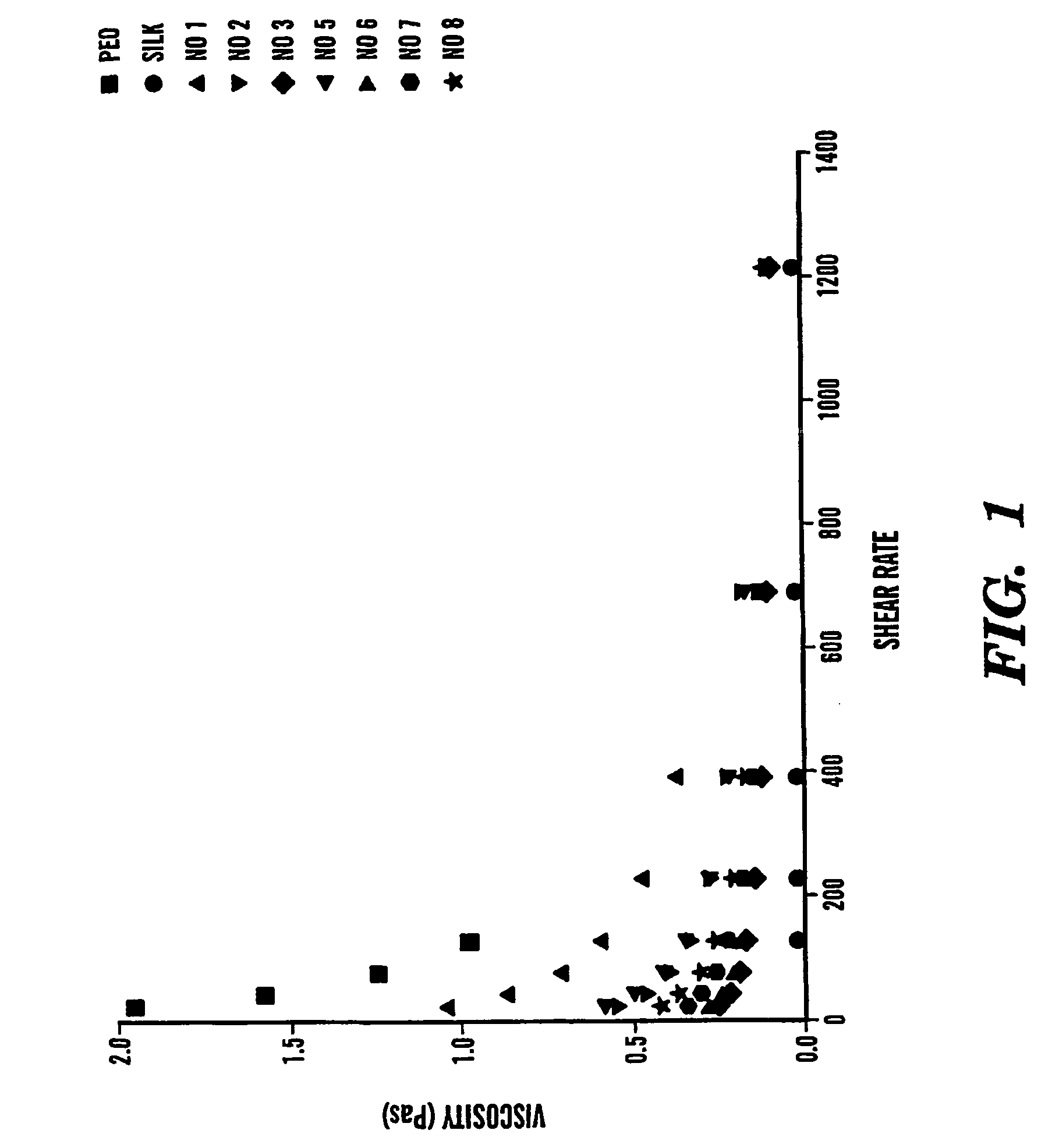

Silk biomaterials and methods of use thereof

ActiveUS7674882B2Avoid problemsReduce usagePeptide/protein ingredientsFilament/thread formingFiberIn vivo

The present invention provides an all-aqueous process and composition for production of silk biomaterials, e.g., fibers, films, foams and mats. In the process, at least one biocompatible polymer, such as poly(ethylene oxide) (PEO) (a well-documented biocompatible material), was blended with the silk protein prior to processing e.g., electrospinning. We discovered that this step avoids problems associated with conformational transitions of fibroin during solubilization and reprocessing from aqueous solution which lead to embrittled materials. Moreover, the process avoids the use of organic solvents that can pose problems when the processed biomaterials are exposed to cells in vitro or in vivo.

Owner:MASSACHUSETTS INST OF TECH +1

Production of Soluble Protein Solutions from Soy ("S701")

ActiveUS20100098818A1Prevent oxidationMilk preparationProtein composition from vegetable seedsProtein solutionSports drink

A soy protein product, which may be an isolate, produces transparent heat-stable solutions at low pH values and is useful for the fortification of soft drinks and sports drinks without precipitation of protein. The soy protein product is obtained by extracting a soy protein source material with an aqueous calcium salt solution to form an aqueous soy protein solution, separating the aqueous soy protein solution from residual soy protein source, adjusting the pH of the aqueous soy protein solution to a pH of about 1.5 to about 4.4 to produce an acidified clear soy protein solution, which may be dried, following optional concentration and diafiltration, to provide the soy protein product.

Owner:BURCON NUTRASCI MB

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com