Patents

Literature

14040 results about "Spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spinning is a manufacturing process for creating polymer fibers. It is a specialized form of extrusion that uses a spinneret to form multiple continuous filaments. There are many types of spinning: wet, dry, dry jet-wet, melt, gel, and electrospinning.

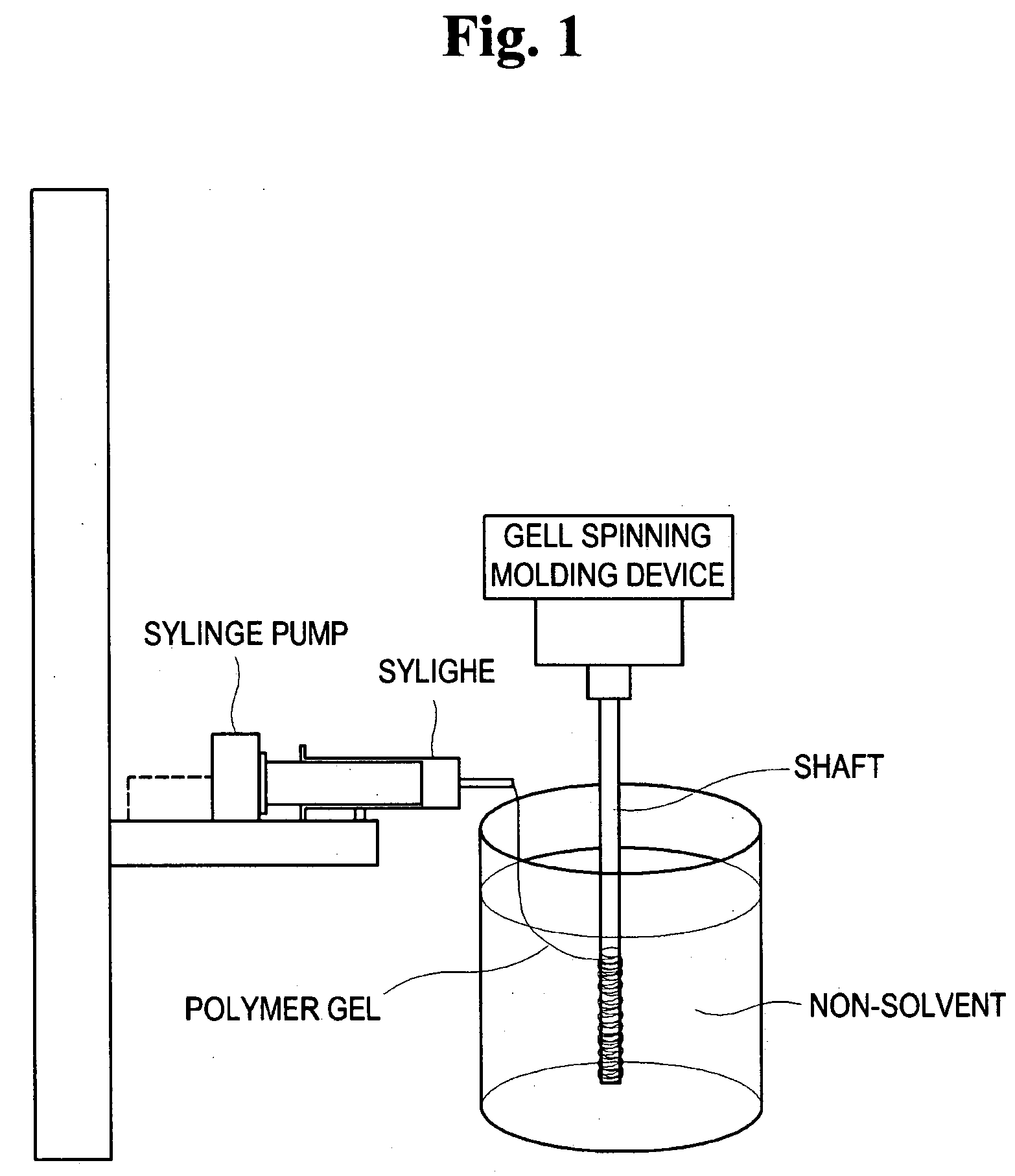

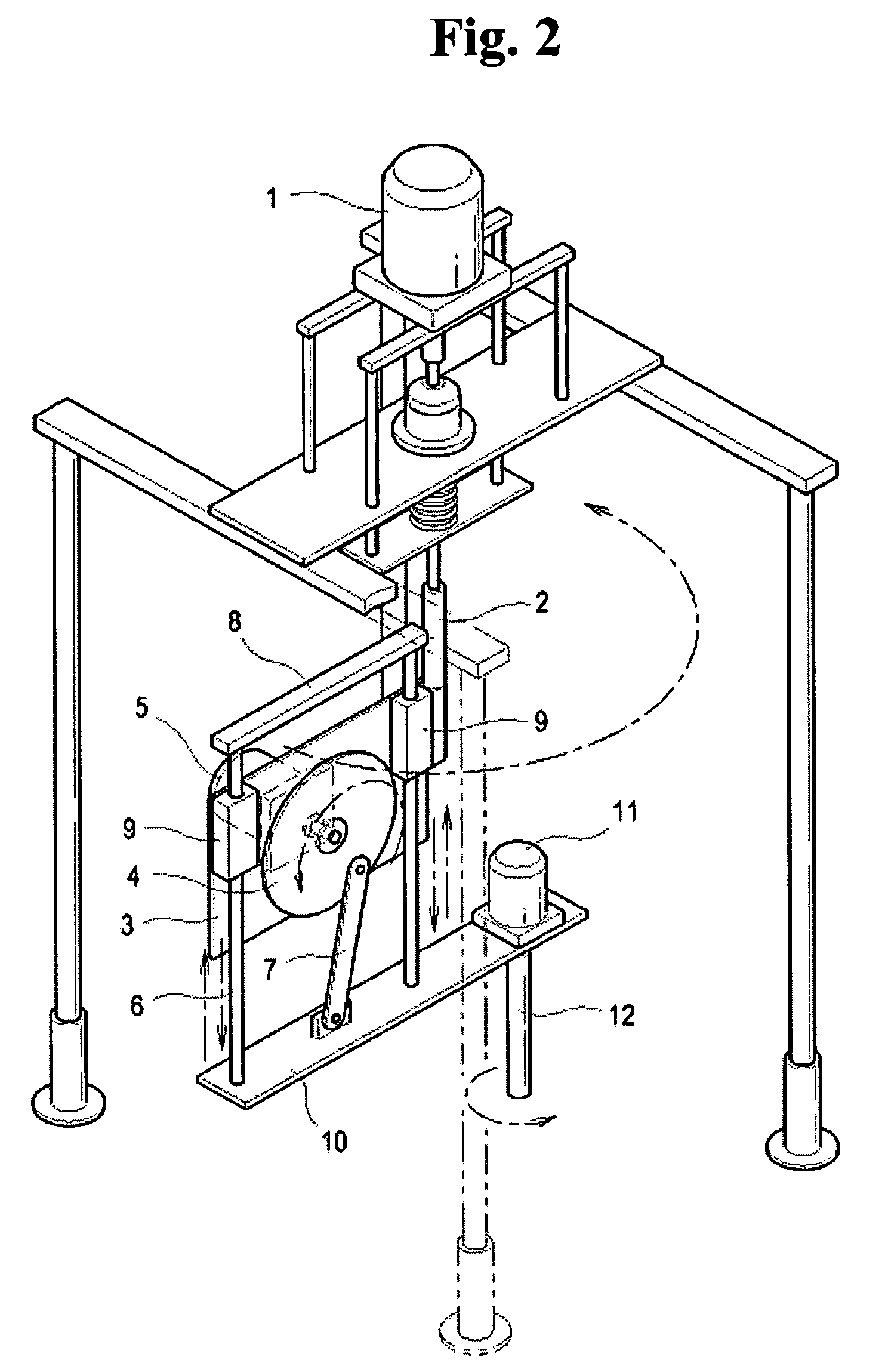

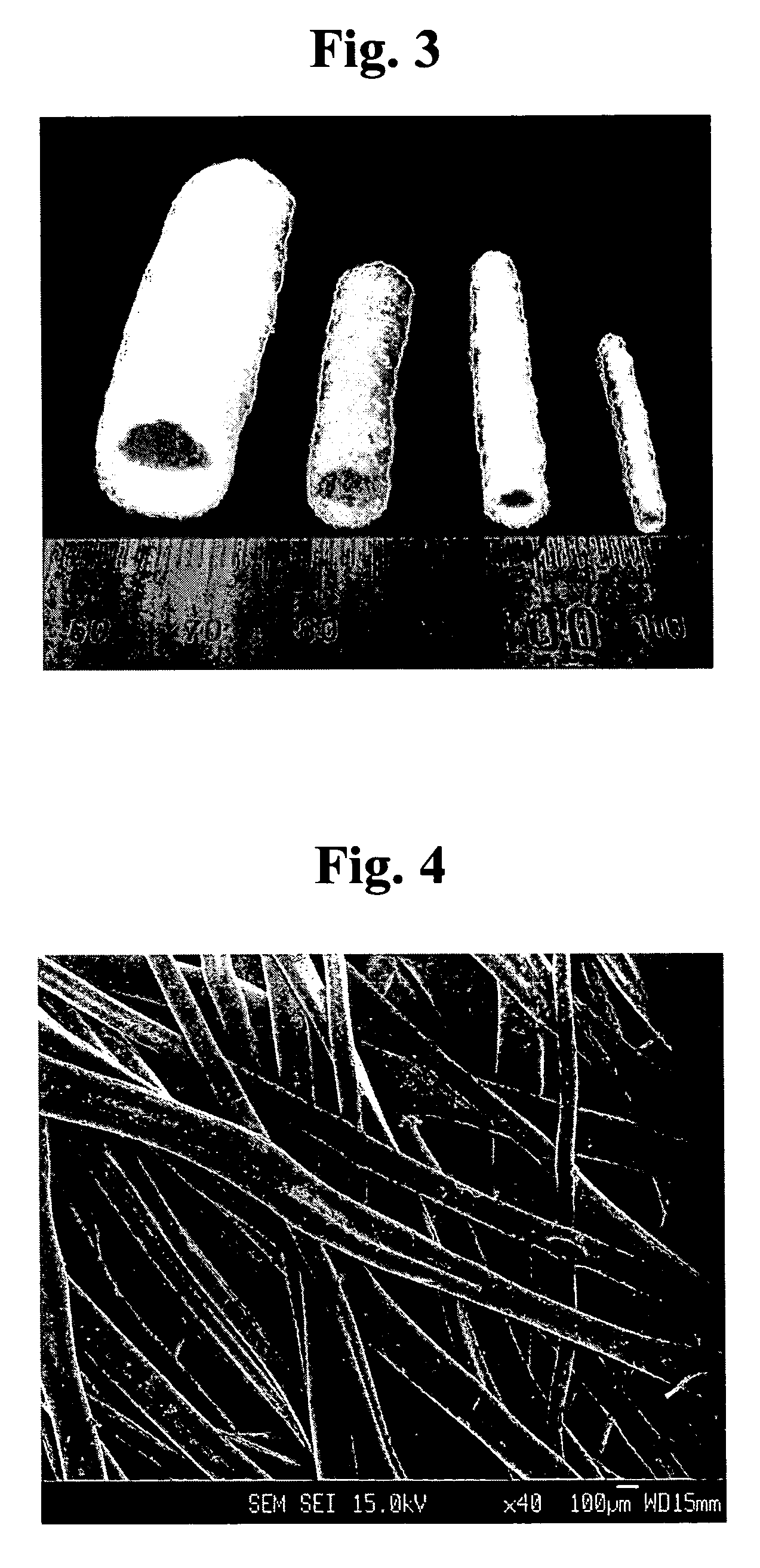

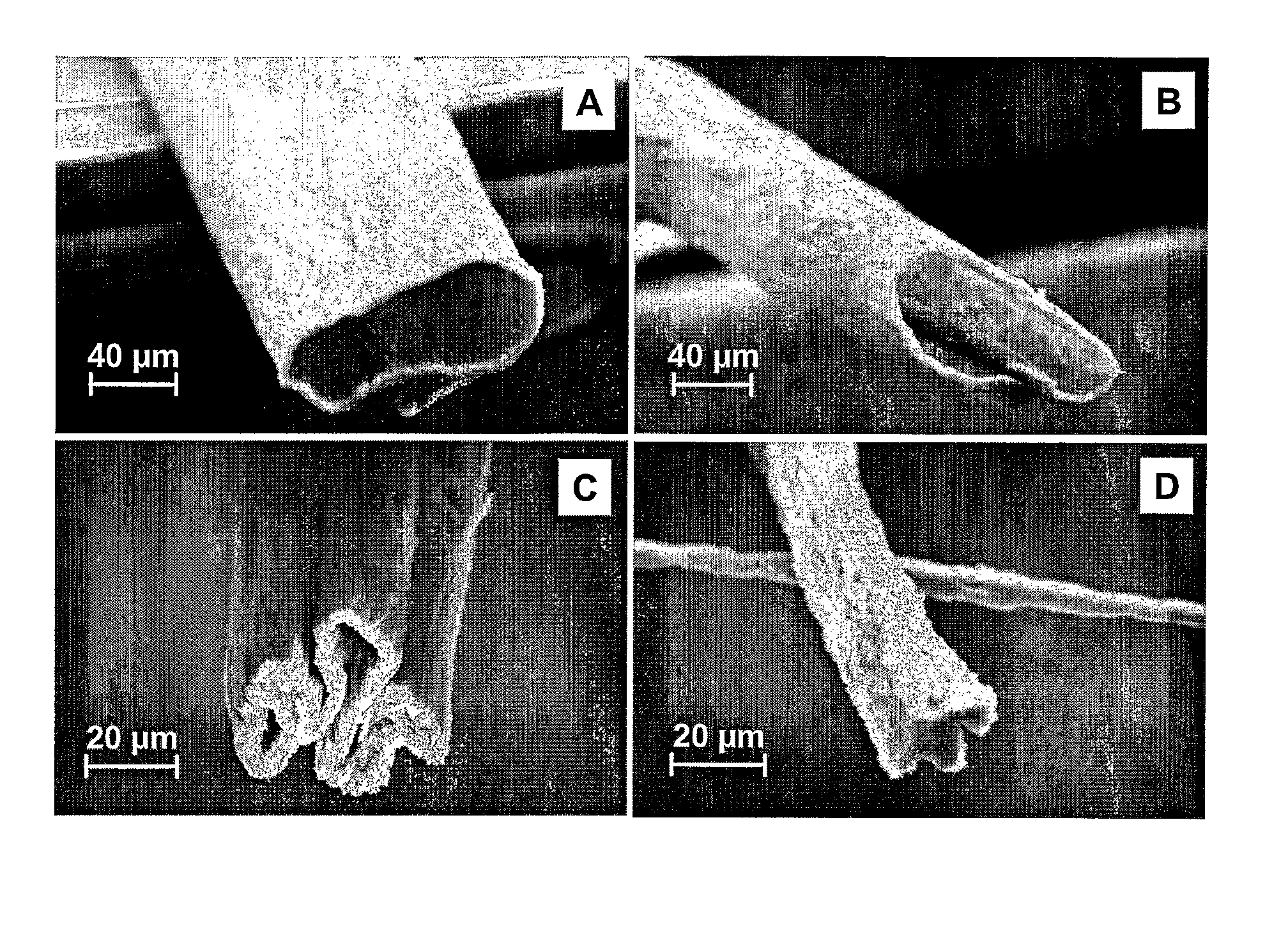

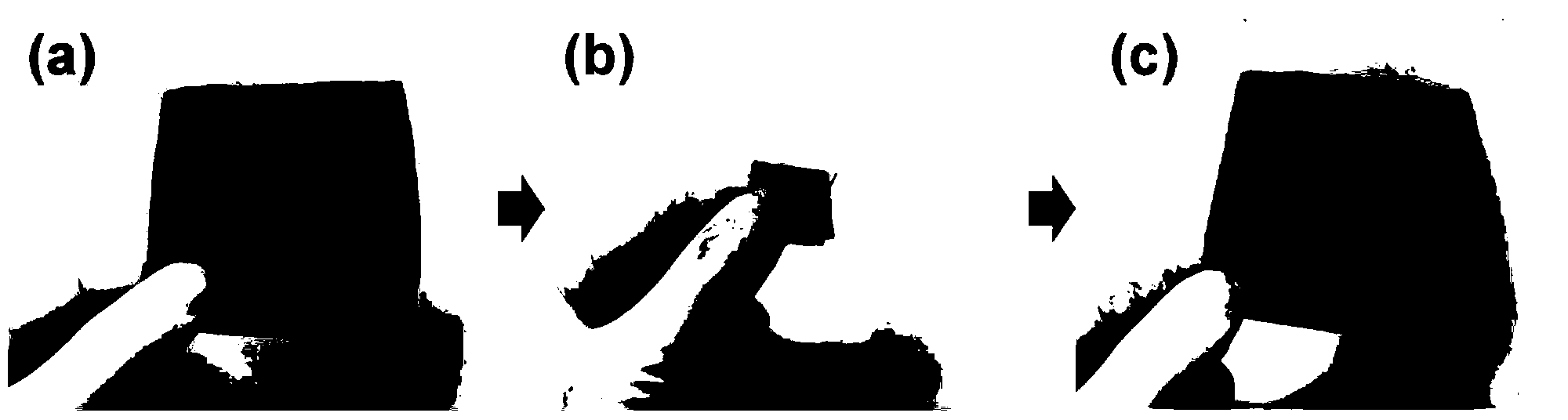

Method for preparing porous polymer scaffold for tissue engineering using gel spinning molding technique

InactiveUS20070009570A1Uniform pore sizeImprove interconnectivitySuture equipmentsCeramic shaping apparatusPolymer scienceSpinning

The present invention relates to a method of preparing a porous polymer scaffold for tissue engineering using a gel spinning molding technique. The method of the present invention can prepare a porous polymer scaffold having a uniform pore size, high interconnectivity between pores and mechanical strength, as well as high cell seeding and proliferation efficiencies, which can be effectively used in tissue engineering applications. Further, the method of the present invention can easily mold a porous polymer scaffold in various types such as a tube type favorable for regeneration of blood vessels, esophagus, nerves and the like, as well as a sheet type favorable for regeneration of skins, muscles and the like, by regulating the shape and size of a template shaft.

Owner:KOREA INST OF SCI & TECH

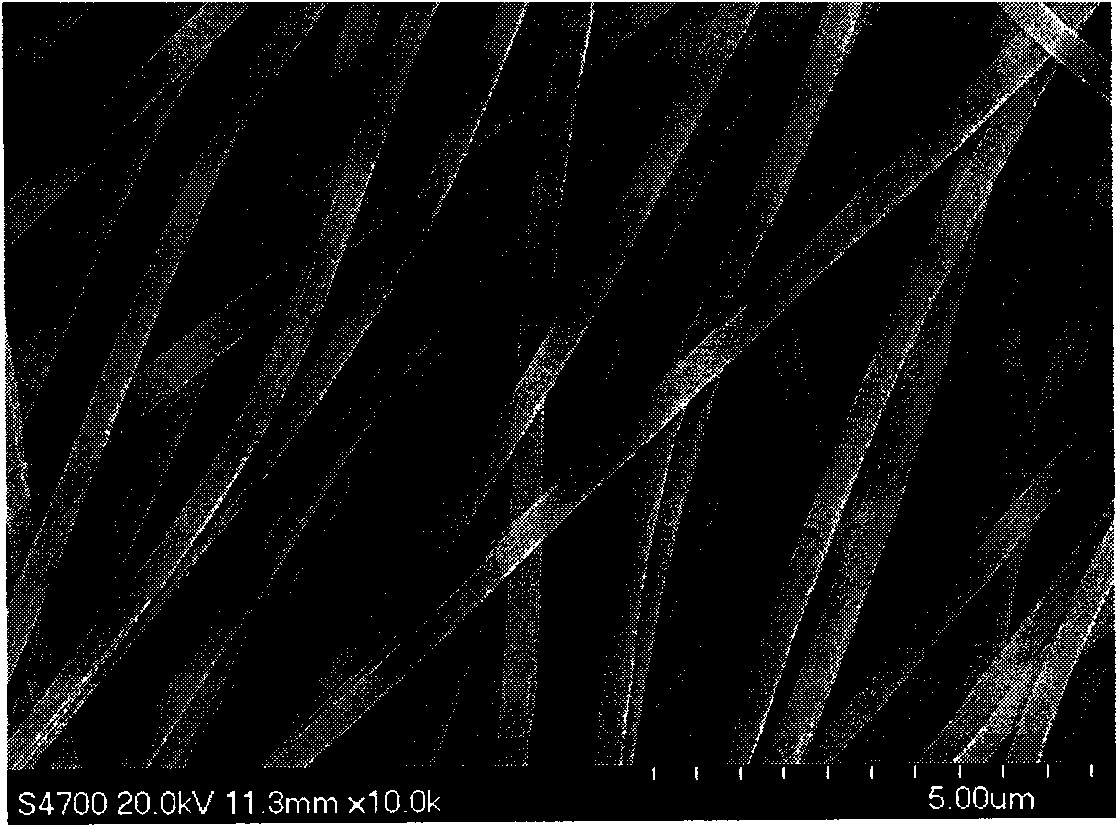

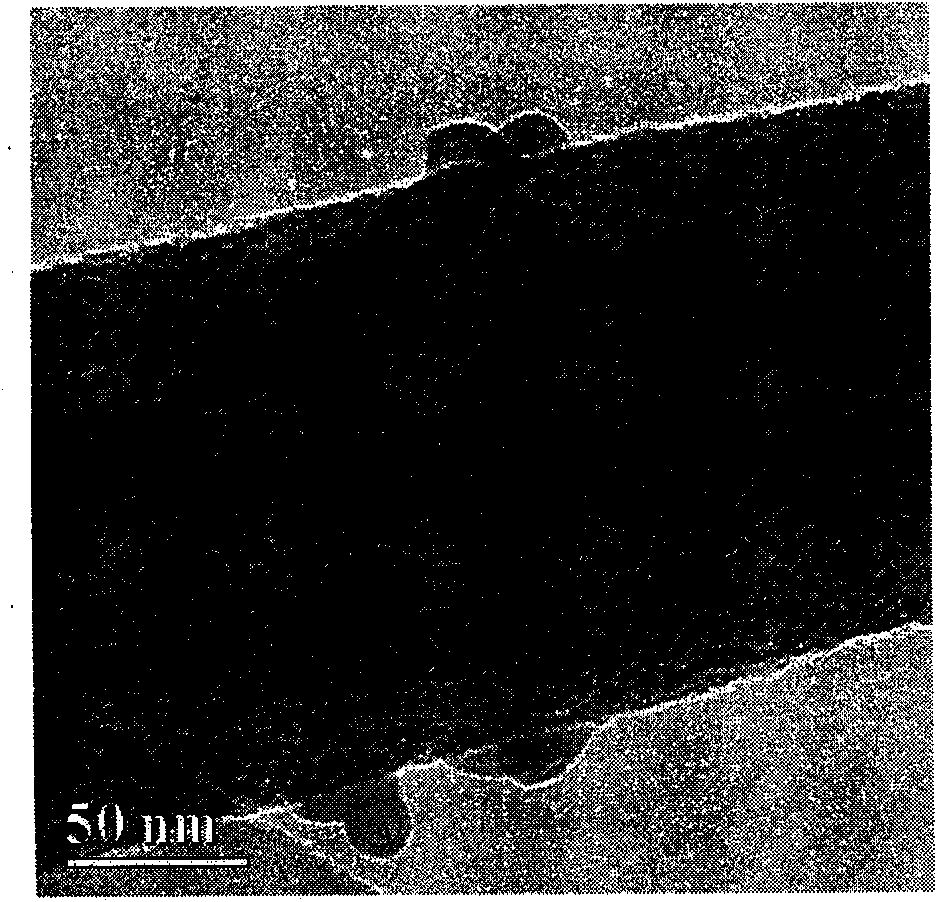

Polymer-Free Carbon Nanotube Assemblies (Fibers, Ropes, Ribbons, Films)

InactiveUS20070243124A1Improve mechanical propertiesHigh mechanical strengthMaterial nanotechnologyPigmenting treatmentCarbon nanotubeElectromechanical actuator

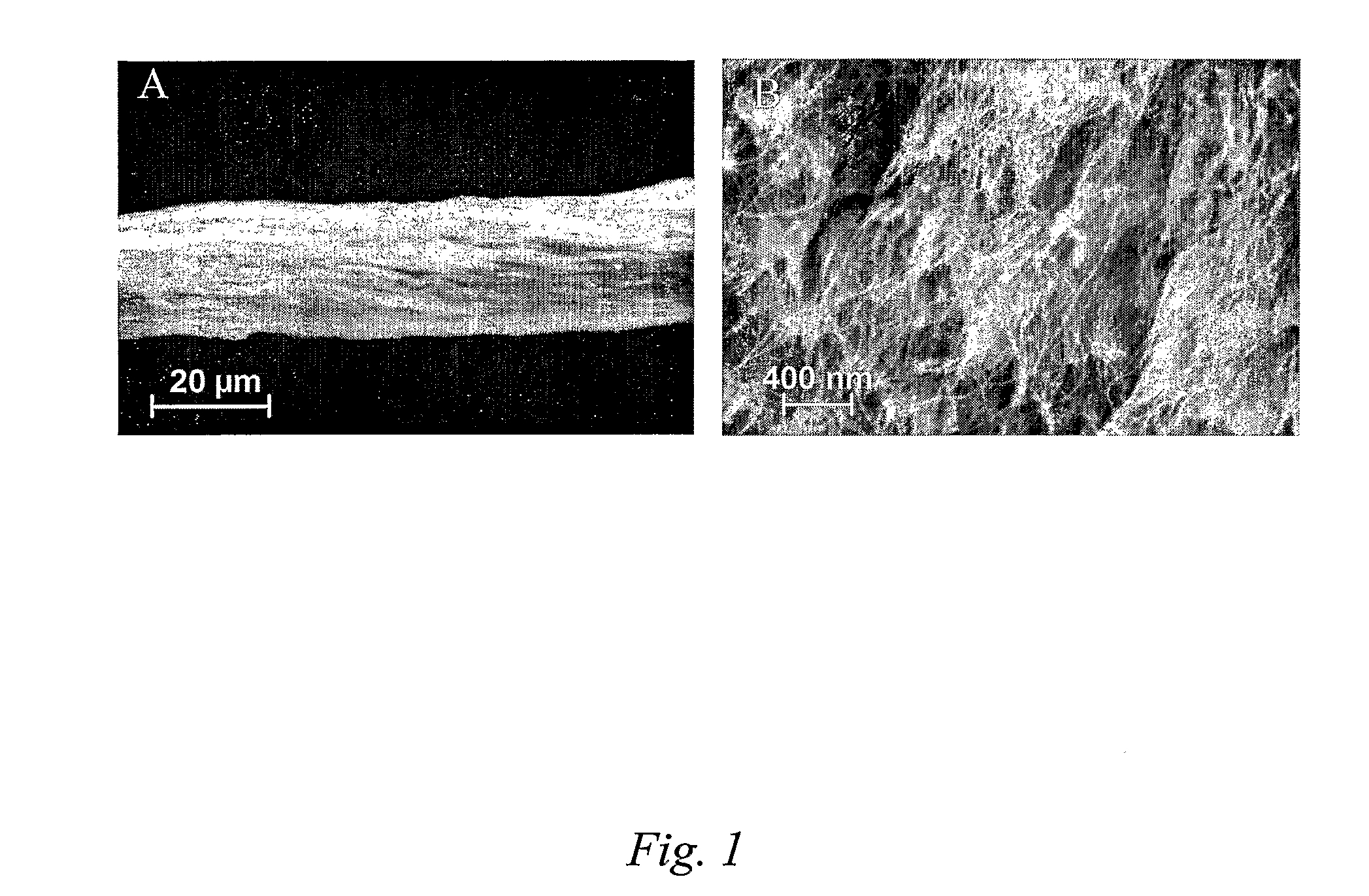

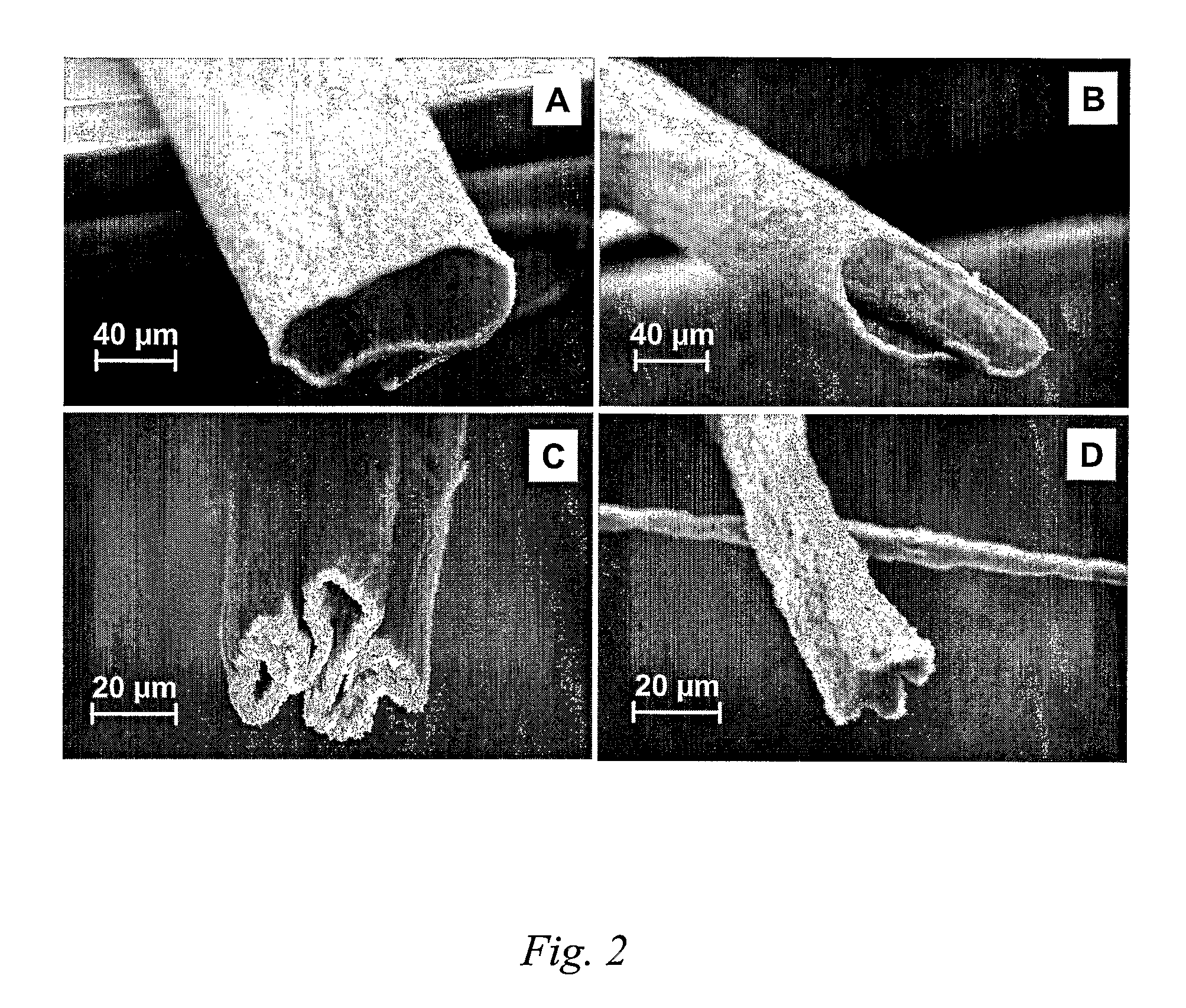

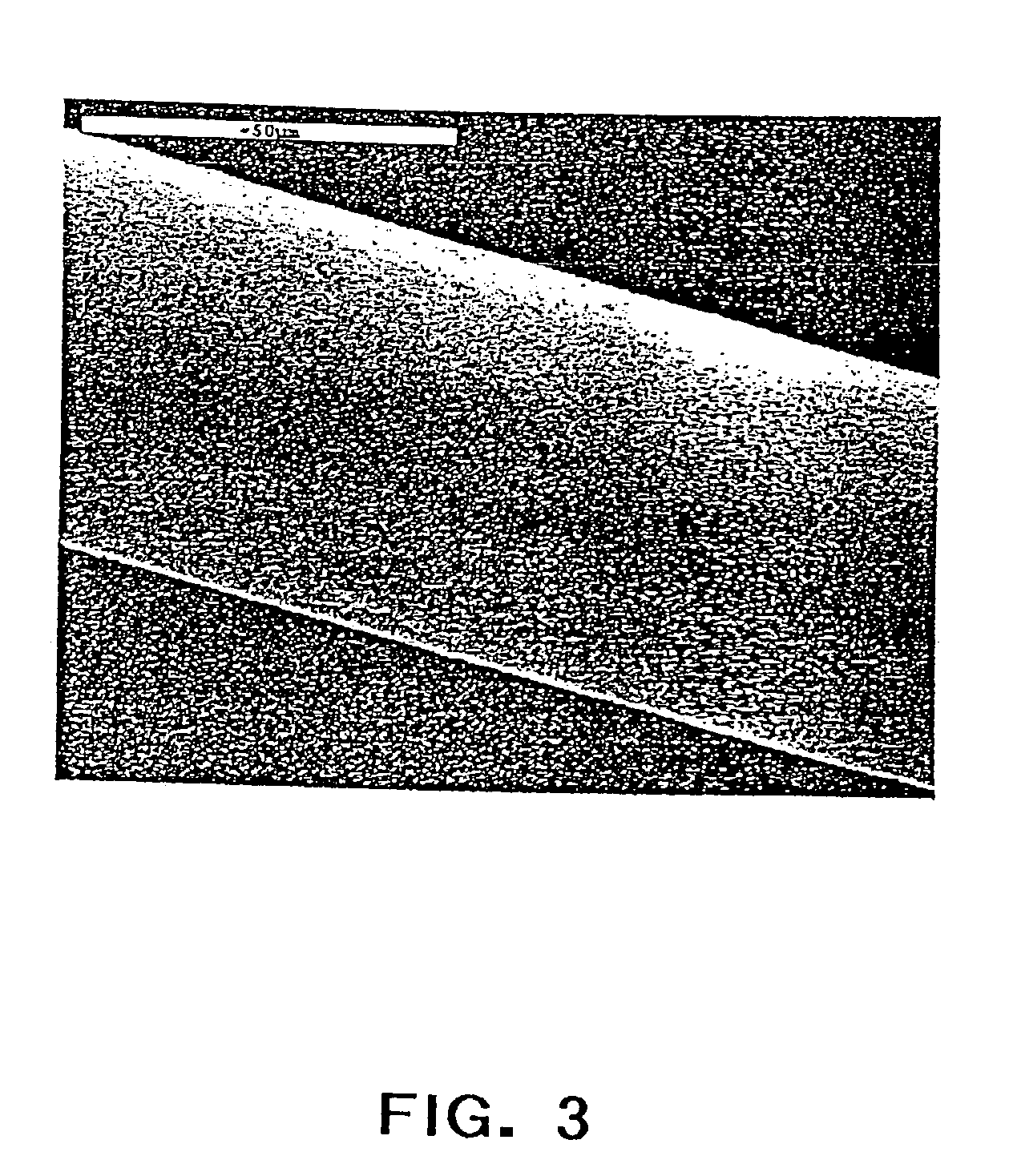

Process, apparatus, compositions and application modes are provided that relate to nanofiber spinning without the use of superacids in the spinning solution. The methods employ either acids or bases for a flocculation solution. The advances disclosed therein enable the use of nanofibers, including carbon nanotubes, for a variety of applications including, but not limited to, electromechanical actuators, supercapacitors, electronic textiles, and in devices for electrical energy harvesting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

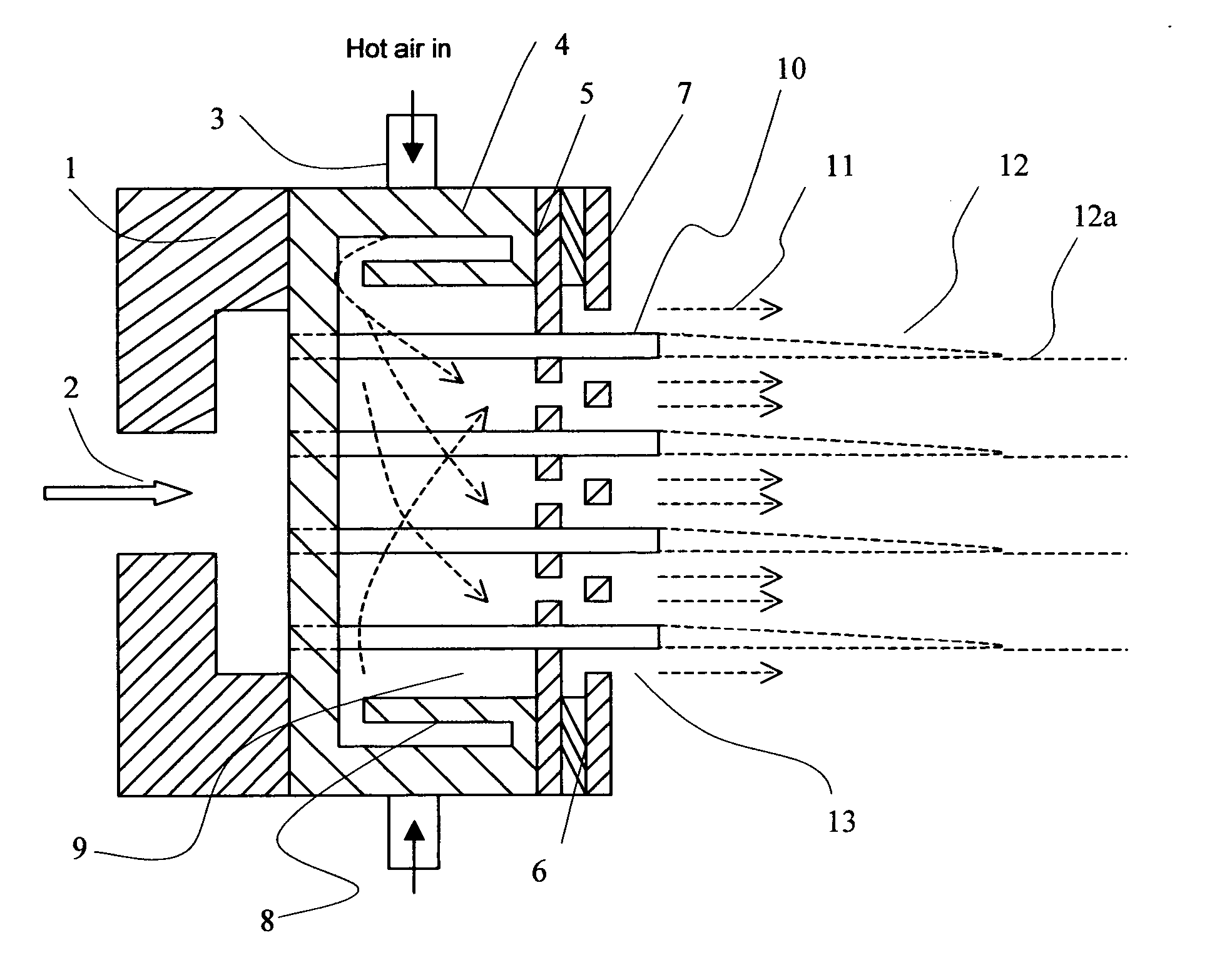

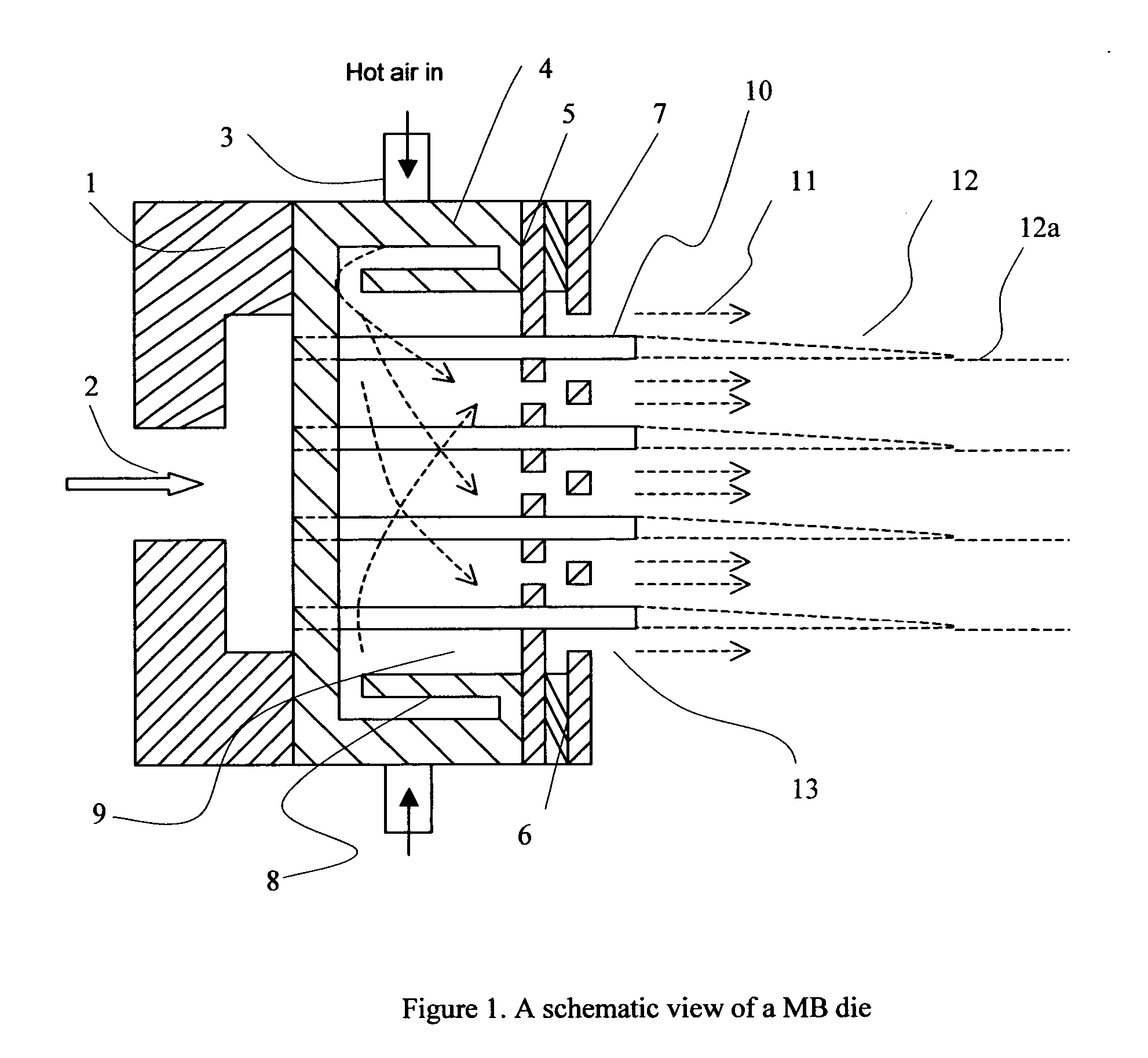

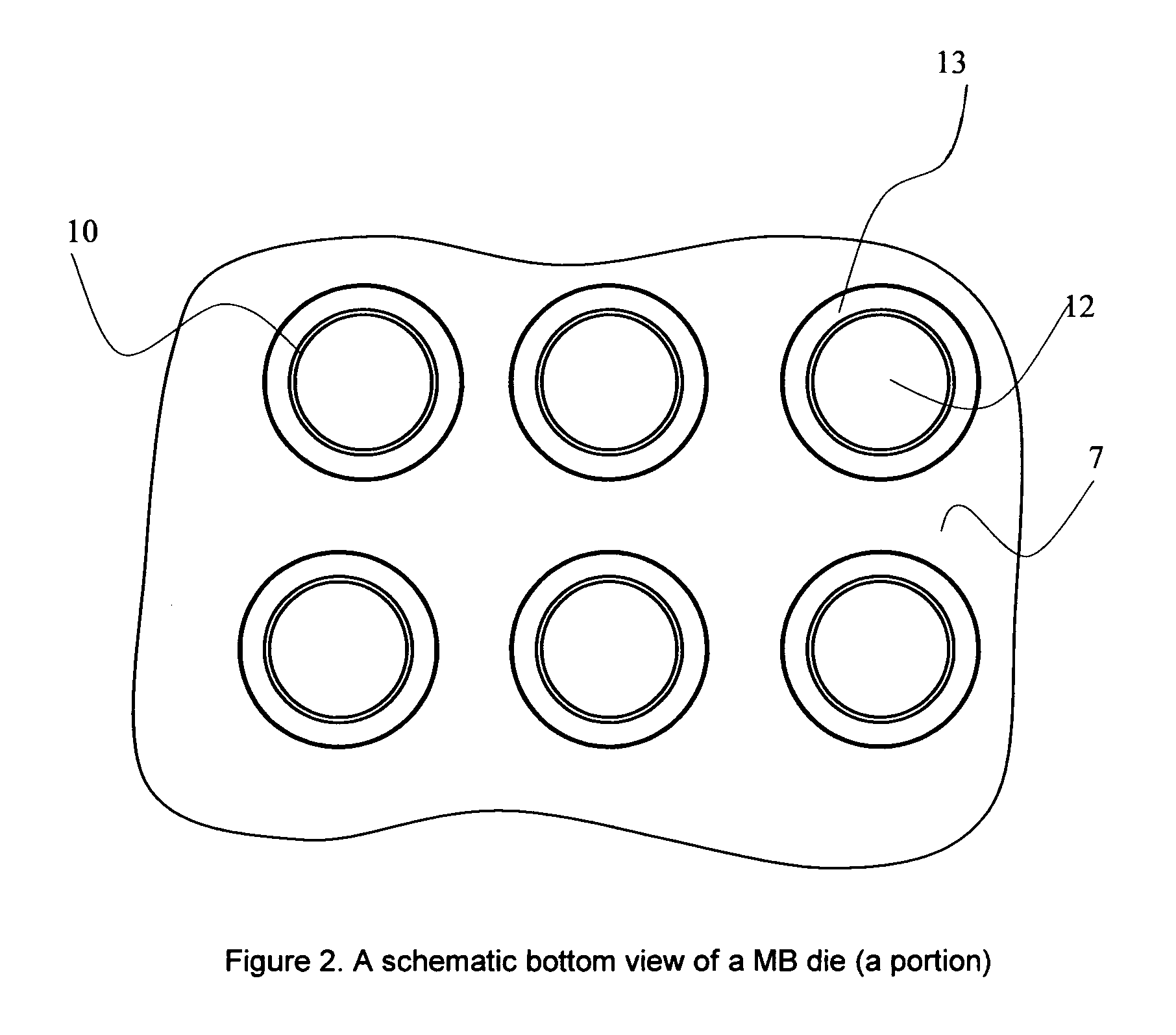

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

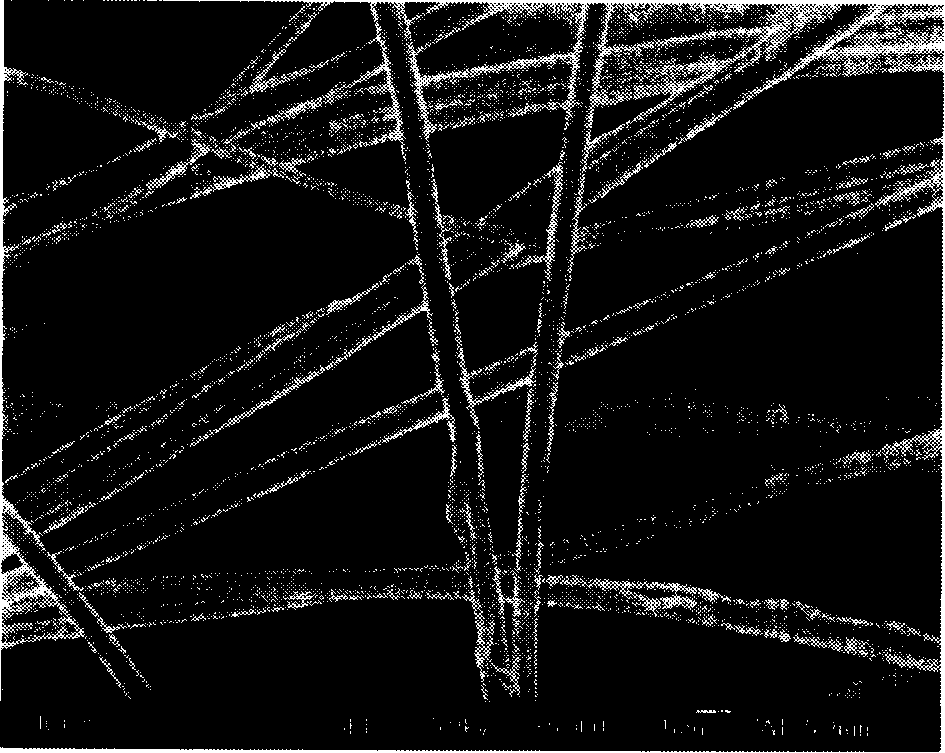

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

ActiveUS20070018361A1Broaden applicationEasy to controlElectric discharge heatingInorganic material artificial filamentsFiberElectrospinning

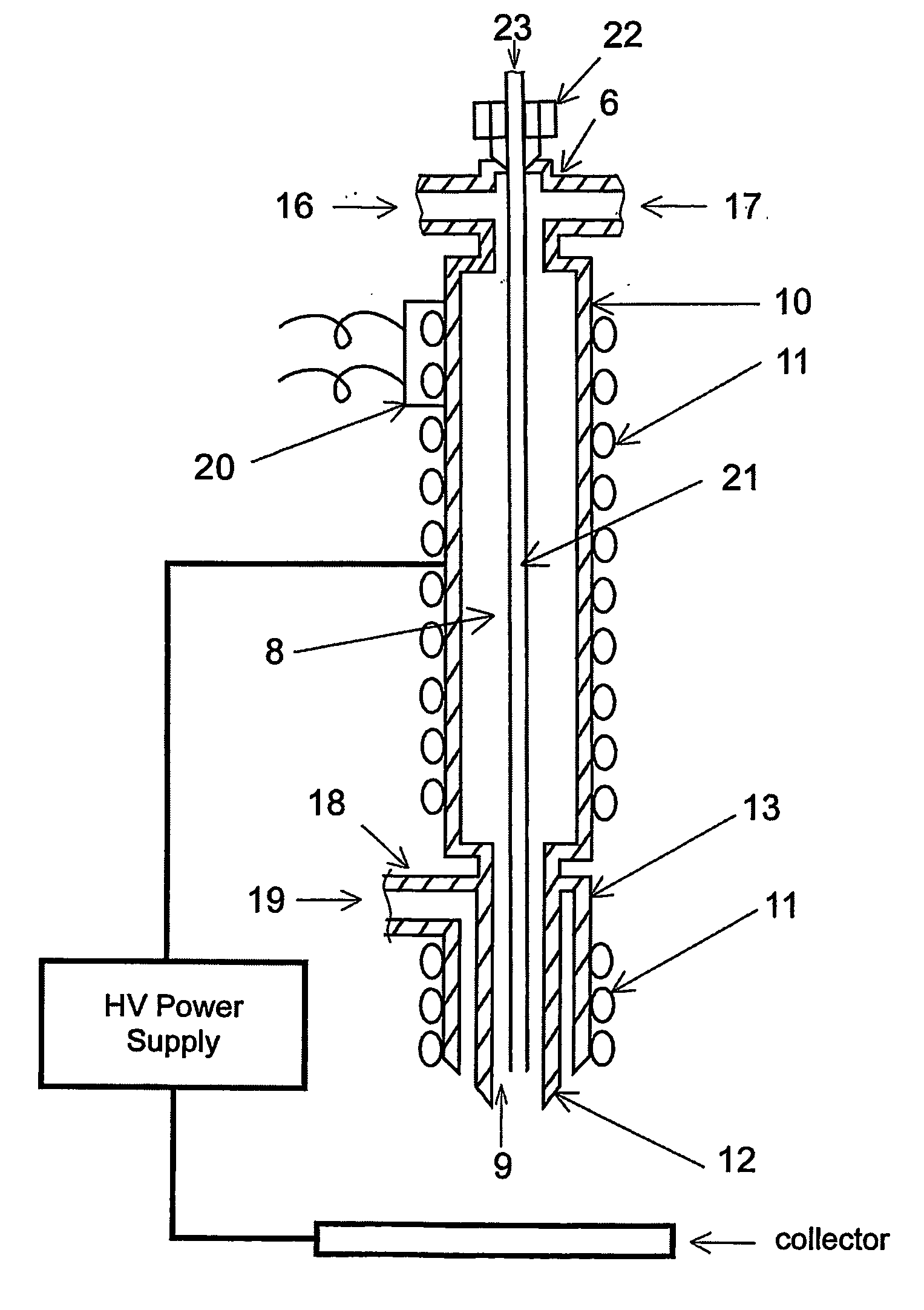

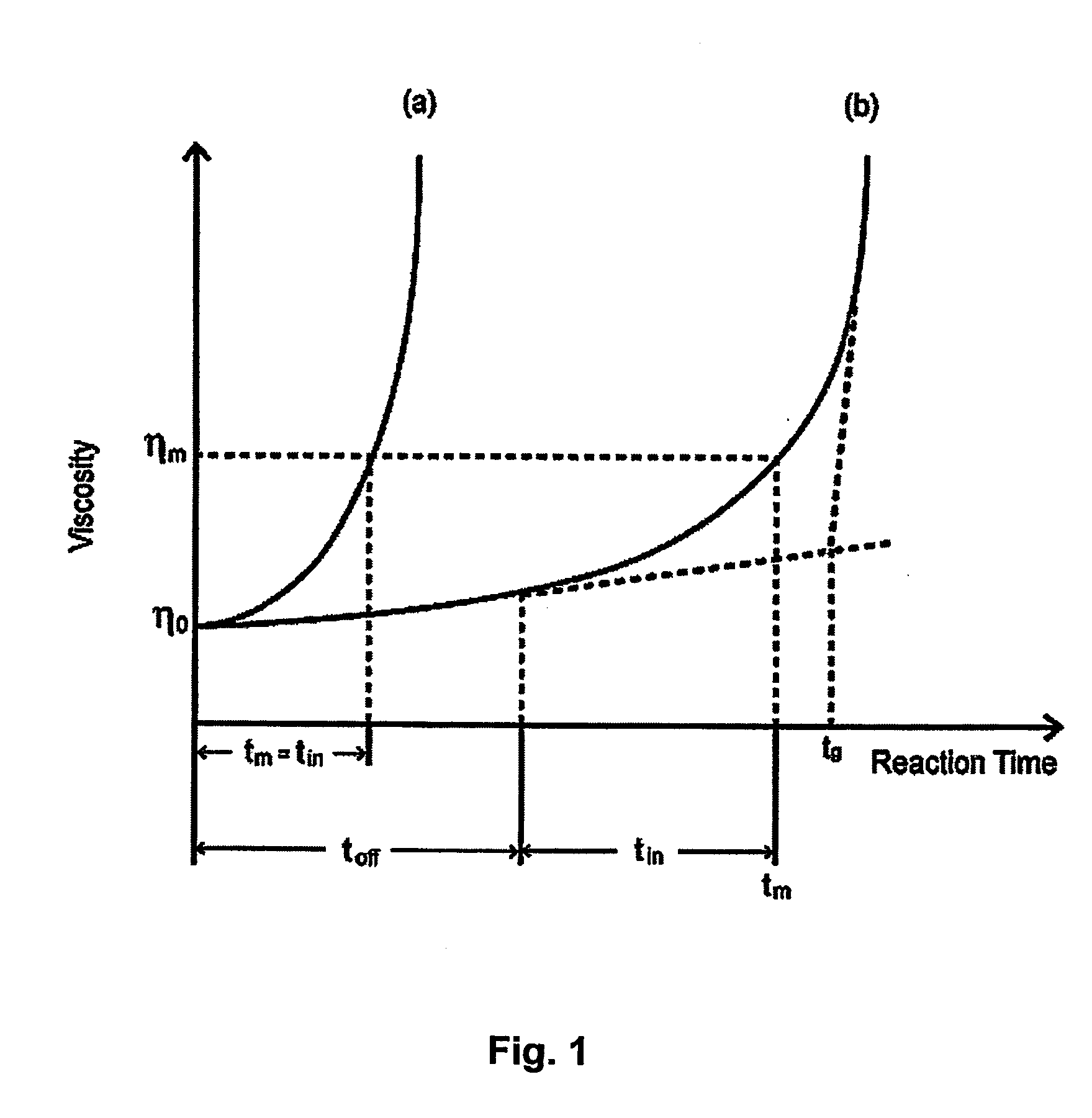

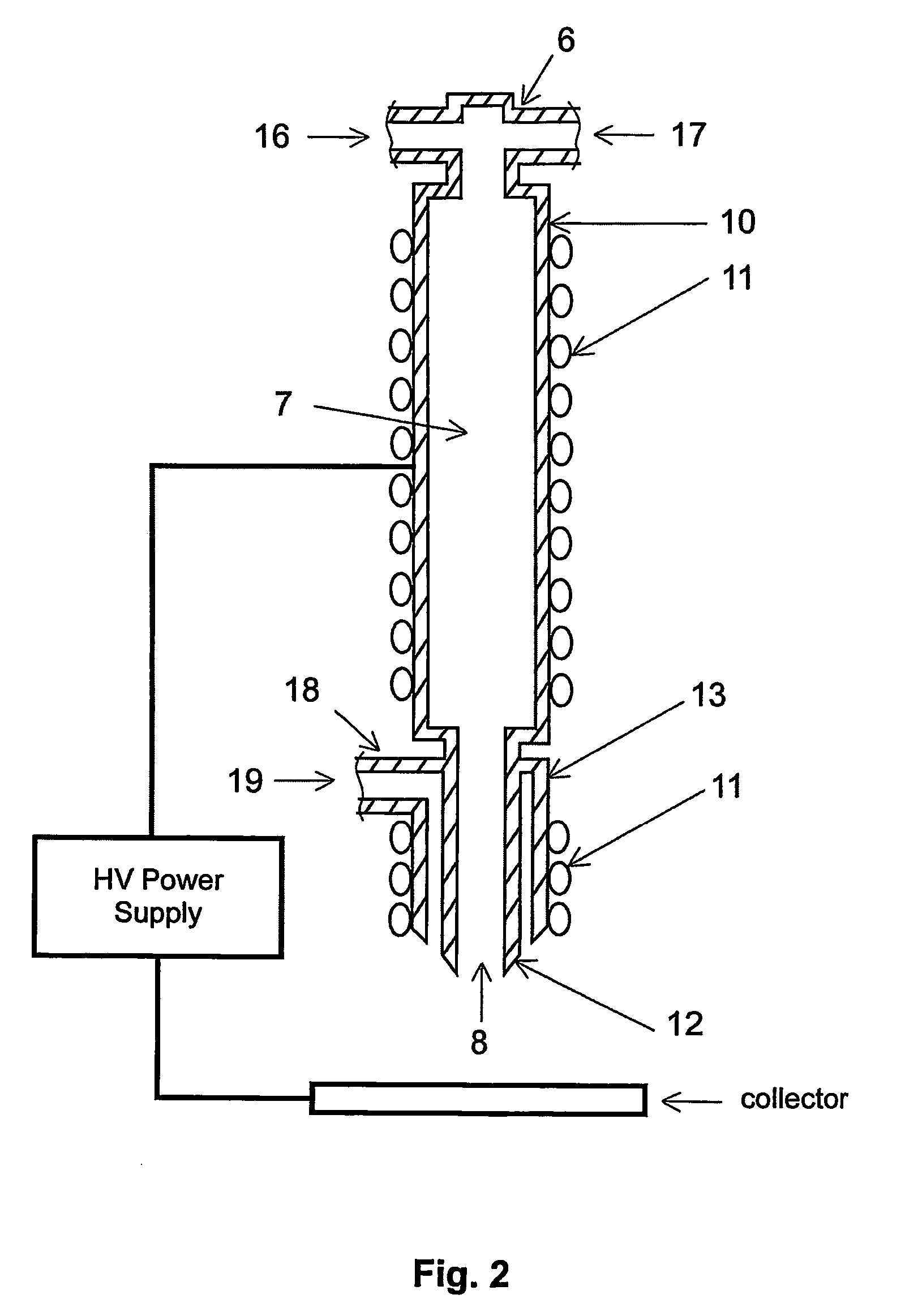

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

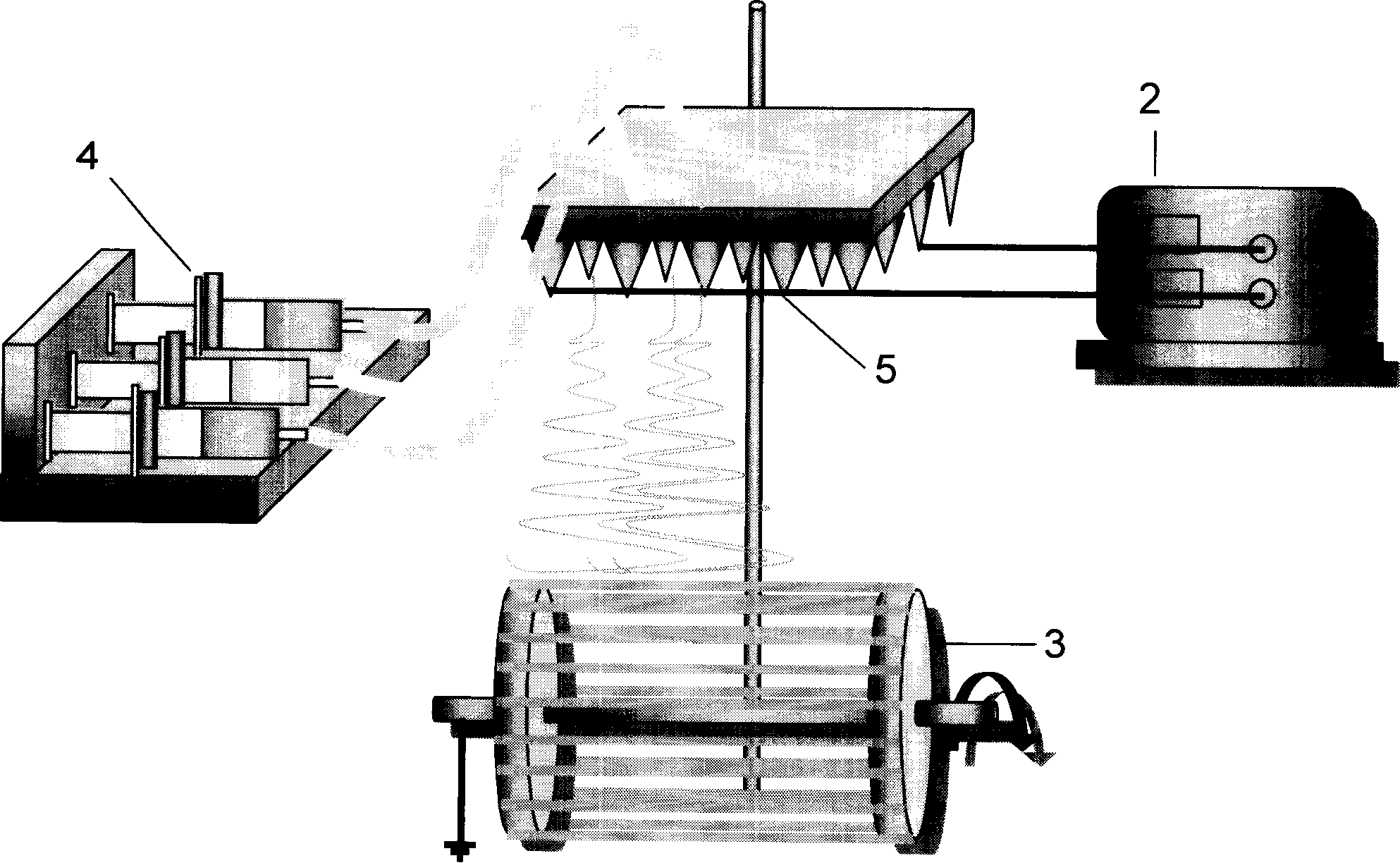

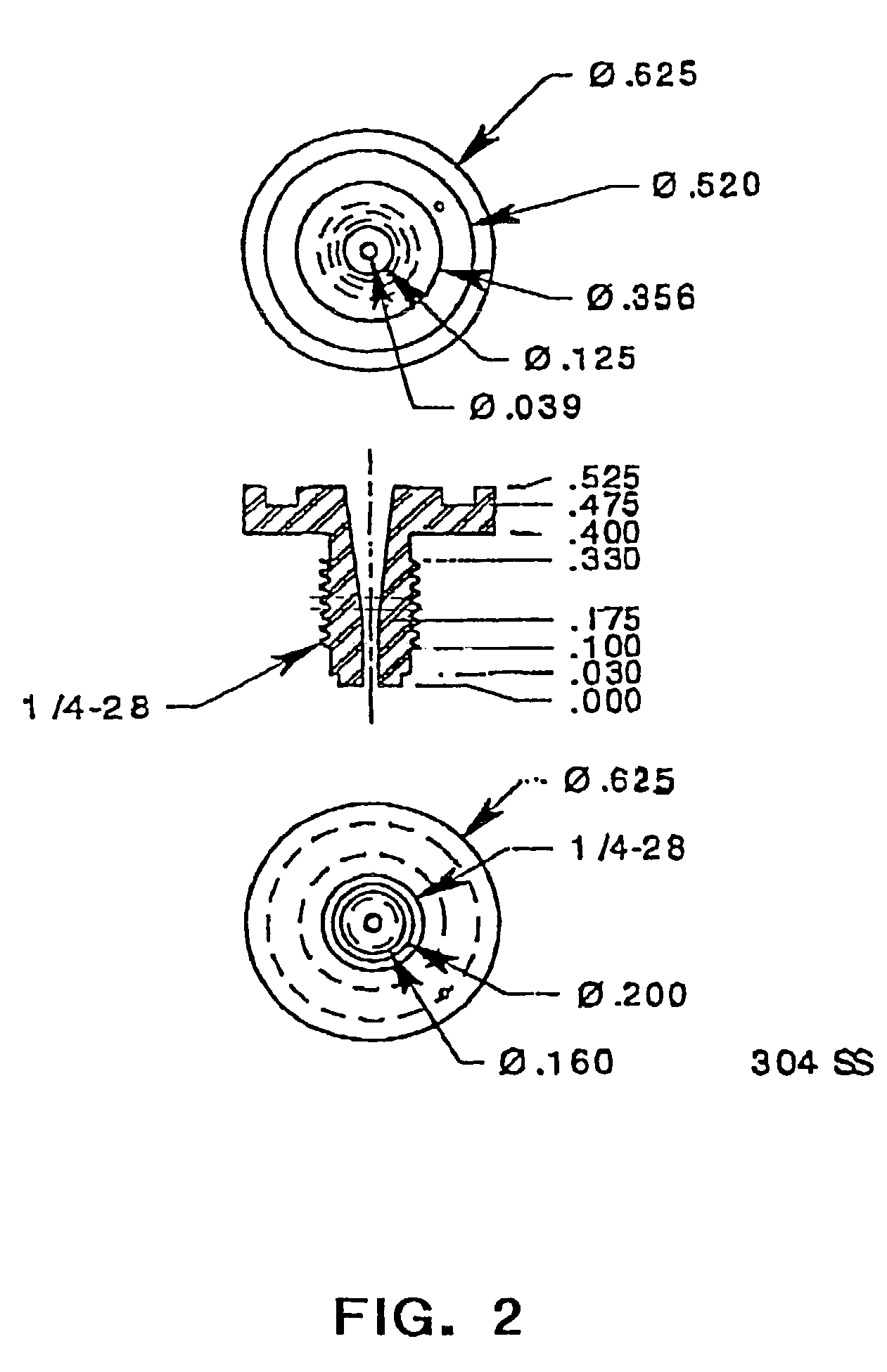

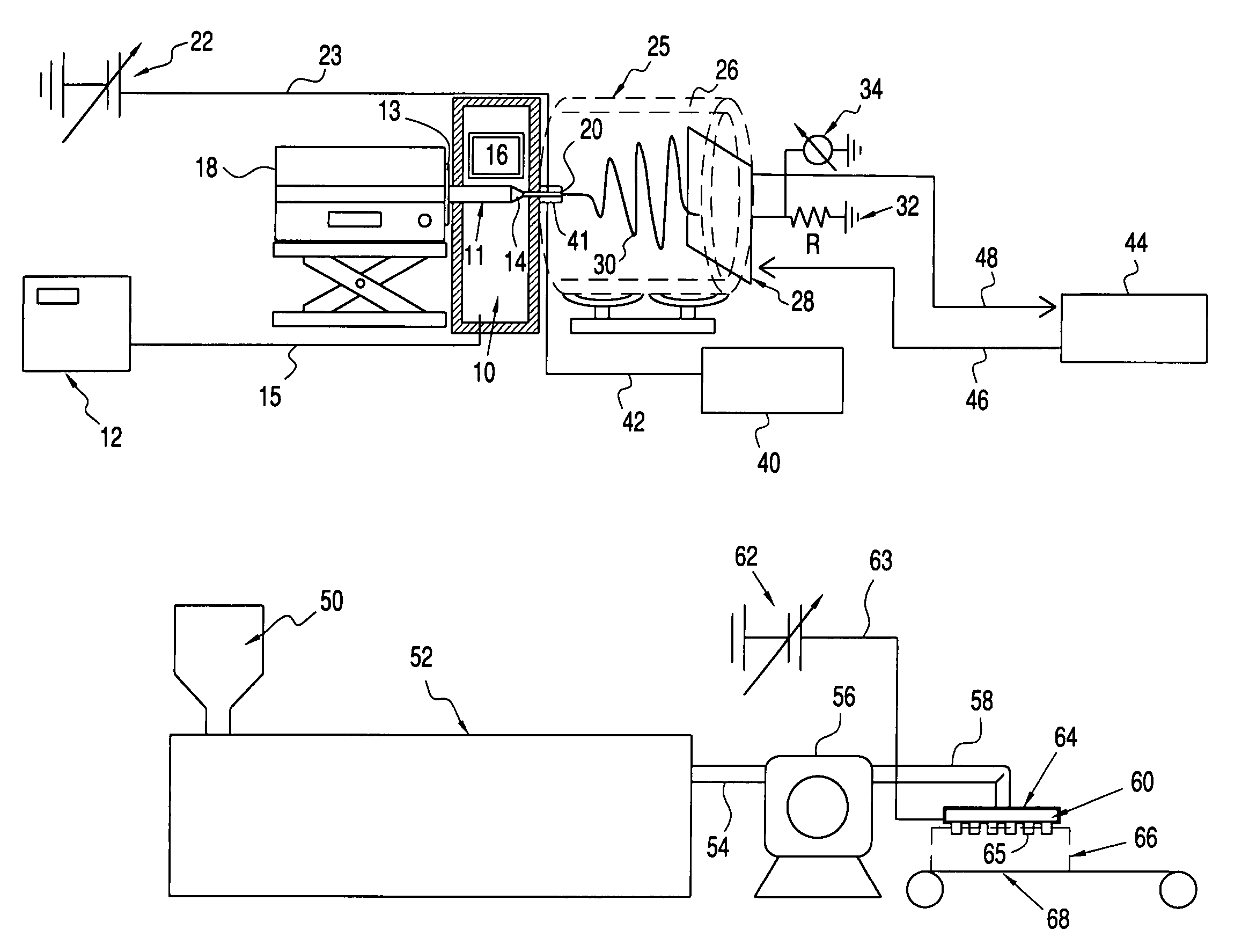

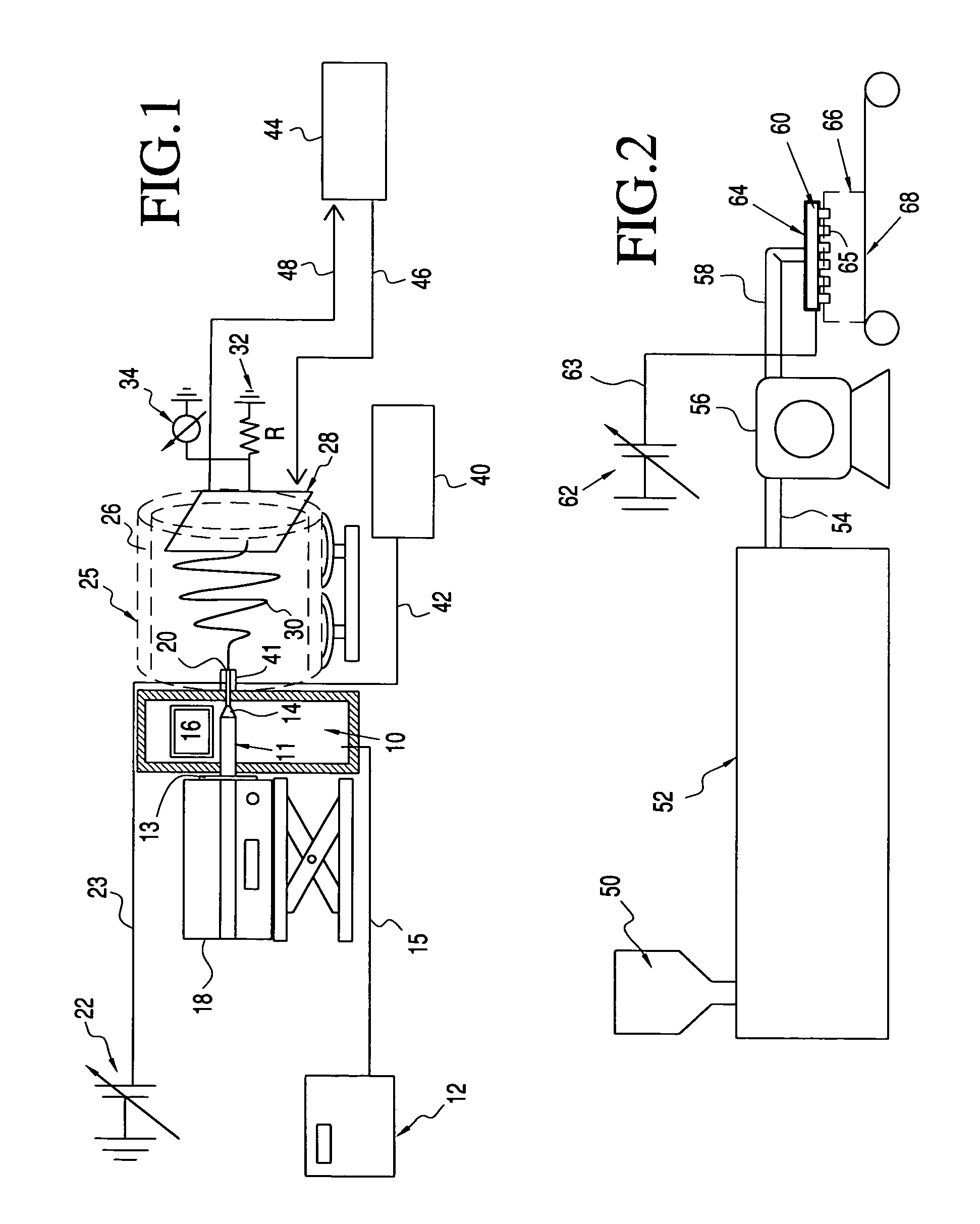

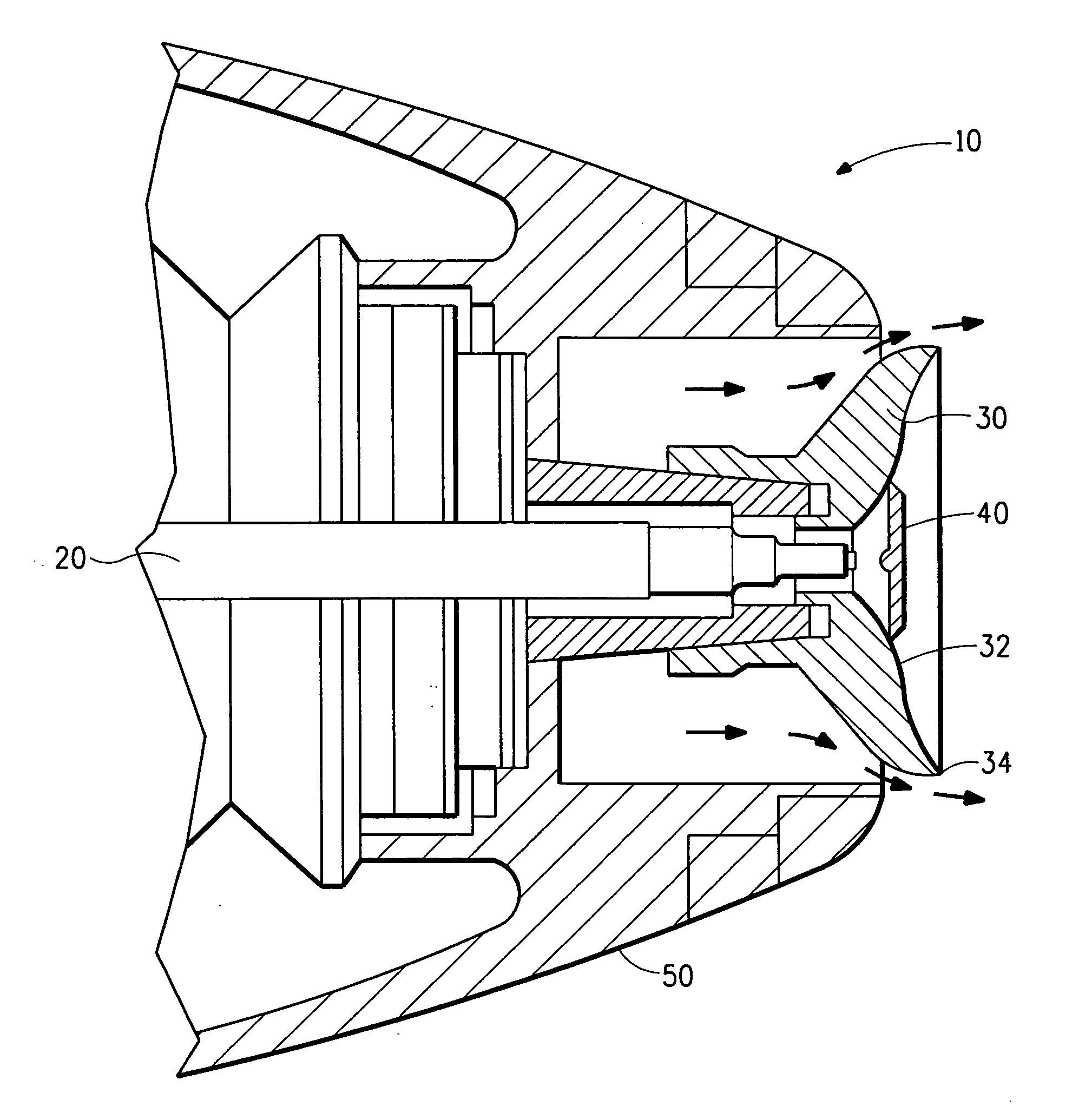

Apparatus and methods for electrospinning polymeric fibers and membranes

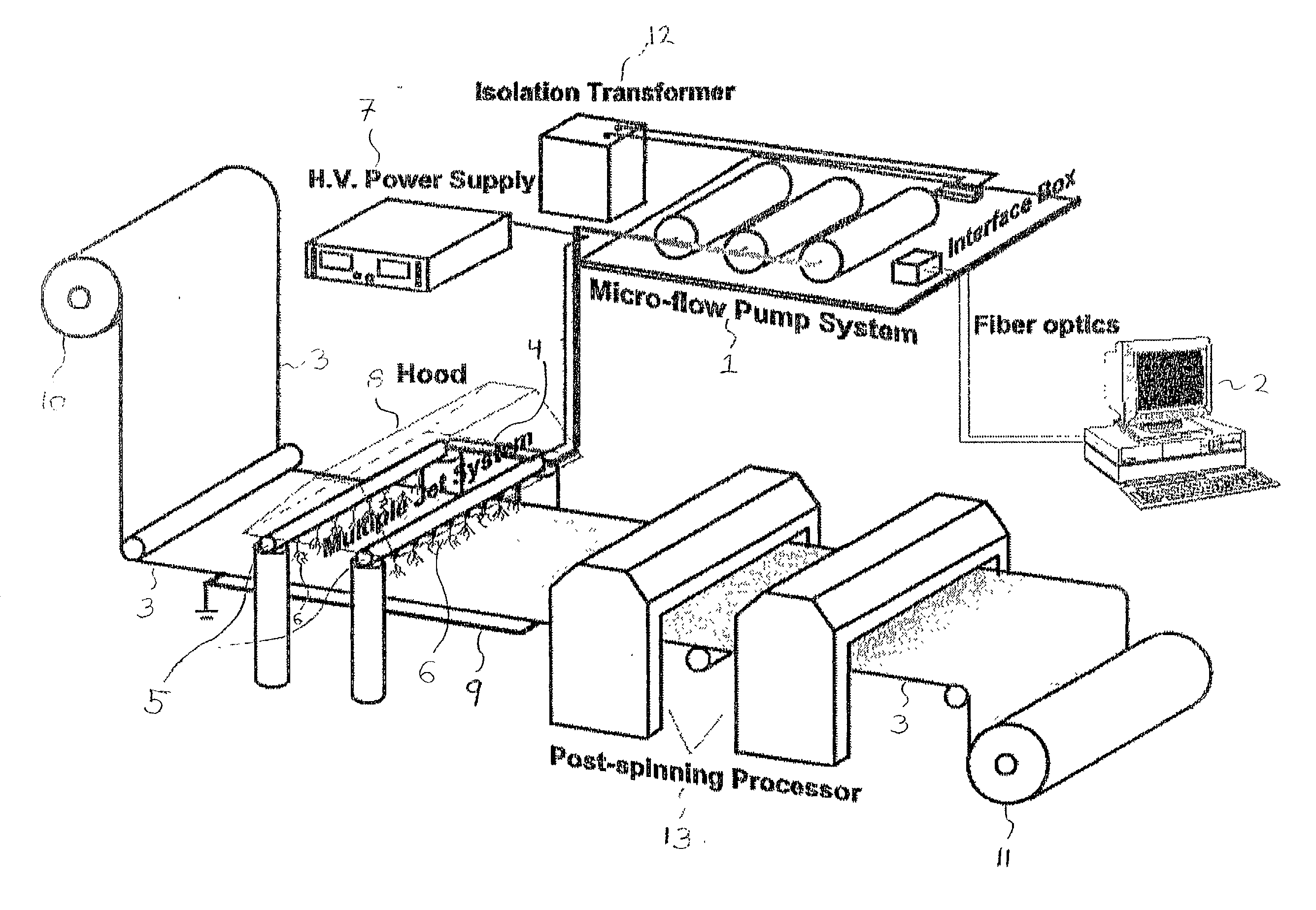

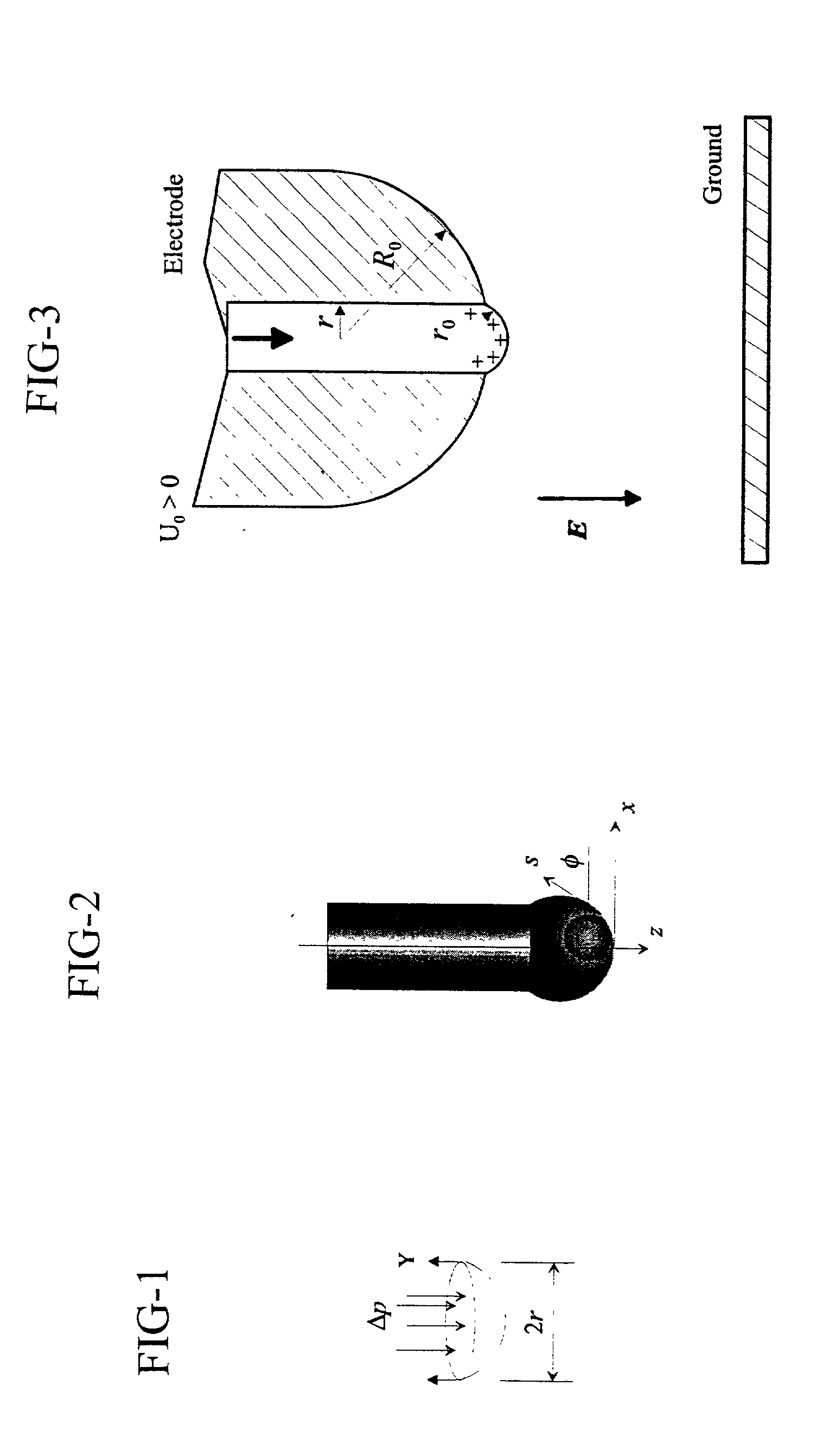

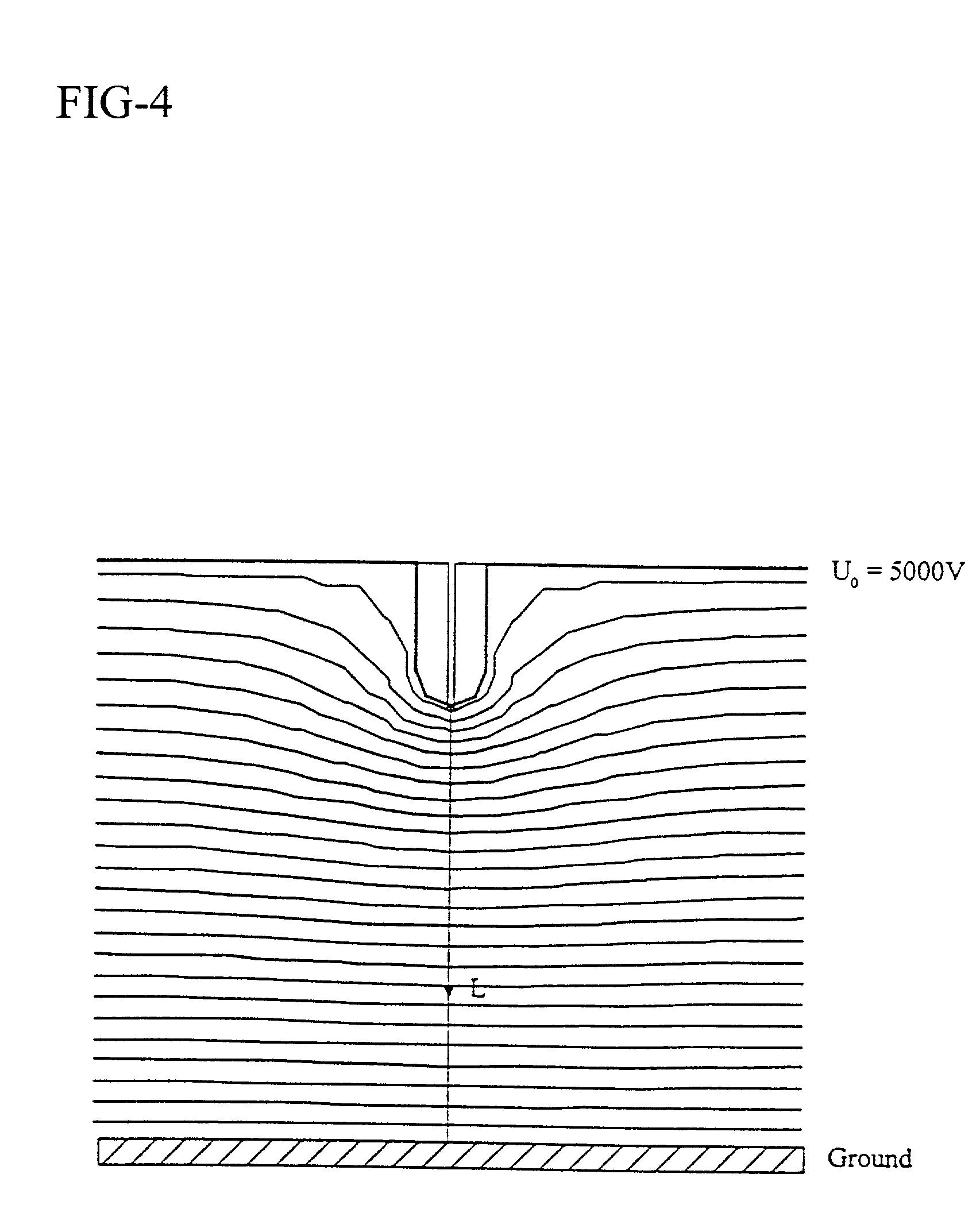

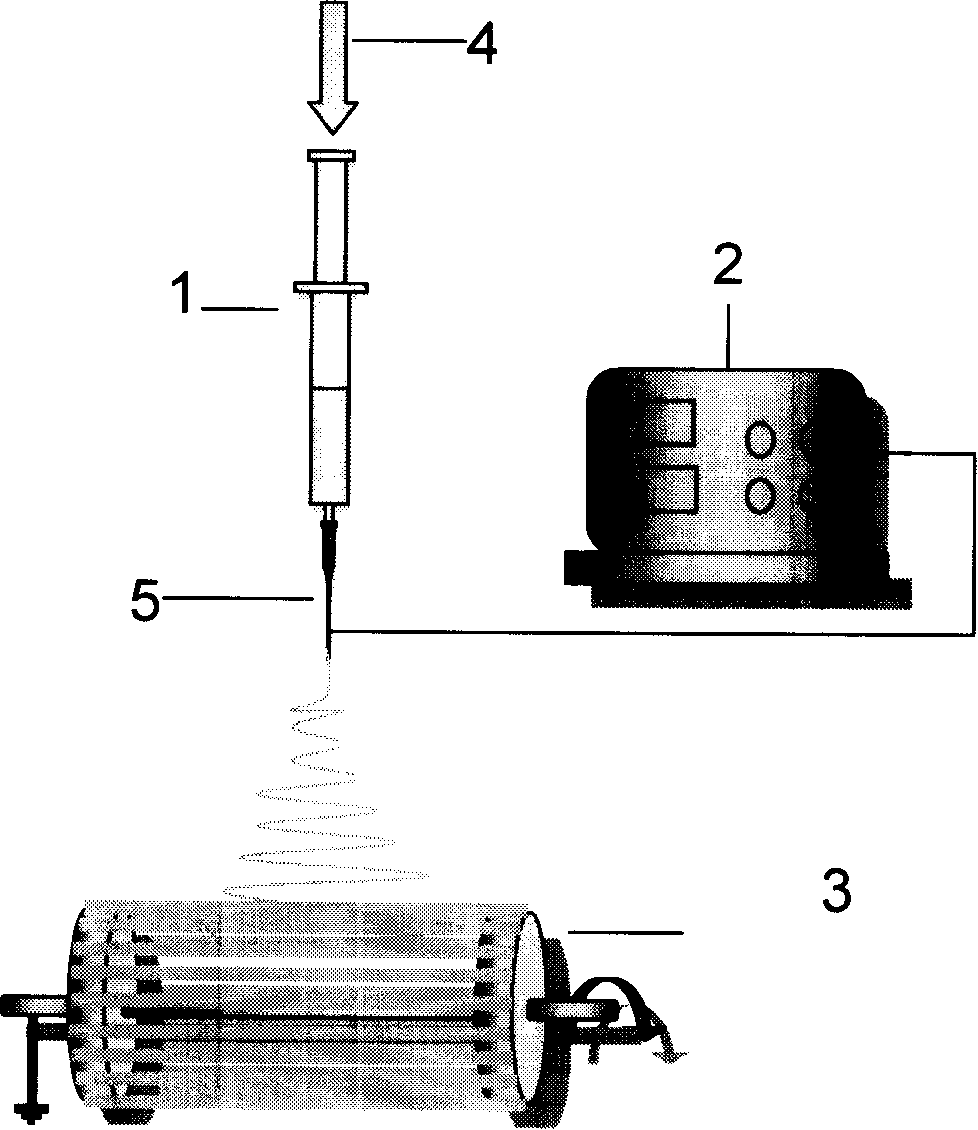

An apparatus and methods for electrospinning polymer fibers and membranes are described. The methods include in one aspect electrospinning a polymer fiber from a conducting fluid containing the polymer in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. In another aspect the methods include forming an electrospinning jet stream of the conducting fluid and electrically controlling the flow characteristics of the jet stream. In yet another aspect the methods include forming a plurality of electrospinning jet streams of the conducting fluid and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets for delivering the conducting fluid, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a means for controlling the flow characteristics of conducting fluid from at least one spinneret independently from the flow characteristics of conducting fluid from another spinneret. An improved conducting fluid introduction device which includes a plurality of spinnerets, each for independently delivering a controlled quantity of conducting fluid at a controlled pressure or flow rate, the spinnerets being charged at an electric potential and being disposed relative to each other to normally interfere with the electric field produced by adjacent spinnerets, each of the spinnerets having a tip at which conducting fluid exits configured to have an electrostatic field strength at each tip stronger than the liquid surface tension at each of the tips is also described.

Owner:RES FOUND THE

Biopolymer nano tunica fibrosa material capable of being biological degraded and absorbed, preparing method and uses of the same

InactiveCN101172164AGood biocompatibilityPromote degradationSurgeryFilament/thread formingFiberCellulose

The invention relates to compound millimicron fibrous membrane material of cellulose and cellulose matrix which can perform the biological degradation and the biological absorption and a preparation method thereof and an industry and medical purpose, and belongs to the biological macro-molecule non woven fabric material field which can perform the biological degradation and the biological absorption. Electrostatic spinning equipment is used to obtain the fibrous membrane material which can perform the biological degradation and the biological absorption, the weight of the cellulose is taken as basic reference, the component of the material comprises cellulose more than 0 and less than or equal to 100 weight parts, other biomacromolecule more than and equal to 0 and less than 100 weight parts, 0 to 10 weight parts of curative drug or 0 to 50 weight parts of inorganic catalyzer and / or 0 to 50 weight parts of inorganic strengthening agent. The material of the invention has good biological compatibility, biological degradation property and degradation absorptivity, and can be used for haemostasia material, wound cladding material, organization engineering supporting rack material, the transportation and release of medicine, artificial skin and blood vessel, and postoperation anti blocking material, beauty material and catalyzer carrier, filtering membrane and radiation protection material and so on.

Owner:INST OF CHEM CHINESE ACAD OF SCI

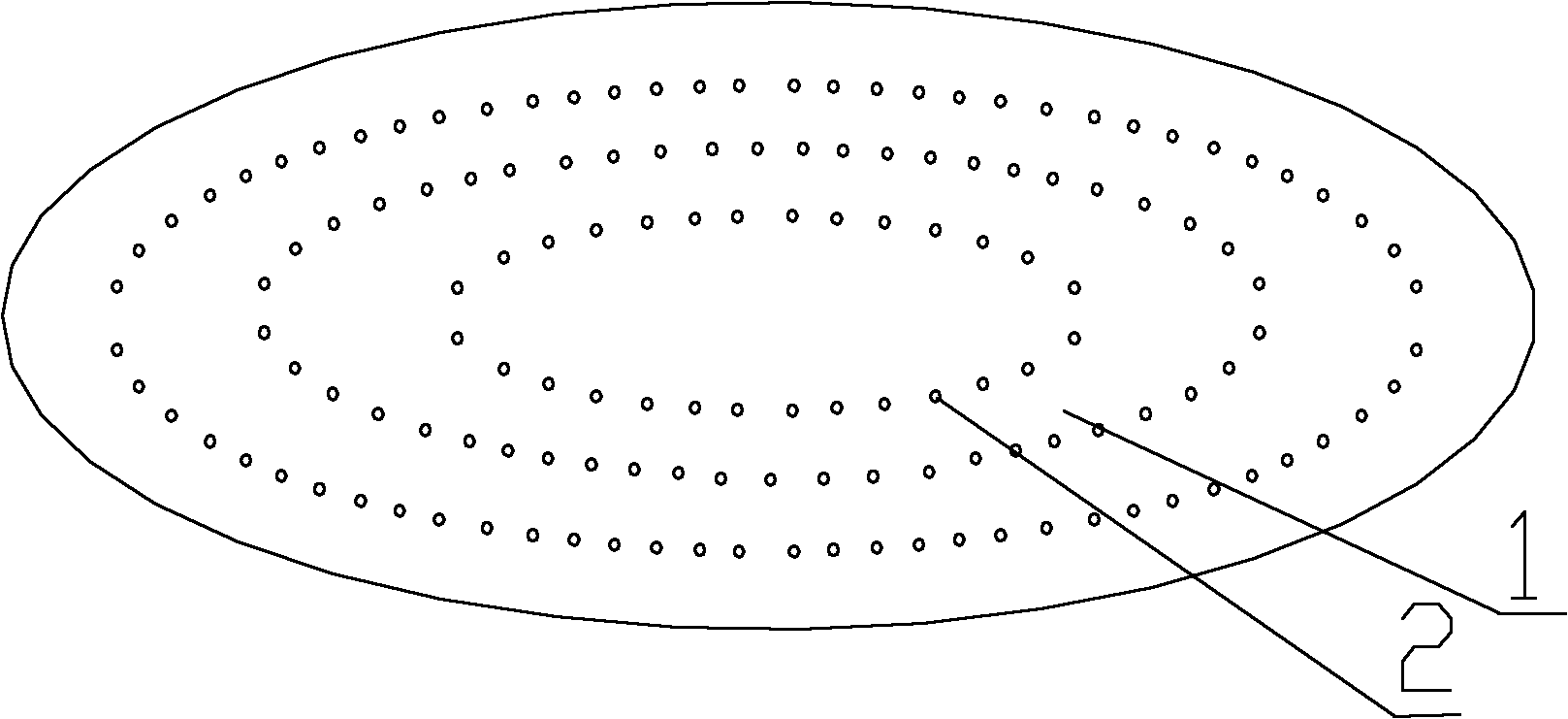

Special-shaped spinneret plate for spinning heavy denier yarns

InactiveCN102851757AImprove cooling uniformityImprove dyeing effectFilament/thread formingPolymer scienceSpinning

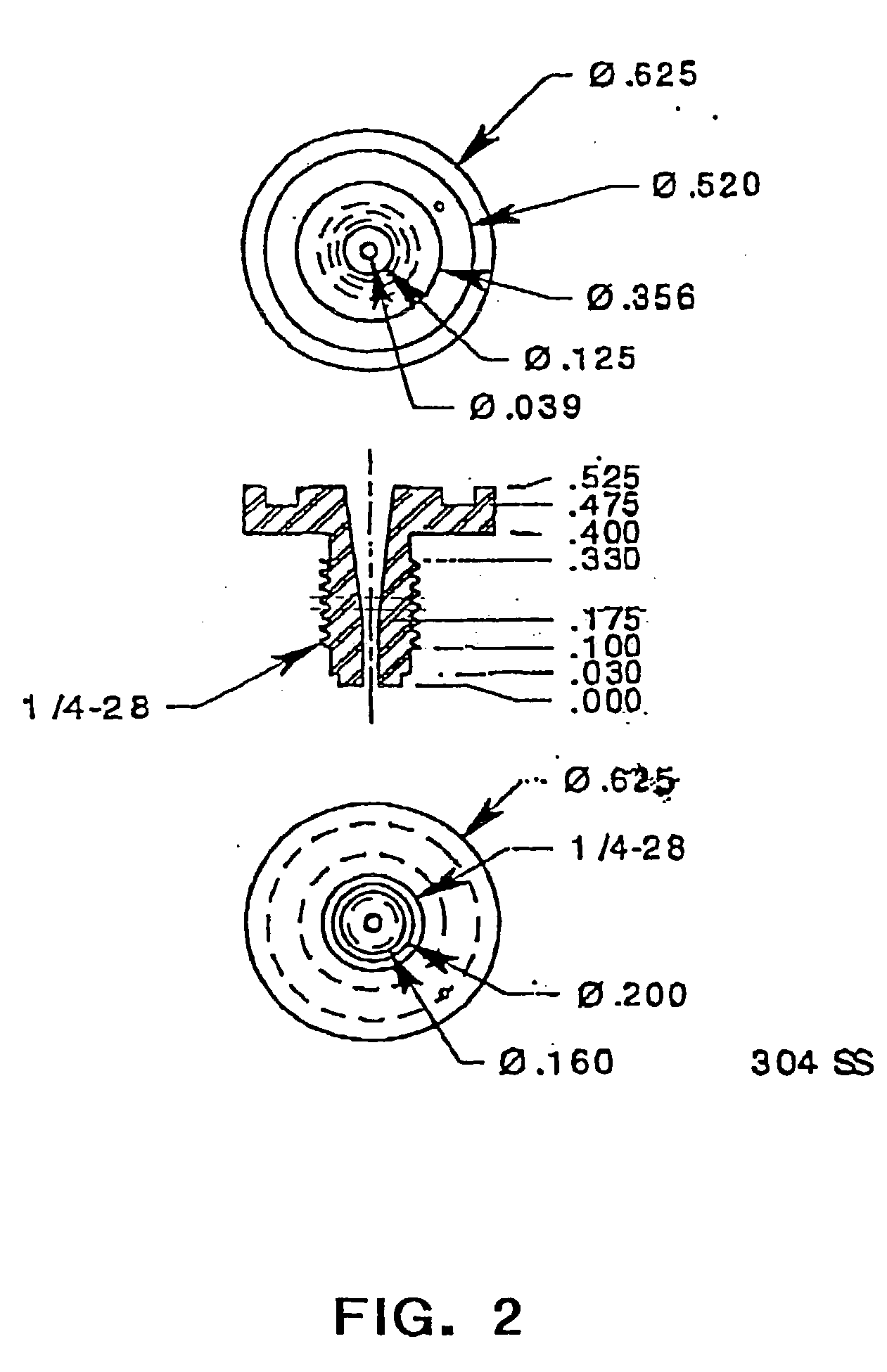

A special-shaped spinneret plate for spinning heavy denier yarns comprises an elliptic body (1). 90-192 spinning holes (2) are arranged on the body (1). One side of each spinning hole (2) is a feed inlet. The other side of each spinning hole (2) is a discharge outlet. The plurality of spinning holes (2) are arranged in a three-layered concentric ellipse structure from inside to outside. The spinneret plate is capable of producing glazed heavy denier yarns of 300-500D. Due to heavier filament number, diameters of micropores are slightly larger than those of round holes of products of conventional specification, and flow speed of melts in the micropores can be lowered effectively. In addition, the ellipse spinneret plate is different from conventional round spinneret plates, distribution of the micropores is facilitated, enhancement of cooling effect of spun fibers is facilitated, cooling uniformity of the heavy denier yarn is improved, and dyeing effect of the heavy denier yarn is also improved.

Owner:JIANGSU HUAYA FIBER

Methods and apparatus for spinning spider silk protein

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:SANTE BIOMATERIALS

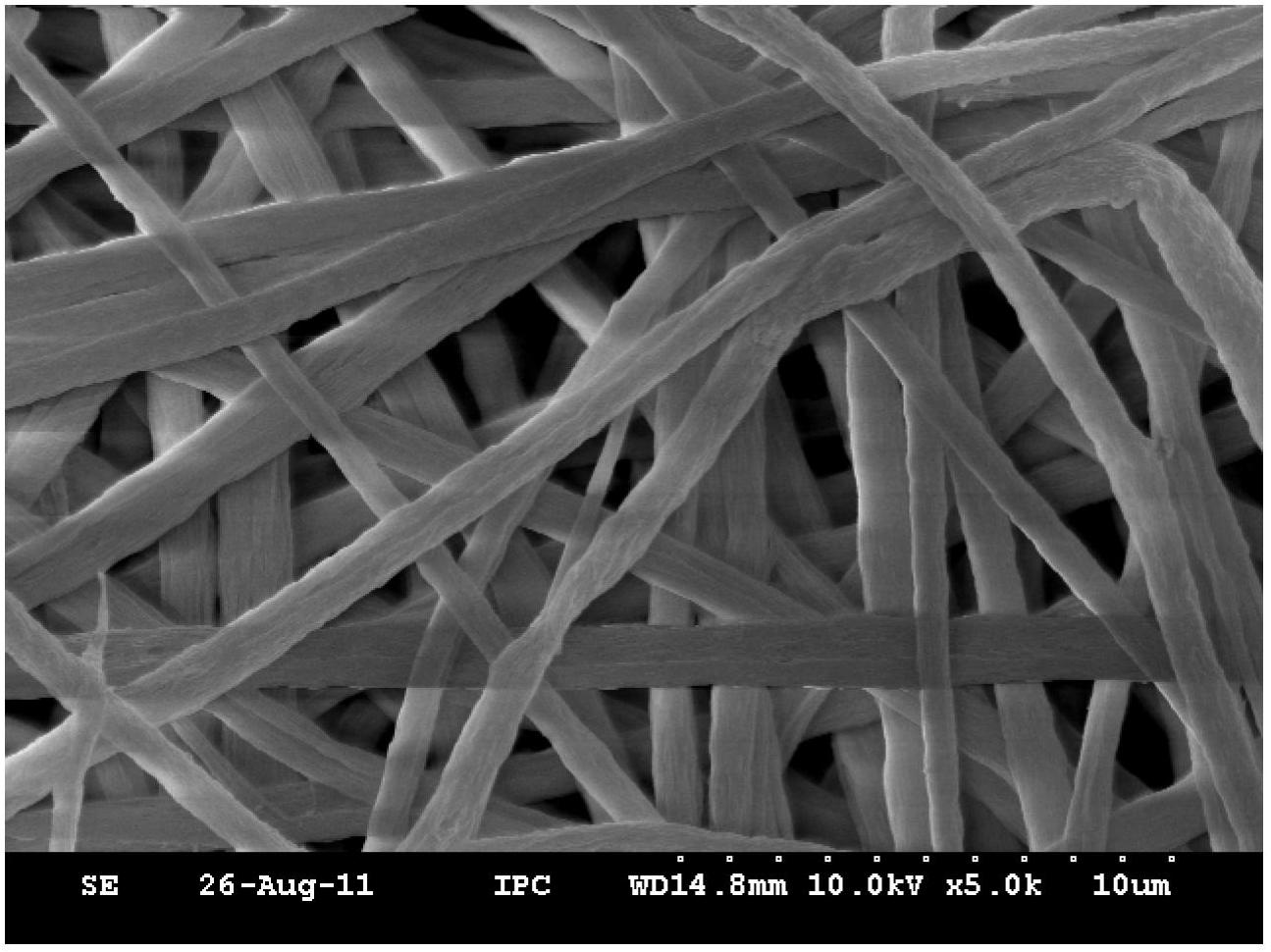

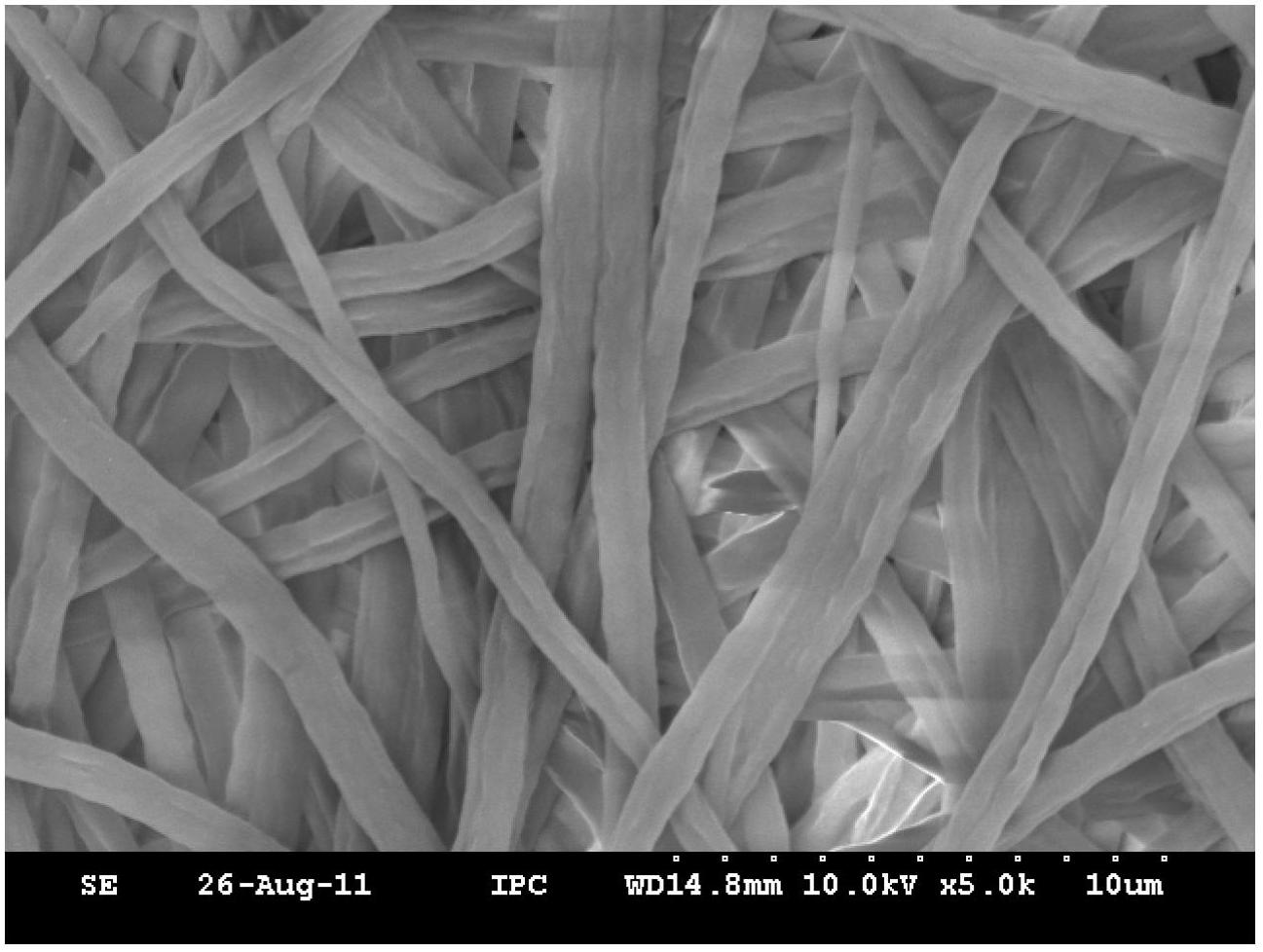

Porous carbon fiber, and preparation method and application thereof

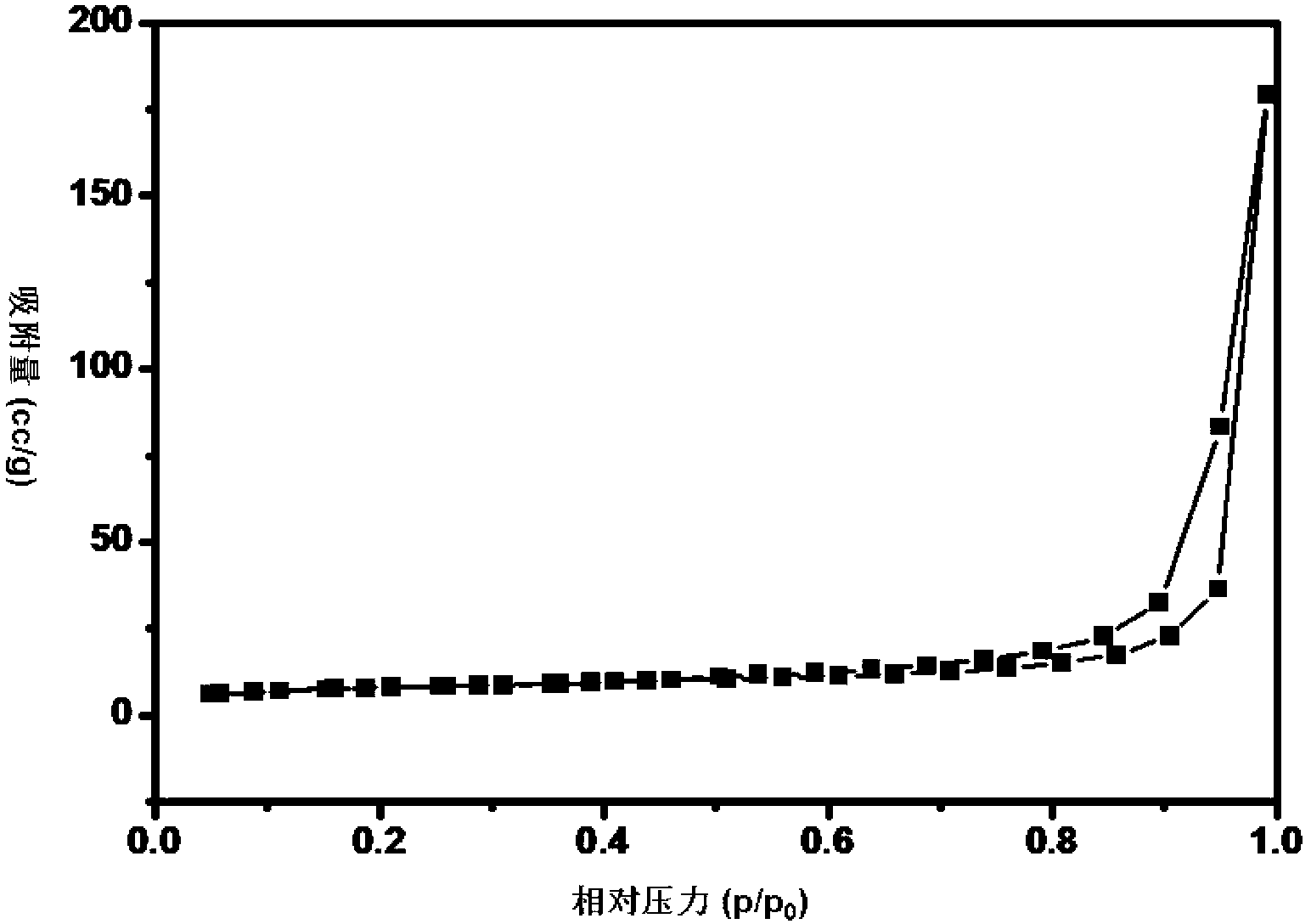

ActiveCN103225135AEasy to makeLow costFilament/thread formingArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a porous carbon fiber and a preparation method thereof. The method comprises the following steps: spinning a spinning liquid composed of a pore forming agent, a high polymer and an organic solvent, carbonizing, and pickling to obtain the porous carbon fiber. The method has the advantages of simple preparation, high output and low cost, and allows the porous carbon fiber simultaneously having micro-pores, meso-pores and macro-pores to be prepared; and the carbon fiber prepared in the invention is more flexible than that of carbon fibers prepared through other methods.

Owner:INST OF CHEM CHINESE ACAD OF SCI

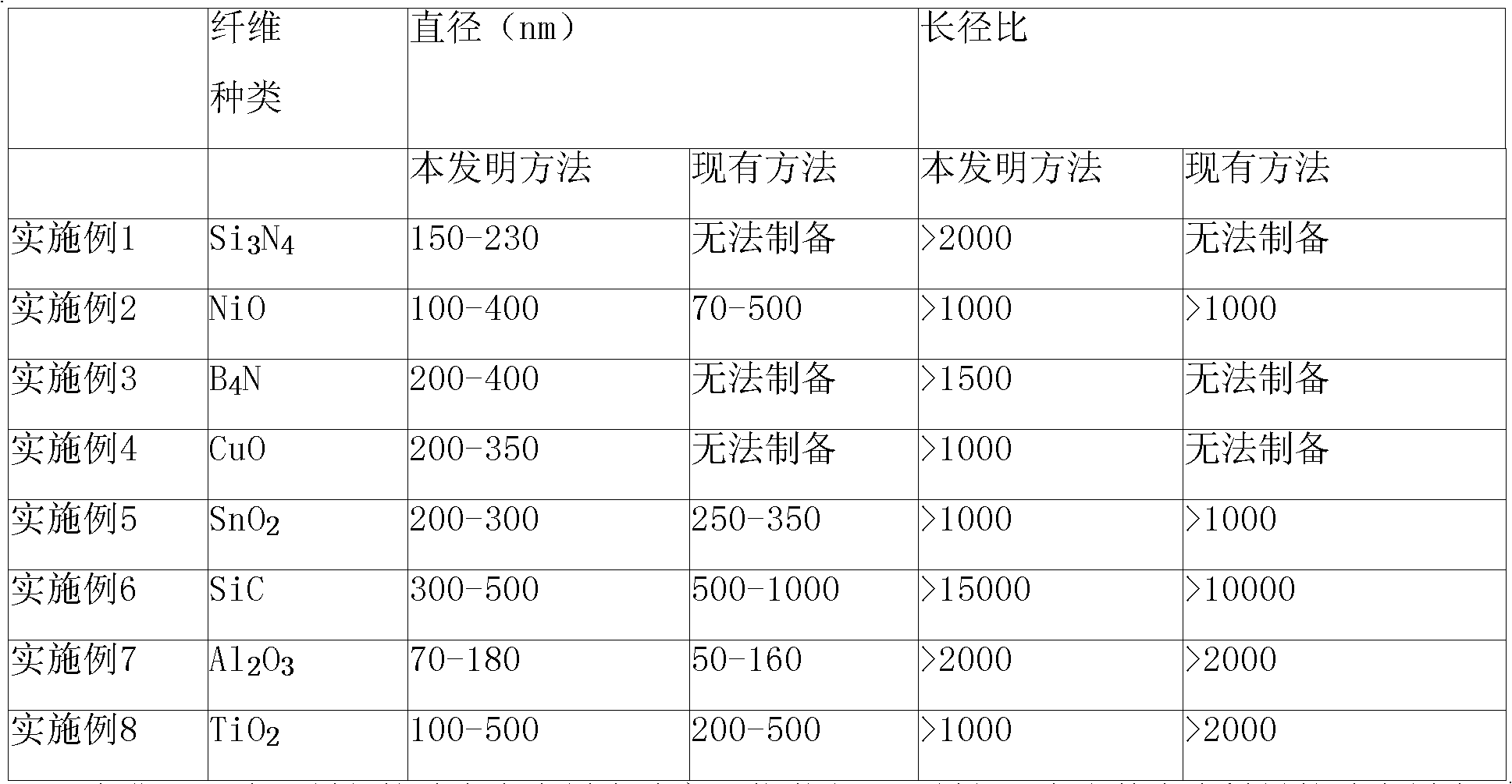

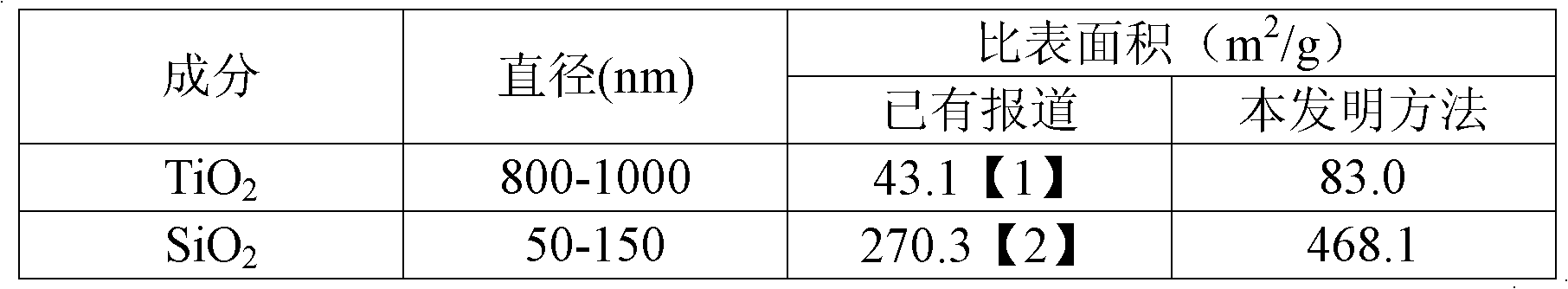

Method for preparing nano ceramic fibers

InactiveCN101880917AAverage diameter distributionHigh aspect ratioInorganic material artificial filamentsFilament/thread formingFiberWater baths

The invention discloses a method for preparing nano ceramic fibers, which is implemented by the following steps: 1, preparing 3 to 15 volume percent of 10 to 30 nanometer ceramic nanoparticles, 5 to 30 volume percent of spinnable high polymer, 0.5 to 5 volume percent of dispersant and the balance of solvent, wherein the total volume of the raw materials is 100 volume percent; 2, adding the spinnable high polymer into the solvent, heating the mixture in a water bath with magnetic stirring to obtain solution of spinnable high polymer; 3, adding the ceramic nanoparticles and the dispersant into the solution of spinnable high polymer obtained by the step 2, keeping the temperature of the mixture constant in a water bath, performing dispersion and ultrasonic dispersion, and performing swelling at a constant temperature to obtain ceramic nanoparticle / spinnable high polymer / solvent spinning solution; 4, controlling the electrostatic spinning process parameters of the spinning solution obtained by the step 3 to obtain nano fibers; and 5, sintering the nano fibers at 400 to 1,200 DEG C to obtain nano ceramic fibers.

Owner:XIAN UNIV OF TECH

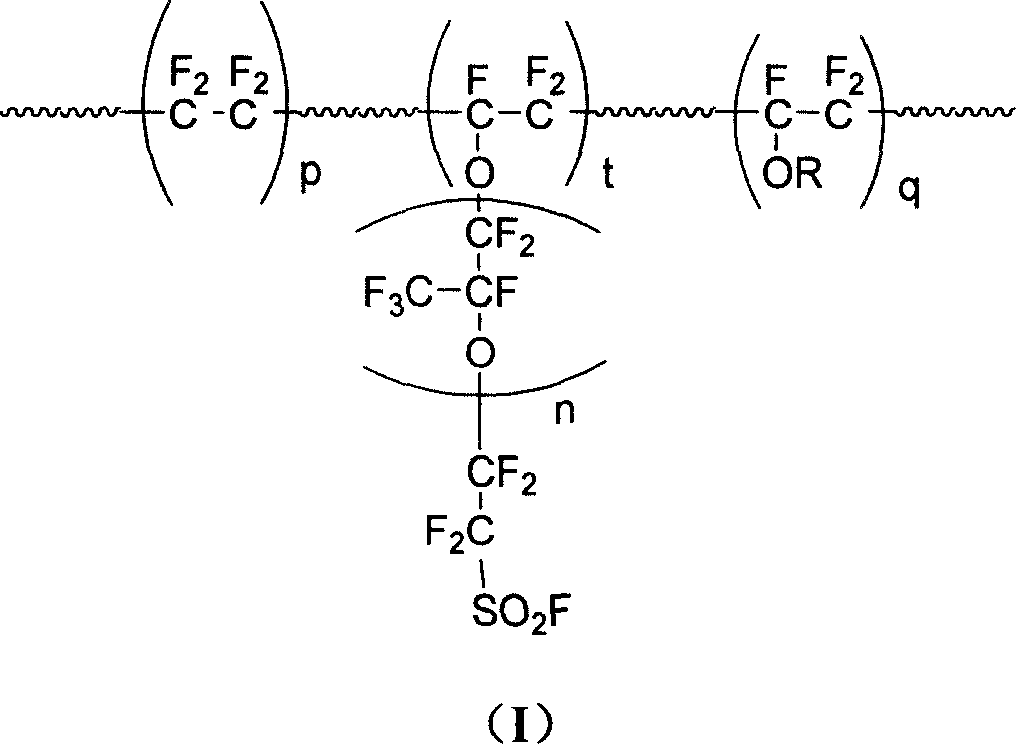

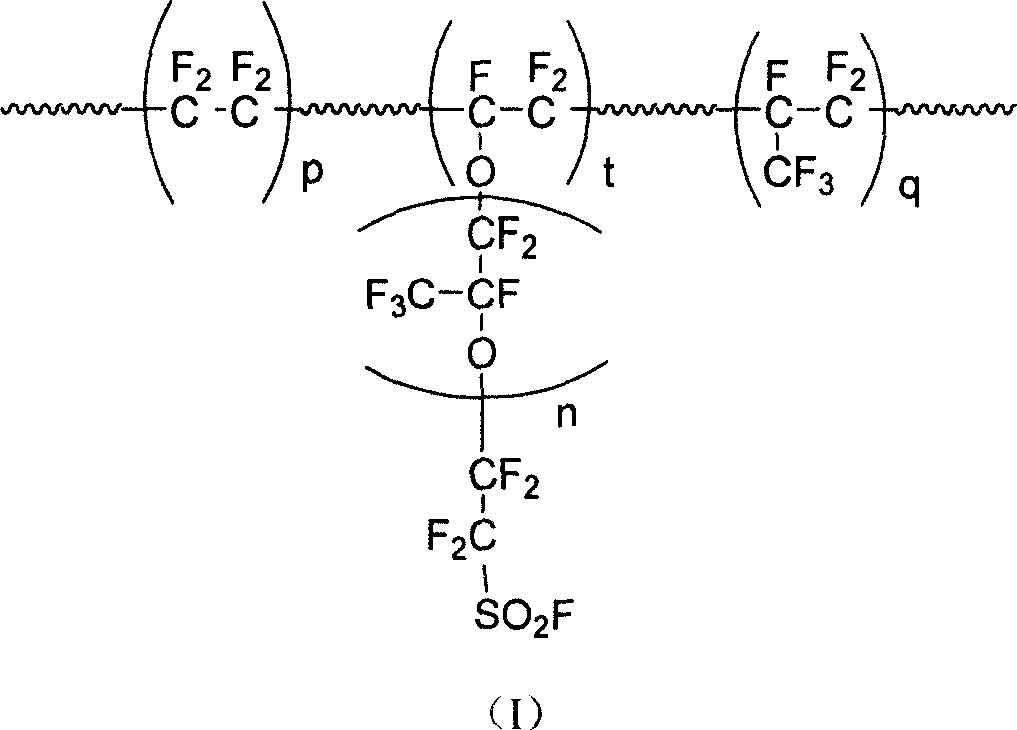

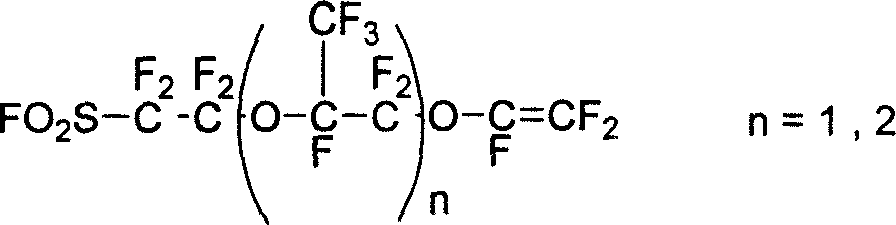

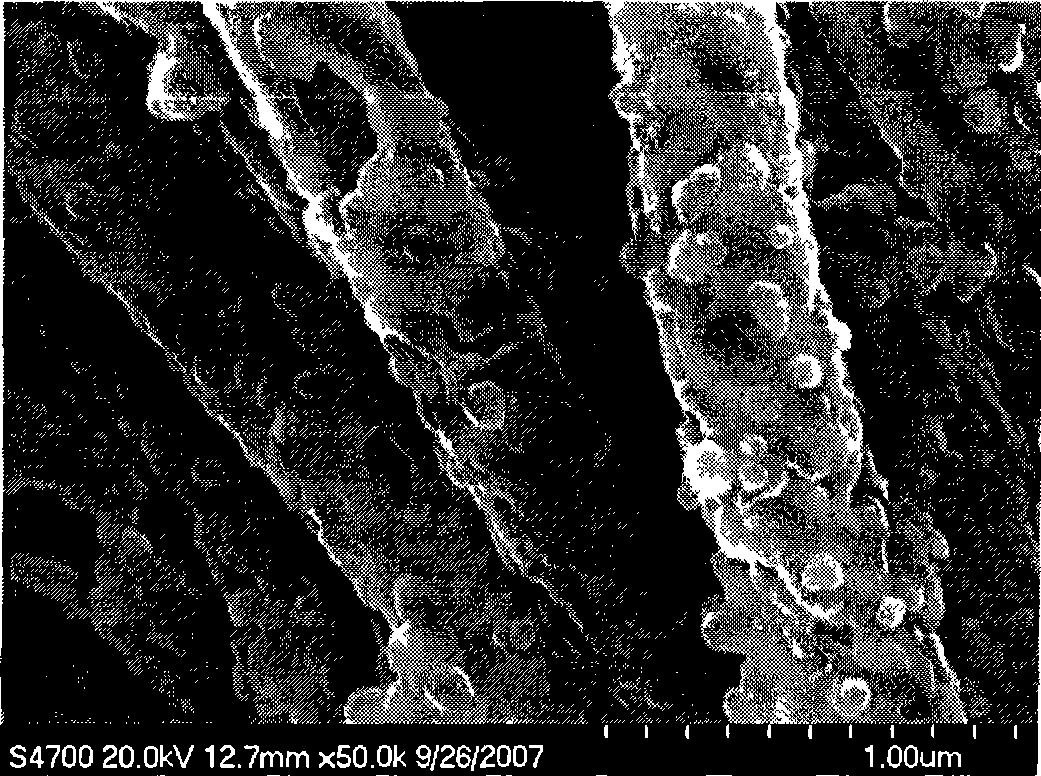

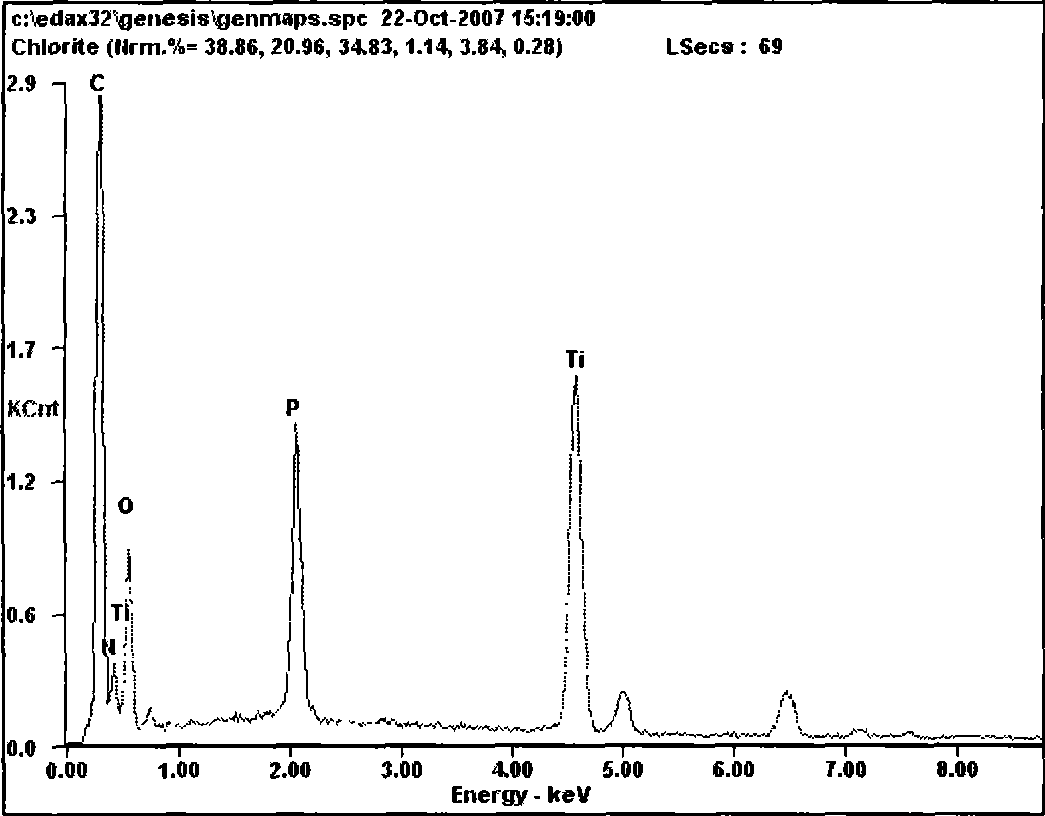

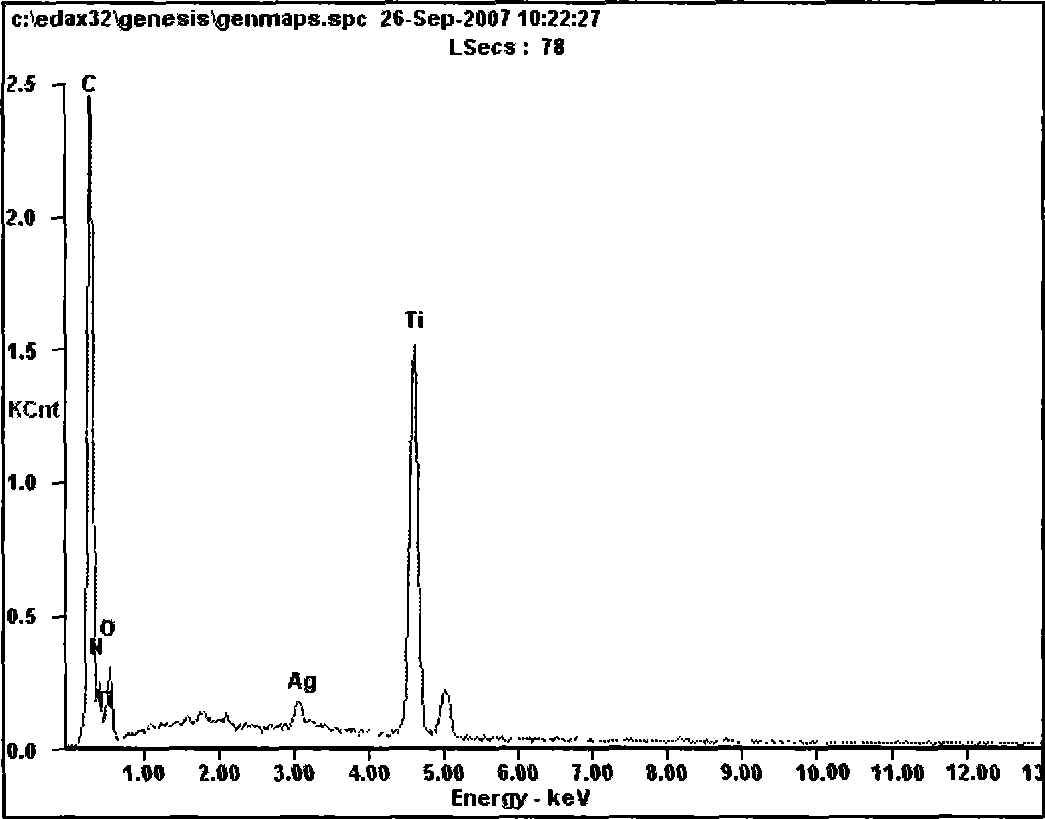

Polymer of containing fluorin, and application as material of ion exchange fiber

InactiveCN101003588AIncrease the effective areaLower resistanceMelt spinning methodsVinyl etherAlkali ions

This invention discloses a fluorine-containing polymer and its application as ion exchange fiber material. The fluorine-containing polymer is a perfluoro resin containing sulfonylfluoride groups, and is shown in formula 1. The fluorine-containing polymer has ion exchange function, and is prepared by free radical copolymerization of perfluorosulfonyl vinyl ether, tetrafluoroethylene and hexafluoropropylene in the presence of dispersant, solvent and initiator. The dispersant / solvent is mixed solution of melamine derivative containing linear perfluoro hydrocarbon and water. The fluorine-containing polymer can be melt-spun into polymer fibers, which can be woven into fiber network that can be used as the reinforcing network material for ion exchange membranes and chlor-alkali ion membrane to reinforce and improve the ion exchange ability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

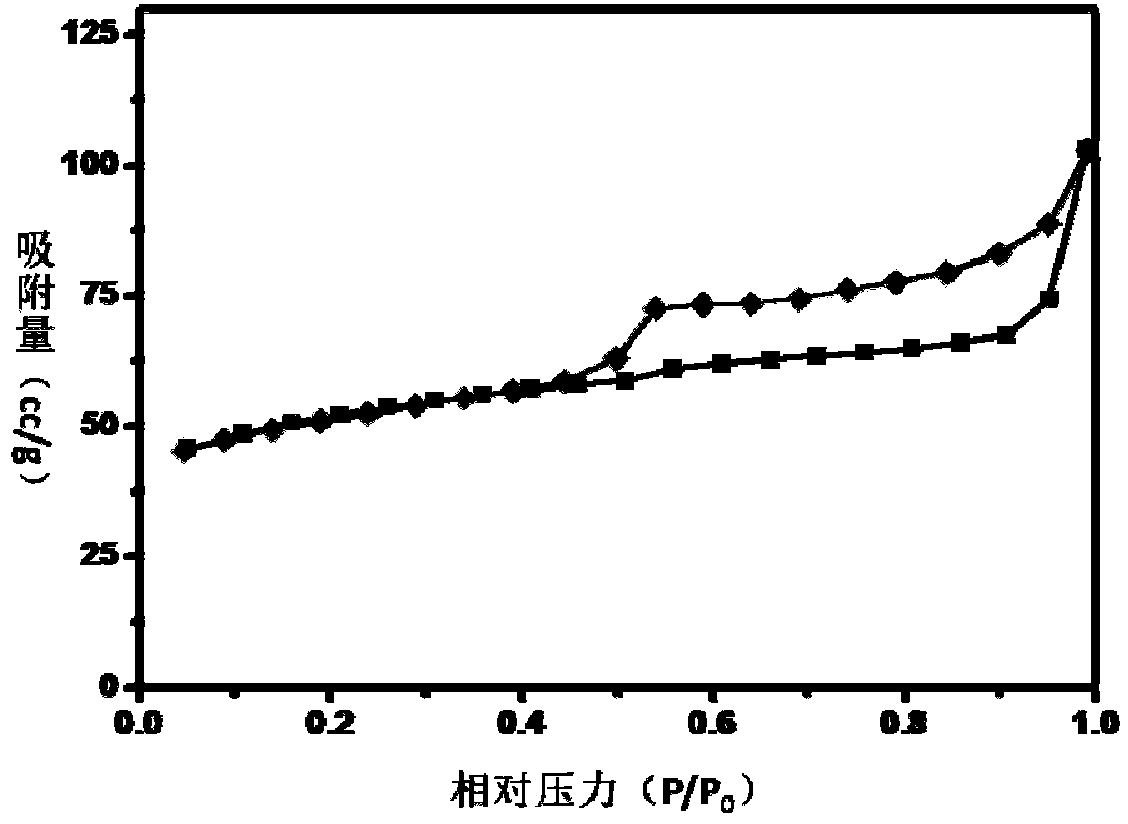

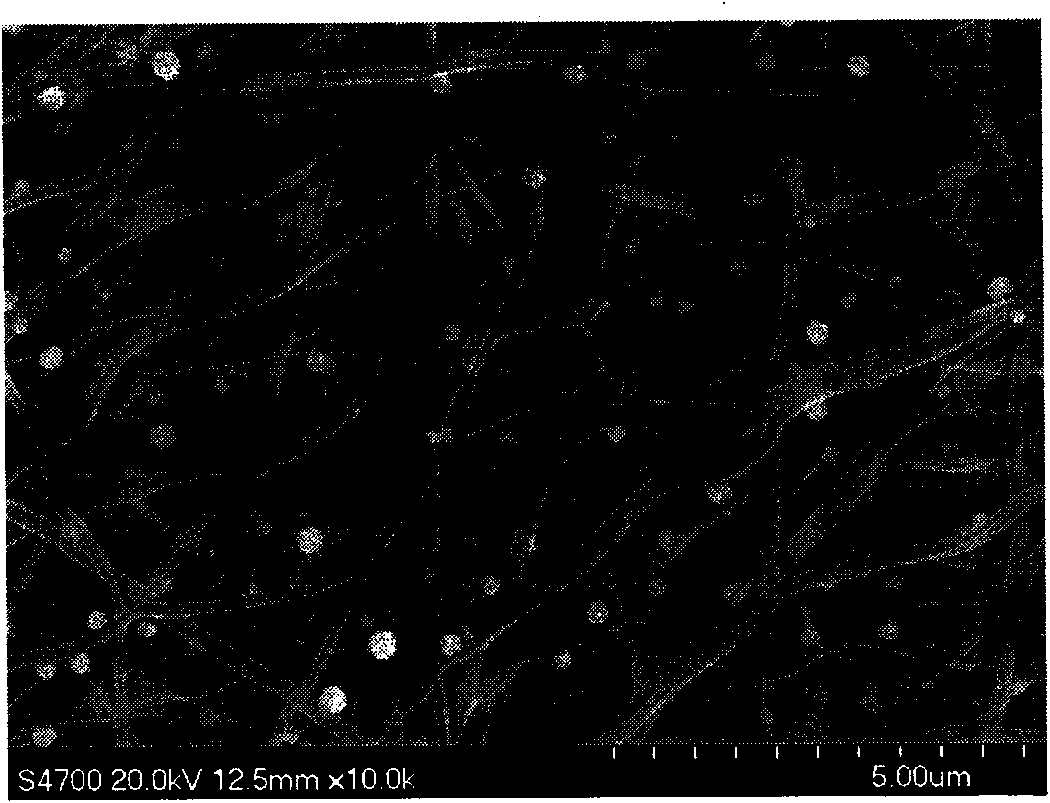

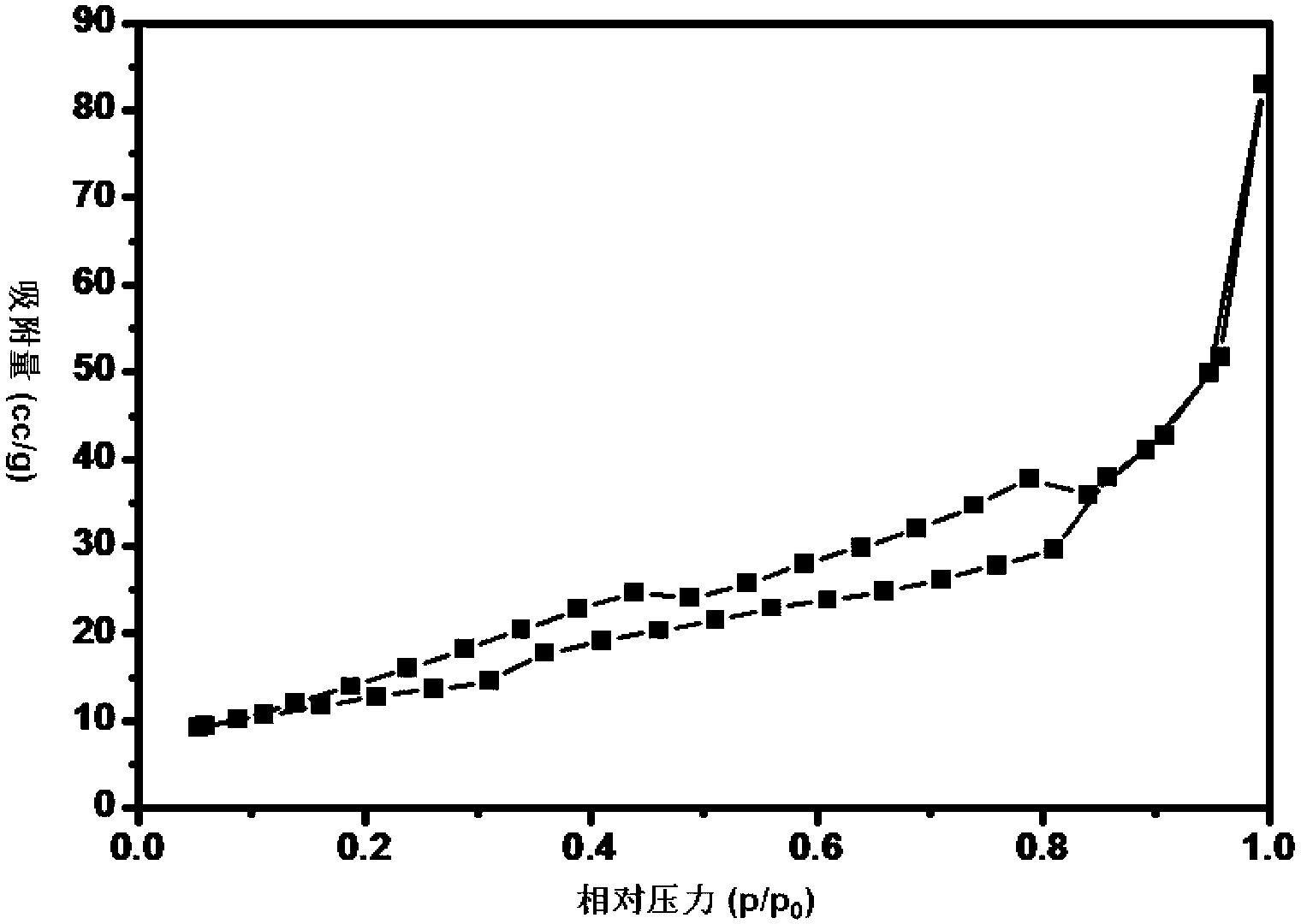

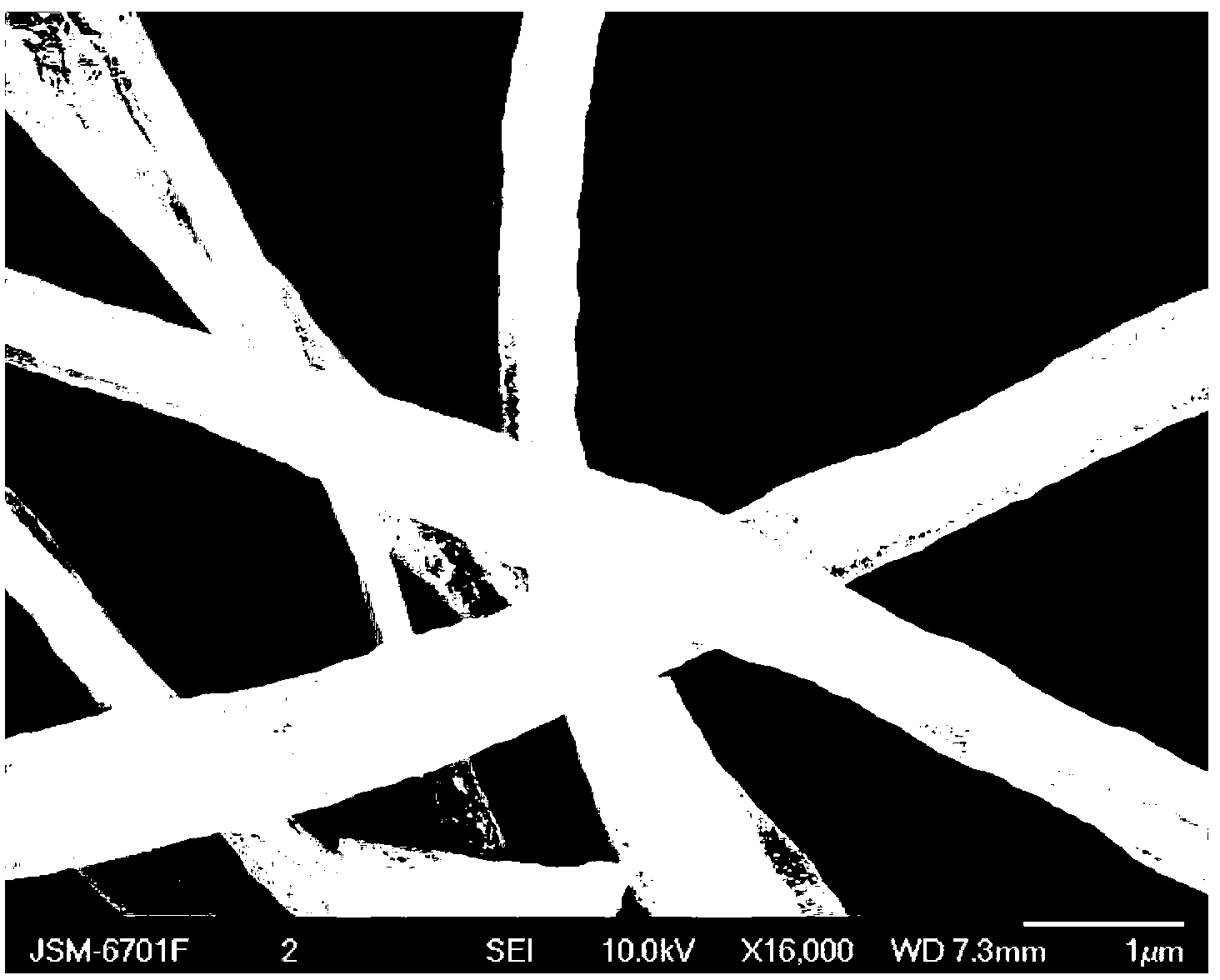

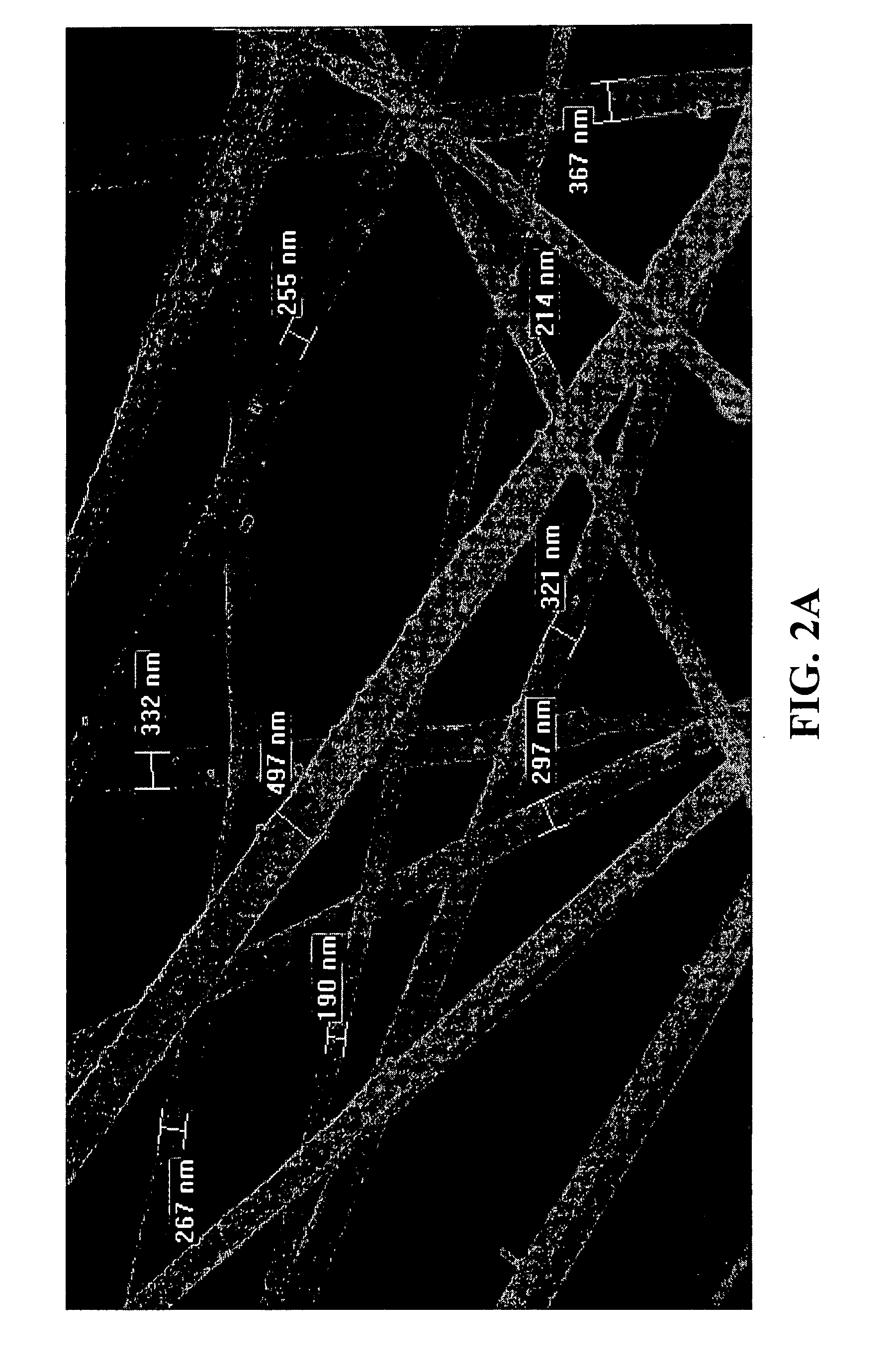

Porous carbon nanometer fiber-supported nanocrystal catalyst and preparation method thereof

InactiveCN101455975AModerate grain sizeSuitable structurePhysical/chemical process catalystsPorous carbonElectrospinning

The invention provides a porous-carbon nano-fiber supported nano-grain catalyst and a preparation method thereof. A porous polyacrylonitrile-based carbon nano-fiber supported nano-grain catalyst is prepared by adopting an electrostatic spinning process, constant-tension hot stretching, preoxidation and chemical activation at a temperature between 500 and 1,000 DEG C. Porous-carbon nano-fiber has the diameter between 100 and 500 nanometers, the aperture between 1 and 500 nanometers, the porosity between 0.1 and 1.0 cm<3> / g and the specific surface area between 100 and 2,000 m<2> / g, and catalyst particles supported on the surface of the nano-fiber has the aperture between 1 and 100 nanometers and the weight percentage content between 1 and 40 percent. The preparation method has the advantage of simple process, and can prepare the porous-carbon nano-fiber supported nano-grain catalyst with high porosity, large specific surface area, strong adsorption activity and catalytic efficiency through the chemical activation at a low temperature.

Owner:BEIJING UNIV OF CHEM TECH

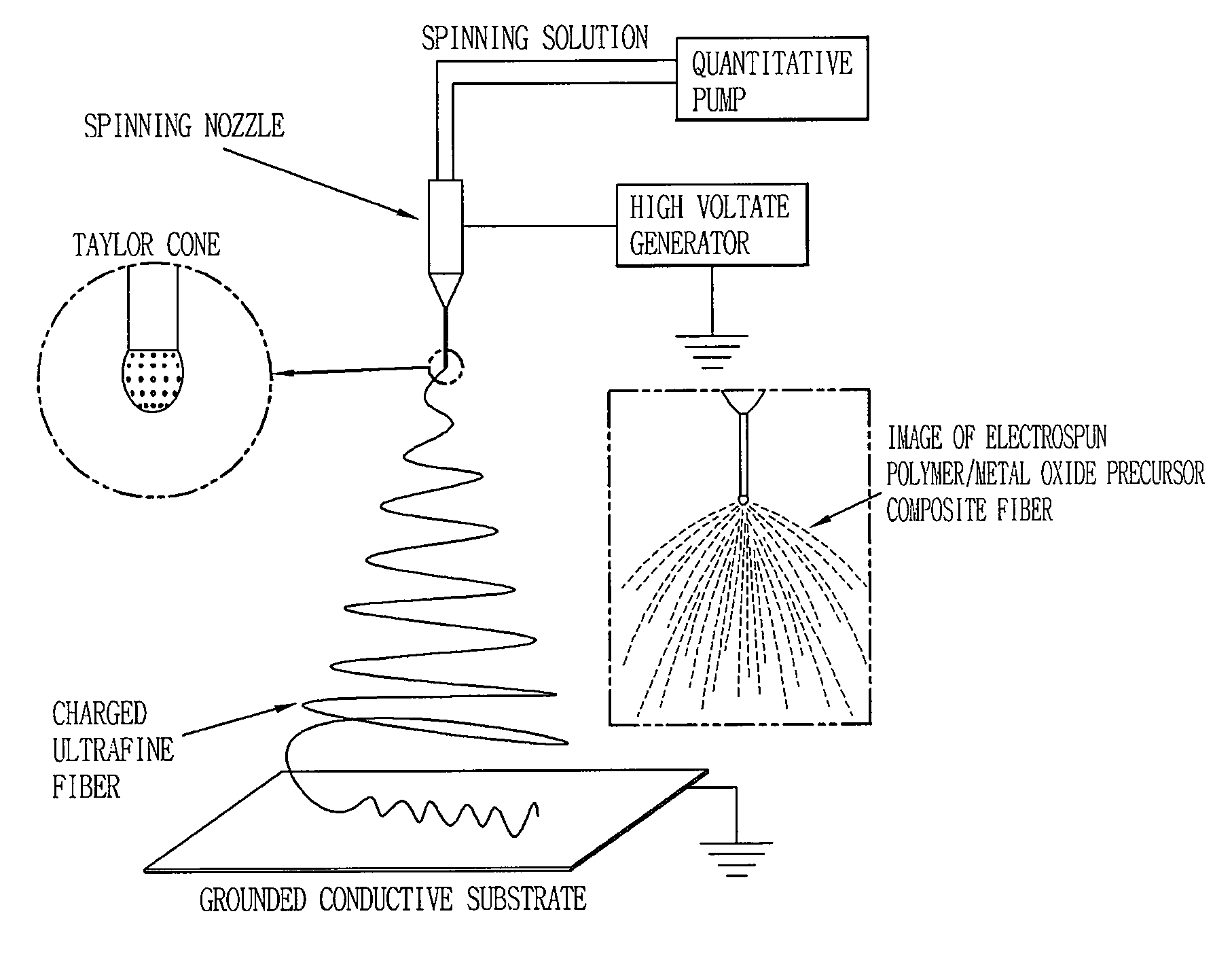

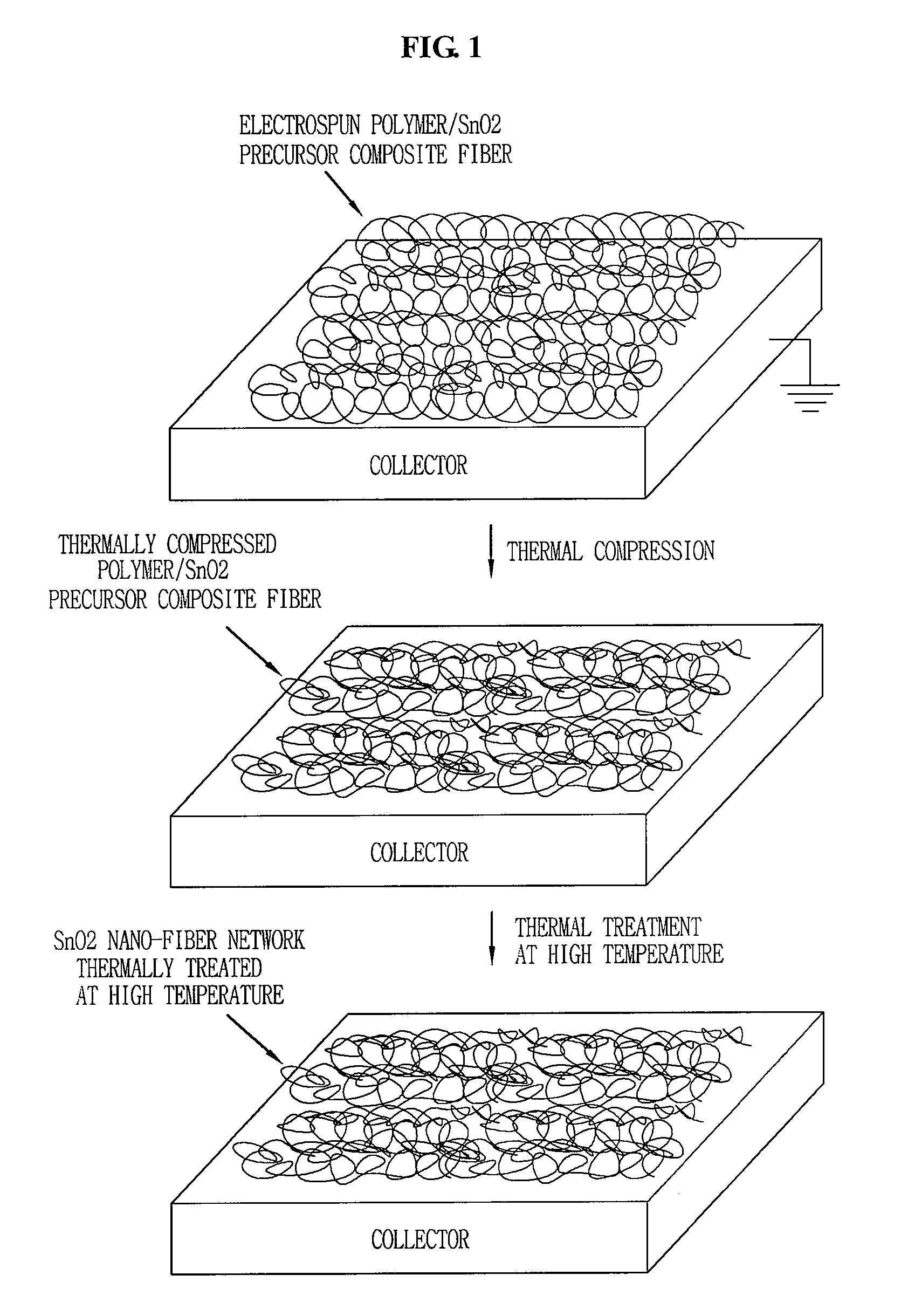

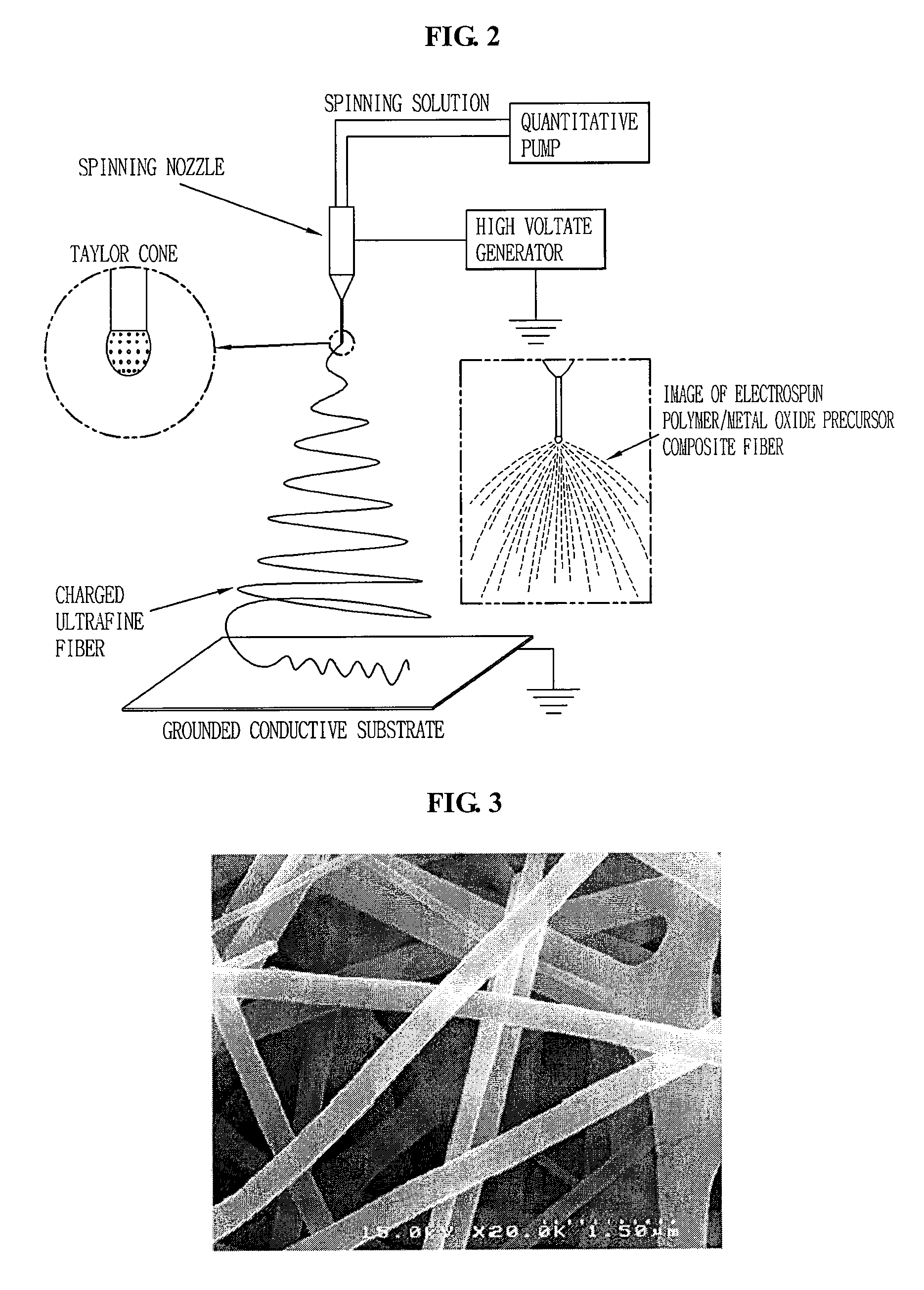

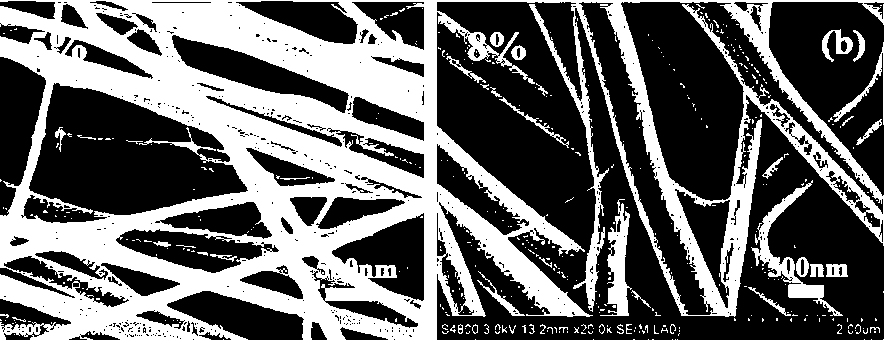

Anode for secondary battery having negative active material with nano-fiber network structure and secondary battery using the same, and fabrication method of negative active material for secondary battery

InactiveUS20080274403A1Maximize cycling characteristicIncrease speedElectrode rolling/calenderingMaterial nanotechnologyCurrent collectorFiber network

Owner:KOREA INST OF SCI & TECH

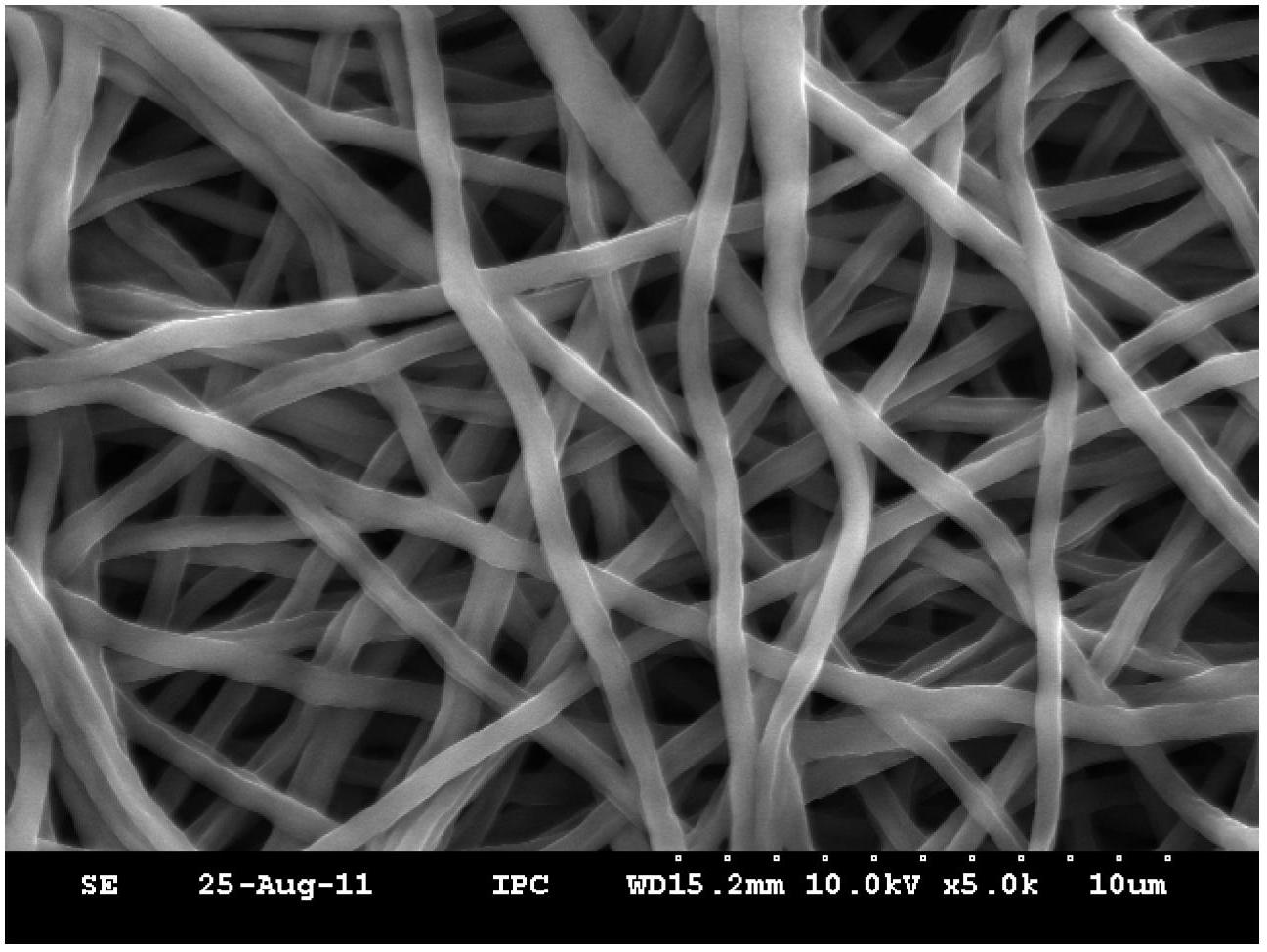

Silk fibroin nanofiber membrane and preparation method thereof

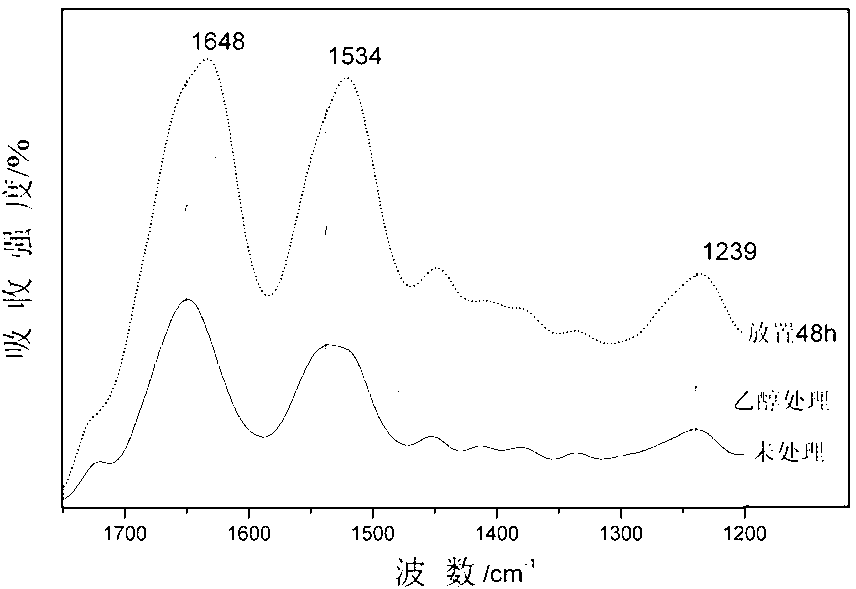

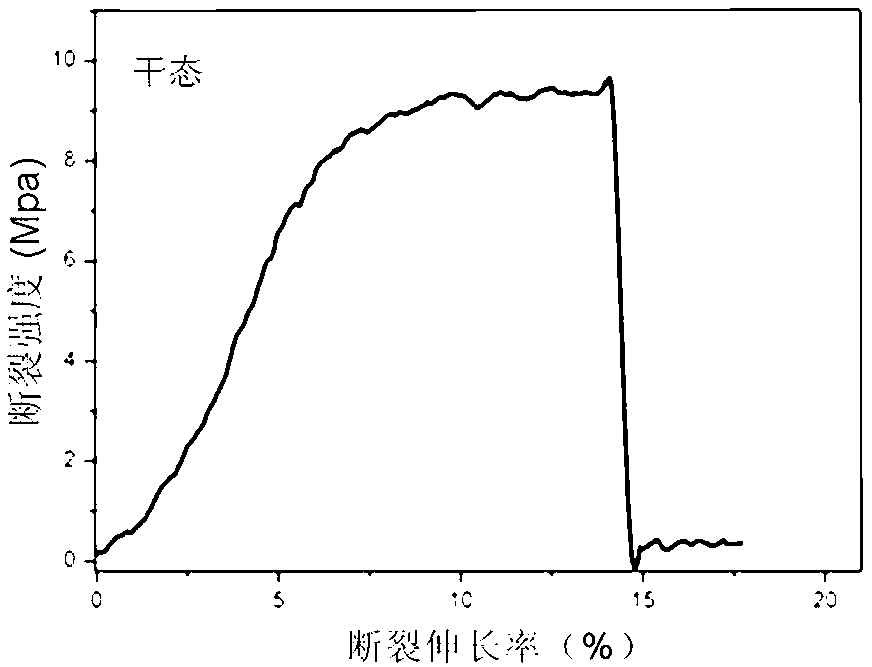

The invention discloses a silk fibroin nanofiber membrane and a preparation method of the silk fibroin nanofiber membrane. The preparation method comprises the following specific steps of: dissolving natural silk taken as a main raw material by an acid salt solution, forming a membrane, desalting the membrane, dissolving the membrane by methanoic acid and hexafluoroisopropanol to prepare a spinning solution, and carrying out electrostatic spinning to prepare the silk fibroin nanofiber membrane. The silk fibroin nanofiber membrane comprises fibers with the diameter of 10nm-10 microns and has the excellent mechanical property, the breaking strength of greater than 8Mpa at dry state, the breaking elongation of greater than 15% at dry state, the breaking strength of greater than 1Mpa at wet state and the breaking elongation of greater than 100% at wet state. In addition, the silk fibroin nanofiber membrane prepared by the method is stable and controllable in structure, has good biocompatibility and can serve as a medicinal biological material. The preparation method disclosed by the invention is simple and short in flow path, has high film formation and spinning efficiency and is suitable for industrialization large-scale production.

Owner:上海丝波敦生物科技有限公司

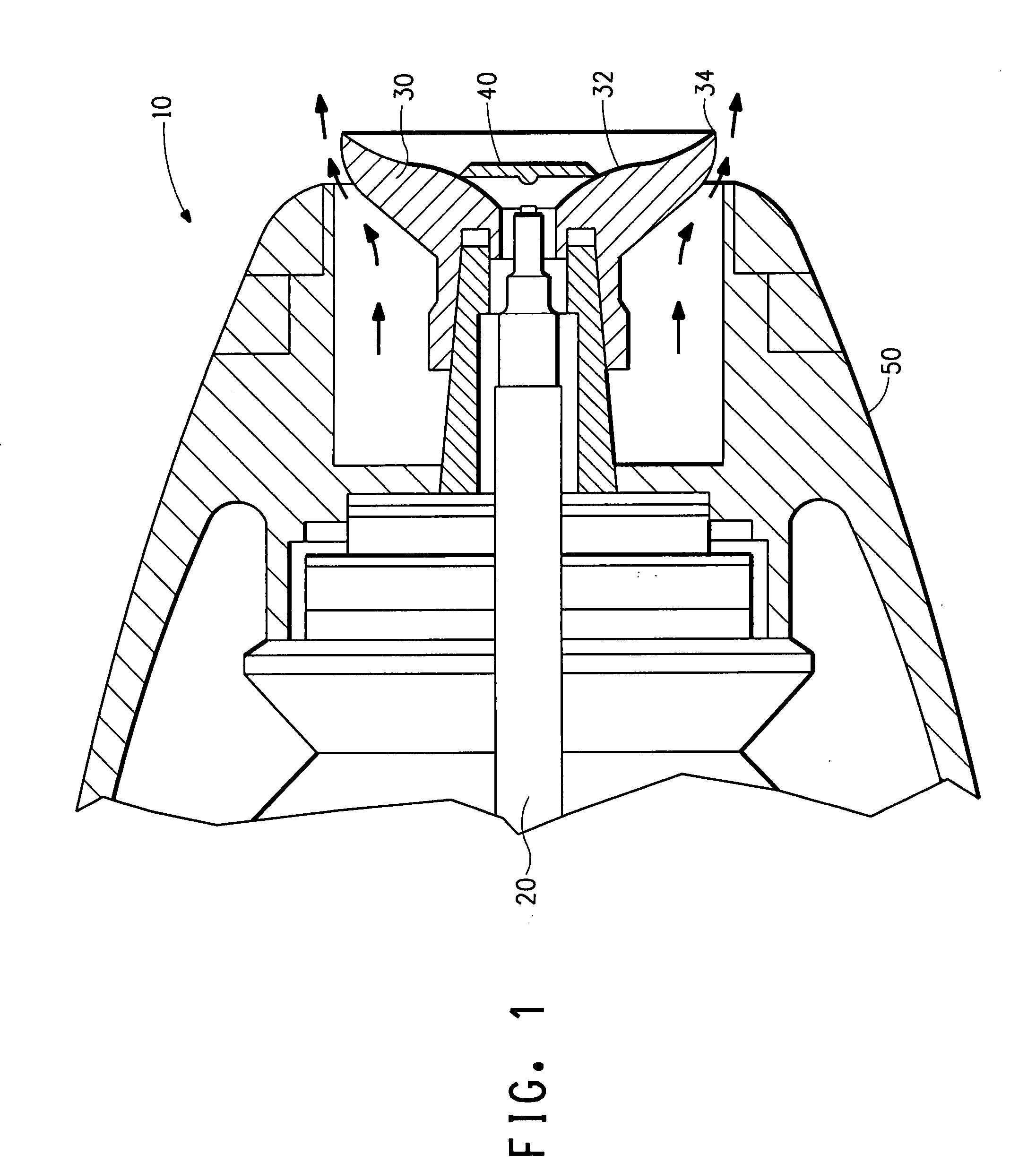

Apparatus and method for elevated temperature electrospinning

ActiveUS7326043B2Avoid disadvantagesConfectioneryWood working apparatusElectrical resistance and conductanceSpinning

Elevated temperature electrospinning apparatus comprises a pump upstream of or containing a resistance heater, means to shield applied electrostatic field from the resistance heater, and a temperature modulator for modulating temperature in the spinning region.

Owner:CORNELL RES FOUNDATION INC

Antibiotic nanometer fibrous material and method for preparing the same

InactiveCN1467314ASimple processing technologyGood effectArtifical filament manufactureFiberRepair tissue

An antibacterial nano-class fibre material contains superfine high-molecular fibres (60-98 wt.%) and antibacterial agent (2-40 wt.%), and is prepared through dispersing or dissolving one or more high-molecular material in solvent to become transparent solution or mixture, dispersing the superfine particle of antibacterial agent (less than 20 microns) in said solution, and electric spinning. It can be used as protecting material, disinfecting filter material and tissue covering material for repairing tissue or promoting healing of tissue.

Owner:SOUTHEAST UNIV

A cigarette filter filament and preparation method thereof

InactiveCN1961765ANo pollutionReduce pollutionTobacco smoke filtersHeating/cooling textile fabricsPolyesterPolymer resin

The invention relates to a tobacco filter tip and relative preparation, wherein it is formed by spinning the lactic acid polymer resin, drawing, coiling and shaping, while the line density is 2-6dtex, the beam density is 3-6ktex, the coil number is 15-30n / 25mm. And it uses the adhesive method similar acetate fabric. Therefore, its polymer structure and large specific area can support the adsorption on organic, and filter the solid particle.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method for high strength macro graphene conductive fiber

ActiveCN102534868AEasy to manufactureImprove solubilityArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a preparation method for high strength macro graphene conductive fiber. According to the method, graphite is oxidized to obtain a graphene oxide; the graphene oxide is dispersed in water or a polar organic solvent to prepare a spinning liquid sol with the mass concentration of 1-20%; the spinning liquid sol is transferred to a spinning device; the spinning liquid is continuously extruded from a spinning head capillary at a uniform speed; the extruded spinning liquid enters a solidification liquid; the solidified primary fiber is collected by using a polytetrafluoroethylene roller; a drying treatment is performed to obtain the graphene oxide fiber; the graphene oxide fiber is subjected to chemical reduction to obtain the graphene fiber. According to the present invention, the spinning process is simple; the operation is performed at the room temperature; no strong corrosive reagent is used; the process has the characteristics of green environmental protection; the prepared graphene fiber has characteristics of good conductivity, excellent mechanical property and good toughness, can be woven into the pure graphene fiber cloth, can further be woven into various fabrics with other fibers, and can further be added to the polymer as the conduction enhancing additive and the like; the prepared graphene fiber can replace the carbon fiber to use in a plurality of fields.

Owner:杭州德烯科技集团有限公司

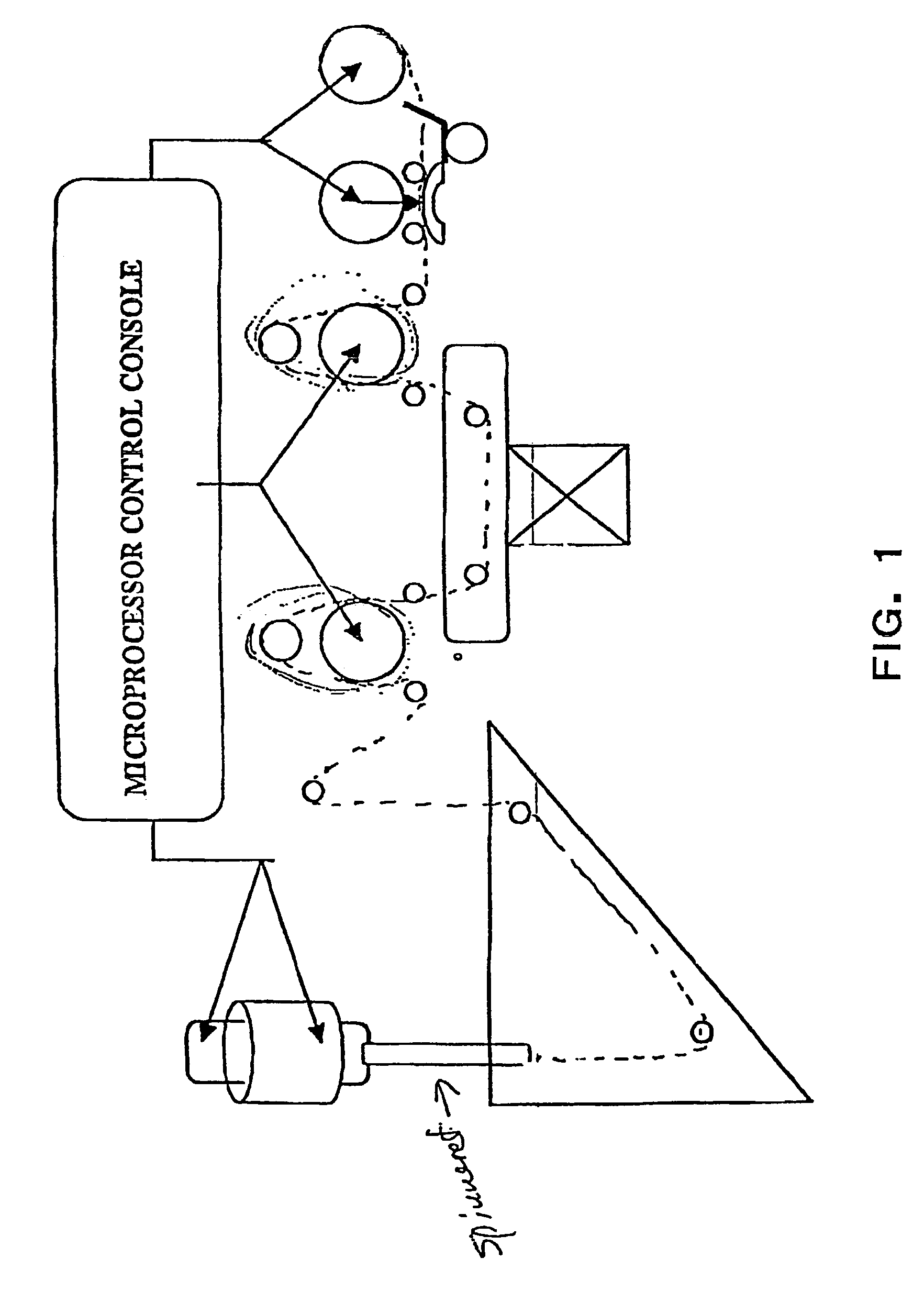

Methods and apparatus for spinning spider silk protein

InactiveUS20040102614A1Good birefringence propertyPrevents fiber formationFungiBacteriaBiotechnologyProtein fiber

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:SANTE BIOMATERIALS

Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

ActiveCN101626075AExcellent discharge performance and charge-discharge cycle stabilitySimple configuration processElectrode manufacturing processesSolventCarbon composites

The invention relates to stannum / carbon nano-fiber composite film material used in the negative electrode of a lithium ion battery and a preparation method thereof and also provides an assembly method of the stannum / carbon nano-fiber composite film material generated according to the preparation method and used as the electrode of the lithium ion battery. The preparation method comprises the following steps: preparing an uniform spinning solution by mixing a stannum precursor compound, a solvent, a precursor polymer of carbon nano-fibers and an organic solvent together; obtaining a polymer nano-fiber film by electro spinning according to a suitable electrostatic spinning technology; and obtaining a stannum / carbon nano-fiber composite film used in the negative electrode of the lithium ion battery through final treatment technologies, such as preoxidation, carbonization, and the like, thereby effectively collaborating the electrochemical performance of stannum / carbon nano-fibers and improving the specific capacity, the first charge-discharge efficiency and the cycle performance of the lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Methods for producing di-block polymers

The current major way of making nanofibers is electrospinning. However, the minimum fiber diameter is limited to be about 300–500 nm, which is not compliant with the physical definition of nano structures (in the region of 1 to 100 nm). Futher, the productivity is relatively low. This invention provides a method for manufacturing a nano-sized di-block polymer including at least a hard-segment polymer and a soft-segment polymer. First, a sample containing the hard-segment polymer, the soft-segment polymer, and a catalyst is dissolved in a first solvent. Then the dissolved sample is cast on substrate, and then the first solvent to is removed form a dried sample. Finally, the nano-sized di-block polymer is formed by crew-cutting.

Owner:THE HONG KONG POLYTECHNIC UNIV

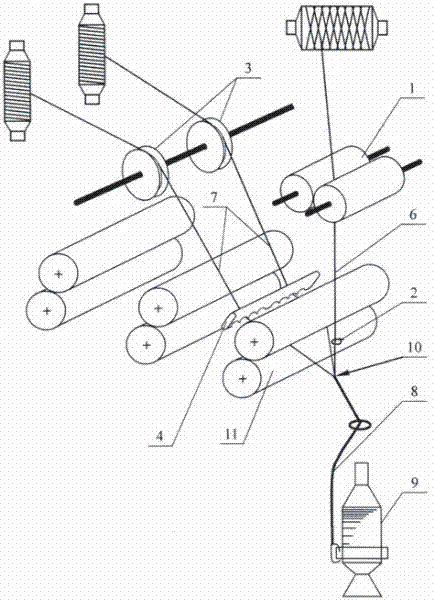

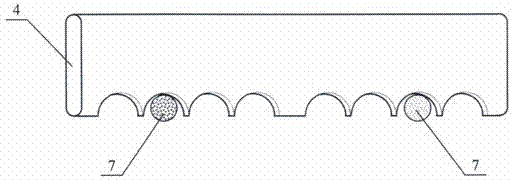

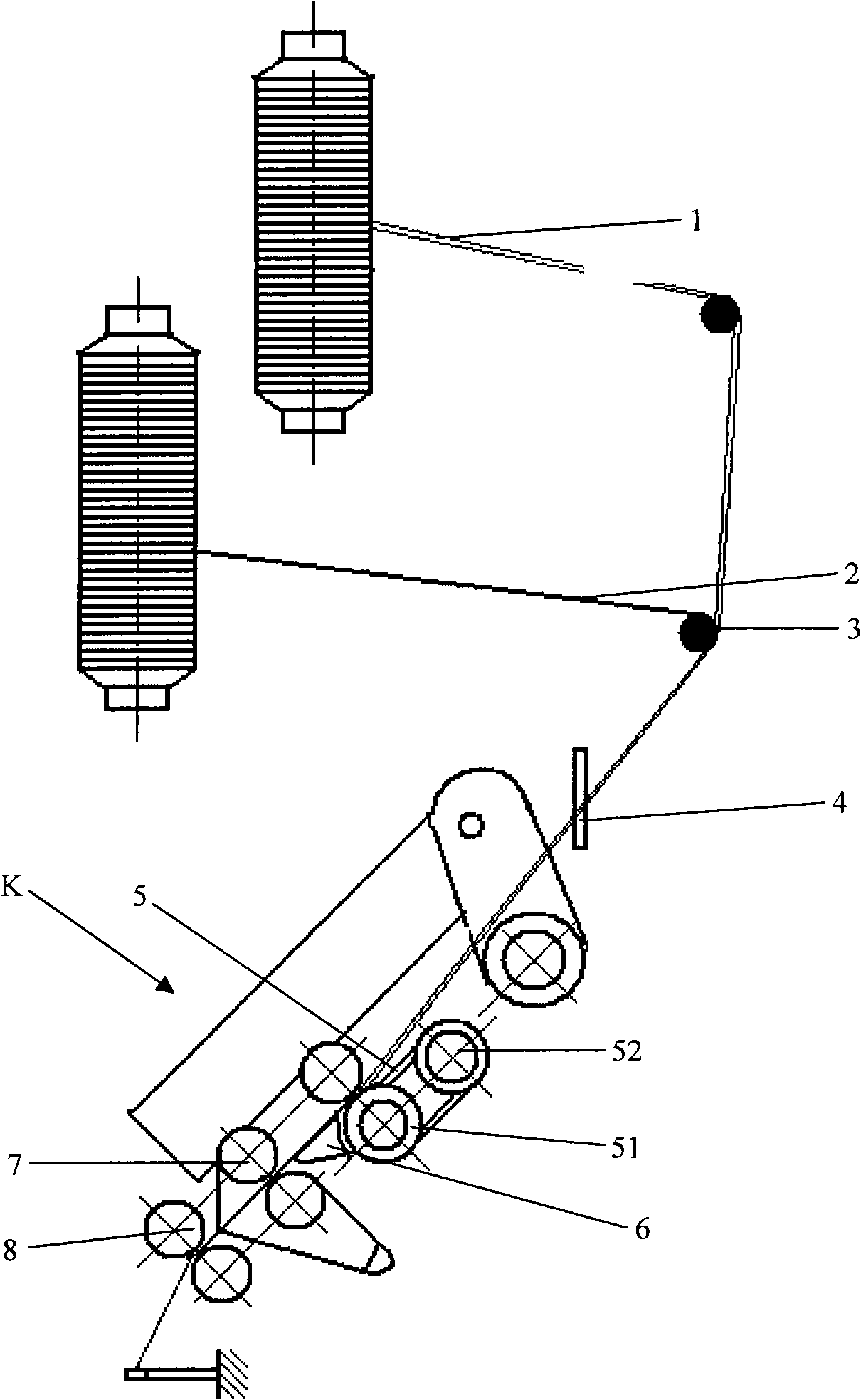

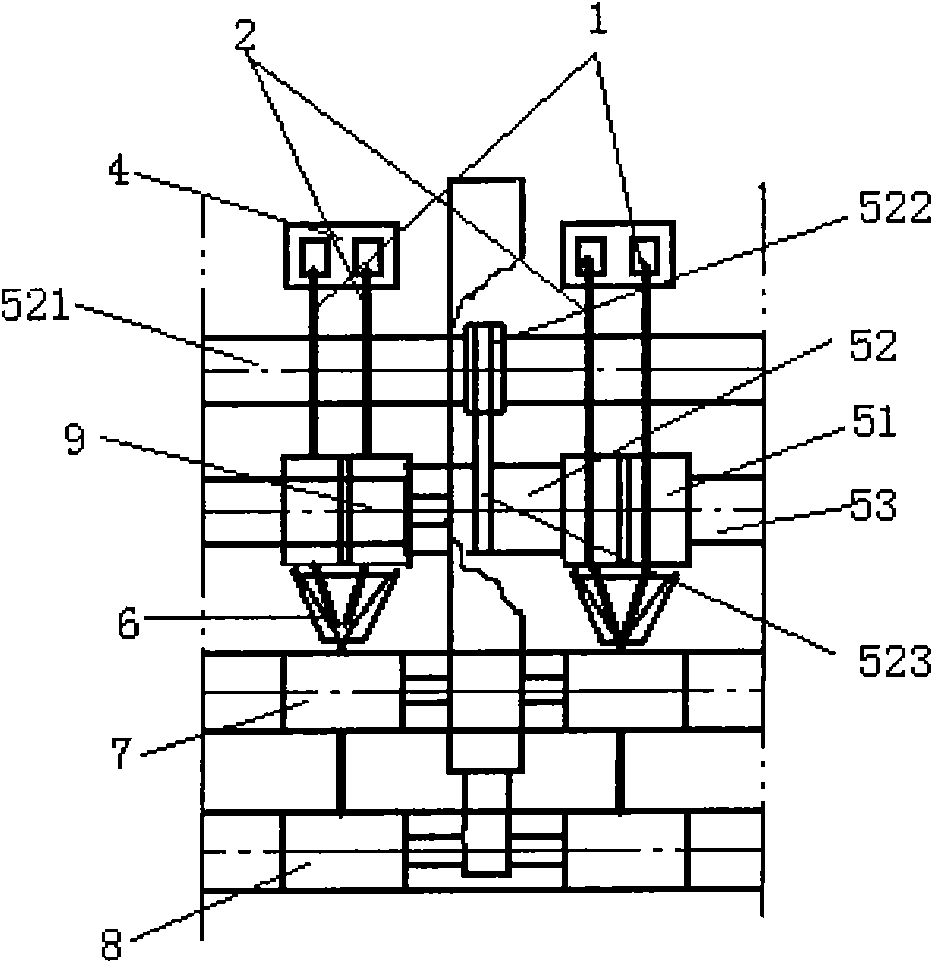

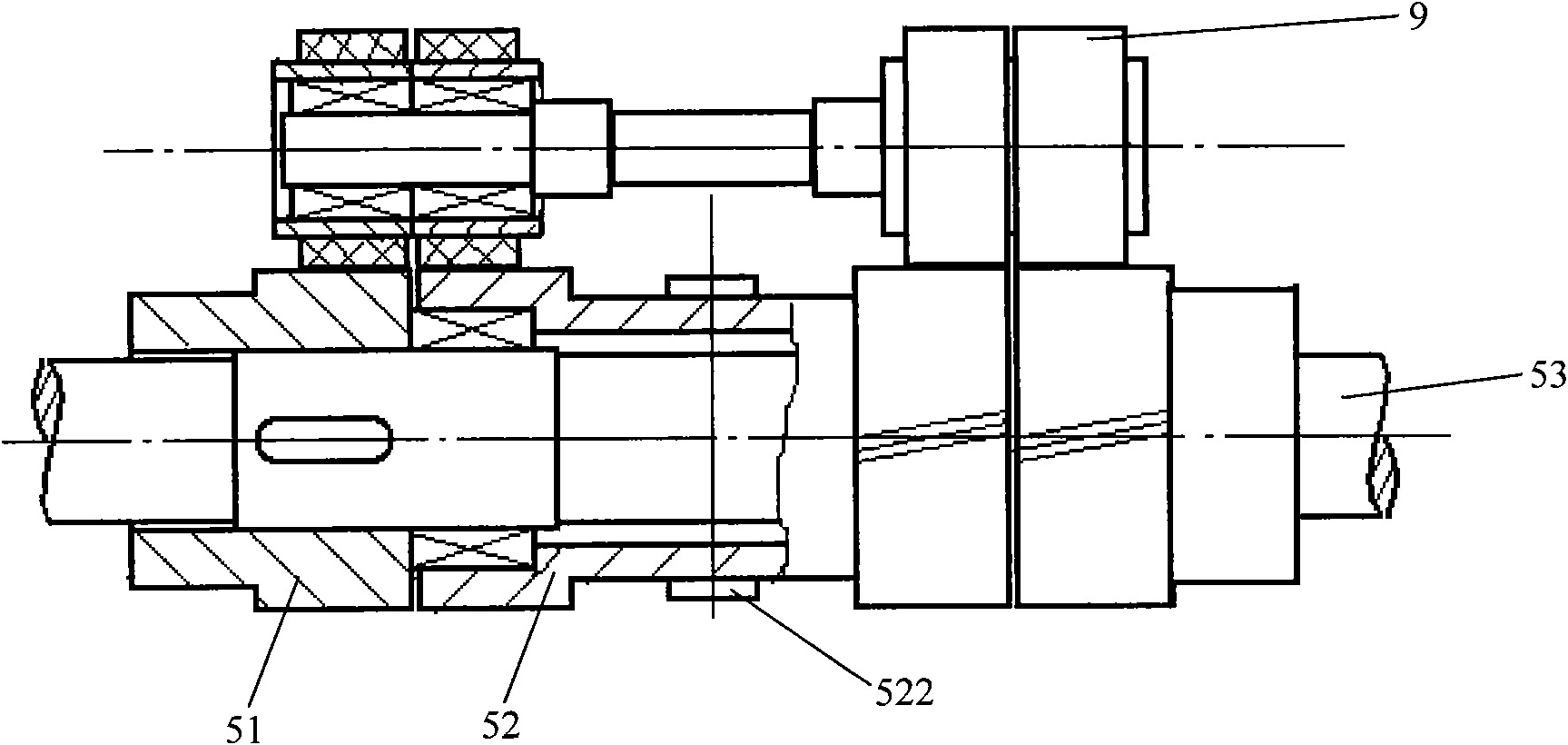

Composite spinning device and spinning method for chemical fiber filament coated rigid fiber filament

The invention provides a composite spinning device and a spinning method for covering rigid fiber filaments with chemical fiber filaments. The composite spinning device comprises a ring spinning frame, and is characterized by also comprising an unreeling roller, a positioning yarn guide, a tension disk and a multi-position yarn guide, wherein the positioning yarn guide is positioned behind a feed jaw of a front roller pair of the ring spinning frame; and the multi-position yarn guide is positioned in front of an output jaw of the front roller pair of the multi-position yarn guide. The rigid fiber filaments which unreeled from a rigid fiber filament drum pass through the unreeling roller and the positioning yarn guide in sequence and then are converged with two bundles of chemical fiber filaments which are unreeled from a chemical fiber filament drum, are fed into the front roller pair through the tension disk and the multi-position yarn guide and are output from the front roller pair at a convergent point; meanwhile, the chemical fiber filaments and the rigid fiber filaments are twisted at the convergent point to form a composite yarn under the action of rotation of a spindle of the ring spinning frame. Through the device and the method, the problems of high brittleness of carbon fibers and high probability of bending and brittle fracture of fibers during back-roll and weaving can be solved.

Owner:DONGHUA UNIV

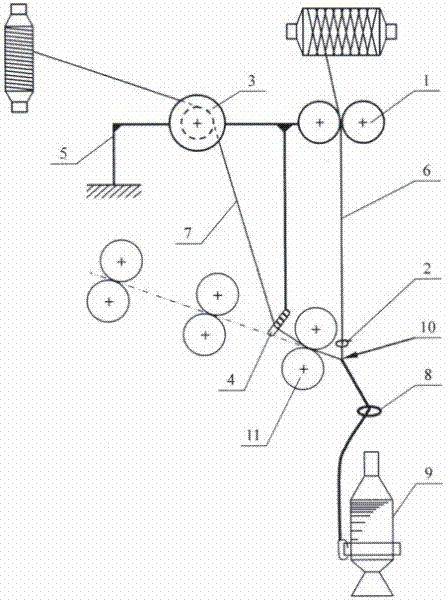

Ring spinning method and device of equi-linear density space dyed yarn

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

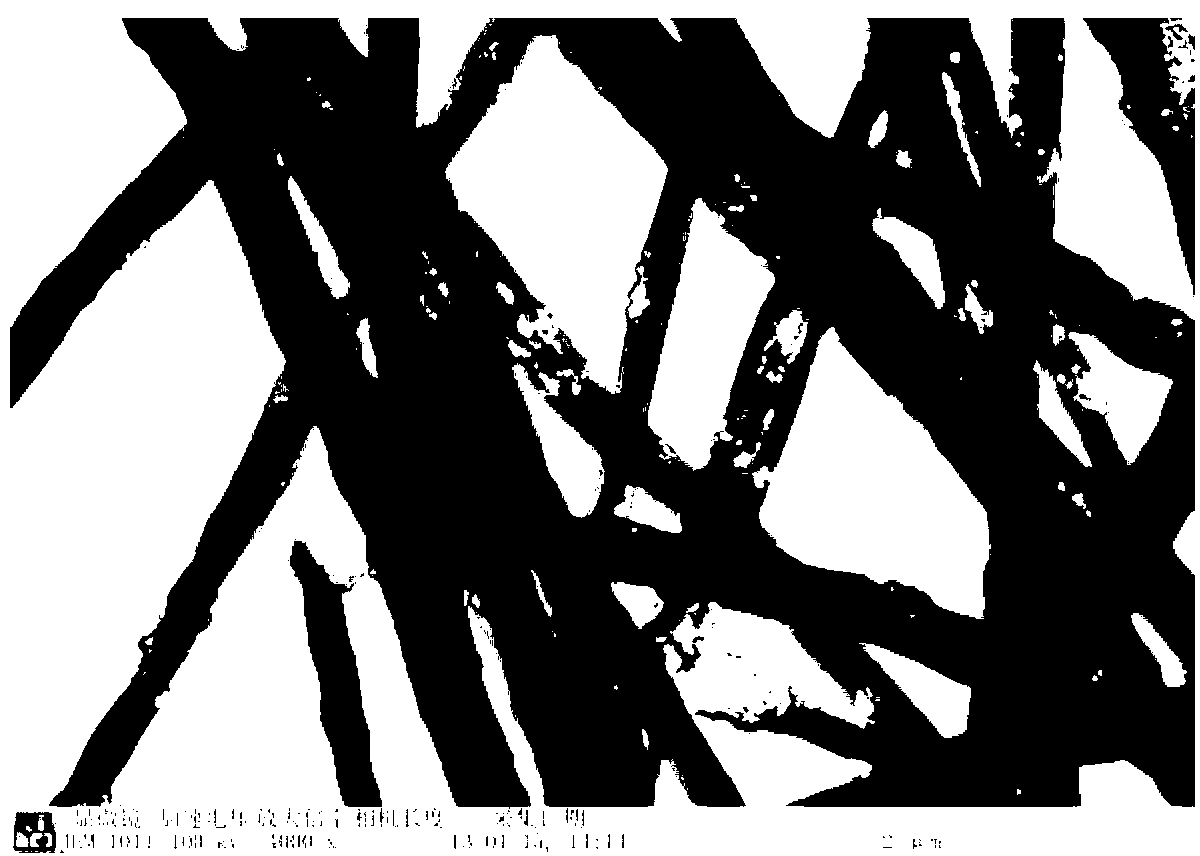

Multi-hole carbon fiber and preparation method thereof

ActiveCN103014921AEasy to makeLow costSemi-permeable membranesFilament/thread formingFiberCarbon fibers

The invention discloses a multi-hole carbon fiber and a preparation method thereof. The method comprises the following steps: spinning solution composed of pore former, high polymer and organic solvent is used for spinning and then carbonization to obtain the multi-hole carbon fiber. The method has the following advantages: 1, the preparation is simple, the yield is high, and the cost is low; 2, the sizes of holes of the multi-hole carbon fiber can be controlled conveniently by changing the preparation parameters; 3, the used pore former can performing pore-forming in a self sublimation manner and can be reclaimed for use, so that the preparation cost can be lowered greatly; and 4, the obtained carbon fiber has a multi-hole structure, so that the bendability is improved, and the carbon fiber can be bent and folded at will instead of being broken, and can support a finished film independently.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing polyacrylonitrile-based porous hollow carbon fibers by coaxial electrospinning

InactiveCN102691136ALarge specific surface areaImprove efficiencyCatalyst carriersOther chemical processesPolymer scienceCarbon fibers

The invention discloses a method for preparing PAN (polyacrylonitrile)-based porous hollow carbon fibers by coaxial electrospinning. The method includes the steps: mixing polyacrylonitrile with additives to serve as outer solution; taking inner polymer to serve as inner solution; inputting the outer solution and the inner solution into outer layers and inner layers of coaxial needles respectively at the constant flow velocity and in the constant velocity ratio for electrospinning so that PAN-based sheath-core composite fibers are obtained; and subjecting the PAN-based sheath-core composite fibers to washing, pre-oxidation and carbonization so that the PAN-based porous hollow carbon fibers are obtained. The PAN-based porous hollow carbon fibers combine structural characteristics of original porous carbon fibers and original hollow carbon fibers, the specific surface area of the fibers can be greatly increased, and use efficiency of materials is improved. When the PAN-based porous hollow carbon fibers prepared by the method are applied to gas adsorption, gas can enter hollow portions of the fibers more easily, so that adsorbability is enhanced while time required by adsorption is shortened.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

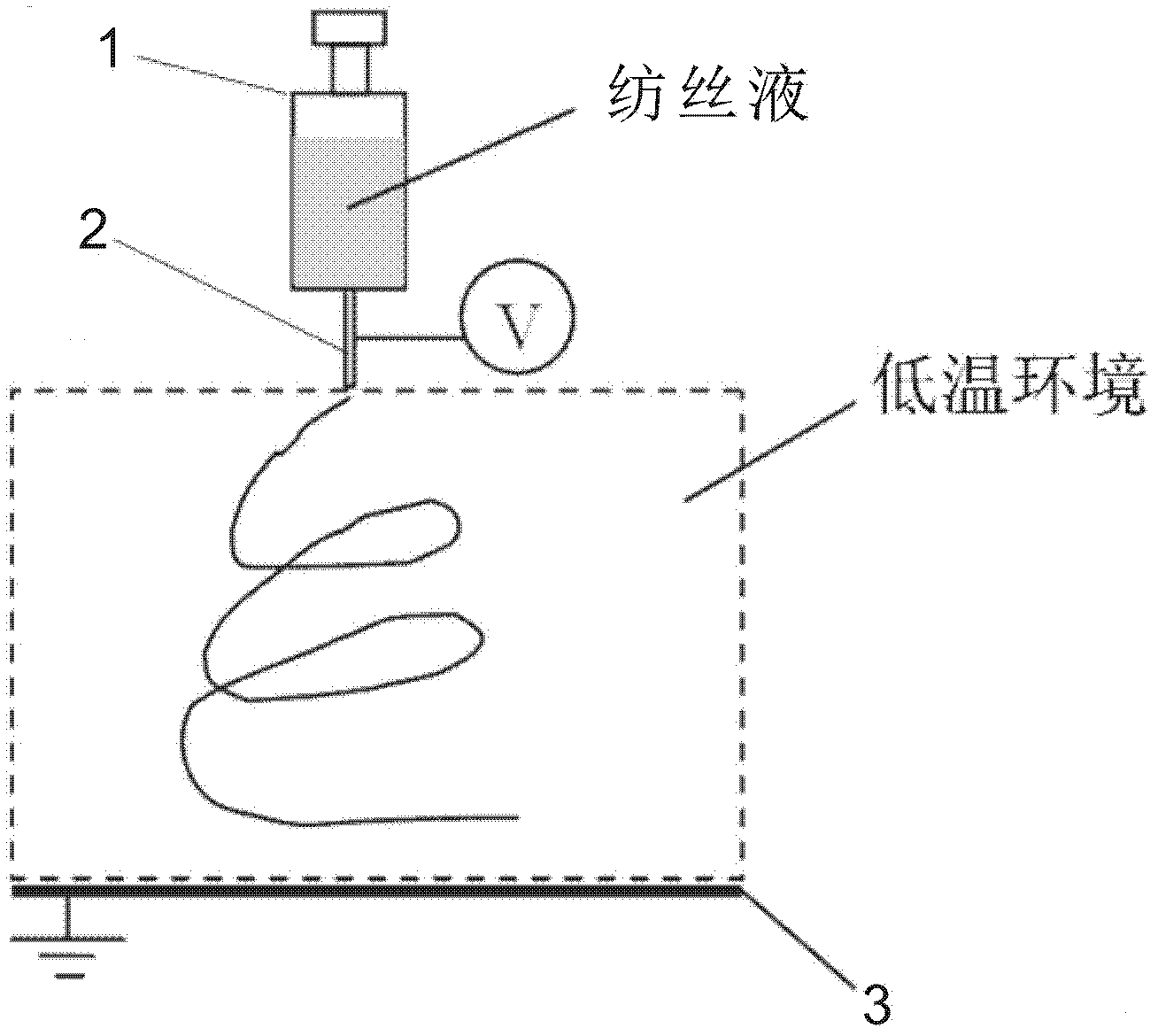

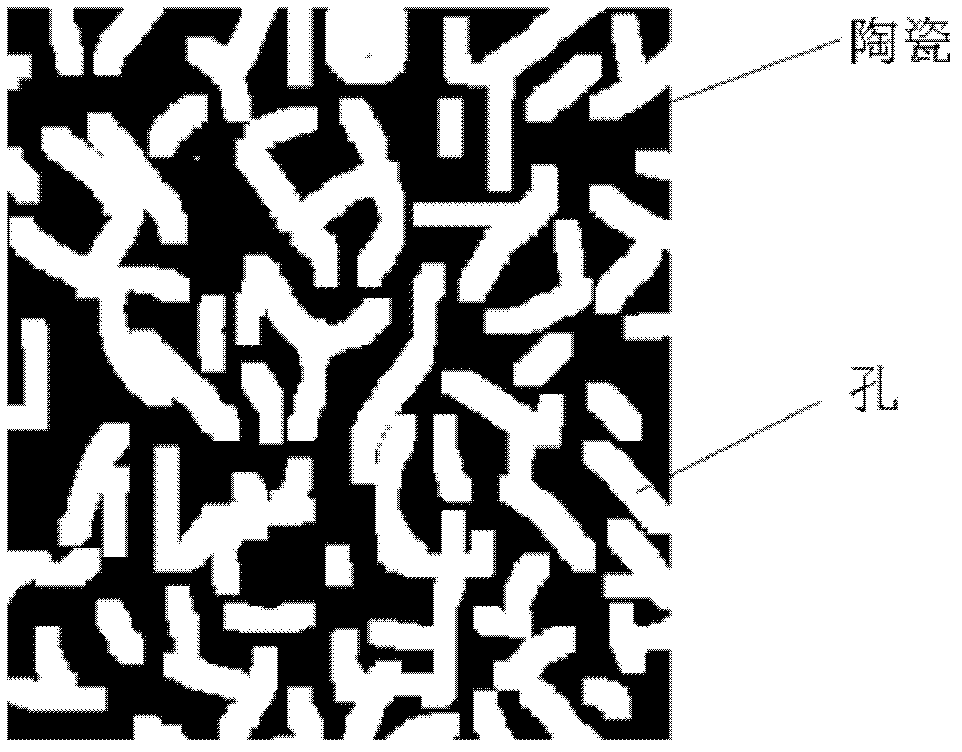

Method for preparing micro/nano porous ceramic fibers by low-temperature electrostatic spinning

The invention relates to a method for preparing micro / nano porous ceramic fibers by low-temperature electrostatic spinning. With combining electrostatic spinning technology and freeze-drying technology, the micro / nano porous ceramic fibers are prepared by freeze-drying and sintering after electrostatic spinning at a low temperature; and the method comprises four steps of preparing a spinning solution, electrostatic spinning at a low temperature, freeze-drying and sintering. The method for preparing micro / nano porous ceramic fibers by low-temperature electrostatic spinning can obtain an extremely high specific surface area, and is beneficial to improving performances of contacting, catalyzing, separating and sensing of ceramic fibers, and has wide application prospects in fields of biomedicine, filter materials, catalyst carriers, fuel cells, electronic element appliances and the like.

Owner:XIAN UNIV OF TECH

Method for preparing high-strength conductive graphene fiber by large-size graphene oxide sheet

ActiveCN102534869AWide variety of sourcesConvenient sourceGrapheneArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a method for preparing high-strength conductive graphene fiber by a large-size graphene oxide sheet. The method comprises the steps of: oxidizing expanded graphite and obtaining graphene oxide; dispersing the graphene oxide into water, carrying out centrifugal classification treatment on the dispersed graphene oxide, and obtaining the large-size even graphene oxide sheet; and finally, dispersing the graphene oxide into water or polar organic solvent, preparing spinning solution liquid crystal sol with the mass concentration of 1-20%, transferring the spinning solution liquid crystal sol into a spinning device, continuously squeezing spinning solution out from a spinning head capillary tube at the uniform velocity, leading the squeezed spinning solution into solidification liquid, drying the solidified primary fiber, obtaining graphene oxide fiber, and then obtaining the graphene fiber by chemical reduction. A spinning technology is simple; and the obtained graphene fiber is good in electrical conductivity, excellent in mechanical property and better in toughness, can be woven into pure-graphene fiber cloth, and also can be woven with other fibers in a blending way so as to make various functional fabrics, so that the high-strength conductive graphene fiber can be used for replacing carbon fiber in a plurality of fields.

Owner:杭州德烯科技集团有限公司

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

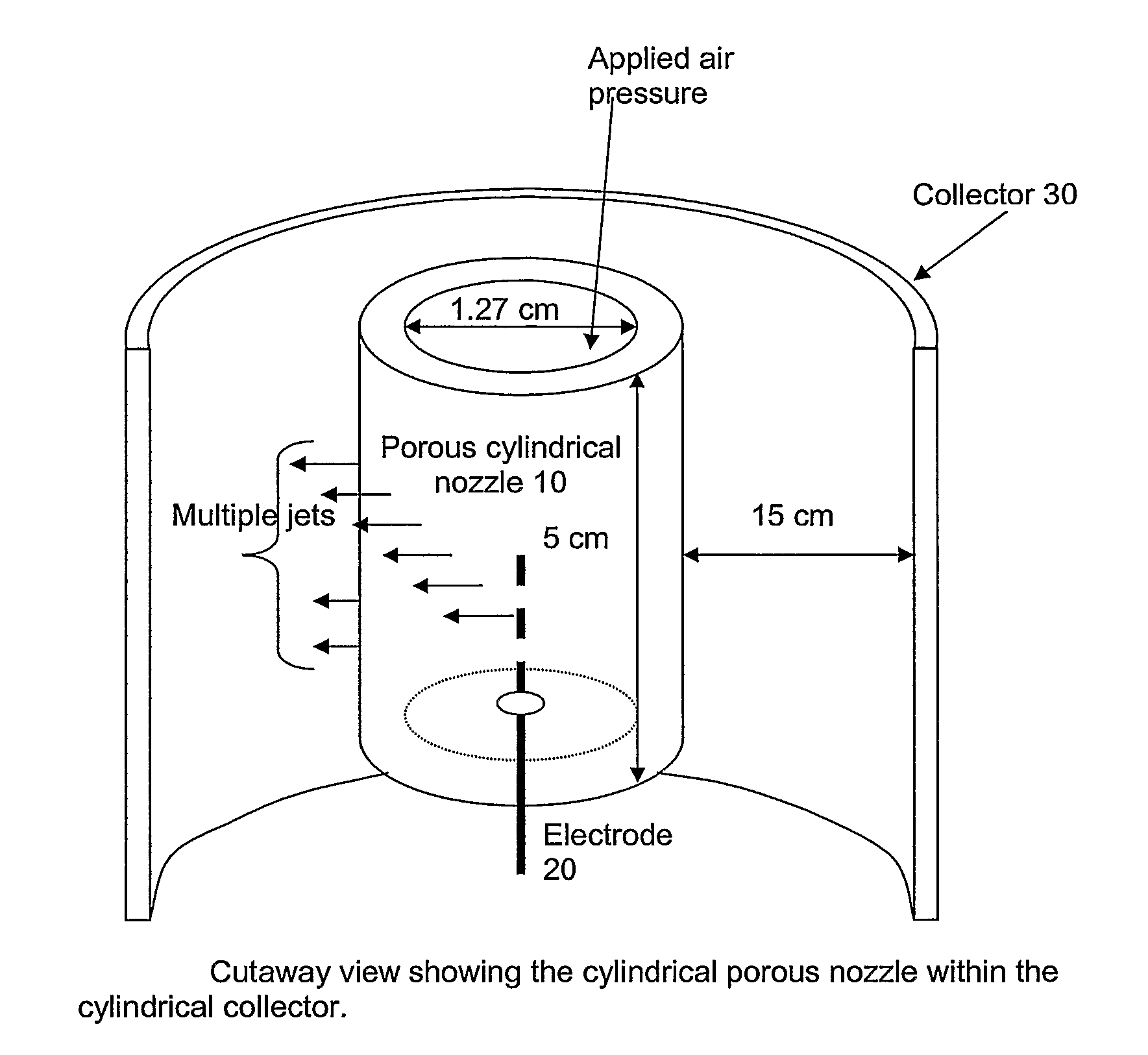

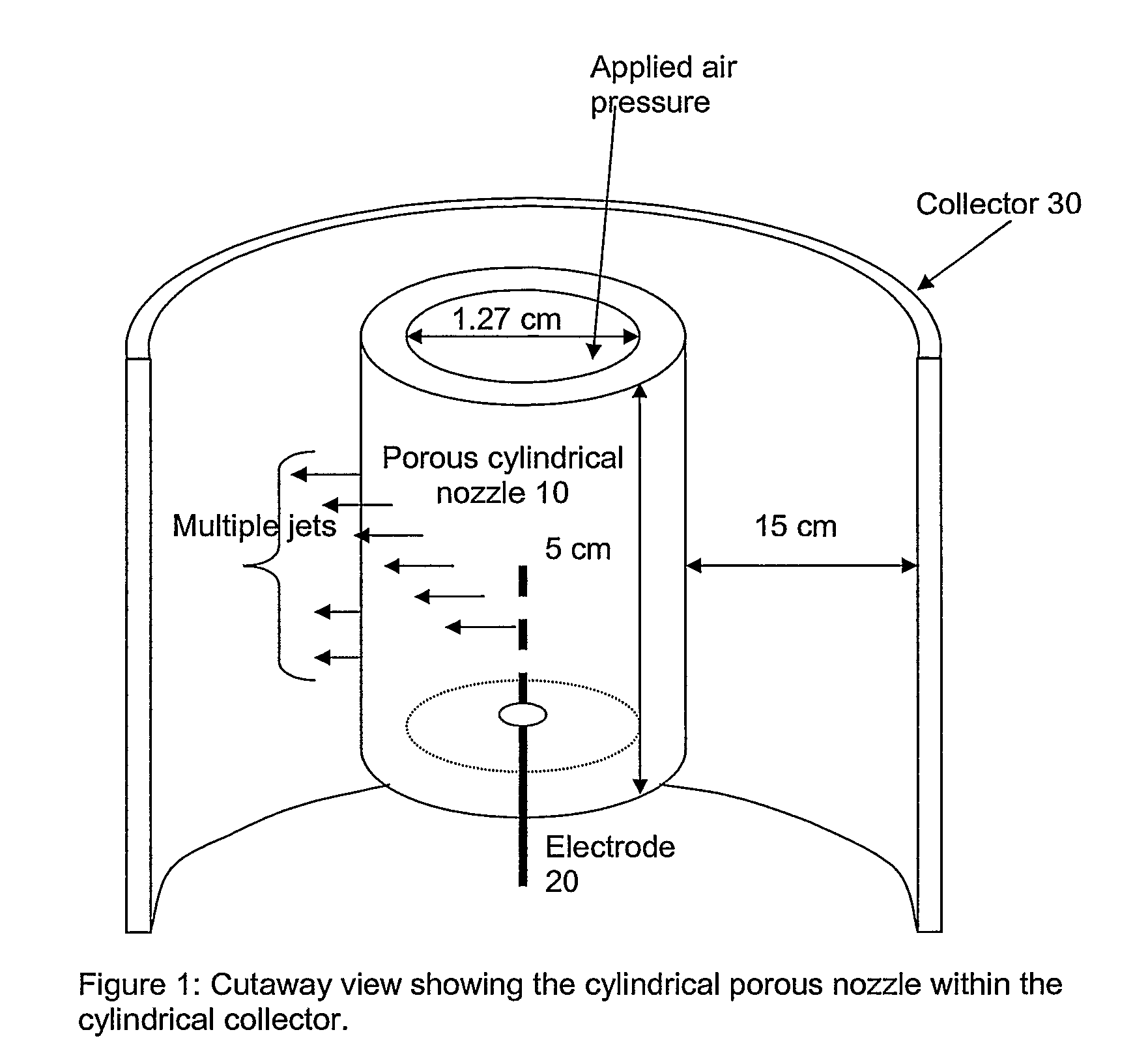

Method and device for producing electrospun fibers

The present invention relates to methods for producing fibers made from one or more polymers or polymer composites, and to structures that can be produced from such fibers. In one embodiment, the fibers of the present invention are nanofibers. The present invention also relates to apparatus for producing fibers made from one or more polymers or polymer composites, and methods by which such fibers are made.

Owner:AKRON THE UNIV OF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com