Patents

Literature

2139 results about "Vinyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Divinyl ether is the organic compound with the formula O(CH=CH₂)₂. It is a colorless, volatile liquid that has mainly been of interest as an inhalation anesthetic. It is prepared by treating bis(chloroethyl) ether with base.

Ink compositions for ink jet printing

InactiveUS6310115B1Reduce viscosityLow viscosityLiquid surface applicatorsOrganic chemistryPolymer chemistryAcrylate

Owner:AGFA NV

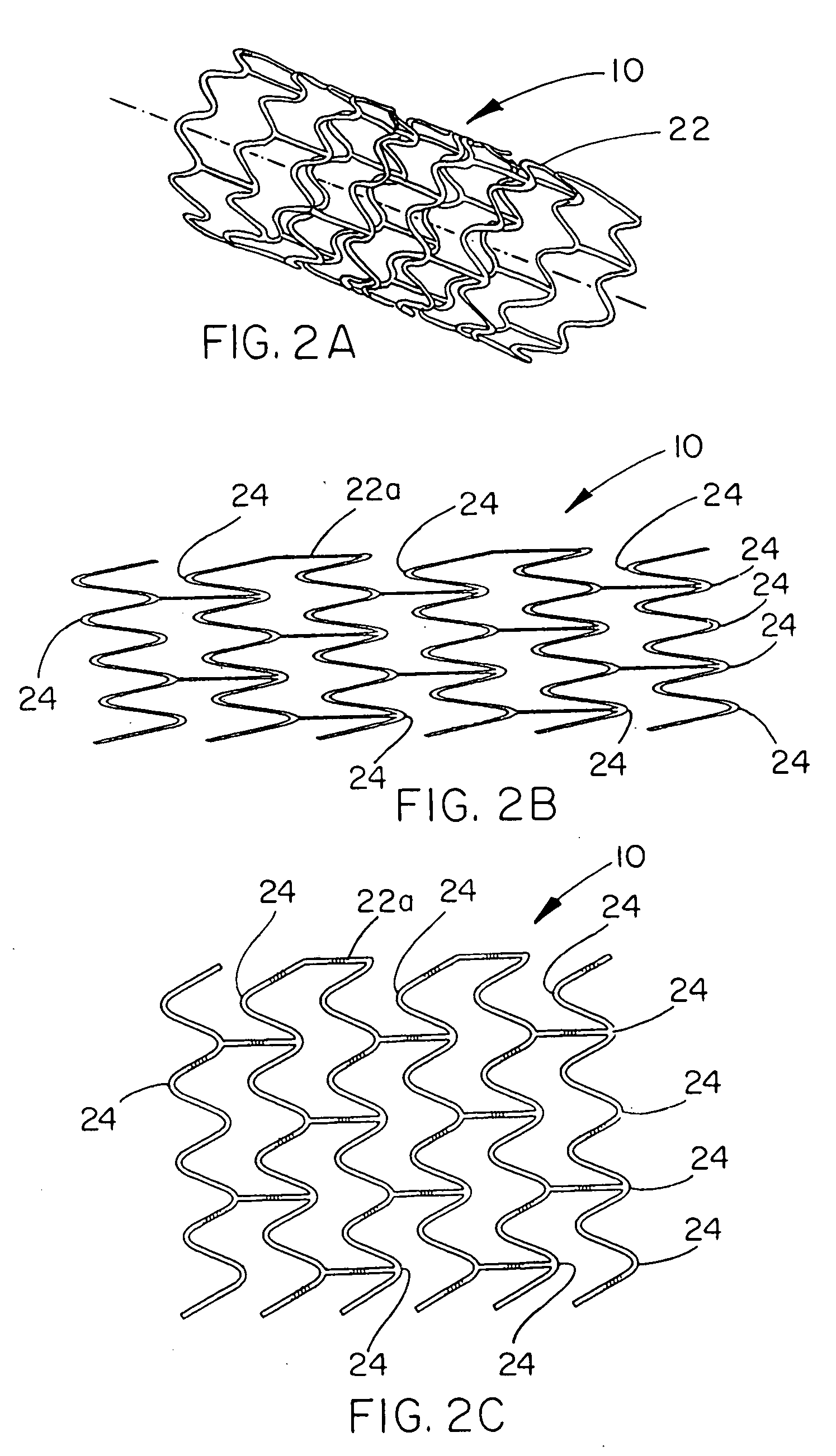

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

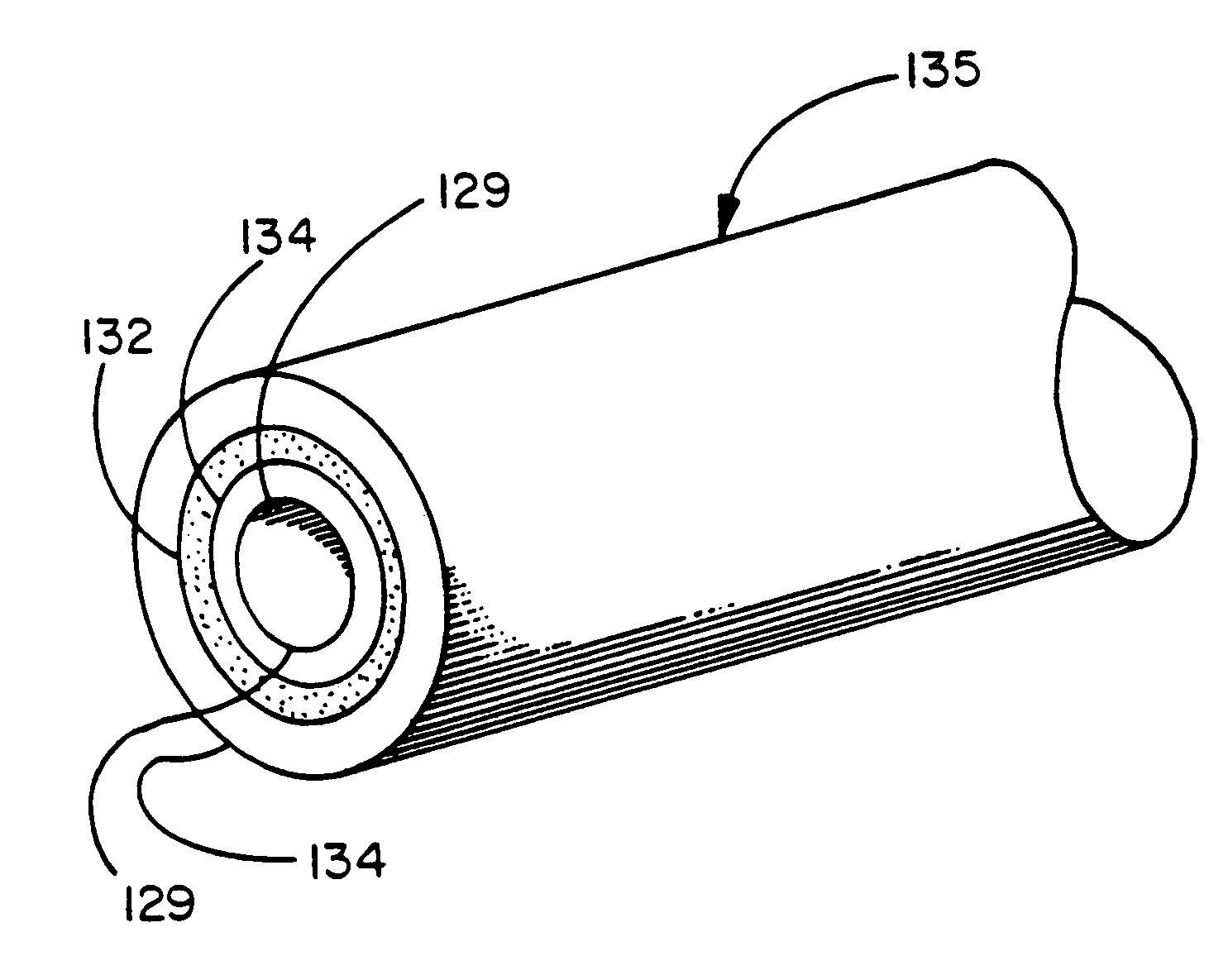

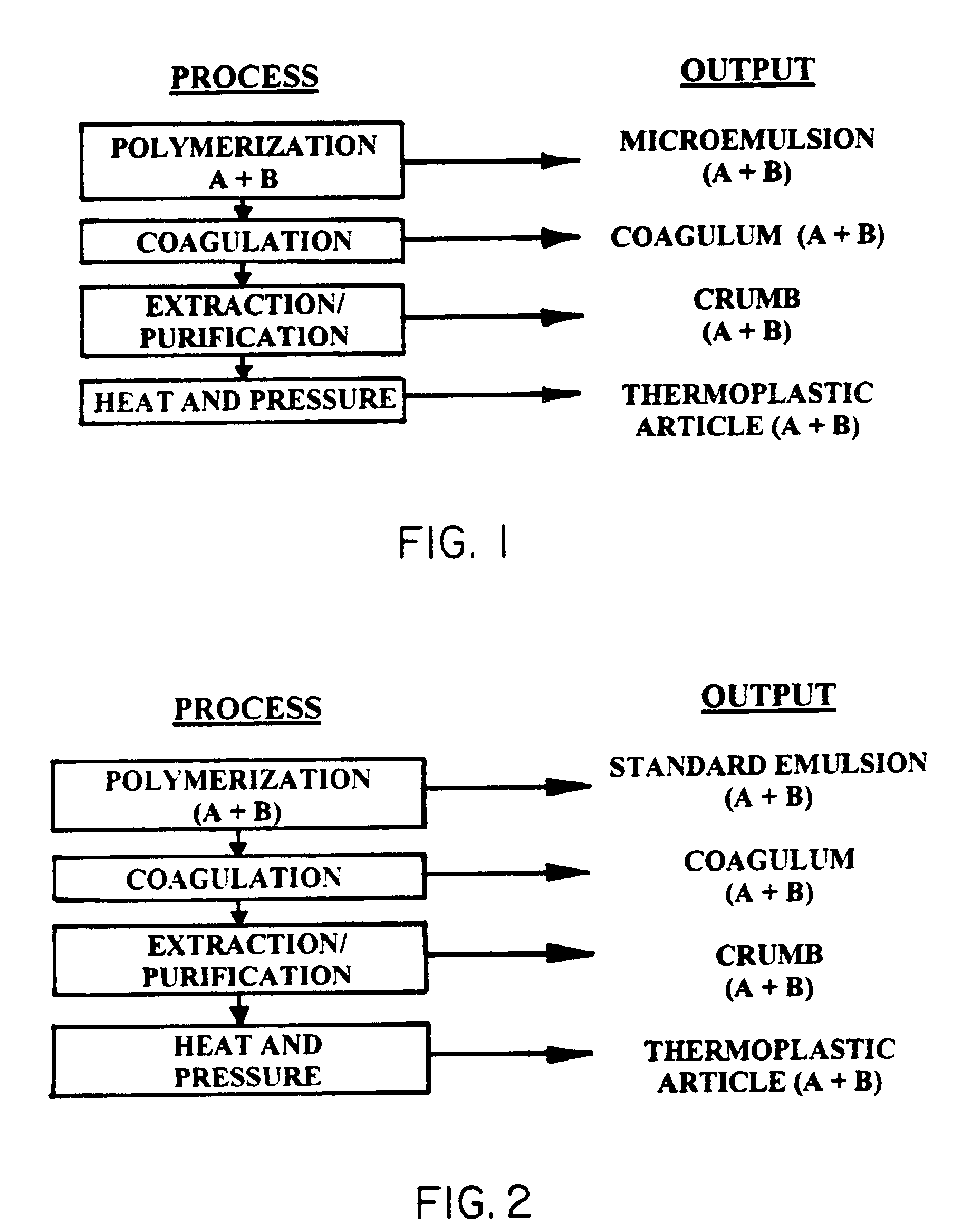

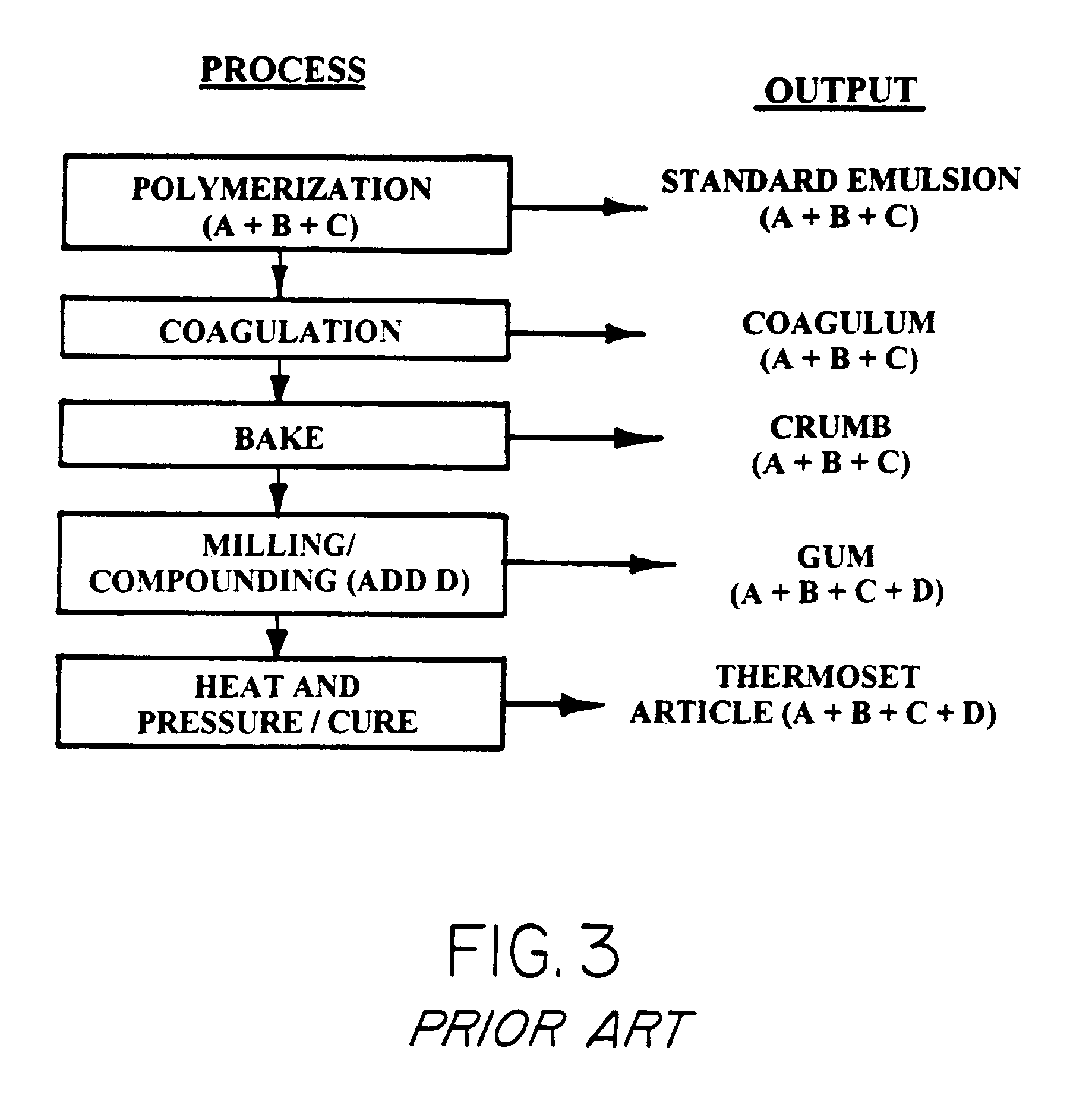

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

Reactive diluent and curable resin composition

InactiveUS20030199655A1Effect is not sufficientLow water resistanceFatty acid chemical modificationFatty acids production/refiningVinyl etherHydrogen atom

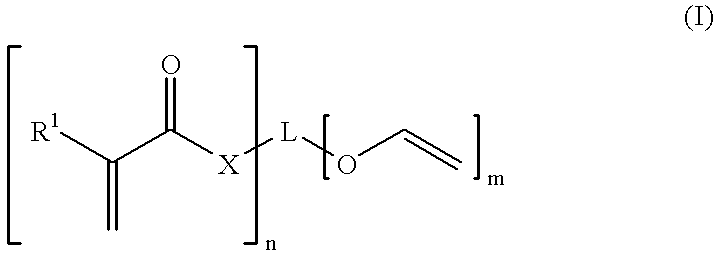

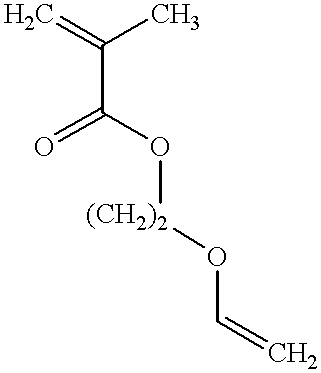

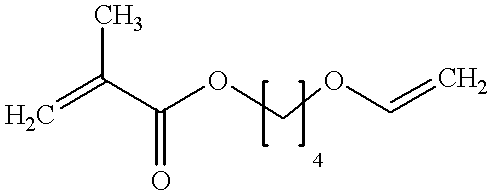

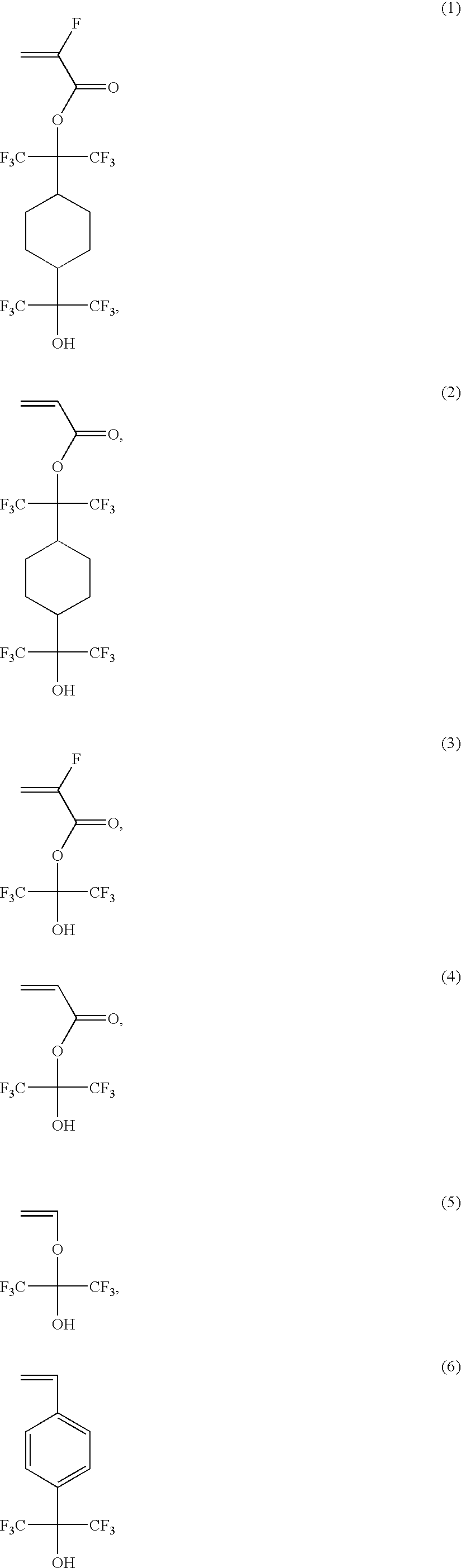

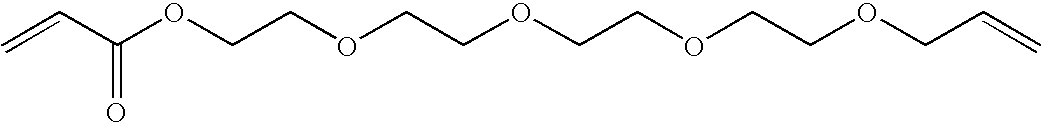

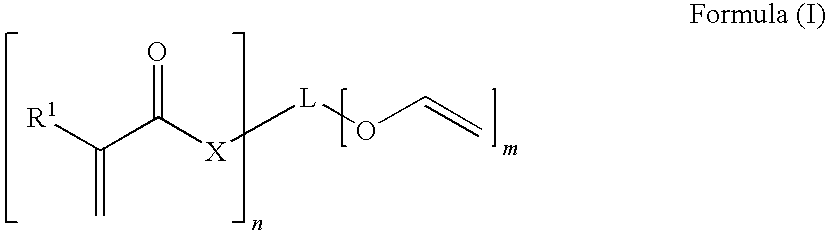

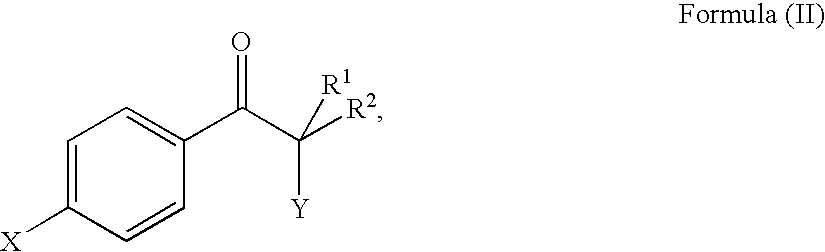

The present invention provides a reactive diluent composition which overcomes drawbacks of both the radical-cure and the cationic-cure reactive diluents and can be applied in a broad variety of uses such as paints, inks, adhesives, pressure sensitive adhesives, surface-modifiers, and molding materials; a curable resin composition containing the same; an activated energy ray-curable resin composition; and an activated energy ray-curable ink composition for ink-jet printing. A reactive diluent composition comprising a vinyl ether group-containing (meth)acrylic ester represented by the following general formula (1): CH2=CR<1>-COO-R<2>-O-CH=CH-R<3> (1) wherein R<1 >represents a hydrogen atom or a methyl group; R<2 >represents an organic residue of 2 to 20 carbon atoms; R<3 >represents a hydrogen atom or an organic residue of 1 to 11 carbon atoms and a hydroxyl group-containing polymerizable compound and / or divinyl ether.

Owner:NIPPON SHOKUBAI CO LTD

Reactive diluent and curable resin composition

InactiveUS6767980B2Effect is not sufficientLow water resistanceFatty acid chemical modificationFatty acids production/refiningVinyl etherHydrogen atom

The present invention provides a reactive diluent composition which overcomes drawbacks of both the radical-cure and the cationic-cure reactive diluents and can be applied in a broad variety of uses such as paints, inks, adhesives, pressure sensitive adhesives, surface-modifiers, and molding materials; a curable resin composition containing the same; an activated energy ray-curable resin composition; and an activated energy ray-curable ink composition for ink-jet printing.A reactive diluent composition comprisinga vinyl ether group-containing (meth)acrylic ester represented by the following general formula (1):wherein R<1 >represents a hydrogen atom or a methyl group; R<2 >represents an organic residue of 2 to 20 carbon atoms; R<3 >represents a hydrogen atom or an organic residue of 1 to 11 carbon atoms anda hydroxyl group-containing polymerizable compound and / or divinyl ether.

Owner:NIPPON SHOKUBAI CO LTD

Liquid inks comprising a stable organosol

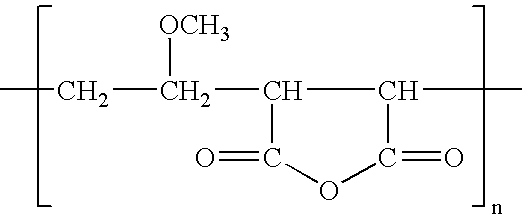

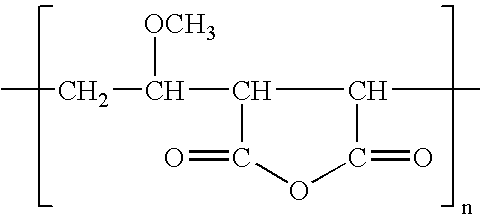

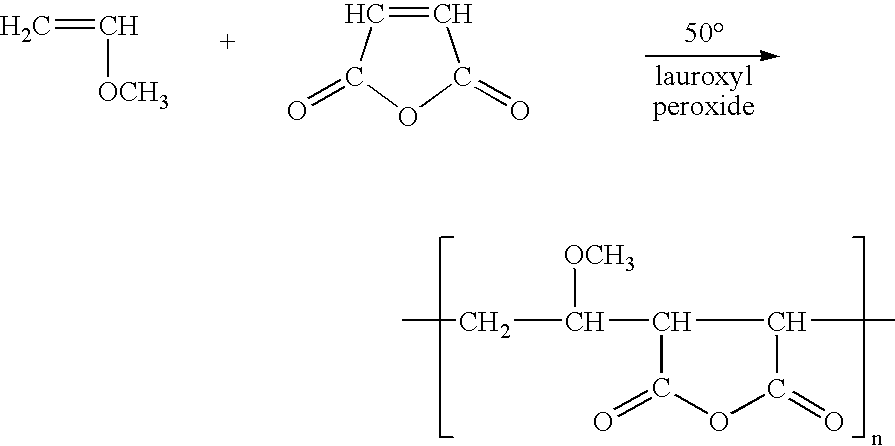

InactiveUS20020128349A1Good dispersionAvoid resistanceDuplicating/marking methodsInksMethacrylateDispersion stability

A liquid ink comprises (a) a carrier liquid having a Kauri-Butanol number less than 30; (b) a graft copolymer comprising a (co)polymeric steric stabilizer covalently bonded to a thermoplastic (co)polymeric core that is insoluble in the carrier liquid; and (c) a colorant, wherein the steric stabilizer comprises units derived from 3,3,5-trimethylcyclohexyl methacrylate, and the thermoplastic (co)polymeric core comprising units derived from at least a polymerizable monomer selected from the group consisting of (meth)acrylates having aliphatic amino radicals, nitrogen-containing heterocyclic vinyl monomers, N-vinyl substituted ring-like amide monomers, aromatic substituted ethylene monomers containing amino radicals, and nitrogen-containing vinylether monomers. The organosol provides improved liquid electrophotographic and electrographic ink compositions with improved dispersion stability, chargeability, and blocking resistance so that improved print quality or ink transfer performance are obtained.

Owner:S PRINTING SOLUTION CO LTD

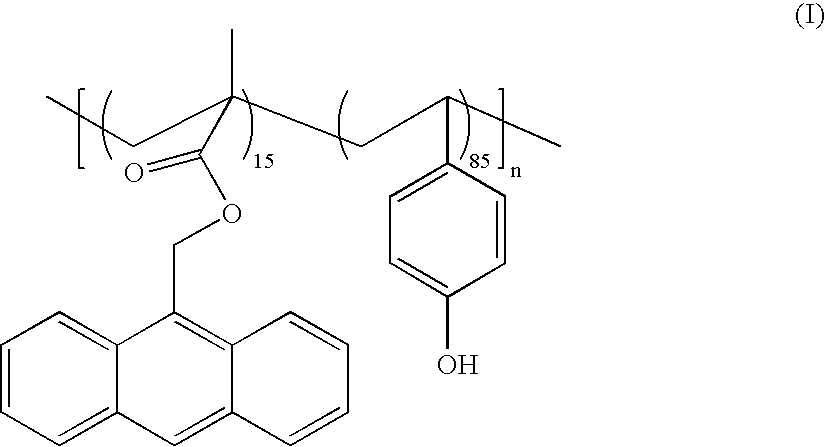

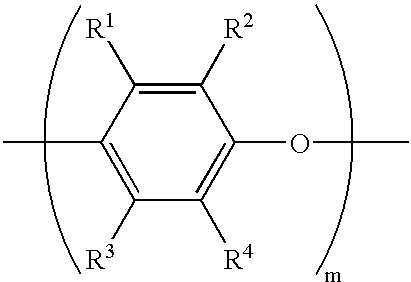

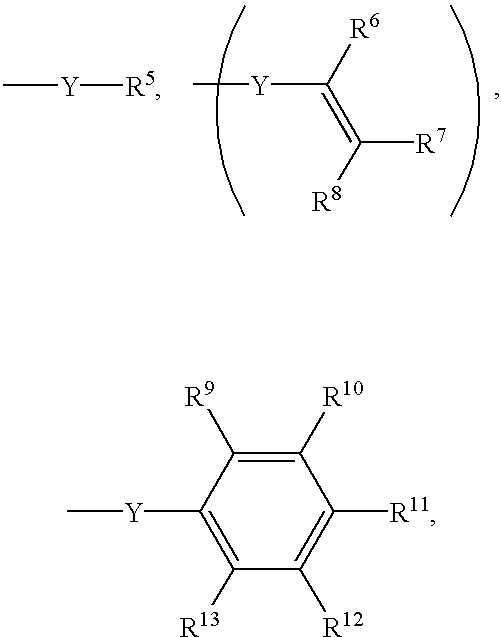

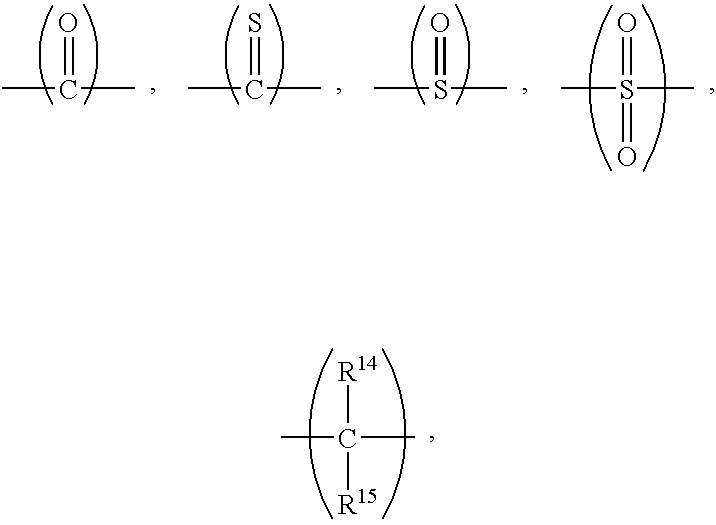

Positive-working photoimageable bottom antireflective coating

The present invention relates to a positive bottom photoimageable antireflective coating composition which is capable of being developed in an aqueous alkaline developer, wherein the antireflective coating composition comprises a polymer comprising at least one recurring unit with a chromophore group and one recurring unit with a hydroxyl and / or a carboxyl group, a vinyl ether terminated crosslinking agent, and optionally, a photoacid generator and / or an acid and / or a thermal acid generator. The invention further relates to a process for using such a composition.

Owner:AZ ELECTRONICS MATERIALS USA CORP

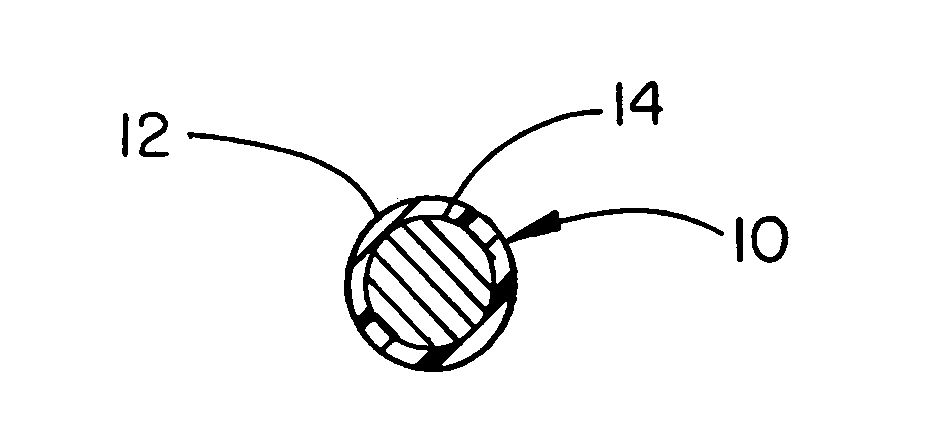

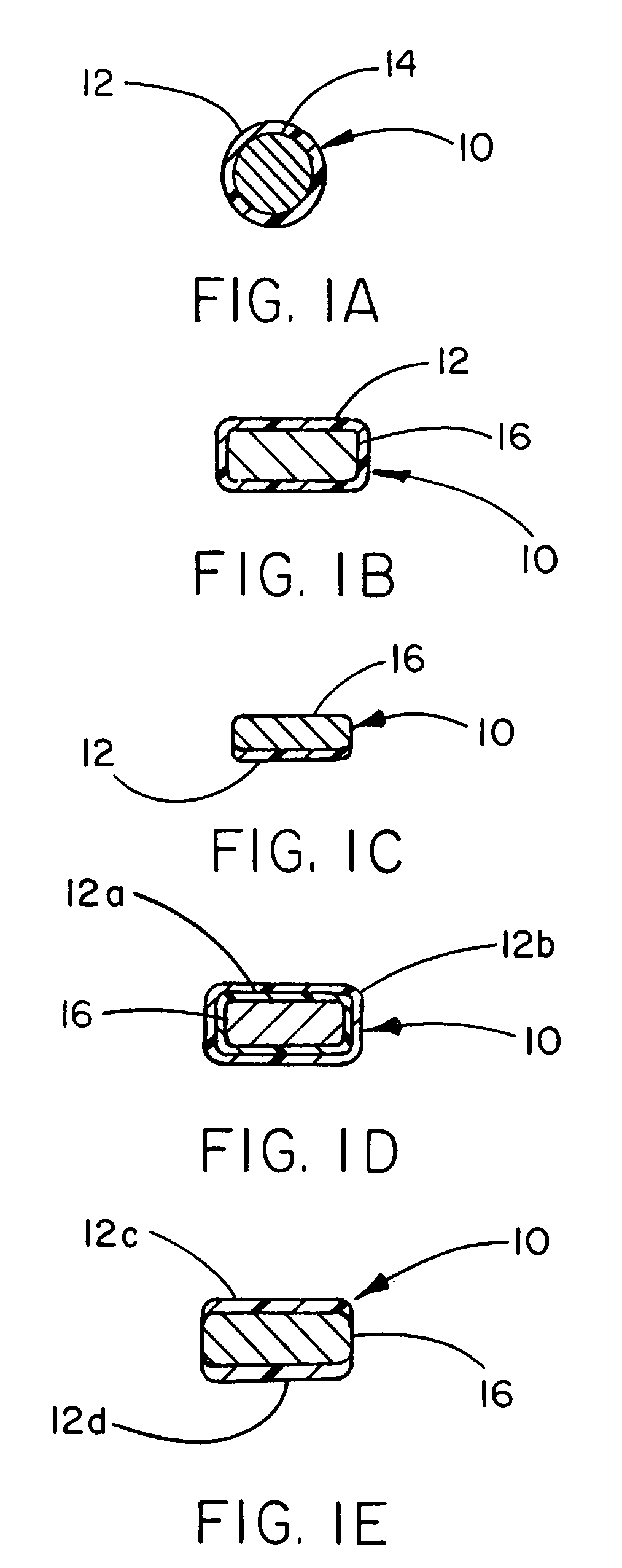

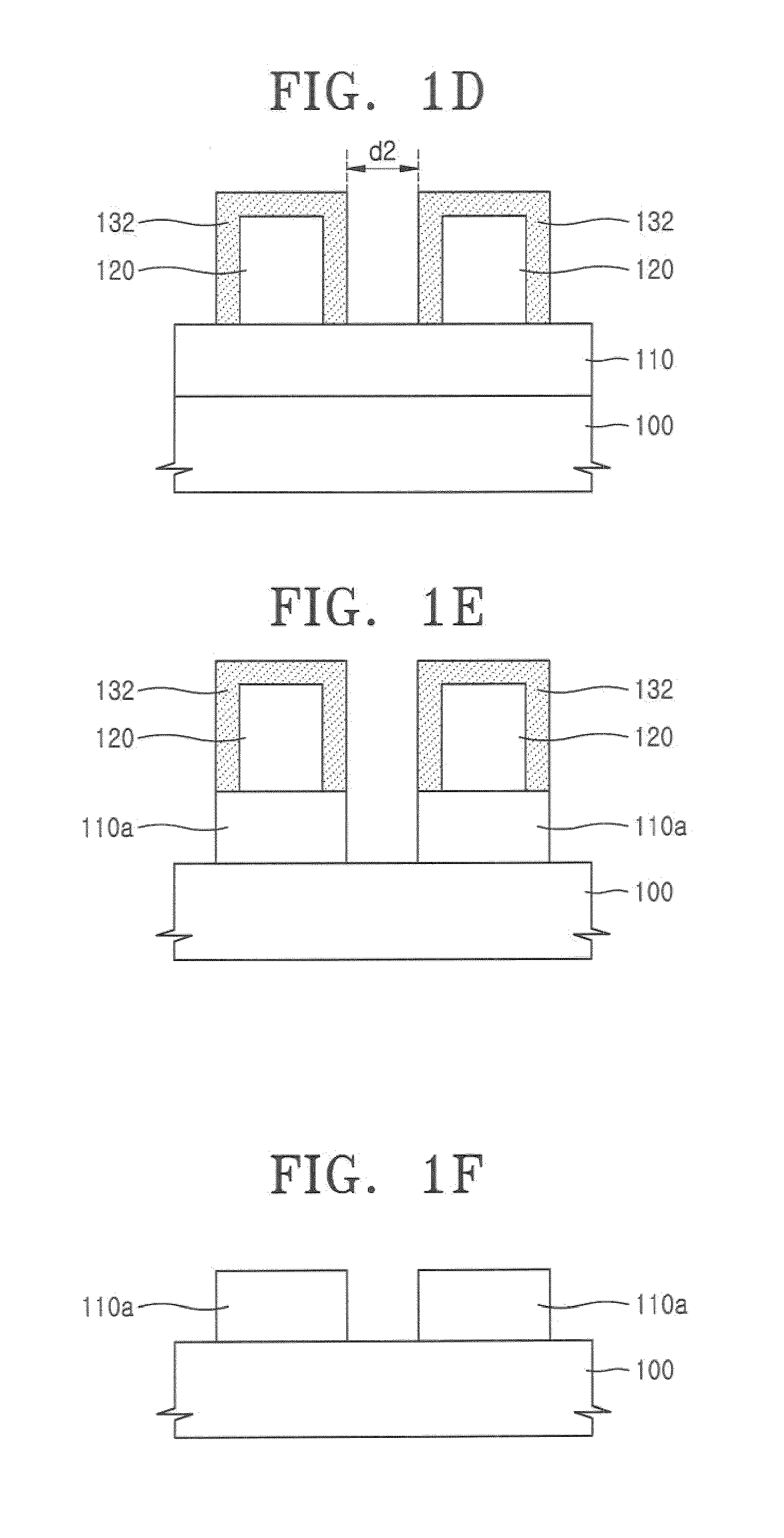

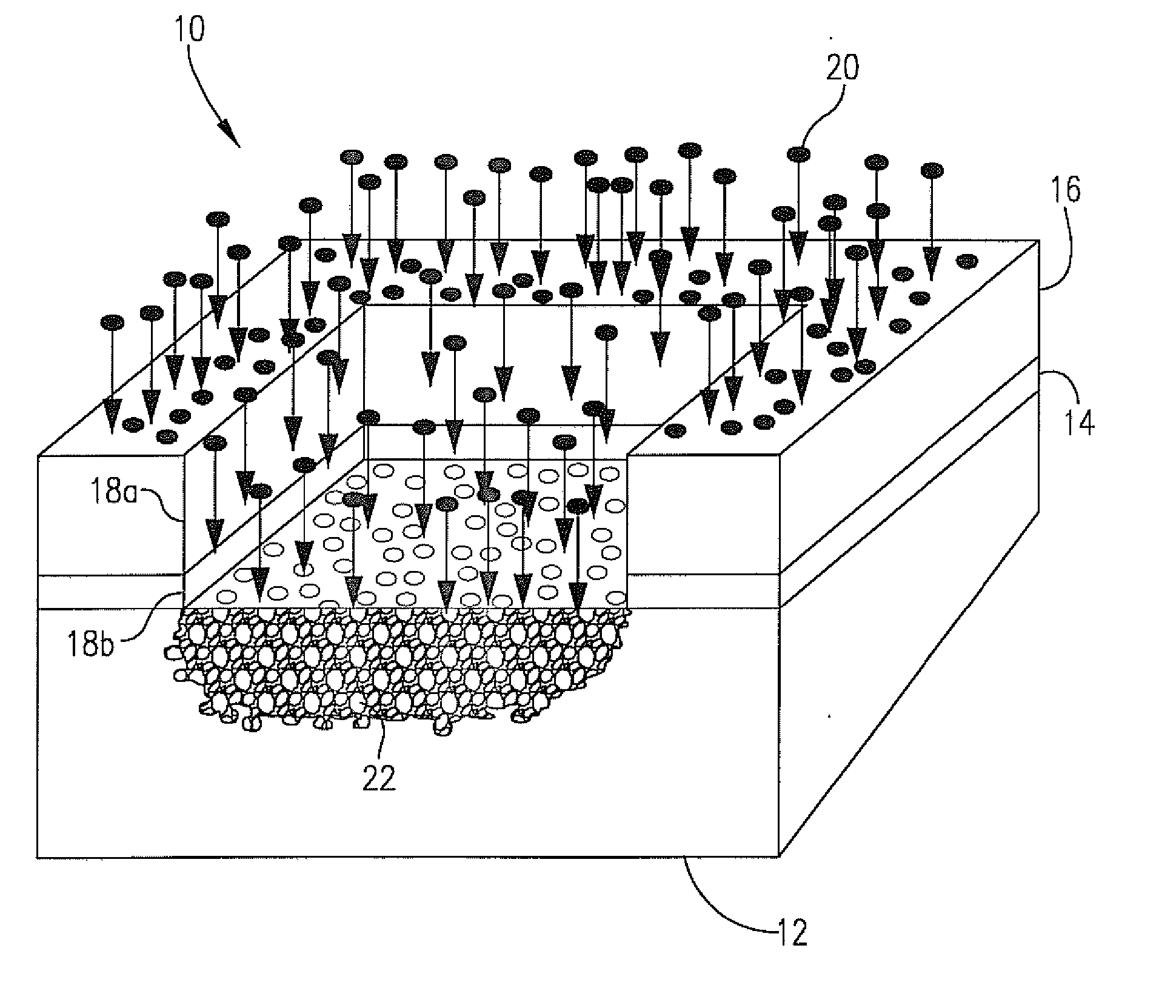

Thermoplastic fluoropolymer-coated medical devices

A medical device provided with at least a partial surface coating of a thermoplastic copolymer of tetrafluoroethylene and perfluoroalkylvinylether that is free of cross-linking monomers and curing agents. The fluoropolymer coating is preferably an amorphous thermoplastic, is highly inert and biocompatible, has elastomeric characteristics that provide desirable mechanical properties such as good flexibility and durability. These characteristics allow the coating to be considered “functionally transparent” because it withstands mechanical deformations required for the assembly, deployment, expansion, and placement of medical devices, without any adverse effect on the mechanical and biological functionality of the coated device. Further, its inertness, derived from the perfluorocarbon structure, contributes to its functionally transparent nature. The coating can be provided with various liquid or solid additives, can be loaded with large quantities of additives including a wide range of therapeutic agents, and has excellent drug elution characteristics when elutable additives are used. The desirable mechanical characteristics are surprising given the absence of cross-linking monomers and curing agents that would otherwise render such materials inadequately biocompatible. The perfluoroalkylvinylether may be perfluoromethylvinylether, perfluoroethylvinylether or perfluoropropylvinylether.

Owner:WL GORE & ASSOC INC

Acid sensitive ARC and method of use

InactiveUS6110653APhotosensitive materialsSemiconductor/solid-state device manufacturingVinyl etherCross-link

A composition used to form an acid sensitive +E,uns a+EE nti+E,uns r+EE eflective +E,uns c+EE oating (ARC) includes a water soluble resin and a cross-linker. Radiation adsorptive components may be provided as part of the resin or, more preferably, as a separate dye. The composition may be applied on a substrate as a radiation adsorbing layer and additionally cross-linked to form an acid sensitive, water insoluble ARC on which a +E,uns p+EE hoto+E,uns p+EE atterning +E,uns r+EE esist (PPR) layer may be formed. Being acid sensitive, selected portions of an ARC formed from the composition may be removed by a suitable reversal of the cross-linking followed by a develop step, preferably with an aqueous developer, more preferably de-ionized water. The water soluble resin is preferably hydroxystyrene-sulfonated styrene copolymer, poly(2-isopropenyl-2-oxazoline), or poly(acrylic acid), the cross-linker is preferably an acetal diacid or a water soluble divinyl ether, and the dye is preferably 9-anthracene methanol or a squaric acid derivative. If a suitable +E,uns p+EE hoto+E,uns a+EE cid +E,uns g+EE enerator (PAG) is included then an ARC formed from such components may exhibit a photosensitivity similar to or even lower than that of the overlying PPR. The photosensitivity is preferably less than about 900 mJ / cm2, more preferably 100 mJ / cm2 or less.

Owner:IBM CORP

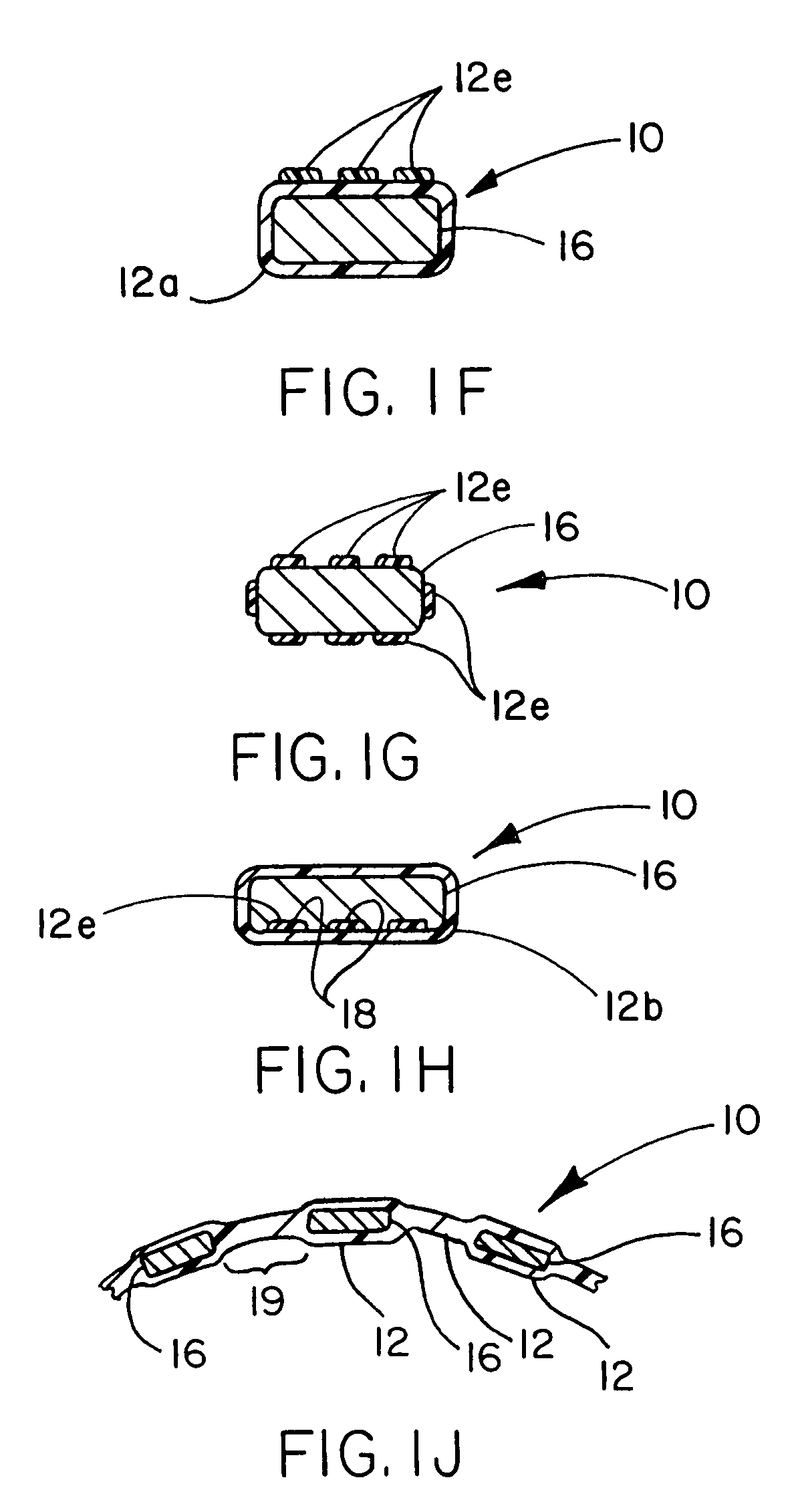

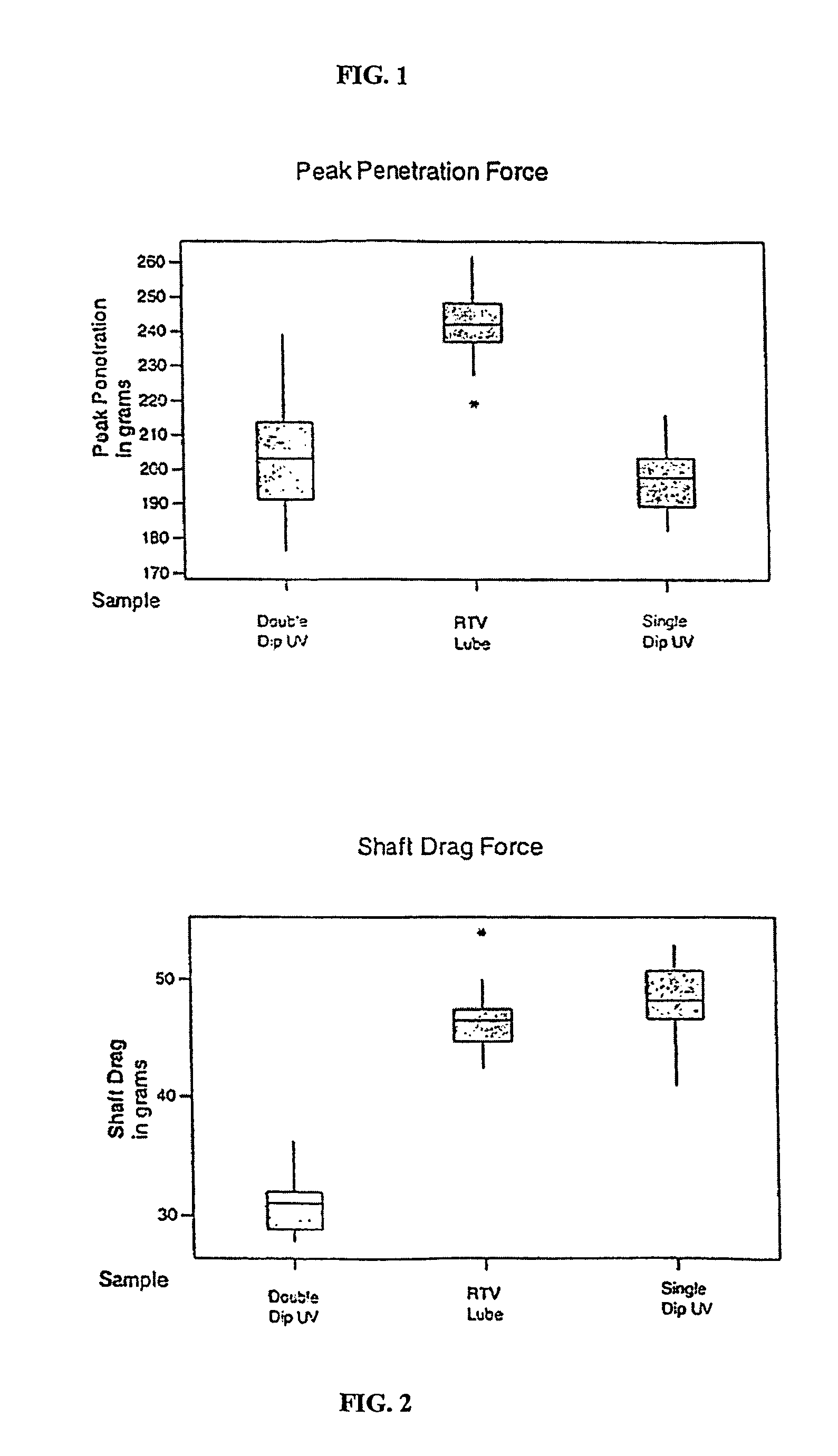

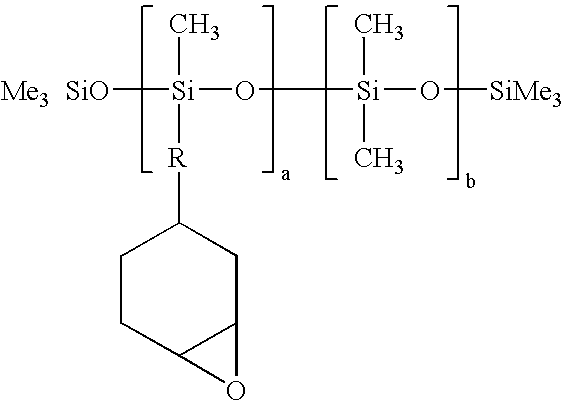

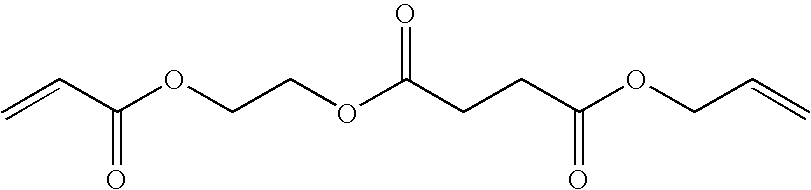

Medical device lubricant comprising radiation curable silicon material

ActiveUS7354628B2Improve performanceEliminate delaysIncision instrumentsSurgical needlesEpoxyVinyl ether

Owner:CARDINAL HEALTH IRELAND UNLTD

Curable liquids and inks for toys and food packaging applications

A free radical curable liquid for inkjet printing of food packaging materials includes no initiator or otherwise one or more initiators selected from the group consisting of non-polymeric di- or multifunctional initiators, oligomeric initiators, polymeric initiators, and polymerizable initiators; and a polymerizable composition of the liquid consists essentially of: a) 25-100 wt % of one or more polymerizable compounds A having at least one acrylate group G1 and at least one second ethylenically unsaturated polymerizable functional group G2 selected from the group consisting of a vinlyether group, an allylether group, and a allylester group; b) 0-55 wt % of one or more polymerizable compounds B selected from the group consisting of monofunctional acrylates and difunctional acrylates; and c) 0-55 wt % of one or more polymerizable compounds C selected from the group consisting of trifunctional acrylates, tetrafunctional acrylates, pentafunctional acrylates and hexafunctional acrylates. If the weight percentage of compounds B>24 wt %, then the weight percentage of compounds C>1 wt %, and all weight percentages of A, B, and C are based upon the total weight of the polymerizable composition. At least one polymerizable compound B or C is present in the polymerizable composition if the free radical curable liquid contains no initiator.

Owner:AGFA NV

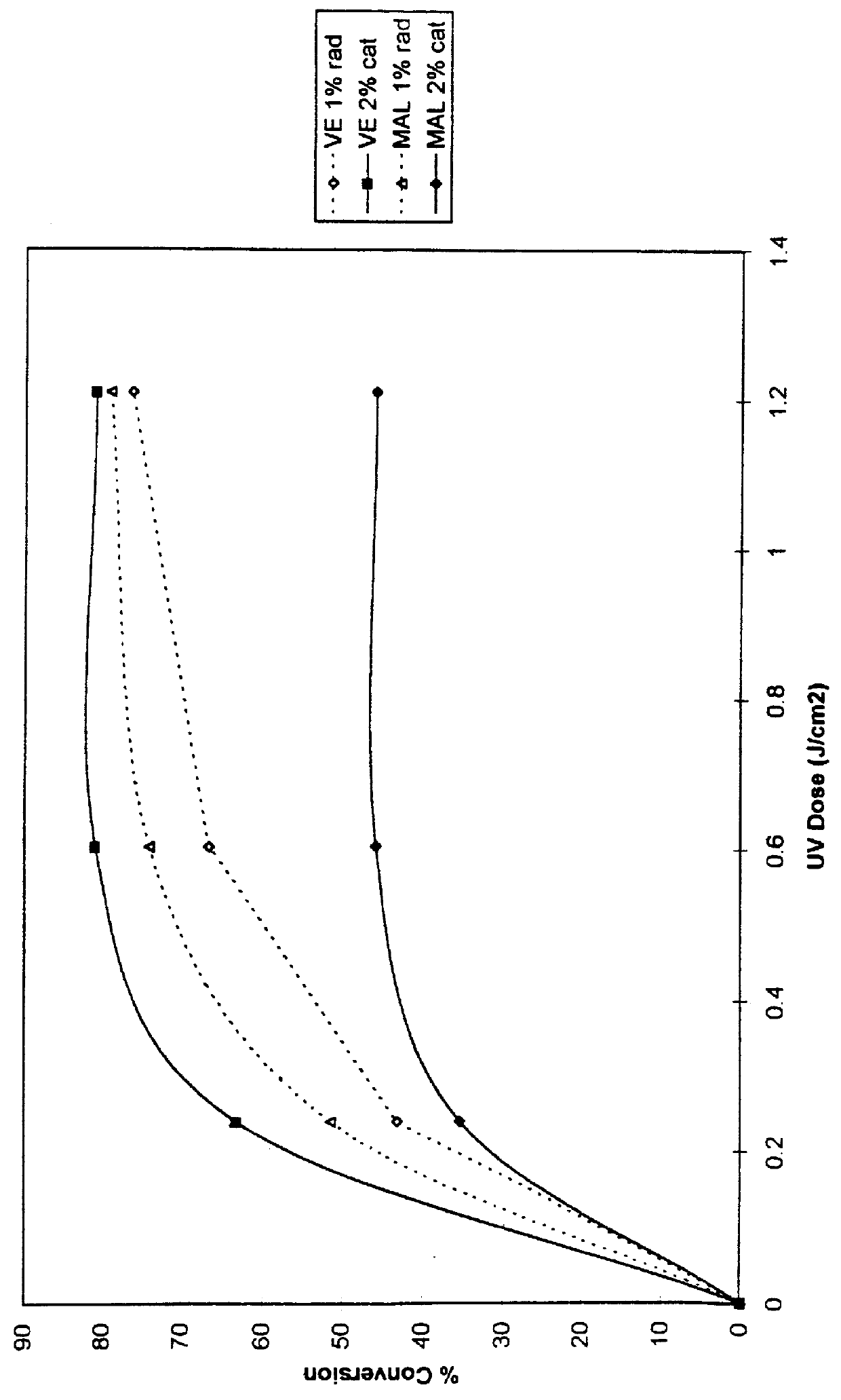

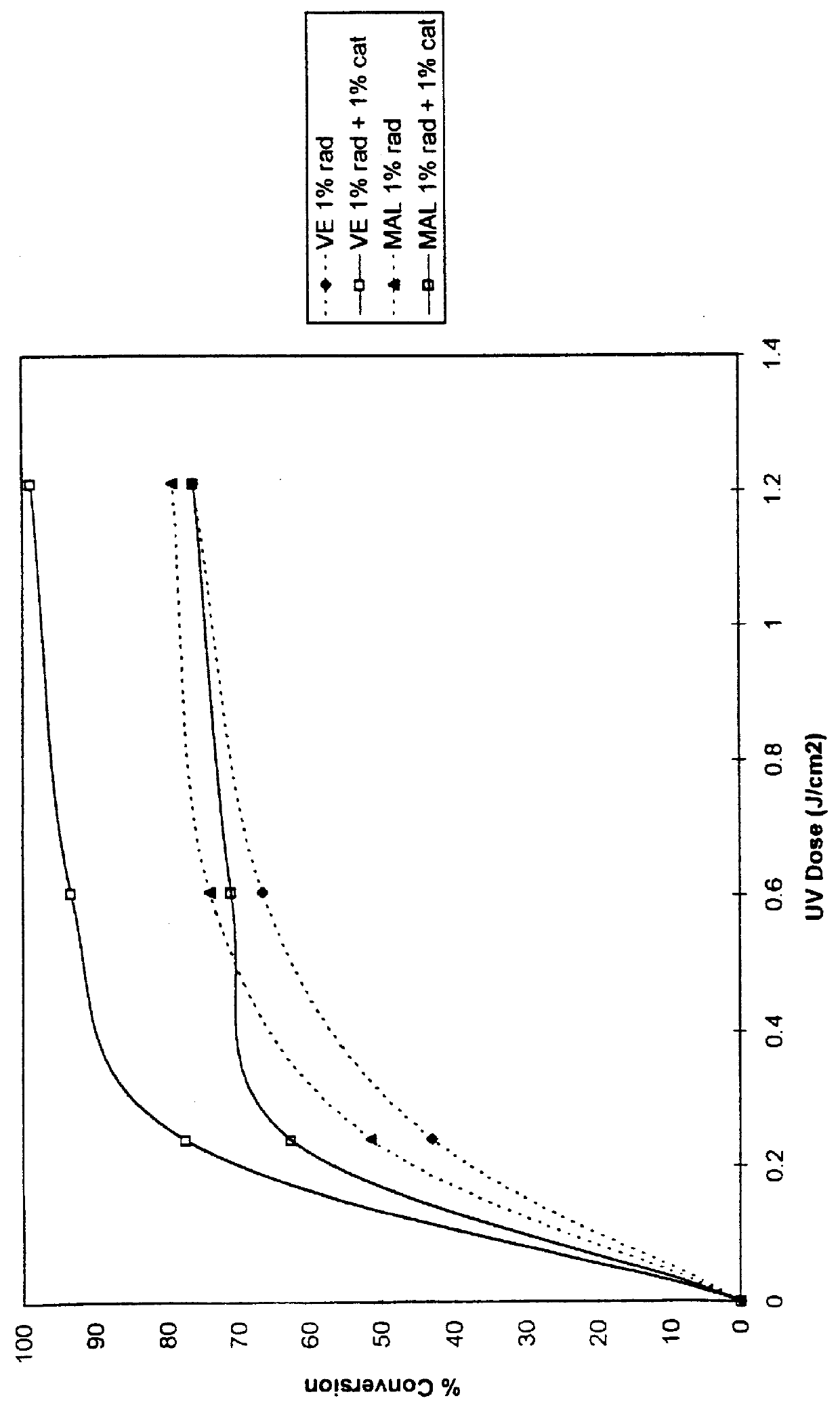

Photopolymerization process and composition employing a charge transfer complex and cationic photoinitiator

InactiveUS6127447AAccelerating polymerizationExtend curing timePhotomechanical apparatusOptical articlesVinyl etherCharge-transfer complex

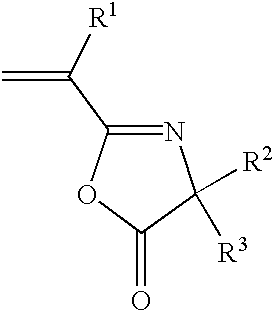

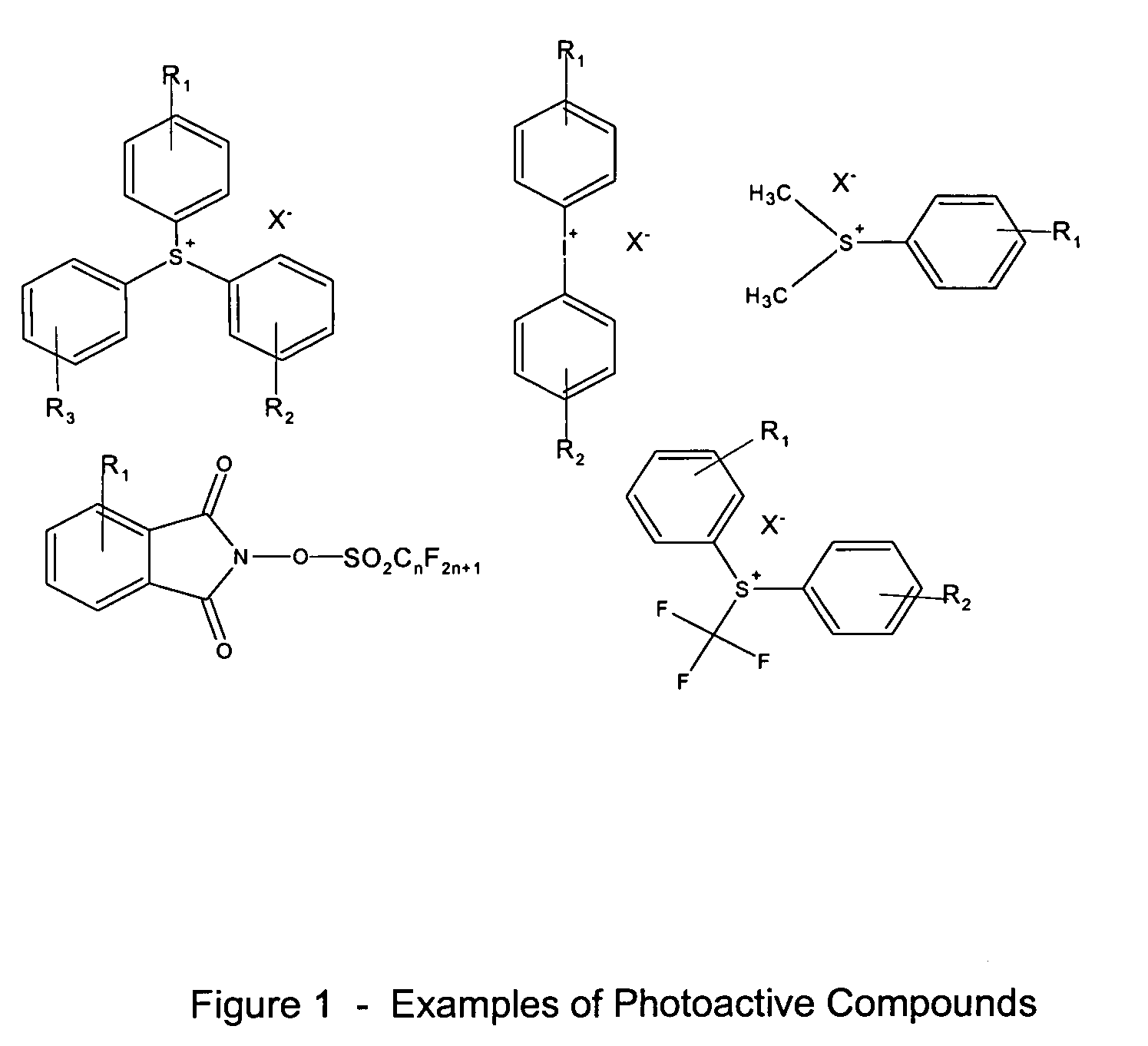

A radiation curable coating composition is provided and includes an effective amount of cationic photoinitiator, in combination with a charge transfer complex, the charge transfer complex comprising at least one electron withdrawing reactant component and at least one electron donating reactant component free radically reactive therewith, the electron withdrawing reactant component comprising an unsaturated nitrogen containing compound and the electron donating reactant component comprising an unsaturated compound having at least one vinyl ether group, the electron donating reactant component may be separate from or structurally incorporated within the electron withdrawing reactant component and an effective amount of a cationic photoinitiator. A photopolymerization process employing the composition is also provided.

Owner:FUSION UV SYST

Radiation curable inkjet fluids and inks improved for photoyellowing

ActiveUS20100330296A1Intuitive effectEasy to observeLiquid surface applicatorsImpression capsVinyl etherTM compound

A radiation curable inkjet fluid includes a radiation curable composition including at least 25 wt % of a vinylether acrylate and at least 15 wt % of a polymerizable compound including at least three acrylate groups, each wt % being based upon the total weight of the radiation curable composition; and a photoinitiator including a tertiary amine group and 0 to 3 wt % of isopropylthioxanthone based upon the total weight of the radiation curable inkjet fluid. Also, an inkjet printing method using the radiation curable inkjet fluid.

Owner:AGFA NV

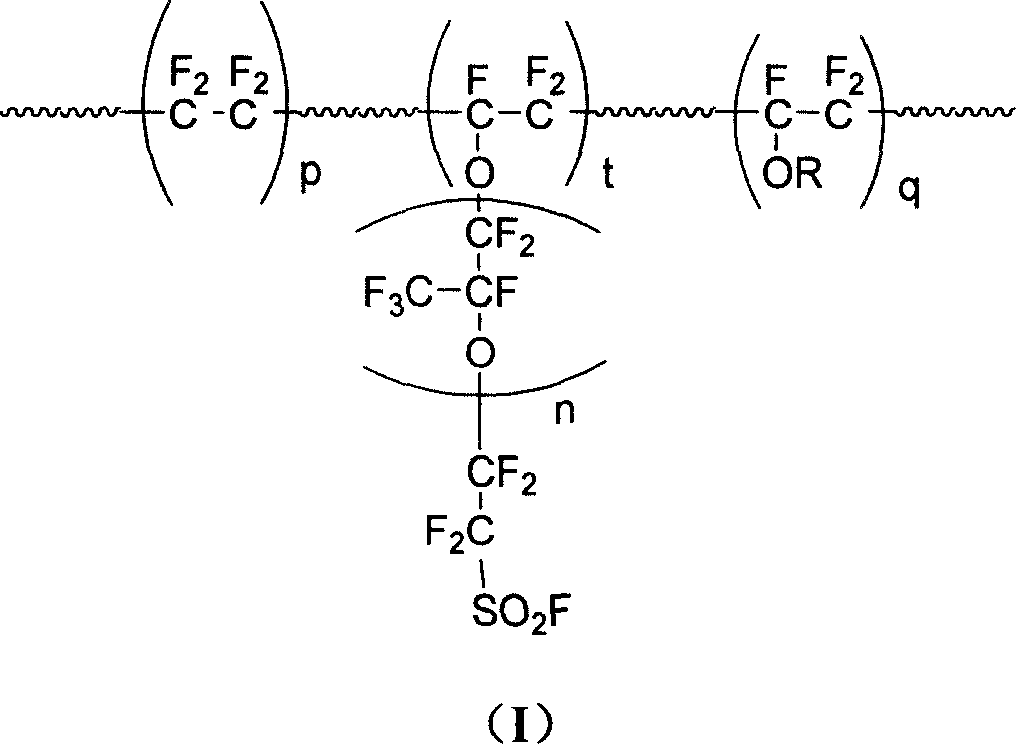

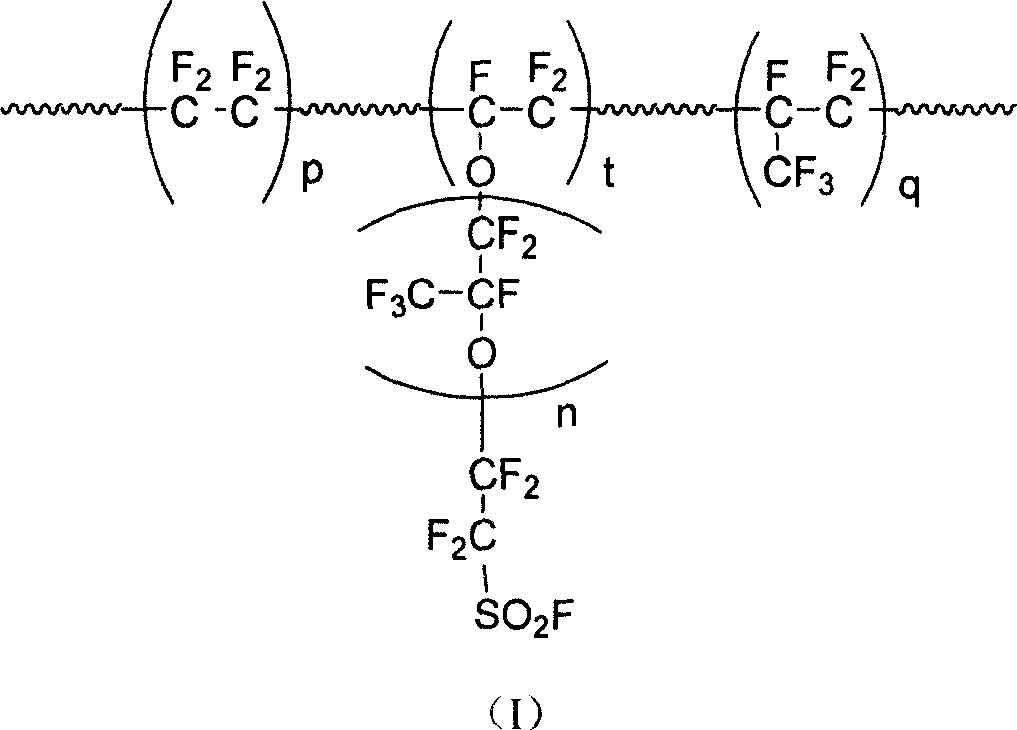

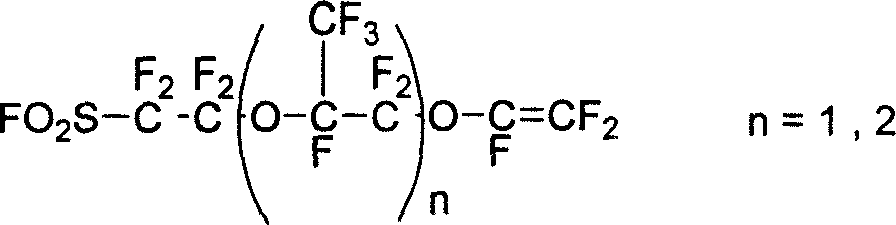

Polymer of containing fluorin, and application as material of ion exchange fiber

InactiveCN101003588AIncrease the effective areaLower resistanceMelt spinning methodsVinyl etherAlkali ions

This invention discloses a fluorine-containing polymer and its application as ion exchange fiber material. The fluorine-containing polymer is a perfluoro resin containing sulfonylfluoride groups, and is shown in formula 1. The fluorine-containing polymer has ion exchange function, and is prepared by free radical copolymerization of perfluorosulfonyl vinyl ether, tetrafluoroethylene and hexafluoropropylene in the presence of dispersant, solvent and initiator. The dispersant / solvent is mixed solution of melamine derivative containing linear perfluoro hydrocarbon and water. The fluorine-containing polymer can be melt-spun into polymer fibers, which can be woven into fiber network that can be used as the reinforcing network material for ion exchange membranes and chlor-alkali ion membrane to reinforce and improve the ion exchange ability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Modified membranes

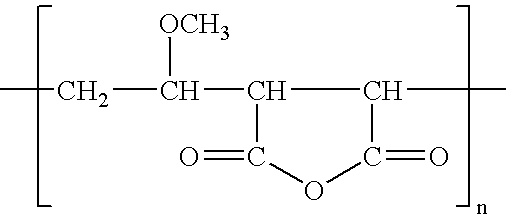

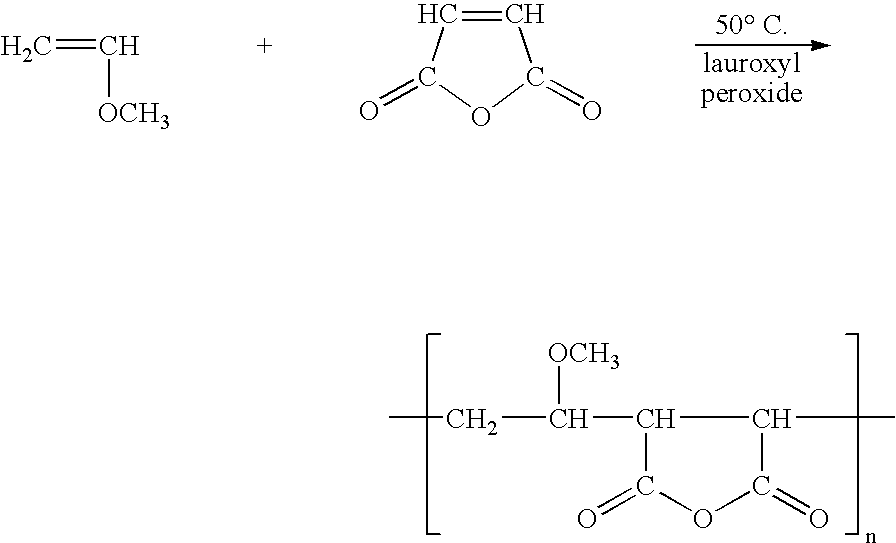

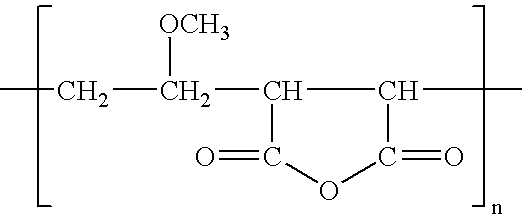

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

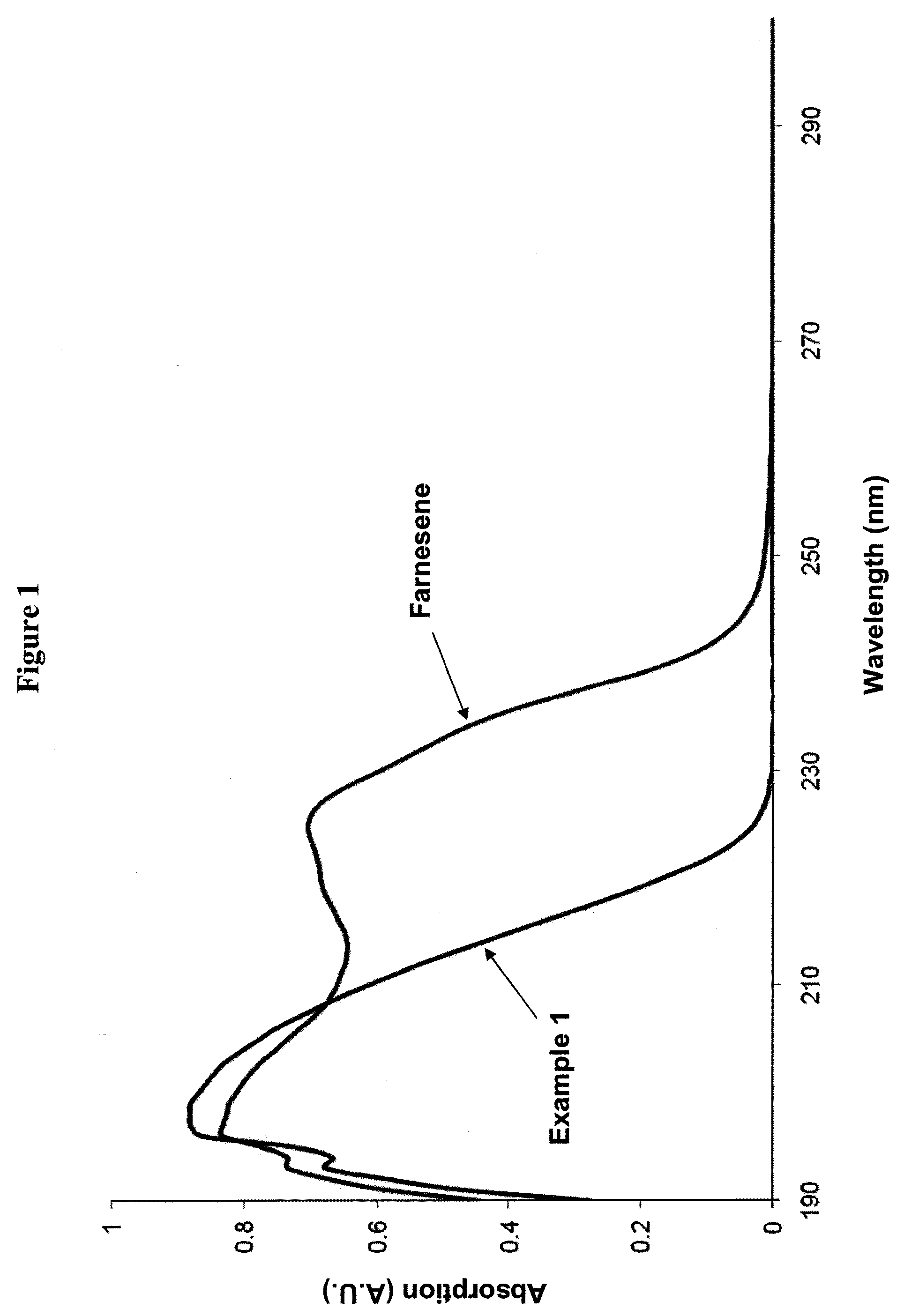

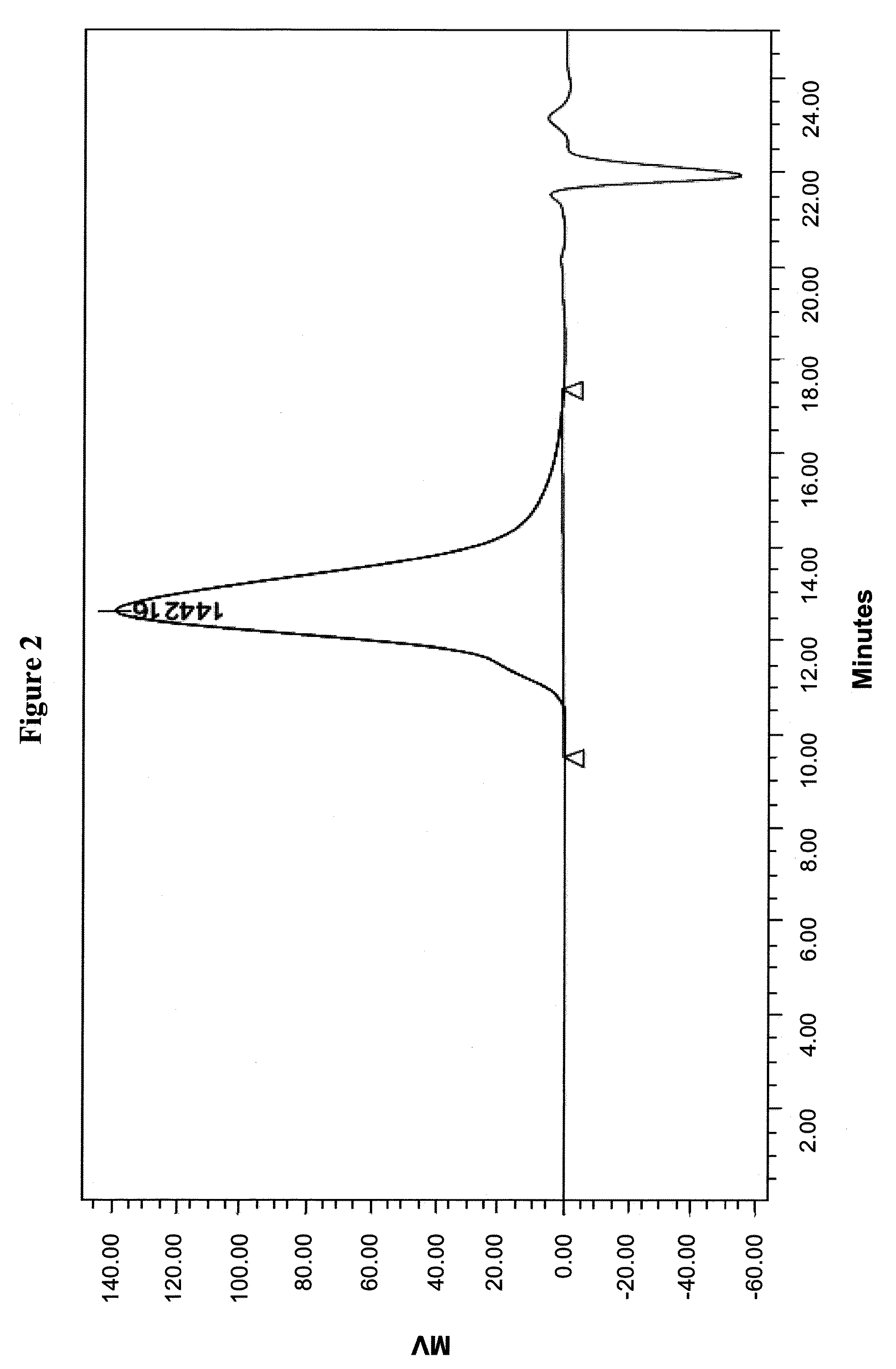

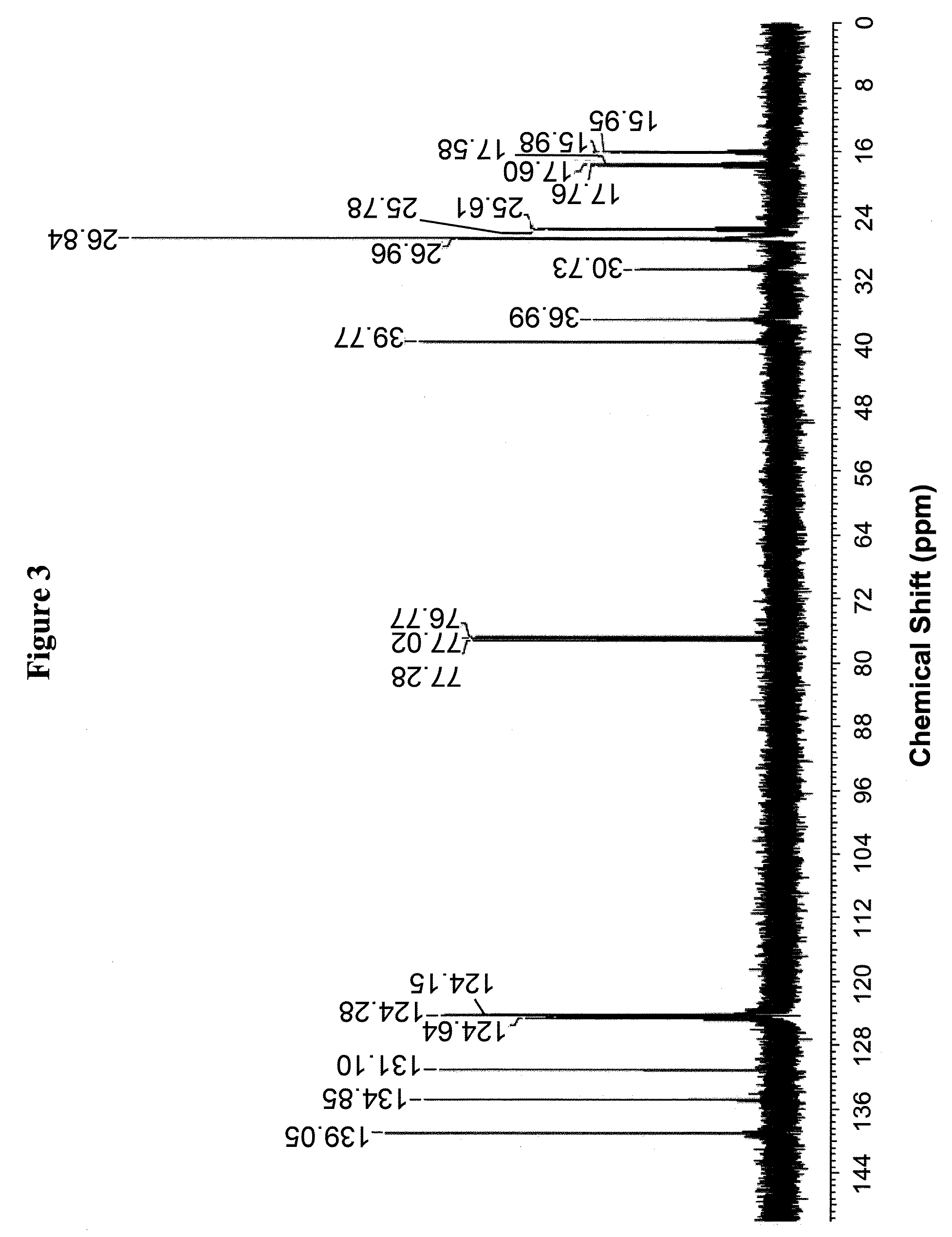

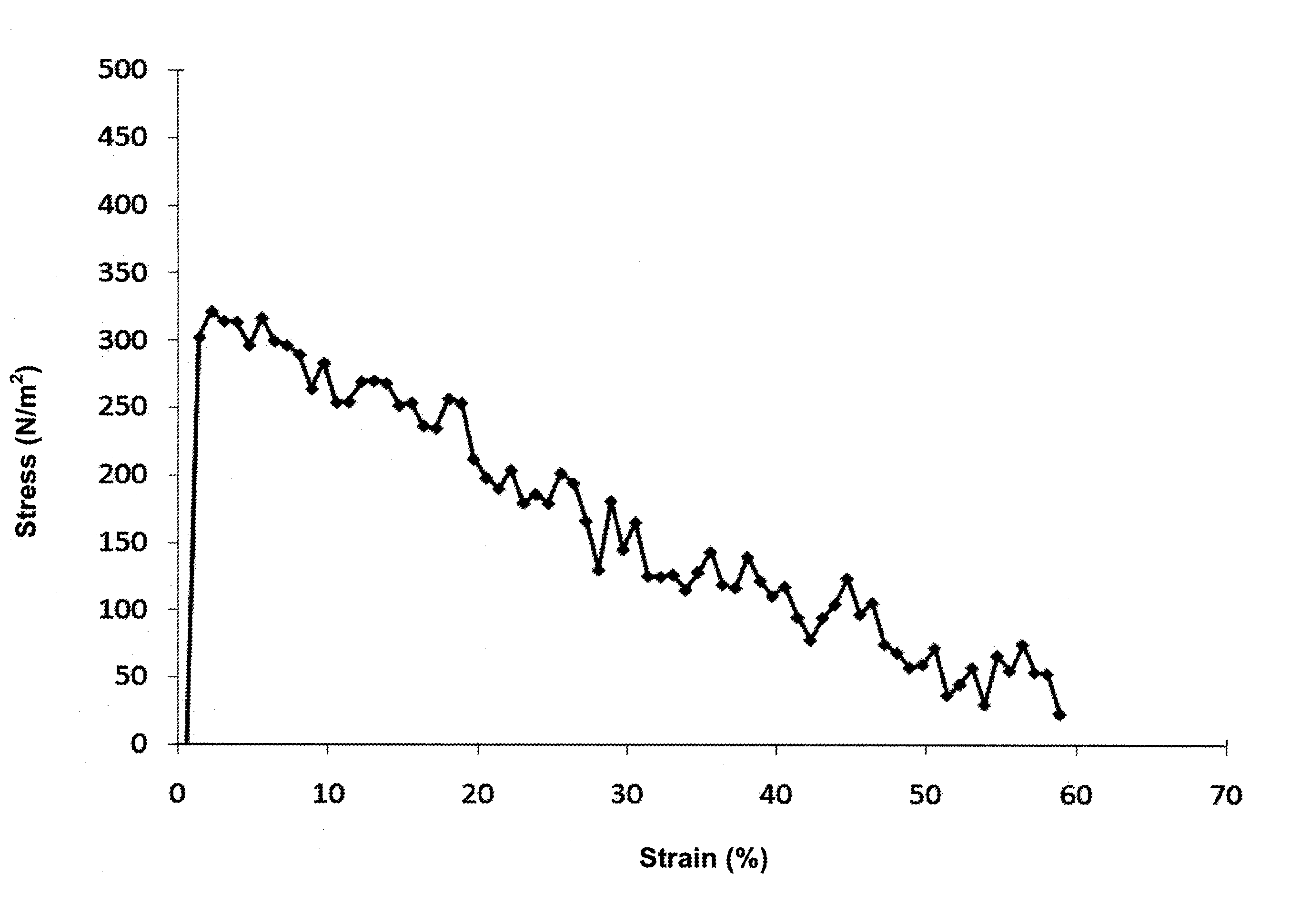

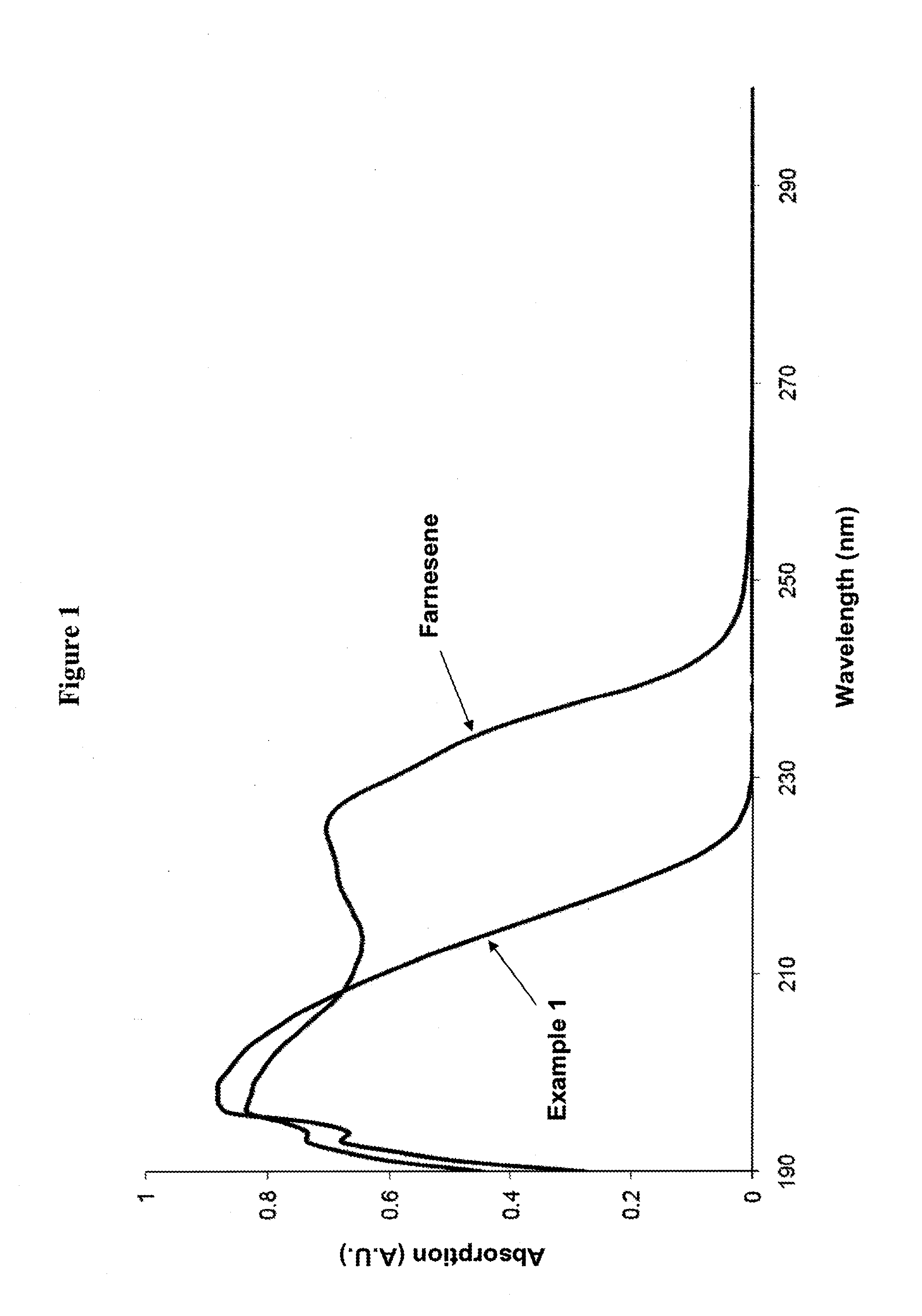

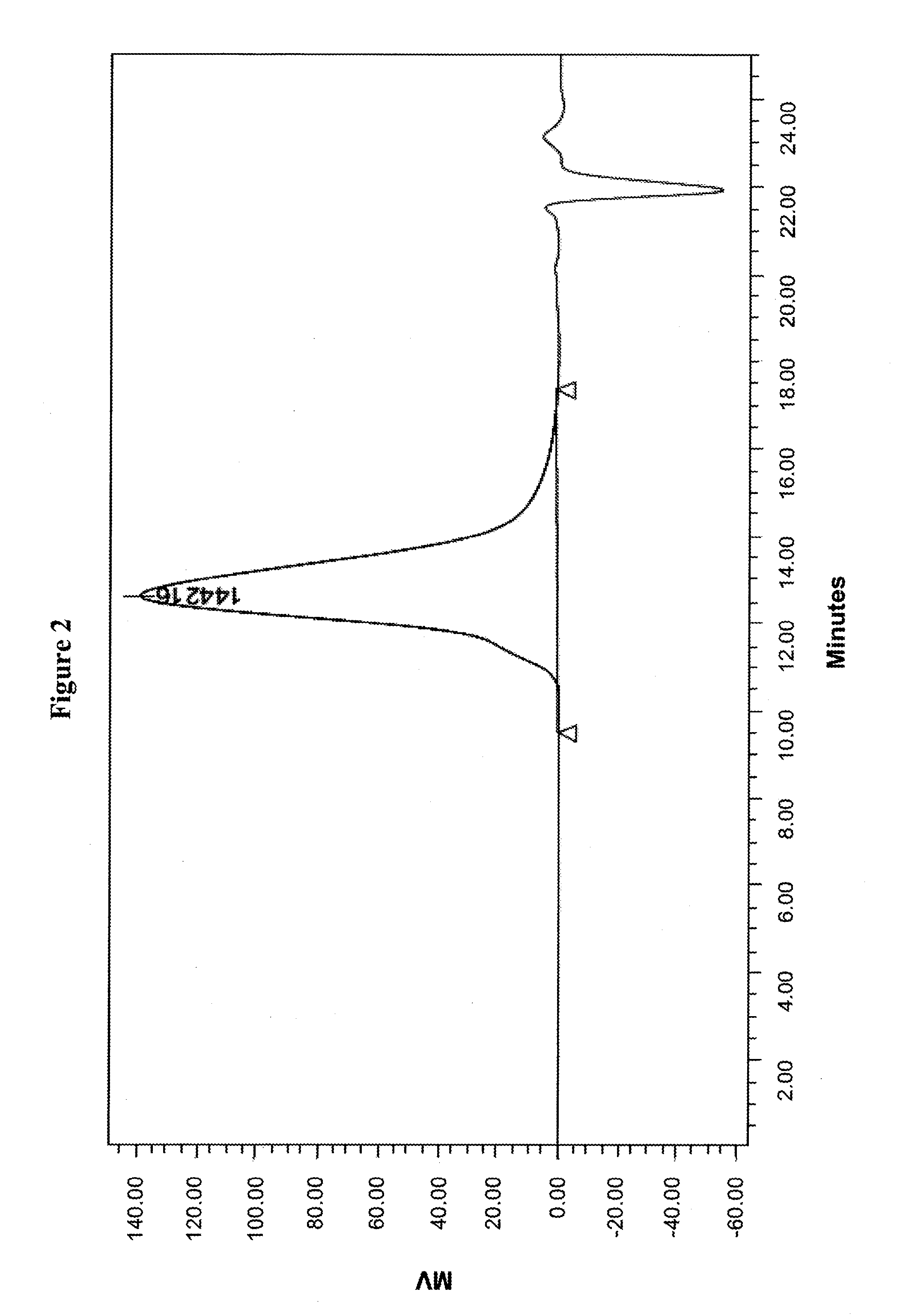

Farnesene interpolymers

Farnesene interpolymer comprises units derived from a farnesene (e.g., α-farnesene or β-farnesene) and units derived from at least one vinyl monomer. The farnesene interpolymer can be prepared by copolymerizing the farnesene and at least one vinyl monomer in the presence of a catalyst. In some embodiments, the farnesene is prepared from a sugar by using a microorganism. In other embodiments, the at least one vinyl monomer is ethylene, an α-olefin, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof.

Owner:AMYRIS INC

Modified membranes

InactiveUS6884350B2Reduce dirtEssential mechanical properties of the membranesMembranesSemi-permeable membranesVinyl etherPolyamide

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

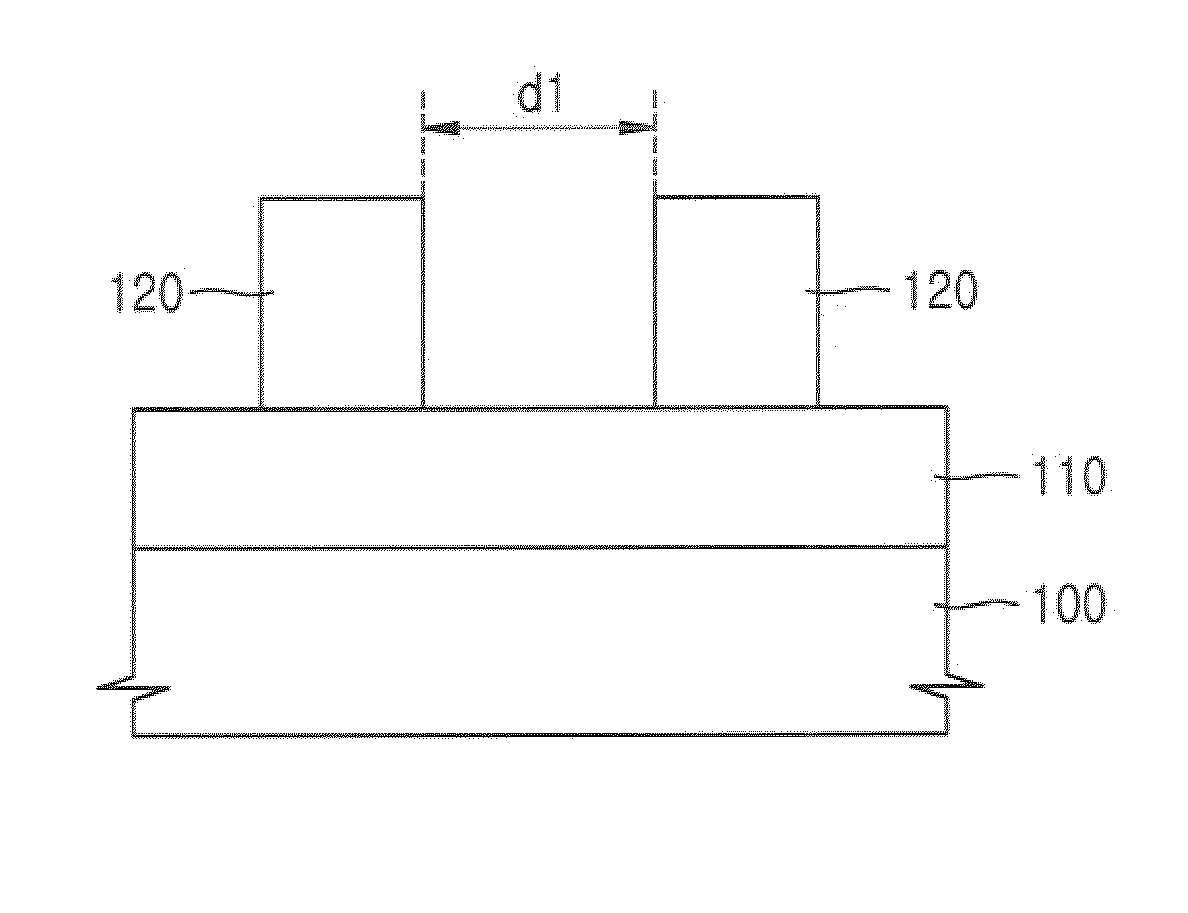

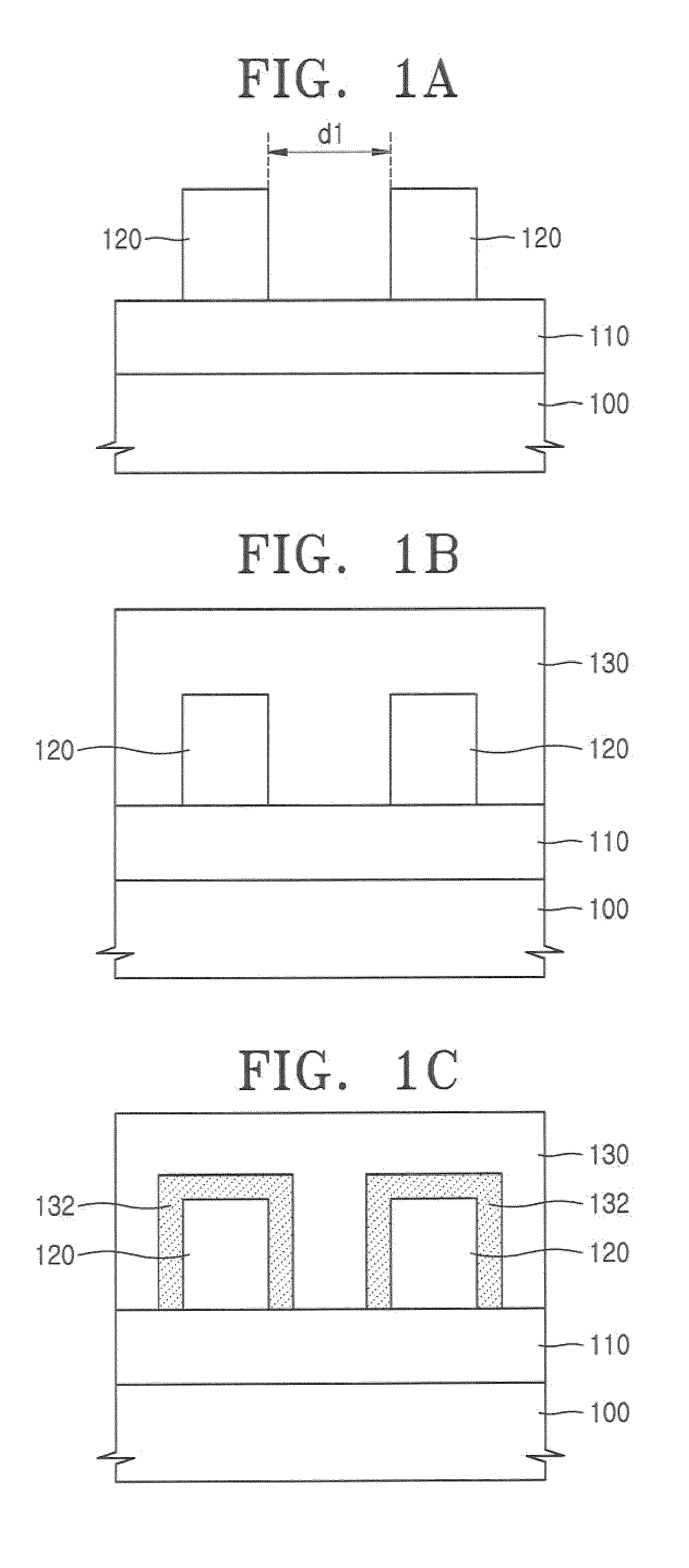

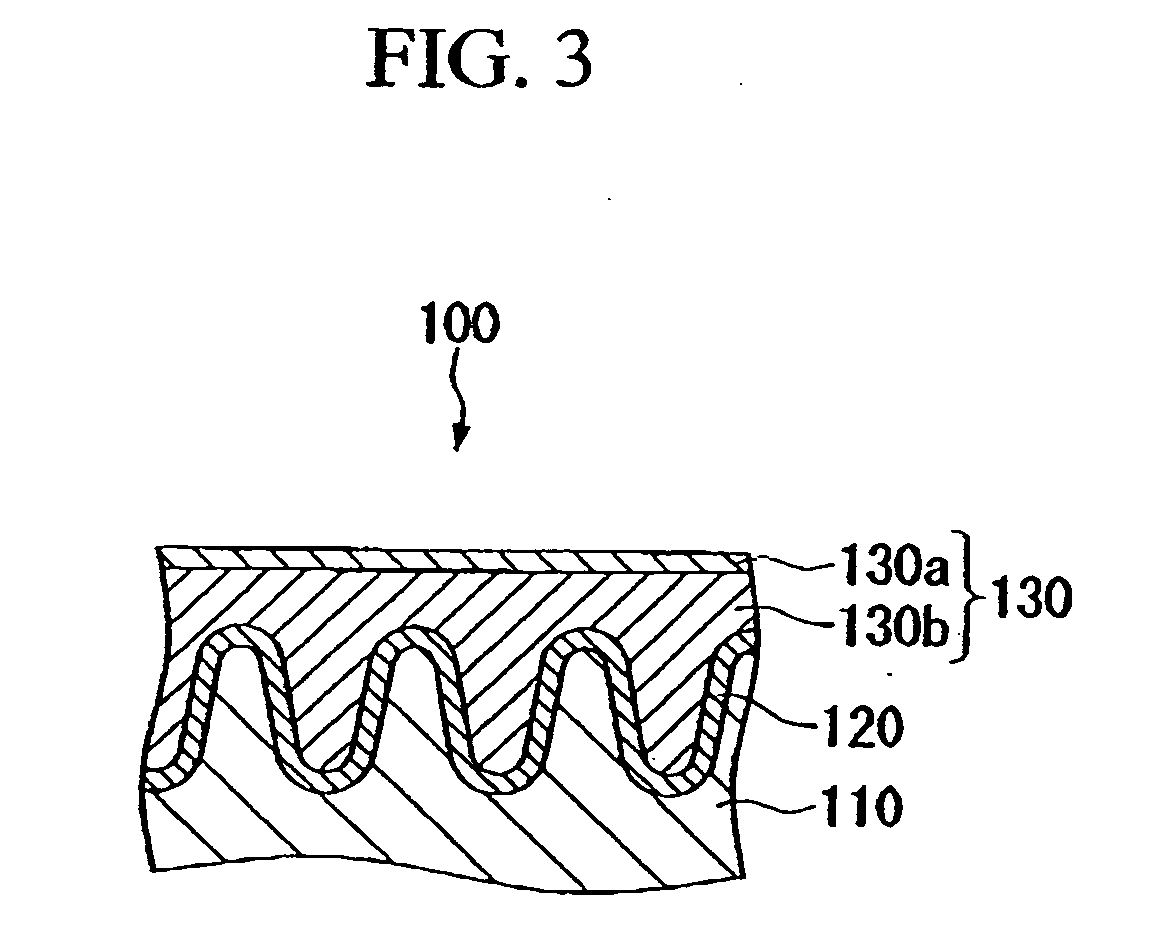

Coating Compositions for Use in Forming Patterns and Methods of Forming Patterns

InactiveUS20080113300A2Increased durabilityReduce distortionSemiconductor/solid-state device manufacturingPhotosensitive material processingVinyl etherOrganic solvent

A coating composition for forming etch mask patterns may include a polymer and an organic solvent. The polymer may have an aromatic ring substituted by a vinyl ether functional group. The polymer may be, for example, a Novolak resin partially substituted by a vinyl ether functional group or poly(hydroxystyrene) partially substituted by a vinyl ether functional group.

Owner:SAMSUNG ELECTRONICS CO LTD

Thermoplastic fluoropolymer-coated medical devices

A medical device provided with at least a partial surface coating of a thermoplastic copolymer of tetrafluoroethylene and perfluoroalkylvinylether that is free of cross-linking monomers and curing agents. The fluoropolymer coating is preferably an amorphous thermoplastic, is highly inert and biocompatible, has elastomeric characteristics that provide desirable mechanical properties such as good flexibility and durability. These characteristics allow the coating to be considered “functionally transparent” because it withstands mechanical deformations required for the assembly, deployment, expansion, and placement of medical devices, without any adverse effect on the mechanical and biological functionality of the coated device. Further, its inertness, derived from the perfluorocarbon structure, contributes to its functionally transparent nature. The coating can be provided with various liquid or solid additives, can be loaded with large quantities of additives including a wide range of therapeutic agents, and has excellent drug elution characteristics when elutable additives are used. The desirable mechanical characteristics are surprising given the absence of cross-linking monomers and curing agents that would otherwise render such materials inadequately biocompatible. The perfluoroalkylvinylether may be perfluoromethylvinylether, perfluoroethylvinylether or perfluoropropylvinylether.

Owner:WL GORE & ASSOC INC

Photocurable Ink Composition for Ink Jet Recording and Ink Jet Recording Method

ActiveUS20130010039A1Improve curing effectPoor in curabilityMeasurement apparatus componentsInksVinyl etherHydrogen atom

The present invention provides a photocurable ink composition for ink jet recording with excellent curability. The photocurable ink composition for ink jet recording includes polymerizable compounds, a photopolymerization initiator, and a colorant, wherein the polymerizable compounds include a vinyl ether group-containing (meth)acrylate represented by general formula (I):CH2═CR1—COOR2—O—CH═CH—R3 (I)(wherein R1 is a hydrogen atom or a methyl group, R2 is a divalent organic residue having 2 to 20 carbon atoms, and R3 is a hydrogen atom or a monovalent organic residue having 1 to 11 carbon atoms) and phenoxyethyl (meth)acrylate.

Owner:SEIKO EPSON CORP

Photocurable ink composition, recording method, recording apparatus, photocurable ink jet recording ink composition, and ink jet recording method

ActiveUS20120274717A1Improve curing effectAvoid it happening againInksPrintingVinyl etherHydrogen atom

A photocurable ink composition includes polymerizable compounds and a photopolymerization initiator. The polymerizable compounds include vinyl ether group-containing (meth)acrylic esters represented by the following Formula (I):CH2═CR1—COOR2—O—CH═CH—R3 (I)(wherein, R1 represents a hydrogen atom or a methyl group; R2 represents a divalent organic residue having 2 to 20 carbon atoms; and R3 represents a hydrogen atom or a monovalent organic residue having 1 to 11 carbon atoms), dipropylene glycol di(meth)acrylate, and monofunctional (meth)acrylate having an aromatic ring skeleton. The ink composition includes a coloring material.

Owner:SEIKO EPSON CORP

Adhesive compositions comprising a polyfarnesene

Adhesive composition comprises a polyfarnesene and a tackifier. The polyfarnesene can be a farnesene homopolymer derived from a farnesene (e.g., α-farnesene or β-farnesene) or a farnesene interpolymer derived from a farnesene and at least a vinyl monomer. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof. The composition disclosed herein can be used as a hot melt adhesive, a pressure sensitive adhesive or the like.

Owner:AMYRIS INC

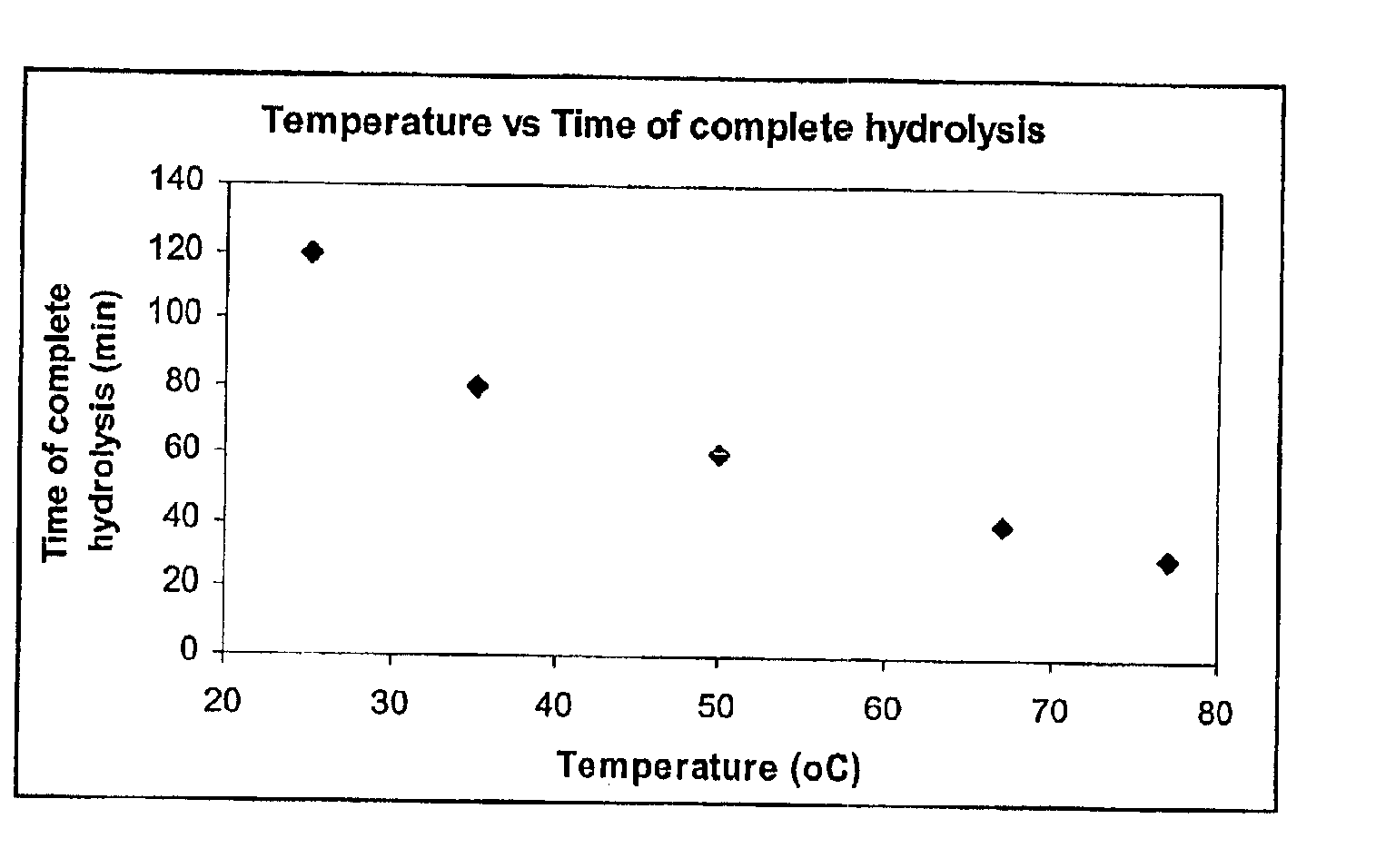

Dental impression composition on functionalized polyethers

A dental impression composition comprises a polyether derivative functionalized via the hydroxyl groups of a polyether polyol with groups such as aziridine, epoxide and unsaturated substituents including (meth)acrylic, allyl, vinyl, vinyl ether or maleate groups, wherein the level of cyclic oligomeric polyethers is less than 5.0 weight percent.

Owner:3M DEUTLAND

Thermoset composition, method, and article

InactiveUS20030215588A1Improve as-molded surface characteristics of polyReduce shrinkage on moldingSynthetic resin layered productsThin material handlingVinyl etherPolystyrene

A curable composition includes a functionalized poly(arylene ether), an alkenyl aromatic monomer, an acryloyl monomer, and a polymeric additive effective selected from polystyrene, poly(styrene-maleic anhydride), poly(styrene-methyl methacrylate), polybutene, poly(ethylene-butylene), poly(vinyl ether), poly(vinyl acetate), and combinations thereof. The composition exhibits low shrinkage on curing and improved surface smoothness. It is useful, for example, in the manufacture of automotive body panels.

Owner:SABIC INNOVATIVE PLASTICS IP BV

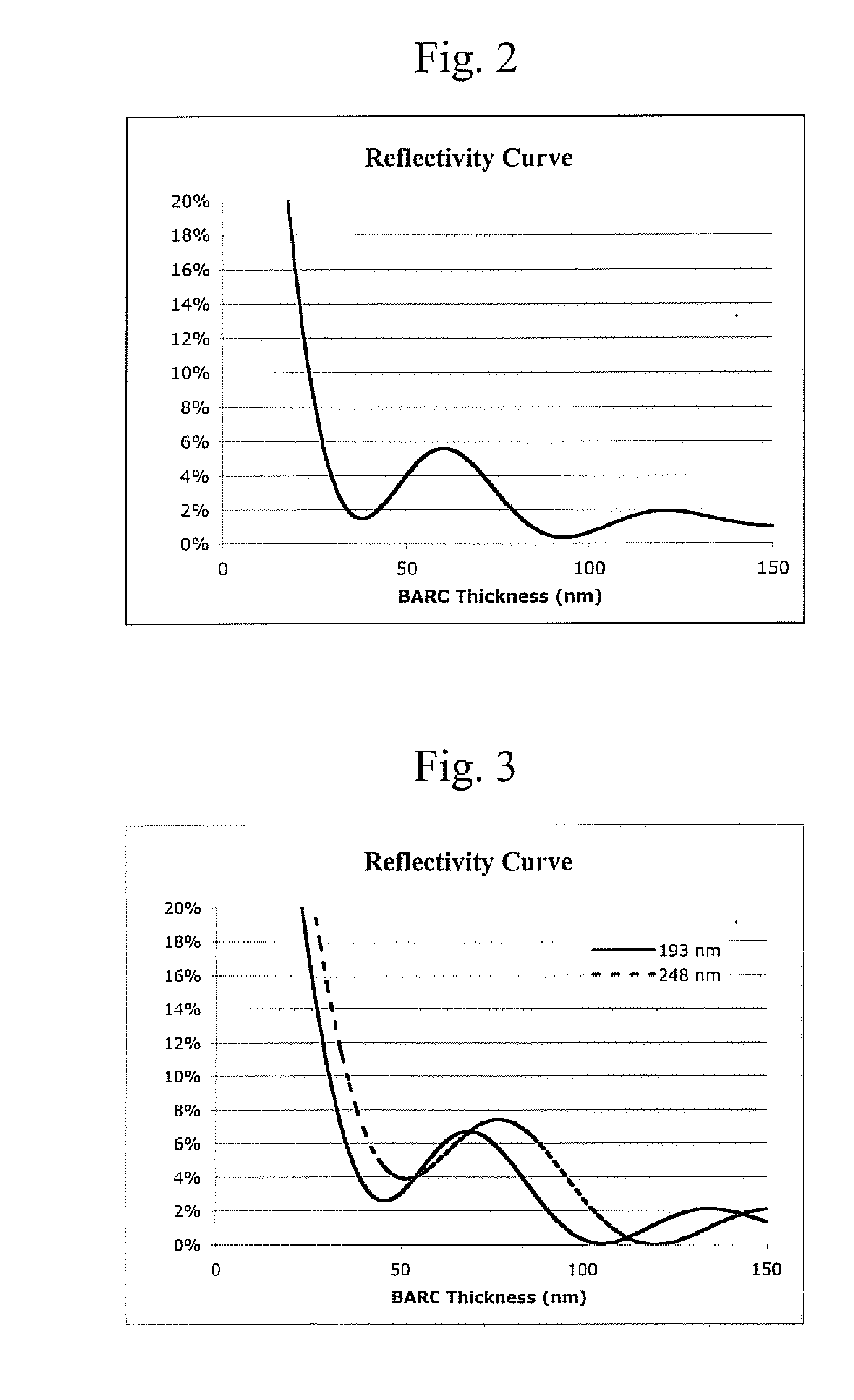

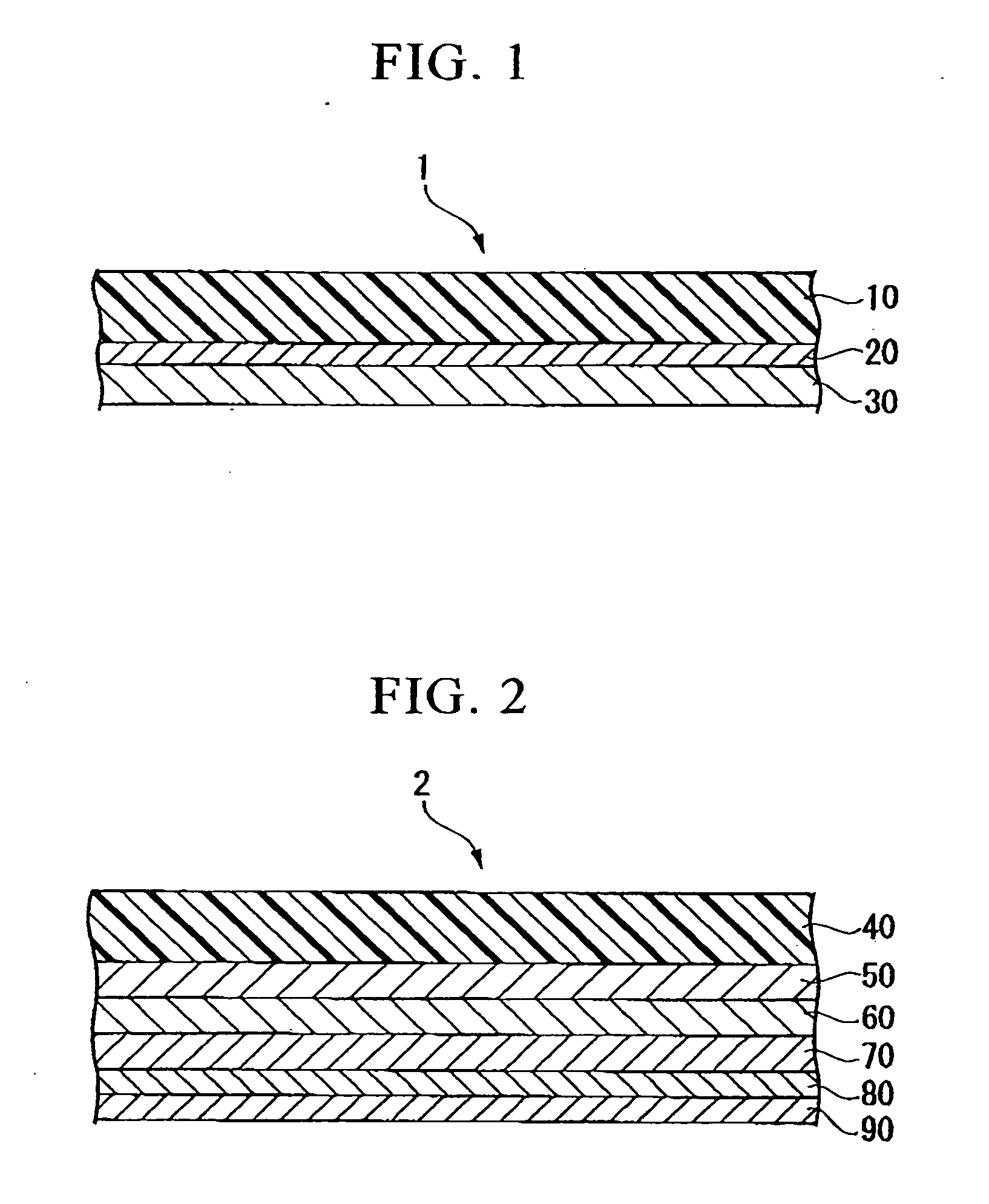

Anti-reflective coatings using vinyl ether crosslinkers

InactiveUS20070207406A1High percent solubilityReduce production processOrganic chemistrySilver halide emulsionsVinyl etherAnti-reflective coating

Novel, developer soluble anti-reflective coating compositions and methods of using those compositions are provided. The compositions comprise a polymer and / or oligomer having acid functional groups and dissolved in a solvent system along with a cross linker, a photoacid generator, and optionally a chromophore. The preferred acid functional group is a carboxylic acid, while the preferred crosslinker is a vinyl ether crosslinker. In use, the compositions are applied to a substrate and thermally crosslinked. Upon exposure to light (and optionally a post exposure bake), the cured compositions will decrosslink, rendering them soluble in typical photoresist developing solutions (e.g., alkaline developers). In one embodiment, the compositions can be used to form ion implant areas in microelectronic substrates.

Owner:BREWER SCI

High vinyl ether modified sinterable polytetrafluoroethylene

InactiveUS6870020B2Improve the level ofEasy to processPigmenting treatmentSynthetic resin layered productsVinyl etherTetrafluoroethylene

Modified polytetrafluoroethylene powder of a sinterable copolymer of tetrafluoroethylene containing about 0.5 to about 10 weight % of fluorinated vinyl ether, the copolymer having a melt creep viscosity of greater than about 1×106 Pa·S. In preferred embodiments, the sinterable copolymer has a melt creep viscosity of greater than about 1×107 Pa·S and fluorinated vinyl ether content of from about 1 to about 7 weight %. The polymer has a combination of a high level of fluorinated vinyl ether and a melt creep viscosity which is high enough to enable the fabrication of articles by sintering.

Owner:THE CHEMOURS CO FC LLC

High melt flow fluoropolymer

ActiveUS7122609B2Quality improvementLong extrusion runPlastic/resin/waxes insulatorsInsulated cablesVinyl etherPolymer science

The present invention relates to a partially-crystalline copolymer comprising tetrafluoroethylene, hexafluoropropylene in an amount corresponding to a hexafluoropropylene index (HFPI) of from about 2.8 to 5.3, and preferably from about 0.2% to 3% by weight of perfluoro(alkyl vinyl ether), said copolymer being polymerized and isolated in the absence of added alkali metal salts, having a melt flow rate of within the range of about 30±3 g / 10 min, and having no more than about 50 unstable endgroups / 106 carbon atoms can be extruded at high speed onto conductor over a broad polymer melt temperature range to give insulated wire of high quality.

Owner:THE CHEMOURS CO FC LLC

Conductive composition and production method thereof, antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium, and capacitors and production method thereof

ActiveUS20060062958A1Improve conductivityImprove heat stabilityHybrid capacitor electrolytesHybrid capacitor electrodesVinyl etherConductive polymer

A conductive composition comprises a π conjugated conductive polymer, a dopant composed of polyanion, and at least one crosslinking site forming compound selected from (a) compounds having a glycidyl group and (b) compounds having a hydroxyl group and one selected from the group consisting of allyl, vinyl ether, methacryl, acryl methacrylamide, and acrylamide groups. An antistatic coating material comprises a π conjugated conductive polymer, polyanion, at least one crosslinking site forming compound selected form the above (a) and (b), and a solvent. An antistatic coating is formed by applying the above-mentioned antistatic coating material. In a capacitor comprising an anode composed of a valve metal porous body; a dielectric layer formed by oxidizing the suds of the anode; and a cathode formed on the dielectric lays, the cathode has a solid electrolyte layer formed by crosslinking complexes of a π conjugated conductive polymer and a dopant composed of a polyanion.

Owner:SHIN-ETSU POLYMER CO LTD

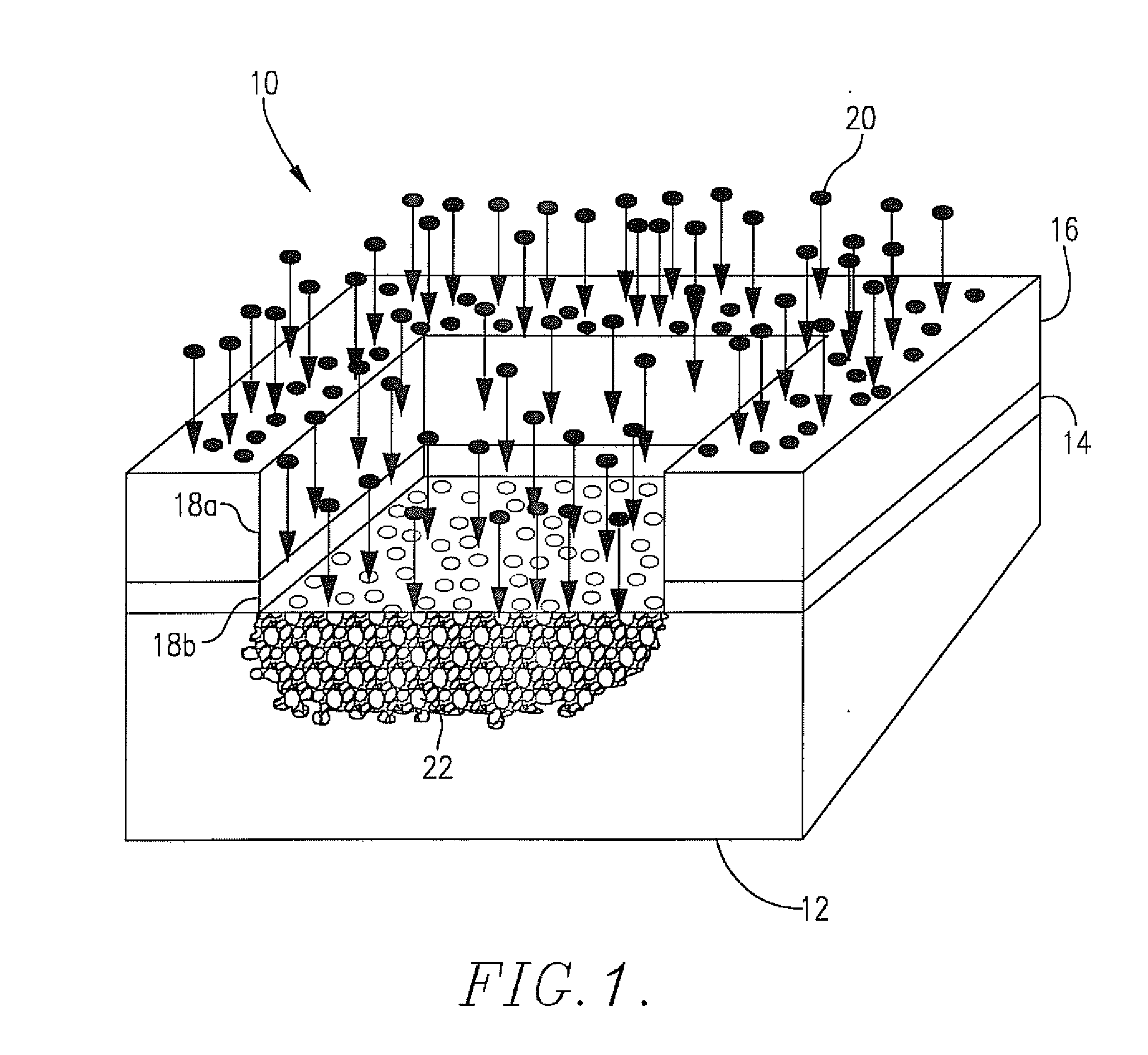

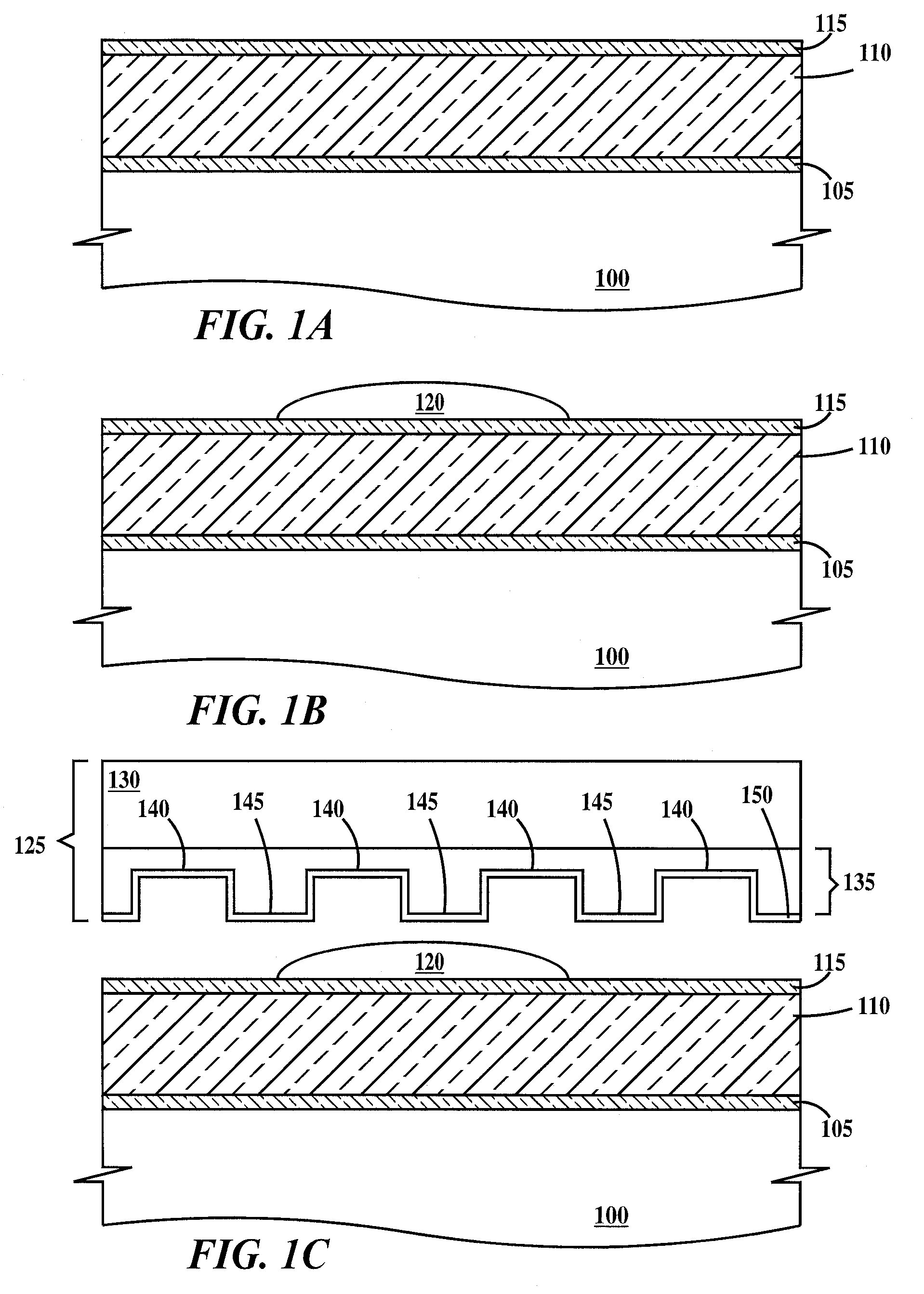

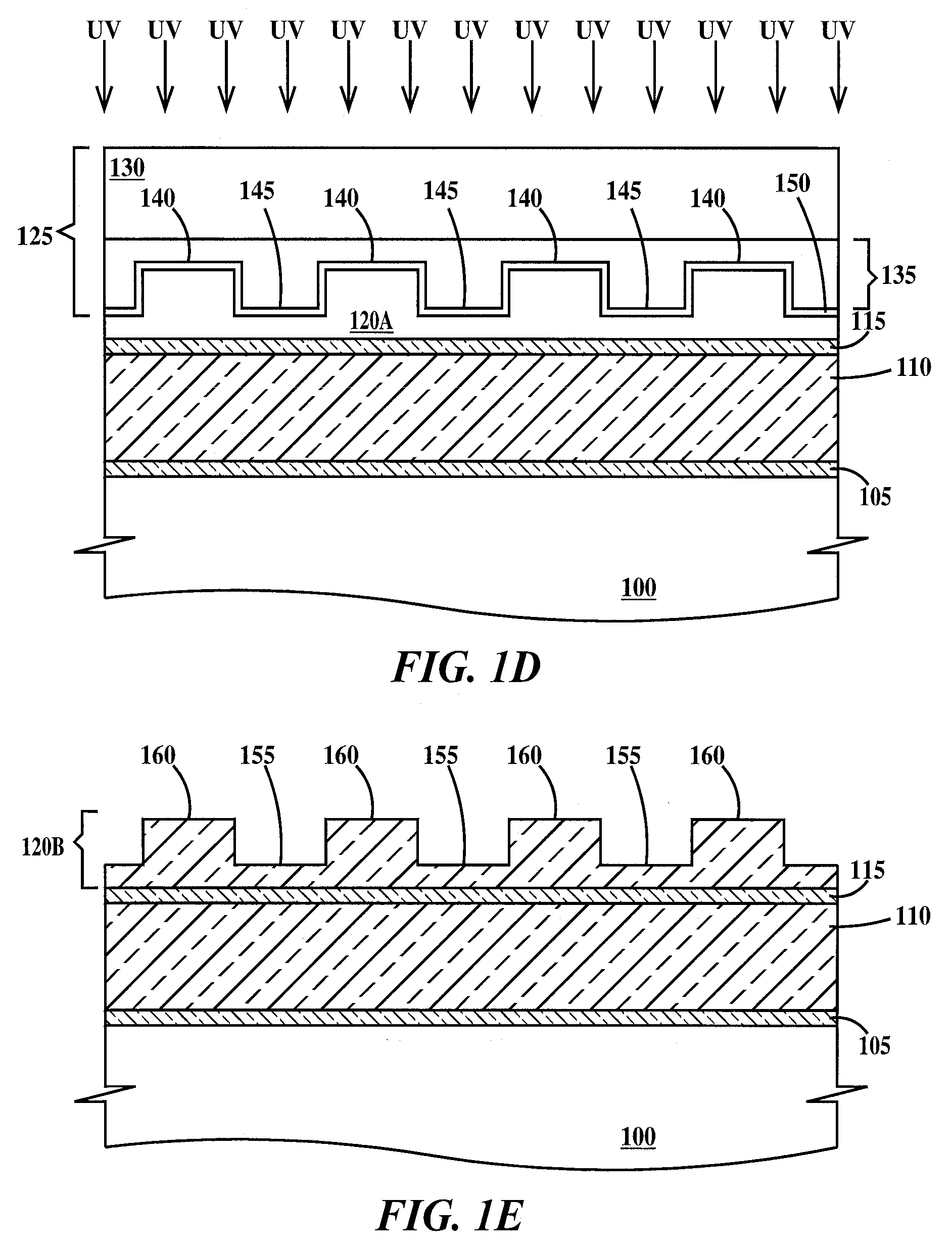

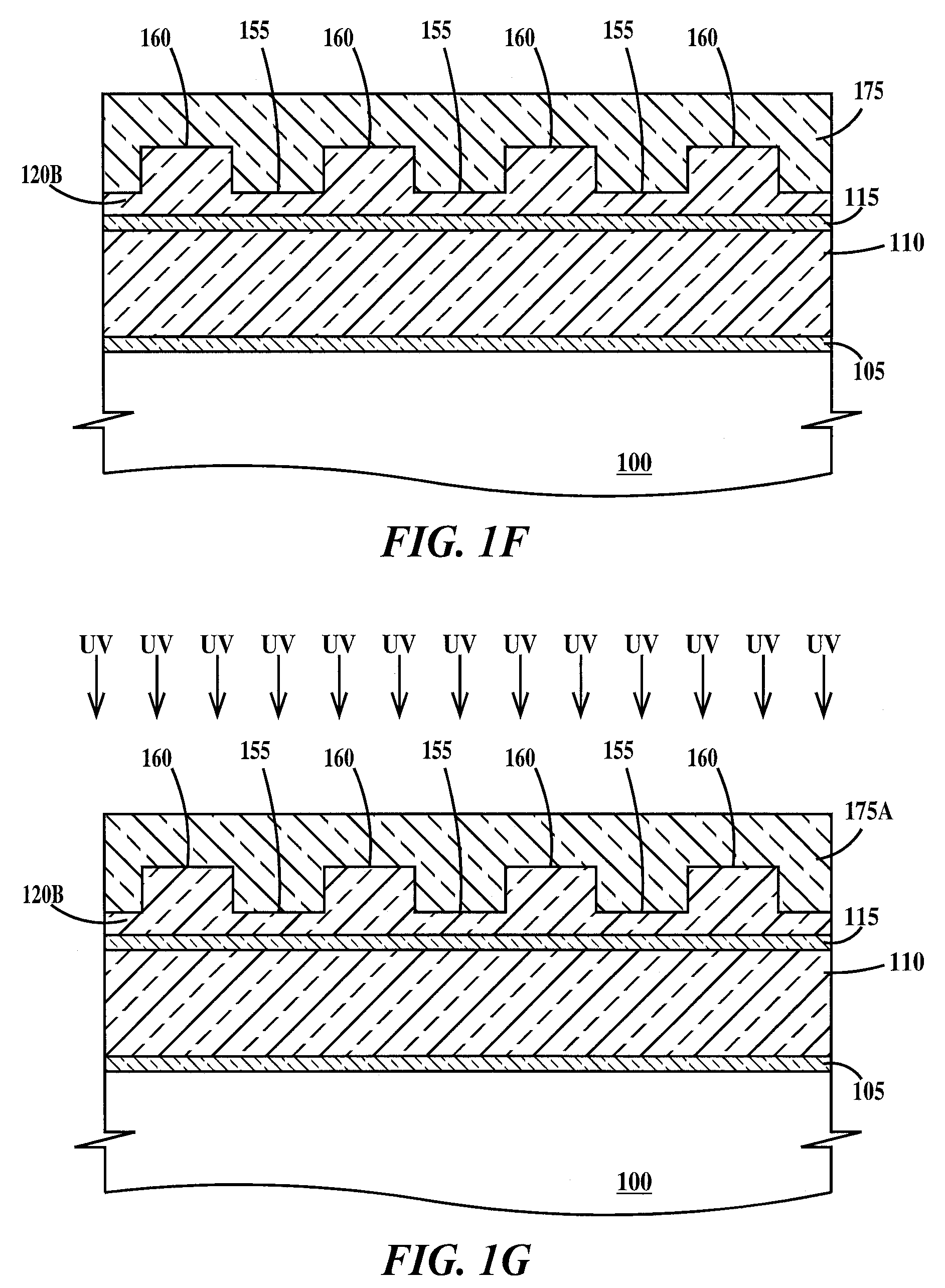

Aromatic vinyl ether based reverse-tone step and flash imprint lithography

A molding composition and a method of forming an pattern. The method includes forming on a substrate a molding layer of a molding composition of aromatic divinyl ethers; pressing the template into the molding layer, the template having a relief pattern, the molding layer filling voids in the relief pattern, the template not contacting the substrate; exposing the molding layer to actinic radiation, the actinic radiation converting the molding layer to a cured molding layer having thick and thin regions corresponding to the relief pattern; removing the template; filling the thin regions of the relief pattern with a backfill material; removing regions of the molding layer not protected by the backfill material to expose regions of the substrate; forming trenches in the exposed regions of the substrate; and removing any remaining molding layer and backfill material. A transfer layer may be used between the molding layer and the substrate.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com