Patents

Literature

1177 results about "Dispersion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispersions are unstable from the thermodynamic point of view; however, they can be kinetically stable over a large period of time, which determines their shelf life. This time span needs to be measured in order to ensure the best product quality to the final consumer. “Dispersion stability refers to the ability of a dispersion to resist change in its properties over time.” D.J. McClements.

Liquid inks comprising a stable organosol

InactiveUS20020128349A1Good dispersionAvoid resistanceDuplicating/marking methodsInksMethacrylateDispersion stability

A liquid ink comprises (a) a carrier liquid having a Kauri-Butanol number less than 30; (b) a graft copolymer comprising a (co)polymeric steric stabilizer covalently bonded to a thermoplastic (co)polymeric core that is insoluble in the carrier liquid; and (c) a colorant, wherein the steric stabilizer comprises units derived from 3,3,5-trimethylcyclohexyl methacrylate, and the thermoplastic (co)polymeric core comprising units derived from at least a polymerizable monomer selected from the group consisting of (meth)acrylates having aliphatic amino radicals, nitrogen-containing heterocyclic vinyl monomers, N-vinyl substituted ring-like amide monomers, aromatic substituted ethylene monomers containing amino radicals, and nitrogen-containing vinylether monomers. The organosol provides improved liquid electrophotographic and electrographic ink compositions with improved dispersion stability, chargeability, and blocking resistance so that improved print quality or ink transfer performance are obtained.

Owner:S PRINTING SOLUTION CO LTD

Cellulose dispersion

InactiveUS6541627B1Good dispersionImprove stabilitySugar derivativesCellulose coatingsCelluloseDispersion stability

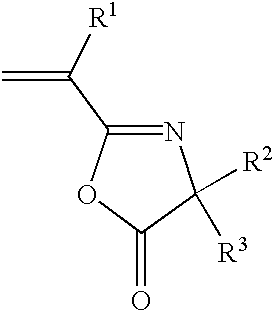

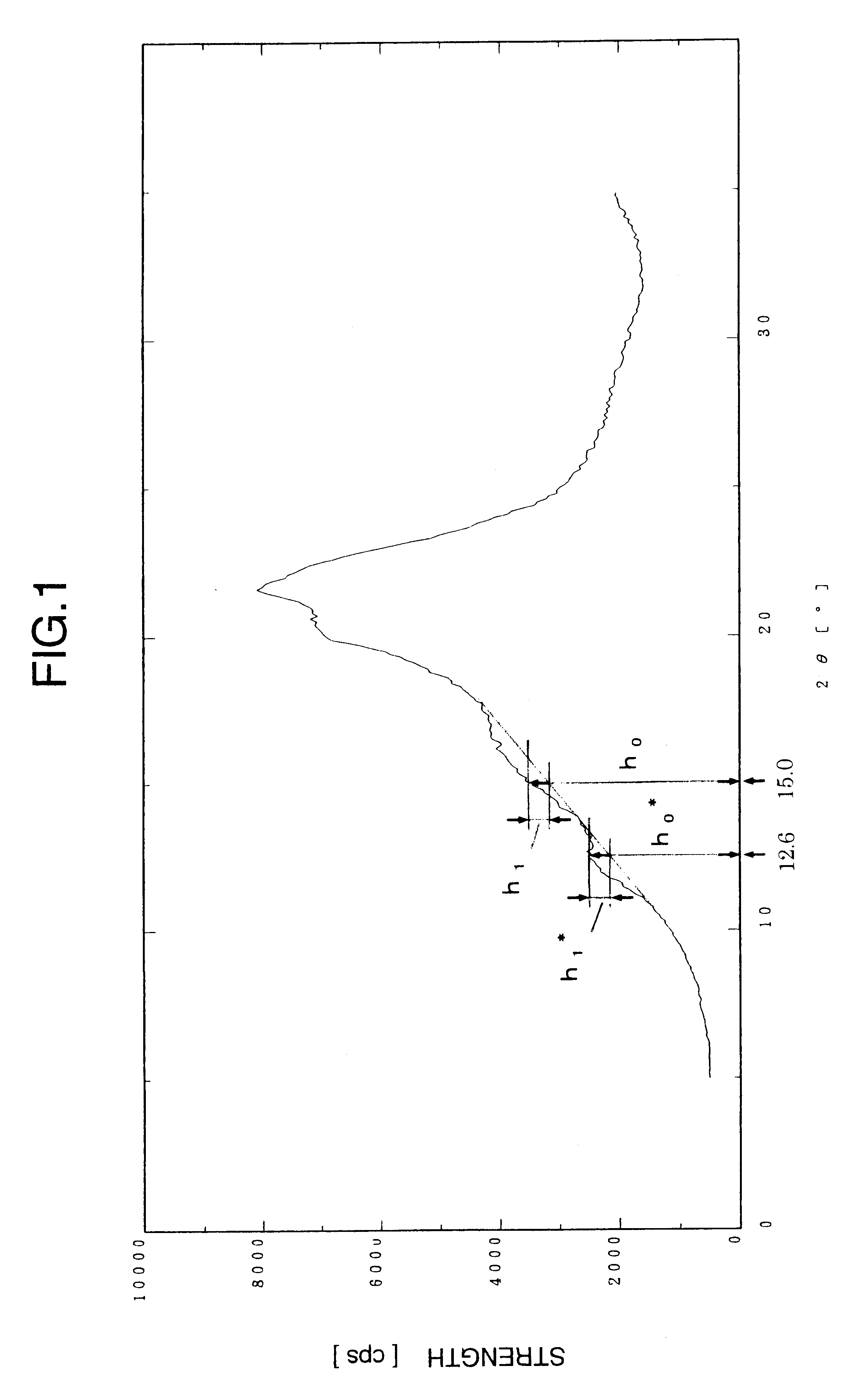

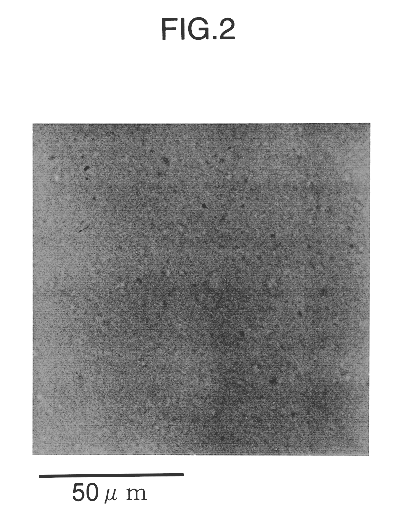

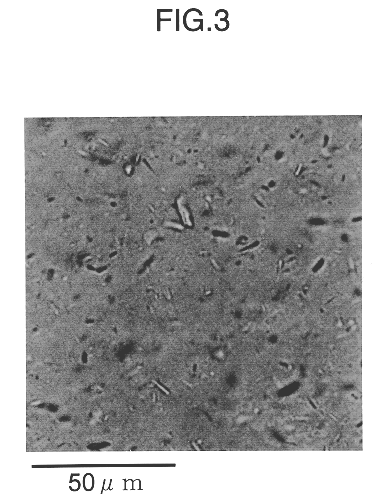

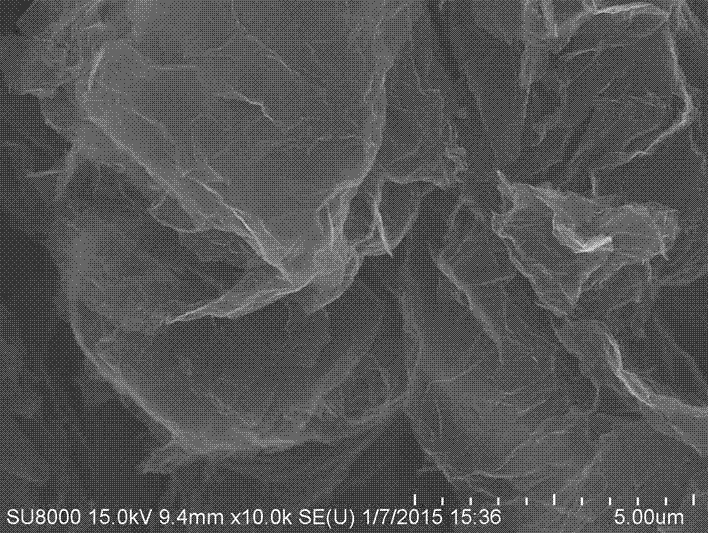

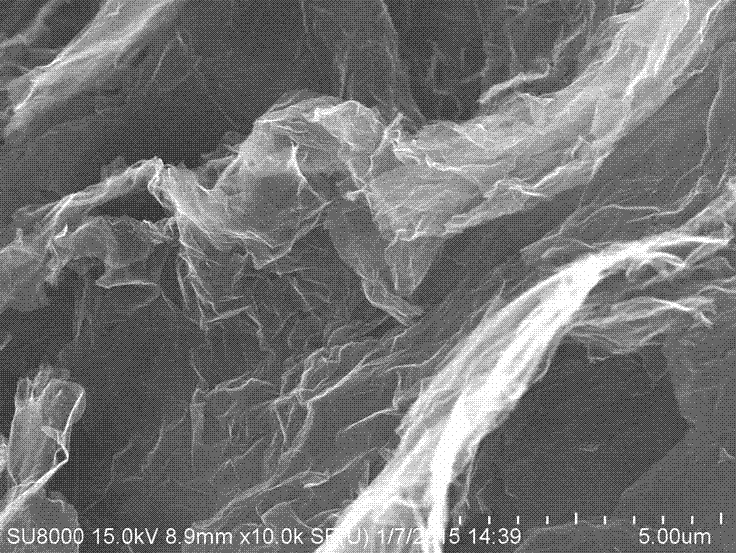

A cellulose dispersion which is a dispersion comprising a dispersing medium and a cellulose having a fraction of cellulose I type crystal component of not more than 0.1 and a fraction of cellulose II type crystal component of not more than 0.4 and in which the average particle diameter of the constitutive cellulose is not more than 5 mum. A cellulose particulate and a cellulose composite particulate which have an average particle diameter of 0.2 to 20 mum, a ratio of long diameter (L) to short diameter (D) observed through a scanning electron microscope (L / D) of not more than 1.2 and a coefficient of aggregation of 1.0 to 3.0. The present invention provides a cellulose dispersion which has an excellent effect such as dispersion stability or the like and is high in transparency. Moreover, it provides a cellulose particulate and a cellulose composite particulate which have such performances as no rough feel, excellent rolling properties, high dispersibility and the like.

Owner:ASAHI KASEI KK

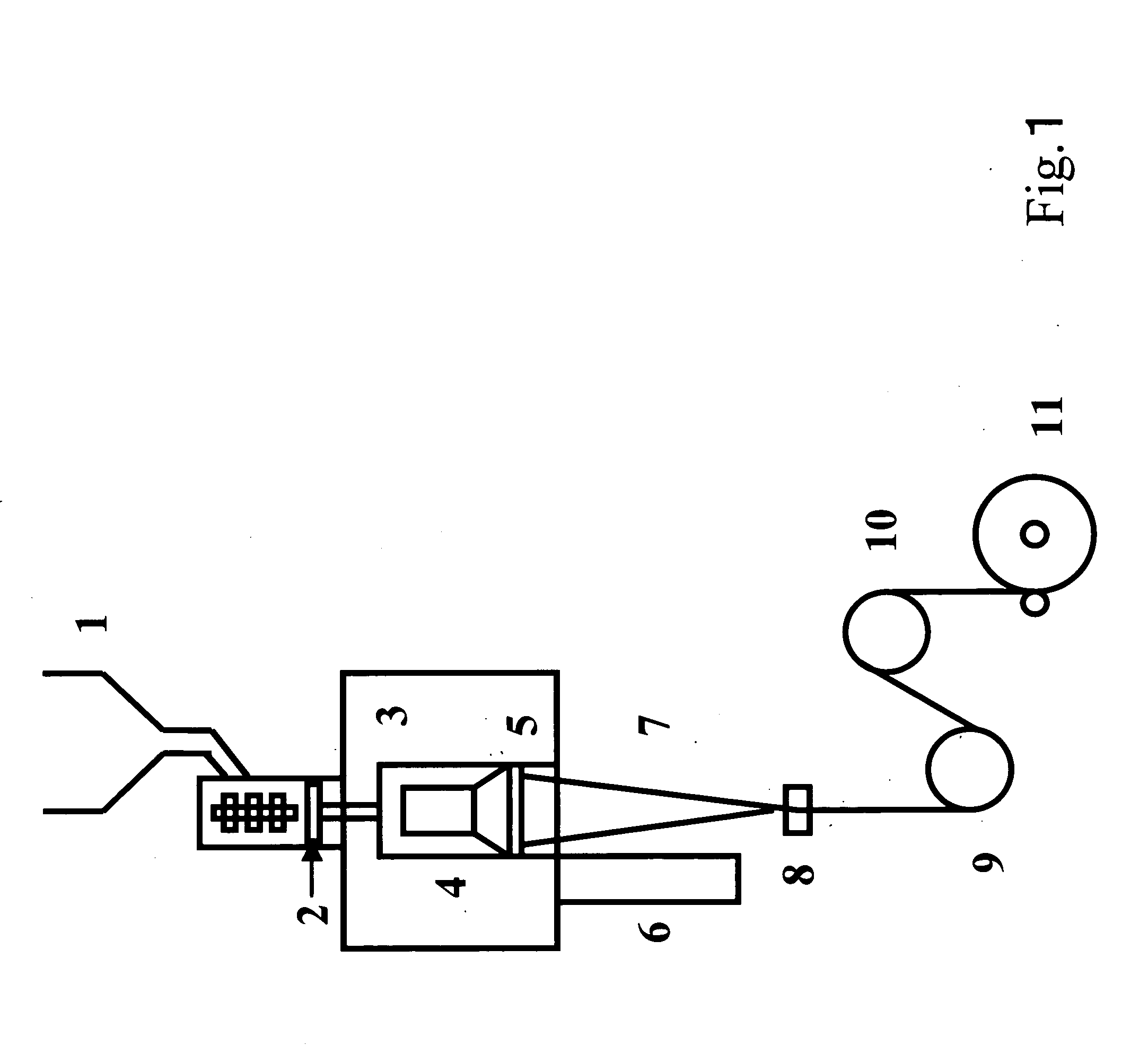

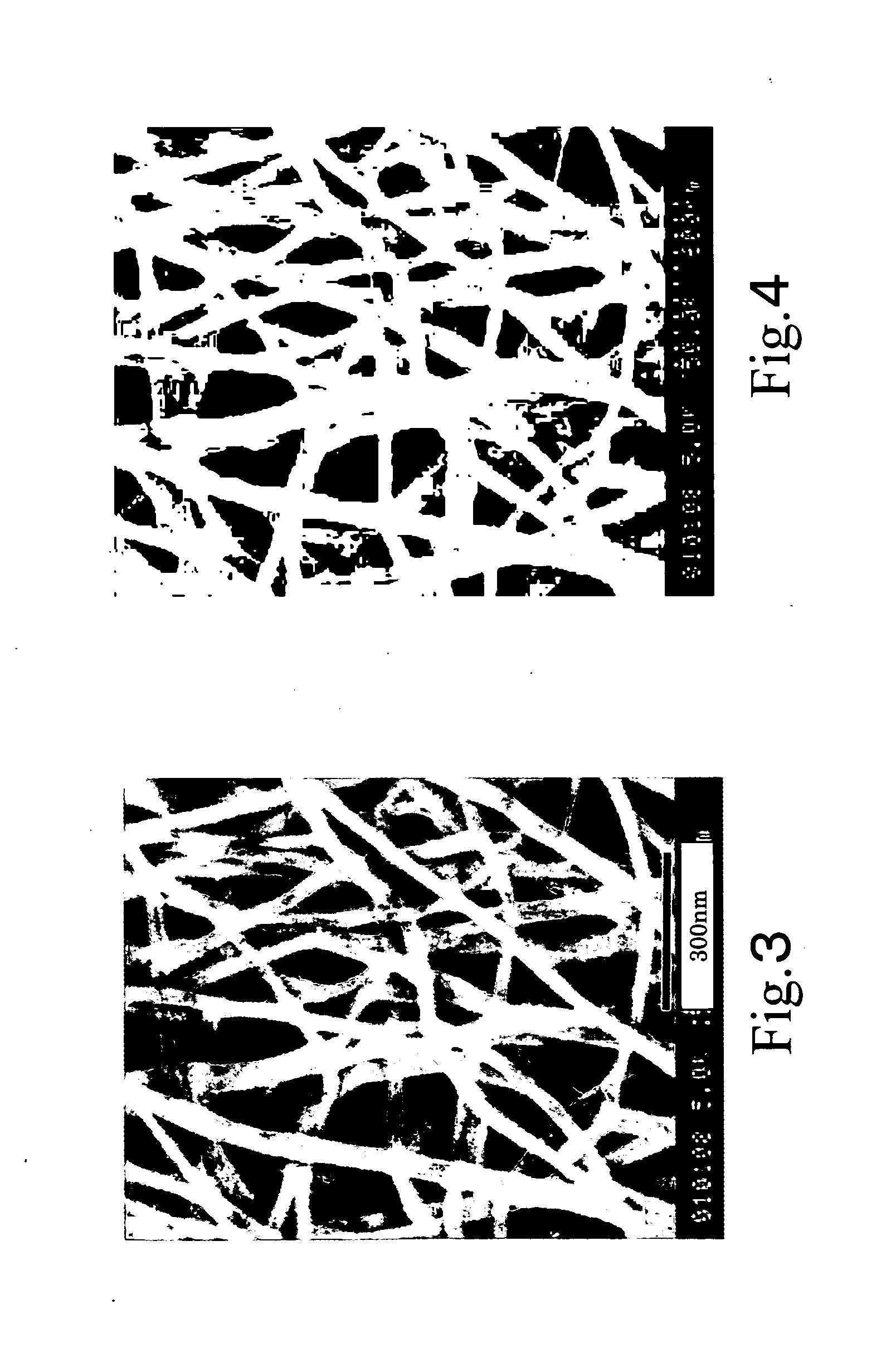

Nano-Fiber Compound Solutions, Emulsions And Gels, Production Method Thereof, Nano-Fiber Synthetic Papers, And Production Method Thereof

ActiveUS20070196401A1High affinitySoft skinCosmetic preparationsNon-fibrous pulp additionDispersion stabilityEmulsion

This invention provides compound solutions, emulsions and gels excellent in homogeneous dispersibility and long-term dispersion stability and also excellent in the properties as cosmetics, using disarranged nanofibers not limited in either form or polymer, widely applicable and small in the irregularity of single fiber diameter. This invention also provides a method for producing them. Furthermore, this invention provides synthetic papers composed of fibers, small in pore area and uniform in pore size, using disarranged nanofibers, and also provides a method for producing them. This invention provides compound solutions, emulsions, gels and synthetic papers containing disarranged nanofibers of 1 to 500 nm in number average diameter and 60% or more in the sum Pa of single fiber ratios.

Owner:TORAY IND INC

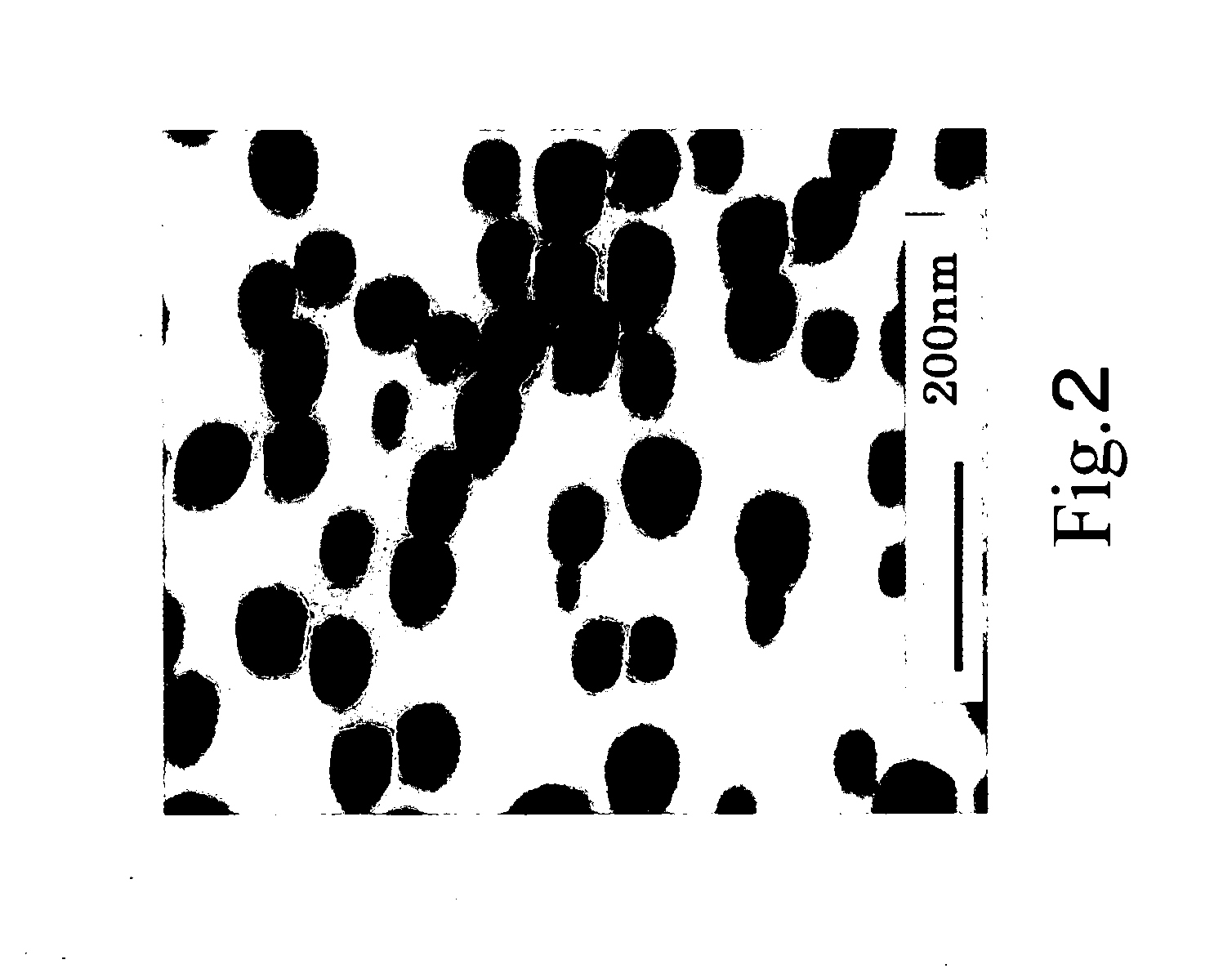

Method for producing silver nanoparticles and conductive ink

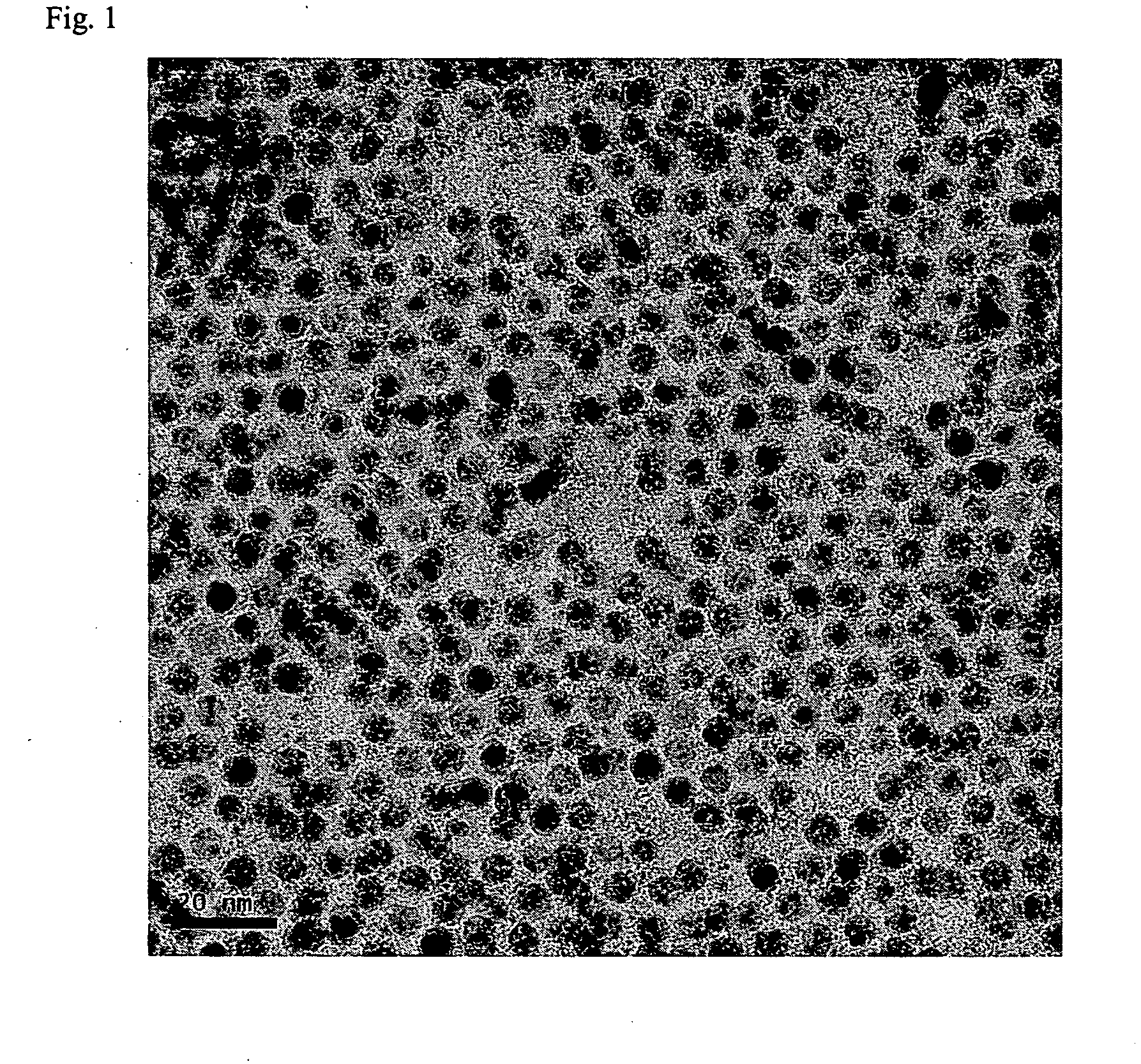

InactiveUS20090223410A1Uniform sizeHigh yield rateMaterial nanotechnologyMetal-working apparatusDispersion stabilityOxygen

A method of producing metal nanoparticles in a high yield rate and uniform shape and size, which is thus suitable for mass production. In addition, metal nanoparticles are provided that have superior dispersion stability when re-dispersed in various organic solvents, which thus suitable for use as a conductive ink having high conductivity. The method of producing nanoparticles includes mixing a metal precursor with a copper compound to a hydrocarbon based solvent, mixing an amine-based compound to the mixed solution of the metal precursor with copper compound and hydrocarbon based solvent, and mixing a compound including one or more atoms having at least one lone pair, selected from a group consisting of nitrogen, oxygen, sulfur and phosphorous to the mixed solution of the amine-based compound, metal precursor with a copper compound and hydrocarbon based solvent.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

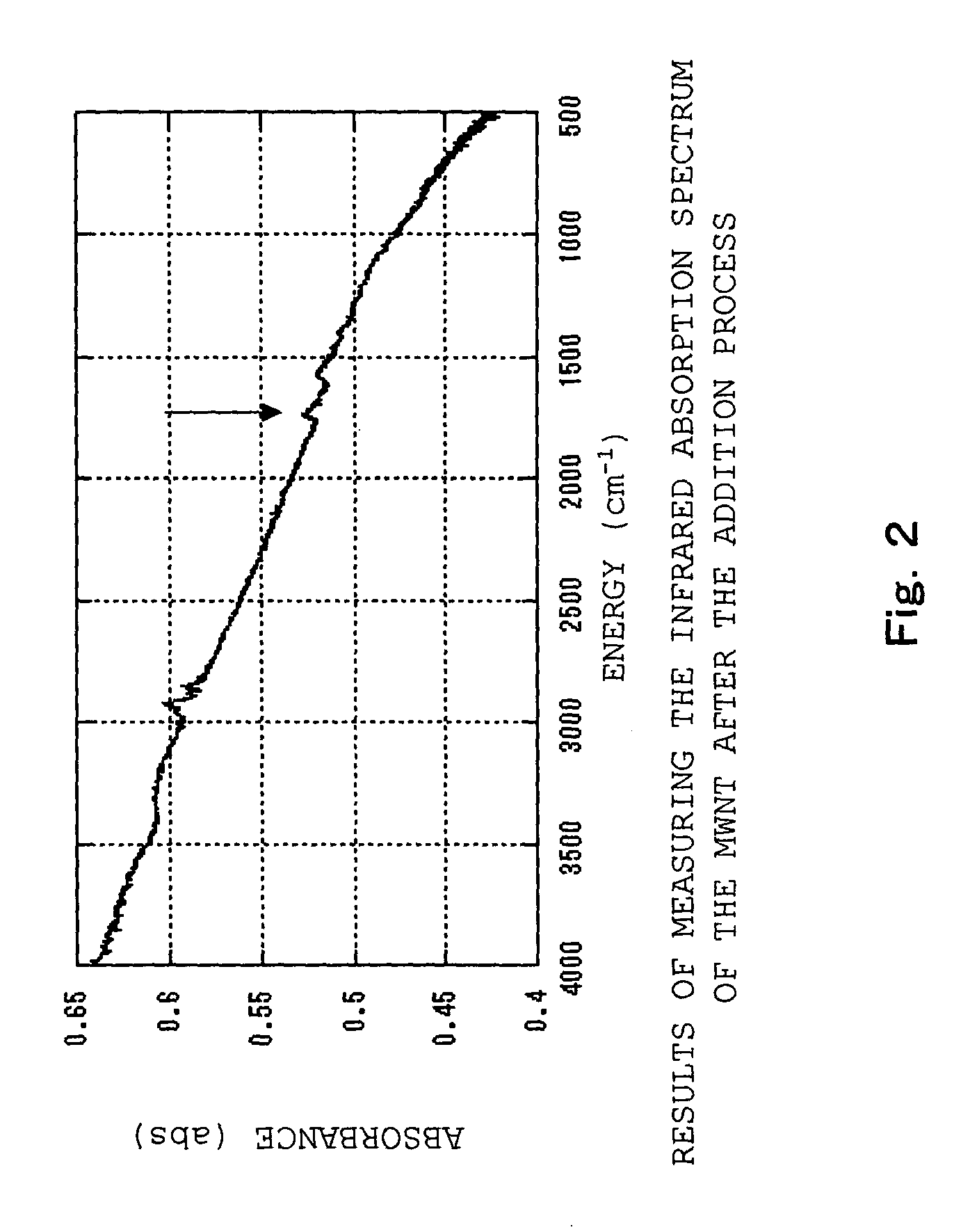

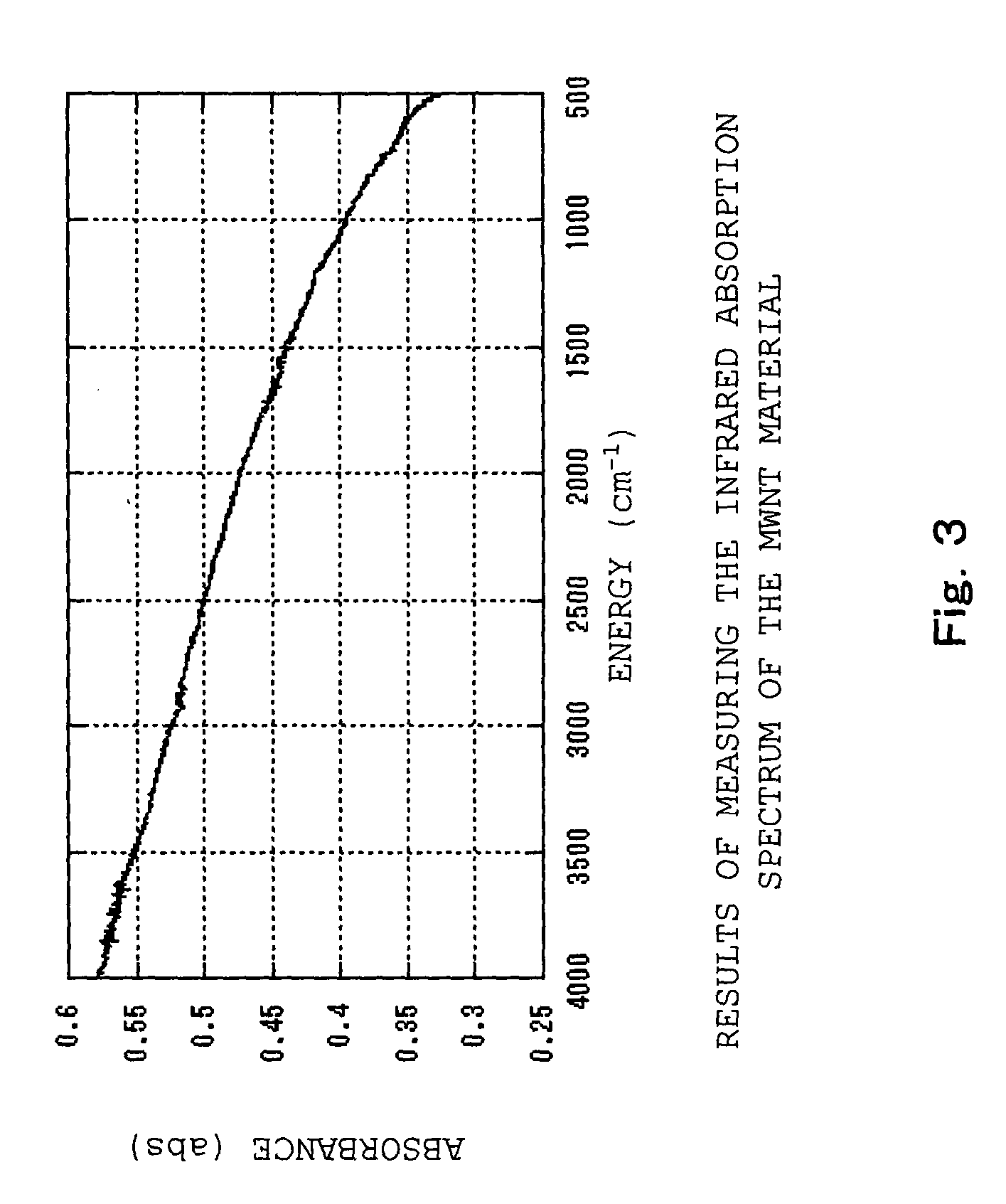

Carbon nanotube dispersion liquid and method for producing the same and polymer composite and method for producing the same

InactiveUS20040136894A1Easy to storeGood dispersionMaterial nanotechnologyIndividual molecule manipulationDispersion stabilityActive agent

By employing a method of producing a carbon nanotube dispersion liquid, in which a carbon nanotube modified with a basic or acidic functional group is dispersed in a polar solvent having a polarity opposite to a polarity of the functional group, there is provided a carbon nanotube dispersion liquid having a high dispersion stability, in which a carbon nanotube is uniformly dispersed without using any surfactant or the like. By using the carbon nanotube dispersion liquid, a polymer composite in which a carbon nanotube is uniformly dispersed without being mixed with an impurity can be provided. In addition, a method for producing the polymer composite by relatively simple procedures is also provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

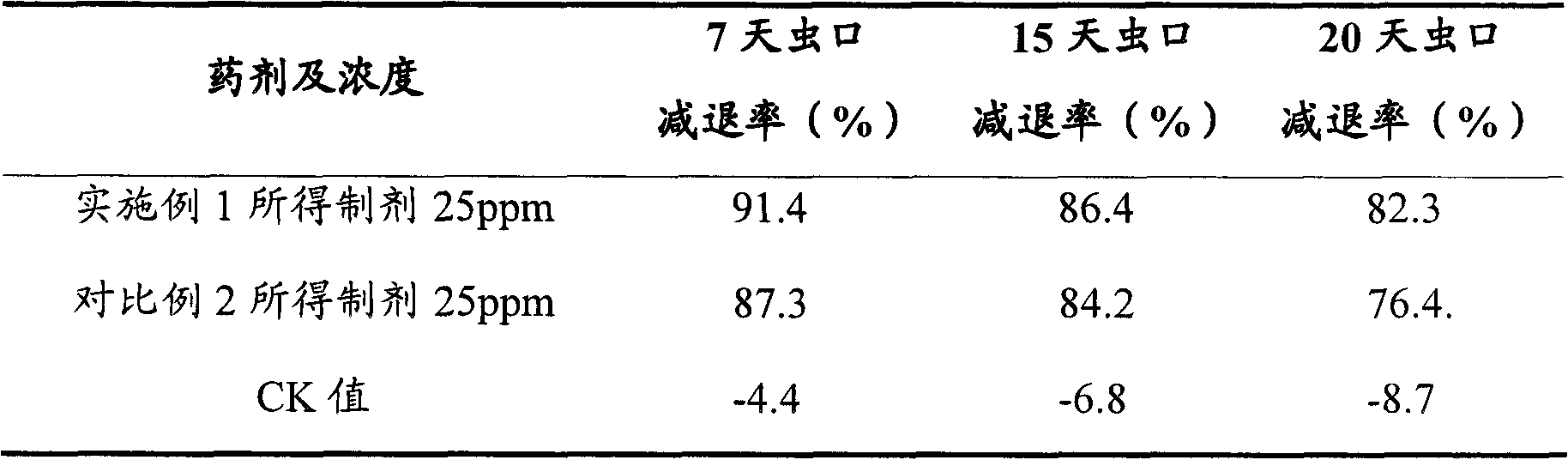

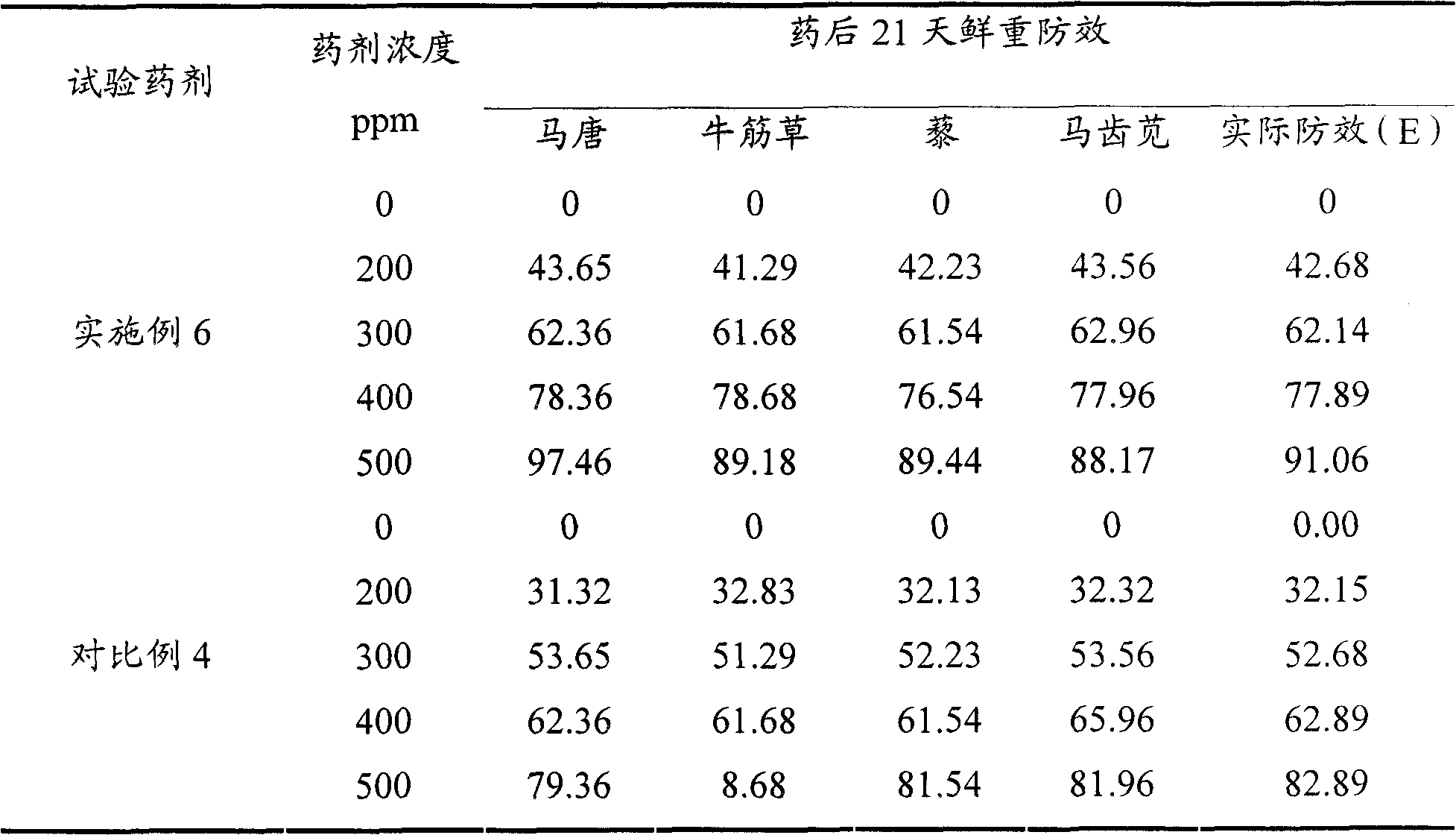

Pesticide oil suspension agent and preparation method thereof

ActiveCN101785455ASmall particle sizeGood spreadabilityBiocideFungicidesDispersion stabilityVegetable oil

The invention provides a pesticide oil suspension agent and a preparation method thereof; the pesticide oil suspension agent contains a pesticide active component, emulsifier, defoamer and a dispersion medium; and the dispersion medium is methyl oleate or the mixture of oil methyl ester and vegetable oil. The method for preparing the pesticide oil suspension agent comprises the following steps that: the dispersion medium and the emulsifier are mixed and emulsified; other components are added in to be mixed into pulp; and the pulp is ground by a grinder to prepare the oil suspension agent. Thepesticide oil suspension agent of the invention has small average grain size and high dispersion stability, has good extendibility and permeability on plant leaves, and improves the medicine effect of the product; and the preparation method of the pesticide oil suspension agent has simple process and low cost, facilitates industrial production, and has wide production application prospect.

Owner:SHENZHEN NOPOSION AGROCHEM

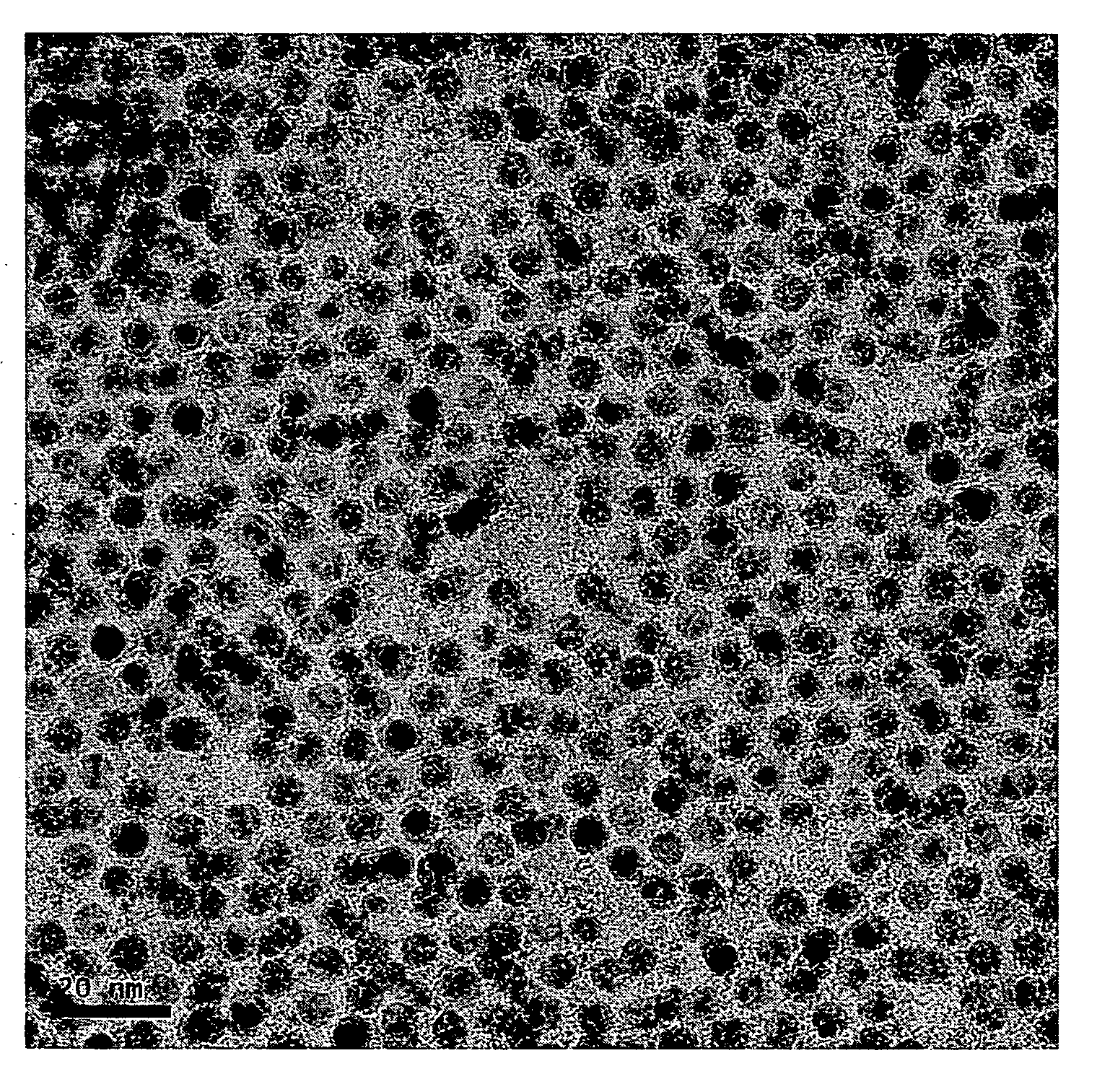

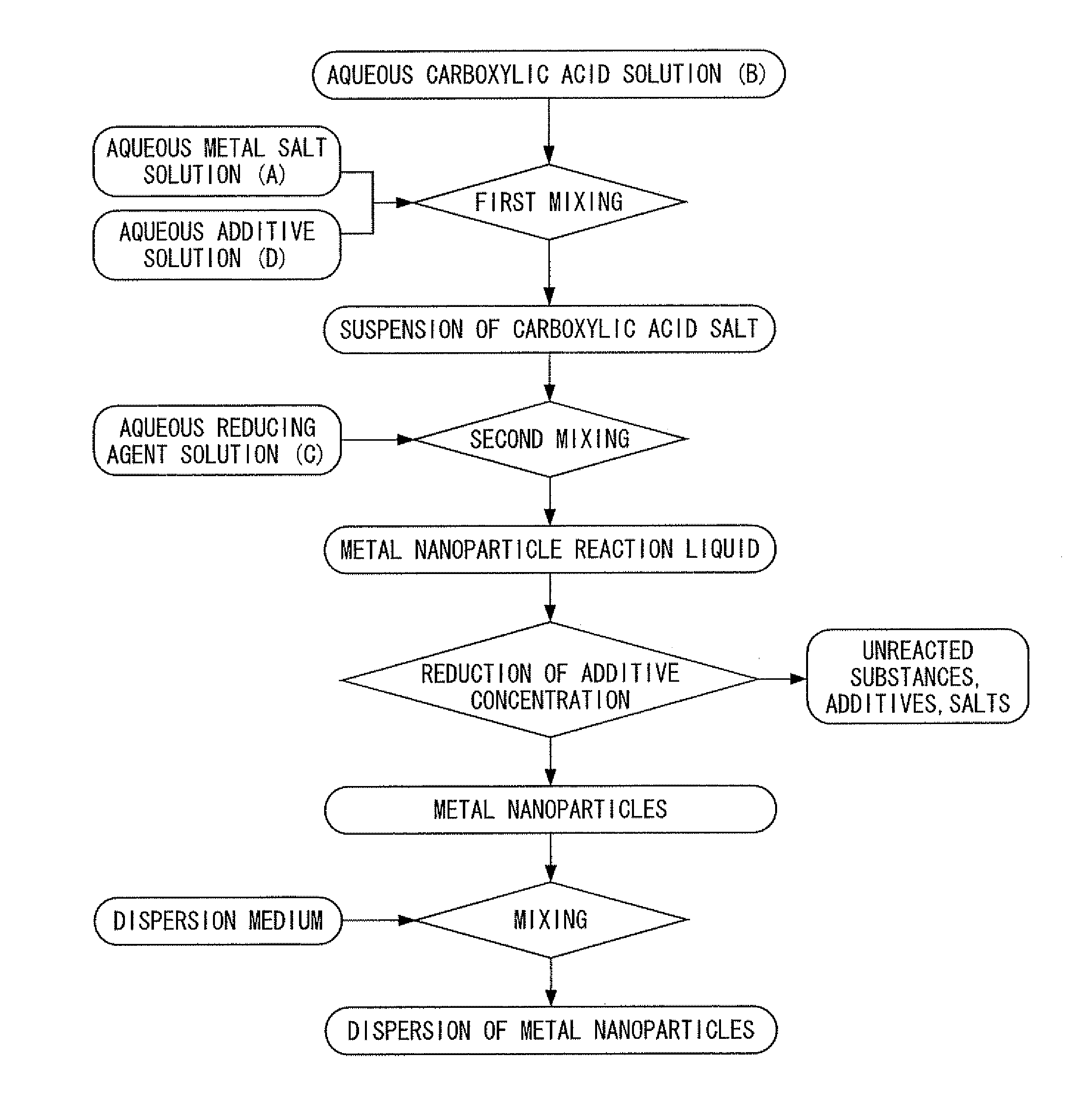

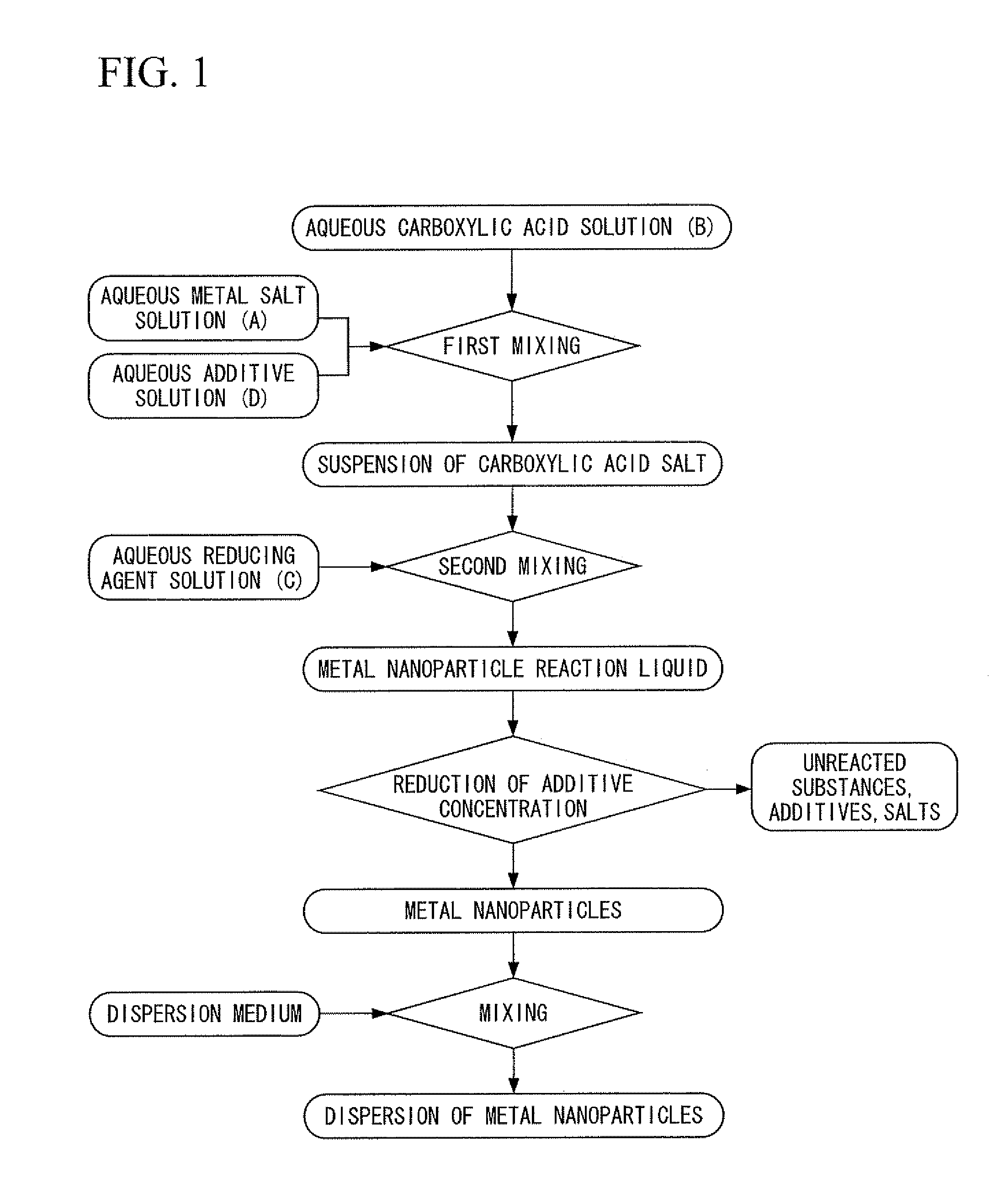

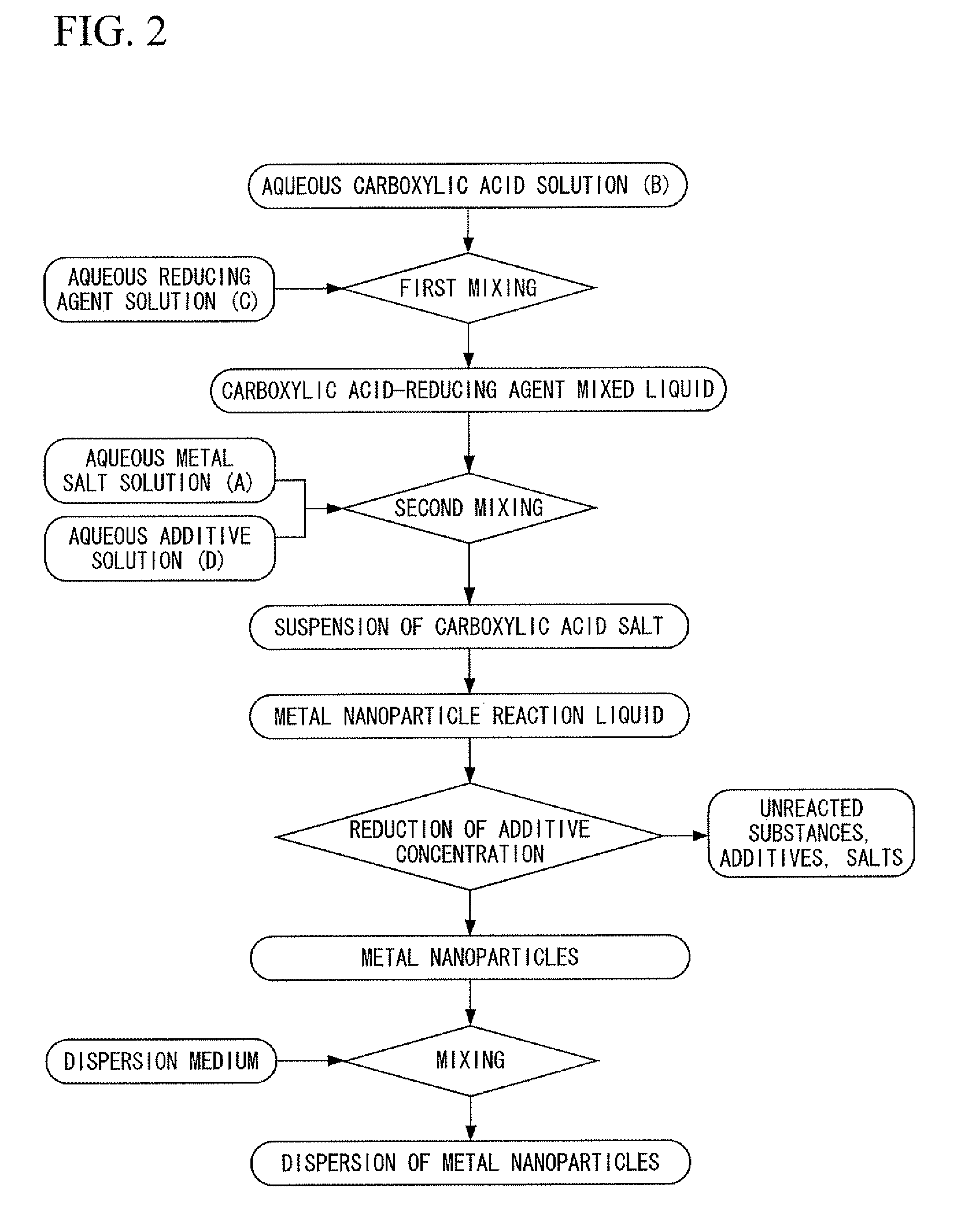

Dispersion of metal nanoparticles, method for producing the same, and method for synthesizing metal nanoparticles

ActiveUS20100101637A1Reduce solubilityIncrease productionMaterial nanotechnologyTransportation and packagingDispersion stabilityNanometre

The present invention aims to provide a method for producing a dispersion of metal nanoparticles which enables to control the shape and the particle diameter over a wide range, a dispersion of metal nanoparticles having superior dispersion stability, and a method for producing the same. In addition, the present invention further aims to provide a dispersion of metal nanoparticles which has a volume resistivity of 2×10−6 to 6×10−6 Ω·cm and is suitable for use as an electrically conductive material, and a method for producing the same. Moreover, the present invention further aims to provide a method for synthesizing metal nanoparticles which can produce metal nanoparticles suitable for use as electrically conductive materials by synthesizing the metal nanoparticles from a insoluble metal salt which is free of corrosive materials.

Owner:MITSUBISHI MATERIALS CORP

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

White inkjet ink improved for dispersion stability

ActiveUS20100302300A1Improve the problemMeasurement apparatus componentsInksDispersion stabilityChemistry

An inkjet printing method includes the steps ofa) providing a white inkjet ink and at least one colour inkjet ink to an inkjet printer; andb) jetting the white inkjet ink at a higher temperature than the colour inkjet ink onto an ink-receiver. The difference in jetting temperature between the white inkjet ink and the colour inkjet ink is at least 5° C. Inkjet ink sets and inkjet printers are also disclosed.

Owner:AGFA NV

Preparation method of white paint ink used for textile inkjet printing

ActiveCN102925002ALong term storageImprove dispersion stabilityInksDyeing processDispersion stabilityPolymer science

The invention relates to a preparation method of white paint ink used for textile inkjet printing and belongs to the technical fields of fine chemical industry and material science. The white paint ink used for inkjet printing provided by the invention is formed by the steps of mixing oxide / polymer nano composite particle dispersoid serving as a white colouring agent with a water-soluble cosolvent, a surface active agent and deionized water, stirring and filtering. The white paint ink prepared by adopting the preparation method provided by the invention has good dispersion stability and storage stability, and the preparation method of white pigment ink provided by the invention has the characteristics of low equipment investment, simple production process, stable product quality and the like and is suitable for mass production.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

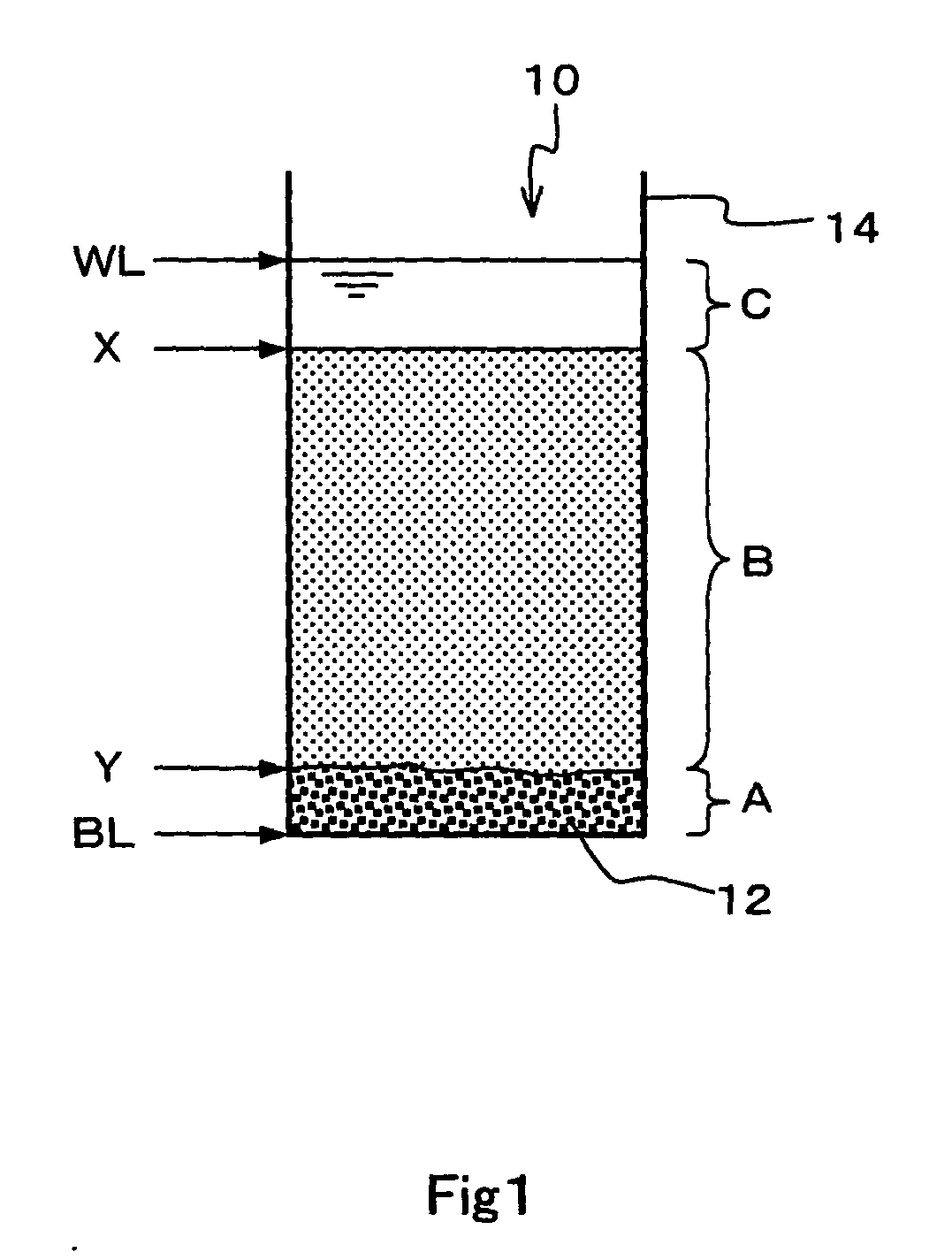

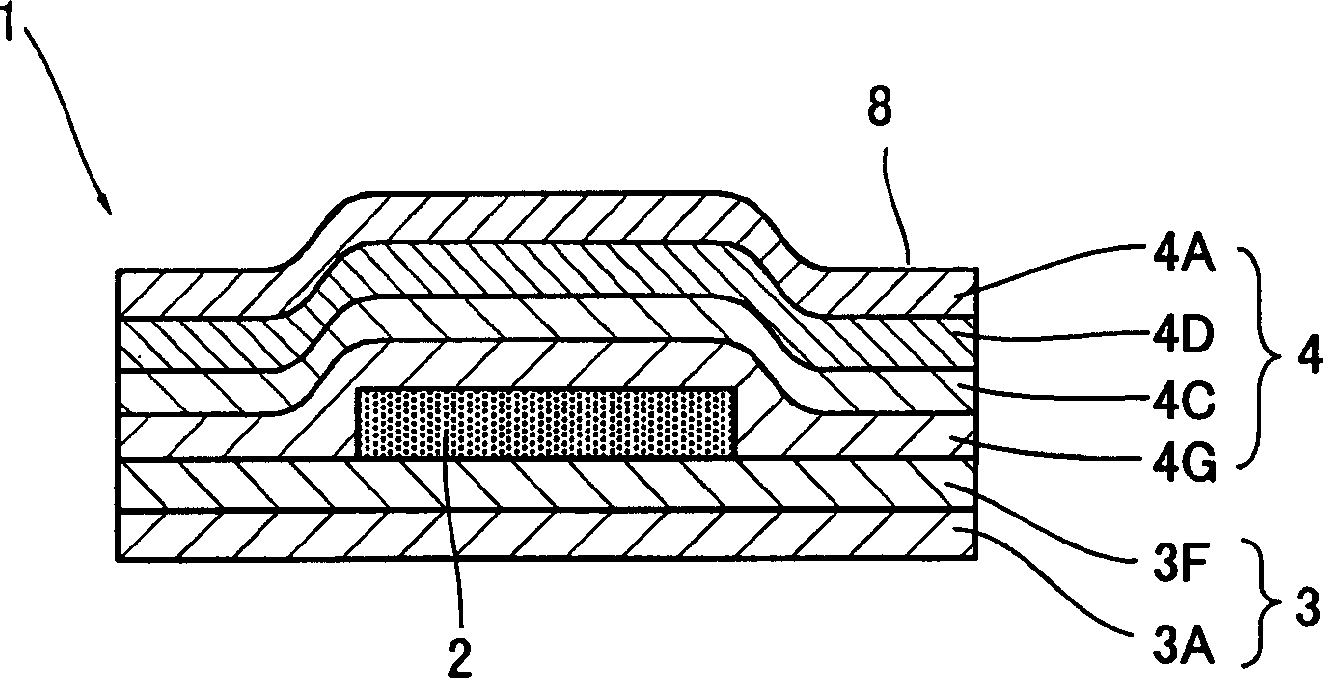

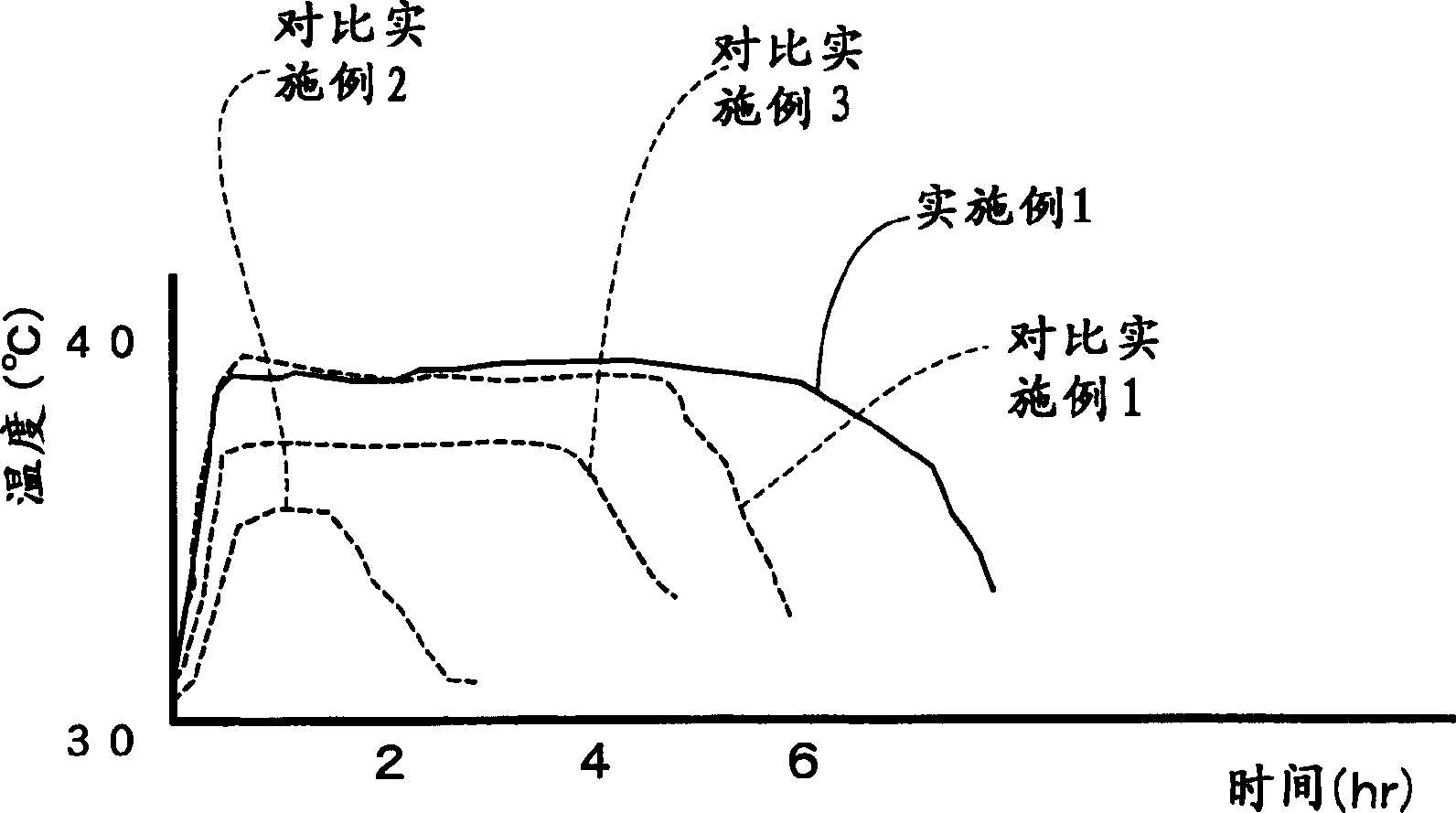

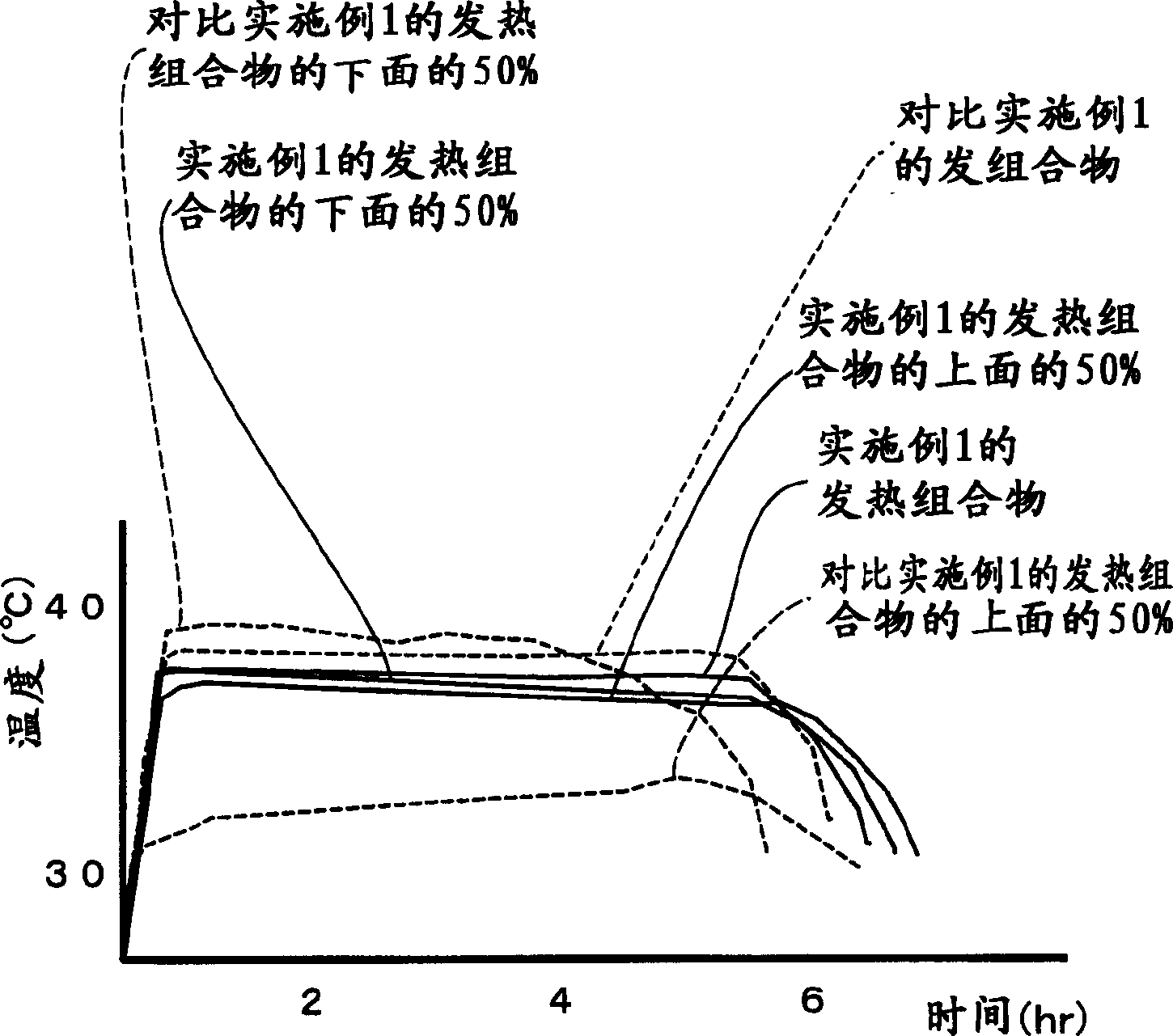

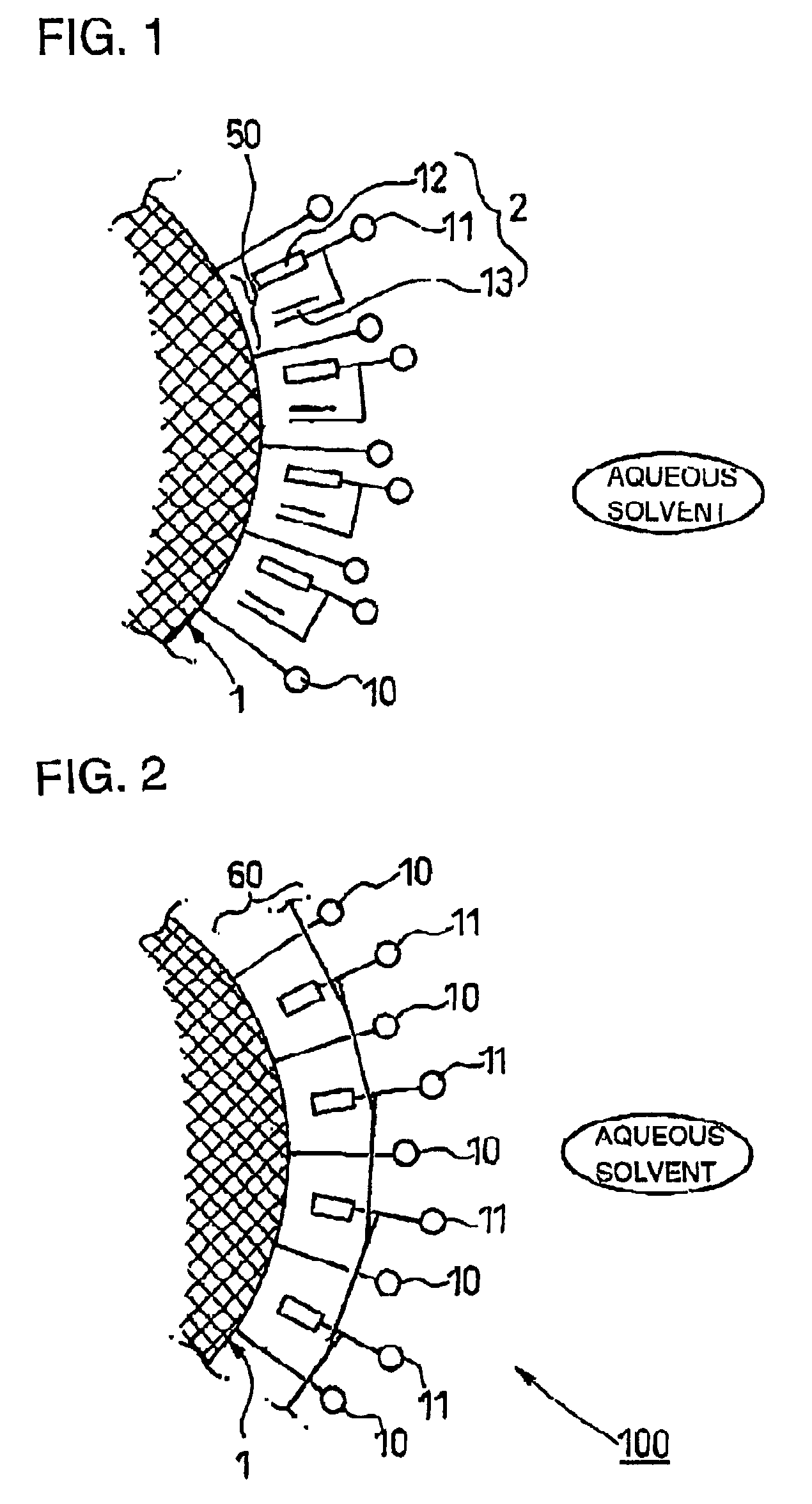

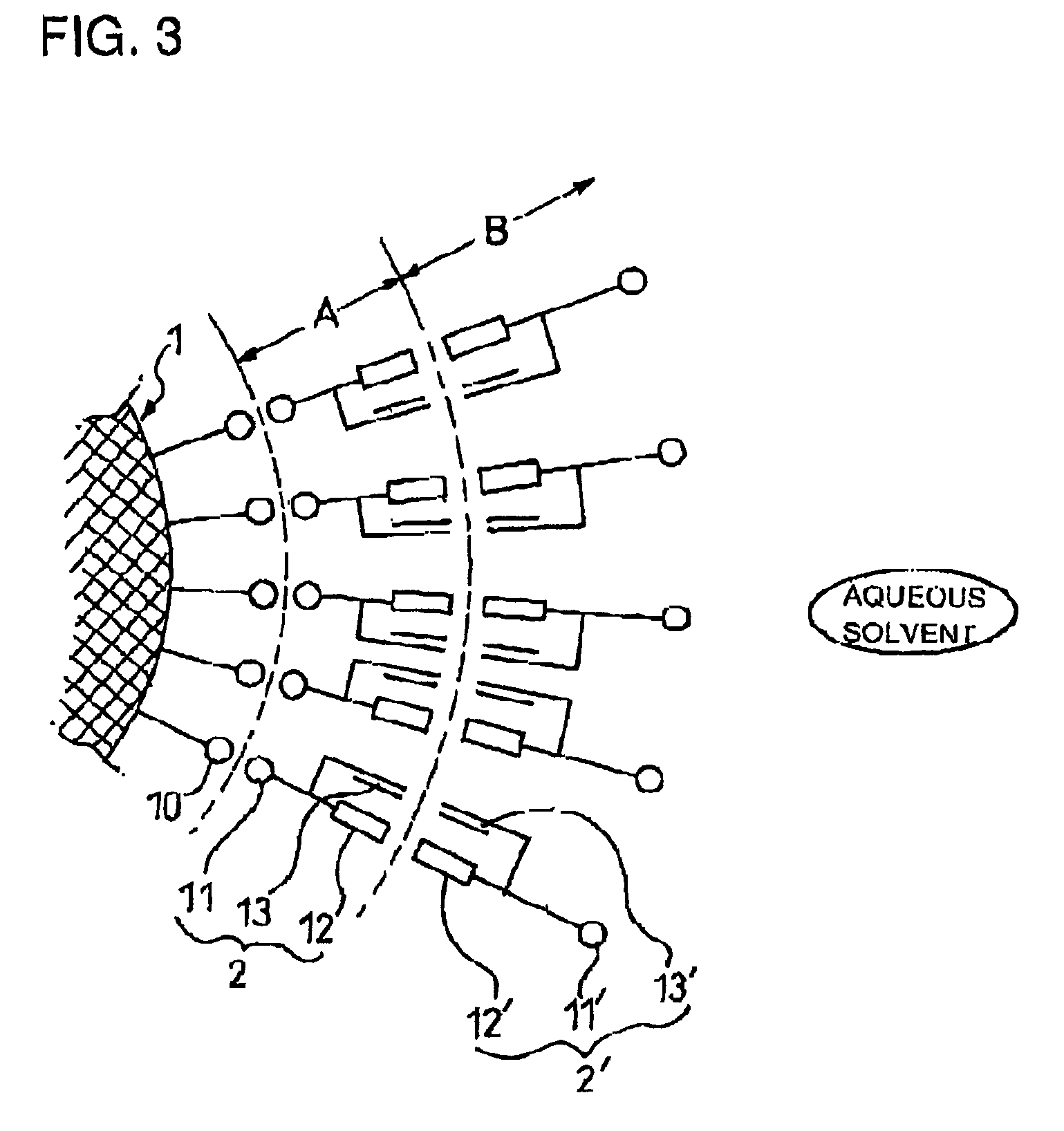

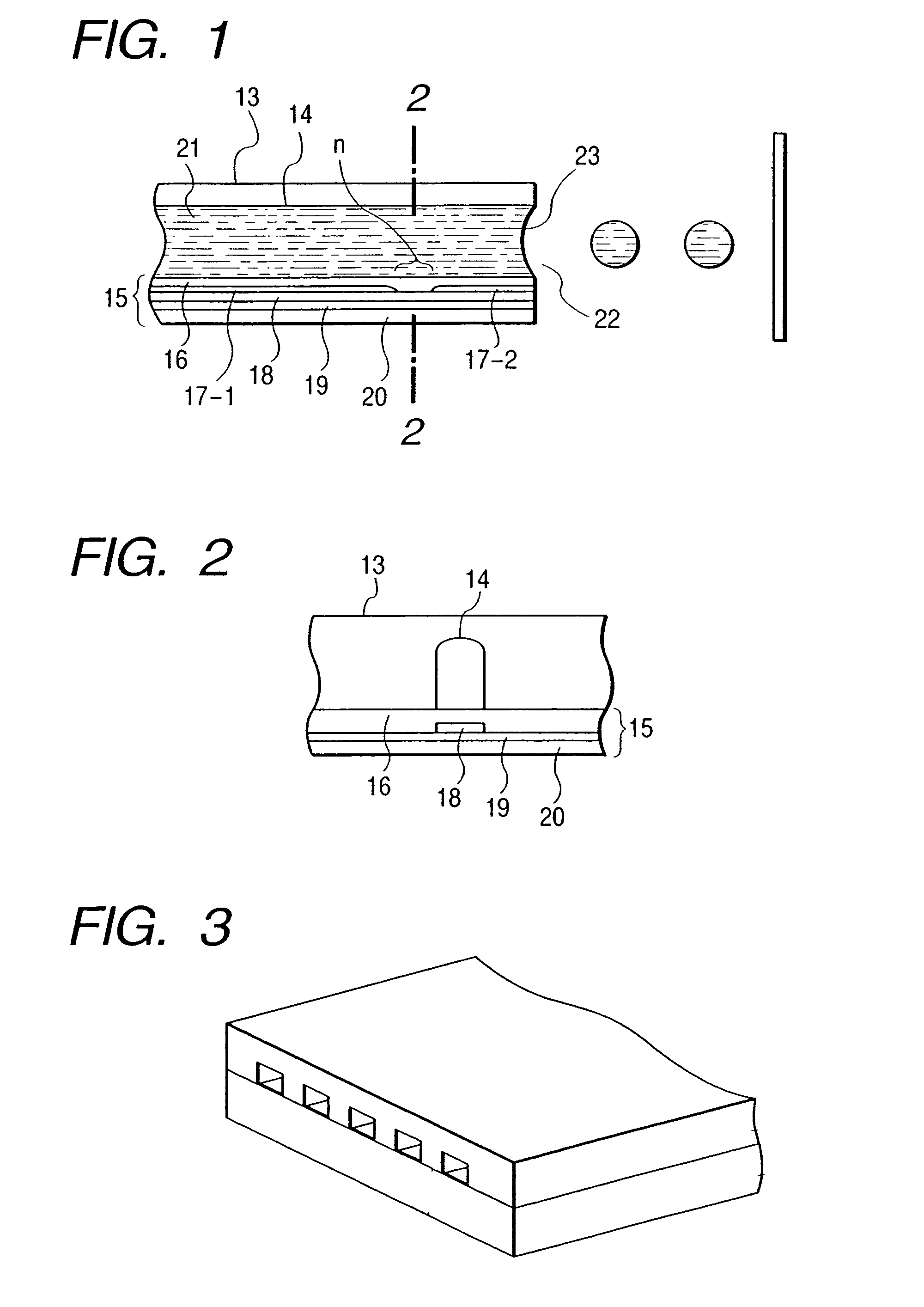

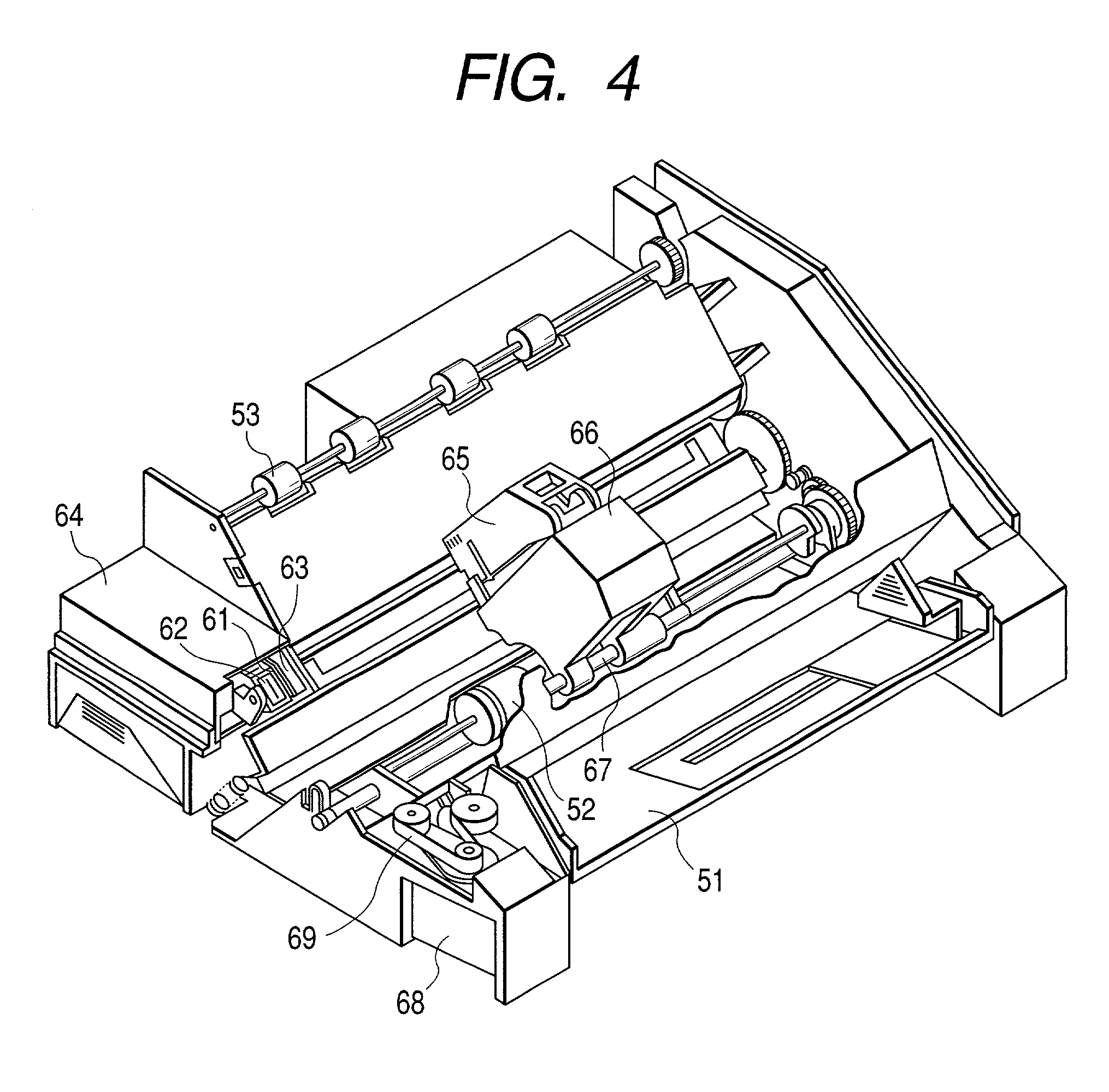

Exothermic composition and exothermic article using composition, and method for producing exothermic article

InactiveCN1491271AAccurate Guaranteed QuantityHas dispersion stabilityExothermal chemical reaction heat productionHeat-exchange elementsDispersion stabilityChemical composition

It relates to a heat-generating composition having such dispersion stability that withstands continuous molding, and has excellent drainage property, excellent heat-generating characteristics, excellent molding property and excellent shape retaining property, without becoming viscous, and relates to a heat-generating body using the same and a process for producing the heat-generating body. It contains, as essential components, a heat-generating substance generating heat upon reaction with oxygen, a carbon component, an oxidation promoter and water, characterized in that the composition further contains a water separation-preventing stabilizer in a proportion of from 0.001 to 0.25 part by mass per 100 parts by mass of the heat-generating composition, and has a water mobility value of from 7 to 40 and a separation degree of from 0 to 30.

Owner:MYCOAL

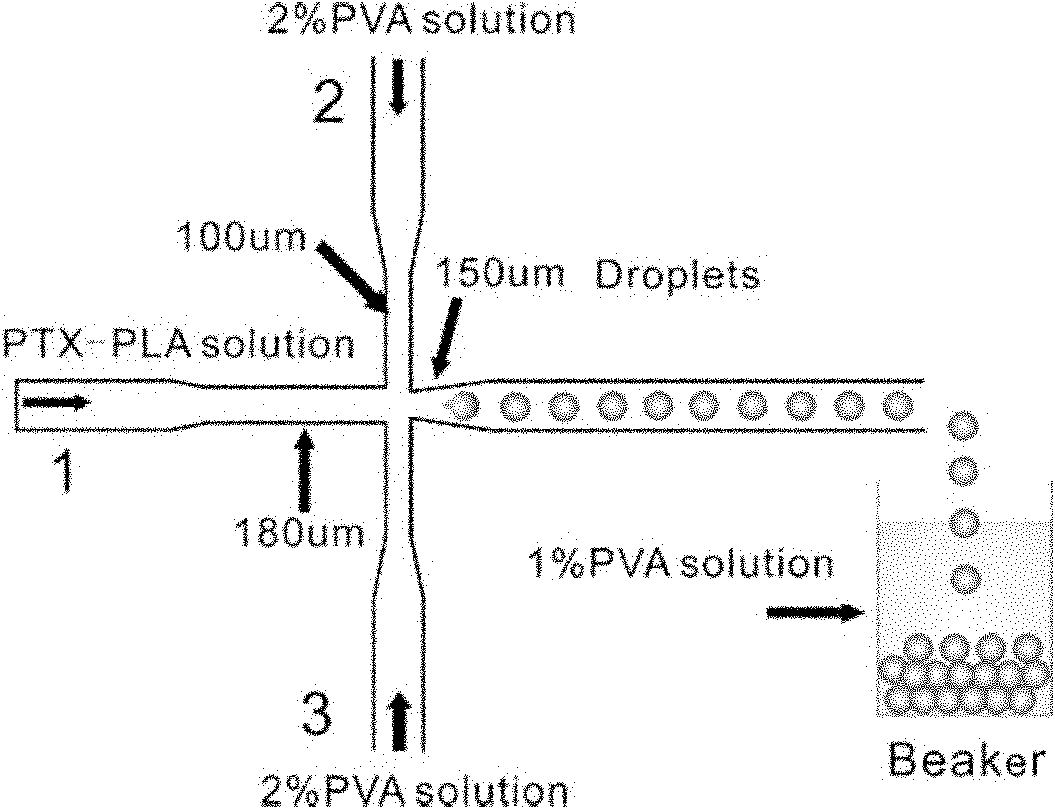

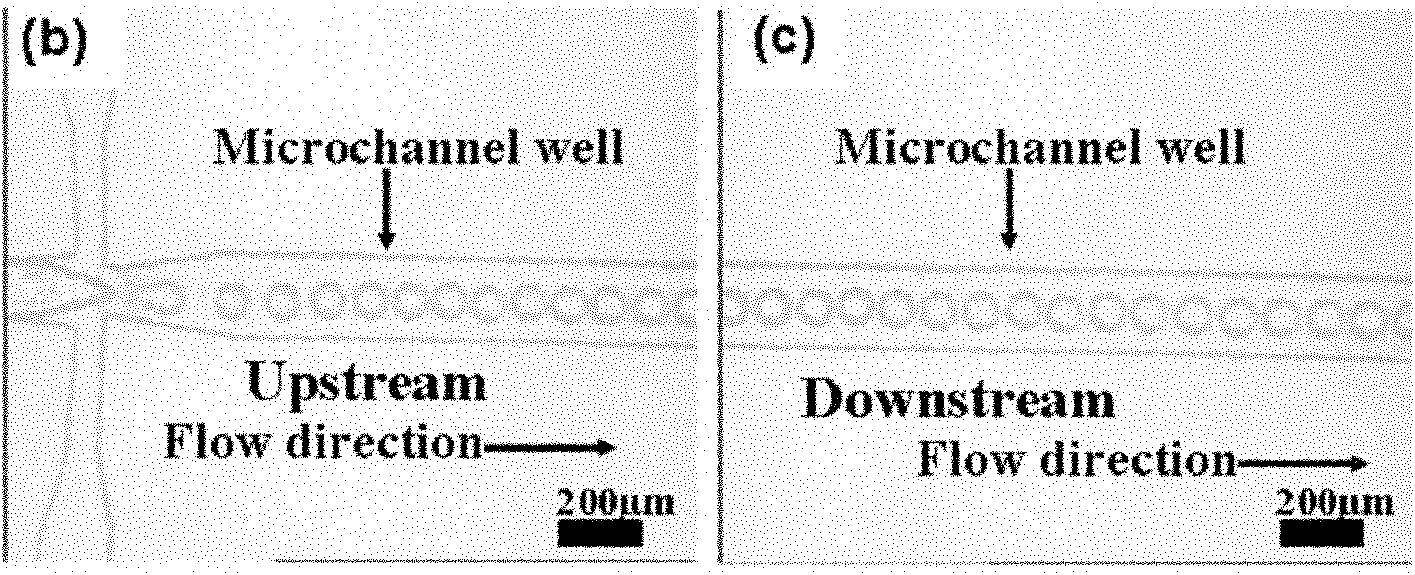

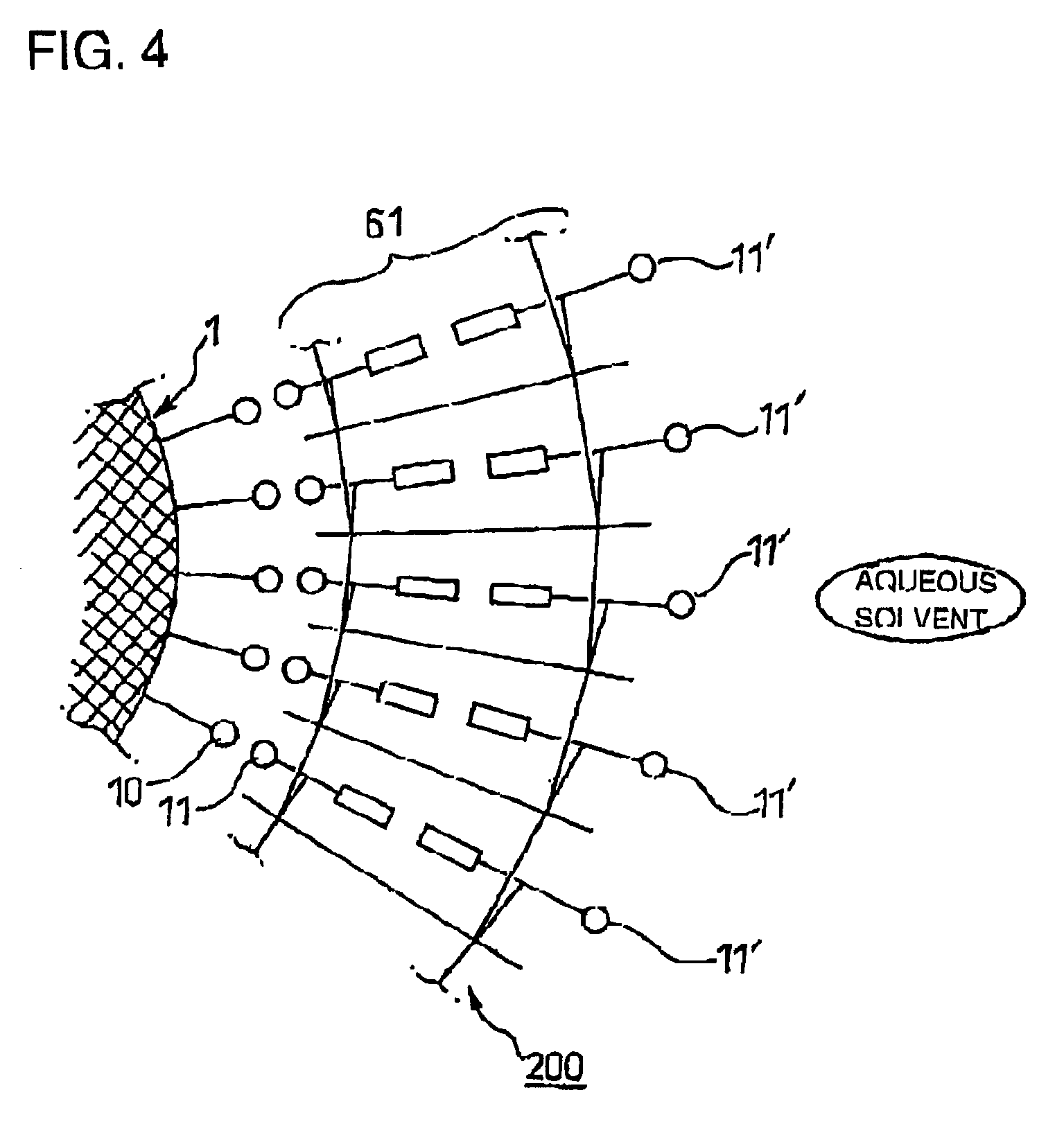

Method for preparing mono-disperse microemulsion, liposome and microsphere based on microfluidic technology

InactiveCN102068409ABest size rangeHigh activityImmobilised enzymesGranular deliveryDispersion stabilityOil phase

The invention discloses a method for preparing mono-disperse microemulsion, liposome and microspheres based on a microfluidic technology. The method comprises the following steps: taking aqueous solution (or oily solution) of a hydrophilic medicine (or a lipid-soluble medicine) as a disperse phase; taking an oil phase (or an aqueous phase) as a continuous phase; and respectively conveying the disperse phase and the continuous phase into corresponding micro-channels of a microfluidic chip device, shearing the phases into mono-disperse liquid drops of the encapsulated medicine, then curing the liquid drops by a certain curing method, and finally obtaining the medicine-carrying liposome, microspheres or the biodegradable microspheres with uniform size and dispersion stability. Under an optimum condition, the diameter distribution coefficients of the microemulsion and the microspheres can be less than 5%, and the diameter is 10-500microns. By utilizing the method, the problems such as uneven size, low embedding rate, poor dispersibility, poor targeting property, low bioavailability, low bioactivity of enzyme and cells, immune suppression and the like of the medicine-carrying microemulsion, the liposome and the microspheres prepared by the traditional ultrasonic method, agitation emulsification method and film hydration-dispersion method are solved.

Owner:TSINGHUA UNIV

Microencapsulated pigment, production process therefor, aqueous dispersion and ink jet recording ink

InactiveUS7074843B2Good dispersionImprove stabilityDuplicating/marking methodsInksDispersion stabilityHigh density

Provided are ink jet ink excellent in dispersion stability and ejection stability and capable of forming images with fastness, abrasion resistance, color developability, and high density with little feathering; a microencapsulated pigment (MCP) providing the ink and a process of making the same; and an aqueous dispersion of the MCP. The MCP comprises pigment particles having a hydrophilic group on their surface (hydrophilized pigment particles) and coated with a polymer by emulsion polymerization. The process comprises emulsion polymerization in the presence of the hydrophilized pigment particles. The ink essentially contains the MCP and water.

Owner:SEIKO EPSON CORP

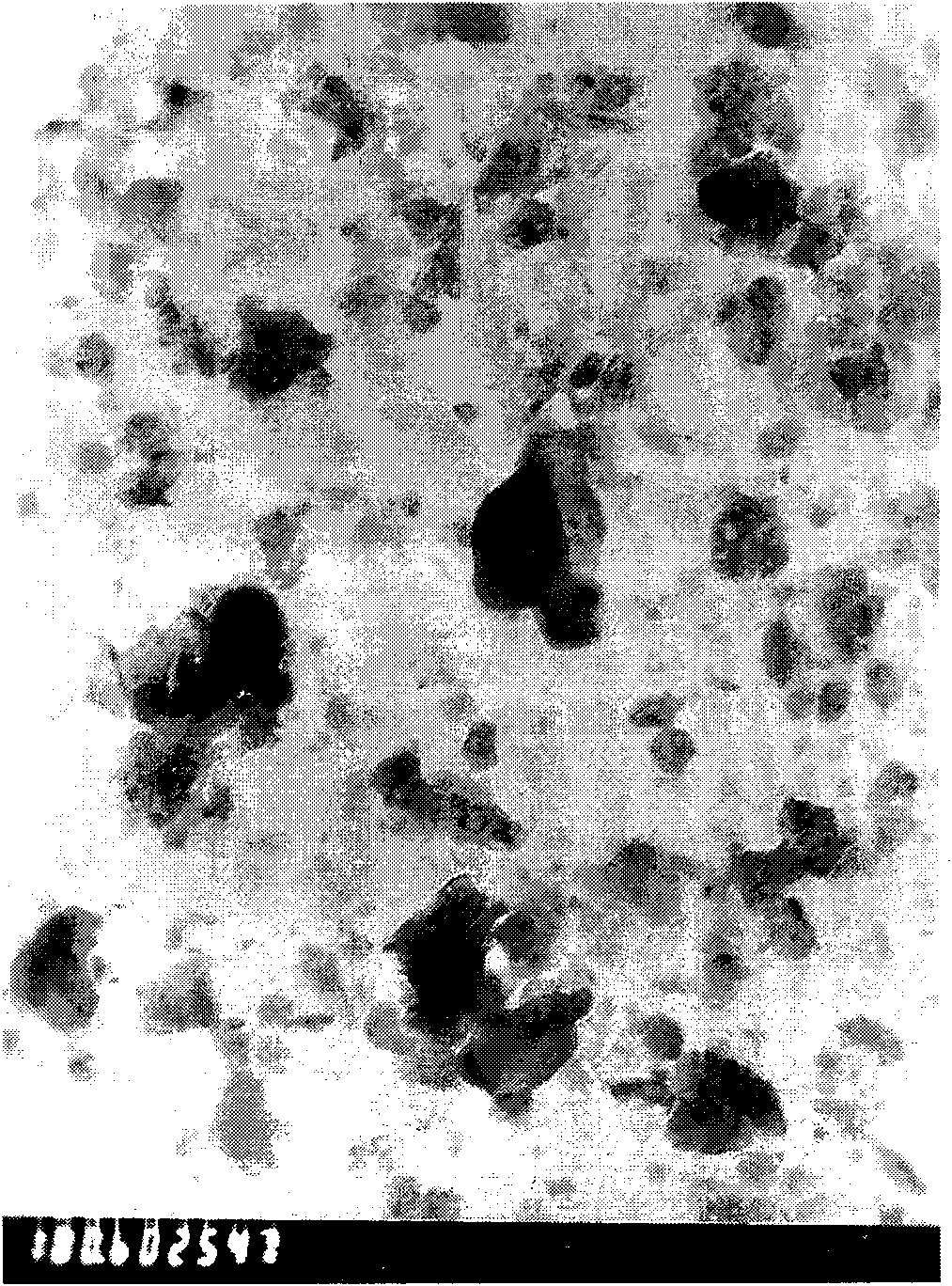

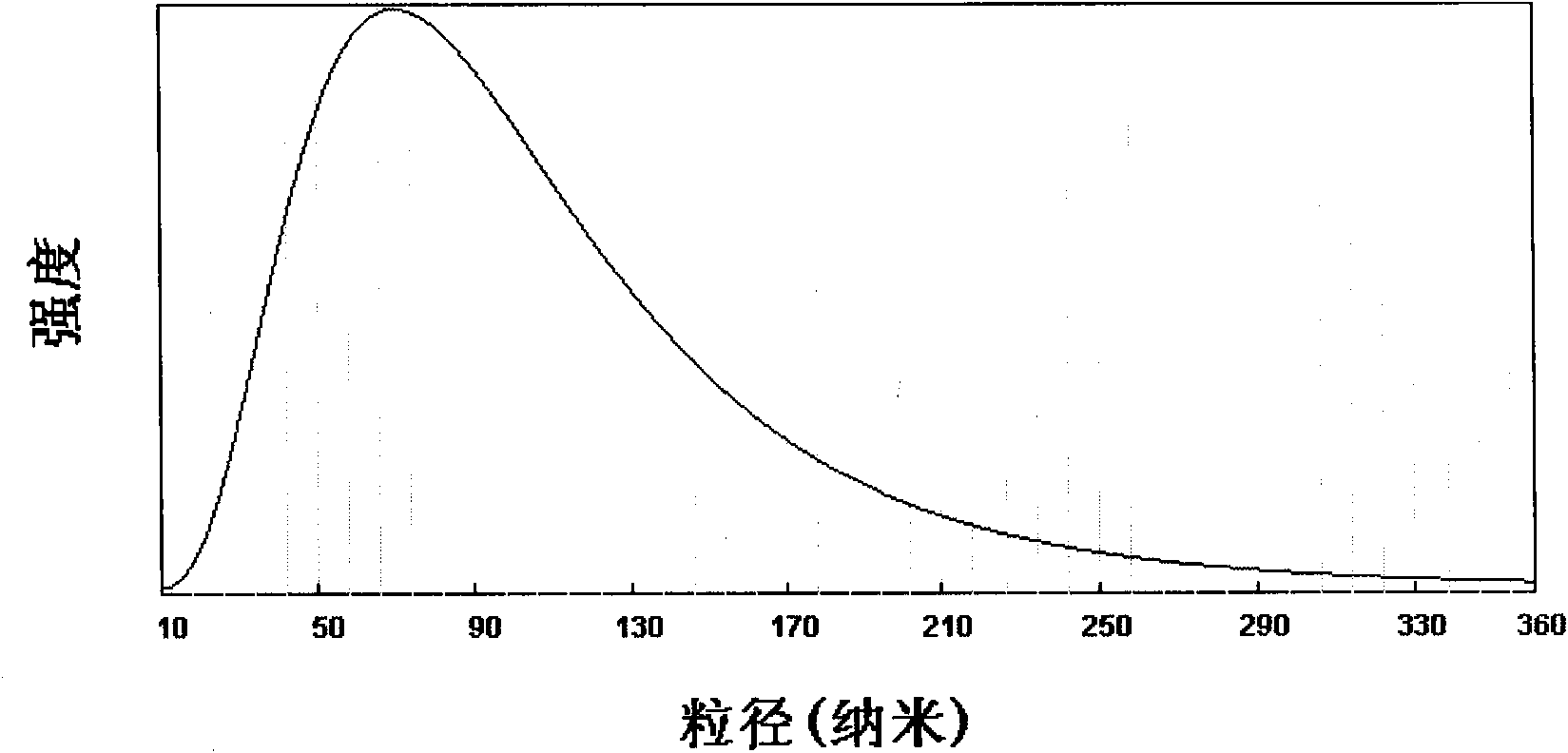

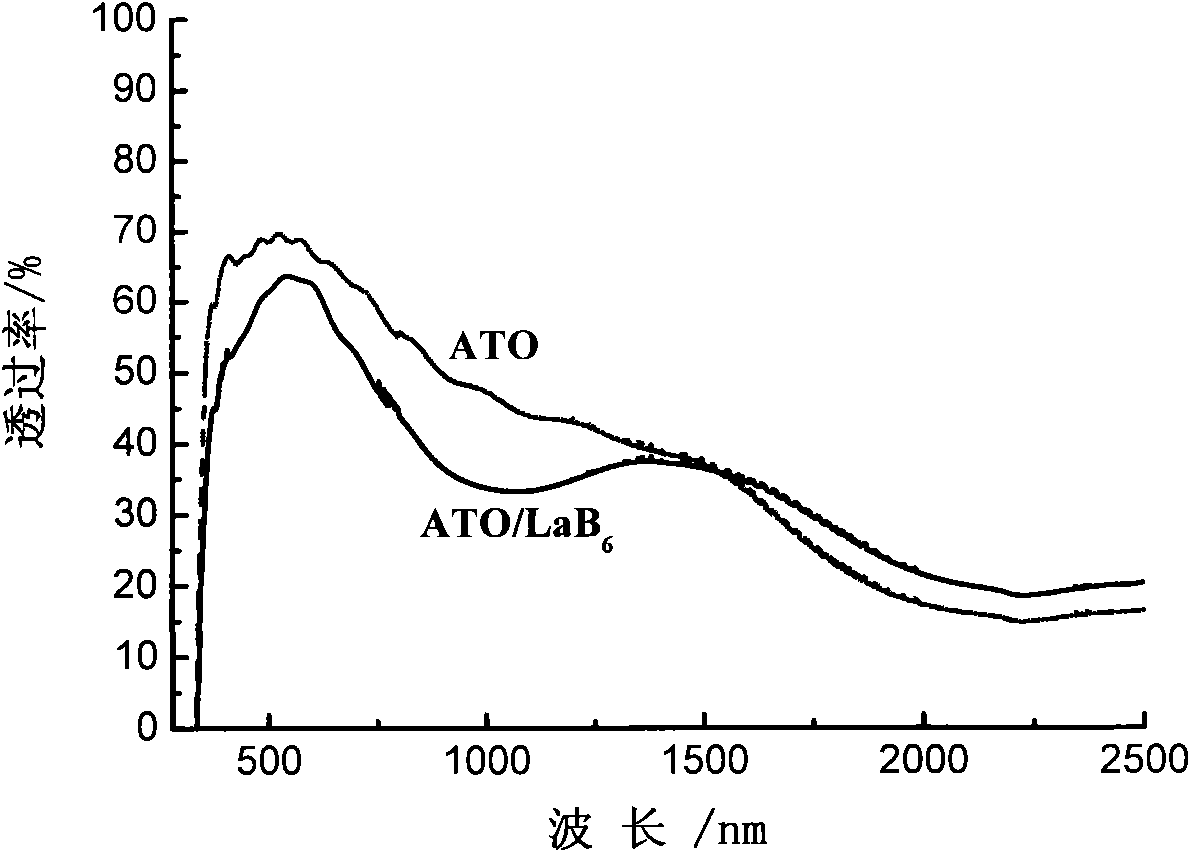

Transparent heat insulation coating material, preparation method and application thereof

InactiveCN101550307AImprove adhesionGood infrared blocking performancePolyurea/polyurethane coatingsPolyester coatingsDispersion stabilityPolyester

The invention relates to a transparent heat insulation coating material, the preparation method and the application thereof. The material is made from the raw material of lanthanum hexaboride / tin indium oxide or lanthanum hexaboride / tin antimony oxide, by the steps of pretreating by ultrasonic dispersion, and grinding to prepare nanometer slurry with heat insulation function, wherein the nanometer slurry has particle sizes mainly between 10nm and 200nm, the average particle size between 50nm and 120nm, and superior dispersion stability; mixing the nanometer slurry with film forming substance, auxiliary agent and solvent, to obtain the transparent heat insulation coating material. The coating material can obstruct more than 80% of infrared light, has a visible light transmittance above 60%, achieves excellent transparency and sunshine energy shielding effect; can be directly coated on transparent glass, polycarbonate, synthetic glass and polyester; and achieves the aims of energy conservation and heat insulation.

Owner:FUDAN UNIV +1

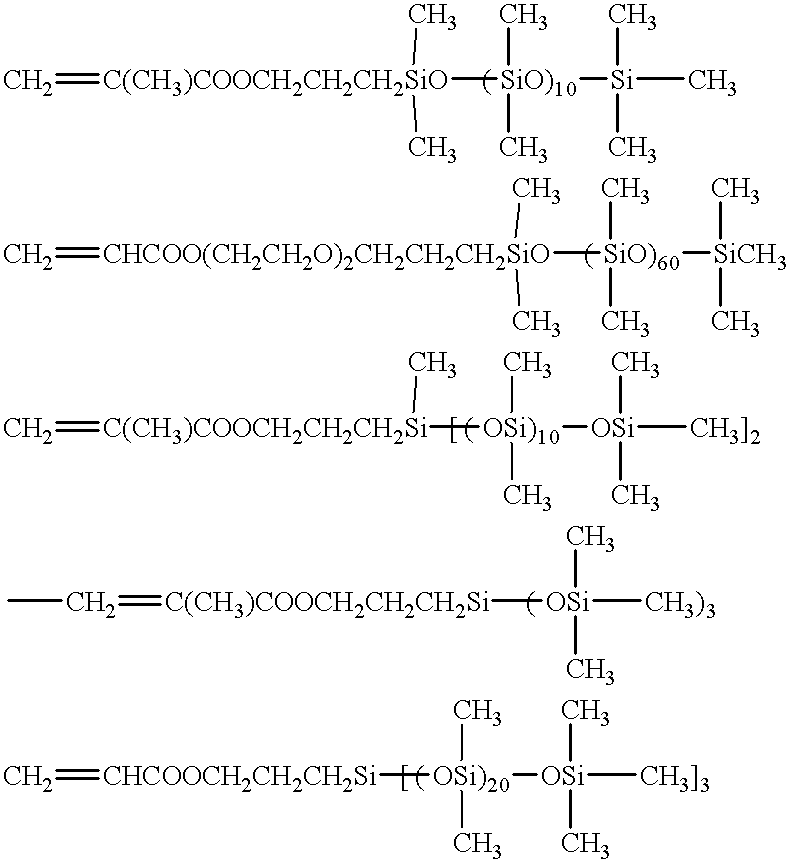

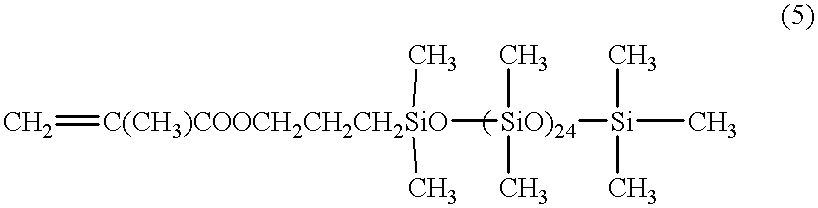

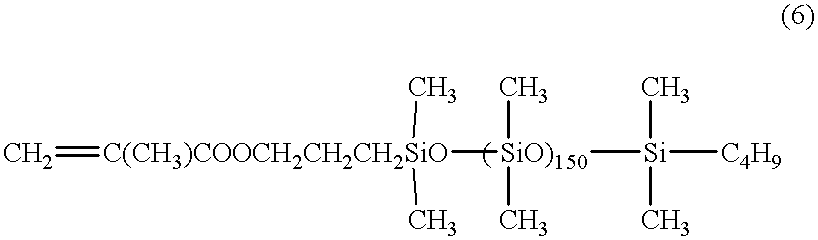

Powder composition, a powder dispersion in oil and a cosmetic composition containing said powder composition and a powder dispersion in oil

InactiveUS6342239B1Less cohesivenessGood dispersionCosmetic preparationsPowder deliveryDispersion stabilityNitrogen

A powder composition comprising, a copolymer containing (A) an organopolysiloxane monomer, one or more kinds of monomer selected from a group composed by (B) a monomer containing nitrogen group, a monomer possessing a polyoxyalkylene group, a monomer possessing a polylactone group, a monomer possessing a hydroxyl group and a monomer possessing an anionic group and a powder. Further, a powder dispersion in oil comprising said copolymer, powder and oil, and a cosmetic composition containing them. Said powder composition and a powder dispersion in oil have a less cohesion of powder particles and is superior in a dispersing ability and a dispersion stability, and the cosmetic composition which contains said powder composition has a good stability and gives an excellent sensation at the actual use.

Owner:KOBAYASHI KOSE CO LTD

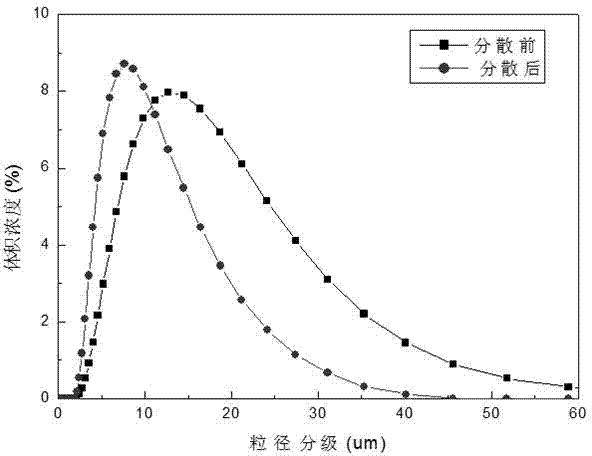

Method for preparing grapheme dispersion liquid

ActiveCN104772064AShorten dispersion timeIncrease productivityMixer accessoriesDispersion stabilityColloid

The invention discloses a method for preparing grapheme dispersion liquid. The method comprises the following steps: (1) uniformly mixing grapheme and a dispersant in a solvent to obtain a uniformly mixed solution; and (2) dispersing the uniformly mixed solution by a dispersing device for 0.5-24 hours to obtain the grapheme dispersion liquid, wherein the rotation speeds of a high shearing dispersion head and a colloid grinding disc are regulated to be within 100-14000rpm, the rotation speed of an electric mixer is at 10-2000rpm, an energy-concentration ultrasonic probe is additionally arranged, the ultrasonic frequency is within 20-80kHz and the dispersion temperature is 0-20 DEG C after being regulated by a cooling system. According to the method for preparing the grapheme dispersion liquid, the dispersion time is saved and the production efficiency is improved due to the adoption of multiple dispersion methods and synergic action, the cost is low, the operation is easy, and the method is nontoxic, free of pollution and beneficial for batch production, has high dispersion stability and a bright prospect of large-scale industrial application.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Colored fine resin particles and production process thereof, aqueous dispersion of colored fine resin particles and production process of aqueous dispersion of colored fine resin particles, ink , ink cartridge, recording unit, ink-jet recording apparatus, and ink-jet recording process

InactiveUS7008977B2Good rub-off resistanceExcellent water fastnessInksOrganic dyesDispersion stabilityWater insoluble

The invention provides colored fine resin particles useful as coloring materials for inks which can provide images having good water fastness, weather fastness and rub-off resistance and are excellent in dispersion stability, and a production process thereof. The colored fine resin particles have a structure in which a pigment coated with a water-insoluble resin is encapsulated with a copolymer composed of at least a polymerizable unsaturated monomer and a reactive emulsifier.

Owner:CANON KK

White inkjet ink improved for dispersion stability

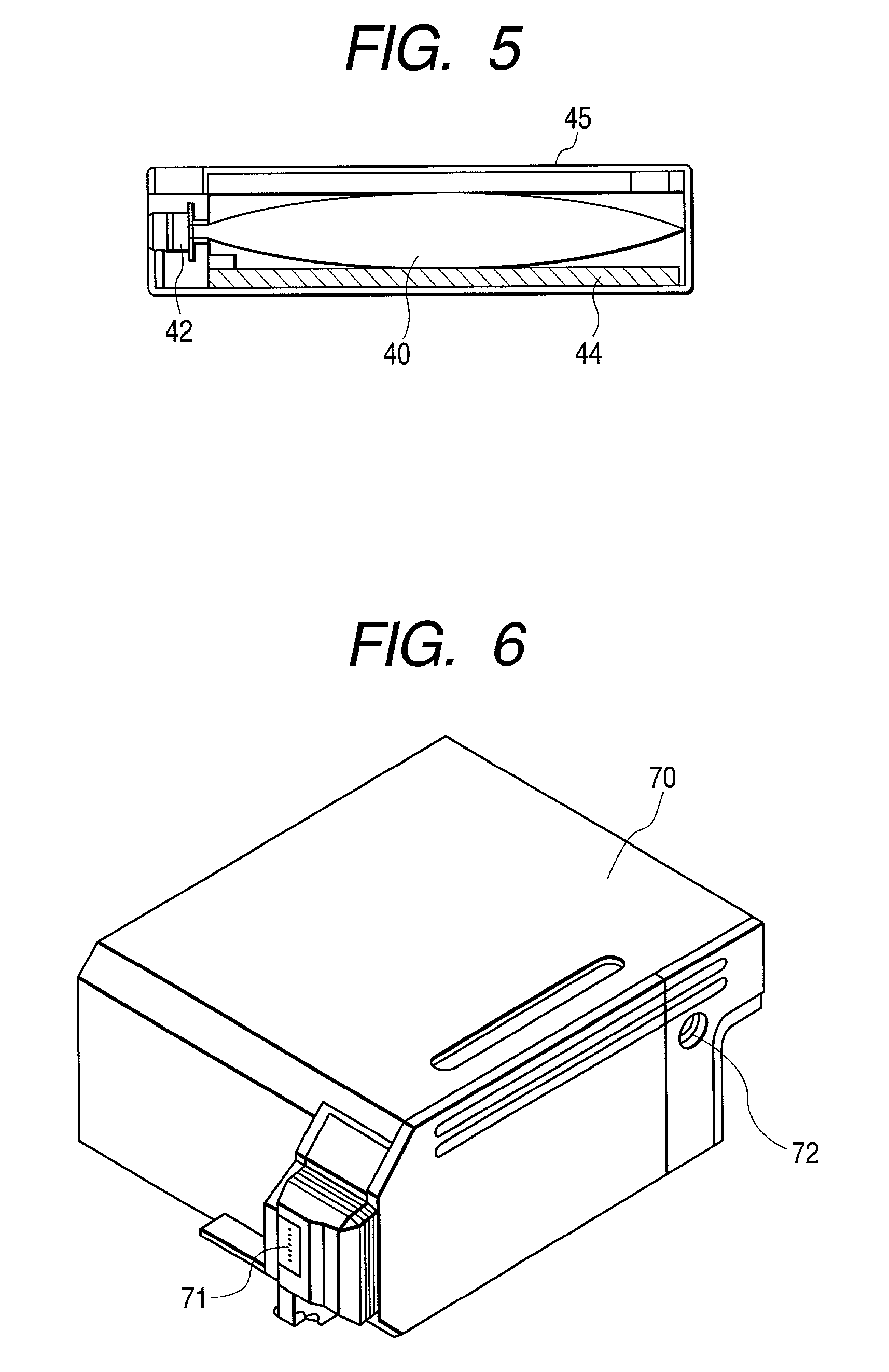

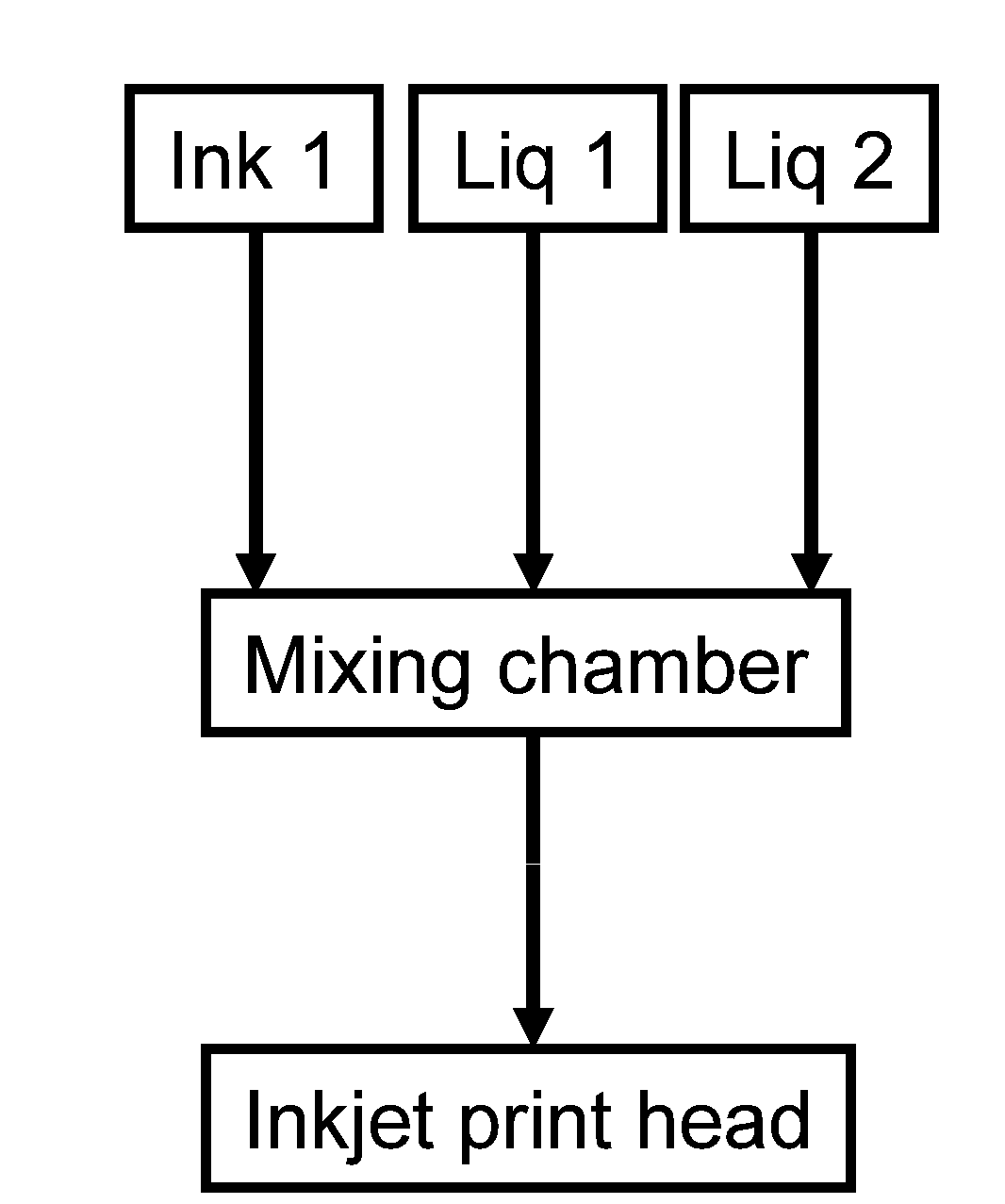

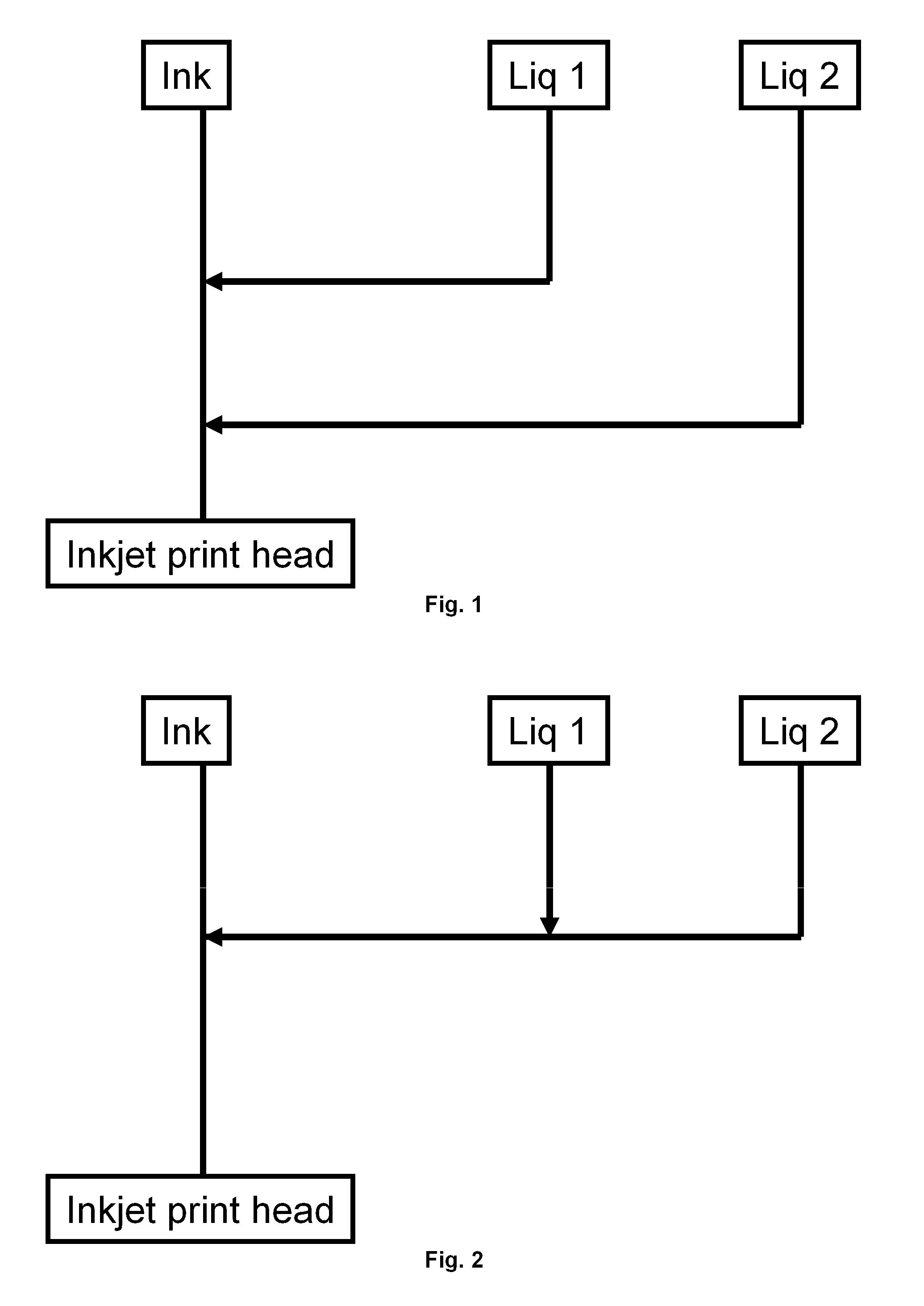

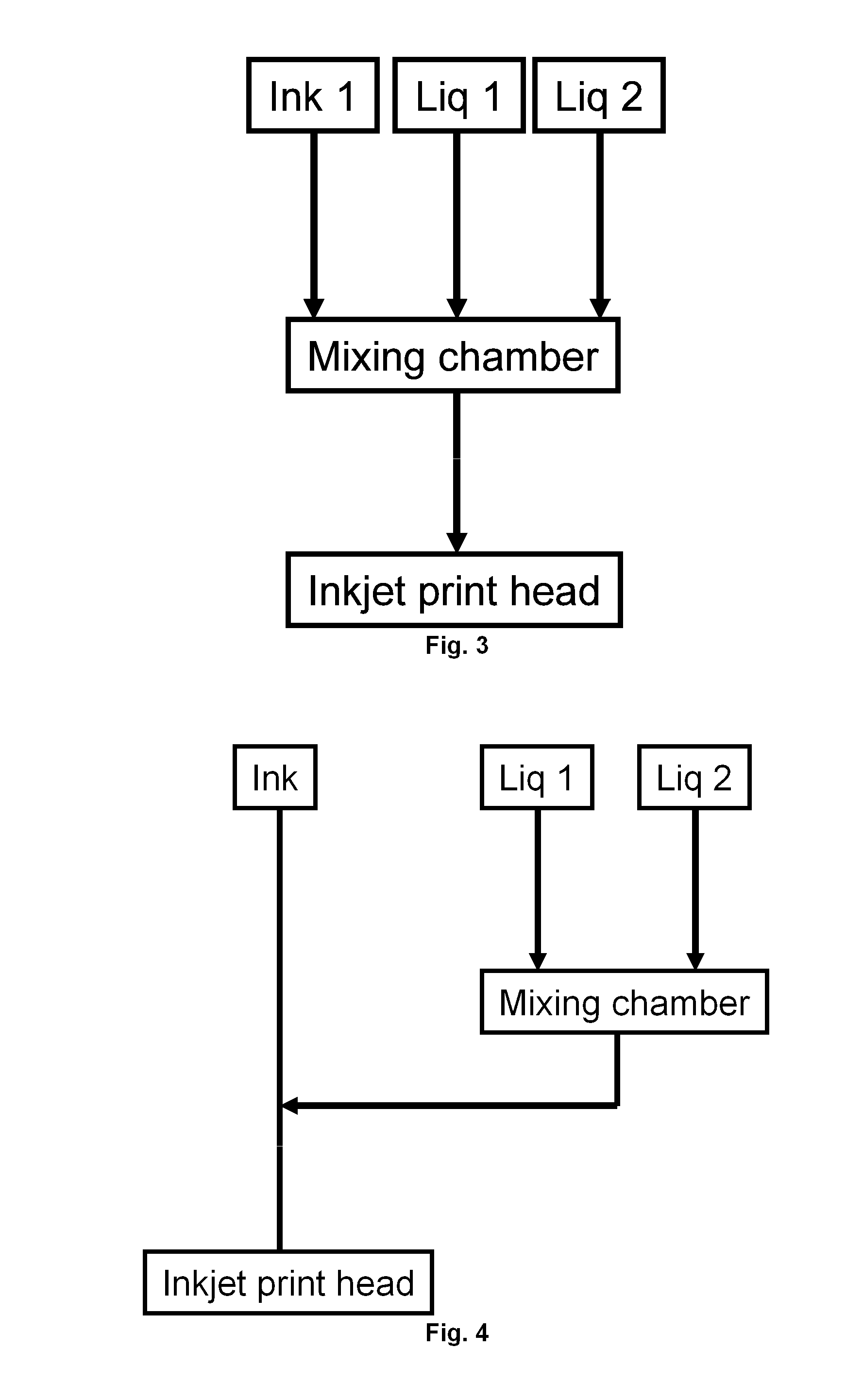

ActiveUS20100039463A1Improve the problemReduce precipitationMeasurement apparatus componentsDuplicating/marking methodsDispersion stabilityRefractive index

An inkjet printing method includes in order the steps of: a) providing to an inkjet printer one or more colorless liquids and a white ink including a pigment with a refractive index greater than 1.60; b) mixing the white ink in a controlled amount with the one or more colorless liquids to form a white ink-mixture wherein the viscosity is reduced by at least 5 mPa·s by reference to the white ink when measuring the viscosity at 40° C. with a Brookfield DV-II+Pro at 12 rotations per minute; and c) printing the white ink-mixture with the inkjet printer onto an ink-receiver. Additionally, a color inkjet ink set includes the one or more colorless liquids and the white ink, and an inkjet printer for use in the inkjet printing method.

Owner:AGFA NV

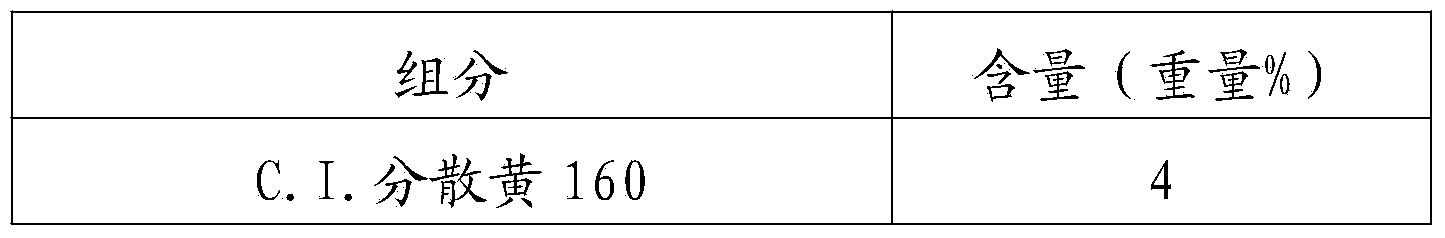

Composition comprising ubiquinone

InactiveUS7026361B2Improve bioavailabilityImprove dispersion stabilityOrganic active ingredientsPowder deliverySuspended particlesDispersion stability

This invention relates to a composition comprising ubiquinone having superior dispersion-stability in an aqueous solution and high bioavailability. The ubiquinone(s) is dispersed and emulsified in an aqueous solution of a water-soluble material in the presence of an organic acid(s) to form a protective colloid, the average particle size of the suspended particles being not more than 5 μm. The liquid composition can be adsorbed in or carried on an excipient, or dried.

Owner:NISSHIN PHARMA INC +1

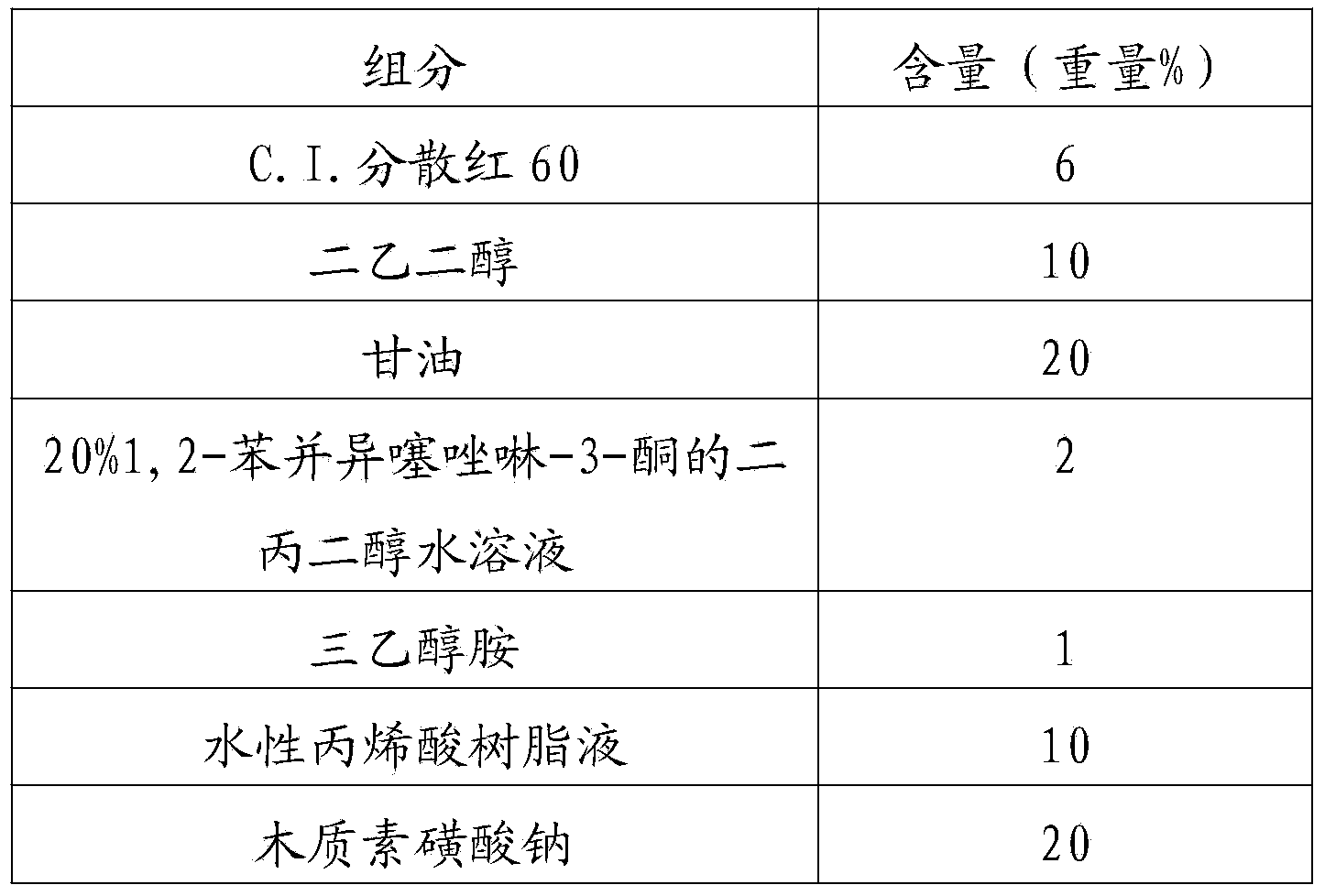

Sublimation ink-jetting ink used for industrial nozzle and manufacturing method thereof

The invention relates to an ink-jetting ink, in particular to a sublimation ink-jetting ink used for an industrial nozzle and a manufacturing method thereof. The sublimation ink-jetting ink comprises, by weight, 1-6% of disperse dyes, 10-14% of wetting agents, 5-20% of viscosity adjusting agents, 0.1-2% of bactericides, 0.01-1% of pH buffering agent, 1-10% of liquid resin, 0.1-40% of disperse agents, 0.01-5% of antifoaming agents, 0.1-5% of surface active agents, 0.01-2% of metal ion chelating agents and 10-80% of purified water. The manufacturing method of the sublimation ink-jetting ink used for the industrial nozzle includes color paste manufacturing and finished product manufacturing. The sublimation ink-jetting ink used for the industrial nozzle is simple in manufacturing method, smooth in ink jetting, free of blocking the nozzle, good in dispersion stability, free of going bad or denaturing even if being stored for a long time and low in cost, and diameters of dispersed ink points are even.

Owner:山东力美喷墨科技有限公司

Pigment containing ink and production method thereof

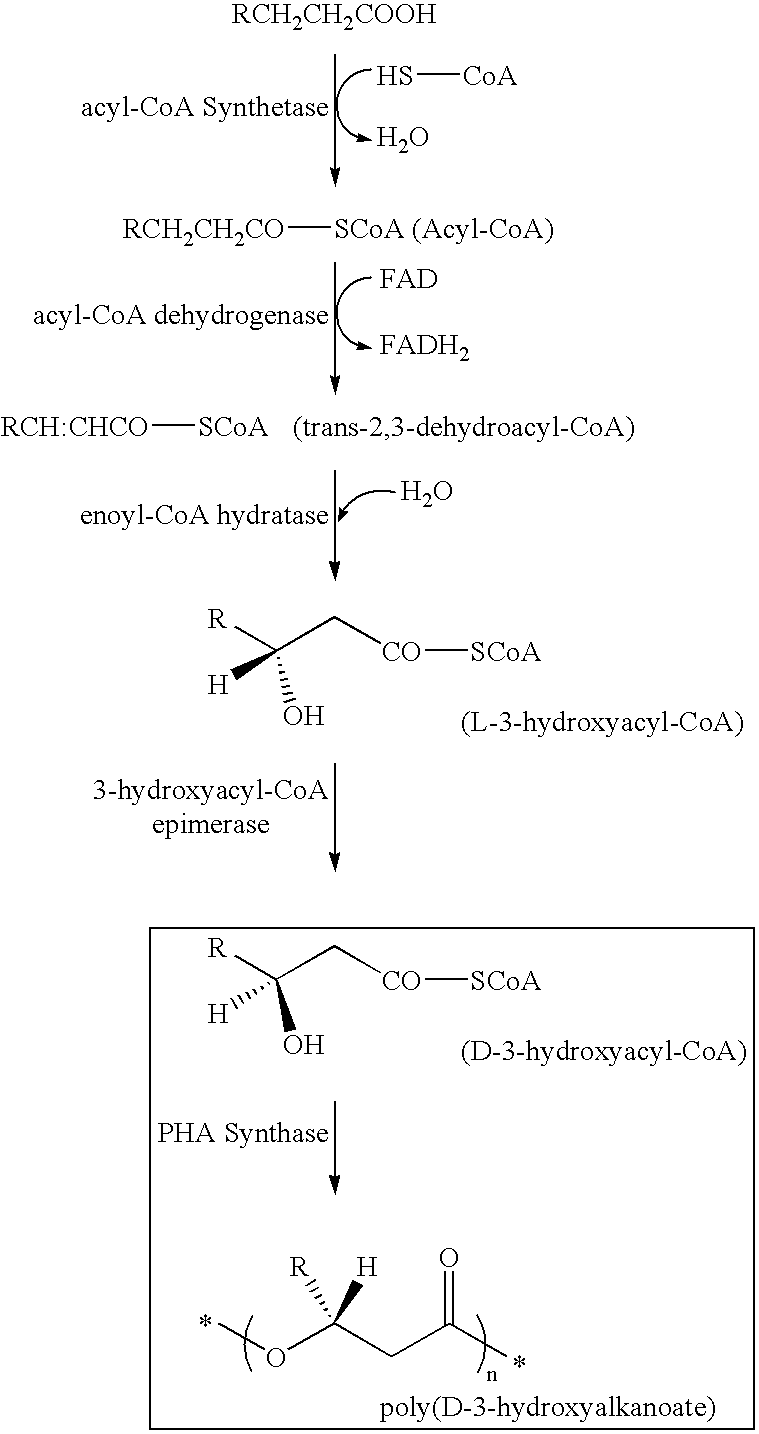

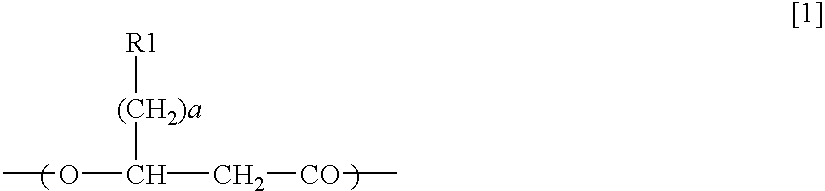

InactiveUS6916861B2Contained in a fine microcapsule easilyImprove propertiesHydrolasesMicroorganism based processesDispersion stabilityPolyhydroxyalkanoates

A micro-capsulated pigment containing pigment ink being excellent in density, fineness, transparency, and coloring and color rendering properties required for ink solutions and having excellent dispersibility and dispersion stability with time due to the reduced particle size is provided. At least a color material with at least part of the surfaces of pigment particles covered with polyhydroxyalkanoate, and a medium for dispersion of the color material are used to obtain the pigment ink.

Owner:CANON KK

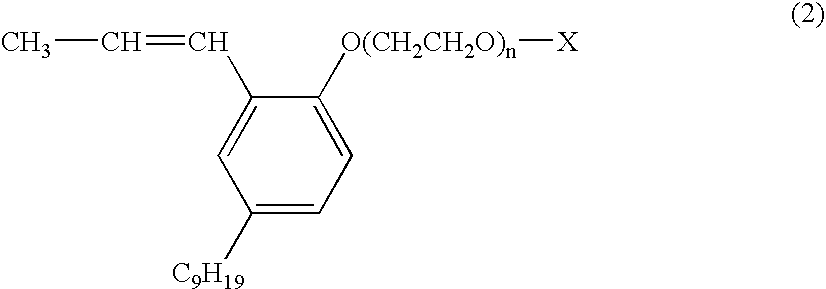

Method for Producing Metal Particle Dispersion, Conductive Ink Using Metal Particle Dispersion Produced by Such Method, and Conductive Coating Film

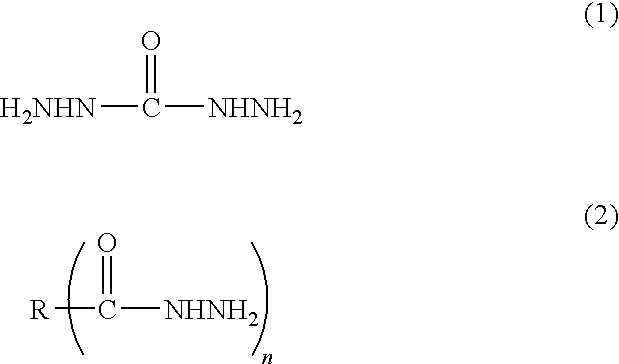

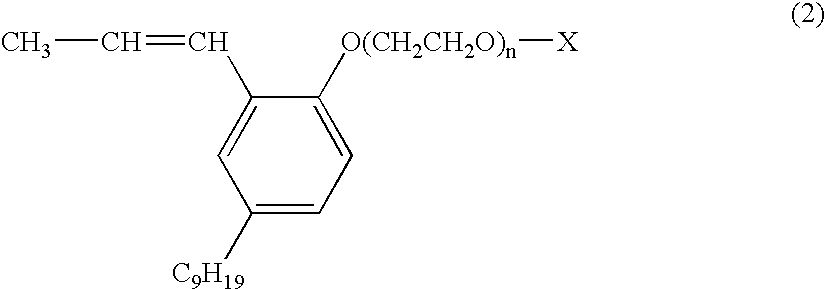

ActiveUS20090258202A1Safe handlingFast progressMaterial nanotechnologyLayered productsDispersion stabilityLiquid medium

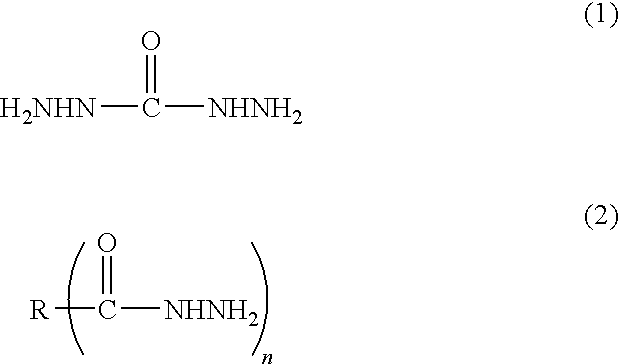

Disclosed is a method for producing a metal particle dispersion wherein a metal compound is reduced by using carbodihydrazide represented by the formula (1) below or a polybasic acid polyhydrazide represented by the formula (2) below (wherein R represents an n-valent polybasic acid residue) in a liquid medium. By reducing the metal compound in the presence of a compound having a function preventing discoloration of the metal, there can be obtained a metal particle dispersion having excellent discoloration preventing properties. Metal particles produced by such methods have a uniform particle diameter and are excellent in dispersion stability. By using a conductive resin composition or conductive ink containing a metal particle dispersion obtained by such production methods, there can be formed a conductive coating film, such as a conductive circuit or an electromagnetic layer, having good characteristics.

Owner:TOYO INK SC HOLD CO LTD

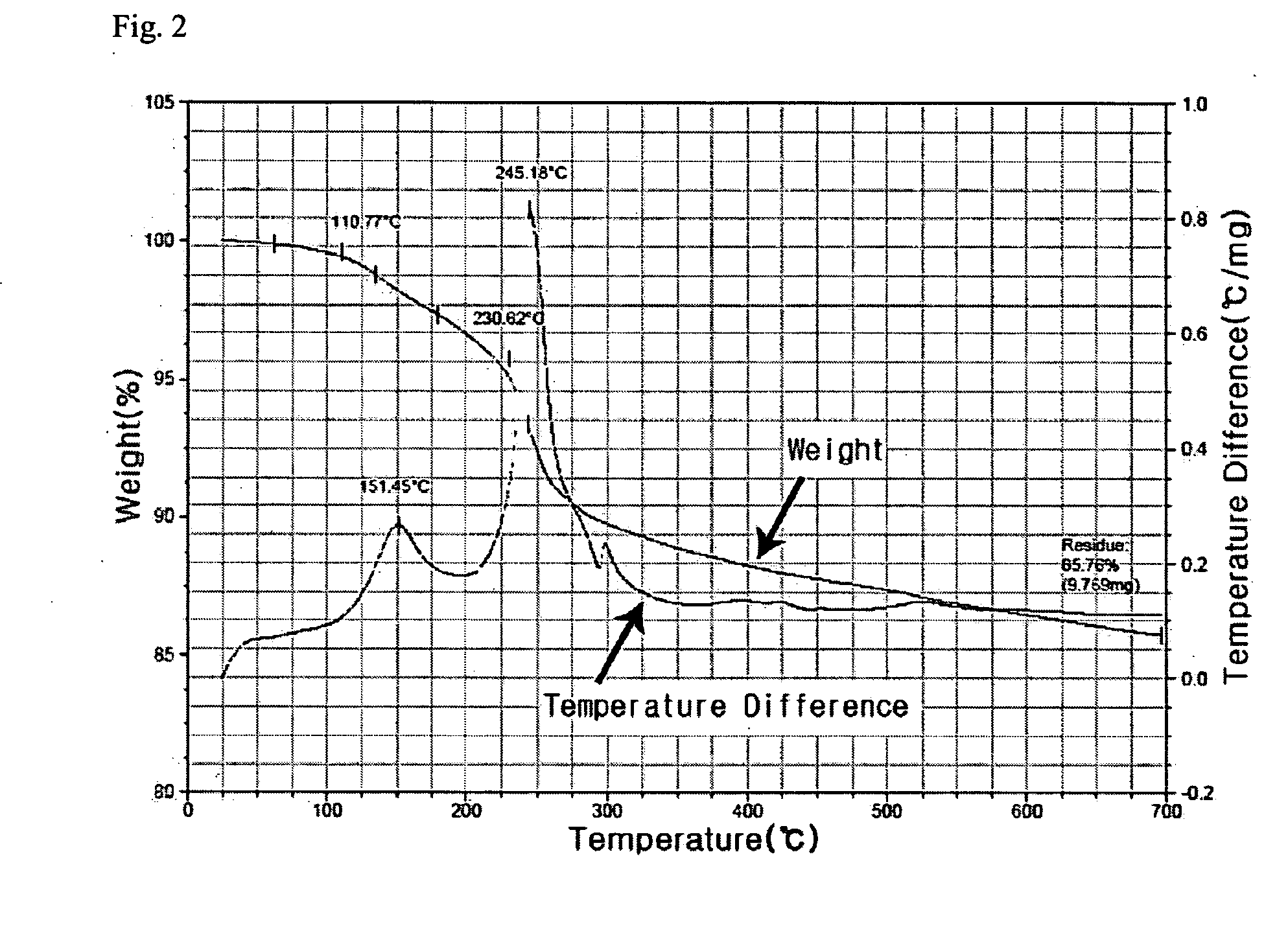

Photocatalyst containing metallic ultrafine particles and process for producing said photocatalyst

InactiveUS7759281B2Improve dispersion stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationDispersion stability

There is disclosed a photocatalyst which comprises a substrate having a photocatalytic function and metallic nanocolloid particles that are supported on the substrate by the use of a metallic nanocolloid liquid substantially free from a protective colloid formation agent. A highly active photocatalyst containing metallic ultrafine particles is provided by bringing a substrate such as fine particles having a photocatalytic function into contact with a metallic nanocolloid liquid which is substantially free from a protective colloid formation agent, and which has favorable dispersion stability even if containing metallic nanocolloid particles in a relatively high concentration. Accordingly the photocatalyst containing metallic ultrafine particles can be produced at a low cost without being restricted on the place of production.

Owner:NIPPON SHEET GLASS CO LTD

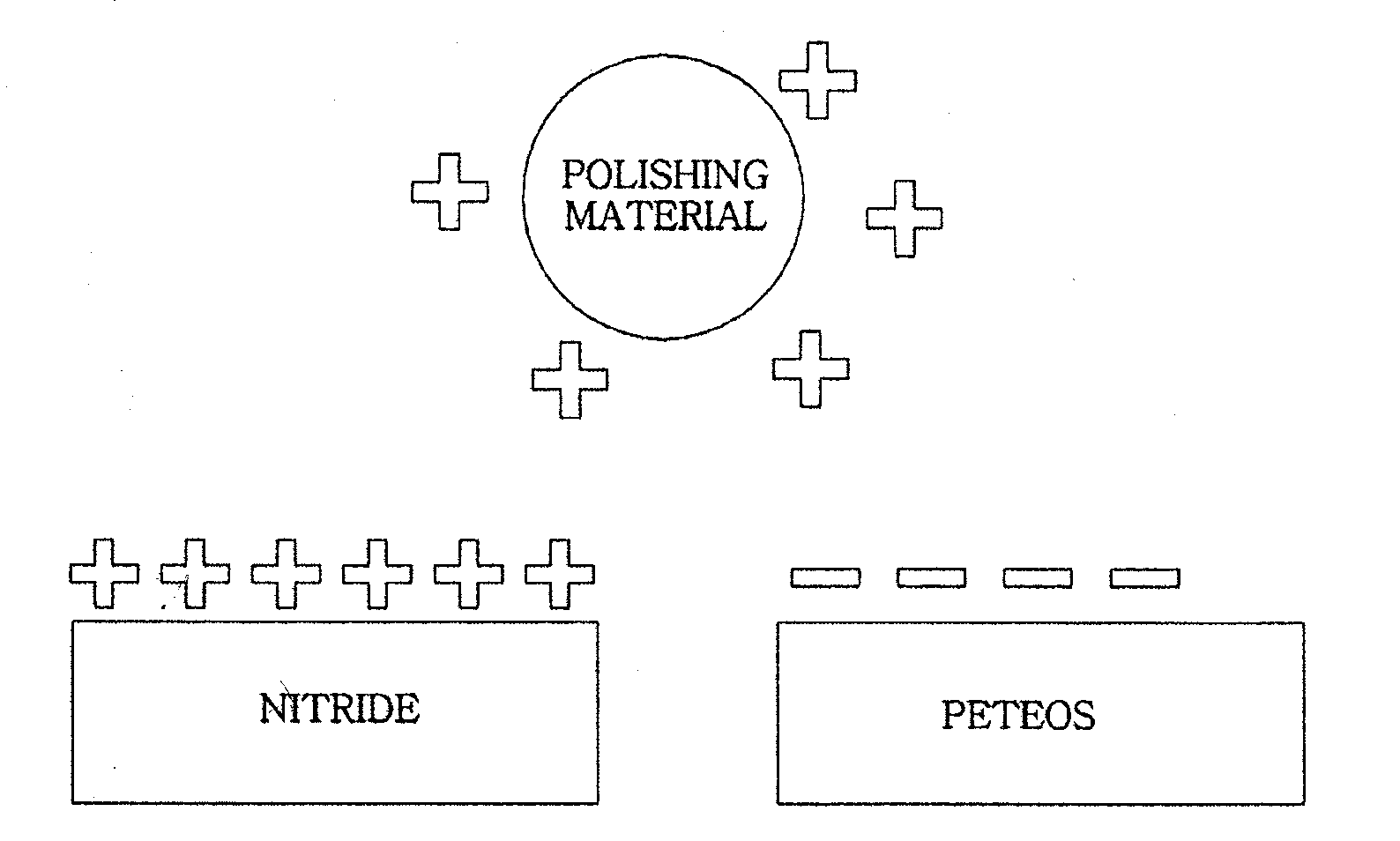

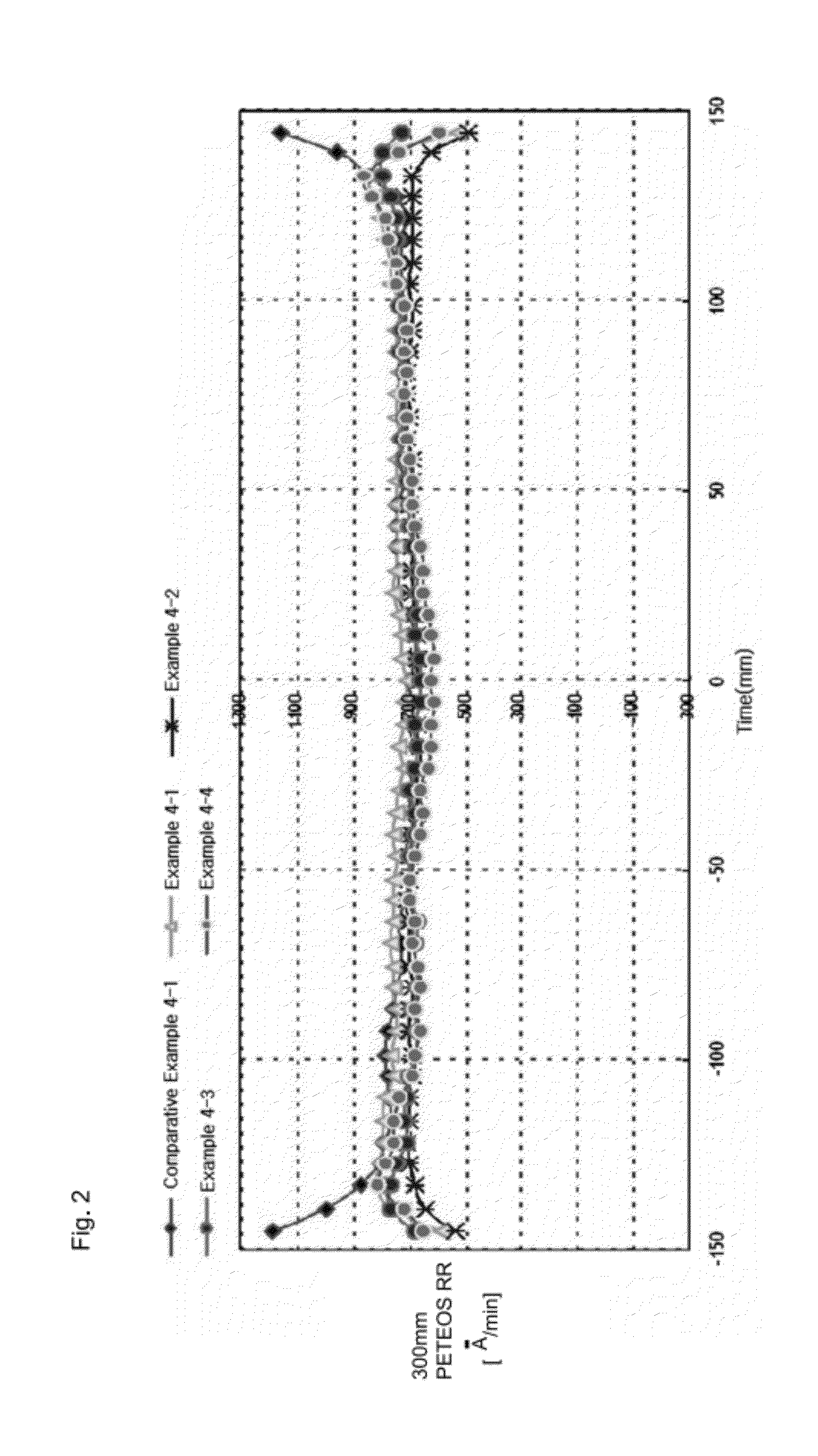

Chemical mechanical polishing slurry composition and method for producing semiconductor device using the same

ActiveUS20120156874A1High polishing rateExcellent degree of planarizationOther chemical processesSemiconductor/solid-state device manufacturingDispersion stabilitySlurry

A slurry composition for chemical mechanical polishing, including 0.1% to 20% by weight of an aminosilane-surface treated polishing agent; 0.001% to 5% by weight of an additive selected from amino acids, amino acid derivatives, salts thereof, and combinations thereof; 0.0001% to 0.5% by weight of a corrosion inhibitor; and 0.01% to 5% by weight of an oxidizing agent, with the balance being a solvent, is provided. The slurry composition for chemical mechanical polishing has a conspicuously high polishing rate for silicon oxide films, is capable of selectively preventing the removal of silicon nitride films, does not cause an imbalance in polishing, gives an excellent degree of planarization, has excellent stability over time and dispersion stability, causes less generation of particles and scratches, and produces very satisfactory polished surfaces of barrier metal films and oxide films.

Owner:SOULBRAIN CO LTD

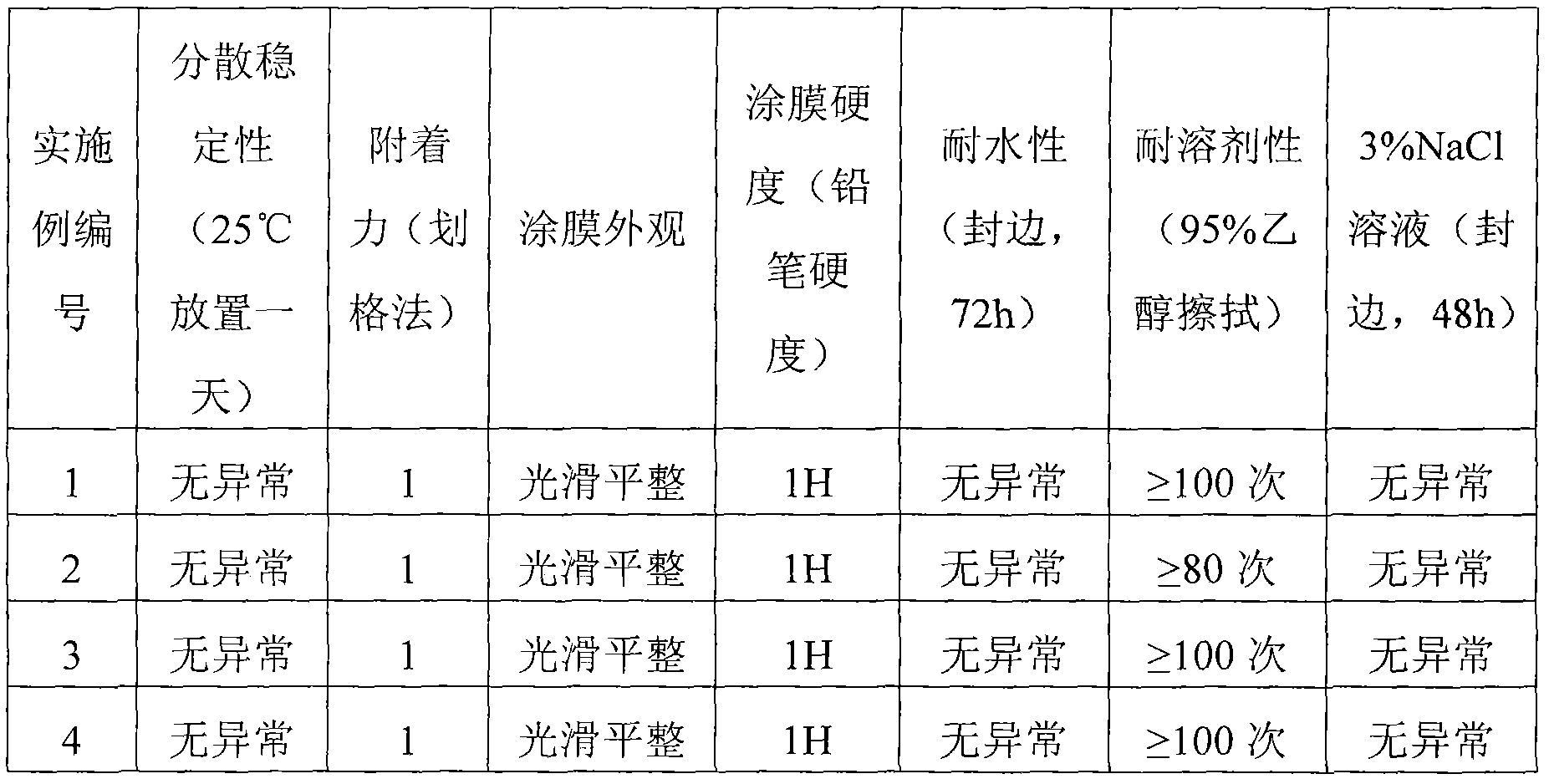

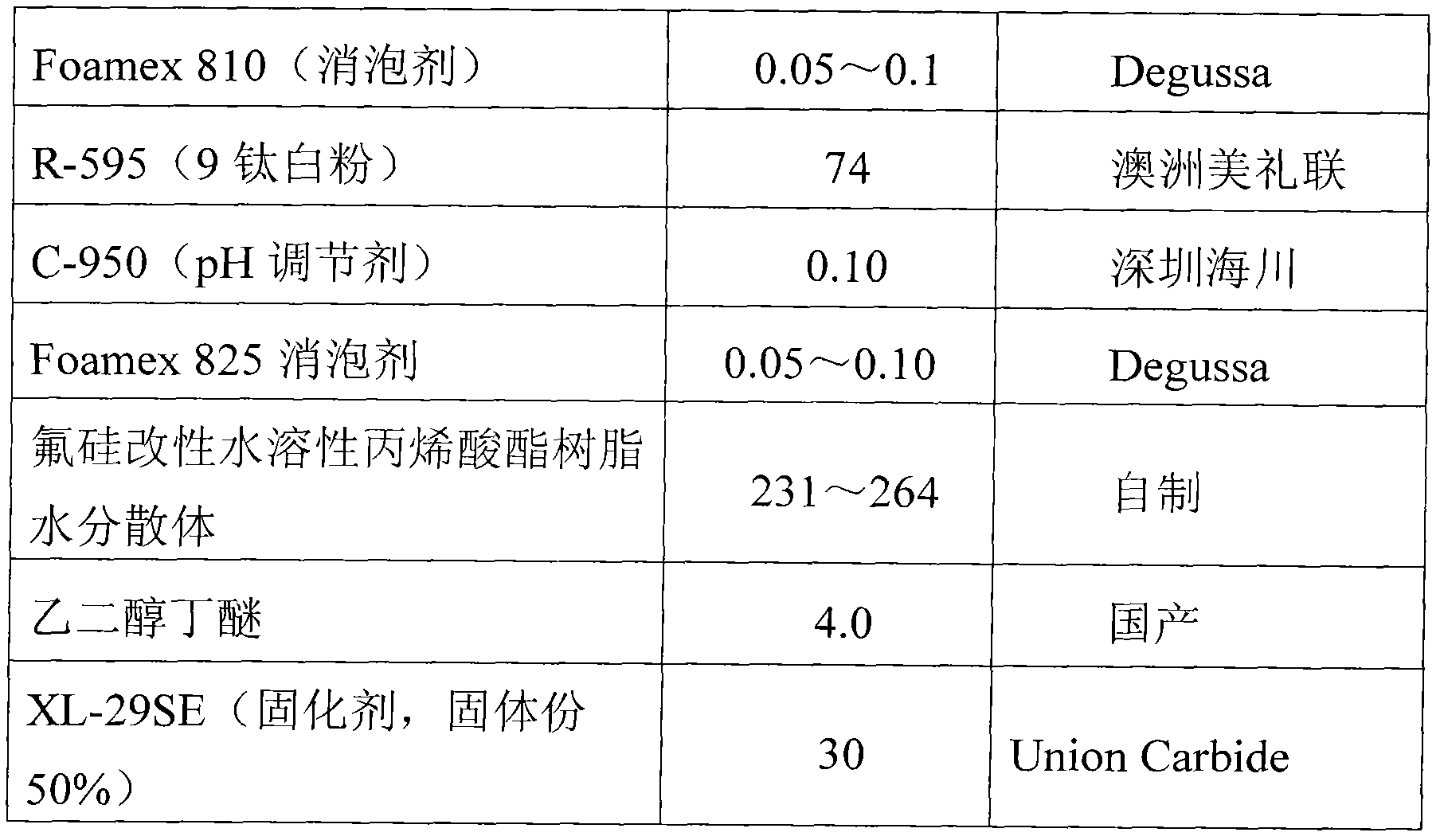

Fluosilicic modification water-soluble acrylic resin dispersion and application thereof

The invention provides a fluosilicic modification water-soluble acrylic resin dispersion and an application thereof. The dispersion is prepared from 20-50% of non-functional (methyl) acrylic ester, 5-35% of fluorinated acrylic ester monomer, 5-15% of carboxyl group-containing alkene monomer, less than or equal to 15% of vinyl monomer, 2-20% of (methyl) hydroxyl acrylate, 1-5% of organic silicon modified monomer, 15-30% of low carbon alcohol, 0.5-4% of inhibitor and 0.1-1.8% of molecular regulator according to a radical solution polymerization method. Based on solid parts, the acidic value of the dispersion is 20-100 mg KOH / g; the glass-transition temperature is 5-40 DEG C; the dispersion has a good appearance and dispersion stability as well as good water diluent property; a film obtained by cross-linking and curing a polycarbodiimide cross-linking agent and the dispersion has excellent water tolerance, solvent tolerance, high temperature tolerance, smooth property, stain tolerance and humidity resistance; the adhesion and hardness are improved; and the dispersion has strong practicable value and can be used for substrates such as wooden wares, metals, plastics and the like.

Owner:JIANGSU BLUESTAR GREEN TECH

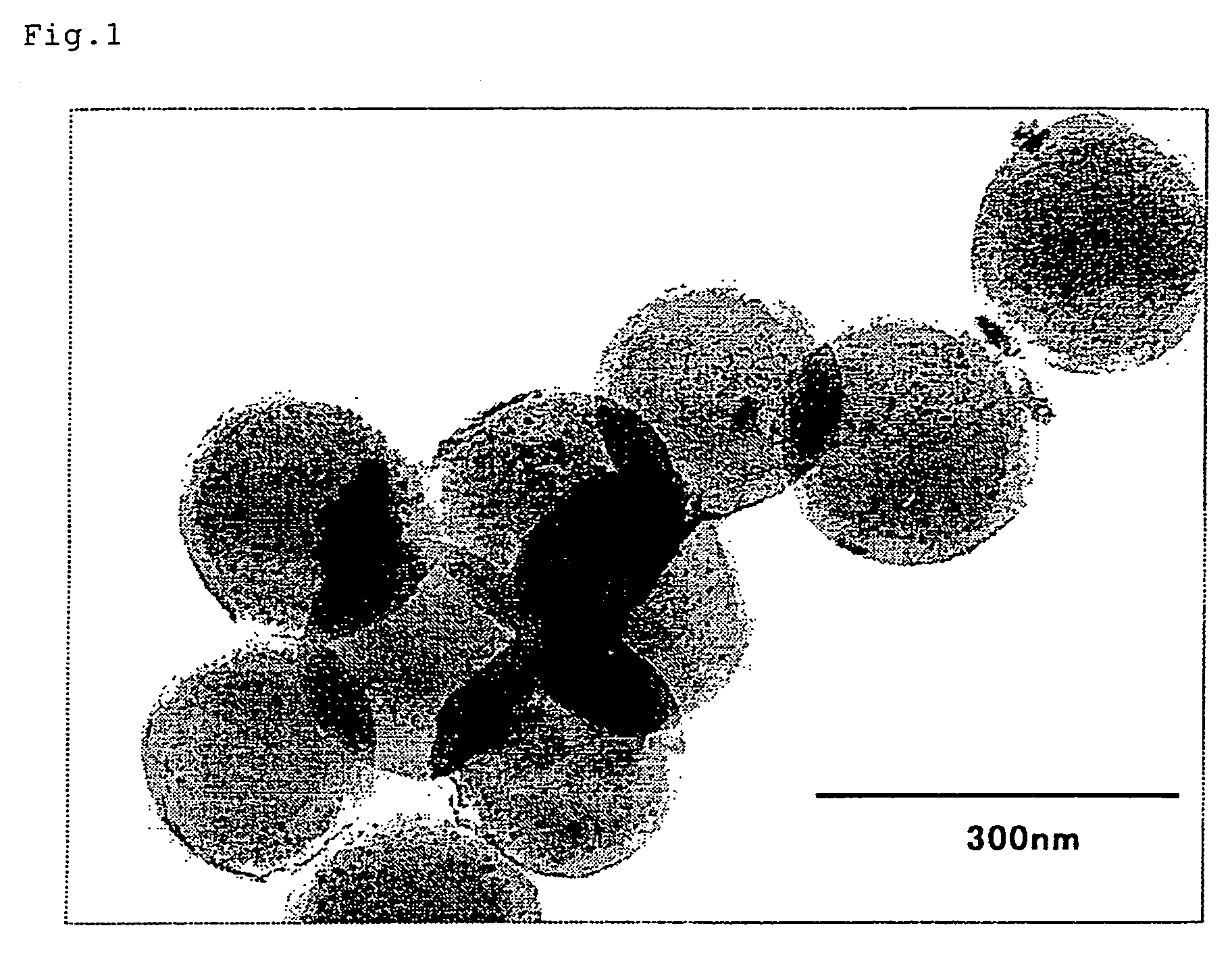

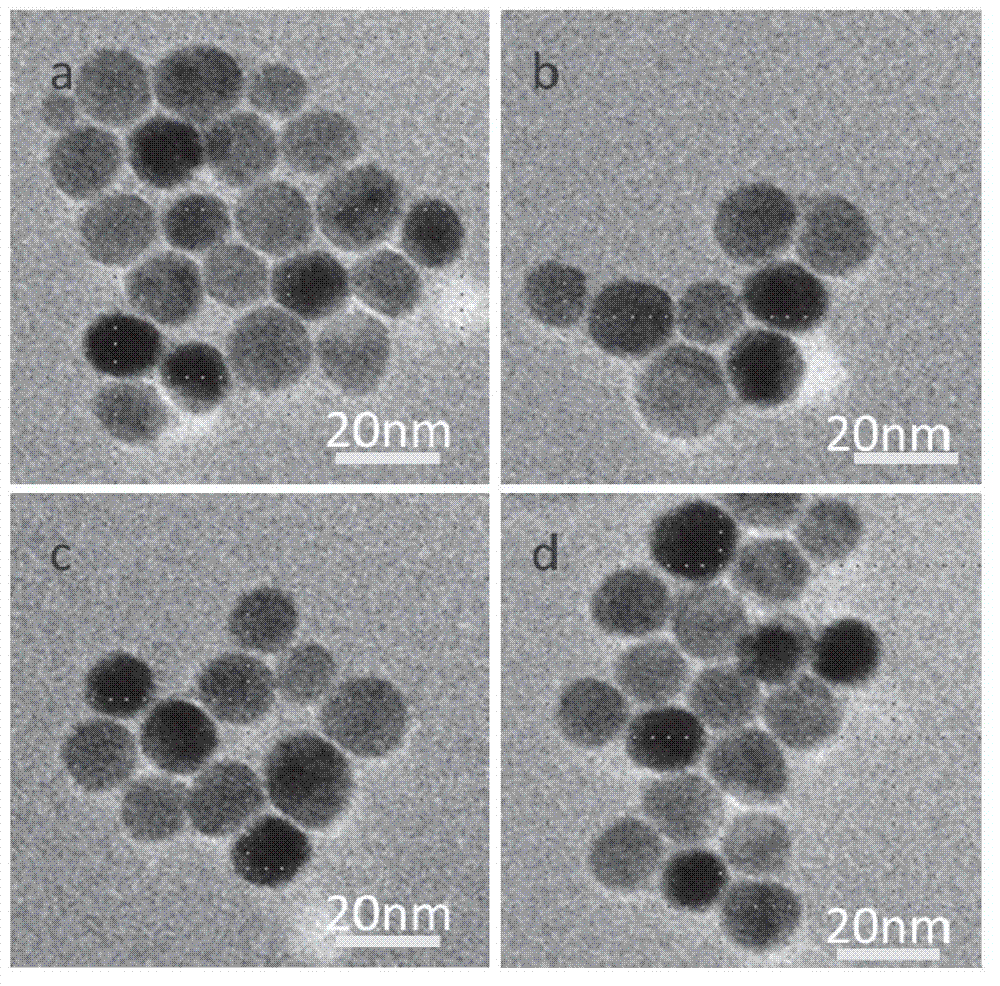

Particle having magnetic material incorporated therein, process for producing the same, particle for immunoaasay and method of immunoassay

InactiveUS20060188932A1Magnetic homogeneityImprove dispersion stabilityNanomagnetismPharmaceutical non-active ingredientsDispersion stabilityOragene

It is an object of the present invention to provide magnetic substance-encapsulated particles which have uniform magnetism, high dispersion stability and a narrow particle size distribution, a method of producing the same, particles for immunoassay formed by using the magnetic substance-encapsulated particles and a method of immunoassay in which the magnetic substance-encapsulated particles or the particles for immunoassay are used. The present invention relates to a magnetic substance-encapsulated particle, which comprises an organic polymer material and a magnetic substance having an average particle size of 1 to 30 nm, the magnetic substance being contained within a particle in a state of being dispersed.

Owner:SEKISUI CHEM CO LTD

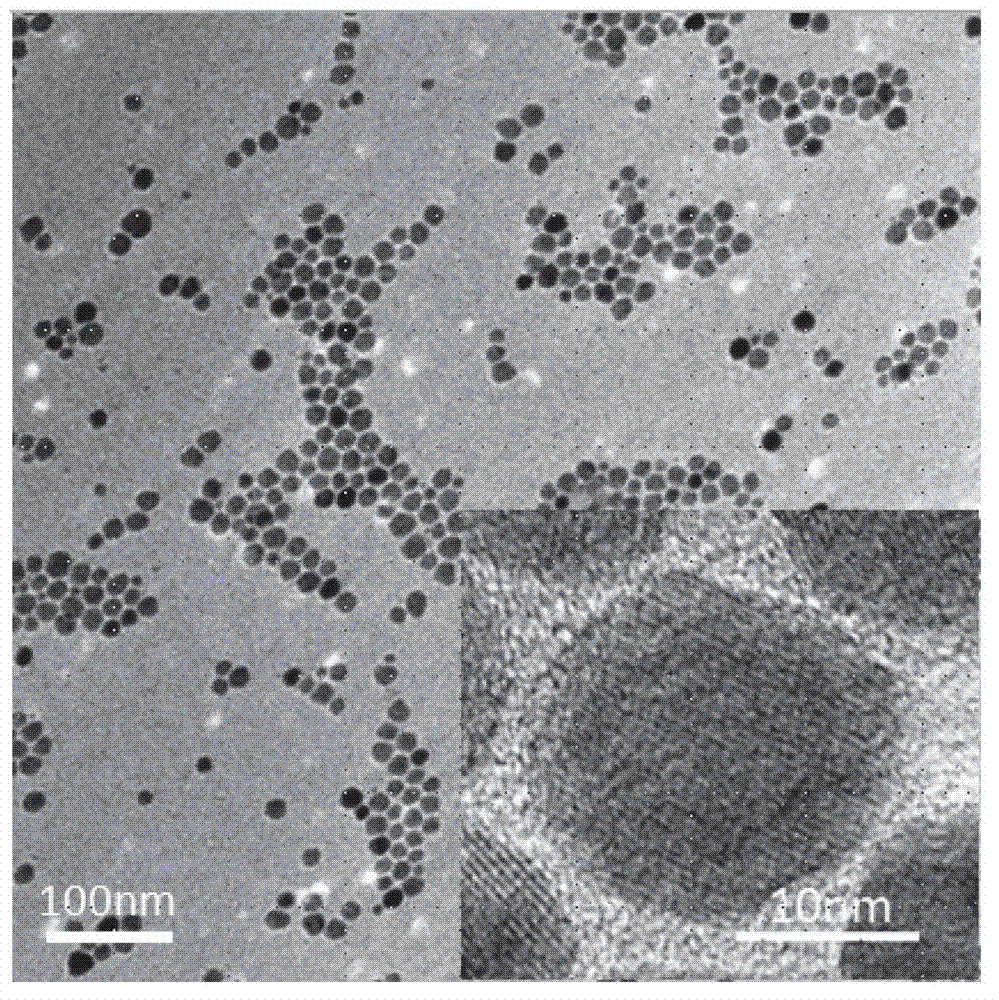

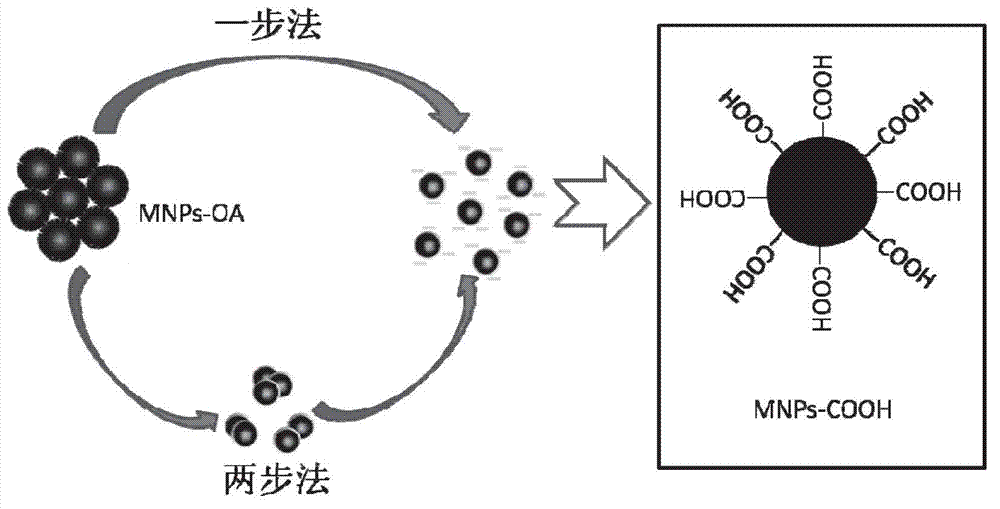

Fe3O4 nano-particles with high dispersion stability in water phase, and preparation method thereof

InactiveCN102815753AImprove dispersion stabilityImprove hydrophilicityFerroso-ferric oxidesNanotechnologyDispersion stabilitySolvent

The invention discloses Fe3O4 nano-particles with high dispersion stability in water phase, and a preparation method of the Fe3O4 nano-particles. The surface ligand of each Fe3O4 nano-particle is poly-carboxyl organic molecule with three or more carboxyl groups; the preparation method of the Fe3O4 nano-particles comprises the steps of: firstly, taking high boiling point organic solvent as solvent and oleic acid as the ligand; carrying out high-temperature thermal decomposition on iron oleate to obtain mono-dispersed oil-soluble Fe3O4 nano-particles; and then, adopting a method of ligand exchange, and using the poly-carboxyl organic molecules to replace the oleic acid ligands on the surfaces of the oil-soluble Fe3O4 nano-particles to obtain the water-soluble Fe3O4 nano-particles. The preparation method is convenient in operation process, low in requirement for equipment and low in price of the needed raw materials, and by-products are pollution-free. The water-soluble Fe3O4 nano-particles have better water system dispersion stability within the pH value range of 2-13, and a new economical and practical method is provided for preparing hydrophilic Fe3O4 nano-particles applied to the biological medicine field.

Owner:SHANGHAI JIAO TONG UNIV

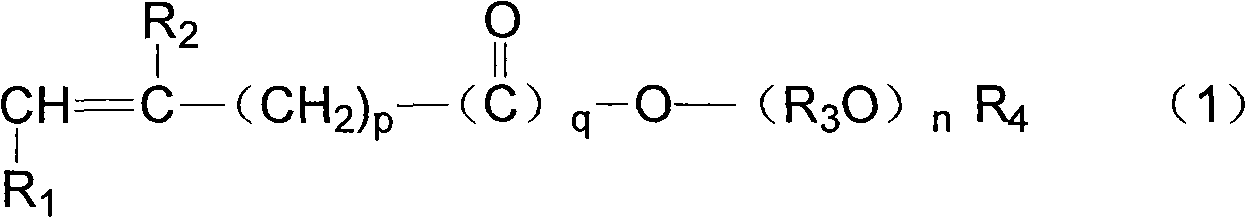

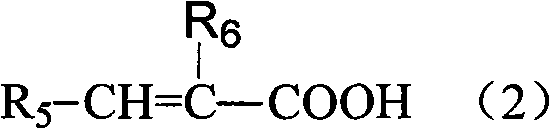

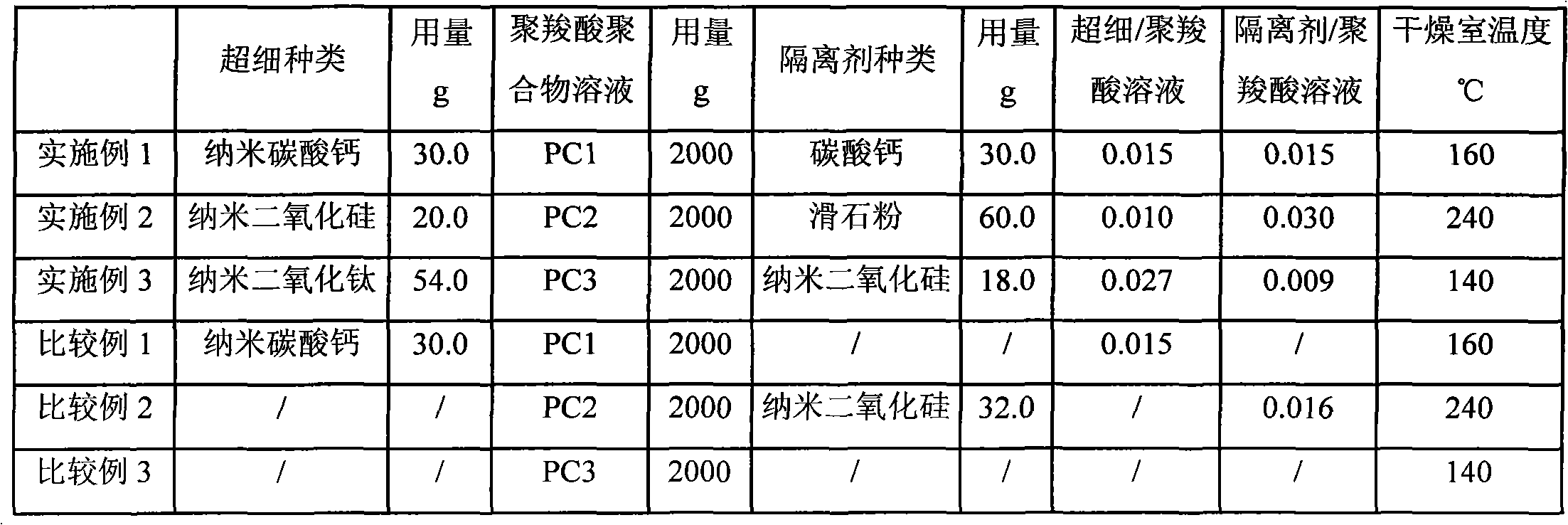

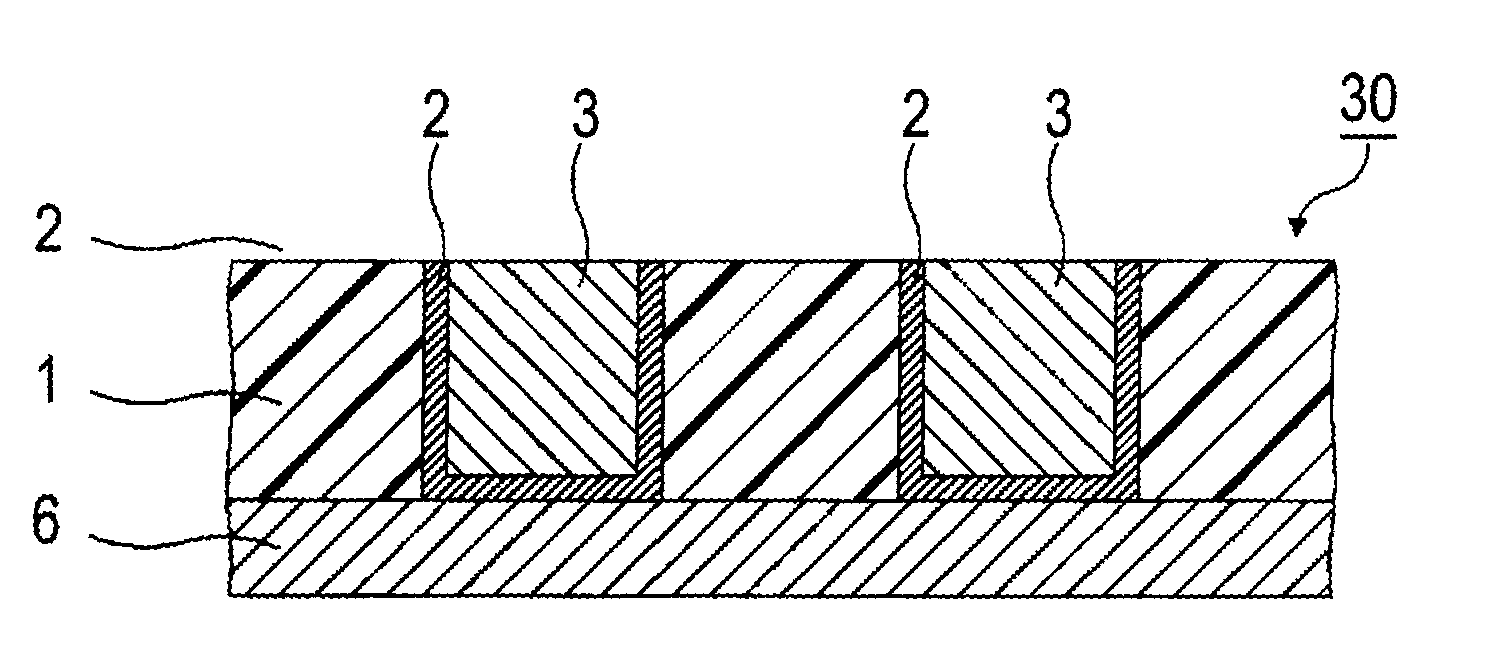

Method for preparing powdery polycarboxylic acid hyperdispersant

InactiveCN101962273AGood dispersionImprove dispersion stabilitySolid waste managementDispersion stabilityPolymer science

The invention discloses a method for preparing a powdery polycarboxylic acid hyperdispersant. The method comprises the following steps of: a) adding superfine inorganic powder or sol into solution of polycarboxylic acid polymer and uniformly mixing to obtain polycarboxylic acid slurry, wherein the solid content of the solution of polycarboxylic acid polymer is 10 to 60 percent, and the weight ratio of the superfine inorganic powder or sol to the solution of polycarboxylic acid polymer is 0.001 to 20; and b) forming atomized droplets from the polycarboxylic acid slurry which is obtained in the step a by using an atomizer, and introducing the atomized droplets into a dying chamber to dry and dewater; and when the polycarboxylic acid slurry is atomized and dried, simultaneously adding an inorganic separant into the dying chamber to prevent the formed powder from sticking to walls and caking so as to obtain the powdery polycarboxylic acid hyperdispersant. The product obtained by the invention has the advantages of high neat cement paste dispersibility, high dispersion stability and high anti-caking performance.

Owner:SHANGHAI SUNRISE CHEMISTRY CO LTD

Cmp polishing liquid and polishing method

ActiveUS20120094491A1High barrier film polishing speedGood dispersionOther chemical processesSemiconductor/solid-state device manufacturingSilica particleDispersion stability

The invention relates to a CMP polishing liquid comprising a medium and silica particles as an abrasive grain dispersed into the medium, characterized in that:(A1) the silica particles have a silanol group density of 5.0 / nm2 or less;(B1) a biaxial average primary particle diameter when arbitrary 20 silica particles are selected from an image obtained by scanning electron microscope observation is 25 to 55 nm; and(C1) an association degree of the silica particles is 1.1 or more. The invention provides a CMP polishing liquid which has the high barrier film polishing speed, the favorable abrasive grain dispersion stability, and the high interlayer dielectric polishing speed, and a polishing method producing semiconductor substrates or the like, that have excellent microfabrication, thin film formation, dimension accuracy, electric property and high reliability with low cost.

Owner:RESONAC CORP

Silicone modified acrylic-polyurethane heterocomplexing water dispersion and preparing method thereof

The invention provides an organosilicon modified acrylic polyurethane heterozygous aqueous dispersion as well as its preparing method, including the steps: make polyurethane prepolymer with hydrophilic group, make polyurethane prepolymer with side-chain activity double bonds, make propenoate monomer and anion polyurethane dispersion, and finally obtain it, which has interpenetrating network structure and nuclear shell structure. It has good heat resistance and solvent resistance, the performance advantages of polyurethane, crylic acid and organosilicon, and good dispersion stability; it has wide applications to monocomponent water carpentry paint and basal material in building paint, and its storage is stable.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com