Patents

Literature

148results about How to "Shorten dispersion time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire extinguishing agent and preparation method thereof

ActiveCN103007478AImprove fire extinguishing efficiencyReduce dispersion speedFire extinguisherSURFACTANT BLENDLiquid gas

The invention provides a fire extinguishing agent. The fire extinguishing agent is prepared by evenly mixing 1-25 parts of hydrophilic solid powder and 100 parts of water or water solution, and then adding 0.001-2 parts of surfactant for evenly mixing; and then adding 2-100 parts of hydrophobic solid particles. The invention provides a preparation method of the fire extinguishing agent. Compared with the existing fire extinguishing agent, the fire extinguishing agent can simultaneously play stifling, cooling and chemical inhibition roles, and the fire extinguishing efficiency is high; according to the fire extinguishing agent, due to addition of the surfactant in the water phase, the dispersion of rotating speed in preparation process can be lowered, the dispersion time can be shortened, and the preparation efficiency can be improved; and with the fire extinguishing agent, the adhesion property of solid gas interface and liquid gas interface can be greatly improved, the usage amount for extinguishing fire can be greatly reduced, and the fire extinguishing property can be obviously improved.

Owner:广州神州安防科技有限公司

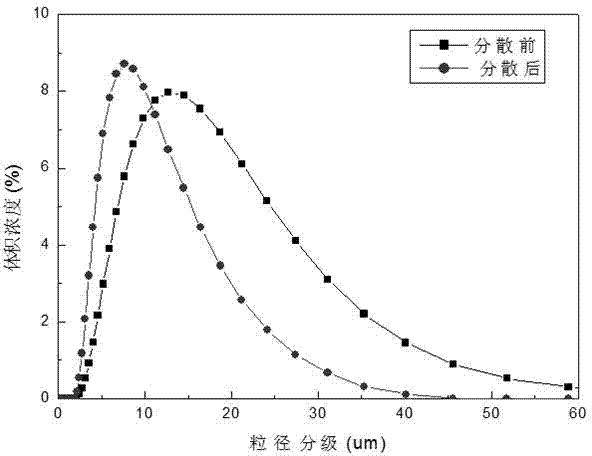

Method for preparing grapheme dispersion liquid

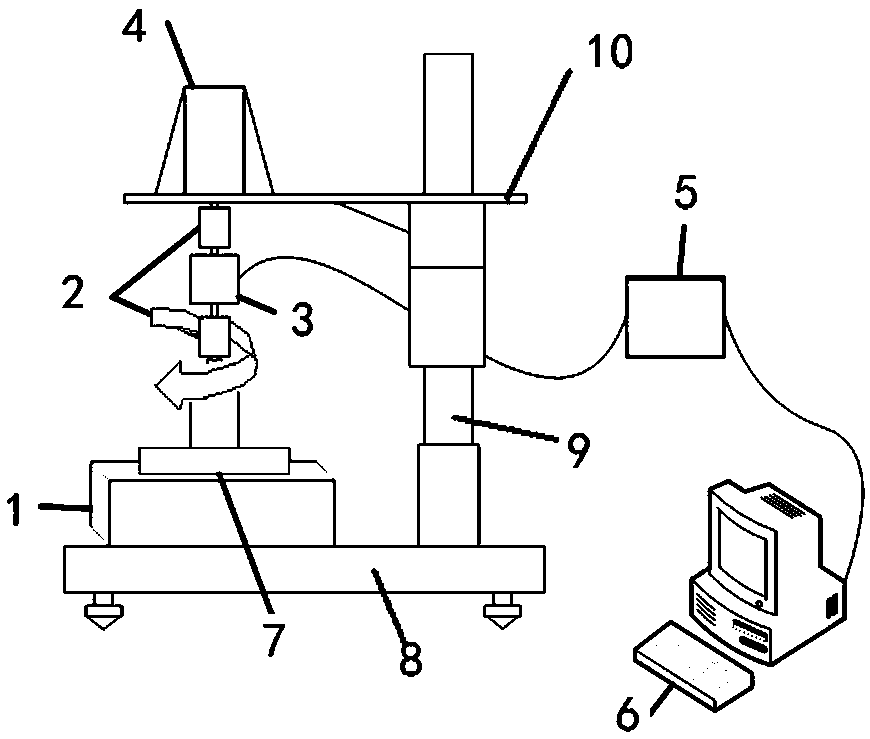

ActiveCN104772064AShorten dispersion timeIncrease productivityMixer accessoriesDispersion stabilityColloid

The invention discloses a method for preparing grapheme dispersion liquid. The method comprises the following steps: (1) uniformly mixing grapheme and a dispersant in a solvent to obtain a uniformly mixed solution; and (2) dispersing the uniformly mixed solution by a dispersing device for 0.5-24 hours to obtain the grapheme dispersion liquid, wherein the rotation speeds of a high shearing dispersion head and a colloid grinding disc are regulated to be within 100-14000rpm, the rotation speed of an electric mixer is at 10-2000rpm, an energy-concentration ultrasonic probe is additionally arranged, the ultrasonic frequency is within 20-80kHz and the dispersion temperature is 0-20 DEG C after being regulated by a cooling system. According to the method for preparing the grapheme dispersion liquid, the dispersion time is saved and the production efficiency is improved due to the adoption of multiple dispersion methods and synergic action, the cost is low, the operation is easy, and the method is nontoxic, free of pollution and beneficial for batch production, has high dispersion stability and a bright prospect of large-scale industrial application.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Fire extinguishing agent

ActiveCN103007479AImprove fire extinguishing efficiencyReduce dispersion speedFire extinguisherMass ratioSolid particle

The invention provides a fire extinguishing agent. The fire extinguishing agent is prepared by mixing and dispersing hydrophobic solid particles, water-soluble surfactant and water solution according to mass ratio of (5-100):(0.001-2):100. The fire extinguishing agent can simultaneously play stifling, cooling and chemical inhibition roles, and the fire extinguishing efficiency is high. Compared with the existing fire extinguishing agent, according to the fire extinguishing agent, due to addition of the surfactant in the water phase, the dispersion of rotating speed in preparation process can be lowered, the dispersion time can be shortened, and the preparation efficiency can be improved; and with the fire extinguishing agent, the adhesion property of solid gas interface and liquid gas interface can be greatly improved, the usage amount for extinguishing fire can be greatly reduced, and the fire extinguishing property can be obviously improved.

Owner:XIAN UNIV OF SCI & TECH

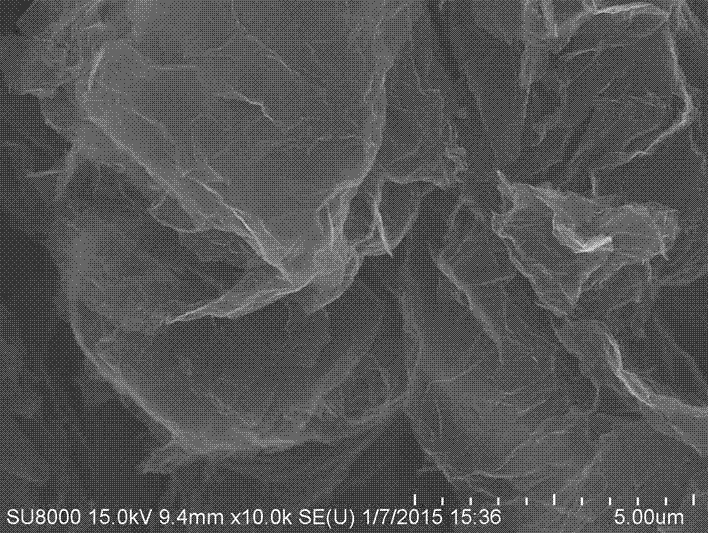

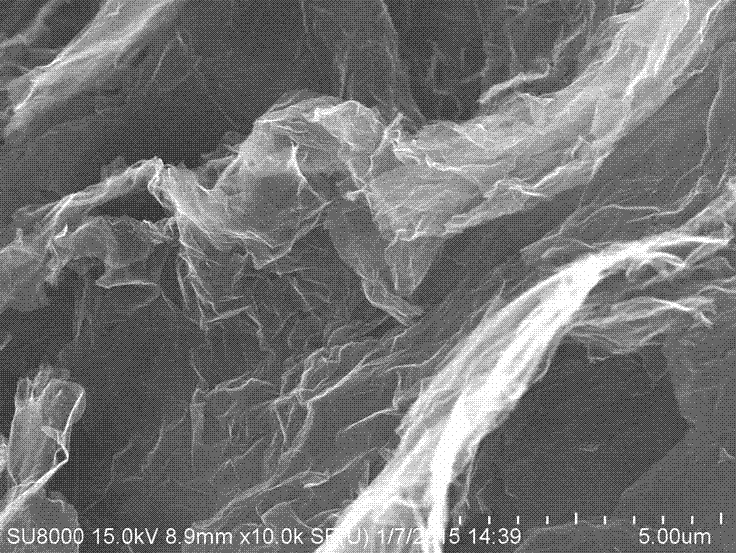

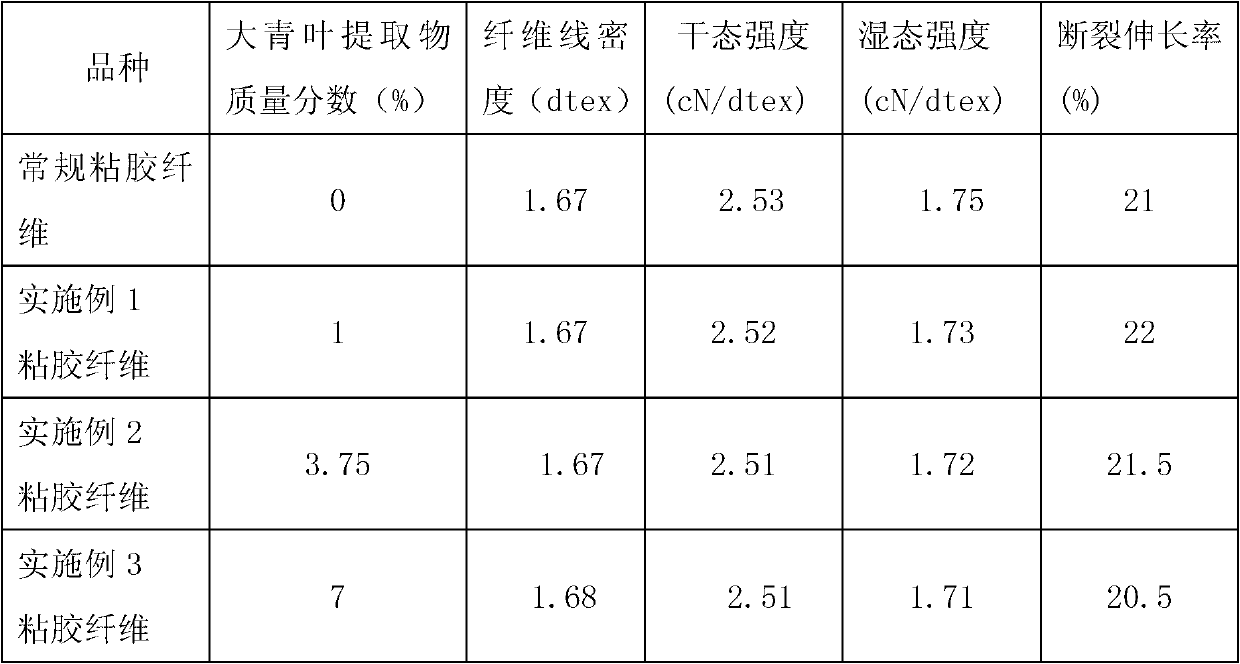

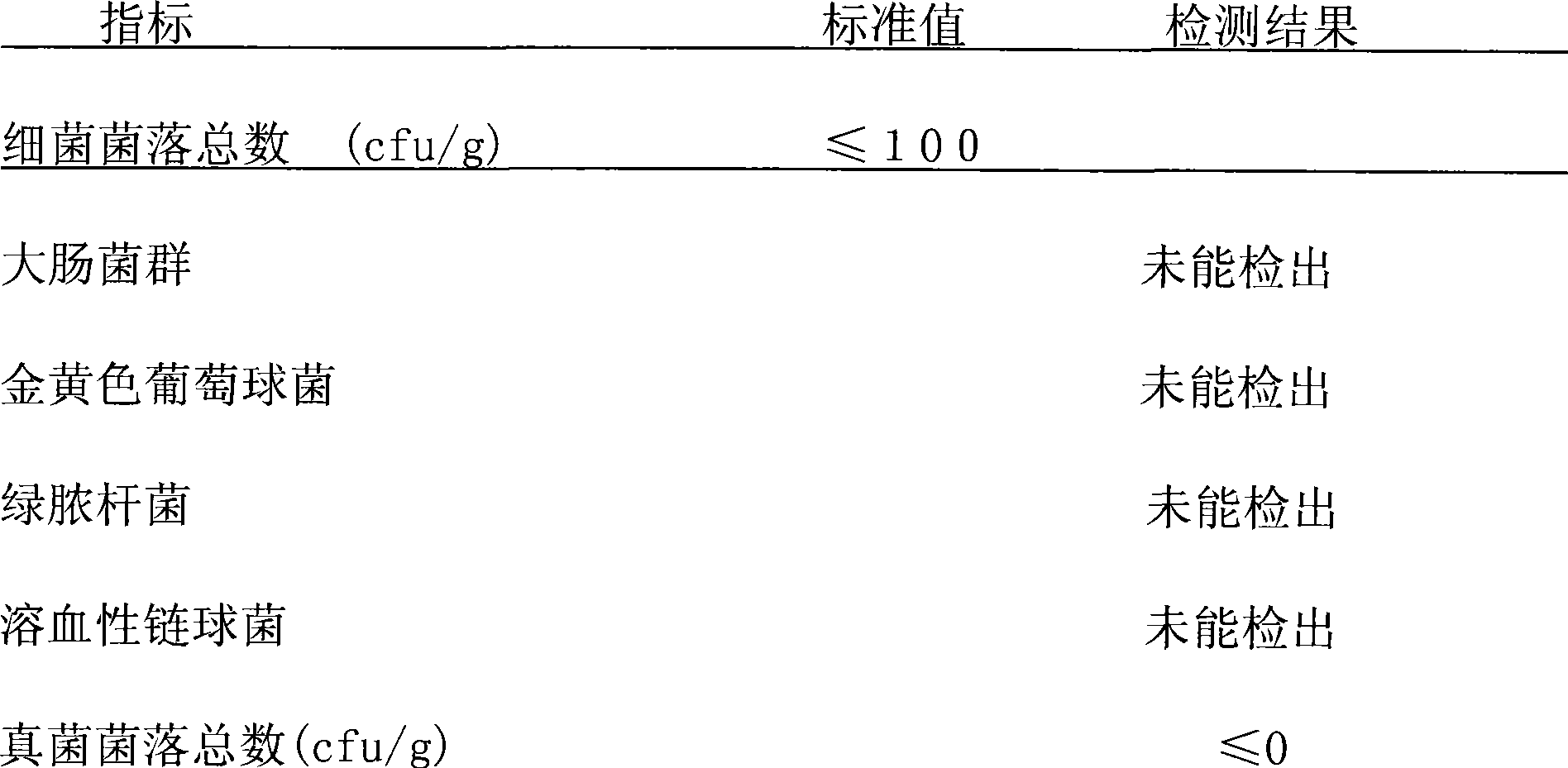

Viscose containing natural antimicrobials and preparation method thereof

InactiveCN102926013AImprove antibacterial functionNo side effectsArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentViscose fiberStock solution

The invention provides viscose containing natural antimicrobials. The viscose containing the natural antimicrobials comprises the viscose and the antimicrobials contained in the viscose. The viscose containing the natural antimicrobials is characterized in that the antimicrobials is natural indigowoad leaf extract powder, a natural indigowoad leaf extract powder solution added with dispersing agent is added into a viscose filature stock solution, the additive amount of the natural indigowoad leaf extract powder is 1%-7% of the quality of the viscose filature stock solution, the additive amount of the dispersing agent in the natural indigowoad leaf extract powder solution is 0.1%-1.0% of the quality of water in the natural indigowoad leaf extract powder solution. The preparation method of the viscose comprises the steps of dissolving the indigowoad leaf extract powder into water and adding the dispersing agent to obtain the indigowoad leaf extract powder solution, adding the indigowoad leaf extract powder solution to the viscose filature stock solution according to a ratio of 10%-14% of the quality of the viscose filature stock solution, and then shaping a obtained solution according to conventional wet spinning jet process to obtain the viscose. The viscose has a durable antibacterial function and has no side effect on human bodies. The preparation method has reasonable and simple technology, and is suitable for industrialized production.

Owner:单修铎

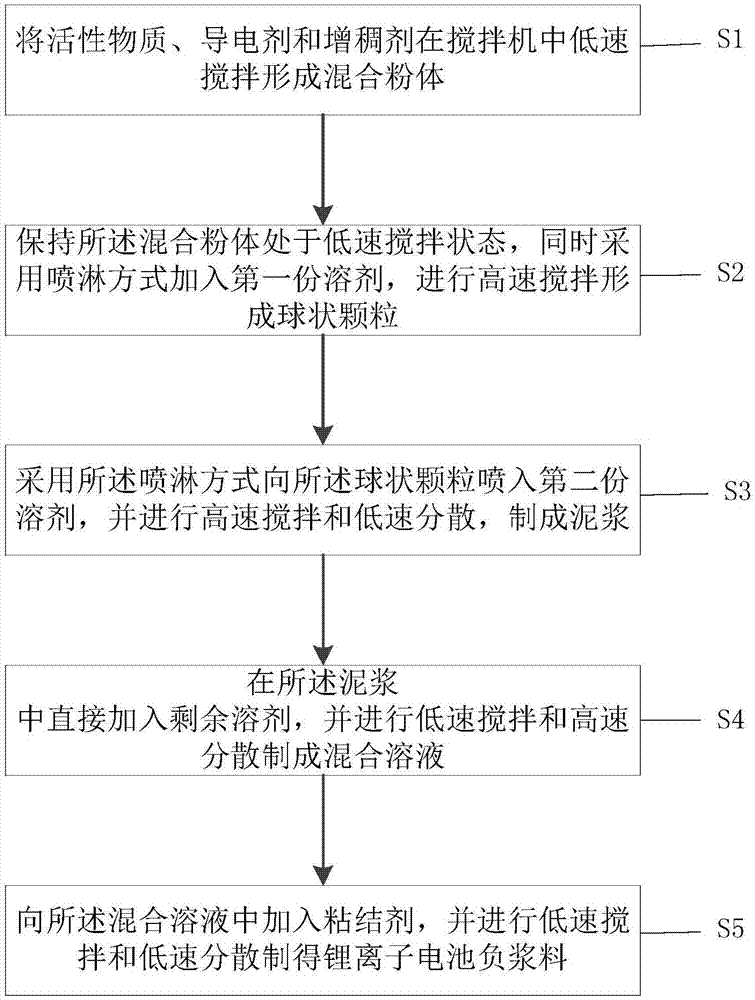

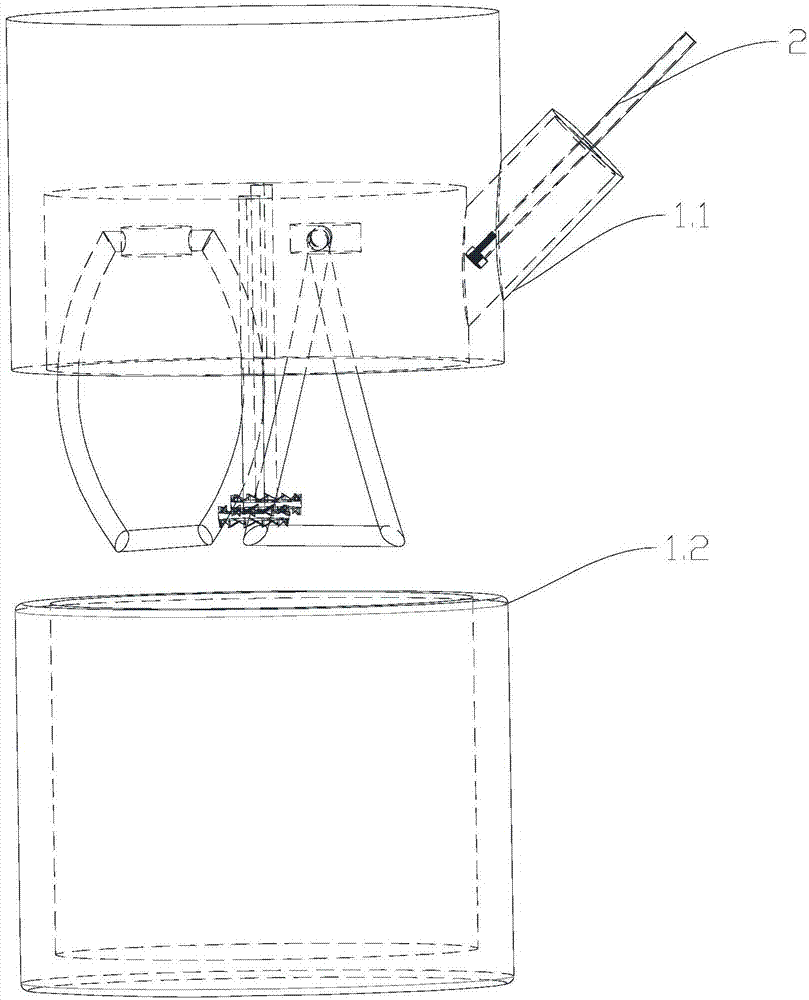

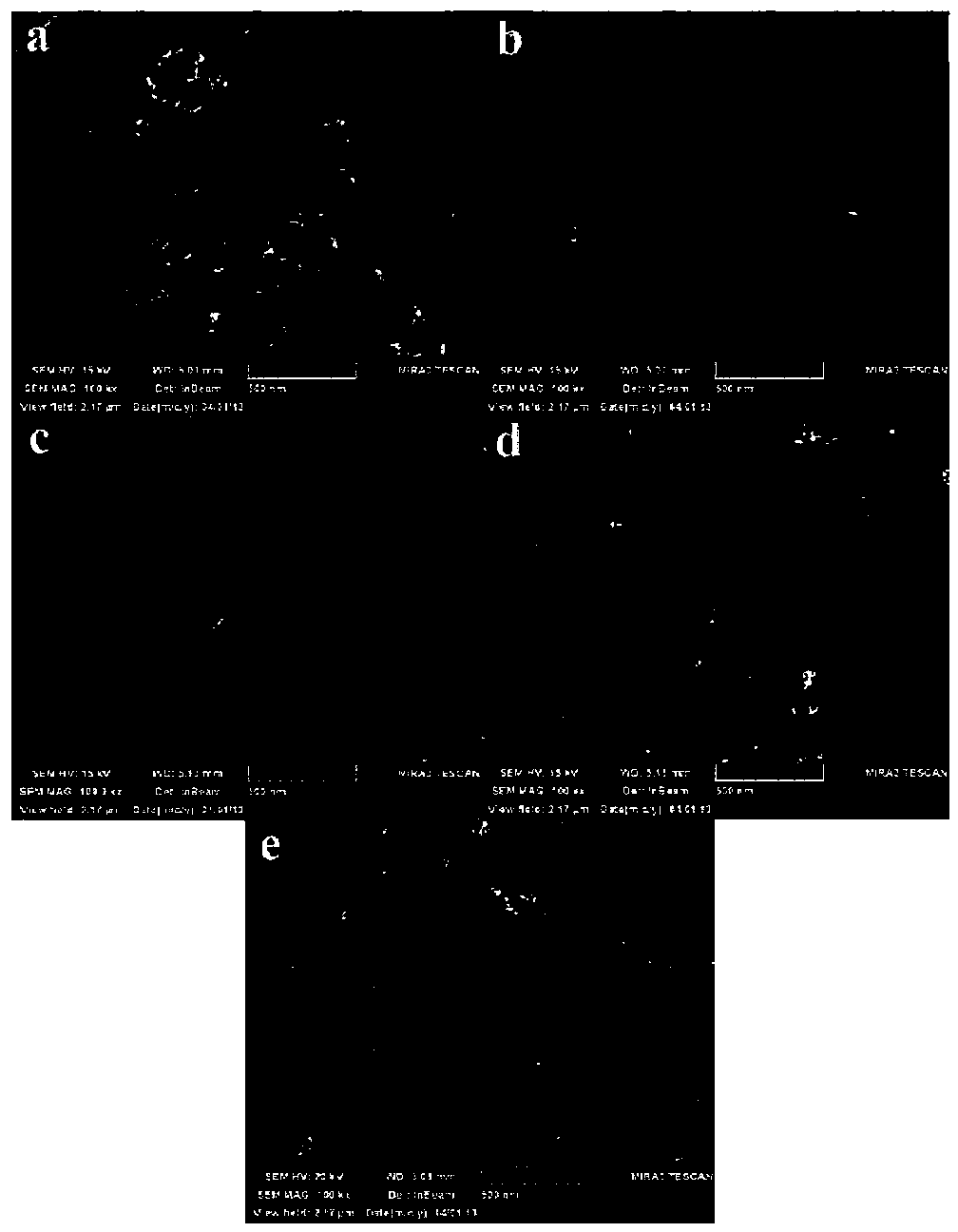

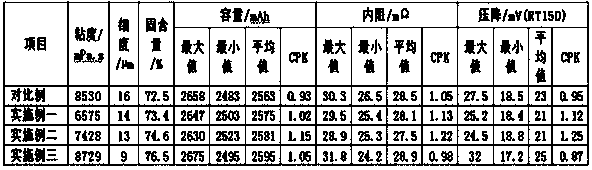

Negative pole slurry of lithium ion battery, rapid preparation method thereof and negative pole piece of lithium ion battery

ActiveCN107293706AImprove stabilityEasy to spreadElectrode thermal treatmentSecondary cellsAdhesivePole piece

The invention discloses negative pole slurry of a lithium ion battery, a rapid preparation method thereof and a negative pole piece of the lithium ion battery. The preparation method comprises the following steps: stirring an active substance, a conducting agent and a thickening agent in a stirring machine at a low speed to form mixed powder, then in the state that low-speed stirring of the mixed powder is maintained, adopting a spraying manner to add a first solvent, carrying out high-speed stirring to form spherical particles, then adopting the spraying manner again to inject a second solvent into the spherical particles, carrying out high-speed stirring and low-speed dispersion to prepare slurry, then directly adding remaining solvent, carrying out low-speed stirring and high-speed dispersion to prepare a mixed solution, finally adding an adhesive, and carrying out low-speed stirring and low-speed dispersion to prepare the negative slurry of the lithium ion battery. The addition of the solvents adopts stirring and spraying manners, and the power is rapidly moistened to form the uniform spherical particles, so that the total mixing time is reduced, the production efficiency is improved, and the equipment energy consumption is reduced. The negative pole slurry of the lithium ion battery prepared by the method has high stability, and the negative pole piece dried and prepared by the negative pole slurry coated on a current collector is relatively attractive in appearance.

Owner:HUIZHOU TOPBAND ELECTRICAL TECH CO LTD

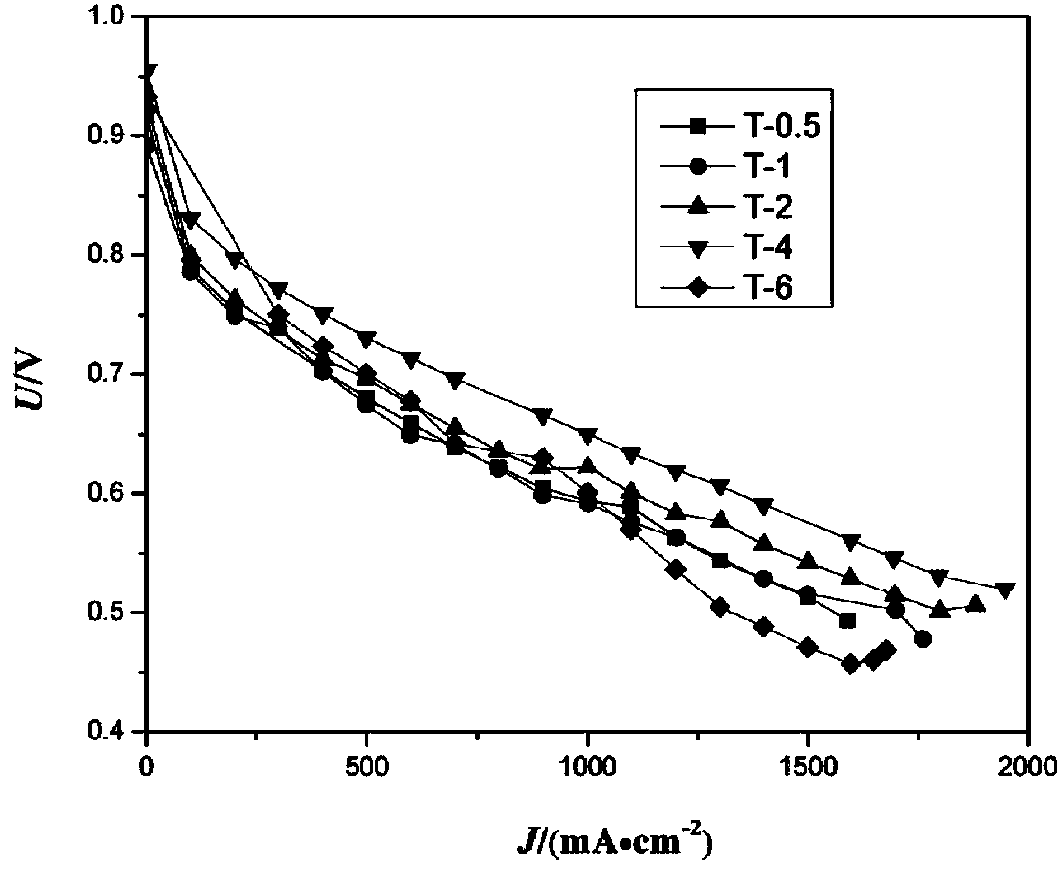

Membrane electrode for fuel cell and preparation method thereof

InactiveCN103515622AShorten dispersion timeImprove dispersion efficiencyFinal product manufactureCell electrodesSolventCatalysis

The invention discloses a membrane electrode for a fuel cell, and a preparation method and a packaging method thereof. A catalysis layer of the membrane electrode provided by the invention is composed of a catalyst slurry on a proton exchange membrane. The catalyst slurry comprises a catalyst, a binder, a disperse solvent, a thickening agent and an additive, and the catalyst is one selected from a Pt catalyst or a Pt alloy catalyst. The preparation method of the membrane electrode provided by the invention comprises the steps of preparation of the catalyst slurry for the membrane electrode, coating of the catalyst slurry and assembly of the membrane electrode. The preparation method of the catalyst slurry provided by the invention can shorten disperse time of the slurry and increase disperse efficiency, and the obtained catalyst slurry can realize transfer rate of 100% in a membrane electrode subassembly preparation process by a transfer printing method, so as to substantially increase utilization rate of the catalyst and electrochemical performance of the membrane electrode and effectively reduce the production cost of the fuel cell.

Owner:TSINGHUA UNIV +1

Environment friendly bacteriostatic water color ink for tipping paper

ActiveCN101429364ABacteriostaticEnhance the antibacterial effect of the mediumInksWater basedCalcium bicarbonate

The invention provides an environment-friendly bacteriostatic water-based ink for tipping paper, which is characterized by consisting of the following raw materials in mass percentage: 45 to 55 percent of water, 3 to 10 percent of ethanol, 1 to 3 percent of antibacterial agent, 2 to 4 percent of anti-settling agent, 9 to 15 percent of titanium dioxide, 4 to 6 percent of calcium bicarbonate, 1 to 3 percent of GR organic dye, 5 to 10 percent of GR organic dye yellow, 1 to 3 percent of GR organic dye black, and 18 to 25 percent of binder. The environment-friendly bacteriostatic water-based ink can greatly reduce usage amount of ink and contents of arsenic, mercury and lead, prevents heavy metals such as the arsenic, the mercury, the lead, cadmium, nickel and chromium in a print from causing harm to human body, improves working environment, delays dispersing time of the antibacterial agent, increases antibacterial effect, has better viscosity stability and low inflammability, can simplify workload for printing and washing, and improves production efficiency.

Owner:楚雄市华丽包装实业有限责任公司

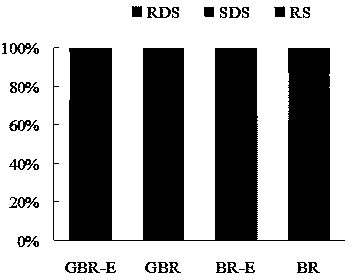

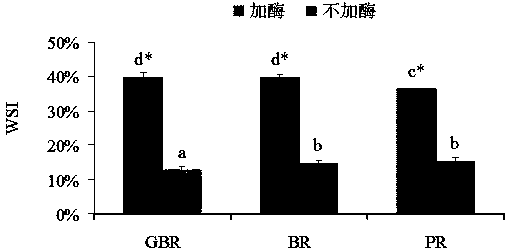

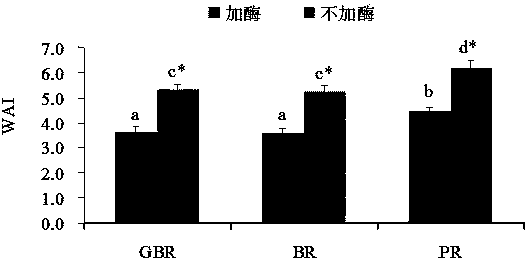

Processing method for improving digestibility and reconstituability of instant brown rice powder

The invention discloses a processing method for improving digestibility and reconstituability of instant brown rice powder. The processing method comprises the following steps: (1) germinating rice and then removing rich husk so as to obtain germinated brown rice; (2) crushing the germinated brown rice, sieving the crushed germinated brown rice with a 60-mesh sieve, sprinkling a high-temperature alpha-amylase weak solution into obtained brown rice powder, adjusting moisture content to 10 to 20%, carrying out uniform mixing, then carrying out sealing with a sealing bag, placing the sealing bag in a refrigerator with a temperature of 4 DEG C and balancing moisture for 10 to 20 h, wherein the sprinkling amount of the alpha-amylase weak solution is 40 to 60 U / g, i.e., 40 to 60 U units of the alpha-amylase weak solution is sprinkled into each g of the brown rice powder; and (3) after moisture balancing, carrying out extrusion cooking and crushing so as to obtain the instant brown rice powder. According to the invention, through effective combination of germination, enzymatic hydrolysis with high-temperature alpha-amylase and extrusion cooking, digestibility and reconstituability of the instant brown rice powder are improved to a greatest extent.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

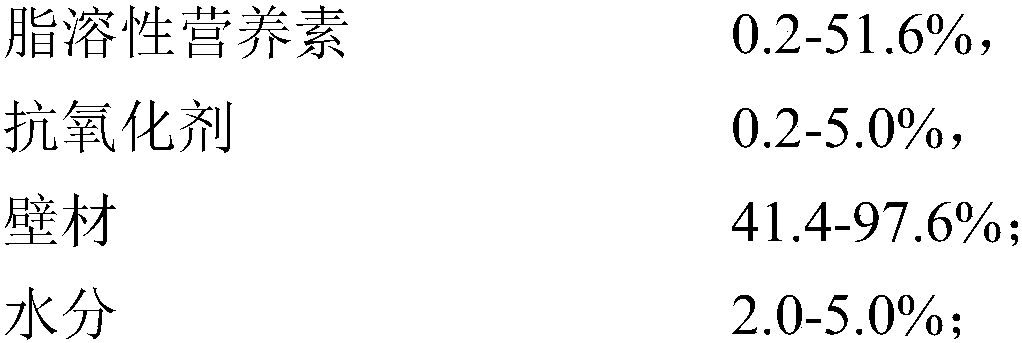

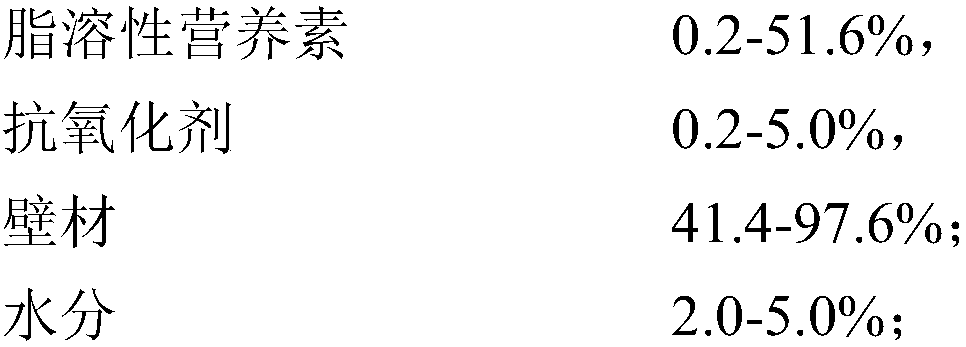

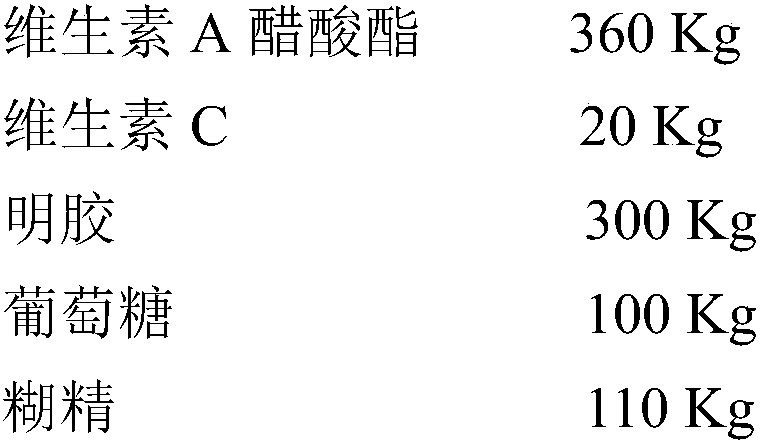

Fat-soluble nutrient microcapsules and preparation method thereof

ActiveCN107594597AReduce lossesHigh retention rateVitamin food ingredientsAccessory food factorsAntioxidantNutrient

Owner:ZHEJIANG NHU CO LTD +1

Gravure printing ink for poly(ethylene terephthalate) (PET) base material and preparation method for gravure printing ink

The invention discloses gravure printing ink for a poly(ethylene terephthalate) (PET) base material and a preparation method for the gravure printing ink, and aims to provide ink having the advantages of good fluidity, high adhesion, high gloss, simple and feasible preparation method, safe use and environment friendliness, and a preparation method thereof. The ink comprises the following components: an organic pigment or an inorganic pigment, resin, an adhesion promoter, a dispersing agent and the balance of organic mixed solvent. The ink is prepared by the following steps of: mixing dimethyl carbonate, ethyl acetate and n-propyl alcohol to obtain a mixed solvent, and dissolving the resin; and mixing with the organic pigment or the inorganic pigment, stirring and dispersing to obtain a semi-finished product of color paste, fully grinding on a sand mill, adding the adhesion promoter and the dispersing agent, fully stirring, and filtering off components of which the fineness is more than 15mu m by using a filtering machine to obtain the gravure printing ink for the PET base material.

Owner:TONGLING JINTAI CHEM INDAL

Dispersing agent for positive and negative electrode materials of lithium ion battery

ActiveCN102064326AImprove low temperature performanceImprove securityCell electrodesEngineeringSurface-active agents

The invention discloses a dispersing agent for positive and negative electrode materials of a lithium ion battery. A surface active agent of the dispersing agent is modified polyoxyethylene ether. Compared with the prior art, the dispersing agent has the advantages that 1) an addition method is simple; 2) the dispersing effect is good; 3) the application range is wide; 4) the electrochemical performance is stable; 5) the low-temperature performance of the battery can be improved; and 6) the safety performance of the battery can be improved, and safety tests in terms of over-charging, nail penetrating, side compression, weight impact and the like are improved.

Owner:NINGDE AMPEREX TECH

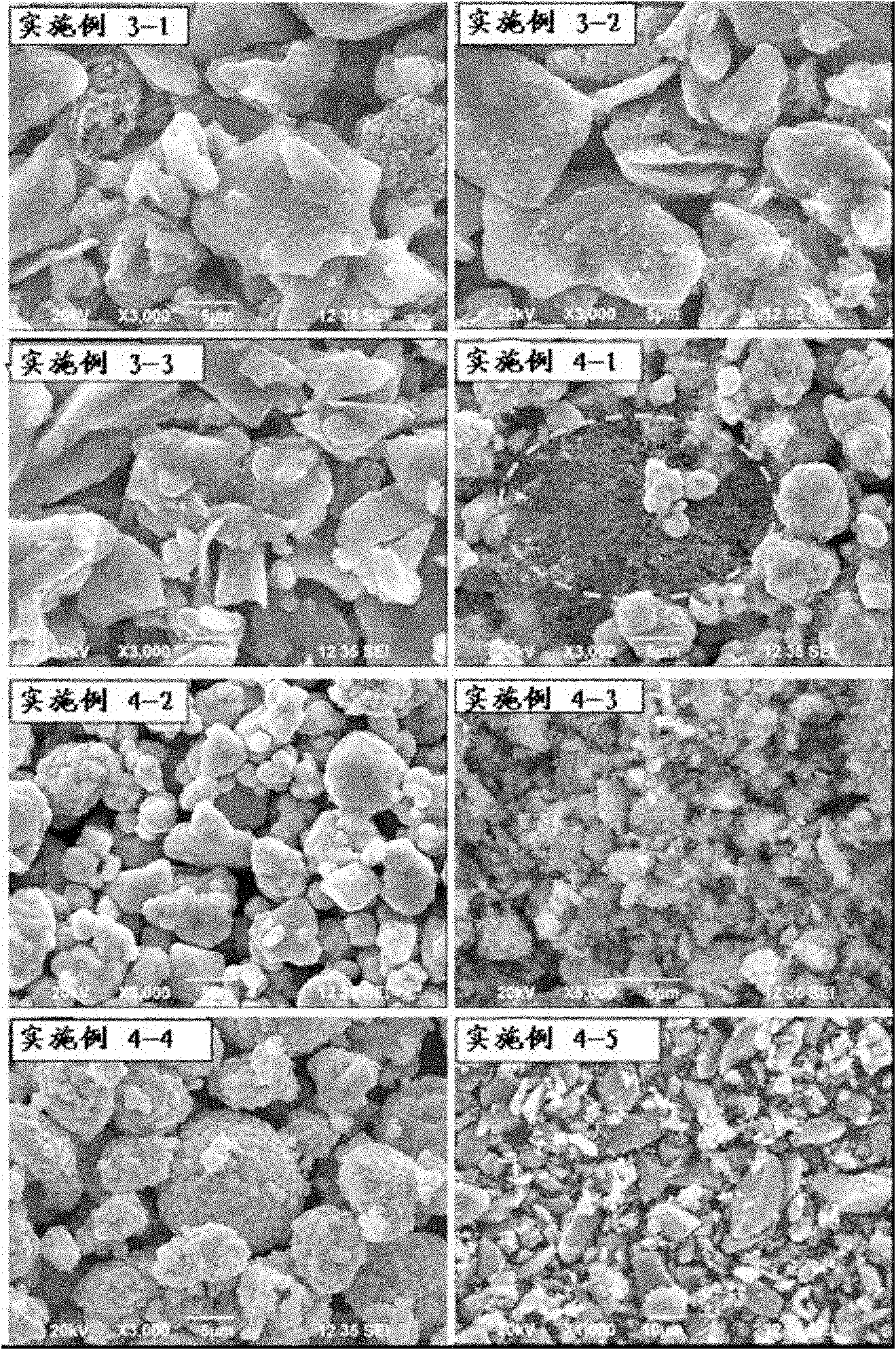

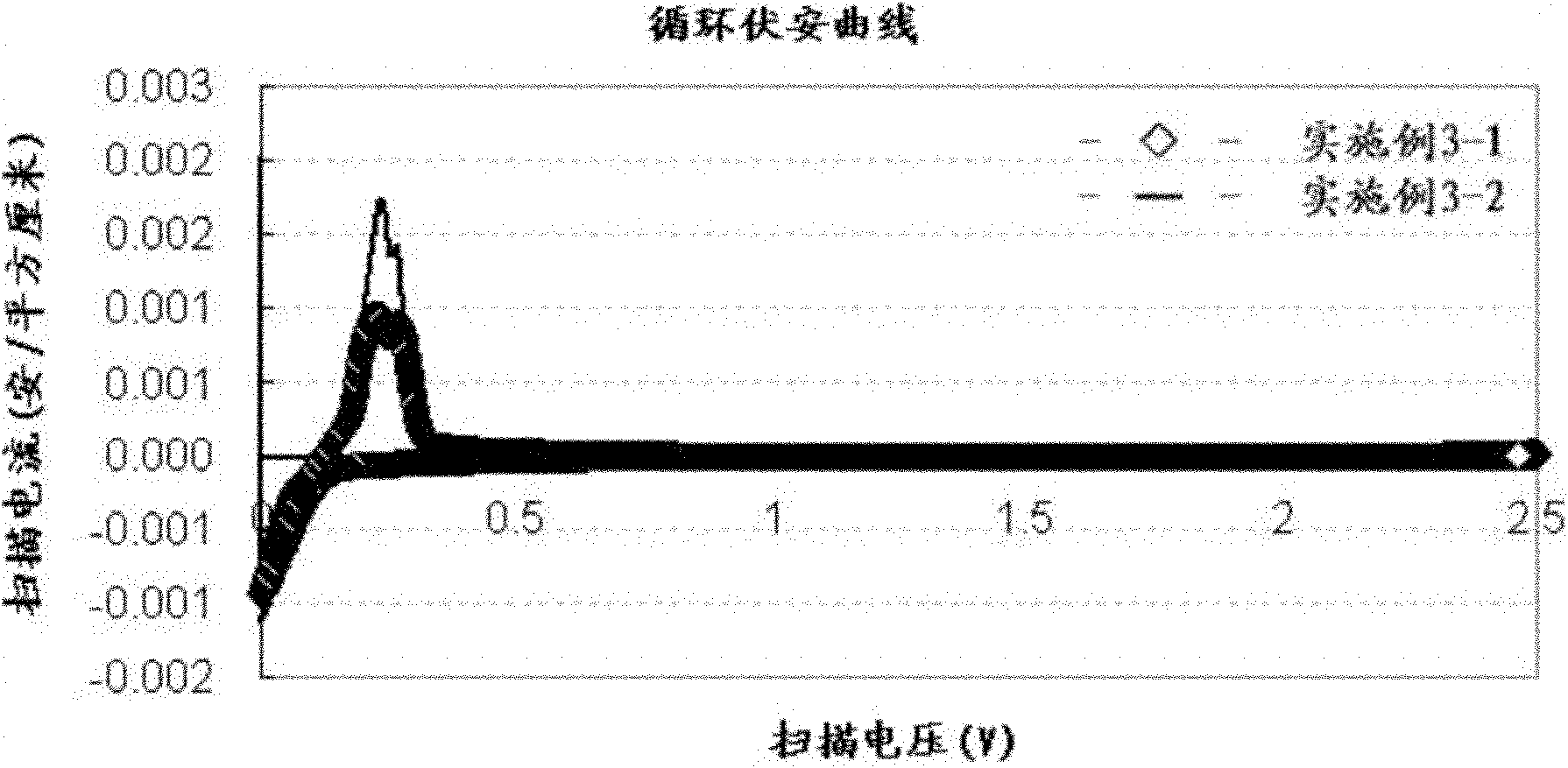

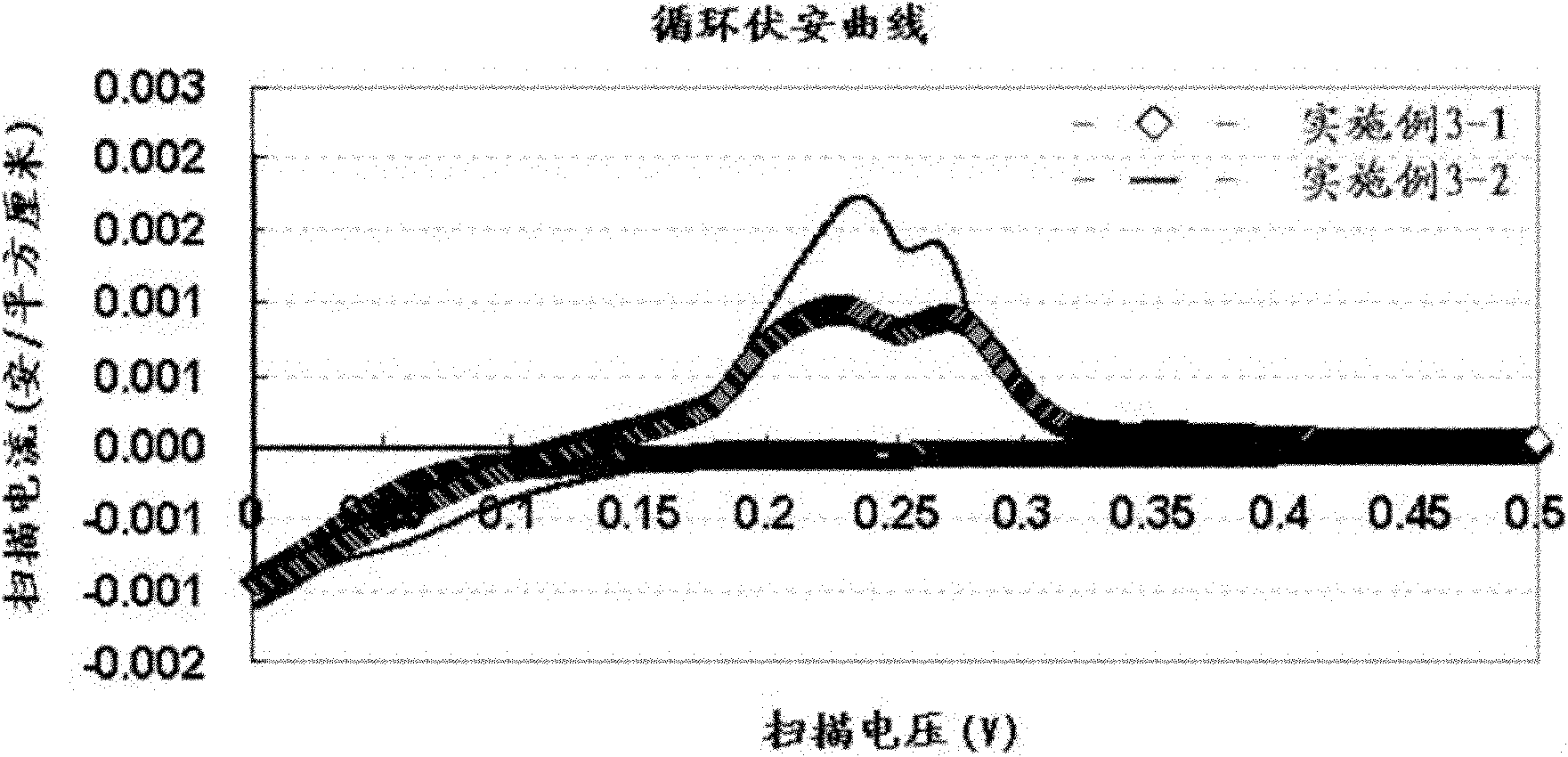

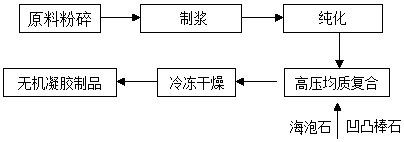

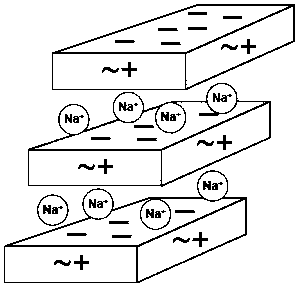

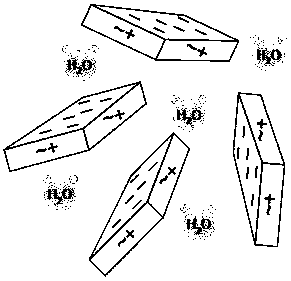

Preparation method for high-dispersibility high-viscosity magnesium aluminum silicate inorganic gel

InactiveCN107902662AGood rehydrationShorten dispersion timeAluminium silicatesFreeze-dryingAluminum silicate

The invention discloses a preparation method for a high-dispersibility high-viscosity magnesium aluminum silicate inorganic gel. The preparation method comprises the following steps: crushing a raw magnesium aluminum silicate material; mixing the raw magnesium aluminum silicate material, a modifier and water according to a certain mass ratio under stirring so as to prepare ore pulp; subjecting theore pulp to separation and purification by using a dynamic separation and purification process in virtue of a centrifugal force field and taking suspension; compounding the suspension with a functional mineral with a certain mass percent to form a multi-component mineral and carrying out high-pressure homogenization and compounding; and drying a homogenization product so as to prepare an inorganic gel product. According to the invention, a compact three-dimensional net structure is formed after compounding of the functional mineral and high-pressure homogenization; and since vacuum freeze-drying and dehydration are carried out, the physical structure and molecular structure of the magnesium aluminum silicate inorganic gel are maintained, excellent rehydration performance is obtained, andhydration dispersion time is greatly reduced. The preparation method is simple in steps and easy to implement. The prepared magnesium aluminum silicate inorganic gel has good practicability and wide applicability.

Owner:安徽国创非金属矿业科技有限公司

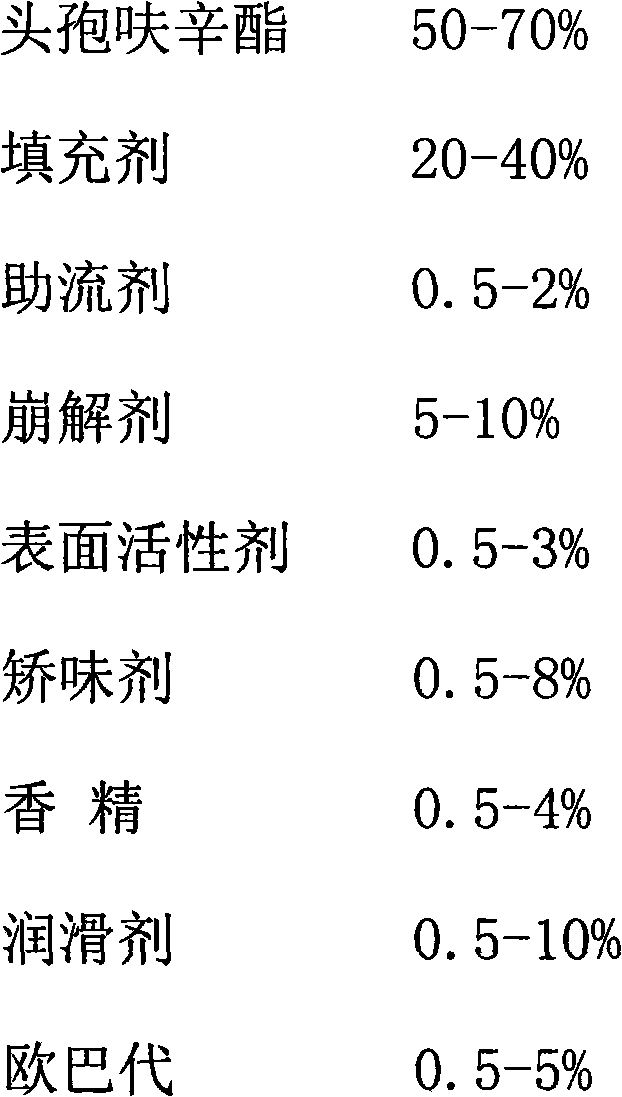

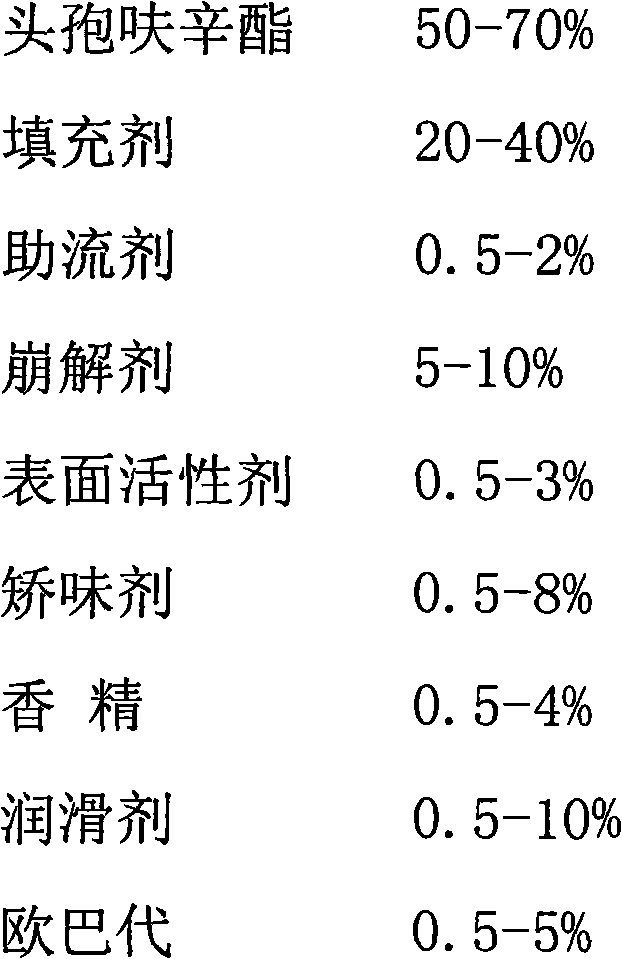

Dispersible tablet of cefuroxime axetil

InactiveCN102697747AReduce dosageShorten dispersion timeAntibacterial agentsOrganic active ingredientsSurface-active agentsMedical prescription

The invention provides a dispersible tablet of cefuroxime axetil, wherein the preparation formula includes cefuroxime axetil, loading agents, flow aid, disintegrating agents, surface-active agents, flavoring agents, lubricant, essence, and coating powder. According to the invention, specific disintegrating agents are adopted, meanwhile, the use amount of the disintegrating agents is not increased, the dispersion time of the dispersible tablet is shortened, and the dissolution rate of the dispersible tablet is improved; and meanwhile, flavoring agents and essence are added in the formula to mask bitter of the dispersible tablet of cefuroxime axetil, so that the mouth feel of a patient taking the dispersible tablet of cefuroxime axetil can be improved.

Owner:GUANGZHOU NANXIN PHARMA

Rana japonica oil polypeptide micro-capsule powder and preparation method thereof

InactiveCN104432040ARetain activityAvoid wastingFood dryingFood preparationCyclodextrinCellulose methyl

The invention discloses a rana japonica oil polypeptide micro-capsule powder and a preparation method thereof. The rana japonica oil polypeptide micro-capsule powder is prepared from the following components by weight percent: 10-20% of rana japonica oil polypeptide core material, 30-50% of maltodextrin, 10-20% of sodium carboxymethyl cellulose, 5-20% of beta-cyclodextrin and 5-10% of porous starch. The rana japonica oil polypeptide core material is prepared by treating a dry product of rana japonica oil in the following steps: selecting, soaking, performing colloid milling and performing enzymolysis by papain. The preparation method of the rana japonica oil polypeptide micro-capsule powder mainly comprises the following steps: 1, preparing a rana japonica oil polypeptide core material solution; 2, mixing solutions; 3, performing treatment of shearing emulsification; 4, performing spray drying and obtaining a finished product. In the preparation method disclosed by the invention, the rana japonica oil polypeptide micro-capsule powder is prepared by using a rana japonica oil polypeptide enzymolysis solution as a raw material and adopting a technology of low-temperature spray drying by appropriate wall material compatibility. The biological activity of polypeptide in the rana japonica oil enzymolysis solution is retained, and many performances of a product are improved. The rana japonica oil polypeptide micro-capsule powder not only can be preserved for a long time as a raw material for further processing, but also can be directly applied as a product, so that a new approach is provided for the deep processing of rana japonica.

Owner:HARBIN MO MEDICAL BIOLOGICAL TECH CO LTD

Lithium ion battery and positive electrode slurry stirring method therefor

InactiveCN110165146AImprove production pass rateHigh product consistencyCell electrodesTransportation and packagingDispersityManganate

The invention provides a lithium ion battery and a positive electrode slurry stirring method therefor, and belongs to the technical field of lithium ion batteries. The positive plate of the lithium battery comprises a positive current collector and positive slurry coated on the positive current collector, wherein the positive electrode slurry contains a positive electrode active substance, a conductive agent and a binder; the positive electrode active substance is a mixture of lithium nickel cobalt manganate, lithium iron phosphate and lithium manganite; a mixer circulating water temperature control regulating system comprises a temperature frequency conversion regulating switch and a circulating water heating system in the stirring process of the positive electrode slurry of the lithium ion battery, and the circulating water temperature of the circulating water heating system is set to be 45-75 DEG C. The dispersity of the lithium battery positive electrode slurry is improved, the stirring time is shortened, the production qualification rate and the consistency of the lithium batteries are improved, and the lithium battery positive electrode slurry has higher convenience and operability and economic and practical values.

Owner:HENAN FUSEN NEW ENERGY TECH

Forest frog oil polypeptide microencapsulation and preparation method thereof

InactiveCN103932183AReduce viscosityHigh dry matter contentFood homogenisationFood ingredientsChemistryWhey protein powder

The invention discloses a preparation method of forest frog oil polypeptide microencapsulation. The preparation method comprises the main steps of carrying out controllable enzymatic hydrolysis on forest frog oil to obtain a polypeptide core material solution, slowly adding a wall material under the mixing condition (wherein the wall material is prepared from the following components in percentage by weight: 1-10 percent of concentrated whey powder, 1-10 percent of maltodextrin and 0.5-5 percent of beta-cyclodextrine), adding 0.1-1 percent of monoglyceride, carrying out high-speed shearing and homogenizing treatment to obtain an emulsified feed liquid, and carrying out low-temperature spray drying treatment to obtain forest frog oil polypeptide microcapsule powder. With the adoption of the forest frog oil polypeptide microencapsulation, the content of a forest frog oil polypeptide core material is above 10 percent, the embedding rate is above 60 percent, the powder collection rate is above 53 percent, and the sensory property of the forest frog oil polypeptide microencapsulation powder is good without fishy smell; compared with core material spray drying powder without microencapsulation, the forest frog oil polypeptide microencapsulation powder has the advantages that the moisture content is lowered by above 30 percent, the solubility is increased by 3.5 percent, the hygroscopicity is lowered by 22 percent, and the dispersion time is shortened by above 30 percent. The preparation method has the characteristics that by virtue of the microencapsulation method, the fishy smell of a forest frog oil polypeptide product is removed effectively, the raw material waste is avoided, the operation is simplified and industrial production can be promoted.

Owner:JILIN UNIV

Preparation method of high-dispersity g-C3N4/TiO2 photocatalyst inorganic hydrosol

ActiveCN106238088AImprove stabilityImprove hydrophilic abilityGas treatmentPhysical/chemical process catalystsDispersityHydrogen

The invention discloses a preparation method of high-dispersity g-C3N4 / TiO2 photocatalyst inorganic hydrosol and belongs to the field of functional materials. The method comprises the following steps of: adding a g-C3N4 / TiO2 photocatalyst into a water solution containing an inorganic dispersant according to a certain ratio under a stirring condition; adding a small amount of peptizing agent and adjusting the pH (Potential of Hydrogen) value of a suspension solution; and carrying out shear emulsifying and stirring treatment to obtain the stable high-dispersity g-C3N4 / TiO2 photocatalyst neutral inorganic hydrosol. A preparation process has a simple flow and is simple and convenient to operate; an organic dispersant and a solvent are not used and the preparation cost is low; the prepared photocatalyst hydrosol has high dispersity and stability and is suitable for preparing photocatalyst slurry and a coating agent; the application of the photocatalyst to the field of a coating material is facilitated.

Owner:XINXIANG UNIV

High shearing production method for film coating agent

ActiveCN101559231AOvercoming electrostatic attractionAvoid destructionPharmaceutical delivery mechanismPharmaceutical non-active ingredientsLow speedPlasticizer

The invention relates to a high shearing production method for a film coating agent. The innovation of the invention is that the production method comprises the following steps of: refining of a colorant, coating of the colorant, compounding of the coated colorant, and plasticization of a mixture. The invention provides the innovative high shearing production method for the film coating agent, adopts a high-speed shearing mode to perform dry dispersion on an insoluble colorant, coats a surfactant to prevent the colorant from agglomerating at the same time, finishescomplete mixing of a film former and even distribution of a plasticizer under low-speed shearing conditions, and has the advantages of high production efficiency, low energy consumption, good application performance of obtained finished products of the coating agents and the like.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

Waterproof paint for building material and preparation method thereof

InactiveCN107011772AStrong corrosion resistanceIncreased durabilityAntifouling/underwater paintsPaints with biocidesEpoxyEmulsion

The invention discloses a waterproof paint for a building material, belonging to the technical field of building materials. The waterproof paint comprises the following raw materials by weight: 50 to 60 parts of epoxy resin emulsion, 3 to 10 parts of polyacrylate, 1 to 5 parts of a dispersing agent, 40 to 45 parts of cement, 8 to 12 parts of talcum powder, 0.2 to 5 parts of a dehydrating agent, 0.5 to 2 parts of a silane coupling agent, 0.2 to 0.4 part of an antiseptic, 1 to 3 parts of a polycarboxylate water reducer, 5 to 10 parts of pigment, 0 to 2 parts of a pH value regulating agent, 3 to 6 parts of a plasticizer, 0 to 2 parts of an antifoaming agent and 0.8 to 1 part of a liquid aromatic. The invention also discloses a preparation method for the waterproof paint for the building material. The waterproof paint provided by the invention has good corrosion resistance, durability, impermeability, compactness and high adhesion stress; and the preparation method is simple and reliable.

Owner:合肥慧林建材有限公司

The method of improving the oil absorption value of white carbon black products

InactiveCN102295845AHigh oil absorption valueReduce the impactPigment physical treatmentFiltrationEconomic benefits

The invention discloses a method for improving an oil absorption value of a white carbon black product. In order to overcome the defects that after performing pressure filtration, white carbon black prepared by the existing gel method is pulped for 2-3 hours, and the oil absorption value of white carbon black is reduced because of destruction of a mechanical force to a secondary structure of white carbon black, and the like, the method disclosed by the invention shortens the dispersing time of white carbon black slurry by shortening the pulping time of white carbon black, and refines the pulped white carbon black by using a refining pump. The method is used for improving the oil absorption value of the white carbon black product; and by using the method, the oil absorption value of white carbon black is improved by 0.3-0.4, and simultaneously, power consumption can be saved by about 55 kilowatt-hours when each ton of white carbon black is produced. Thus, the method has obvious economic benefits.

Owner:台泥(怀化)水泥有限公司

Water-based color paste and preparation method thereof

InactiveCN101845252AImprove light fastnessShorten grinding timeDyeing processPigment pastesWater basedLow speed

The invention discloses a water-based color paste and a preparation method thereof. The water-based color paste comprises a dispersant, water, an organic pigment and a preservative. The preparation method of the water-based color paste comprises the following steps: firstly, preparing a high-efficiency dispersant; adding 20-22% of high-efficiency dispersant, 41-45% of water, 35-45% of organic pigment and 0.15-0.25% of preservative into a dispersion machine; dispersing at low speed for 10 minutes; after all components are fully wetted, dispersing at high speed for 30 minutes; mixing all components into slurry; after dispersing, injecting the slurry into a horizontal sand mill for milling for 8-16 hours at the temperature lower than 20 DEG C to obtain the water-based color paste; then, filtering the color paste, and discharging the filtered color paste; and finally, detecting the discharged color paste. The invention has the advantages of simple preparation method, safety and environmental protection, shortens the reaction time, improves the production efficiency, and ensures the dispersibility of products.

Owner:LIWANG CHEM NANTONG

Method for preparing aluminium borate whisker preform

The invention discloses a preparation method for an aluminum borate whisker preform which is characterized by comprising the following steps: according to the proportion, aluminum borate whisker, aluminum phosphate, water and sodium polyacrylate are placed in an agitator, the rotating speed of which is adjusted to be 180 to 220 revolutions per second; the mixture is stirred and dispersed for a plurality of times in a time-shared way, and then mixed slurry is obtained; 80 percent of water in the mixed slurry is filtered and the rest is placed in a concave mould for pressure maintaining for five to eight minutes; the mould is taken off to gain a bisque of the preform; the dried bisque of the preform is sintered at the temperature of 800 to 900 DEG C in a muffle furnace for two to three hours; the bisque is cooled with the furnace and the whisker preform is obtained. In the method, the sodium polyacrylate with concentration of 0.3 to 0.5 percent is taken as dispersant, the aluminum borate whisker is stirred and dispersed for a plurality of times in the time-shared way, and meanwhile the aluminum phosphate is added as adhesives, so that the whisker is guaranteed to be fully soaked and then dispersed, and meantime, the adhesives is totally fused into the slurry. Compared with the present ultrasonic dispersion technique, the method shortens the original dispersion time of one to two hours to 3.5 to 5.5 minutes, thus reducing the cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Black polyimide film and preparation method thereof

The invention relates to a black dulling polyimide film, belongs to the field of high polymer materials, and particularly relates to a black polyimide film and a preparation method thereof. The black polyimide film comprises black mixed solution and polyamic acid resin, wherein the black mixed solution is composed of carbon powder and a dimethylacetamide solution. The black polyimide film comprises 5-15 parts of black mixed solution and 70-215 parts of polyamic acid resin. The black mixed solution comprises, by weight parts, 1-3 parts of carbon powder and 4-12 parts of dimethylacetamide solution. Packing adopted for the black polyimide film has good dyeing capability, is excellent in color stabilizing performance and can be well dispersed in the polyamic acid resin to form uniform and stable suspension. Compared with the prior art, according to the black polyimide film and the preparation method, the dispersion time of the carbon powder is shortened, the dispersion effect is guaranteed; and the produced film is stable in thermal properties, high in coefficient of thermal expansion and thermal decomposition temperature, and wide in use range.

Owner:万达集团股份有限公司

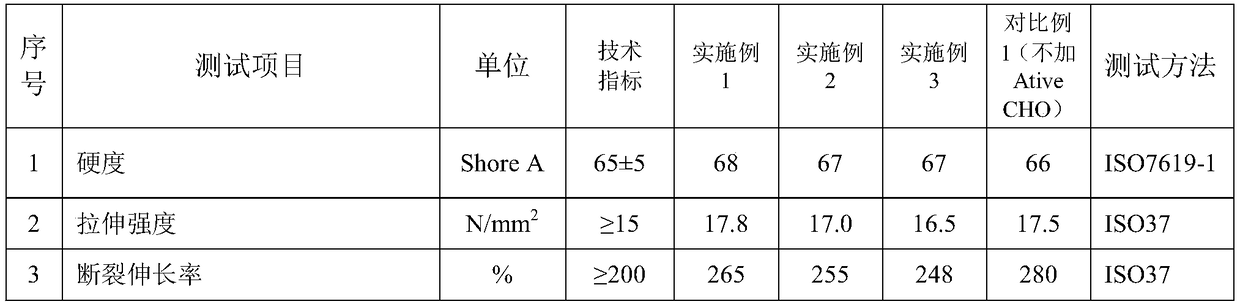

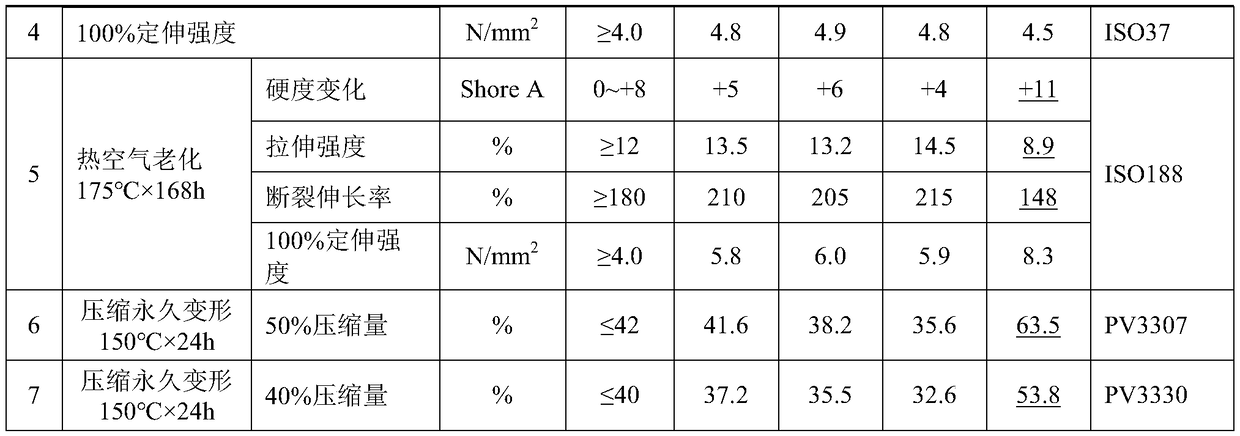

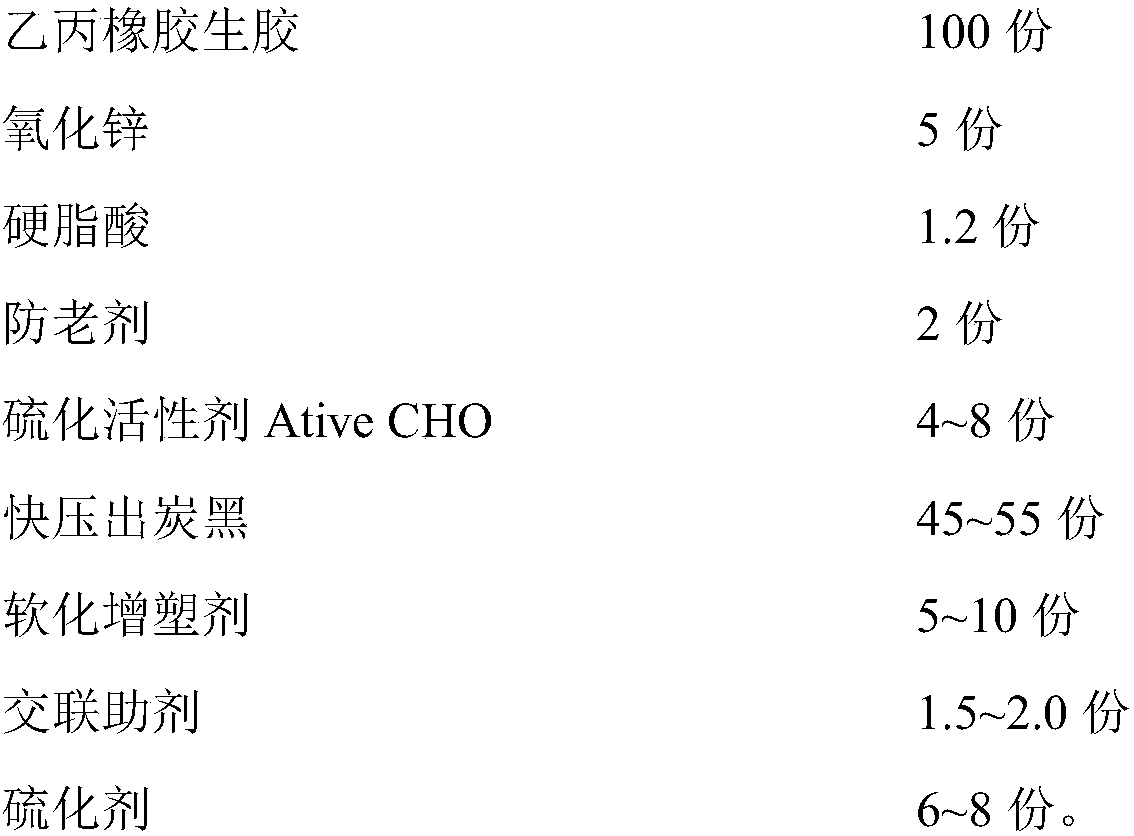

Low-compressive creep and high temperature-resistant ethylene propylene rubber material and preparation method thereof

The invention discloses a low-compressive creep and high temperature-resistant ethylene propylene rubber material and a preparation method thereof, and belongs to the technical field of rubber. The rubber material comprises the following components in parts by weight: 100 parts of raw ethylene propylene rubber, 5 parts of zinc oxide, 1.2 parts of stearic acid, 2 parts of an antiager 445, 4-8 partsof Ative CHO, 45-55 parts of fast extruding carbon black N550, 5-10 parts of a softening and plasticizing agent S2550, 1.5-2.0 parts of a crosslinking auxiliary agent N308E and 6.0-8.0 parts of a vulcanizing agent GF-45. The rubber material has excellent high temperature resistance, has good physical properties after aging at 175 DEG C, has a significant advantage of low compression set, and meets performance requirements of German Volkswagen PV3330 and PV3307 standards on the compression set.

Owner:南京金三力高分子科技有限公司

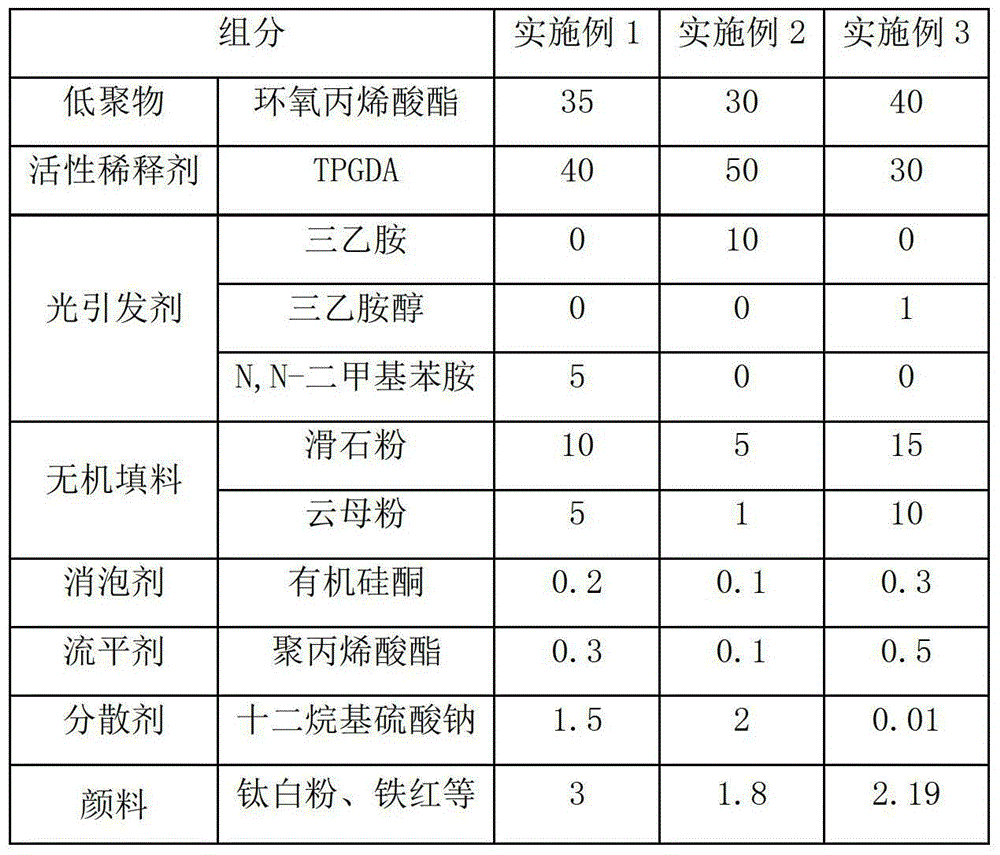

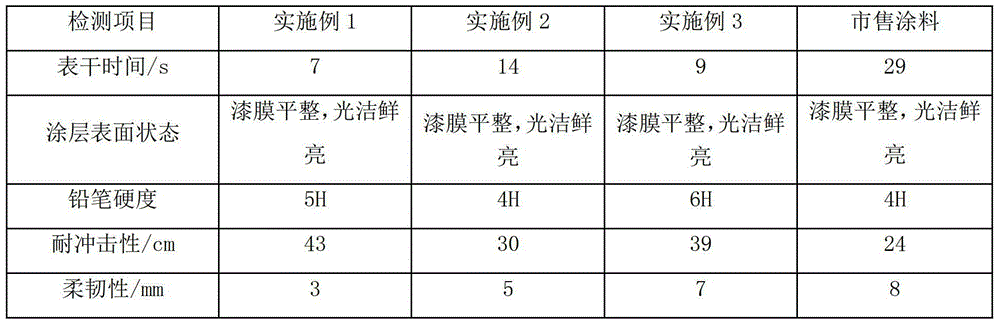

Heat-resistant insulating paint with fast curing speed

The invention provides a heat-resistant insulating paint with fast curing speed. The heat-resistant insulating paint comprises the following ingredients in parts by weight: 30-40 parts of epoxy acrylate, 30-50 parts of activated diluent, 1-10 parts of photoinitiator, 5-15 parts of talcum powder, 1-10 parts of mica powder, 0.1-0.3 parts of defoaming agent, 0.1-0.5 parts of levelling agent, 0.01-2 parts of wetting dispersing agent, and the balance of pigment, wherein the mass ratio of epoxy resin to acrylic acid in the epoxy acrylate is 2:1, and the activated diluent is triuret propylene glycol diacrylate. The heat-resistant insulating paint with fast curing speed has the advantages of being fast to cure, and good in impact resistance and flexibility and other mechanical properties, the paint is good in insulation and heat resistance, as well as green and environmentally-friendly, thus being a heat-resistant insulating paint which is wide in application range and suitable for use in large-scale production.

Owner:江苏达胜热缩防护用品有限公司

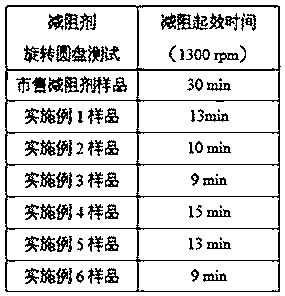

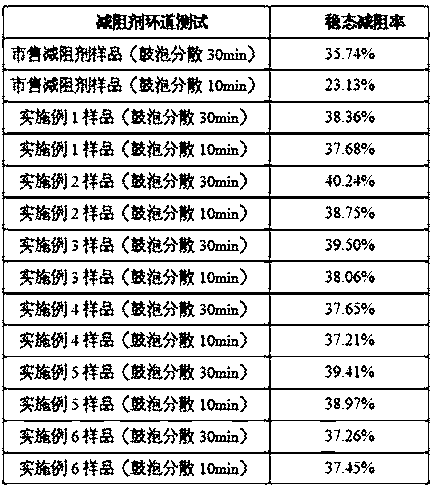

Polymer drag reducer swelling treatment method for shortening onset time of drag reducer

ActiveCN108980621AReduce swellingRapid drag reduction and output increase effectPipeline systemsBulk chemical productionChemistryDrag reducing agent

The invention relates to a polymer drag reducer swelling treatment method for shortening the onset time of a drag reducer. According to the technical scheme, the method comprises the following steps of firstly, cutting a polymer solid body into pieces, and placing the pieces into a reaction still; secondly, filling the reaction still with carbon dioxide to enable the reaction still to be in the supercritical state; thirdly, after polymers swell, deloading the carbon dioxide in the reaction still and taking out samples; fourthly, weighing the samples, and placing the samples into a freezing barrel for low-temperature treatment; fifthly, transferring the samples into a crusher to be roughly broken and ground; and sixthly, adding parting agents, and after ball milling and mixing, obtaining apulpous oil product drag reducer product which takes effect quickly. The polymer drag reducer swelling treatment method for shortening the onset time of the drag reducer has the beneficial effects that treatment is carried out through supercritical fluid before low-temperature crushing to enable the polymers to have the swelling effect and then be subjected to low-temperature crushing and grinding, the technological requirements for sufficient isolation and suspension are met, and therefore, with the treatment method, the time for swelling, dissolution and dispersion of the drag reducer in theoil product can be shortened, and the drag reducer can show the drag reduction and delivery quantity increase effects more quickly.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

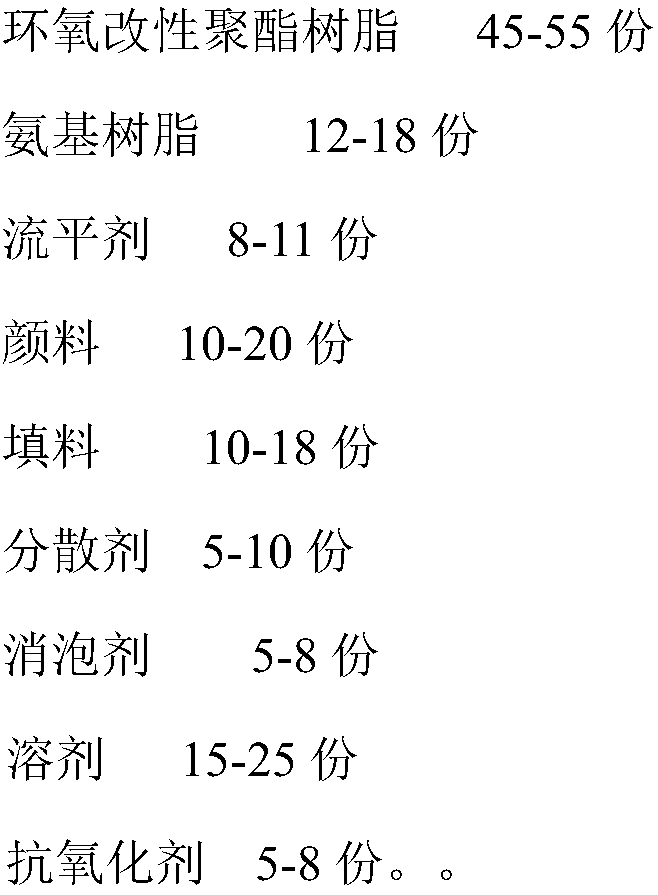

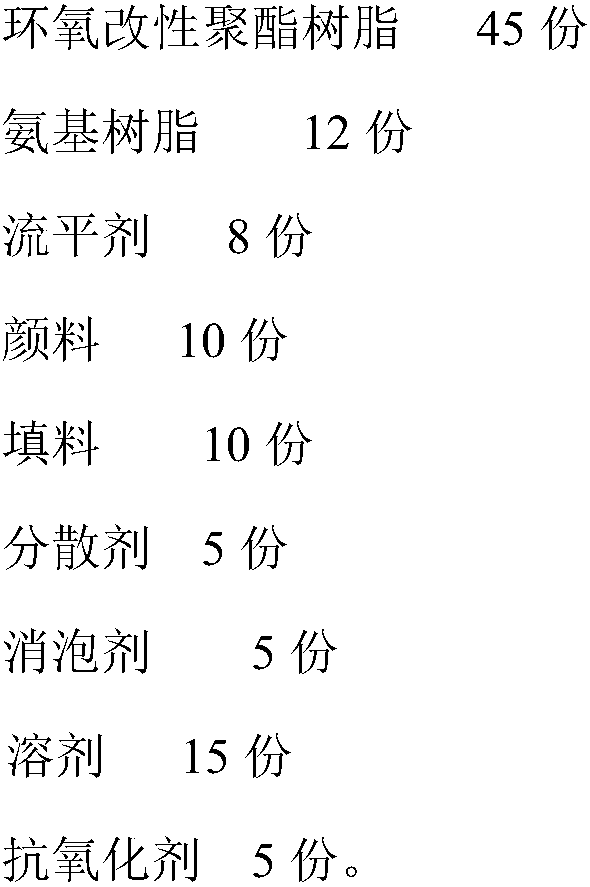

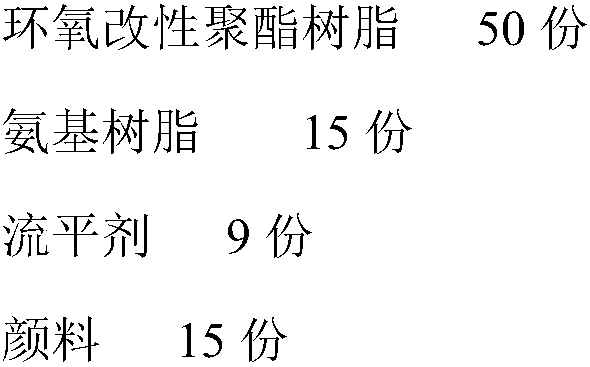

Coil coating and preparation method thereof

ActiveCN108441090AHigh hardnessImprove toughnessFireproof paintsAntifouling/underwater paintsEpoxyAntioxidant

The invention belongs to the technical field of coatings, in particular to a coil coating and a preparation method thereof. The coil coating comprises 45-55 parts of epoxy modified polyester resin, 12-18 parts of amino resin, 8-11 parts of a leveling agent, 10-20 parts of pigment, 10-18 parts of filler, 5-10 parts of a dispersant, 5-8 parts of an antifoaming agent, 15-25 parts of a solvent and 5-8parts of an antioxidant. The problems of poor adhesion, low flexibility, poor scratch resistance and poor acid and alkali resistance of coil coatings in the prior art are solved.

Owner:DONGGUAN DAXING CHEM

Fluorescent powder dispersion method

InactiveCN101173169AShorten the process manufacturing cycleShorten dispersion timeLuminescent compositionsPhosphorBrightness perception

The invention relates to a method for dispersing phosphor, which adopts the process that: first, the phosphor, water and dispersant are mixed and then dispersed by a dispersion machine; after being dispersed, a dispersing ball is fished out and then the phosphor serum is separated by decompressing dispatch; at last, the separated phosphor serum is dehydrated in order obtain dispersed green emitting phosphor. The invention has the advantages of simple technology, short cycle for manufacturing phosphor, low manufacturing cost of phosphor, small decreasing extent of phosphor brightness and high phosphor brightness. The invention adopts a columniform nylon ball with smaller specific gravity than the phosphor and small impact to the phosphor; therefore, the ball can open the phosphor for agglomerating without damaging the surface of single phosphor crystal, thus, the decreasing extent of dispersed phosphor brightness is very small and the brightness of the product coated with phosphor is high.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Method for improving dispersibility of organic soil

InactiveCN101948116AIncreased dispersionImprove dispersion stabilitySilicon compoundsOrganic solventRandom order

The invention provides a method for improving dispersibility of organic soil. The method comprises the following steps of: (1) taking the organic soil, organic solvent and oil-soluble nonionic surfactant; and (2) mixing the organic soil, the organic solvent and the oil-soluble nonionic surfactant in random order to form mixed solution; stirring the mixed solution at room temperature for uniform dispersion, wherein for the oil-soluble nonionic surfactant which is solid at the room temperature, the oil-soluble nonionic surfactant is stirred on the premise of ensuring the dissolution temperatureof the solid oil-soluble nonionic surfactant after being mixed with the organic soil and the organic solvent; and obtaining an organic soil colloidal dispersion system with good dispersibility and high stability after stirring for uniform dispersion. The method has simple and convenient operation, and can effectively improve the dispersion degree of the organic soil in the non-polar solvent and the stability of the dispersion system colloid, obviously shorten the dispersion time of the organic soil in the non-polar solvent, reduce the energy consumption and reduce the cost.

Owner:SHANDONG UNIV +1

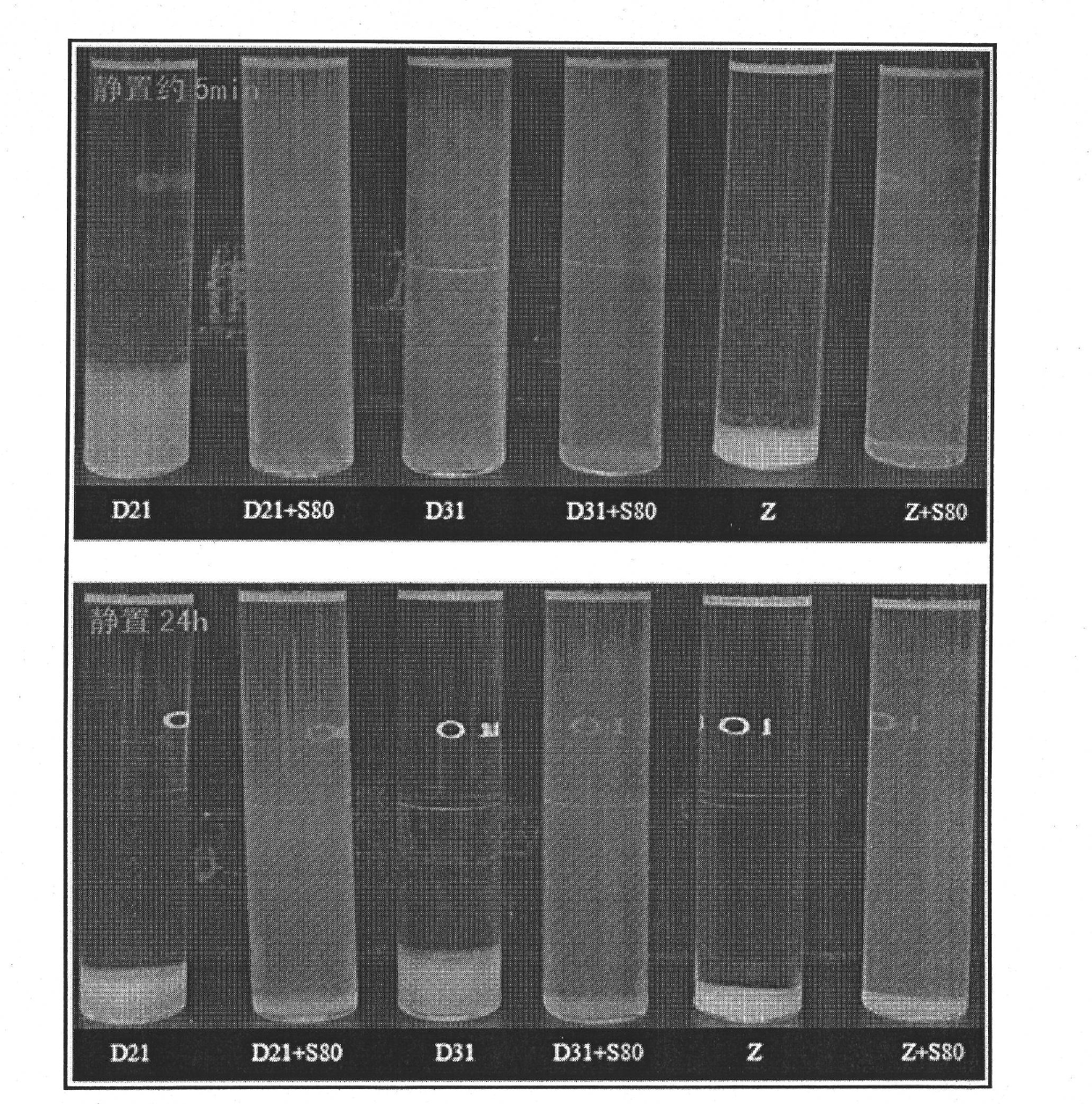

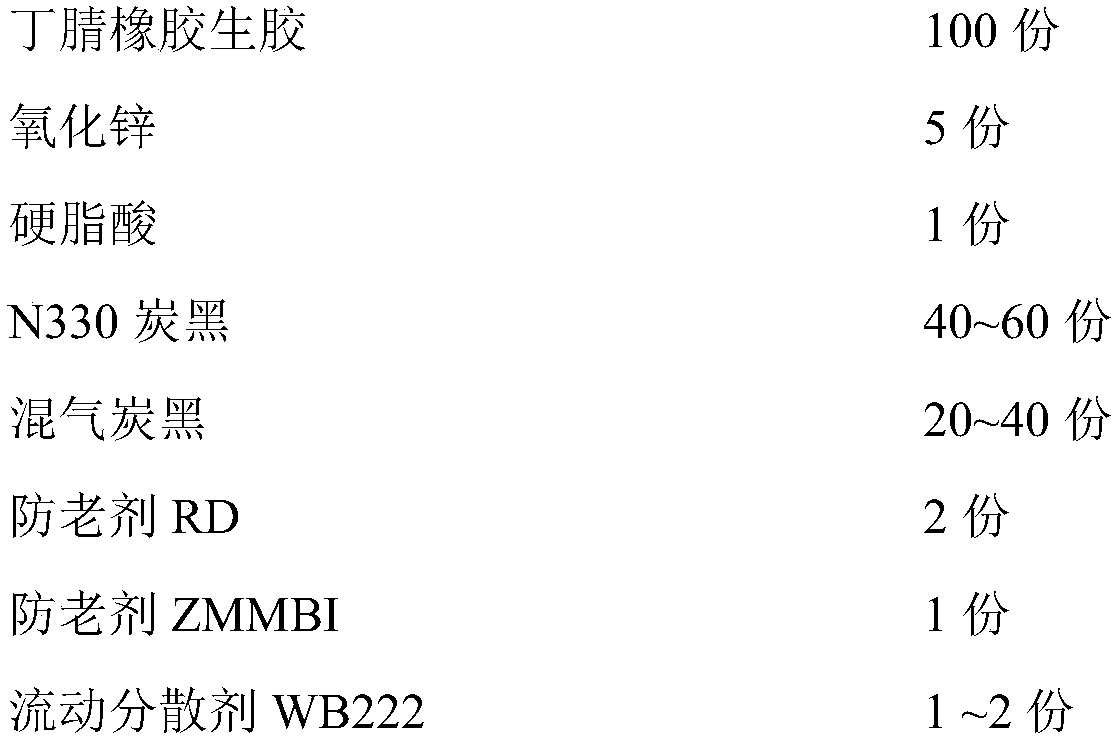

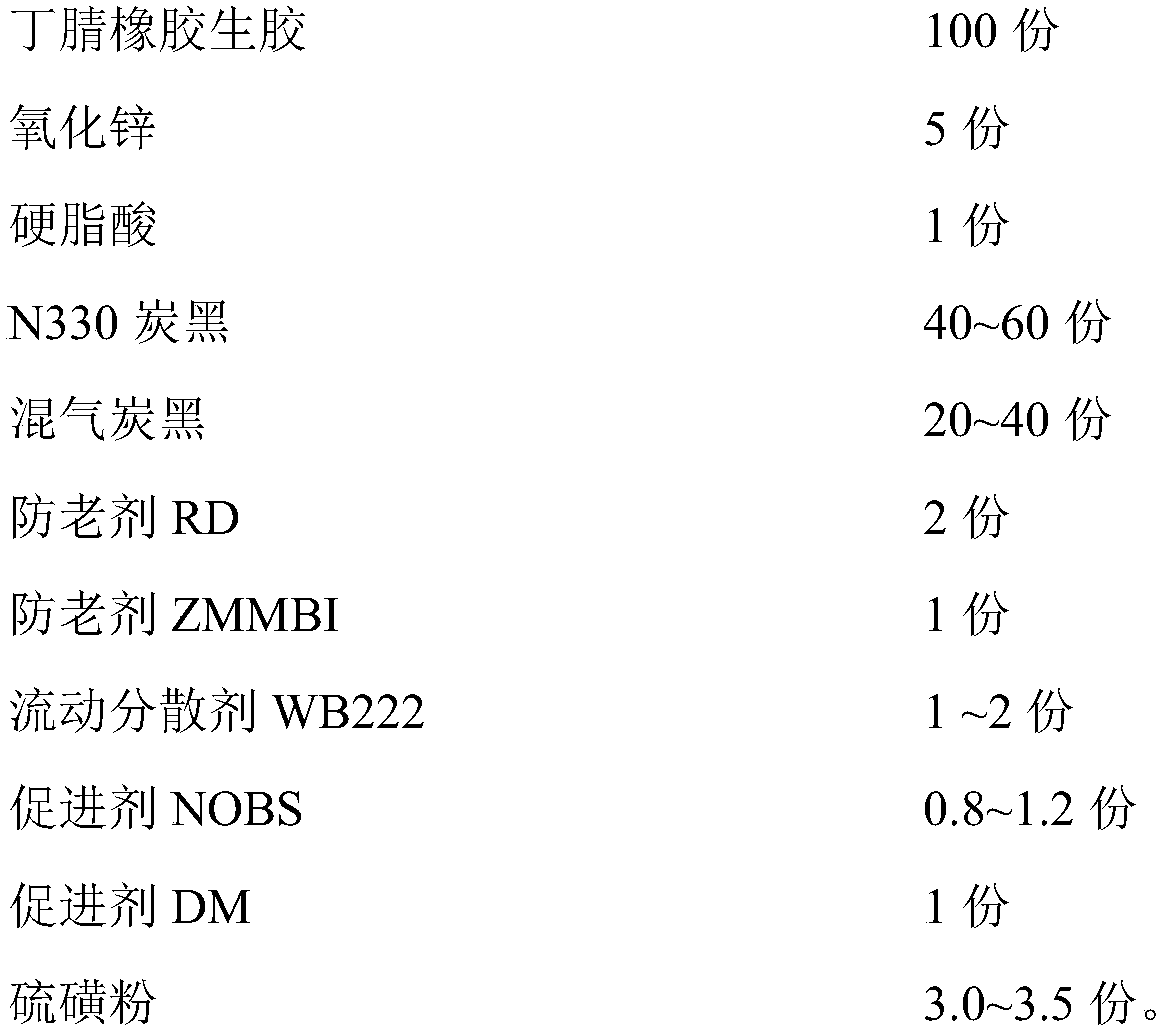

High-hardness butyronitrile rubber material for preventing scorching and preparation method thereof

The invention discloses a high-hardness butyronitrile rubber material for preventing scorching and a preparation method thereof, and belongs to the technical field of rubbers. The rubber material is prepared from, 100 parts of butyronitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 40-60 parts of N330 carbon black, 20-40 parts of gas-mixture carbon black, 2 parts of anti-aging agent RD, 1 part of antioxidant ZMMBI, 2 parts of flow dispersant WB222, 0.8-1.2 parts of accelerator NOBS, 1 part of accelerator DM and 3.0-3.5 parts of sulfur powder. Through the improvement ofa formulation and the preparation method, the scorching prevention purpose can be achieved without adding a scorching retarder in the process of preparing the high-hardness butyronitrile rubber. The high-hardness butyronitrile rubber material prepared by the method has hardness of 85 or more than 85 Shore A, elongation at break is not less than 250%, and the obtained butyronitrile rubber materialhas no scorching phenomenon and good process performance.

Owner:南京金三力高分子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com