Patents

Literature

1158results about How to "Strong corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmentally-friendly corrosion-resistant chromium-free chemical conversion liquid and method for preparing chemical conversion film

InactiveCN102409325AEasy to store and transportStrong corrosion resistanceAnti-corrosive paintsMetallic material coating processesSolventCorrosion resistant

The invention relates to the field of aluminum alloy surface treatment, in particular relates to an environmentally-friendly corrosion-resistant chromium-free chemical conversion liquid and an application thereof in an environmentally-friendly corrosion-resistant chromium-free chemical conversion film with aluminum alloy coating adhesion for ships, and solves the problems of incapability of meeting the requirements on corrosion resistance and coating adhesion in the current environmentally-friendly chemical conversion treating process. The prepared chemical conversion film has excellent corrosion resistance and coating adhesion, is convenient in construction and can be used for substituting for a traditional chromium-containing chemical conversion and phosphate treatment process. The environmentally-friendly corrosion-resistant chromium-free chemical conversion liquid mainly comprises the components of silane, corrosion inhibition components and a solvent. The chromium-free chemical conversion film construction modes comprise dipping, roller painting and spraying, and the curing modes comprise natural curing and heating curing. The environmentally-friendly corrosion-resistant chromium-free chemical conversion film in the invention has excellent corrosion resistance and coating adhesion, can be used for substituting for a traditional chromium-containing chemical conversion and phosphate treatment process, and is applicable to aluminum alloys for ships such as 5xxx and 6xxx series aluminum alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

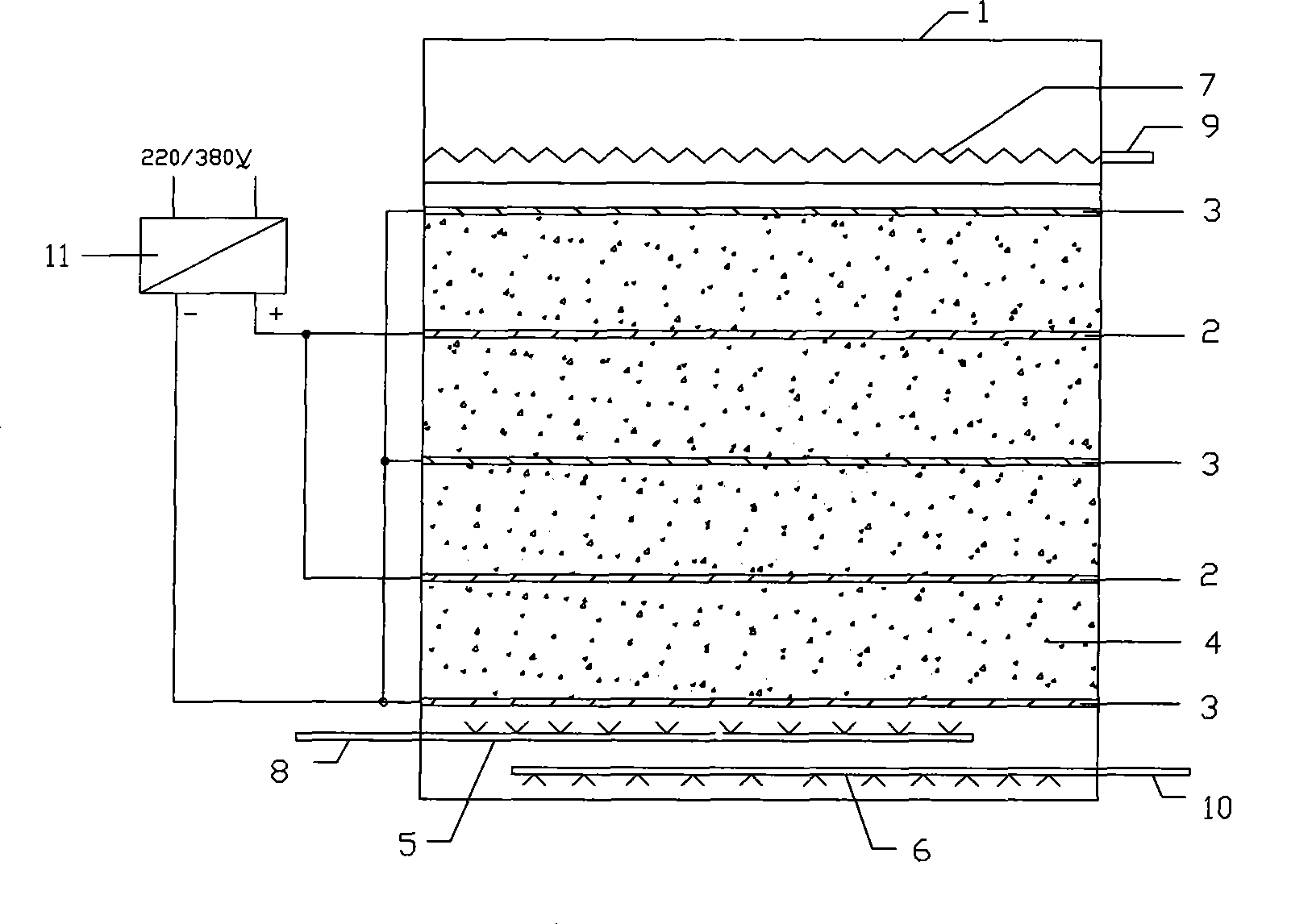

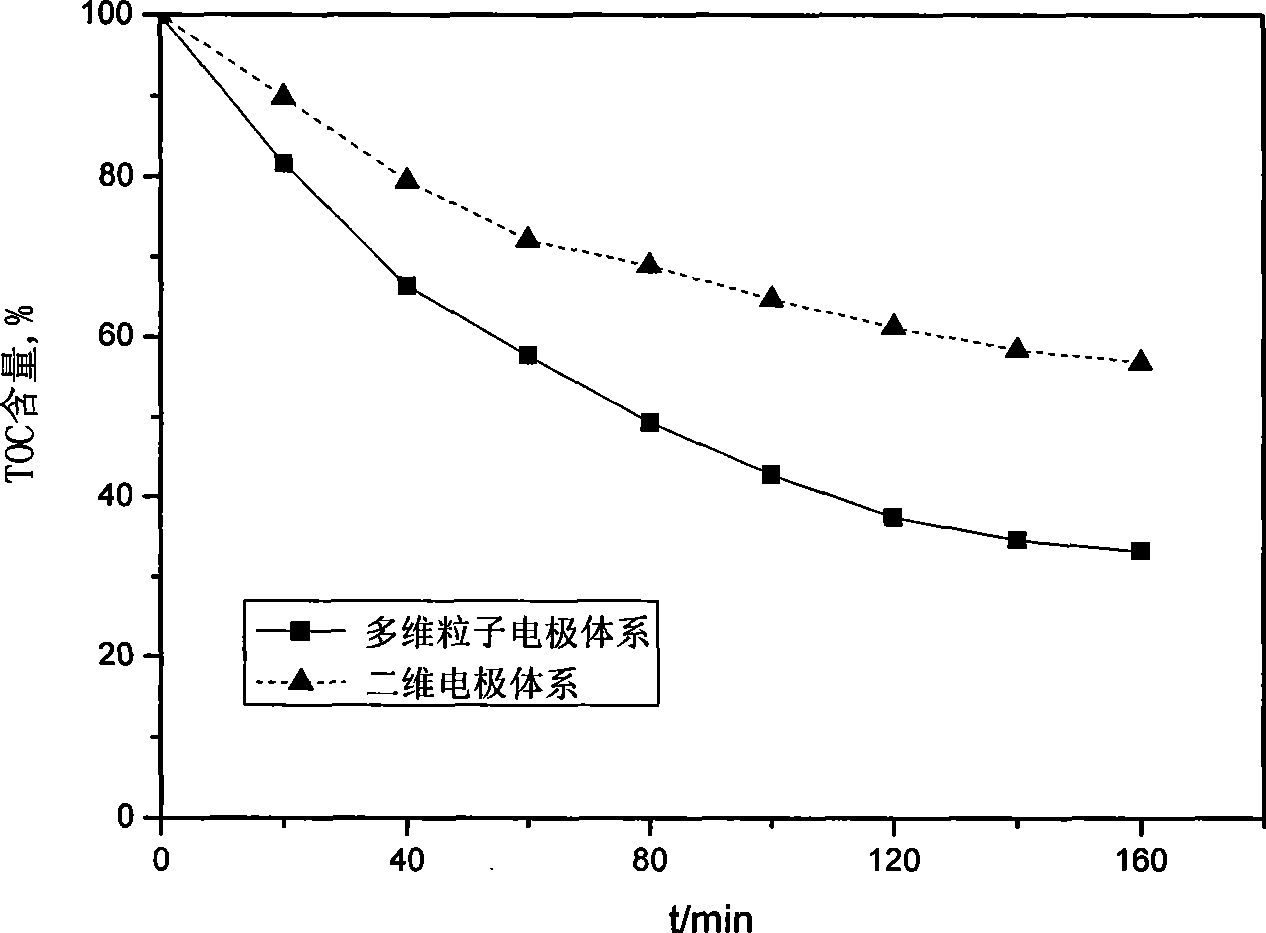

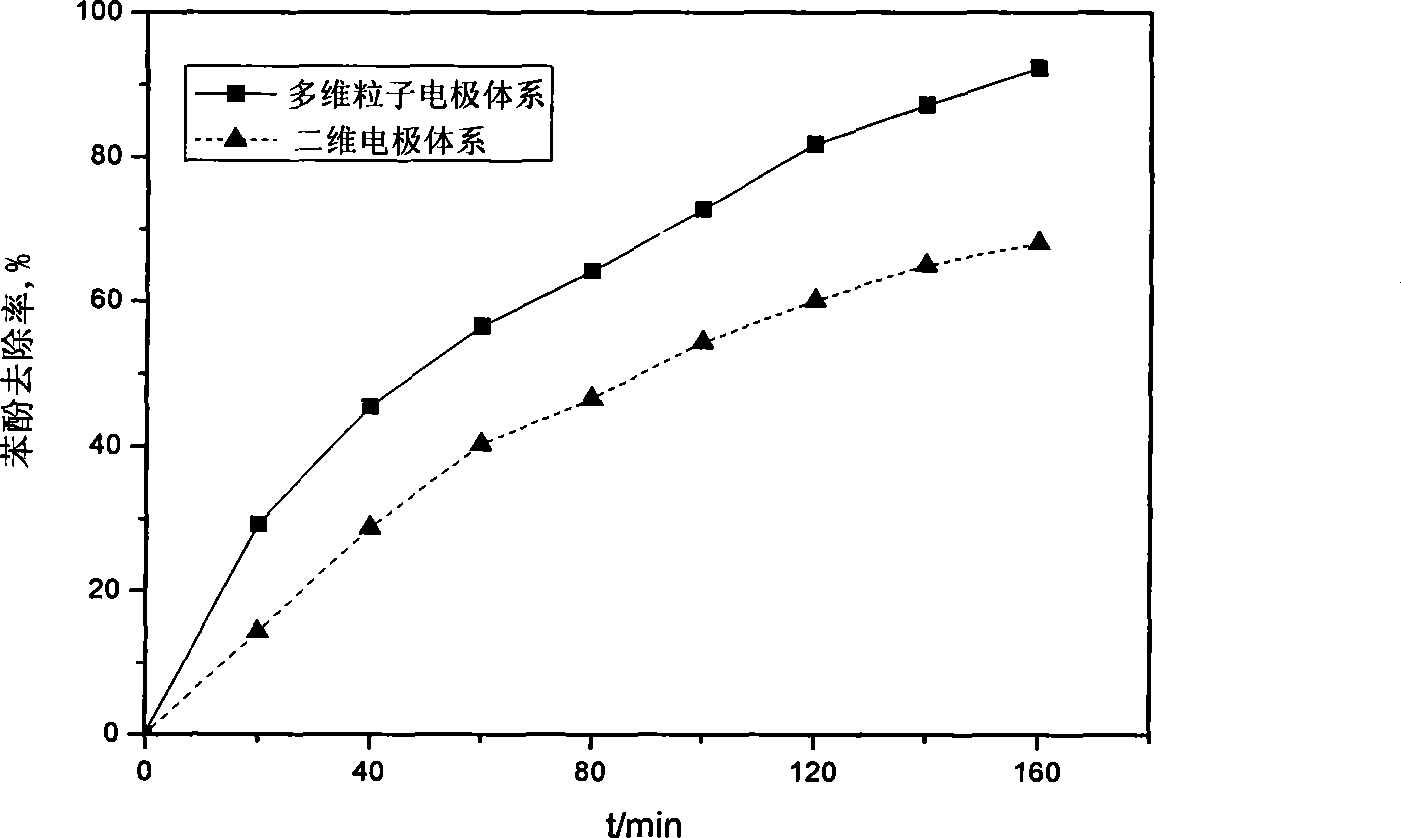

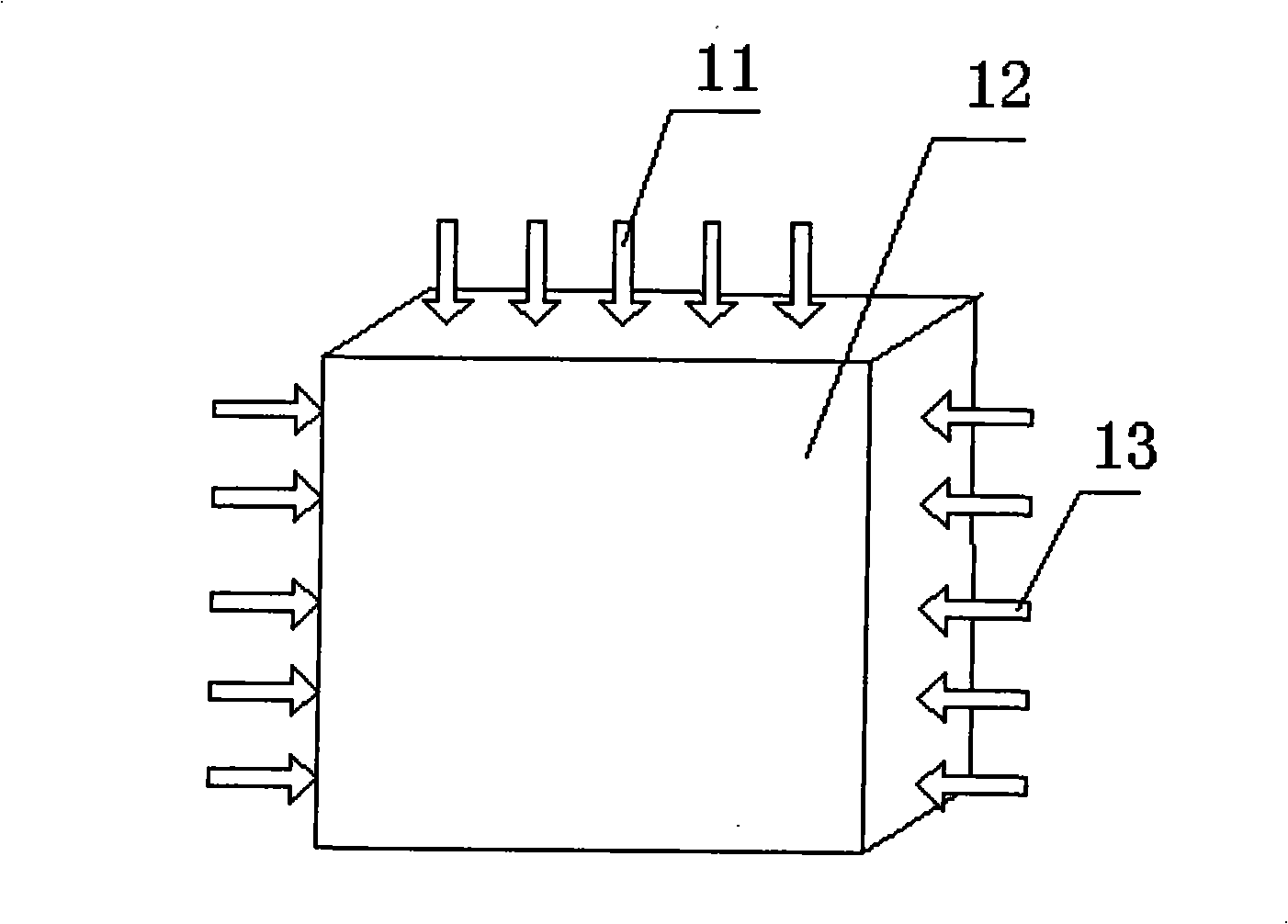

Wastewater treatment device of horizontal polar plate multi-electrodes electrocatalysis reactor

ActiveCN101423266AGuaranteed to alternateAvoid short circuitWater/sewage treatment by electrochemical methodsElectricityWater flow

Horizontal polar plate multi-dimensional electrode electrocatalysis reactor wastewater treatment equipment comprises a shell, a cathode plate and an anode plate which are relatively parallel, a particle electrode filled between the cathode plate and the anode plate, a water distributor, a water inlet pipe, an aerator, an air inlet pipe, an effluent weir trough, a water outlet pipe and a power supply; the cathode plate and the anode plate are respectively connected with the cathode and the anode of the power supply; a plurality of through holes are distributed on the cathode plate and the anode plate which are horizontally positioned in the shell of the equipment; the water distributor, the water inlet pipe, the aerator and the air inlet pipe are positioned at the lower part of the shell of the equipment; and the effluent weir trough and the water outlet pipe are arranged at the upper part of the shell of the equipment. After being evenly distributed by the water distributor, the wastewater flows across a reactor from bottom to top; the horizontal polar plate structure design not only avoids the short circuit of water flow and improves the mass transfer effect, but also ensures that the wastewater can alternatively flow across the cathode plate and the anode plate and the oxidation reaction of the anode plate and the reduction reaction of the cathode plate coexist in a system, and causes different organic pollutants in wastewater which can be degraded by the oxidation reaction and the reduction reaction to be degraded and treated.

Owner:南京赛佳环保实业有限公司

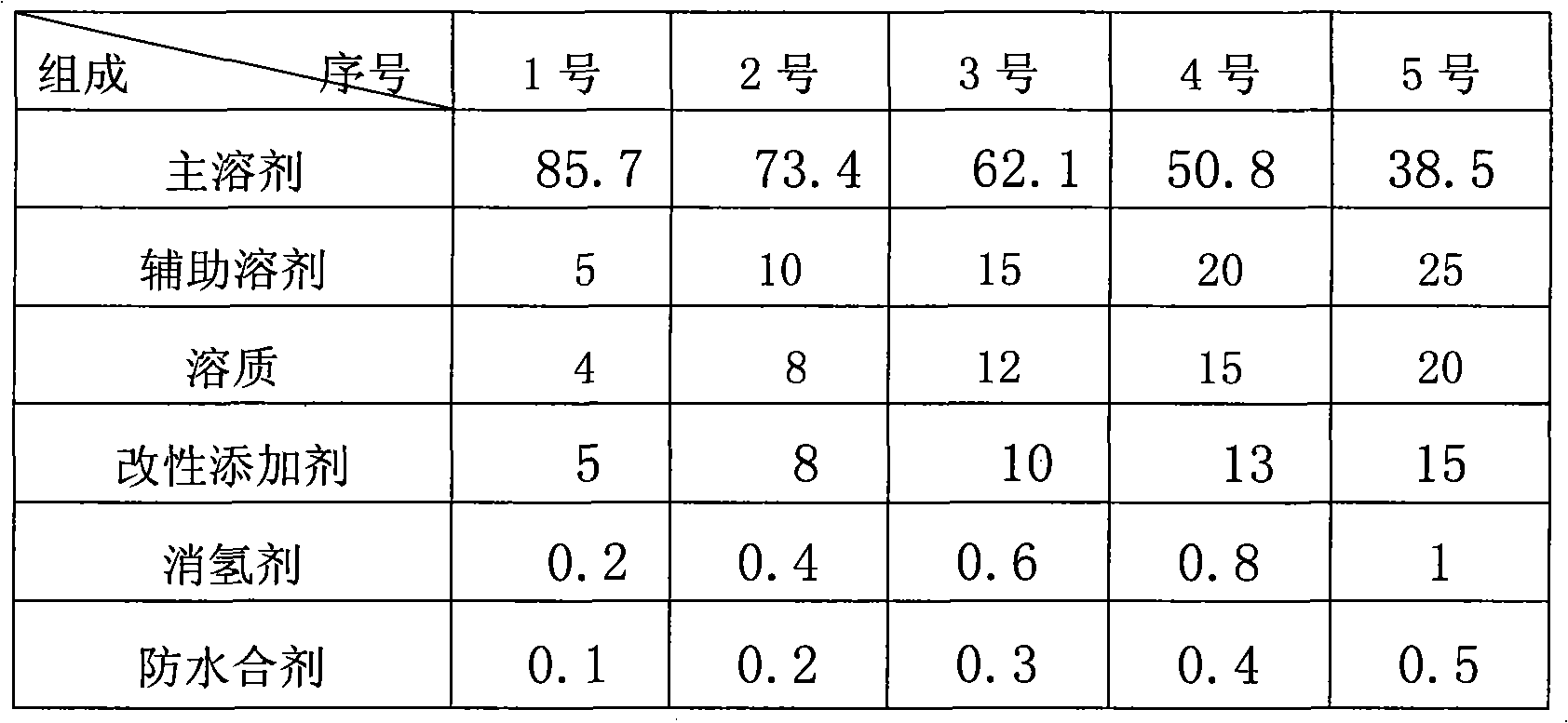

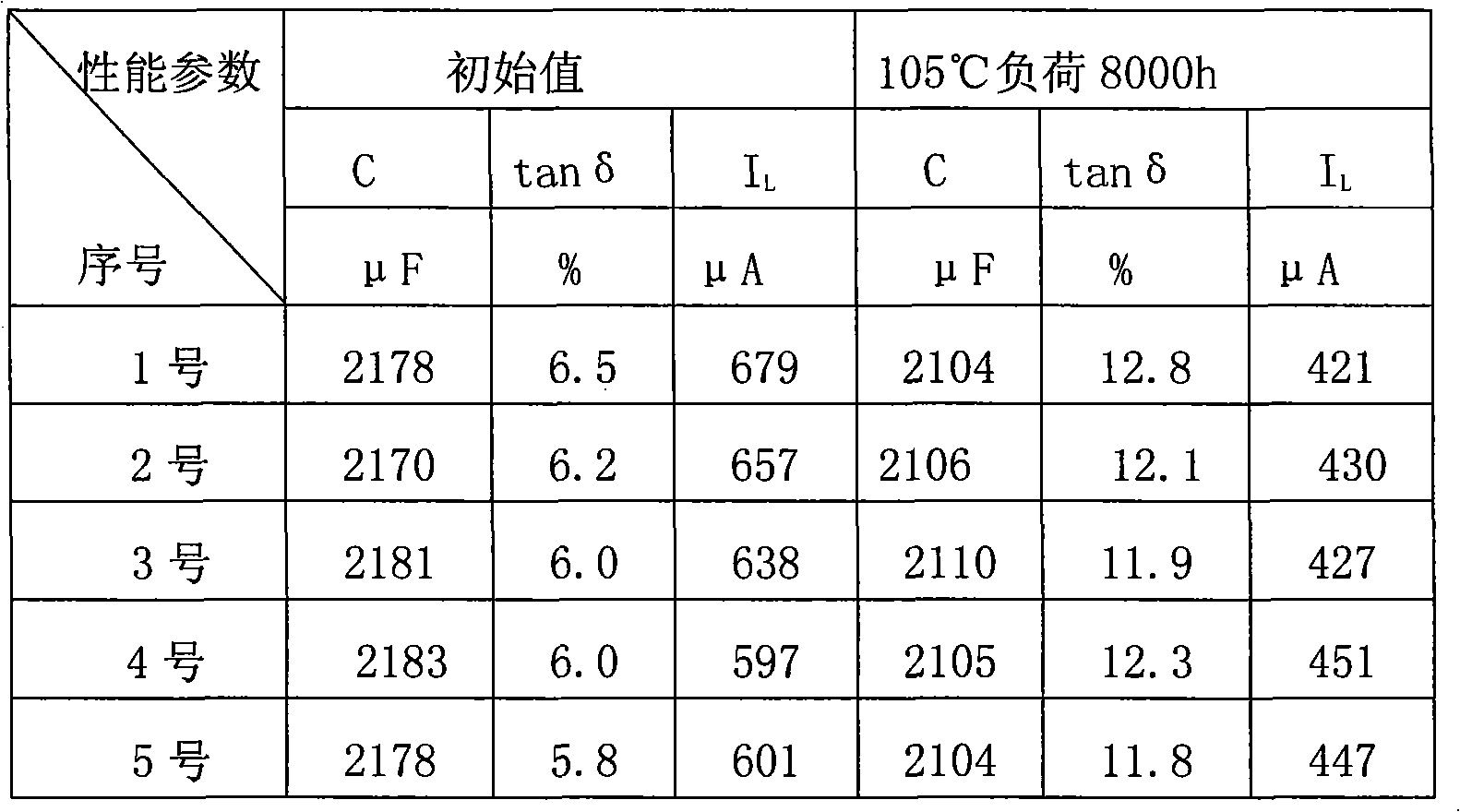

Electrolysis solution and preparation method thereof as well as preparation method for obtained aluminum capacitor

ActiveCN101556867AIncrease the flash voltageStrong corrosion resistanceLiquid electrolytic capacitorsChemistryCorrosion

The invention relates to electrolysis solution and a preparation method thereof as well as a preparation method for an obtained aluminum capacitor. The electrolysis solution is composed by the components according to the following weight by parts: 38.5-85.7 wt % of primary solvent, 5-25 wt % of auxiliary solvent, 4-20 wt % of solute, 5-15 wt % of modified additive, 0.2-1 wt % of hydrogen eliminating agent and 0.1-0.5 wt % of waterproof combination agent. The primary solvent is glycol; the auxiliary solvent is one or more of tributyl phosphate, mono butyl ester phosphate, diglycol dibutyl ether; the solute is one or more of ammonium sebacate, 1.6-dodecyl ammonium bisgallic acid, 1.10-dodecyl ammonium bisgallic acid organic carboxylate. In the preparation method for the aluminum capacitor using the electrolysis solution, positive pressure and vacuum-pumping is required to be applied in an impregnation tank in an alternate recycle way with the recycle impregnation interval period being 20-60min.The electrolysis solution has the characteristics of high temperature resistance, high sparking pressure and strong corrosion resistance. The screw large capacitor has a service life of 8,000 hours at 105 DEG C or 2,000 hours at 125 DEG C.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

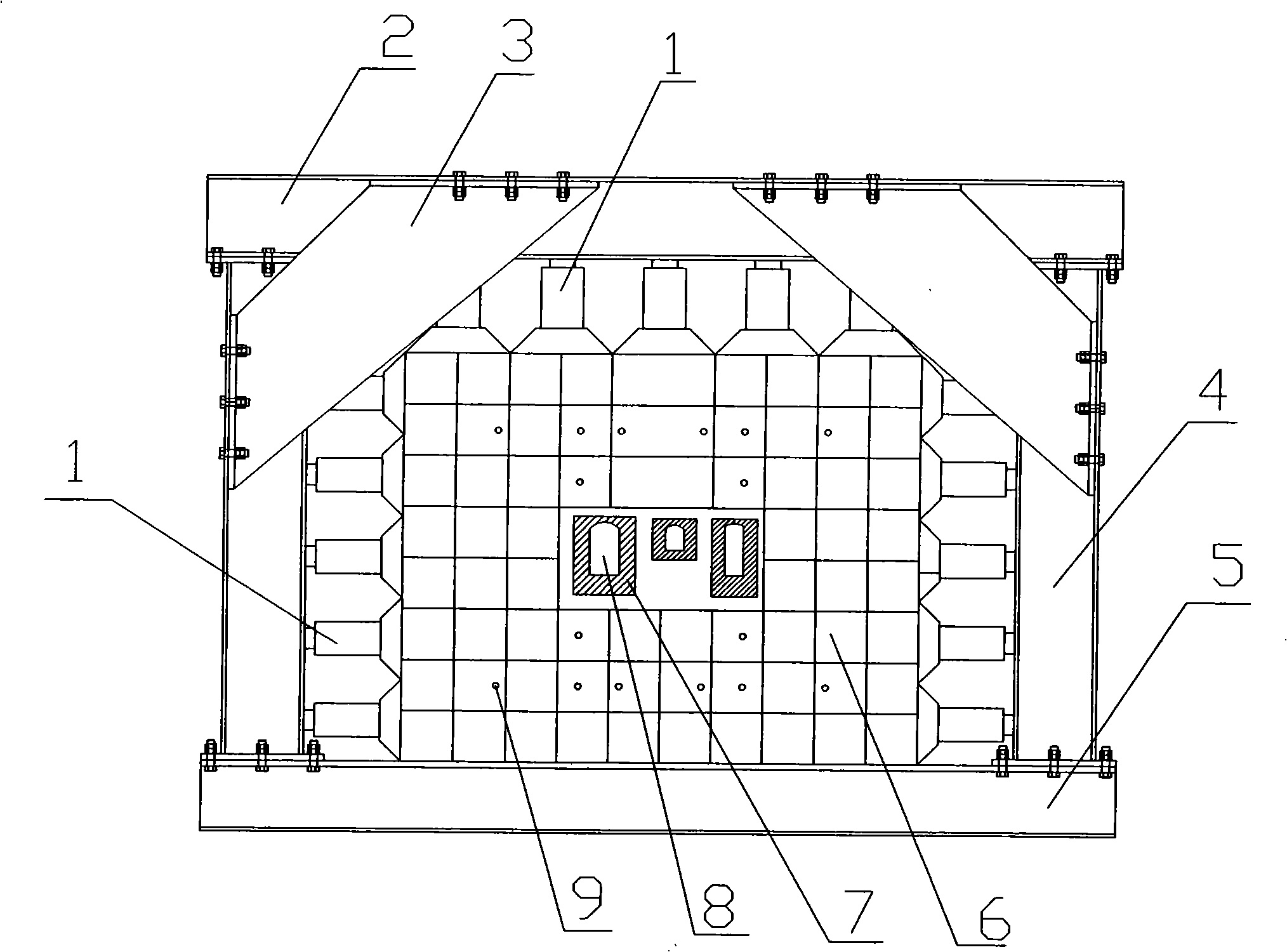

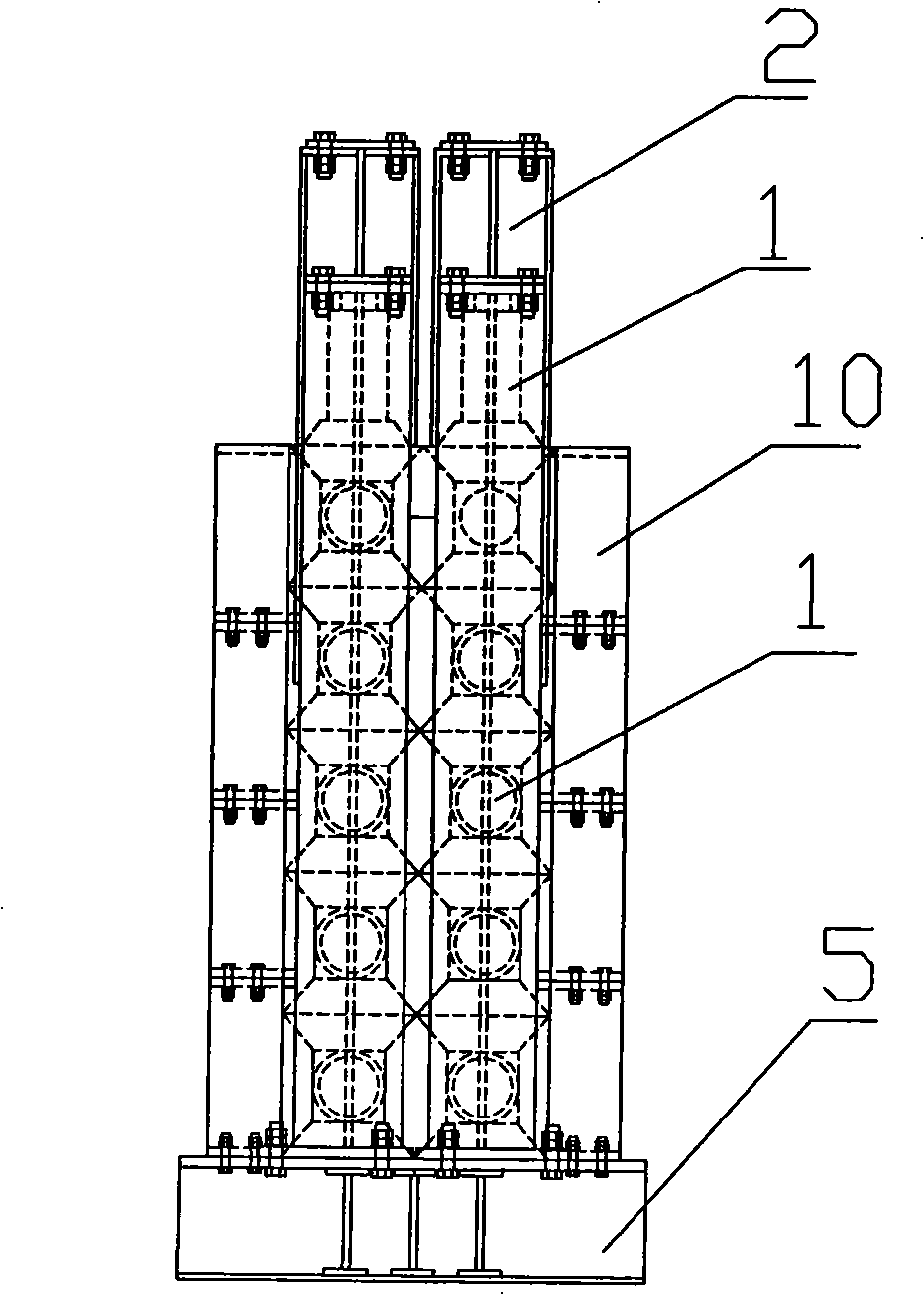

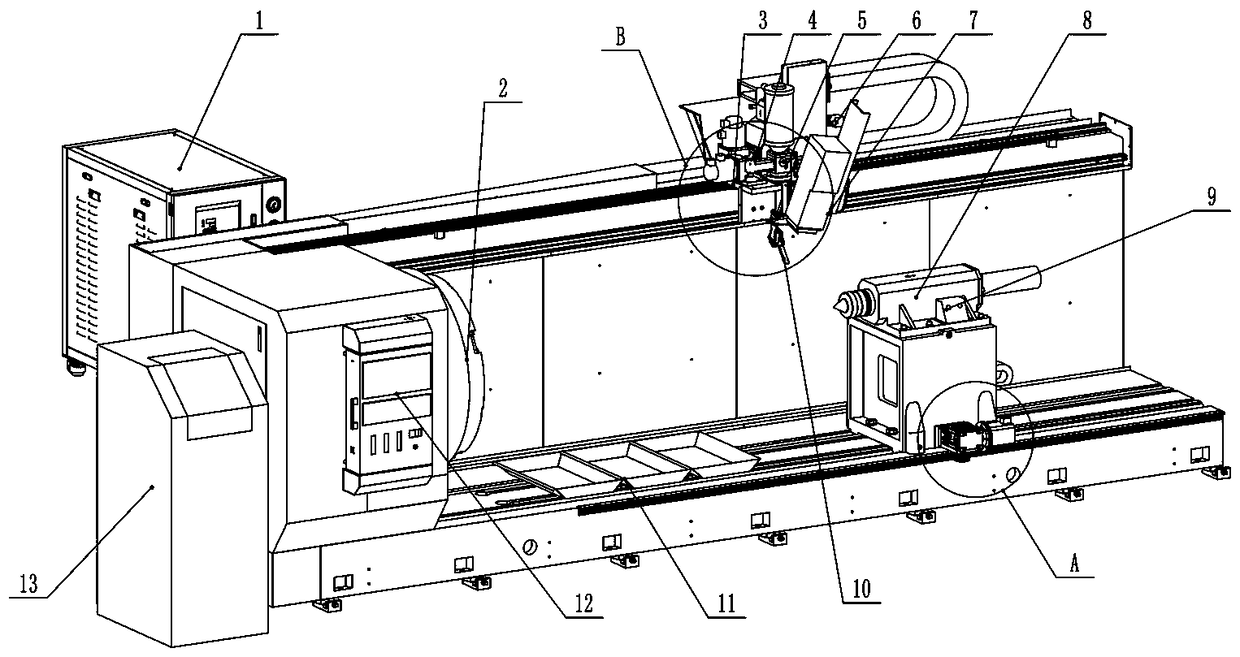

High-ground stress quasi-3D visible model testing bench frame apparatus

InactiveCN101344444AGood impact toughnessStrong corrosion resistanceForce measurementCorrosion resistantHigh intensity

The invention discloses a test bench device of quasi three-dimensional visualization models with high geostress and comprises a reaction wall device, a door-typed reaction frame is arranged in the side periphery of the reaction wall device, a hydraulic loading device is arranged between the door-typed reaction frame and a model body, and a plurality of observing windows are arranged surrounding the position of a perforated chamber on the reaction wall device. The test bench device can be used for implementing the experimental research on the geomechanical plane strain models in the stability research of underground engineered tunnels under high geostress condition. The test bench device has the following advantages: 1. a steel frame of the model adopts a high-intensity alloy steel material, thus having good intensity, rigidity and toughness, strong corrosion resistant capacity, and repeated and recycled use in a long time; 2. an external loading method is adopted, thus conveniently realizing jobs such as the installation and the replacing of loading equipment such as hydrostatic triggers, etc.; 3. a toughened glass is arranged surrounding a hole of the reaction wall, thus being convenient for observing the deformation and the crack propagation situation in the surrounding of the hole; 4. an assorted control system of hydraulic loading is combined, thus conveniently realizing graded loading and simulating real geostress distribution situation as accurately as possible.

Owner:SHANDONG UNIV

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

Dry type working liner material for erosion resistance continuous casting tundish

InactiveCN1800105AImprove high temperature strength and slag erosion resistanceExtended service lifeTundishOxide

The invention relates to an amorphous refractory; especially to an erosion resistance concast intermedium finish-go-home work sark. It uses magnetite as main raw material and the light-burned magnesium oxide, boric acid, silicon powder and aluminum powder as accelerator and the resin, starch gum and so on as insurance contract. It adds one or some kinds of chrome green, compound chrome-magnesite brick, magnesite-chrome brick. The raw material is that (wt%): the magnesite 5-1mm is 10-35%, 1-0.2mm is 10-35%, <=0.074mm is 20-40%, <=0.088mm admixture is 5-20%, <=0.088mm accelerator is 1-5%, starch gum is 5-12%. Each raw material has a certain quality technology index.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Corrosion-resistance stainless steel electric welding rod used for nuclear power and production method thereof

ActiveCN103008913AStrong corrosion resistanceImprove impact performanceWelding/cutting media/materialsSoldering mediaNuclear powerNickel alloy

The invention discloses a corrosion-resistance stainless steel electric welding rod used for nuclear power and a production method thereof, and relates to a nuclear power product. The corrosion-resistance stainless steel electric welding rod used for the nuclear power consists of a chrome-nickel alloy welding core and a coating covered on the surface of the welding core, wherein the chrome-nickel alloy welding core comprises the following ingredients: less than or equal to 0.01wt% of C, 1.00-2.50wt% of Mn, less than or equal to 0.030wt% of Si, 19.6-21.0wt% of Cr, 9.6-10.6wt% of Ni, less than or equal to 0.20wt% of Mo, less than or equal to 0.10wt% of Co, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of V, less than or equal to 0.035wt% of N, less than or equal to 0.015wt% of S, less than or equal to 0.012wt% of P and the balance of Fe and impurities. Compared with the prior art, the corrosion-resistance stainless steel electric welding rod used for the nuclear power, which is disclosed by the invention, has the advantages of good molten slag liquidity during welding, stable electric arc, big electric arc blowing force, even molten slag coverage, small splashing, excellent slag removal, small welding smoke, light welding line, attractive appearance, moderate welding bead height and good full-position operation performance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Anti-corrosive paint of epoxy resin based on aqueous bitumen, and preparation method

InactiveCN1760291AReduce corrosion rateStrong corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsChemistryEmulsion

A kind of anticorrosion asphalt-based epoxy resin water paint is proportionally prepared from modified asphalt emulsion, epoxy resin emulsion, solidifying agent emulsion, filler, assistant and water. Its advantages are high hardness, resistance to corrosion and abrasion, adhesion and softening point, and low pollution.

Owner:NORTHWEST NORMAL UNIVERSITY

Process for magnesium alloy surface micro-arc oxidation

InactiveCN1772968ASmall coefficient of thermal expansionStrong corrosion resistanceAnodisationAluminateMicro arc oxidation

The present invention relates to a magnesium alloy surface microarc oxidation method. Said method includes the following steps: (1), pretreatment; (2), preparing alkaline silicate electrolyte or alkaline aluminate electrolyte; and (3), placing the pretreated magnesium alloy in the alkaline silicate electrolyte or alkaline aluminate electrolyte and making microarc oxidation; applying DC current, continuously rising voltage, constant current, current density is 1-15 A / sq.dm, galvanization time is 5-90 min and electrolyte temperature is less than 40 deg.C.

Owner:HARBIN INST OF TECH

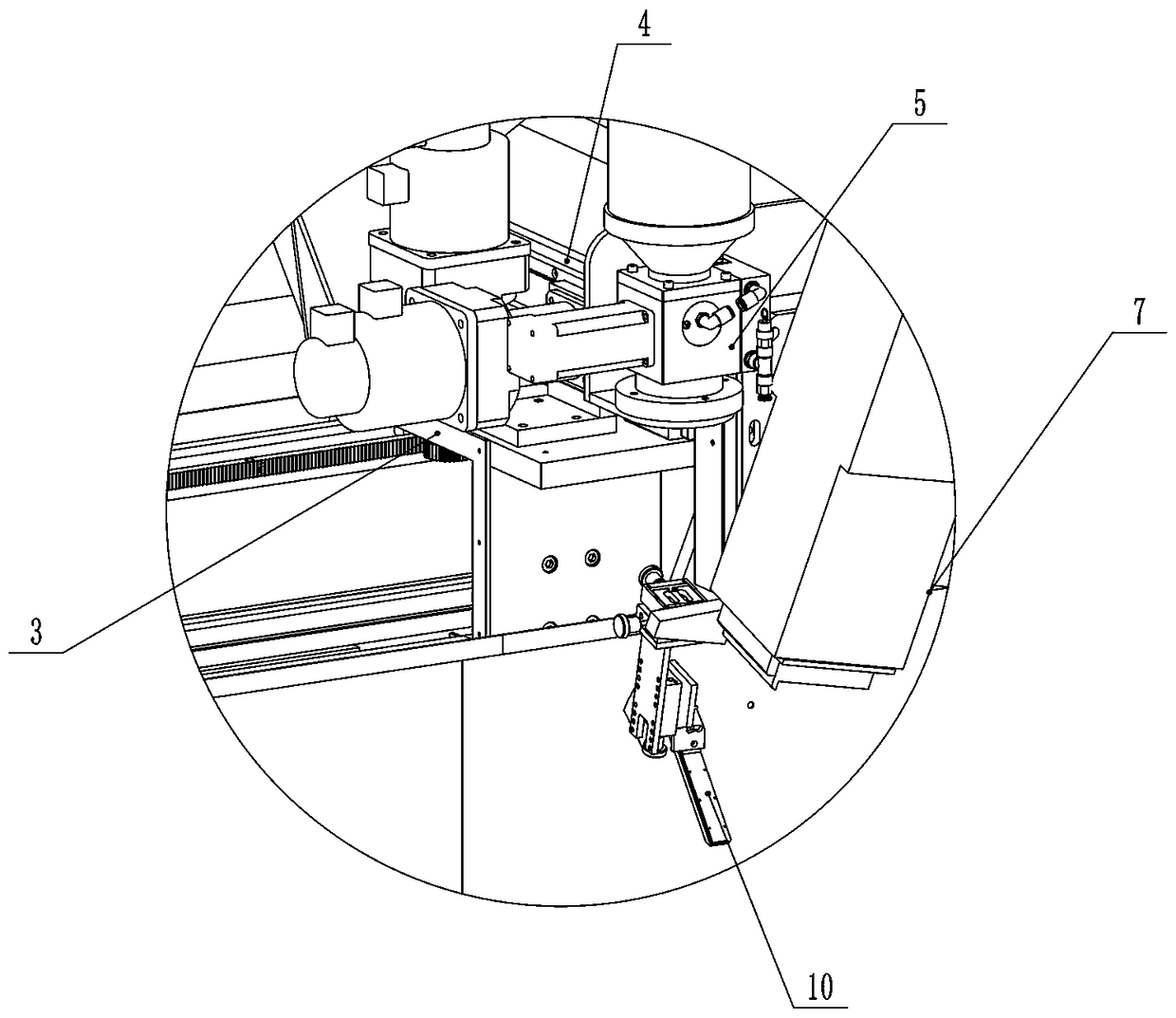

Hydraulic support plunger outer surface laser cladding repairing method

ActiveCN108559996AGuaranteed performanceImprove performanceMetallic material coating processesHardnessOptoelectronics

The invention discloses a hydraulic support plunger outer surface laser cladding repairing method. The hydraulic support plunger outer surface laser cladding repairing method comprises the following steps that firstly, turning is carried out on the outer surface of a hydraulic support plunger to be repaired to remove a fatigue layer and an electroplated layer on the outer surface of the hydraulicsupport plunger, and the outer surface of the hydraulic support plunger is washed; secondly, iron-base alloy powder for laser cladding is put into laser cladding equipment, the laser cladding equipment is used for carrying out laser cladding on the outer surface of the hydraulic support plunger, and a laser cladding layer is formed; thirdly, rough turning is carried out on the hydraulic support plunger which is subjected to laser cladding; fourthly, abrasive machining and polishing treatment are carried out on the hydraulic support plunger which is subjected to rough turning, and the roughnessRa of the outer surface of the polished hydraulic support plunger is smaller than or equal to 0.4; and fifthly, checking and flaw detection are carried out on the outer surface of the polished hydraulic support plunger, and laser cladding repairing of the outer surface of the hydraulic support plunger is completed after it is ensured that no defect exists. The laser cladding layer formed throughthe repairing method is high in hardness, large in thickness and high in corrosion resistance and longer in service life.

Owner:河南省煤科院耐磨技术有限公司

Neutral boron silicate glass used for medicinal mold-formed bottle and manufacturing method thereof

InactiveCN101186437AImprove performanceSmall coefficient of thermal expansionElectric furnaceGlass productionSilicate glassHeat stability

Neutral borosilicate glass used for moulding medicinal bottles is provided, which pertains to the technology filed of glass containing aluminum, boron, 40 percent to 90 percent (by weight) of silicon dioxide and provides neutral borosilicate glass meeting the standard of medical packaging container (material) YBB00292002, YBB00322002. The glass contains 8-12 percent of B2O3 with expansion coefficient of 4.0-5.0 multiplied by 10<-6> / K, as well as a series of excellent physical and chemical properties such as good heat stability, strong acid-resistance, alkali-resistance, water-resistance and erosion-resistance. The invention adopts cold furnace top and deep bed, recycles volatiles of boron during the course of melting, thus effectively reducing boron volatilization, preventing unfavorable phenomenon from taking place, for example, the combined material layer from incrustation and reversing, and obtaining comparatively good economic benefit and quality benefit.

Owner:SHANDONG PHARMA GLASS

High-wear-resistant ceramic tile and preparation method thereof

The invention discloses a high-wear-resistant ceramic tile and a preparation method thereof. The high-wear-resistant ceramic tile is prepared from the following raw materials in parts by weight: 40-50 parts of zircon sand, 20-30 parts of sea sand, 25-35 parts of soapstone, 10-20 parts of pitchstone, 5-15 parts of coal gangue, 20-30 parts of white corundum, 10-15 parts of diatomite, 12-24 parts of cordierite, 4-8 parts of nano titanium carbide, 6-12 parts of light magnesium oxide, 3-6 parts of a graphite powder, 5-10 parts of cement slag, 15-20 parts of modified clay, and 2-5 parts of precipitated barium sulfate. The zircon sand, the white corundum, the precipitated barium sulfate, nano titanium carbide and other raw materials are added into the ceramic tile, so that the wear resistance of the ceramic tile can be significantly improved, the room-temperature wearing capacity is not more than 10 cm<3>, and the ceramic tile has the advantages of high strength, good heat resistance, good water resistance, strong anti-erosion ability, long service life, and wide market prospect.

Owner:安徽省亚欧陶瓷有限责任公司

Novel stainless bearing steel and method for manufacturing same

InactiveCN101117688AGood mechanical propertiesImprove corrosion resistanceTrace elementWear resistance

The present invention relates to a novel stainless bearing steel and the making method with a weight percentage of components as follows: C 0.3-0.6 percent, Cr 14.00-17.00 percent, Ni 0.29-2.50 percent, Mo 1.00-3.00 percent, N 0.10-0.30 percent, Mn less than or equal to 1.00 percent, Si less than or equal to 1.00 percent, S less than or equal to 0.03 percent, P less than or equal to 0.035 percent, trace element less than or equal to 0.50 percent and the remainder is Fe. Compared with the prior art, the novel stainless bearing steel has an excellent mechanical property, wearing resistance performance and processing performance, is high in hardness, powerful in wearing resistance, suitable for moderate corrosive surroundings such as oceans, petroleum, chemical engineering, foodstuff, paper making and so on and is convenient for manufacturing rolling and sliding bearings of various types.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

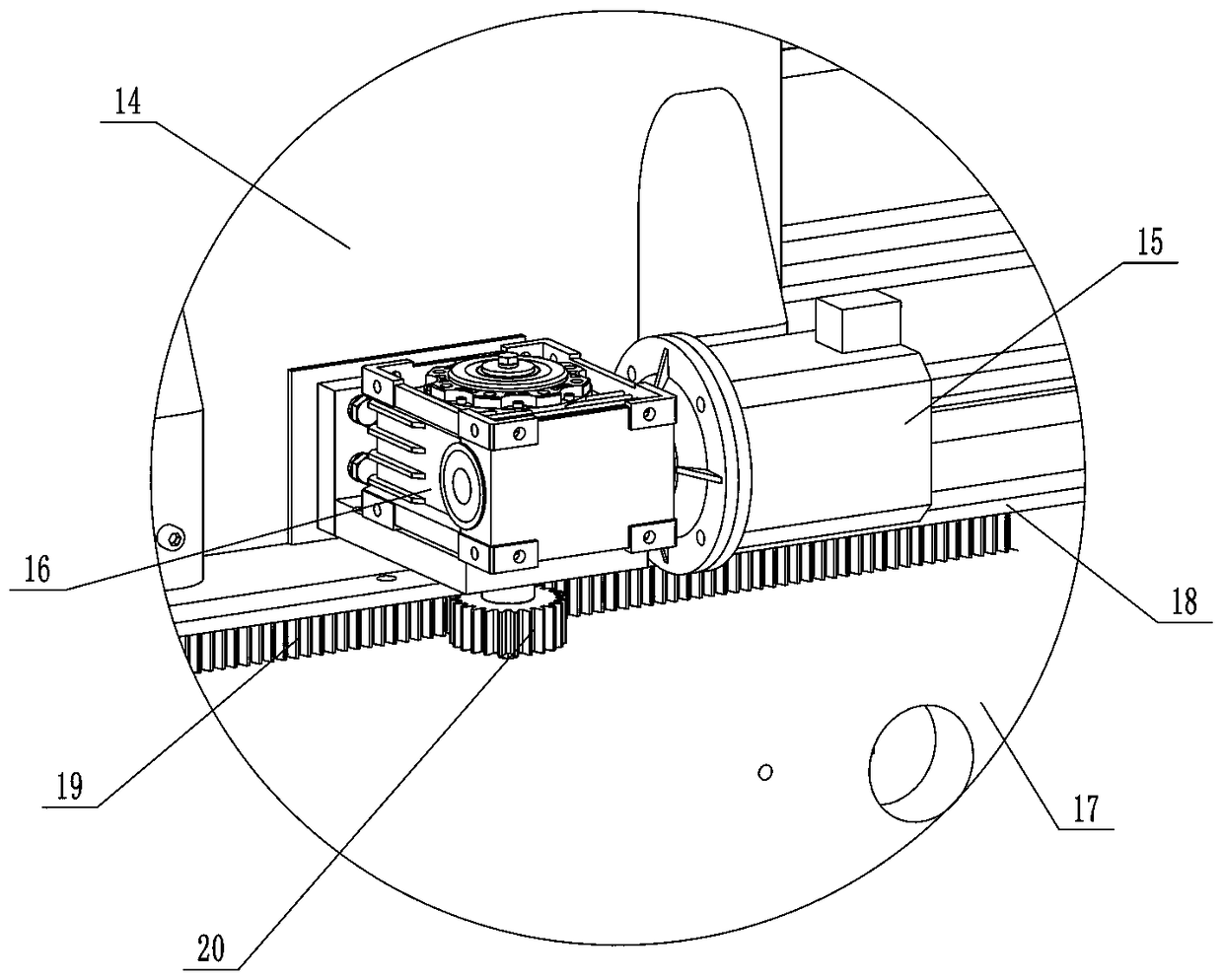

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

Environment-friendly polyaniline modified aluminium powder anti-corrosive coating and preparation method thereof

ActiveCN101643619AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPetrochemicalCorrosion

The invention relates to coating technology, in particular to an environment-friendly polyaniline modified aluminium powder anti-corrosive coating and a preparation method thereof to solve the problemthat the prior aluminium powder coating has poor corrosion resistance, and is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating comprises a film forming matter, polyaniline modified aluminium powder and the like. A polyaniline coating layer is formed on the surface of the aluminium powder by an oxidative polymerization method; the treated aluminium powder has passivating effect on metal; and a phytic coating layer on the surface of the aluminium powder also has corrosion inhibiting effect on the metal. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

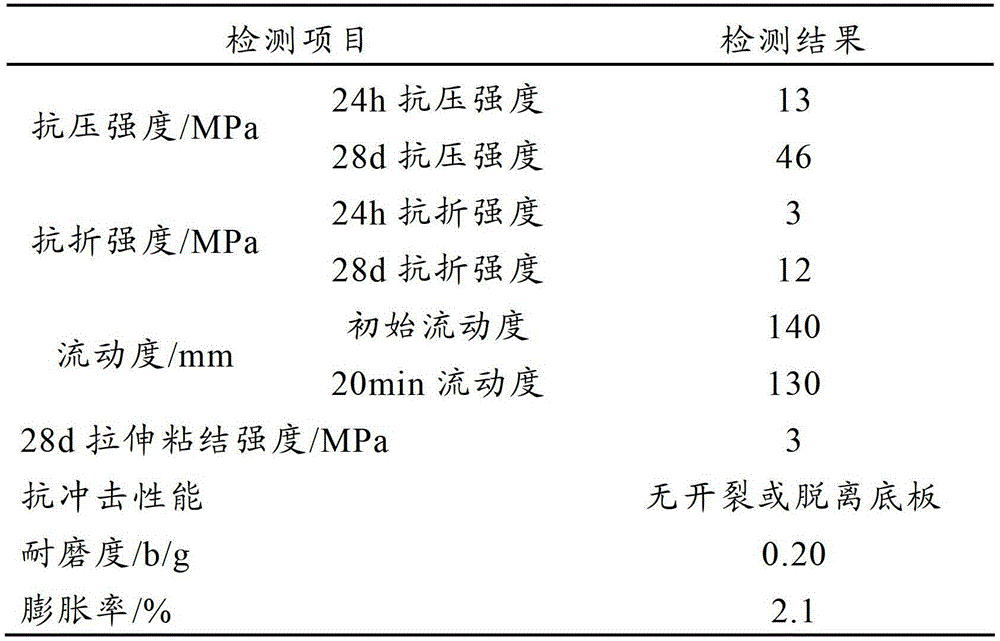

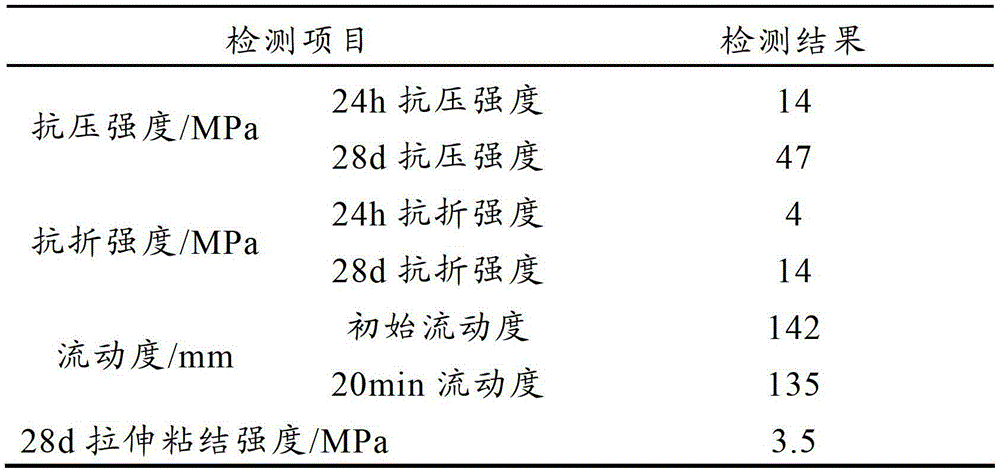

Self-levelling underlayment material

The invention relates to the technical field of chemical new materials for roads and bridges and provides a self-levelling underlayment material. The self-levelling underlayment material comprises 40-100 parts by weight of sand, 40-100 parts by weight of cement, 2-30 parts by weight of gypsum, 2-30 parts by weight of inorganic fluoride, 0.1-15 parts by weight of water reducer, 4-15 parts by weight of swelling agent, 0.1-10 parts by weight of tackification and water retention agent and 0.1-15 parts by weight of fibers. The self-levelling underlayment material has the following advantages: the swelling agent is added, so that the surface compactness of a self-levelling underlayment can be improved, cracks generated by contraction can be relieved, and thus the service life of the self-levelling underlayment is prolonged.

Owner:HUBEI UNIV

Environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating and preparation method thereof

ActiveCN101643620AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPhytic acidPetrochemical

The invention relates to coating technology, in particular to an environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating and preparation method thereof, which solves theproblem that the prior micaceous iron oxide coating has poor anticorrosion performance, and needs to be matched with pigments containing lead and chromate during manufacturing. The environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating comprises film-forming material, polyaniline modified micaceous iron oxide, and the like. As polyaniline coating layers are formedon the surfaces of the micaceous iron oxide by an oxidative polymerization method, the treated micaceous iron oxide has the effect of passivating metal, and phytic-acid coating layers on the surfacesof the micaceous iron oxide play a role in inhibiting corrosion of metal. The environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating has strong corrosion resistance andpermeation resistance, can be applied to heavy-duty engineering of petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, ships and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

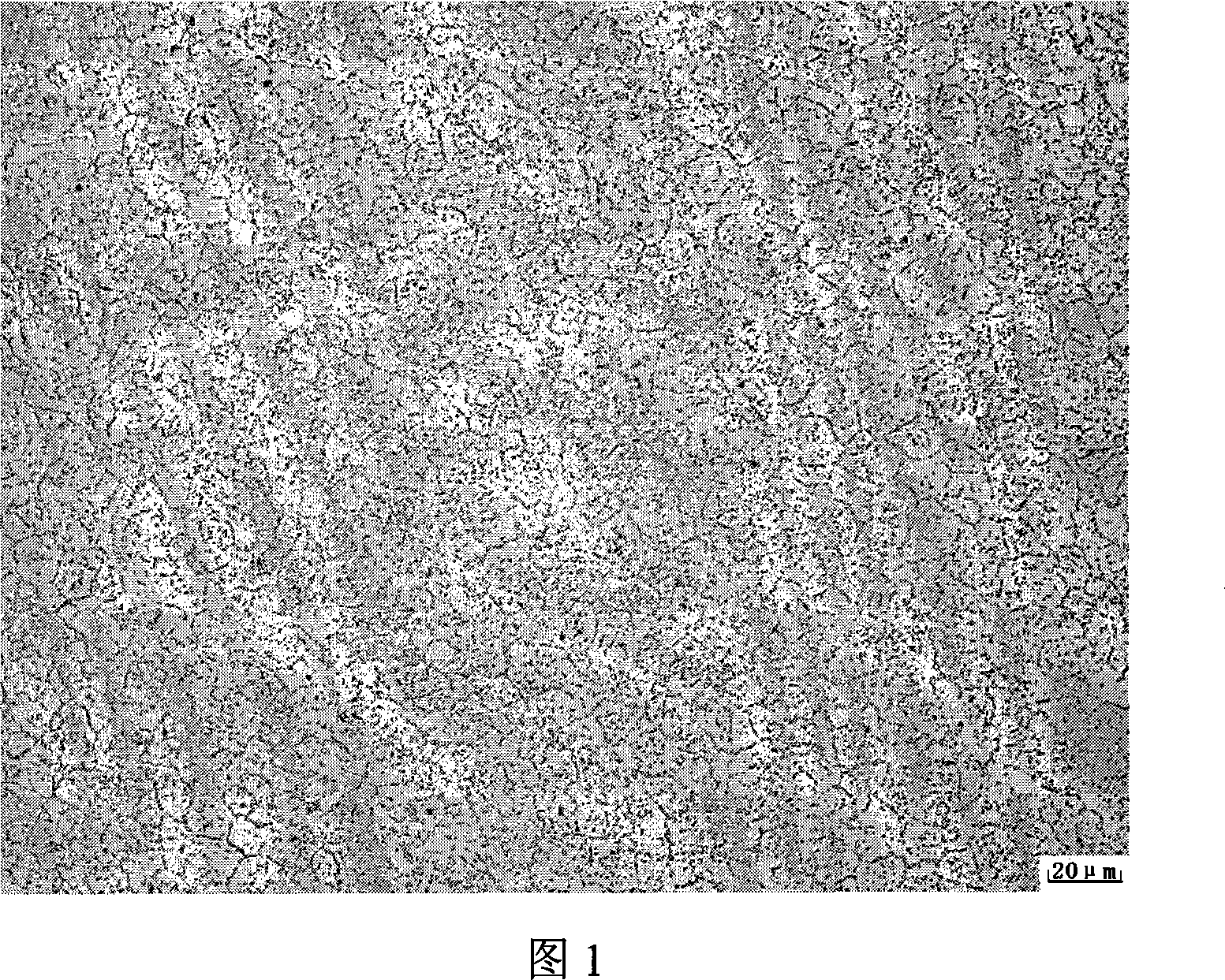

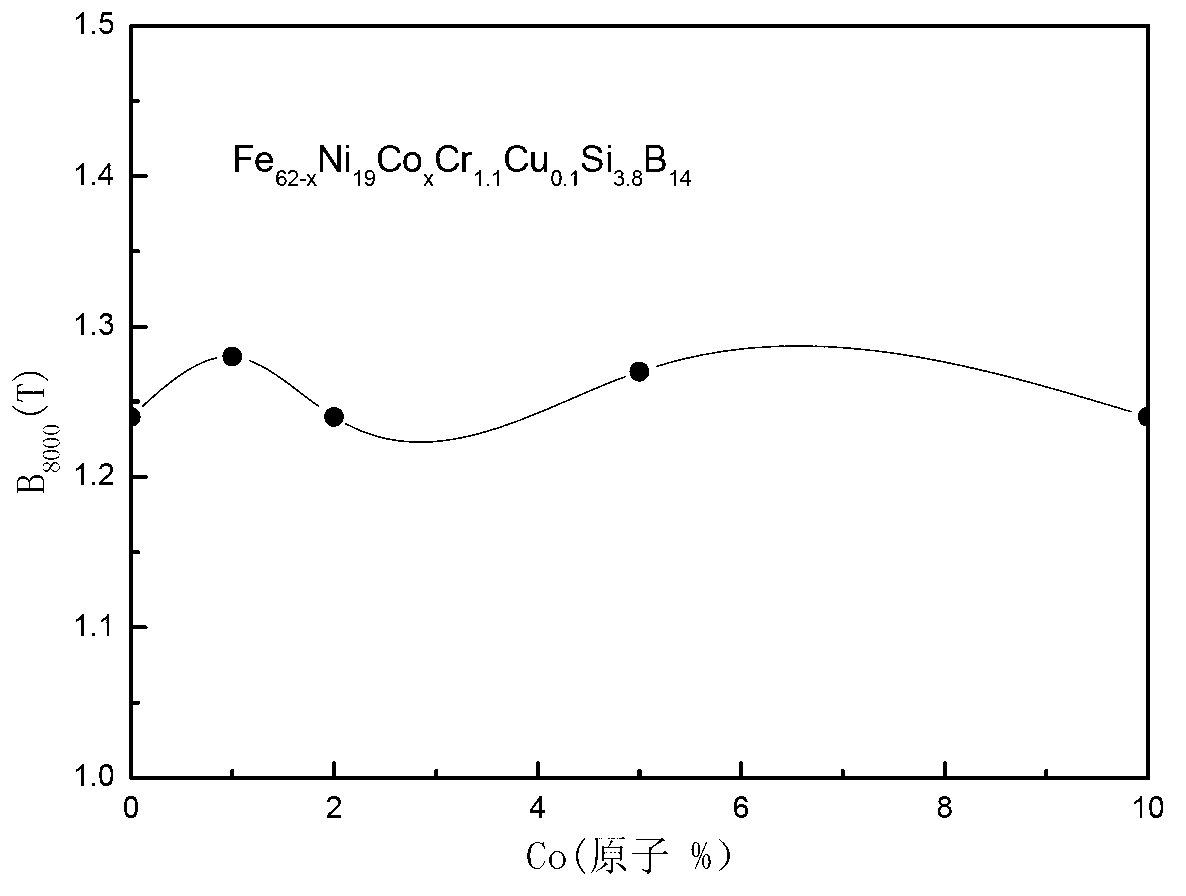

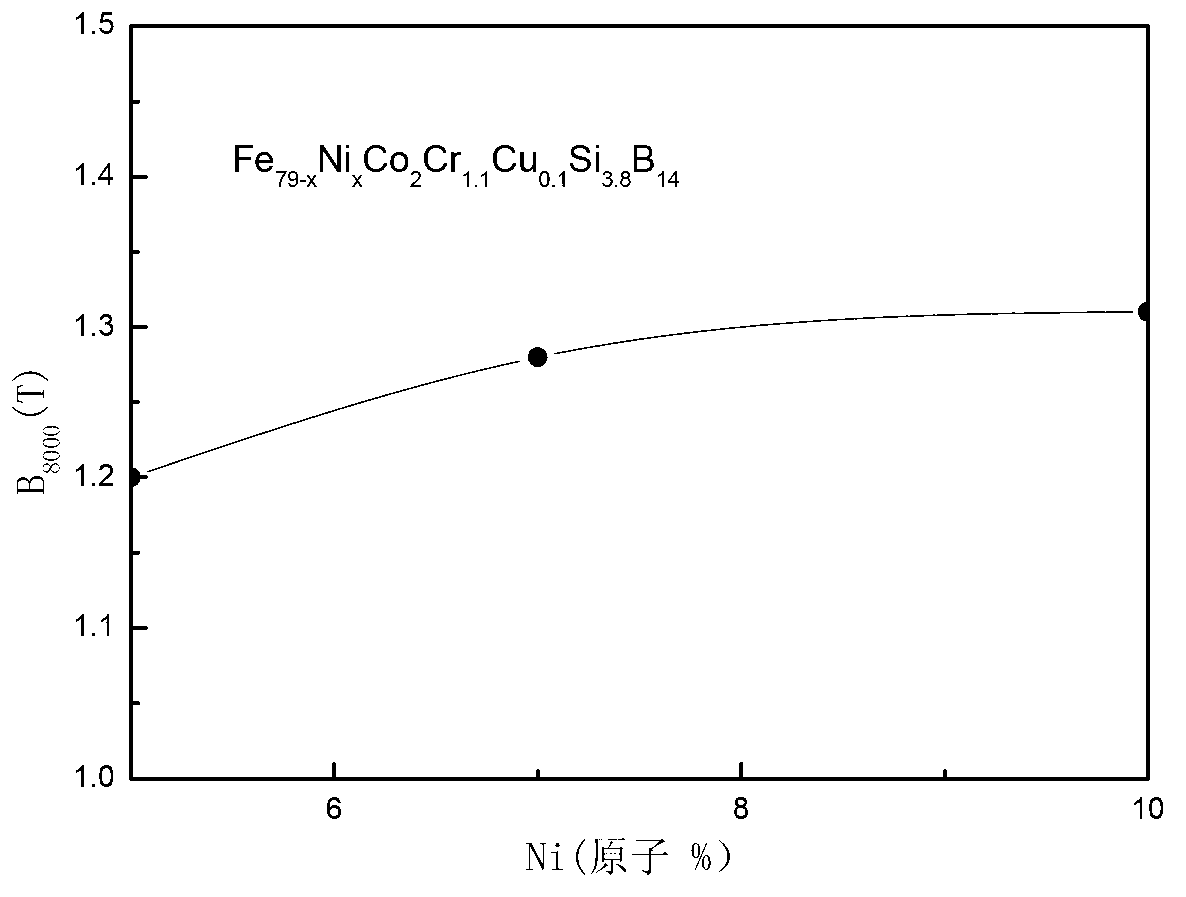

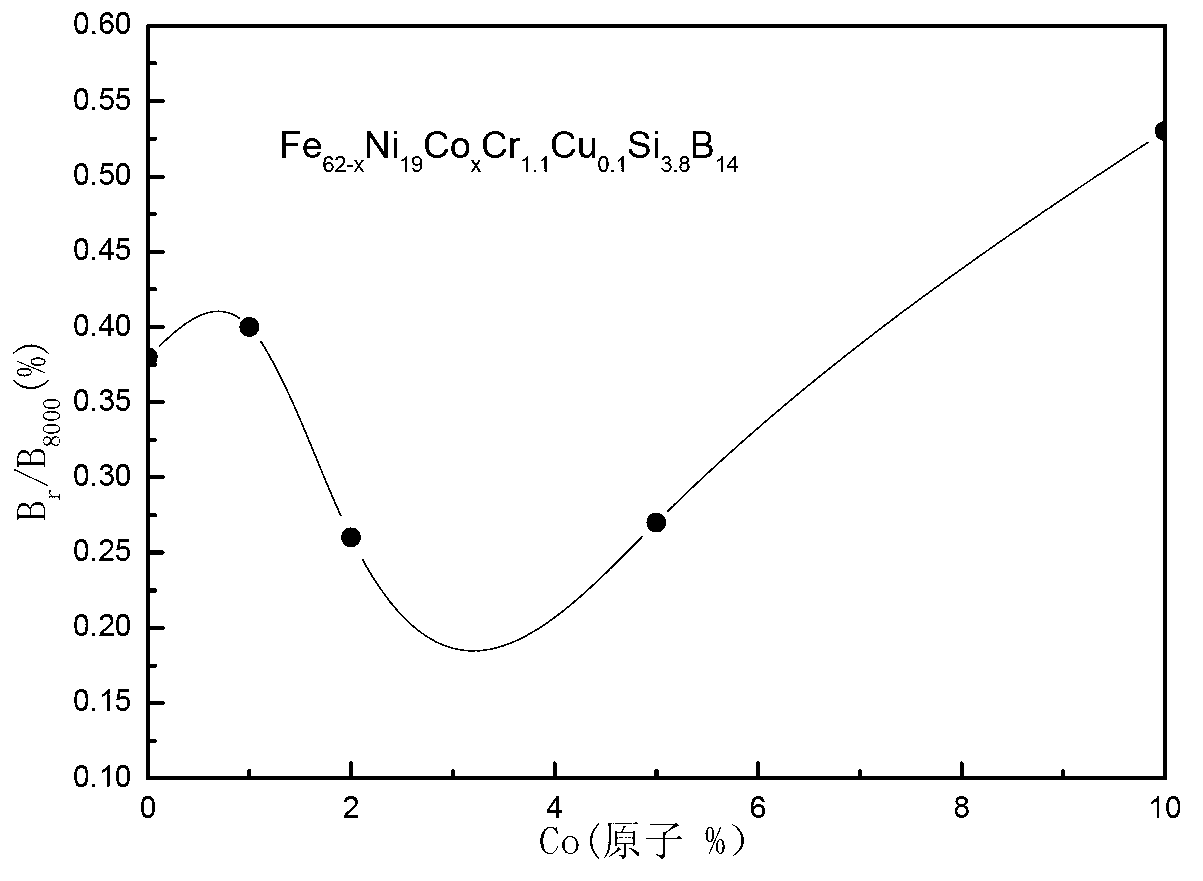

Magnetic core of low conductive magnet, manufacturing method and application thereof

ActiveCN103258612ALow coercivityStrong corrosion resistanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureAlloyAlternating current

The invention relates to a magnetic core of a low conductive magnet, a manufacturing method and and application thereof. The magnetic core of the low conductive magnet is made of ferromagnetic magnetically soft alloy, the molecular formula of the alloy is FeaMbCucSidBeM'fXg, wherein M represents Ni and / or Co, M' represents at least one element among V, Ti, Nb, Mo, Cr, Hf, Ta and W, and X represents P, Ge, C and impurities. With atomic percent as the unit, a, b, c, d, e, f and g meet the following conditions: b is larger than or equal to 5 and is smaller than or equal to 40, c is larger than or equal to 0.05 and is smaller than or equal to 1, d is larger than or equal to 1 and is smaller than or equal to 8, e is larger than or equal to 10 and is smaller than or equal to 20, f is larger than or equal to 0.5 and is smaller than or equal to 5, g is larger than or equal to 0 and is smaller than or equal to 0.5, d and e are larger than or equal to 10 and are smaller than or equal to 25, and a is equal to 100 minus b minus c minus d minus e minus f minus g. The microstructure of the using state of the alloy is an amorphous state. The magnetic core is low in magnetic conductivity, high in anti-saturation performance and high in modulation property to alternating current and direct current components. Further, a B-H loop line is of a linear shape, and the magnetic conductivity of the linear B-H loop line is high in modulation property in the alternating current and the direct current.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Polyaniline modified glass flake heavy-duty anti-corrosive coating and preparation method thereof

ActiveCN101643615AAchieve passivationImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPhytic acid

The invention relates to coating technology, in particular to a polyaniline modified glass flake heavy-duty anti-corrosive coating and a preparation method thereof to solve the problems that when theprior glass flake anti-corrosive coatings are constructed, most of the glass flake anti-corrosive coatings require to coat primer on the surface of steel or other metal matrix to improve the corrosionresistance and prevent corrosion between the coat and the interface of the matrix, and the like. The polyaniline modified glass flake heavy-duty anti-corrosive coating comprises epoxy resin, a polyaniline modified glass flake, an amine curing agent and the like. A polyaniline coating layer is formed on the surface of the glass flake by an oxidative polymerization method; the glass flake after thetreatment has the passivating effect on metal; and a phytic coating layer on the surface of the glass flake also has the corrosion inhibiting effect on the metal. The polyaniline modified glass flakeheavy-duty anti-corrosive coating has strong corrosion resistance and permeability resistance, can be applied to heavy-duty anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like, and is particularly suitable for protecting wave splashing zones and tidal difference zones.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Lignose raw lacquer composite coating

InactiveCN101302397ALow costStrong corrosion resistanceNatural resin coatingsLignin material coatingsChemistryLacquer

The invention discloses lignin raw lacquer composite coating. The lignin raw lacquer composite coating prepared mainly comprises raw lacquer, lignin, functional auxiliary agent and diluting agent. The lignin raw lacquer composite coating introduces the lignin extracted from sulphite liquor into the raw lacquer, and effectively utilizes the lignin in the sulphite liquor and reduces the cost when the performance of the raw lacquer is maintained simultaneously. The product is acid resistant, alkali resistant, water resistant, oil resistant and abrasion resistant, has high glossiness and strong adhesion, and is suitable for anti-corrosive application in deep color hardwood furniture and the industry.

Owner:中华全国供销合作总社西安生漆涂料研究所

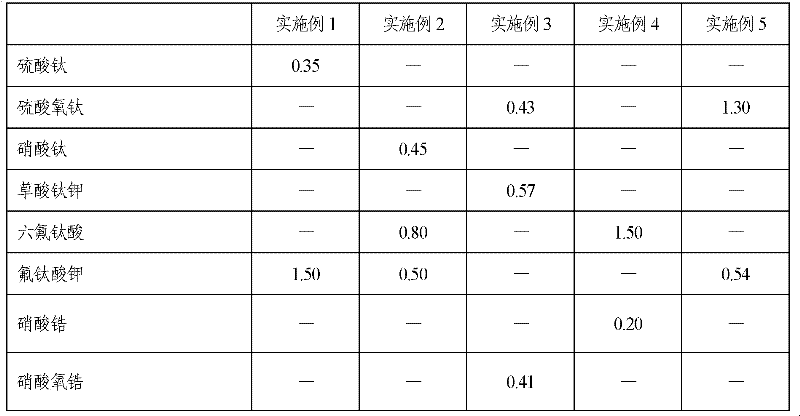

Aluminium alloy chromium-phosphorus-free nanoscale chemical conversion liquid for ships and method for preparing conversion film

InactiveCN102409324AStrong corrosion resistanceGood organic coating adhesionMetallic material coating processesComposite oxideEtching

The invention relates to the field of an aluminium alloy decoration and protection coating for ships, and in particular relates to a novel aluminum alloy chromium-phosphorus-free nanoscale chemical conversion liquid for ships and an application of the chemical conversion liquid in a chemical conversion film. The chromium-phosphorus-free nanoscale chemical conversion liquid is prepared from a titanium salt, a zirconium salt, a silicon compound, an accelerator, a pH modifier, a surfactant and the like. The film-forming process of the chromium-phosphorus-free nanoscale chemical conversion film successively comprises the following steps of degreasing, washing, acidic etching, washing, chemical conversion, washing and drying. The chromium-phosphorus-free chemical conversion film is prepared from nanoscale titanium oxide, zirconium oxide, alumina and other composite oxides, has excellent corrosion resistance and organic coating adhesion, and can be used as an aluminum alloy surface decoration and protection coating for ships. The chemical conversion film prepared from the chemical conversion liquid in the invention does not contain chromium and phosphorus elements, has excellent corrosion resistance and organic coating adhesion, is simple in construction and convenient in maintenance, and is applicable to construction of large-area aluminum alloy sections.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Diamond composite plating layer

InactiveCN102199764AImprove bindingStrong corrosion resistanceLiquid/solution decomposition chemical coatingCorrosionMicro particles

The invention discloses a diamond composite plating layer, which is plated on surfaces of a steel-iron alloy. The diamond composite plating layer comprises an inner layer and an outer layer, wherein the inner layer is a transition layer which is formed by plating chemical nickel containing phosphorus in a chemical nickel plating mode, and the outer layer is formed by carrying out co-deposition on diamond particles and a nickel-phosphorus alloy to the plating layer in a chemical nickel plating mode so as to form a nickel-phosphorus-diamond particle composite plating layer. By using the technical scheme, the transition layer can improve the bonding force of the plating layer, prevent the diamond particles from directly contacting the steel-iron alloy, and prevent the diamond particles from being absorbed by the steel-iron alloy in a carbon atom form; the nickel-based diamond particle composite plating layer is a high-temperature (140 DEG C) wear-resistant composite plating layer, does not need heat treatment, has apparent hardness higher than 700 HV, and has no influence on the physical properties of a base material; and the nickel base of the composite plating layer is a nickel-phosphorus alloy, therefore the plating layer has excellent corrosion resistance.

Owner:芜湖海成科技有限公司

Casing of electronic device

InactiveCN1419404AWith metallic textureStrong corrosion resistanceMolten spray coatingSurface reaction electrolytic coatingAnodizingMetal

A casing of electronic devices comprises a plastic casing, a metal coating and an oxidized layer formed on the surface of the metal coating by anodizing. The method for manufacturing the casing of electronic devices, including the following steps: (1) ejecting and forming the above plastic casing; (2) forming in metal coating on the surface of the plastic casing; (3) anodizing the plastic casing with the metal coating. In such a way, the casing of electronic devices has a metal sense and a strong erosion resistance. The method can continue the tinctorial processing after the step (3) to acquire the required color or pattern.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

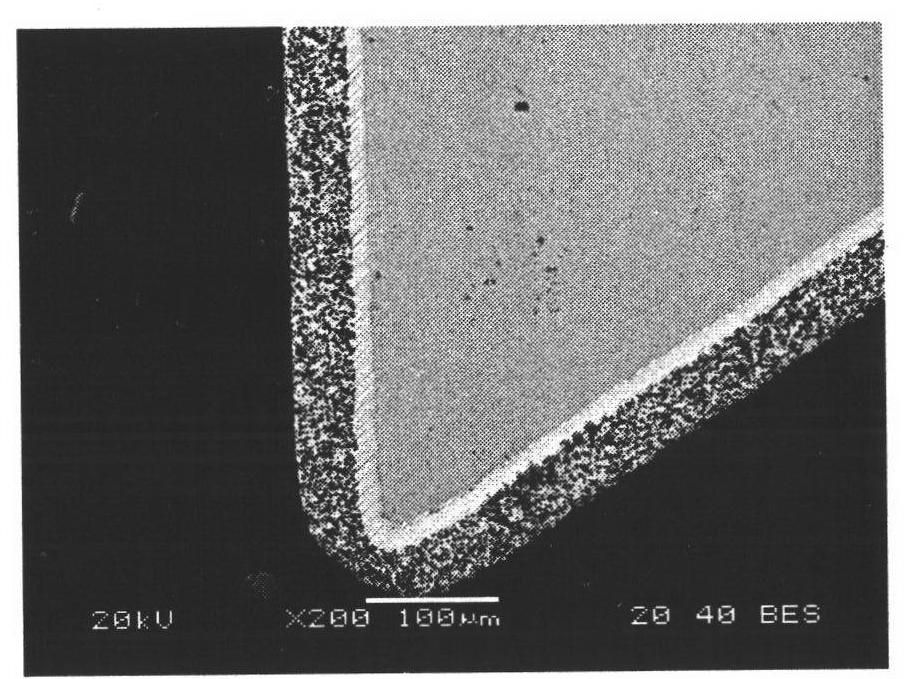

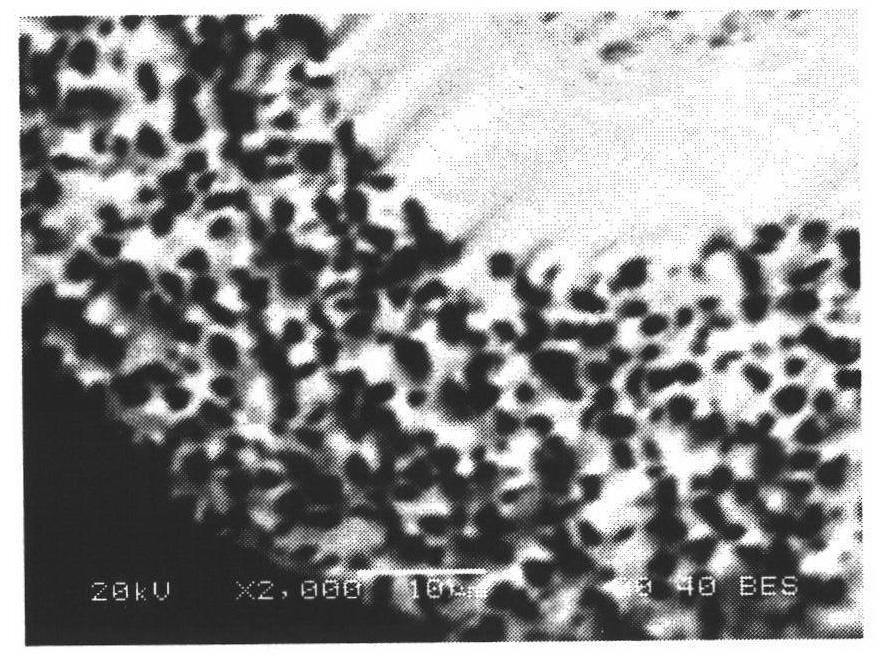

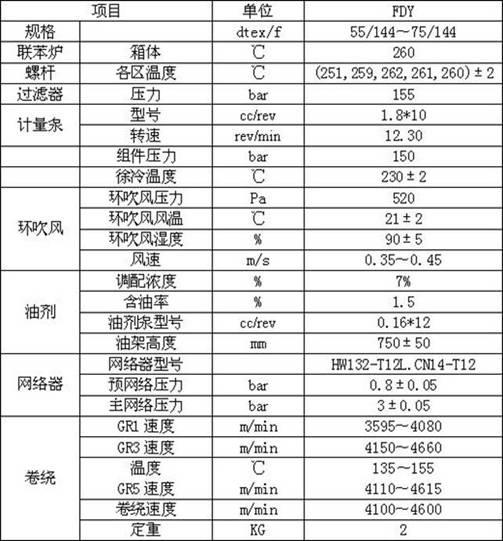

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

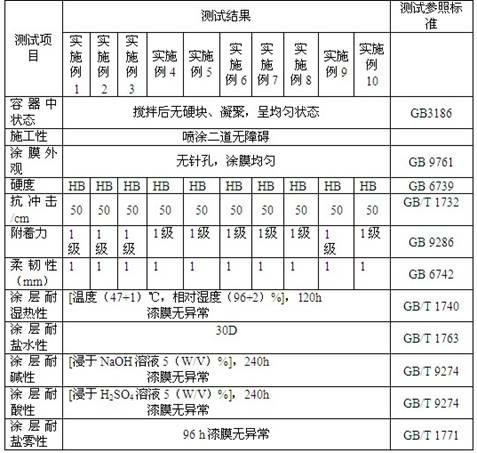

Baking varnish for magnesium aluminum alloy base material and preparation and using methods thereof

ActiveCN102181214AGood adhesionStrong corrosion resistancePretreated surfacesEpoxy resin coatingsEpoxyPolyester

The invention discloses a baking varnish for a magnesium aluminum alloy base material and preparation and using methods thereof. The preparation method comprises the following steps of: (1) adding polyester modified acrylic resin, epoxy resin, an anti-forming agent, a dispersing agent, a wetting agent, a leveling agent, and a part of solvent in a certain ratio into a stirring kettle sequentially and stirring; (2) adding color paste, filler, and an antisetting agent and stirring in a high speed; and (3) finally adding amino resin, adhesion promoter, and residual solvent and uniformly stirring to finish the whole preparation process of the polyester baking varnish. The using method of the prepared polyester baking varnish for the magnesium aluminum alloy base material comprises the following steps of: weighing the polyester baking varnish for the magnesium aluminum alloy base material, stirring uniformly in the weight ratio of the polyester baking varnish to diluents of 1:(0.4-0.6), spraying to the magnesium aluminum alloy base material, placing for 10 to 20 minutes, baking at the temperature of between 150 and 170 DEG C for 20 to 30 minutes, and baking and curing to obtain the polyester baking varnish layer.

Owner:肇庆千江高新材料科技股份公司

Blackening liquid for chromium-free titanium-zinc panel surface and using method of blackening liquid

InactiveCN103849868ASimple compositionStrong corrosion resistanceMetallic material coating processesAluminium chlorideChromium free

The invention discloses blackening liquid for a chromium-free titanium-zinc panel surface and a using method of the blackening liquid. Raw materials of the blackening liquid comprise a main salt, auxiliary components, a complexing agent, a pH conditioning agent and water, wherein the main salt is one or several of molybdate with the massic volume concentration of 5-40g / L or sodium tungstate with the massic volume concentration of 0.5-10g / L or copper sulfate with the massic volume concentration of 0.5-20g / L or silver nitrate with the massic volume concentration of 5-40g / L; the auxiliary components comprise nickel sulfate with the concentration of 1.0-4g / L, sodium sulfite with the concentration of 0.5-4g / L, sodium thiosulfate with the concentration of 1.0-5g / L, aluminium chloride with the concentration of 2.0-5g / L, zinc chloride with the concentration of 2.0-5g / L and fluoric acid with the concentration of 0-40g / L. A black protective layer of a titanium-zinc panel is obtained by a series of treatment of the titanium-zinc panel workpiece. The black protective layer of the titanium-zinc panel is compact, uniform, pitch-black and glossy and has the characteristics of being low in cost, chromium-free, environmental-friendly and the like, the performances of the titanium-zinc panel can reach the level of foreign products, and therefore, the titanium-zinc panel has relatively strong application prospect and market competitiveness.

Owner:ZHEJIANG UNIV OF TECH +1

Method for electrodepositing wearable thick chromium coating in trivalency chromium coating solution

The invention discloses a method to produce the hard chrome plating with 30-50 mu m thickness in the trivalence chrome electroplate liquid. The present process has many disadvantages such as the plating thickness can not over 10 mu m and it can not be used to resist polish. The invention is to select the proper additive and control the condition in the base electrolyte containing the chromium chloride to produce the 800Hv hardness chrome plate with smooth surface, also after heating treatment, the hardness can reach above 1400Hv. The chrome plate has no crack and the thickness can reach 50 mu m. The anti-wear character is better than the traditional sexivalent chrome electrical sediment process in the invention. So the plating layer can be used the anti-wear layer of work-piece.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Acid bright copper-plating electroplating process

The invention relates to an acid bright copper-plating electroplating process. The process comprises the steps of preparation of a copper plating solution, workpiece pretreatment, acid bright copper plating and the like. The process can continuously plate multiple copper coatings which are some millimeters thick on the surface of a metal substrate without electroplating for several times; the process guarantees good binding force between electroplated cast copper and the substrate, and can bear external force from turning, milling, drawing, externally throwing and other machining; and a plating solution is good in stability and uniform in surface.

Owner:河南江河机械有限责任公司

Surface treating agent for galvanized steel sheet

InactiveCN102245807AStrong corrosion resistanceGood lookingAnti-corrosive paintsMetallic material coating processesDiammonium carbonateSheet steel

Disclosed is a surface treating agent for a galvanized steel sheet that can provide a surface treated galvanized steel sheet, which has various excellent properties such as excellent corrosion resistance and corrosion resistance after alkali degreasing, particularly has a good balance among corrosion resistance, appearance, and grounding properties in a formed film, and also has well balanced excellent properties regarding anti-dew condensation properties and coatability (coating film adhesion). The surface treating agent for a galvanized steel sheet comprises zirconium ammonium carbonate (A), a compound (B), which contains in one molecule two or more functional groups (a) represented by -SiR1R2R3, in which the molecular weight per functional group (a) (average molecular weight / number of functional groups) is in the range of 100 to 5000, an organic phosphonic acid (C), a metal compound (D) containing at least one metal element selected from the group consisting of Zr, Ti, Co, Fe, V, Ce, Mo, Mn, Mg, Al, Ni, Ca, W, Nb, Cr, and Zn, and water. The surface treating agent has a pH value of 6 to 11.

Owner:NIHON PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com