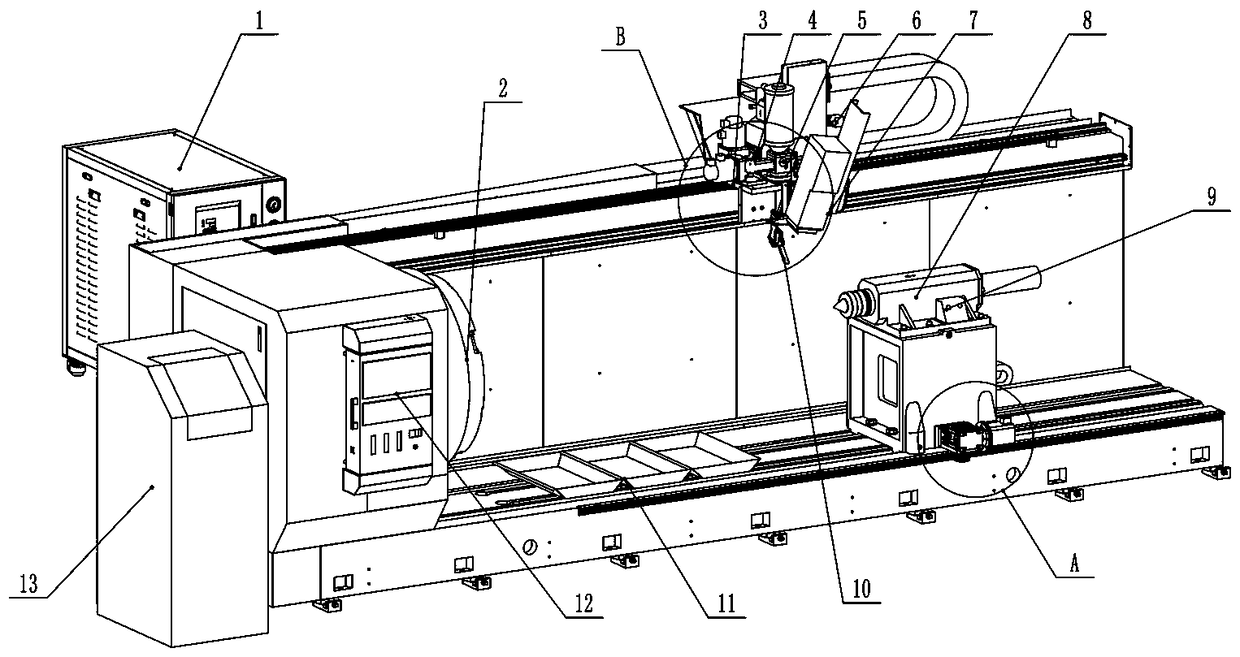

Hydraulic support plunger outer surface laser cladding repairing method

A technology of laser cladding and hydraulic support, applied in the direction of coating, metal material coating process, etc., can solve the problems of limited coating thickness, short service life, environmental pollution, etc., to improve corrosion potential, strong corrosion resistance, improve The effect of abrasion and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

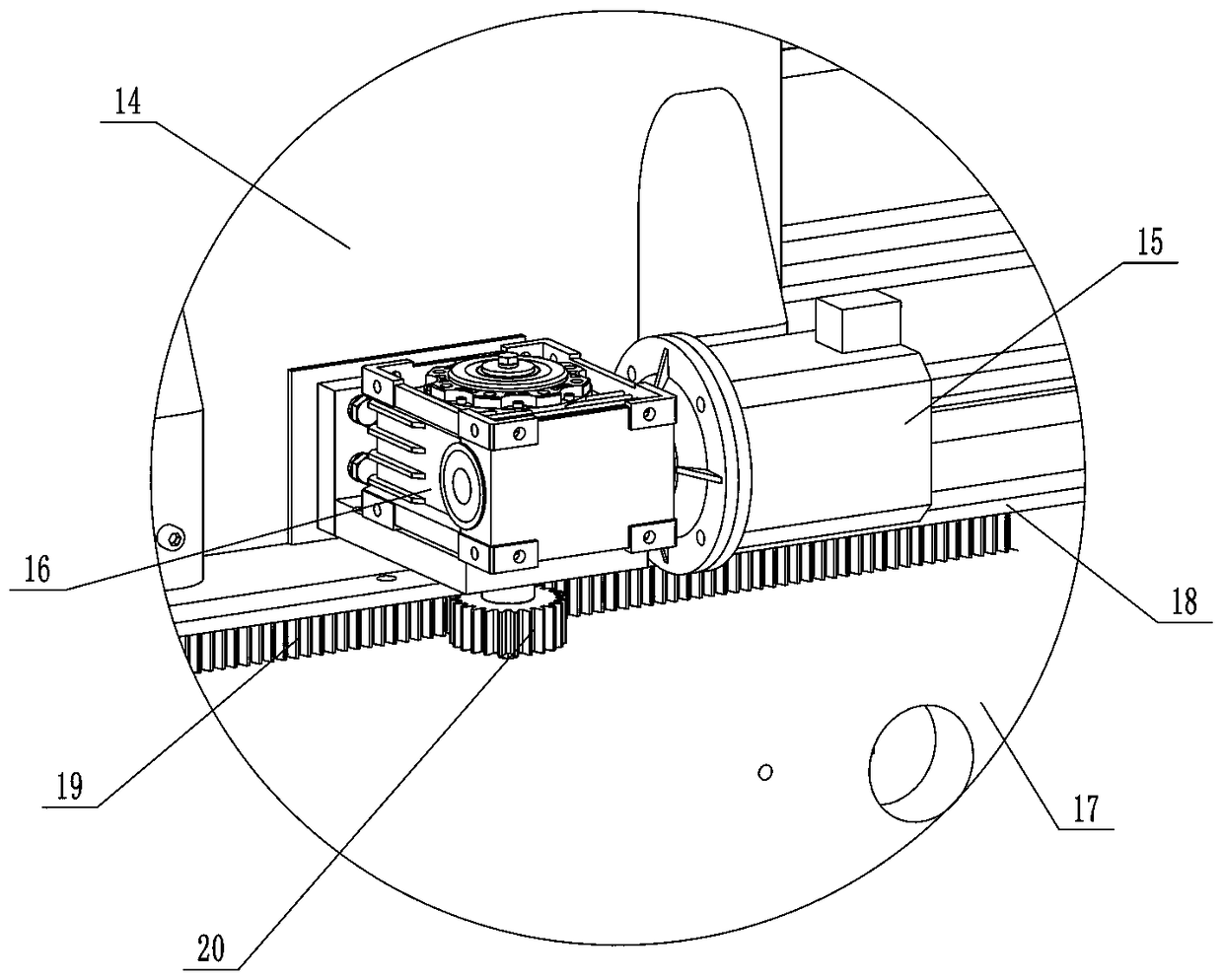

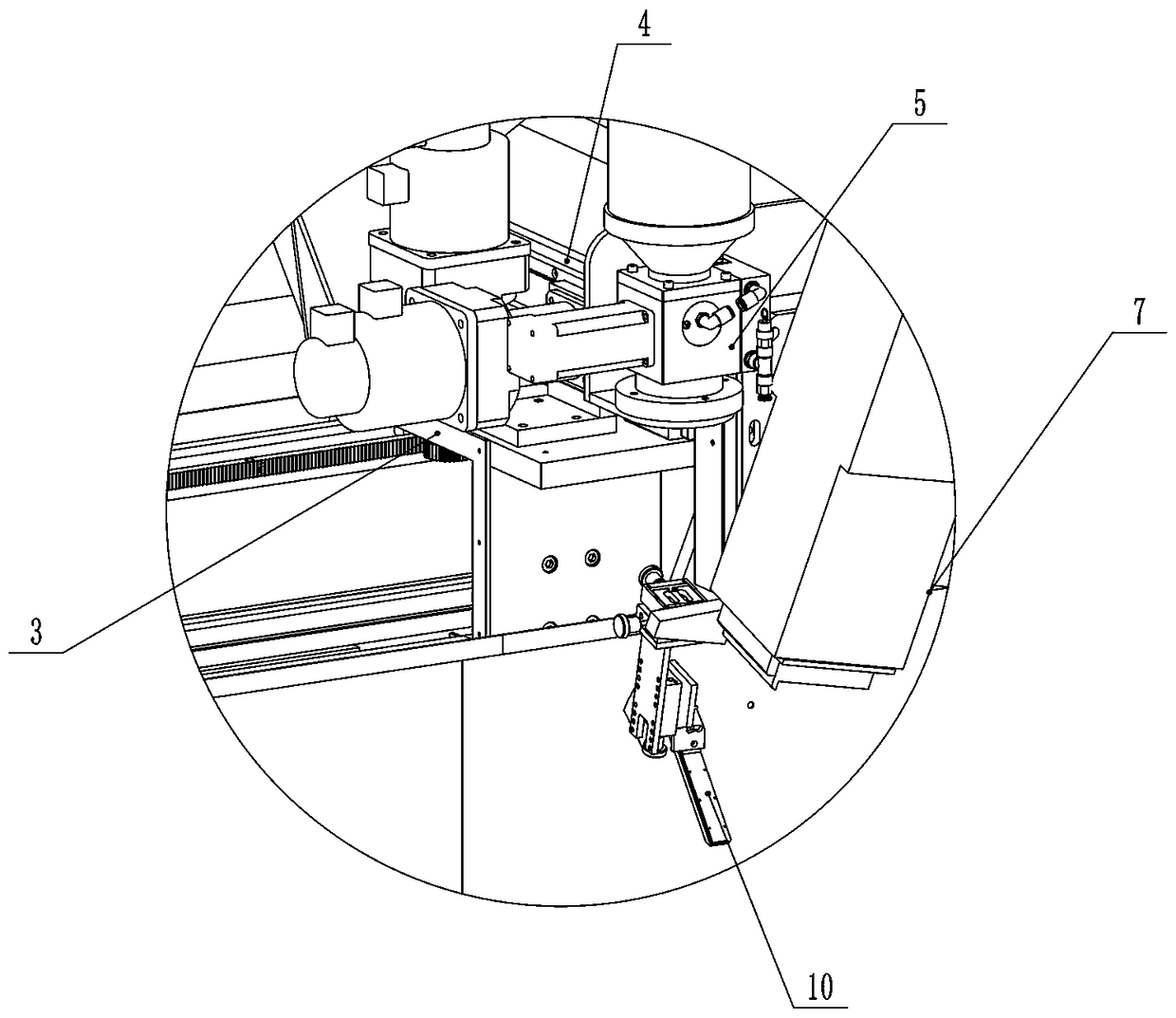

Method used

Image

Examples

Embodiment 1

[0045] An iron-based alloy powder for laser cladding, in terms of mass percentage, the composition of the iron-based alloy powder for laser cladding is: Cr 18.5%, Ni 3.5%, Si 2.0%, B 1.0%, C 0.2% , Mn 0.3%, Mo 0.4%, V0.3%, and the balance is Fe.

Embodiment 2

[0047] An iron-based alloy powder for laser cladding, in terms of mass percentage, the composition of the iron-based alloy powder for laser cladding is: Cr 18%, Ni 5%, Si 2%, B 0.4%, C 0.3% , Mn 0.2%, Mo 0.4%, V0.1%, and the balance is Fe.

Embodiment 3

[0049] An iron-based alloy powder for laser cladding, in terms of mass percentage, the composition of the iron-based alloy powder for laser cladding is: Cr 20%, Ni 6%, Si 2.5%, B 1%, C 0.1% , Mn 0.5%, Mo 0.5%, V0.3%, and the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com