Patents

Literature

10261 results about "Polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing and buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop. Technically polishing refers to processes that use an abrasive that is glued to the work wheel, while buffing uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process while buffing is less harsh, which leads to a smoother, brighter finish. A common misconception is that a polished surface has a mirror bright finish, however most mirror bright finishes are actually buffed.

Polishing pad and multi-layer polishing pad

InactiveUS20040014413A1Improve flatnessEffectively suppressed from occurringSemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessBiomedical engineering

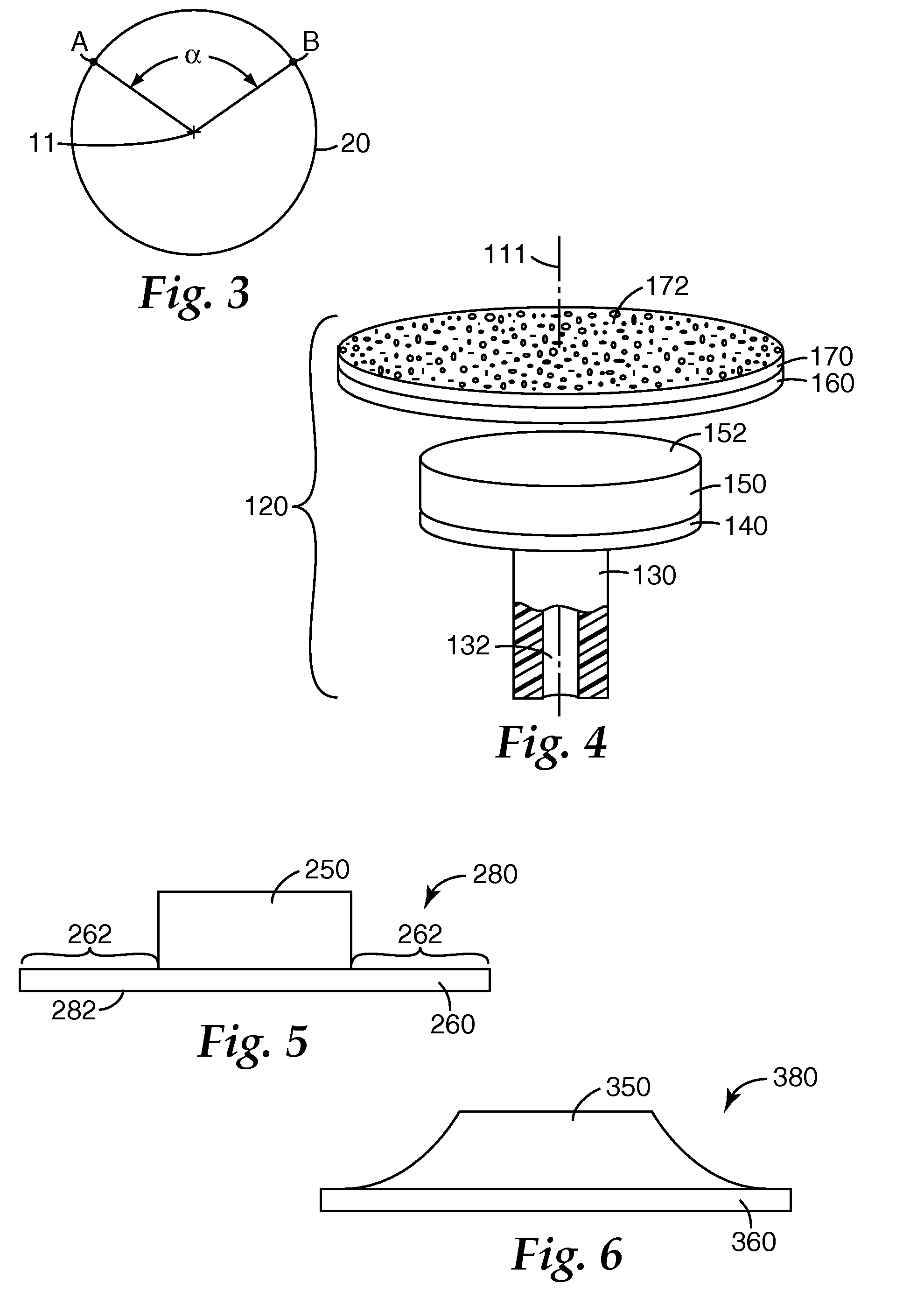

The present invention intends to provide a polishing pad and a multi-layer polishing pad that can particularly effectively suppress scratch from occurring. The polishing pad of the invention comprises at least one part selected from a groove (a) having at least one kind of shape selected from annular, lattice-like and spiral form on a polishing surface side, a concave portion (b) and a through hole (c). In the above, surface roughness of an inner surface of the part is 20 mum or less and the polishing pad is used for chemical mechanical polishing.

Owner:JSR CORPORATIOON

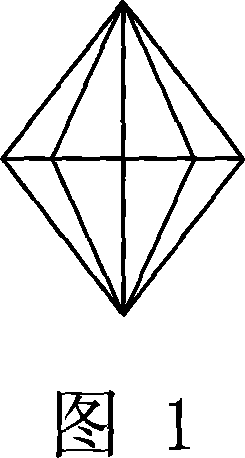

Method for polishing and grinding hydrant drill end and special polishing grinder

ActiveCN101073876AImprove processing efficiencyImprove qualityEdge grinding machinesConvex sideEngineering

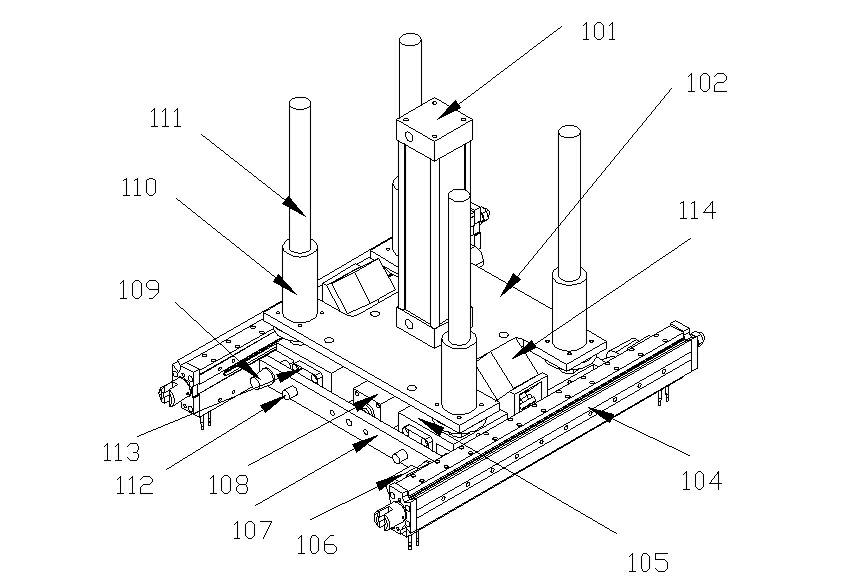

The invention is concerned with simulation diamond end face polishing-grinding machining method and the expert polishing-grinding machining. Set stuff and put molding plastics-absorption tray on fixture tray and make the concave face of plastics-absorption tray upside, and the simulation diamond adsorbs on the convexity of the bottom to plastics-absorption tray. Set plastics-absorption tray on the polishing-grinding machining and mill the tine end of simulation diamond on calm millstone. The polishing-grinding machining relates rack with a level millstone at its middle, and there are two level trays. They are centrosymmetric to the axis of millstone on top of millstone and have plastics-absorption tray on them. There is up and down equipment for tray on top of level tray which connecting with two turning axes on two sides of millstone with level rack, and the other end of turning axis has running equipment of turning axis. It has large machining amount of each time, high produce efficiency, good ratio to excellent stuff, long work time, easy operation without waste of material.

Owner:虞雅仙

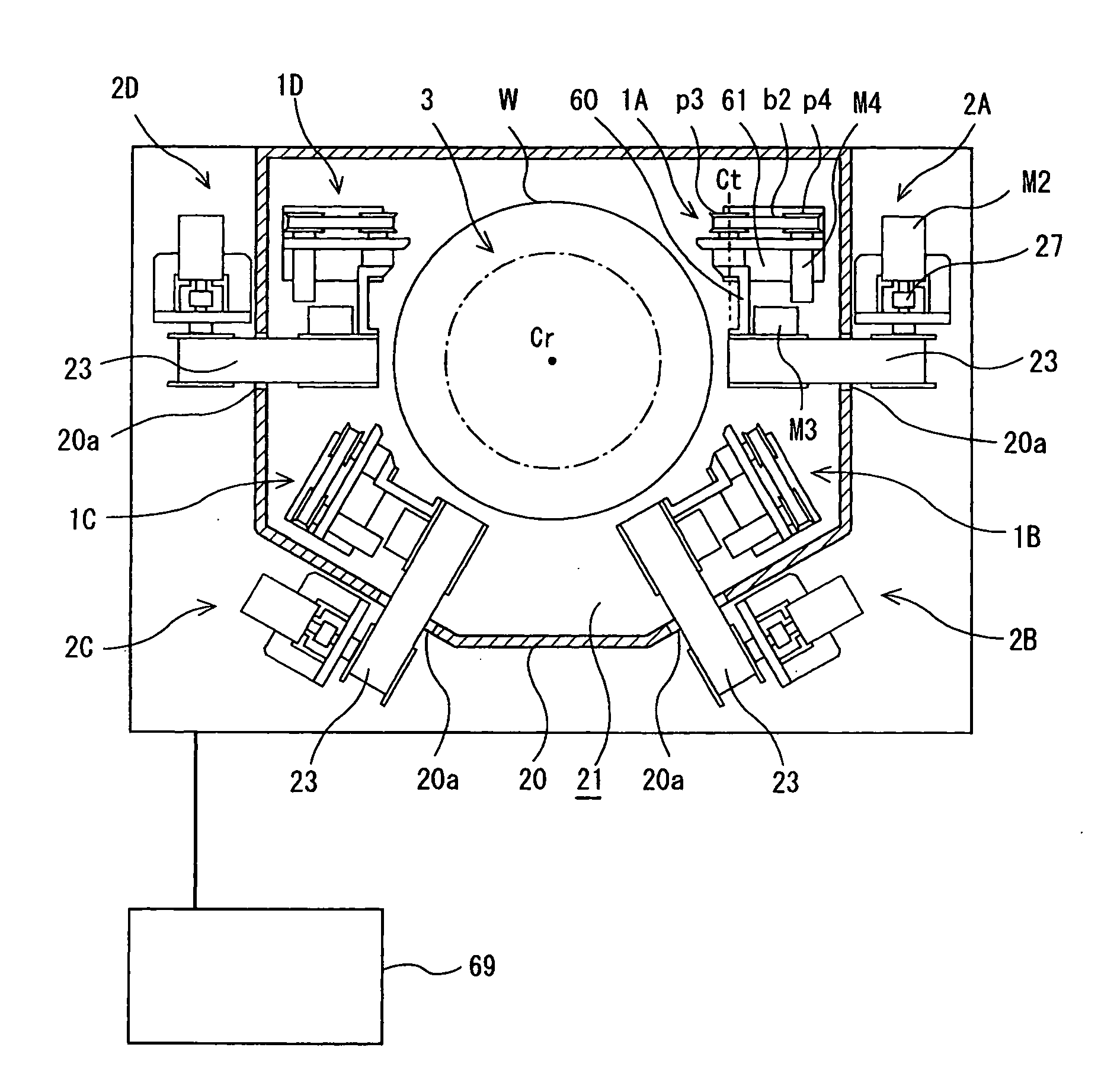

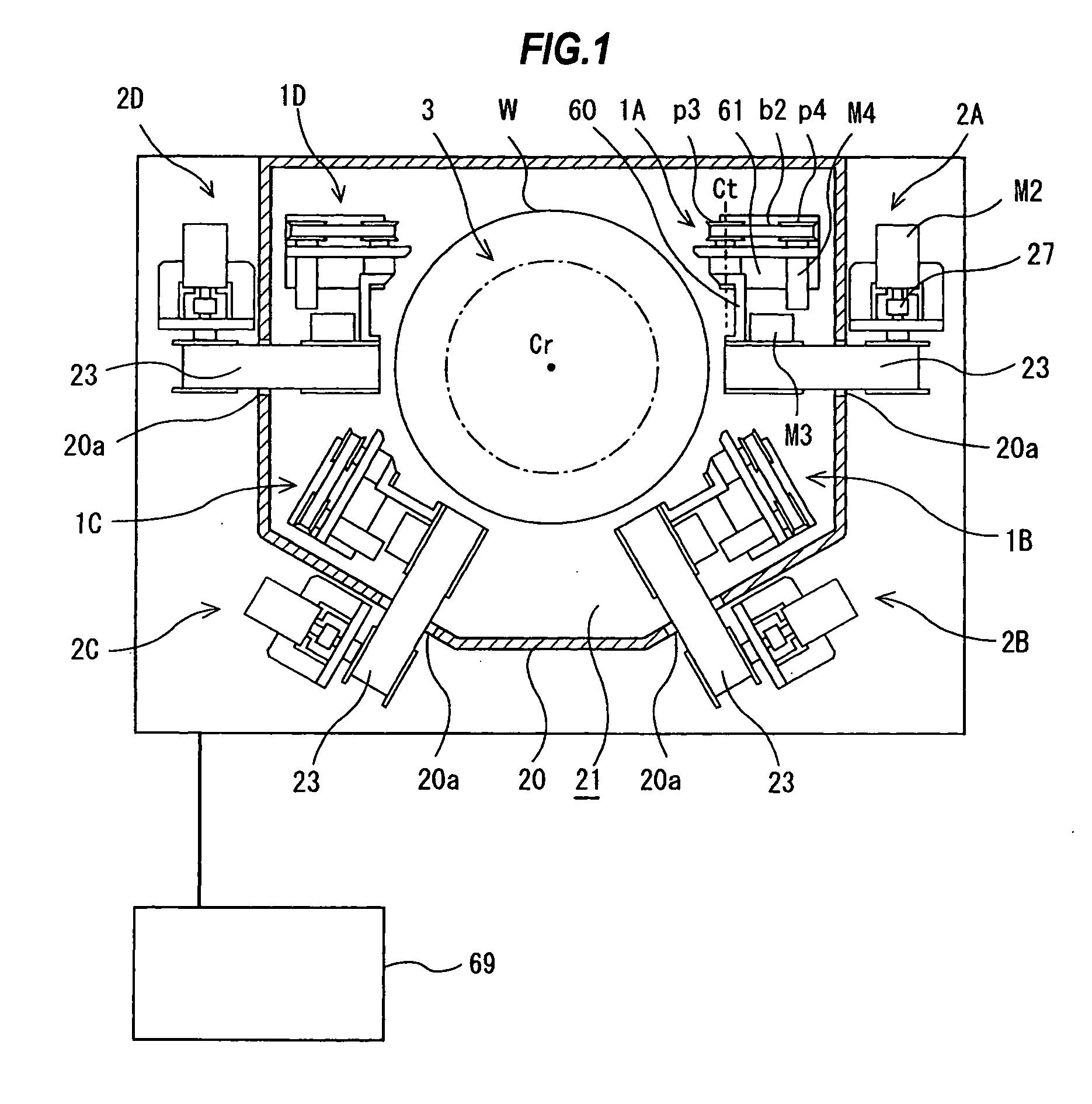

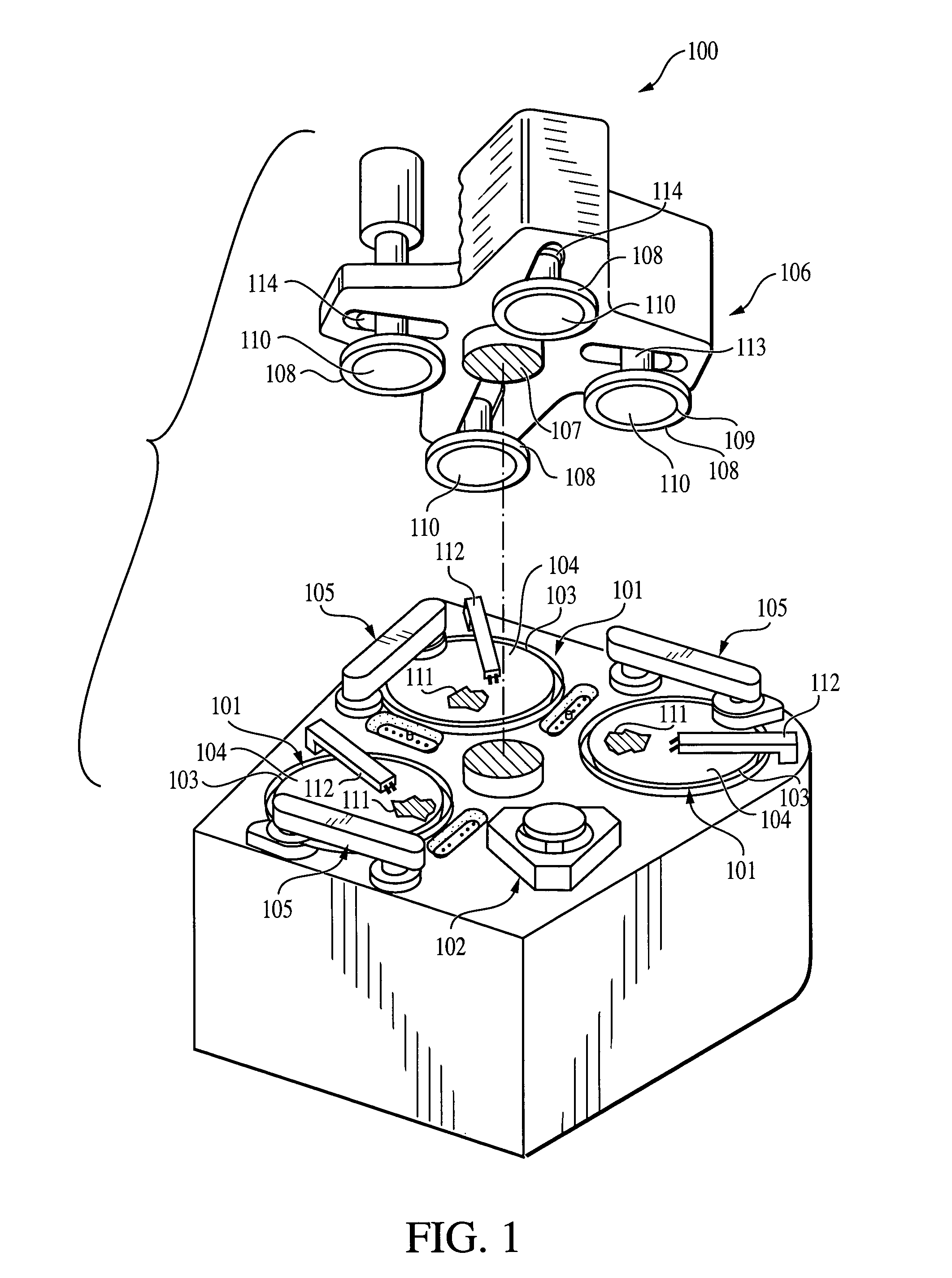

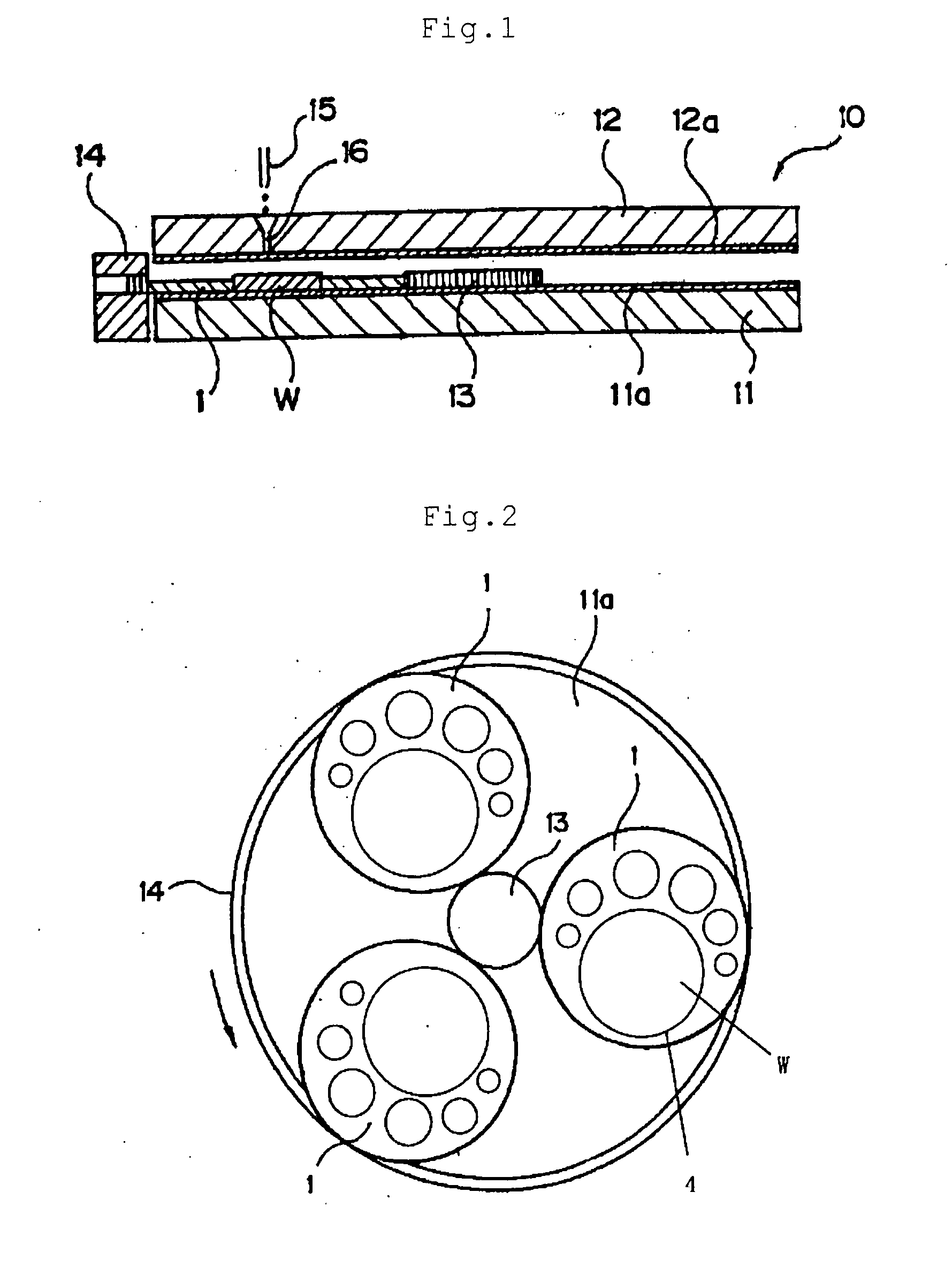

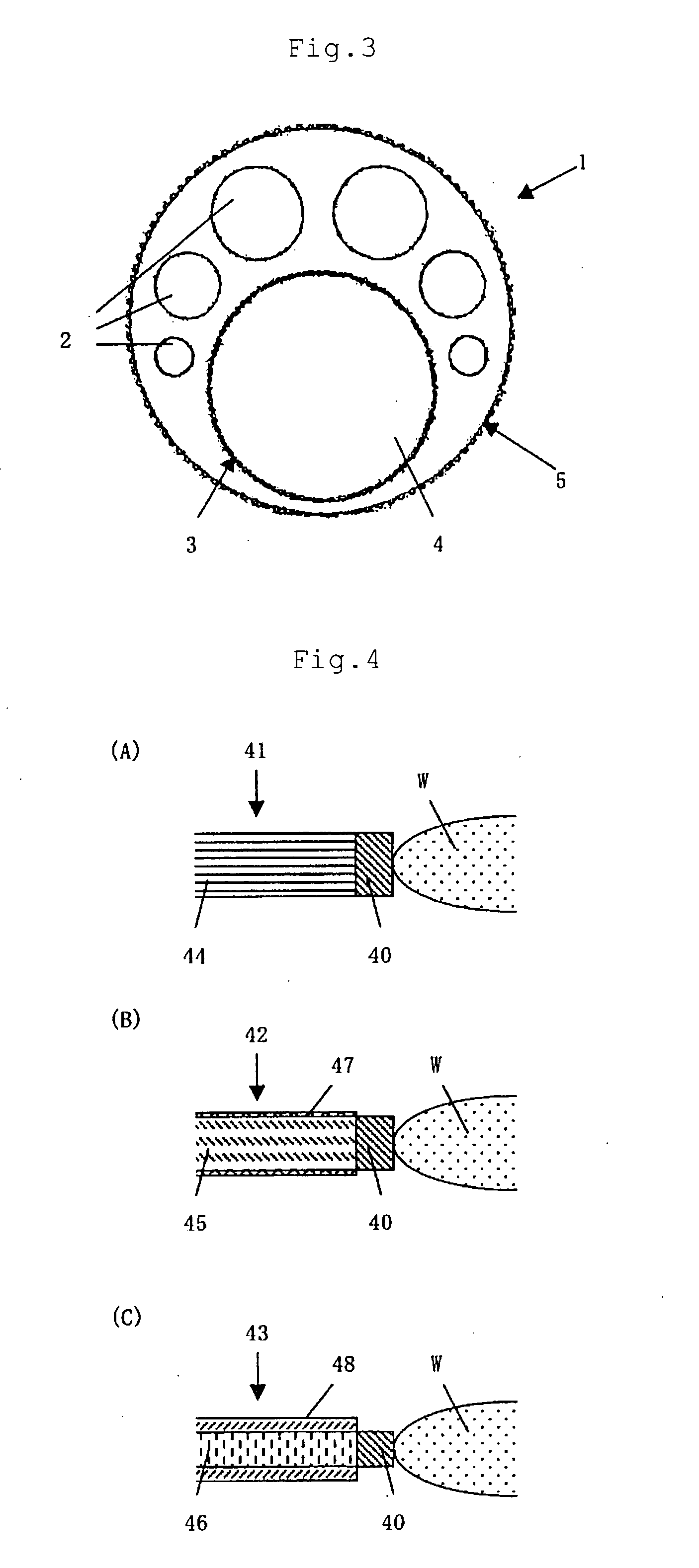

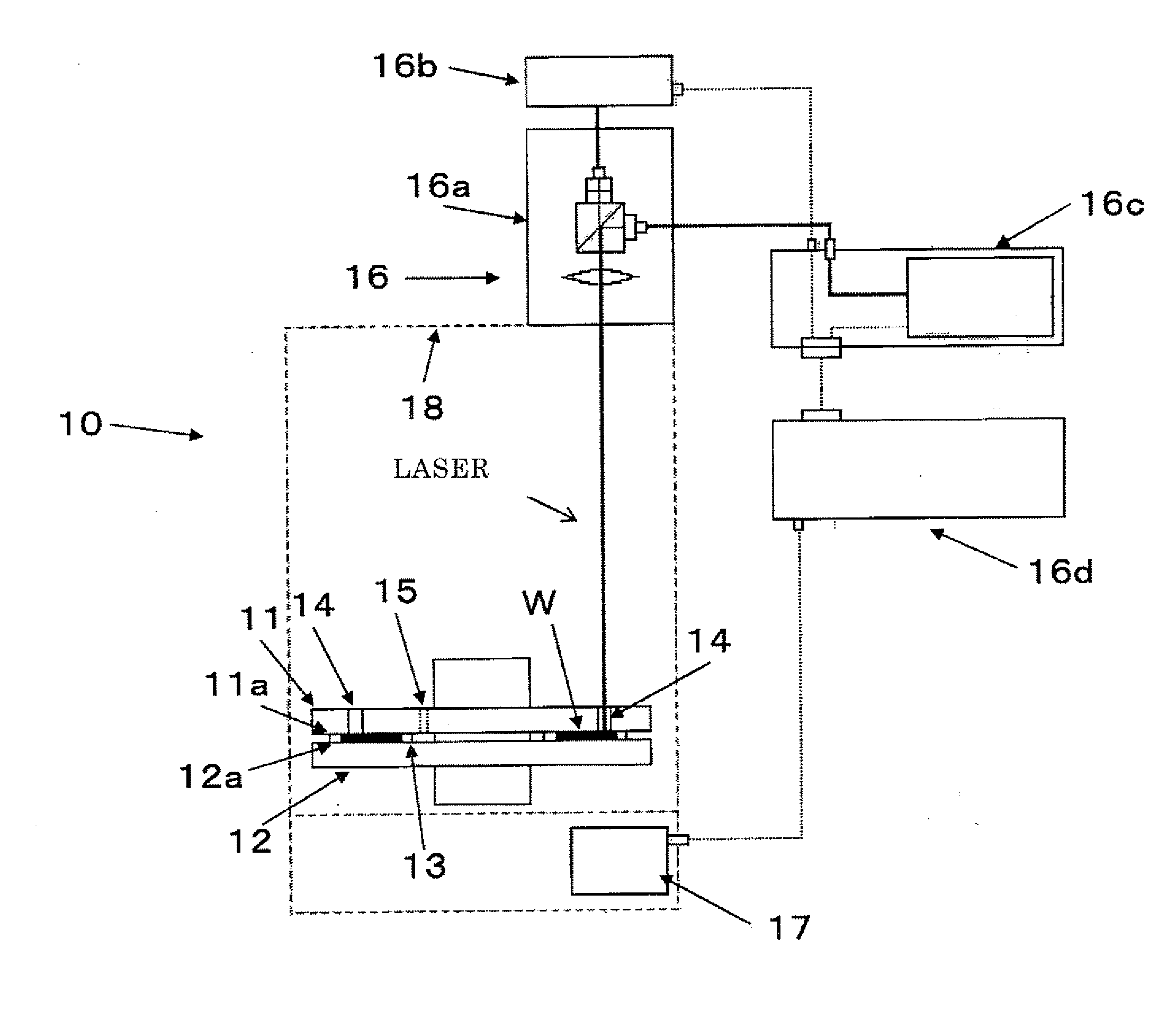

Polishing apparatus and polishing method

ActiveUS20090142992A1Easy to replaceShorten polishing timeGrinding drivesSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

The present invention provides a polishing apparatus for polishing a periphery of a substrate. This polishing apparatus includes a rotary holding mechanism configured to hold the substrate horizontally and rotate the substrate, plural polishing head assemblies provided around the substrate, plural tape supplying and recovering mechanisms configured to supply polishing tapes to the plural polishing head assemblies and recover the polishing tapes from the plural polishing head assemblies, and plural moving mechanisms configured to move the plural polishing head assemblies in radial directions of the substrate held by the rotary holding mechanism. The tape supplying and recovering mechanisms are located outwardly of the plural polishing head assemblies in the radial directions of the substrate, and the tape supplying and recovering mechanisms are fixed in position.

Owner:EBARA CORP

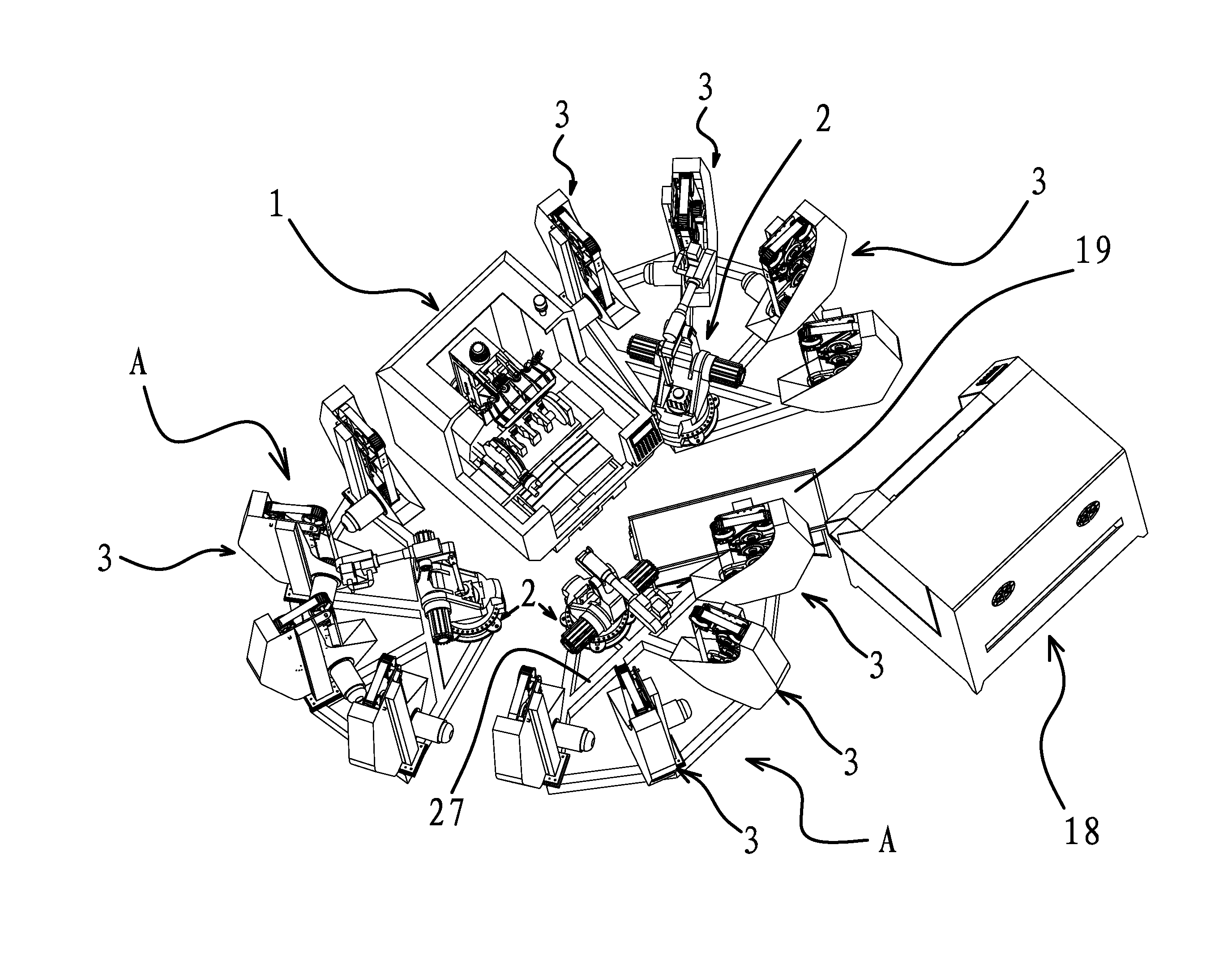

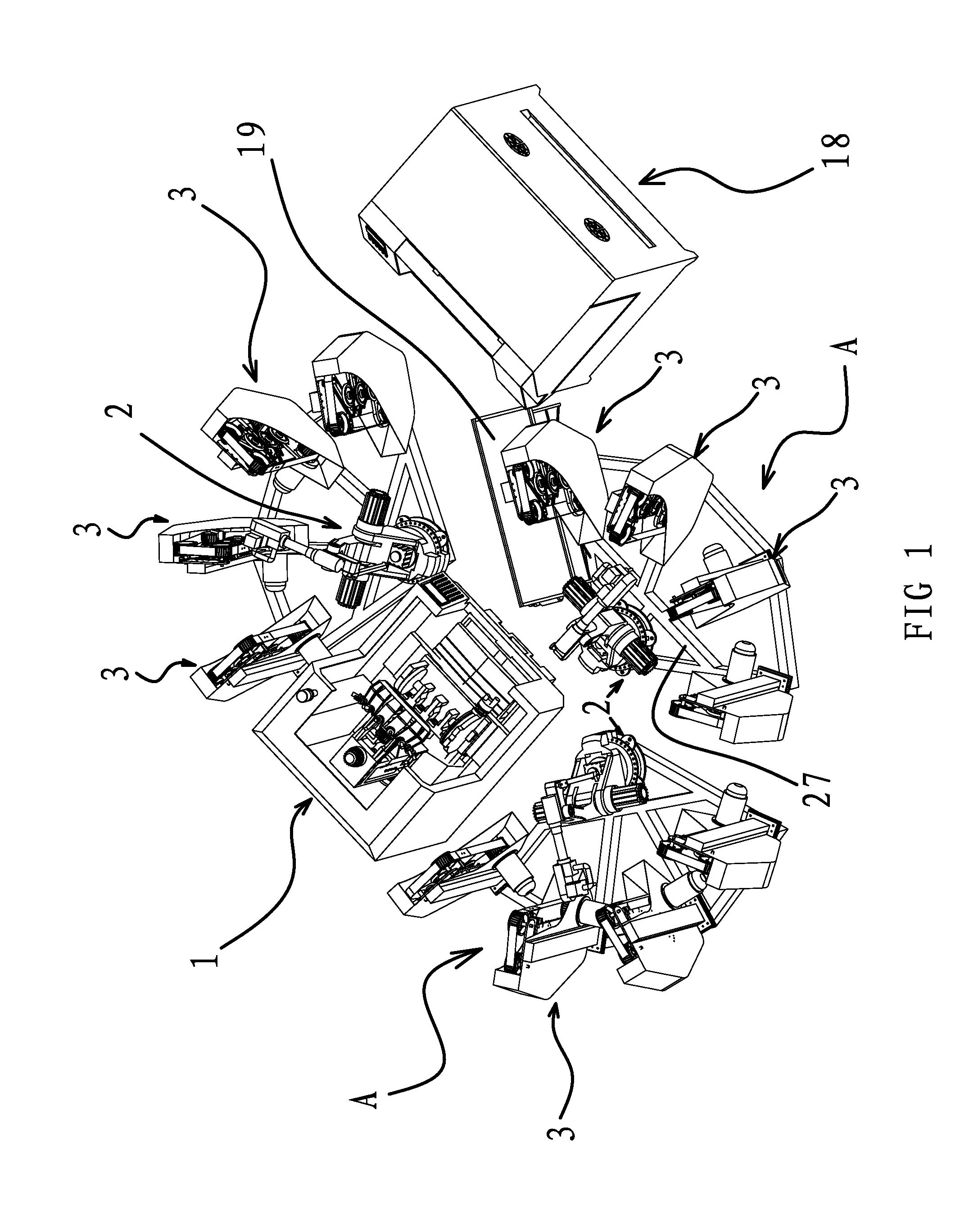

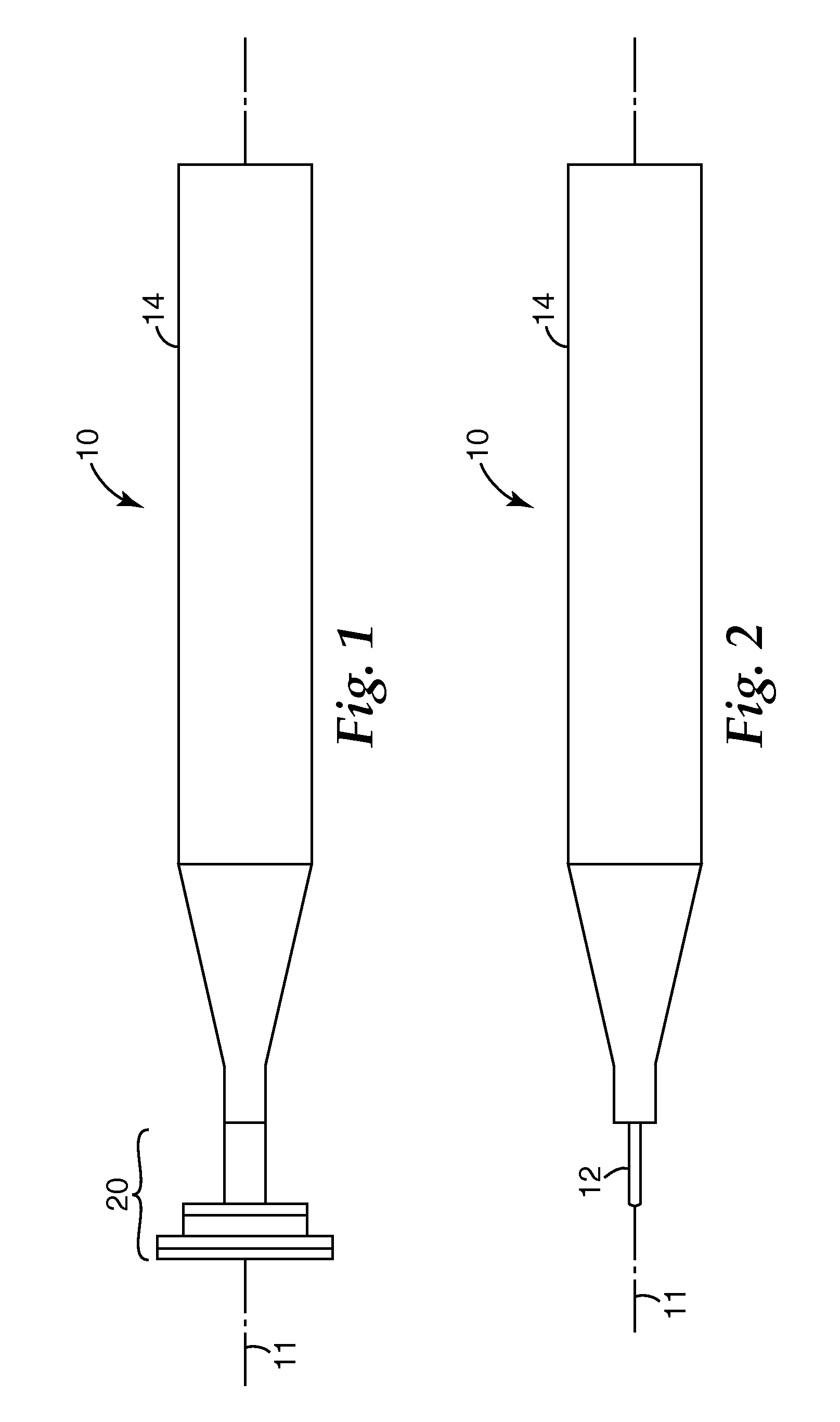

Surface Processing System for a Work Piece

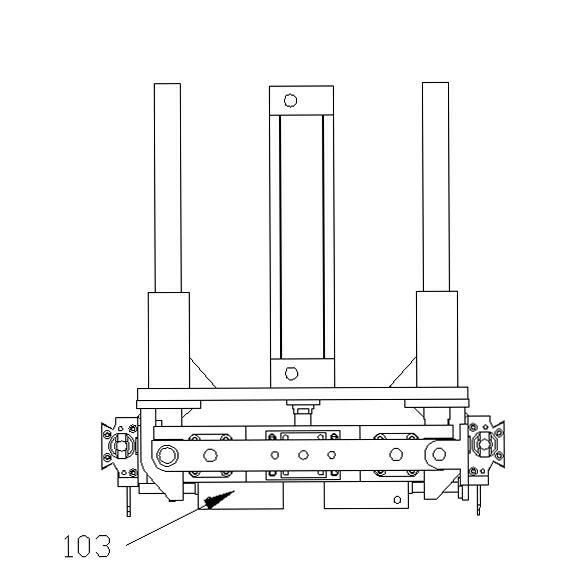

InactiveUS20150044944A1Guaranteed to workImprove production efficiencyEdge grinding machinesBelt grinding machinesManipulatorMachining

The present invention provides a surface processing system for a work piece in the mechanical technical field. The system comprises at least one group of polishing units. A manipulator and several polishers with different polishing precisions are provided on the polishing units. The polishers are arranged around the manipulator in turn. The work piece could be moved by the manipulator between the processing center and the polishing units. The machined work piece is loaded by the manipulator for one time when the manipulator is located at the processing center. When the manipulator is located at the polishing units, the manipulator keeps holding the work piece and transfers the work piece in a preset sequence to each polisher corresponding to the polishing unit where the manipulator is located. The surface of work pieces having different wall thicknesses and complex surfaces could be processed in a large batch with a high efficiency.

Owner:TAIZHOU FEDERAL ROBOT TECH

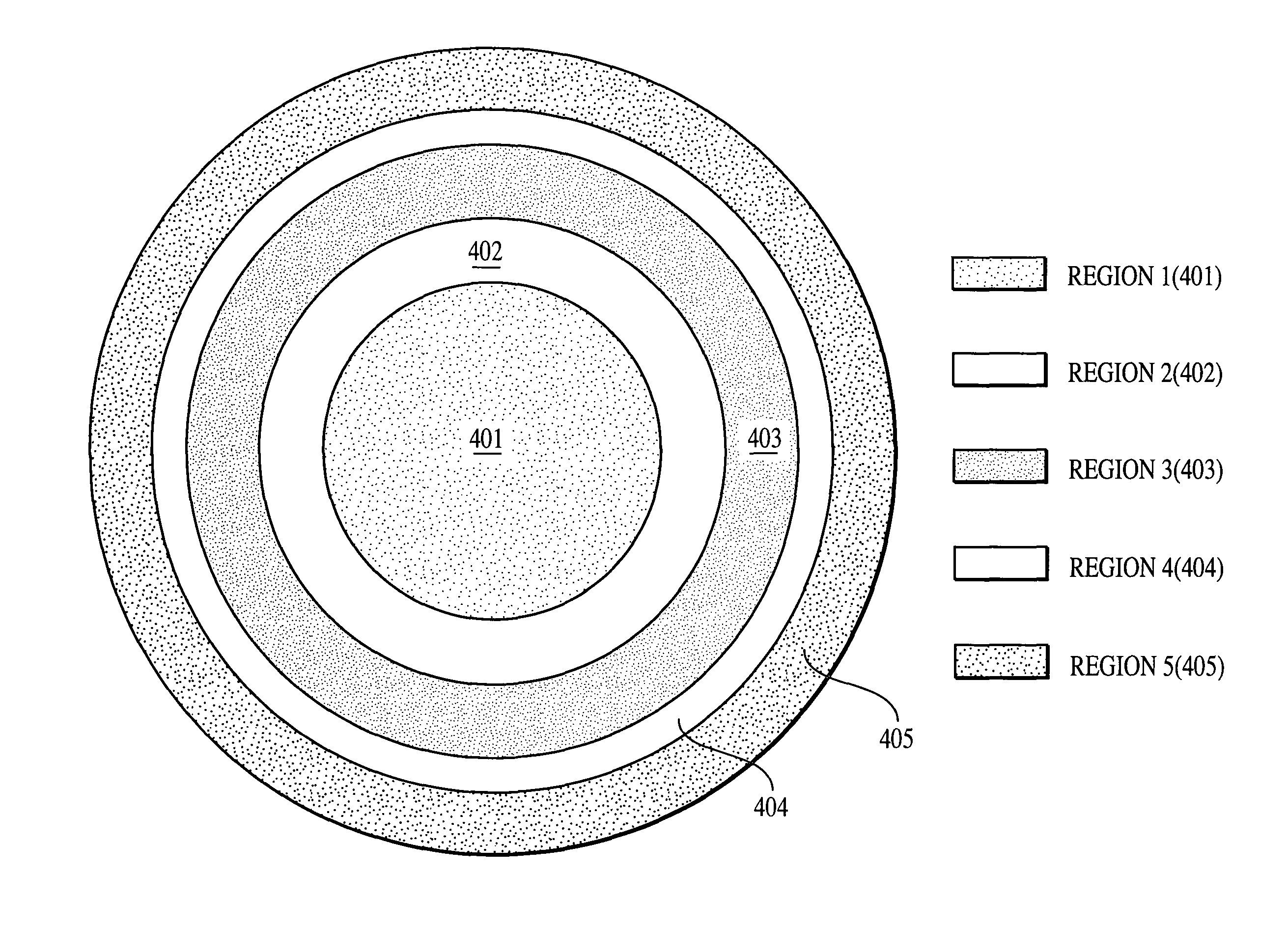

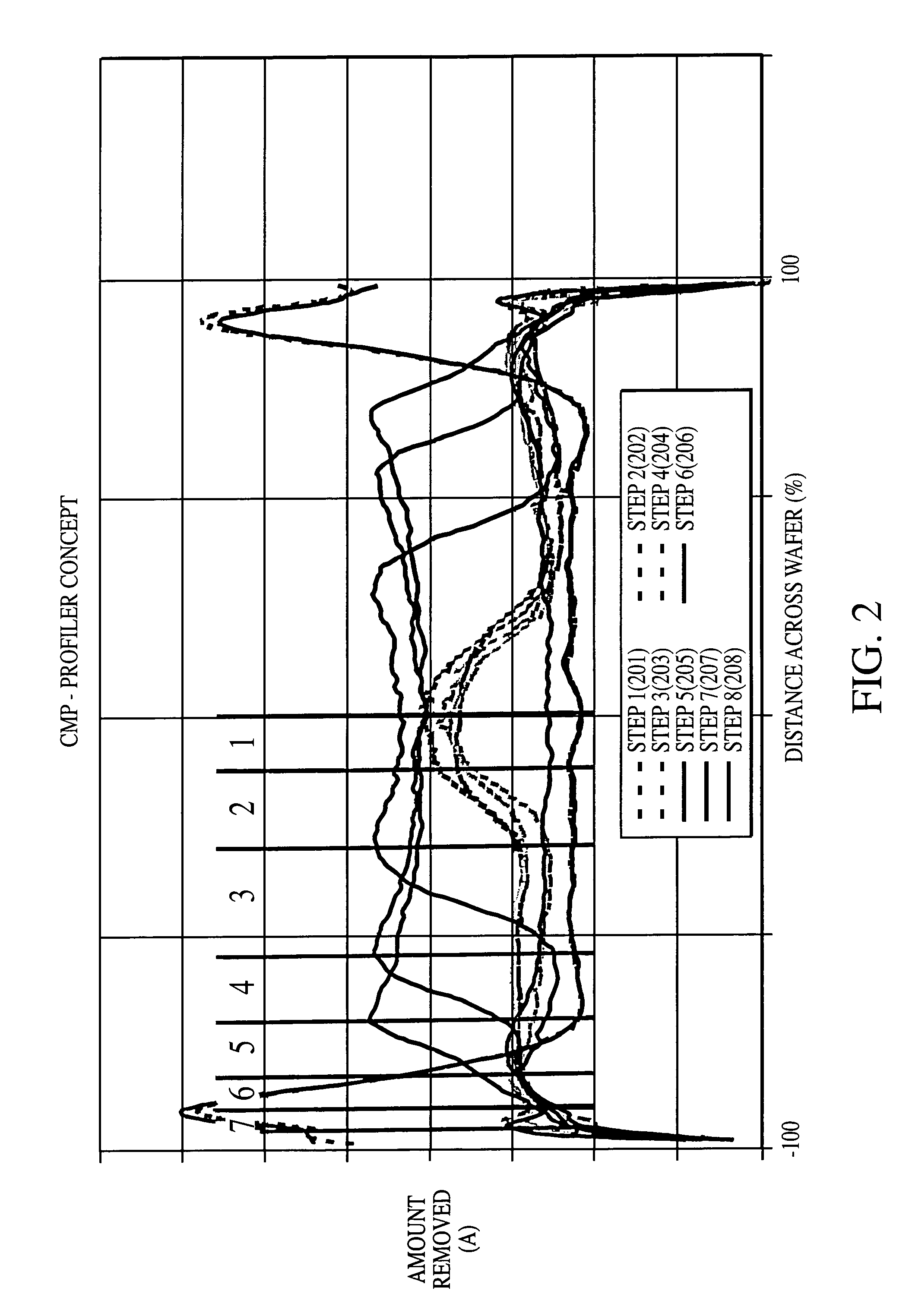

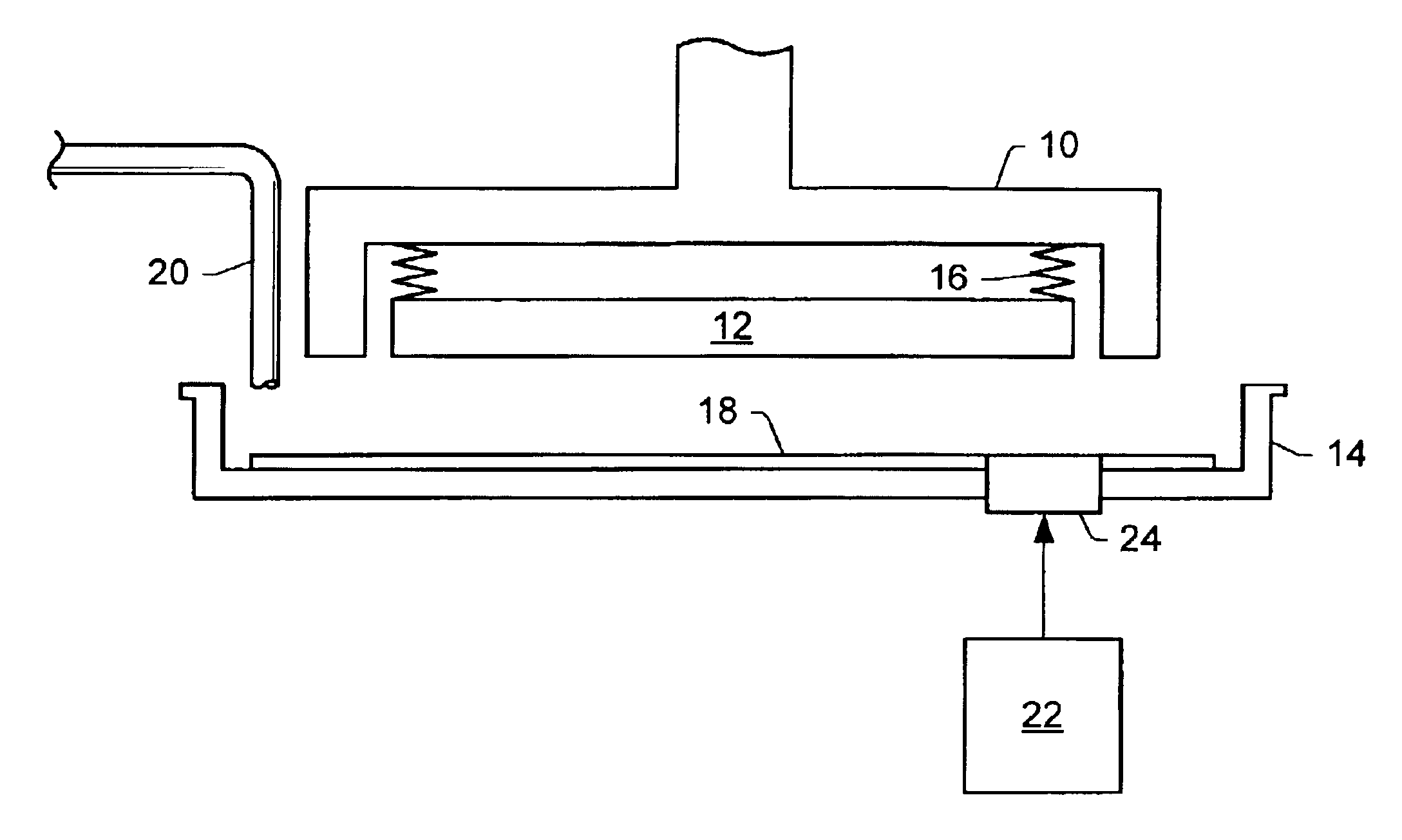

Feedback control of a chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS7160739B2Optimal Operational ControlImprove resultsSemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d)calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

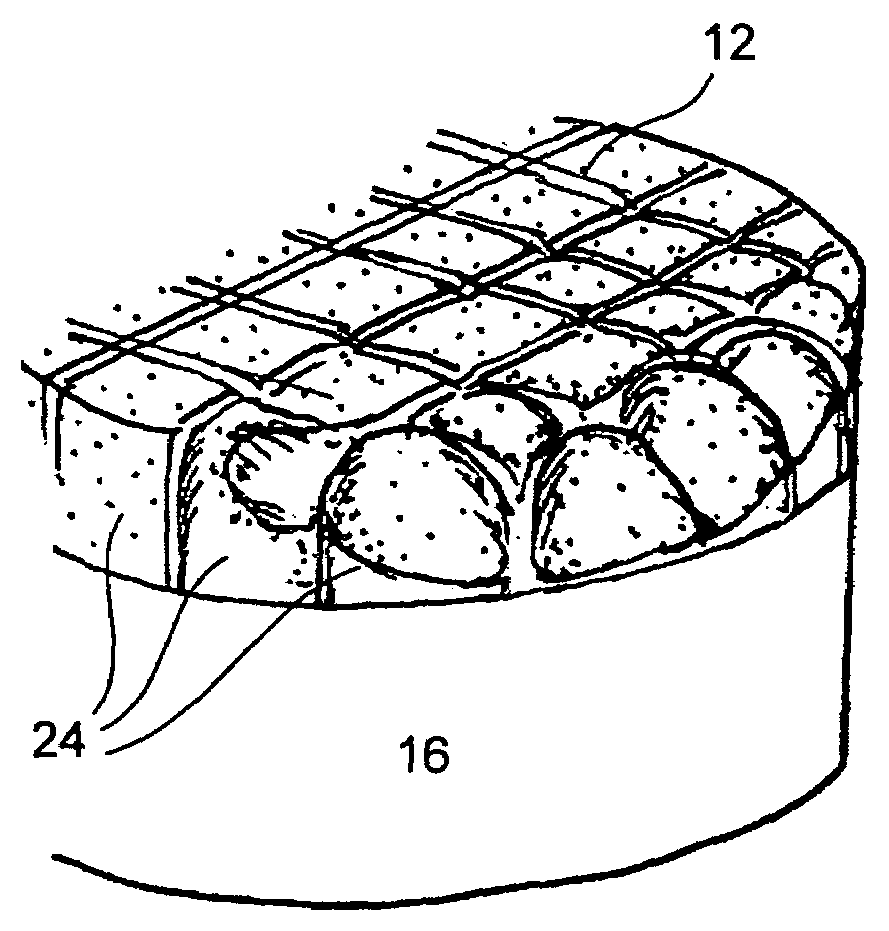

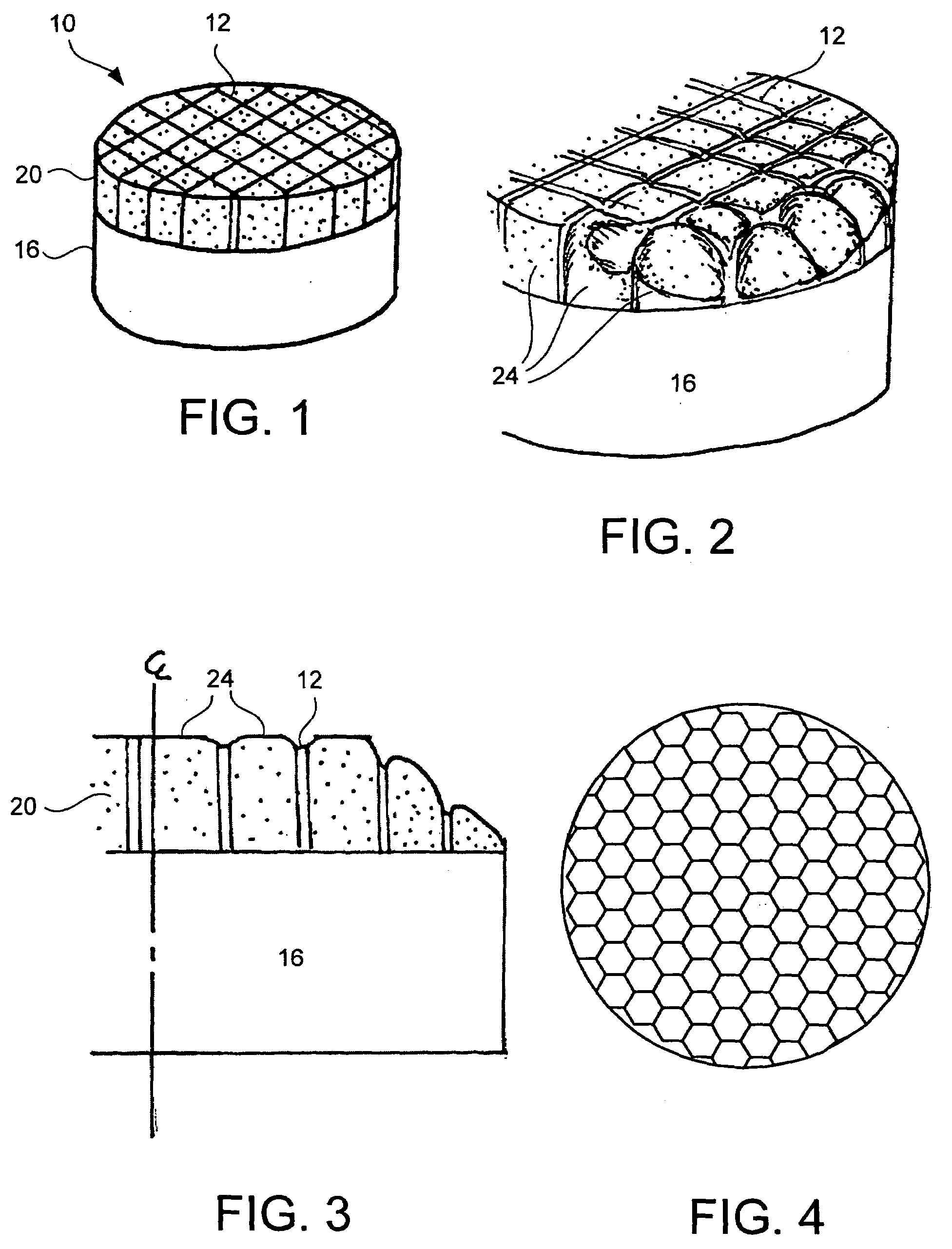

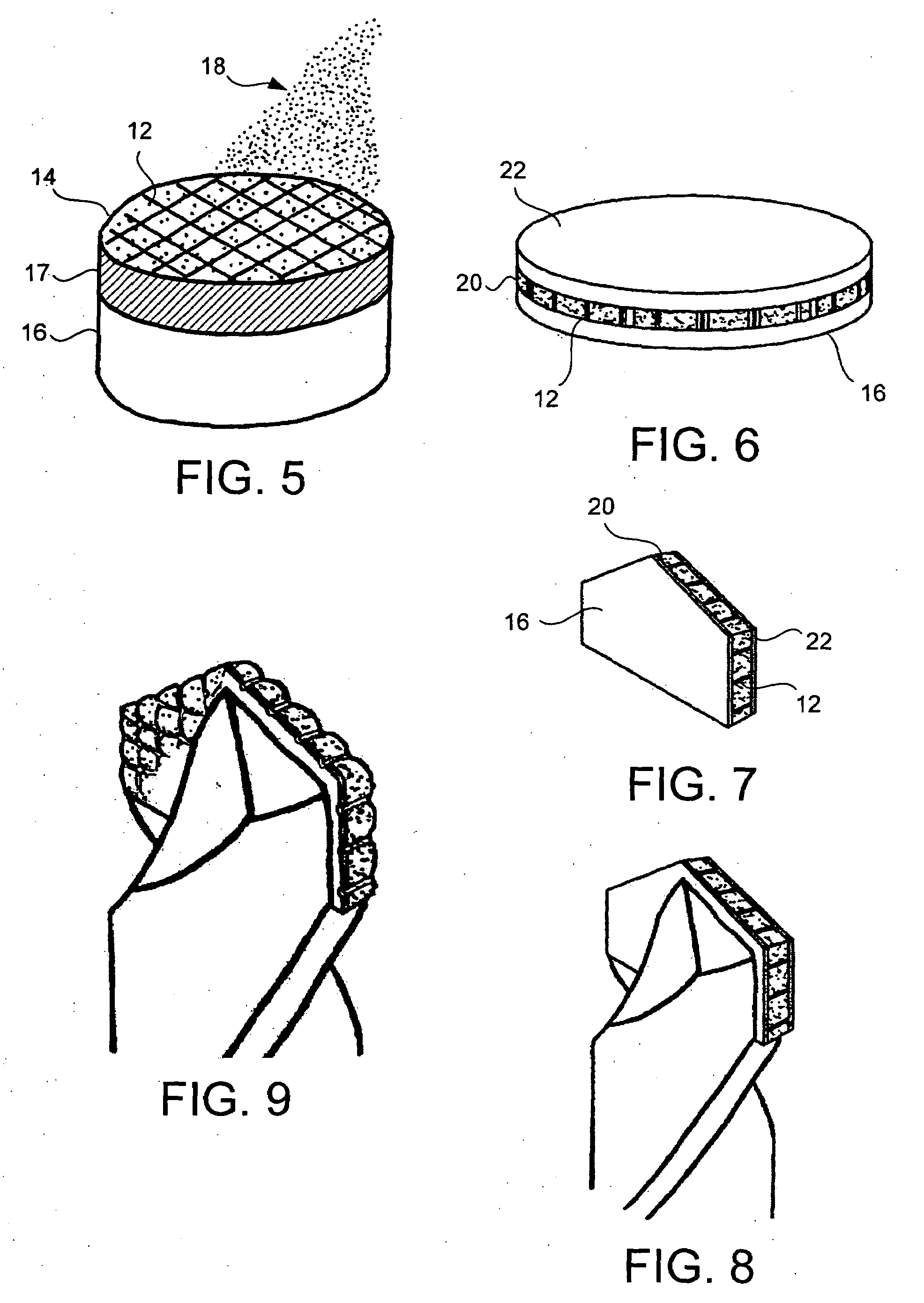

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS20080023230A1Wide applicationProperty is limitedPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Abrasive articles, rotationally reciprocating tools, and methods

InactiveUS20080233845A1Surface defectControl impactEdge grinding machinesSupport wheelsMaterials sciencePolishing

Methods of abrading surfaces by rotationally reciprocating abrasive surfaces in contact with the surfaces, abrasive articles for use in rotationally reciprocating tools, and methods of removing defects in a surface, where the methods include sanding using a rotationally reciprocating abrasive surface followed by one or more polishing operations are disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

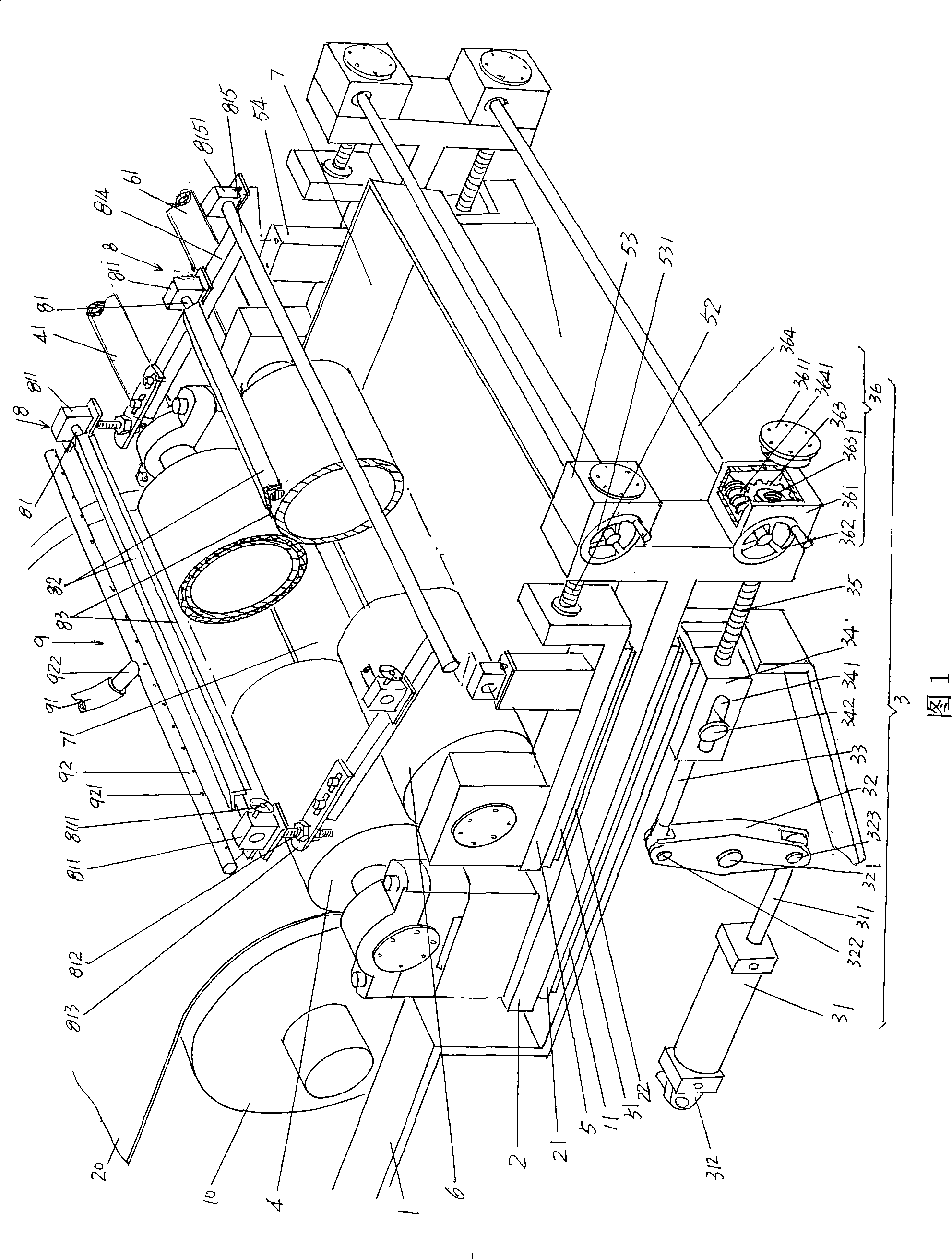

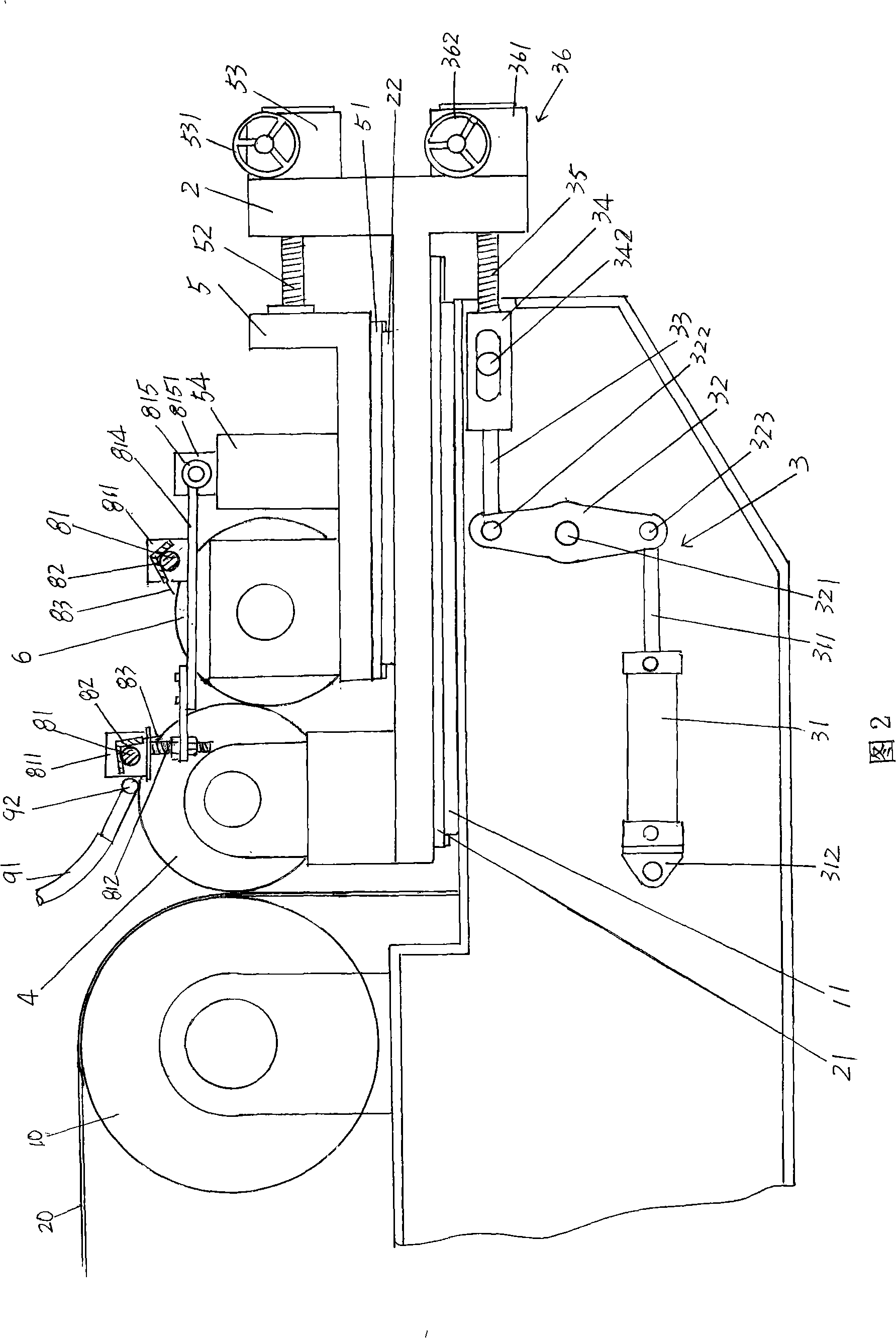

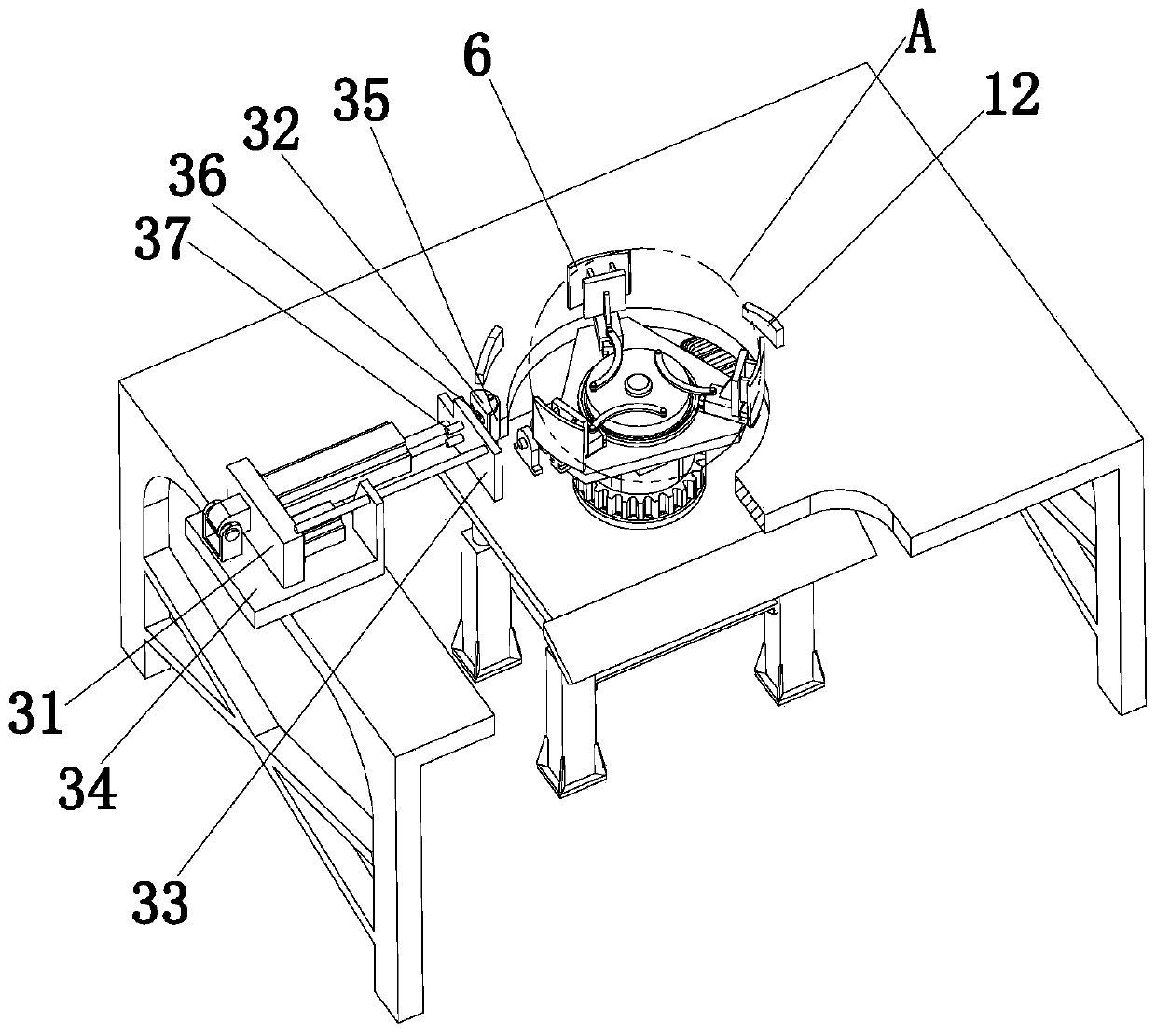

Full-automatic ornament grinding and polishing machine

ActiveCN102152190AReduce volumeSimple structureEdge grinding machinesMetal working apparatusEngineeringManipulator

The invention relates to a grinding and polishing machine for processing ornamental artificial gems, crystals or glass beads, in particular to a full-automatic ornament grinding and polishing machine. The invention discloses the full-automatic ornament grinding and polishing machine with the characteristics of one-step product forming, integration of all working procedures, high production efficiency and simple structure. The invention realizes the full-automatic processing of crystal diamonds and other ornaments by using one machine. In a main scheme provided by the invention, a spindle assembly is arranged in the middle of a rack, the upper end of the spindle assembly is provided with a turntable, the turntable is provided with a plurality of cantilevers which are uniformly distributed by taking a center axis position of the spindle assembly as a center, and the tail end of each cantilever is provided with a mechanical arm; a feeding and discharging integrated assembly, at least onefront grinding integrated assembly, at least one front polishing integrated assembly, a through-connection integrated assembly, at least one rear grinding integrated assembly and at least one rear polishing integrated assembly are respectively distributed on the rack in a working sequence; and all the assemblies are connected end to end.

Owner:ZHEJIANG JINJIU MACHINERY

Flexible polishing sheet and production method thereof

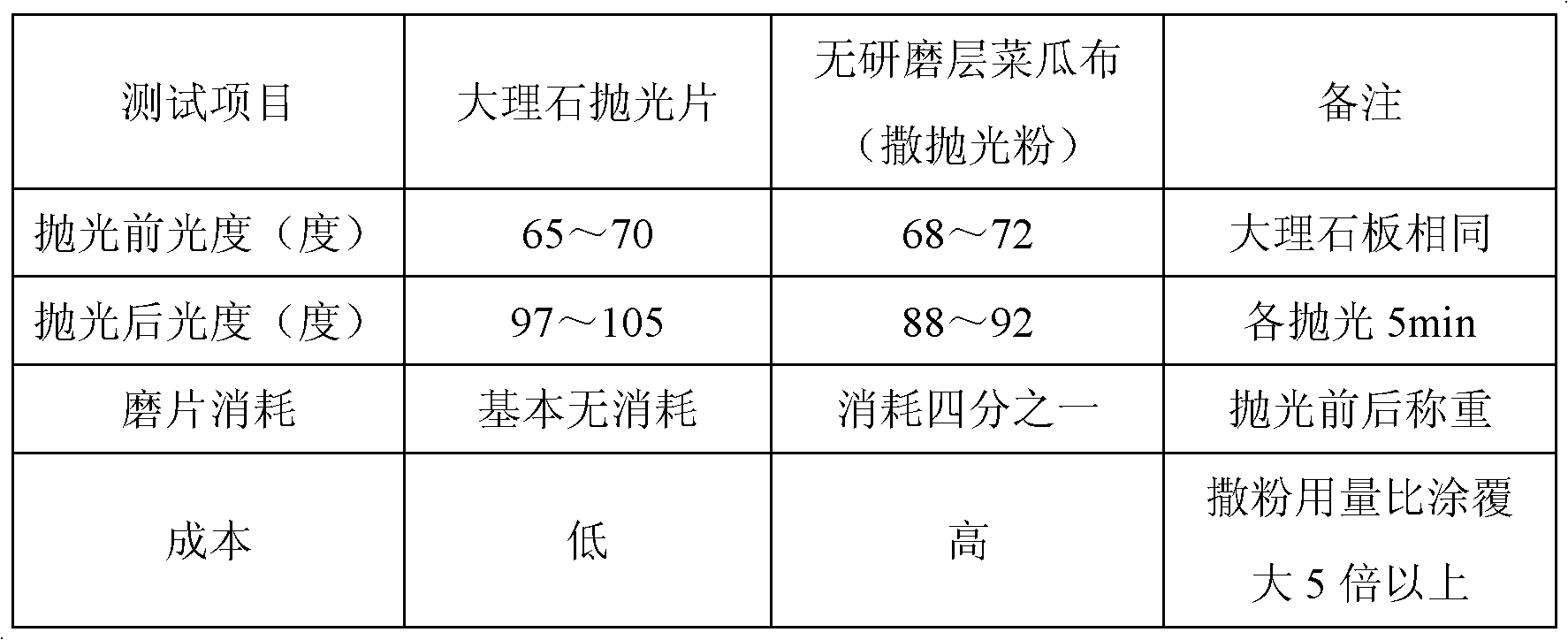

Disclosed are a flexible polishing sheet and a production method thereof. The flexible polishing sheet is high in grinding efficiency, fast in polishing and brightening rate, long in service life and low in cost, and is provided with a flexible base layer and a polishing layer coated on the surface of the flexible base layer, or the flexible polishing sheet is made of fibers and polishing abrasive material by mixing and hot pressing, and the mass ratio of the fibers to the polishing abrasive material is (20-40):(80-60). The flexible polishing sheet can be used for directly polishing a material with no extra polishing powder or polishing paste to be added on the surface of the material, so that great loss of polishing materials is avoided, cost is saved, brightening speed is fast during polishing, efficiency is high, and the flexible polishing sheet is resistant to wearing and long in service life. The flexible polishing sheet can be easily made into large-sized flexible polishing products, the polishing area is enlarged evidently, and the polishing efficiency is improved. The flexible polishing sheet can also be made into highly flexible polishing products of different granularities from thickness to fineness, and can be used for polishing uneven surfaces, edge and corner surfaces and the like step by step.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

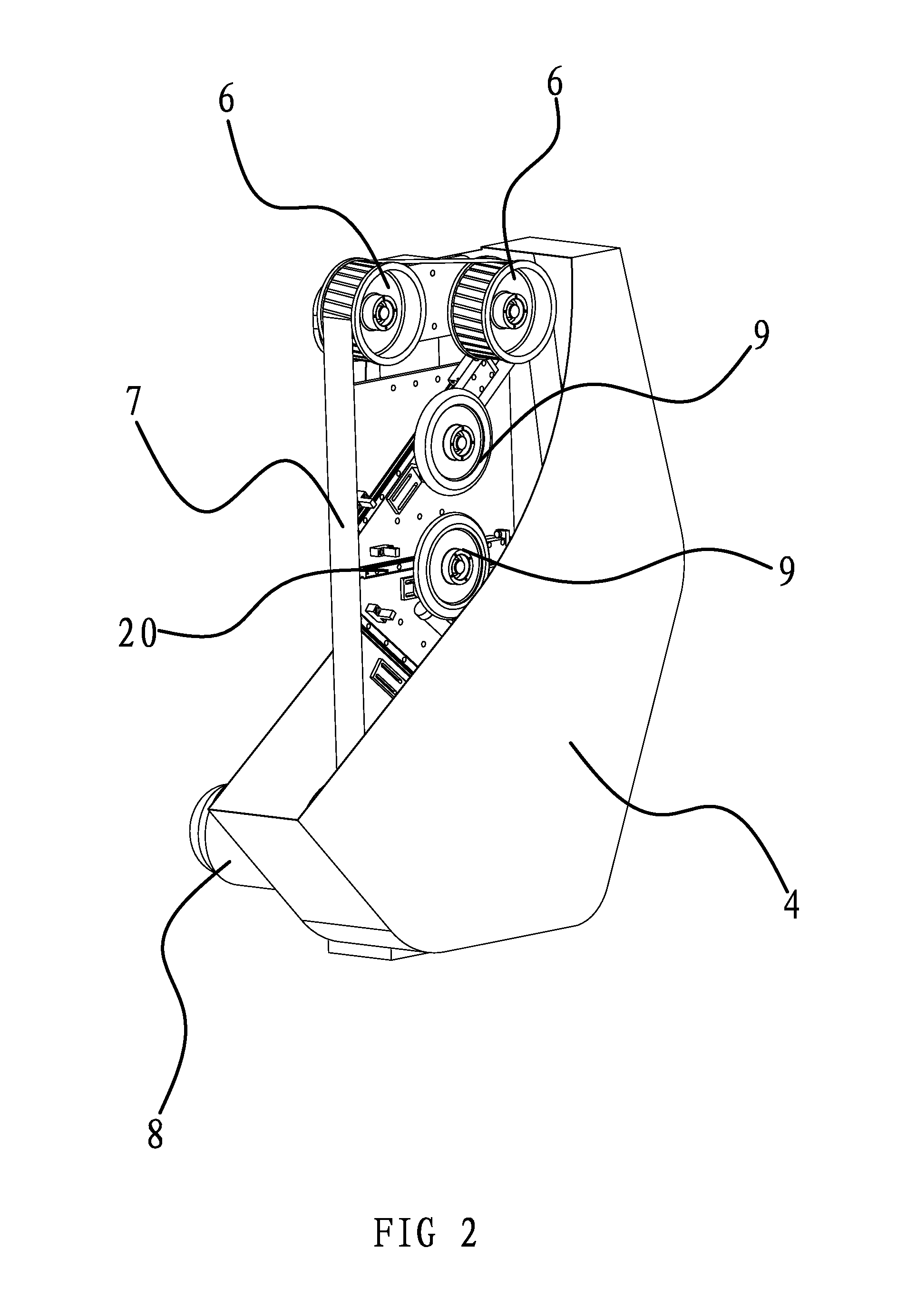

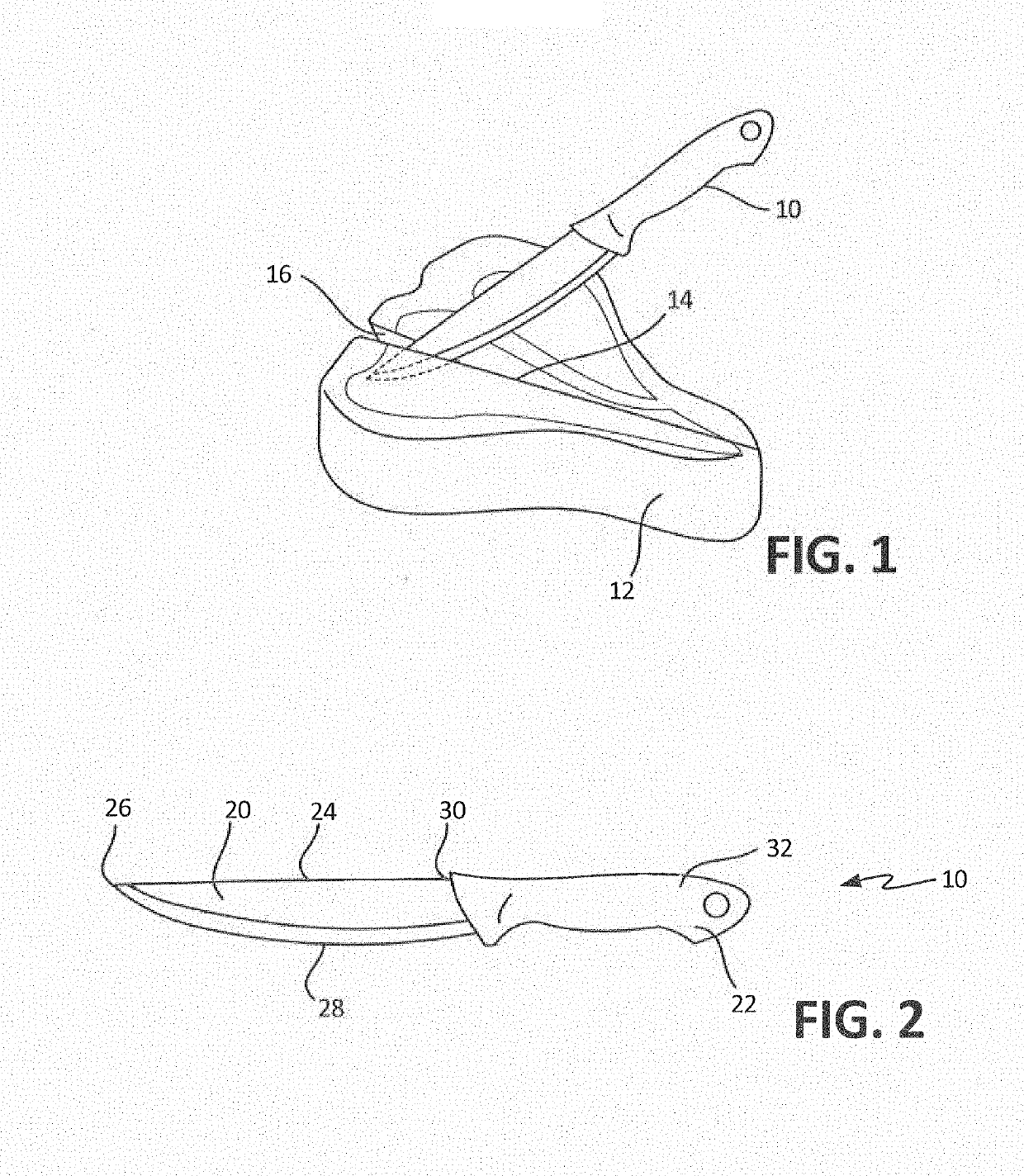

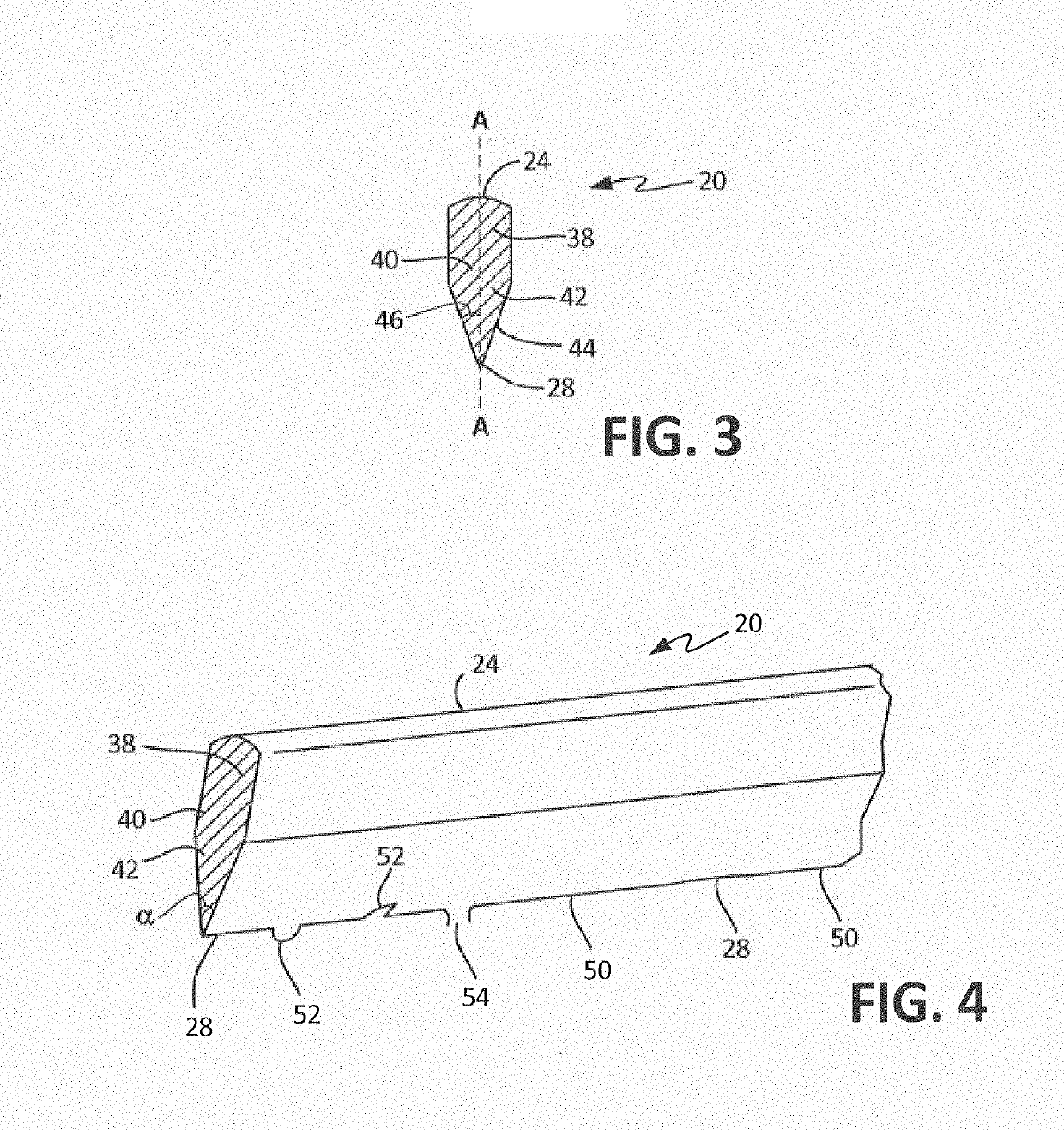

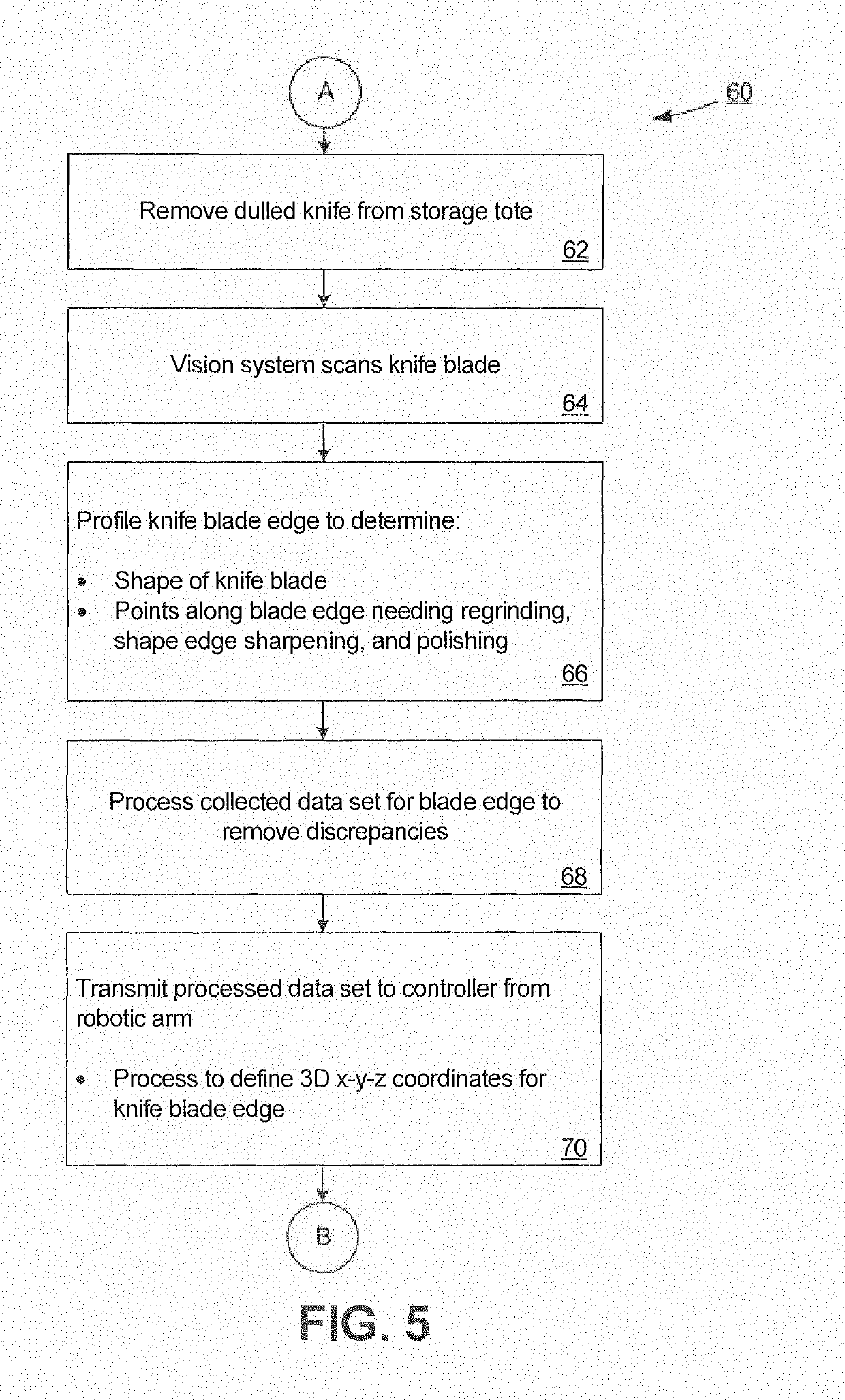

Robotic hand tool sharpening and cleaning apparatus

ActiveUS20190210177A1Improve throughputLess operator repetitive stressProgramme controlProgramme-controlled manipulatorCamera imageRobotic hand

An automated hand tool sharpening and cleaning system for sharpening the two opposed cutting edges of domestic, industrial, sport, or hobby hand tool like a knife blade is provided by the invention. The apparatus comprises a six-axis robotic arm, a pneumatic gripper, a vision sensor camera for profiling the blade edges, a robotic controller, and sequentially-arranged grinding, coarse sharpening, fine sharpening, and buffing rotating wheel assemblies used to grind, sharpen, and buff or polish the cutting edges of the knife blade. The blade cutting edges are profiled by the camera image that is processed by associated software to define the blade by multiple points defined along its edge, followed by a set of algorithms that are used to clean up any discrepancies in the profile data. The resulting corrected profile data is then translated into a set of machine control commands fed to the robotic arm and pneumatic gripper via the robot controller for manipulating the knife blade edges via the robotic arm with respect to each of the grinding, coarse sharpening, fine sharpening, and buffing / polishing wheels and an associated wash station for remove bits of metal and other residue resulting from the sharpened knife blade.

Owner:RAZOR EDGE SYST

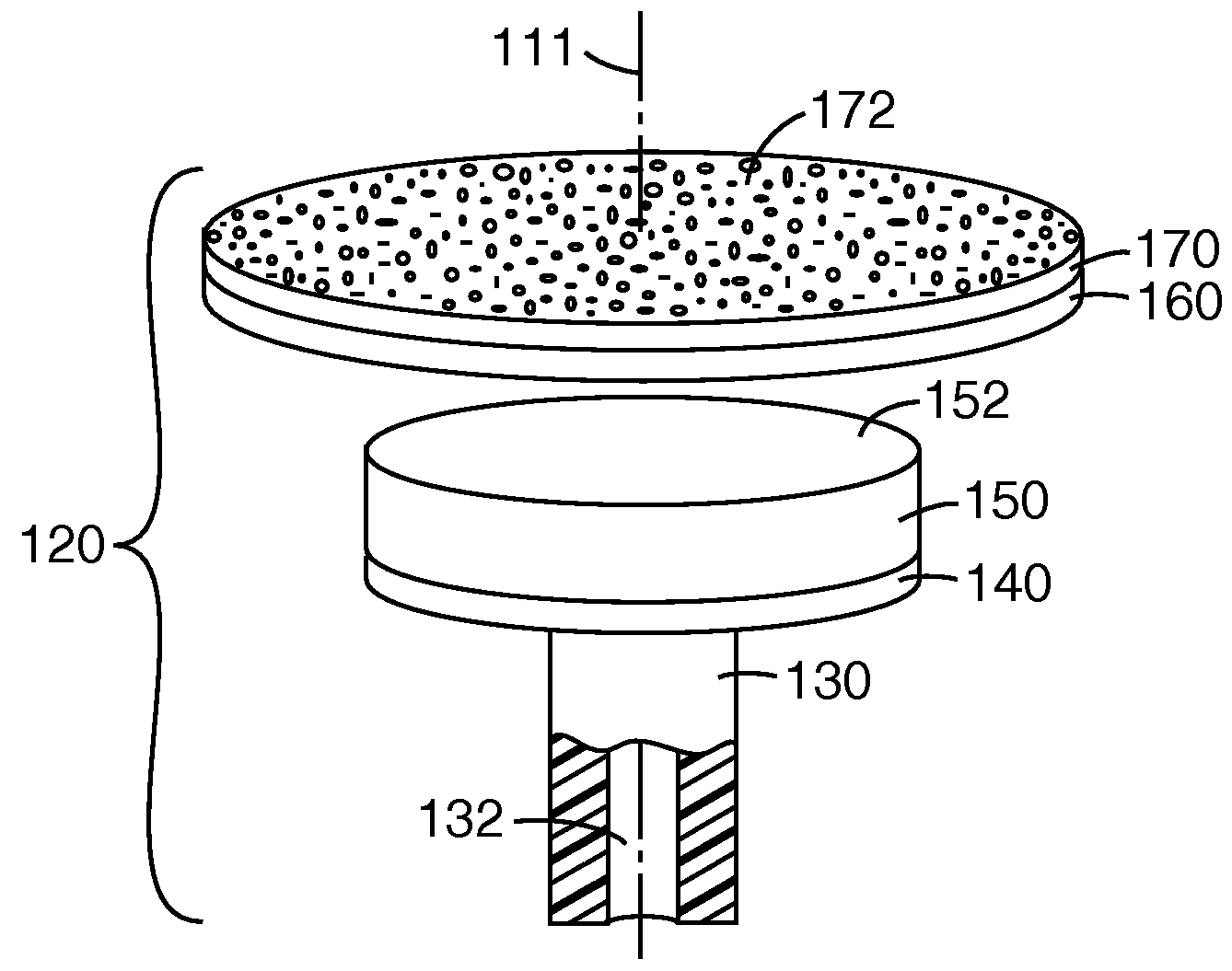

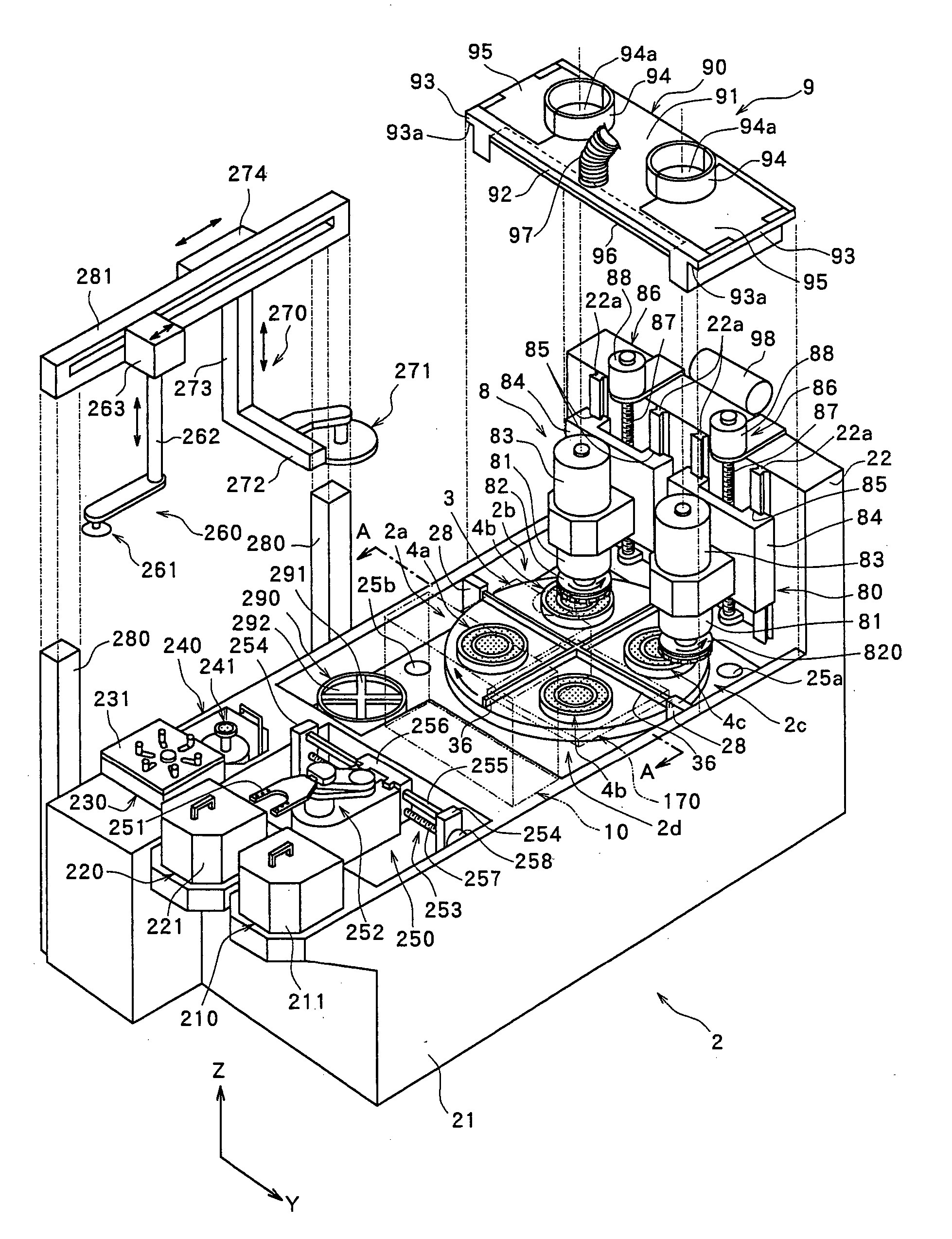

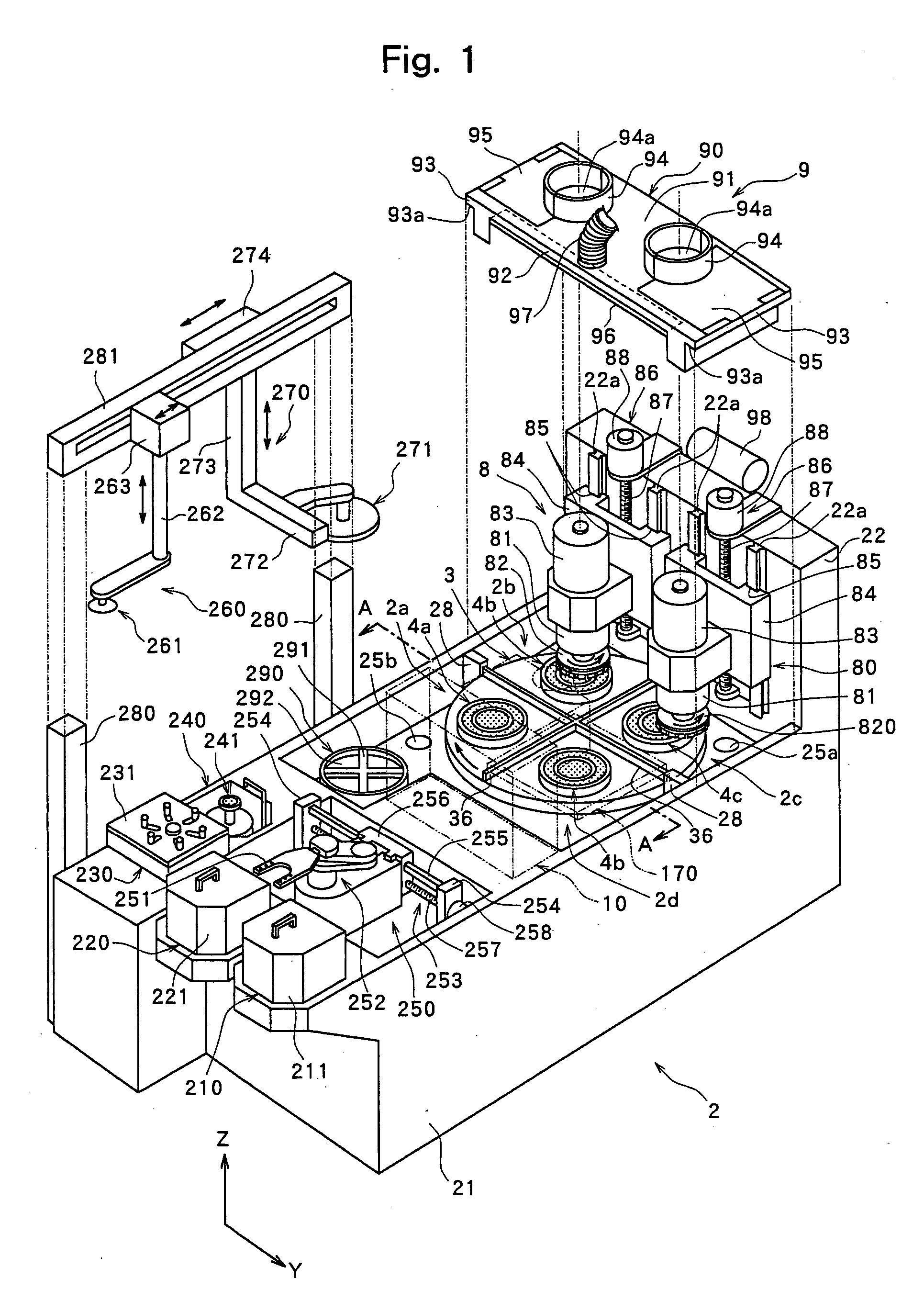

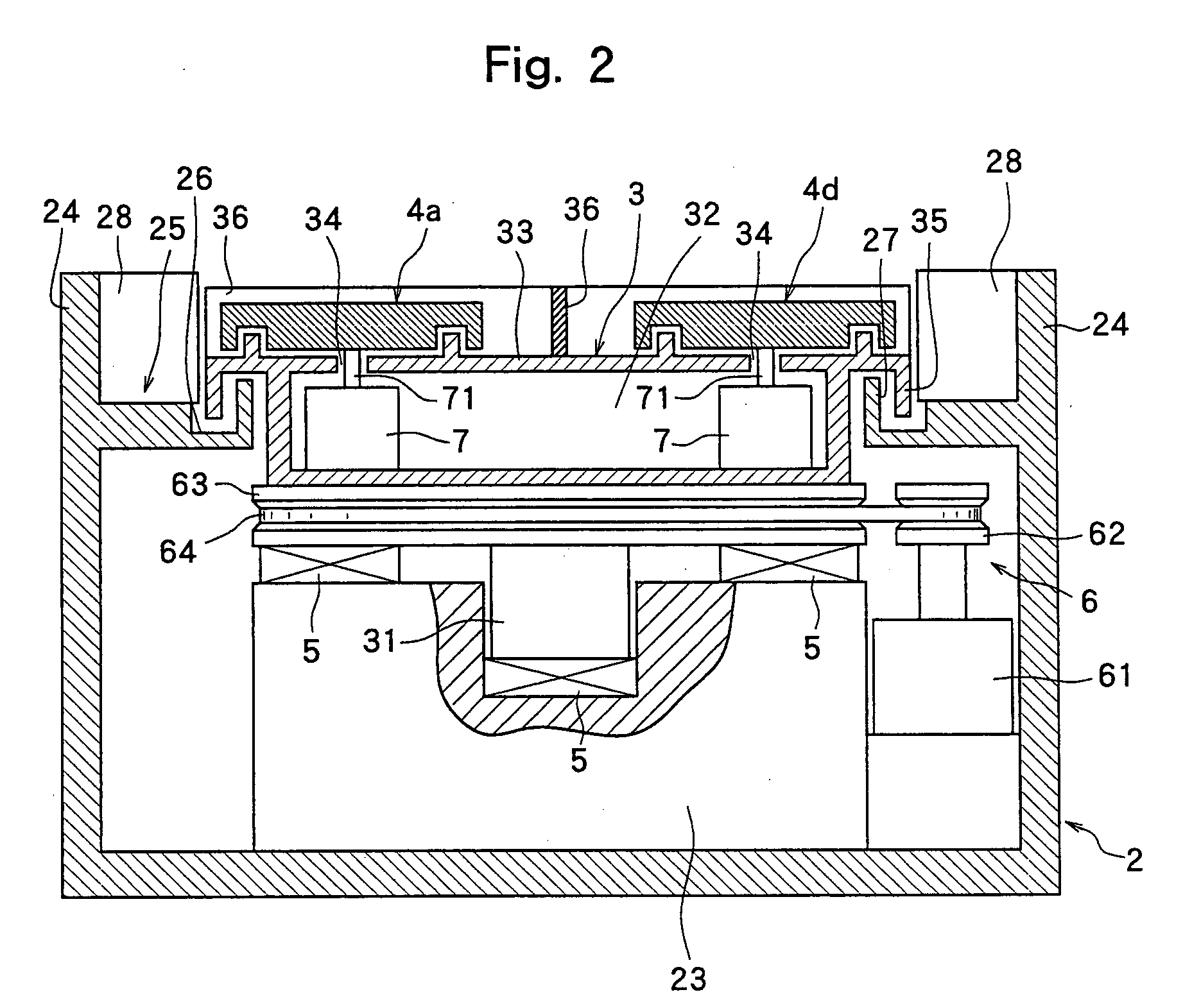

Wafer processing machine

A wafer processing machine comprising a turntable, a plurality of chuck tables mounted on the turntable, a grinding means for grinding a wafer held on the chuck table, and a multipurpose polishing means for polishing the ground surface of a wafer held on a chuck table, wherein the multipurpose polishing means comprises a mounter for detachably mounting a polishing tool, a spindle unit for rotating the mounter, a spindle unit support means for supporting the spindle unit in such a manner that the spindle unit can move in a direction perpendicular to the holding surfaces of the chuck tables and in a direction parallel to the holding surfaces of the chuck tables, a first polishing-feed means for moving the spindle unit in a direction perpendicular to the holding surfaces of the chuck tables, and a second polishing-feed means for moving the spindle unit in a direction parallel to the holding surfaces of the chuck tables.

Owner:DISCO CORP

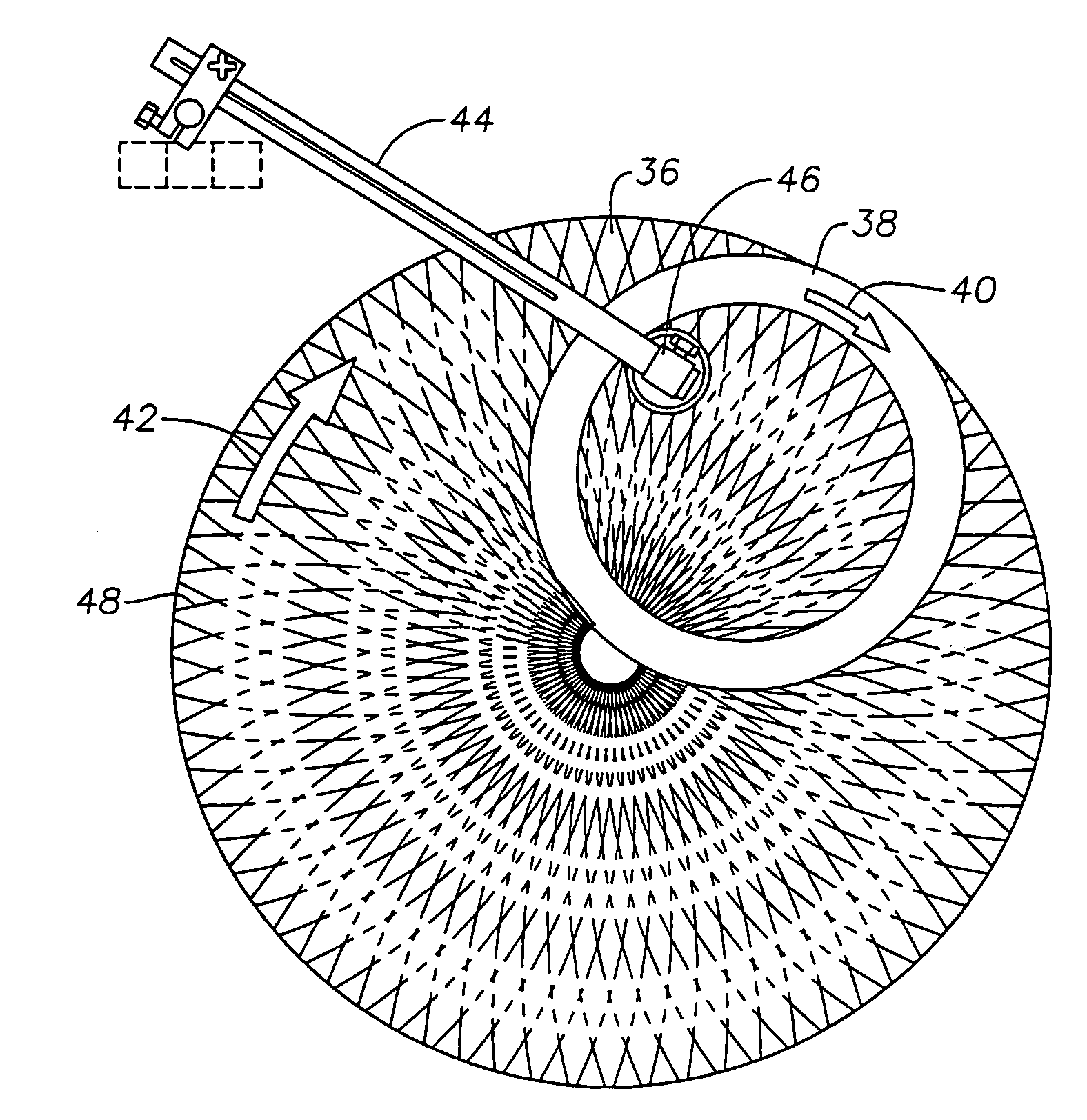

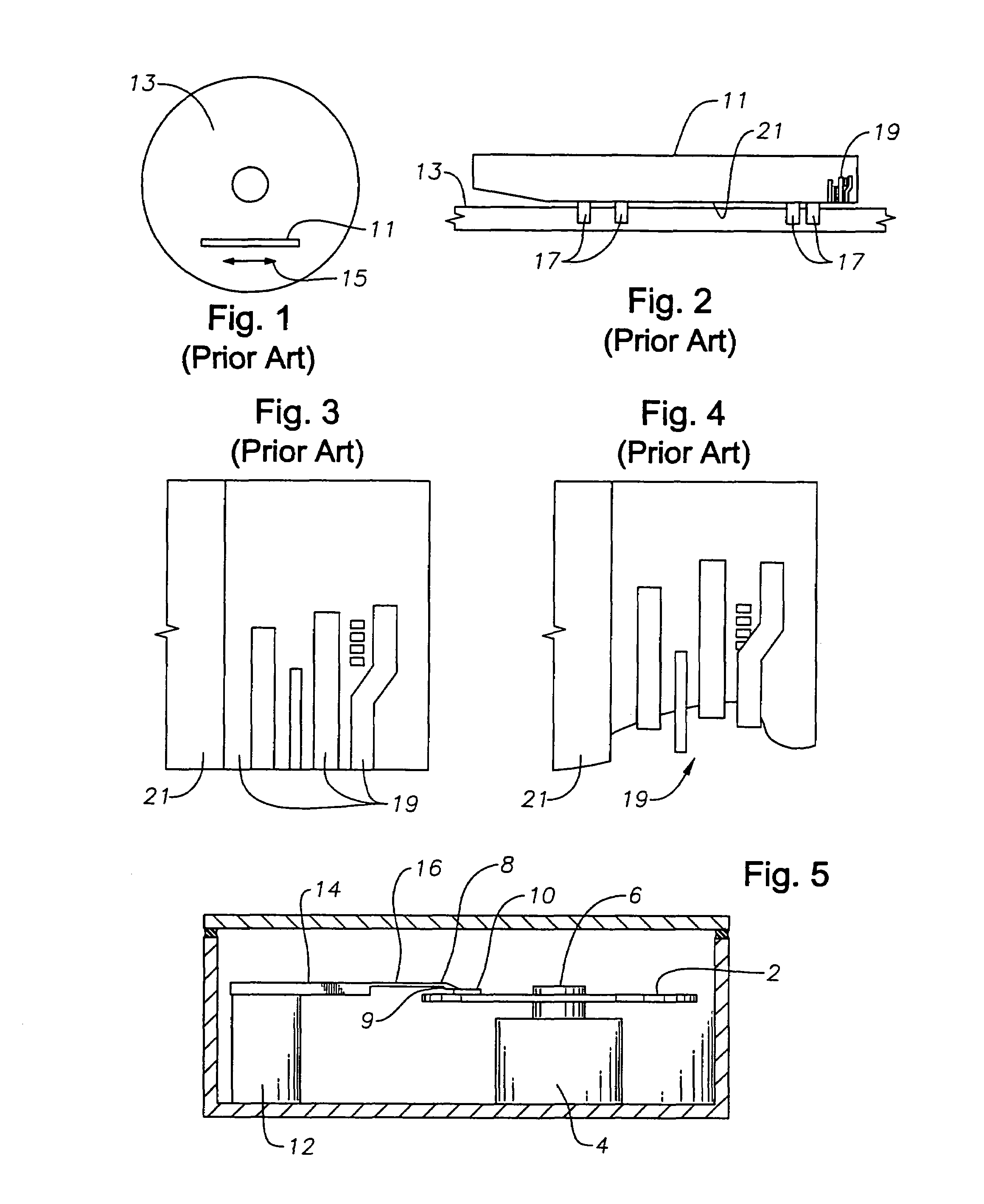

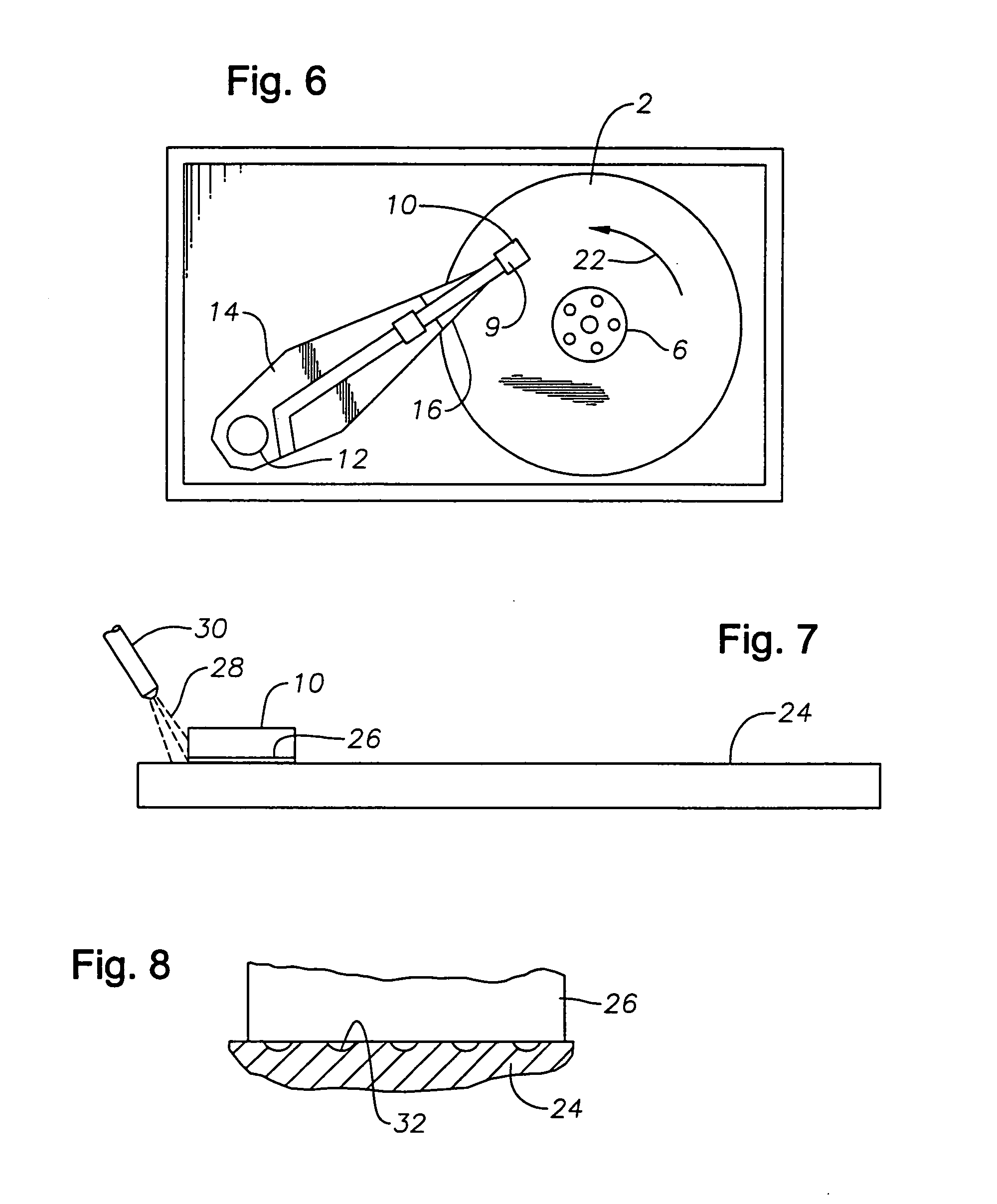

Apparatus and method for precise lapping of recessed and protruding elements in a workpiece

InactiveUS6935013B1Reduce height differenceDeep textureElectrical transducersDecorative surface effectsElectricityEngineering

A lapping method utilizing textured and conditioned lapping plates most suitable for finishing magnetic heads resulting in improved surface quality, less sensitivity to electrical shorts due to smears, and reduced surface height difference between the head elements exposed at the slider air bearing surface. A rough lapping phase is followed by a polishing phase that maintains the same mechanical motion between the work piece and lapping plate but utilizes only the lapping plate without abrasives of any kind to polish the work piece surface, and to clean up any deep textured marks resulting from the diamond slurry phase. A conductive liquid is utilized to provide lubrication and to minimize static charge.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method for processing steel plate with colorful coating layer and transfer device used by the method

The invention relates to a processing method for a colorful coating steel plate and a transfer printing device used by the method. The method comprises the following steps: uncoiling a steel plate to be coated; carrying out pretreatment, namely, carrying out the chemical treatment of the uncoiled steel plate after cleaning and drying the steel plate, and drying the steel plate again to obtain the steel plate to be coated; carrying out priming, namely priming the two surfaces of the steel plate to be coated; carrying out drying, namely roasting the primed steel plate in a baking furnace to obtain the steel plate for transfer printing; carrying out transfer printing, namely sending the steel plate for transfer printing into more than one set of transfer printing device for continuous transfer printing, and roasting the steel plate after each time of transfer printing so as to obtain a semi-finished product of the colorful coating steel plate which has the surfaces to be polished; and carrying out surface polishing, namely painting clear lacquer on the surfaces of the semi-finished product of the colorful coating steel plate, drying the steel plate, and coiling the steel plate after cooling down the steel plate to obtain the colorful coating steel plate which has more than one color or pattern on the surfaces. The processing method has the advantages that the obtained colorful coating steel plate has ideal beautification and decoration effects; and the recommended transfer printing device can ensure more than one colorful effect on the steel plate.

Owner:CHANGSHU HUAYE STEEL STRIP

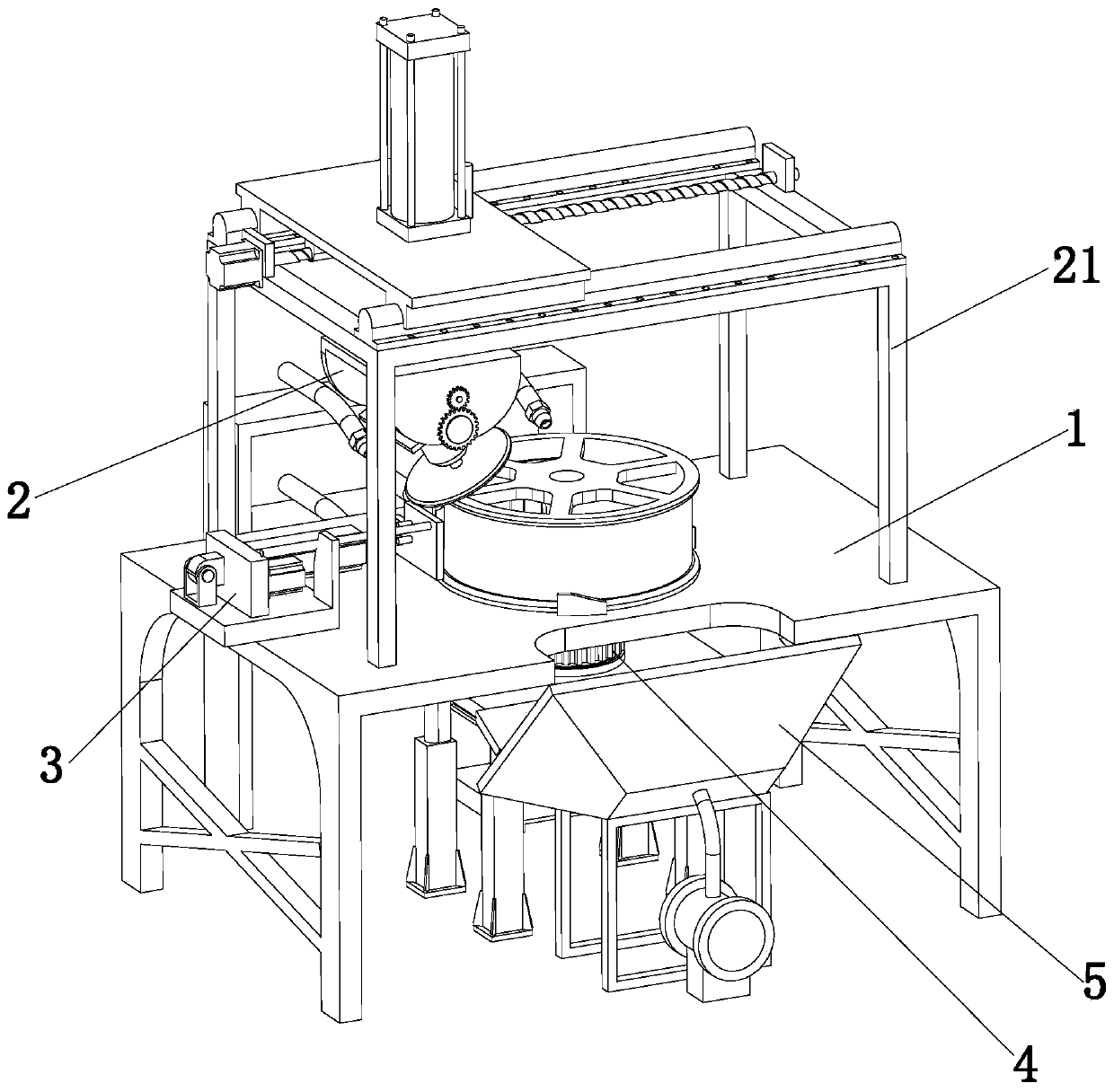

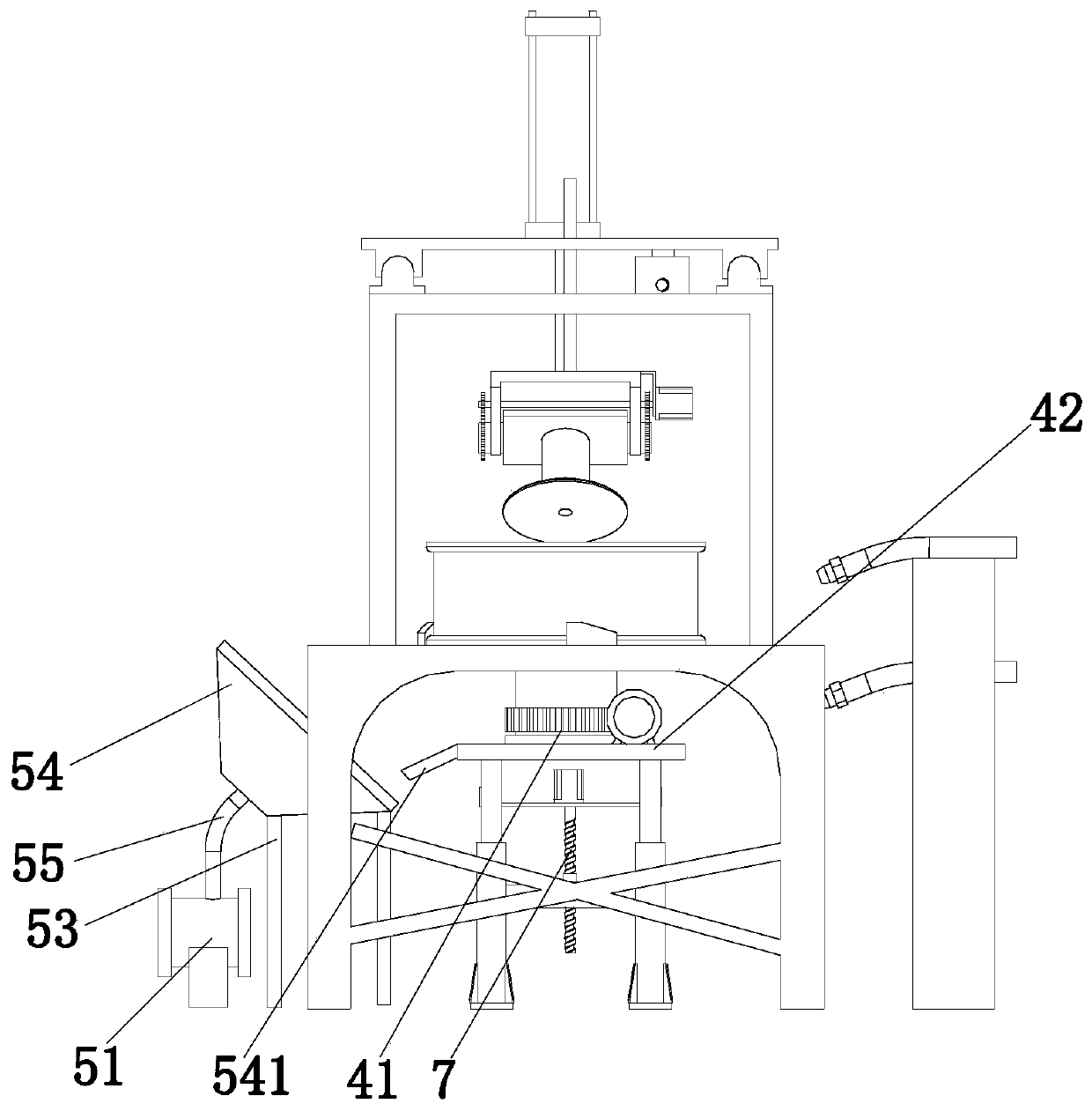

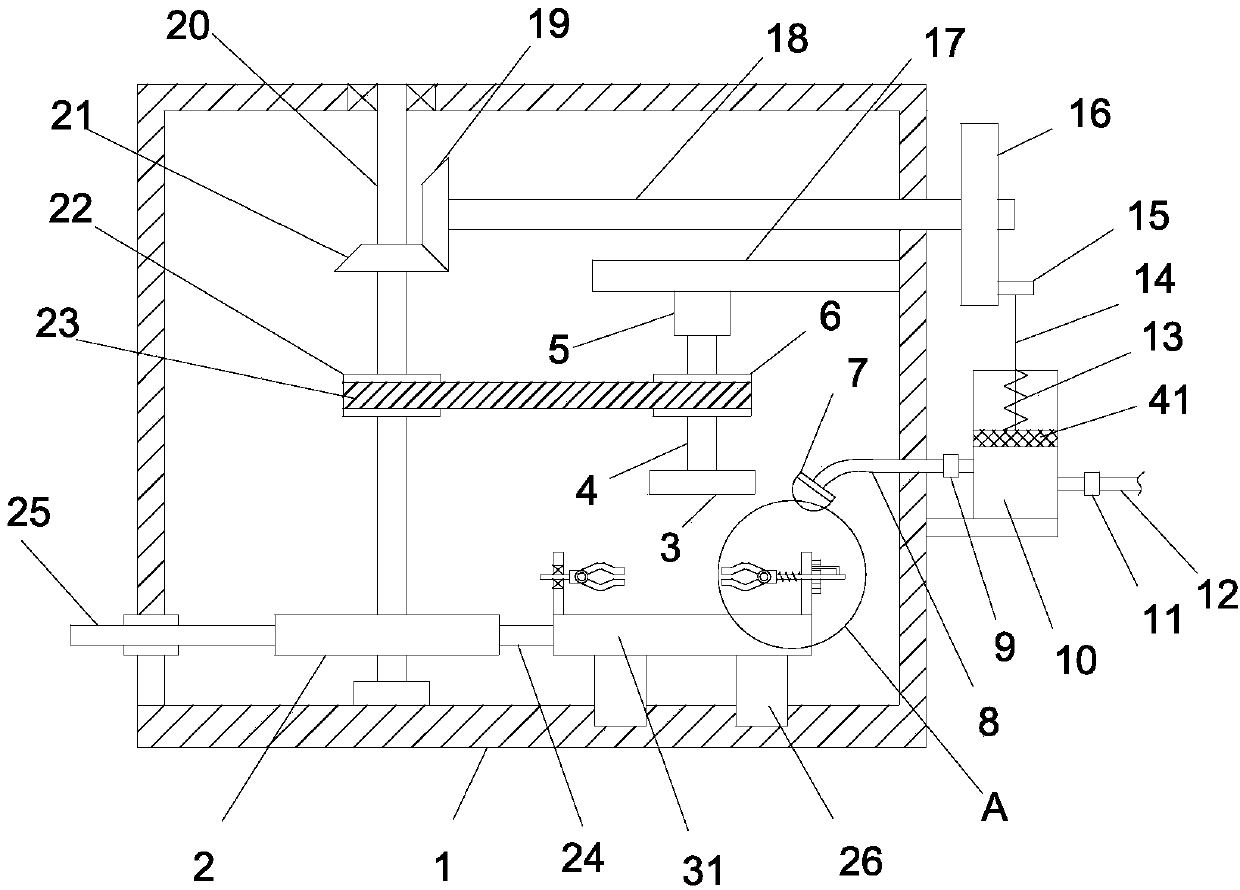

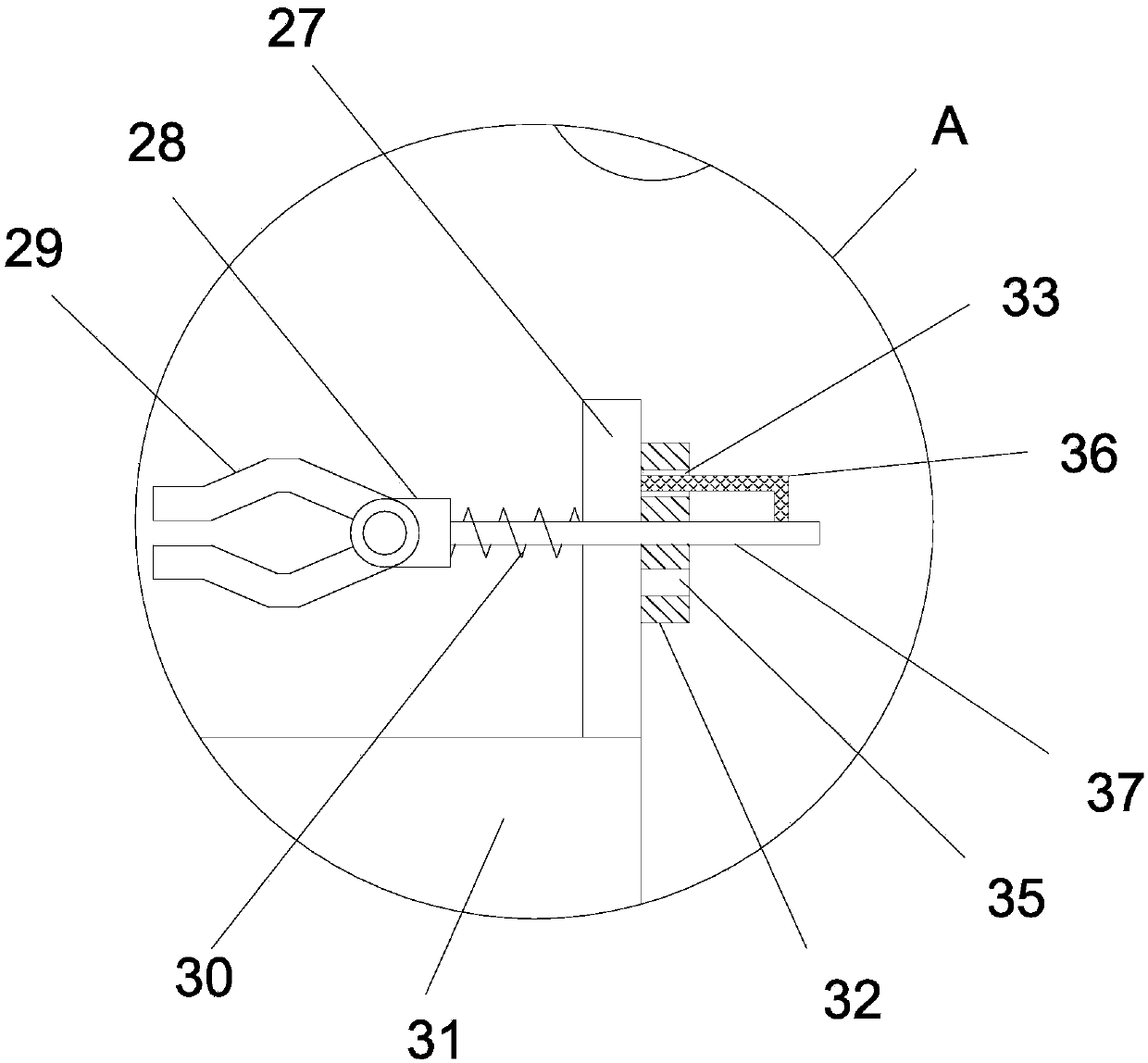

Polishing device for hub processing of new energy automobile

ActiveCN111230710ARealize polishing workRealize polishing and chamfering operationsEdge grinding machinesGrinding carriagesDrive wheelNew energy

The invention discloses a polishing device for hub processing of a new energy automobile, and relates to the technical field of automobile part processing. The polishing device comprises a worktable,a hub top polishing mechanism, a hub side polishing mechanism and a hub limiting rotation mechanism, wherein the hub top polishing mechanism is arranged above the worktable, the hub side polishing mechanism is arranged at the top of the worktable, and the hub limiting rotation mechanism is arranged below the worktable; the hub limiting rotation mechanism comprises a height adjustment assembly, a hub inner circle fixing assembly for clamping a hub inner circle and a rotating assembly for driving the hub to rotate, and a through hole is formed in the top of the worktable so that the hub inner circle fixing assembly can lift and pass through the through hole. According to the invention, the polishing device can clamp the hub inner circle and drive the hub to rotate under the action of the hublimiting rotation mechanism, the angle adjustment of a grinding wheel can be realized through the hub side polishing mechanism, and then polishing chamfering operation on the top surface of the hub is realized.

Owner:山东荣升重型机械股份有限公司

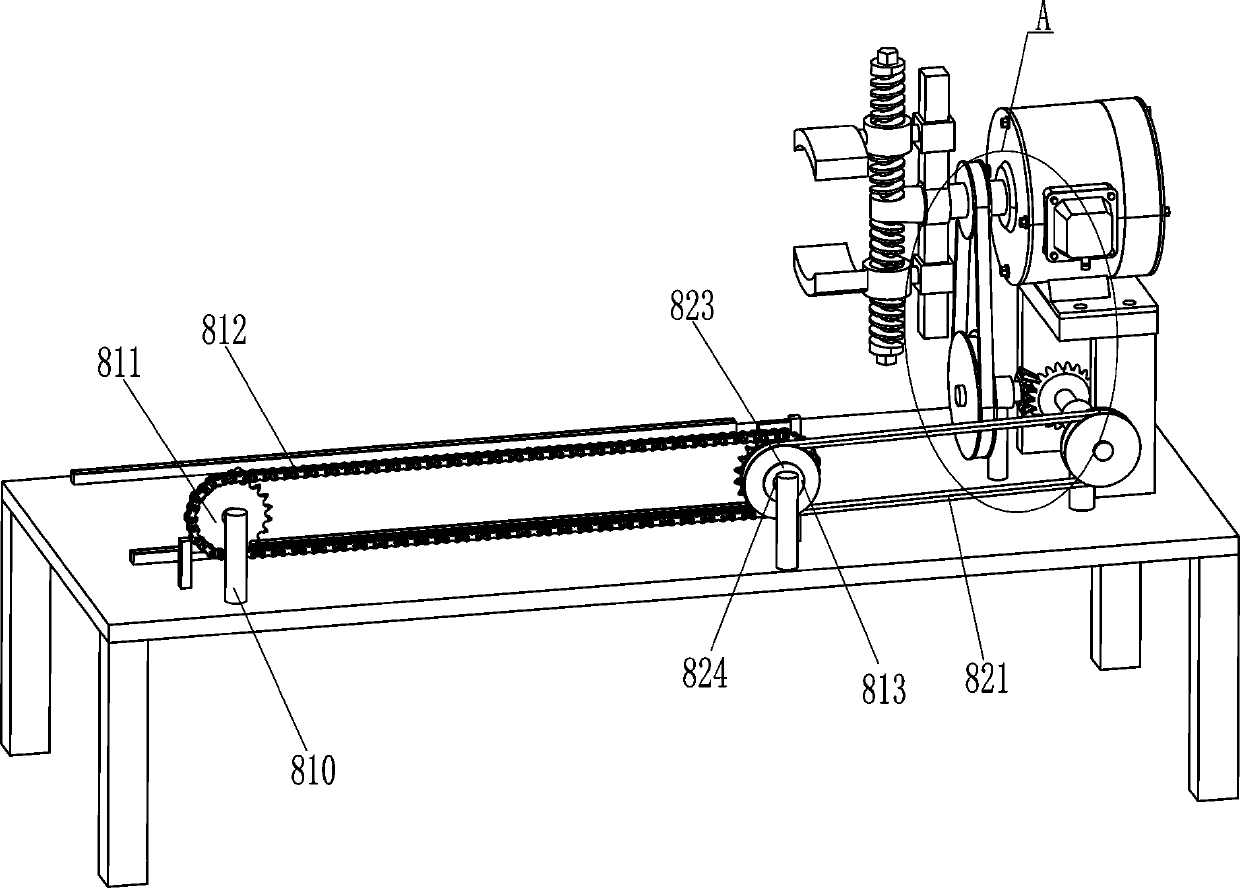

Round wood grinding and polishing equipment

ActiveCN111515777AShorten the timeUniform speedRevolution surface grinding machinesGrinding drivesElectric machinePolishing

The invention relates to grinding and polishing equipment, in particular to round wood grinding and polishing equipment. The technical problem of the invention is about provision of the round wood grinding and polishing equipment which can make working personnel easier and save time. The round wood grinding and polishing equipment comprises an operating table, a speed reducing motor, a clamping component, guide rails and the like; the upper side of the operating table is in bolt connection with the speed reducing motor and at least two guide rails; and the clamping component is mounted on thespeed reducing motor and is used for clamping a round wood. According to the round wood grinding and polishing equipment, the round wood can be driven to rotate clockwise through the speed reducing motor; the round wood can be ground by the grinding component, so that the round wood can be rotated automatically and can be ground automatically; therefore, people can be easier and time can be saved;and the leftward moving speed of a grinding wheel can be more uniform through a moving component, so that the grinding and polishing quality of the round wood is not affected.

Owner:QINGDAO SHUNNENG MACHINERY CO LTD

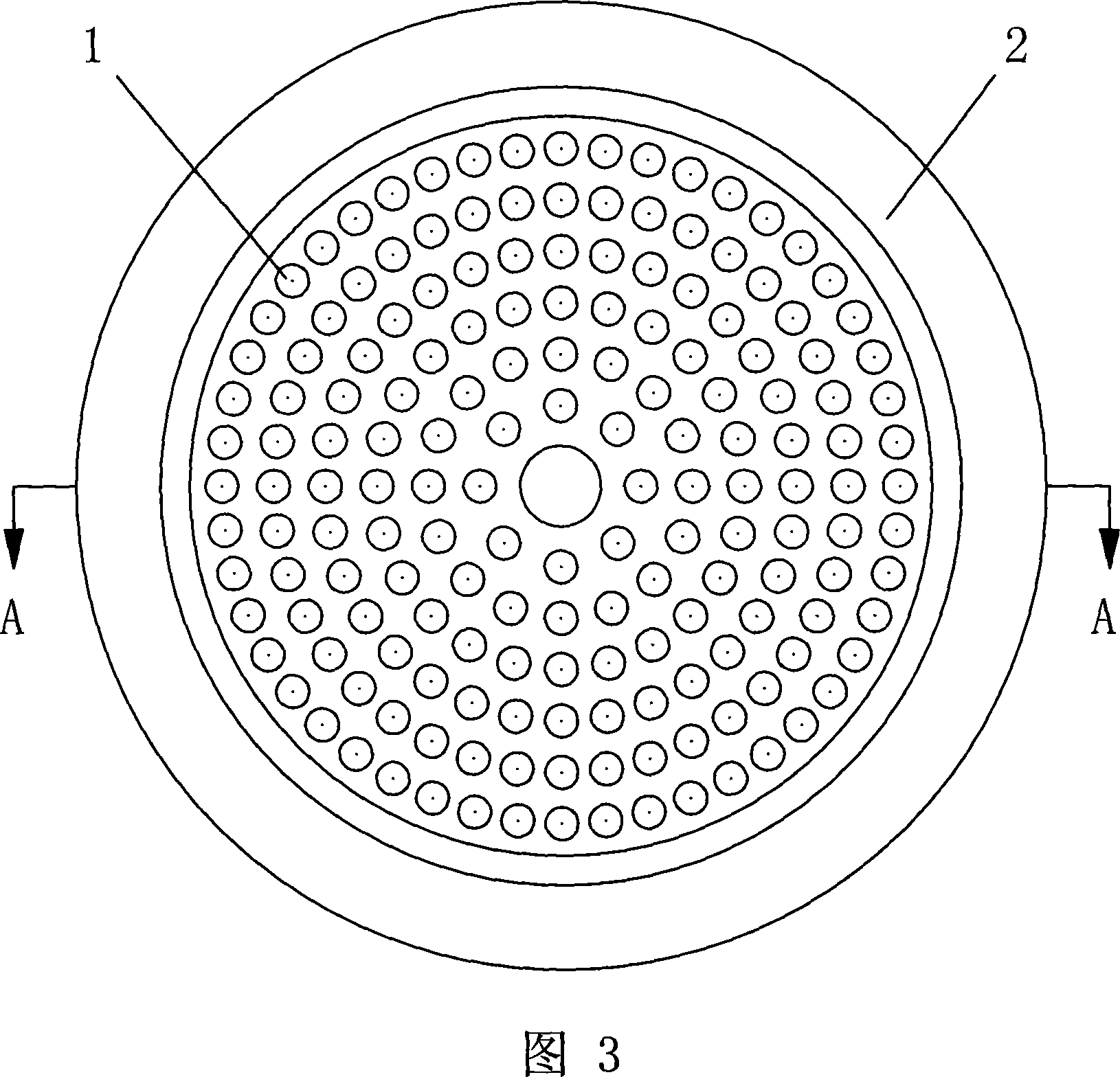

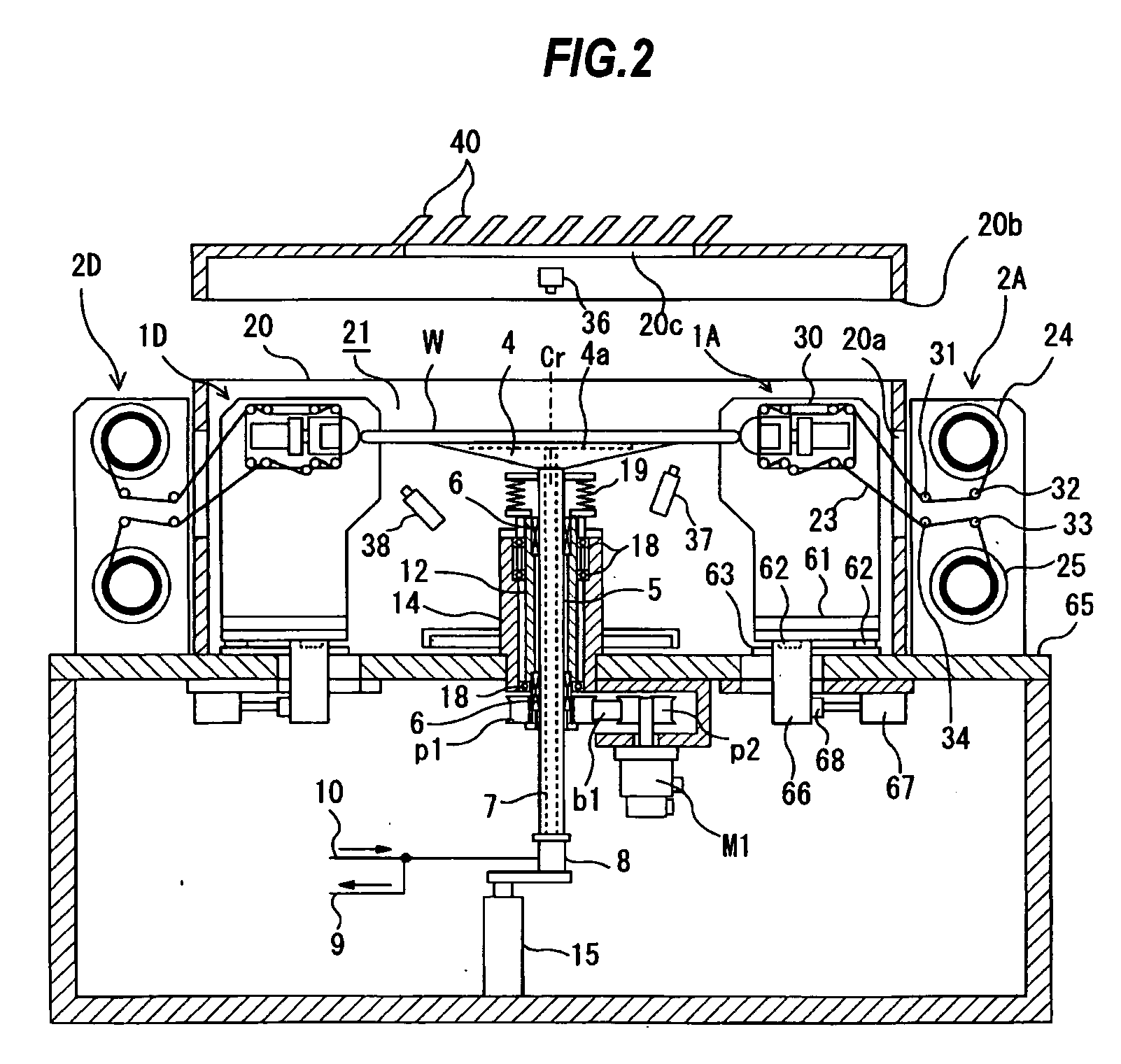

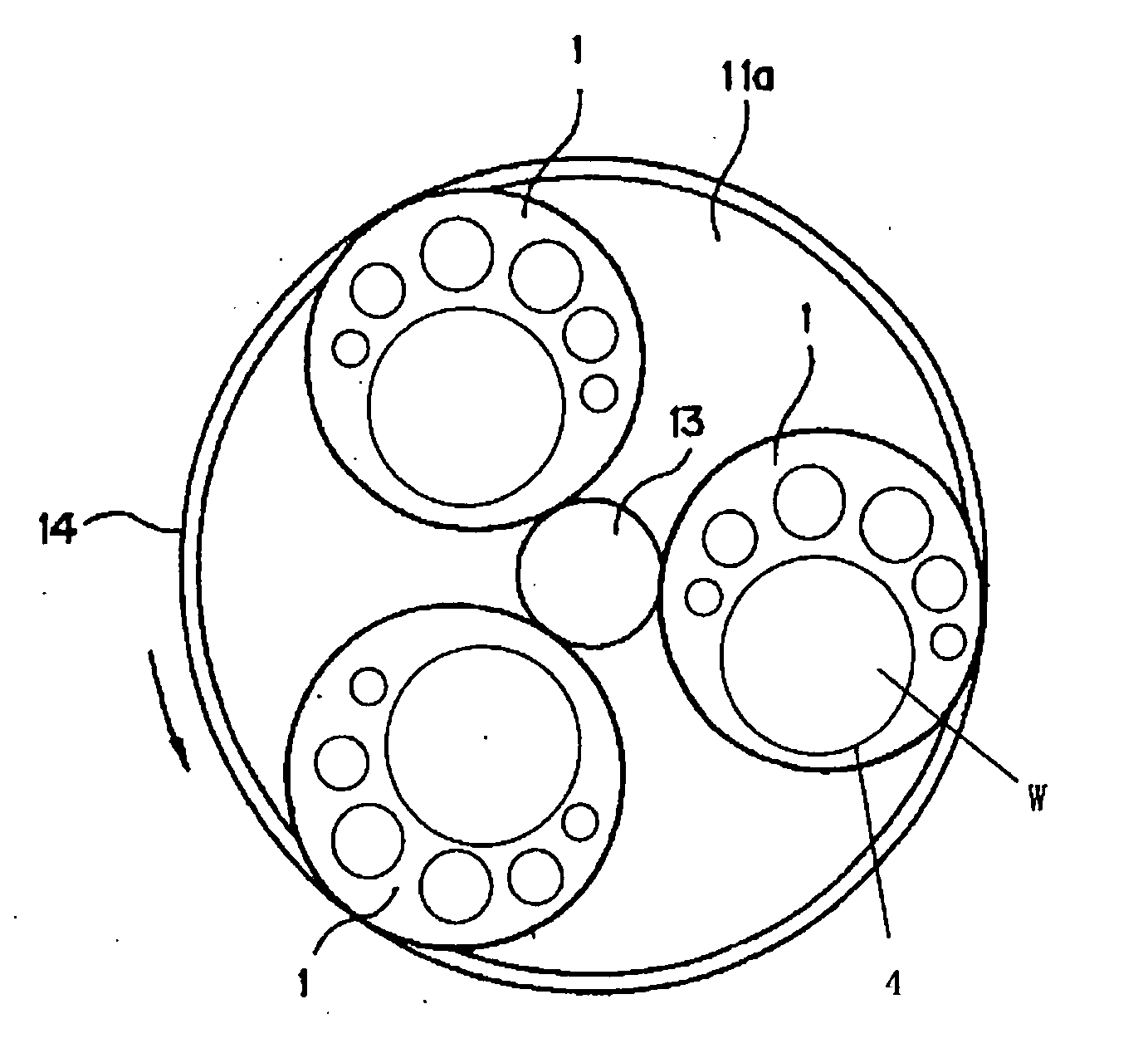

Carrier For Double-Side Polishing Apparatus, Double-Side Polishing Apparatus And Double-Side Polishing Method Using The Same

InactiveUS20080166952A1Improve carrier strengthHigh strengthEdge grinding machinesSemiconductor/solid-state device manufacturingTitaniumEngineering

The present invention is a carrier for a double-side polishing apparatus in which, in a double-side polishing apparatus, the carrier is set between upper and lower turn tables to which polishing pads are attached, and a holding hole to hold a wafer sandwiched between the upper and lower turn tables in polishing is formed in the carrier, wherein the carrier is made of titanium. Thereby, there is provided a carrier for a double-side polishing apparatus in which the strength of the carrier itself is high, and at the same time, contamination of a wafer such as a silicon wafer by impurities is suppressed, and sag in a peripheral portion of the wafer after being polished is suppressed.

Owner:SHIN-ETSU HANDOTAI CO LTD

Metallographic etched process for displaying G Cr15 original austenite grain border

InactiveCN101187606AShorten the timeGood reproducibilitySurface/boundary effectPreparing sample for investigationAlcoholMetallography

A metallographic corrosion method for displaying a GCr15 original austenitic grain boundary comprises adding picric acid 5g into distilled water100ml and mixing continuously, then adding sodium dodecyl benzene sulfonate 5ml 50% and mixing, finally adding ferric chloride 2g, and using after placing for 24 hours. A sample is grinded roughly, grinded finely, polished, cleared, dried, immersed into caustic erodent for 2-5 minutes according to normal method under a quenching tempering condition until etched surface is changed into silver grey, cleaned up through flowing water, cleaned with alcohol 95%, and dried. If the sample is over-corroded, polishing paste W0.5-1.0 or metallographic polishing egent0.5-1.0 is added on silk polishing cloth, the sample is polished slightly with hands, then cleaned with alcohol 95%, and dried. According to practical condition, grain granularity measurement can adopt methods of picture contrast, grid, intercept, quantitative metallography, and the like, to assess according to relevant standards.

Owner:LUOYANG BEARING SCI & TECH CO LTD

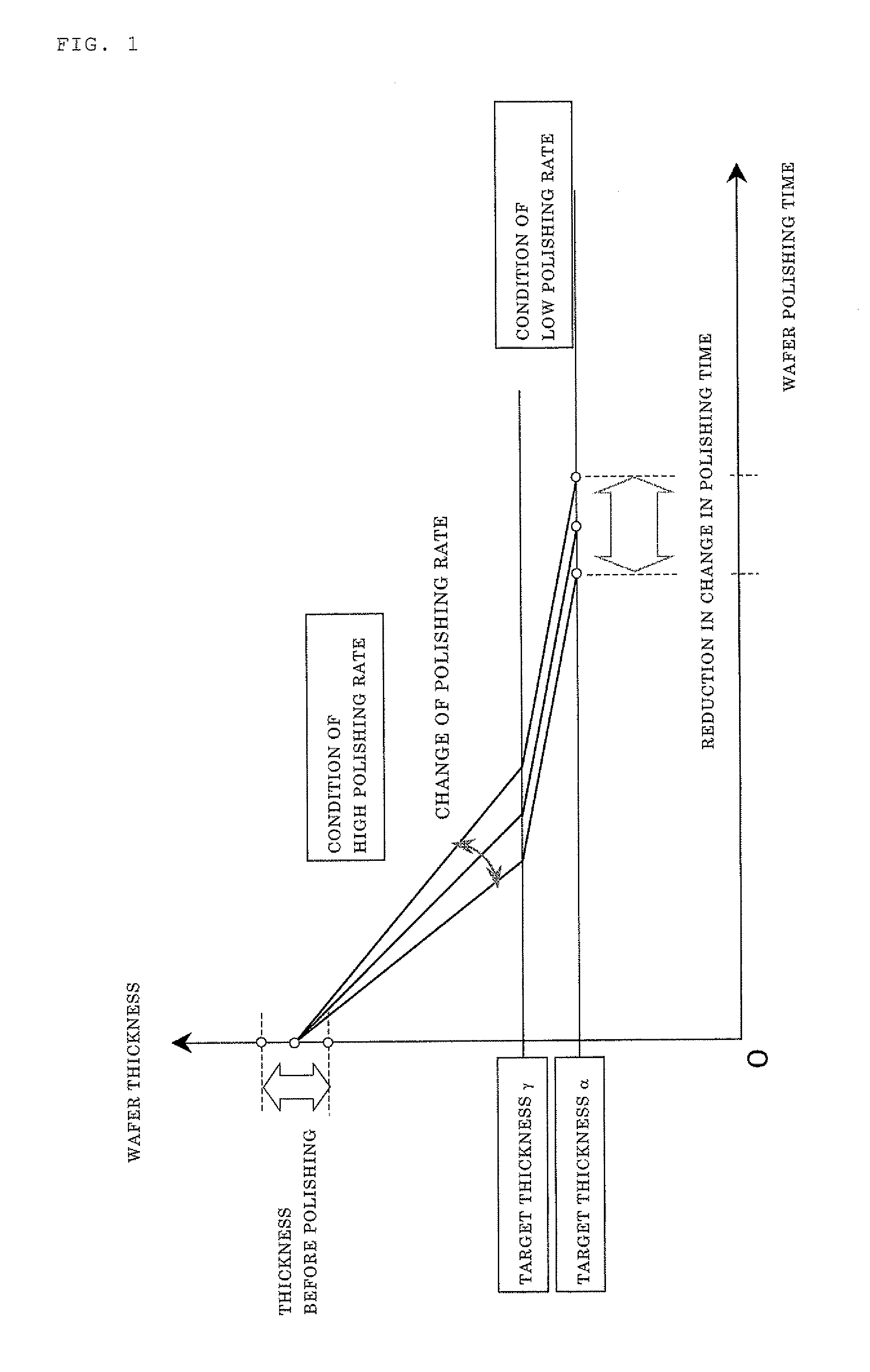

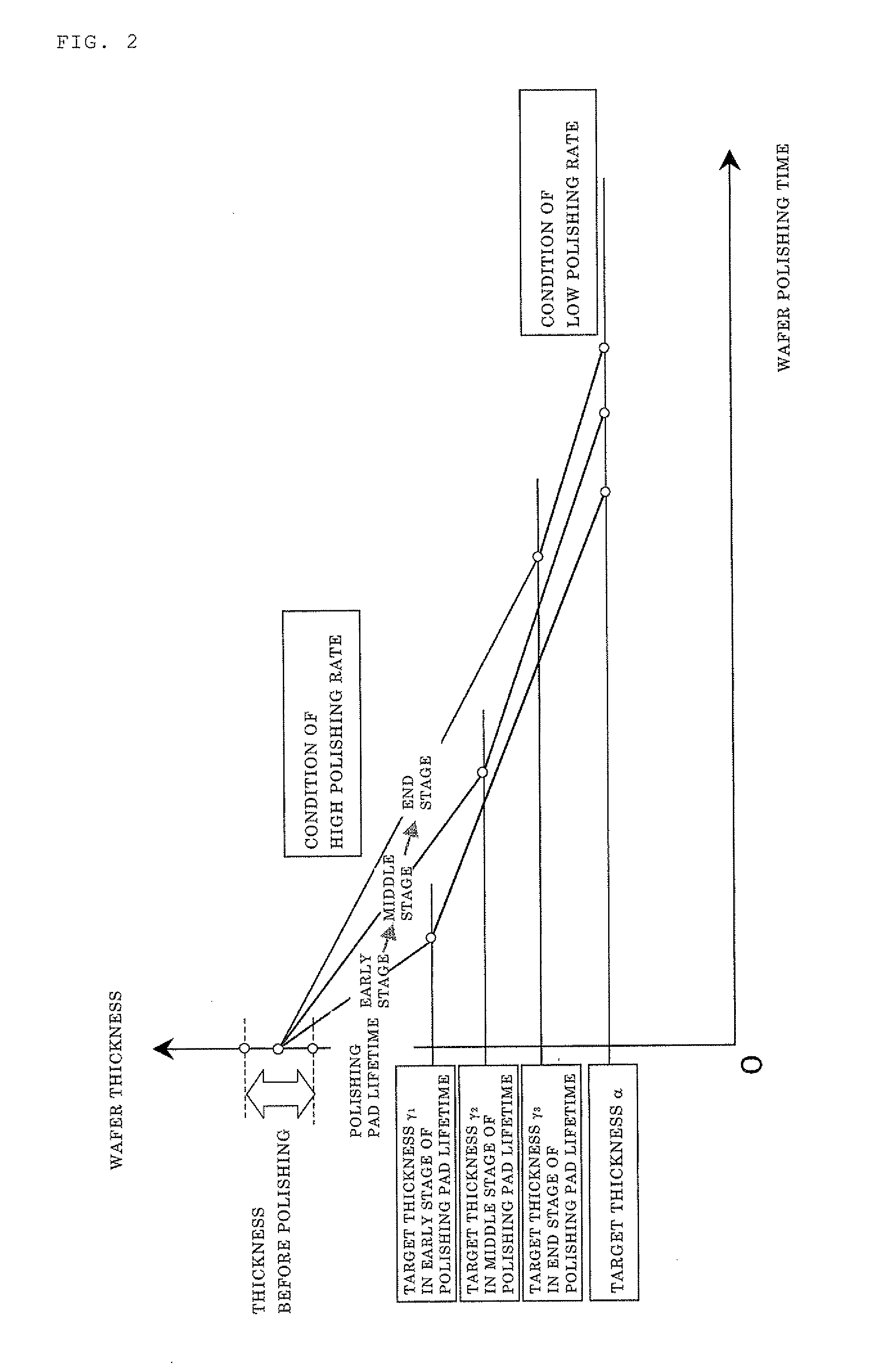

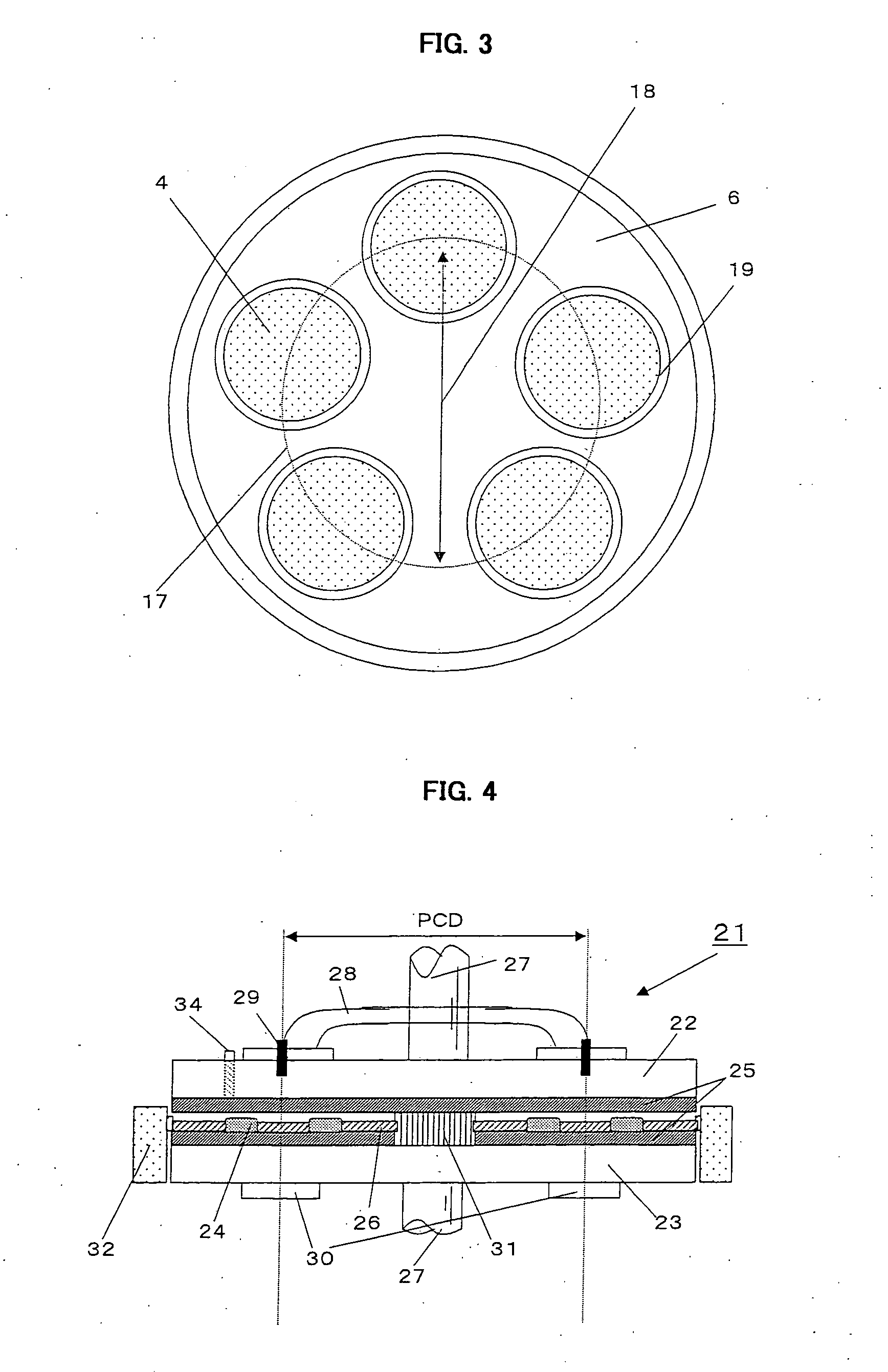

Wafer polishing method and double-side polishing apparatus

ActiveUS20110130073A1Easy to getImprove flatnessEdge grinding machinesSemiconductor/solid-state device testing/measurementWaferingPolishing

The present invention is a wafer polishing method including simultaneously polishing both surfaces of a wafer by pressing and rubbing the wafer, while holding the wafer with: a lower turn table having a flat polishing-upper-surface rotationally driven; an upper turn table having a flat polishing-lower-surface rotationally driven, the upper turn table being arranged with facing to the lower turn table; and a carrier having a wafer-holding hole for holding the wafer, wherein the polishing is performed while measuring a thickness of the wafer through a plurality of openings provided between a rotation center and an edge of the upper turn table or the lower turn table, and switching a polishing slurry with a polishing slurry having a different polishing rate during the polishing of the wafer. As a result, there is provided a wafer polishing method that can manufacture a wafer having a high flatness and a high smoothness at high productivity and high yield.

Owner:SHIN-ETSU HANDOTAI CO LTD

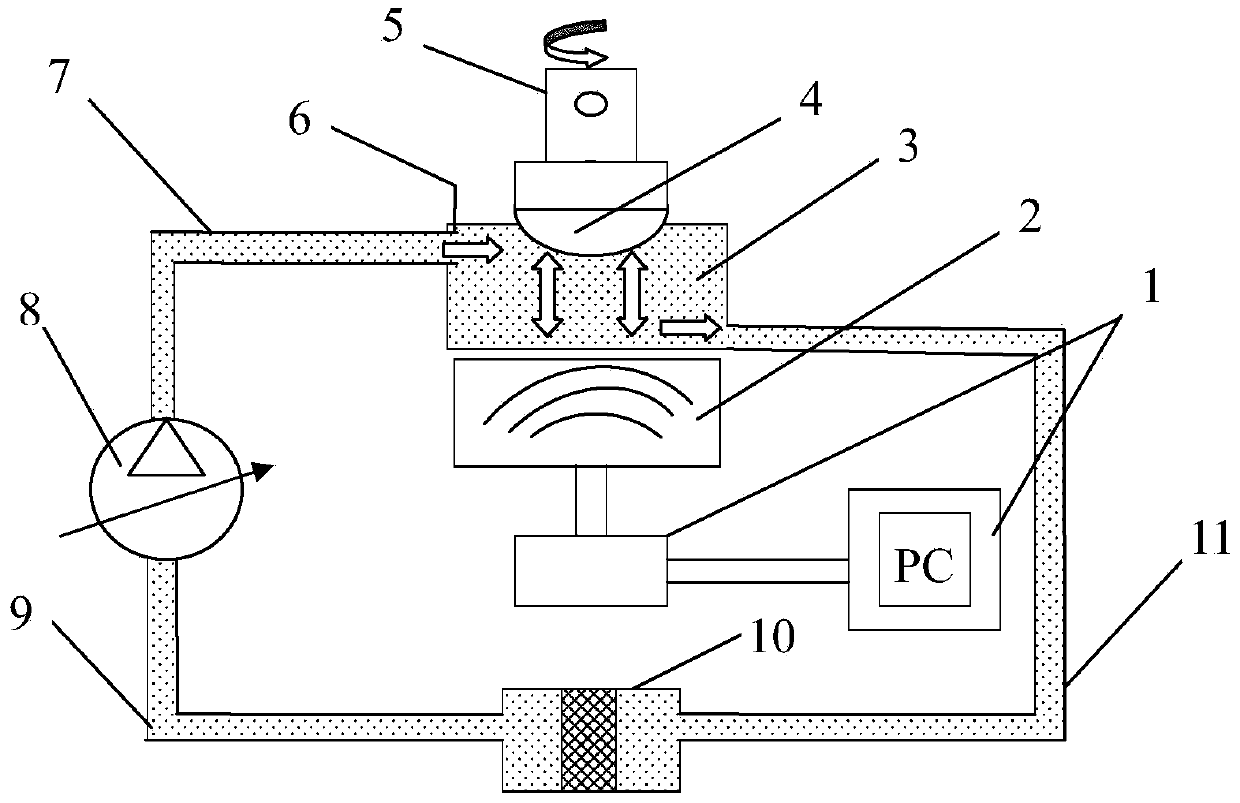

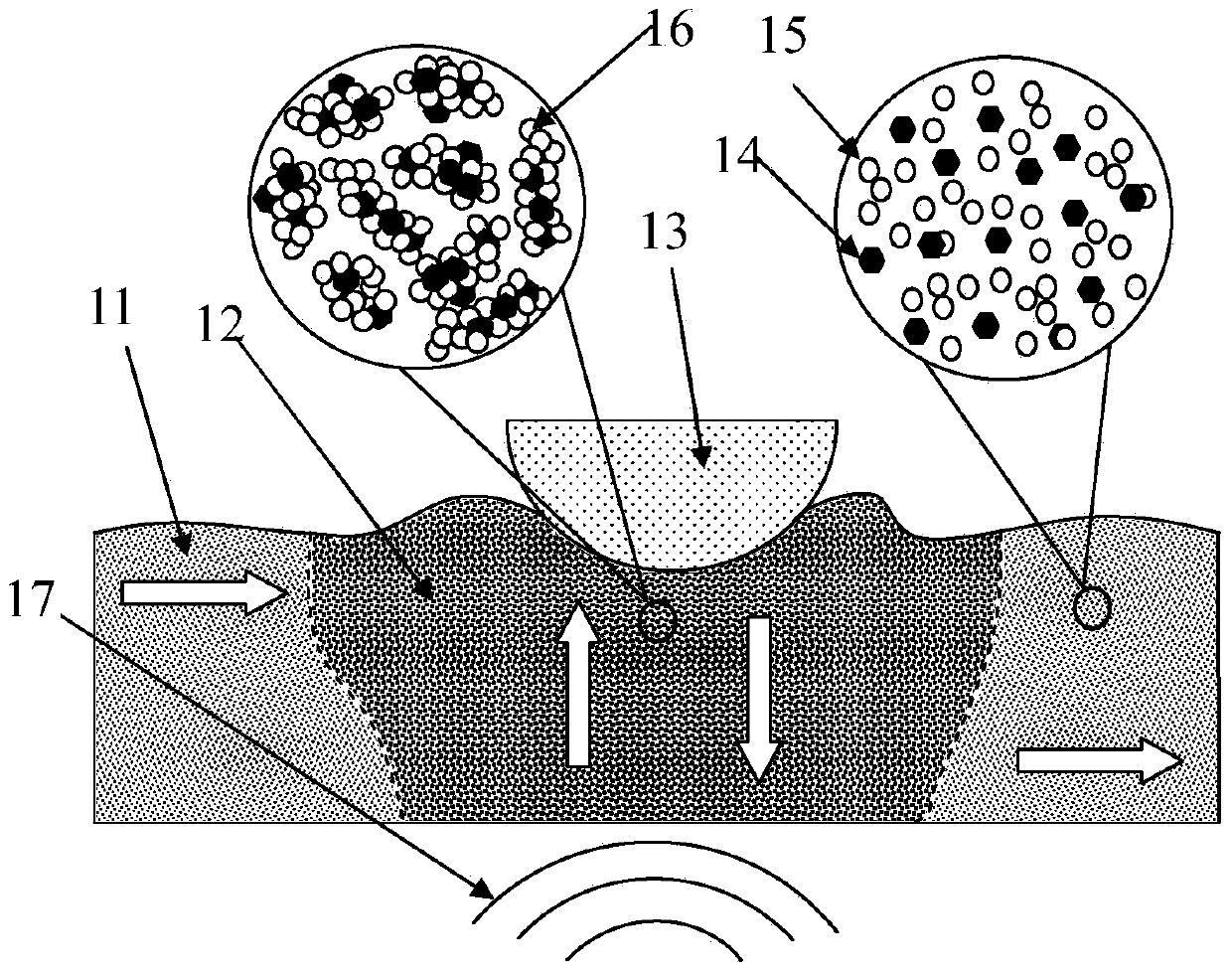

Ultrasonic control shear thickening and polishing method and device

An ultrasonic control shear thickening and polishing method comprises the following steps of 1 adding a non-Newtonian fluid polishing solution mixed with abrasive particles and having the shear thickening effect into a polishing pond and fixing a workpiece on a clamp, wherein the clamp is located above the polishing pond; 2 starting a polishing solution circulating system to enable the non-Newtonian fluid polishing solution to be circularly pumped out of the bottom of the polishing solution and fed into the upper portion of the polishing pond; 3 starting an ultrasonic wave generating device, and meanwhile setting the vibration frequency and vibration amplitude to enable the non-Newtonian fluid polishing solution in the polishing pond to rapidly vibrate and produce a strong shear thickening phenomenon; 4 adjusting the clamp to enable the workpiece to perform relative motion, wherein the abrasive particles having the polishing effect produce the micro-cutting effect or chemical mechanical effect on the workpiece to remove materials on the workpiece surface, and accordingly the workpiece surface polishing is achieved. The invention further provides an ultrasonic control shear thickening and polishing device. The ultrasonic control shear thickening and polishing method and device is high in polishing efficiency and low in cost.

Owner:ZHEJIANG UNIV OF TECH

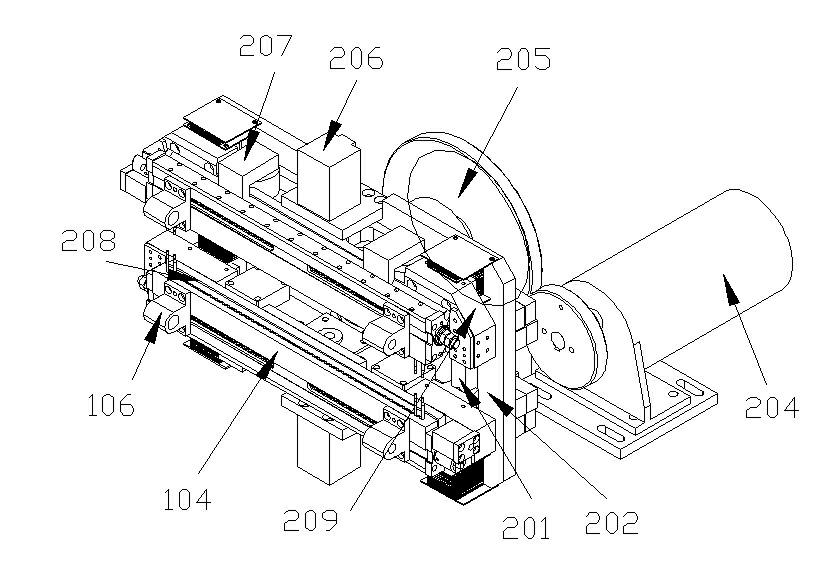

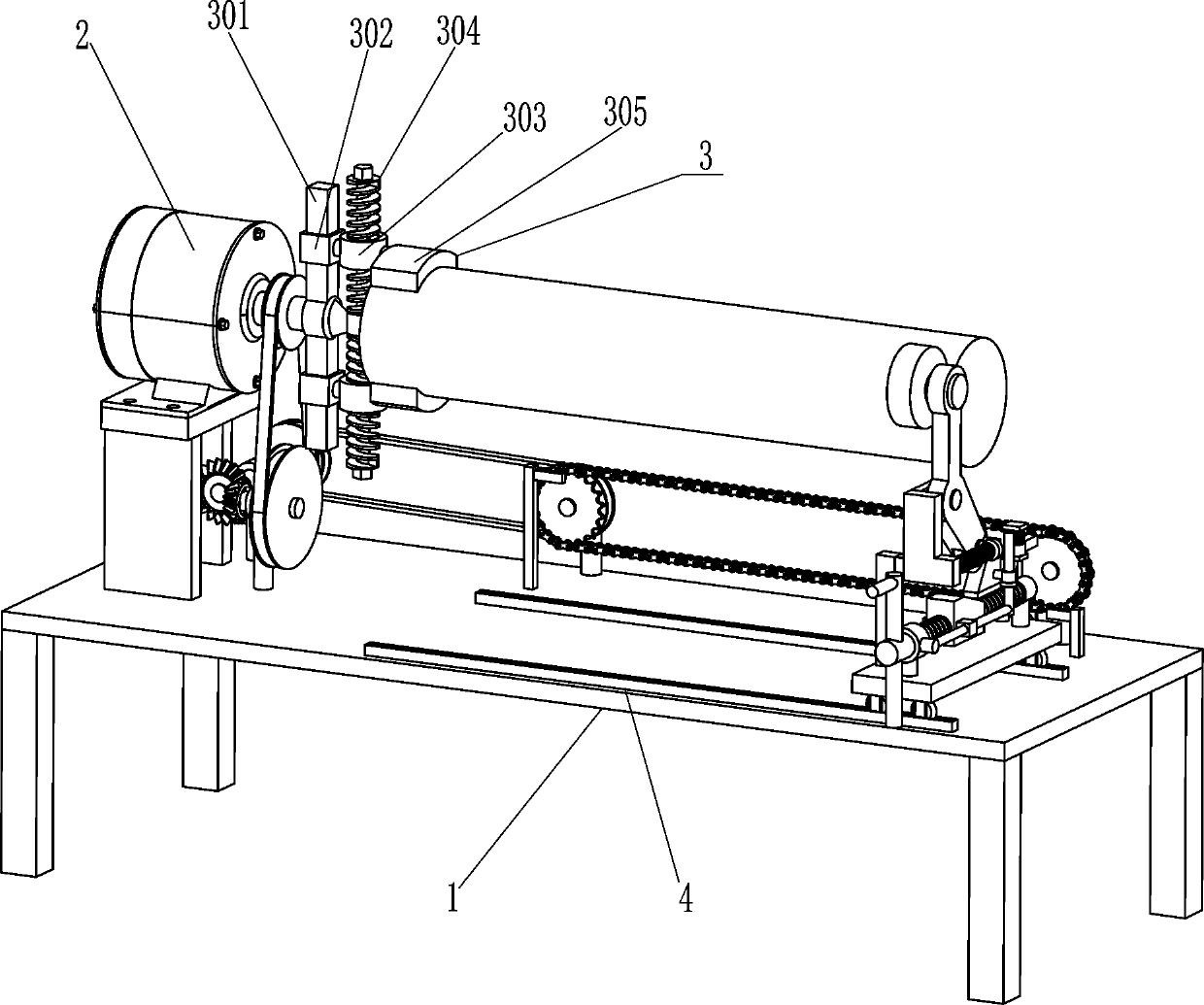

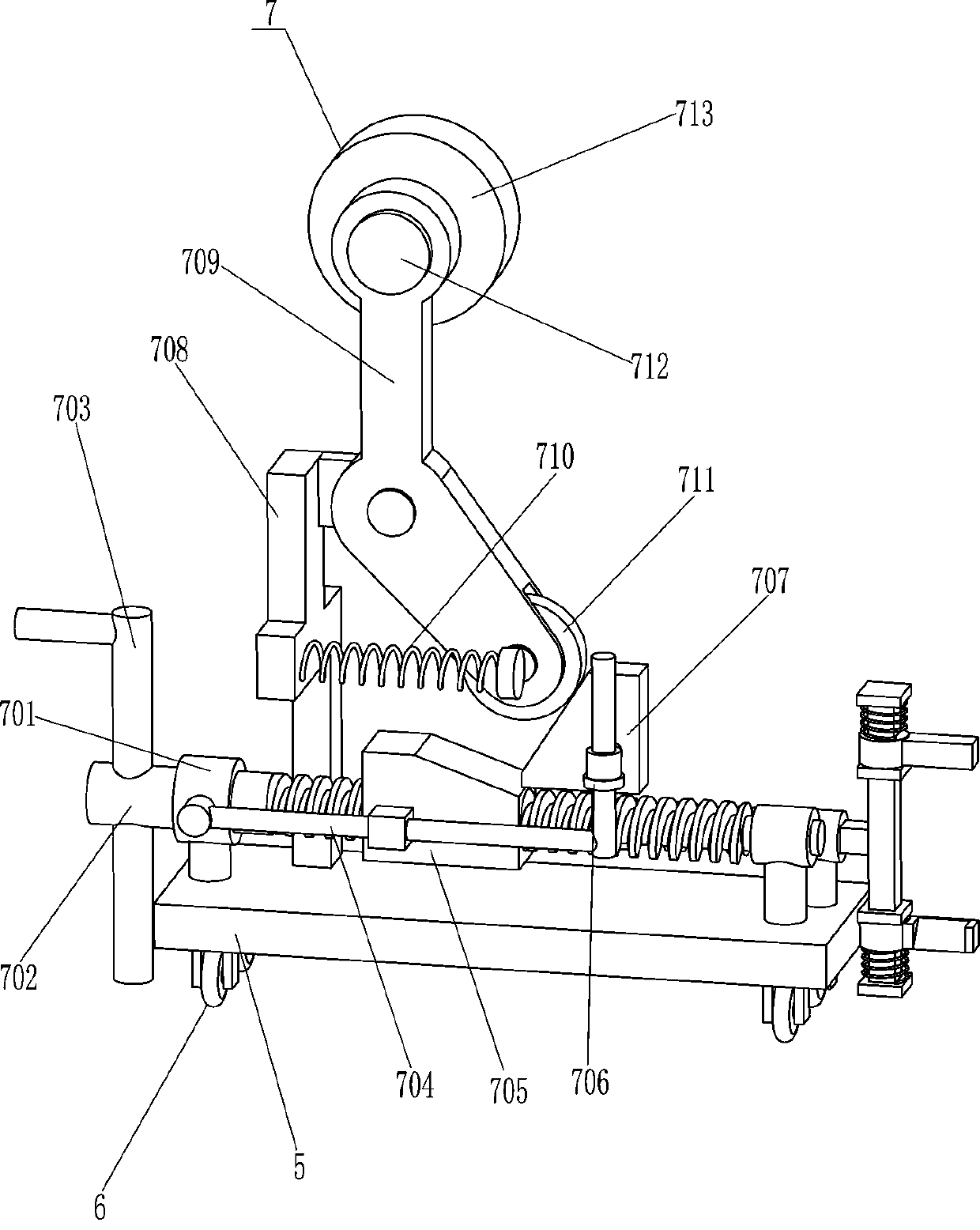

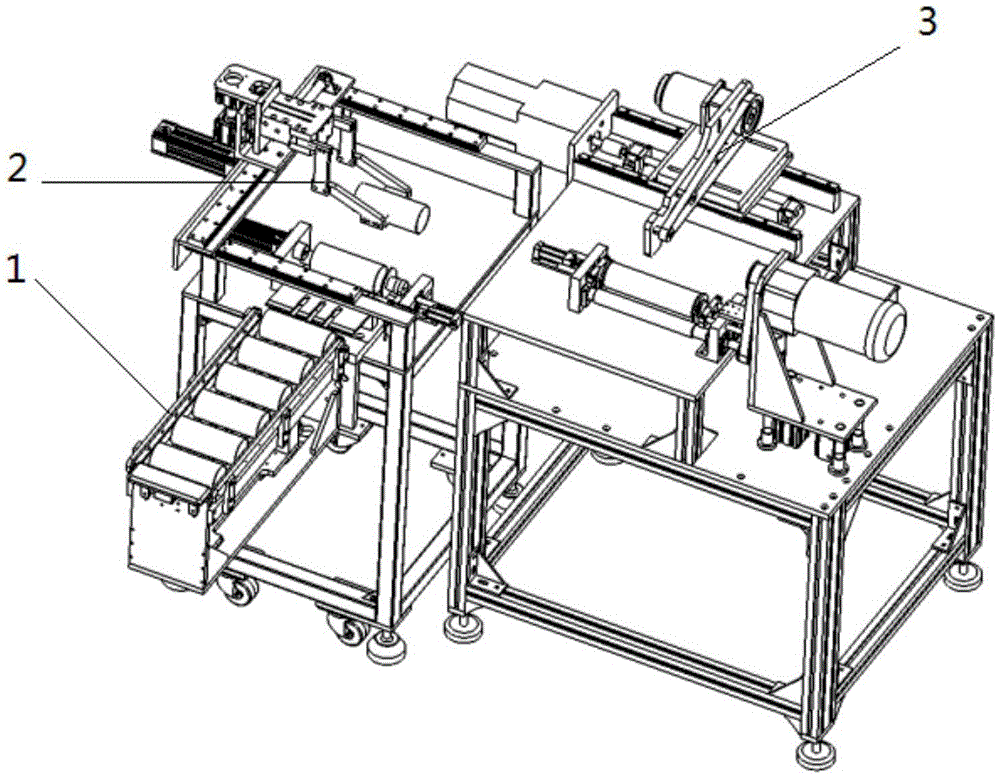

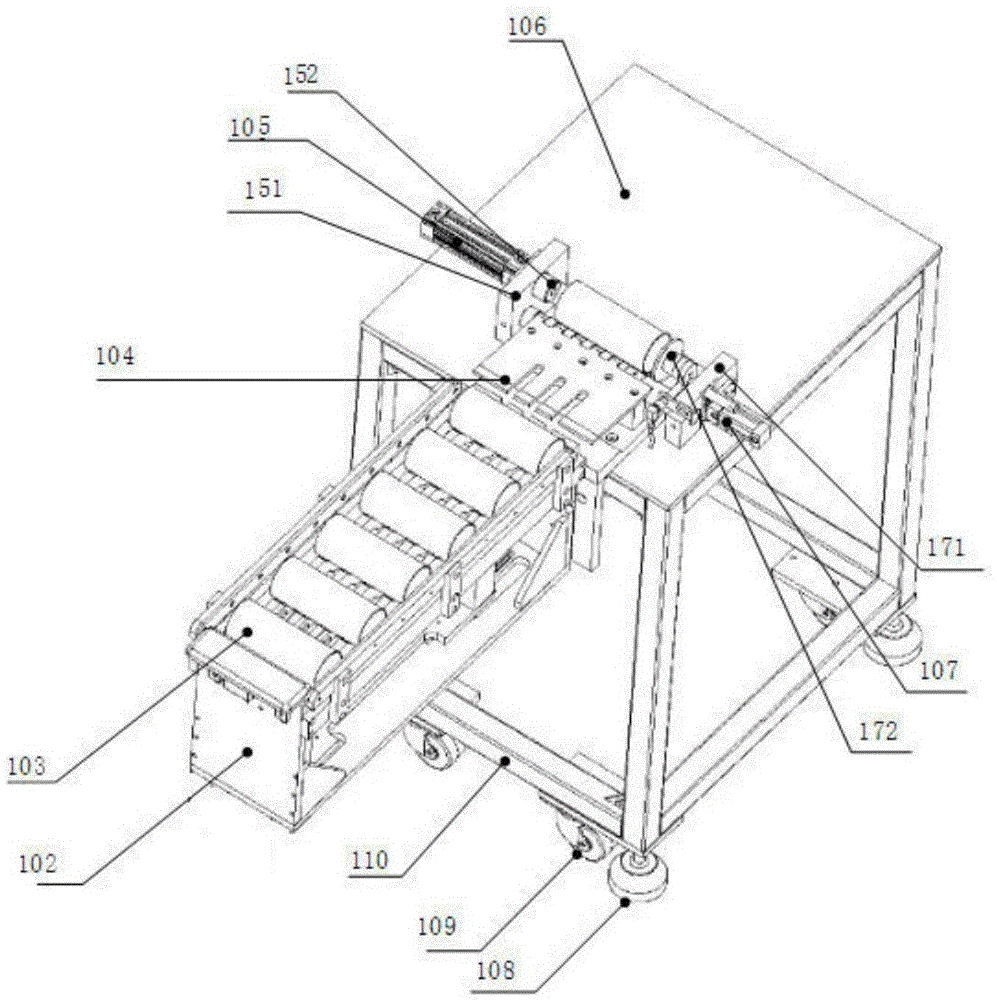

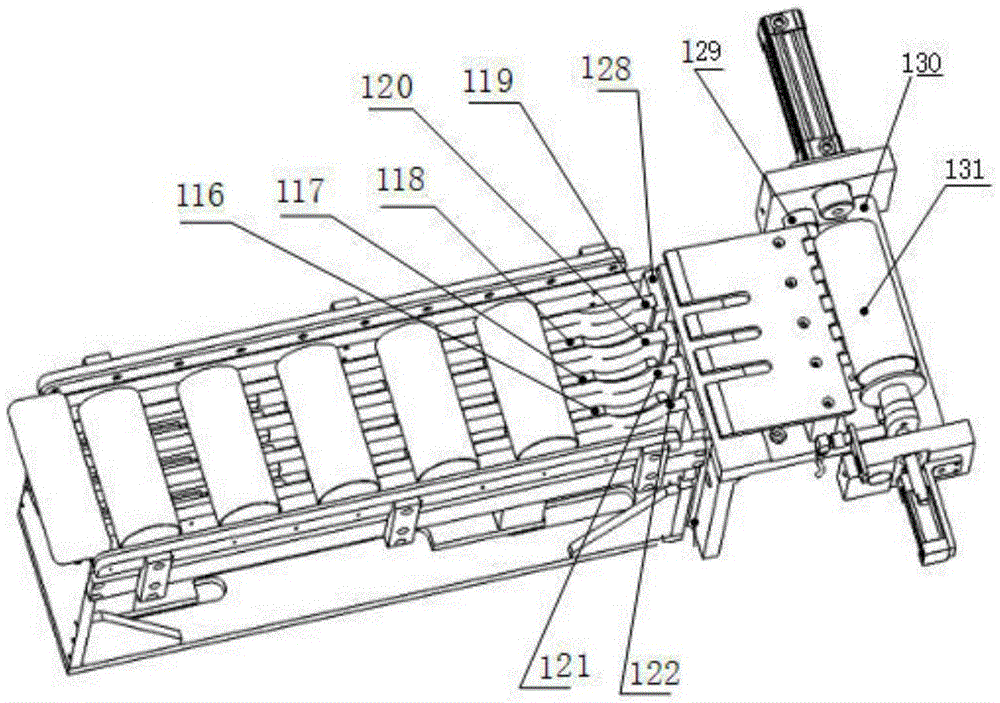

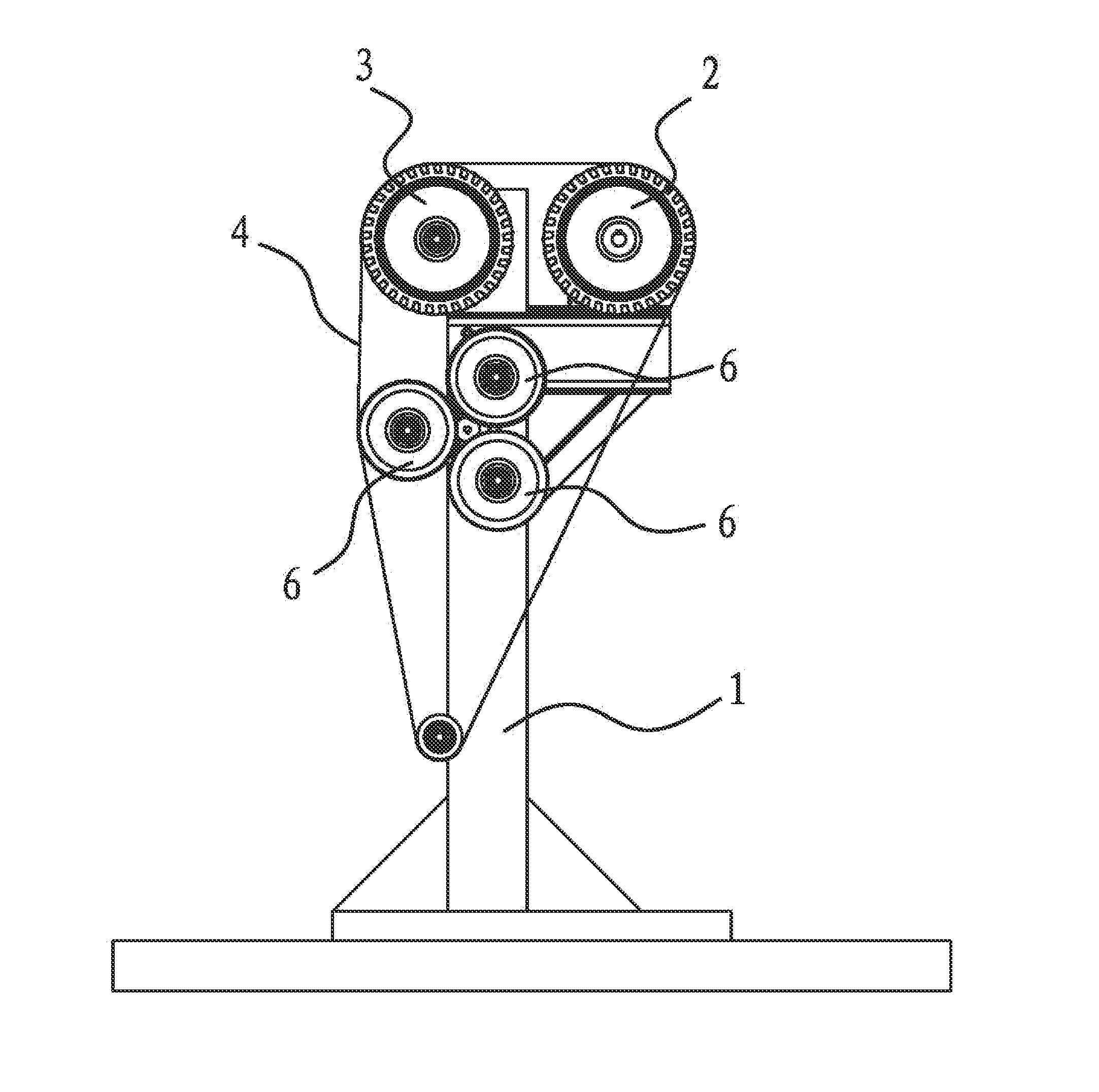

Automatic polishing system for cylindrical workpiece

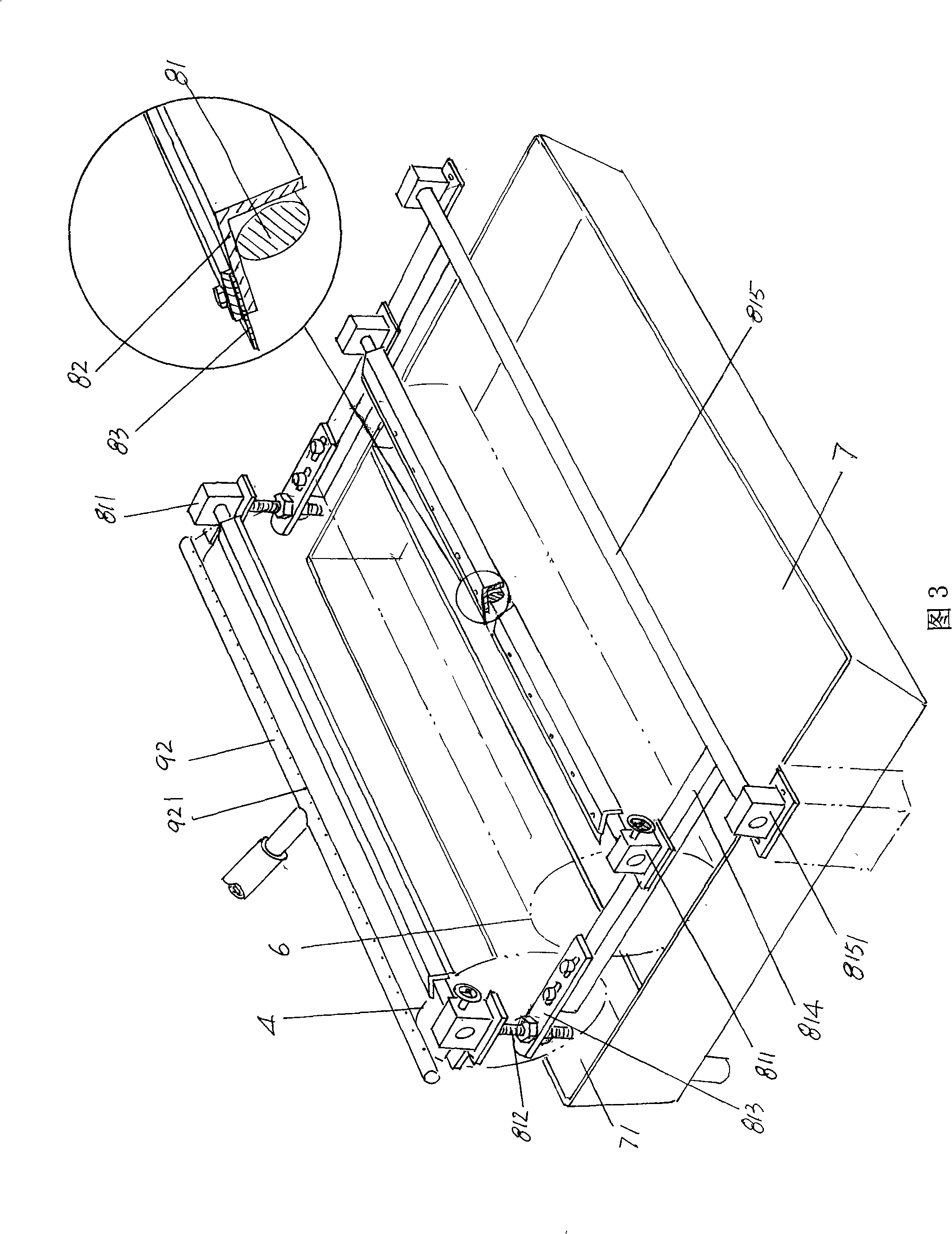

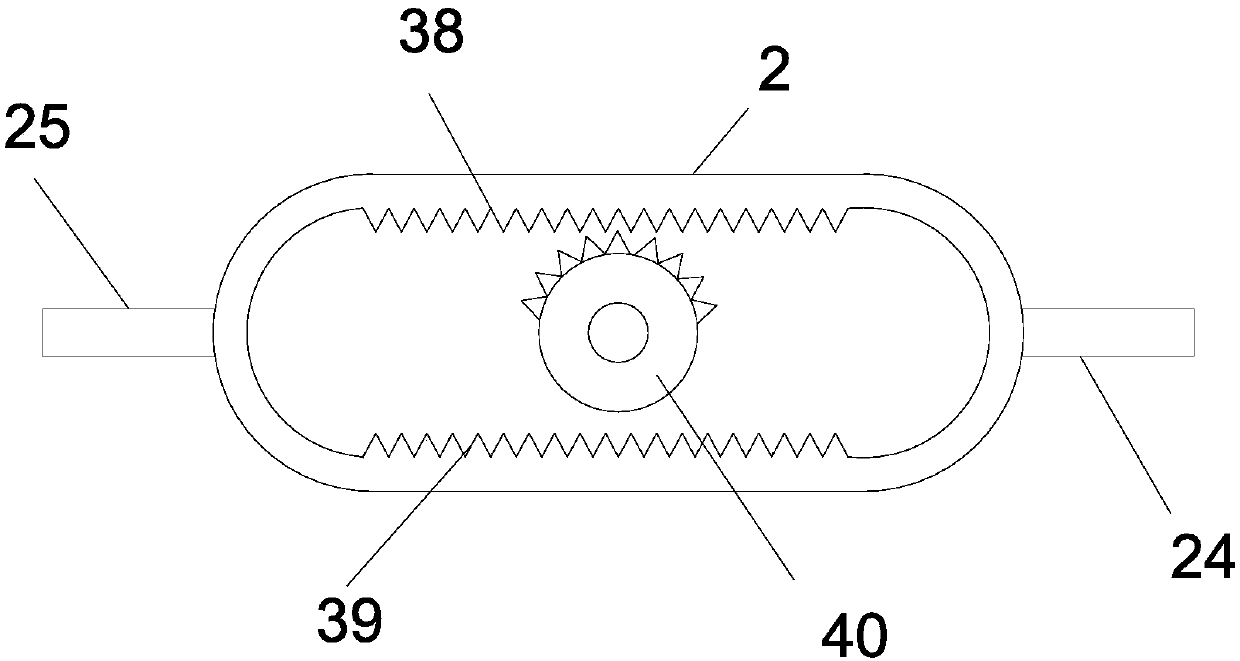

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

Dust reduction type steel plate double-face efficient polishing device

PendingCN107695810AWide range of grindingImprove grinding efficiencyPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftPolishing

The invention discloses a dust reduction type steel plate double-face efficient polishing device which comprises an operation chamber. A driven shaft is vertically and rotationally arranged in the operation chamber, and a polishing plate is coaxially and fixedly installed at the bottom end of a driving shaft; a guide rod connected with the left side wall of the operation chamber in a sliding manner is horizontally arranged at the left end of a dual-rectangle-shaped frame, and a sliding rod movably connected with a vertical plate is horizontally arranged at the right end of a support; and a limiting spring is arranged on the sliding rod on the vertical plate at the right end of the upper surface of a bearing table in a sleeving manner, a positioning disc is fixedly installed on the right side of the vertical plate at the right end, a center hole is formed in the center of the positioning disc, and an upper positioning hole and a lower positioning hole which are subject to up-and-down vertical symmetry with respect to the center of the center hole are formed in the positioning disc. The dust reduction type steel plate double-face efficient polishing device is ingenious in structure and reasonable in design; the polishing plate is driven by a driving motor to achieve rotary polishing on a steel plate, the polishing scope is wider, and the steel plate polishing efficiency is improved; and the sliding rod is rotated to drive an L-shaped positioning shaft to rotate, and therefore double-face polishing on the steel plate can be achieved, and the overturning operation is easy and convneient.

Owner:ZHENGZHOU UNIV

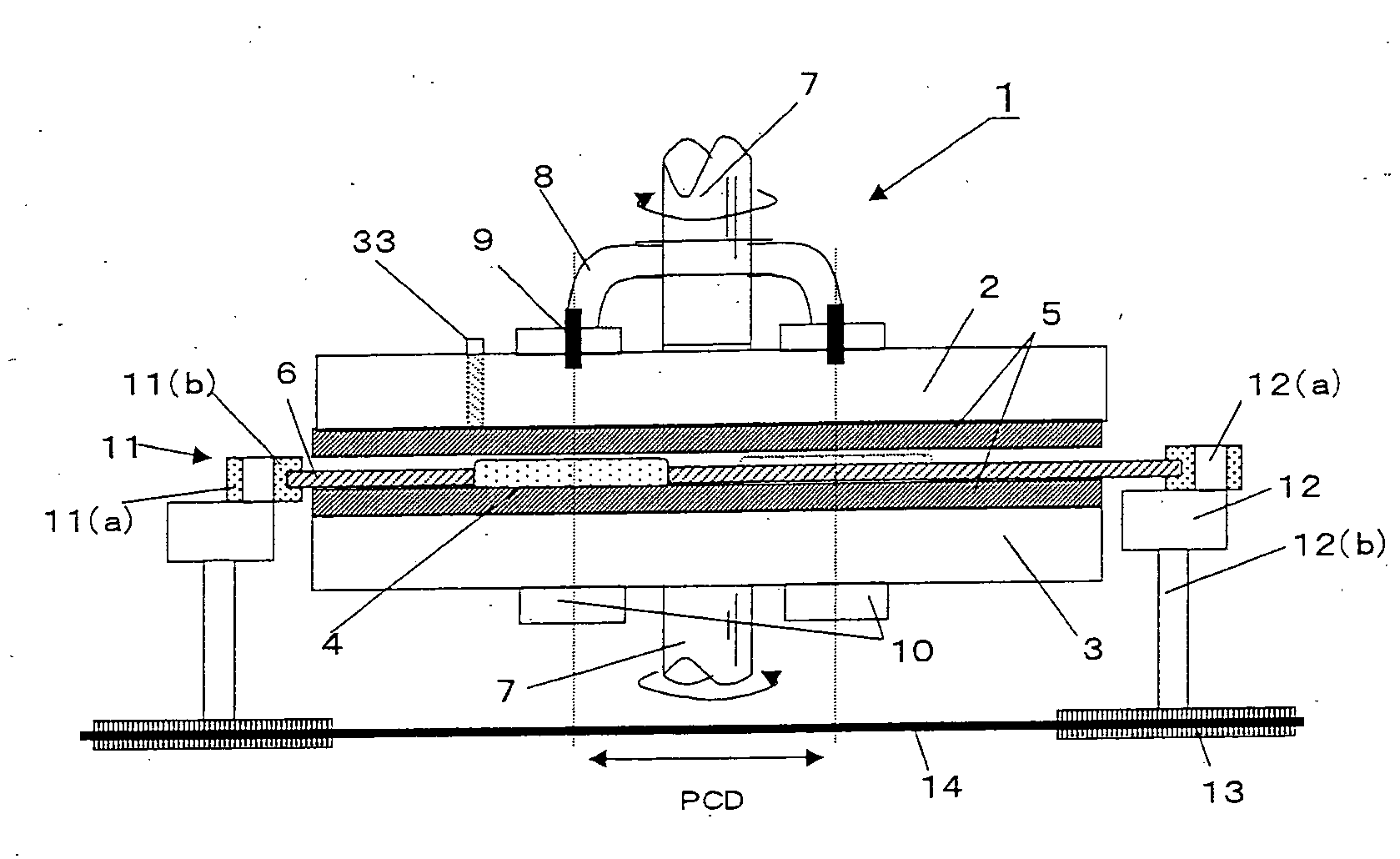

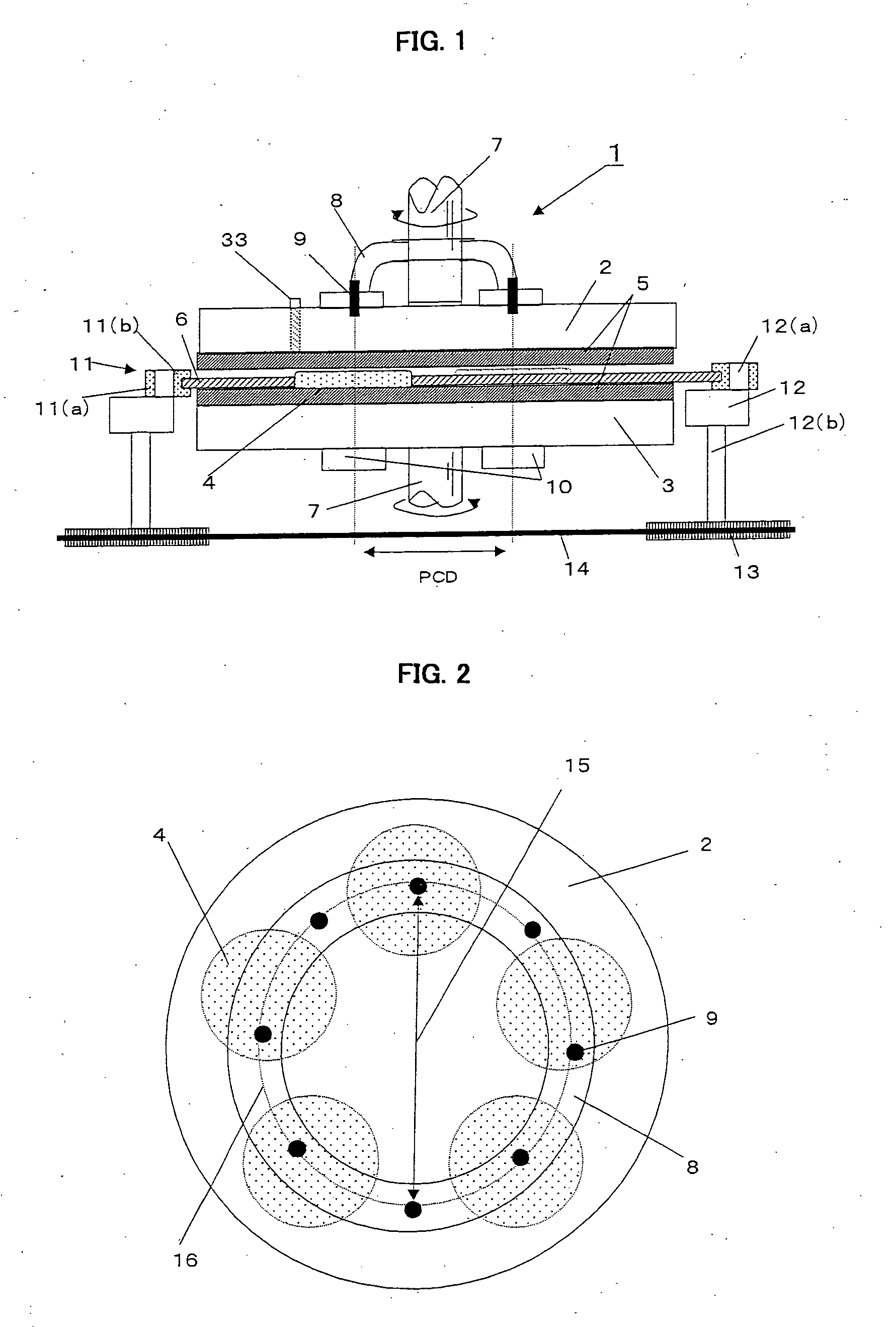

Double side polishing device for wafer and double side polishing method

InactiveUS20050124264A1High precision without deteriorating wafer shapeGood precisionEdge grinding machinesPolishing machinesEngineeringSlurry

The present invention provides a wafer double-side polishing apparatus comprising at least a carrier plate having wafer holding holes; upper and lower turn tables to which polishing pads are attached; and a slurry supply means; with wafers held in the wafer holding holes, the carrier plate being moved between the upper and lower turn tables while supplying slurry, to simultaneously polish both front and back surfaces of wafers, wherein a PCD of upper turn table load supporting points that is a diameter of a circle joining load supporting points of the upper turn table coincides with a PCD of centers of the wafer holding holes on the carrier plate that is a diameter of a circle joining each center of the wafer holding holes on the carrier plate. Thereby, there can be provided a wafer double-side polishing apparatus and method in which it is possible to control wafer shape by deforming turn tables with excellent responsiveness, and to polish the wafers stably with high precision without deteriorating wafer shape.

Owner:SHIN-ETSU HANDOTAI CO LTD

Steel for a plastic molding die

To provide a steel for plastic molding die which possesses enough hardness, wear resistance and corrosion resistance, and is excellent in high-precision processability and mirror polishing properties. The steel for a plastic molding die contains not more than 0.80 wt% C, not less than 0.01 wt% and less than 1.40 wt% Si, not less than 0.05 wt% and not more than 2.0 wt% Mn, not less than 0.005 wt% and not more than 1.00 wt% Ni, not less than 13.0 wt% and not more than 20.0 wt% Cr, not less than 0.20 wt% and not more than 4.0 wt% Mo + 1 / 2 W, not less than 0.01 wt% and not more than 1.00 wt% V, not less than 0.36 wt% and not more than 0.80 wt% N, not more than 0.02 wt% O, not more than 0.80 wt% A1, and the remainder substantially including Fe and unavoidable impurities.

Owner:DAIDO STEEL CO LTD

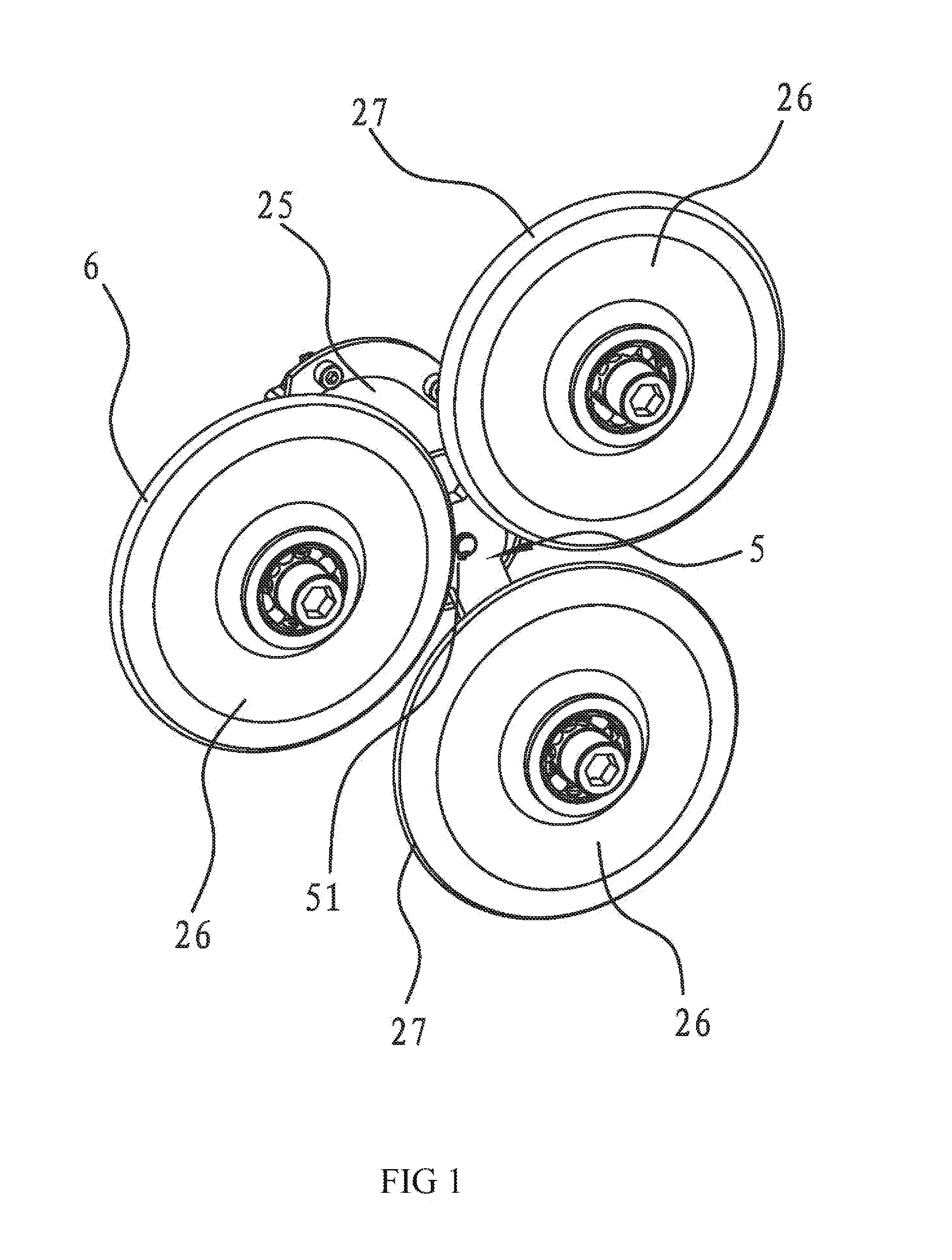

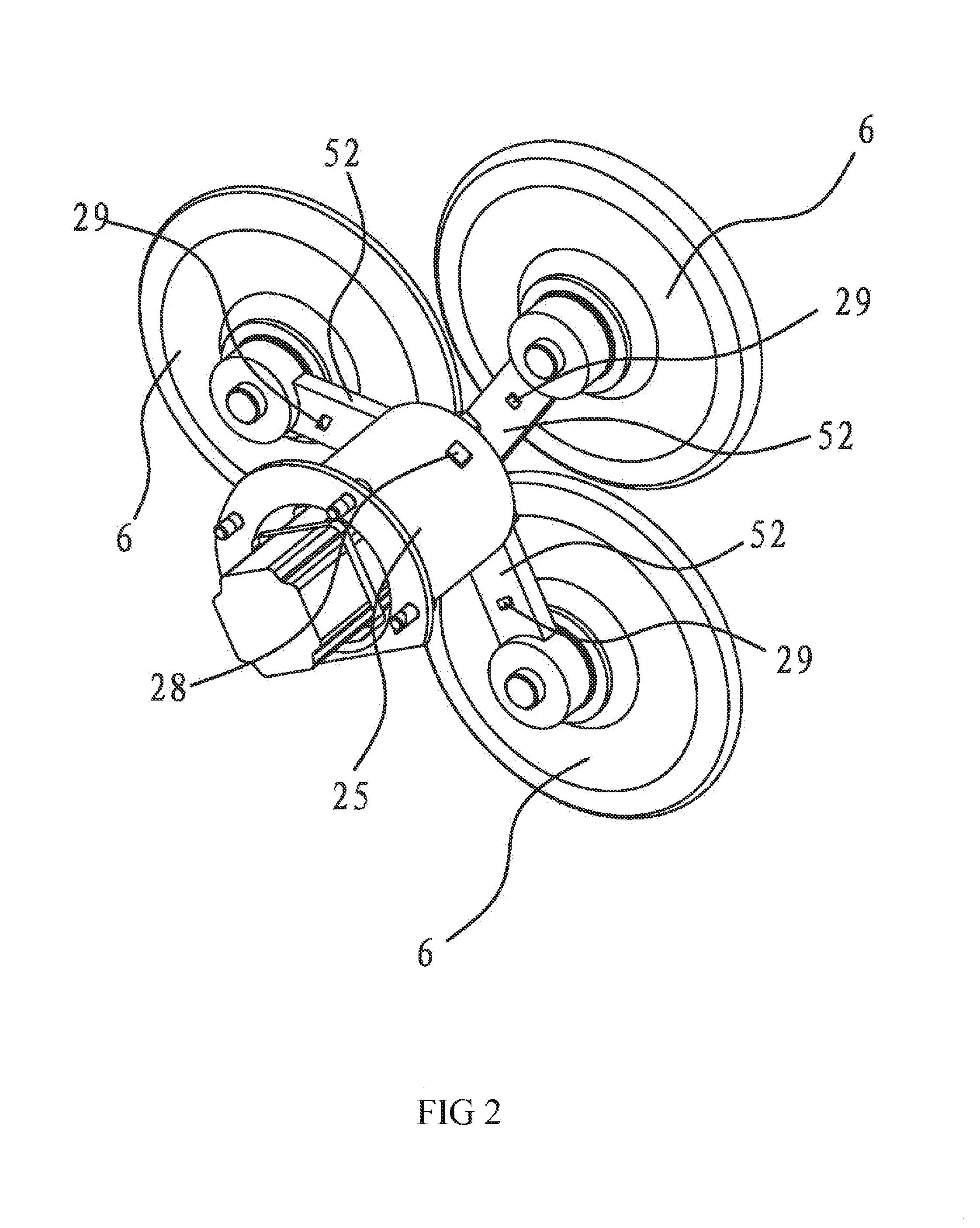

Abrasive belt polishing finisher

InactiveUS20150375357A1Guaranteed operational reliabilityAvoid supportBelt grinding machinesElectric machineryEngineering

The invention discloses an abrasive belt polishing finisher in the field of mechanical technology, which addresses inconvenient operation of the existing polishing finishers. The abrasive belt polishing finisher includes a motor and a connection support. The central section of the connection support is fixedly connected with the output shaft of the motor. Several self-rotable connection support finishing wheels are provided around the connection support. The curve surface of the rim of each of the support finishing wheels has a different curvature. Each connection support finishing wheel is distributed on the same circle centered on the output shaft of the motor. The connection support is driven by the motor into rotation to press and position one of the connection support finishing wheels against the back of the abrasive belt in the polishing finisher. The abrasive belt polishing finisher could satisfy continuous polishing treatment for different curved surfaces.

Owner:TAIZHOU FEDERAL ROBOT TECH

Austenitic stainless steel with excellent polishing performance and manufacturing method thereof

InactiveCN102162075AImprove grinding effectImprove surface polishing performanceTemperature control deviceFurnace typesElectrolysisAcid washing

The invention discloses an austenitic stainless steel with excellent polishing performance. The austenitic stainless steel comprises the following chemical components in percentage by weight: 16 to 20 percent of Cr, 7 to 15 percent of Ni, less than or equal to 2 percent of Mn, 0.2 to 2 percent of Cu, less than or equal to 0.05 percent of Al, less than or equal to 0.5 percent of Si, 0.03 to 0.1 percent of C, less than or equal to 0.05 percent of N, 0.01 to 0.06 percent of P, 0.003 to 0.05 percent of S, 0.05 to 0.5 percent of V, and the balance of iron and inevitable impurities. A manufacturing method for an austenitic stainless steel cold-rolled plate comprises the following steps of: heating a continuous cast plate blank to the temperature of between 1,100 and 1,300 DEG C; performing rough rolling at the temperature of between 1,000 and 1,250 DEG C; performing final rolling at the temperature of between 950 and 1,100 DEG C; performing quick cooling; coiling at the temperature of less than 700 DEG C; performing hot rolling to form a hot-rolled plate of the required specification; annealing the hot-rolled plate at the temperature of between 950 and 1,200 DEG C; removing oxide skin by adopting a continuous acid washing process of phosphorus breakage, shot blasting, electrolysis and mixed acid washing; performing cold rolling, wherein the overall reduction rate is more than 50 percent; and performing continuous annealing at the temperature of between 950 and 1,200 DEG C, or performing full-hydrogen bright annealing at the temperature of between 950 and 1,200 DEG C. The austenitic stainless steel cold-rolled plate has completely improved grinding performance and surface polishing performance, and is particularly suitable for the industries of building decoration, plastic dies, food sanitation, electronics and the like with strict polishing performance requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

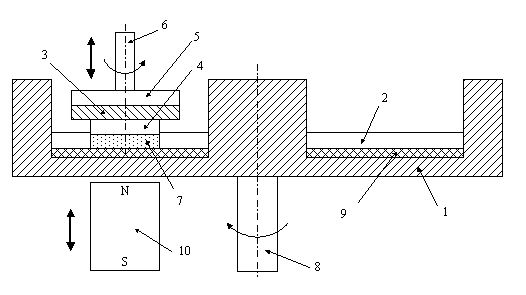

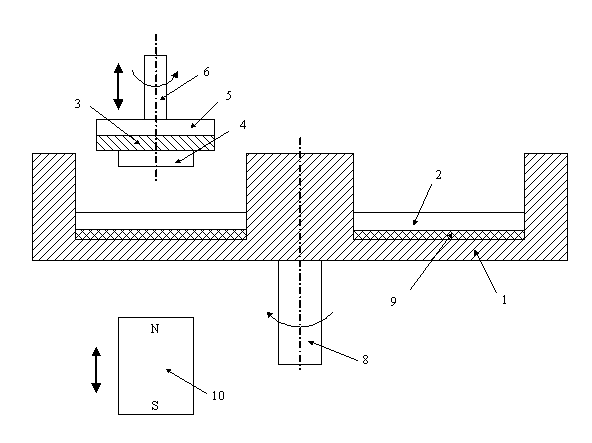

Surface contact magneto-rheological flat polishing device and method with uniform magnetic field

The invention discloses a surface contact magneto-rheological flat polishing device and method with a uniform magnetic field. The surface contact magneto-rheological flat polishing device with the uniform magnetic field comprises a polishing head, a polishing groove fixed onto a main shaft and a magnetic pole arranged under the polishing groove. The magnetic pole maintains a certain gap from the outer surface of the bottom of the polishing groove; the polishing head comprises a workpiece shaft and a non-magnetic-conducted clamp fixed to the lower end of the workpiece shaft, and a soft magnetic plate is arranged between the non-magnetic-conducted clamp and the workpiece shaft; the polishing head is arranged above the polishing groove; the uniform magnetic field is formed between the magnetic pole and the soft magnetic plate; and the polishing groove is filled with magneto-rheological fluid. The surface contact magneto-rheological flat polishing device and method with the uniform magnetic field can achieve the large-area uniform polishing of a super-smooth large-size flat element and improve the polishing efficiency effectively; reduces the complexity of the motion mode of a workpiece to simplify the device structure; enables the magnetic field to be not easy to attenuate and obtains the uniform magnetic field with a magnetic pole gap of 30 mm; and can achieve demagnetization easily.

Owner:HUNAN UNIV

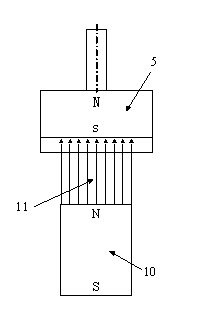

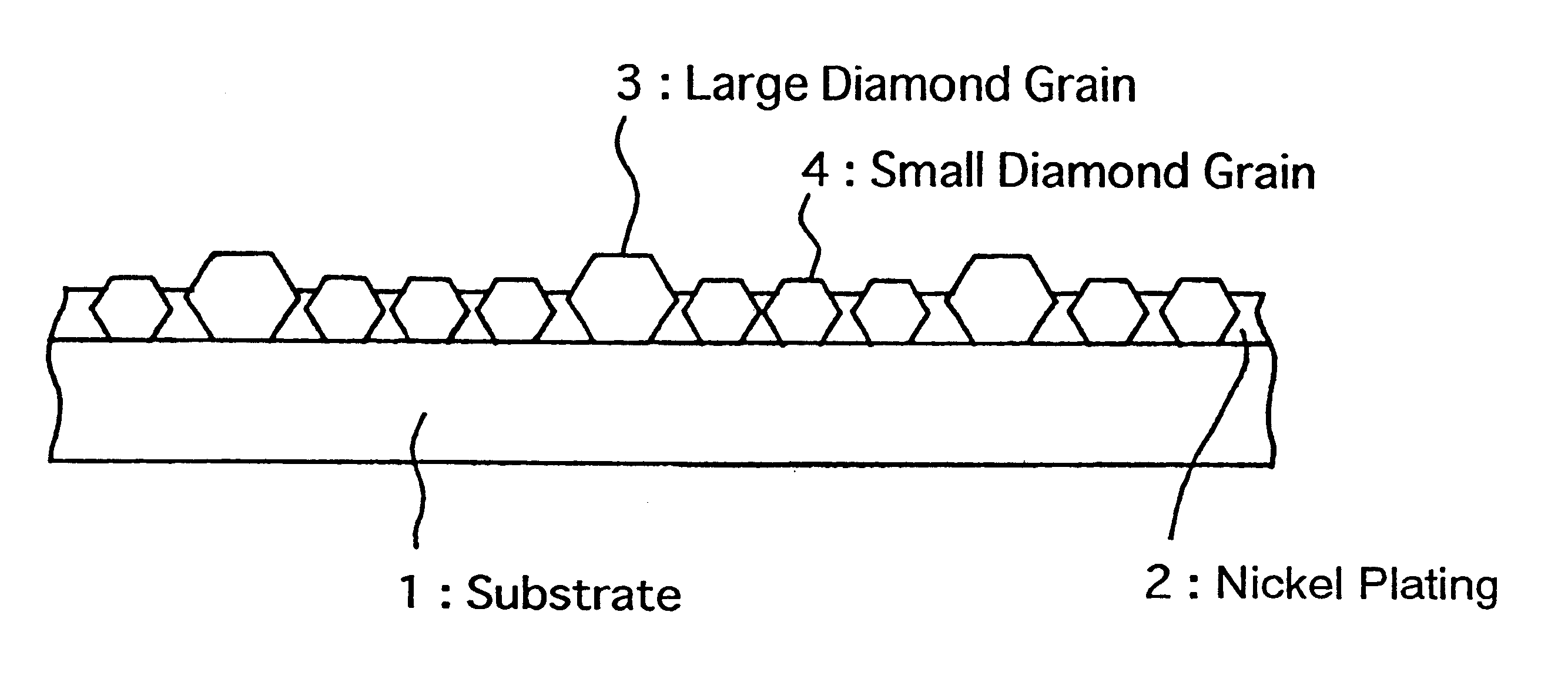

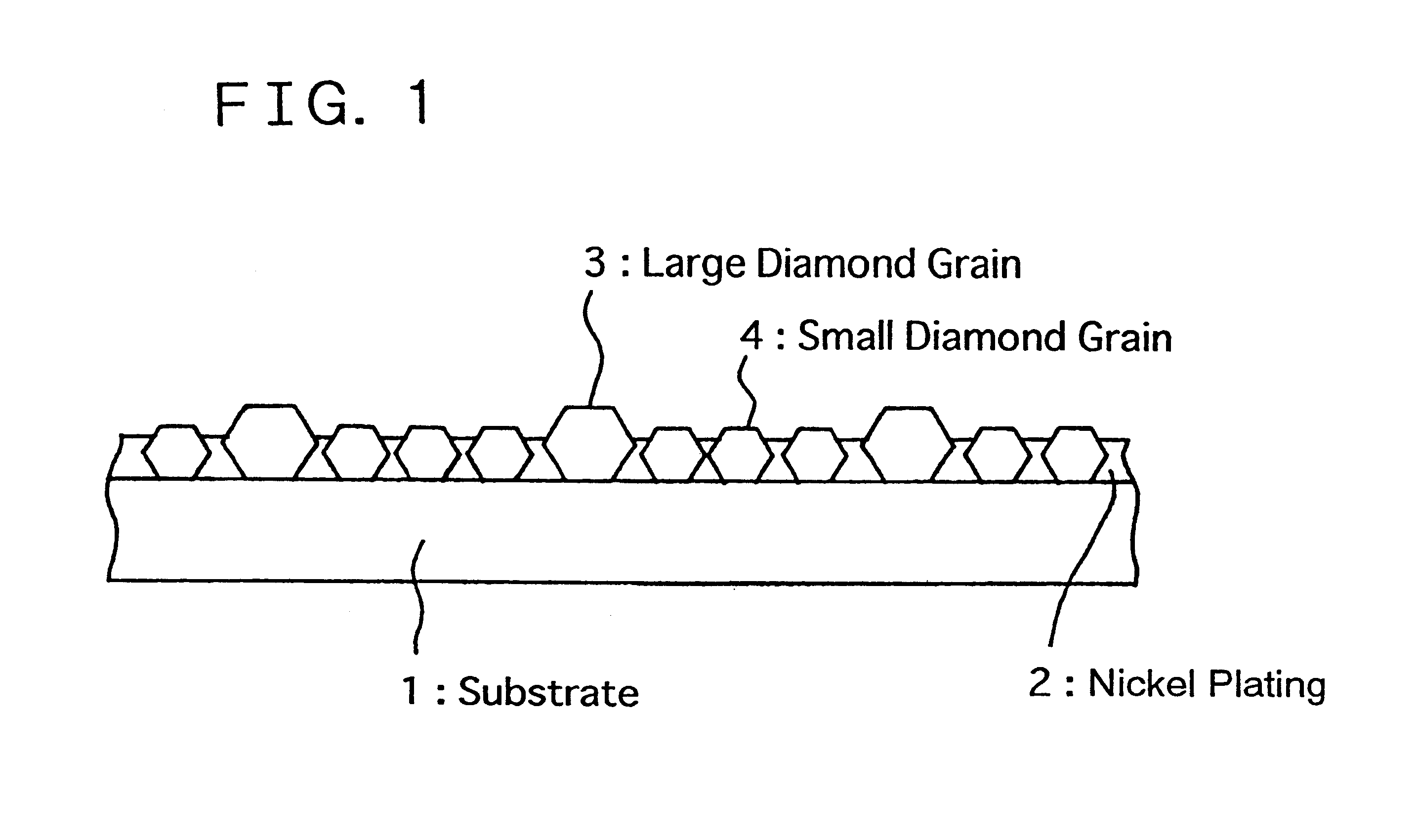

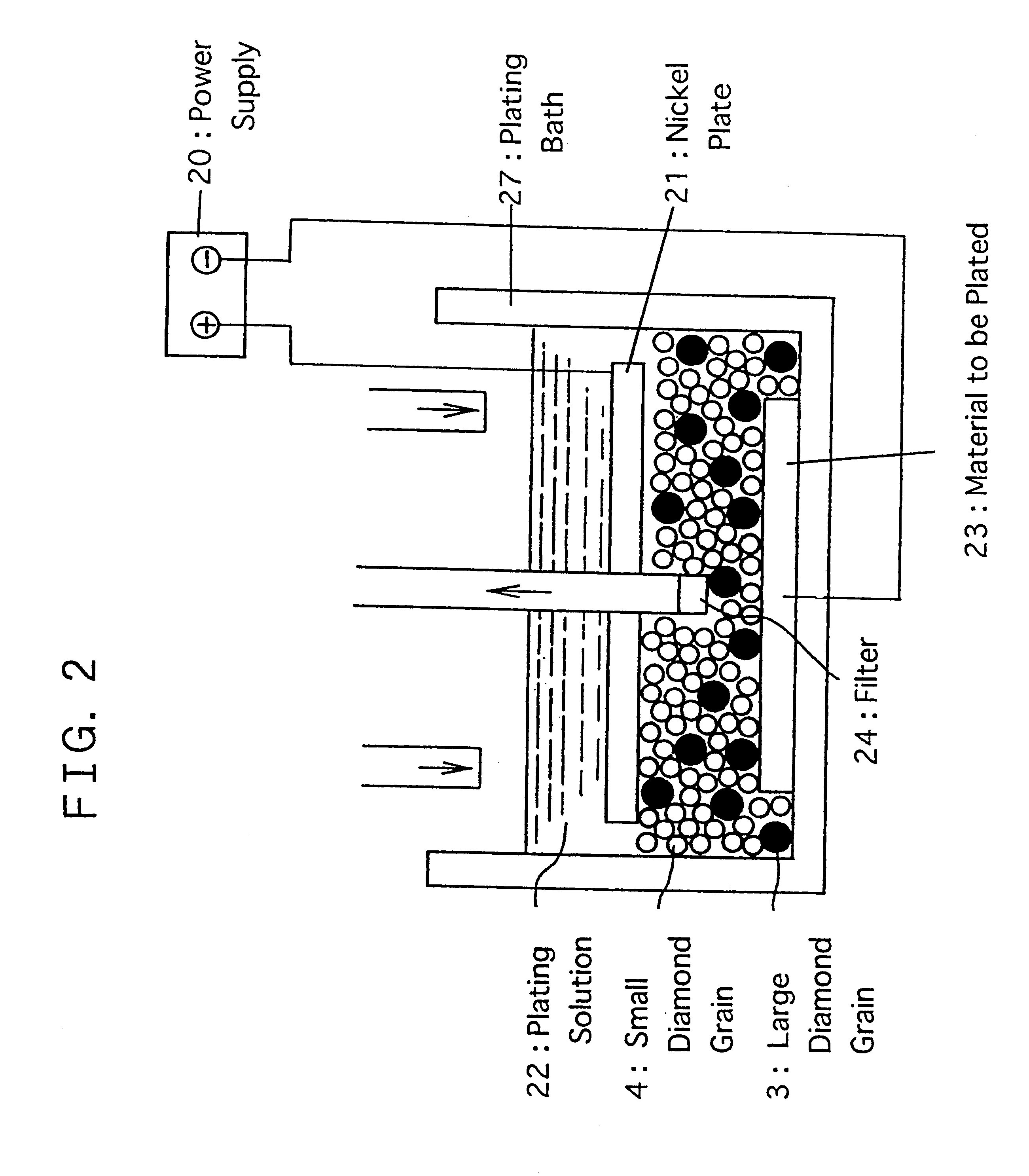

Dressing tool for the surface of an abrasive cloth and its production process

InactiveUS6306025B1Short lifeSimple processElectrolytic coatingsGrinding drivesForeign matterForeign substance

Onto the surface of a dressing tool for removing the clogging of an abrasive cloth, diamond grains of plural groups each having a different average particle diameter are subjected to be mixed and then fixed. In this state, the upper end of small diamond grains 4 is projected over nickel plating 2. Thereby foreign substances aggregated in the concave of the abrasive cloth are effectively removed and at the same time wearing the surface of the nickel plating 2 is prevented. Achieved are the stabilization of a polishing speed in polishing and the inhibition of dropping out diamond grains and wearing nickel plating in dressing.

Owner:NEC ELECTRONICS CORP

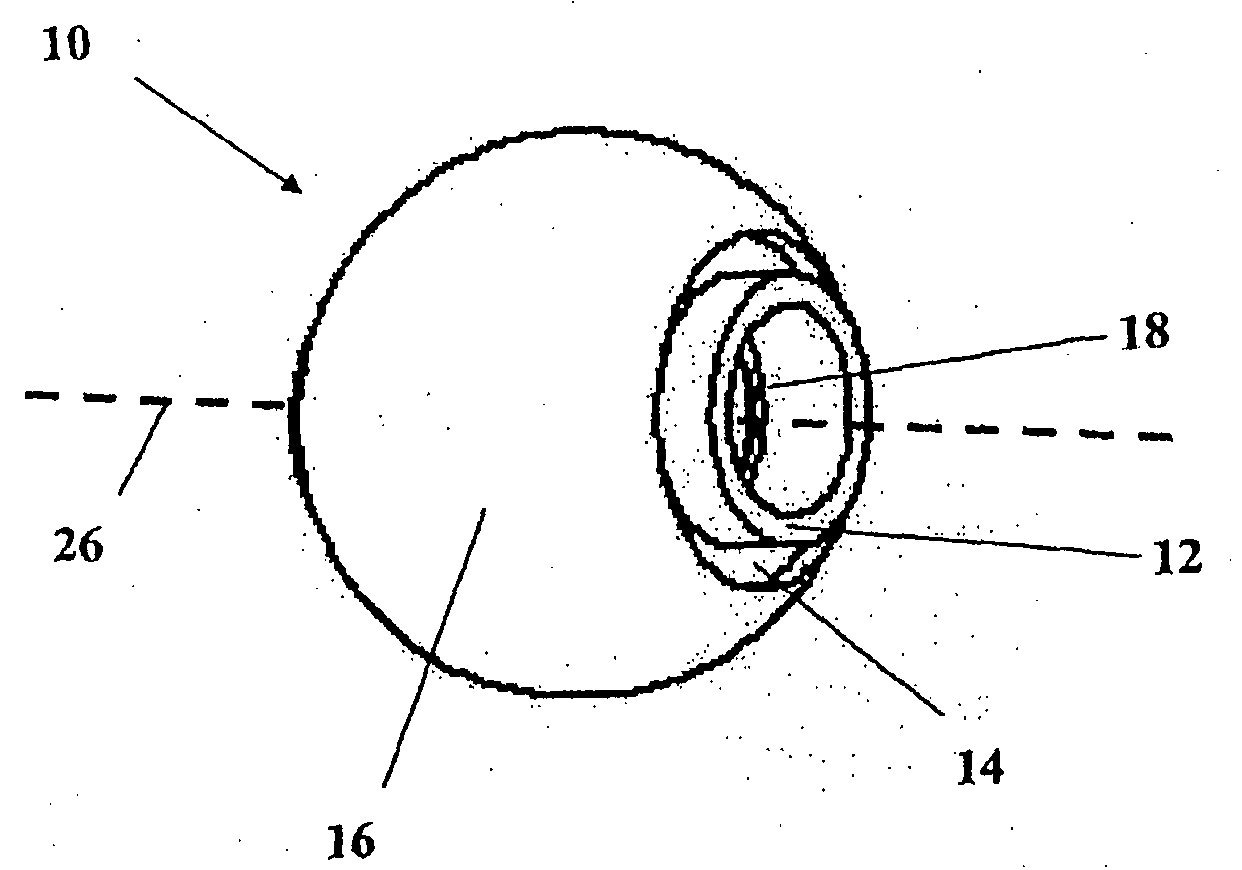

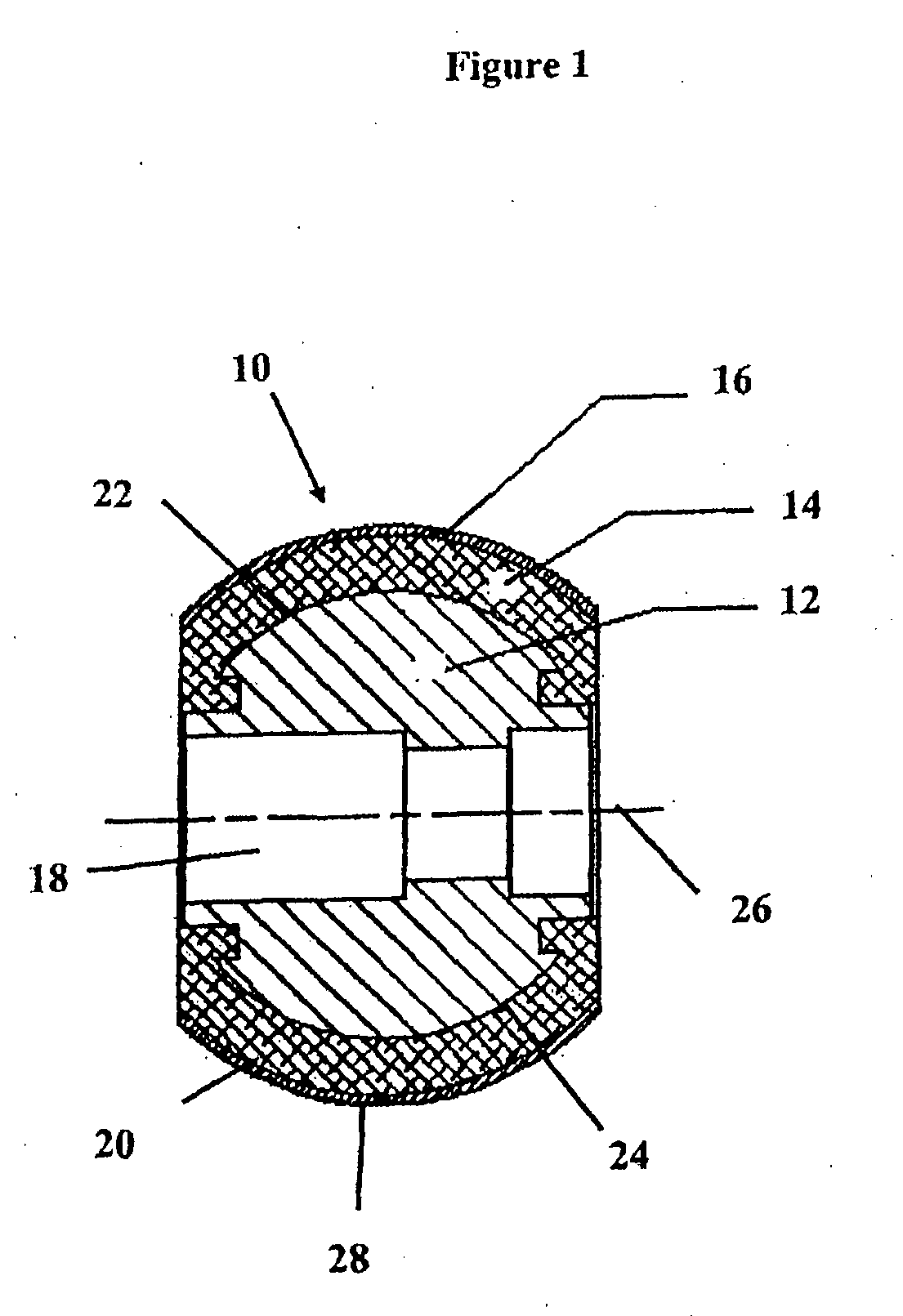

Polishing wheel

InactiveUS20090088055A1Reduce surface roughnessRevolution surface grinding machinesOptical surface grinding machinesElastomerEngineering

A polishing wheel (10) arranged to polish an article. The polishing wheel comprises a hub (12) pro-vided with an axial cavity (18) coaxial with an axis (26). The polishing wheel further comprises a substrate layer (14) being made of an elastomer material affixed to the hub (12) and coaxial with the axis (26). The substrate layer (14) has an outer surface (20) having a substantially symmetrical shape with respect to the axis (26). The polishing wheel (10) further comprises a continuous cover layer (16) affixed to the outer surface (20) and coaxial with the axis (26). The continuous cover layer (16) is made of an elastomer material covering substantially entirely the outer surface (20).

Owner:ESSILOR INT CIE GEN DOPTIQUE

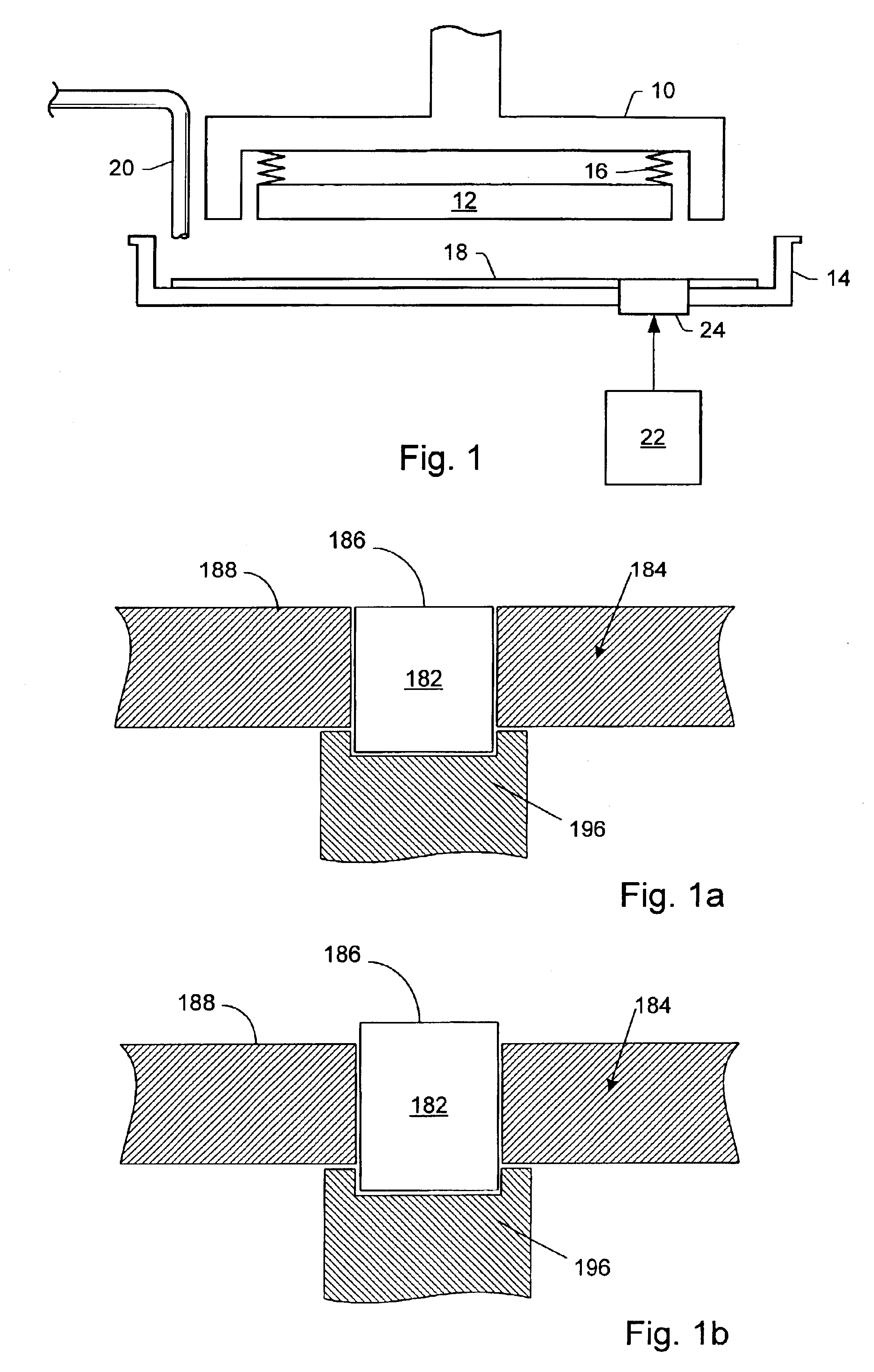

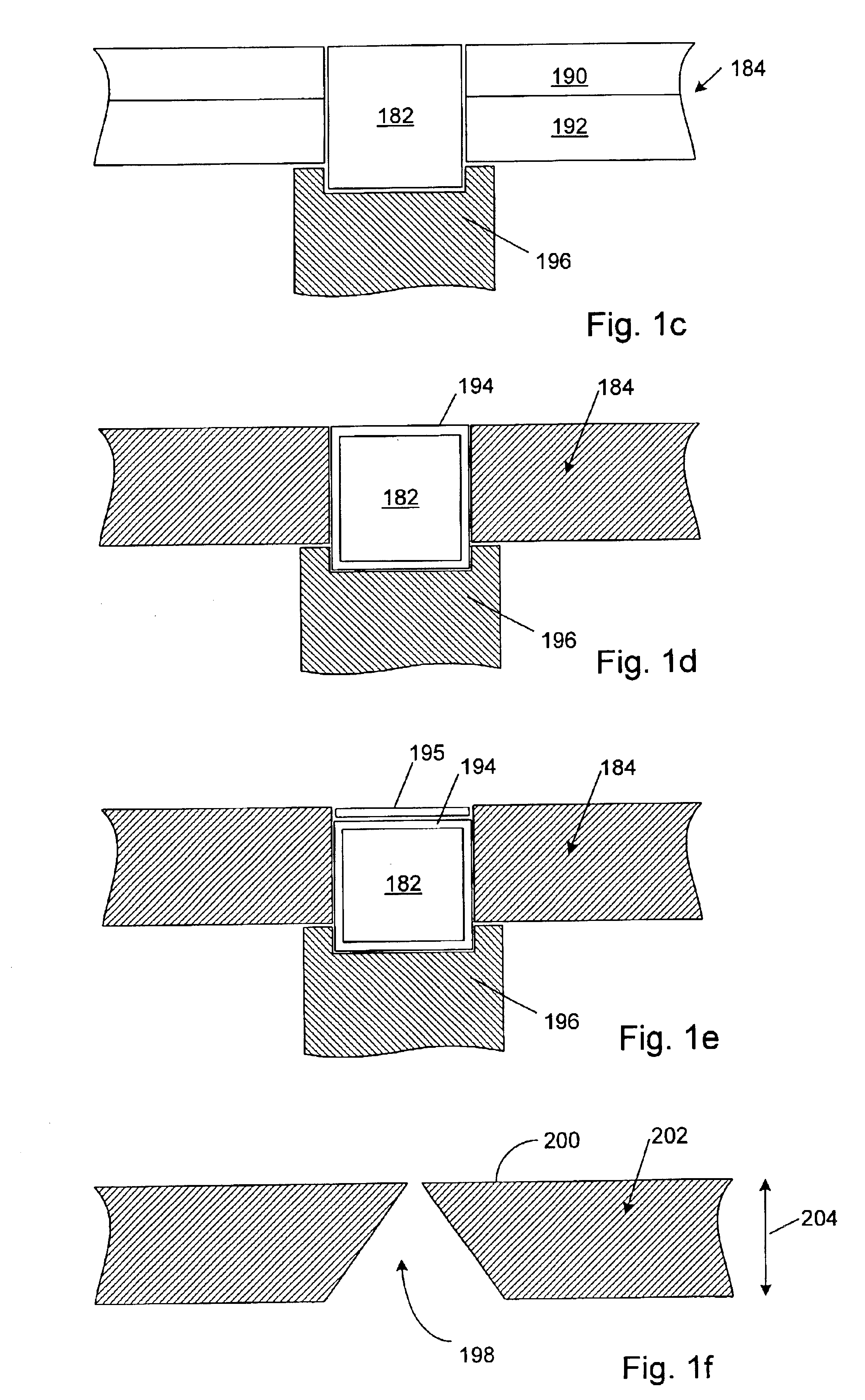

Windows configurable to be coupled to a process tool or to be disposed within an opening in a polishing pad

InactiveUS6866559B2Reduce dishing and erosionShorten speedAbrasion apparatusLapping machinesEngineeringMechanical engineering

Windows configurable to be coupled to a process tool or to be disposed within an opening in a polishing pad are provided. One window includes a first portion and a second portion. The first portion includes a first material, and the second portion includes a second material different than the first. Another window includes a substantially transparent gel. In some instances, the gel includes a triblock copolymer and a plasticizing oil. An additional window includes an upper window, a housing, and a diaphragm. The housing may allow a fluid to flow into and out of a space between the housing and the diaphragm. In another embodiment, a window includes a layer of material coupled to lateral surfaces of the window. In some cases, the window may be disposed within an opening in a polishing pad, and movement of the window within the polishing pad may compress the layer of material.

Owner:KLA TENCOR CORP

Compound polishing powder for polishing optical elements, preparation method and polishing technology

ActiveCN101362925BImprove effectivenessImprove machining accuracyOptical surface grinding machinesOther chemical processesSurface finishGranularity

The invention provides a compound polishing powder of a polishing optical element, a preparation method and a polishing process, belonging to expendable material used for polishing the optical element, the preparation method and the polishing process of the polishing powder; wherein, the polishing powder comprises 0.5-3 of Cr2O3 powder and 1 of Al2O3 according to the weight proportion; the granularity of the Cr2O3 powder is ranging from 0.05 microns to 0.10 microns and the granularity of the Al2O3 powder is ranging from 0.05 microns and 0.10 microns; the polishing process comprises the steps as follows: 1) installing polishing formworks for the optical element; 2) filling the polishing powder; 3) arranging a lens disc; 4) fixing the lens disc; 5) rubbing and polishing. The polishing formwork comprises 500 of polishing asphalt and 20-200 of Al2O3 according to the weight parts; in the polishing process, the polishing powder and the polishing formwork can be used for polishing the optical element which is made of zinc selenide, with the surface smoothness of more than 20-10.

Owner:CHENGDU Z & Z OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com