Patents

Literature

5513results about "Belt grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

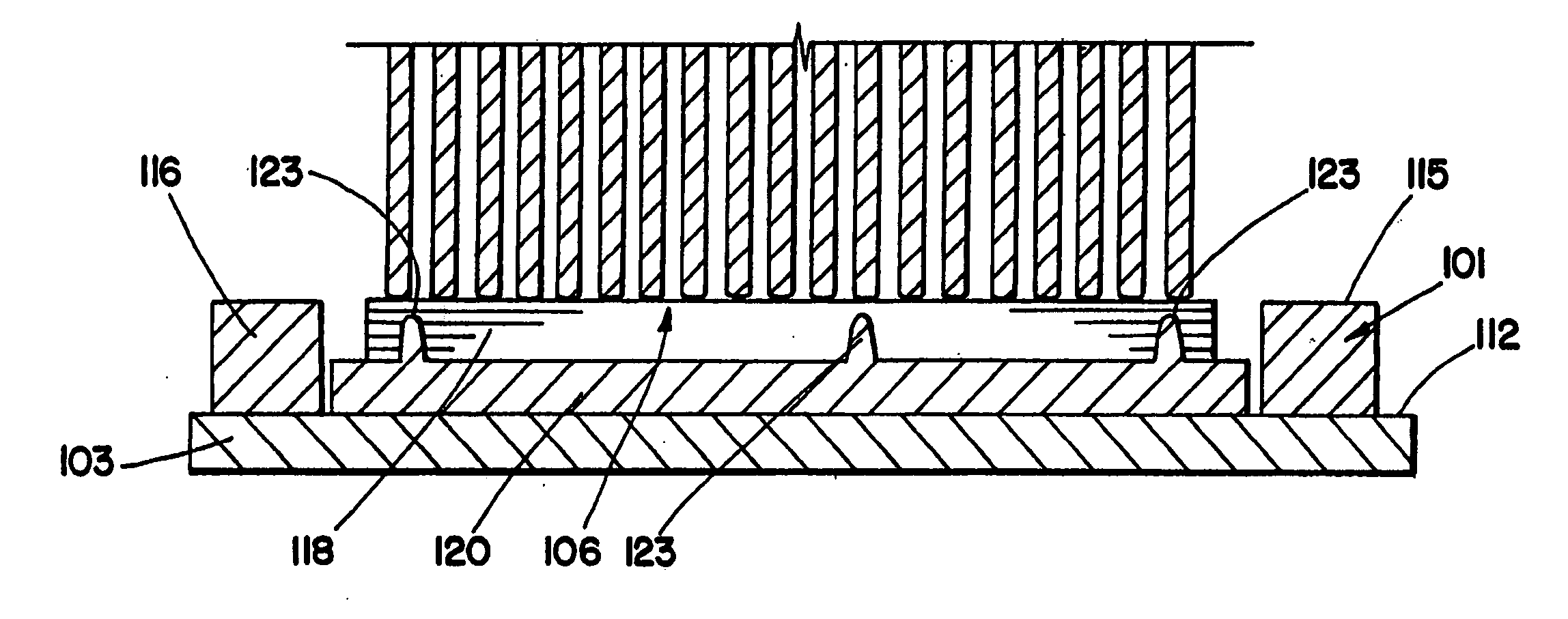

Wafer carrier checker and method of using same

ActiveUS20060252351A1Grinding drivesBelt grinding machinesSemiconductorElectrical and Electronics engineering

A tool and method for assessing whether a disk carrier, and especially a carrier for holding semiconductor disks, is properly dimensioned. The tool has a body that includes a socket in which a portion of the disk carrier will seat fully if the disk carrier is properly dimensioned. Alignment structures may be provided in the socket to align with features of the carrier to assist in determining whether the disk carrier is properly dimensioned. The socket may include two spaced apart cavities that correspond with end portions of walls of the disk carrier.

Owner:MICREL

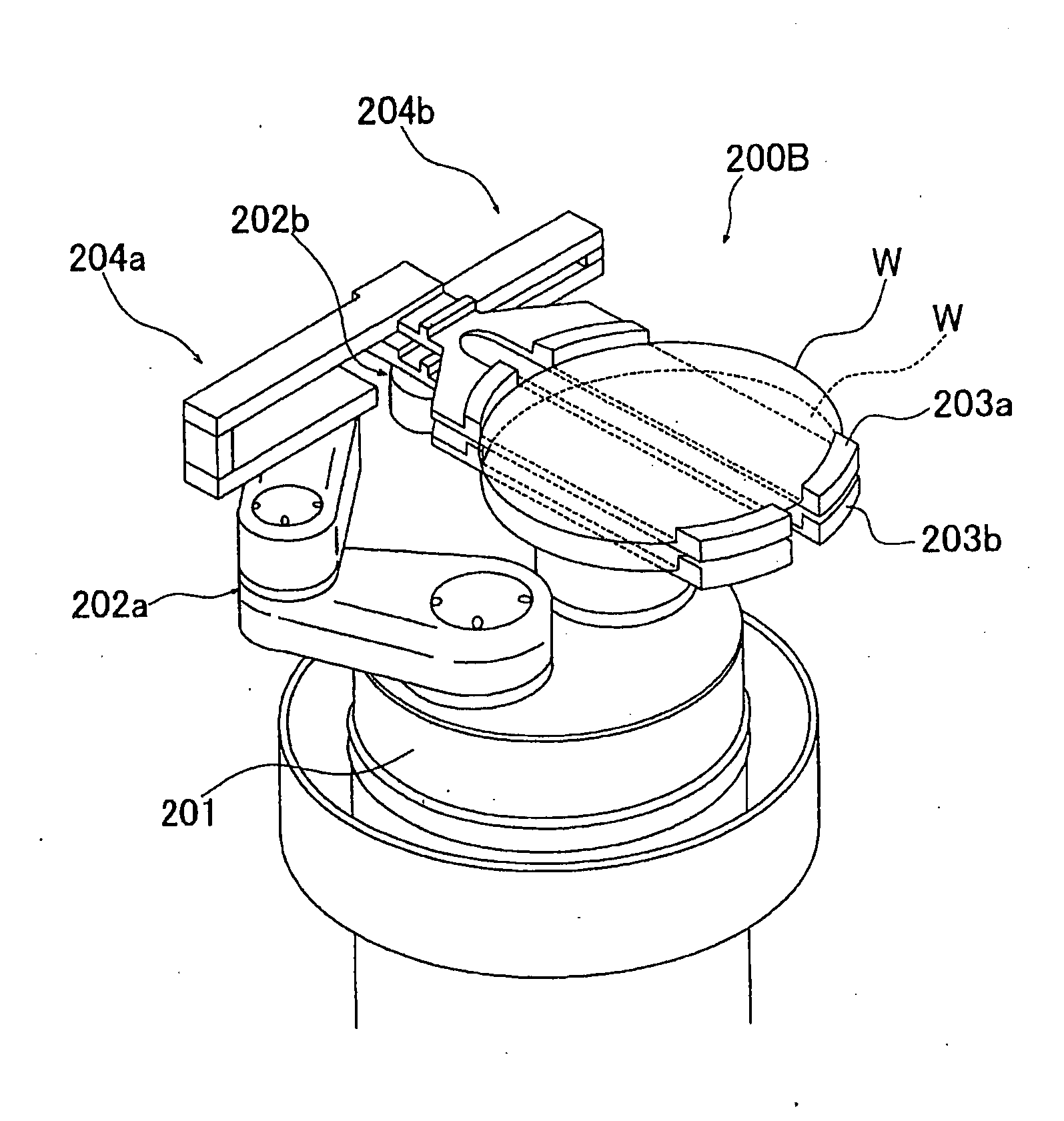

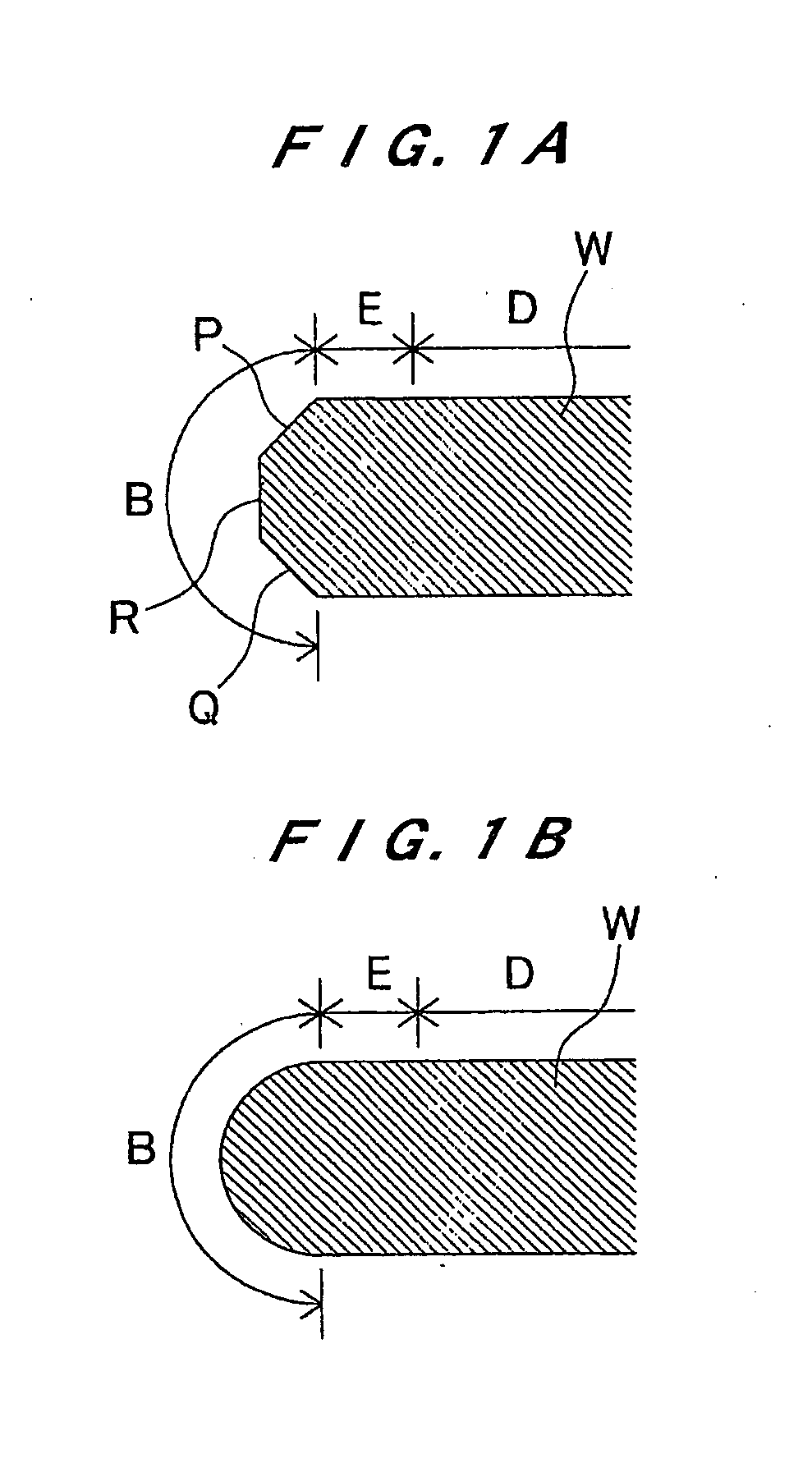

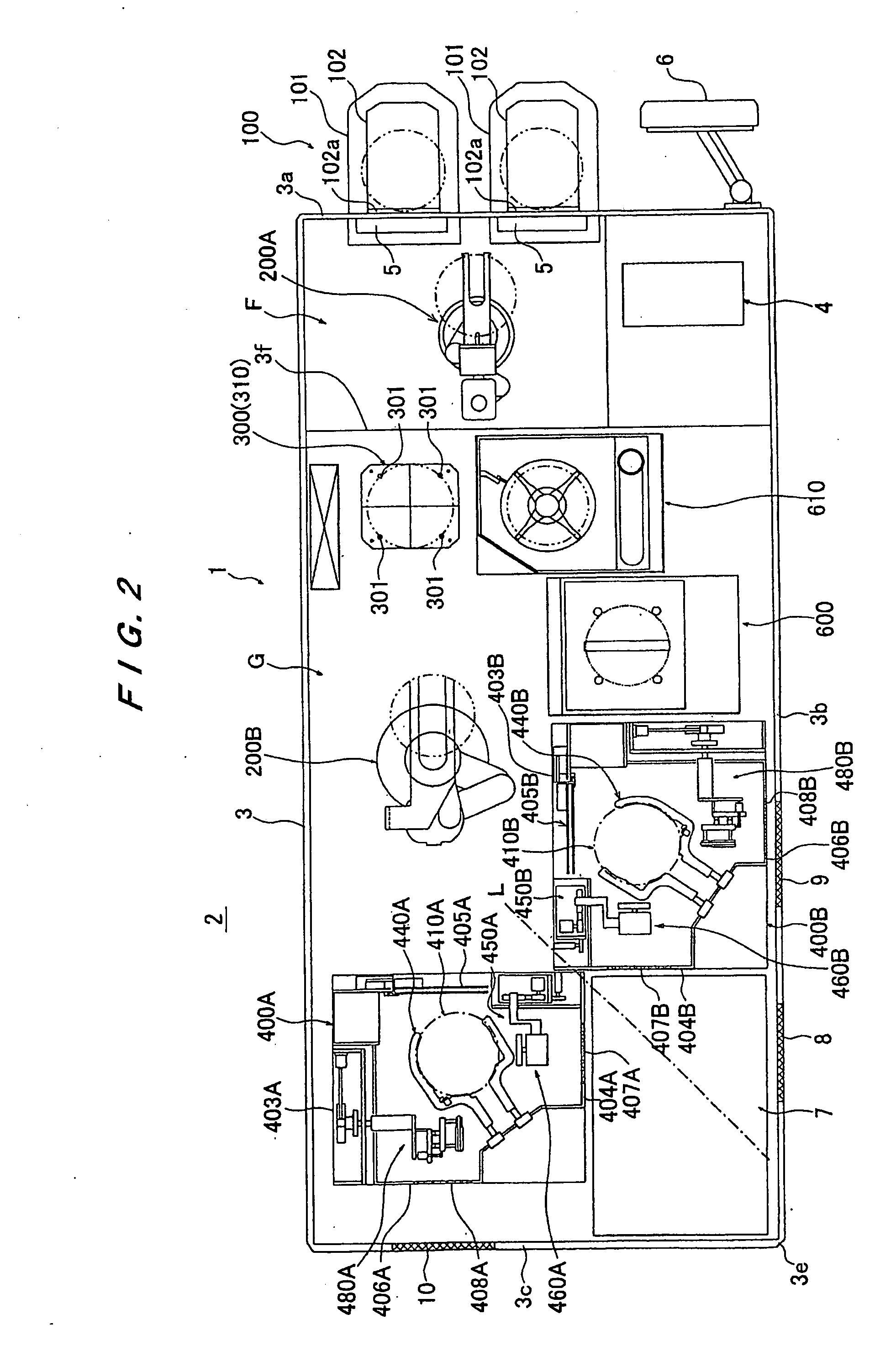

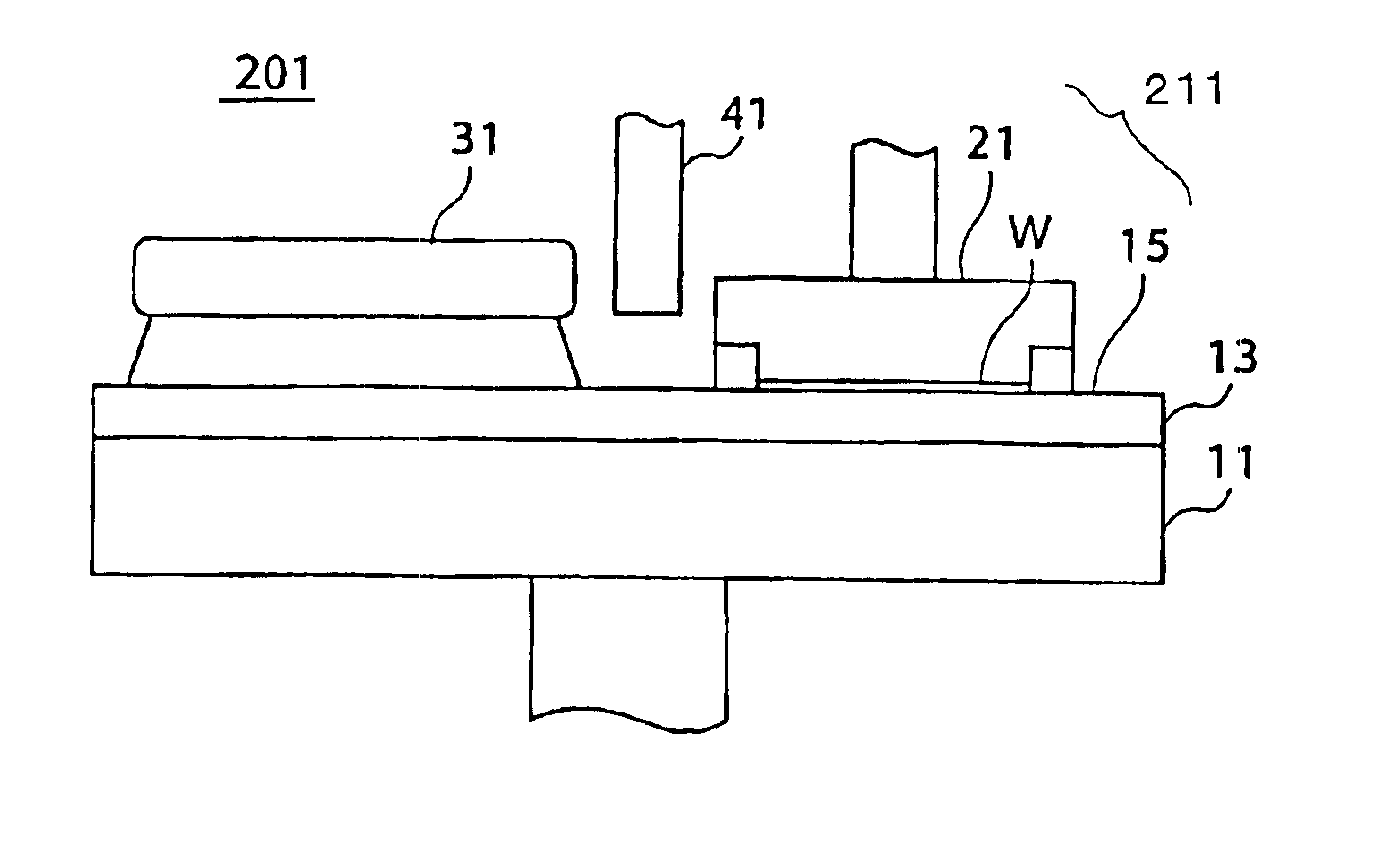

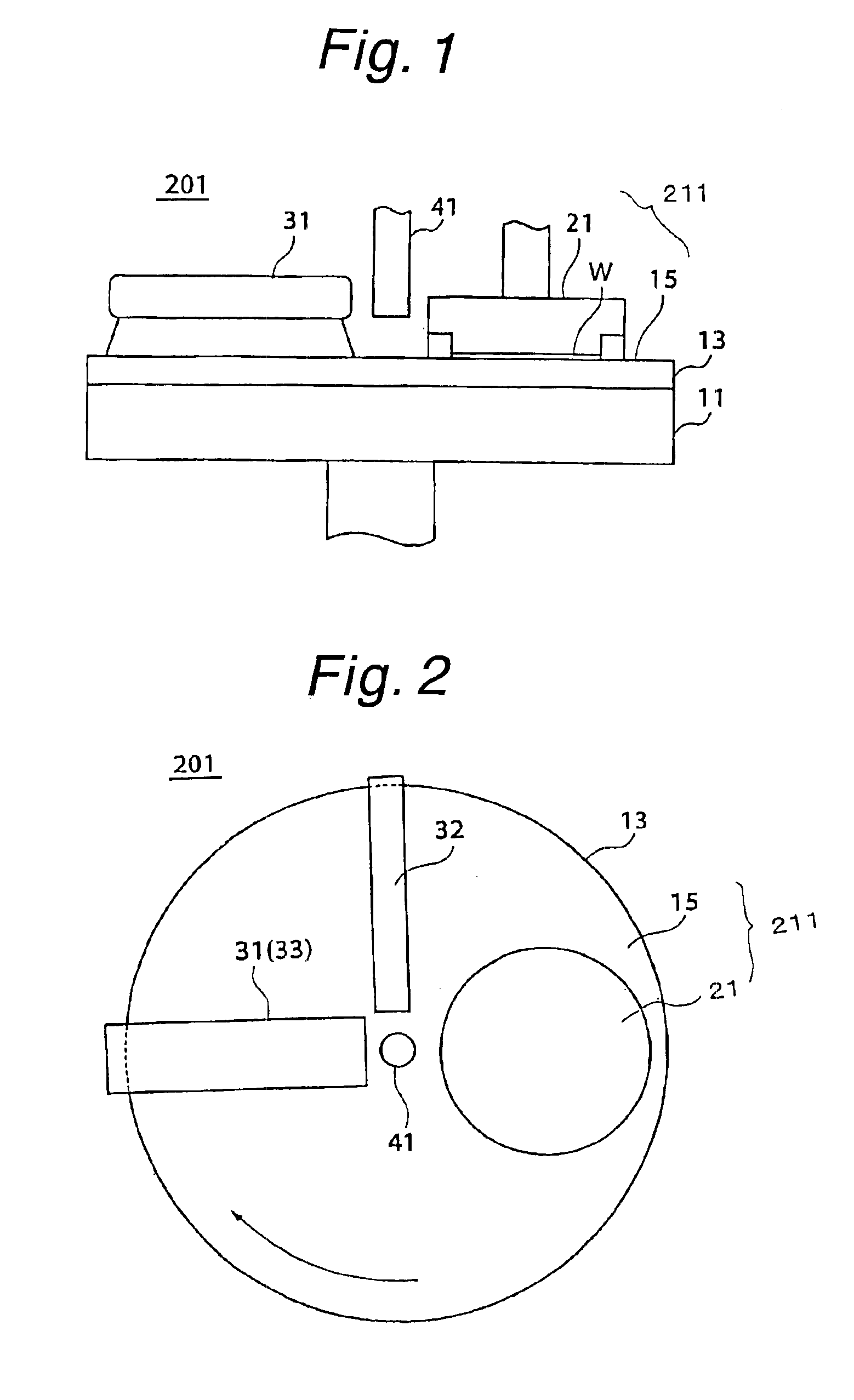

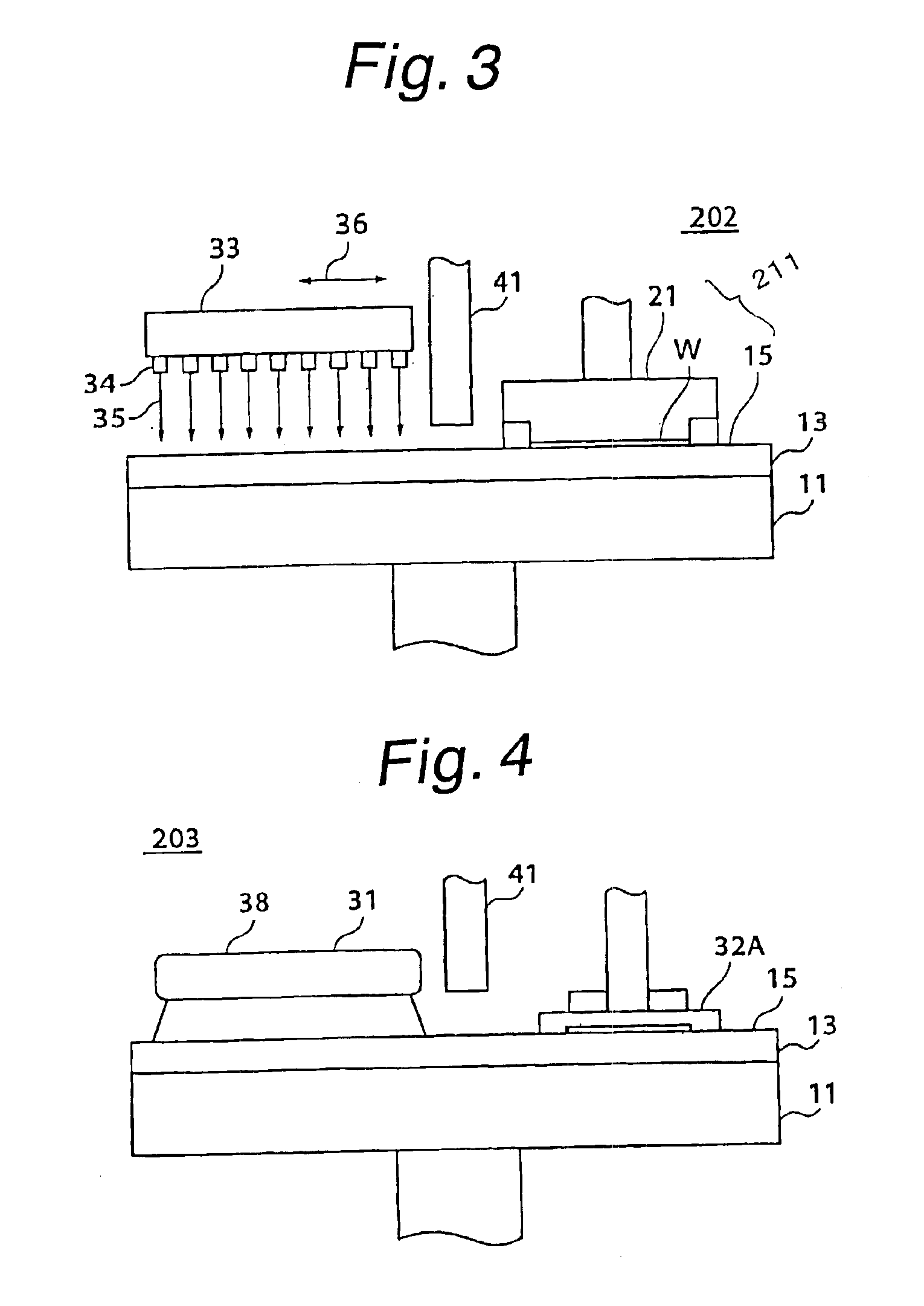

Substrate processing apparatus

InactiveUS20090017733A1Improve processing efficiencyEfficiently conductedEdge grinding machinesPolishing machinesEngineering

A substrate processing apparatus (1) has a first polishing unit (400A) and a second polishing unit (400B) for polishing a peripheral portion of a substrate. Each of the two polishing units (400A, 400B) includes a bevel polishing device (450A, 450B) for polishing a peripheral portion of a substrate and a notch polishing device (480A, 480B) for polishing a notch of a substrate. The substrate processing apparatus (1) has a maintenance space (7) formed between the two polishing units (400A, 400B). The bevel polishing devices (450A, 450B) in the two polishing units (400A, 400B) face the maintenance space (7) so as to be accessible from the maintenance space (7).

Owner:EBARA CORP

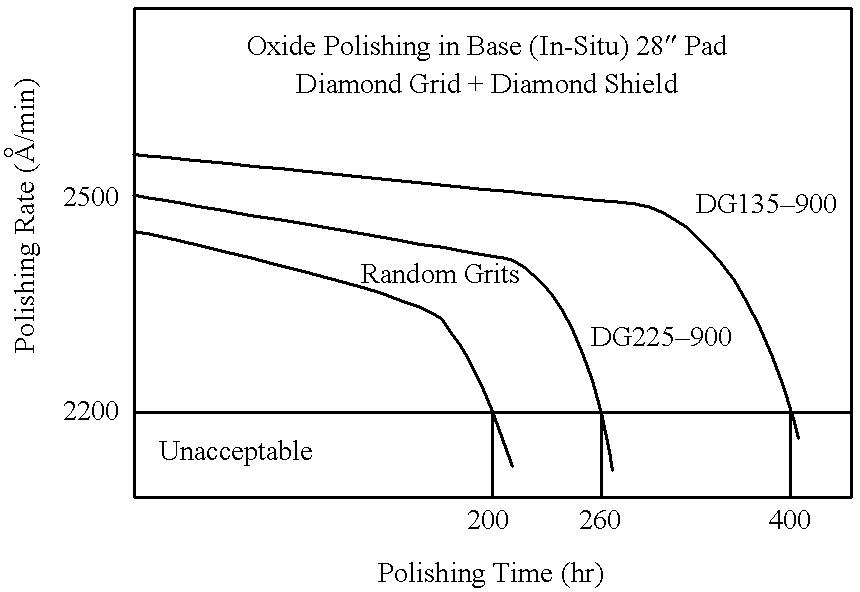

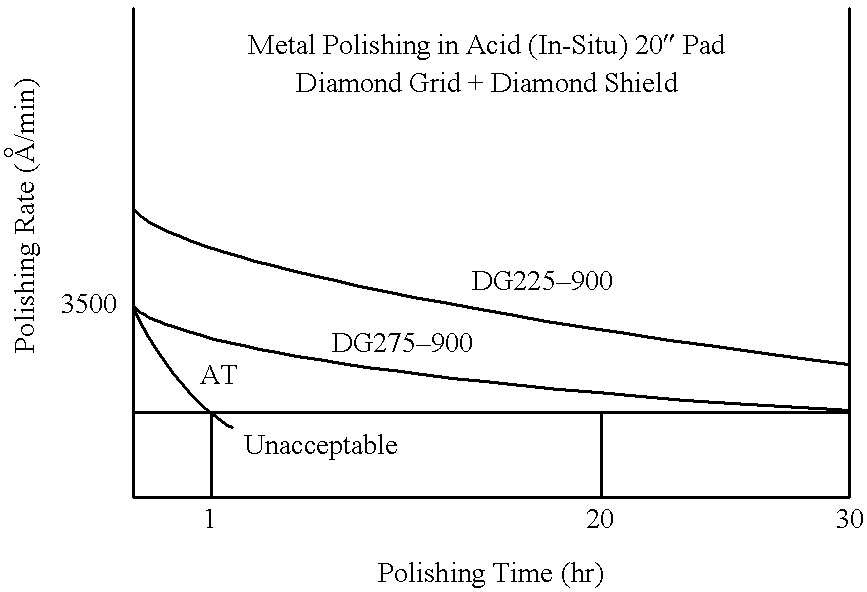

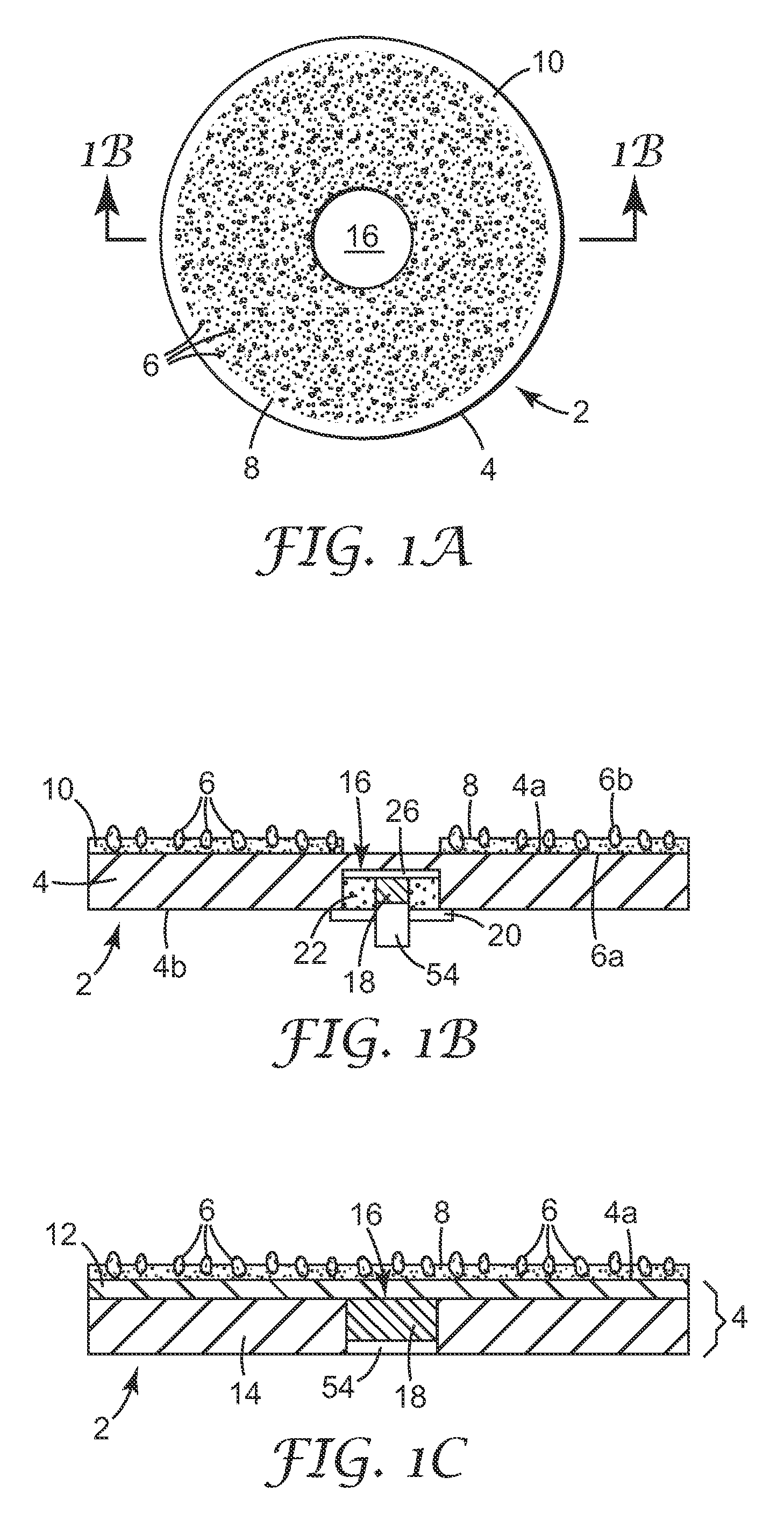

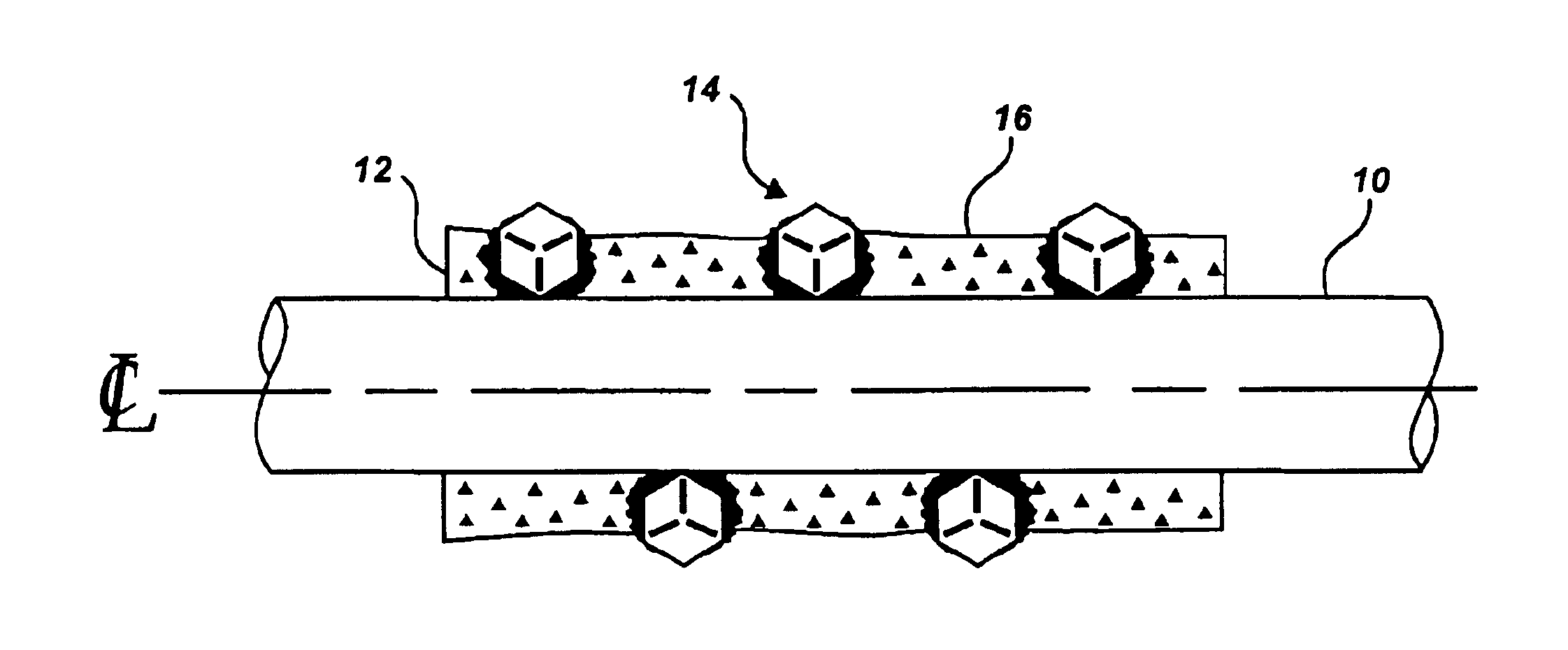

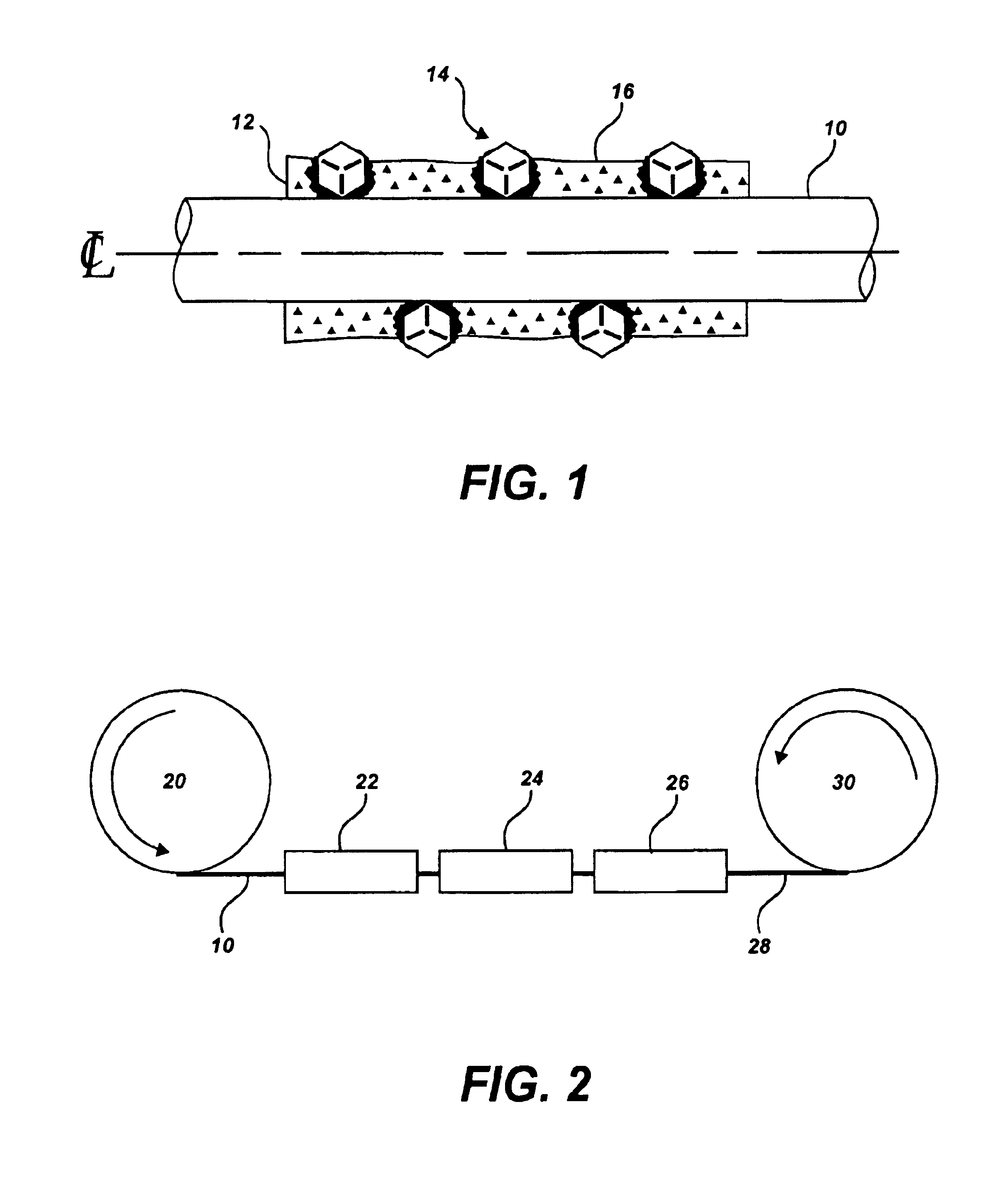

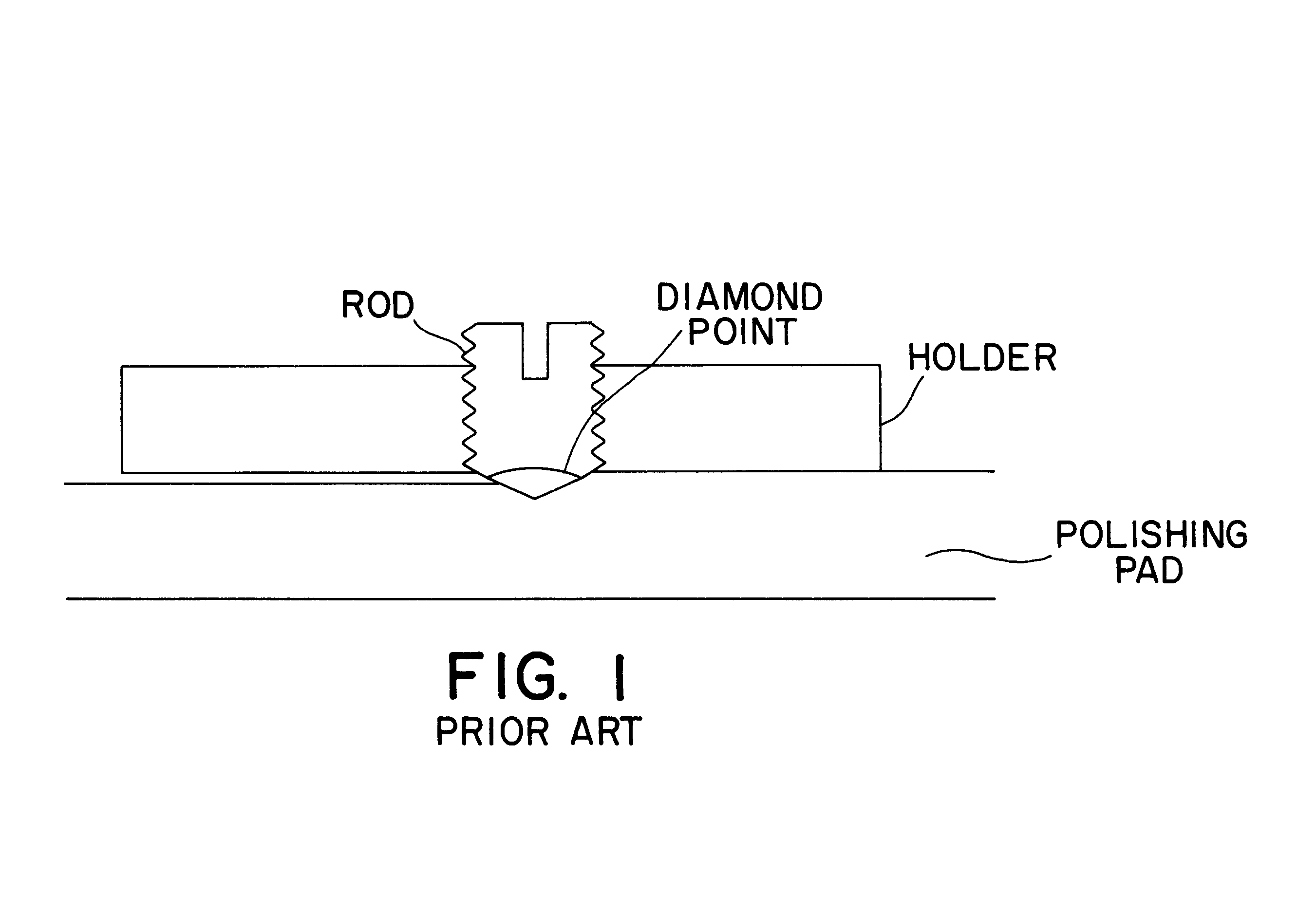

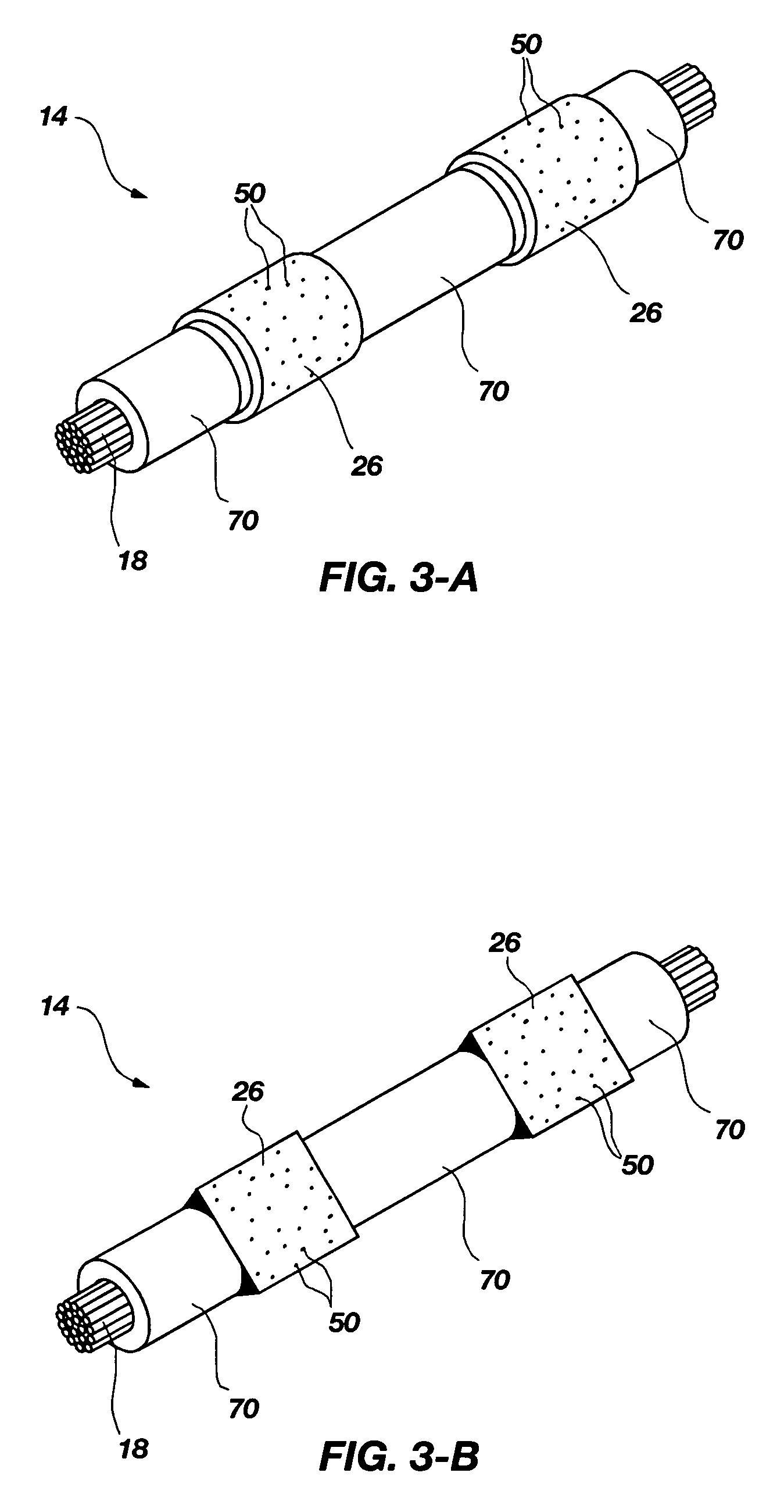

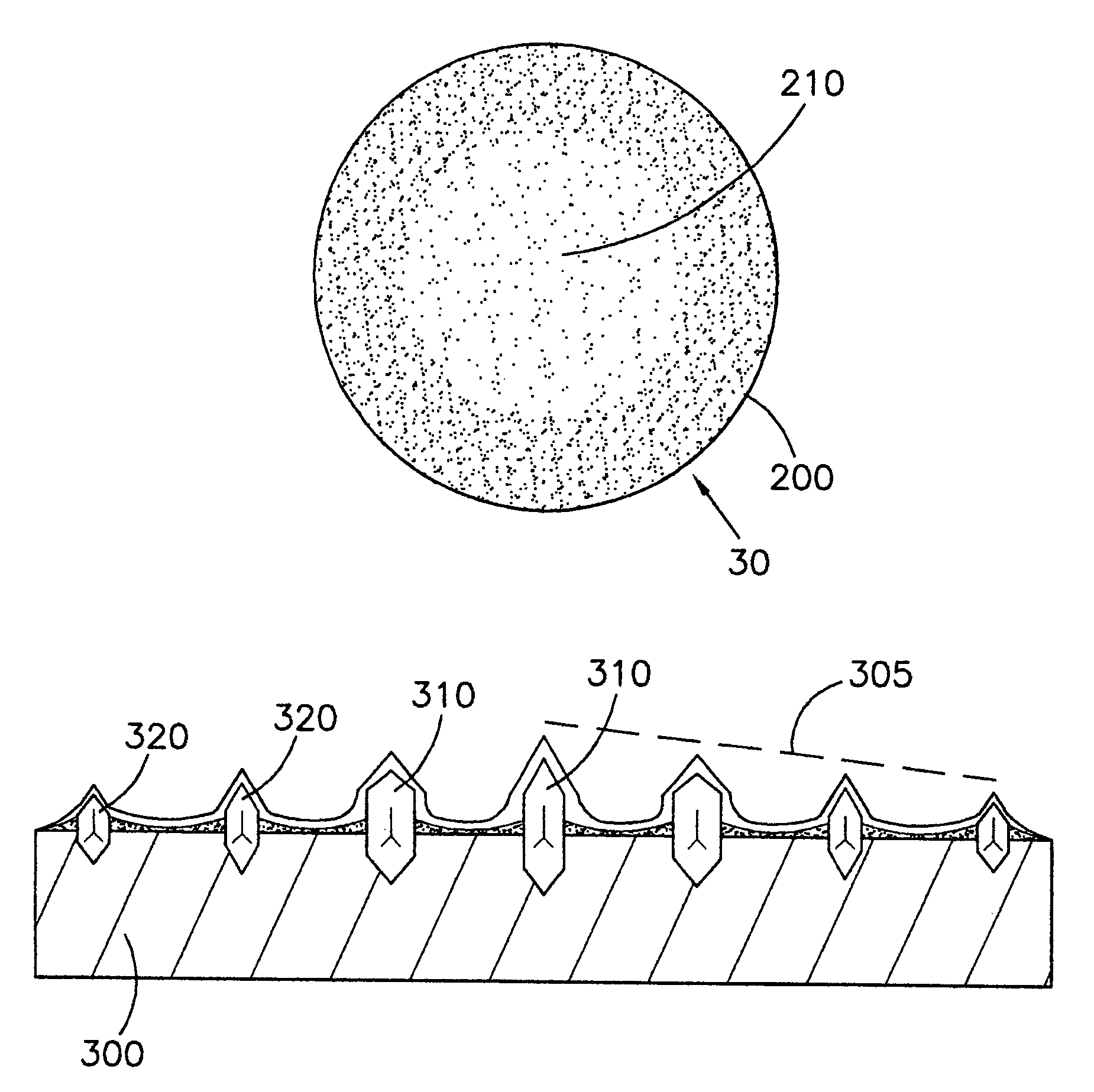

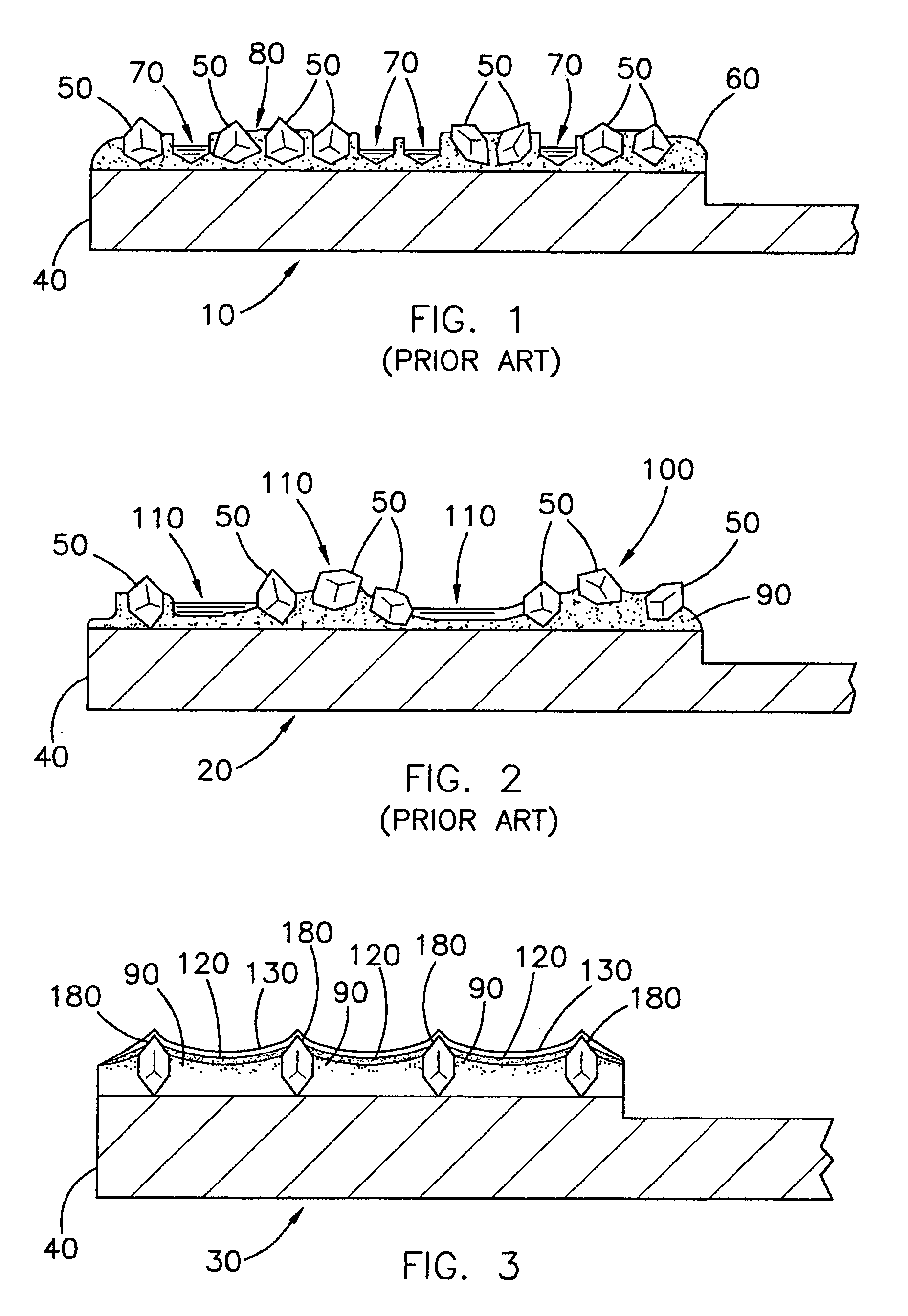

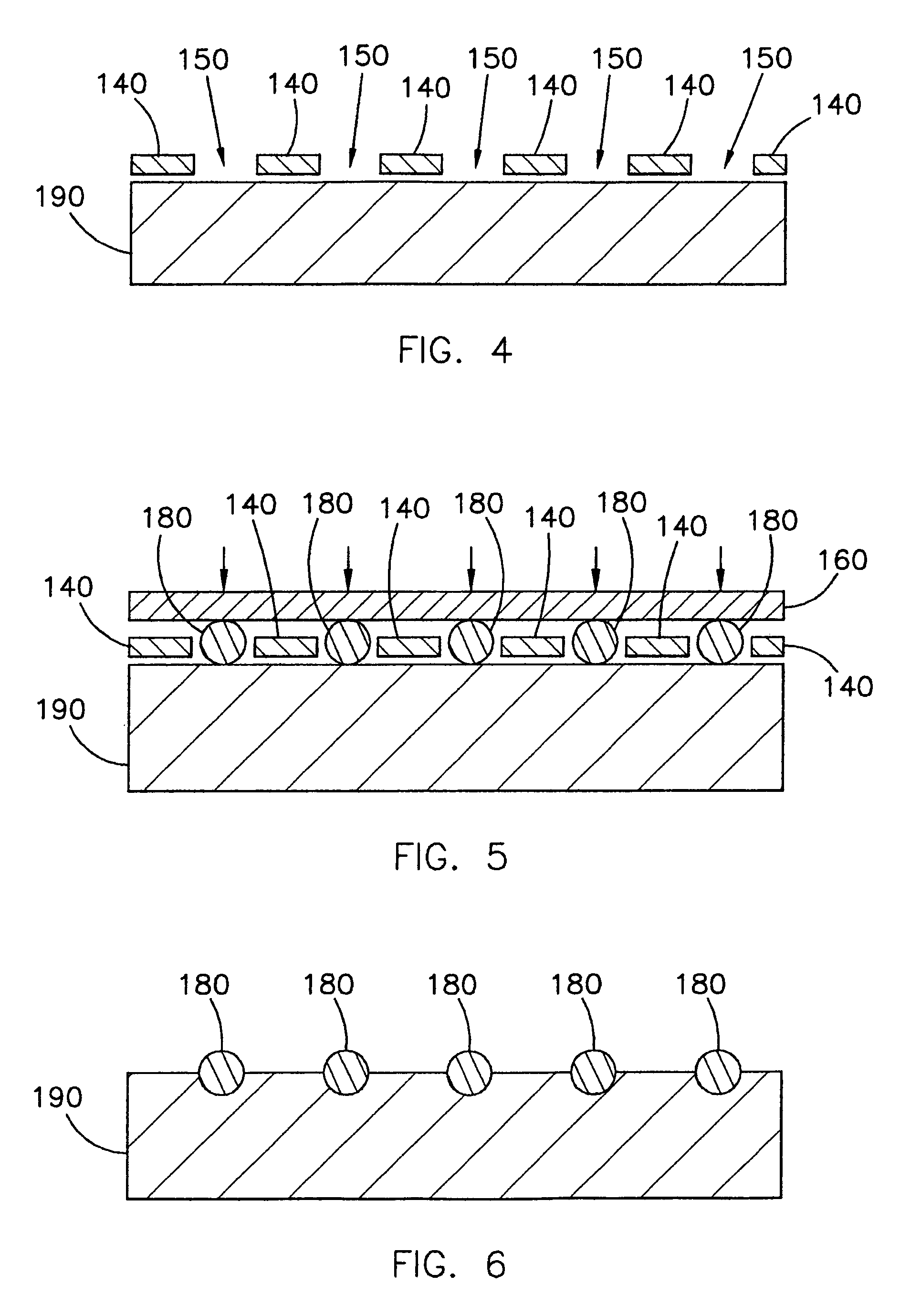

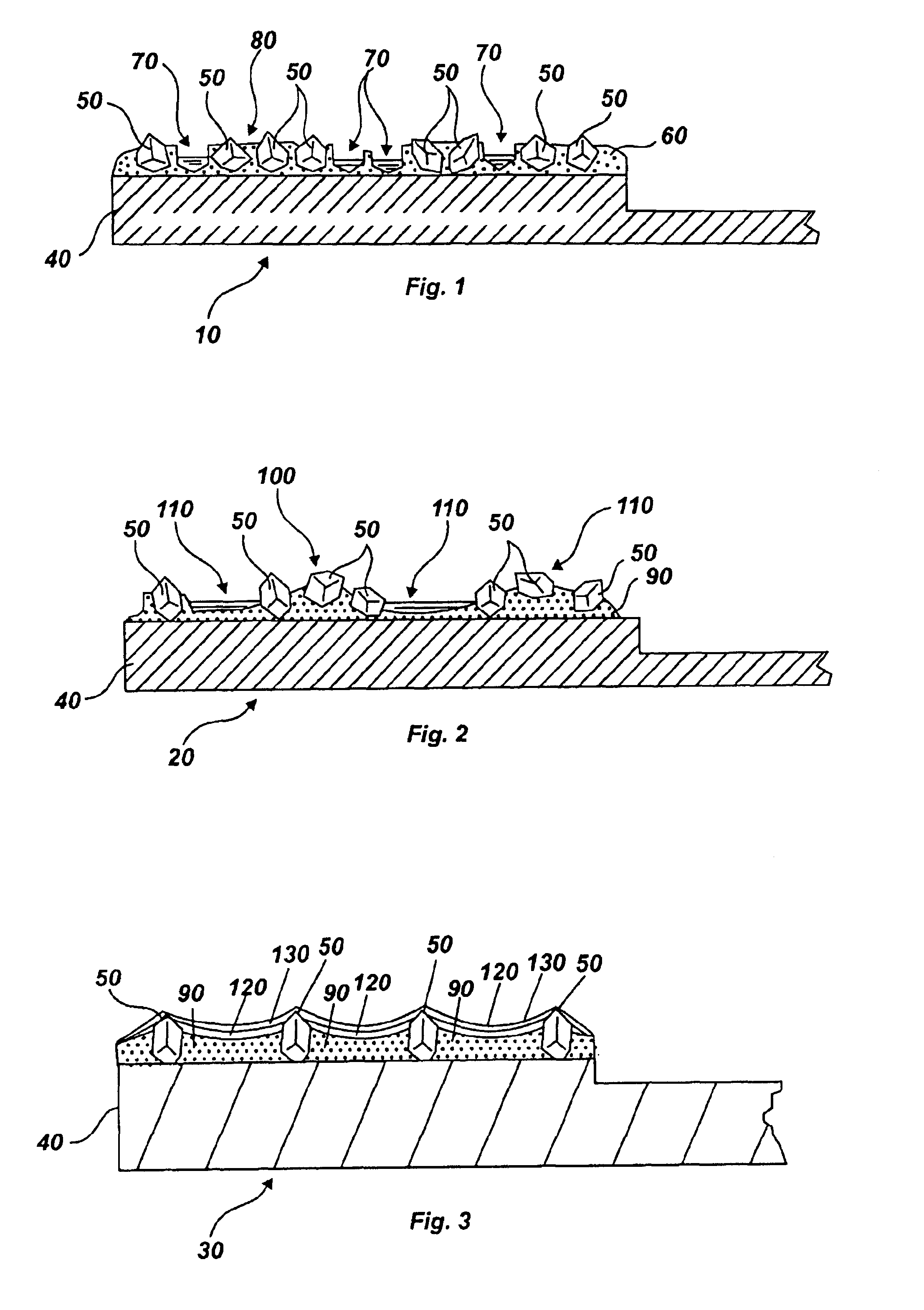

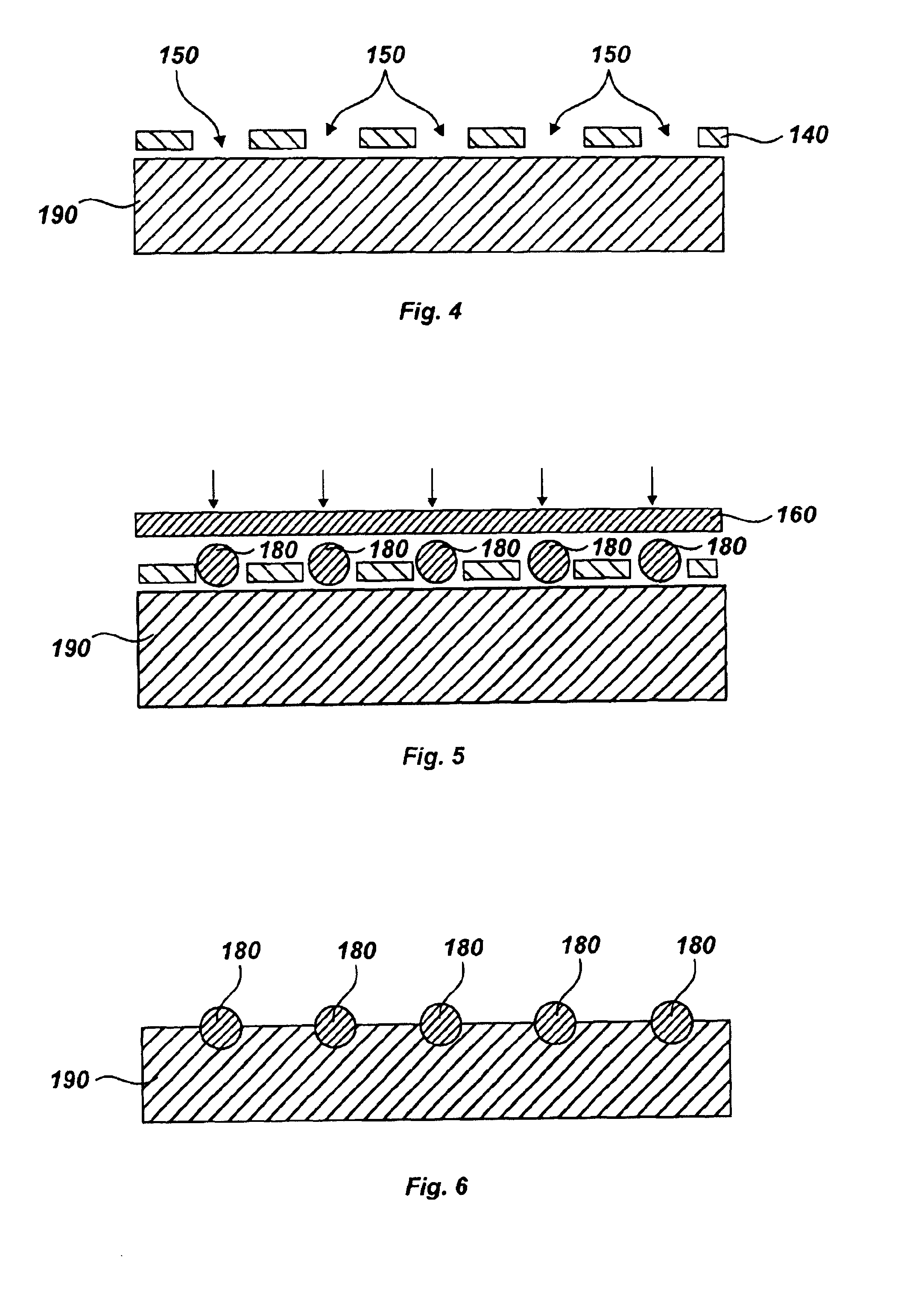

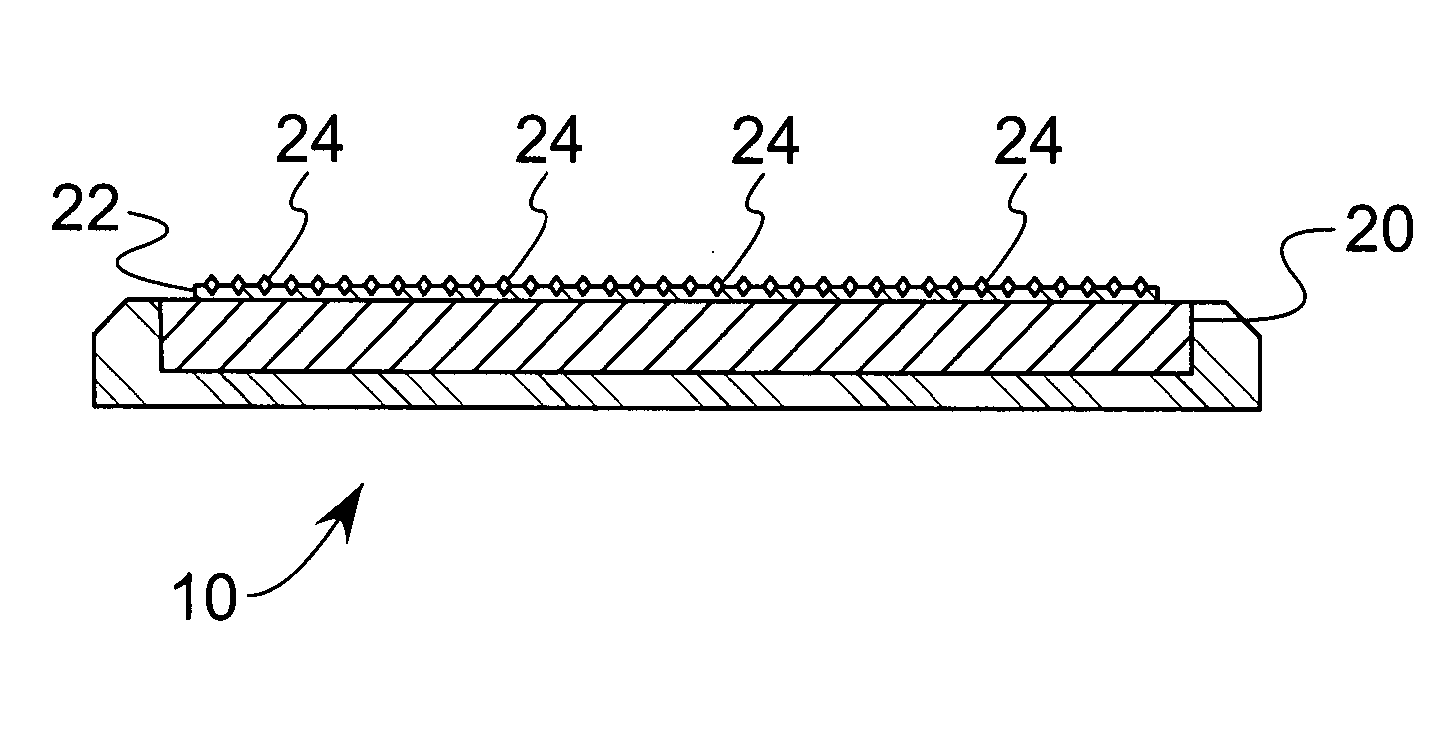

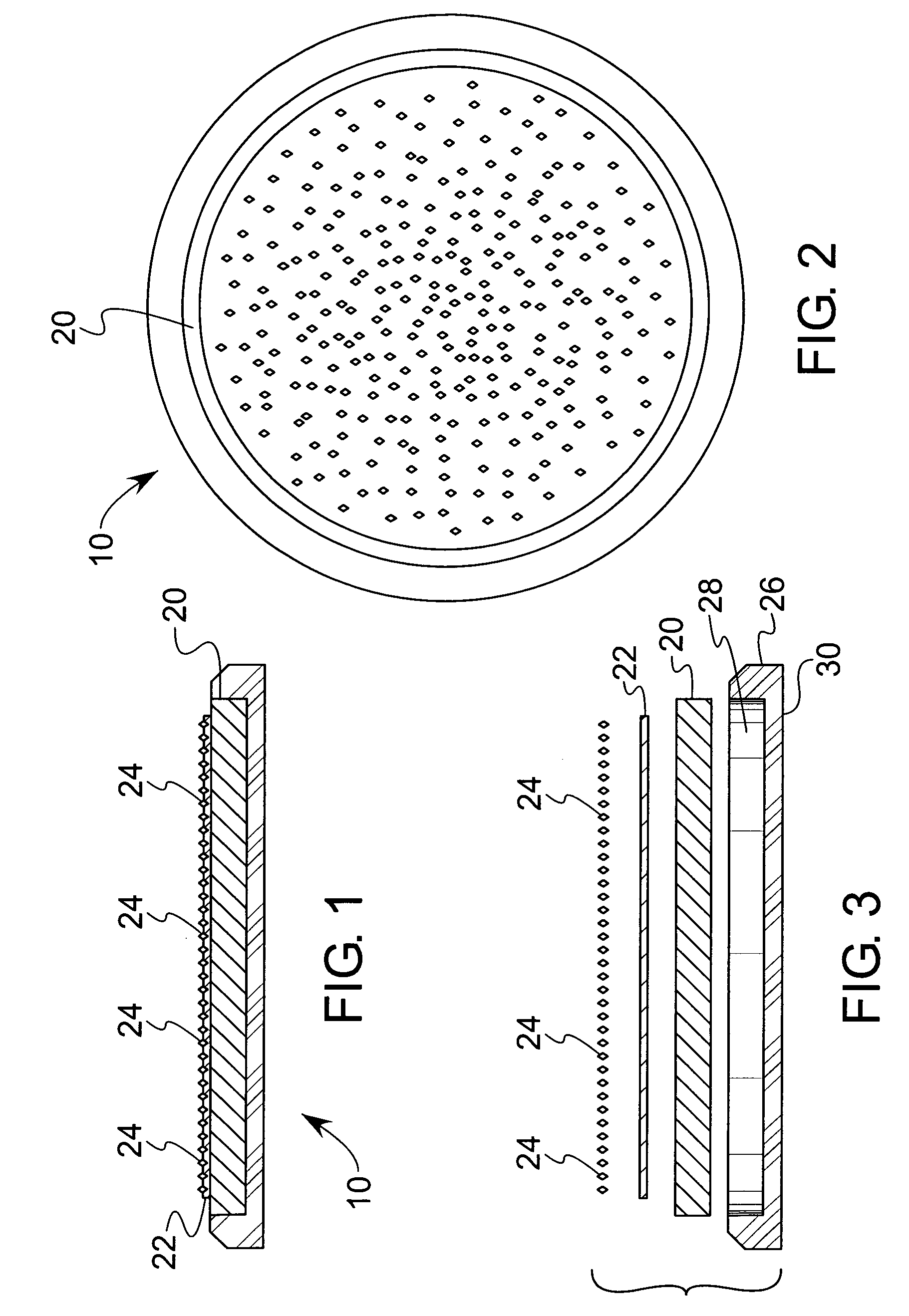

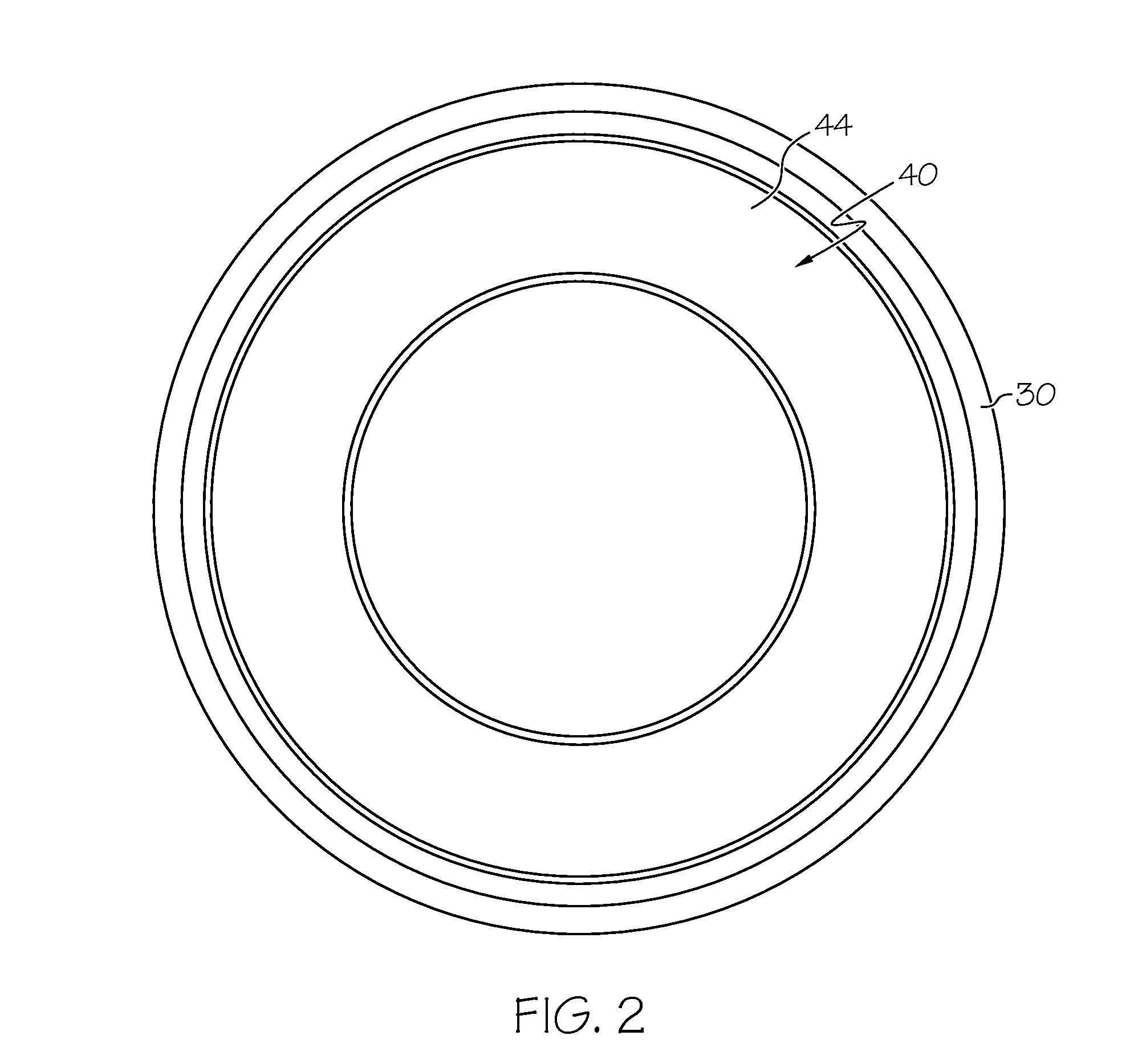

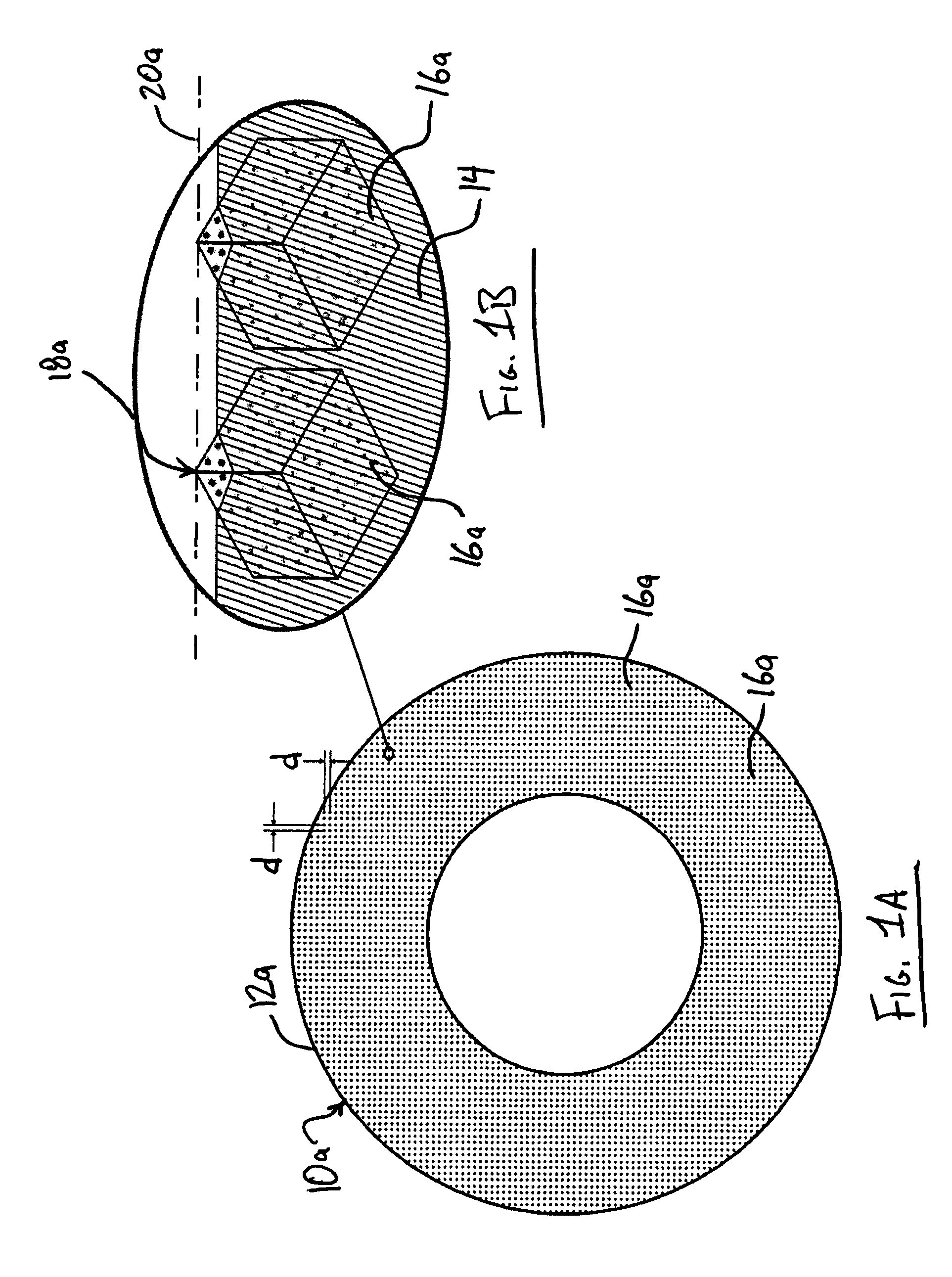

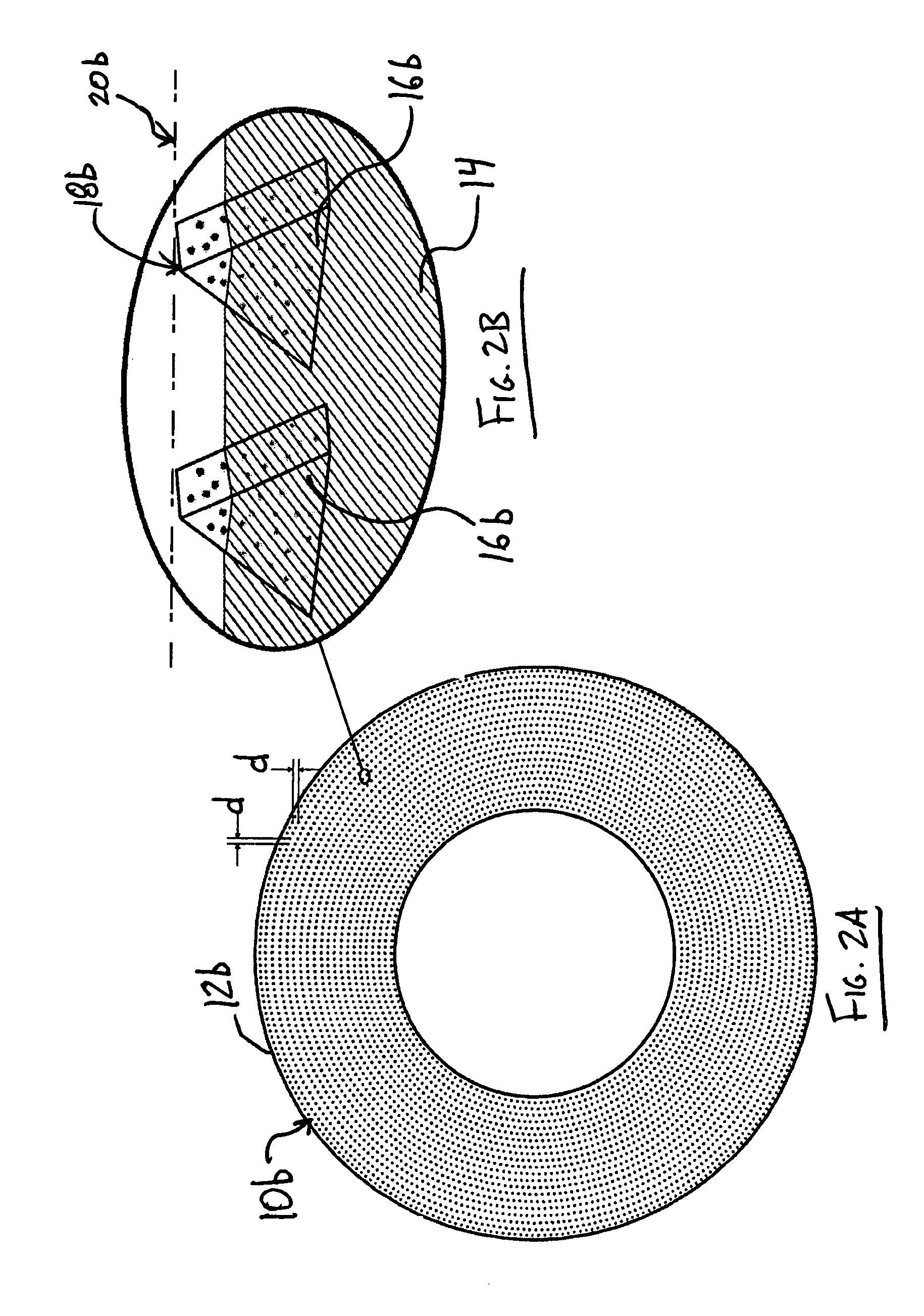

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

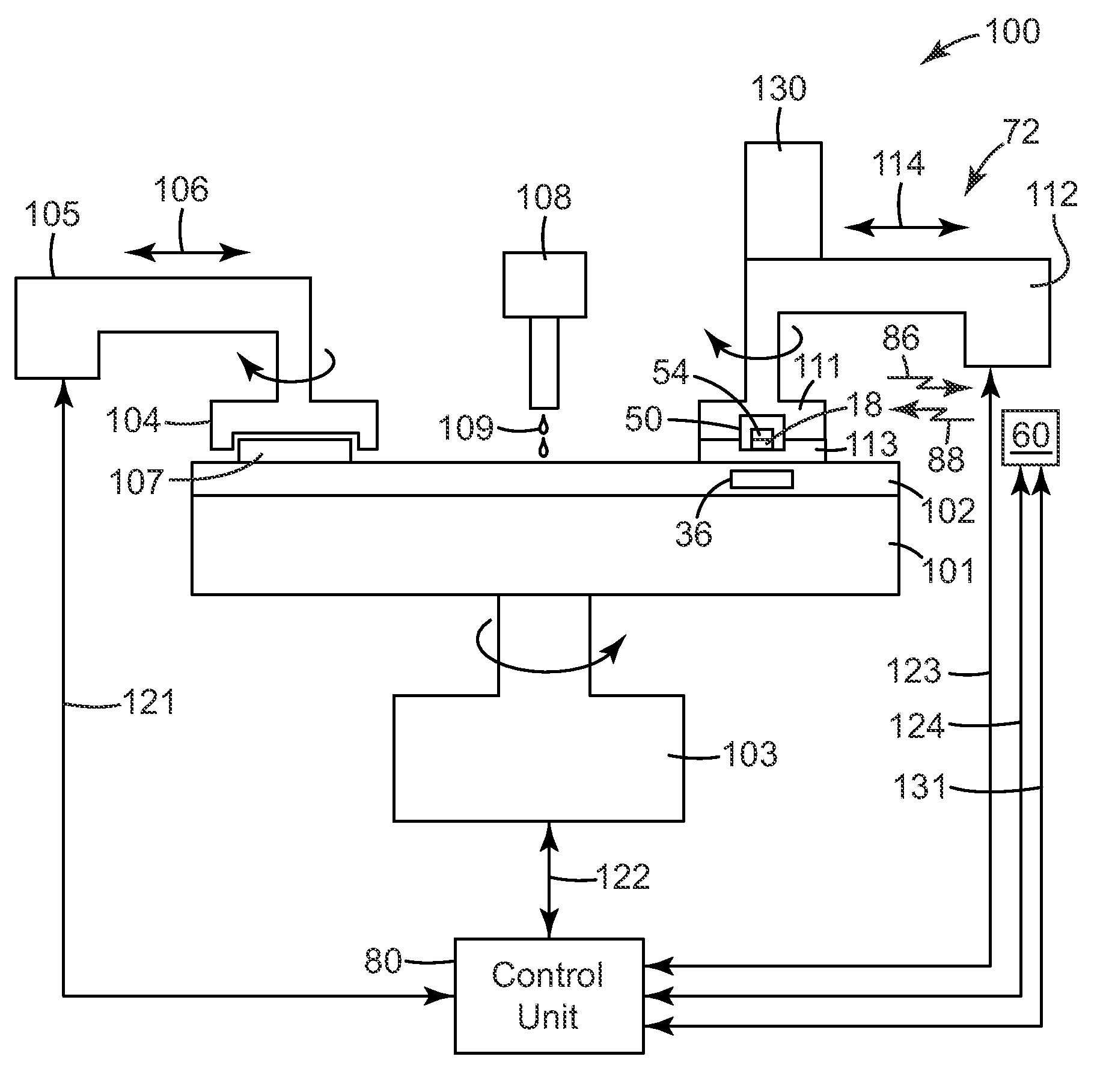

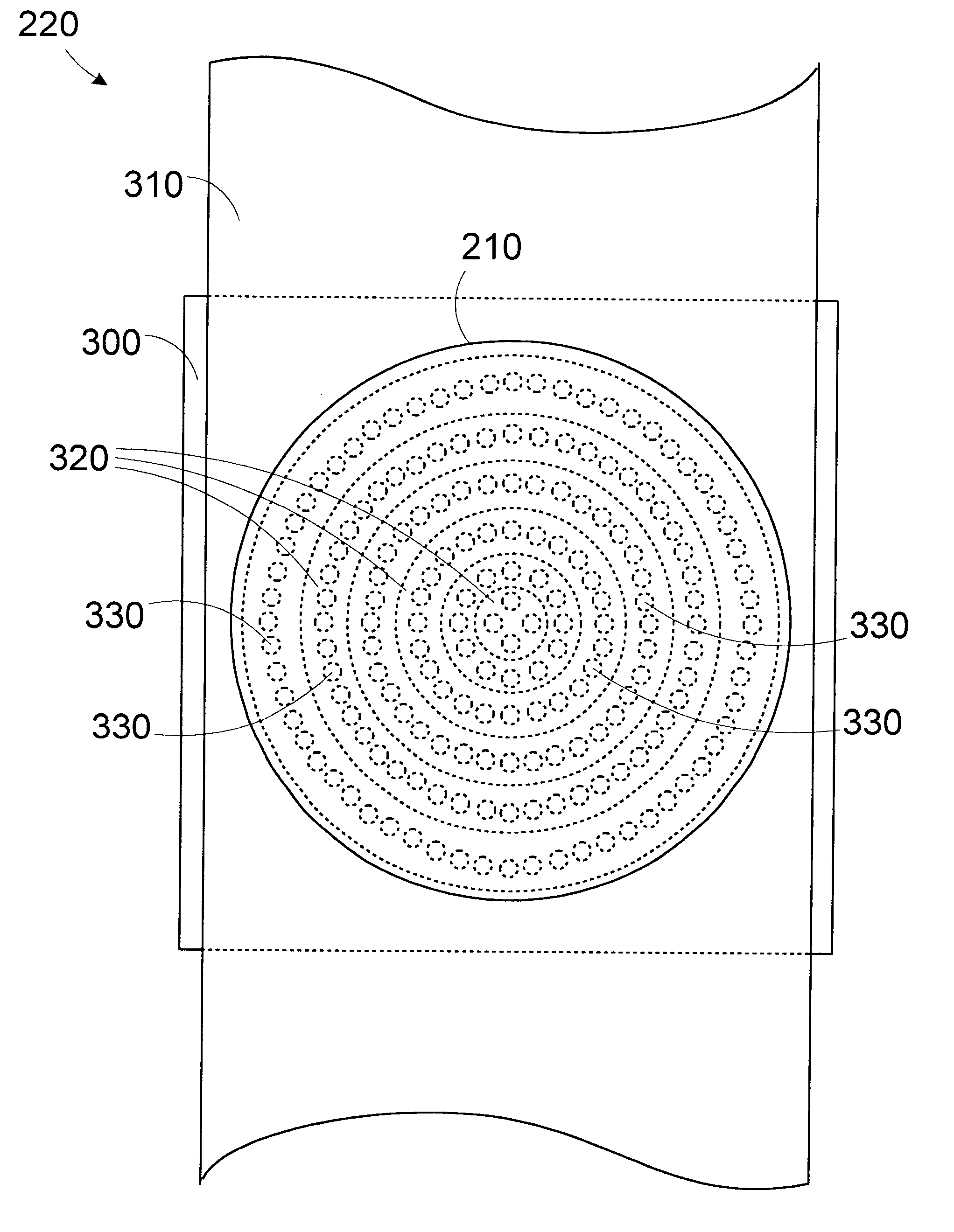

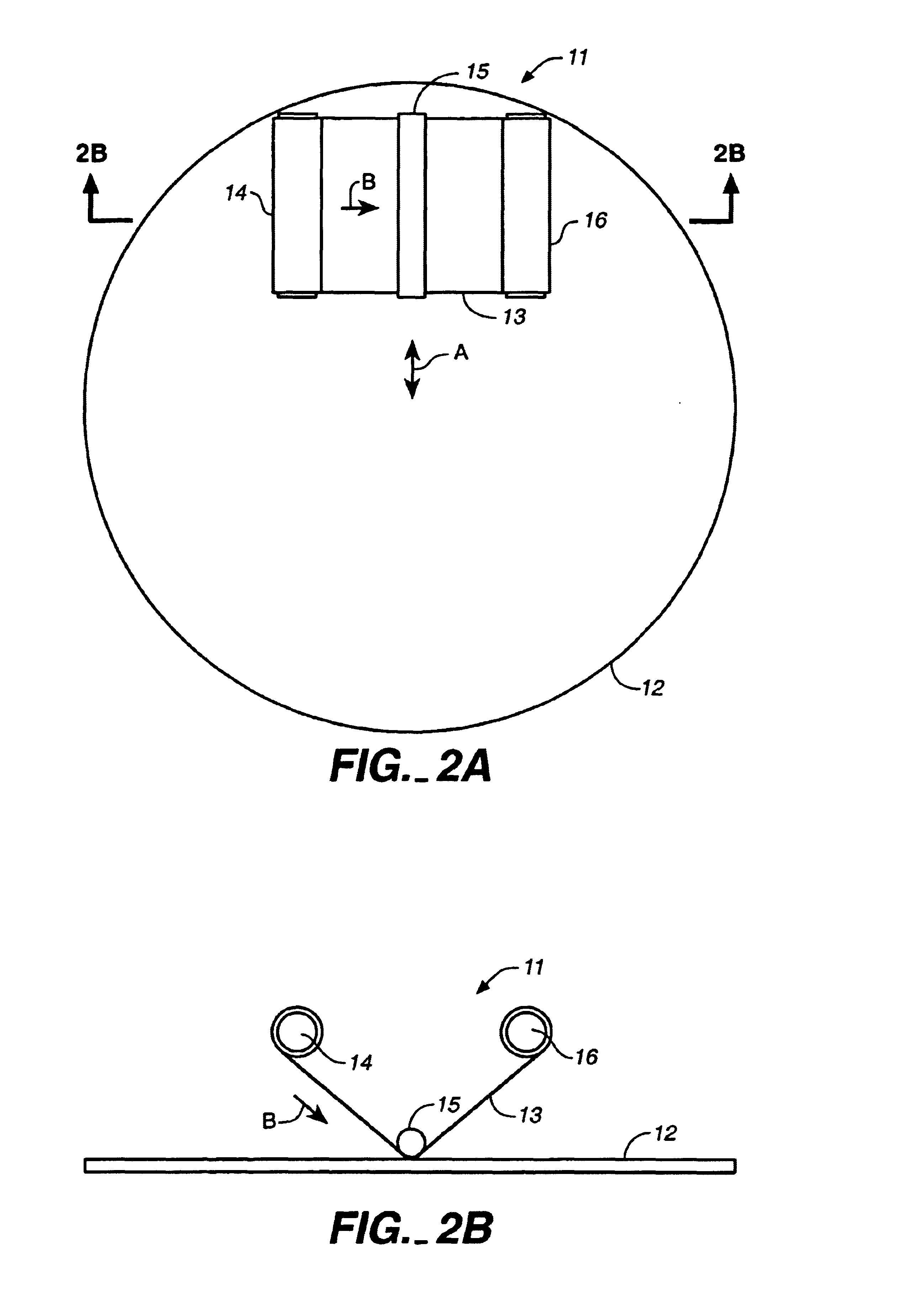

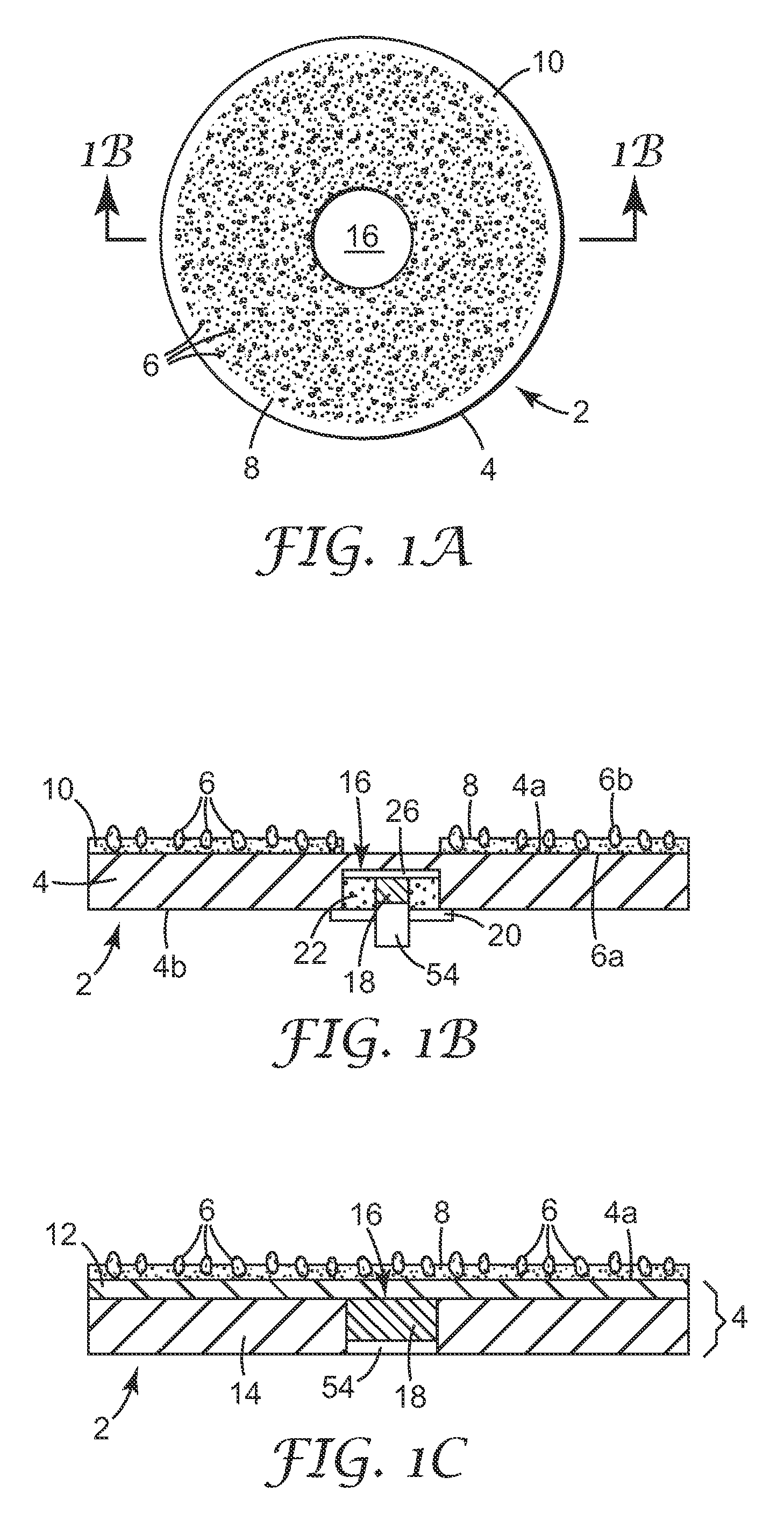

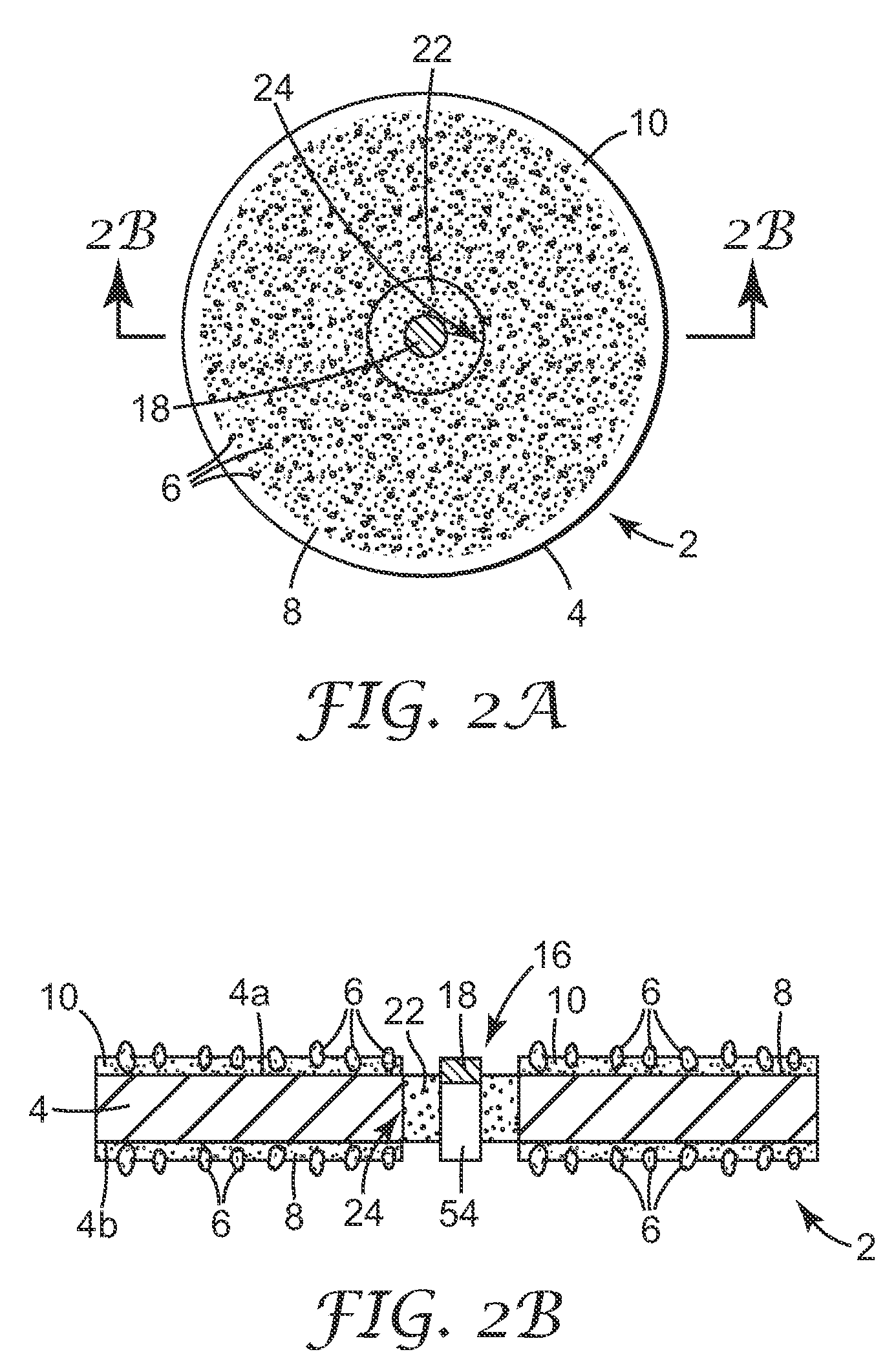

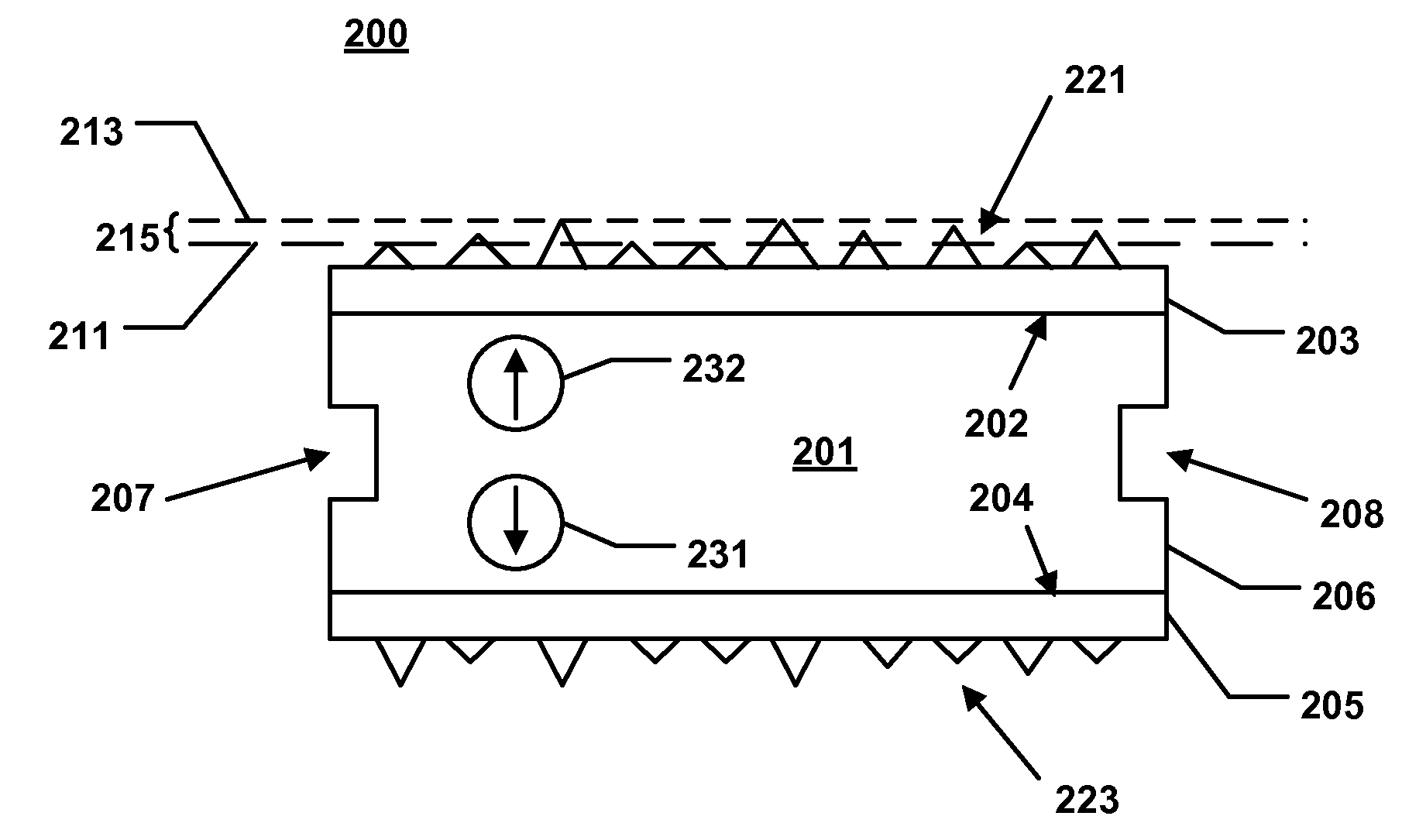

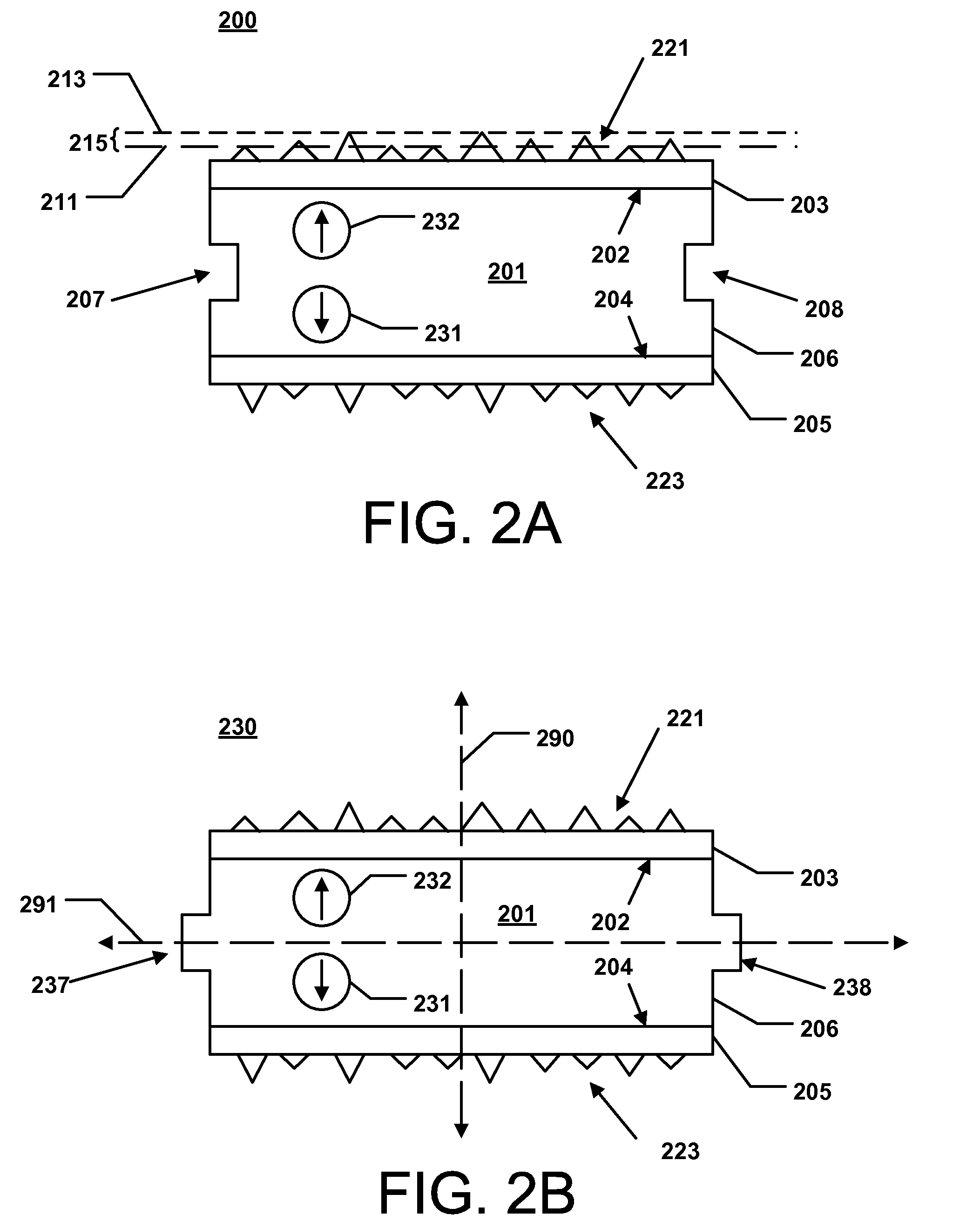

Abrasive Articles, CMP Monitoring System and Method

ActiveUS20080004743A1Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, a means for providing CMP information positioned near the substrate, and a transmitter positioned near the substrate and adapted to transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner having a means for communicating CMP information, a CMP process monitoring system, and a method for conditioning a CMP pad.

Owner:3M INNOVATIVE PROPERTIES CO

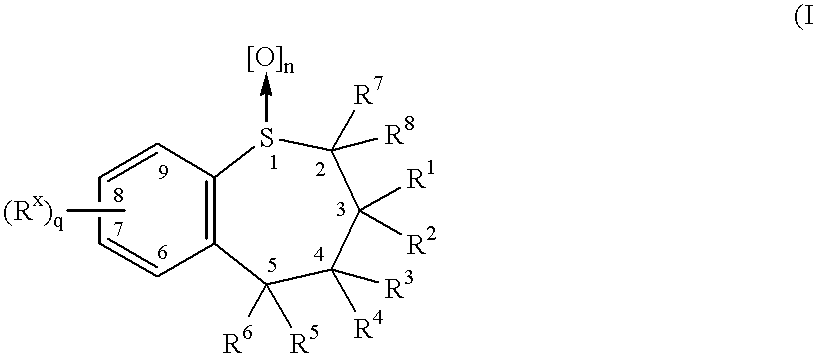

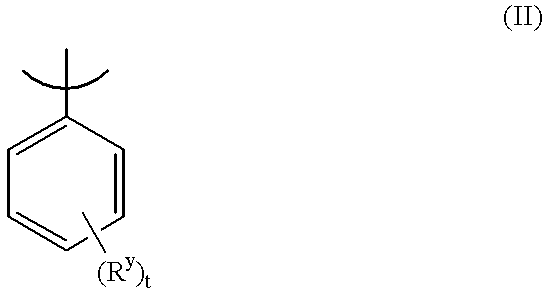

Benzothiepines having activity as inhibitors of ileal bile acid transport and taurocholate uptake

Provided are novel benzothiepines, derivatives, and analogs thereof; pharmaceutical compositions containing them; and methods of using these compounds and compositions in medicine, particularly in the prophylaxis and treatment of hyperlipidemic conditions such as those associated with atherosclerosis or hypercholesterolemia, in mammals.

Owner:GD SEARLE & CO

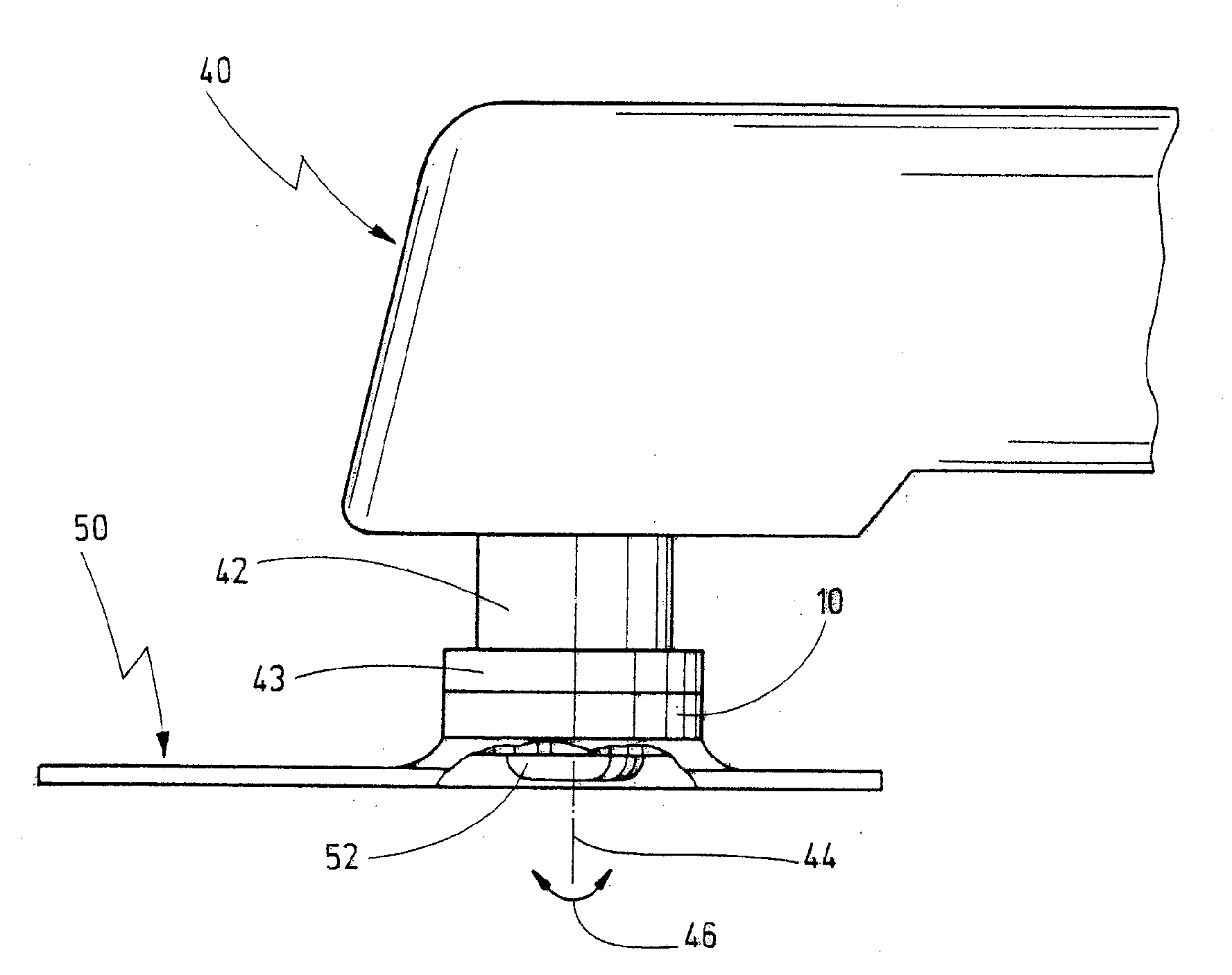

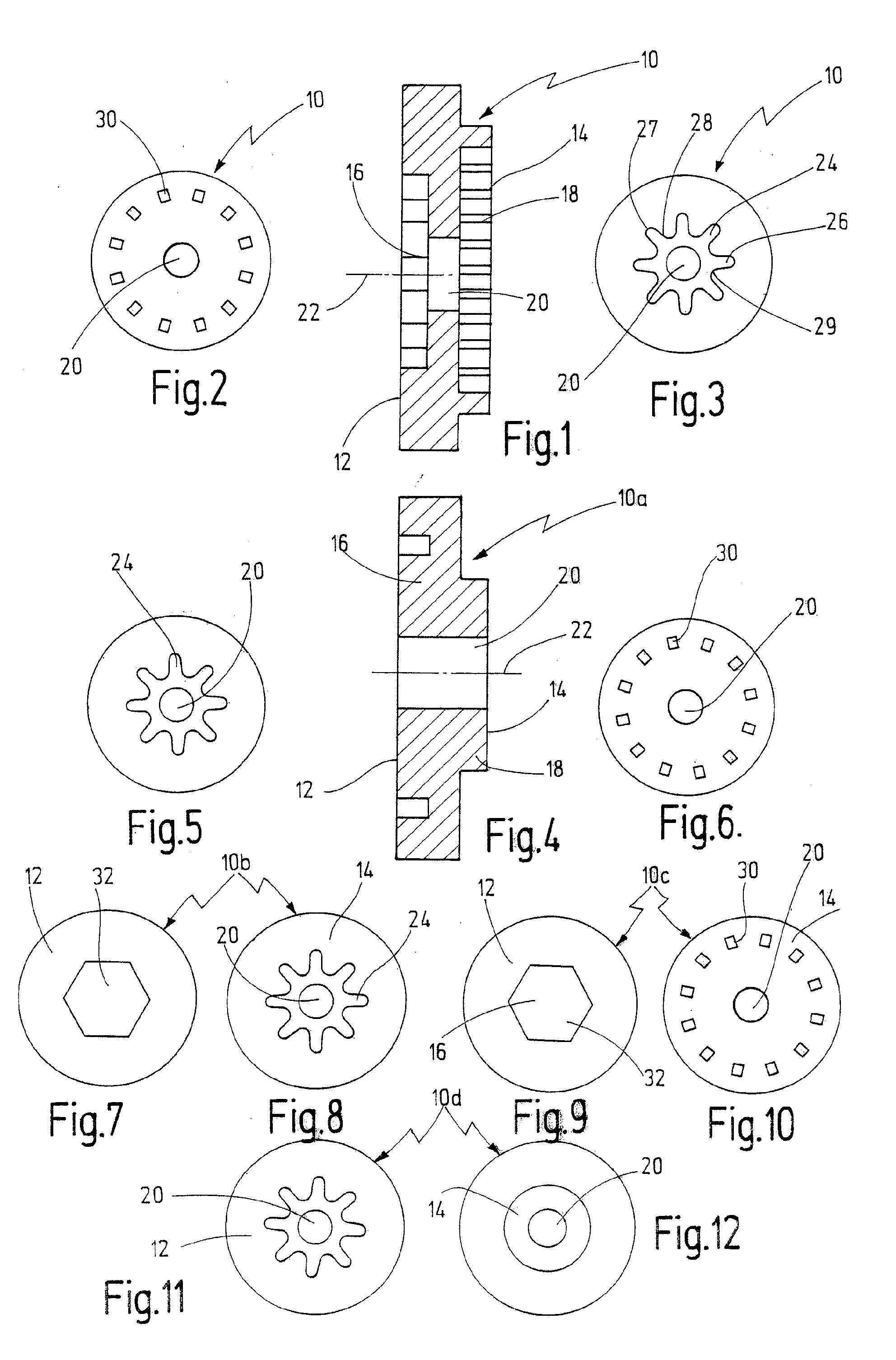

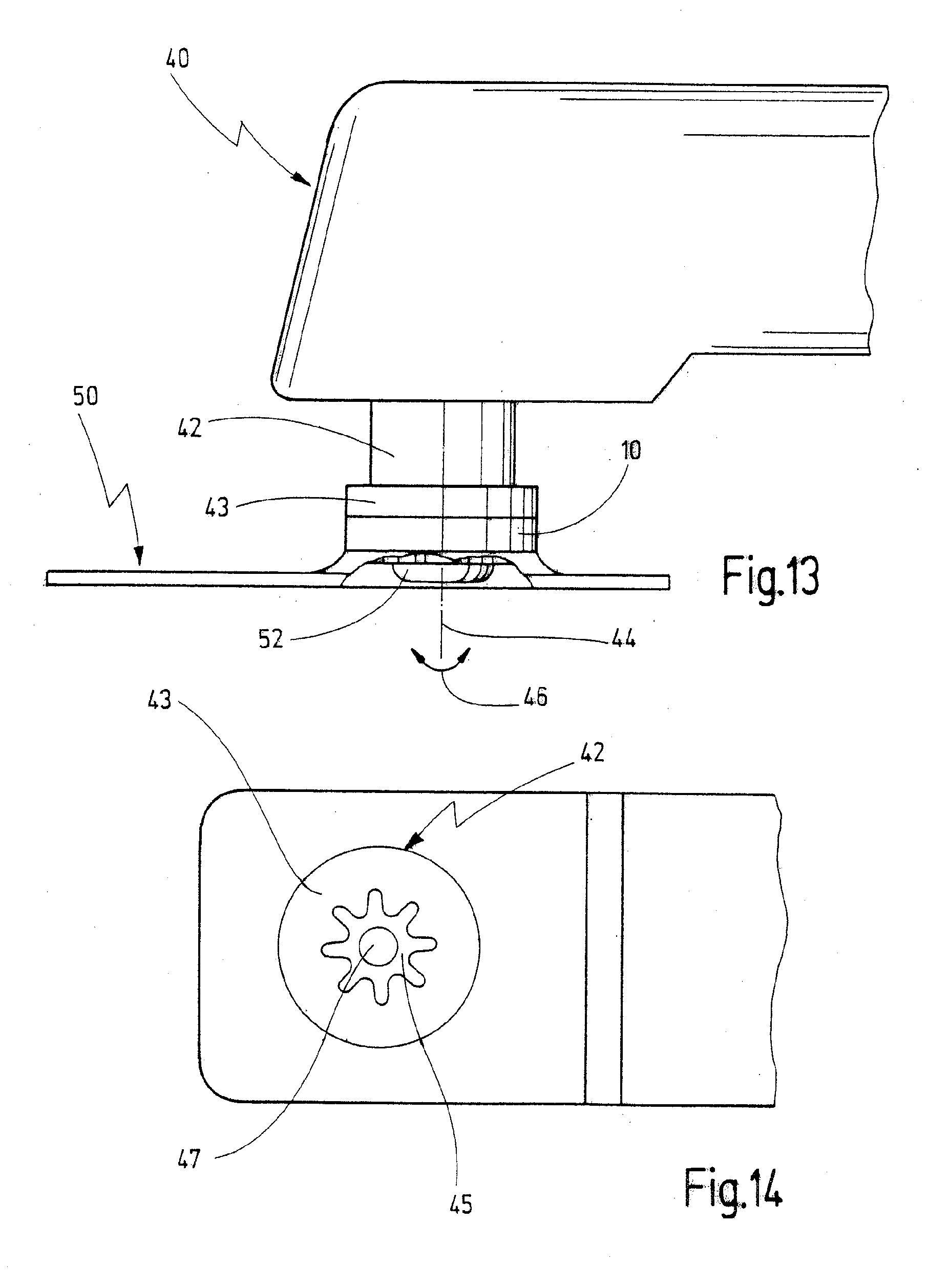

Adapter For Mounting A Tool On An Oscillating Drive

ActiveUS20100056029A1Reduce tool typesLow costGrinding wheel securing apparatusGrinding drivesMating connectionDrive shaft

An adapter is disclosed for mounting a tool on an oscillating drive having a drive shaft that can be driven to oscillate about its longitudinal axis, wherein the adapter is passed by a central opening, and has at its drive end at least one positive-locking element for positive connection with the tool, the positive-locking element having the shape of a regular polygon, or a plurality of positive-locking elements arranged on a circle concentric to the center axis, or a plurality of outwardly extending convex projections having rounded tips and being connected with neighboring projections via rounded concave lateral flanks, wherein the positive-locking elements on the drive end are configured for positive-locking connection with a matching positive-locking counter-element on the drive shaft, and wherein the adapter has a second receptacle on its tool end for effecting connection with a tool having a shape different from the first receptacle and being configured as a circle, or as a plurality of positive-locking elements arranged along a circle concentric to the center axis, or as plurality of outwardly extending convex projections with rounded tips and being connected with neighboring projections via rounded concave lateral flanks.

Owner:C & E FEIN GMBH & CO KG

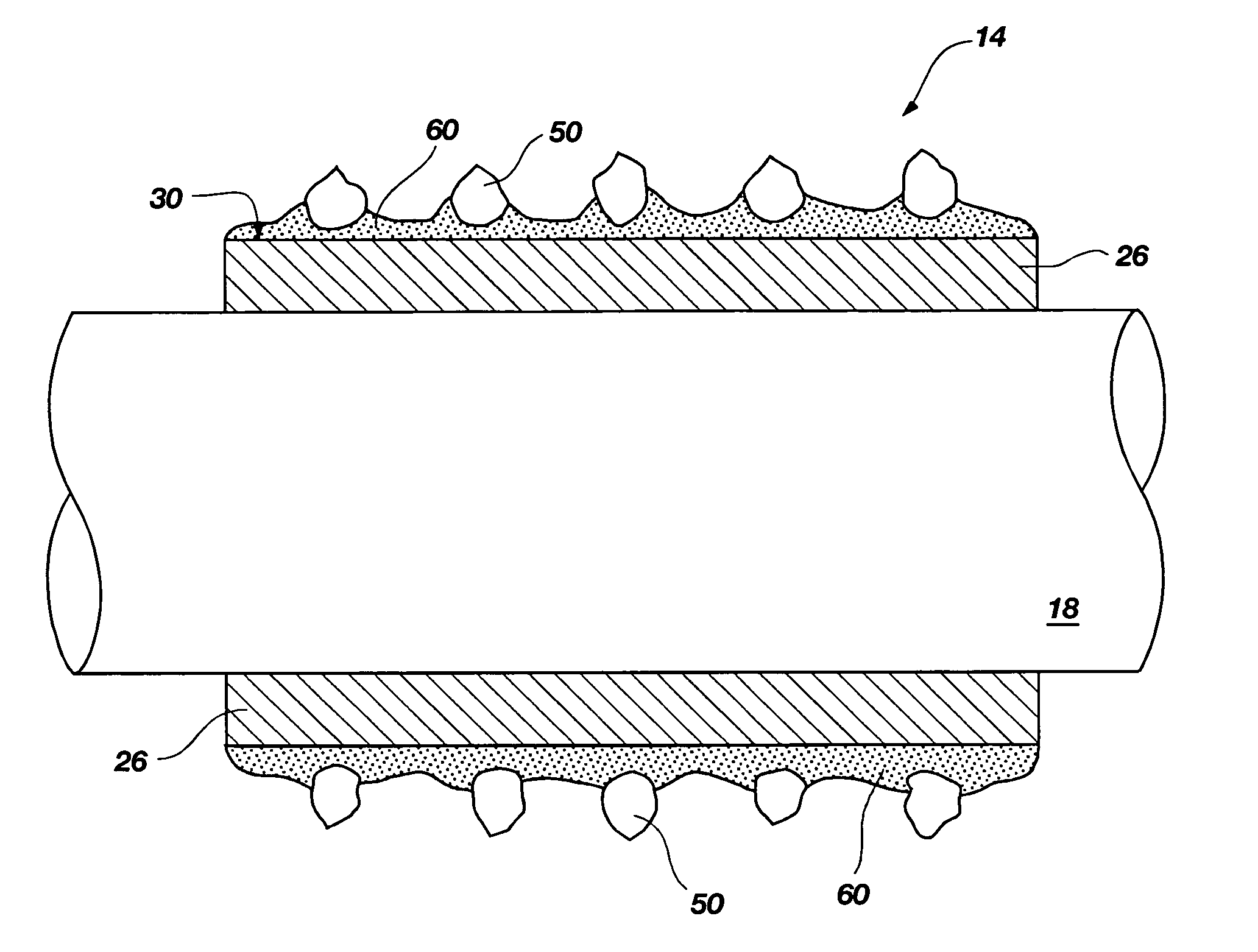

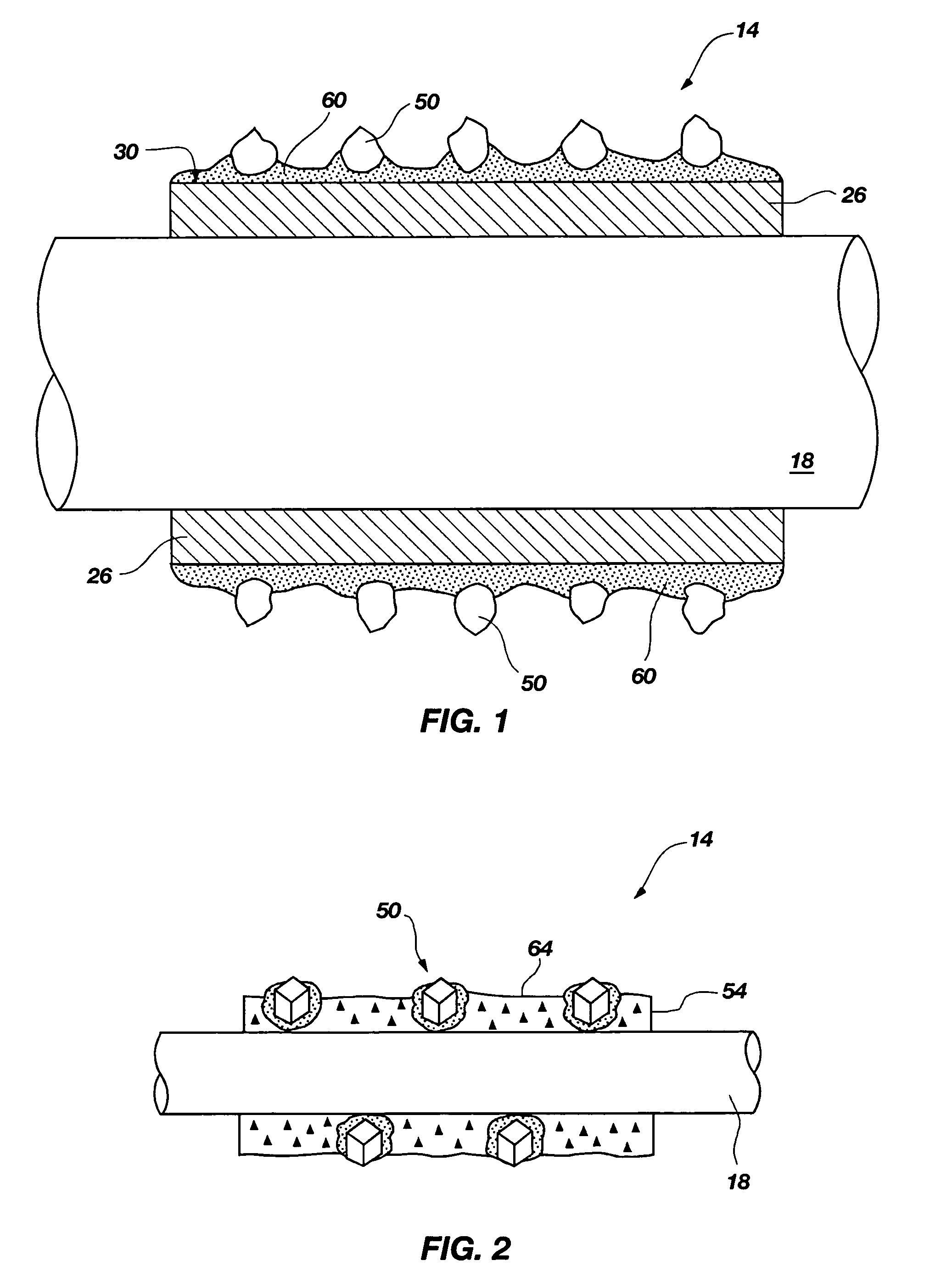

Superabrasive wire saw and associated methods of manufacture

InactiveUS6915796B2Improving particle retentionHigh material removal ratePigmenting treatmentOther chemical processesWire rodAlloy

A superabrasive wire saw having a plurality of individual coated superabrasive particles attached to a wire with an organic binder is disclosed and described. The superabrasive particle can be coated with a solidified coating of a molten braze alloy that is chemically bonded to the superabrasive particle. The organic binder can optionally contain filler materials and / or an organometallic coupling agent to improve the retention of coated superabrasive particles. The resulting superabrasive wire saws can be produced having diameters of less than 0.5 mm which significantly reduce kerf loss. Various methods for making and using such a superabrasive wire saw are additionally disclosed and described.

Owner:SUNG CHIEN MIN

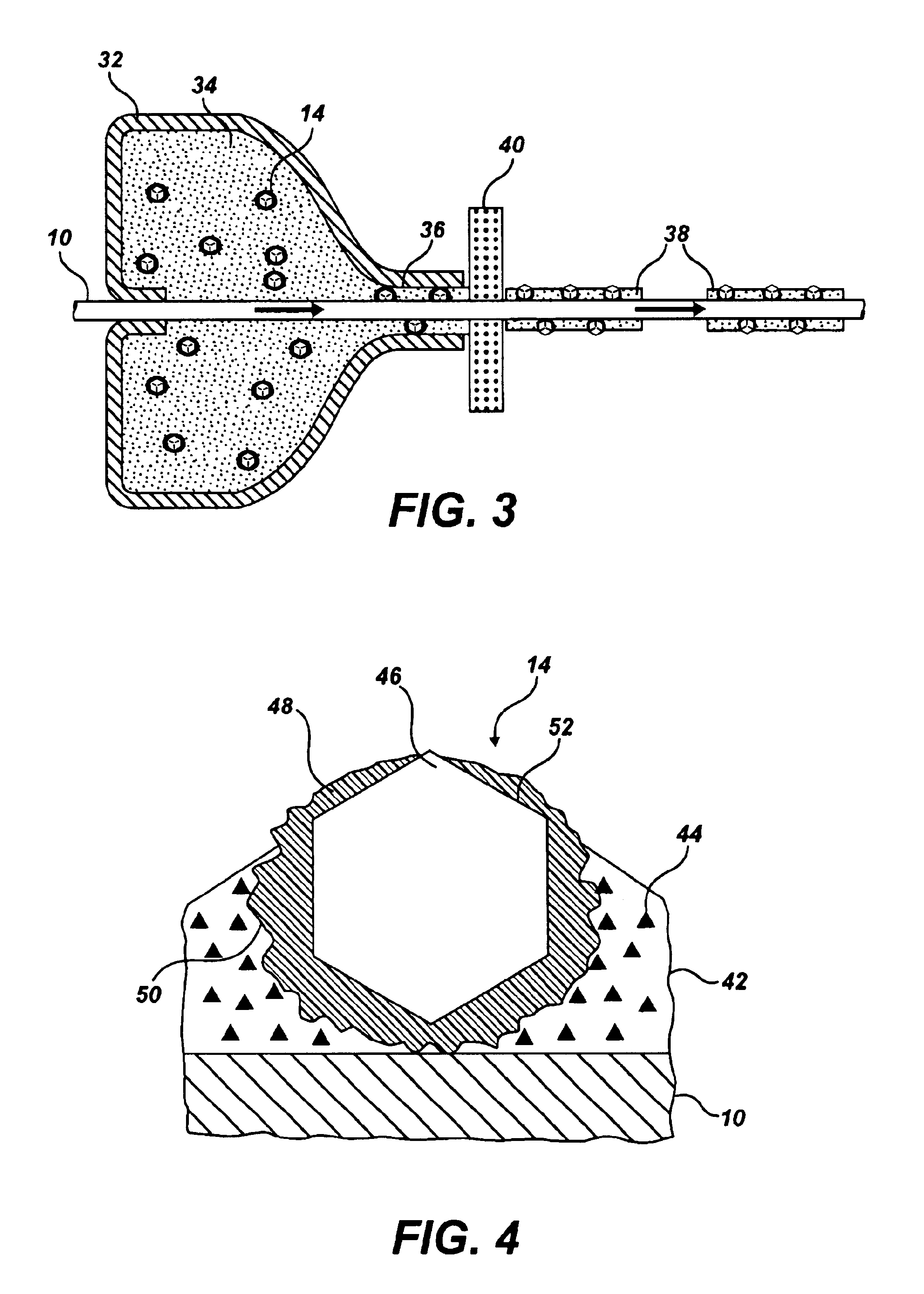

Polishing pad conditioning system

InactiveUS6508697B1Polishing machinesRevolution surface grinding machinesPiezo electricWaste material

A system for conditioning rotatable polishing pads used to planarize and polish surfaces of thin film integrated circuits deposited on semiconductor wafer substrates, microelectronic, and optical system. The system has a pad conditioning apparatus, process fluids, a vacuum capability to pull waste material out of the conditioning pad, self-contained flushing means, and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:BENNER ROBERT LYLE +2

Reciprocating wire saw for cutting hard materials

InactiveUS7089925B1Low costIncrease valueBelt grinding machinesMetal sawing toolsEngineeringWire saw

The present invention features a reciprocating wire saw particularly adapted or configured for cutting hard materials. In one aspect, the reciprocating wire saw comprises (a) a flexible wire; (b) a plurality of cutting segments fittable onto the flexible wire, wherein each of the cutting segments comprises an outer surface; and a (c) plurality of superabrasive particles braze bonded onto the outer surface of the cutting segments to form a cutting wire. In another aspect, the reciprocating wire saw comprises a plurality of superabrasive particles braze bonded directly to the wire itself to form a cutting wire. The cutting wire is unique in that it comprises a pre-determined superabrasive particle concentration and is configured to cut various materials, such as granite, in a reciprocating manner.

Owner:KINIK

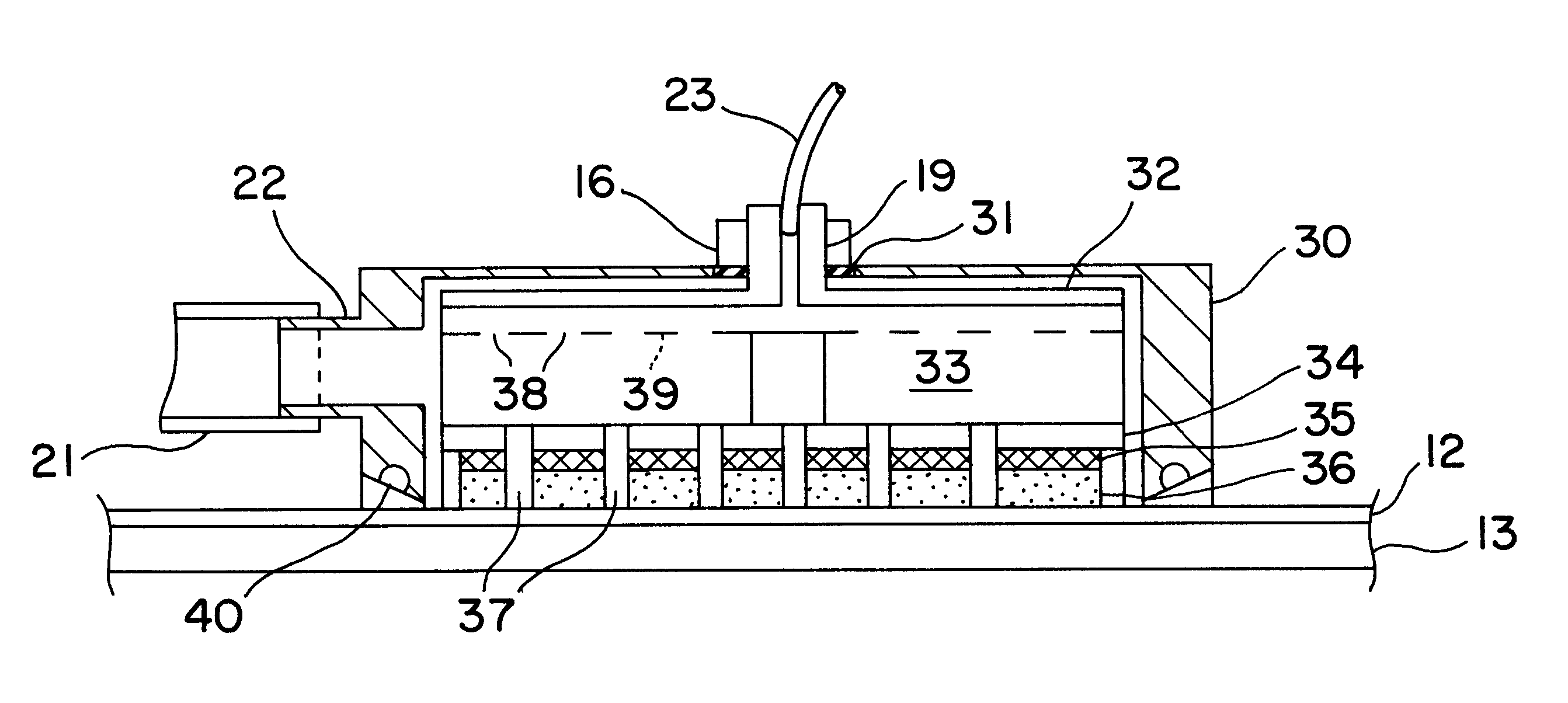

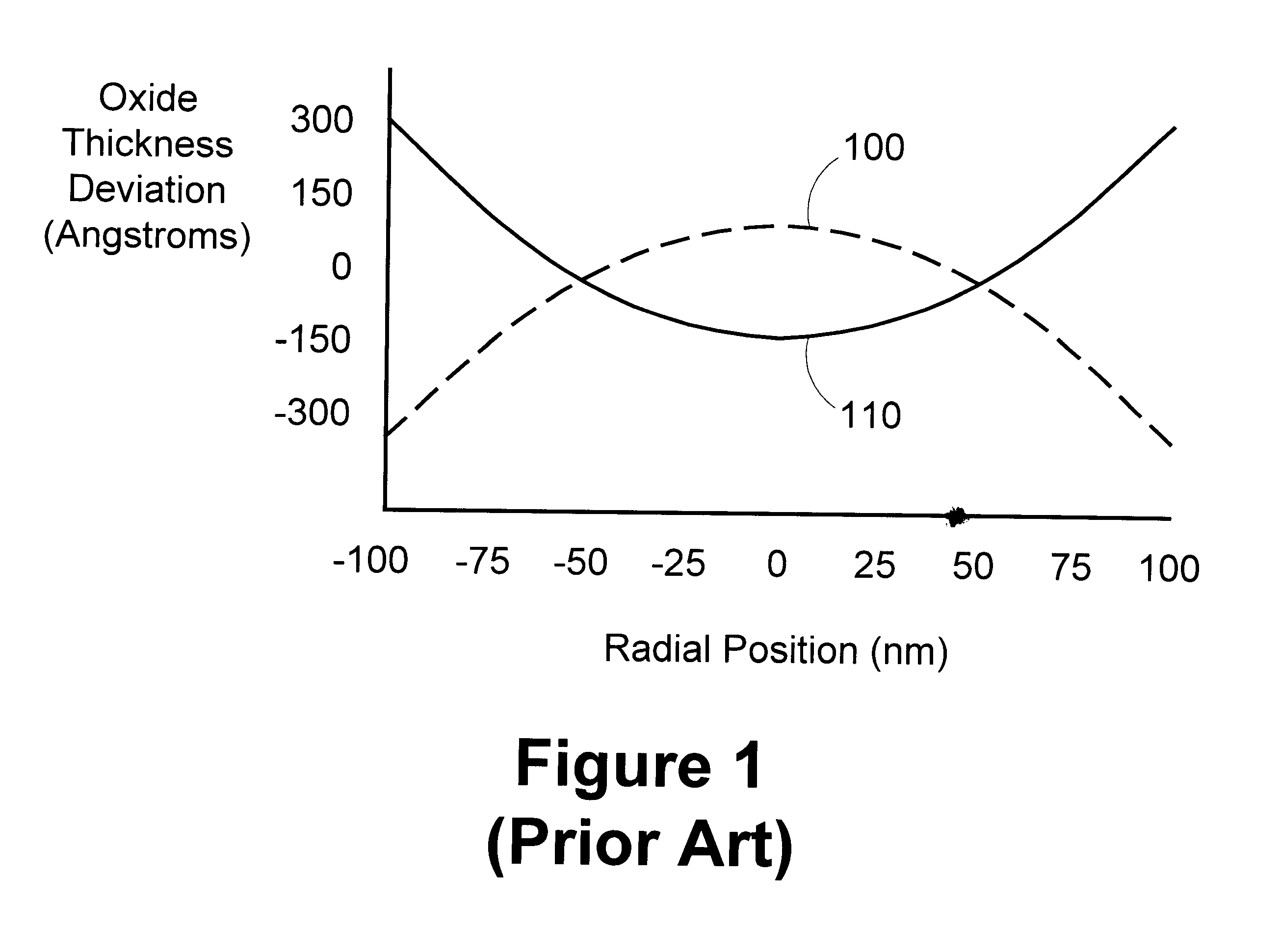

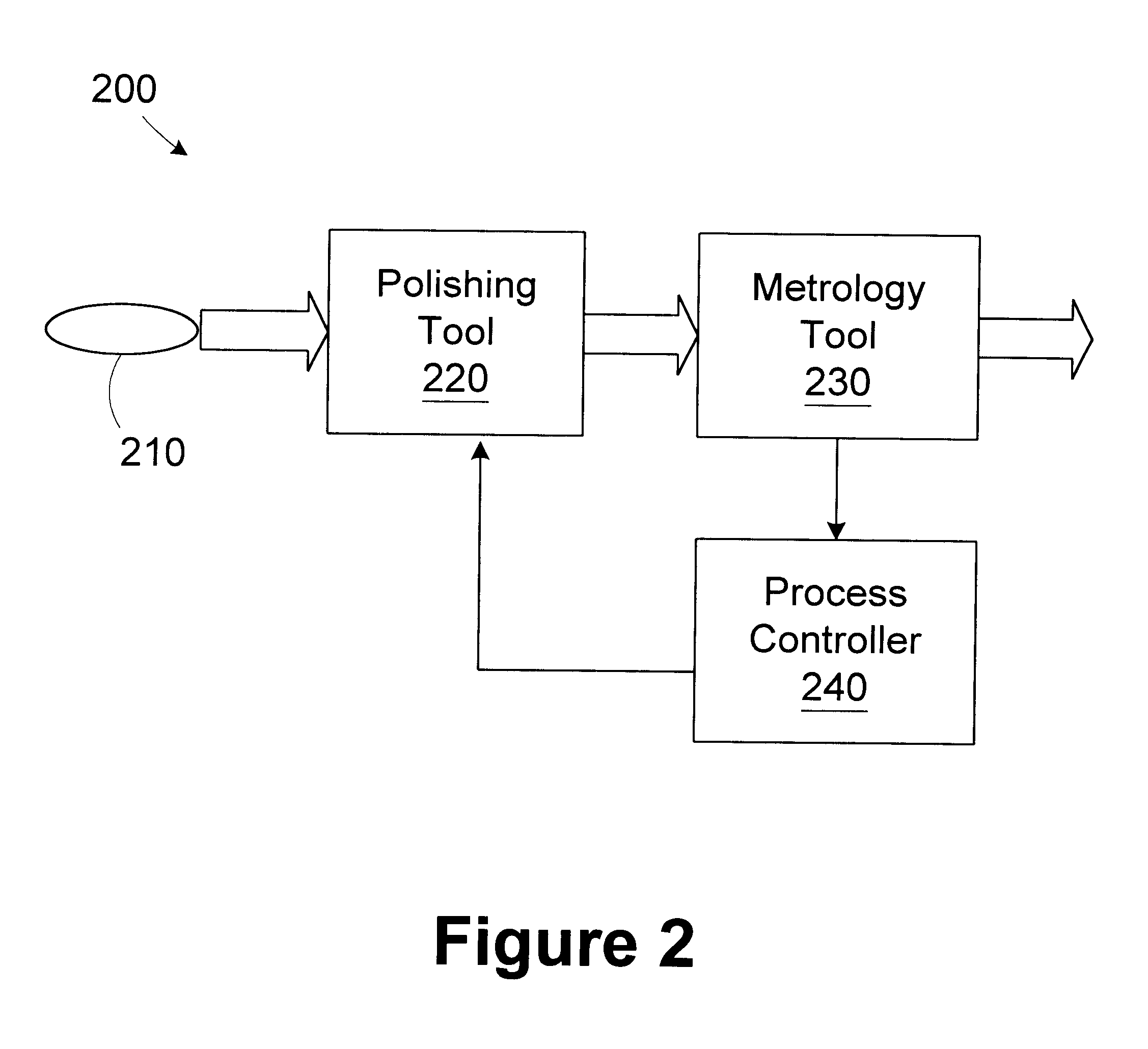

Method and apparatus for post-polish thickness and uniformity control

A method for polishing wafers includes providing a wafer having a process layer formed thereon; providing a polishing tool having a plurality of control zones and being adapted to polish the process layer based on an operating recipe, the operating recipe having a control variable corresponding to each of the control zones; measuring a pre-polish thickness profile of the process layer; comparing the pre-polish thickness profile to a target thickness profile to determine a desired removal profile; determining values for the control variables associated with the control zones based on the desired removal profile; and modifying the operating recipe of the polishing tool based on the values determined for the control variables. A processing line includes a polishing tool, a metrology tool, and a process controller. The polishing tool is adapted to polish a wafer having a process layer formed thereon based on an operating recipe. The polishing tool includes a plurality of control zones and the operating recipe includes a control variable corresponding to each of the control zones. The metrology tool is adapted to measure a pre-polish thickness profile of the process layer. The process controller is adapted to compare the pre-polish thickness profile to a target thickness profile to determine a desired removal profile, determine values for the control variables associated with the control zones based on the desired removal profile, and modify the operating recipe of the polishing tool based on the values determined for the control variables.

Owner:GLOBALFOUNDRIES INC

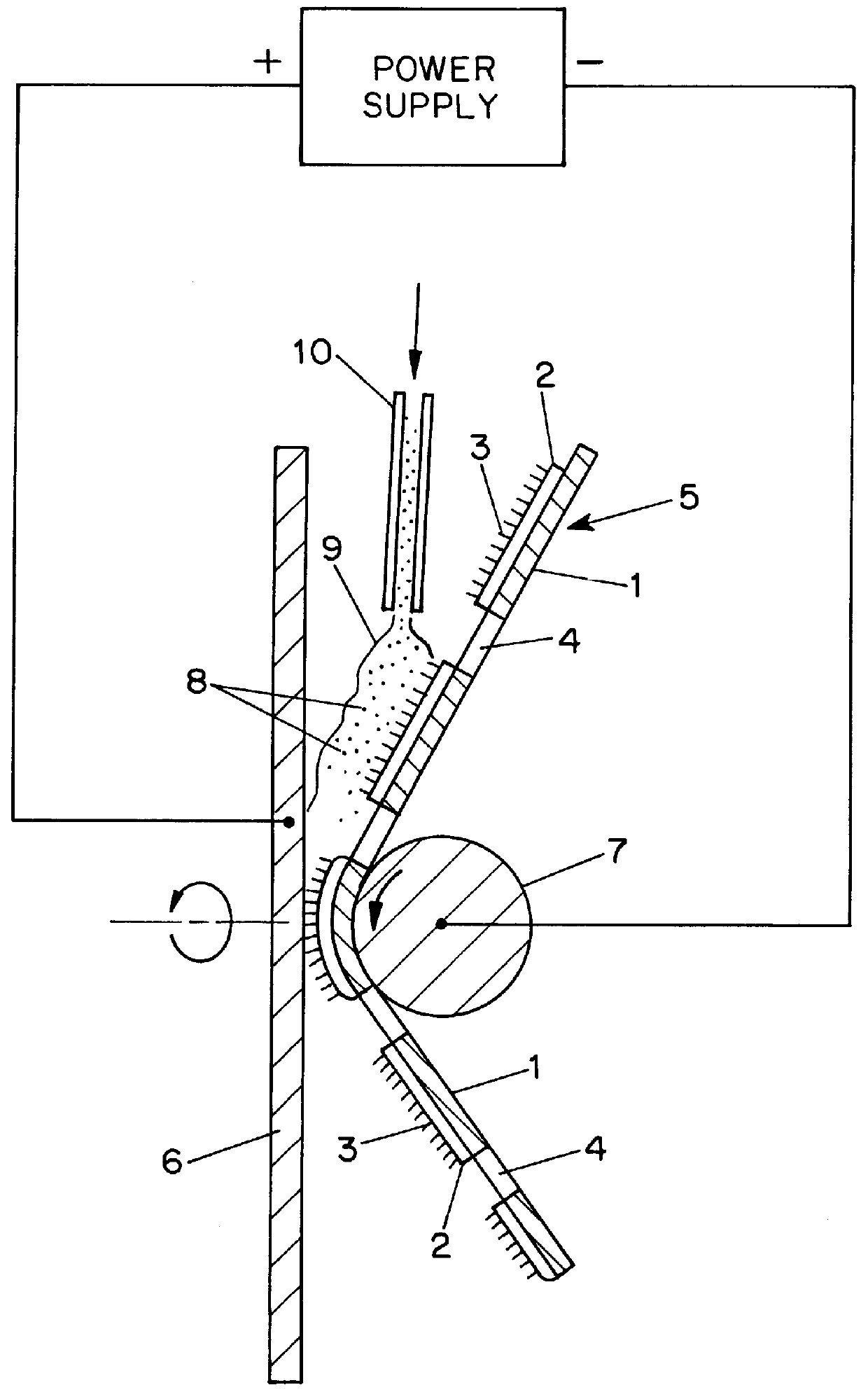

Combination electrolytic polishing and abrasive super-finishing method

InactiveUS6074284AHigh surface finishEfficient supplyBelt grinding machinesAbrasion apparatusFiberElectrolytic agent

An abrasive super-finishing method for workpieces, such as metallic thin-film magnetic discs, employs a polishing / texturing material having a backing, such as synthetic resin film or woven material or non-woven cloth, and a layer which can hold abrasive grains on the backing, such as flocked fibre or a porous polymer foam, on one surface of the backing. An electrolytic solution in which abrasive grains are suspended is supplied to the polishing / texturing material to conduct polishing or texturing of the workpiece surfaces. The workpiece is connected to an anode and a pressure roller or a cathode bar is connected to a cathode. A voltage is applied between the workpiece and the pressure roller or cathode bar to conduct simultaneously electrolytic polishing and abrasive polishing / texturing.

Owner:UNIQUE TECH INT PTE

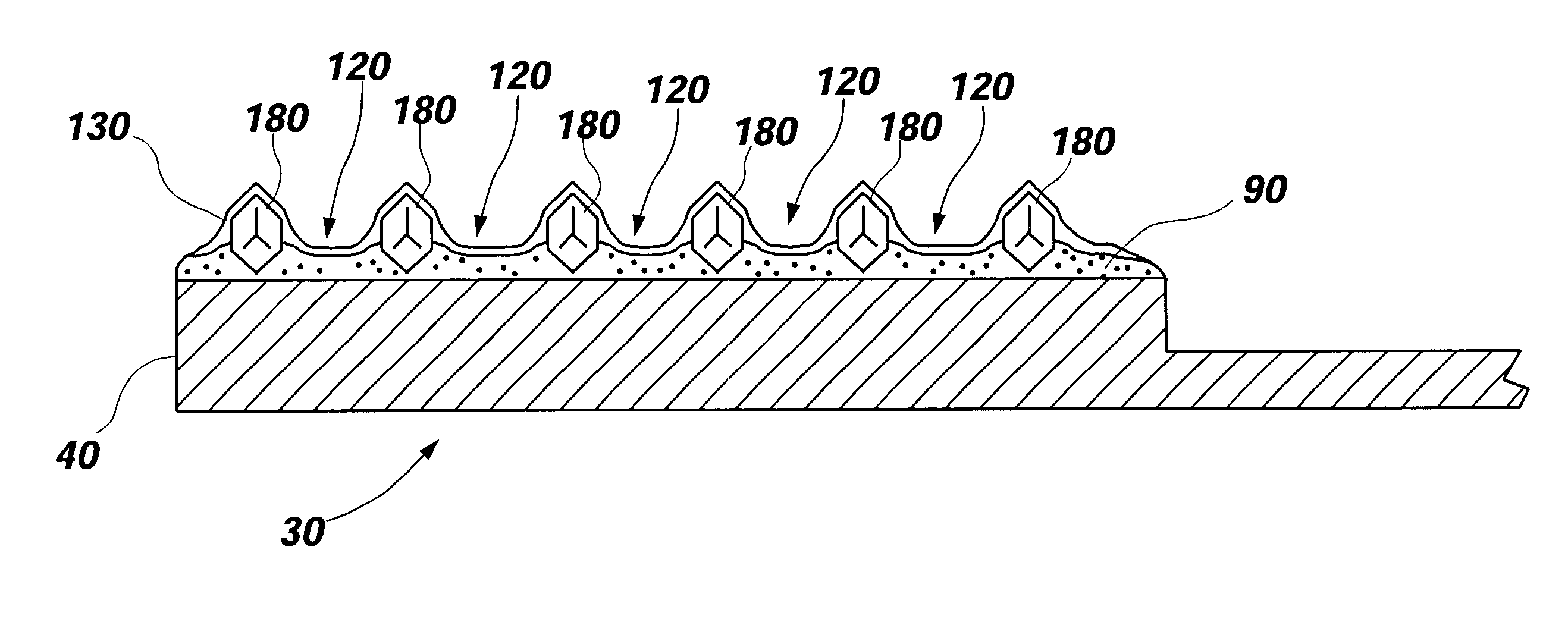

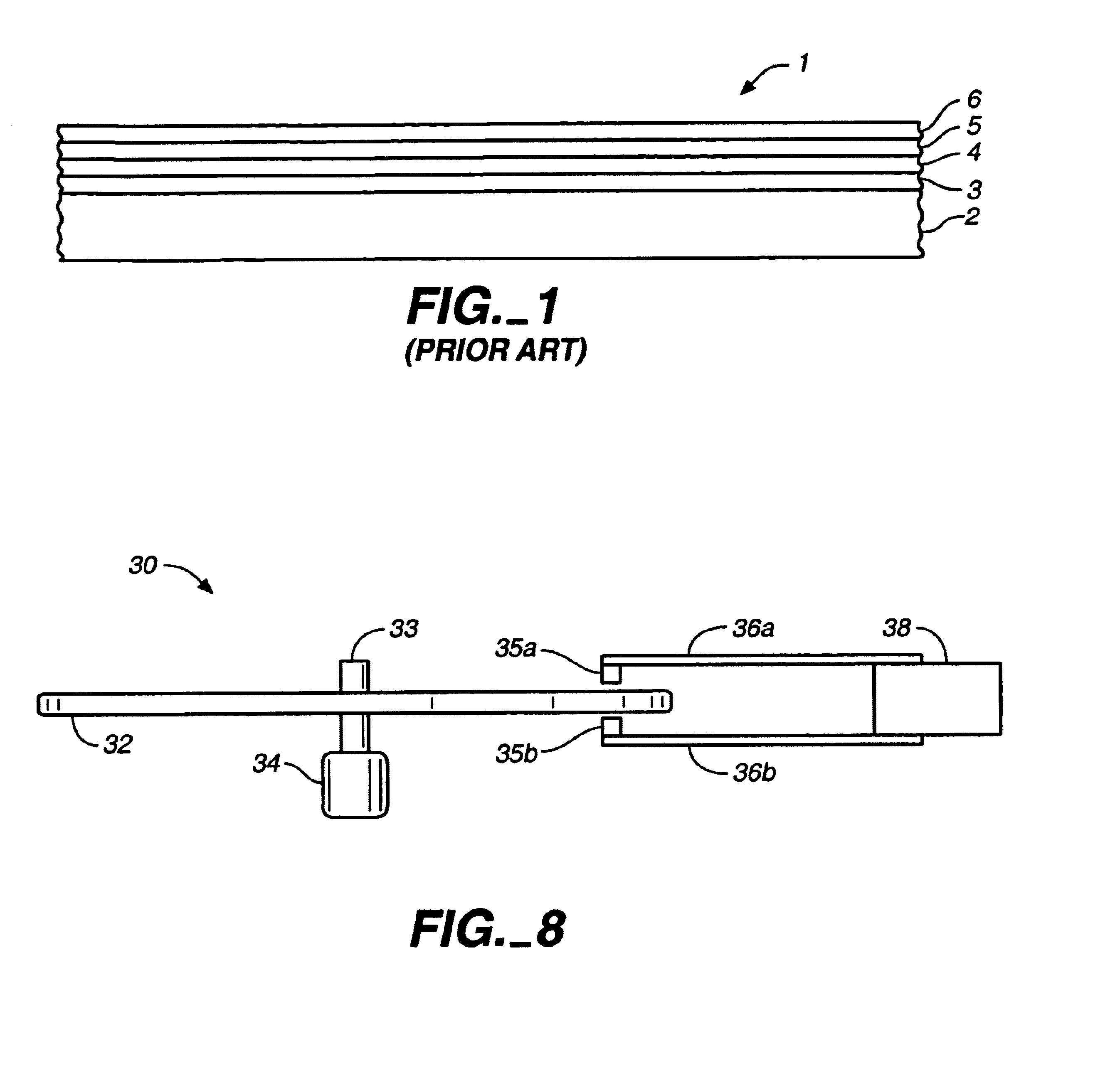

Backup shoe for microfinishing and methods

InactiveUS20050245179A1Revolution surface grinding machinesBelt grinding machinesSupport surfaceMetallic Nickel

A shoe for supporting an abrasive tape having an abrasive face and an opposed back face, wherein the shoe comprises a support surface including a frictional engagement material for frictionally engaging the back face of the abrasive tape. The frictional engagement material comprises a plurality of individual frictional engagement areas on a flexible substrate, each frictional engagement area having a plurality of abrasive particles. In an exemplary embodiment, the frictional engagement material comprises diamond abrasive particles retained in a nickel matrix supported on a flexible mesh substrate. The support surface of the shoe may be curvilinear, arcuate, convex, or concave.

Owner:3M INNOVATIVE PROPERTIES CO

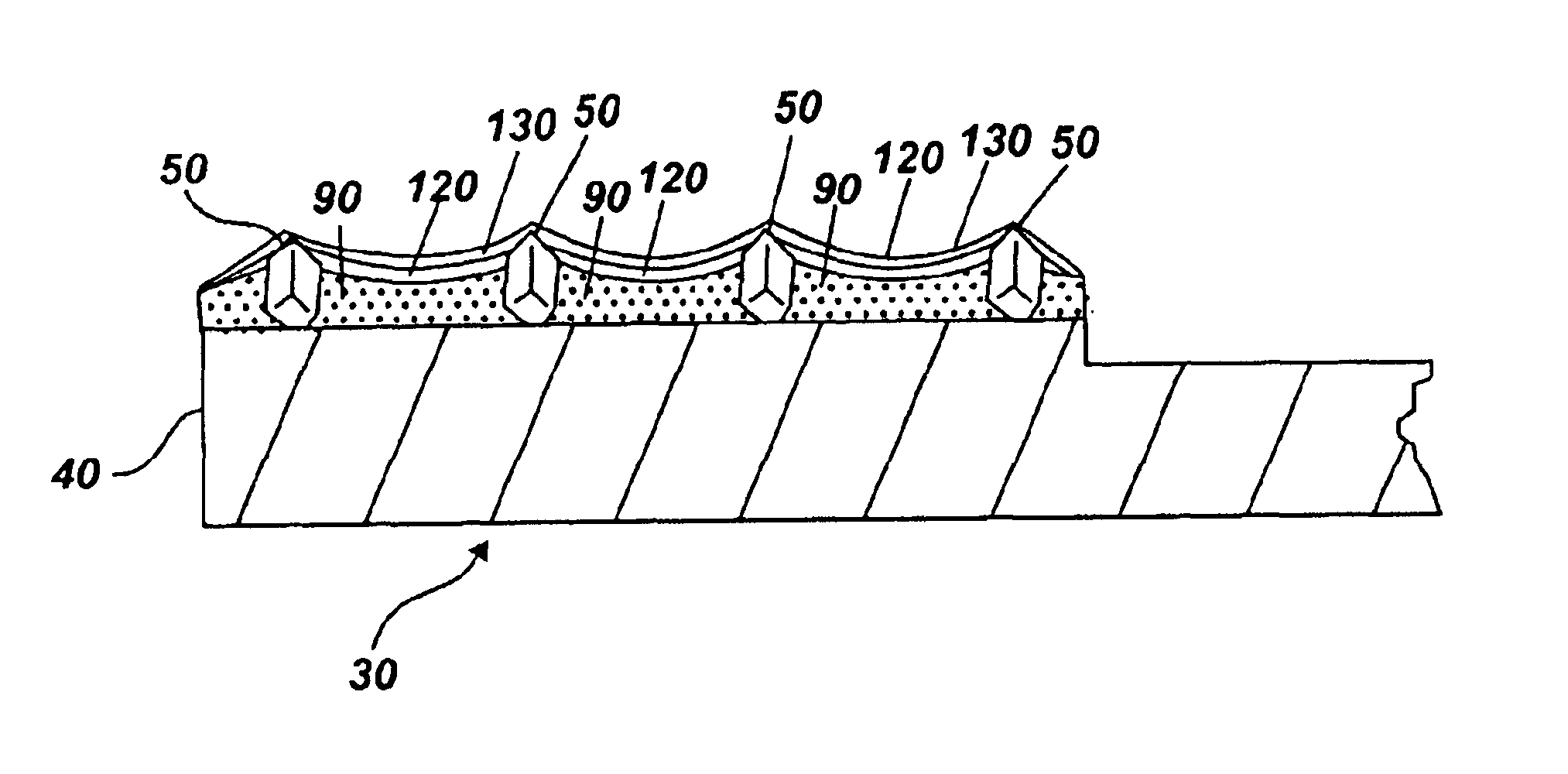

Contoured CMP pad dresser and associated methods

InactiveUS7201645B2Increase loadImprove permeabilityPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Owner:KINIK

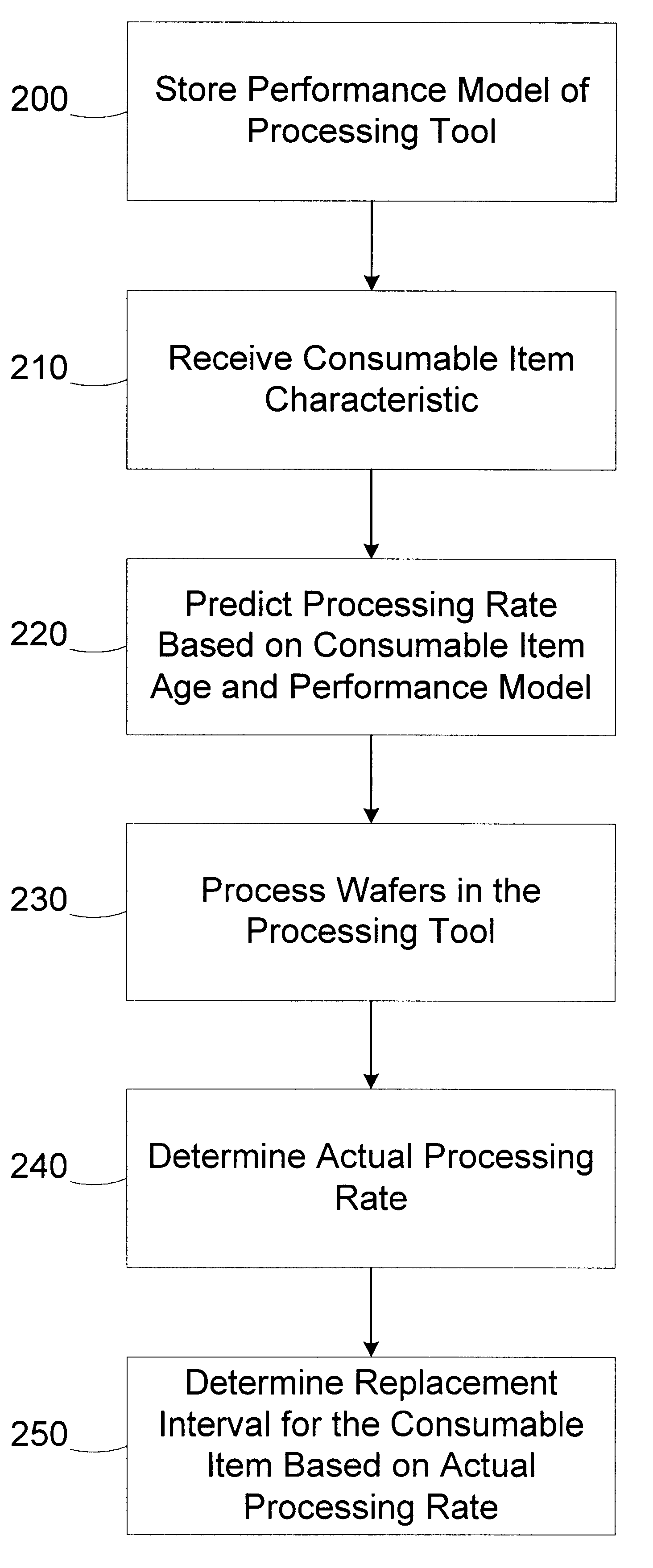

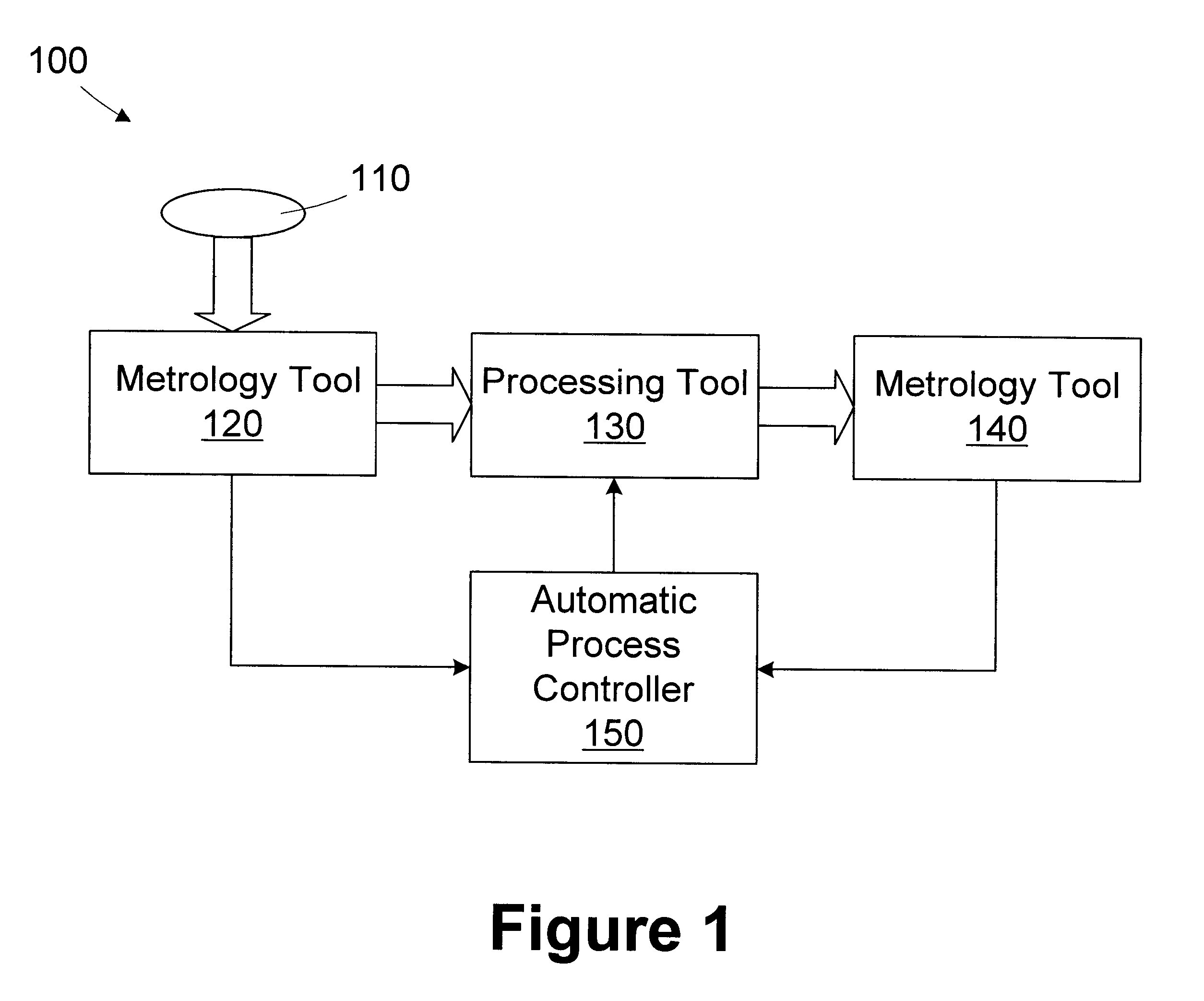

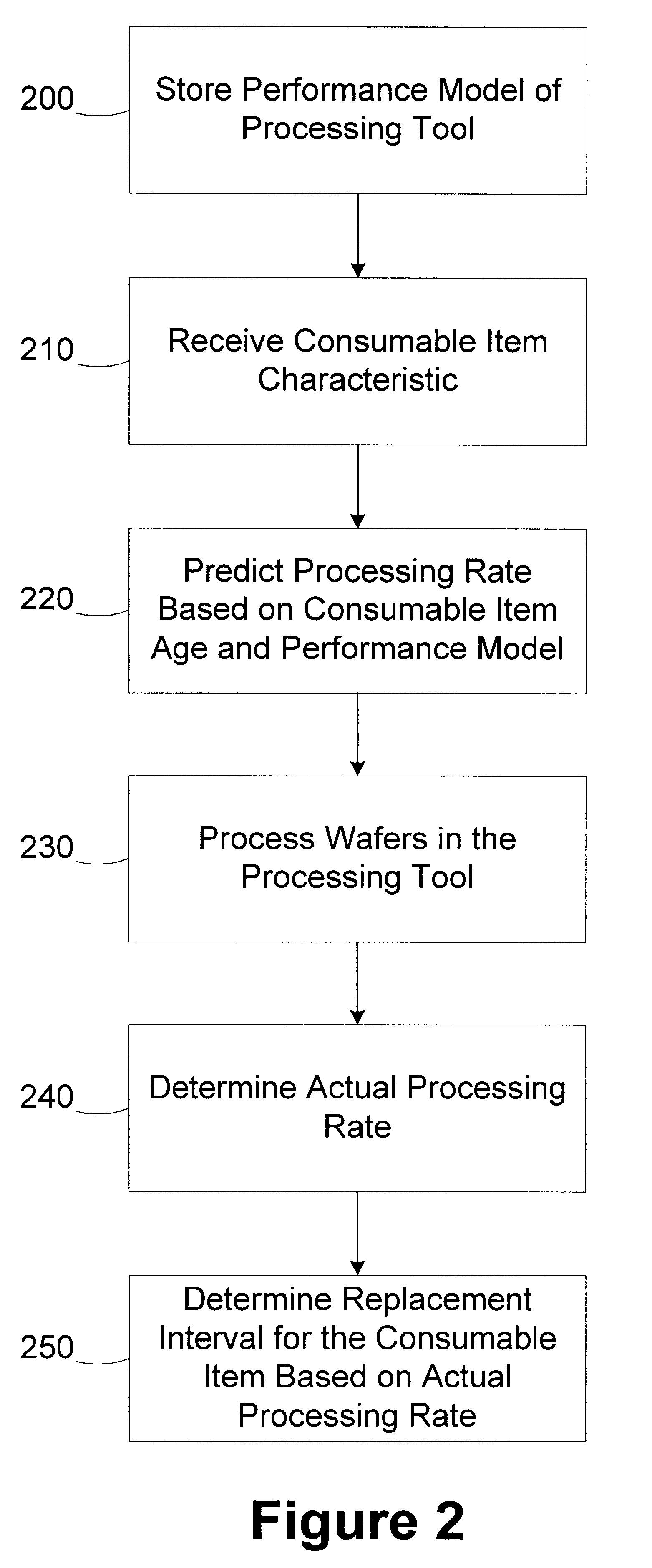

Method and apparatus for monitoring consumable performance

InactiveUS6567718B1Polishing machinesRevolution surface grinding machinesParallel computingAutomatic process control

A method for monitoring consumable performance in a processing tool comprises storing a performance model of the processing tool; receiving a consumable item characteristic of a consumable item in the processing tool; determining a predicted processing rate for the processing tool based on the consumable item characteristic and the performance model; determining an actual processing rate of the processing tool; and determining a replacement interval for the consumable item based on at least the actual processing rate. A processing system includes a processing tool and an automatic process controller. The processing tool is adapted to process wafers and includes a consumable item.

Owner:GLOBALFOUNDRIES US INC

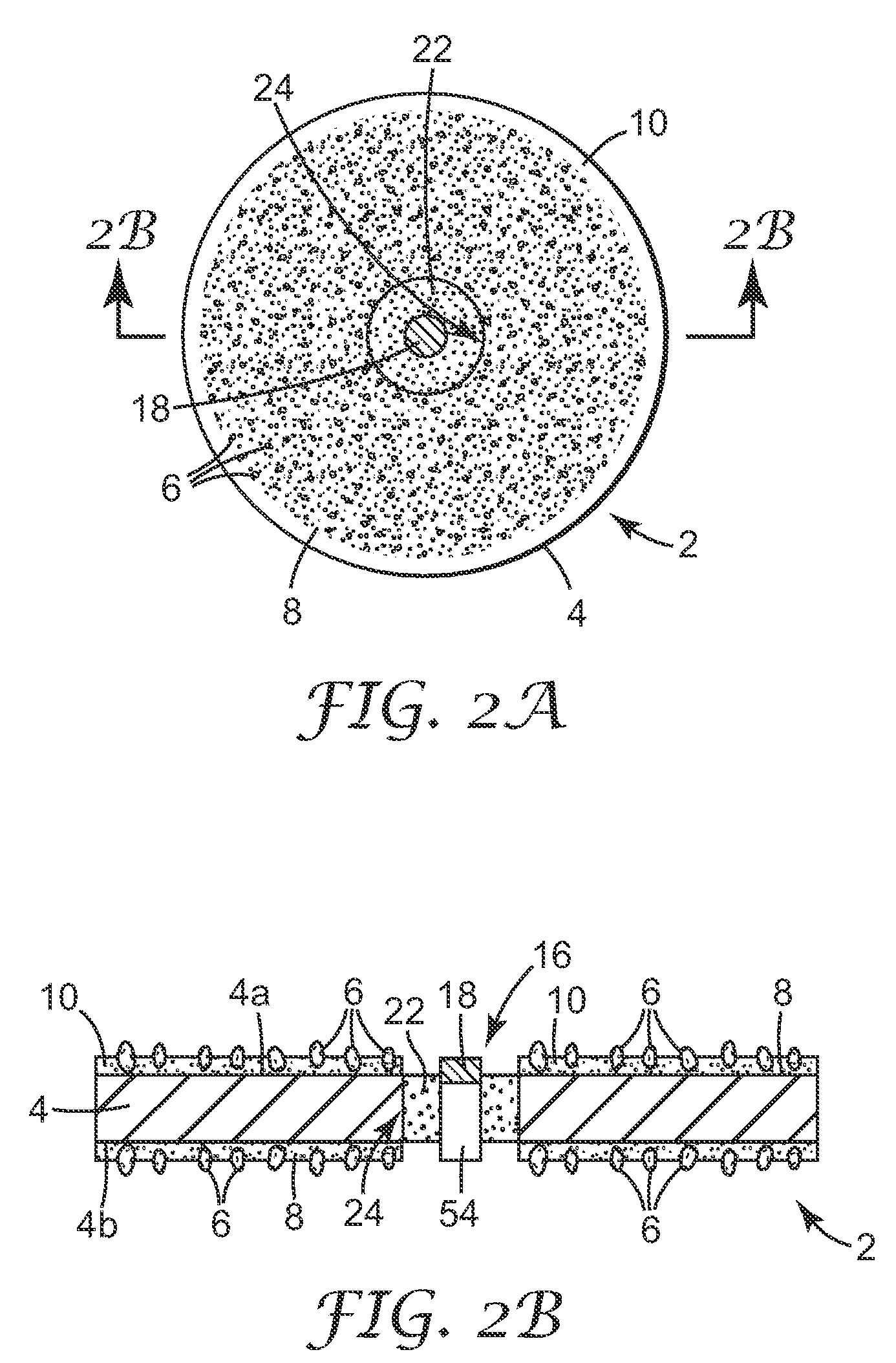

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

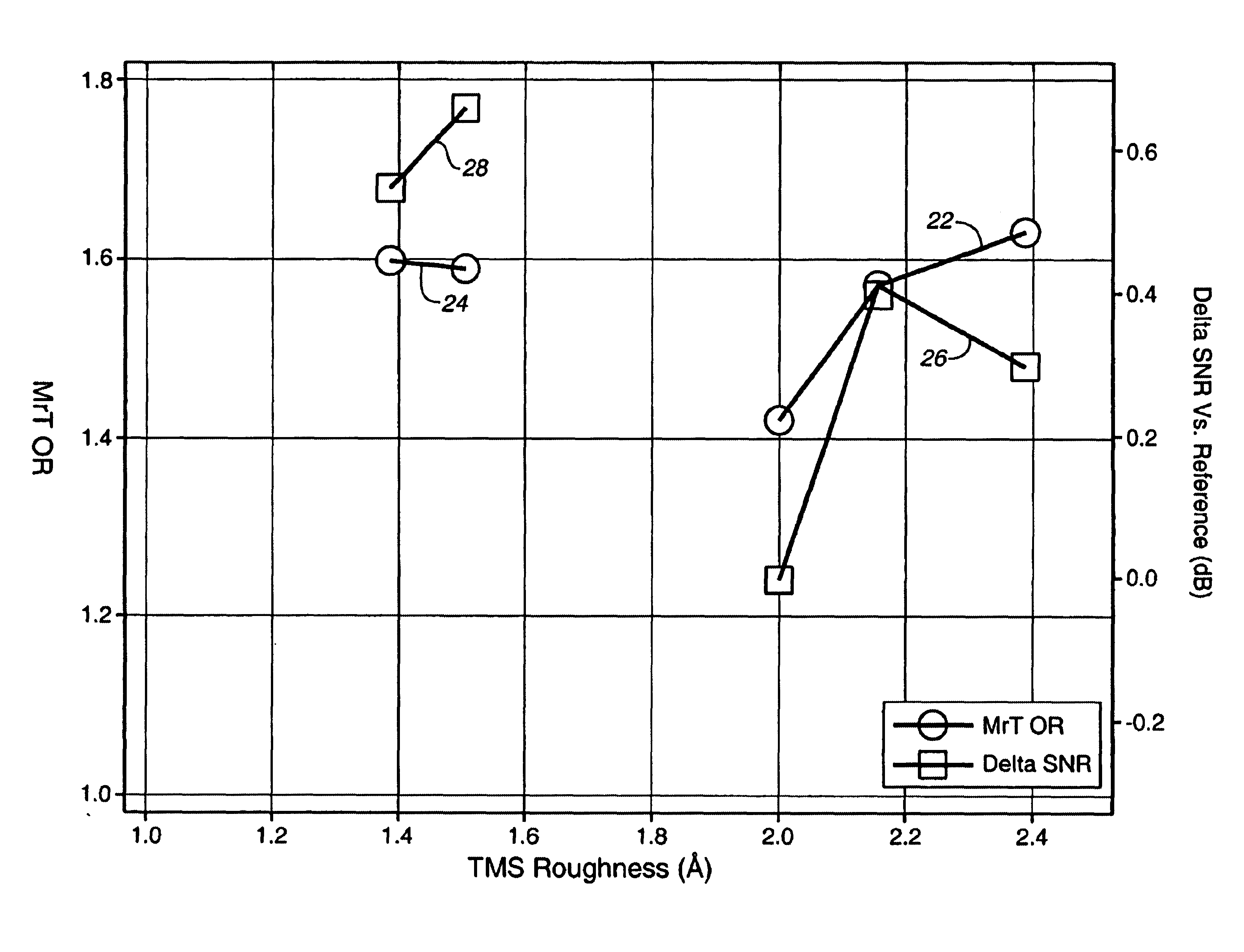

Texturing of magnetic disk substrates

InactiveUS6972135B2Uniform particle sizeLarge low-frequencyMagnetic materials for record carriersBase layers for recording layersNanometreMaterials science

A method for texturing a substrate for a magnetic disk comprises abrading the substrate using nano-sized diamond particles (e.g. having a diameter less than or equal to 20 nm). A magnetic layer is then deposited over the substrate. Even when the texture is extremely smooth (e.g. less than about 2.2 ÅRa), the disk still exhibits good Hc and MrT orientation ratios, SNR and PW50.

Owner:WD MEDIA

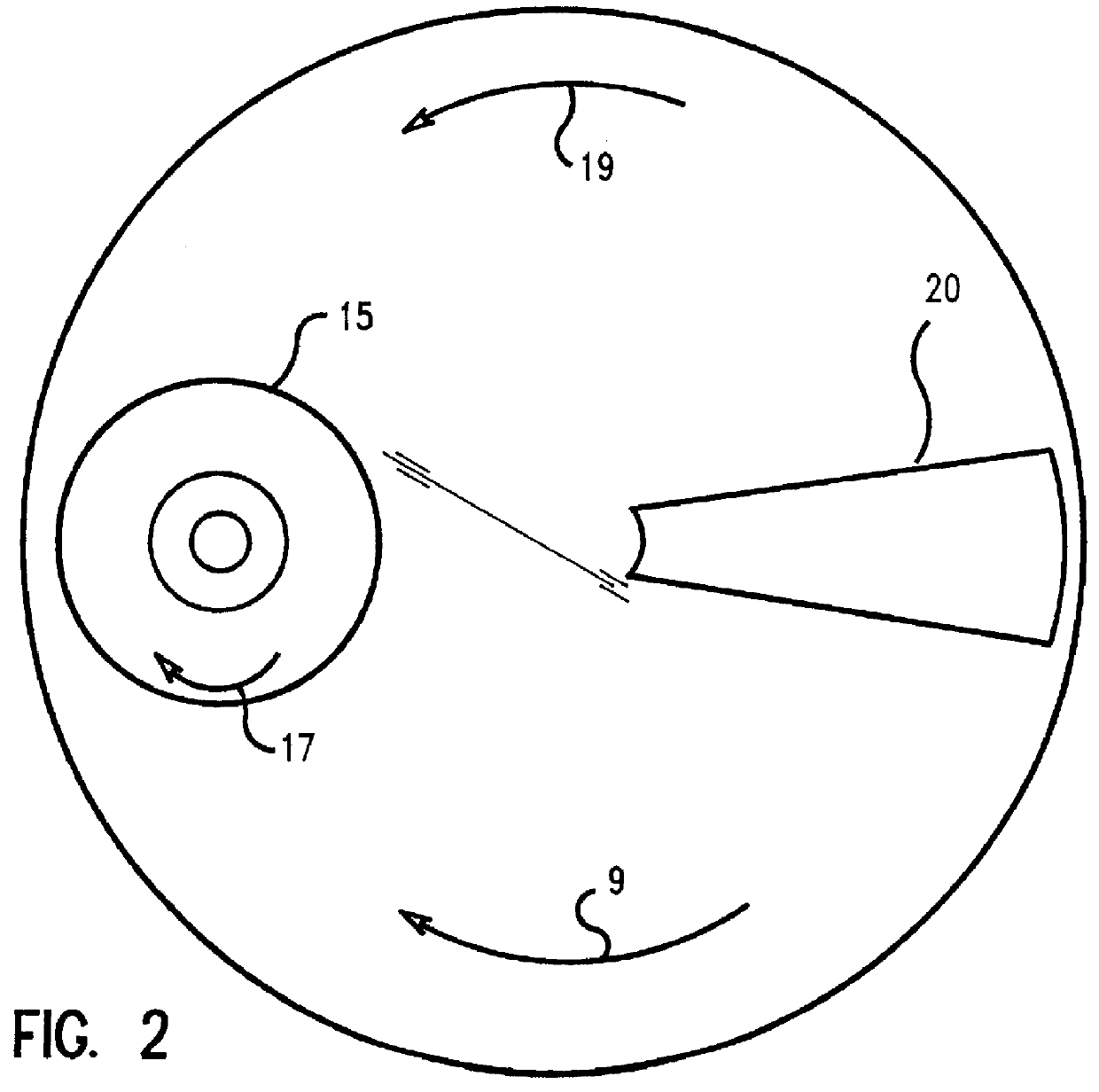

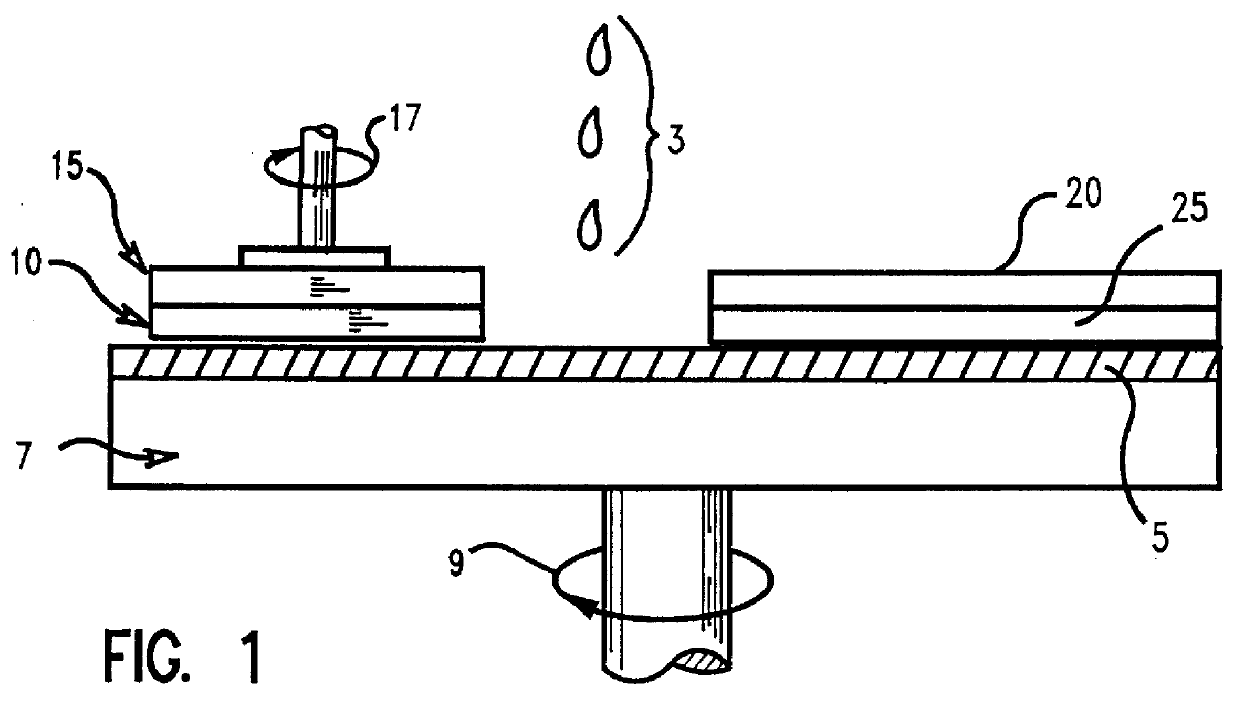

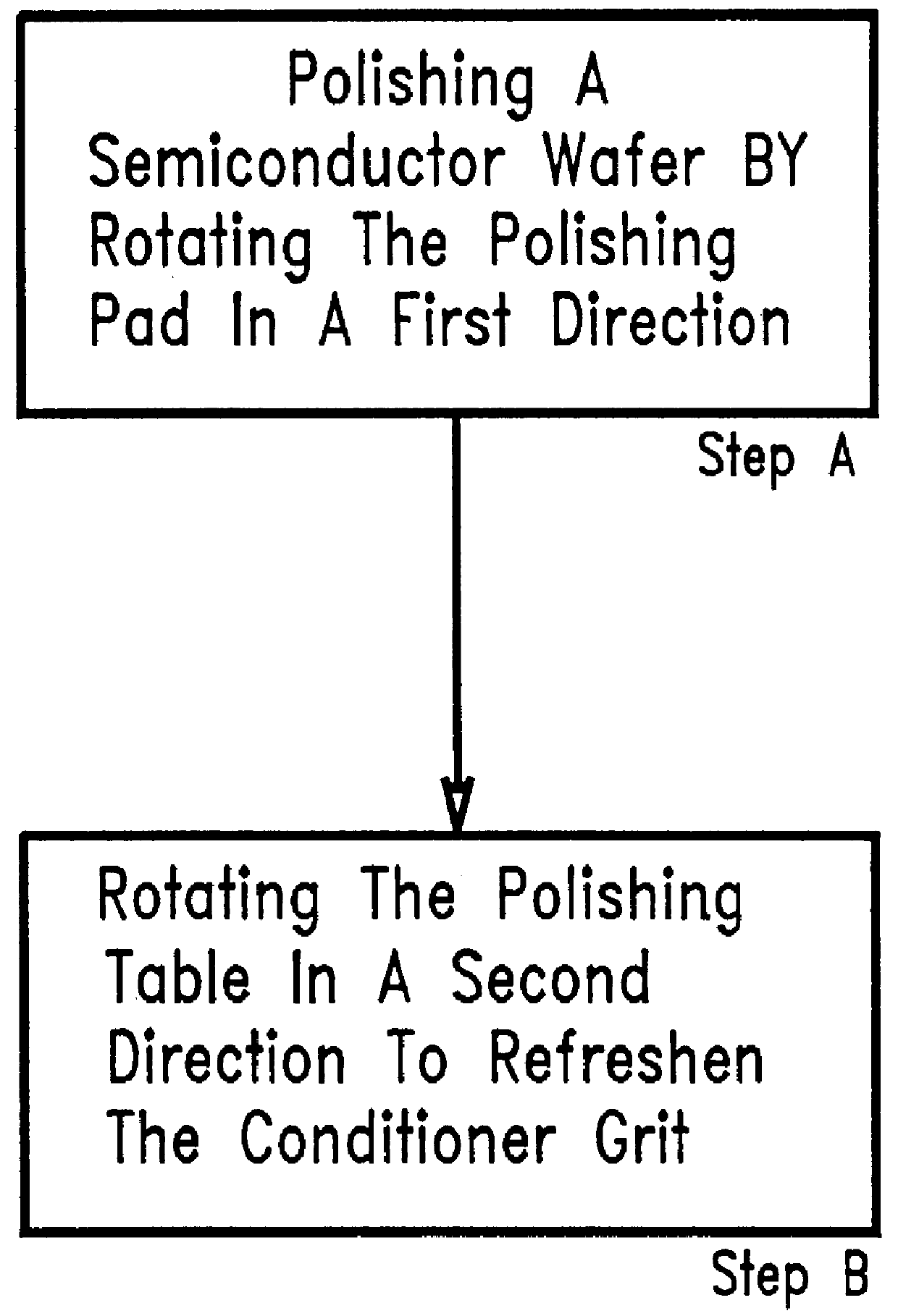

In-situ pad conditioning process for CMP

InactiveUS6022266AGood conditioning effectGrinding drivesBelt grinding machinesSlurryImproved method

Owner:GOOGLE LLC

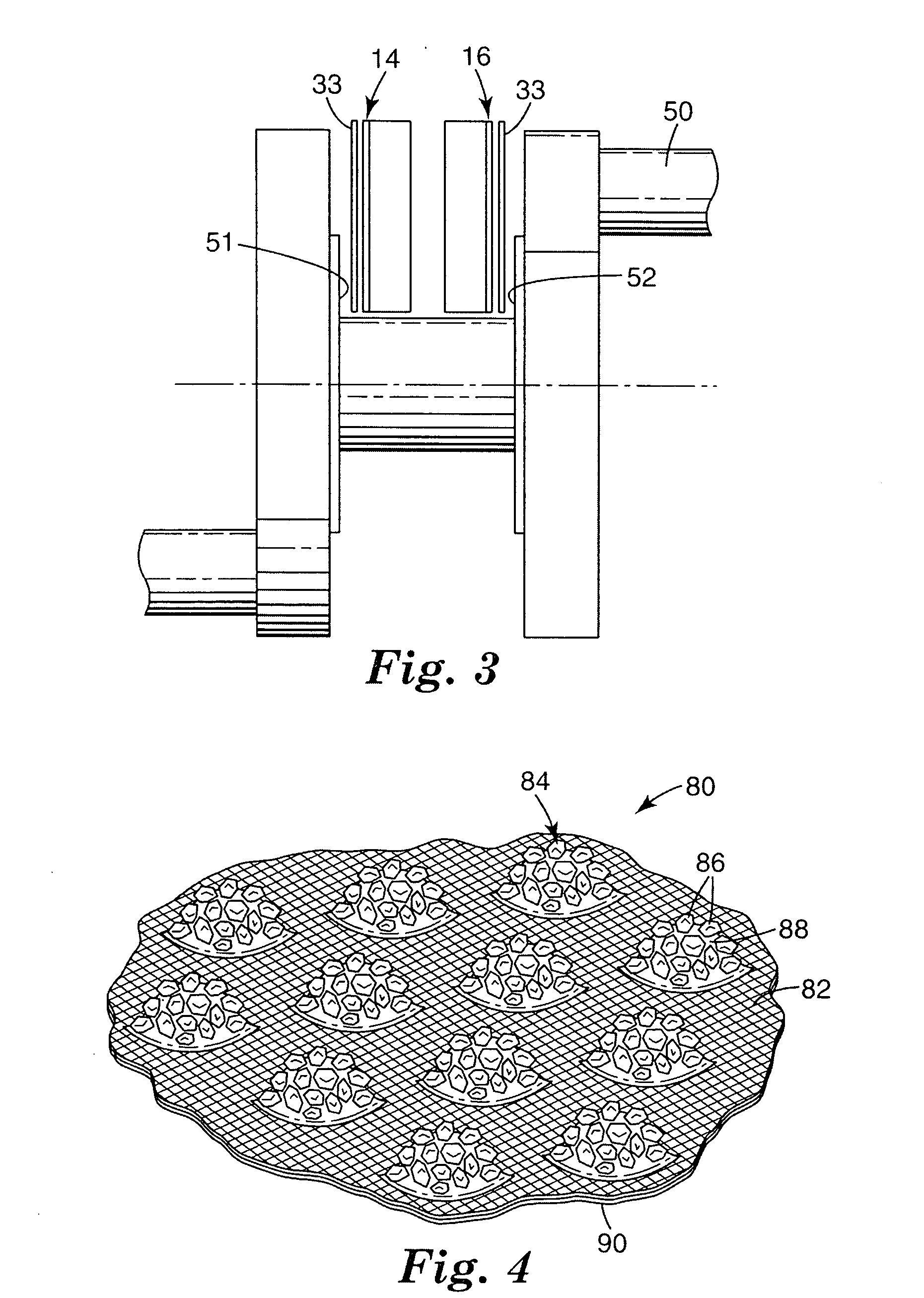

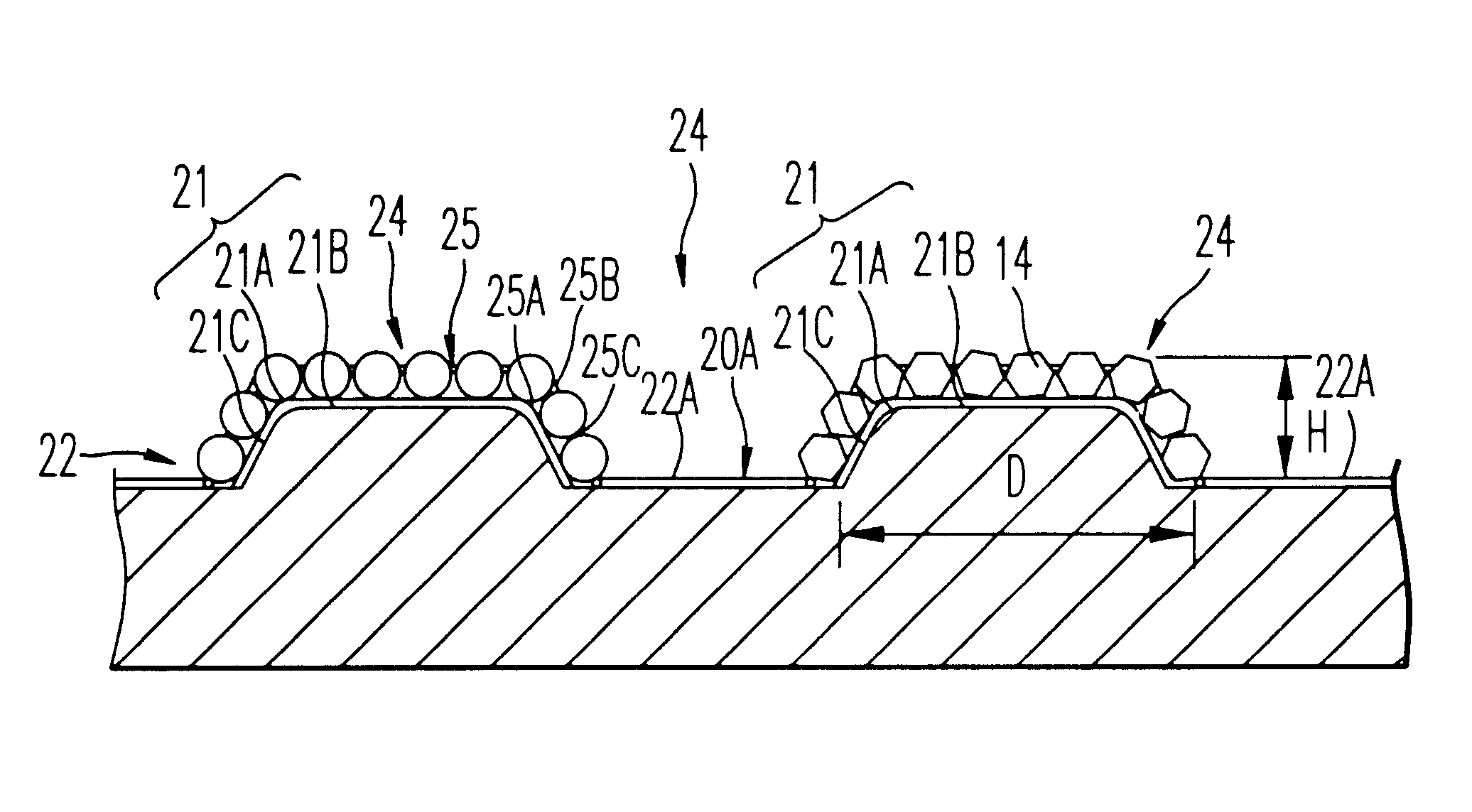

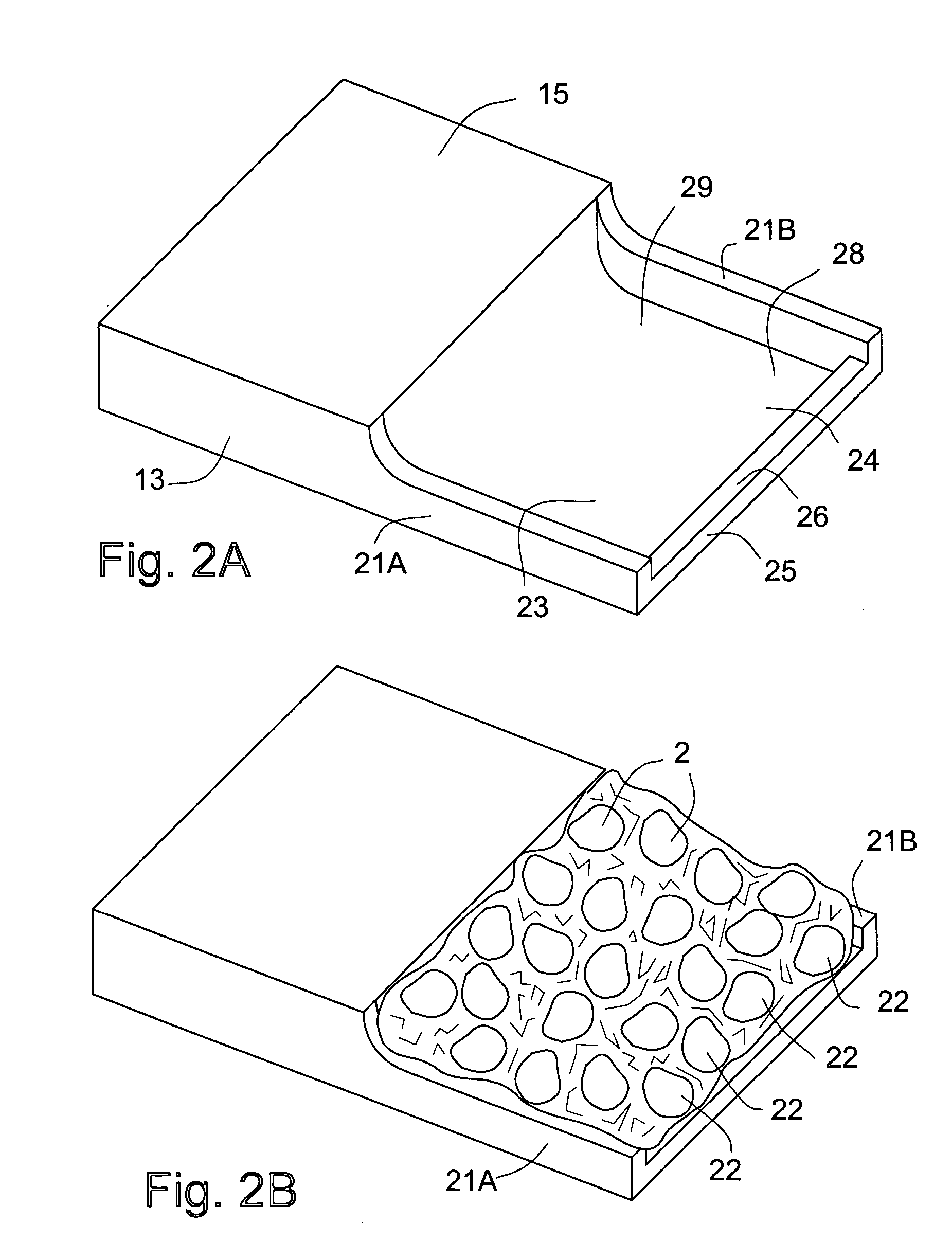

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

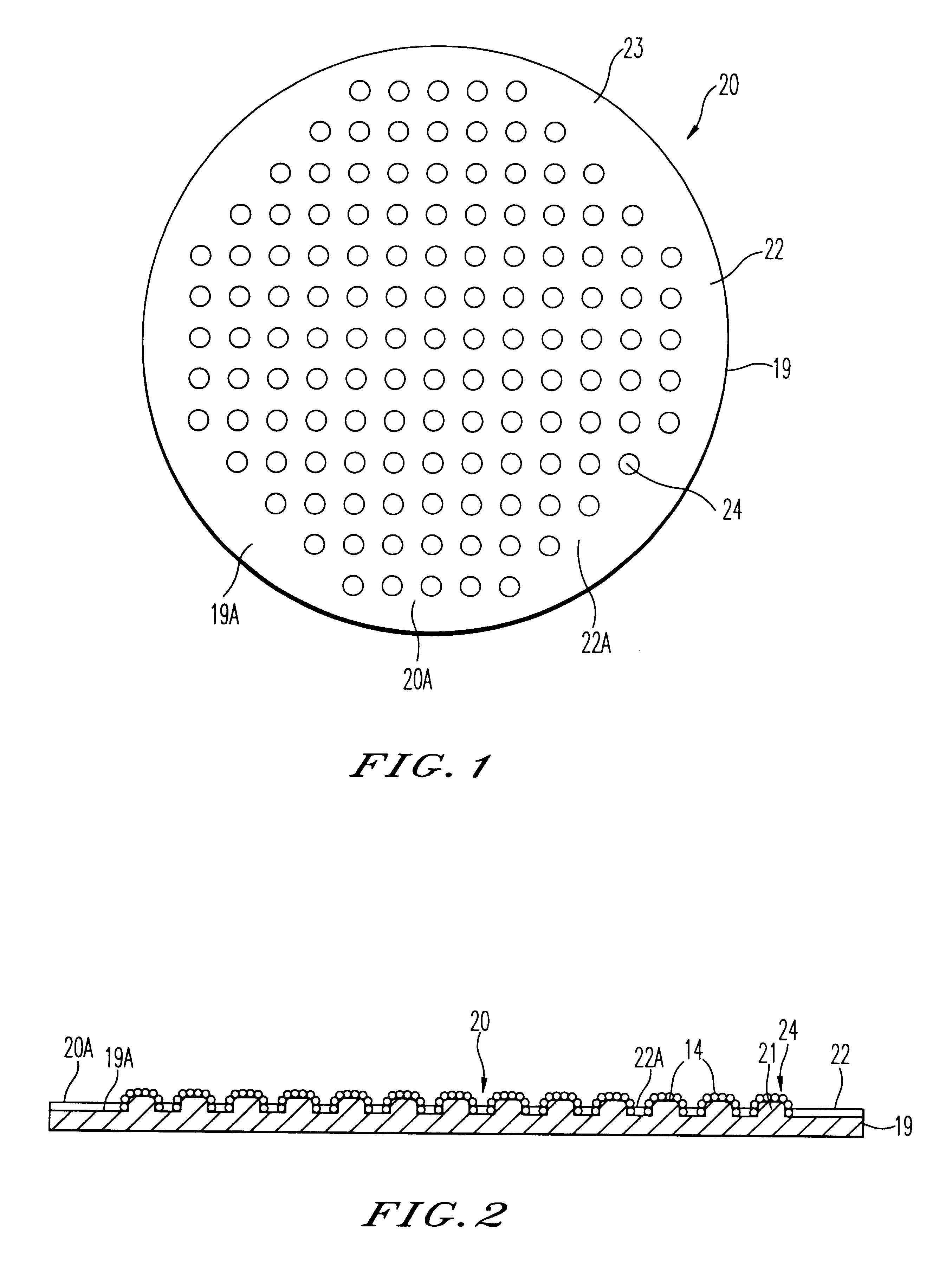

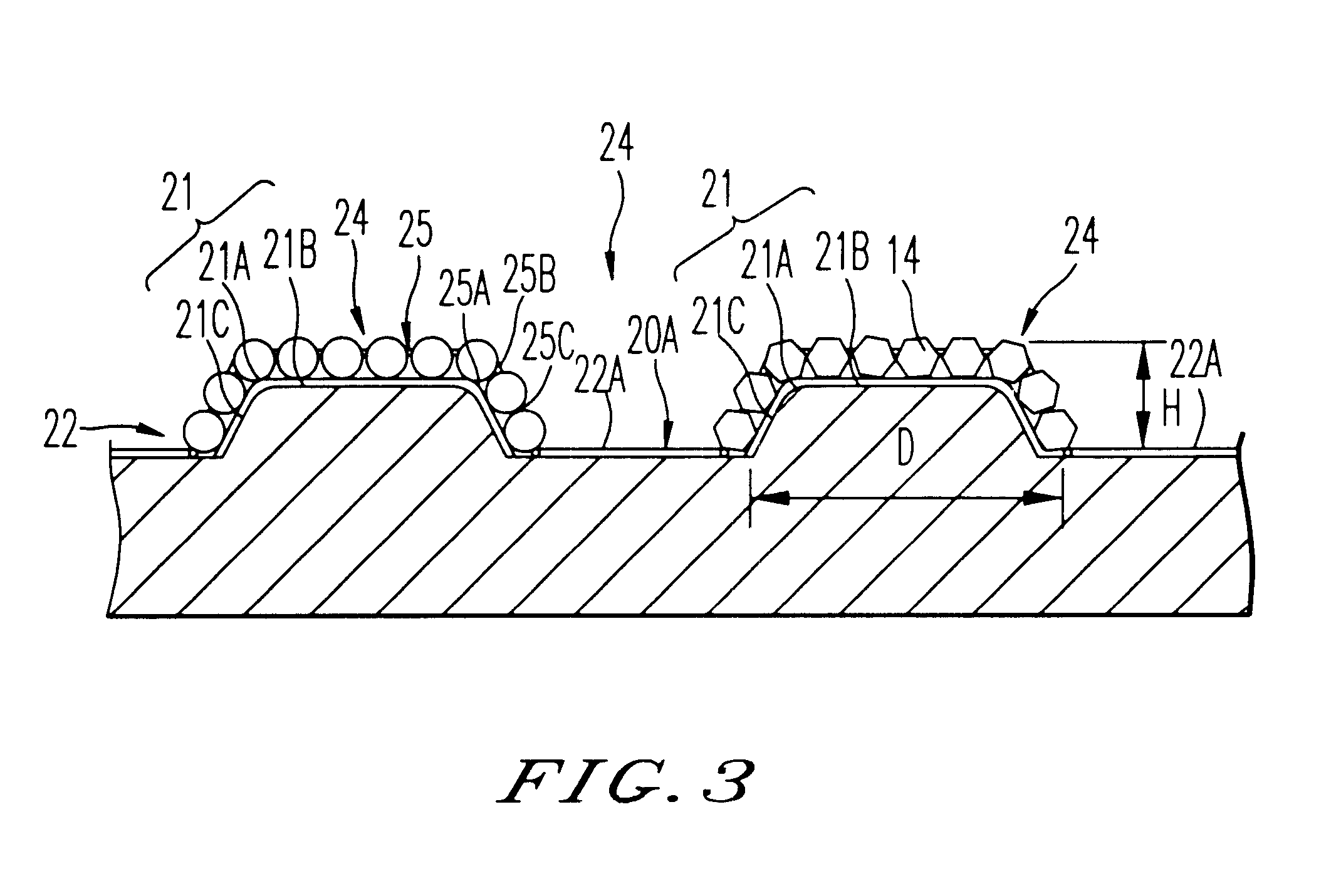

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

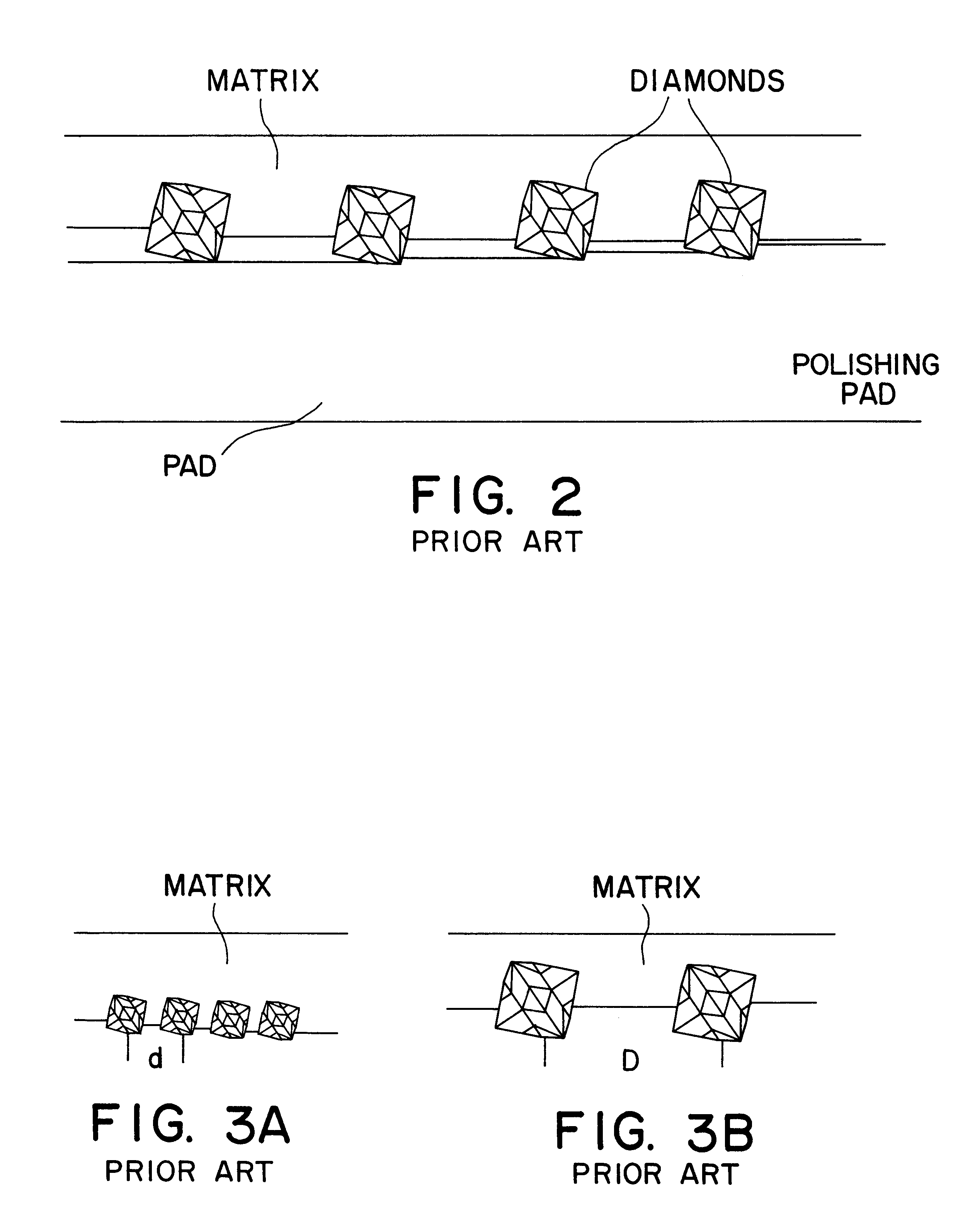

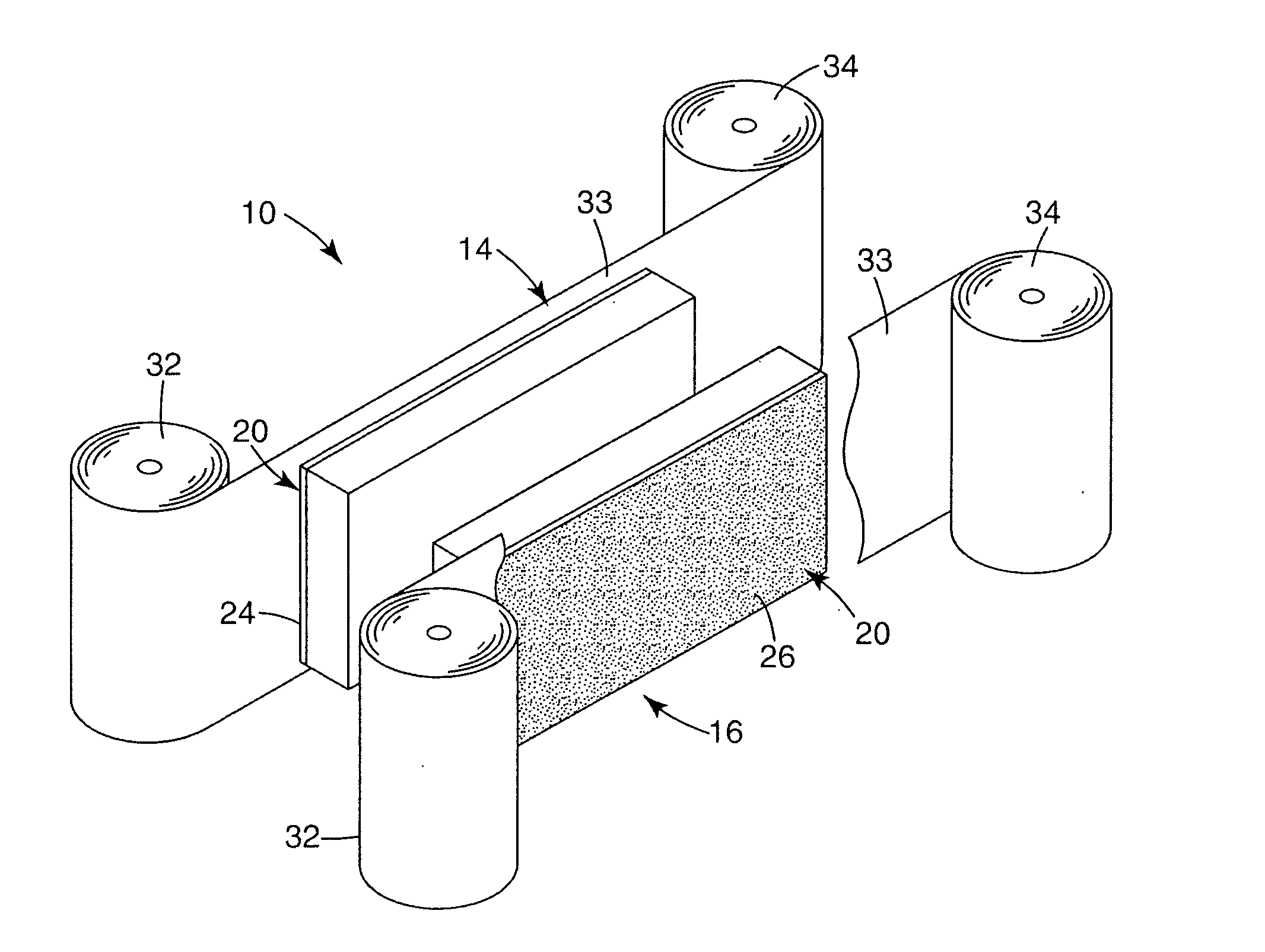

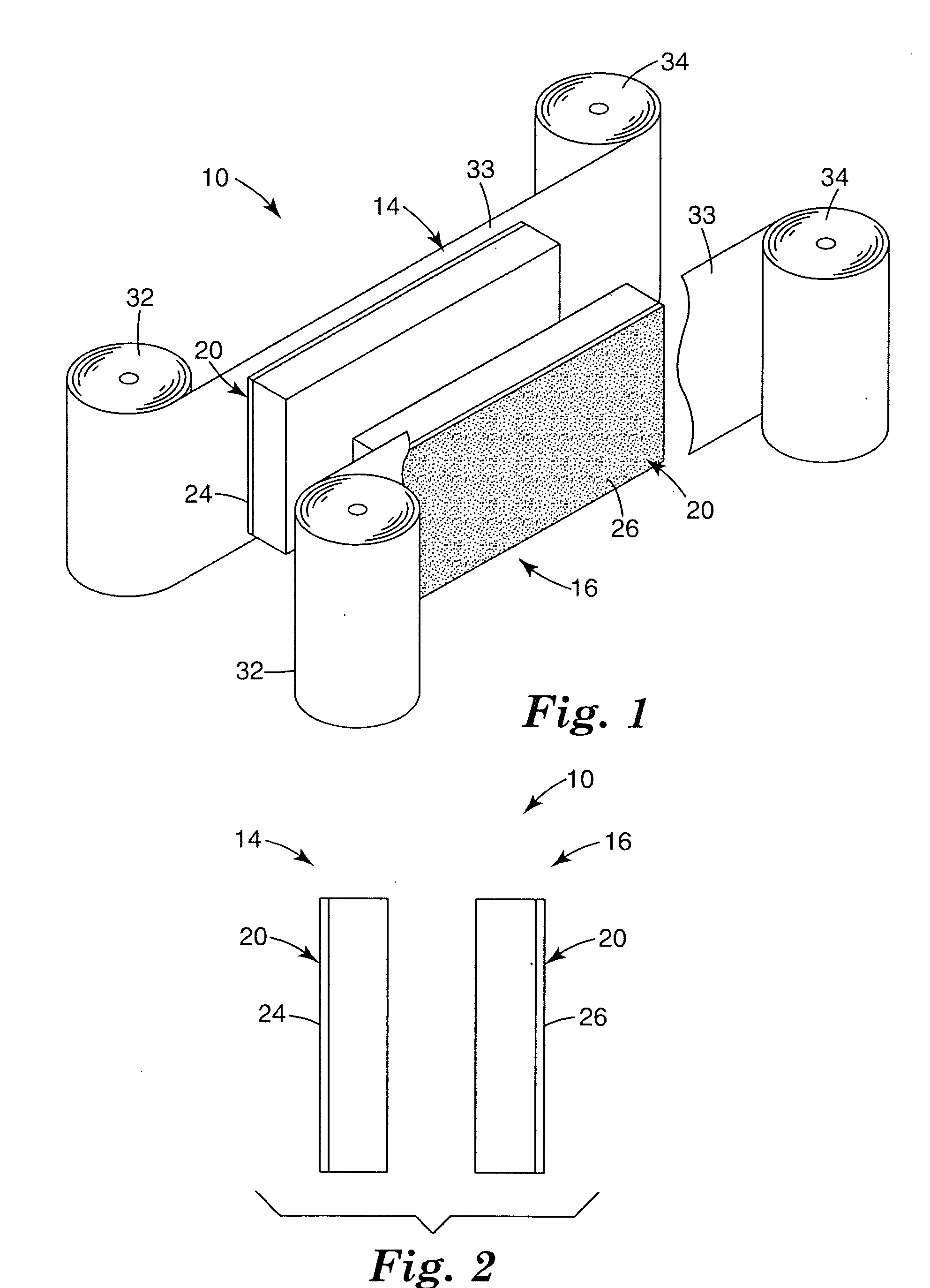

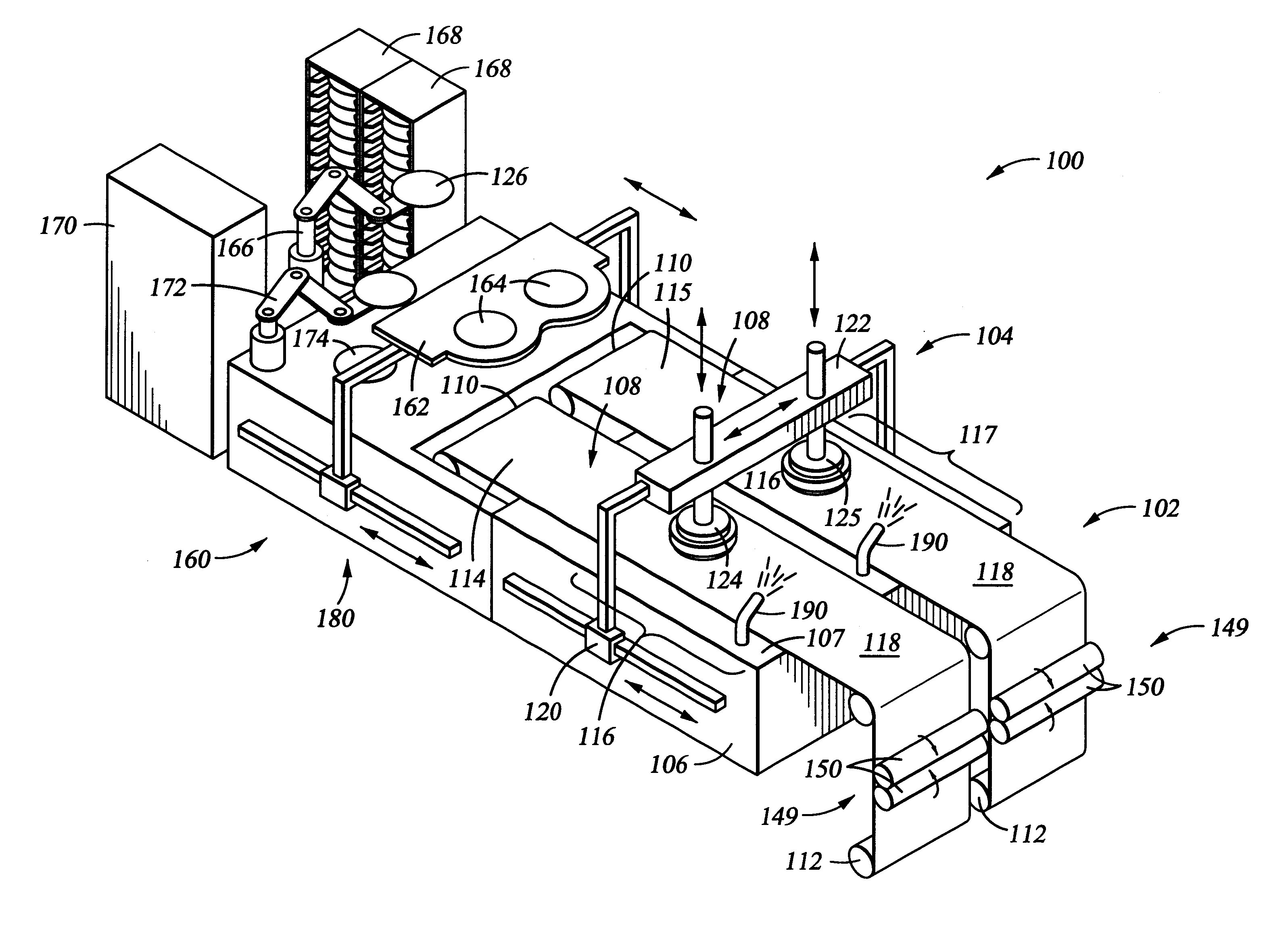

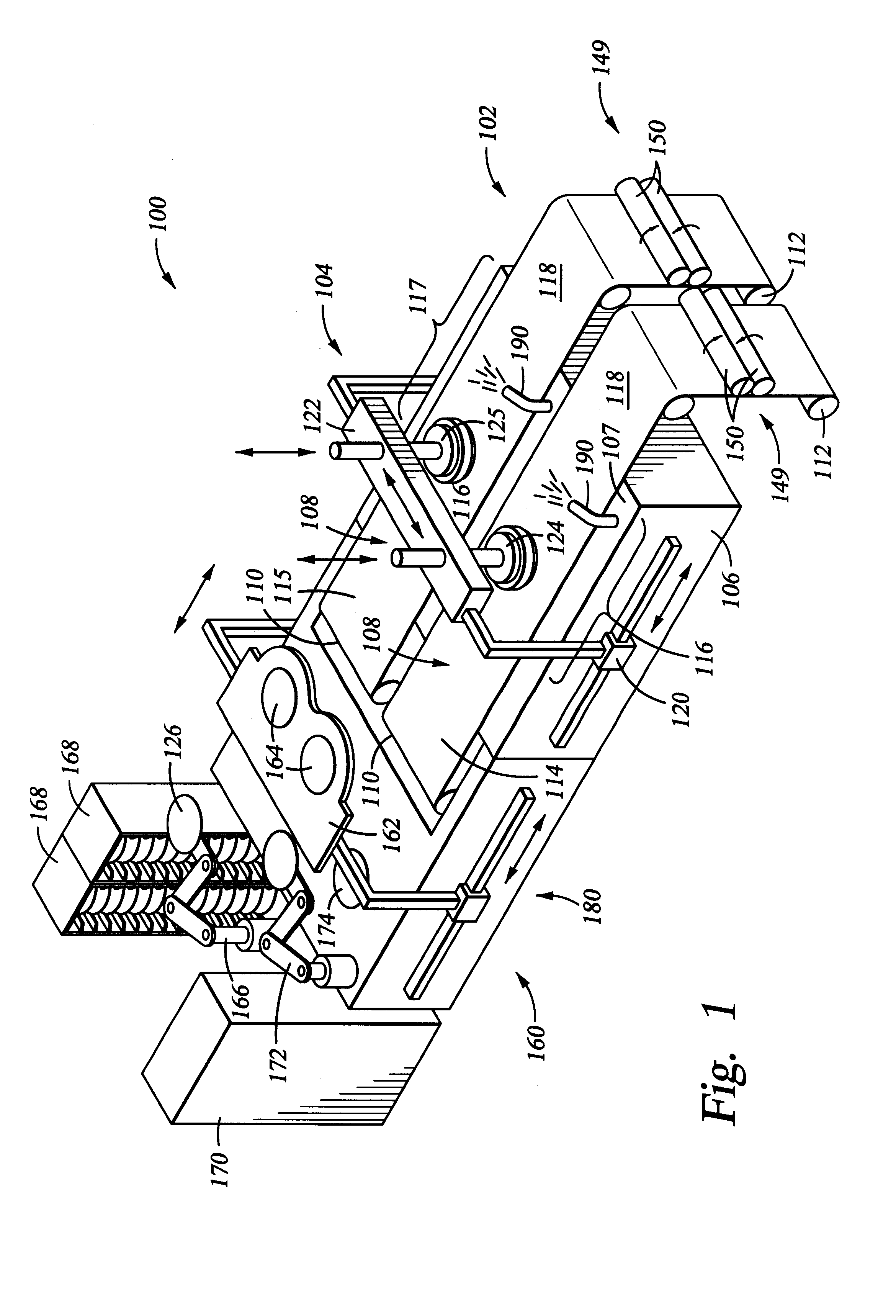

Planarization system with multiple polishing pads

InactiveUS6626744B1Edge grinding machinesPolishing machinesElectrical and Electronics engineeringHead position

An apparatus for simultaneously polishing wafers including at least a first and a second web of polishing media. At least two polishing heads are provided on a carrier coupled to a drive system such that one polishing head positions a wafer against the first web and a second polishing head positions a second wafer against the second web. The drive system imparts a programmed polishing motion or pattern to the polishing heads.

Owner:APPLIED MATERIALS INC

Texturing of magnetic disk substrates

InactiveUS20050142990A1Uniform particle sizeLarge low-frequencyBase layers for recording layersBelt grinding machinesNanometreMaterials science

A method for texturing a substrate for a magnetic disk comprises abrading the substrate using nano-sized diamond particles (e.g. having a diameter less than or equal to 20 nm). A magnetic layer is then deposited over the substrate. Even when the texture is extremely smooth (e.g. less than about 2.2 Å Ra), the disk still exhibits good Hc and MrT orientation ratios, SNR and PW50.

Owner:HOMOLA ANDREW

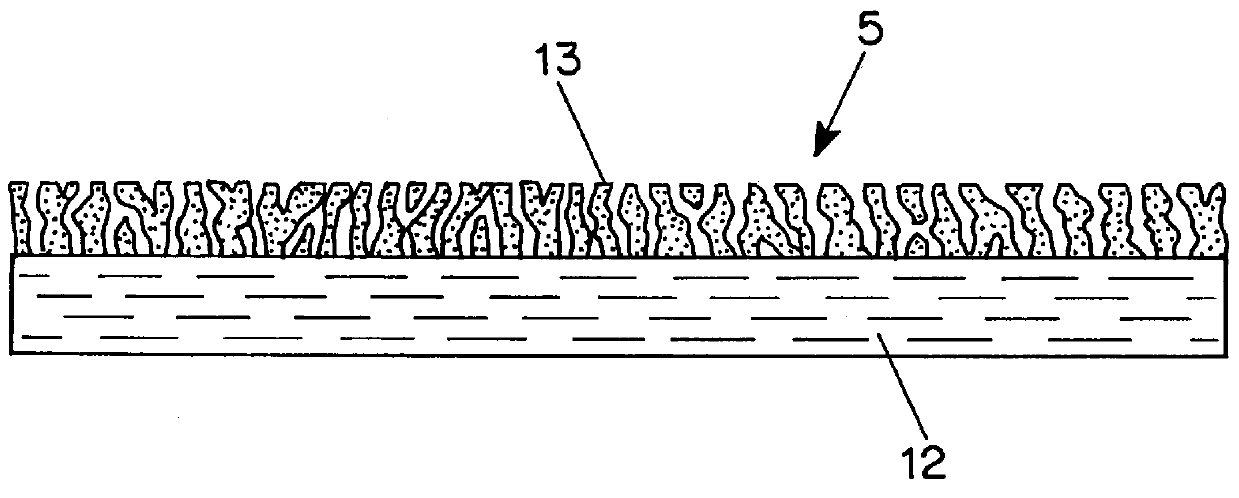

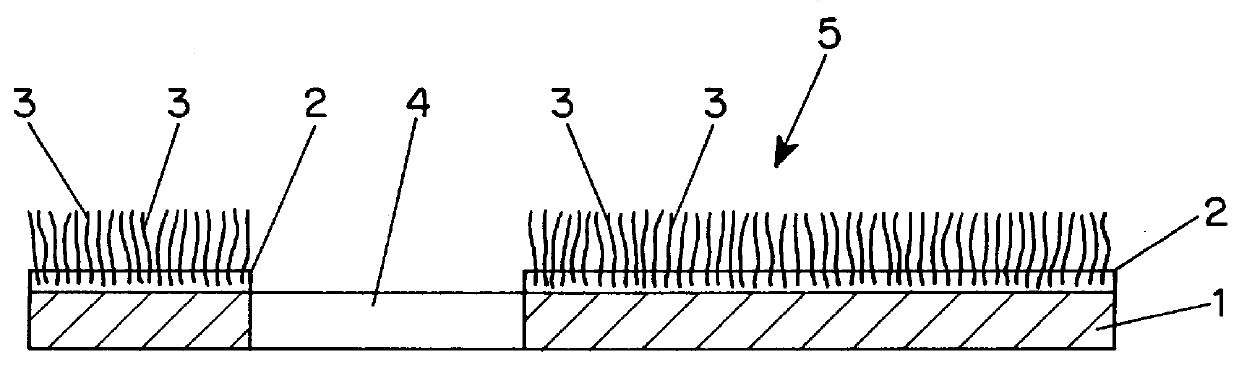

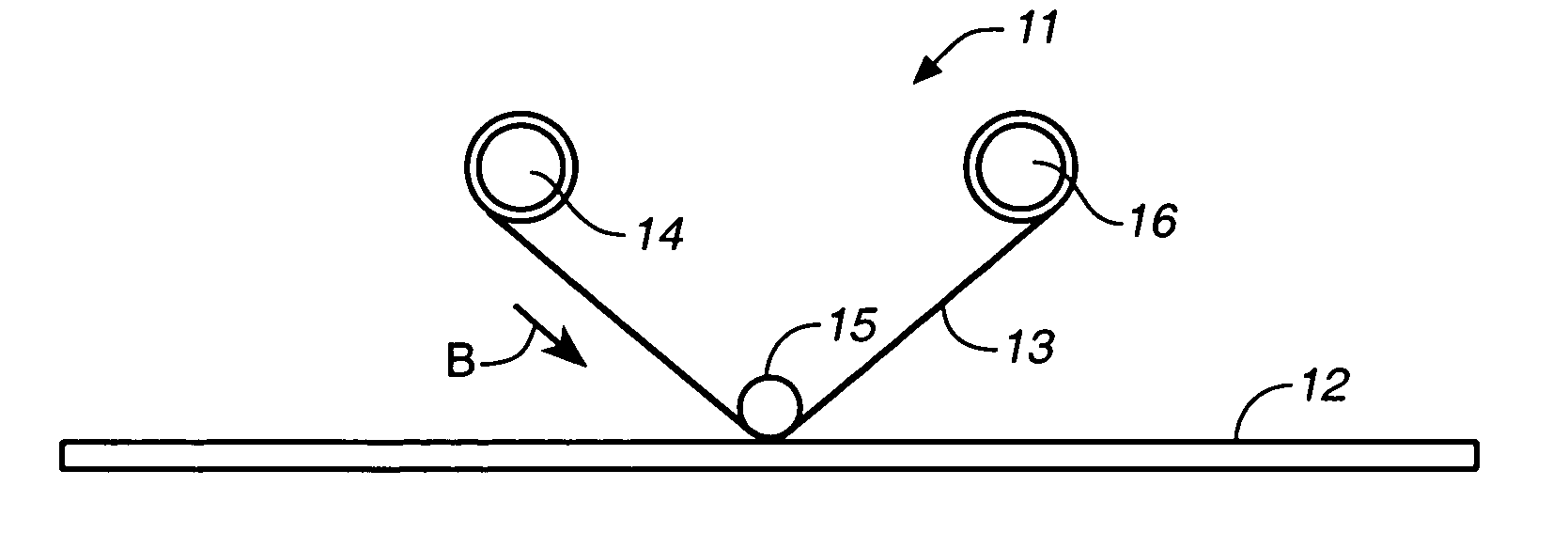

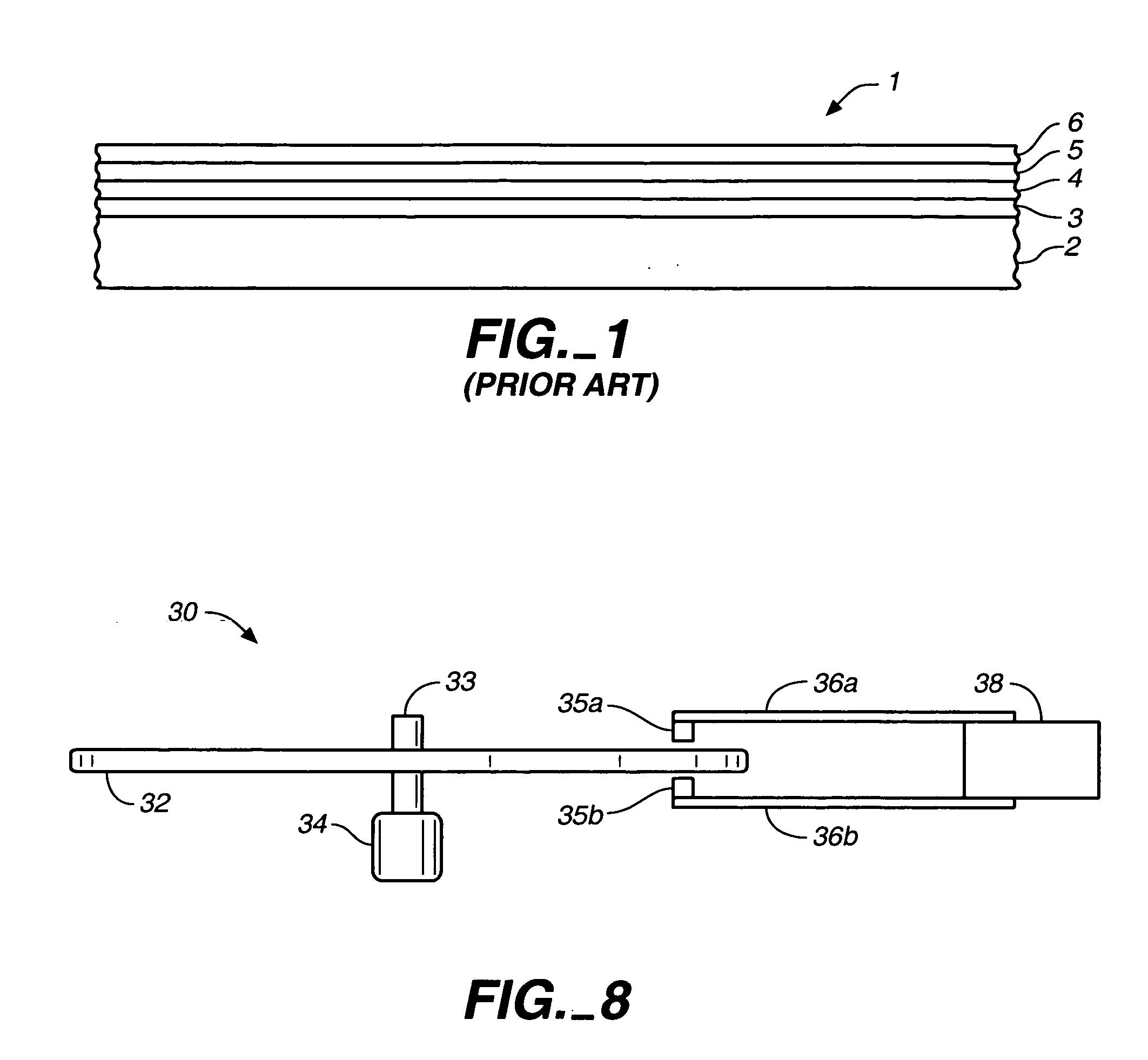

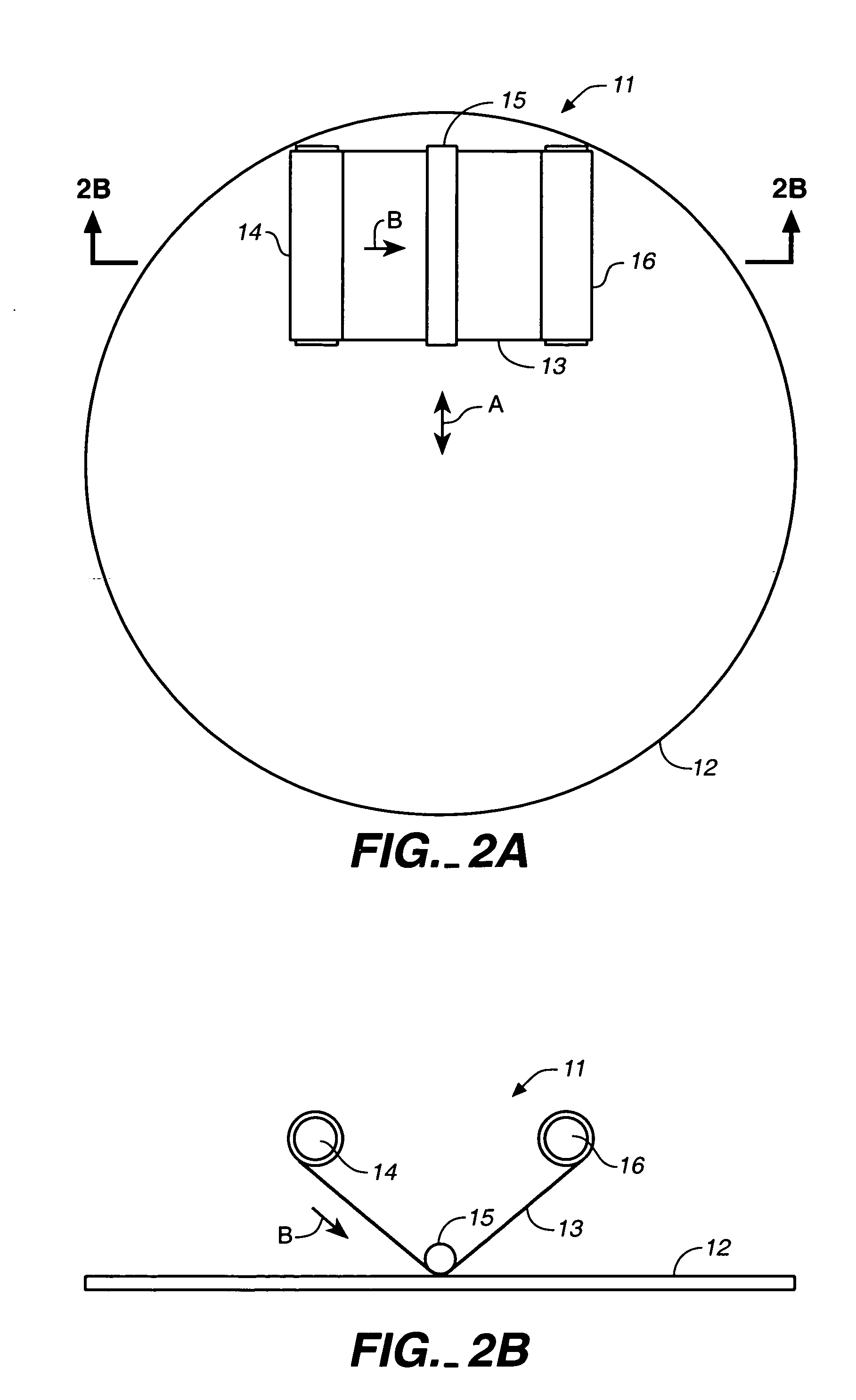

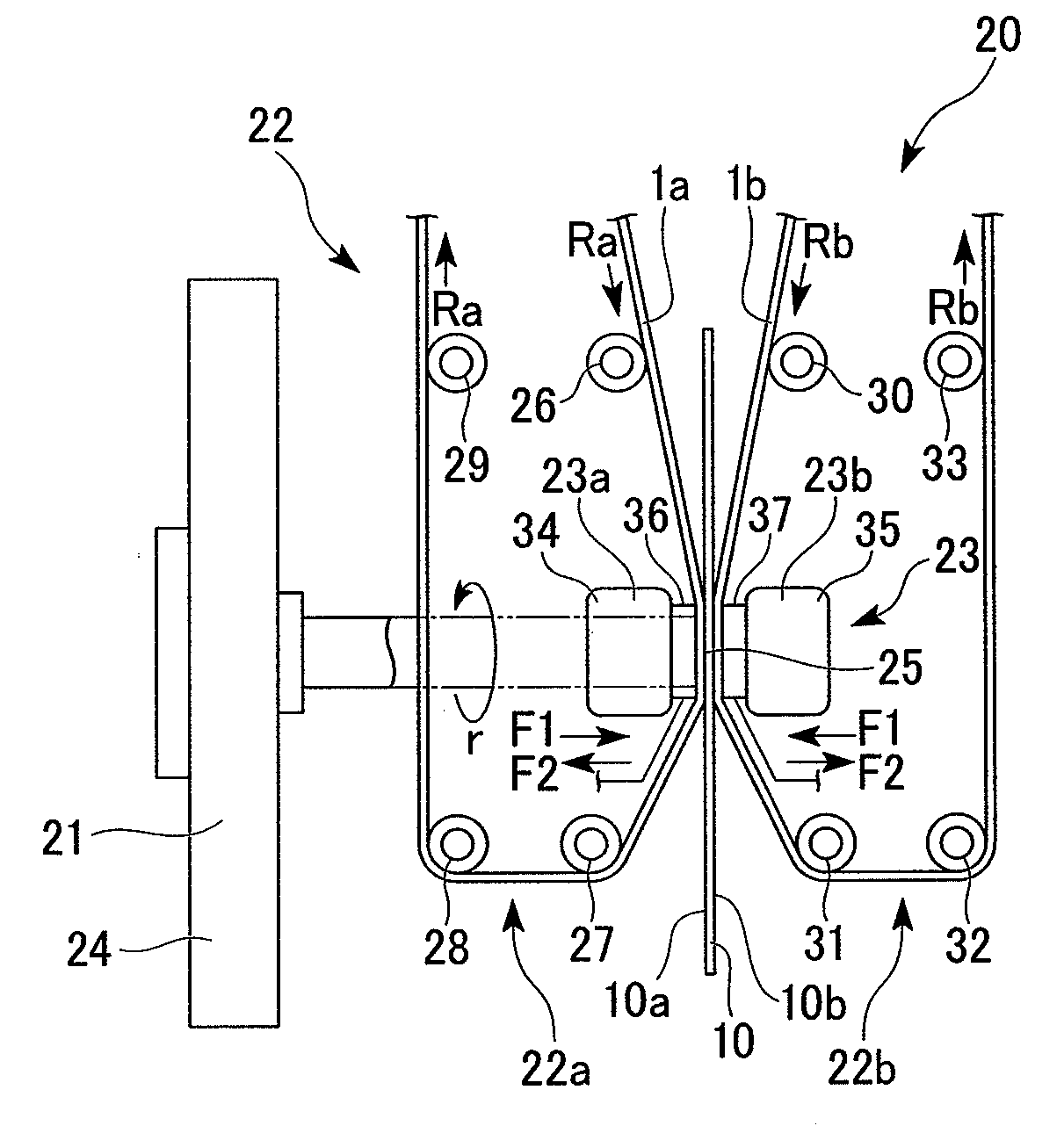

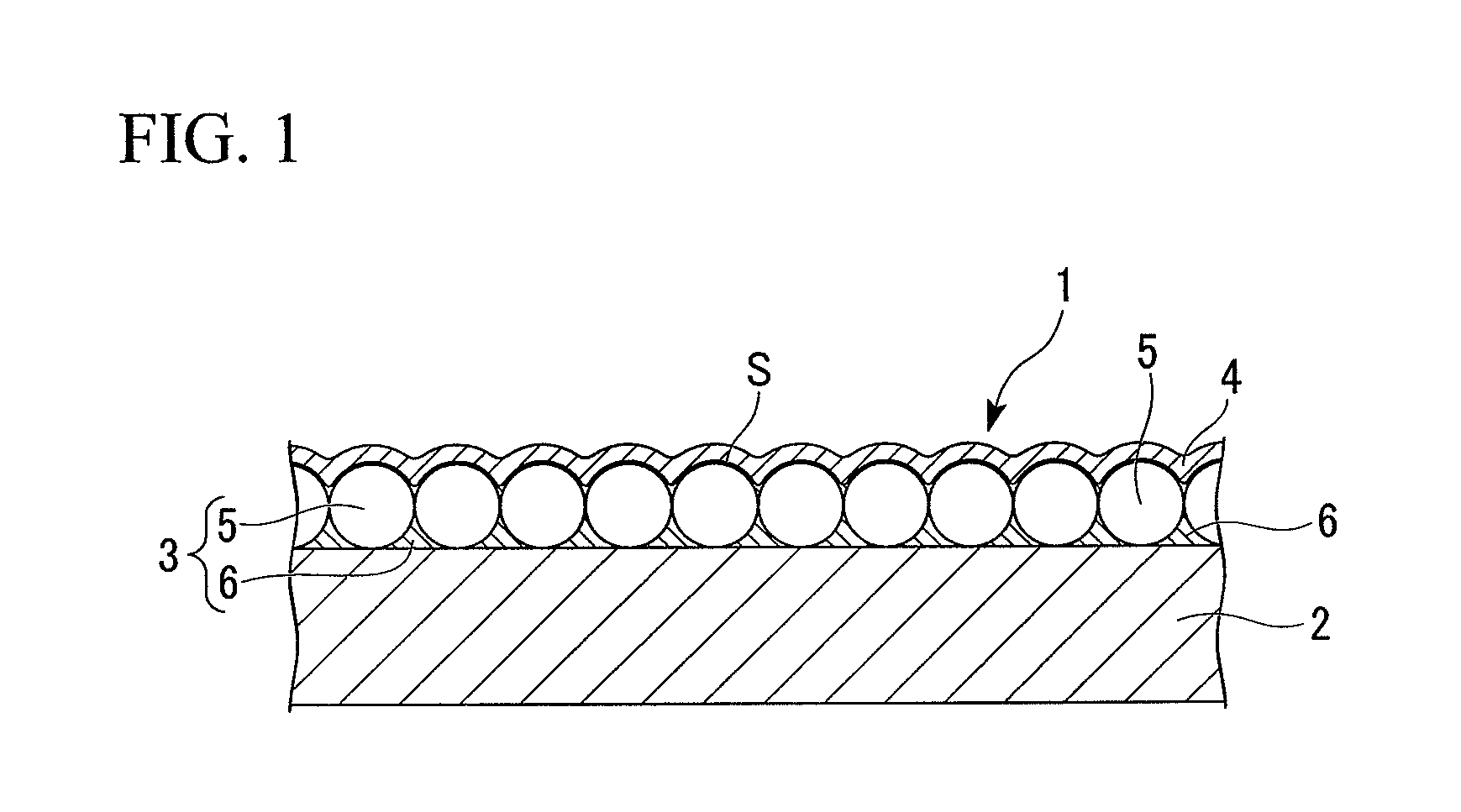

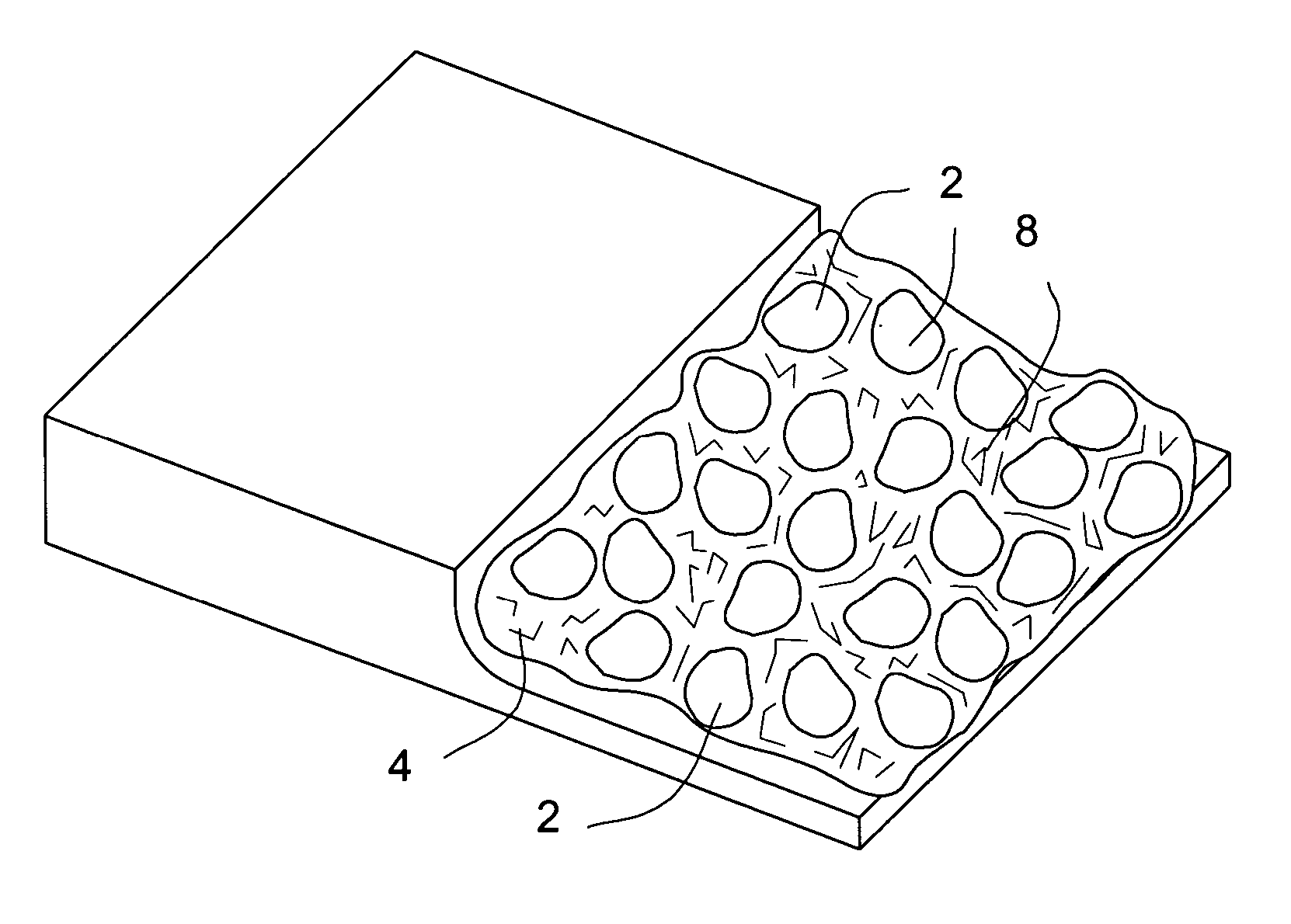

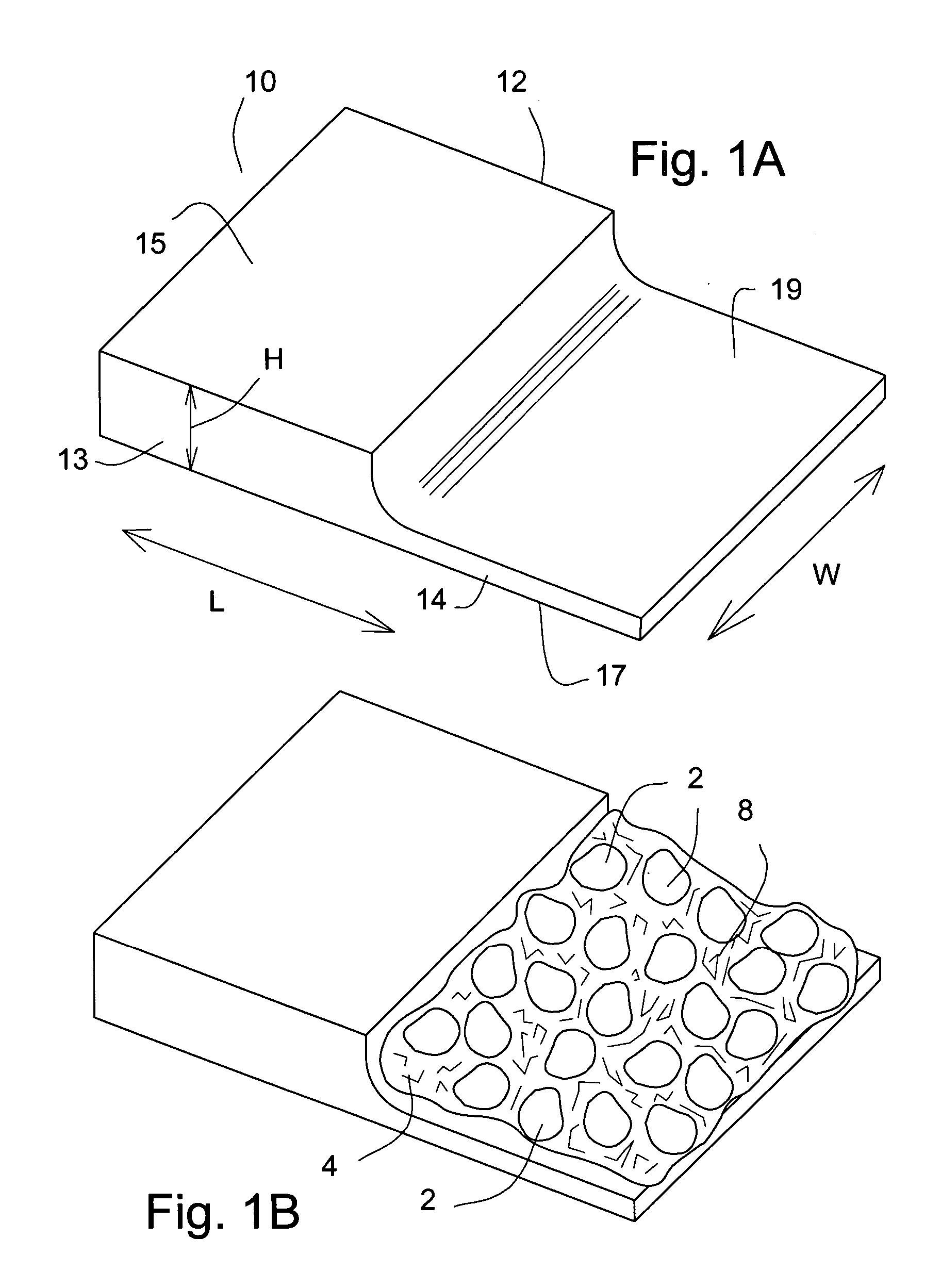

Abrasive tape, method for producing abrasive tape, and varnishing process

ActiveUS20100003900A1Avoid surface contaminationFlat surfaceOther chemical processesBelt grinding machinesSlurryCoating

There are provided an abrasive tape capable of suppressing contamination of a magnetic disk due to shattered abrasive particles and smoothing the surface of the magnetic disk; a method for producing an abrasive tape; and a varnishing process. An abrasive tape 1 produced according to the method for producing an abrasive tape of the invention is used in a process for varnishing a magnetic disk and produced according to a process for preparing a slurry by kneading and dispersing abrasive particles 5 and a binding agent 6; a process for forming a coating film by applying the slurry on a support 2; a process for forming an abrasive particle layer 3 by hardening the coating film; and a process for forming a coating layer 4 on the surface of the abrasive particle layer 3.

Owner:RESONAC CORP

Abrasive articles, CMP monitoring system and method

ActiveUS7840305B2Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, and at least one of a radio frequency identification (RFID) tag, a RFID tag reader, or a sensor for providing CMP information to a transmitter positioned near the substrate, the transmitter positioned near the substrate and adapted to wirelessly receive CMP information and wirelessly transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner for wirelessly communicating CMP information to a remote receiver, a CMP process monitoring system for wirelessly communicating CMP information to a remote receiver, and a method for conditioning a CMP pad using a CMP process monitoring system for wireless communicating CMP information to a remote receiver.

Owner:3M INNOVATIVE PROPERTIES CO

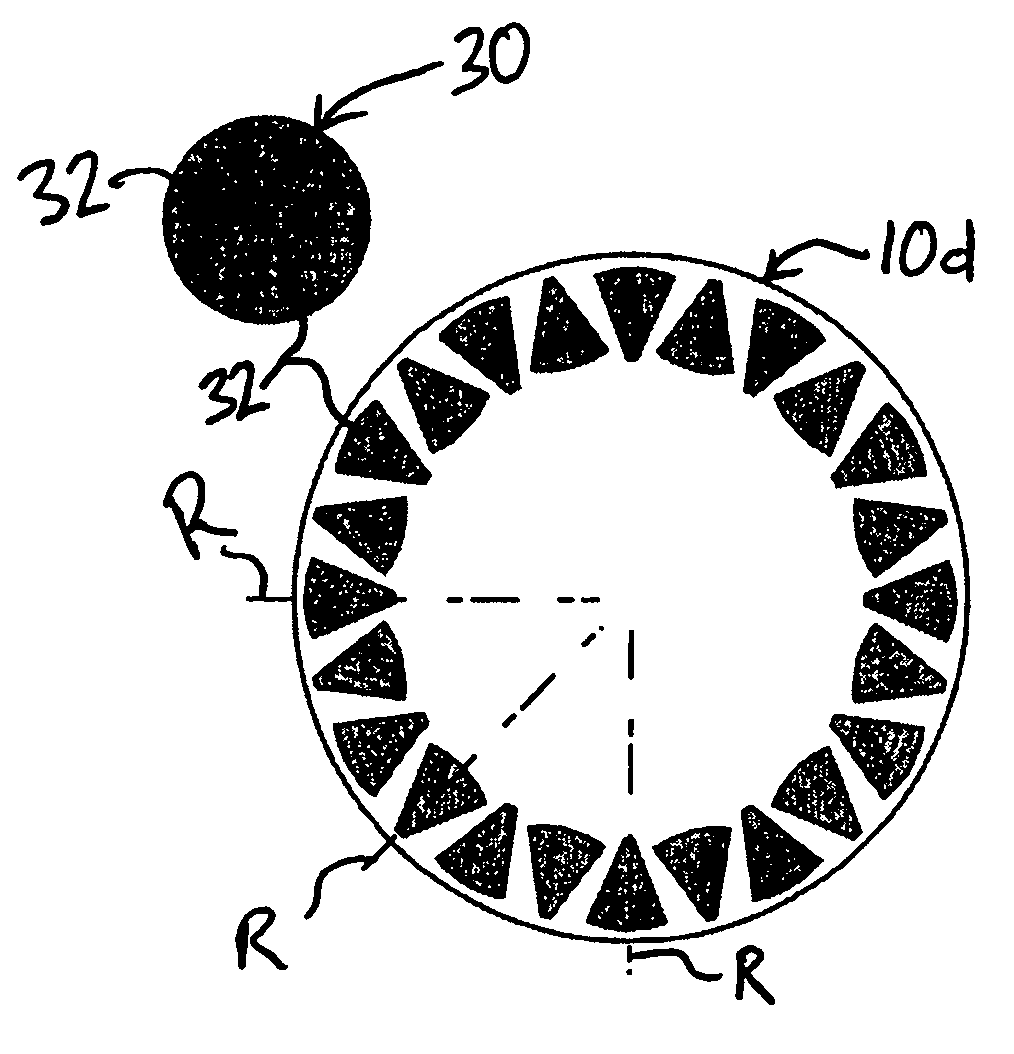

CMP diamond conditioning disk

A method of making and the resulting non-metallic CMP conditioning pad comprising a non-metallic substrate and a single layer of abrasive particles bonded to the substrate by a non-metallic bonding medium. Preferred substrates include aluminum oxide and graphite. A bonding system employing finely powdered aluminum oxide particles mixed with a suitable adhesive is employed to bond the abrasive layer to the aluminum oxide substrate. Silicon carbide particles mixed into a compatible adhesive carrier including a polymer composition is preferred for bonding the abrasive particle layer to a graphite or carbide substrate.

Owner:ABRASIVE TECH

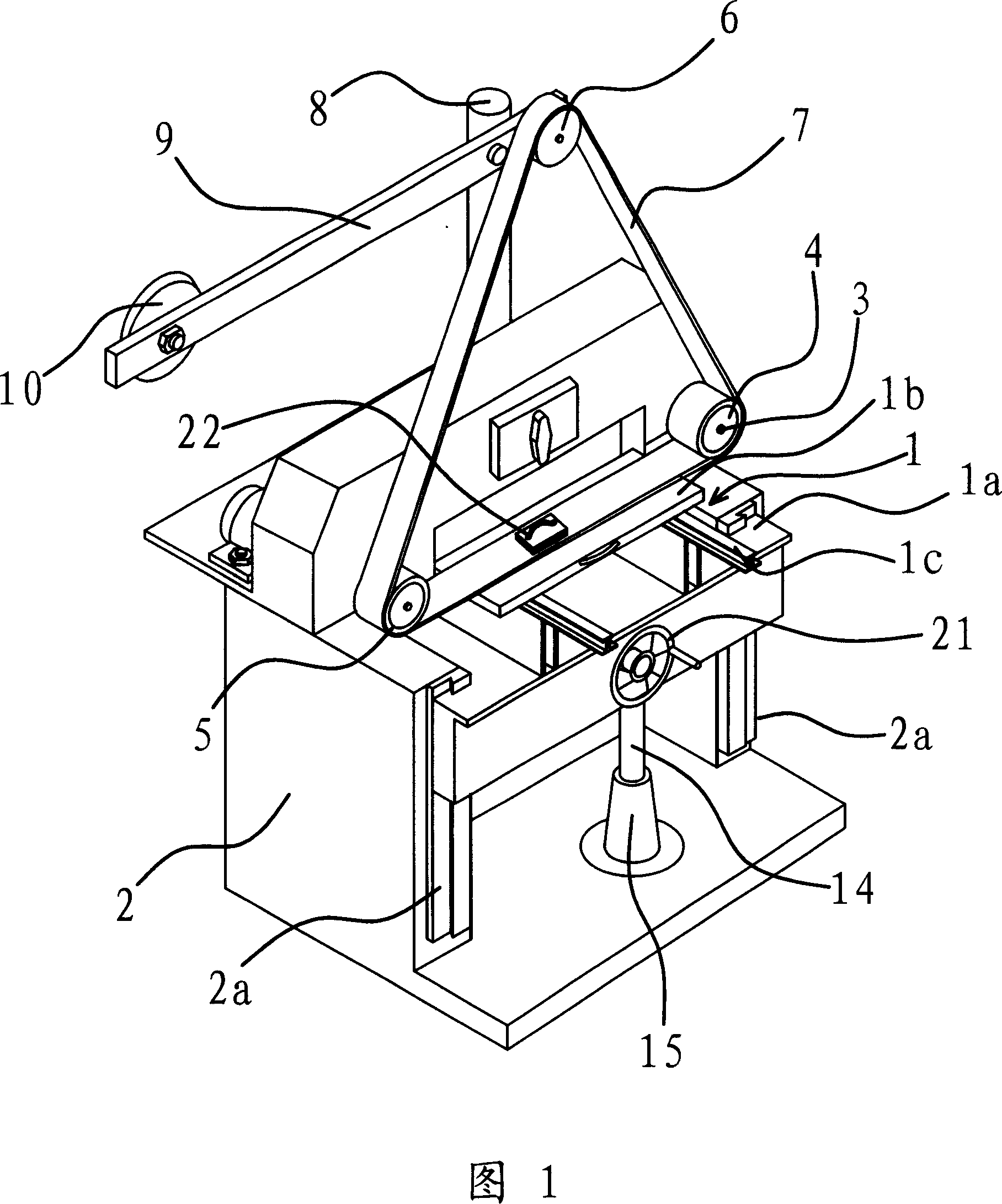

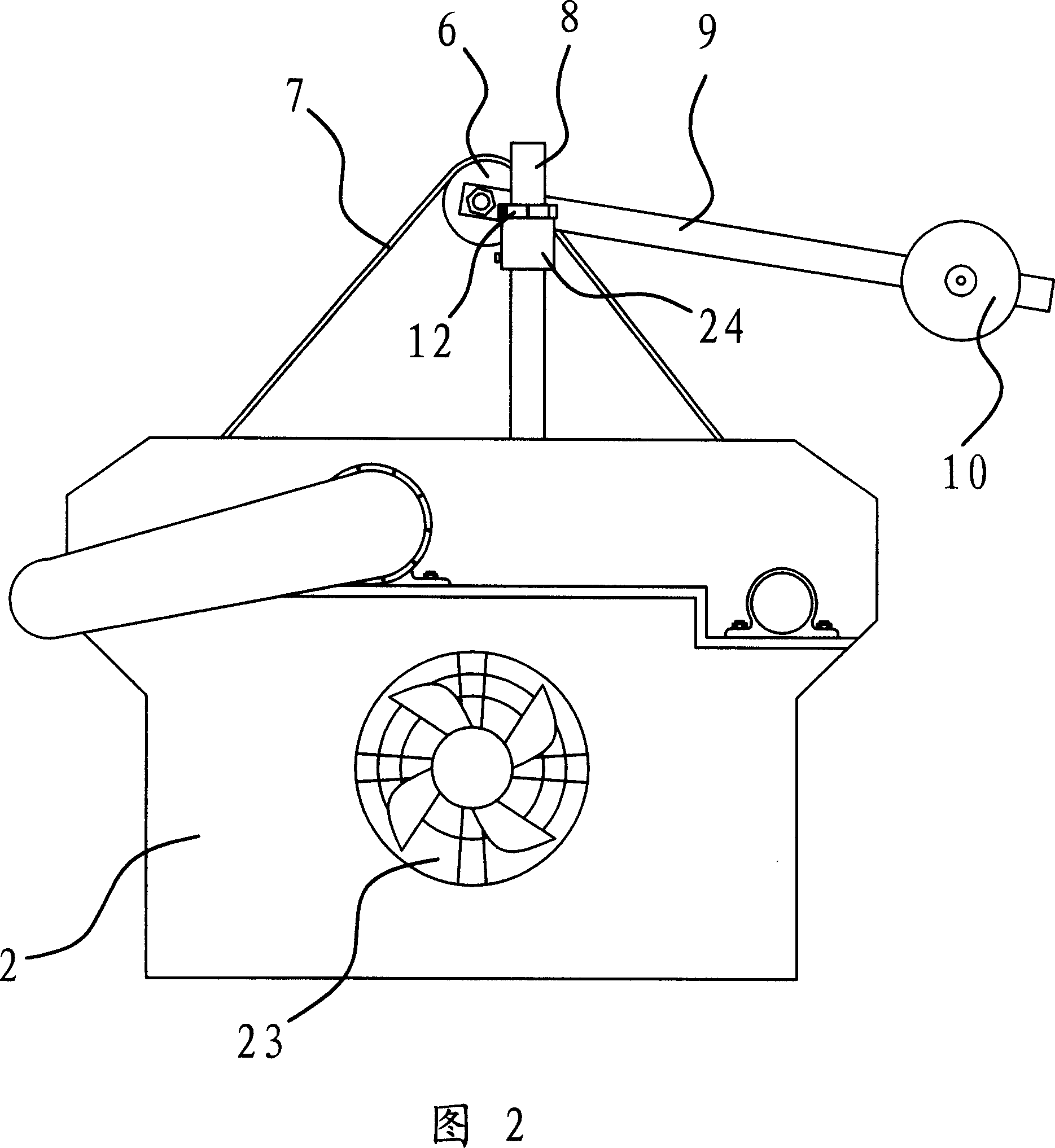

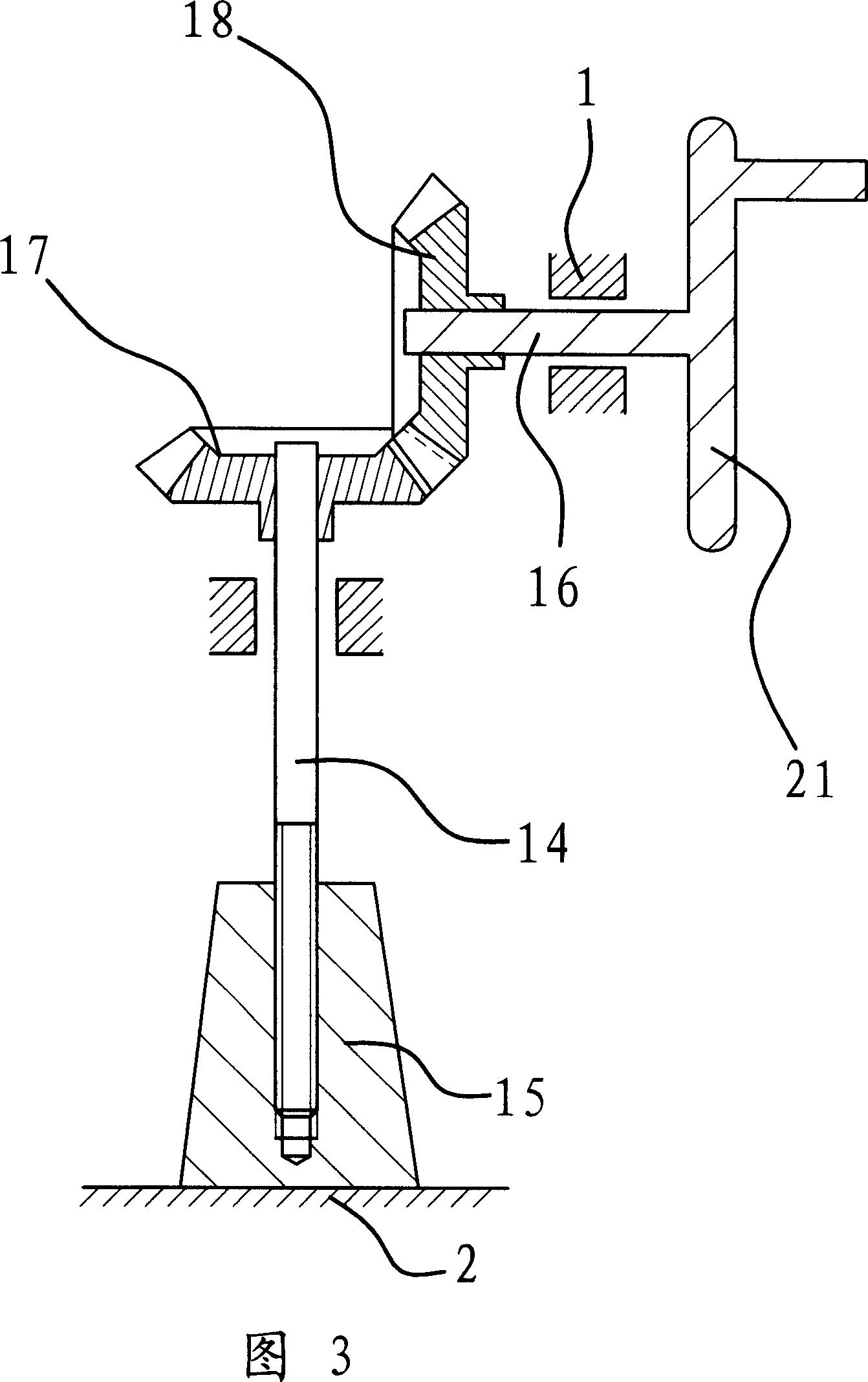

Flat grinding abrasive belt polishing machine

InactiveCN1962191ATension free adjustmentVarious adjustment methodsBelt grinding machinesEngineeringMechanical engineering

The invention relates to a plat frost belt furnishing device, wherein it comprises a frame with work bench; the rotation axle of frame connected to the power device; the rotation axle is connected to the active wheel; the frame is mounted with inactive wheel and tension wheel; the active, inactive and tension wheels are sheathed with abrasive belt; the work bench is near and parallel to the abrasive belt; the frame has post with the tension wheel; there is a tension device between the tension wheel and the post to move the tension wheel. The invention has long service life, high produce efficiency and simple operation.

Owner:江苏优氟防腐科技有限公司

Abrasive tool for use as a chemical mechanical planarization pad conditioner

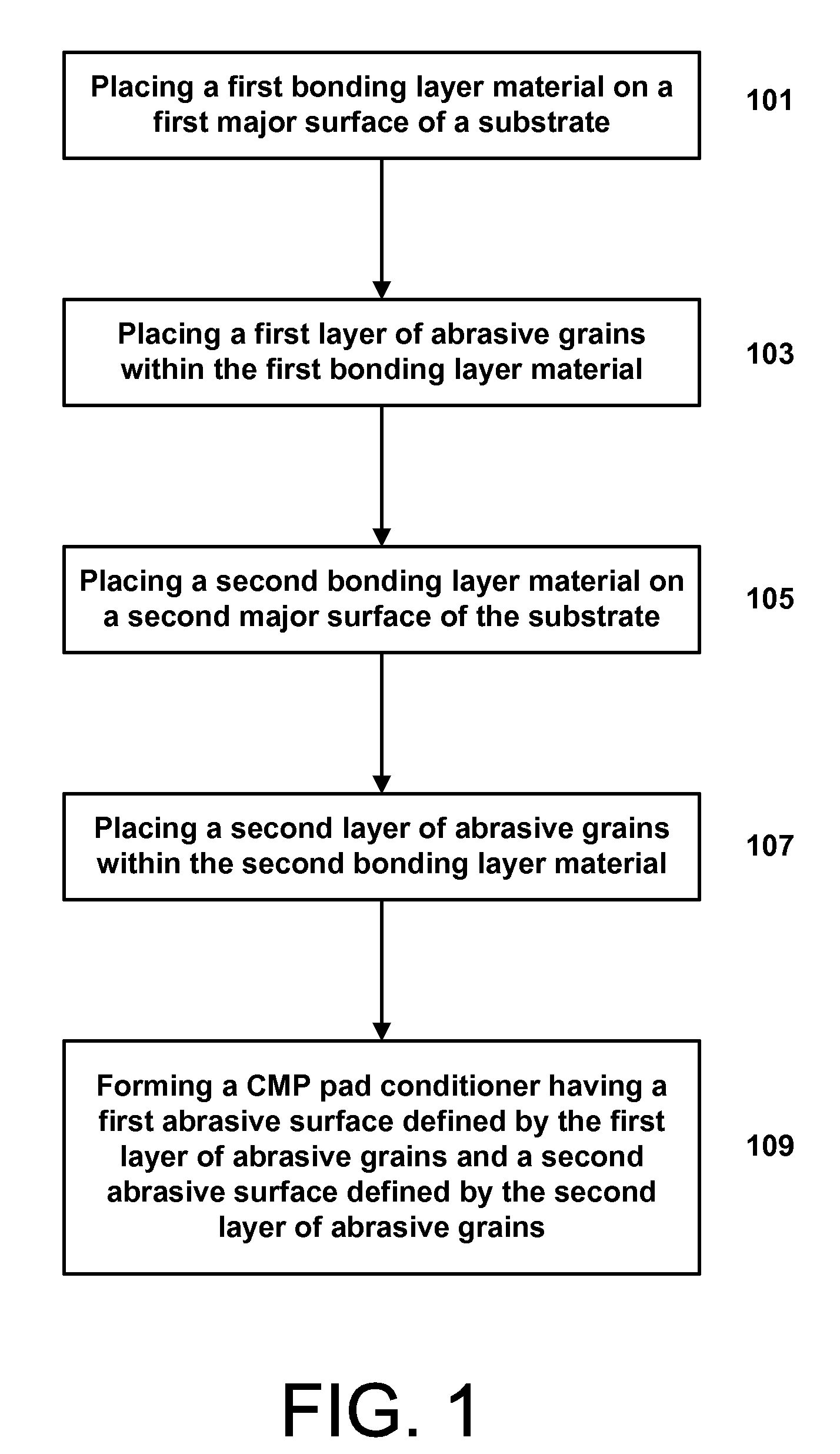

An abrasive tool including a CMP pad conditioner having a substrate including a first major surface, a second major surface opposite the first major surface, and a side surface extending between the first major surface and the second major, wherein a first layer of abrasive grains is attached to the first major surface and a second layer of abrasive grains is attached to the second major surface. The conditioner further includes a first sealing member extending in a peripheral direction along a portion of the side surface of the substrate.

Owner:SAINT GOBAIN ABRASIVES INC +1

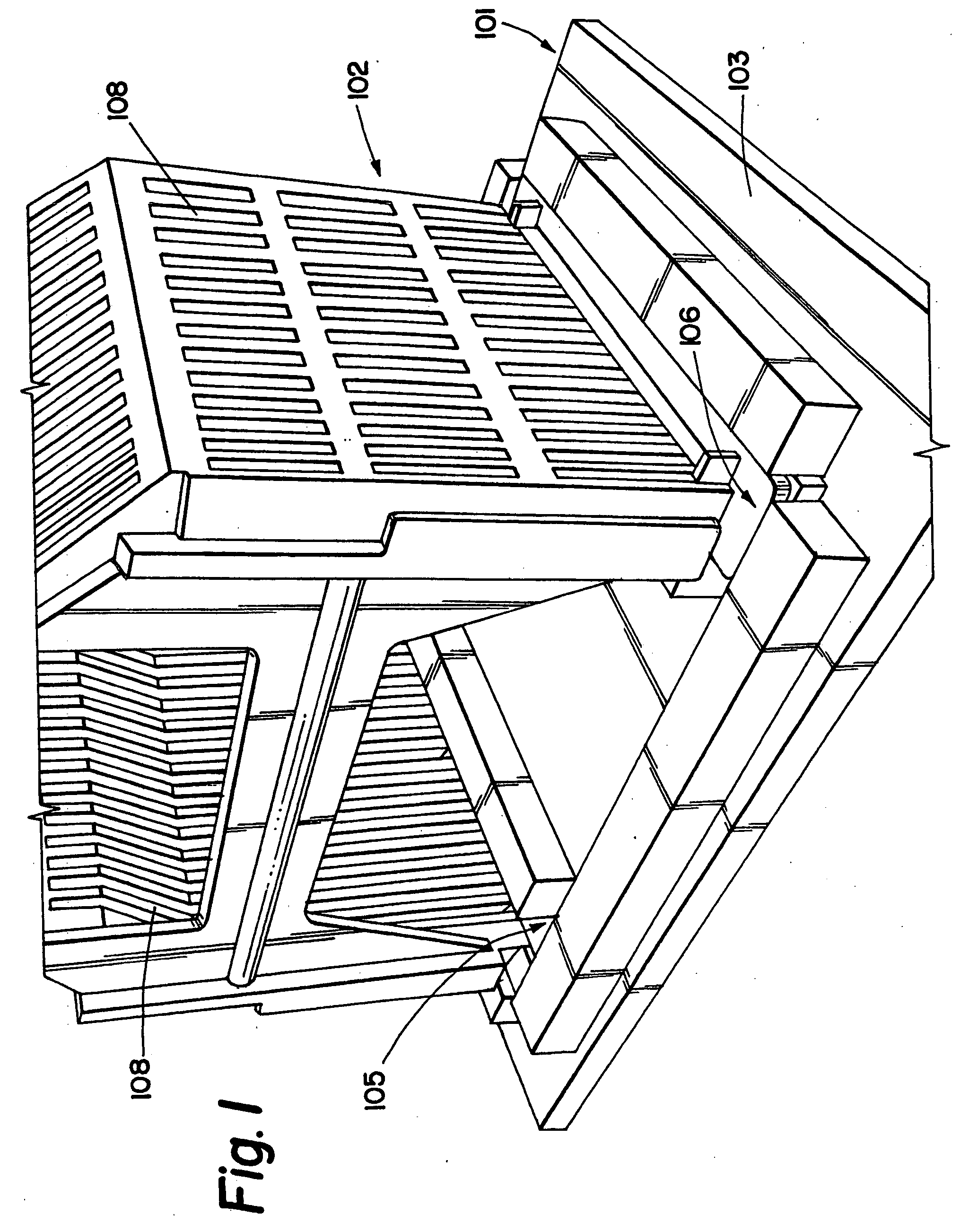

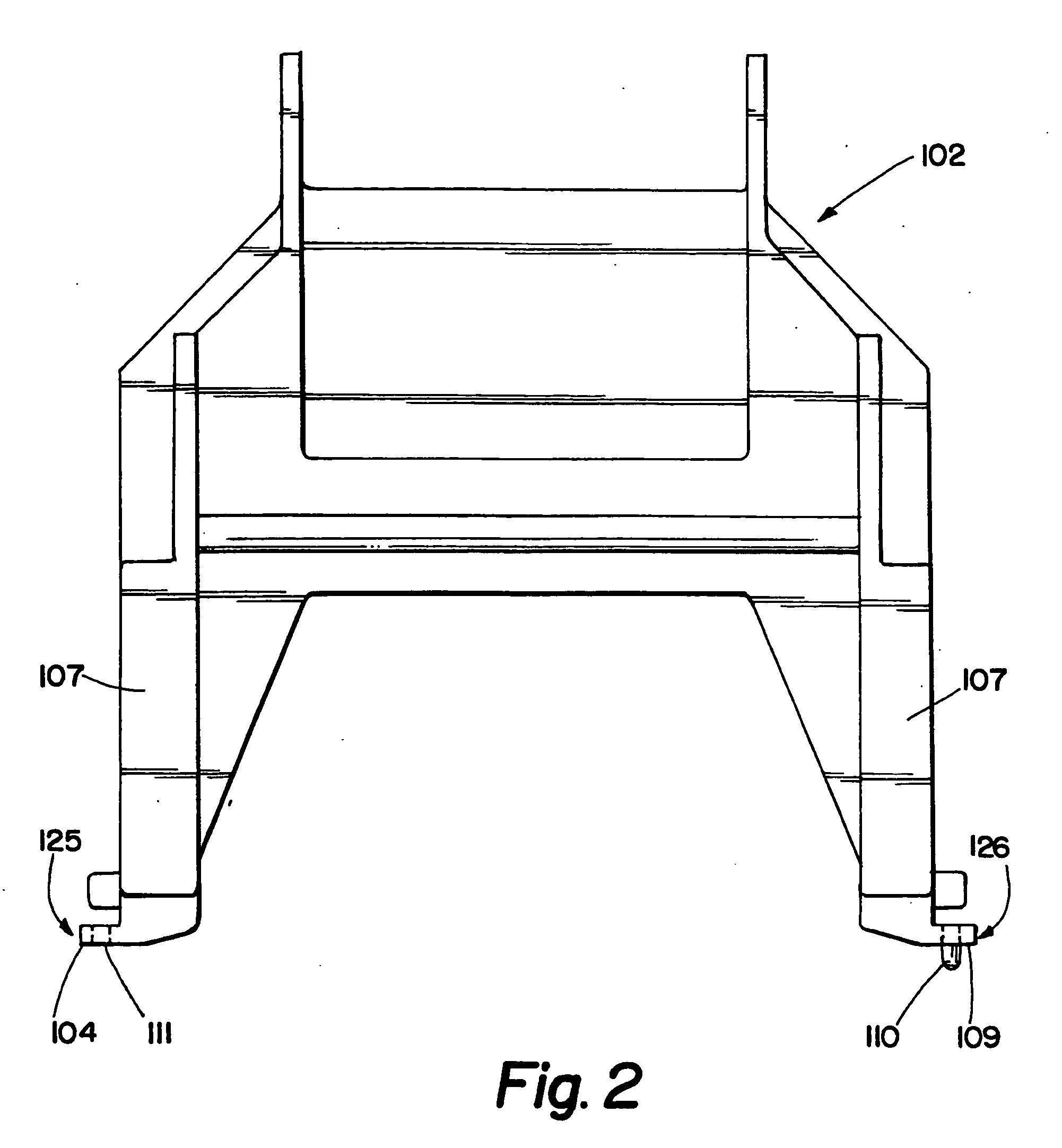

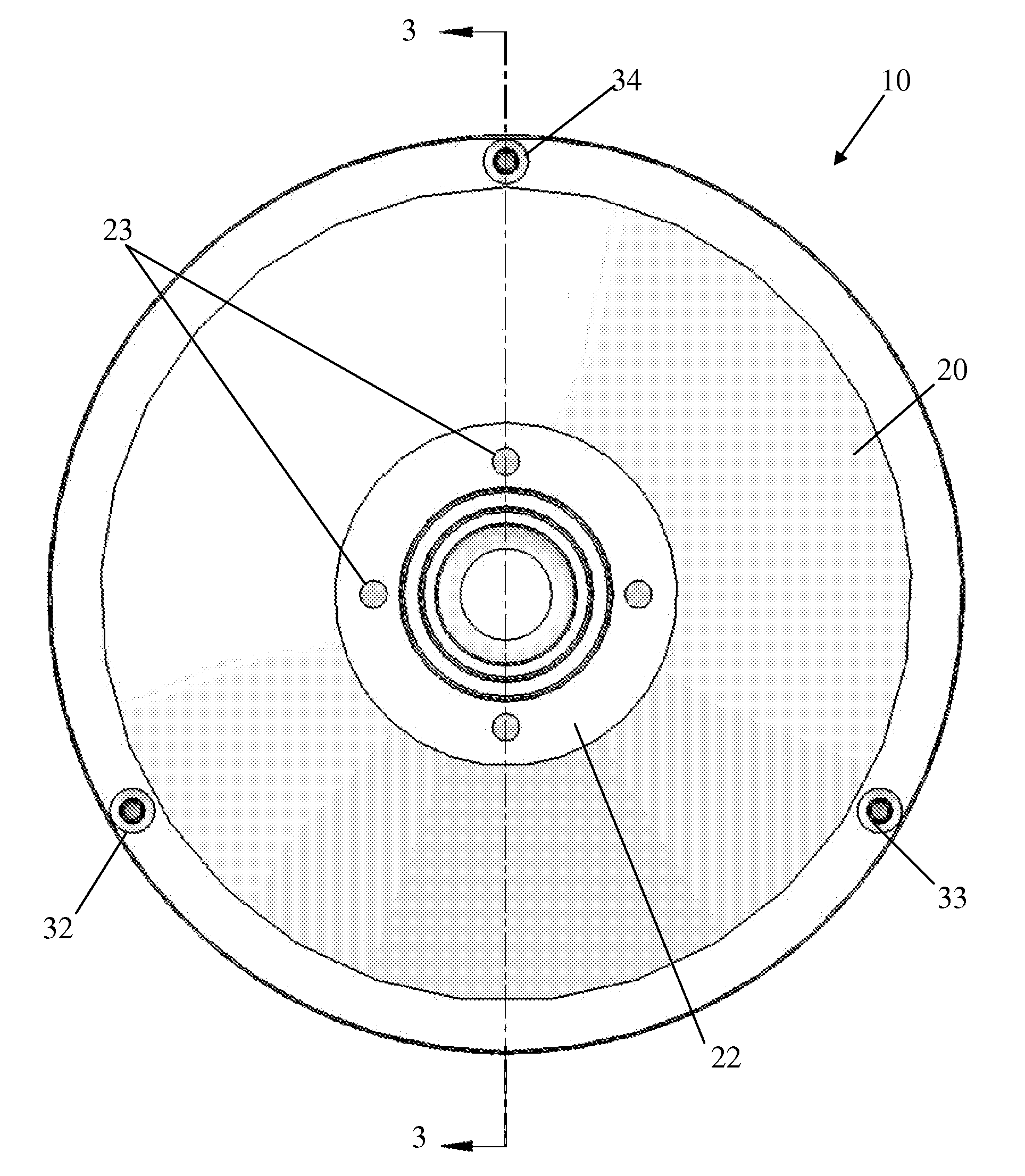

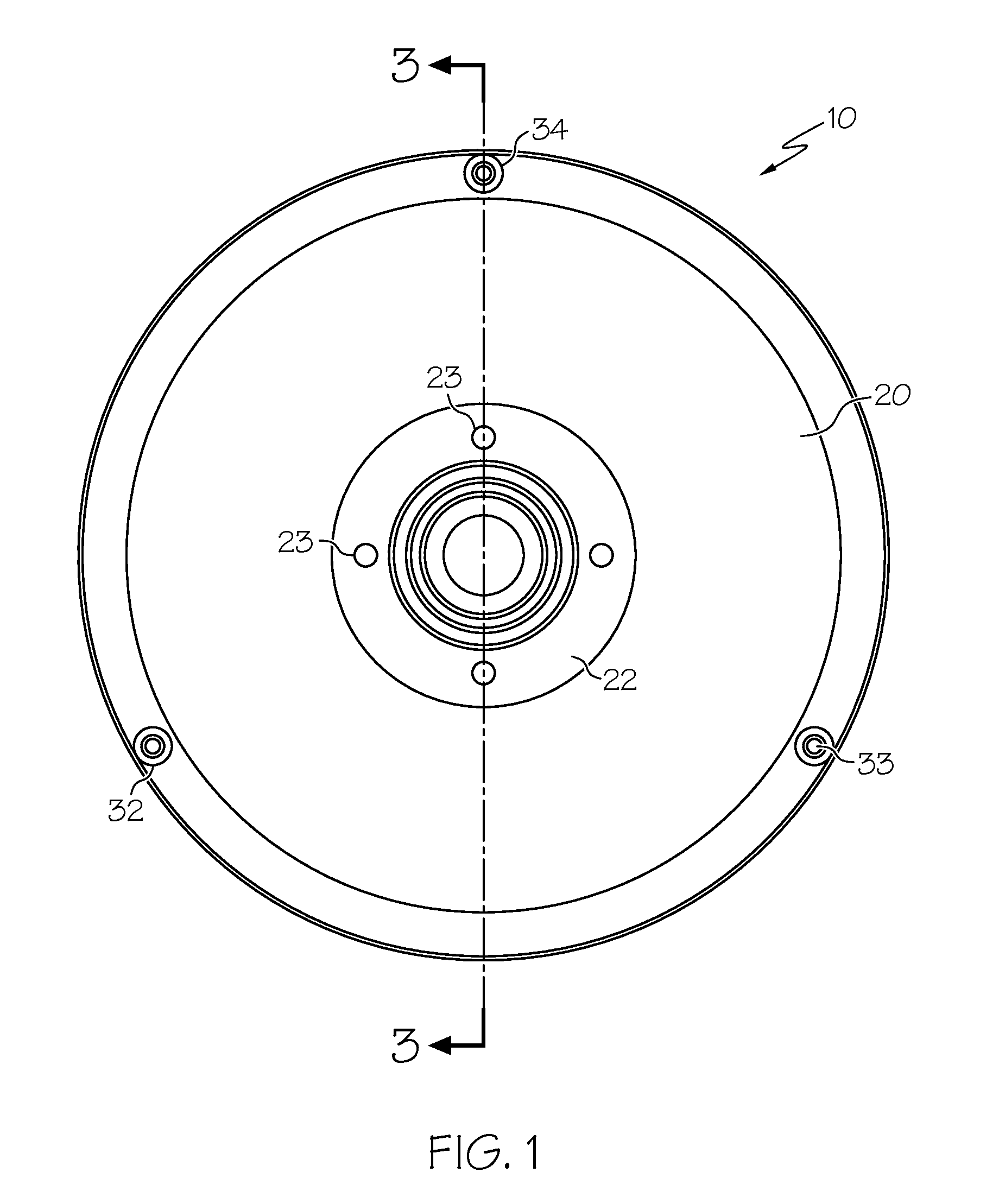

Multiple-sided cmp pad conditioning disk

InactiveUS20110097977A1Efficiently provideGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A conditioning tool for restoring a used CMP polishing pad to an operable condition. The tool includes a base that attaches to a driven machine and has a surface from which a shoulder protrudes that receives a peripheral edge of a disk. The disk has two opposing surfaces, each of which is substantially planar and has abrasive mounted thereon. The disk's peripheral edge is held in place between the base shoulder and a ring that has a shoulder that is complementary to the disk's peripheral edge. The ring is fastened to the base with the abrasive of the first disk surface protruding through an aperture in the ring, and the opposing disk surface spaced from the base's surface. After the disk's first surface is worn, the disk can be turned around to expose the opposite surface's abrasive to a CMP pad.

Owner:ABRASIVE TECH

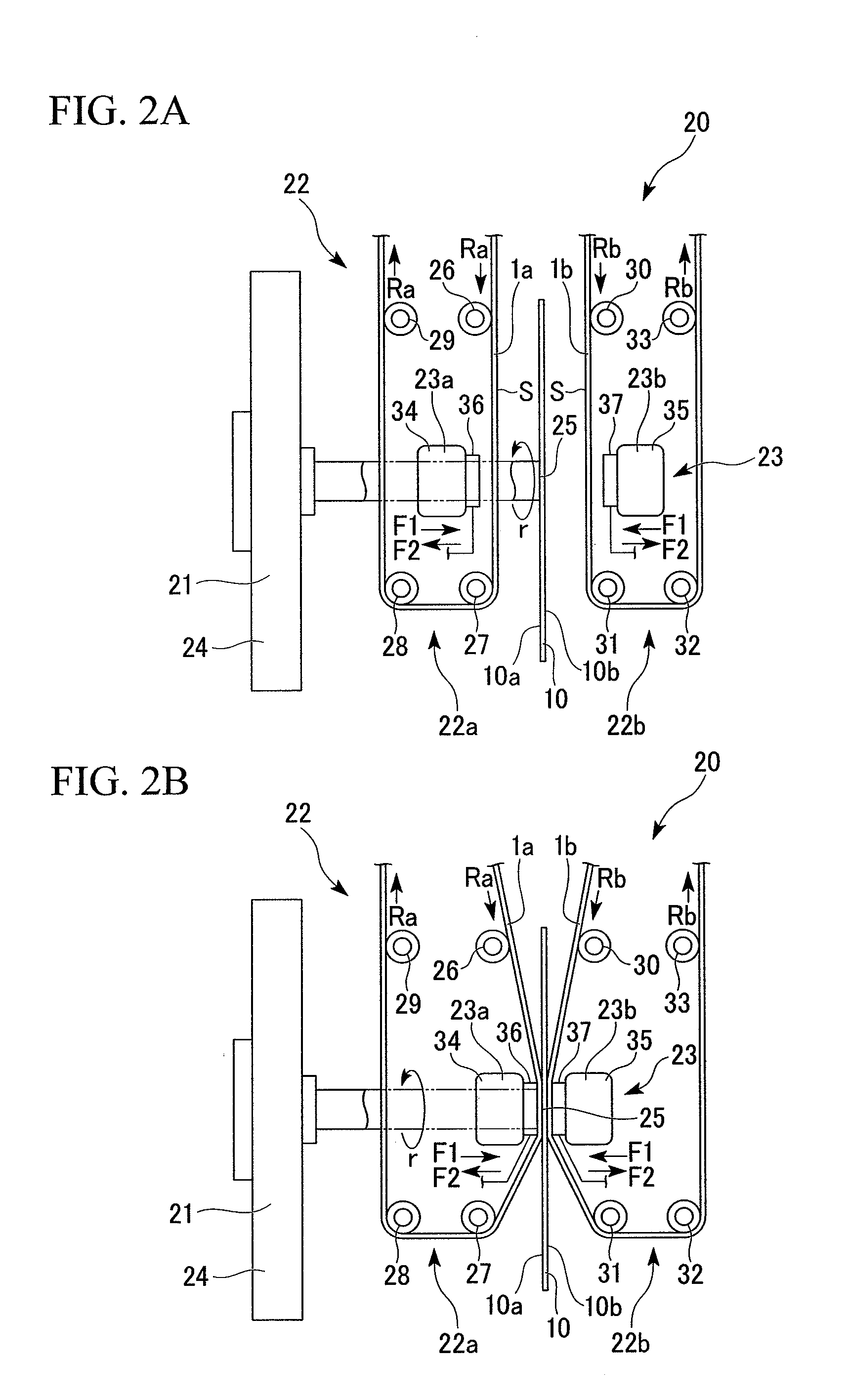

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

Superhard cutters and associated methods

A cutting device comprises a plurality of individual polycrystalline cutting elements secured in a solidified organic material layer. Each of the plurality of individual polycrystalline cutting elements has a substantially matching geometric configuration.

Owner:KINIK

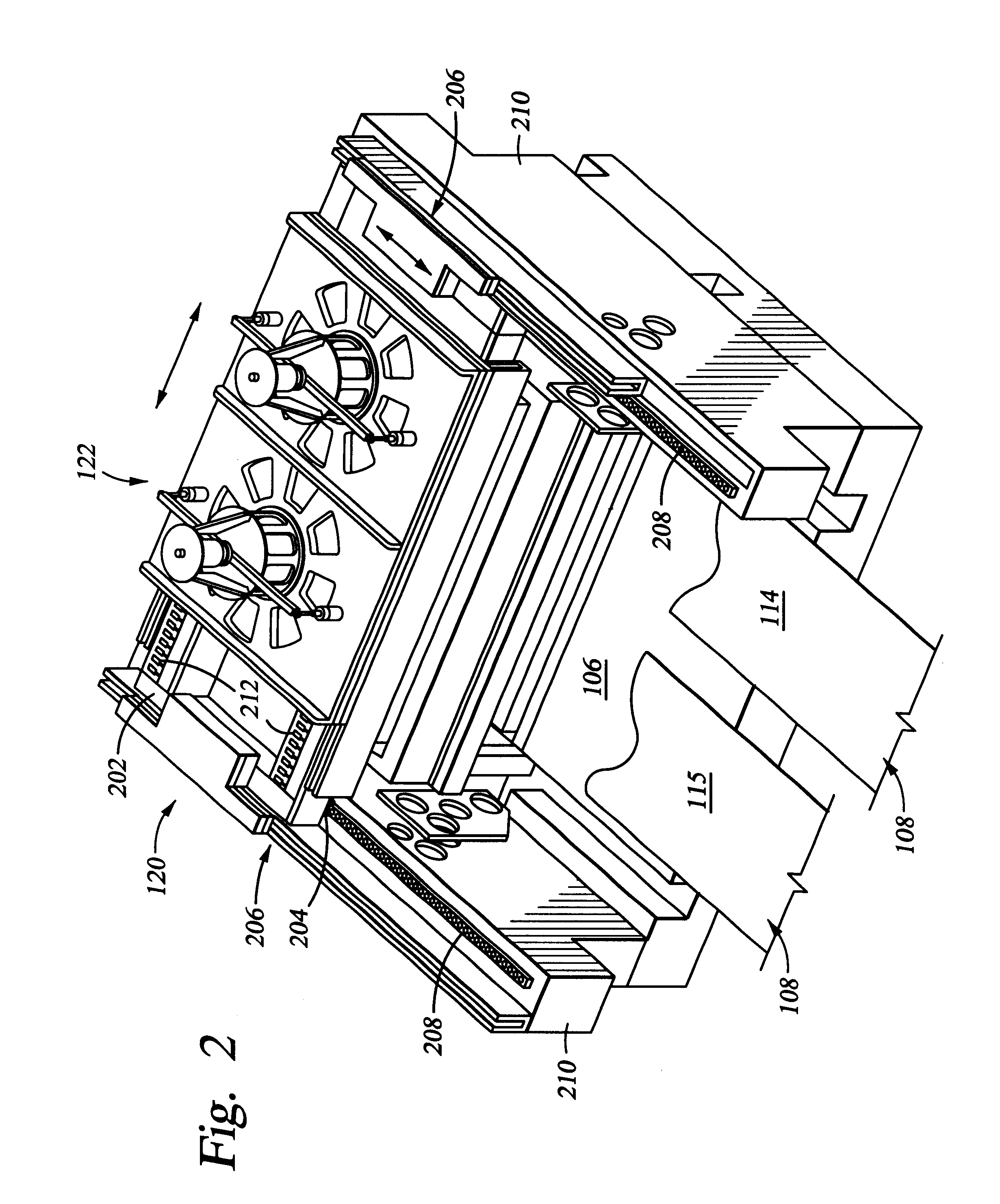

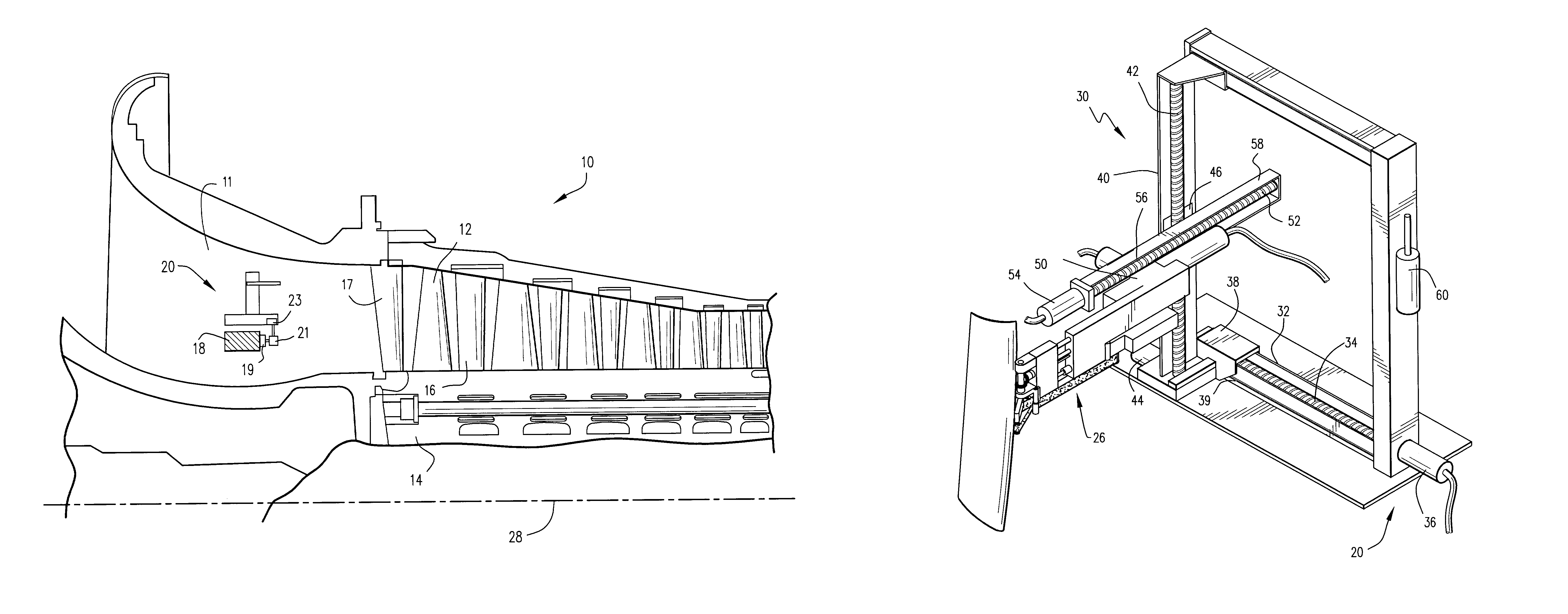

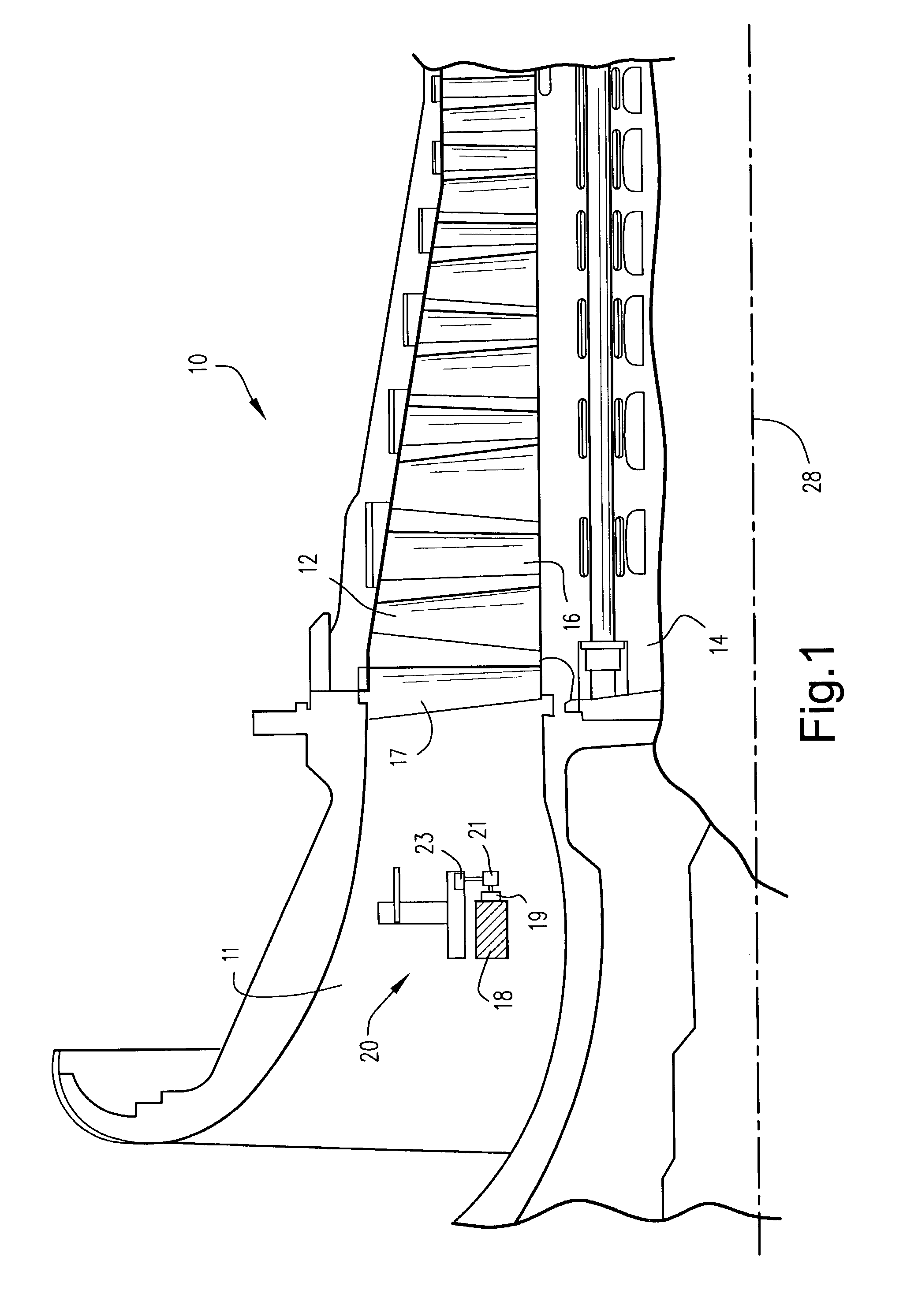

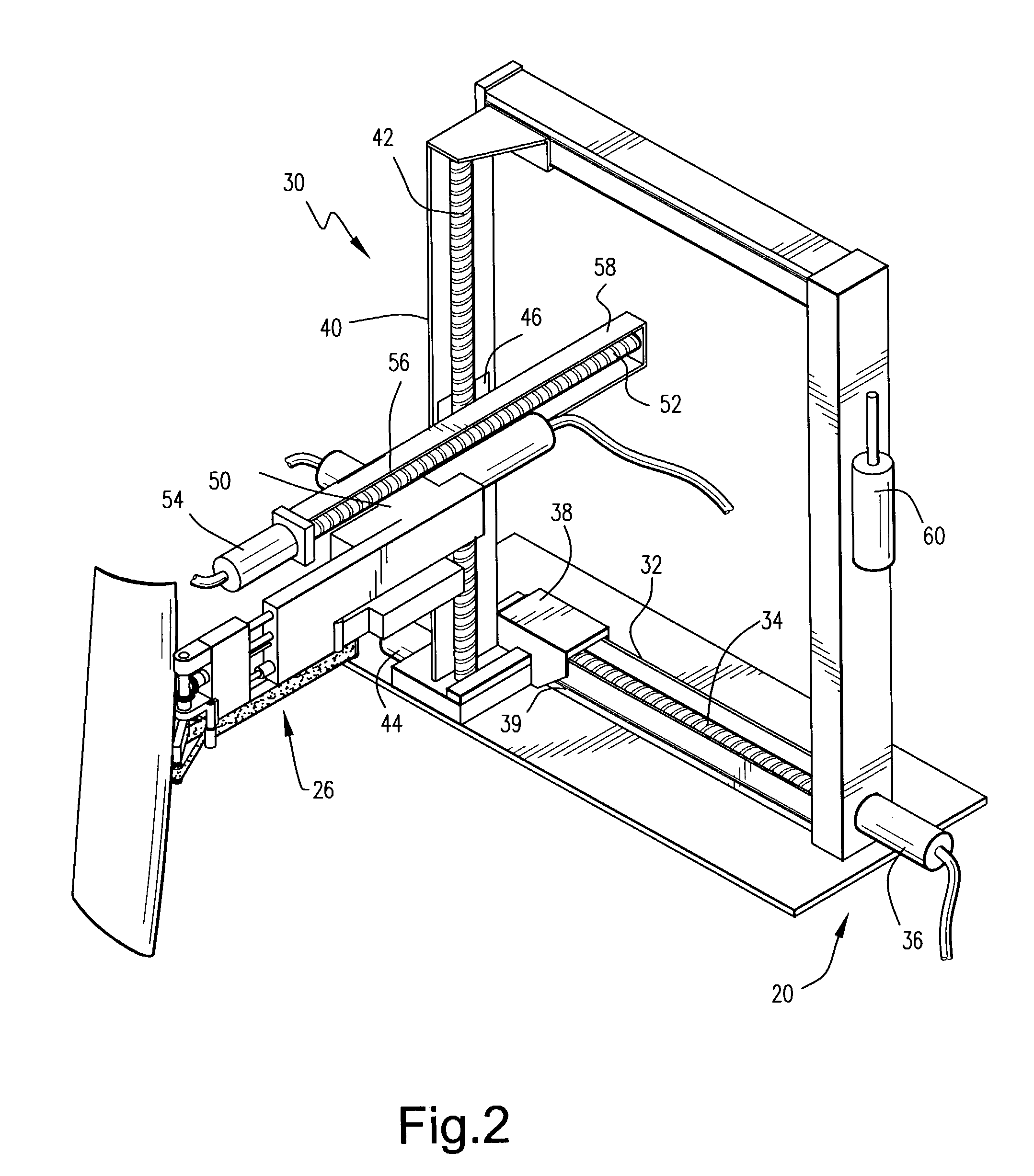

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

Brazed diamond dressing tool

A dressing blade for finishing and reconditioning new and used abrasive grinding and cutting tools has a slab-shaped shank with an extension protruding longitudinally from the shank. Superabrasive grains are disposed on the surface of the extension and held in place by a brazed metal composition. This composition is formed by brazing a powdered mixture of brazing metal components and active metal components. Specific extension configurations are provided which allow aligning the superabrasive grains in single layer arrangement for precise dressing and simple fabrication of the tool. The novel dressing tool exhibits excellent wear characteristics.

Owner:SAINT GOBAIN ABRASIVES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com