Patents

Literature

355 results about "Braze alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

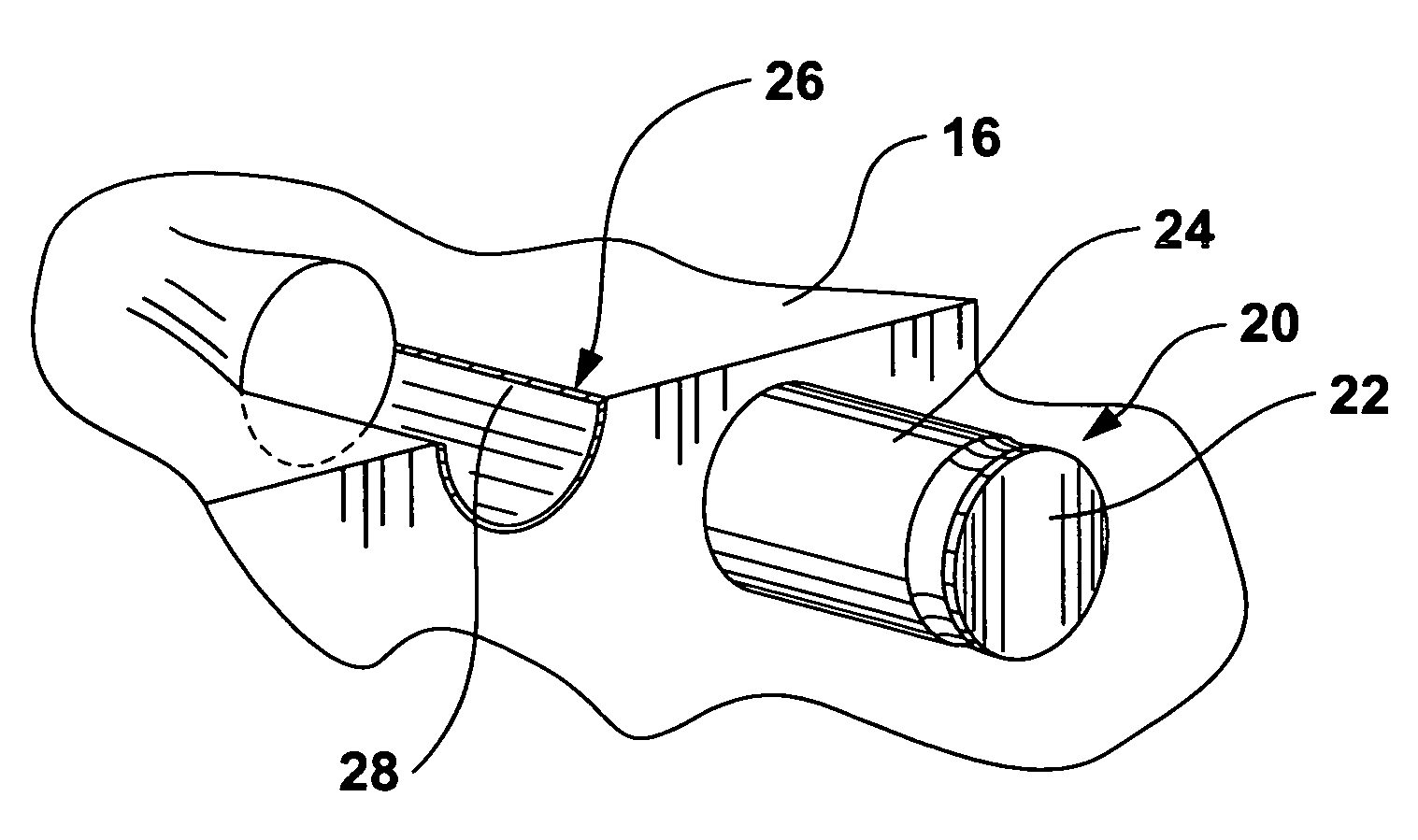

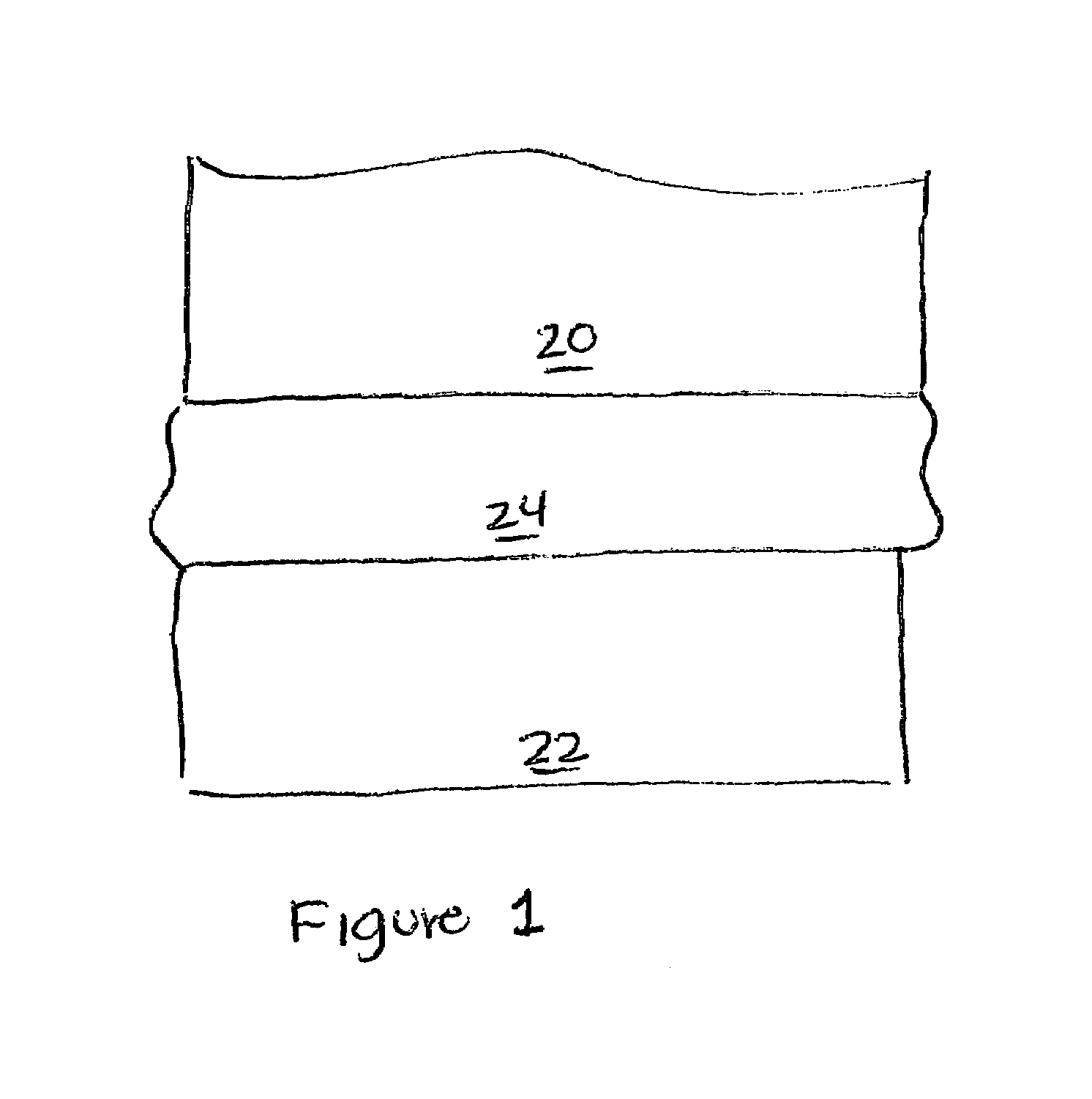

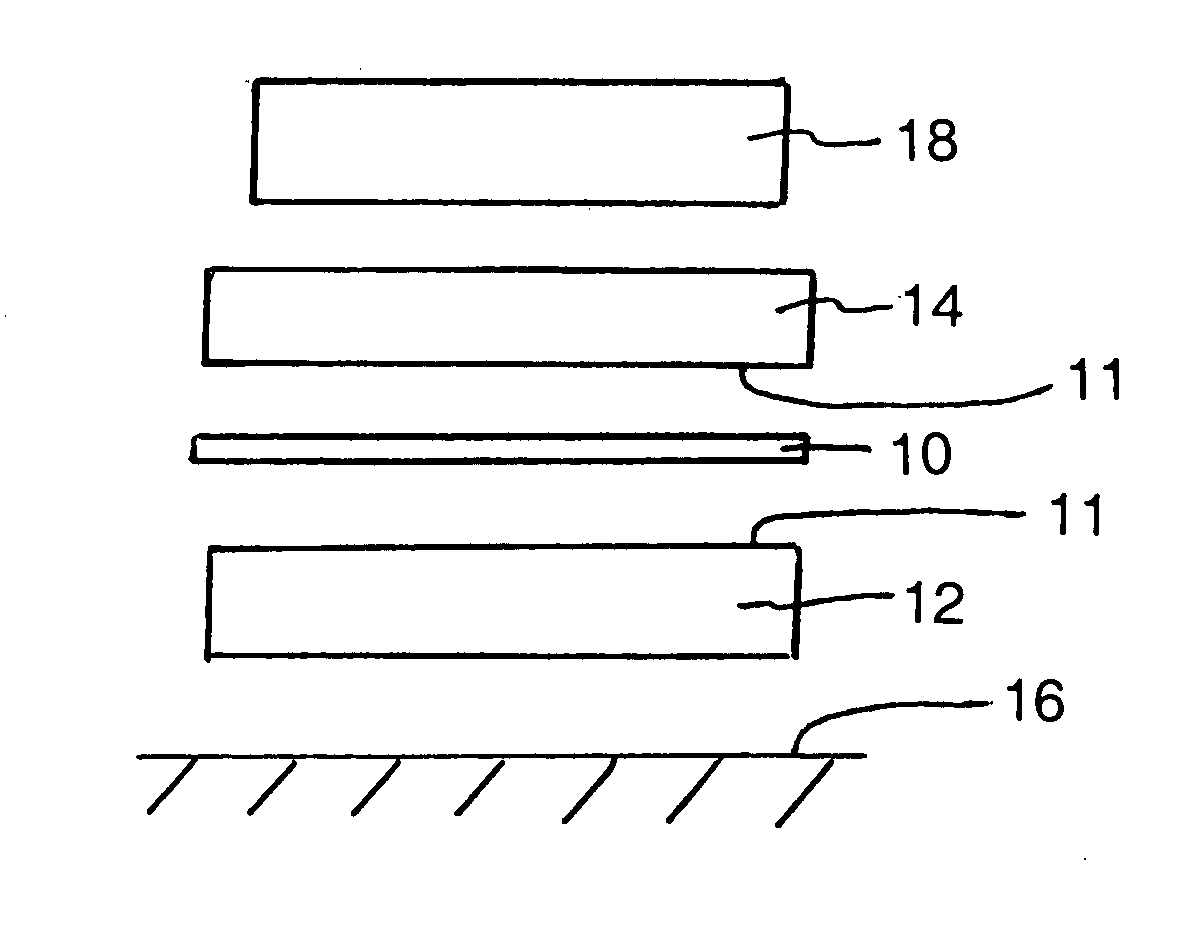

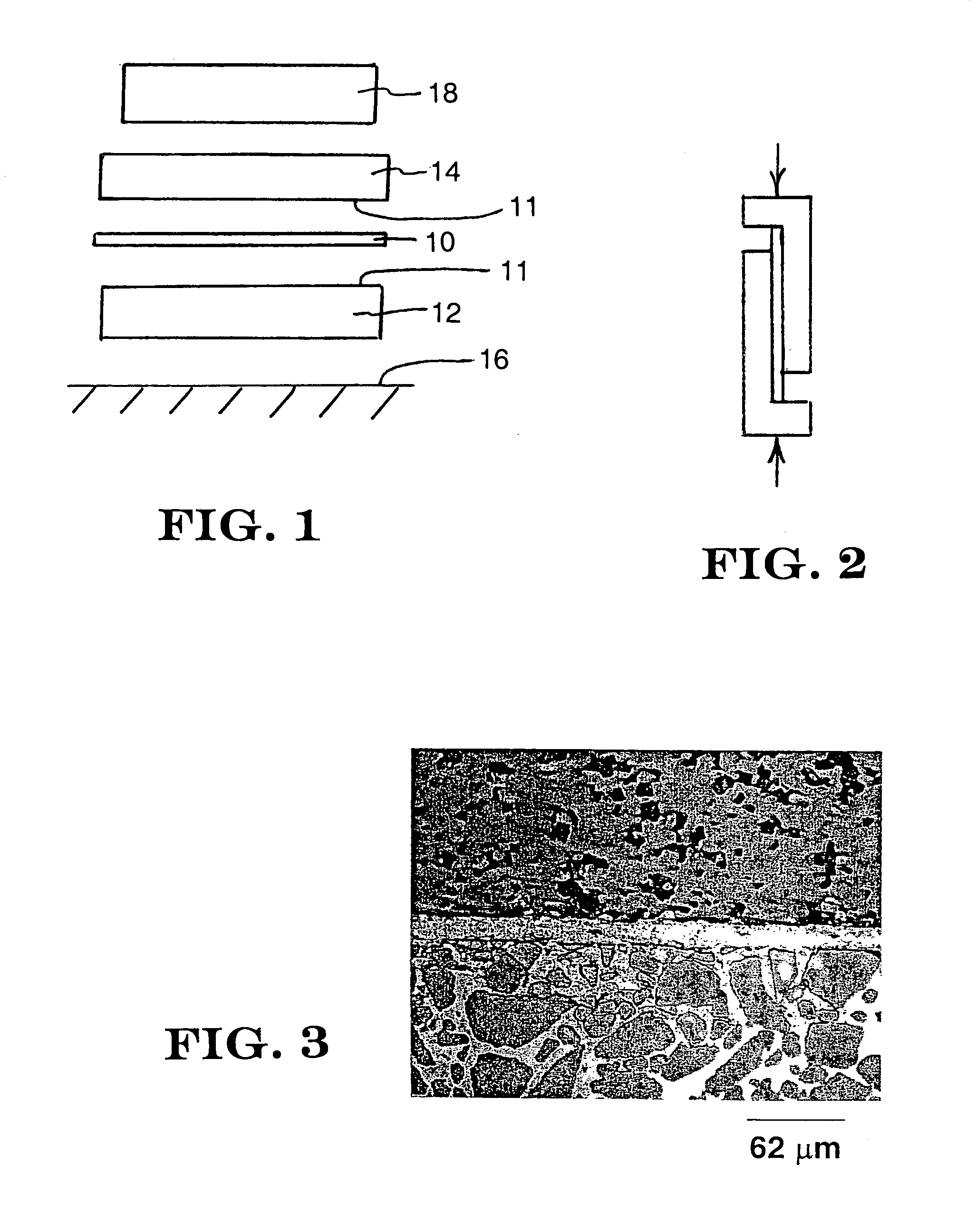

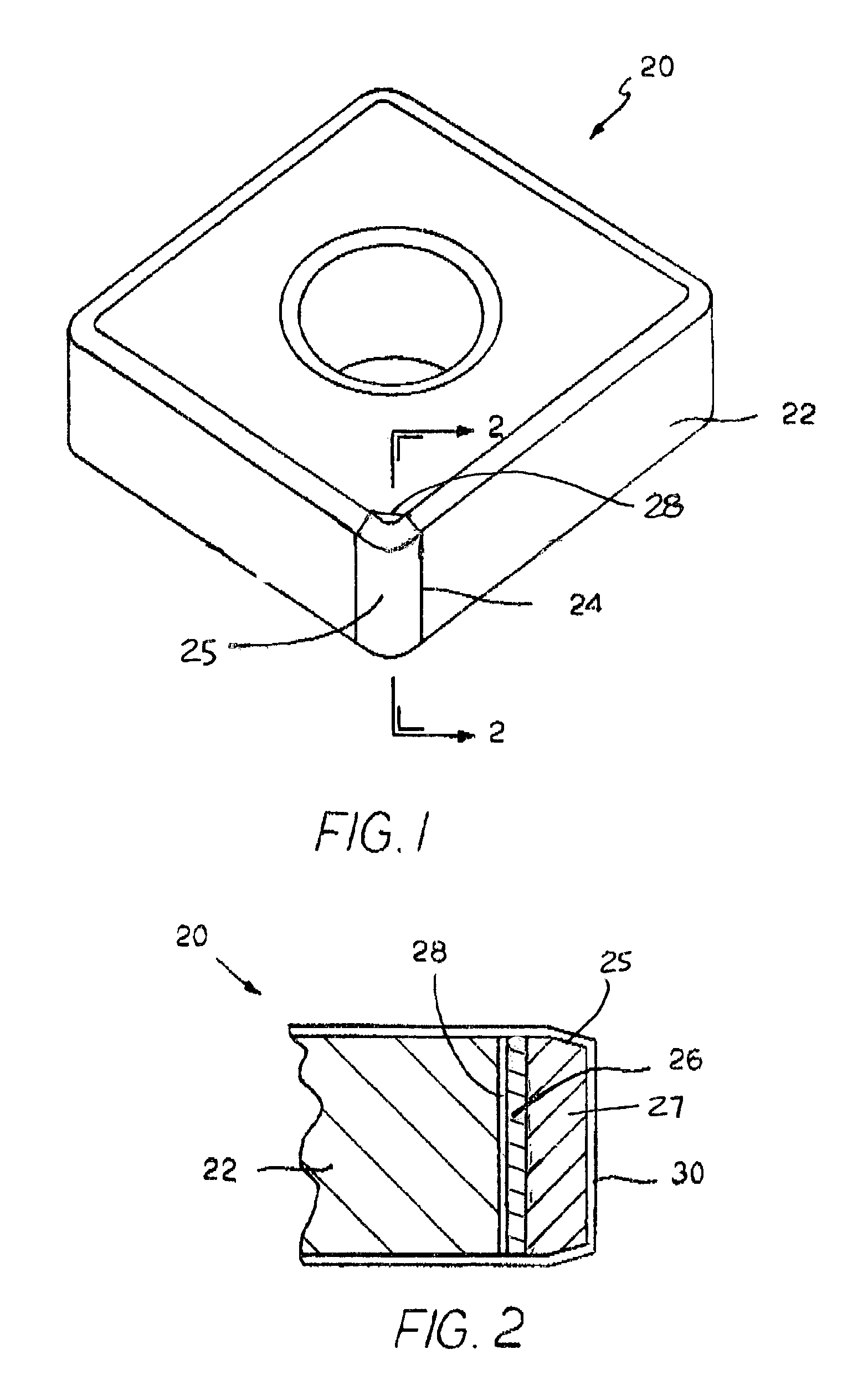

Braze system and method for reducing strain in a braze joint

A system for joining a pair of structural members having widely differing coefficients of thermal expansion is disclosed. A mechanically "thick" foil is made by dispersing a refractory metal powder, such as molybdenum, niobium, tantalum, or tungsten into a quantity of a liquid, high expansion metal such as copper, silver, or gold, casting an ingot of the mixture, and then cutting sections of the ingot about 1 mm thick to provide the foil member. These foil members are shaped, and assembled between surfaces of structural members for joining, together with a layer of a braze alloy on either side of the foil member capable of wetting both the surfaces of the structural members and the foil. The assembled body is then heated to melt the braze alloy and join the assembled structure. The foil member subsequently absorbs the mechanical strain generated by the differential contraction of the cooling members that results from the difference in the coefficients of thermal expansion of the members.

Owner:SANDIA NAT LAB

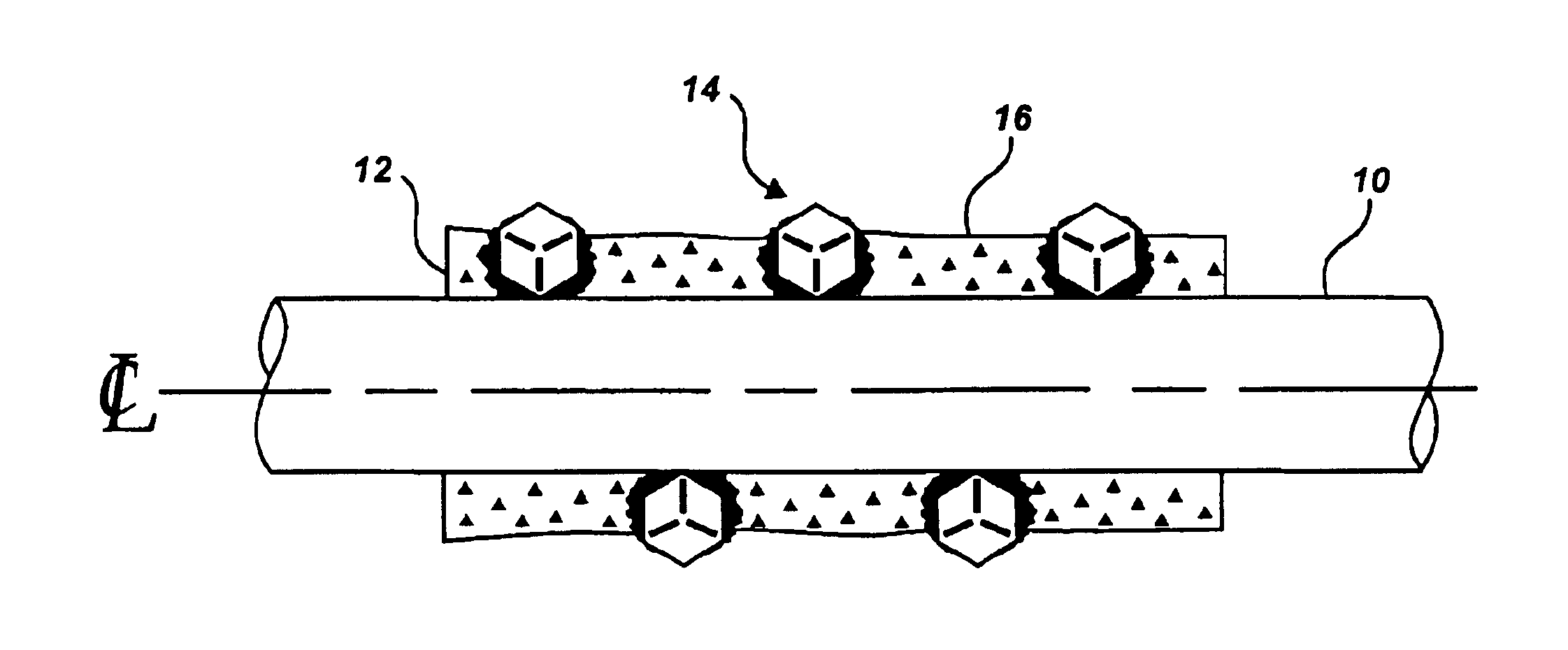

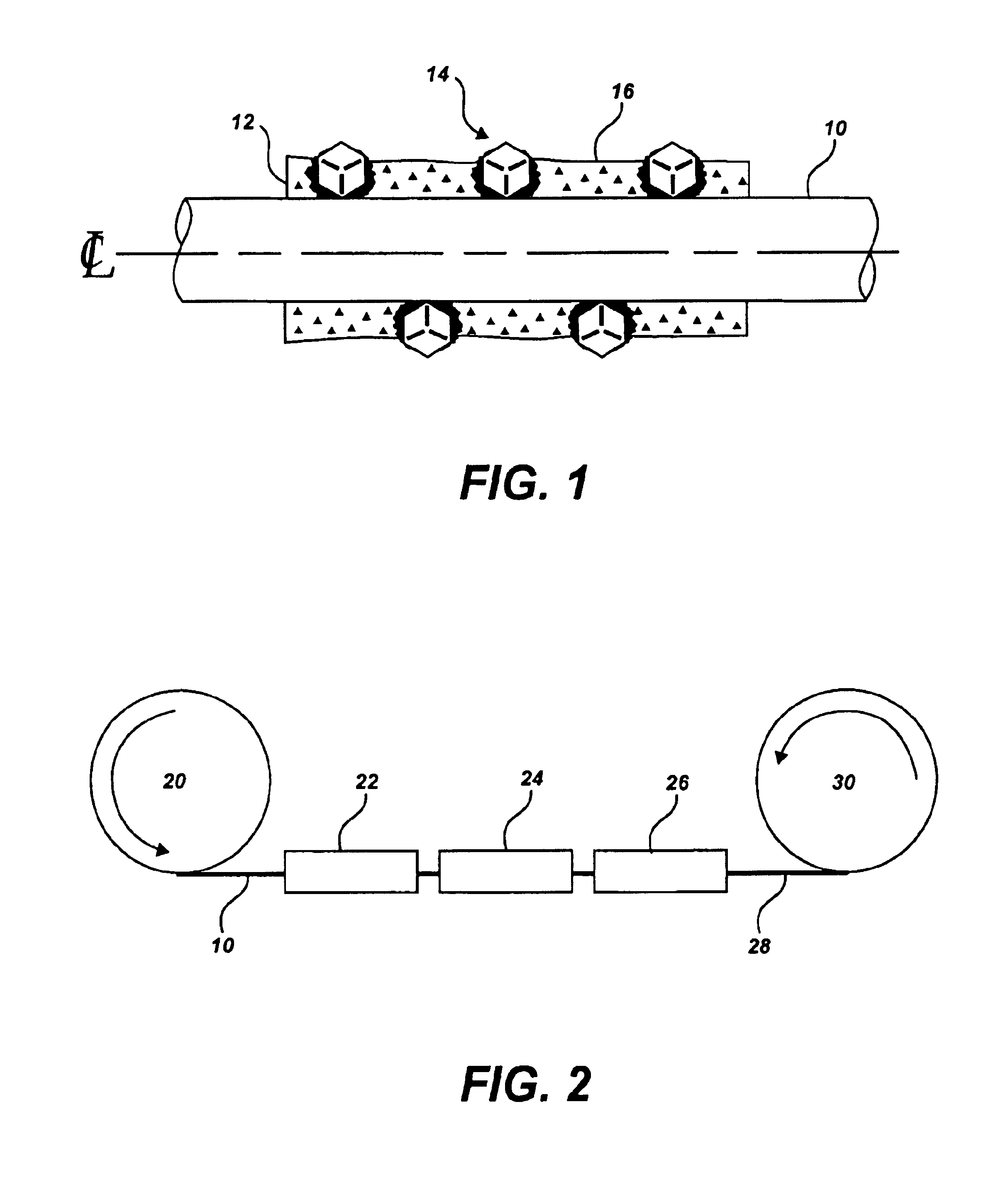

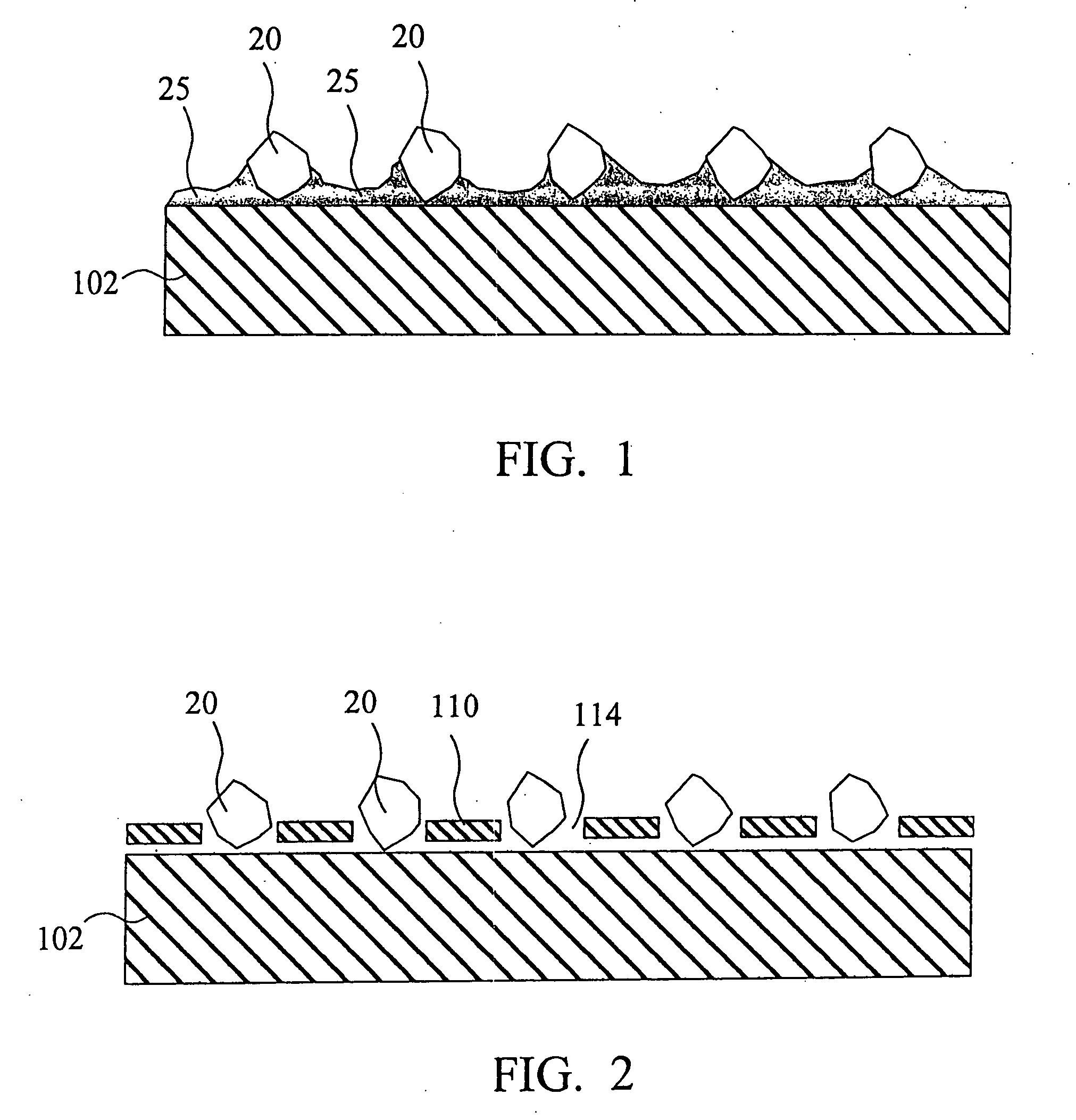

Superabrasive wire saw and associated methods of manufacture

InactiveUS6915796B2Improving particle retentionHigh material removal ratePigmenting treatmentOther chemical processesWire rodAlloy

A superabrasive wire saw having a plurality of individual coated superabrasive particles attached to a wire with an organic binder is disclosed and described. The superabrasive particle can be coated with a solidified coating of a molten braze alloy that is chemically bonded to the superabrasive particle. The organic binder can optionally contain filler materials and / or an organometallic coupling agent to improve the retention of coated superabrasive particles. The resulting superabrasive wire saws can be produced having diameters of less than 0.5 mm which significantly reduce kerf loss. Various methods for making and using such a superabrasive wire saw are additionally disclosed and described.

Owner:SUNG CHIEN MIN

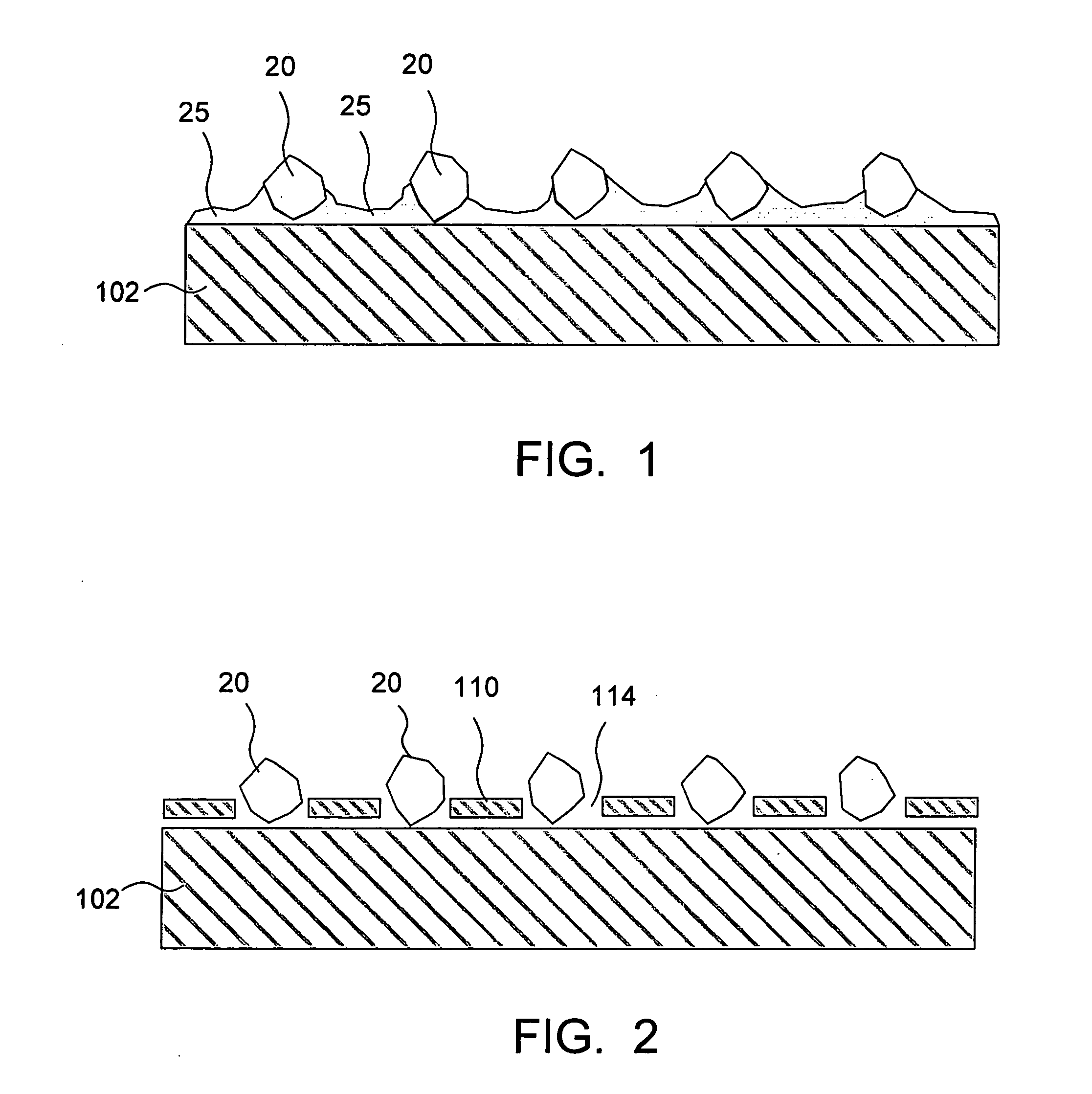

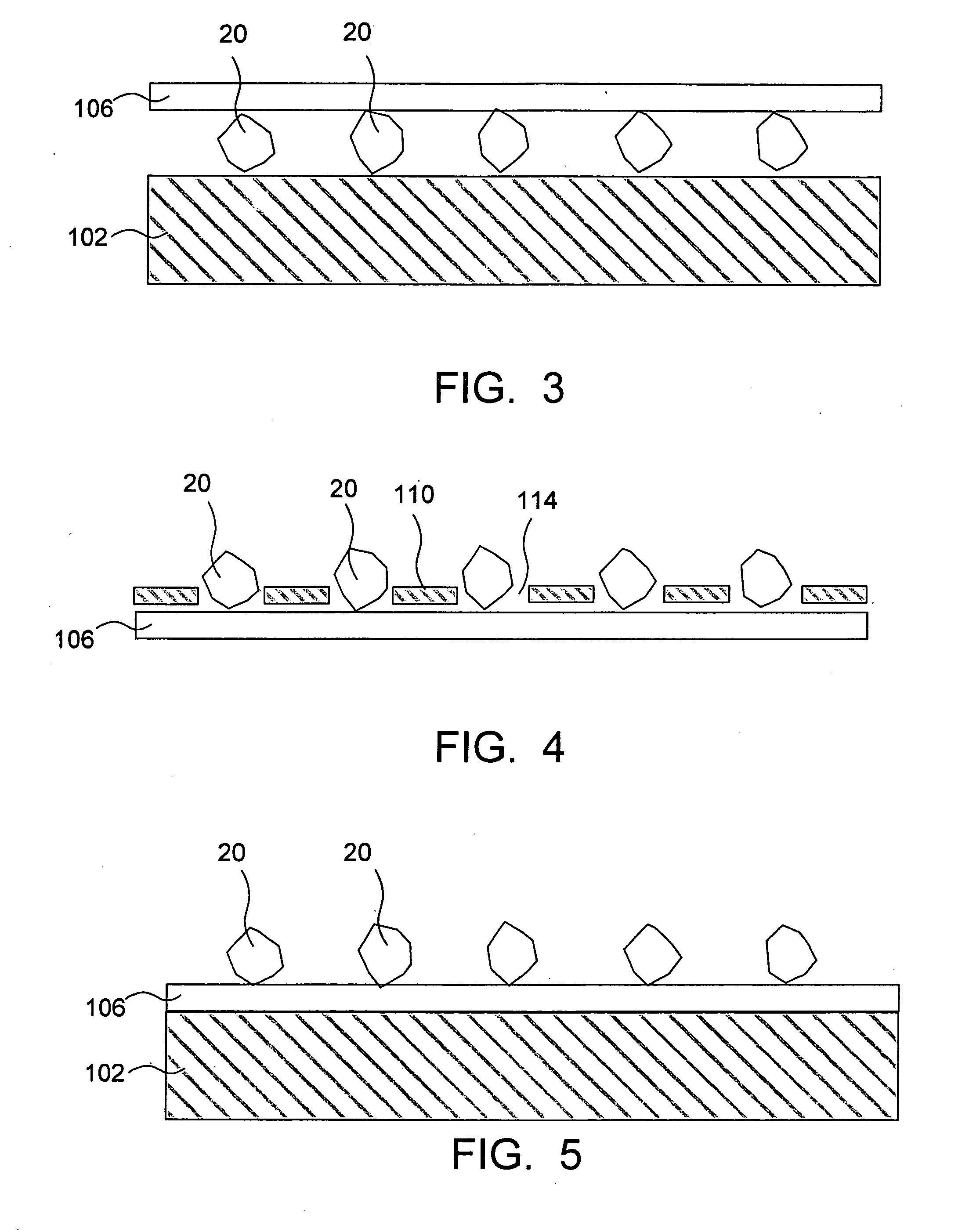

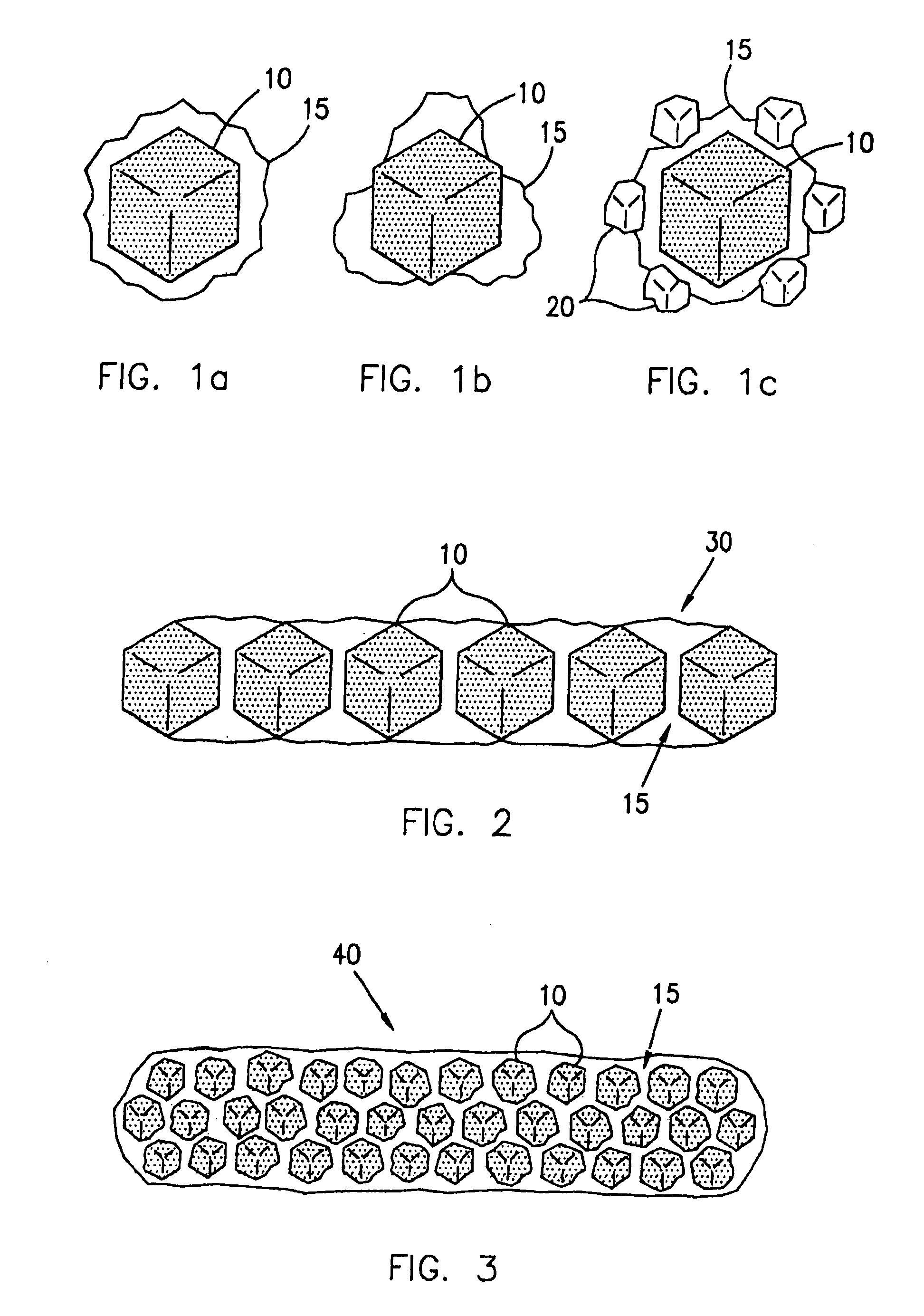

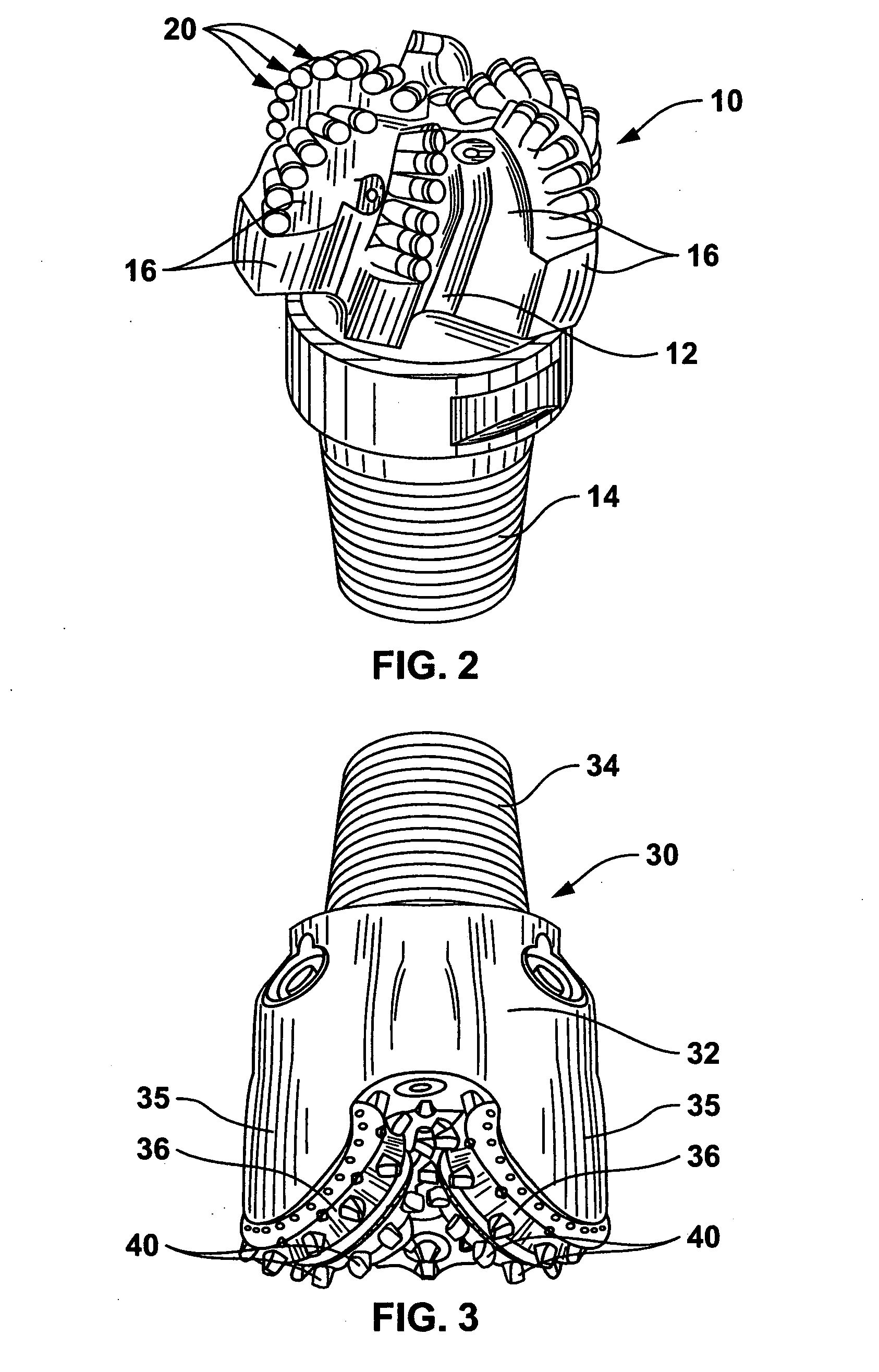

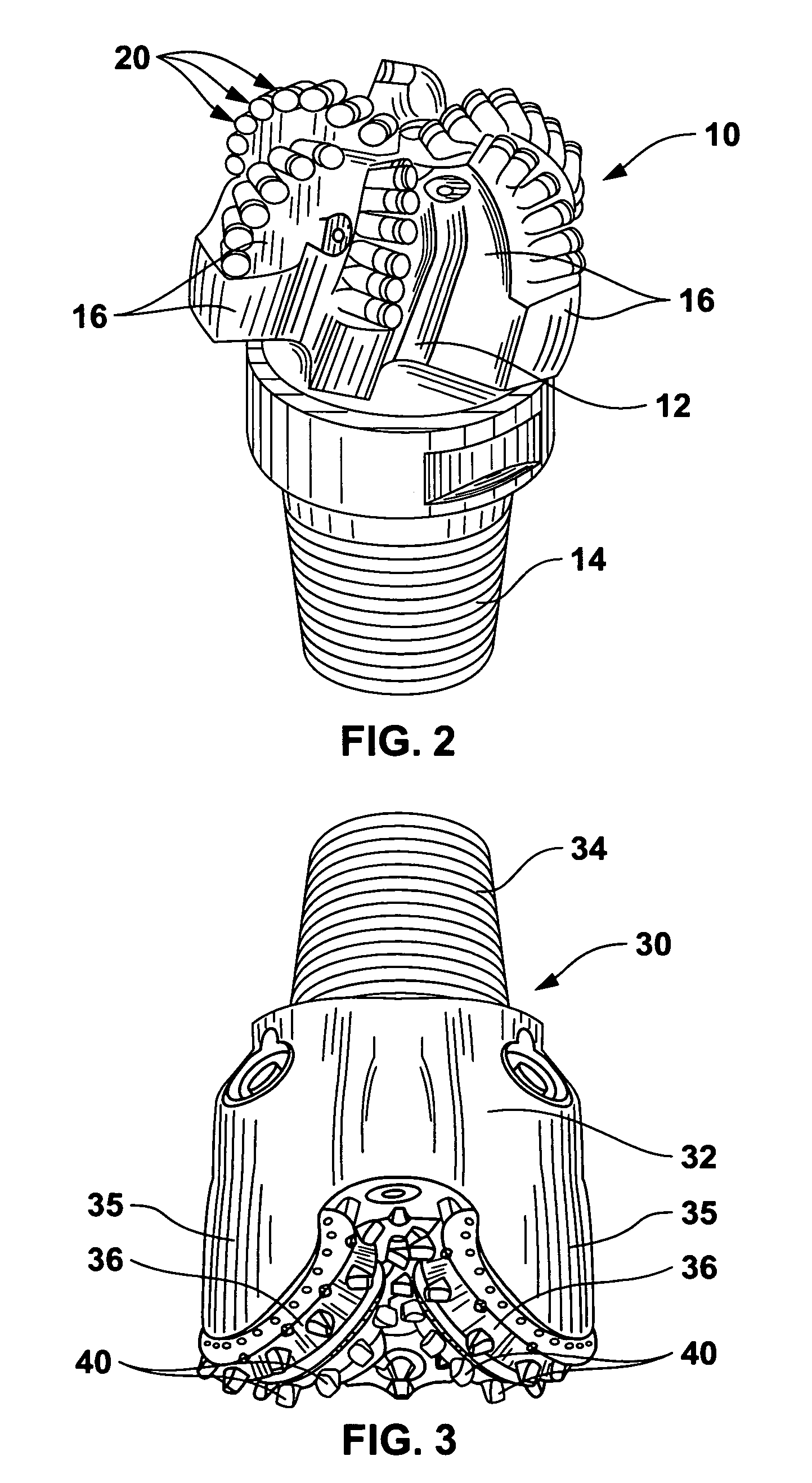

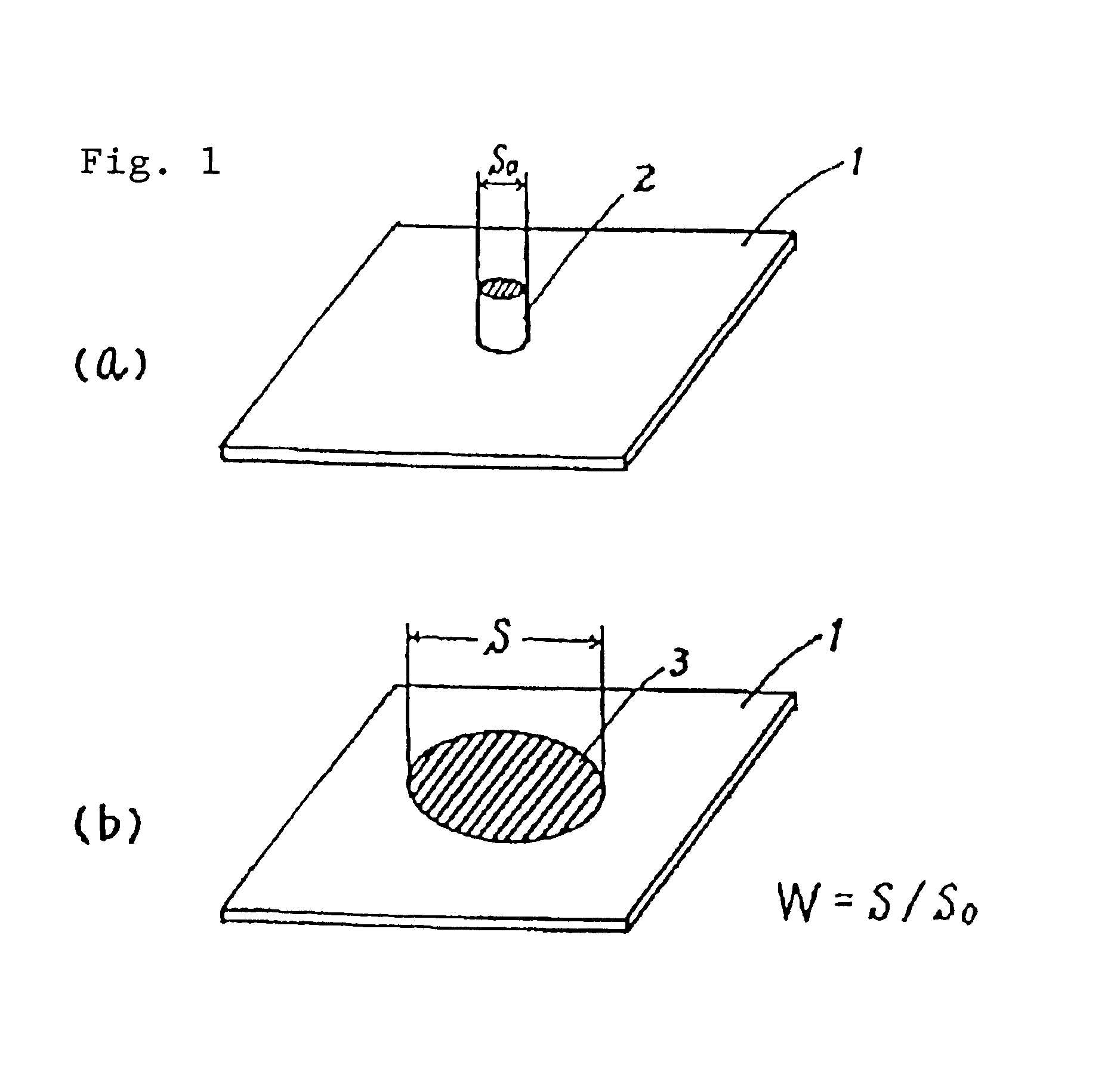

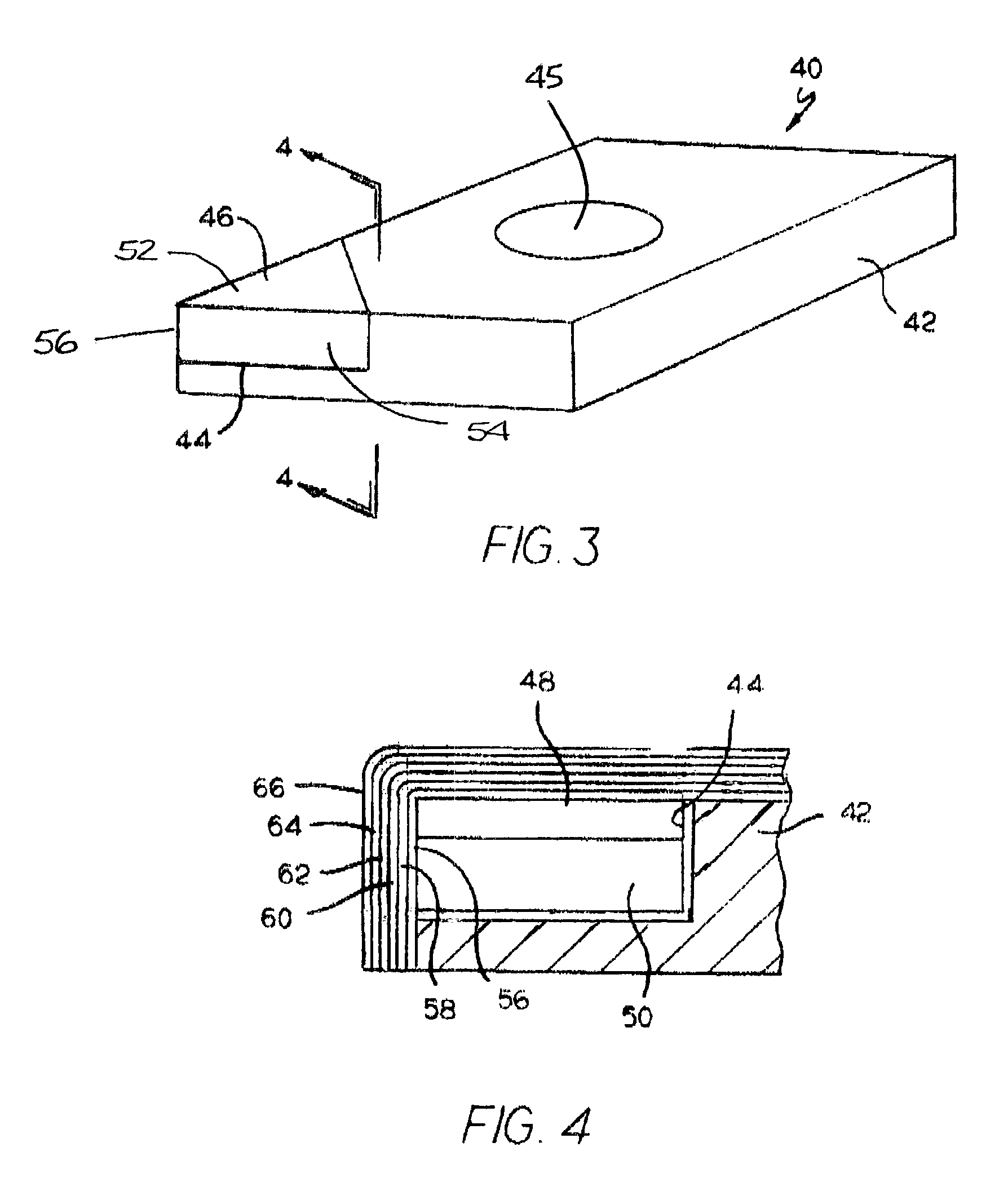

Brazed diamond tools and methods for making the same

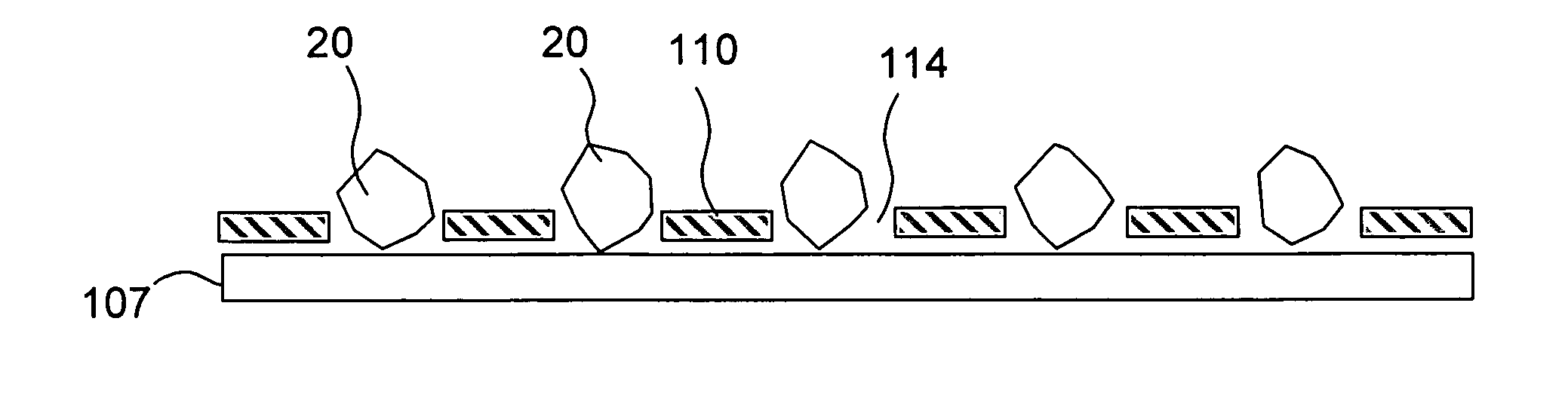

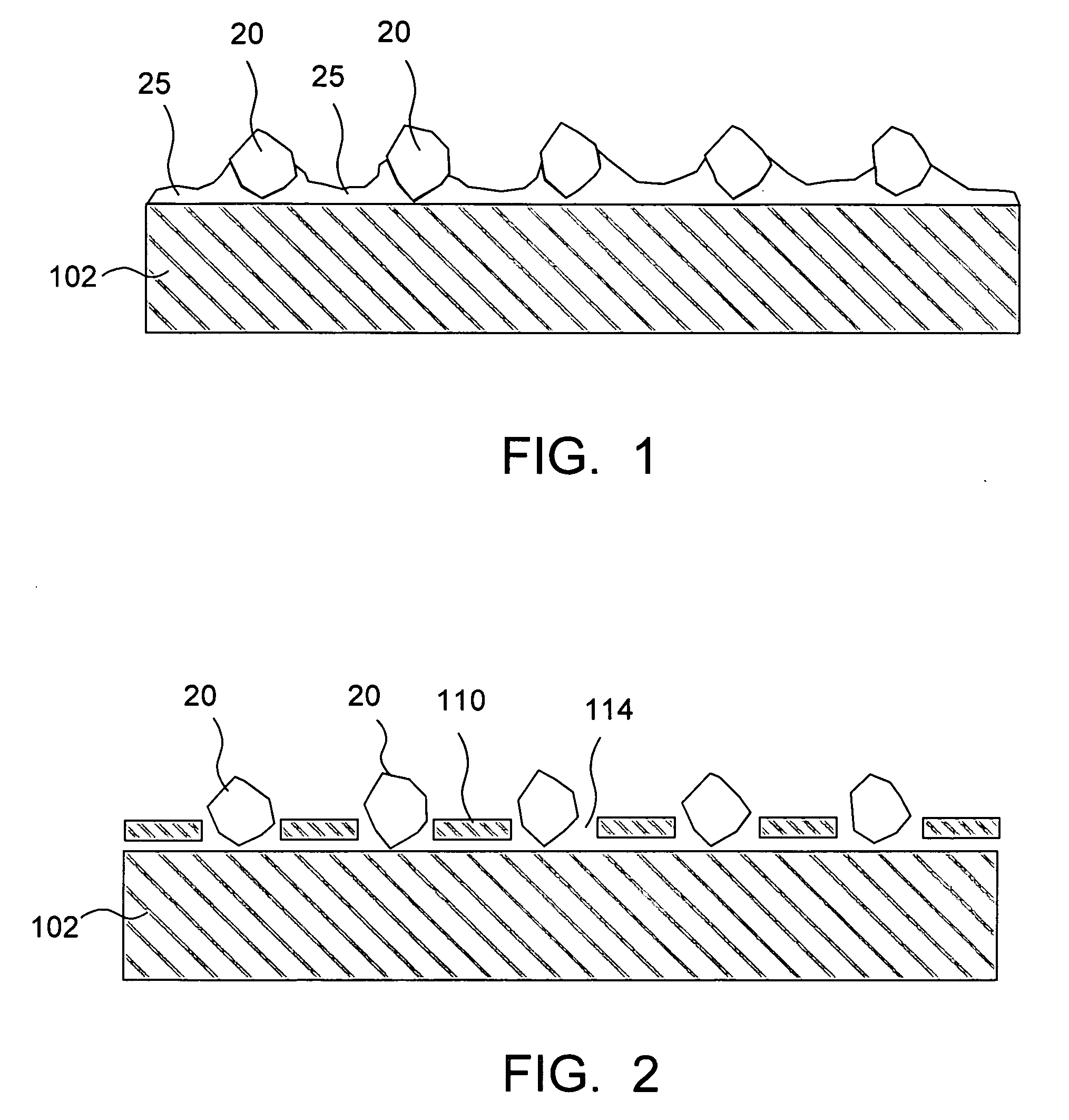

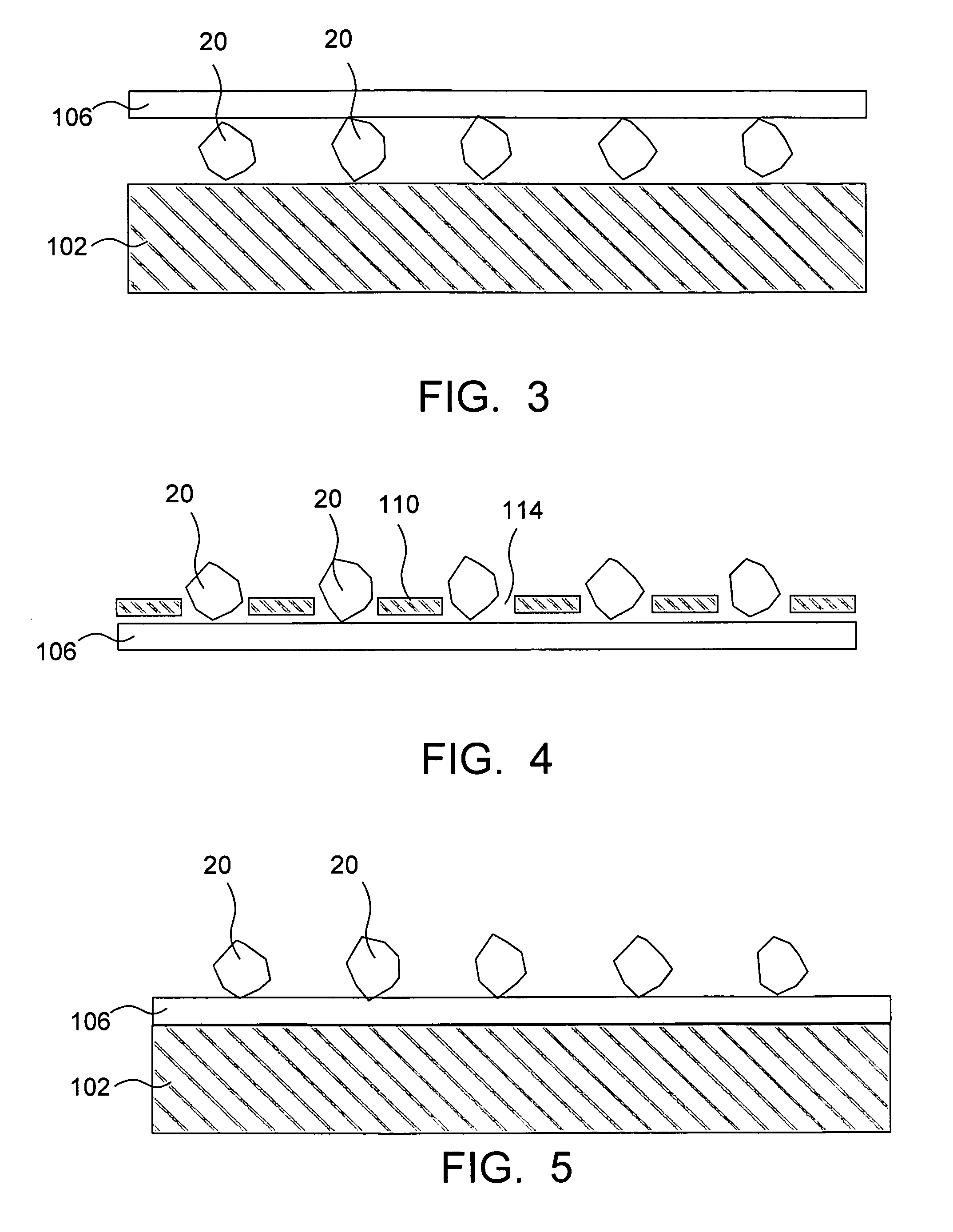

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

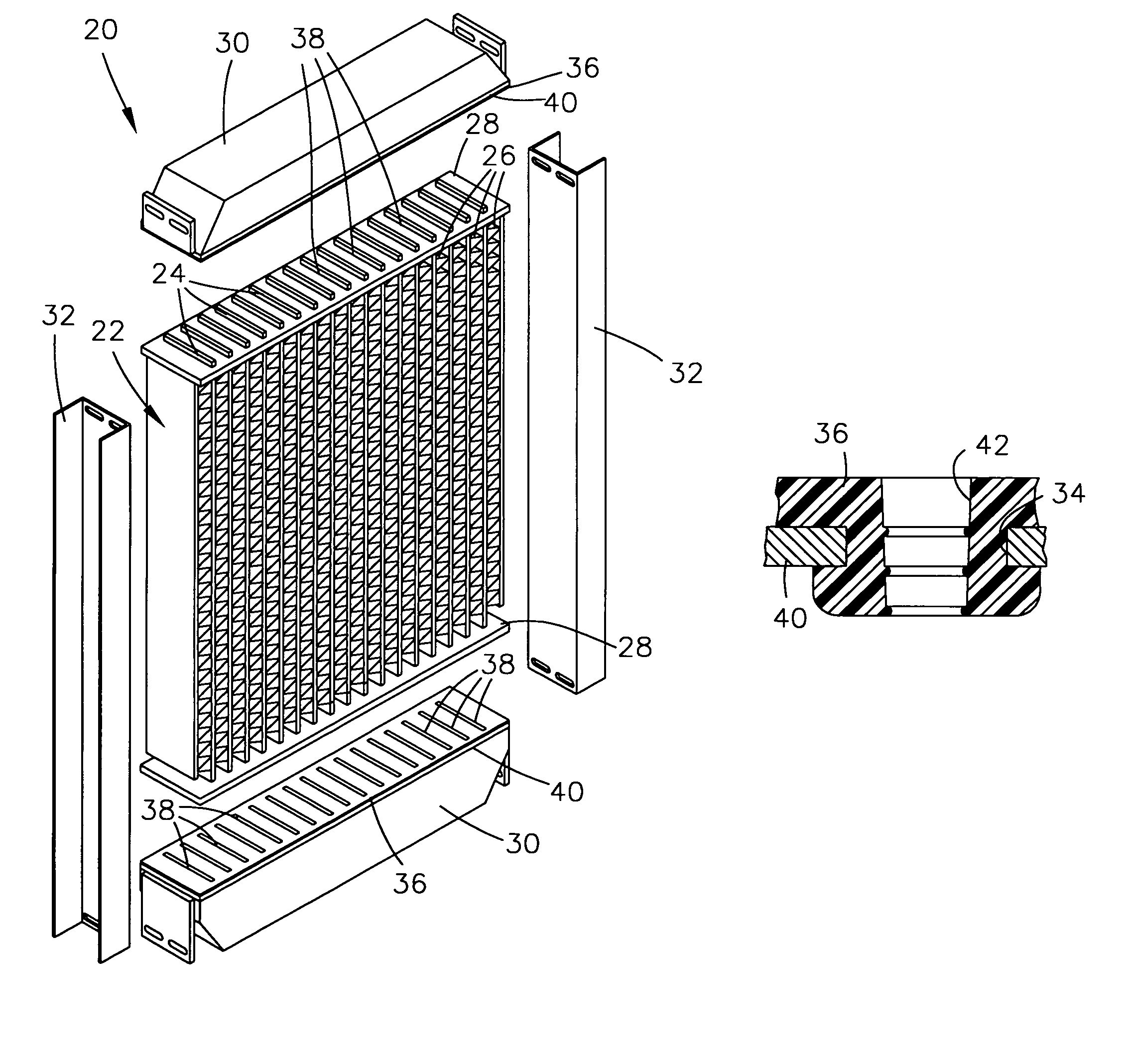

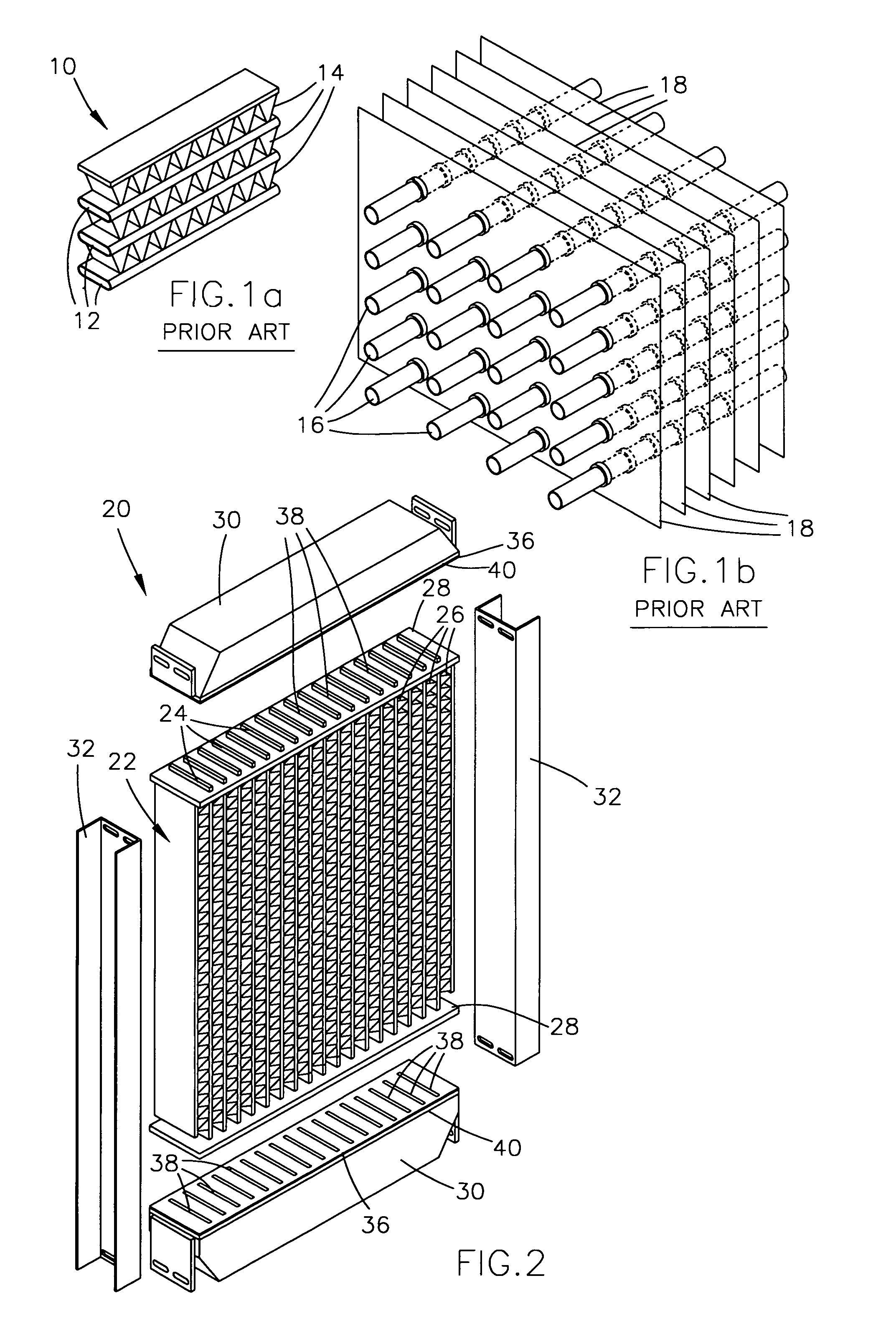

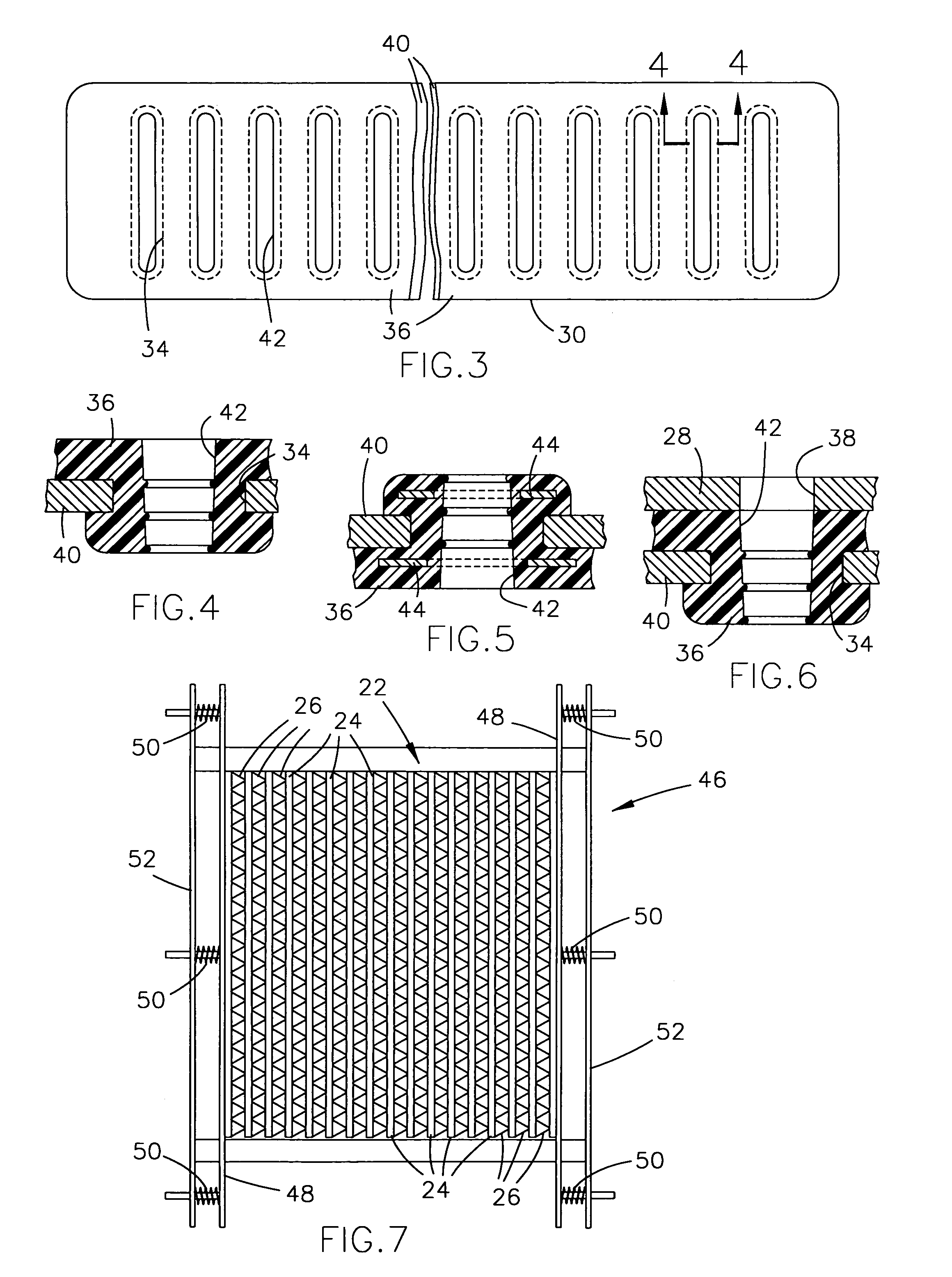

Modular heat exchanger having a brazed core and method for forming

InactiveUS7234511B1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

An improved modular heat exchanger suitable for automotive applications, and particularly radiators for heavy duty equipment, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The ability to use a brazed core assembly within a modular heat exchanger construction promotes enhanced heat transfer efficiencies associated with the use of flat tubes and sinusoidal centers, as compared to mechanically-joined round tubes and fins. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by eliminating core shrinkage attributable to the use of clad aluminum alloy components to construct the core assembly. In two embodiments, core shrinkage is physical suppressed through the use of an expandable brazing fixture or the inclusion of sub-headers in the brazed core assembly. In a third embodiment, a clad slurry containing a braze alloy is deposited prior to brazing on a core assembly composed of unclad tubes and centers.

Owner:LESAGE PHILIP GEORGE

Copper based brazing alloy

InactiveCN1799760AWide range of usesEasy to operateWelding/cutting media/materialsSoldering mediaManganeseMetallic materials

Owner:罗成林 +2

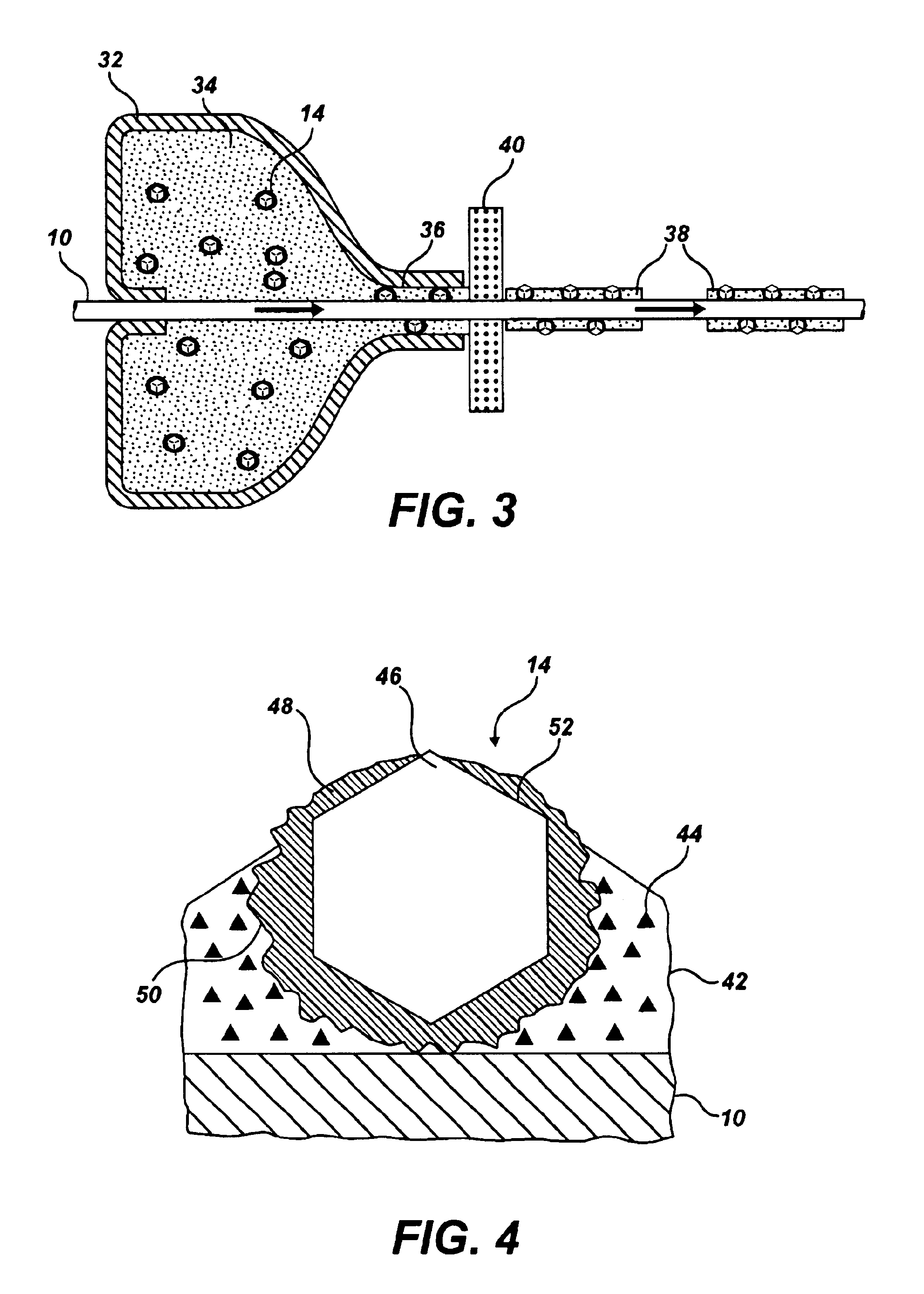

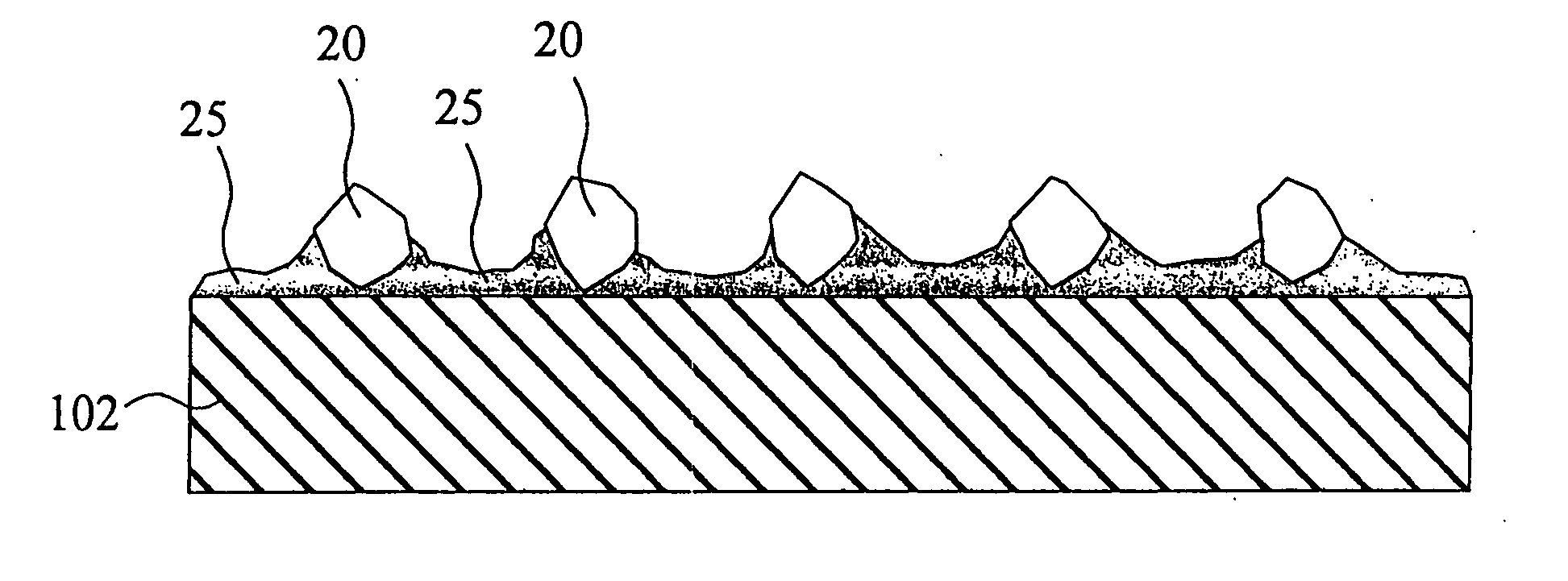

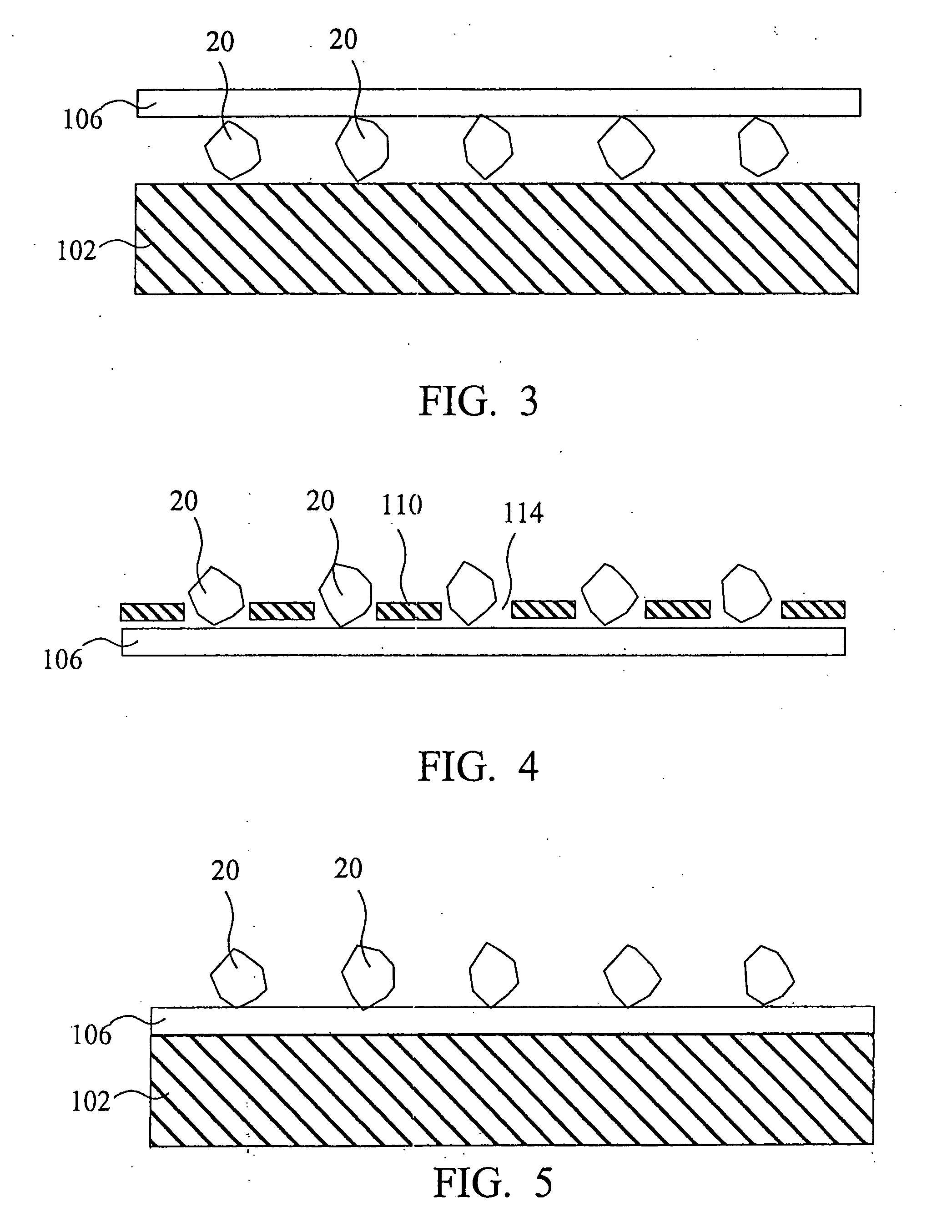

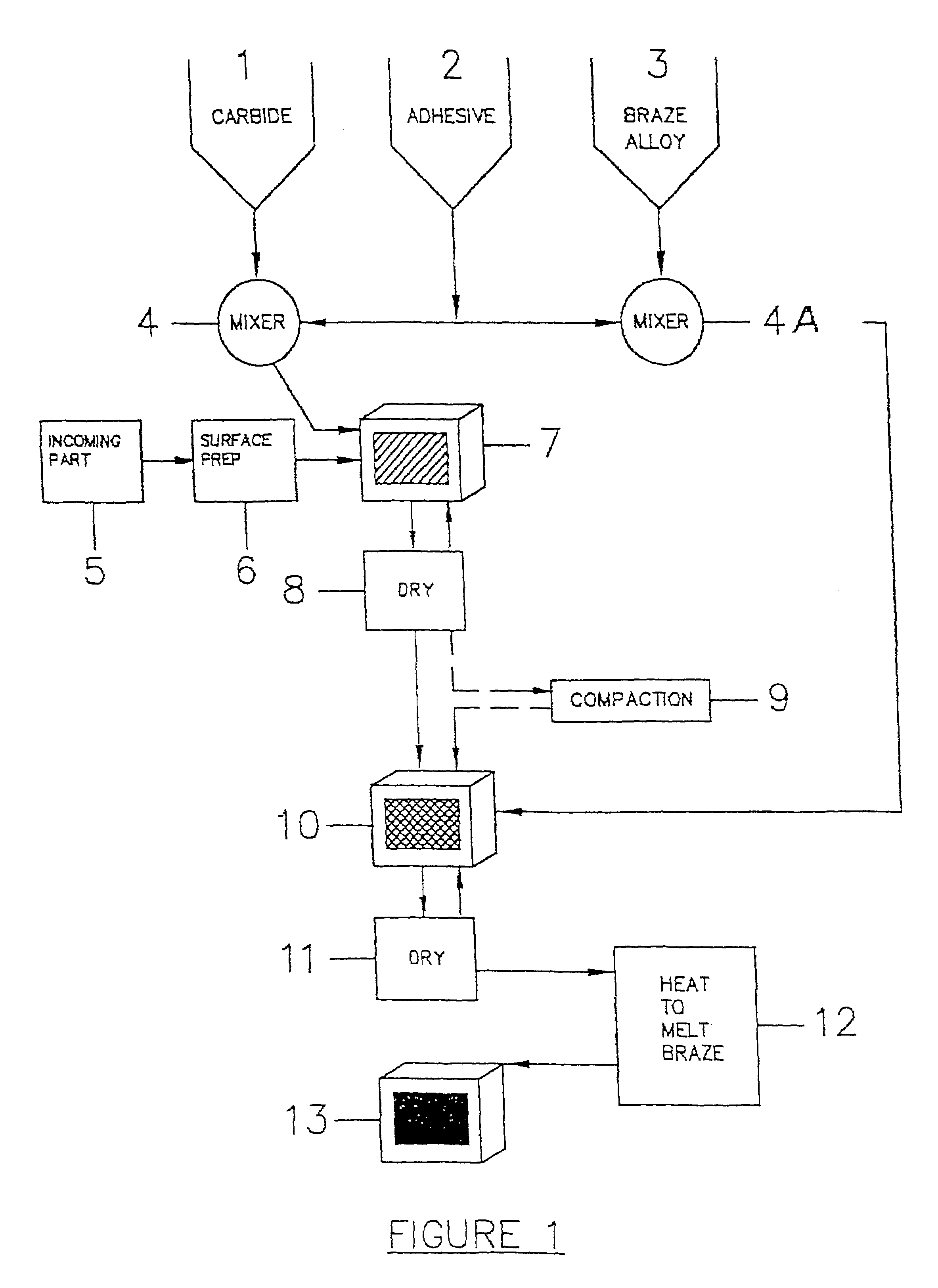

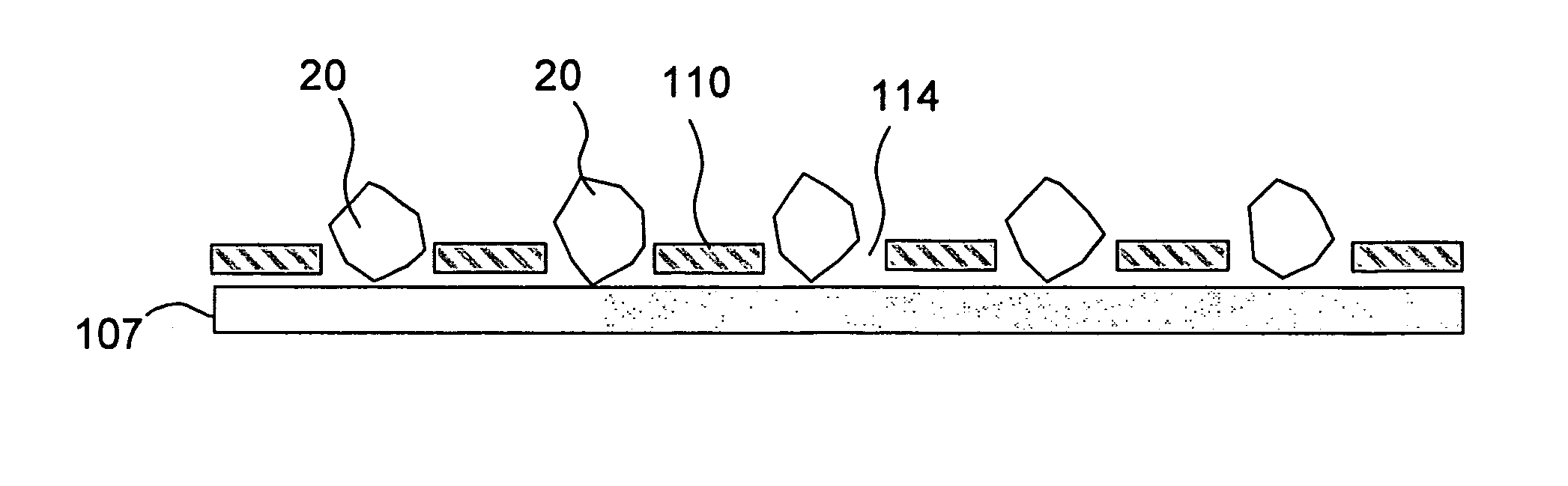

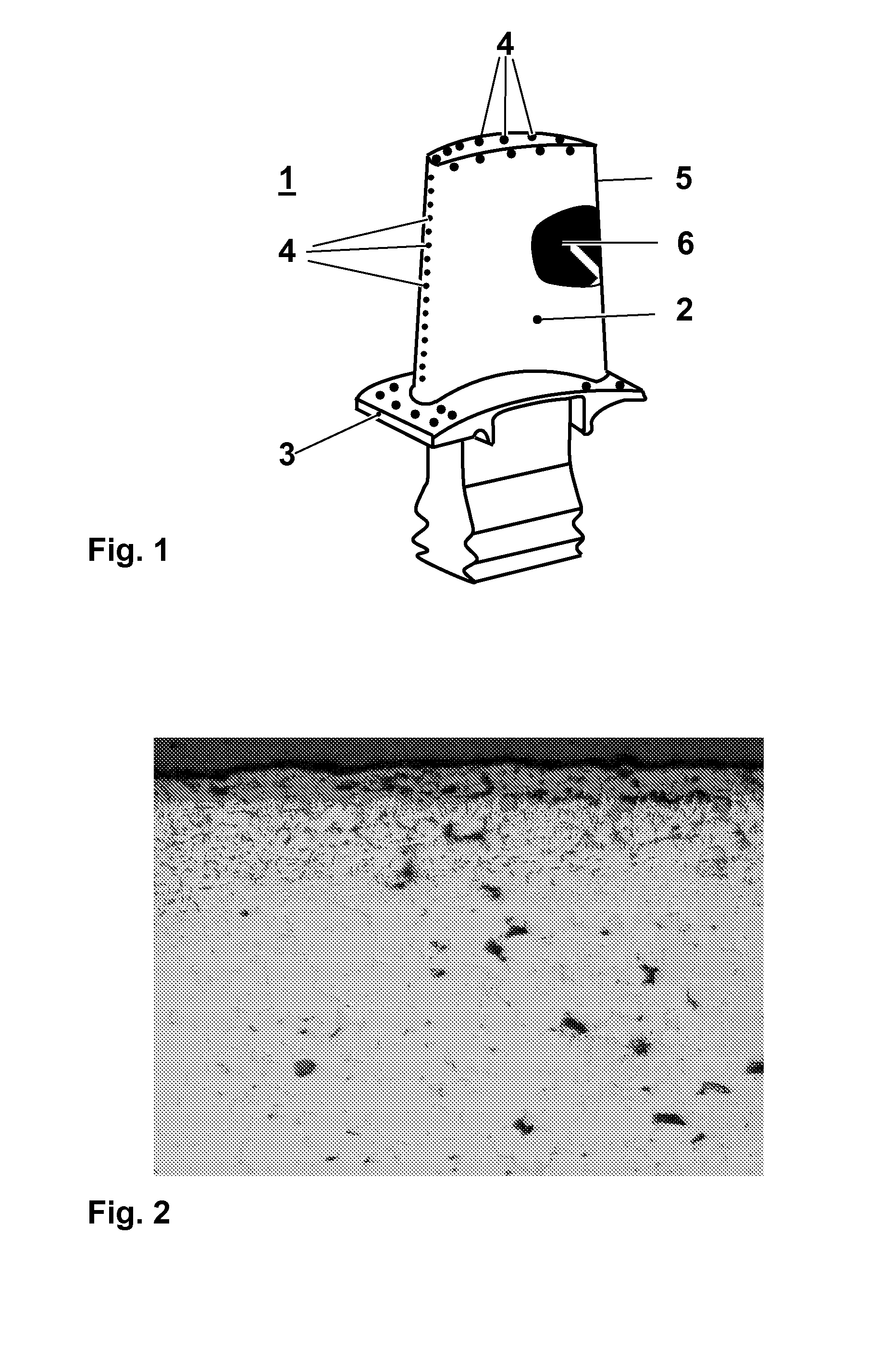

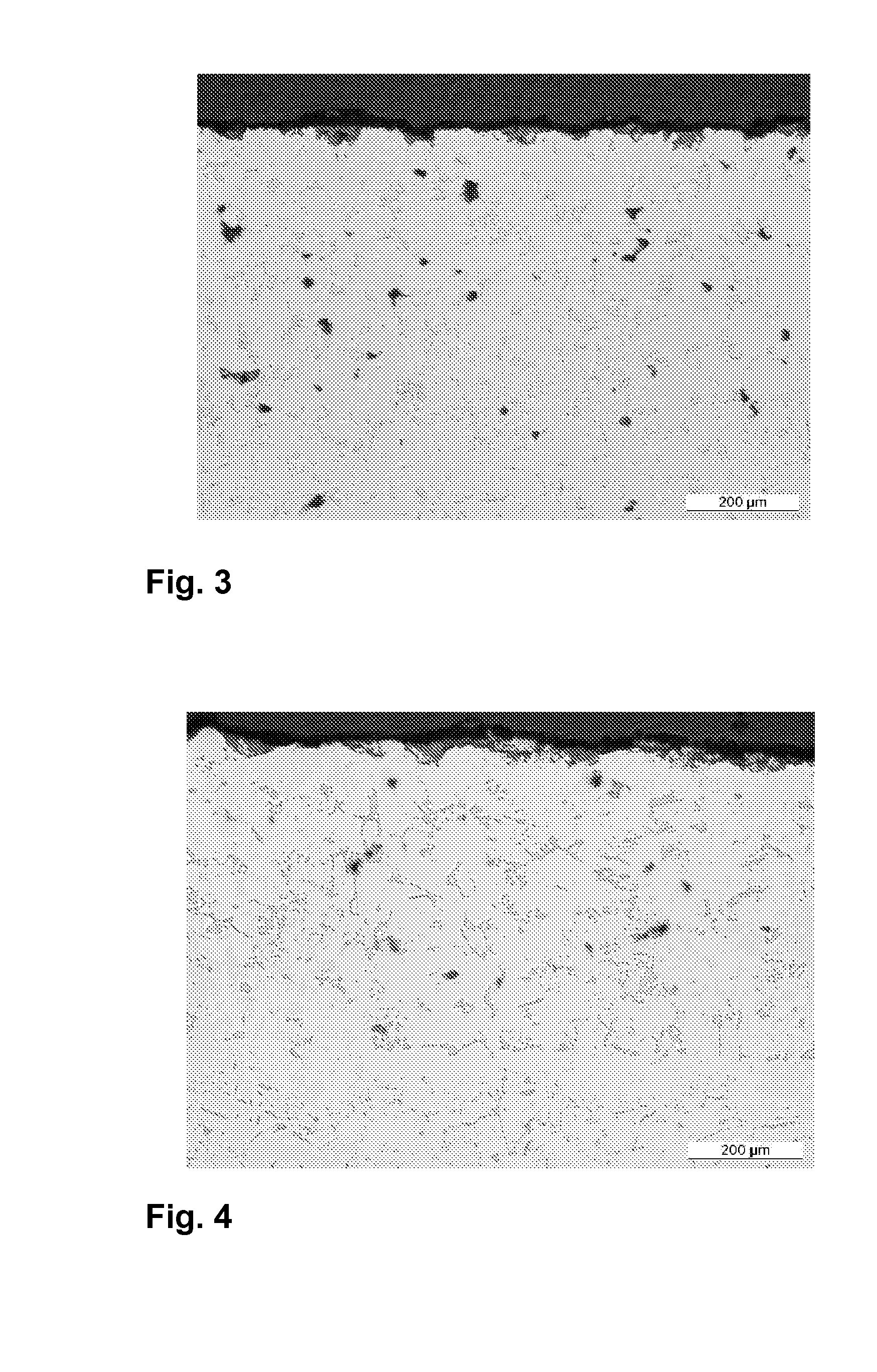

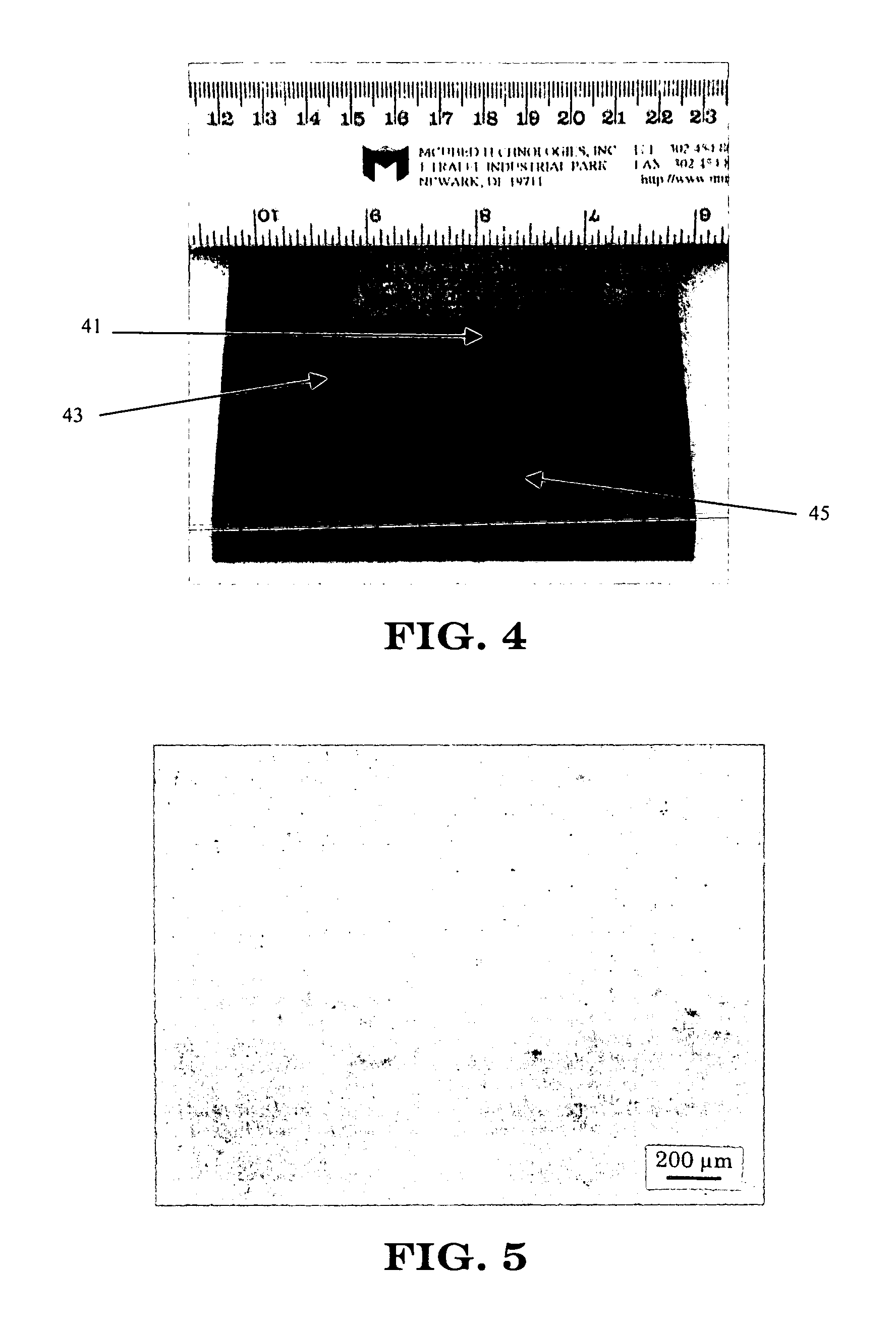

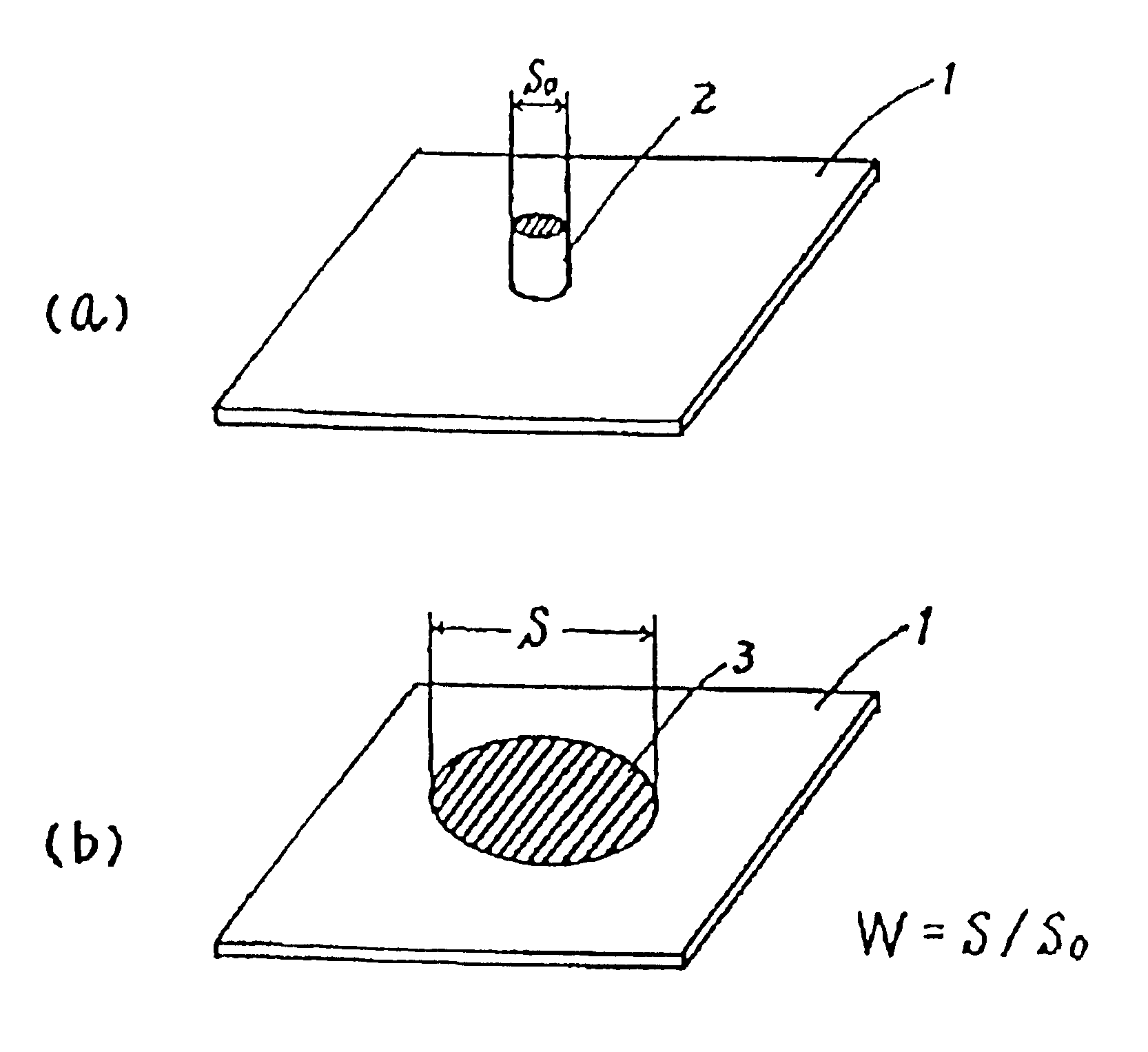

Process for making wear-resistant coatings

InactiveUS7262240B1Readily be sprayed onto substrateHigh viscosityAnti-corrosive paintsMetallic material coating processesCross-linkWear resistant

A paint system and process are disclosed for hardfacing metal surfaces. In one embodiment of the process, a paint including a dispersion of hard particles is first applied as a coating to a surface. Next, a paint including a dispersion of a braze alloy is applied over the layer of hard particles. The surface is then heated to cause the braze alloy to melt and infiltrate into the hard particles thereby bonding them to the metallic surface. In another embodiment, a first layer of adhesive is applied, and a hardfacing powder is applied onto the adhesive. Then a second layer if adhesive is applied, and a braze alloy powder is applied onto the second adhesive. Then the material is heated as in the first embodiment. In another embodiment, paint containing hard particles is coated onto the substrate, and an acid-containing cross-linked copolymer in the paint is then neutralized to increase the viscosity of the paint to prevent running.

Owner:KENNAMETAL INC

Brazed diamond tools and methods for making the same

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

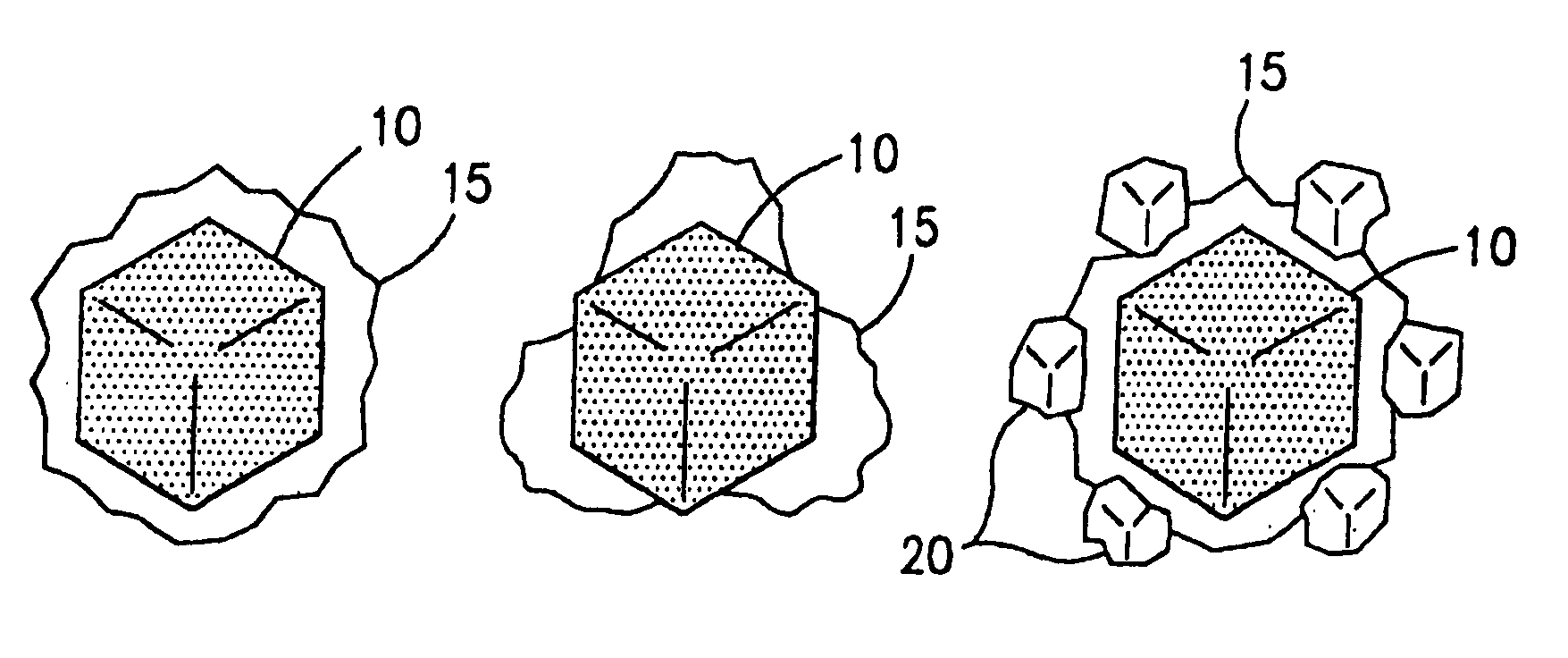

Molten braze-coated superabrasive particles and associated methods

A superabrasive particle coated with a solidified coating of a molten braze alloy that is chemically bonded to the superabrasive particle is disclosed and described. In one aspect, the reactive metal alloy may be chemically bonded to at least about 80% of an outer surface of the superabrasive particle. Various methods for making and using such a coated superabrasive particle are additionally disclosed and described.

Owner:KINIK

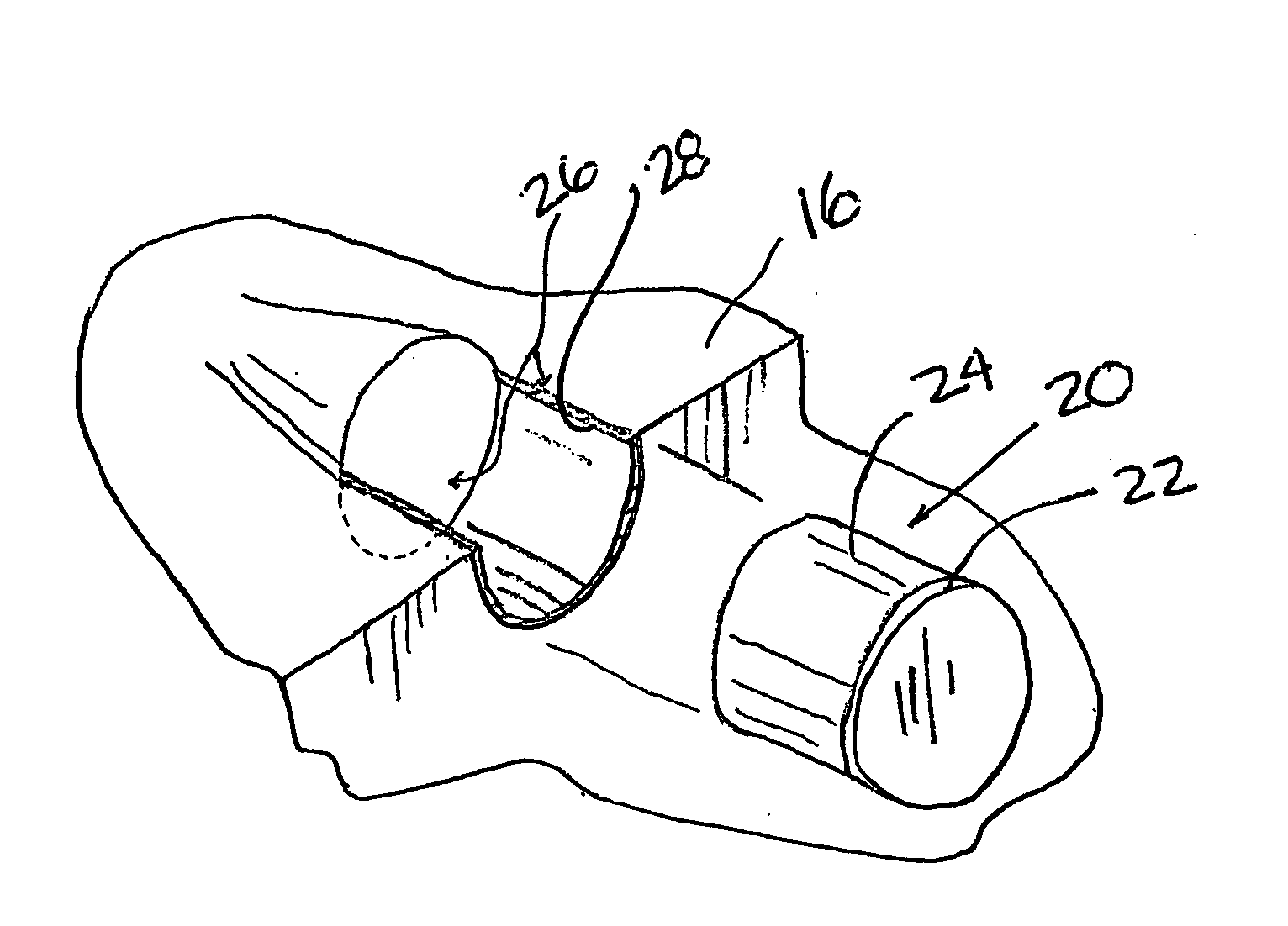

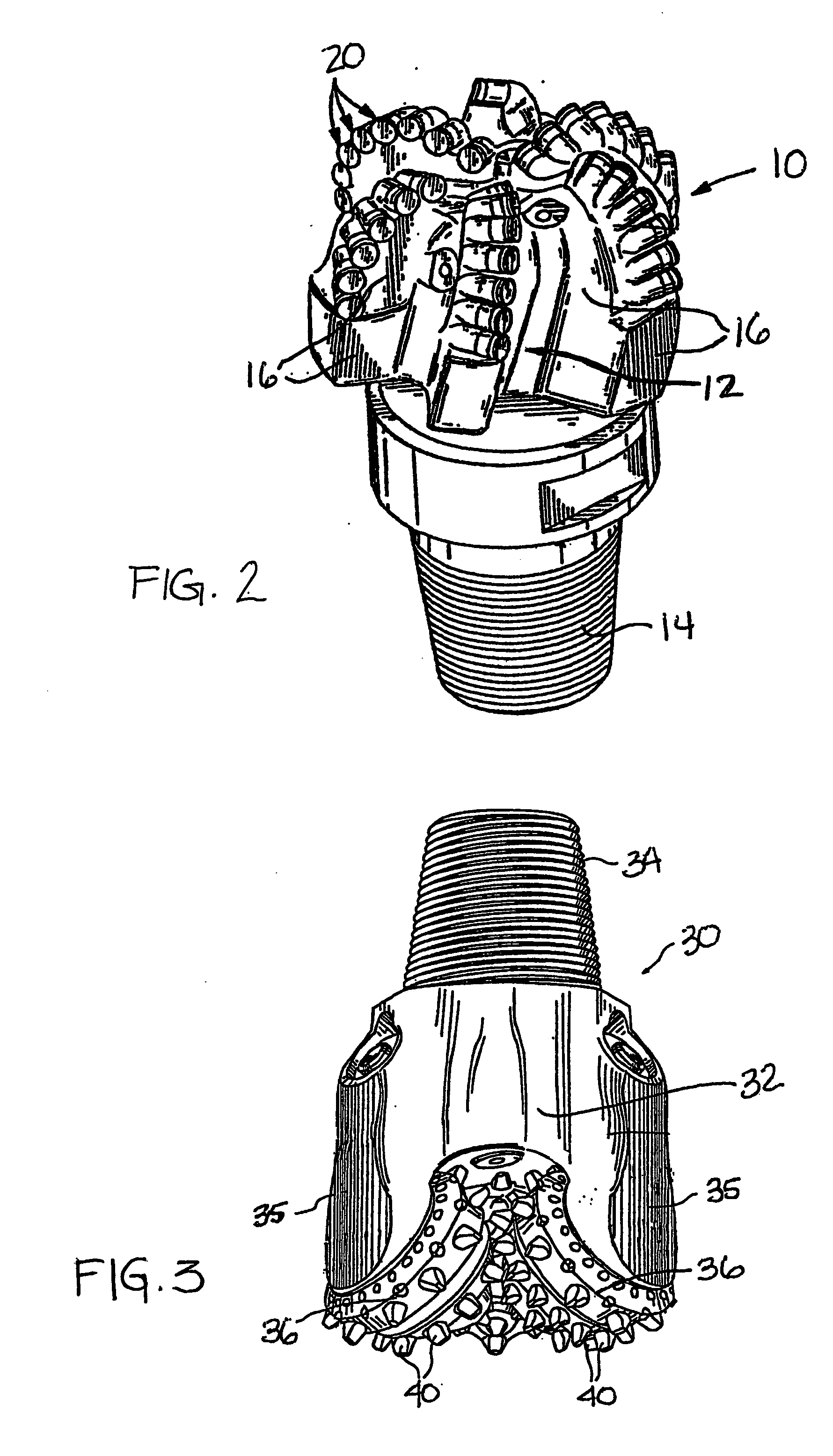

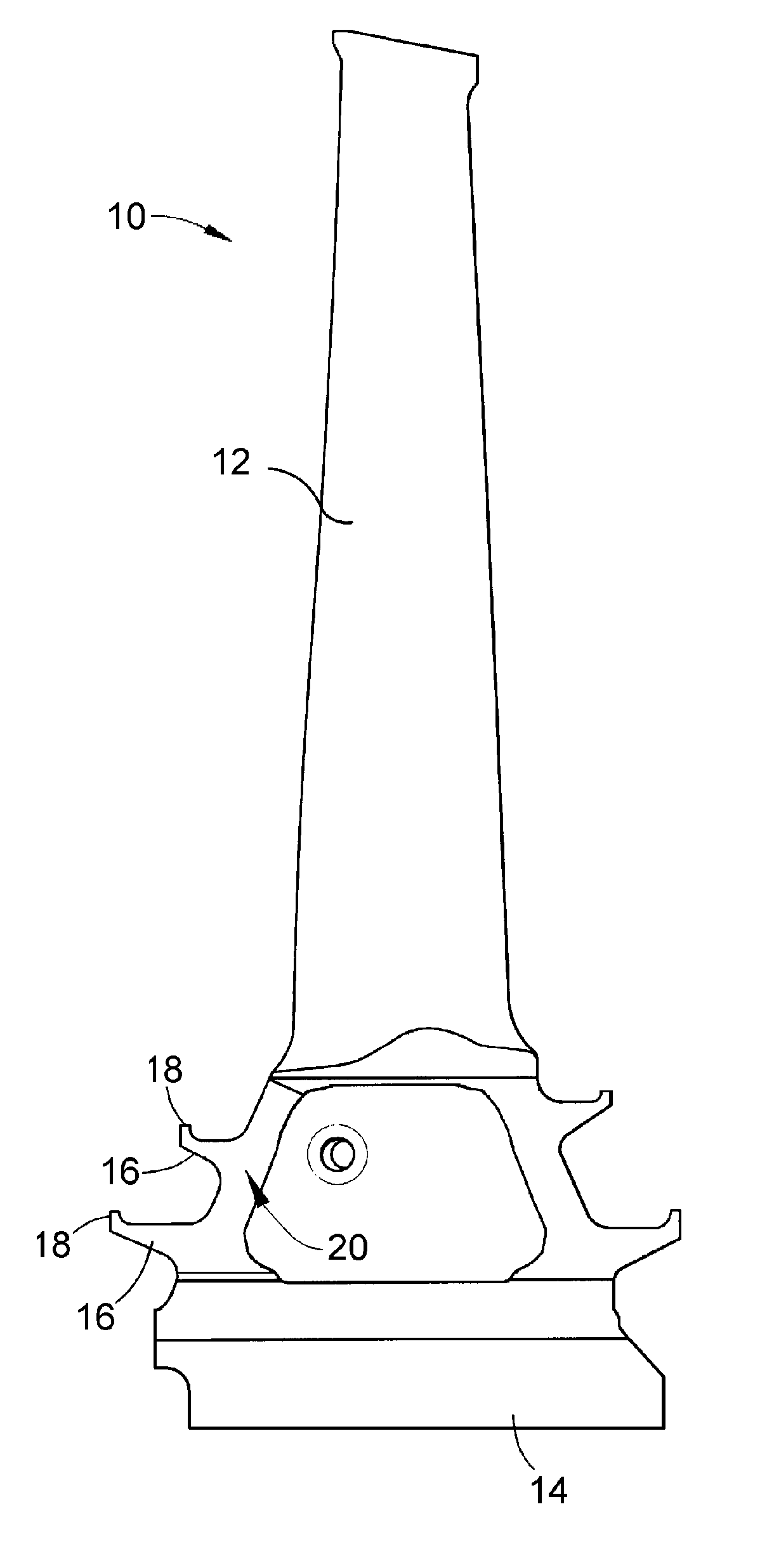

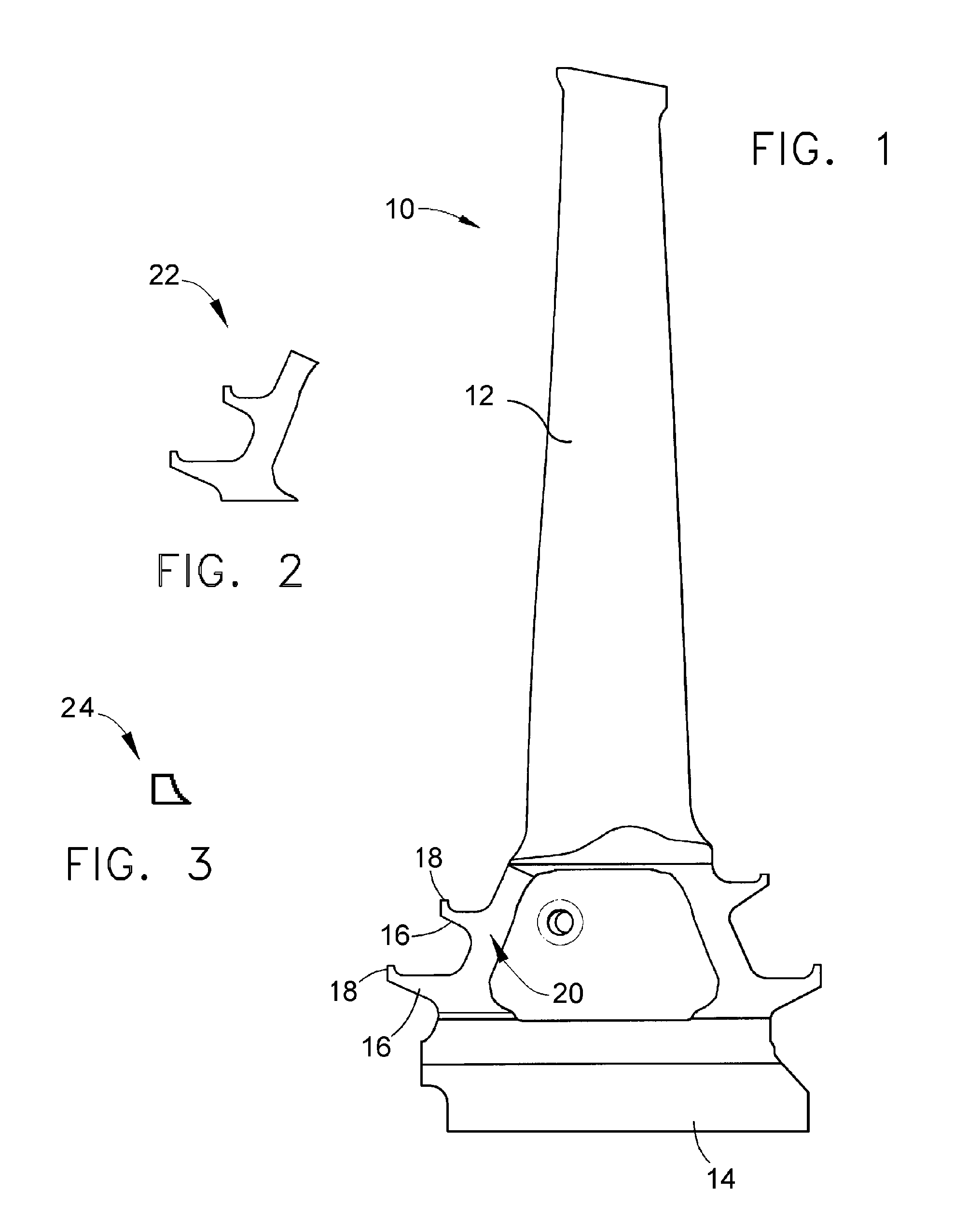

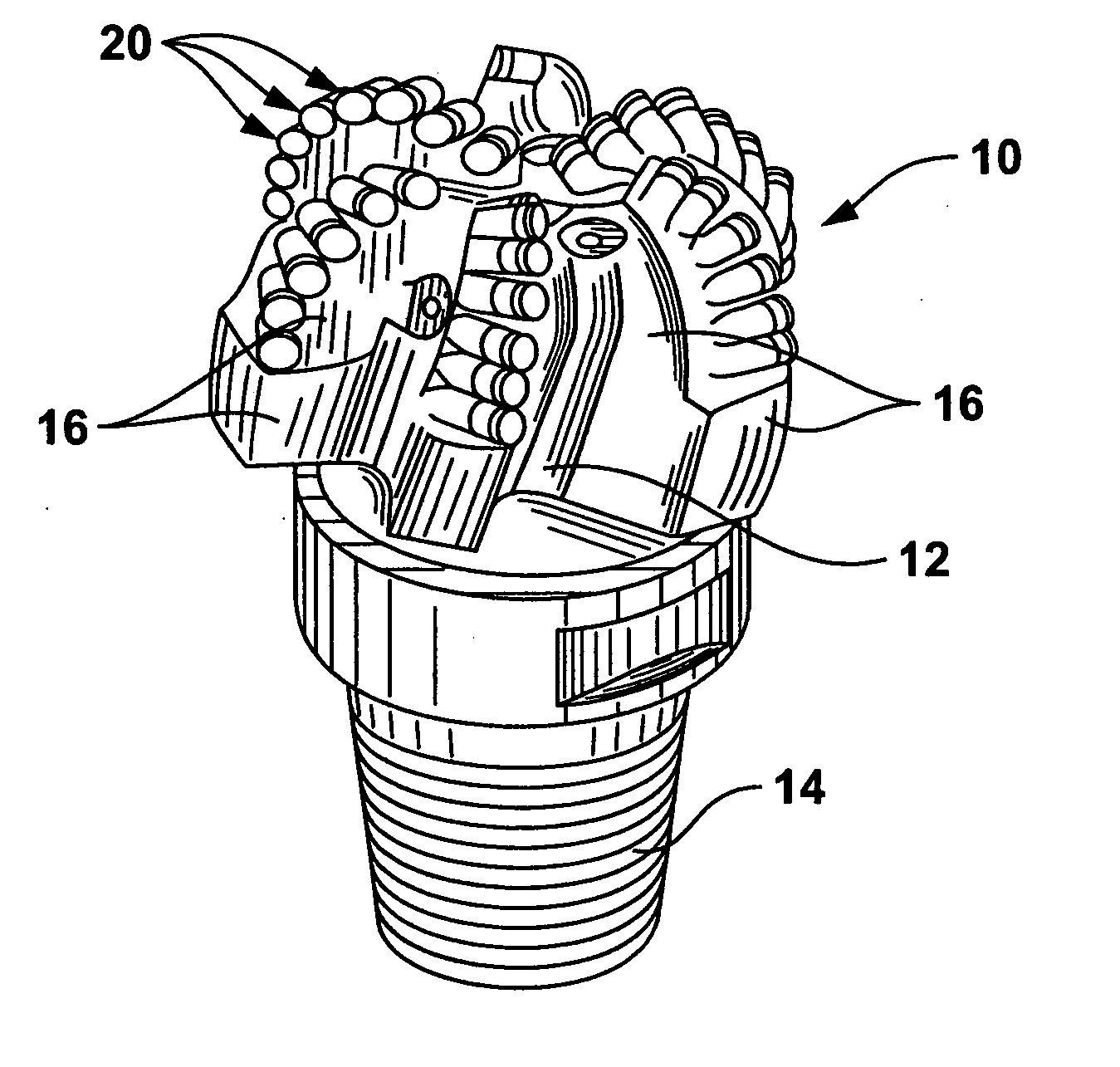

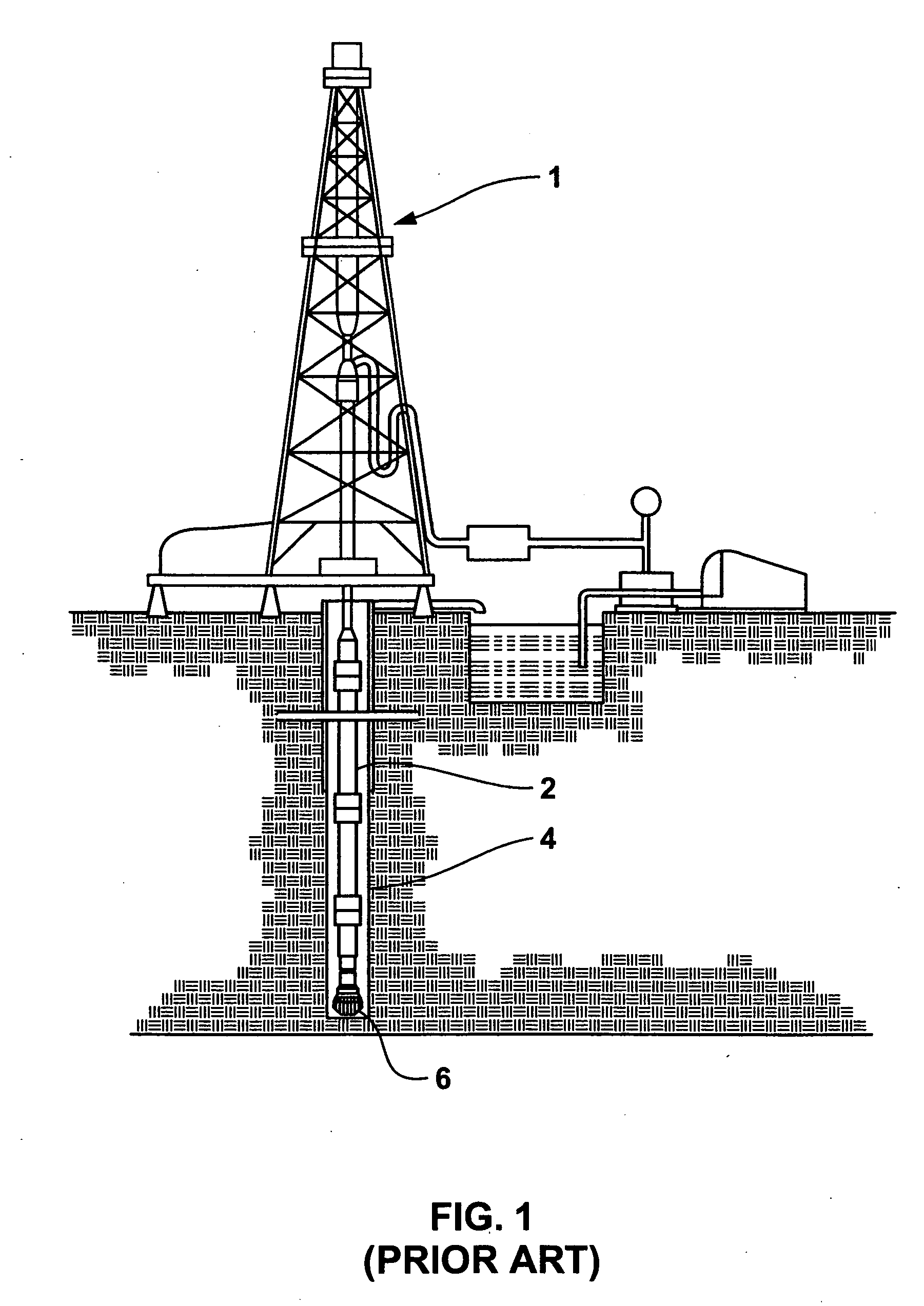

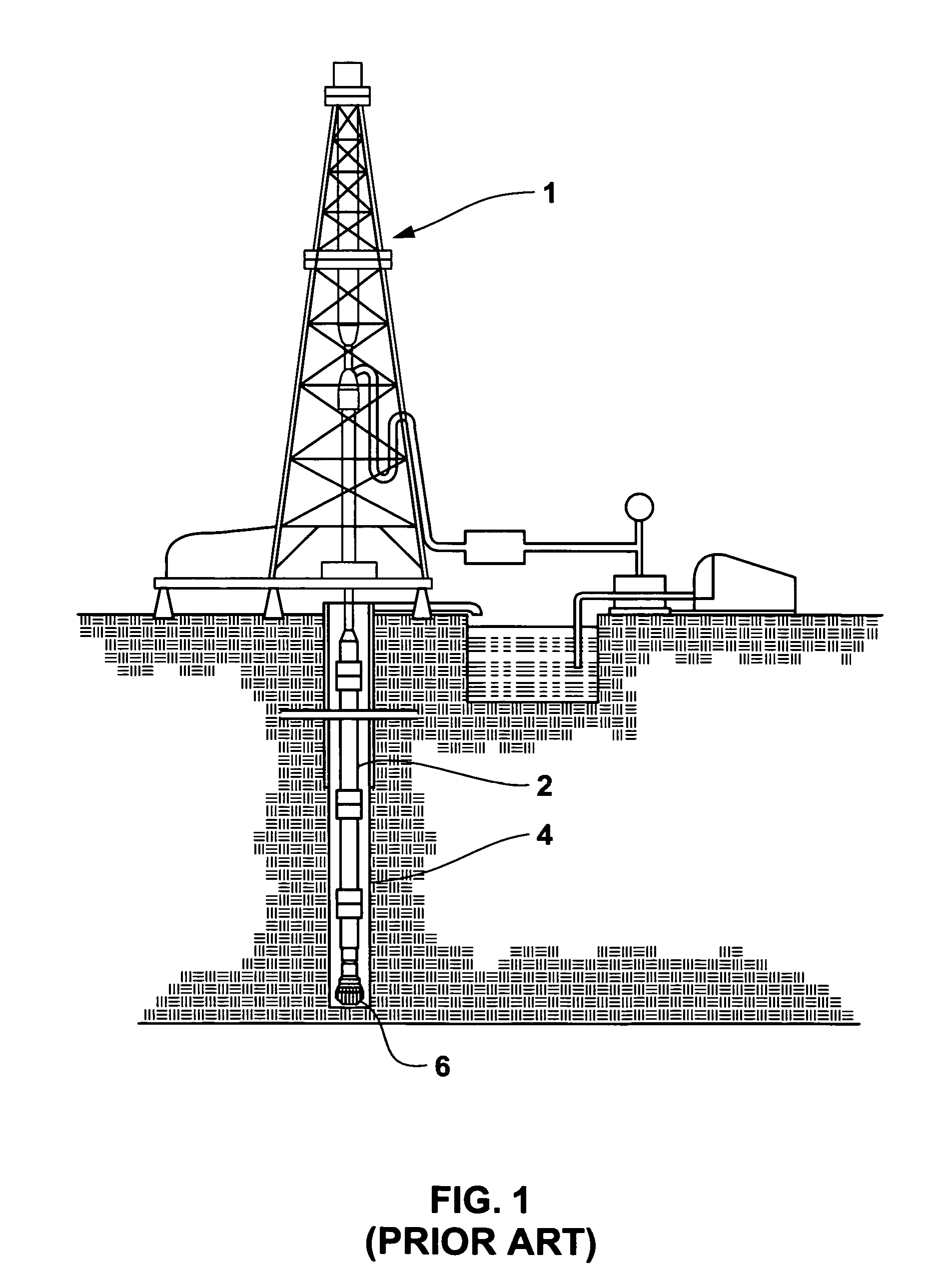

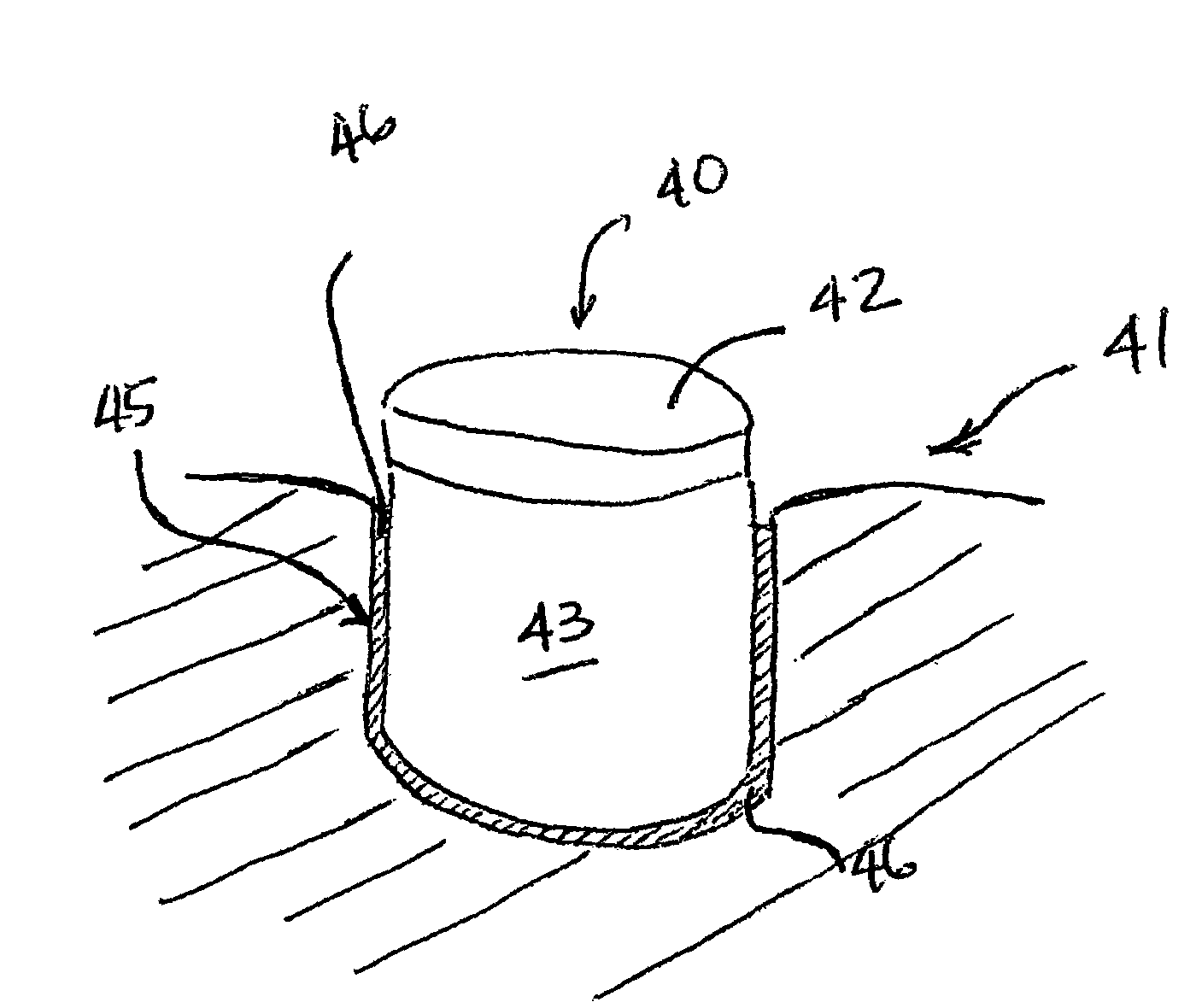

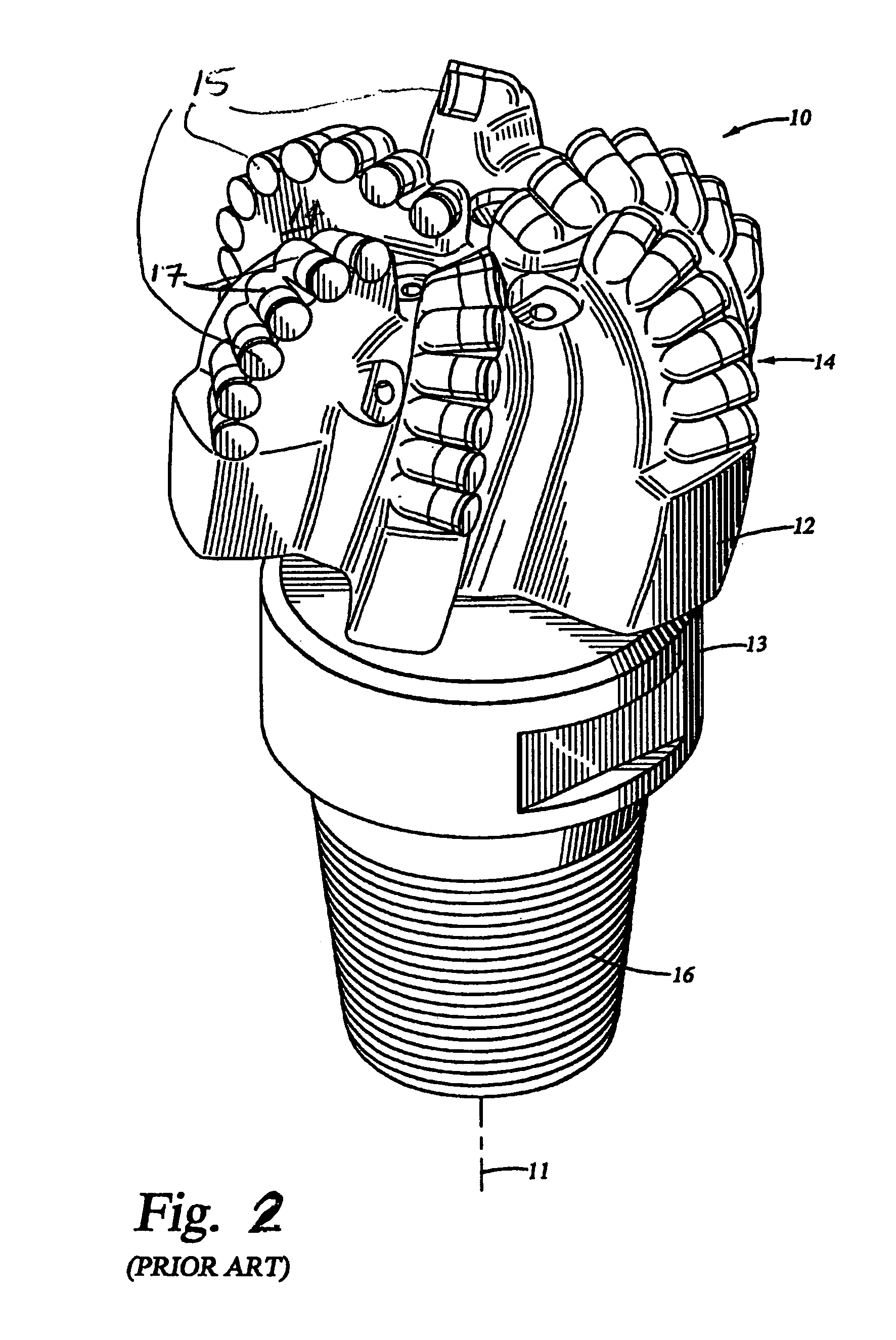

Braze alloy for drilling applications

A down hole cutting tool includes a cutting element support structure. The cutting element support structure has at least one cavity formed therein. A cutting element is disposed in the cavity. Braze alloy is also disposed in the cavity between the cutting element and the cutting element support structure. The braze alloy comprises between about 0.5% and about 10% by weight of at least one selected from the group of gallium (Ga), indium (In), thallium (Tl). Methods for building a down hole tool using the braze alloy are also disclosed.

Owner:SMITH INT INC +1

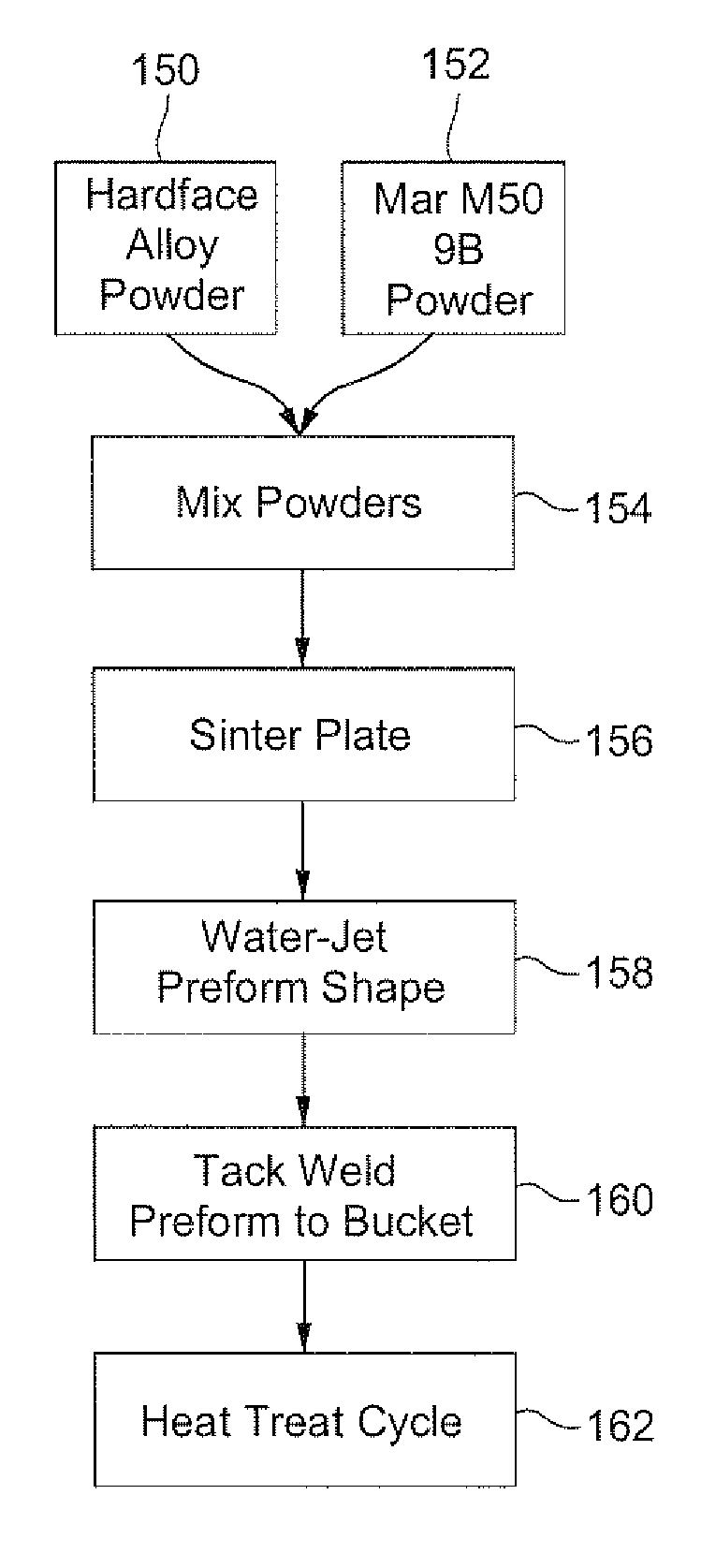

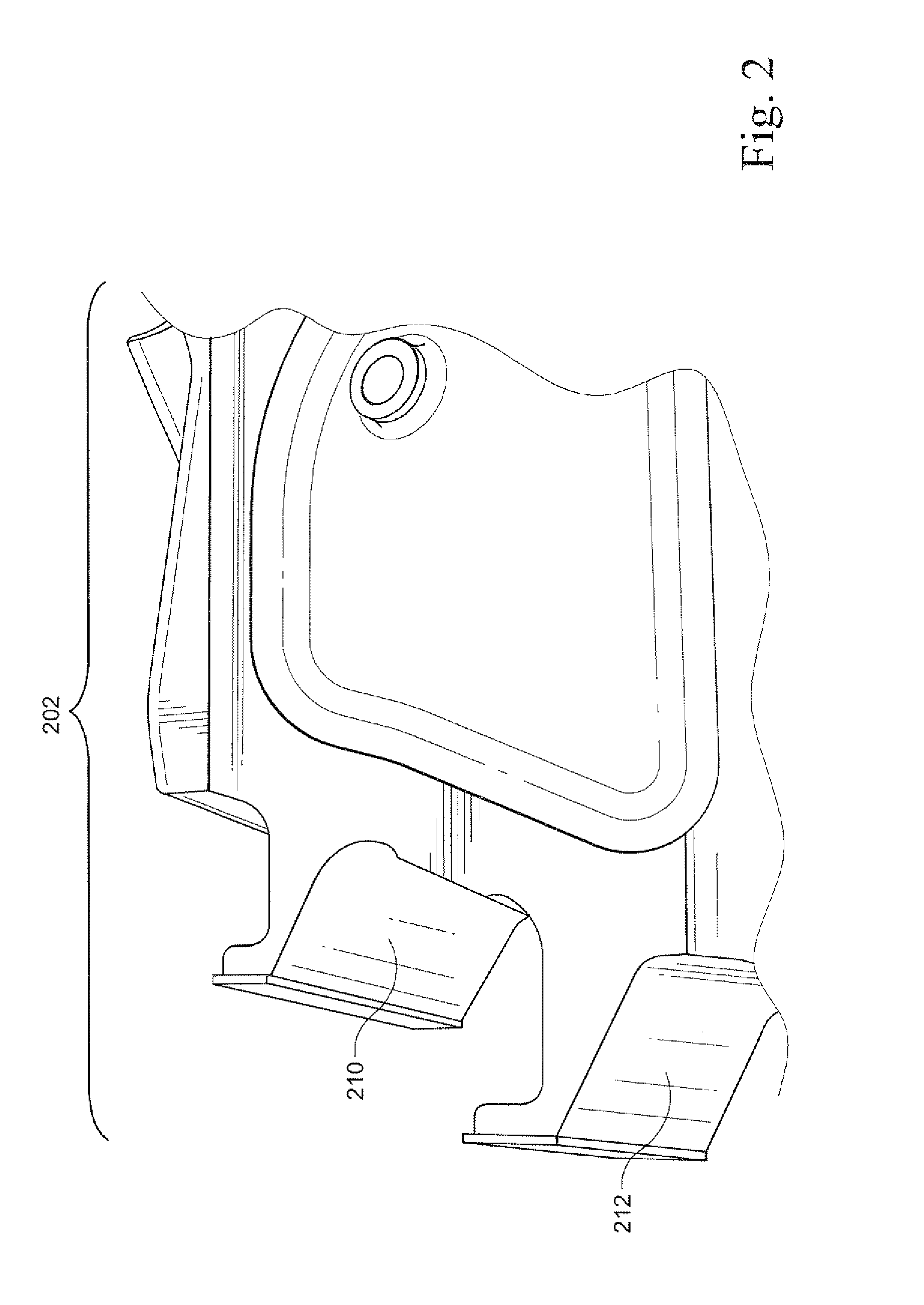

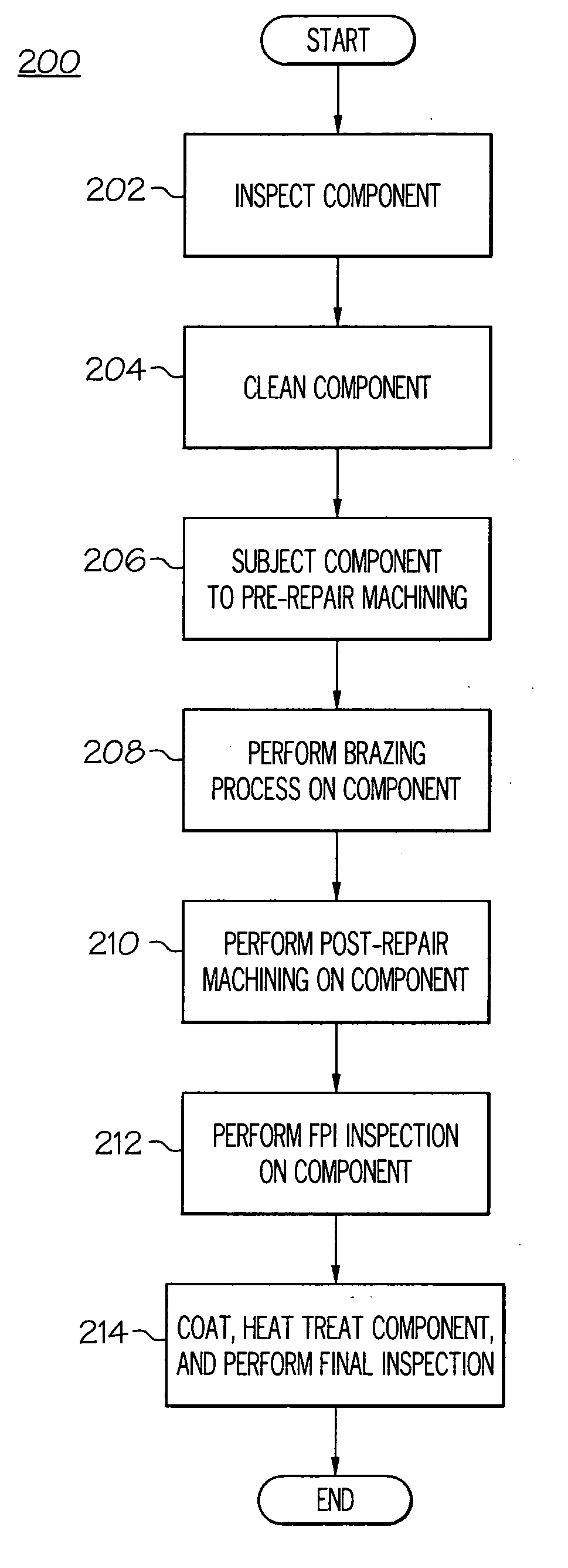

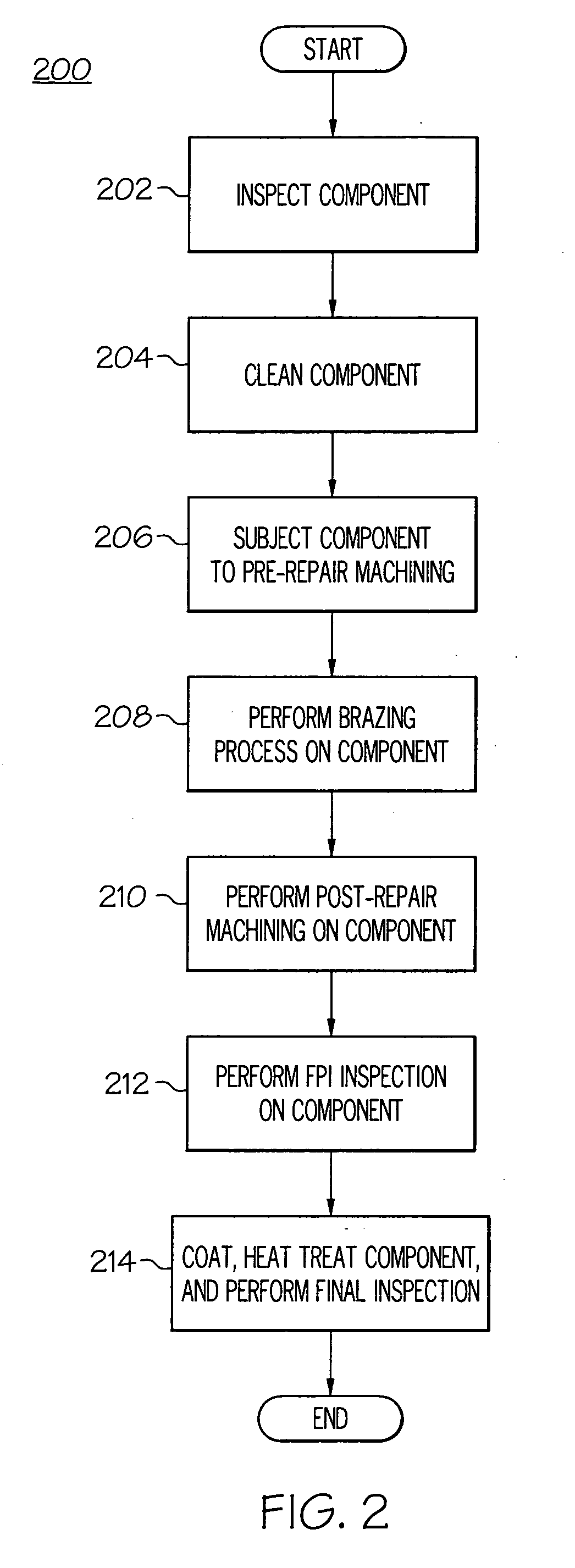

Preform and method of repairing nickel-base superalloys and components repaired thereby

InactiveUS20060134454A1Minimize distortionEasy to crackBlade accessoriesSolid state diffusion coatingPowder mixtureWear resistant

A process for repairing a turbine component of a turbomachine, as well as a sintered preform used in the process and a high gamma-prime nickel-base superalloy component repaired thereby. The sintered preform contains a sintered mixture of powders of a cobalt-base braze alloy and a cobalt-base wear-resistant alloy. The braze alloy constitutes at least about 10 up to about 35 weight percent of the sintered preform and contains a melting point depressant such as boron. The preform is formed by mixing powders of the braze and wear-resistant alloys to form a powder mixture, and then sintering the powder mixture. To use the preform, a surface portion of the turbine component is removed to expose a subsurface portion, followed by diffusion bonding of the preform to the subsurface portion to form a wear-resistant repair material containing the braze alloy dispersed in a matrix of the wear-resistant alloy.

Owner:GENERAL ELECTRIC CO

Braze alloy

A braze alloy is described which includes indium and / or thallium as alloying elements. For example, between about 0.5% and about 10% by weight of indium (In) and / or thallium (Tl) can be added to a braze alloy to reduce the braze temperature without substantially effecting braze strength. Braze alloys that are alloyed to including indium (In) and / or thallium (Tl) can be use in brazing cutting elements to drilling tools. These alloying elements may also be added to braze alloys used for other applications to reduce braze temperature.

Owner:KEMBAIYAN KUMAR T

Braze Alloy And The Use Of Said Braze Alloy

InactiveUS20080017694A1Improve oxidation resistanceImprove the immunityCooking-vessel materialsTurbinesBraze alloyCobalt

The invention relates to an oxidation and corrosion resistant braze alloy consisting of (wt.-%) 10-15% Cr, 4.5-6% Al, 0.17-0.3% Y, 8-12% Co, 0-4% W, 2.5-5% Ta, 2.0-3.5% B with Cr+Al>15%, Cr / Al≦3 and Al+Ta>7.5%, remainder Nickel and unavoidable impurities and to the use of this alloy for brazing onto a Nickel based or a Cobalt based superalloy article. The braze alloy can either be used in pure form as a paste or a foil or as a blend in a blend braze paste, in a braze tape or in a pre-sintered braze sheet.

Owner:ALSTOM TECH LTD

Braze alloy and method of use for drilling applications

A down hole cutting tool includes a cutting element support structure. The cutting element support structure has at least one cavity formed therein. A cutting element is disposed in the cavity. Braze alloy is also disposed in the cavity between the cutting element and the cutting element support structure. The braze alloy comprises between about 0.5% and about 10% by weight of at least one selected from the group of gallium (Ga), indium (In), thallium (Tl). Methods for building a down hole tool using the braze alloy are also disclosed.

Owner:SMITH INT INC +1

Braze alloys

An improved braze alloy is microalloyed to include about 0.0005 wt % to about 0.5 wt % of at least one aggressively surface acting element selected from tellurium (Te), selenium (Se), antimony (Sb), bismuth (Bi), and gallium (Ga), or any combination thereof. The braze alloys may include at least about 30% by weight of at least one base metal selected from the group of silver (Ag), copper (Cu), gold (Au), nickel (Ni), or aluminum (Al). In one example, a silver braze alloy suitable for brazing a cutter to a drill bit body is microalloyed to improve a characteristic of the braze material.

Owner:SMITH INT INC

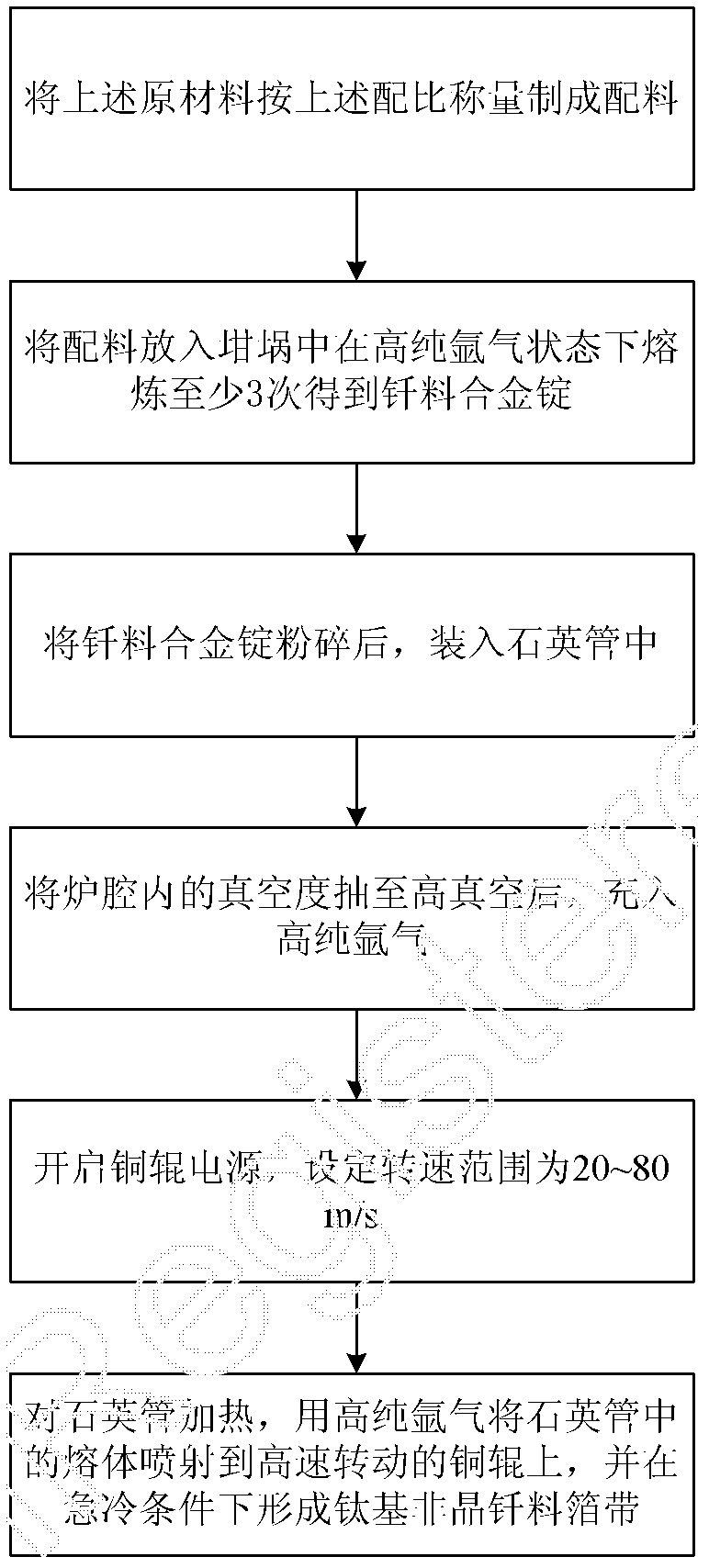

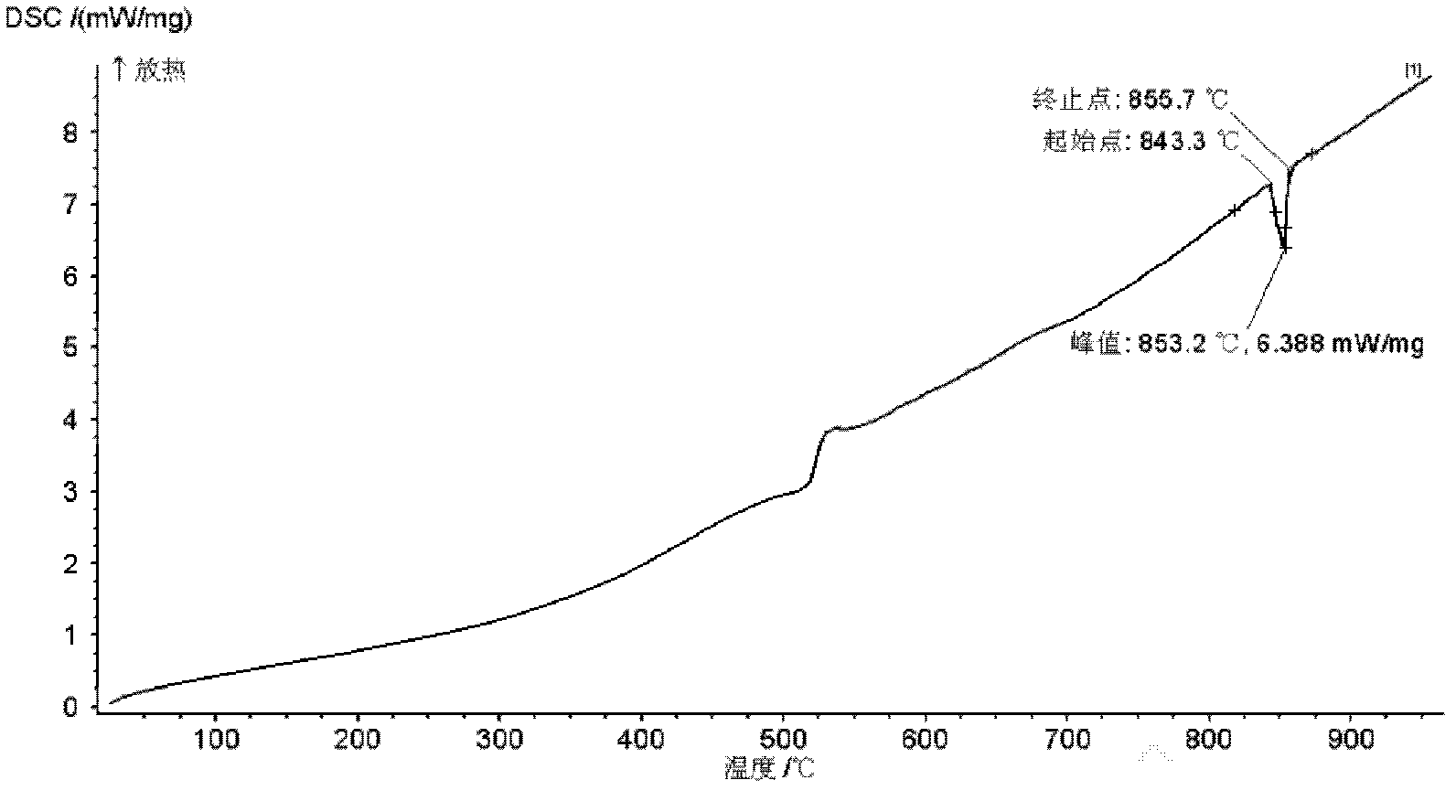

Titanium-based amorphous brazing alloy foil strip for brazing and preparation method for foil strip

InactiveCN102430874ABright surfaceNeat edgesWelding/cutting media/materialsSoldering mediaSurface brightnessBraze alloy

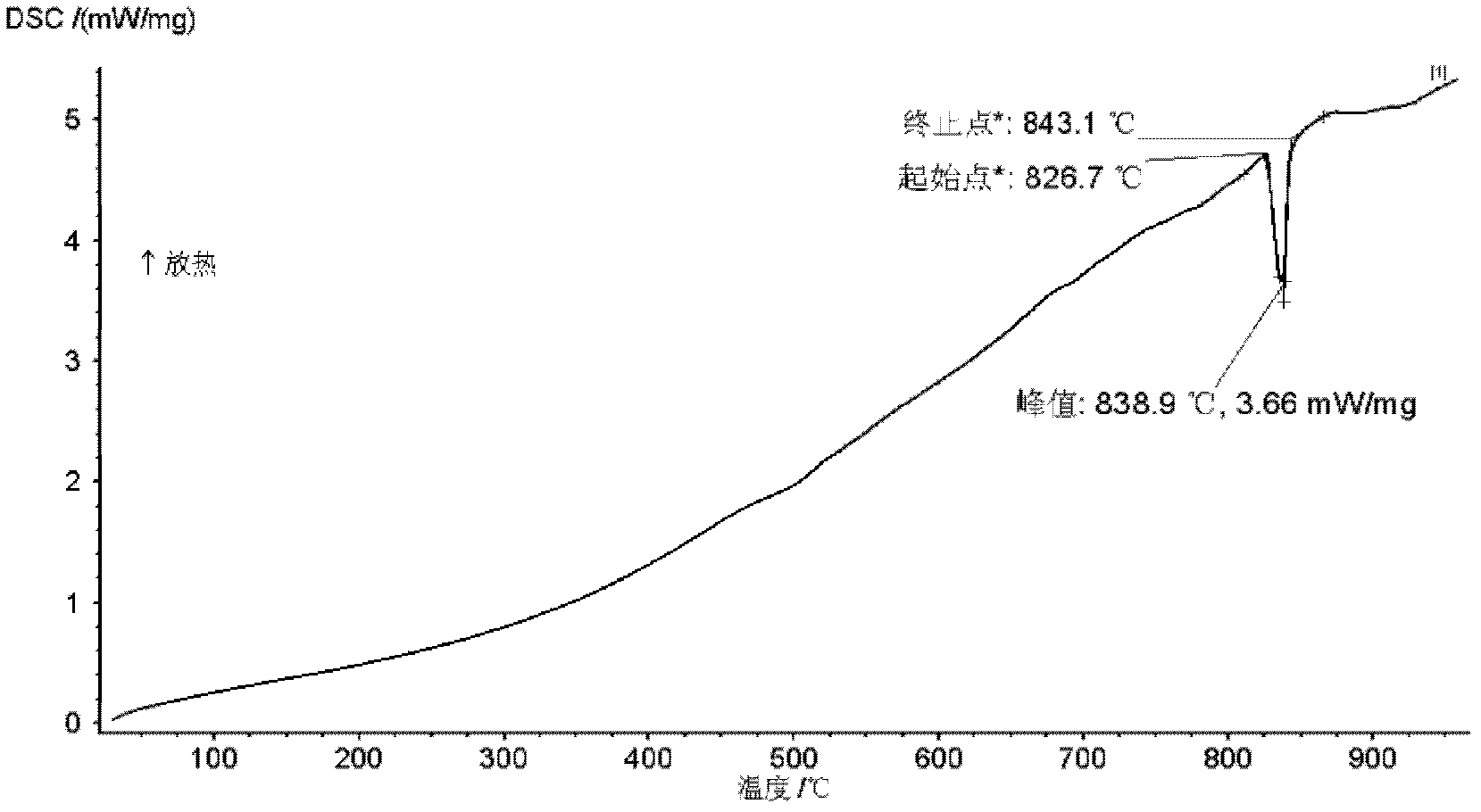

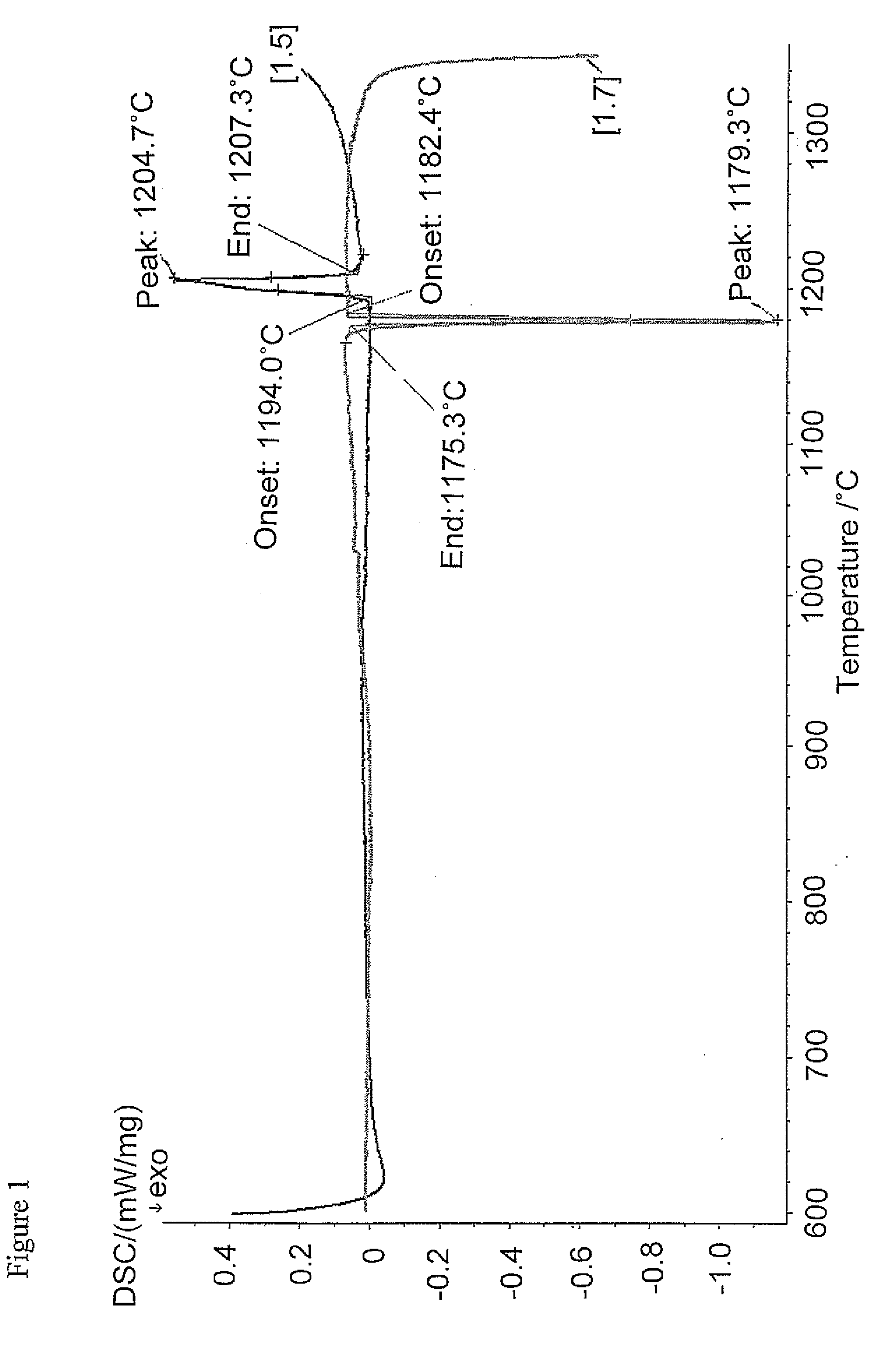

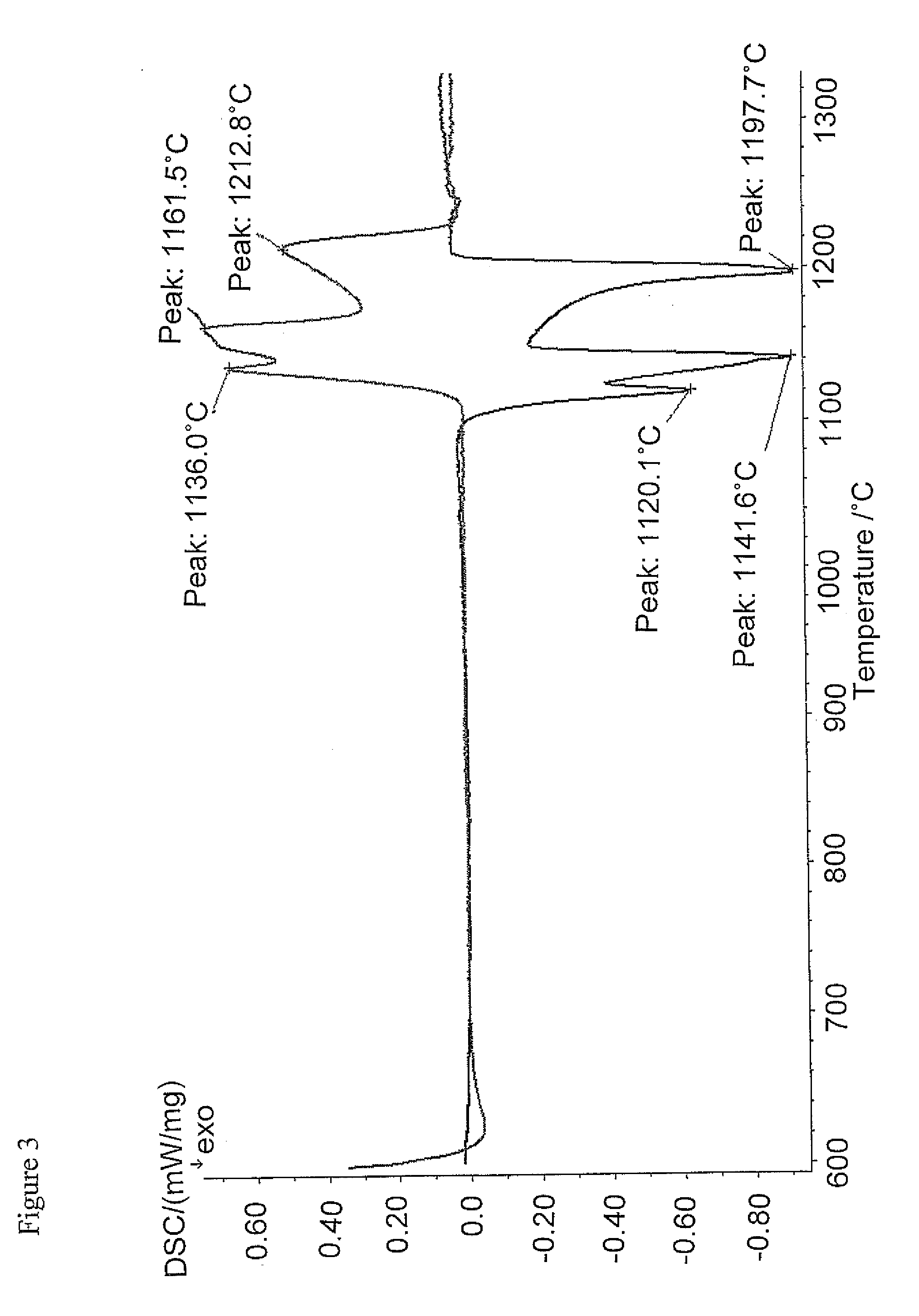

The invention provides a titanium-based amorphous brazing alloy foil strip for brazing and a preparation method for the foil strip. Components of the brazing alloy foil strip by percentage include 35-50% of Ti (titanium), 25-35% of Zr (zirconium), 10-24% of Cu (copper), 5-15% of Ni (nickel) and 0.5-8% of Co (cobalt). The method for preparing the brazing alloy foil strip includes the steps: weighing raw materials according to the proportion to prepare ingredients; placing the ingredients into a crucible and smelting the ingredients for at least three times in a high-purity argon state to obtain brazing alloy ingots; crushing the brazing alloy ingots and then placing the crushed brazing alloy ingots into a quartz tube; pumping a furnace chamber into high vacuum and then charging high-purity argon; turning on a copper roller power supply and setting the range of rotating speeds; and heating the quartz tube, spraying melts in the quartz tube onto a copper roller rotating at a high speed and forming the titanium-based amorphous brazing alloy foil strip under the condition of quenching. The brazing alloy foil strip has the advantages of surface brightness, uniformity of composition and the like, the negative effects of eutectic composition brazing alloy brittleness and over-high welding temperature on base metal can be avoided, and assembly and gap filling are easier when complex structural components are brazed.

Owner:BEIJING UNIV OF TECH

Low-melting boron-free braze alloy compositions

ActiveUS20100038412A1Suppressing melting temperatureWelding/cutting media/materialsSoldering mediaHafniumBraze alloy

Nickel-based low-melting boron-free braze alloy compositions include varying amounts of the alloying elements cobalt, chromium, hafnium, zirconium together with optionally titanium and aluminum. The braze alloys can be used as a stand alone braze alloy or in combination with other filler alloys to create braze joints with desirable joint geometries and properties. The braze alloy compositions can be used to join and repair different superalloy articles such as gas turbine components for high temperature applications.

Owner:HUANG XIAO

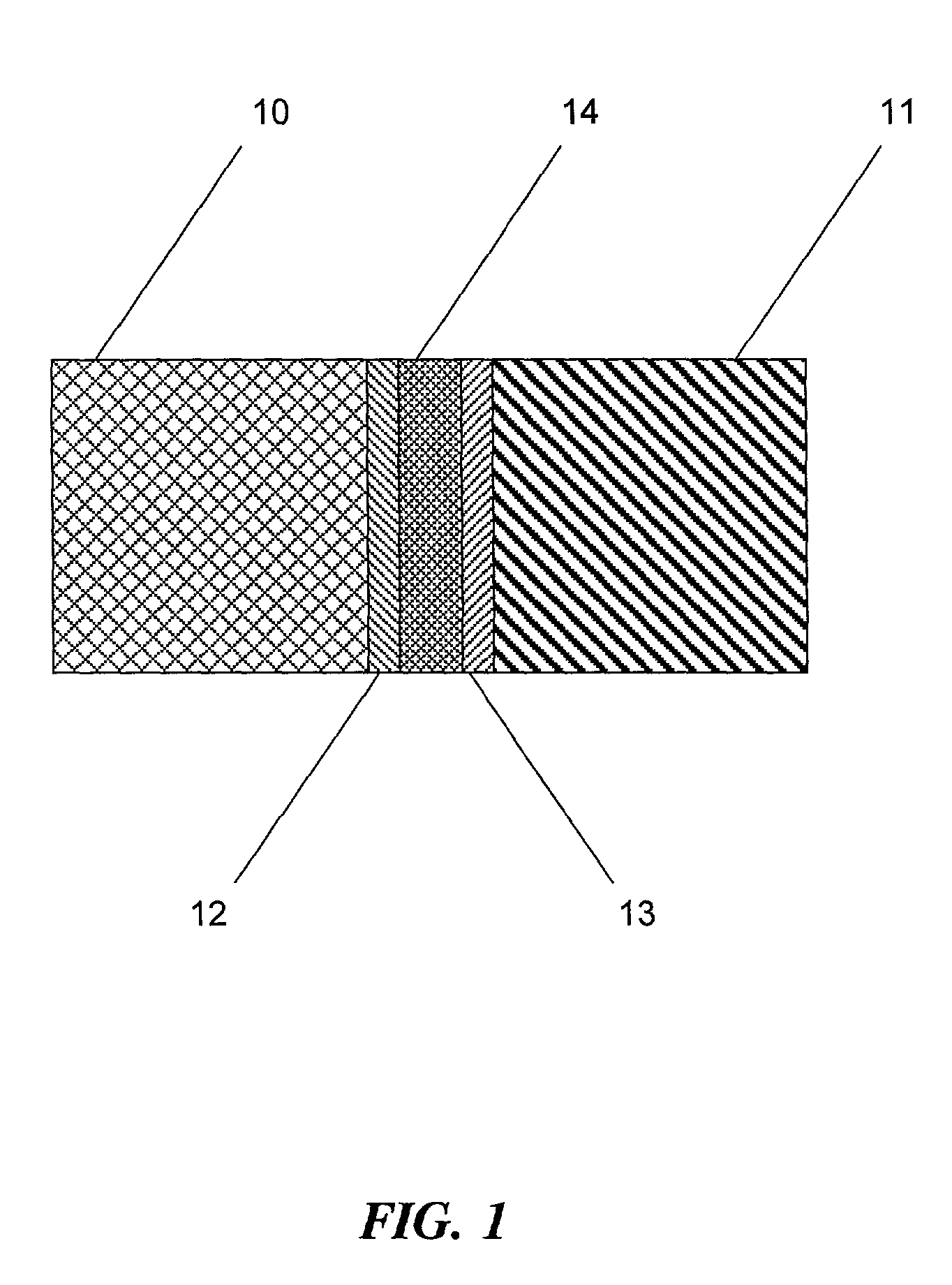

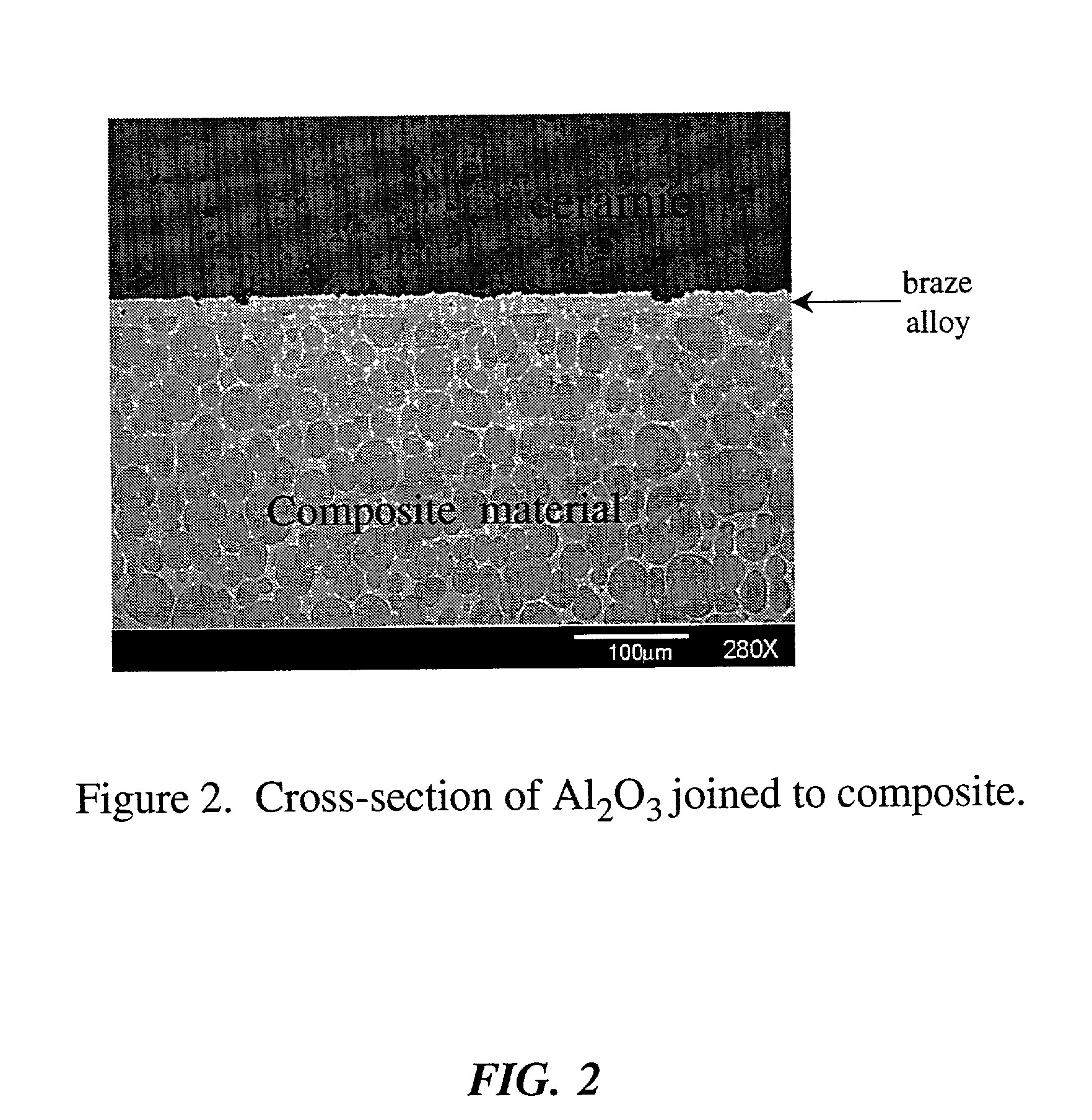

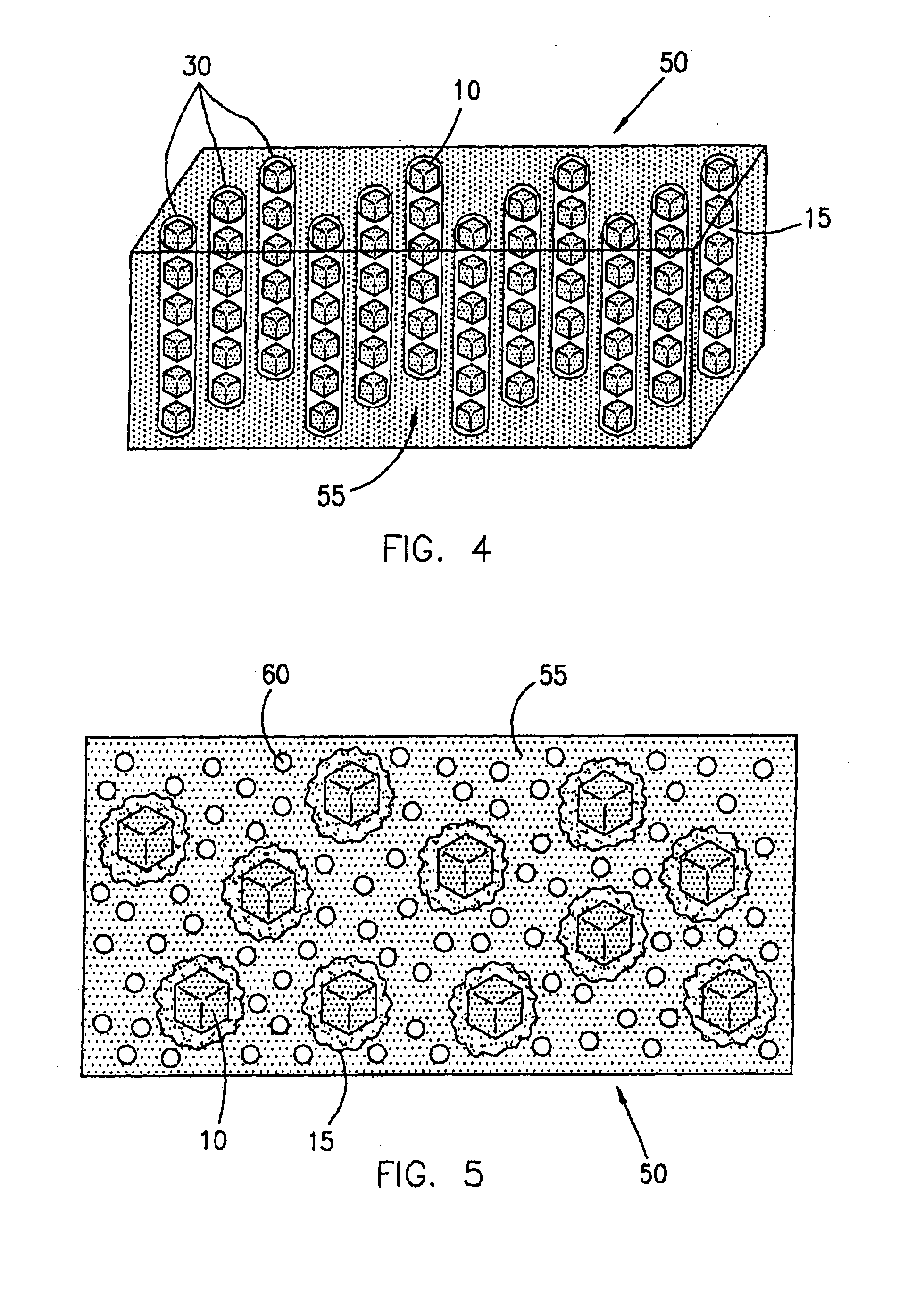

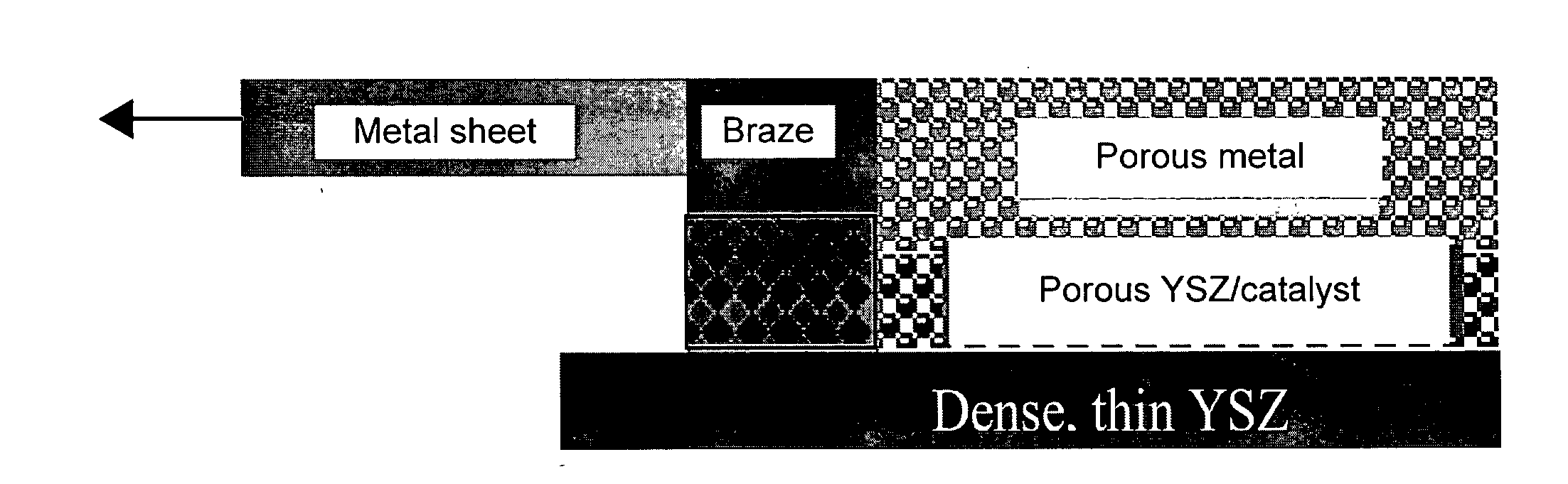

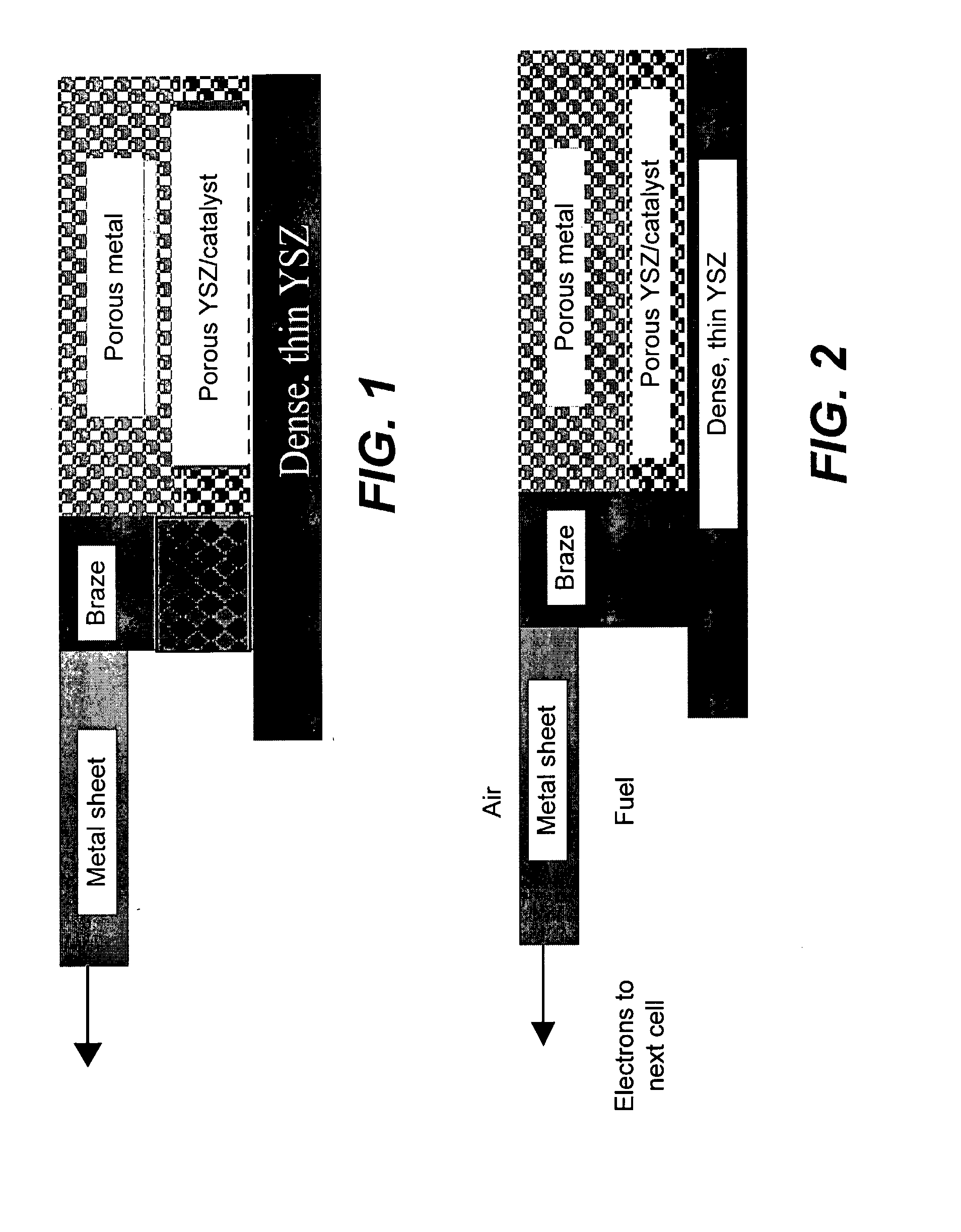

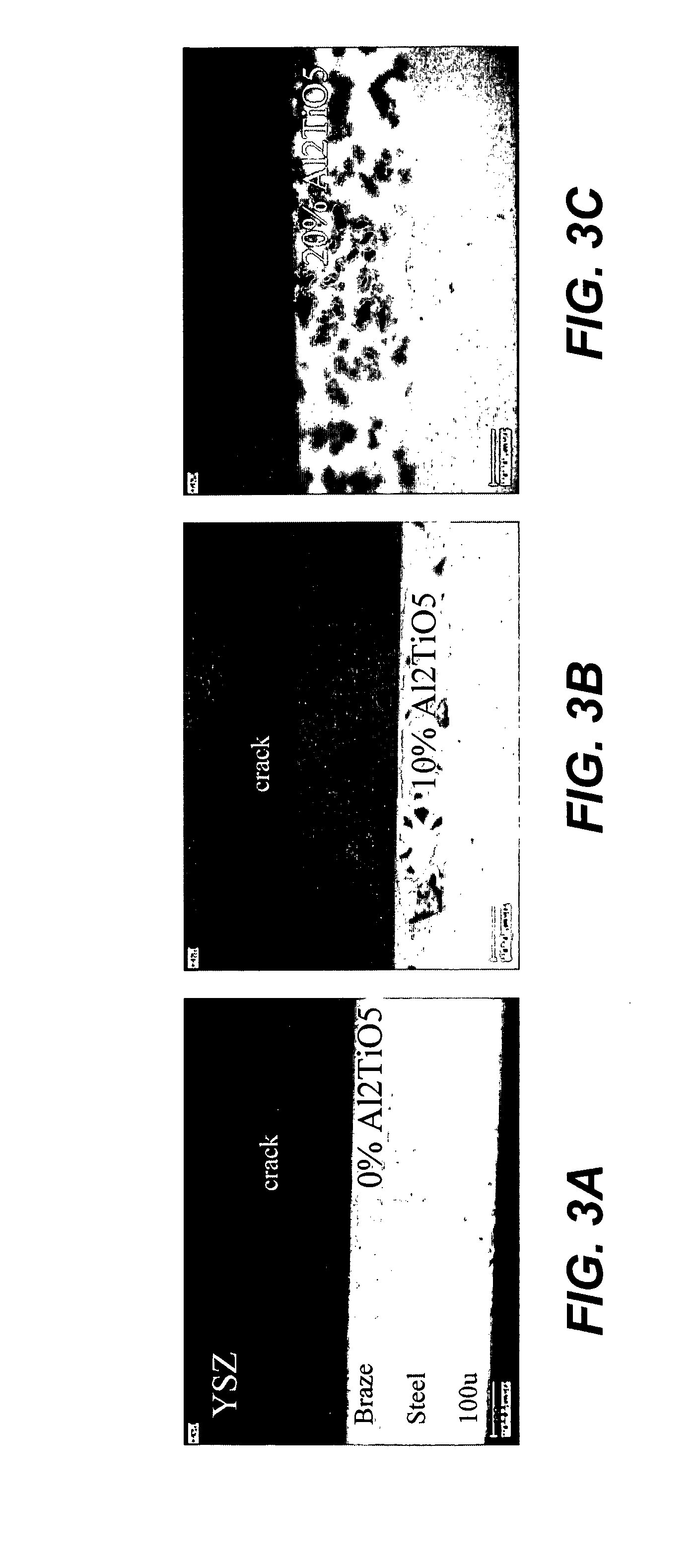

Braze System With Matched Coefficients Of Thermal Expansion

InactiveUS20080131723A1Reduce thermal stressPromote wettingExhaust apparatusFinal product manufactureParticulatesBraze alloy

A CTE modified braze composition that can be utilized to manufacture a strong, gastight joint where at least one of the joining members comprises a ceramic (e.g., a ceramic or a cermet). The braze composition is formulated so as to reduce the thermal stress that results from the mismatch of thermal expansion coefficients between a ceramic joining member and the braze or other joining members. The braze composition comprises a braze alloy in powder, paste or bulk form mixed with one or more particulate or fibrous fillers that exhibit a low (i.e., no more than 6 ppm / K) or negative coefficient of thermal expansion. The braze composition can be used to join members, at least one of which comprises ceramic, and to a composite member produced by joining the two or more members.

Owner:RGT UNIV OF CALIFORNIA

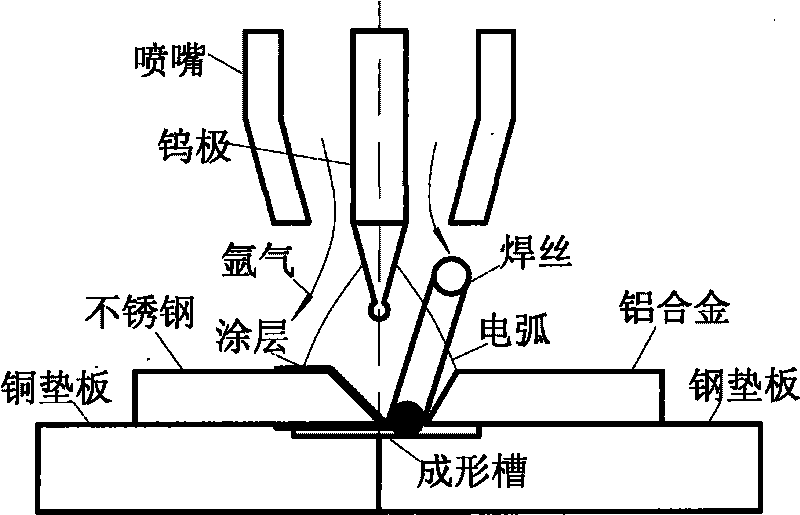

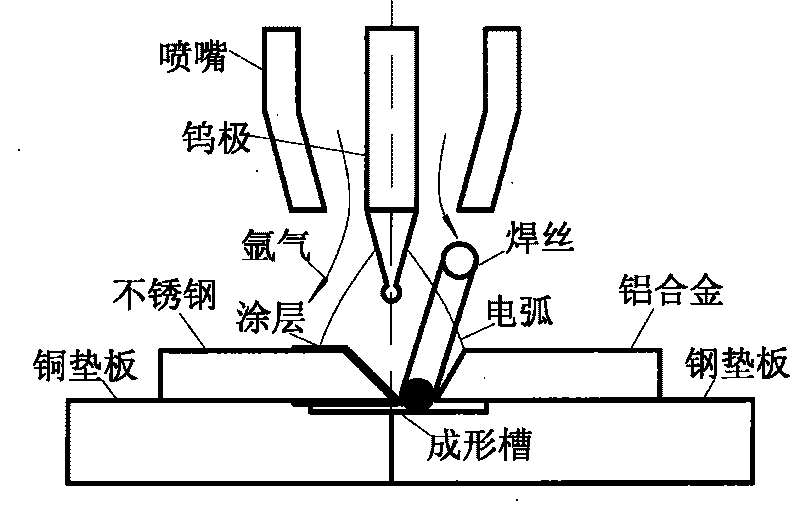

Assistant coating TIG fusing-brazing method suitable for aluminum/steel dissimilar alloy butting

InactiveCN101745709AImprove adhesionEasy to shapeSoldering apparatusWelding/soldering/cutting articlesSheet steelButt joint

The present invention provides an assistant coating TIG fusing-brazing method suitable for aluminum / steel dissimilar alloy butting. In the assistant coating TIG fusing-brazing method, a TIG electric arc is used as a heat source, and an assistant coating and joint groove design and a welding technology are used. In a welding process, electric arc heat firstly enables an assistant coating to fuse to form a liquid film at a steel groove surface; the TIG electric arc is covered on welding wires to directly heat the welding wires and a fused bath, while not to directly heat steel plates, so a fused phenomenon is avoided to be generated on steel surfaces; the welding wires are fused rapidly to moisten and spread rapidly on the steel groove surface under the function of the assistant coating; the welding wires are fed continuously to be fused to fill welding seams gradually; and meanwhile the electric arc walks rapidly, and brazing alloy spreading is stopped when the heat source is moved away. The welding process is stable, and butting joints of aluminum / steel dissimilar alloy TIG fusing-brazing with good formation are obtained.

Owner:HARBIN INST OF TECH

Nickel-based braze alloy compositions and related processes and articles

InactiveUS20050067061A1Improve solubilityPrevents and minimizes formationBlade accessoriesGas turbine plantsBraze alloyCobalt

A nickel-based braze composition is described, containing nickel, palladium, and restricted amounts of boron and silicon. The composition can also contain tantalum, titanium, and zirconium, as well as aluminum, chromium, and cobalt. A method for joining two metal components, using the braze composition, is also described. The braze composition can also be used to fill cracks or other cavities in a component, e.g., a gas turbine part formed from a nickel-based superalloy. Articles of manufacture which contain the braze composition are also described.

Owner:GENERAL ELECTRIC CO

Braze alloy composition with enhanced oxidation resistance and methods of using the same

A cobalt-based braze alloy composition comprises: 22 to 24.75% chromium by weight; 9 to 11% nickel by weight; 6.5 to 7.6% tungsten by weight; 3 to 4% tantalum by weight; 0.55 to 0.65% carbon by weight; 0.3 to 0.6% zirconium by weight; 0.15 to 0.3% titanium by weight; 1.5 to 2.6% boron by weight; 1 to 10% silicon by weight; and cobalt. There are also provided methods of using the same.

Owner:GENERAL ELECTRIC CO

Activated diffusion brazing alloys and repair process

The present invention provides a low-melt nickel-based alloy powder applied in an activated diffusion brazing repair on gas turbine components. In one embodiment, and by way of example only, the low-melt alloy powder comprises between about 6.7% and about 9.2% by weight Cr, between about 9.7% and about 10.3% by weight Co, between about 3.7% and about 4.7% by weight W, between about 3.3% and about 6.3% by weight Ta, between about 3.6% and about 5.2% by weight Al, between about 1.3% and about 4.0% by weight Hf, between about 0.02% and about 0.06% by weight C, between about 1.0% and about 3.2% by weight B, and Ni. Optionally, the low-melt alloy powder may include between about 1.4% and about 3.2% by weight Re.

Owner:HONEYWELL INT INC

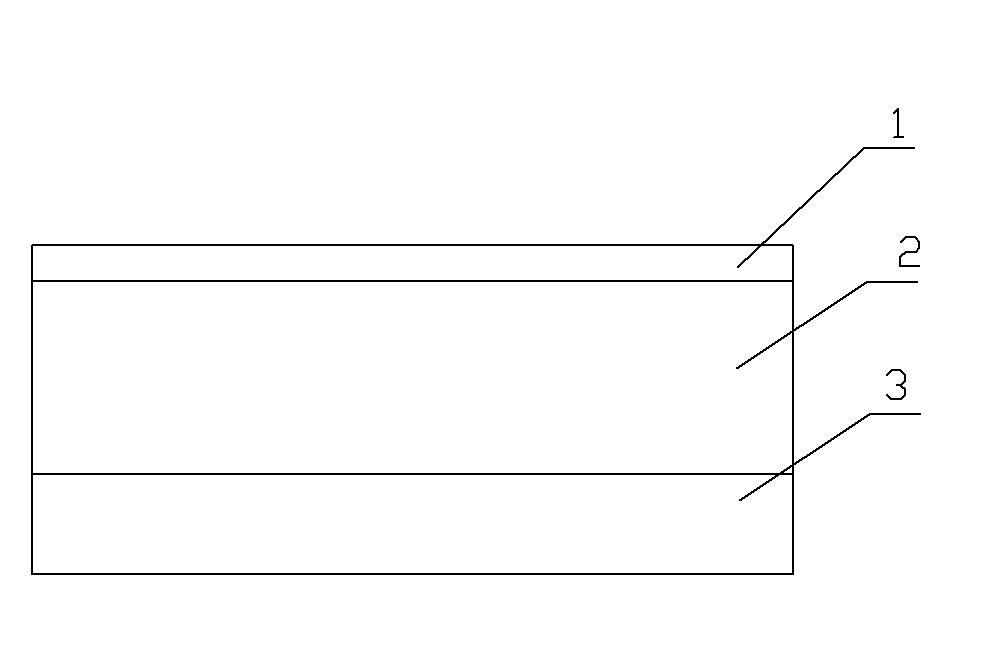

Aluminium brazing sheet

InactiveUS20120177947A1Quality improvementIncrease demandWelding/cutting media/materialsHeat exchange apparatusBraze alloyMelting temperature

A multi layered aluminum alloy brazing sheet including a core material, an intermediate layer on at least one side of the core material, the intermediate layer comprising an Al—Si braze alloy, and a thin covering layer on top of the intermediate layer, The core material and the covering layer have a higher melting temperature than the Al—Si braze alloy. The covering layer includes Bi 0.01 to 1.0 wt-%, Mg≦0.01 wt-%, Mn≦1.0 wt-%, Cu≦1.2 wt-%, Fe≦1.0 wt-%, Si≦4.0 wt-%, Ti≦0.1 wt-%, Zr, Cr, V and / or Sc in total ≦0.2%, and unavoidable impurities each in amounts less than 0.05 wt-%, and a total impurity content of less than 0.2 wt-%, the balance including aluminium. A heat exchanger including the alloy brazing sheet.

Owner:GRAENGES SWEDEN AB

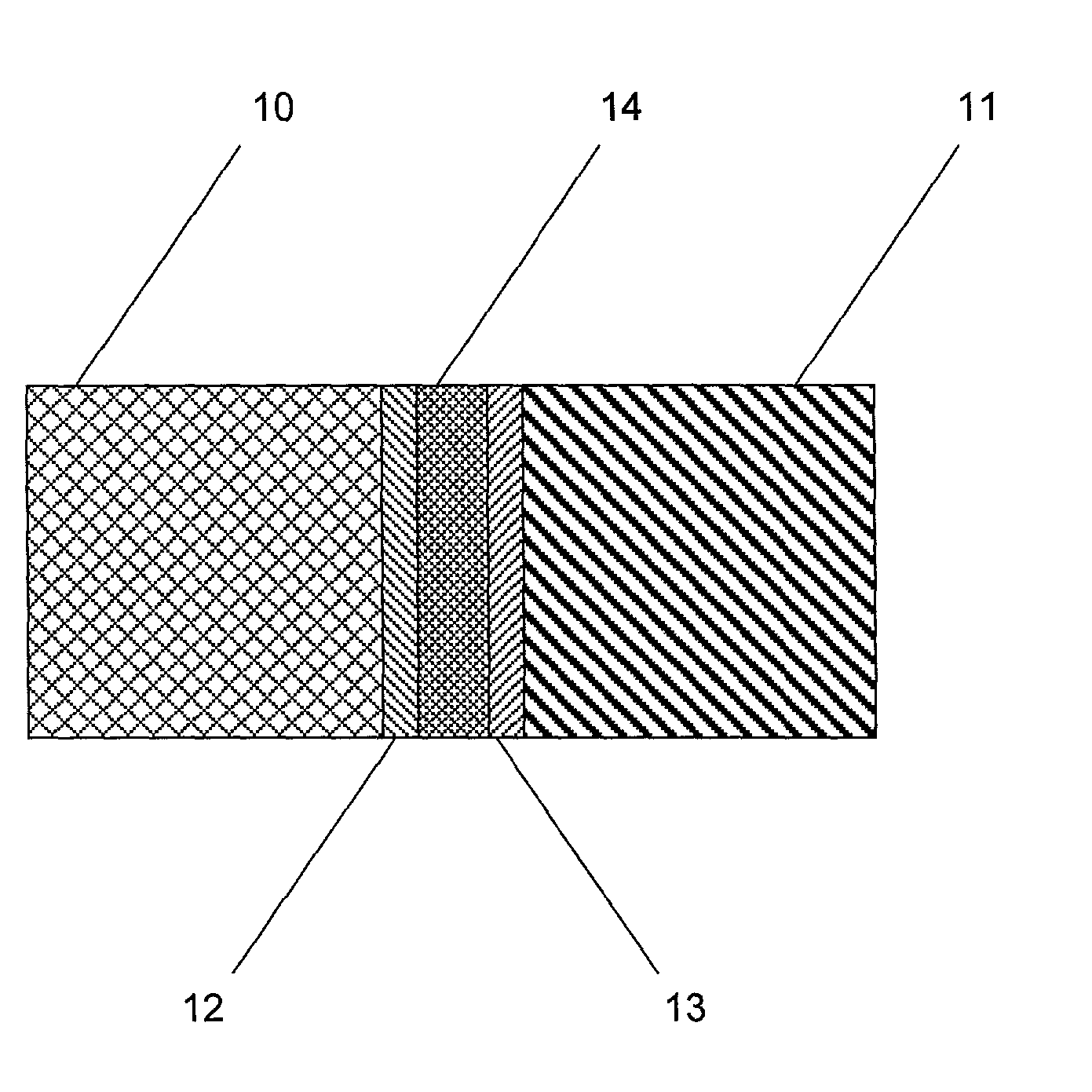

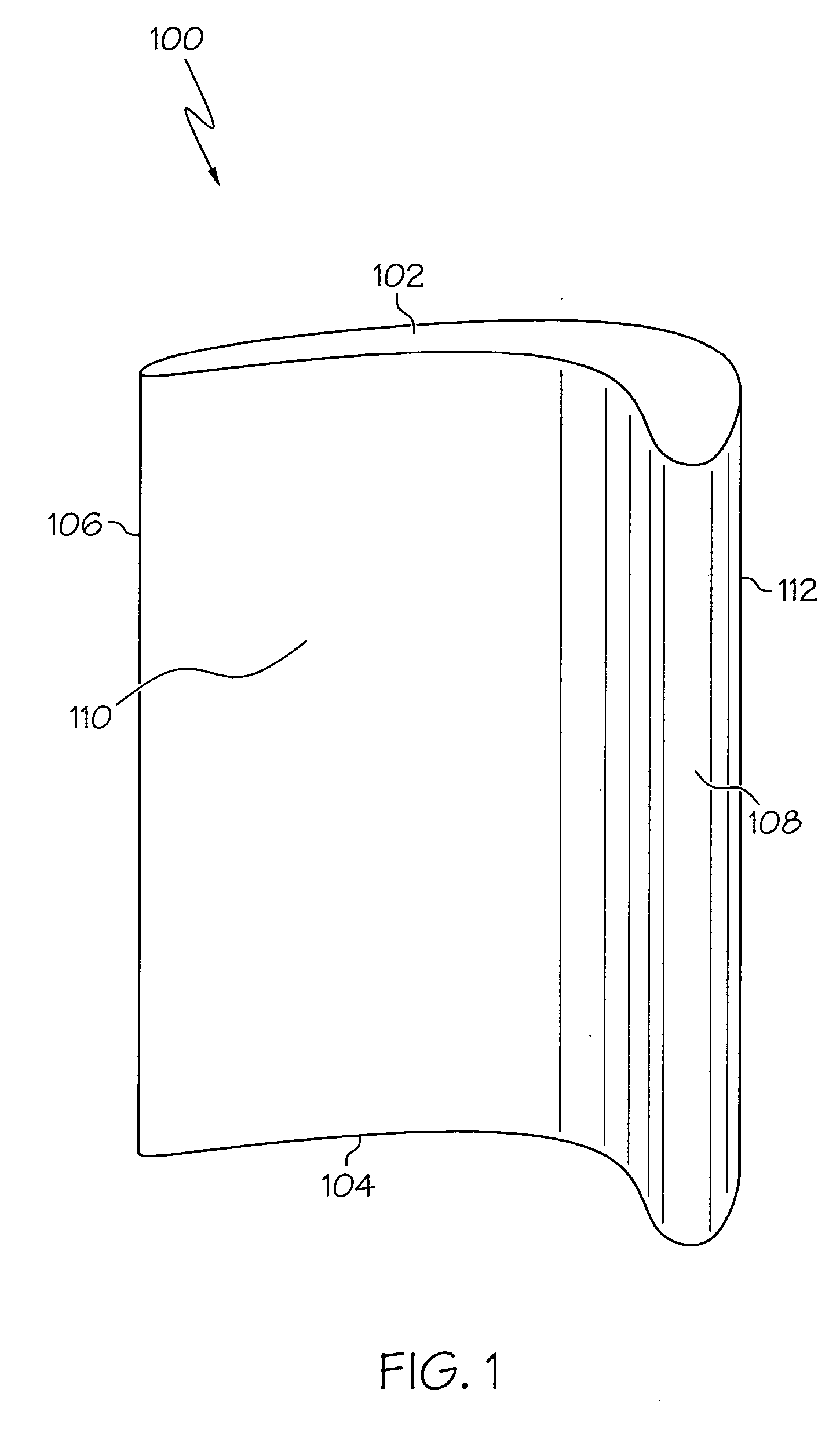

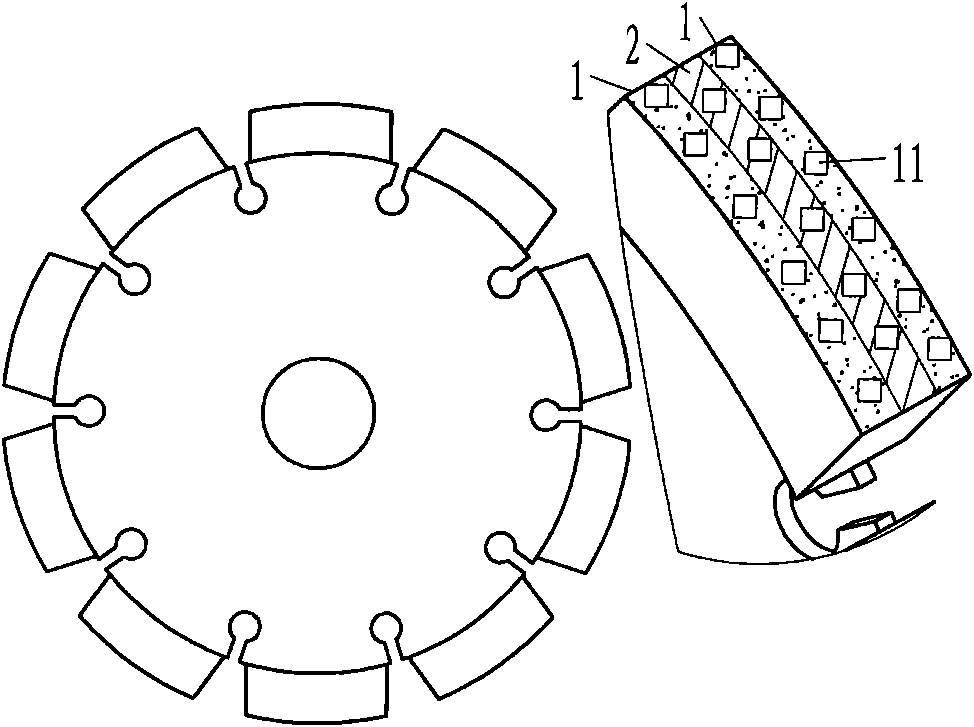

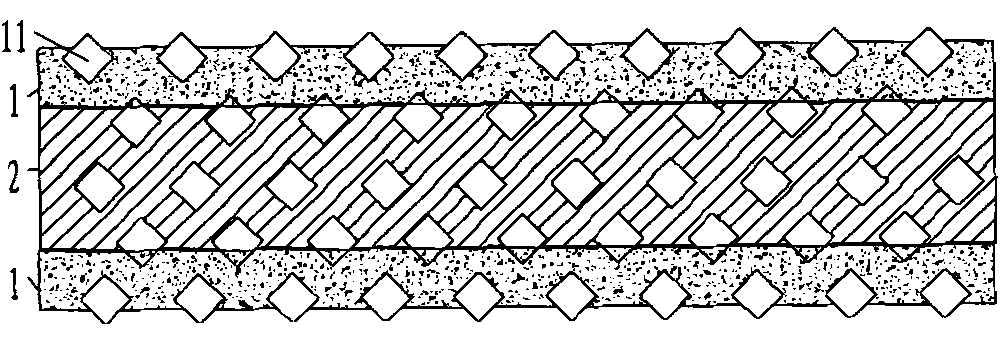

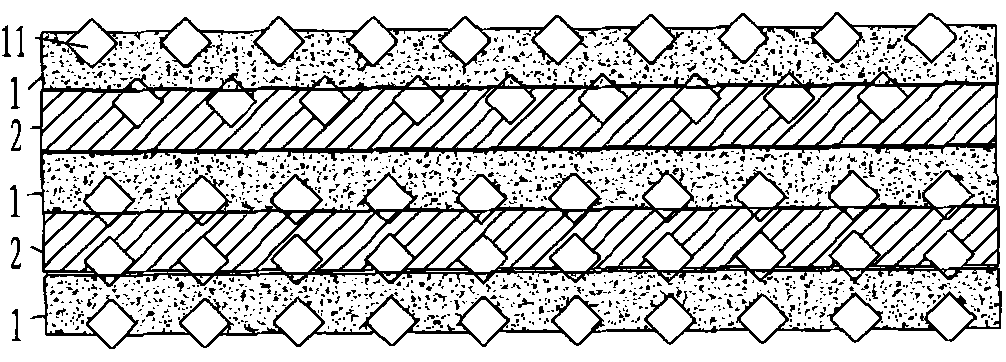

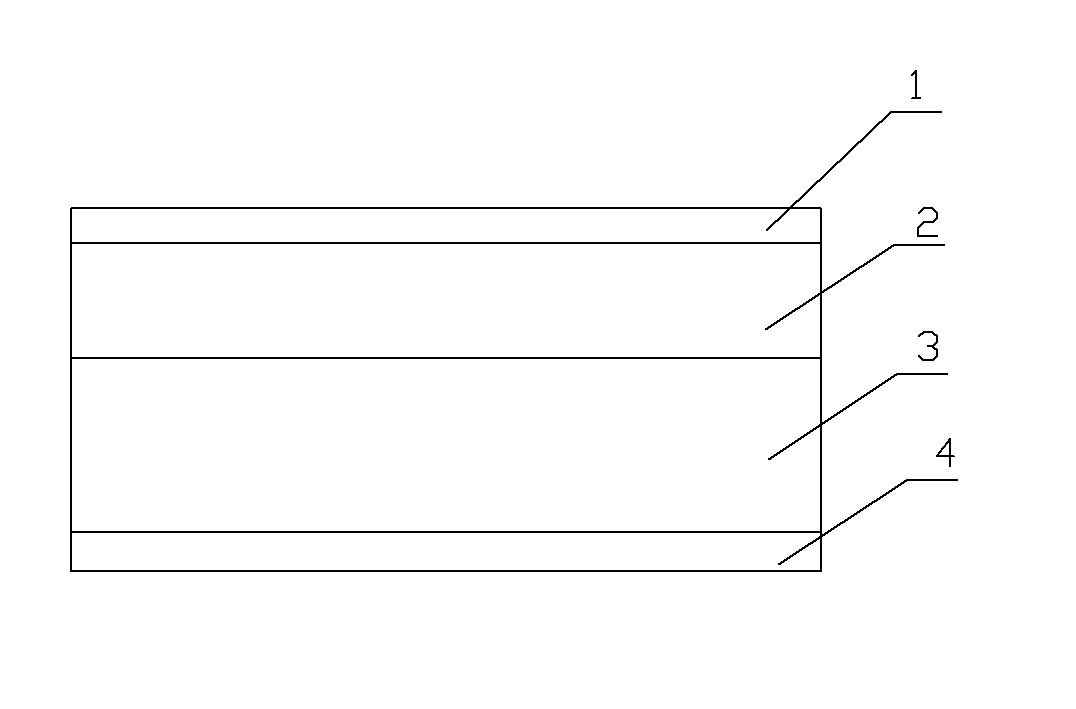

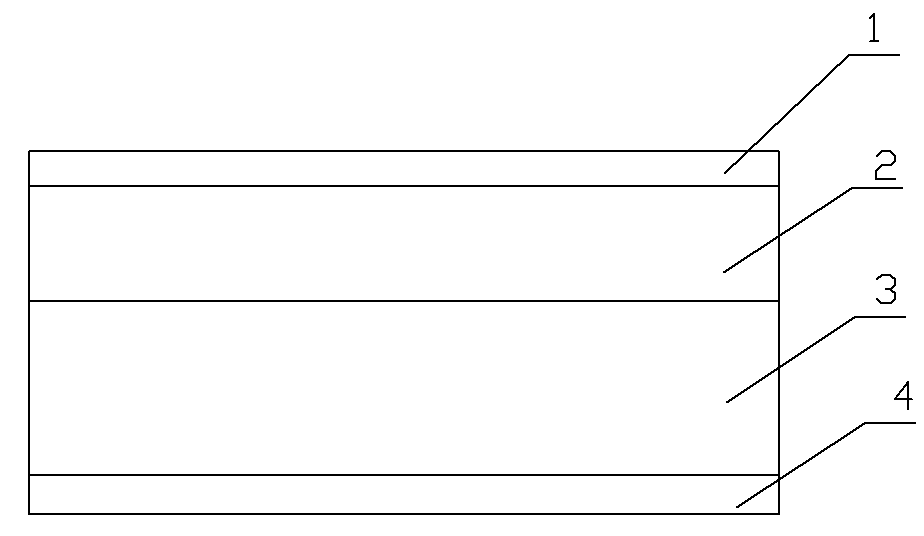

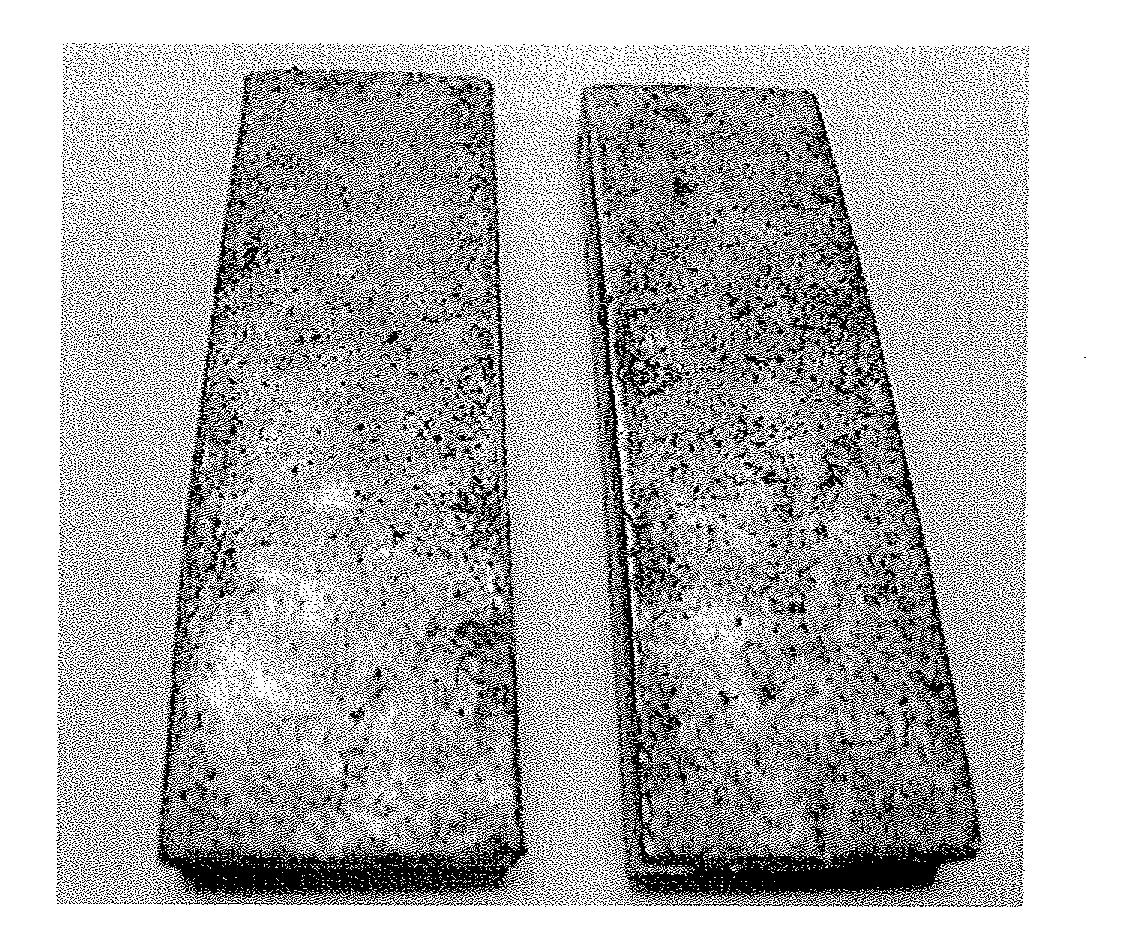

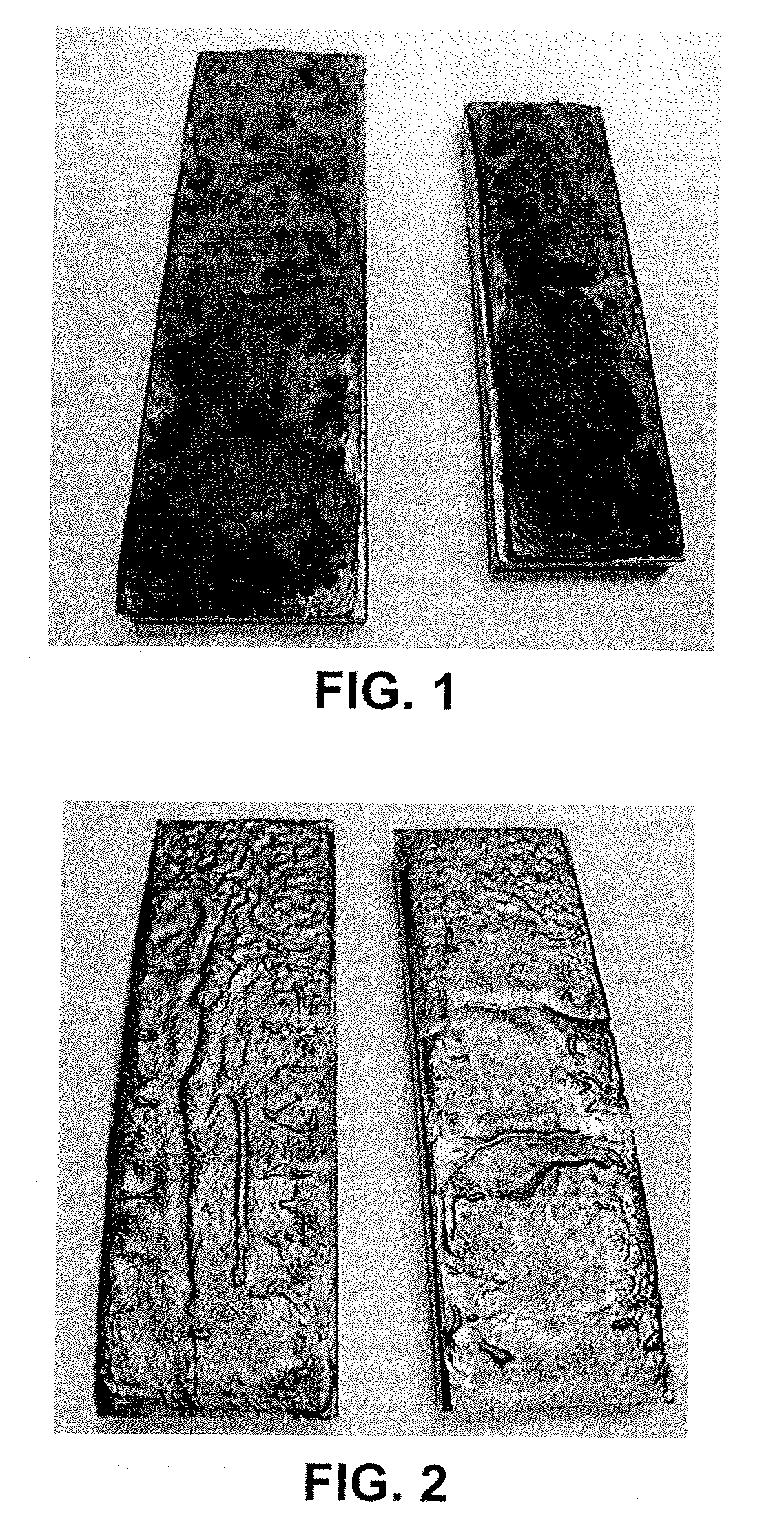

Brazing-hot pressing diamond tool and manufacturing method thereof

The invention relates to a grinding tool, in particular to a brazing-hot pressing diamond tool. The diamond tool consists of a steel matrix and a diamond tool bit, wherein the diamond tool bit consists of a plurality of alloy layers which are vertical to a working surface of the tool bit; the alloy layers are prepared from two alloy matrixes with different formulas by a vacuum hot pressing method; a prearranged diamond abrasive particle layer is arranged inside each alloy matrix layer; outer layers on two sides of the tool bit are brazing alloy matrix layers (1); a single-layer prearranged diamond abrasive particle layer is arranged inside each brazing alloy matrix layer (1); an intermediate layer of the tool bit is a pre-alloying matrix layer (2); and a single-layer or multi-layer prearranged diamond abrasive particle layer is arranged inside the pre-alloying matrix layer (2). The brazing-hot pressing diamond tool solves the problem that a multi-layer brazing tool is covered by a thick solder layer so as to cause low exposure effect and also solves the problem that a sintered diamond tool is insufficient in diamond holding force so as to make the diamond fall off too early. Therefore, the service life of the diamond tool is greatly prolonged and the processing efficiency thereof is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Method for brazing ceramic-containing bodies, and articles made thereby

InactiveUS7270885B1Reduce the temperatureSemiconductor/solid-state device manufacturingWelding/cutting media/materialsReaction bonded silicon carbideLithography process

Ceramic-containing bodies can be bonded to other ceramic-containing bodies, or to metals or metal-containing bodies, by way of an aluminum-silicon brazing alloy. Such alloys feature high thermal conductivity and a melting range intermediate to Cu—Sil and Au—Si. By metallizing the surface of an aluminum- or silicon-containing ceramic body, for example, with silicon or aluminum, the formation of deleterious intermetallic phases at the brazing interface is avoided. This technique is particularly useful for joining reaction-bonded silicon carbide (RBSC) composite bodies, and particularly such composite bodies that contain appreciable amounts of aluminum as a metallurgical modification of the residual silicon phase. Interestingly, when the RBSC body contains minor amounts of the aluminum alloying constituent, or none, the metallization layer is not required. The resulting bonded structures have utility as mirrors, as packaging for electronics, and in semiconductor lithography equipment, e.g., as electrostatic chucks for supporting a silicon wafer during the lithography process.

Owner:M CUBED TECH

Multilayer aluminium brazing sheet for fluxfree brazing in controlled atmosphere

InactiveUS20150165564A1Improve visual appearanceIncrease costCooking-vessel materialsWelding/cutting media/materialsBraze alloyMelting temperature

An aluminium brazing sheet comprising an aluminium alloy core material covered by an interlayer and an Al—Si braze alloy is disclosed. The interlayer consists of an aluminium alloy comprising ≦1.0% Si and 0.1-2.5% Mg. The Al—Si braze alloy comprises 5-14% Si and 0.01-1.0% Bi. The core material and the interlayer has a higher melting temperature than the braze alloy.

Owner:GRAENGES SWEDEN AB

Ni-base brazing alloy

InactiveUS6696017B2Influences the melting point of the obtained alloyHigh strengthWelding/cutting media/materialsSoldering mediaMisch metalBraze alloy

The present invention relates to a Ni-base brazing alloy. The alloy has a good wettability toward a material to be brazed when melting, an excellent corrosion resistance and a high strength. The alloy is used for process of joining two pieces of metal such as stainless steel. The alloy contains Cr in an mount of 25 to 35% by weight, P in an amount of 4 to 8% by weight, Si in an amount of 3 to 6% by weight, wherein the total amount of P and Si is 9 to 11.5% by weight, at least one selected from a group consisting of Al, Ca, Y and misch metal in an amount of 0.01 to 0.10% by weight, and the balance of Ni and unavoidable impurities.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

Multilayer composite belt for brazing type heat exchanger and manufacturing method thereof

ActiveCN101972926AGuaranteed service lifeExtended service lifeMetal layered productsPlate heat exchangerBraze alloy

The invention provides a multilayer composite belt for a brazing type heat exchanger and a manufacturing method thereof. The multilayer composite belt for a brazing type heat exchanger manufactured by the method has greater anticorrosion performance, improves the service life of the heat exchanger and meets the requirement of high quality heat exchanger. The multilayer composite belt for a brazing type heat exchanger comprises a core alloy layer, wherein two sides of the core alloy layer are respectively coated with an anticorrosive alloy layer and a brazing alloy layer. The invention is characterized in that a brazing alloy layer is coated on the external side of the anticorrosive alloy layer is coated with a brazing alloy layer. The manufacturing method comprises the following steps of: preparing the core alloy, anticorrosive alloy and brazing alloy panel veneers by smelting, casting, face-milling, heating, hot rolling and rolling; combining the panel veneers, heating the combined panel veneers to 450-550 DEG C in a heat furnace, hot-rolling - compositing and cutting to obtain the multilayer composite belt.

Owner:YINBANG CLAD MATERIAL

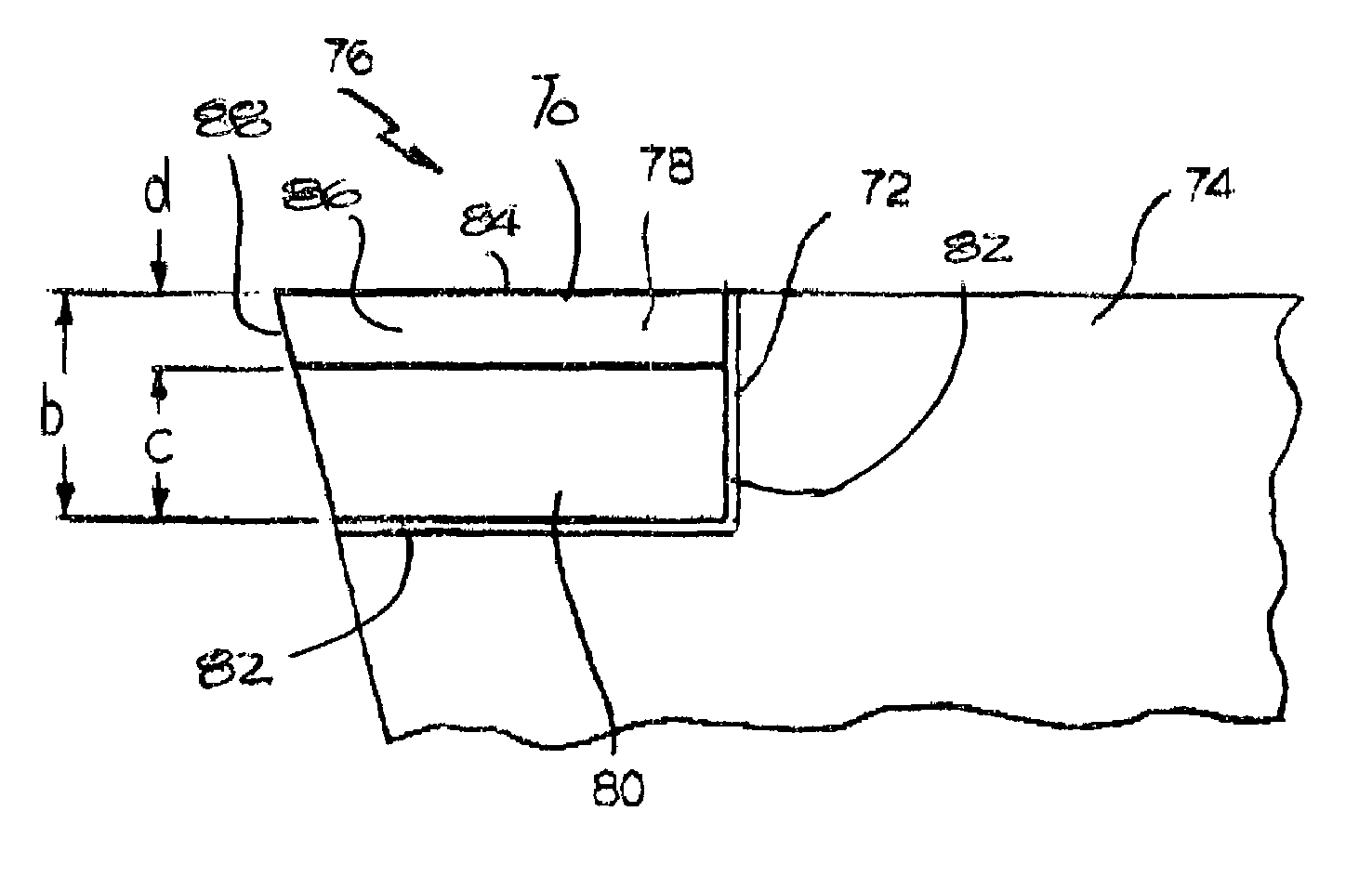

Brazed Claddings for Cast Iron Substrates

InactiveUS20100215983A1Resistance to integrityResistance to propertiesMetallic material coating processesWelding/cutting media/materialsBraze alloyPhysical property

The present invention discloses abrasion resistant claddings for cast iron substrates comprising hard particles and nickel-based braze alloys. The cladding material can be brazed on cast iron substrates at lower temperatures than conventional cladding materials, providing highly increased abrasion resistance to the cast iron substrate materials without adversely affecting the physical properties and structural integrity of such substrates.

Owner:KENNAMETAL INC

Coated cutting tool with brazed-in superhard blank

ActiveUS7592077B2Tool workpiece connectionSemiconductor/solid-state device detailsBoron nitrideBraze alloy

A coated cutting tool that comprises a body containing a pocket. The tool further includes a polycrystalline cubic boron nitride blank that is brazed into the pocket using a braze alloy. The braze alloy has a liquidus temperature of at least about 900 degrees Centigrade. There is a coating applied to the cutting tool.

Owner:KENNAMETAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com