Patents

Literature

32 results about "Reaction bonded silicon carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reaction bonded silicon carbide, also known as siliconized silicon carbide or SiSiC, is a type of silicon carbide that is manufactured by a chemical reaction between porous carbon or graphite with molten silicon. Due to the left over traces of silicon, reaction bonded silicon carbide is often referred to as siliconized silicon carbide, or its abbreviation SiSiC.

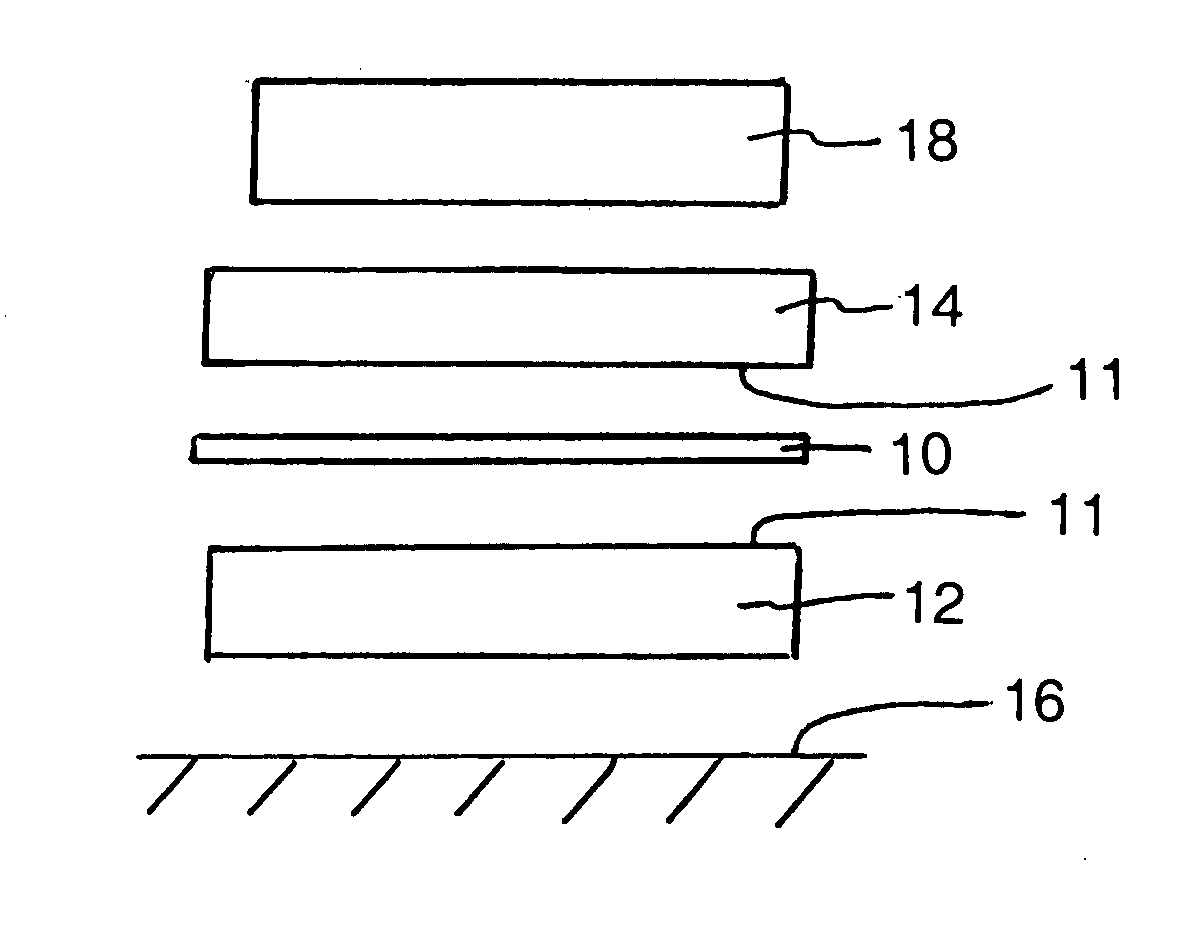

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

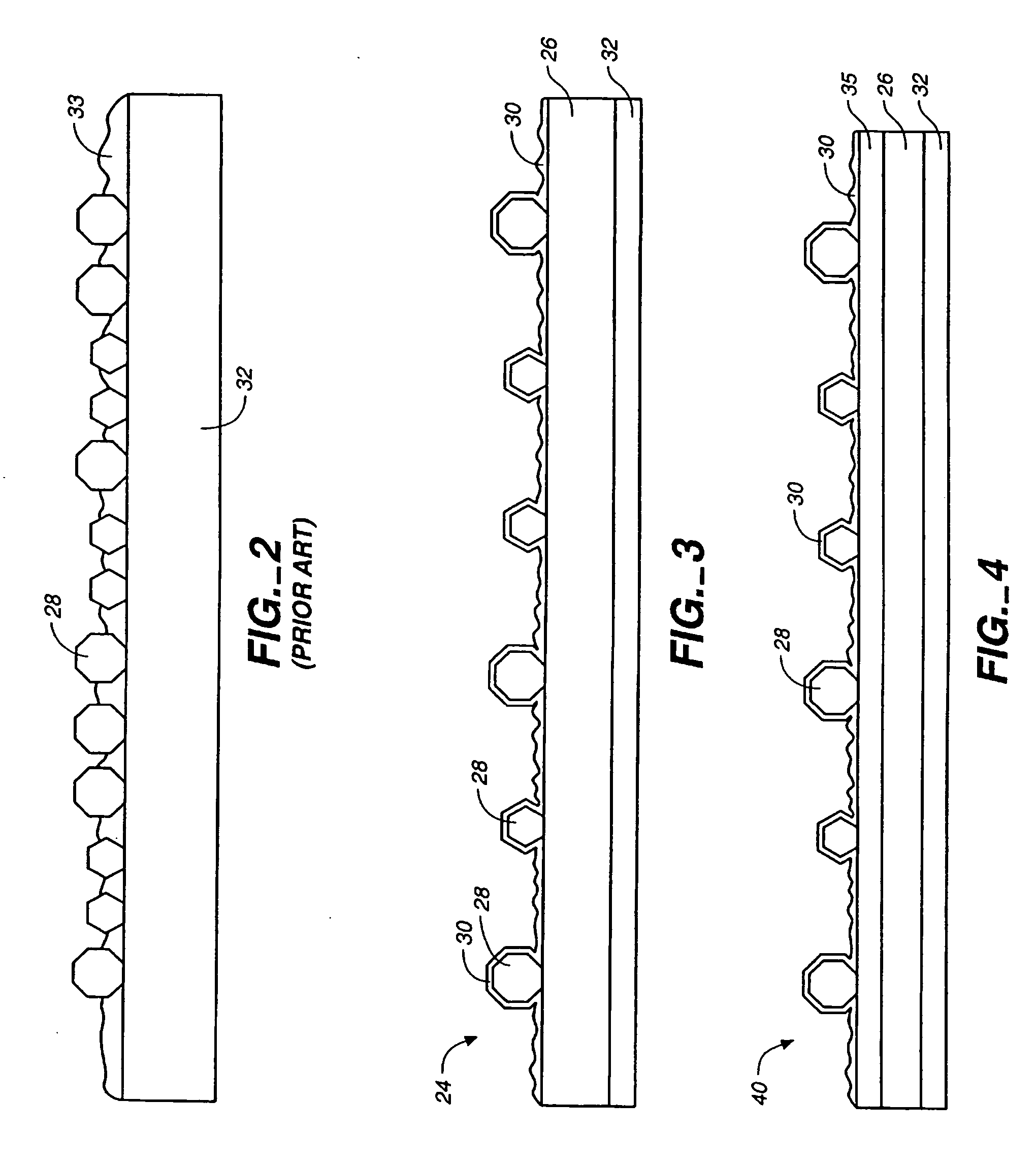

InactiveUS20050025973A1Improve adhesionLow costPigmenting treatmentEngine sealsReaction bonded silicon carbideComposite substrate

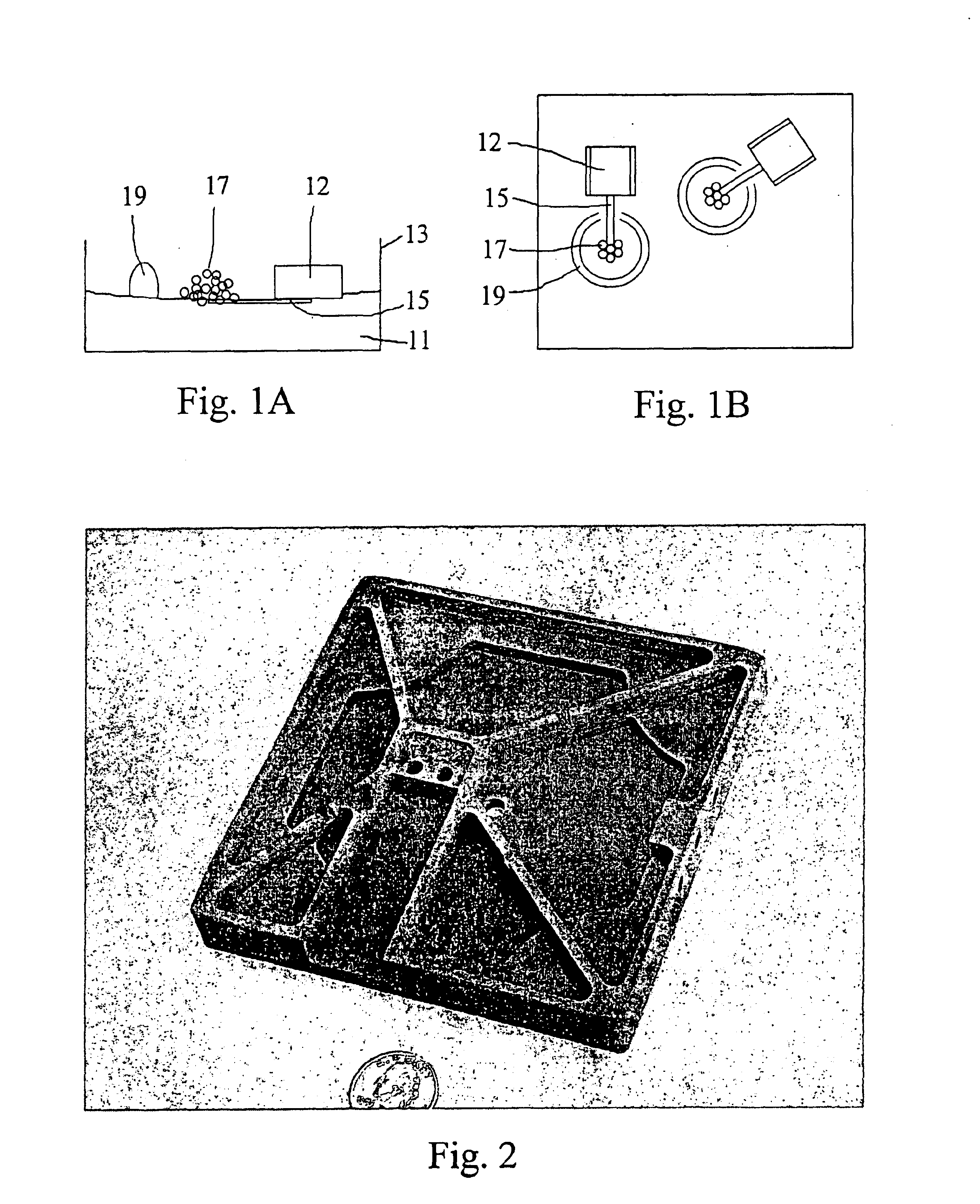

The present invention relates to a composite material and the method of making same, which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Chemical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:MORGAN ADVANCED CERAMICS

Boron carbide composite bodies, and methods for making same

InactiveUS6862970B2Less expensivelyLow production costDoor/window protective devicesLayered productsReaction bonded silicon carbideHigh stiffness

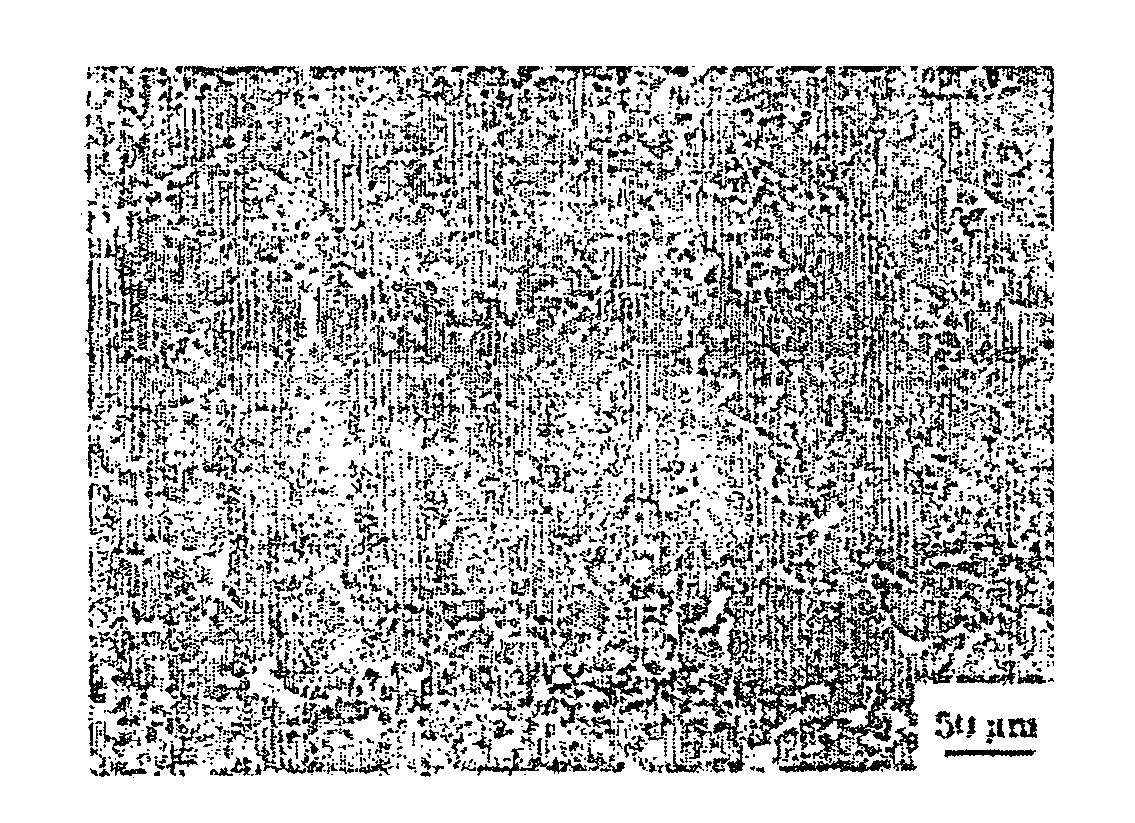

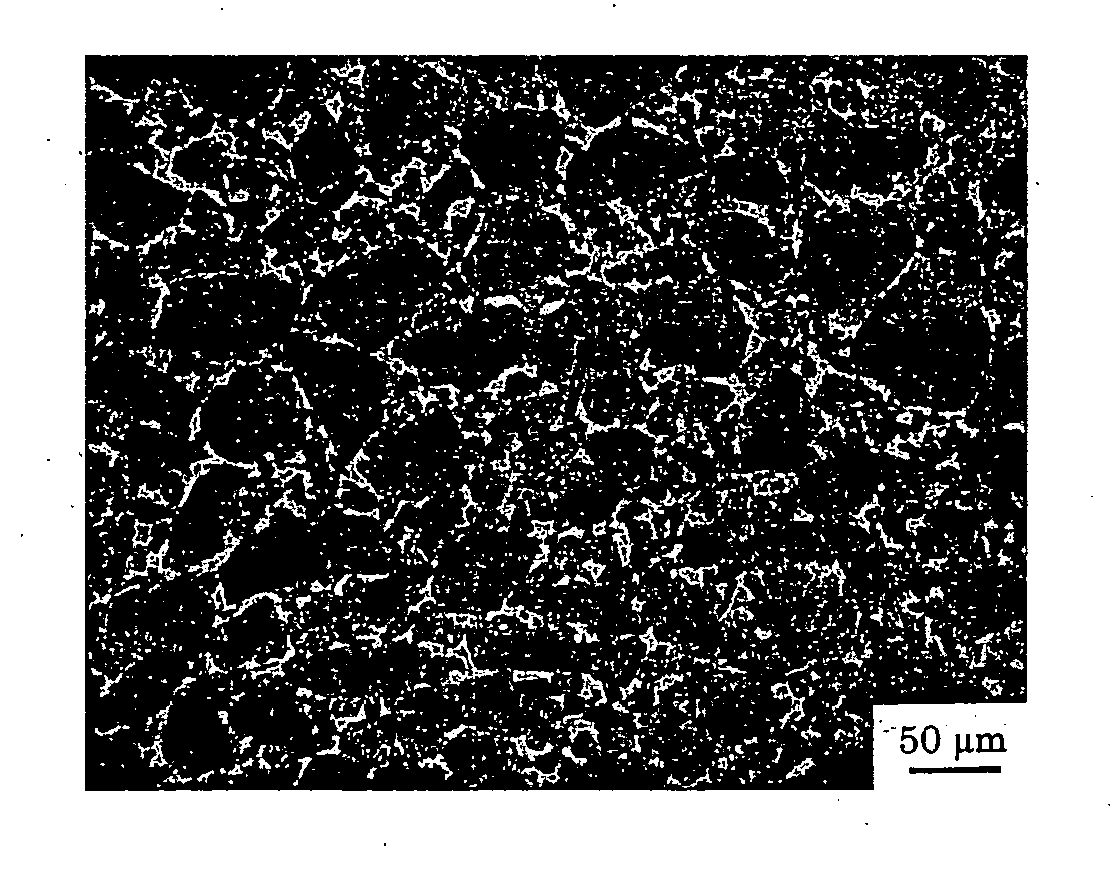

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon carbide matrix produced by the reactive infiltration of an infiltrant having a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction-bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC +1

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050276979A1Improve adhesionLow costLiquid surface applicatorsEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same ,which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Cheniical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:BEST ENGINEERED SURFACE TECH LLC

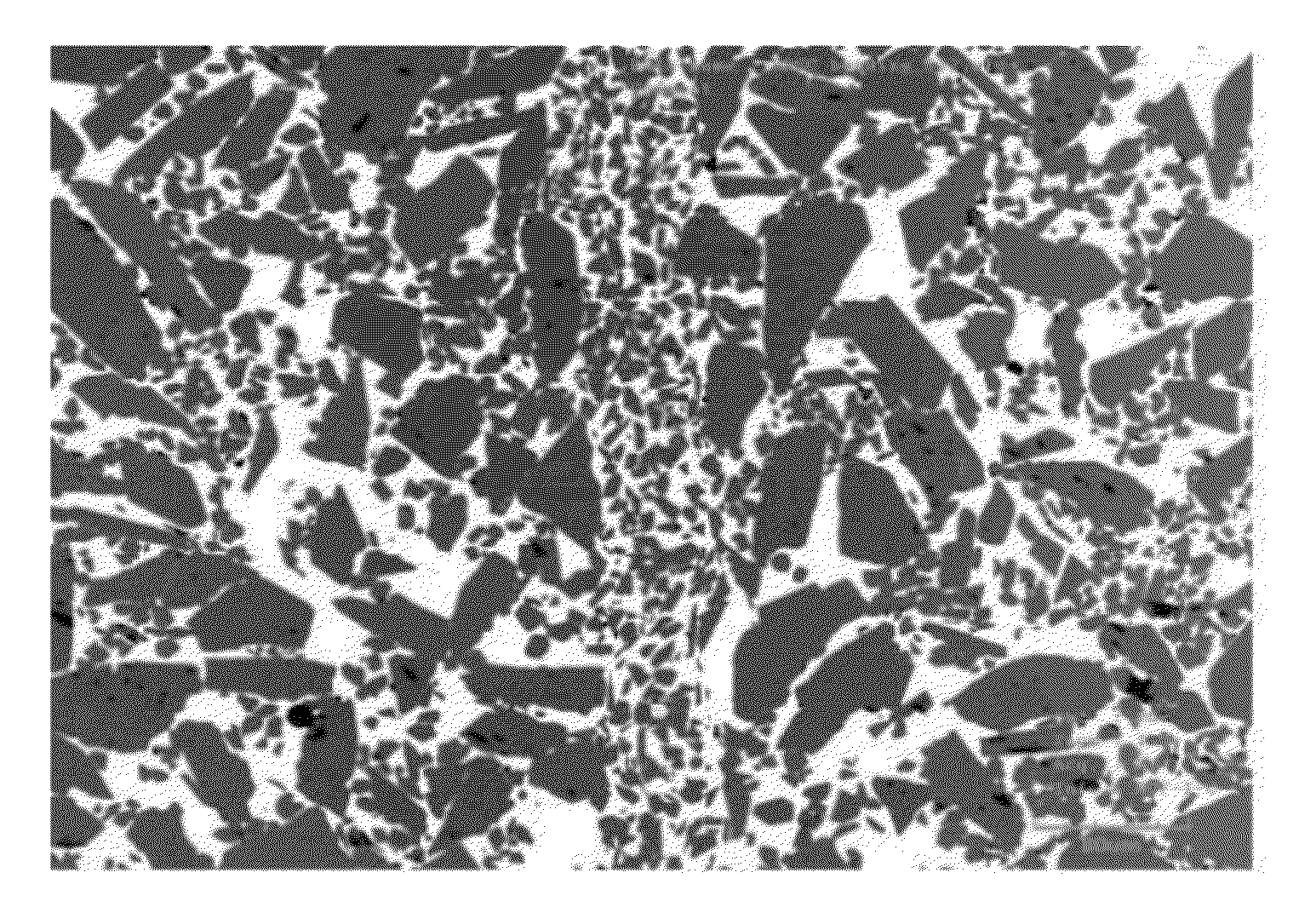

Ceramic-rich composite armor, and methods for making same

InactiveUS7104177B1Reduce manufacturing costHighly dimensionally accurate shaped articleCeramic layered productsArmour platesReaction bonded silicon carbideGrain growth

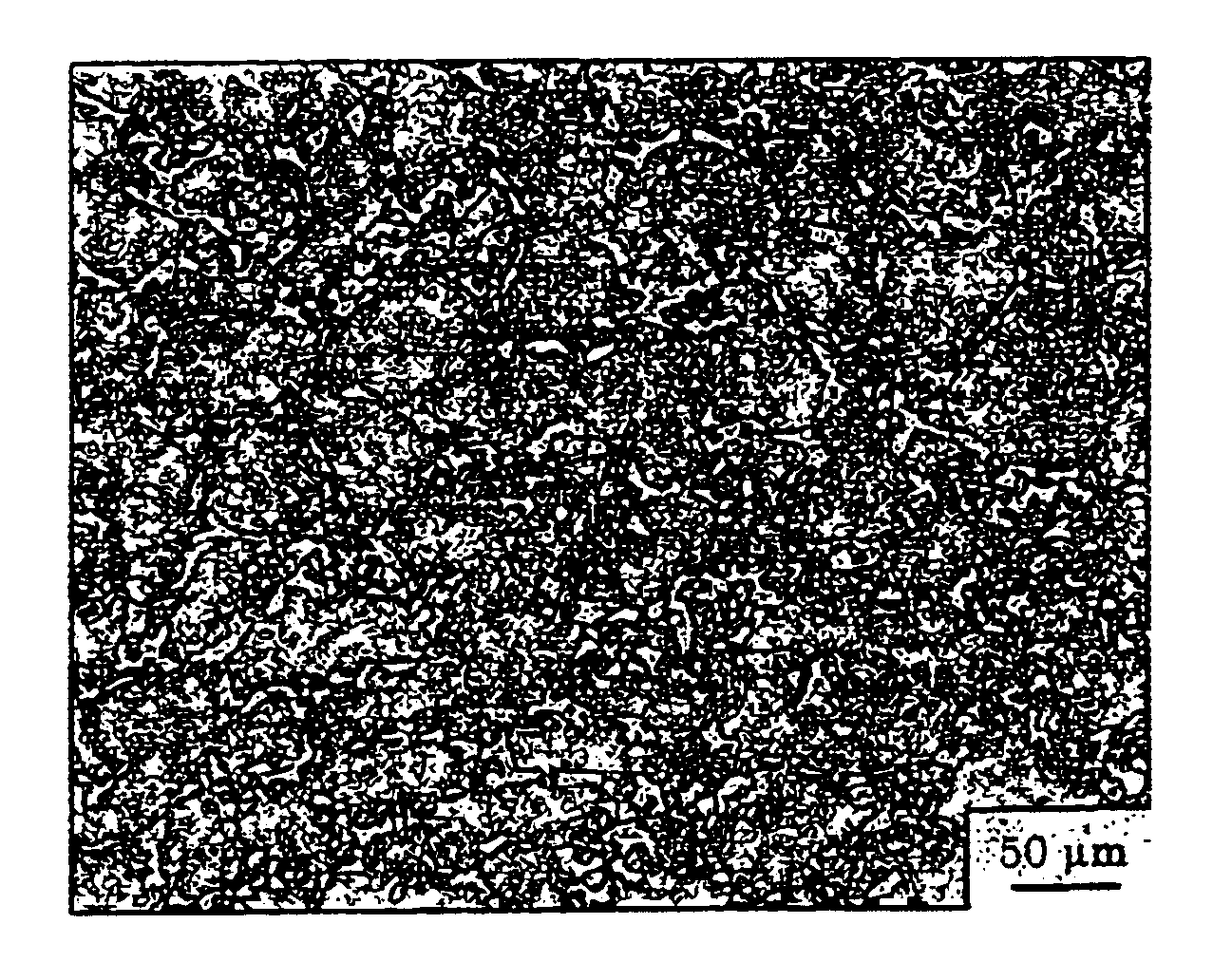

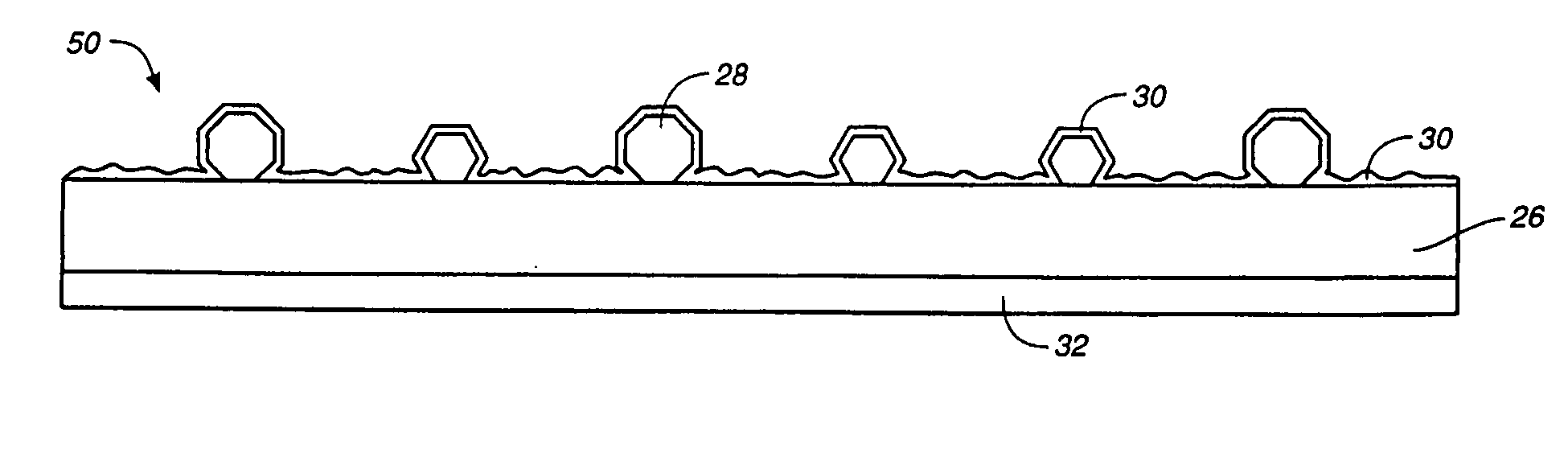

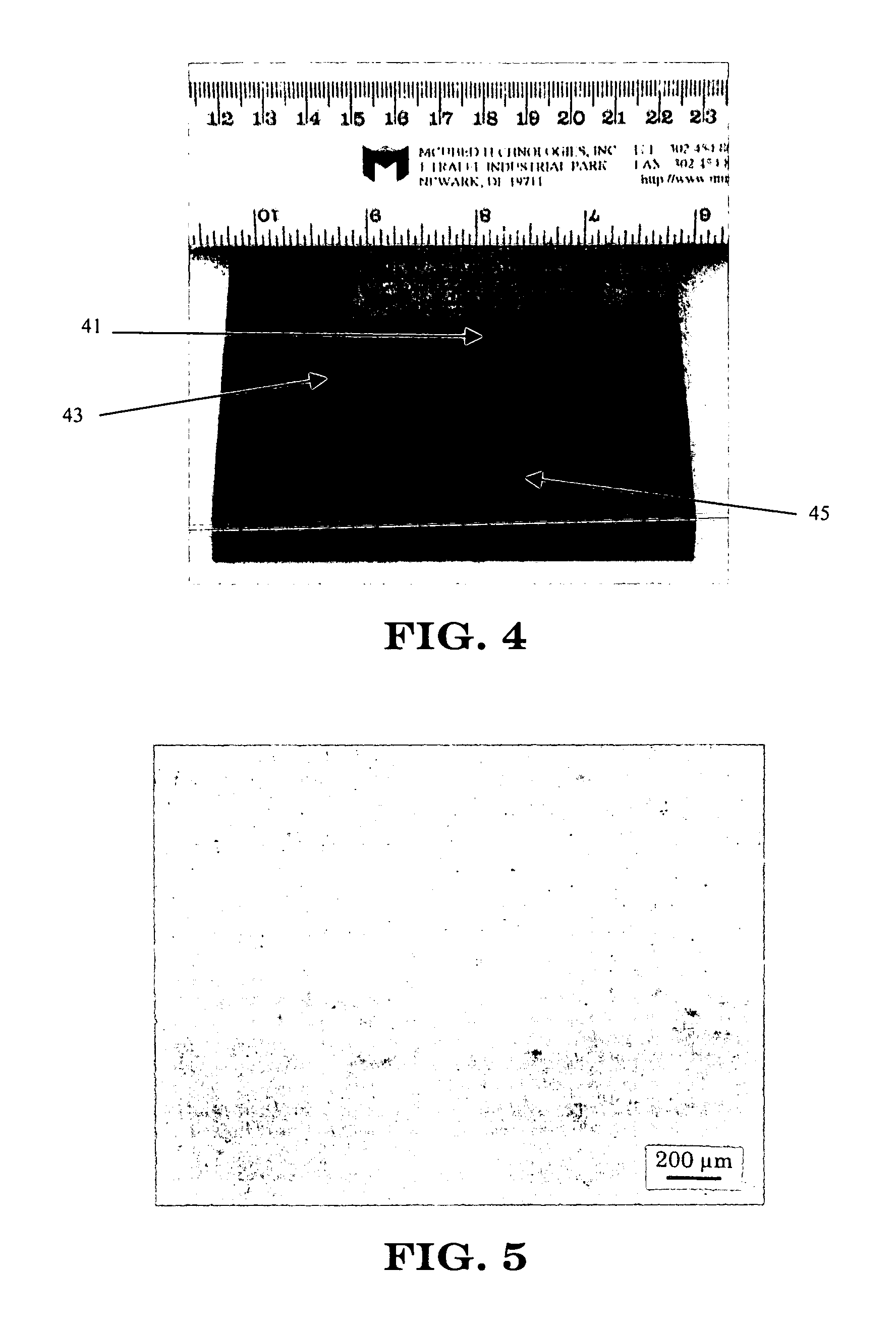

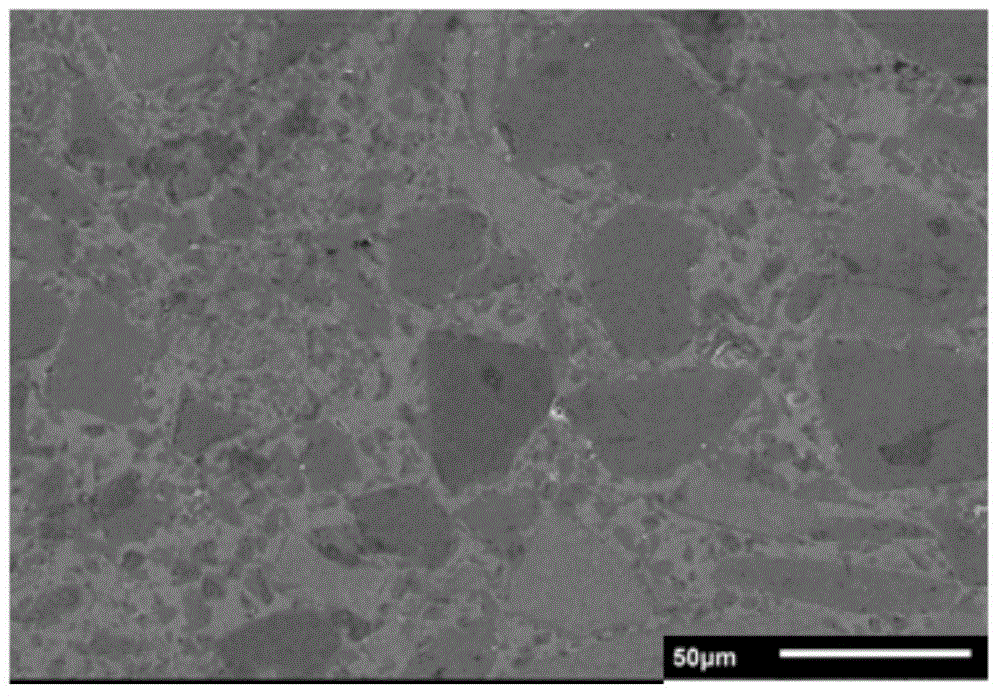

Silicon infiltration technology, e.g., siliconizing or reaction-bonding, is used to produce ceramic-rich composite bodies having utility as ballistic armor. In the main embodiment of the invention, the ballistic armor includes a reaction-bonded silicon carbide body (RBSC). Good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers, and by limiting the size of the morphological features making up the composite body. This control of “grain size” can be accomplished by controlling the size of the largest particles making up the porous mass to be infiltrated, but also of importance is controlling the processing conditions, particularly by controlling the factors that cause grain growth, coarsening of microstructure, and / or grain coalescence.

Owner:II VI DELAWARE INC

Microwave processing of composite bodies made by an infiltration route

InactiveUS20040238794A1Speed up total cycle time requiredShorten cycle timeConductive materialCeramic shaping apparatusReaction bonded silicon carbideInfiltration route

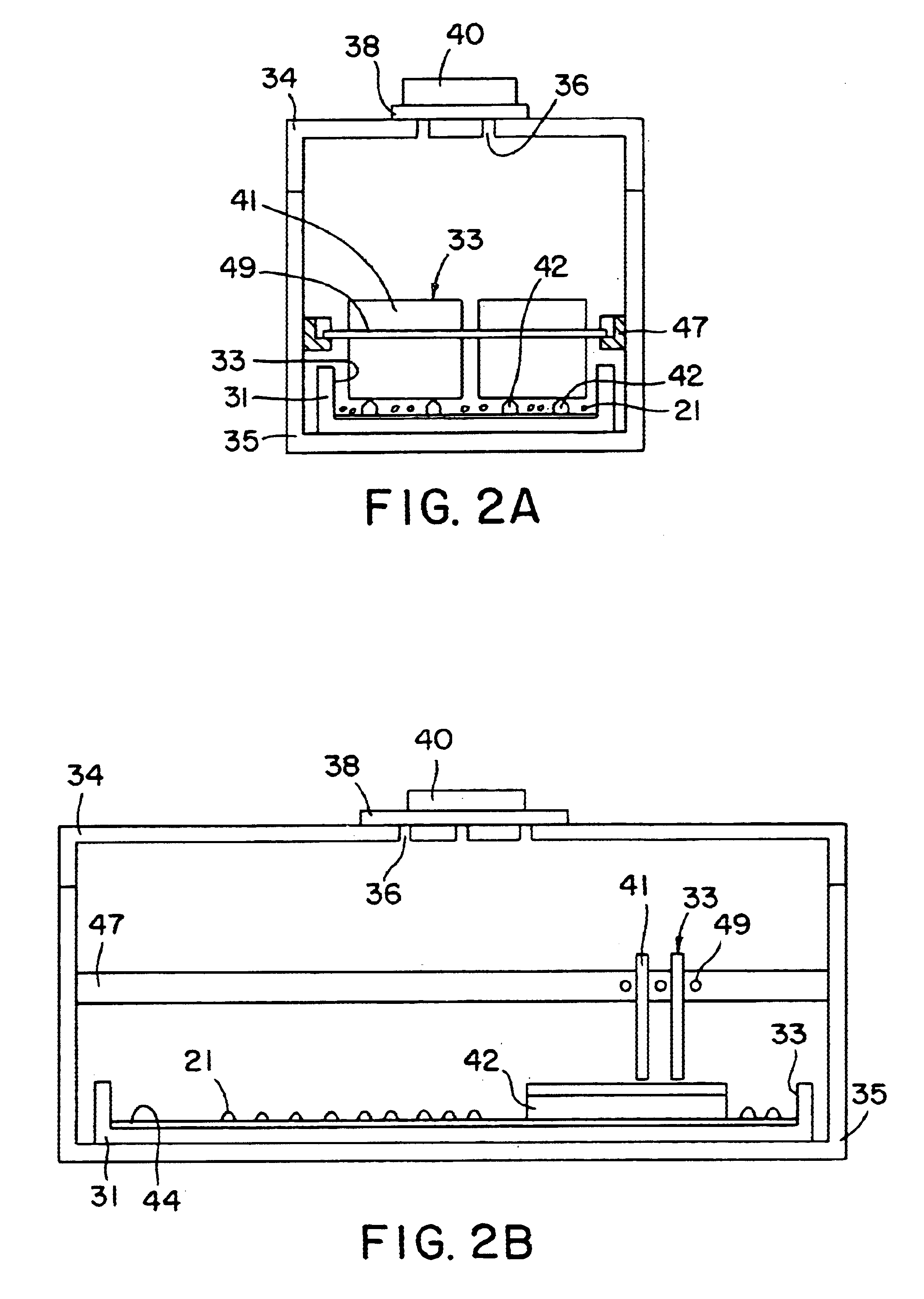

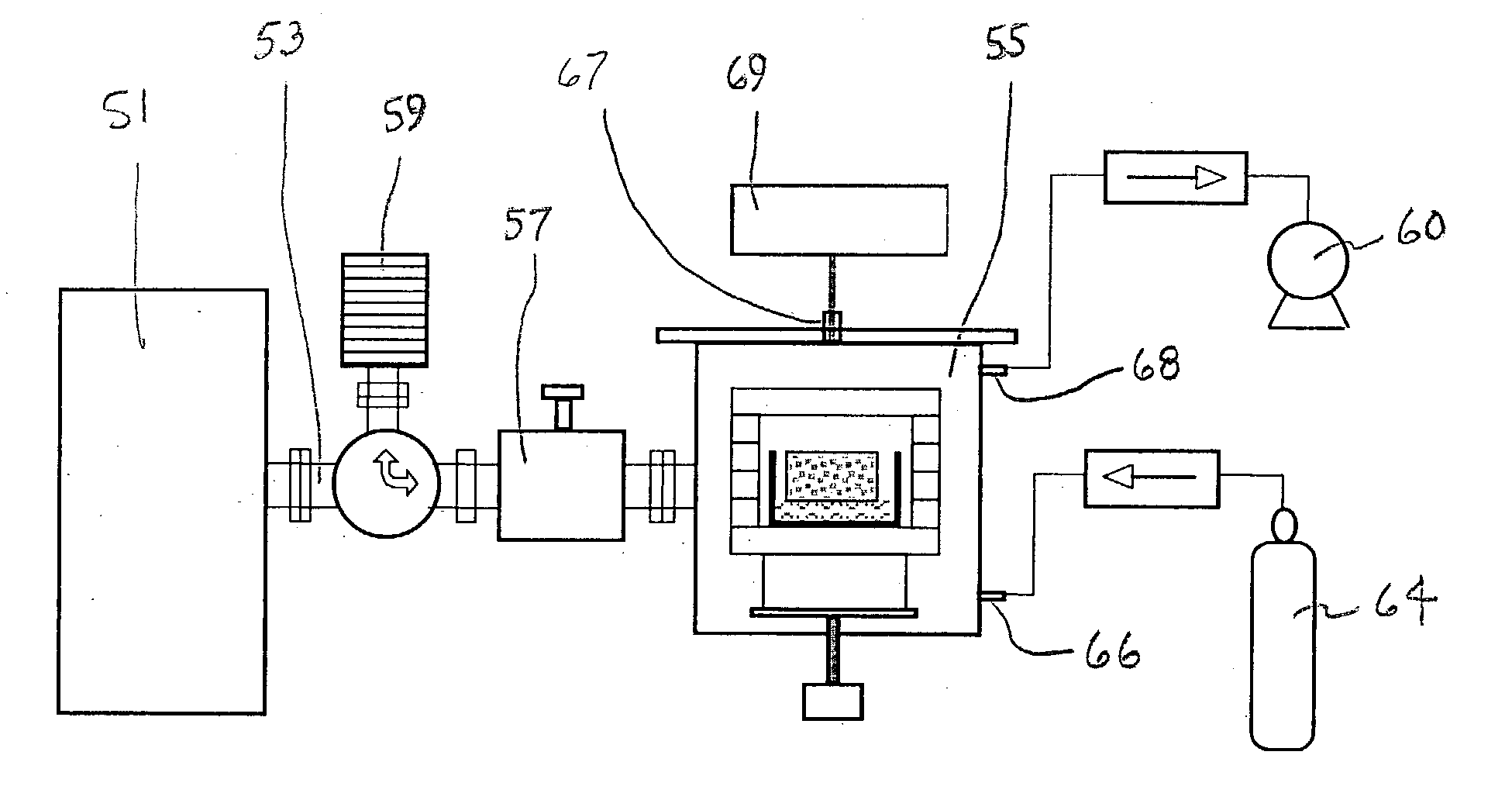

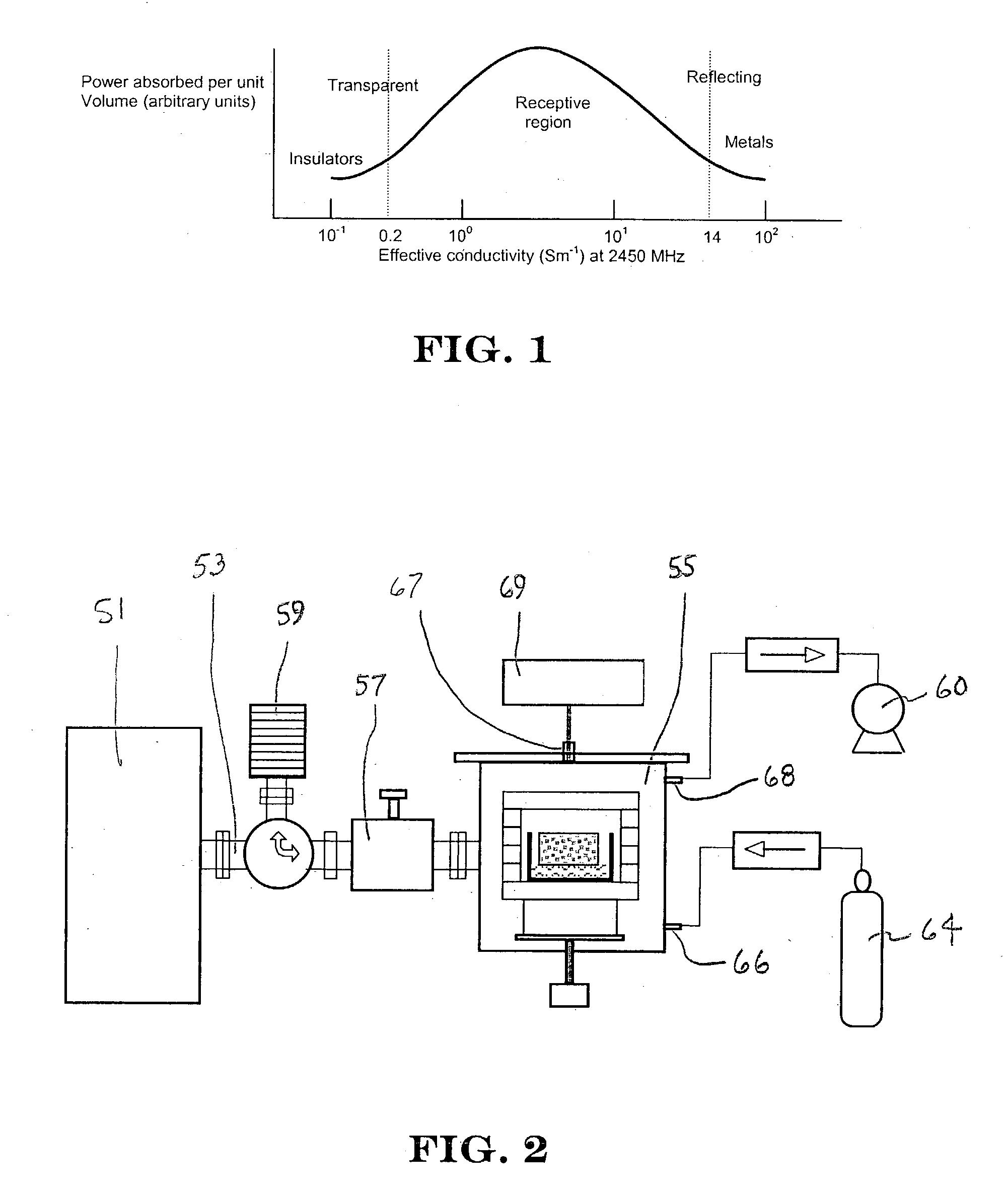

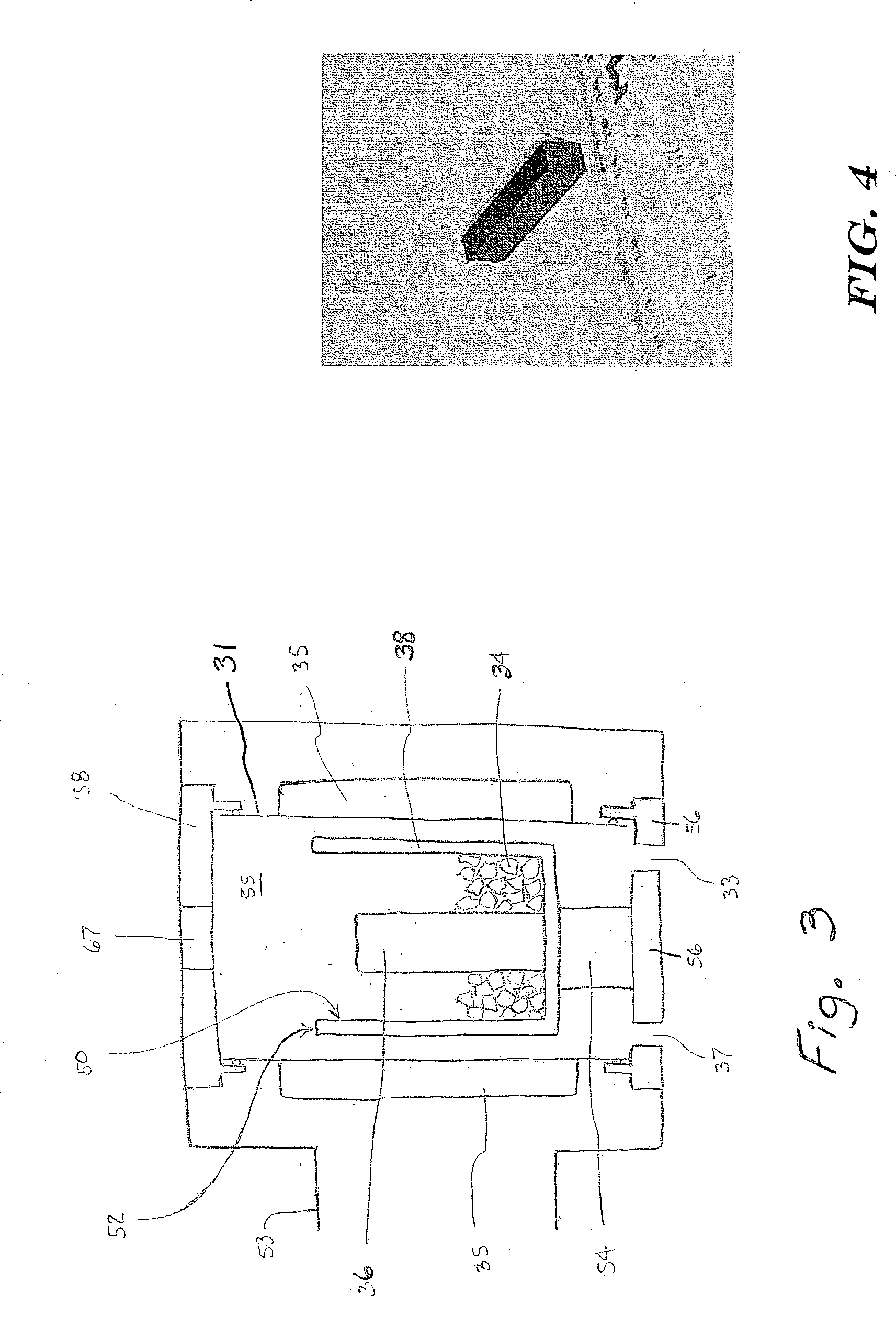

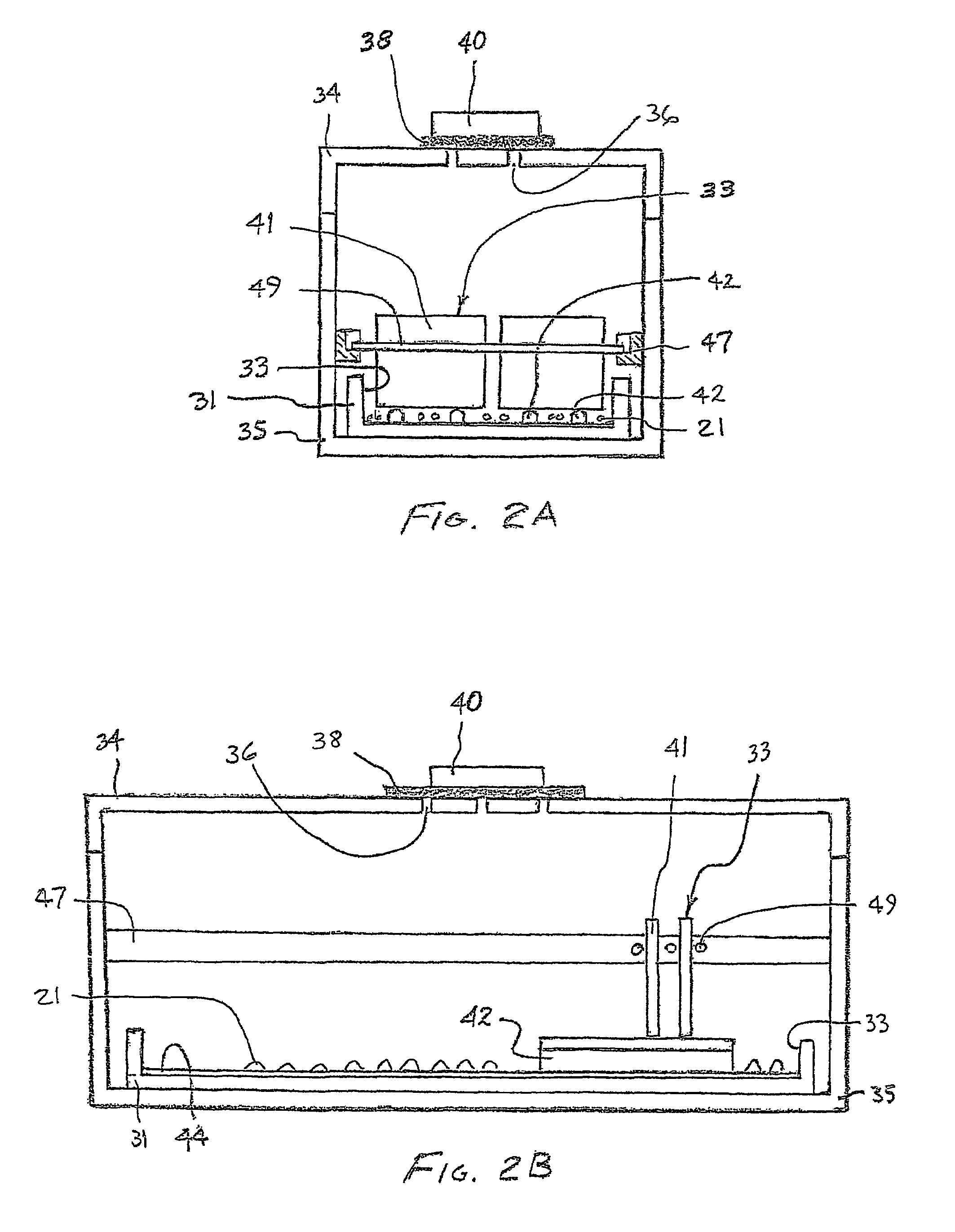

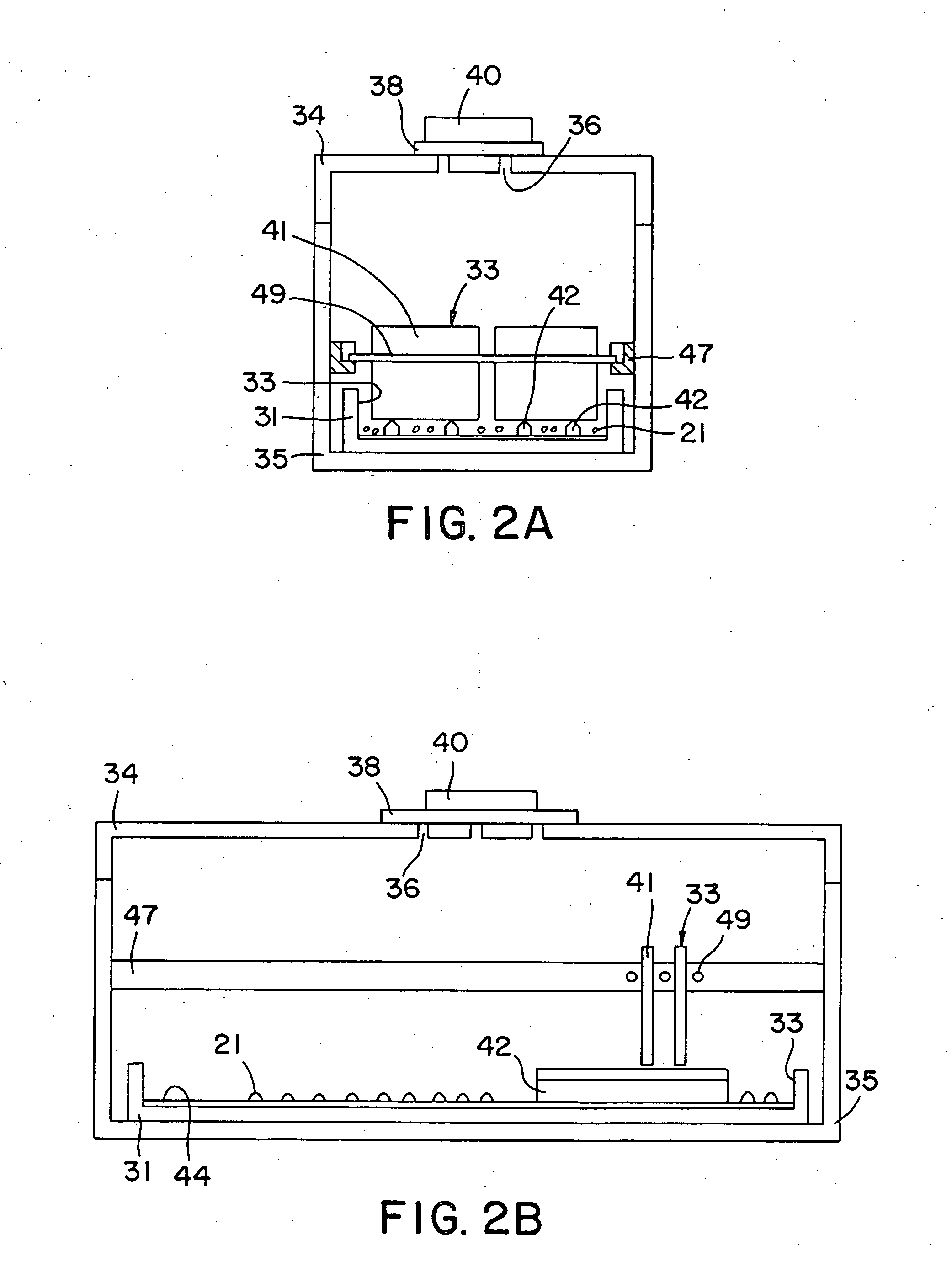

Metal-ceramic composite materials made by an infiltration technique have now been prepared using microwave energy as the heat source for thermal processing. Specifically, microwave energy has been used to heat and melt a source of silicon metal, which in turn has infiltrated carbon-containing preforms to make reaction-bonded silicon carbide composites, respectively. Both the time-at-temperature as well as the overall thermal cycle time have been greatly reduced, implying a large cost savings.

Owner:M CUBE TECH INC

Method for brazing ceramic-containing bodies, and articles made thereby

InactiveUS7270885B1Reduce the temperatureSemiconductor/solid-state device manufacturingWelding/cutting media/materialsReaction bonded silicon carbideLithography process

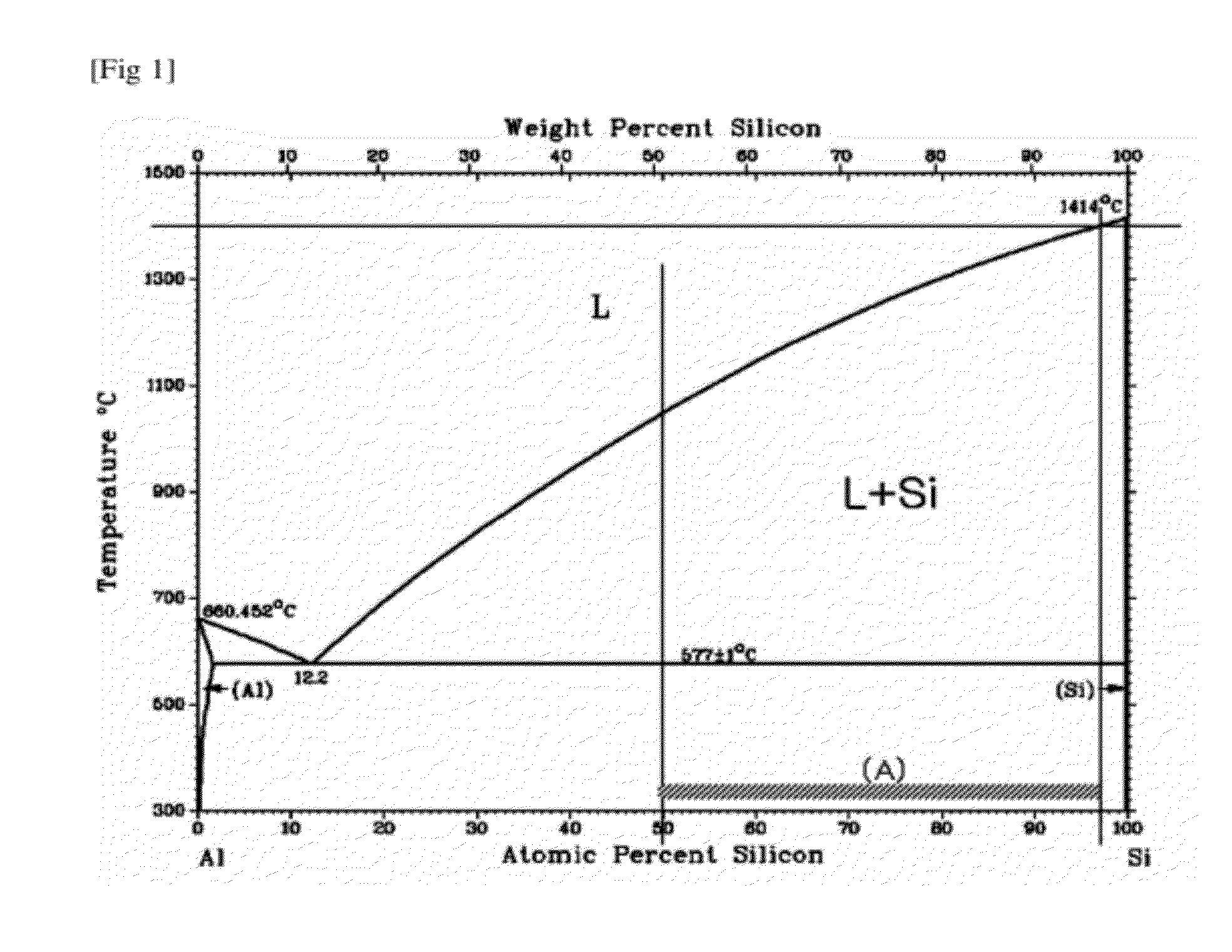

Ceramic-containing bodies can be bonded to other ceramic-containing bodies, or to metals or metal-containing bodies, by way of an aluminum-silicon brazing alloy. Such alloys feature high thermal conductivity and a melting range intermediate to Cu—Sil and Au—Si. By metallizing the surface of an aluminum- or silicon-containing ceramic body, for example, with silicon or aluminum, the formation of deleterious intermetallic phases at the brazing interface is avoided. This technique is particularly useful for joining reaction-bonded silicon carbide (RBSC) composite bodies, and particularly such composite bodies that contain appreciable amounts of aluminum as a metallurgical modification of the residual silicon phase. Interestingly, when the RBSC body contains minor amounts of the aluminum alloying constituent, or none, the metallization layer is not required. The resulting bonded structures have utility as mirrors, as packaging for electronics, and in semiconductor lithography equipment, e.g., as electrostatic chucks for supporting a silicon wafer during the lithography process.

Owner:M CUBED TECH

A kind of preparation method of reaction sintered silicon carbide ceramics

The invention discloses a method for preparing reaction sintered silicon carbide ceramics. Firstly, waste silicon carbide powder, silicon carbide powder material, adhesive and solvent are added into a ball mill in proportion, and then the mixed powder is put into a drying oven to dry, and then Put the powder into the mold, pressurize it into a blank, then crush the blank, sieve, and then evenly distribute the sifted powder in the cavity of the mold, mold it again into a green body, and heat up and dry it after debinding , place the green body in a graphite crucible, add metal silicon into the crucible, put the crucible into a high-temperature vacuum sintering furnace for sintering, and then lower the temperature to obtain a reaction-sintered silicon carbide ceramic. The invention has a simple process and is suitable for large-scale industrial production, and can not only effectively solve the problems of environmental pollution and resource waste caused by a large amount of silicon carbide waste, but also reduce the raw material price of reaction sintered silicon carbide materials.

Owner:JIANGSU TAYAL PHOTOVOLTAIC AUXILIARY MATERIAL

Boron carbide composite bodies, and methods for making same

InactiveUS7332221B2Reduce gravityReduce quality problemsConductive materialCellulosic plastic layered productsReaction bonded silicon carbideHigh stiffness

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC

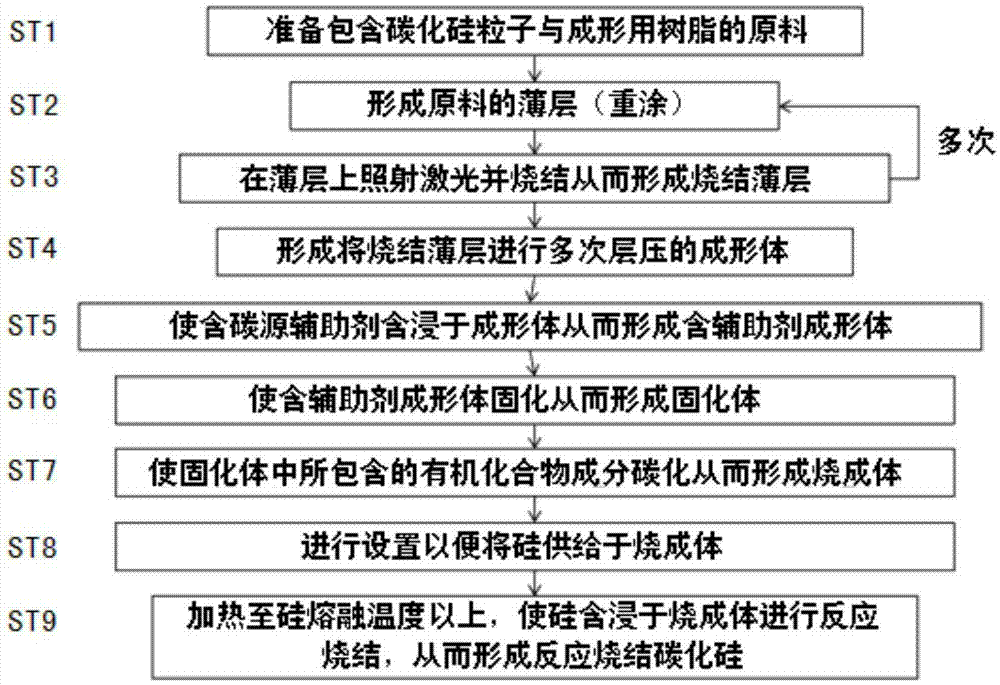

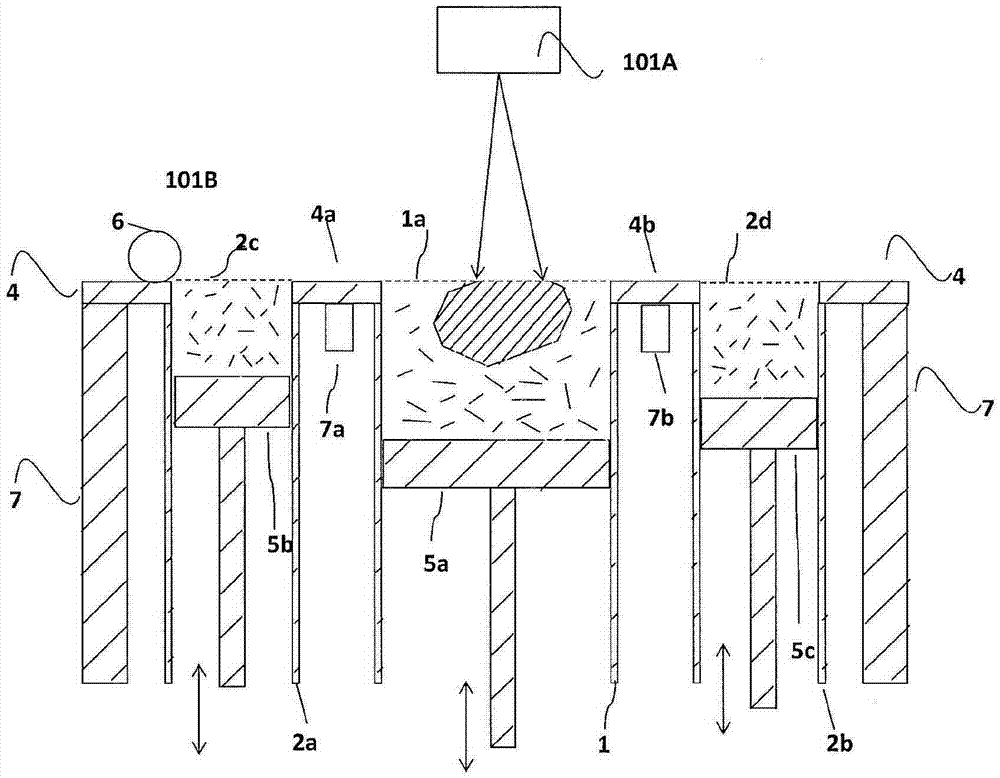

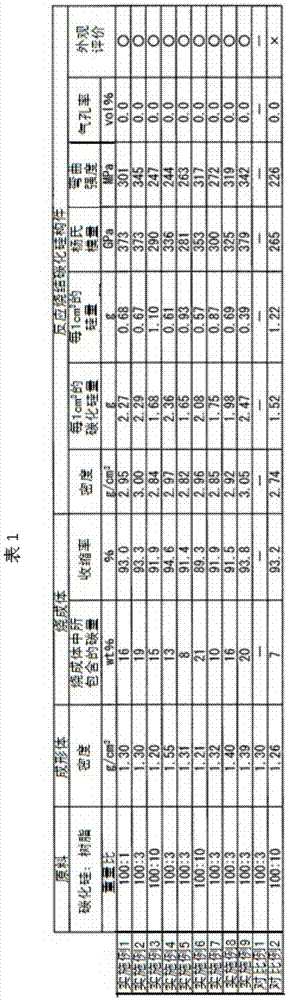

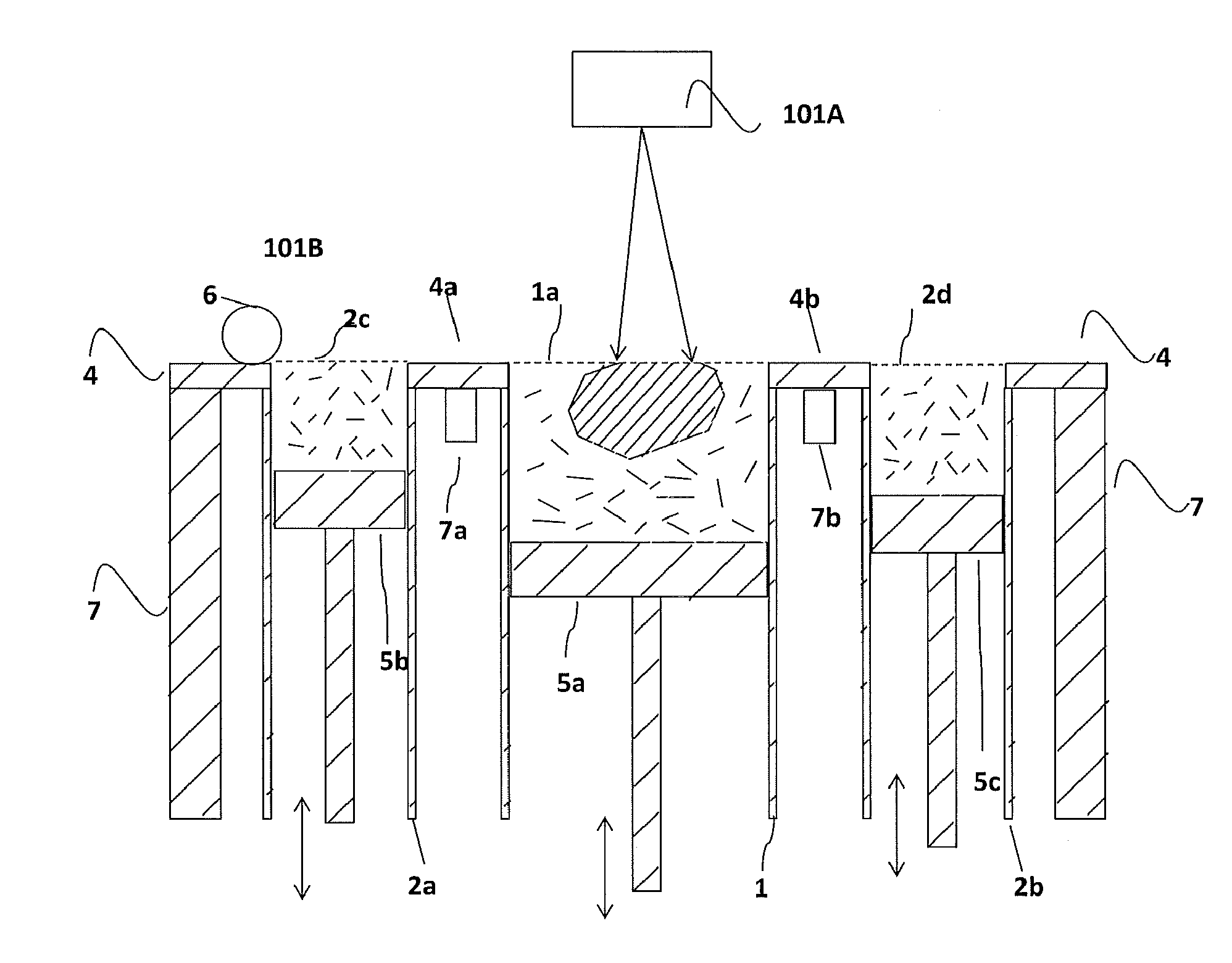

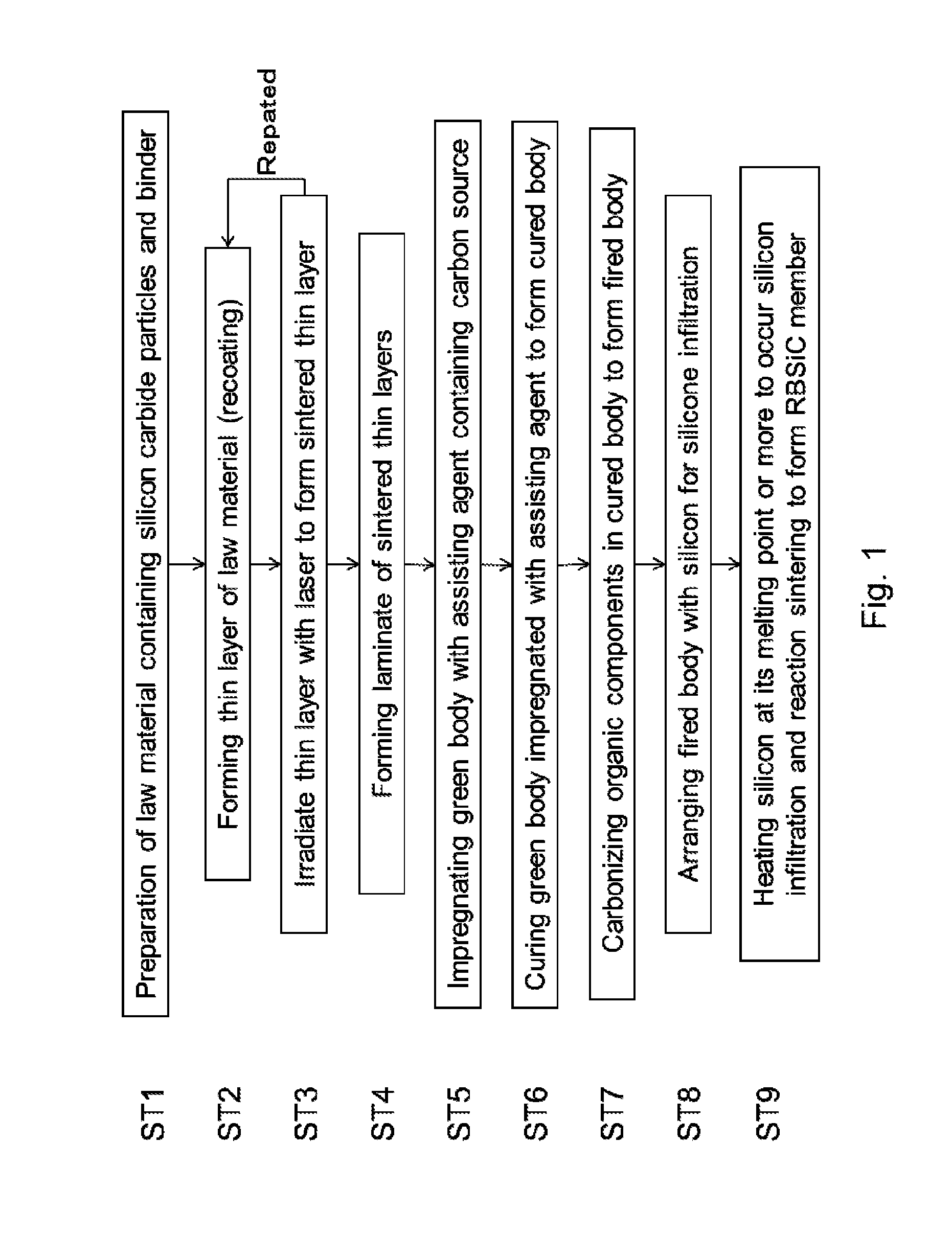

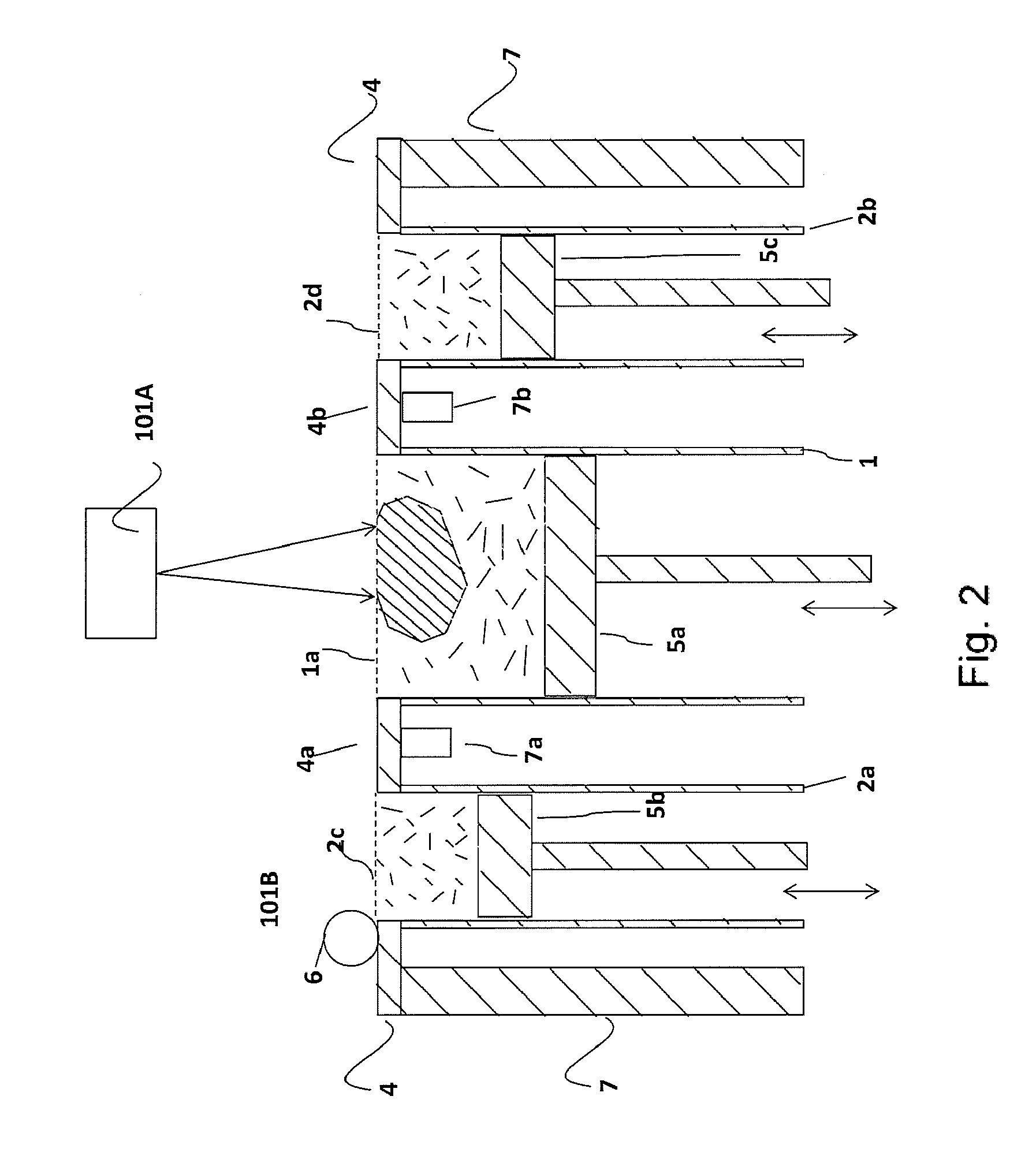

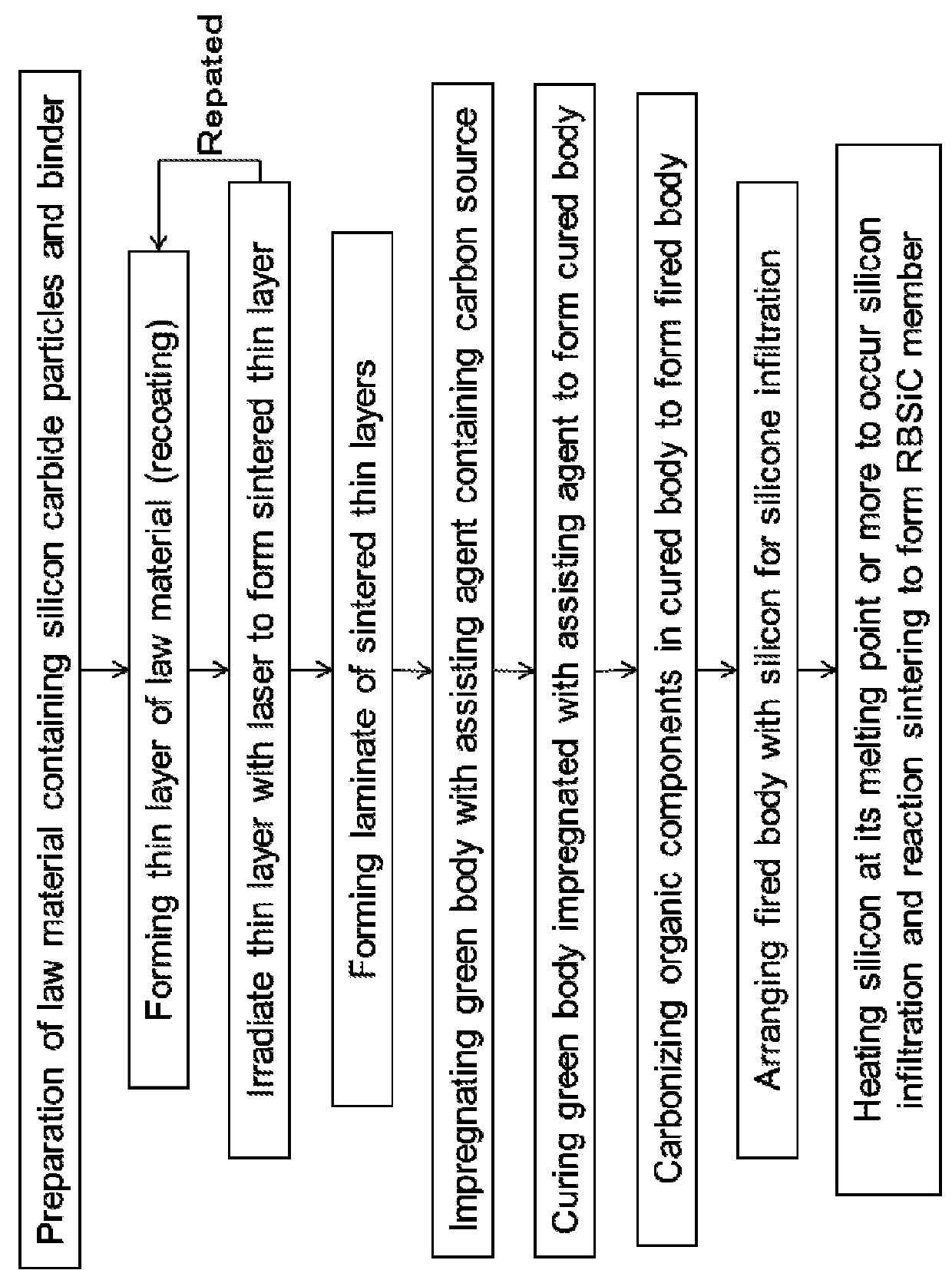

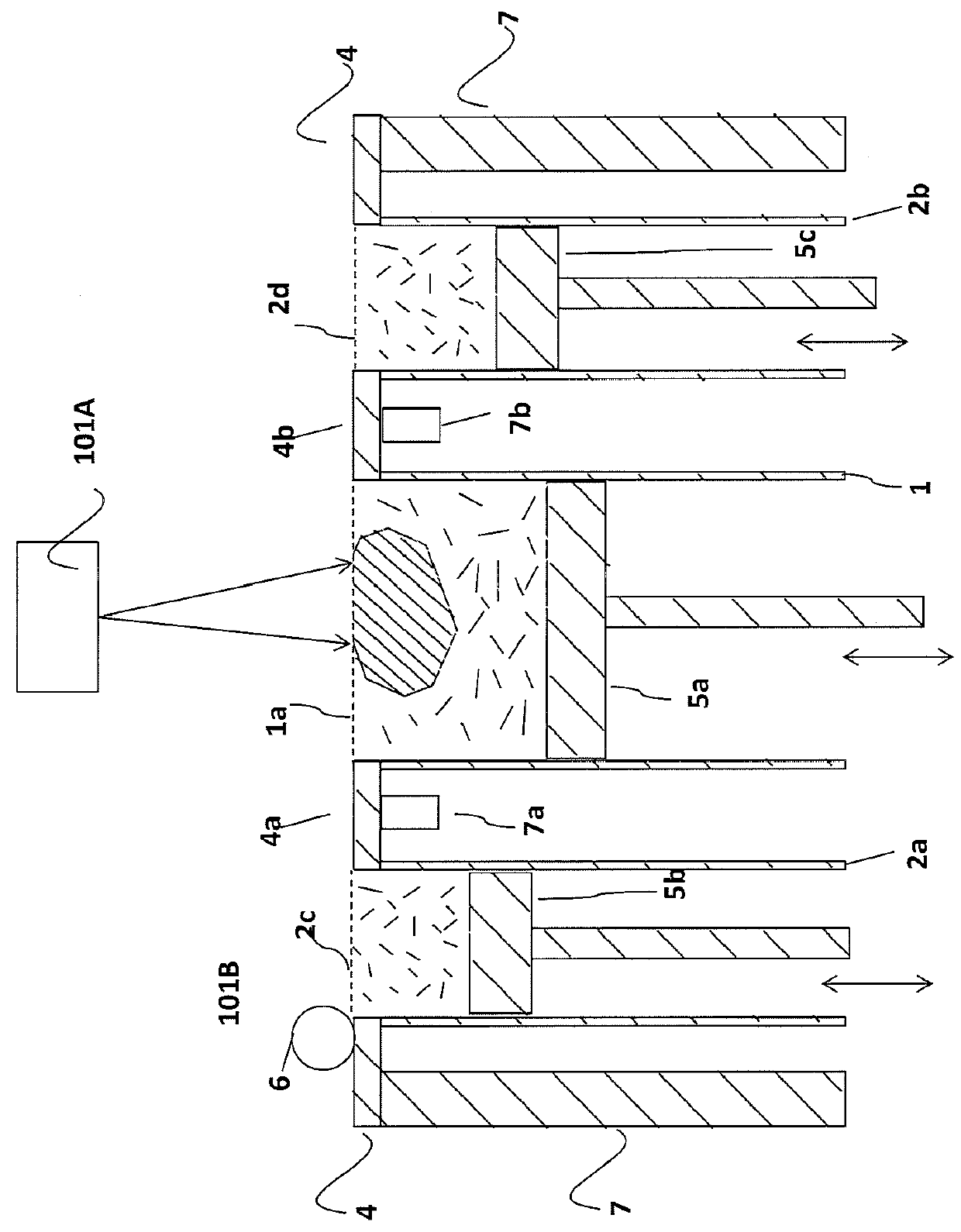

Process for producing reaction bonded silicon carbide member

InactiveCN105439564AImprove rigidityHigh strengthAdditive manufacturing apparatusCeramic shaping apparatusSimple Organic CompoundsSelective laser sintering

Disclosed is a process for producing a RBSiC member that has a large size and a complicated shape and possesses ceramic properties. The process is a Selective Laser Sintering process which includes providing a raw material containing silicon carbide particles and a binder, forming a thin layer of the raw material, and sintering the thin layer by irradiating a desired area in the thin layer with laser to form a sintered thin layer, repeating the step of forming the sintered thin layer to obtain a green body, impregnating the green body with a carbon source and curing the green body impregnated with the carbon source to give a cured body, carbonizing an organic compound component in the cured body to give a fired body, infiltrating the fired body with silicon, and subjecting the fired body to reaction sintering to give a RBSiC member, wherein the fired body contains 8% to 30% by weight of carbon.

Owner:TOTO LTD

Process for producing reaction bonded silicon carbide member

InactiveUS20160083300A1Excellent ceramic propertySatisfactory amountAdditive manufacturing apparatusLayered productsSimple Organic CompoundsSelective laser sintering

Disclosed is a process for producing a RBSiC member that has a large size and a complicated shape and possesses ceramic properties. The process is Selective Laser Sintering process which includes providing a raw material containing silicon carbide particles and a binder, forming a thin layer of the raw material, and sintering the thin layer by irradiating a desired area in the thin layer with laser to form a sintered thin layer, repeating the step of forming the sintered thin layer to obtain a green body, impregnating the green body with a carbon source and curing the green body impregnated with the carbon source to give a cured body, carbonizing an organic compound component in the cured body to give a fired body, and infiltrating the fired body with silicon and subjecting the fired body to reaction sintering to give a RBSiC member, wherein the fired body contains 8% to 30% by weight of carbon.

Owner:TOTO LTD

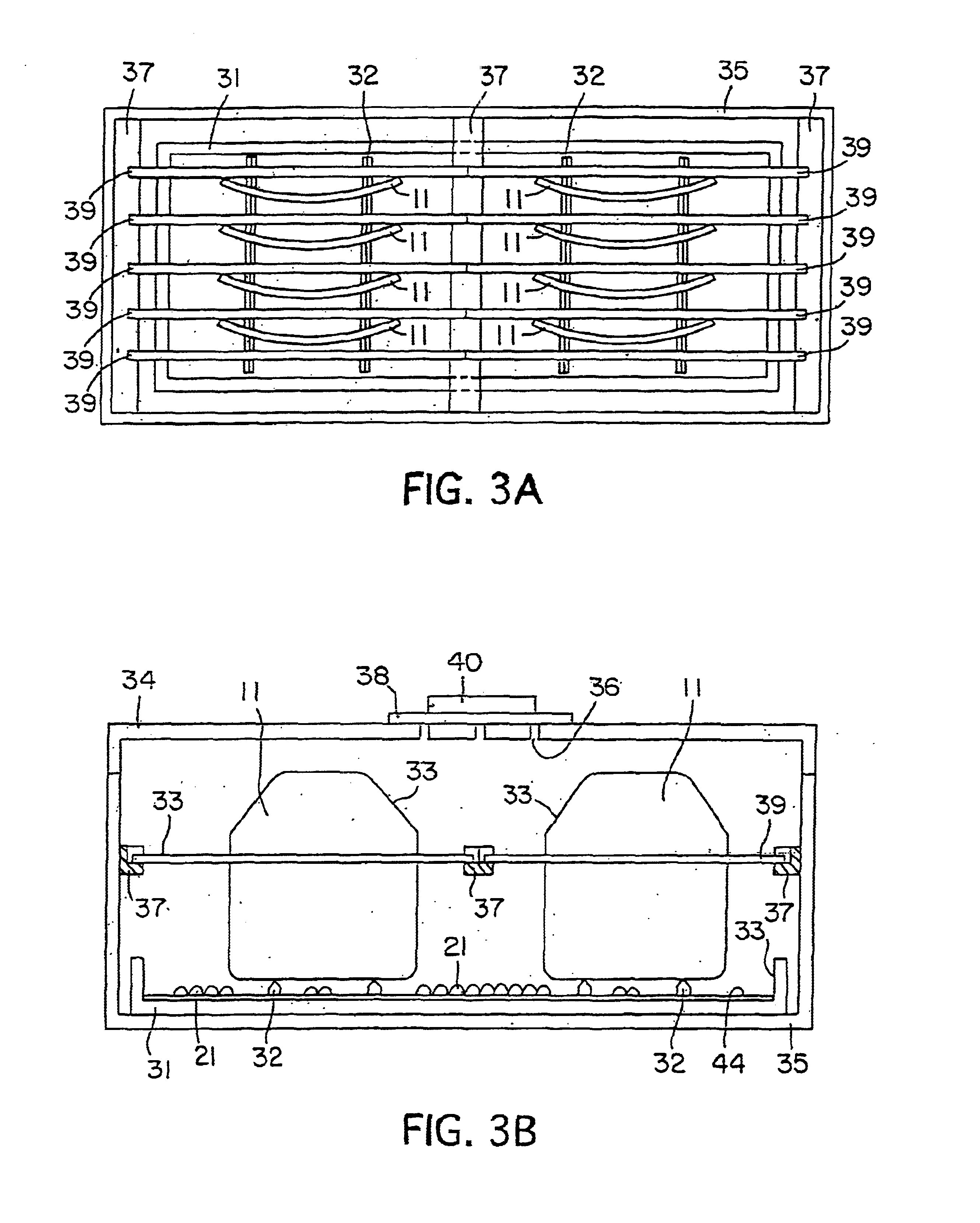

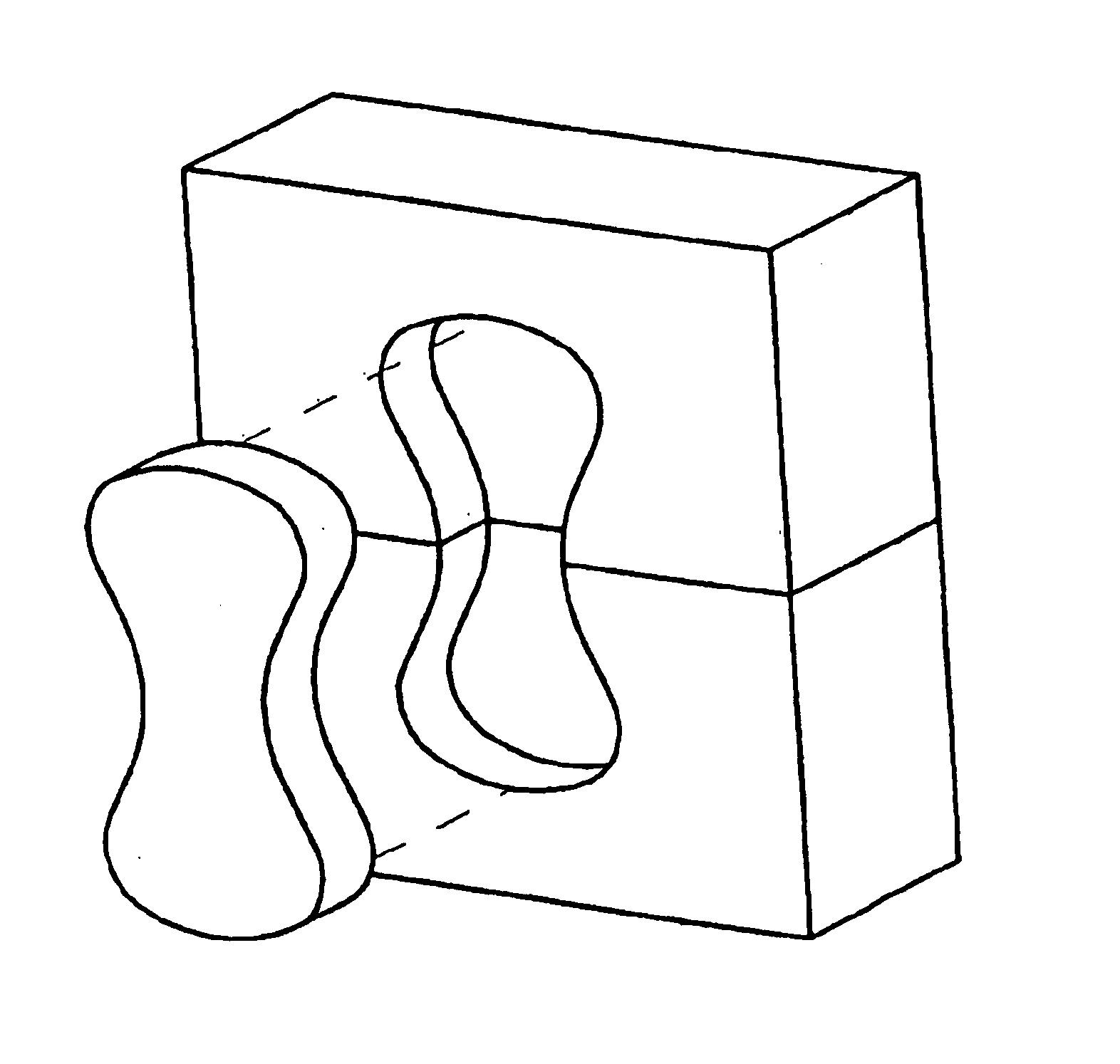

Methods for making composite bonded structures

InactiveUS6863759B2Small sizeLamination ancillary operationsFilm/foil adhesivesReaction bonded silicon carbideAdhesive

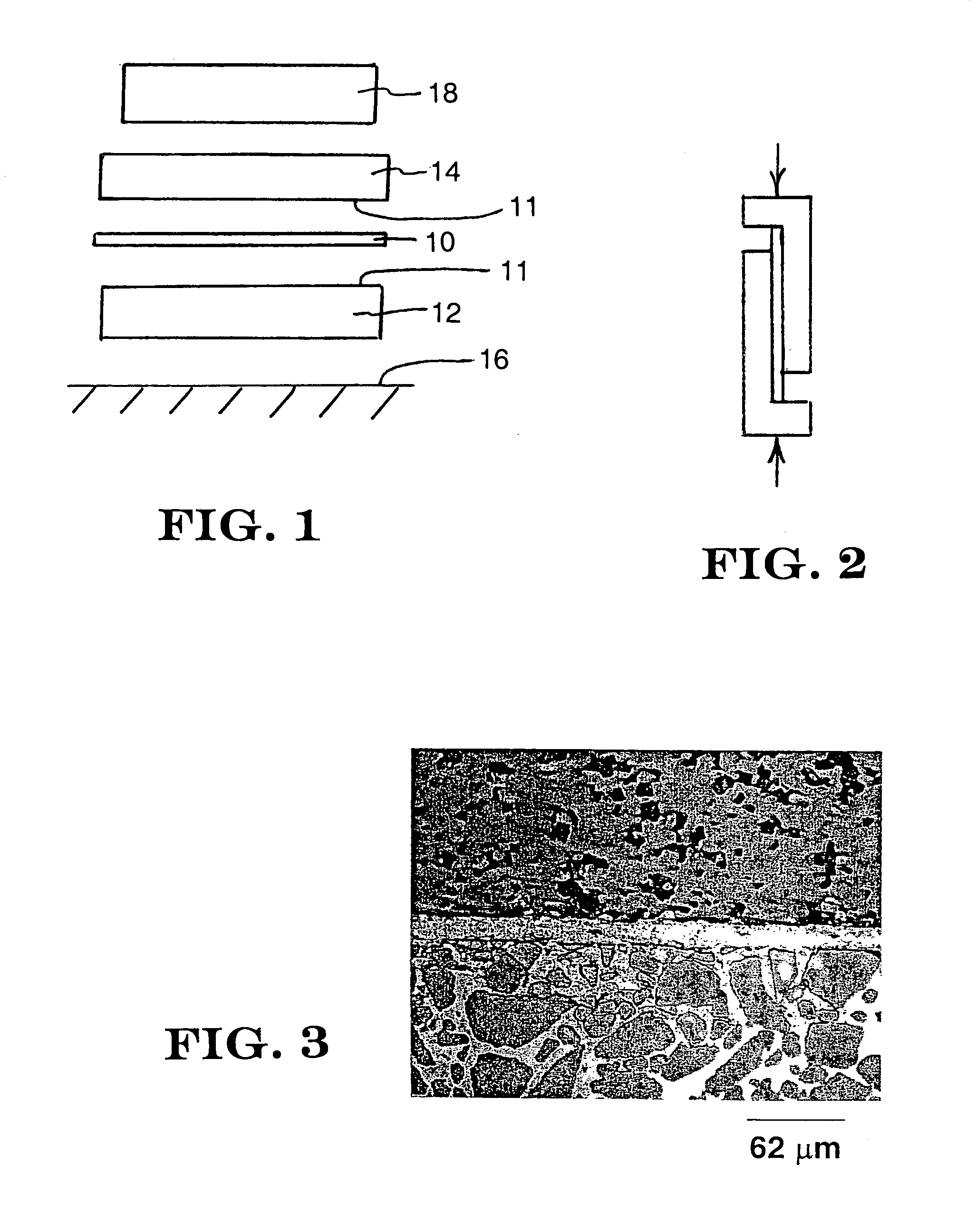

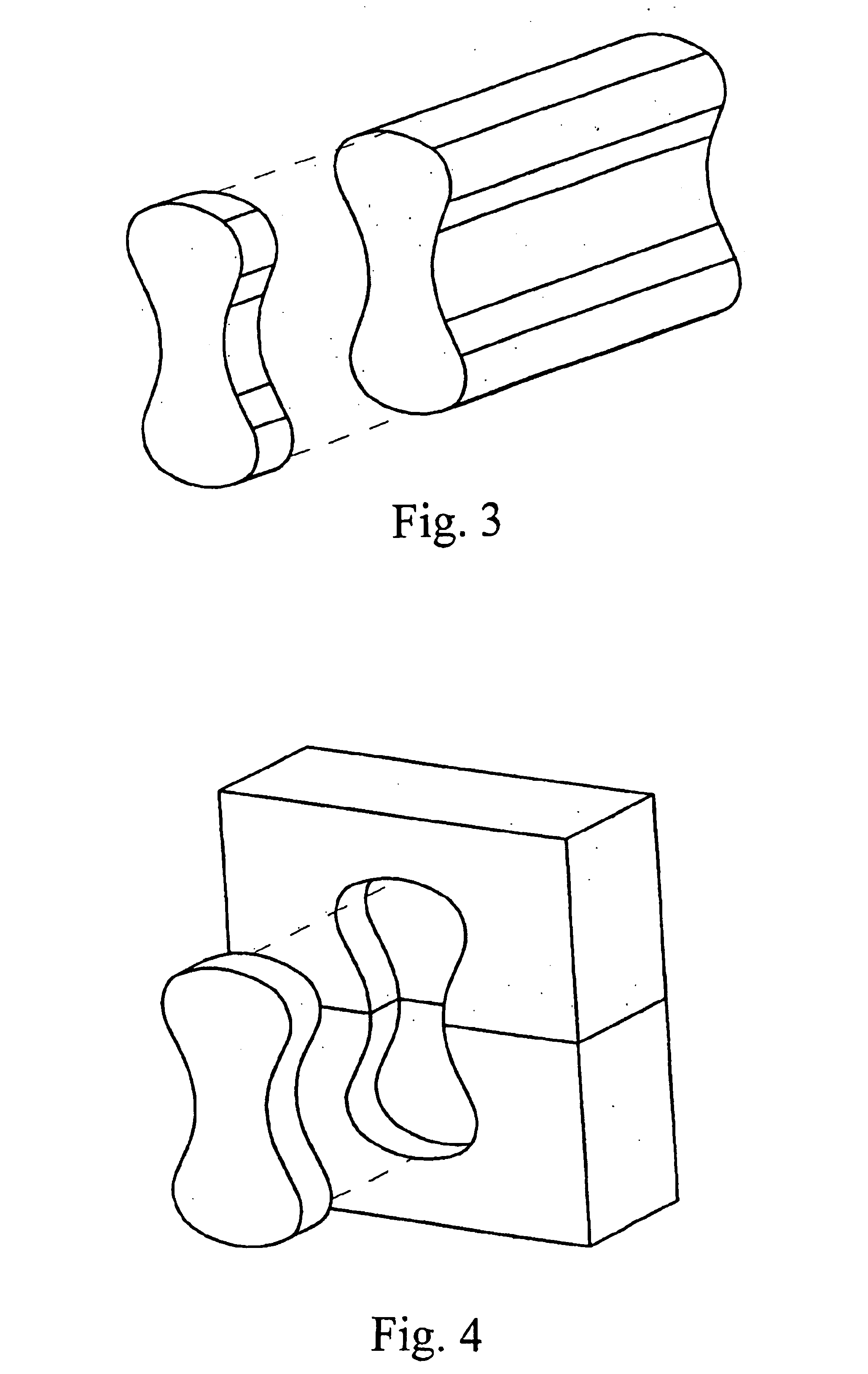

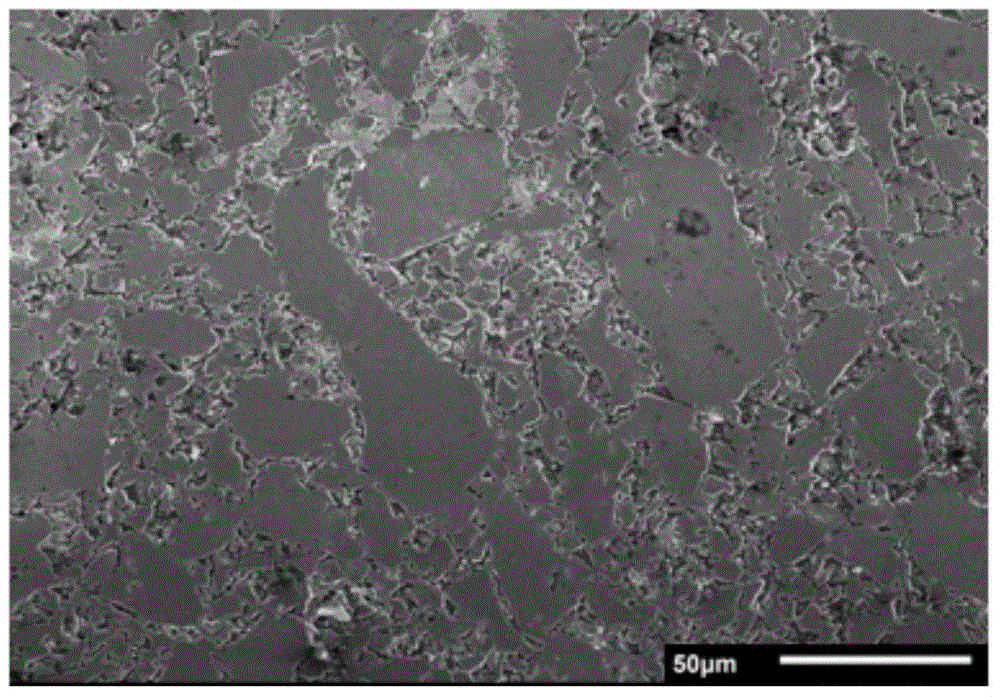

Techniques to bond two or more smaller bodies or subunits to produce a unitary SiC composite structure extend the capabilities of reaction-bonded silicon carbide, for example, by making possible the fabrication of complex shapes. In a first aspect of the present invention, two or more preforms are bonded together with a binder material that imparts at least strength sufficient for handling during subsequent thermal processing. In a second aspect of the present invention, instead of providing the subunits to be bonded in the form of preforms, the subunits may be dense, SiC composite bodies, e.g., RBSC bodies. In each of the above embodiments, a preferable means for bonding two or more subunits combines aspects of adhesive and mechanical locking characteristics. One way to accomplish this objective is to incorporate a mechanical locking feature to the joining means, e.g., a “keyway” feature. The mechanical locking feature thus substitutes for, or supplements the binder qualities of the adhesive, which is especially important when the adhesive itself may be or become weak due to, for example, thermal processing.

Owner:BUSINESS ALLIANCE CAPITAL

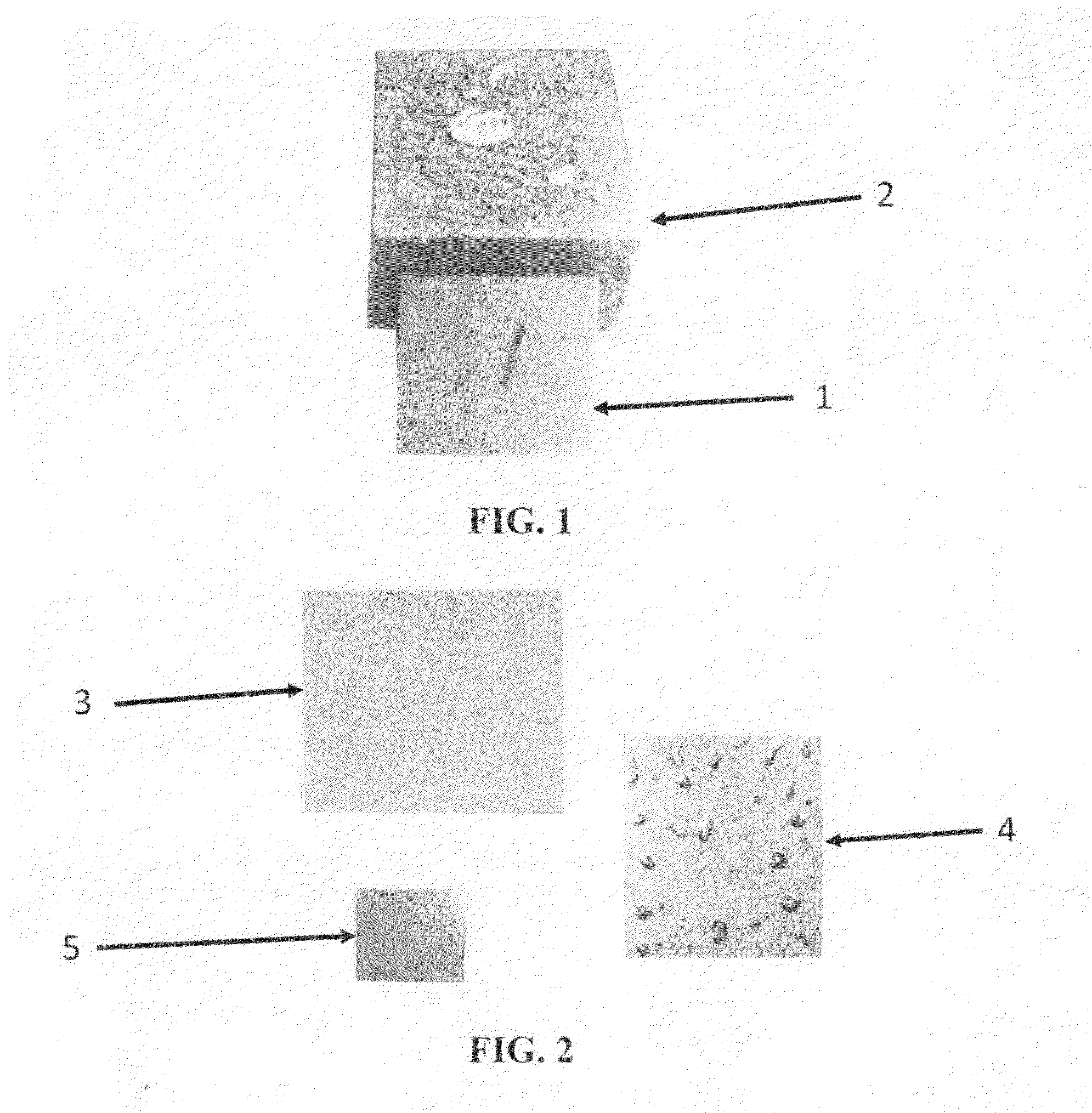

Preparation method of RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer

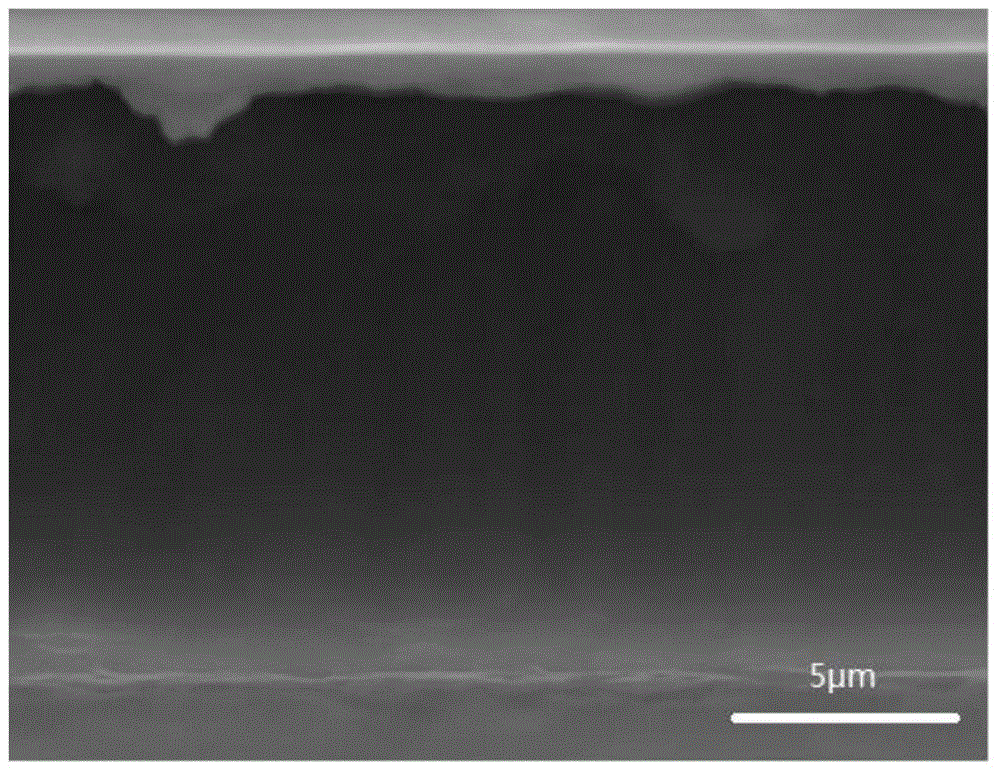

InactiveCN104451580AImprove optical qualityRaise the incident energyVacuum evaporation coatingSputtering coatingReaction bonded silicon carbideSurface cleaning

The invention provides a preparation method of an RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer, and belongs to the technical field of thin film deposition. The method comprises the following steps: I, preparing filming conditions: mounting a Si target on a twin sputtering cathode of a filming machine, performing surface cleaning treatment on the RB-SiC substrate, fixing to a filming machine workpiece clamp, vacuuming the filming machine and roasting the RB-SiC substrate; II, performing surface treatment on the surface of the Si target of the sputtering cathode: introducing Ar gas into the sputtering cathode, and adjusting medium frequency power supply power to perform sputtering pre-treatment on the surface of the Si target; III, preparing the Si modification layer: increasing the medium frequency power supply power and Ar ventilation volume, and depositing the Si modification layer on the RB-SiC substrate by using a medium frequency magnetron sputtering technology. The preparation process is greatly simplified, the compactness of the film layer is high, the film is uniform, the polishing characteristic is obviously improved, and the optical quality of the surface of the polished substrate is greatly improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Boron carbide composite bodies, and methods for making same

InactiveUS20060169128A1Reduce gravityReduce quality problemsLayered productsArmour platesReaction bonded silicon carbideHigh stiffness

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon carbide matrix produced by the reactive infiltration of an infiltrant having a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction-bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC

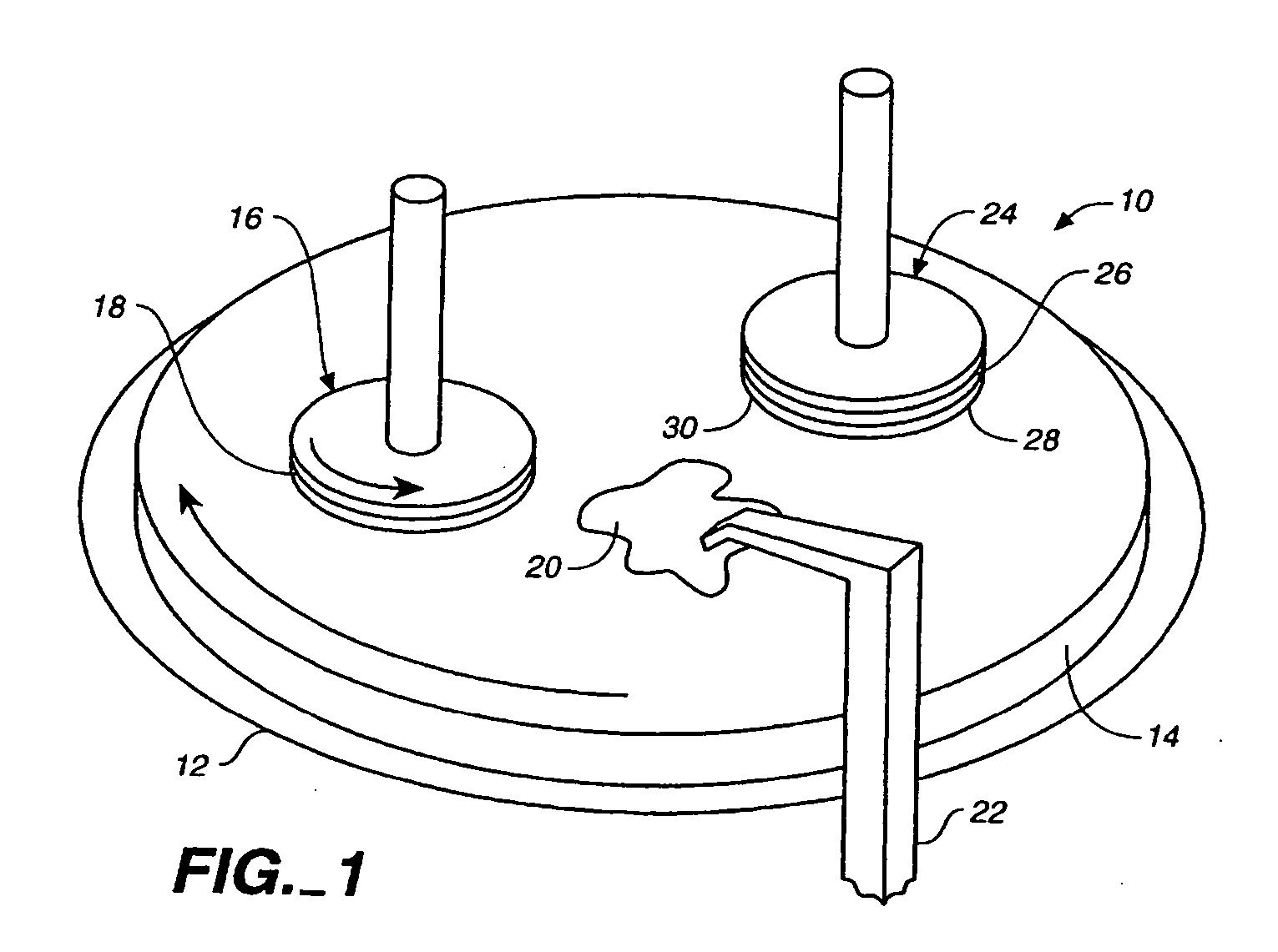

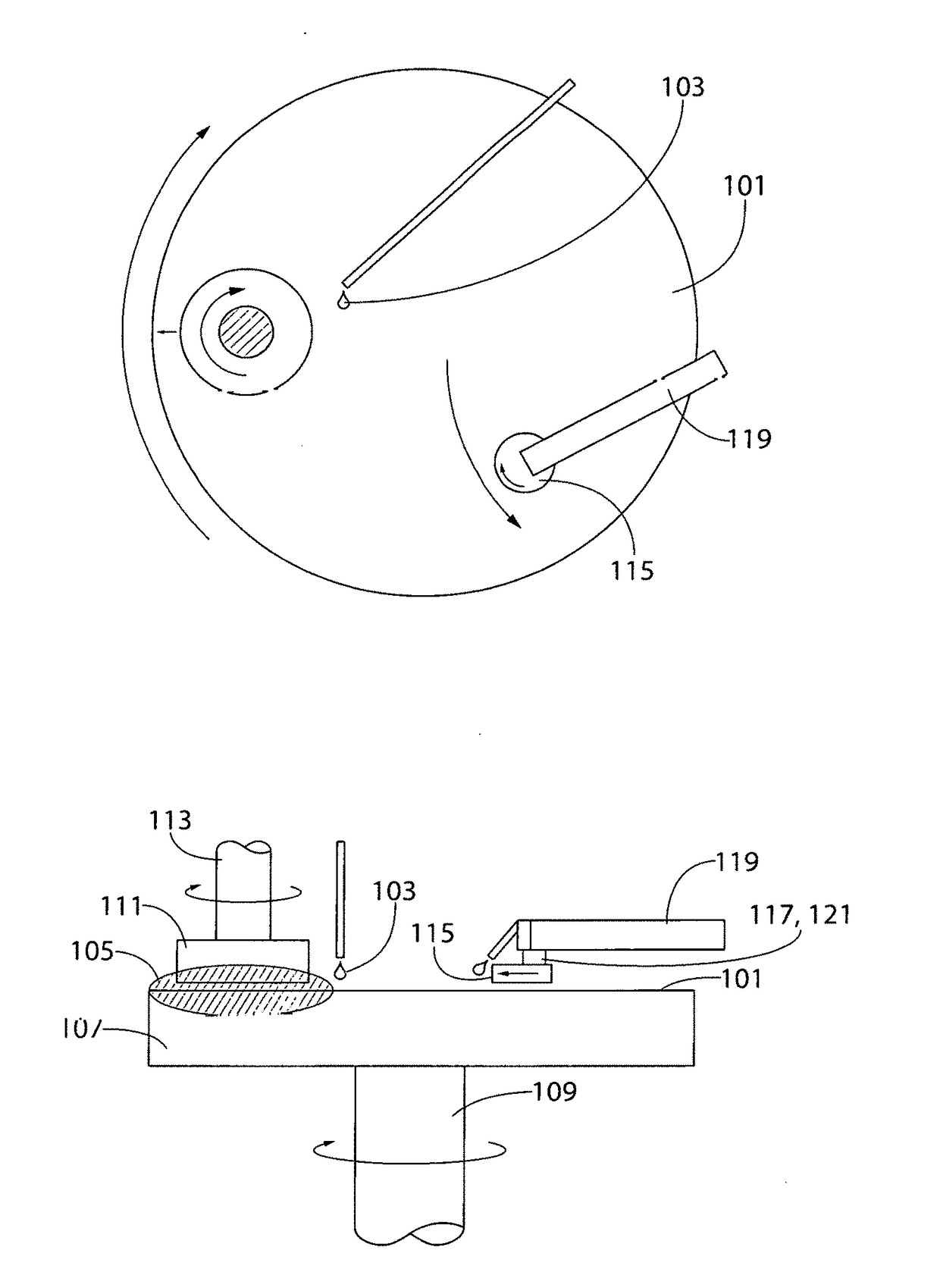

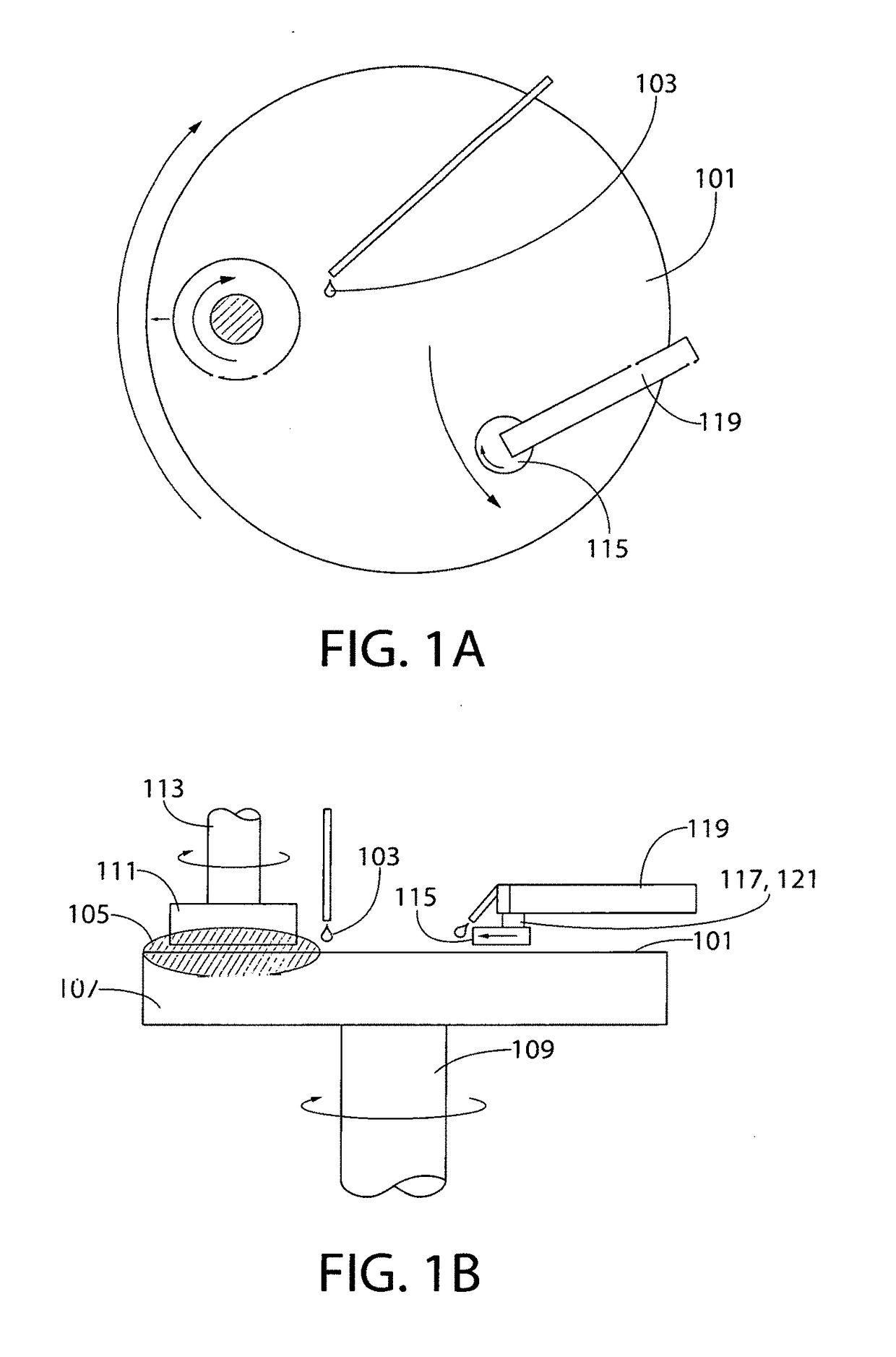

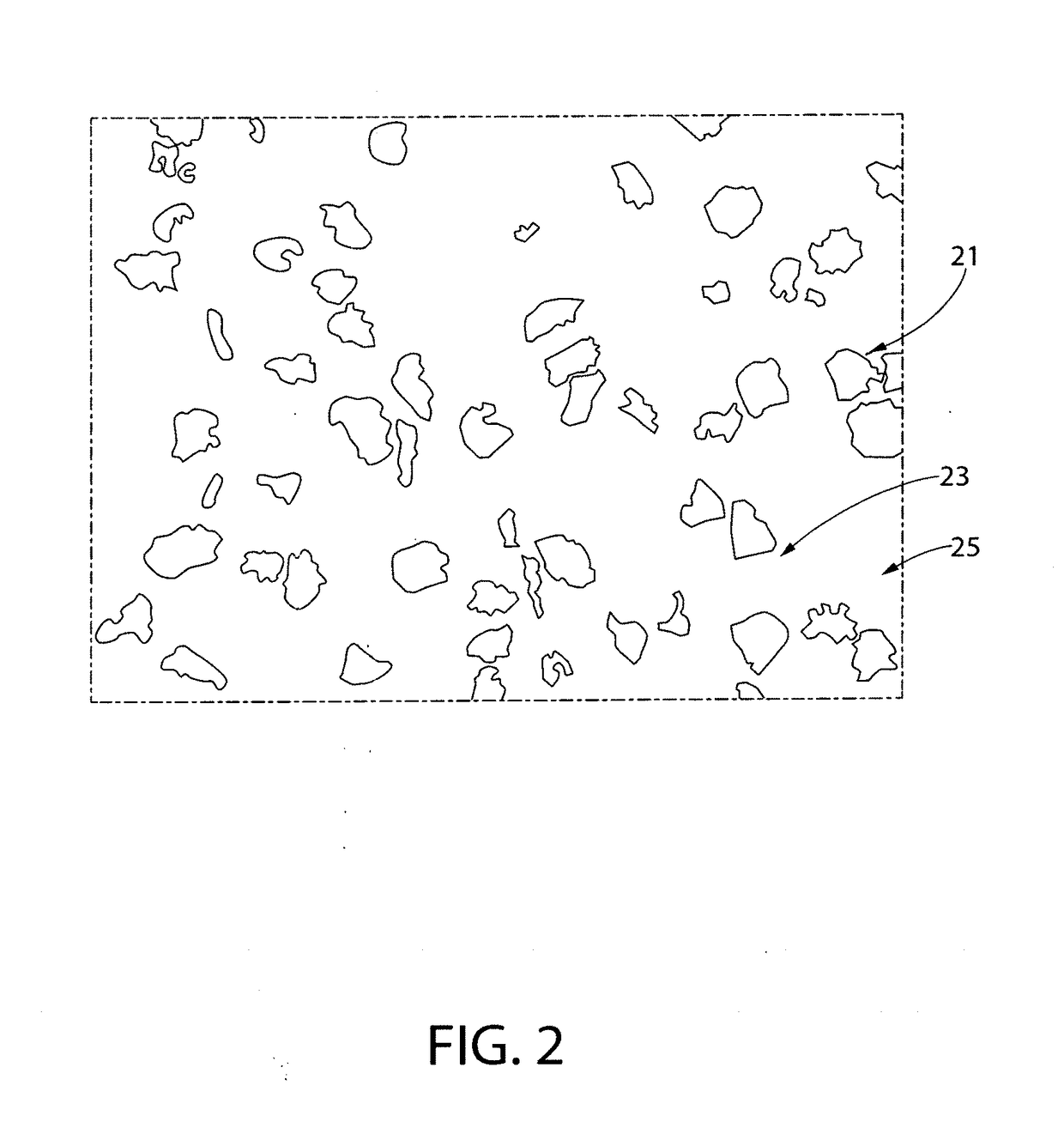

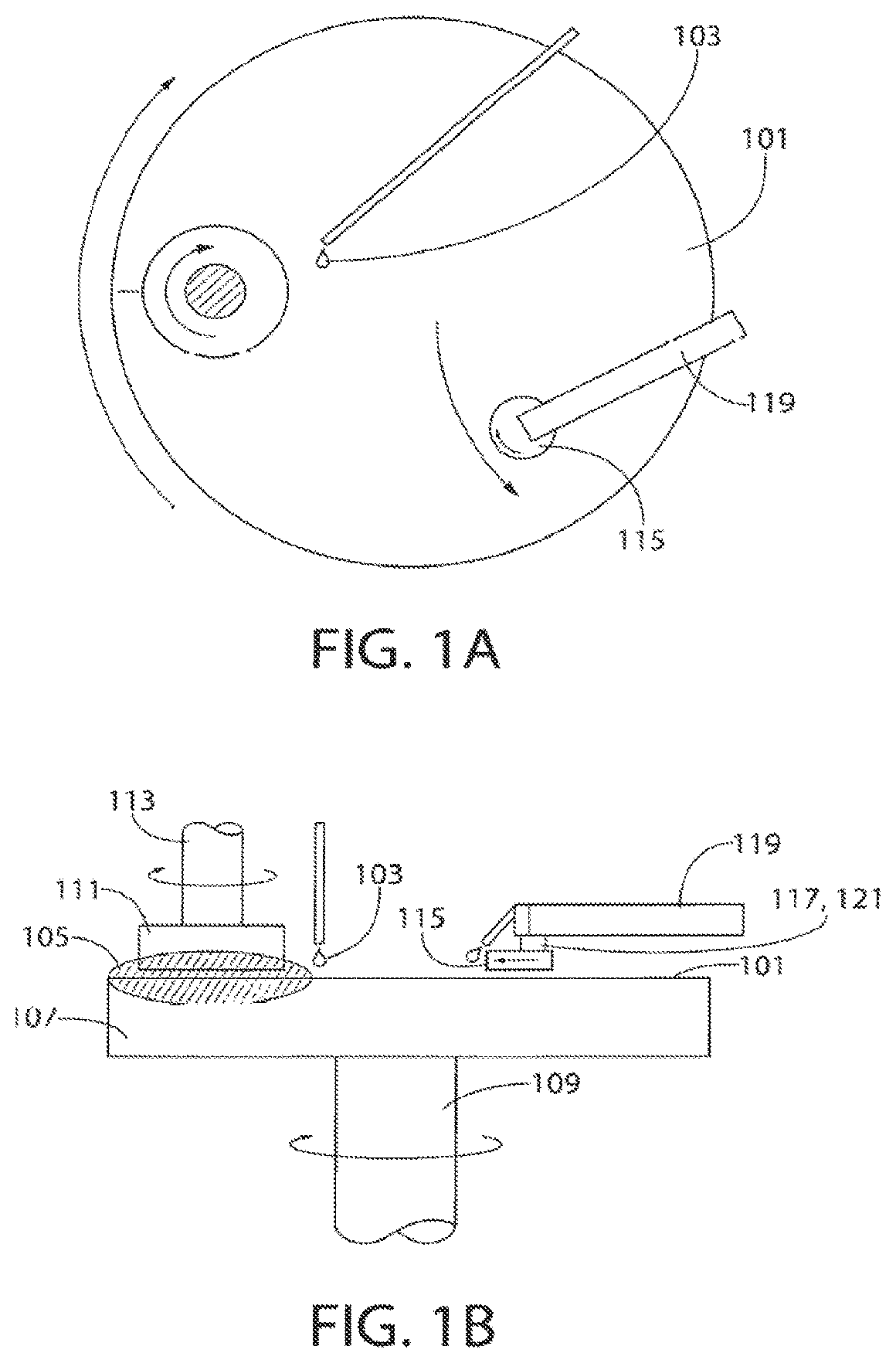

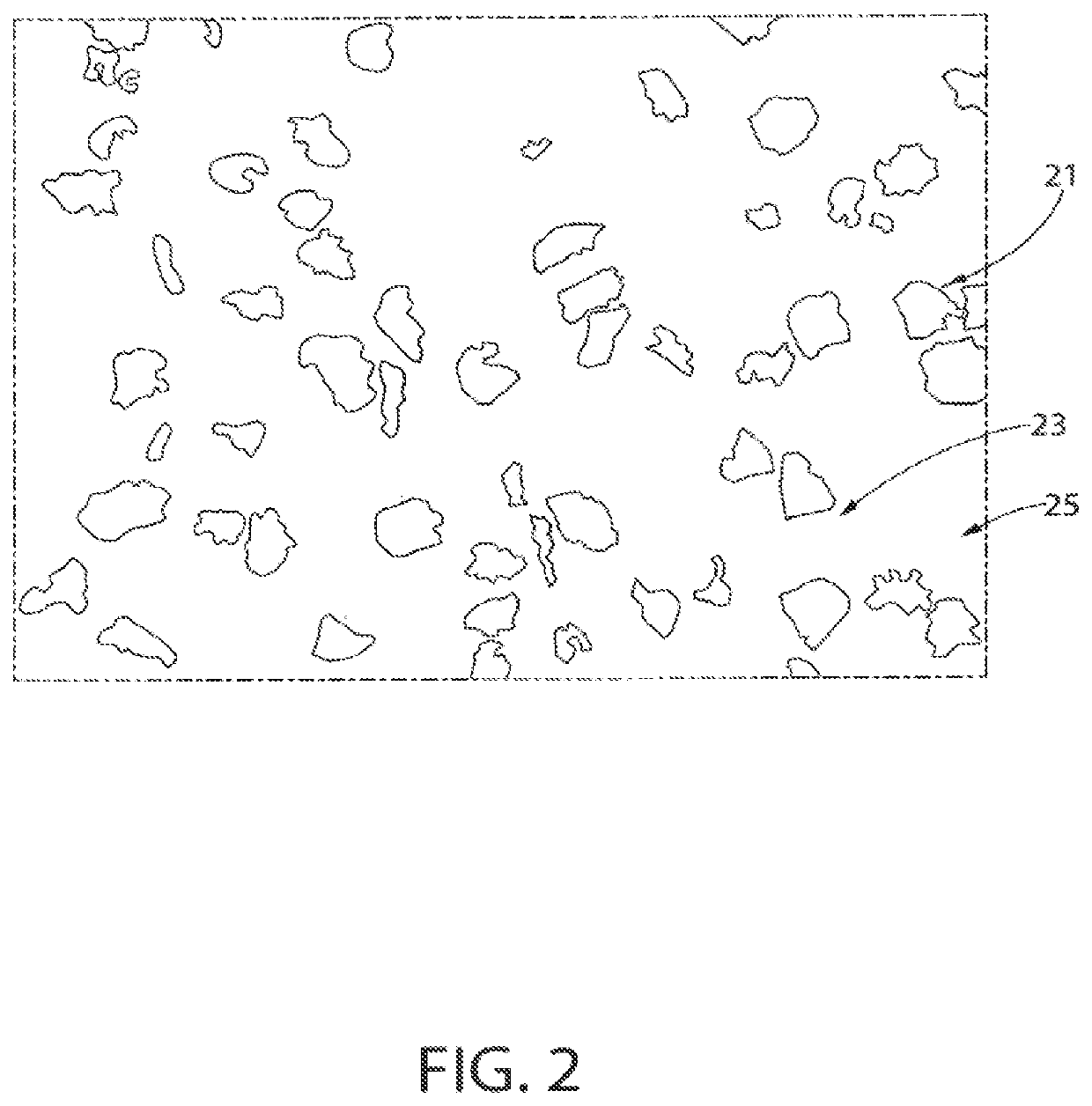

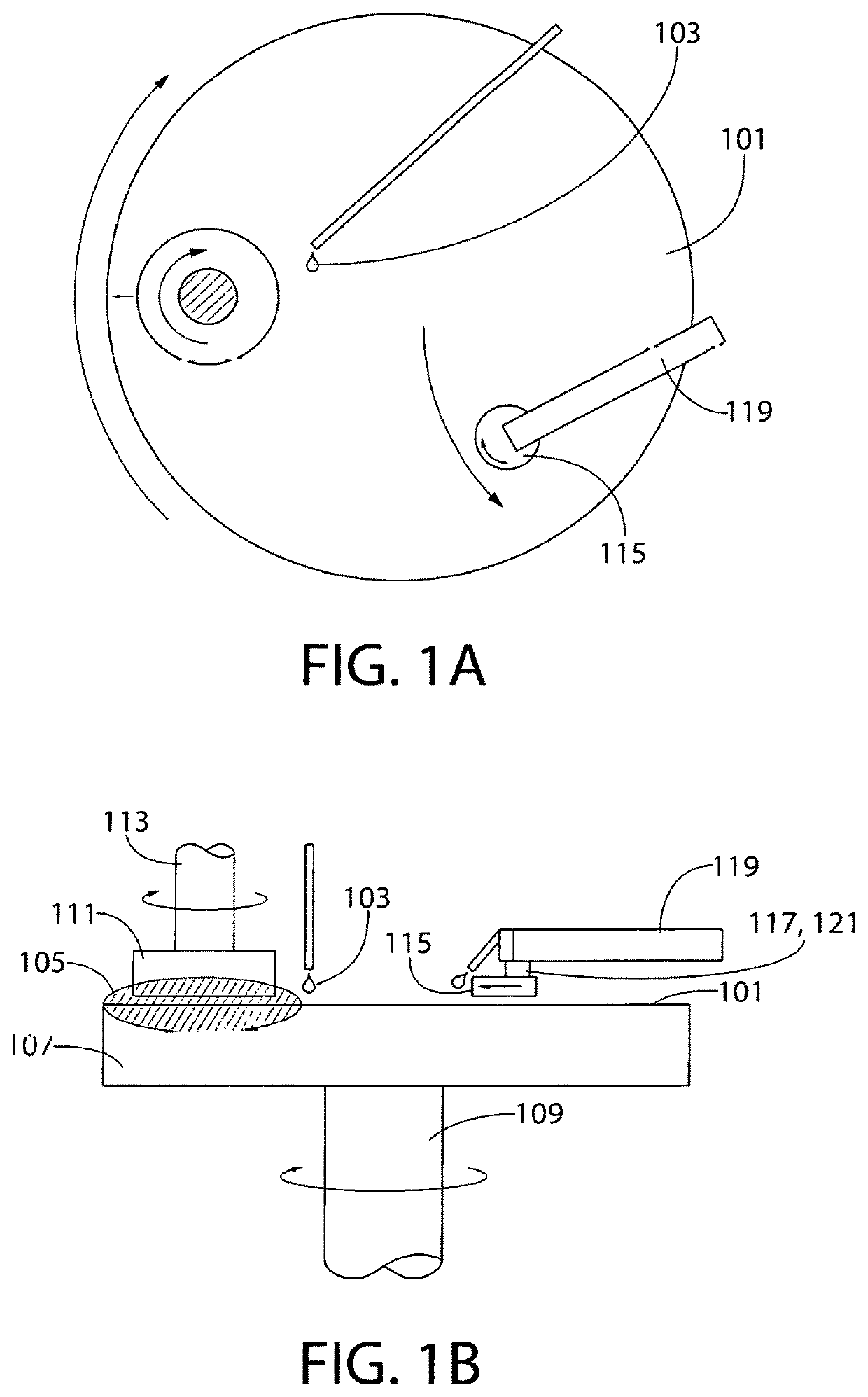

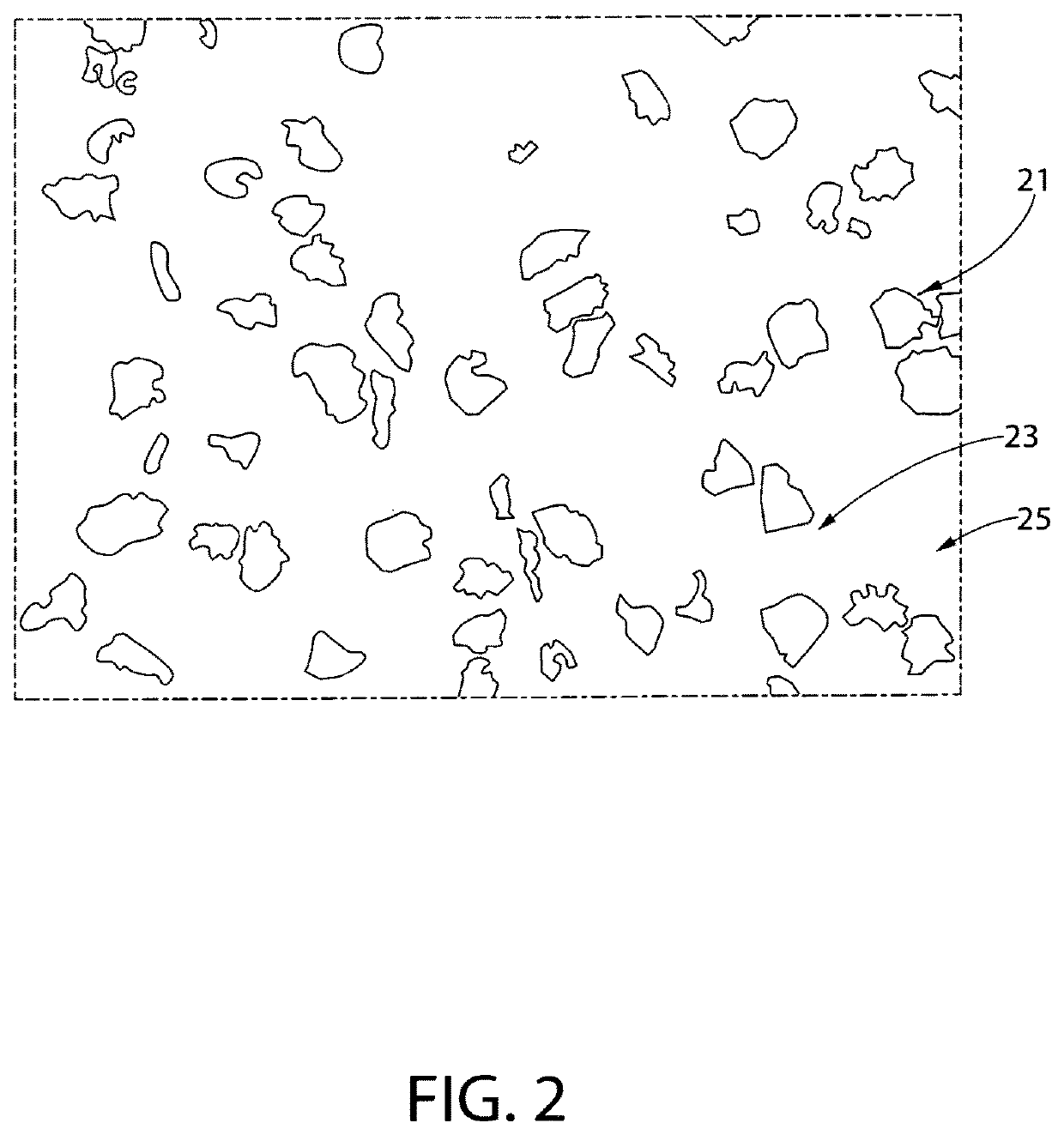

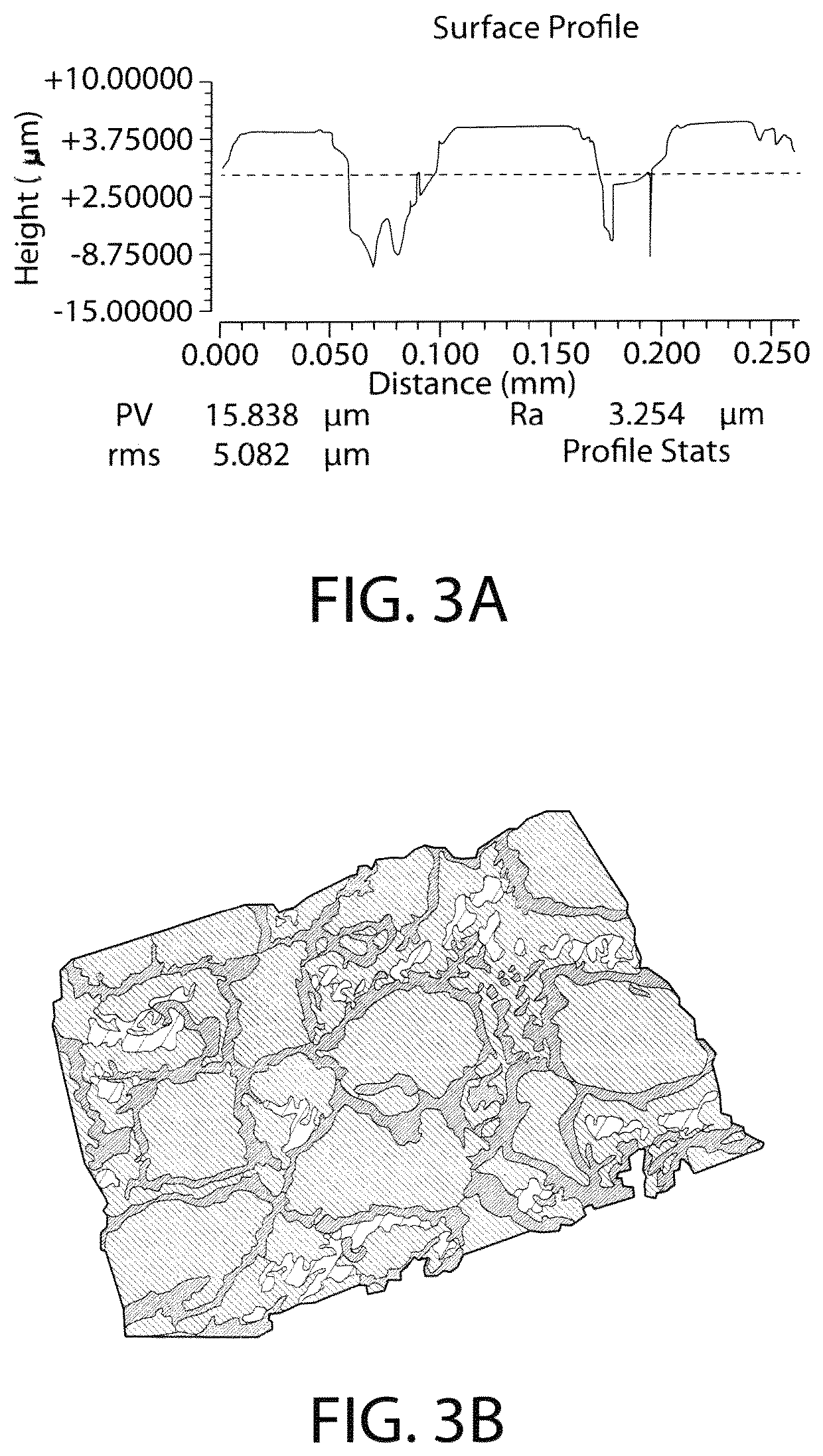

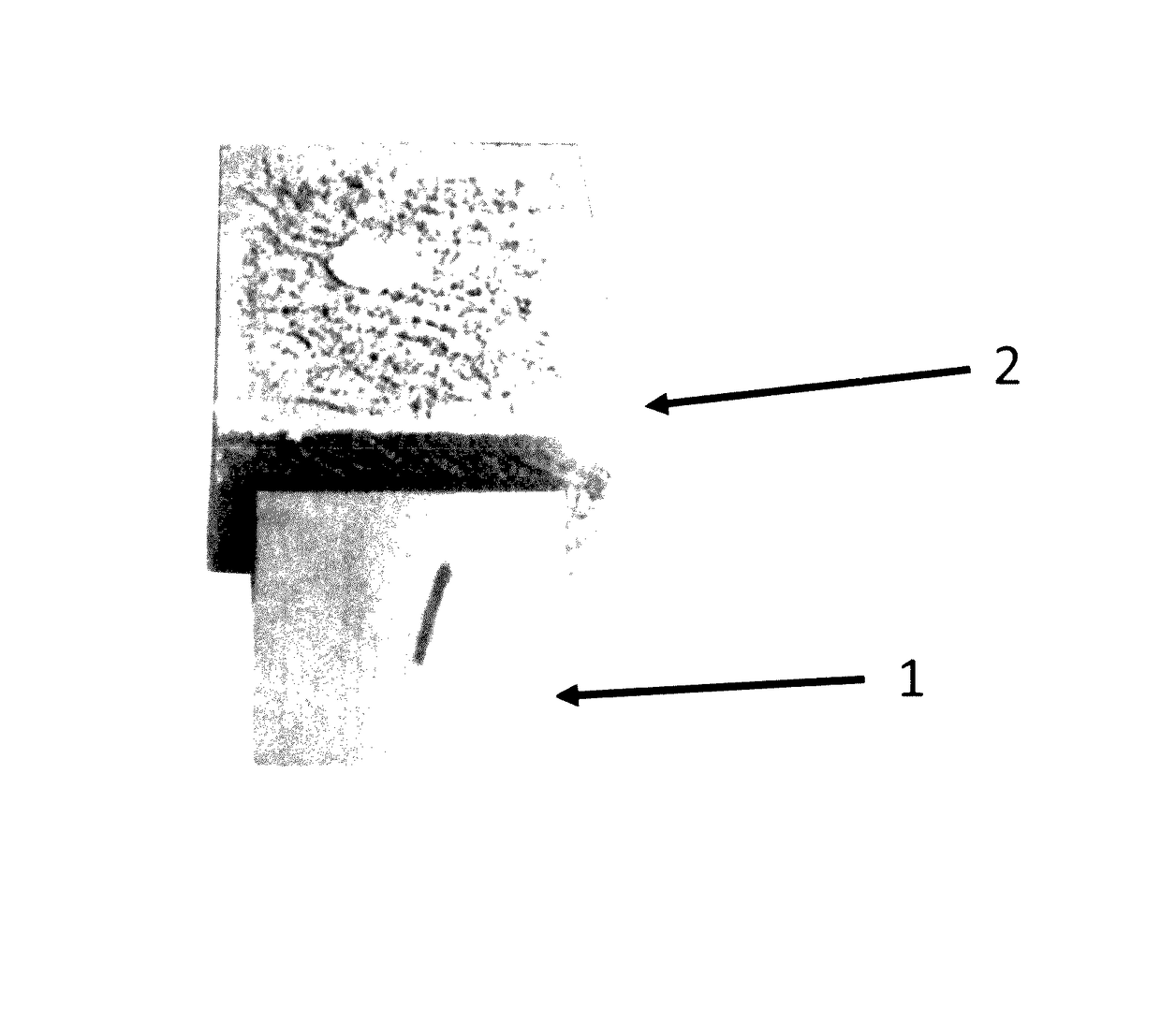

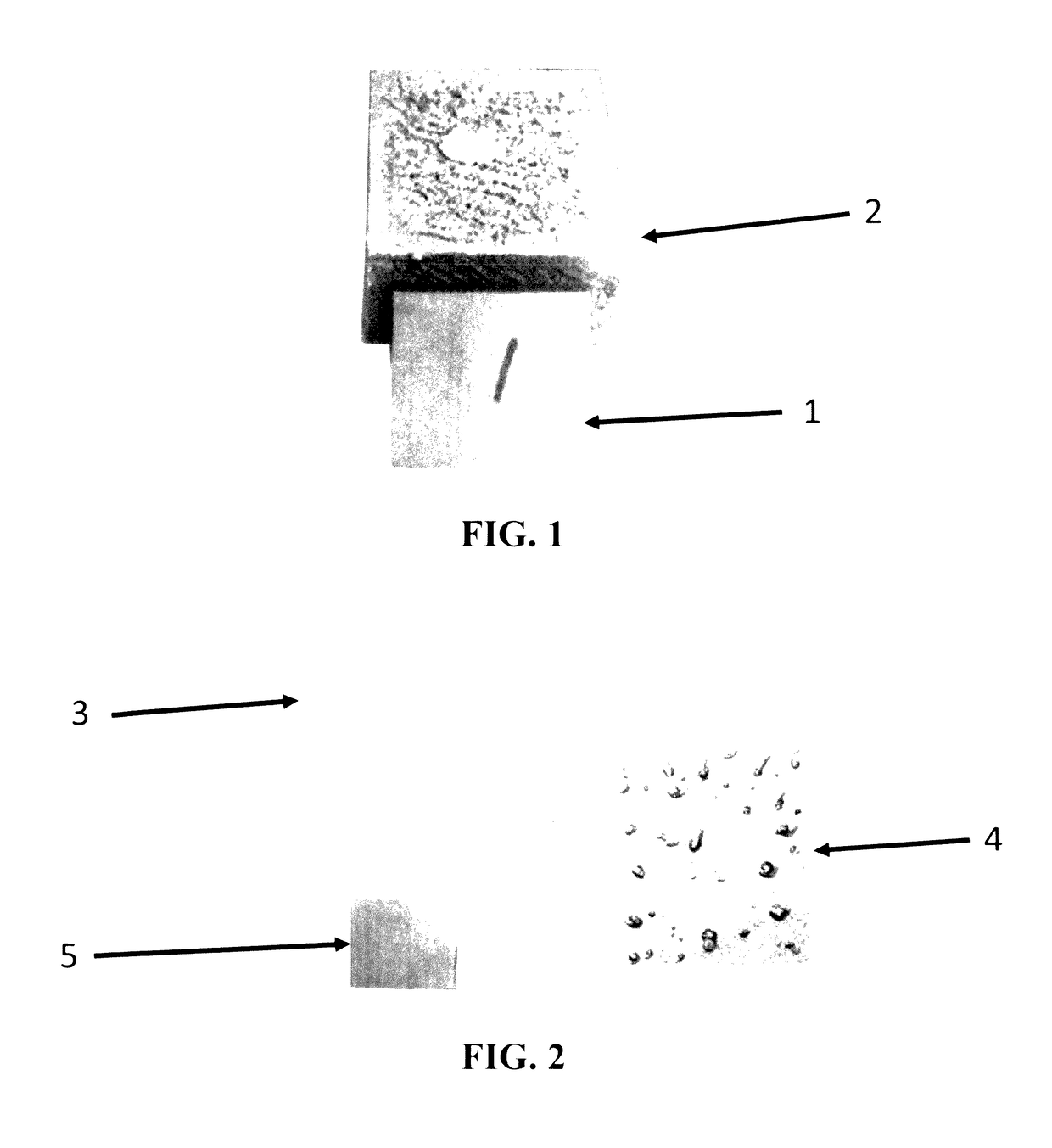

Diamond Composite CMP Pad Conditioner

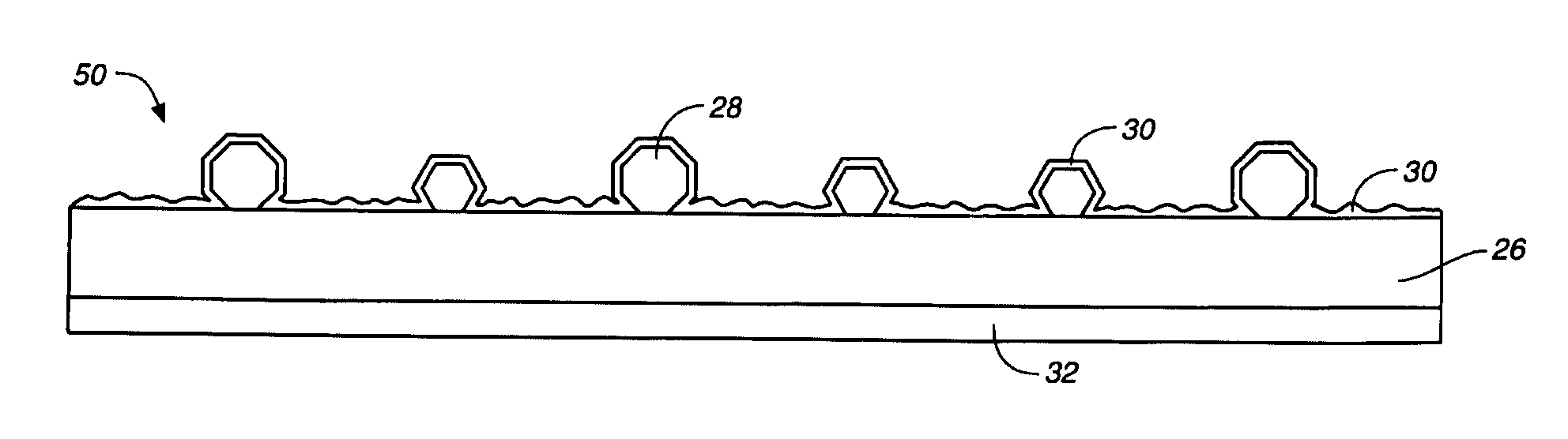

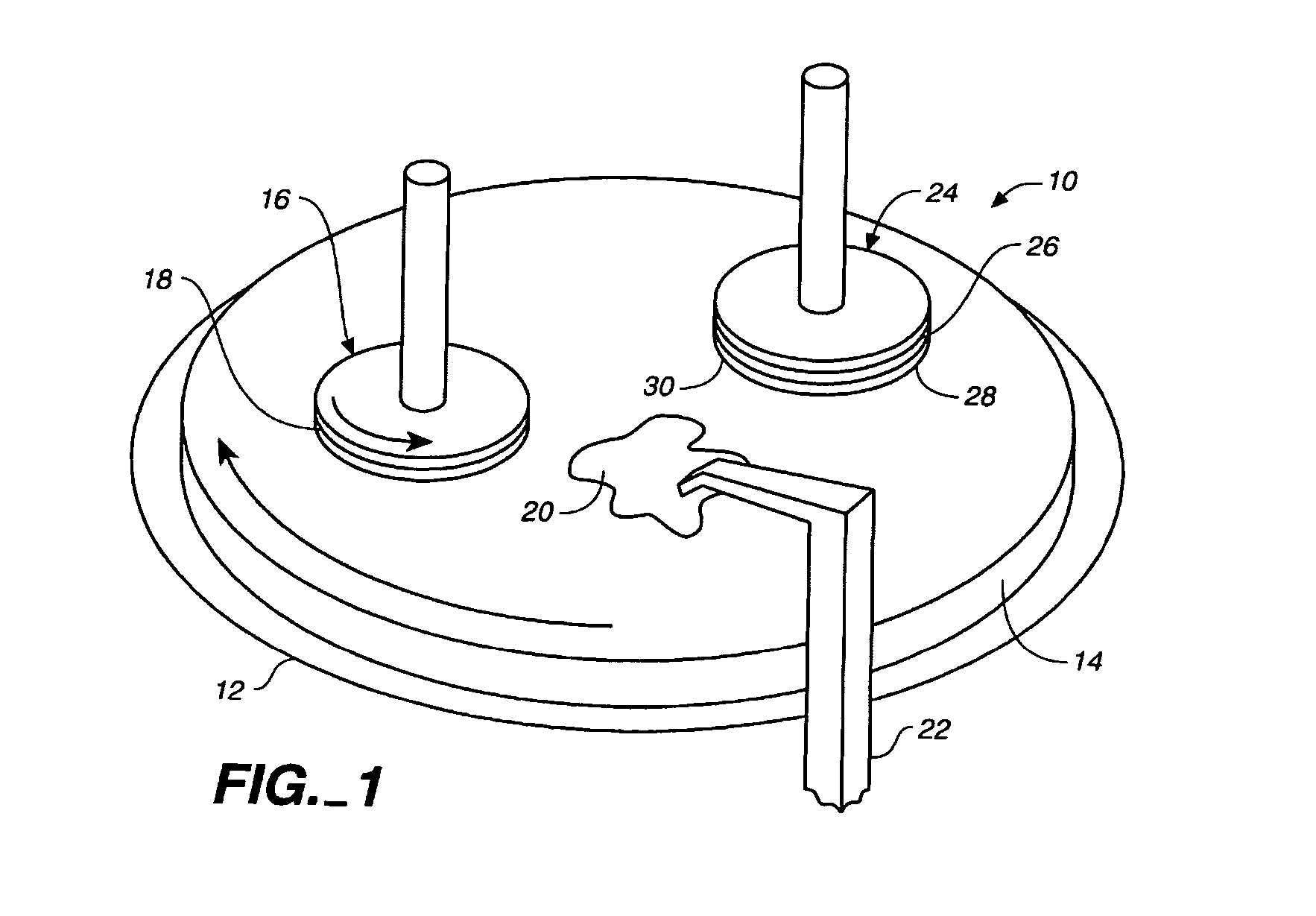

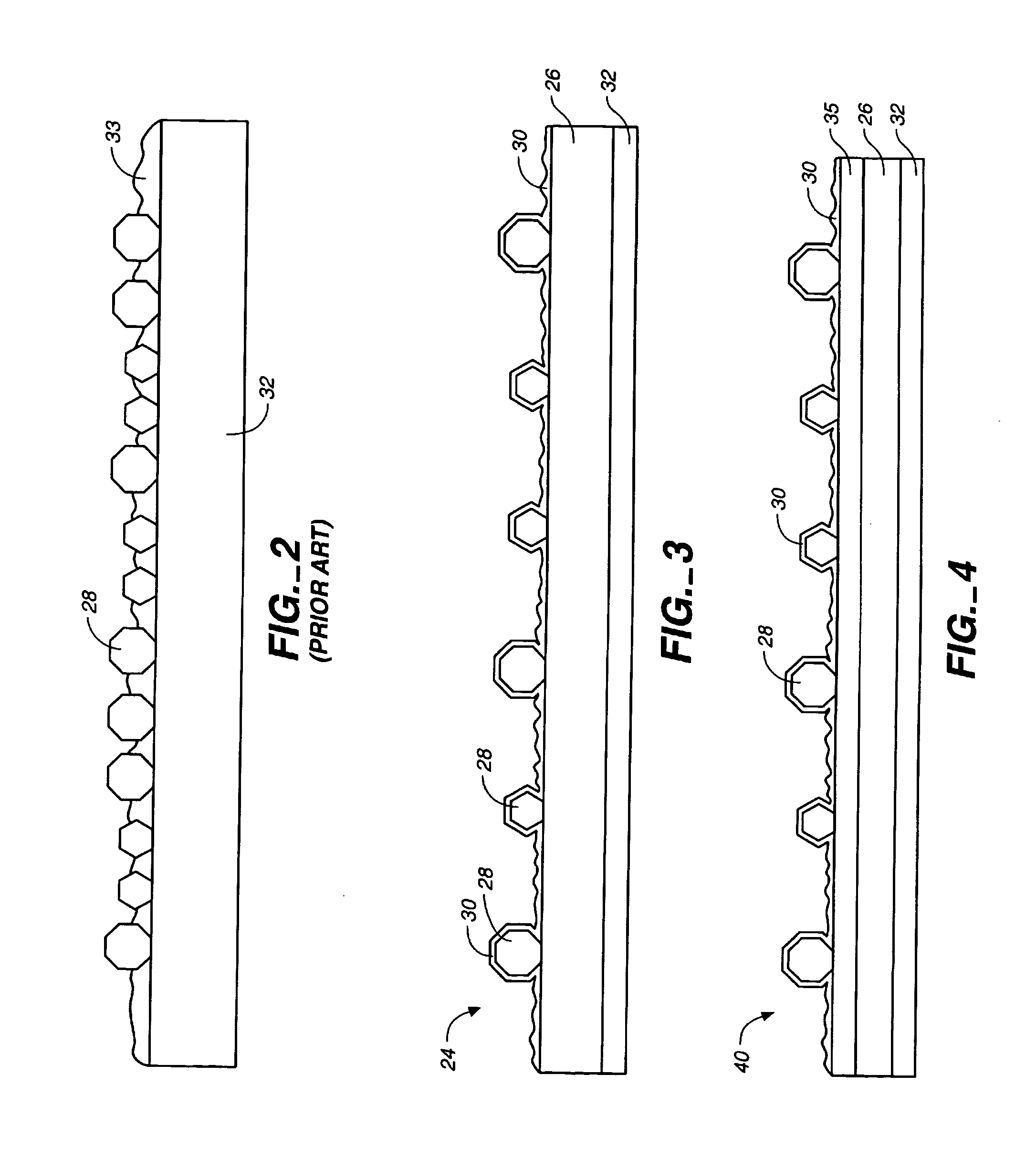

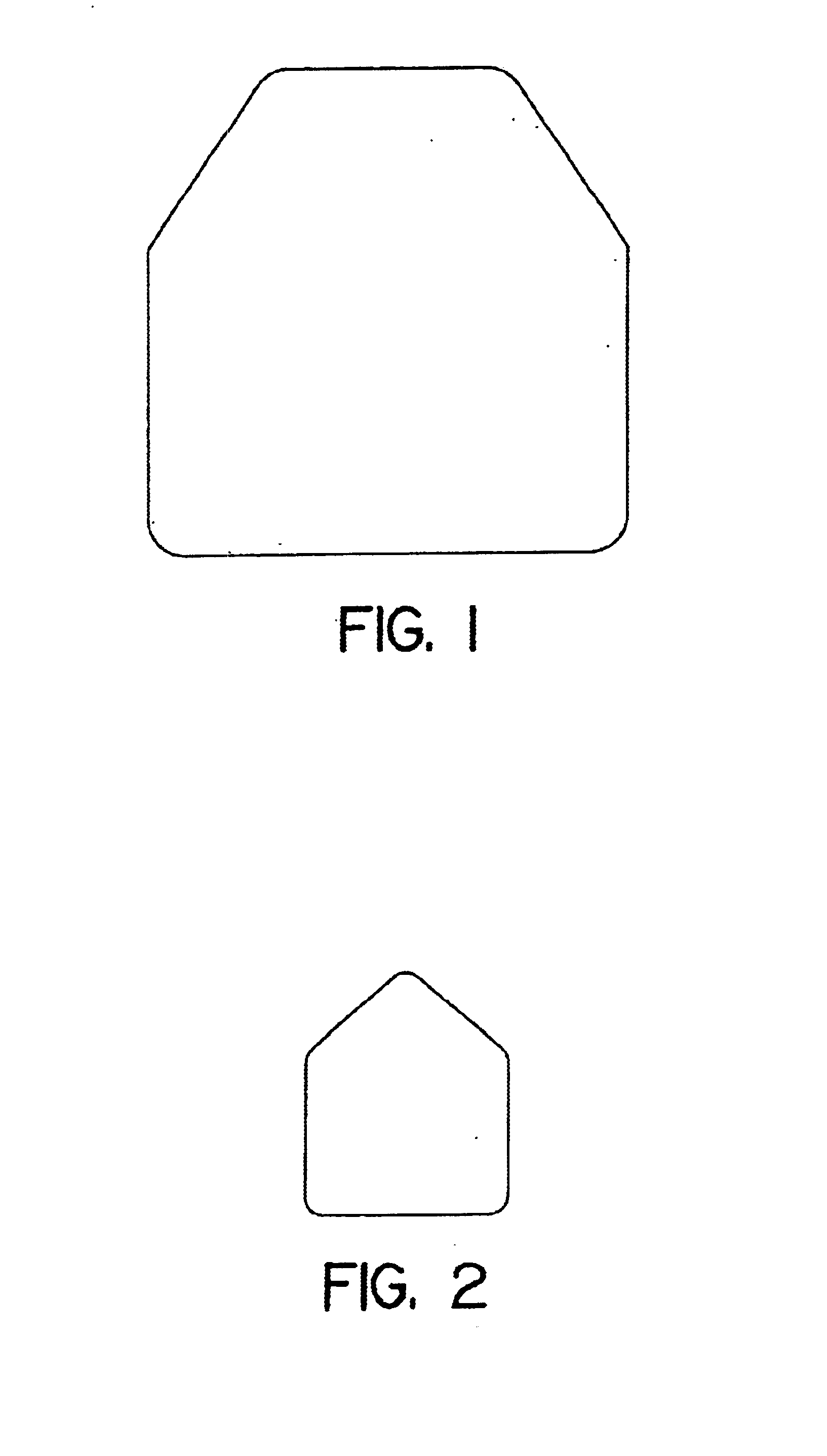

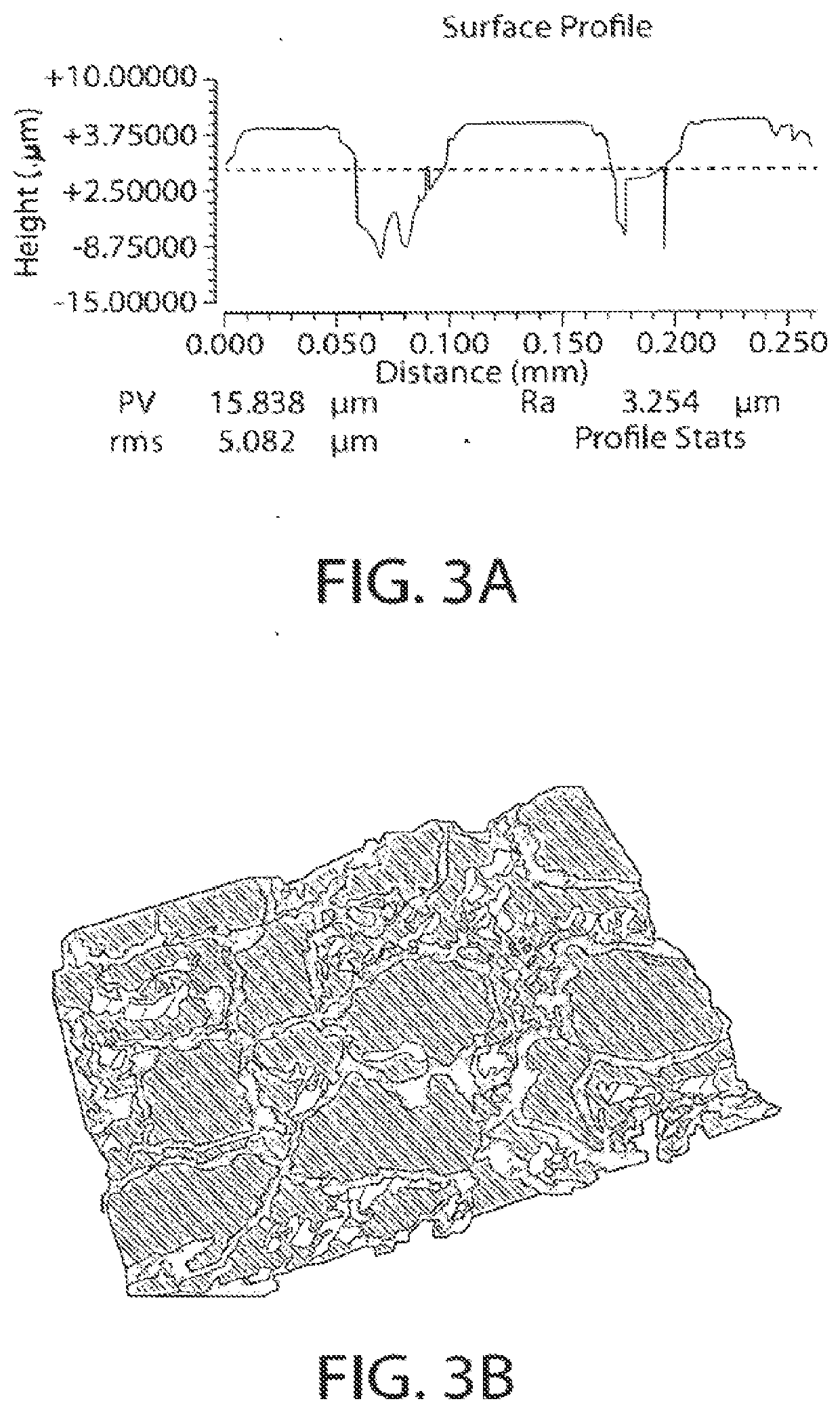

ActiveUS20170291279A1Semiconductor/solid-state device manufacturingLapping machinesReaction bonded silicon carbideElectrical discharge machining

A chemical-mechanical polishing / planarization pad conditioner body made from diamond-reinforced reaction bonded silicon carbide, with diamond particles protruding or “standing proud” of the rest of the surface, and uniformly distributed on the cutting surface. In one embodiment, the diamond particles are approximately uniformly distributed throughout the composite, but in other embodiments they are preferentially located at and near the conditioning surface. The tops of the diamond particles can be engineered to be at a constant elevation (i.e., the conditioner body can be engineered to be very flat). Exemplary shapes of the body may be disc or toroidal. The diamond particles can be made to protrude from the conditioning surface by preferentially eroding the Si / SiC matrix. The eroding may be accomplished by electrical discharge machining or by lapping / polishing with abrasive.

Owner:II VI DELAWARE INC

Preparation method of reaction-bonded silicon carbide

The invention provides a preparation method of reaction-bonded silicon carbide. A monomer, a crosslinking agent dispersant and a raw material are mixed in a ball milling mode, silicon carbide / carbon black water-based suspensoid of a high solid-phase content and low adhesion is obtained, a green body is formed through a gel injection molding process, and the silicon carbide is obtained after a high-temperature reaction. By means of the preparation method, the silicon carbide in a complex shape can be prepared, sintering time is short, and the preparation method is suitable for preparing large-size silicon carbide products and low in cost.

Owner:洛阳暖盈电子技术有限公司

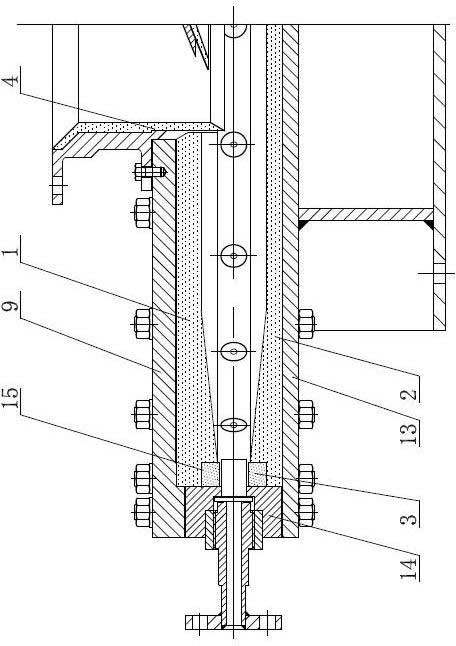

Large high temperature resistant flat ceramic jet mill

ActiveCN102284335AHigh strengthImprove wear resistanceGrain treatmentsCircular discReaction bonded silicon carbide

The invention discloses a large high-temperature resistance flat type ceramic jet mill. In the jet mill, a metal upper cover, a middle ring and a lower cover are buckled one another to form a flat circular disc, wherein an upper cover liner is arranged inside the upper cover, a lower cover liner is arranged inside the lower cover, and middle ring liners are arranged on outer edges of the upper cover liner and lower cover liner; and the upper cover liner, the lower cover liner and the middle ring liners form a closed crushing cavity. On the flat type jet mill, reaction-bonded silicon carbide is adopted as a liner material, the abrasive resistance is good, and the finished product quality is greatly improved; and according to the block structure of the invention, the manufacture difficulty of the reaction-bonded silicon carbide liner component is greatly reduced, the size limitation to conventional production equipment is broken through, so that a large high-temperature resistance flat type ceramic jet mill with the diameter of over 1m can be manufactured, and the jet mill is in the international leading position to meet the material crushing production requirement of automation, high yield and high quality.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Reaction Bonded Silicon Carbide Bodies Made From High Purity Carbonaceous Preforms

A process for producing reaction bonded silicon carbide (RBSC) from high purity, porous, essentially all-carbon preforms through contacting said preforms with silicon metal at room temperature, and subsequently heating to melt silicon metal and cause infiltration into said preform causing reaction to silicon carbide and leaving residual silicon, to result in a dense silicon carbide-silicon composite. The process offers the ability to produce RBSC with higher purity, higher strength, and lower cost as long as the carbonaceous preforms are of sufficient purity and pore size distribution to allow for uniform, crack-free bulk bodies to be fabricated.

Owner:BRACAMONTE LORI

Binder for rbsc assembly and method of binding rbsc assembly using the same

InactiveUS20120107512A1Improve productivityEasy to manufacturePigmenting treatmentPretreated surfacesReaction bonded silicon carbideMixing ratio

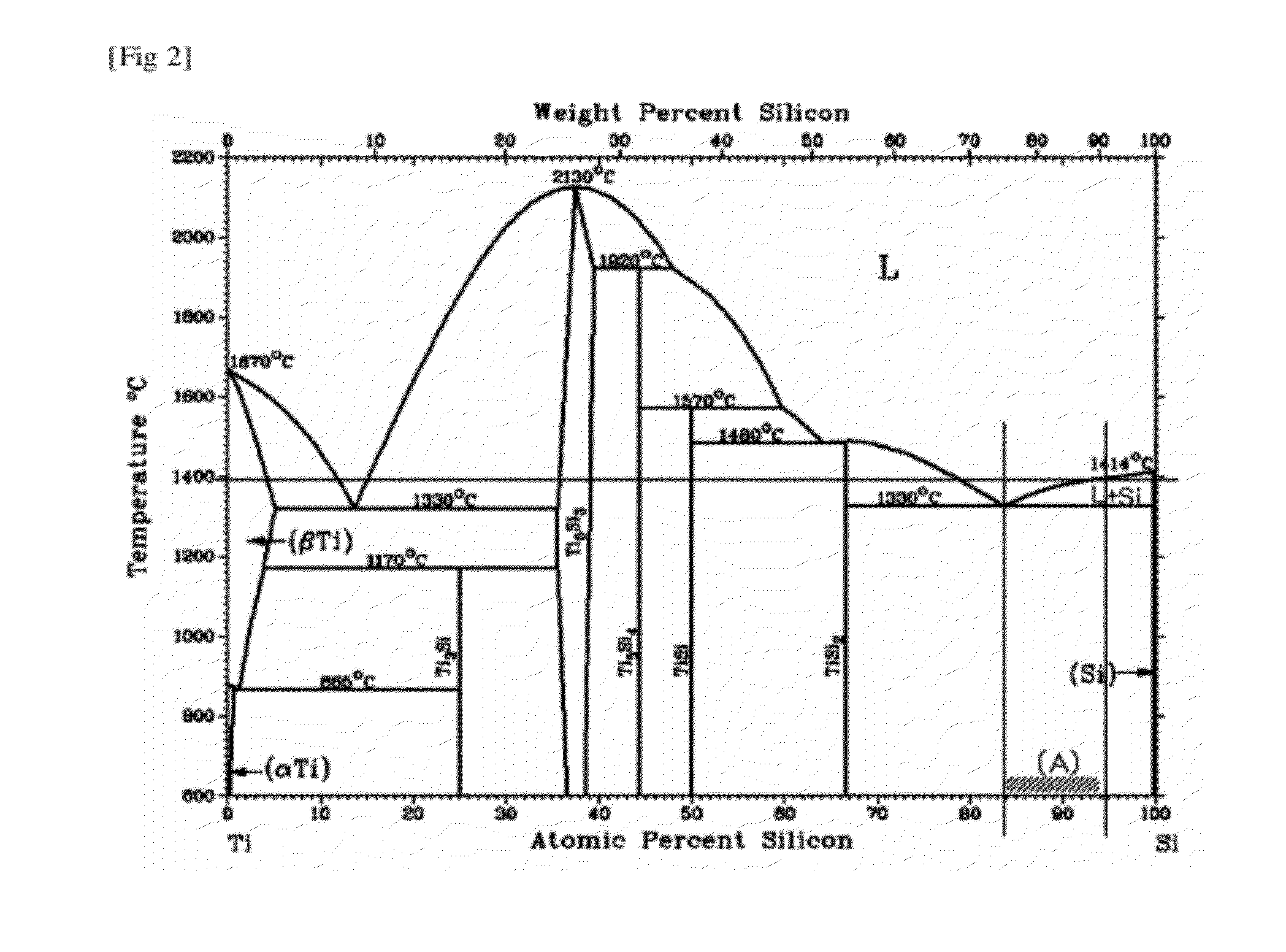

The invention relates to a binder for binding RBSC (reaction-bonded silicon carbide), which is used to prepare RBSC assembly, wherein it includes a sintered body obtained by sintering a mixed powder of at least one substance selected from the group having Al, Ti, Fe, Mg, Cu and Ge, and silicon, or a powder obtained by milling the sintered body; and with regard to the mixing ratio of the mixed powder, the maximum amount of silicon is an amount rendering the complete melting temperature of phase in phase diagram of the mixed powder to be at most 1400° C., and the minimum amount of silicon is a larger value of either 50 at % or the minimum amount of silicon in silicon+liquid phase zone of the phase diagram, and a method of binding RBSC using the same.

Owner:SKC SOLMICS

Process for producing reaction bonded silicon carbide member

InactiveUS9994487B2Excellent ceramic propertyHigh porosityAdditive manufacturing apparatusCeramic shaping apparatusSimple Organic CompoundsReaction bonded silicon carbide

Disclosed is a process for producing a RBSiC member that has a large size and a complicated shape and possesses ceramic properties. The process is Selective Laser Sintering process which includes providing a raw material containing silicon carbide particles and a binder, forming a thin layer of the raw material, and sintering the thin layer by irradiating a desired area in the thin layer with laser to form a sintered thin layer, repeating the step of forming the sintered thin layer to obtain a green body, impregnating the green body with a carbon source and curing the green body impregnated with the carbon source to give a cured body, carbonizing an organic compound component in the cured body to give a fired body, and infiltrating the fired body with silicon and subjecting the fired body to reaction sintering to give a RBSiC member, wherein the fired body contains 8% to 30% by weight of carbon.

Owner:TOTO LTD

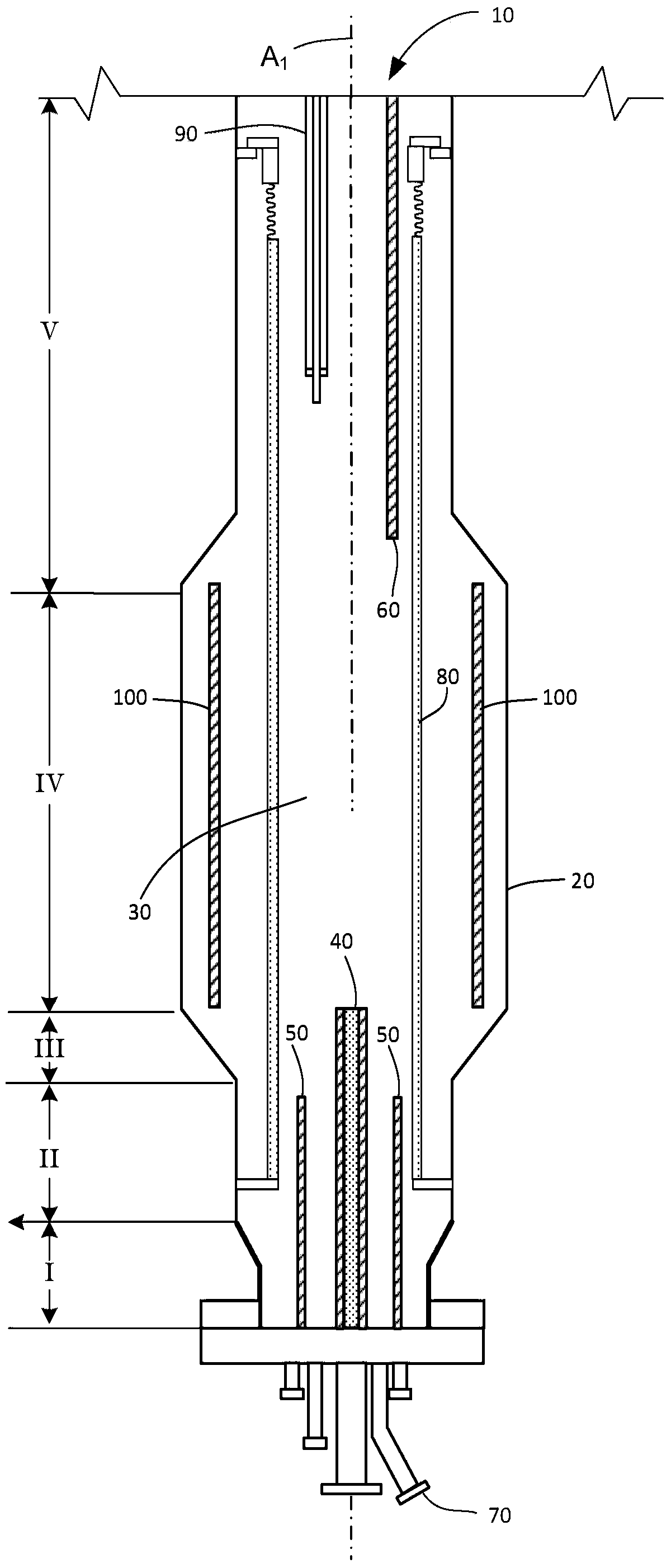

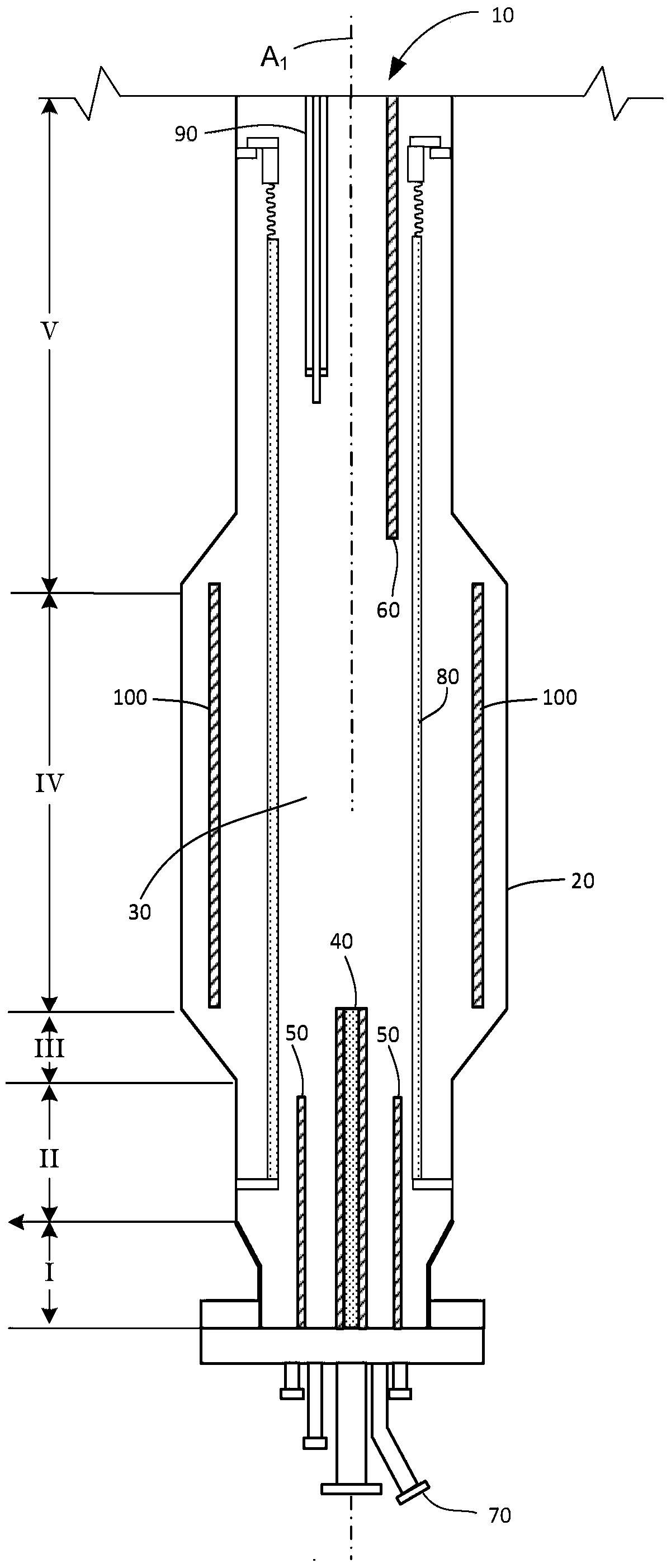

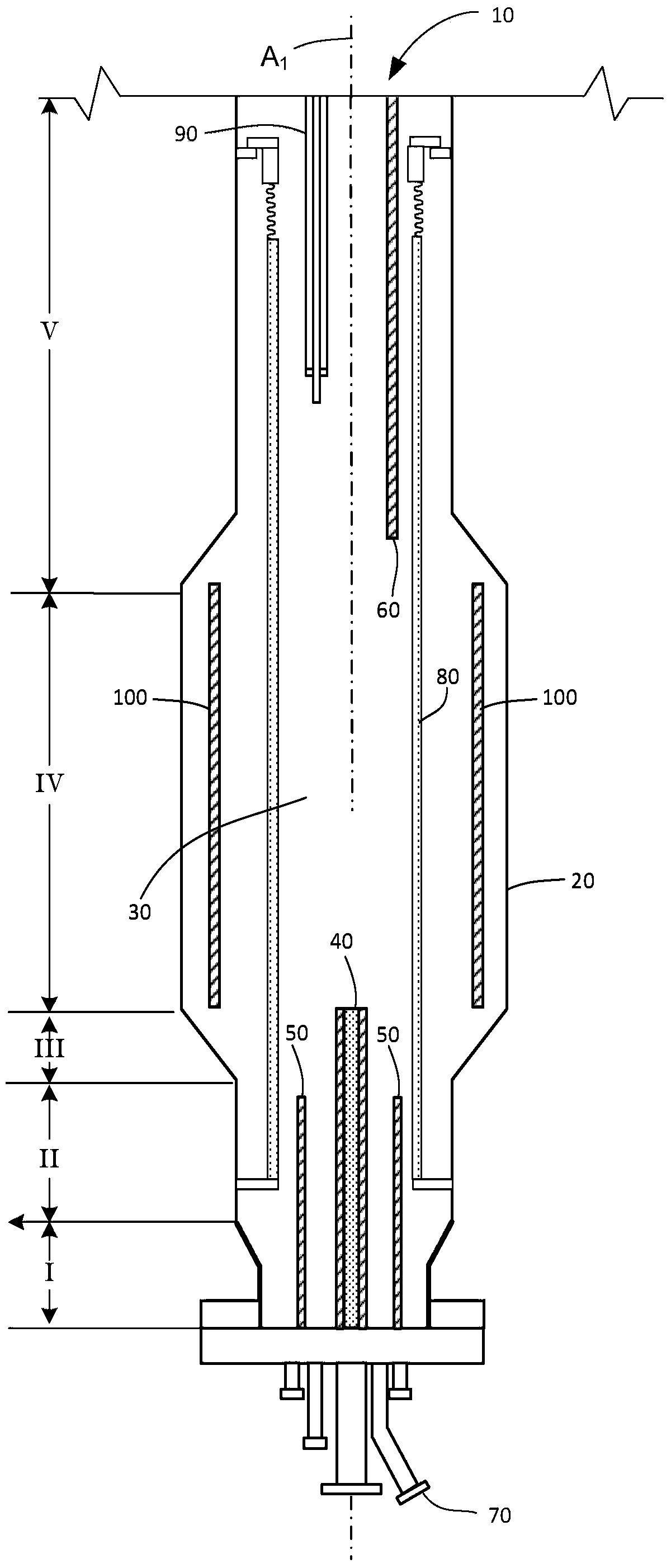

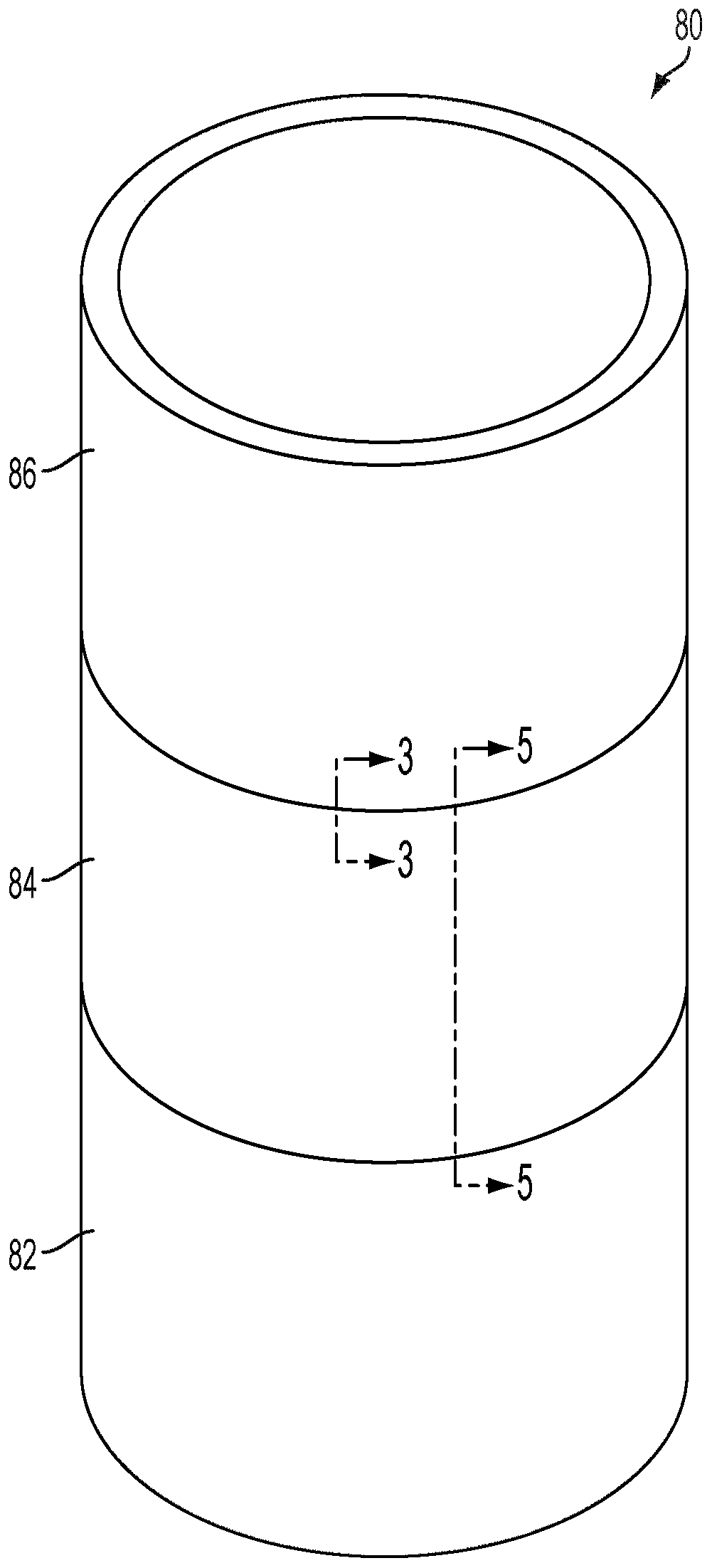

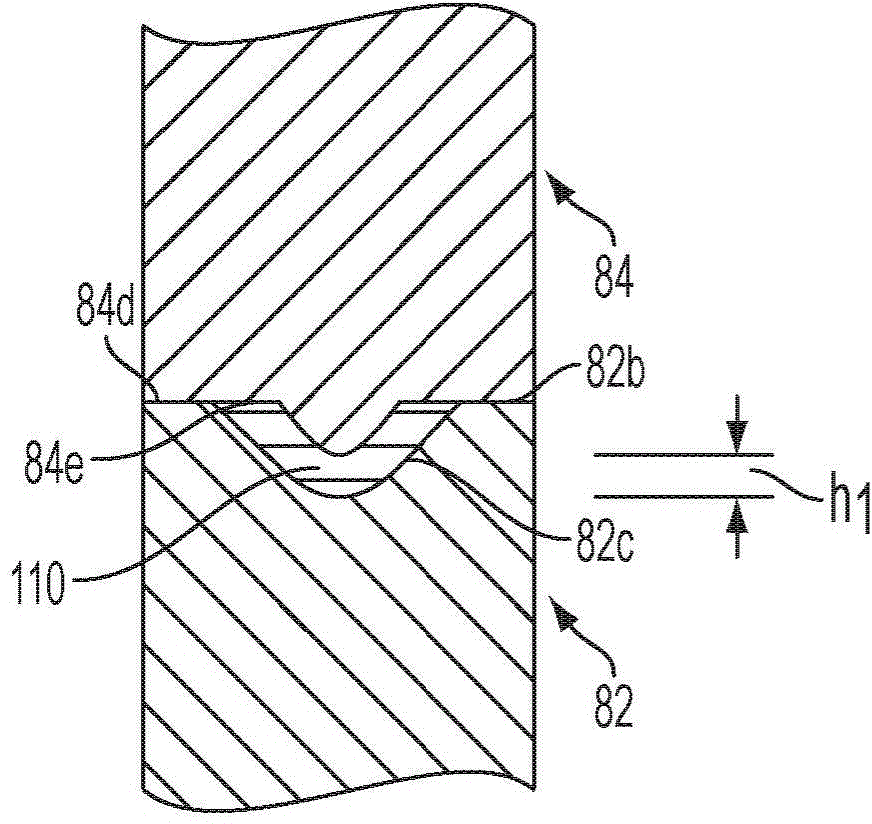

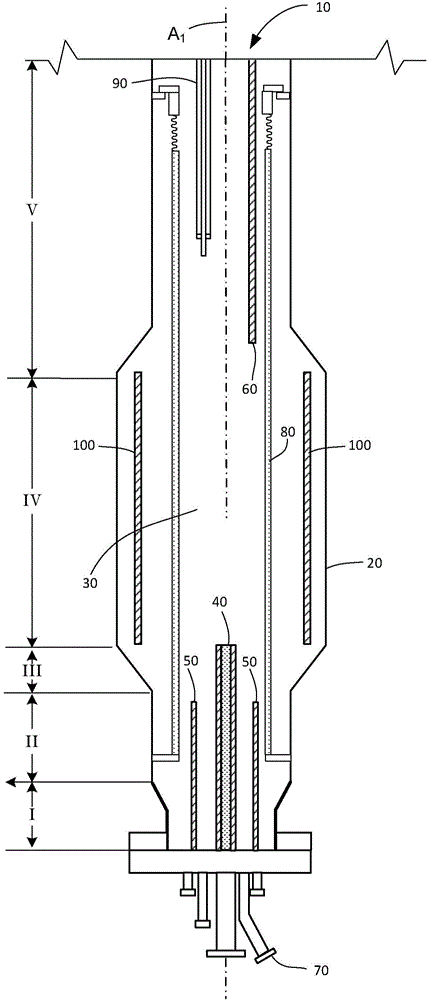

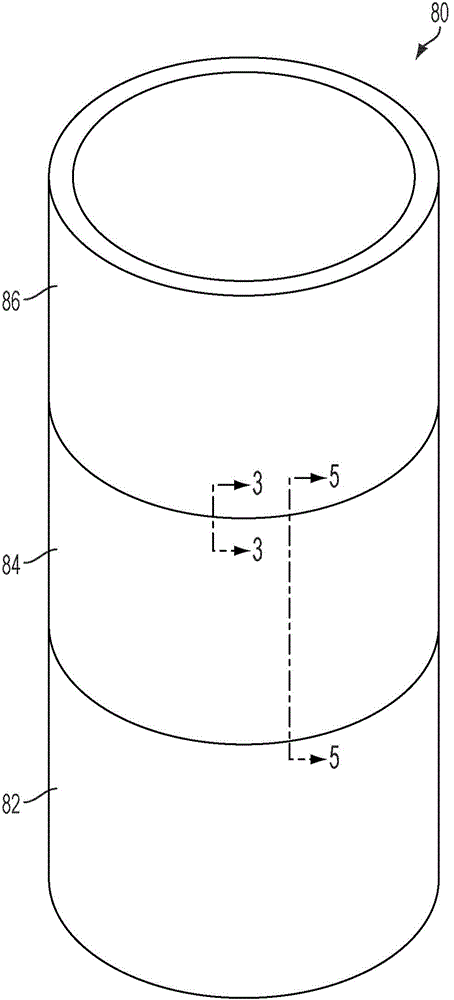

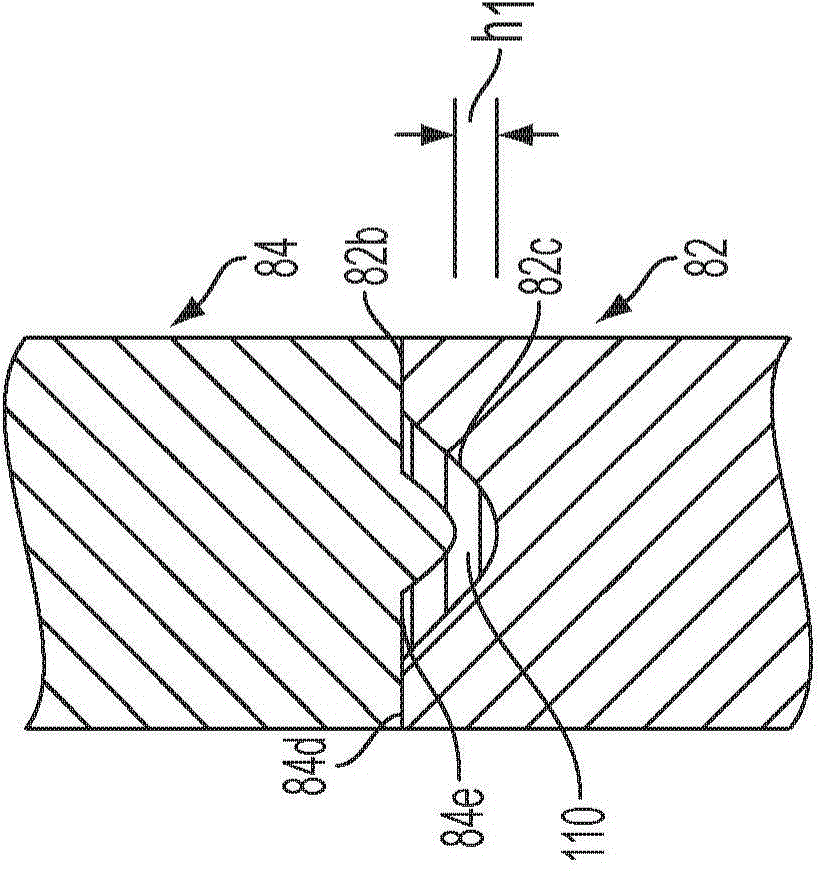

High-purity silicon for forming silicon carbide for use in fluidized bed reactors

ActiveCN105463405BPolycrystalline material growthChemical/physical/physico-chemical processesCarbide siliconReaction bonded silicon carbide

The present invention relates to high purity silicon for forming silicon carbide for use in fluidized bed reactors. The invention also discloses segmented silicon carbide liners, in particular segmented silicon carbide liners for use in fluidized bed reactors for the production of polysilicon-coated granular materials, and methods for making and using said segmented silicon carbide liners method. A non-contaminating adhesive material for joining the silicon carbide segments is also disclosed. One or more of the silicon carbide segments may be constructed from reaction bonded silicon carbide.

Owner:SHAANXI NON FERROUS TIAN HONG REC SILICON MATERIAL CO LTD

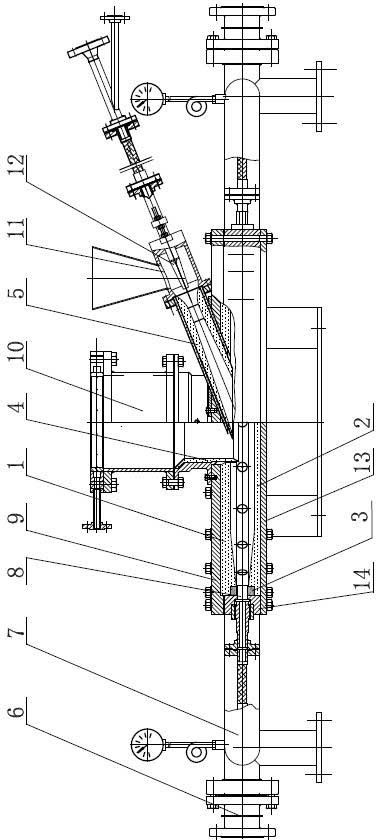

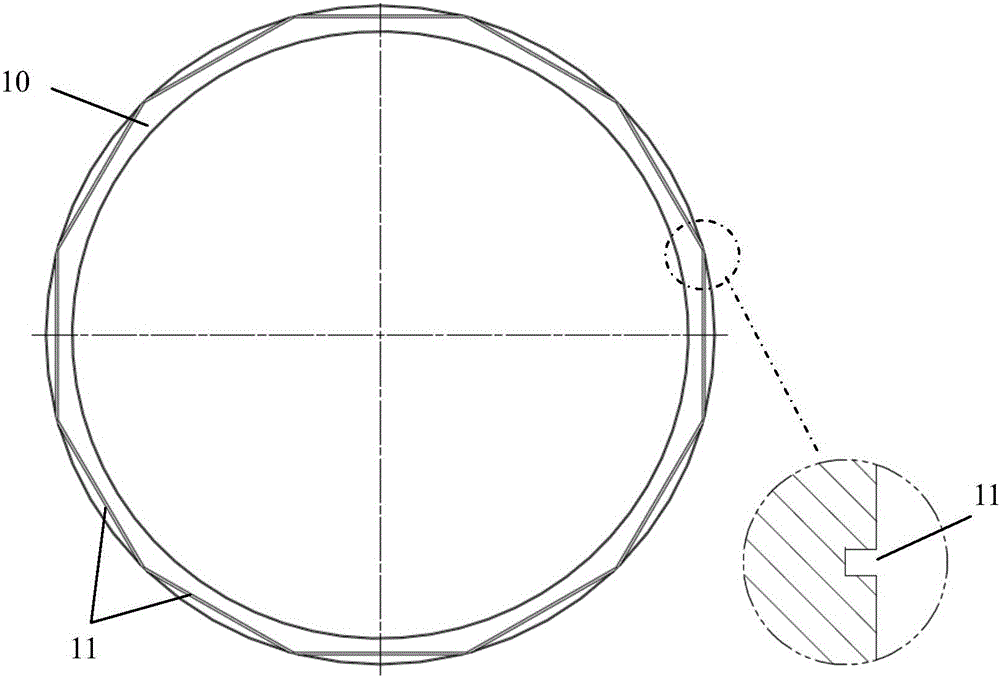

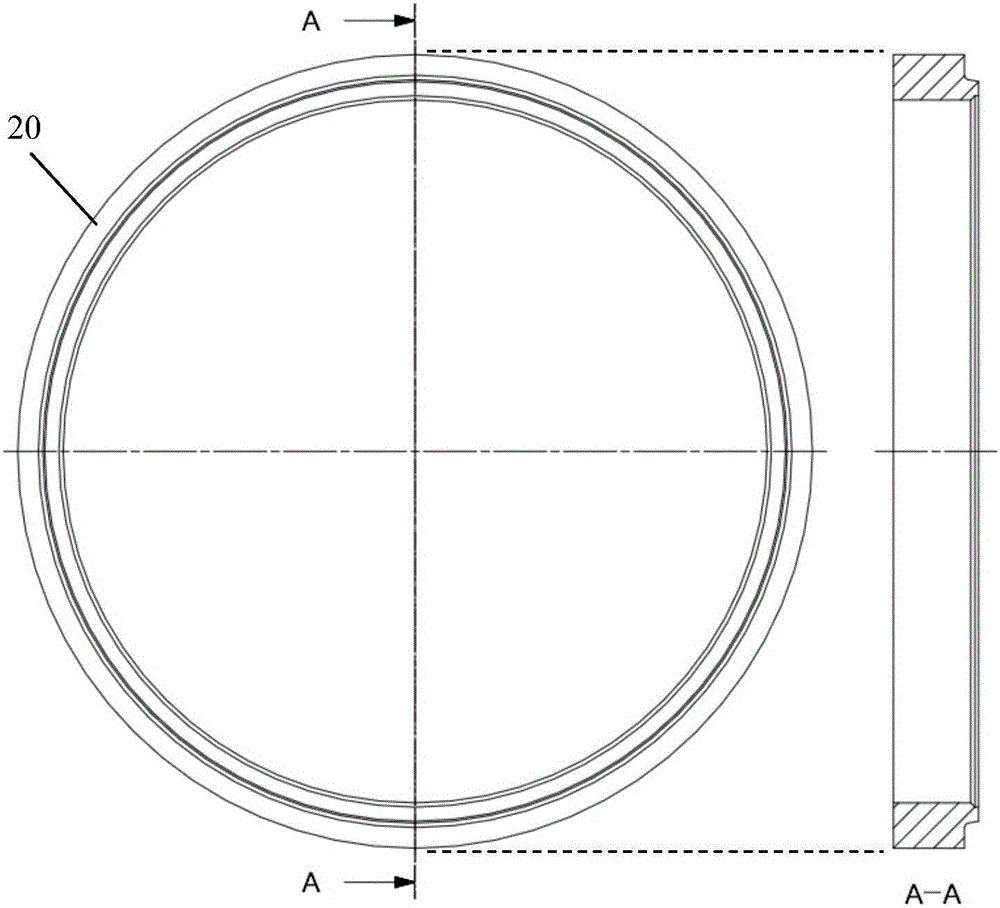

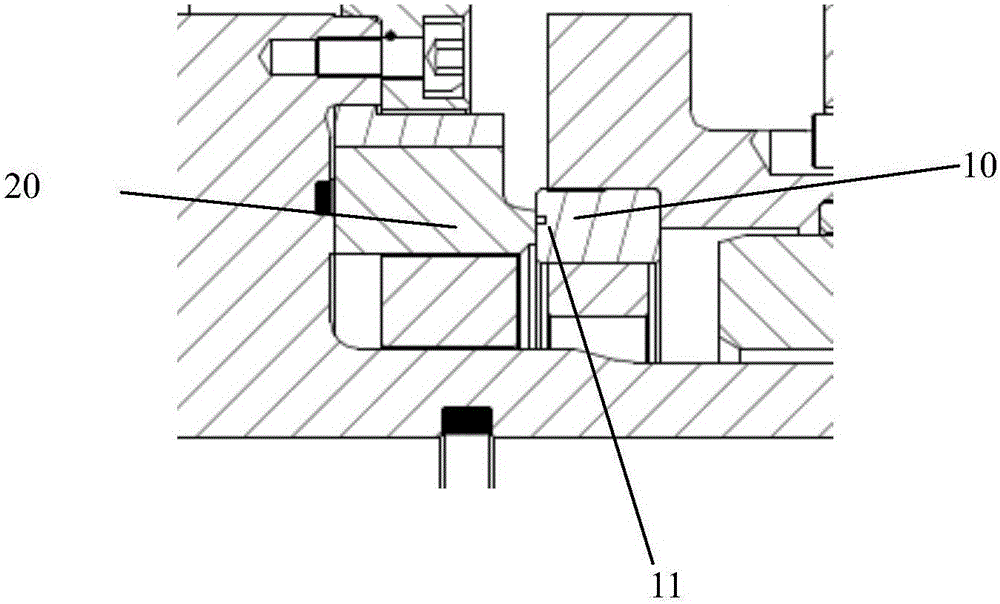

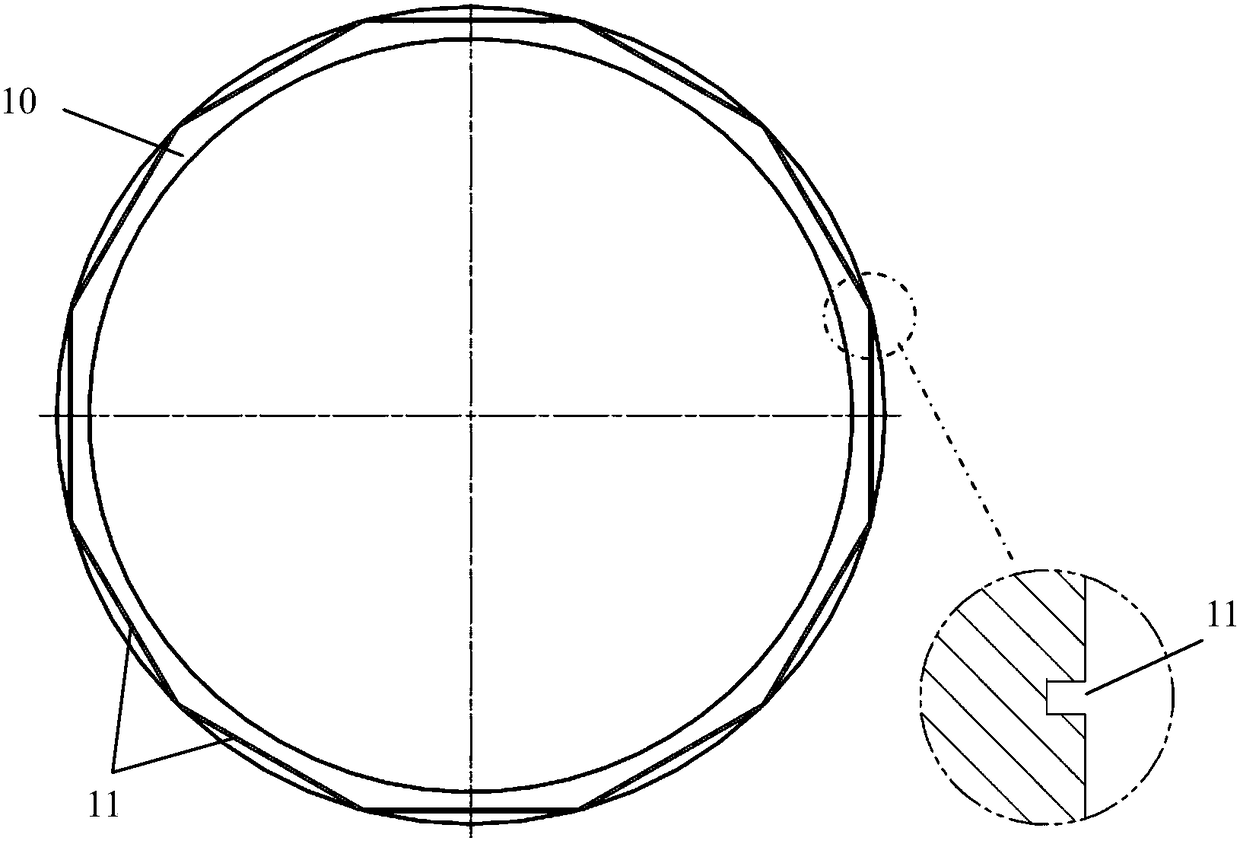

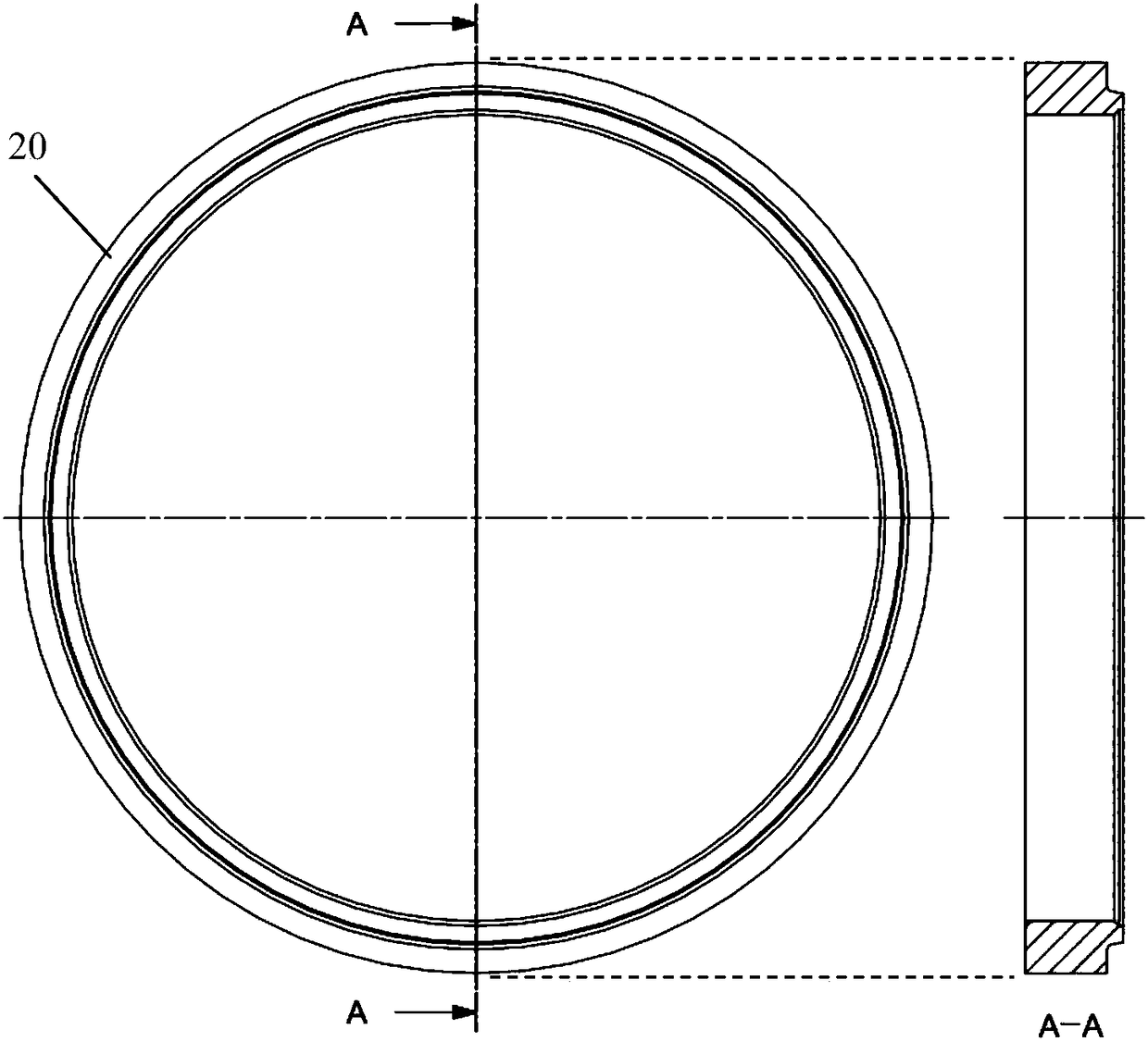

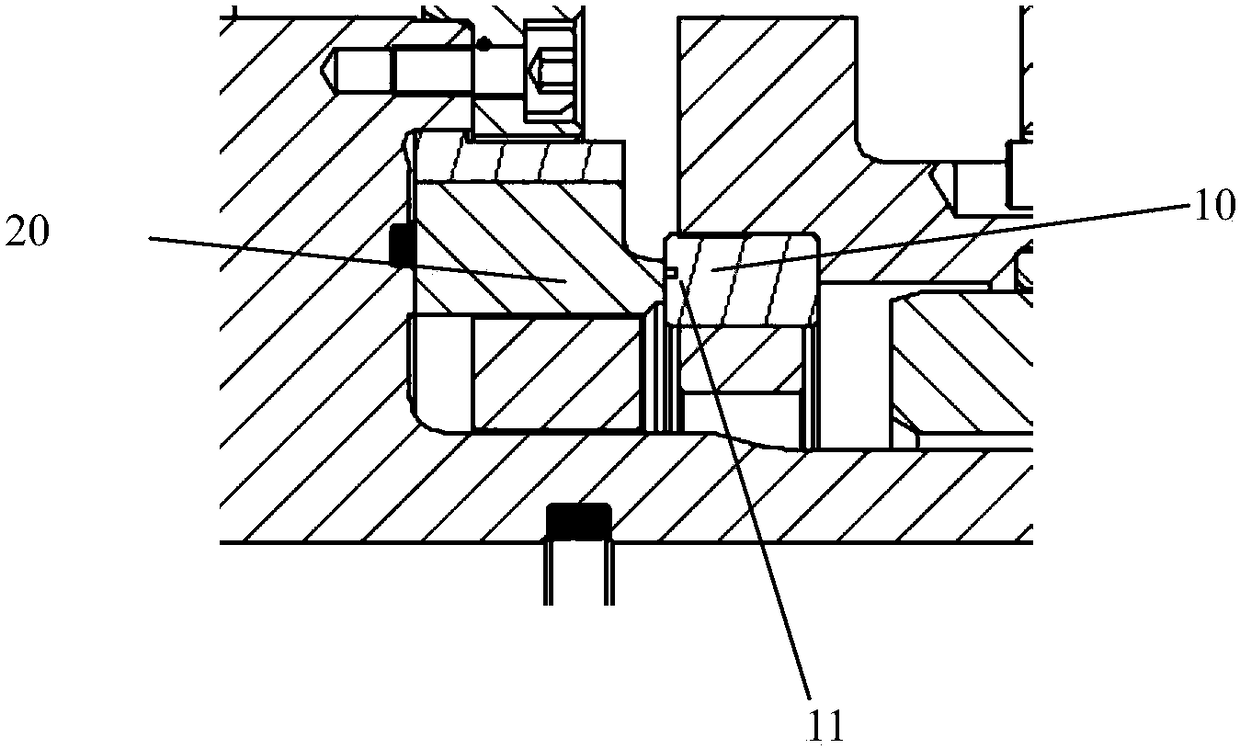

Fluid dynamic pressure type mechanical sealing face structure

ActiveCN105952899ASimple structureInnovative designEngine sealsPump componentsReaction bonded silicon carbideWorking environment

The invention relates to a fluid dynamic pressure type mechanical sealing face structure. Twelve grooves are formed in a sealing end face of a stationary ring, and a regular dodecagon can be formed by connecting the twelve grooves. The grooves are in mutual communication. The connection position of any two adjacent grooves communicates with the outer circumferential surface of the stationary ring. A rotating ring rotates along with a shaft connected with the rotating ring to produce a centrifugal effect, fluid in the grooves is driven to rotate, and therefore a liquid membrane is formed between a sealing end face of the rotating ring and the sealing end face of the stationary ring. The stationary ring and the rotating ring are made from a silicon carbide-graphite composite material, and machined with the reaction bonded silicon carbide and carbon technology. The fluid dynamic pressure type mechanical sealing face structure is suitable for a nuclear main pump, and a good sealing function in a high pressure and radioactivity working environment is achieved.

Owner:SEC KSB NUCLEAR PUMPS & VALVES

Methods of forming diamond composite cmp pad conditioner

PendingUS20220297260A1Semiconductor/solid-state device manufacturingLapping machinesCarbide siliconReaction bonded silicon carbide

Methods of forming chemical-mechanical polishing / planarization pad conditioner bodies made from diamond-reinforced reaction bonded silicon carbide, with diamond particles protruding or “standing proud” of the rest of the surface, and uniformly distributed on the cutting surface. In one embodiment, the diamond particles are approximately uniformly distributed throughout the composite, but in other embodiments they are preferentially located at and near the conditioning surface. The tops of the diamond particles can be engineered to be at a constant elevation (i.e., the conditioner body can be engineered to be very flat). Exemplary shapes of the body may be disc or toroidal. The diamond particles can be made to protrude from the conditioning surface by preferentially eroding the Si / SiC matrix. The eroding may be accomplished by electrical discharge machining or by lapping / polishing with abrasive.

Owner:II VI DELAWARE INC

Hydrodynamic mechanical seal surface structure

ActiveCN105952899BRealize the sealing functionAchieving sealing propertiesEngine sealsPump componentsReaction bonded silicon carbideWorking environment

The invention relates to a fluid dynamic pressure type mechanical sealing face structure. Twelve grooves are formed in a sealing end face of a stationary ring, and a regular dodecagon can be formed by connecting the twelve grooves. The grooves are in mutual communication. The connection position of any two adjacent grooves communicates with the outer circumferential surface of the stationary ring. A rotating ring rotates along with a shaft connected with the rotating ring to produce a centrifugal effect, fluid in the grooves is driven to rotate, and therefore a liquid membrane is formed between a sealing end face of the rotating ring and the sealing end face of the stationary ring. The stationary ring and the rotating ring are made from a silicon carbide-graphite composite material, and machined with the reaction bonded silicon carbide and carbon technology. The fluid dynamic pressure type mechanical sealing face structure is suitable for a nuclear main pump, and a good sealing function in a high pressure and radioactivity working environment is achieved.

Owner:SEC KSB NUCLEAR PUMPS & VALVES

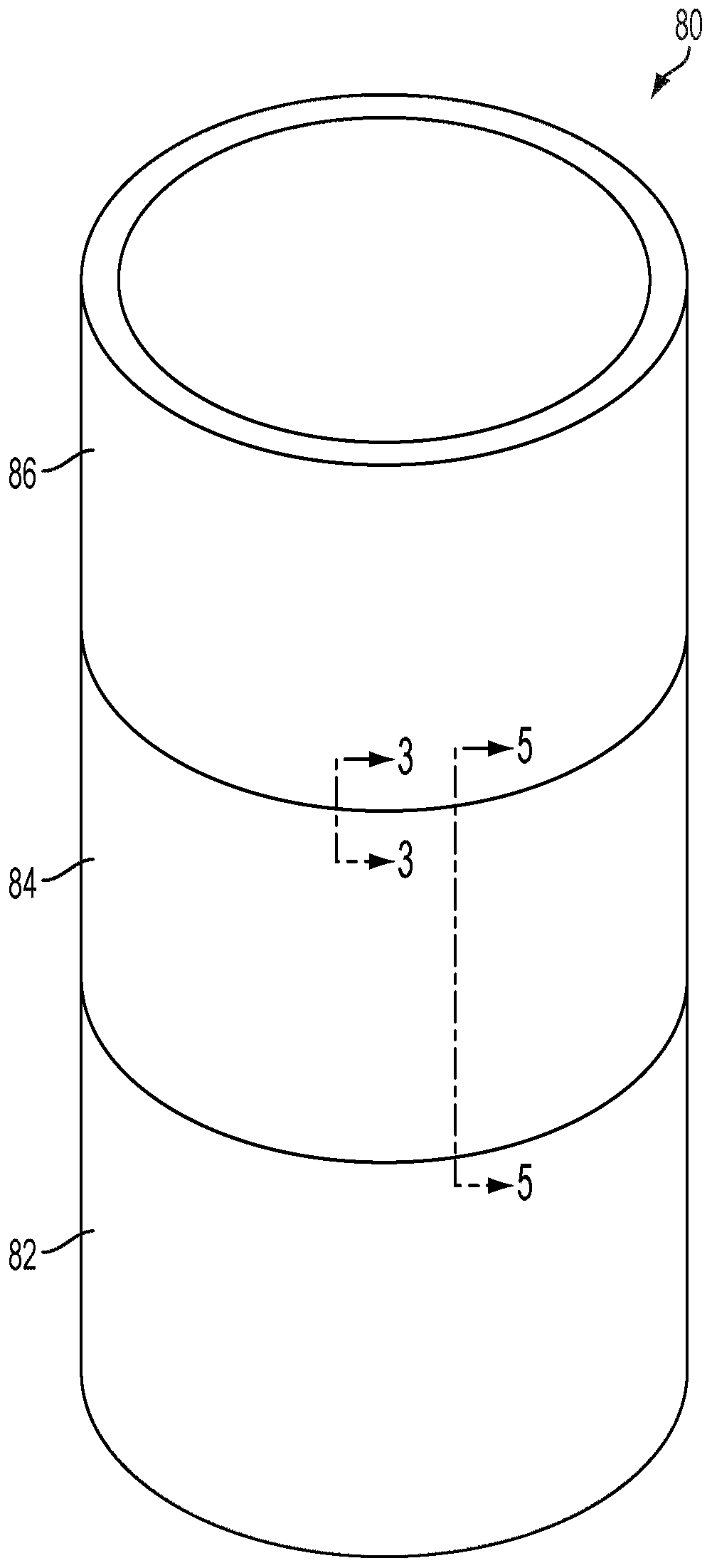

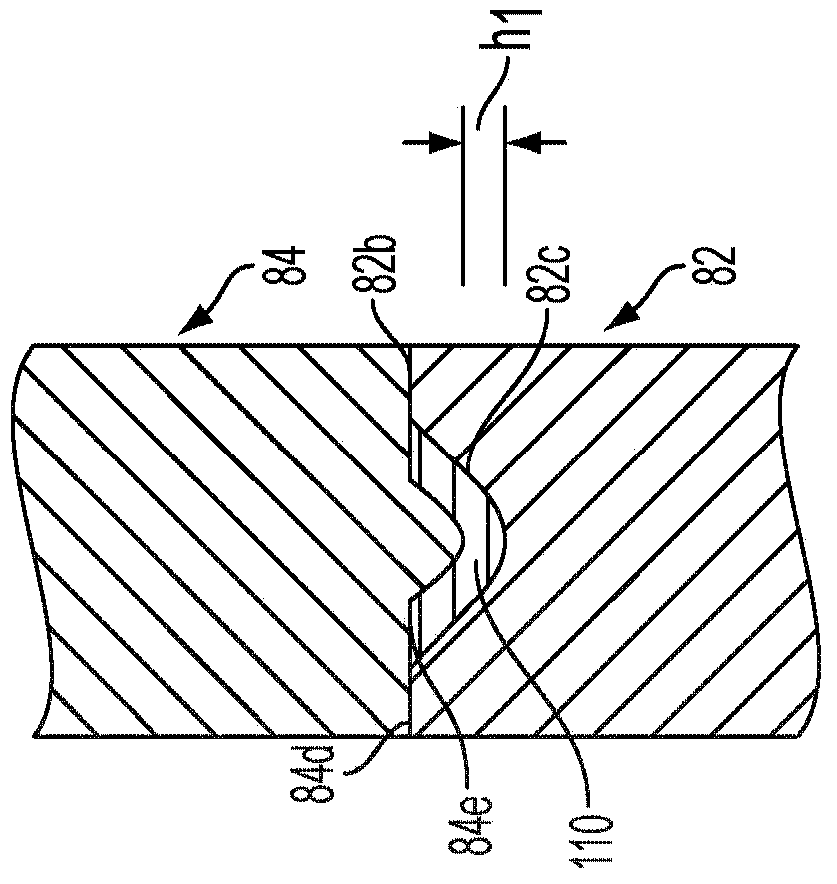

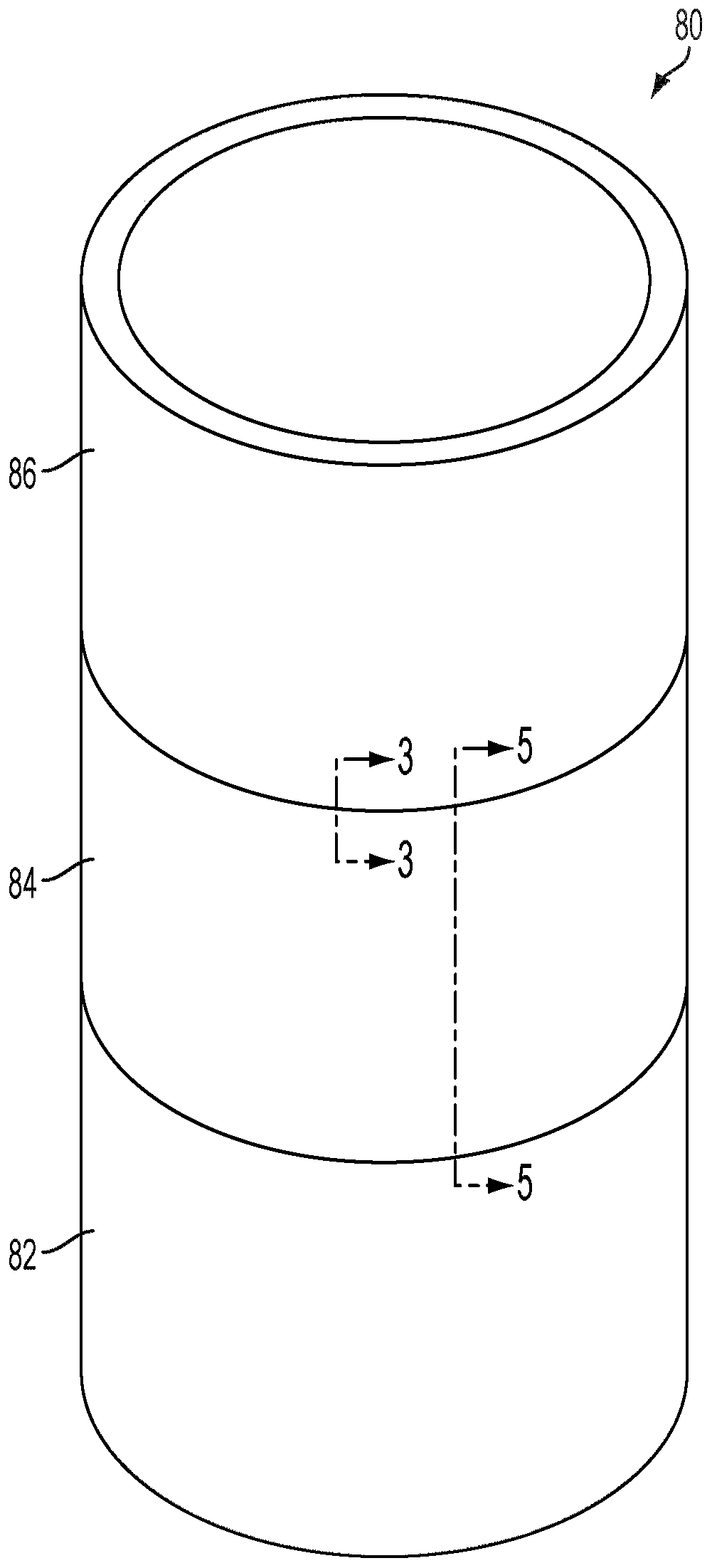

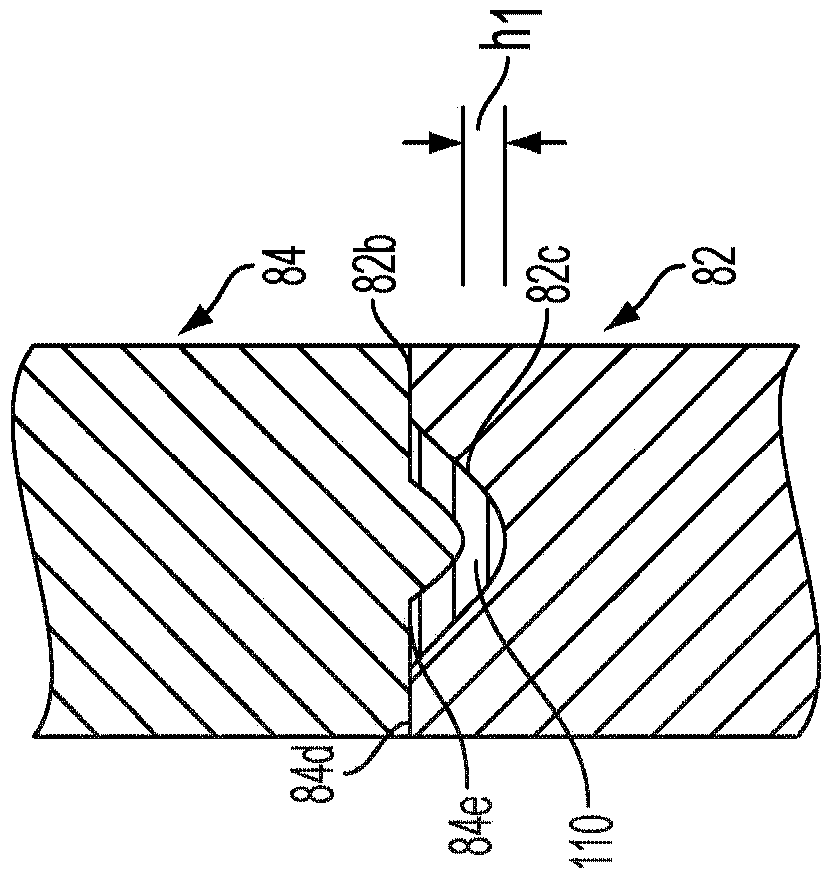

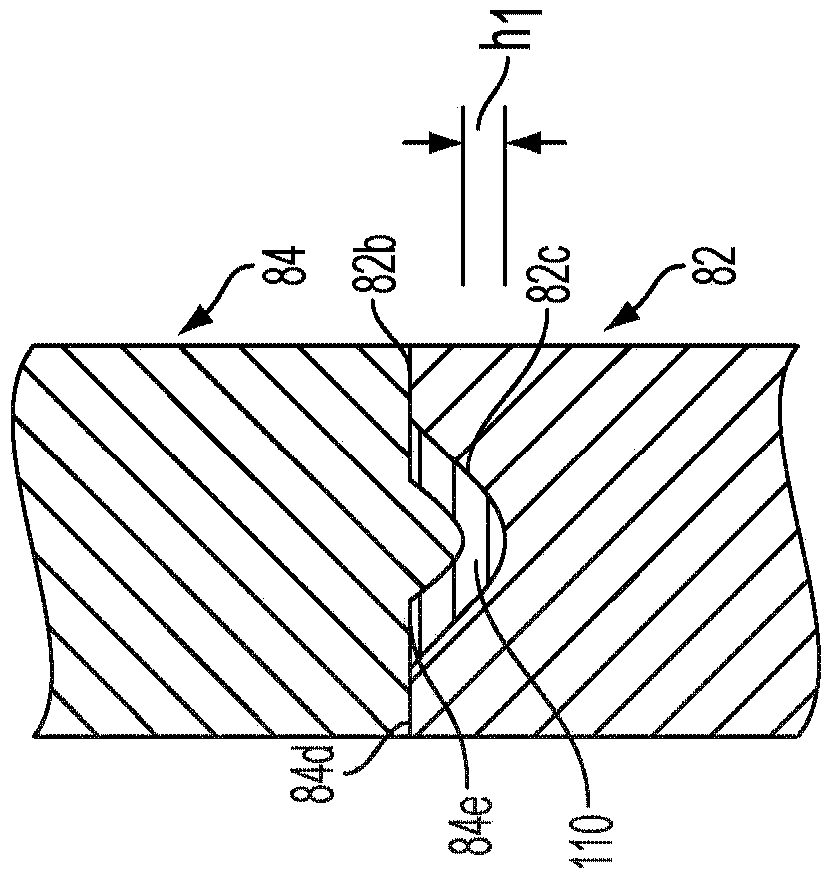

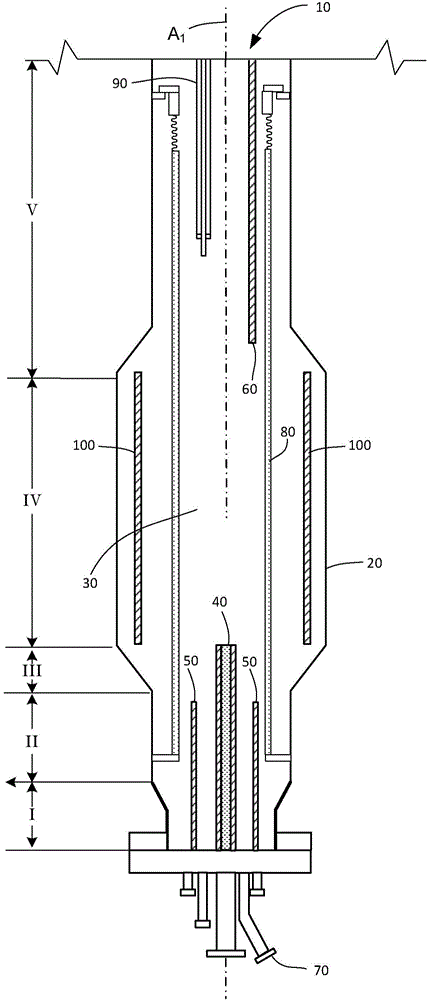

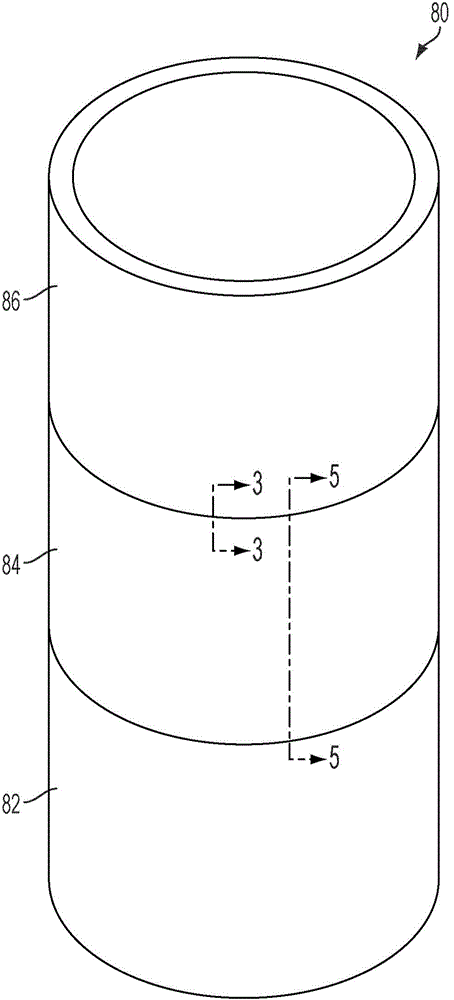

Joint Design of Segmented Silicon Carbide Lining in Fluidized Bed Reactor

ActiveCN105366680BSiliconChemical/physical/physico-chemical processesReaction bonded silicon carbideFluidized bed

Disclosed are segmented silicon carbide liners, particularly segmented silicon carbide liners for use in fluidized bed reactors for the production of polysilicon-coated granular materials, and methods of making and using said segmented silicon carbide liners . A non-contaminating adhesive material for joining the silicon carbide segments is also disclosed. One or more of the silicon carbide segments may be constructed from reaction bonded silicon carbide.

Owner:SHAANXI NON FERROUS TIAN HONG REC SILICON MATERIAL CO LTD

Diamond composite CMP pad conditioner

ActiveUS11370082B2Semiconductor/solid-state device manufacturingLapping machinesCarbide siliconReaction bonded silicon carbide

Owner:II VI DELAWARE INC

Reaction bonded silicon carbide bodies made from high purity carbonaceous preforms

A process for producing reaction bonded silicon carbide (RBSC) from high purity, porous, essentially all-carbon preforms through contacting said preforms with silicon metal at room temperature, and subsequently heating to melt silicon metal and cause infiltration into said preform causing reaction to silicon carbide and leaving residual silicon, to result in a dense silicon carbide-silicon composite. The process offers the ability to produce RBSC with higher purity, higher strength, and lower cost as long as the carbonaceous preforms are of sufficient purity and pore size distribution to allow for uniform, crack-free bulk bodies to be fabricated.

Owner:BRACAMONTE LORI

Contamination-free bonding material for segmented silicon carbide linings in fluidized bed reactors

Owner:SHAANXI NON FERROUS TIAN HONG REC SILICON MATERIAL CO LTD

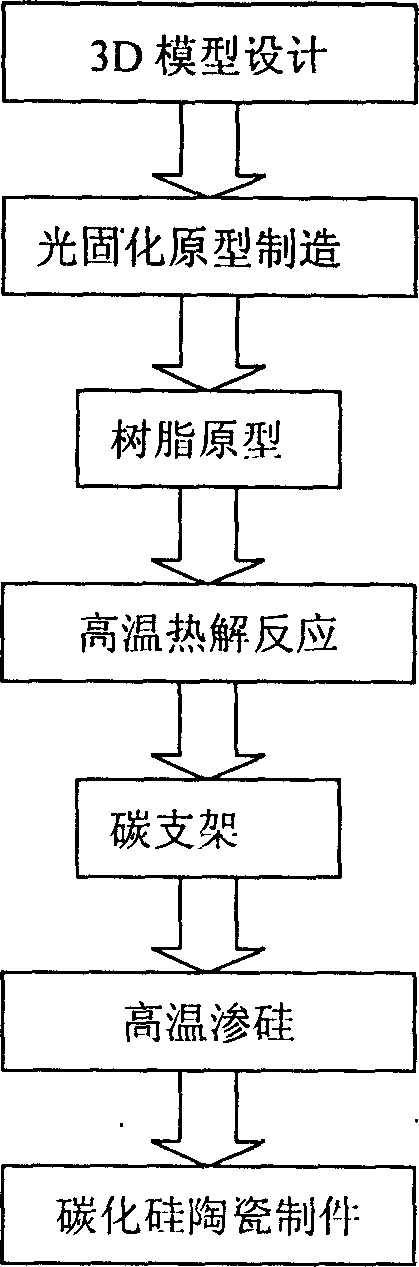

Technological process of forming composite silicon carbide ceramic material based on pyrolysis of photocured prototype

InactiveCN1253410CRealize moldless precision manufacturingSpeed up developmentReaction bonded silicon carbideCeramic composite

Owner:XI AN JIAOTONG UNIV

Segmented silicon carbide liner

Segmented silicon carbide liners for use in a fluidized bed reactor for production of polysilicon-coated granulate material are disclosed, as well as methods of making and using the segmented silicon carbide liners. Non-contaminating bonding materials for joining silicon carbide segments also are disclosed. One or more of the silicon carbide segments may be constructed of reaction-bonded silicon carbide.

Owner:SHAANXI NON FERROUS TIAN HONG REC SILICON MATERIAL CO LTD

High-purity silicon to form silicon carbide for use in fluidized bed reactor

ActiveCN105463405APolycrystalline material growthChemical/physical/physico-chemical processesReaction bonded silicon carbideFluidized bed

The invention relates to high-purity silicon to form silicon carbide for use in fluidized bed reactor. Segmented silicon carbide liners, in particular, segmented silicon carbide liners for use in a fluidized bed reactor for production of polysilicon-coated granulate material are also disclosed, as well as methods of making and using the segmented silicon carbide liners. Non-contaminating bonding materials for joining silicon carbide segments also are disclosed. One or more of the silicon carbide segments may be constructed of reaction-bonded silicon carbide.

Owner:SHAANXI NON FERROUS TIAN HONG REC SILICON MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com