Patents

Literature

820 results about "Face structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

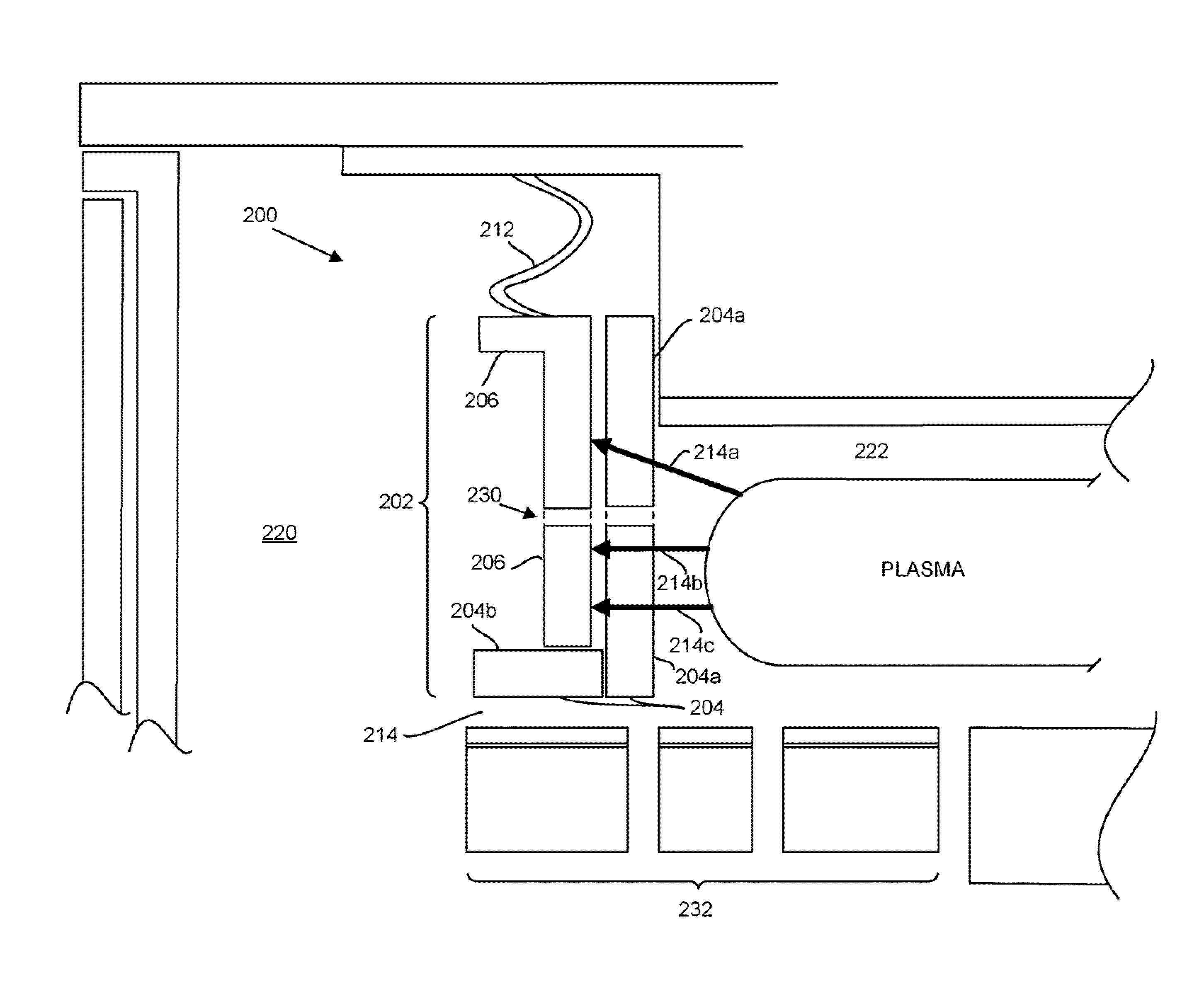

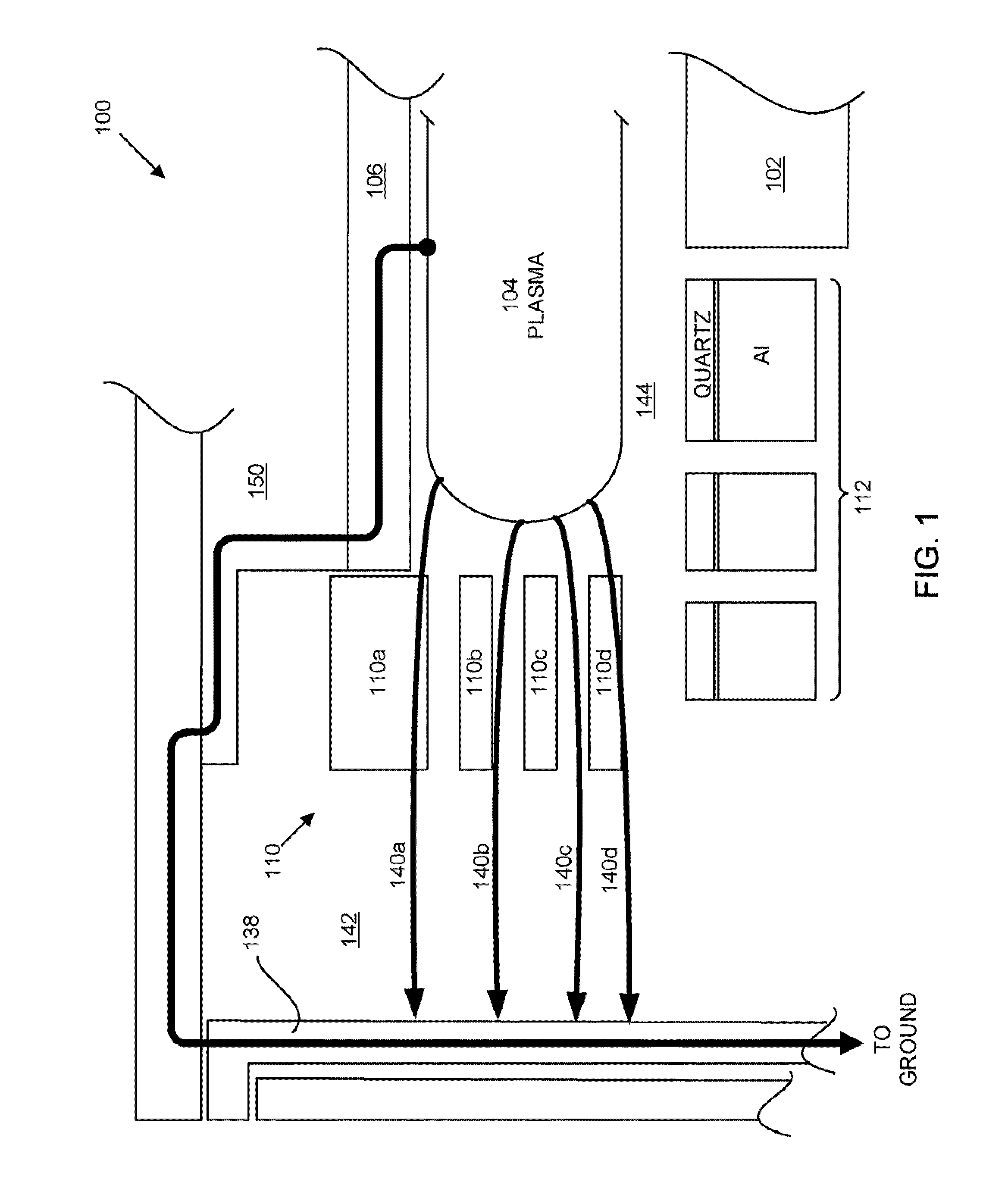

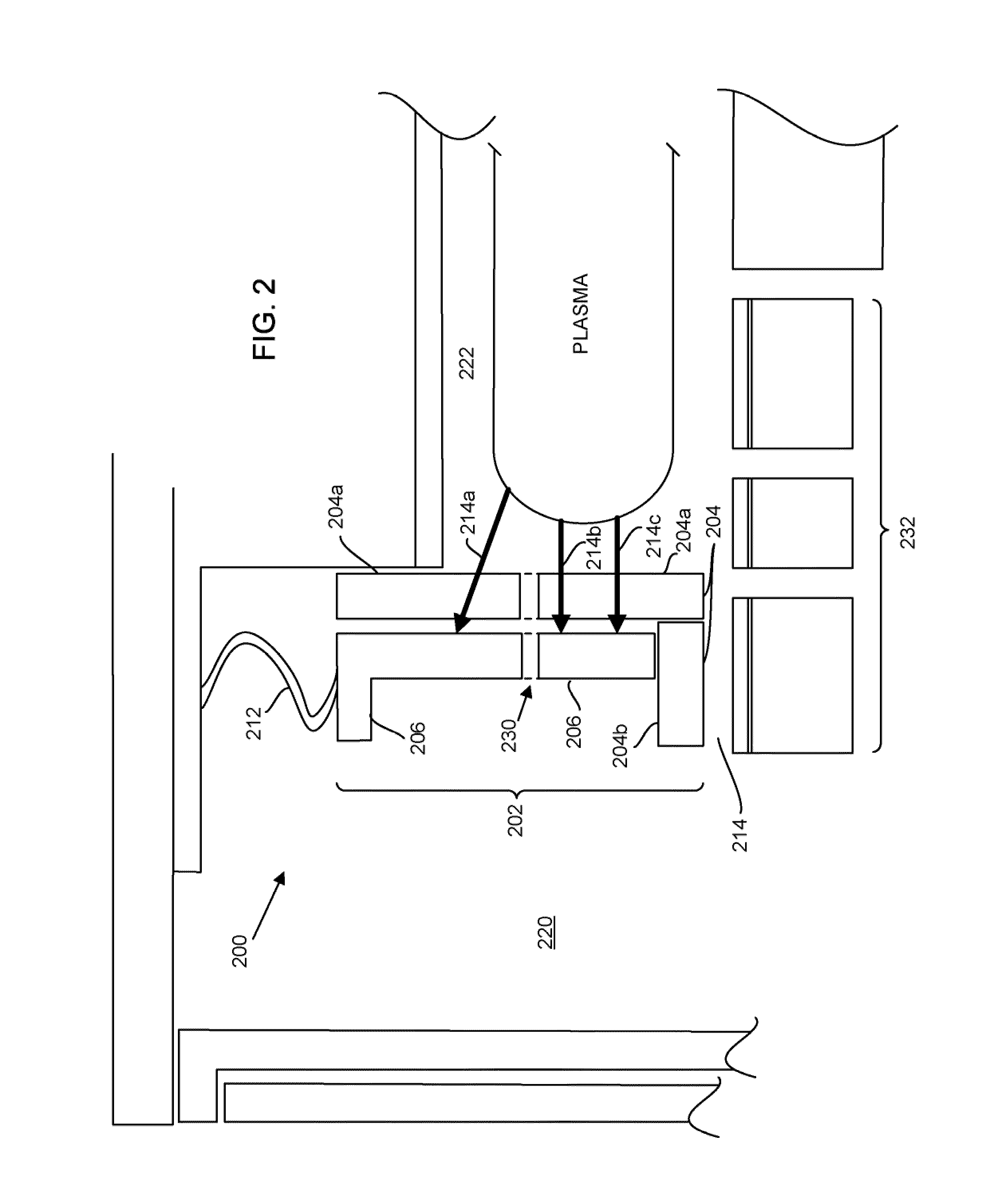

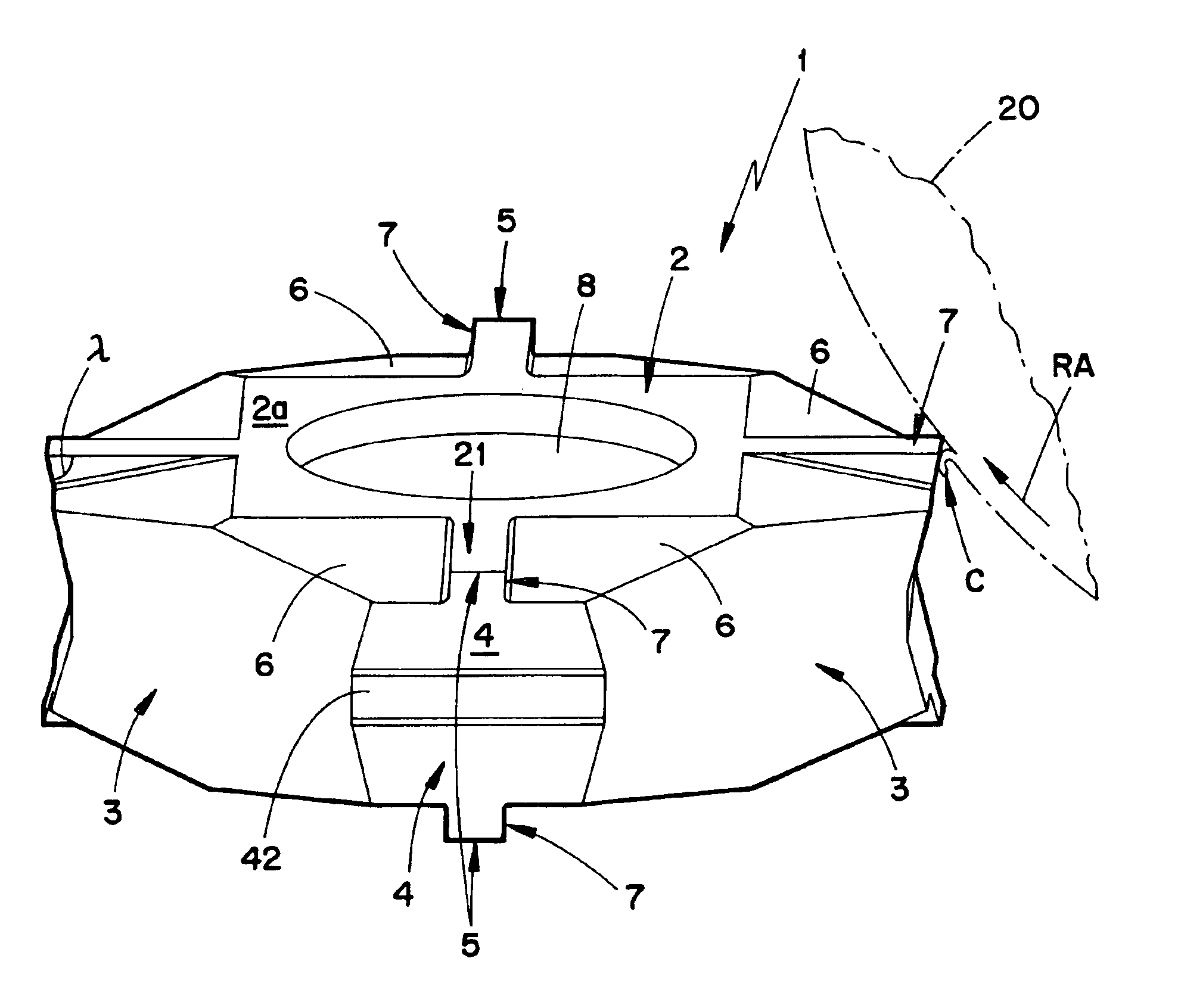

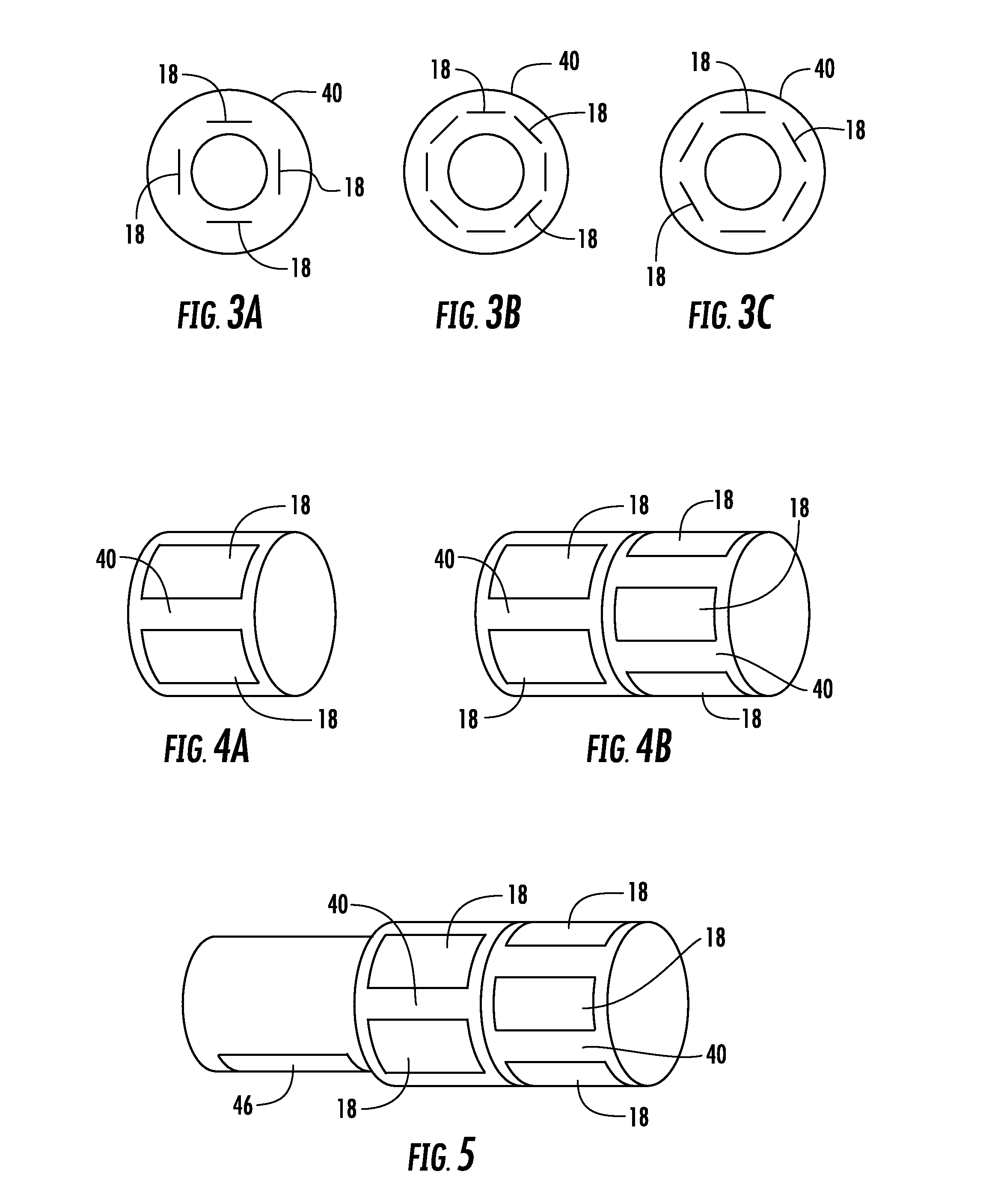

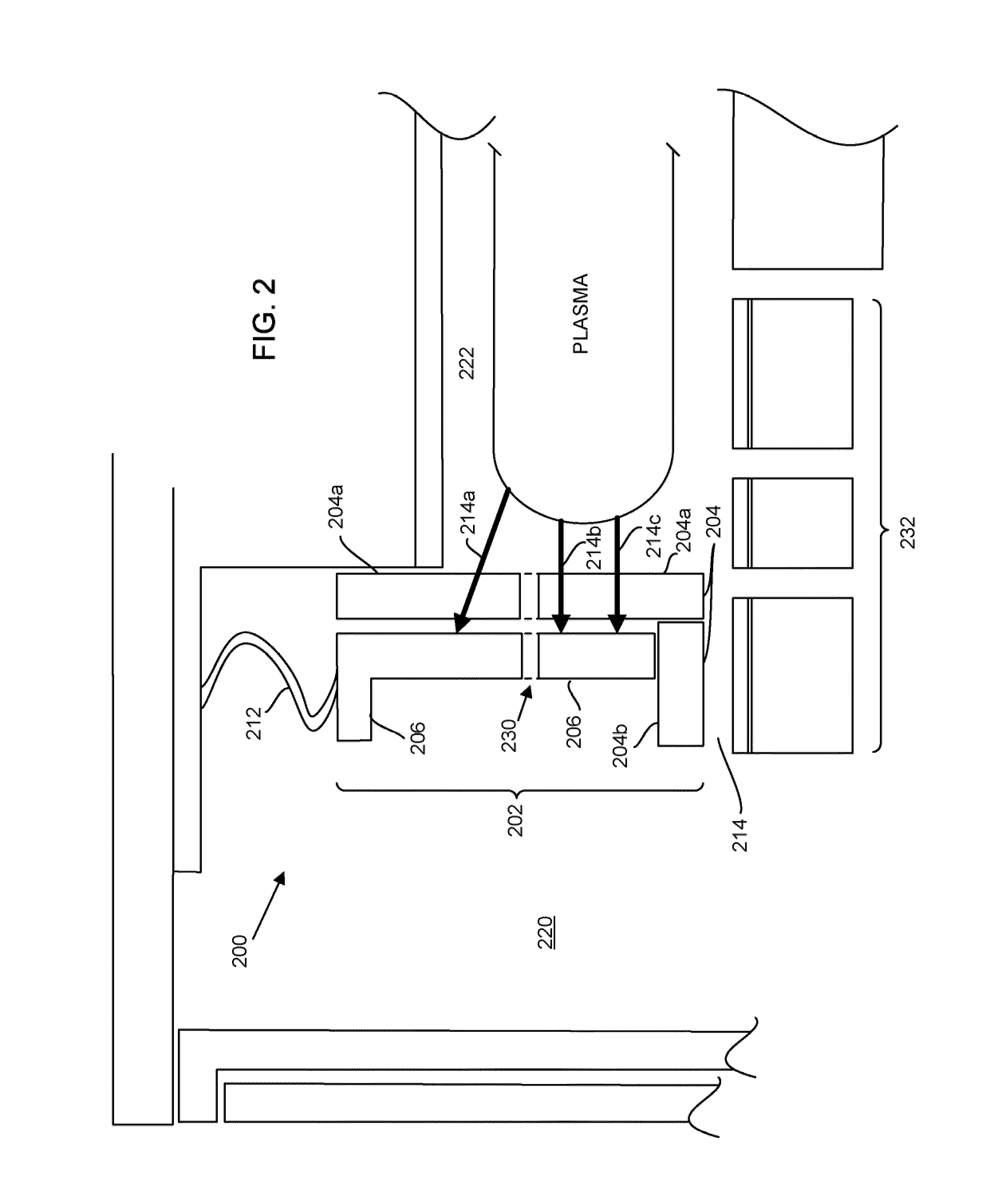

Plasma confinement structures in plasma processing systems

ActiveUS8540844B2Electric discharge tubesSemiconductor/solid-state device manufacturingPower flowEngineering

A movable plasma confinement structure configured for confining plasma in a plasma processing chamber during plasma processing of a substrate is provided. The movable plasma confinement structure includes a movable plasma-facing structure configured to surround the plasma. The movable plasma confinement structure also includes a movable electrically conductive structure disposed outside of the movable plasma-facing structure and configured to be deployed and retracted with the movable plasma-facing structure as a single unit to facilitate handling of the substrate. The movable electrically conductive structure is radio frequency (RF) grounded during the plasma processing. The movable plasma-facing structure is disposed between the plasma and the movable electrically conductive structure during the plasma processing such that RF current from the plasma flows to the movable electrically conductive structure through the movable plasma-facing structure during the plasma processing.

Owner:LAM RES CORP

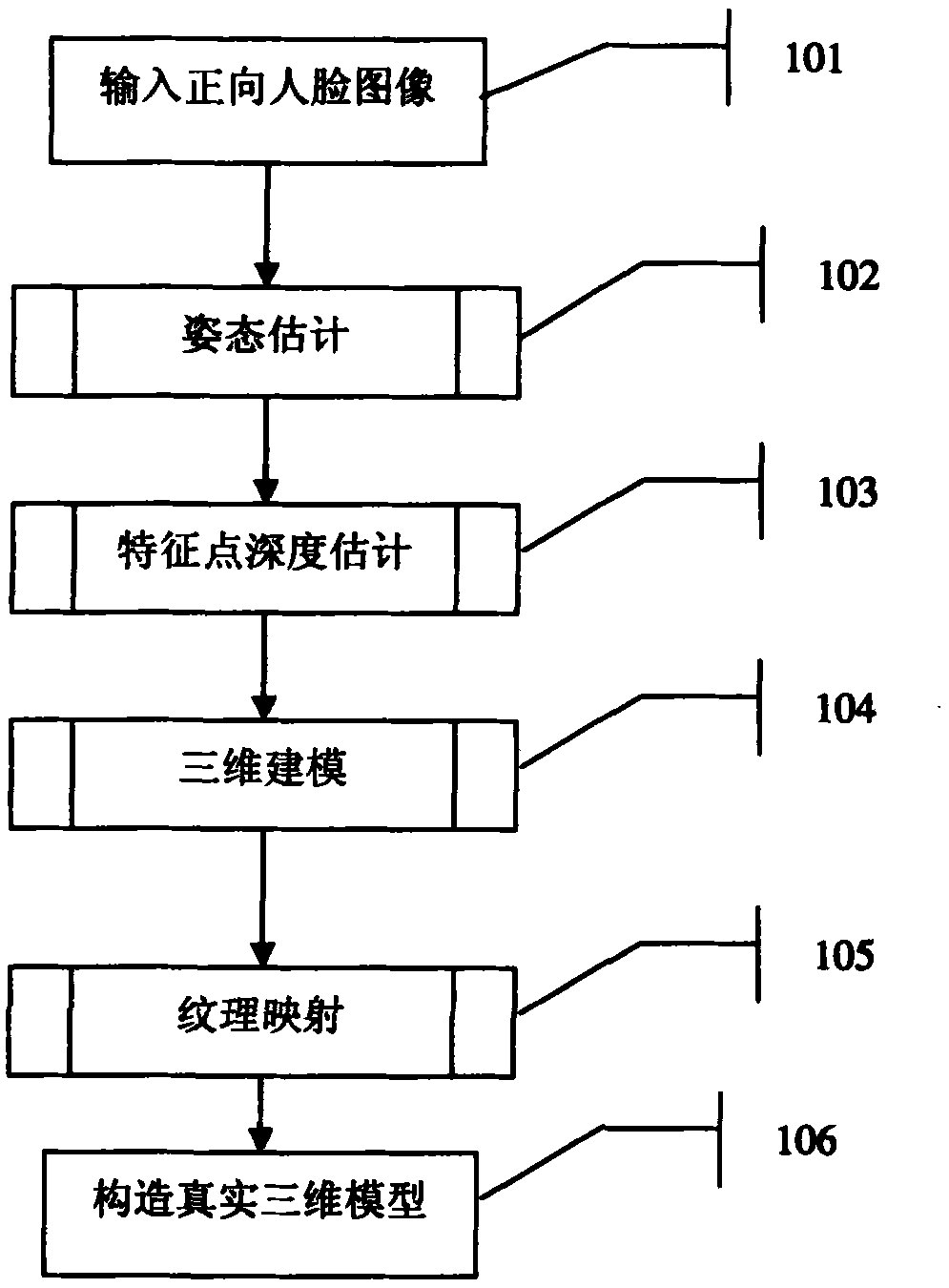

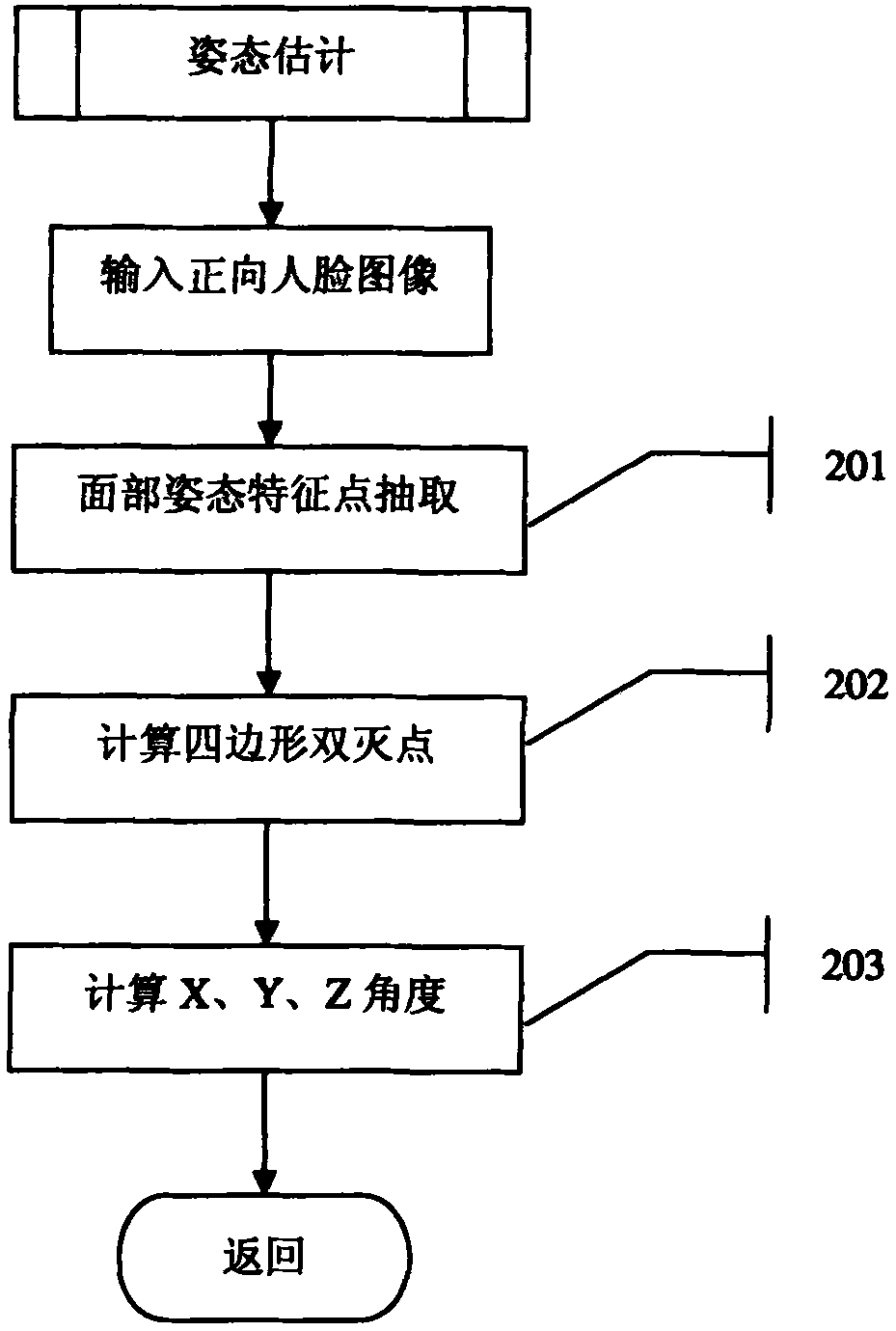

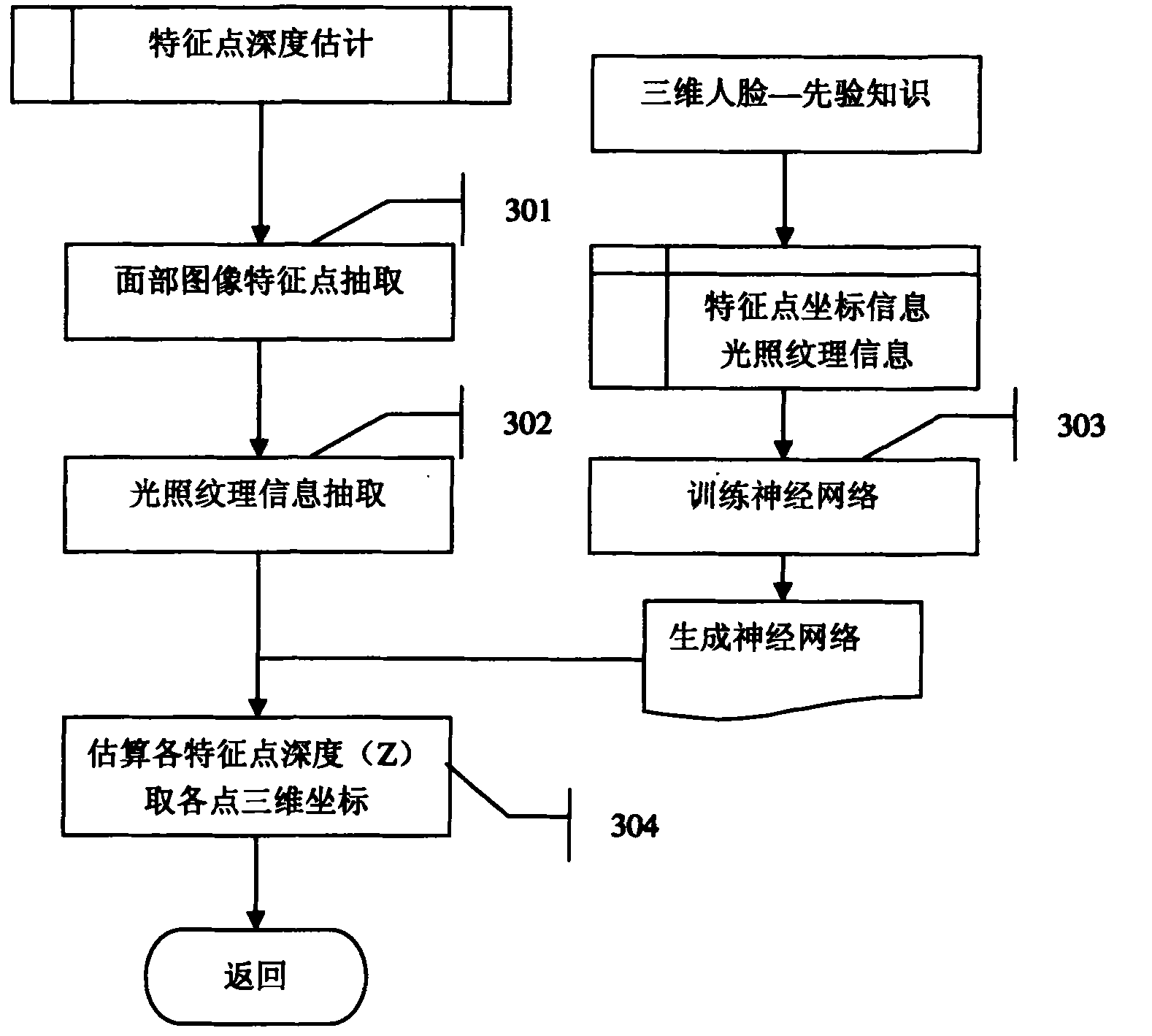

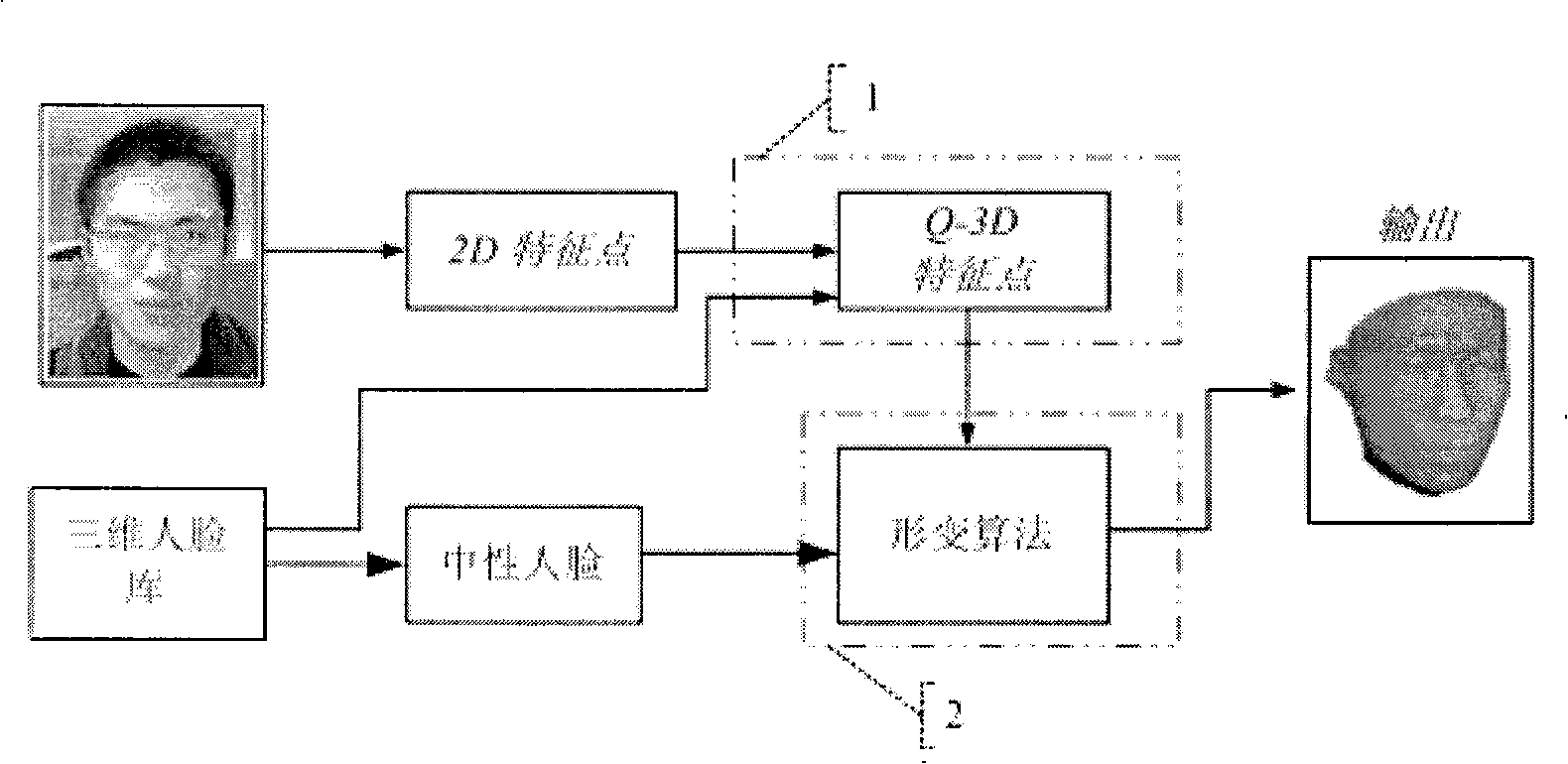

Method and device for reconstructing three-dimensional face based on single face image

InactiveCN102054291AReduce modeling timeLow costNeural learning methods3D modellingPattern recognitionComputer graphics (images)

The invention discloses a method and a device for reconstructing a three-dimensional face based on a single face image. The method comprises the following steps of: performing posture recognition on a face image by utilizing face structure priori knowledge, and estimating rotating direction and angle of a face plane by combining face measurement and projective geometry so as to set a rotating angle of the three-dimensional face; estimating the depth of two-dimensional characteristic points on the face image by adopting an artificial neural network, and acquiring three-dimensional coordinates of the characteristic points; converting a common three-dimensional face model into a specific model by adopting a Dirichlet free deformation algorithm; and mapping the three-dimensional face model by adopting characteristic points extracted from the two-dimensional image. Therefore, the true three-dimensional model is constructed through the single face image, the three-dimensional modeling accuracy is effectively improved, the three-dimensional modeling time is shortened and the three-dimensional modeling cost is reduced.

Owner:XIAMEN MEIYA PICO INFORMATION

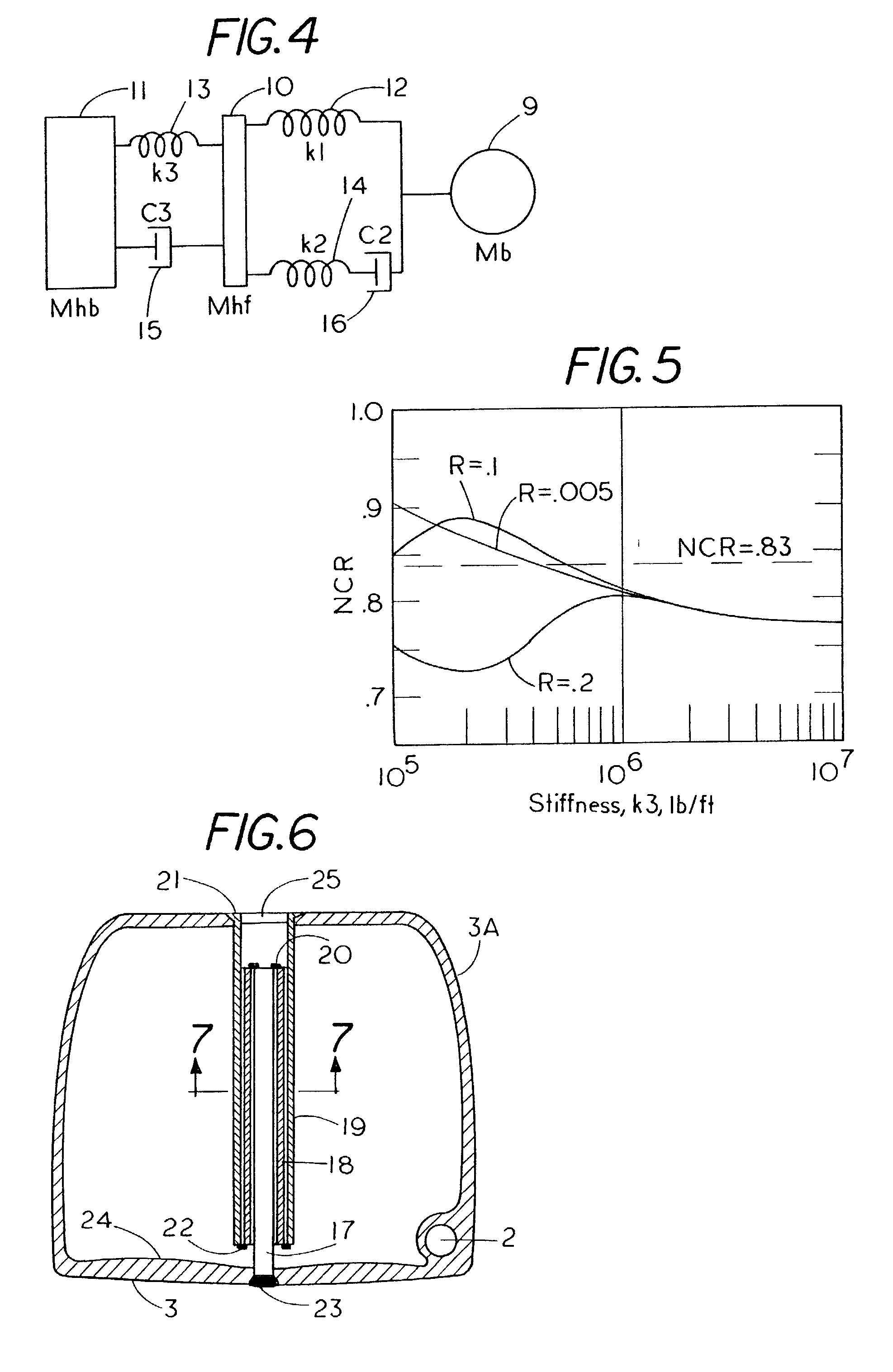

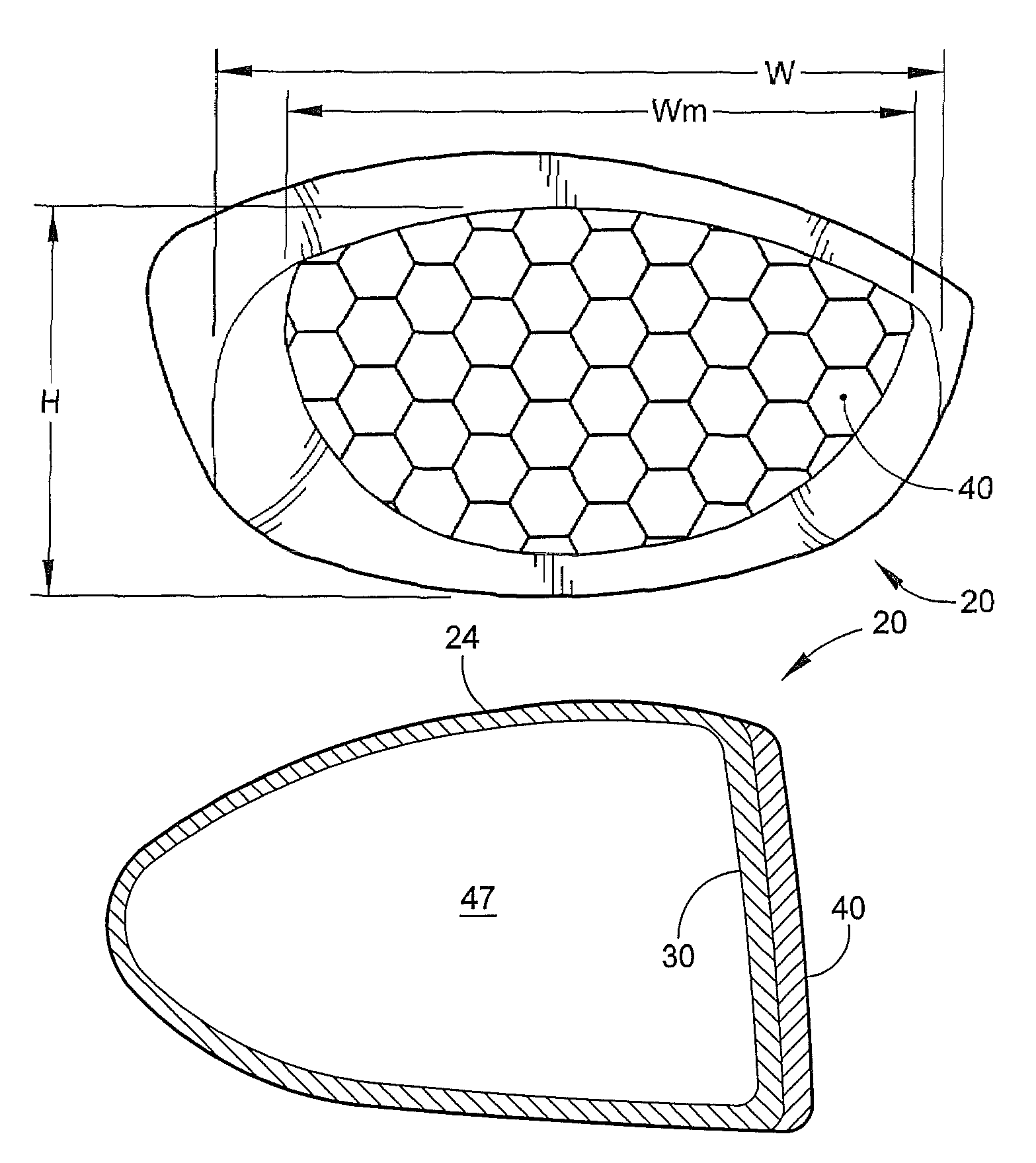

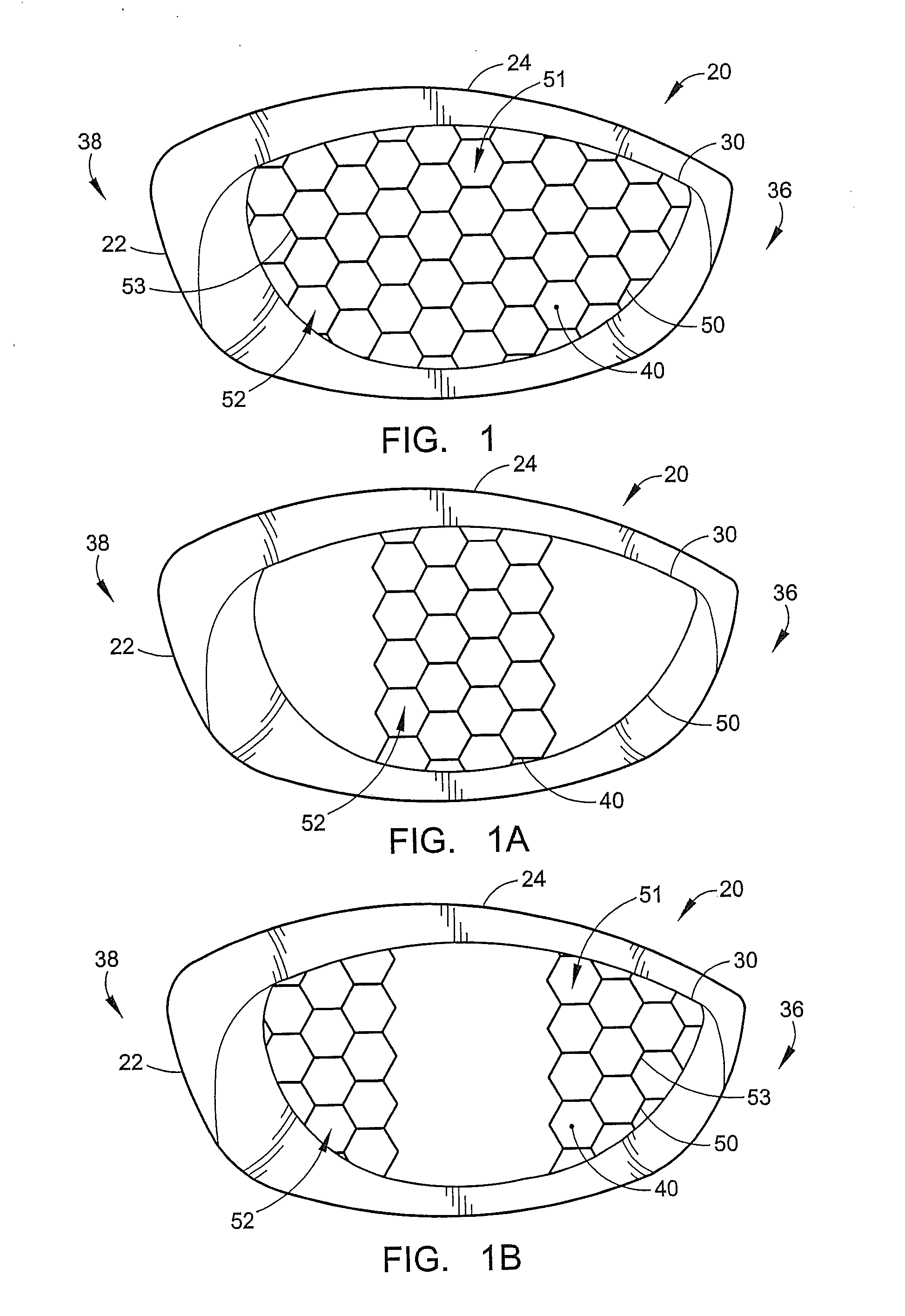

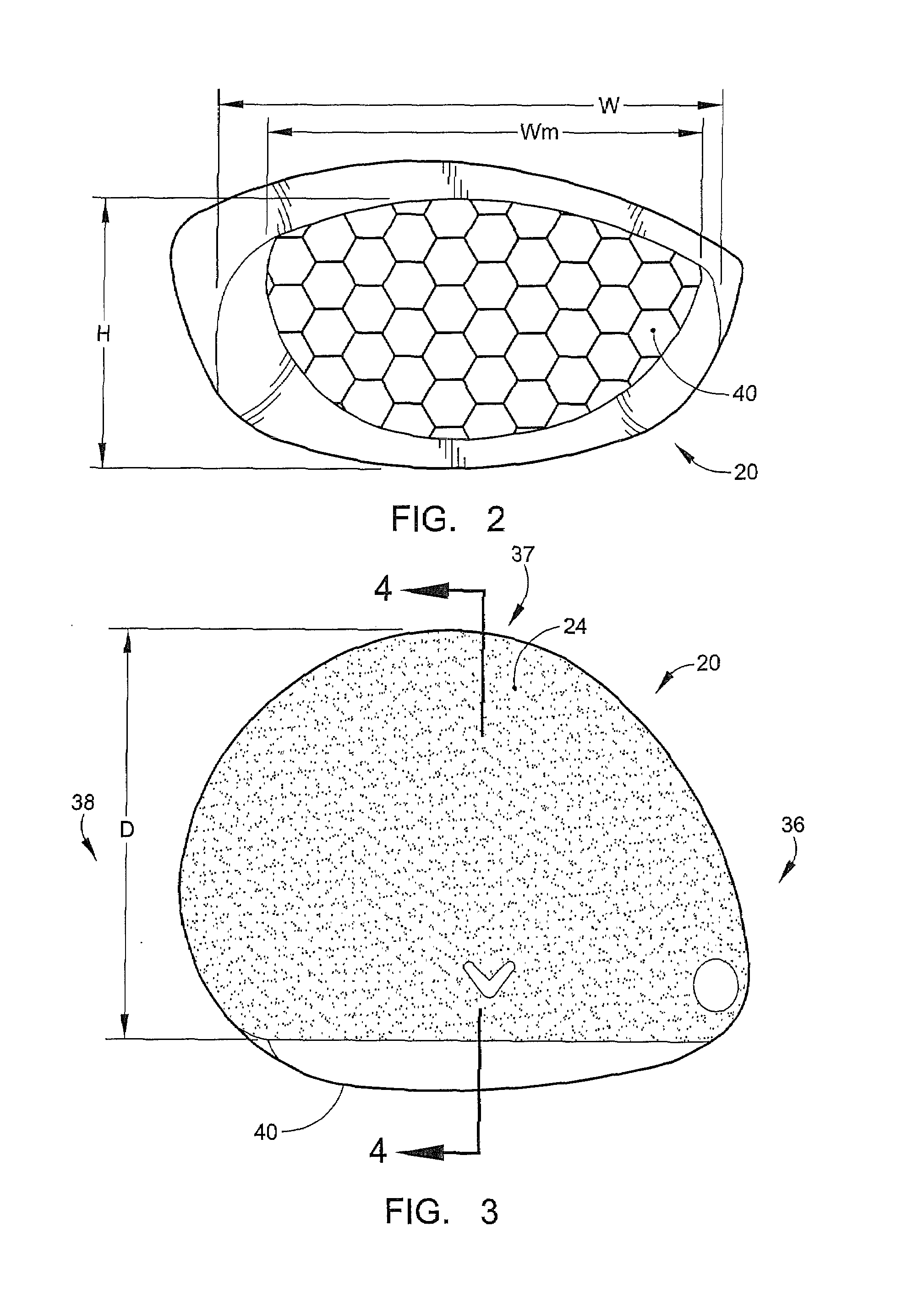

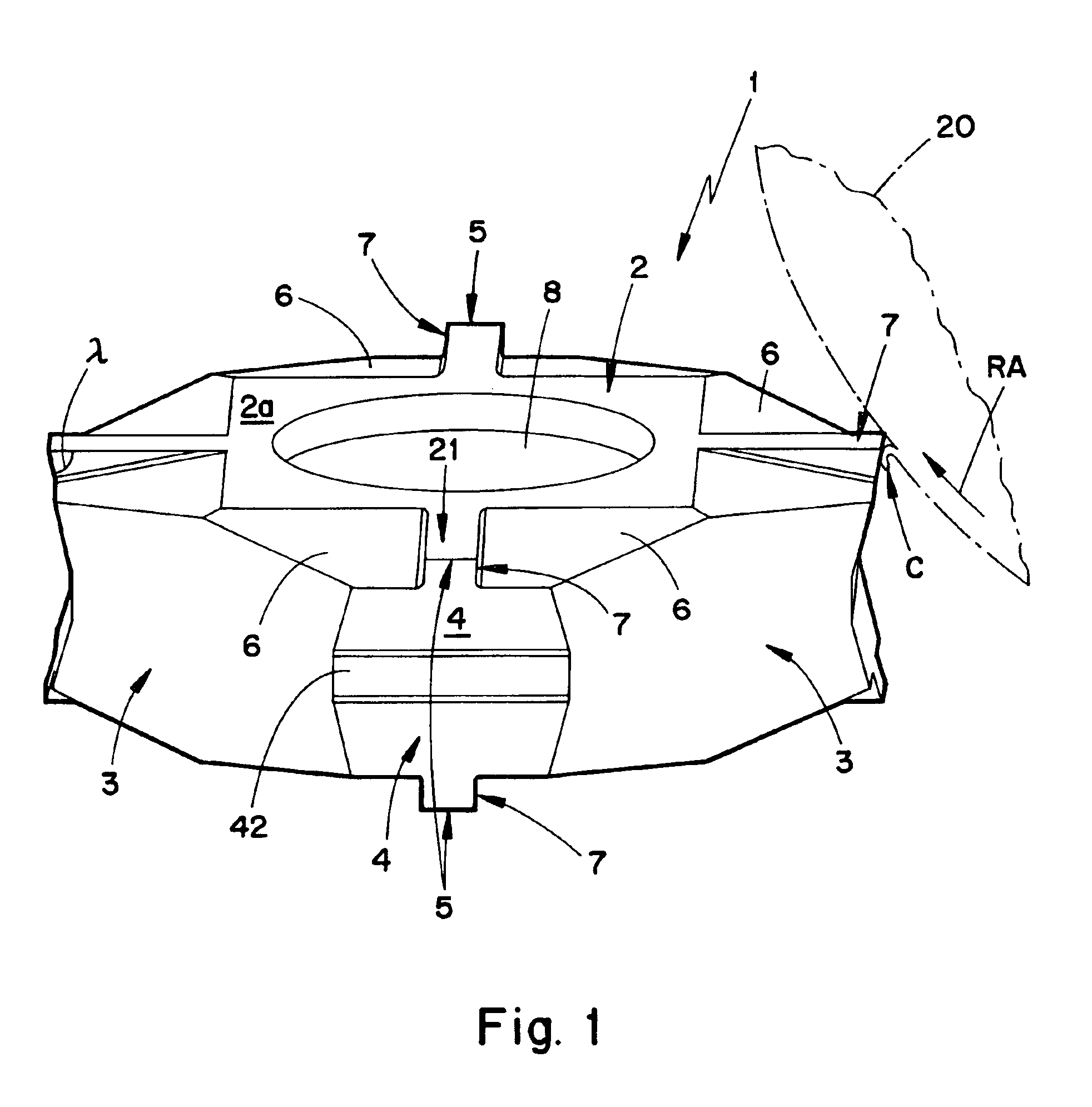

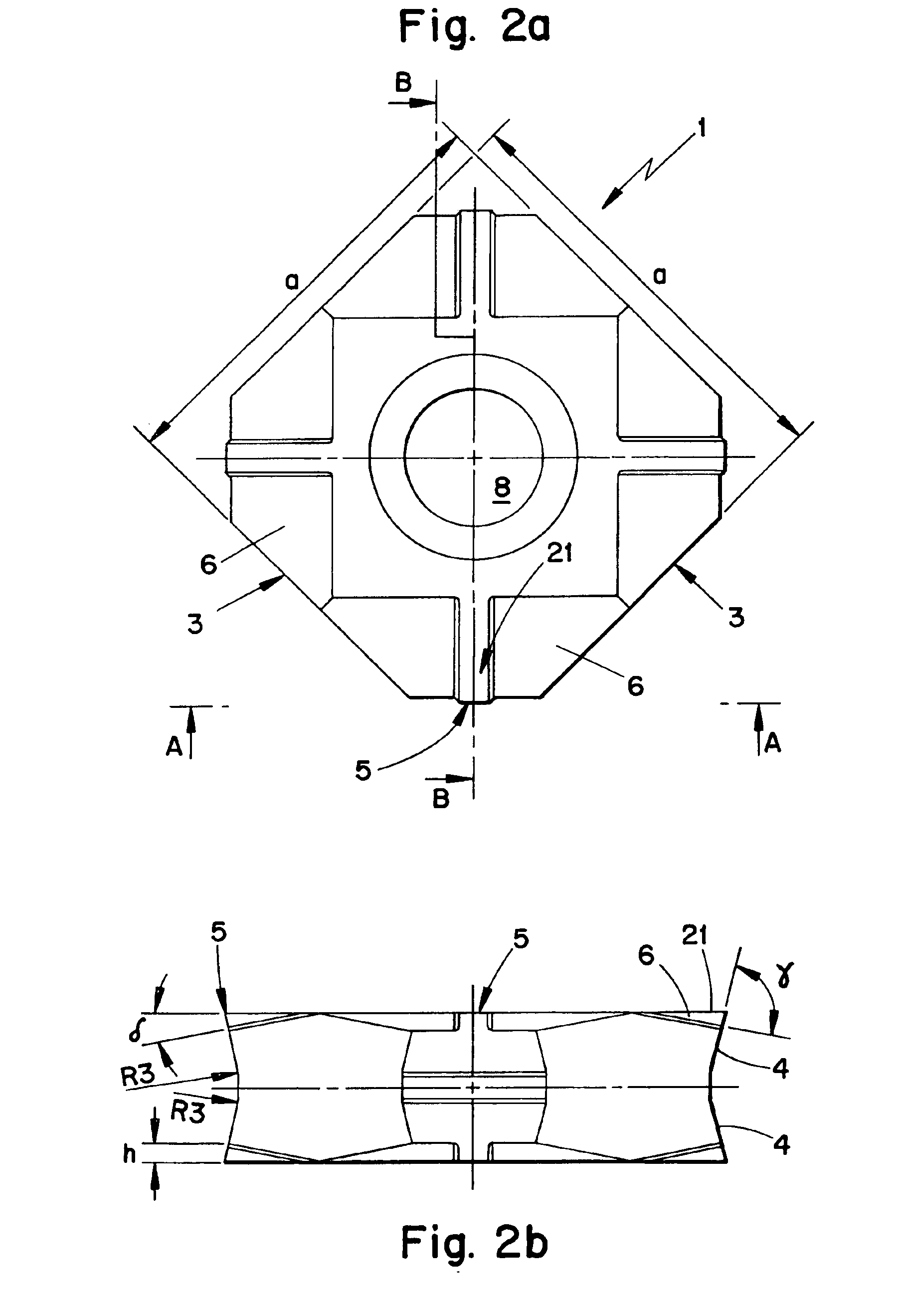

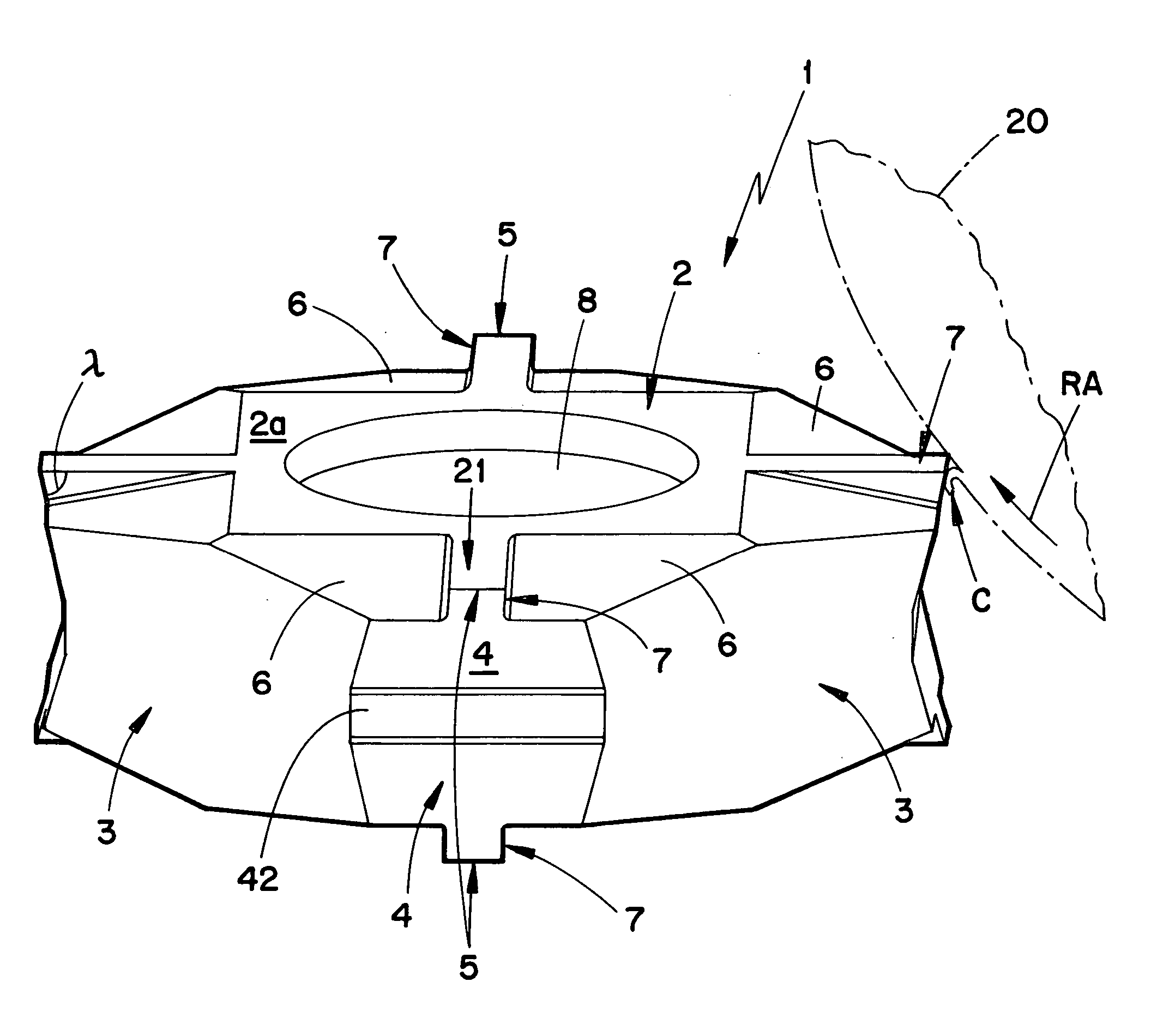

Optimally elastic golf club head

A golf club head is composed of elastic substructures having moderate elasticity and consisting of a face, outer shell, and inner structure in which said elastic substructures that cooperate so as to provide larger impulses to the ball at impact, due to combined elastic properties of the club face for hits at all locations on the face. This allows better distance of shots when loft angle and other design details are appropriately chosen. The structure also minimizes variations of angular orientation of the face surface at the point of impact for all such hits. The elastic substructures can take several forms such as an internal elastic support around the periphery of the face structure, an internal support for the central part of the face structure, and an elastic structure attached to the front side of the face structure, an elastic outer shell, and their combinations. The structure also provides adequate strength, and minimum weight such that a maximum amount of concentrated mass can be located in advantageous places as far as practical from the center of gravity of the head so as to realize maximum moments of inertia about the center of gravity.

Owner:ORIGIN INC +1

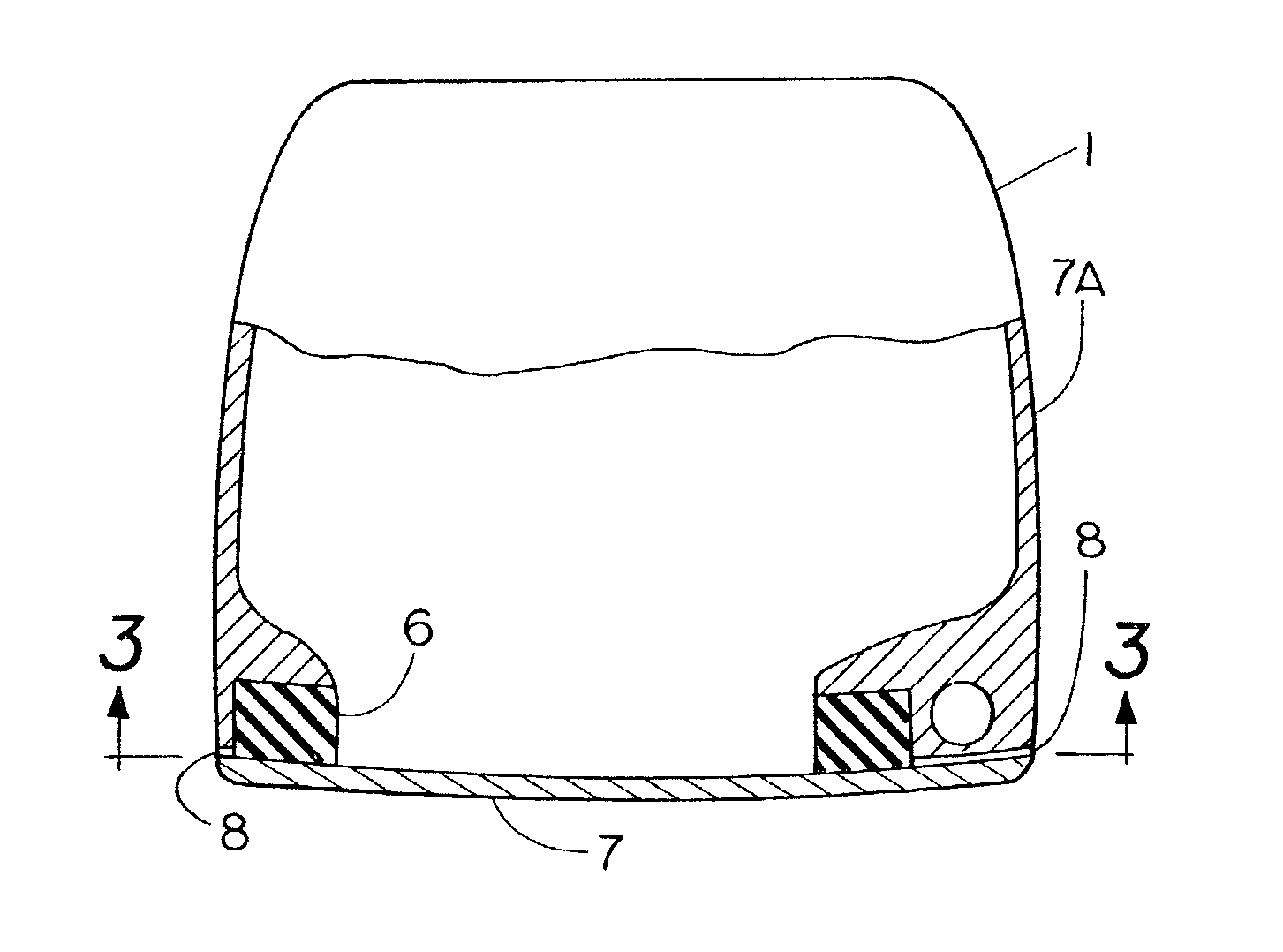

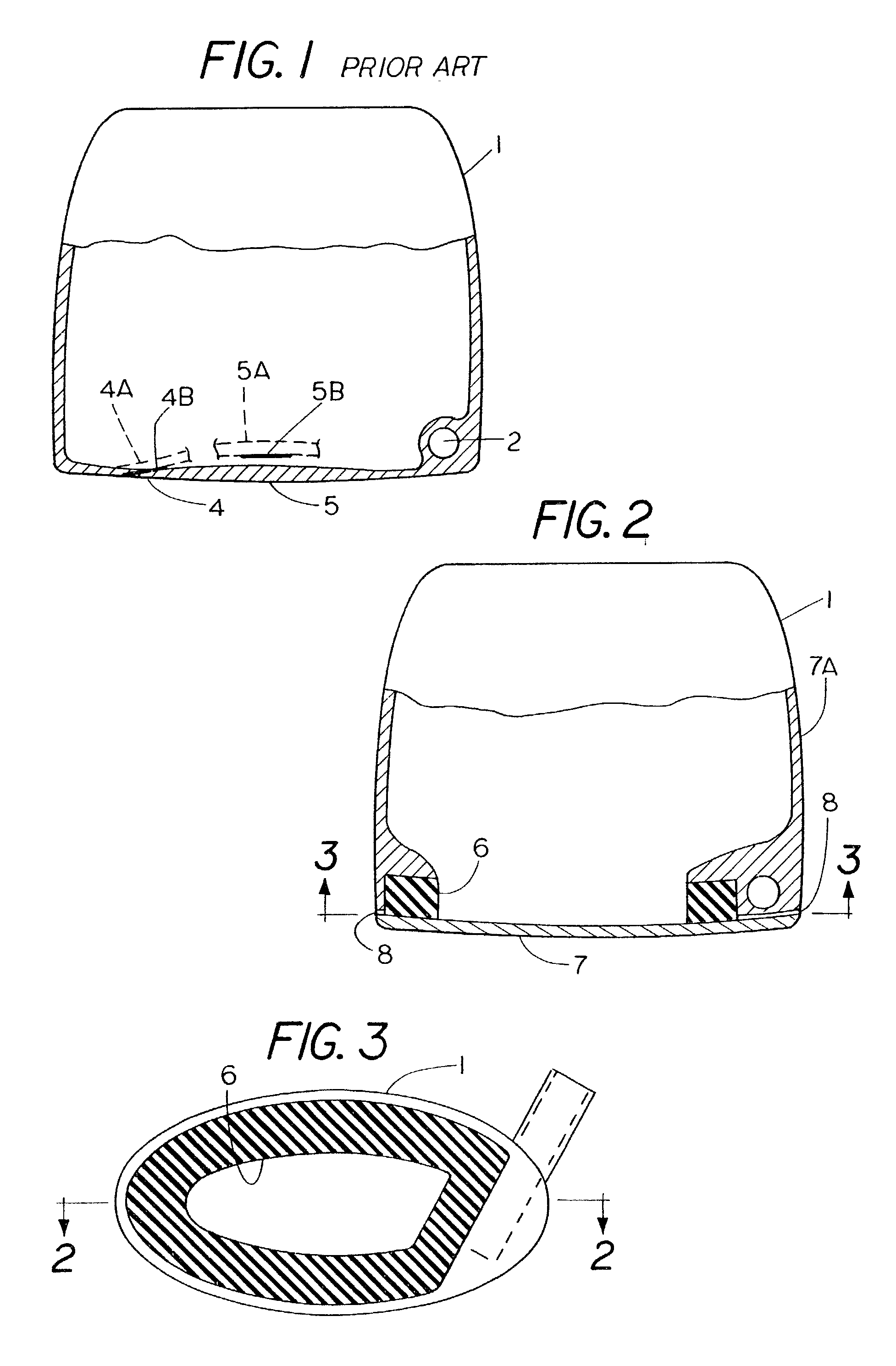

Method and apparatus for forming a face structure for a golf club head

A golf club head having a multiple material face is disclosed herein. The golf club head has a coefficient of restitution value greater than 0.83 and a characteristic time value of less than 257 milliseconds. The golf club head is preferably composed of a titanium alloy with a polymer layer disposed over a titanium alloy front wall. A preferred polymer is a polyurethane polymer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

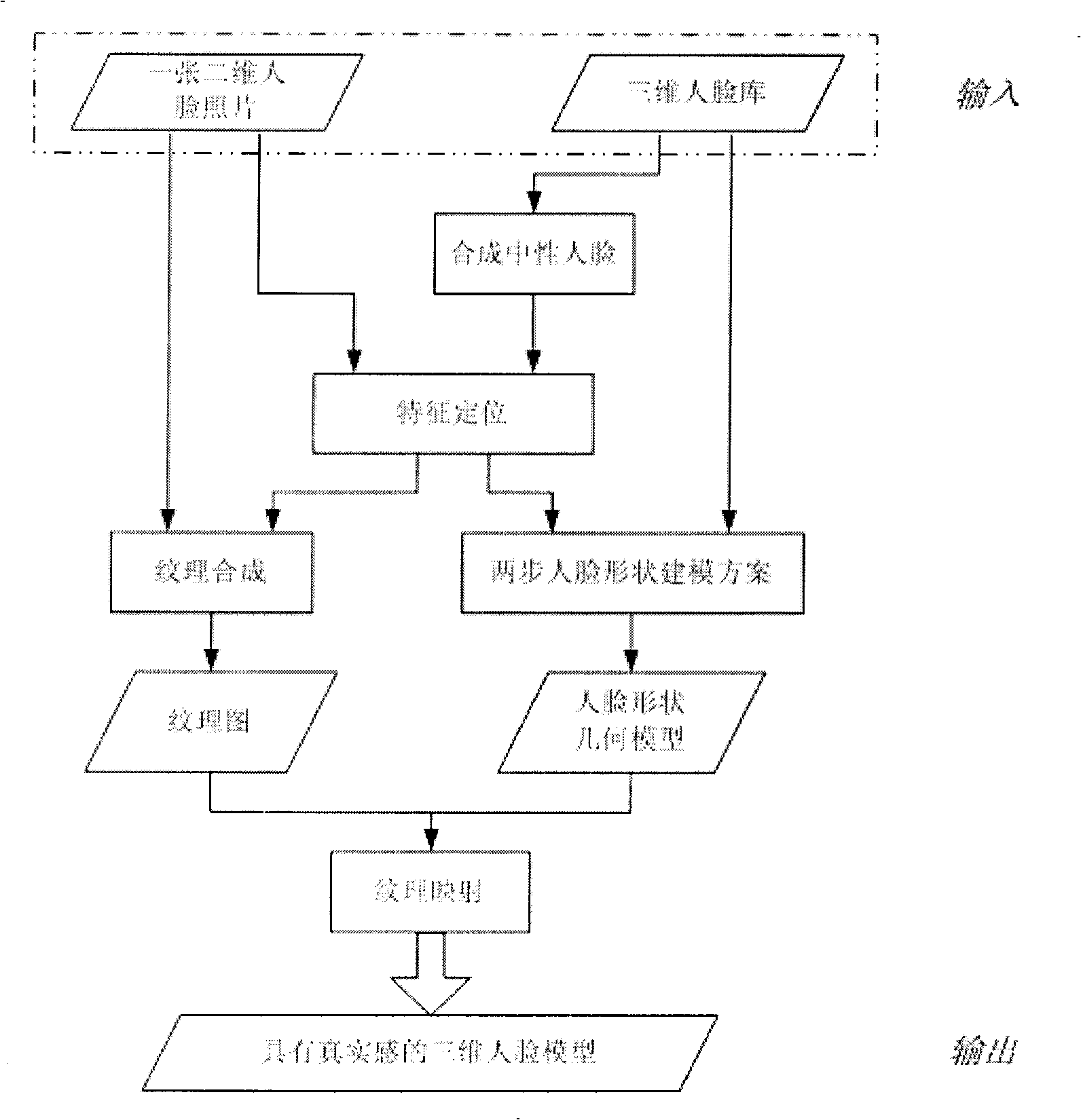

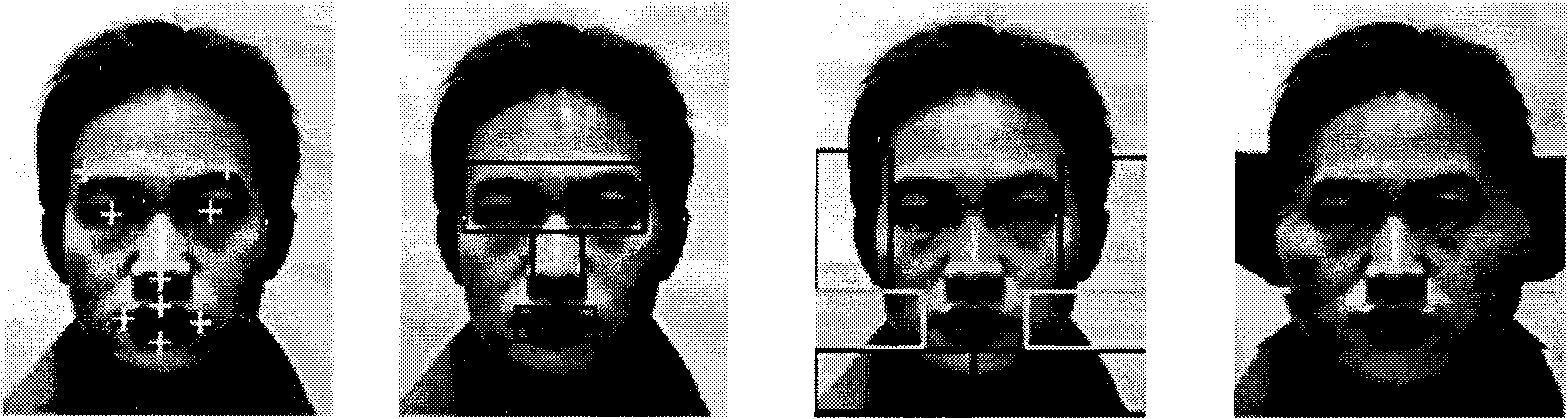

Three-dimensional human face reconstruction method and system based on two-step shape modeling

InactiveCN101404091AImprove accuracyStrong sense of reality3D-image rendering3D modellingPattern recognitionGraphics

The invention discloses a method for carrying out the three-dimensional human face modeling by a single human face photo to obtain a realistic human face, and the method belongs to the field of graphics and images. The method utilizes a priori knowledge of a human face structure to estimate the depths of two-dimensional feature points on the photo, thereby obtaining similar three-dimensional coordinates; the similar three-dimensional feature points are taken as control points, and the dirichlet free deformation algorithm is adopted to realize the fitting of the neutral human face to the specific human face. Then, a method which is based on the regional expansion is adopted to realize the texture synthesis and the mapping, and the region which is not covered is repaired by adopting the interpolation or the block filling method. The method has simple calculation, high modeling accuracy and can rapidly utilize a small number of feature points to realize the three-dimensional modeling of the human face on the single photo, and the generated three-dimensional human face model has very strong realistic feeling under various postures due to the accurate estimation of the depths of the feature points. The method can also be used for the three-dimensional reconstruction of other objects.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

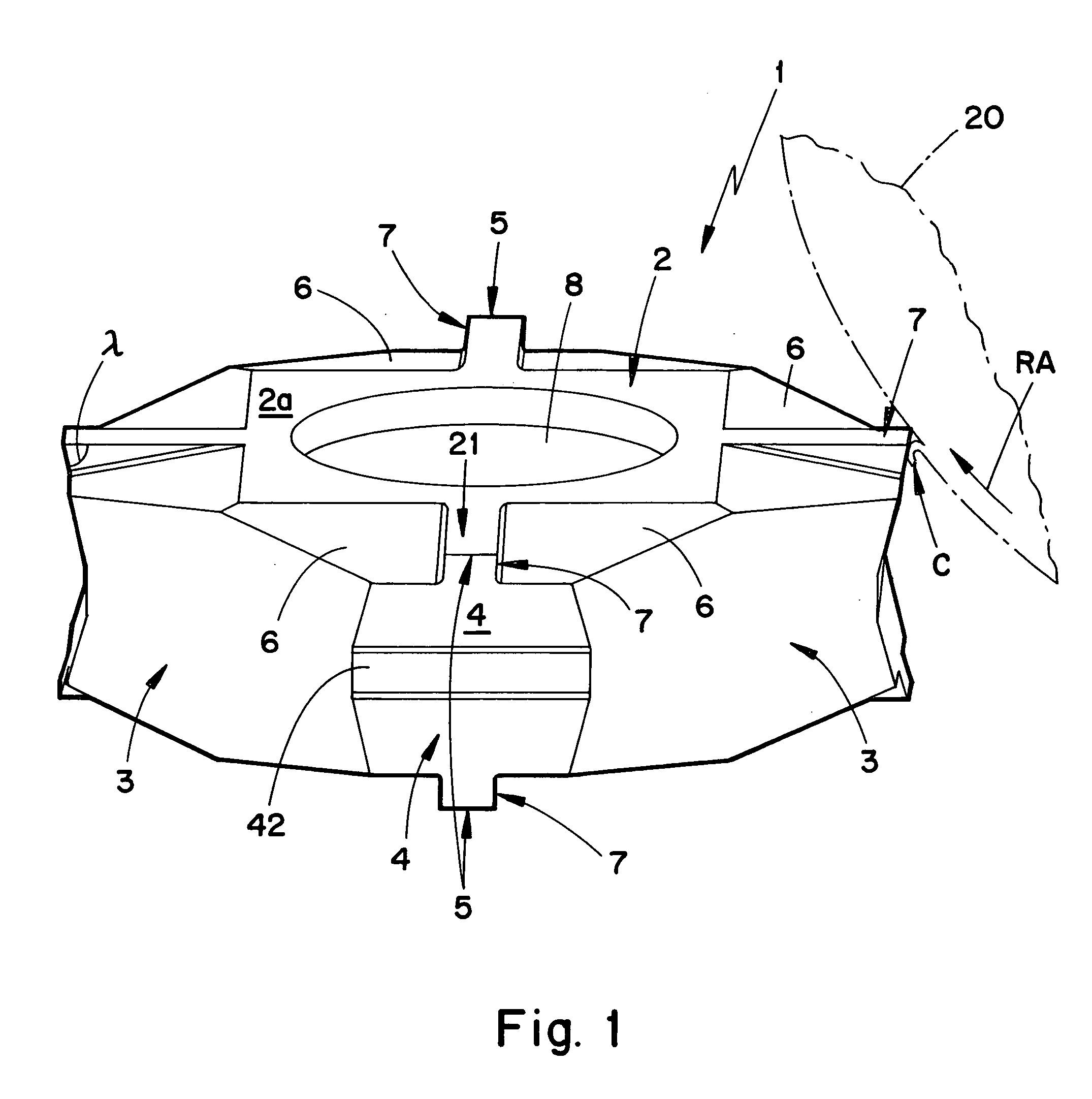

Cutting insert for turning and milling

A cutting insert comprises first and second polygonally-shaped main faces arranged substantially parallel to one another, and a side face structure interconnecting the first and second main faces to define a peripheral edge. At least the first main face includes at least one projection extending to the peripheral edge, the projection formed by: a portion of the first main surface (defining a relief surface), a portion of the side face structure (defining a rake surface), and a portion of the peripheral edge (defining a cutting edge). The insert includes support surfaces defined by a portion of the second main face, and by portions of the side surface structure other than the rake surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

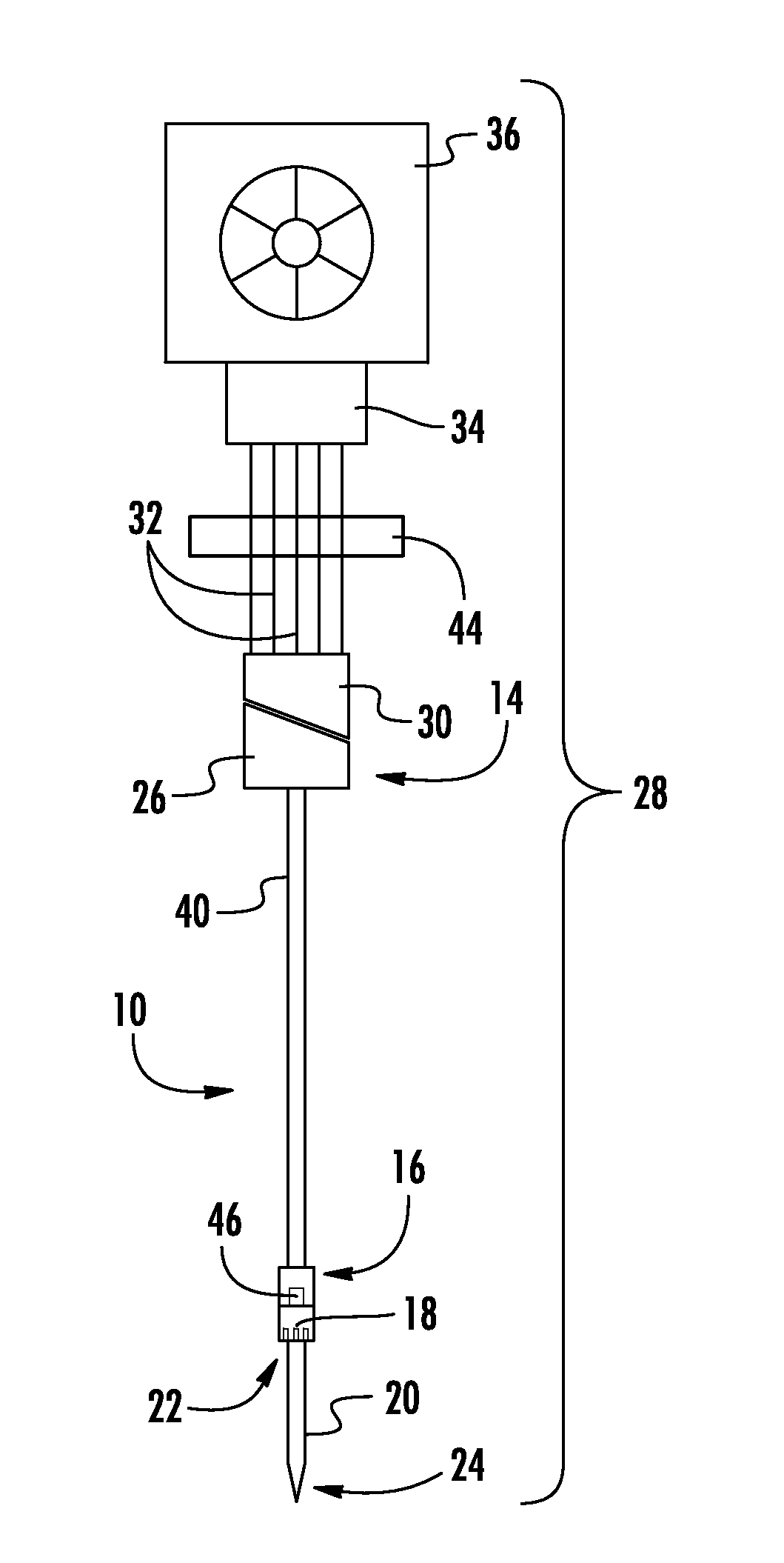

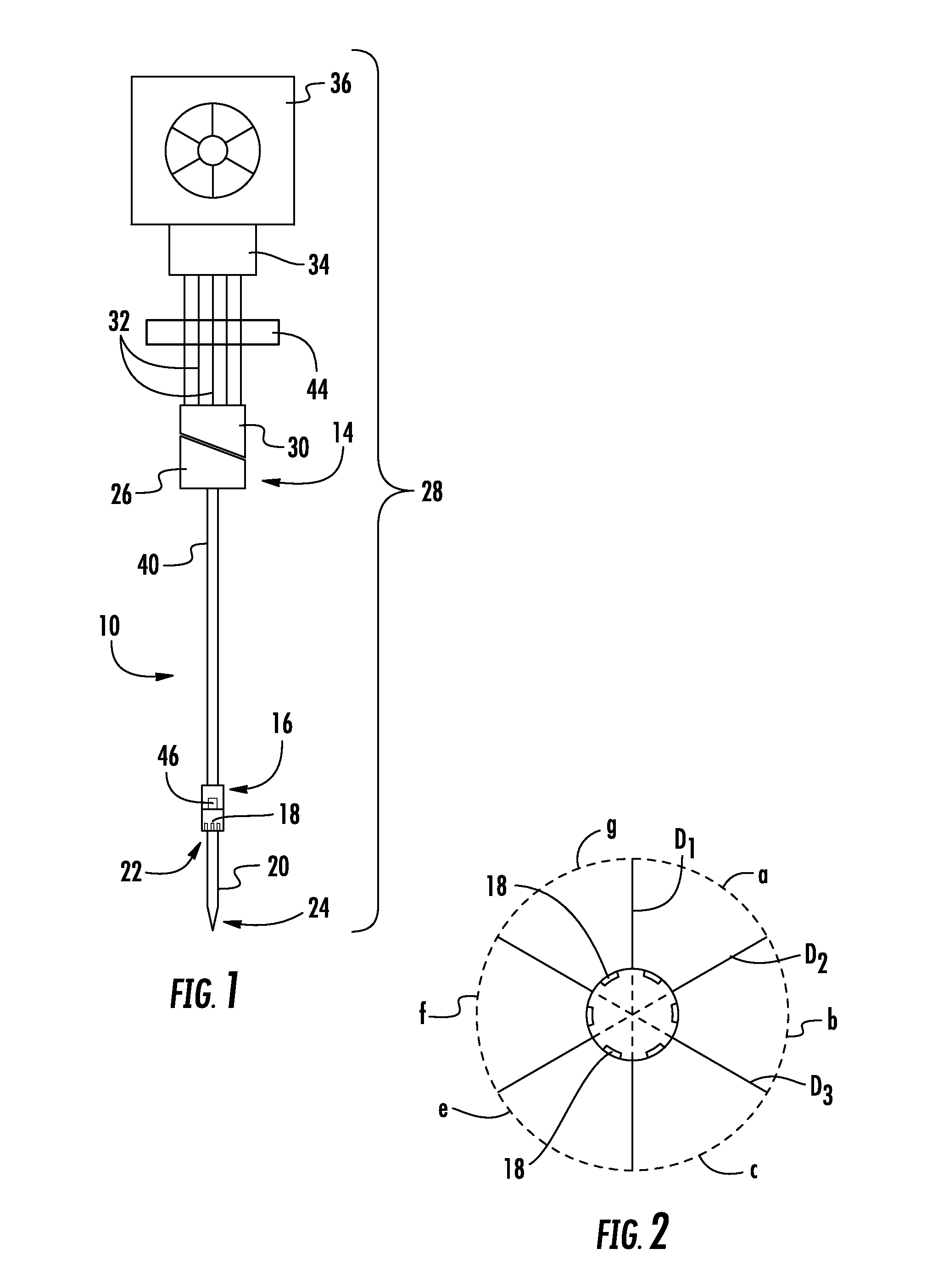

Distance, diameter and area determining device

The invention describes a novel implementation of ultrasound or OCT technology to approximate the dimensions of fluid-filled structures (when using ultrasound technology) or other structures (when using OCT technology). The invention in a preferred embodiment is an elongated member such as a catheter that uses ultrasound or OCT technology to approximate the dimensions of a structure into which the catheter has been placed. In a preferred embodiment, the catheter includes multiple ultrasound transducers arranged in an annular or circumferential configuration on, embedded into or within the body of the elongated member so that distance measurements can be obtained between the elongated member and the wall of the immediately facing structure (e.g., a fluid-filled lumen). Utilizing these measurements, the present invention approximates for the physician the shape and size of the structure into which the elongated member is placed. The invention also includes a method for producing three-dimensional images from two-dimensional images.

Owner:PROVISIO MEDICAL INC

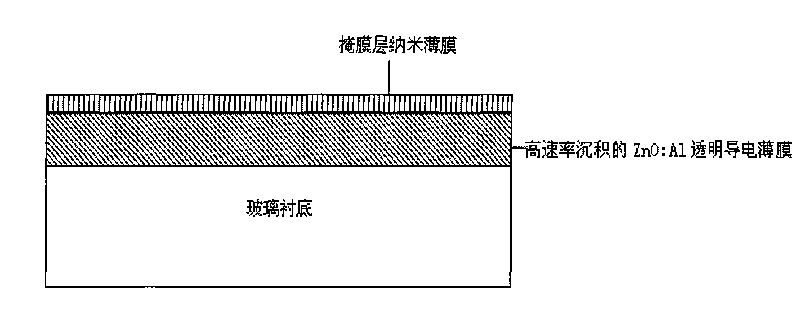

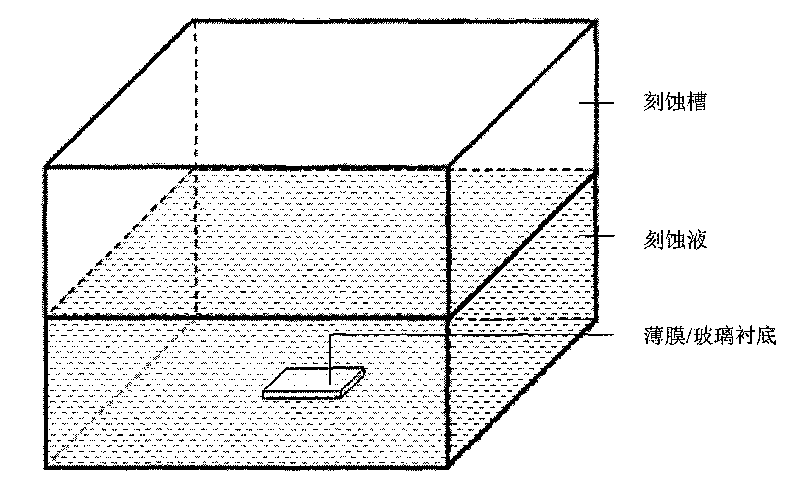

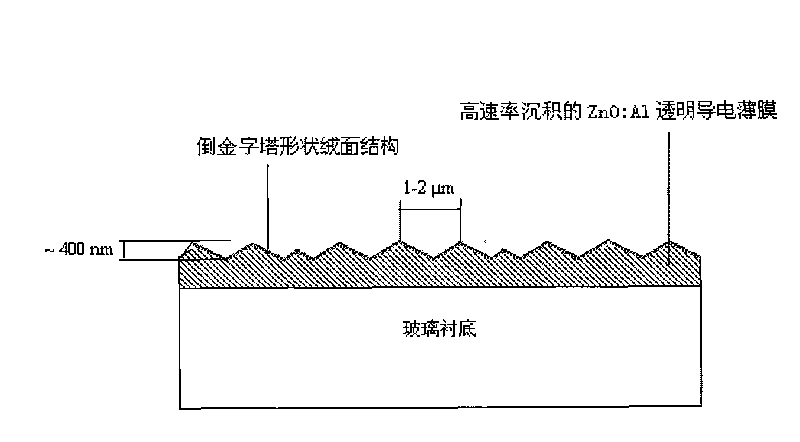

Method for preparing pile face doped zinc oxide transparent conductive film

InactiveCN101692357AImprove trapping effectImprove photoelectric conversion efficiencyConductive layers on insulating-supportsFinal product manufactureAluminum doped zinc oxideTrapping

The invention discloses a method for preparing a pile face doped zinc oxide transparent conductive film. The method comprises magnetic control sputtering growth of an aluminum doped zinc oxide(ZnO:Al) transparent conductive film, preparation of a masking layer nanometer film and formation of a pile face structure by the wet method chemical etching treatment of the deposited transparent conductive film at a later stage. The ZnO:Al transparent conductive film is prepared by the non-reaction magnetic control sputtering deposition, and the target materials used in the magnetic control sputtering are ZnO:Al203 ceramic target materials at doping concentrations; and the pyramid-inversed pile face ZnO:Al transparent conductive film is prepared by designing a masking layer for the ZnO:Al transparent conductive film and adopting the wet method chemical etching. The method has the advantages that: the process is simplified; the cost is reduced; and the conductive film prepared by the method has good light trapping effect and can be widely used in various highly efficient photoelectric devices, flat panel displayers and film solar cells to improve efficiency of the devices, in particular in the preparation of the silicon film solar cells to improve the photoelectric conversion efficiency of the solar cells.

Owner:EAST CHINA NORMAL UNIV

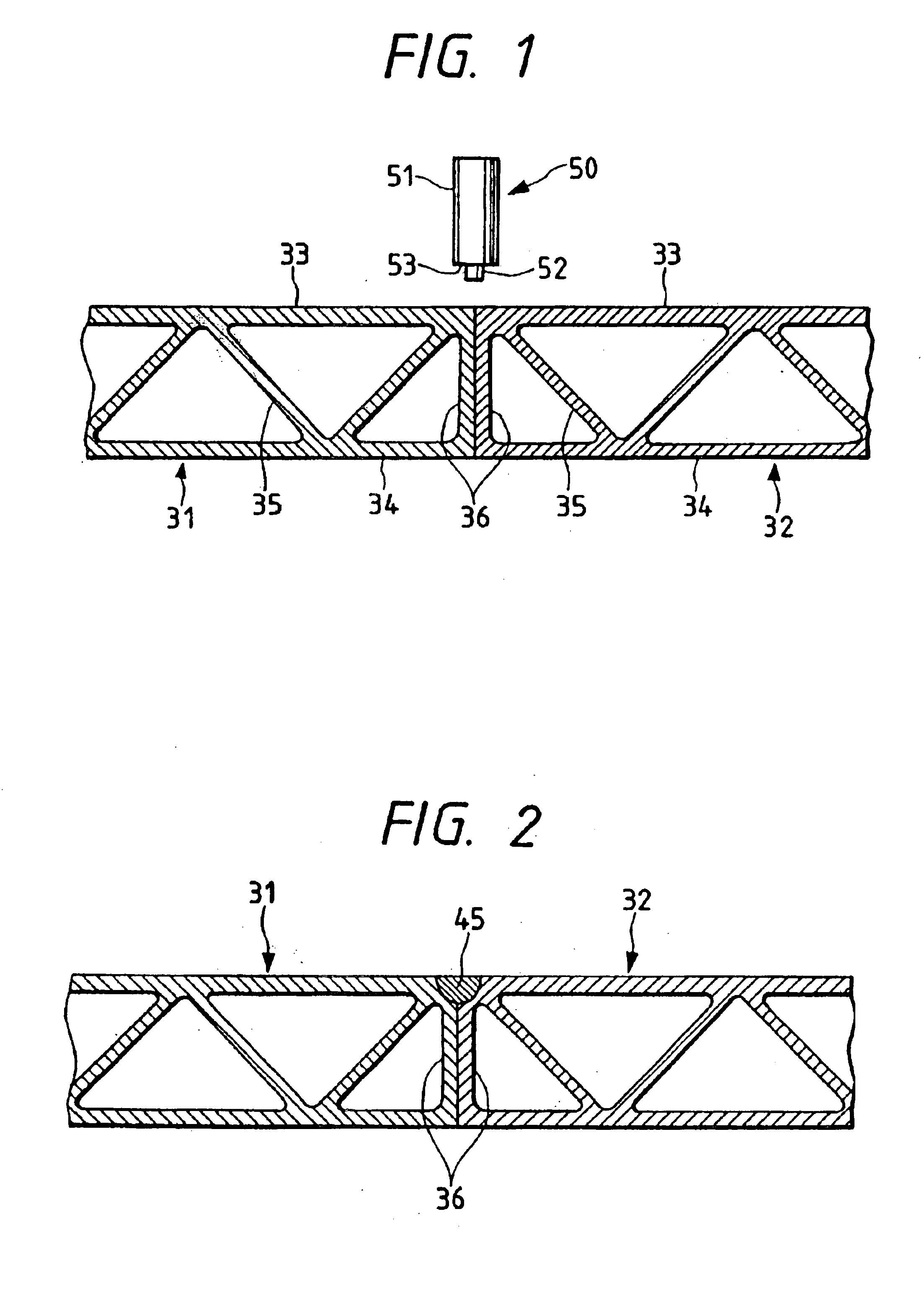

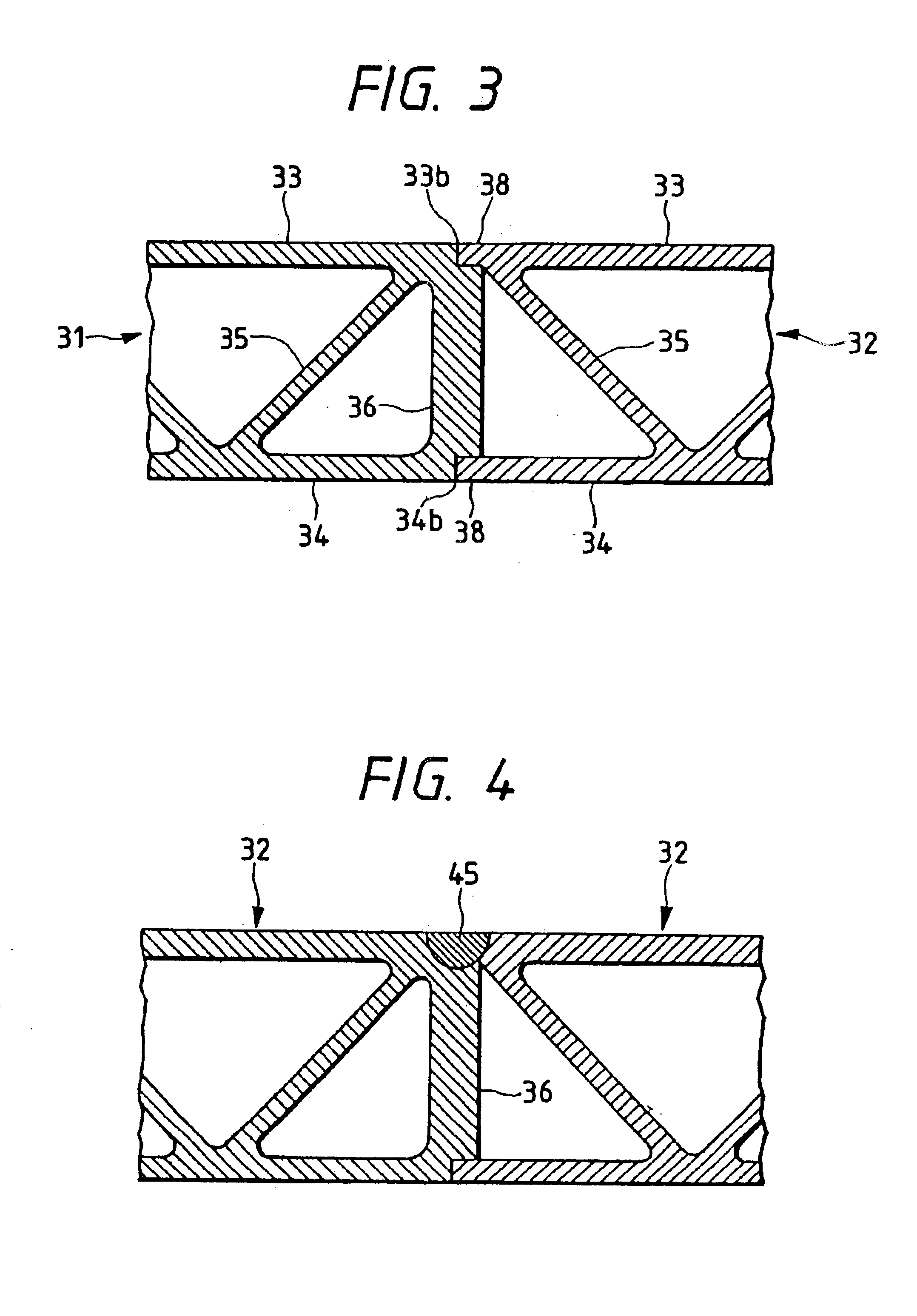

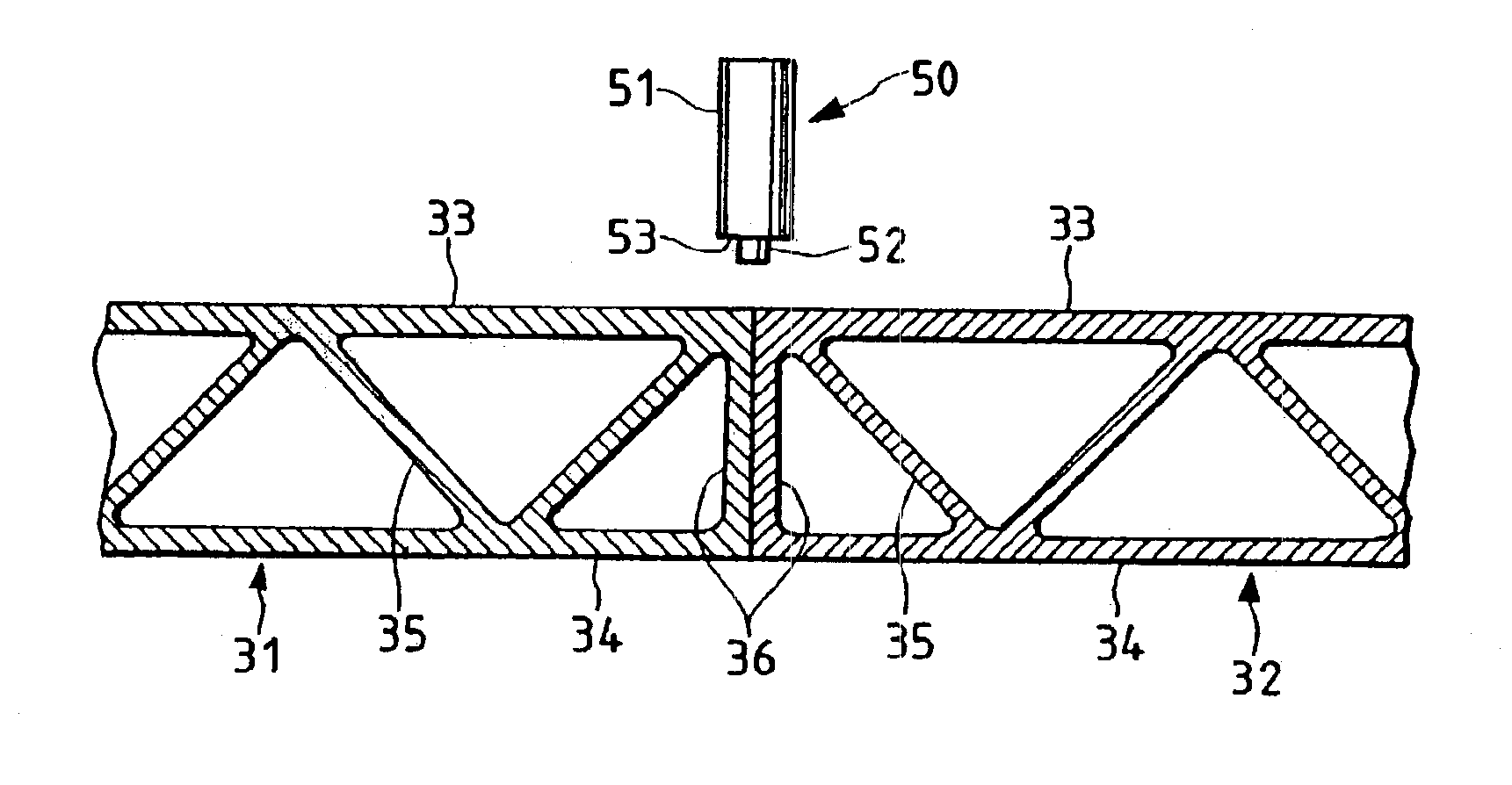

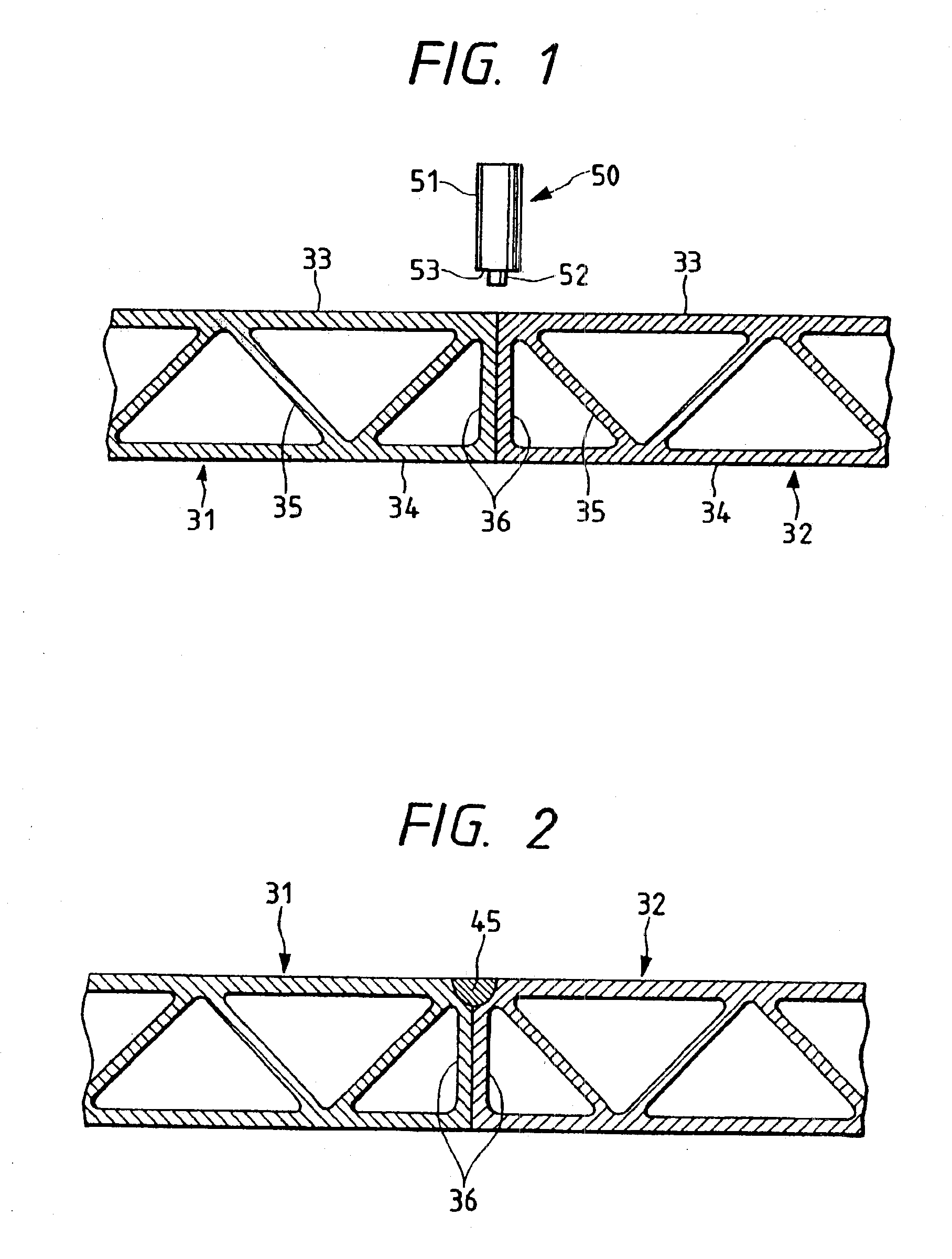

Friction stir welding method and structure body formed by friction stir welding

InactiveUS6840426B2Small overall deformationShort timeConstruction materialLayered productsFriction weldingParallel plate

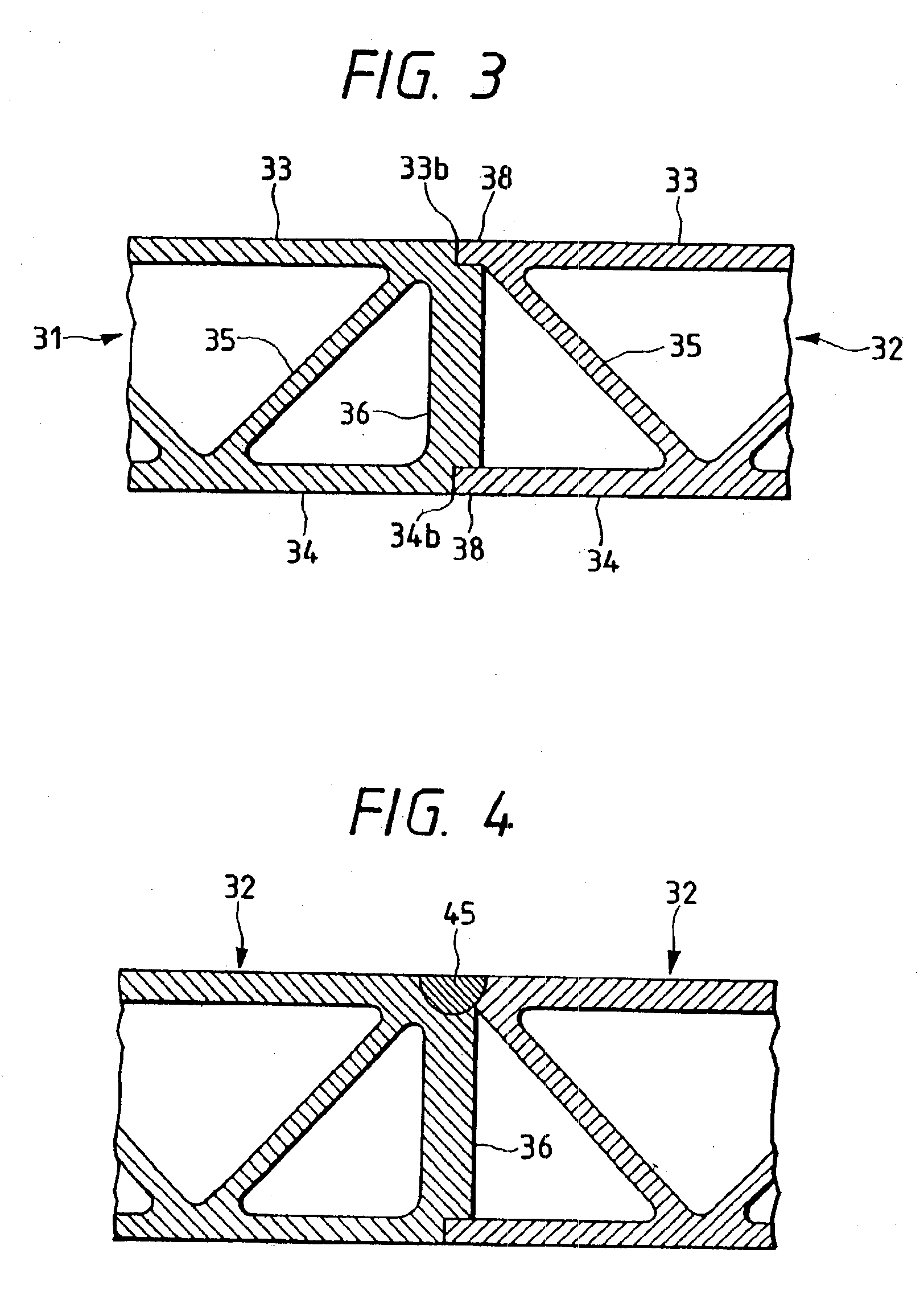

This invention provides a configuration of a joint that allows a satisfactory welded joint to be formed with reduced deformation of the joint region when two-face structures (panels) are friction-welded end to end. The panels 31, 32 each have two substantially parallel plates 33, 34 and a third member 35 connecting the two plates 33, 34. The end portions of the plates 33, 34 of one panel 32 are friction-welded to the end portions of the plates 33, 34 of the other panel 32. At least one of the panels has a plate 36 at its end for connecting the plates 33 and 34 and has a rigidity to support a pressing force produced during the friction welding.

Owner:HITACHI LTD

Cutting insert for turning and milling

A cutting insert comprises first and second polygonally-shaped main faces arranged substantially parallel to one another, and a side face structure interconnecting the first and second main faces to define a peripheral edge. At least the first main face includes at least one projection extending to the peripheral edge, the projection formed by: a portion of the first main surface (defining a relief surface), a portion of the side face structure (defining a rake surface), and a portion of the peripheral edge (defining a cutting edge). The insert includes support surfaces defined by a portion of the second main face, and by portions of the side surface structure other than the rake surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

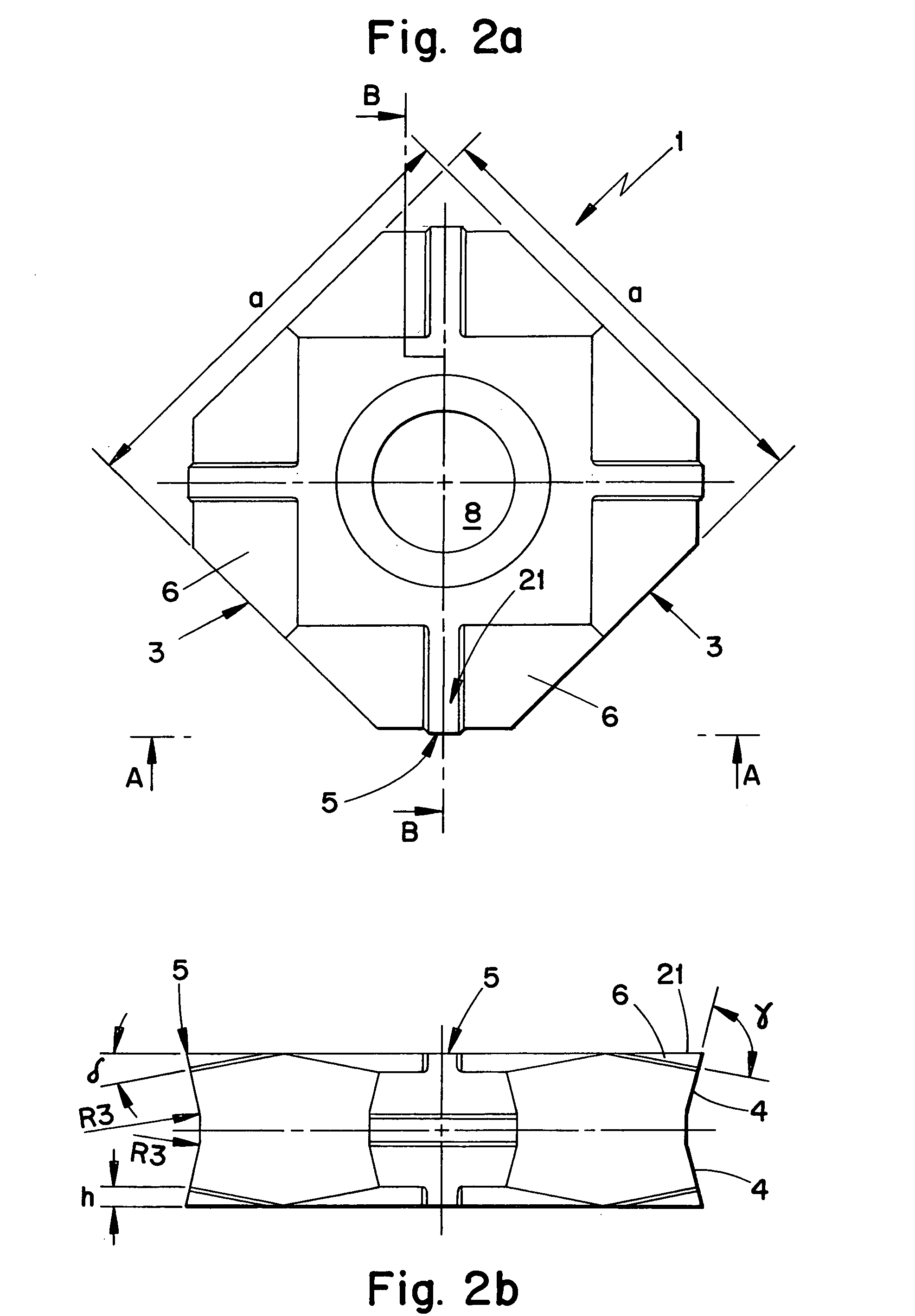

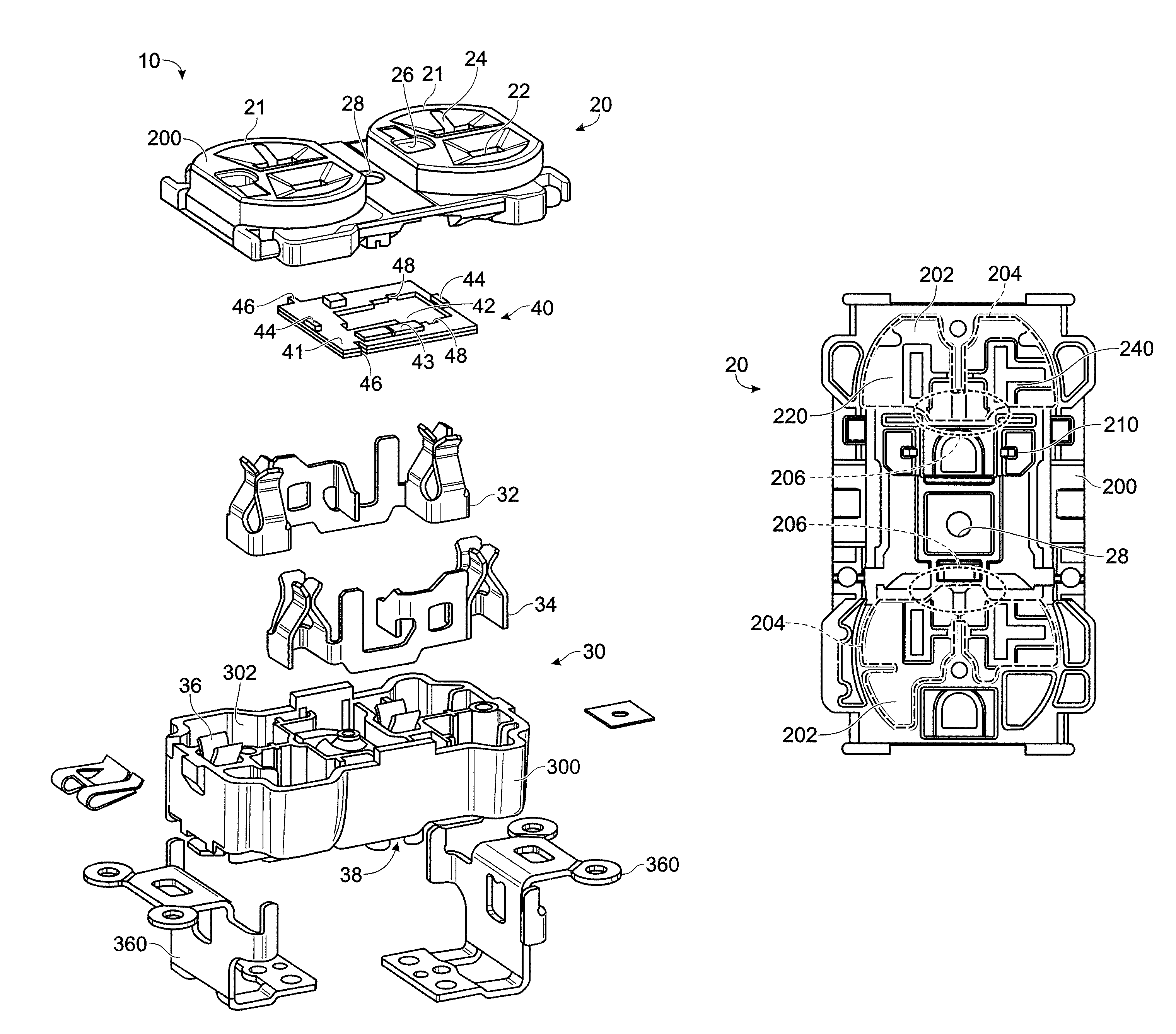

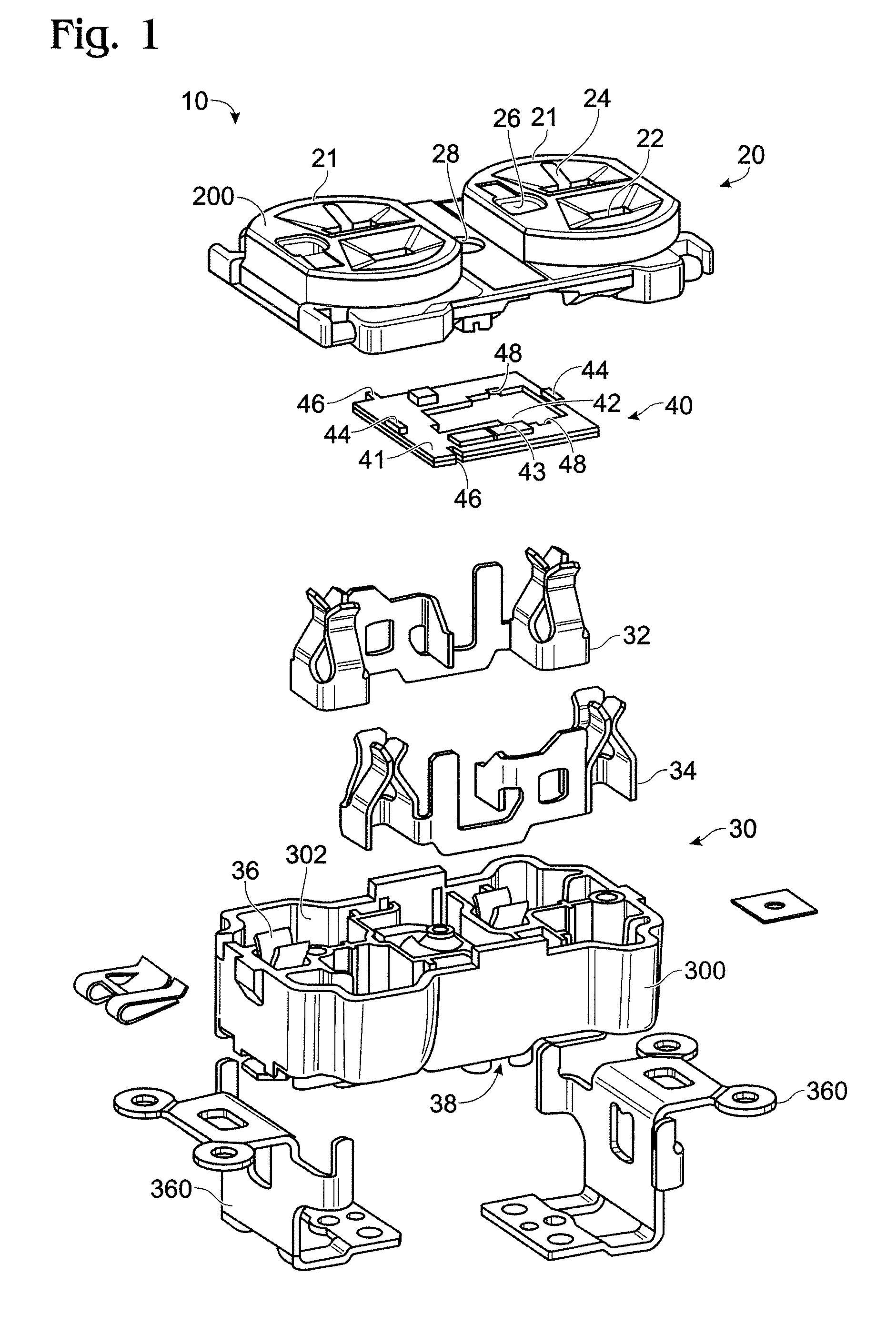

Illuminated face receptacle structure

InactiveUS7736174B2Precise positioningTwo pole connectionsPoint-like light sourceEngineeringLight emitting device

The present invention is directed to an electrical wiring device having a body and a cover coupled to the body including a receptacle face structure which forms an interior region with at least one reflective surface. At least one light emitting device is disposed in the interior region which is configured to emit illumination into at least one neutral opening and a hot opening.

Owner:PASS SEYMOUR

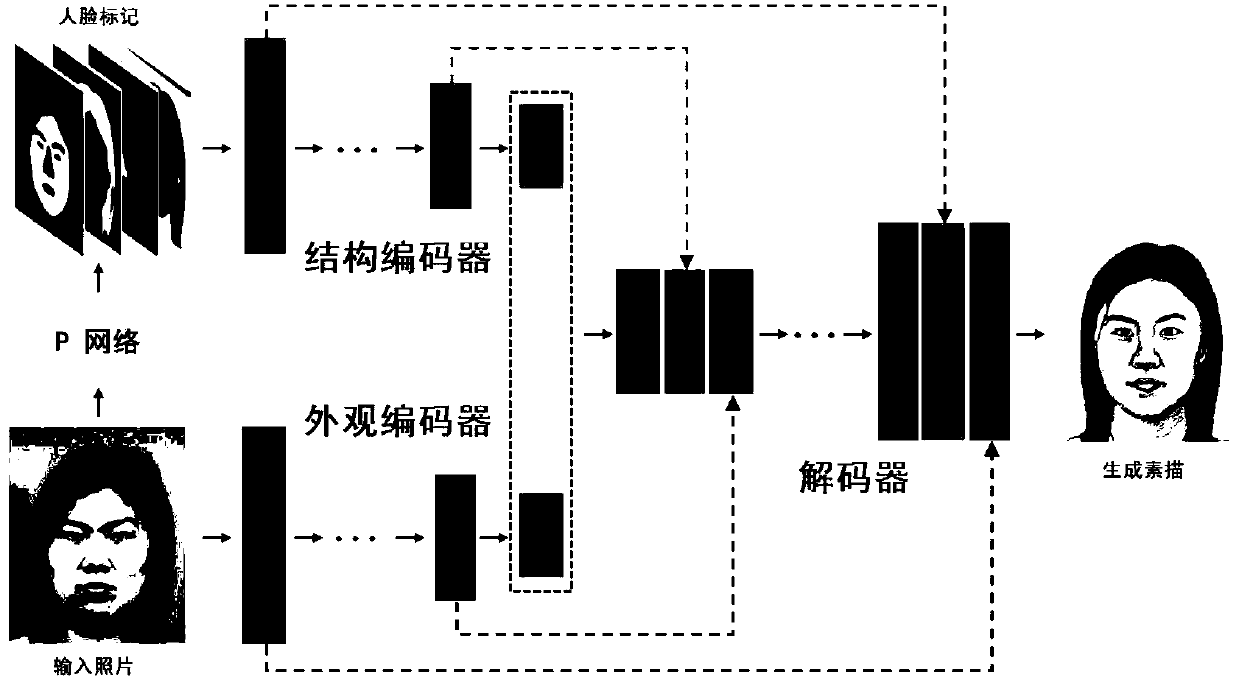

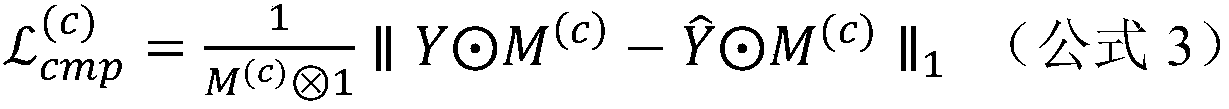

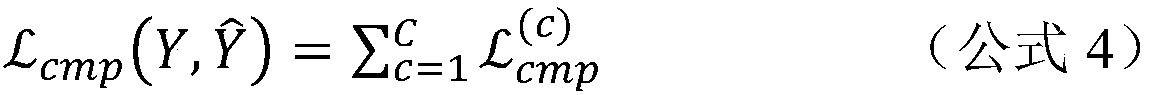

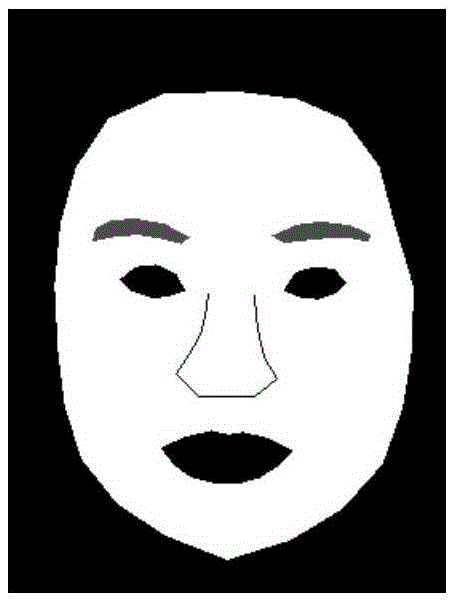

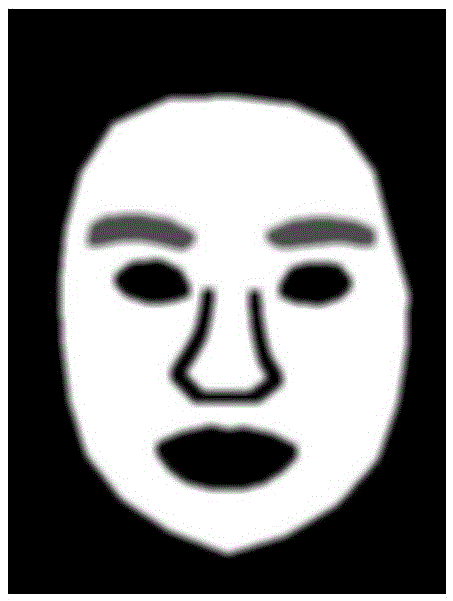

Portrait generation method based on face structure information

ActiveCN108596024AUnreasonable structureImprove accuracyCharacter and pattern recognitionNeural learning methodsCountermeasureAlgorithm

The invention discloses a portrait generation method based on the face structure information. The method comprises the following steps: 1, carrying out data preprocessing on an original image, a target image and the face structure information; 2, carrying out feature extraction and feature fusion at the input end of an image generator through a face structure information model; 3, adopting a combination loss function based on face structure components for the loss function part of the image generator; 4, generating a countermeasure network by using the generator, and distinguishing by using adiscriminator; 5, carrying out model training, and training neural network parameters through a reverse propagation algorithm. According to the invention, a neural network model generated from a facephoto to a portrait is provided. The invention particularly provides a method for carrying out network parameter optimization by utilizing the guidance information of a face part through a portrait generator to generate a portrait and calculating the loss of each part by means of the part information so as to optimize network parameters. Based on the method, the best effect in the generation fieldof face photos and portraits is obtained.

Owner:HANGZHOU DIANZI UNIV

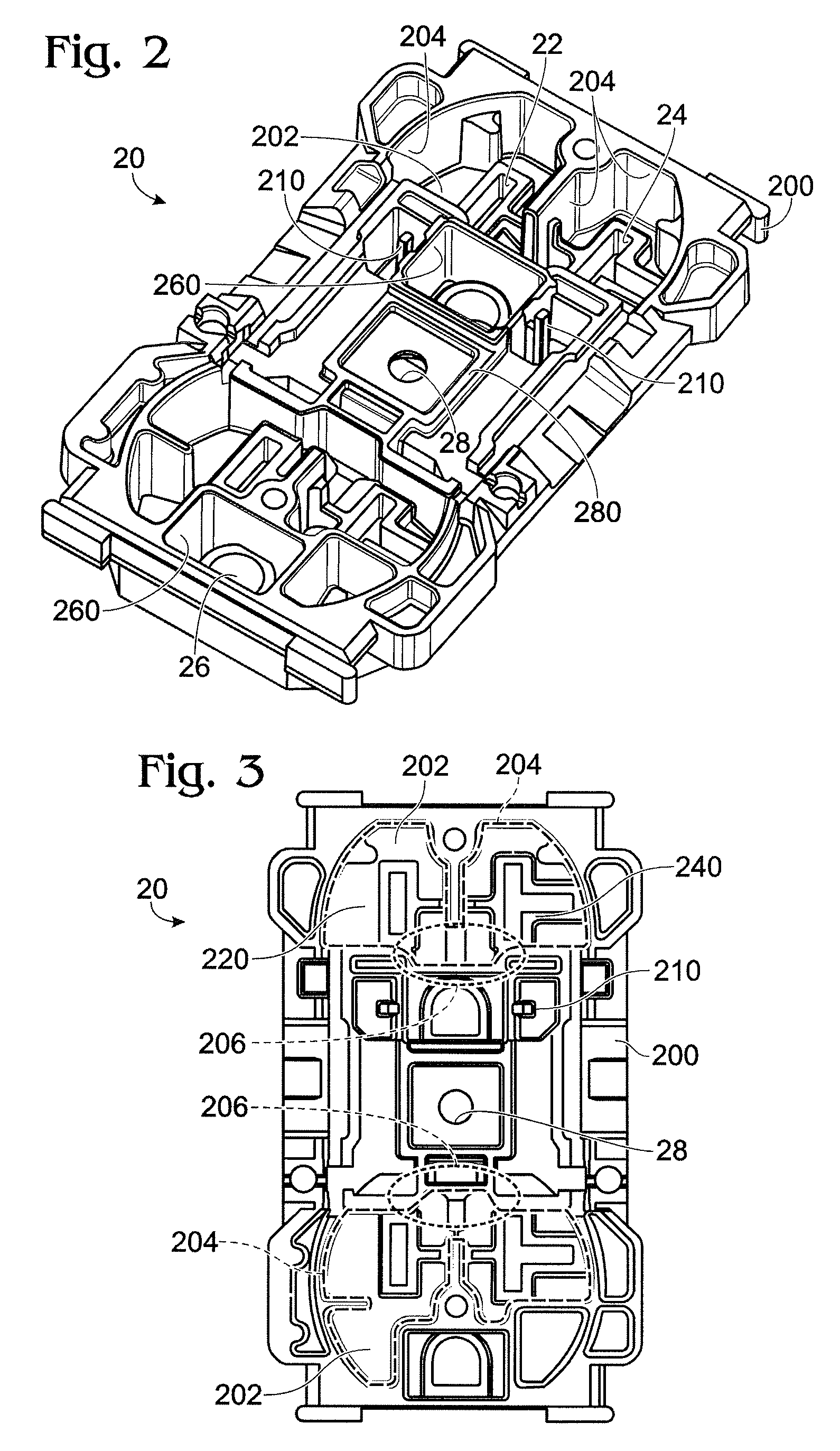

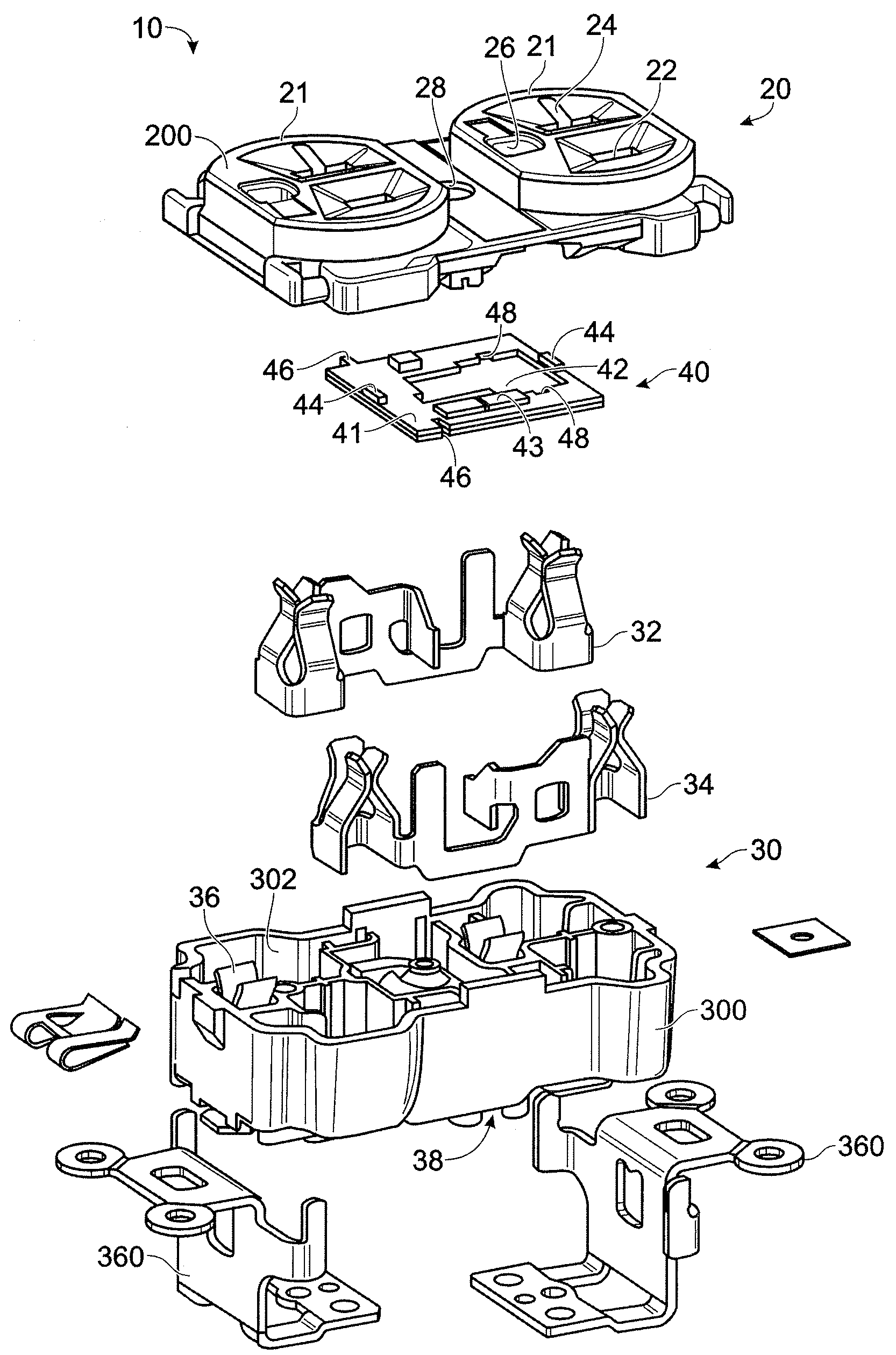

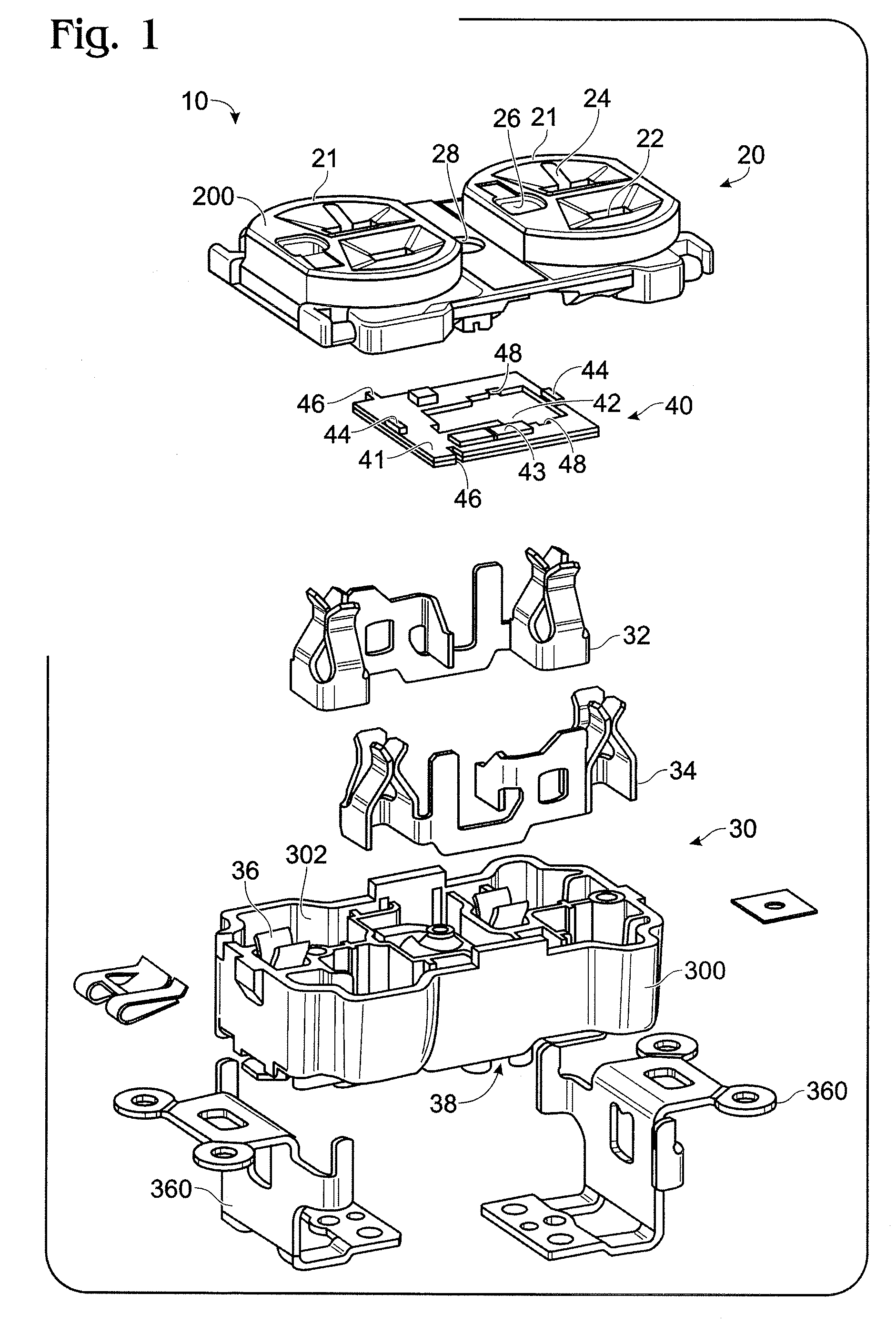

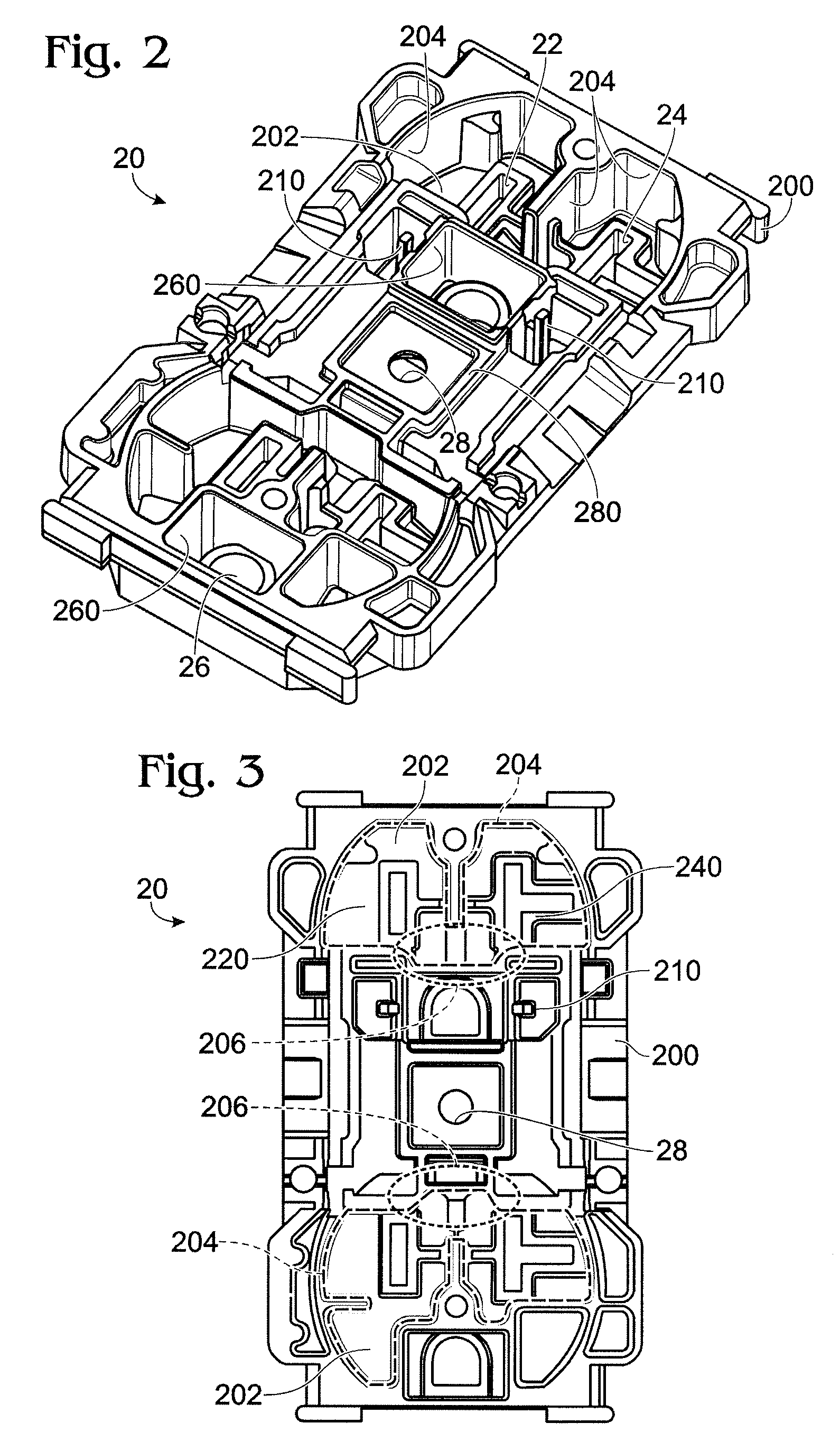

Illuminated Face Receptacle Structure

InactiveUS20090141477A1Precise positioningTwo pole connectionsPoint-like light sourceEngineeringNeutral line

The present invention is directed to an electrical wiring device that includes a body member including a hot line terminal interface element and a neutral line terminal interface element accessible from an exterior portion of the body member. The body member also includes a hot load contact structure electrically coupled to the hot line terminal interface element and a neutral load contact structure electrically coupled to the neutral line terminal interface element, both the hot load contact structure and the neutral load contact structure being disposed in an interior portion of the body member. A cover member is coupled to the body member and including at least one receptacle face structure. The at least one receptacle face structure includes a set of receptacle outlet openings formed in a substantially planar portion thereof. The set of receptacle outlet openings includes a neutral opening and a hot opening in alignment with the neutral load contact structure and the hot load contact structure, respectively, the at least one receptacle face structure forming an interior region including at least one reflective surface formed therein. A light emission circuit assembly includes at least one light emitting device disposed in the interior region. The at least one light emitting device being is offset a predetermined distance from an interior surface of the substantially planar portion. The at least one light emitting device is configured to emit illumination in a plane that is substantially parallel to the interior surface such that the emitted illumination is diffusely reflected by the at least one reflective surface onto the interior surface of the planar portion and into the neutral opening and the hot opening.

Owner:PASS SEYMOUR

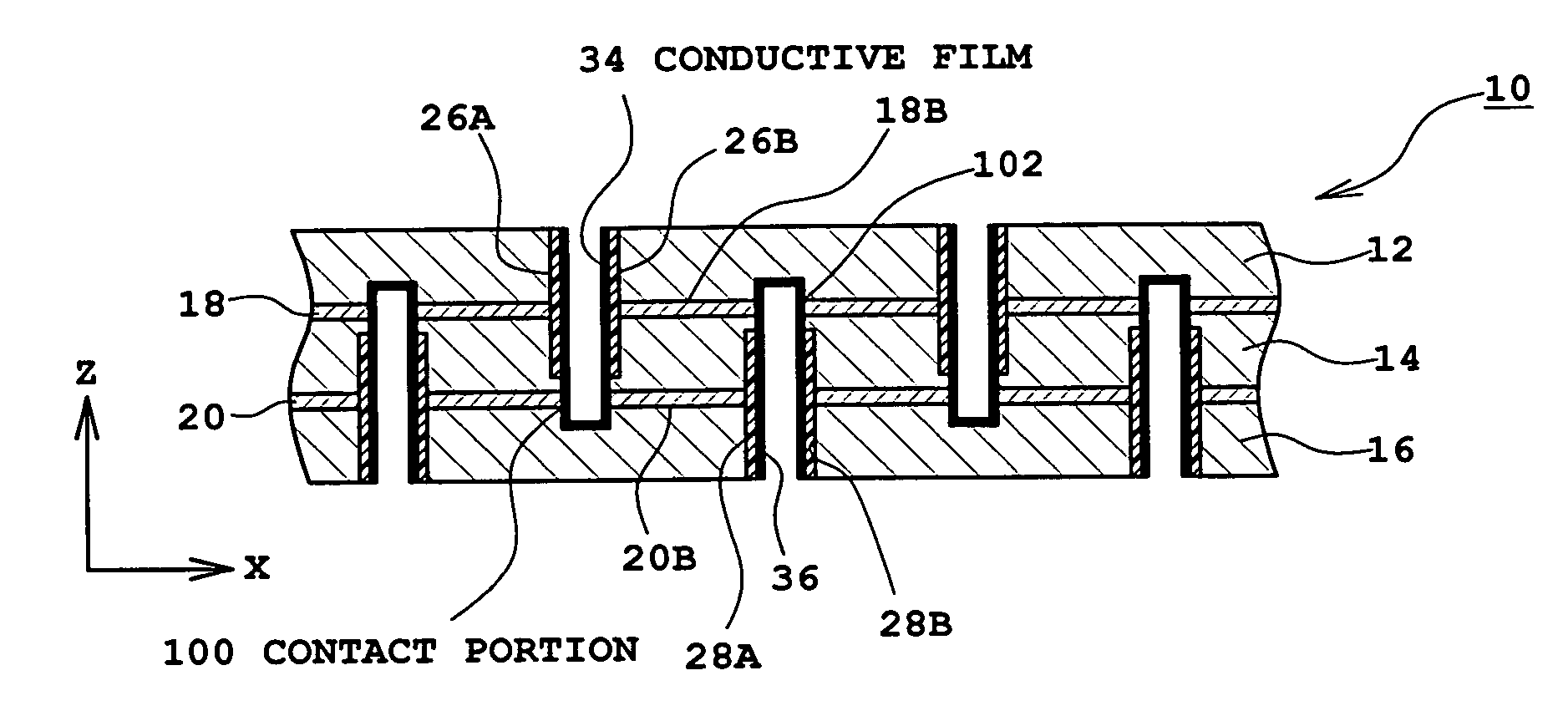

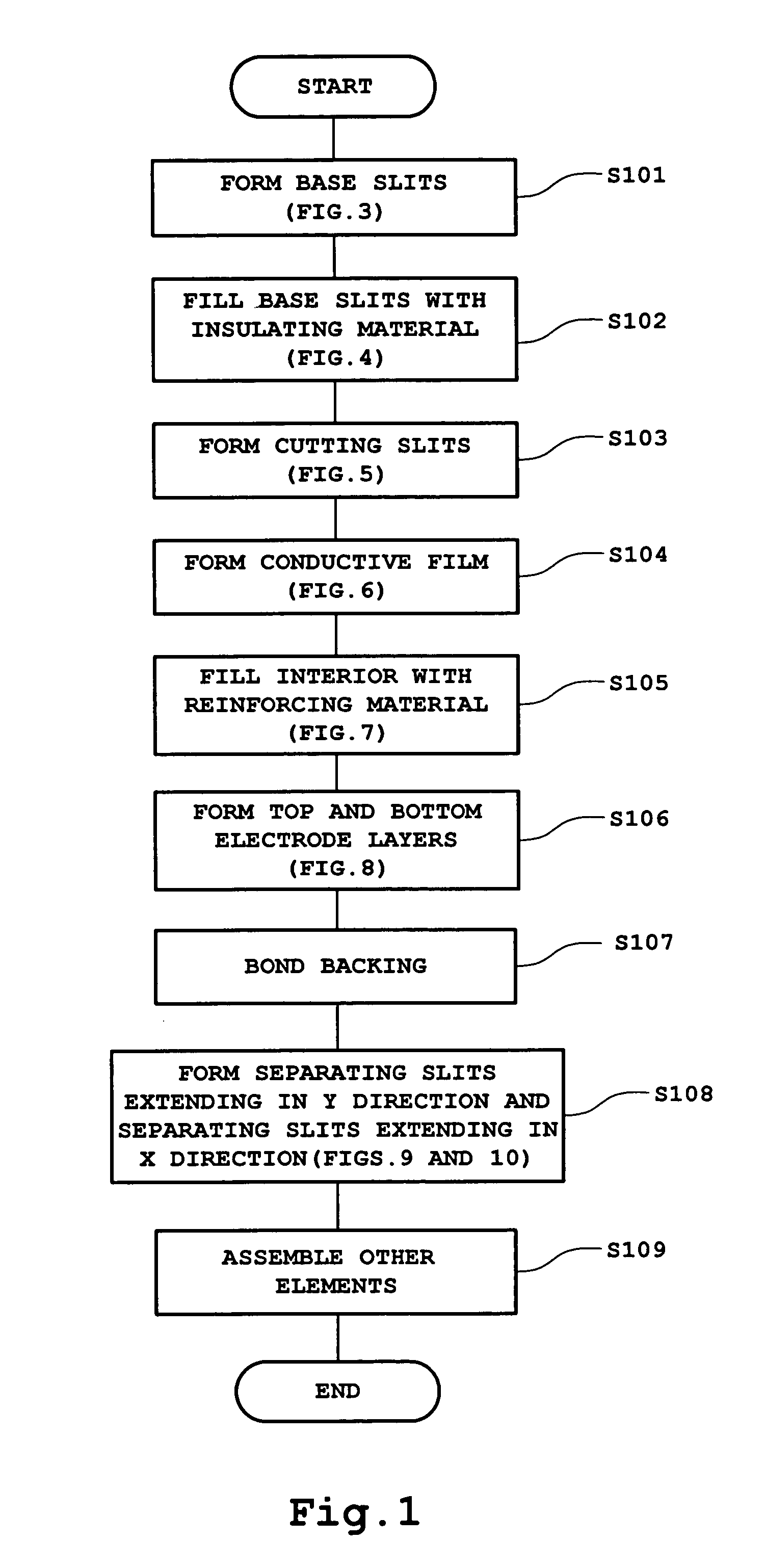

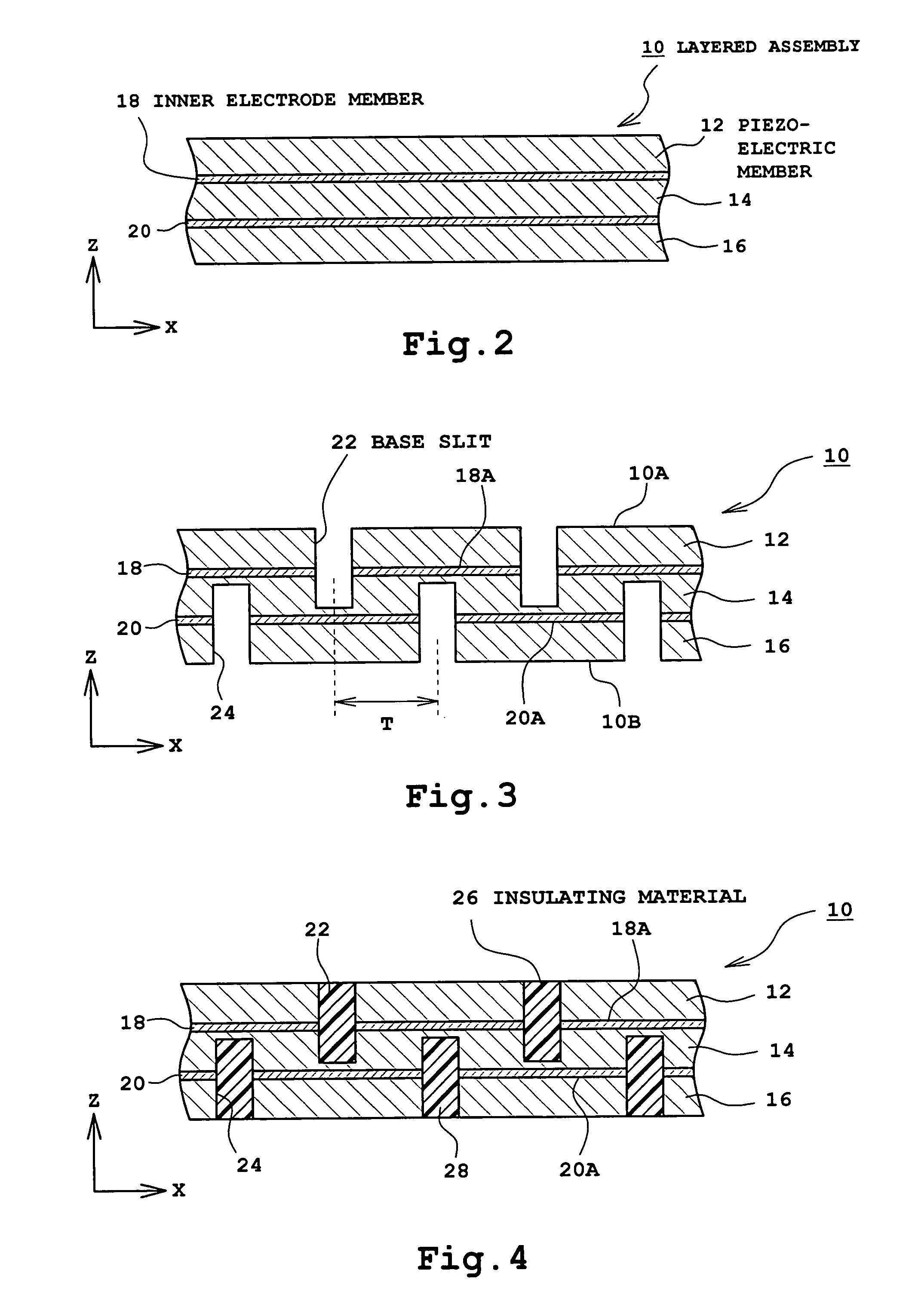

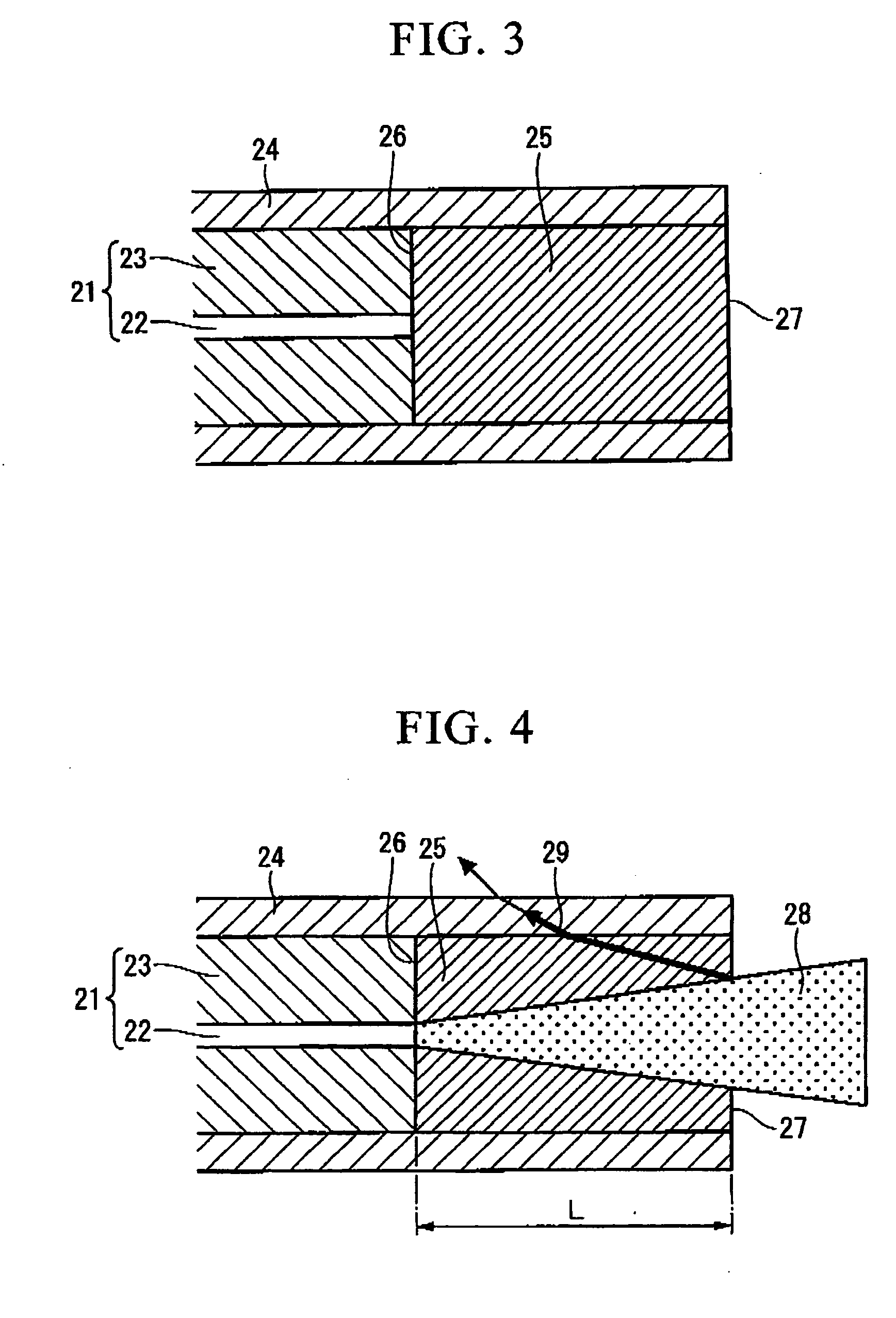

Ultrasonic probe and manufacturing method thereof

InactiveUS7148607B2Improve performanceEasy to manufactureUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblyBiological bodyLiving body

An ultrasonic probe for use in an ultrasonic diagnosis apparatus for a living body comprises an array transducer made up of a plurality of layered transducer elements. A specified structure (face-to-face structure) is created across two adjacent transducer elements. In each transducer element, a first vertical electrode layer for ground is connected with a top electrode layer and an inner electrode layer, and a second vertical electrode layer for signal is connected with a bottom electrode layer and an inner electrode layer. When creating the specified structure, steps including formation of slits in a layered assembly and filling of the slits or the like are repeated. By finally forming a plurality of separating slits, the layered assembly is divided into a plurality of transducer elements. On the other hand, each transducer element is compounded in the horizontal direction. The compounding is performed at any stage of before, during or after formation of the specified structure.

Owner:ALOKA CO LTD

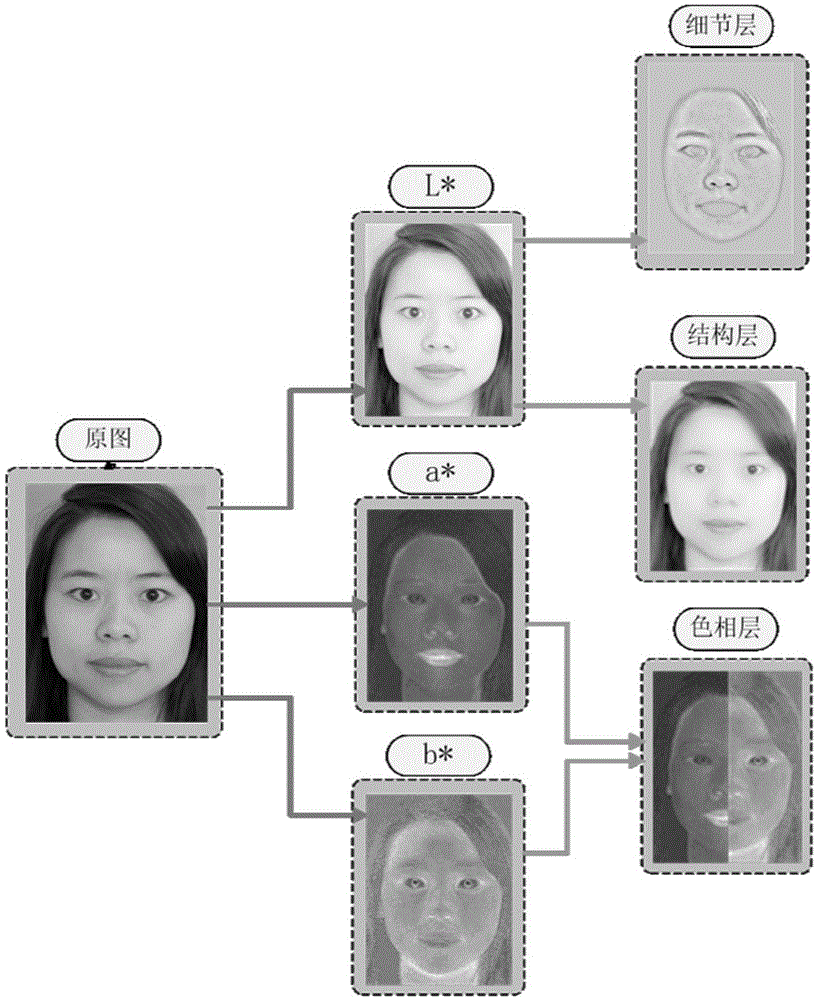

Facial image layer decomposition method based on improved guide filter

ActiveCN105469407ASmooth edgesSmall time complexityImage enhancementImage analysisPattern recognitionInformation layer

The invention provides a facial image layer decomposition method based on an improved guide filter, and the method comprises the steps: carries out the improved guide filtering of a facial image brightness channel, obtaining a human face structure information layer, further carrying out differential operation, and obtaining a texture detail layer. According to the invention, the method carries out the regularization factor adaptive adjustment optimization of a guide filter and Gaussian blurring and corrosion processing of a parameter matrix image, and obtains different filtering effects of a facial image in different regions. The method is used for a digital makeup system, obtains an excellent layer decomposition effect, and remarkably reduces the time complexity of layer decomposition.

Owner:SOUTH CHINA UNIV OF TECH

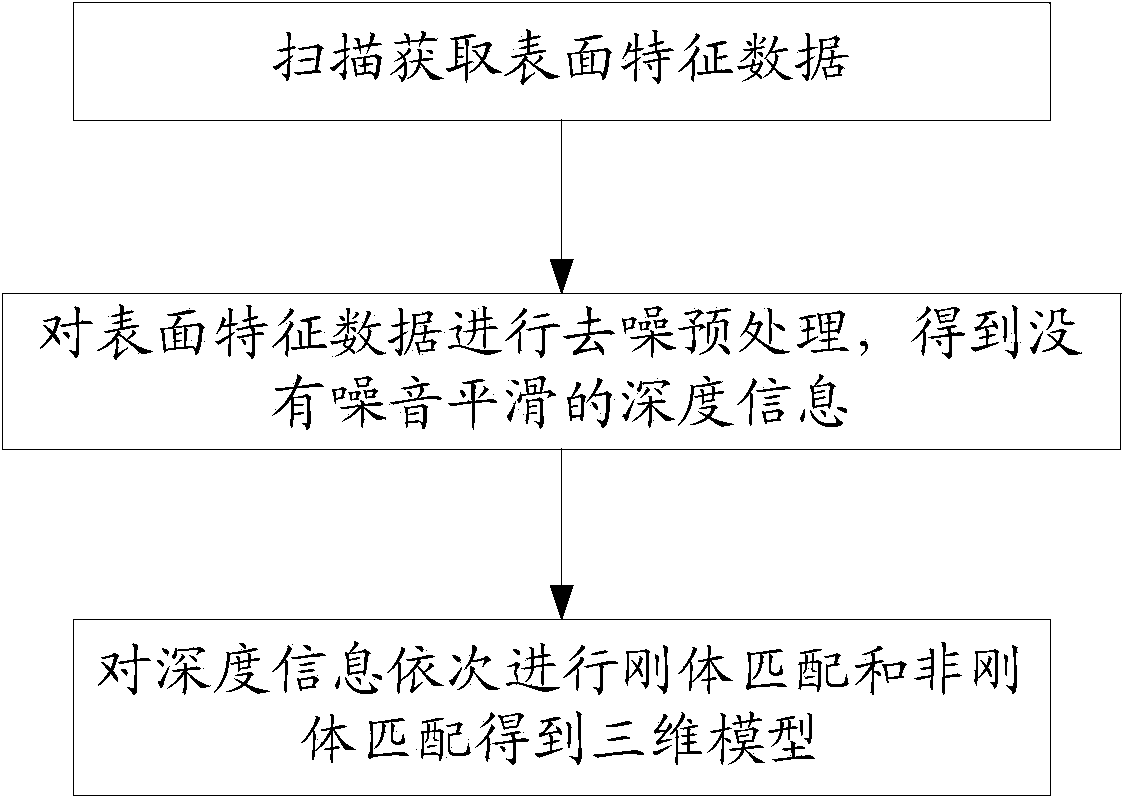

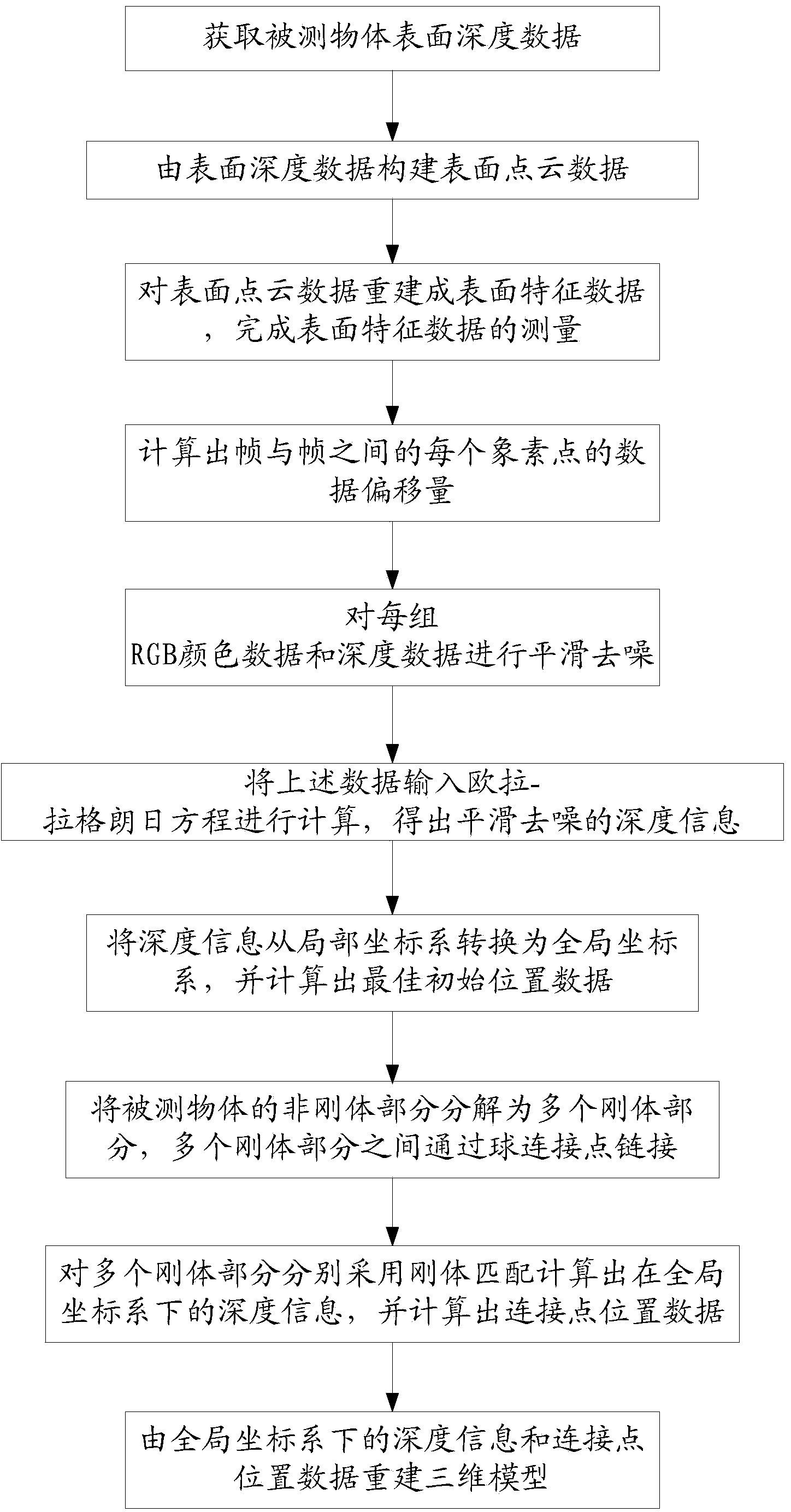

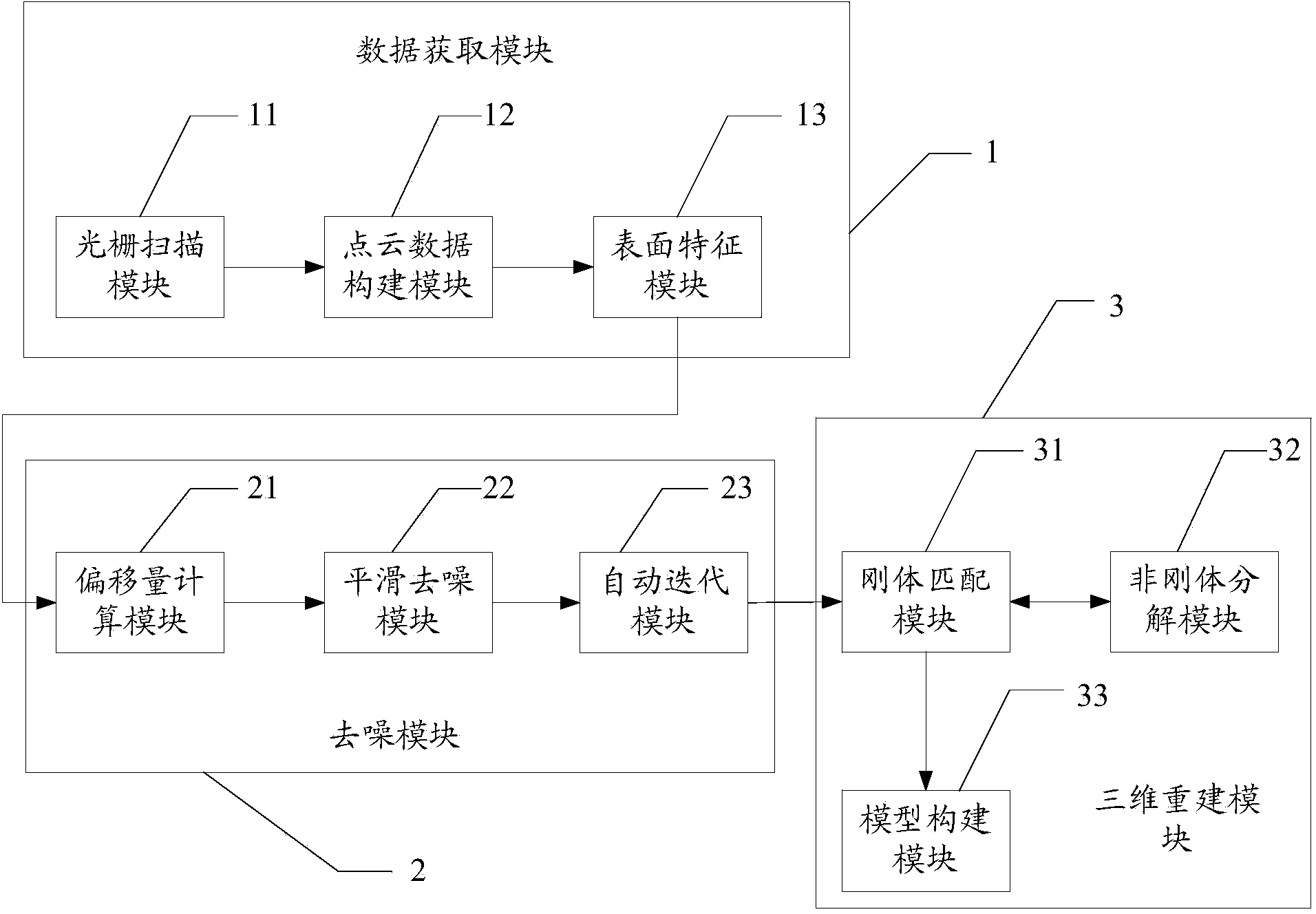

Digital human body three-dimensional reconstruction method and system based on Kinect device

ActiveCN103955963AShort scan timeShort computing time3D modellingReconstruction methodSystem stability

The invention relates to a digital human body three-dimensional reconstruction method based on a Kinect device. The method specifically includes the following steps that firstly, scanning is performed, and surface feature data are obtained; secondly, denoising preprocessing is performed on the surface feature data, and smooth depth information without noise is obtained; thirdly, rigid-body matching and non-rigid-body matching are sequentially performed on the depth information, and a three-dimensional model is obtained. According to the digital human body three-dimensional reconstruction method, the scanning time is short, the scanning process is simple, a hardware device needed in scanning is simple, coordination with other people or instructions learning in advance are not needed in the scanning process, the result geometric accuracy is high, the face structure, the clothes texture structure and the like are quite clear, due to a test, the system stability is high, a one-button mode is adopted in a whole system, a user does not need to set any parameter or change, a final result can be obtained as long as one button is pressed, the operation time is short, and a color map is automatically generated.

Owner:崔岩

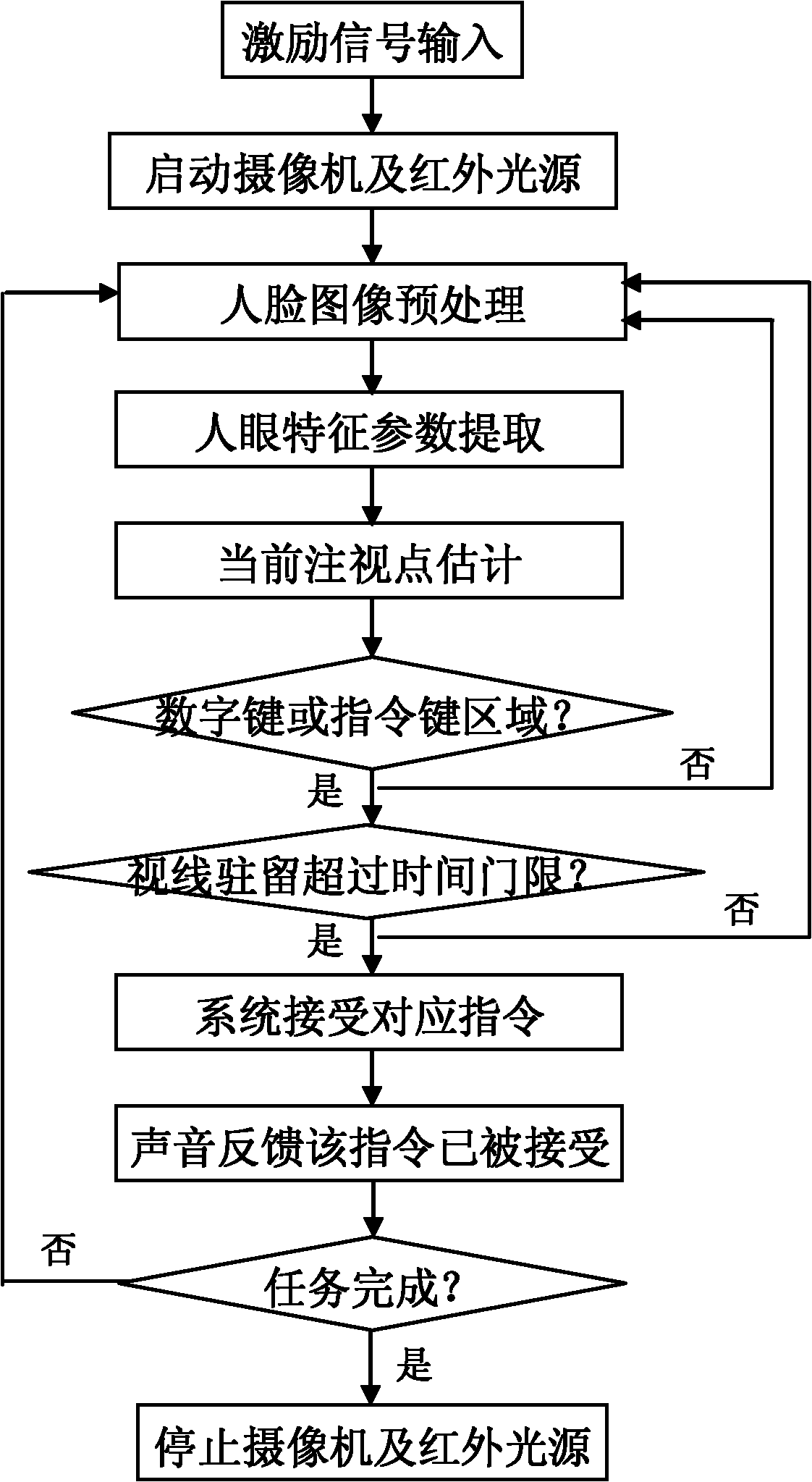

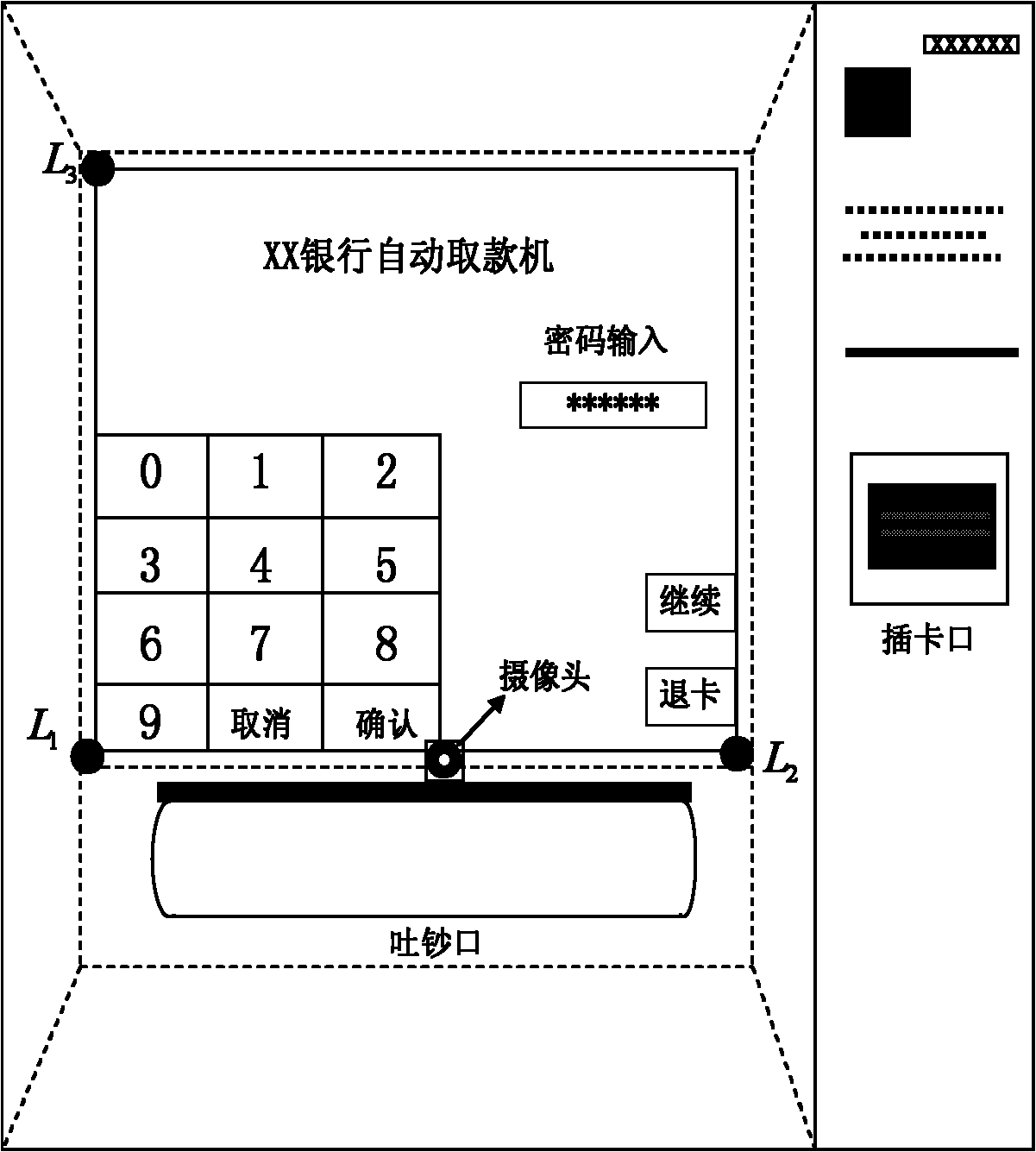

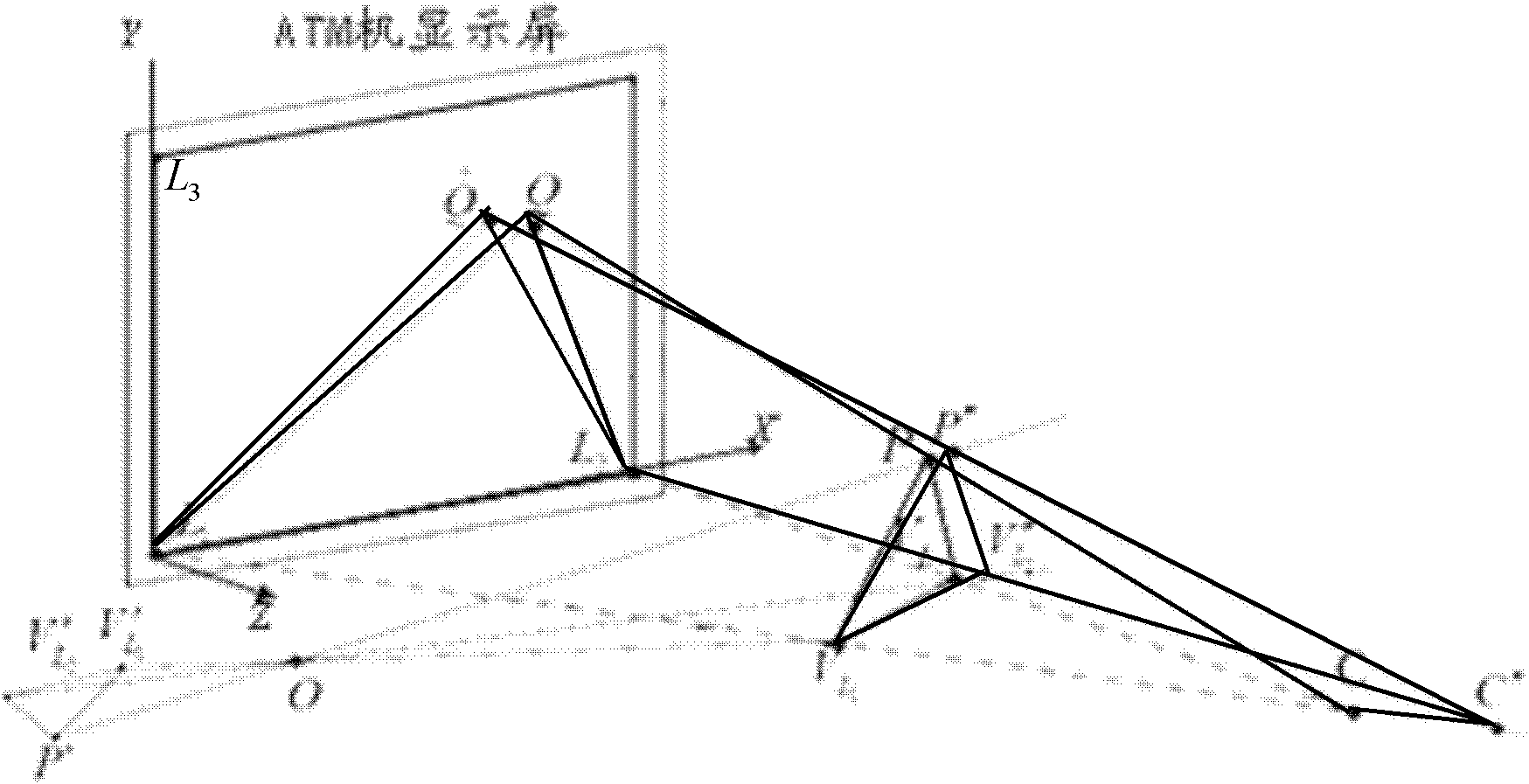

Method for controlling password input based on eye-gaze tracking

InactiveCN102129554AAvoid cross infectionImprove securityInput/output for user-computer interactionCharacter and pattern recognitionBacterial virusFixation point

The invention provides a method for controlling the password input based on eye-gaze tracking, specifically comprising the following steps of: (1) preprocessing face images and extracting eye characteristic parameters: detecting a face according to face structure characteristics, and extracting the eye characteristic parameters in a face area according with the face structure characteristics; (2)estimating the current fixation point position: realizing the estimation from the eye characteristic parameters to the current fixation point position by using double light source eye-gaze tracking based on similar triangles; and (3) controlling a password input operation according to the fixation point position: controlling the password input operation by utilizing a time threshold and sound feedback according to the fixation point position. The invention can effectively prevent user password from being stolen, avoids the cross infection among different individuals by residual bacterial virus on a keyboard because the password is not inputted through the keyboard and has the characteristics of simpleness, convenience and higher safety.

Owner:SHANDONG UNIV

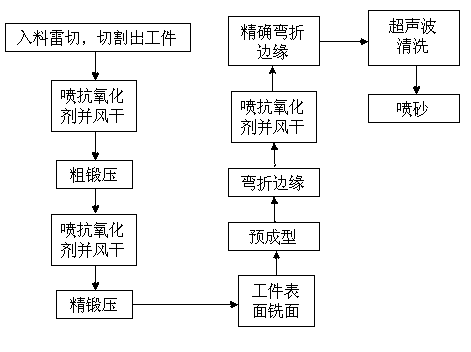

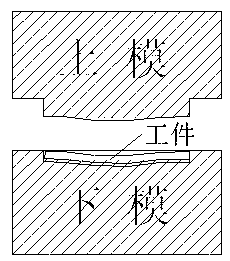

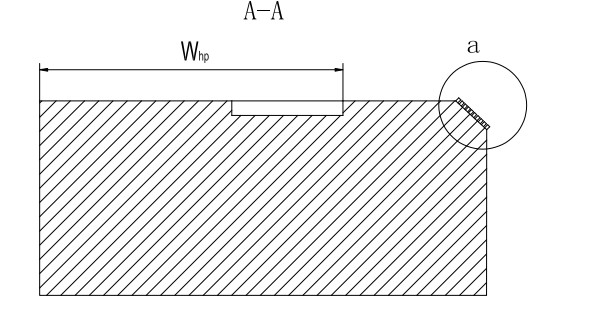

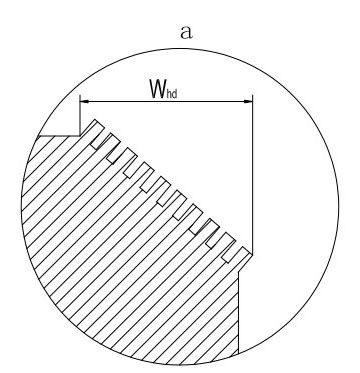

Manufacture method of golf club head striking face and golf club head striking face structure

ActiveCN102989144AQuality improvementRealize rapid prototypingGolf clubsRacket sportsPunchingEngineering

The invention relates to a manufacture method of a golf club head striking face and a golf club head striking face structure. The manufacture method of the golf club head striking face includes utilizing a laser device to conduct laser cutting on a plate to form a work piece, utilizing an oil press to conduct coarse forging and pressing to form a preliminary hollow outline shape, utilizing the oil press to conduct fine forging and pressing to form an accurate middle outline shape, utilizing a machining machine platform to conduct face milling on the front face of the work piece, utilizing the oil press to preform the work piece to enable the work piece to be formed into a bending shape with the curve radius range to be 100mm-500mm, utilizing a punching machine or the oil press to punch the work piece vertically to enable the edge of the work piece to be bent backwards to form a 'C' shaped or an 'L' shape and utilizing the oil press to punch the work piece vertically to conduct accurate bending and reshaping on the edge of the work piece. The forging and pressing mode is utilized to form the work piece in extruding mode and achieve quick forming of a product. A spraying gun is utilized to spray antioxidant or parting agent on the surface of the work piece after the forging and pressing process, and the surface is aired. The method can improve quality of the work piece in the middle manufacture process and improve pass ratio and machining efficiency.

Owner:吴景霖

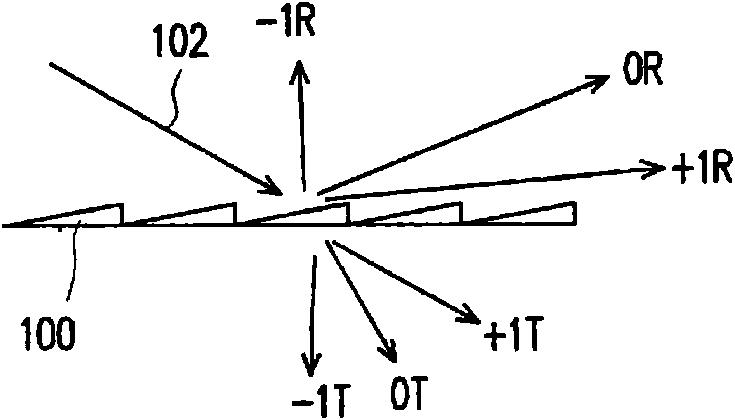

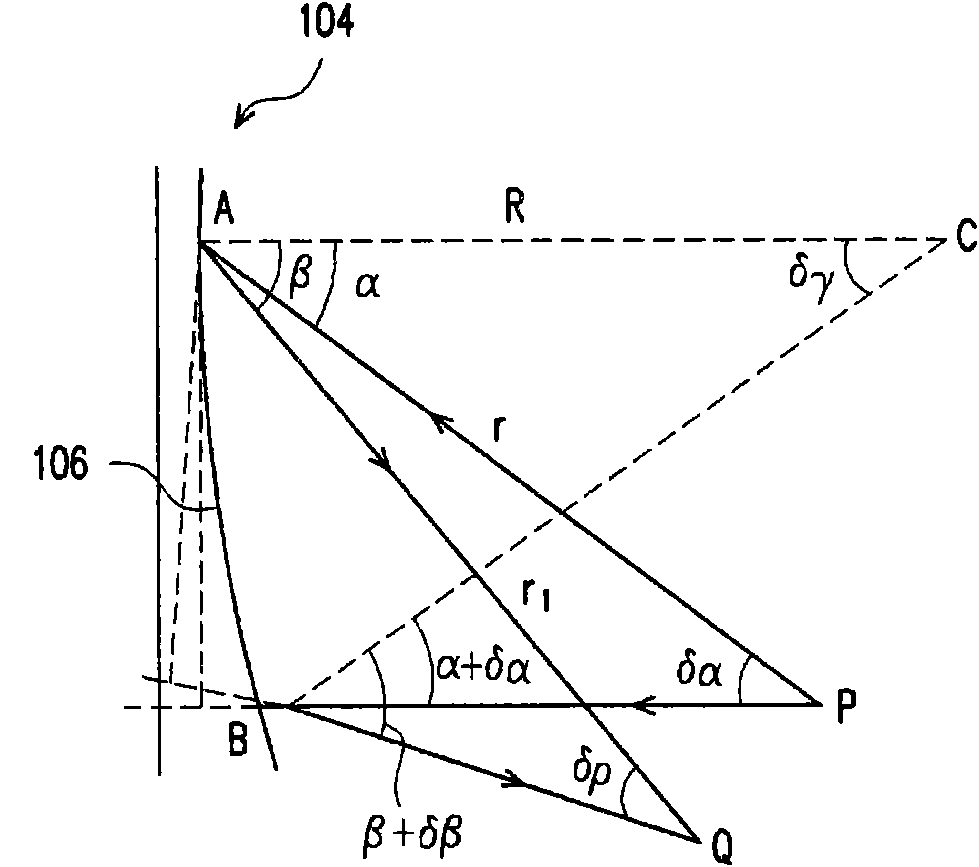

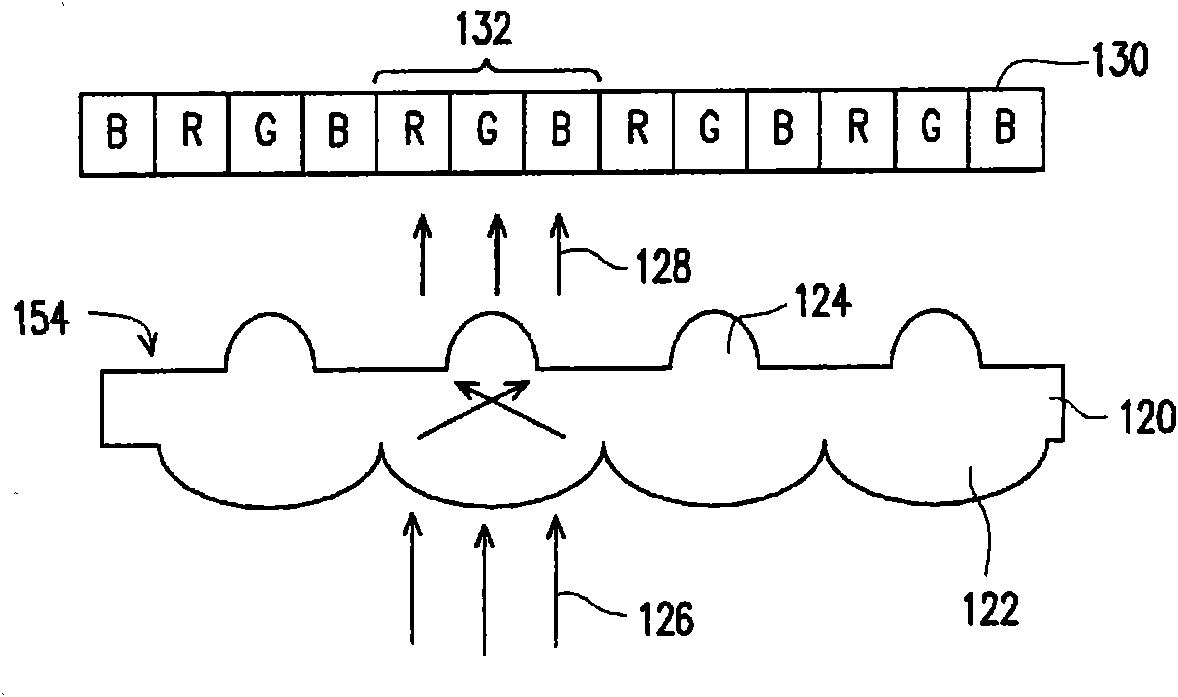

Color split optical element and image panel device

The invention discloses a color split optical element and an image panel device. The color separating optical element has an integrated double-face structure, and each face comprises a micro / nano structure. The optical element can split beams and colors for an incident light source containing different wavelengths. In a space, the primary incident light source is equally split into array beams according to the intensity, and meanwhile the beams with different wavelengths are split into sub light sources according to the wavelengths to form the color split transmission function of color arrays. The optical element of adjustable light wave colors can convert a broadband incident light source into sub beams of array split colors (split waves) and split beams.

Owner:IND TECH RES INST

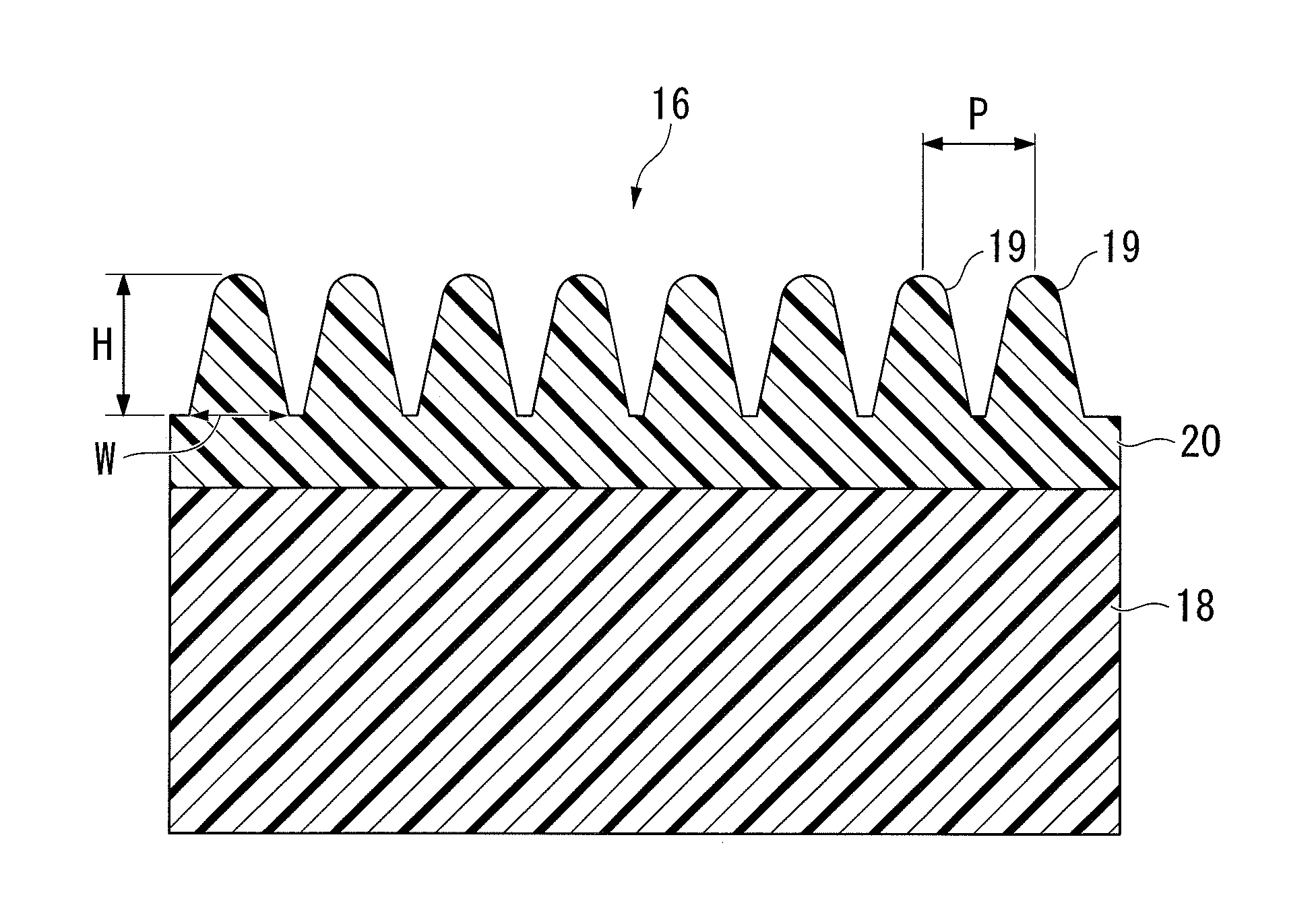

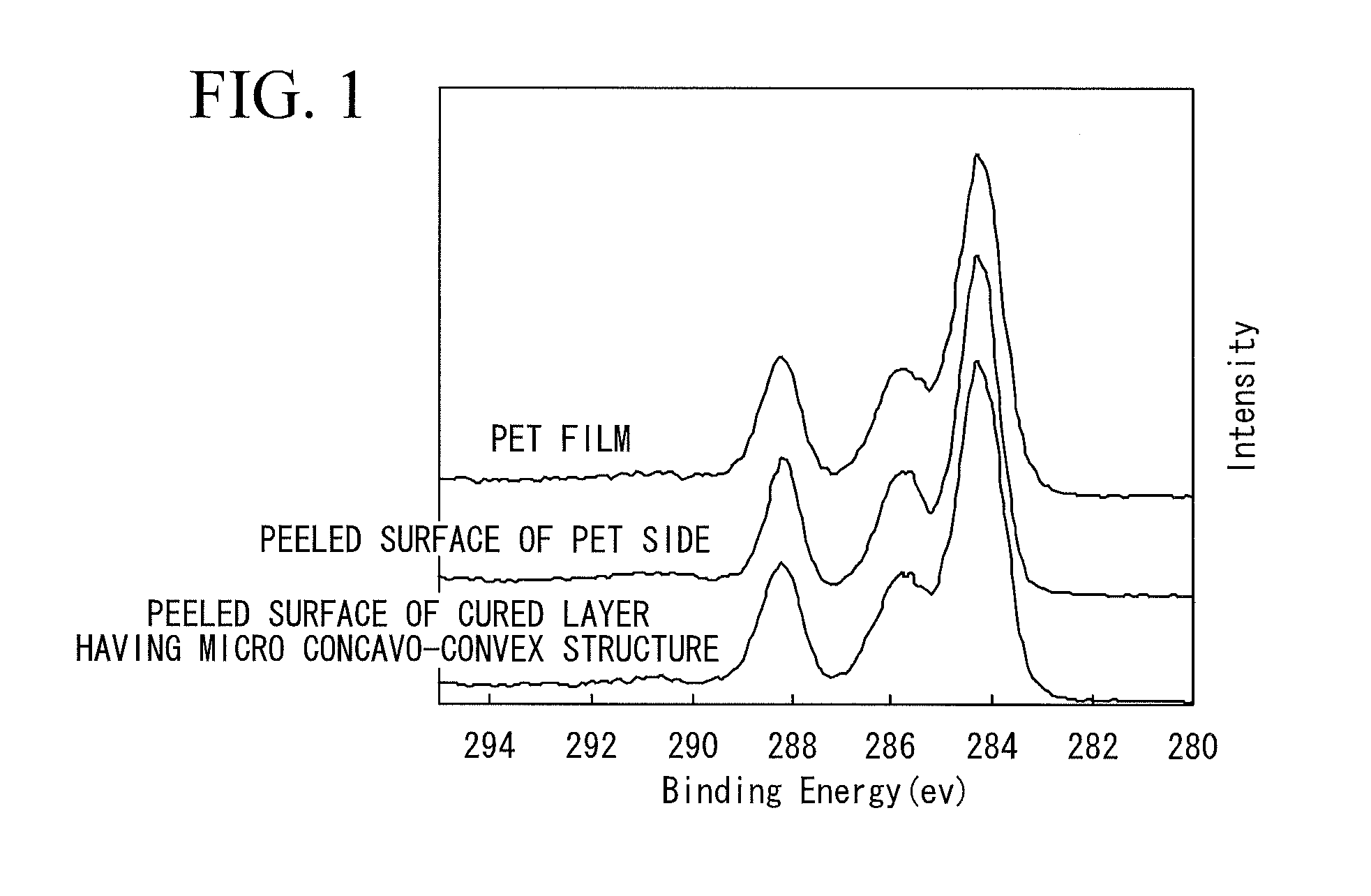

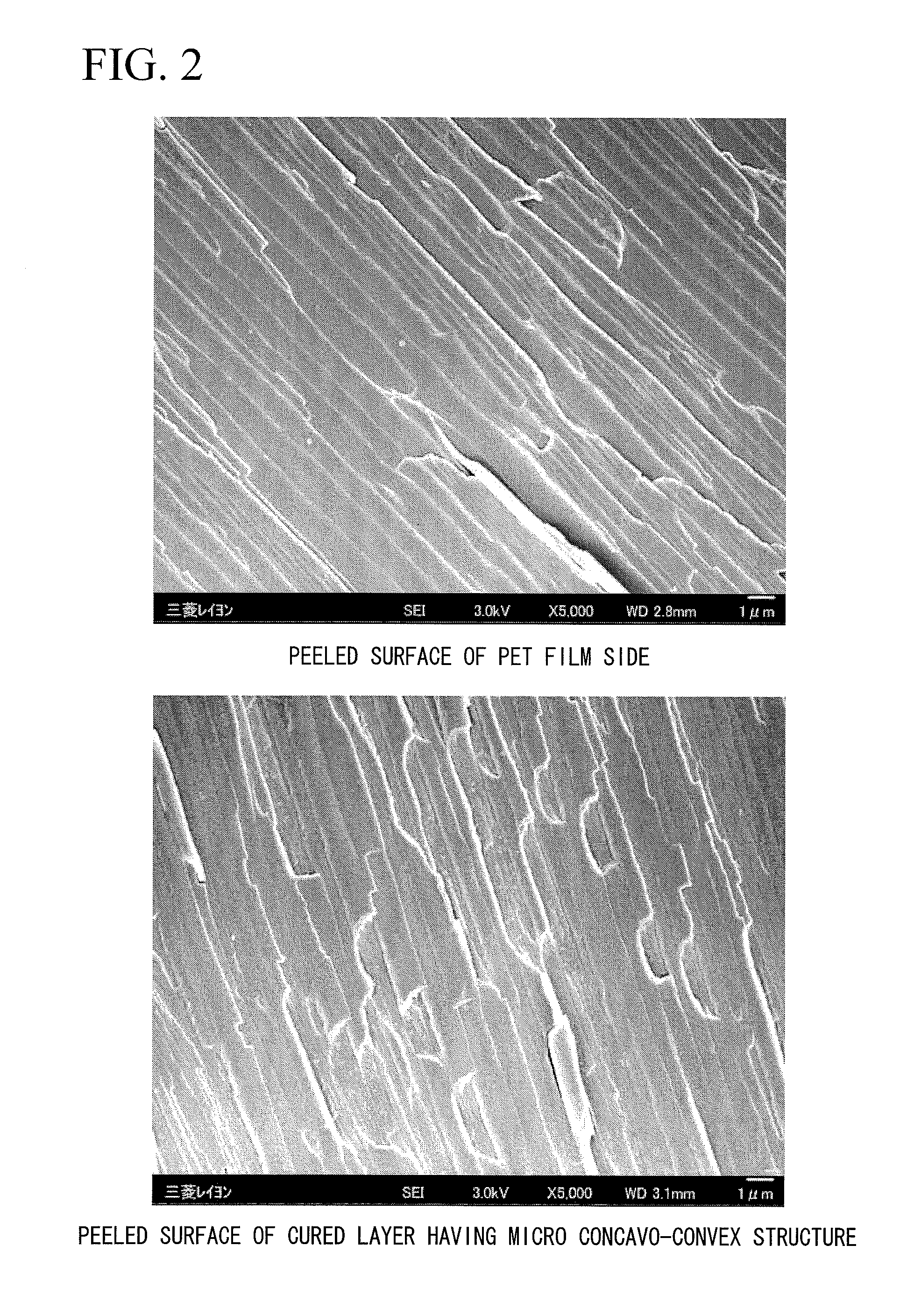

Process for producing film

InactiveUS20110318539A1Stable preparationSynthetic resin layered productsThin material handlingUltravioletPhotochemistry

The present invention provides a method making it possible to stably prepare a transparent film in which a cured layer having a micro protrusion and recess face structure is formed on the surface of a base material film. The preparation method of the present invention includes a step of sandwiching an active energy beam-curable resin composition including a photopolymerization initiator which can initiate polymerization of a polymerizable compound by absorbing light between the surface of a base material film which is supported by a supporting film, and a mold which has an inverse structure of the micro protrusion and recess face structure on the surface; a step of obtaining the transparent film supported by the supporting film by means of irradiating the active energy beam-curable resin composition with ultraviolet rays from the supporting film side; and a step of separating the transparent film and the mold.

Owner:MITSUBISHI RAYON CO LTD

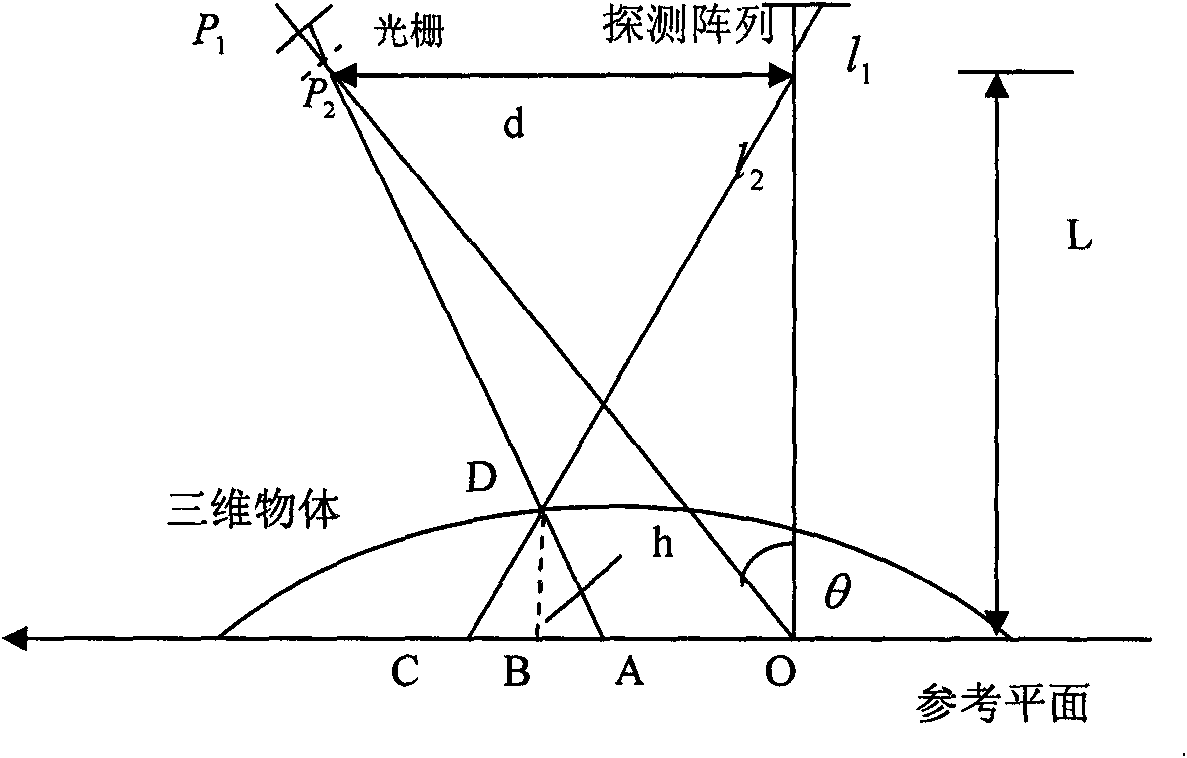

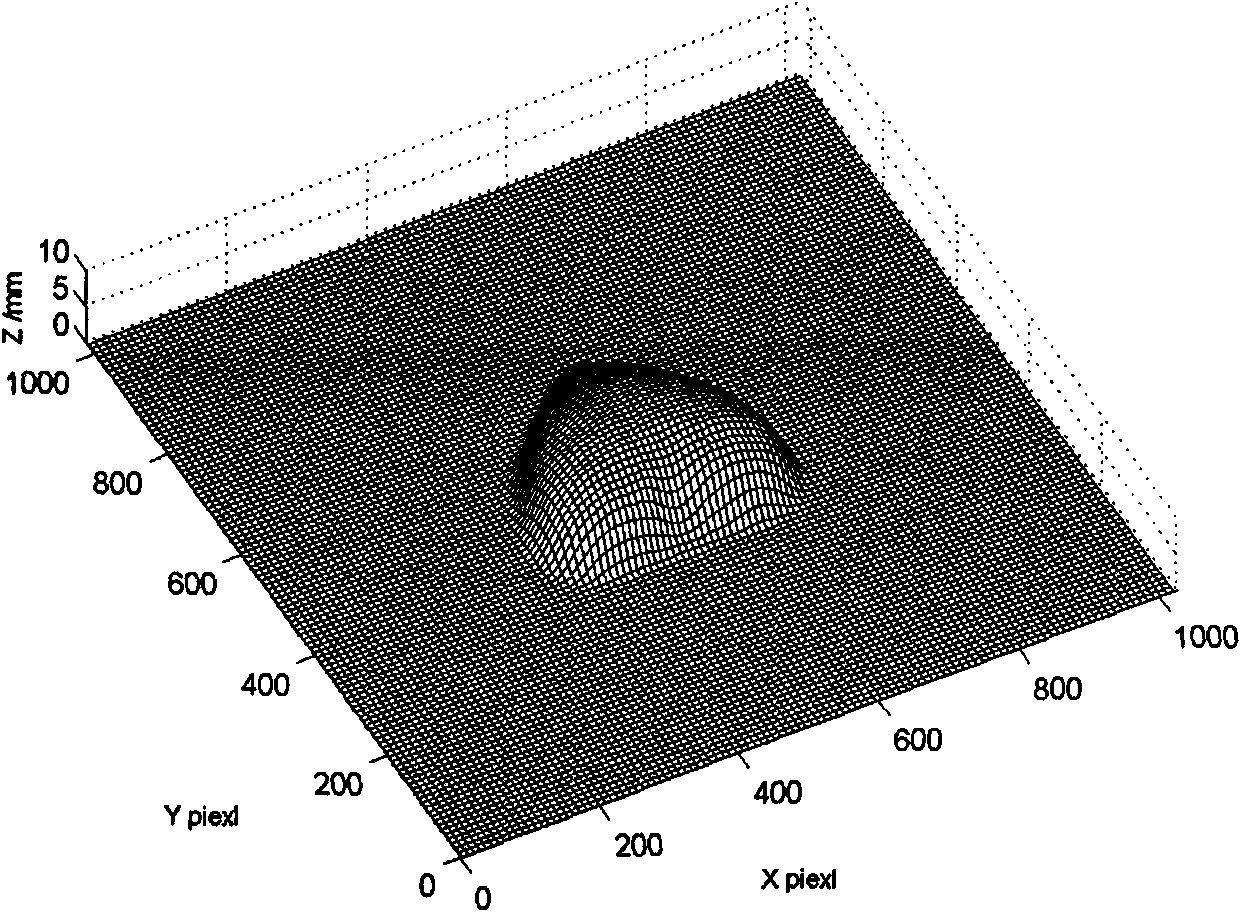

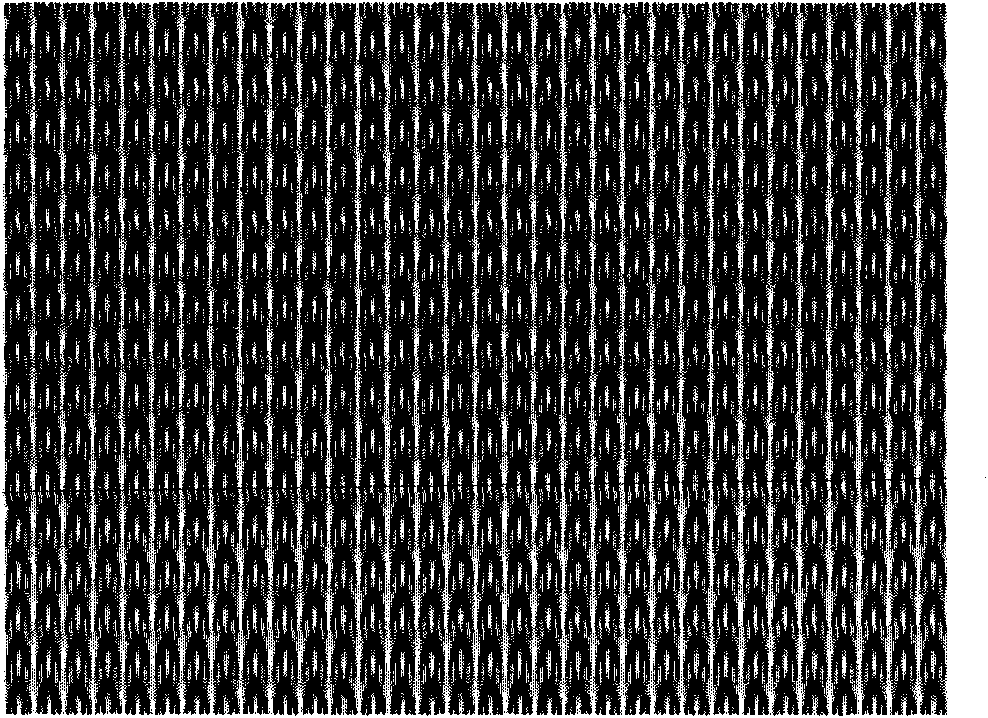

Method for realizing real-time three-dimensional shape measurement by using unequal step phase shifting cross grating

InactiveCN101655359AReal-time measurementHigh measurement accuracyUsing optical meansFrequency spectrumGrating

The invention provides a method for measuring three-dimensional shapes and deformation of objects in real time by using unequal step phase shifting cross grating in the three-dimensional sensor technology. The invention is characterized by using computers to design the unequal step phase shifting cross grating of codes, adopting an optical projection means to image a face structured tuned templateof the grating on the surface of an object by projection, using a pick-up device to record the deforming fringe pattern of the object, subsequently processing the deforming fringes by a Fourier transform spectrum filtering method and unequal step phase shifting phase measuring profilometry, accurately restoring the three-dimensional shape of the object and obtaining such digital information as deformation of the object and the like by further analyzing the data processing results. The method can be used for measurement study of the characteristics of the object surface with the characteristicof diffuse reflection. The method has the advantages of high measurement precision, quick response and good capability of obtaining the three-dimensional shape data and the like of the object in realtime.

Owner:SICHUAN UNIV

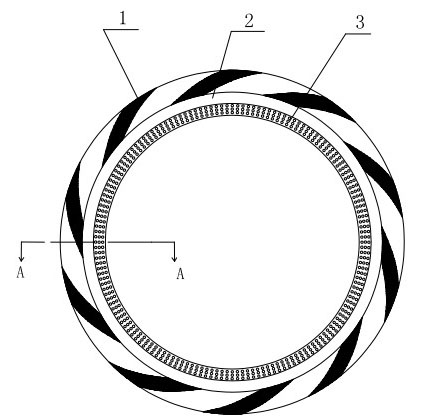

Self-sealed zero leakage hydrophobic molded surface mechanical sealing end face structure

ActiveCN101975274AReduce leakageReduce or avoid wear and tearEngine sealsDynamic pressureFace structure

The invention discloses a self-sealed zero leakage hydrophobic molded surface mechanical sealing end face structure, which comprises a dynamic ring and a static ring which are mechanically sealed, wherein at least one sealed end face of the dynamic ring or the static ring is a composite molded surface consisting of a microgroove dynamic pressure ring belt, a sealed dam and a hydrophobic molded surface distributed in turn from high to low direction. The structure has the advantages that: the self-sealing property of the narrow hydrophobic molded surface can obviously reduce the leakage and even reaches zero leakage; by adopting one or more hydrophobic molded surfaces, the abrasion of the end faces can be reduced or avoided, and the integral sealing property and the abrasion resistance of mechanical seal can be greatly improved; and by adopting the combination mode of the microgroove dynamic pressure ring belt and the hydrophobic molded surface, a lubricating medium can be stored in the end faces to prevent dry grinding of the end faces when the machine is started and improve the opening property and the reliability of mechanical seal.

Owner:SICHUAN ZIGONG IND PUMP

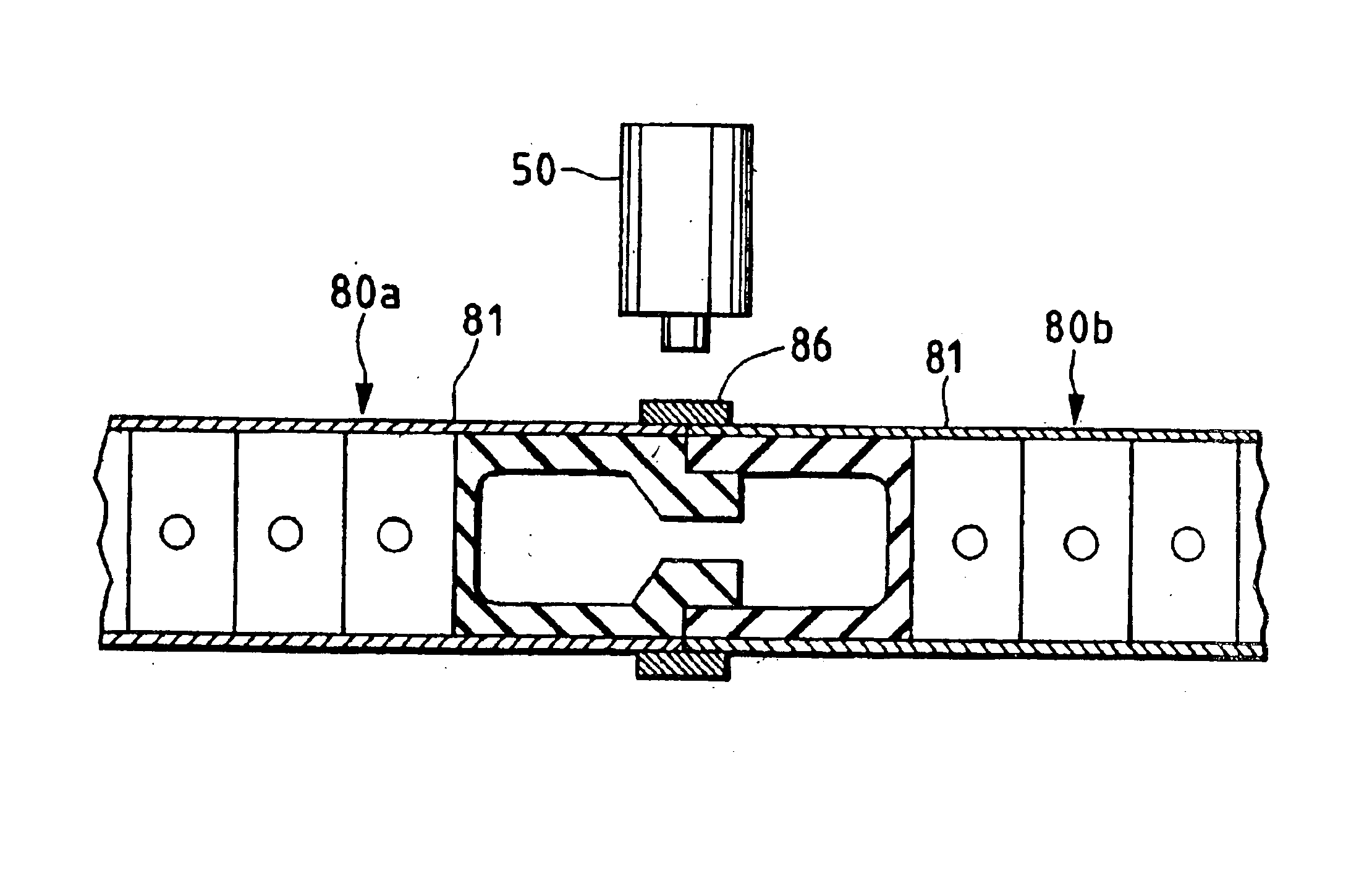

Friction stir welding method of opposite sides of panels

InactiveUS6862860B2Deformation MinimizationShort timeConstruction materialLayered productsFriction weldingParallel plate

This invention provides a configuration of a joint that allows a satisfactory welded joint to be formed with reduced deformation of the joint region when two-face structures (panels) are friction-welded end to end. The panels 31, 32 each have two substantially parallel plates 33, 34 and a third member 35 connecting the two plates 33, 34. The end portions of the plates 33, 34 of one panel 32 are friction-welded to the end portions of the plates 33, 34 of the other panel 32. At least one of the panels has a plate 36 at its end for connecting the plates 33 and 34 and has a rigidity to support a pressing force produced during the friction welding.

Owner:HITACHI LTD

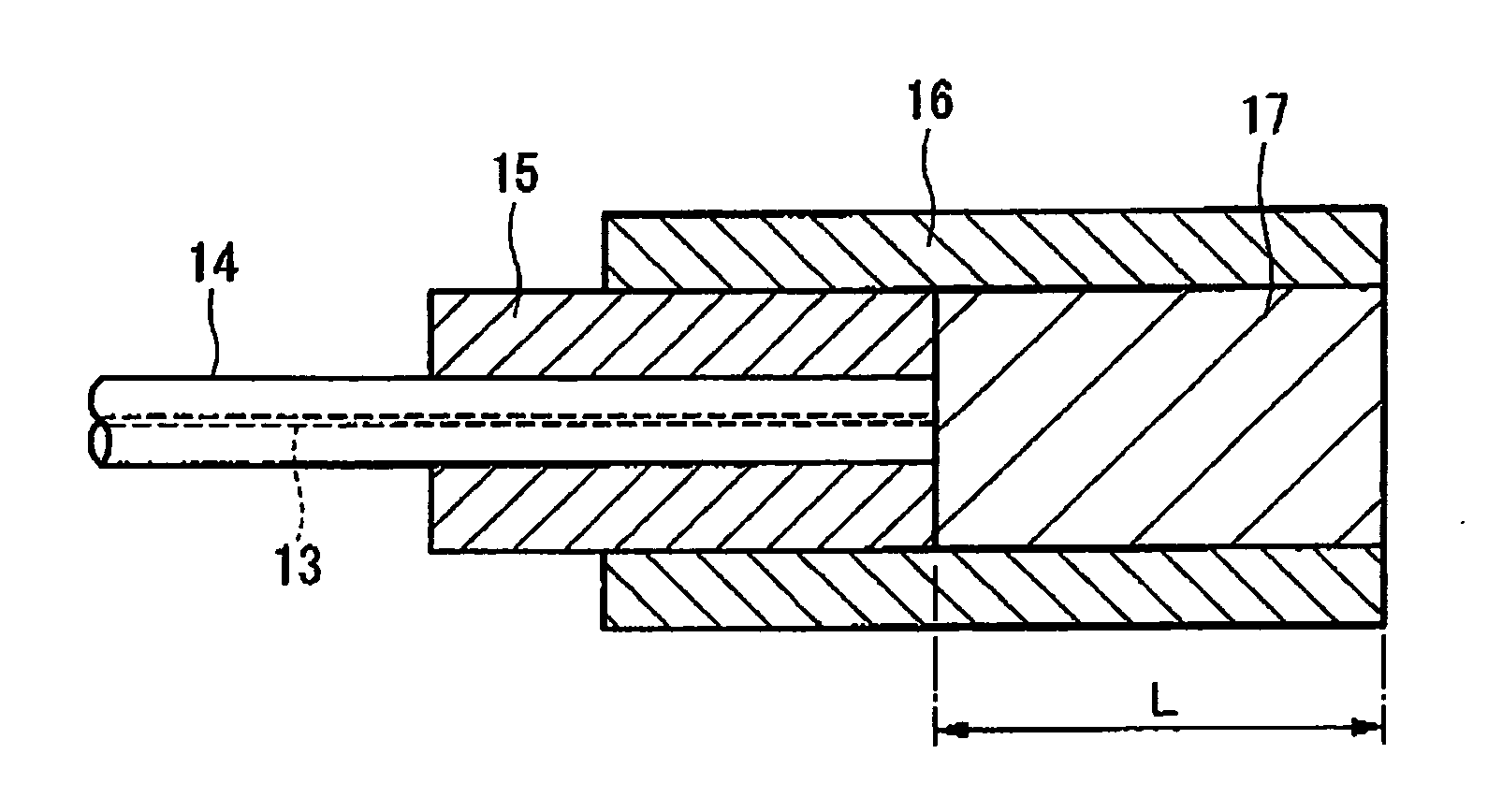

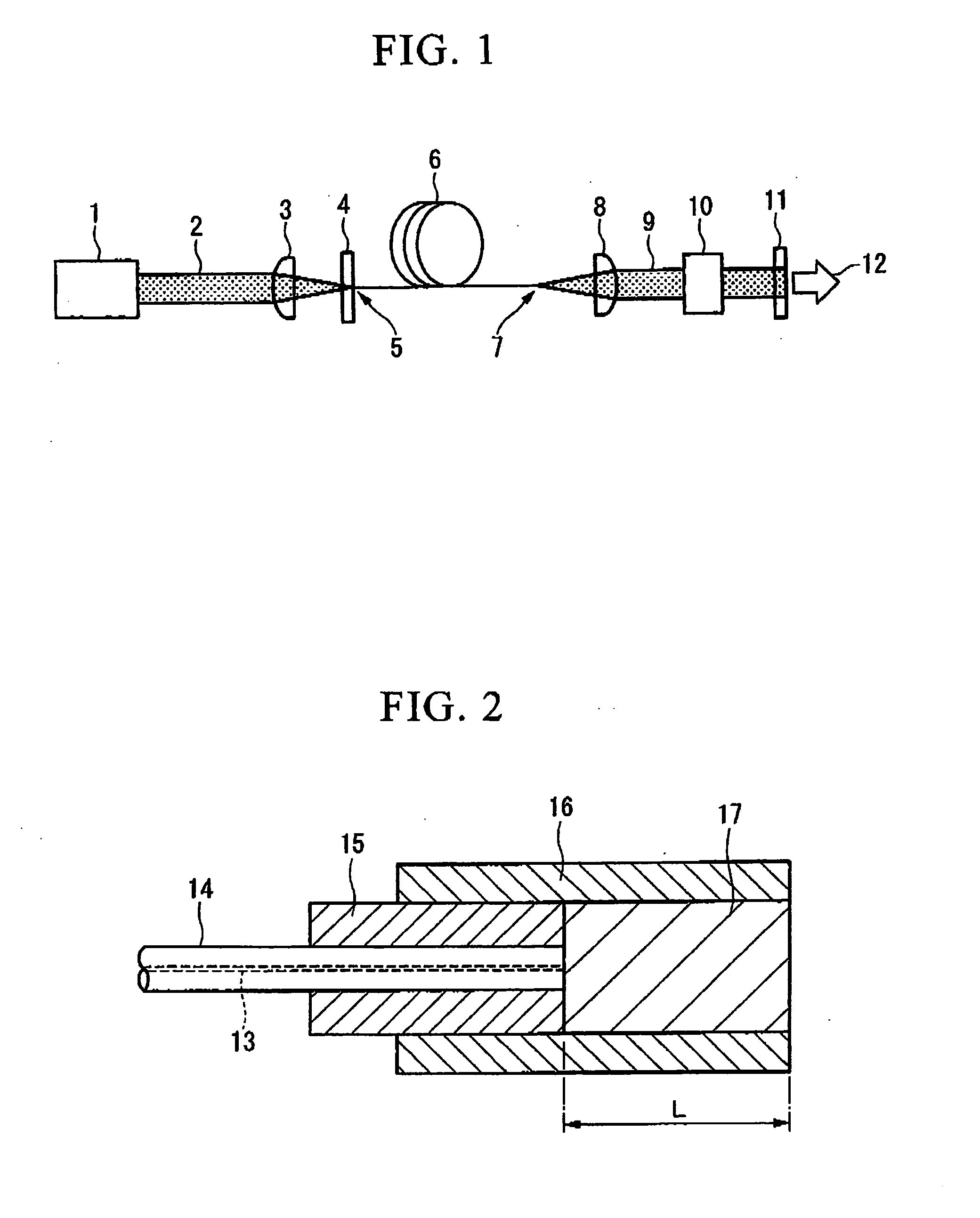

End face structure of optical fiber, optical fiber laser, and laser processing apparatus

ActiveUS20050244101A1Low costAvoid damageLaser using scattering effectsOptical fibre with graded refractive index core/claddingLaser processingRefractive index

An end face structure of an optical fiber includes a coreless fiber fused to an emitting end face of the fiber optical fiber and a coating material disposed around at least the coreless fiber, a refractive index of the coating material being higher than a refractive index of the coreless fiber.

Owner:THE FUJIKURA CABLE WORKS LTD

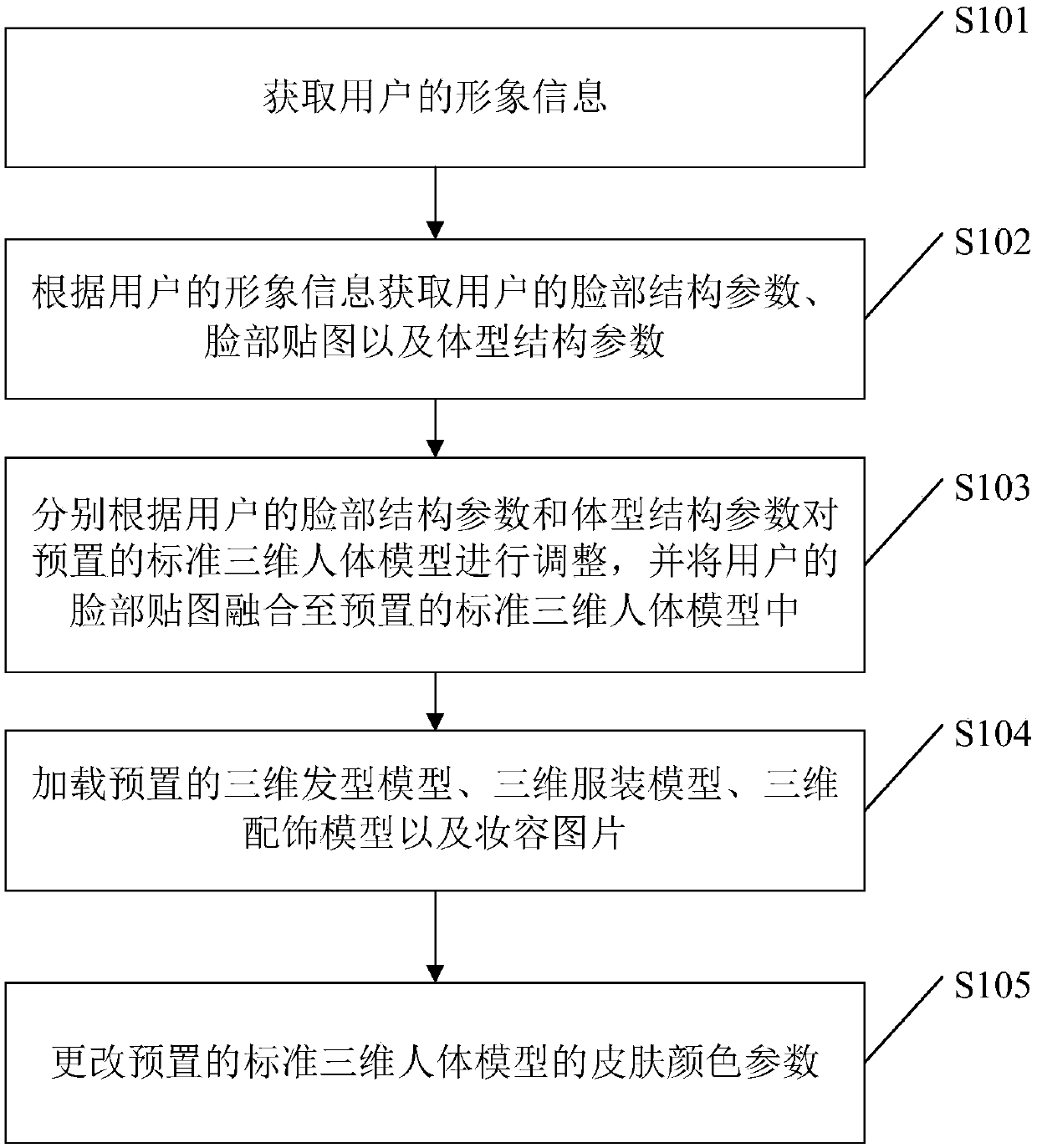

Method and system for creating 3D human body model based on user image

InactiveCN107680167AImprove user experienceImage enhancementImage analysisBody shapeHuman-body model

The embodiments of the invention disclose a method and a system for creating a 3D human body model based on user image. Image information of a user is acquired from a photo or video containing user image, the face structure parameters, face attached picture and body shape structure parameters of the user are obtained, and a preset standard 3D human body model is adjusted according to the face structure parameters and the body shape structure parameters to get a 3D human body model of the user. The face attached picture is fused together with the original face attached picture of the preset standard 3D human body model so that the 3D human body model of the user obtained can be identified as the 3D human body model of the user. Compared with the prior art, the image of the user is combinedwith the 3D human body model in the embodiment of the invention, so that the user experience in e-business, pan entertainment, game, image and other fields is greatly improved.

Owner:深圳羽迹科技有限公司

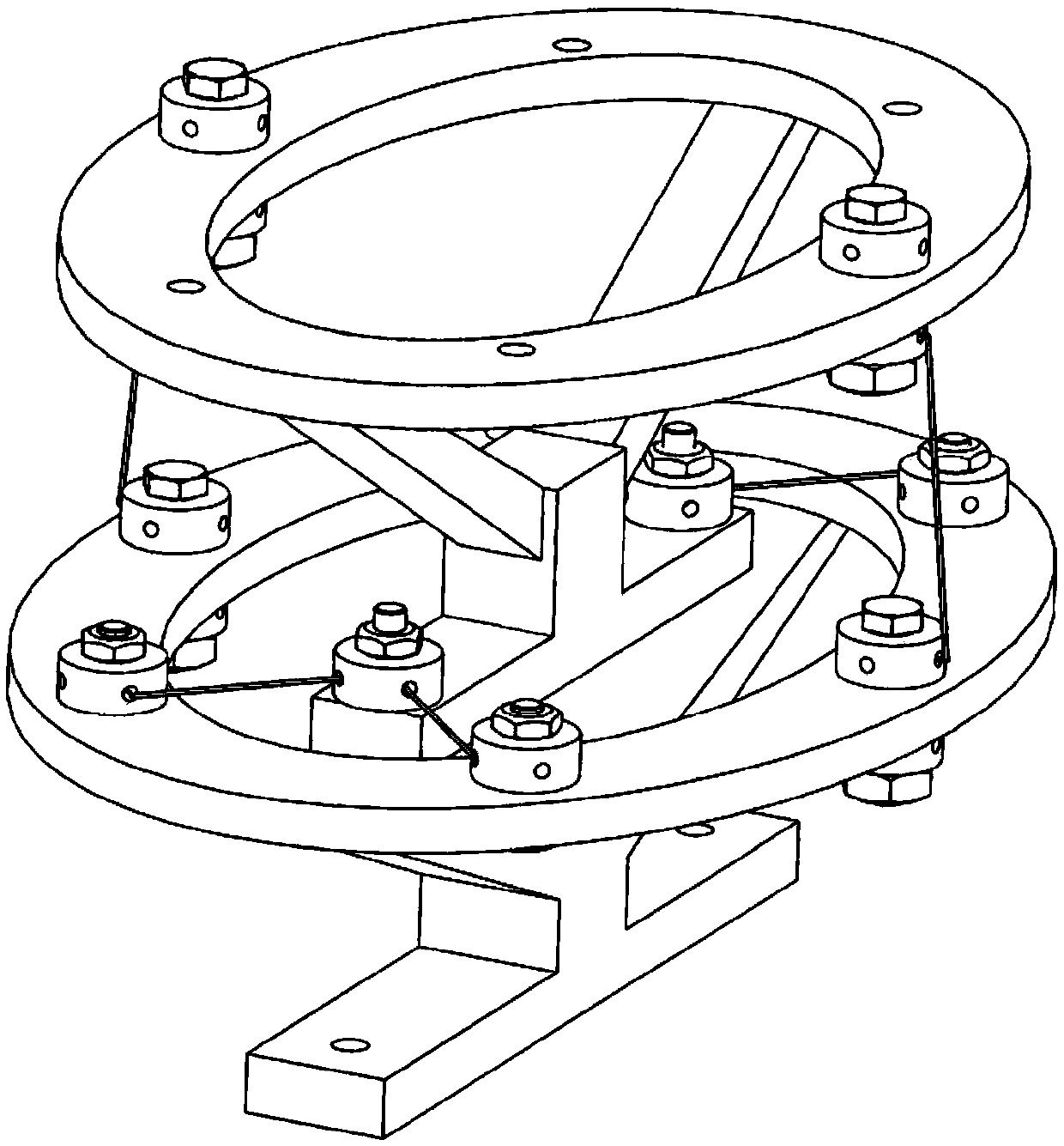

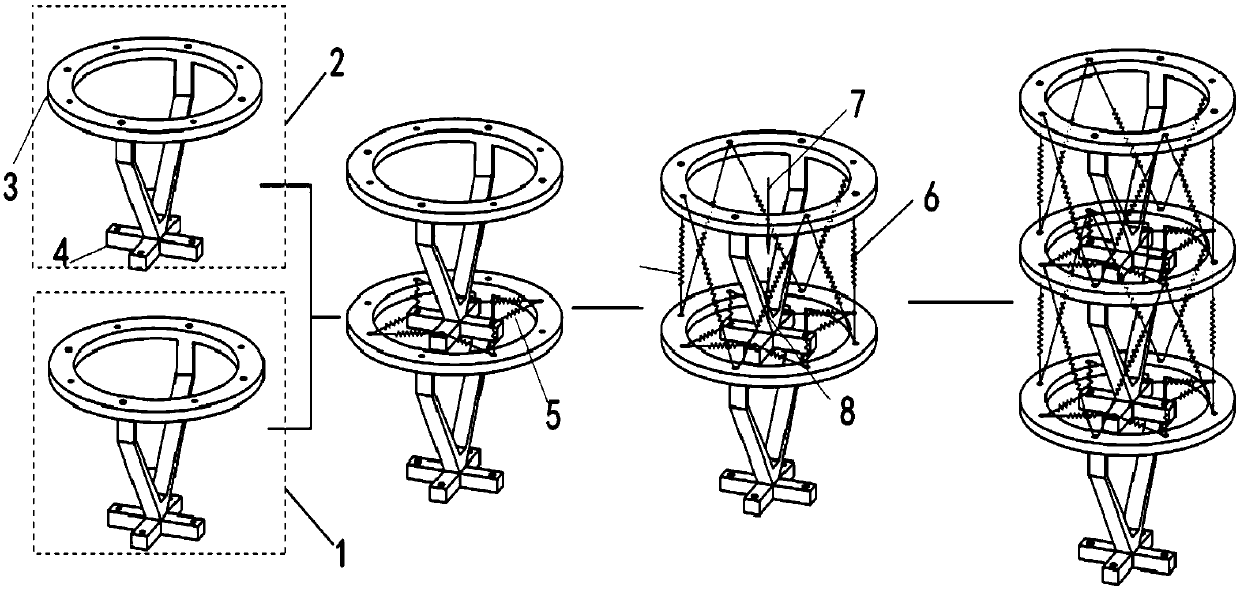

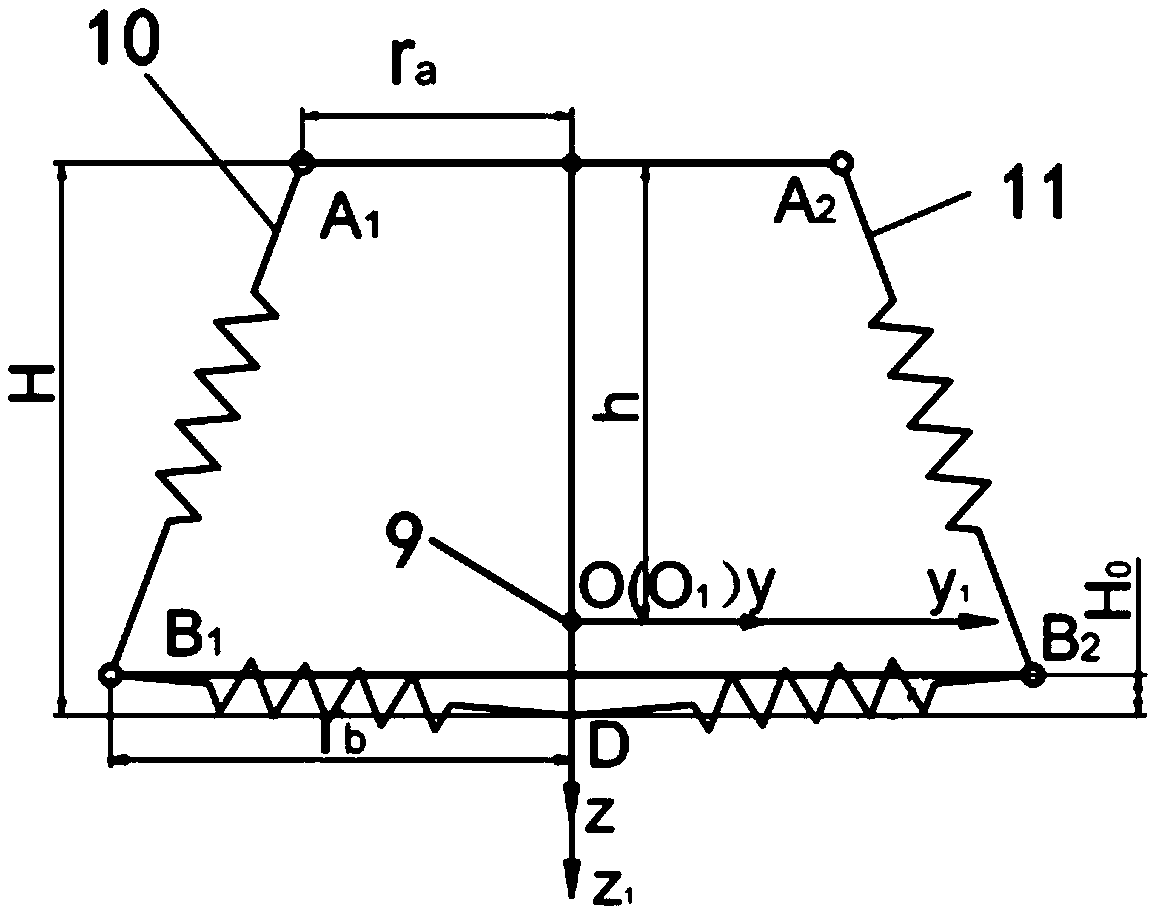

Tensioning floating type flexible joint and design method thereof

ActiveCN109015740AImprove the state of stressLittle driving force requiredGeometric CADJointsPull forceDegrees of freedom

The invention relates to a tensioning floating type flexible joint and a design method thereof. The flexible joint comprises a foundation platform, a driven platform and a plurality of tension elementsets. The upper face structure of the foundation platform is connected with the lower face structure of the driven platform by the horizontal tension element sets. The upper face structure of the foundation platform is connected with the upper face structure of the driven platform by the axial-directional tension element sets. In this way, the driven platform can be supported in a suspension mode. The axial-directional tension element sets provide pulling force vertical downwards. The horizontal tension element sets provide tension force vertical upwards for confronting, and therefore the driven platform can rotate around the foundation platform in a suspension mode without direct mechanical contact. The design method comprises degree of freedom decoupling and uniform dimensionalization stiffness anisotropic design index. The joint can reduce or even eliminate mechanical abrasion and friction caused by mechanical contact, can improve the stress state of the structure, and can reduce driving force demands.

Owner:HARBIN INST OF TECH

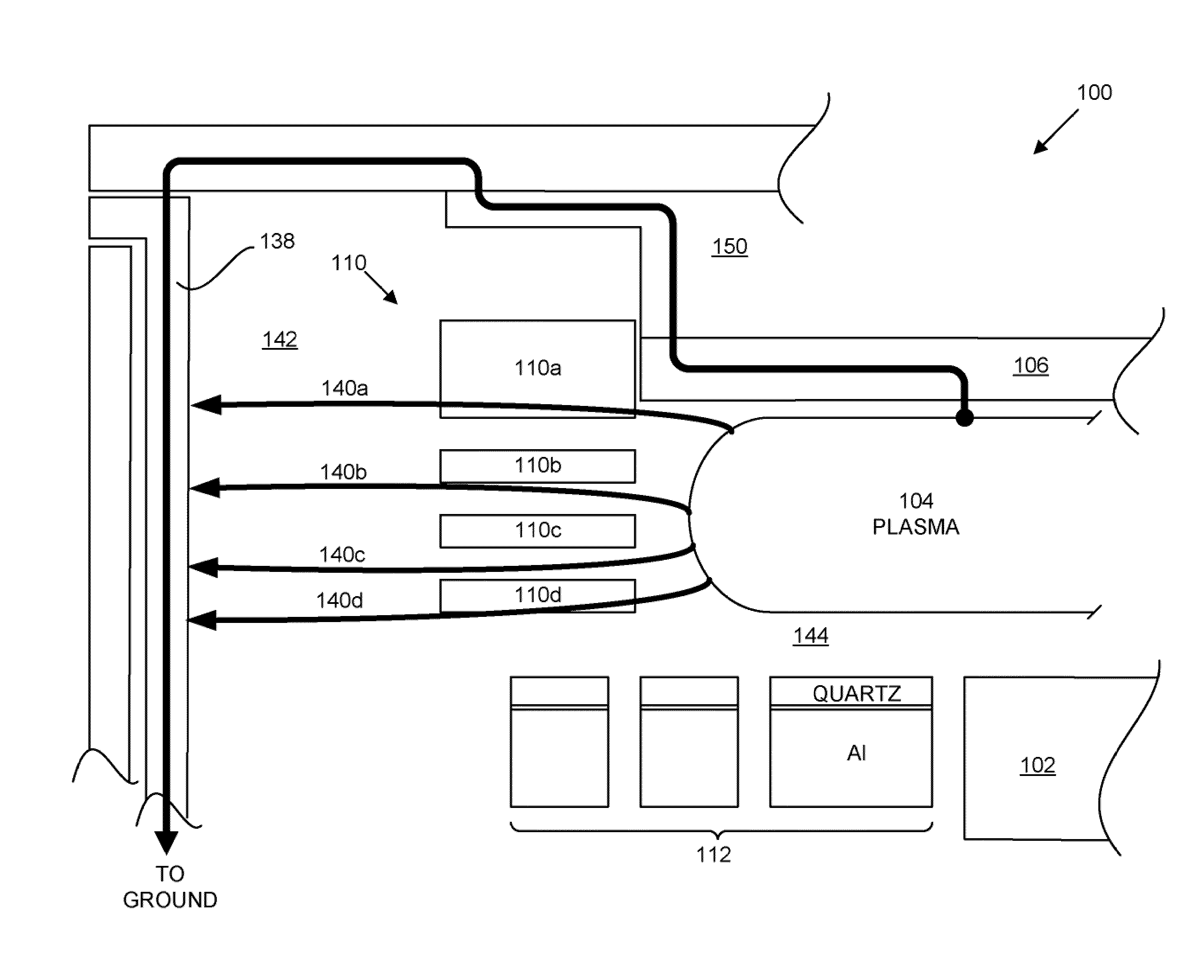

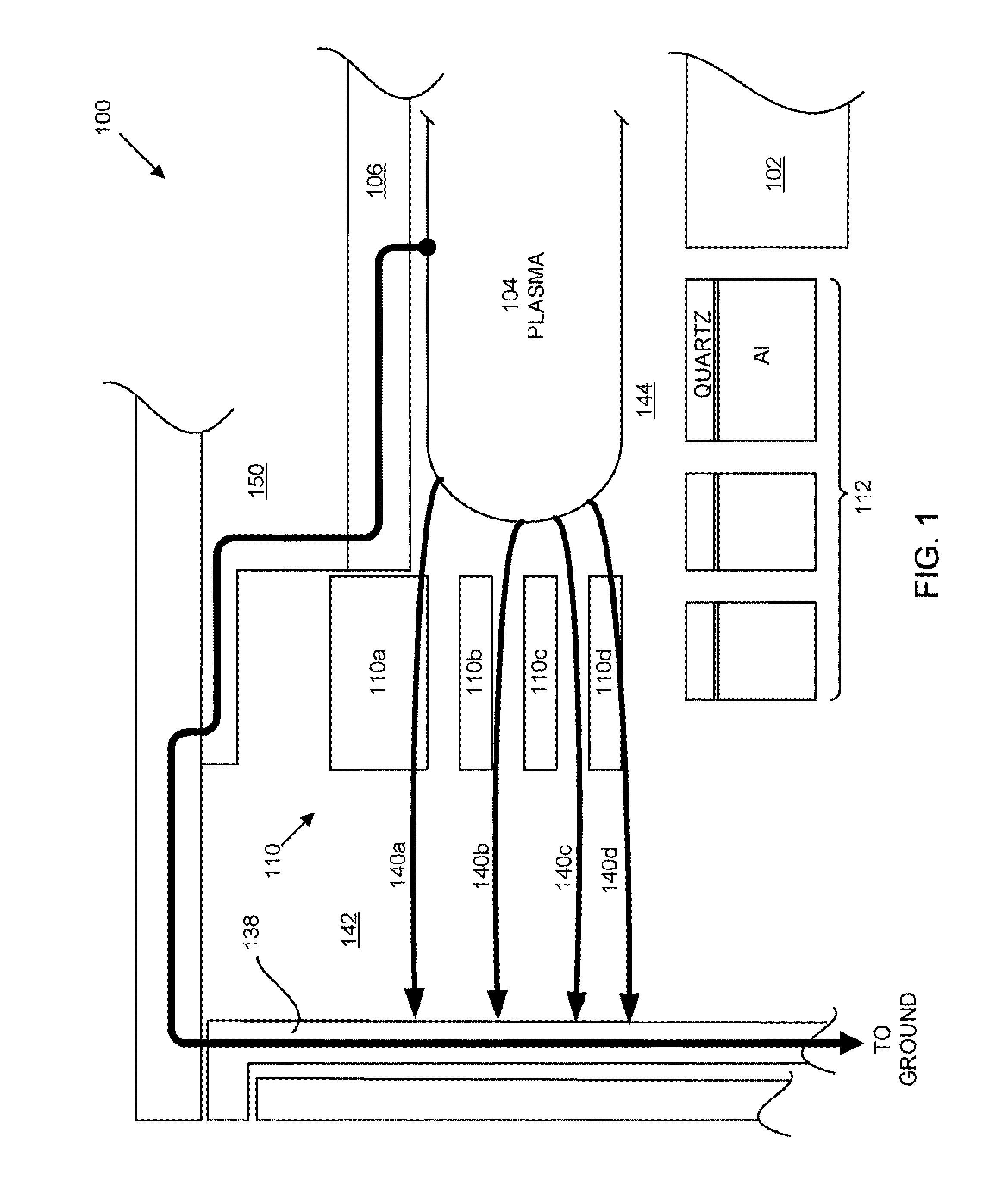

Plasma confinement structures in plasma processing systems

ActiveUS20100154996A1Easy to carryWave amplification devicesElectric discharge tubesEngineeringPlasma confinement

A movable plasma confinement structure configured for confining plasma in a plasma processing chamber during plasma processing of a substrate is provided. The movable plasma confinement structure includes a movable plasma-facing structure configured to surround the plasma. The movable plasma confinement structure also includes a movable electrically conductive structure disposed outside of the movable plasma-facing structure and configured to be deployed and retracted with the movable plasma-facing structure as a single unit to facilitate handling of the substrate. The movable electrically conductive structure is radio frequency (RF) grounded during the plasma processing. The movable plasma-facing structure is disposed between the plasma and the movable electrically conductive structure during the plasma processing such that RF current from the plasma flows to the movable electrically conductive structure through the movable plasma-facing structure during the plasma processing.

Owner:LAM RES CORP

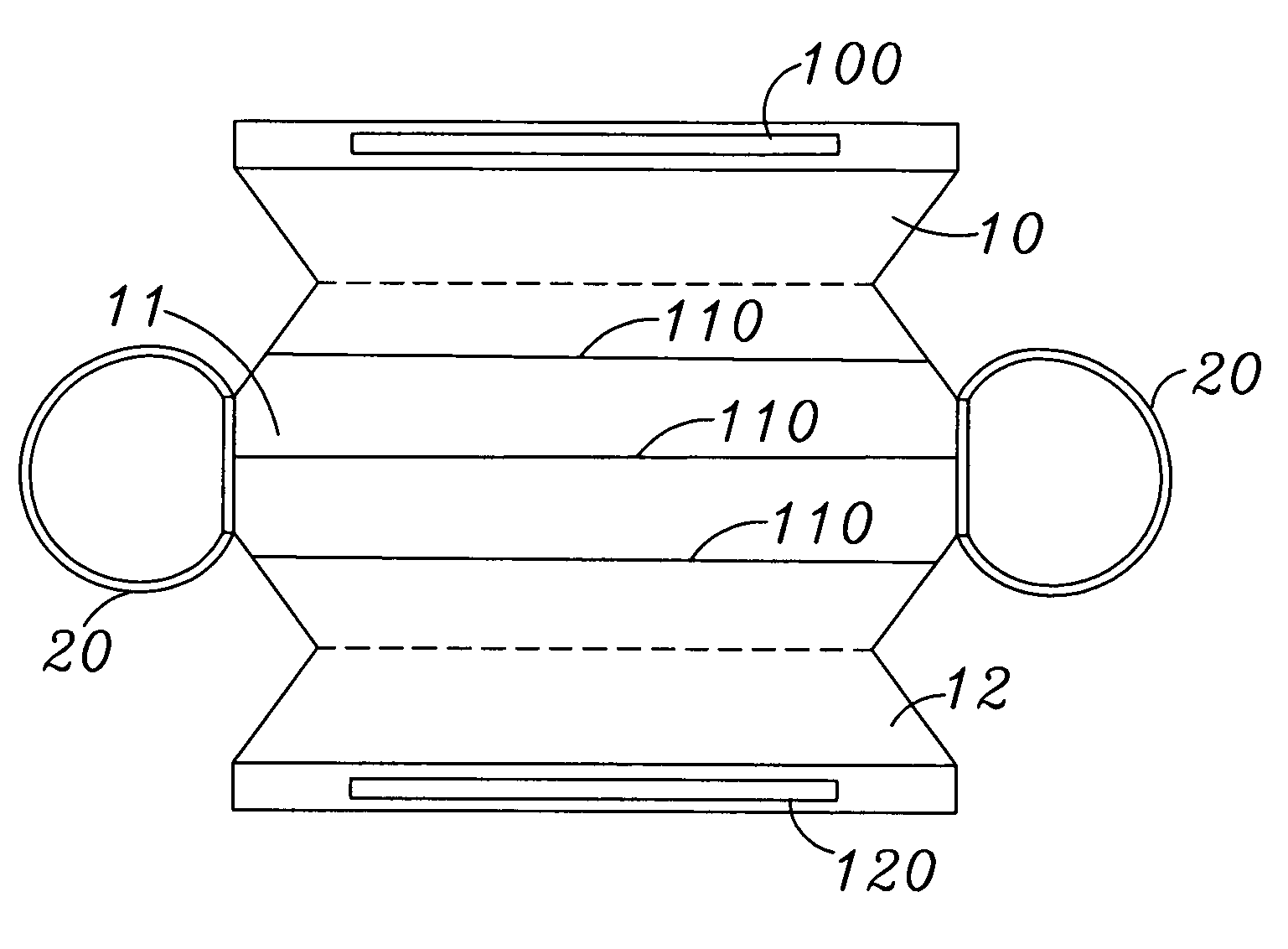

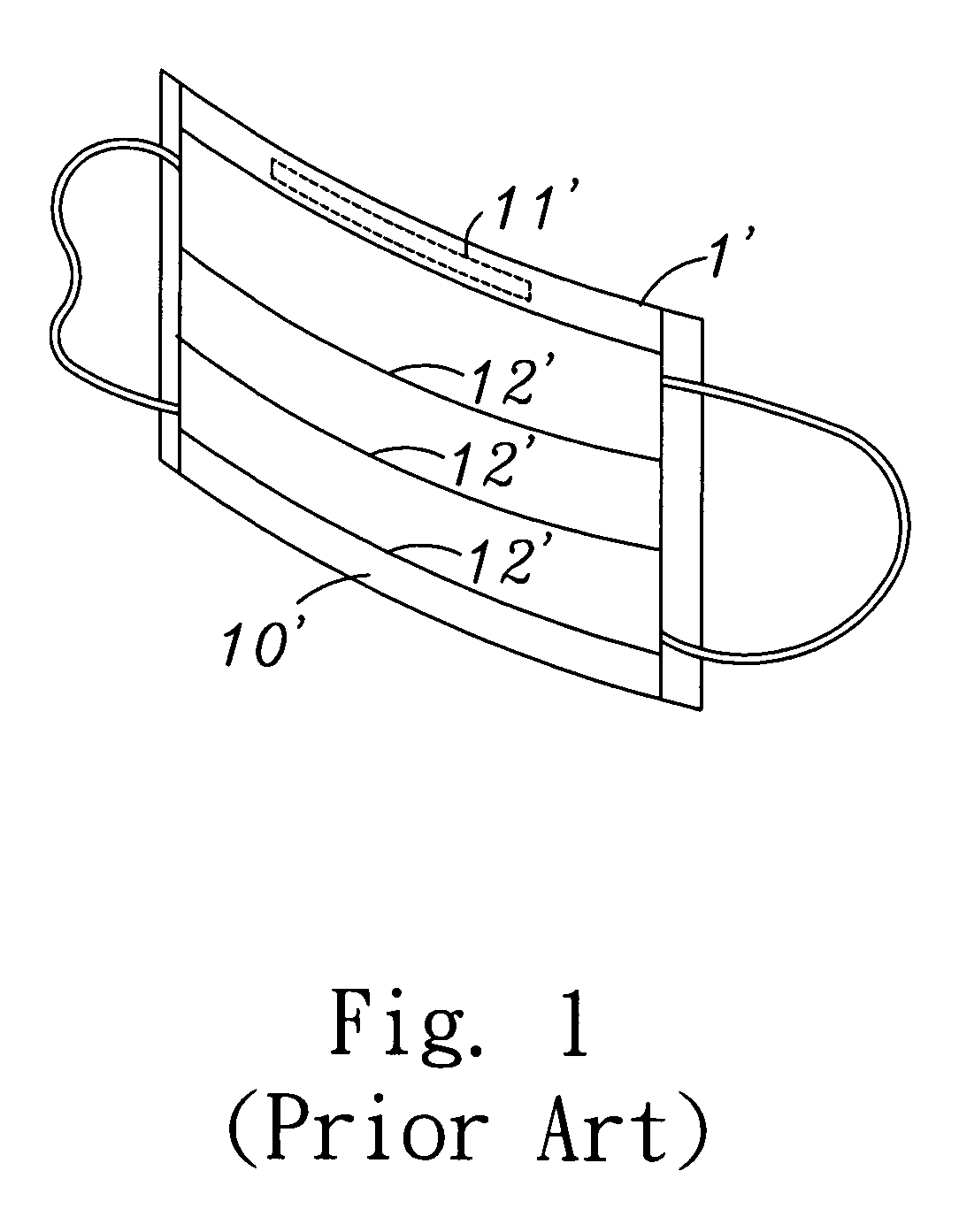

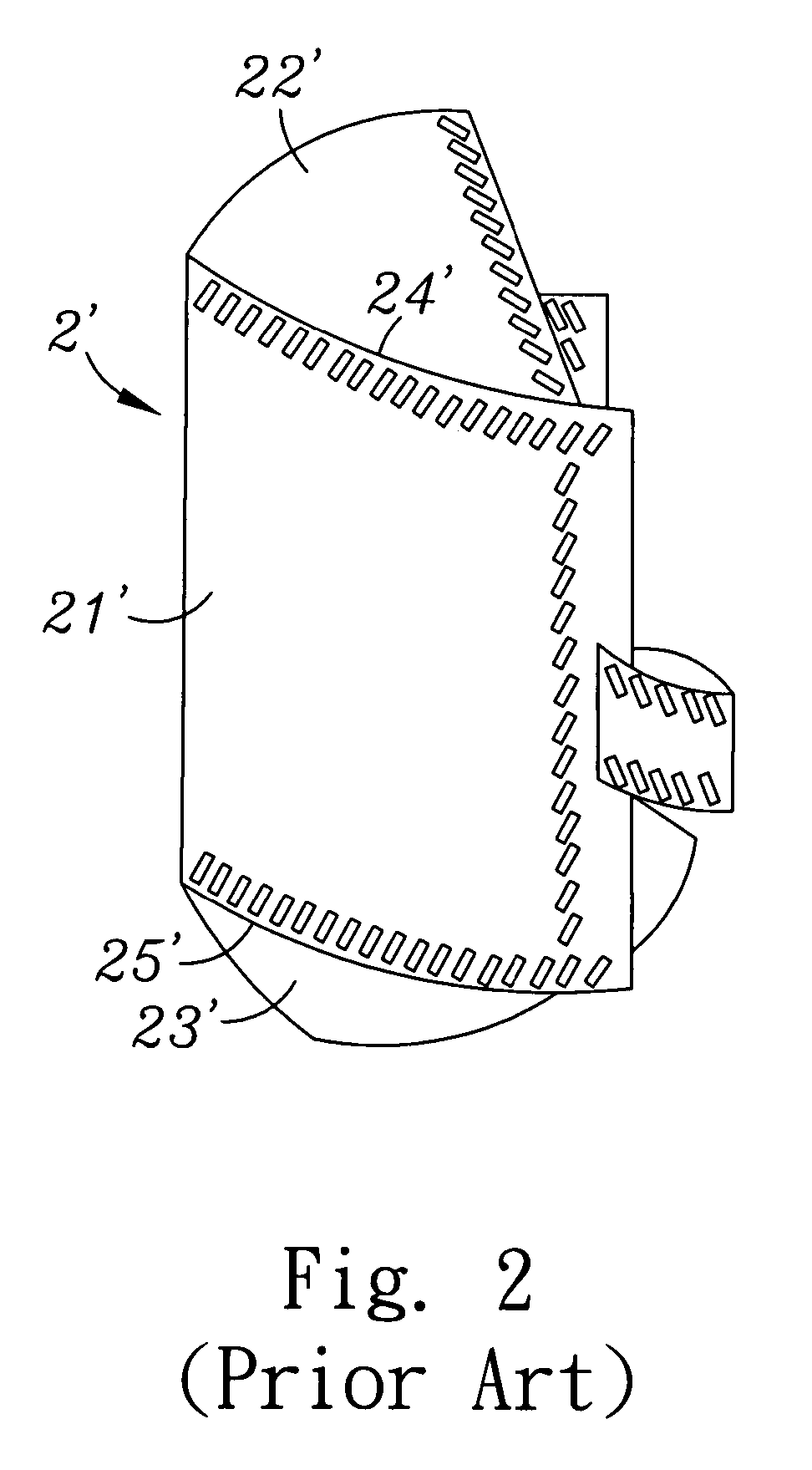

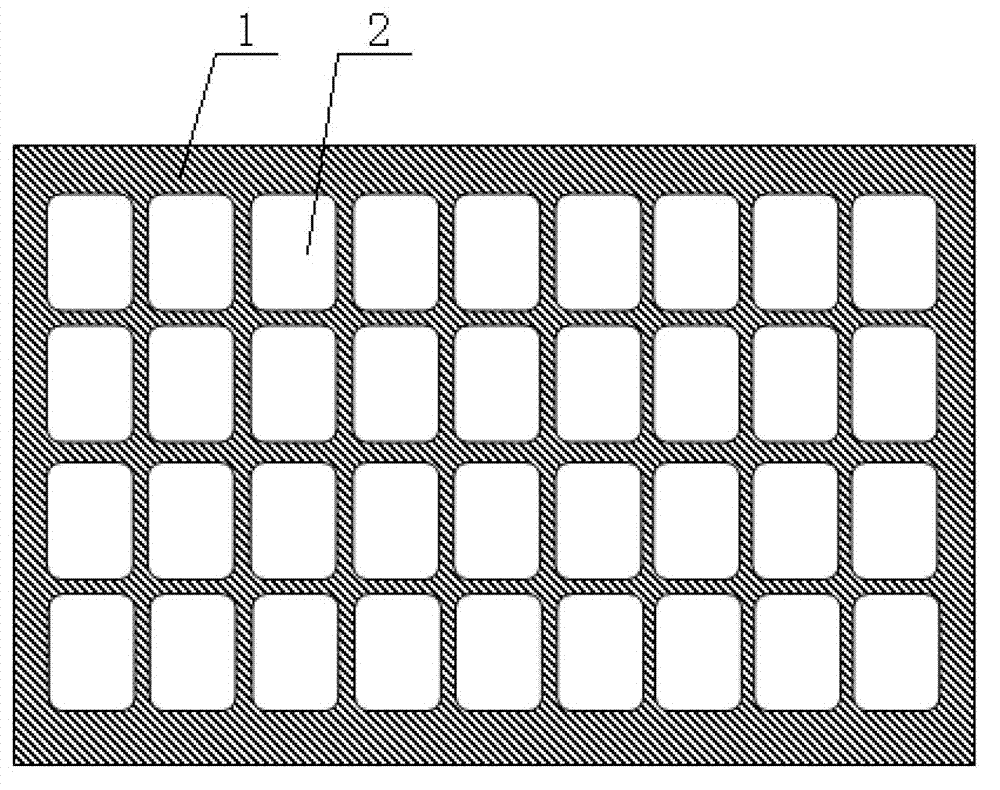

Face mask structure

ActiveUS7210482B2Reduce material consumptionIncrease the fermentation areaBreathing filtersBreathing masksInterior spaceEngineering

A face mask structure has an upper mask portion, a middle mask portion, and a lower mask portion, which are formed integrally. The upper mask portion has an upper metal stripe disposed at a proper position thereof. The lower mask portion has a lower metal stripe disposed at a proper position thereof. The upper and lower mask portions are folded in opposite directions. When in use, the upper and lower mask portions are spread out to support the middle mask portion. In this way, the face mask structure becomes fitting in with the shapes of human faces. Furthermore, the middle mask portion has multiple folding portions. When in use, the folding portions are stretched out to increase filtering area. Thereby, the inner space of the face mask structure is increased, the air-invasion rate is reduced, and the filtering efficiency is thus improved.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE +1

Production process for cover plate silicon-aluminum glass with capacitance touch function

ActiveCN102736813AImprove cutting efficiencyImprove yieldInput/output processes for data processingGuidance systemCapacitance

The invention discloses a production process for cover plate silicon-aluminum glass with a capacitance touch function. The method comprises the following steps of (1) slitting silicon-aluminum glass into base material size and polishing edge and chamfering; (2) printing a protective film on two sides of an OGS (optical guidance system) product area of the silicon-aluminum glass; (3) plating a resistant and protective layer on two sides of the silicon-aluminum glass in a vacuum coating manner; (4) tearing down the protective film and carrying out a chemical tempering process on the resistant and protective layer on the surface of the silicon-aluminum glass; (5) coating a pattern layer on the OGS product area; (6) manufacturing a capacitance touch screen with a single face structure in the OGS product area; (7) coating an organic coating layer in the OGS product area; and (8) cutting in a coating area. According to the production process, the cover plate silicon-aluminum glass with the capacitance touch function can be produced efficiently, the cutting efficiency is high and the rate of finished products is high.

Owner:WUHU TOKEN SCI

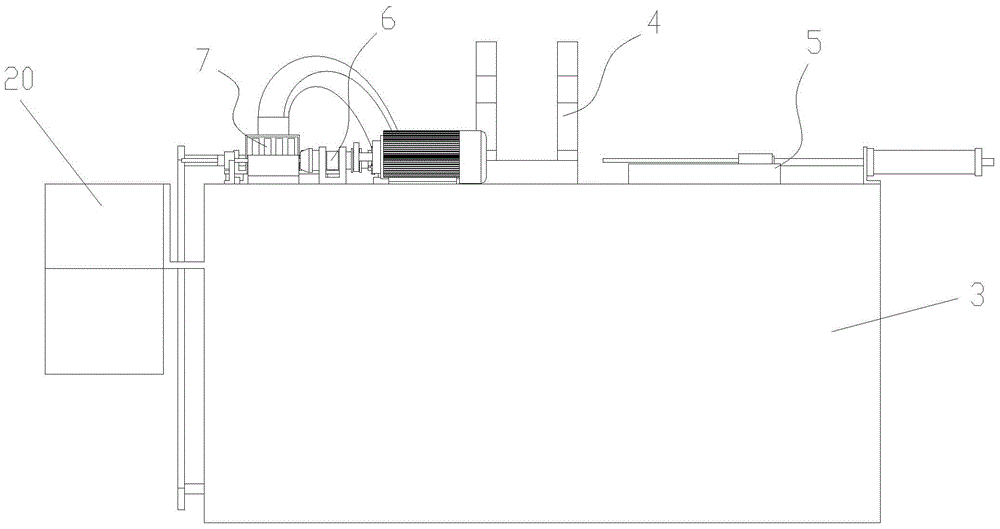

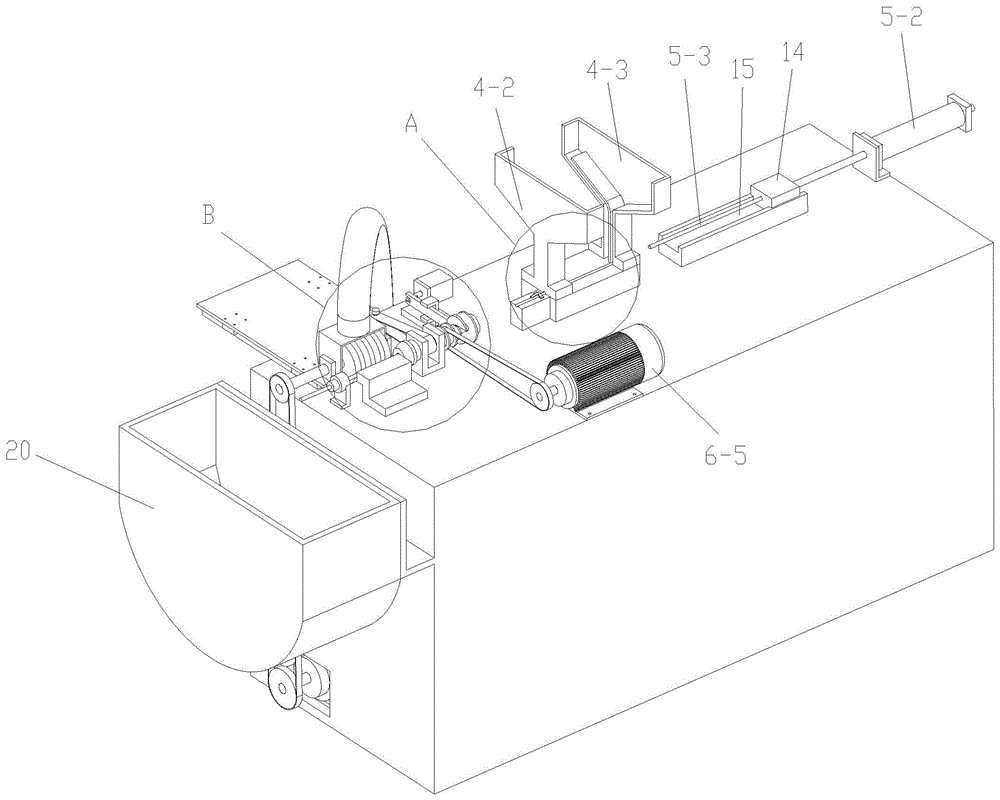

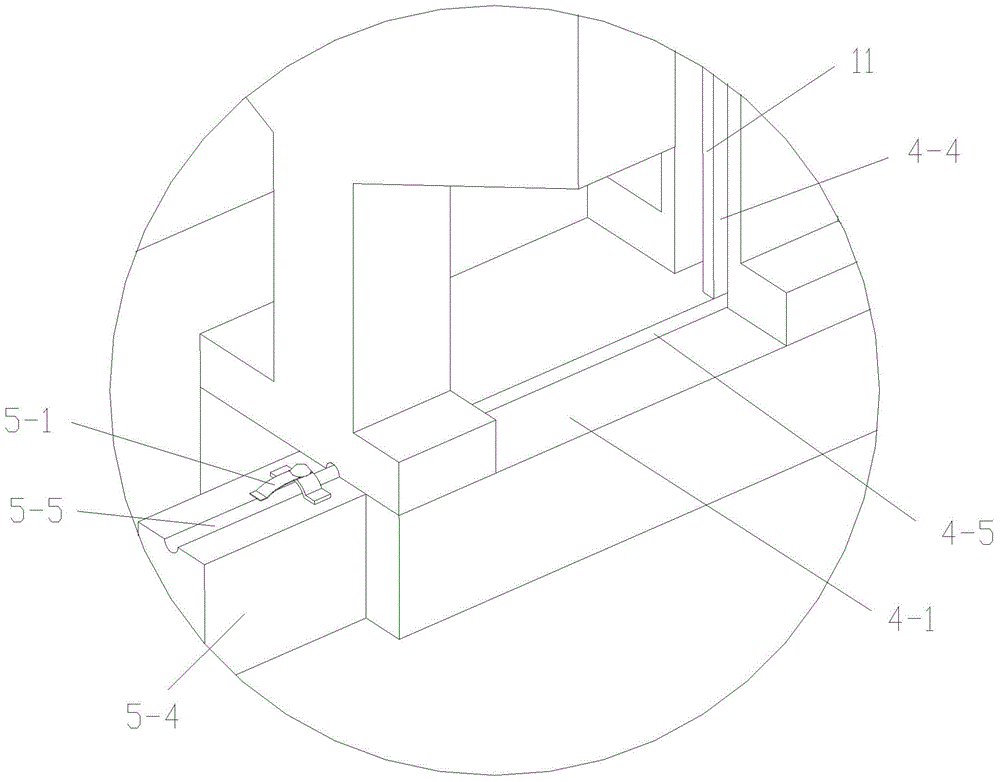

Pencil, pencil processing method and pencil groove milling machine for machining pencil

ActiveCN104589842AImprove skid resistanceHigh strengthWriting connectorsNon-propelling pencilsEngineeringFace structure

An antiskid pencil comprises a pen rod, a set of annular grooves arranged at a spaced mode are formed in the outer surface of the pen rod, and the annular grooves are of a concave arc-face structure. A method for machining the antiskid pencil includes the first step that a proper plate is selected, and the thickness of the plate is 120% that of a standard plate; the second step that a groove is planed in the plate, and a pencil core is placed in the machined groove; the third step that the plate is cut and is machined into pencil blank; the fourth step that a set of annular grooves are simultaneously ground in the outer surface of the pencil blank through a pencil groove milling machine; the fifth step the surface of the pencil is painted. The pencil groove milling machine used for machining the pencil includes a rack, a blanking mechanism used for containing pencils and allowing the pencils to fall down one by one is arranged on the rack, the bottom end of the blanking mechanism is connected with a feed mechanism in a matched mode, the feed mechanism is connected with a clamping mechanism used for locating the pencils, and the clamping mechanism is provided with a groove milling mechanism used for milling grooves in the pencils in a matched mode.

Owner:浙江艾特佳文化用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com