Patents

Literature

55results about How to "Realize rapid prototyping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for auxiliary heating type ultrasound rapid forming

ActiveCN103600166AAvoid formingGuaranteed solid phase junction propertiesNon-electric welding apparatusNumerical controlMetal foil

The invention belongs to the technical field of rapid forming, and particularly relates to a method for achieving multilayer bead welding of metal foil strips through combination of extra auxiliary heating and ultrasonic welding. According to the method, preheating is conducted on metal foil or a base body material in rapid forming, the metal foil or the base body material is softened through preheating conducted by an external heating field, good gas protection is provided, and the welding thickness and width of a metal foil sheet are increased under the condition that the ultrasonic welding power is limited, so that multilayer one-time ultrasonic bead welding or multilayer multi-time ultrasonic bead welding of the metal foil is achieved and a three-dimensional solid block is formed in the solid-phase connection mode. Finally, a machining platform controlled by a numerical control program is applied, so that geometrical characteristic machining of a needed part is achieved. A metal piece obtained according to the method has the advantages of being low in cost, high in efficiency, compact in organization, free of casting-state structure, capable of achieving rapid forming of a functionally gradient material and the like.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

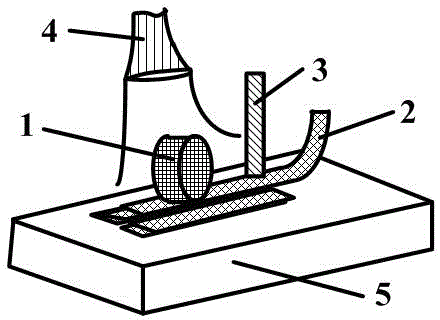

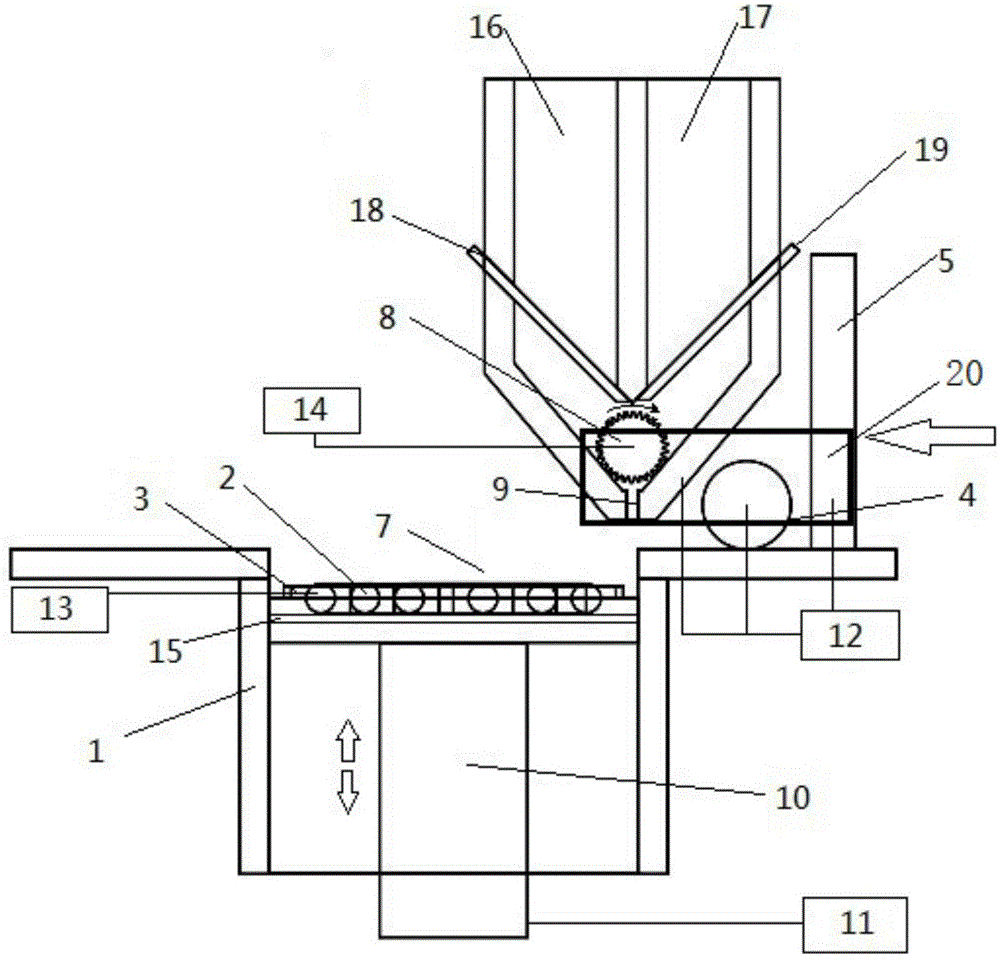

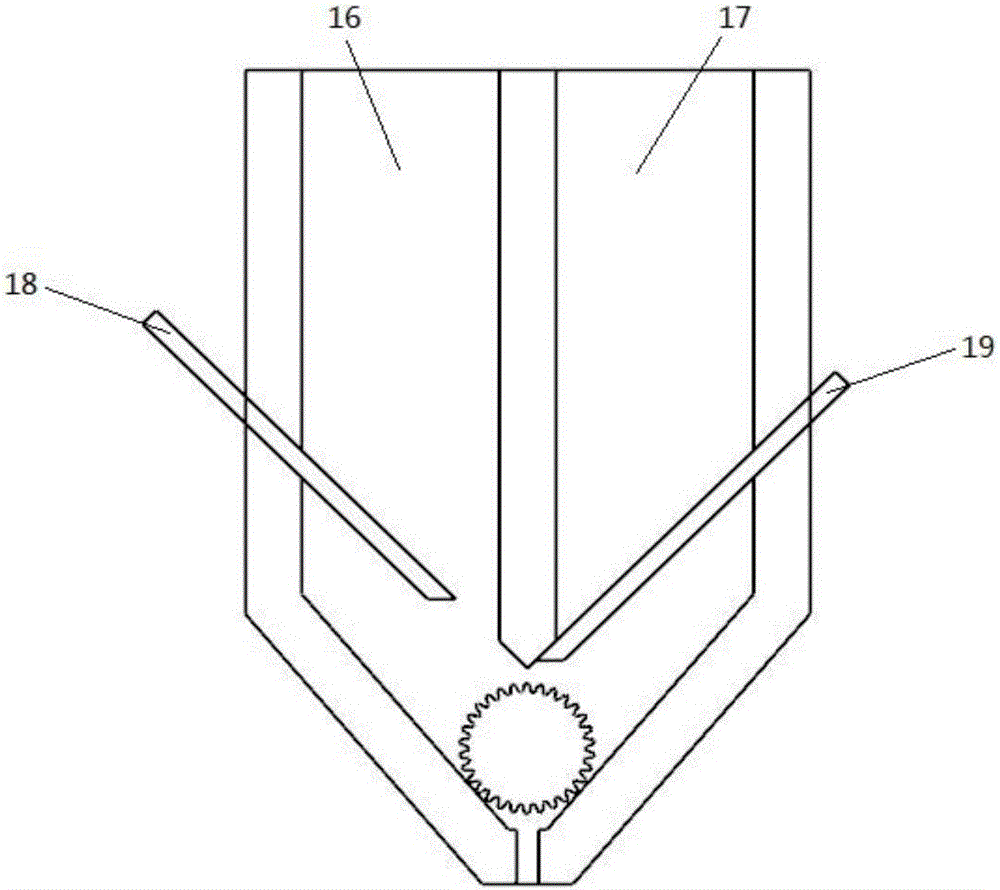

Double-powder quick molding and uniform spreading device

InactiveCN105728721ALay evenlyRealize rapid prototypingAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyEngineering

The invention aims to provides a double-powder quick molding and uniform spreading device which comprises a lifting working platform, a linear module fixedly connected with the lifting working platform, a powder pressing roller arranged on a linear module sliding block, a powder scraper, a powder supply body, a lifting platform arranged in a working platform molding cylinder and a heating device arranged on the lifting platform, wherein a baffle is arranged in the powder supply box to divide the powder supply box into a plurality of chambers with the same volume; a switch for controlling the falling of a powder is arranged at a powder outlet part of each chamber; a powder supply shaft with a gear-shaped section is arranged at a powder outlet of the powder supply box; and the powder supply shaft is tangent to a wedged edge of the powder outlet of the powder supply box. The double-powder quick molding and uniform spreading device realizes quick molding of two powders at any ratio on each layer according to a two-dimensional diagram, ensures that all layers of a molded part have gradient differences, and thus reduces time waste caused by the reason that only one powder can be used in one cycle. The double-powder quick molding and uniform spreading device can uniformly heat the powders that a high energy density beam acts on, detect a temperature field and control interpass temperature, thus reducing residual stress caused by nonuniform temperature.

Owner:NANJING UNIV OF SCI & TECH

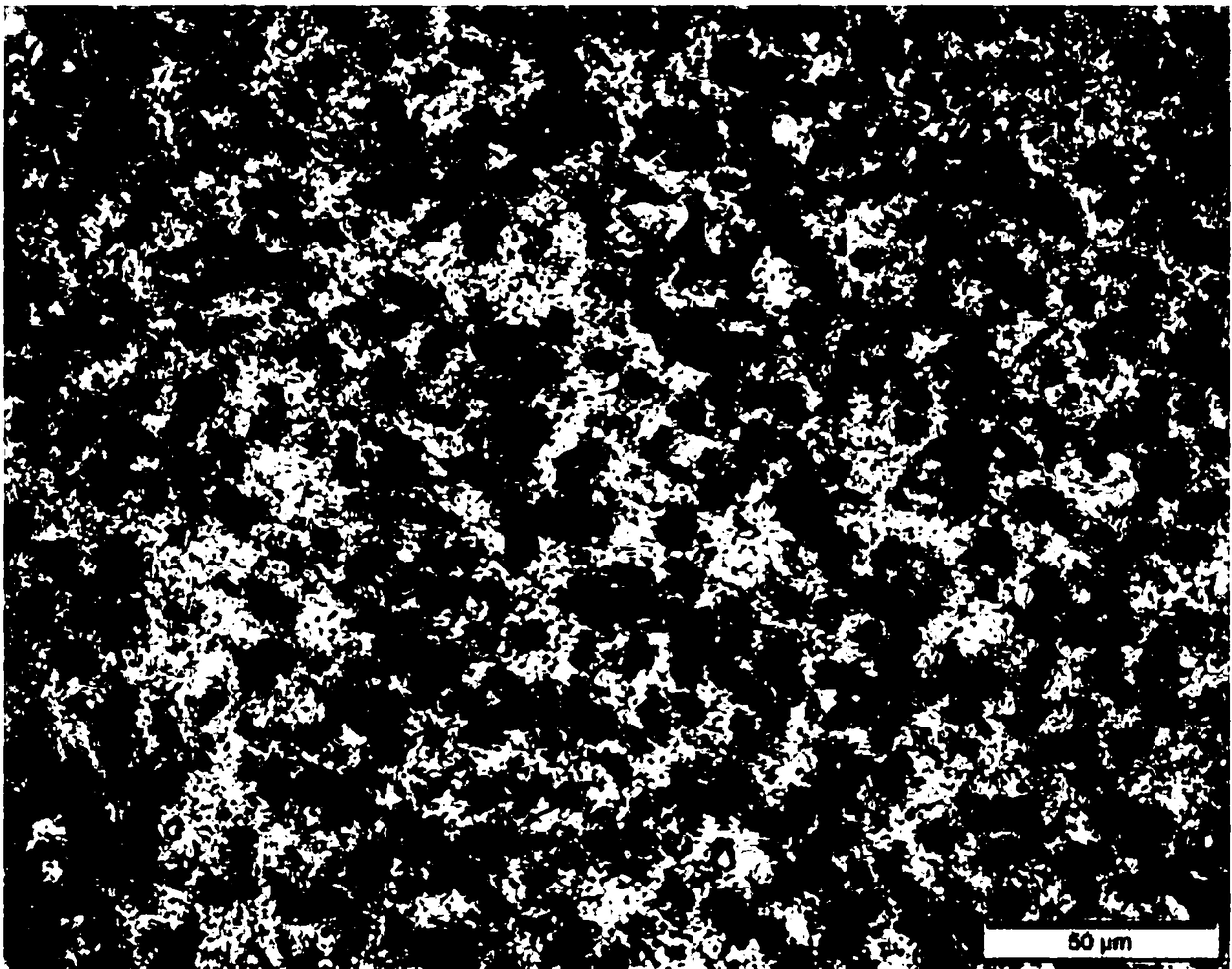

Neutron absorbing material rapid semi-solid state temperature zone forming method

The invention relates to a neutron absorbing material rapid semi-solid state temperature zone forming method, and belongs to the technical field of semi-solid state forming. The method is suitable forsemi-solid state forming plate blanks of particle (nano and micro scale) reinforced metal base composites. The method comprises the steps that a ball milling technology is adopted to prepare boron carbide and aluminum alloy mixed powder, and through isostatic cool pressing, a green body is obtained; technologies of hot pressing sintering, hot isostatic pressing and the like are carried out on solid and liquid two-phase semi-solid state temperature zone of an aluminum alloy, a high-compactness composite with ceramic particles evenly dispersed and distributed in an aluminum alloy base body isobtained, hot forging pressing, hot extrusion or hot rolling treatment is carried out on the aluminum alloy base body deformation temperature zone, heat treatment is carried out, and a high-compactness aluminum-based boron carbide neutron absorbing material with the uniform structure is made. Non-metallic materials are easily added, the preparing time is short, the material compactness is high, micrograph morphology is good, and production cost is low.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Water column forming method of spherical molecular sieve

ActiveCN104383967AImprove adhesionReduce production process stepsCatalyst carriersCatalyst activation/preparationNano al2o3Manganese

The invention relates to a water column forming method of a spherical molecular sieve. The water column forming method is characterized by comprising the following steps: 1, beating a molecular sieve, a binding agent and water uniformly; 2, adding an alginate solution, and stirring uniformly at high speed to prepare a suspended sizing agent; 3, dropping the suspended sizing agent to a polyvalent metal cation water solution to form gel particles; and 4, taking the gel particles out, drying and roasting to obtain the product, wherein the dry-basis mass rate of the molecular sieve to the binding agent in the step 1 is (0.2-3):1, and the binding agent is alumina hydrogel, nanometer aluminum oxide sol or silica sol; the soluble alginate in the step 2 is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, the content of alginate in the suspended sizing agent is 0.3-5w%, and total dry-basis content of the molecular sieve and the binding agent in the suspended sizing agent is 5-30w%; the polyvalent metal cation water solution in the step 3 is a saline solution containing aluminum, zinc, calcium, copper, ferrum, ferrous, cobalt, manganese or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

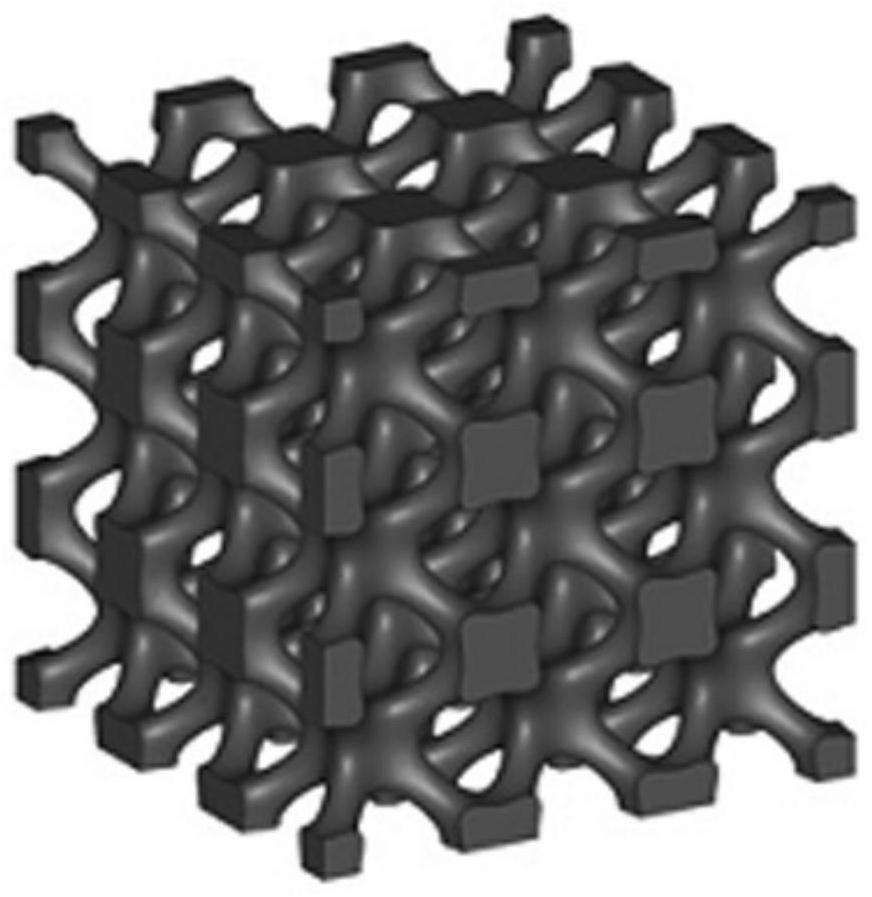

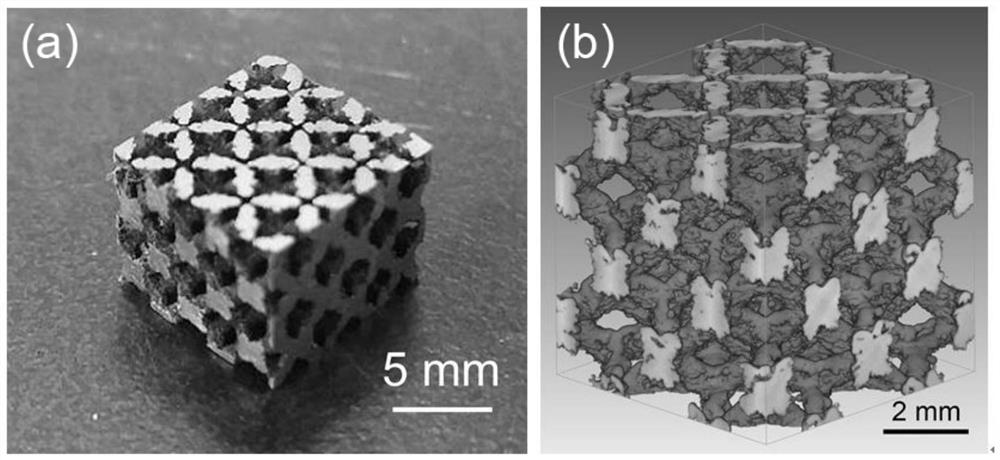

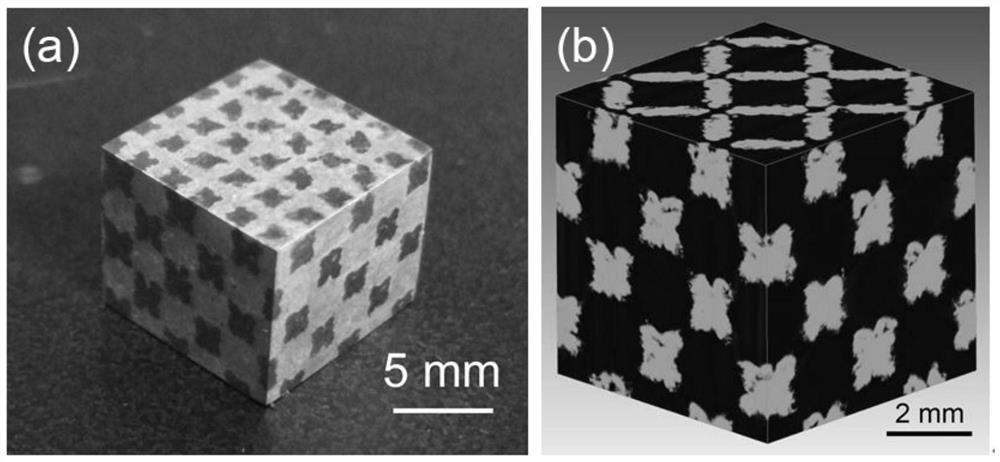

Shape memory alloy reinforced magnesium-based composite material with three-dimensional interpenetrating network structure and preparation method thereof

ActiveCN111745162AImprove interface strengthIdeal reinforcementAdditive manufacturing apparatusMagnesium matrix compositeShape-memory alloy

The invention relates to a magnesium-based composite material with a three-dimensional interpenetrating network structure and reinforced by a 3D-printed shape memory alloy reinforcement framework anda preparation method thereof. The composite material is composed of a shape memory alloy reinforcing body with the volume fraction of 10%-80% and a magnesium or magnesium alloy matrix, has the three-dimensional interpenetrating network structure and is characterized in that the reinforcing body and the matrix respectively have independent topological structures and are inserted and complementarilycombined in a three-dimensional space. The preparation method of the composite material comprises the following steps that the shape memory alloy reinforcement framework with the network topology structure is prepared by adopting a 3D printing technology, the framework is infiltrated by molten magnesium or magnesium alloy melt under a vacuum or protective atmosphere, and the composite material isobtained after solidification and cooling. The composite material is high in strength, large in plasticity, high in controllability of structure and mechanical property, has a certain shape memory effect, namely the room temperature deformation can be partially or completely recovered above the martensite transformation temperature and has considerable application prospect as a novel structural and functional integrated material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

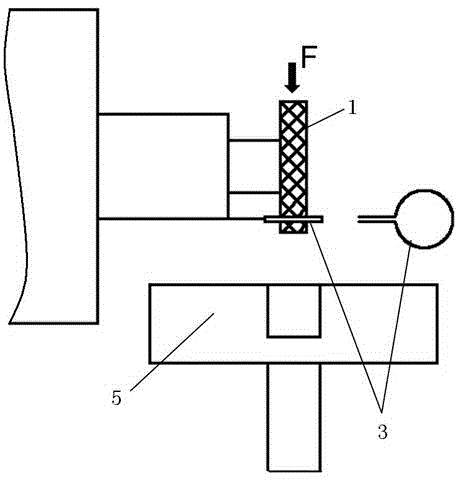

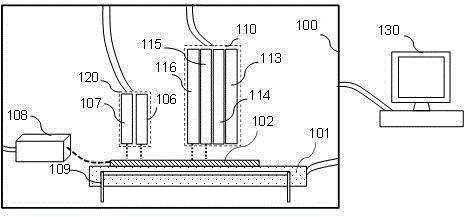

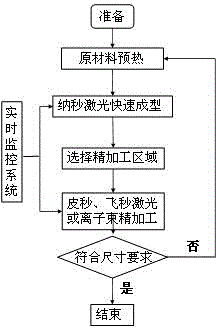

Quick forming device and method based on femtosecond laser and ion beam composite technology

ActiveCN104889570ARapid prototypingRealize point-by-point controlLaser beam welding apparatusPicosecond laserClosed loop

The invention provides a quick forming device and method based on a femtosecond laser and ion beam composite technology. The device mainly comprises a nanosecond-picosecond-femtosecond laser device, an ion beam device and a real-time monitoring system, nanosecond laser is used for conducting scanning sintering on raw materials, the real-time monitoring system performs real-time processing, part morphology, microcosmic structure and ingredient measurement and analysis and feeds analysis results to a control system, and the nanosecond-picosecond-femtosecond laser, ion beams and the real-time monitoring system forma closed-loop system so as to effectively machining and detection coordination if picoseconds laser, femtosecond laser or ion beams are needed to perform further finish machining. The quick forming device and method achieve quick forming of complicated parts and precise machining of the microcosmic structure, improve the microcosmic structure and quality control capacity by using the real-time monitoring system and is used for manufacturing high-strength, high-accuracy and complicated-structure parts.

Owner:WUHAN FINEMEMS

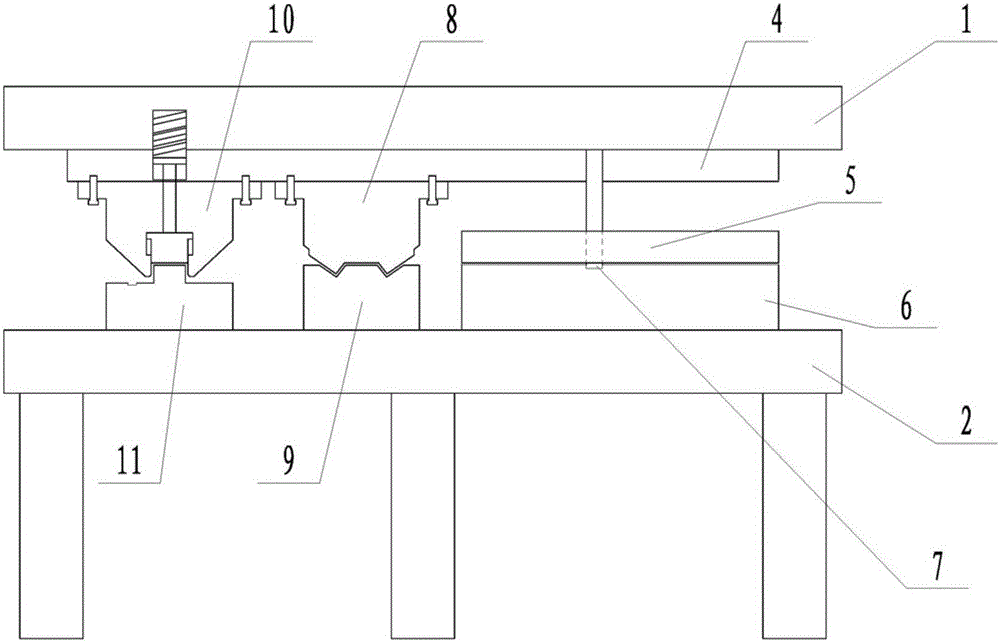

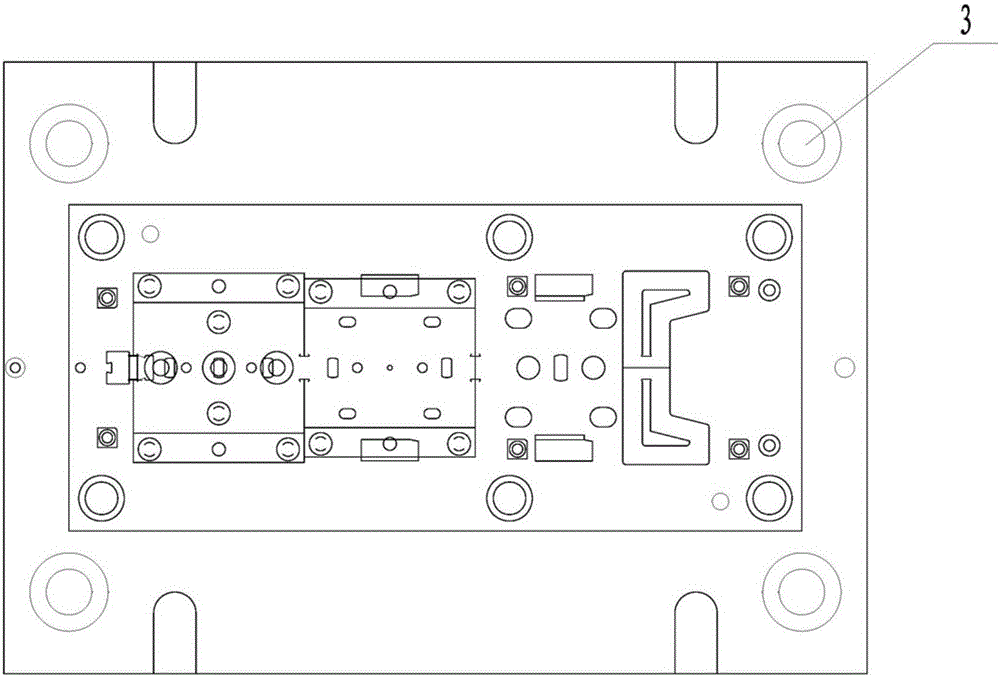

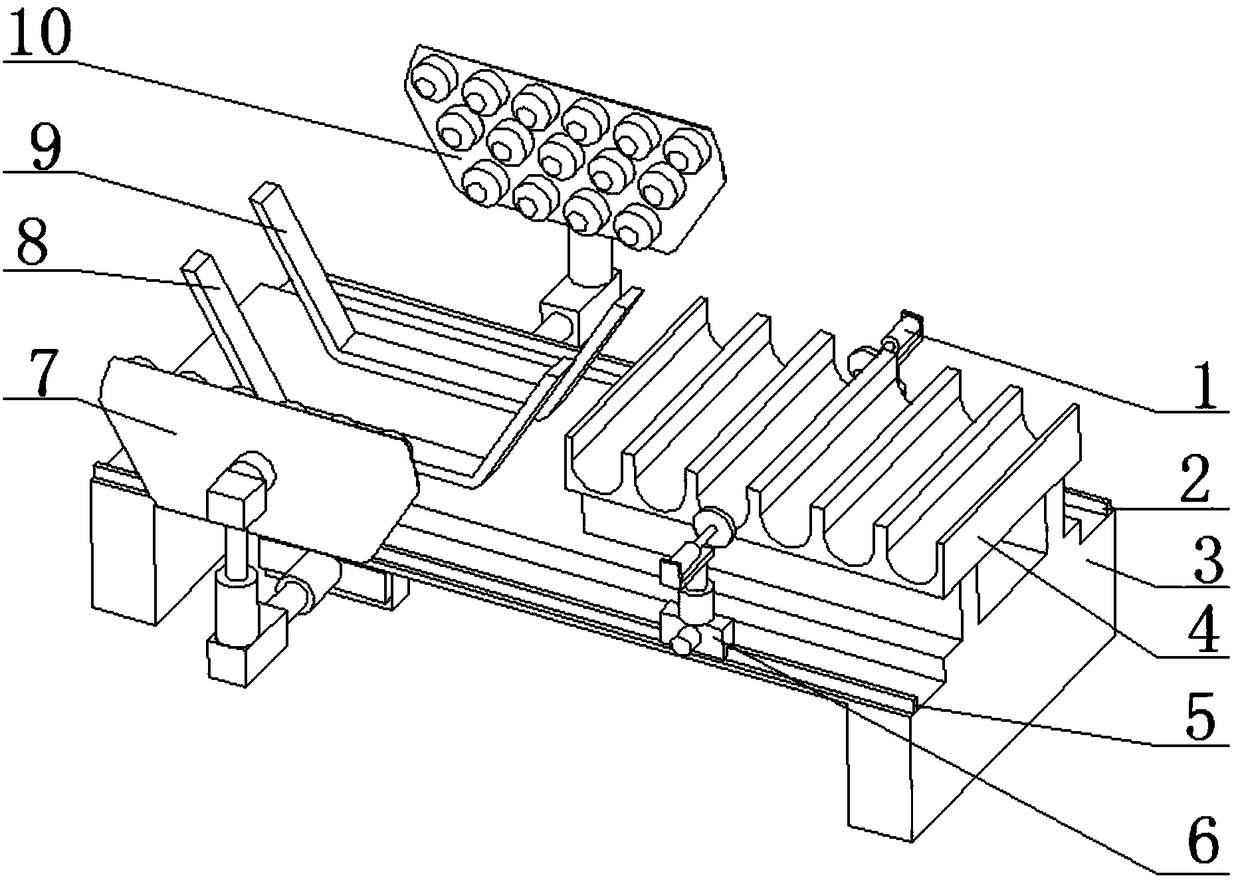

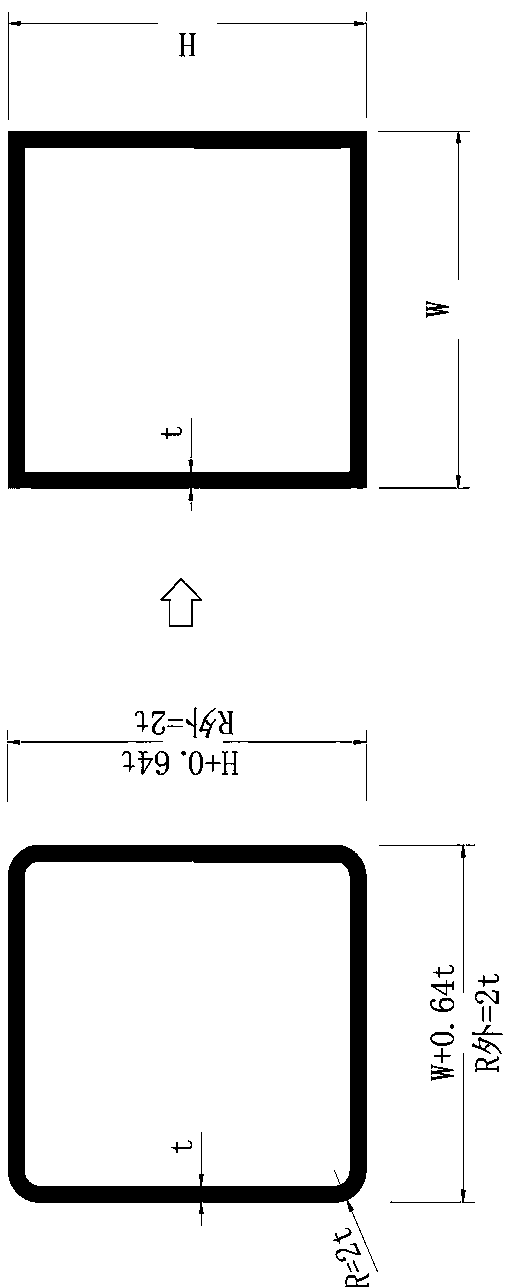

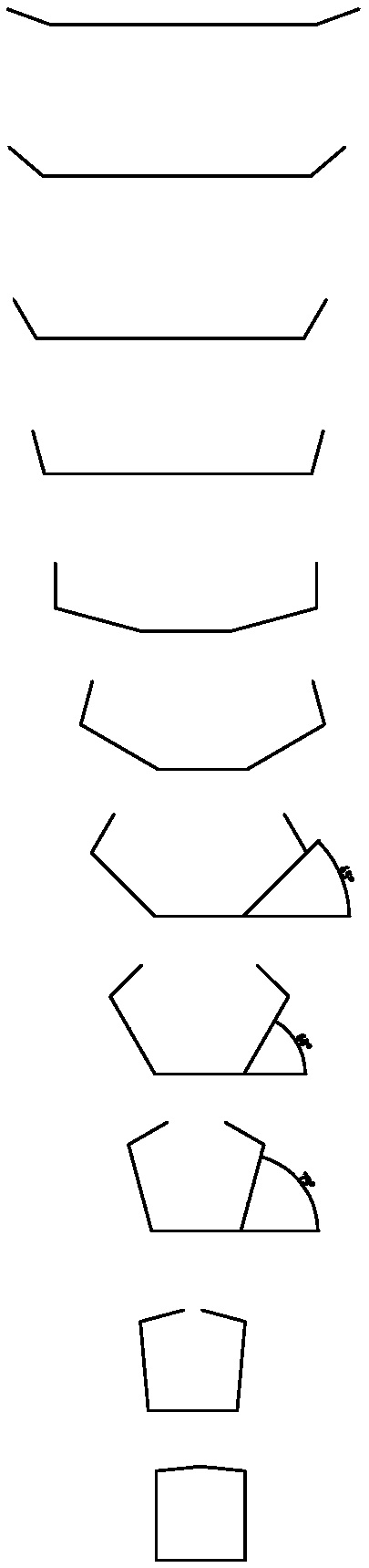

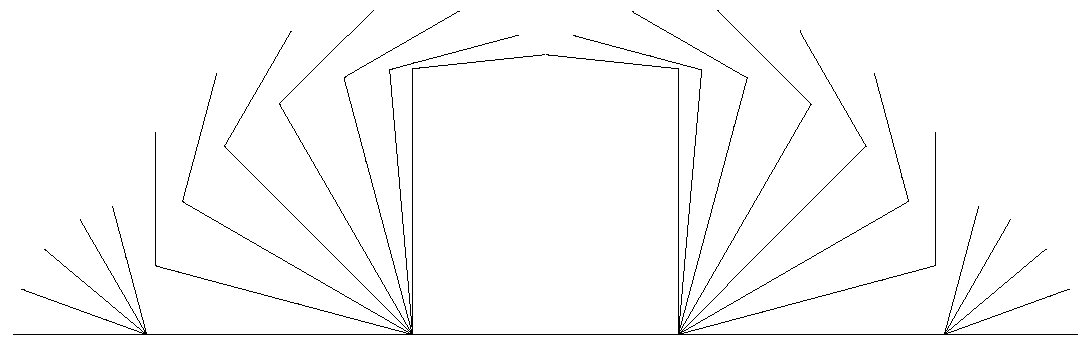

Goods shelf square tube insert progressive die

PendingCN105750411AReduce manufacturing costShorten the production cycleShaping toolsEngineeringMachining

The invention discloses a goods shelf square tube insert progressive die.The progressive die comprises an upper die base and a lower die base, wherein guiding holes are formed in the four corners of the upper die base, guiding rods are arranged at the four corners of the lower die base, the guiding holes and the guiding rods correspond in position, and an upper die plate is arranged on the upper die base.A machining die is arranged at the right side of the progressive die and comprises a machining punch plate and a base plate, wherein a machining punch is arranged on the machining punch plate.A forming die and a shaping die are arranged at the left side of the progressive die, wherein the forming die comprises an upper forming die body and a lower forming die body, and the shaping die comprises an upper shaping die body and a lower shaping die body.The upper die plate of the machining die, the upper forming die body and the upper shaping die body are arranged on the upper die plate, and the base plate of the machining die, the lower forming die body and the lower shaping die body are arranged on the lower die base.

Owner:浙江上扬商业设备科技股份有限公司

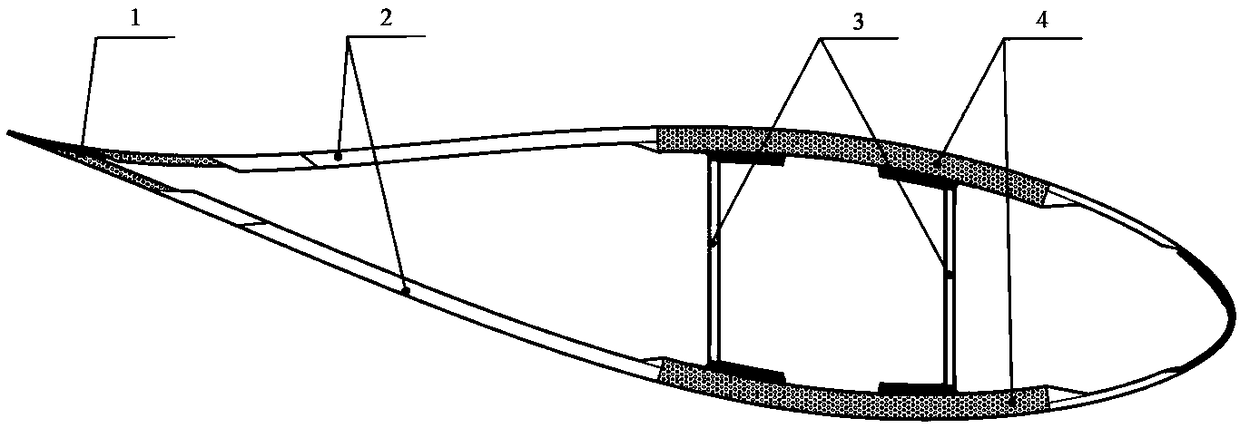

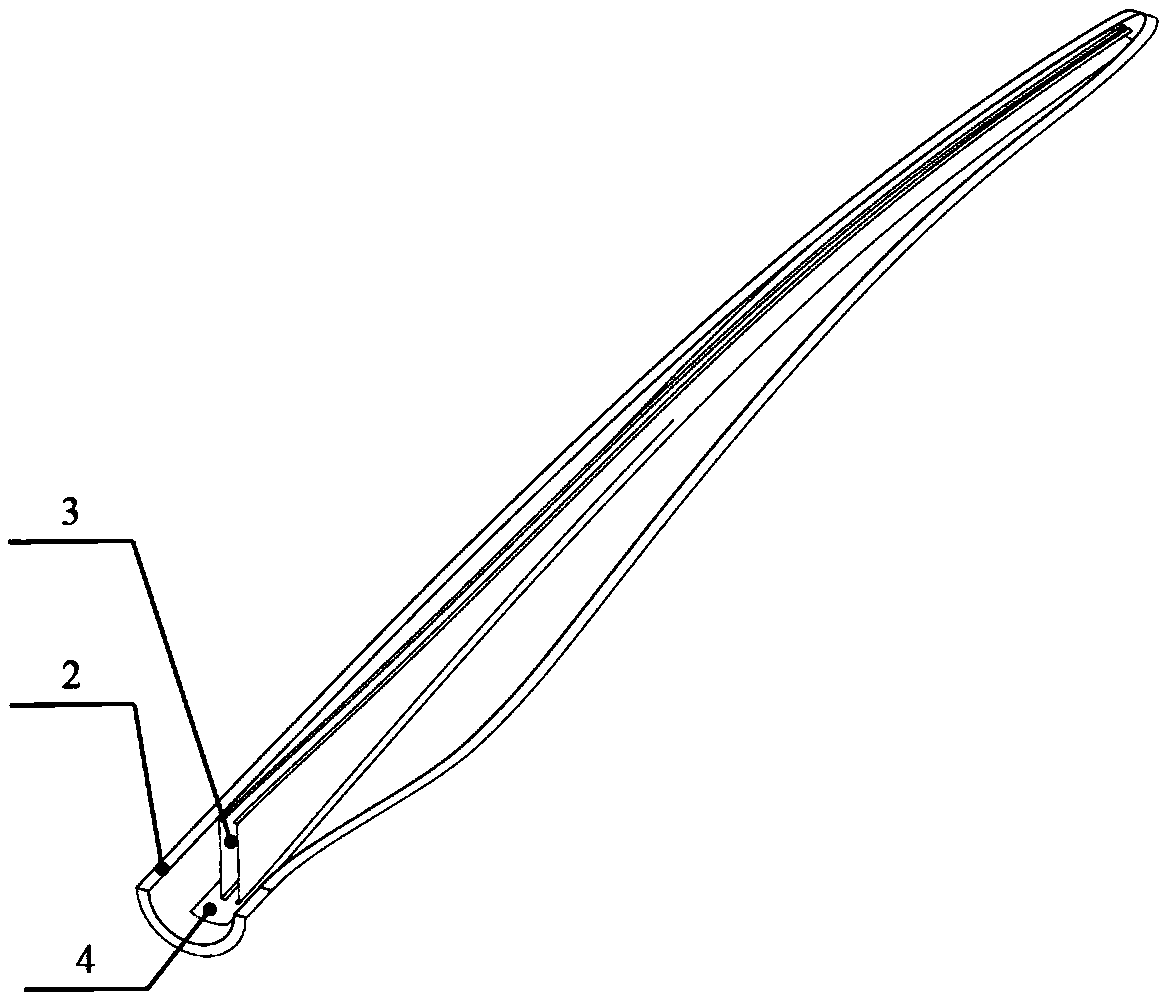

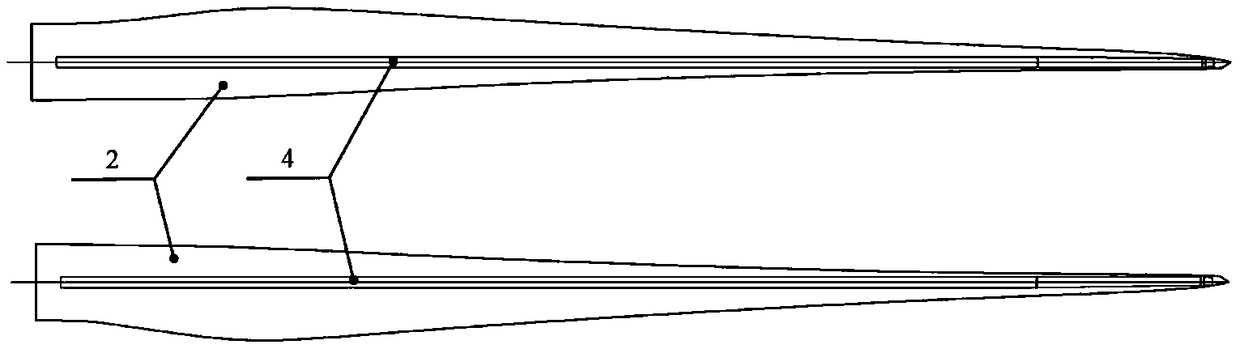

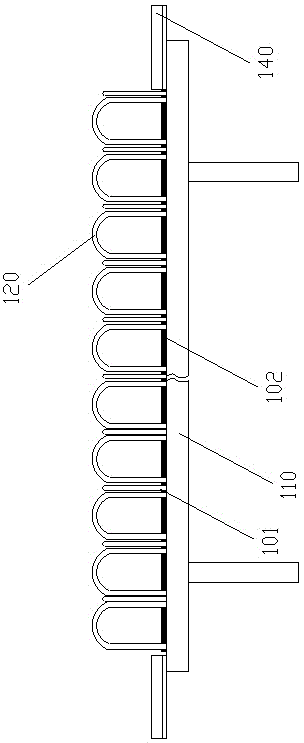

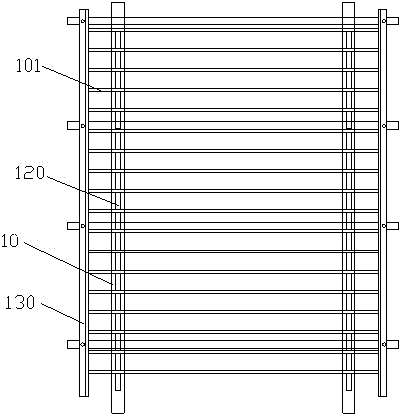

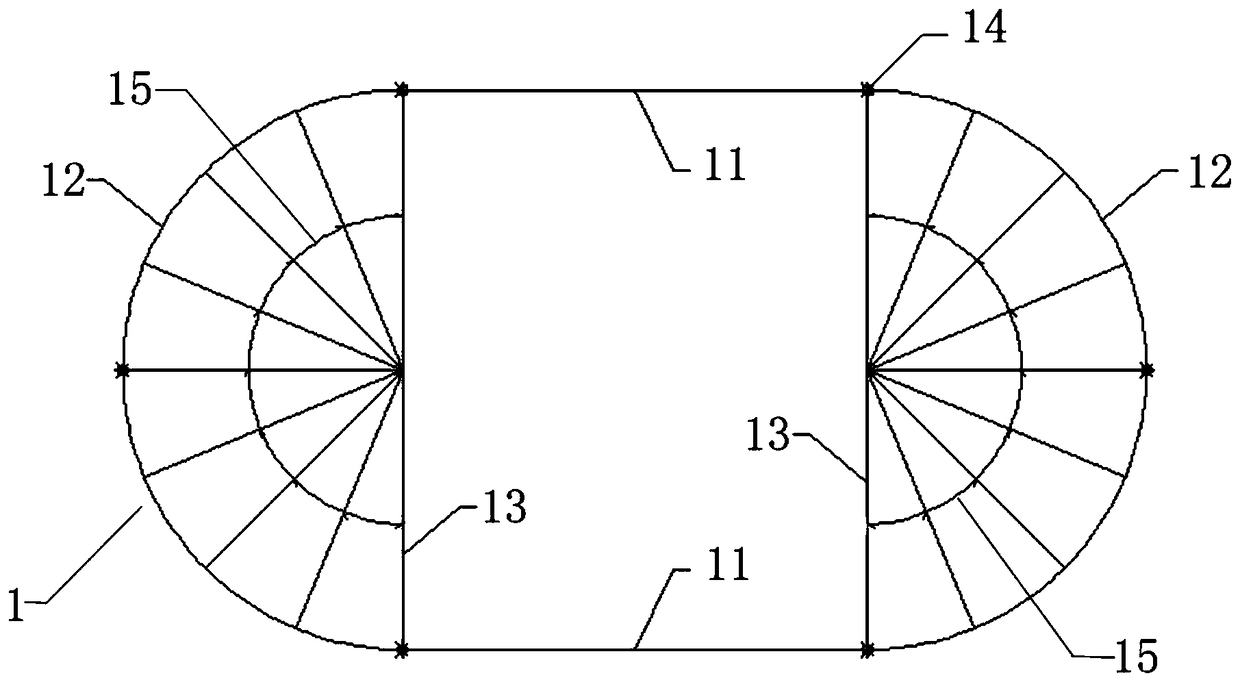

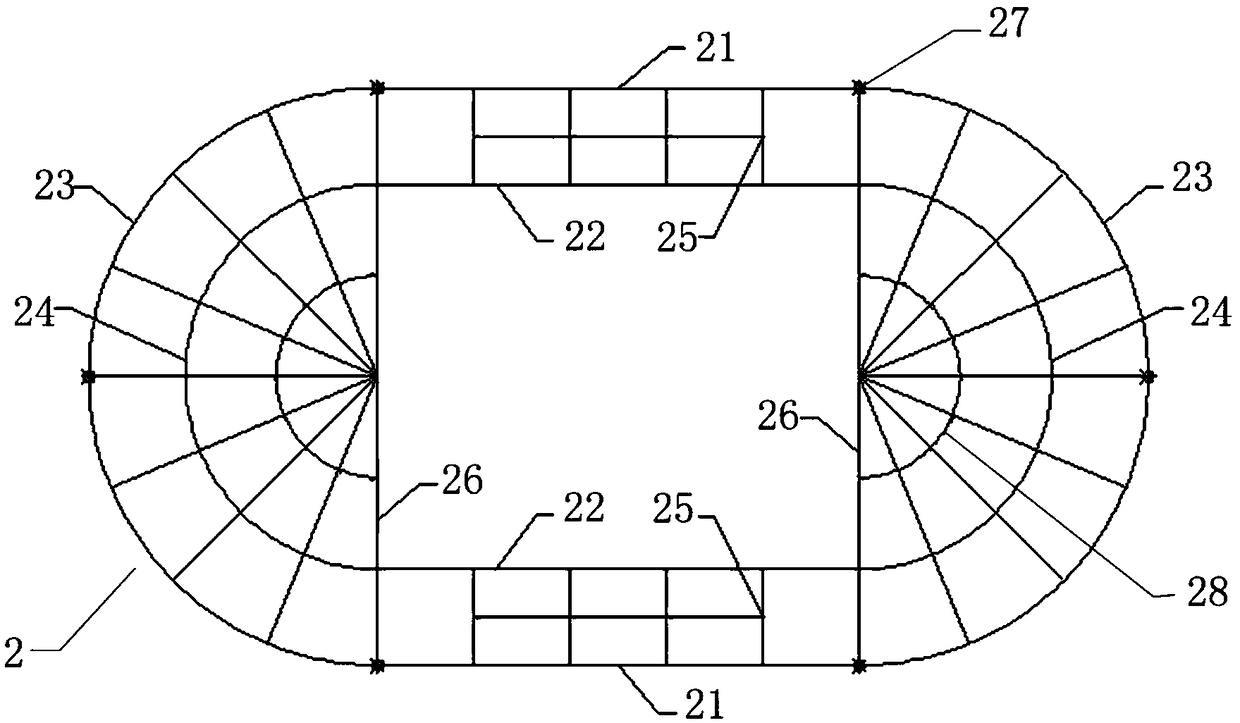

Preparation method of wind turbine blade

ActiveCN109109341AReduce the difficulty of bondingAvoid forming defects such as wrinklesDomestic articlesSuction stressTurbine blade

The invention discloses a preparation method of a wind turbine blade. The method comprises the following steps: laying fiberglass cloth, girders and a sandwich core in a suction side / pressure side shell mold, then carrying out vacuum resin infusion, solidifying and demoulding to obtain an integral body of shells and the girders; laying the fiberglass cloth, a core material and the fiberglass clothsequentially in a wind turbine blade prefabrication trailing edge mold, carrying out vacuum resin infusion, solidifying and demoulding to obtain a prefabricated trailing edge; molding the prefabricated trailing edge integrally by using the trailing edge of the suction side shell and the trailing edge of the pressure side shell; respectively sticking the two ends of a leading edge web and a trailing edge web with the suction side girder and the pressure side girder, and enabling the suction side shell to be partially stuck with the front edge part of the pressure side shell; sticking the prefabricated trailing edge with the suction side shell and the pressure side shell to obtain the wind turbine blade. The prefabricated trailing edge can be used for detailing control of a vertex, so thatthe molding defects such as folds are avoided to the utmost extent; the sticking surfaces of the prefabricated trailing edge and the shells are planes, so that the sticking difficulty is greatly reduced, and the quality is also guaranteed.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

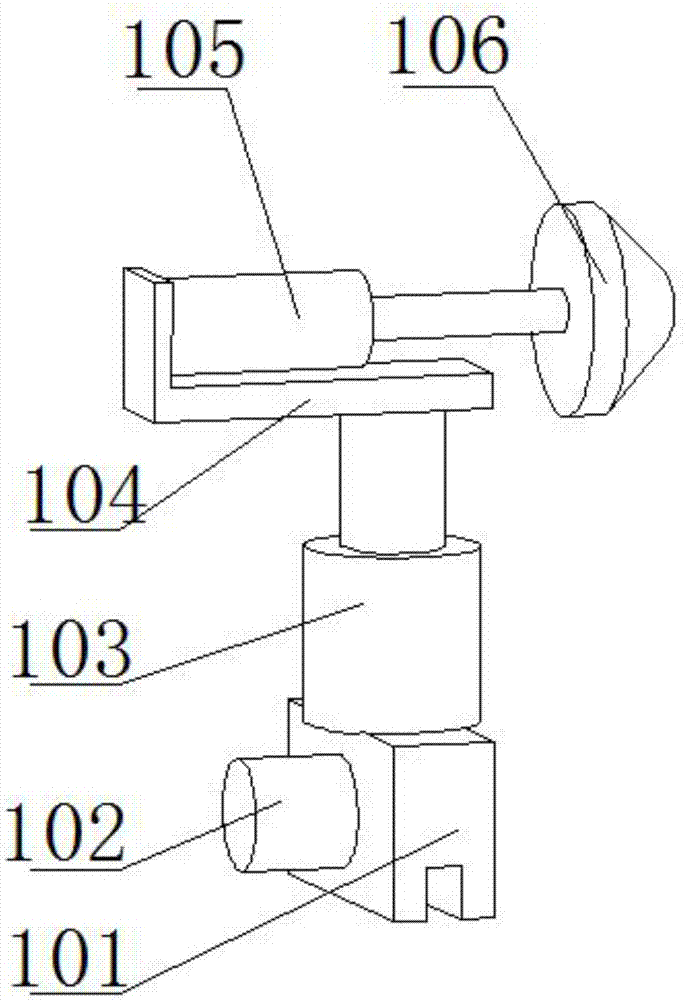

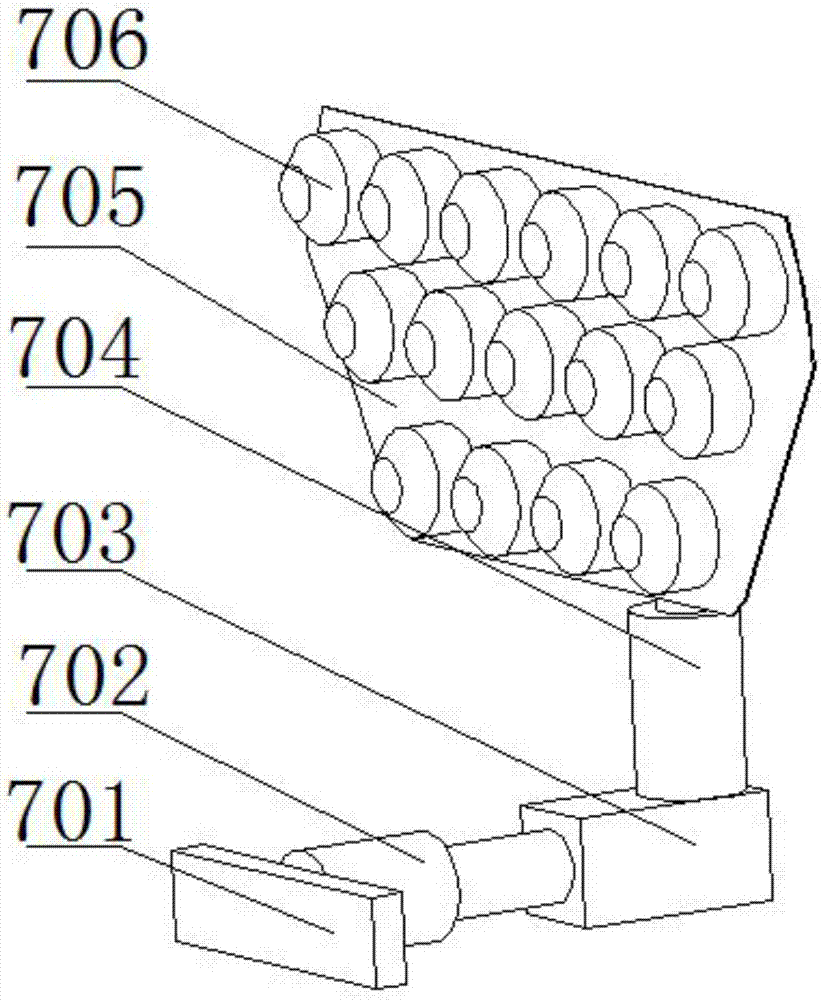

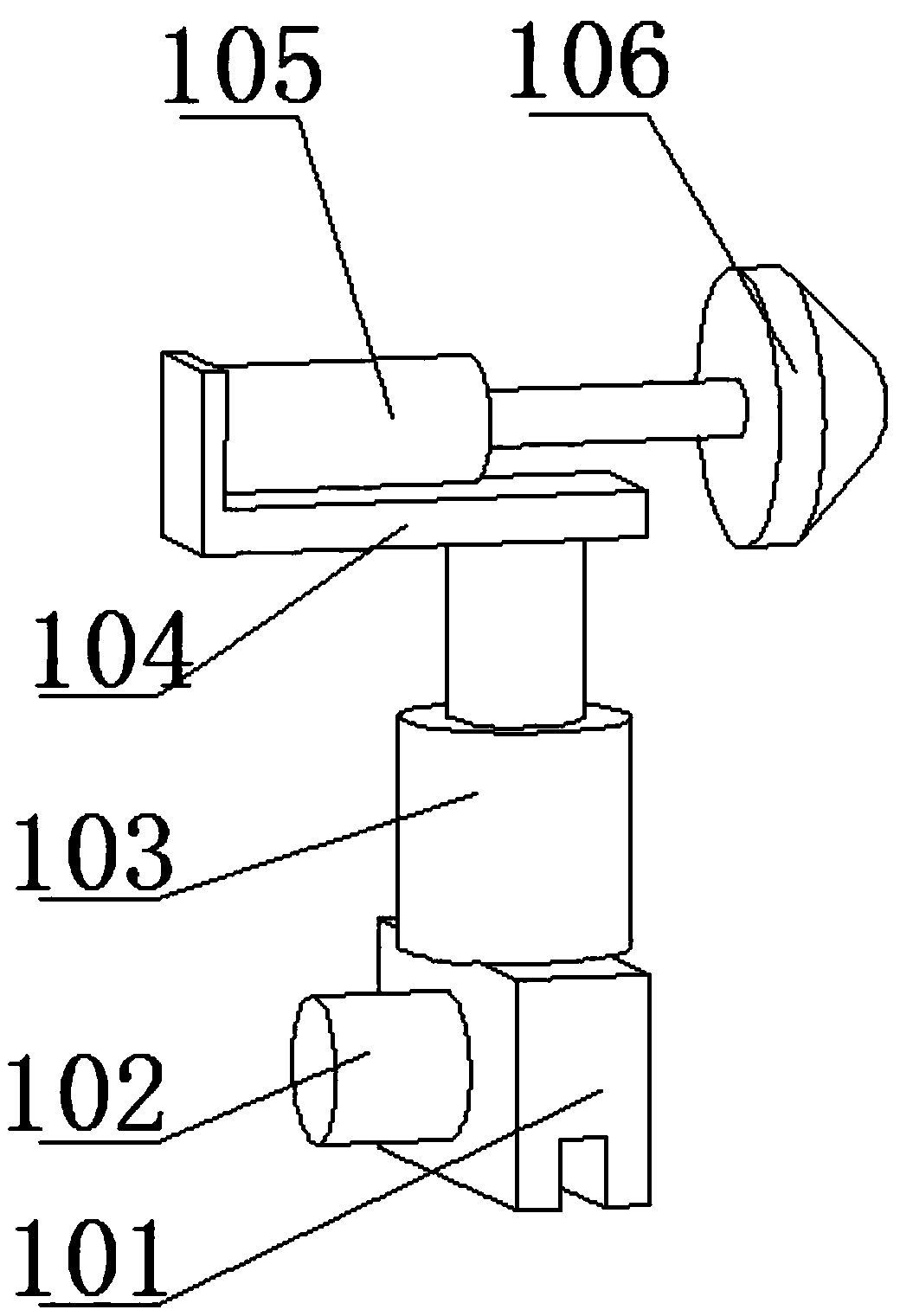

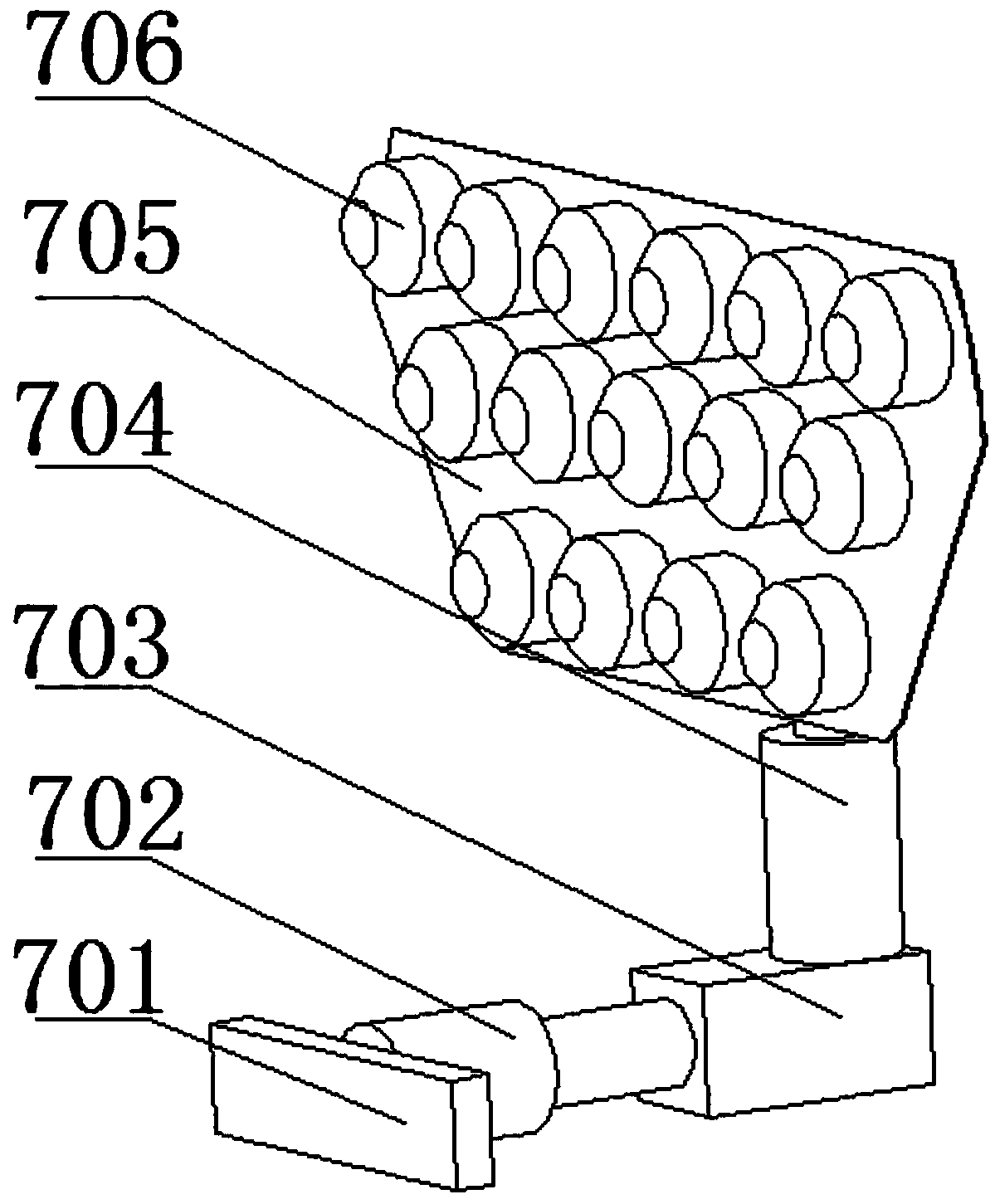

Steel tube hexagonal binding device

ActiveCN106904306ARealize rapid prototypingBundling machine detailsConveyor partsEngineeringMechanical engineering

The invention discloses a steel tube hexagonal binding device and belongs to the field of electromechanical equipment. The steel tube hexagonal binding device is composed of a first holding assembly, a first guide rail, a main frame, a steel tube trough body, a second guide rail, a second holding assembly, a first overturning assembly, a first semi-hexagon supporting rod, a second semi-hexagon supporting rod and a second overturning assembly, and is characterized in that the first guide rail and the second guide rail are mounted on the main frame; the steel tube trough body is mounted at one end of the main frame; the first holding assembly and the second holding assembly are mounted on the first guide rail and the second guide rail correspondingly; the first semi-hexagon supporting rod and the second semi-hexagon supporting rod are mounted at the other end of the main frame; and the first overturning assembly and the second overturning assembly are mounted on the main frame. The steel tube hexagonal binding device has the beneficial effect that rapid steel tube hexagonal forming is achieved.

Owner:WUXI HUADI MACHINERY EQUIP

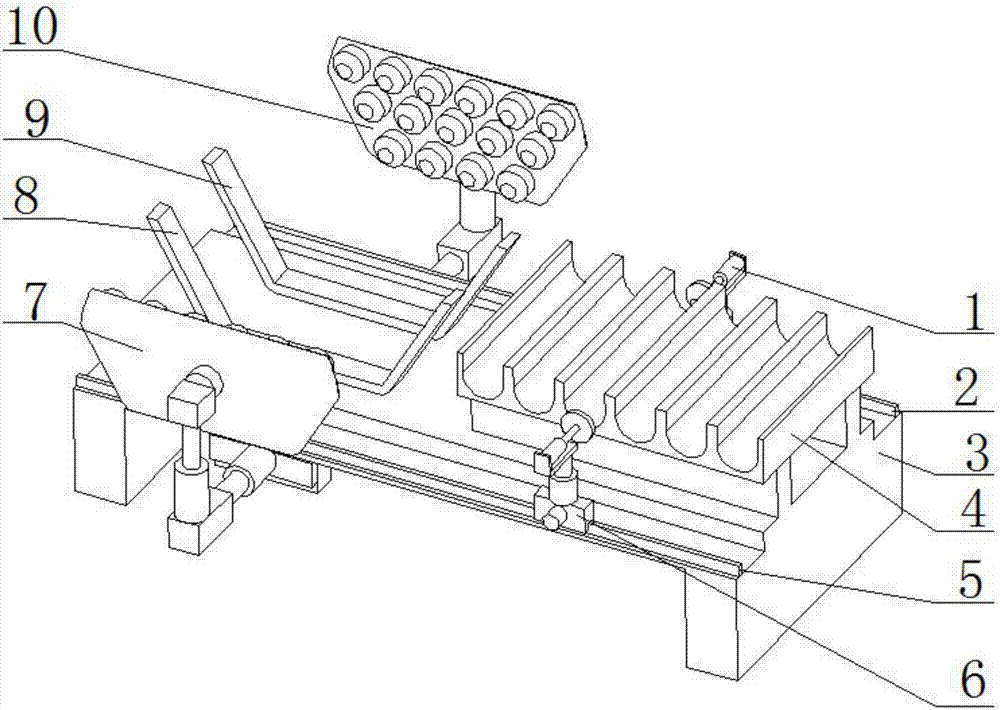

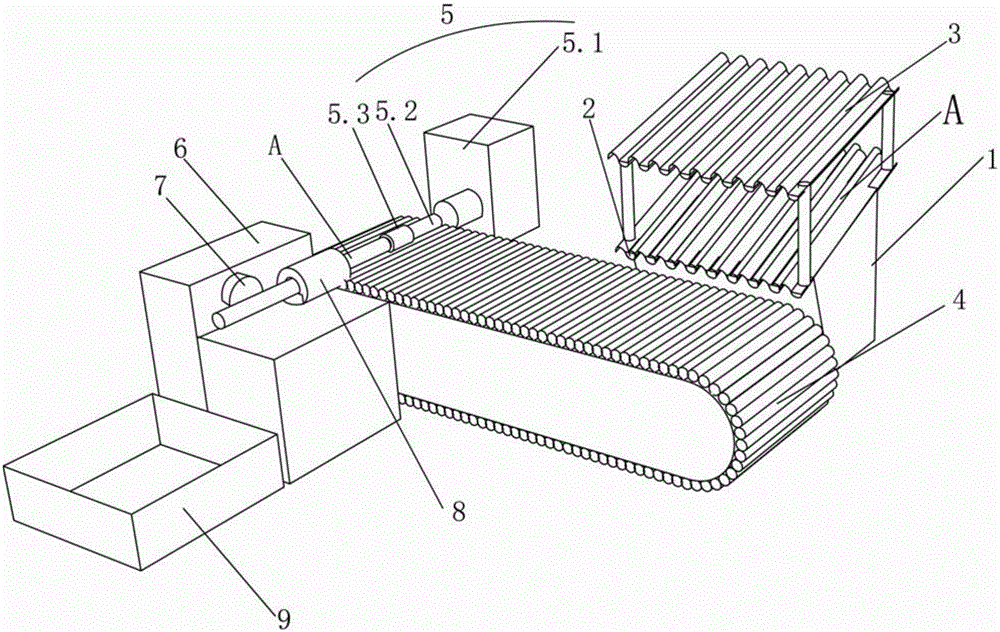

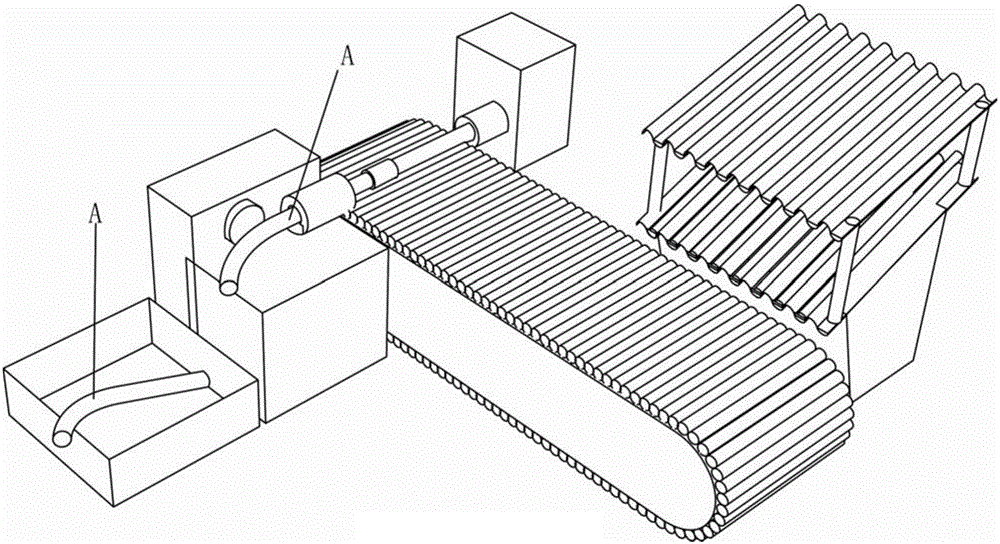

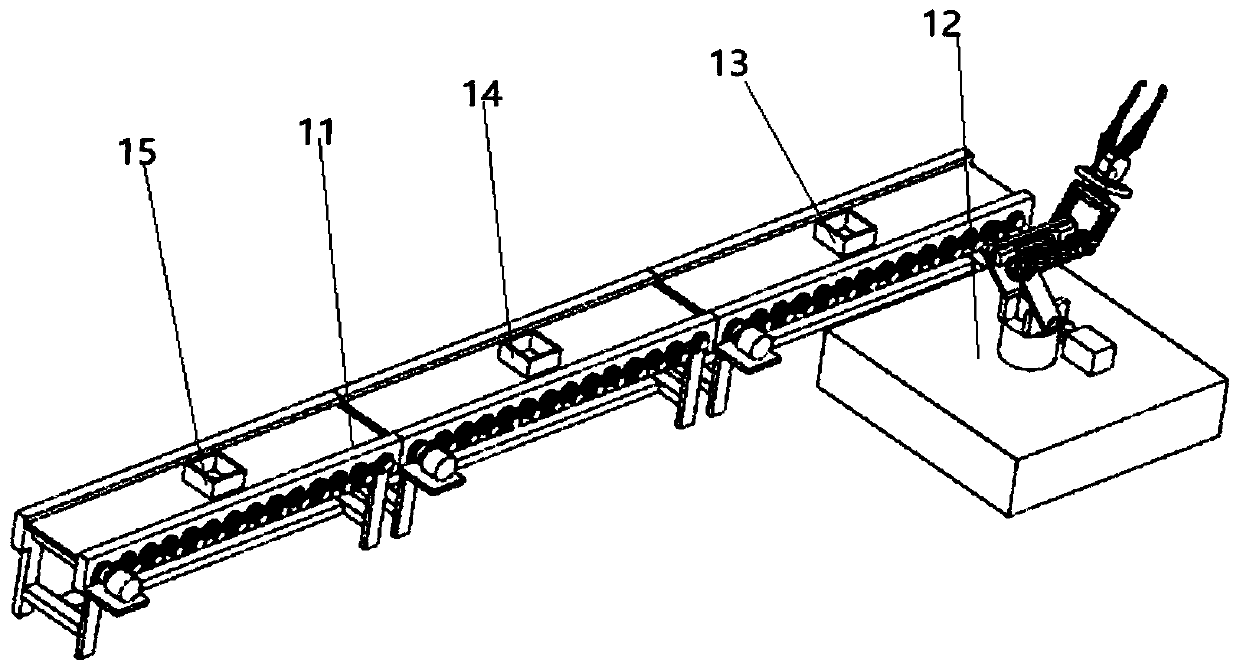

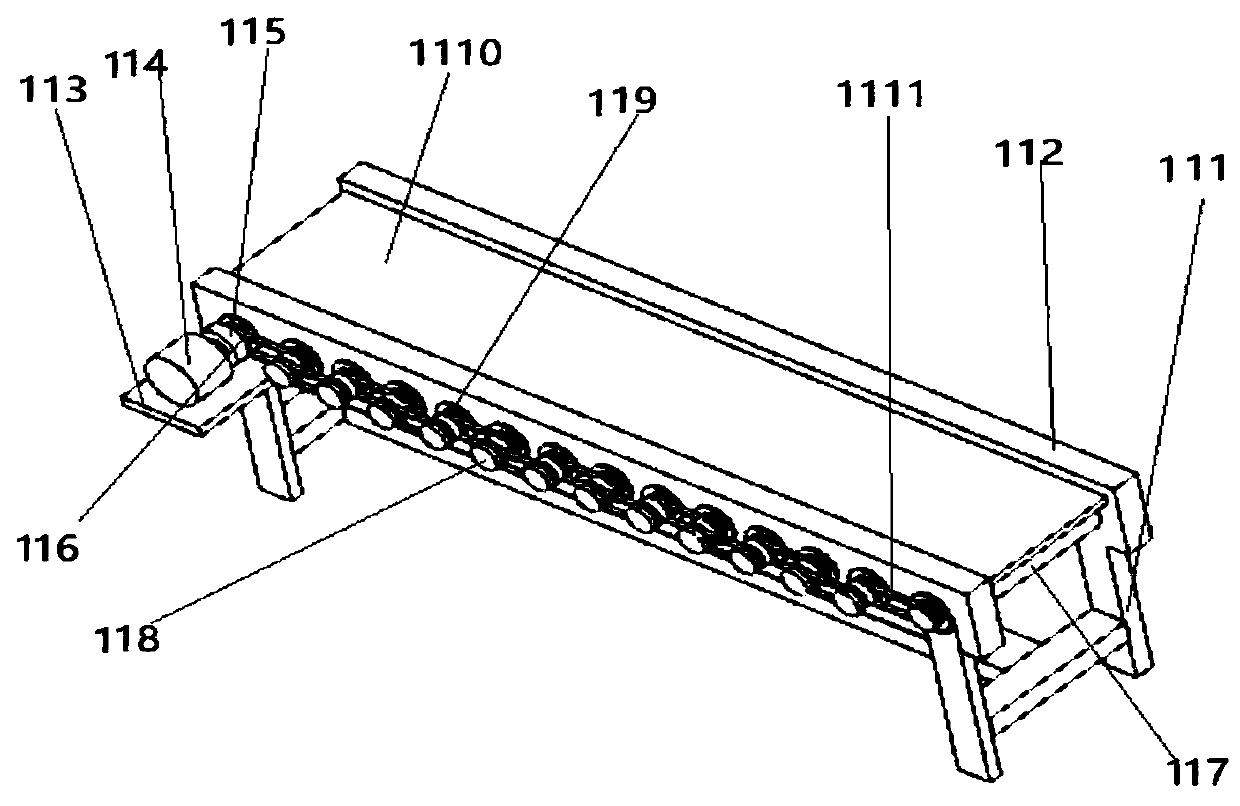

Air conditioner pipe bending machine

InactiveCN105107895ARealize automatic feeding processSimple structureMetal-working feeding devicesStripping-off devicesEngineeringMechanical engineering

The invention discloses an air conditioner pipe bending machine which comprises a feeding device, an automatic transport device and a bending device. The air conditioner pipe bending machine is characterized in that the feeding device is provided with tanks matched with air conditioner pipes, and automatic baffles which can be opened and closed are arranged at the bottoms of the tanks; the automatic transport device is arranged on the side portion of the feeding device and comprises a conveying device which is provided with grooves, and the grooves are matched with the air conditioner pipes; the air conditioner pipe bending device is arranged on the side portion of the feeding device.

Owner:LIUZHOU YINONG TECH

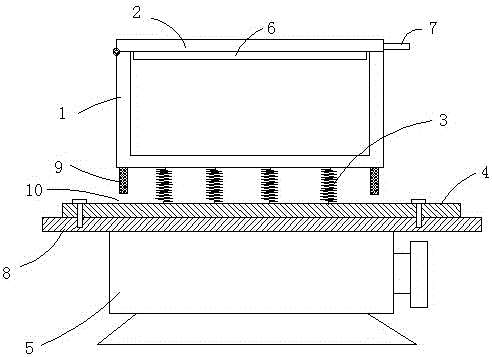

Foamed sponge forming die with vibrating device

InactiveCN106584753ARealize rapid prototypingReduce the presence of air bubblesRapid prototypingAir bubble

The invention discloses a foamed sponge forming die with a vibrating device. The foamed sponge forming device comprises a lower die body and an upper die cover. The profile of the lower die body is of a cuboid box-shaped structure. An open box opening is formed in the upper portion of the lower die body. A cover plate is configured to the upper die cover. The edge of a plate body of the cover plate is movably connected with the edge of the upper box opening of the lower die body. The vibrating device is arranged on the lower portion of the lower die body. The vibrating device comprises multiple compression springs, a vibrating plate and a motor. The vibrating plate is horizontally arranged on the lower portion of the lower die body. The compression springs are fixed between the vibrating plate and a lower box body of the lower die body. The motor is fixed to a lower plate body of the vibrating plate. By the adoption of the foamed sponge forming die with the vibrating device, fast forming of foamed sponge is achieved effectively, bubbles in the forming process can be reduced, the forming quality is improved, and the practicability is high.

Owner:苏州恒昇海绵机械制造有限公司

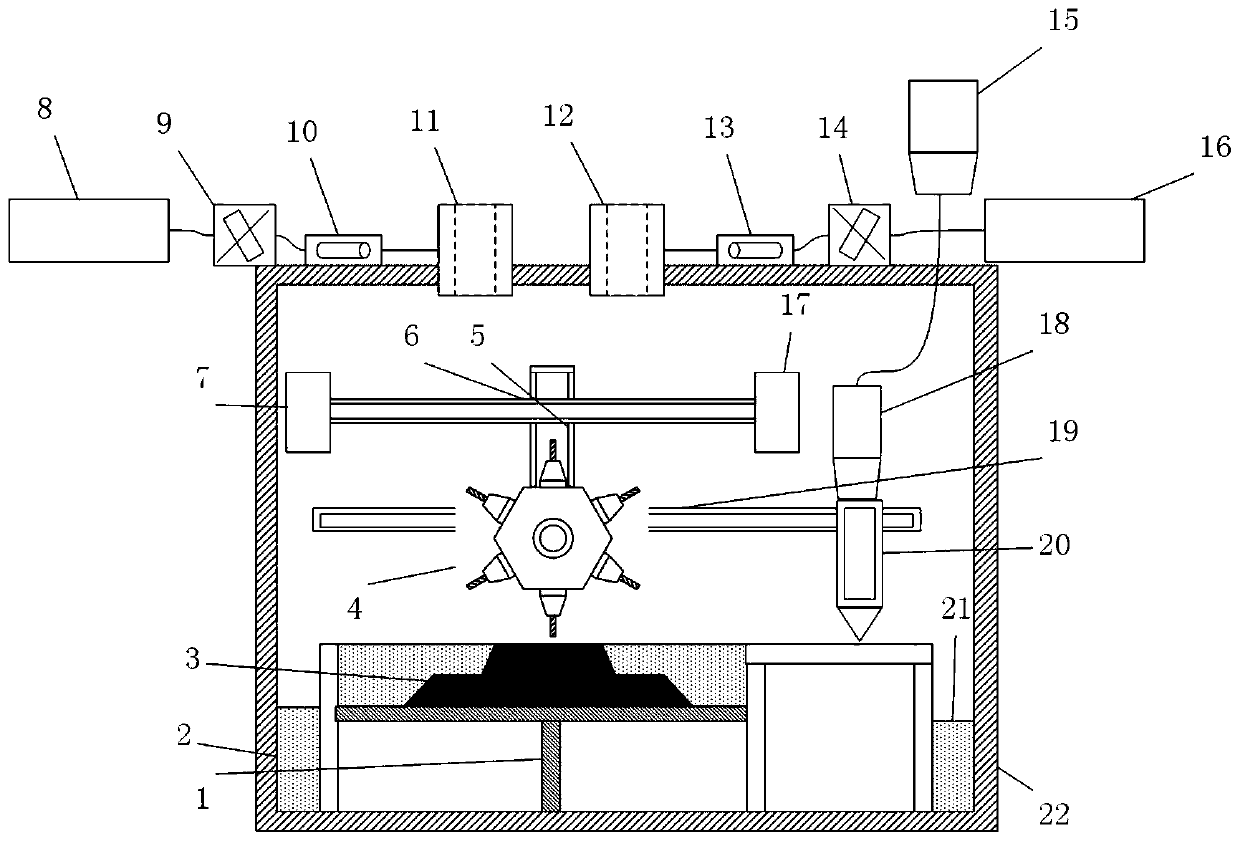

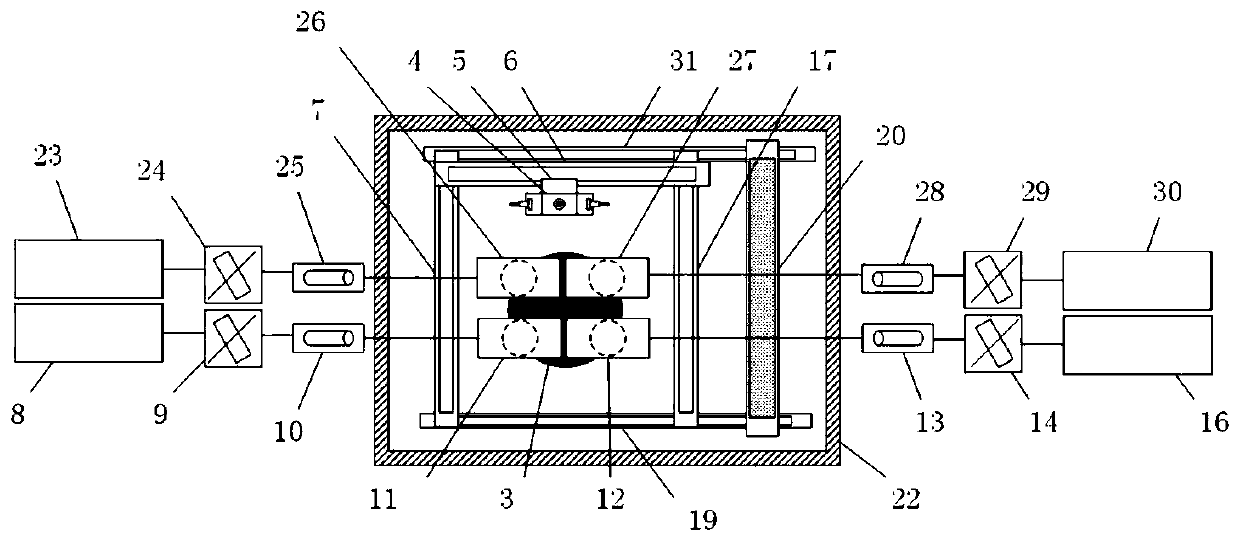

Four-laser four-galvanometer selective laser melting additive and subtractive forming device and method

PendingCN110523988ARealize rapid prototypingReduce processing timeAdditive manufacturing apparatusIncreasing energy efficiencyGalvanometerOptoelectronics

The invention discloses a four-laser four-galvanometer selective laser melting additive and subtractive forming device and method; the forming device includes a sealed forming chamber; a machining forming platform, an industrial personal computer, powder feeding and spreading equipment, circulating purification equipment and milling equipment are arranged in the sealed forming chamber; the machining forming platform is provided with a to-be-machined part. The forming device is characterized in that it further comprises galvanometer light path equipment. The galvanometer light path equipment comprises four scanning galvanometers and four lasers. The four scanning galvanometers are arranged over the machining forming platform, the four scanning galvanometers are arranged in a 2 * 2 mode, a laser excitation light source is input into the scanning galvanometers through a light valve steering unit and a variable beam expanding collimating mirror unit, and the industrial personal computer isconnected with galvanometer light path equipment to achieve simultaneous machining of four areas of the same part.

Owner:SOUTH CHINA UNIV OF TECH

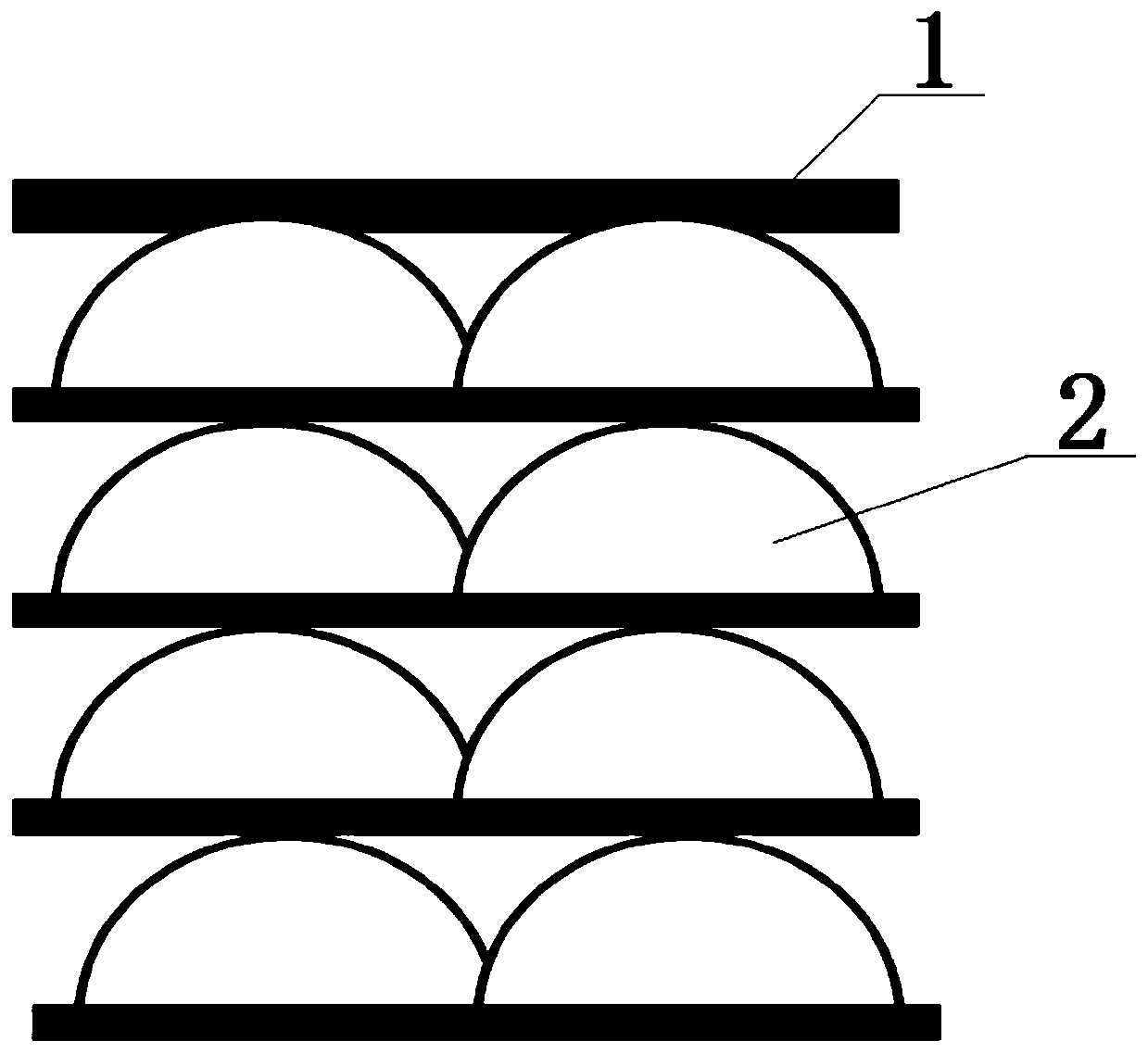

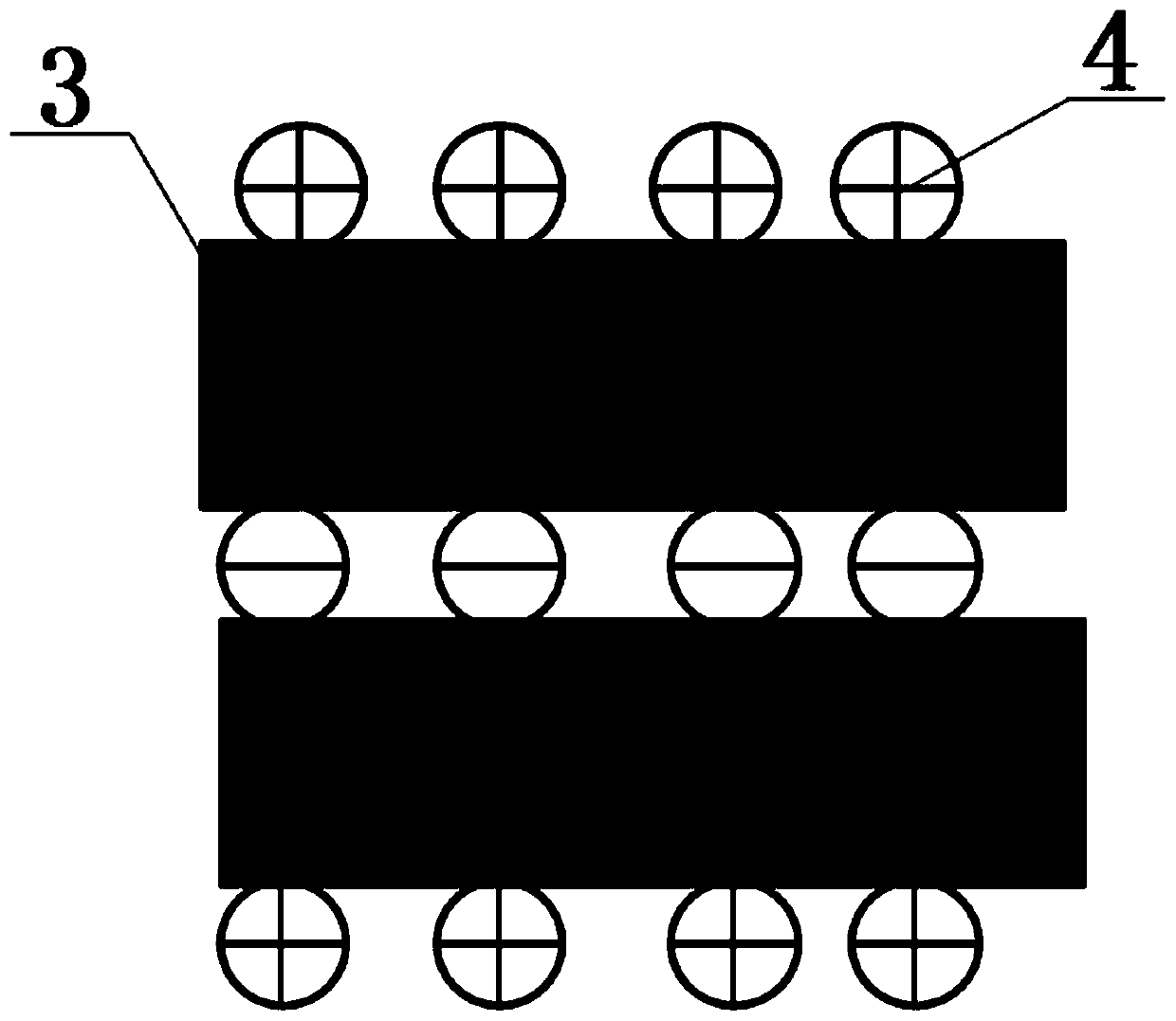

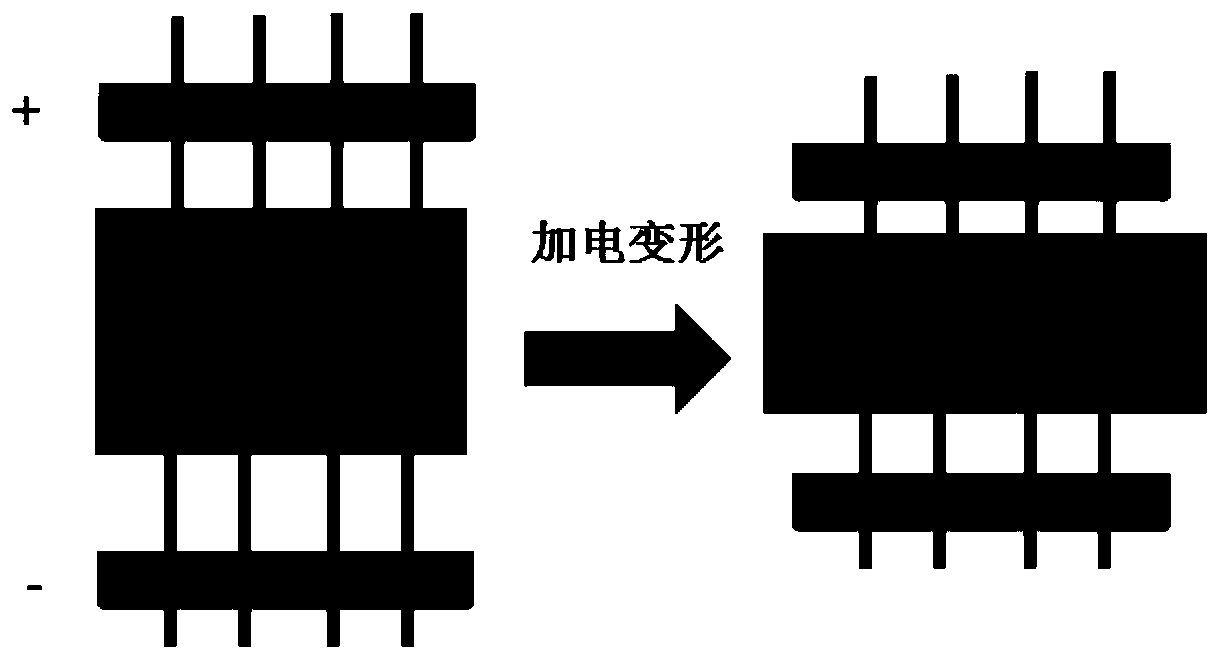

PVC-gel artificial muscle integrated printing method

ActiveCN109795103AGuaranteed rigidityRealize rapid prototypingAdditive manufacturing apparatus3D object support structuresGel electrodeCarbon nanotube

The invention discloses a PVC-gel artificial muscle integrated printing method. The method includes the steps that polyvinyl chloride, adiponitrile poly butylene terephthalate and tetrahydrofuran areused as PVC-gel core layer materials, carbon nanotubes and silicon rubber or polyvinyl chloride and ultra-long carbon tubes and adiponitrile poly butylene terephthalate are used as electrode raw materials, and fully flexible integrated PVC-gel artificial muscles are prepared through a 3D direct writing device printing process. According to the PVC-gel artificial muscle integrated printing method,a 3D printing technology is combined with the fully flexible PVC-gel artificial muscles, the 3D printing technology is applied into an integrated preparation process of a PVC-gel electrode and a corelayer, rapid prototyping of structures of the fully flexible PVC-gel artificial muscles is realized, the cost of manufacturing the fully flexible PVC-gel structures is lowered, and application of thematerial in the fields such as medical treatment, aerospace, soft robots is expanded.

Owner:XI AN JIAOTONG UNIV

A hexagonal binding device for steel pipes

ActiveCN106904306BRealize rapid prototypingBundling machine detailsConveyor partsStrappingEngineering

The invention discloses a steel tube hexagonal binding device and belongs to the field of electromechanical equipment. The steel tube hexagonal binding device is composed of a first holding assembly, a first guide rail, a main frame, a steel tube trough body, a second guide rail, a second holding assembly, a first overturning assembly, a first semi-hexagon supporting rod, a second semi-hexagon supporting rod and a second overturning assembly, and is characterized in that the first guide rail and the second guide rail are mounted on the main frame; the steel tube trough body is mounted at one end of the main frame; the first holding assembly and the second holding assembly are mounted on the first guide rail and the second guide rail correspondingly; the first semi-hexagon supporting rod and the second semi-hexagon supporting rod are mounted at the other end of the main frame; and the first overturning assembly and the second overturning assembly are mounted on the main frame. The steel tube hexagonal binding device has the beneficial effect that rapid steel tube hexagonal forming is achieved.

Owner:WUXI HUADI MACHINERY EQUIP

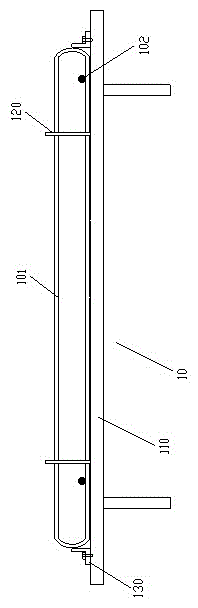

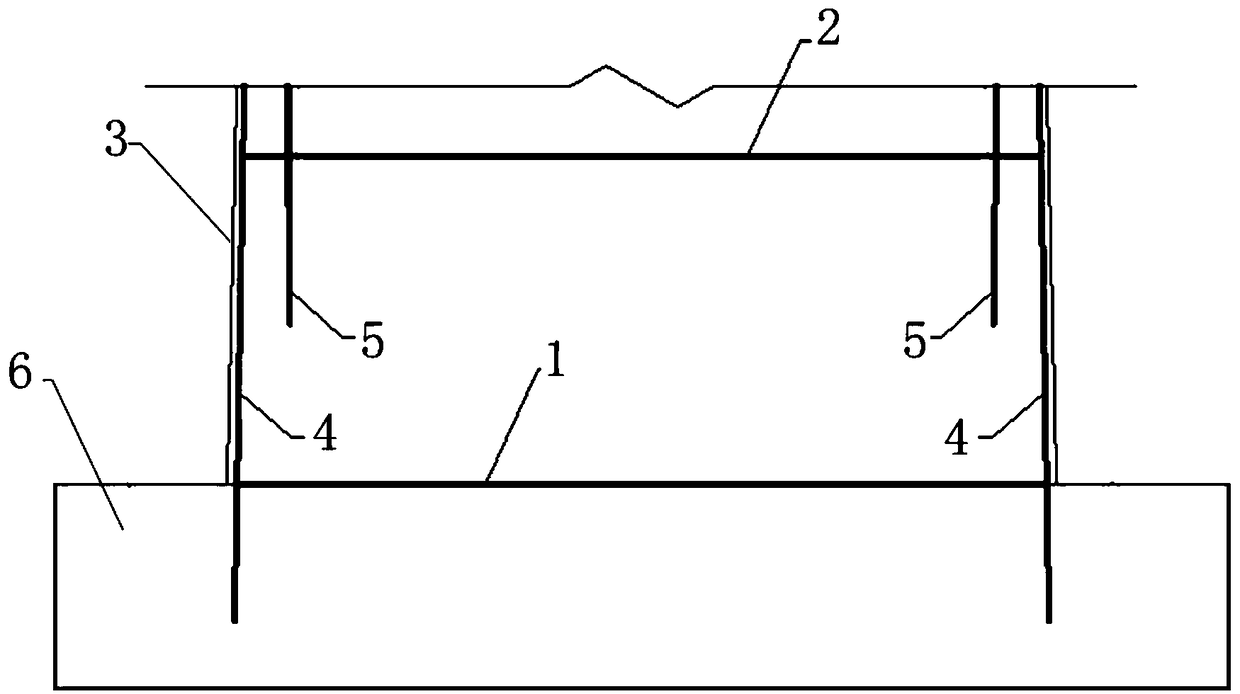

Prefabricated small box girder reinforcing steel bar tire membranization mounting device and method

InactiveCN105019361ARealize rapid prototypingEnsure stabilityBridge erection/assemblyStructural engineeringBox girder

The invention relates to a prefabricated small box girder reinforcing steel bar tire membranization mounting device and method. The device comprises a top plate tire membrane for prefabricating a top plate reinforcing steel bar framework and a web tire membrane for prefabricating a bottom plate and a web reinforcing steel bar framework. The top plate tire membrane comprises a supporting table for erecting top reinforcing steel bars, gratings for allowing top plate reinforcing steel bars to be arranged are arranged on the upper surface of the supporting table, and transverse reinforcing steel bars locating plates are arranged on the two sides of the supporting table and fixedly connected with the supporting table through bolts. The web tire membrane comprises a bottom table arranged on the ground, the two sides of the bottom table are hinged to inclined frames for erecting and abutting against web plate vertical reinforcing steel bars, supporting rods hinged to the inclined frames are arranged on the two sides of the inclined frames, transverse convex rods for erecting web plate horizontal reinforcing steel bars are arranged on the inclined frames towards the inner sides, locating cross rods are arranged at the upper ends of the inclined frames, and locating grooves are formed in the locating cross rods. According to the device and method, a small box girder reinforcing steel bar tire membrane can be fast molded conveniently through the top plate tire membrane and the web tire membrane, and meanwhile the structural stability of the tire membrane is guaranteed through locating mechanisms on all the tire membranes.

Owner:福建省高速公路建设总指挥部 +2

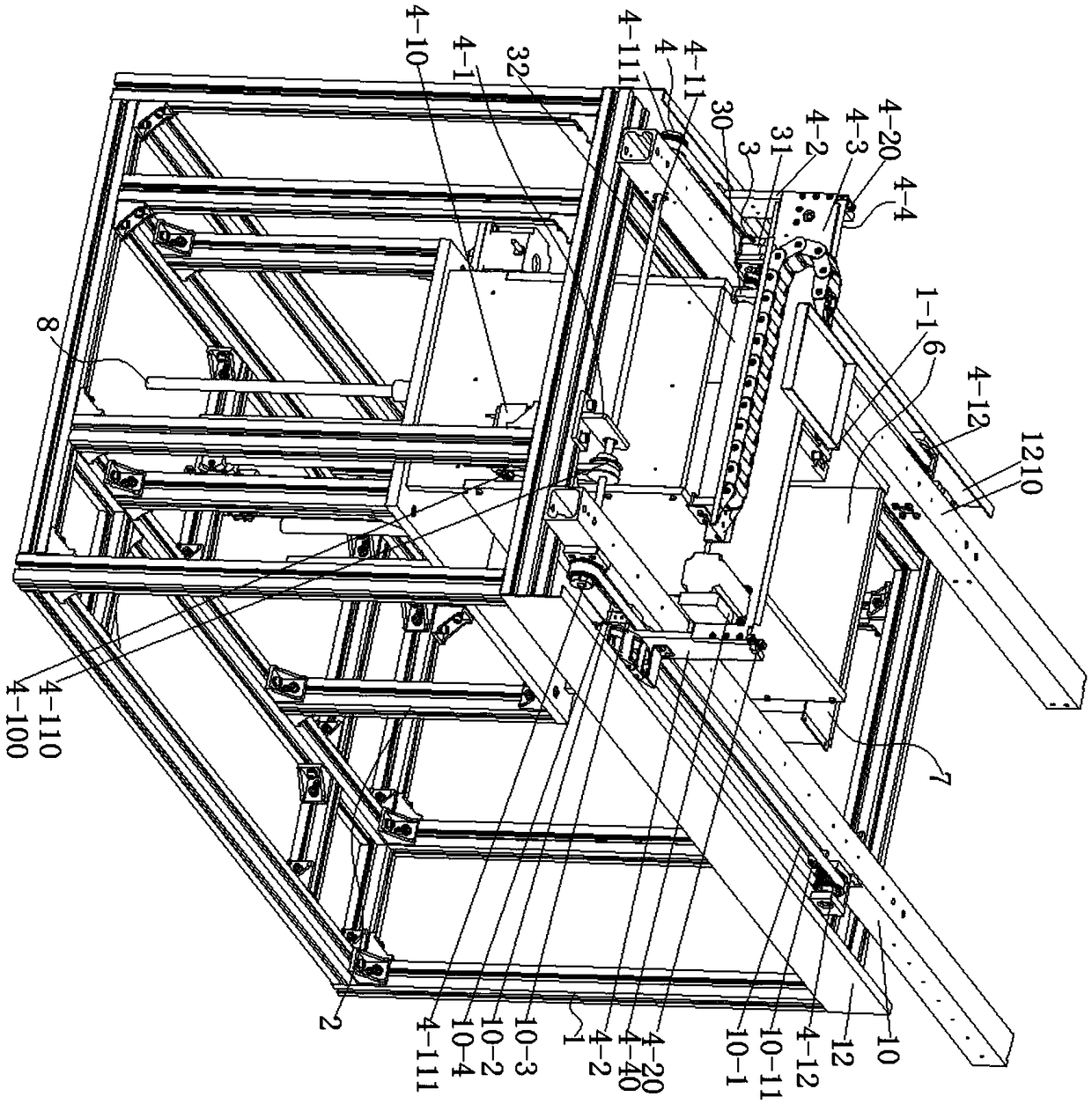

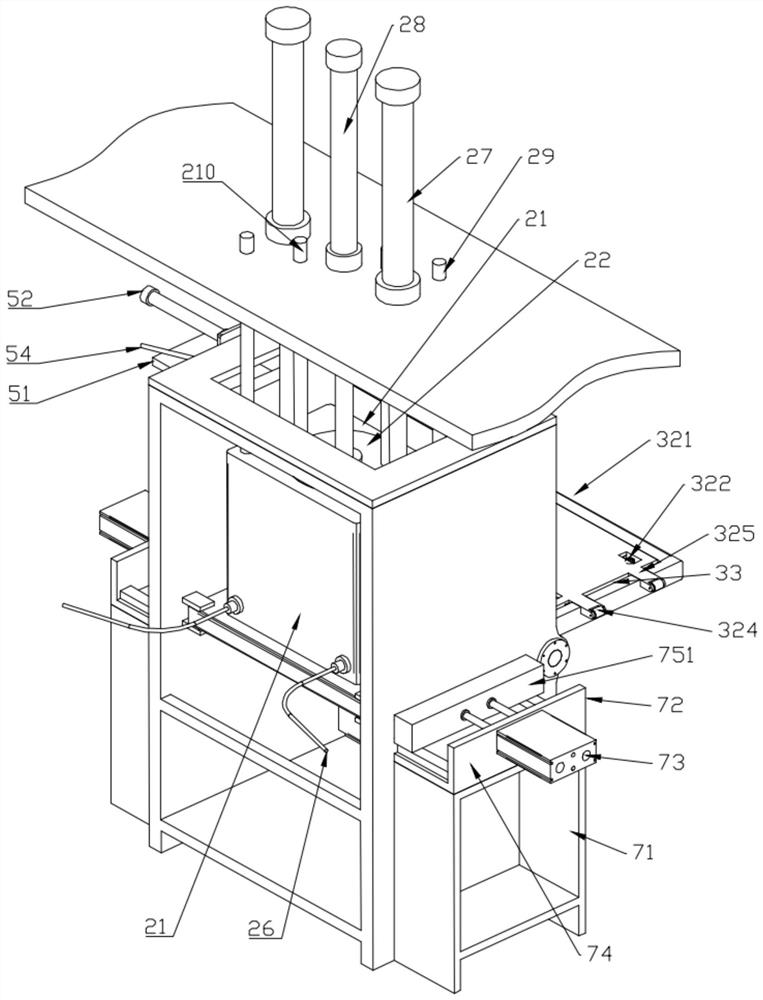

Sand mould 3D rapid molding equipment using slab printer

InactiveCN108943705ASave raw materialsGood particle sizeManufacturing driving means3D object support structuresSpray nozzlePiston

The invention discloses sand mould 3D rapid molding equipment using a slab printer. The sand mould 3D rapid molding equipment comprises an outer frame, an inner frame, a scraper mechanism, the slab printer, a sand feeding box, a molding sand box, a recovering hopper, a first Z-direction mechanism, a second Z-direction mechanism, a platform plate and a spraying nozzle; the bottoms of the inner frame and the outer frame are connected, two longitudinal beams are arranged at the upper end of the outer frame in parallel, and a side surrounding plate is arranged on the side face of the outer frame;the scraper mechanism is connected with the lower portion of the back end of the slab printer, the platform plate is connected with the upper end of the inner frame, the sand feeding box is connectedwith the platform plate, the molding sand box is connected with the platform plate, the recovering hopper is connected with the molding sand box, a first piston plate is arranged in the sand feeding box, and a second piston plate is arranged in the molding sand box; and the middle portion of the first Z-direction mechanism is connected with the platform plate, the top end of the first Z-directionmechanism is connected with the first piston plate, the middle portion of the second Z-direction mechanism is connected with the platform plate, the top end of the second Z-direction mechanism is connected with the second piston plate, a spraying nozzle support is arranged on the side face of the spraying nozzle, the spraying nozzle is connected with the slab printer through the spraying nozzle support, powder paving is carried out layer by layer, the spraying nozzle sprays out binders, and layer-by-layer printing is achieved.

Owner:安徽卓锐三维科技有限公司

Method for making pteroceltis tatarinowii bonsai through pruning, branch abandoning and grafting

InactiveCN105900773AImprove production efficiencyRealize rapid prototypingGraftingCultivating equipmentsEcological environmentRootstock

The invention discloses a method for making pteroceltis tatarinowii bonsai through pruning, branch abandoning and grafting. A traditional pteroceltis tatarinowii bonsai making method is overturned, traditional bark grafting, notch grafting and other grafting methods are borrowed to graft pteroceltis tatarinowii seedings to cut thick abandoned pteroceltis tatarinowii branches so that they heal and grow to wholes, absorbable nutriments are supplied to trunks of the thick pteroceltis tatarinowii branches, the thick pteroceltis tatarinowii branches grow into stump bonsai after one grow cycle of cultivation and maintenance, and then pruning and art processing are performed to make pteroceltis tatarinowii bonsai blanks. The purpose of rapidly forming the pteroceltis tatarinowii bonsai is achieved, a making cycle is about 2-3 years, the traditional making cycle of more than 10 years or even decades of years is greatly shortened, the bonsai making efficiency is greatly improved, the increasingly booming market demands are met, scion materials are abandoned branches pruned from big trees or branch sections reasonably cut from adult tress in nursery land, stock materials are one or two years old of seedlings with complete root systems, the phenomena of disorder collecting and digging of big pteroceltis tatarinowii trees are decreased, and the ecological environment is protected..

Owner:TAISHAN RES INST OF FORESTRY

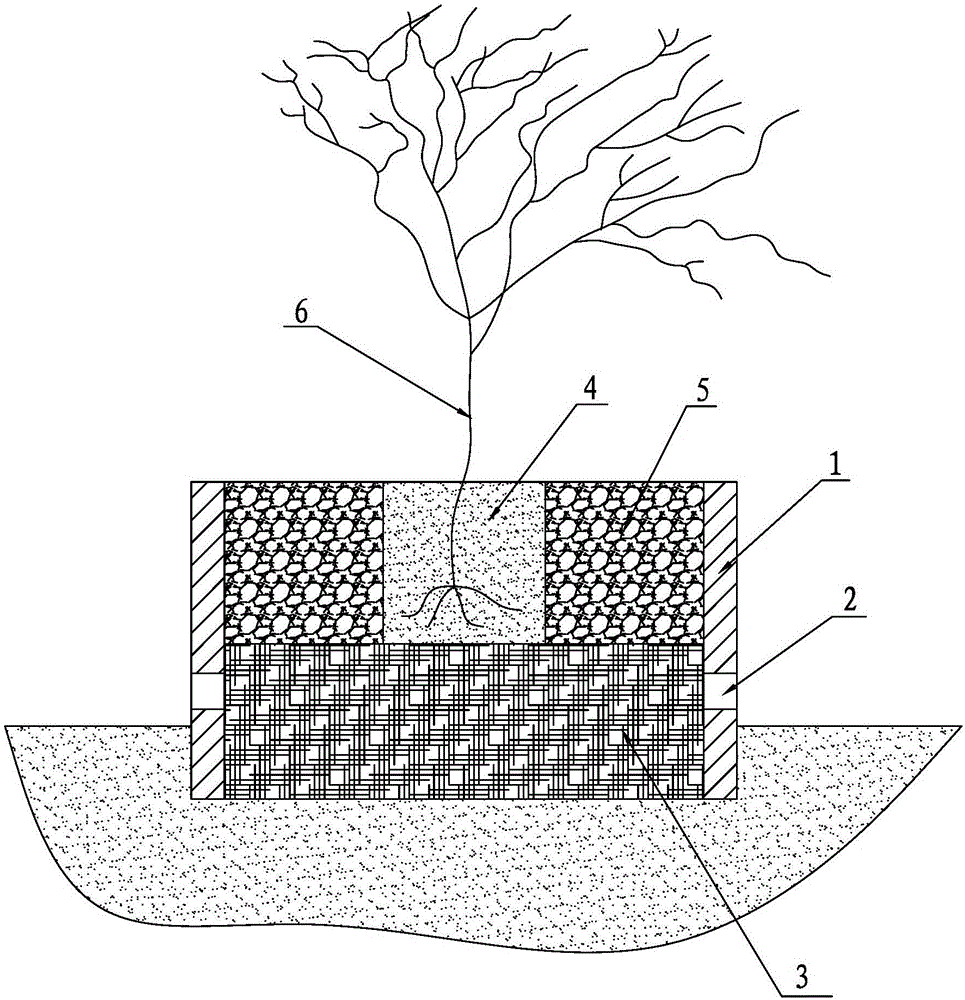

Multilayer fertilization method for increasing content of vineyard soil organic matter at a time

InactiveCN106688782AFast growthImprove quality and efficiencyFertilising methodsCultivating equipmentsFertilizerRoot system

Disclosed is a multilayer fertilization method for increasing the content of vineyard soil organic matter at a time. The method comprises the steps that a grape root restriction pool is pre-embedded in a grape seedling planting region, a base fertilizer fermentation material is laid at the bottom of the grape root restriction pool, cultivation soil is piled up in the center above the base fertilizer fermentation material, seedling protection fertile soil is tamped on the periphery of the cultivation soil, grape seedlings are transplanted to the center of the circle of the cultivation soil in spring 15 days after effectiveness, the grape root system is 10 cm away from the top face of the base fertilizer fermentation material, watering is performed, and all soil materials are watered thoroughly inside the grape root restriction pool. By adopting the fertilization method, the temperature of the grape rhizosphere is higher than the conventional temperature 5 days after grapes are transplanted, grape new roots grow earlier and germinate earlier, the soil fertility is good enough, the growth speed is increased, molding can be achieved one year after planting, and the high-yield level can be achieved in the second year. The content of vineyard soil organic matter can be increased to 10% at a time, the grape quality is improved obviously, the grape soluble solid content can be increased by 2.5%, and the grape production benefits are increased obviously.

Owner:常州市金坛区园艺技术指导站

Straw mixing foaming forming mechanism for cake-shaped bricks

InactiveCN111618980AIncrease productivityNovel structural designDischarging arrangementMouldsProcess engineeringManufacturing engineering

The invention discloses a straw mixing foaming forming mechanism for cake-shaped bricks, and relates to the field of environmental protection equipment. The straw mixing foaming forming mechanism comprises a rack, a forming mold, a rotary platform, a power mechanism, a material injection mechanism and a locking mechanism. According to the straw mixing foaming forming mechanism, the rapid forming of the cake-shaped bricks is realized by adopting a foaming forming process, the rotary platform capable of freely rotating by 360 degrees plays two roles of foaming forming and product discharging, the two roles can be synchronously performed, and compared with traditional step-by-step production equipment, the production efficiency is remarkably improved.

Owner:房文浩

Method for producing archaistic tree bonsai by black pine pruning and living body grafting survival

The invention discloses a method for producing archaistic tree bonsai by black pine pruning and living body grafting survival, which relates to the field of botanical horticulture and overturns conventional methods for producing black pine bonsai. By adopting conventional grafting techniques, such as bark grafting and heteromorphic inarching, black pine seedlings are grafted onto a cut black pine bough, so that the black pine seedlings and the black pine bough are united to grow together, supplying nutrient to the black pine bough for absorption, a black pine bough tree bonsai is grown up after a growth cycle of cultivation and maintenance, and pruning and artistic processing are then performed to produce a black pine tree bonsai rough. The purpose of rapidly forming the tree of the black pine bonsai is realized, the traditional production period is shortened from more than ten years or even tens of years to two to three years, the efficiency of tree bonsai is greatly increased, and the constantly rocketing market demand is satisfied; because grafting materials are discarded branches cut from big trees or branch sections reasonably cut from grown trees in a seedling nursery and stock materials are 1-to-2-year-old black pine seedlings with complete root systems, the phenomenon of excessively digging big black pines is reduced, and thereby the ecological environment is protected.

Owner:SHANDONG PROVINCE FOREST TREE SEEDLING & FLOWER STATION

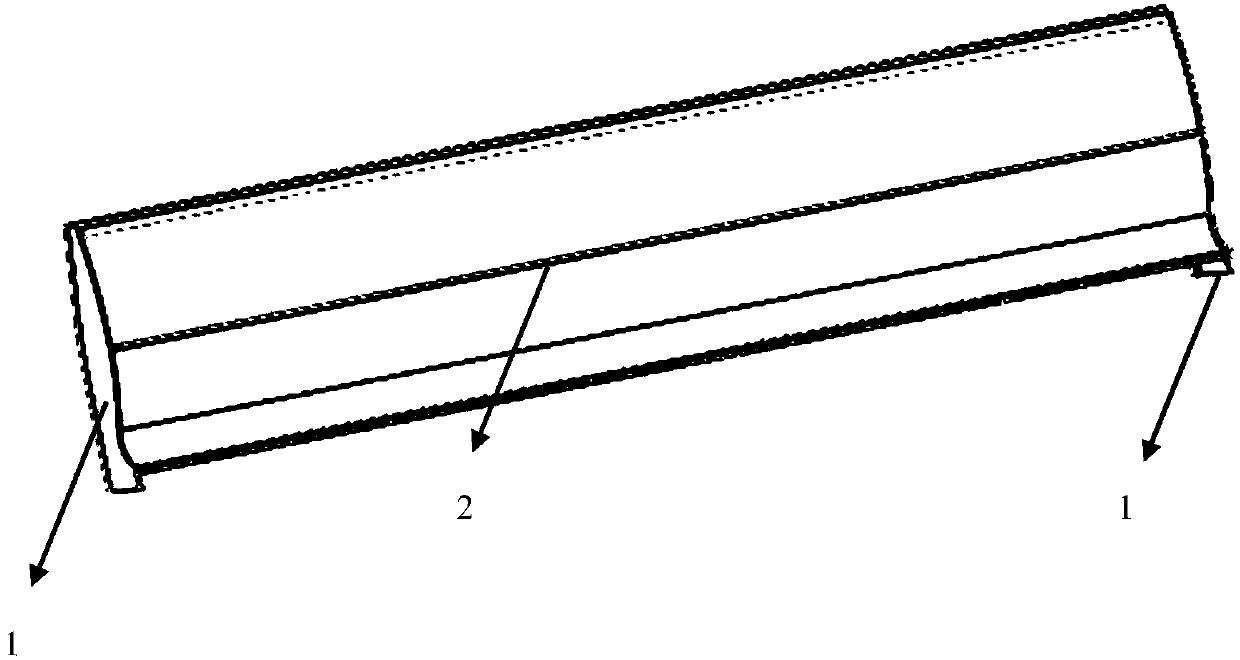

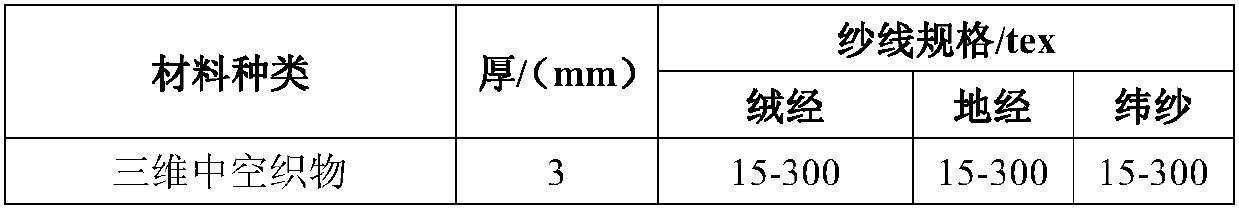

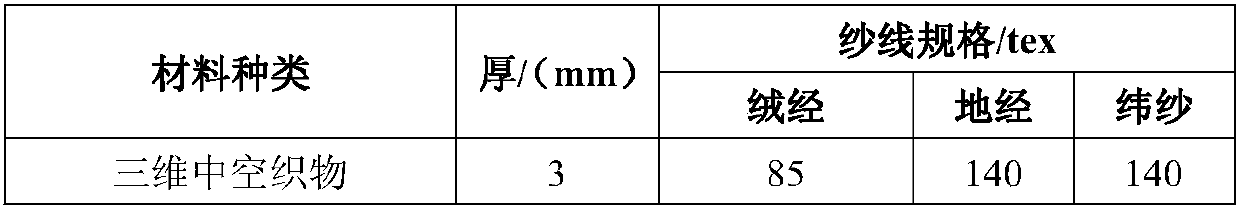

Preparation method of lightweight hollow woven fabric type composite material seat backrest

ActiveCN107856370AImprove mechanical propertiesEasy misalignmentGlass/slag layered productsSeatsFiberEngineering

The invention discloses a preparation method of a lightweight hollow woven fabric type composite material seat backrest. The seat backrest comprises two supporting plates, and a supporting surface which is arranged between the two supporting plates, wherein the two supporting plates are manufactured through fiber preforms; the supporting surface is manufactured through three-dimensional hollow woven fabrics. According to the method, the fiber preforms are used as the supporting plates, so that the problem of easy deviating of the conventional paving layers can be solved, and the mechanical property of the seat backrest is obviously improved; moreover, the preform paving and vacuum flow guiding integrated forming technology is performed, thus quick forming is achieved, and the problems suchas weak interface is avoided; the requirement on lightweight railcars in future can be met; in addition, the mechanical property of the seat backrest can be further improved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

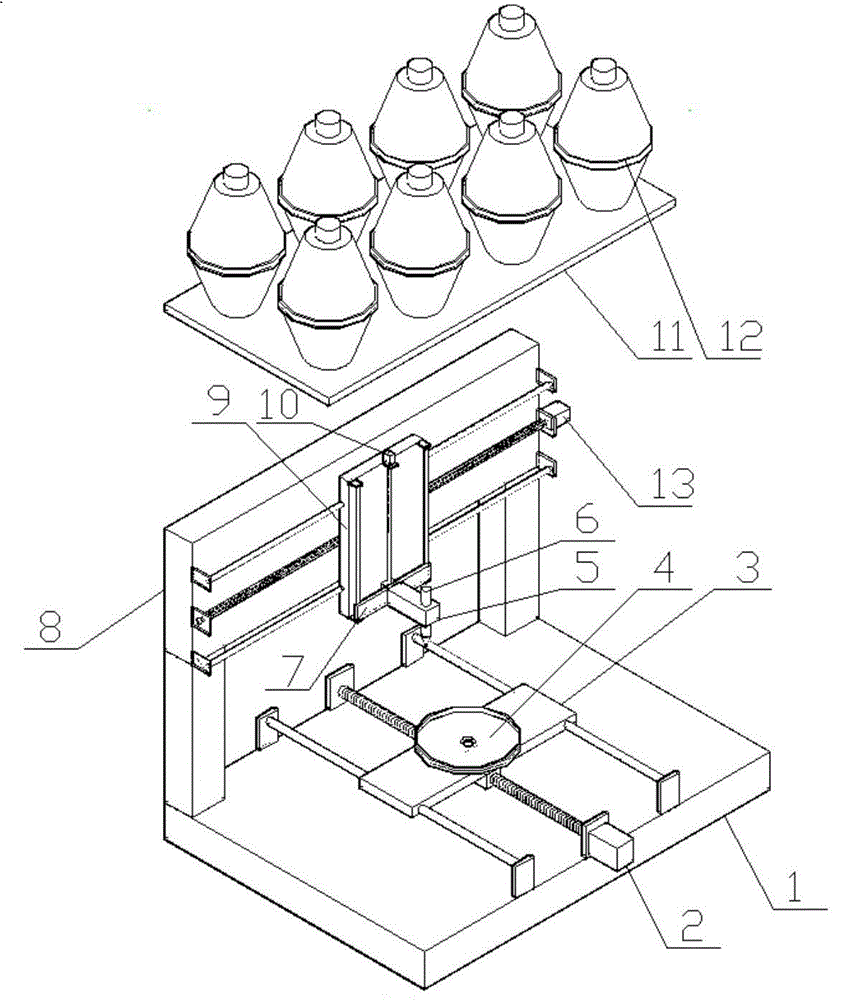

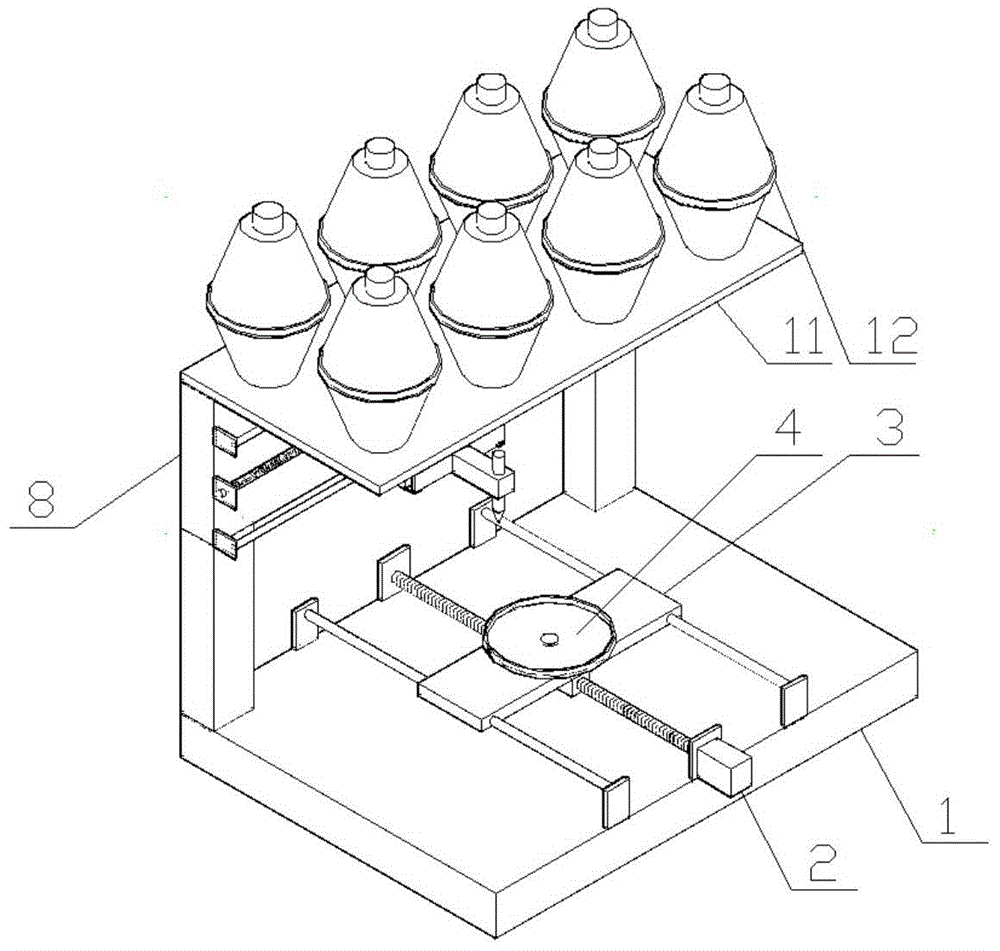

Novel 3D cake rapid molding machine

InactiveCN104642440ARealize rapid prototypingPre-baking dough treatmentMolding machineRapid prototyping

The present invention discloses a novel 3D cake rapid molding machine which can realize the function of automatically processed cakes and at the same time can rapidly mold cakes by using a variety of cake molding raw materials. The novel 3D cake rapid molding machine comprises an X movable plate, a Y movable plate and a Z movable plate which are respectively driven by an X drive electric motor, a Y drive electric motor and a Z drive electric motor; a rotary base rotatably mounted on the Y movable plate and the Z movable plate arranged on the X movable plate; a printer head plate mounting bracket mounted on the Z movable plate, a printer head vertically mounted on the printer head plate mounting bracket, a feed inlet arranged on the top end of the printer head; a base, a bracket, a horizontal fixing plate mounted on the top end of the bracket, multiple supply tanks fixedly mounted on the horizontal fixing plate, and discharge ports of the supply tanks extending to the lower part of the fixing plate. When the top feed inlet of the printer head print head goes deep into the discharge ports in the bottoms of the supply tanks, the supply tanks can fill cake molding raw materials for the printer head.

Owner:XIAN JIALE CENTURY ELECTROMECHANICAL TECH

Large pier reinforcing steel positioning device and installation method thereof

InactiveCN109322248APrecise positioningAvoid uneven spacingBridge structural detailsBridge erection/assemblyBridge engineeringInstability

The invention belongs to the technical field of bridge engineering construction, and particularly relates to a large pier reinforcing steel positioning device and an installation method thereof. The large pier reinforcing steel positioning device includes a bottom layer reinforcing steel positioning fixture and an upper layer reinforcing steel positioning fixture, the bottom layer reinforcing steel positioning fixture includes first positioning reinforcing steel, second positioning reinforcing steel and first strengthening reinforcing steel, and the upper layer reinforcing steel positioning fixture includes third positioning reinforcing steel, fourth positioning reinforcing steel, fifth positioning reinforcing steel, sixth positioning reinforcing steel, second strengthening reinforcing steel, and third strengthening reinforcing steel. According to the large pier reinforcing steel positioning device and the installation method thereof, by arranging the bottom layer reinforcing steel positioning fixture and the upper layer reinforcing steel positioning fixture, accurate positioning of reinforcing steel can be realized, and the phenomena of uneven spacing of the reinforcing steel, displacement of the reinforcing steel and instability of a reinforcing cage are effectively avoided.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

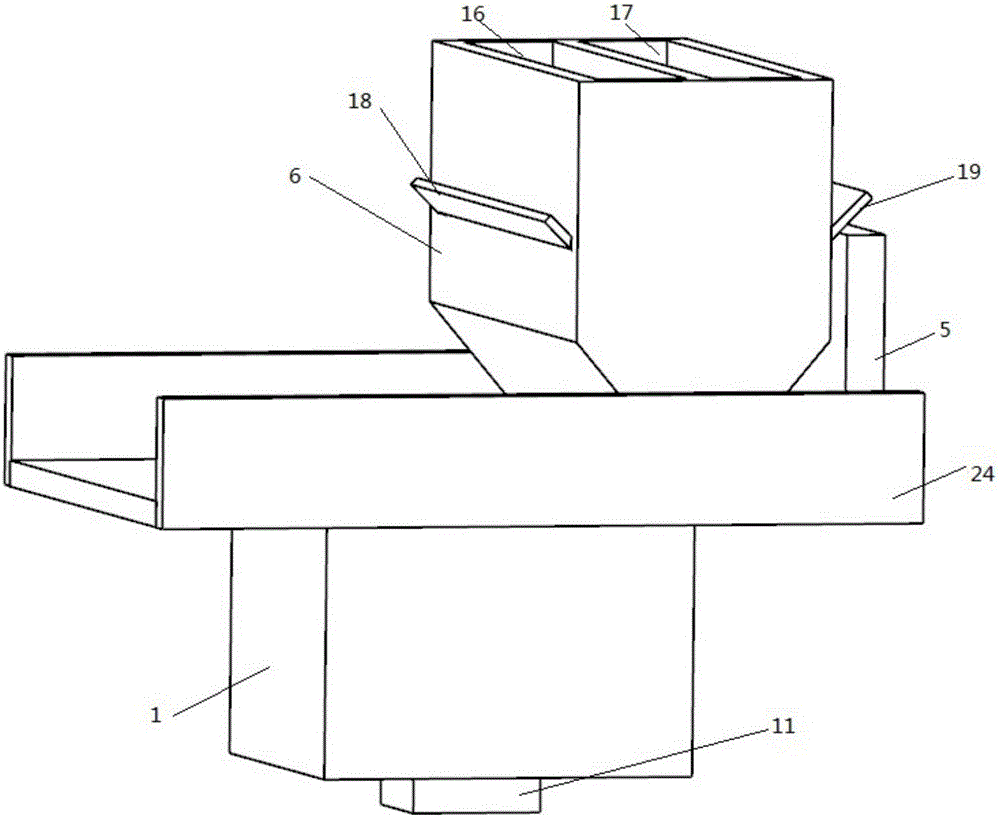

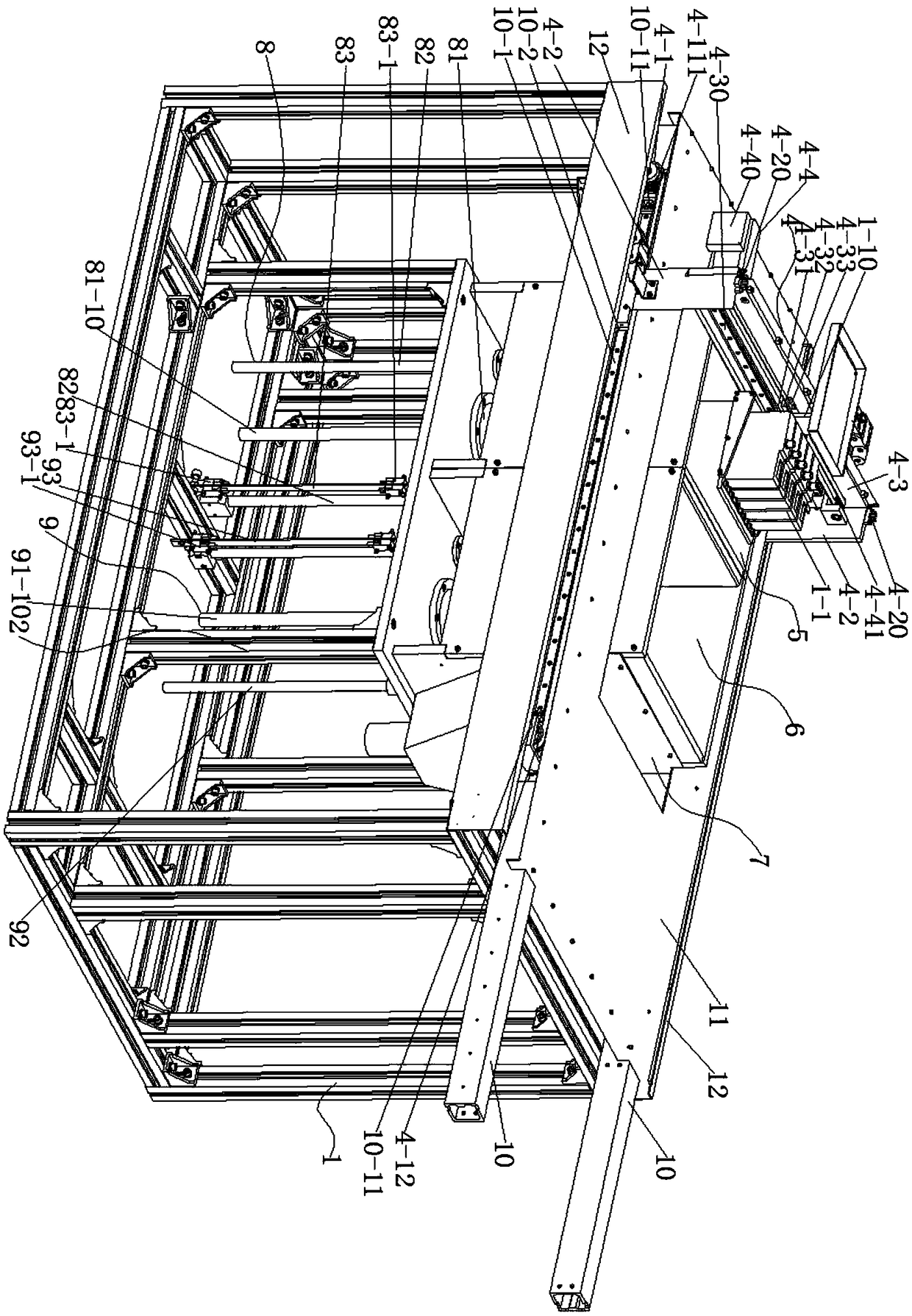

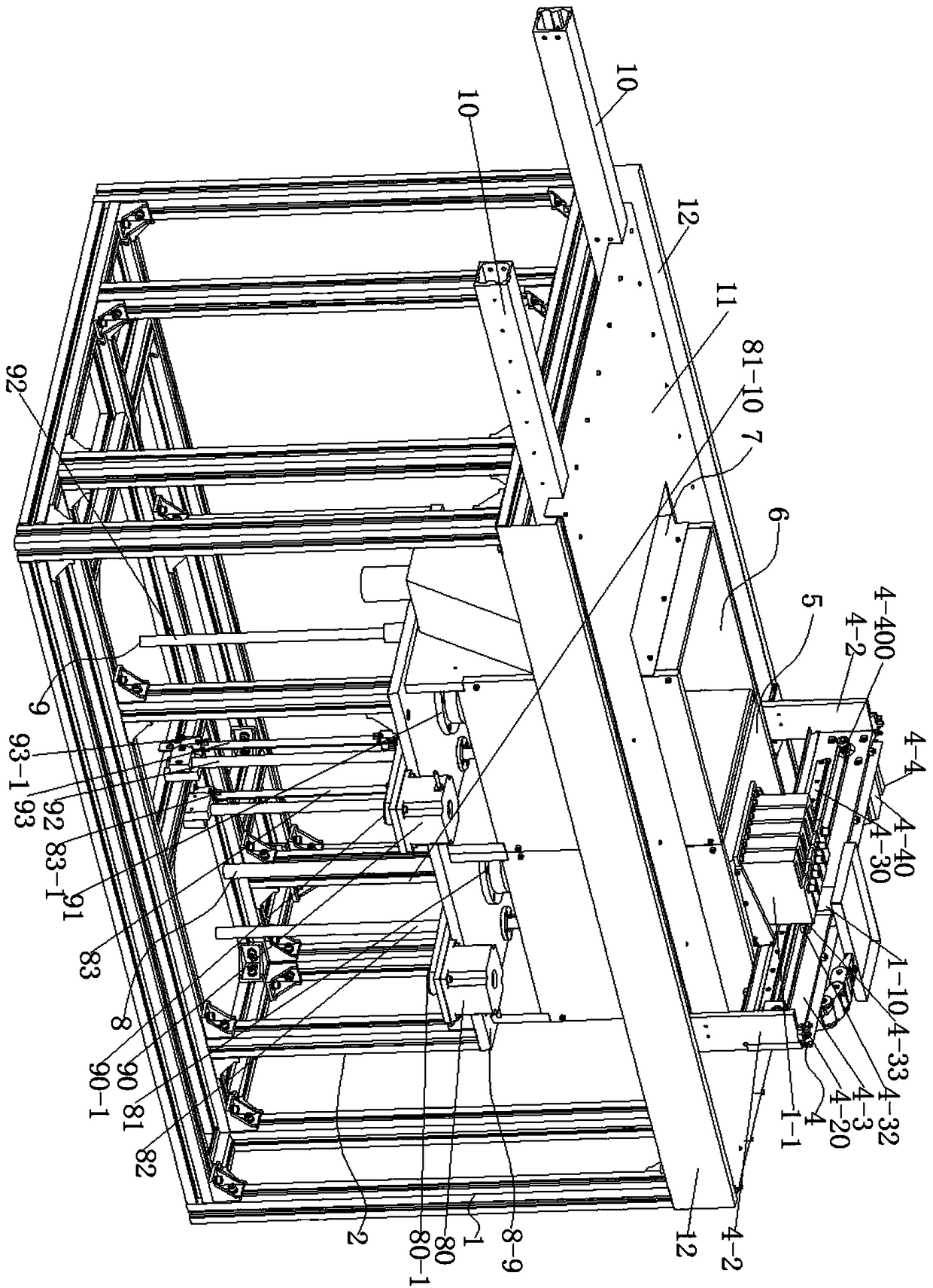

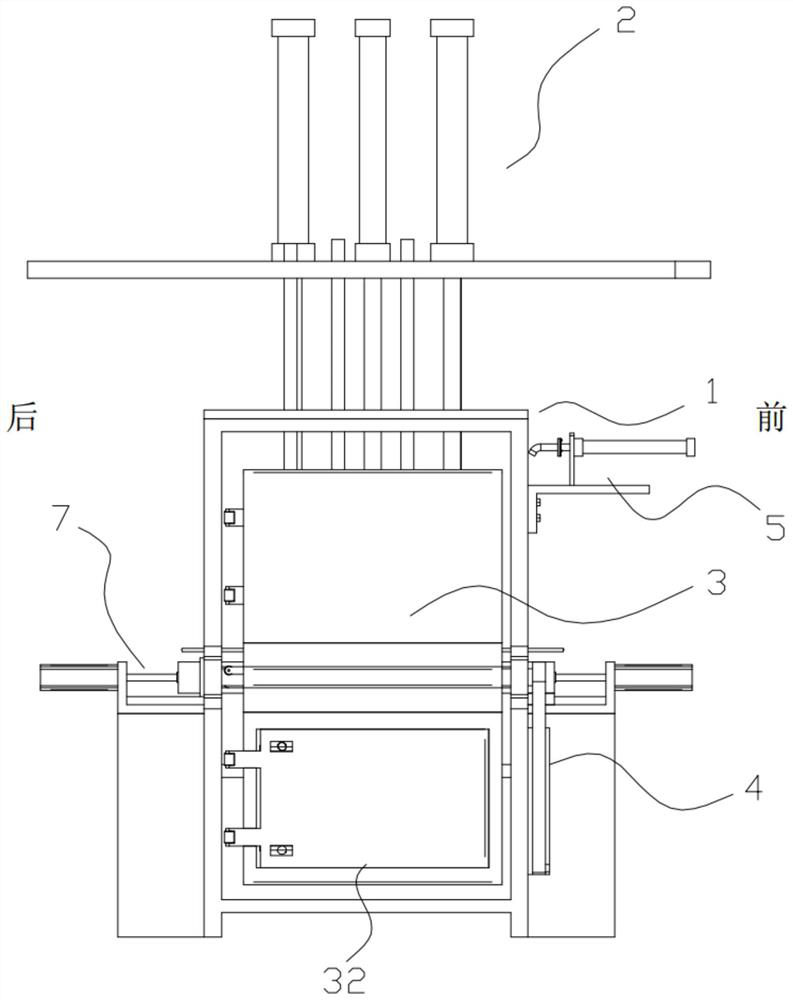

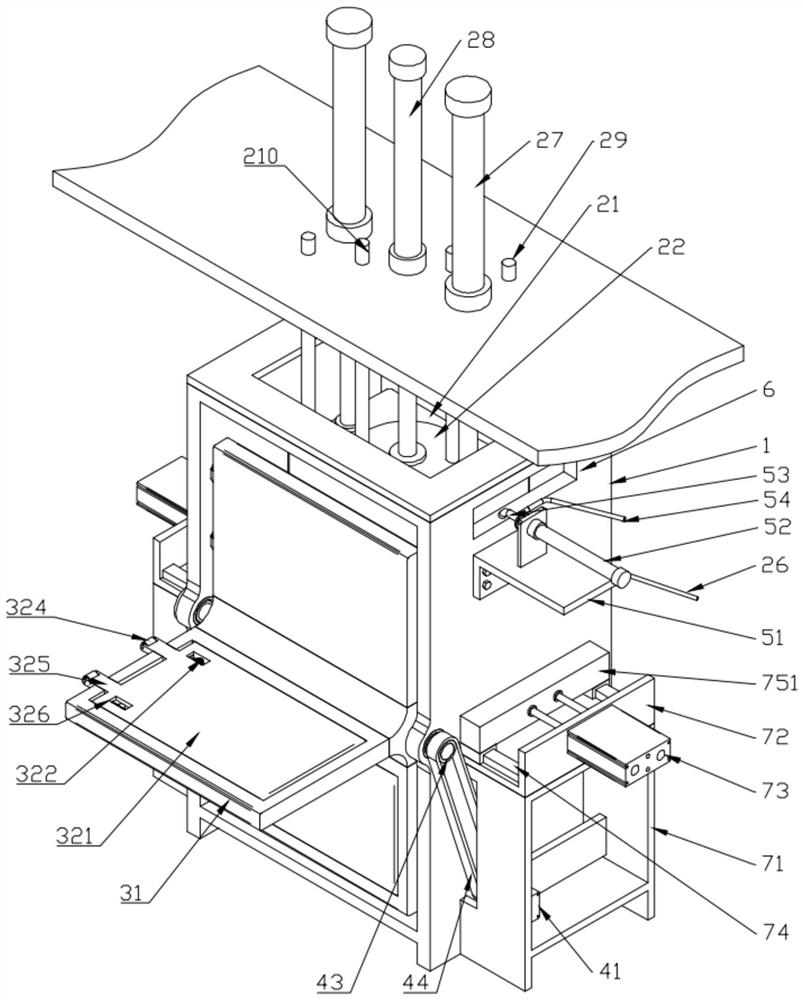

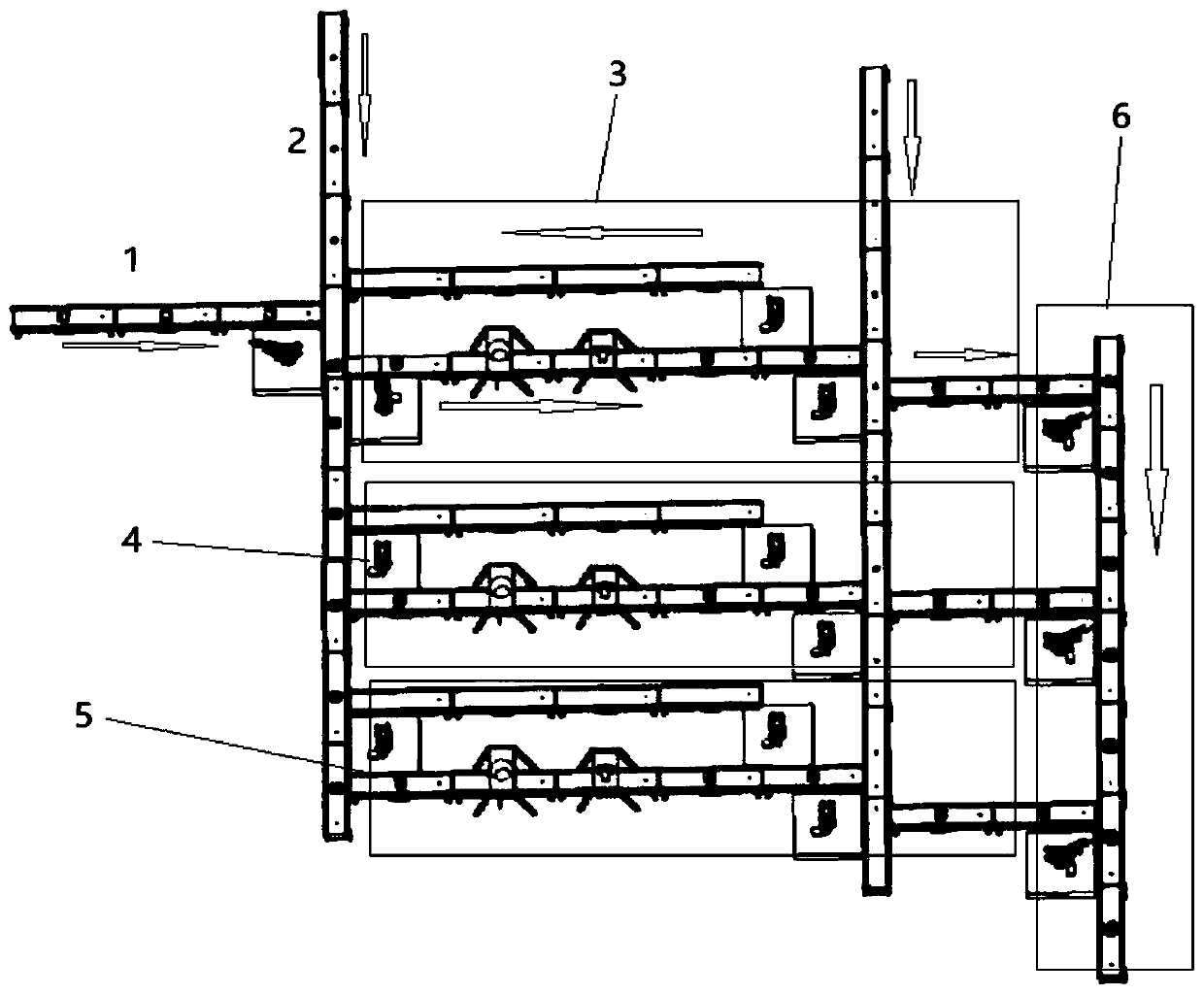

Automatic complicated-shaped three-section type sand box mold forming device

PendingCN110039002ARealize rapid prototypingImprove casting precisionMoulding plantsFoundry mouldsMaterials scienceProduction line

The invention discloses an automatic complicated-shaped three-section type sand box mold forming device. The automatic complicated-shaped three-section type sand box mold forming device comprises a casting sand box feeding-in device, a three-section sand mold feeding-in device, a casting sand mold bottom, a casting sand mold middle portion, a casting sand mold top and a mold forming device body. The casting sand box feeding-in device and the three-section sand mold feeding-in device are vertically connected. The three-section sand mold feeding-in device is vertically connected to the inlet ends of the casting sand mold bottom, the casting sand mold middle portion and the casting sand mold top. The casting sand mold bottom, the casting sand mold middle portion and the casting sand mold topare arranged side by side. The mold forming device body is perpendicularly connected to the outlet ends of the casting sand mold bottom, the casting sand mold middle portion and the casting sand moldtop. The casting sand box feeding-in device conveys a bottom casting sand box, a middle casting sand box and a top casting sand box to the three-section sand mold feeding-in device, then the casting sand boxes and a sand mold are placed and fed to the mold forming device body to complete preparation work before casting. The automatic complicated-shaped three-section type sand box mold forming device achieves fully mechanized control of the production line, is stable and reliable in work and long in service life, saves cost and improves work efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

Vehicle sharp-corner square-pipe production line

PendingCN111168338AFast molding speedGood qualityOther manufacturing equipments/toolsAutomotive engineeringEngineering

The invention discloses a vehicle sharp-corner square-pipe production line. The production line comprises a feeding machine (1), a preliminary forming roller unit (2), welding equipment (3), water cooling equipment (4), a heater (5), a thermal forming roller unit (6), a reshaping roller unit (7) and a straightening mechanism (8). According to the production line, the characteristics of the cold rolling technology are fully exerted, meanwhile, the thermal forming and welding technologies are creatively applied to the cold rolling production line, the problems about quick forming of sharp-cornersquare-pipe type parts are solved, and the production line has the characteristics of high forming speed, high quality, low cost and capability of saving raw materials.

Owner:江苏顺力冷弯型钢实业有限公司

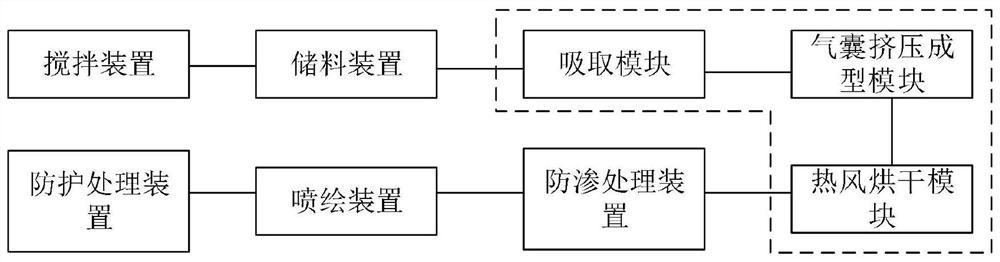

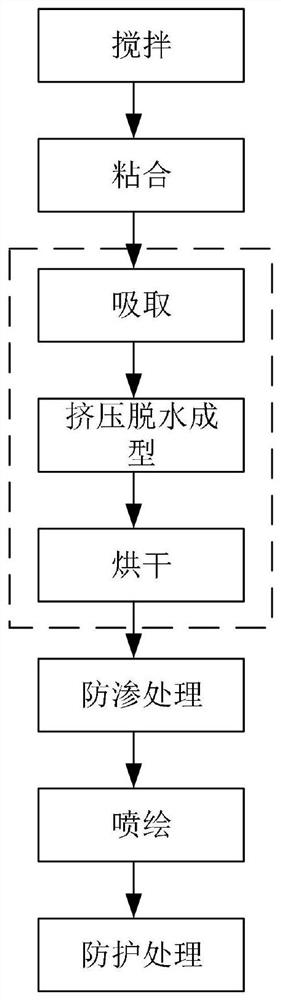

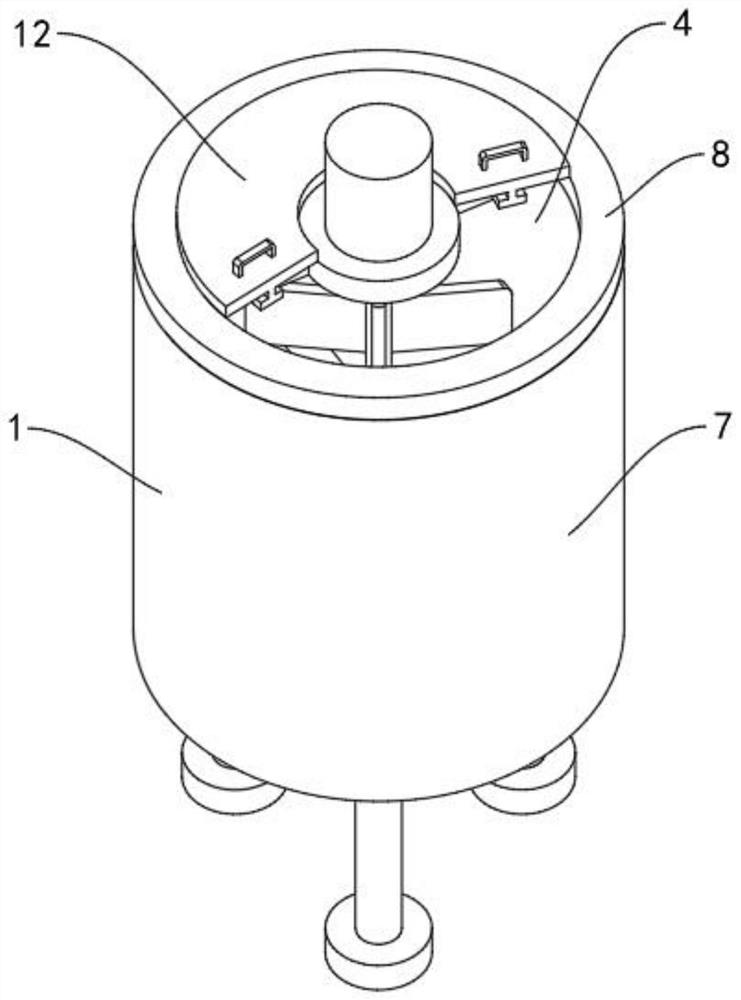

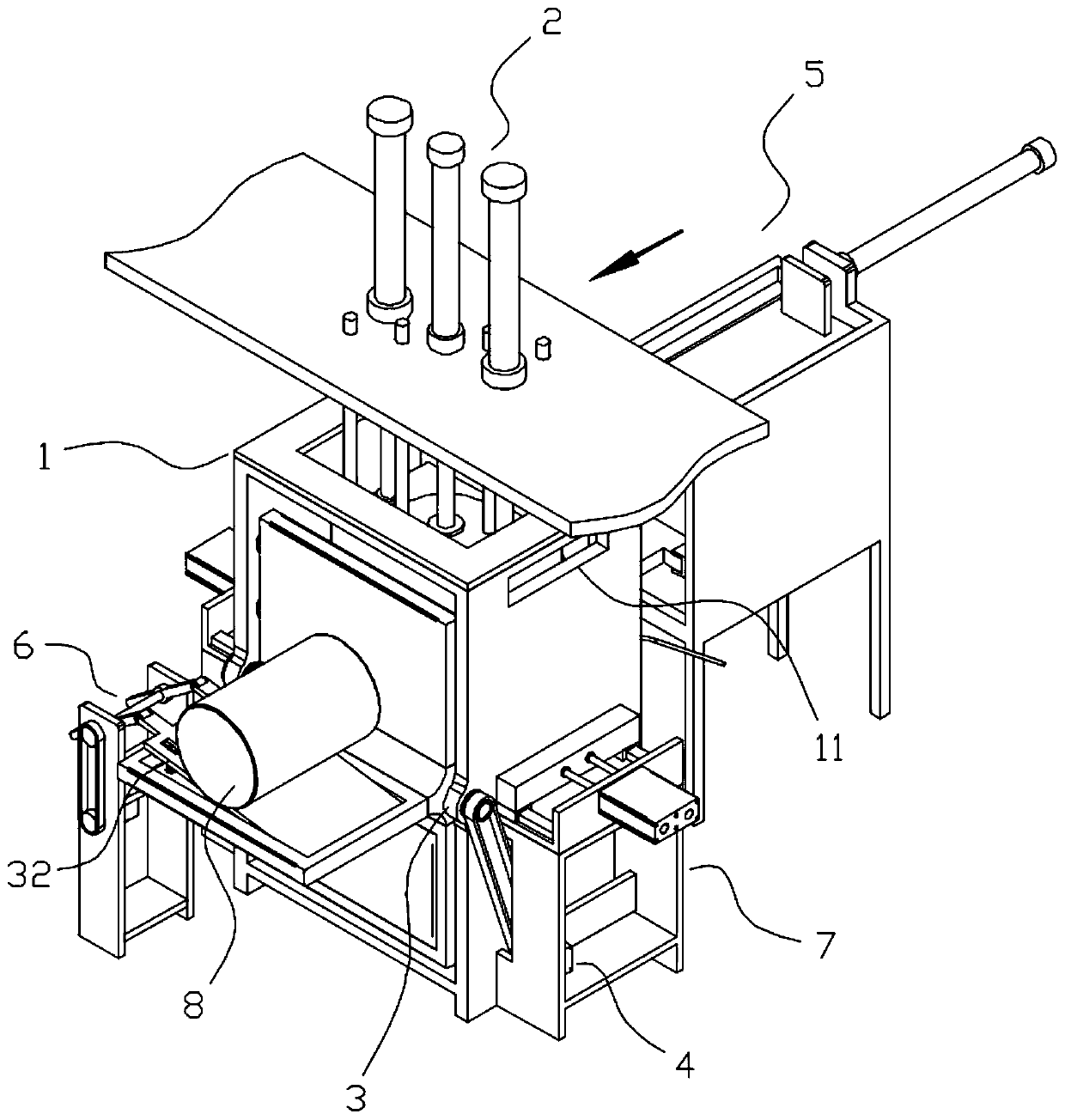

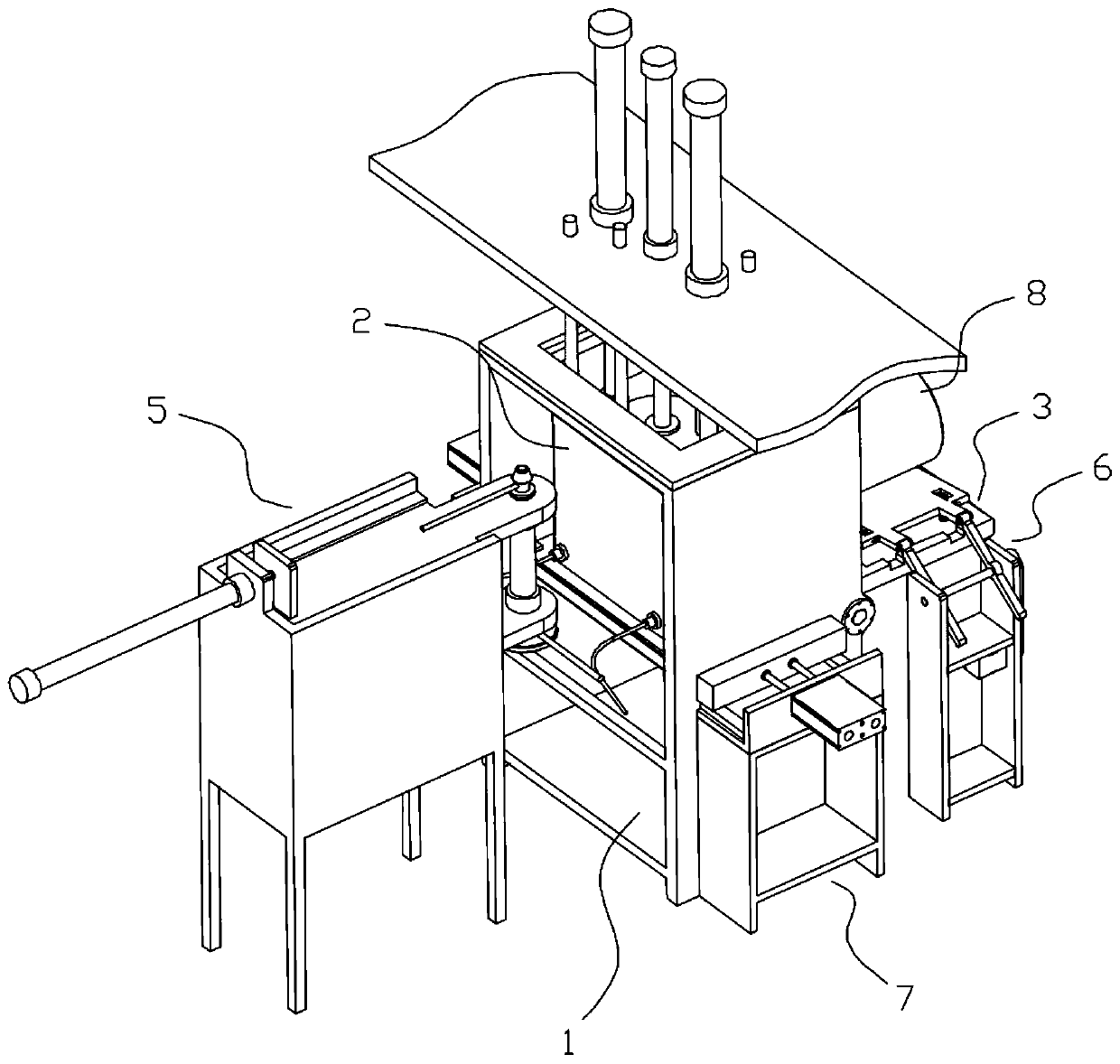

Processing system and processing method for paper pulp molded product

InactiveCN112832062ARealize automatic processingRealize rapid prototypingTransportation and packagingRotary stirring mixersFiberAdhesive

The invention discloses a processing system for a paper pulp molded product. According to the processing system, a stirring device is used for mixing and stirring added waste paper and water into paper pulp; a storage device is used for storing paper pulp and receiving a fed adhesive to obtain synthetic paper pulp; a forming device comprises a suction module, an air bag extrusion forming module and a hot air drying module, wherein the suction module is used for sucking fibrous materials in the synthetic paper pulp and sending the fibrous materials into an air bag mold where a reinforcing framework is placed in advance, and the air bag extrusion forming module conducts extrusion dehydration forming by controlling an air bag in the air bag mold to realize expansion, and the hot air drying module performs drying; an anti-seepage treatment device is used for forming an anti-seepage layer; a spraying and drawing device is used for spraying and drawing patterns on the anti-seepage layer; and a protection treatment device is used for forming a protection layer. With the system, rapid forming of the paper pulp molded product can be achieved, and processing efficiency is effectively improved; and the reinforcing framework is arranged in the manufactured paper pulp molded product, and therefore, the structural strength of the paper pulp molded product can be effectively improved.

Owner:王福刚

Straw mixed foaming forming equipment

ActiveCN111516103ARealize rapid prototypingIncrease productivityDischarging arrangementMouldsProcess engineeringIndustrial engineering

The invention discloses straw mixed foaming forming equipment, and relates to the field of environmental protection equipment. The straw mixed foaming forming equipment comprises a rack, a forming die, a rotary platform, a power mechanism, a locking mechanism, a spraying mechanism and a lifting mechanism. Rapid forming of cake-shaped bricks is achieved through a foaming forming process, a rotary platform capable of freely rotating by 360 degrees achieves two functions of foaming forming and product discharging, the two functions can be achieved synchronously, and compared with traditional step-by-step type production equipment, the production efficiency is remarkably improved.

Owner:黑龙江省鑫众鑫科技有限公司

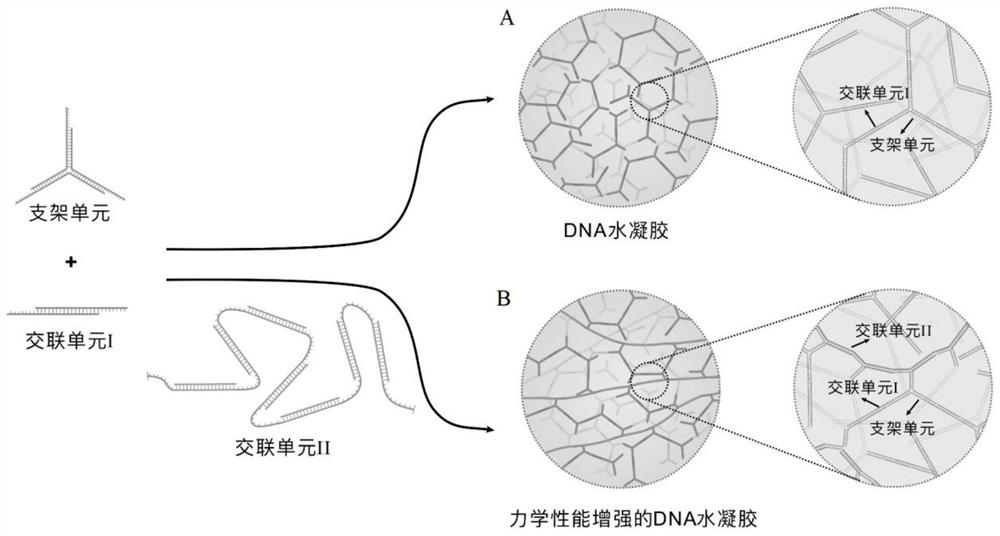

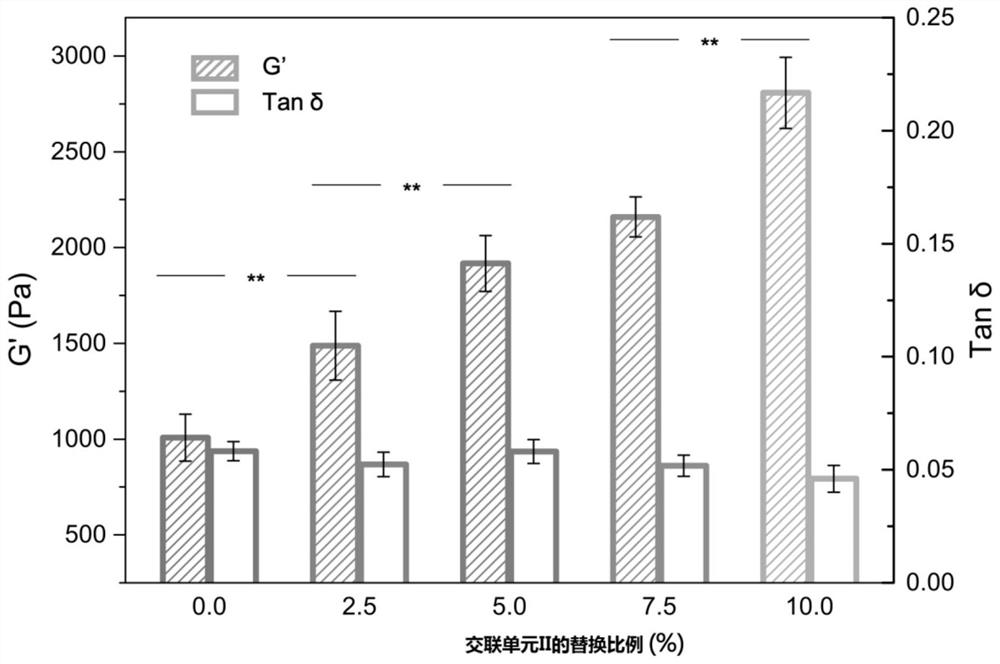

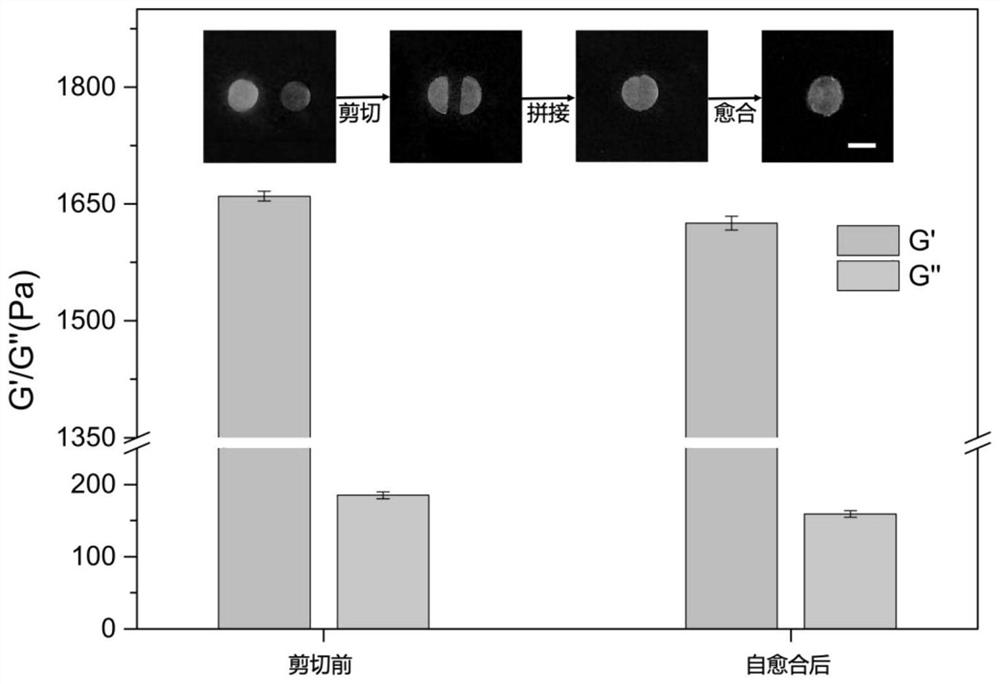

Nucleic acid hydrogel with improved mechanical properties as well as preparation method and application thereof

ActiveCN113083172AControl mechanical propertiesHigh mechanical strengthGel preparationColloidal chemistry detailsFlexible electronicsCompatibilization

The invention belongs to the technical field of high polymer materials and biology, and particularly relates to nucleic acid hydrogel with improved mechanical properties and a preparation method and application thereof. The nucleic acid hydrogel is formed by respectively cross-linking a scaffold unit with a cross-linking unit I and a cross-linking unit II, and the nucleic acid hydrogel has improved mechanical strength and stability. Meanwhile, the nucleic acid hydrogel keeps the dynamic characteristics of supramolecular hydrogel, has the properties of rapid prototyping, shear thinning, injectability, self-repairing property, thermoplasticity and the like, also has good biological compatibility, has good application prospects in the biomedical fields of drug delivery, cell culture differentiation, protein production, immuno-regulation and the like, and has important application prospects in the flexible electronic fields of wearable equipment, artificial skin, soft robots and the like.

Owner:TSINGHUA UNIV

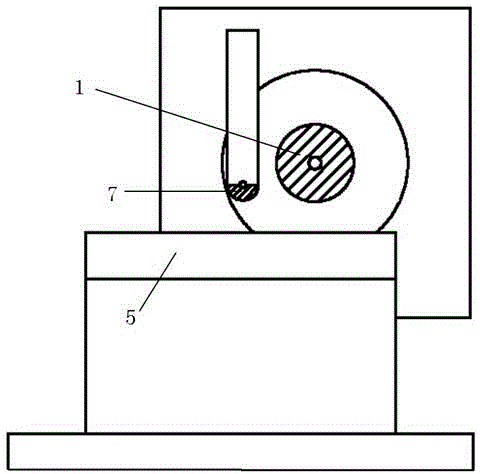

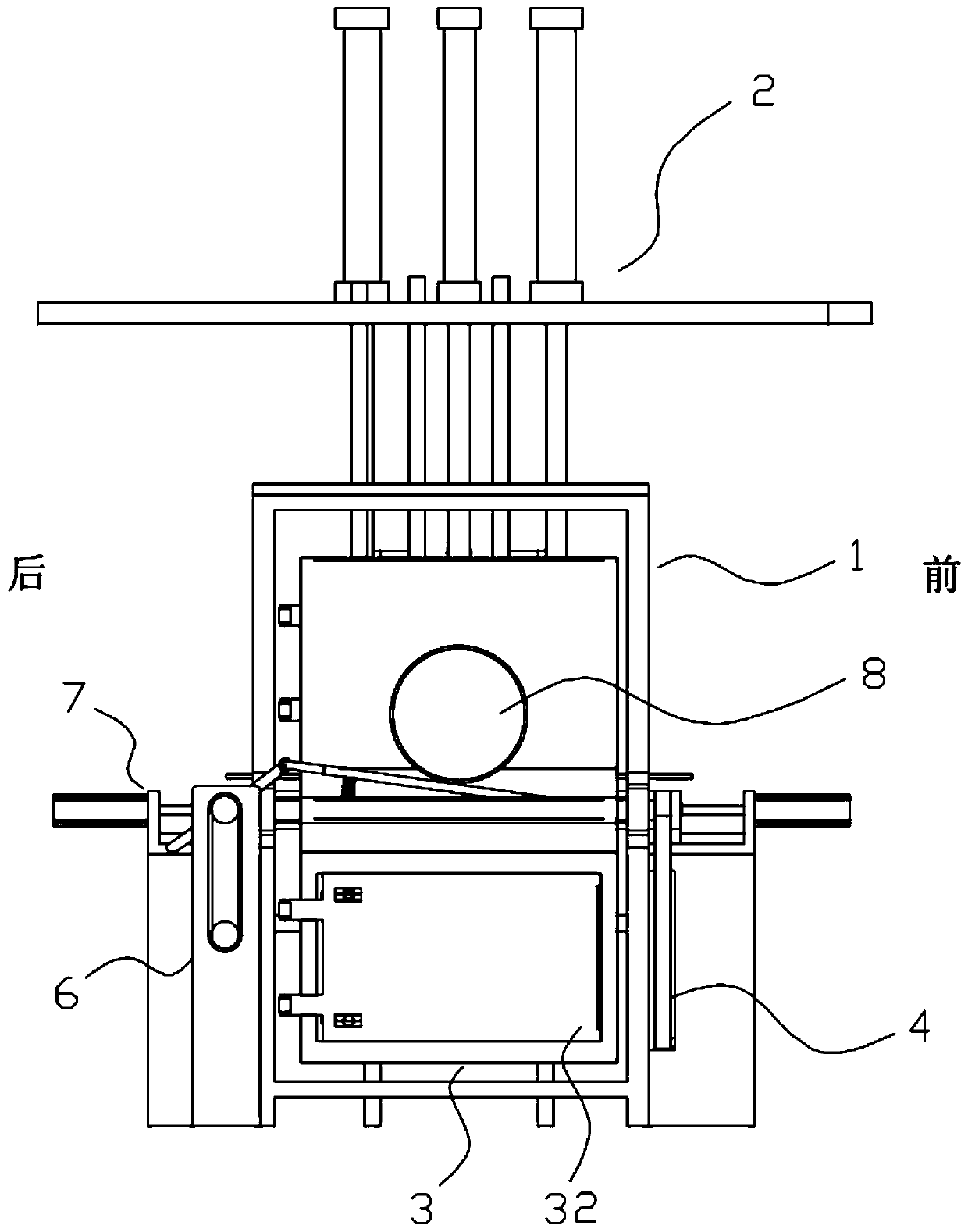

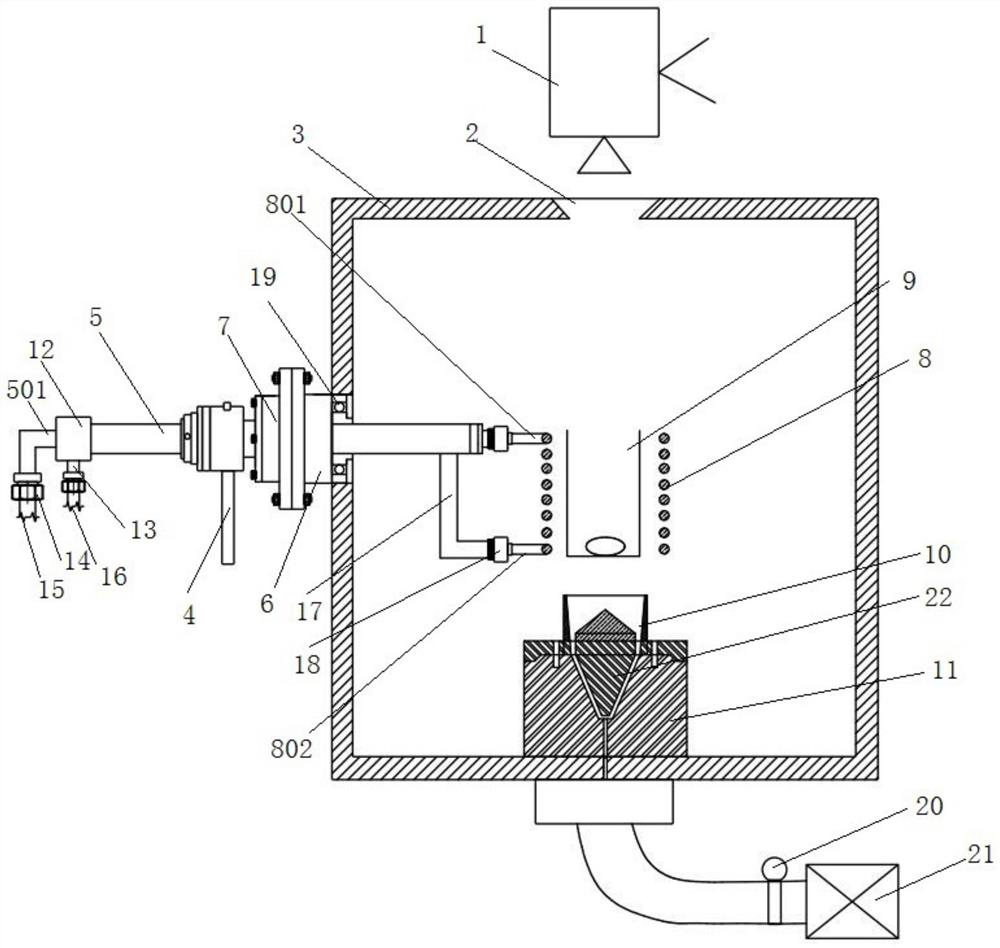

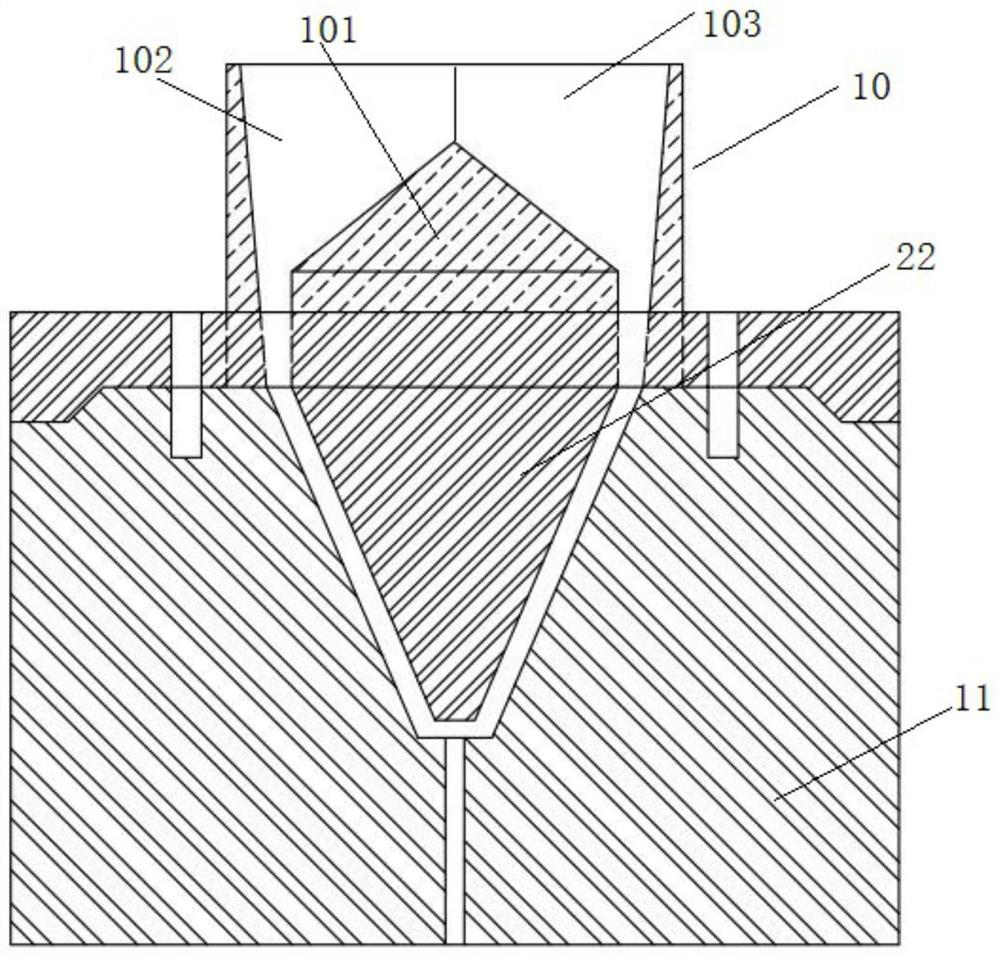

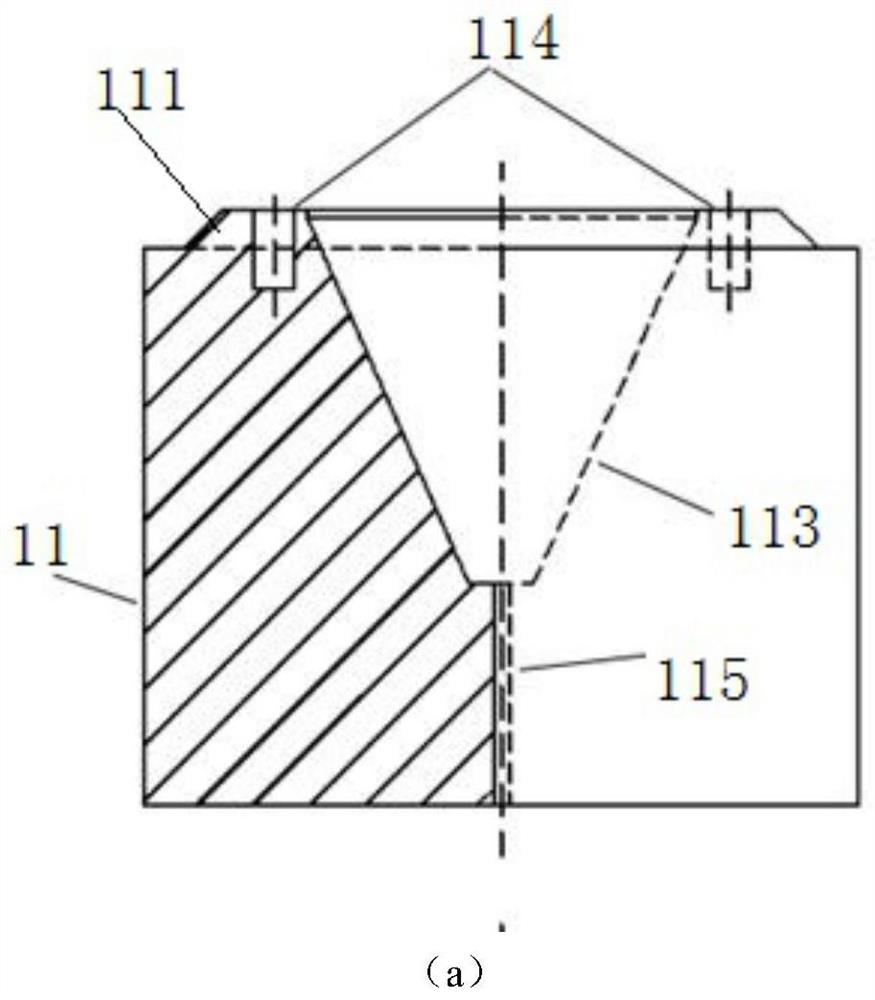

Forming device and preparation method of amorphous alloy near-net-shape casting

ActiveCN111822673AImprove bindingRealize rapid prototypingIncreasing energy efficiencyCasting parameters measurement/indication devicesMoulding deviceCopper mold

The invention provides a forming device of an amorphous alloy near-net-shape casting. The forming device comprises a vacuum chamber, an infrared thermometer, a water cooling system, a copper mold, a pouring cup, a crucible and an induction coil. The invention further provides a preparation method of the amorphous alloy near-net-shape casting combining casting and suction casting. The preparation method comprises the steps that S1, alloy raw materials are weighed; S2, the alloy raw materials are cleaned and dried; S3, the vacuum chamber is vacuumized; S4, the amorphous alloy near-net-shape casting is prepared; and S5, the amorphous alloy near-net-shape casting is subjected to aftertreatment. According to the forming device and the preparation method, rapid forming of large-size amorphous alloy is achieved, and the problems that a traditional casting method is poor in mold filling capacity, and the large-size amorphous alloy cannot be prepared through a traditional suction casting methodare solved through a casting-suction casting method.

Owner:XIAN TECHNOLOGICAL UNIV

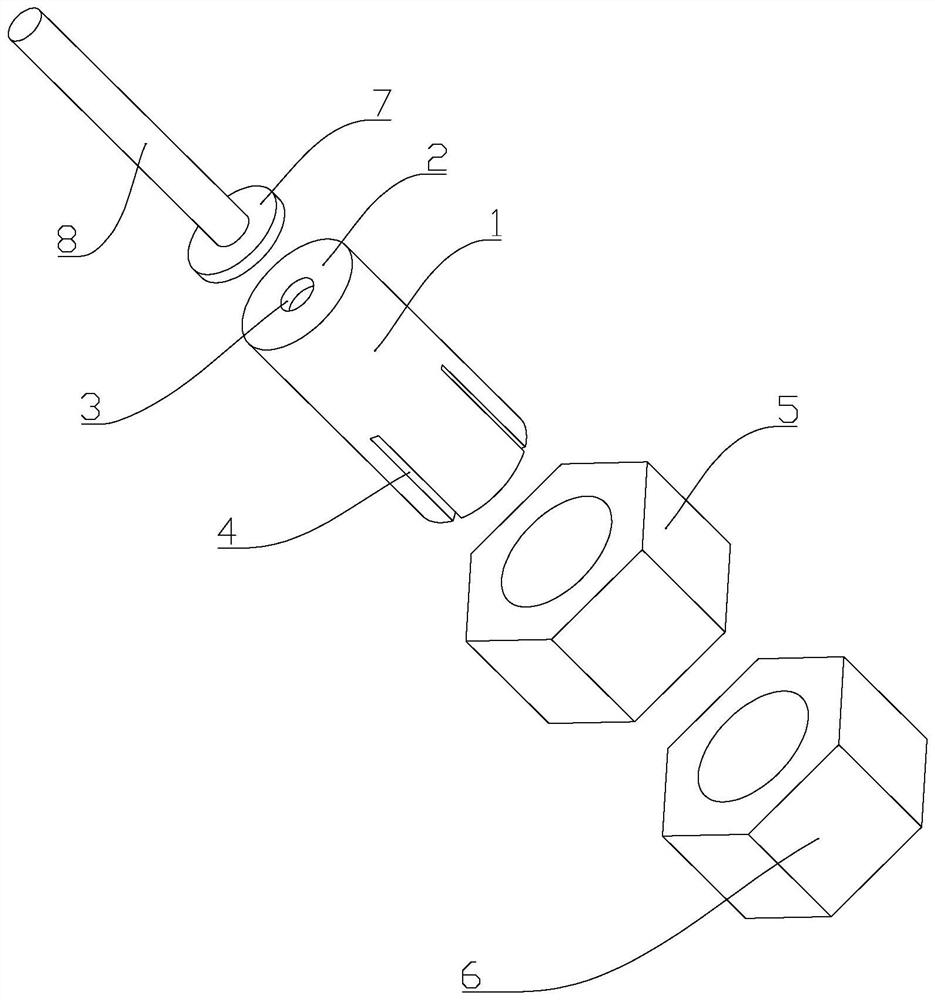

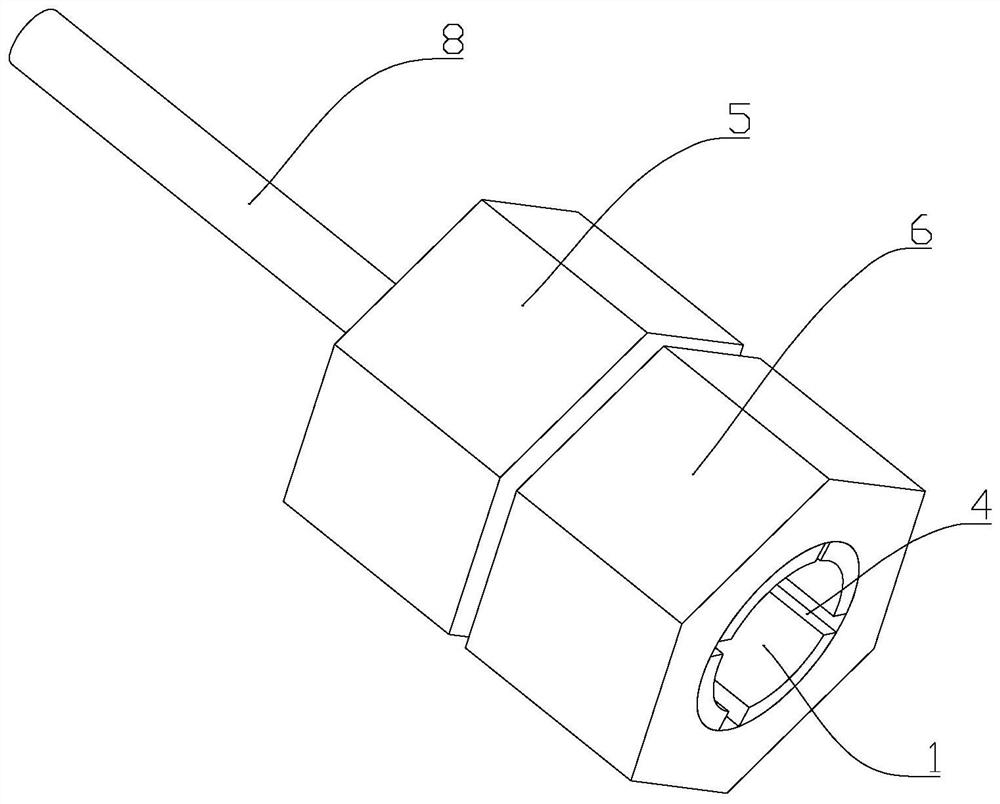

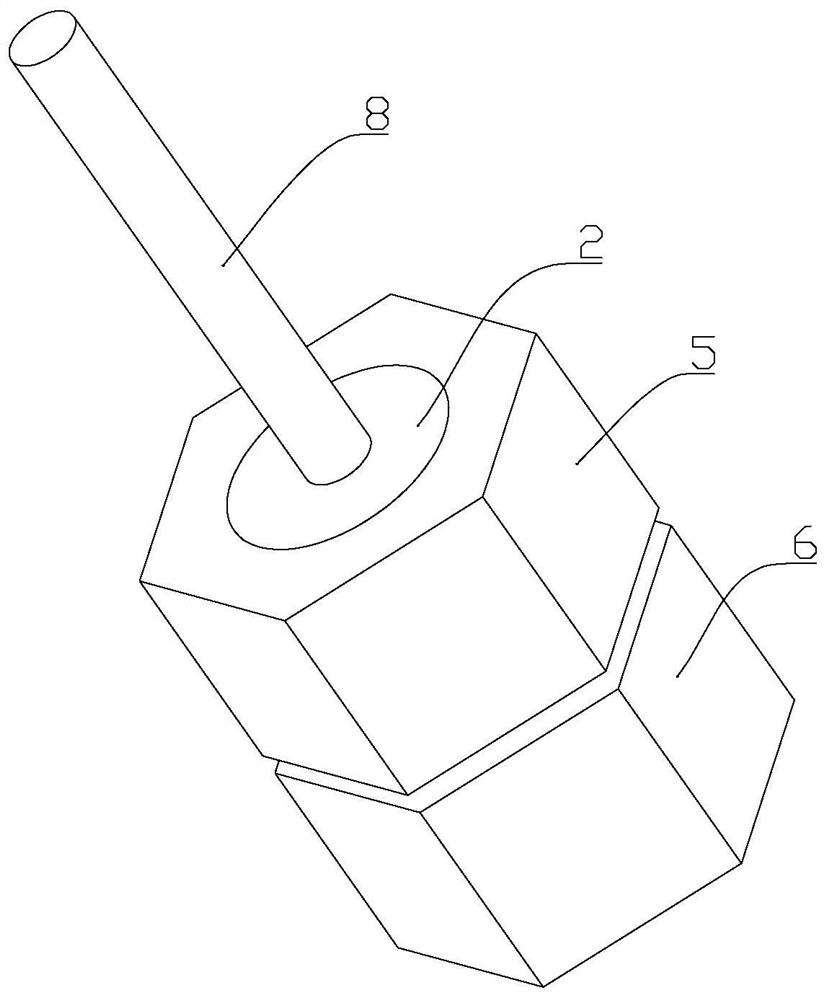

End lead head forming device for steel wire rope

The invention discloses an end lead head forming device for a steel wire rope. The device comprises a round pipe; threads are arranged on the outer side arc face of the round pipe; a sealing plate is fixed to one end of the round pipe; a through hole coaxial with the round pipe is formed in the center of the sealing plate; at least one sliding groove is formed in the other end, opposite to the sealing plate, of the round pipe in the axial direction of the round pipe; a first nut and a second nut are arranged on the outer sides of the two ends of the round pipe in a matched mode respectively; an ejector block sliding in the axial direction of the round pipe is arranged in the round pipe; an ejector rod is fixed to the end, facing the sealing plate, of the center of the ejector block; and the ejector rod is in clearance fit with the through hole. According to the invention, a lead head at the end of the steel wire rope is rapidly formed, the problems in the background technology are effectively solved, and the device is easy to operate and convenient to use.

Owner:CHANGXING DUZUN INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com