Patents

Literature

222results about How to "Rapid prototyping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

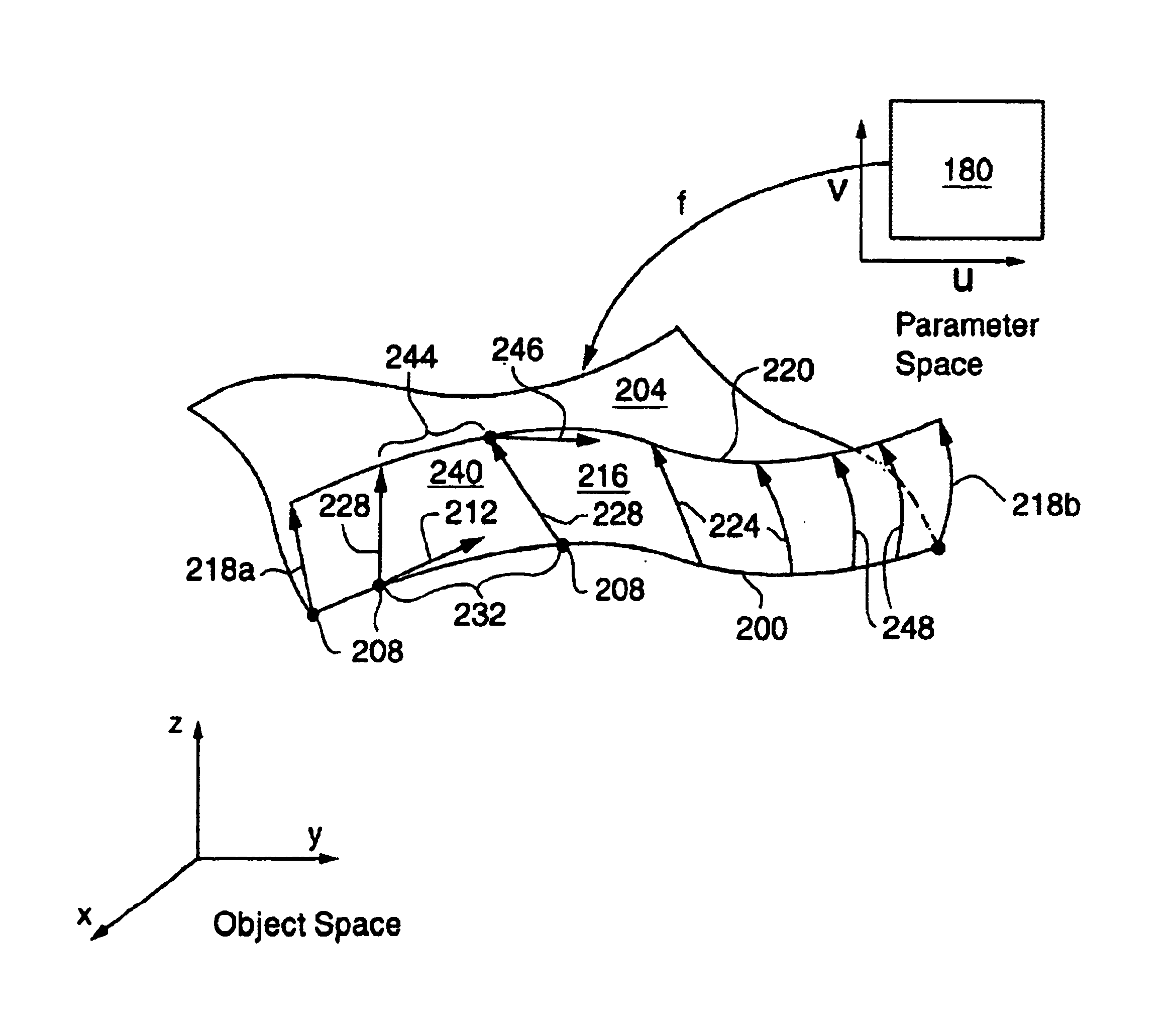

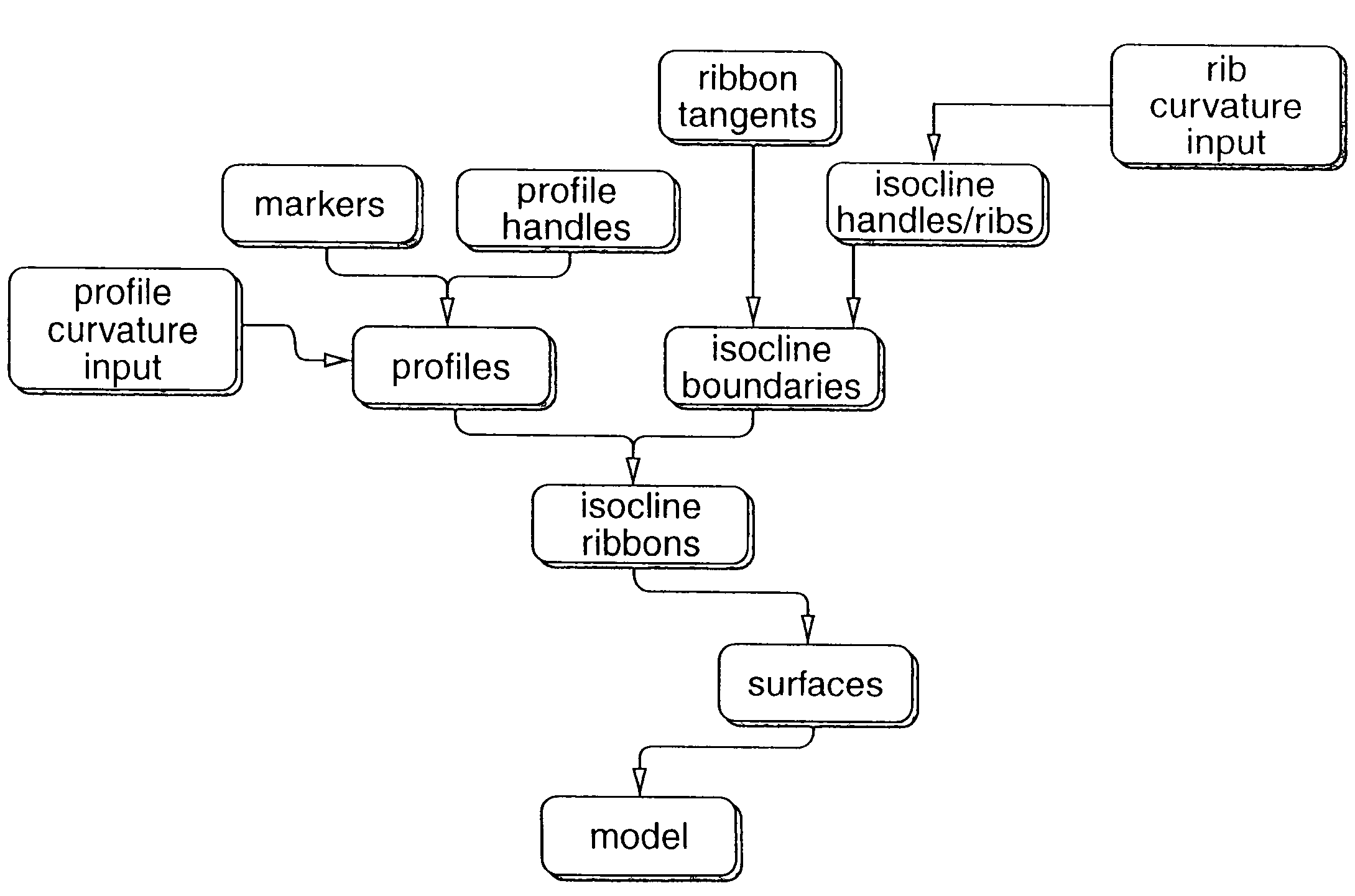

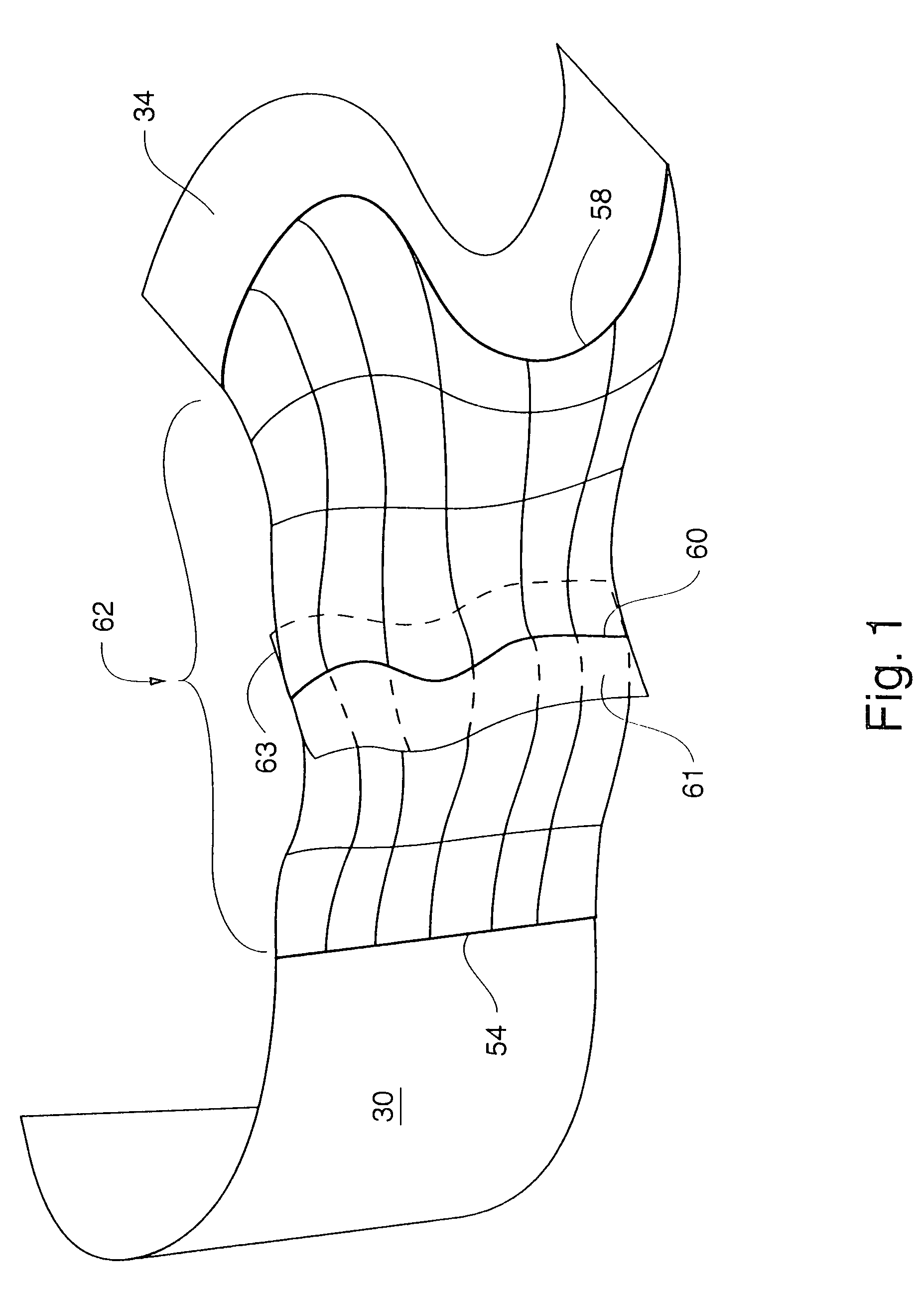

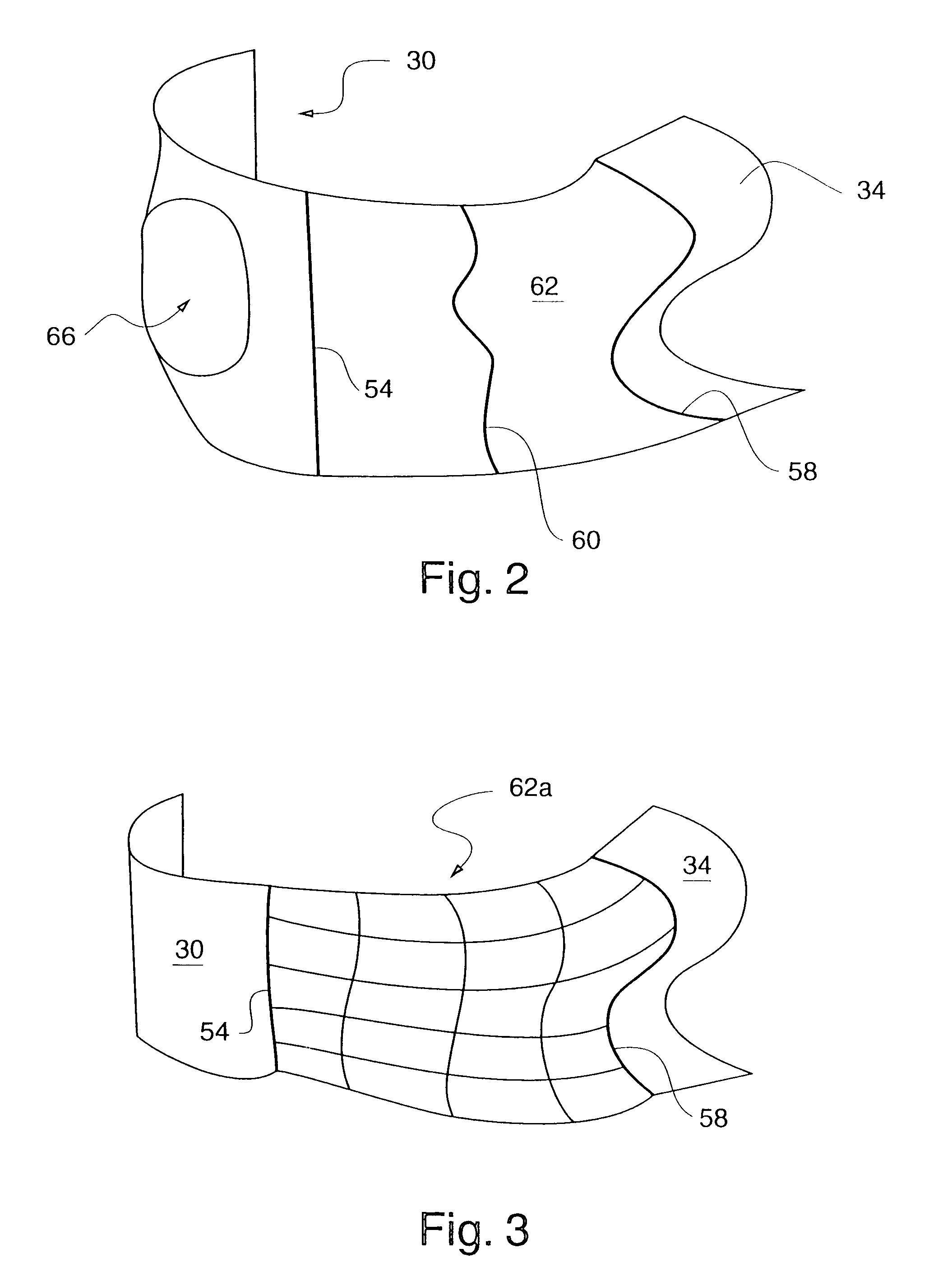

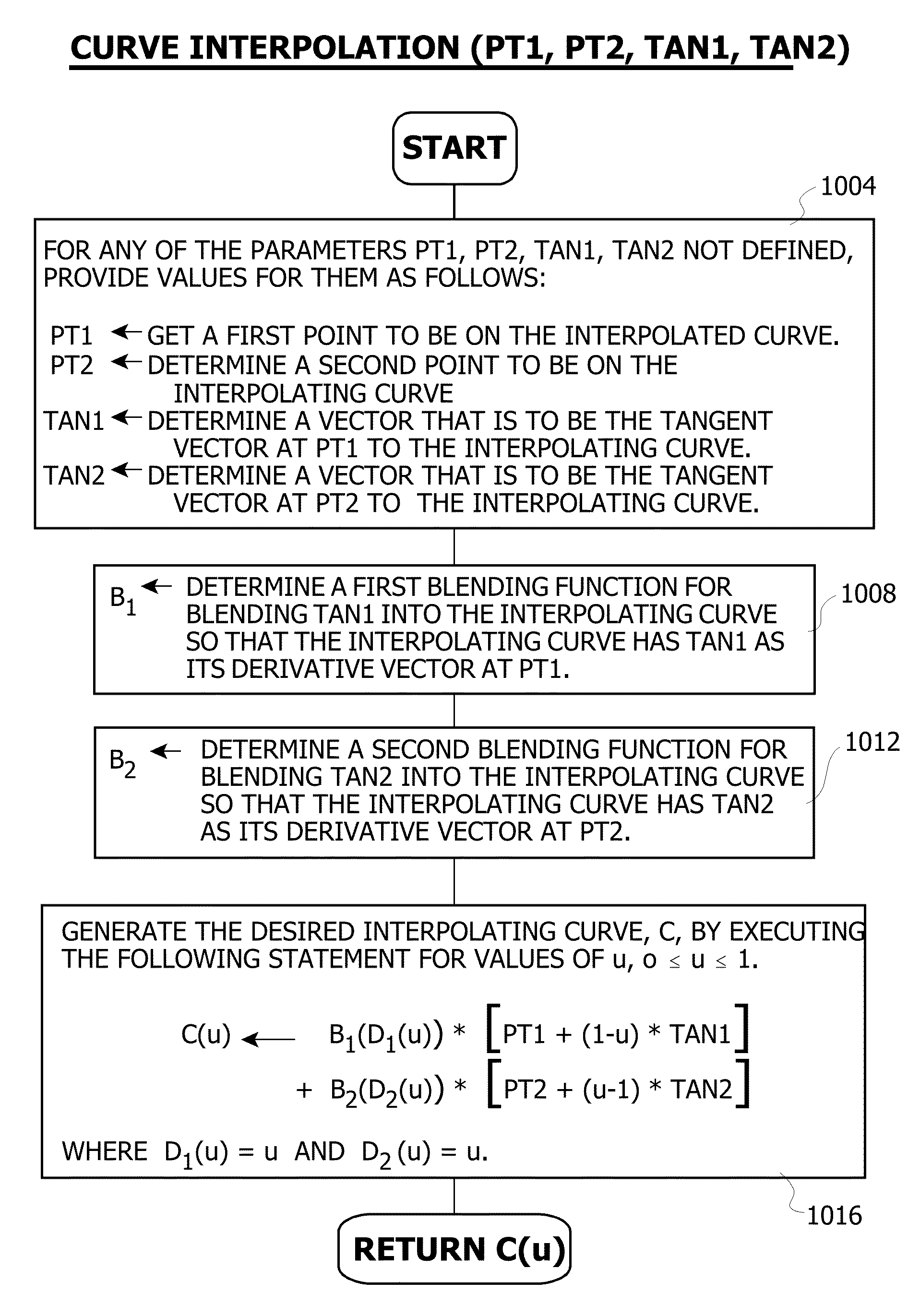

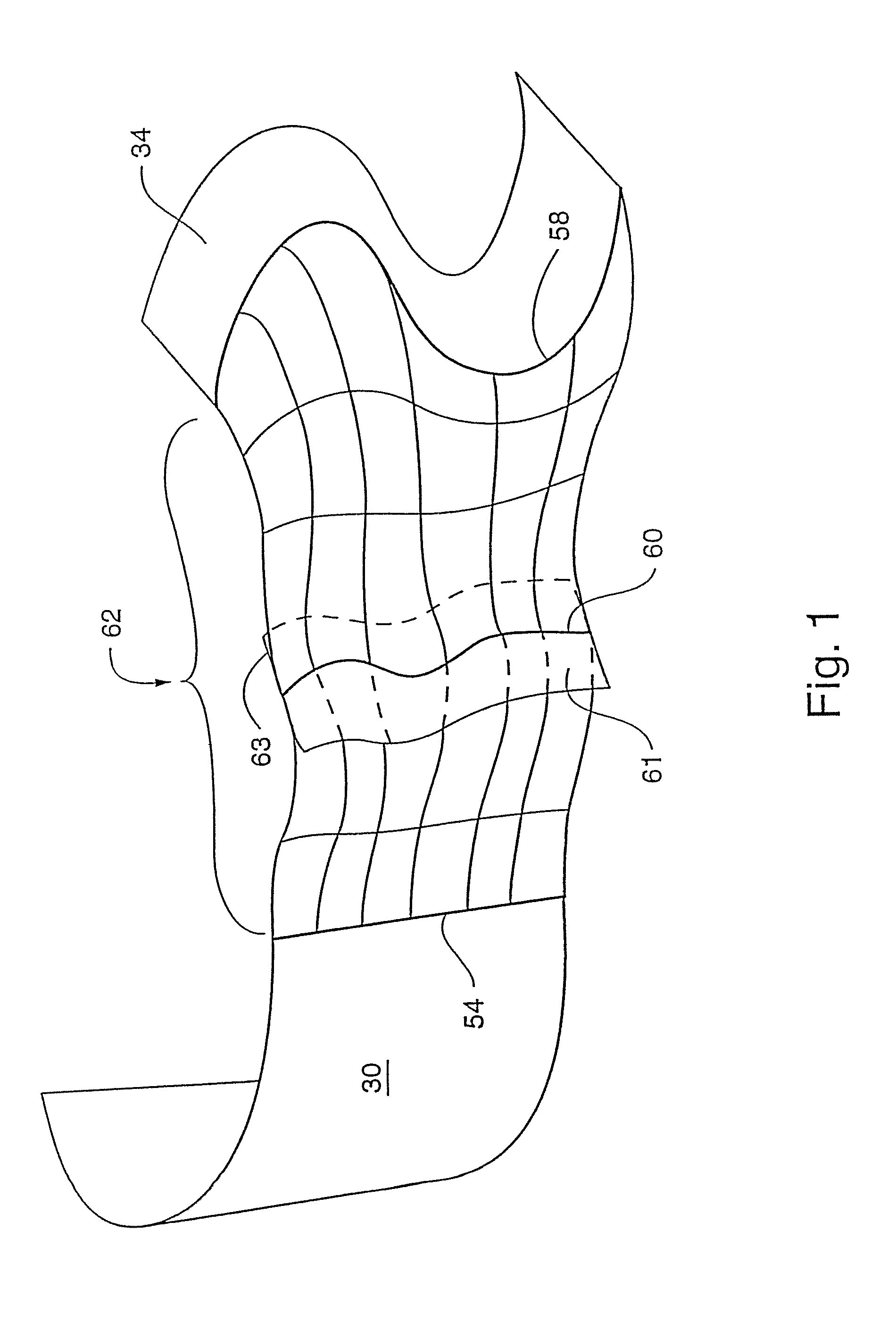

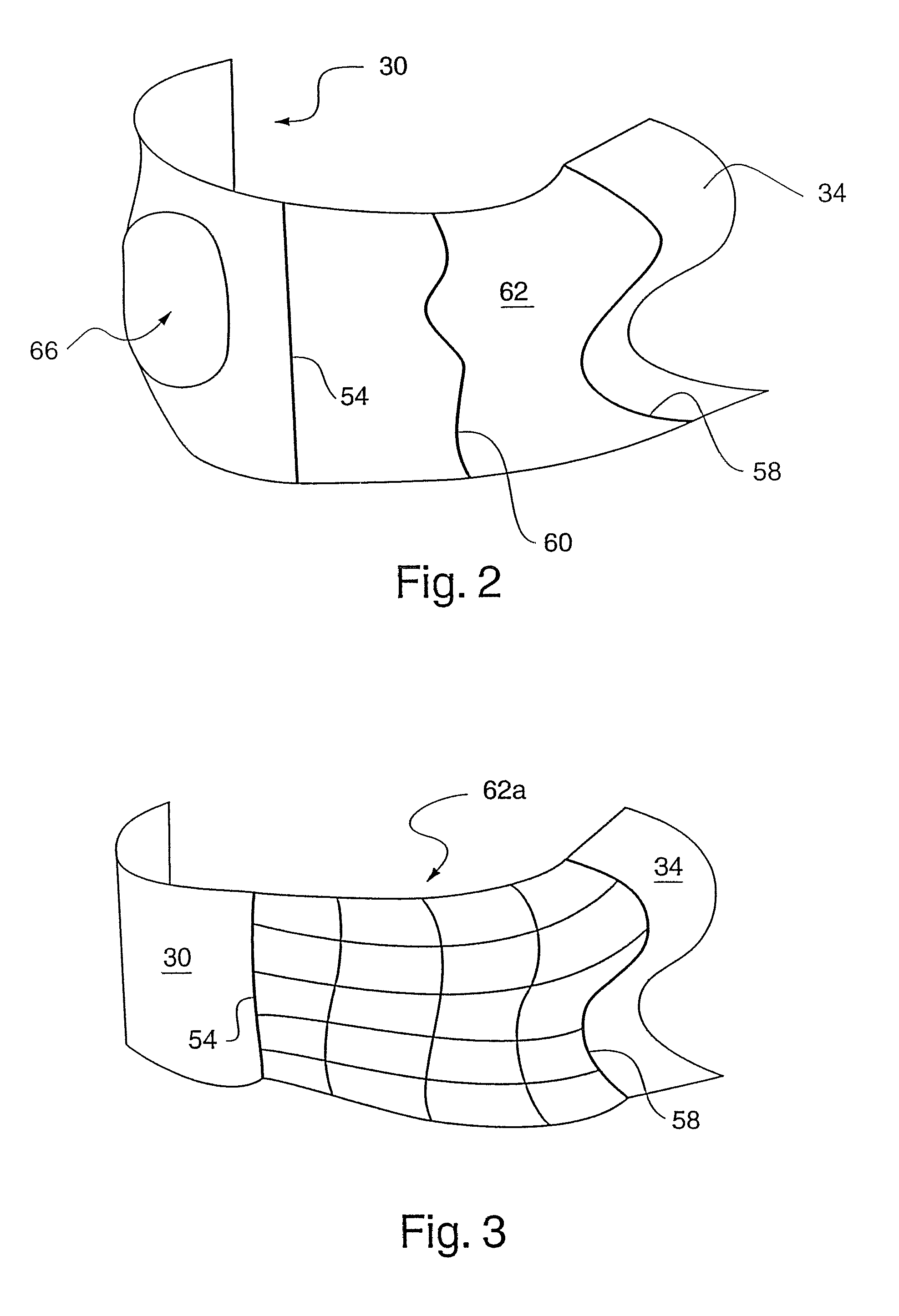

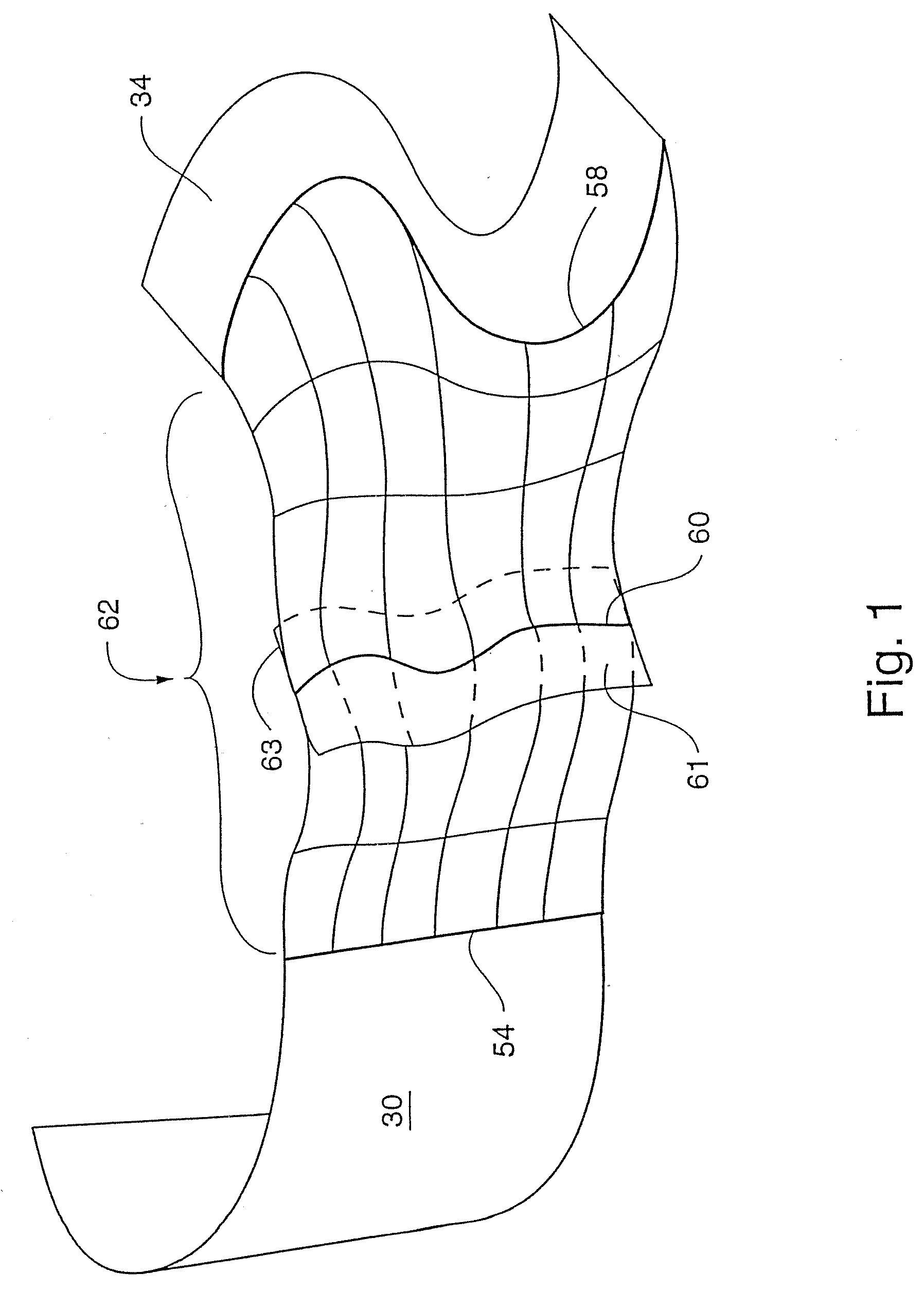

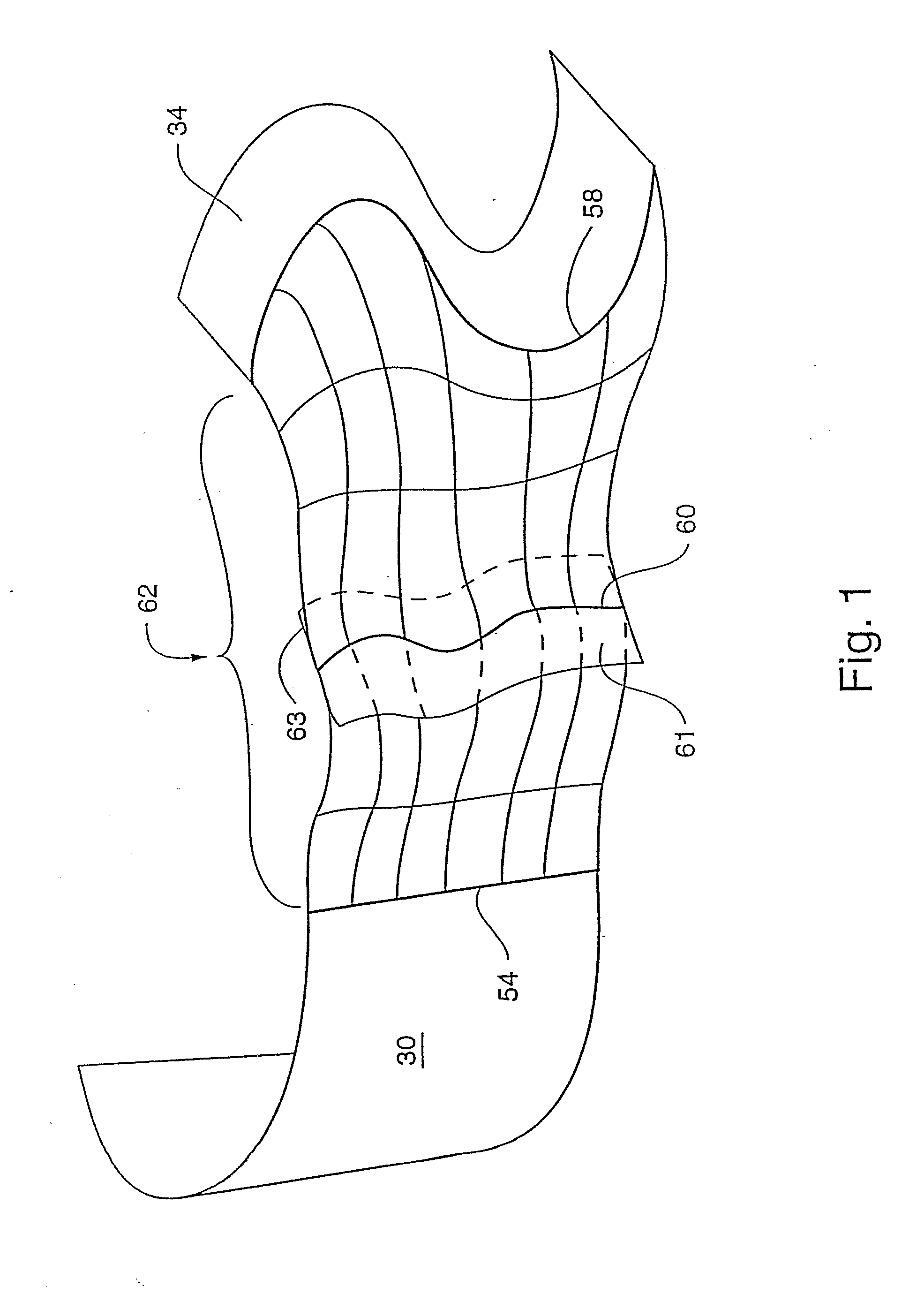

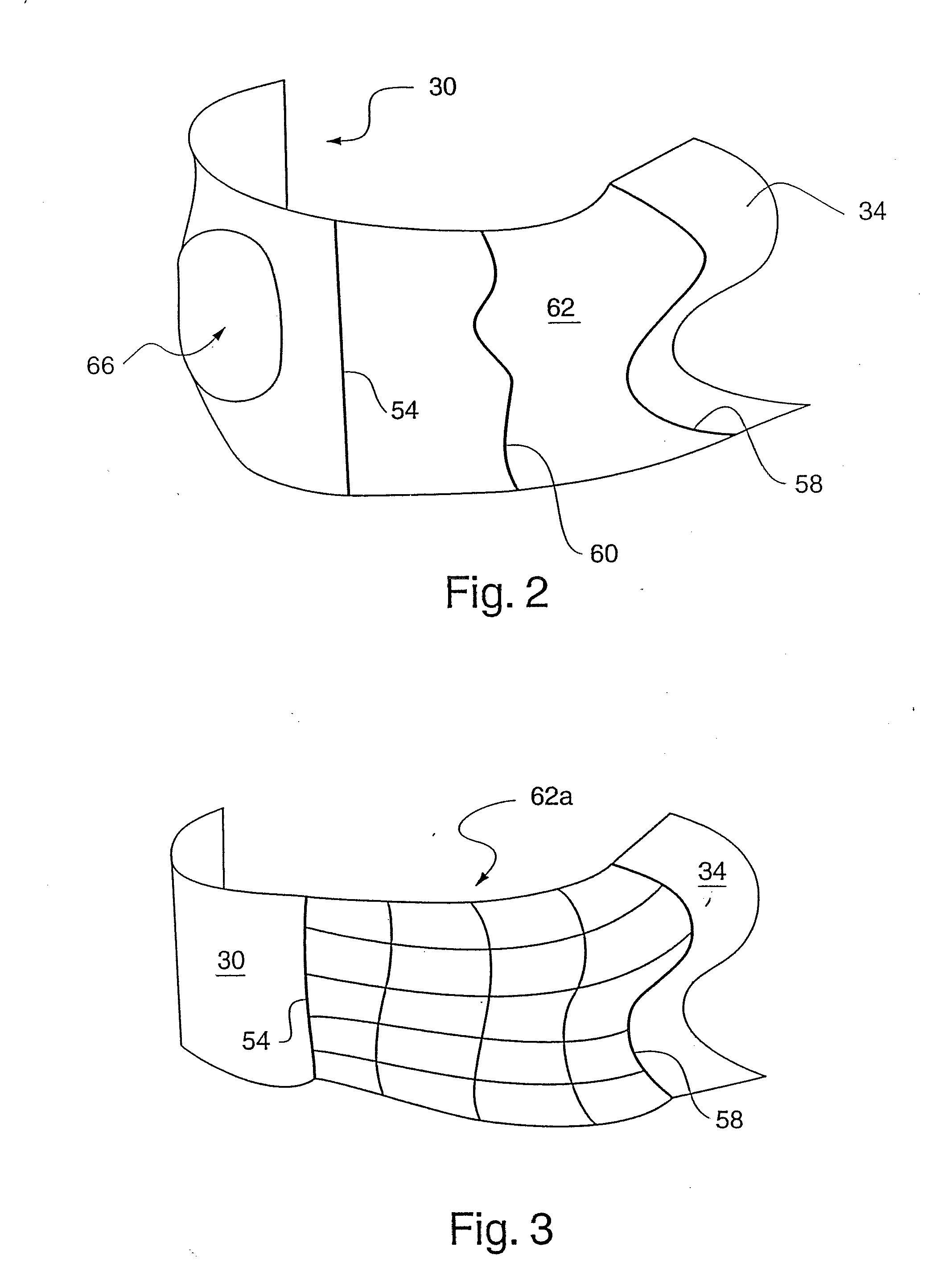

Geometric design and modeling system using control geometry

InactiveUS7196702B1Efficient regenerationComputationally efficientData processing applications3D-image renderingComputer Aided DesignAnimation

A method and system for computer aided design (CAD) is disclosed for designing geometric objects. The present invention interpolates and / or blends between such geometric objects sufficiently fast so that real time deformation of such objects occurs while deformation data is being input. Thus, a user designing with the present invention obtains immediate feedback to input modifications without separately entering a command for performing such deformations. The present invention utilizes novel computational techniques for blending between geometric objects, wherein weighted sums of points on the geometric objects are used in deriving a new blended geometric object. The present invention is particularly useful for designing the shape of surfaces. Thus, the present invention is applicable to various design domains such as the design of, e.g., bottles, vehicles, and watercraft. Additionally, the present invention provides for efficient animation via repeatedly modifying surfaces of an animated object such as a representation of a face.

Owner:CAD-SENSE LLC

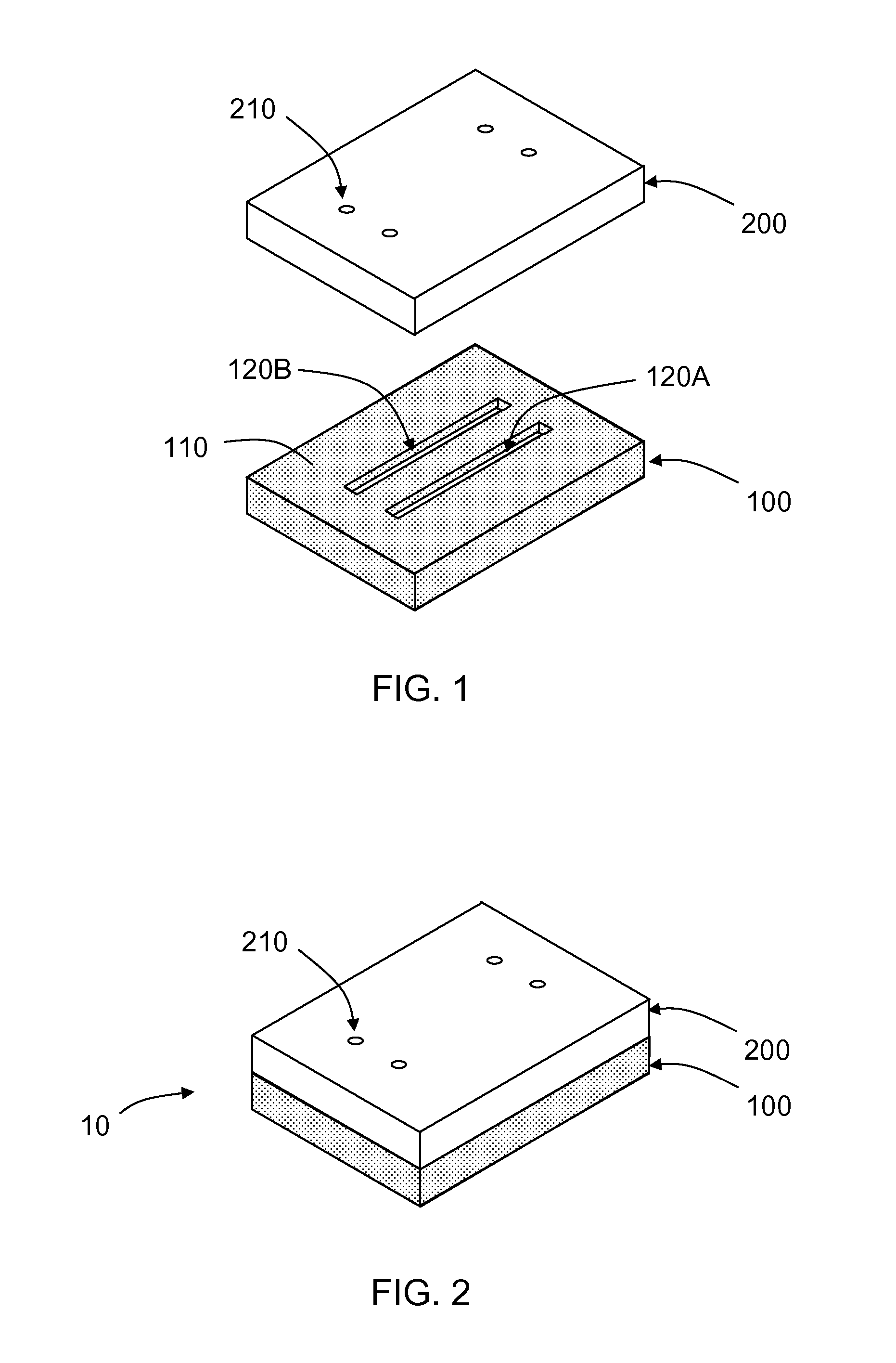

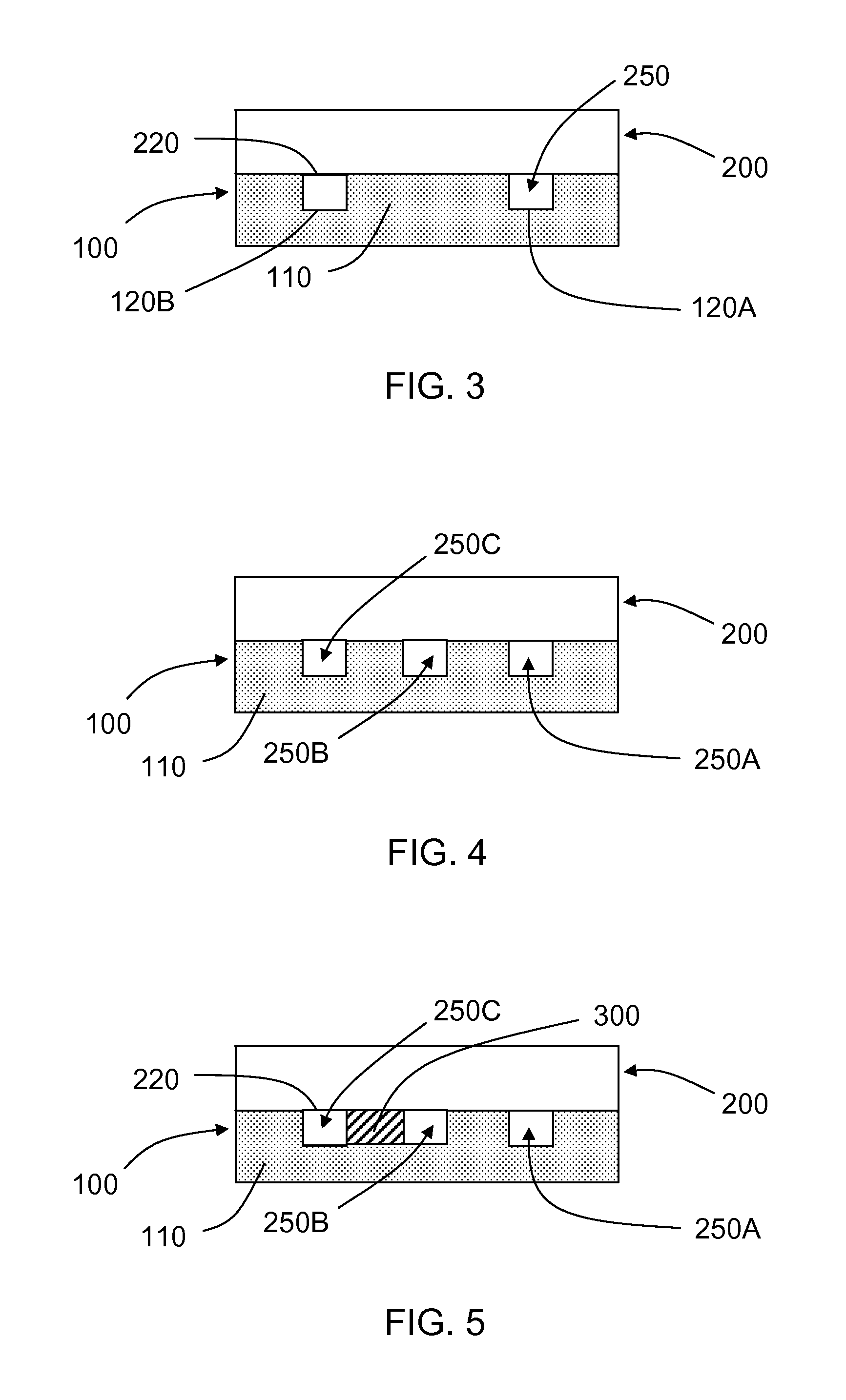

Microporous Microfluidic Device

InactiveUS20120070878A1Efficient transportSimple processBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringDimethyl siloxane

A micro fluidic apparatus includes (i) a first conduit; (ii) a second conduit; and (iii) a first interconnected microporous network in communication with the first and second conduits and configured to allow diffusion of gas between the first and second conduits. The microporous network comprises poly(dimethylsiloxane) (PDMS) and prevents flow of aqueous fluid between the first and second conduits through the microporous network.

Owner:CORNING INC

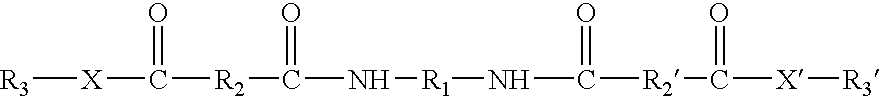

Ultra-Violet Curable Gellant Inks For Three-Dimensional Printing And Digital Fabrication Applications

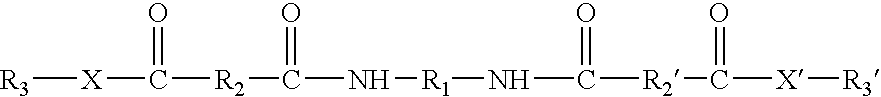

InactiveUS20100055484A1Rapid prototypingPrevent spreadAdditive manufacturing apparatusSynthetic resin layered productsWaxPrepolymer

A method for fabricating a three-dimensional object including depositing a first amount of an ultraviolet curable phase change ink composition comprising an optional colorant and a phase change ink vehicle comprising a radiation curable monomer or prepolymer; a photoinitiator; a reactive wax; and a gellant upon a print region surface; successively depositing additional amounts of the ultraviolet curable phase change ink composition to create a three-dimensional object; and curing the ultraviolet curable phase change ink composition.

Owner:XEROX CORP

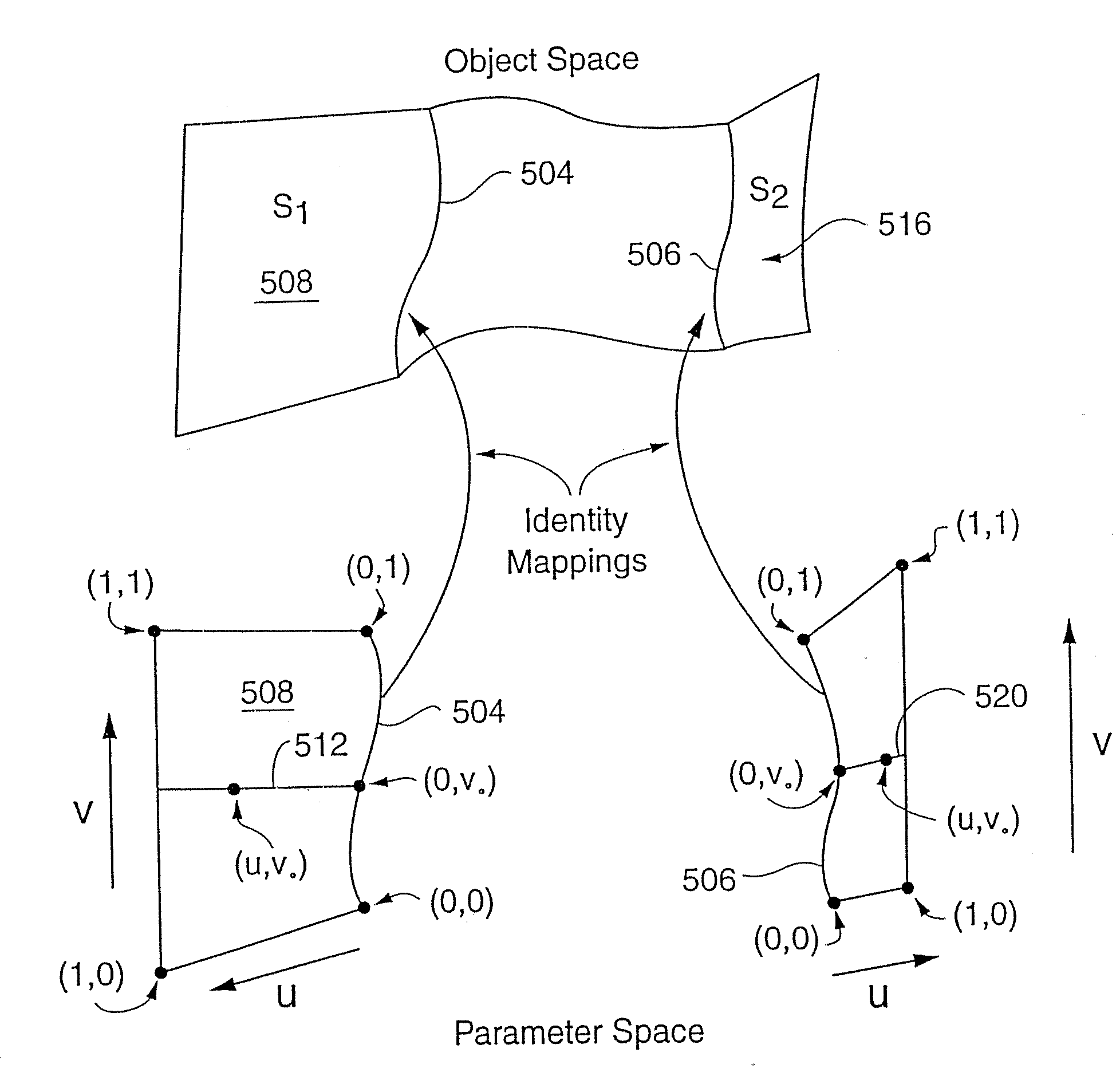

Computational geometry using control geometry having at least two dimensions

InactiveUS7236167B2Computationally efficientImprove computing efficiencyData processing applications3D-image renderingComputer Aided DesignAnimation

A method and system for computer aided design (CAD) is disclosed for designing geometric objects. The present invention interpolates and / or blends between such geometric objects sufficiently fast so that real time deformation of such objects occurs while deformation data is being input. Thus, a user designing with the present invention obtains immediate feedback to input modifications without separately entering a command for performing such deformations. The present invention utilizes novel computational techniques for blending between geometric objects, wherein weighted sums of points on the geometric objects are used in deriving a new blended geometric object. The present invention is particularly useful for designing the shape of surfaces. Thus, the present invention is applicable to various design domains such as the design of, e.g., bottles, vehicles, and watercraft. Additionally, the present invention provides for efficient animation via repeatedly modifying surfaces of an animated object such as a representation of a face.

Owner:CAD-SENSE LLC

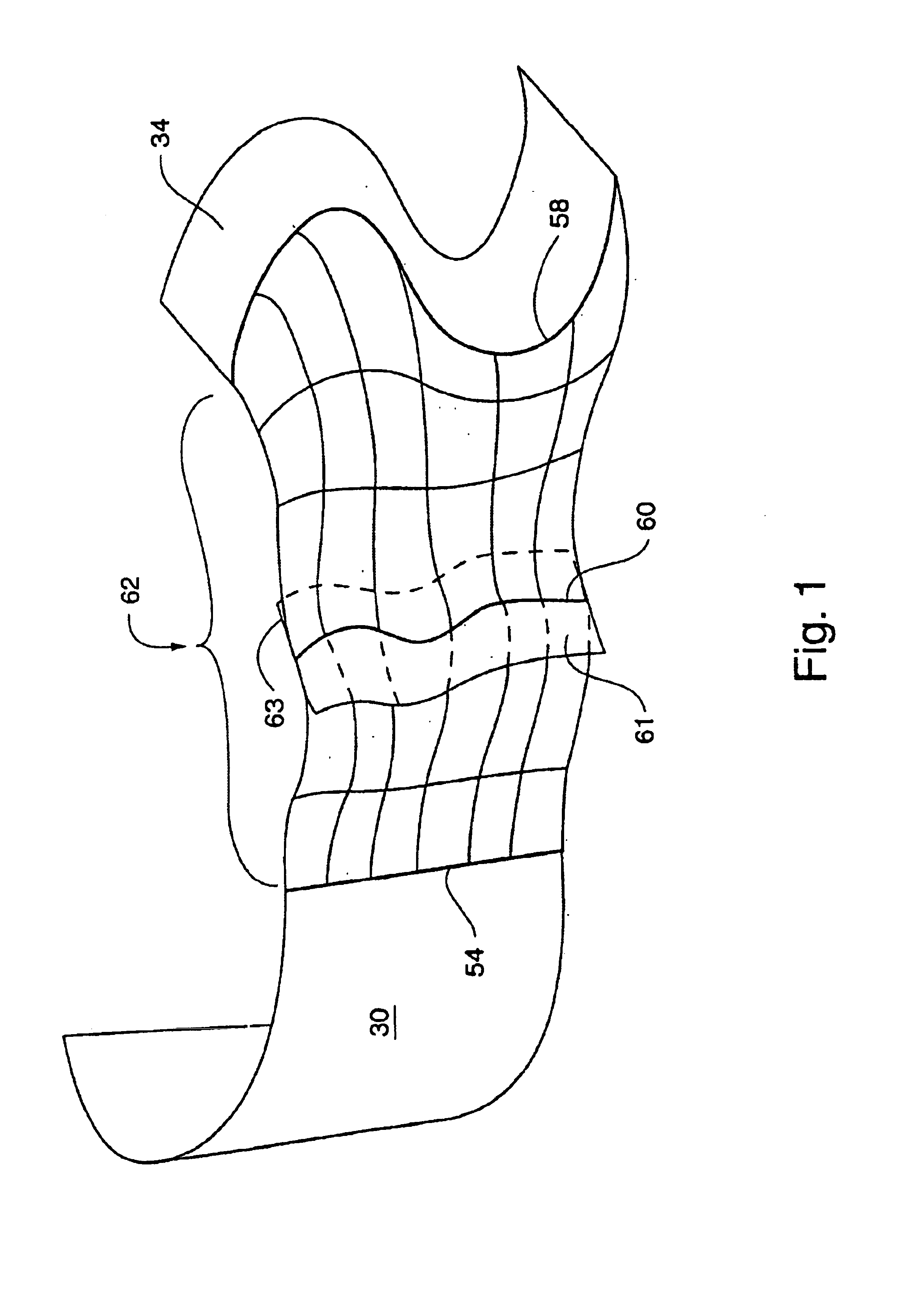

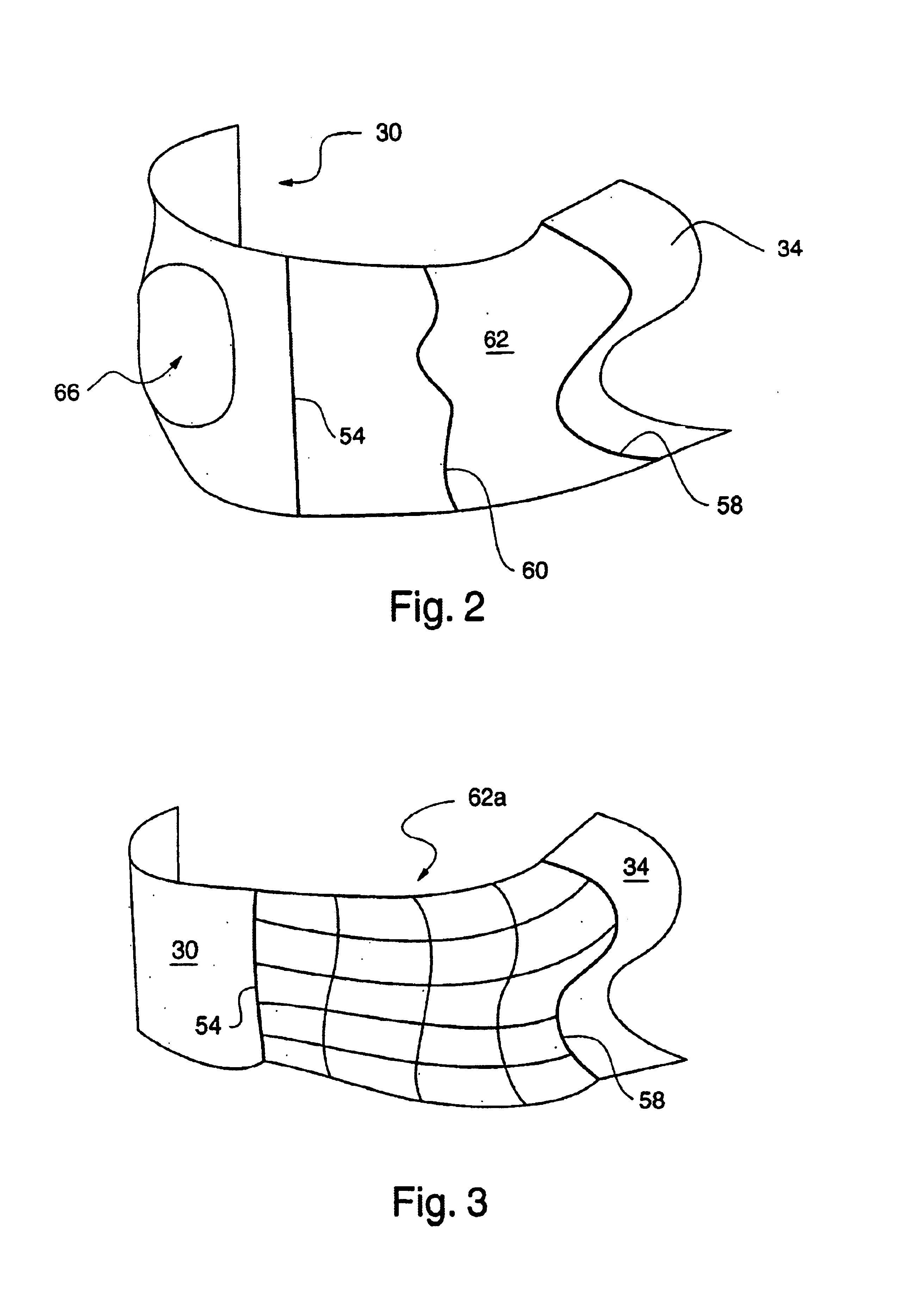

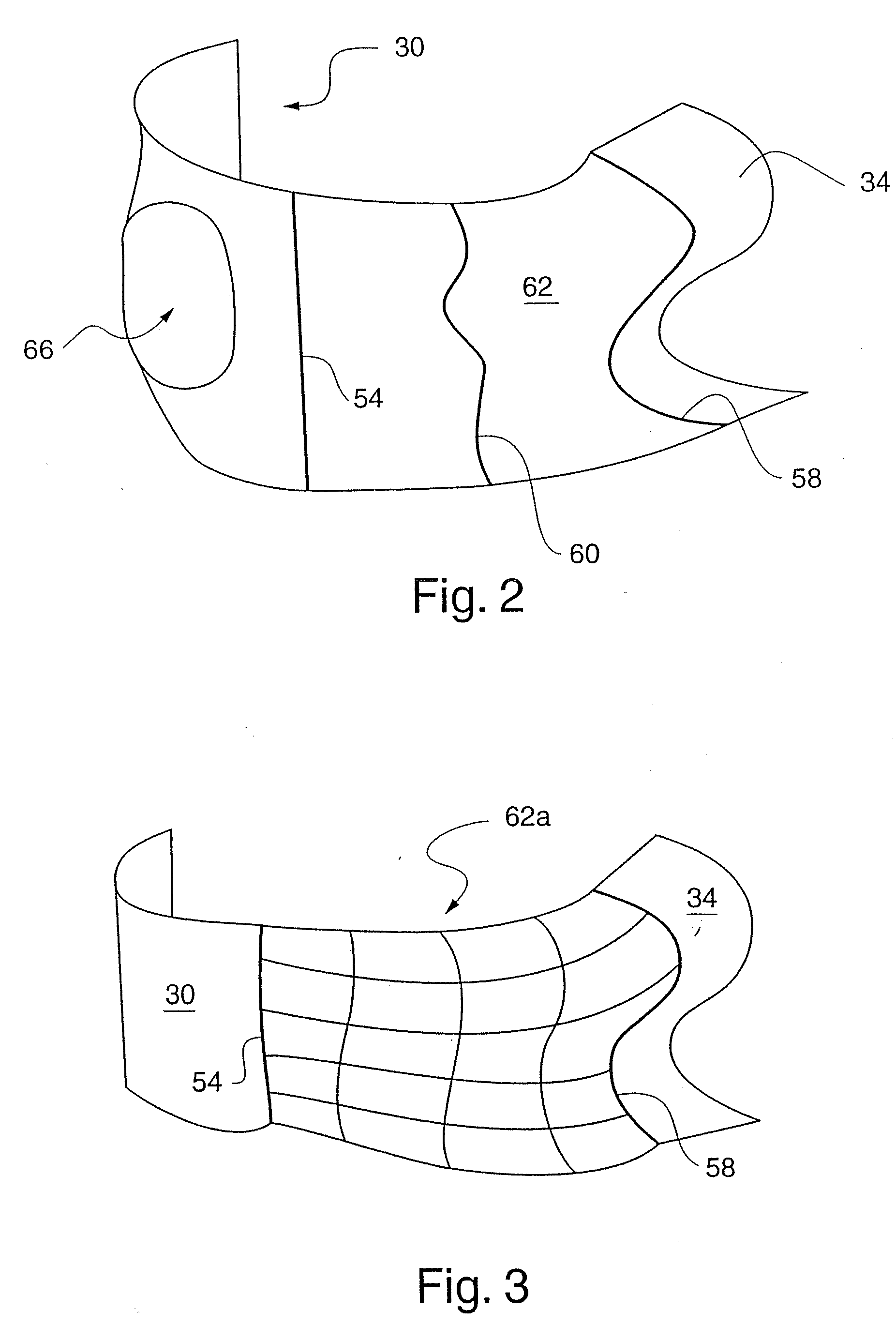

Surface patch techniques for computational geometry

InactiveUS8836701B1Fine surfaceImproved visualGeometric CADDrawing from basic elementsComputer Aided DesignMorphing

A method and system for computer aided design (CAD) is disclosed for designing geometric objects, wherein interpolation and / or blending between such objects is performed while deformation data is being input. Thus, a designer obtains immediate feedback to input modifications without separately entering a command(s) for performing such deformations. A novel N-sided surface generation technique is also disclosed herein to efficiently and accurately convert surfaces of high polynomial degree into a collection of lower degree surfaces. E.g., the N-sided surface generation technique disclosed herein subdivides parameter space objects (e.g., polygons) of seven or more sides into a collection of subpolygons, wherein each subpolygon has a reduced number of sides. More particularly, each subpolygon has 3 or 4 sides. The present disclosure is particularly useful for designing the shape of surfaces. Thus, the present disclosure is applicable to various design domains such as the design of, e.g., bottles, vehicles, and watercraft. Additionally, the present disclosure provides for efficient animation via repeatedly modifying surfaces of an animated object such as a representation of a face.

Owner:CAD-SENSE LLC

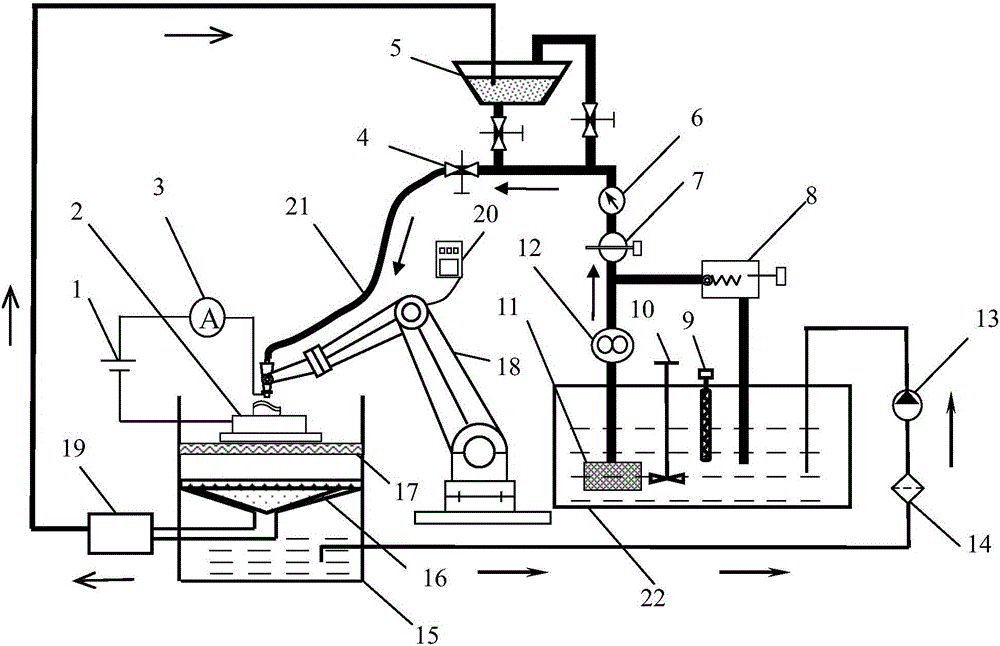

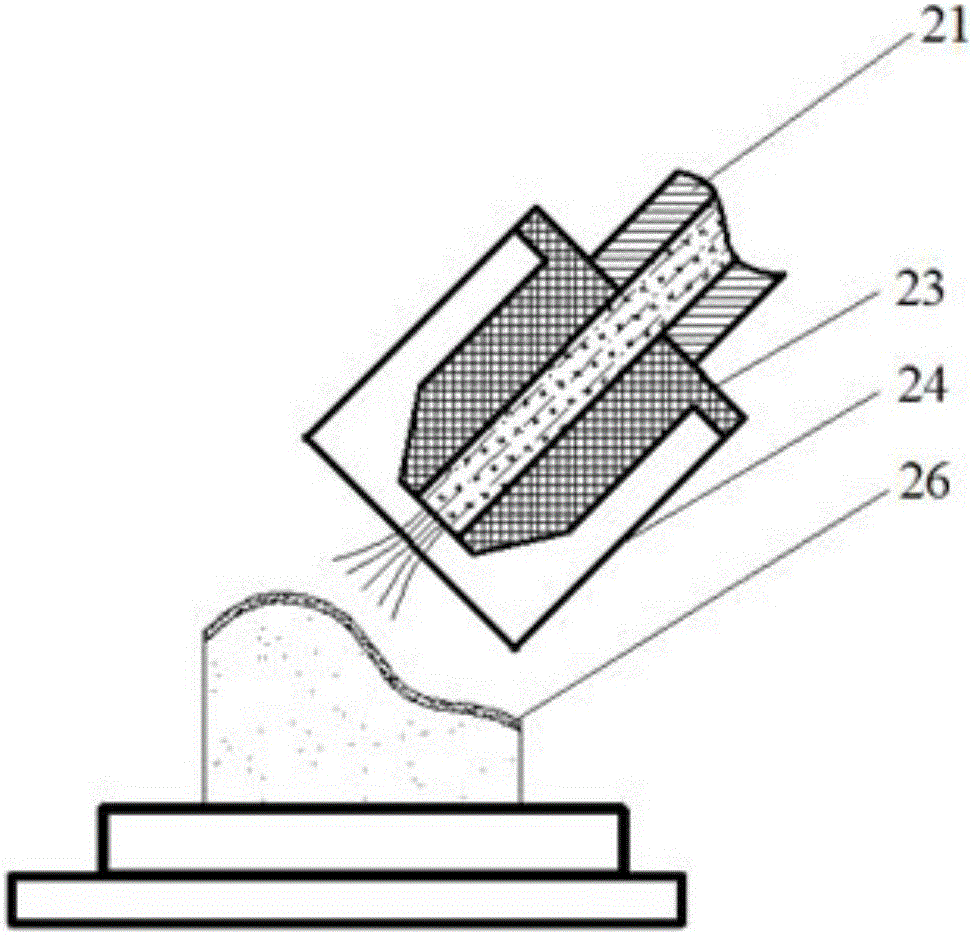

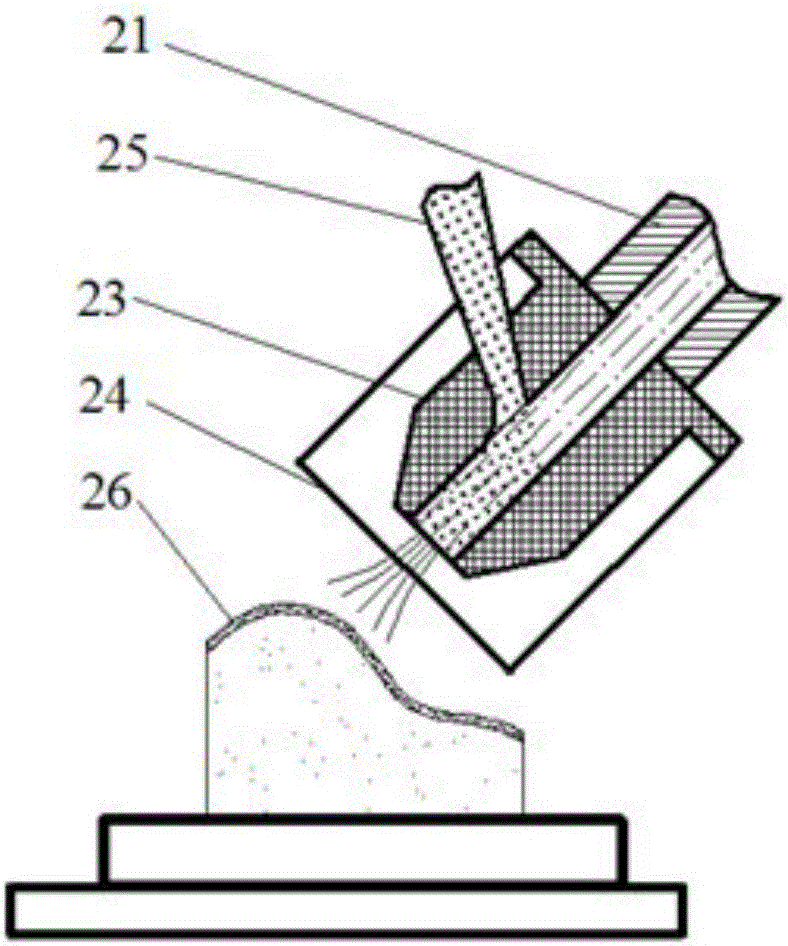

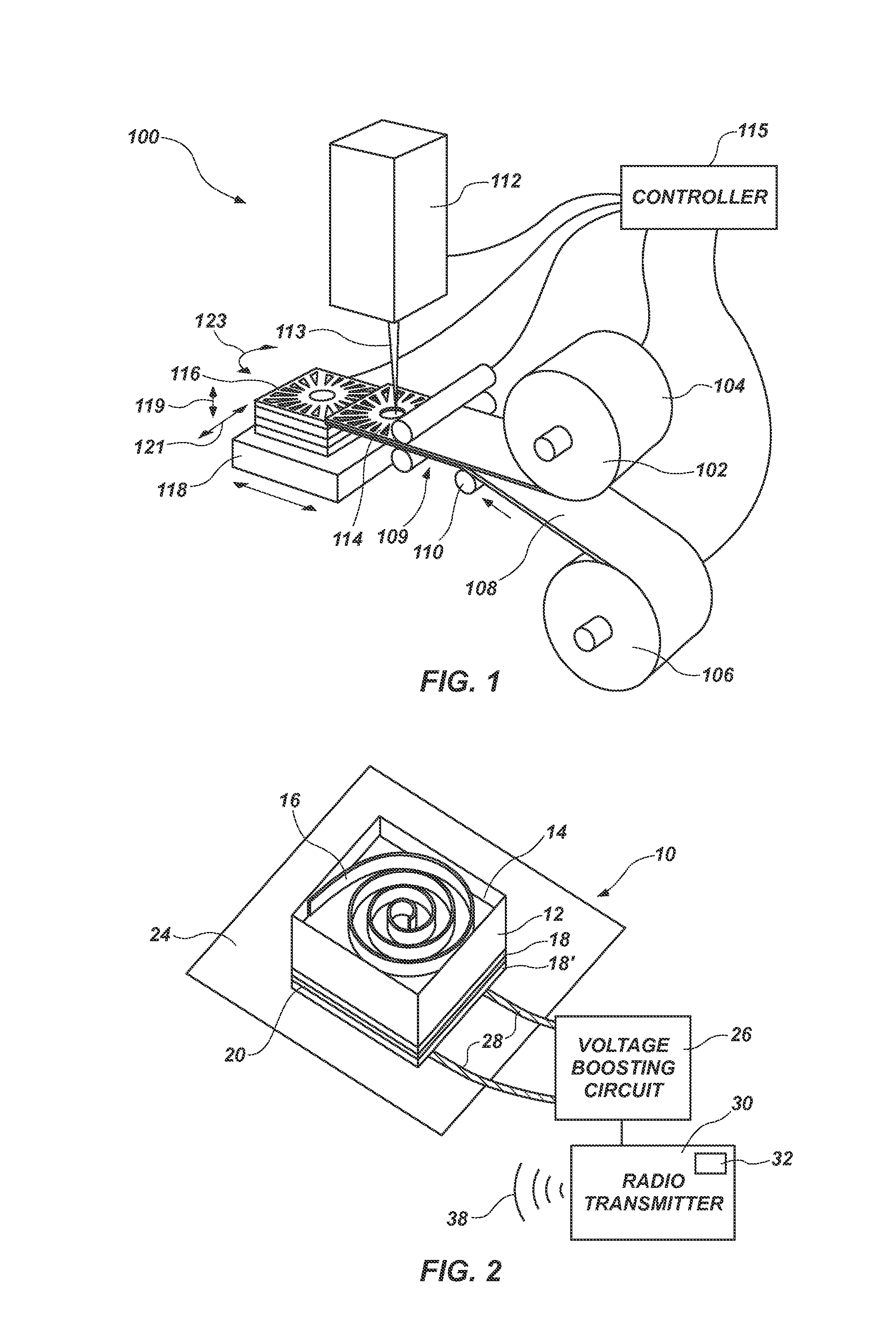

Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

InactiveCN105951141ARemove in timeInhibit nodulationElectrolysis componentsElectrolytic coatingsNumerical controlImpurity

The invention provides a three-dimensional surface shot peening jet electrodeposition manufacturing method and device. According to the manufacturing method and device, a deposition solution and hard particles are mixed and deposit on a conductive substrate in a spraying manner, so that the rapid manufacturing technology of electrodeposition is realized, the growth rate of grains in the electrodeposition process is slowed down, the purpose of refining the grains is reached, and the quality of a deposition layer is dramatically improved; with combination of the shot peening strengthening technology and the electrodeposition technology, the defects of loose texture, pockmarks, pits and the like of the deposition layer caused by single electrodeposited cathode hydrogen evolution and impurity adhesion can be effectively overcome, and the hardness and the compactness of the deposition layer are improved; meanwhile, by introducing a five-axis linkage numerical control machining system, processing formation of a three-dimensional space can be realized, and the uniformity and the shape accuracy of the deposition layer are improved; and the technology can be widely applied to production of noble metal devices and parts in complex shapes and can also be used for surface rapid coat-plating, a strengthening technology and the like.

Owner:JIANGSU UNIV

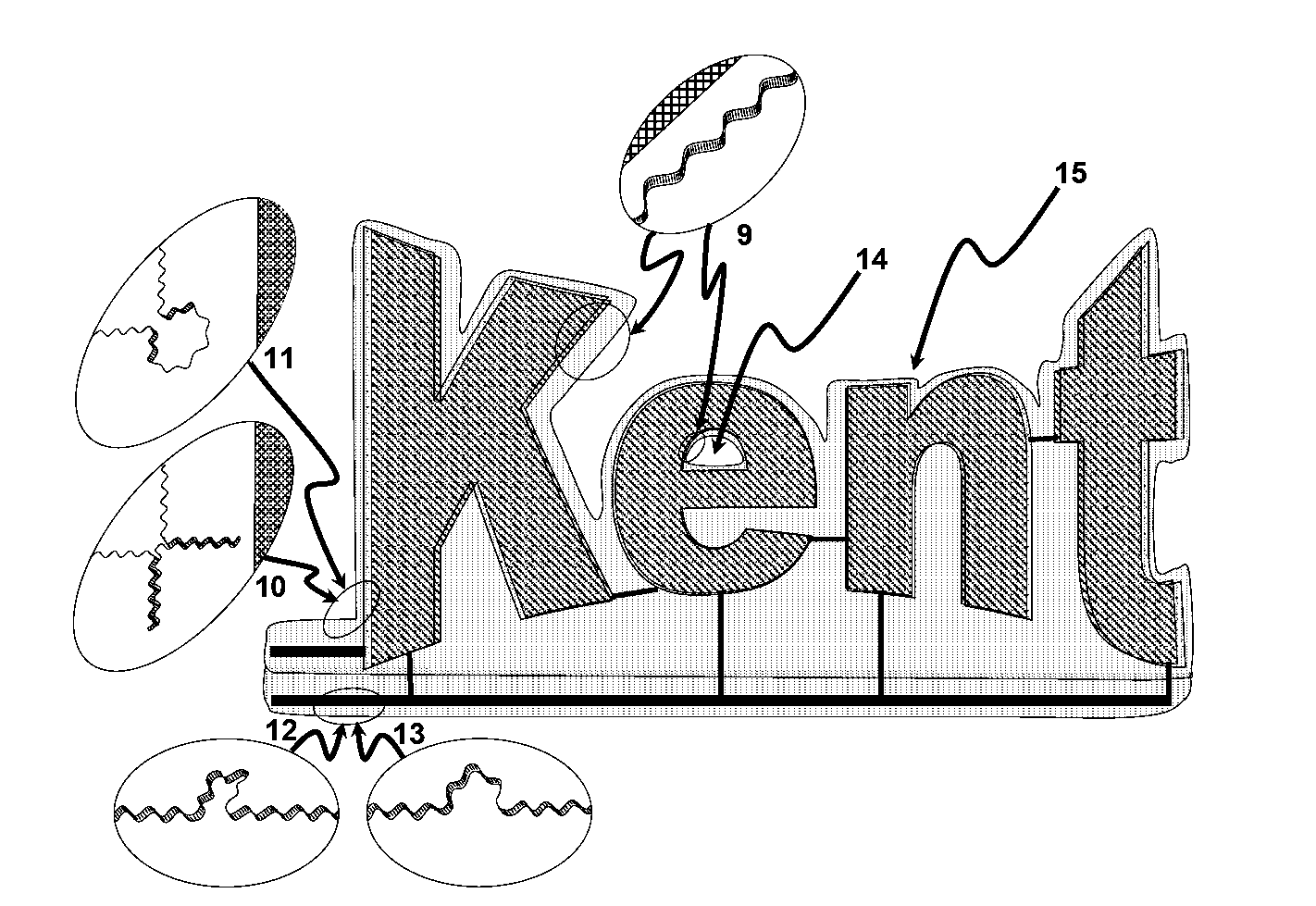

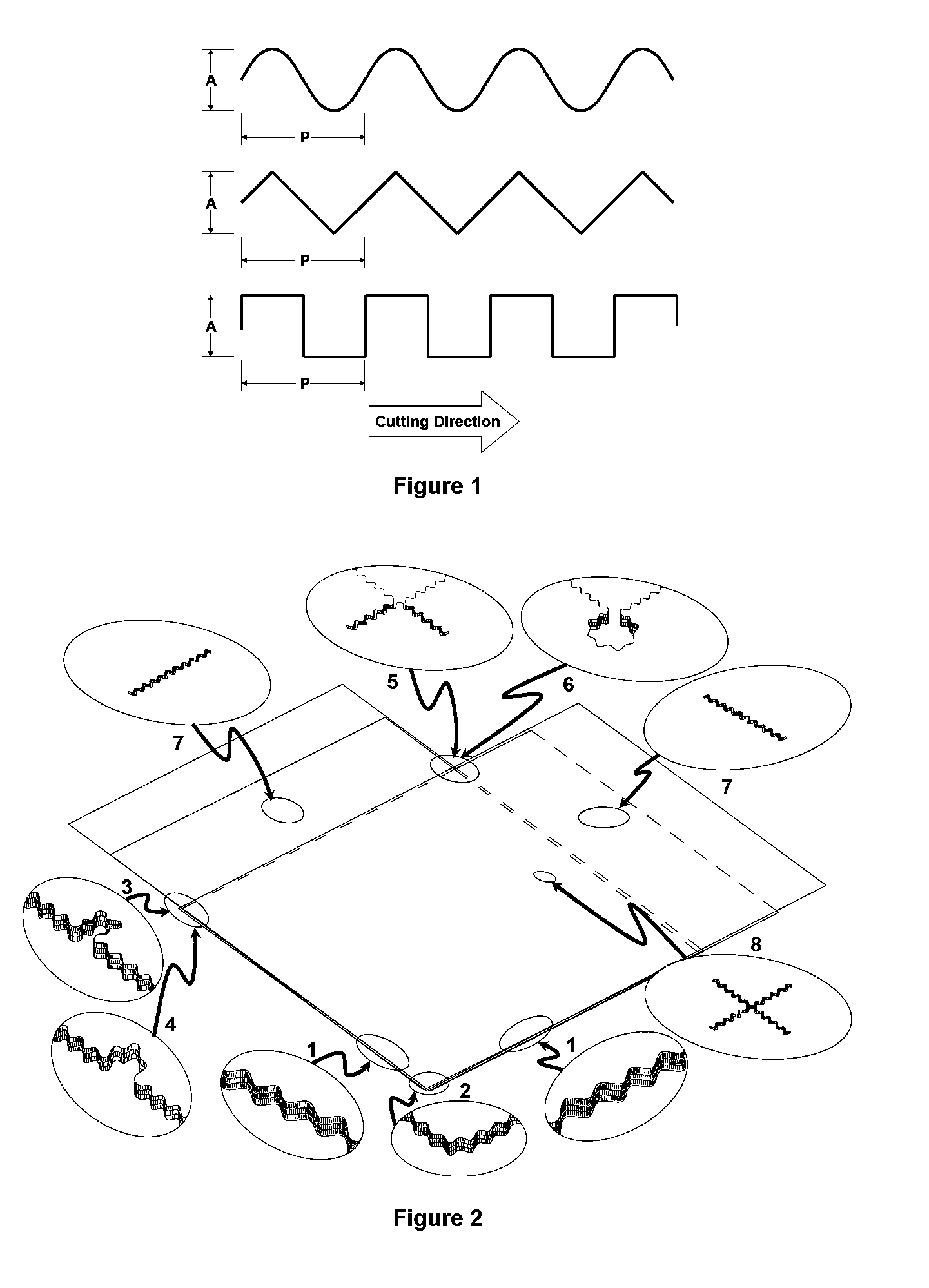

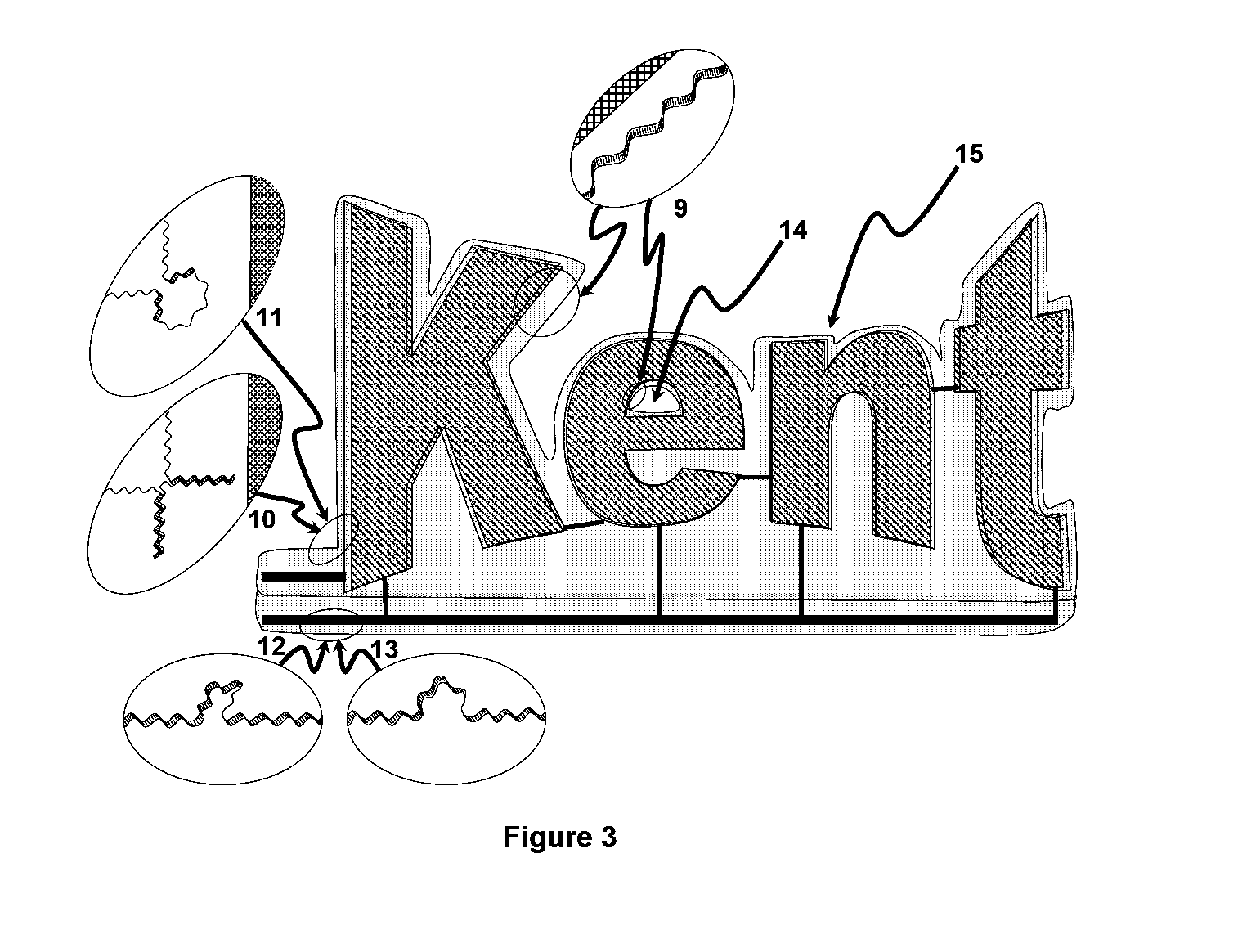

Method of simultaneous singulation and edge sealing of plastic displays

ActiveUS20070277659A1Unique electro-optical featureAvoids tendencyAdhesive processesAutomatic control devicesRoll-to-roll processingLiquid-crystal display

The production of liquid crystal displays (LCDS) on plastic substrates is desirable over glass substrates so that the finished product is thinner, lighter, and more robust. Plastic substrates can enable the use of new and different processing techniques which are not possible on glass such as roll-to-roll processing. This invention discusses an advancement which is laser cutting a plastic substrate and display layer. One aspect of the invention is laser cutting and welding together two or more plastic substrates and LCD layer therebetween from a larger sheet or roll of plastic LCDs.

Owner:KENT DISPLAY SYST

Computational Geometry Using Control Geometry Having At Least Two Dimensions

InactiveUS20070176923A1Computationally efficientImprove computing efficiencyData processing applicationsDrawing from basic elementsComputer Aided DesignAnimation

A method and system for computer aided design (CAD) is disclosed for designing geometric objects. The present invention interpolates and / or blends between such geometric objects sufficiently fast so that real time deformation of such objects occurs while deformation data is being input. Thus, a user designing with the present invention obtains immediate feedback to input modifications without separately entering a command for performing such deformations. The present invention utilizes novel computational techniques for blending between geometric objects, wherein weighted sums of points on the geometric objects are used in deriving a new blended geometric object. The present invention is particularly useful for designing the shape of surfaces. Thus, the present invention is applicable to various design domains such as the design of, e.g., bottles, vehicles, and watercraft. Additionally, the present invention provides for efficient animation via repeatedly modifying surfaces of an animated object such as a representation of a face.

Owner:CAD-SENSE LLC

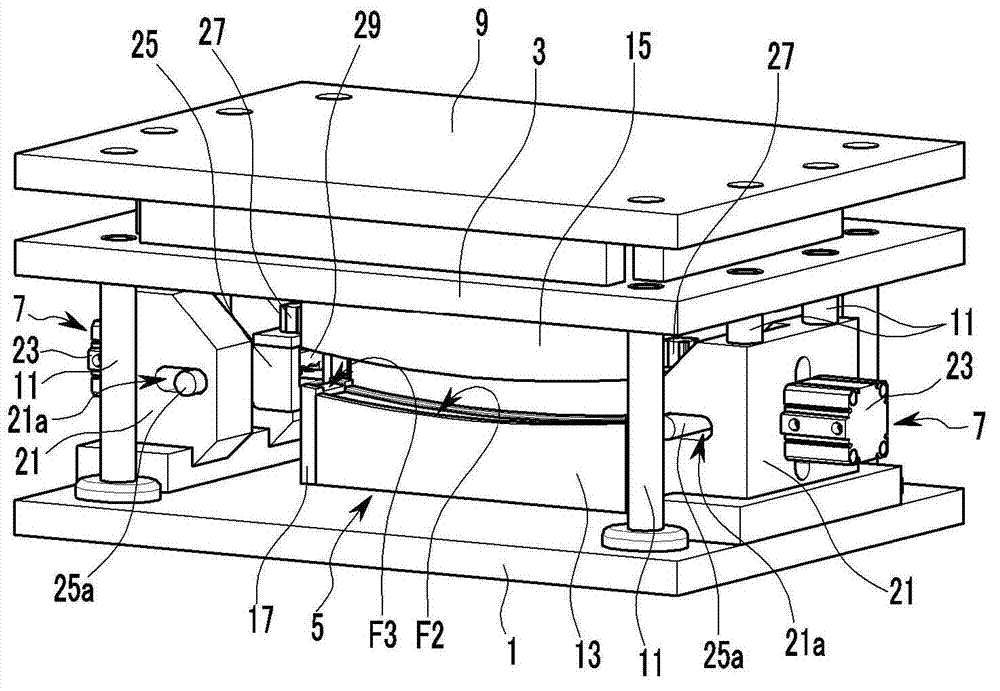

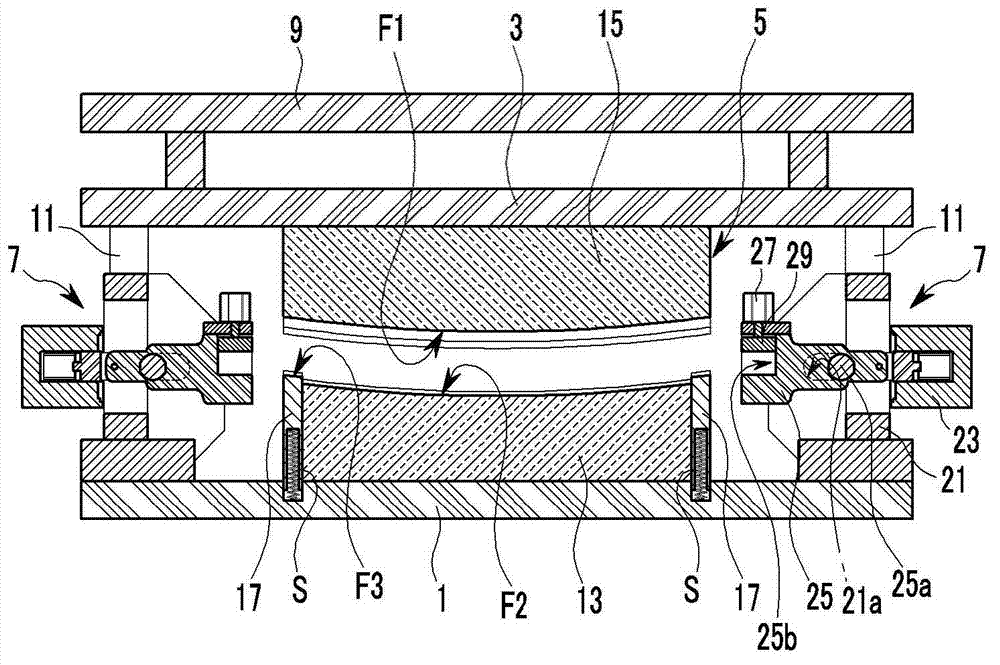

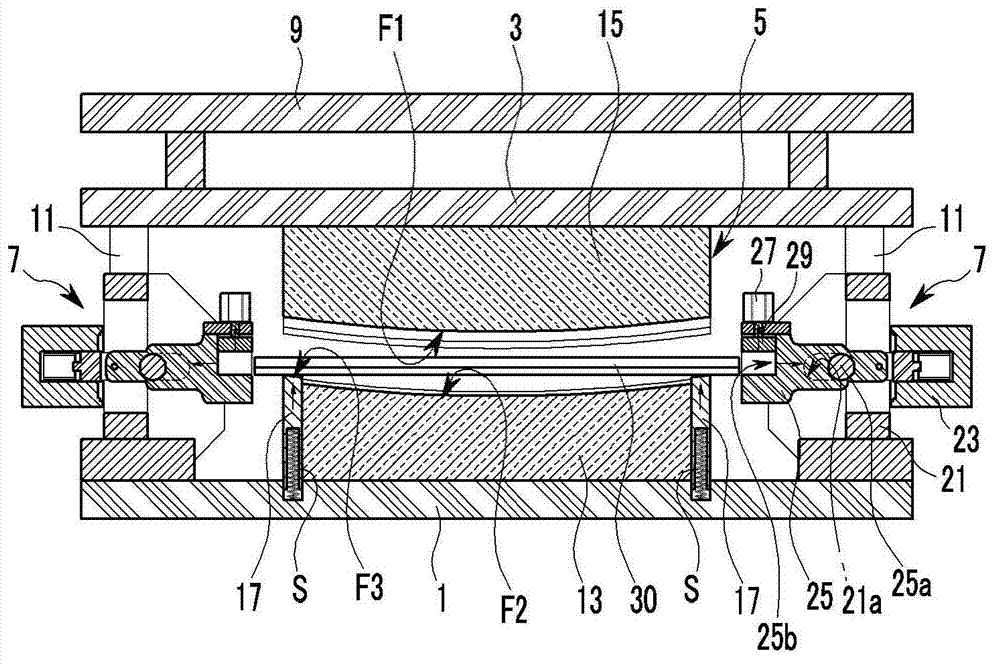

Bending press system

A bending press system is disclosed. The bending press system may include: at least one guide post; a slide plate mounted at a slider so as to be slidable upwardly or downwardly along the guide post; a bending die including a lower die having an upper surface and an upper die having a lower surface corresponding to the upper surface of the lower die and mounted on a lower surface of the slide plate, and adapted to bend an object supplied between the lower die and the upper die to have a predetermined curvature; and a pair of clamping means mounted respectively at both sides of the bending die corresponding to the bending die and adapted to clamp both end portions of the object.

Owner:SUNG WOO HITECH

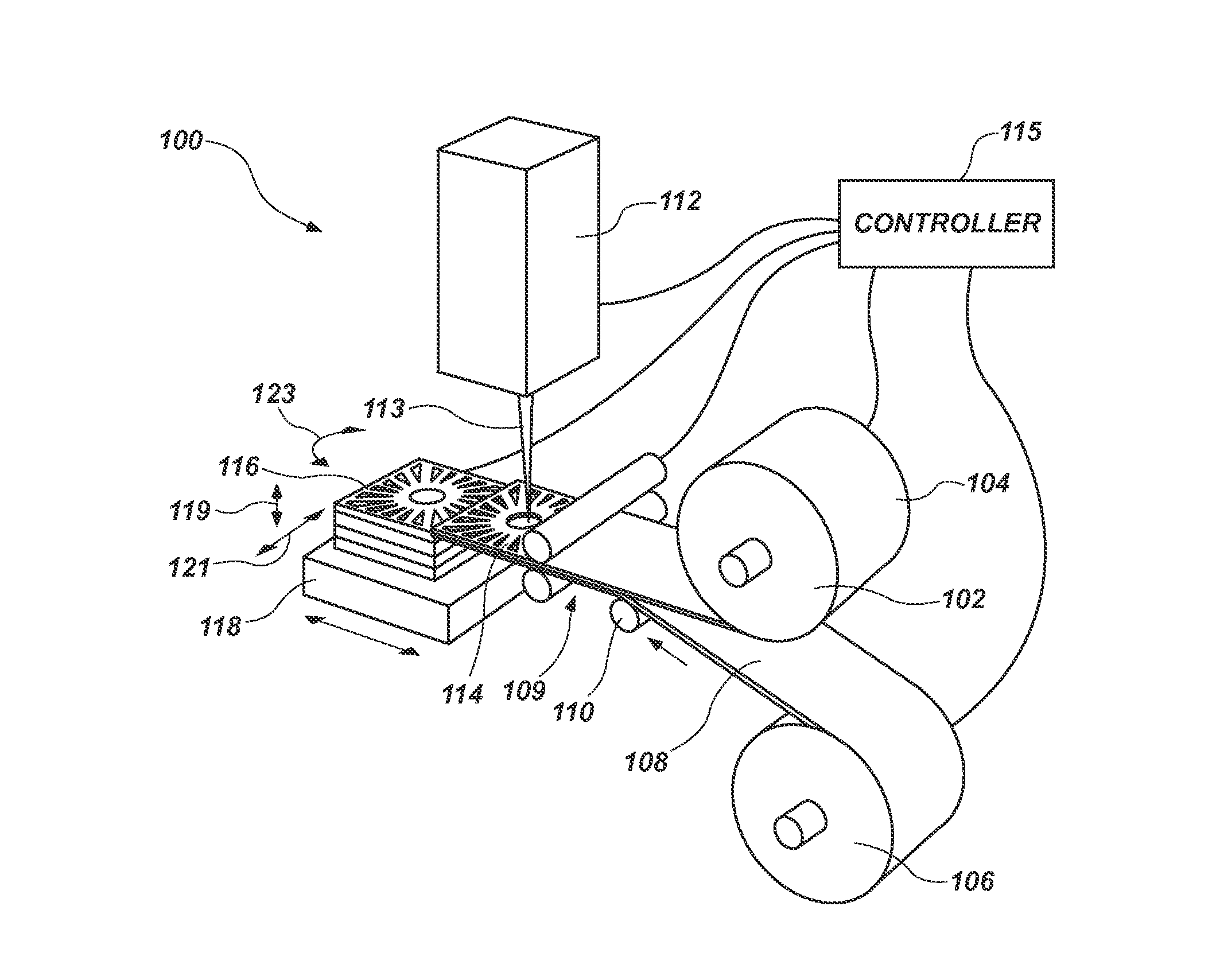

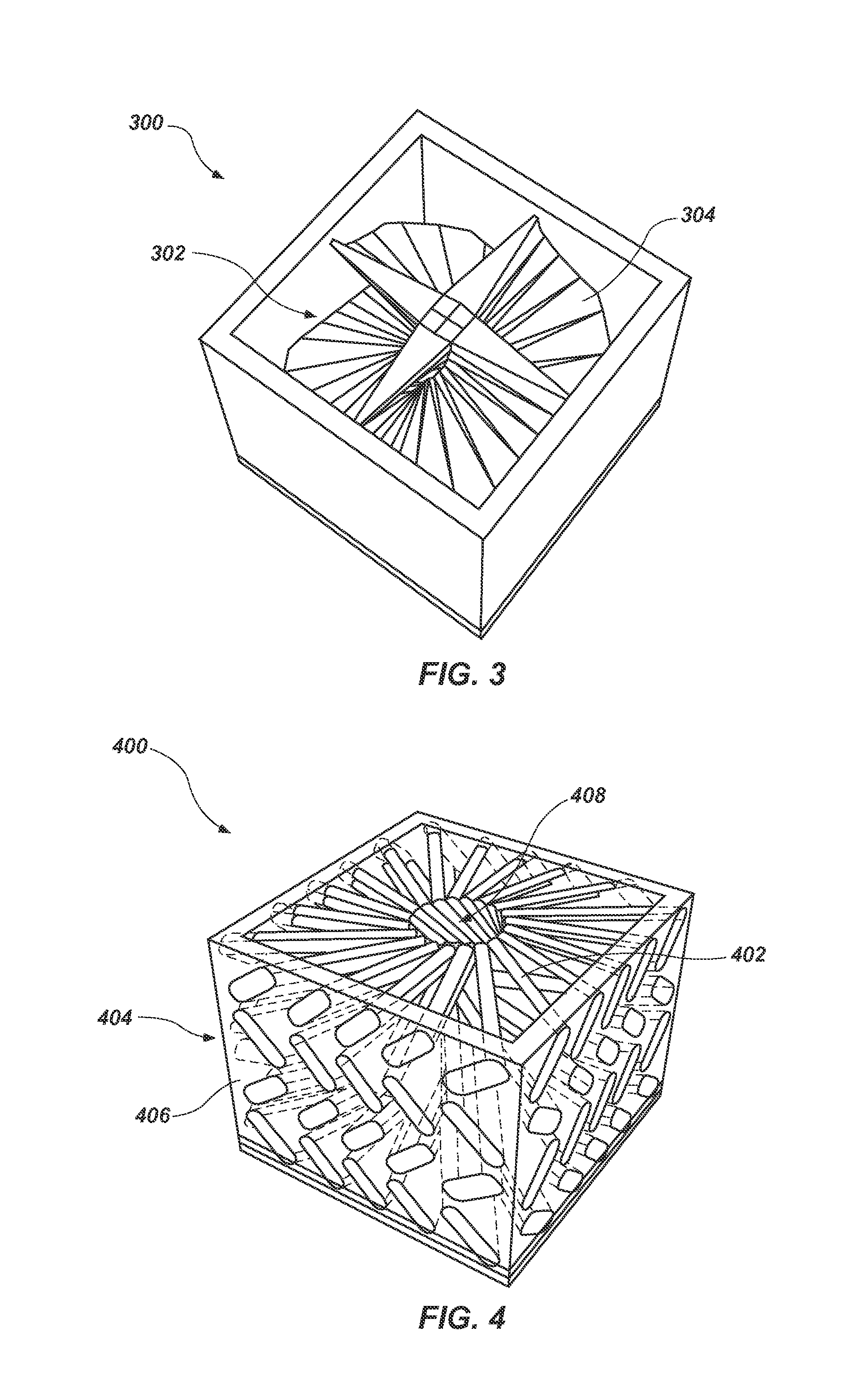

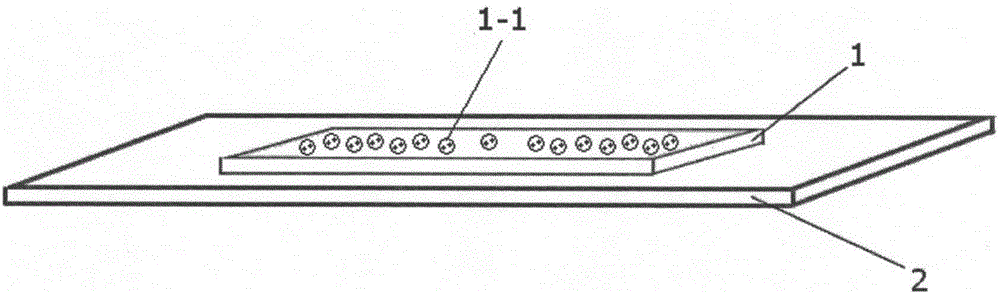

System and method for additive fabrication using laminated sheets

ActiveUS9550349B1Rapid prototypingFast formingAdditive manufacturing apparatusLamination ancillary operationsComputer generationThermal energy harvesting

A method for fabricating a part includes sectionalizing a computer-generated representation of a part into strata having an order, forming layers corresponding to the strata from sheet material, stacking at least two of the layers in the order, and joining the layers together. The method is suitable for producing a phase-change material container for a thermal energy harvesting device, for example.

Owner:THE BOEING CO

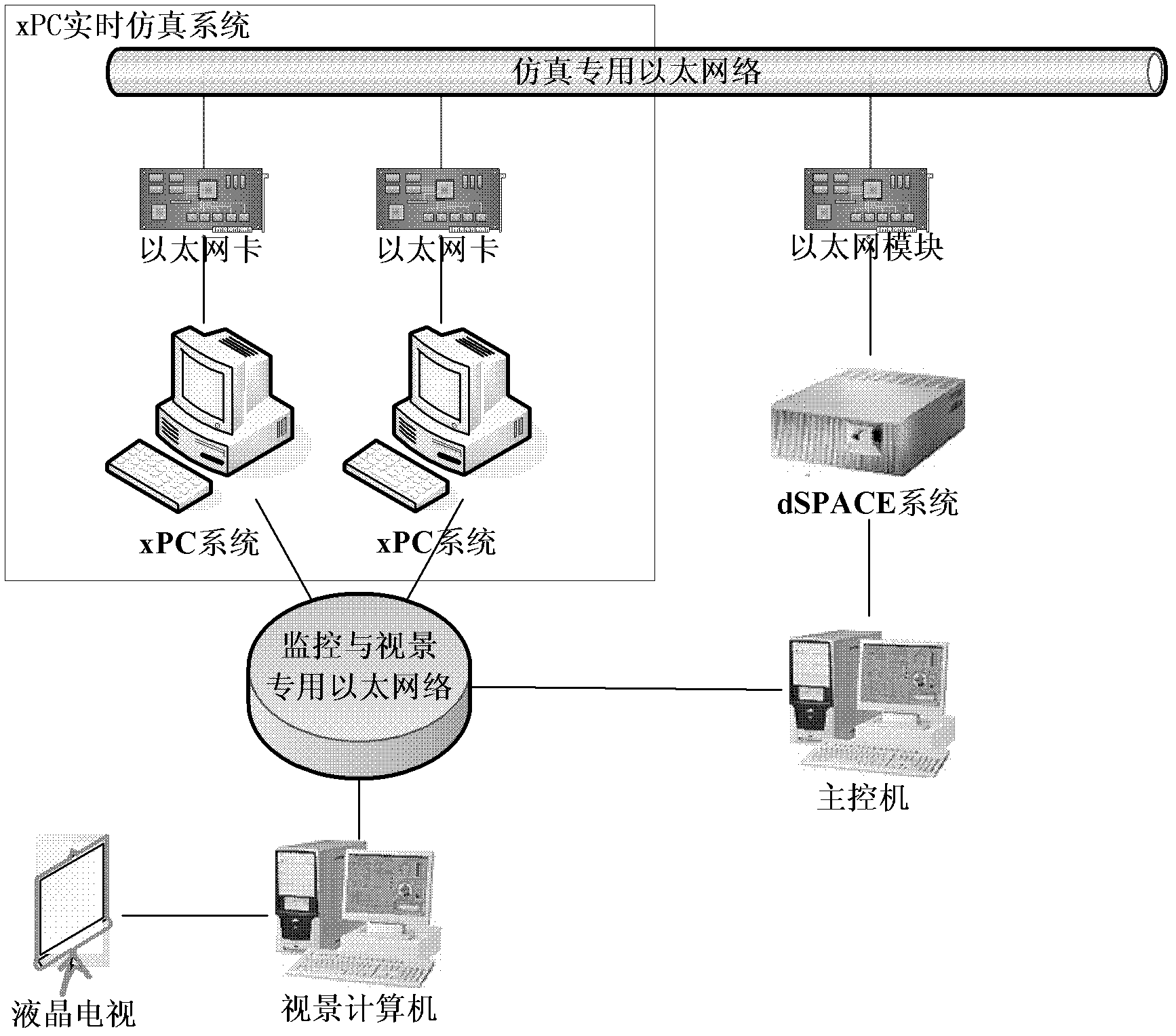

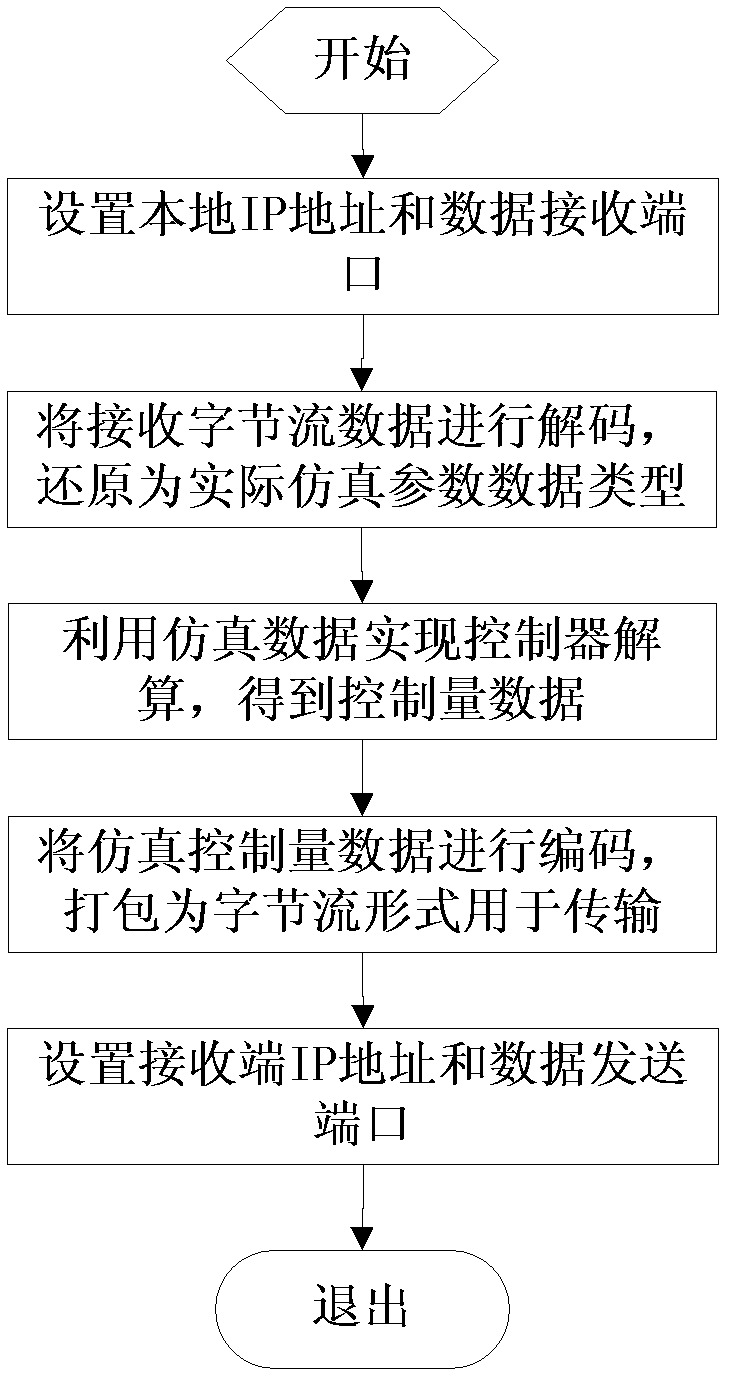

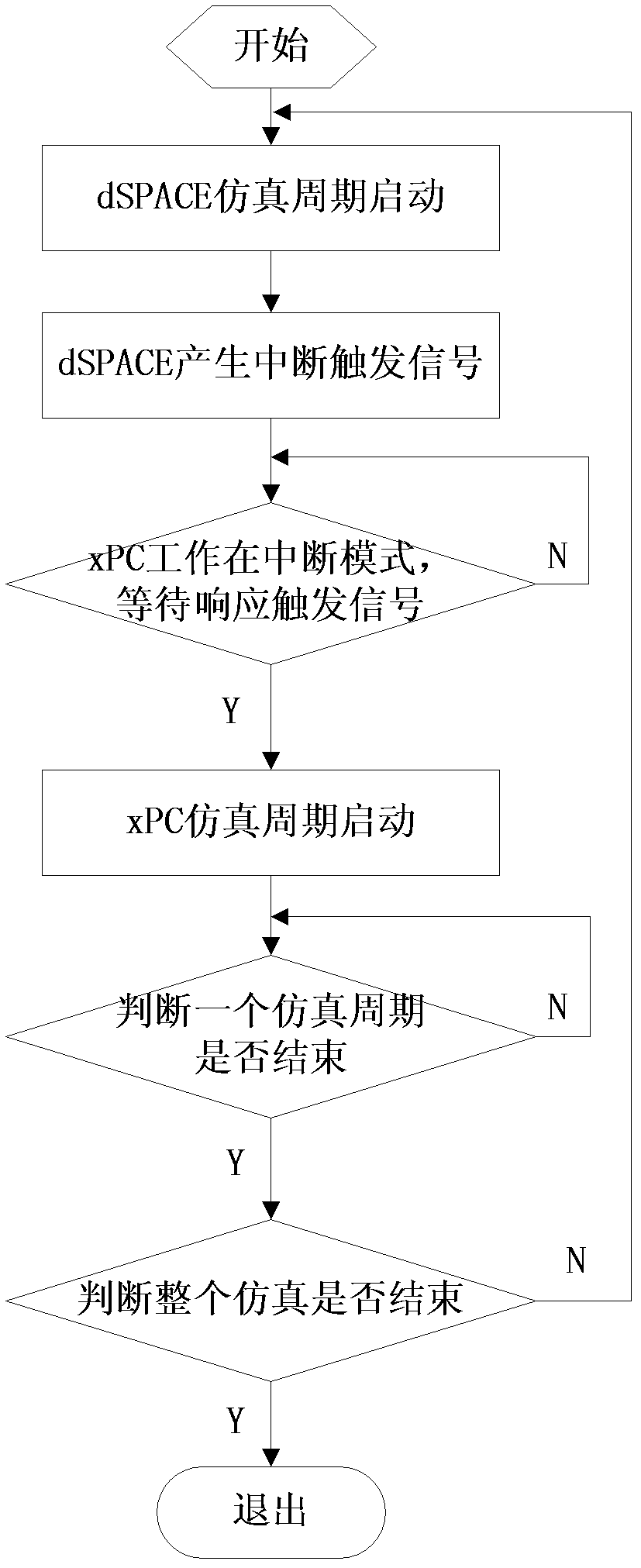

Visual emulation method of near-space flying vehicle based on distributed framework

ActiveCN102426424ARapid prototypingFully validated controlSimulator controlReal-time simulationMonitoring system

The invention belongs to the technical field of flight simulation. The defects that the conventional visual emulation is slow in modeling and has higher requirements on the modeling technique of a user are solved; an effective emulation method combining a distributed emulation framework and real-time visual emulation is provided; the technical scheme adopted by the invention is a visual emulationmethod of a near-space flying vehicle based on the distributed framework; the method is realized by means of the following three parts: namely, a special real-time emulation system Ethernet network for emulation, a special Ethernet network for monitoring and visual transmission, and a dSPACE monitoring system based on an optical fiber; and the method comprises the following steps of an emulation communication step of the distributed framework, an emulation scheduling step of the distributed framework, an Ethernet transmission step of real-time emulation data, and a visual emulation step. The visual emulation method of the near-space flying vehicle based on the distributed framework is mainly applied to occasions of the flight simulation.

Owner:TIANJIN UNIV

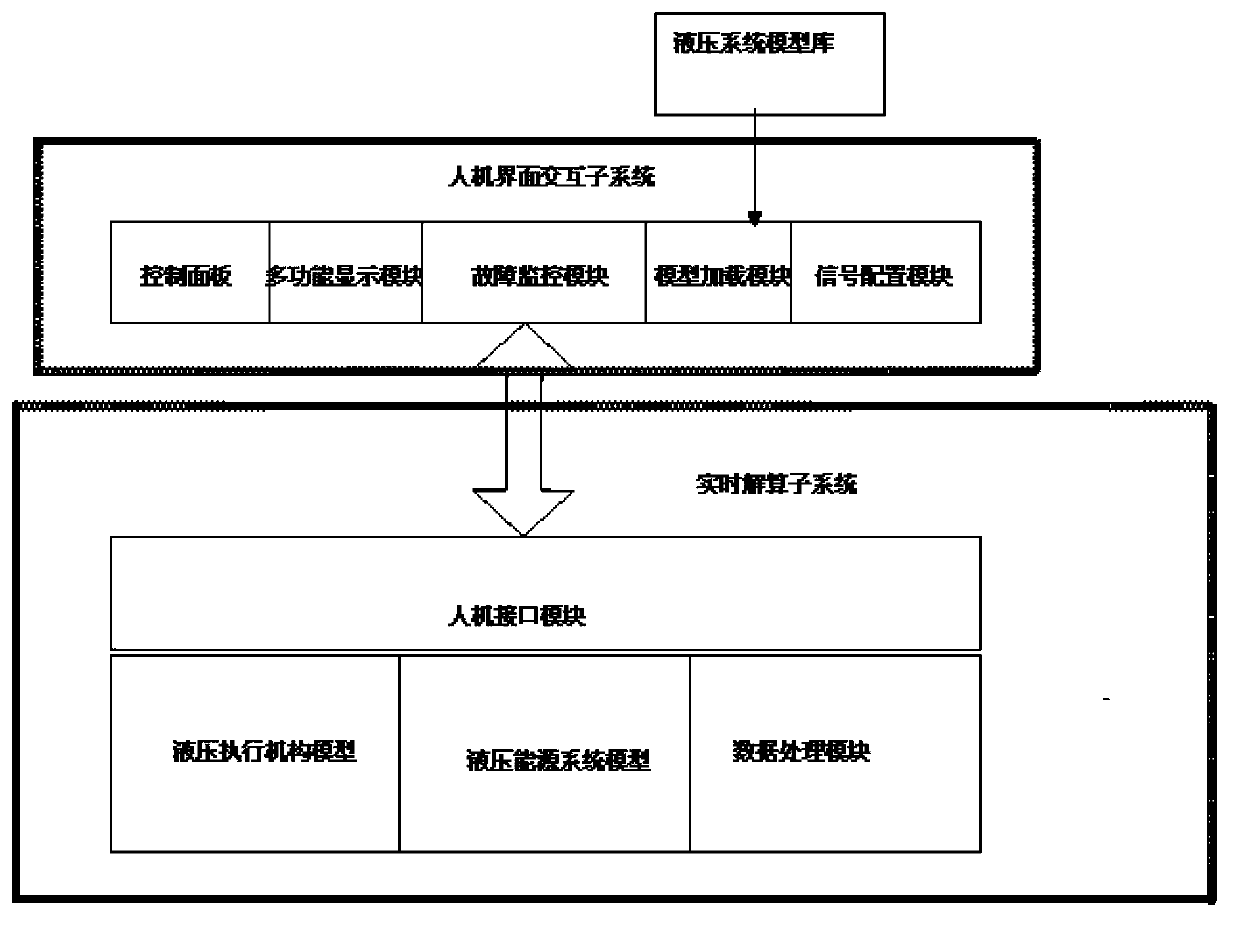

Real-time simulation system of large aircraft hydraulic system

InactiveCN103970024ARapid prototypingInsight and Acquisition QualitySimulator controlHuman–machine interfaceReal-time simulation

The invention belongs to the technical field of design of airborne hydraulic systems and relates to a real-time simulation system of a large aircraft hydraulic system. The real-time simulation system of the large aircraft hydraulic system comprises a human-computer interface interaction subsystem and a real-time calculating subsystem which are connected through the real-time Ethernet. The real-time simulation system of the large aircraft hydraulic system is based on the advanced design ideas such as distributed type parallel simulation and system integrated modeling, rapidly achieves rapid prototyping of a control system, aims to build a multi-system integrated digital model, tries to comprehensively reflect the complex integration and coupling among multidisciplinary subsystems such as a mechanical subsystem, a hydraulic subsystem, an electrical subsystem, an electronic subsystem and a control subsystem, and sees through and obtains more qualities of the large aircraft hydraulic system clearly.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Highly-tough hole-adjustable gel artificial blood vessel and making method thereof

The invention relates to a highly-tough hole-adjustable gel artificial blood vessel and a making method thereof. The gel artificial blood vessel contains, by mass, 9-15% of an olefin monomer M1, 1-3% of a biological polymer M2, 0-0.02% of a chemical crosslinking agent M3 and 4-10% of an ionic crosslinking agent M4. The making method comprises the following steps: making a gel artificial blood vessel base by using the M1 and M2 as functional monomers and the M3 as a chemical crosslinking agent in an aqueous solution, and reinforcing by utilizing the M4 as an ionic crosslinking agent to make the highly-tough hole-adjustable gel artificial blood vessel. The gel artificial blood vessel made through the method has the advantages of high strength, toughness and resilience, difficult damage under the action of external forces comprising the pulling, bending, twisting and the like, rapid original shape recovery, multi-crosslinked network structure, and adjustment of the hole dimension through a crosslinking degree. The gel artificial blood vessel is suitable for the biological field, the medical field, the tissue engineering field, the adsorption field and the like.

Owner:TIANJIN POLYTECHNIC UNIV

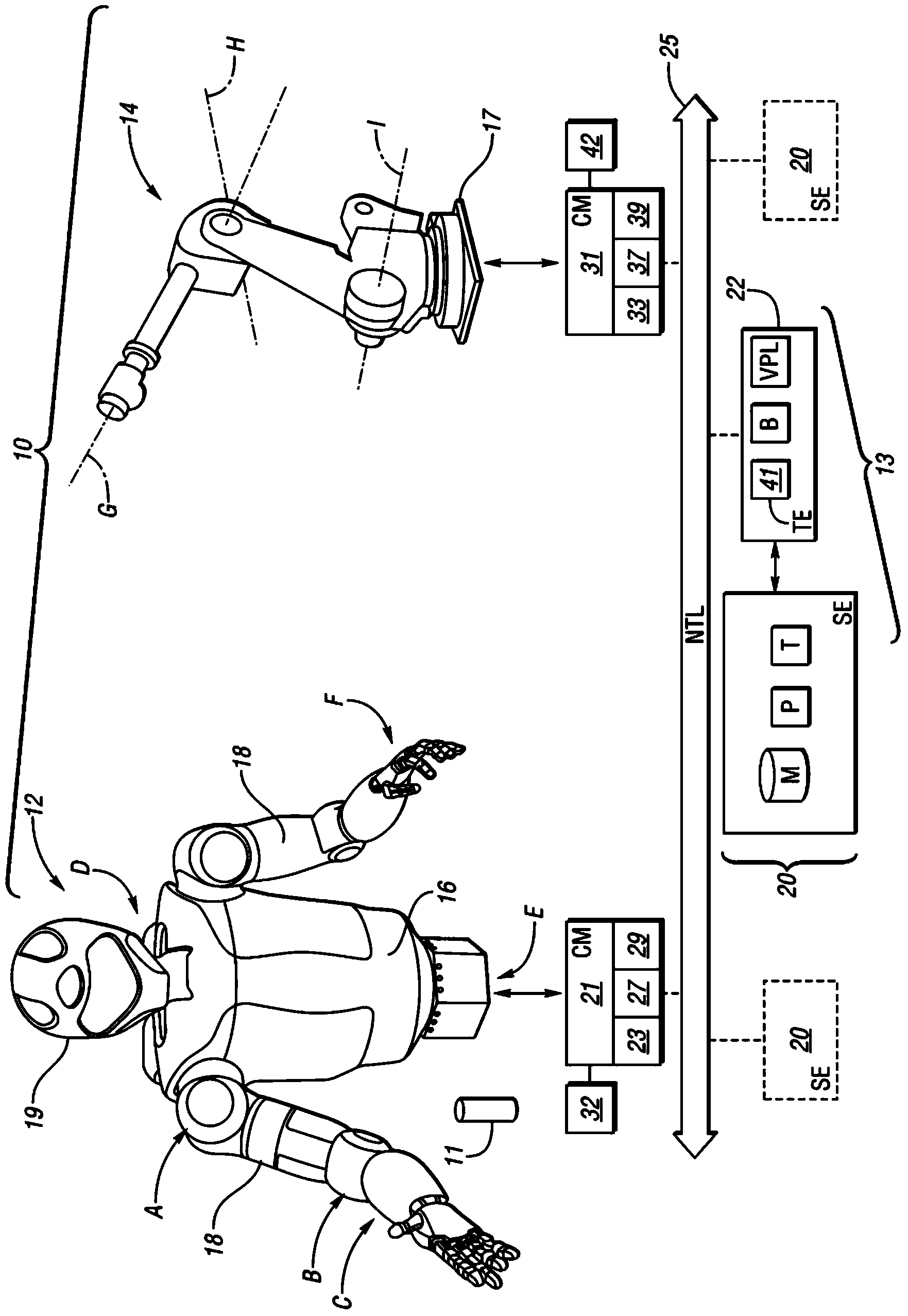

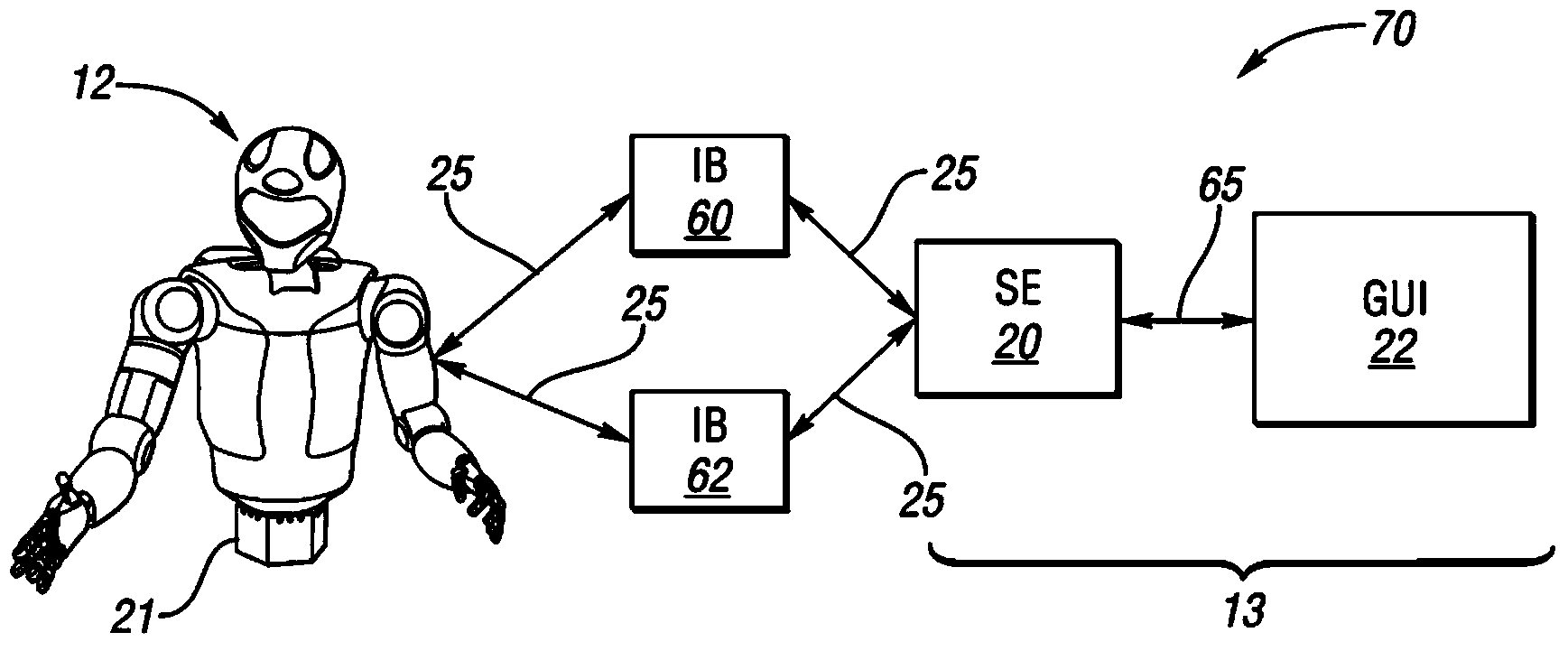

Robot task commander with extensible programming environment

ActiveCN104049573ARapid prototypingQuick configurationProgramme-controlled manipulatorProgramme total factory controlTransport layerVisual programming language

A system for developing distributed robot application-level software includes a robot having an associated control module which controls motion of the robot in response to a commanded task, and a robot task commander (RTC) in networked communication with the control module over a network transport layer (NTL). The RTC includes a script engine(s) and a GUI, with a processor and a centralized library of library blocks constructed from an interpretive computer programming code and having input and output connections. The GUI provides access to a Visual Programming Language (VPL) environment and a text editor. In executing a method, the VPL is opened, a task for the robot is built from the code library blocks, and data is assigned to input and output connections identifying input and output data for each block. A task sequence(s) is sent to the control module(s) over the NTL to command execution of the task.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

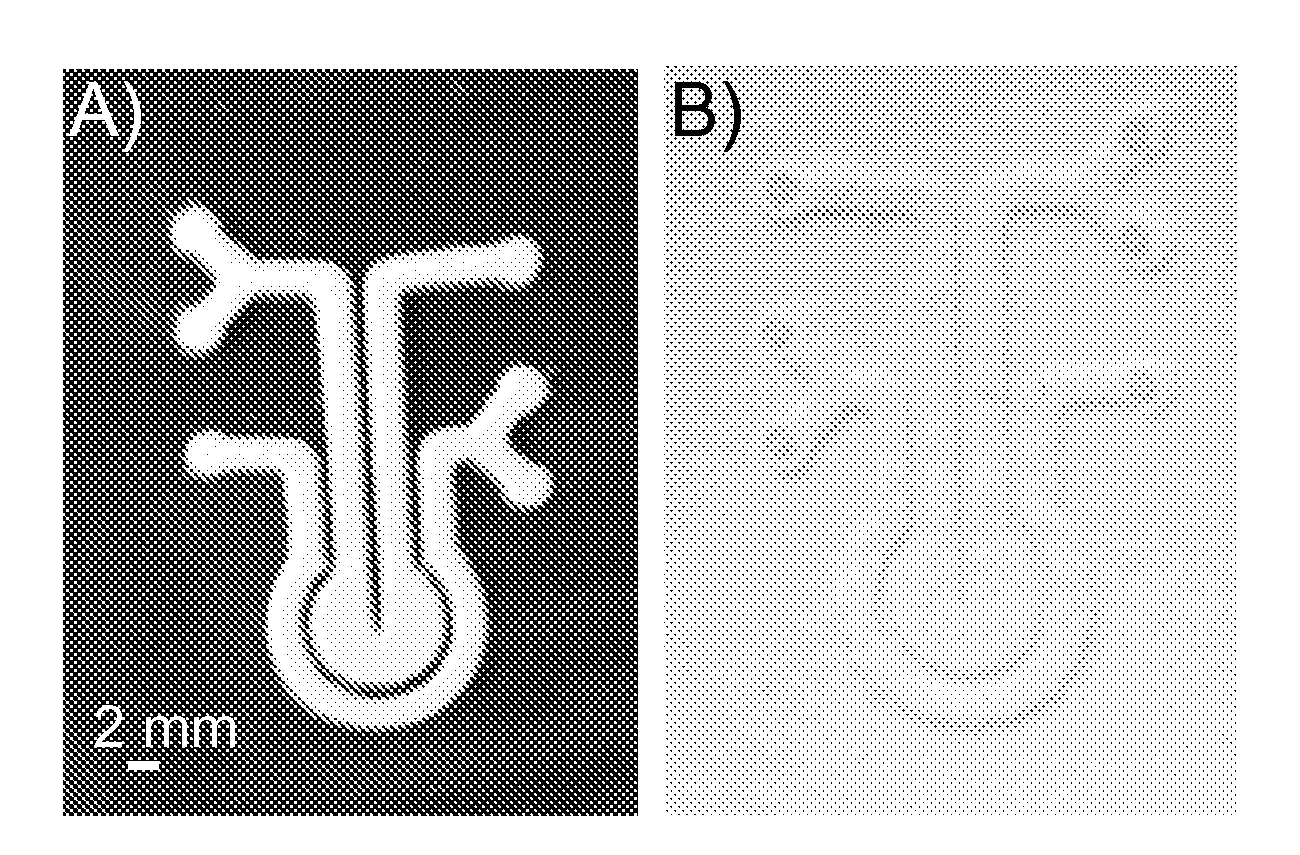

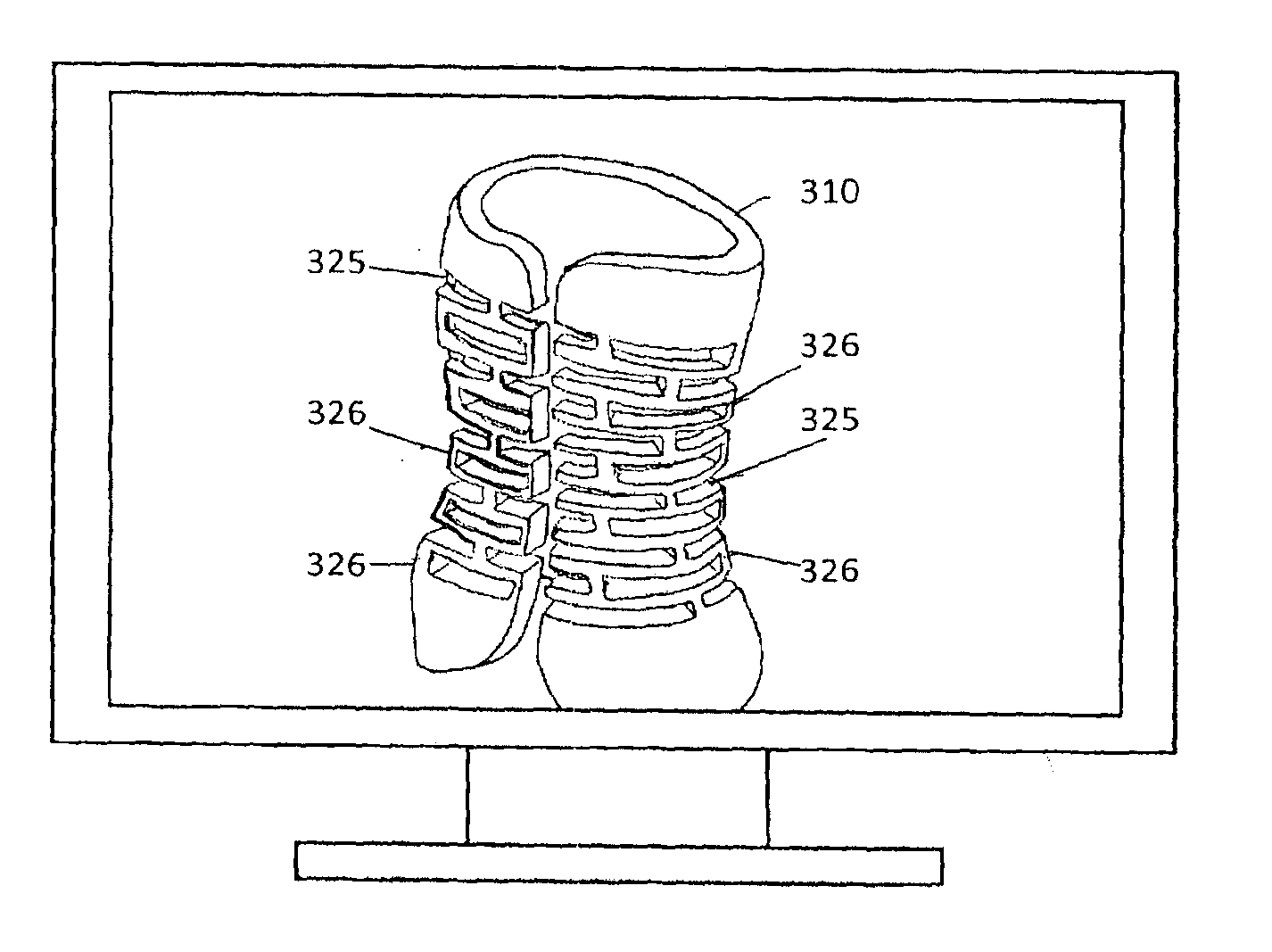

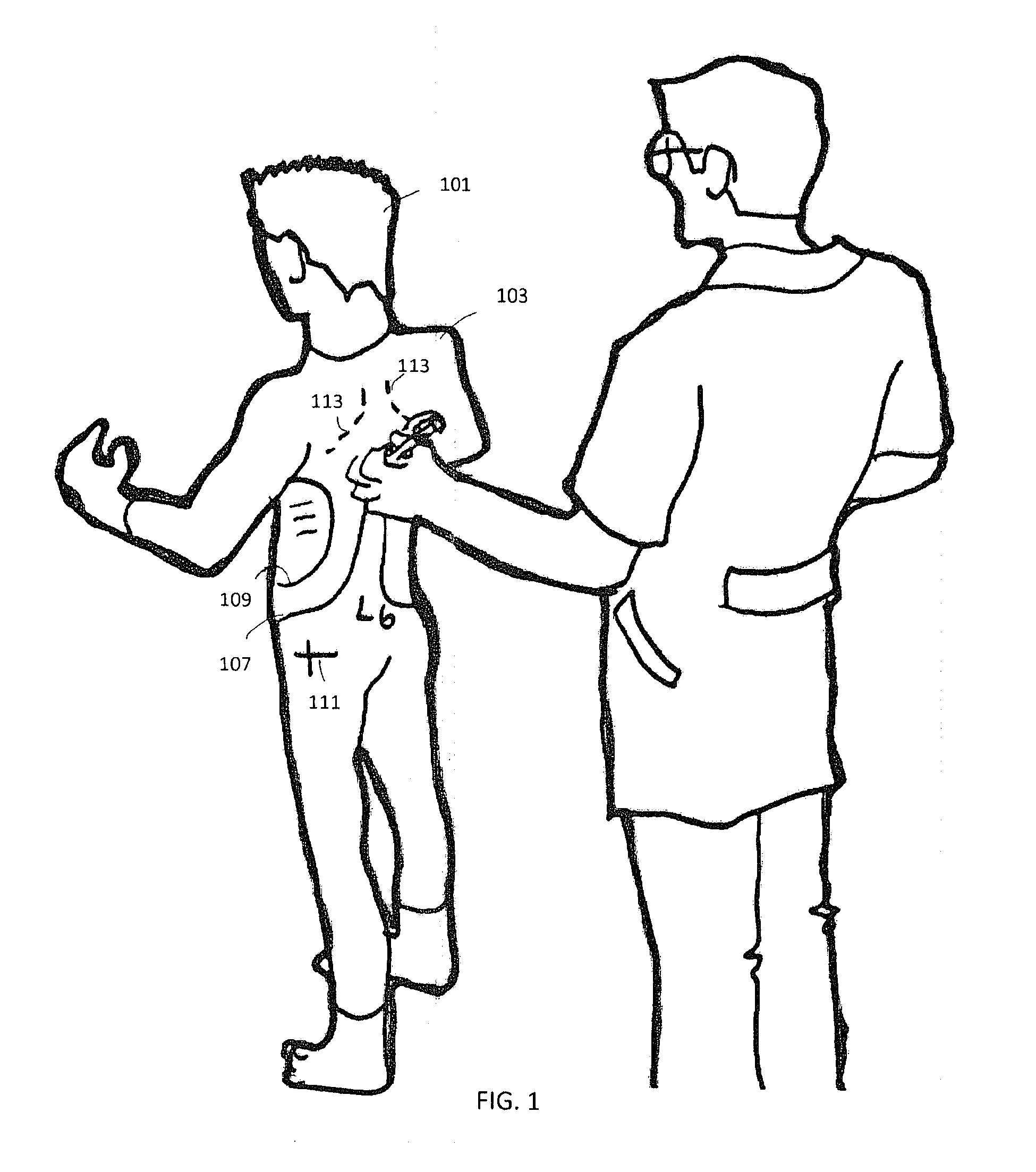

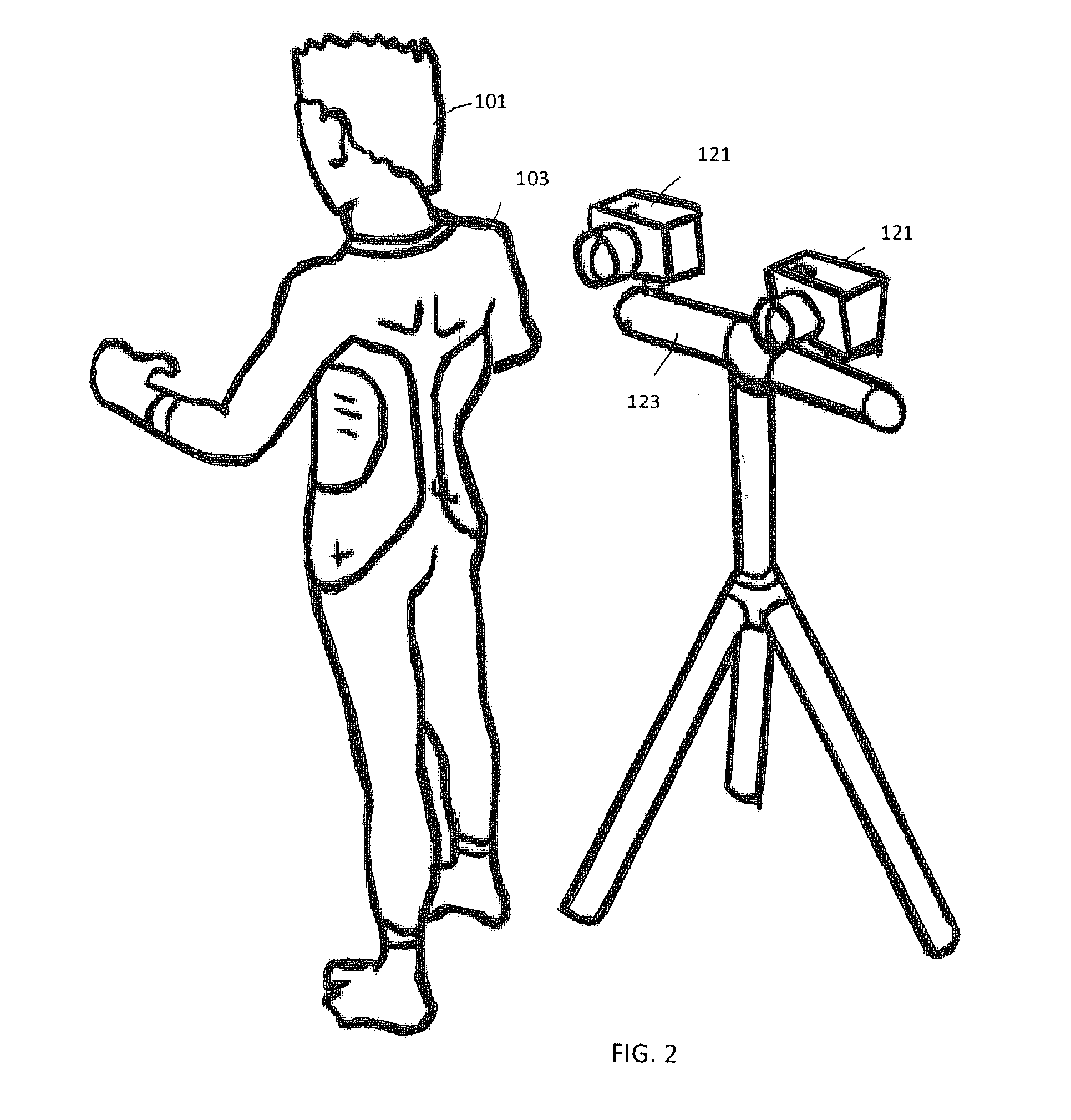

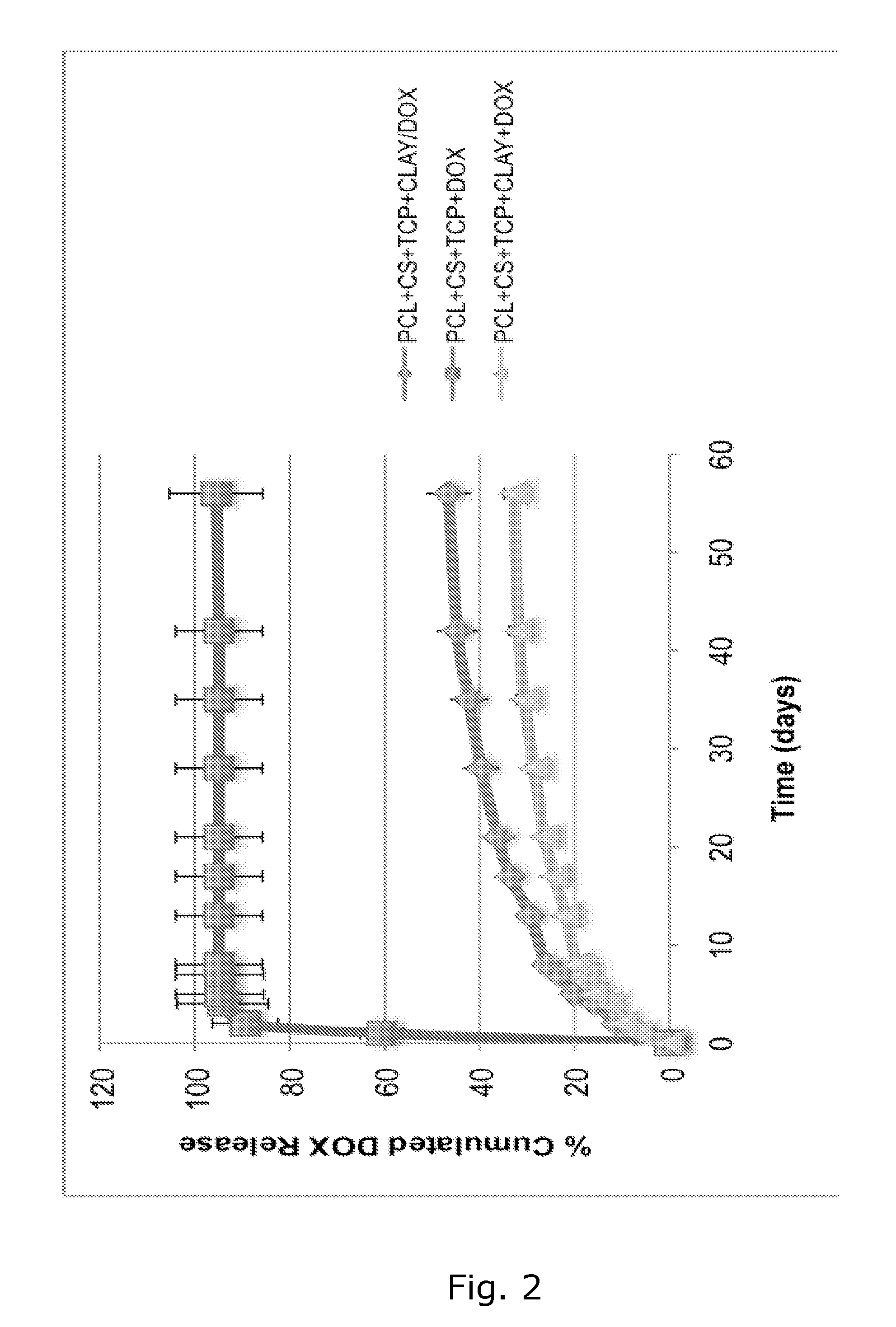

Modular custom braces, casts and devices and methods for designing and fabricating

ActiveUS20150328016A1Improve comfort and hygieneRapid prototypingOrthopedic corsetsComputer aided designModularityBiomedical engineering

Owner:3D SYST INC

Novel straw insulation board and preparation method thereof

ActiveCN103626433AFlame retardantWater resistantSolid waste managementKaolin clayProcess engineering

The invention discloses a novel straw insulation board, and the straw insulation board is prepared from the following raw materials in parts by weight: 40-80 parts of straw, 5-20 parts of epoxy glue, 1-10 parts of univalent dihydric phosphate powder, 3-20 parts of metallic oxide powder, 0.5-5 parts of borate powder, 3-6 parts of jade powder, 8-12 parts of pearlite, 5-10 parts of modified kaolin and 30-50 parts of water. The straw insulation board comprises a core material layer and a cladding layer, the core material layer is mainly prepared by press-forming the epoxy glue, the jade powder, the pearlite and the straw, the surface cladding layer is obtained by mainly uniformly cladding an inorganic cementing material with an adhesion effect on the surface layer of the straw board, and therefore, the novel straw insulation board using the straw as a board is obtained. The novel straw insulation board has excellent performances of fast forming, preserving heat and insulating, flame retarding, mould proofing and high strength, and has a clear market prospect whether being applied to the building field or other related fields in future.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

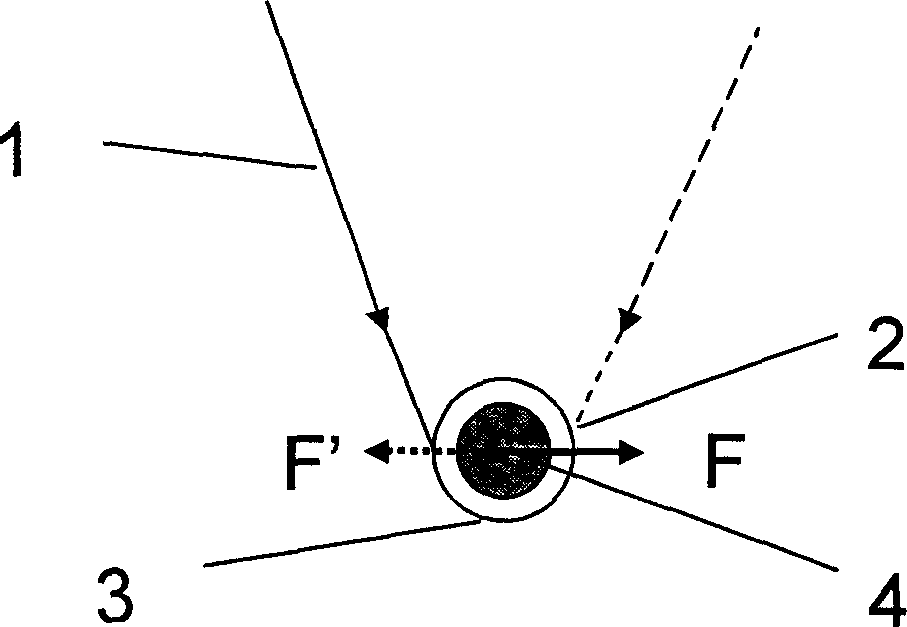

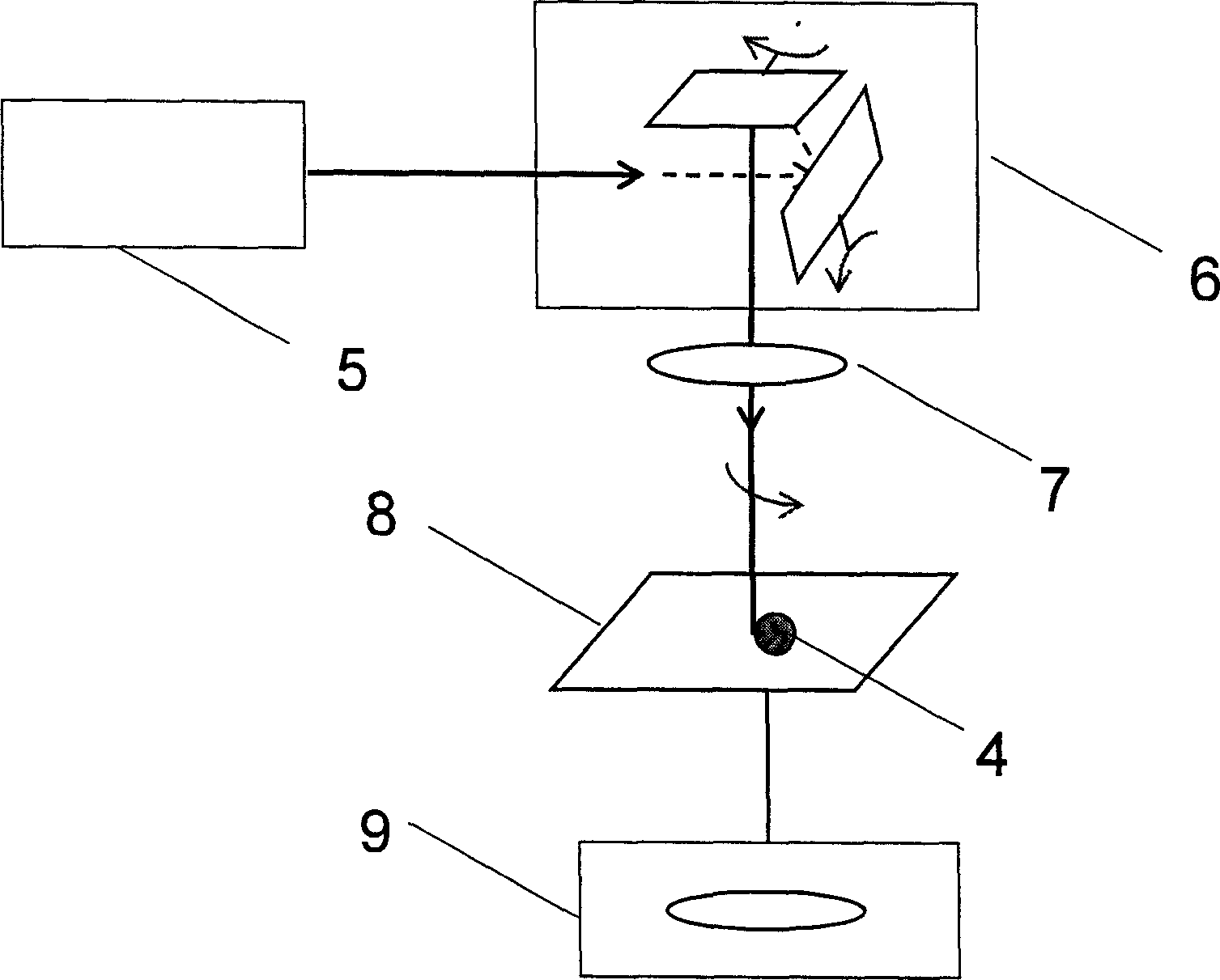

Laser cell microoperation control method and device for metal particle

InactiveCN1830752ADirect manipulationRapid prototypingTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLight beamOptoelectronics

A method for manipulating the laser tweezers of metallic micro-particles features that a 2D scanning polarizer system is used to control the circular scanning of laser beam around metallic micro-particles, and the action force of laser beam to each metallic micro-particle points to the curvature center of scanning trace, so gathering the metallic micro-particles in the center. Its apparatus is composed of laser device, focusing lens, 2D moving platform, microscopic observing system, and 2D scanning polarizer system.

Owner:BEIJING UNIV OF TECH

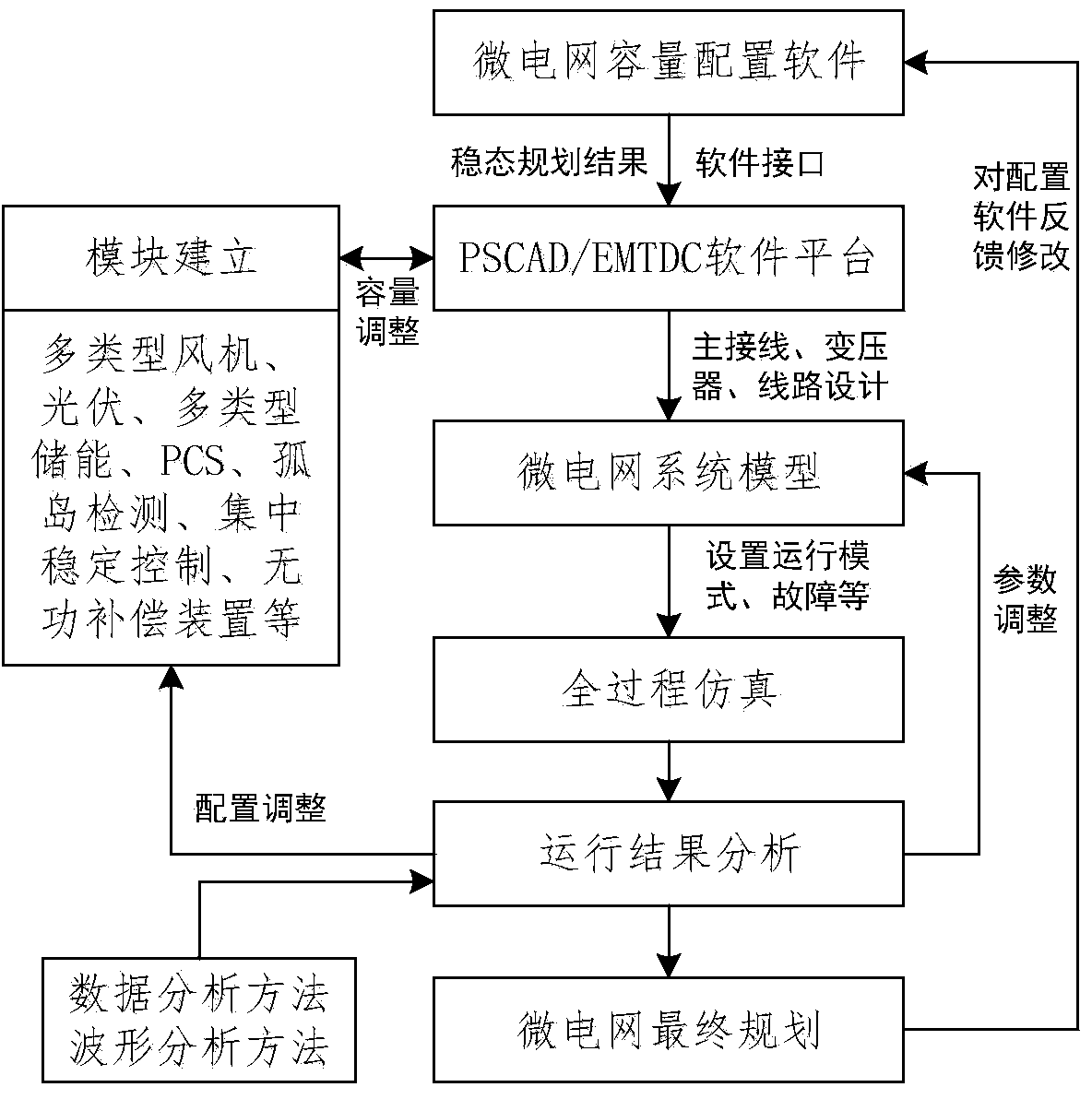

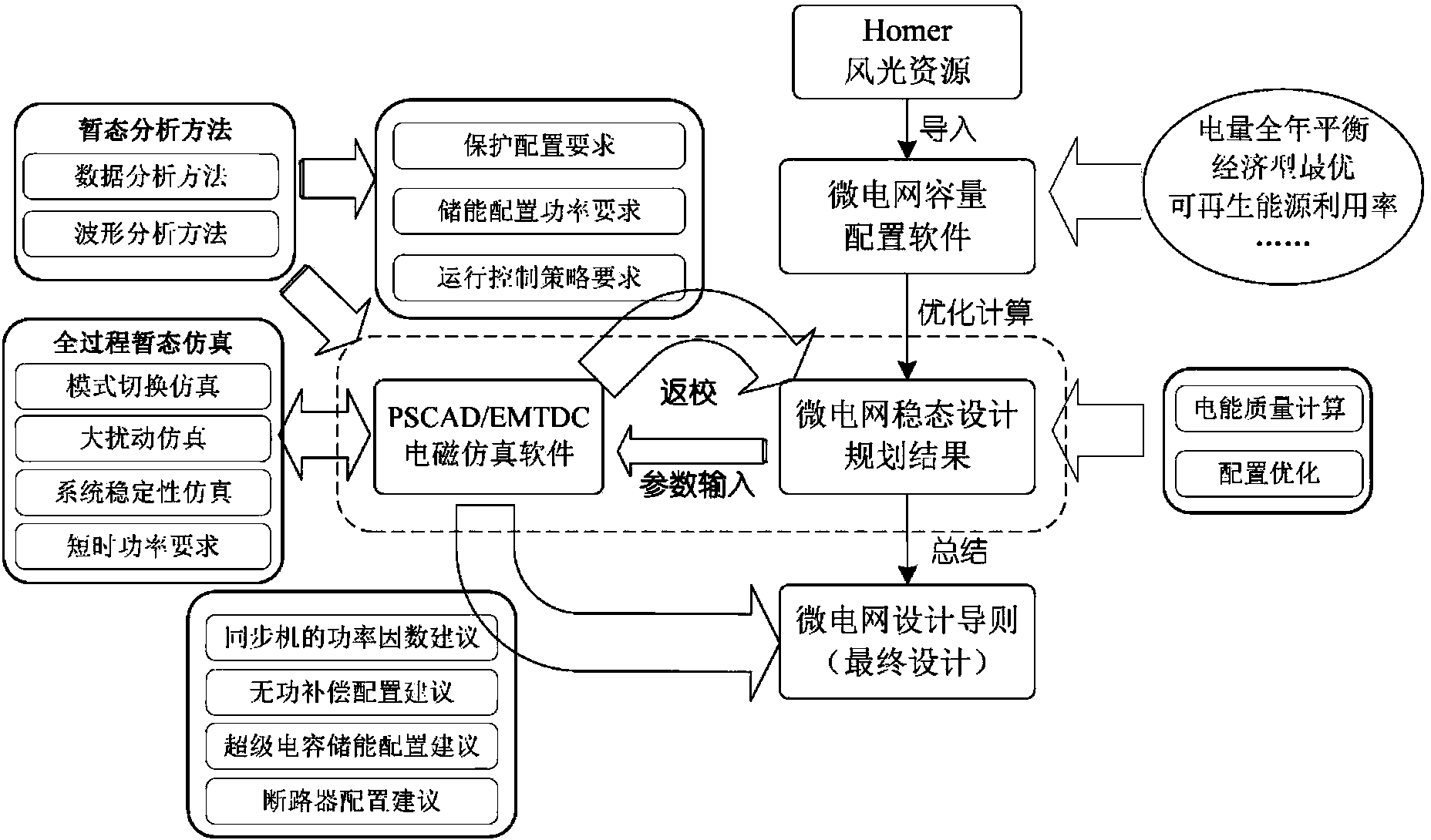

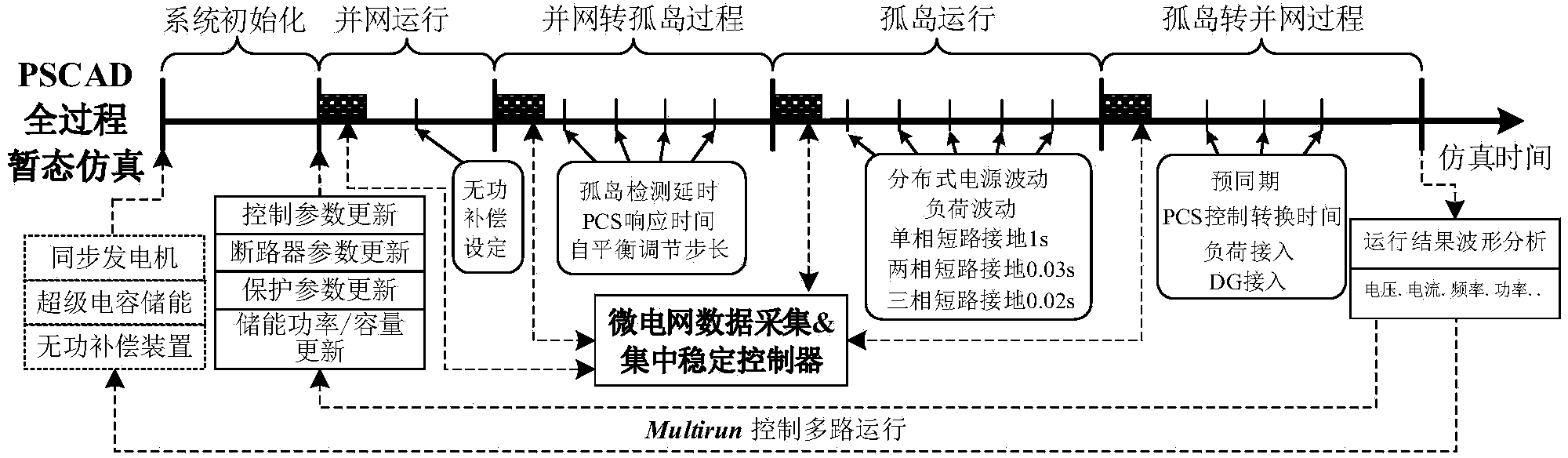

Whole process transient state simulation method supporting microgrid planning design

ActiveCN104268345AIncrease capacityOvercome limitationsSpecial data processing applicationsWaveform analysisPower systems computer aided design

The invention discloses a whole process transient state simulation method supporting a microgrid planning design. The whole process transient state simulation method supporting the microgrid planning design comprises the steps of building a microgrid model in PSCAD (Power System Computer Aided Design) or EMTDC (Electromagnetic Transients including DC) simulation software based on the planning result of the microgrid planning software, accomplishing microgrid transient state simulation in various working conditions through a microgrid whole process transient state simulation method, performing data analysis and waveform analysis of the simulation result through the whole process transient state simulation method, judging the microgrid running characteristics under the configuration and performing feedback compensation on a micro source capacity, putting forward an improvement program of the microgrim equipment configuration according to the analysis result and obtaining a reliable and stable microgrid planning result. According to the whole process transient state simulation method supporting the microgrid planning design, microgrid basic equipment is comprehensively taken into consideration, microgrid planning requirements in different conditions and working conditions can be met, and high adaptability can be obtained; feedback compensation supporting of the microgrid planning design from the perspect of microgrid transient state stability, limitation of an original microgrid planning method is solved and high practicability and project application values are obtained.

Owner:SOUTHEAST UNIV

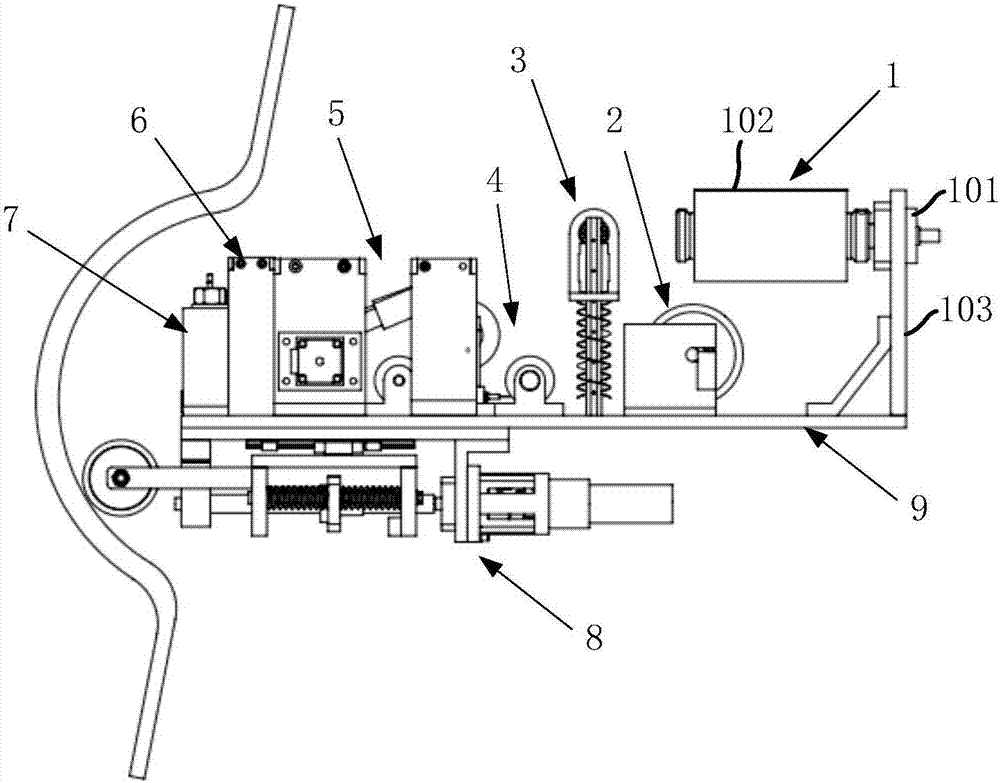

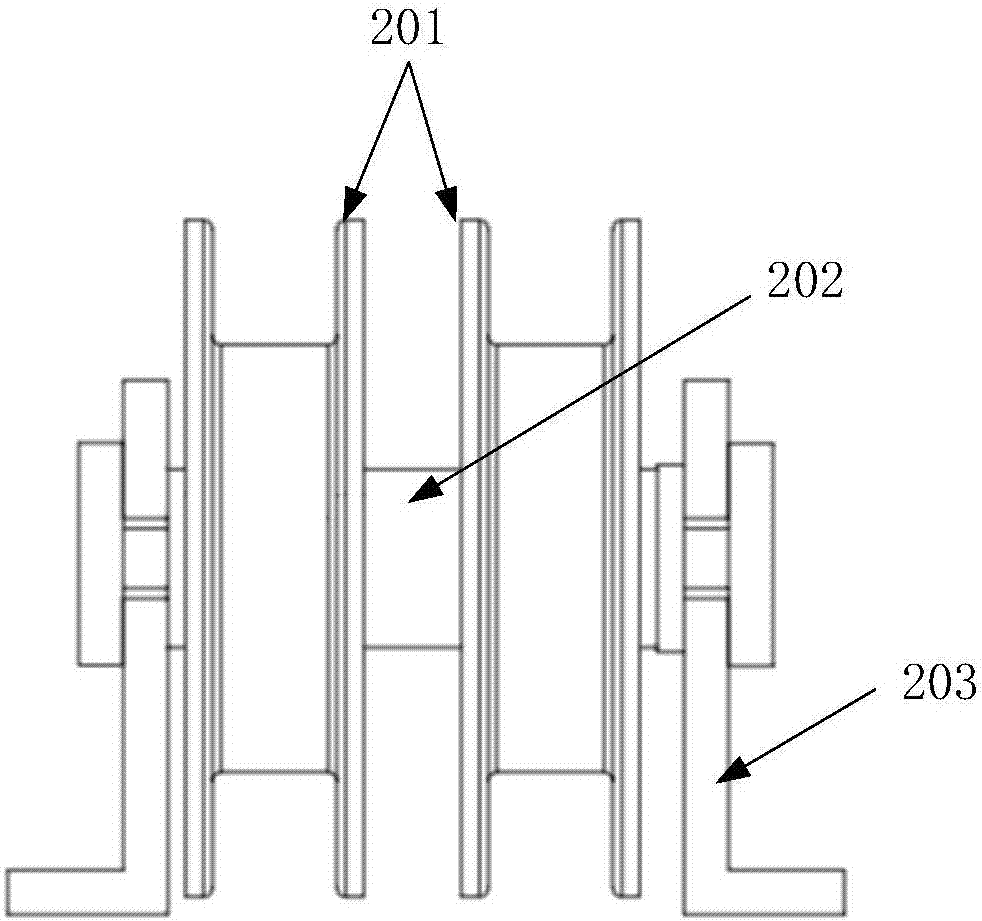

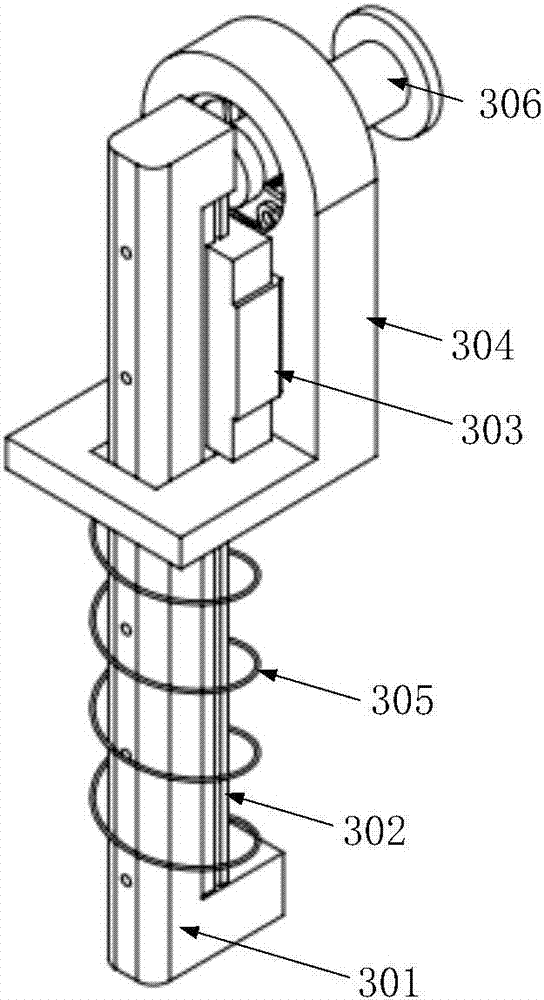

Carbon fiber integrated laying device

The invention discloses a carbon fiber integrated laying device. The device comprises a material supply unwinding mechanism, a guide mechanism, a tension adjusting mechanism, a tension measuring mechanism, a re-feeding mechanism, a clamping mechanism, a shear mechanism and a compaction mechanism located below the bottom plate, wherein the material supply unwinding mechanism, the guide mechanism, the tension adjusting mechanism, the tension measuring mechanism, the re-feeding mechanism, the clamping mechanism and the shear mechanism are located above the bottom plate. Fibers on the material supply unwinding mechanism pass through the re-feeding mechanism, the clamping mechanism and the shear mechanism and then are compacted and cured on the surface of a mold through the compaction mechanism, in the above transmission process, guidance through the guide mechanism is achieved, the fiber bundle tension is adjusted passively through the tension adjusting mechanism, and the fiber bundle tension is measured through the tension measuring mechanism. Through elastic force effect of a spring, the distance between a compaction roller of the compaction mechanism and the surface of the mold can be passively adjusted, and therefore the device can meet the mold laying requirements of different curve faces and control requirements of a monofilament bundle.

Owner:BEIHANG UNIV

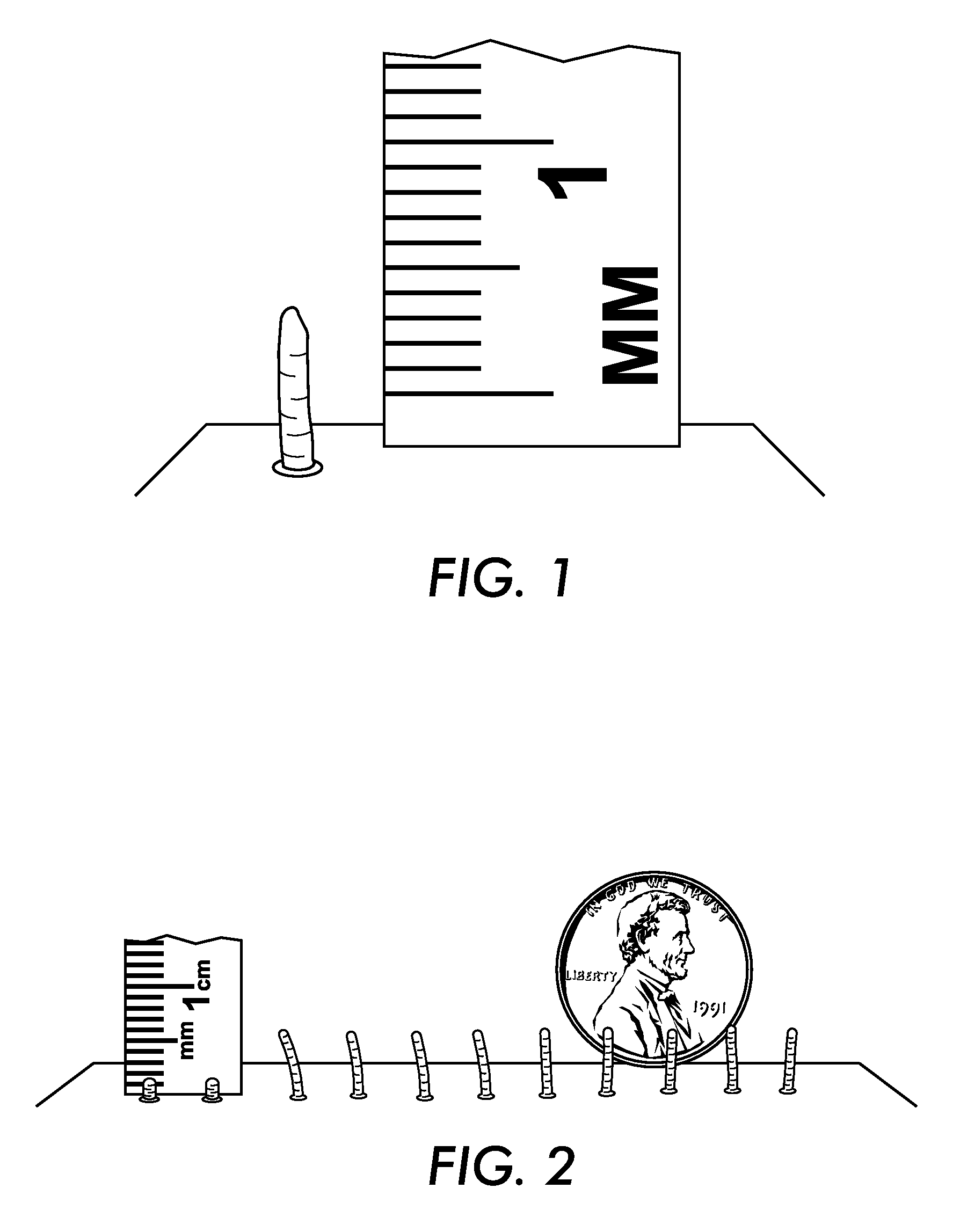

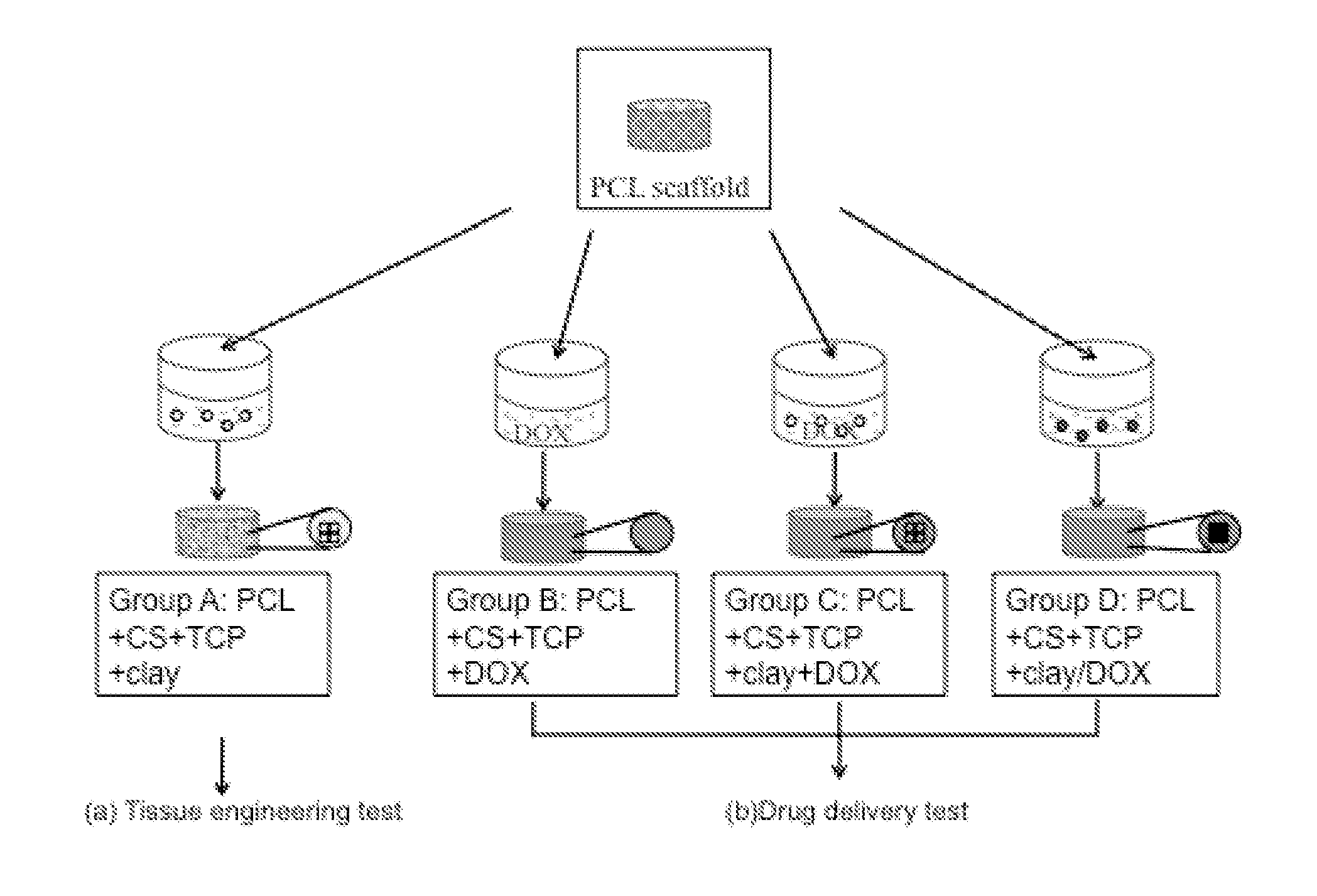

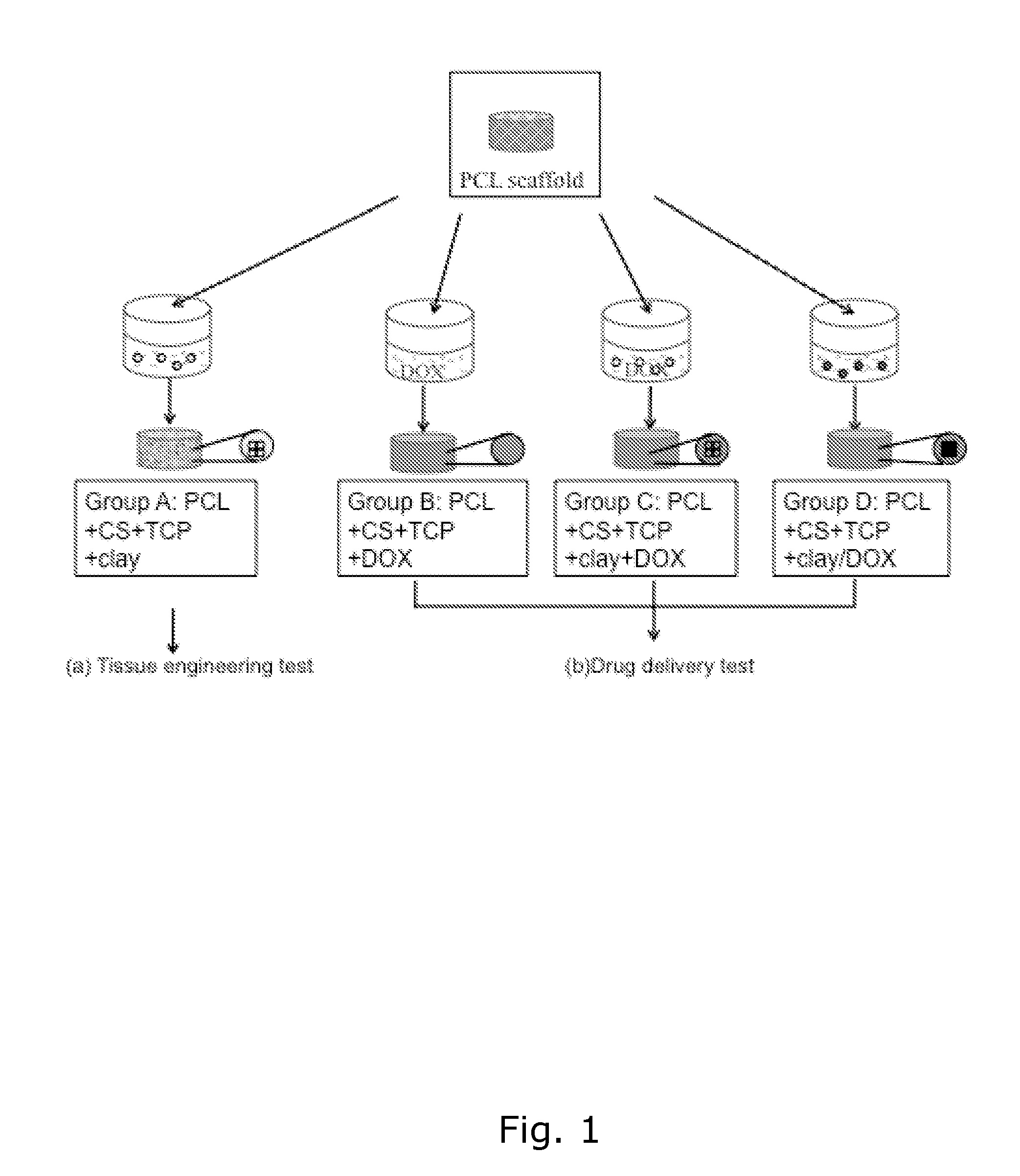

Tissue scaffold with controlled drug release

InactiveUS20130211543A1Promote tissue ingrowthSufficient supportTissue regenerationProsthesisControl releaseIon exchange

A three-dimensional hybrid scaffold capable of supporting cell activities such as growth and differentiation, and capable of controlled release of active pharmaceutical ingredients, characterized in that the scaffold comprises a first and a second biocompatible material, said first material shaped as a framework forming one or more open networks of voids, said second material comprising an ion exchange material, said ion exchange material being loaded with one or more active pharmaceutical ingredients.

Owner:NYGAARD JENS VINGE +5

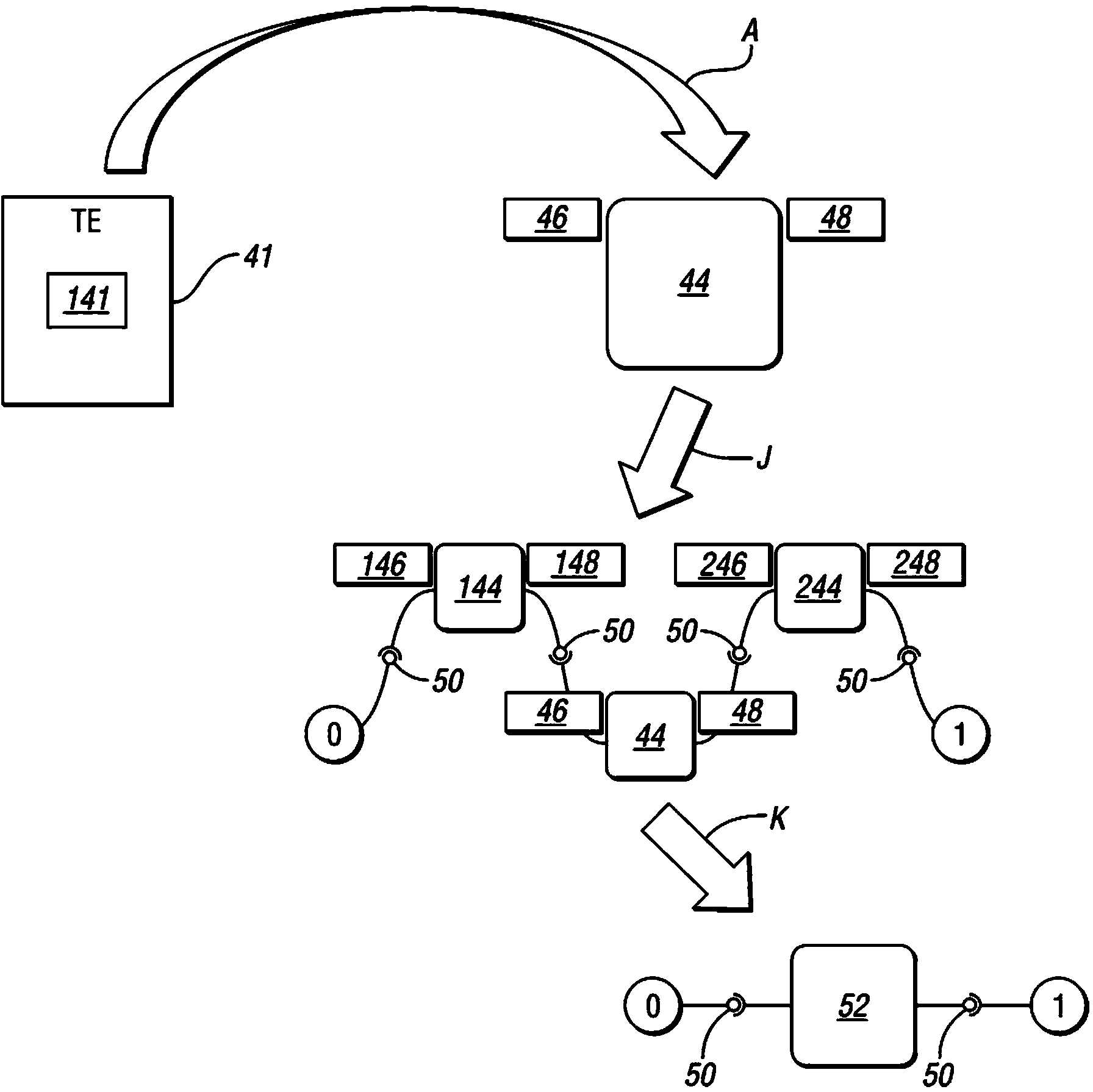

Surface patch techniques for computational geometry

InactiveUS20140354639A1Computationally efficientImprove computing efficiencyGeometric CADConstraint-based CADComputer Aided DesignAnimation

A method and system for computer aided design (CAD) is disclosed for designing geometric objects, wherein interpolation and / or blending between such objects is performed while deformation data is being input. Thus, a designer obtains immediate feedback to input modifications without separately entering a command(s) for performing such deformations. A novel N-sided surface generation technique is also disclosed herein to efficiently and accurately convert surfaces of high polynomial degree into a collection of lower degree surfaces. E.g., the N-sided surface generation technique disclosed herein subdivides parameter space objects (e.g., polygons) of seven or more sides into a collection of subpolygons, wherein each subpolygon has a reduced number of sides. More particularly, each subpolygon has 3 or 4 sides. The present disclosure is particularly useful for designing the shape of surfaces. Thus, the present disclosure is applicable to various design domains such as the design of, e.g., bottles, vehicles, and watercraft. Additionally, the present disclosure provides for efficient animation via repeatedly modifying surfaces of an animated object such as a representation of a face.

Owner:CAD-SENSE LLC

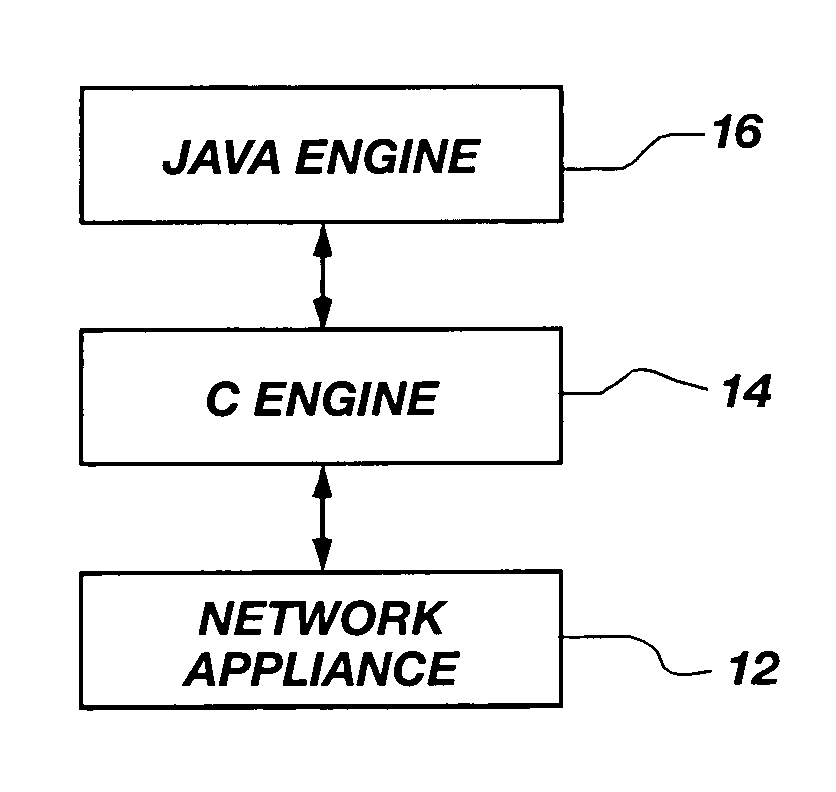

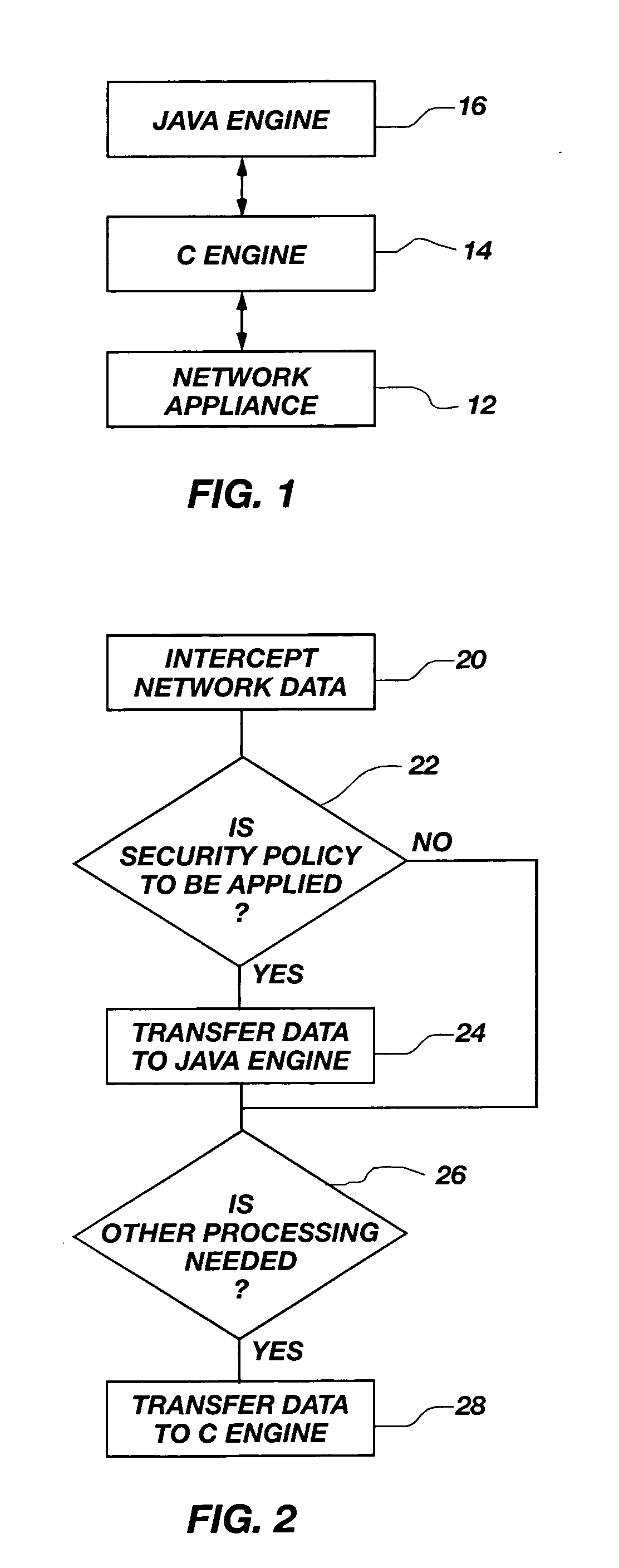

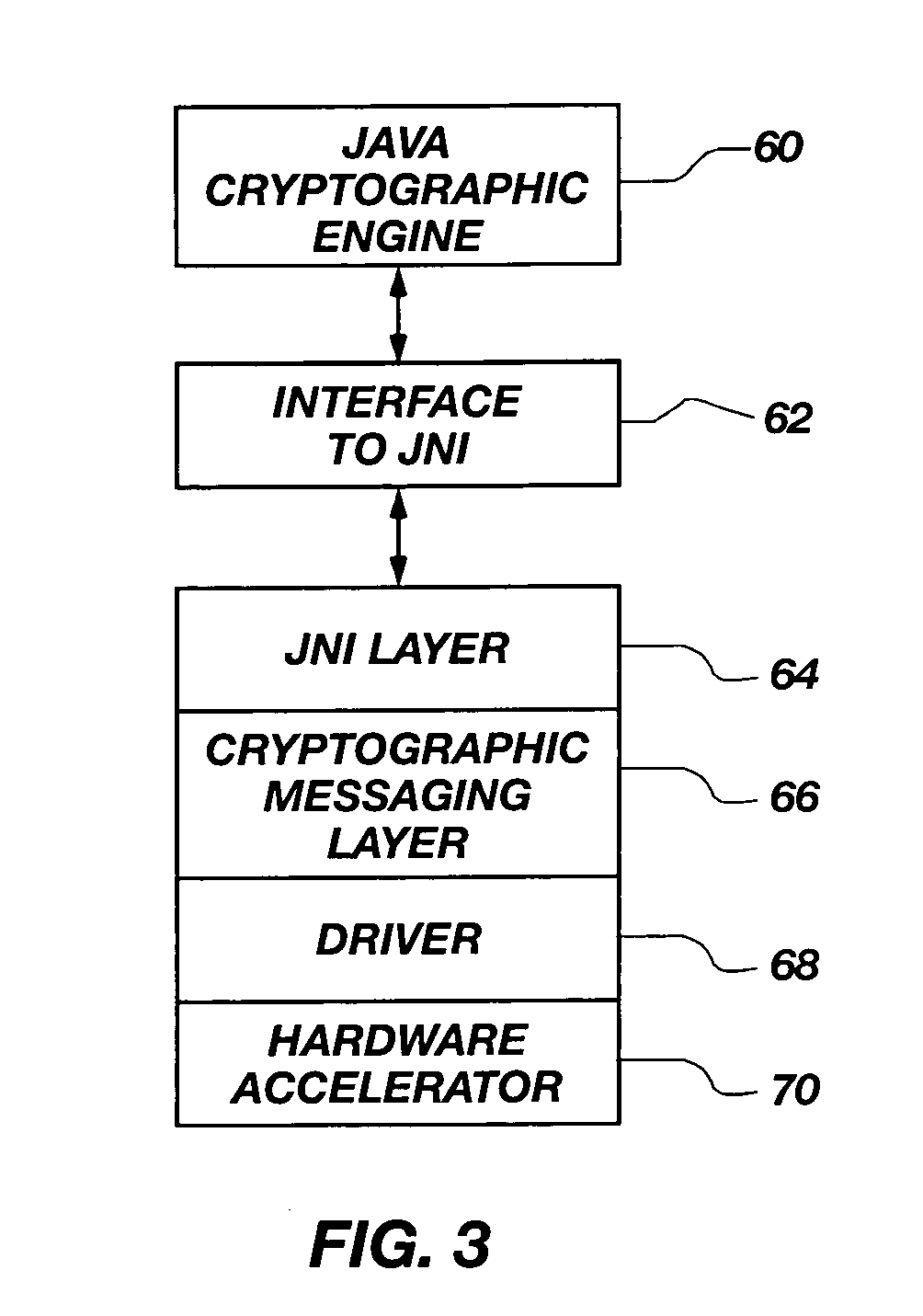

Hybrid Java-C network appliance

InactiveUS20050132210A1Quick updateReduce edgeUnauthorized memory use protectionHardware monitoringXML EncryptionIntegrated software

A network appliance that runs both C and Java integrated software to provide a flexible architecture for rapid prototyping of XML security functionality, including SSL acceleration, XML encryption, XML decryption, XML signature, and XML verification, while the network appliance continues to provide high-speed performance.

Owner:YUNIS MAMOON +2

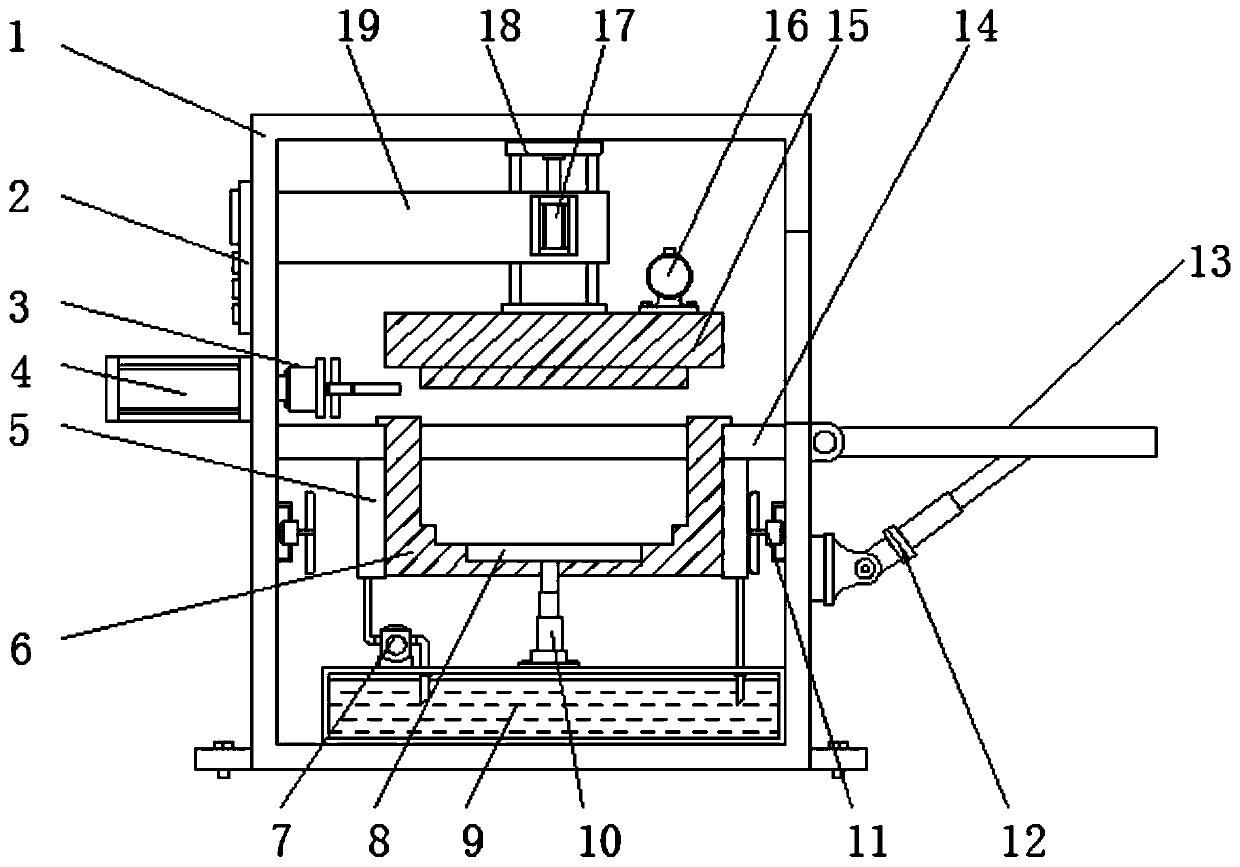

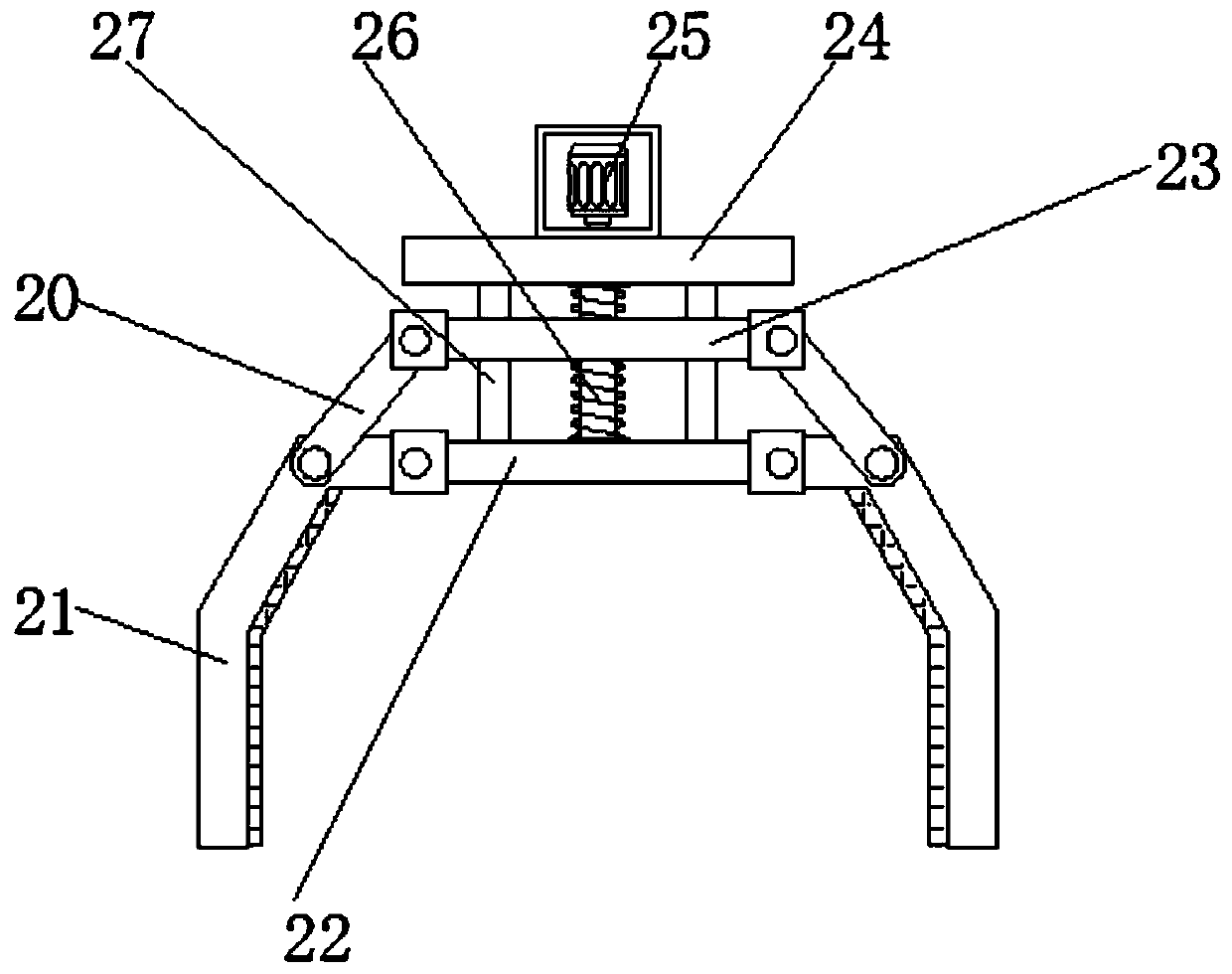

Rapid forming machining die used for machining aluminum part

The invention discloses a rapid forming machining die used for machining an aluminum part. The rapid forming machining die comprises an outer shell, a vibrating motor and a servo motor. A supporting arm is arranged on one side in the shell. An upper die is movably arranged at the bottom end of the supporting arm. The vibrating motor is installed on one side of the top end of the upper die. A partition plate is arranged below the upper die. A lower die is arranged at the top end of the partition plate. A first water cooling fin and a second water cooling fin are arranged on the two sides of thelower die correspondingly. A water tank is arranged at the bottom end in the outer shell. A water pump is installed on one side of the top end of the water tank. A first electric telescopic rod is installed in the middle of the top end of the water tank, and extends into the lower die, and a top plate is arranged in the middle of the top end of the water tank. A first air cylinder is arranged onone side of the outer shell. The output end of the first air cylinder extends into the outer shell and is provided with a mechanical grabbing hand. A controller is installed on one side of the outer shell. The rapid forming machining die facilitates rapid forming and demolding of the aluminum part, the working efficiency is improved, and the rapid forming machining die is easy to use and popularize.

Owner:NANTONG ZHONGHUI MOLD CO LTD

Manufacturing method of edible printing ink for ink jet printing and using method thereof

The invention provides a preparation method and application method of edible ink for inkjet printing. This ink can form printed records with good identification and certain water resistance on the surface of various foods (including tablets), food contact materials, food packaging materials, etc. The raw materials of this inkjet ink are approved food additives, including shellac, cellulose resin, ethanol, water and so on. The manufacture method of this ink-jet ink is: a, food coloring is dispersed or dissolved in the aqueous solution that contains cellulose resin to make color base dispersion, contains the water more than 50wt% in this dispersion; B, shellac Dissolve in dehydrated alcohol and make shellac solution, contain the dehydrated alcohol more than 50wt% in this shellac solution; c, color paste dispersion is dispersed in shellac solution again, add a certain amount of conductive salt sodium lactate, pH Regulator ammonium carbonate, humectant, emulsifier, defoamer, etc.; d, filter filling.

Owner:HUBEI KEYIHUA SANDT CO LTD

Highly-elastic non-supported environmentally-friendly gel mask and preparation method thereof

ActiveCN103520070AModerate viscosityIncrease elasticityCosmetic preparationsToilet preparationsCross-linkReaction temperature

The invention relates to a highly-elastic non-supported environmentally-friendly gel mask and a preparation method thereof. The gel mask is formed by dissolving an olefin monomer M1, a biological polymer M2, a chemical cross-linking agent M3, a physical cross-linking agent M4, plant extract essential oil, whitening components and anti-ageing active components in water, and polymerizing. The preparation method comprises the following steps: 1, preparing aqueous solutions of the M1, M2, M3 and M4; 2, preparing an essence liquid; 3, mixing to prepare a prepolymer liquid; 4, preparing the gel mask; and 5, packaging the gel mask. The gel mask prepared through the method has the advantages of moderate viscosity, good elasticity, good ductility and toughness, no need of the application of a non-woven fabric to improve the mechanic strength, carrying convenience, adjustable thickness, and repeatable use, and allows the viscoelasticity, the skin endophilicity and the moisture retention performance of the mask to be adjusted by adjusting the monomer concentration, the feeding ratio, the whitening and anti-ageing active components, the reaction temperature, the water content and the feeding sequence. The gel mask can be used in the fields of skin care, moisture retention, beauty treatment, anti-ageing and the like.

Owner:上海宜侬生物科技有限公司

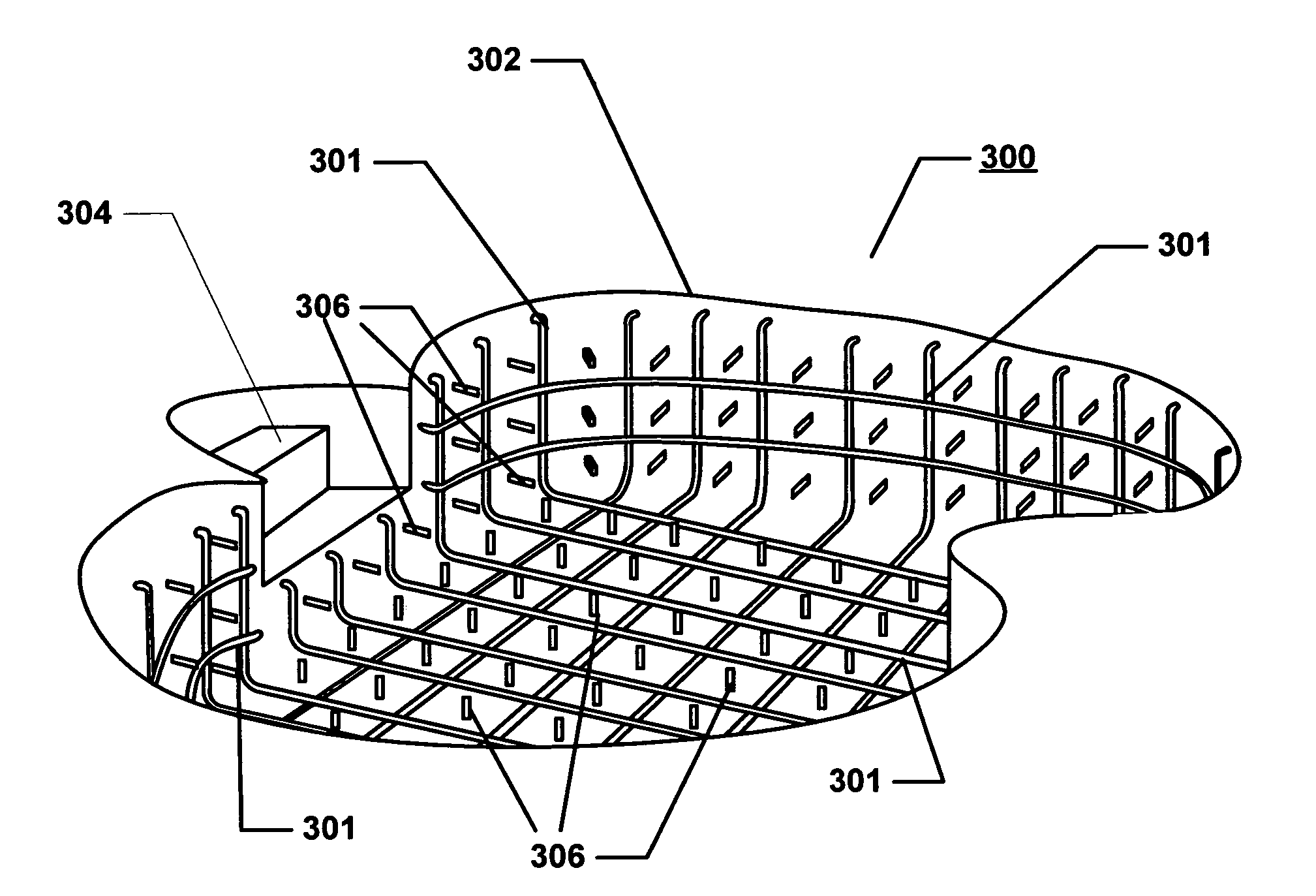

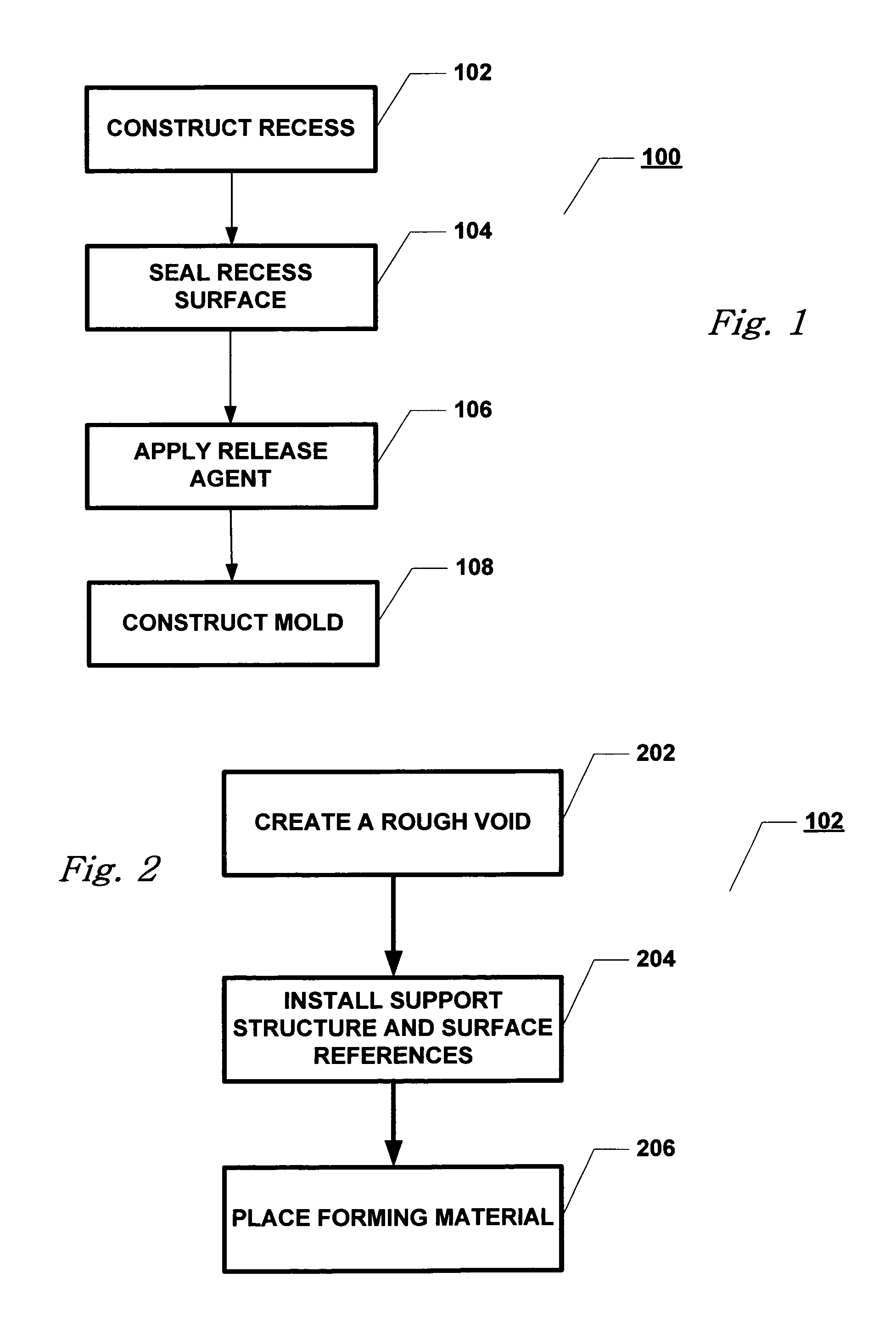

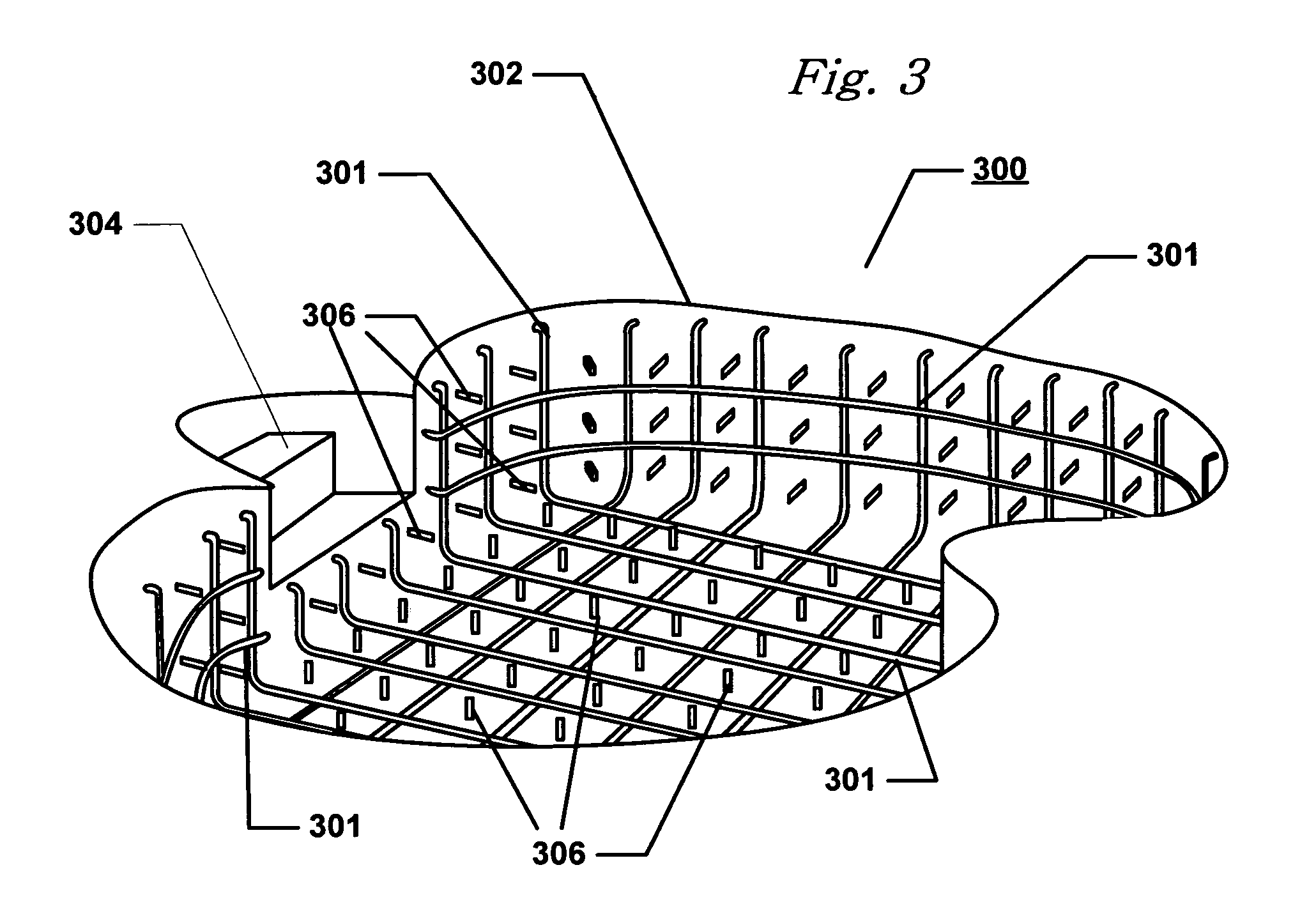

Method of rapid mold development for swimming pools, spas and ponds

InactiveUS7311867B1Low costEasy maintenanceMouldsCeramic shaping liningsThermal expansionHeat transfer coefficient

A method for fabricating a pool mold comprising the steps of creating a recess, the recess having the general shape and contour of the desired finished pool and is installed with support materials and surface references. A layer of forming material is place over the support materials and surface references and formed to desired contour and grade. The forming material has substantially uniform coefficients of thermal expansion and heat transfer. The surface of the recess is sealed and coated with a release agent. A mold is then fabricated within the recess.

Owner:LATHAM POOL PROD

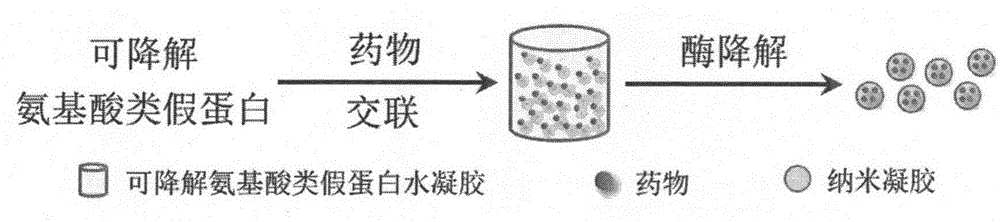

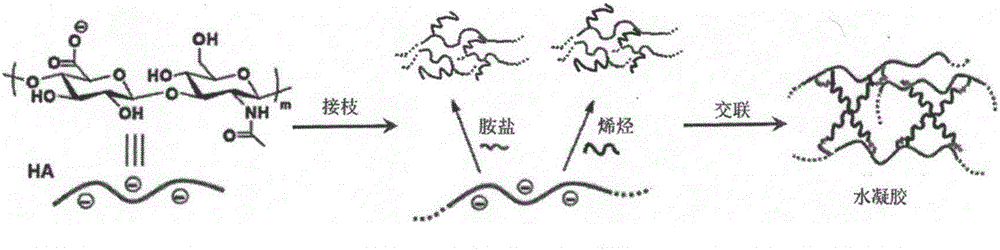

Drug-loaded hyaluronic acid nanofiber composite dressing and preparation method thereof

InactiveCN105816903AWide variety of sourcesGood biocompatibilityAbsorbent padsBandagesFiberBiocompatibility Testing

The invention discloses a drug-loaded hyaluronic acid / nano fiber composite dressing and a preparation method thereof. The composite dressing comprises a hydrogel layer and a nanofiber layer formed by cross-linking hyaluronic acid macromers compounded with each other, and the drug-loaded nanogel is loaded in the hydrogel layer. The preparation method includes preparation of drug-loaded nanogel; synthesis of photo-crosslinkable or chemically crosslinkable monomers of hyaluronic acid macromolecules; The hyaluronic acid-based hydrogel is prepared; the hyaluronic acid-based hydrogel is combined with the nanofiber membrane to obtain a drug-loaded hyaluronic acid / nanofiber composite dressing. The raw materials used in the present invention have good biocompatibility. By combining two different structures of hydrogel and nanofiber, the wound exudate can be absorbed and diverted, and the overall stability of the dressing can be improved at the same time, which has long-acting antibacterial properties. , Anti-protein adsorption, anti-fouling, heat insulation and other functions.

Owner:DONGHUA UNIV

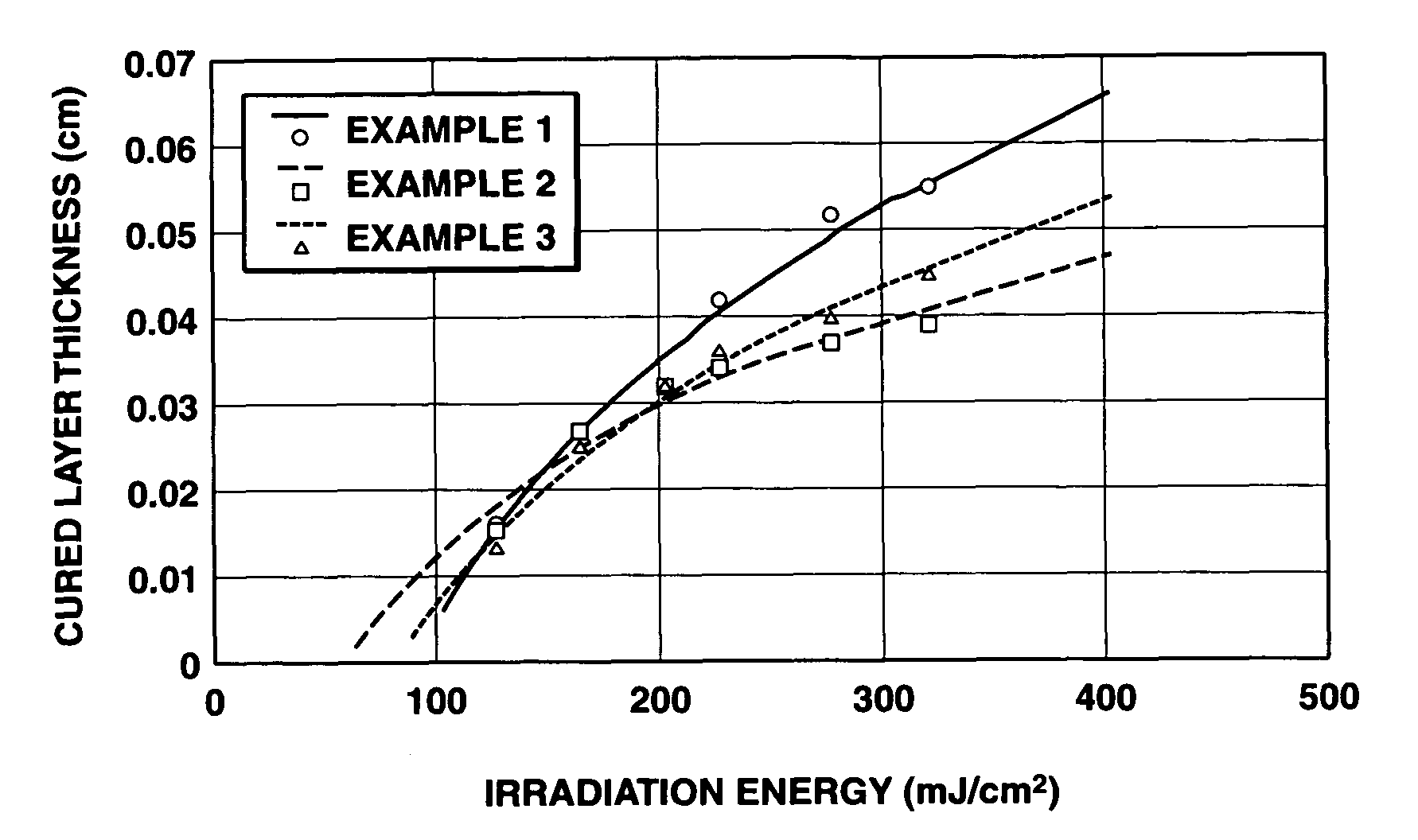

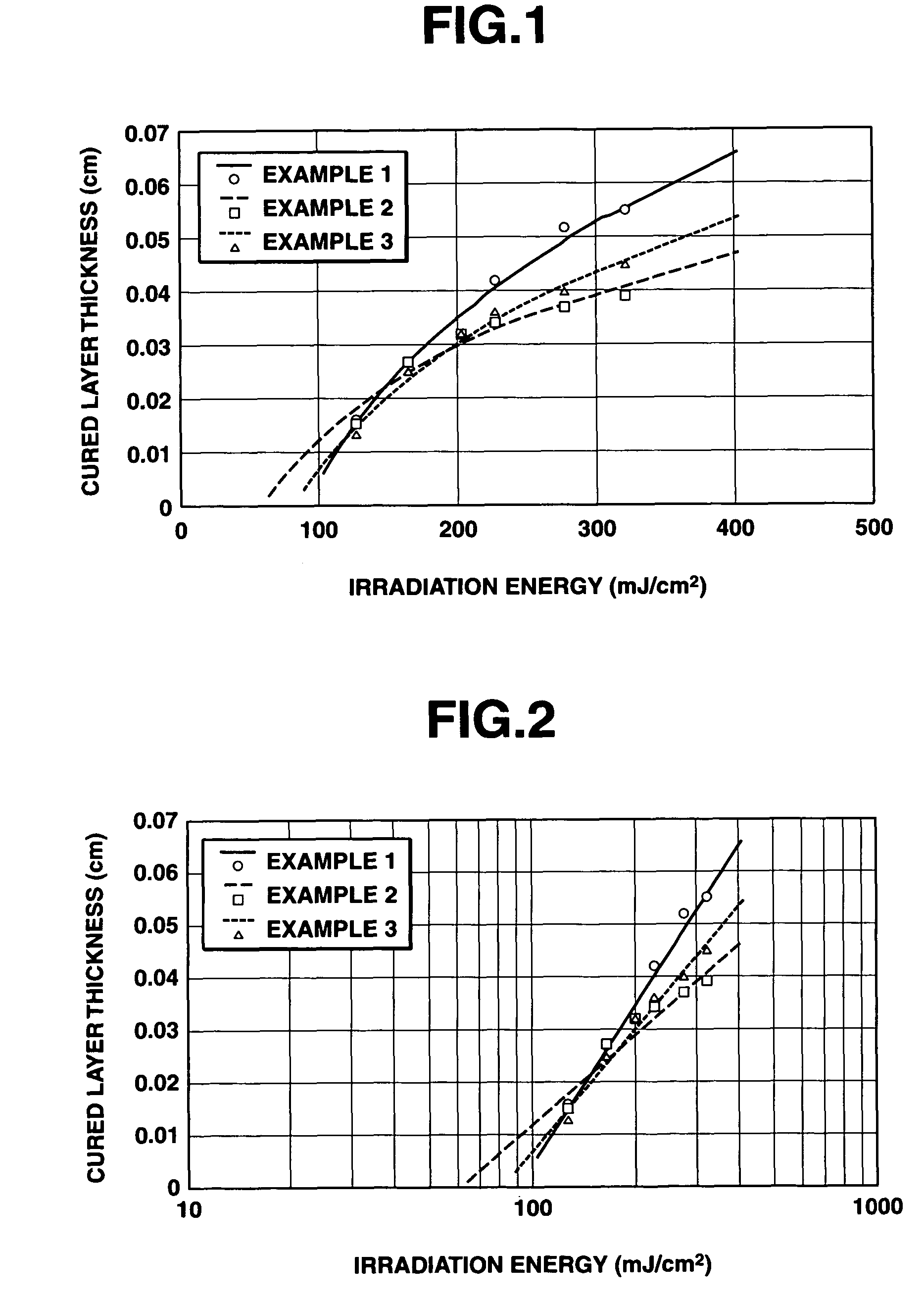

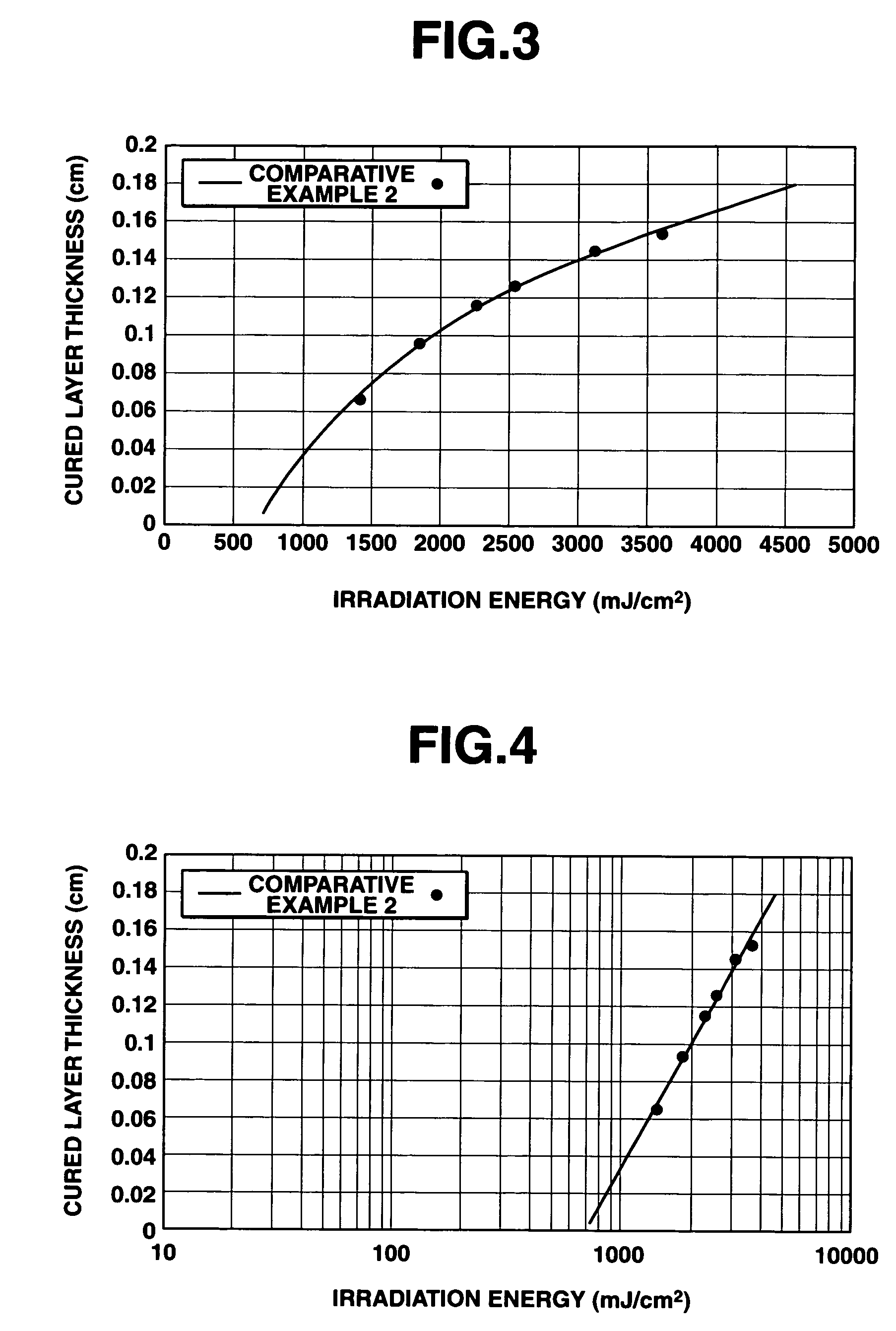

Rapid prototyping resin compositions

ActiveUS8293810B2Improve stabilityLittle viscosity buildupAdditive manufacturing apparatusFibre treatmentPolymer scienceStereolithographies

A resin composition suited for rapid prototyping is provided comprising (I) an actinic energy radiation-curable silicone composition, (II) an actinic energy radiation-sensitive polymerization initiator, and (III) an actinic energy radiation absorber. The resin composition experiences little viscosity buildup and maintains fluidity during long-term storage at elevated temperature, and is effective in rapid prototyping or shaping by stereolithography using any actinic energy radiation.

Owner:CMET +1

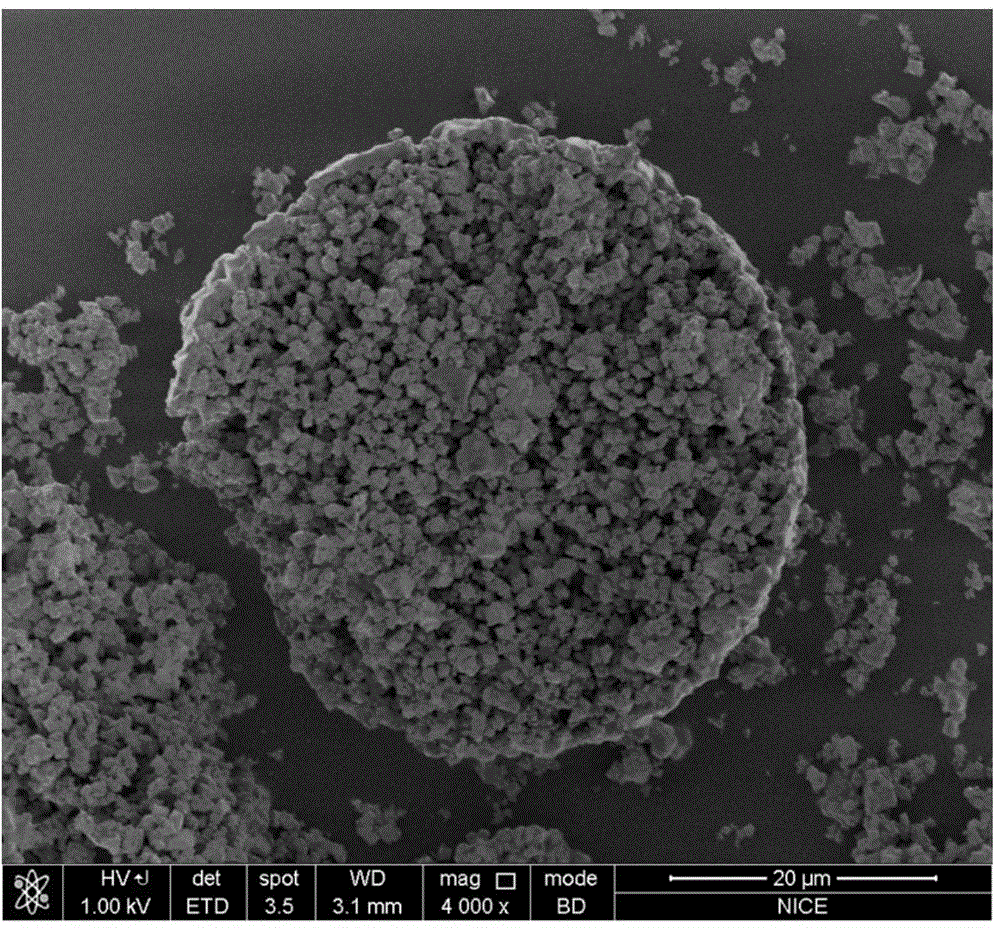

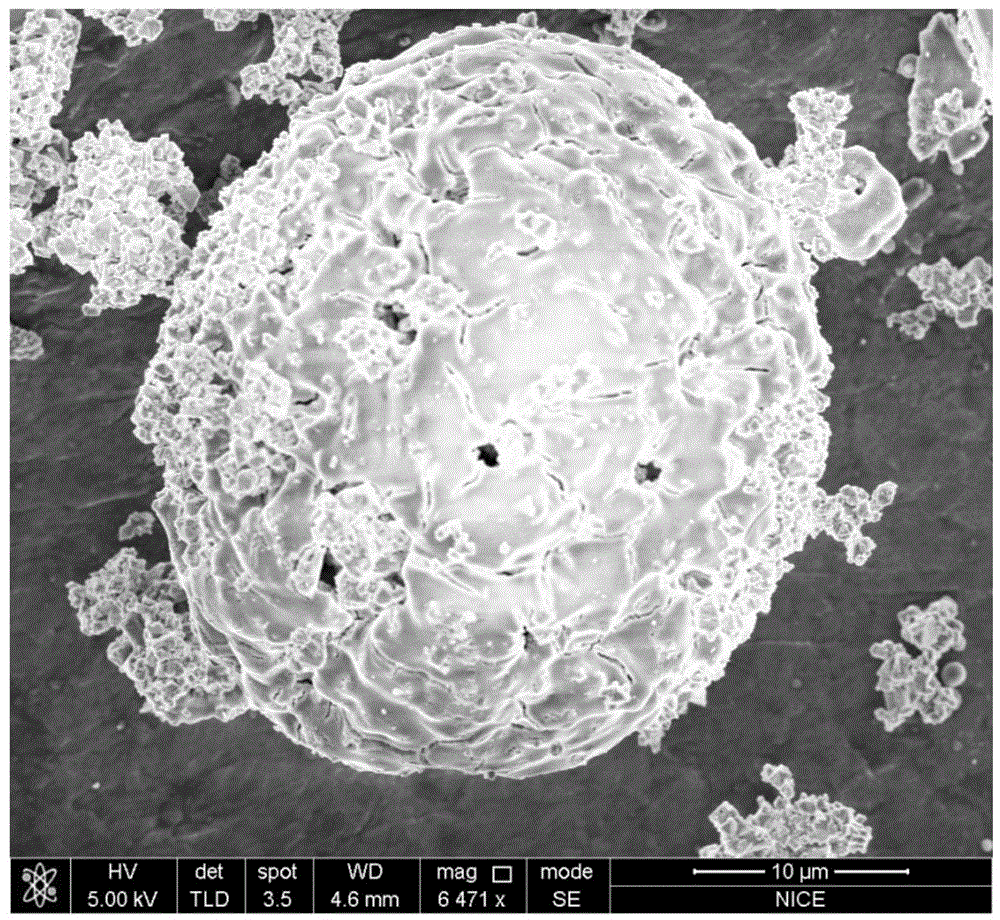

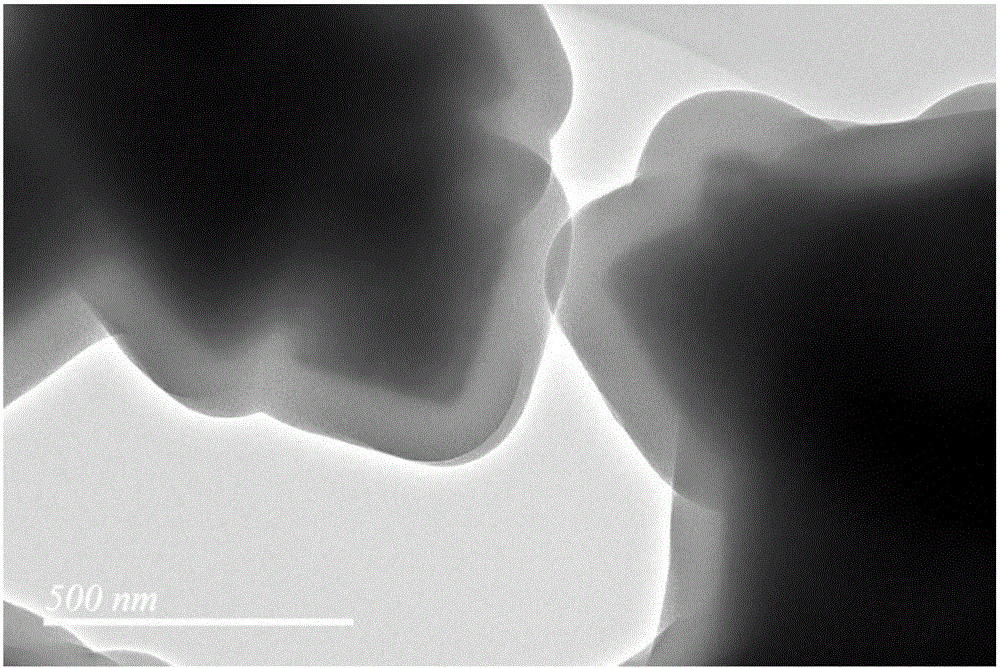

Composite magnetic micro-sphere and method for preparing same

ActiveCN105749824AEase of rapid prototypingEasy industrial scale-upInorganic material magnetismMicroballoon preparationChemical industryIndustrial scale

The invention relates to a composite magnetic micro-sphere and a method for preparing the same, in particular to a composite magnetic micro-sphere with permanent magnetism and coated core-shell structures and a method for preparing the composite magnetic micro-sphere.The composite magnetic micro-sphere and the method have the advantages that the composite magnetic micro-sphere is easy to quickly form, industrial scale-up can be facilitated, and technological processes are short and are high in yield; the composite magnetic micro-sphere has large particles and is excellent in sphericity degree and coating rate and high in specific saturation magnetization; the composite magnetic micro-sphere is applicable to the fields of catalysis, chemical separation, modern coal, petroleum and natural gas chemical industry and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Production method of optical fiber distribution box

InactiveCN105929498ARapid prototypingShort processFibre mechanical structuresEngineeringRapid prototyping

The invention discloses a production method of an optical fiber distribution box and belongs to the optical cable tool technical field. The production method includes the following steps of: step one, material selection; step two: material cutting; step three, punching; step four, polishing: the front surfaces and back surfaces of plates in the step three are polished, and the plates are cleared after polishing; step five, bending: lines are drawn at bending portions according to bending machining, and bending slits are cut at the portions where the lines are drawn through a cutting machine, and then, the plates are bent into a box body through a bending machine; step six, welding; step seven, strength test: the welded box body is arranged on a strength testing machine so as to be subjected to pressure testing, and whether welding joints and the plates satisfy requirements is judged through measurement, if the welding joints and the plates are unqualified, re-machining is carried out, when the welding joints and the plates are qualified, the method enters a welding joint treatment step; step eight, welding joint treatment; step nine, surface treatment; step ten, paint spraying; and step eleven, check and packaging. The method of the invention has the advantages of convenience in rapid shaping, high strength, convenient use, convenient and simple operation, and simple and fast process, and can improve the quality of products.

Owner:HENAN HAOFANG COMM ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com