Patents

Literature

800results about How to "Remove in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

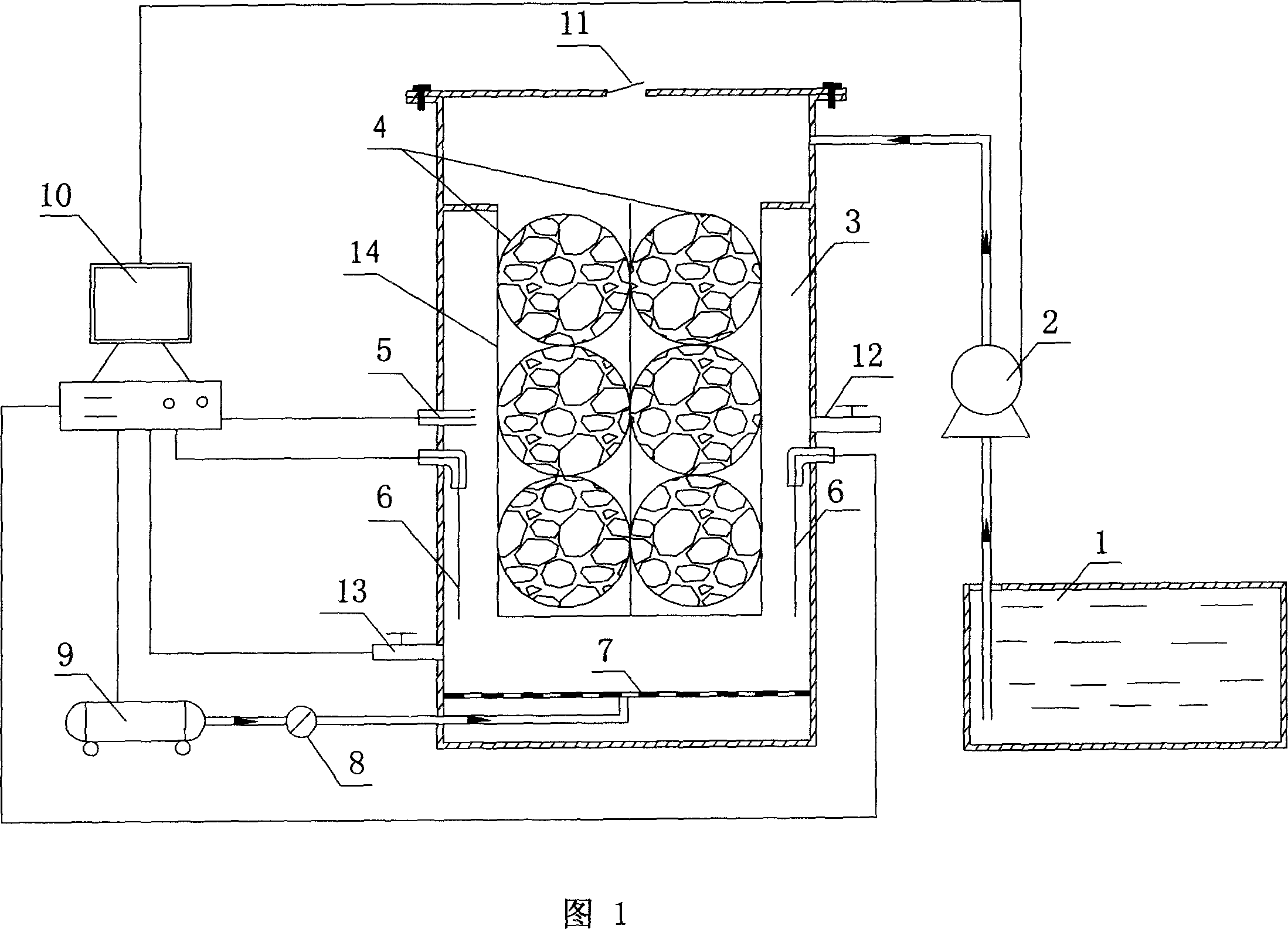

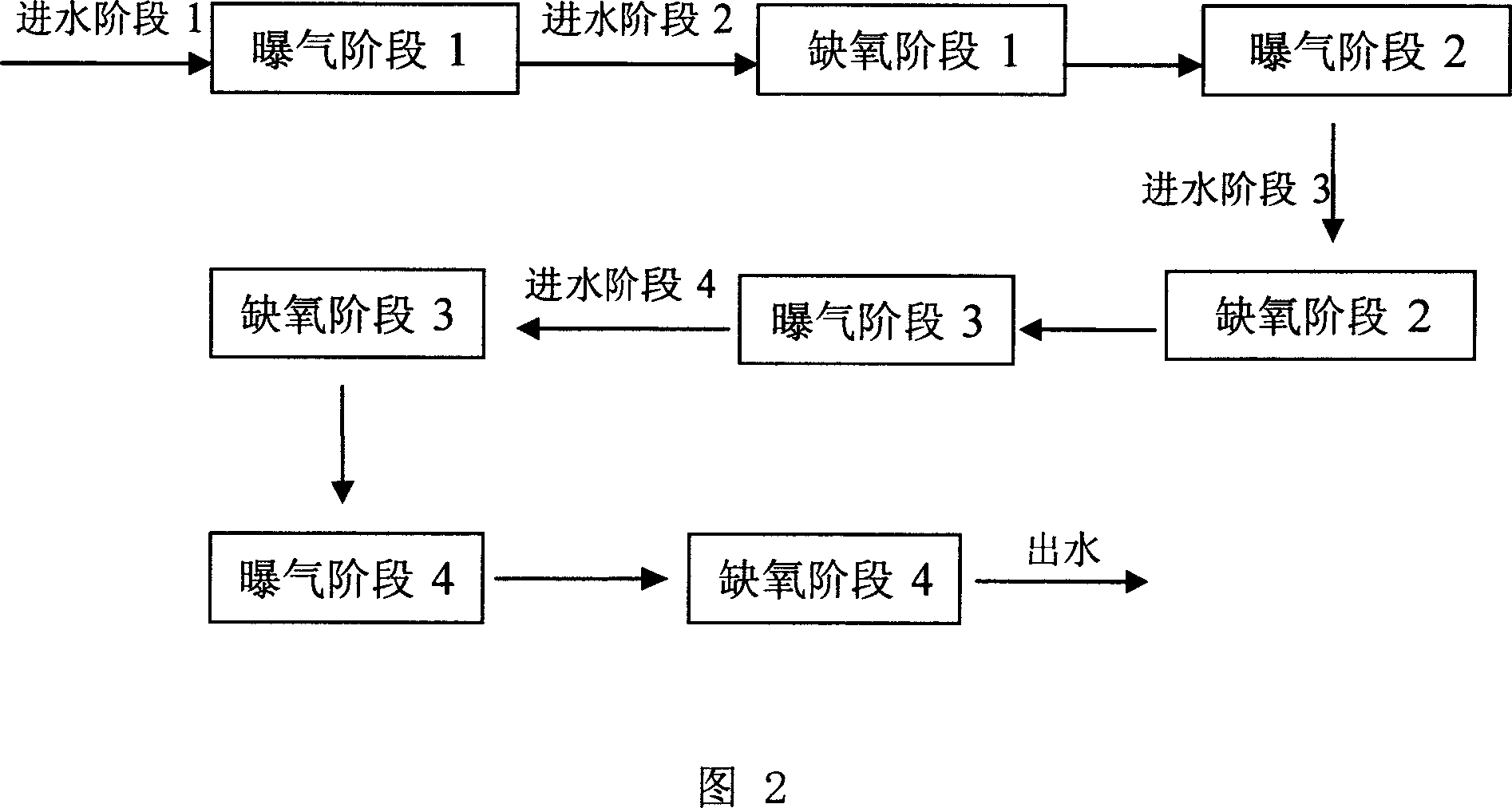

Operation mode and apparatus of short distance nitration-anaerobic ammoxidation batched biomembrane denitrogenation

InactiveCN1927739AToxic reductionControl the maximum cumulative concentrationTreatment with aerobic and anaerobic processesSludgeElectron donor

One kind of short range nitrifying-anaerobic aminoxidizing sequencing batch type denitrifying biomembrane mode and plant is disclosed. The limited aerating mode with real-time control of the sewage temperature inside the reactor and high frequency alternation between aeration and anaeration can inhibit the growth of nitrite oxidizing bacteria and denitrifying bacteria so that the aminoxidizing bacteria and the anaerobic aminoxidizing bacteria become the dominant bacteria in the nitrifying and denitrifying stages. In the nitrifying stage, nitrification is stopped in the nitrite step; and in the denitrifying stage, ammonia nitrogen acts as the direct electron donor to reduce nitrite. The plant is provided with fixed spherical composite stuffing with spherical shell of polypropylene and filled inside biological composite material. Sectional discrete water feeding mode is adopted to feed the sewage to be treated in four stages into the reactor.

Owner:HUNAN UNIV

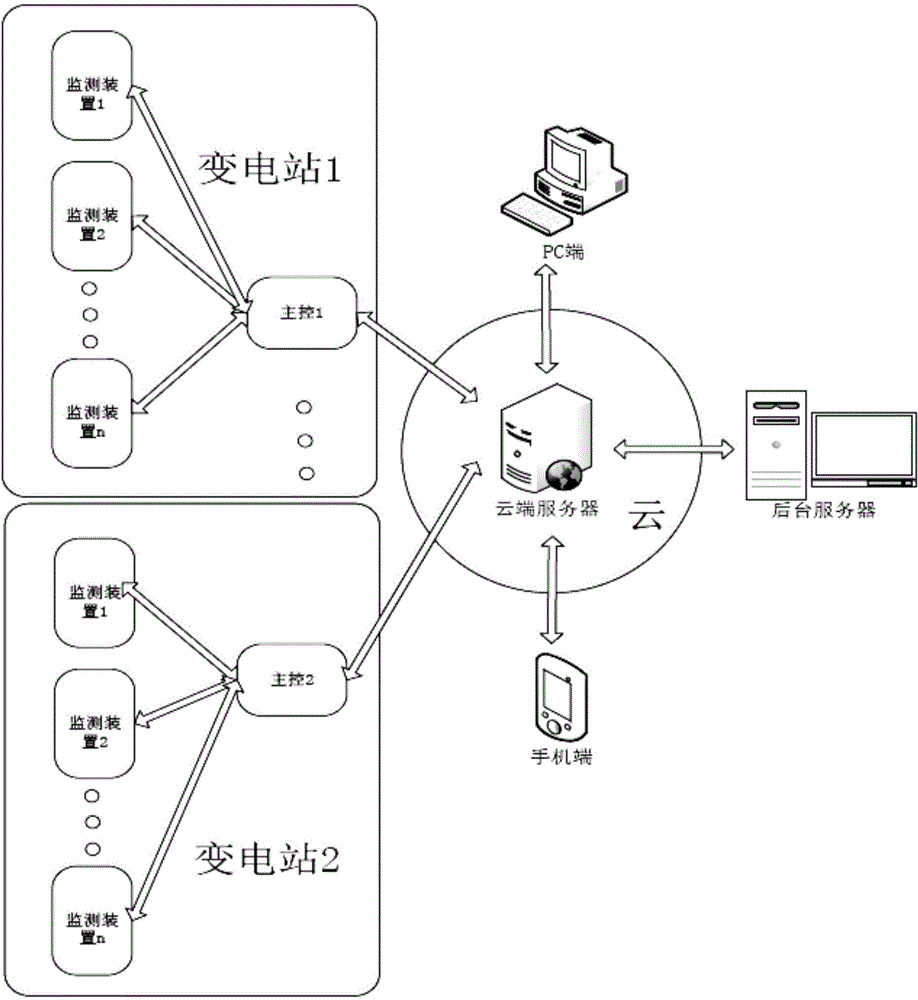

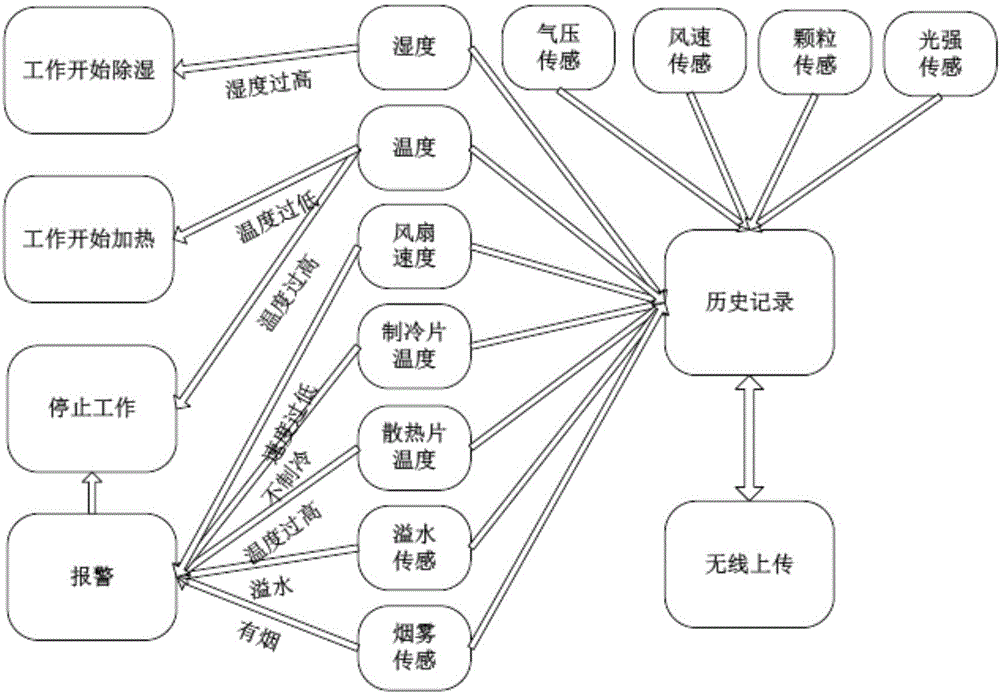

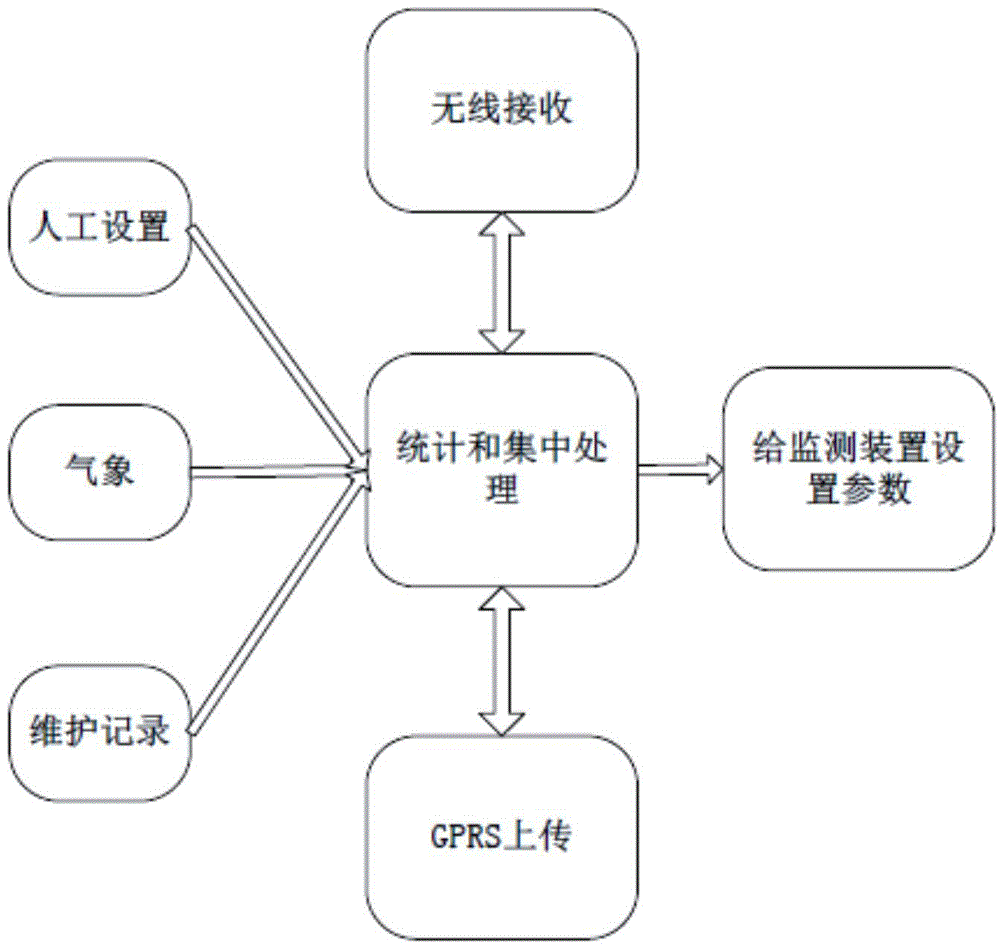

Intelligent electrical equipment environment monitoring system based on cloud computing and big data analysis

InactiveCN104950769AImprove scalabilityReduce construction pressureProgramme controlComputer controlReal-time dataMonitoring system

The invention discloses an intelligent electrical equipment environment monitoring system based on cloud computing and big data analysis. The system comprises a cloud server, an intelligent master control device, monitoring devices and communication equipment communicating with the cloud server, wherein the monitoring devices are used for acquiring related data of an electrical equipment environment and transmitting the data to the intelligent master control device; the intelligent master control device is used for controlling the monitoring devices and transmitting the data received from the monitoring devices to the cloud server; the cloud server is used for receiving and storing the related data of the electrical equipment environment; a user accesses the cloud server through a mobile phone or a computer and then controls the master control device and the monitoring devices remotely. The system depends on cloud computing to perform big data analysis on online meteorological information, real-time data and historical data, intelligently monitors the monitoring devices of all nodes, evaluates the monitoring effectiveness, analyzes potential risks effectively and solves problems by which people are puzzled for many years about outdoor electrical equipment microenvironments, online micrometeorology monitoring, real-time intelligent control and the like.

Owner:JIANGSU LIDE INTELLIGENT MONITORING TECH CO LTD

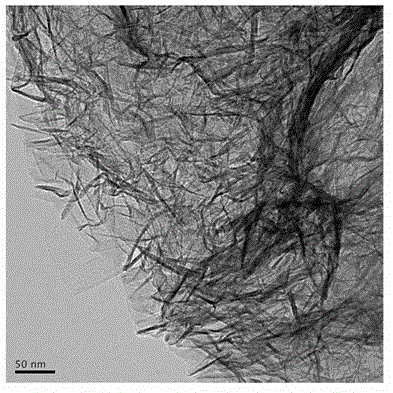

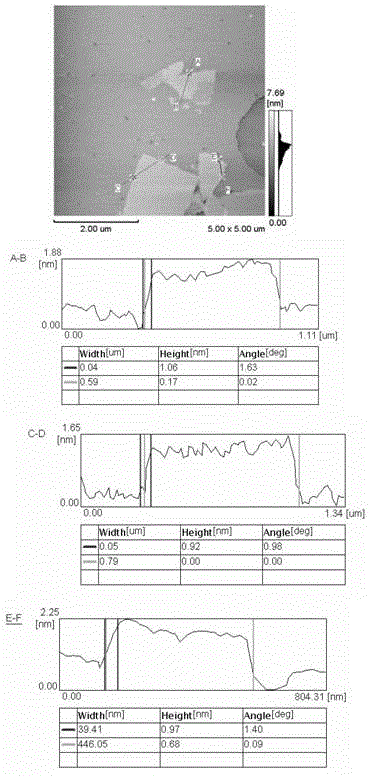

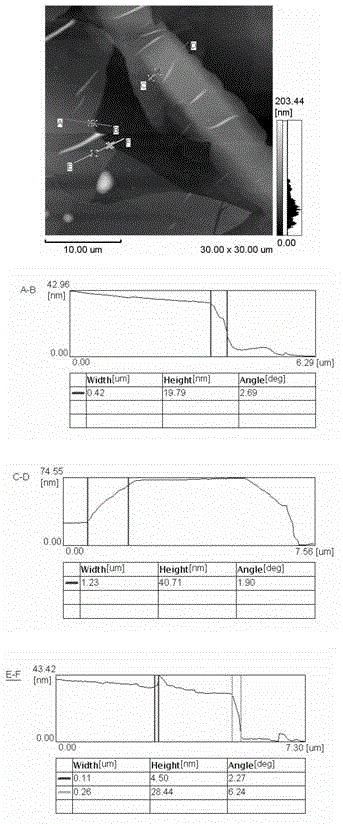

High-thermal conductivity lubricating oil and preparation method thereof

ActiveCN102911762AImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

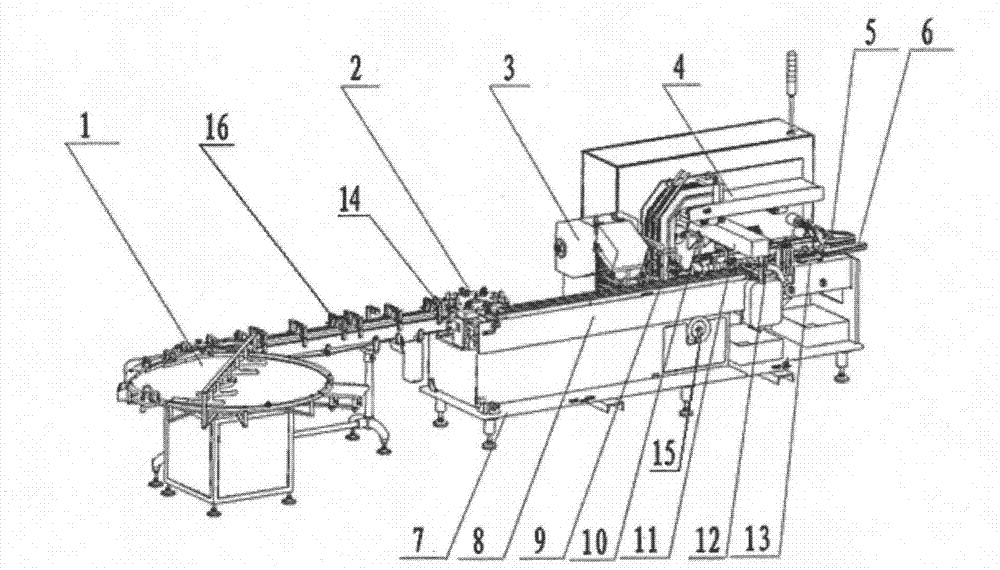

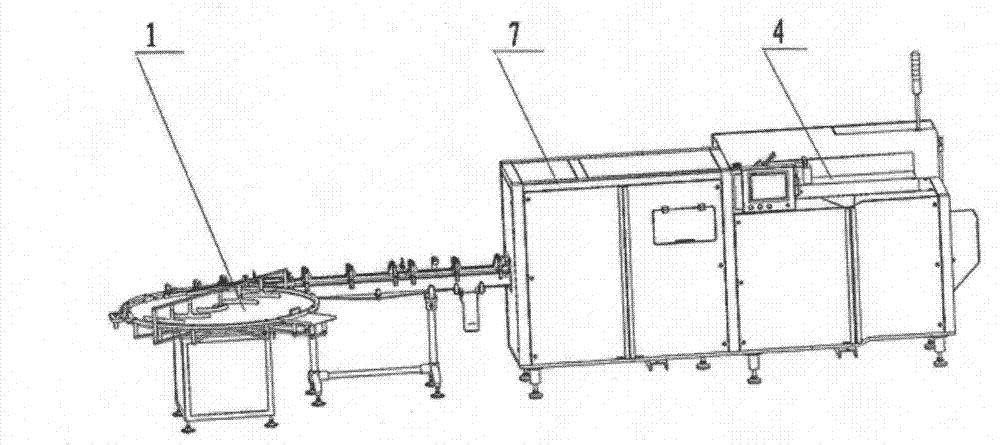

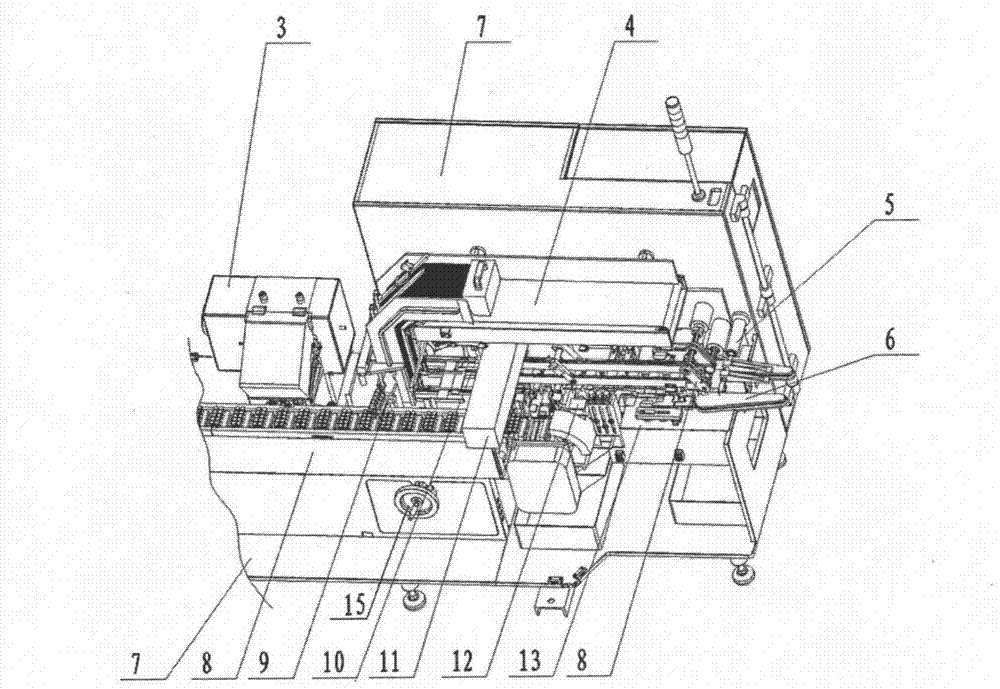

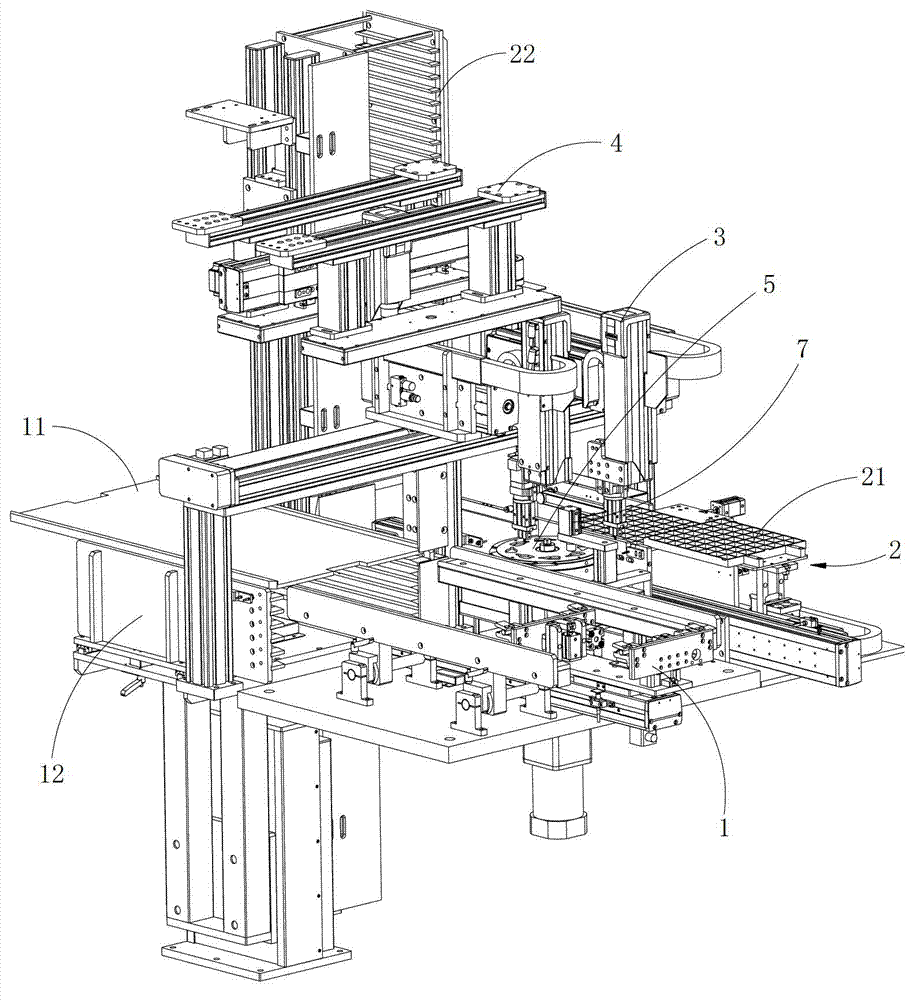

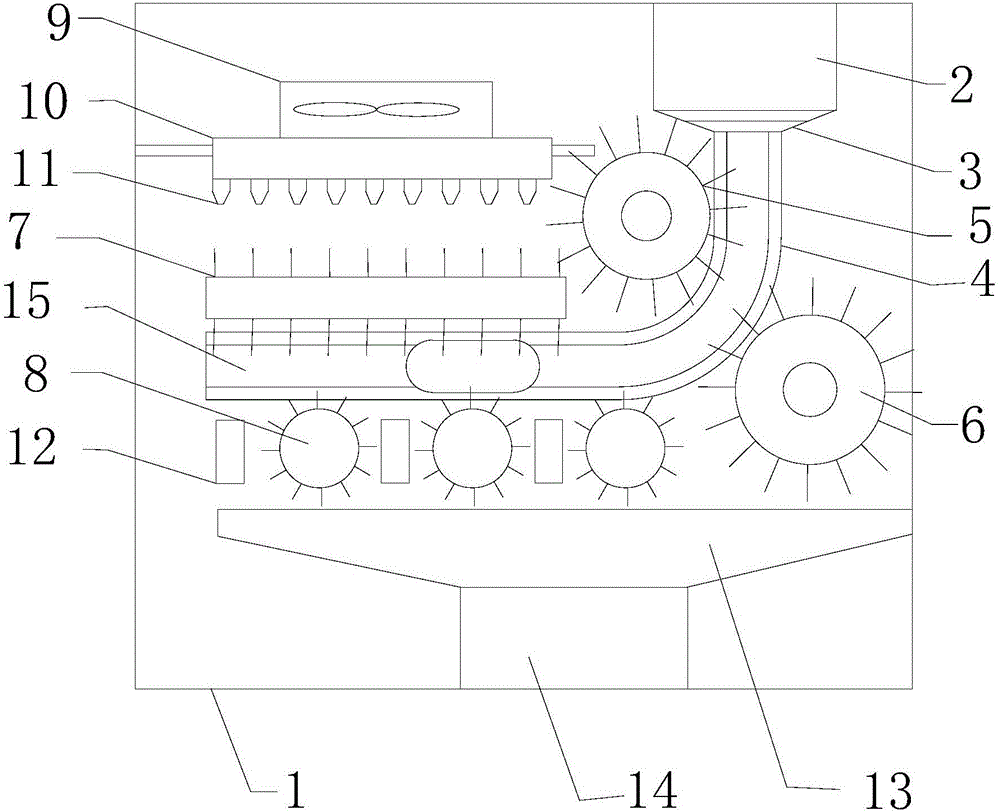

Full-automatic batch type boxing machine

The invention discloses a full-automatic batch type boxing machine. The full-automatic batch type boxing machine comprises an automatic feeding bottle managing rotary disc, a penicillin bottle indexing rotary disc feeding mechanism and a batch type conveying device which is arranged an integral machine frame; the upper side of the batch type conveying device is provided with a specification feeding device, a paper box loading device, a paper box following box opening mechanism, a drug loading device, a full-automatic steel mold printing mechanism and a full-automatic tongue inserting type box sealing device which are sequentially connected; an output end of the batch type conveying device is provided with a lateral clamping type elastic conveying device. The full-automatic batch type boxing machine is simple in structural design, accurate in control, high in automation and in intelligence, simplifies a mechanical mechanism of the boxing machine, improves the automatic degree of the boxing machine, achieves stable and high speed box packing of multiple drugs, enables the integral package process not to need manual intervention and reduces risks of package from manual operation.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

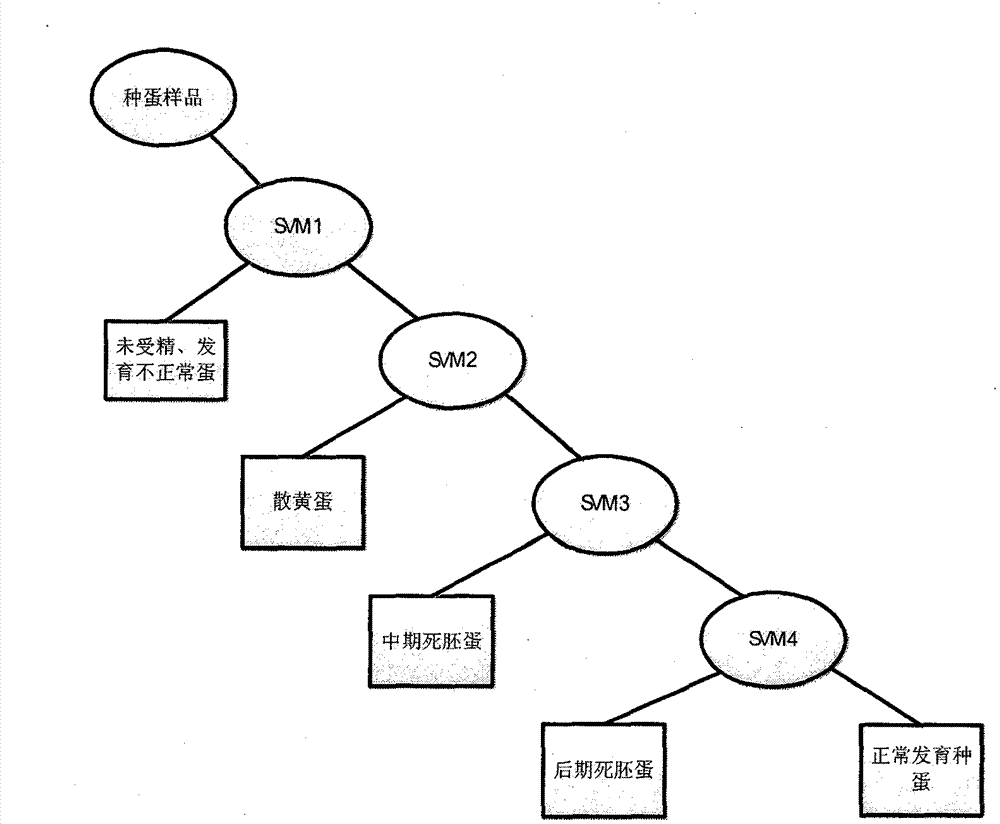

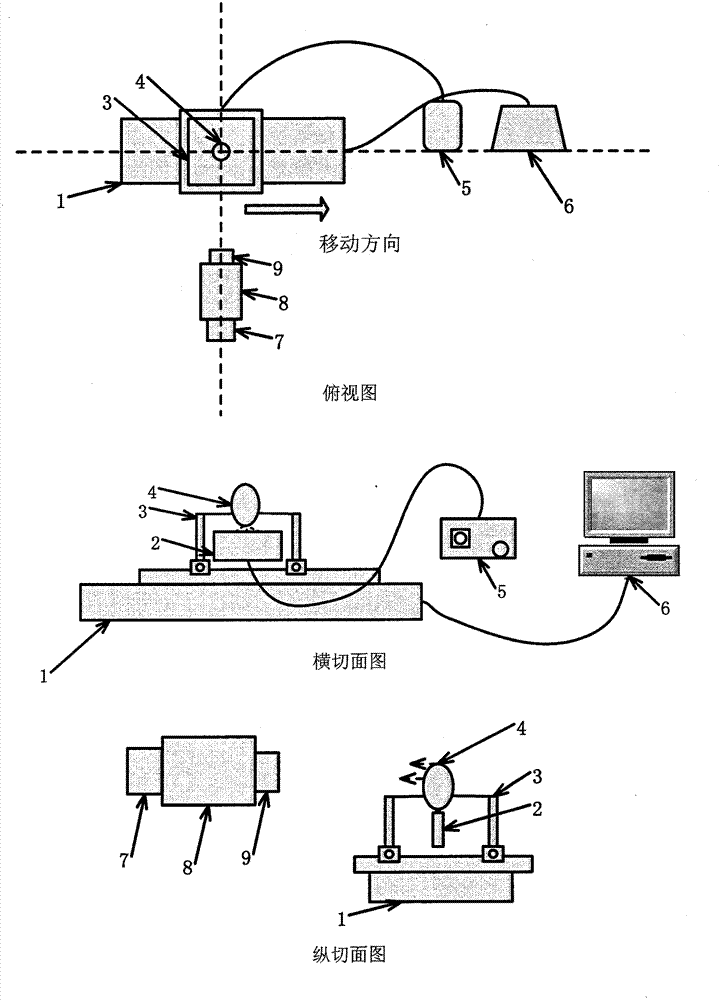

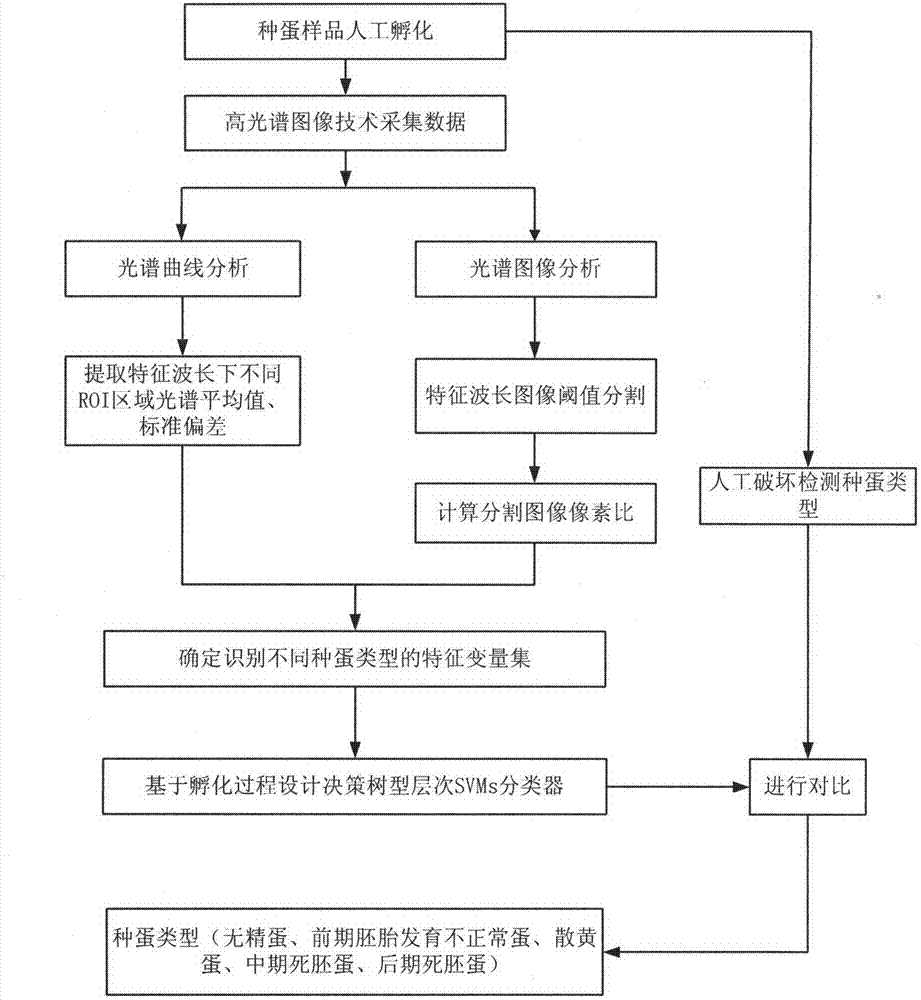

Device and method for recognizing hatching egg incubation based on hyperspectrum

ActiveCN103033512ASolve the problem that the hatching cannot be accurately judgedRemove in timeColor/spectral properties measurementsAvicultureSupport vector machine classifierEmbryo

The invention discloses a device and a method for recognizing hatching egg incubation based on hyperspectrum and belongs to the technical field of detection of agricultural products. The method comprises the following steps of: acquiring a hyperspectral image in the whole incubation process through a hyperspectral imager, analyzing the difference between different types of hatching egg images and the spectrum, extracting corresponding image and spectrum characteristic parameters, and optimizing a variable set which reflects the hatching egg incubation characteristics on the basis. According to the actual production conditions, a hierarchical support vector machine classifier based on a decision-making tree type is designed, and a hatching egg incubation determination model is established. According to the method, infertile eggs, eggs with abnormal early embryonic development, scattered yellow eggs, middle dead embryonic eggs and later-stage dead embryonic eggs are accurately recognized, an effect of monitoring the incubation process is achieved, manual detection can be completely replaced, and the method has significance and application values for improving the automation level of detecting the national poultry incubation quality.

Owner:NINGXIA JIUSANLING ECOLOGICAL AGRI & ANIMAL HUSBANDRY CO LTD

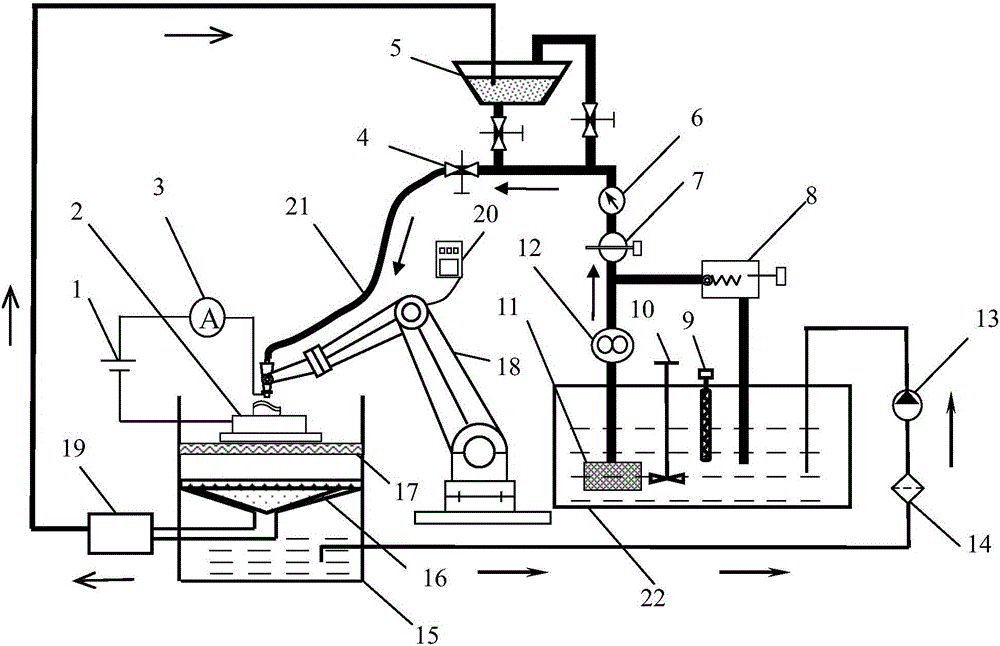

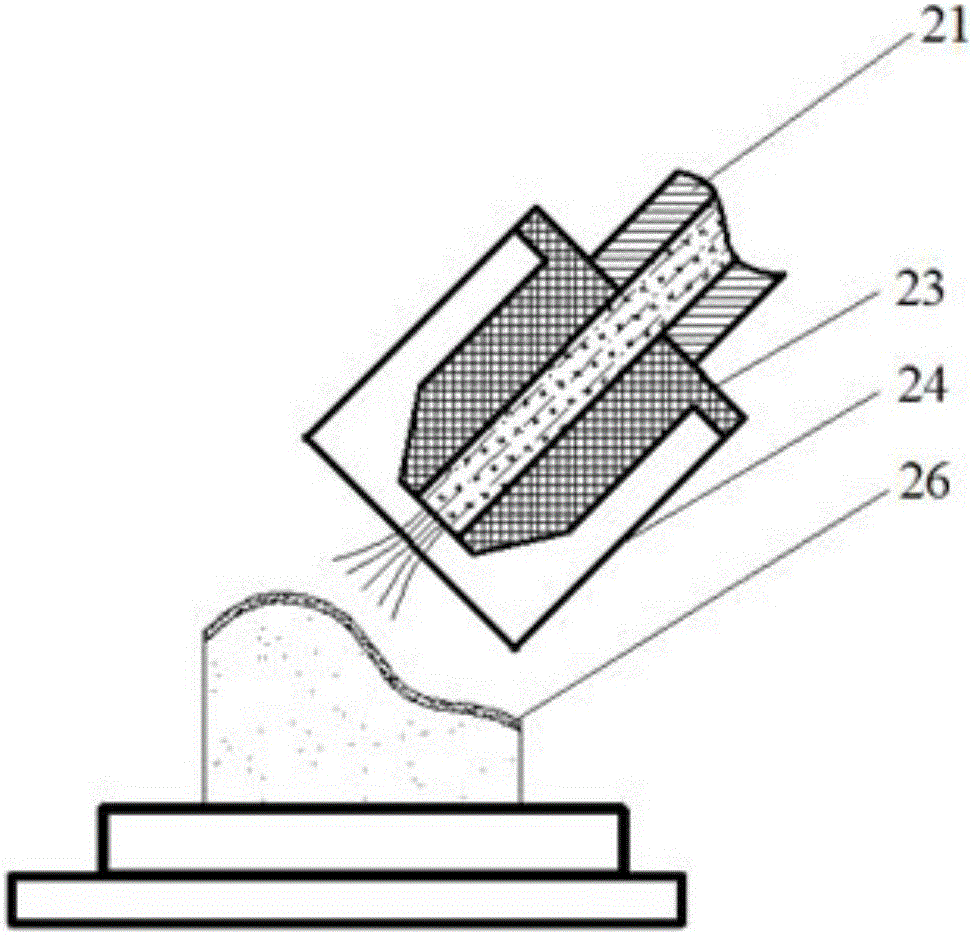

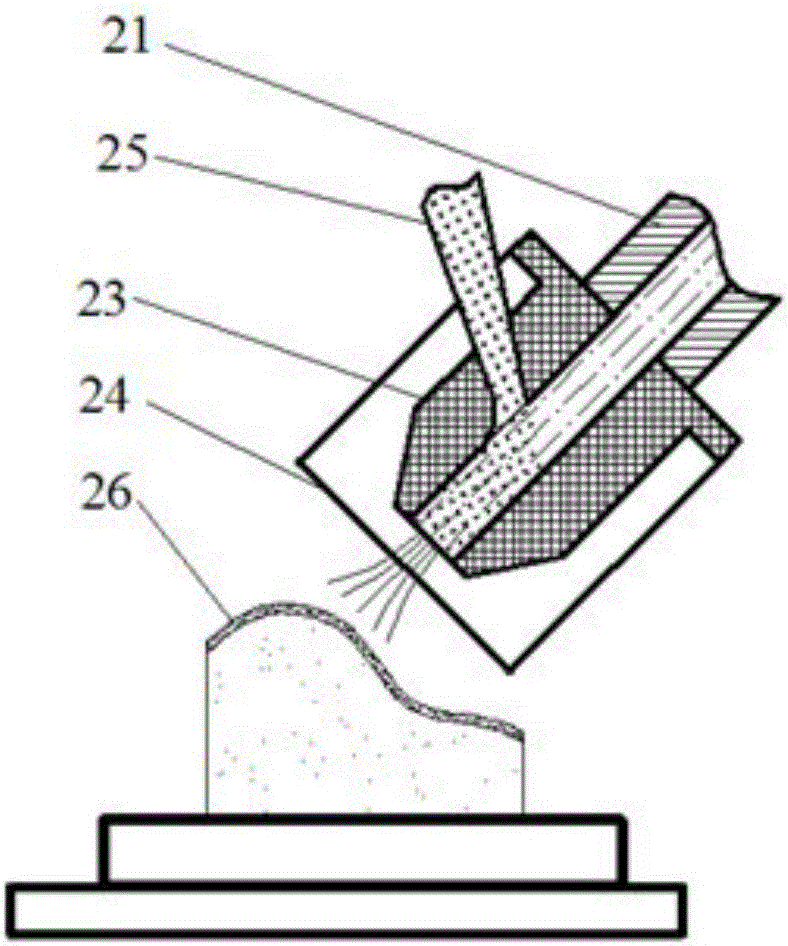

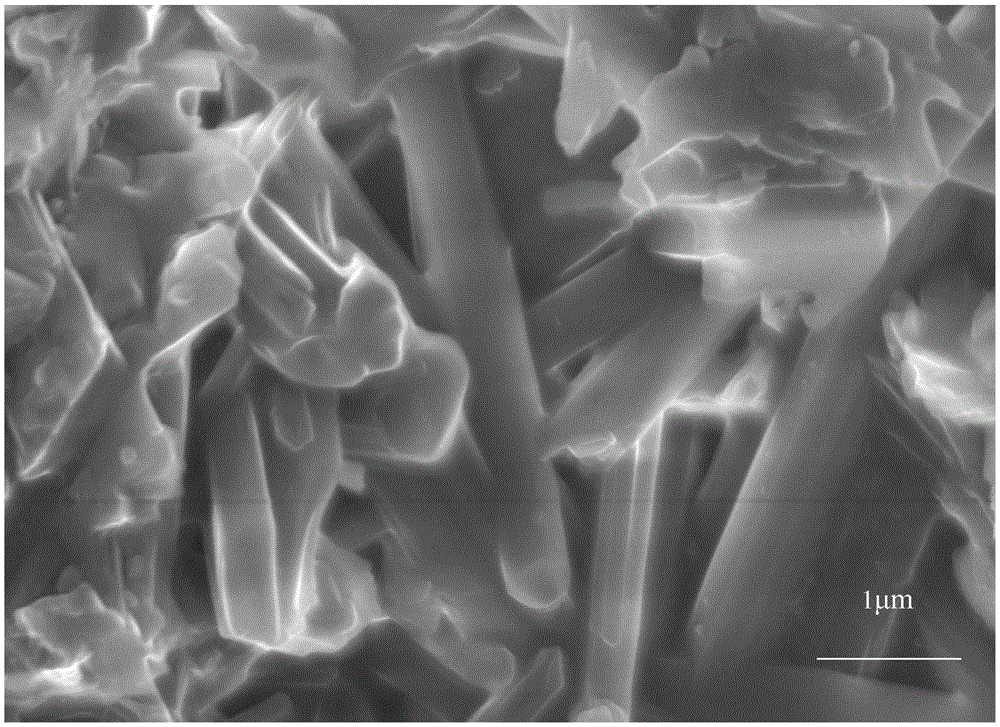

Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

InactiveCN105951141ARemove in timeInhibit nodulationElectrolysis componentsElectrolytic coatingsNumerical controlImpurity

The invention provides a three-dimensional surface shot peening jet electrodeposition manufacturing method and device. According to the manufacturing method and device, a deposition solution and hard particles are mixed and deposit on a conductive substrate in a spraying manner, so that the rapid manufacturing technology of electrodeposition is realized, the growth rate of grains in the electrodeposition process is slowed down, the purpose of refining the grains is reached, and the quality of a deposition layer is dramatically improved; with combination of the shot peening strengthening technology and the electrodeposition technology, the defects of loose texture, pockmarks, pits and the like of the deposition layer caused by single electrodeposited cathode hydrogen evolution and impurity adhesion can be effectively overcome, and the hardness and the compactness of the deposition layer are improved; meanwhile, by introducing a five-axis linkage numerical control machining system, processing formation of a three-dimensional space can be realized, and the uniformity and the shape accuracy of the deposition layer are improved; and the technology can be widely applied to production of noble metal devices and parts in complex shapes and can also be used for surface rapid coat-plating, a strengthening technology and the like.

Owner:JIANGSU UNIV

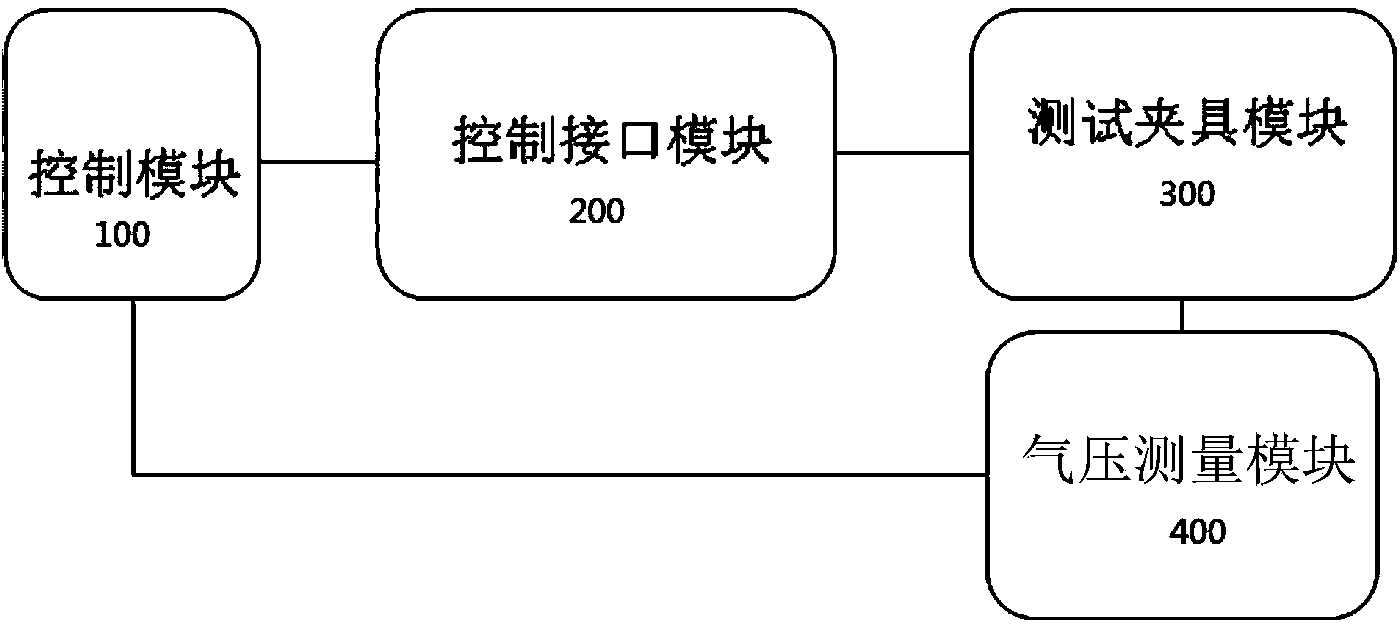

Airtightness automatic test system and test method

InactiveCN103837312ARemove as soon as possibleRemove in timeMeasurement of fluid loss/gain rateVacuum pumpingComputer module

Disclosed is an airtightness automatic test method which includes the following steps: (1) a to-be-tested product is placed on a lower die of a test clamp module of the airtightness test system and a control module drives an upper die to descend so as to press tightly the to-be-tested product so that a sealed cavity is formed between the to-be-tested product and the lower die; (2) the control module controls a vacuum pumping and air pressure measurement module to extract air from the sealed cavity via an air extraction hole until a specified time so as to generate a negative pressure; (3) within a specific air pressure test time, air pressure changes in the sealed cavity are measured at different periods and leakage measurement values which are calculated according to current air pressure values at different time periods are compared with maximum leakage quantities which are set respectively so that the qualified rate of the to-be-tested product is controlled according to the time-slice comparison result.

Owner:赛龙通信技术(深圳)有限公司

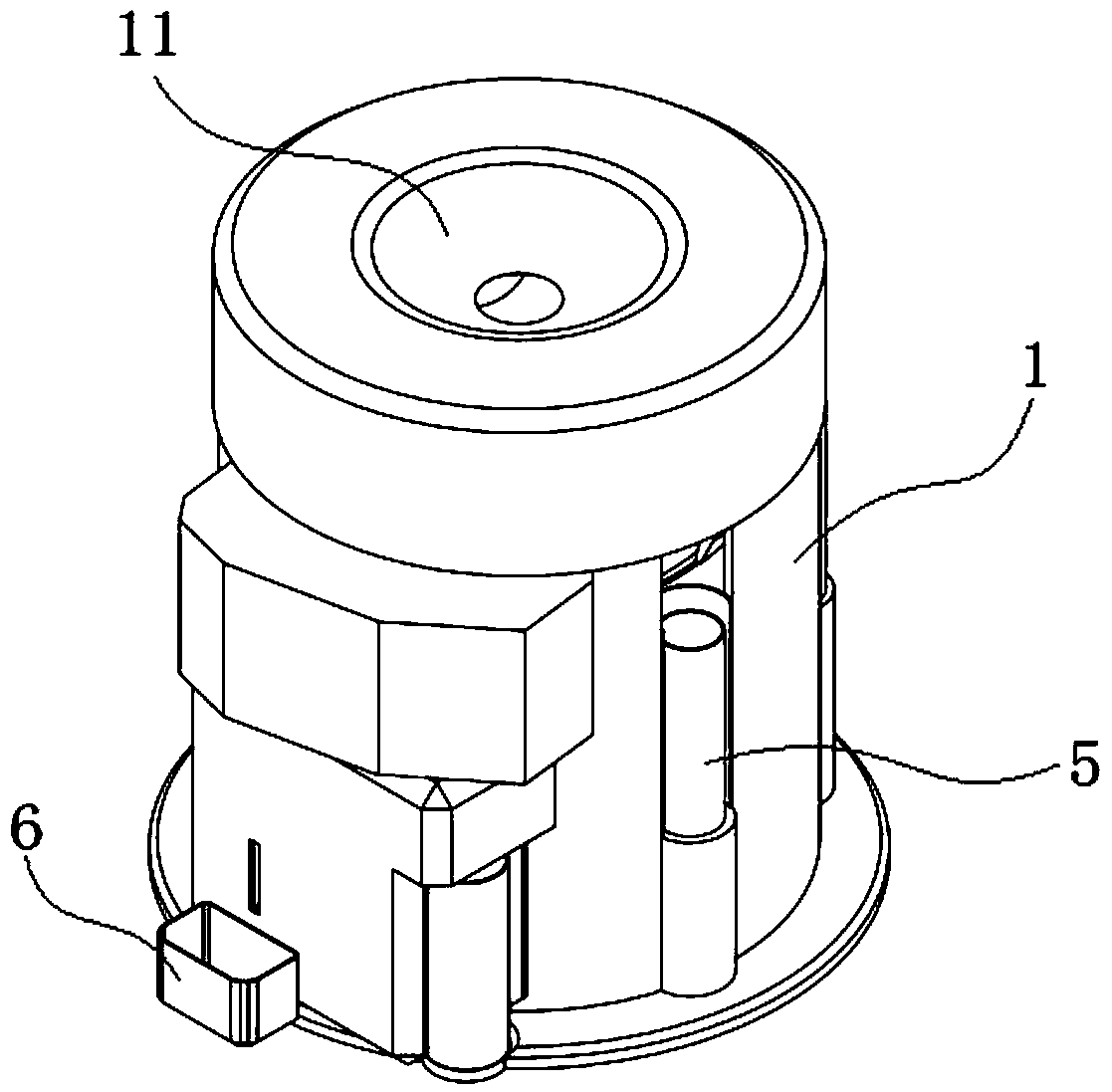

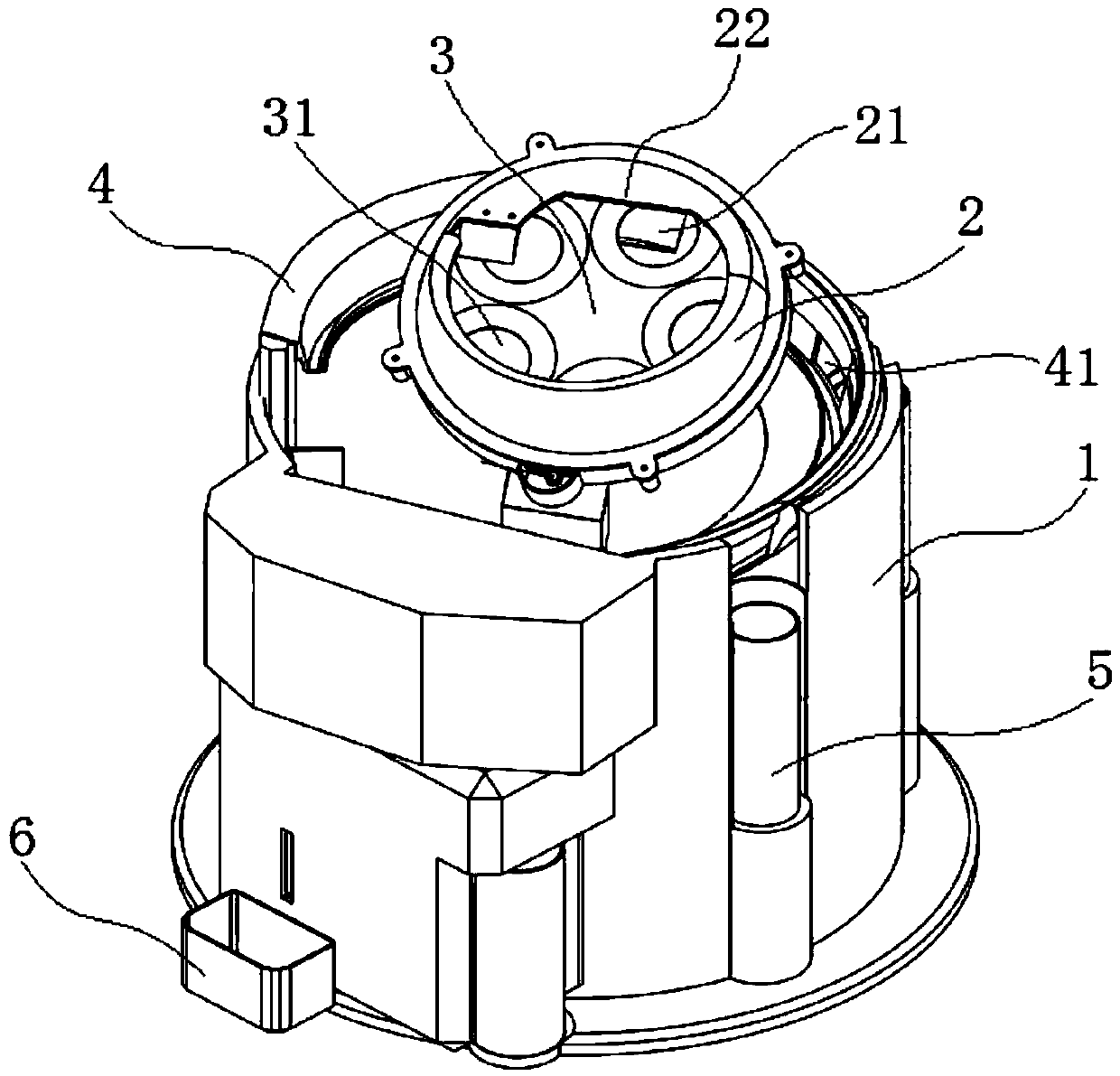

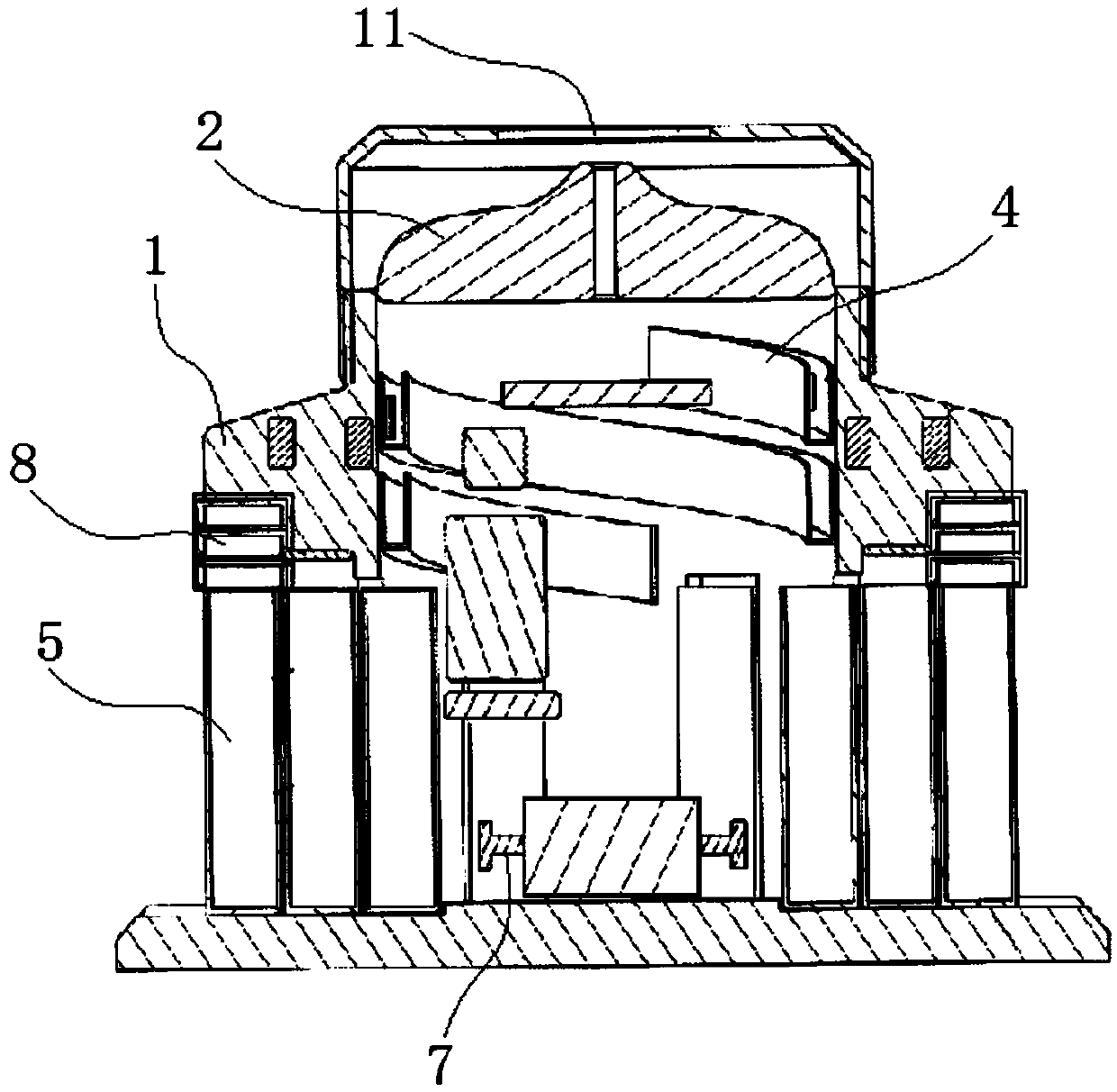

Coin sorting device

InactiveCN105374104ARealize automatic sortingLow costCoin testingCentrifugal forceElectrical and Electronics engineering

The invention discloses a coin sorting device. The coin sorting device comprises a housing, wherein the upper end of the housing is provided with a coin inlet; a coin storage chamber which is arranged in the housing in an inclined manner; a rotary disk, wherein the rotary disk is arranged on the bottom part of the coin storage chamber in a rotary manner, a plurality of coin storage cavities are formed in the rotary disk in a concave manner, the highest part on the bottom part of the coin storage chamber is provided with a coin discharge port corresponding to the coin storage cavities, and the coin discharge port is provided with a coin discharge switch; a rotation mechanism which is used for driving the rotary disk to rotate; a sorting channel, wherein the sorting channel is arranged in the housing and spirally extends downwards, an upper inlet of the sorting channel is corresponding to the coin discharge port, and three coin outlets are formed in the external side wall of the sorting channel; and package cylinders, wherein one package cylinder is arranged below each coin outlet. According to the invention, coins slide downwards in the sorting channels, and centrifugal forces are generated, so that the coins different in size are enabled to be discharged from the three different coin outlets, automatic sorting is realized, and the sorting is accurate and high in efficiency.

Owner:GUANGXI UNIV

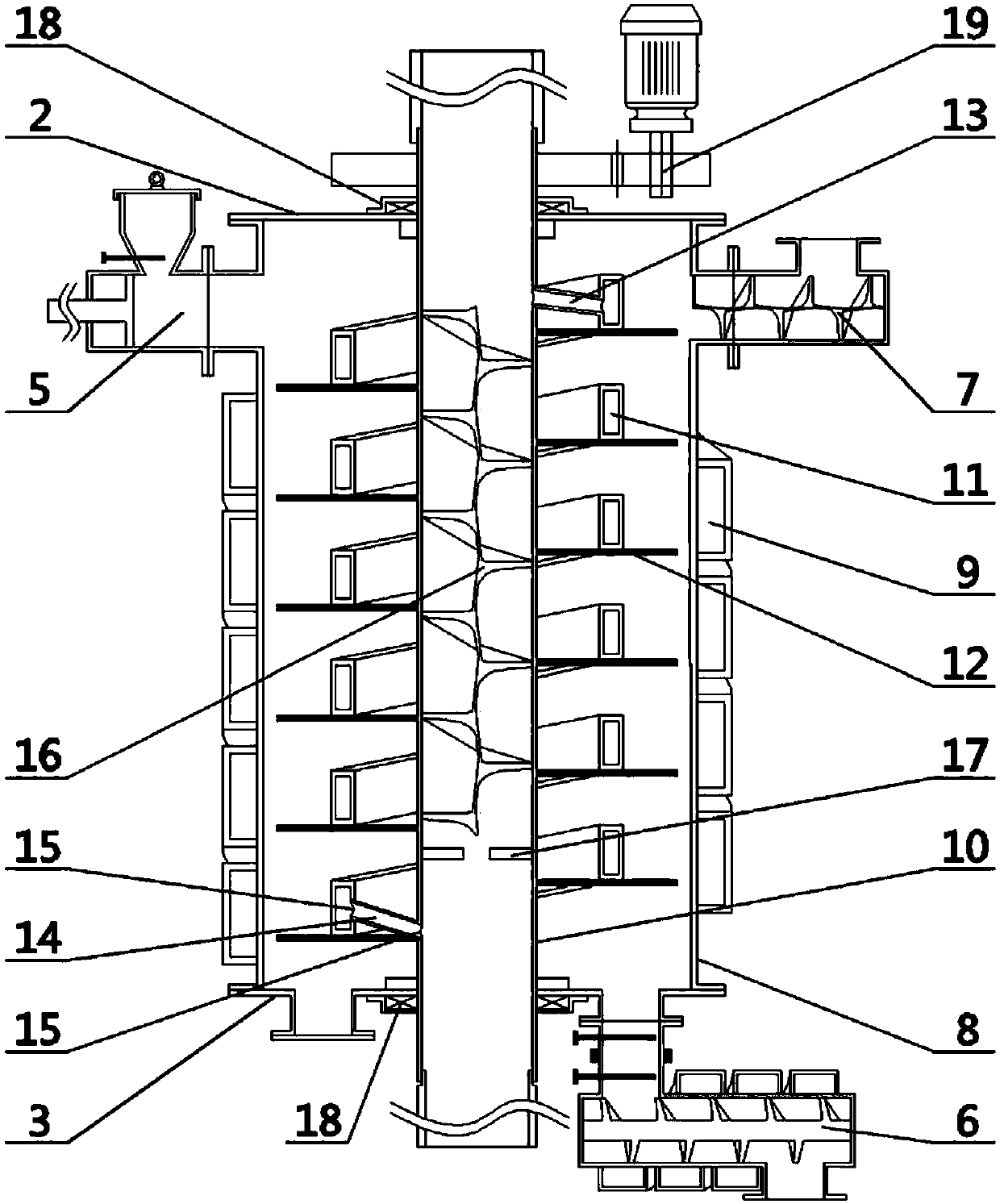

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

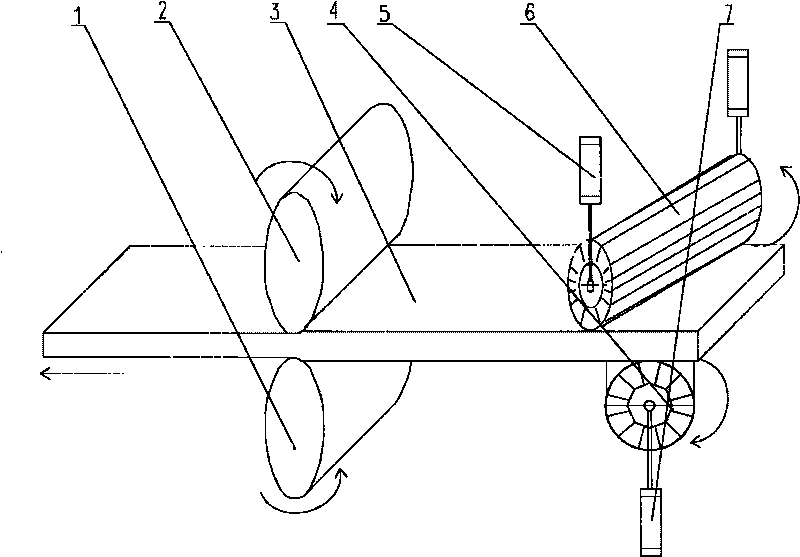

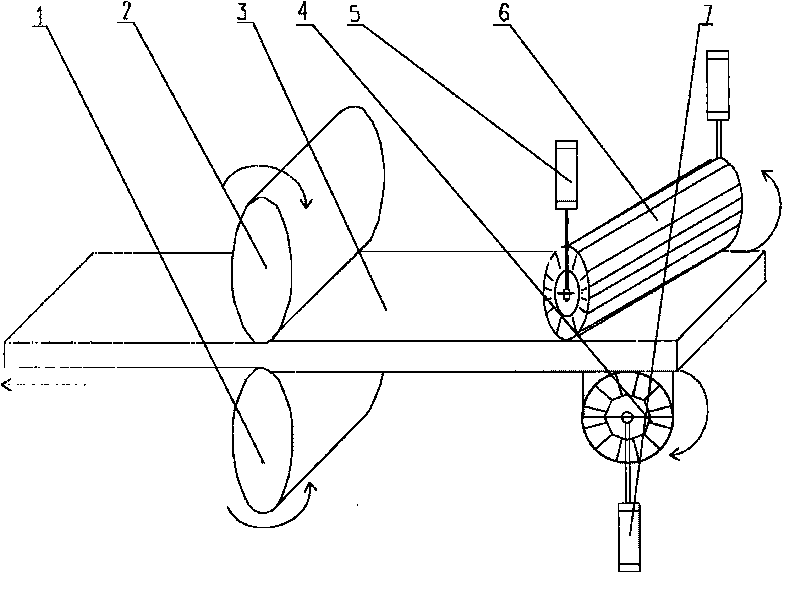

Novel process for on-line removing of scale at surface of hot-rolled copper plate belt

InactiveCN101698197ASuperiorRemove in timeWork treatment devicesCleaning using toolsSurface oxidationIngot

The invention discloses a novel process for the on-line removing of scale at the surface of a hot-rolled copper plate belt, which is a process for scraping, brushing and purging scale at the surface of a blank ingot during hot rolling. The process comprises the following steps: scraping and brushing the scale on the upper surface or the lower surface of a rolled piece (3) by a scraping and brushing roller at the inlet side and the outlet side of a working roller, scraping off the scale which already turns up because of hot rolling, and avoiding pressing into the inside of the rolled piece during rolling; the process can solve the long-term puzzling problem of the pressing-in of the scale in the hot-rolling process of a copper plate belt, can be used for common hot-rolling materials, also can be used for hot-rolling quenching materials, can lower the energy consumption and the cost, can improve the labour production conditions of workers and can better produce a blank used for a cold-rolling copper plate belt with no scale pressed into the surface.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

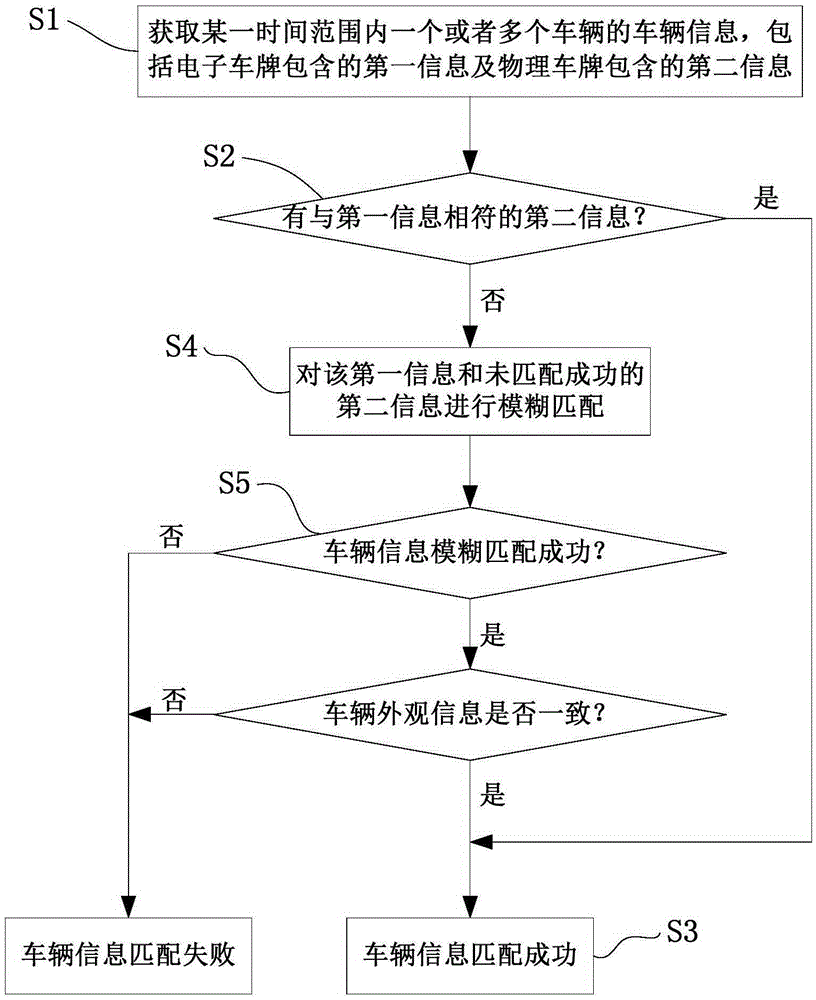

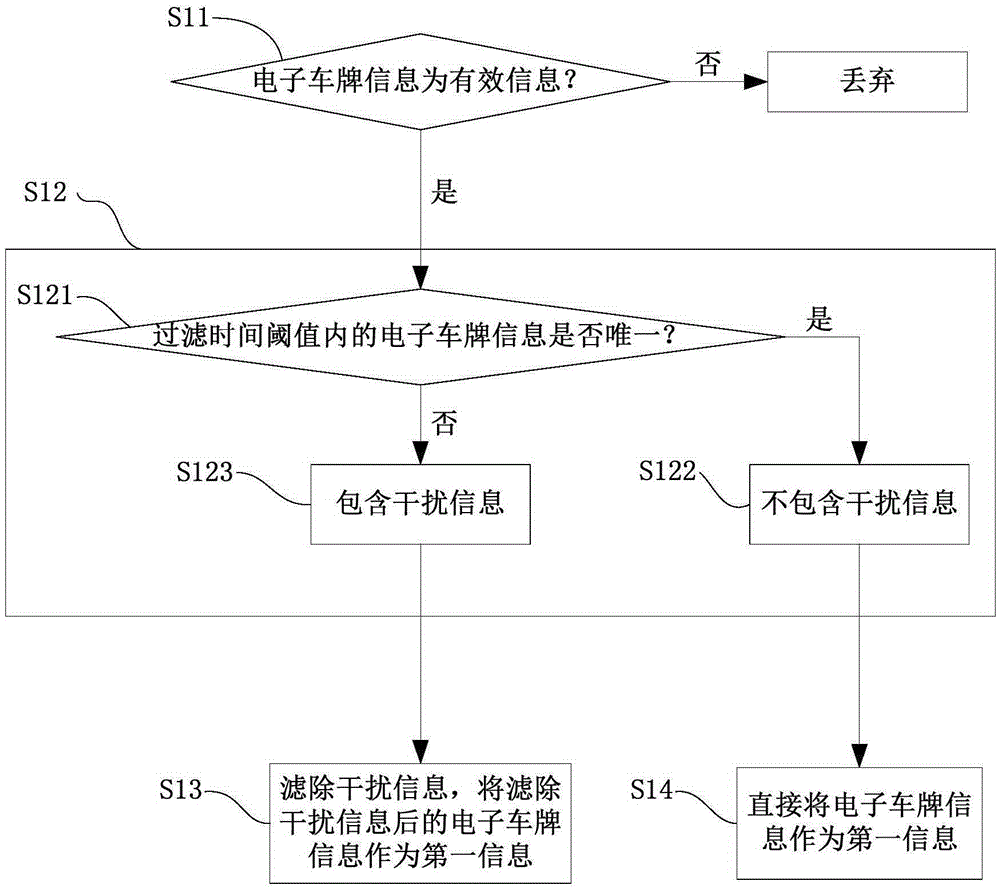

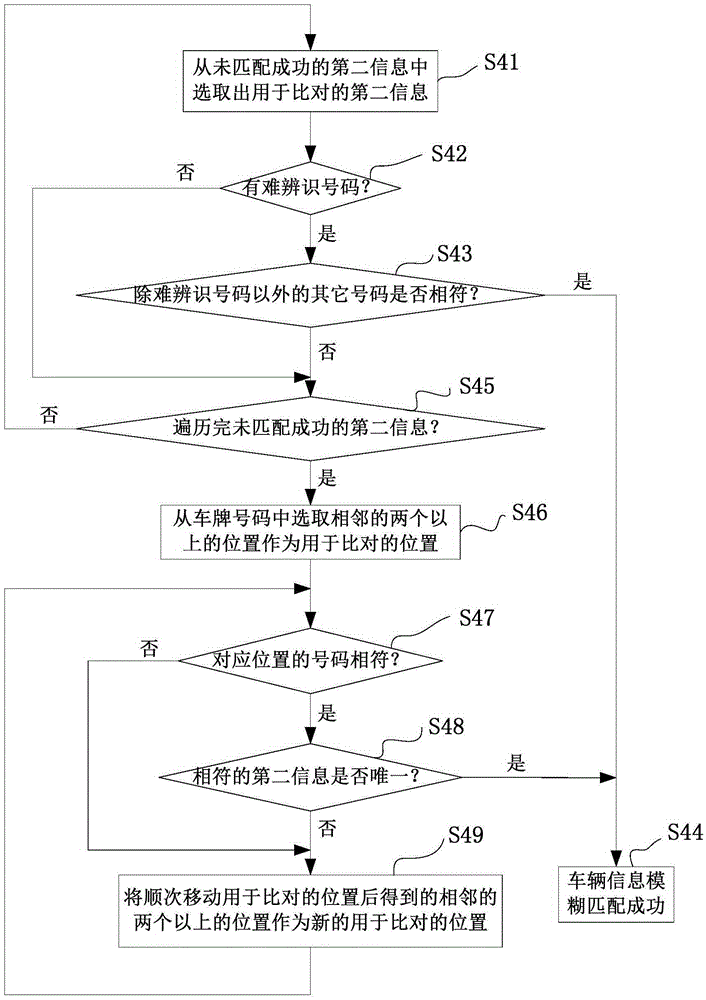

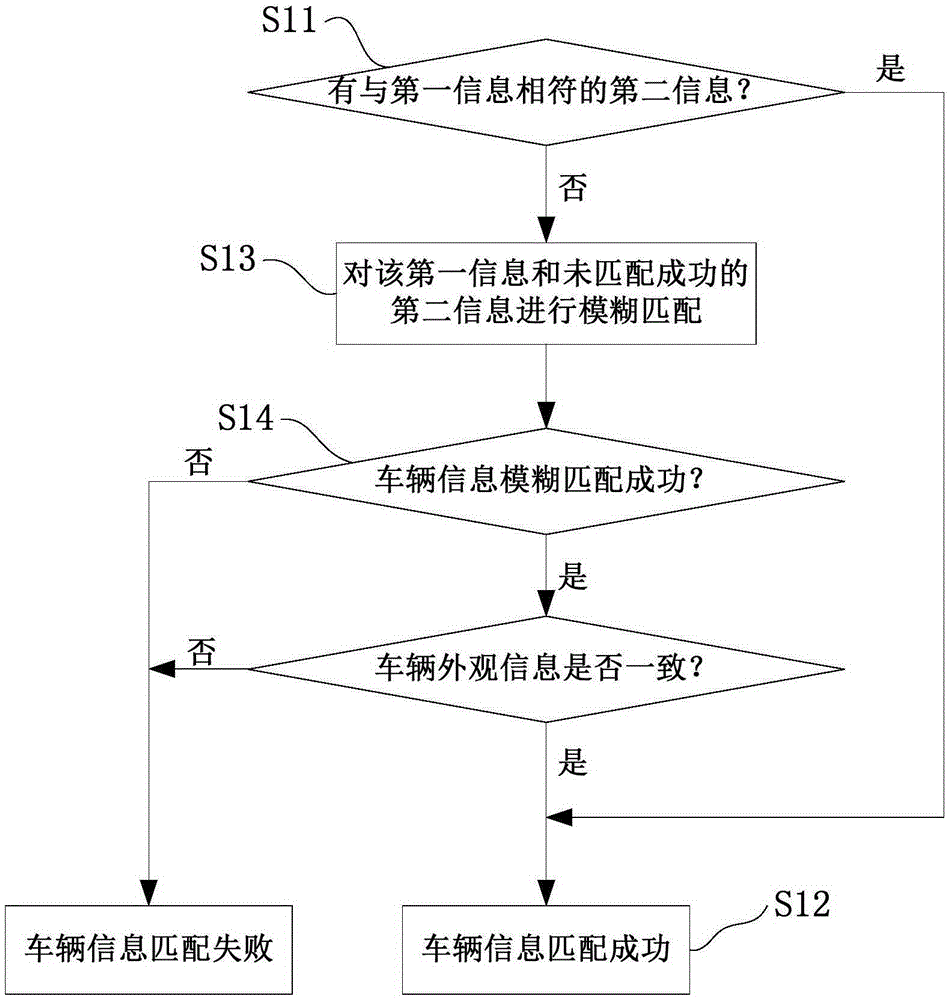

Vehicle information matching method and system, and monitoring device

ActiveCN105279971AImprove accuracyAvoid repeating the judgment processRoad vehicles traffic controlTime rangeIlluminance

The invention provides a vehicle information matching method and system, and a monitoring device. The method comprises the steps: obtaining first information of electronic license plates of one or more vehicles and second information of physical license plates in a certain time period; judging whether there is second information accordance with certain first information or not; determining that the vehicle information matching of a vehicle corresponding to the first information is successful if there is the second information accordance with certain first information, or else, carrying out fuzzy matching of the first information with the unsuccessfully matched second information in the vehicle information. In other words, the method and system still can correct the second information in a fuzzy matching mode under the conditions that an external environment is severe (strong light, misty rain, or poor light), or a physical license plate cannot be recognized because the physical license plate is polluted or shaded (inaccurate second information of the physical license plate) and there is wrong recognition, and improve the accuracy of vehicle information recognition.

Owner:BEIJING E HUALU INFORMATION TECH +1

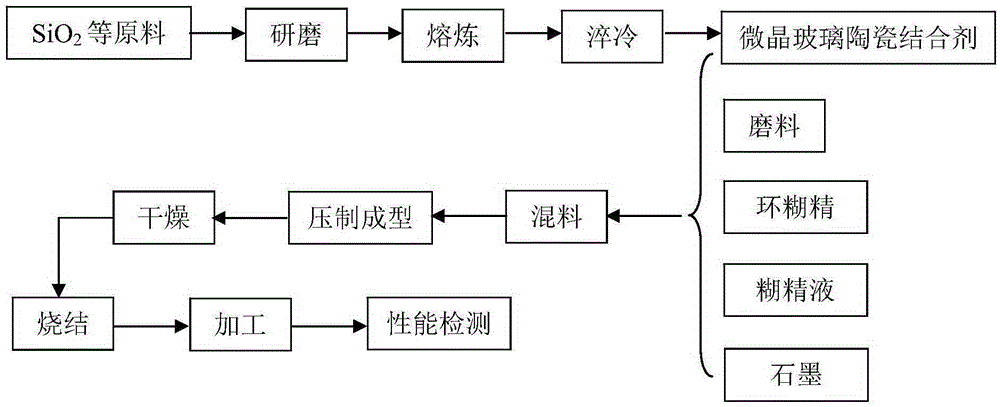

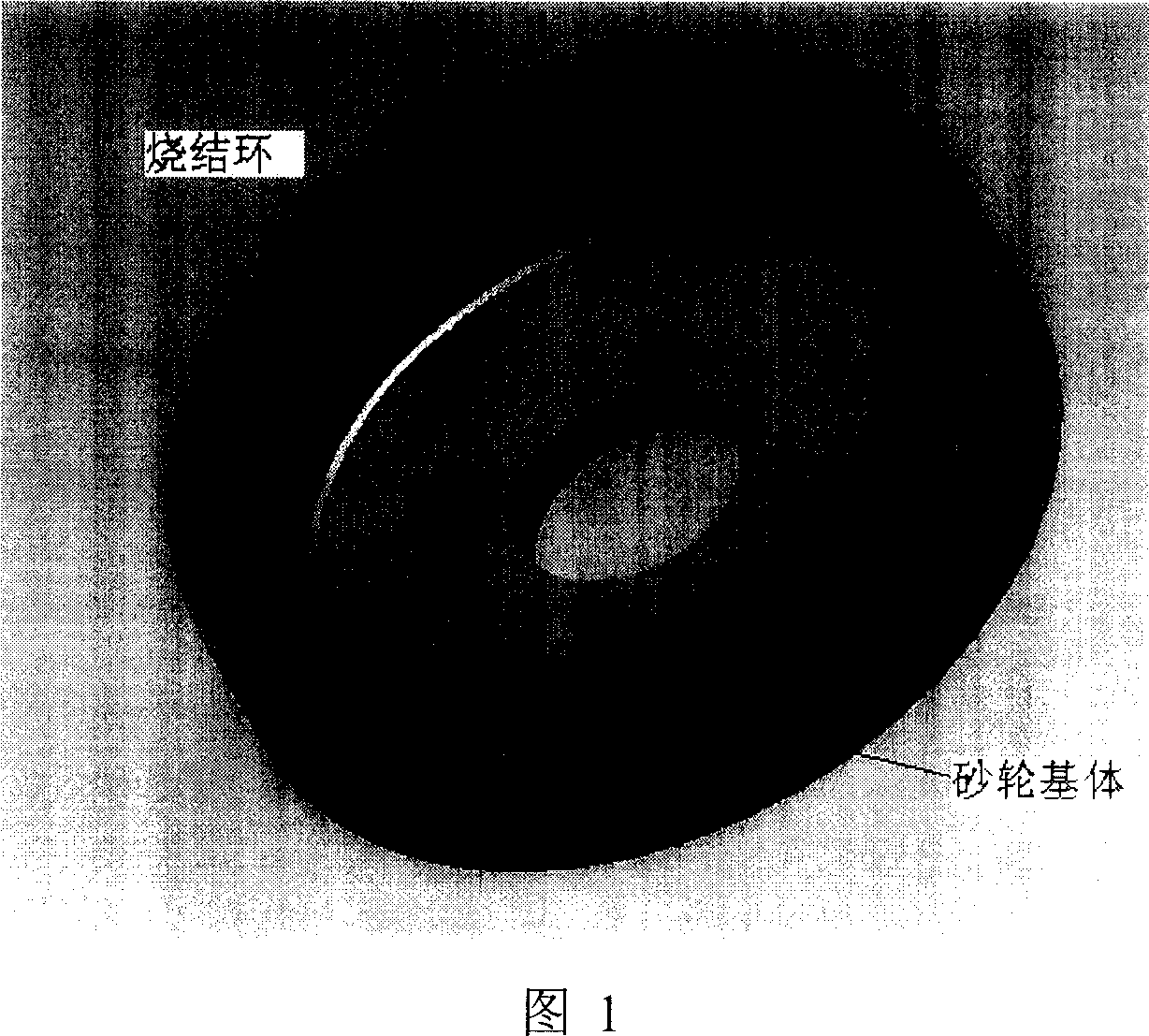

Microcrystalline glass ceramic binding agent, preparing method thereof, SG grinding wheel and preparing method thereof

ActiveCN105252435ASmall coefficient of thermal expansionLow crystallization temperatureAbrasion apparatusGrinding devicesTO-18Materials science

The invention discloses a microcrystalline glass ceramic binding agent, a preparing method thereof, an SG grinding wheel and a preparing method thereof. The binding agent is prepared from, by weight percentage, 40% to 65% of SiO2, 6% to 20% of Al2O3, 5% to 18% of Na2O, 0.5% to 5% of CaO, 3% to 10% of K2O, 8% to 35% of B2O3, 0.5% to 2% of MgO and 2% to 6% of TiO2. The microcrystalline glass ceramic binding agent is formed by reasonably selecting the raw materials, the scientific ratio is adopted, the binding agent has the beneficial effects of being low in thermal expansion coefficient and crystallization temperature and high in strength accordingly, the microcrystalline glass ceramic binding agent is suitable for being used as a binding agent of the SG grinding wheel, the firing temperature of the SG grinding wheel is greatly reduced, and the firing time of the SG grinding wheel is greatly shortened; and meanwhile the work efficiency and the machining accuracy of the SG grinding wheel are improved, grinding heat is reduced, and the service life of the grinding wheel is prolonged.

Owner:白鸽磨料磨具有限公司

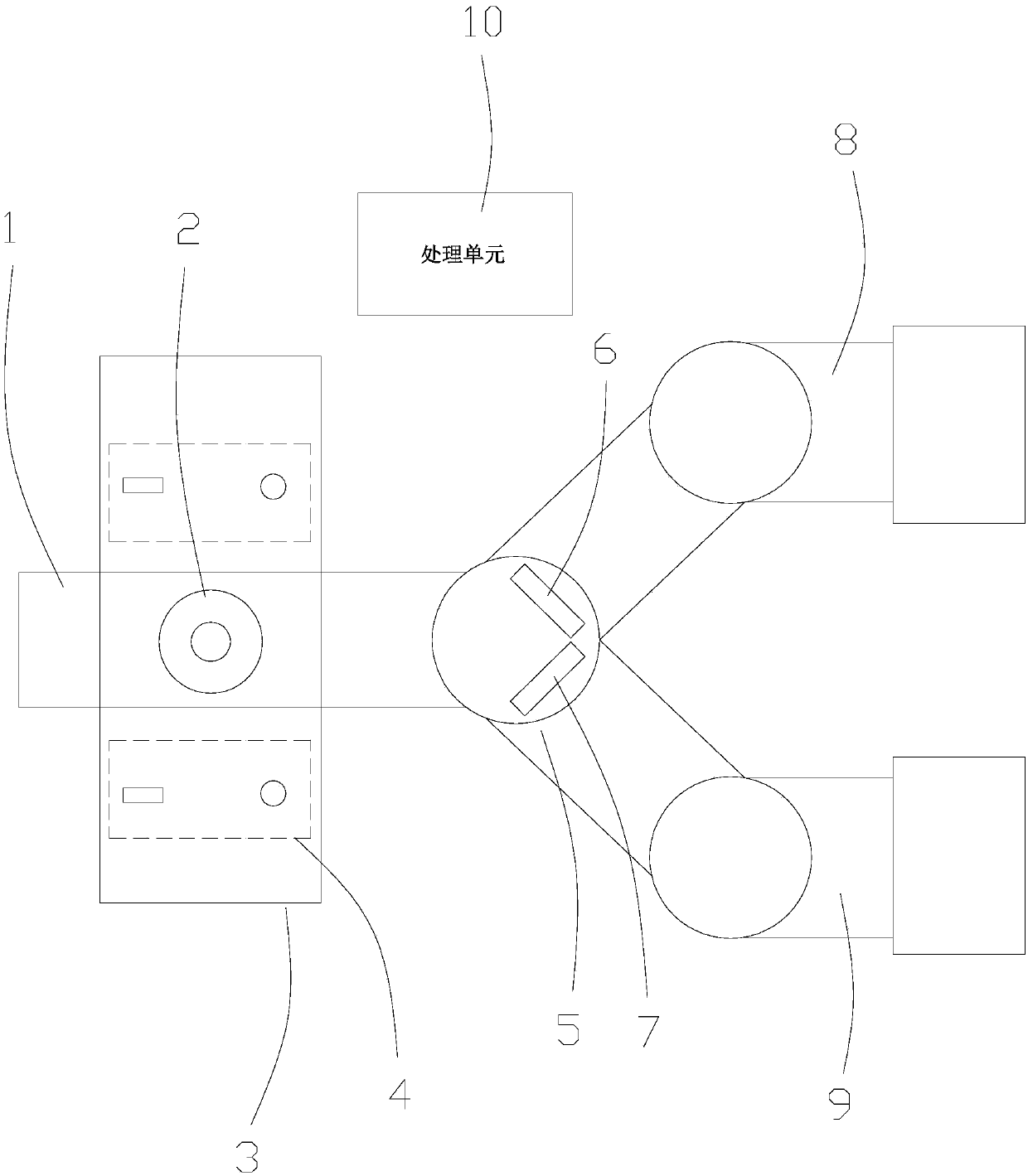

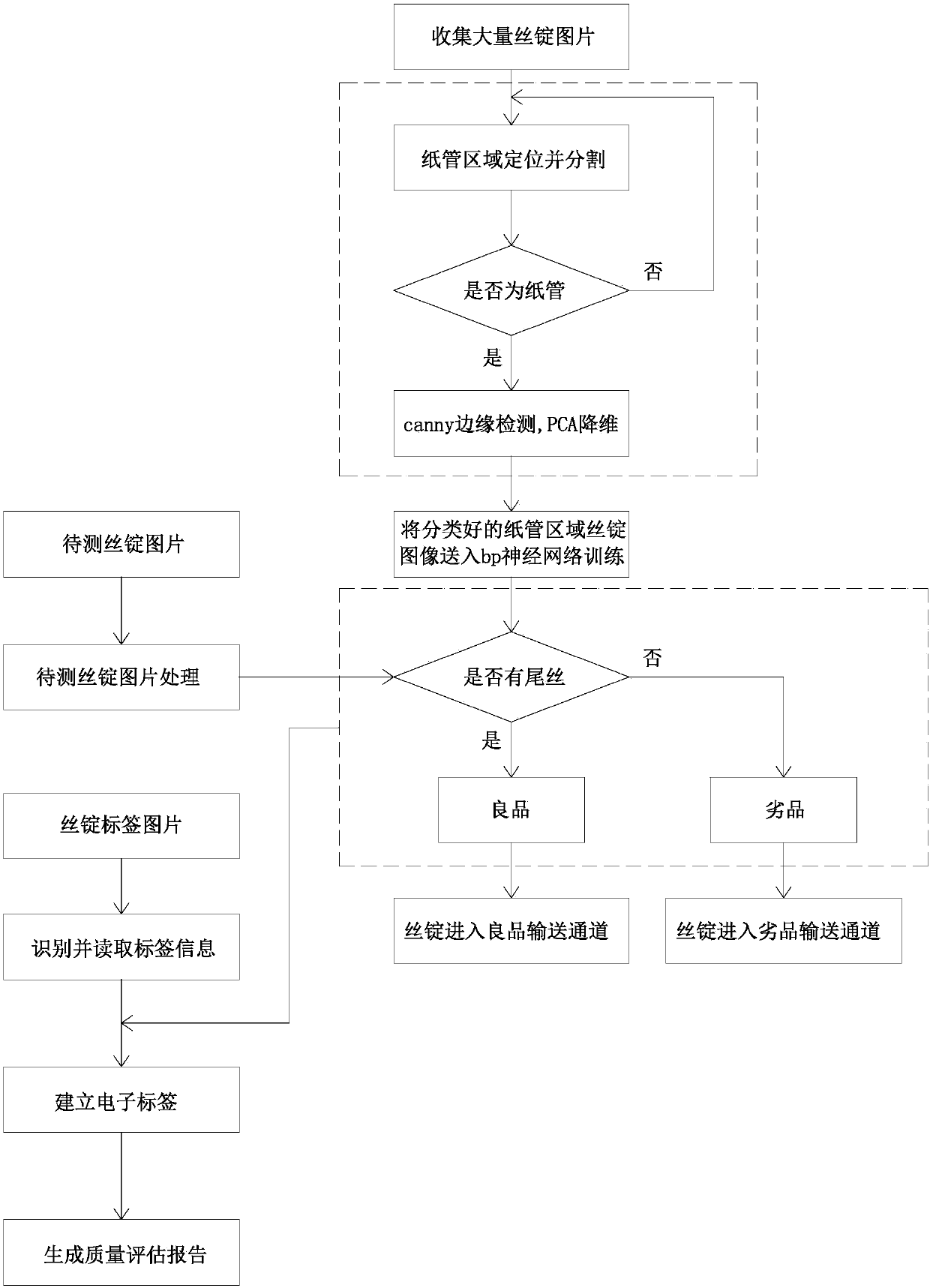

Chemical fiber tail fiber appearance defect detecting system and method

ActiveCN109550712ADoes not affect normal productionRealize online processing flowMaterial analysis by optical meansSortingFiberStructural engineering

The invention discloses a chemical fiber tail fiber appearance defect detecting system and method. The system comprises a tray for carrying a fiber ingot, and a conveying belt for conveying the tray.The fiber ingot is provided with a label. A hidden box is arranged on the conveying belt. A sorting unit is arranged on a transmission belt of the hidden box. An image collecting unit for collecting alabel image and a fiber ingot image is arranged in the hidden box. The image collecting unit sends collecting information to a processing unit to carry out tail fiber defect detection. The system recognizes and reads the label information from the label image, screens a to-be-detected image provided with a fiber ingot paper tube from the fiber ingot image, detects the edge of a paper tube area ofthe to-be-detected image, extracts the main feature describing the paper tube area, brings the to-be-detected image after being processed into a tail fiber classifier to be classified, obtains the fiber ingot tail fiber detecting information and sends the information to the sorting unit, and the sorting unit sorts qualified fiber ingot products and reject fiber ingot products according to fiber ingot tail fiber classification. The system saves the cost, the working efficiency is higher, and detecting is more accurate.

Owner:杭州慧知连科技有限公司

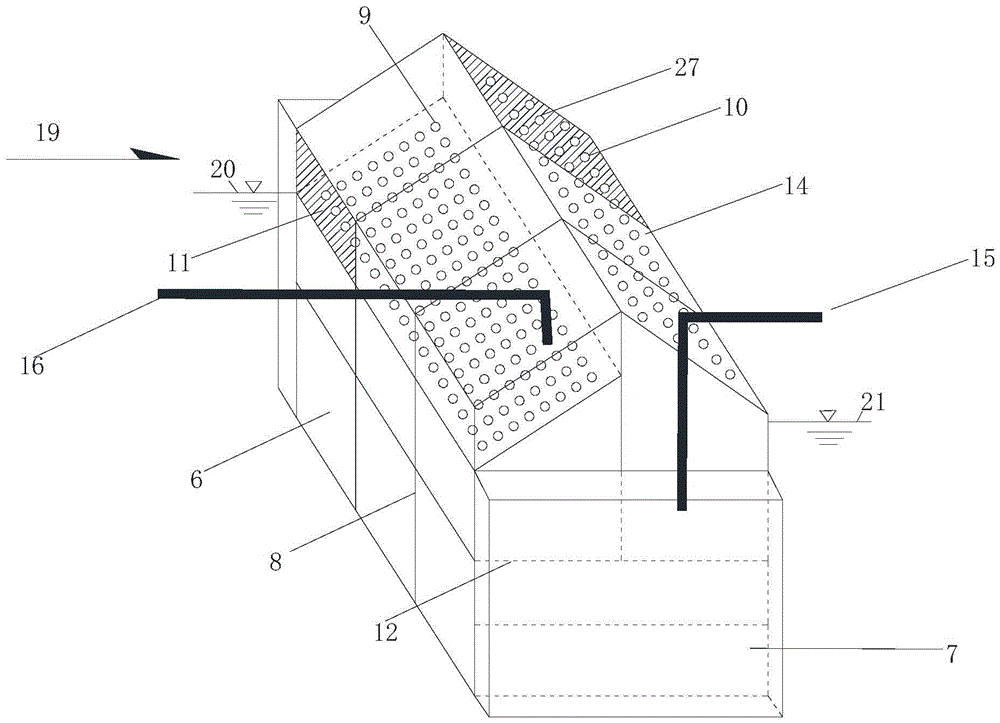

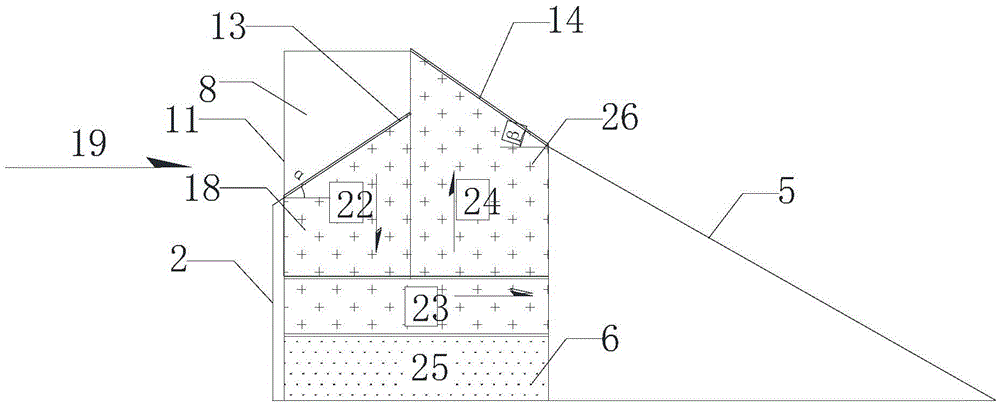

Assembled emergency water purification soft dam and method for purifying minitype river course by using water purification soft dam

ActiveCN105585107ATo achieve the effect of purifying sewageRemove in timeBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentEcological environmentFiltration

The invention discloses an assembled emergency water purification soft dam and a method for purifying a minitype river course by using a water purification soft dam. The water purification soft dam is composed of a dam foundation, a main dam body, a barrier and a supporting frame, wherein the main dam body is divided into two ore more than two independent water purification units by one or a plurality of partitions along the river cross section; and each region is composed of a downstream unit, a horizontal unit and an upstream unit along the water flow direction. The river water filtration and back flushing of the soft dam are carried out synchronously, and the back flushing wastewater is independently treated in a different position. The soft dam is easy to assemble and disassemble, has the characteristics of recyclable materials, small habitat fragmentation influence and the like, can purify polluted river water, and is suitable for the fields of river pollution treatment and ecological environment protection during minitype river course partial building works.

Owner:ZHEJIANG YUTENG BAINUO ENVIRONMENTAL PROTECTION TECH CO LTD

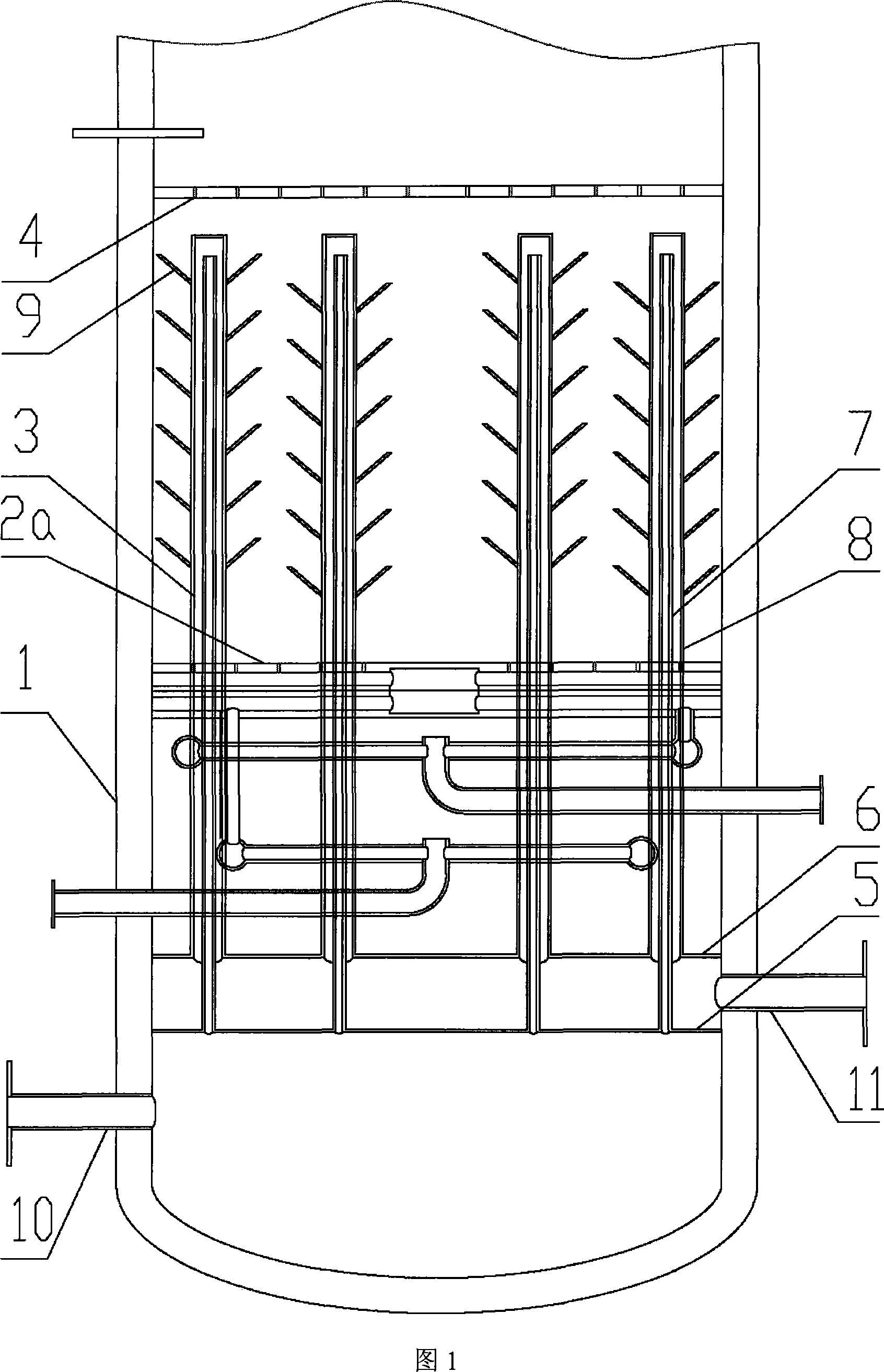

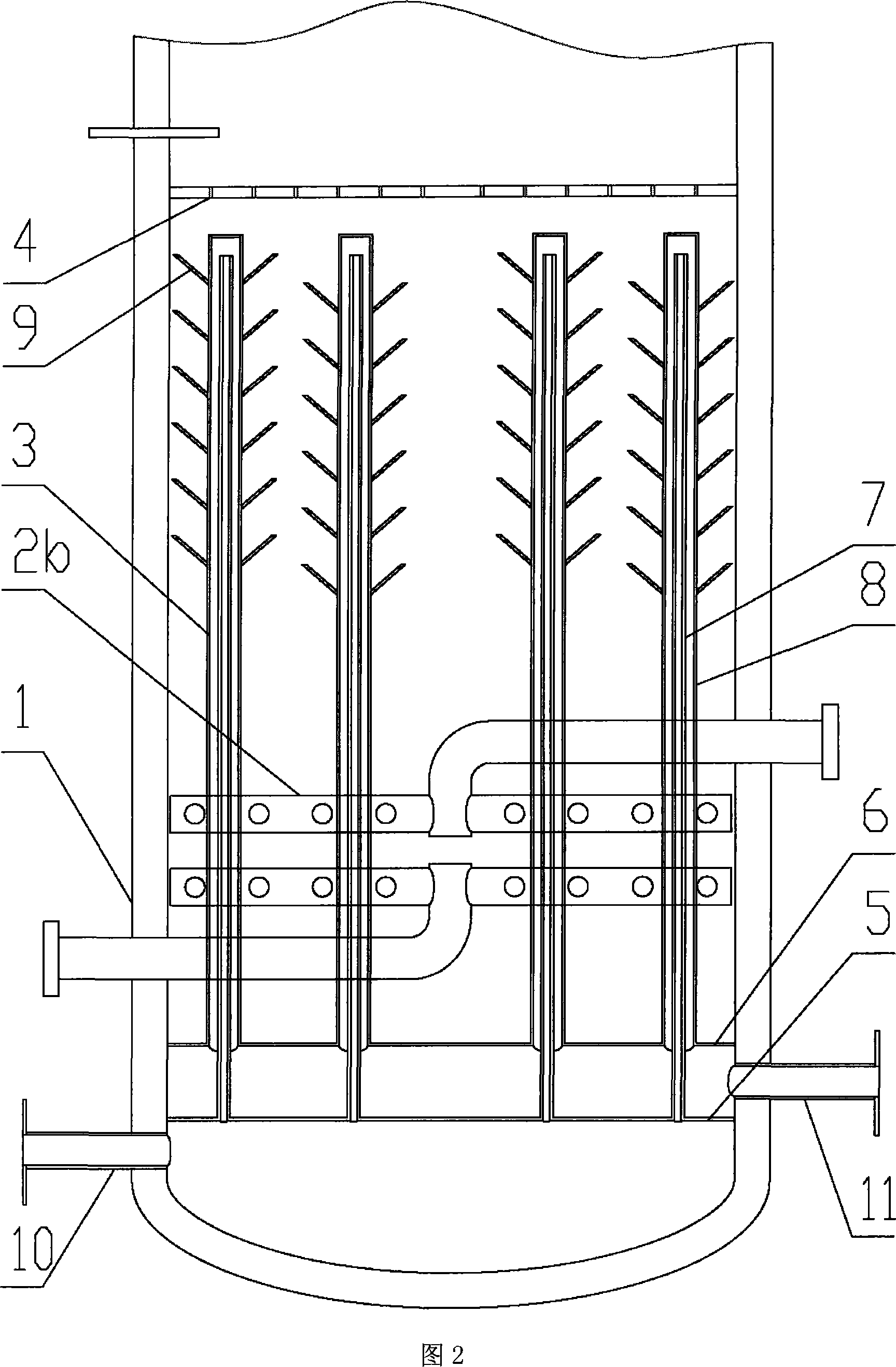

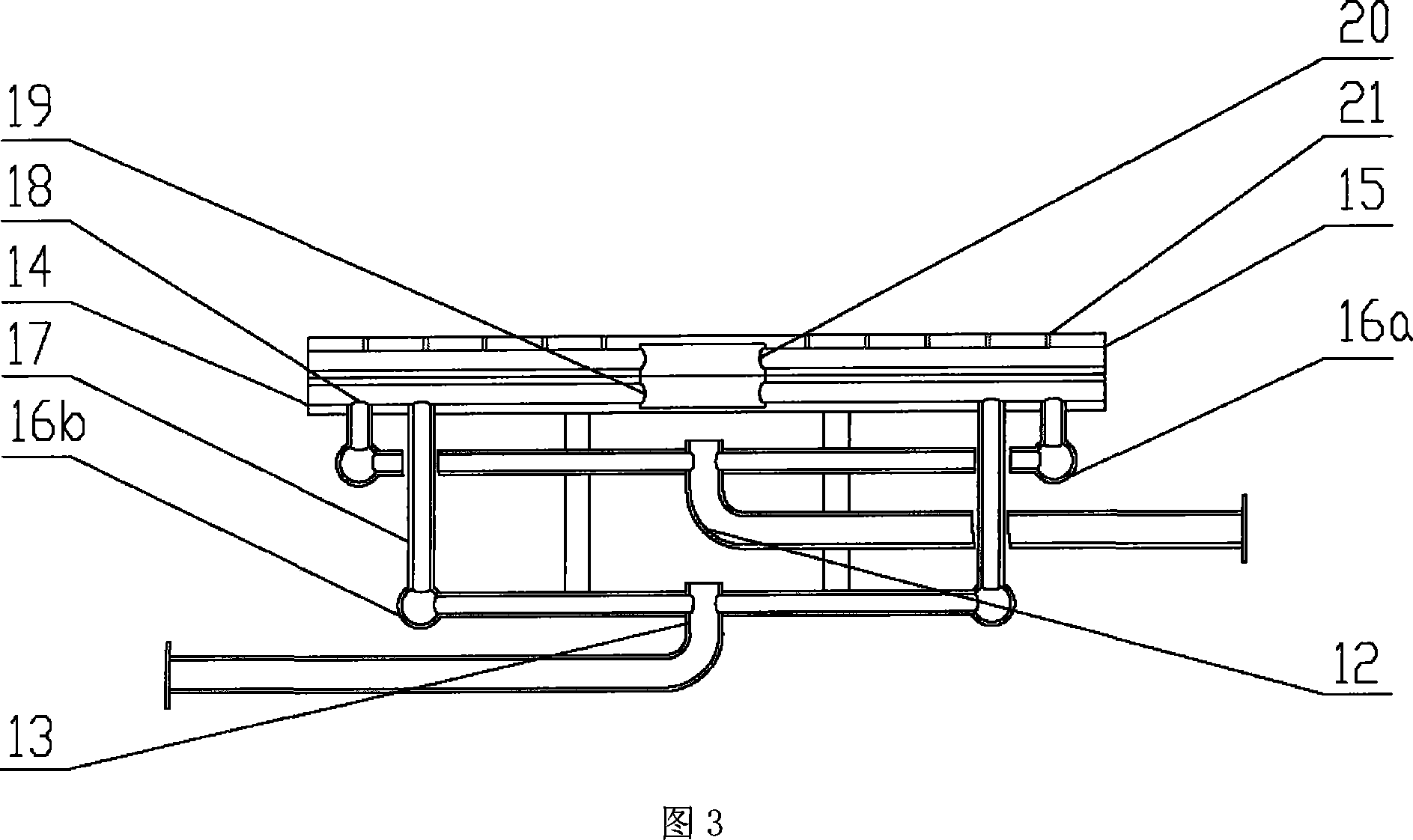

Methane and oxygen pre-mixer

InactiveCN101125282AEvenly distributedRemove in timeHydrogenFlow mixersNuclear engineeringPartial oxidation

The present invention relates to a methane and oxygen pre-mix device, mainly consists of a casing, a gas distributed system, a heat exchange system and a multiorifice gas distribution plate; the gas distributed system adopts the rotational flow or the circular flow gas distributed system; the rotational flow gas distributed system consists of a methane air intake system, an oxygen air intake system, an upper distributor and a lower distributor; the circular flow gas distributed system consists of center feed pipes, cross feed pipes and ring gas distributor of the methane and the oxygen; the heat exchange system consists of an upper separator, a lower separator, a centre internal pipe, an external pipe, a metal fin, a heat exchange medium inlet pipe and a heat exchange medium outlet pipe; via the gas distributed system, the methane and the oxygen have a preliminary mixture in a smaller space, then by the stimulant fluidized bed consisting of the centre internal pipe, the external pipe and the metal fin, circuitously flowing upwards, achieving a molecular level mixture at the exit. The present invention effectively increases the pre-mix effect and guarantees the inflaming retarding and explosion prevention of the pre-mix chamber, having a good function in the industry of methane partial oxidation to syngas.

Owner:TSINGHUA UNIV

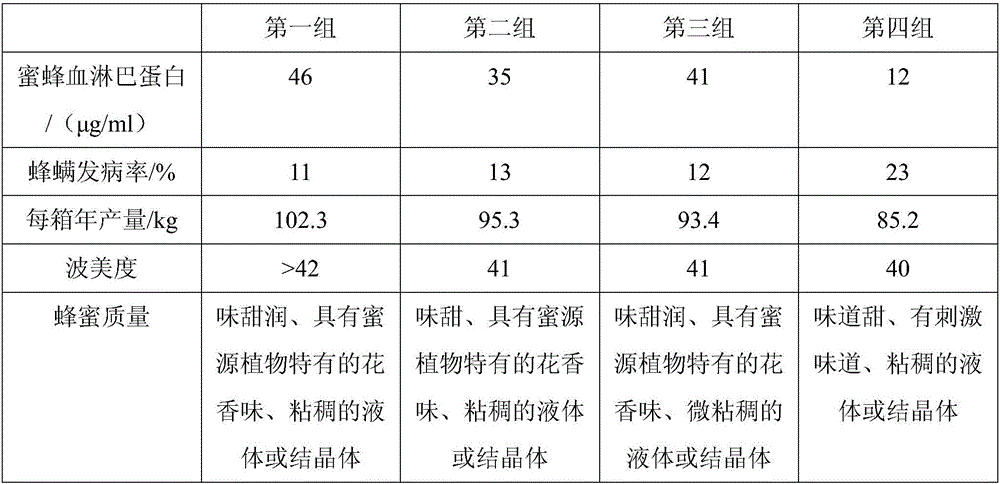

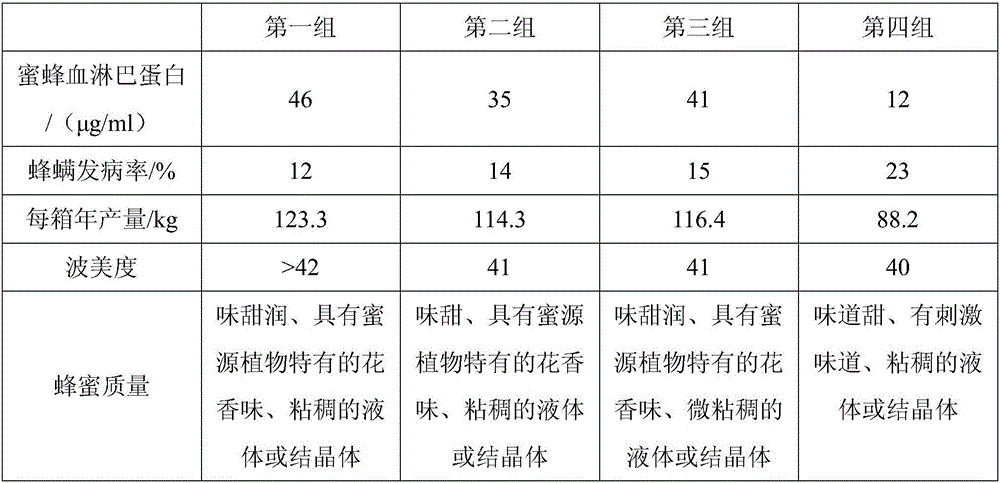

Method for breeding honeybees

InactiveCN106212388AImprove reproductive efficiencyIncrease productivityAnimal feeding stuffAccessory food factorsFruit juiceAnimal science

The invention provides a method for breeding honeybees and belongs to the technical field of animal husbandry. The breeding method comprises following steps: first, selecting a honeybee breeding ground, establishing beehives and eliminating honeybee mites by applying miticides to the beehive regularly; feeding with forage a during nights and additionally feeding with forage b during spawning period of queen bees; the forage a comprises following raw materials: honey, white sugar, banana juice, watermelon juice, sugar cane juice, apple juice, citric acid, edible salt and water; the forage b comprises following raw materials: pollen, soy flour and protein powder. The breeding method is safe and reliable; through breeding ground selecting, bee mite killing and scientific forage feeding, bee colony is gradually developed, wherein the forage is prepared from natural raw materials which can bring sufficient sugar and nutrient for the honeybees, promote well development of honeybees, reduce morbidity, increase the quality and edible safety of honey.

Owner:陆川县乌石镇万意养蜂专业合作社

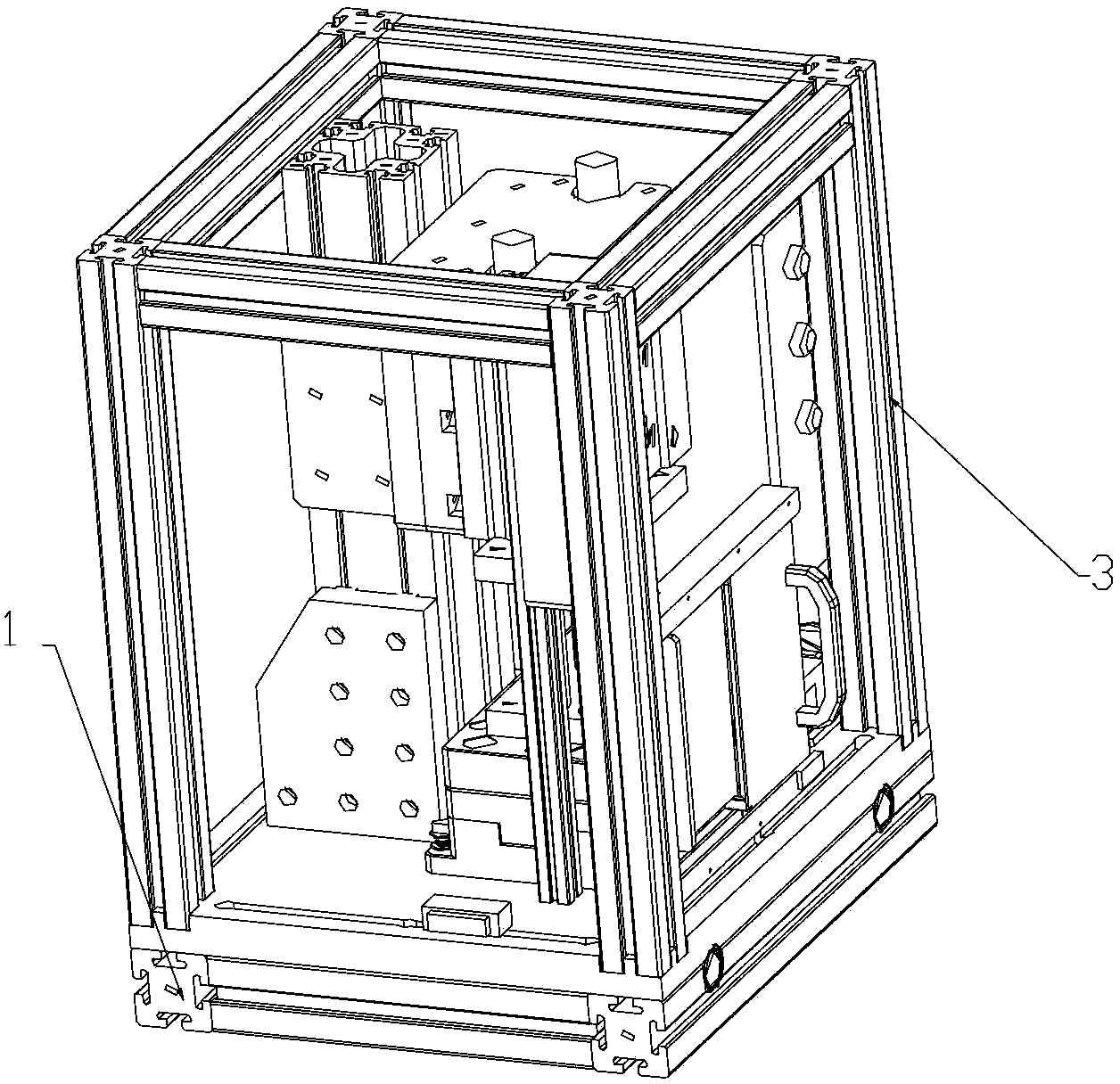

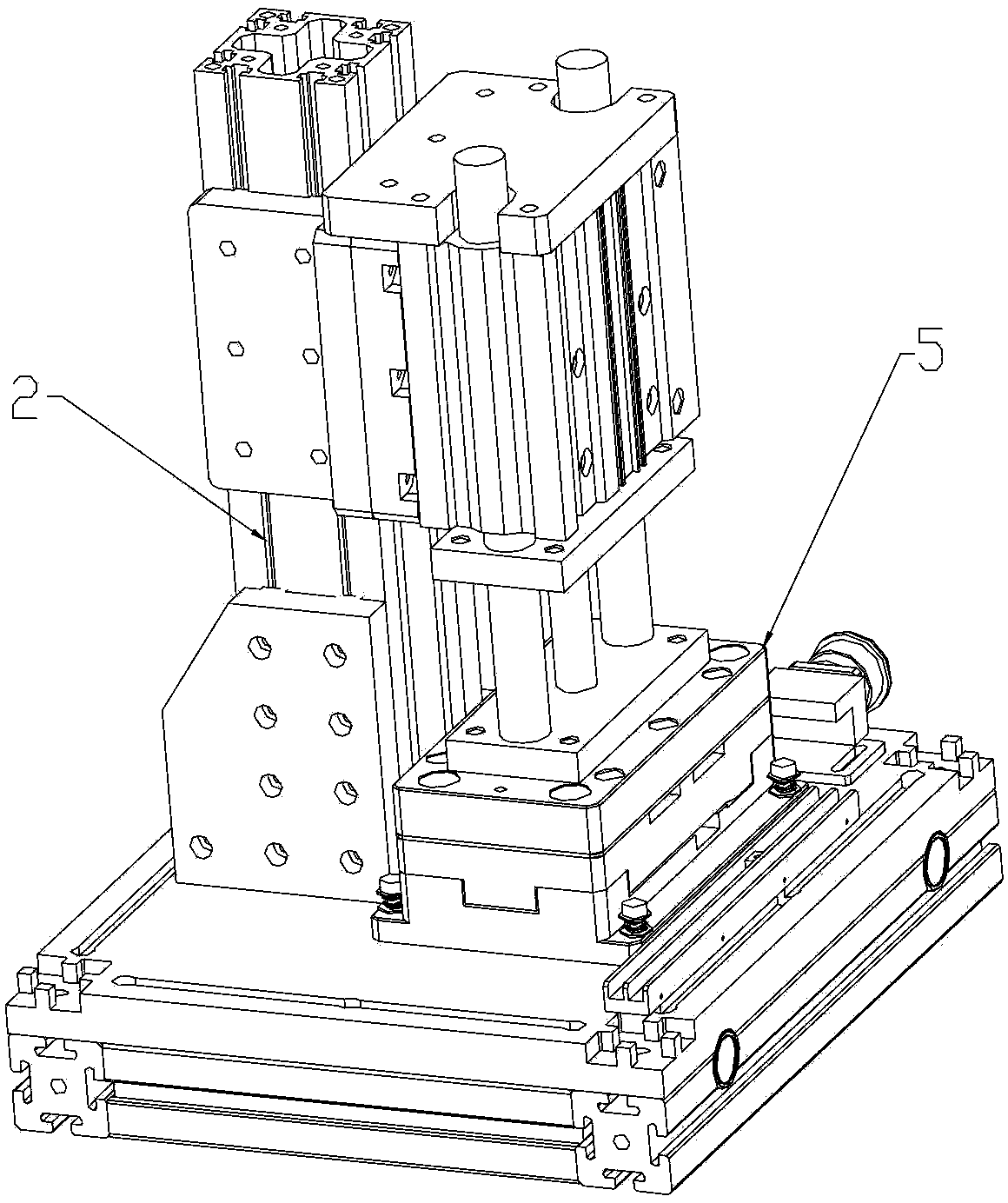

Aging test equipment for electronic products

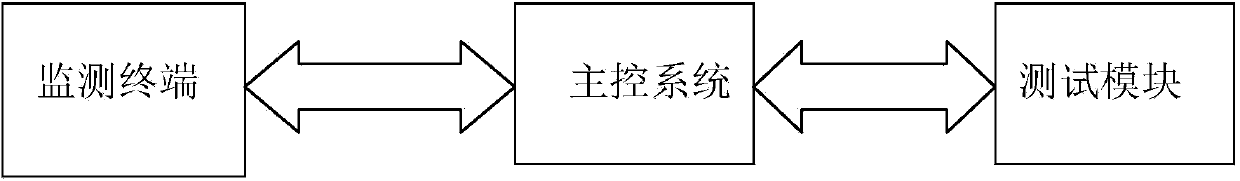

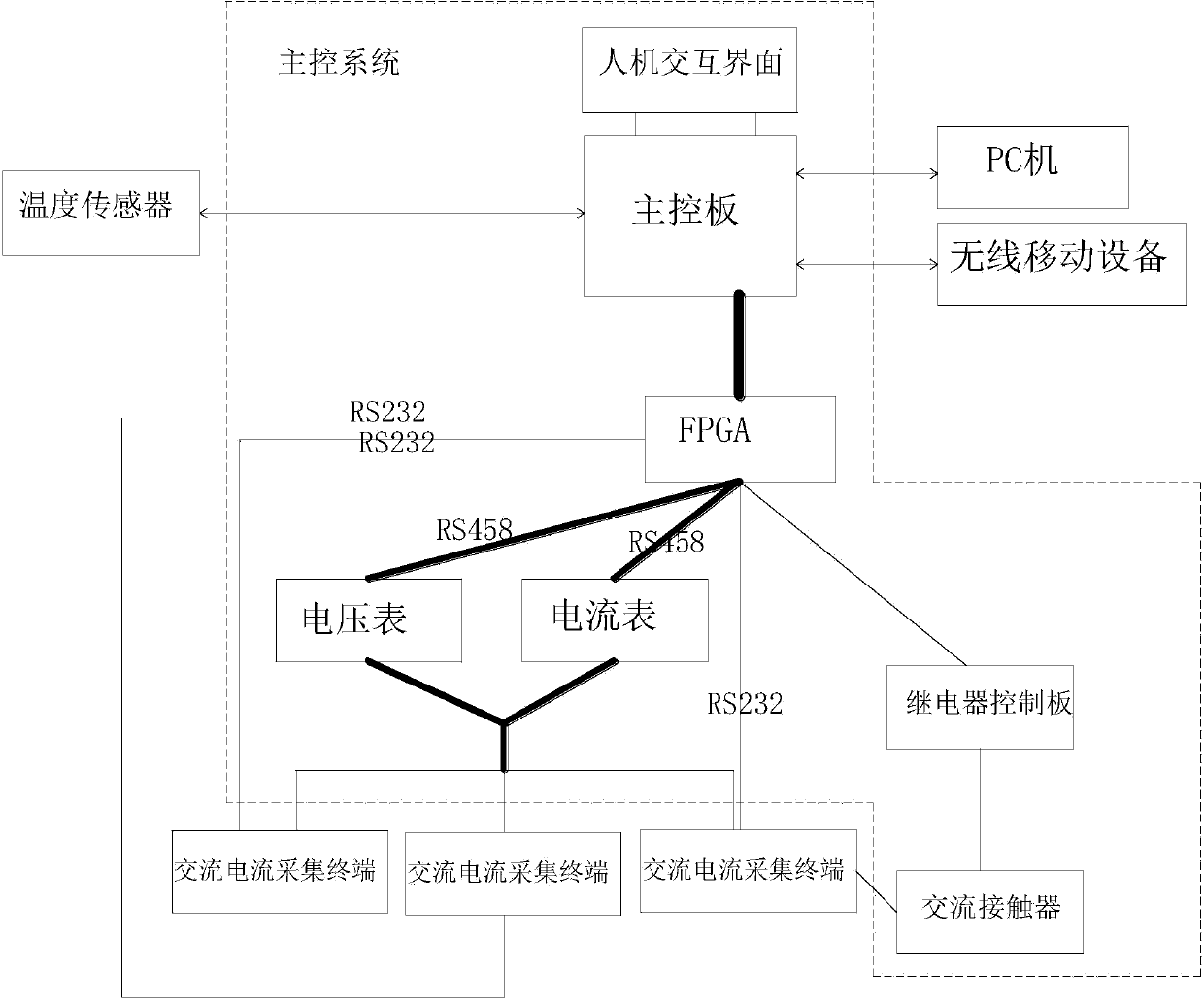

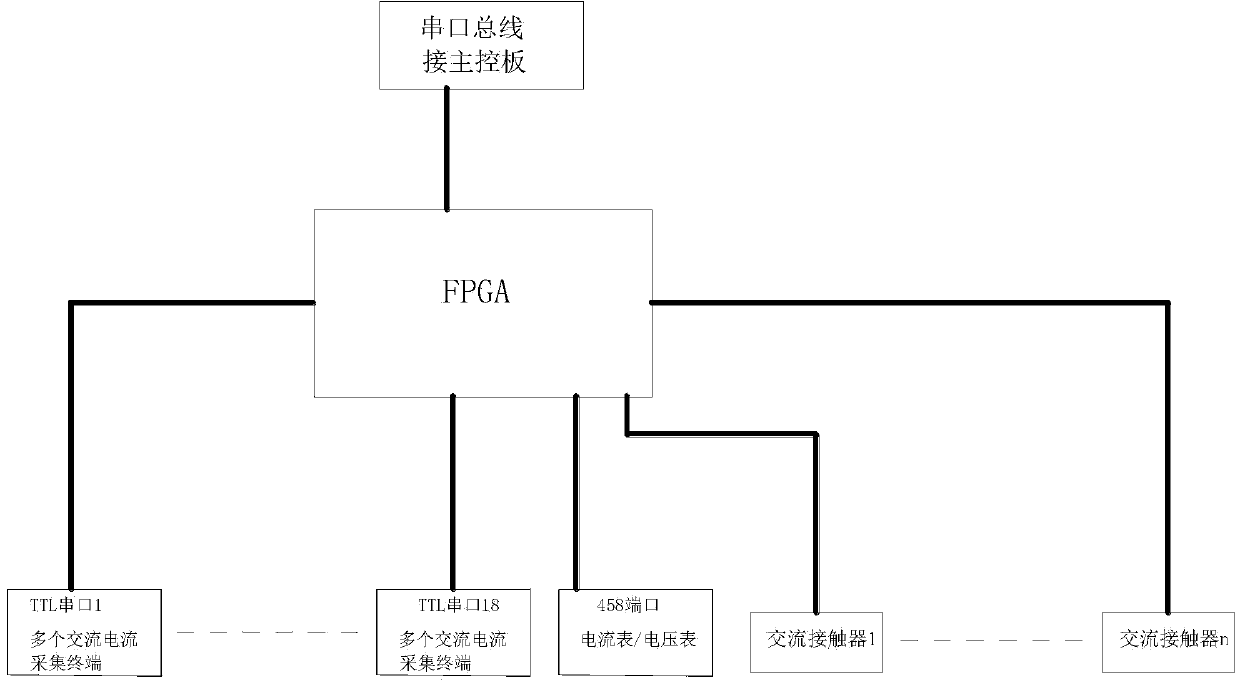

The invention particularly relates to aging test equipment for electronic products. The aging test equipment comprises a test module, a main control system and a monitoring terminal. The test module is in signal connection with the main control system, the main control system is connected with the monitoring terminal, the test module comprises a plurality of alternating-current acquisition terminals, and the main control system comprises a service processing module. The service processing module comprises a main control panel, an FPGA, an ampere meter, a voltmeter and a switch module, wherein the FPGA is respectively and electrically connected with the ampere meter and the voltmeter through ports 458, the FPGA is electrically connected with the alternating-current acquisition terminals which are grouped and combined into a bus and are connected with the ampere meter and the voltmeter respectively, and the FPGA is connected with the main control panel through a serial port bus. The aging test equipment for the electronic products can adapt to the electronic products of different kinds and different powers, can test the electronic products uniformly in batch on a large scale, is high in aging test efficiency and can meet the industrialization demands.

Owner:松阳西屏永新机械厂

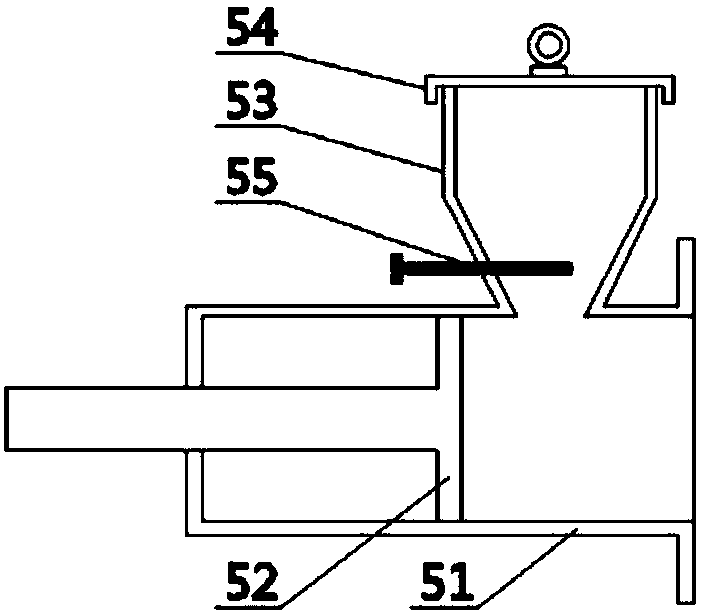

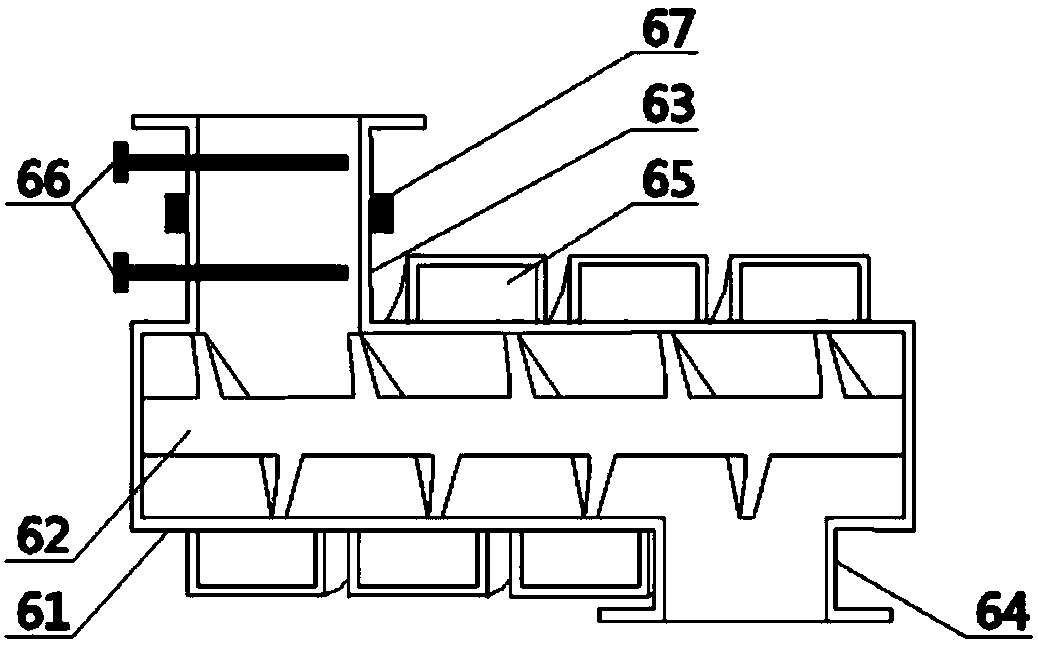

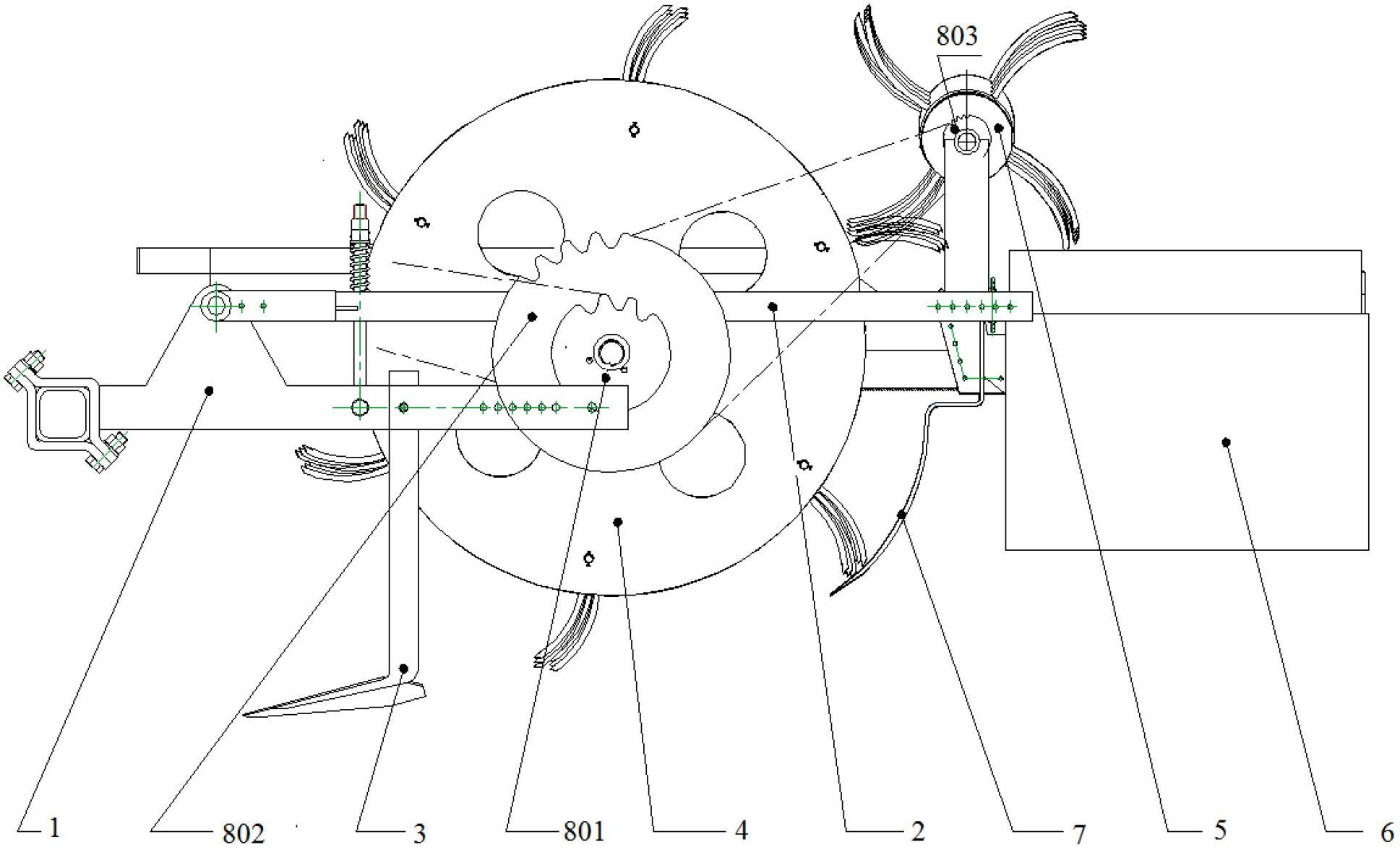

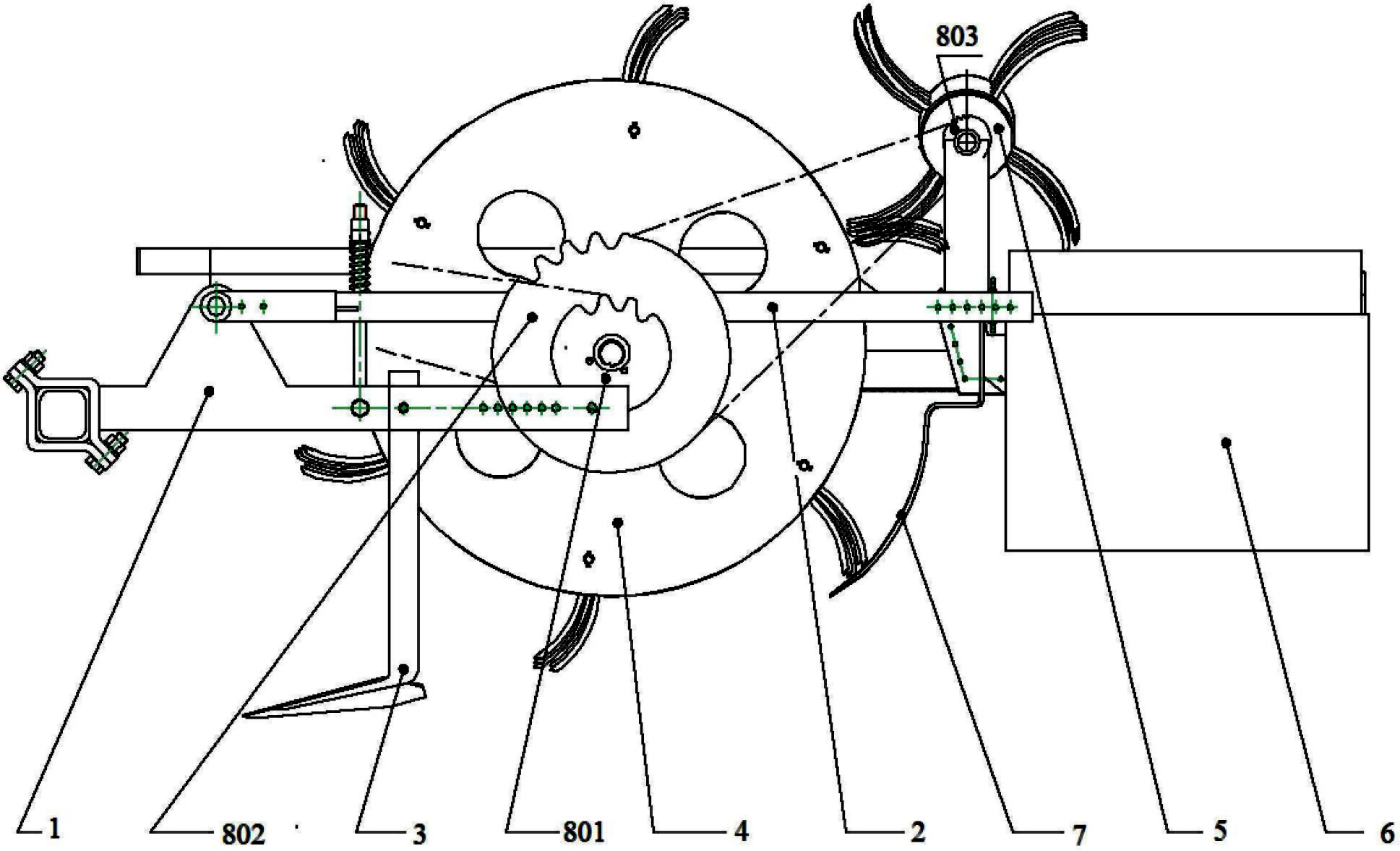

Film-picking and film-unloading mechanism for residual film recovery of straight-rod crops

InactiveCN102668939AReasonable configurationSimple structureGatherer machinesPlant protective coveringsDrive shaftEngineering

The invention belongs to the field of minitype agricultural machinery, and in particular relates to a film-picking and film-unloading mechanism for residual film recovery of straight-rod crops. A frame is connected with a profiling frame; a break shovel is arranged under the middle of the frame; a film-picking component and a film-unloading component are arranged in parallel on the profiling frame according to front and back positions; a first transmission wheel and a second transmission wheel which synchronously move are arranged on a drive shaft of the film-picking component; a third transmission wheel is arranged on a drive shaft of the film-unloading component; the first transmission wheel is connected with a traction mechanism through a chain; the second transmission wheel and the third transmission wheel are driven by the chain; film-rising shovels are arranged behind the film-picking component and on the profiling frame under the film-unloading component; and a film collection box is arranged at the rear end of the profiling frame. The mechanism is reasonable in arrangement, simple in structure and reliable in film-picking and film-unloading, low in cost and is convenient and feasible, and is convenient to mount and repair; and moreover, the mechanism can continuously operate, and the film can be picked cleanly.

Owner:CHINA AGRI UNIV

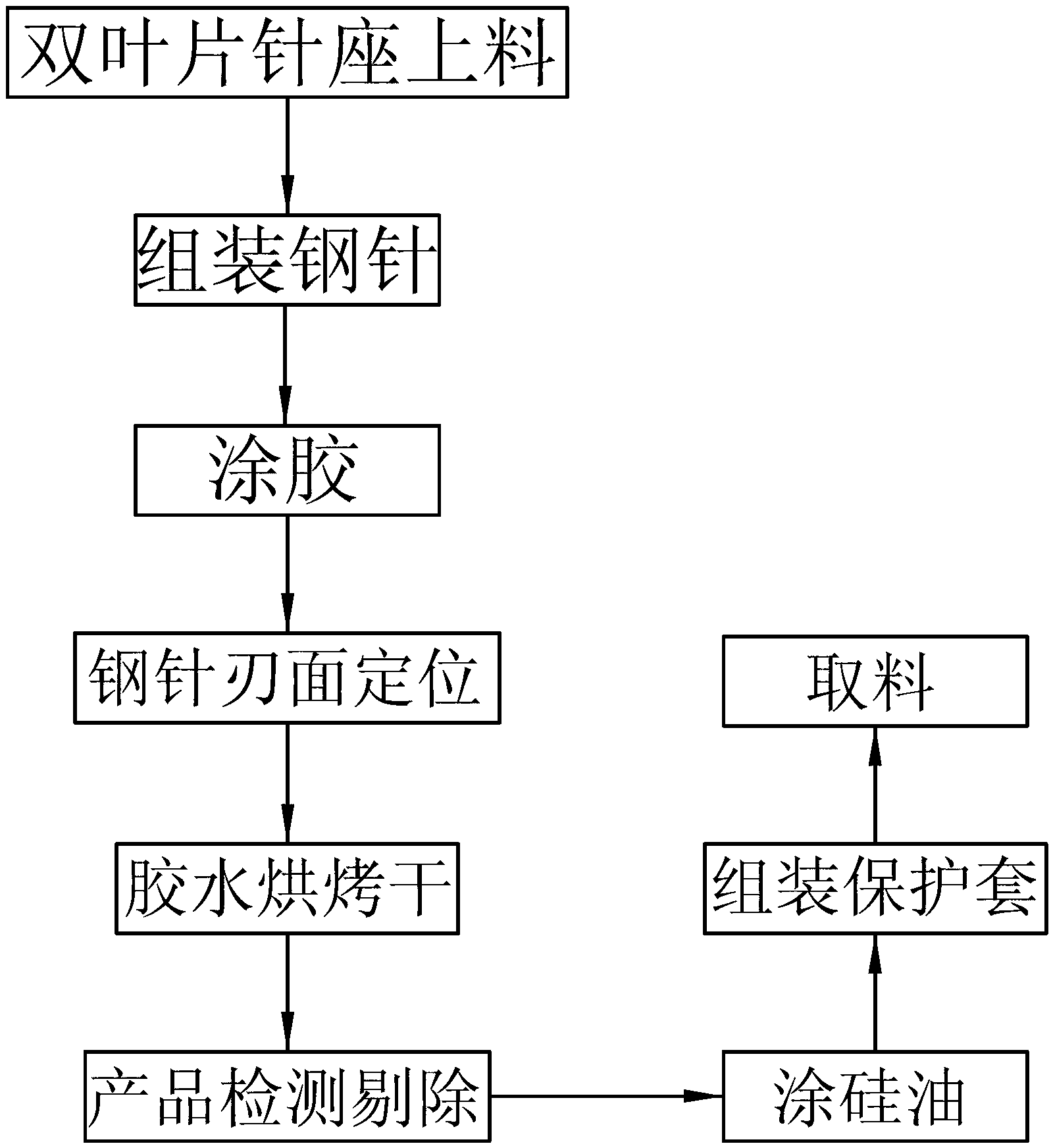

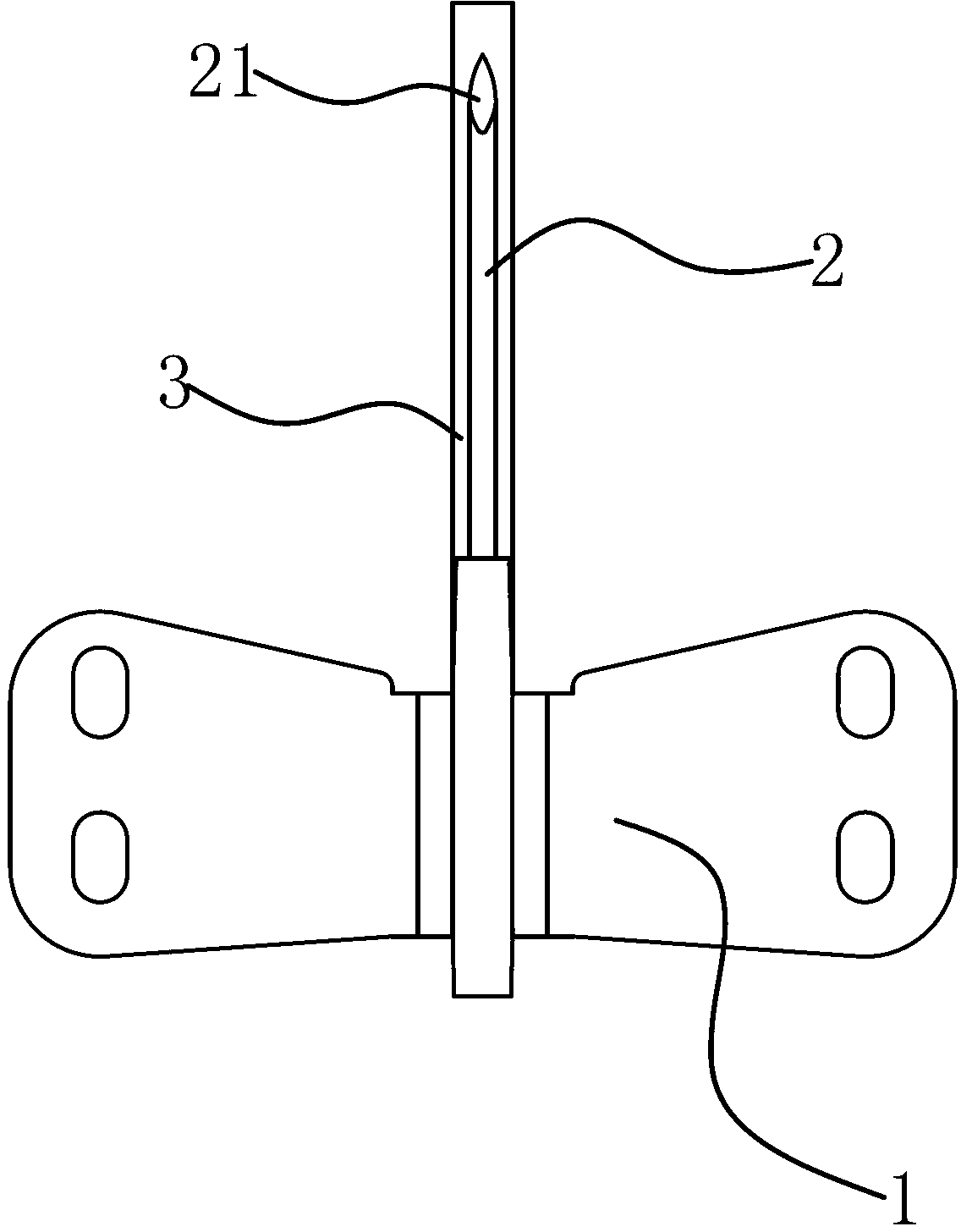

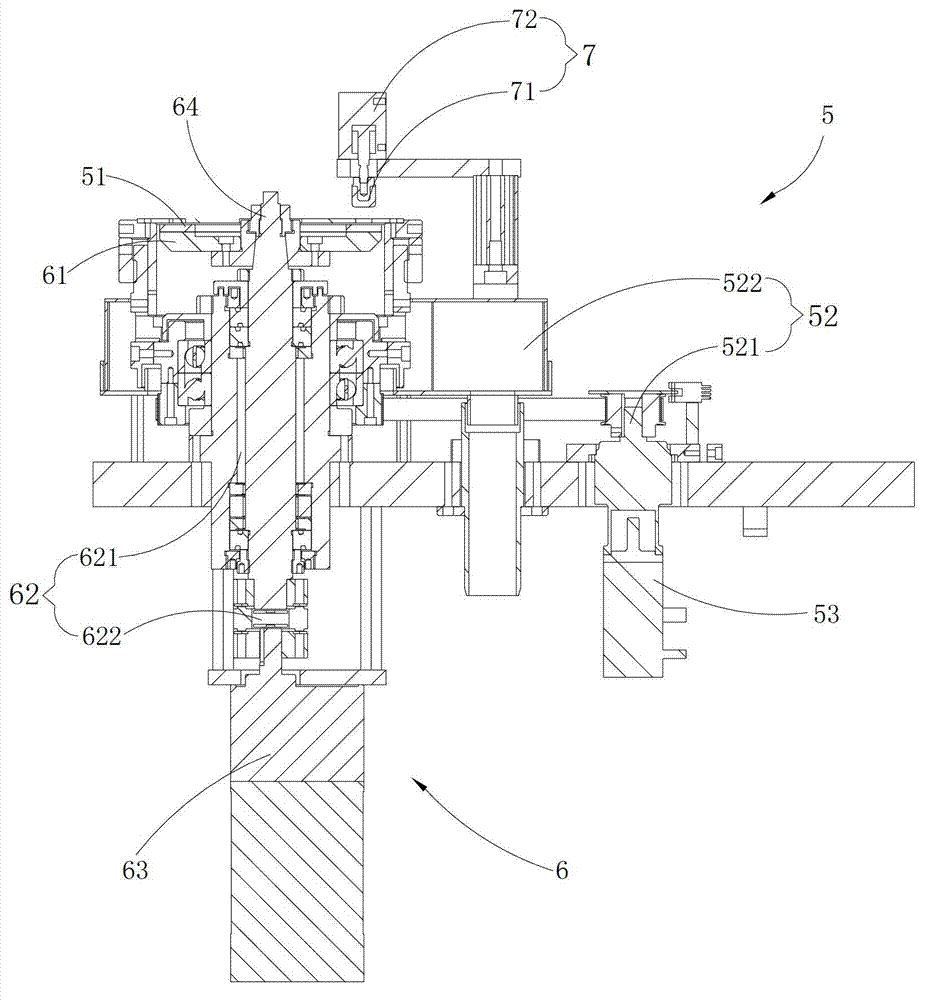

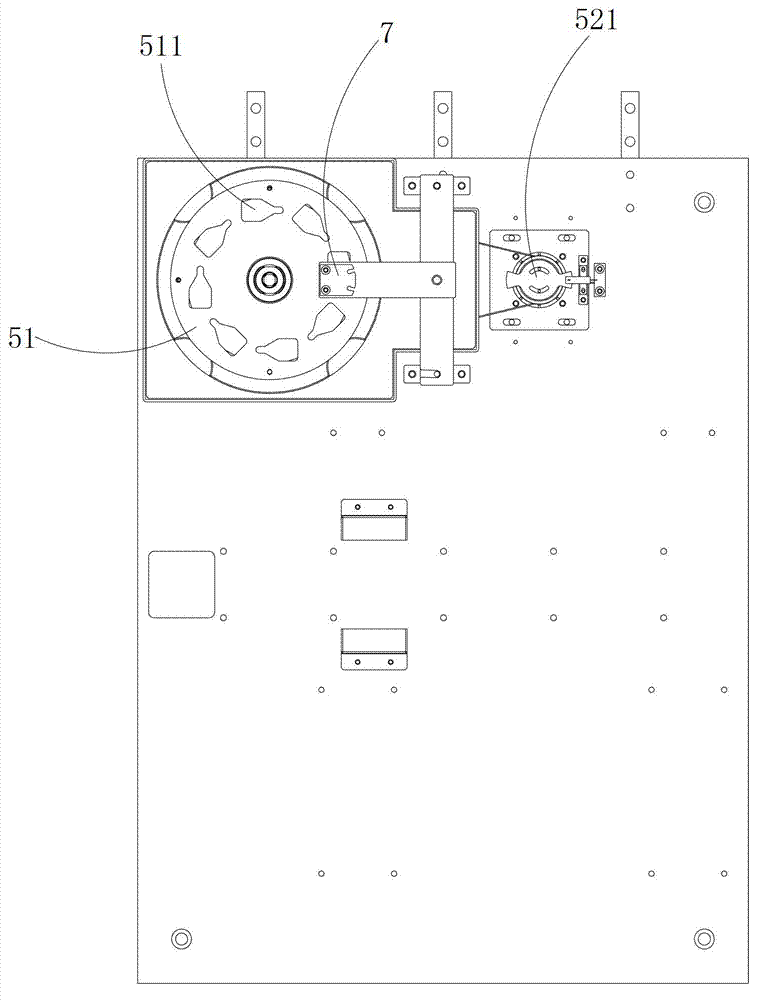

Assembly technology of medical venous needle

The invention provides an assembly technology of a medical venous needle and belongs to the technical field of medical devices. The assembly technology of the medical venous needle solves the technical problems that the assembly quality and the assembly efficiency of a product are lower in the prior art. The venous needle comprises a double-vane needle stand, a steel needle and a protective sleeve. The assembly technology comprises the following processes of: A, charging materials to the needle stand, B, assembling the steel needle, C, applying glue, D, drying the glue, E, assembling the protective sleeve, and F, taking out the venous needle. The assembly technology has the advantages of good assembly quality, high assembly efficiency and the like.

Owner:MAIDER MEDICAL IND EQUIP

Melon grafting method

InactiveCN102293105ARemove in timeIncrease humiditySeed and root treatmentHorticultureRootstockHigh survival rate

The invention discloses a melon grafting and grafting method, comprising: rationally selecting rootstocks, determining a suitable sowing date, seed treatment and germination, cultivating rootstocks and scion seedlings, grafting methods and management after grafting. The advantages are: high survival rate and no pollution to the environment.

Owner:刘秀英

Bee breeding method

InactiveCN106172250AImprove reproductive efficiencyIncrease productivityBiocideAnimal feeding stuffItalian beePollen

The invention provides a honeybee breeding method and belongs to the technical field of animal husbandry. The breeding method includes the following steps: firstly, select a bee breeding place, set up a beehive, and regularly apply acaricide to the beehive to remove bee mites; then, select North China bee, Italian bee and Northeast black bee as parents, Breeding bees with stable and excellent properties as bee species; and feeding feed a made of honey, white sugar, orange juice, tomato juice, longan juice, grape juice, citric acid, edible salt, water, and natural pollen, Feed b made of defatted soybean flour, white sugar and appropriate amount of water. The invention provides a honeybee breeding method. The breeding method is safe and reliable. The North China honeybee, Italian honeybee and Northeast honeybee are scientifically bred to obtain a honeybee with high yield, cold resistance, mite resistance and disease prevention. species, and then fed scientifically and rationally to promote the healthy development of bees, reduce the incidence of morbidity, and improve the quality and food safety of honey.

Owner:陆川县乌石镇万意养蜂专业合作社

Hatching method for adhesive fish egg

InactiveCN101822231ANovel structureRemove in timeClimate change adaptationPisciculture and aquariaWater flowTemperature difference

The invention relates to a hatching method for adhesive fish eggs, belonging to the technical field of fish reproduction. The invention is an improved invention. The fish nests of the invention are flat hatching net sheets sewn by using a frame made of iron wires and polyethylene net sheets. On each hatching net sheet 7000-8000 eggs with grain size of 2mm are evenly distributed. The hatching net sheets on which eggs are distributed are statically placed for two minutes and then are sequentially suspended in a covered hatching pond for hatching in running water. Fifteen to twenty hatching net sheets are placed in each square meter of water surface in the hatching pond. Hatching water flow is controlled to be 3-5m<3> / hour, water temperature is controlled to be 11 DEG C-18 DEG C and daily temperature difference does not exceed 2 DEG C; broken egg skins and other impurities are absorbed out everyday through siphonage; the date that fish fries break through egg membranes is the seventh day to the fifteenth day. The invention has the advantages that the hatching facilities are simple, the operation is convenient, the water flow exchange is good, the damaged eggs and the dead fries can be observed easily and removed in time, the water molds are effectively prevented from breeding, the hatching rate of fertilized eggs is high and the promotion and the popularization are easy.

Owner:云南省水产技术推广站

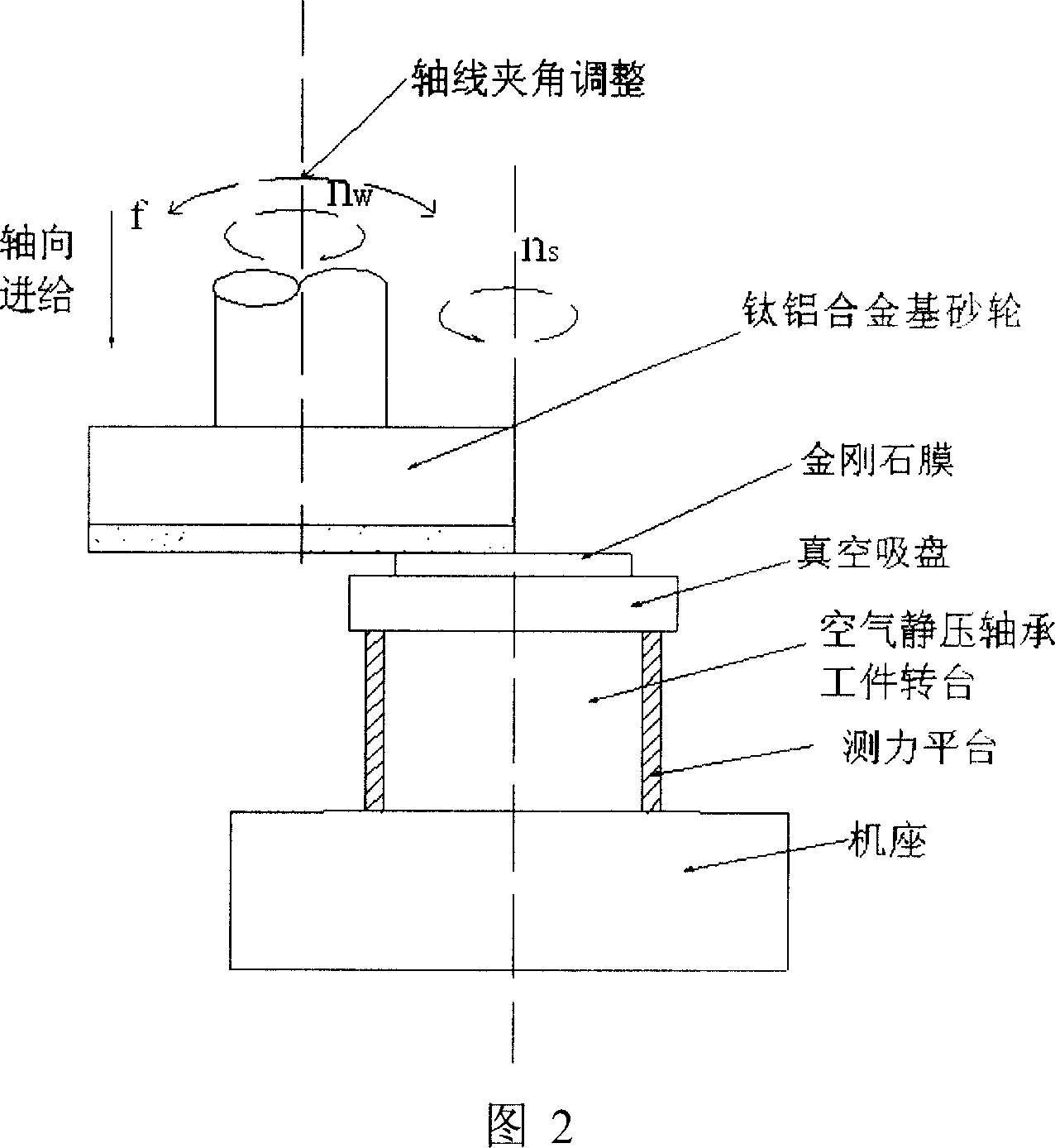

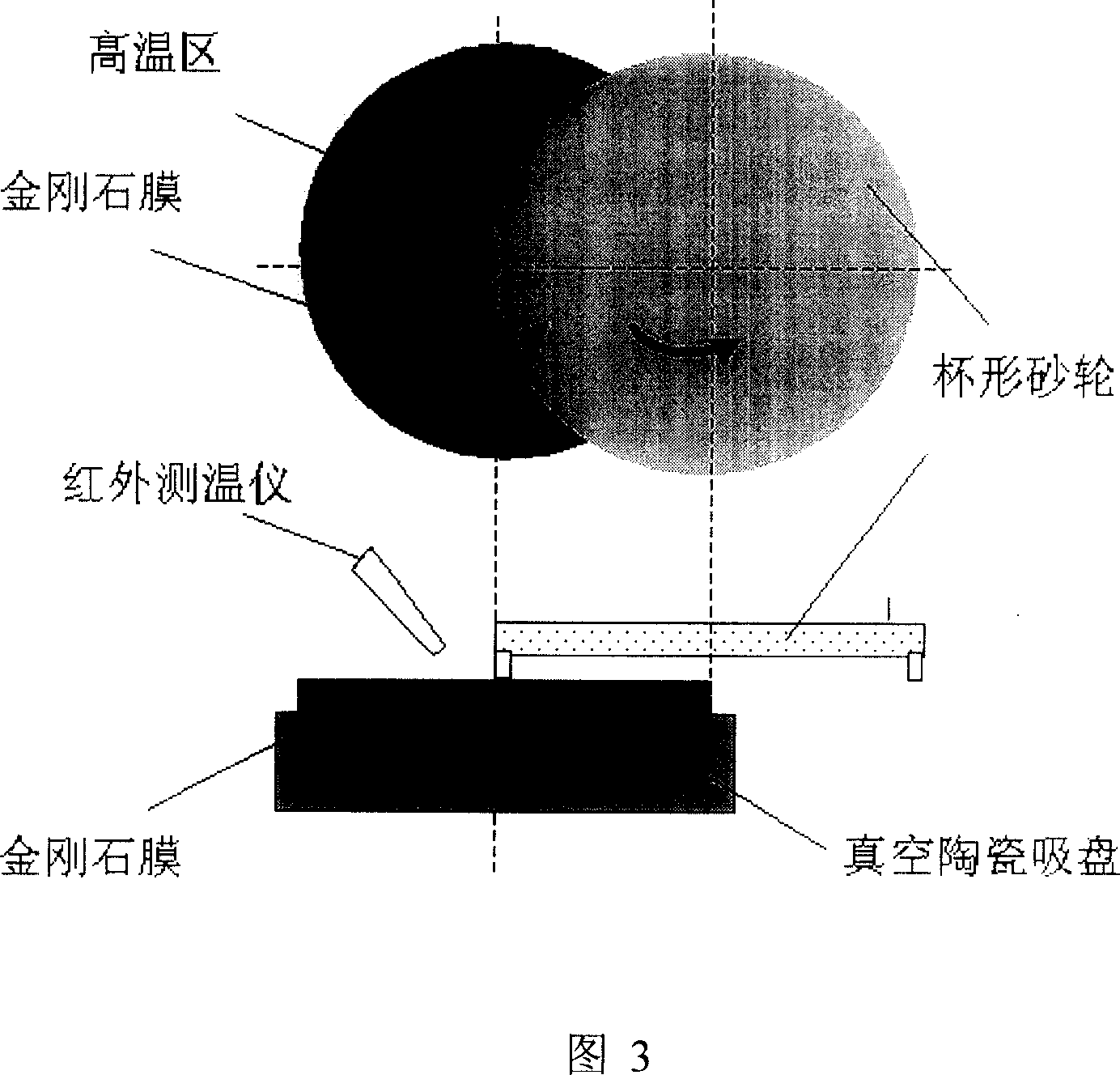

Processing method for flattening large dimension diamond diaphragm

InactiveCN1947939AEfficient processingLow costPlane surface grinding machinesTemperature controlChemical reaction

A method for smoothing and polishing a large-area diamond membrane includes such steps as fixing a CVD diamond membrane (2-5 inches in diameter) onto a bench by vacuum suction cup, installing a cup-shaped abrasive disc to the mainshaft of high-speed super-precision machine-tool, and making the mainshaft and bench to rotate in different directions at 1000-10000 rpm and 0-500 rpm respectively for grinding while controlling the surface temp of diamond membrane to 650-950 deg.C for preventing thermochemical reaction.

Owner:DALIAN UNIV OF TECH

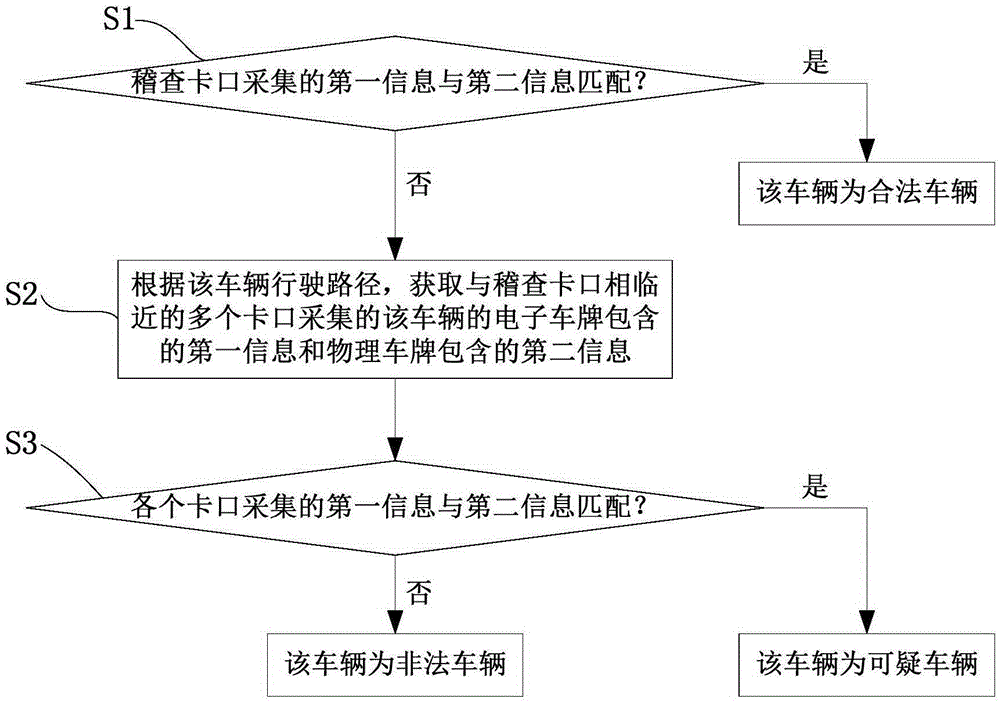

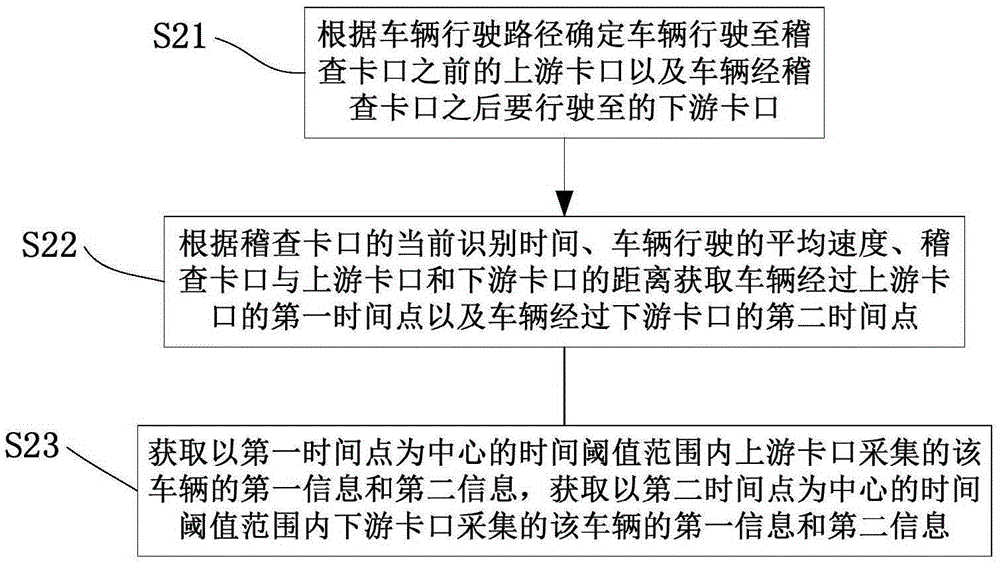

Vehicle identification method, vehicle identification device and inspection system

ActiveCN105225493AAvoid Misjudgment SituationsImprove recognition rateRoad vehicles traffic controlEngineeringLicense

The invention provides a vehicle identification method and a vehicle identification device. The method includes the following steps that: whether first information contained in the electronic license plate of a vehicle is matched with second information contained in the physical license plate of the same vehicle is judged, wherein the first information and the second information are acquired by a certain inspection gate, if the first information is matched with the second information, the vehicle is judged as a legal vehicle; if the first information is not matched with the second information, first information contained in the electronic license plate and second information contained in the physical license plate of the same vehicle acquired by a plurality of inspection gates which are adjacent to the inspection gate are obtained according to the driving path of the vehicle; and whether the first information and the second information which are acquired by each inspection gate are matched with each other is judged, if the first information is not matched with the second information, the vehicle is finally judged as an illegal vehicle. According to the method, when the second information cannot be clearly identified due to poor external environment, and the first information cannot be matched with the second information, the above judgment result can be verified through judging whether the first information and the second information of the same vehicle which are acquired by the plurality of inspection gates which are adjacent to the inspection gate are matched each other, and therefore, misjudgment caused by unclear identification of the physical license plate in a vehicle recognition process can be avoided.

Owner:BEIJING E HUALU INFORMATION TECH +1

Material discharge device

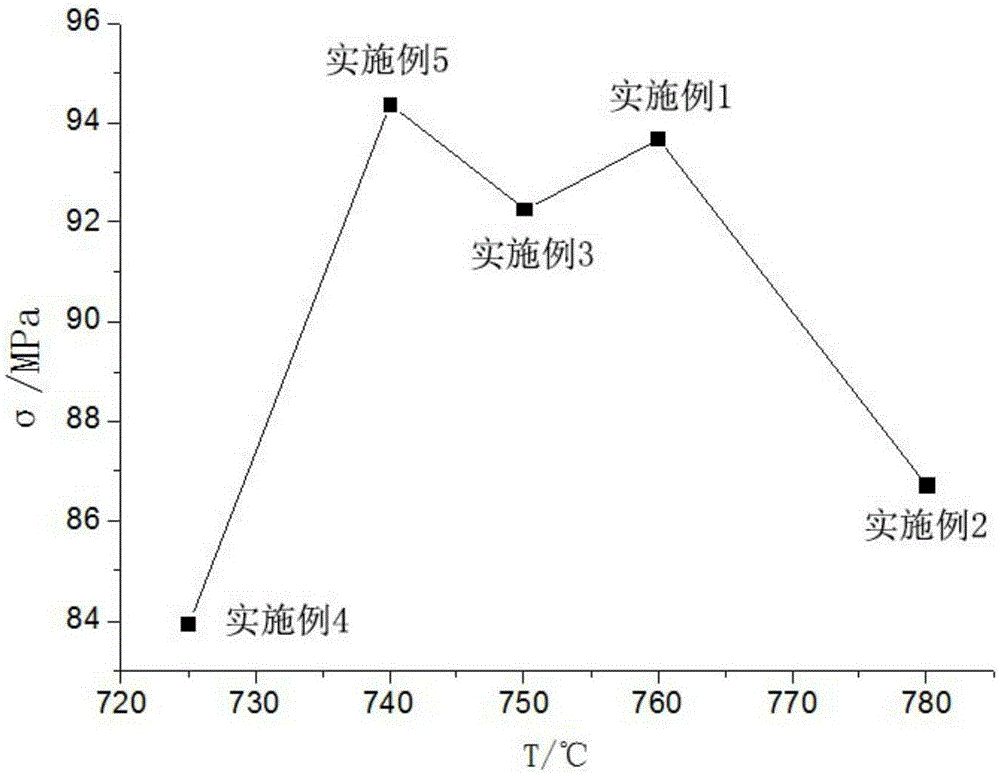

ActiveCN103112714AImprove accuracyRemove in timeLapping machinesConveyor partsEngineeringUltimate tensile strength

The invention belongs to the product collecting and discharging technical field, and discloses a material discharge device. The material discharge device is used for sequentially collecting and discharging of products, wherein the material discharge device comprises a feed mechanism, a material collecting mechanism, a tracking and positioning mechanism, a mechanical hand assembly and a control center. The feed mechanism comprises a feed material plate, a feed material support and a first transmitting mechanism, the material collecting mechanism comprises a material collecting material plate, a material collecting material support and a transmitting platform, and the tracking and positioning mechanism comprises a positioner and a first push rod assembly. The mechanical hand assembly is used for clipping and collecting the products which are arranged disorderly on the feed material plate on the material collecting material plate, and therefore the purpose of sequentially collecting and discharging the products is achieved; the tracking and positioning mechanism is used for tracking and positioning locations of the products, and therefore an accuracy rate of clipping the products of the mechanical hand assembly is effectively improved. Further, the control center is used for uniformly controlling operation of all parts, and therefore the material discharge device is high in automation degree, accurate and reliable in action, and capable of reducing labor intensity of people, reducing output of labor cost, and improving working efficiency.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

High-yield breeding method of honeybees

ActiveCN106070083AImprove reproductive efficiencyIncrease productivityBiocideAnimal feeding stuffAnimal sciencePollen

The invention provides a high-yield breeding method of honeybees and belongs to the technical field of livestock breeding. The breeding method comprises the following steps: firstly, selecting a honeybee breeding farm and arranging beehives; applying miticides to the beehives at a fixed period to remove honeybee mites; feeding feed a in the nighttime of breeding the honeybees; additionally feeding feed b in a spawning period of a queen bee, wherein the feed a is prepared from the following raw materials: honey, white sugar, snow pear juice, Hami melon juice, grapefruit juice, lychee juice, citric acid, table salt and water; and the feed b is prepared from the following raw materials: pollen, skimmed milk powder and protein powder. The breeding method provided by the invention is safe and reliable; bee swarms can become large gradually through selecting the breeding farm, killing the honeybee mites and scientifically and reasonably feeding the feed; the feed is scientifically composed of the natural raw materials and can provide sufficient sugar and nutrients to the honeybees, so that healthy development of the honeybees is accelerated and the morbidity is reduced; and the yield and eating safety of the honeybees are improved.

Owner:陆川县乌石镇万意养蜂专业合作社

Capsule polishing and conveying device

InactiveCN106363512AOrderly rowsRemove in timePolishing machinesGrinding/polishing safety devicesSpray nozzleEngineering

The invention discloses a capsule polishing and conveying device. The capsule polishing and conveying device comprises a rack, a discharging groove, a vibration discharging device, capsule conveying guide rails, an auxiliary discharging brush roller, an auxiliary transition brush roller, a rotary brush roller, feeding brush rollers, an ion blower, an air blowing plate, air gathering spraying nozzles, observation electric eyes, a dust collection hopper and a dust collection motor. By means of the capsule polishing and conveying device, capsules can be synchronously polished in the conveying process, the polishing faces are even, the polishing efficiency is high, the polished capsules are arranged in order, operation of a next working procedure is facilitated, the structure is reasonable, and operation is simple.

Owner:ZHEJIANG CHUNBAO CAPSULES

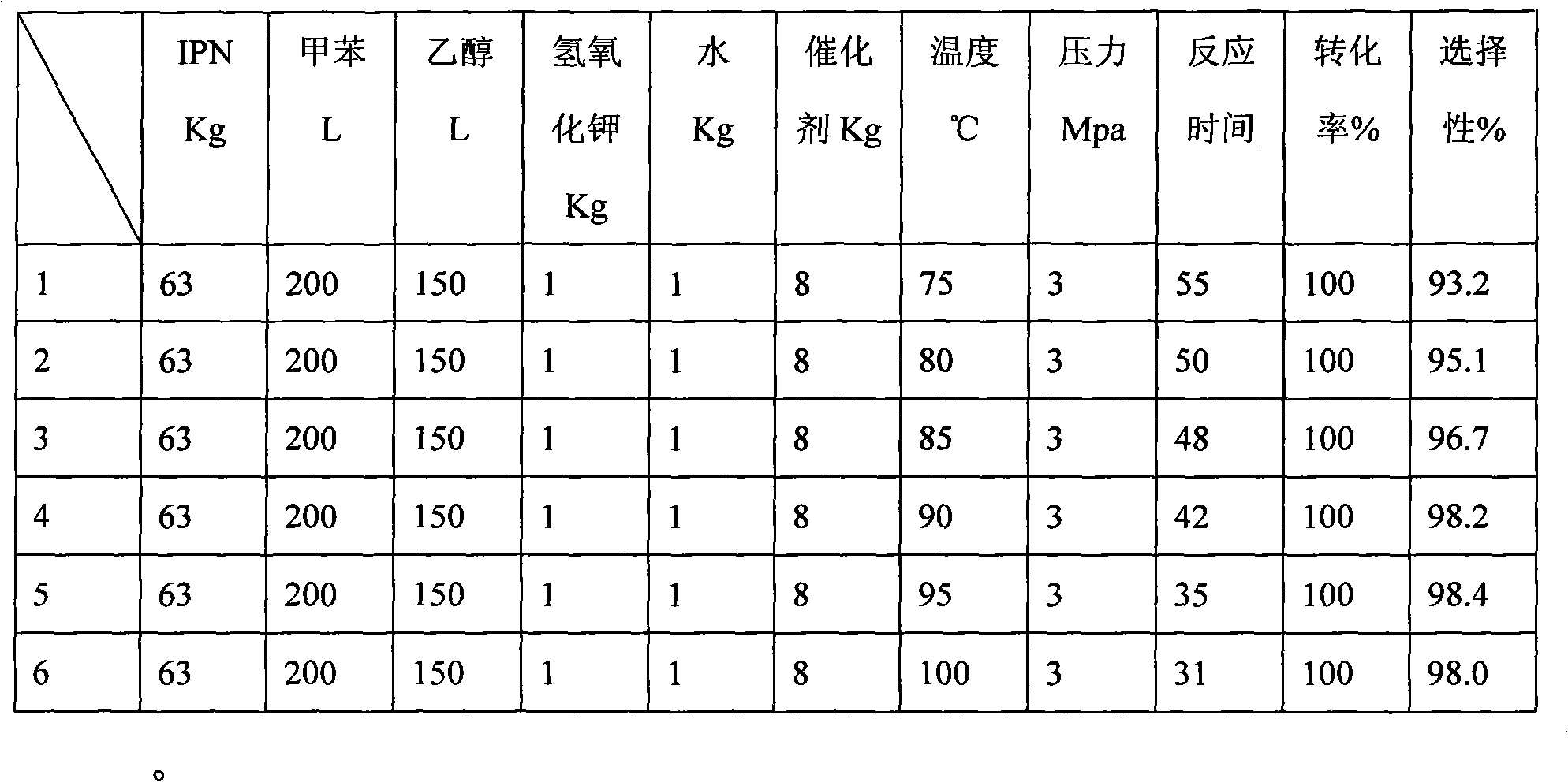

Preparation method of meta-xylylene diamine

ActiveCN101955433AIncrease contactSmall diameterOrganic compound preparationAmino compound preparationXylyleneAlcohol

The invention discloses a preparation method of meta-xylylene diamine. In an autoclave, Raney Nickel is used as a catalyst, the mixture of arene and alcohol is used as a solvent, and a hydrogenation reaction of m-phthalonitrile is performed for 20 to 90 minutes at the temperature of 40 to 120 DEG C and under a pressure of 2 to 10 MPa to generate the meta-xylylene diamine, wherein the hydrogenation reaction is performed by using a hydrogen intake distributor in the autoclave; the heat exchanger of the autoclave employs an external circulating heat exchanger and the reaction liquid in need of exchanging heat is pumped into the external circulating heat exchanger by a high pressure pump to exchange heat. The reaction of the preparation method of meta-xylylene diamine is stable and performed quickly under a low pressure with high yield.

Owner:CAC NANTONG CHEM

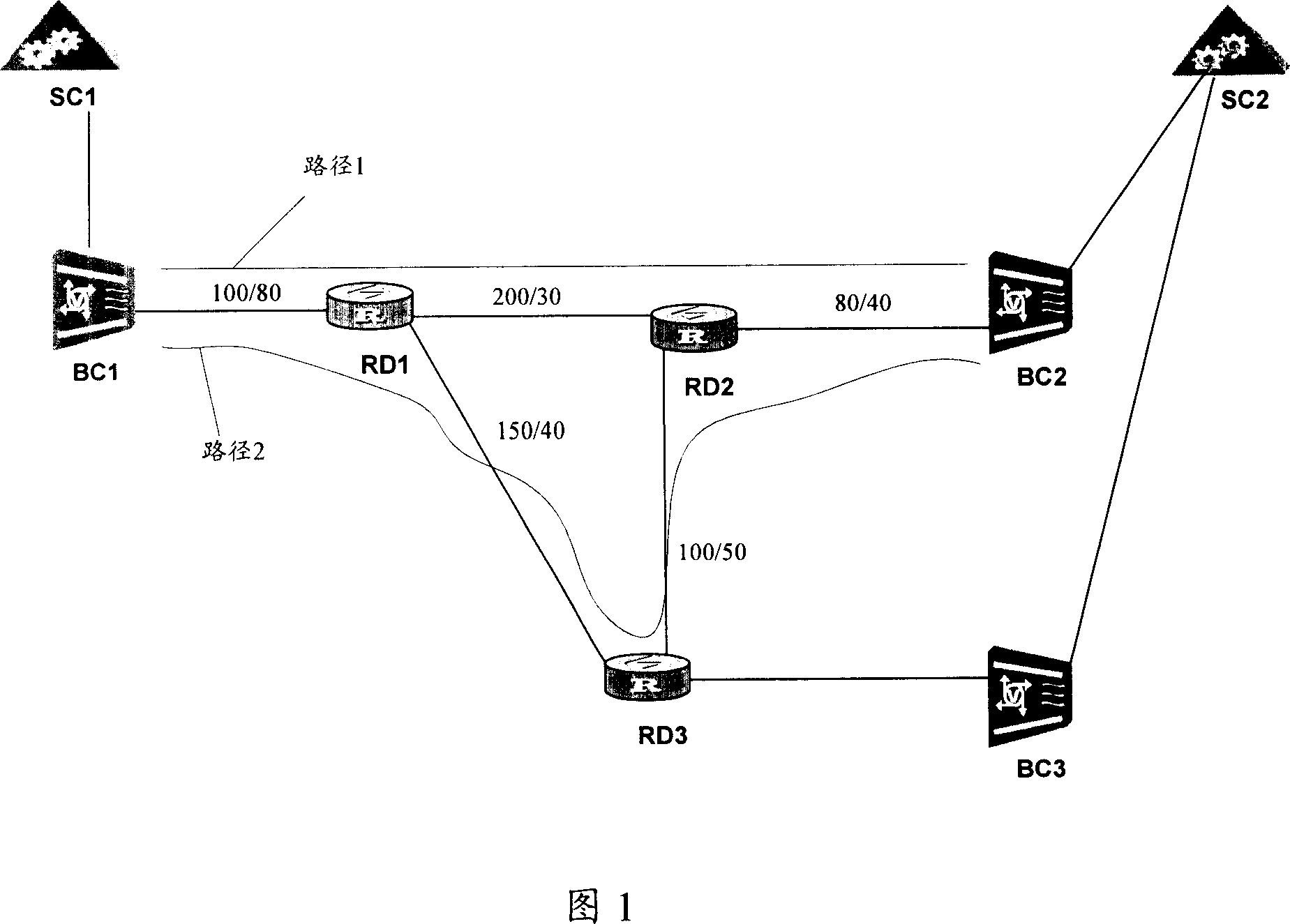

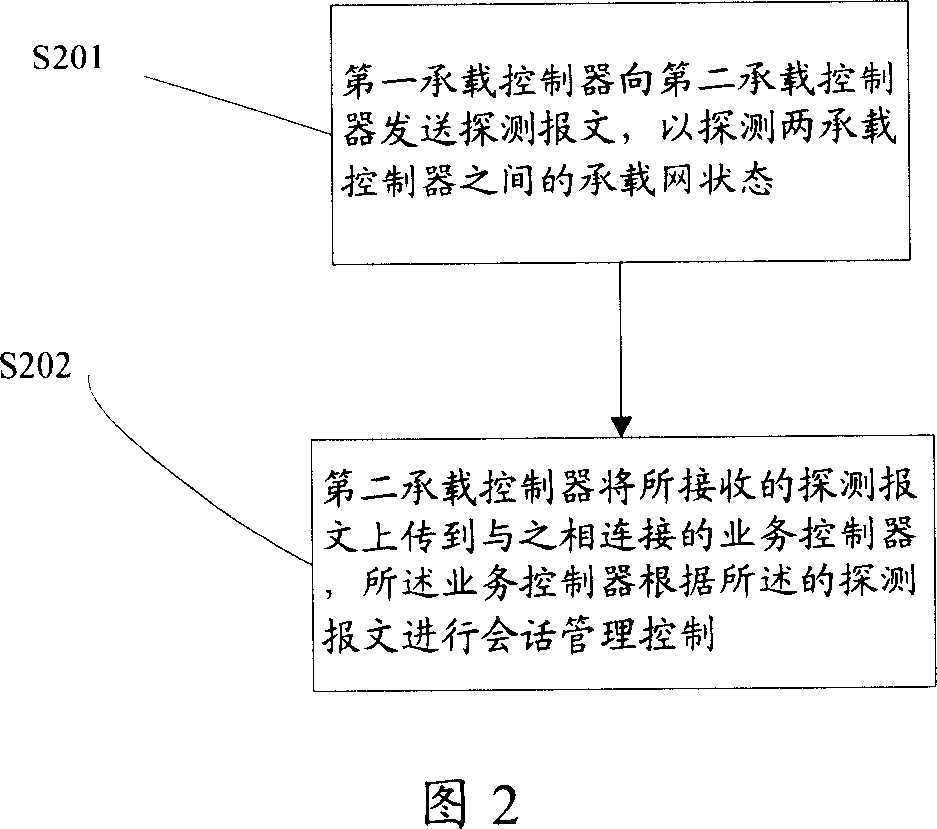

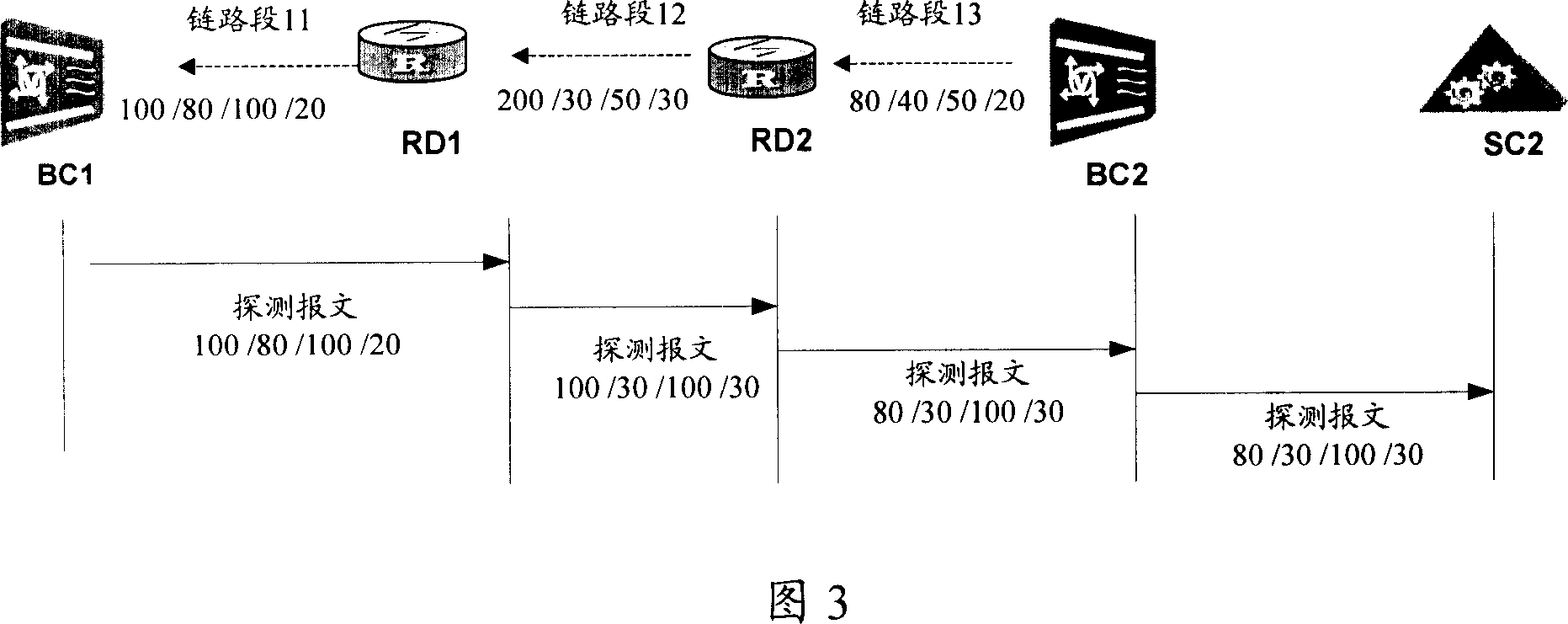

Conversation management control method of IP bearing net

ActiveCN101052037AGuarantee service qualityImprove user experienceData switching networksSession controlSession management

The method comprises: the first bearer controller sends a detection message to the second bearer controller in order to detect the state of bearer network between two bearer controllers; the second bearer controller reports the received detection message to the service controller; according to the detection message, the service controller makes session control. By invention, the service controller can get the state of bearer network in each time interval, and according to the information about the state of bearer network, takes relevant operations.

Owner:HUAWEI TECH CO LTD

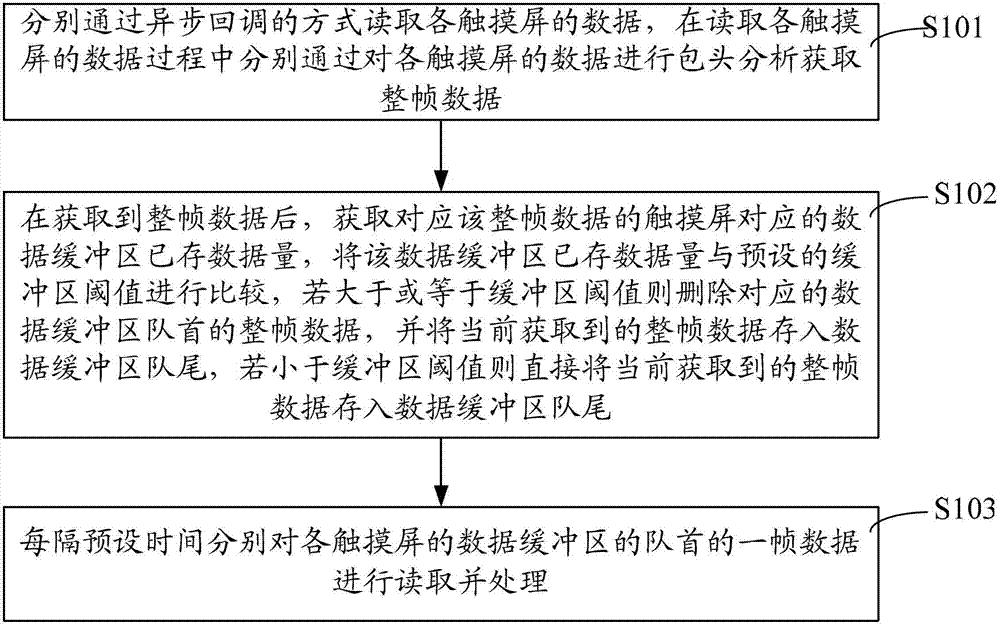

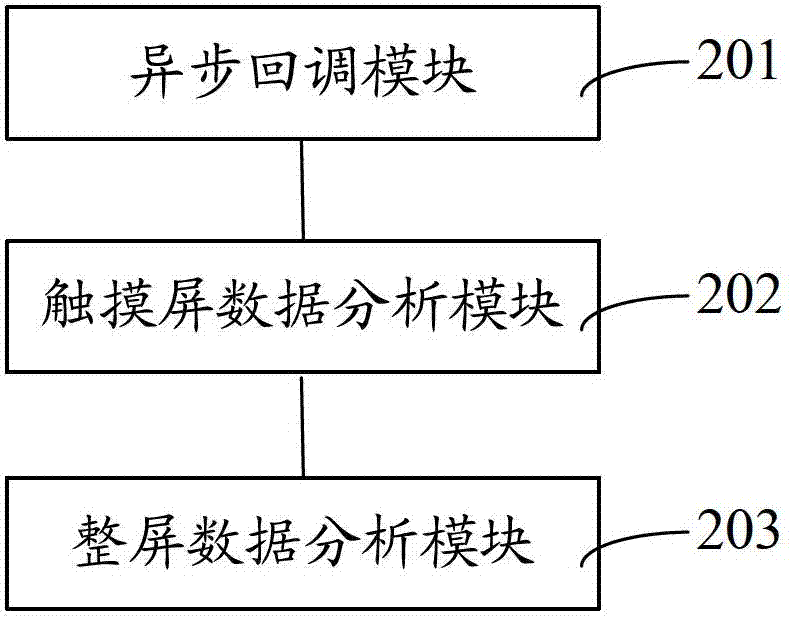

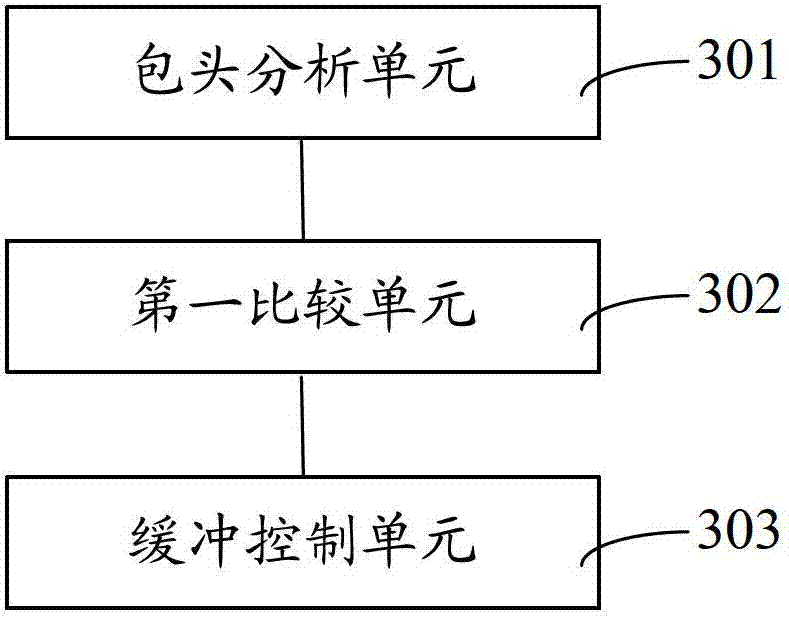

Multi-screen splicing touch control method and system

InactiveCN102789336AAvoid skippingLow latencyInput/output processes for data processingData bufferTime delays

The invention provides a multi-screen splicing touch control method and a system. The method comprises the following steps of: respectively reading the data of each touch screen in an asynchronous callback manner and obtaining whole-frame data through respectively carrying out packet head analysis on the data of each touch screen in the process of reading the data of each touch screen; after the whole-frame data is obtained, obtaining data volume stored in a data buffer area corresponding to the touch screen corresponding to the whole-frame data, comparing the data volume stored in the data buffer area with a preset buffer area threshold value, deleting the whole-frame data of a corresponding data buffer area queue head if the data volume is larger than or equal to the buffer area threshold value and storing the currently-obtained whole-frame data into a data buffer area queue tail; directly storing the currently-obtained whole-frame data into the data buffer area queue tail if the data volume is less than the buffer area threshold value; and respectively reading and processing the one-frame data of the data buffer area queue head on each touch screen every a preset time. The invention can solve the problems of touch time delay caused by data asynchronization and touch interrupt caused by discontinuity.

Owner:GUANGDONG VTRON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com