Preparation method of meta-xylylene diamine

A technology for m-xylylenediamine and isophthalonitrile, which is applied in the field of preparing m-xylylenediamine, can solve problems such as difficulty in meeting heat transfer requirements, catalyst damage, limited heat exchange area, etc., and achieves convenient cleaning and equipment installation, The effect of smooth response and strict response control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

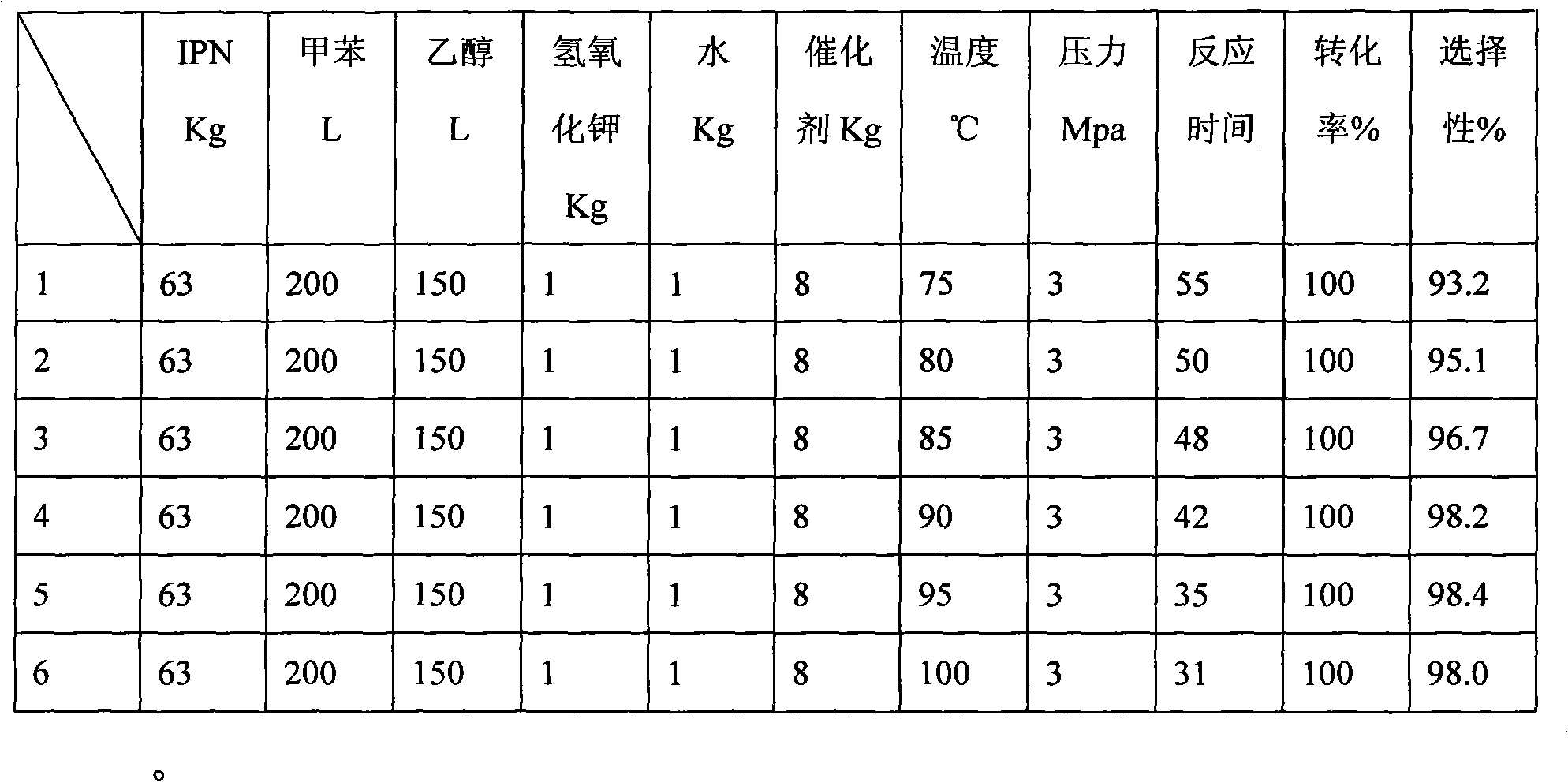

[0024] In the 1m with hydrogen gas inlet distributor and external circulation corrugated casing heat exchanger 3 Drop into 63kg isophthalonitrile (IPN) successively in autoclave, 200L toluene, 150L ethanol, 1Kg potassium hydroxide, 1Kg water and 8Kg Raney's nickel catalyst, close still, use H 2 Fill to 0.3Mpa and replace the air three times, then pass H 2 To the reaction pressure of 2-3pa, turn on stirring and heat to 90-100°C, turn on the high-pressure pump to circulate the reaction liquid once every 10 minutes, and pour 80°C deionized water into the corrugated casing with a flow rate of 20M 3 / h; continuously pass hydrogen until no more hydrogen is absorbed, stop the high-pressure pump at this time, cool the reaction solution to 30°C and stop stirring, and use N 2 Replaced 3 times, settled the reaction solution for 30 minutes to separate the catalyst, pressed out the supernatant (MXDA reaction solution), and used the catalyst in the lower layer. The analytical yield of m-x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com