Patents

Literature

444 results about "Catalytic method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

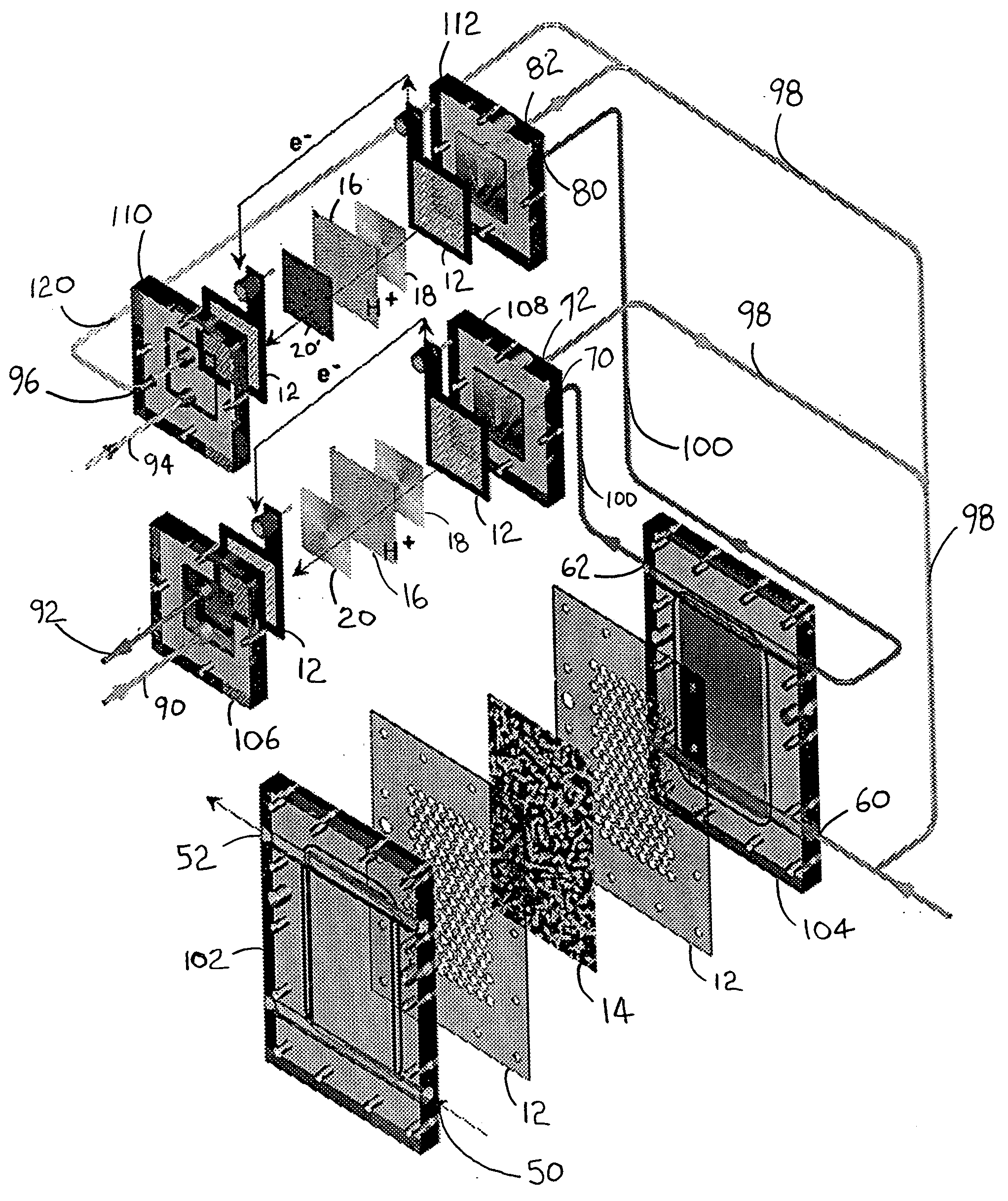

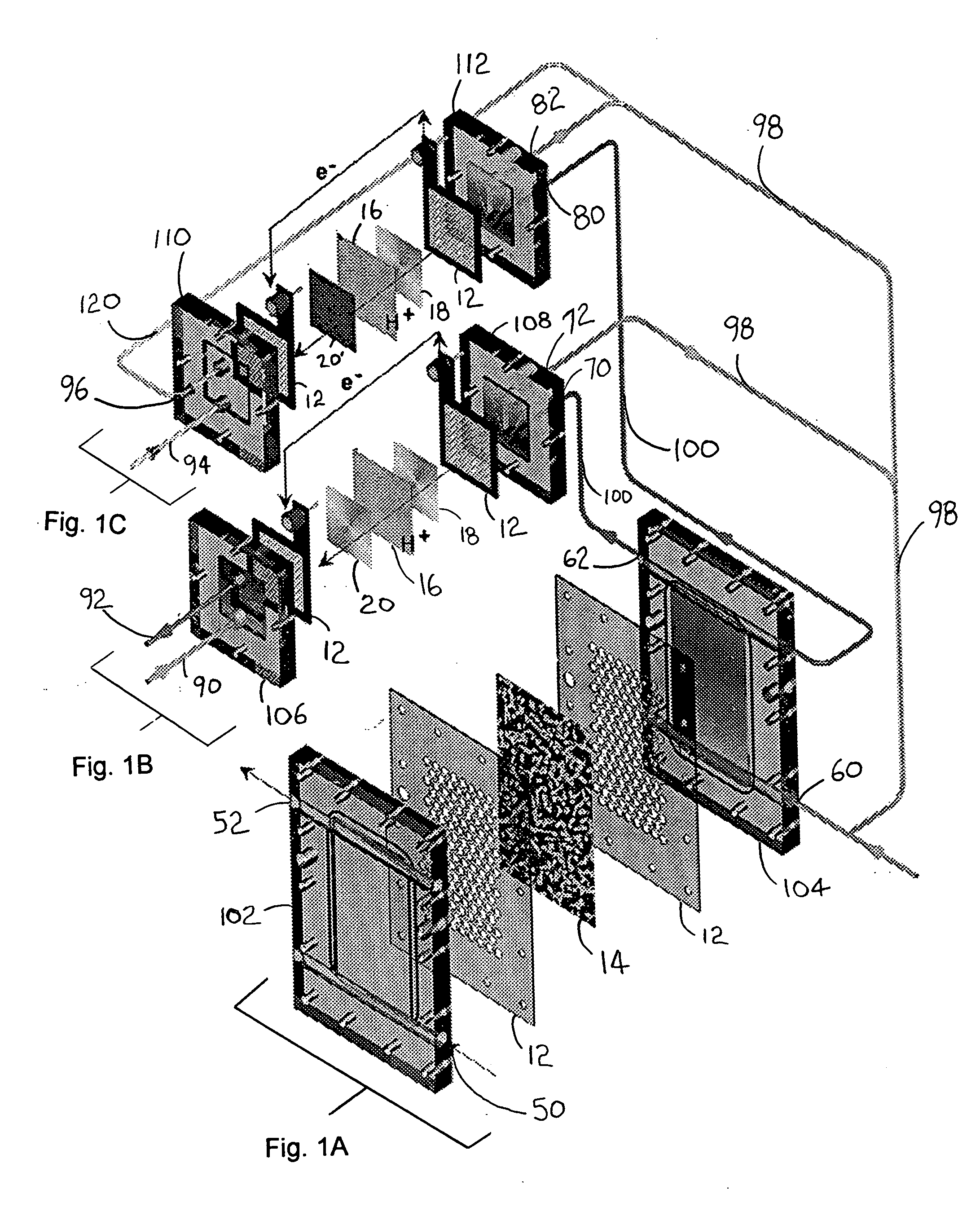

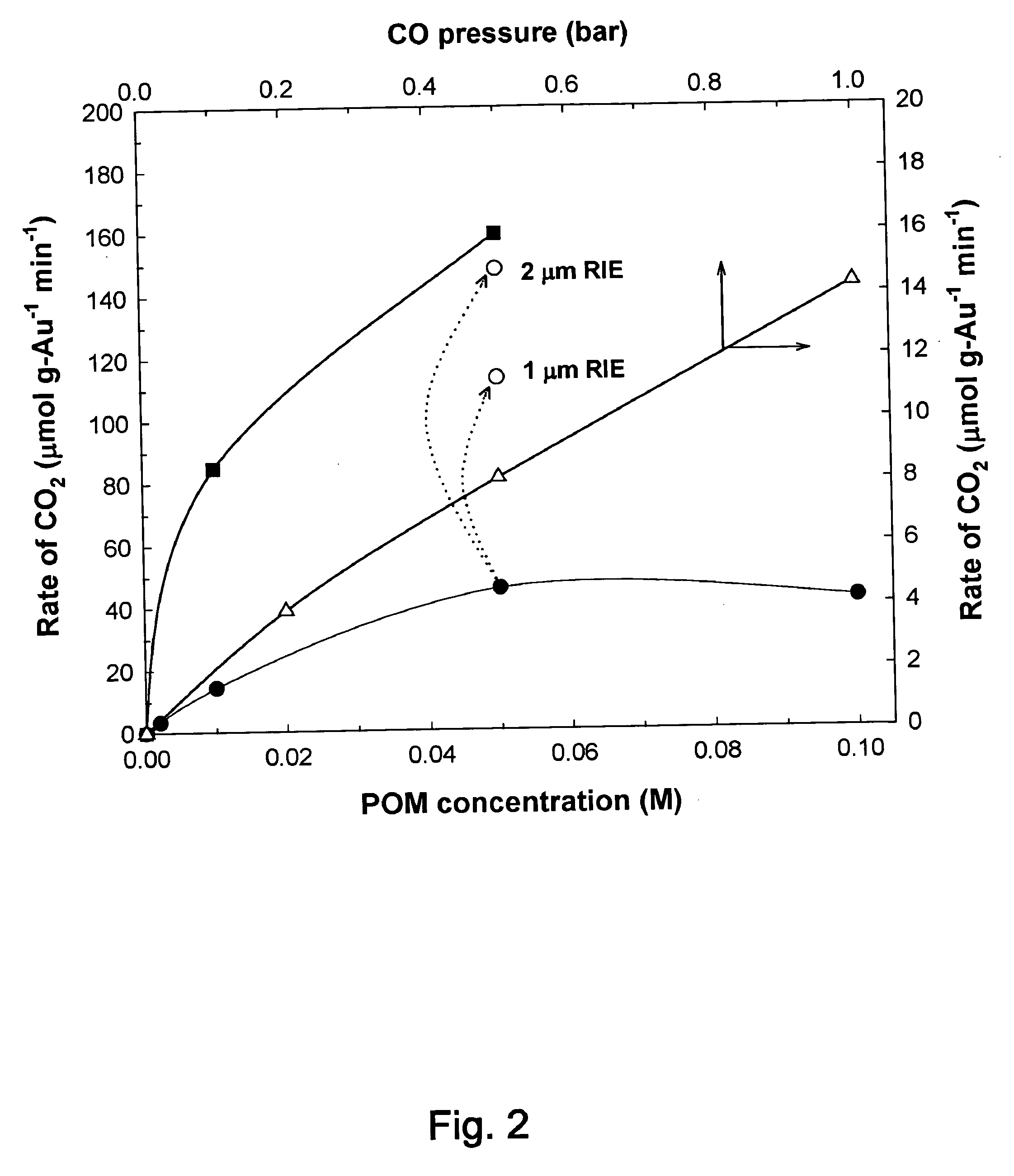

Catalytic method to remove CO and utilize its energy content in CO-containing streams

InactiveUS20060024539A1Low costUse minimizedMaterial nanotechnologyGas treatmentFuel cellsCatalytic method

Disclosed are a reactor and a corresponding method for producing electrical energy using a fuel cell by selectively oxidizing CO at room temperature using polyoxometalate compounds and transition metal compounds over metal-containing catalysts, thereby eliminating the water-gas shift reaction and the need to transport and vaporize liquid water in the production of H2 for fuel cells. The reactor also functions to deplete CO from an incoming gas stream.

Owner:WISCONSIN ALUMNI RES FOUND

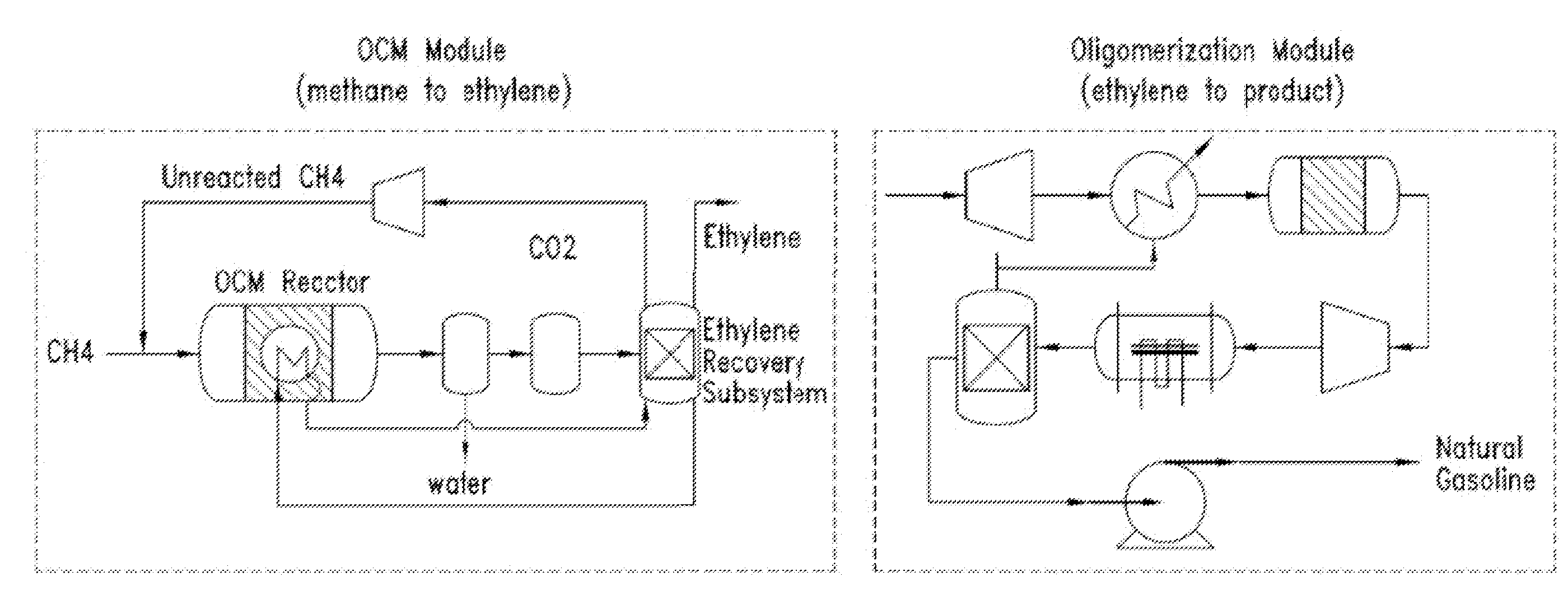

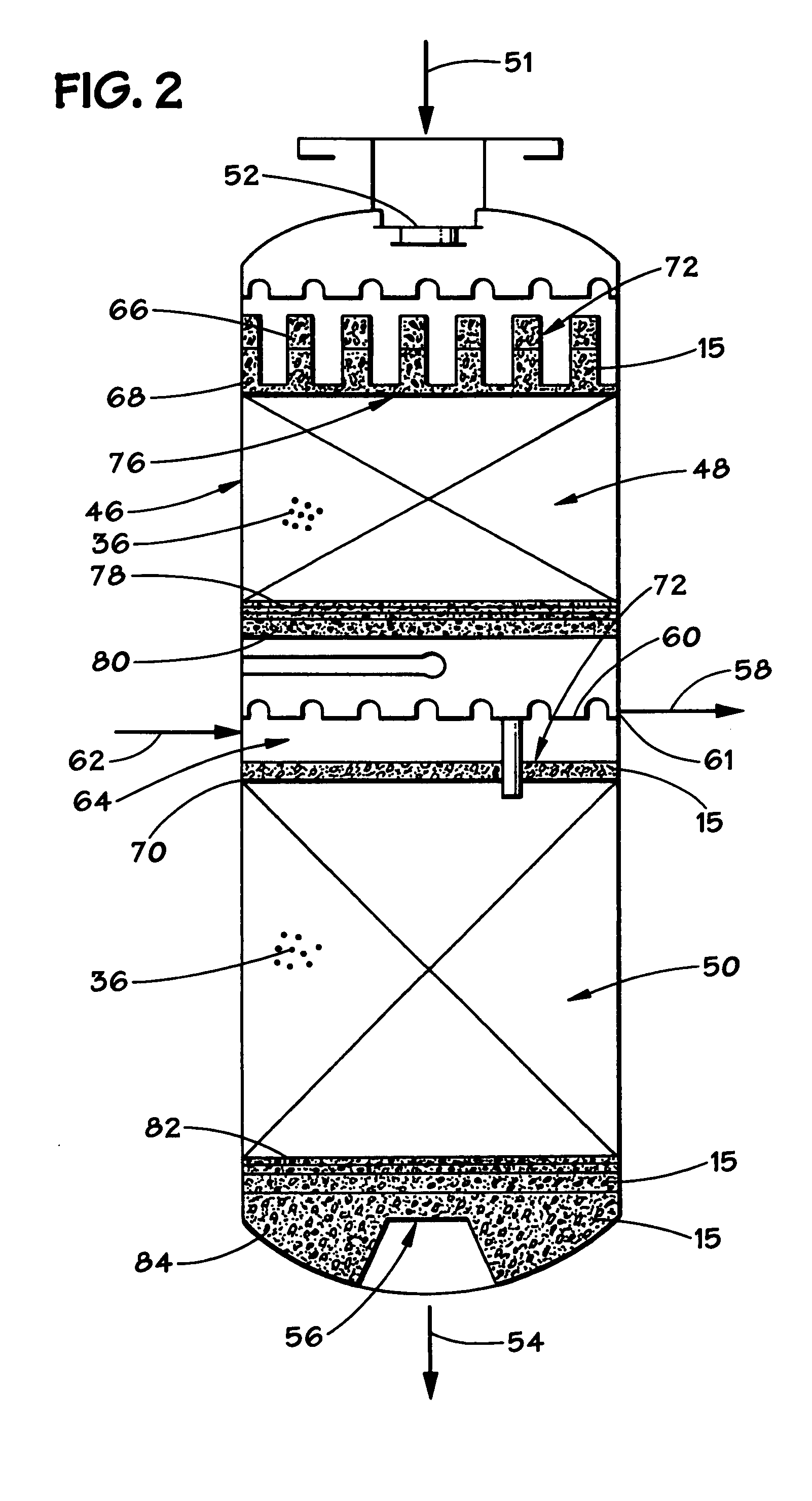

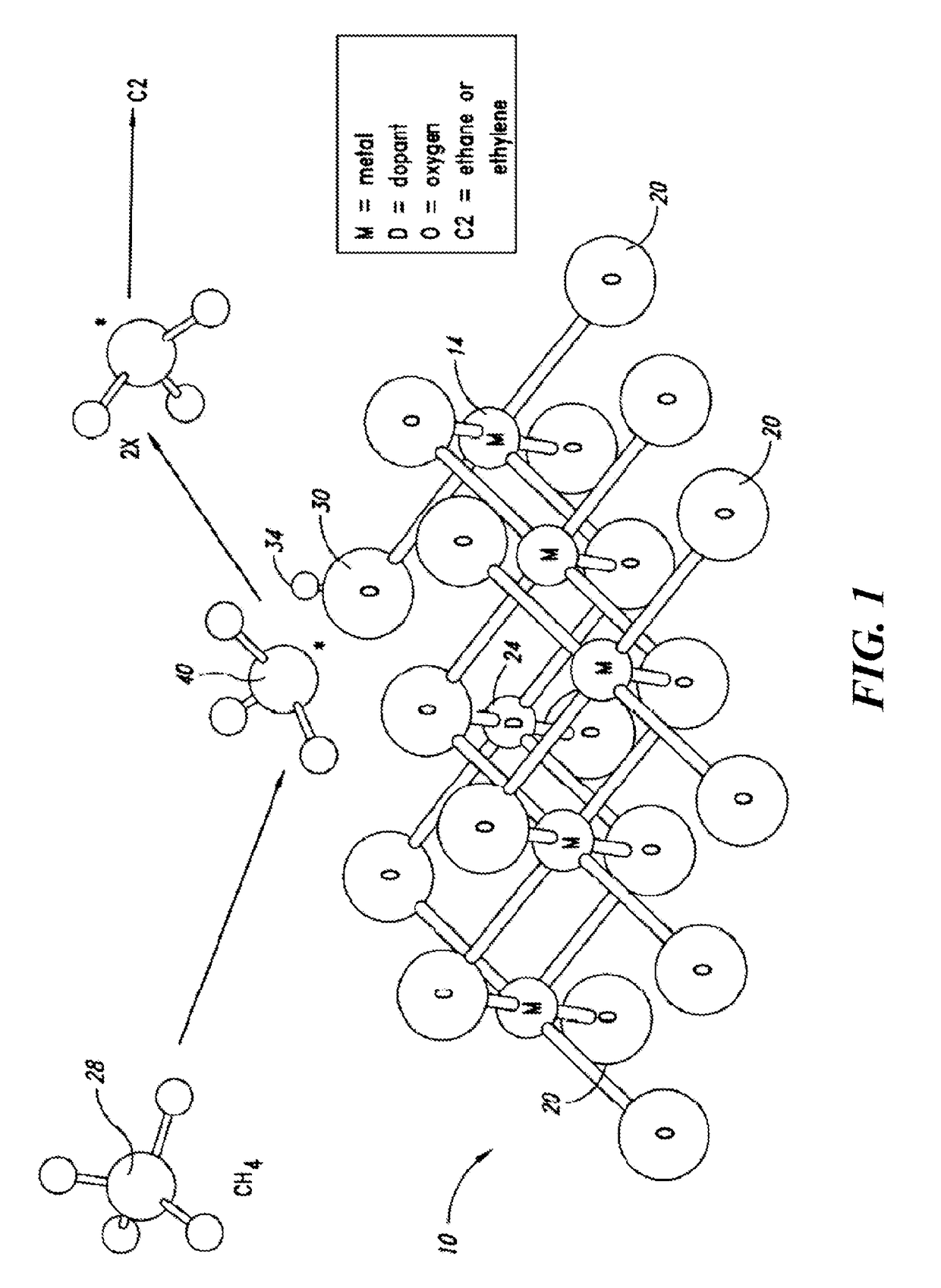

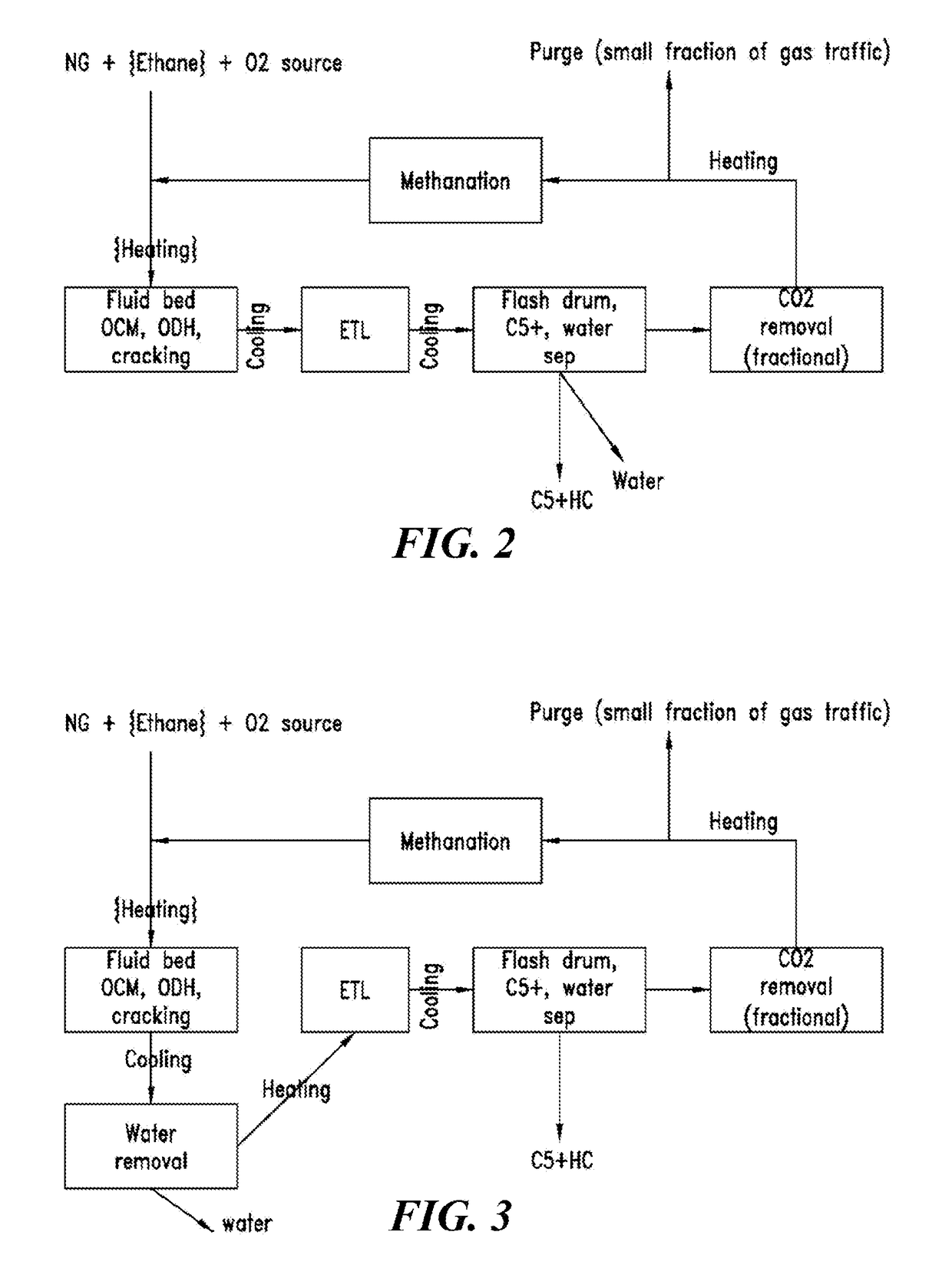

Catalysts for natural gas processes

Catalysts, catalytic forms and formulations, and catalytic methods are provided. The catalysts and catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

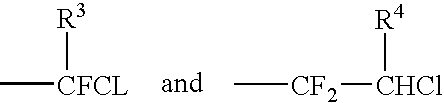

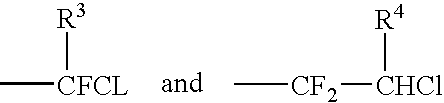

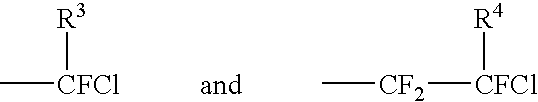

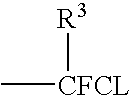

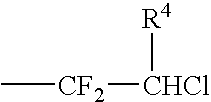

Novel catalytic method for the production of fluoroalkylenes from chlorofluorohydrocarbons

InactiveUS20060217577A1Preparation by dehalogenationPreparation by hydrogen halide split-offCatalytic methodGas phase

A process for producing a producing a product of the formula: R—CF═CHR1 wherein R is F or CF3 and R1 is F when R is F and is H when R is CF3 by reacting a reactant of the formula: CF3—R2 wherein R2 is selected from wherein R3 is H, F or Cl and R4 is H or Cl, in the presence of a suitable catalyst, with a reducing agent selected from methane, methyl chloride and mixtures thereof, in a gas phase reaction.

Owner:HONEYWELL INT INC

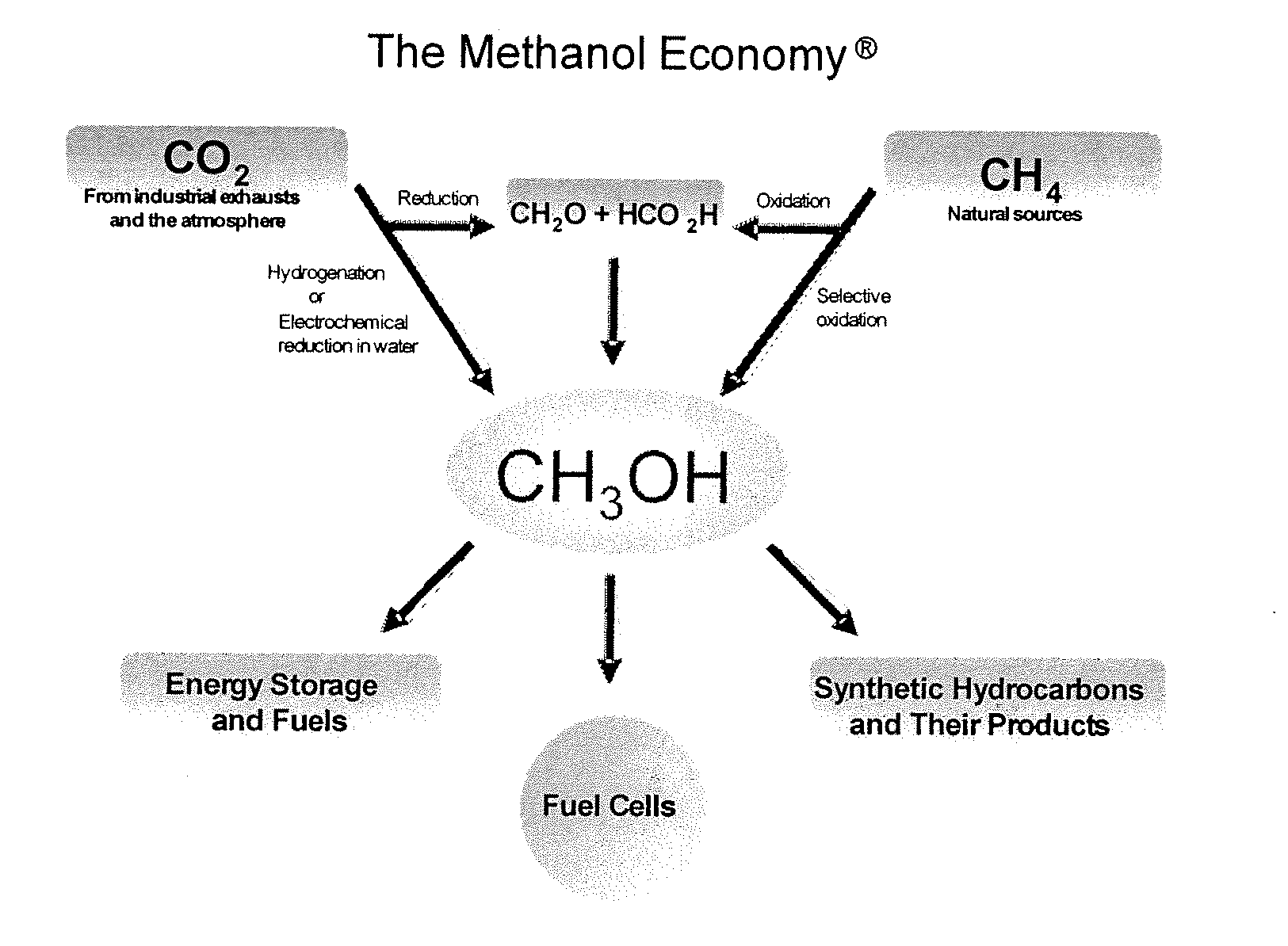

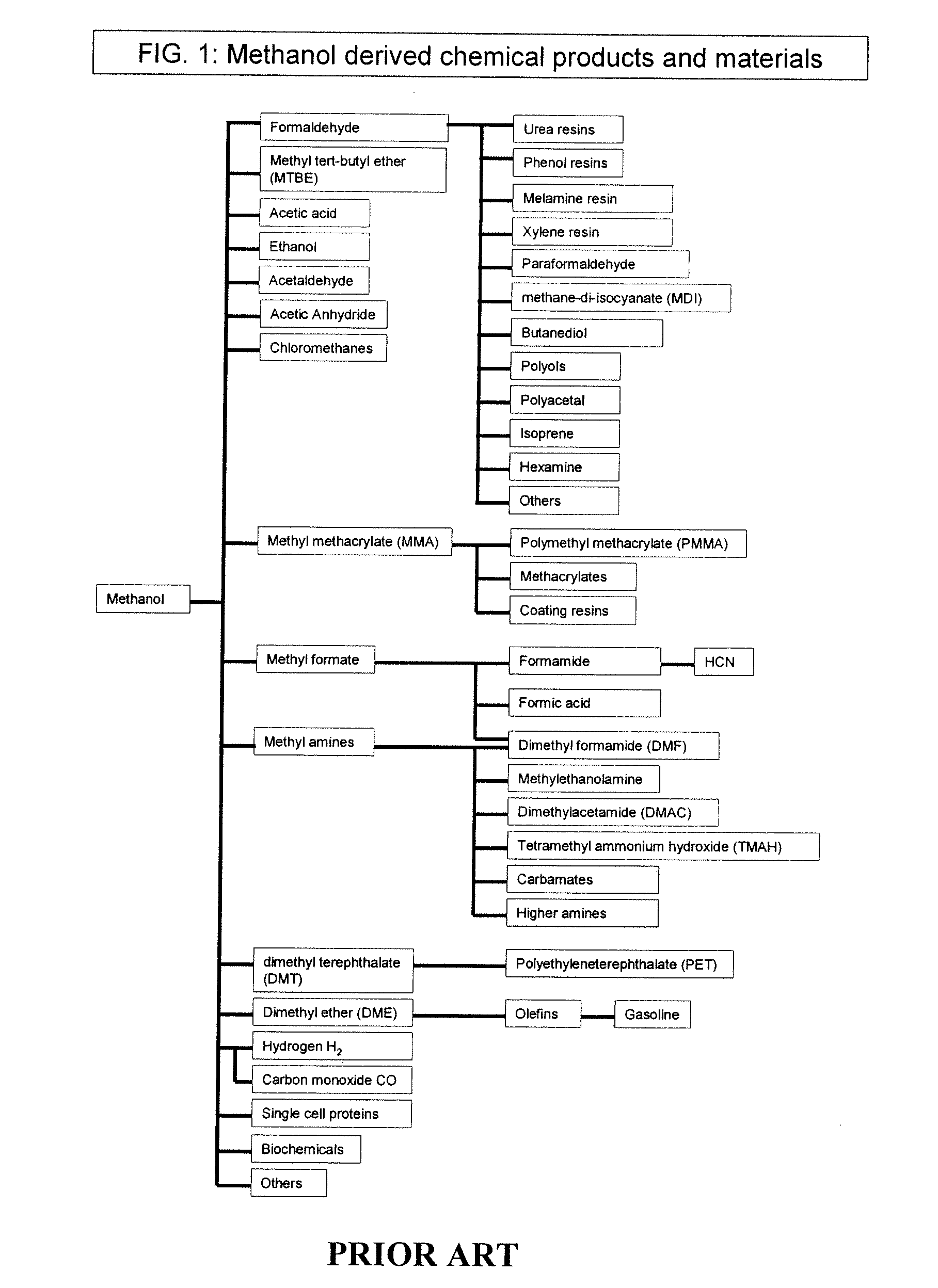

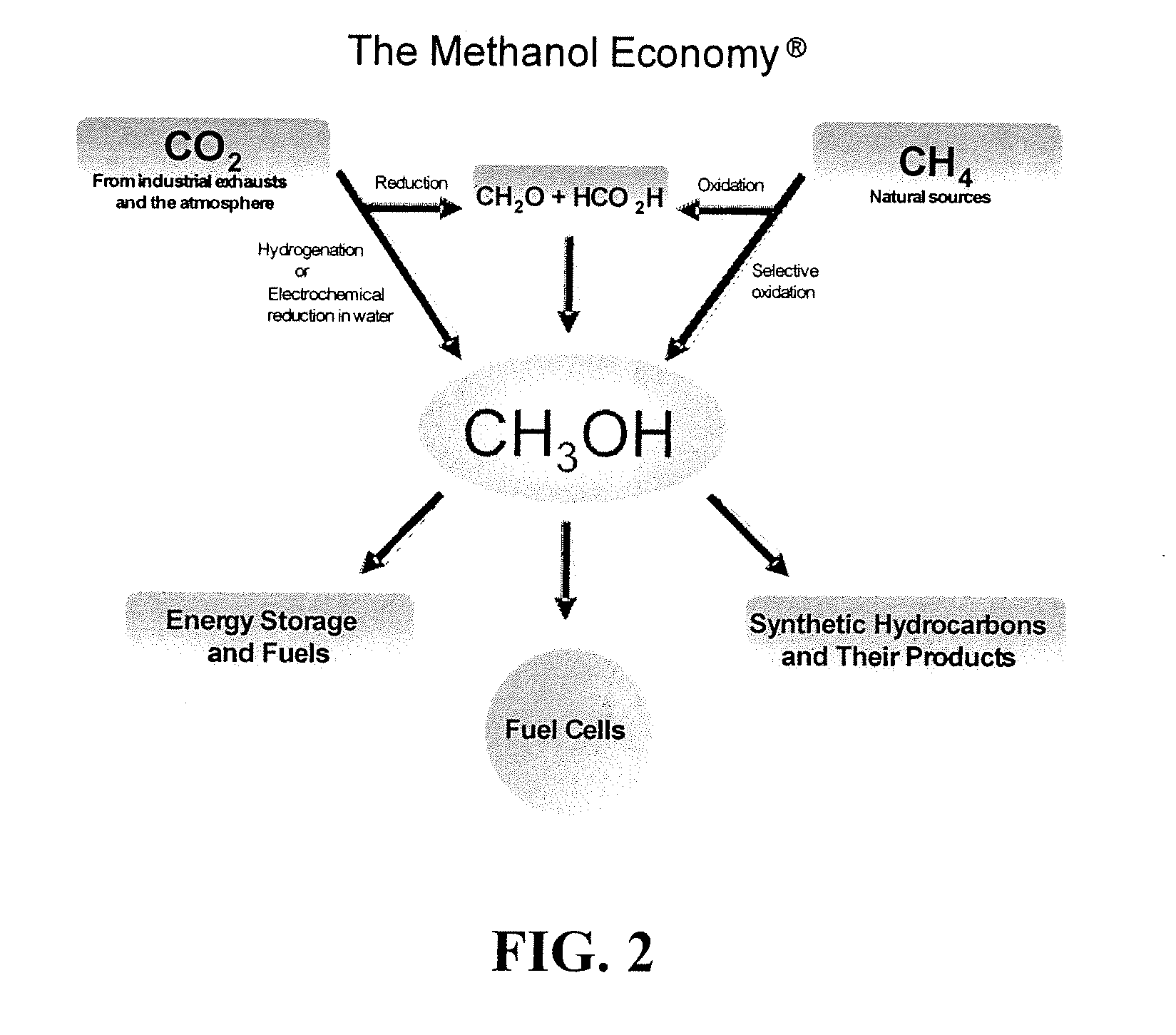

Conversion of carbon dioxide to methanol and/or dimethyl ether using bi-reforming of methane or natural gas

ActiveUS20080319093A1Raw materials are simplePromote recoveryPreparation by oxidation reactionsHydrogenCatalytic methodHydrogen

The invention discloses a method of converting carbon dioxide to methanol and / or dimethyl ether using any methane source or natural gas consisting of a combination of steam and dry reforming, in a specific ratio to produce a 2:1 molar ratio of hydrogen and carbon monoxide with subsequent conversion of the CO and H2 mixture exclusively to methanol and / or dimethyl ether. This method is termed the BI-REFORMING™ process. Dehydrating formed methanol allows producing dimethyl ether (DME) using any suitable catalytic method, including use of solid acid catalysts. When recycling formed water into the bi-reforming step the conversion of carbon dioxide with methane produces exclusively dimethyl ether without any by-product formation and complete utilization of hydrogen

Owner:UNIV OF SOUTHERN CALIFORNIA

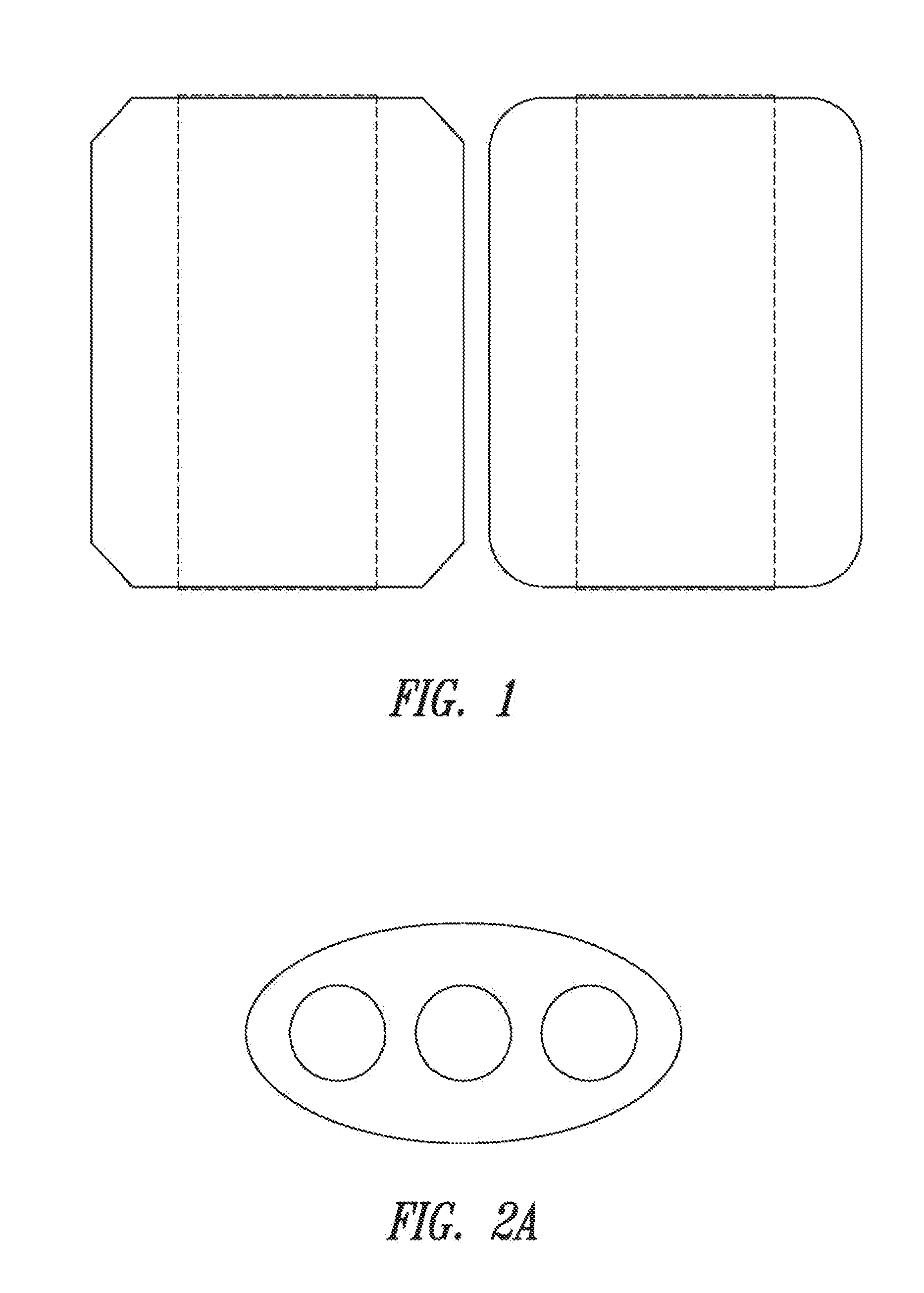

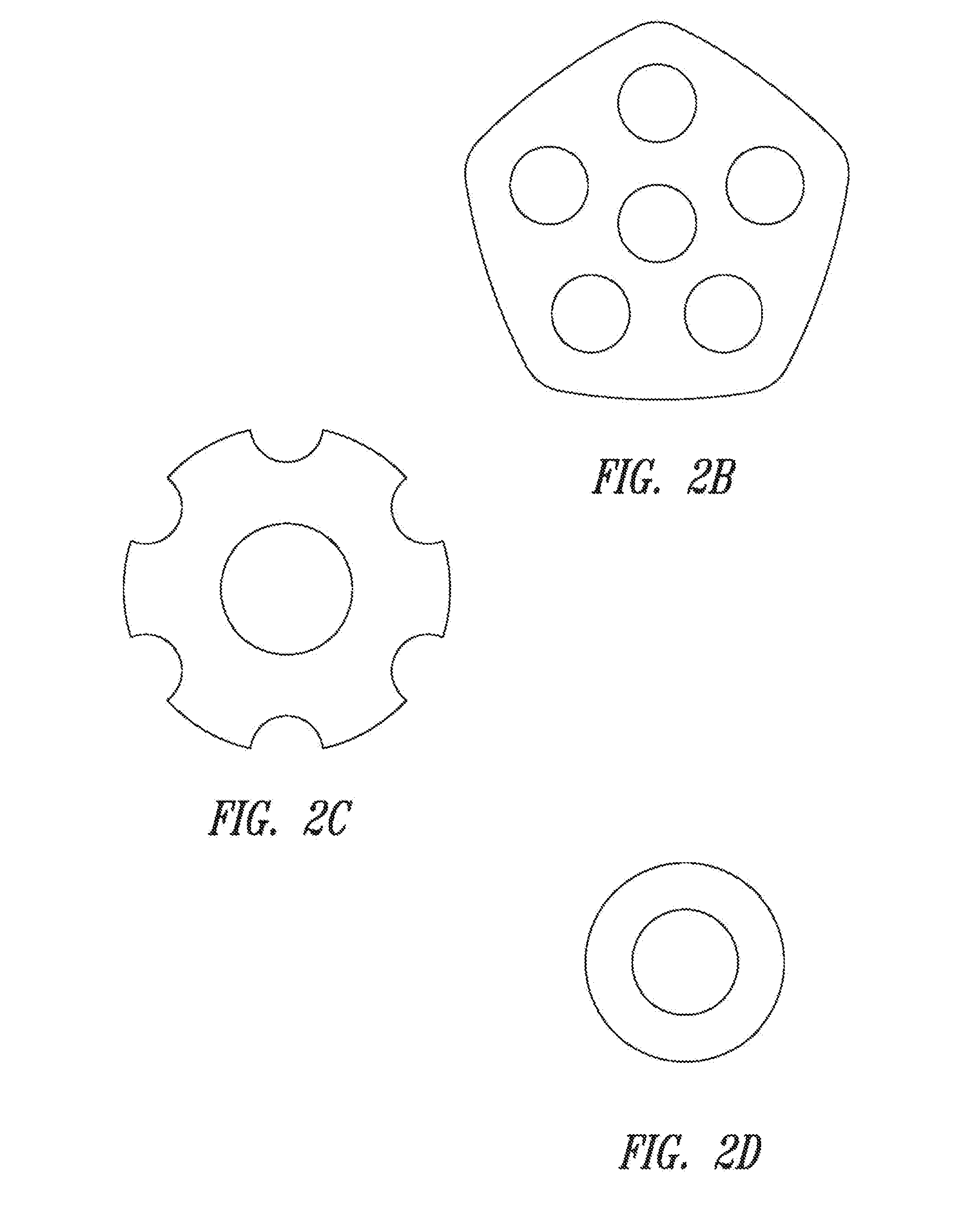

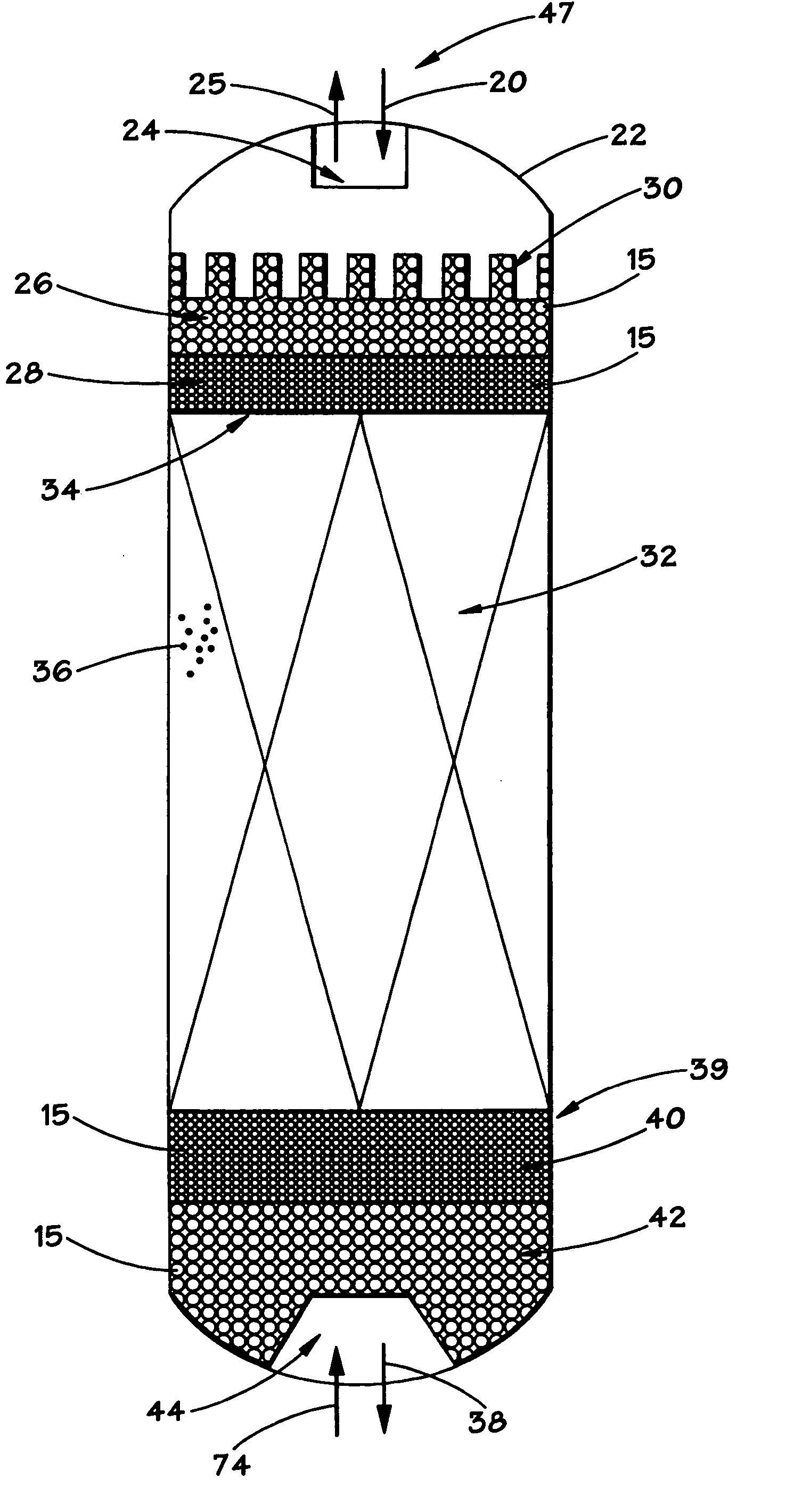

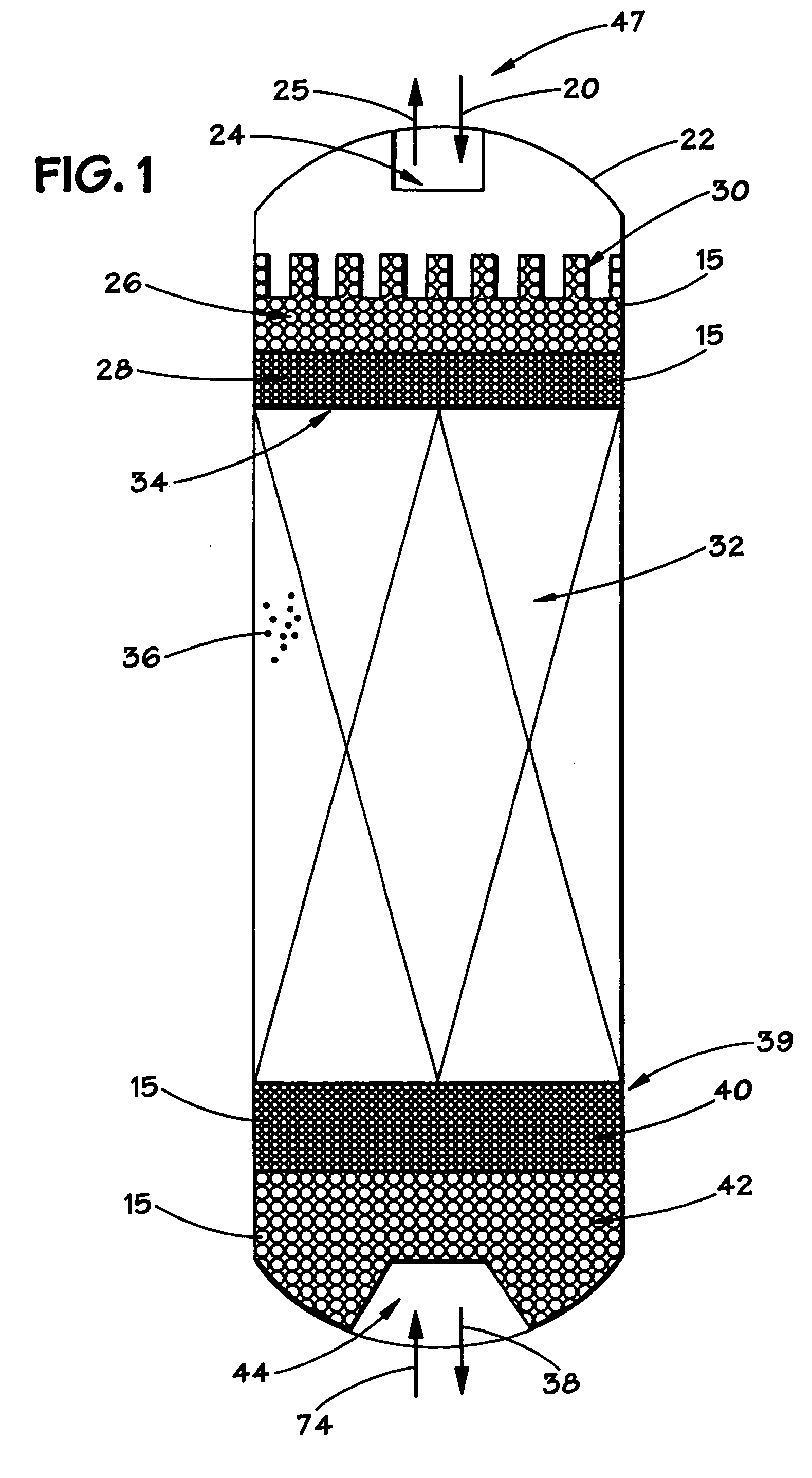

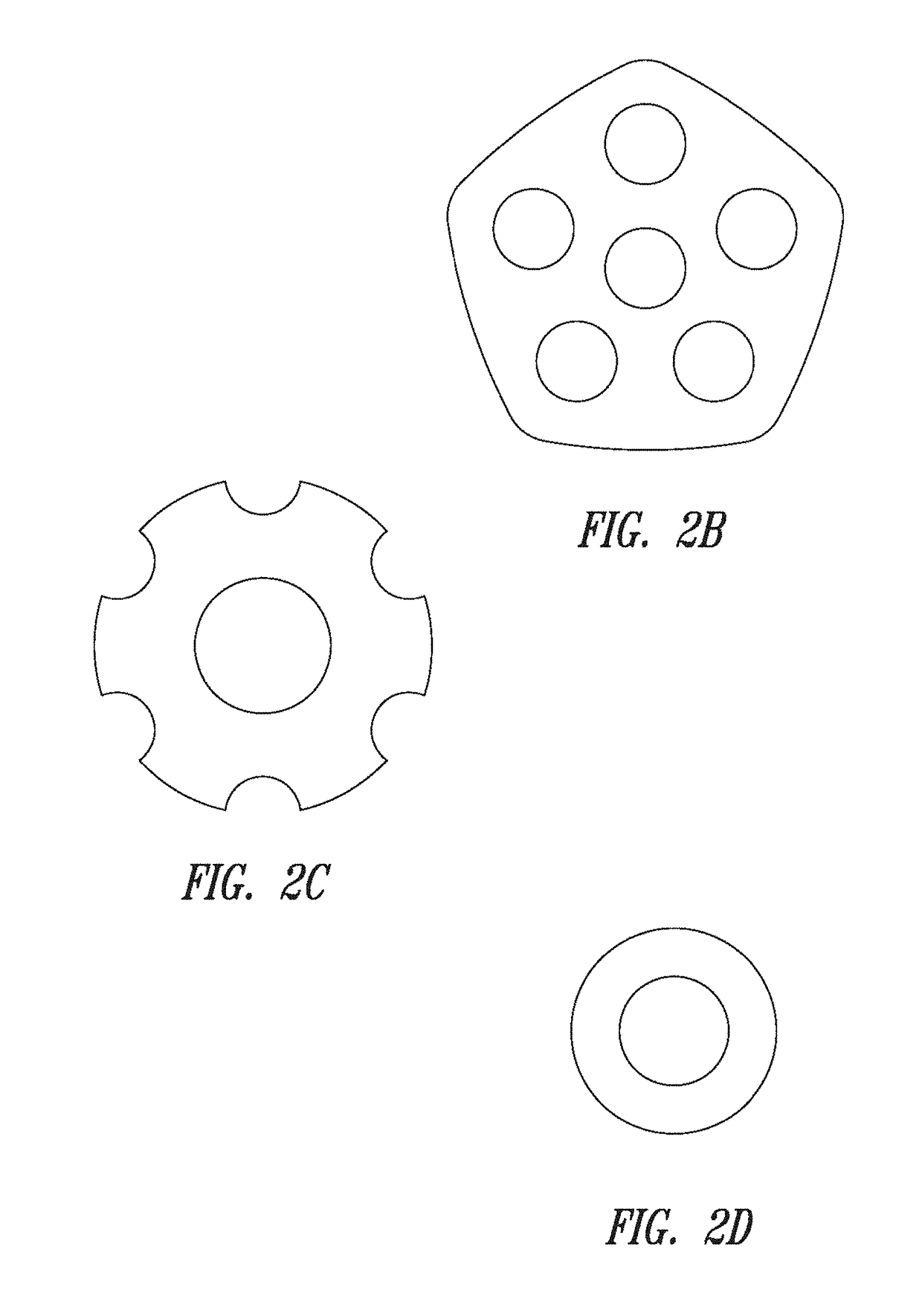

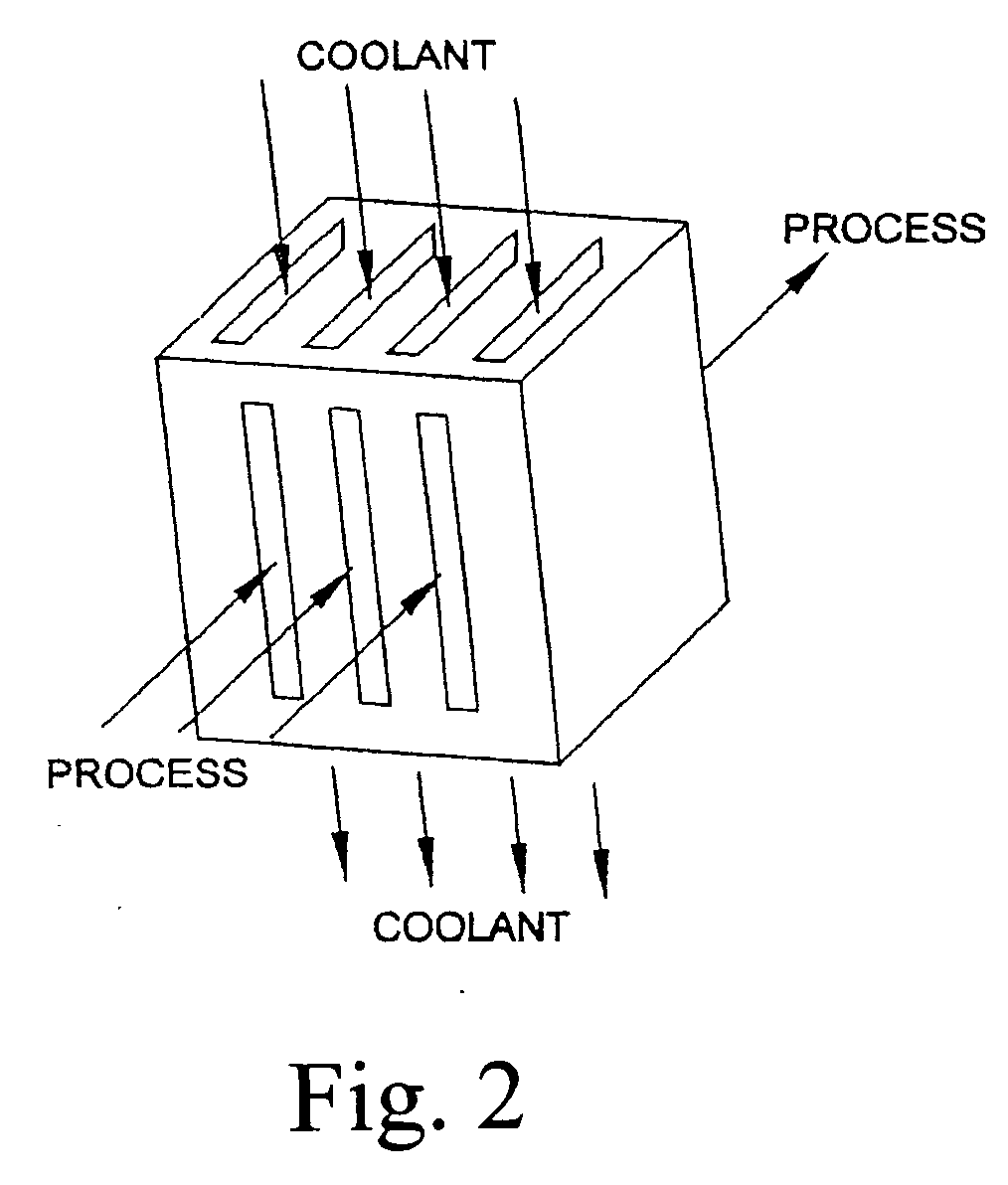

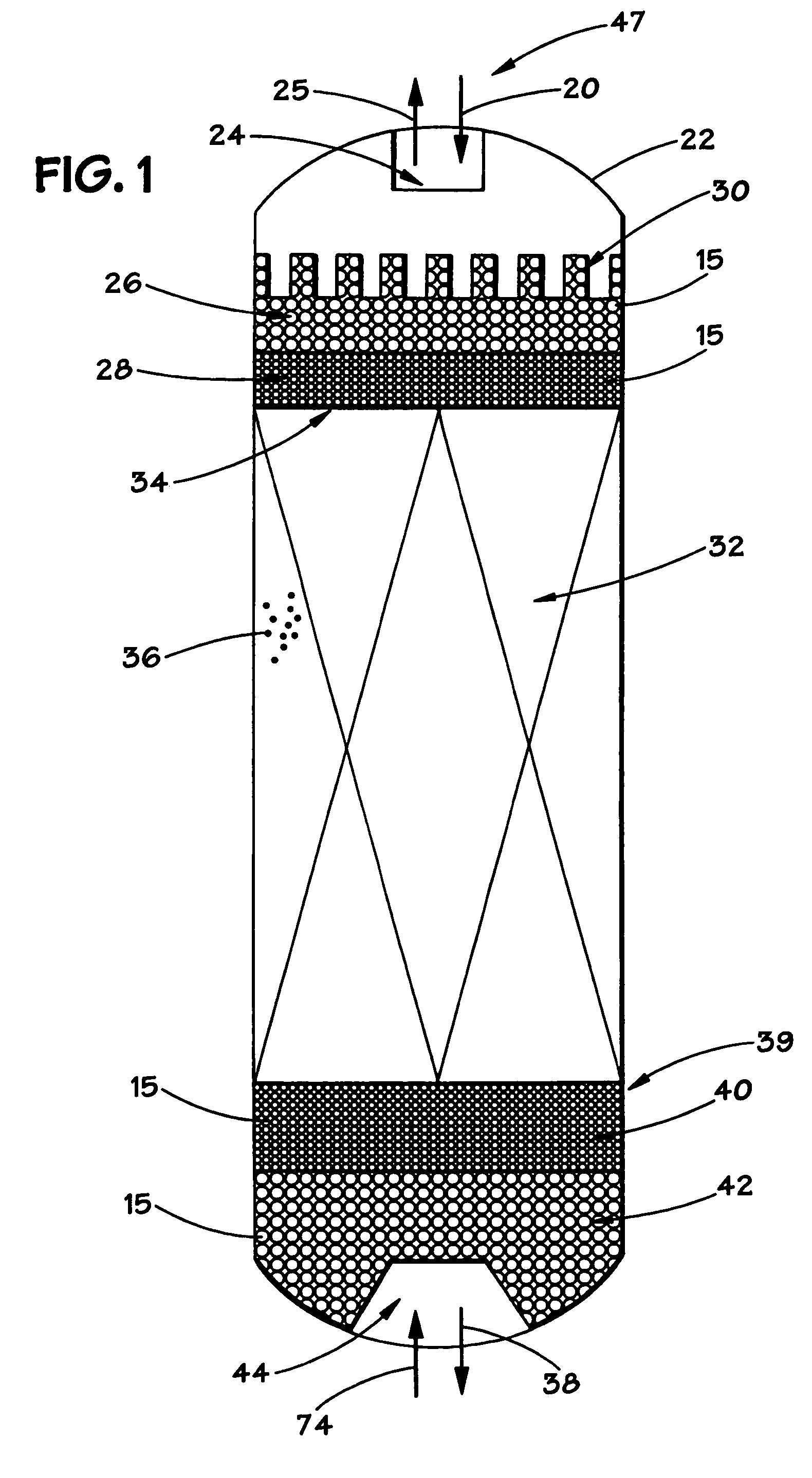

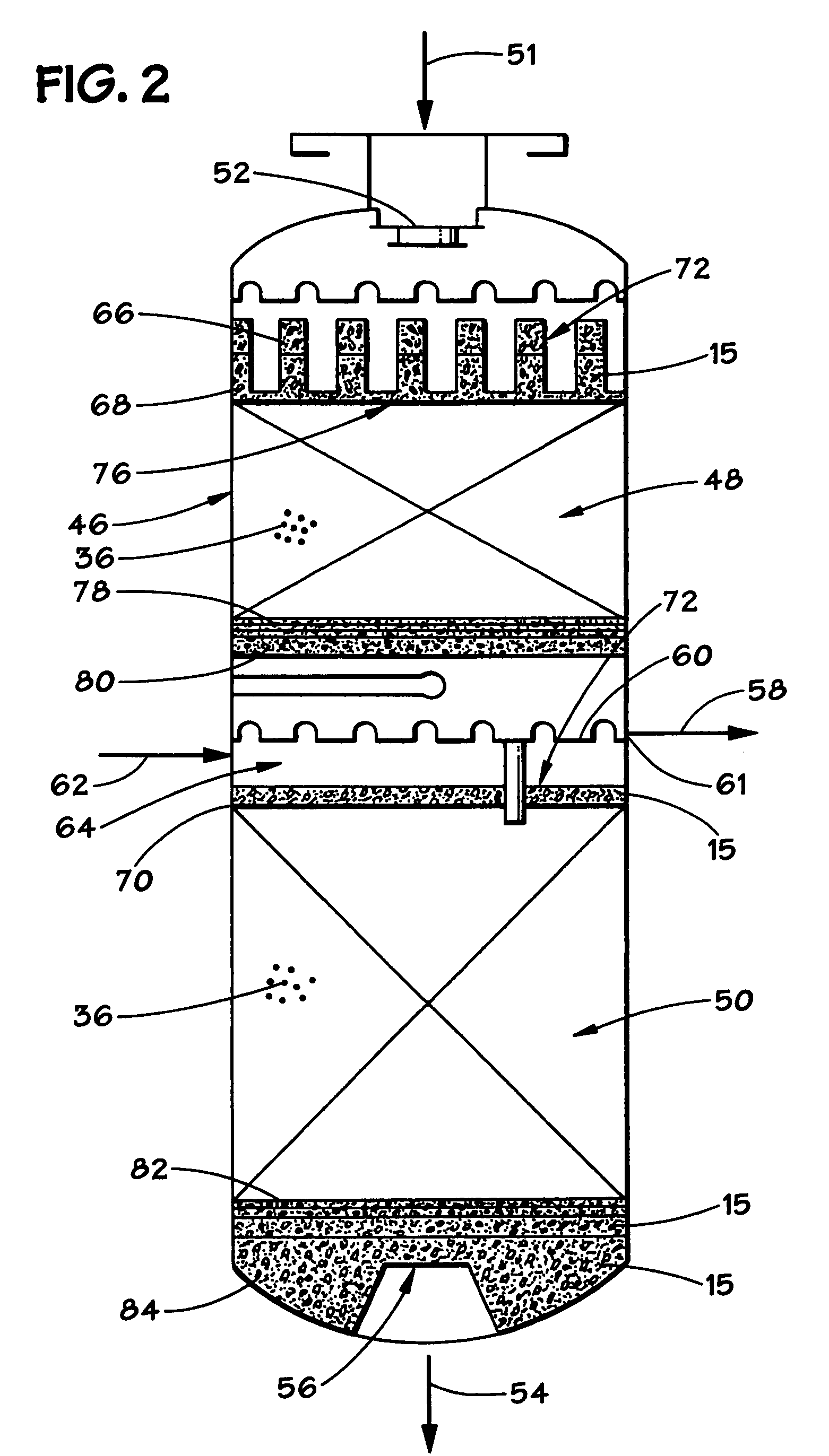

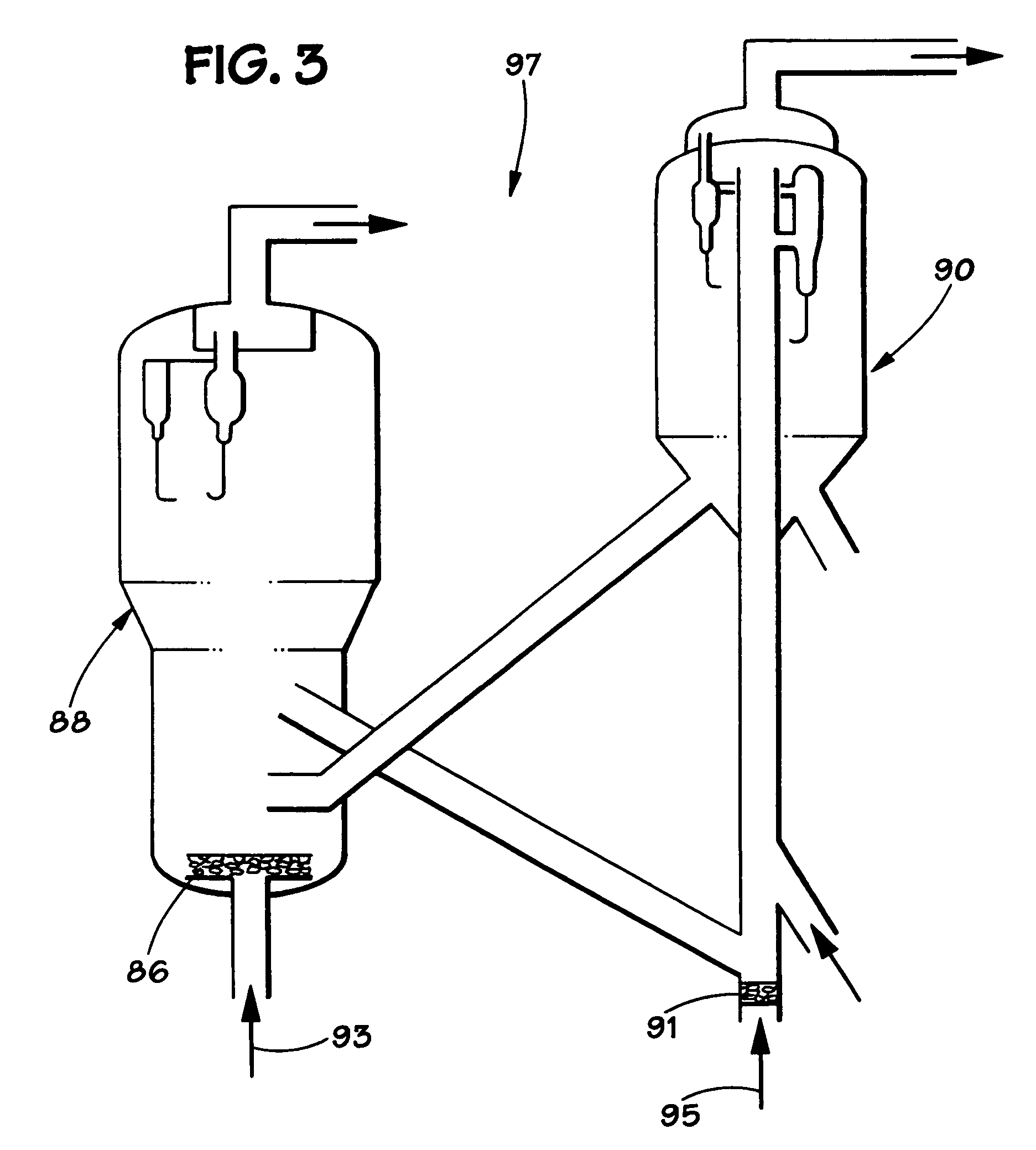

Filtration, flow distribution and catalytic method for process streams

ActiveUS20040192862A1Increased operating lifeExtended run timeDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

Catalysts and methods for natural gas processes

InactiveUS20170267605A1Material nanotechnologyHeterogenous catalyst chemical elementsCatalytic methodOxidative coupling of methane

Catalysts and catalytic methods are provided. The catalysts and methods are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane.

Owner:SILURIA TECH INC

Catalysts for natural gas processes

ActiveUS9751079B2CatalystsHydrocarbon preparation catalystsCatalytic methodOxidative coupling of methane

Catalysts, catalytic forms and formulations, and catalytic methods are provided. The catalysts and catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

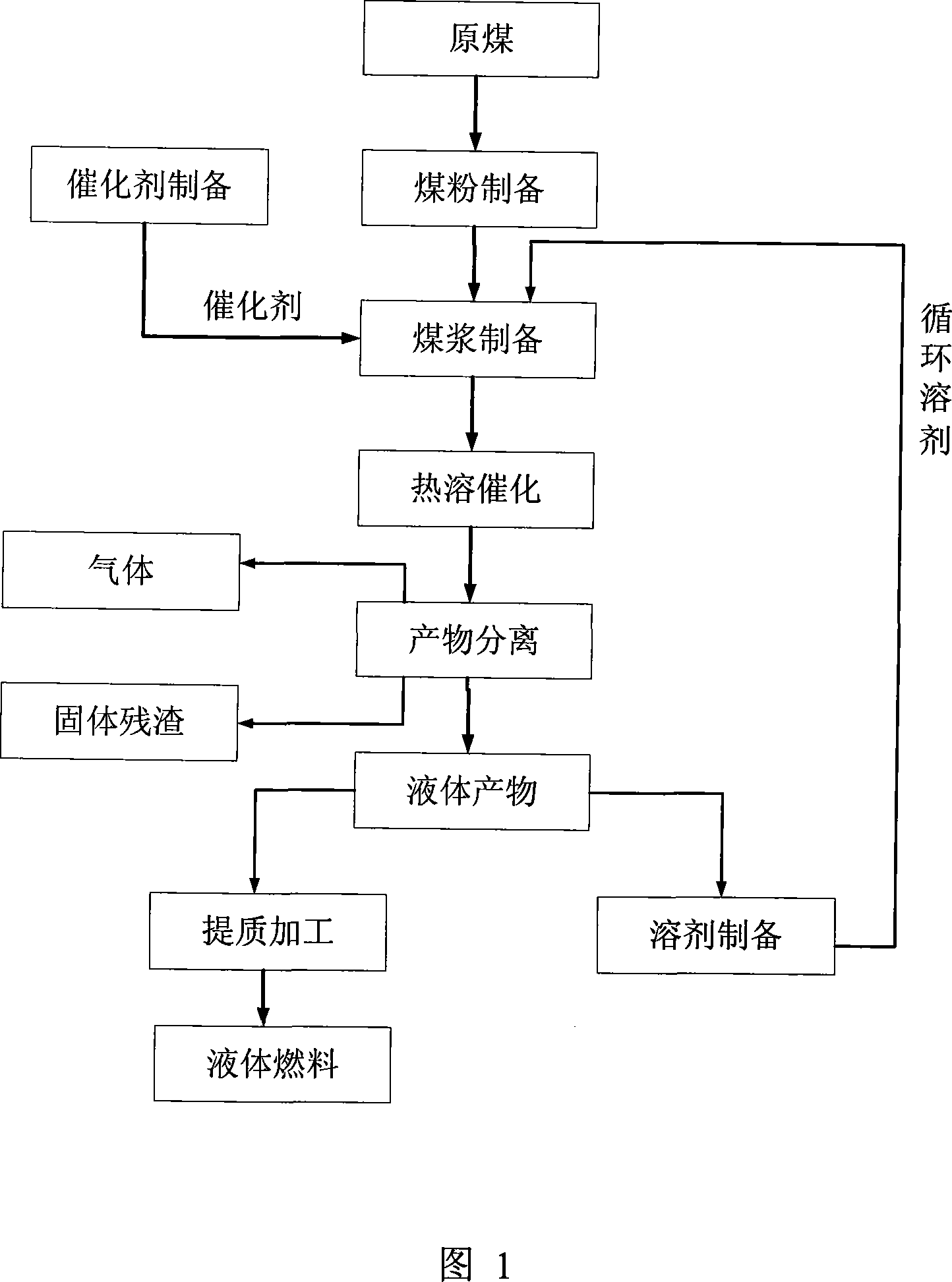

Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

ActiveCN101182421AMild operating conditionsSimple preparation equipmentOrganic-compounds/hydrides/coordination-complexes catalystsMolybdeum compoundsLiquid productForming gas

The invention belongs to the technological field of coal chemical processing and discloses a heat dissolving and catalyzing method using brown coal to prepare liquid fuel. The method comprises the following steps: 1) the brown coal is smashed and dried to prepare pulverized coal; 2) the pulverized coal, solvent and catalyst are stirred and mixed well to prepare coal slurry; wherein, the weight percent of the pulverized coal is 30 percent to 40 percent; the weight percent of the solvent is 60 percent to 70 percent; the quantity of the added catalyst is 0.5 percent to 1 percent of the weight of the pulverized coal; 3) the coal slurry is dissolved by heat and catalyzed to prepare heat dissolved and liquefied products; wherein, the temperature is 390 DEG C to 450 DEG C; the pressure is 5.0MPa to 9.0MPa; the reaction time is 30 minutes to 60 minutes; 4) the heat dissolved and liquefied products are separated to form gas-phase, liquid-phase and solid-phase products; 5) the liquid products are extracted and processed to form liquid fuel. The invention also discloses catalyst and solvent used in the method. The operation condition of the method of the invention is mild; the conversion ratio of the organic substances in the brown coal can achieve a higher level; after being processed, the liquid fuel product can be used for preparing engine fuel suiting national standards; and the preparation equipment is simple; the investment is small; the cost is low; and the invention is a coal liquefaction method suiting the national conditions of China.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

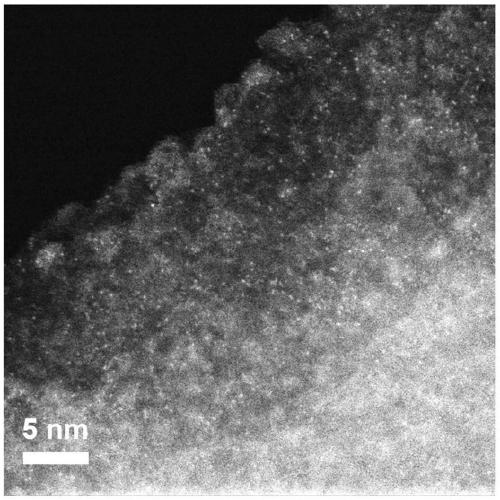

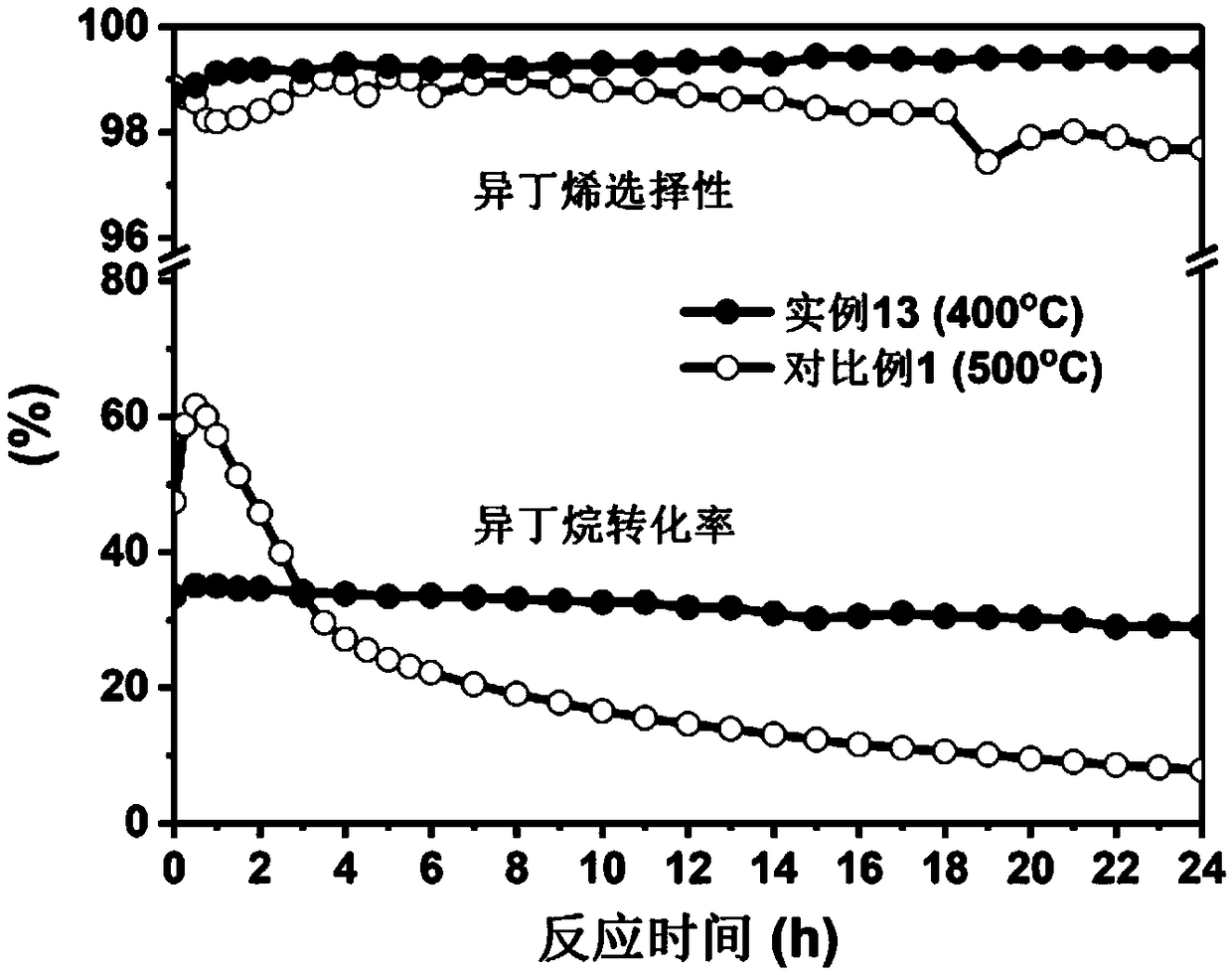

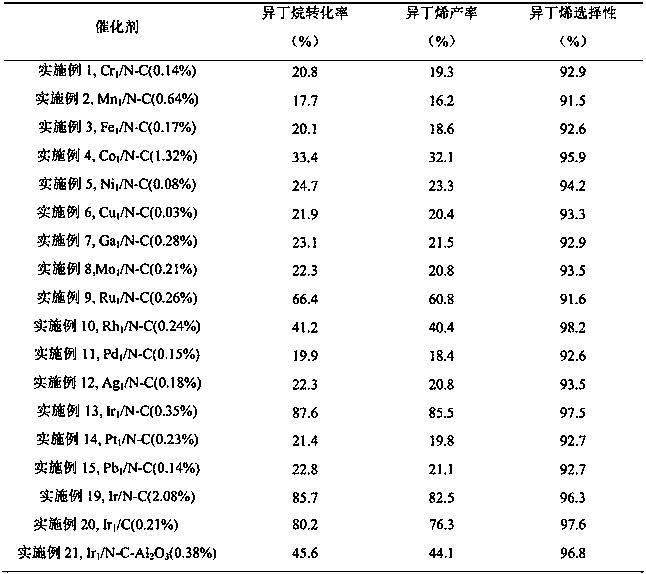

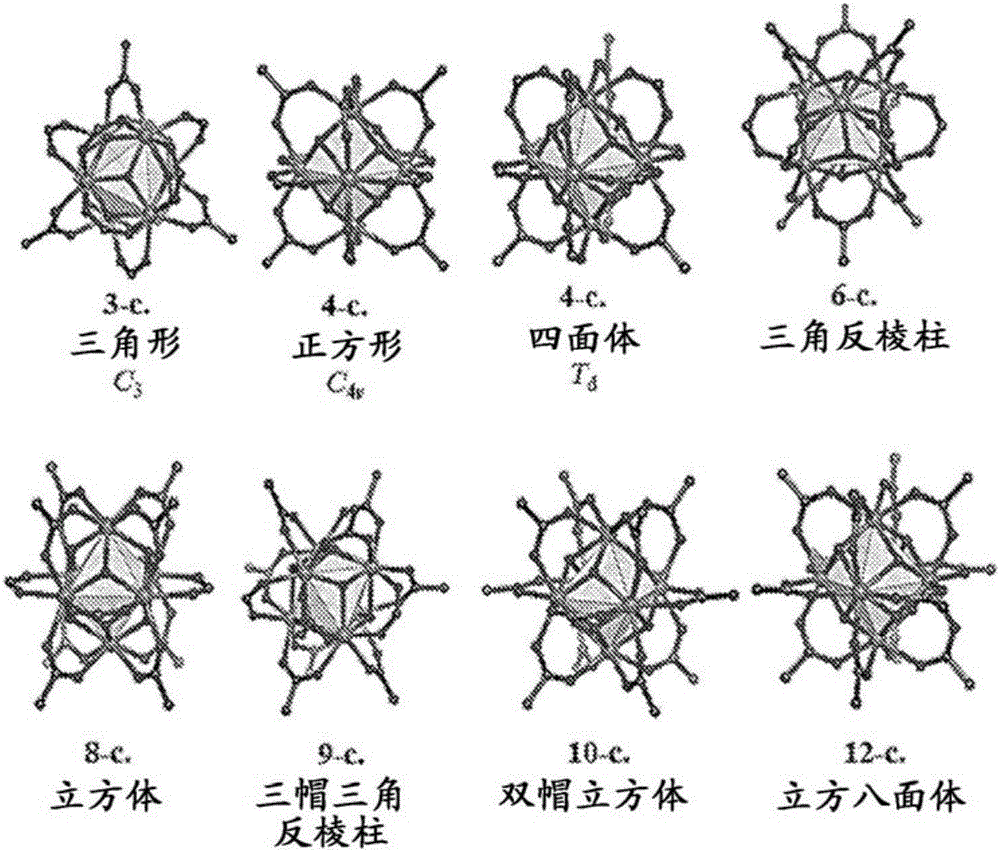

Monoatomic catalyst for preparation of low-carbon olefin by means of dehydrogenation of lower low-carbon hydrocarbons, and catalytic method

ActiveCN109225306ALow costReduce pollutionPhysical/chemical process catalystsCatalystsReaction temperatureDehydrogenation

The invention relates to a monoatomic catalyst for preparation of low-carbon olefin by means of dehydrogenation of low-carbon hydrocarbons, and a catalytic method. The catalyst is obtained by supporting metal active components, dispersed in an isolated monoatomic form, on a carrier, or supporting the metal active components on the carrier in a form in which single atoms and metal nanoparticles coexist. The metals in the metal active components are preferably selected from at least one of chromium, manganese, iron, cobalt, nickel, copper, gallium, molybdenum, ruthenium, rhodium, palladium, silver, iridium, platinum and lead; the carrier is prepared from one or more of a carbon-nitrogen material, a carbon material or oxides. The catalyst provided by the invention can realize the reduction ofmetal consumption and has very good stability; the catalyst can significantly reduce the reaction temperature while guaranteeing high catalytic performance, reduces the energy consumption, effectively avoids the formation of carbon deposit, and increases the production efficiency. The catalyst can catalyze a dehydrogenation reaction of the multiple low-carbon hydrocarbons such as isobutane, n-butane, butene, propane and ethane so as to produce corresponding low-carbon olefin products, thus being wide in application range; the monoatomic catalyst is multiple in preparation methods, wide in rawmaterials, low in cost and suitable for mass industrial production.

Owner:北京博思福催化科技有限公司

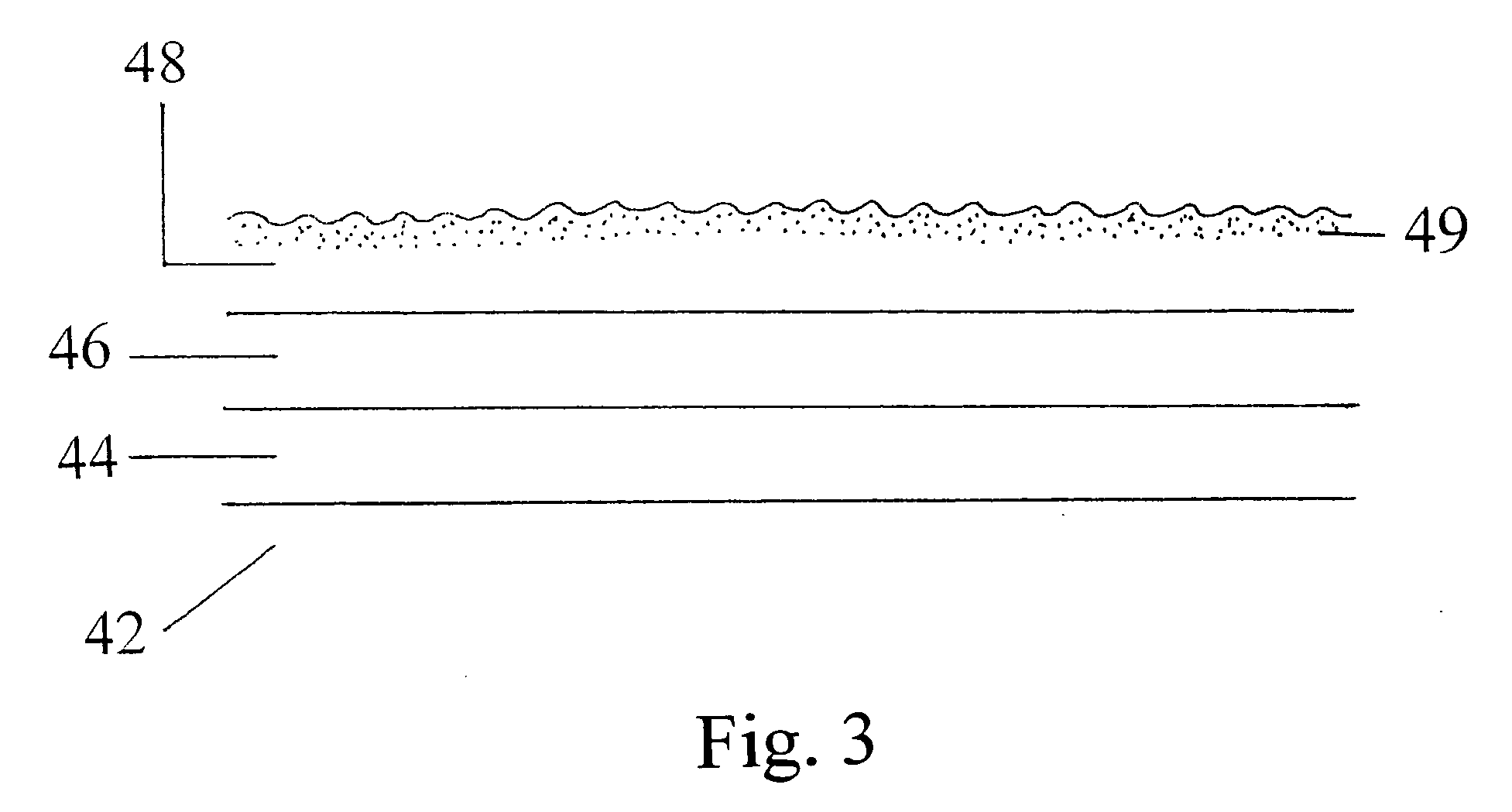

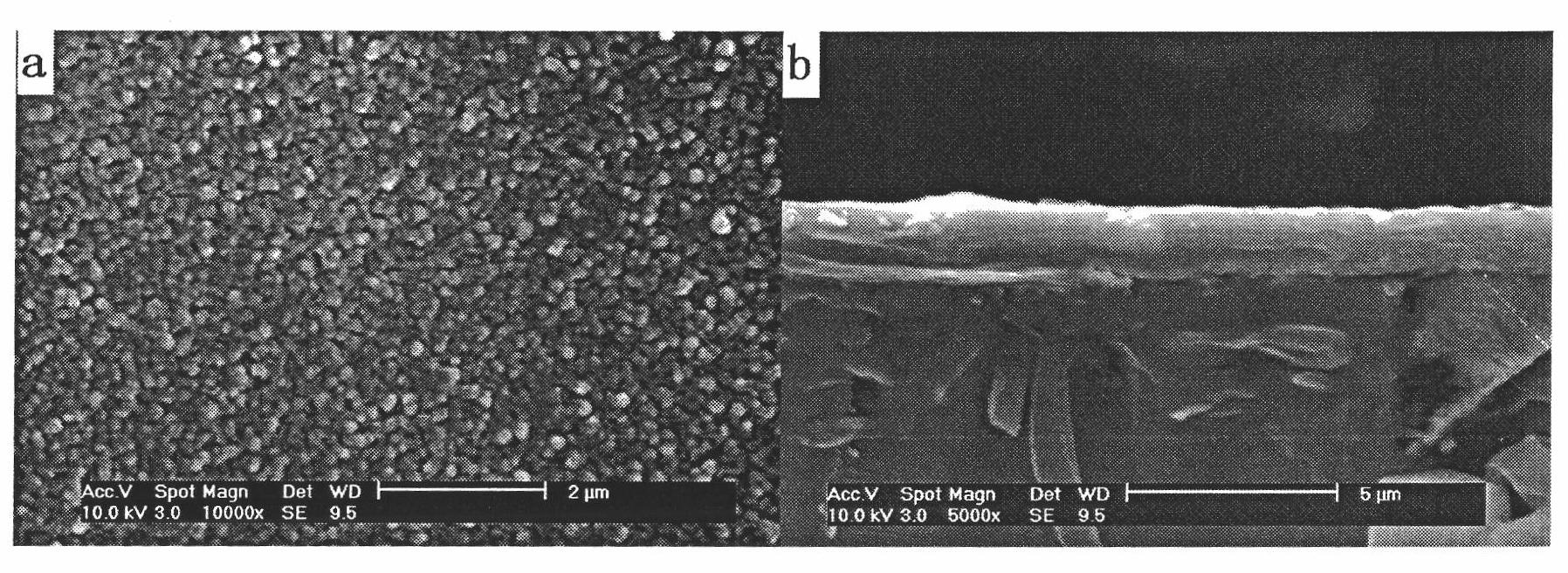

Catalysts having catalytic material applied directly to thermally-grown alumina and catalytic methods using same, improved methods of oxidative dehydrogenation

InactiveUS20050272965A1Improve adhesionHigh activityChemical/physical/physico-chemical microreactorsSolid-state devicesChemical reactionCatalytic method

The invention describes catalysts, methods of making catalysts, methods of making a microchannel reactor, and methods of conducting chemical reactions. It has been discovered that superior performance can be obtained from a catalyst formed by directly depositing a catalytic material onto a (low surface area) thermally-grown alumina layer. Improved methods of conducting oxidative dehydrogenations are also described.

Owner:VELOCYS CORPORATION

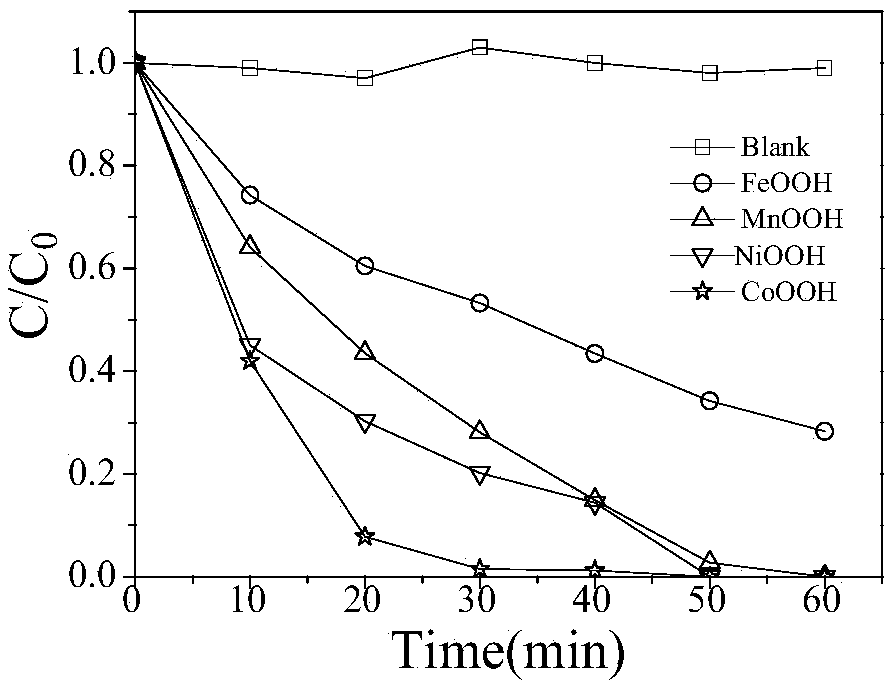

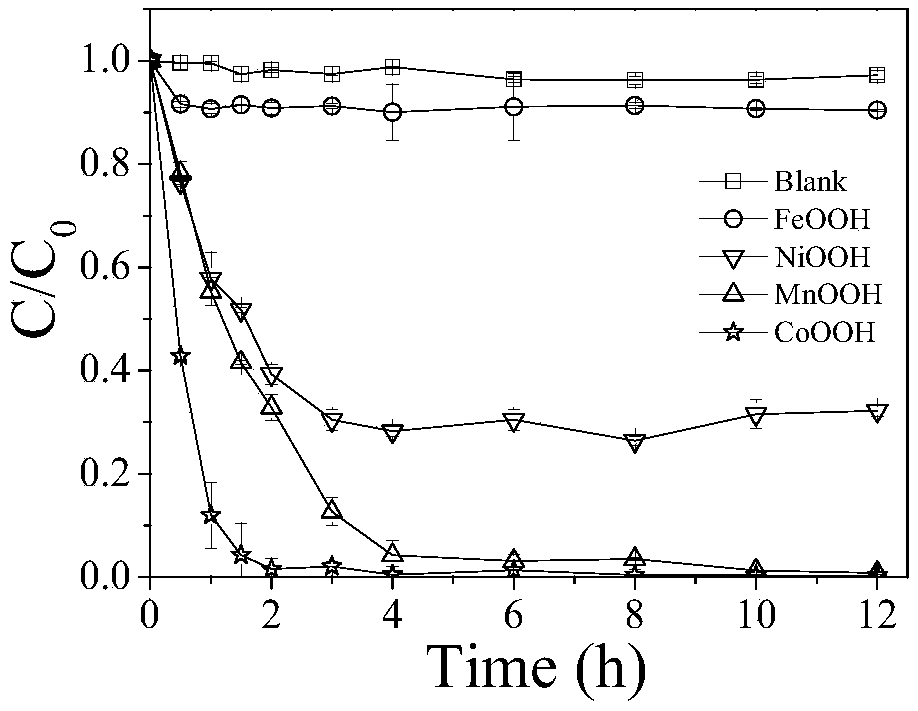

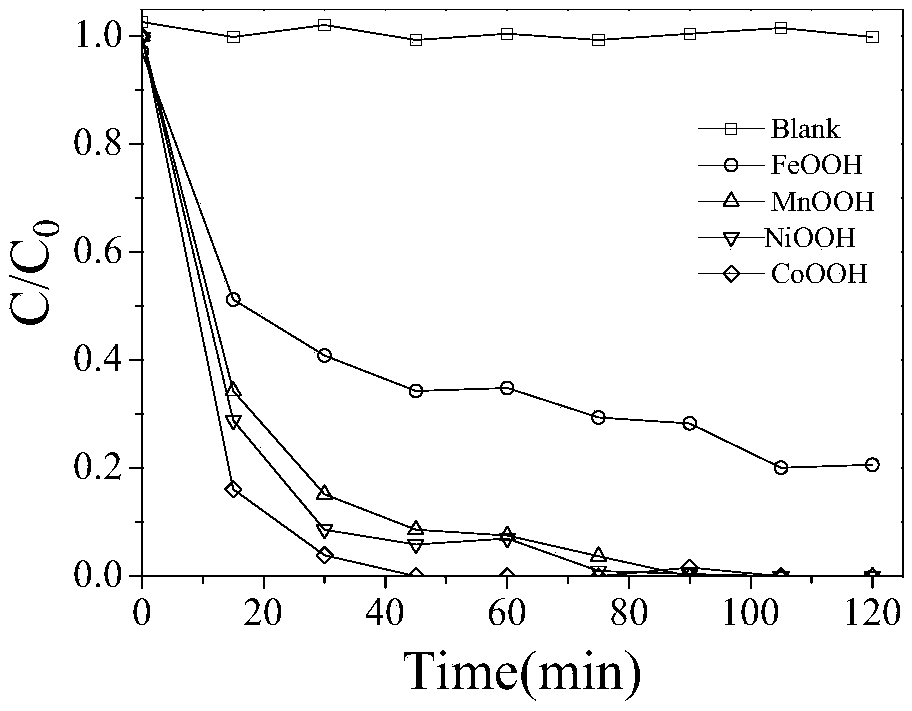

Catalytic method for generating sulfate radicals and active oxygen species as well as advanced oxidation method of organic pollutants difficult to biodegrade

ActiveCN108675430AStable structureImprove removal efficiencyWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsCatalytic methodSulfate radicals

The invention provides a catalytic method for generating sulfate radicals and active oxygen species as well as an advanced oxidation method of organic pollutants difficult to biodegrade. The problemsof low degradation efficiency of organic pollutants and high cost in the prior art are solved. According to the catalytic method for generating sulfate radicals and active oxygen species, a transitionmetal oxyhydroxide-based material serves as a catalyst, and the sulfate radicals, hydroxyl radicals, superoxide radicals and singlet oxygen non-radicals are generated, so that the organic pollutantsdifficult to biodegrade are efficiently oxidized. The transition metal oxyhydroxide-based material serves as the catalyst, the activation efficiency of perosulfate is improved and various radicals andactive oxygen species are generated, so that the oxidative degradation rate of the organic pollutants is increased; and the catalyst has a stable structure, is low in heavy metal dissolution rate inthe catalytic process, avoids secondary pollution, and can be widely applied to treatment of industrial production waste water, treatment of domestic sewage, purification treatment of polluted underground water and surface water as well as treatment of polluted soil.

Owner:JILIN UNIV

Acid, solvent, and thermal resistant metal-organic frameworks

ActiveCN106029674ASemi-permeable membranesGroup 4/14 organic compounds without C-metal linkagesCatalytic methodSolid acid

The disclosure provides for thermal, solvent, and / or acid resistant metal organic frameworks and the use of these frameworks in devices and methods for gas separation, gas storage, and catalysis. The disclosure further provides for MOFs that are strong solid acids, and the use of these strong solid acid MOFs in catalytic devices and catalytic methods.

Owner:RGT UNIV OF CALIFORNIA

Method and Catalyst for the Transalkylation/Dealkylation of Organic Compounds

InactiveUS20080021253A1Improve catalytic selectivityMaximize productionHydrocarbon by isomerisationMolecular sieve catalystsCatalytic methodCrystal structure

The invention relates to a catalytic method for the transalkylation / dealkylation of organic compounds, consisting in bringing a supply comprising organic compounds into contact with a catalyst containing a first zeolitic component that is selected from among: a) one or more zeolites having crystalline structure ITQ-13; b) one or more zeolites having crystalline structure ITQ-13, which are modified either by means of selectivation or with the incorporation of one or more metals, or both; and c) a mixture of a) and b). The invention also relates to a catalyst comprising one or more modified zeolites having crystalline structure ITQ-13.

Owner:CORMA CANOS AVELINO +3

Filtration, flow distribution and catalytic method for process streams

ActiveUS7265189B2Improve processing qualityImproving stream qualityDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

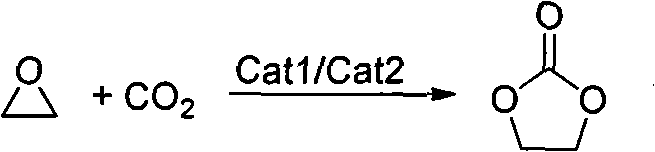

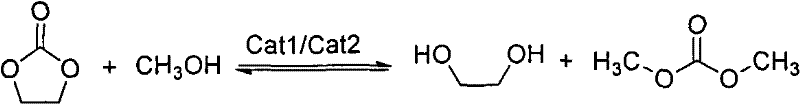

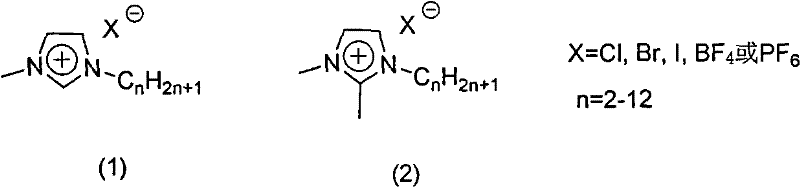

Catalytic method for preparing dimethyl cabonate along with ethylene glycol

ActiveCN102126956AOxygen-containing compound preparationOrganic compound preparationCatalytic methodEthylene oxide

The invention relates to a catalytic method for preparing dimethyl cabonate along with ethylene glycol. The invention is characterized in that ethylene oxide and carbon dioxide are used as raw materials to prepare ethylene carbonate under the catalysis of a composite catalyst; the composite catalyst and cyclic carbonate are not separated and are used to further catalyze the reaction of ethylene carbonate and methanol and prepare dimethyl cabonate and ethylene glycol. The synthesis method is characterized by high catalyst activity, low cost, long service life and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Catalytic method for the production of fluoroalkylenes from chlorofluorohydrocarbons

InactiveUS7135601B2Preparation by dehalogenationPreparation by hydrogen halide split-offCatalytic methodGas phase

A process for producing a producing a product of the formula:R—CF═CHR1 wherein R is F or CF3 and R1 is F when R is F and is H when R is CF3 by reacting a reactant of the formula:CF3—R2 wherein R2 is selected fromandwherein R3 is H, F or Cl and R4 is H or Cl,in the presence of a suitable catalyst, with a reducing agent selected from methane, methyl chloride and mixtures thereof, in a gas phase reaction.

Owner:HONEYWELL INT INC

High heat insulation transparent SiO2 aerogel film material and preparation method thereof

The invention discloses a high heat insulation transparent SiO2 aerogel film material and a preparation method thereof, wherein the preparation method is realized by adopting a sol-gel technique to control the technological condition via using acid / alkali two-step catalytic method, and using hexamethyldisilazane (HMDS) to carry out organic hydrophobic modification on the surface of colloidal particles. The film material and the preparation method thereof are characterized in that the compound precursor sol has stable property, moderate viscidity and long gel time; the prepared aerogel heat insulation film not only has high porosity, low density and low hear conducting coefficient, but also has high light transmissivity and low refractive index, therefore, it is not only fits for the request of high head insulation, but also fits for the transparency request, and can be used as high heat insulation transparent layer of the landing glass of high-rise building and car glass; the row material for preparing aerogel heat insulation film is low in cost, and benefits for realizing commercial application.

Owner:SOUTH CHINA UNIV OF TECH

Catalyst used for preparing tetrachloroethylene and its preparation method and use

InactiveCN101143328AHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsGas phaseCobalt

The invention relates to novel catalyst to prepare tetrachloroethylene in carbon tetrachloride gas-phase catalysis. The invention is characterized in that the catalyst carrier is prepared from soluble salt solution or mixed solution with ammonia in coprecipitation method. And then one or two of the mixtures such as the compounds of platinum, palladium and nickel, etc, together with one or a plurality of the mixtures such as the compounds of silver, cobalt, tin, zinc, copper or iron is / are loaded on the catalyst carrier in conventional equivalent impregnation method or excessive impregnation method. One or two of the composite oxides of alumina, zirconia, silica and titania is / are used as the carrier or carriers of the catalyst. One or two of platinum, palladium or nickel and one or two of silver, cobalt, tin, zinc, copper and iron are used as the active components to form multi-metal catalyst. The catalyst prepared in the method of the invention maintains high transformation rate of carbon tetrachloride, at the same time reduces the production of by-products such as methane, maintains high selectivity of tetrachloroethylene, and maintains a long service life of the catalyst.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Pressure synthesis and refining process of methane chloride

InactiveCN1515528AAvoid quenchingAvoid sudden heatHalogenated hydrocarbon preparationCatalytic methodLiquid methane

The present invention relates to a new process for producing methane chloride by using liquid-phase catalytic method and pressurization process. The hydrogen chloride and methyl alcohol are mixed according to a certain ratio, then placed in a tank reactor with catalyst, and under the condition of a certain temp. and pressure the invented methane chloride can be synthesized. It adopts acid / water washing and alkali-washing processes to remove unreacted methyl alcohol and hydrogen chloride, and adopts concentrated sulfuric acid washing process to remove residual water content and reaction by-product dimethyl ether, then the purified and dried methane chloride gas is undergone the processes of compression and condensation so as to obtain high-purity liquid methane chloride product.

Owner:蓝星安迪苏股份有限公司

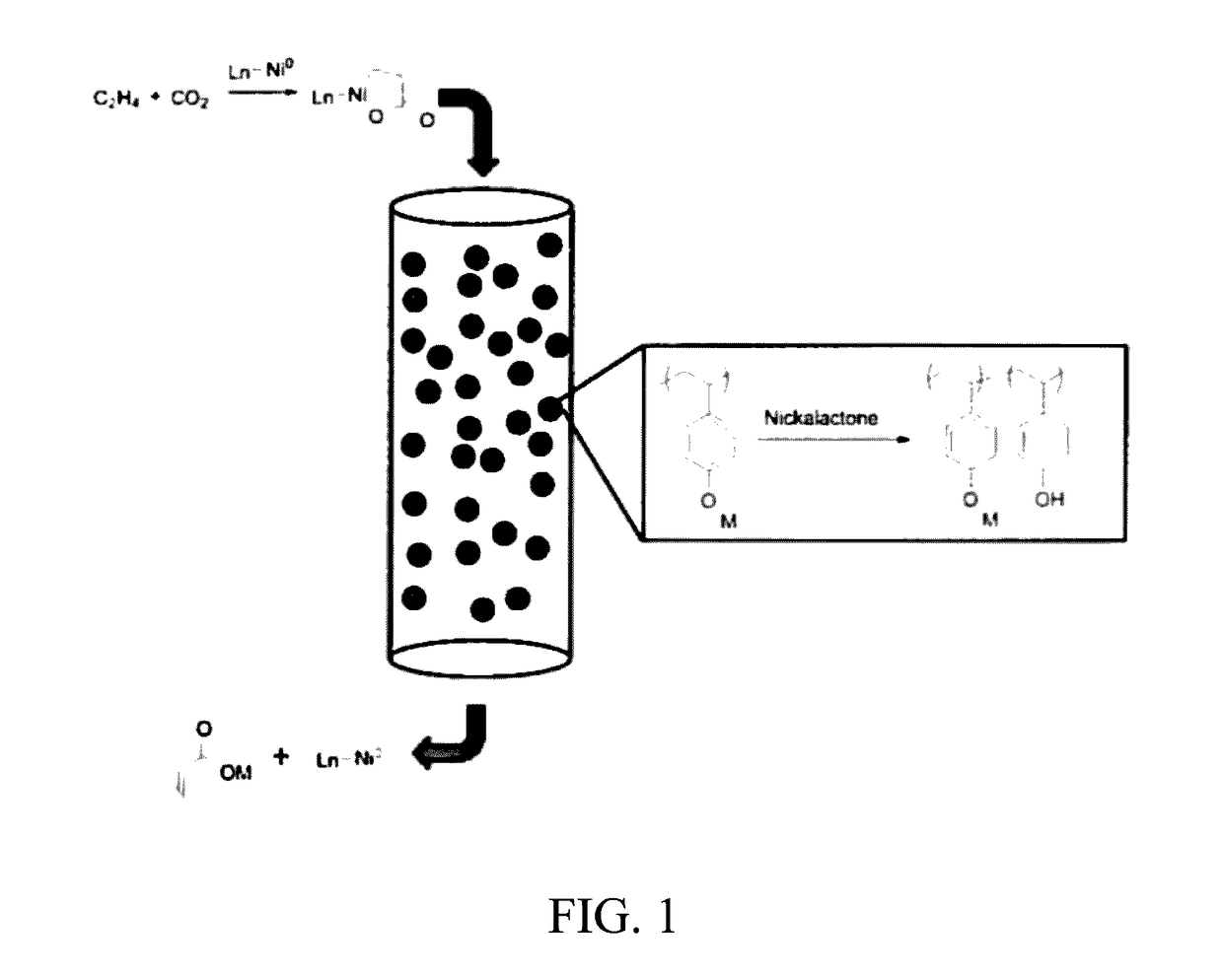

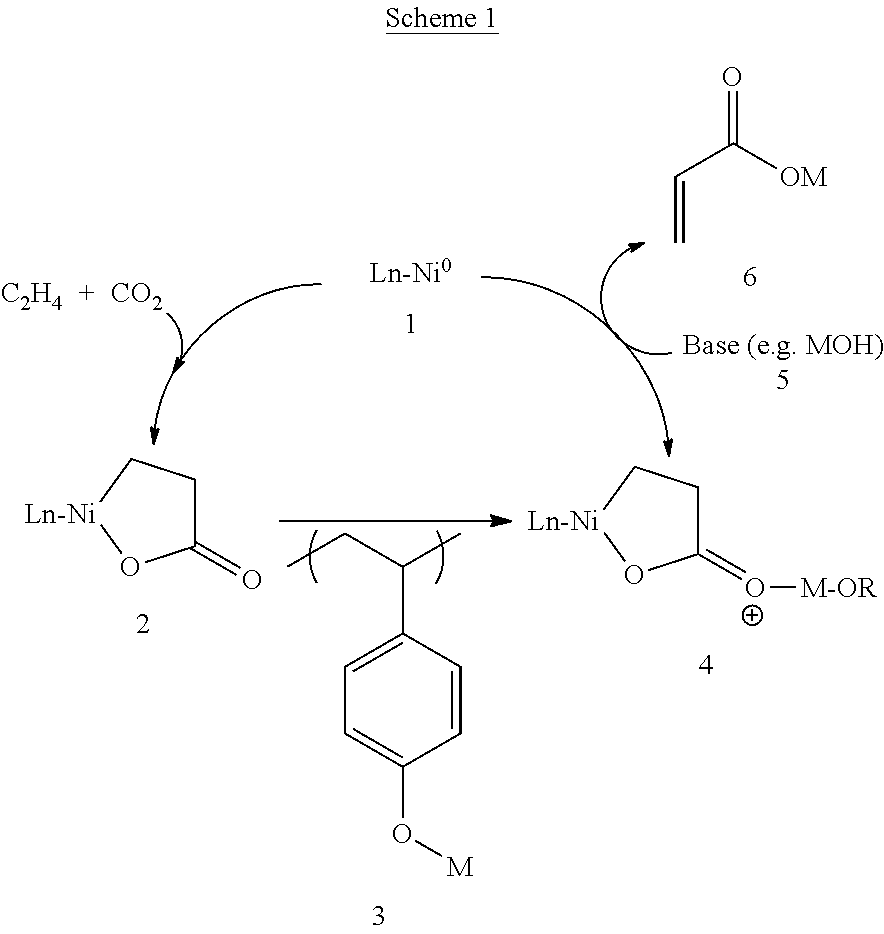

Formation of alpha,beta-unsaturated carboxylic acids and salts thereof from metalalactones and anionic polyelectrolytes

ActiveUS20170166506A1Easy to separateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolyelectrolyteCatalytic method

This disclosure provides for routes of synthesis of acrylic acid and other α,β-unsaturated carboxylic acids and their salts, including catalytic methods. For example, there is provided a process for producing an α,β-unsaturated carboxylic acid or a salt thereof, the process comprising: (1) contacting in any order, a group 8-11 transition metal precursor, an olefin, carbon dioxide, a diluent, and a polyaromatic resin with associated metal cations to provide a reaction mixture; and (2) applying conditions to the reaction mixture suitable to produce the α,β-unsaturated carboxylic acid or a salt thereof. Methods of regenerating the polyaromatic resin with associated metal cations are described.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

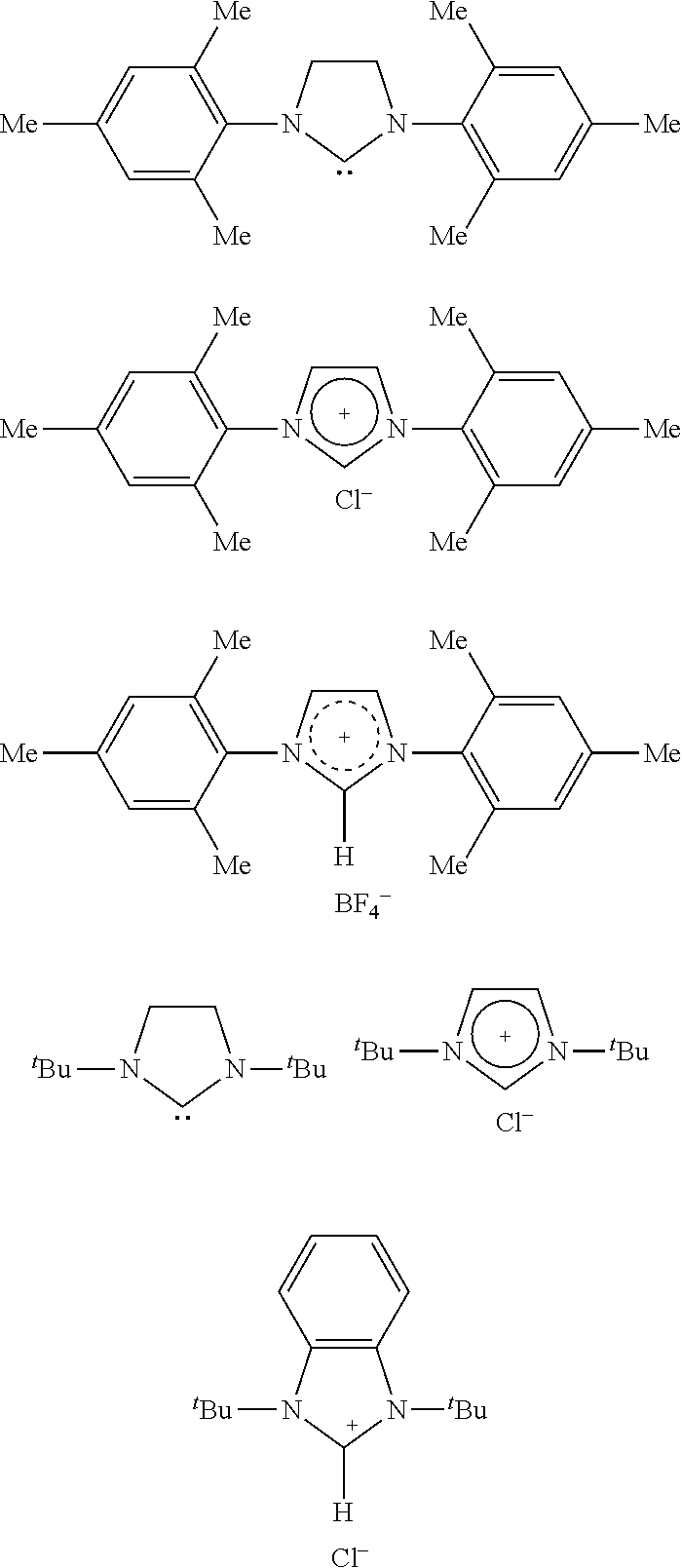

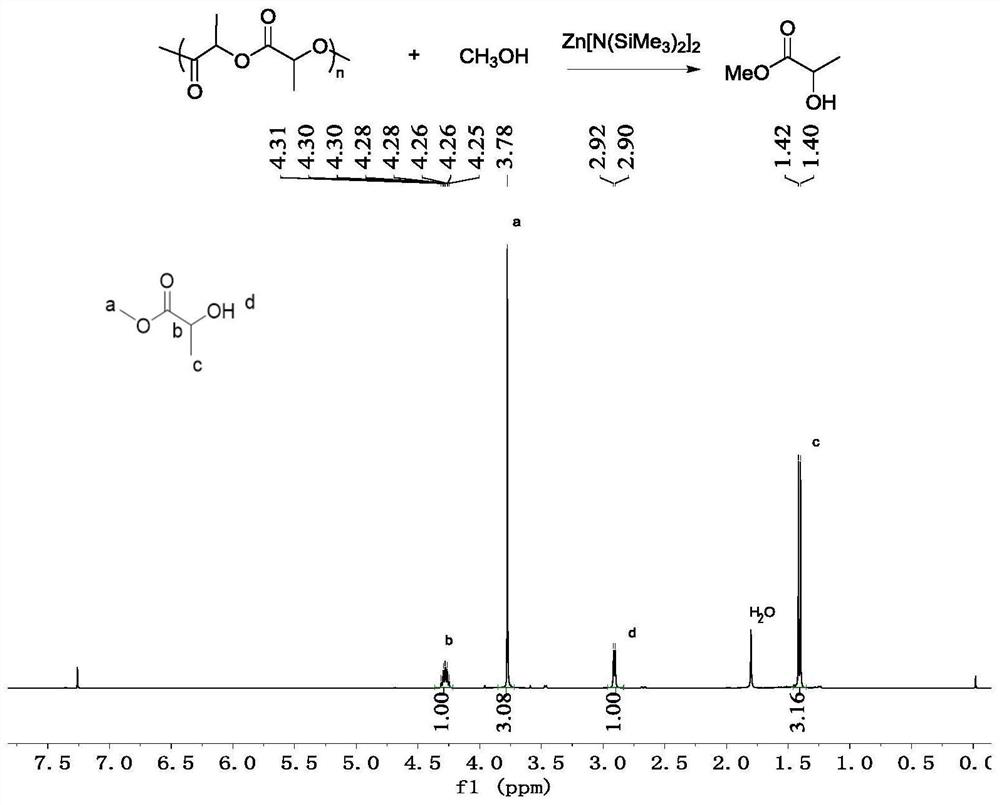

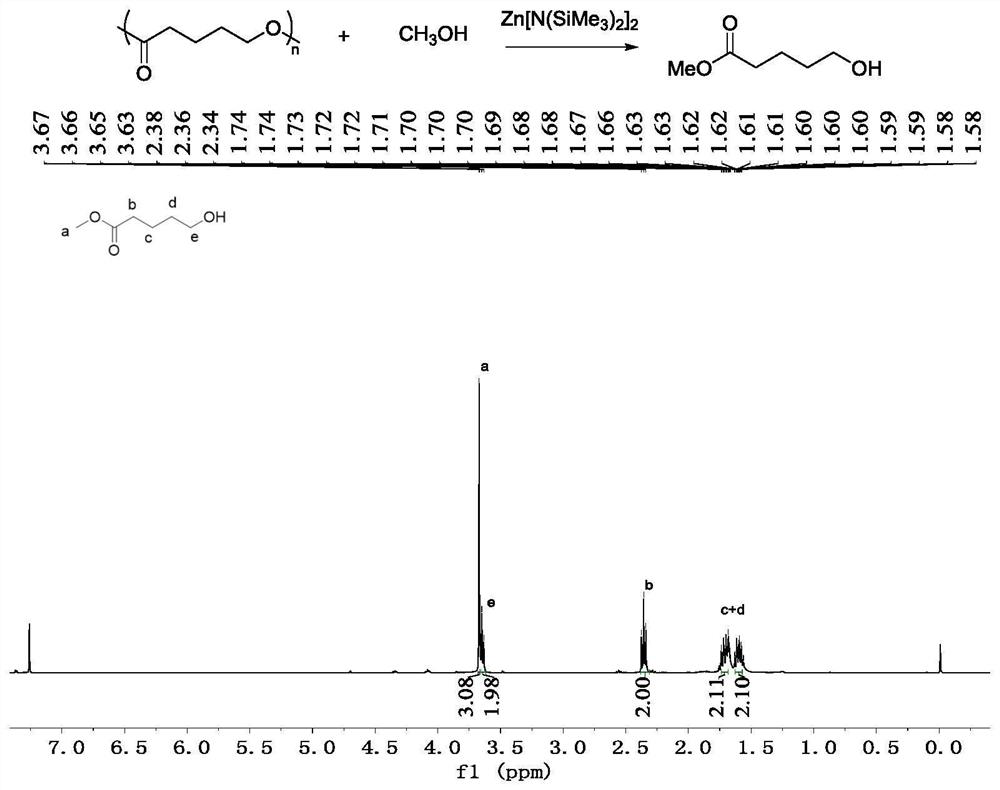

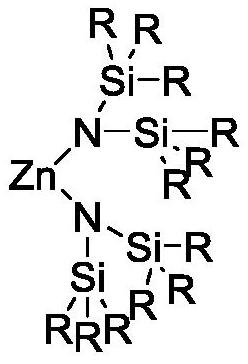

Zinc catalyst applicable to controllable depolymerization of polyester material and catalytic method thereof

ActiveCN112076790AAchieve reuseRealize secondary usePreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterTrans esterification

The invention discloses a zinc catalyst applicable to controllable depolymerization of a polyester material and a catalytic method thereof, and belongs to the technical field of polyester depolymerization. The problems that an existing zinc catalyst used for alcoholysis of waste polyester materials needs to synthesize complex ligands, and the number of synthesis steps is increased are solved. Thecatalyst adopted by the invention is a bis(hexaalkyldisilazane)zinc catalyst with a simple structure, and under the participation of an alcohol compound, the polyester material can be depolymerized into small organic molecules under mild conditions through the transesterification reaction catalyzed by the catalyst, so that the reutilization of waste polyester is realized. The zinc catalyst is adopted to catalyze polyester depolymerization, metal zinc is non-toxic, colorless, cheap and easy to obtain and serves as one of the microelements of a human body, biocompatibility is good, and the production process is more environmentally friendly; the catalyst is simple in structure, few in synthesis steps and more economical in production cost. The catalyst has very good universality, and has a very good depolymerization effect on various polyester materials with different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

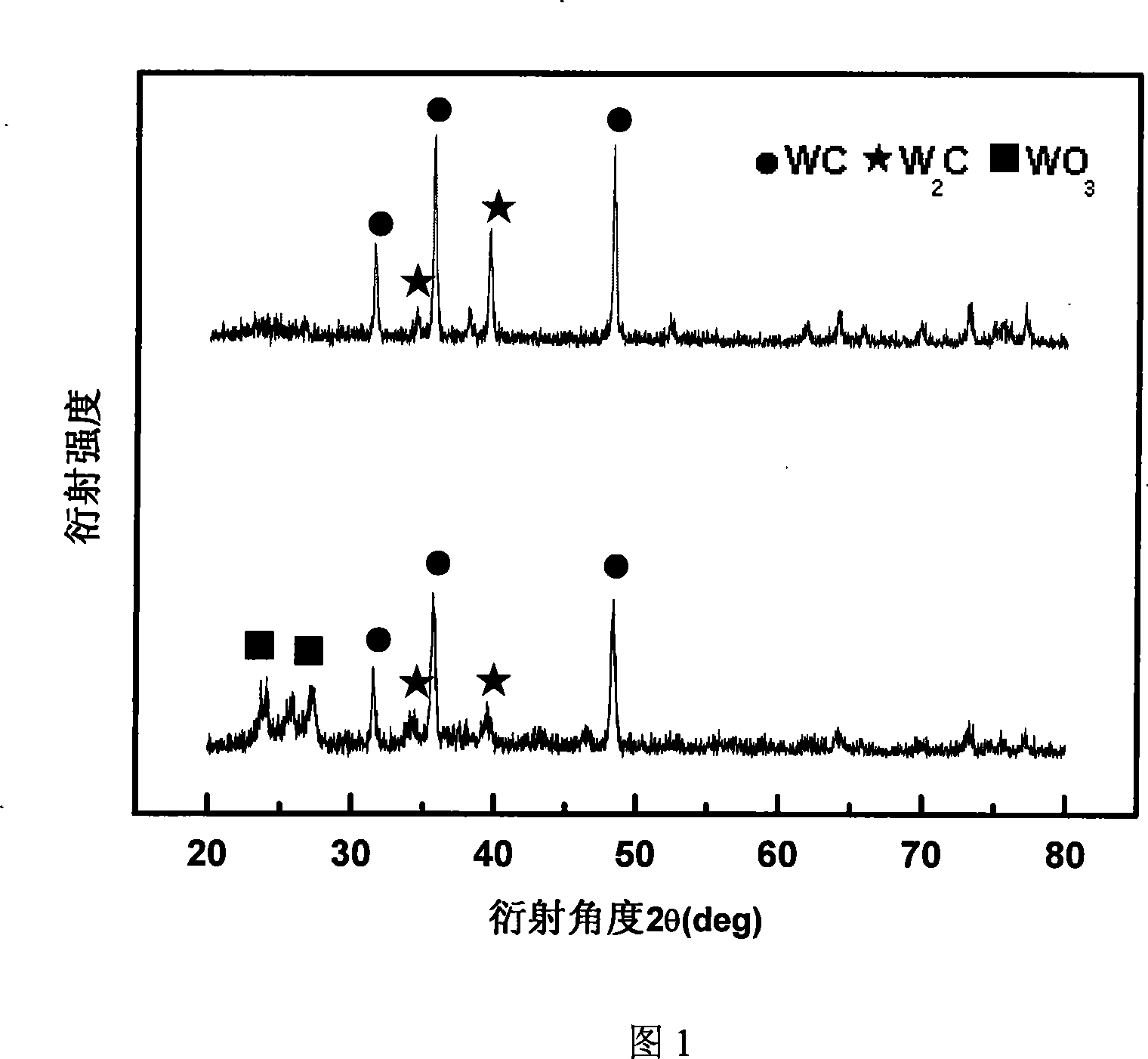

Microwave induction catalytic preparation method of nano tungsten carbide

InactiveCN101181690AFast productionReduce energy consumptionPhysical/chemical process catalystsTungsten/molybdenum carbideCatalytic methodSlurry

The invention discloses a microwave-induced catalytic preparation method of nano-sized tungsten carbide. Preparation steps of the invention are that: (1) a certain mass of tungstenic material is dissolved in a microwave resistant absorption vessel which contains solvent, and dispersant and carbon source are added into the vessel in sequence; the mixture is put into an ultrasonic clearing machineto disperse homogeneously with ultrasonic, and then the mixture is taken out to be stirred till the mixture becomes viscous slurry; (2) the viscous slurry is put into a microwave oven, and drying powder can be obtained by a intermittent microwave heating method, namely, the slurry is heated intermittently; (3) a certain proportion of metallic powder is added into the drying powder, and the obtained mixture is put into a crucible after mixing homogeneous mechanically; after surroundings of the crucible are coated with microwave resistant heat preserving materials, the crucible is put into the microwave oven to be heated constantly, and nano tungsten carbide particles are obtained. The invention adopts the microwave-induced catalytic method, thus the tungsten carbide can be heated to high temperature quickly; the invention is characterized by fast preparation speed and low energy consumption, and purity quotient of the prepared nano tungsten carbide particles is high.

Owner:SUN YAT SEN UNIV

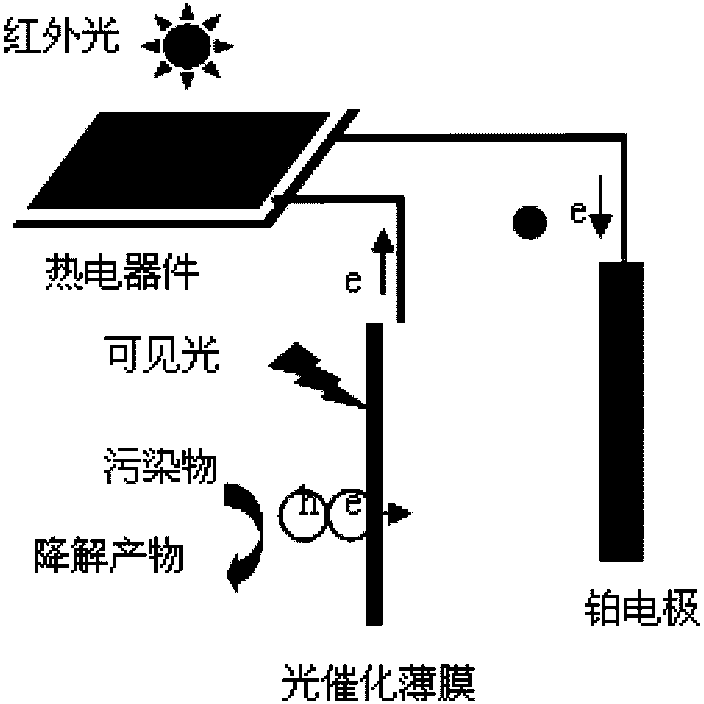

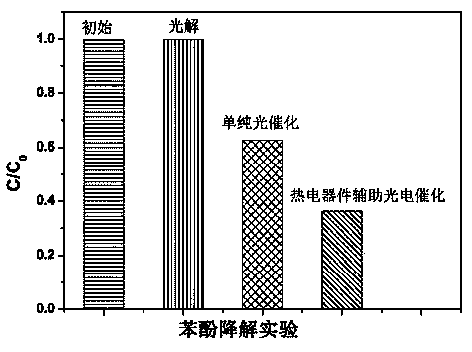

Photoelectric catalytic unit and photoelectric catalytic method

InactiveCN103920442AEasy to separateIncrease profitEnergy based chemical/physical/physico-chemical processesCatalytic methodHeat energy

The invention relates to a photoelectric catalytic unit and a photoelectric catalytic method. The photoelectric catalytic unit comprises a photocatalytic film deposited on a conducting substrate, and a thermoelectric device electrically connected with the photocatalytic film, wherein the surface of the thermoelectric device is provided with a photothermal material. The photoelectric catalytic method comprises the following steps: photogenerated electrons and holes generated on the photocatalytic film deposited on the conducting substrate under the light excitation are utilized to degrade organic pollutants in contact with the photocatalytic film; and the thermoelectric device is utilized to convert heat energy, which is generated by the photothermal material on the surface under the irradiation of visible light or infrared light, into electric energy, and apply the electric energy onto the photocatalytic film electrically connected with the photocatalytic film to promote the separation of the photogenerated electrons and the holes.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

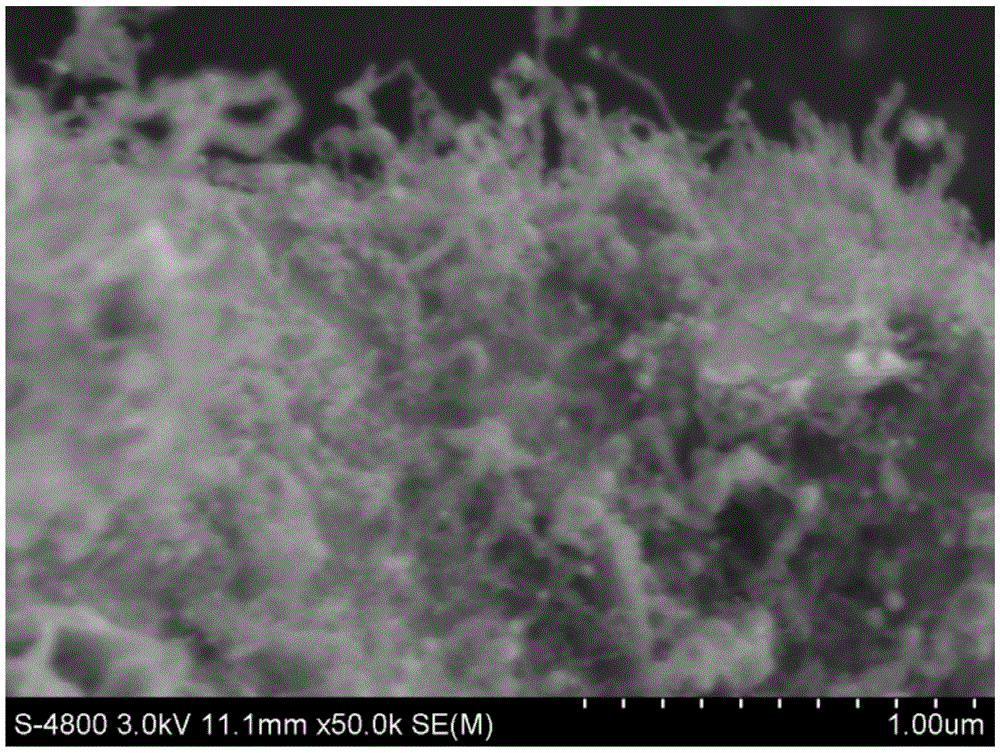

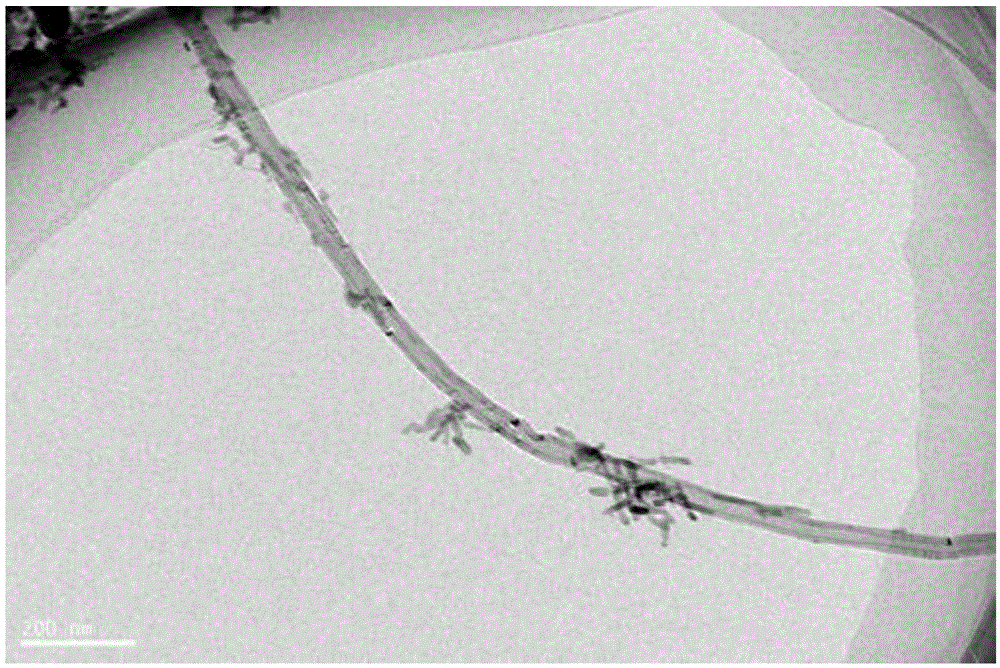

Preparation method of reinforced magnesium matrix composite

ActiveCN105543598AEnsure Structural IntegrityImprove mechanical propertiesNano siliconCatalytic method

The invention provides a preparation method of a reinforced magnesium matrix composite and relates to an alloy which contains non-metal fibers or filaments and is manufactured through contact of fibers or filaments with molten metal. According to the preparation method, carbon nanotubes grow on nano silicon carbide particles in situ with a floating catalytic method, then carbon nanotube-silicon carbide in-situ composite reinforcement phases are prepared, and the carbon nano tube-silicon carbide hybrid reinforced magnesium matrix composite is prepared with a spark plasma sintering process on the basis of mechanical stirring and mixing of a liquid phase. The defects that an existing preparation method of a reinforced magnesium matrix composite has a poor carbon nanotube synthesis effect, structural damage is easily caused, the reinforcement effect is poor, reinforcement phases are non-uniformly distributed in a magnesium matrix, the reinforcement phases and the magnesium matrix have a poor interface reaction easily, carbon nanotube-aluminum oxide composite reinforcement phases have poor structural design and are not suitable for serving as reinforcement phases of the magnesium matrix composite, and the mechanical performance of the prepared magnesium matrix composite is non-ideal are overcome.

Owner:HEBEI UNIV OF TECH

Method for preparing hard carbon negative electrode materials of lithium ion battery

The invention discloses a method for hard carbon negative electrode materials of a lithium ion battery and belongs to the technical field of hard carbon negative electrode materials of the lithium ion battery. By means of the method, one or several kinds with any proportion of sulfuric acid, sulfate, boric acid, borate, phosphoric acid, phosphate, muriatic acid, muriate and ammonia or ammonium salt is / are chosen as a catalyst / catalysts for preparing the hard carbon negative electrode materials of the lithium ion battery in a catalysis method, and compared with the catalysts used in the prior art, the catalysts used in the preparing process of the materials are reduced in low-temperature section stabilized heat treatment temperature, the time is shortened by nearly 10 times, a large number of resources are saved, production cost is reduced, and capacity is improved.

Owner:DONGFANG ELECTRIC CORP LTD

Preparation method of silica aerogel and glass fiber mat composite material

The invention discloses a preparation method of a silica aerogel and glass fiber mat composite material. The preparation method comprises the following steps: glass fiber mat is placed in rolls or in a tiled form into an appropriate container; a novel ''two-step catalytic method'' of acid-catalytic hydrolysis and fluorinion catalytic condensation is adopted during sol-gel process of silica aerogel; the prepared sol-gel precursor solution is injected into the well-laid glass fiber mat, air in the glass fiber mat is exhausted, and gaps in the glass fiber mat are filled with the sol-gel precursor solution; the sol-gel precursor solution is gelated in the gaps of the glass fiber mat so as to obtain a glass fiber met-gel composite material, and the gelated glass fiber mat composite material is rolled-up again; and the rolled-up glass fiber mat and silica aerogel composite material is modified in an ethanol solution of hexamethyl-disilazane, and the gel composite material undergoes supercritical fluid drying to obtain the silica aerogel and glass fiber mat composite material.

Owner:航天海鹰(镇江)特种材料有限公司

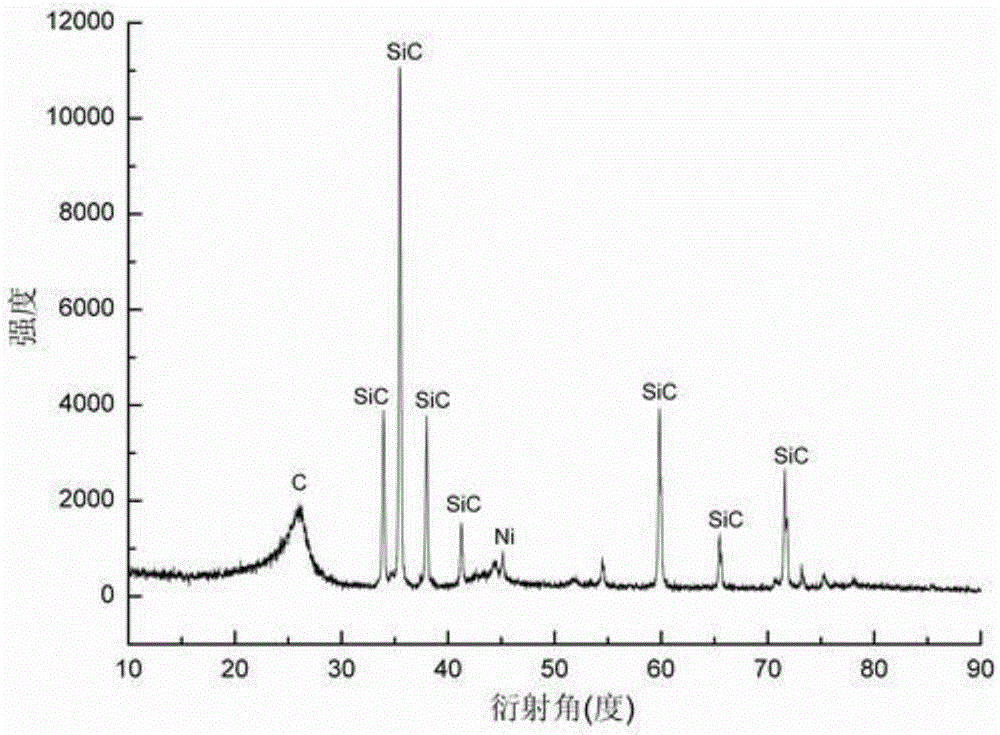

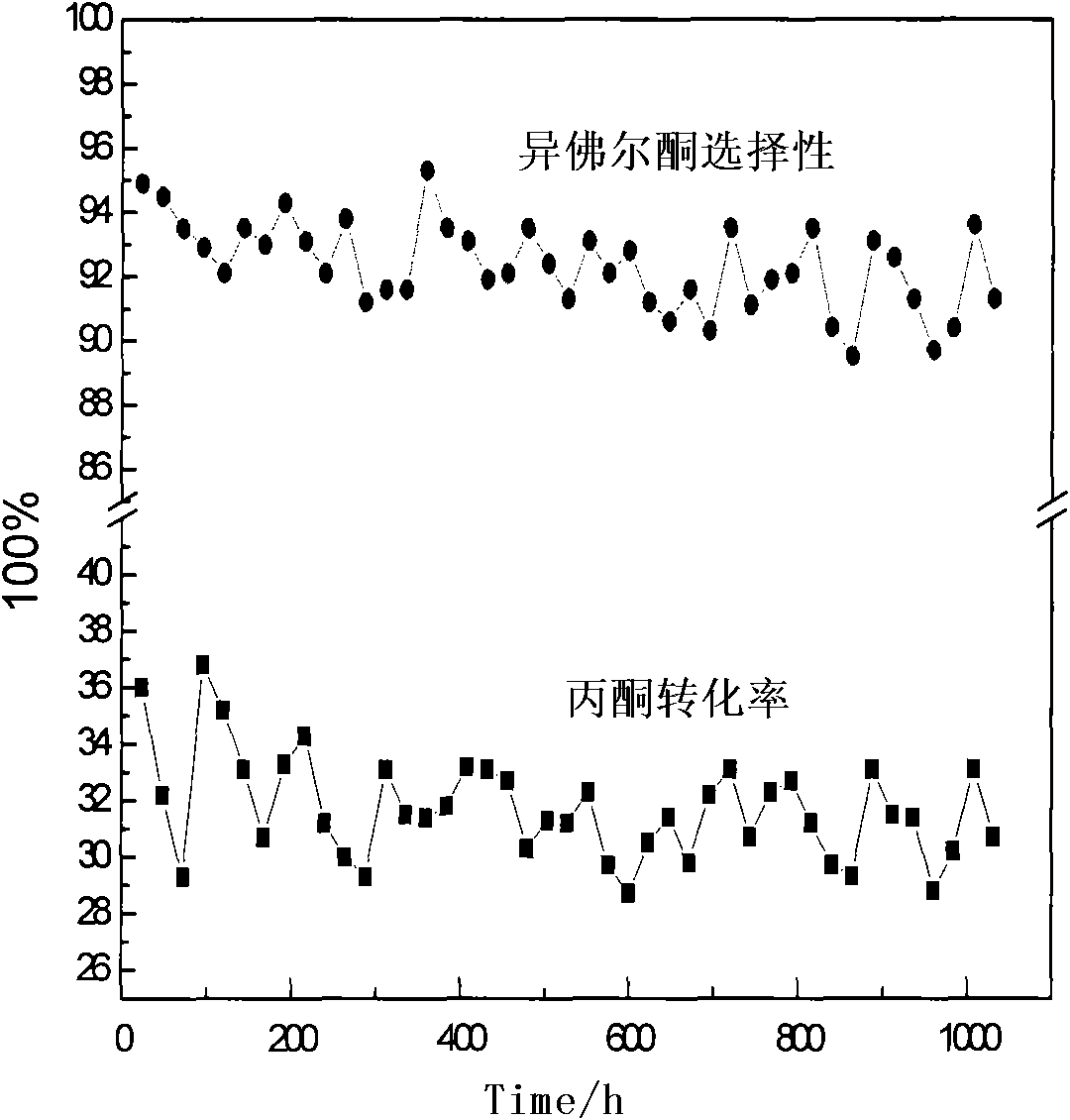

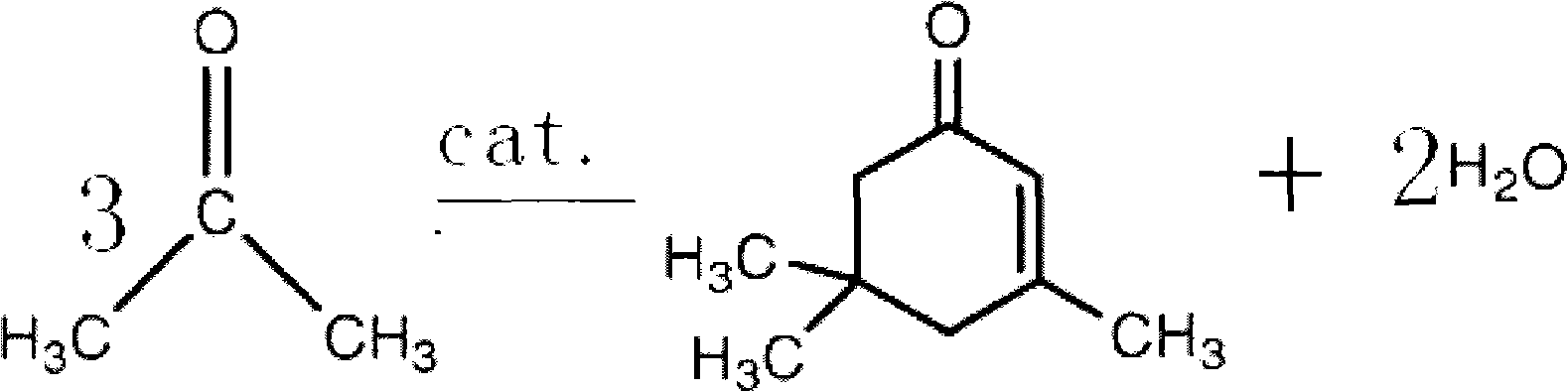

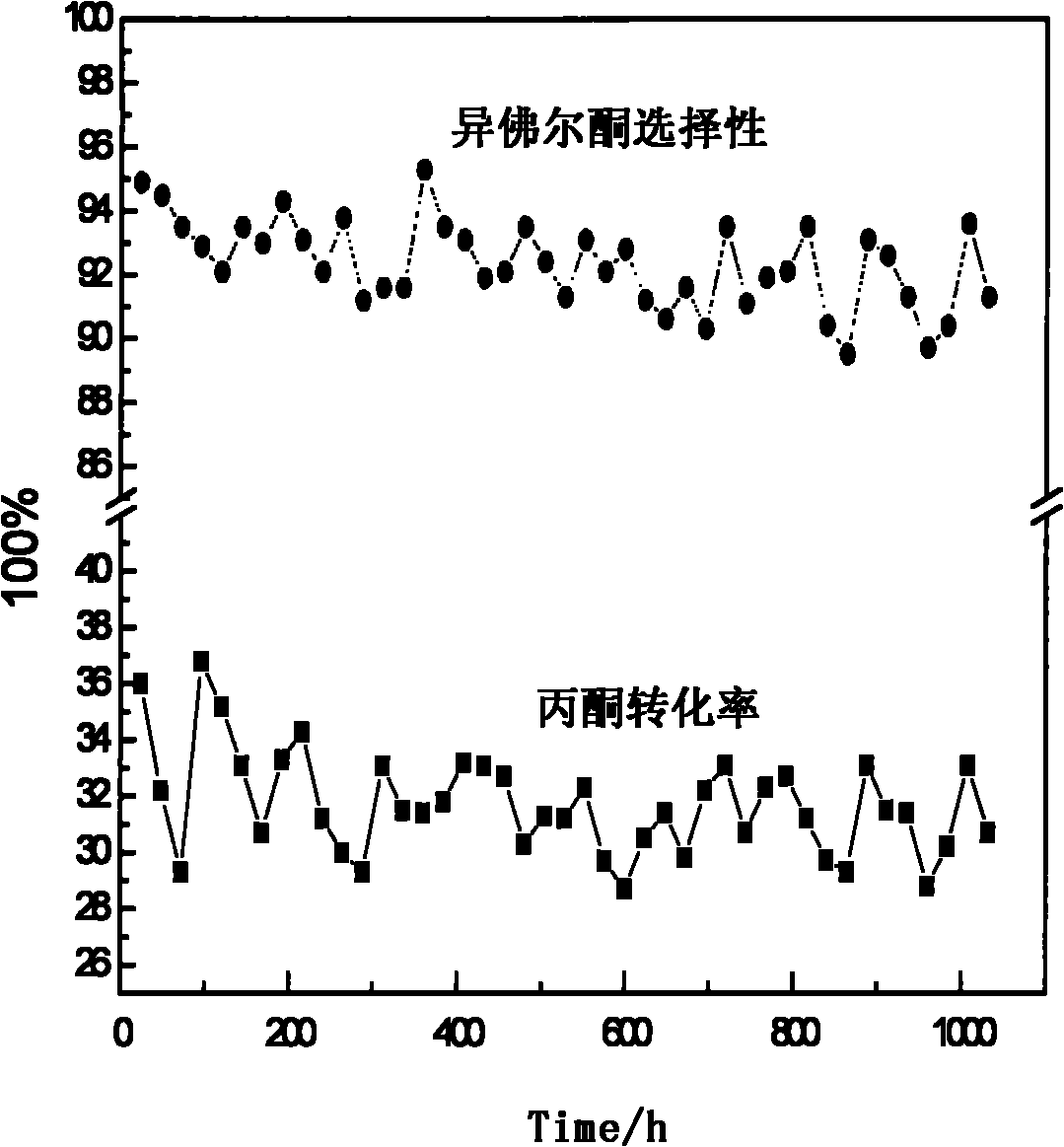

Heterogeneous catalytic method for synthesis of isophorone from acetone

ActiveCN101875602AMild reaction conditionsTechnical securityPhysical/chemical process catalystsOrganic compound preparationCatalytic methodFixed bed

The invention relates to a heterogeneous catalytic method for synthesis of isophorone from acetone. Acetone is used as a raw material, and a magnesium-aluminum composite oxide is used as a catalyst for carrying out catalytic synthesis to obtain isophorone; the magnesium-aluminum composite oxide comprises MgO, Al2O3 and MgAl2O4, the molar ratio of magnesium to aluminum is 0.3-3, the specific surface area is 80-150m<2> / g, and the pore volume is 0.2-0.3cm<3> / g; a fixed bed reactor is used for carrying out synthetic reaction, 20ml of 20 to 40-mesh catalyst is added into a stainless steel reactor of which the inner diameter is 10mm, the reactor is heated to the reaction temperature from the room temperature at the rate of 10 DED C / min after being qualified through an air-tight test, and then, the analytically pure acetone raw material is injected into the reactor by a duplex plunger pump through a preheater; the reaction temperature is 220-290 DEG C; the reaction pressure is normal pressure; and the air speed of the acetone liquid is 0.1-1.0 / h, the selectivity reaches 94.5%, the conversion rate reaches 44.8%, and the stability reaches 1000 hours.

Owner:PETROCHINA CO LTD

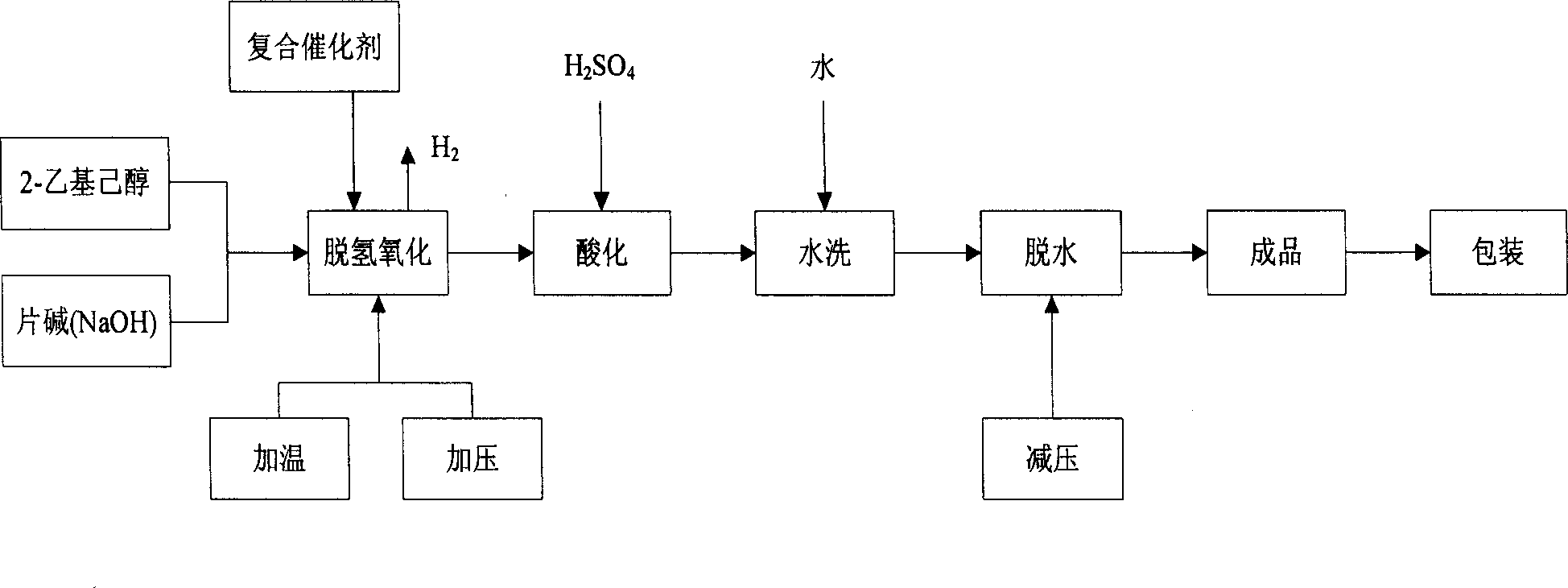

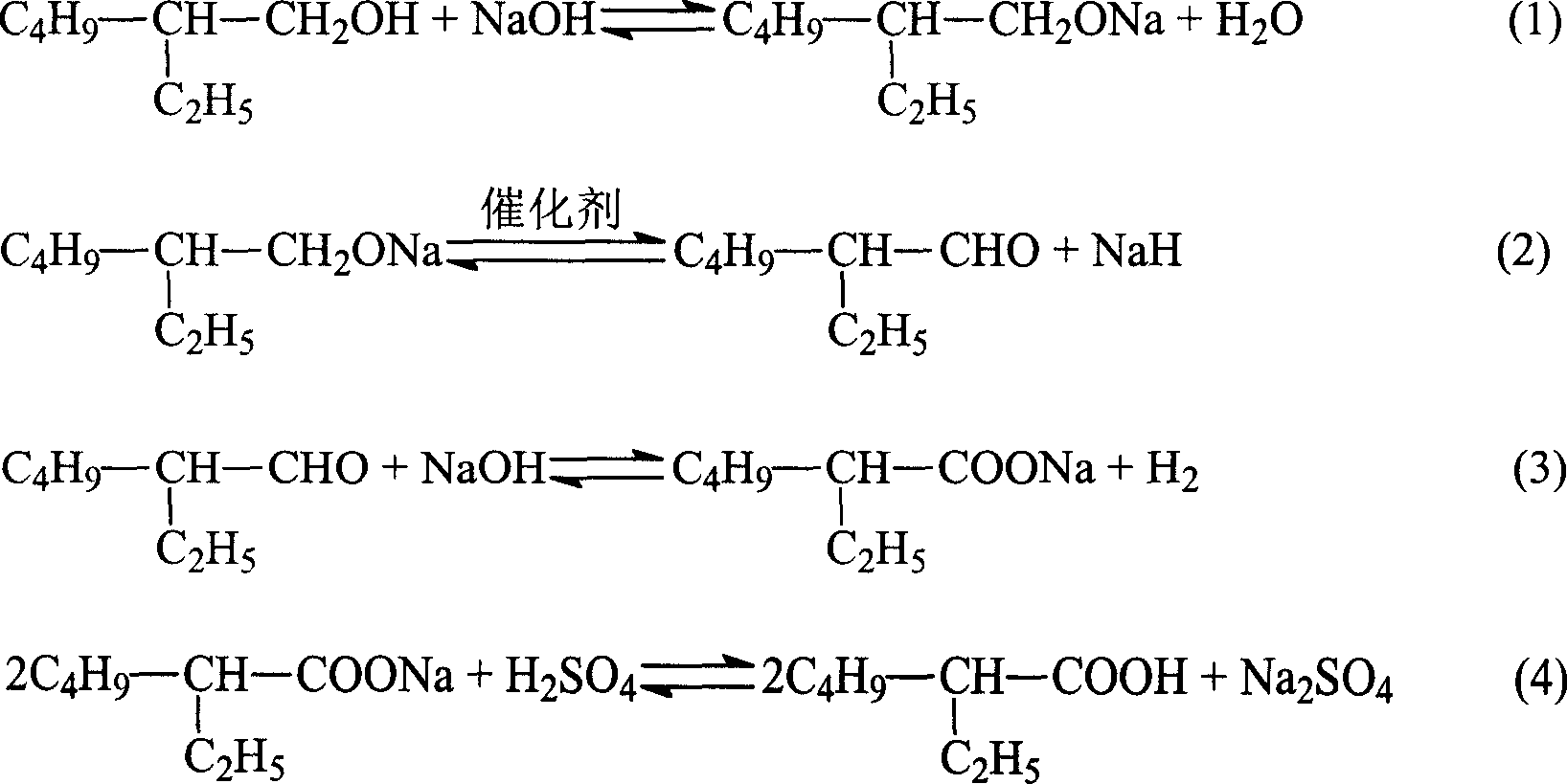

Production of isooctaacid by composite catalytic method

ActiveCN1817845AHigh activityHigh selectivityOrganic compound preparationCarboxylic compound preparationCatalytic methodRare earth

Production of isooacid by composite catalysis is carried out by placing isooctanol and sodium hydrate solution into reactive kettle in proportion=1.2-1.5mol, agitating, adding into composite catalyst with calcium oxide 0.8-1.2 unit mass, vanadic anhydride 0.6-0.9 unit mass and rare earth oxide 0.1-0.4 unit mass, agitating, raising temperature to 240-280 degrees C, alcohol and alkali oxidization reacting for 1.8-2.2hrs, removing hydrogen gas, cooling for reactive materials, adding into 5-10% water to dilute, filtering out solid composite catalyst, adding into H2SO4 solution with content 30-40% to make materials pH value become 3, agitating while acidification reacting for 30-40mins, laying aside while laminating to remove aqueous layer, washing materials by water, decompressing and dewatering to obtain final products. It is cheap, has higher recovery rate and short process flow.

Owner:SHENYANG ZHANGMING CHEM

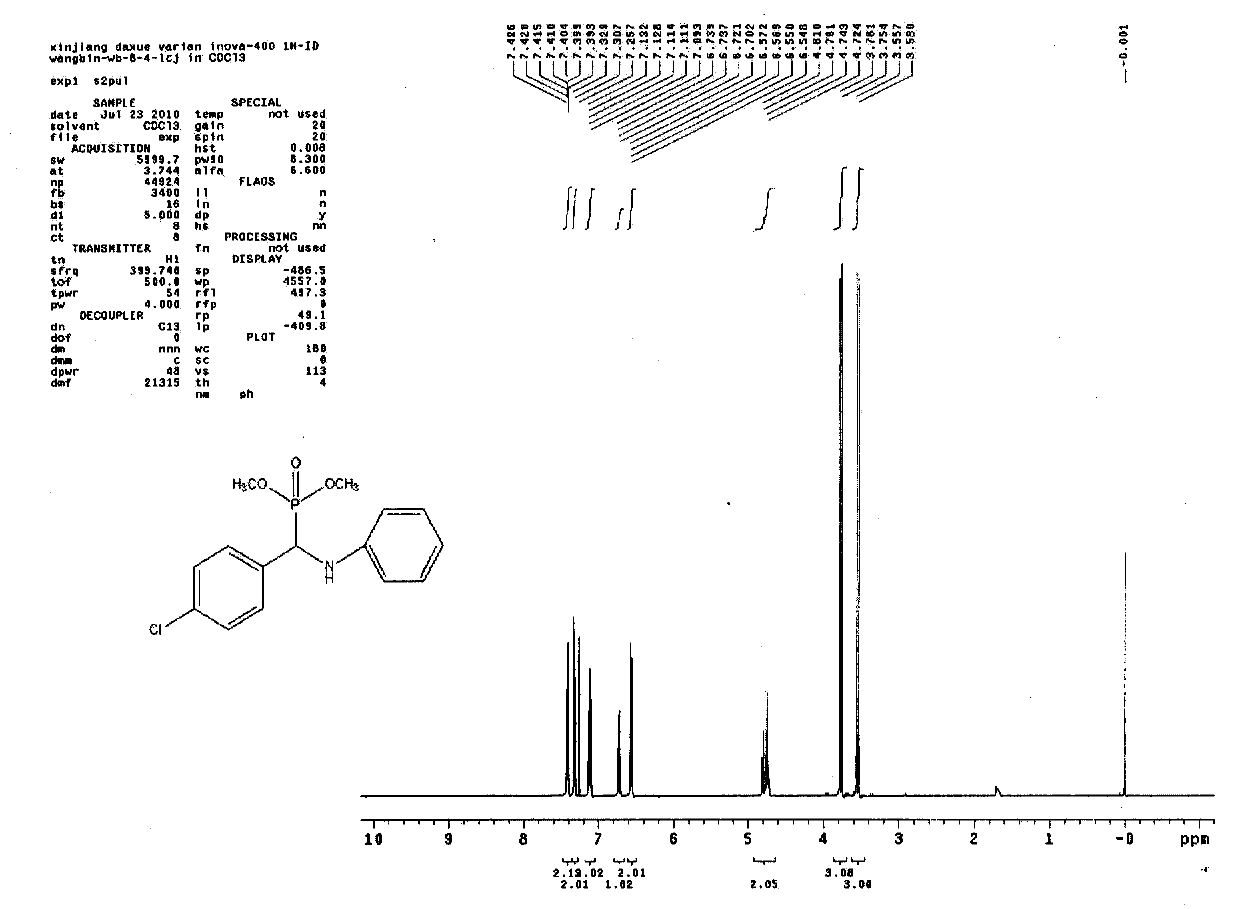

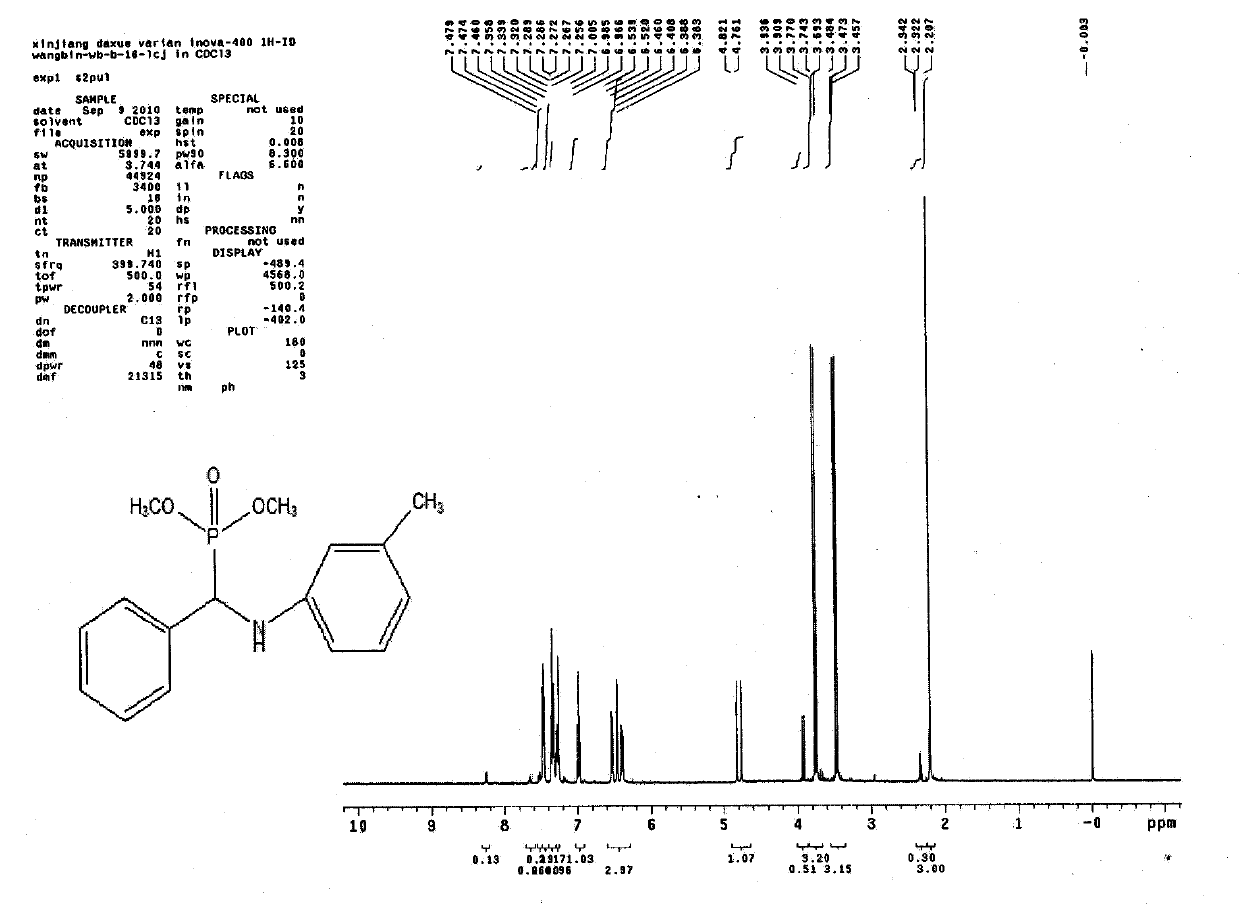

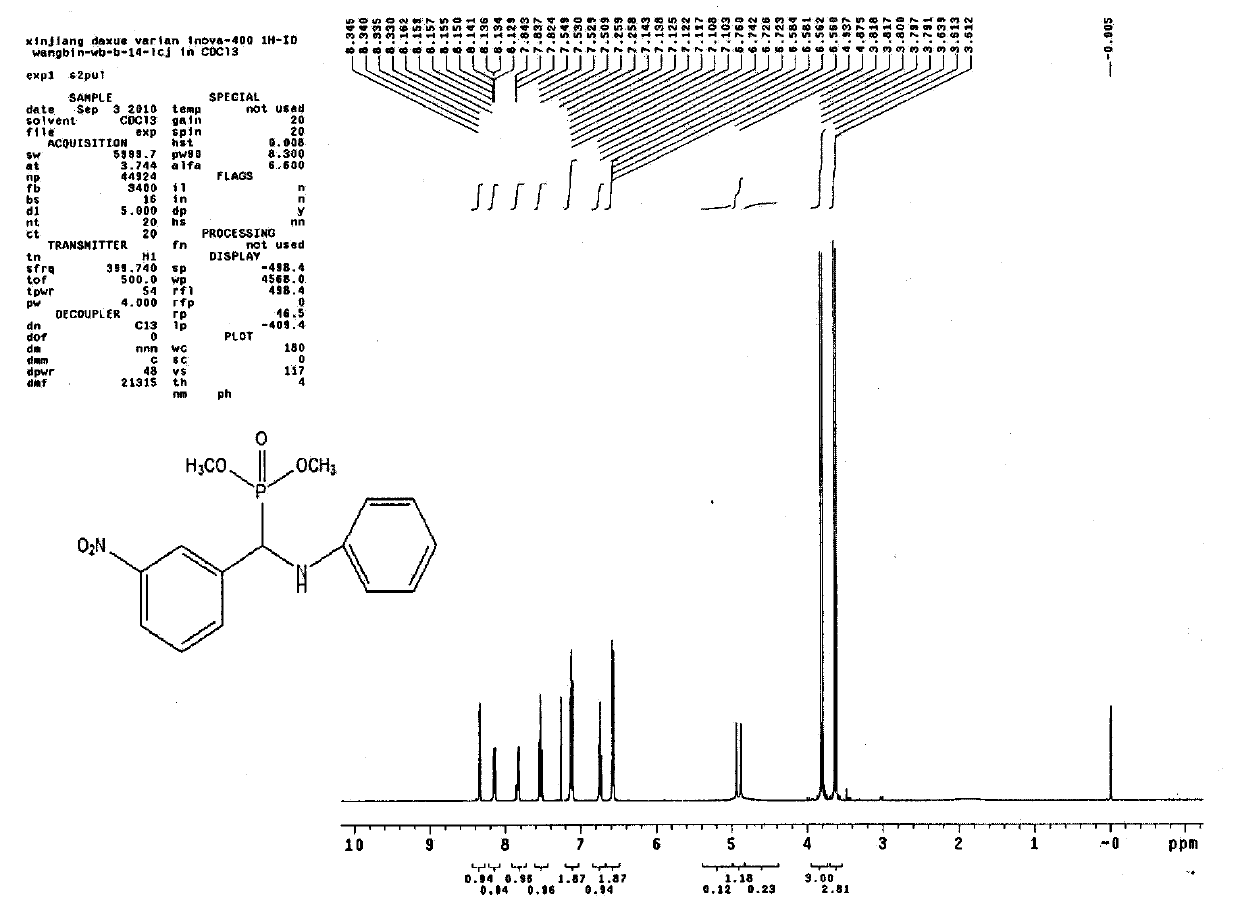

A green method for the synthesis of α-aminophosphonates catalyzed by brφnsted acidic ionic liquids

InactiveCN102276649ASimple and fast operationHigh yieldGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateCatalytic method

The invention relates to a sulfonic acid group functionalized acidic ionic liquid 1-butyl-2-trifluoromethyl-3-sulfonic acid propyl benzimidazole hydrogen sulfate [PSb(2-CF3Bim)][HSO4] A green approach to the catalytic synthesis of α-aminophosphonates. The method has the advantages of simple operation, environmental friendliness, mild reaction conditions, short reaction time, simple post-treatment, high yield and recyclable catalyst.

Owner:XINJIANG UNIVERSITY

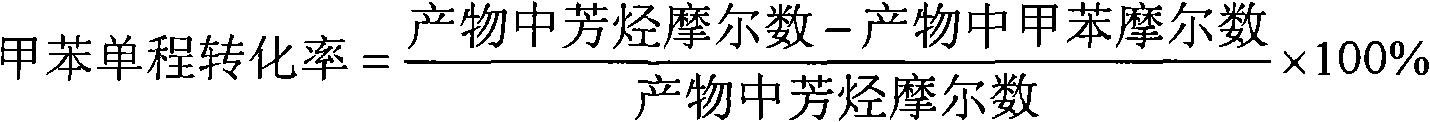

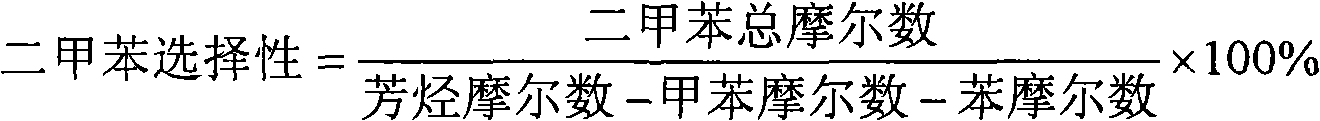

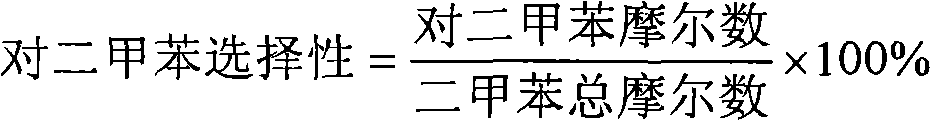

Fluidized catalytic method for toluene methylation

InactiveCN102372582AReduce temperature riseImprove responseHydrocarbon by hydrocarbon and non-hydrocarbon condensationIsomerizationCatalytic method

The invention relates to a fluidized catalytic method for toluene methylation, and mainly solves the problems of great temperature rise of a catalyst bed, many side reactions and low methanol utilization rate in existing technologies. The method comprises the steps of: a) first putting an alkylating reagent methanol into a fixed bed reactor so as to contact with a dehydration catalyst for reaction, thus generating mixed effluent I containing dimethyl ether, water and unreacted methanol; b) mixing a toluene raw material with the reaction effluent I and conducting vaporization so as to obtain a reaction mixture II, which is then subjected to contact with a methylation for reaction catalyst in a fluidized bed reactor, thus obtaining oil-phase reaction effluent III rich in xylene, gas-phase reaction effluent IV and water-phase effluent V; c) separating the oil-phase reaction effluent III, thus obtaining an unconverted toluene fraction containing bits of benzene, a mixed C8 fraction as well as C9 and C9+ heavy aromatic fractions; d) subjecting the mixed C8 fraction to adsorption, crystallization or a adsorption / crystallization combination separation and isomerization system, thus obtaining a paraxylene product, refluxing the unconverted toluene fraction containing bits of benzene, and mixing it with the reaction mixture II in the fluidized bed reactor for conversion. The technical method of the invention well solves the above problems, and can be applied to industrial production of paraxylene preparation through a methylation reaction with toluene as the raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com