Catalytic method for generating sulfate radicals and active oxygen species as well as advanced oxidation method of organic pollutants difficult to biodegrade

A technology of free radicals and active oxygen, applied in the direction of water pollutants, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as refractory biodegradable organic pollutants, and achieve improved removal Efficiency, low heavy metal dissolution rate, and the effect of solving high heavy metal dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

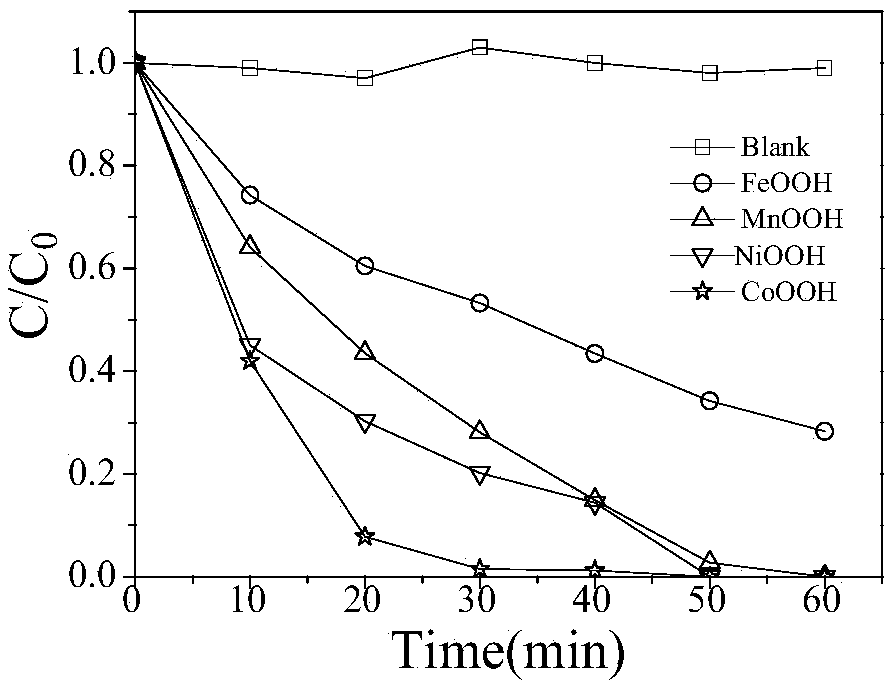

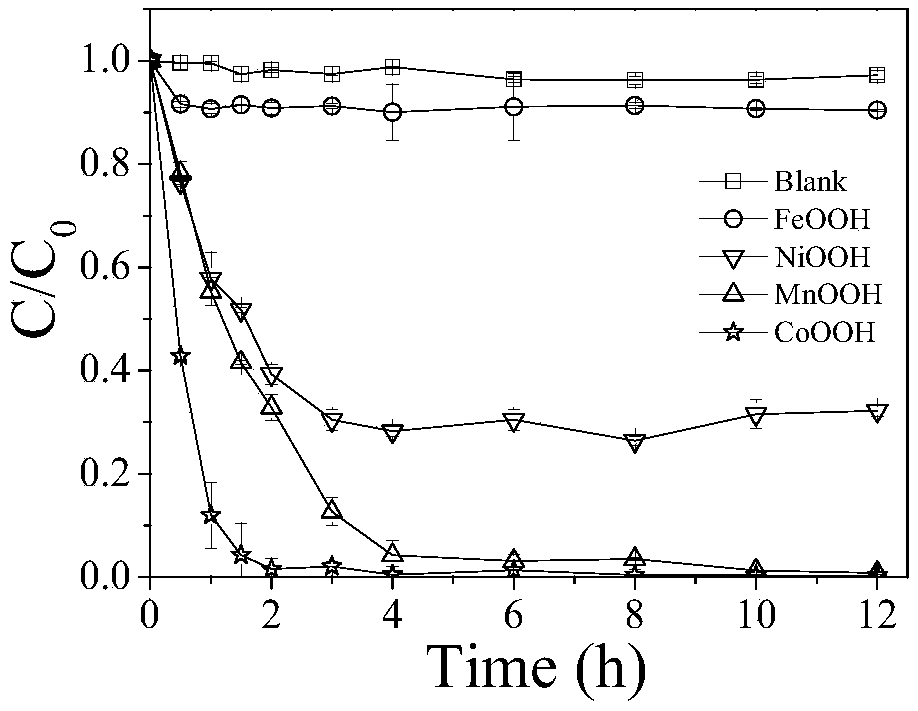

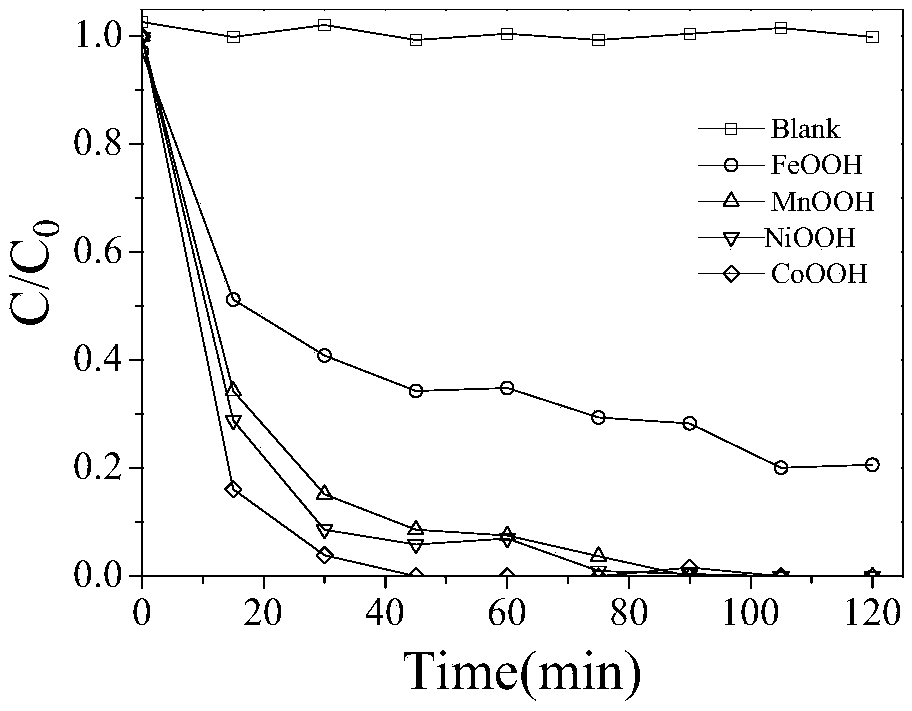

[0057] This embodiment proposes a catalytic method for generating sulfate radicals and active oxygen species, using CoOOH as a catalyst, comprising the following steps:

[0058] Synthesis of CoOOH:

[0059] Step S211, take Co(NO 3 ) 2 ·6H 2 O is dissolved in water to obtain a second solution with a concentration of 0.15 to 0.2 mol / L;

[0060] Step S212, dissolving NaOH in water to prepare a 1mol / L NaOH solution;

[0061] Step S213, according to the volume ratio of 1:1, the NaOH solution is added dropwise to the second solution, the supernatant turns from rose red to transparent, the reaction is complete, and the third solution is obtained;

[0062] Step S214, heating the third solution in a water bath at a constant temperature of 60°C, pouring out the supernatant to obtain a fourth solution;

[0063] In step S215, the fourth solution is placed on a water bath, and H is added dropwise with a molar concentration of 30% while heating and stirring. 2 o 2 , and then in a con...

Embodiment 2

[0070] The present embodiment proposes a kind of catalytic method that produces sulfate radical and reactive oxygen species, and described catalytic method adopts NiOOH as catalyst, comprises the following steps:

[0071] Synthesis of NiOOH:

[0072] Step S220, the NiSO 4 Add solid to water to prepare 0.15~0.3mol / L NiSO 4 solution;

[0073] Step S221, according to the volume ratio of 1:1, the concentration is 0.15~0.3mol / LK 2 S 2 o 8 solution was dropped into the NiSO 4 solution, the sixth solution is obtained;

[0074] Step S222, slowly adding ammonia water to the sixth solution to adjust the pH to pH=7-9;

[0075] Step S223, standing the sixth solution at 35°C for 72 hours to obtain a seventh solution;

[0076] Step S224, centrifuging the seventh solution after standing, washing and drying the obtained solid;

[0077] Step S225, adding the NaOH solid into the NaClO solution with a concentration of 0.15-0.3 mol / L according to the mass fraction of 1%-3% to obtain an e...

Embodiment 3

[0082] This embodiment proposes a kind of catalytic method that produces sulfate radical and reactive oxygen species, adopts MnOOH as catalyst, comprises the following steps:

[0083] Synthesis of MnOOH:

[0084] Step S231, the MnSO 4 ·H 2 O is added in the NaOH solution of 0.1mol / L;

[0085] Step S232, adding 30% to 50% H of the total solution mass to the solution obtained in step S231 2 o 2 and mix well;

[0086] Step S233, adding the solution obtained in step S232 into the reaction kettle, heating to 150°C and keeping it for 15h;

[0087] Step S234, naturally cooling the product in the reactor to room temperature, washing with water until the pH of the solid surface is neutral;

[0088] In step S235, the obtained solid is placed in a vacuum drying oven, and vacuum-dried at 50° C. for 4 hours to obtain manganese oxyhydroxide.

[0089] Complete catalysis:

[0090] Step S131, grinding the solid material of manganese oxyhydroxide into fine particles to obtain manganese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com