Patents

Literature

41results about How to "Reduce production procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

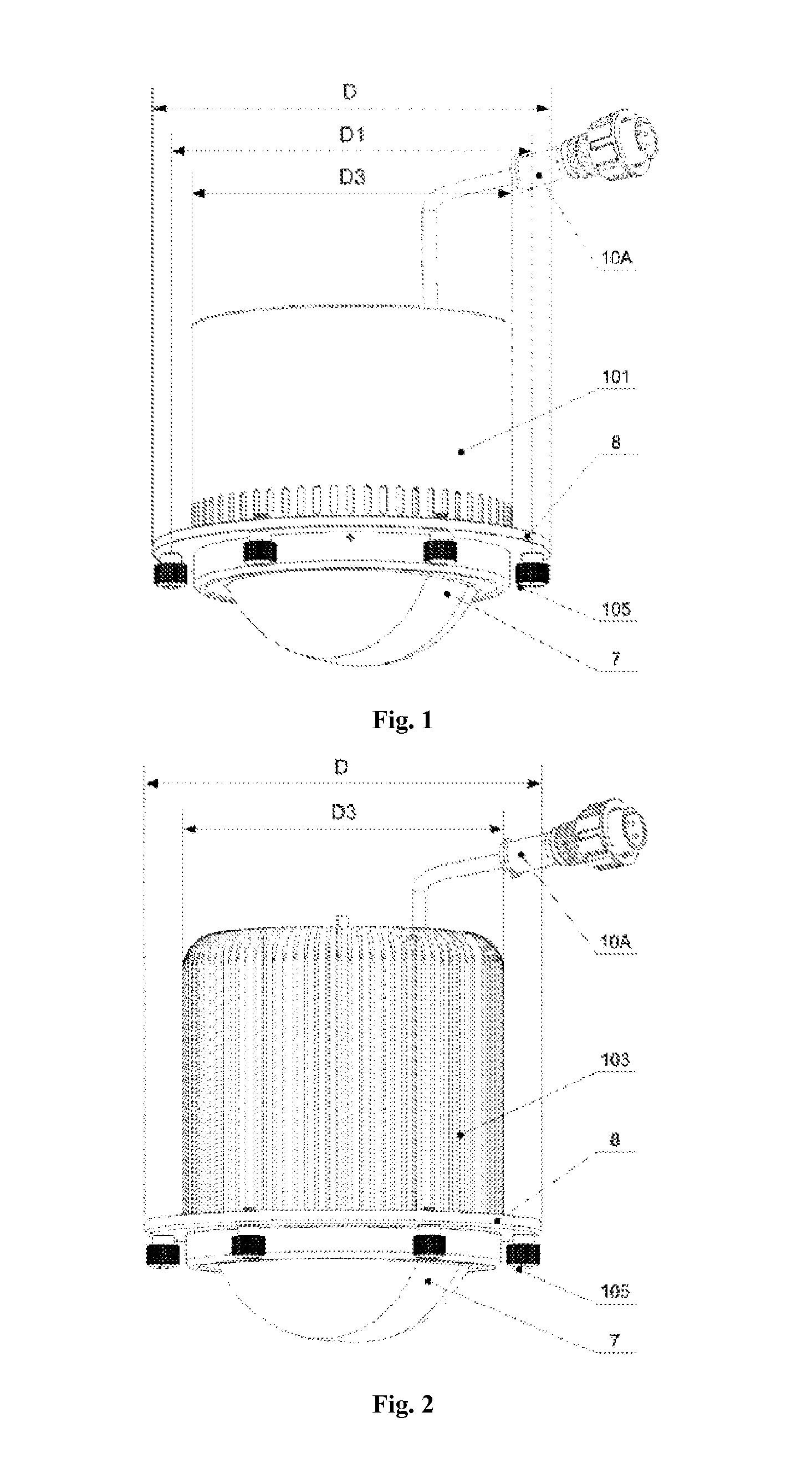

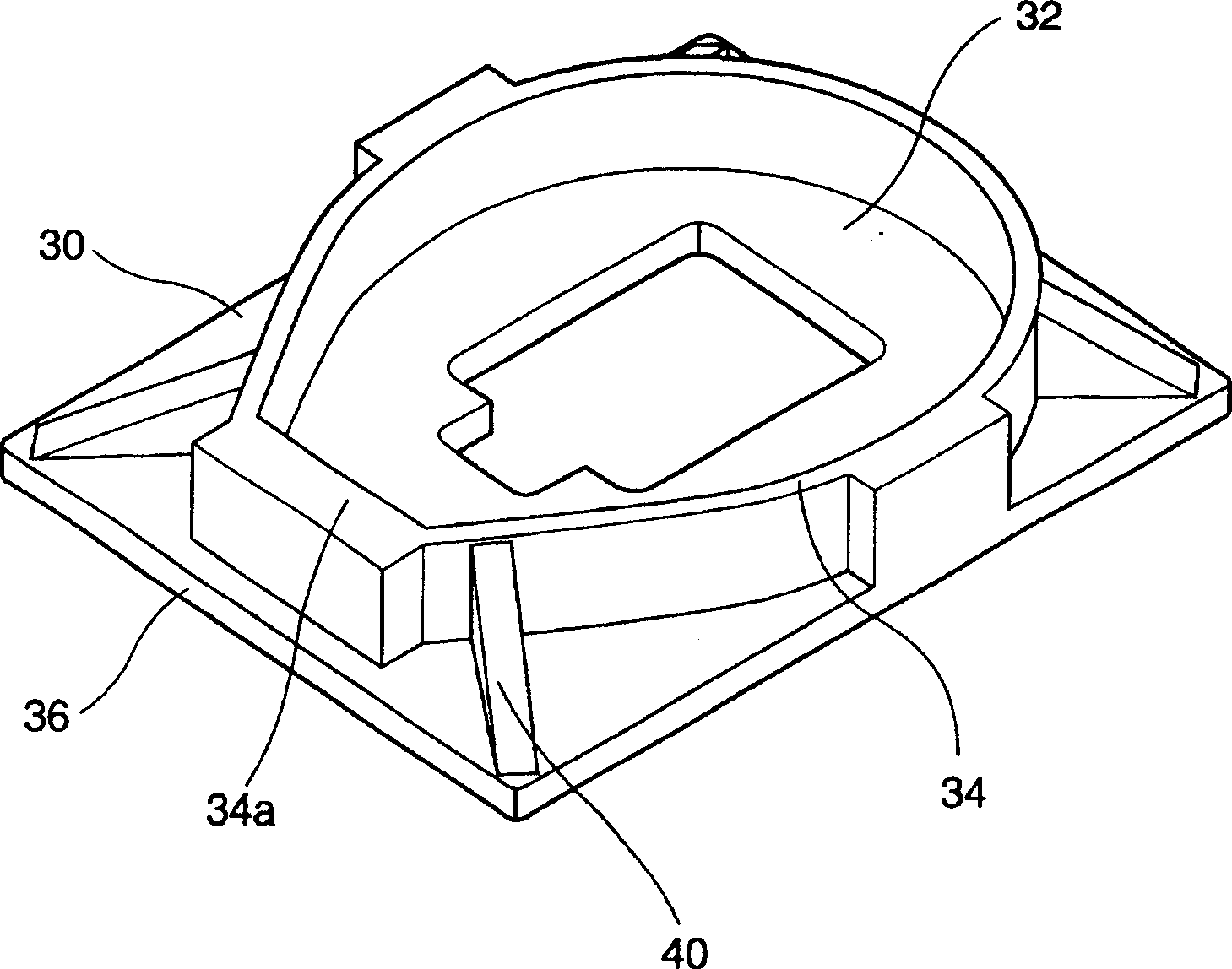

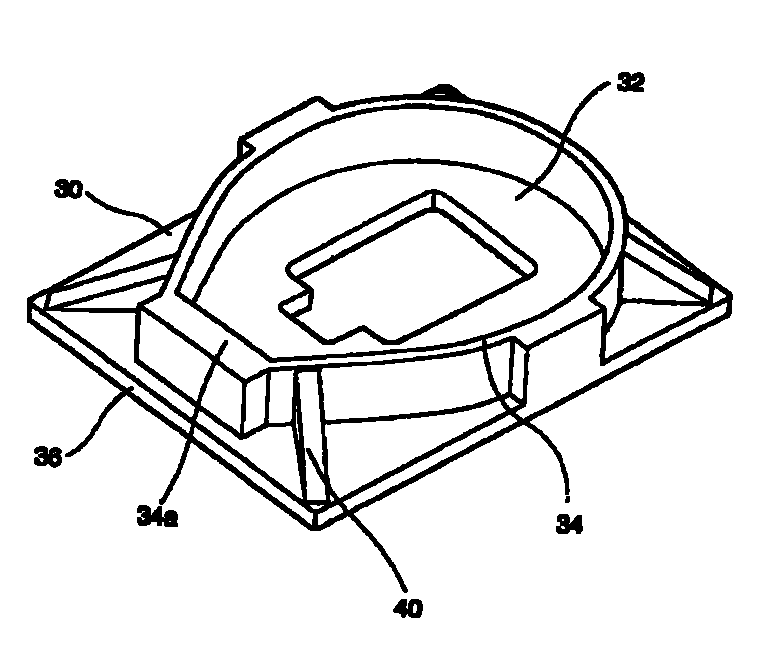

Method for constructing universal LED bulb, snap ring structured LED bulb and LED lamp

InactiveUS20150184837A1Reduce production proceduresImprove mass productionMechanical apparatusLight source combinationsEngineeringLED lamp

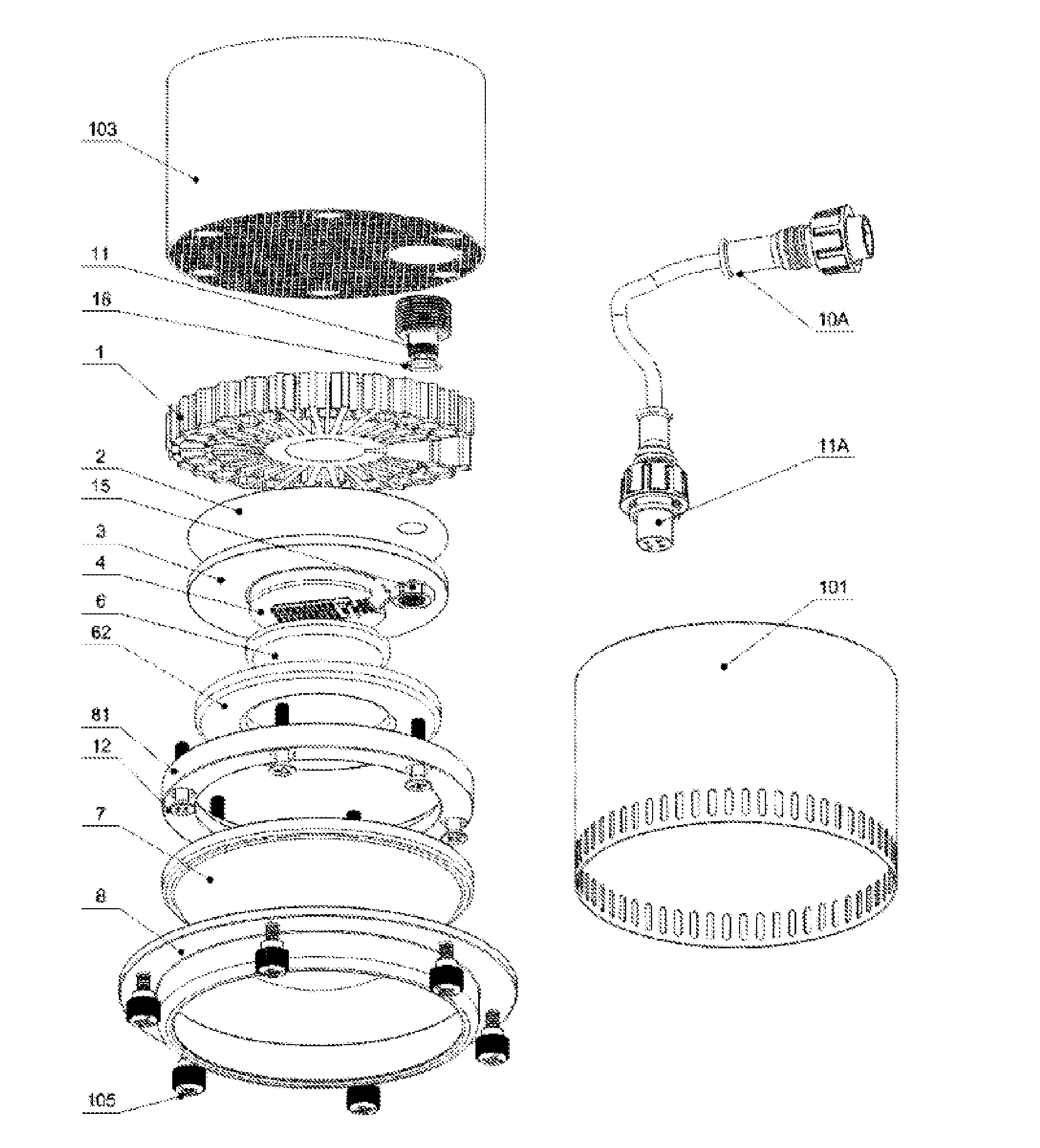

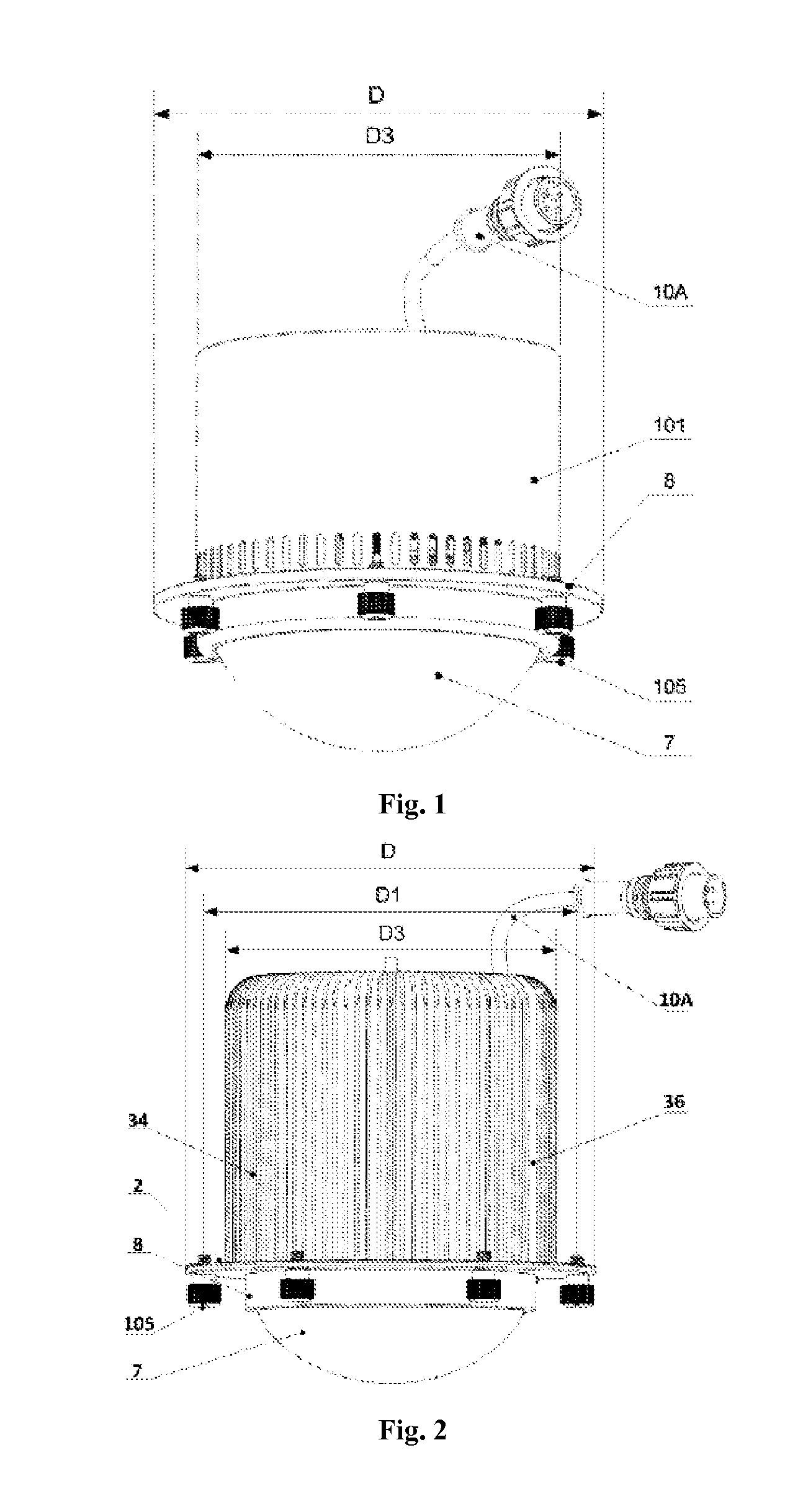

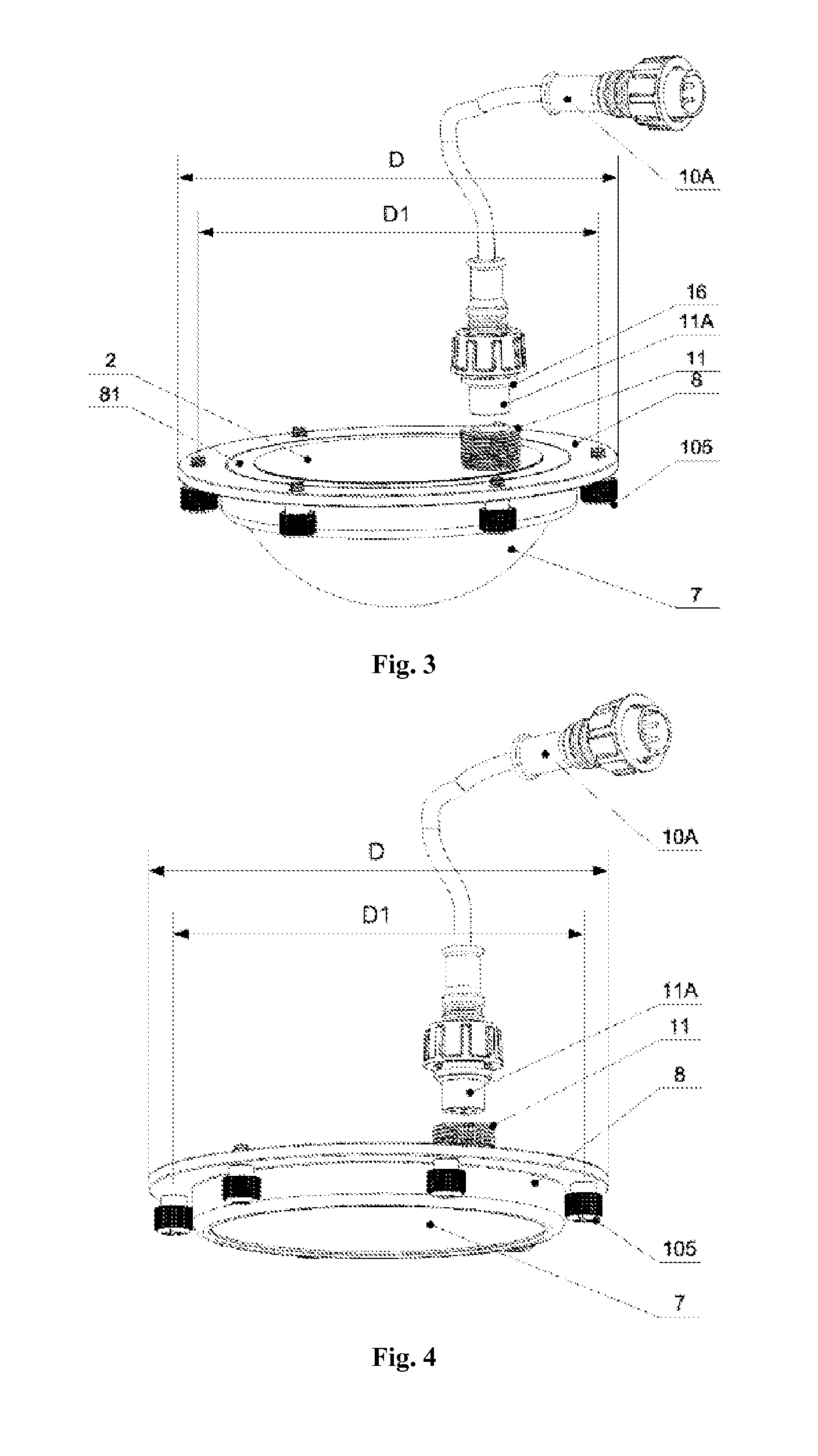

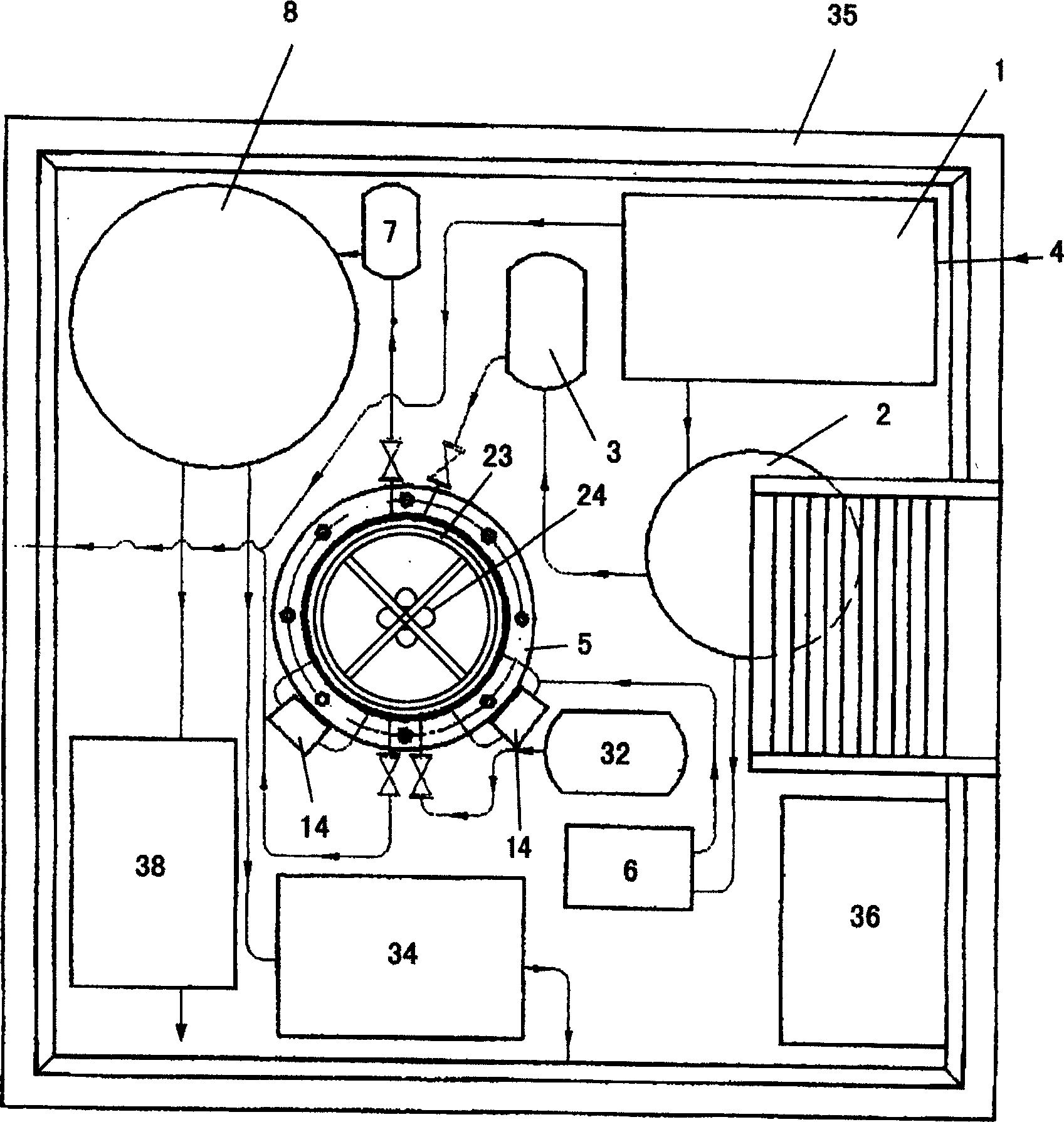

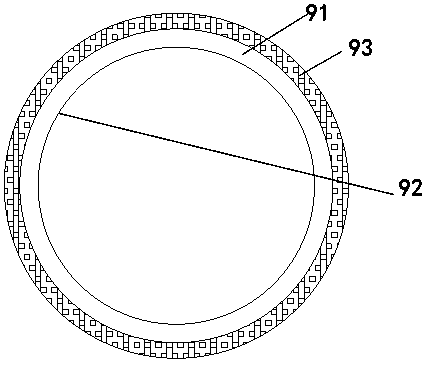

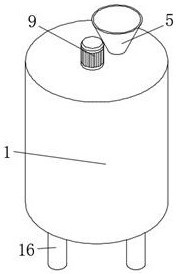

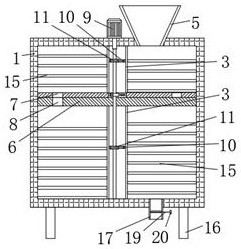

The present invention provides a method for constructing a universal LED bulb, a snap ring structured LED bulb and a lamp. The constructing method comprises: supporting an optical engine core member of the LED bulb in the lens snap ring (8) using a lens snap ring (8) as a supporting main body, using an inner snap ring (81) provided on the inner side of a light distribution optical lens (7) in the optical engine core member as an auxiliary supporting structure, and further using the inner snap ring (81) as an installation base of an optical engine module (4) and a heat conductive bracket (3) or an installation base of an LED bulb radiator (103); the optical engine core member of the LED bulb is composed of the heat conductive bracket (3), the optical engine module (4), the inner snap ring (81) and the light distribution optical lens (7).

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

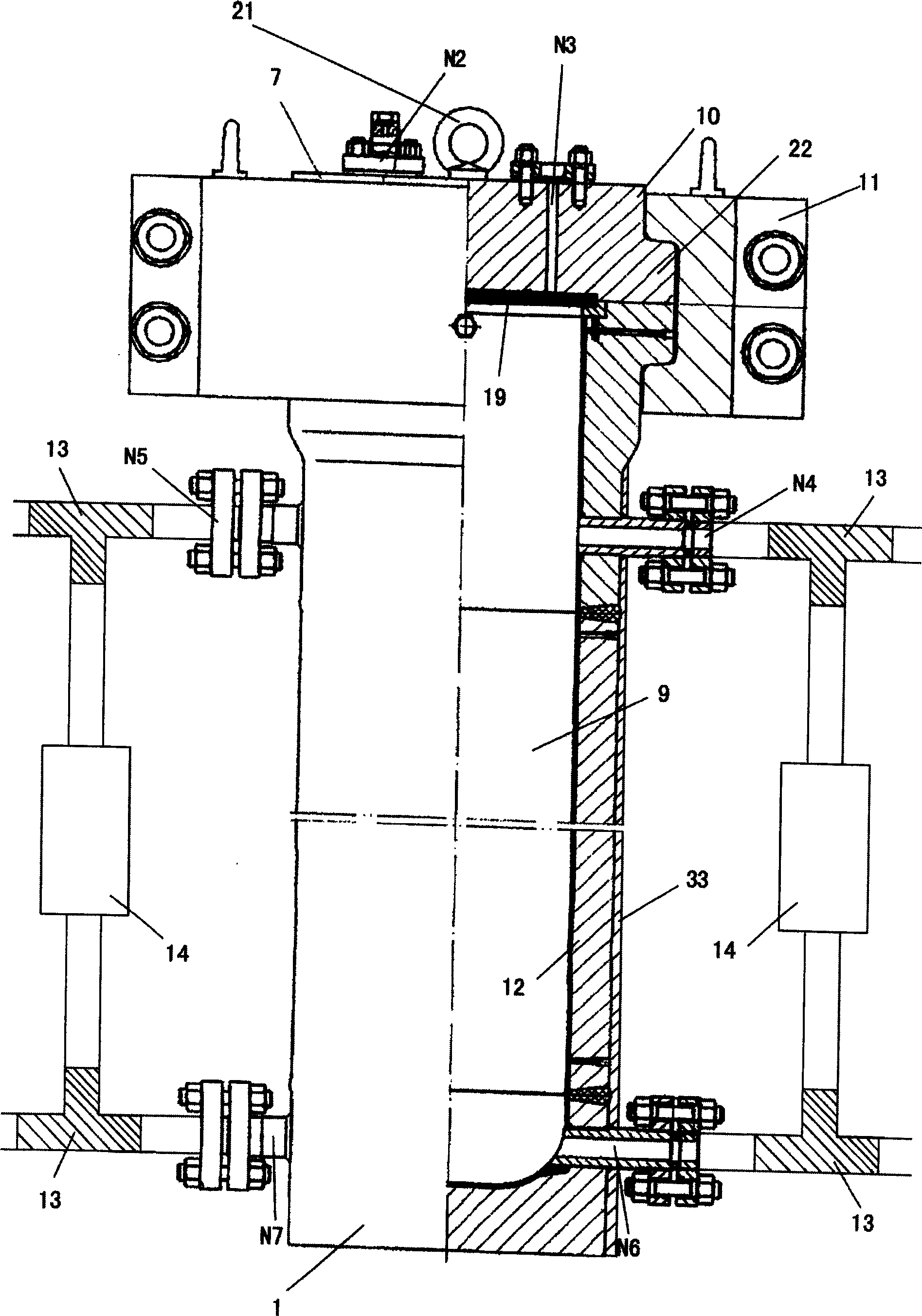

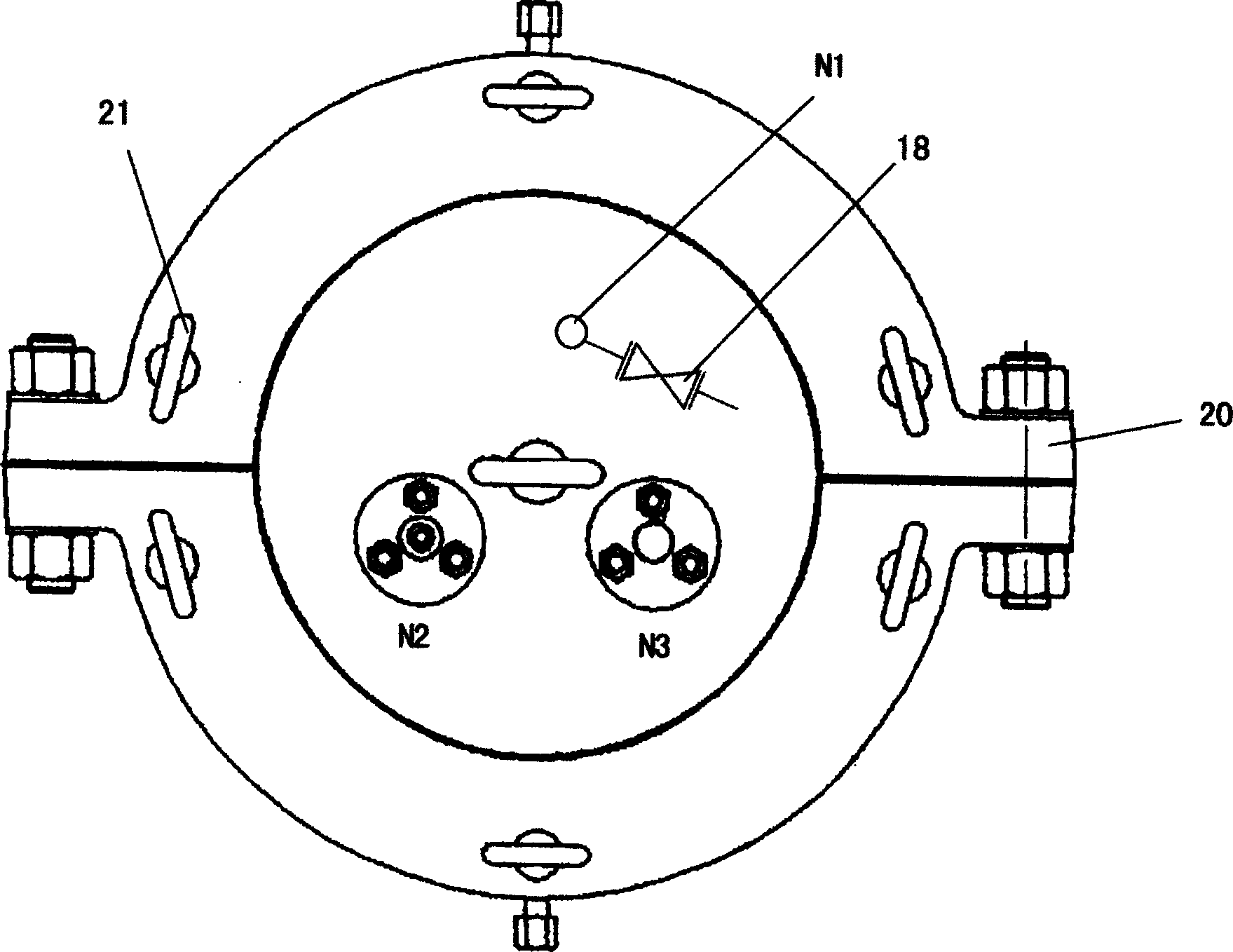

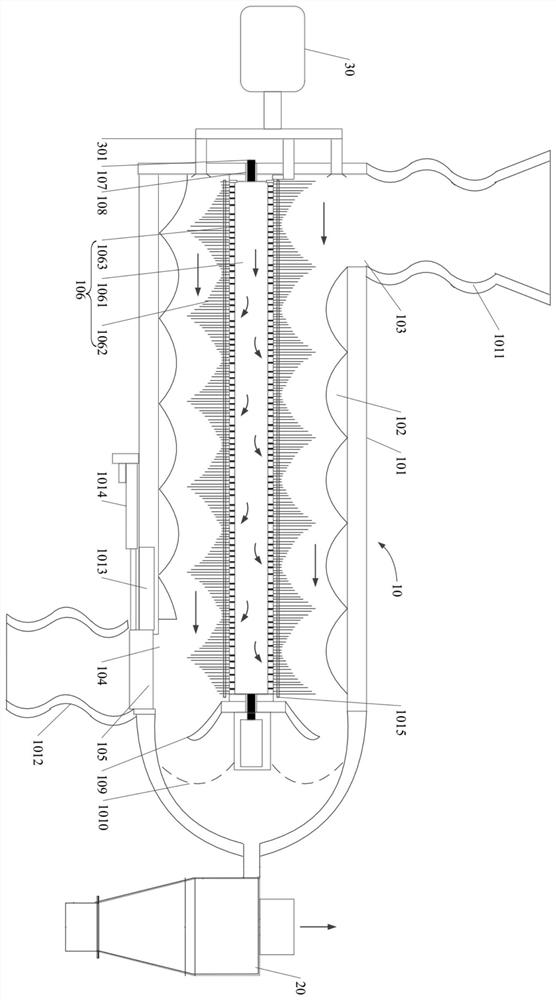

A process for extraction and apparatus thereof

InactiveCN1546195AOvercome unresolvable flawsIncrease profitSolid solvent extractionFood preparationAdditive ingredientSolvent

The invention discloses a kind of extraction method and device. The method includes following steps: crushing and immersing the materials, carries on extraction under pressure of 25MPa-35MPa and frequency between 18 KHz-33 KHz by using water as solvent, the extraction liquid with material active ingredients can be gotten. The invention can protect the biology activity, and it can realize nearly fully extraction of ingredients.

Owner:曹培生

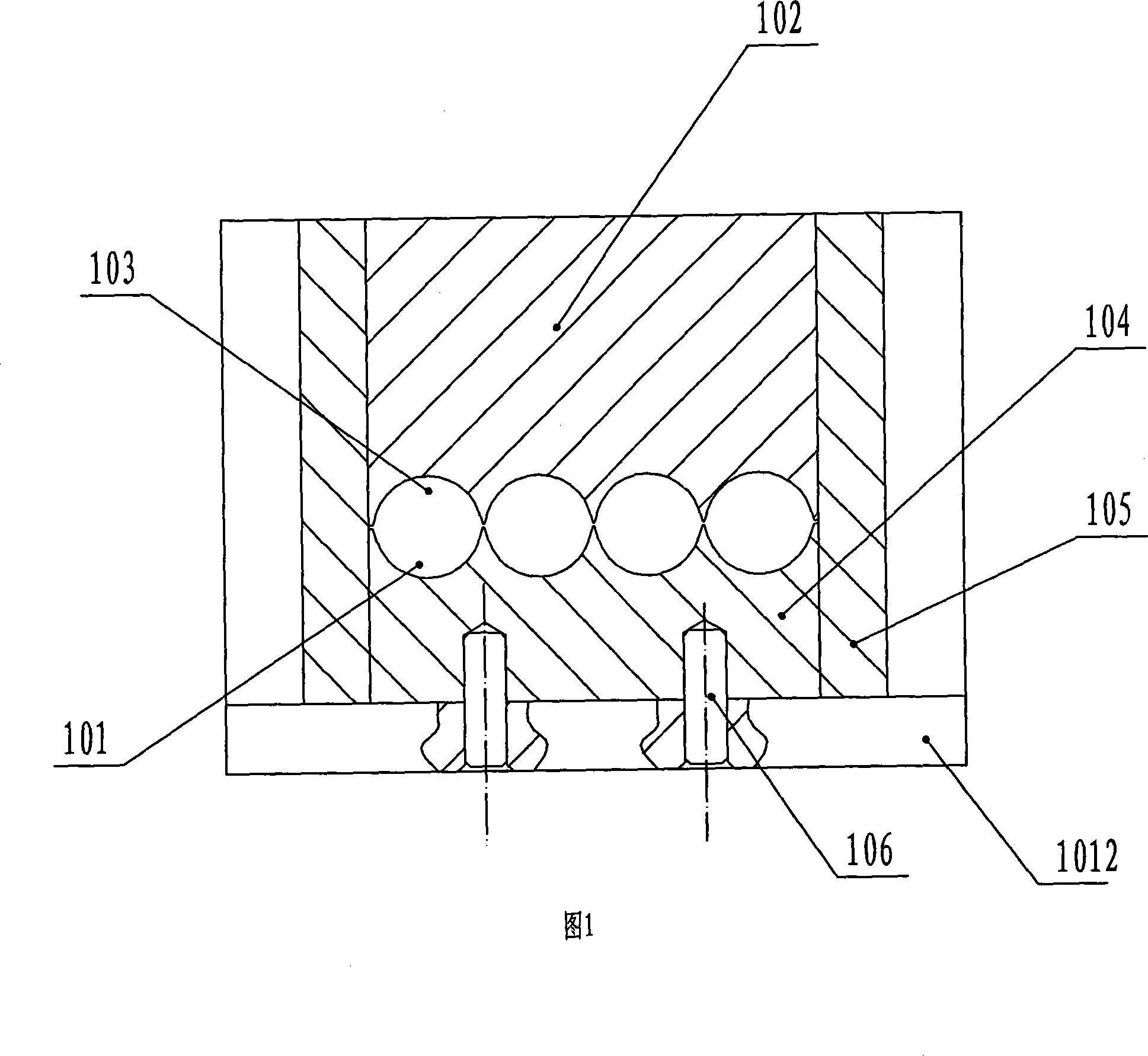

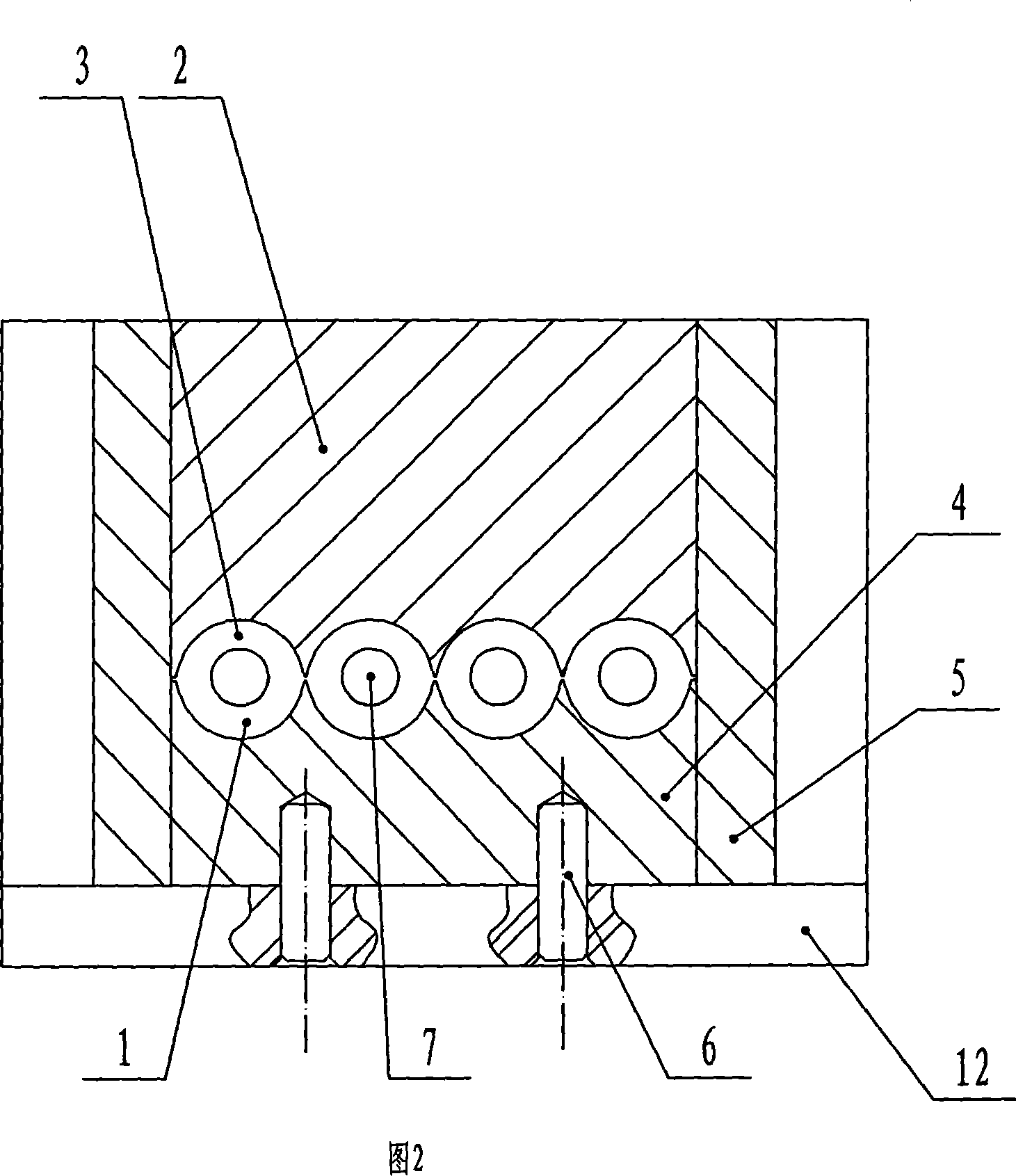

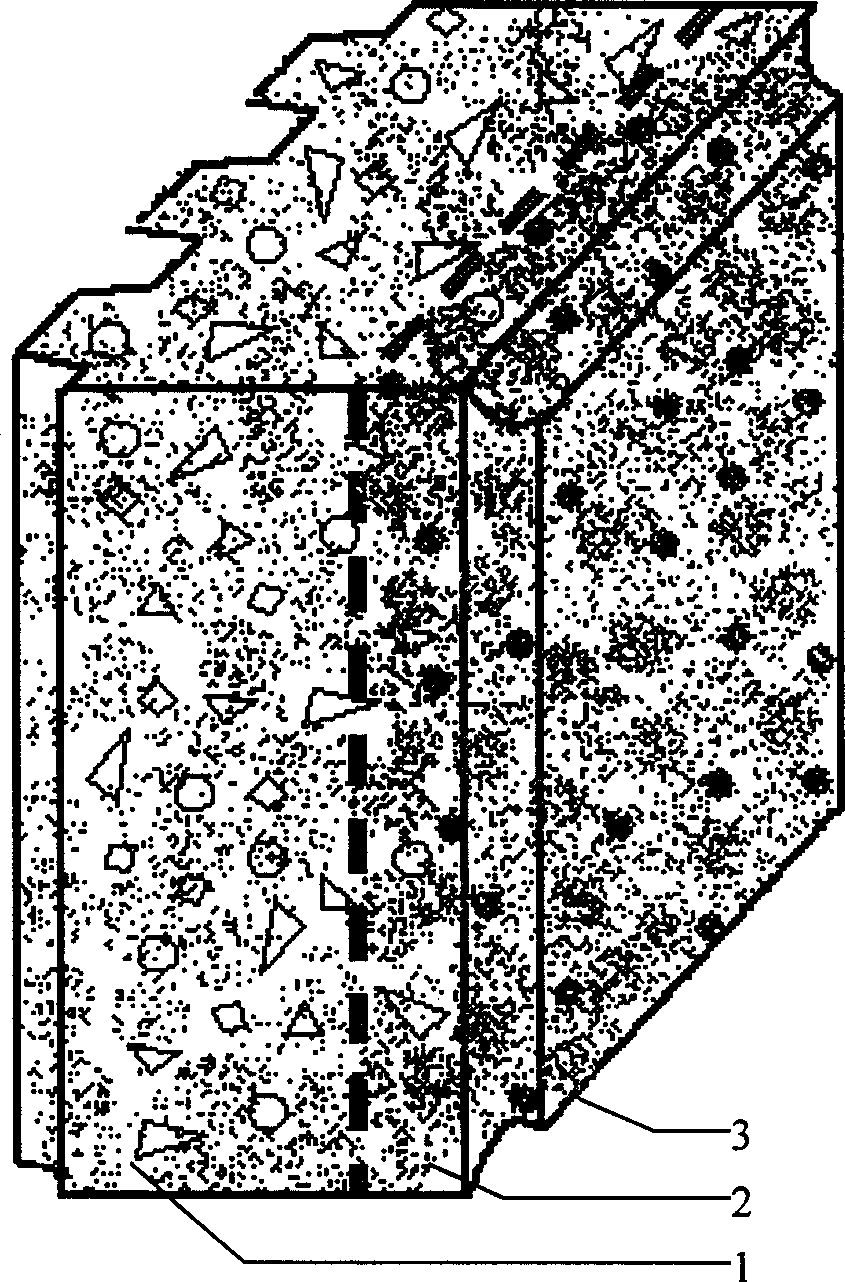

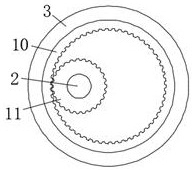

Neodymium-iron-boron cylindrical form permanent magnetic material with longitudinal through-hole molding method and special moulds

The invention discloses a forming method of Nd-Fe-B cylindrical permanent magnetic material which is equipped with a vertical through hole; a metal internal lower mold (4) is combined with a metal external mold and half of the quantitative starch is poured into the combination; and then a first metal internal upper mold is inserted and a magnetic field forming press is used for obtaining the lower cylindrical permanent material; stripping; the first metal upper mold is taken out and a metal round rod (7) is put in the semi-circle hole of lower semi-cylindrical permanent magnetic material and the other half of the starch is poured in and then a second metal internal upper mold (2) is inserted to be formed on the magnetic field forming press; the metal round rod (7) is taken out after stripping and the Nd-Fe-B cylindrical permanent magnetic material (11); the special mold is characterized in that one metal internal lower mold (4) is matched with two metal internal upper mold. The invention reduces the waste of material and promotes the product yield; at the same time, the production efficiency is increased and the production cost is reduced.

Owner:NINGBO JUYOU MAGNETIC IND

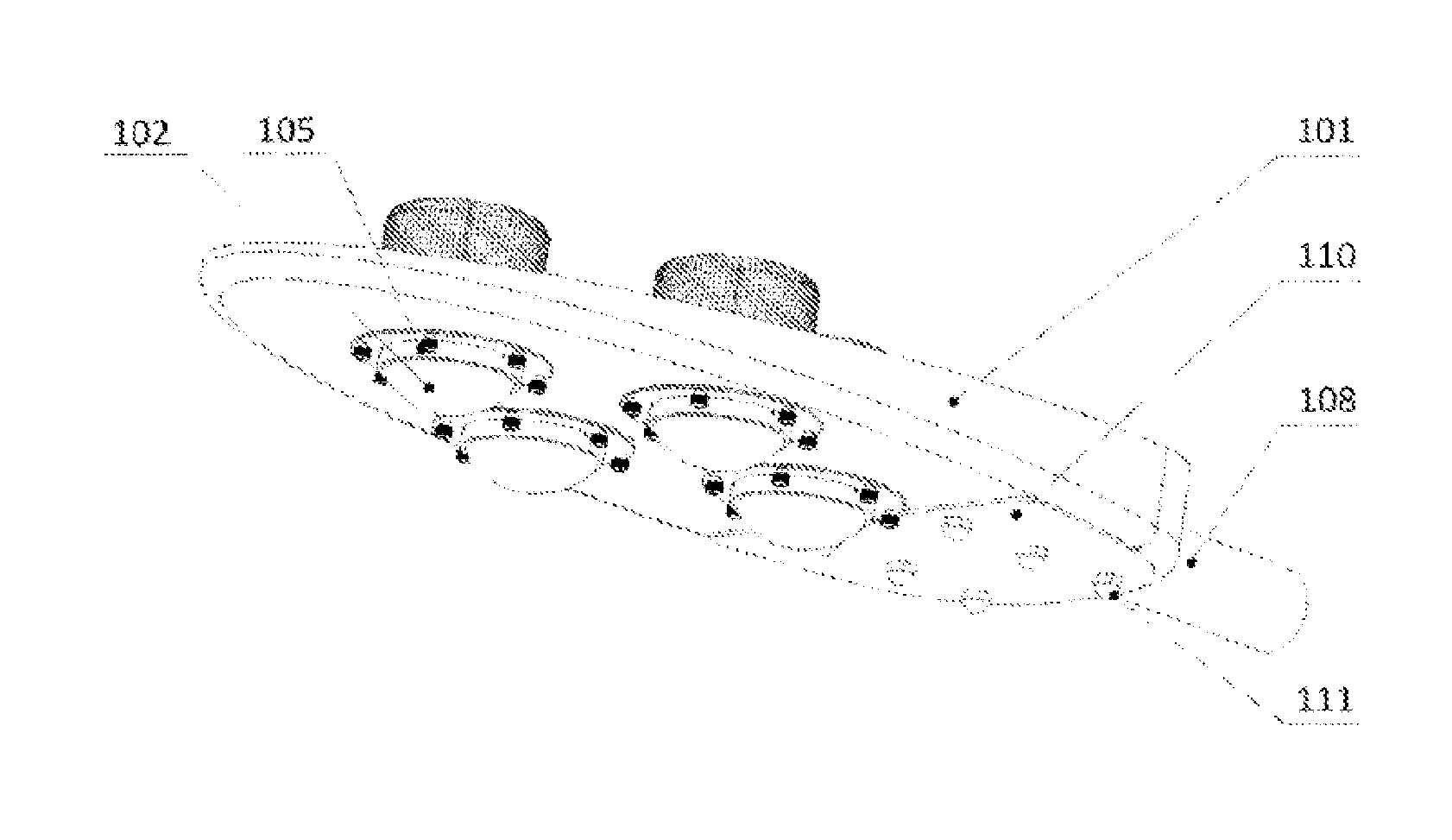

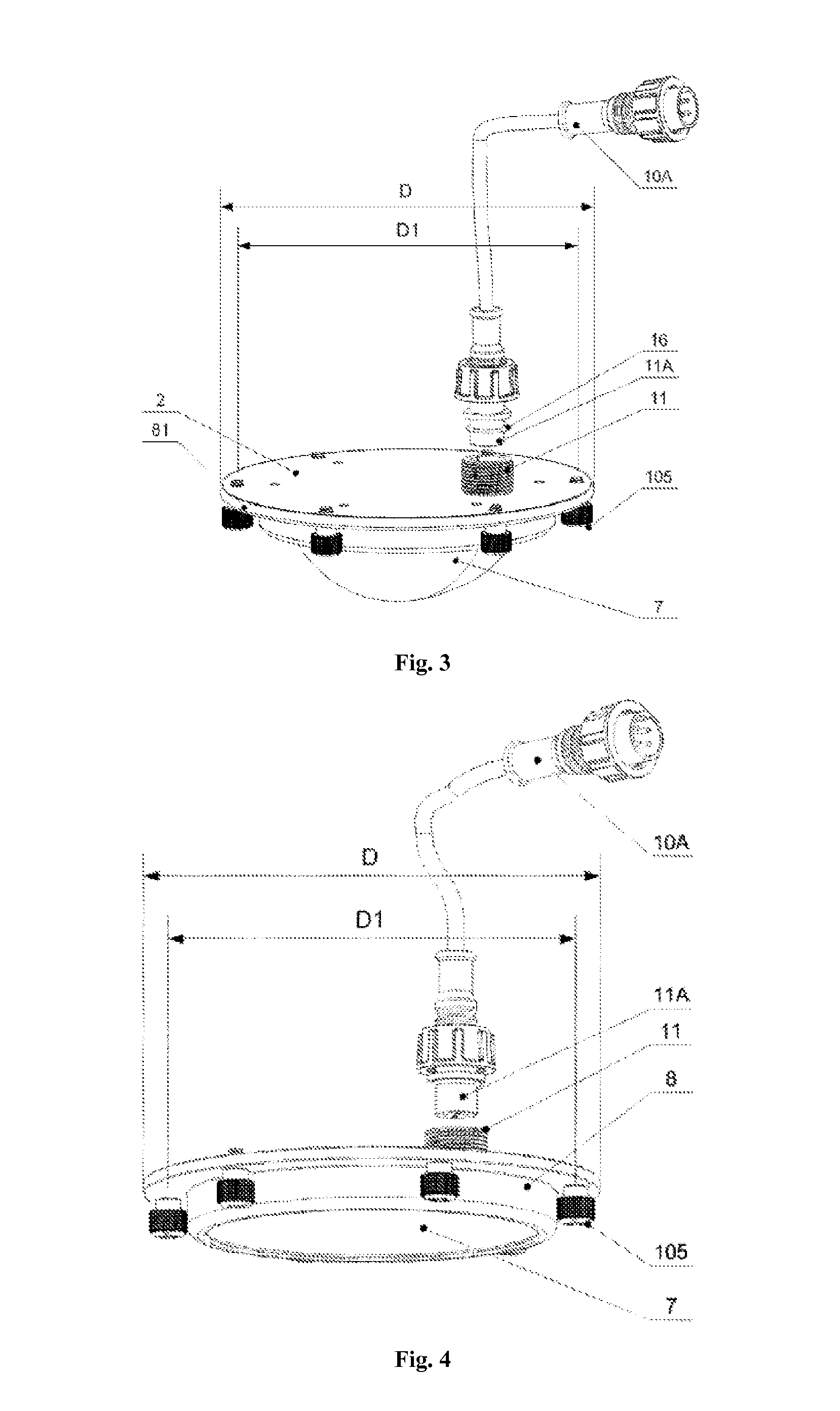

Method for constructing universal LED bulb, flange inner snap ring type LED bulb and lamp

InactiveUS20150204521A1Reduce production proceduresImprove mass productionMechanical apparatusLight source combinationsEngineeringLED lamp

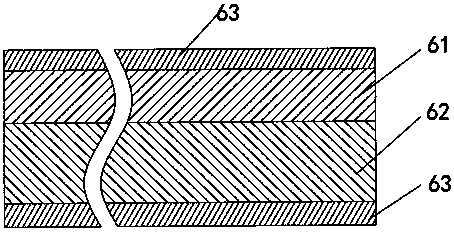

The present invention discloses a method for constructing a universal LED bulb, a flange snap ring type LED bulb and a lamp. A heat conductive bracket (3) with a flange is used as a structure supporting main body of the bulb to establish an optical engine core member of the LED bulb. An inner snap ring (81) fixed to the heat conductive bracket (3) is used to support the optical engine core member in an auxiliary manner. The optical engine core member is composed of the heat conductive bracket (3), an optical engine module (4), the inner snap ring (81), an inner cover (6), an electric connector (11) and a light distribution optical lens (7). The optical engine module (4) is made up of an optical engine die plate, an LED chip and a relevant wiring by bonding and packaging, or is further integrated with a power supply drive chip.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

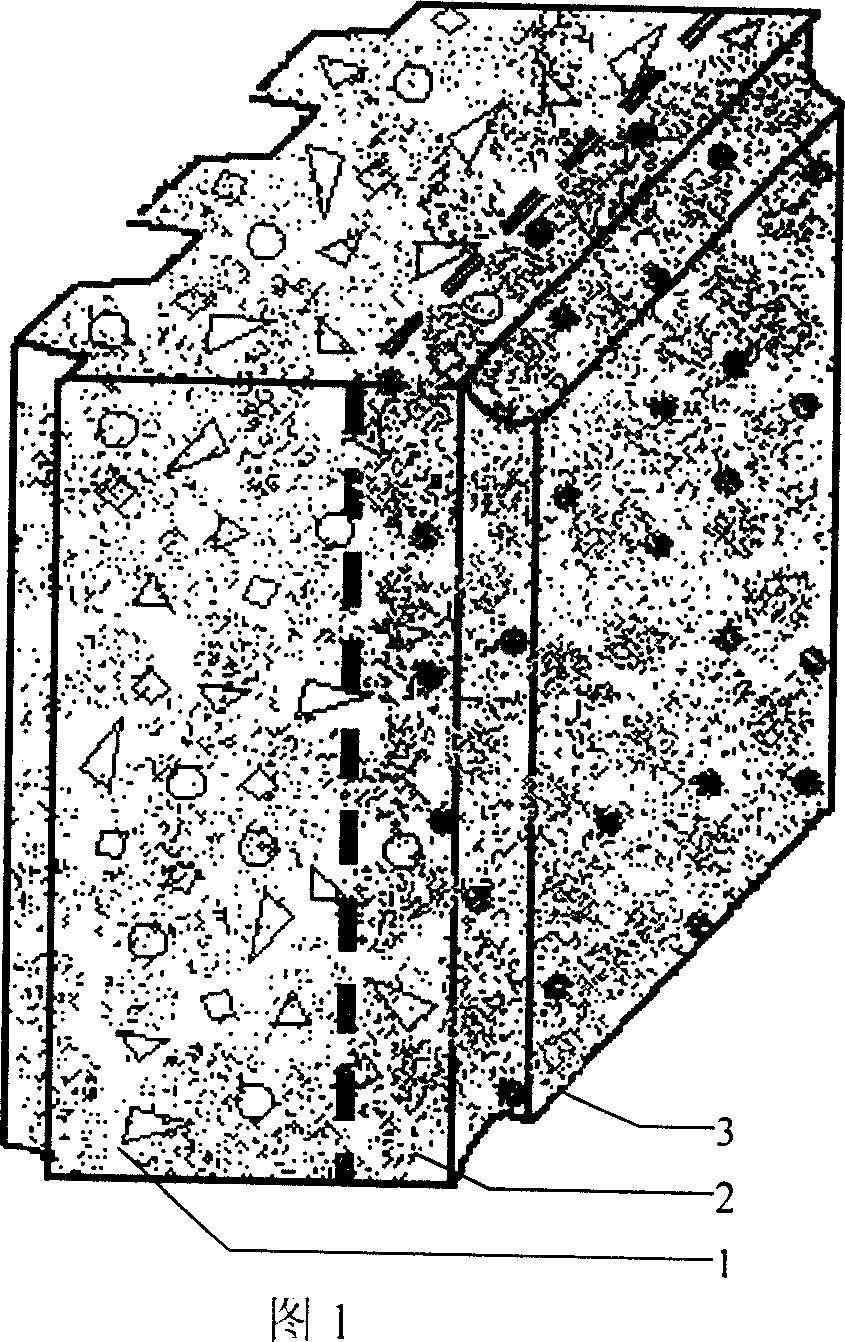

Warm sound-proof decorative materials and prepn. method

This invention is attributed to the field of building materials, concretely speaking, relates to a kind of decoration materials with heat preservation and sound absorption functions and its preparation method. The heat-preserving and sound-absorbing decoration materials comprise a hear-preserving layer, a decoration layer and a mask layer. The heat-preserving layer is made of polybenzene particles, water glass, cement, silica fume, slag powders, fly ash and sand. The decoration layer is made of polybenzene, rubber powders, pigment, cement, silica fume, slag powders and sand. The mask layer is made of organosilicon series of waterproof materials. By the technique of spray stir, layered moulding, compression molding and vapor conservation, the polybenzene particles and the porous structure can help realize highly effective heat preservation. The sound-absorbing structure can be fabricated by compression molding. Fascinating stereo patterns can be organized by alternation of mould shape and pigment. Besides, thanks to the mask layer, wear and decoration properties can be promoted. The product performs excellent heat-preserving, sound-absorbing and decorative functions.

Owner:TONGJI UNIV

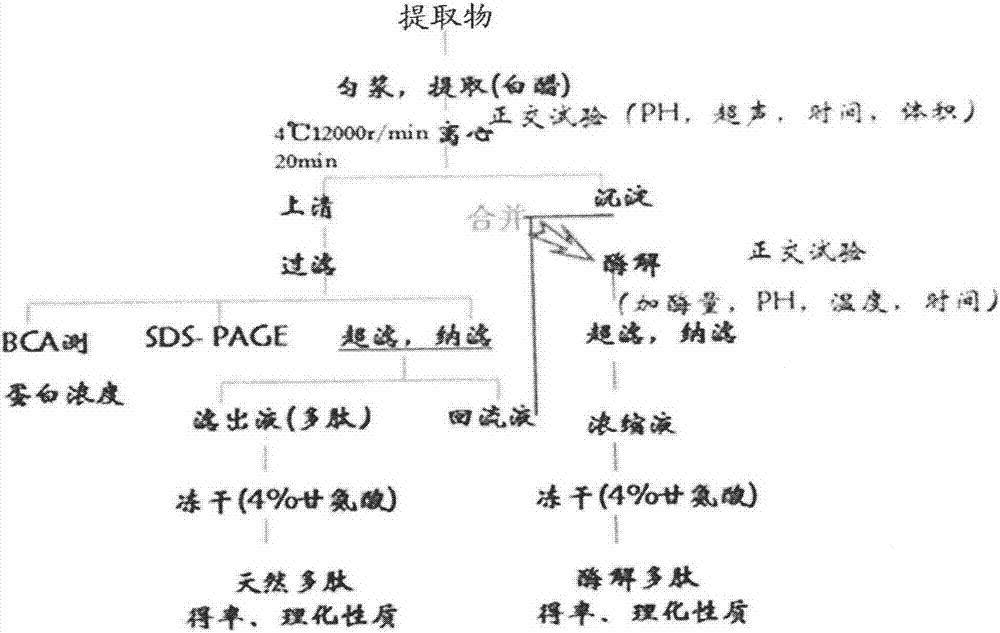

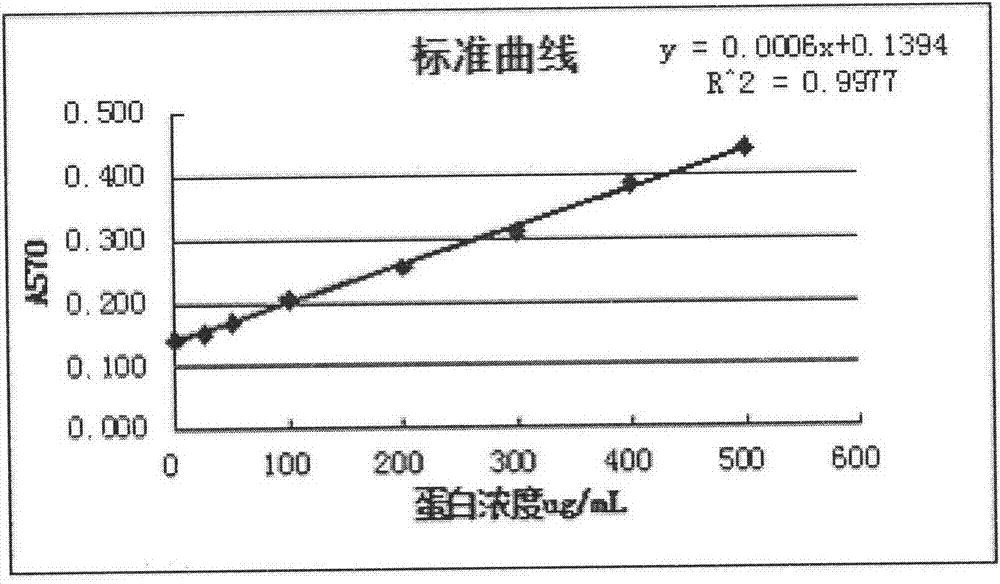

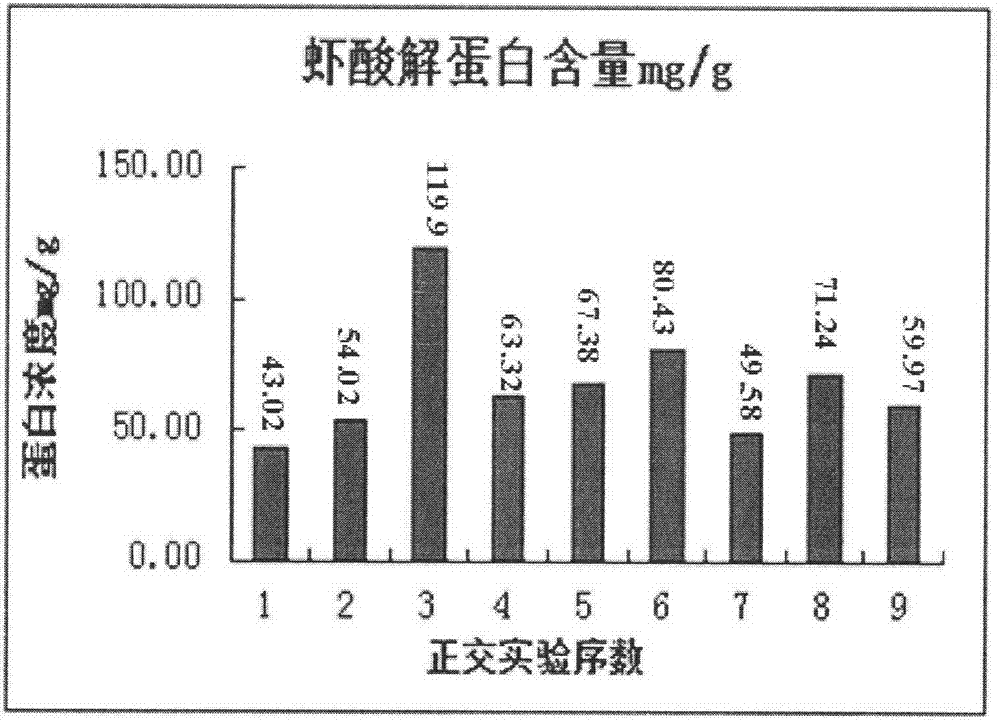

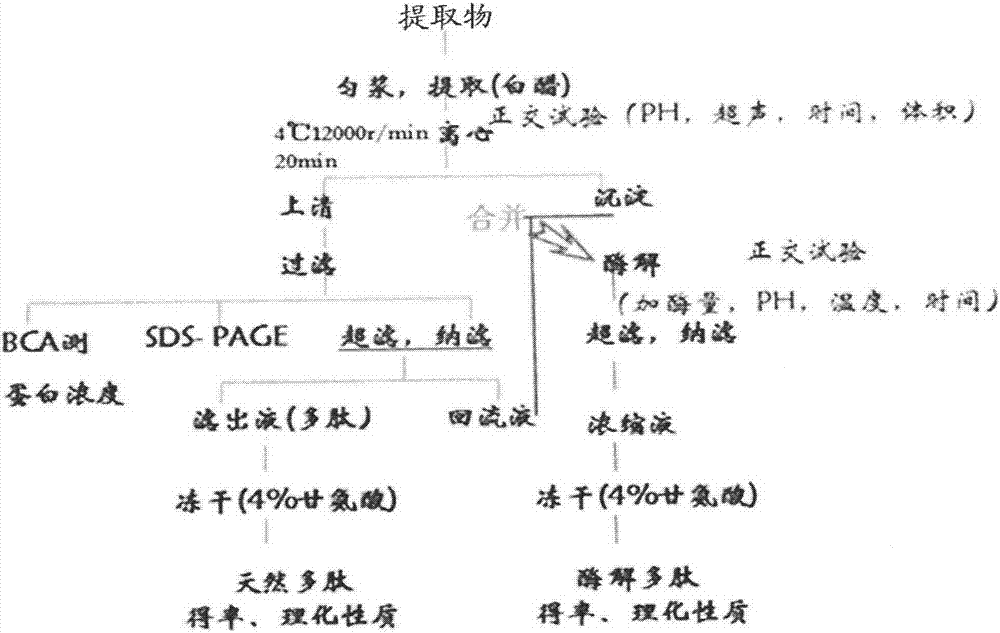

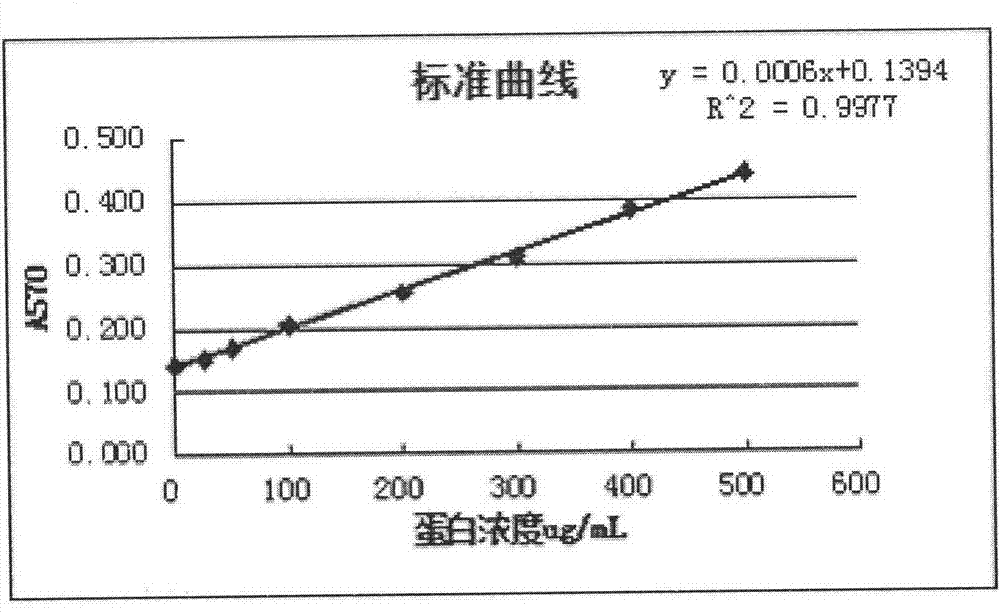

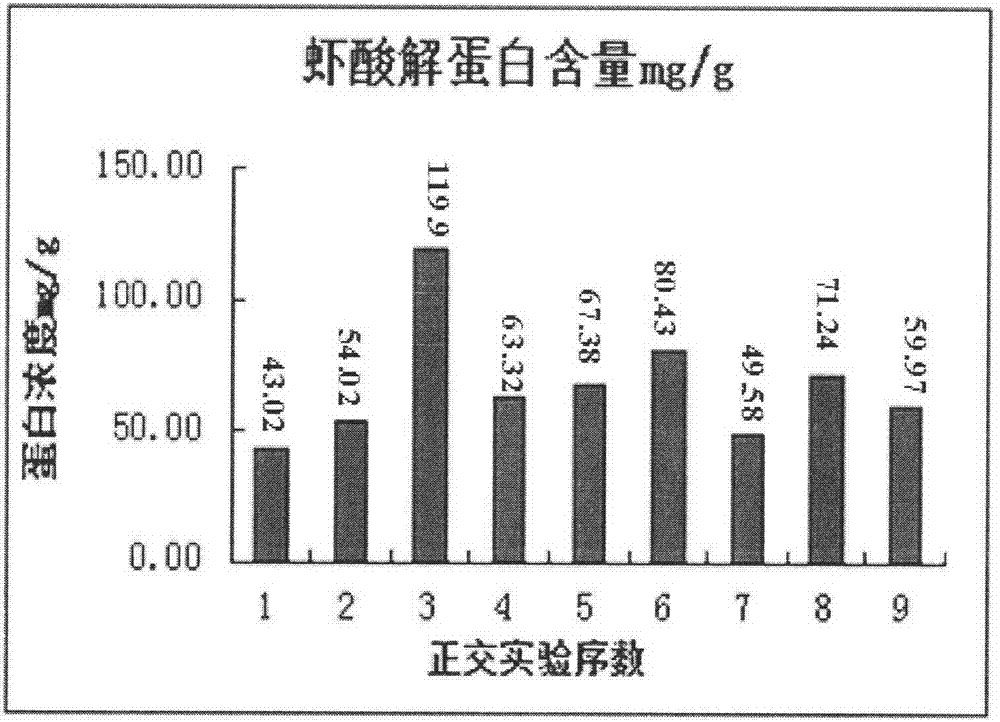

Combined extraction preparation method of complex polypeptide

ActiveCN103882085ASave the tedious processSimple extraction processPeptide preparation methodsFermentationChemistryAcid hydrolysis

The invention provides a combined extraction preparation method of complex polypeptide. According to the combined extraction preparation method, a moderate weak acid method is adopted for extracting natural bioactive polypeptide, then sediments remained and discarded in the polypeptide extraction process with the weak acid method are hydrolyzed by adopting an enzymolysis method, namely the same raw material is subjected to combined polypeptide extraction by respectively adopting the acid hydrolysis method and the enzymolysis method and utilizing the extraction method, extracted raw material or resource is completely utilized, original waste is used to the greates extent, and yield of extracted and prepared combined polypeptide is obviously improved. In addition, valuable natural resources are saved, environmental pollution is reduced, potential safety hazard is eliminated, production period is shortened, extraction reagents and instruments are reduced, investment and production cost are reduced, polypeptide bioavailability is improved, future use application scope is extended, and human body application value is improved.

Owner:大连摩格生物科技有限公司

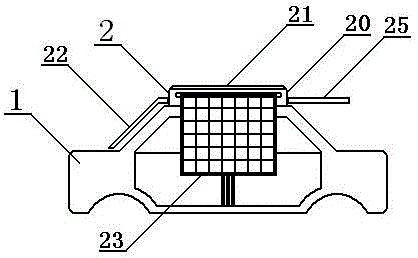

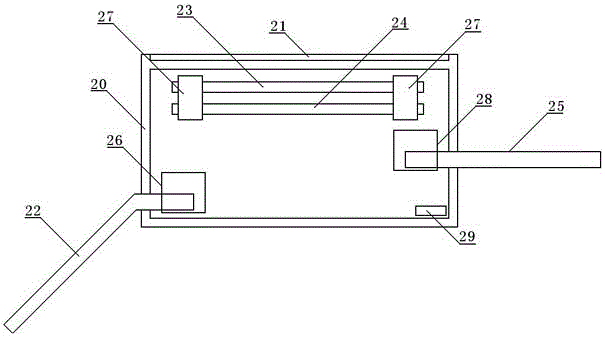

Mixed vehicle roof

PendingCN106740149AIncrease light receiving surfacePowerfulVehicular energy storageElectric/fluid circuitRemote controlSolar cell

The invention discloses a mixed vehicle roof which comprises a vehicle roof body. An extensible solar cell system is fixedly arranged at the top of the vehicle roof body and comprises a shell, solar cells, extensible mechanisms and a control device, an upper solar cell is arranged at the top of the shell, front, rear, left and right solar cells are arranged in the shell, front, rear, left and right extensible mechanisms are arranged on the front, rear, left and right solar cells respectively, and each extensible mechanism is electrically connected with the control device and controlled by the same; the top of the vehicle roof body and the shell of the extensible solar cell system are of an integral structure. The vehicle roof body and the extensible solar cell system are connected to form the integral structure to form the mixed vehicle roof. The mixed vehicle roof has the advantages of reasonable design, needlessness of single mounting, few production procedure, compact structure, supportiveness of manual or remote control, large light receiving area of the solar cells due to contractive structure.

Owner:DONGYING WISCLEAR SOLAR TECH

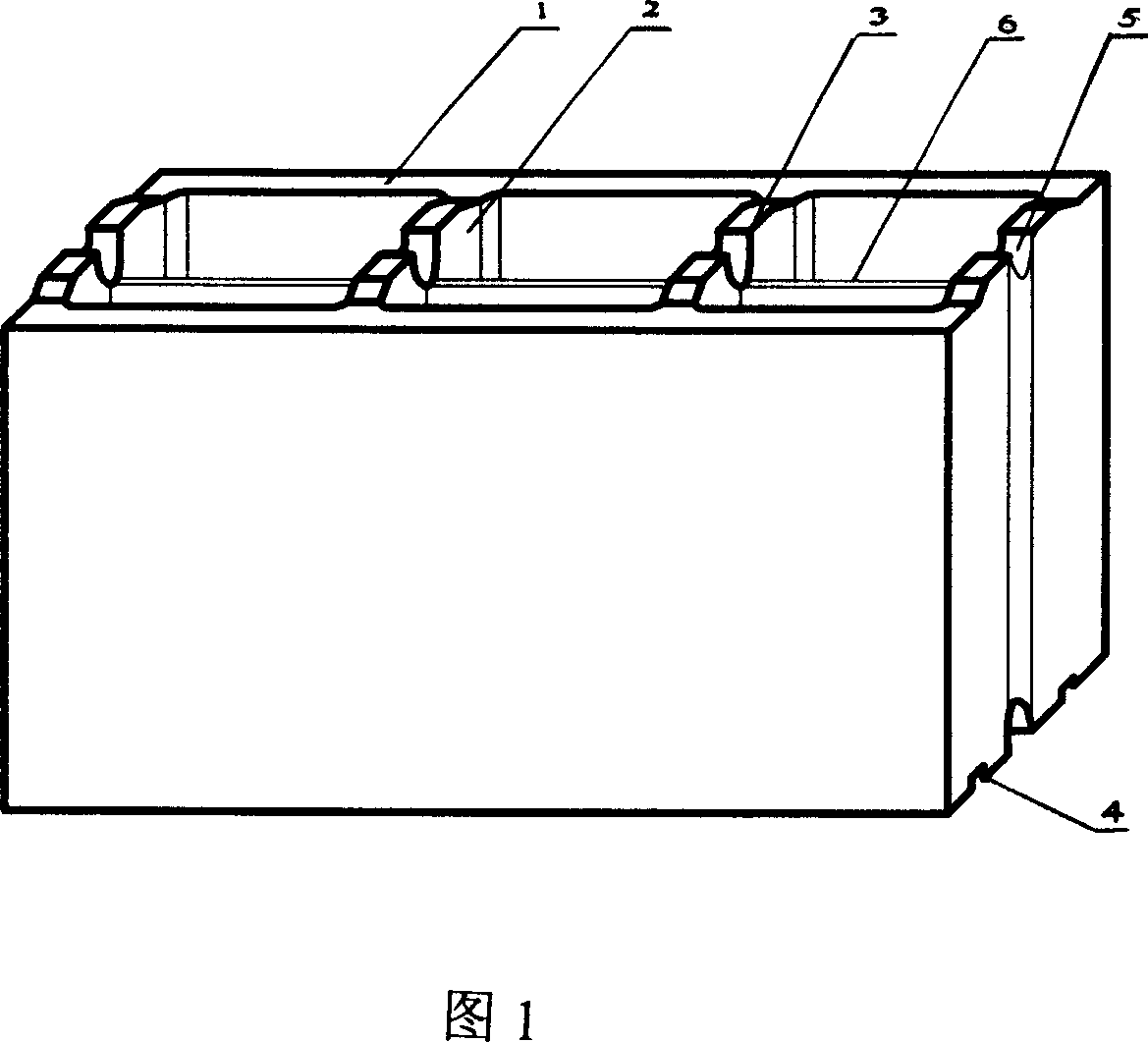

Phosphous plaster double-row-hole energy-saving building brick and all-dry production method thereof

InactiveCN1936227AHigh strengthHigh structural densityConstruction materialCeramic shaping apparatusFluteBrick

The invention discloses a phosphogypsum double-row bore building blocks and the optimum drying producing method. It adopts phosphogypsum as raw material, and taking high pressure molding. The main body includes main wall, rib and protruding rib. The flute matched to protruding rib is set at the bottom of rib. And semicircle orifice is set on the protruding rib. Hard polystyrene clapboard is set between the main paralleled walls. The product has the advantages of high intension, high hollow ratio, good energy saving effect, rapid construction, light weight, and non-shrinking. It decreases drying processes, energy consumption of device and the cost of producing.

Owner:重庆金仓龙新型建材有限公司

Cloth structure with thermoregulation and quick-drying function

The invention relates to a fabric structure that can adjust temperature and can dry rapidly, which is made from yarns of several components by blending a temperature-adjusting cotton and a rapid-drying cotton containing carbon. The invention not only performs good in absorbing moisture, but also can absorb smell. In addition, the invention can effectively improve the shortcomings in the products of same kind, reduce the making procedures and cost, and enlarge the application field of products.

Owner:中良工业股份有限公司

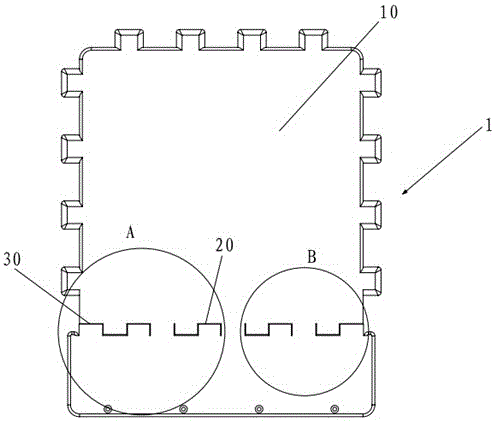

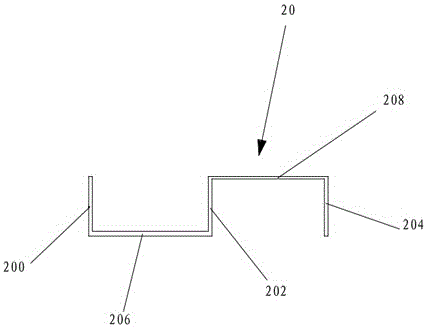

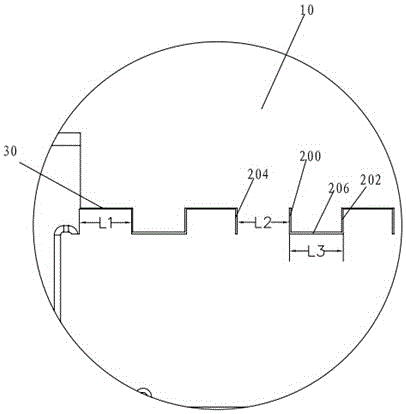

Plate for furniture

InactiveCN105877239AEasy to assembleQuick and easy bendingFurniture partsEngineeringMechanical engineering

Owner:GEXIN XIAMEN SPORTS EQUIP

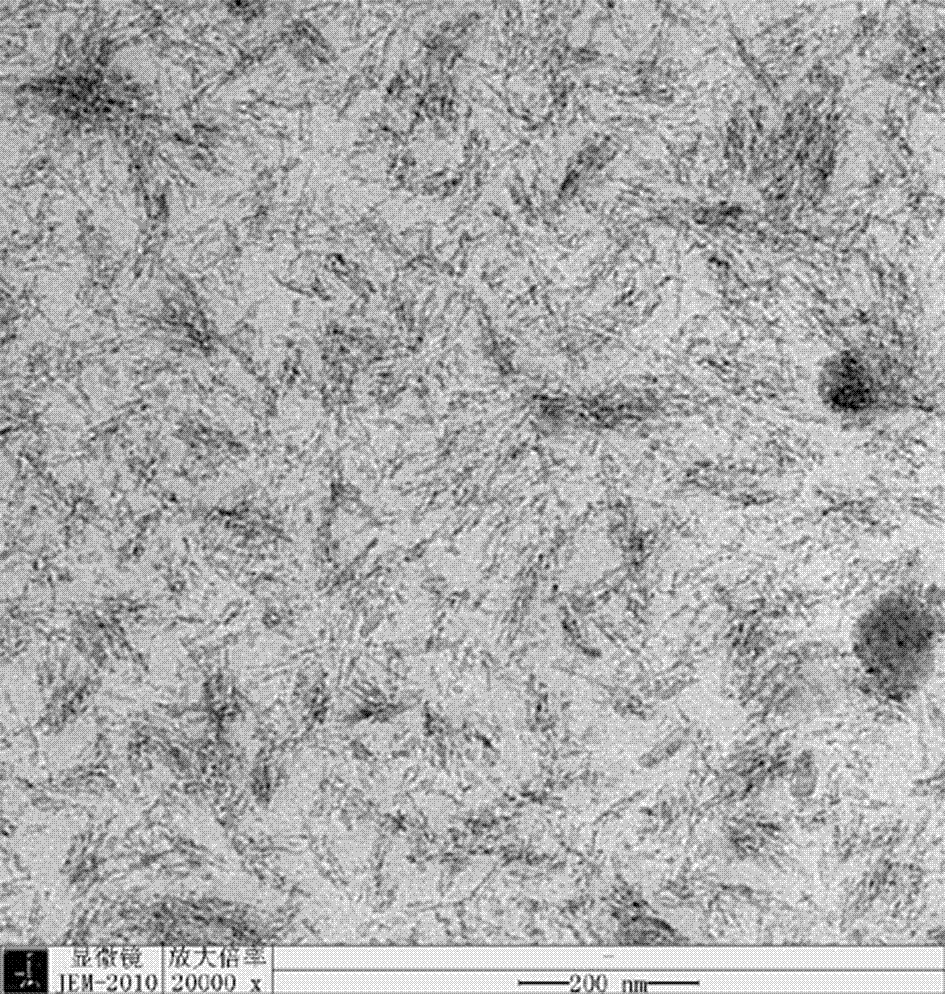

Synthesis method of high-base-number basic zinc carbonate lubricant additive

The invention relates to a synthesis method of a high-base-number basic zinc carbonate lubricant additive, which comprises the following steps: a) respectively preparing a zinc precursor water solution and a precipitant water solution, regulating the pH value of the zinc precursor water solution to 6-9, then heating to 50-100 DEG C, dropwisely adding the precipitant water solution, and reacting under this temperature condition for 0.5-10 hours to obtain stable basic zinc carbonate sol; and b) preparing an organic medium solution of modifier, cooling the basic zinc carbonate sol to 20-80 DEG C, regulating the pH value to 7-10, then adding the organic medium solution of modifier into the basic zinc carbonate sol while stirring, reacting for 0.5-5 hours, obtaining a transparent oil-water two-phase system after the reaction is finished, separating the oil phase, and drying. The base number of the lubricant additive synthesized through the method is up to 250-400 mgKOH / g, and meets the requirements of detersive for high base number and ultra high base number.

Owner:HENAN UNIVERSITY

New method for synthetizing polyaspartic acid by fumaric acid

InactiveCN101787121AReduce production proceduresEasy to operateMicroorganism based processesFermentationBiotechnologyEscherichia coli

The invention discloses a method for synthetizing polyaspartic acid by fumaric acid, which comprises the following steps of (1) fermenting and synthetizing L-polyaspartic acid by taking the fumaric acid and ammonia as raw materials and taking escherichia coli as a catalyst, wherein the molar ratio of the fumaric acid to the ammonia is 1:1; the dosage of the escherichia coli is 0.3-0.5 permillage of the total weight of the raw materials, the fermenting temperature is 36-40 DEG C and the fermenting time is 24 h; and (2) continuously carrying out polycondensation for 10-60min at the temperature of 180-250 DEG C by taking the rough L-polyaspartic acid which is not discolored and obtained in the step (1) as raw material to synthetize the polyaspartic acid. The method can realize the large scale and economization of the production of the polyaspartic acid.

Owner:ANHUI KEBAO BIOLOGICAL ENG CO LTD

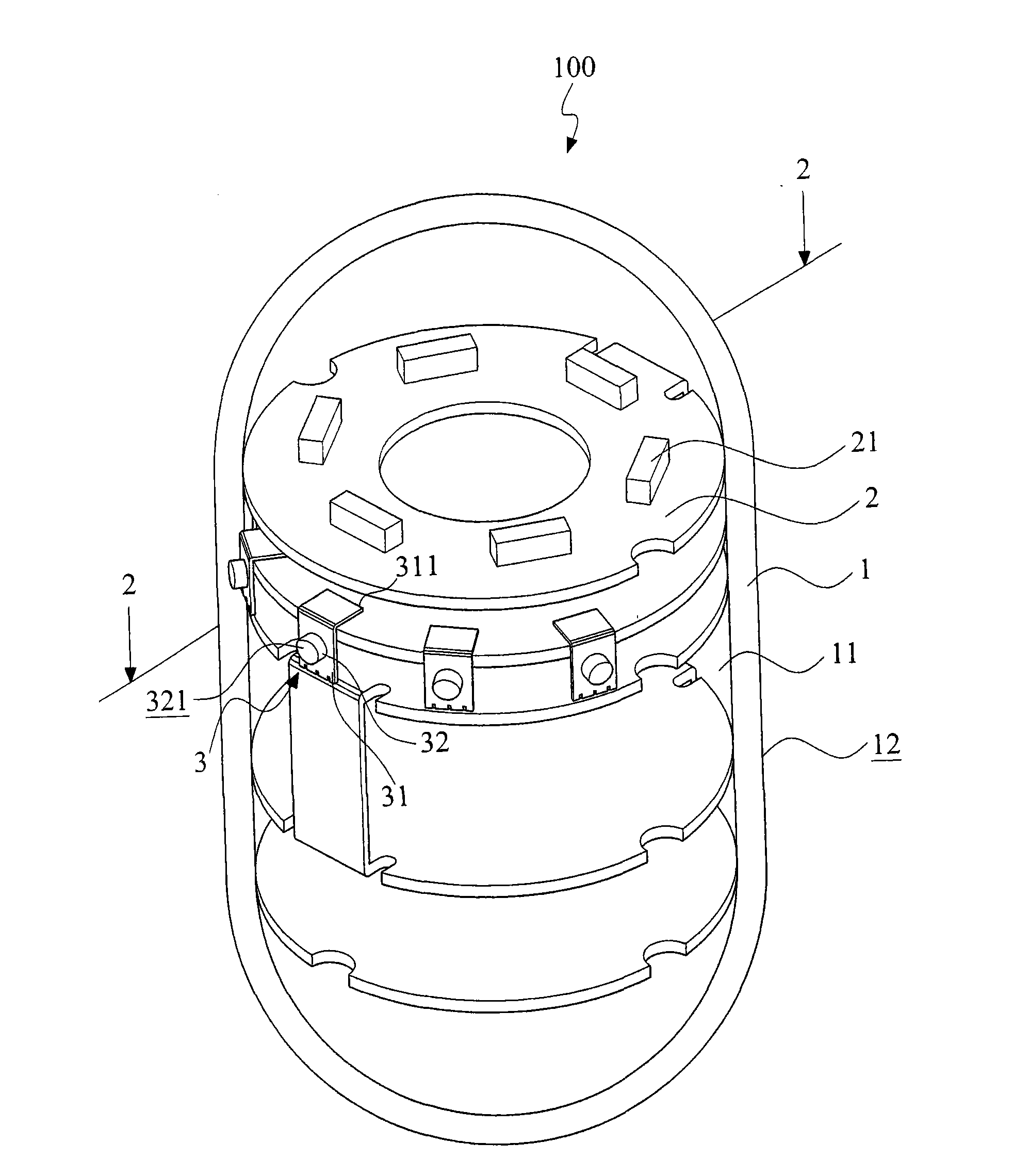

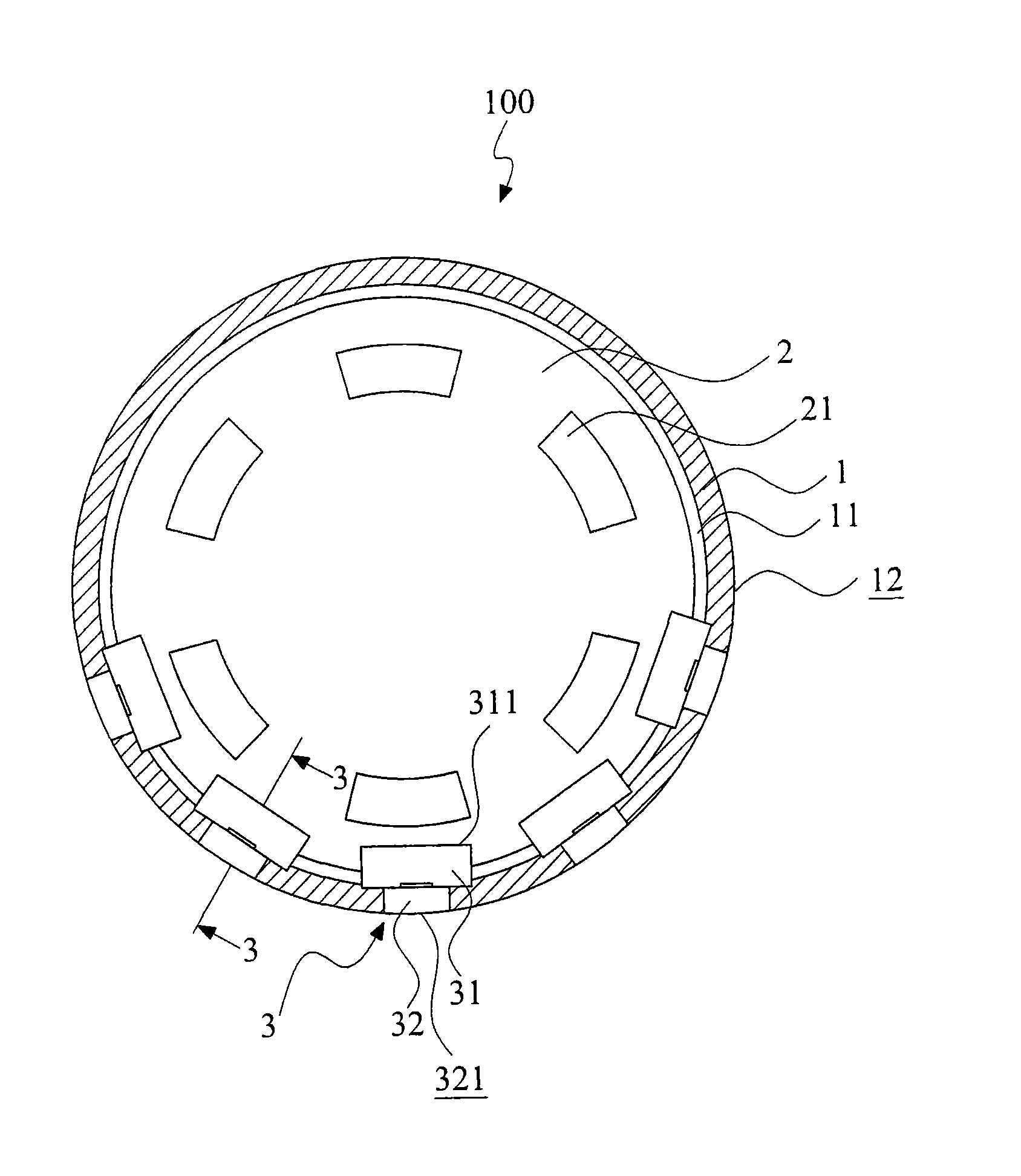

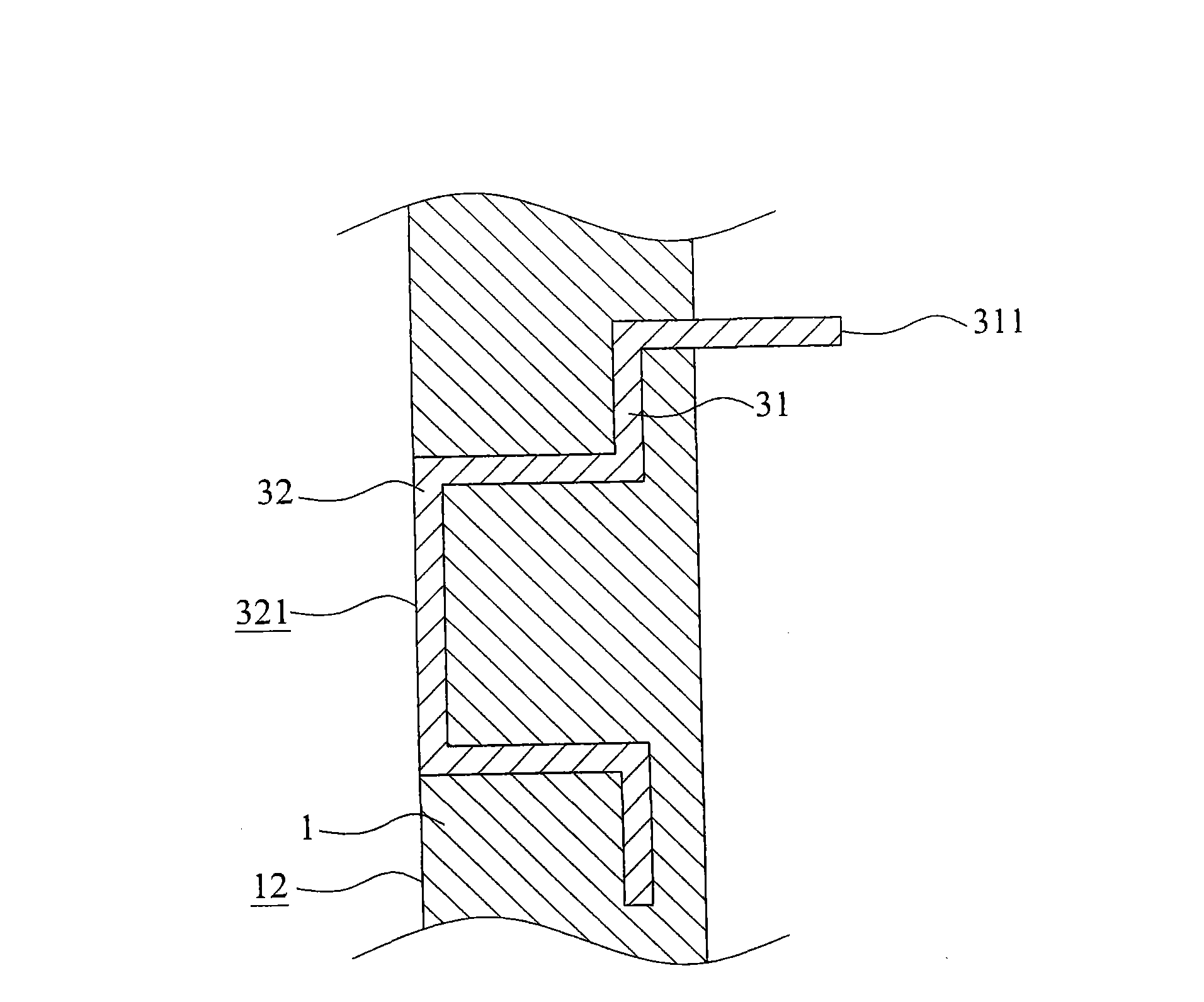

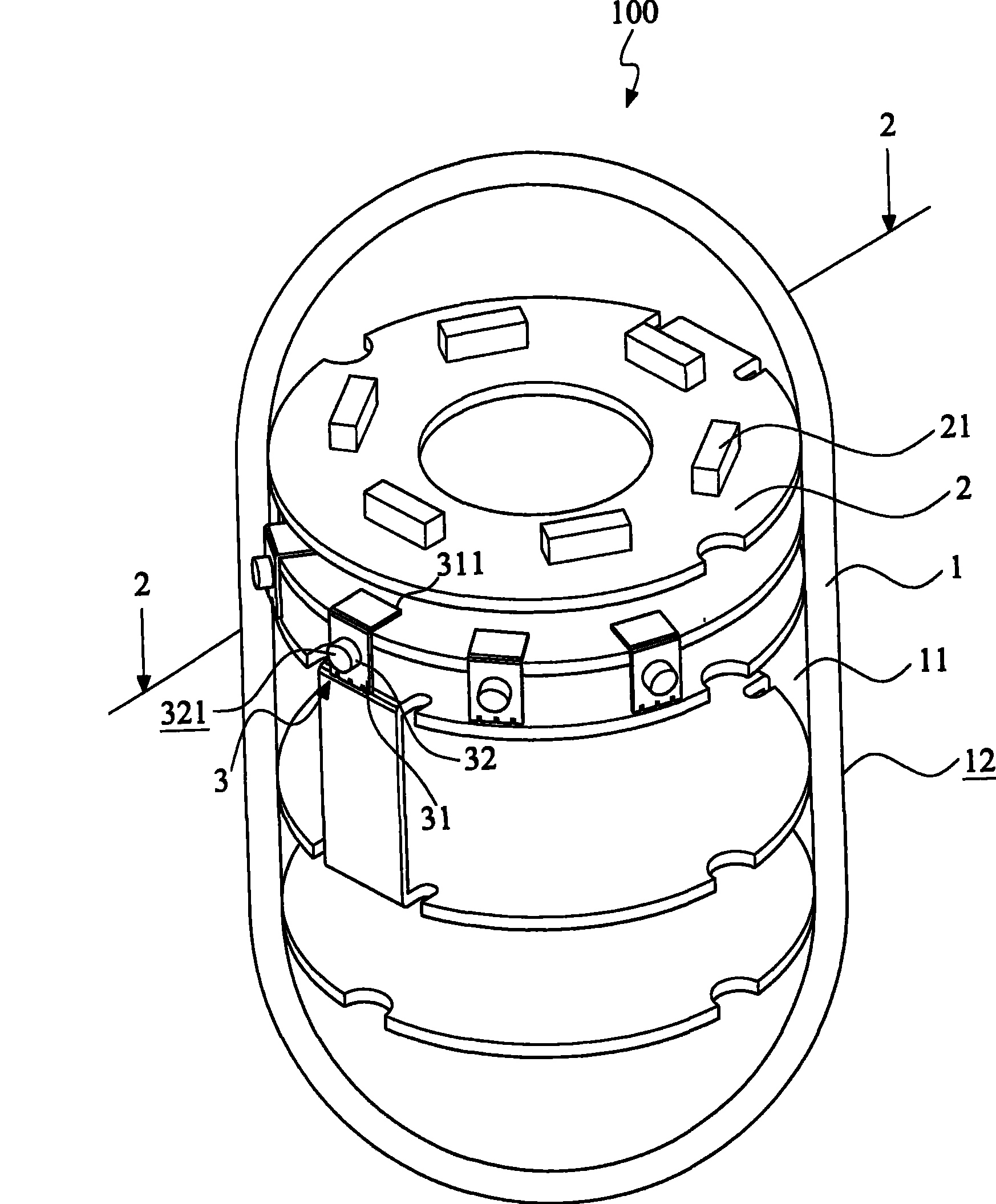

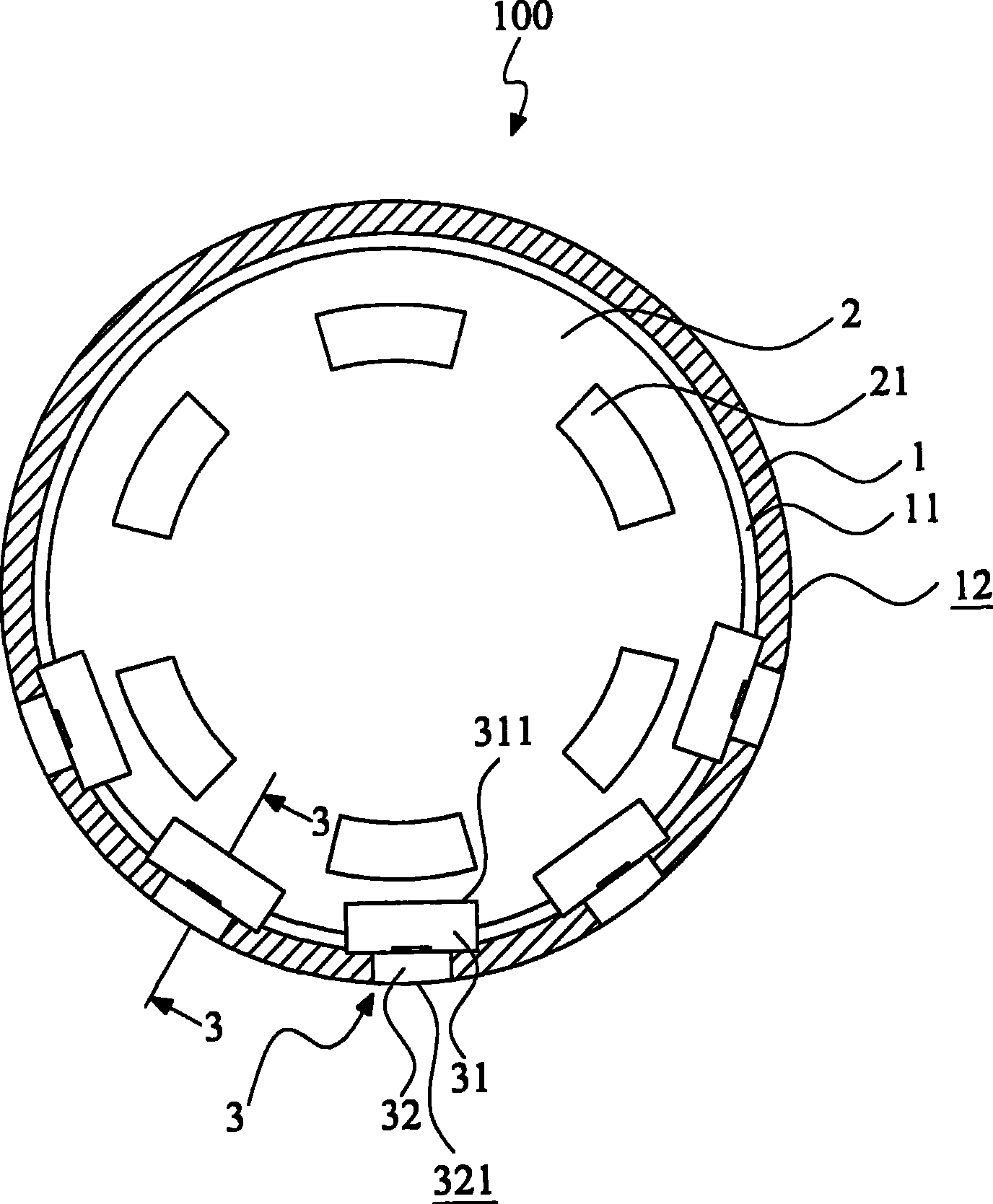

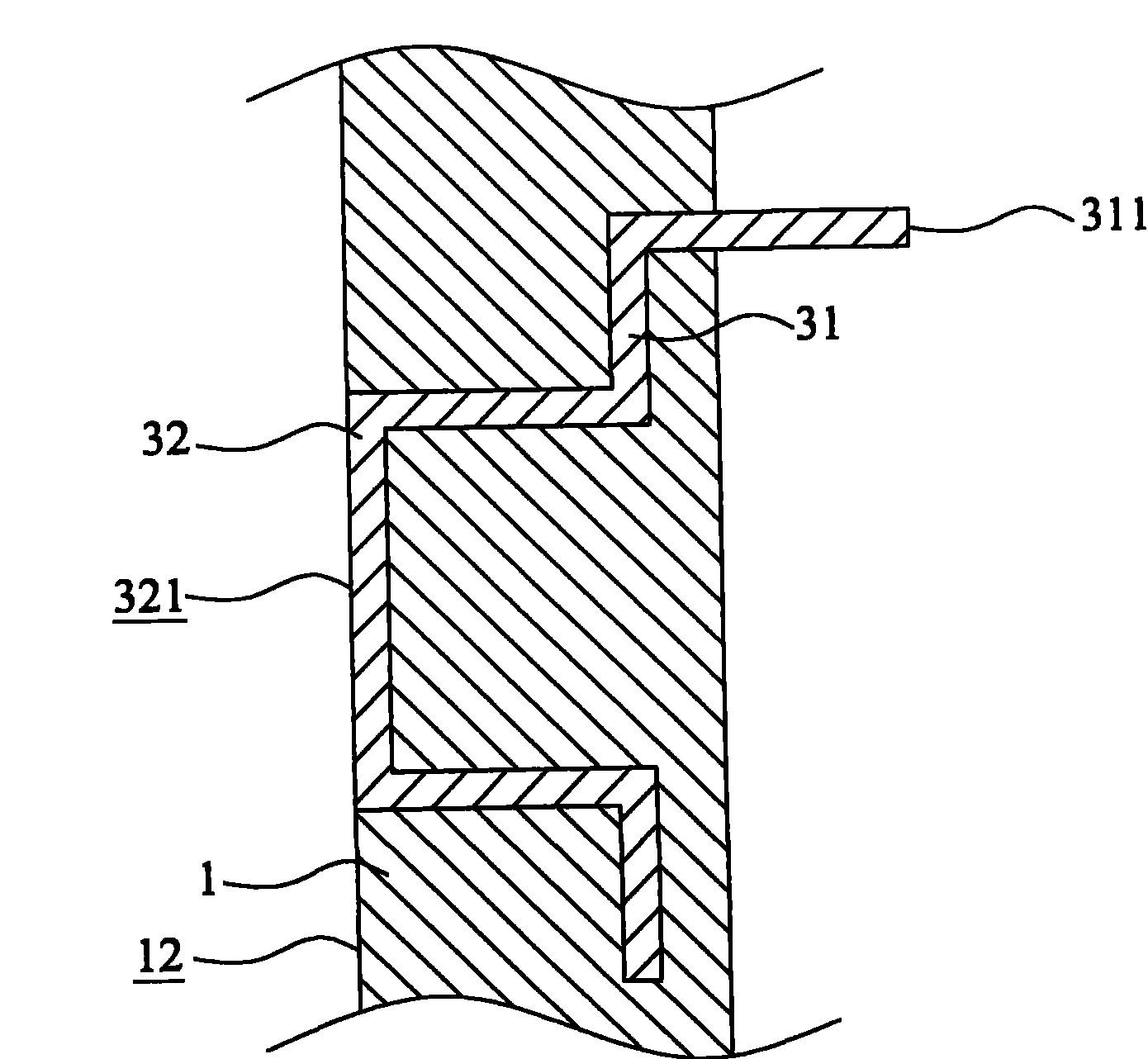

Endoscope capsule with metal implanting contact points

ActiveCN101664301AReduce riskReduce the number of repeated inspectionsSurgeryEndoradiosondesInterior spaceEndoscope

The invention discloses an endoscope capsule with metal implanting contact points, which is used for observing the internal situation of a human digestive system and comprises a capsule shell, a substrate and a plurality of metal implanting contact points, wherein the capsule shell is provided with an closed inner space and an outer surface; the substrate is arranged in the closed inner space of the capsule shell and is provided with a circuit element. The plurality of metal implanting contact points are embedded into selected positions of the capsule shell and comprise a contact point base and an exposed contact point respectively, wherein each contact point base comprises a connecting section which convexly extends to the closed inner space of the capsule shell and is connected with thesubstrate electrically; while each exposed contact point is formed on the contact point base and is provided with an exposed surface exposed out of the outer surface of the capsule shell so as to allow a corresponding signal contact point of a clamping mechanism to contact the exposed contact point.

Owner:INSIGHT MEDICAL SOLUTIONS INC

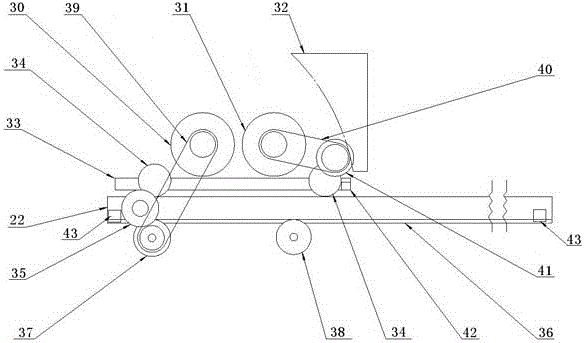

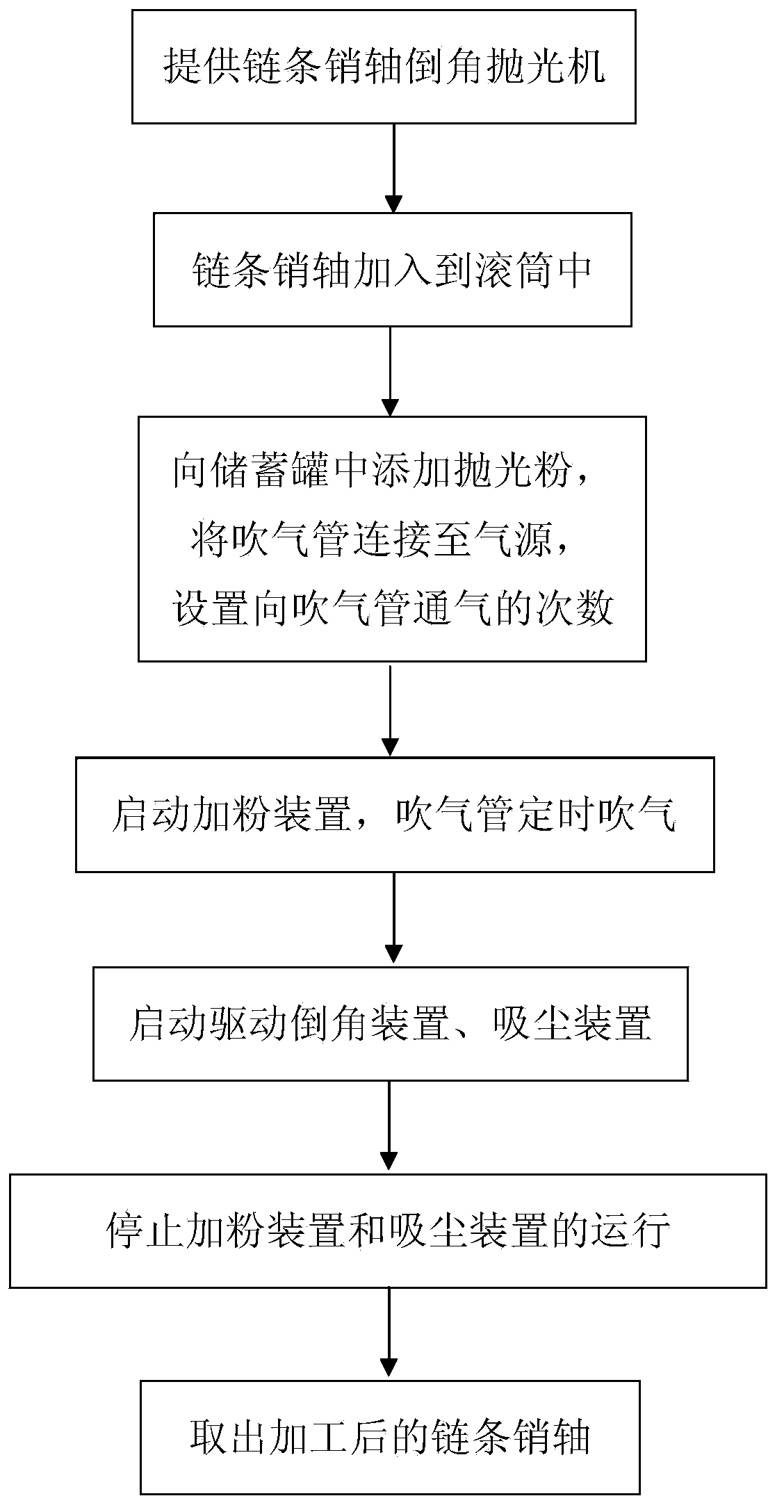

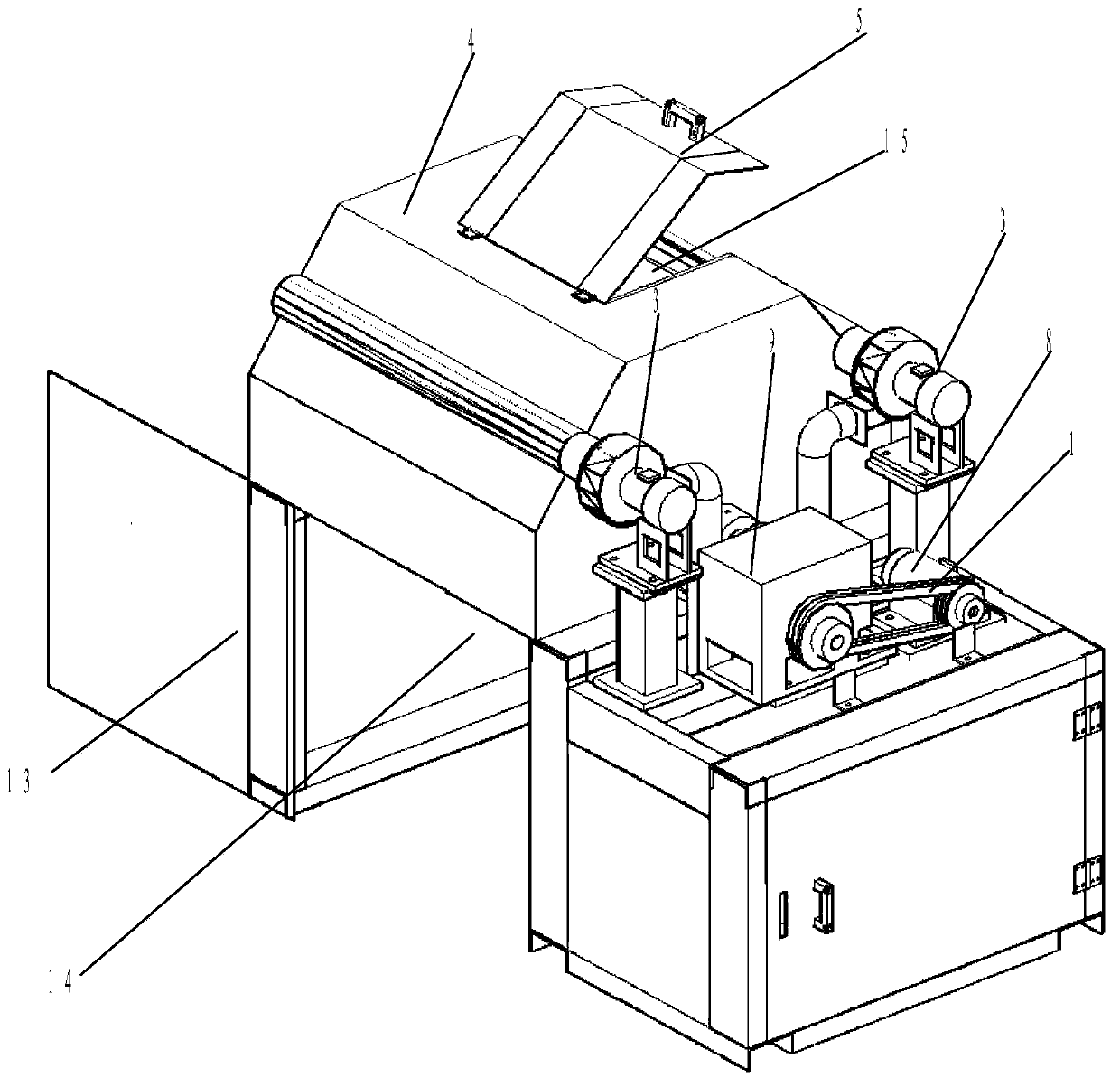

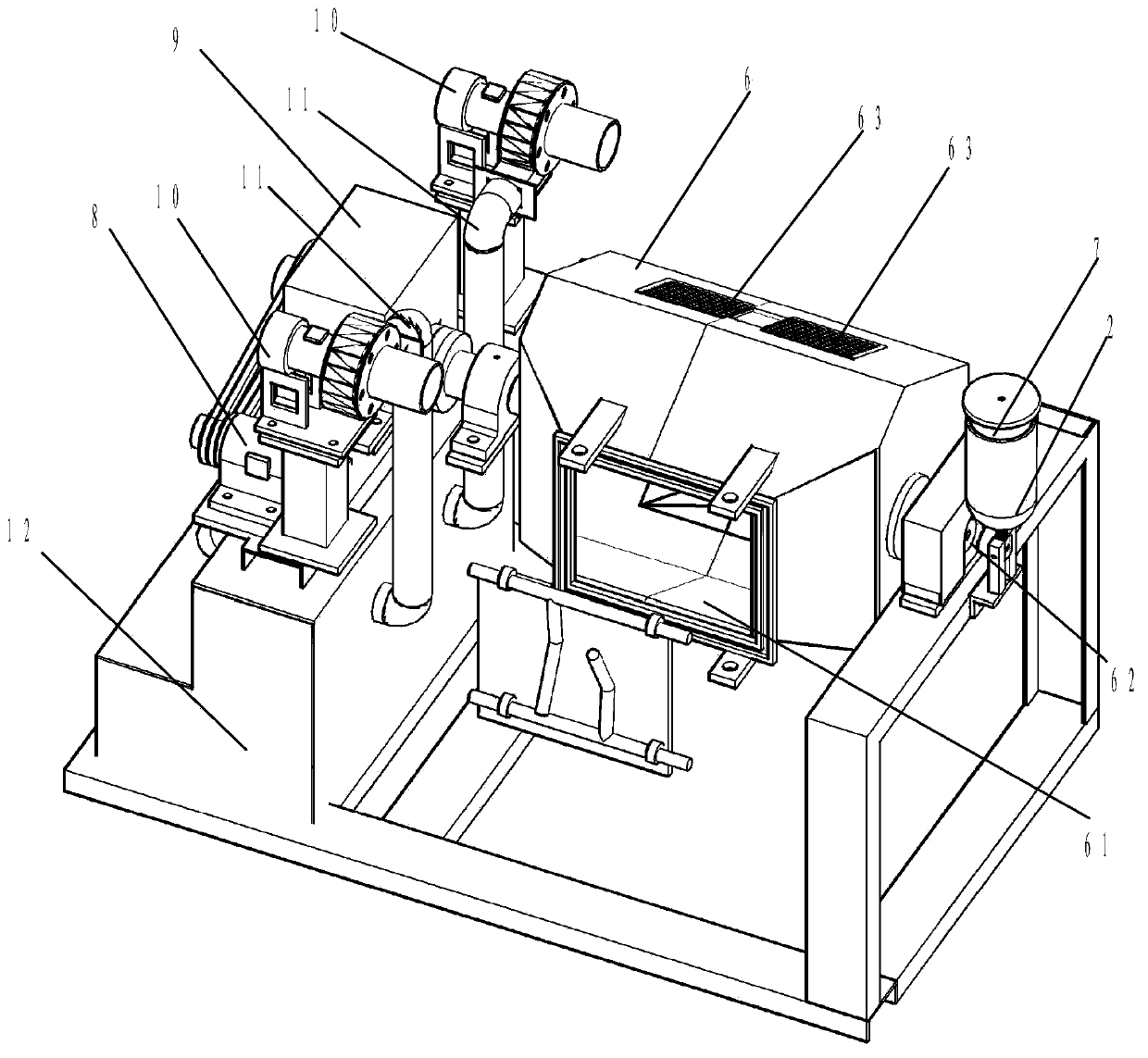

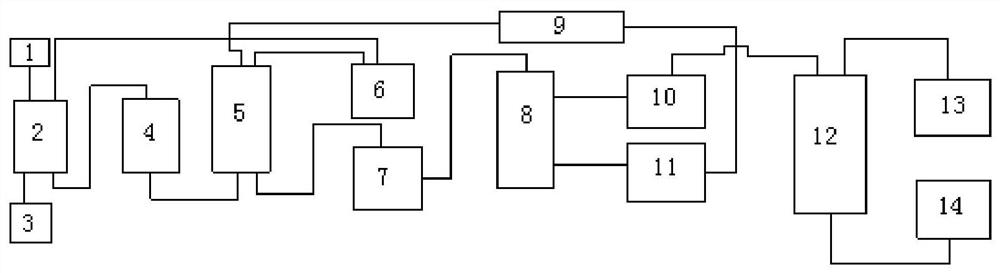

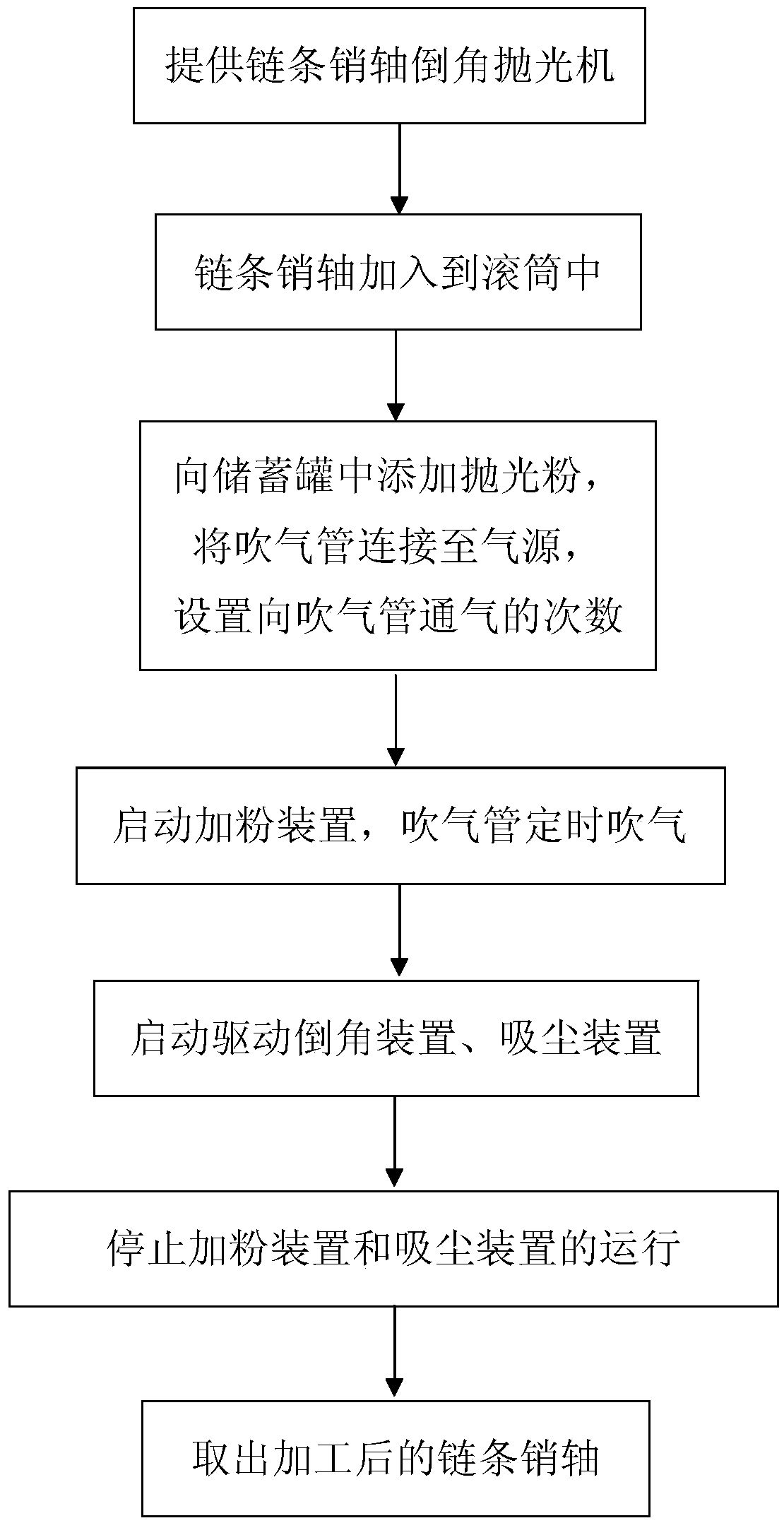

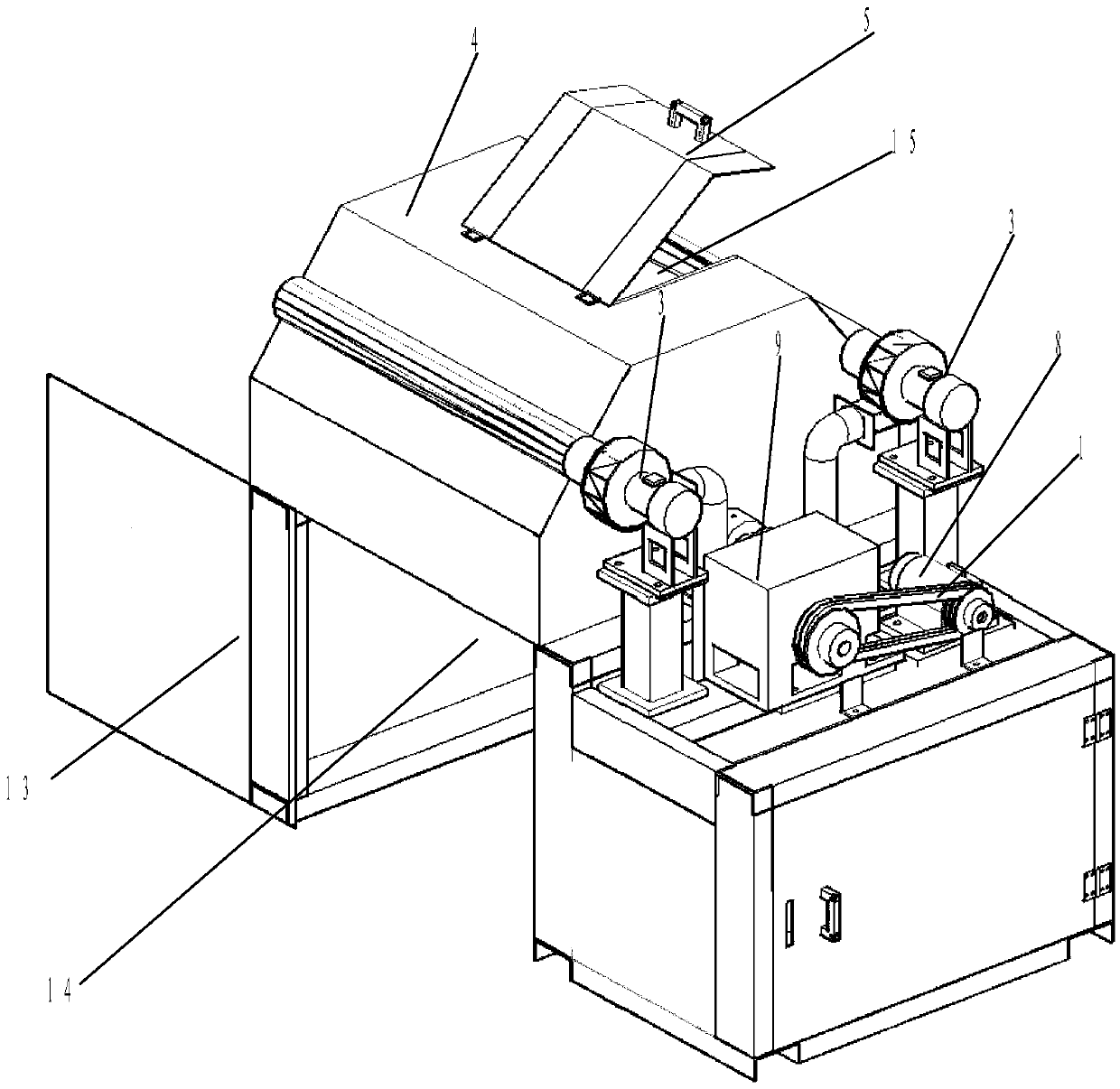

Chamfering and polishing method for chain hinge pin

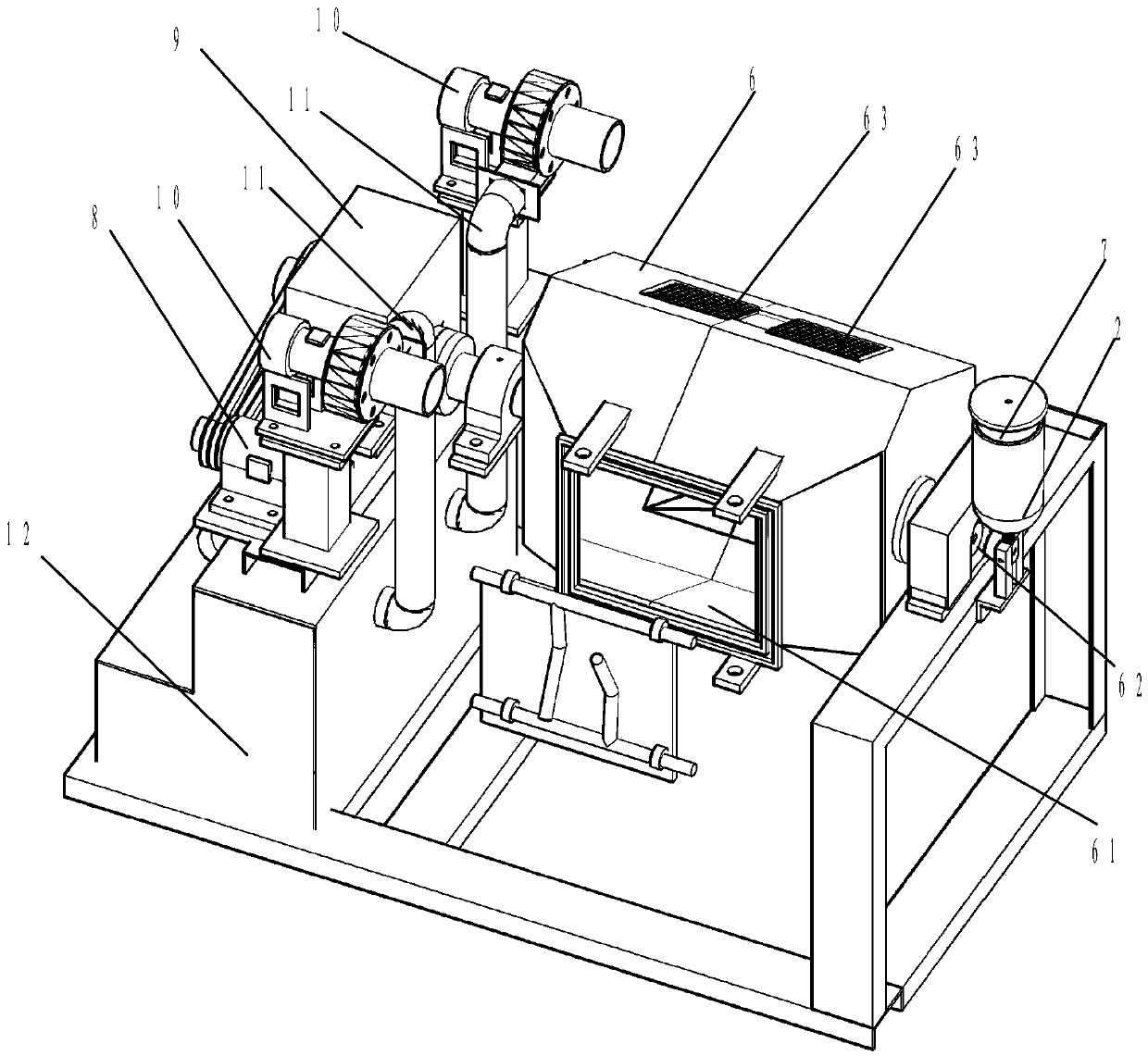

ActiveCN103737447AAchieve mass productionAvoid introducingEdge grinding machinesPolishing machinesEngineeringStorage tank

The invention discloses a chamfering and polishing method for a chain hinge pin. The method comprises the following steps: providing a chain pin shaft chamfering and polishing machine; adding a chain hinge pin into a drum; adding polishing powder into a storage tank of a powder adding device, and setting the air introduction times of an air blowing pipe; starting the powder adding device, and blowing the polishing powder in the powder adding device into the drum; starting a driving chamfering device, and chamfering and polishing the chain hinge pin in the overturned drum; starting a dust-collecting device, and exhausting dust into a dust isolating box of the dust-collecting device through a dust-collecting pipe of the dust-collecting device; stopping the driving chamfering device, the powder adding device and the dust-collecting device; taking the machined chain hinge pin away. By adopting the method, batch production of chain hinge pins is realized, the production efficiency is increased, production procedures are reduced, and the labor force and materials are saved. Moreover, by adopting the method, dust generated by chamfering and polishing of the chain hinge pins can be recovered, thereby realizing zero pollution on the environment.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

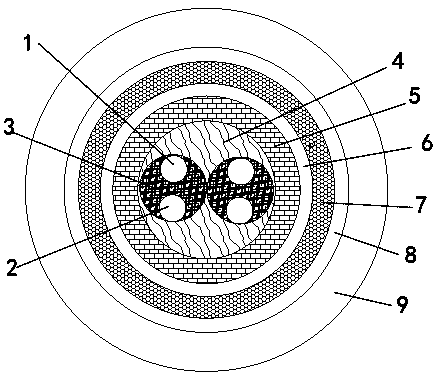

Heavy-type rubber jacketed flexible cable

PendingCN108550415AEnhanced tensile and torsional performanceImprove extrusion resistancePlastic/resin/waxes insulatorsClimate change adaptationFiberCopper conductor

The invention discloses a heavy-type rubber jacketed flexible cable, comprising insulating wire cores, wherein each insulating wire core is formed by longitudinally arranging tin-plated copper conductors and aluminum alloy conductors in parallel at intervals and then jointly extruding a high-elasticity silicone rubber insulating layer; the two insulating wire cores are closely and transversely arranged in parallel and then are wrapped together with metallized paper or semi-conductive tapes as an inner shielding layer, a copper tape outer shielding layer is woven outside the inner shielding layer, a waterproof film is wrapped outside the copper tape outer shielding layer, a ceramic fiber tape is wrapped outside the waterproof film, a low-smoke halogen-free flame-retardant polyolefin oxygenbarrier layer is extruded outside the ceramic fiber tape, and a rubber outer jacket is sleeved outside the low-smoke halogen-free flame-retardant polyolefin oxygen barrier layer. The heavy-type rubberjacketed flexible cable disclosed by the invention not only has excellent mechanical and physical properties, oil resistance, electrical properties, flame resistance and processing performance, but also has the characteristics of no halogen, low smoke volume and the like.

Owner:JIANGSU DONGFENG CABLE

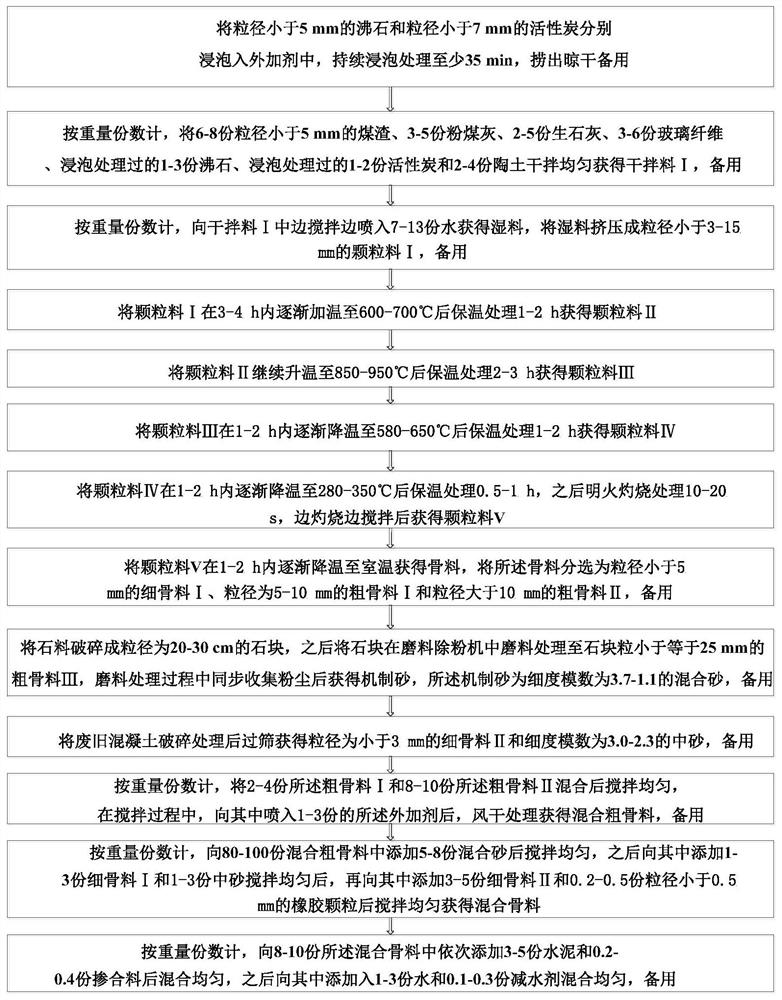

Homogenizing, mixing and feeding device for lithium battery electrodes

InactiveCN113069976AEasy to mix and handleEasy dischargeRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a homogenizing, mixing and feeding device for lithium battery electrodes. The homogenizing, mixing and feeding device comprises a box body, a rotating rod and a striker plate, wherein the top of the box body is fixedly connected with a feeding hopper, and the inner side wall of the box body is horizontally and fixedly connected with a partition plate; the striker plate is rotationally connected to the partition plate, and the upper surface of the striker plate and the upper surface of a bottom plate of the box body are both rotationally connected with a connecting cylinder; and the upper end of the rotating rod is rotationally connected to the top of the box body, the lower end of the rotating rod penetrates through the partition plate and makes contact with the bottom of the box body, and the rotating rod is located in the connecting cylinder and is in transmission connection with the connecting cylinder. According to the homogenizing, mixing and feeding device, multiple materials of a battery electrode can be stirred multiple times, mutual fusion of the multiple raw materials of the battery electrode is promoted, and discharging of the stirred raw materials of the battery electrode is facilitated, so the production procedures of a lithium battery is reduced to a certain extent.

Owner:安徽利维能动力电池有限公司

A board for furniture

InactiveCN105877239BEasy to assembleQuick and easy bendingFurniture partsEngineeringMechanical engineering

Owner:GEXIN XIAMEN SPORTS EQUIP

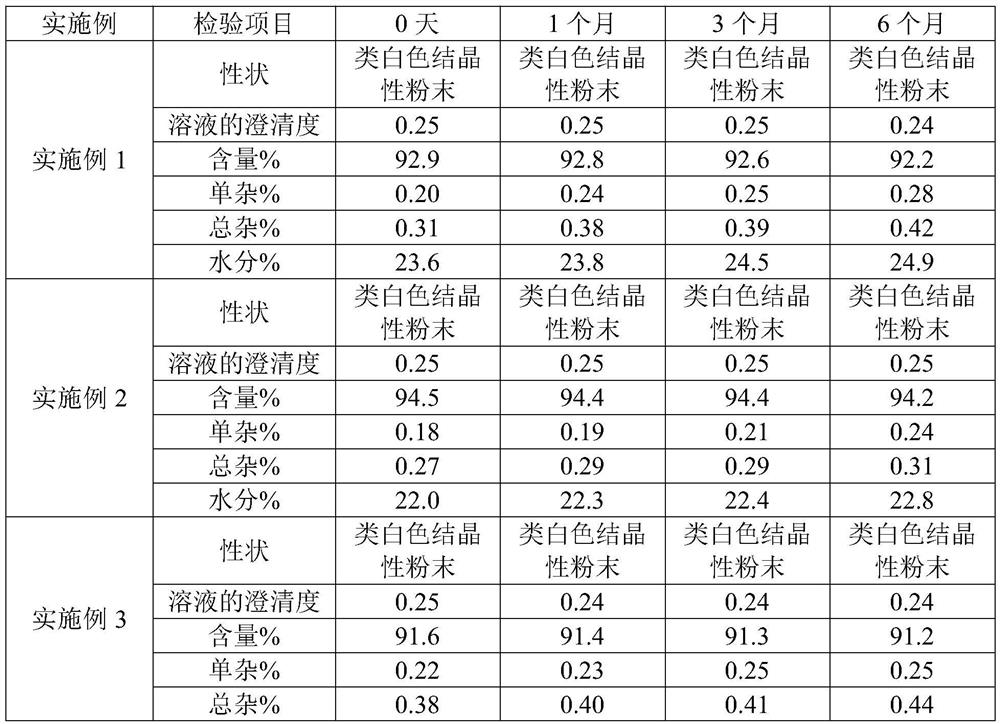

Preparation method of fructose sodium diphosphate powder injection

InactiveCN112110964AHigh yieldImprove quality stabilityEsterified saccharide compoundsSugar derivativesFructoseSodium phosphates

The invention discloses a preparation method of a fructose sodium diphosphate powder injection. According to the method, the yield and quality stability of fructose sodium diphosphate are effectivelyimproved by adopting the modes such as accurately proportioning a ratio of a solute and a solvent, adjusting an addition amount of ethanol, and controlling crystallization temperature and stirring speed in the preparation process. According to the preparation method, seed crystals do not need to be added in the recrystallization process, and the preparation method has the advantages of simple andconvenient operations and simplified production steps. The purity of fructose sodium diphosphate produced by the preparation method is also improved, and the sensitization of fructose sodium diphosphate is reduced.

Owner:HAINAN HUALON PHARM

Transformed yarrowia lipolytica, and building method and application thereof

The invention discloses transformed yarrowia lipolytica, and a building method and application thereof. The transformed yarrowia lipolytica comprises a nucleotide sequence shown as SEQ ID NO:1, and is used for realizing the co-production of single-cell protein and lipase for feed; under the culture conditions that a YPD liquid culture medium is used, the liquid containing quantity is 10 percent, the rotating speed is 250rpm, the culture temperature is 28 DEG C, and the culture time is 84h, the protein content of the transformed yarrowia lipolytica is 60 to 70 percent, and the dry weight is 32g / L to 39g / L; the yield of the lipase for feed is 3200U / ml to 5900U / ml. The transformed yarrowia lipolytica is built by a gene engineering method; the co-production of the single-cell protein and the lipase for feed is realized; meanwhile, the content of two target products is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

A transformation of Yarrowia lipolytica and its construction method and application

ActiveCN106754446BPromote biosynthesisImprove utilizationFungiHydrolasesNucleotideSingle-cell protein

The invention discloses transformed yarrowia lipolytica, and a building method and application thereof. The transformed yarrowia lipolytica comprises a nucleotide sequence shown as SEQ ID NO:1, and is used for realizing the co-production of single-cell protein and lipase for feed; under the culture conditions that a YPD liquid culture medium is used, the liquid containing quantity is 10 percent, the rotating speed is 250rpm, the culture temperature is 28 DEG C, and the culture time is 84h, the protein content of the transformed yarrowia lipolytica is 60 to 70 percent, and the dry weight is 32g / L to 39g / L; the yield of the lipase for feed is 3200U / ml to 5900U / ml. The transformed yarrowia lipolytica is built by a gene engineering method; the co-production of the single-cell protein and the lipase for feed is realized; meanwhile, the content of two target products is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

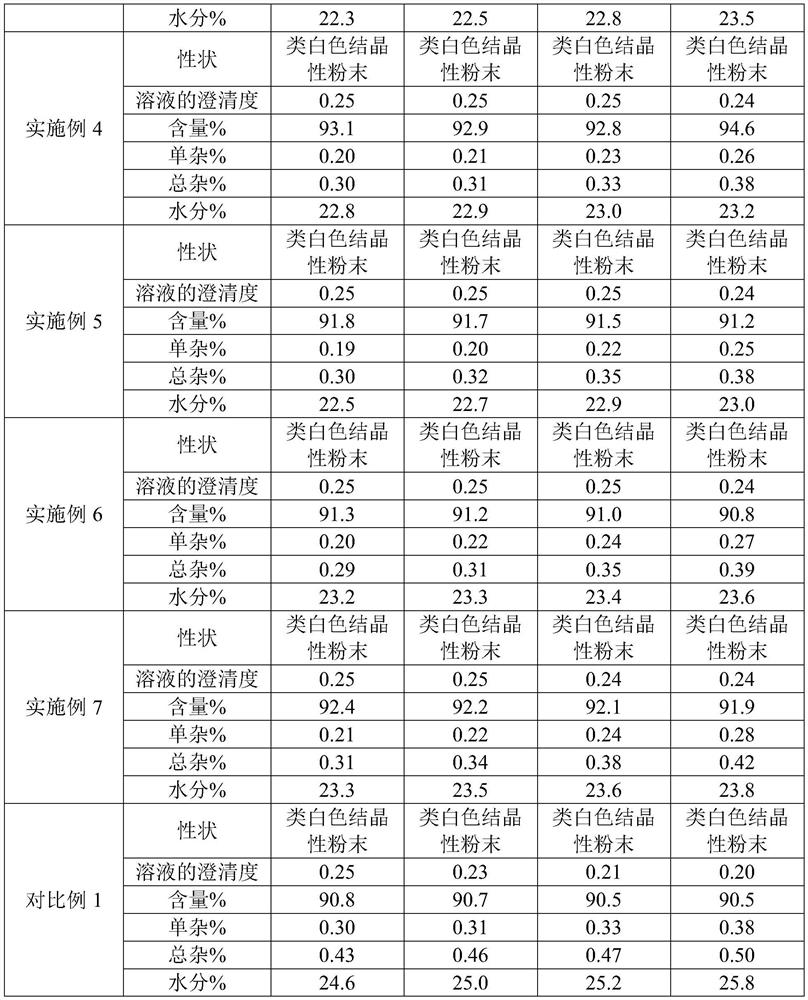

Machine-made sand concrete and its preparation method

ActiveCN108298885BGuaranteed performanceGood sustained release effectCompressive resistanceArchitectural engineering

Owner:CHINA ROAD & BRIDGE

A kind of coated printing medium and preparation method thereof

InactiveCN104149513BExcellent adhesionImprove scratch resistanceDuplicating/marking methodsCross linkerSilicon oxide

The invention discloses a coated printing medium, which is evenly coated on a substrate, and is characterized in that: the coated printing medium consists of 100 parts of water, 8 to 12 parts of di Silicon oxide, 6-10 parts of titanium dioxide, 50-100 parts of PM-2 acrylic synthetic rubber, 50 parts of 676 synthetic rubber, 1.4-2.2 parts of dispersing aid, 0.5 part of defoaming aid, 0.3? Composed of 0.5 parts of leveling aid and 5 parts of crosslinking agent. Compared with the traditional printing medium, the coated printing medium of the present invention can greatly improve the ink adhesion in the ink printing process, increase the printing color density, and greatly improve the scratch resistance of printed products.

Owner:JIANGSU GEMEIGAO DEV CO LTD

A kind of combined extraction and preparation method of composite polypeptide

ActiveCN103882085BEffective filteringQuick second filterPeptide preparation methodsFermentationNatural resourceAcid hydrolysis

The invention provides a combined extraction preparation method of complex polypeptide. According to the combined extraction preparation method, a moderate weak acid method is adopted for extracting natural bioactive polypeptide, then sediments remained and discarded in the polypeptide extraction process with the weak acid method are hydrolyzed by adopting an enzymolysis method, namely the same raw material is subjected to combined polypeptide extraction by respectively adopting the acid hydrolysis method and the enzymolysis method and utilizing the extraction method, extracted raw material or resource is completely utilized, original waste is used to the greates extent, and yield of extracted and prepared combined polypeptide is obviously improved. In addition, valuable natural resources are saved, environmental pollution is reduced, potential safety hazard is eliminated, production period is shortened, extraction reagents and instruments are reduced, investment and production cost are reduced, polypeptide bioavailability is improved, future use application scope is extended, and human body application value is improved.

Owner:大连摩格生物科技有限公司

A double-cycle furfural production system and process

The invention discloses a double-circulation furfural production system, and technology. The technology comprises following steps: 1, corn cob and low concentration acetic acid are subjected to hydrolysis reaction so as to obtain a mixed solution of xylose and acetic acid, wherein the concentration of the low concentration acetic acid is controlled to be 1 to 2%, v / v; 2, acetic acid, sodium chloride, and o-nitroanisole are added into the mixed solution of xylose and acetic acid obtained in step 1, wherein the acetic acid concentration is controlled to be 3 to 6%, v / v, the sodium chloride concentration is controlled to be 5 to 10% by mass, the volume ratio of o-nitroanisole to the mixed solution is controlled to be 1:0.8-1.2, and in the reaction process, the reaction system is stirred continuously; 3, after reaction, the obtained reaction system is allowed to stand for a preset time period for layering, an upper layer water phase is recycled back into the step 1 to provide an acidic environment for corn cob hydrolysis, and a lower layer extracted phase is conveyed into a distillation column for separation of crude furfural and o-nitroanisole; and 4, the o-nitroanisole obtained through separation is recycled back into the step 3.

Owner:山东乔克环境科技有限公司

Warm sound-proof decorative materials and prepn. method

This invention is attributed to the field of building materials, concretely speaking, relates to a kind of decoration materials with heat preservation and sound absorption functions and its preparation method. The heat-preserving and sound-absorbing decoration materials comprise a hear-preserving layer, a decoration layer and a mask layer. The heat-preserving layer is made of polybenzene particles, water glass, cement, silica fume, slag powders, fly ash and sand. The decoration layer is made of polybenzene, rubber powders, pigment, cement, silica fume, slag powders and sand. The mask layer is made of organosilicon series of waterproof materials. By the technique of spray stir, layered moulding, compression molding and vapor conservation, the polybenzene particles and the porous structure can help realize highly effective heat preservation. The sound-absorbing structure can be fabricated by compression molding. Fascinating stereo patterns can be organized by alternation of mould shape and pigment. Besides, thanks to the mask layer, wear and decoration properties can be promoted. The product performs excellent heat-preserving, sound-absorbing and decorative functions.

Owner:TONGJI UNIV

A kind of chain pin shaft chamfer polishing method

ActiveCN103737447BAchieve mass productionAvoid introducingEdge grinding machinesPolishing machinesEngineeringPollution

The invention discloses a chamfering and polishing method for a chain hinge pin. The method comprises the following steps: providing a chain pin shaft chamfering and polishing machine; adding a chain hinge pin into a drum; adding polishing powder into a storage tank of a powder adding device, and setting the air introduction times of an air blowing pipe; starting the powder adding device, and blowing the polishing powder in the powder adding device into the drum; starting a driving chamfering device, and chamfering and polishing the chain hinge pin in the overturned drum; starting a dust-collecting device, and exhausting dust into a dust isolating box of the dust-collecting device through a dust-collecting pipe of the dust-collecting device; stopping the driving chamfering device, the powder adding device and the dust-collecting device; taking the machined chain hinge pin away. By adopting the method, batch production of chain hinge pins is realized, the production efficiency is increased, production procedures are reduced, and the labor force and materials are saved. Moreover, by adopting the method, dust generated by chamfering and polishing of the chain hinge pins can be recovered, thereby realizing zero pollution on the environment.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

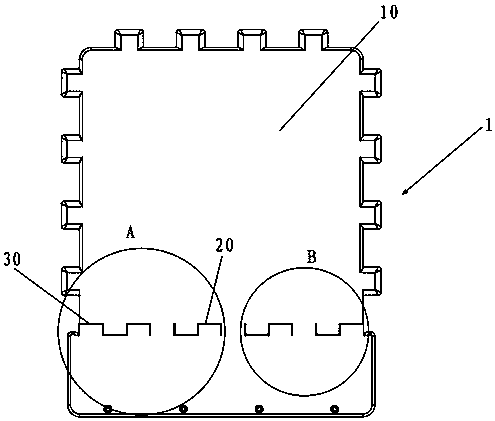

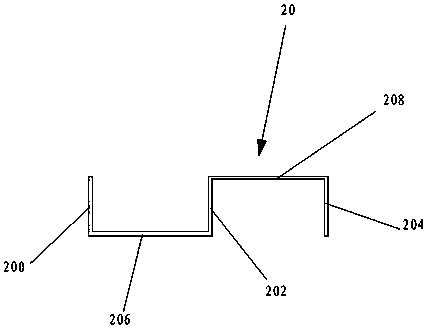

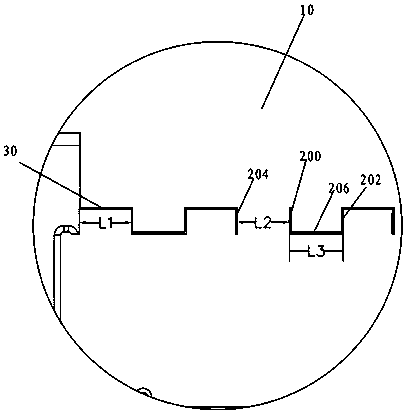

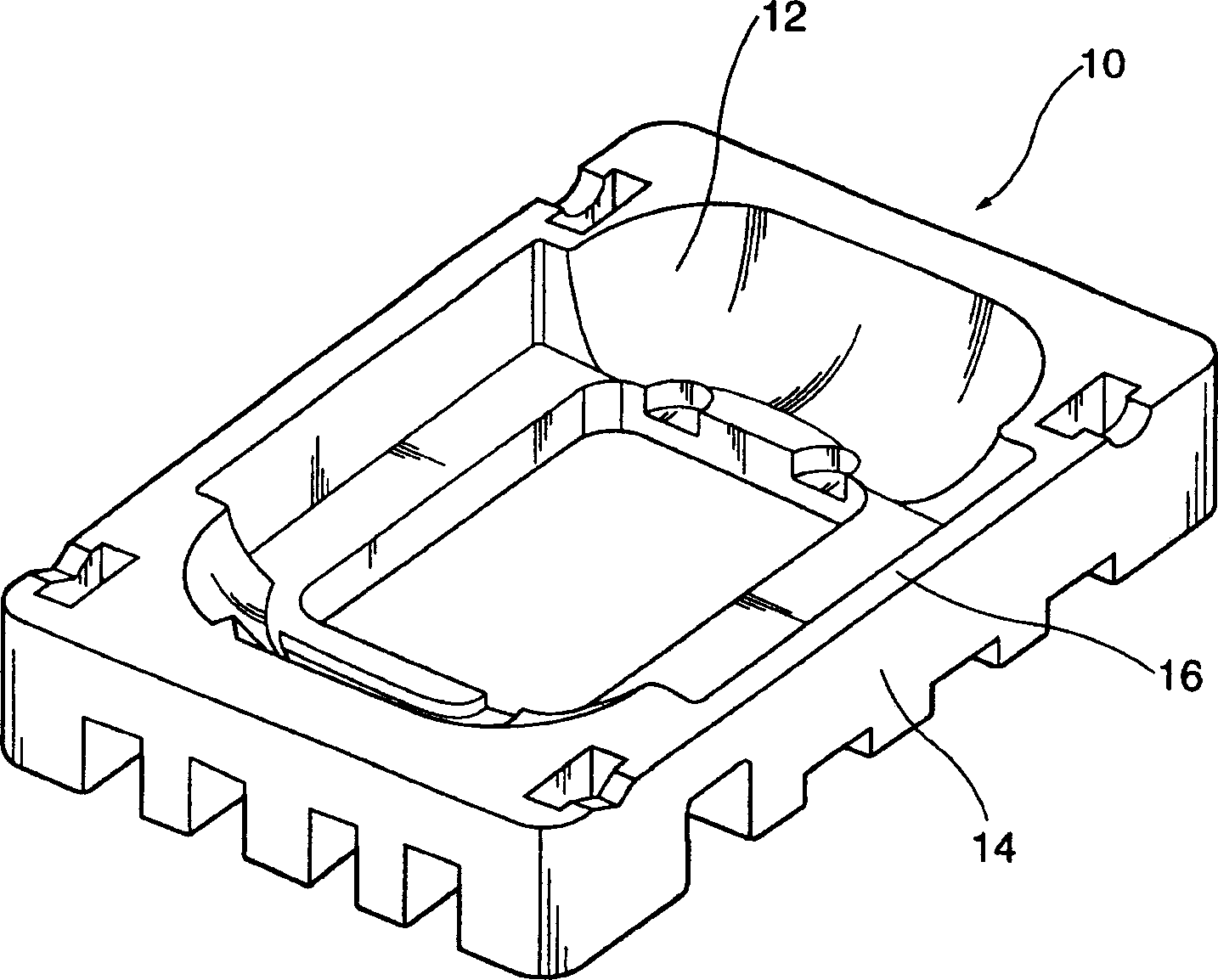

Buffer package material for electric cooker

InactiveCN1277727CLow costSafety protectionContainers to prevent mechanical damageCookerElectrical and Electronics engineering

The present invention relates to an electric cooker special-purpose buffer packaging material made of foamed plastics. Said packaging material for electric cooker includes: a plate bottom layer, setting flange which is formed on the bottom layer, positioned in the inward-recessed position and formed into setting portion for setting electric cooker and reinforced flange which is upward-projected and formed on the bottom layer and is connected with setting flange. Said package structure can save raw material, and can protect finished product safety.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A method for producing furfural by catalyzing xylose extraction with glacial acetic acid under normal pressure

The invention discloses a method for extraction production of furfural by adopting glacial acetic acid to catalyze xylose under normal pressure. The method comprises following steps: 1), acetic acid,ferric chloride and dimethyl phthalate are added to a xylose solution, concentration of acetic acid is enabled to be 3%-6% by mass, v / v, and concentration of ferric chloride is enabled to be 5%-10% bymass; adding volume of dimethyl phthalate is 50%-70% of total volume of a mixed solution; a reaction system is continuously stirred in a reaction process; 2), after the reaction is finished, the mixed solution is left to stand for a set period of time, the reaction system is enabled to stand for layering, and a lower extraction phase is conveyed to a distillation column to separate crude furfuraland dimethyl phthalate; 3), dimethyl phthalate obtained after separation is circulated to the step 2) and used as an extraction agent for furfural, crude furfural obtained after separation is distilled, and refined furfural is obtained.

Owner:山东乔克环境科技有限公司

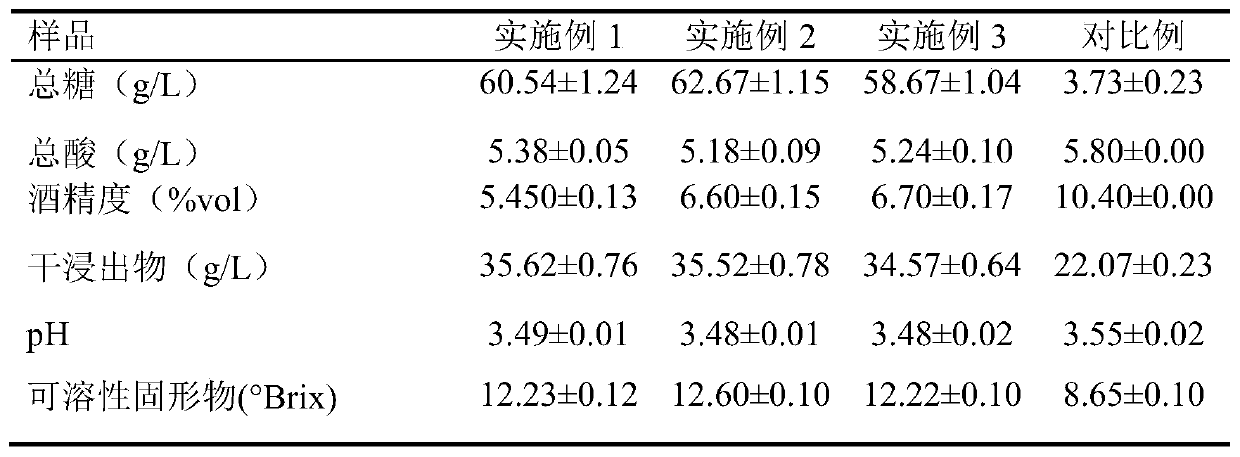

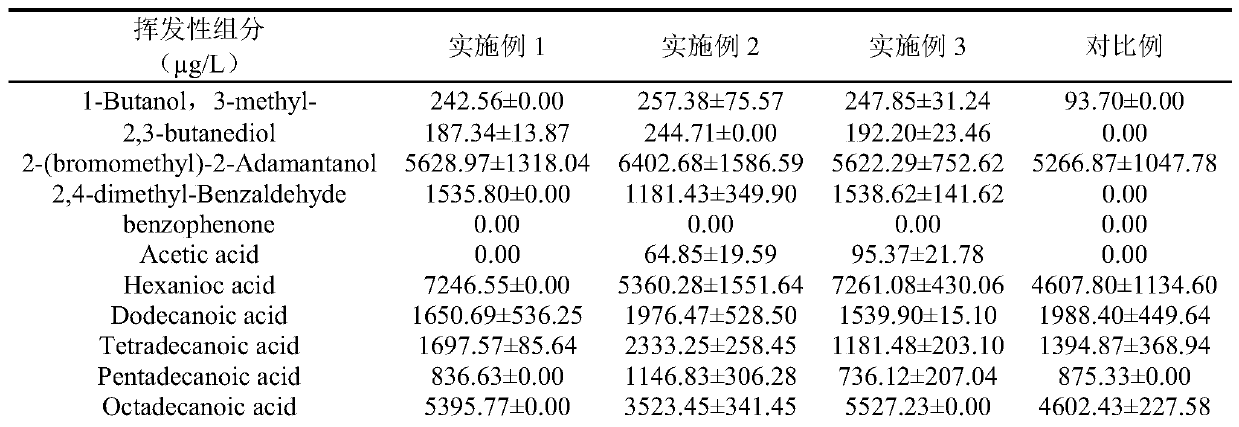

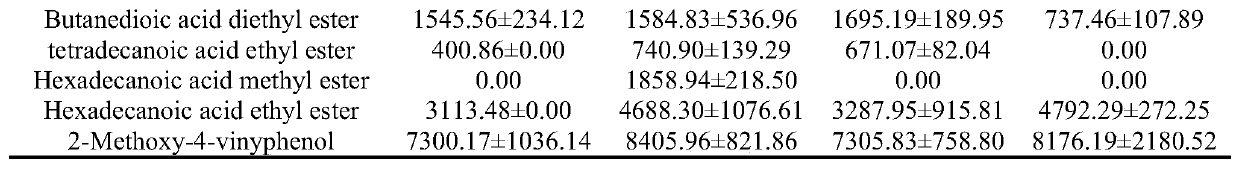

Sweet type pear wine and brewing method thereof

The present invention discloses a brewing method of sweet type pear wine. The method comprises the following steps: (1) washed clean pears are cut into segments and squeezed into juice, and sulfur dioxide is added to the juice; (2) total acid of the juice is adjusted to 4-6 g / L; (3) pectinase is added to the juice, putting still overnight is conducted, then the juice is placed in a fermentation tank, yeasts are inoculated, and the materials are stirred evenly for fermentation; and (4) under 0.04-0.1 MPa and a room-temperature condition, a filtering membrane with a pore size of 200-500 nm is used to conduct filtration of fermentation liquid at a flow rate of 3-5 m / s, and a filtrate is collected. The brewing method can improve automation degree and production efficiency of industrial production, at the same time realizes artificially controllable fermentation termination and clarification sterilization of the pear wine, reduces production processes and lowers production cost.

Owner:SICHUAN UNIV

Endoscope capsule with metal implanting contact points

ActiveCN101664301BReduce riskReduce the number of repeated inspectionsSurgeryEndoradiosondesInterior spaceEndoscope

The invention discloses an endoscope capsule with metal implanting contact points, which is used for observing the internal situation of a human digestive system and comprises a capsule shell, a substrate and a plurality of metal implanting contact points, wherein the capsule shell is provided with an closed inner space and an outer surface; the substrate is arranged in the closed inner space of the capsule shell and is provided with a circuit element. The plurality of metal implanting contact points are embedded into selected positions of the capsule shell and comprise a contact point base and an exposed contact point respectively, wherein each contact point base comprises a connecting section which convexly extends to the closed inner space of the capsule shell and is connected with thesubstrate electrically; while each exposed contact point is formed on the contact point base and is provided with an exposed surface exposed out of the outer surface of the capsule shell so as to allow a corresponding signal contact point of a clamping mechanism to contact the exposed contact point.

Owner:INSIGHT MEDICAL SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com