Patents

Literature

466results about How to "Improve mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

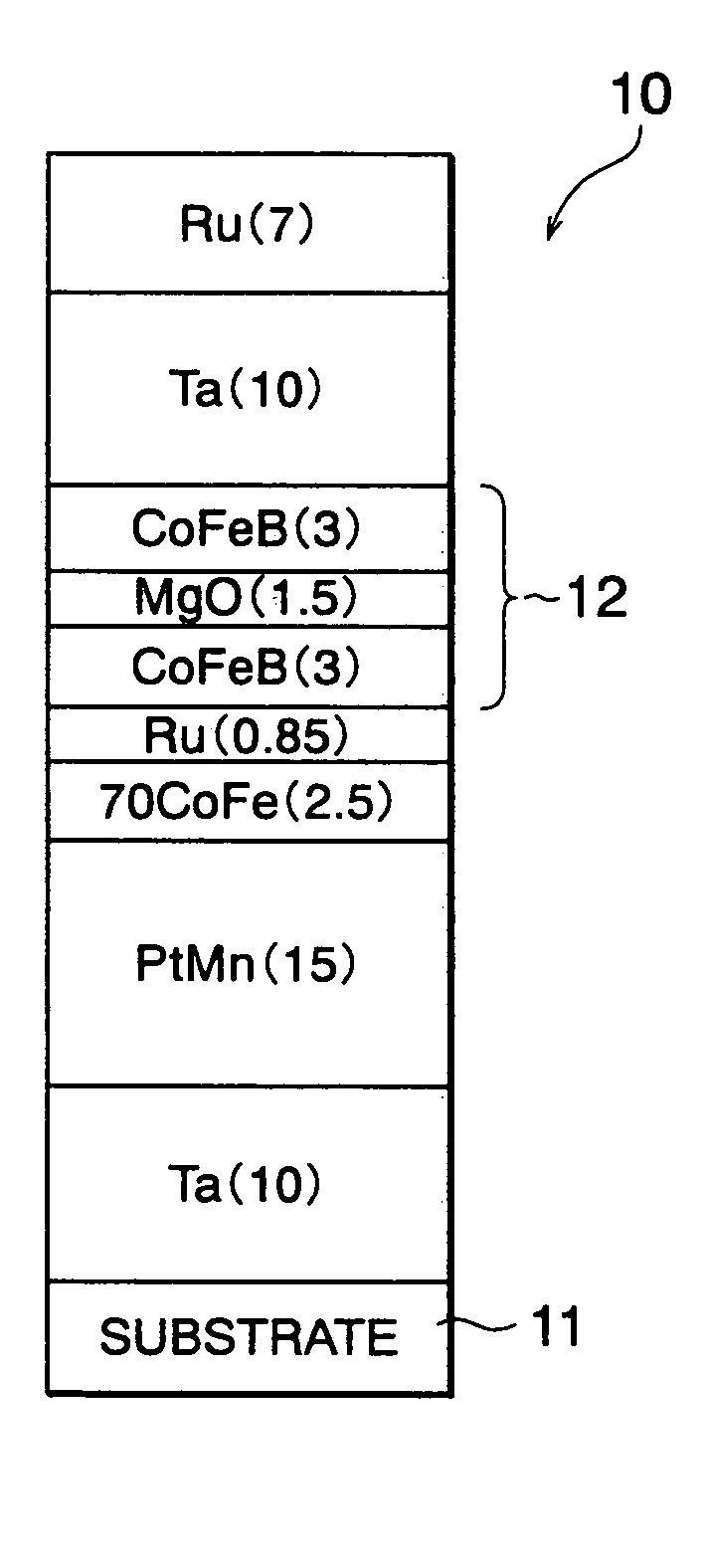

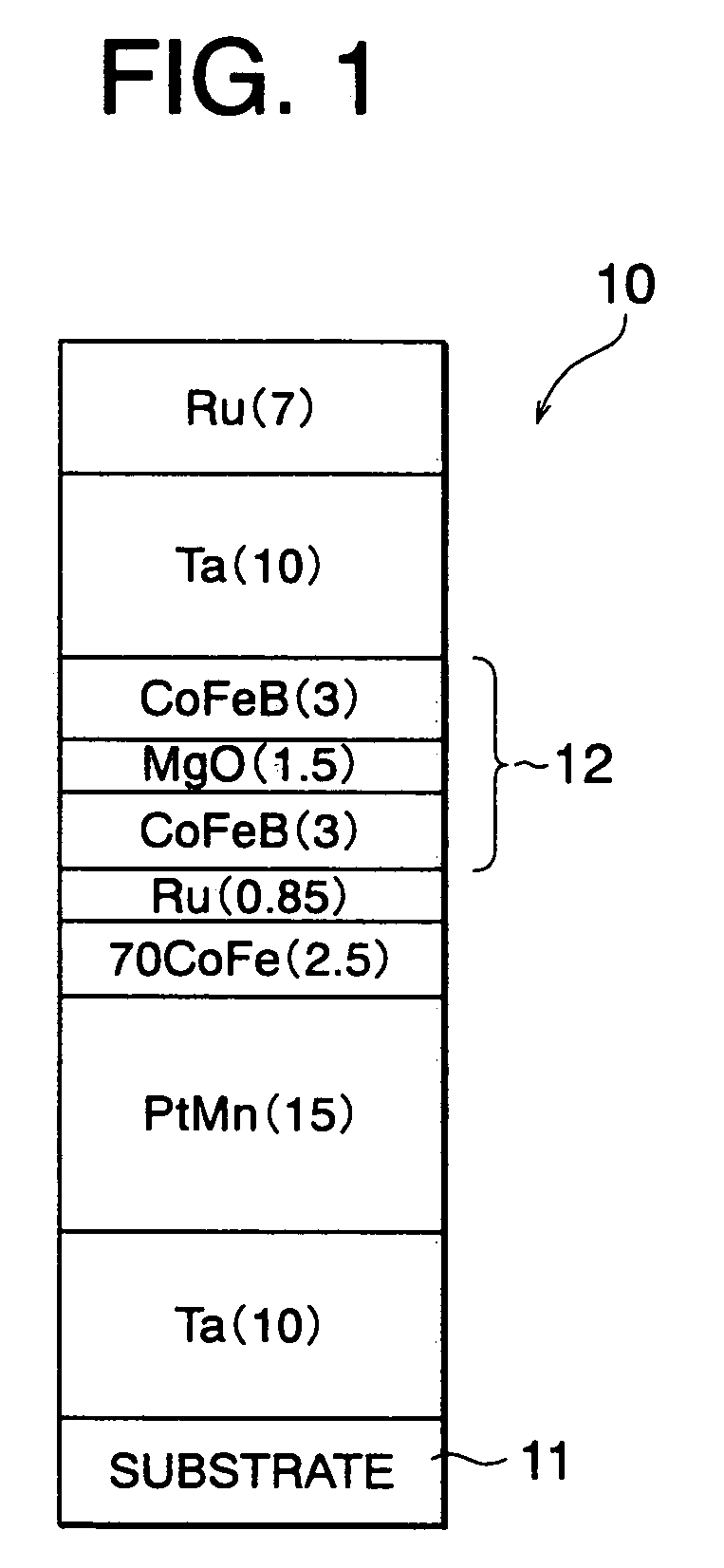

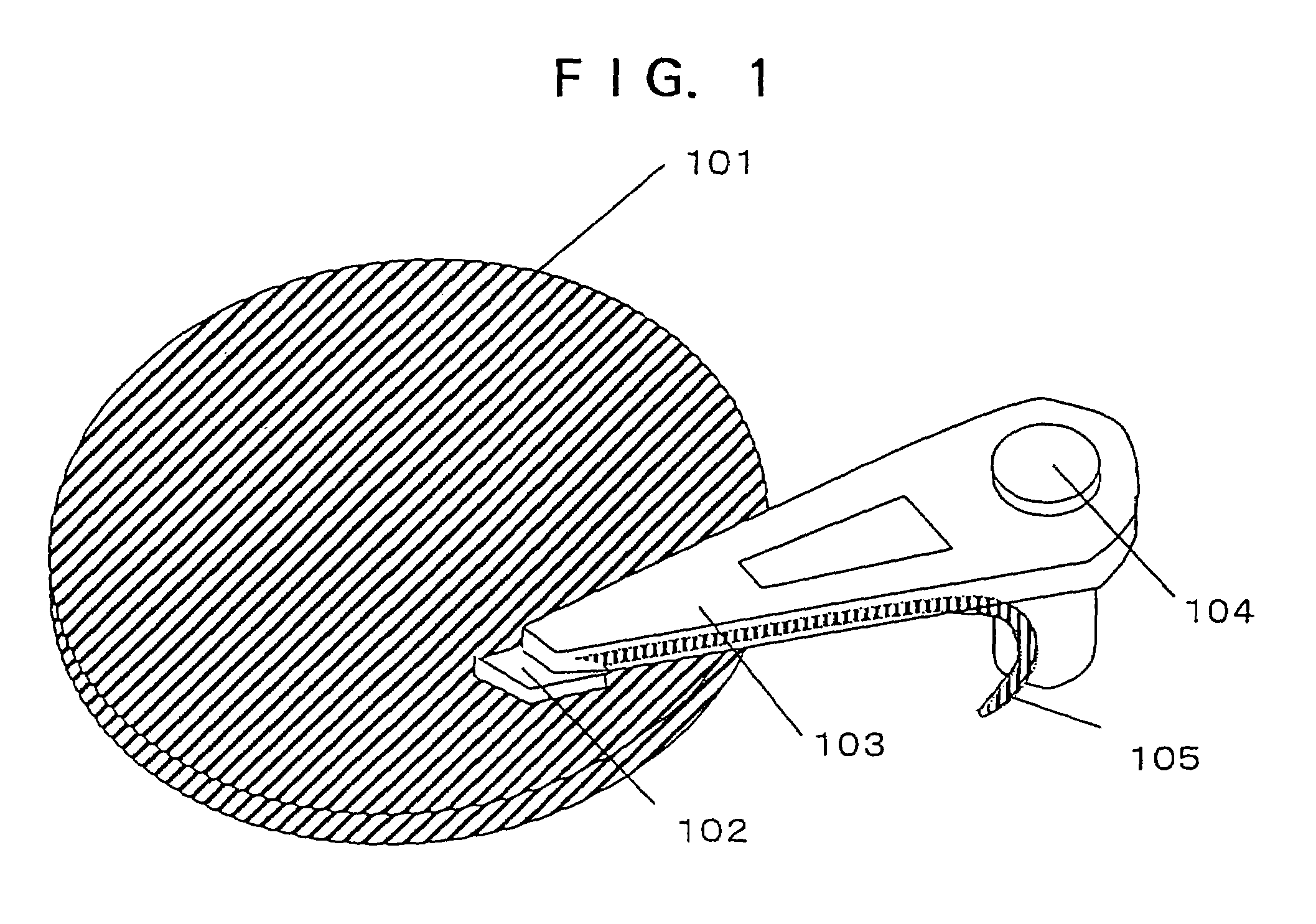

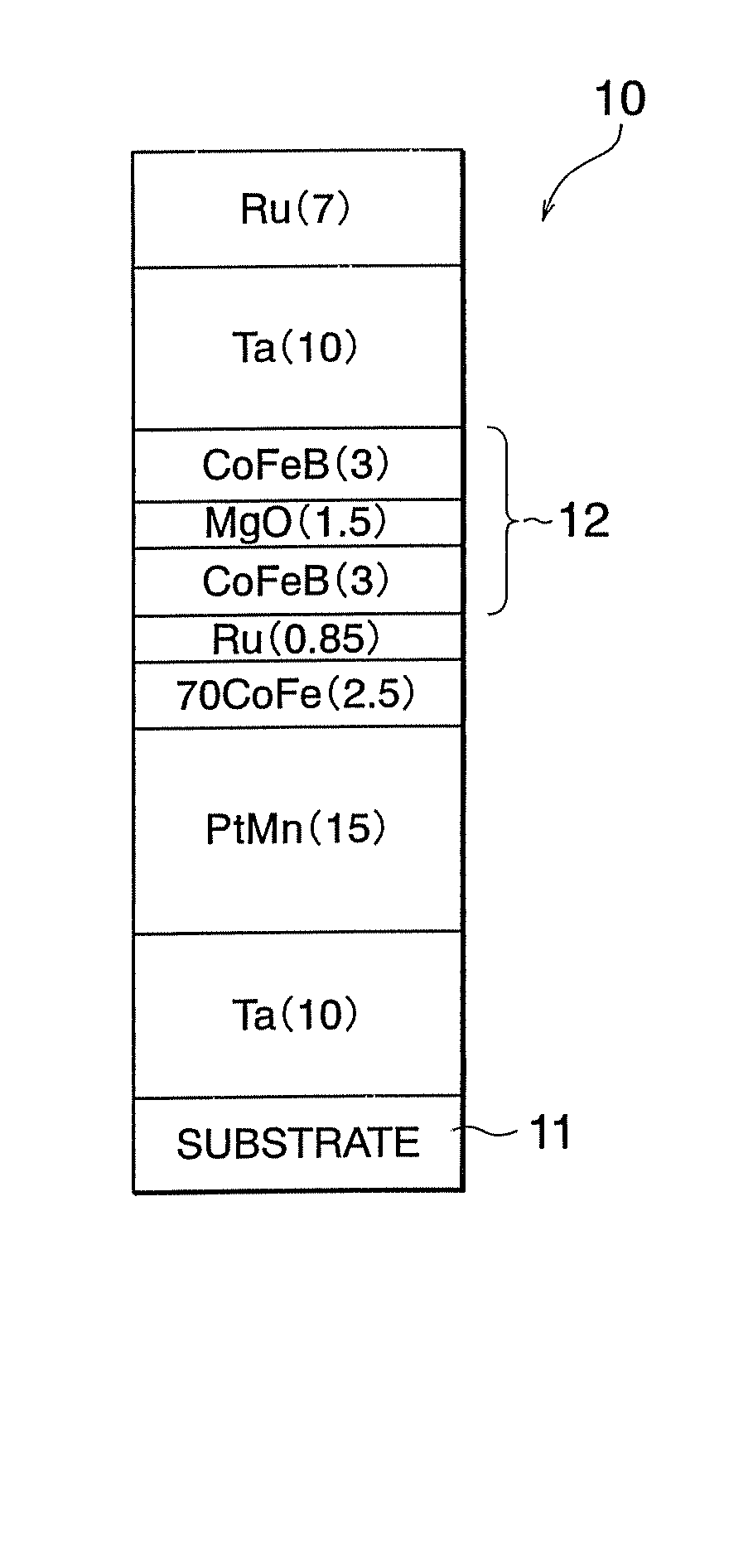

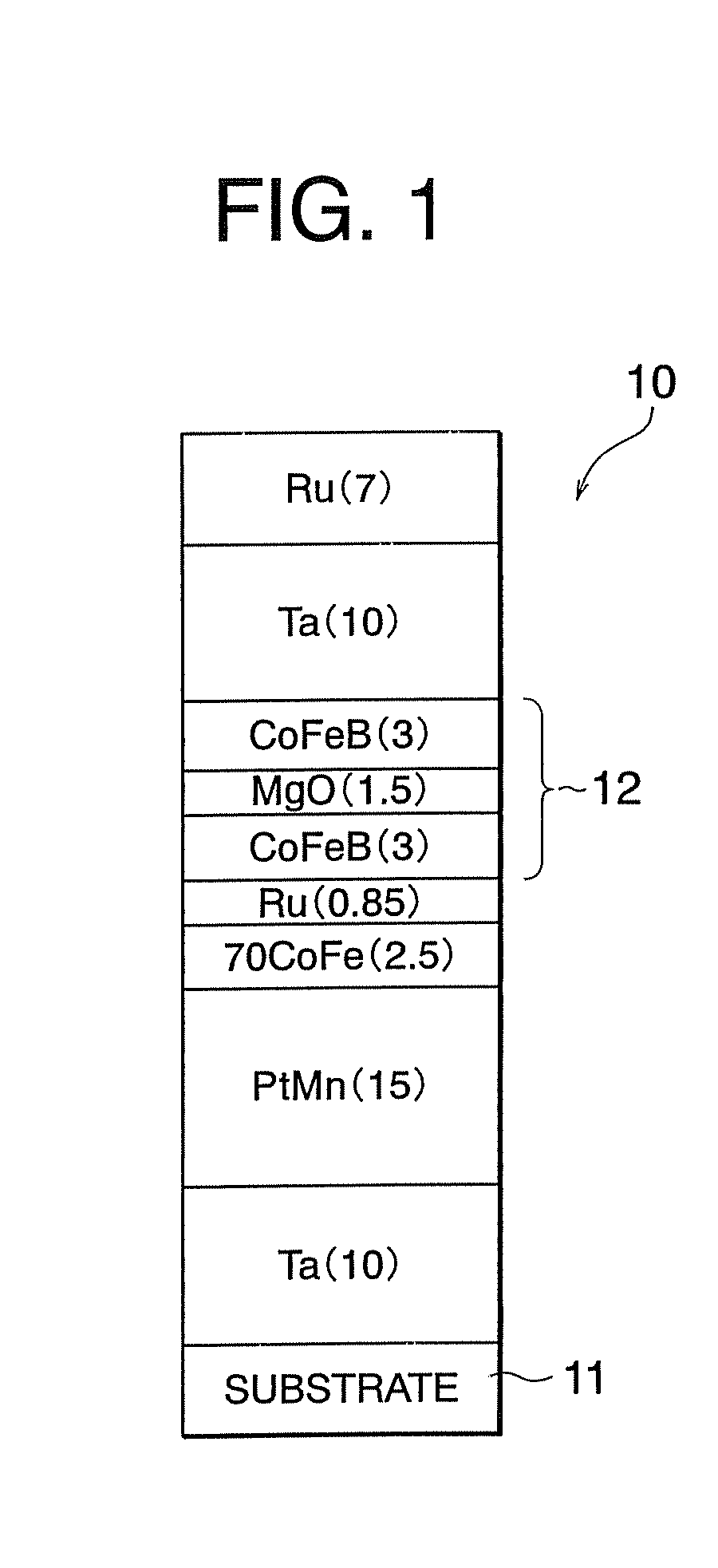

Magnetoresistance effect device and method of production of the same

InactiveUS20060056115A1Increase valueMaintain good propertiesNanomagnetismMagnetic-field-controlled resistorsMethods of productionMolecular physics

A magnetoresistance effect device including a multilayer structure having a pair of ferromagnetic layers and a barrier layer positioned between them, wherein at least one ferromagnetic layer has at least the part contacting the barrier layer made amorphous and the barrier layer is an MgO layer having a highly oriented texture structure.

Owner:CANON ANELVA CORP +1

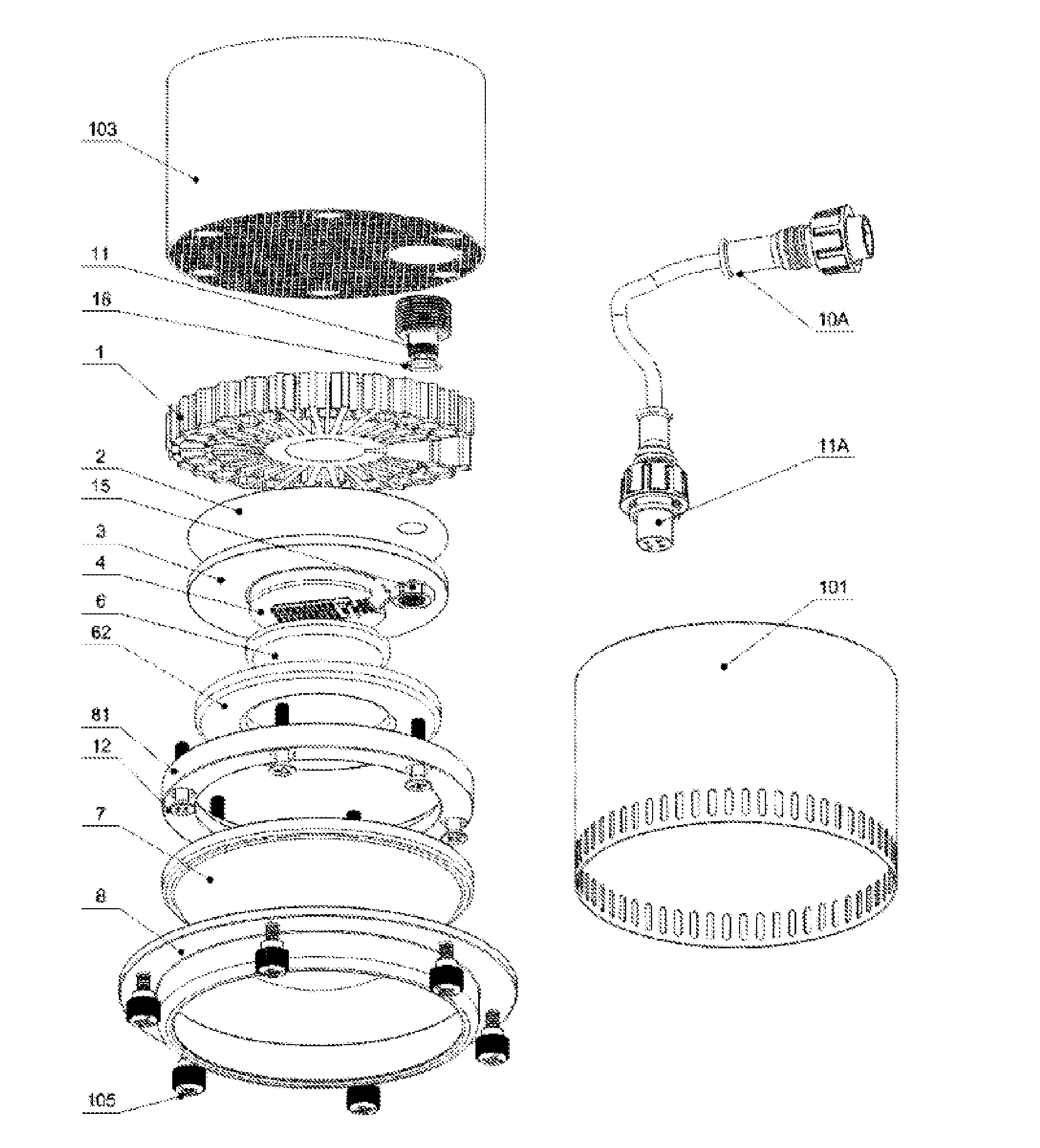

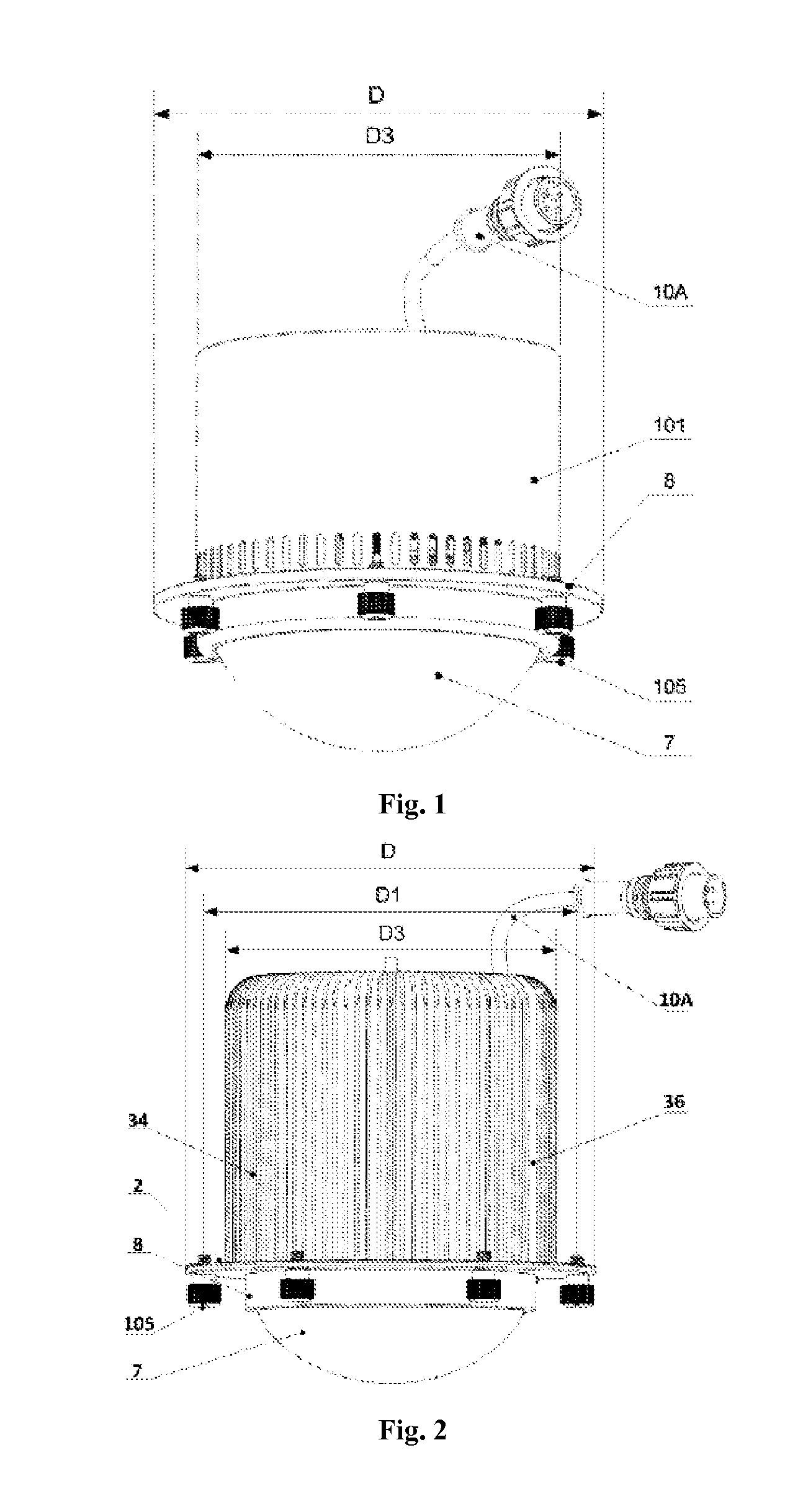

Method for constructing universal LED bulb, snap ring structured LED bulb and LED lamp

InactiveUS20150184837A1Reduce production proceduresImprove mass productionMechanical apparatusLight source combinationsEngineeringLED lamp

The present invention provides a method for constructing a universal LED bulb, a snap ring structured LED bulb and a lamp. The constructing method comprises: supporting an optical engine core member of the LED bulb in the lens snap ring (8) using a lens snap ring (8) as a supporting main body, using an inner snap ring (81) provided on the inner side of a light distribution optical lens (7) in the optical engine core member as an auxiliary supporting structure, and further using the inner snap ring (81) as an installation base of an optical engine module (4) and a heat conductive bracket (3) or an installation base of an LED bulb radiator (103); the optical engine core member of the LED bulb is composed of the heat conductive bracket (3), the optical engine module (4), the inner snap ring (81) and the light distribution optical lens (7).

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

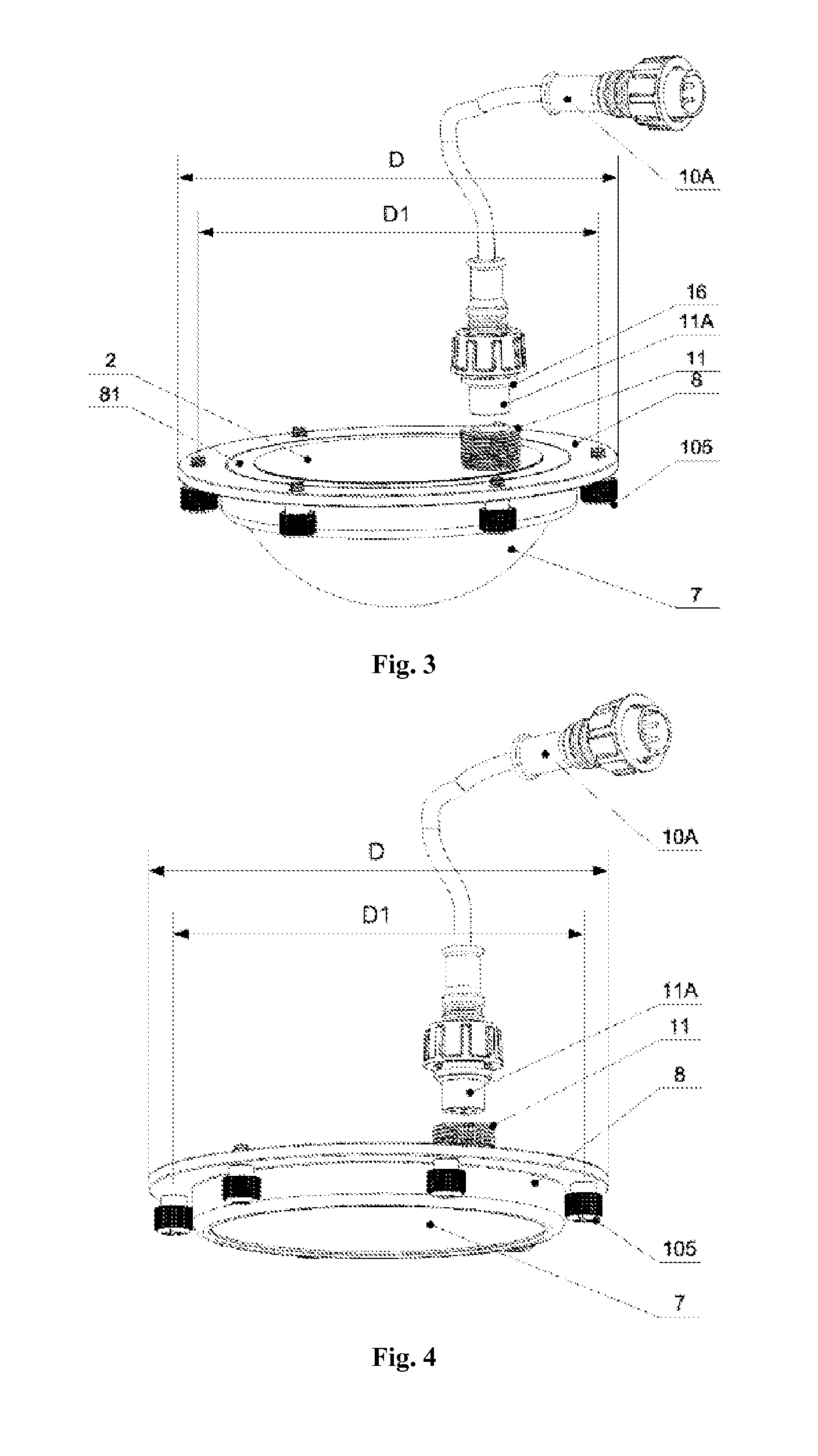

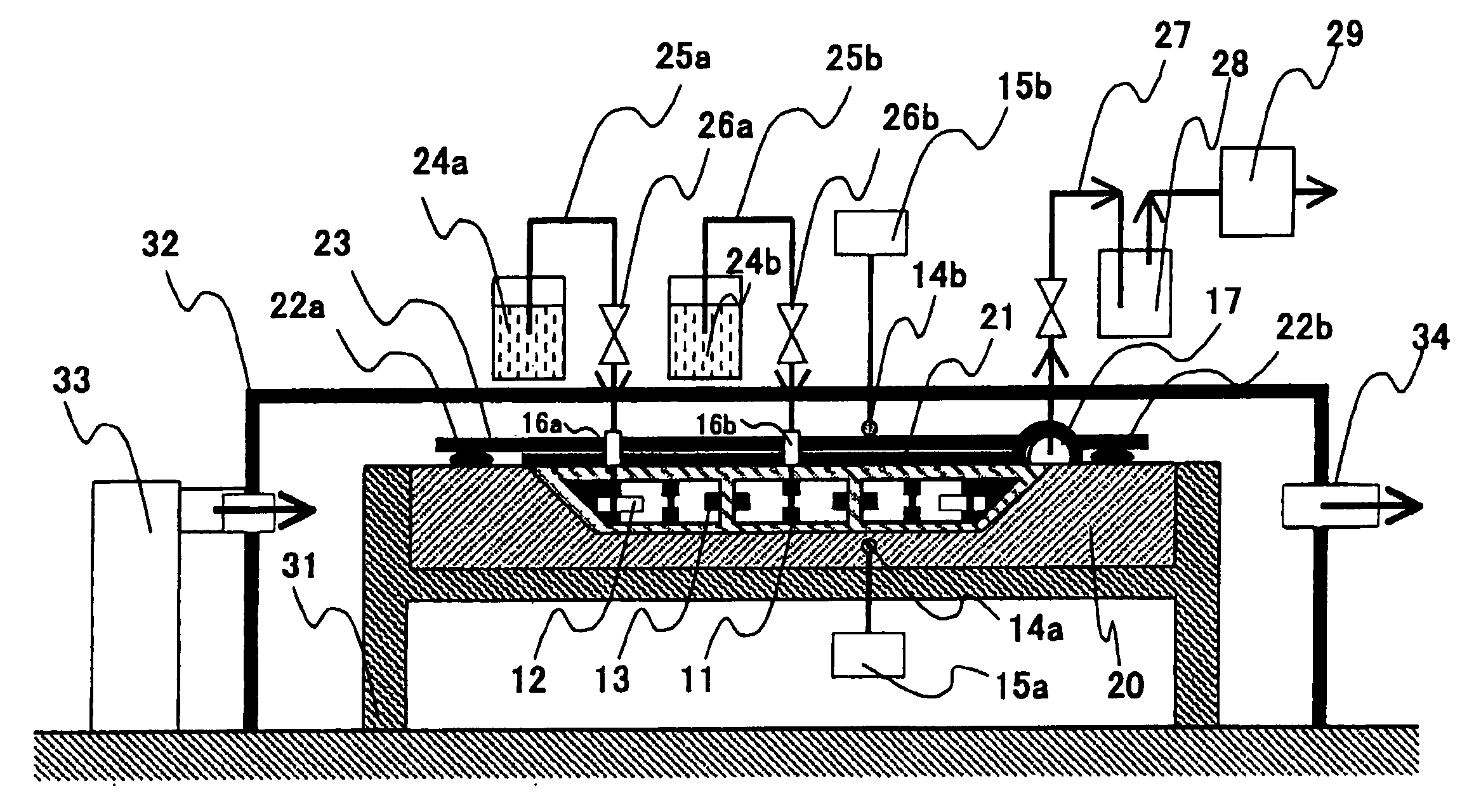

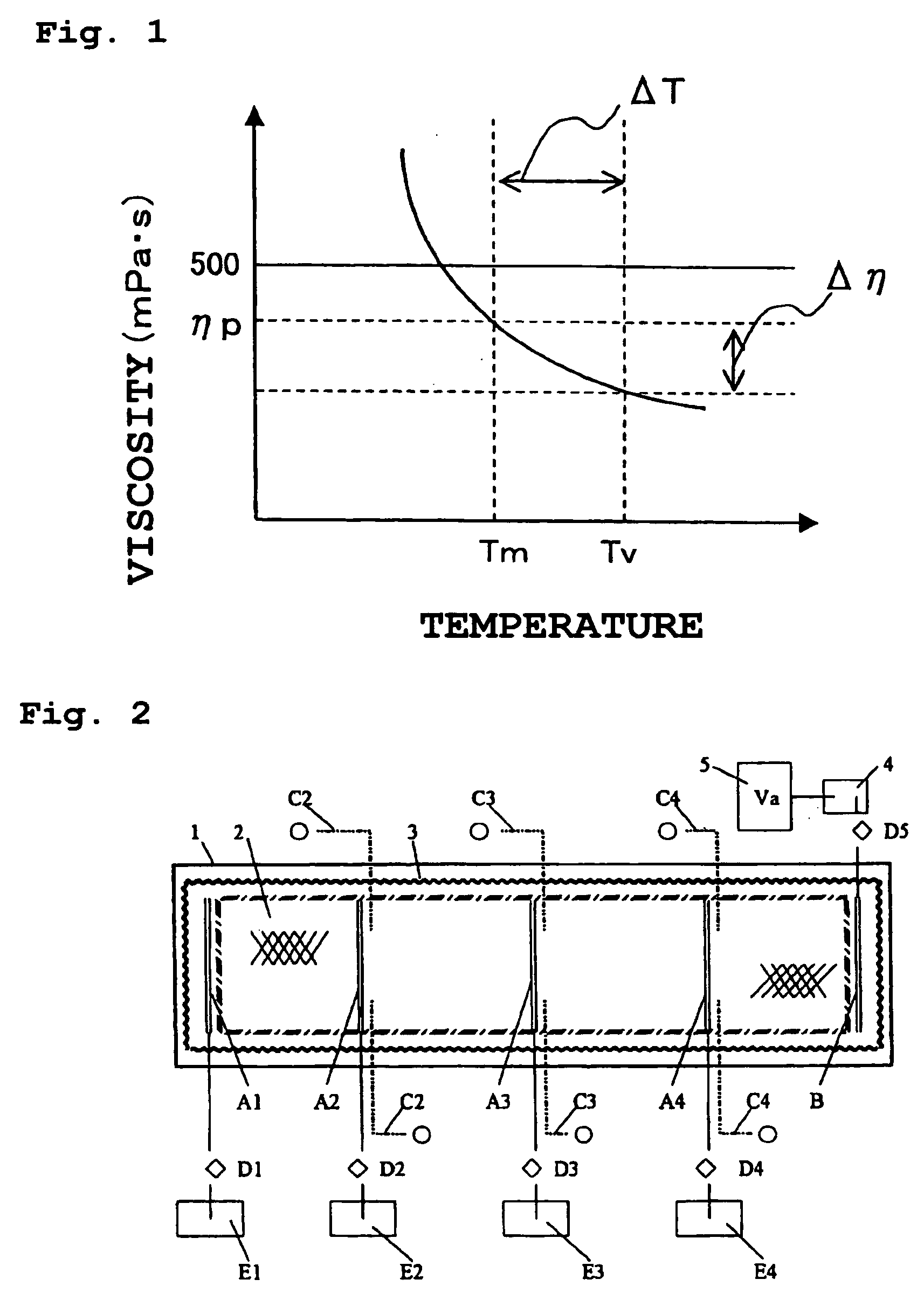

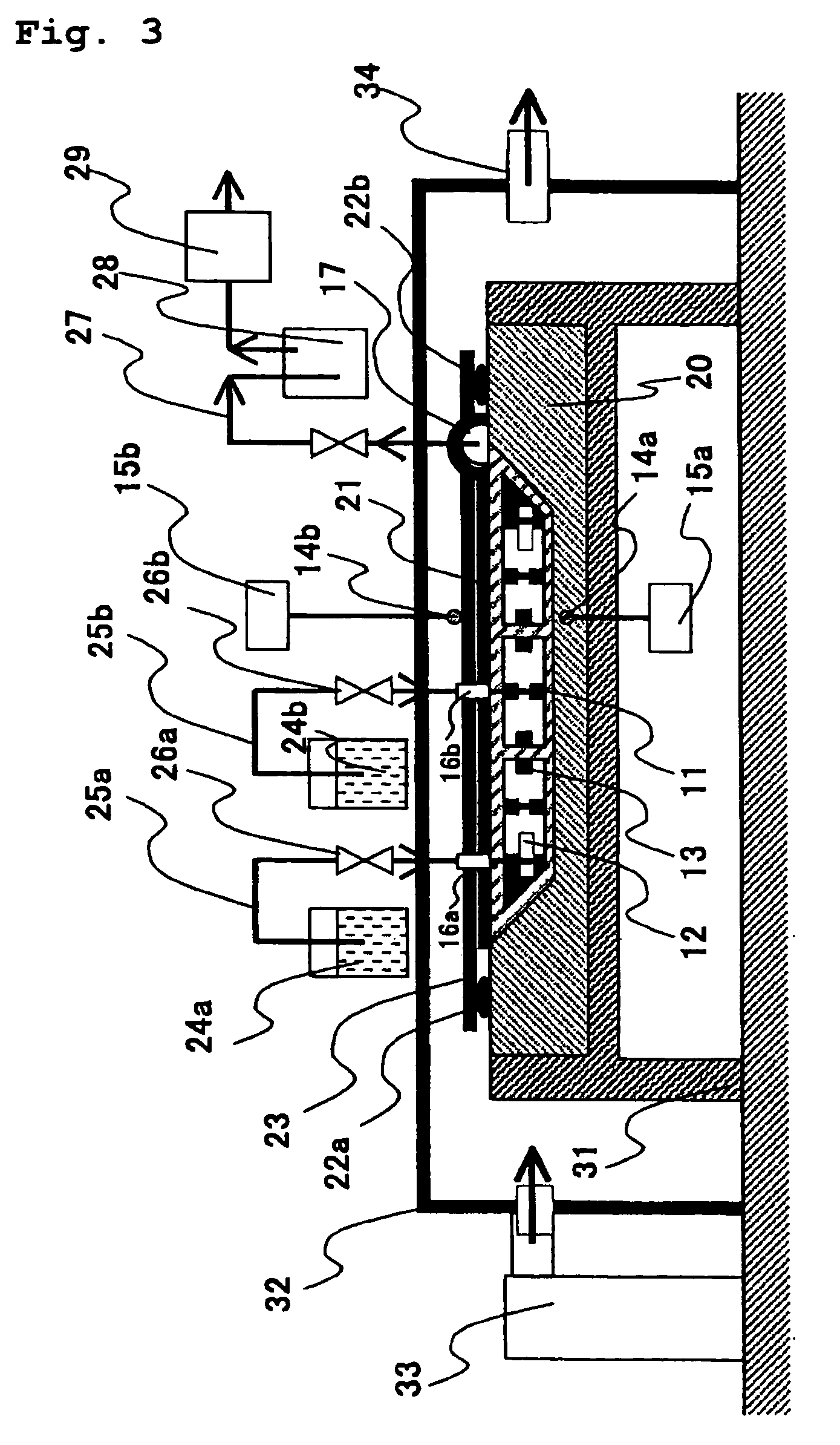

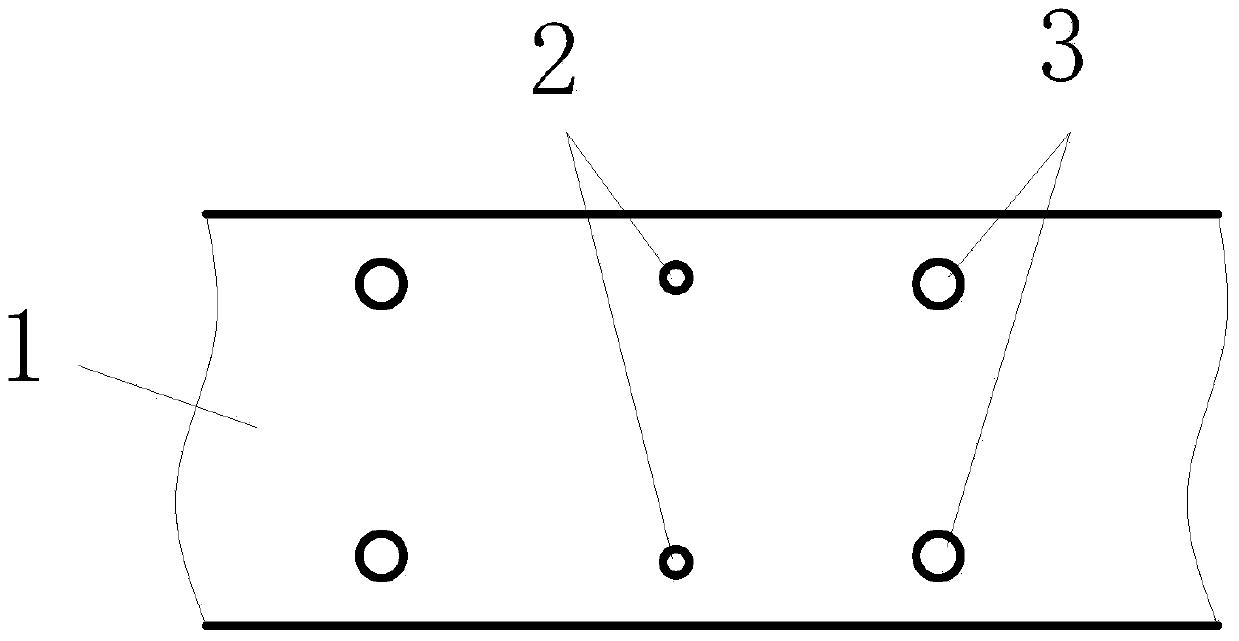

Method for producing upsized frp member

InactiveUS20040130072A1Improve mass productionReduce manufacturing costLamination ancillary operationsLaminationAir cycleFiber

The present invention relates to a method for manufacturing a large FRP member and has the following structure. The method for manufacturing a large FRP member, comprising the following steps (A) to (F). They are: setting step (A) of disposing a preform containing a reinforcing fiber base material on a surface of a molding die; sealing step (B) of covering a molding portion with a bagging material or a mold and providing at least one suction port and at least one resin injection port for sealing; evacuating step (C) of evacuating the molding portion through the suction port; hot-air heating step (D) of heating the molding portion by hot air; resin injection step (E) of injecting a thermosetting resin from the resin injection port for impregnating the reinforcing fiber base material with the resin while a temperature Tm of the molding die and a temperature Tv of the bagging material or the mold are both set to room temperature or more, and a difference DeltaT in temperature between the Tm and the Tv is set to 10° C. or less; and curing step (F) of curing the resin by maintaining the molding portion at a predetermined temperature Tpc which is equal to or more than room temperature. Preferably, the preform described above includes the reinforcing fiber base material and a resin distribution medium. In addition, it is preferable that in the hot-air heating step (D), the molding die be placed in a sealed chamber which is heat insulated with a heat insulating material, the hot air be circulated and supplied, and timing of starting the injection of the resin from a plurality of the resin injection ports be controlled in accordance with signals supplied from resin detection sensors provided in the molding die. The present invention provides a method for manufacturing a large FRP member having superior quality at an inexpensive cost and with high production yield, in which non-impregnated portions and voids are unlikely to be formed.

Owner:TORAY IND INC

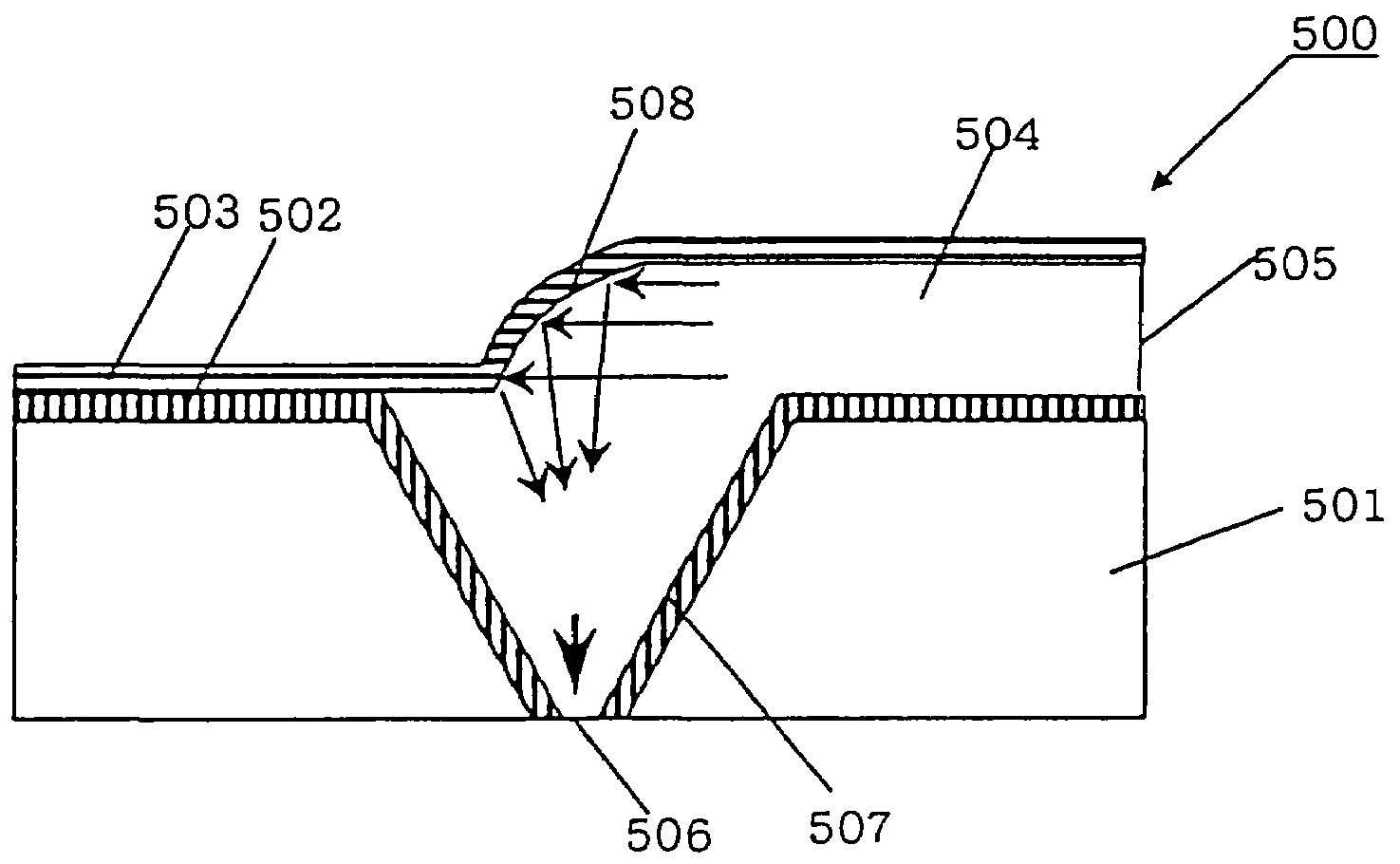

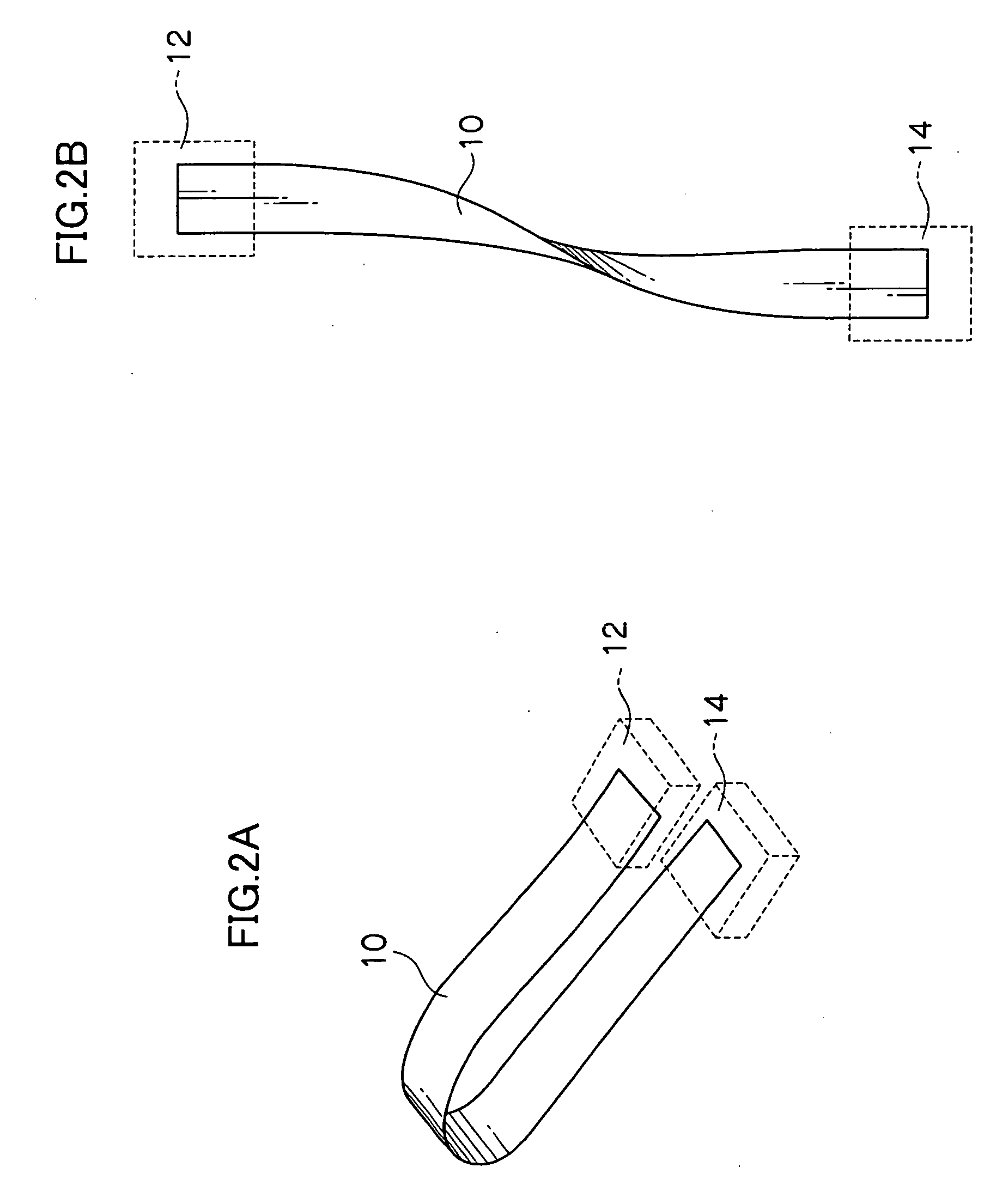

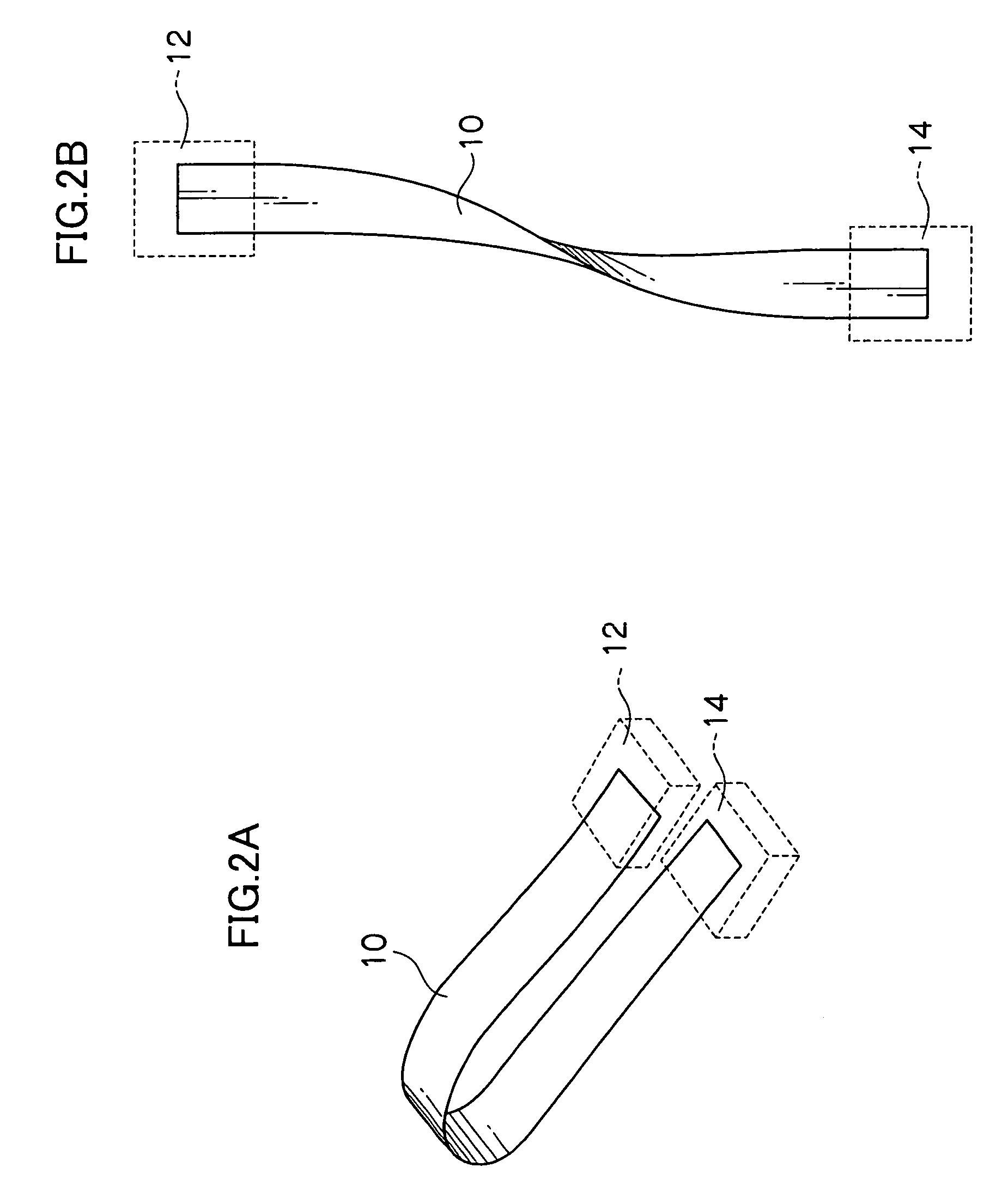

Near-field optical head having tapered hole for guiding light beam

InactiveUS7599277B1High strengthHigh mechanical strengthOptical flying-type headsIntegrated optical head arrangementsPlanar substrateLight reflection

A near-field optical head has a planar substrate having a first surface, a second surface disposed opposite to the first surface, and an inverted conical or pyramidal hole extending through the first and second surfaces. The conical or pyramidal hole has at least one fine aperture formed at an apex thereof and is disposed on the first surface of the planar substrate. An optical waveguide is disposed on the second surface of the planar substrate for propagating light. A light reflection film is disposed in the optical waveguide for reflecting in the direction of the fine aperture light propagated through the optical waveguide.

Owner:SEIKO INSTR INC

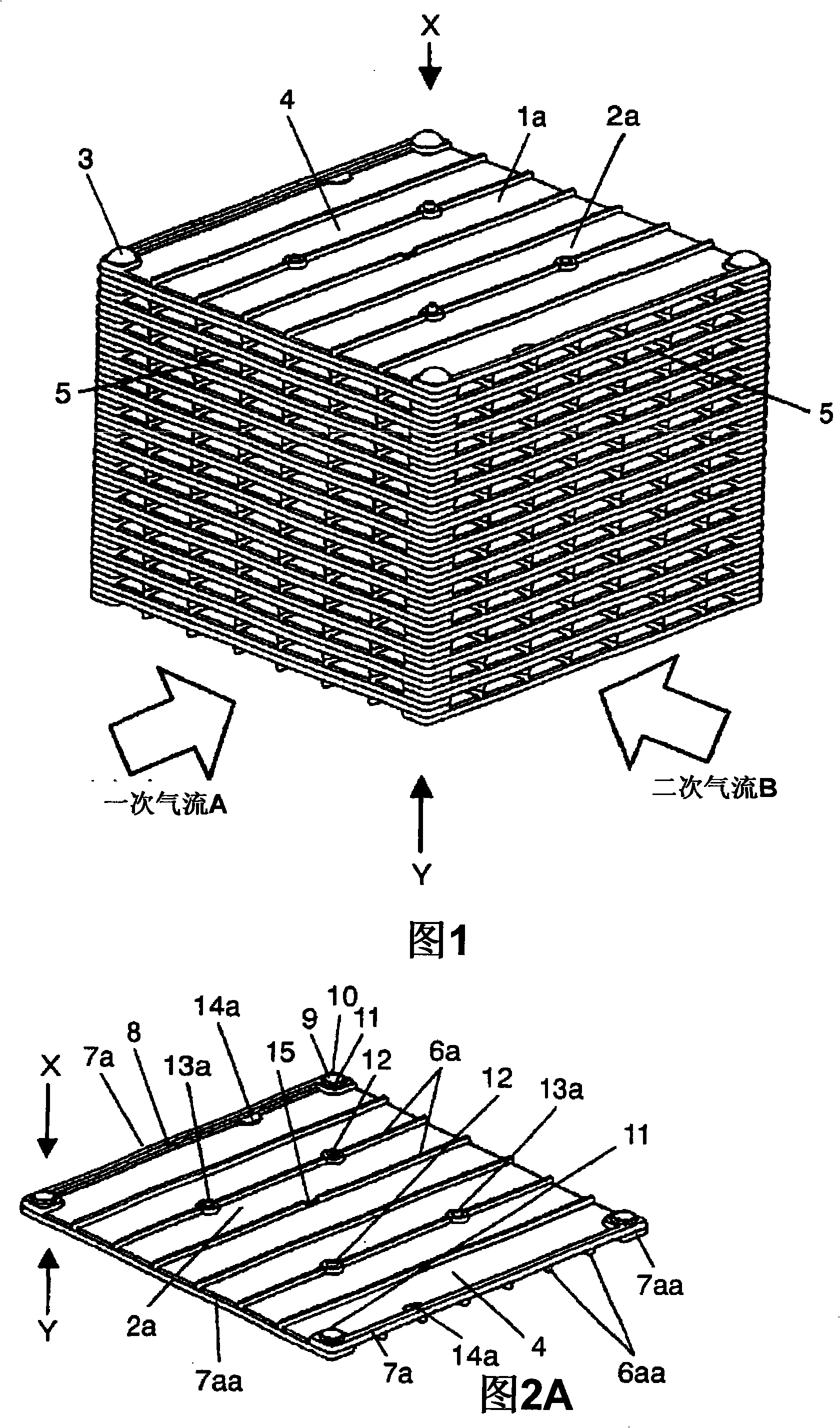

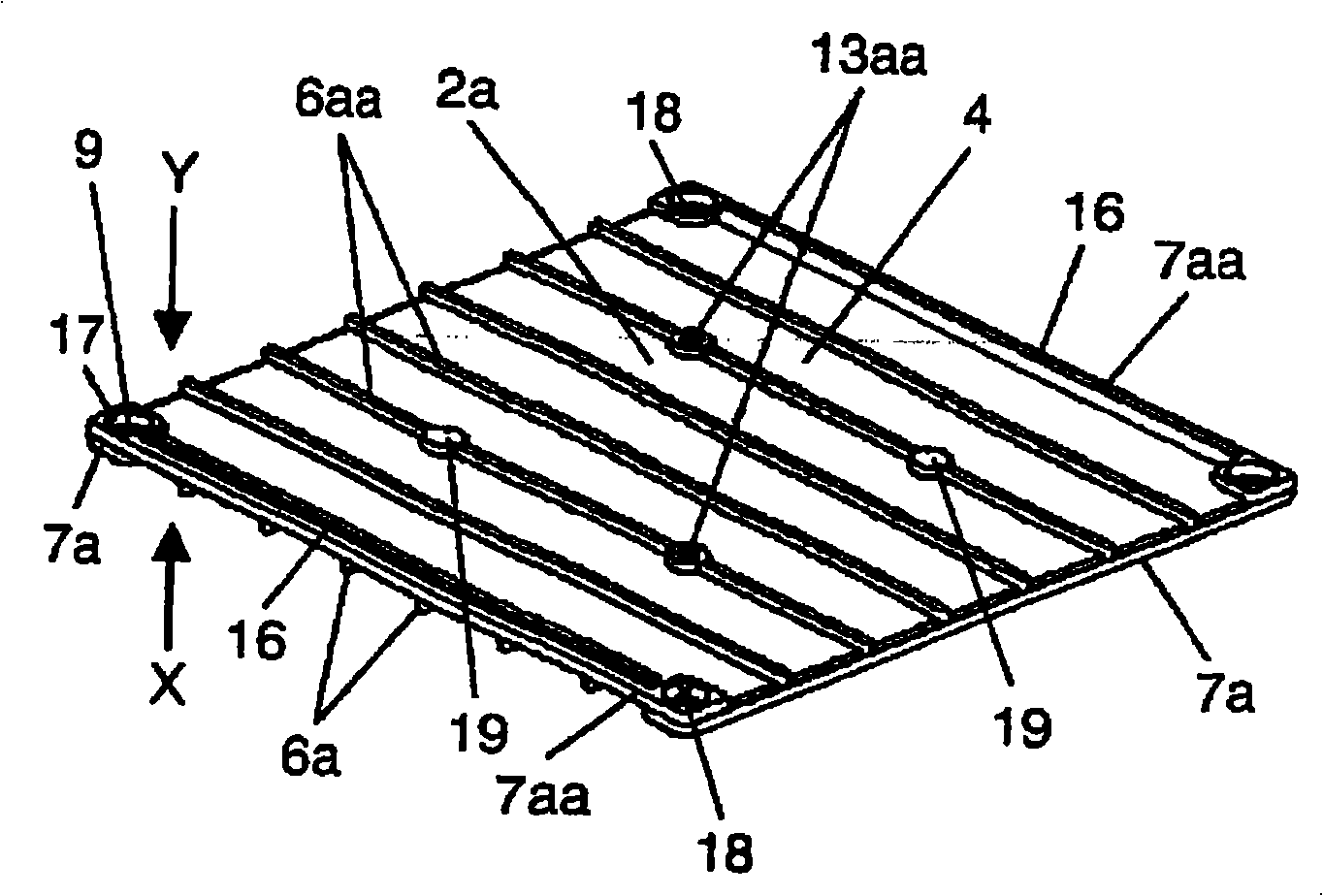

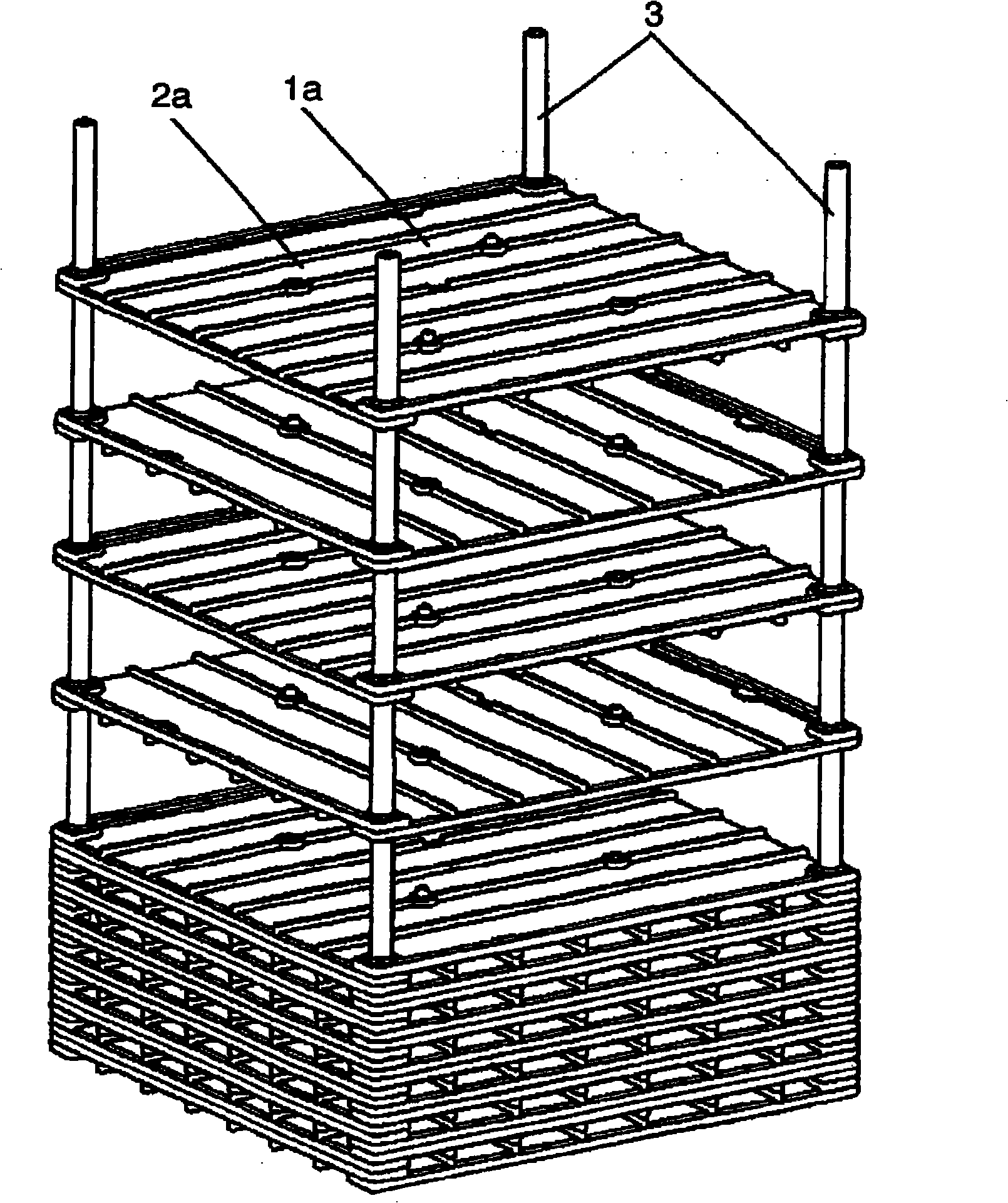

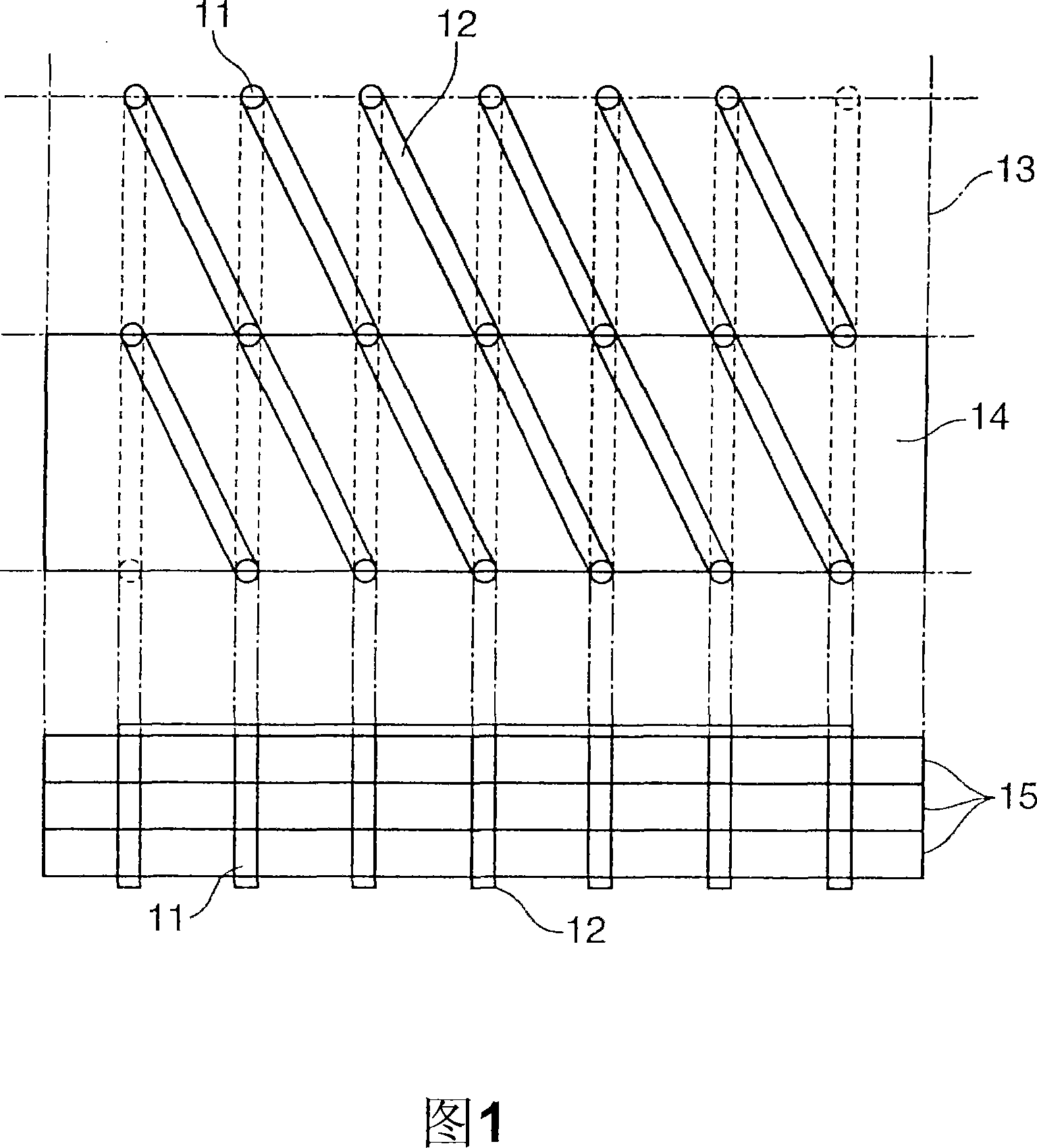

Heat exchanger and its manufacturing method

The present invention provides a heat exchanger for exchanging heat through heat transfer plates by flowing a primary airflow and a secondary airflow in air passages. The heat exchanger comprises a unit element having a heat transfer plate and an air passage formed between the heat transfer plates by stacking the unit elements. Each of the unit elements is structured by molding a space rib for holding the space between the heat transfer plates integrally with a shield rib for shielding the leak of the airflows by use of a resin. The unit element includes an error detection part which can easily detect an error in stacking when the unit elements are stacked.

Owner:PANASONIC CORP

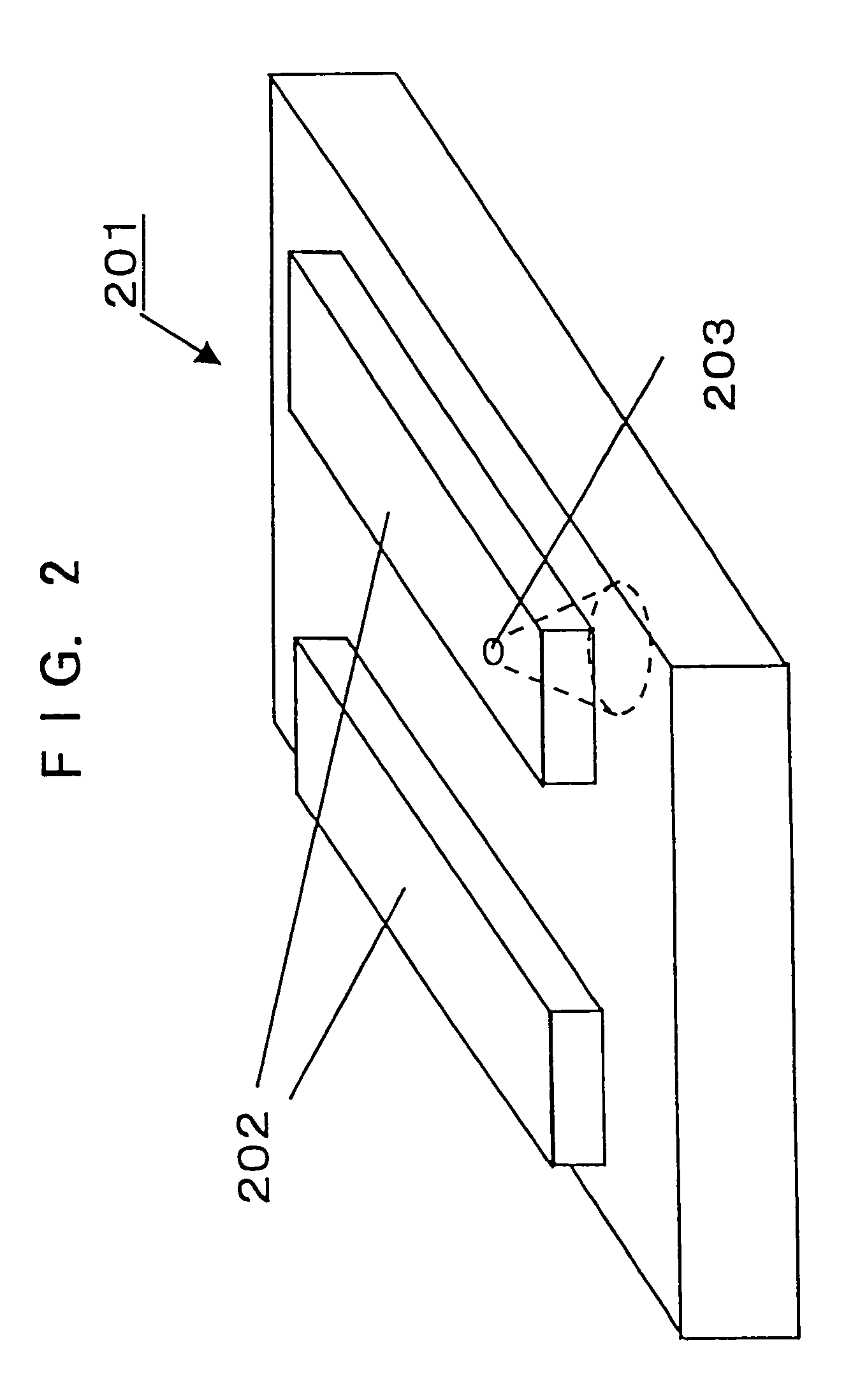

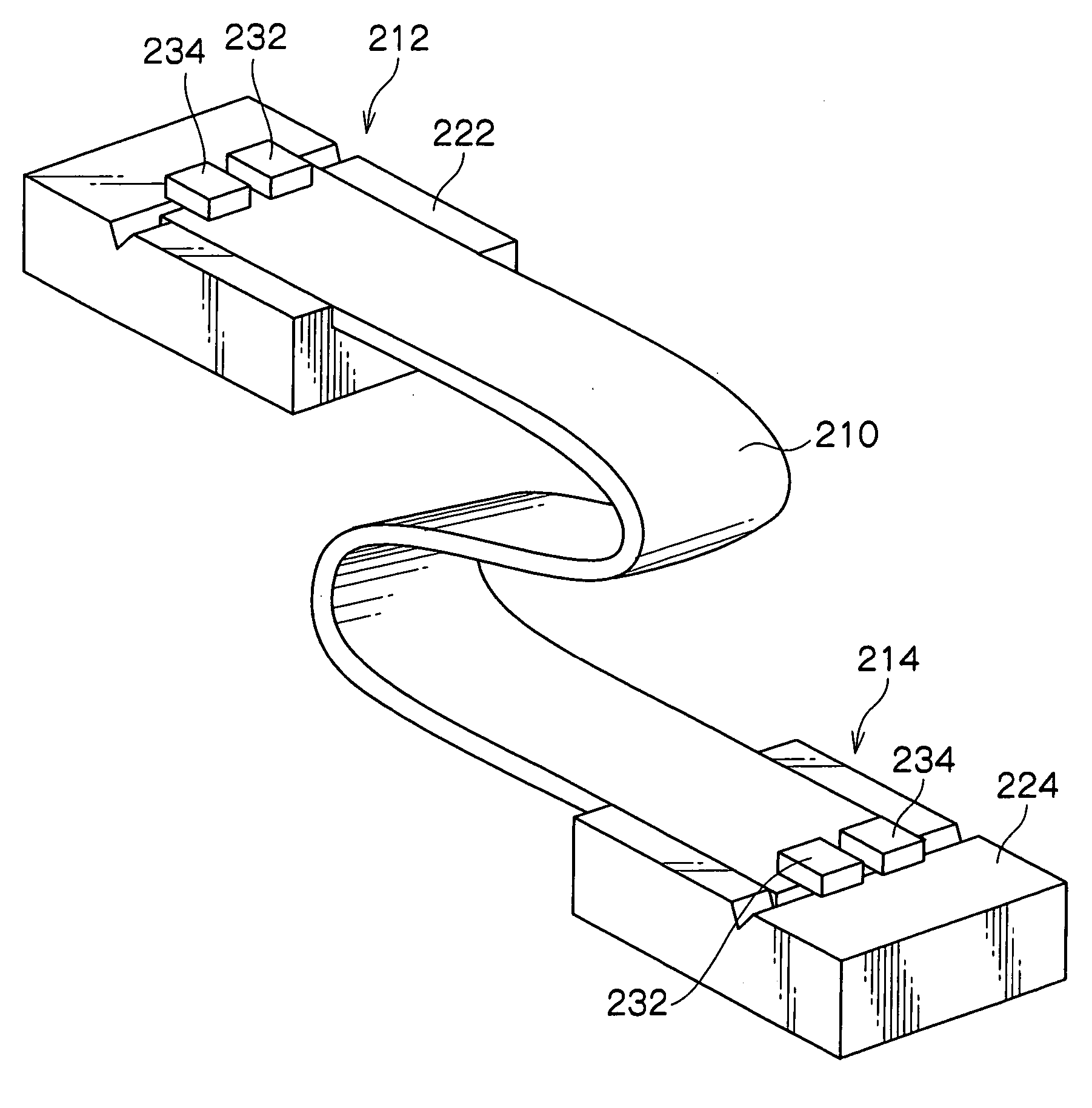

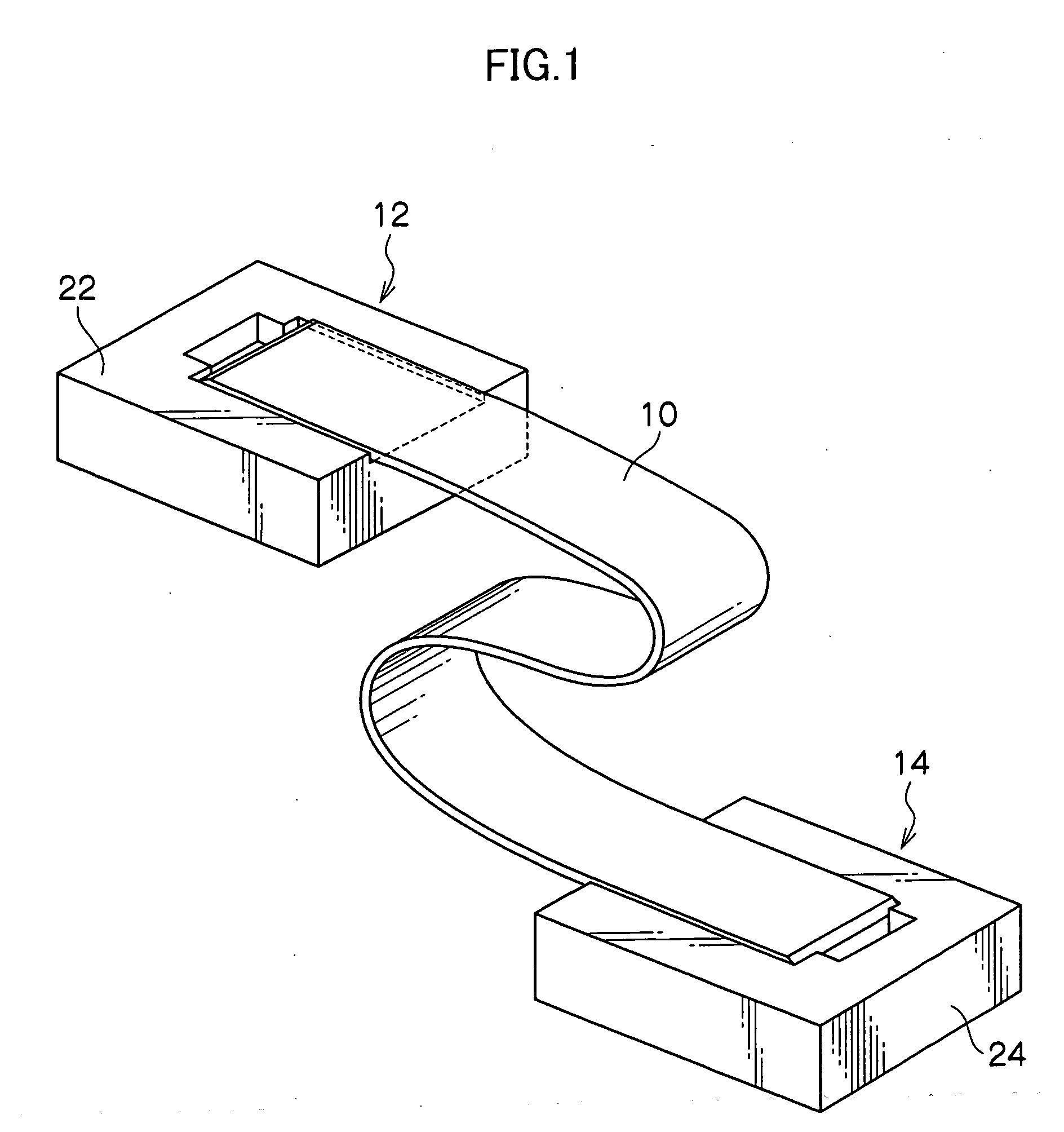

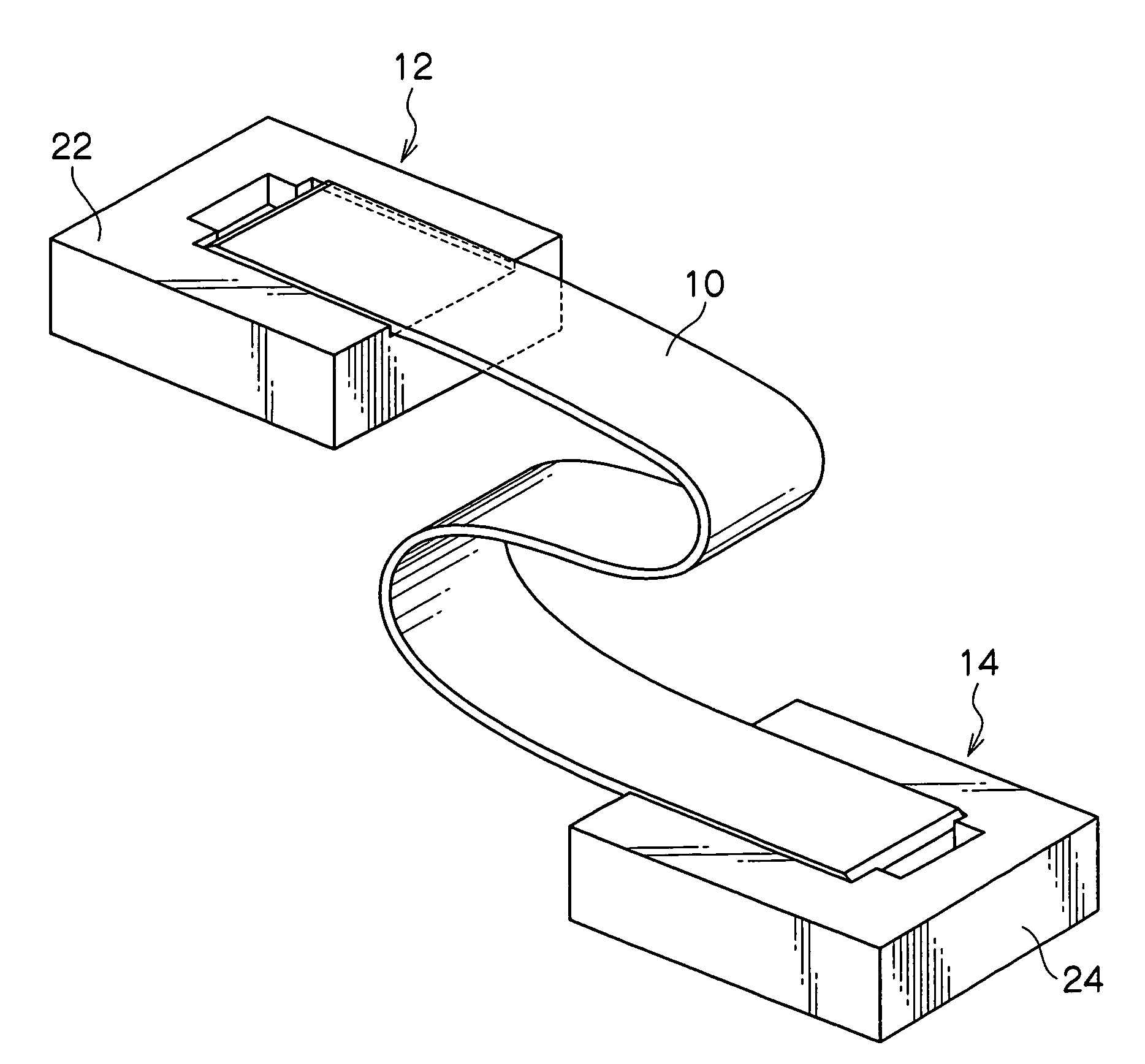

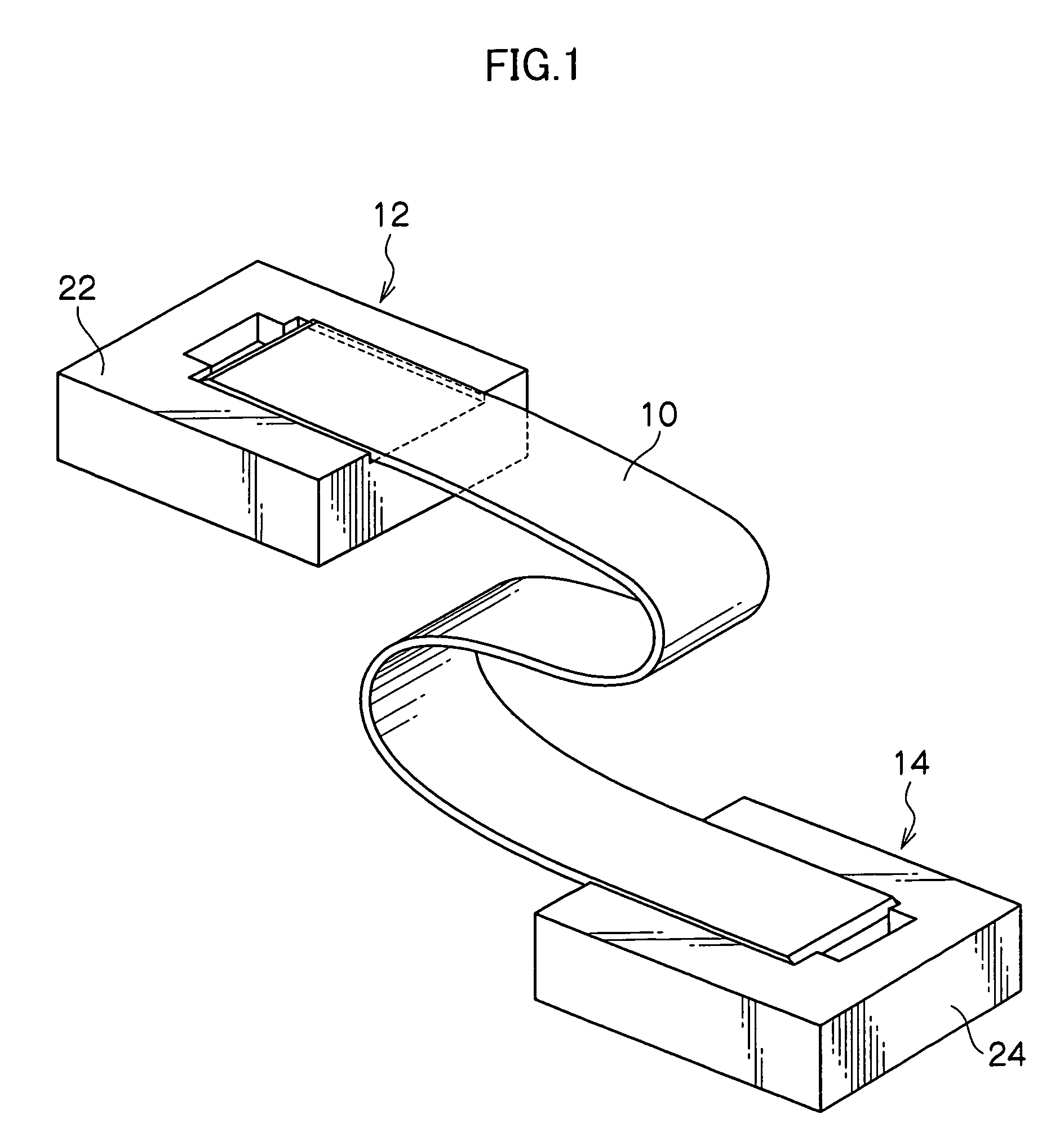

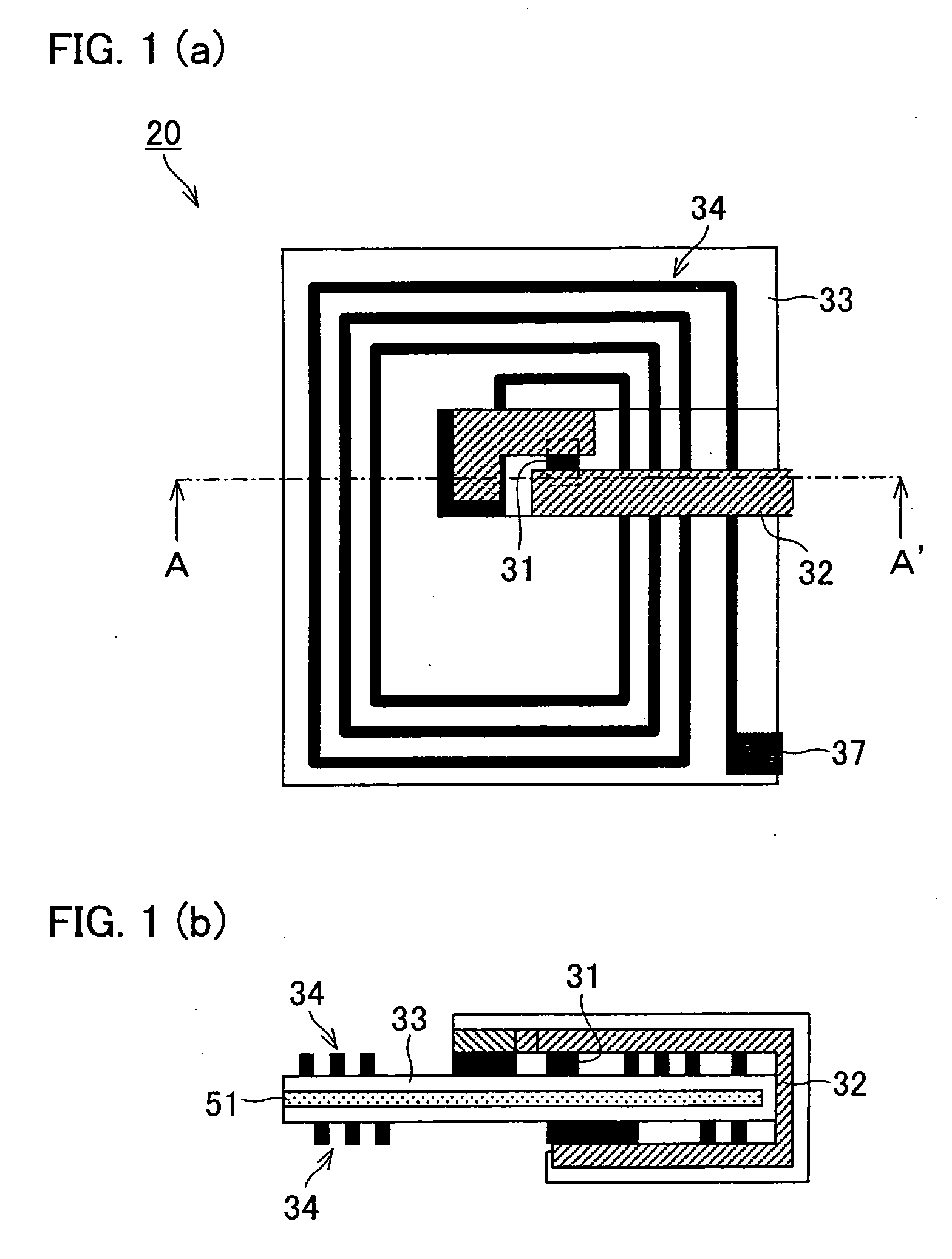

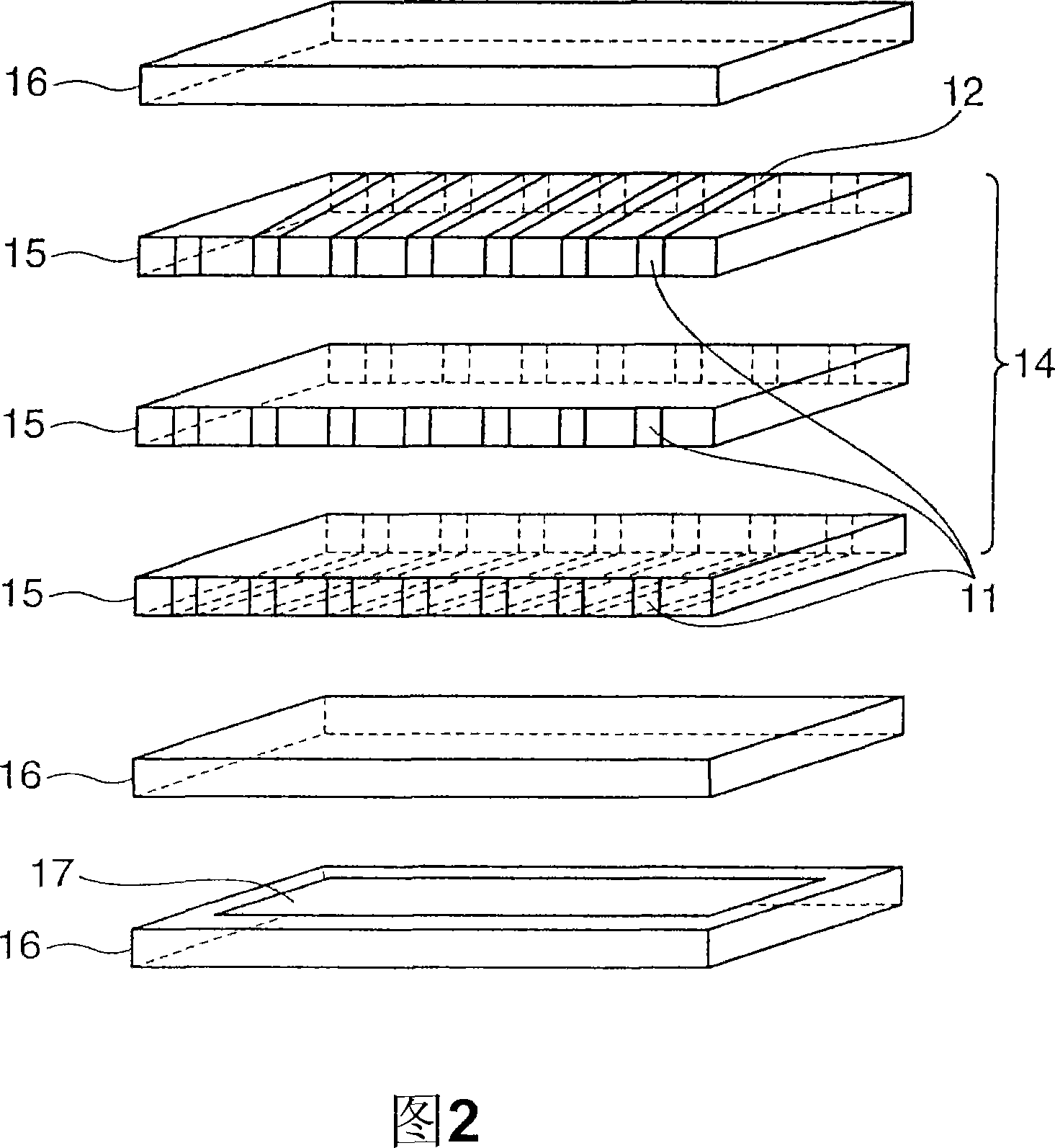

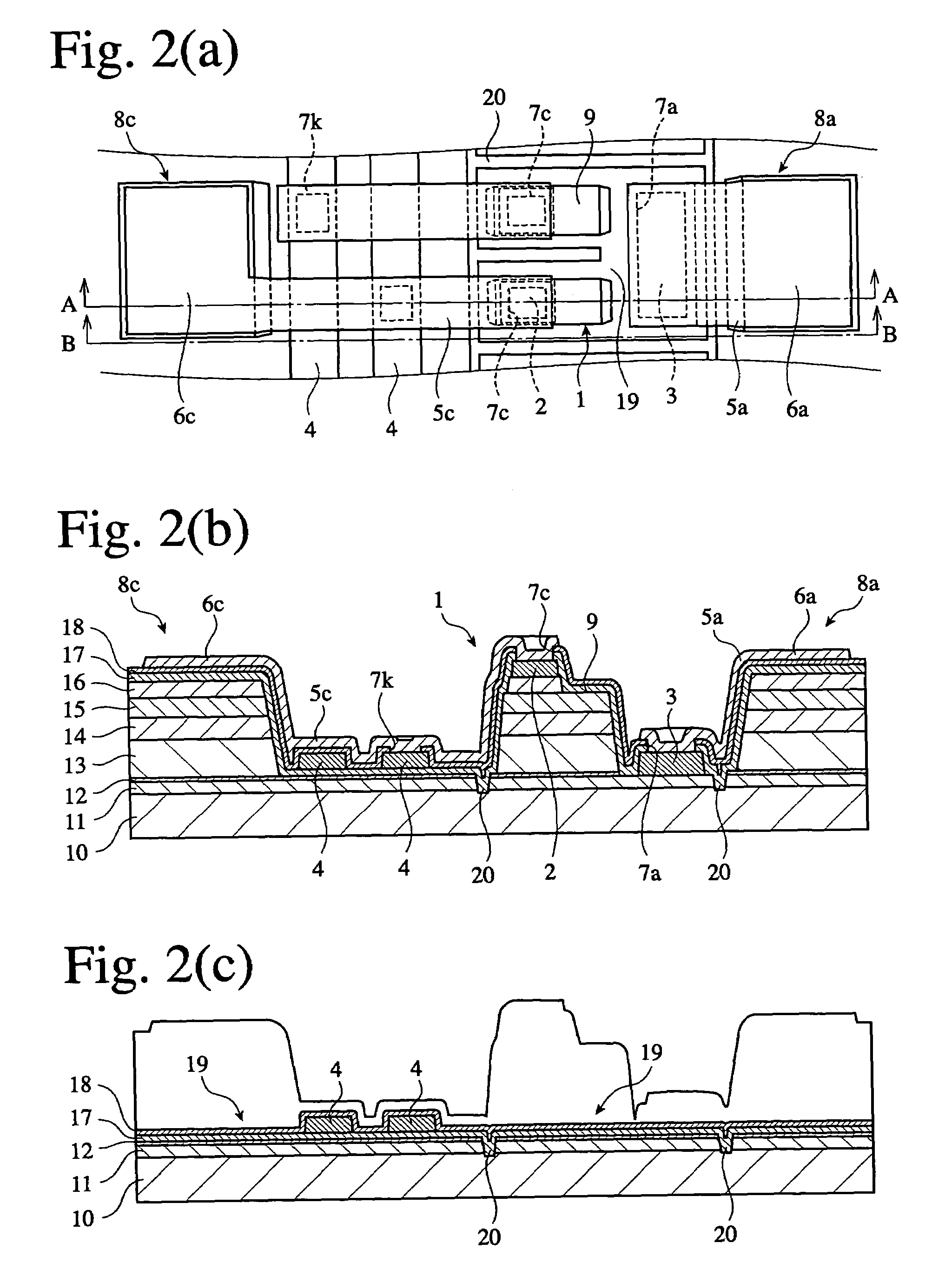

Light transmission and reception module, sub-mount, and method of manufacturing the sub-mount

InactiveUS20060198569A1Low costExcellent in mass producibilityCoupling light guidesMulticore optical fibreOptical receiversLight wave

A light transmission and reception module includes: a belt-shaped macromolecular optical waveguide film having an optical waveguide, an optical transmitter having a light emitting element and a first sub-mount for holding the light emitting element, for holding one end of the macromolecular optical waveguide film on the first sub-mount so that a light emitted from the light emitting element may be coupled to an incident end surface of the optical waveguide, and an optical receiver having a light detecting element and a second sub-mount for holding the light detecting element, for holding the other end of the macromolecular optical waveguide film on the second sub-mount so that the light emitted from an exit end surface of the optical waveguide may be received in the light detecting element.

Owner:FUJIFILM BUSINESS INNOVATION CORP

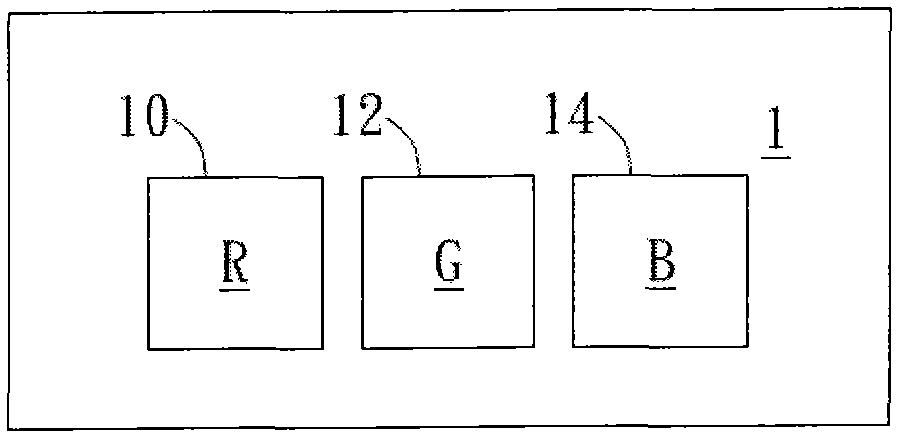

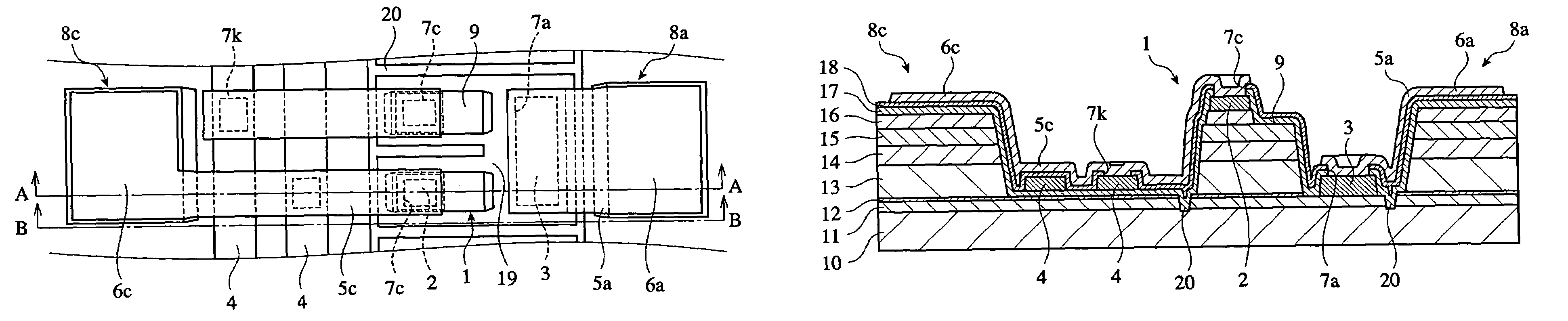

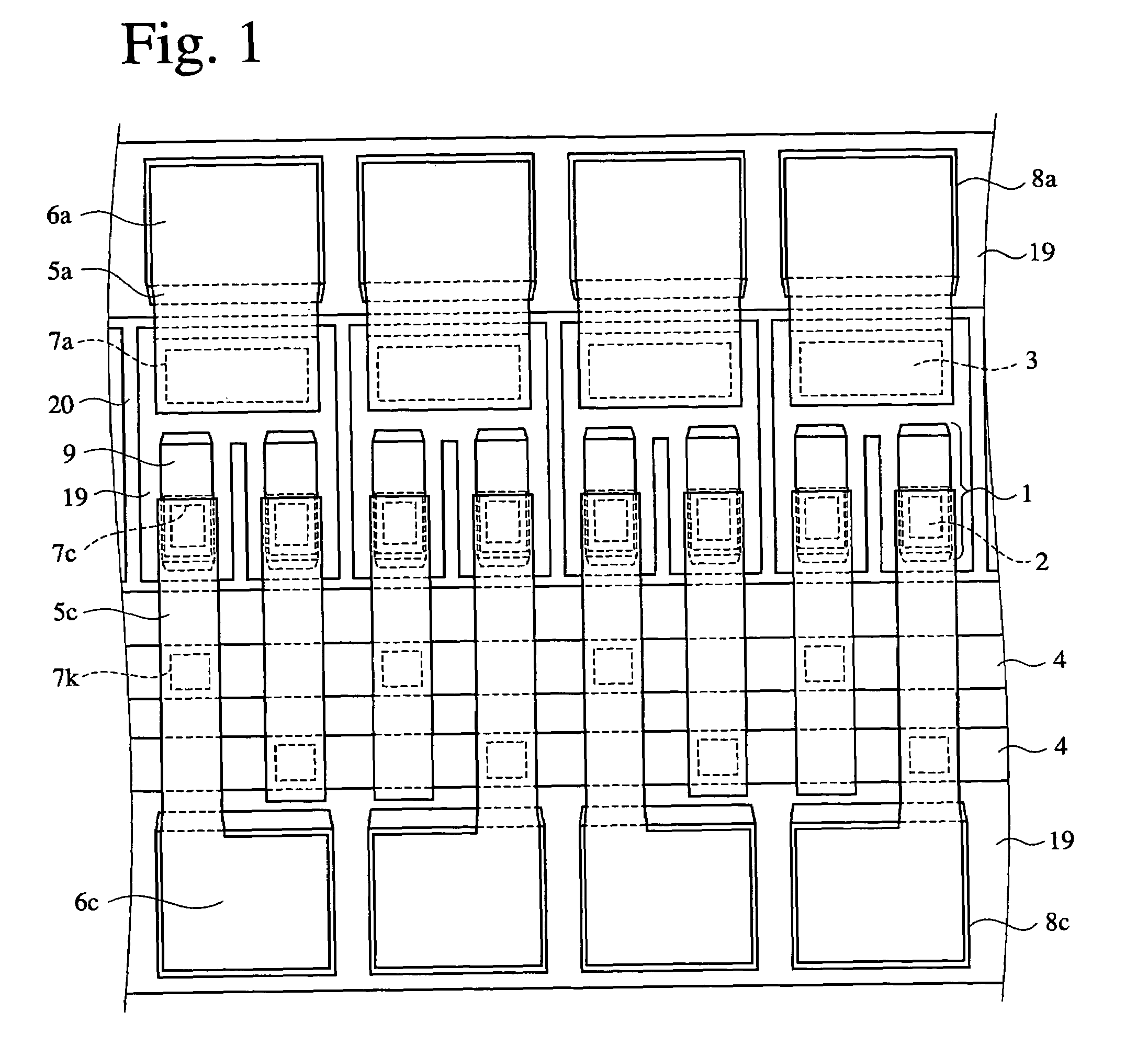

LED apparatus and field sequential display

InactiveCN102427075AImprove efficiencyImprove mass productionSolid-state devicesNon-linear opticsLutetiumDisplay device

An LED apparatus and a field sequential display employing same are disclosed. The LED apparatus includes a substrate, a cup structure, and a dividing structure. The dividing structure divides a containing space formed by the cup structure into a first region and a second region. A first blue-light chip and a first package colloidal are disposed in the first region and a second blue-light chip anda second package colloidal are disposed in the second region. A green-light phosphor is mixed in the second package colloidal to completely convert a monochromatic emission spectrum of a second blue-light band of the second blue-light chip into a monochromatic emission spectrum of a green-light band. The green-light phosphor is selected from one of silicate, oxynitride, lutetium aluminum oxide, and calcium scandium oxide. Characteristic difference among chips of different colors of an LED apparatus can be minimized, thereby improving the entire efficiency.

Owner:AU OPTRONICS CORP

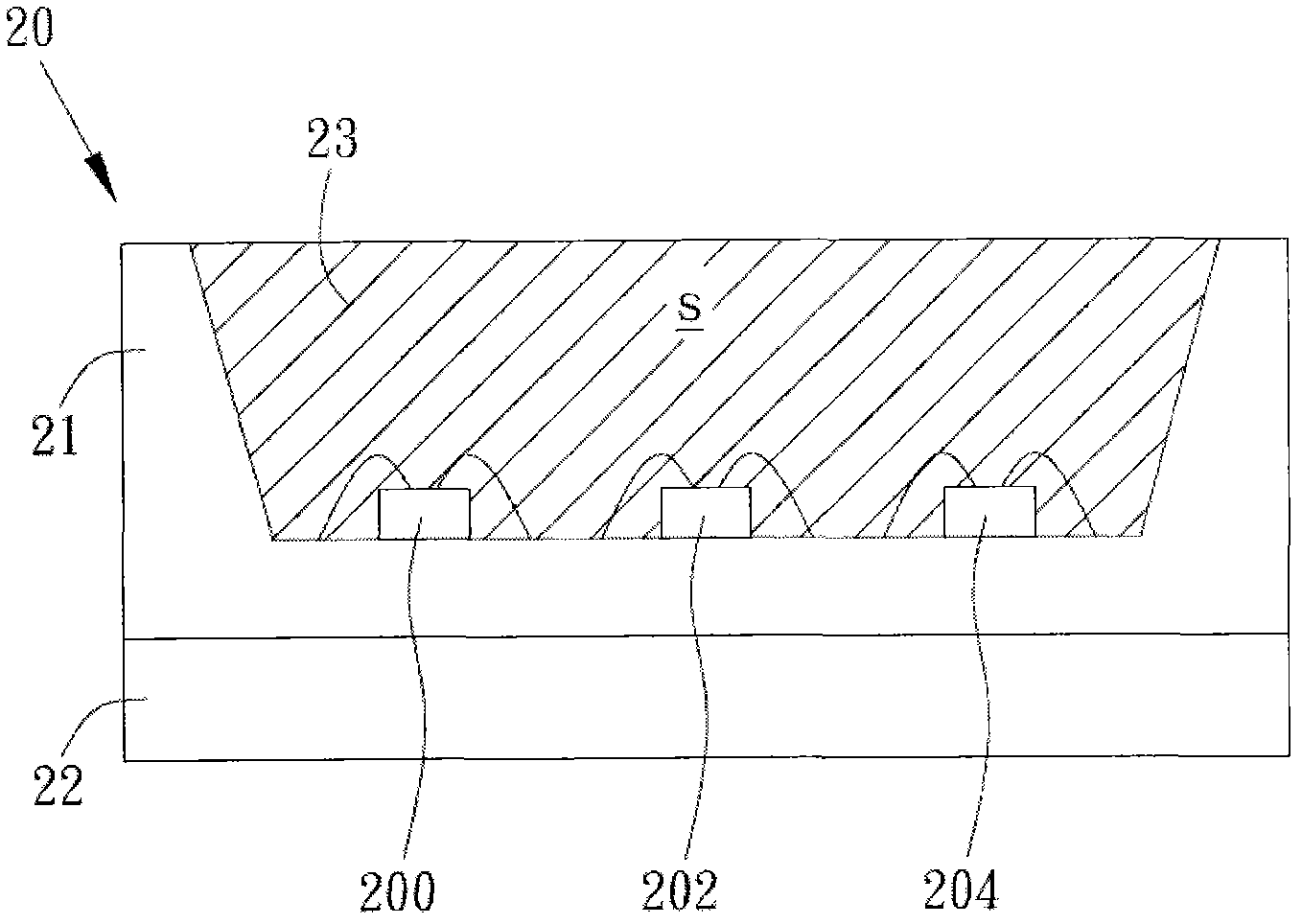

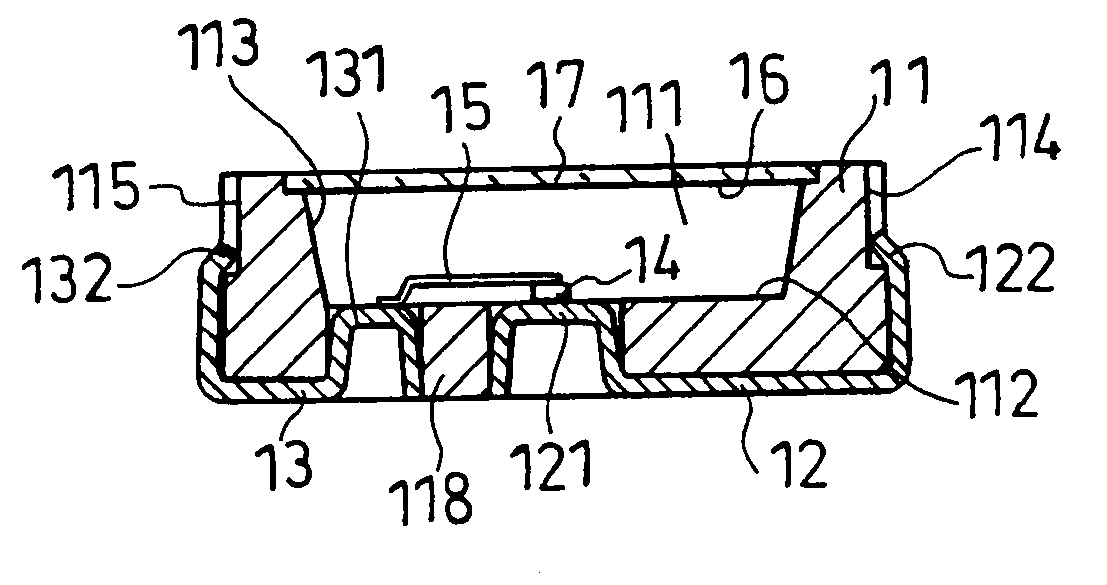

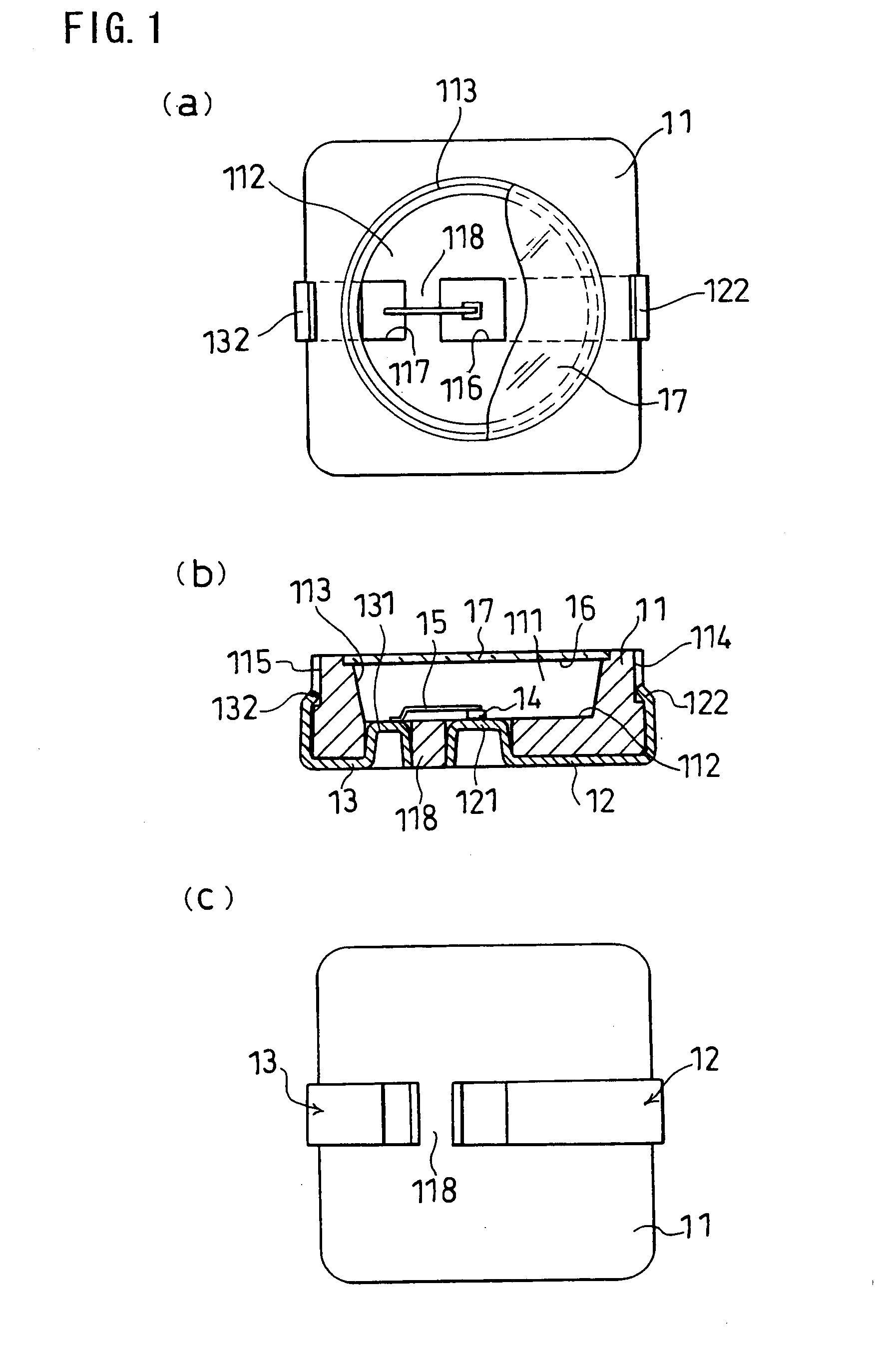

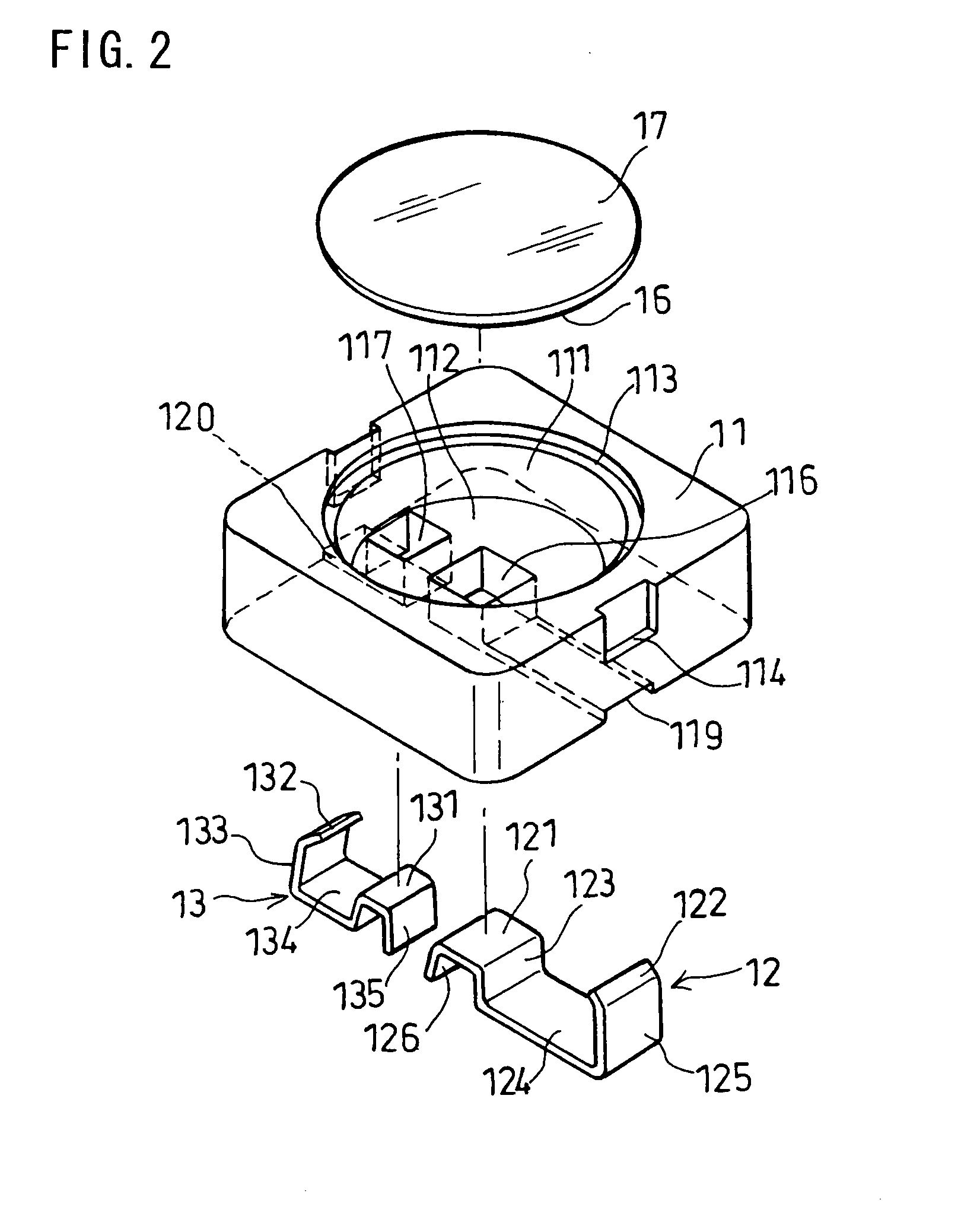

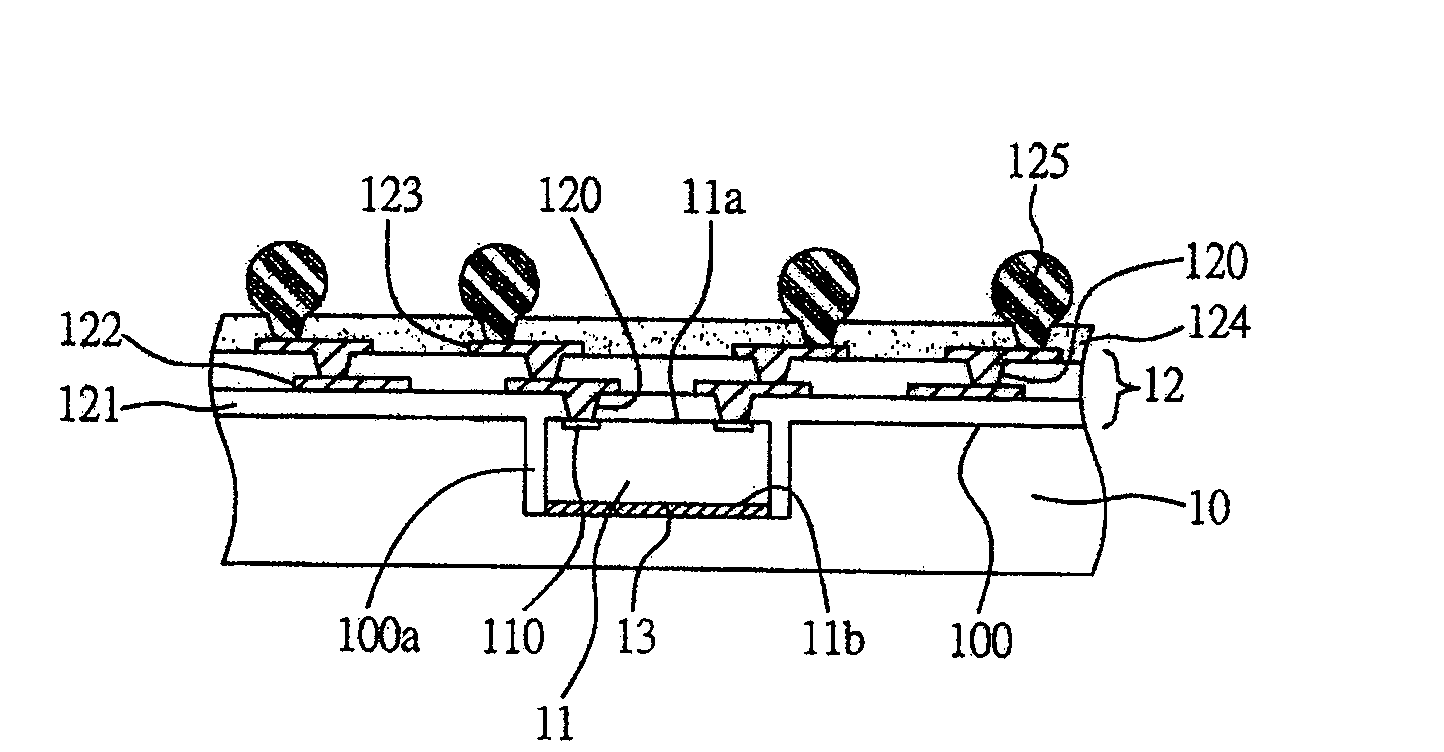

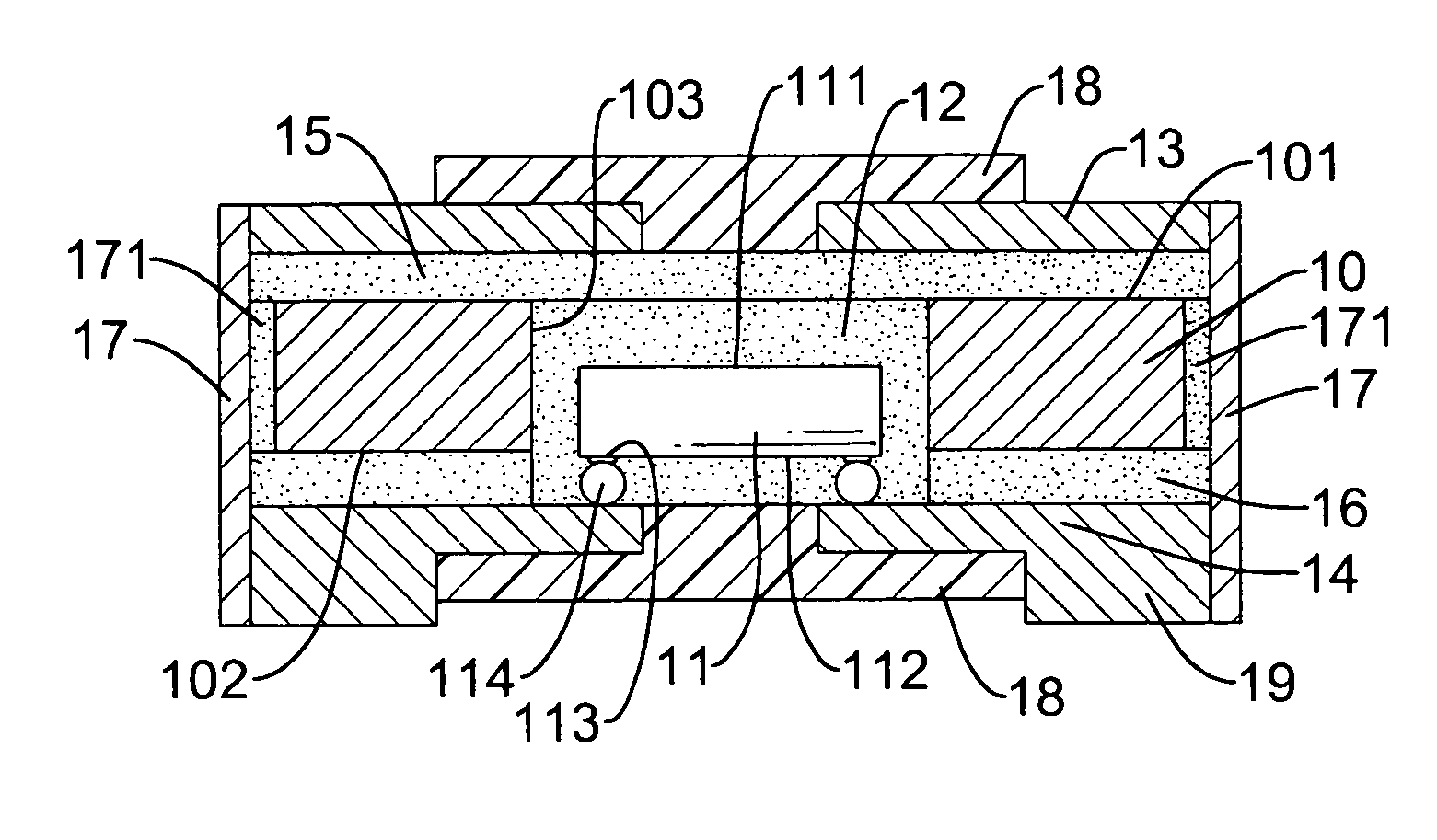

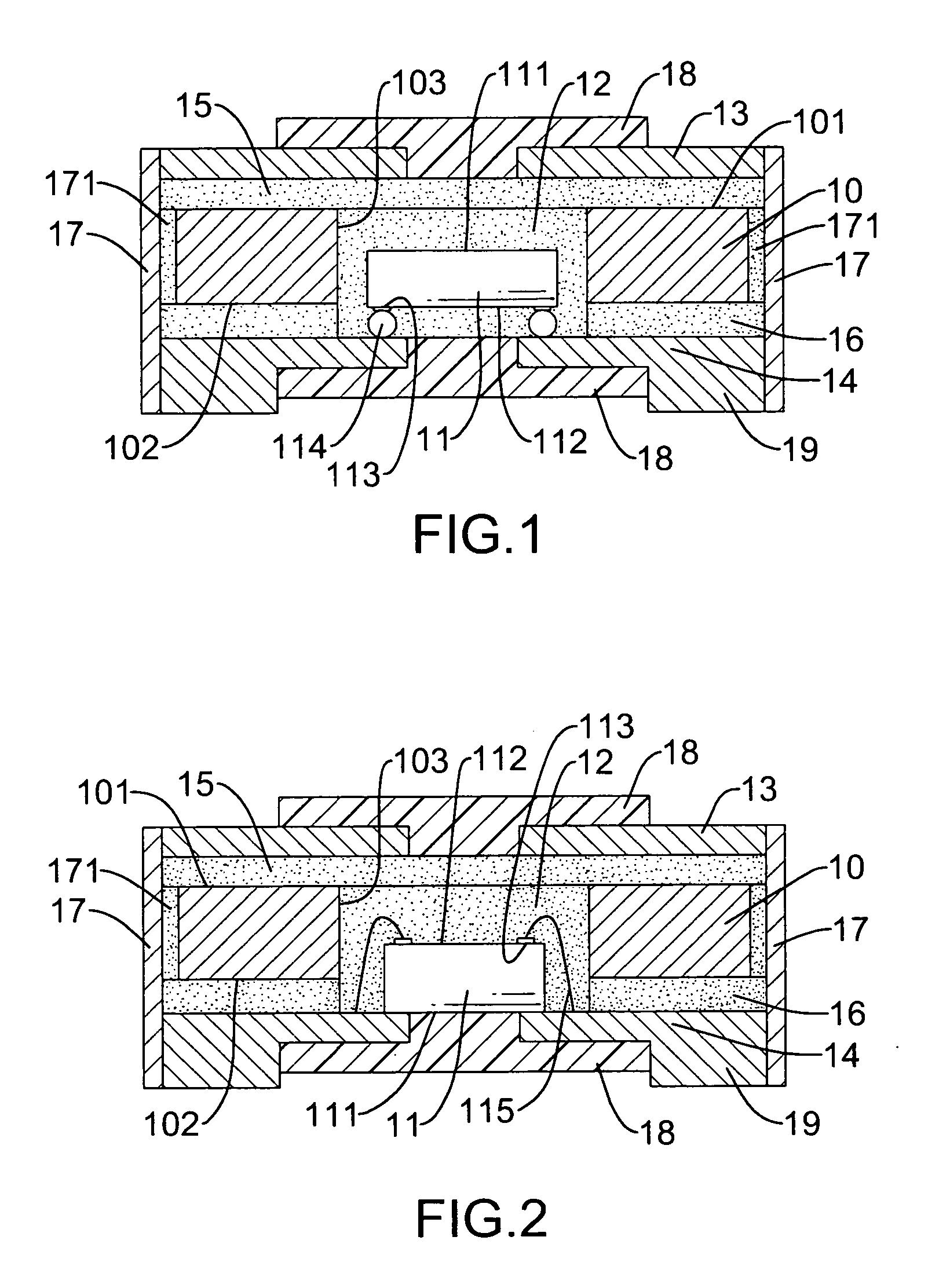

Package for light emitting diode, light emitting device, and light emitting device manufacturing method

InactiveUS20110037091A1Few defectEffective reflectionSolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceLight emitting device

The present invention relates to a light emitting diode package for mounting a light emitting diode, a light emitting diode device with the light emitting diode package mounting a vertical electrode type light emitting diode thereon and a manufacturing method for manufacturing the light emitting device.The light emitting diode package of the invention comprises at least a molding, and a first clip 122 and a second clip 123 fitted on the molding. The molding has at least a first opening 1212 and a second opening 1213 formed in a bottom portion thereof. The molding also has a reflecting portion 1214 formed around the first opening 1212 and the second opening 1213 for reflecting light. The molding further has a fluorescent film member mounting portion 1113 formed integrally for mounting a fluorescent film member 116 in the opening of the reflecting portion 1214. The first clip 122 has a light emitting diode mounting projection formed substantially at the center portion thereof for mounting the light emitting diode and is made to engage resiliently with the molding at both ends thereof. The first clip 122 engages with the molding at both ends thereof. The second clip 123 has a bonding projection formed to engage resiliently with the molding at both ends thereof.

Owner:CI KASEI COMPANY

Paste for electrode forming of solar cell

InactiveCN101304049AImprove efficiencyHigh mechanical strengthFinal product manufactureNon-conductive material with dispersed conductive materialBack surface fieldEngineering

The invention provides a sizing agent for forming an electrode of a solar cell. The sizing agent has the following advantages that: the mechanical strength of the electrode and the closing performance with the base material are good, the back surface field (BSF) effect required by the solar cell can be accomplished thoroughly, the bend of the base material after burned can be restrained, the efficiency of the solar cell can be improved, and the sizing agent is more particularly suitable for burning at high temperature / high speed with excellent mass production. The sizing agent for forming an electrode of a solar cell is characterized in that a) 60-75 parts by weight of aluminum power with at least 1.28 g / cc of tap density, b) 1-5 parts by weight of glass powder, and c) 20-38 parts by weight of organic carrier are included.

Owner:DONGJIN SEMICHEM CO LTD

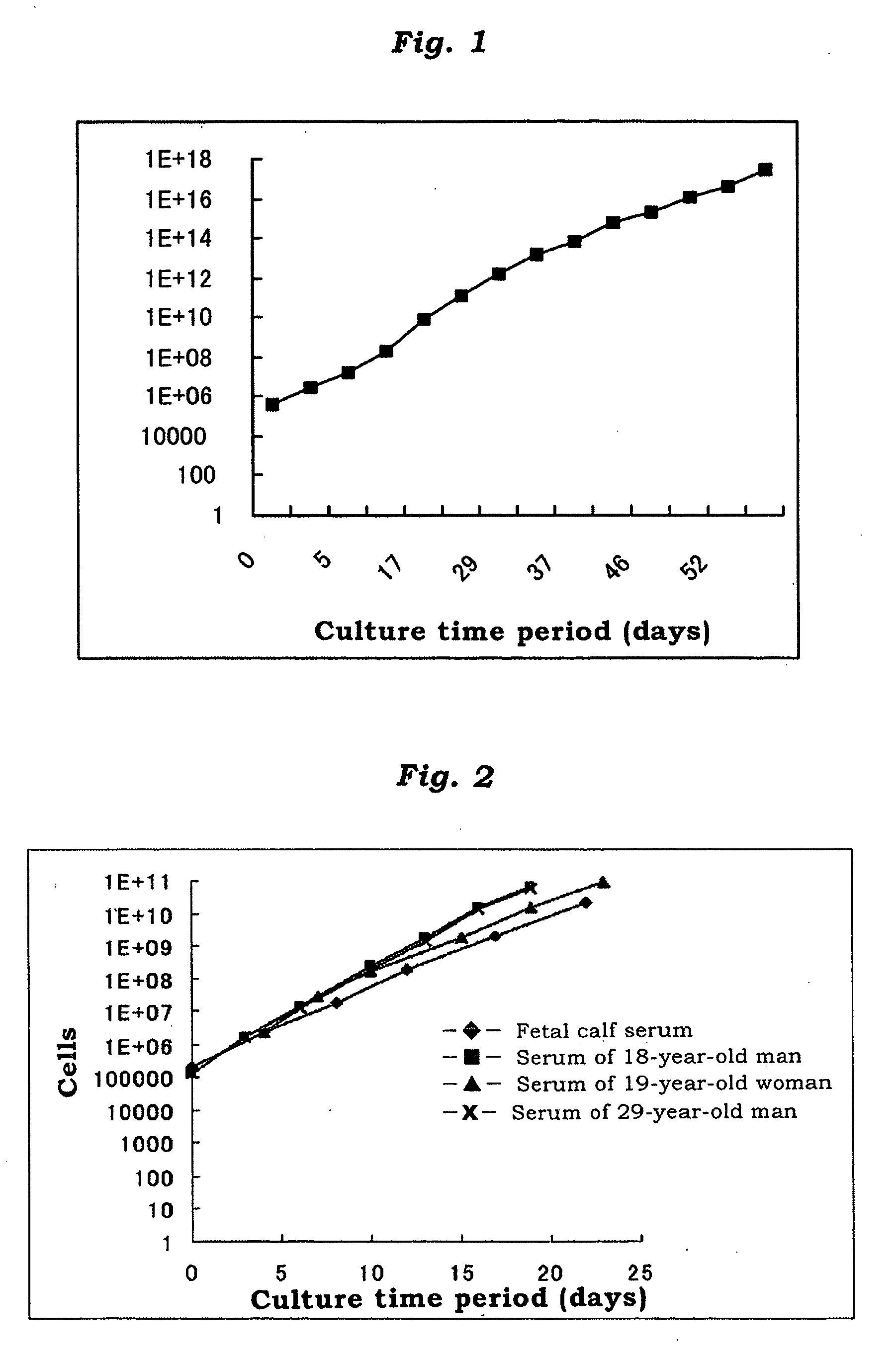

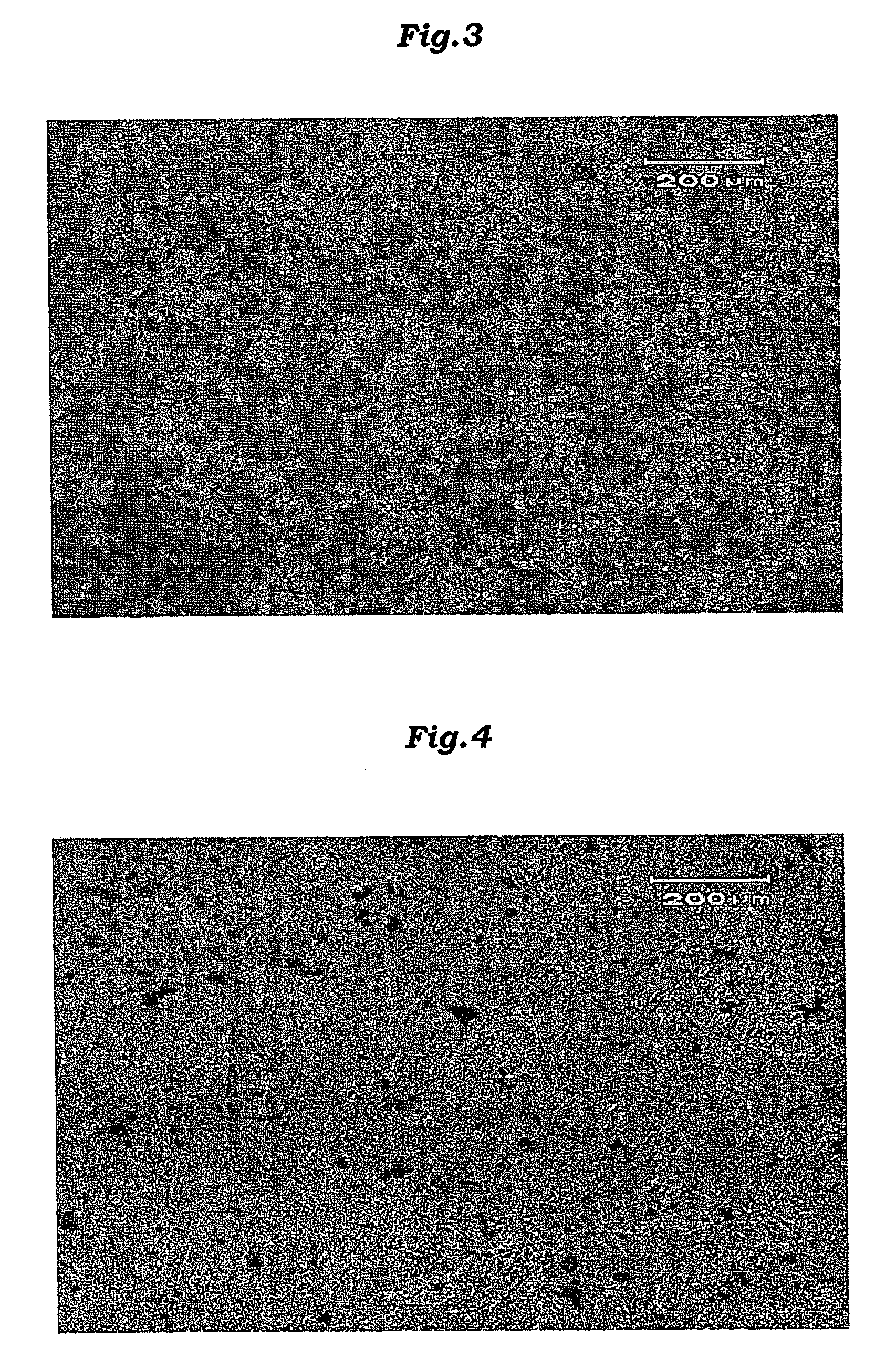

Pluripotent Cells Distributed Ubiquitously In Animal Tissue, Which Proliferate Selectively In Lower-Serum Culture

InactiveUS20070202592A1Lose volumeImprove mass productionArtificial cell constructsSkeletal/connective tissue cellsVascular endotheliumOsteocyte

It is intended to provide a pluripotent cell having the following properties: (1) being contained in a mixed-cell type population obtained by enzymatic treatment of the tissue collected from an animal; (2) being contained in a sedimented cell population obtained by centrifugating the mixed-cell type population of the property (1); (3) selectively proliferating by culturing in a medium containing 2% (v / v) or lower serum and 1 to 100 ng / ml of fibroblast growth factor-2; and (4) being differentiated into cells having the characteristics of adipocytes, osteoblasts, chondrocytes, tendon cells, myocardial cells, myoblasts, neurocytes or vascular endothelial cells by adjusting the culture condition; cells having differentiated from the above cell; and a method of conveniently obtaining the pluripotent cell in a large amount.

Owner:KYOWA HAKKO KIRIN CO LTD +3

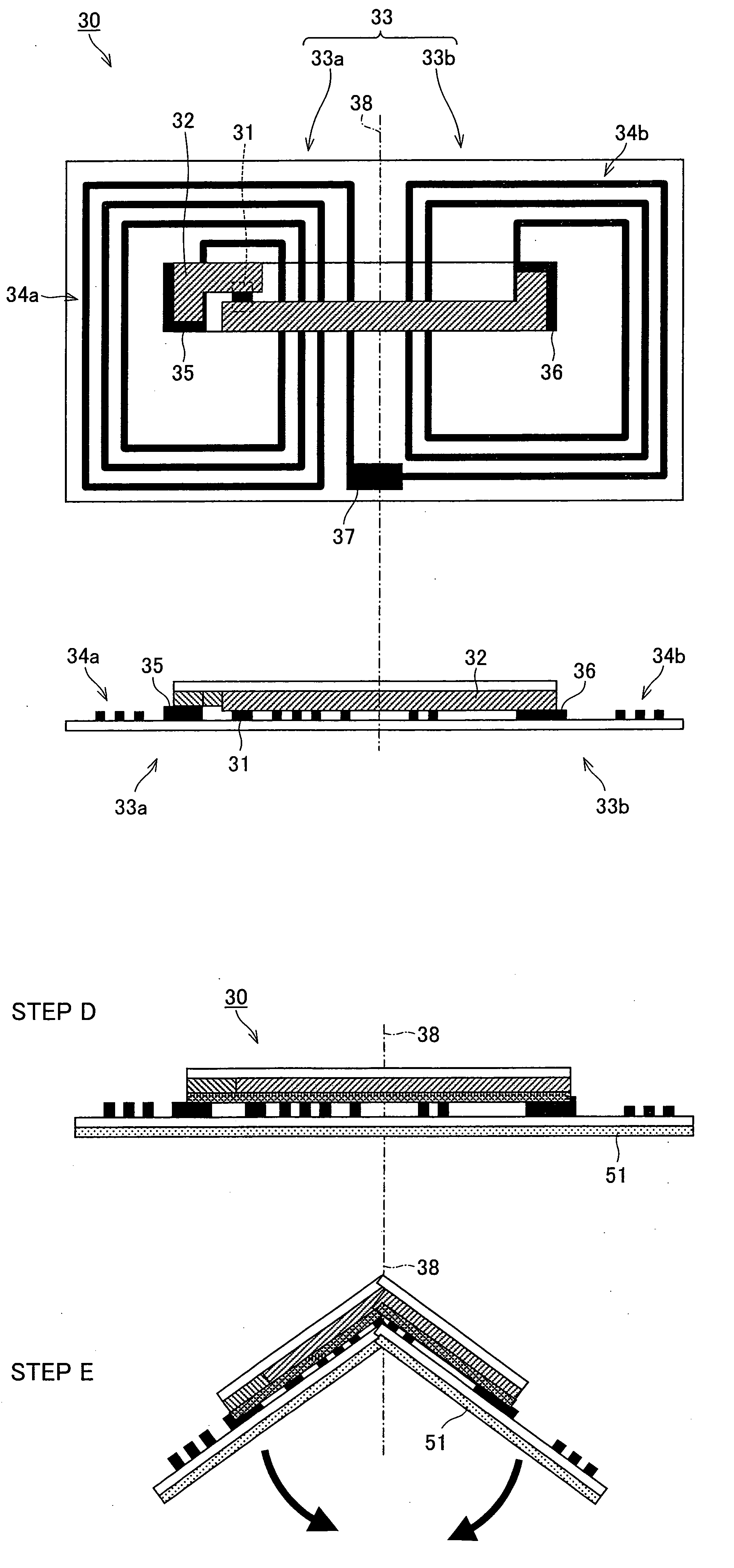

Light transmission and reception module, sub-mount, and method of manufacturing the sub-mount

InactiveUS7343060B2Low costImprove mass productionCoupling light guidesMulticore optical fibreBand shapeWaveguide

Owner:FUJIFILM BUSINESS INNOVATION CORP

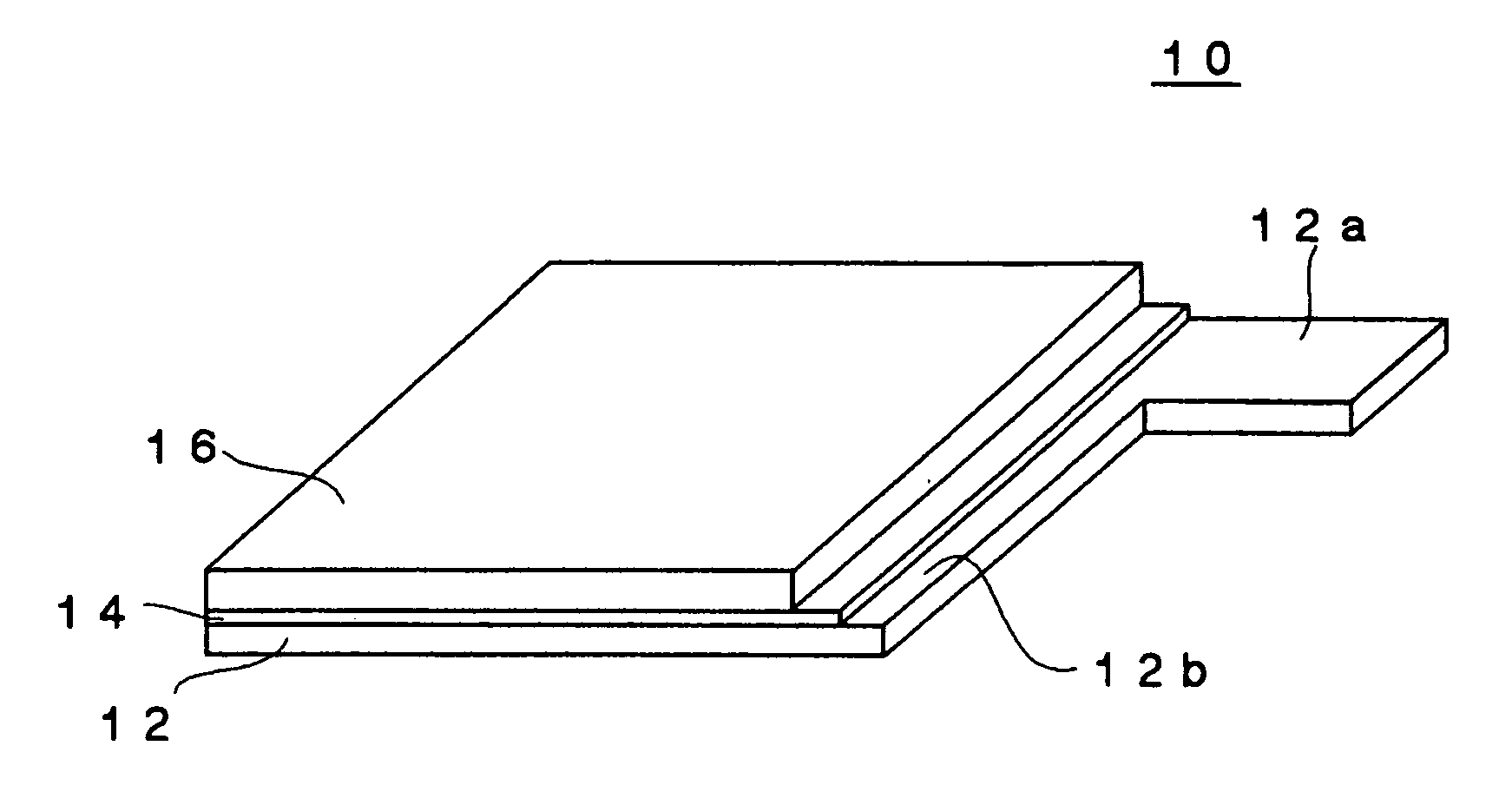

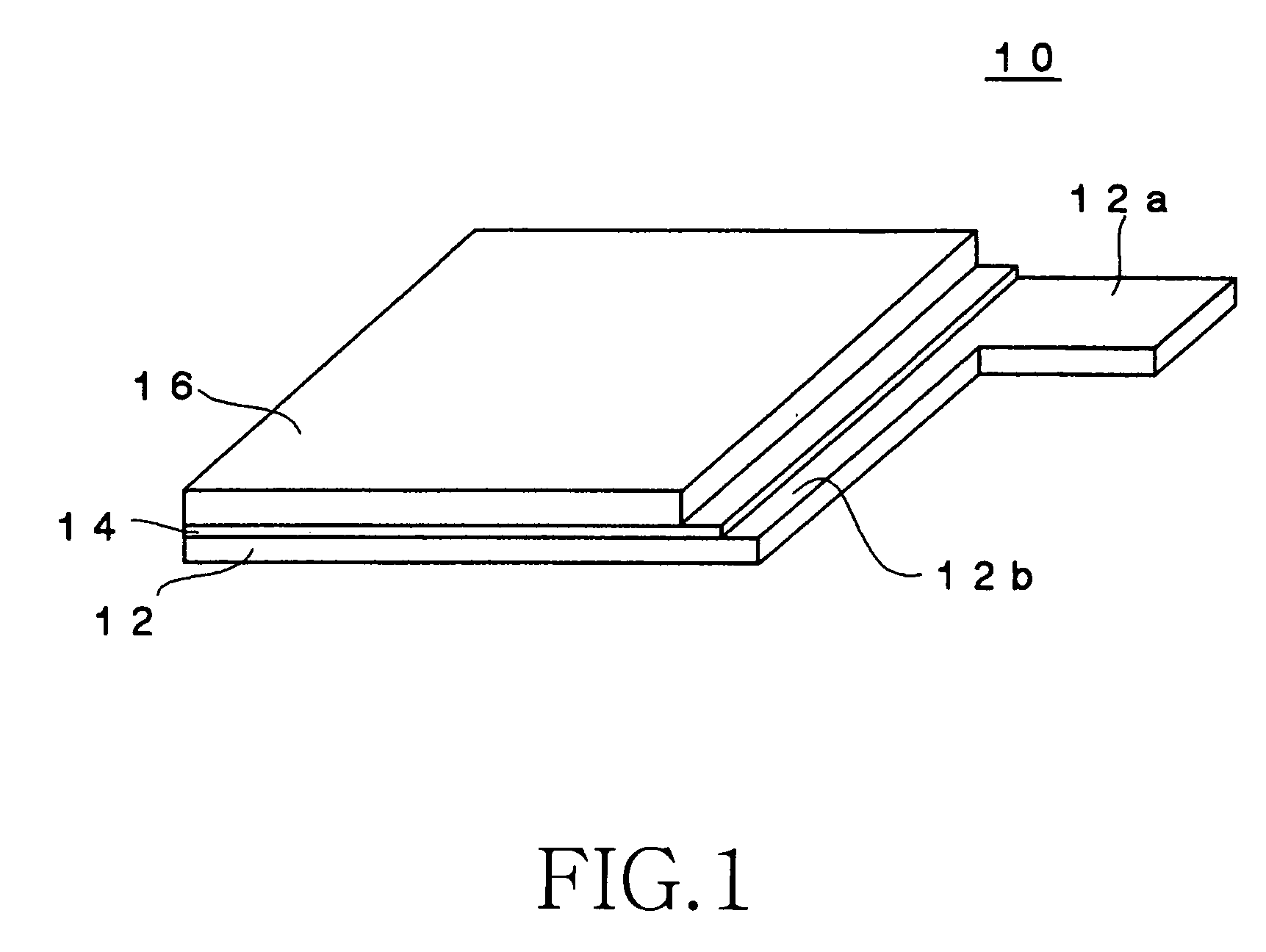

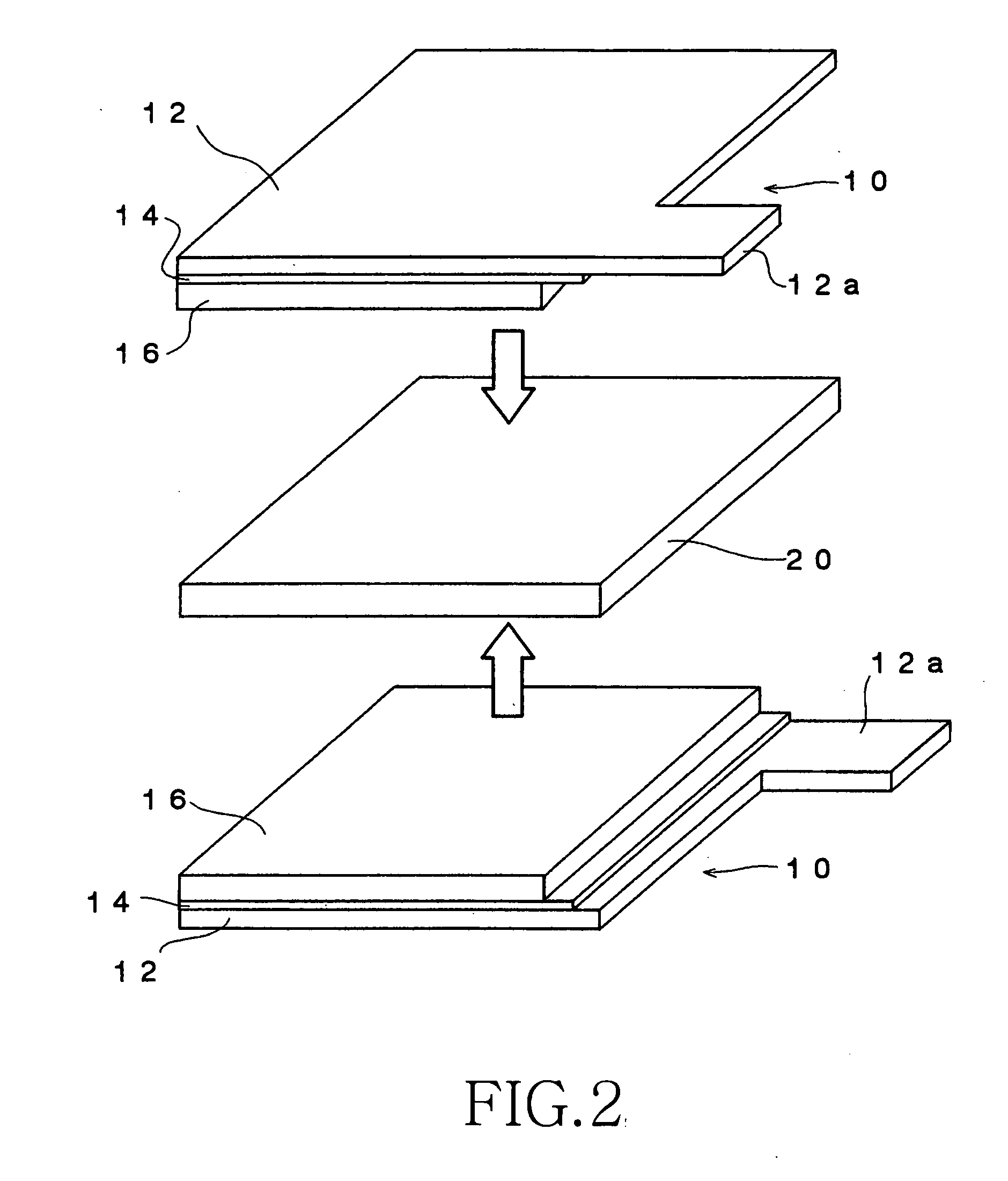

Magnetoresistance effect device

InactiveUS20080055793A1High MR ratioImprove mass productionNanomagnetismMagnetic-field-controlled resistorsMolecular physicsMagnetic layer

A magnetoresistance effect device including a multilayer structure having a pair of ferromagnetic layers and a barrier layer positioned between them, wherein at least one ferromagnetic layer has at least the part contacting the barrier layer made amorphous and the barrier layer is an MgO layer having a highly oriented texture structure.

Owner:ANELVA CORP +1

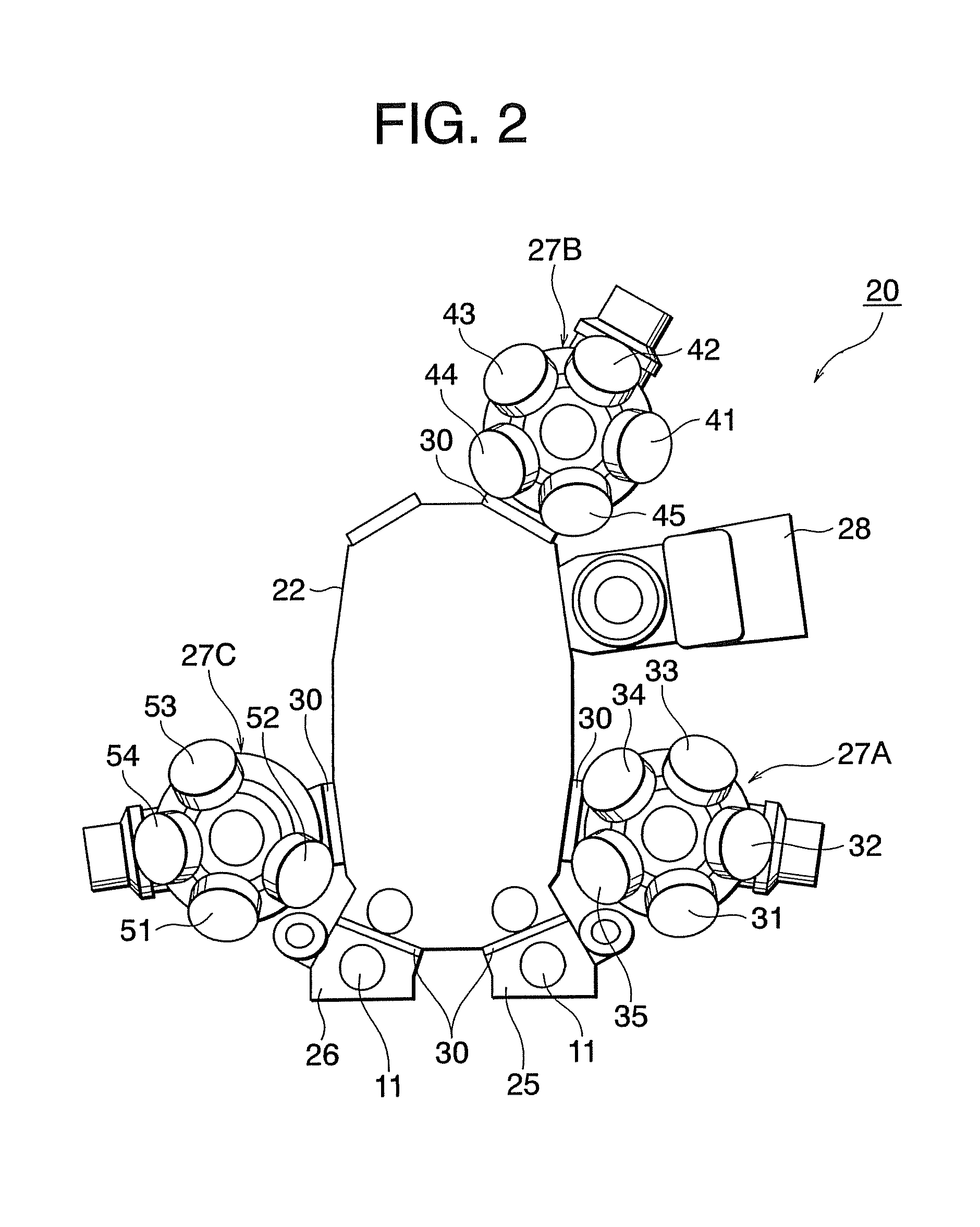

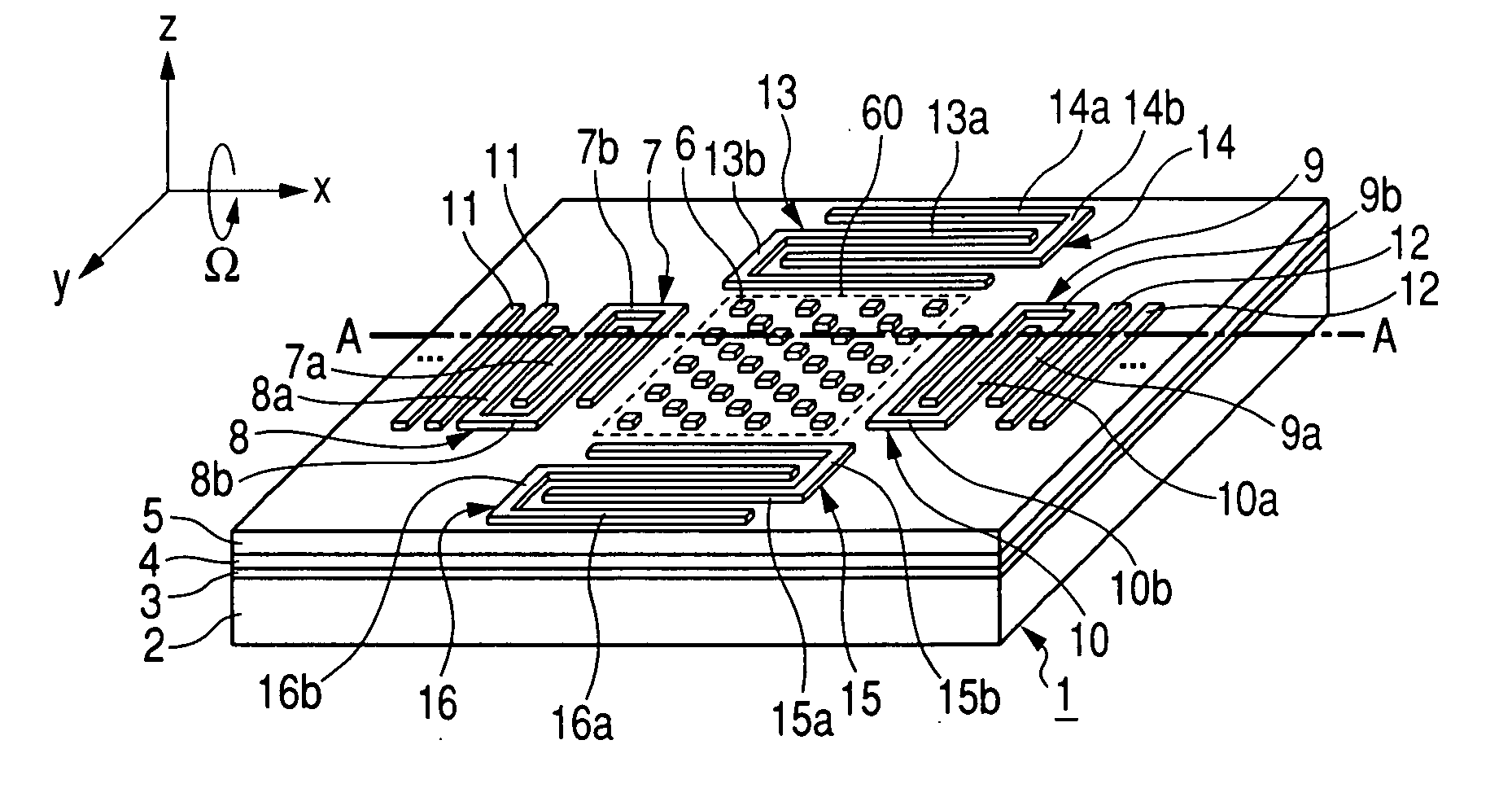

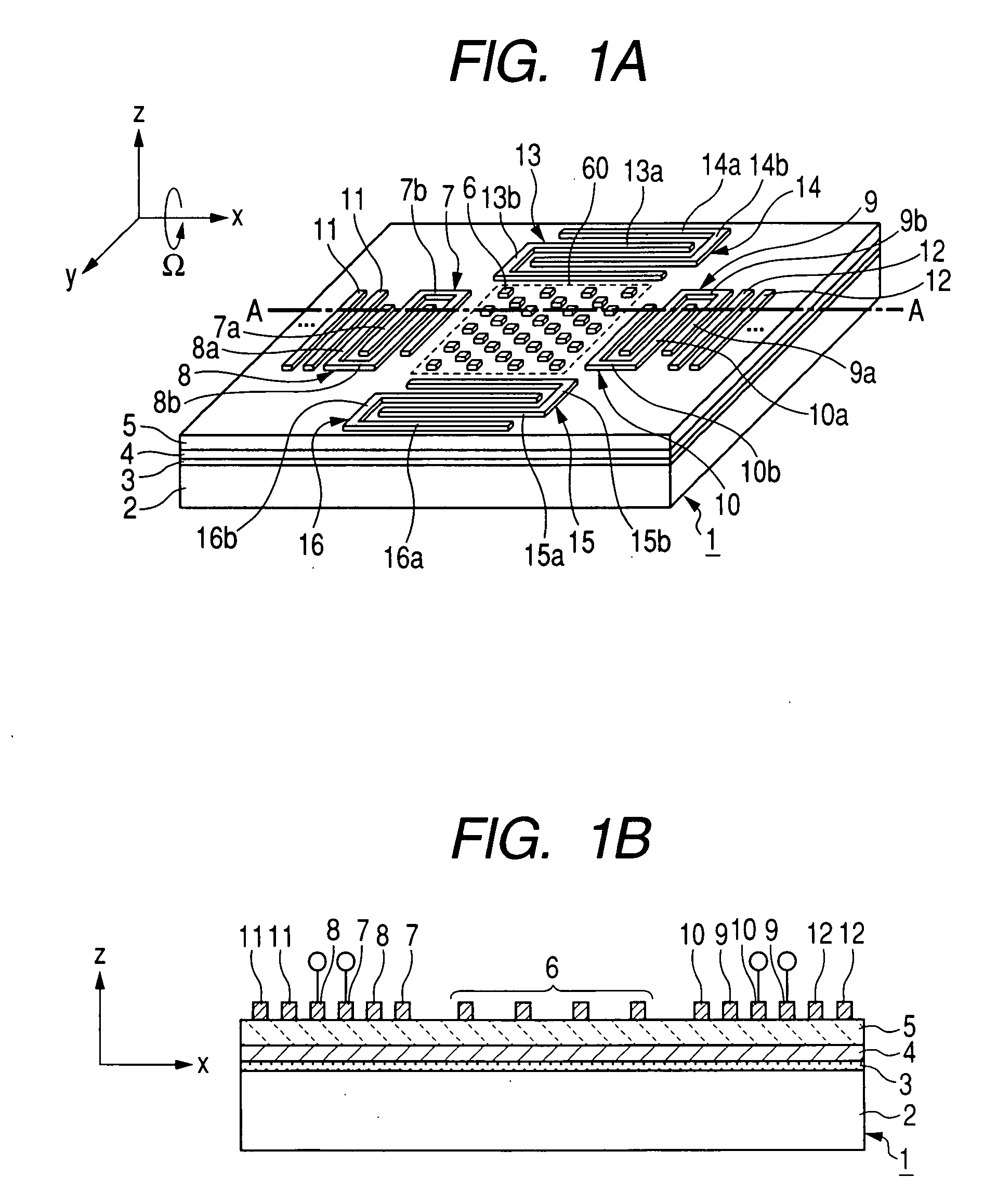

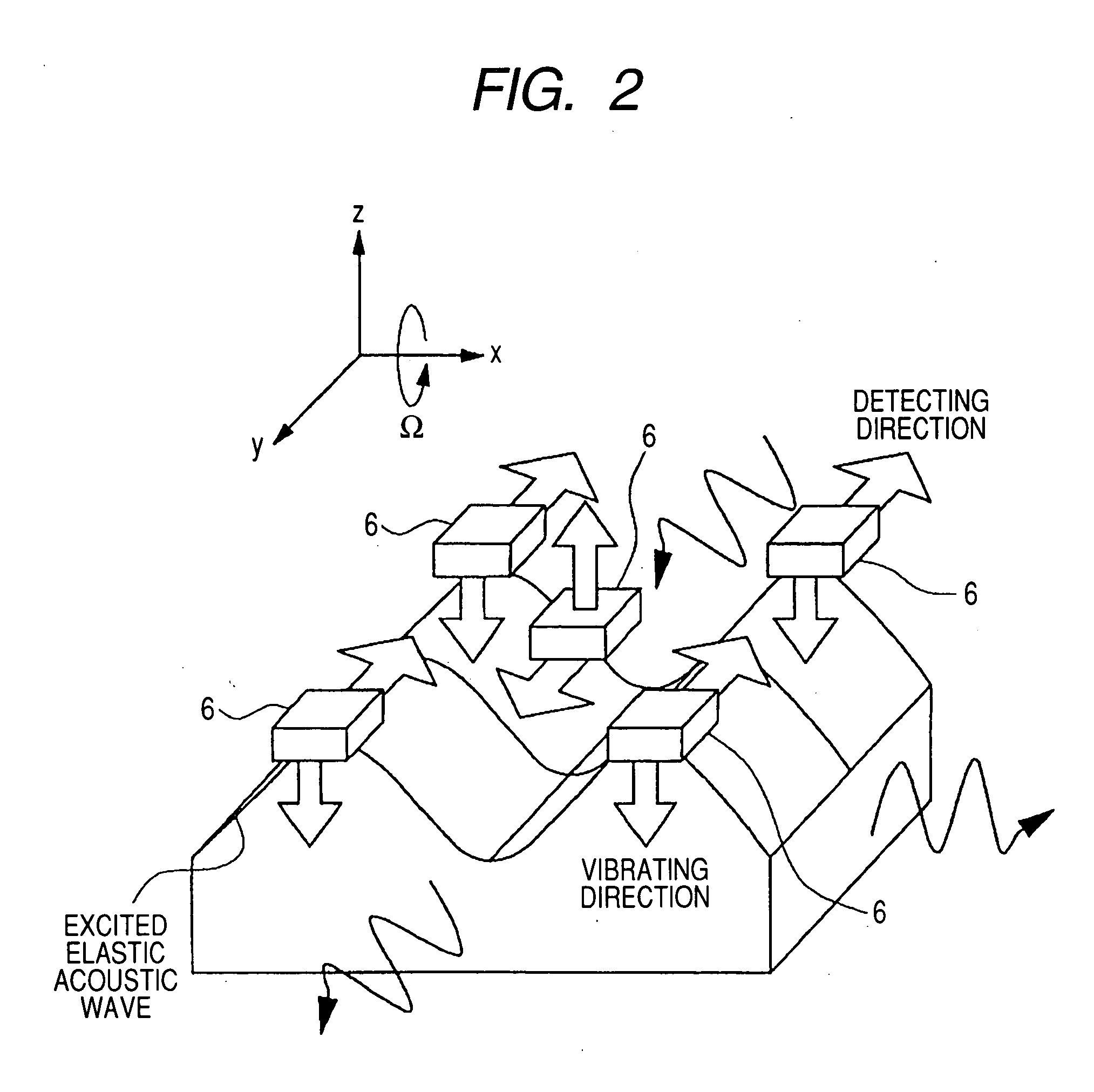

Angular rate sensor

ActiveUS20080028855A1High sensitivityImprove reliabilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsElectricityAngular rate sensor

An angular rate sensor comprises a piezoelectric film having a first and a second surfaces forming an x-y plane and utilizes a perturbation mass coherently vibrating elastic acoustic waves on which a Coriolis force acts when the angular rate sensor undergoes a rotary motion about an x-direction. A first elastic acoustic wave is excited in the piezoelectric film by a driving transducer and a second elastic acoustic wave generated by the Coriolis force proportional to an angular rate of the rotary motion of the angular rate sensor itself is detected by the detecting transducer. The angular rate sensor further comprises at least a first electrode disposed on the first surface of the piezoelectric film for discharging a surface charge caused due to piezoelectric effect at the lower surface of the film in which the first elastic acoustic wave is excited.

Owner:DENSO CORP

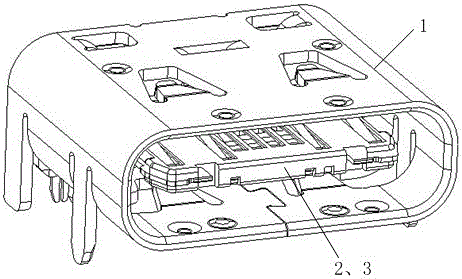

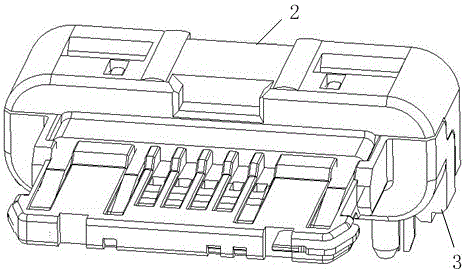

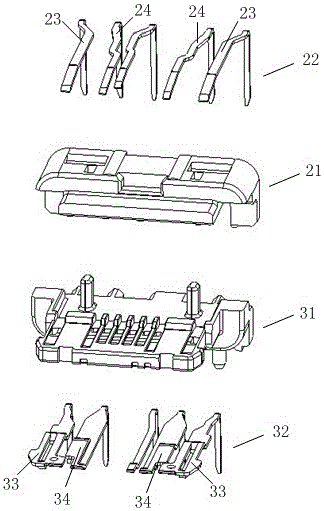

A USB based on a Type C

ActiveCN105024197AReduce compositionSimple structureCoupling contact membersCoupling protective earth/shielding arrangementsEngineeringUSB

The invention provides a USB based on a Type C. The USB comprises a housing, an upper insertion assembly and a lower insertion assembly. The upper insertion assembly comprises an upper insulation body and an upper row of conductive terminals. The lower insertion assembly comprises a lower insulation body, a metal shielding layer and a lower row of conductive terminals. The metal shielding layer and the lower row of conductive terminals are integrally molded. The lower row of conductive terminals comprises lower grounding terminals. Abutting portions of the lower grounding terminals comprise plate-shaped grounding basal bodies and grounding portions formed through projecting downwards from the basal bodies. The grounding portions and the grounding basal bodies are in different planes. The grounding basal bodies are arranged in the lower insulation body. The grounding portions are exposed outside the lower insulation body, and are used for contact with grounding terminals for abutting the USB; and the grounding basal bodies and main body portions of the lower grounding terminals are widened portions. Through adoption of the USB of the invention, the part composition of the product can be reduced; the reliability of the product when heavy currents pass can be raised; and the simplicity can also be raised.

Owner:ALL BEST ELECTRONICS TECH CO LTD

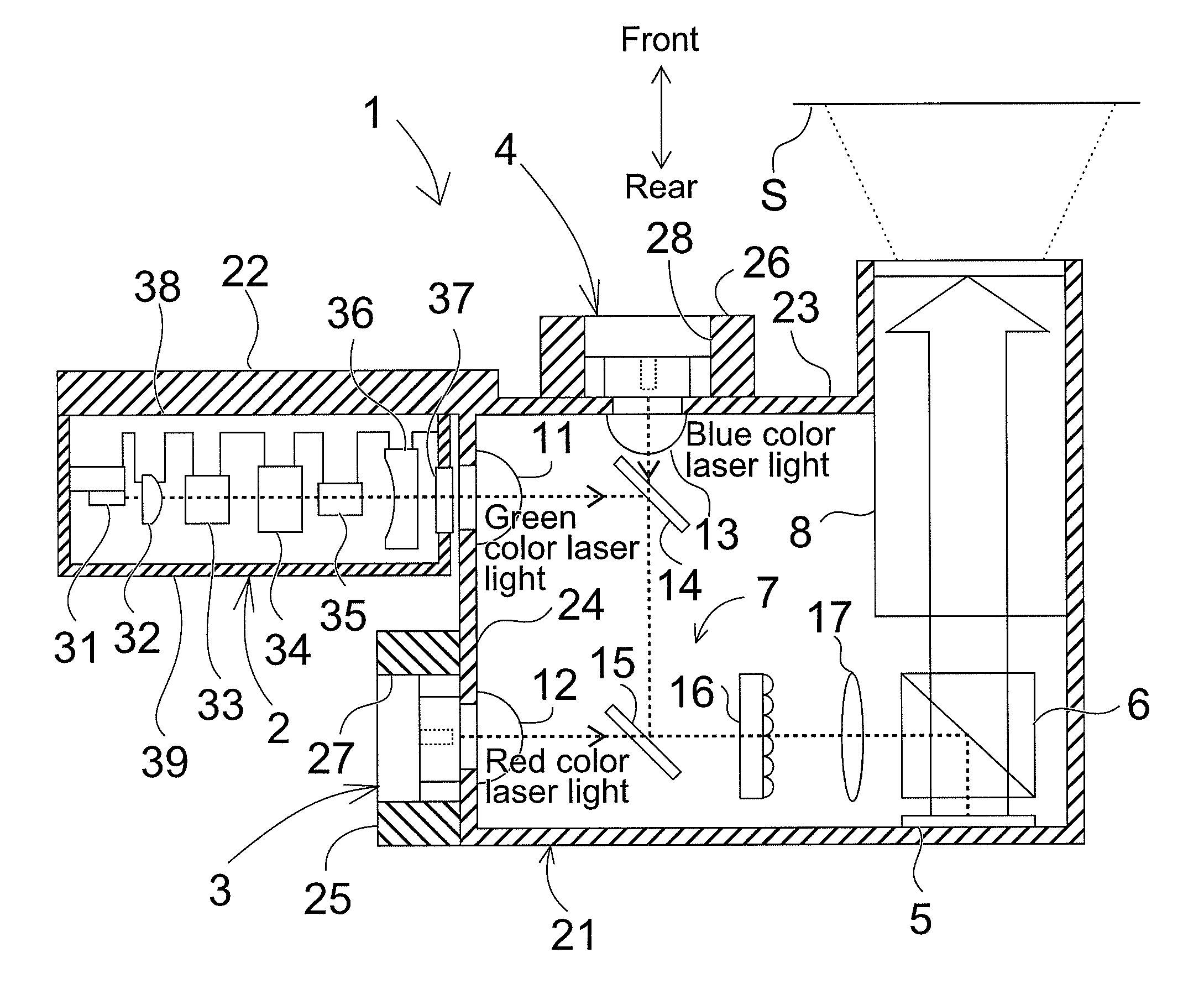

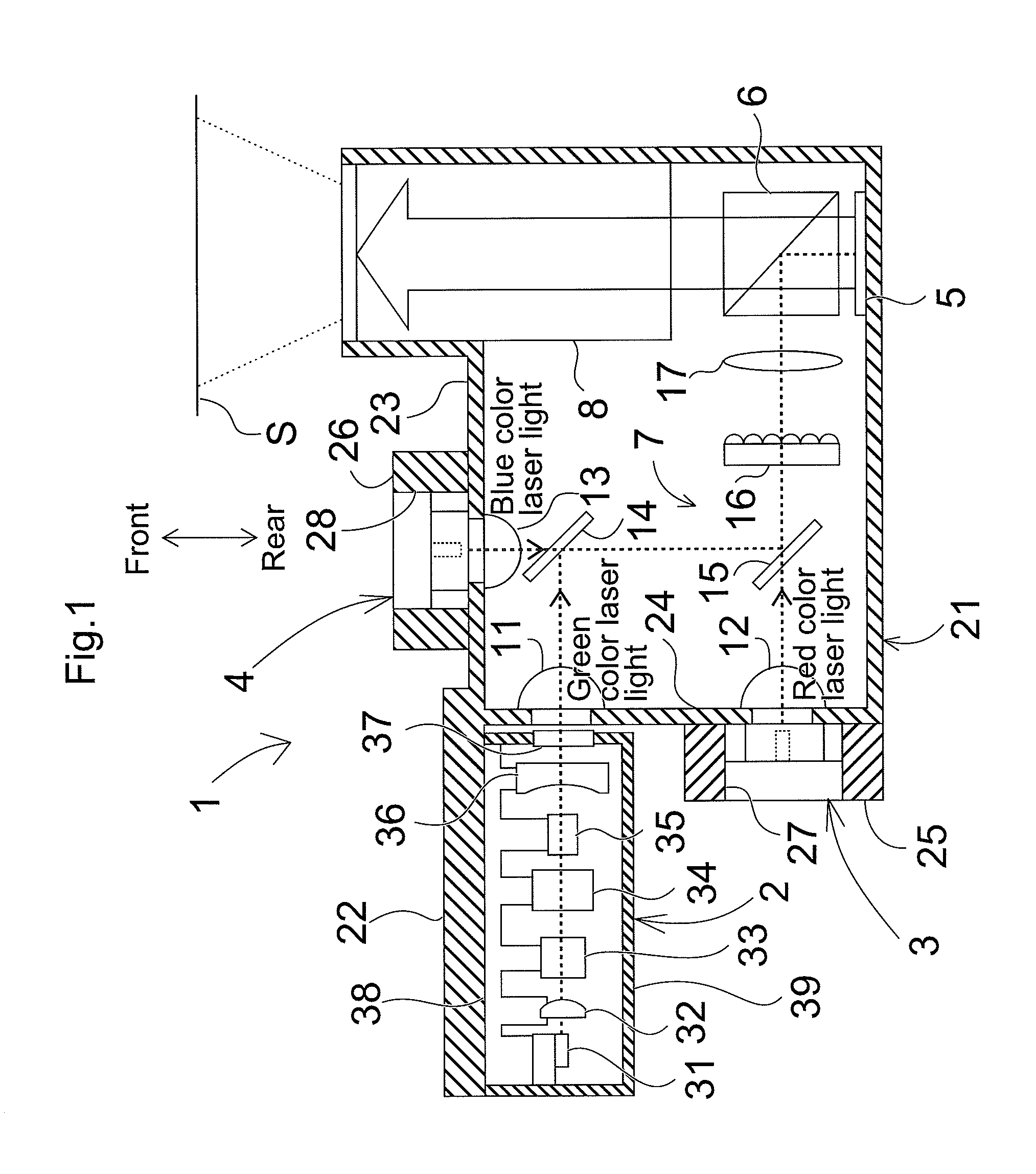

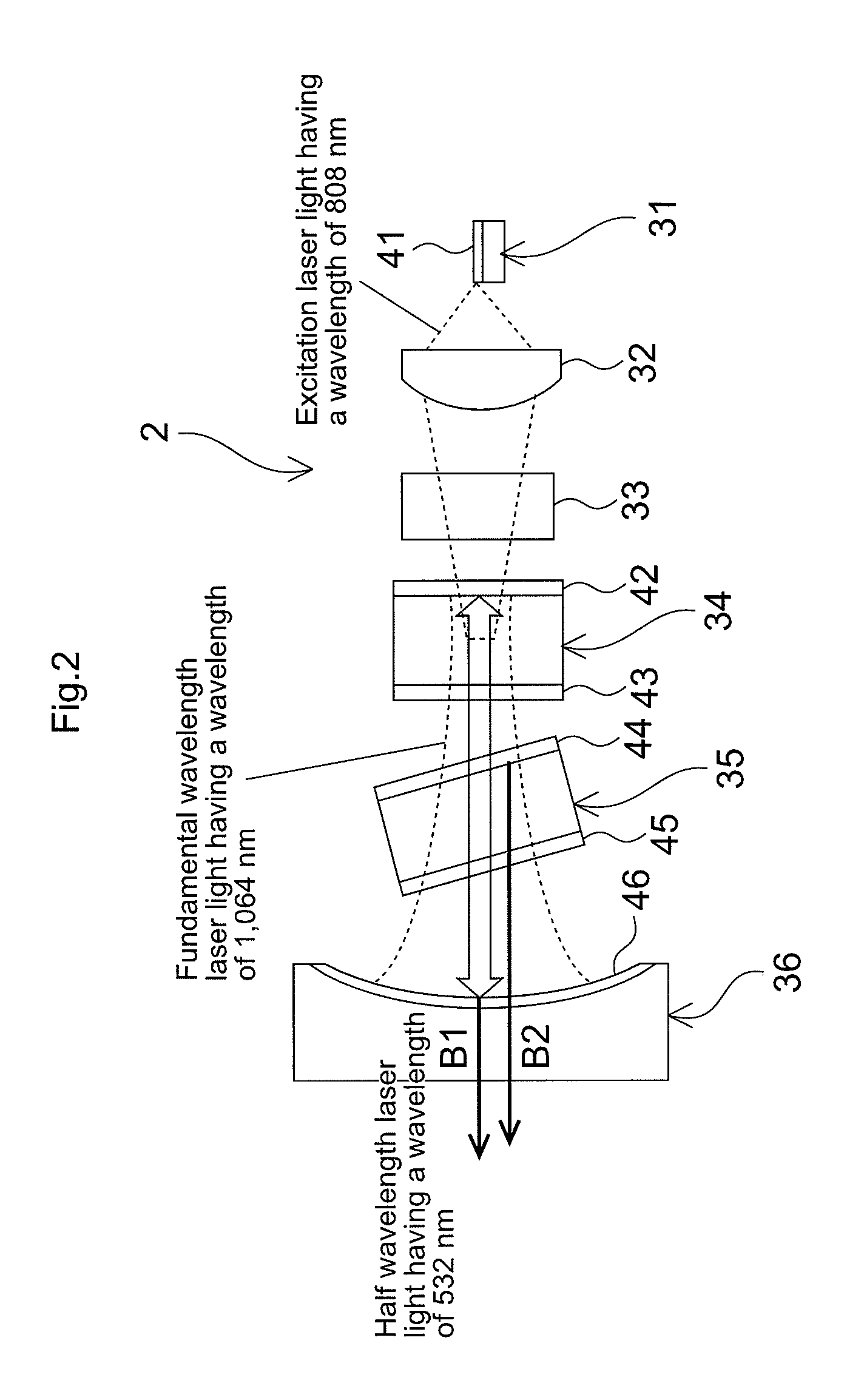

Laser light source apparatus

InactiveUS20120044693A1Low adhesion temperatureImprove heat resistanceLaser detailsLighting support devicesHigh resistanceSilver paste

In order to reduce manufacturing cost of a base supporting a semiconductor laser, without deteriorating accuracy of mounting of the semiconductor laser, a mounting member is provided between the base supporting the semiconductor laser and the semiconductor laser; and the semiconductor laser and the base are fixedly attached with heat-cured silver paste. The silver paste has a lower curing temperature than an assurance temperature of the semiconductor laser, and a higher heat resistance than an operation temperature of the semiconductor laser. The mounting member is formed of a material having a higher heat resistance than the curing temperature of the silver paste.

Owner:PANASONIC CORP

Thin ic tag and method for manufacturing same

InactiveUS20070164867A1Reduce manufacturing costEasy to installOther printing matterAntenna supports/mountingsElectrical conductorEngineering physics

Owner:ORMON CORP

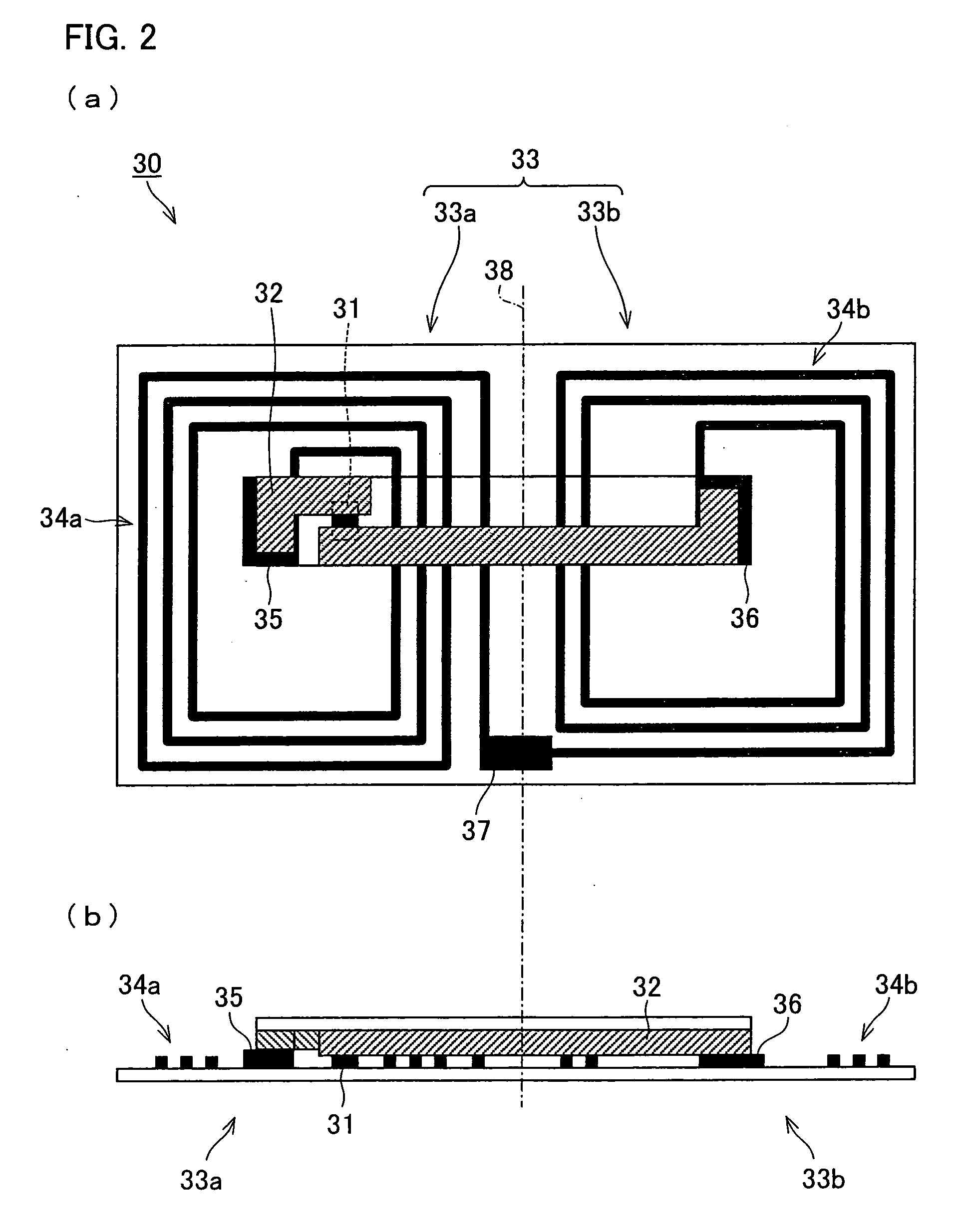

Magnetic antenna

ActiveCN101208830AImprove bindingStable manufacturingLoop antennas with ferromagnetic coreRadiating elements structural formsElectrical polarityMetallic Object

There is provided a magnetic antenna, suitable for use in an RFID tag and an RFID tag reader / writer, which operates stable even if brought close to a metallic object and suitable for mass-production, and a board mounted with the magnetic antenna. The magnetic antenna has a coil comprising a magnetic layer and a conductive layer provided on the magnetic layer via an insulating layer. Alternatively, the magnetic antenna has a plurality of coils each comprising a magnetic layer having a square or rectangular shape and arranged radially. One ends of the coils are connected in series or parallel to one another by the magnetic layers thereof such that the coils have the same polarity. An insulating layer is provided on one or both outer surface of the coils, and a conductive layer is provided on an outer surface of at least one of the insulating layers. The magnetic antenna is produced using an LTCC technology.

Owner:TODA IND

Graphite material, carbon material for battery electrode, and battery

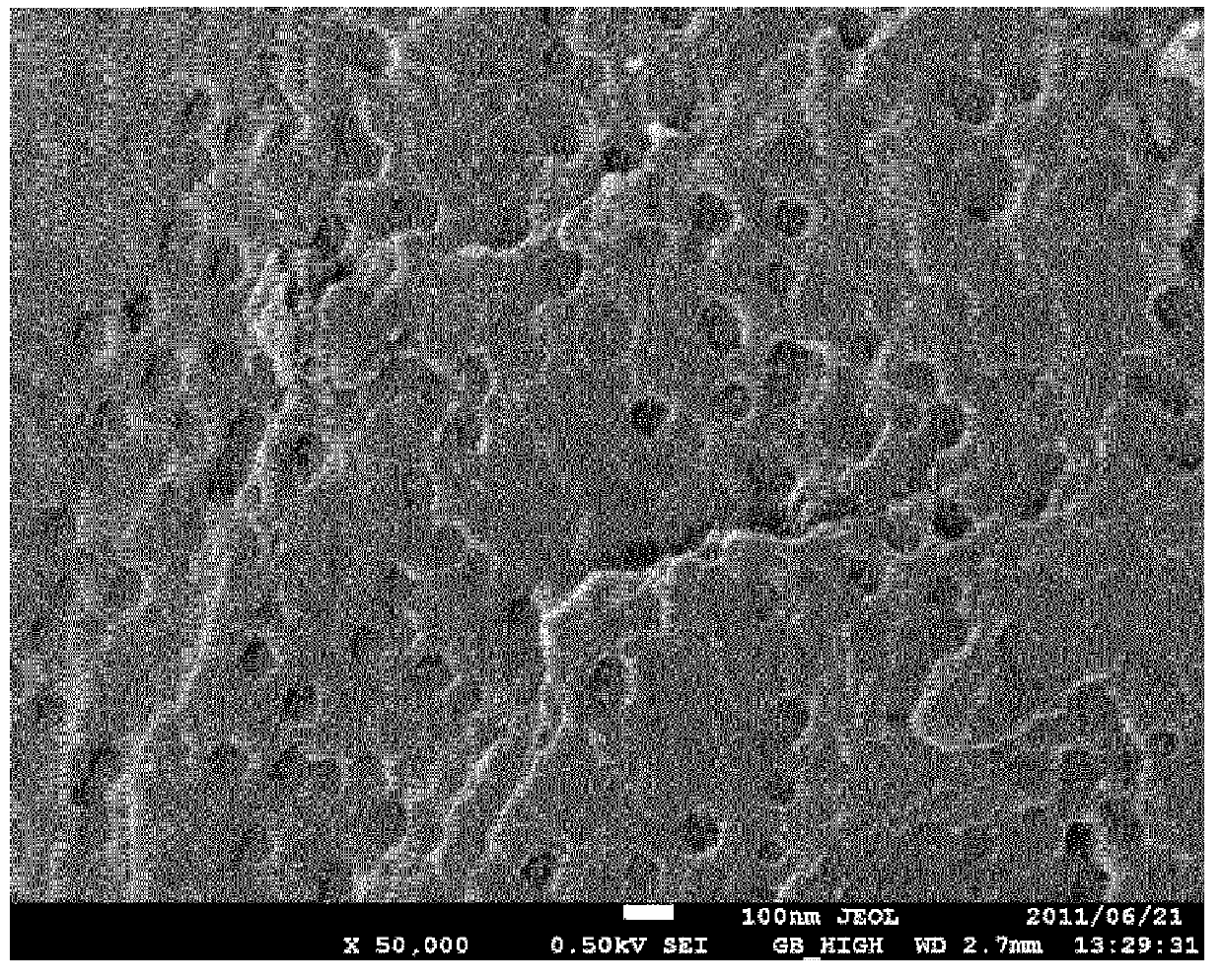

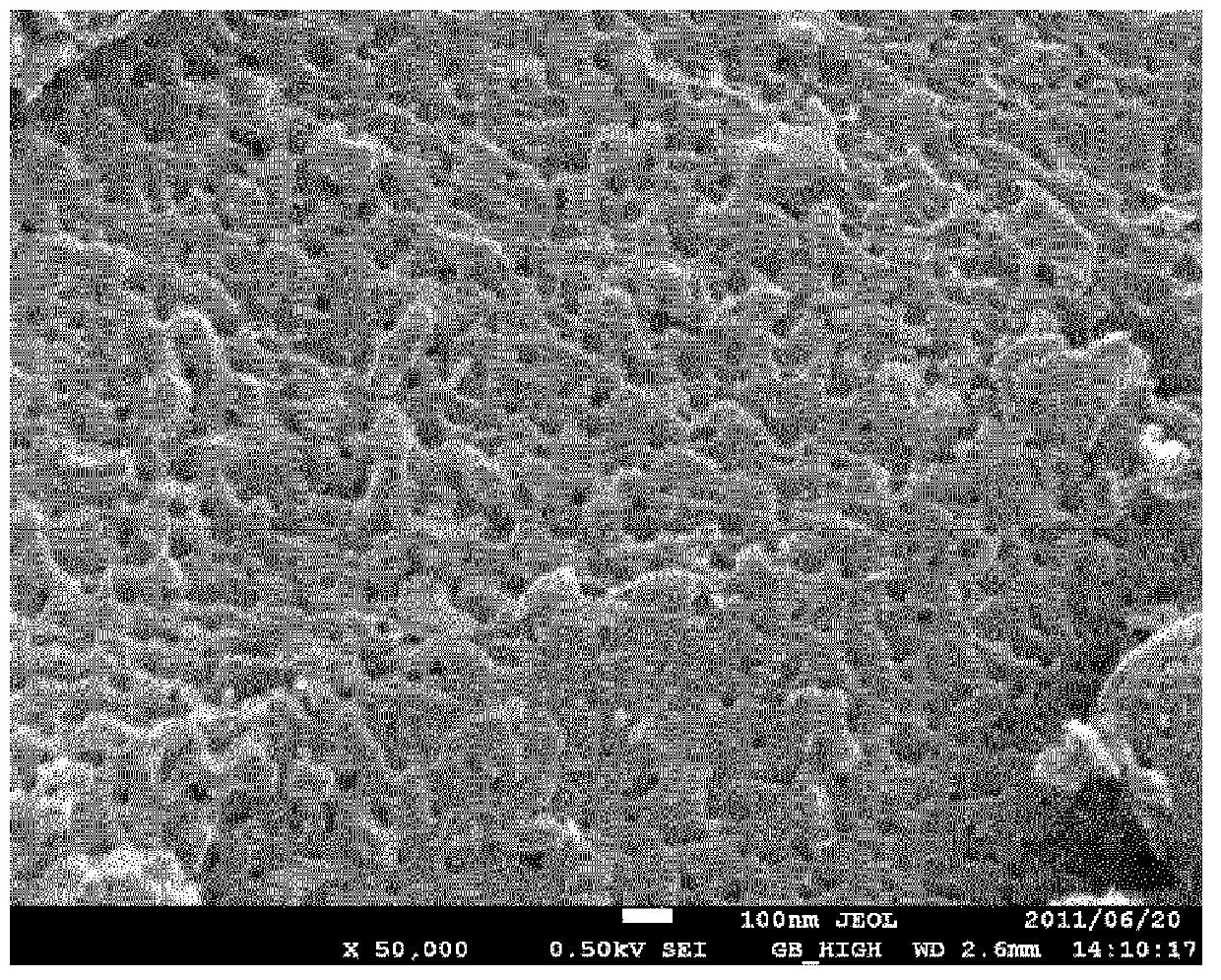

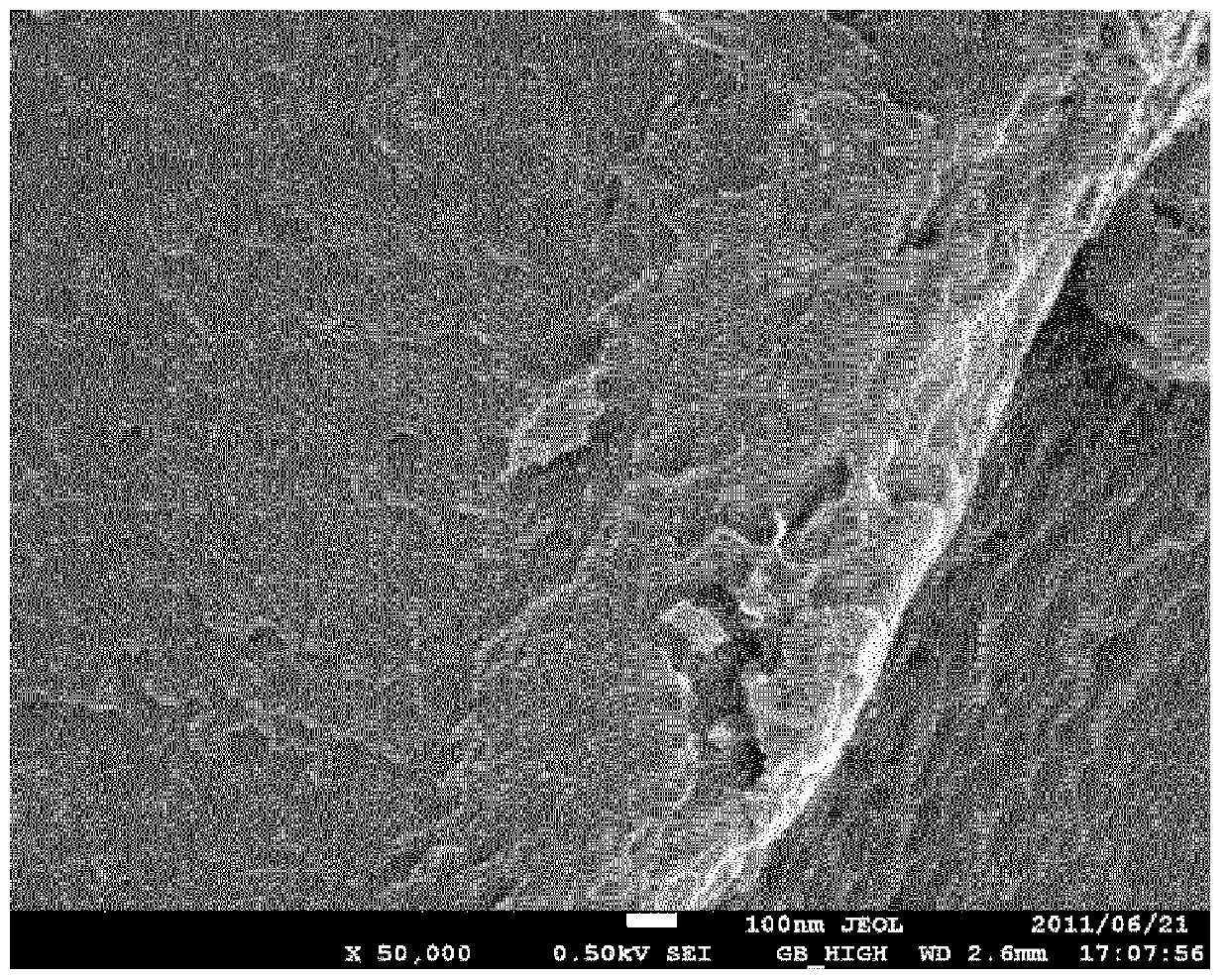

ActiveCN103328377AIncrease energy densityFacilitated DiffusionGraphiteCell electrodesPower flowScanning electron microscope

The present invention provides a graphite material which, when 200 locations in a rectangular area of 6 [mu]m by 8 [mu]m are arbitrarily selected on a graphite material surface image observed by scanning electron microscope, cylindrical pores, which have an opening shape with a diameter of 15 nm to 200 nm, a roundness of 0.75 to 1.0, and a major axis / minor axis ratio of 1.0 to 1.5, are visible on the surface of the graphite material that appears in said area in at least two locations. This graphite material is suitable as an electrode material for rechargeable batteries, and has excellent charge / discharge cycle characteristics and high current load characteristics.

Owner:RESONAC CORPORATION

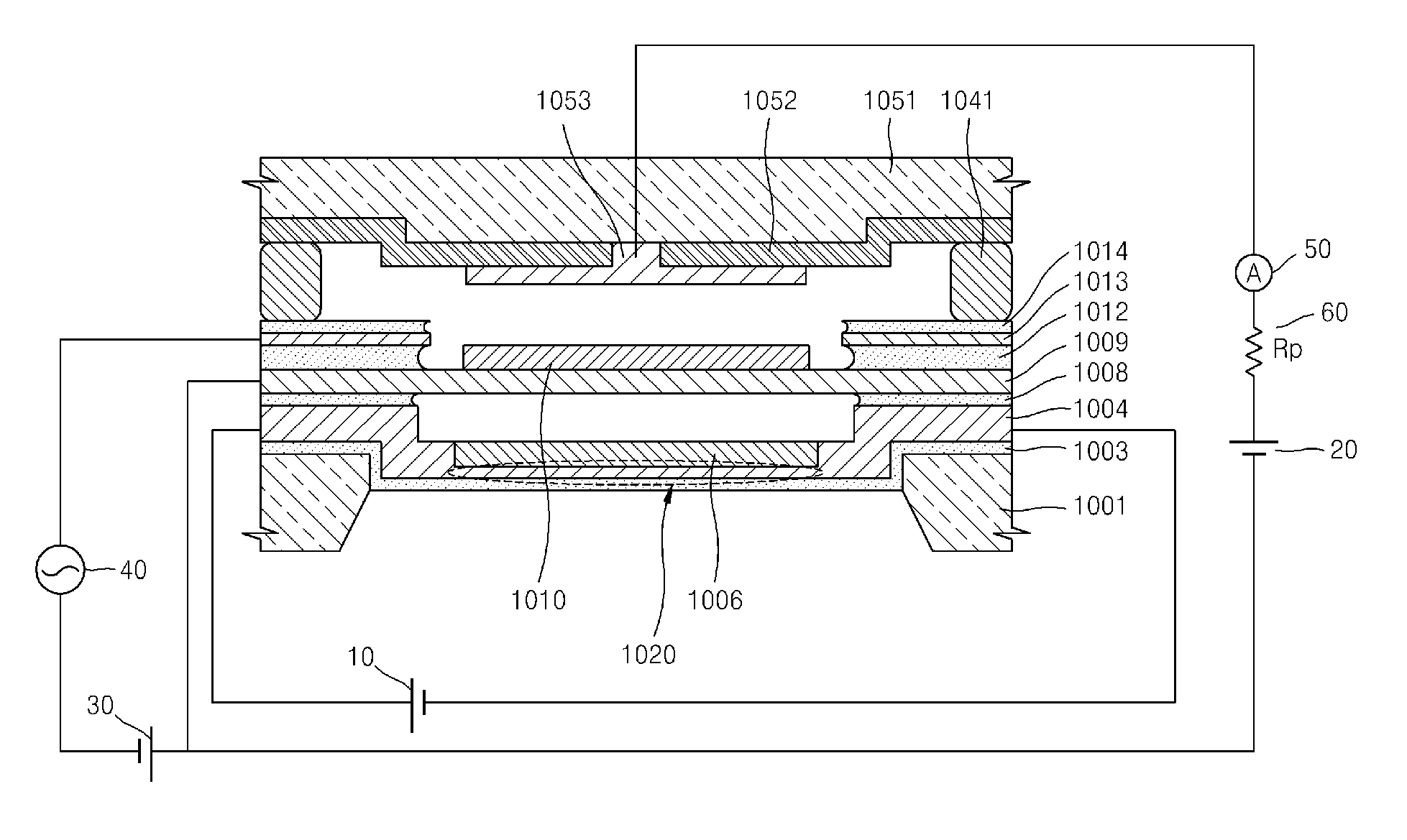

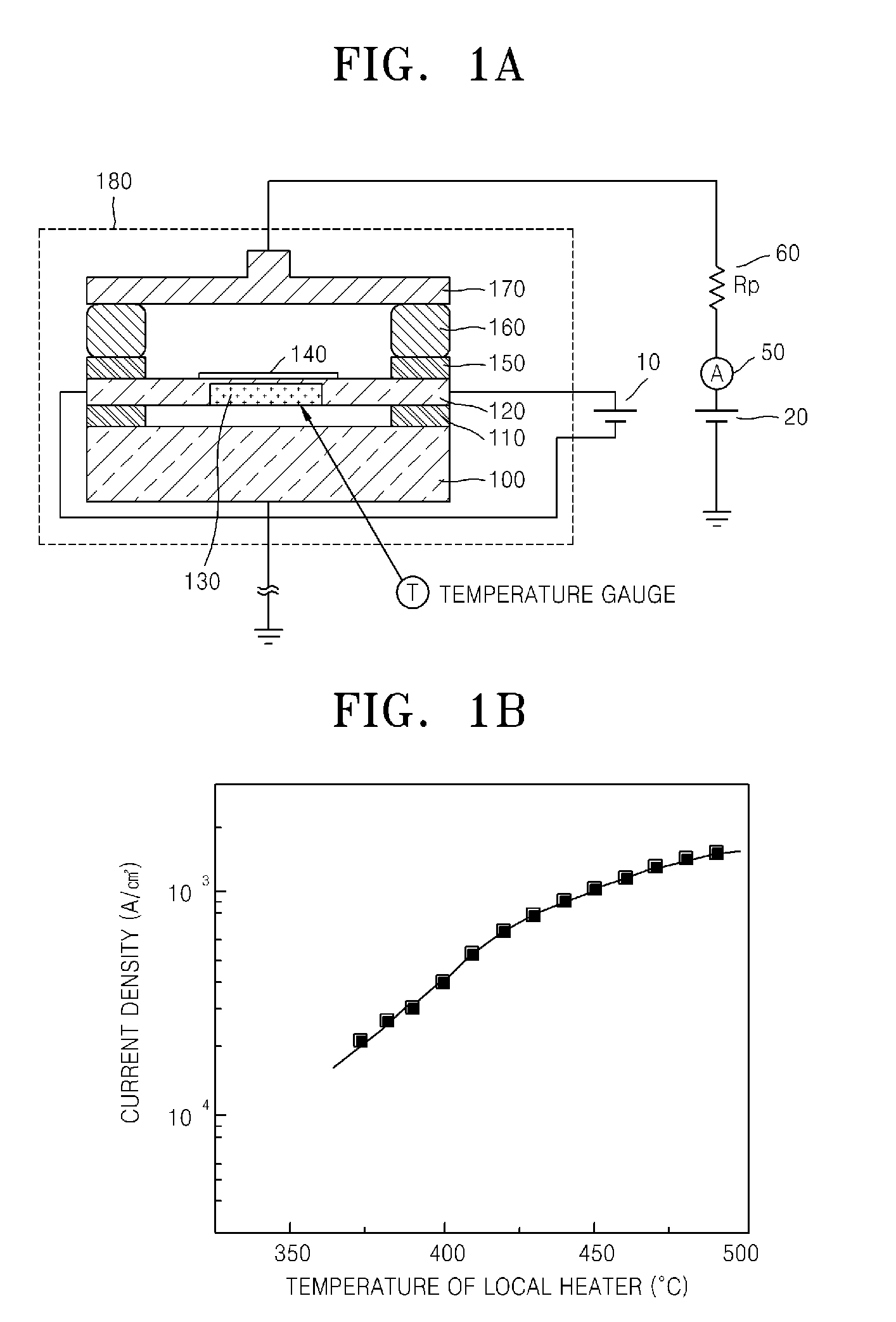

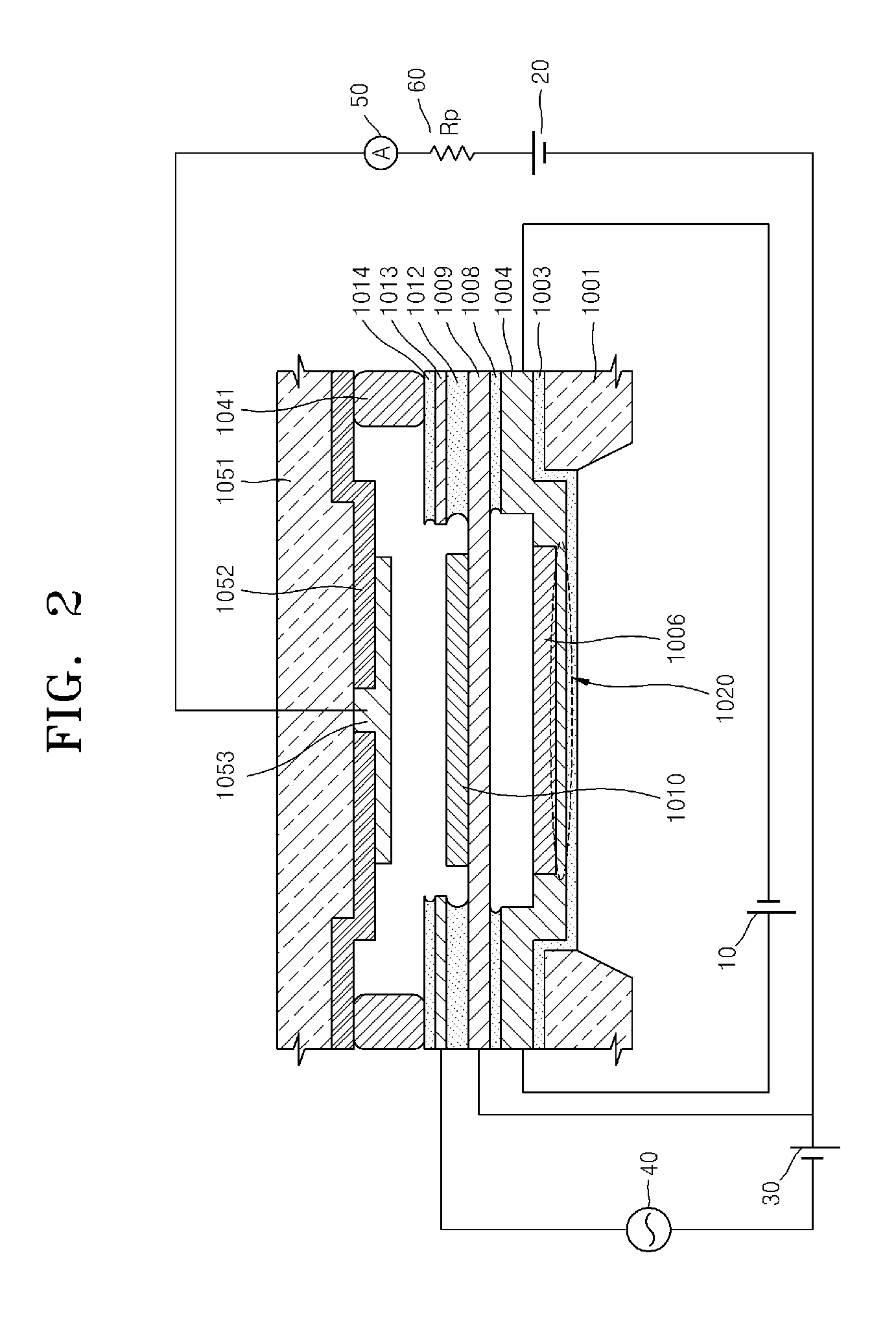

Vacuum channel transistor and diode emitting thermal cathode electrons, and method of manufacturing the vacuum channel transistor

InactiveUS20100102325A1Stable electron emission structureReduce the driving voltageDischarge tube luminescnet screensLamp detailsEngineeringMicroheater

Provided are a transistor and a method of manufacturing the transistor, and more particularly, a vacuum channel transistor emitting thermal cathode electrons and a method of manufacturing the vacuum channel transistor. The vacuum channel transistor includes: a motherboard; a micro heater member having a thin-film structure formed on the motherboard; a cathode member having a thin-film structure spaced apart from a center part of the micro heater member by a first interval and formed on the micro heater member; a gate member formed on both outer walls of upper parts of the cathode member; and an anode member spaced apart from the cathode member by a second interval through spacers disposed on the gate member, wherein a vacuum electron passing area is interposed between the cathode member and the anode member by the second interval.

Owner:ELECTRONICS & TELECOMM RES INST

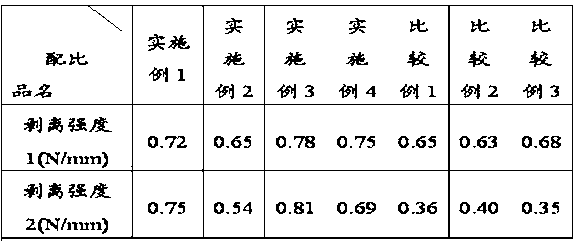

Polyester hot-melt adhesive and coating method thereof

ActiveCN102703013AReduce melt viscosityExcellent film appearanceFilm/foil adhesivesLaminationEpoxyPolyester

The invention relates to the technical field of adhesives, and in particular relates to a polyester hot-melt adhesive. The polyester hot-melt adhesive comprises polyester hot-melt adhesive resin, epoxy resin and curing agents, wherein the mass ratio of the polyester hot-melt adhesive resin to the epoxy resin and to the total amount of the curing agents is 70:(30-99):1. The polyester hot-melt adhesive is low in adhesive strength attenuation, so that the adhesive strength of the polyester hot-melt adhesive on metal can be obviously improved, the melting viscosity of the polyester hot-melt adhesive is reduced, and the film-forming appearance of the polyester hot-melt adhesive is improved; and moreover, the polyester hot-melt adhesive can be prevented from being hydrolyzed, high adhesion of the polyester hot-melt adhesive at low temperature, normal temperature even high temperature is kept, and the mass production property is high.

Owner:东莞市安派电子有限公司

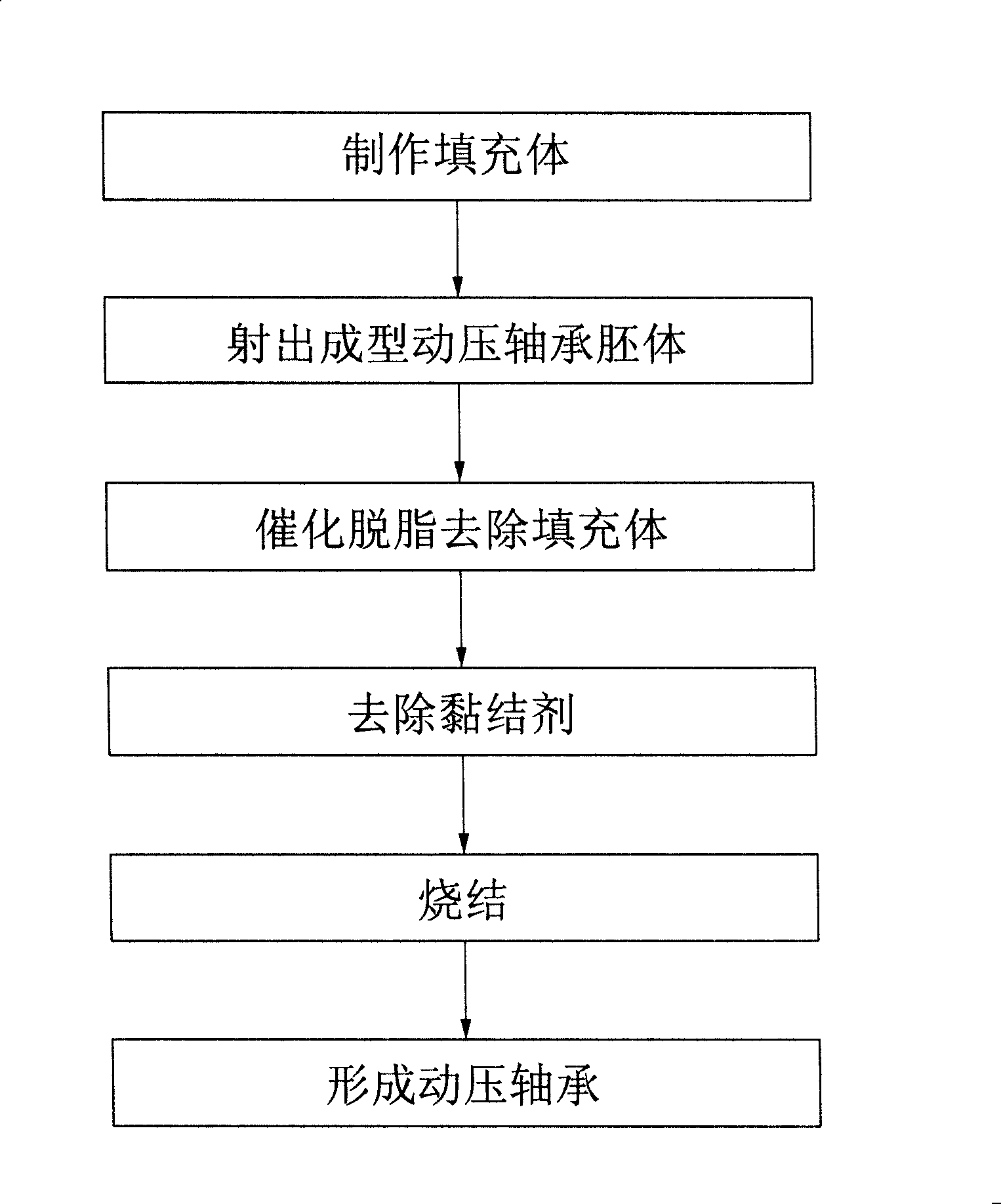

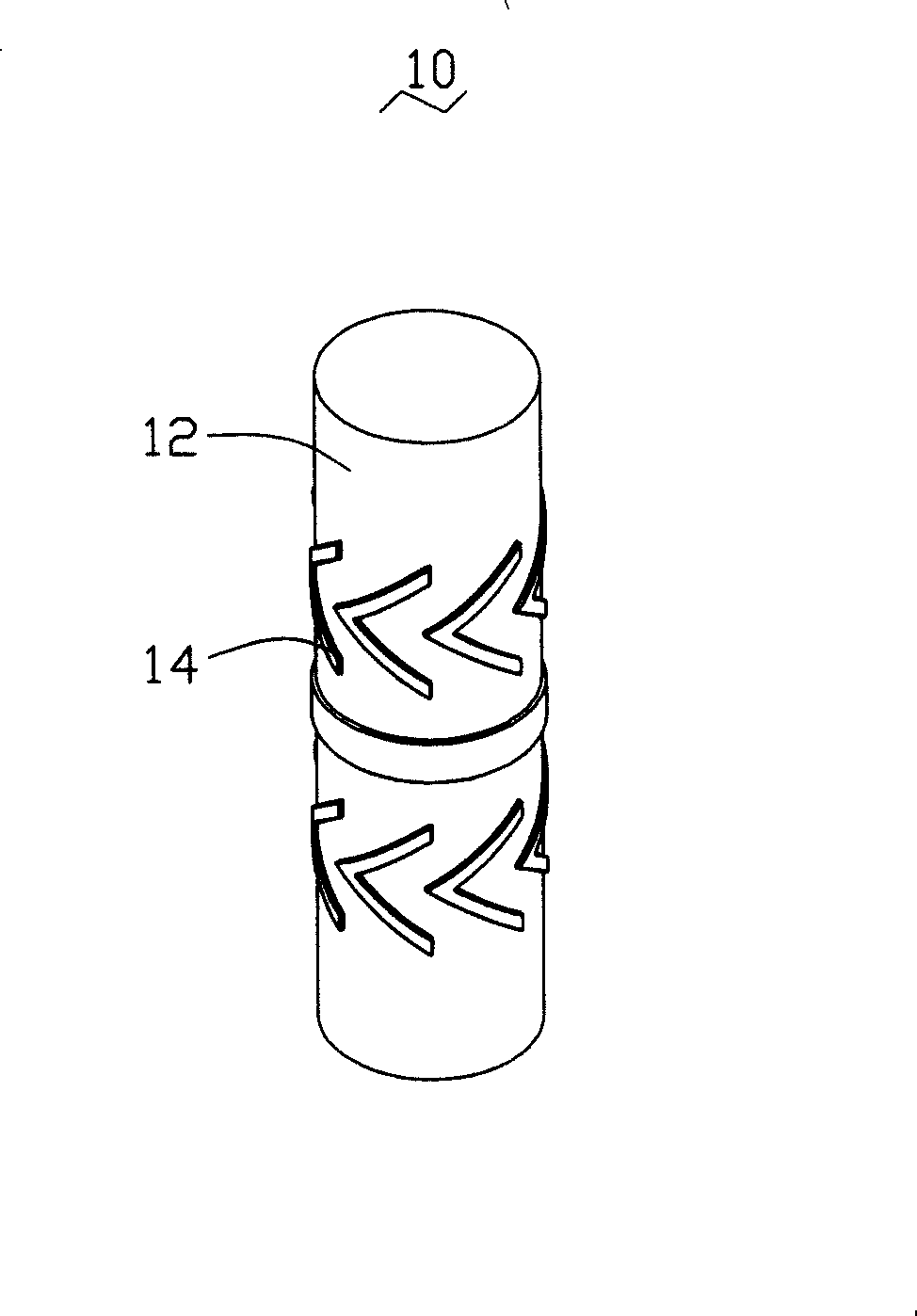

Method for manufacturing hydrodynamic bearing and rotating shaft

InactiveCN101205949AImprove mass productionHigh dimensional accuracyBearing assemblyShaft assemblyEngineeringDynamic pressure

The invention provides a manufacturing method of dynamic pressure bearing, which comprises the following steps: an obturator is provided, the surface of the obturator is convexly provided with a plurality of protrusions; the obturator is arranged in the central position of a hollow bearing mould, and a hollow cavity in the bearing mould is filled with the mode of encapsulation molding to form an embryo of the dynamic pressure bearing; the obturator is removed from the embryo of the dynamic pressure bearing through the mode of catalytically degreasing; binder in the embryo of the dynamic pressure bearing is removed; the embryo of the dynamic pressure bearing is sintered; finally, the dynamic pressure bearing is formed. The dynamic pressure bearing integrally forms the dynamic pressure bearing and a dynamic pressure groove through the method of encapsulation molding, and removes micro-molecular gases which is decomposed from the obturator by using the method of catalytically degreasing, thereby preventing the embryo of dynamic pressure bearing from generating defects as deformation, bending or fracture, etc., improving the mass production capability and the dimensional precision of the dynamic pressure bearing. The invention also provides a manufacturing method of a dynamic pressure rotating shaft.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

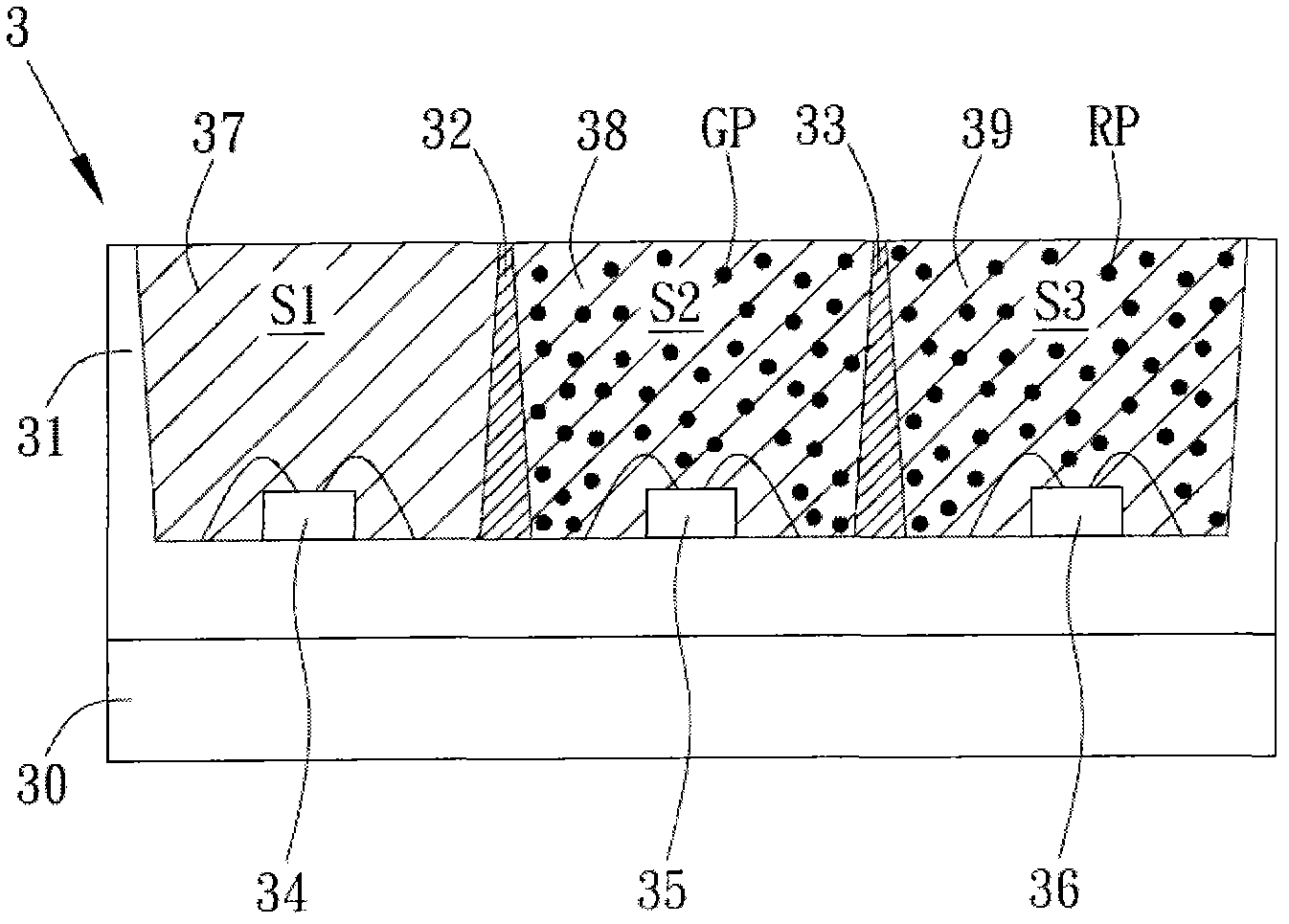

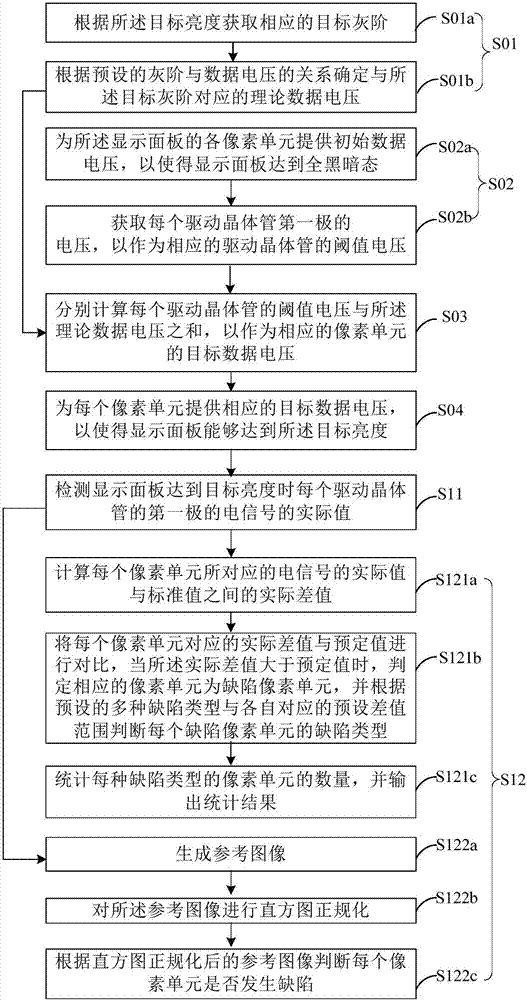

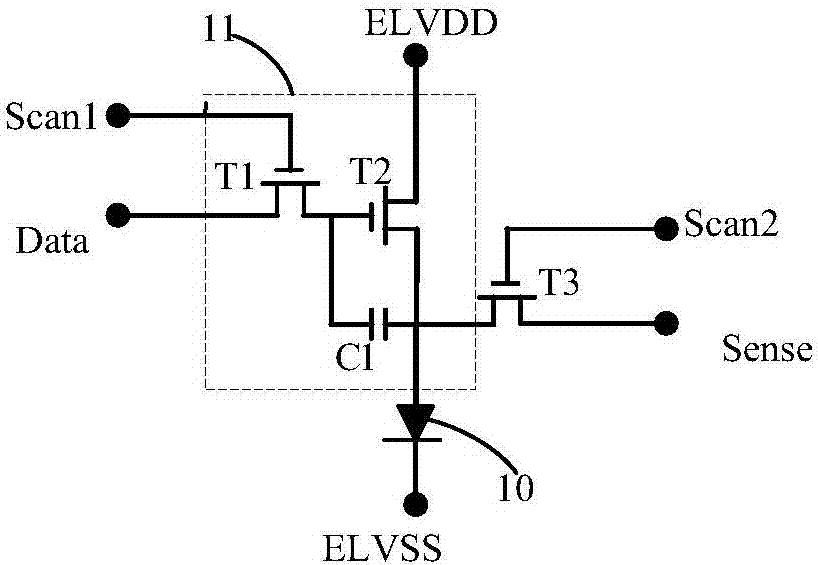

Detection method of display panel, and detection device

ActiveCN106920496AQuick fixImprove detection efficiencyStatic indicating devicesPower flowEngineering

The invention provides a detection method of a display panel. The display panel comprises a plurality of pixel units; each pixel unit comprises a light-emitting diode (LED) and a pixel circuit, wherein the pixel circuit comprises a drive transistor; a first pole of each drive transistor is connected with the corresponding LED. The detection method comprises the steps of when the display panel reaches target brightness, detecting actual values of electrical signals of the first poles of the drive transistors in all the pixel units, wherein each electrical signal comprises a current signal and / or a voltage signal; judging whether all the pixel units have defects or not according to the actual values of the electrical signals corresponding to all the pixel units. Correspondingly, the invention also provides a detection device. The detection method and the detection device can help an operator to rapidly judge whether the pixel units have defects or not.

Owner:BOE TECH GRP CO LTD

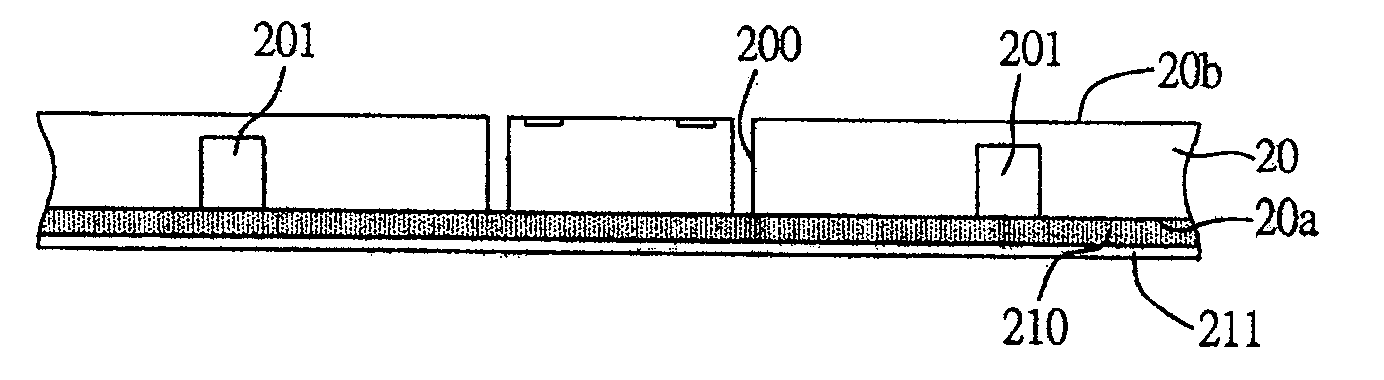

Structure embedded with semiconductor chip and its manufacturing method

ActiveCN100561696CIncrease profitReduce warpageSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The present invention discloses a structure of a embedded semiconductor chip and its manufacturing method, the method mostly provides a loading plate opposing first and second surface, forming multi- through opening in the loading plate, and forming first plow groove surrounding the opening and without through the loading plate at the first surface of the loading plate, and placing the semiconductor chip in the opening severalty, and pressing the first surface of the loading plate and the semiconductor chip on the first dielectric layer for stuffing the first dielectric layer into the first plow groove and the gapping place between the semiconductor chip and the loading plate, forming the second plow groove at the second surface corresponding to the first plow groove position, and the second plow groove is communicated with the first plow groove to forming the plow groove through the loading plate, thereby the subsequent cutting operation can be executed by the through plow groove, furthermore the loading plate space is used efficiently and the typesetting rate is improved, and the molding time is reduced.

Owner:PHOENIX PRECISION TECH CORP

Method for producing electrochemical capacitor electrode

InactiveUS20070025062A1Good characteristicEnhance bondingElectrolytic capacitorsHybrid capacitor electrodesElectrochemistryPorous particle

A method is provided for enhancing the bond between the polarizable electrode layer and the undercoat layer. The method includes a first step for forming an undercoat layer on a collector and a second step for forming a polarizable electrode layer on said undercoat layer. The first step is performed by coating said collector with a coating solution for the undercoat layer that includes electroconductive particles, a first binder, and a first solvent. The second step is performed by coating said undercoat layer with a coating solution for the polarizable electrode layer that includes porous particles, a second binder, and a second solvent. The first solvent can dissolve or disperse said first and second binders. The second solvent can dissolve or disperse said first and second binders. The fusion of the interface between the undercoat layer and the polarizable electrode layer enhances the bond therebetween.

Owner:TDK CORPARATION +1

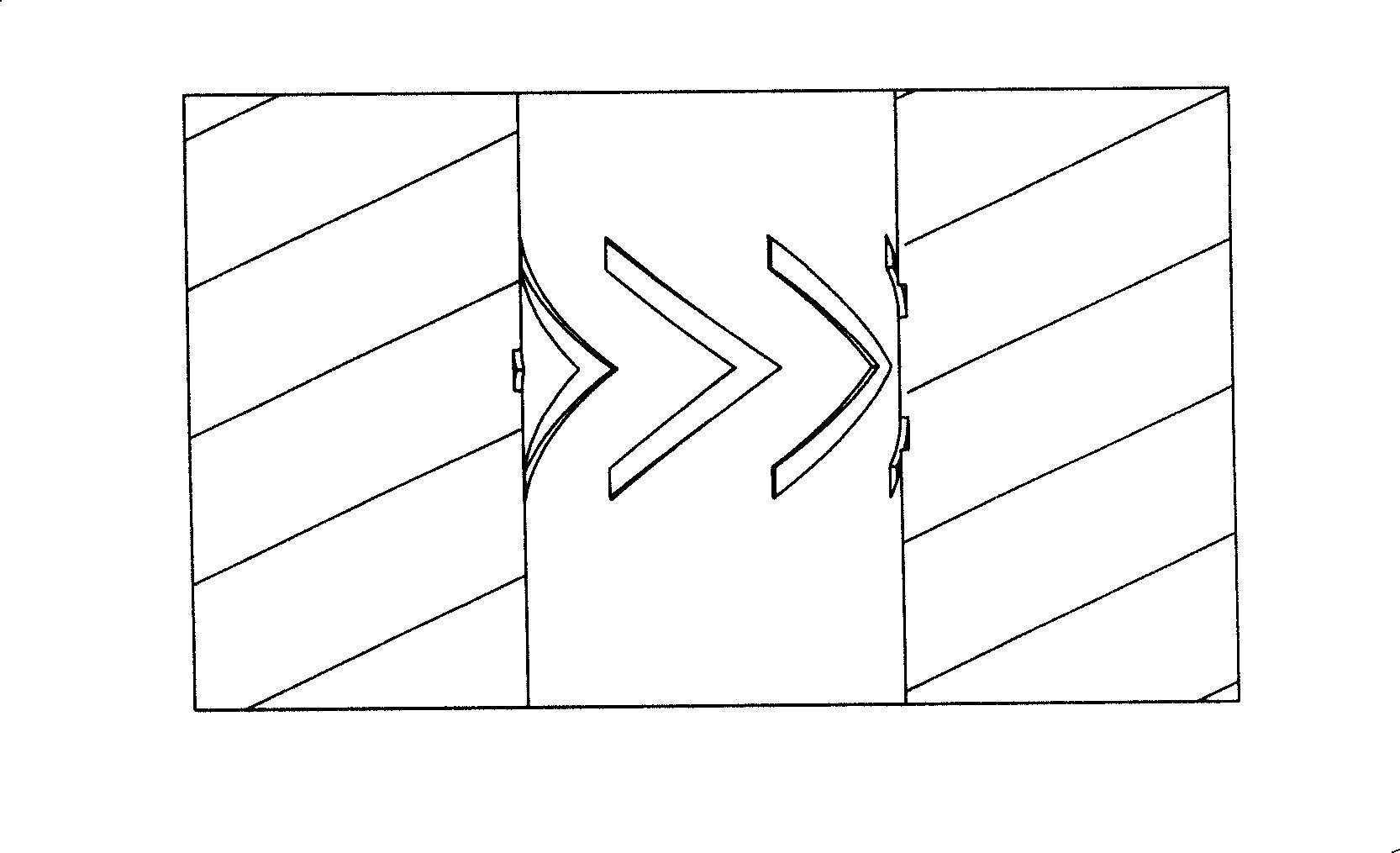

Preparation method of local binderless reinforce panel

ActiveCN103747620AStable positionImprove mass productionPrinted circuit manufactureRubber materialPunching

The invention discloses a preparation method of a local binderless reinforce panel. The preparation method comprises the steps of I, punching a product hole and a base material positioning hole in a base material by utilizing a base material punching die; II, punching an avoiding area and a rubber material positioning hole in a rubber material by utilizing a rubber material punching die; III, centering the punched basal material and the rubber material through a coating guide rod; IV, laminating the centered basal material and the rubber material through a positioning laminating mechanism; V, centering the laminated basal material and the rubber material to a semi-finished product through a centering rod of a forming mechanism; VI, finally placing the semi-finished product into a forming mechanism to be molded in a punching manner so as to form a local binderless reinforce panel. By utilizing the method, the local binderless reinforce panel with precise position and different shapes can be obtained; moreover, continuity in operation can be realized, a foundation is set for realizing the high-quality flexible plate, and the high productivity is greatly improved.

Owner:南通钢安机械制造有限公司

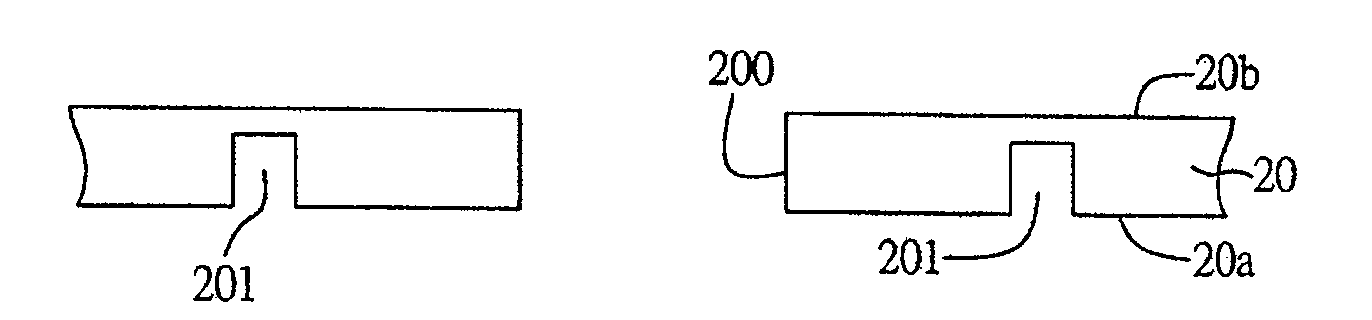

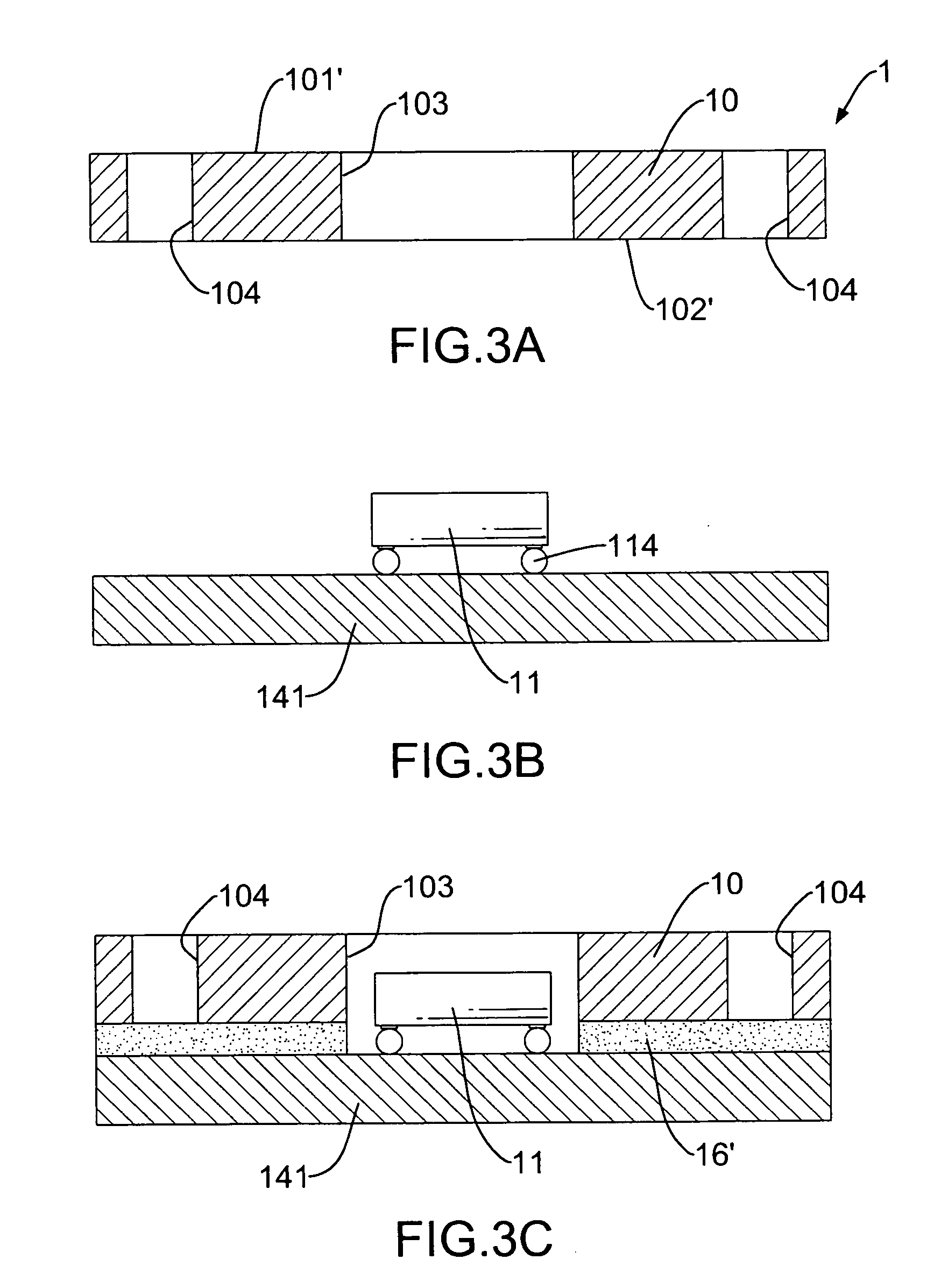

Embedded chip semiconductor having dual electronic connection faces

InactiveUS20050275081A1Improve mass productionSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

An embedded chip semiconductor has a substrate, at least one chip, an encapsulant, two circuit patterns and multiple contact vias. The substrate has a top surface, a bottom surface and at least one chip recess. The at least one chip has multiple terminals and is mounted in a corresponding chip recess. The thickness of the chip is equal to or less than the thickness of the substrate. The encapsulant is formed in the chip recess to hold the chip. The circuit patterns are respectively formed on the top and bottom surfaces of the substrate and one of the circuit patterns is connected to the multiple terminals of the chip. The two circuit patterns on two surfaces of the substrate are connected through the multiple contact vias. Therefore, the semiconductor has dual electronic connection faces to be suitable for different applications.

Owner:CHANG ROGER

Light-emitting diode array

InactiveUS7504772B2Easily controlEtch areaLaser detailsDischarge tube luminescnet screensDiode arrayLight-emitting diode

A light-emitting diode array comprising a conductive layer formed on a substrate, separate light-emitting portions formed on the conductive layer, a first electrode formed on at least part of an upper surface of each light-emitting portion, and a second electrode formed on the conductive layer adjacent to the light-emitting portions; the first electrode comprising a common switching electrode matrix; the second electrode comprising a common electrode divided such that one second electrode exists in every block; and at least one of bonding pads extending to the first common electrode and the second common electrode being formed on a bonding portion formed on the conductive layer like an island, whereby the bonding pads are separate from each other.

Owner:LEXTAR ELECTRONICS CORP

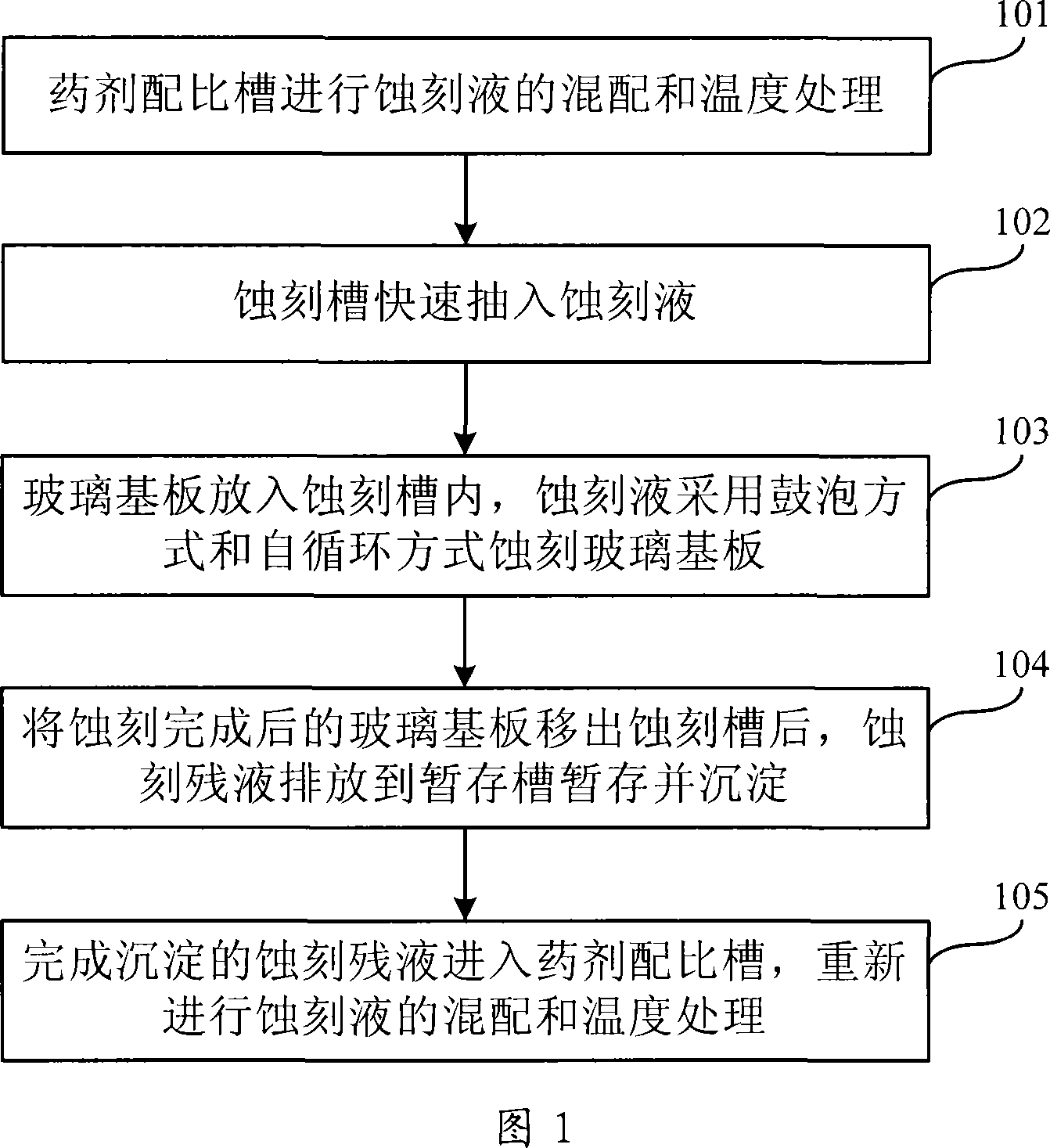

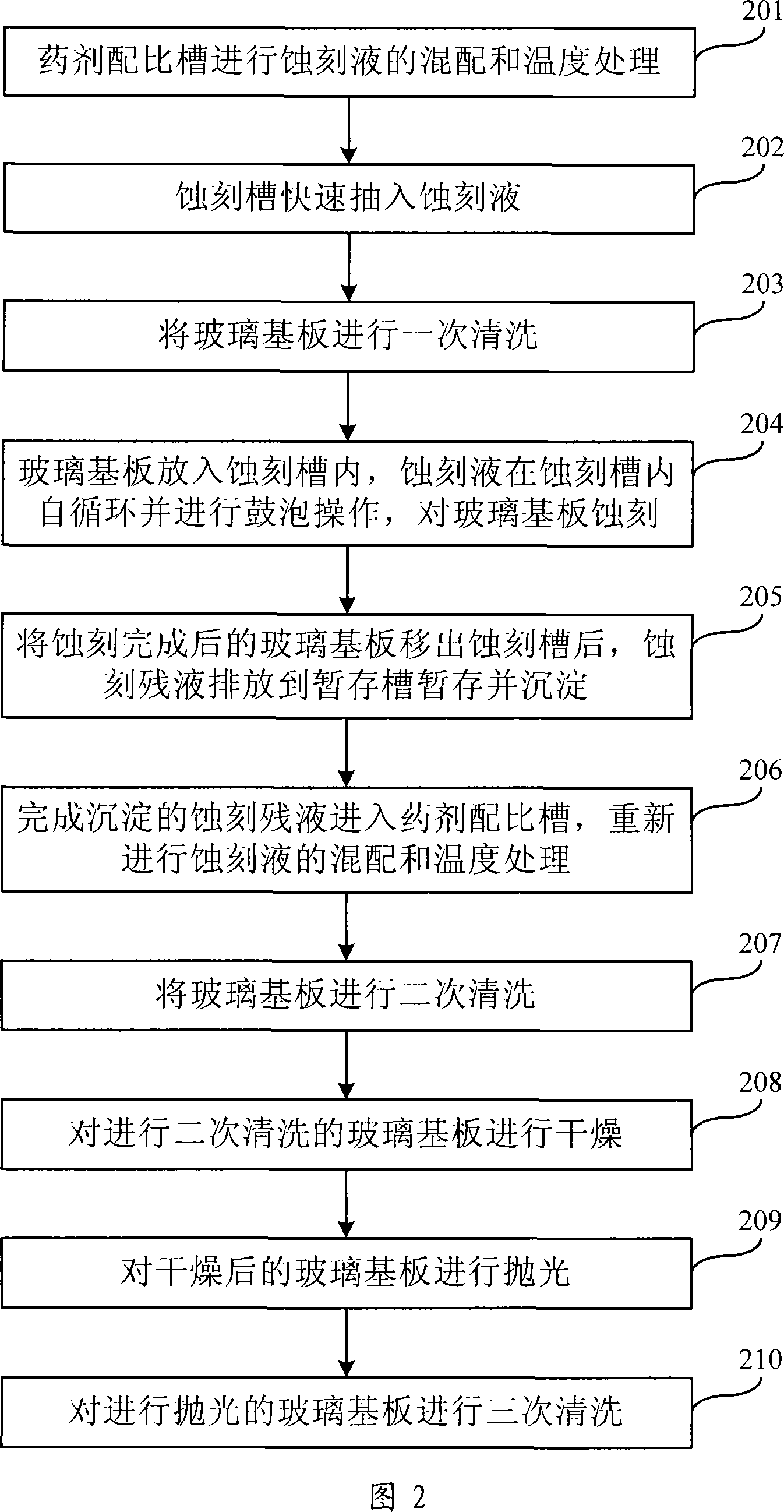

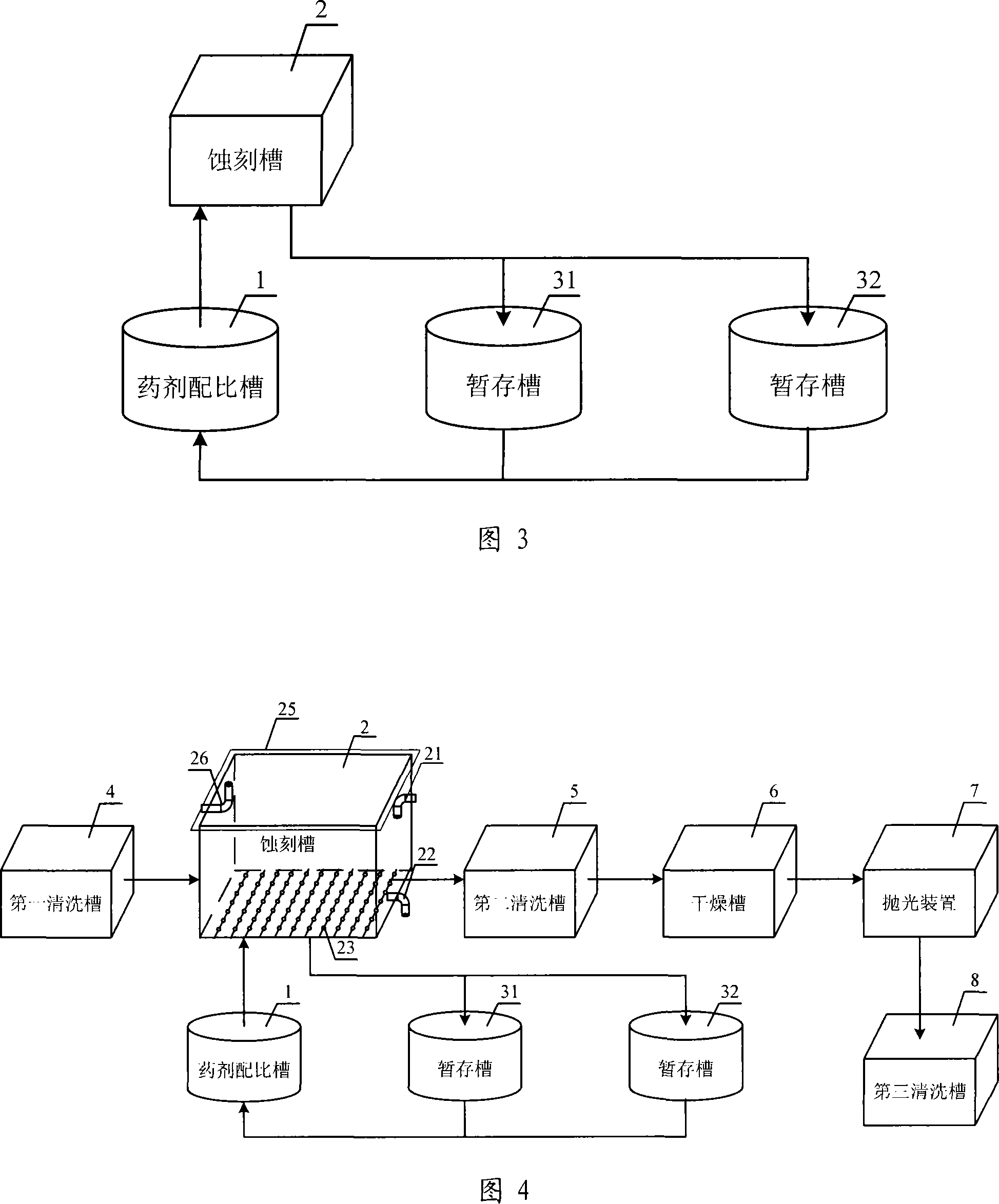

Attenuation method and device for flat glass substrate

ActiveCN101234853AUniform etchingTo achieve the purpose of mass productionFlat glassUltrasound attenuation

The invention relates to a method for thinning a flat glass substrate and a device thereof. First, etching liquor is mixed and processed of temperature treatment in a reagent preparation trough; the prepared etching liquor is quickly pumped into an etching trough. The glass substrate is placed into the etching trough and is etched by adopting a self-circulation way of bubbling and etching. After being etched, the glass substrate is taken out and the etching liquor is quickly poured into a temporary storage trough for a temporary storage and a precipitation. The etching liquor can be re-prepared and reused when the glass substrate is etched next time. The etched and thinned glass substrate is cleaned, dried and polished. The invention provides the method for thinning the flat glass substrate and a device thereof. By adopting the etching method of reagent circulation and bubbling, the aim of batch production can be received, thus supplying a thin glass substrate product and improving the good product rate and production quantity.

Owner:BOE TECH GRP CO LTD +2

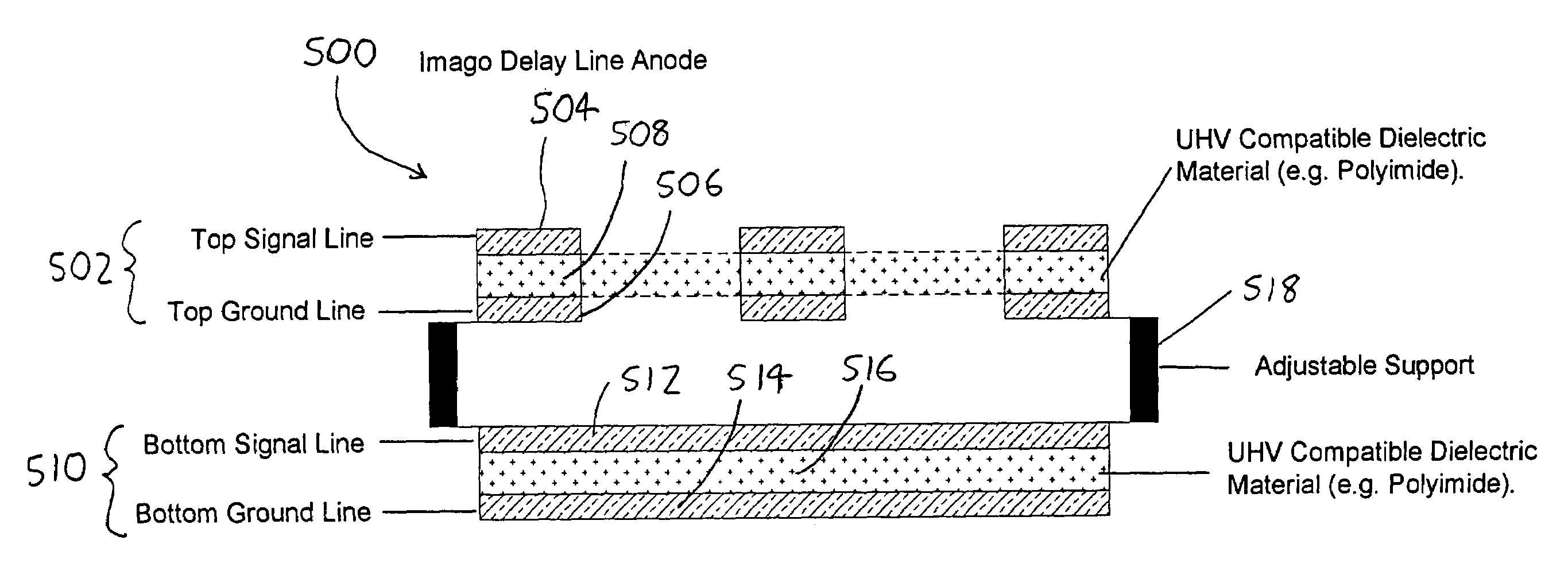

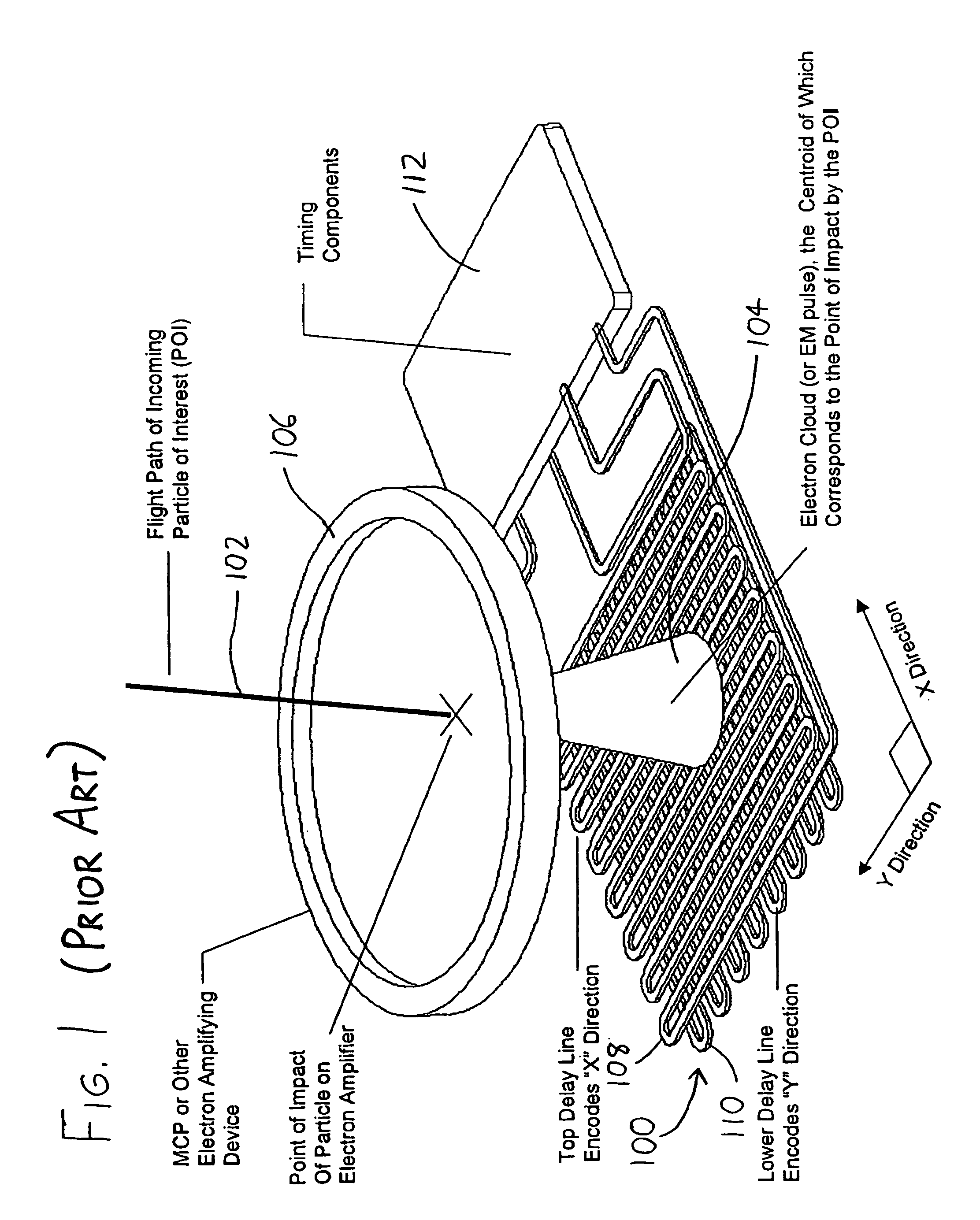

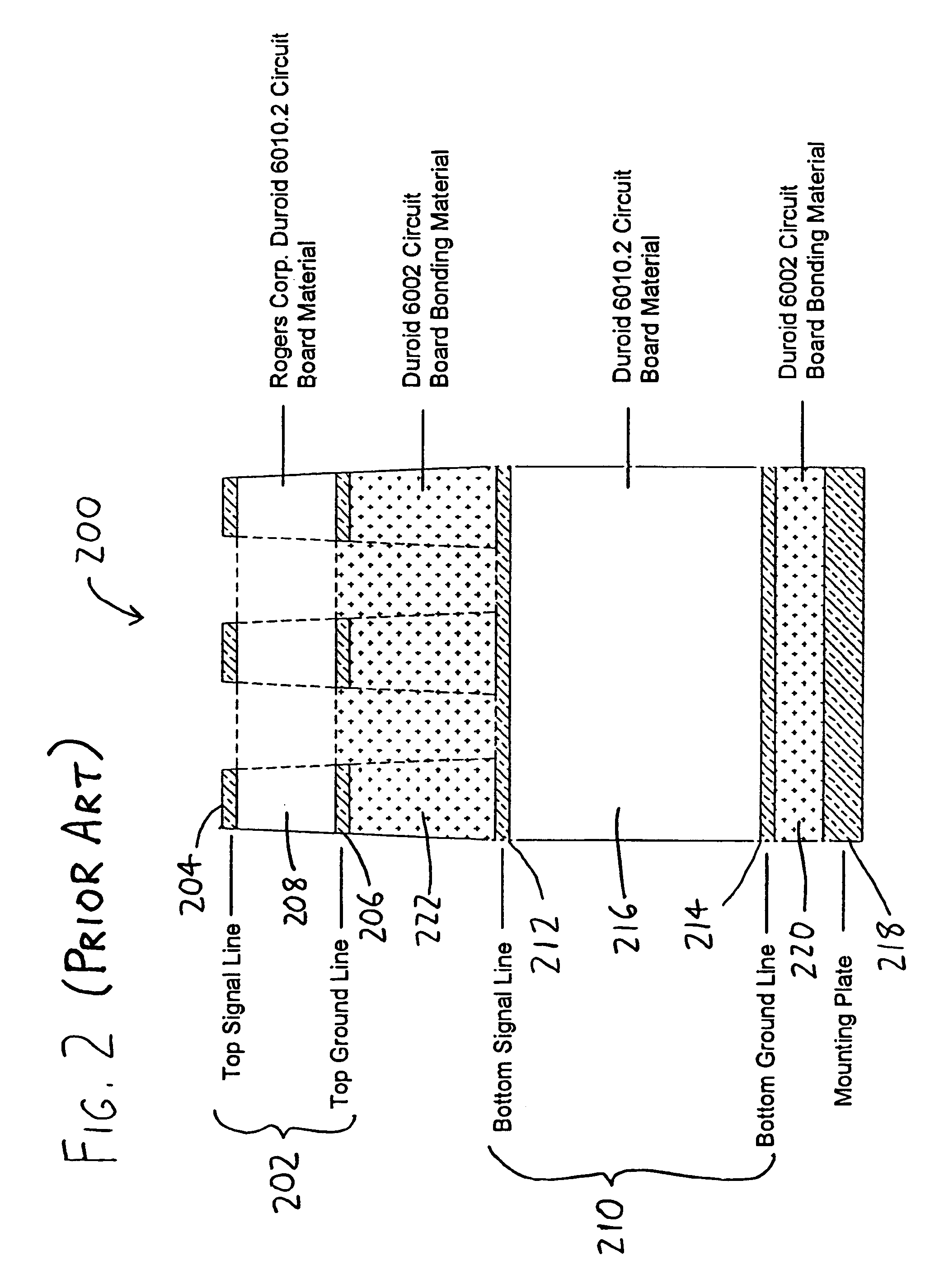

Delay line anodes

InactiveUS7019307B1Improve mass productionLow costMeasurement with semiconductor devicesElectric discharge tubesElectricityFlexible circuits

In detectors for imaging and other applications, delay line anodes are arrayed so as to allow detection of the location and / or timing of particle hits. The anodes are arrayed to provide an upper anode and one or more lower anodes, with particles incident on the upper anode passing in turn to the lower anodes. The anode arrays allow the use of identically manufactured anodes which are maintained in parallel spaced relation along the travel path of the particles of interest without dielectric material or other structure situated between the anodes. The spacing between the anodes is preferably adjustable so as to allow the installer and / or user to modify the performance characteristics of the array. The anodes may be made of pre-formed metal foil signal and ground layers laminated onto opposing sides of a dielectric sheet, or may be etched or otherwise formed from flex circuit material, so that the anodes and the overall array are light weight, compact, and flexible.

Owner:CAMECA INSTR

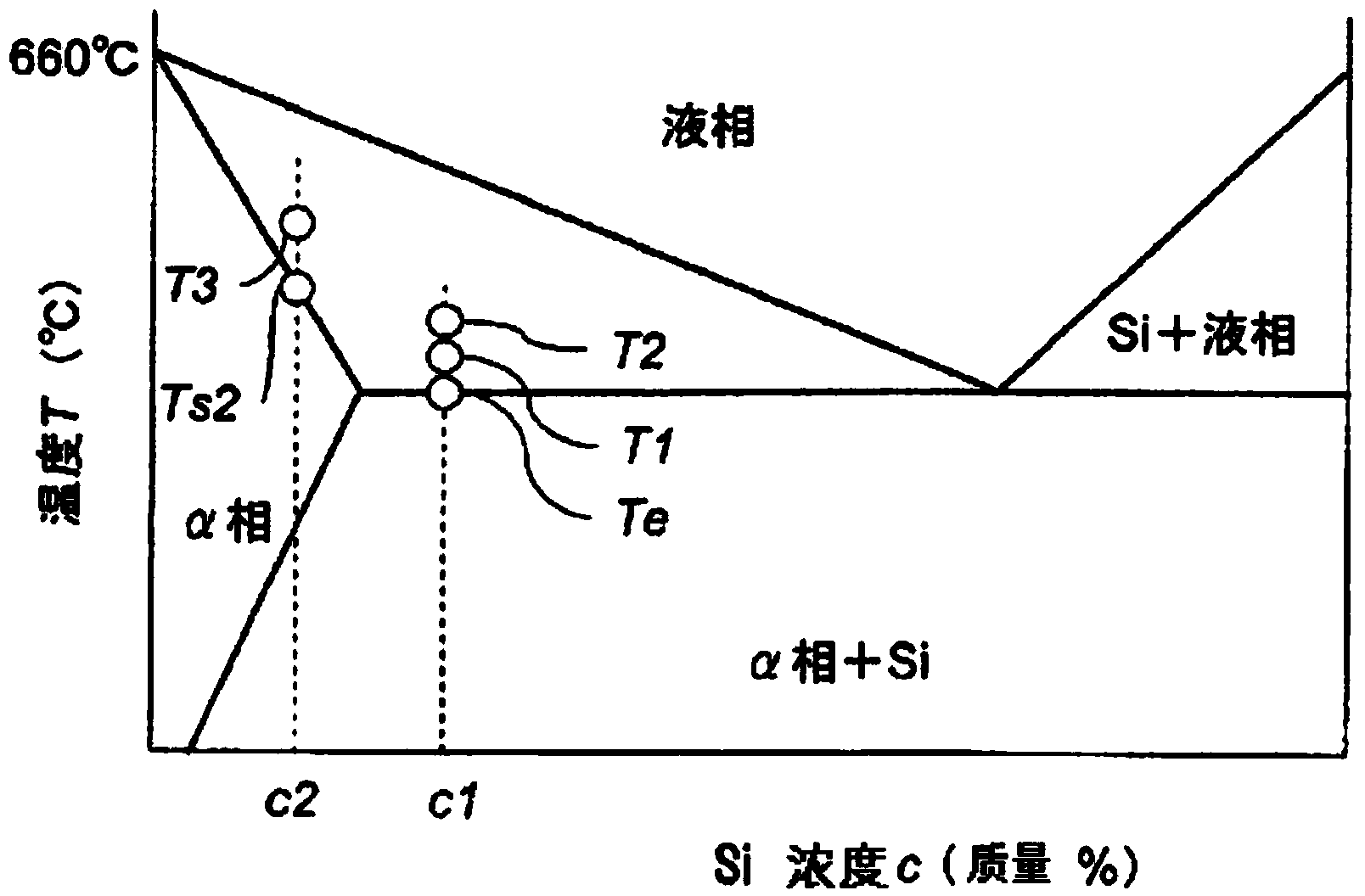

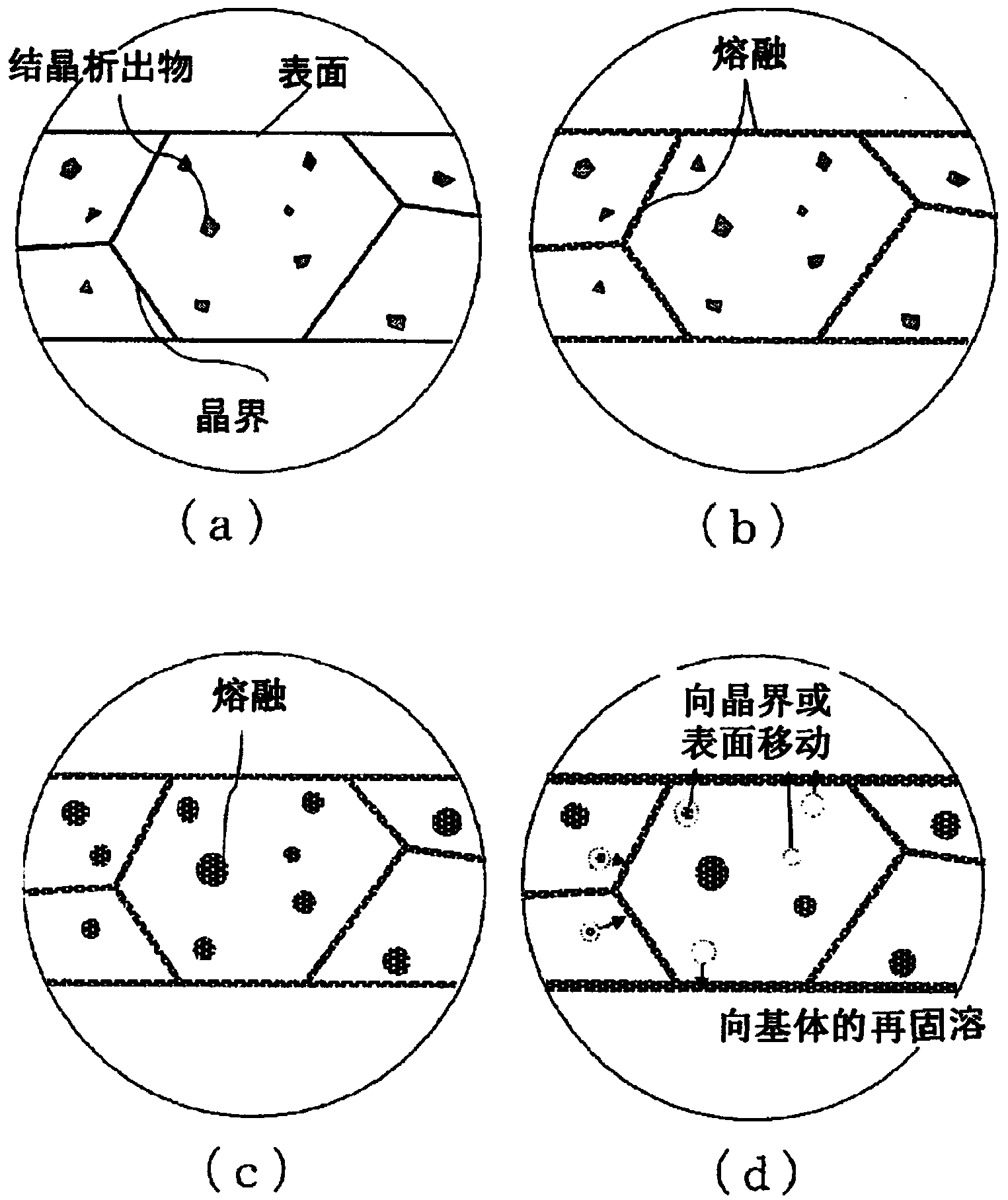

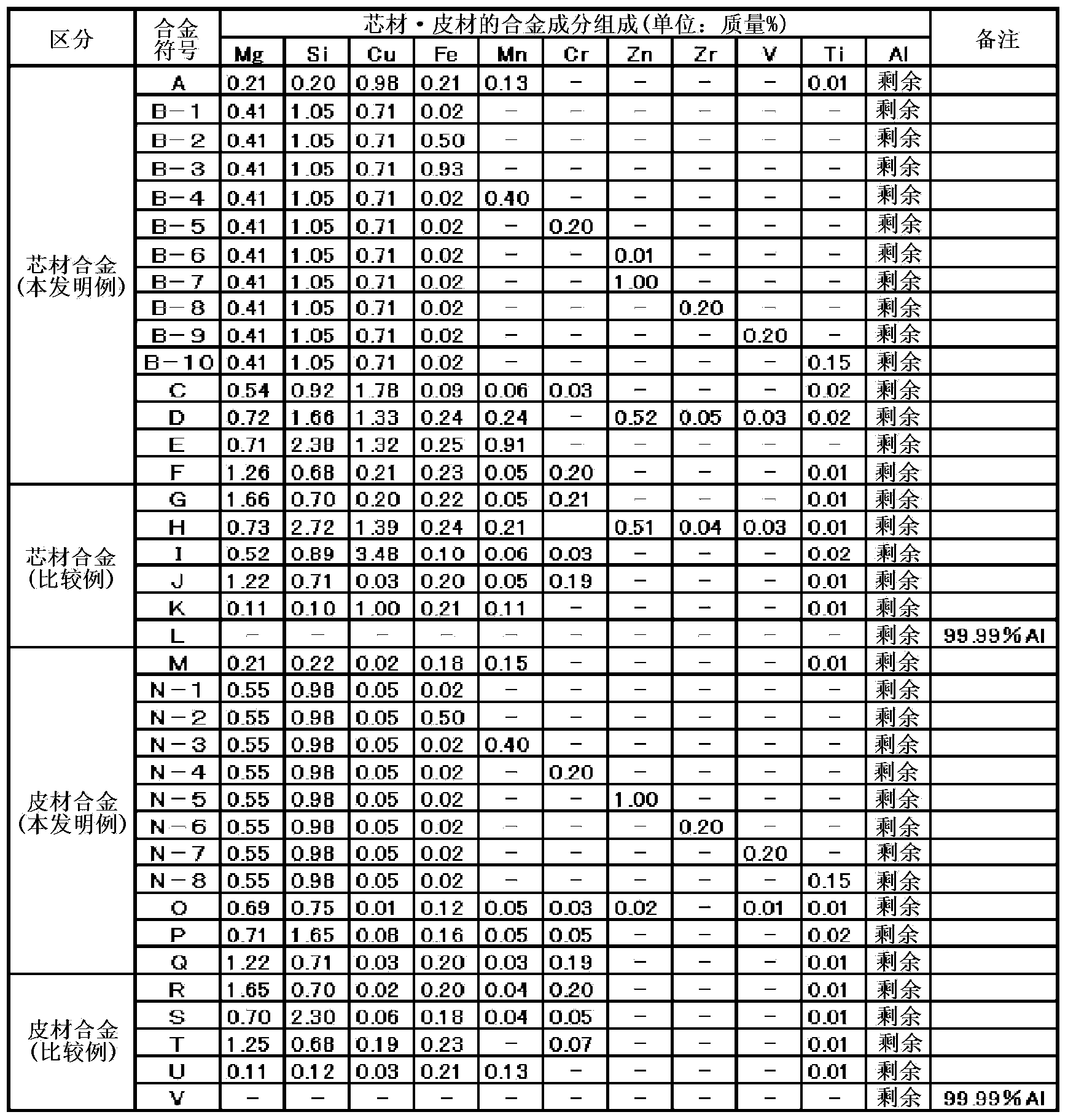

Aluminum alloy clad material for molding

InactiveCN104080935ABad connectionImprove mass productionWelding/cutting media/materialsThin material handlingAlloy coatingImpurity

An aluminum alloy clad material for molding is equipped with: an aluminum alloy core material comprising 0.2-1.5 mass% of Mg, 0.2-2.5 mass% of Si, and 0.2-3.0 mass% of Cu, with the remainder comprising Al and unavoidable impurities; an aluminum alloy coating material that is clad on one or both surfaces of the core material, that has a thickness of 3-30% the total sheet thickness on one surface, and that has a composition comprising 0.2-1.5 mass% of Mg and 0.2-2.0 mass% of Si, with the content of Cu being limited to 0.1 mass% or less and the remainder comprising Al and unavoidable impurities; and an aluminum alloy insert material that is interposed between the core material and the coating material and that has a solidus temperature of at most 590 DEG C.

Owner:FURUKAWA SKY ALUMINUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com