Patents

Literature

545 results about "Back surface field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface passivated photovoltaic devices

InactiveUS20060255340A1Raise the level of dopingReduce potential barrierSolid-state devicesPhotovoltaic energy generationSemiconductor materialsBack surface field

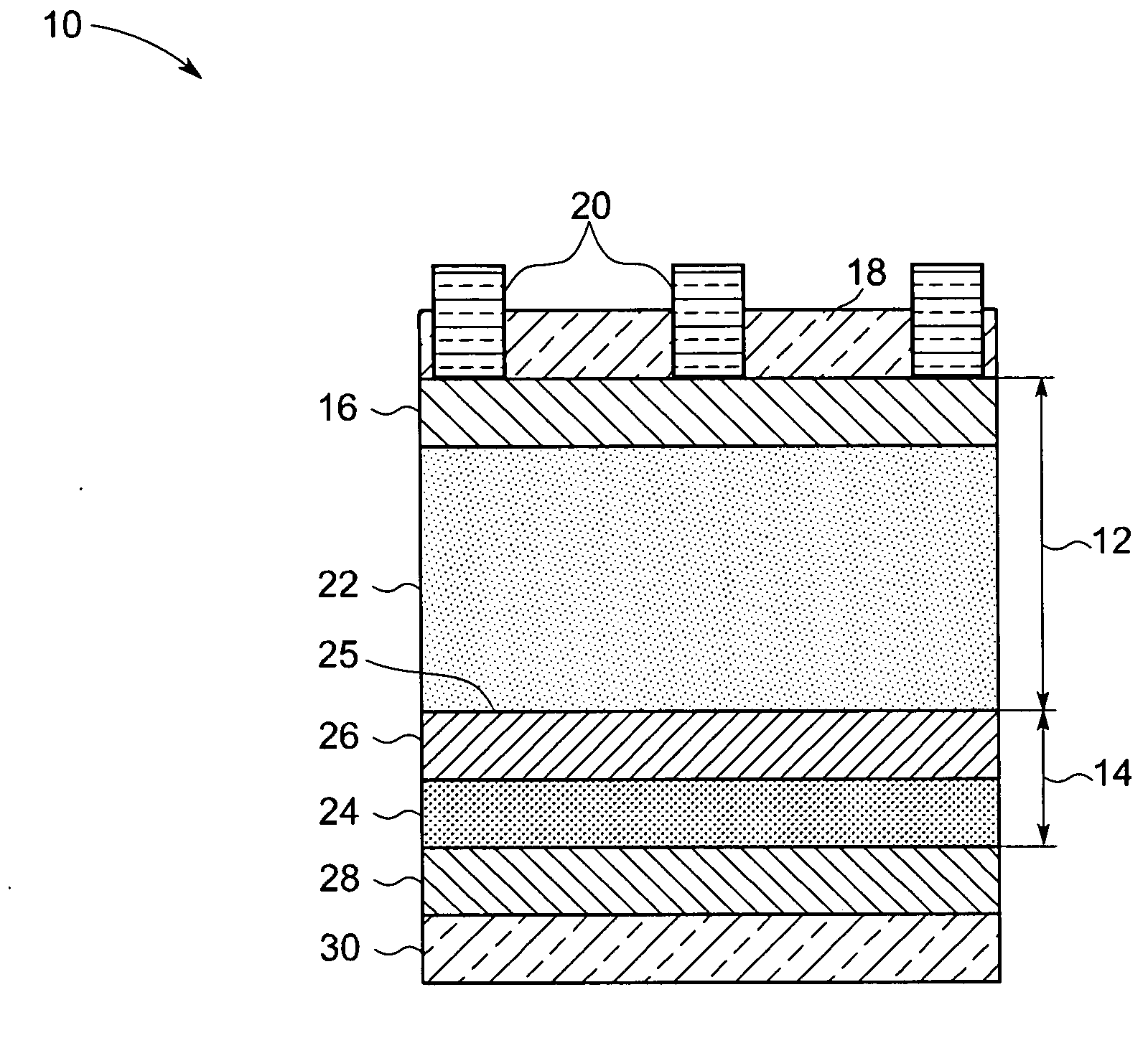

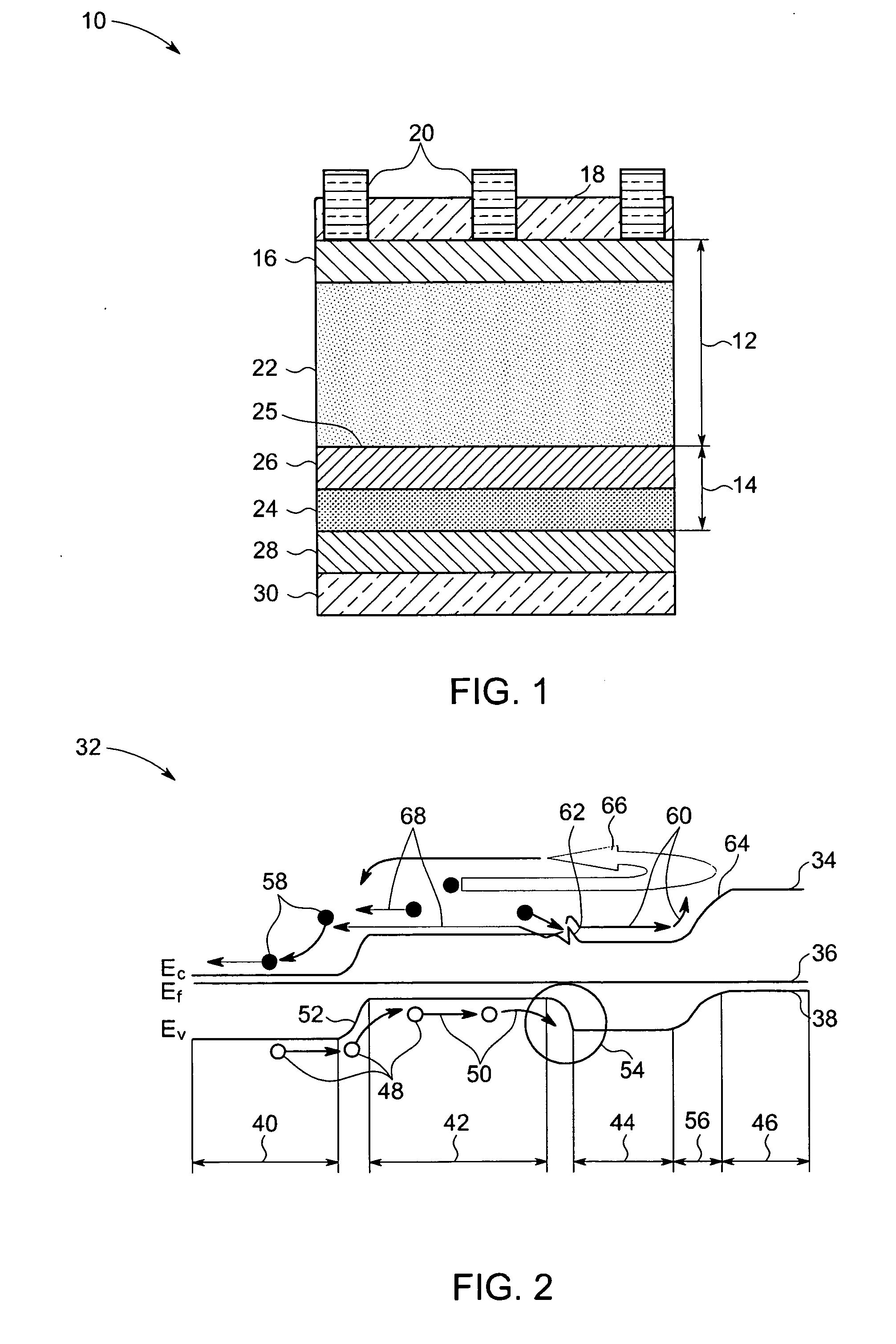

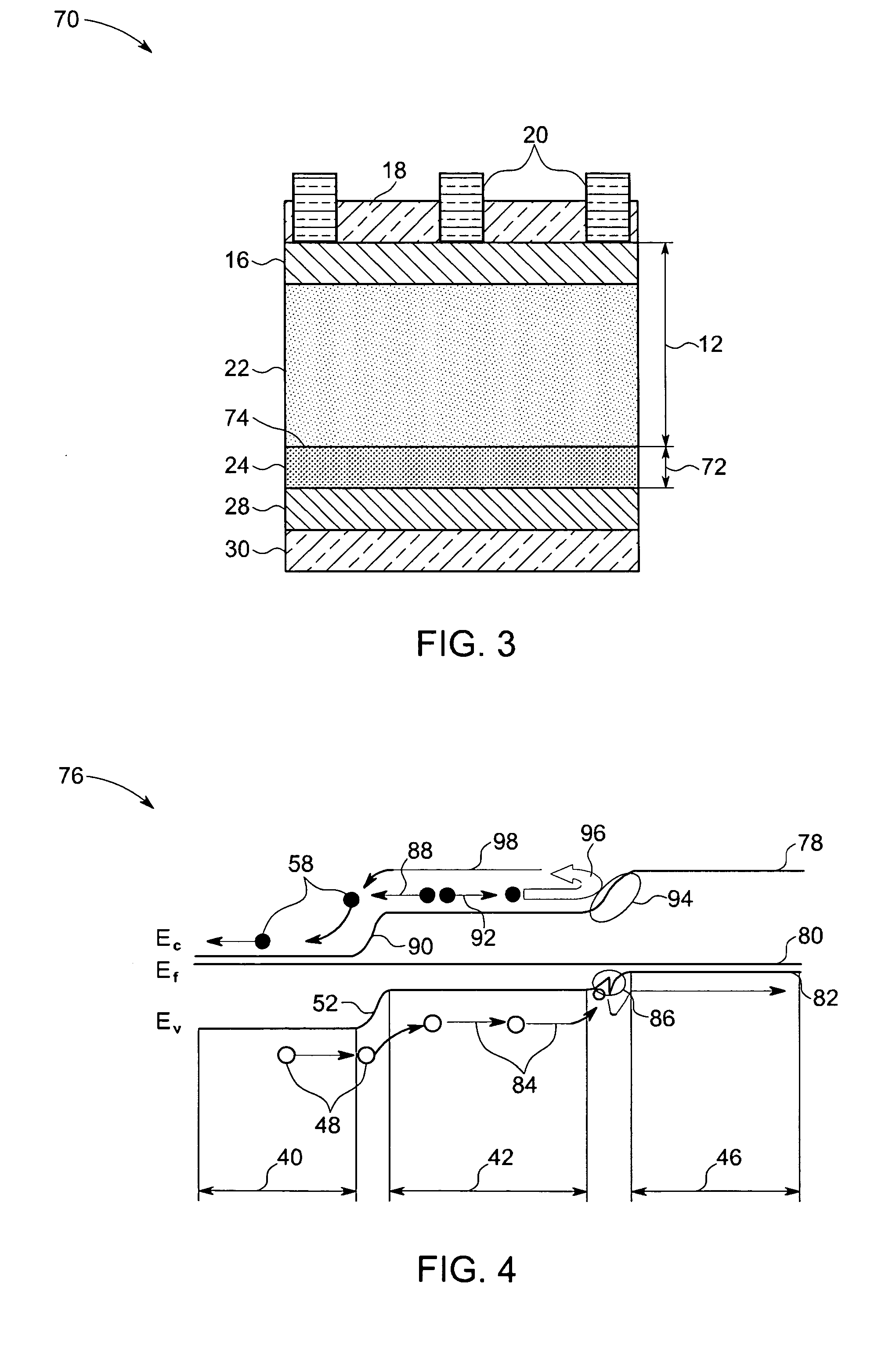

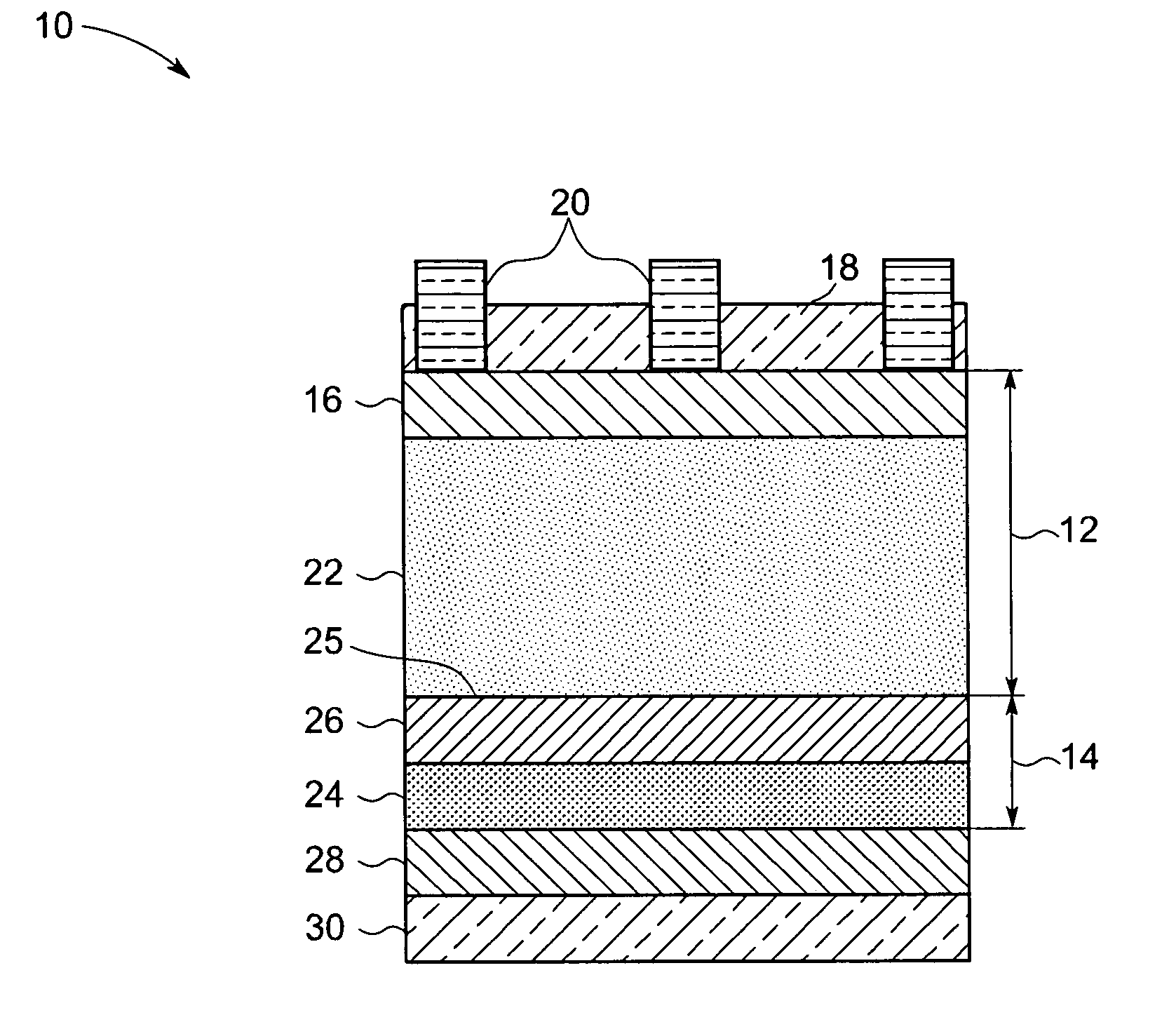

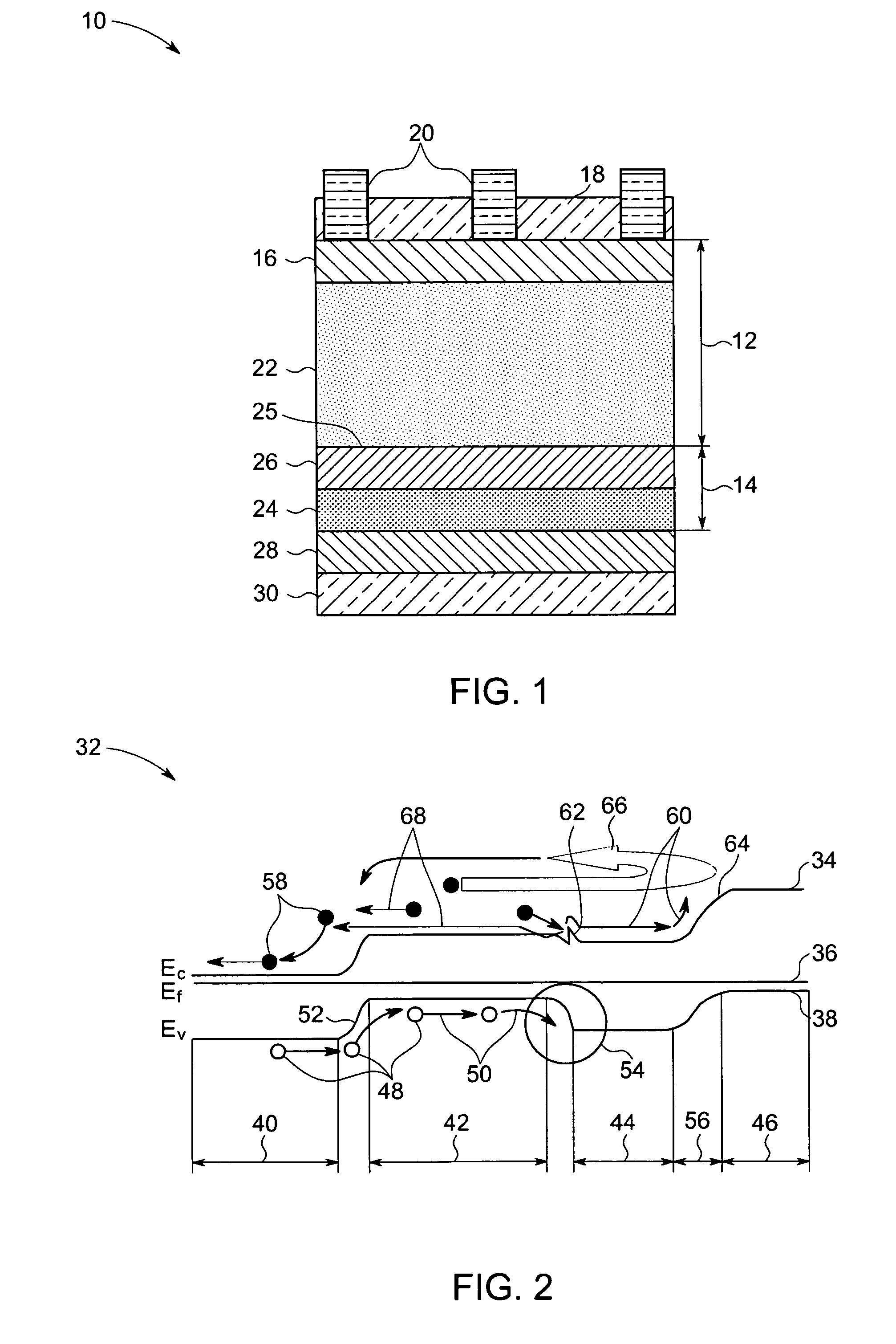

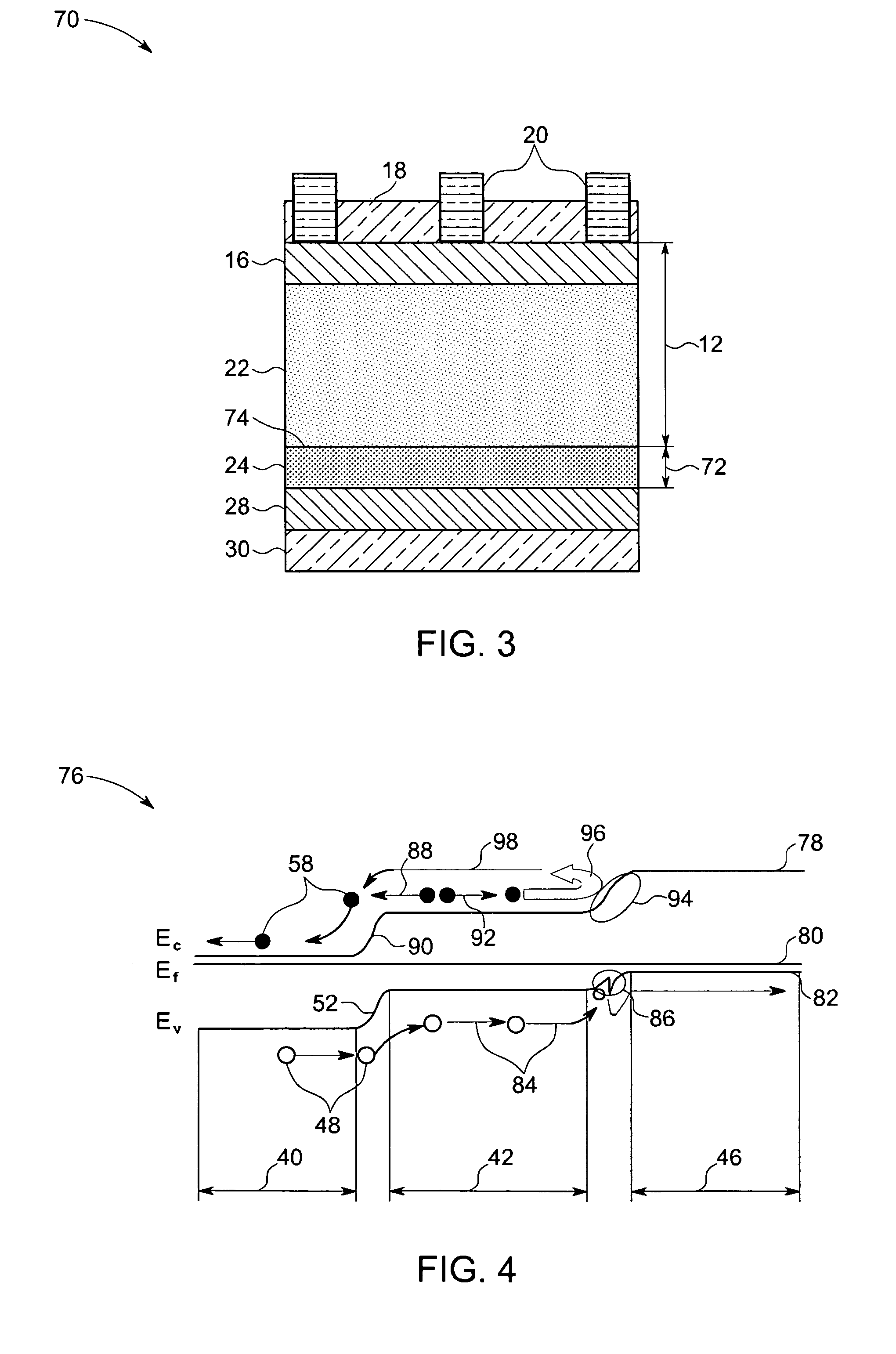

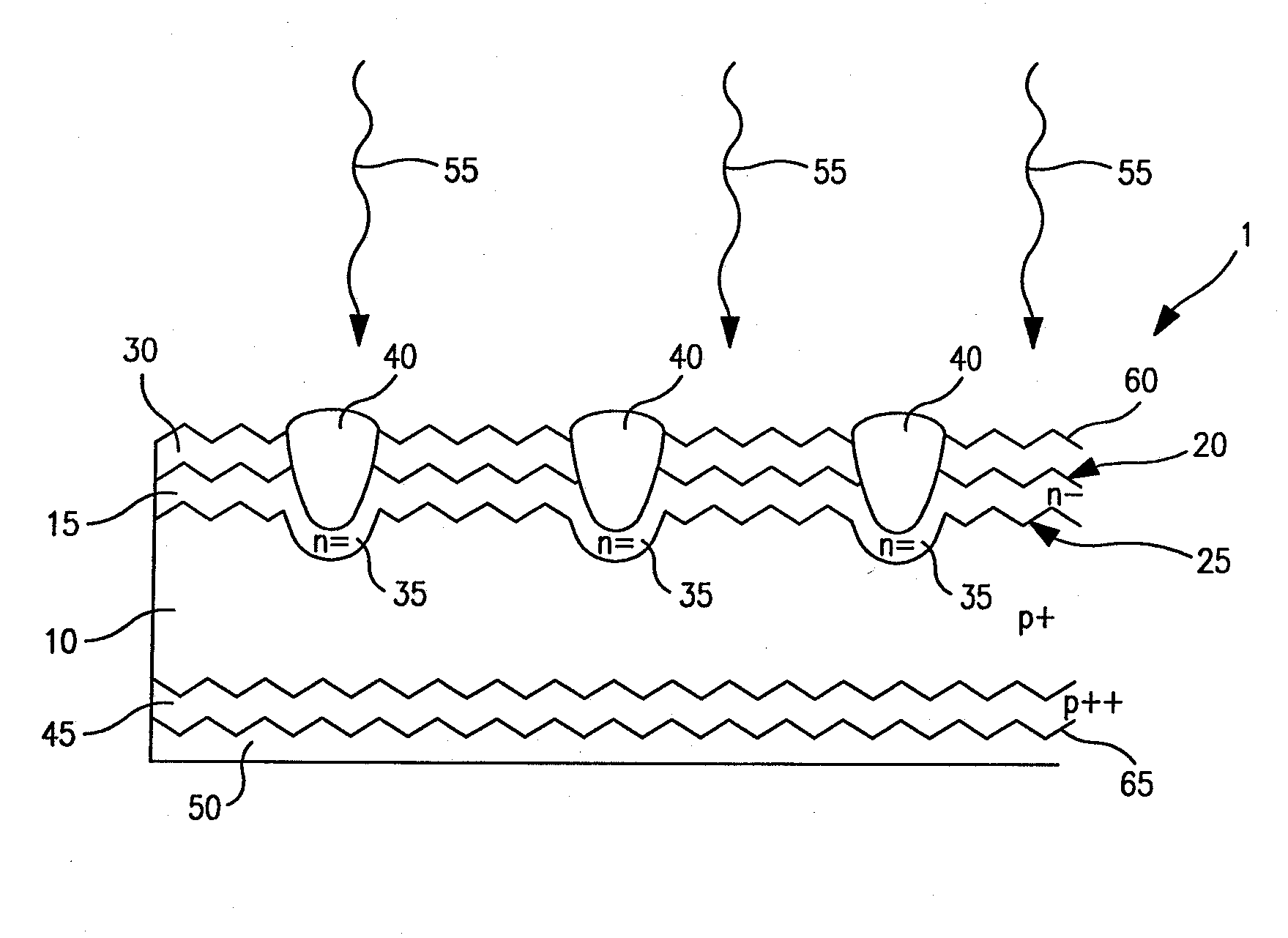

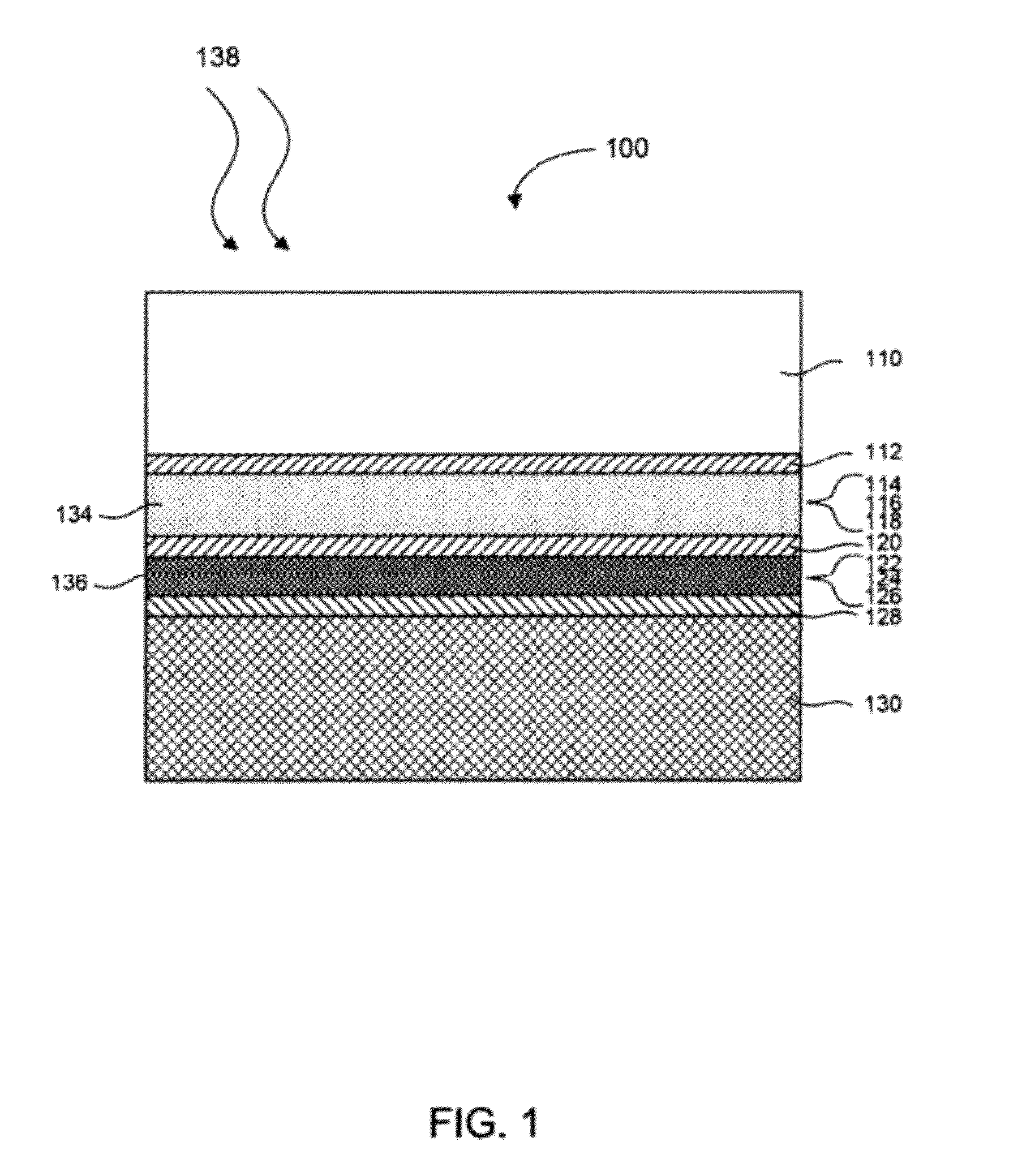

A photovoltaic device comprising a photovoltaic cell is provided. The photovoltaic cell includes an emitter layer comprising a crystalline semiconductor material and a lightly doped crystalline substrate disposed adjacent the emitter layer. The lightly doped crystalline substrate and the emitter layer are oppositely doped. Further, the photovoltaic device includes a back surface passivated structure coupled to the photovoltaic cell. The structure includes a highly doped back surface field layer disposed adjacent the lightly doped crystalline substrate. The highly doped back surface field layer includes an amorphous or a microcrystalline semiconductor material, wherein the highly doped back surface field layer and the lightly doped crystalline substrate are similarly doped, and wherein a doping level of the highly doped back surface field layer is higher than a doping level of the lightly doped crystalline substrate. Additionally, the structure may also include an intrinsic back surface passivated layer disposed adjacent the lightly doped crystalline substrate, where the intrinsic back surface passivated layer includes an amorphous or a microcrystalline semiconductor material.

Owner:GENERAL ELECTRIC CO

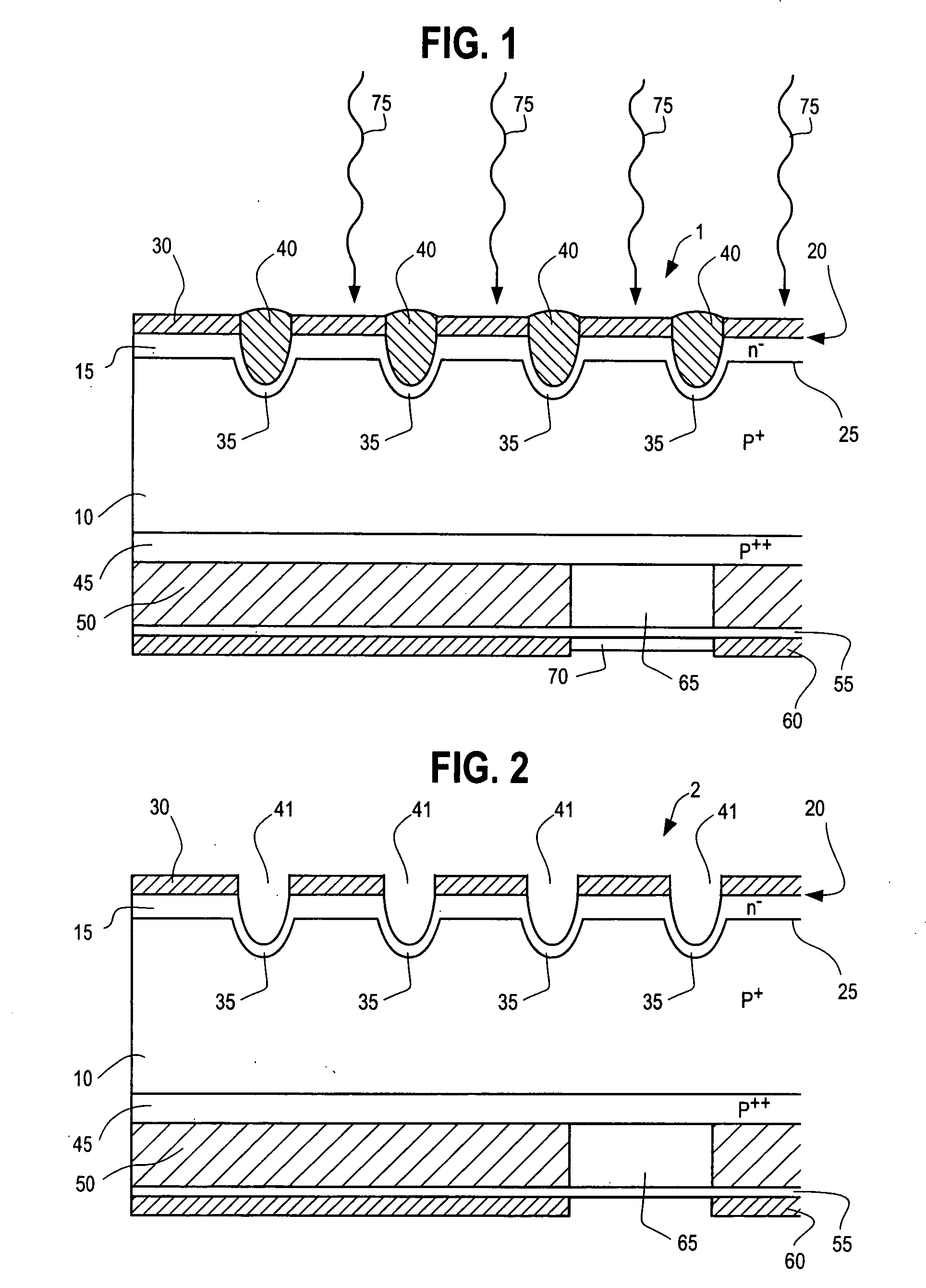

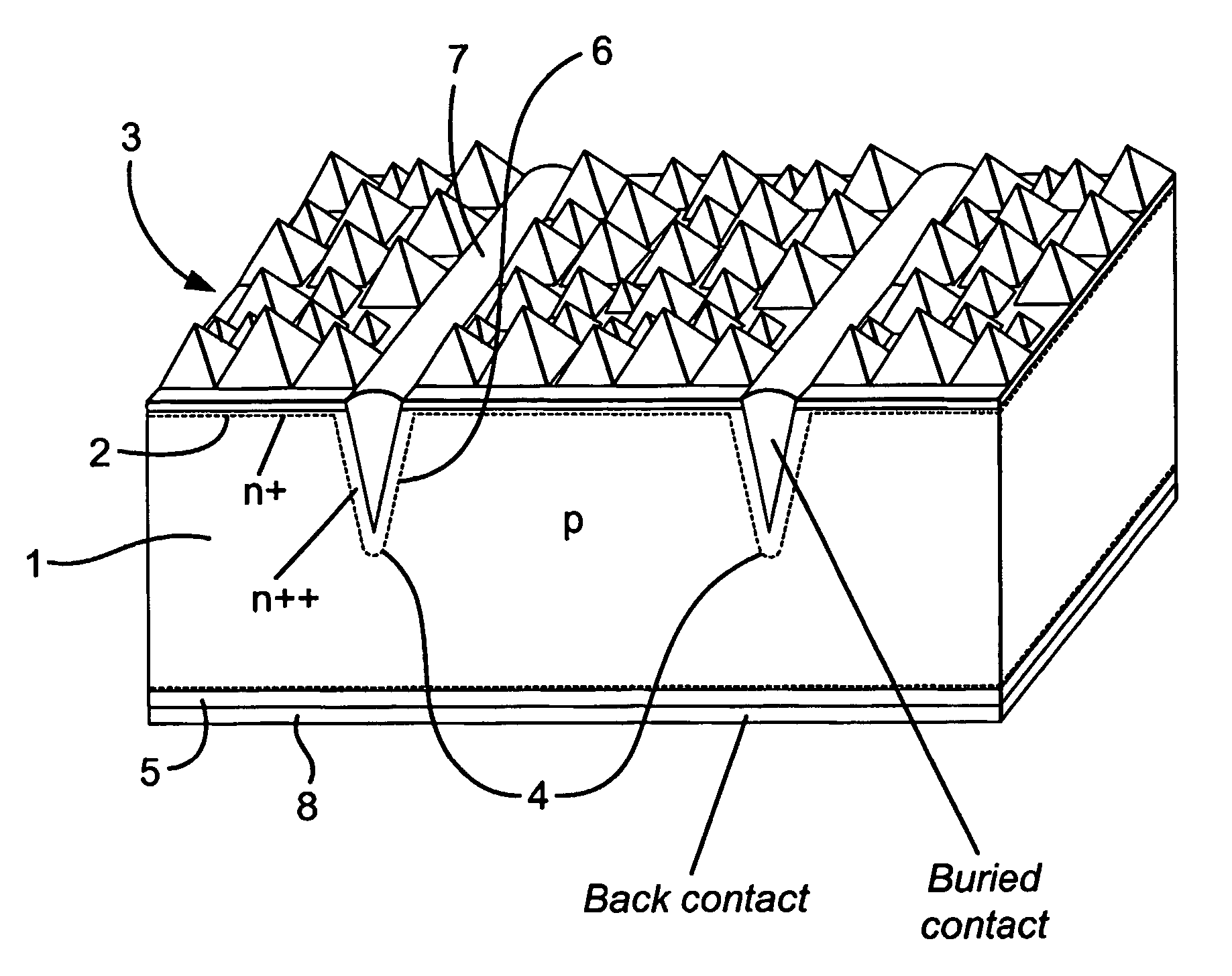

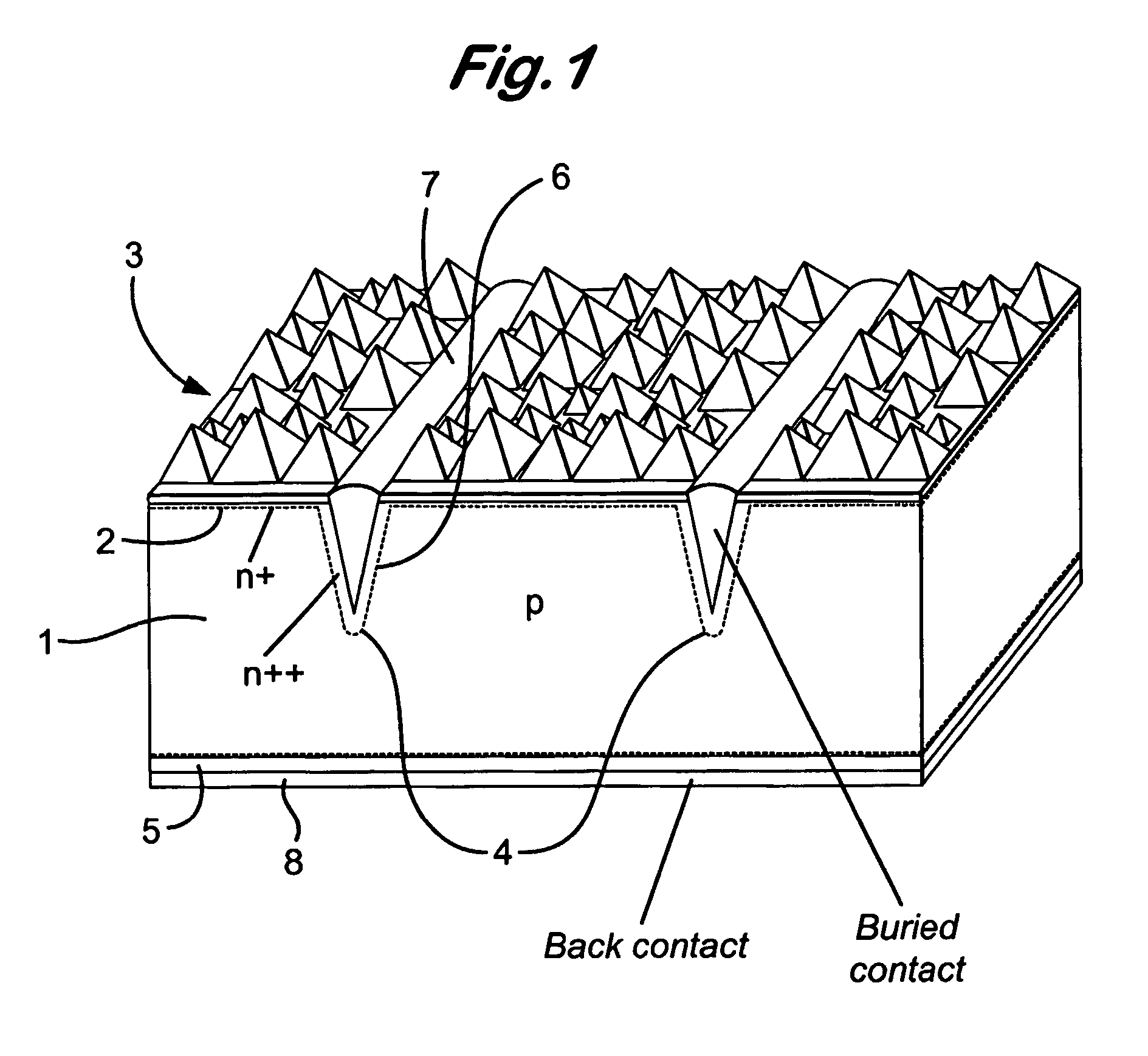

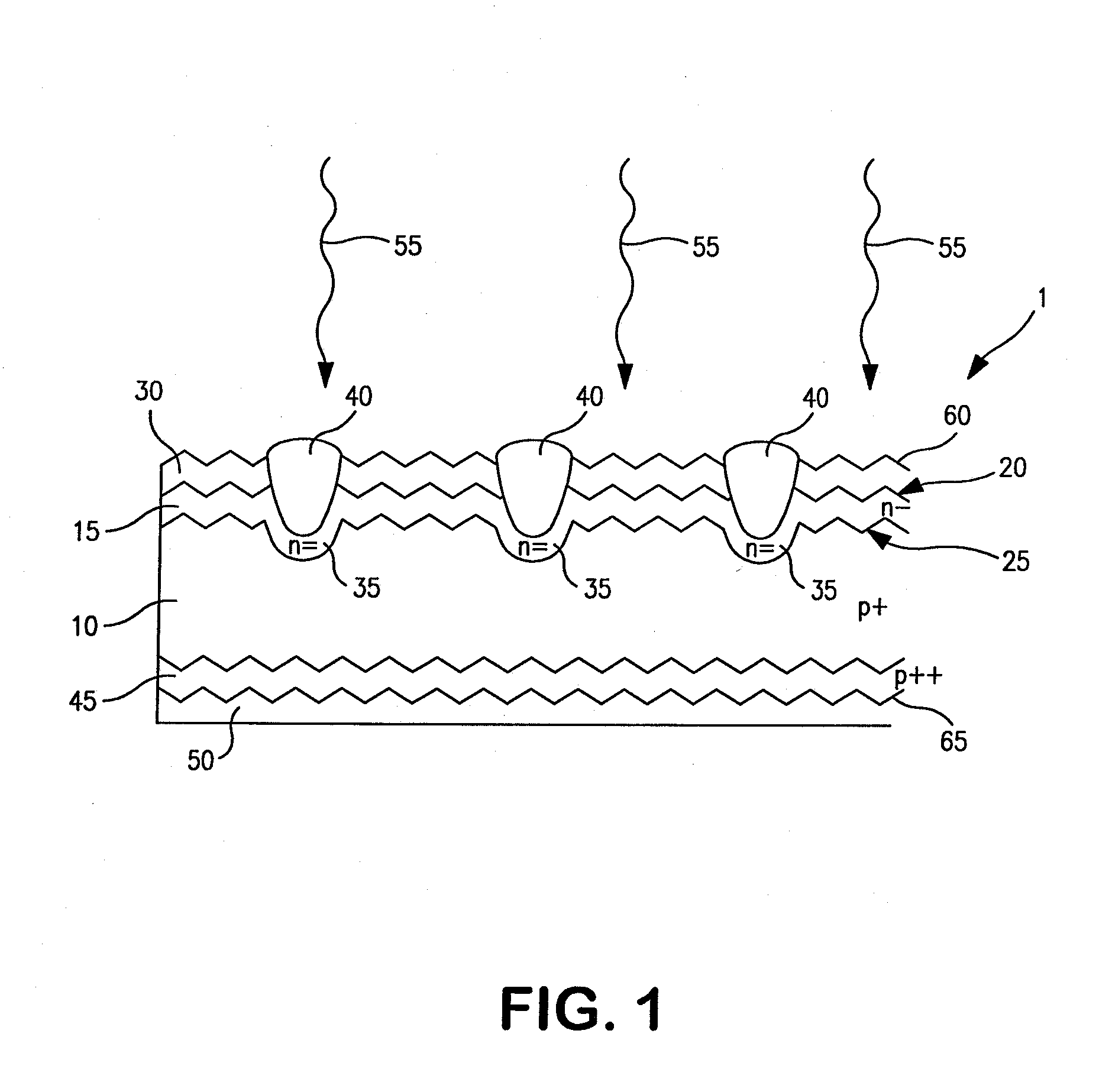

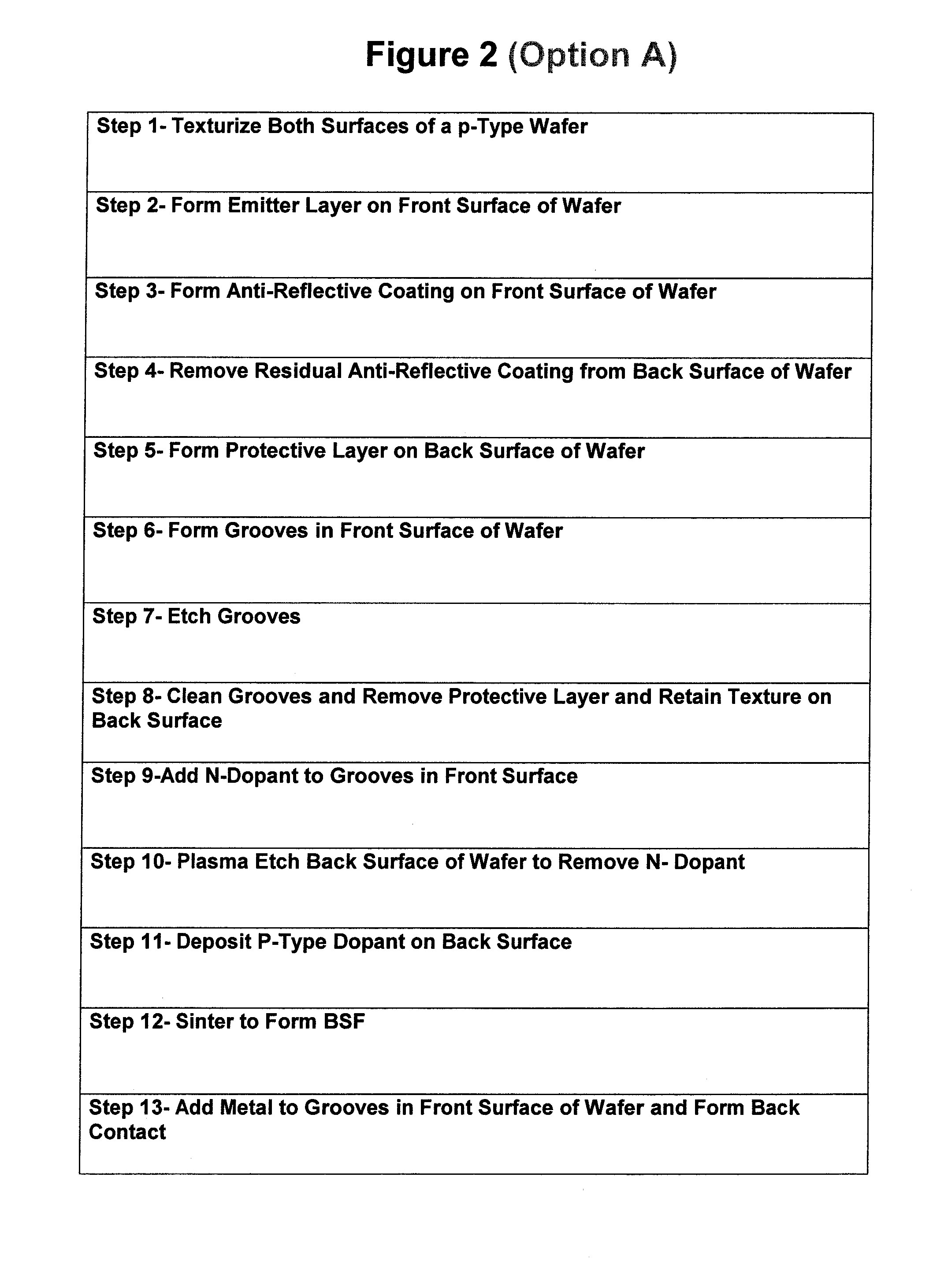

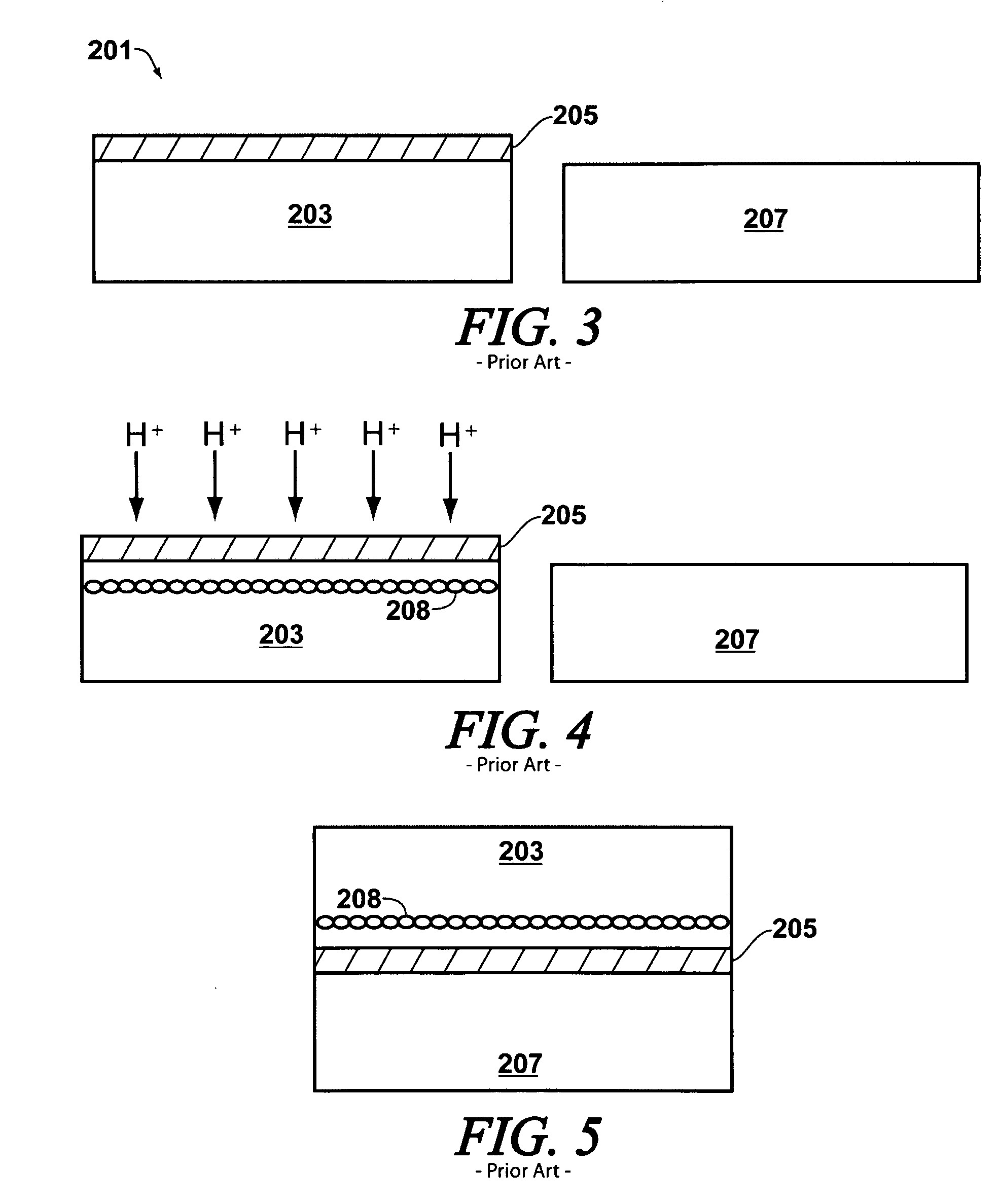

Process for manufacturing photovoltaic cells

InactiveUS20050268963A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationBack surface fieldEngineering

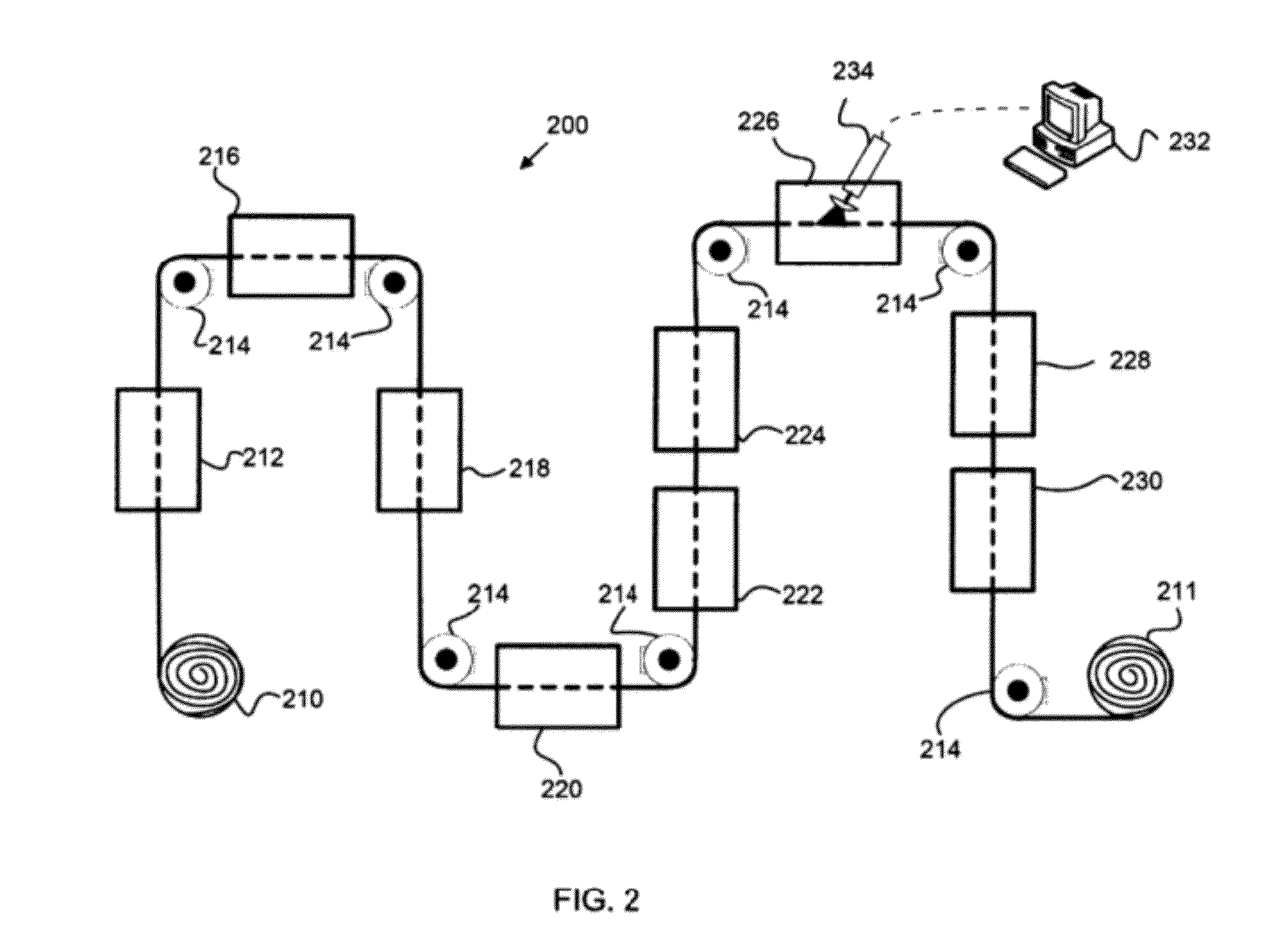

A process for making a photovoltaic cell using a semiconductor wafer doped with a first dopant, the wafer comprising a front surface and a back surface, the process comprising the steps of forming a first layer on the front surface of the wafer, the first layer comprising a second dopant of a conductivity type opposite the first dopant; depositing a surface coating on the front surface over the first layer; forming grooves in the front surface after depositing the surface coating thereon; adding a second dopant to the grooves; depositing a doping material on the back surface; treating the wafer having the doping material deposited thereon to form a back surface field, masking at least a portion of the back surface of the wafer after the treating; and adding a conductive material to the grooves to form an electrical contact.

Owner:BP CORP NORTH AMERICA INC

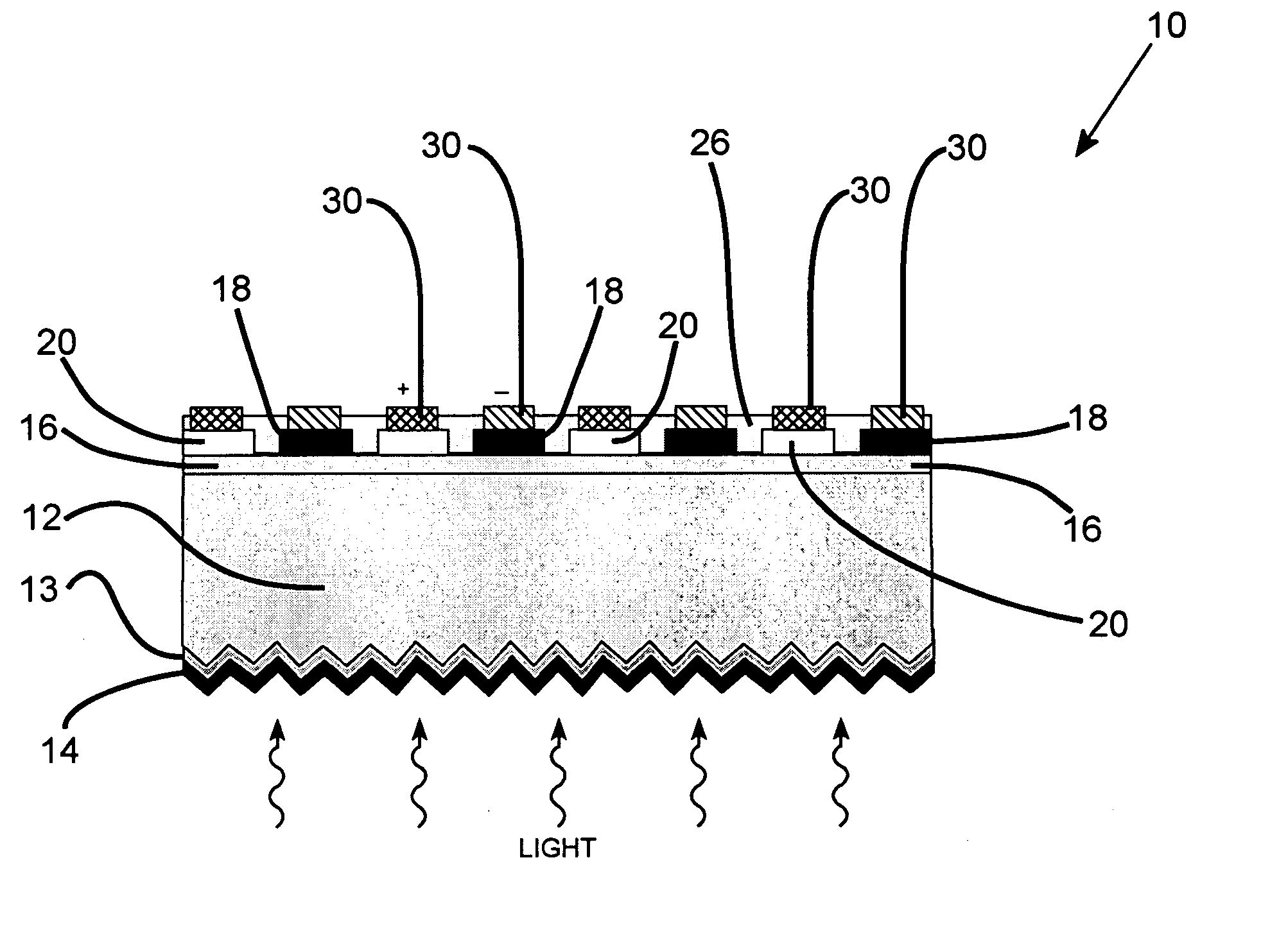

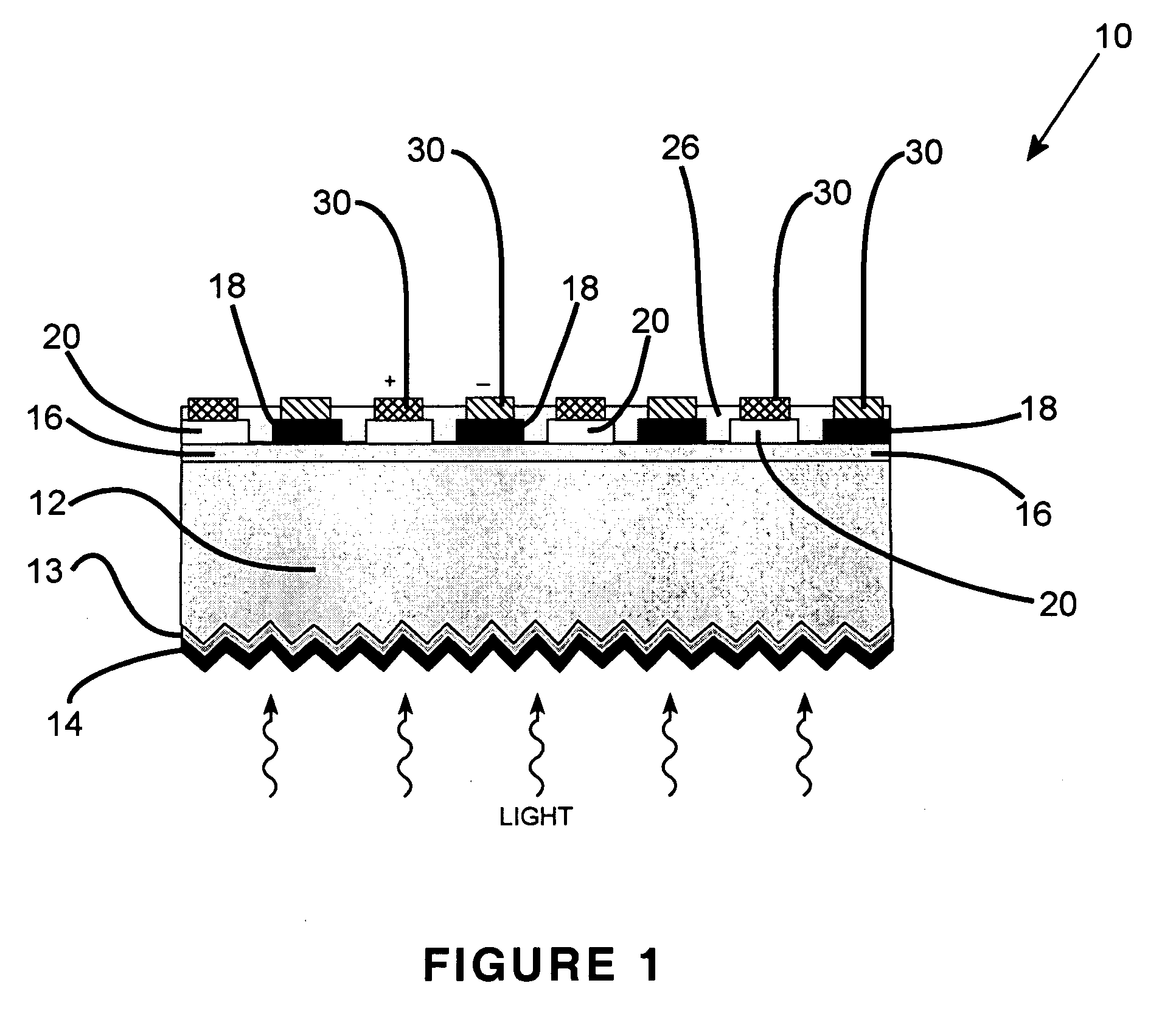

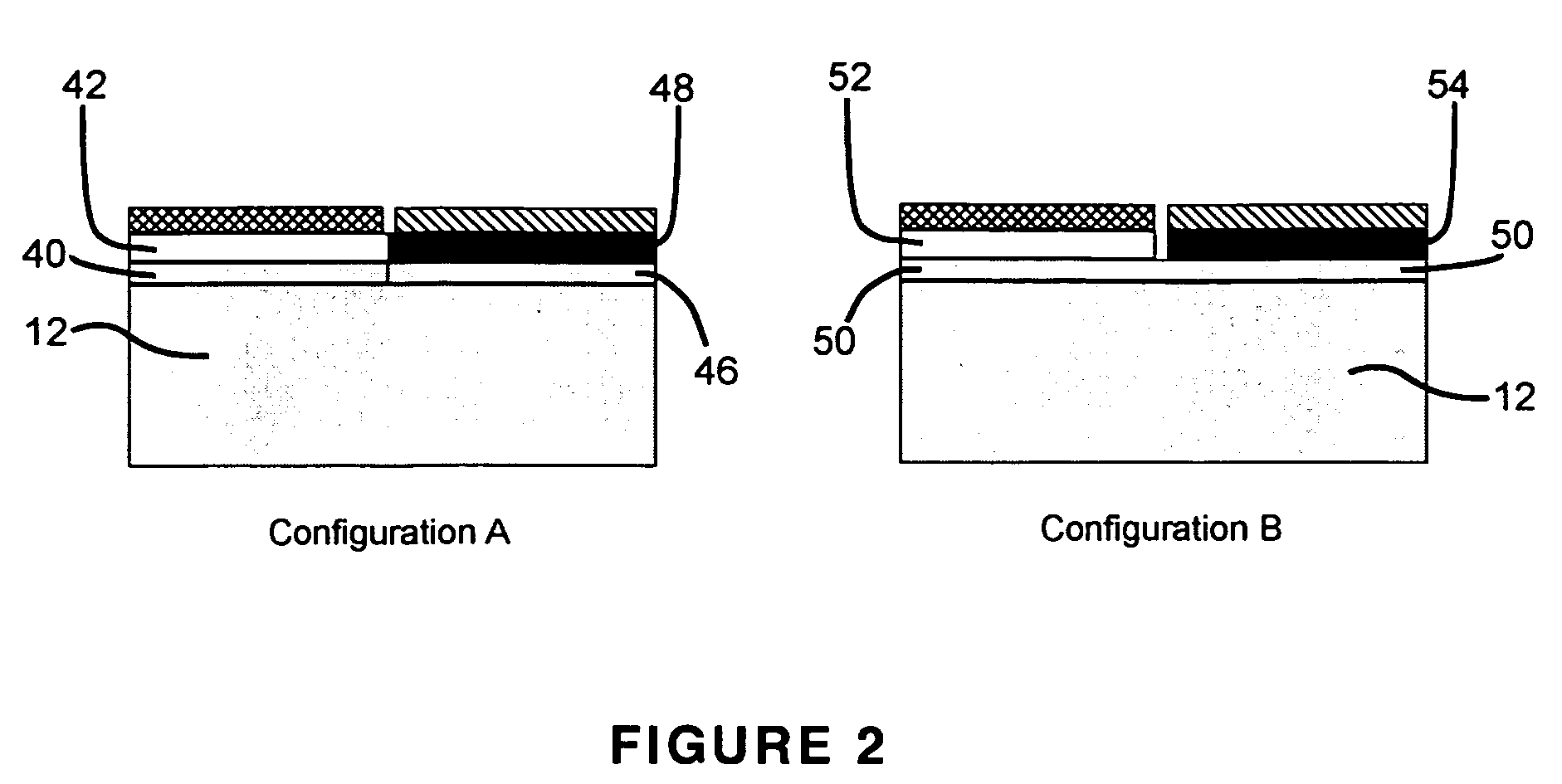

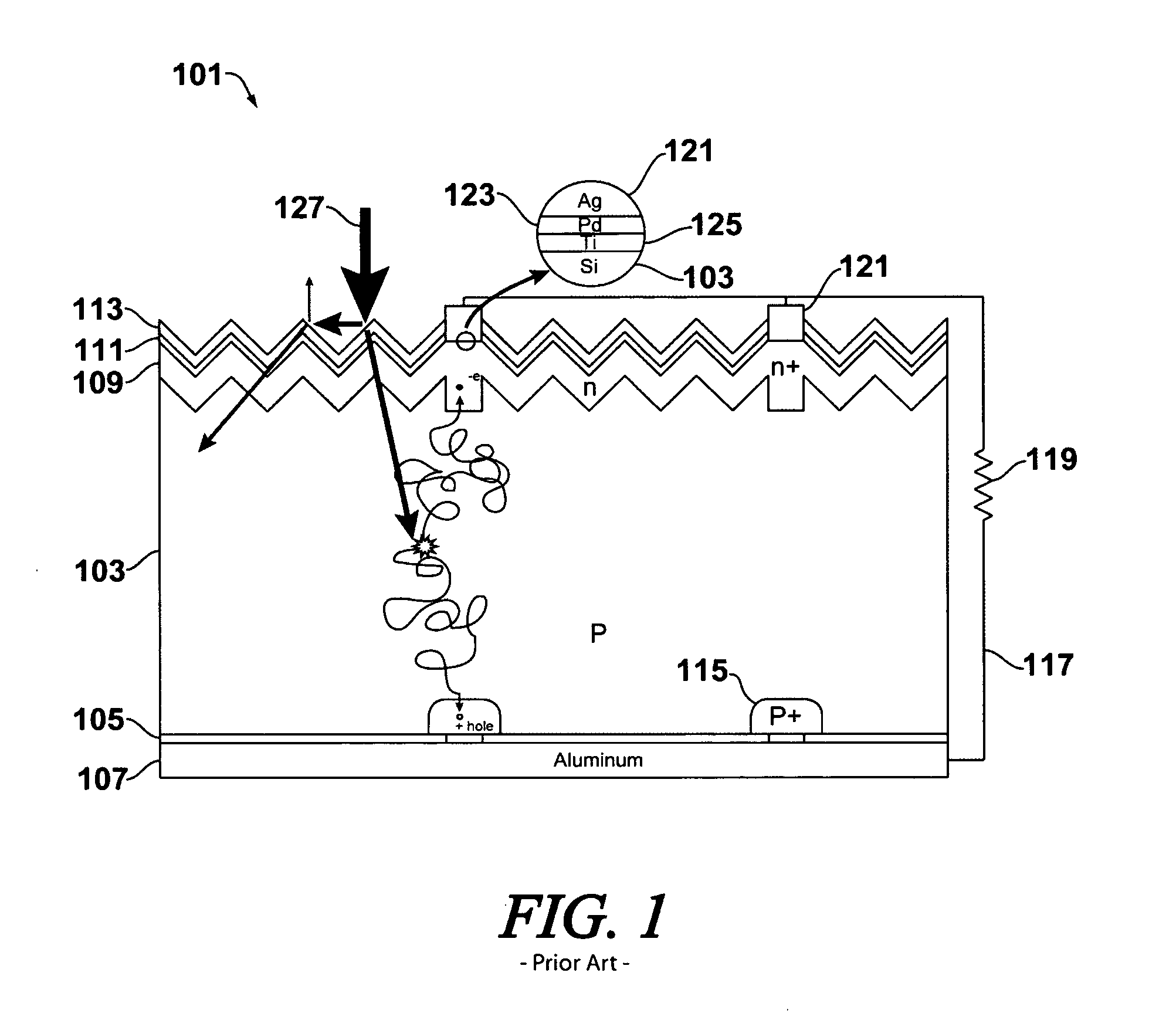

Solar cell

InactiveUS20070169808A1Low costEasy to usePhotovoltaic energy generationSemiconductor devicesHeterojunctionManufacturing technology

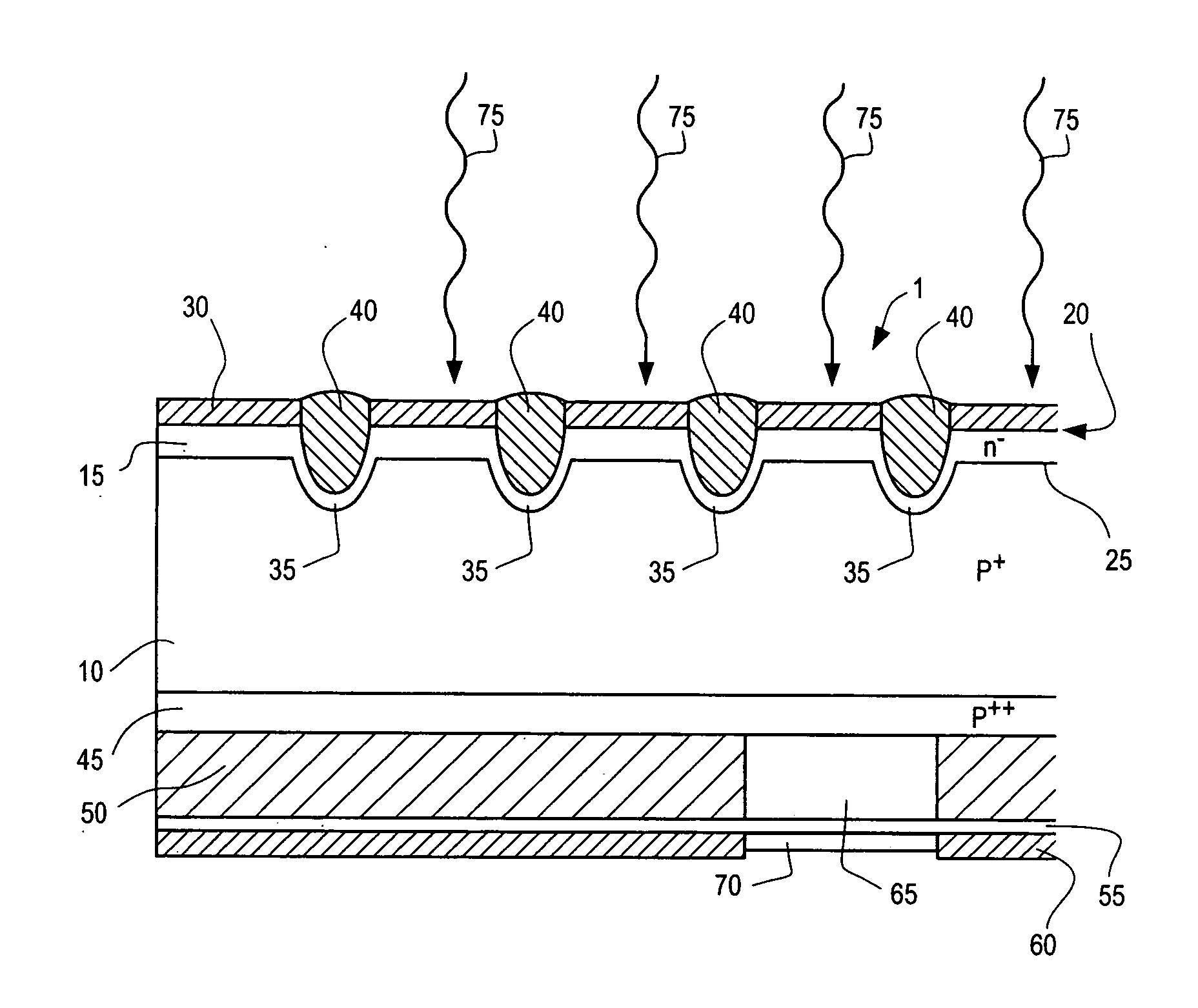

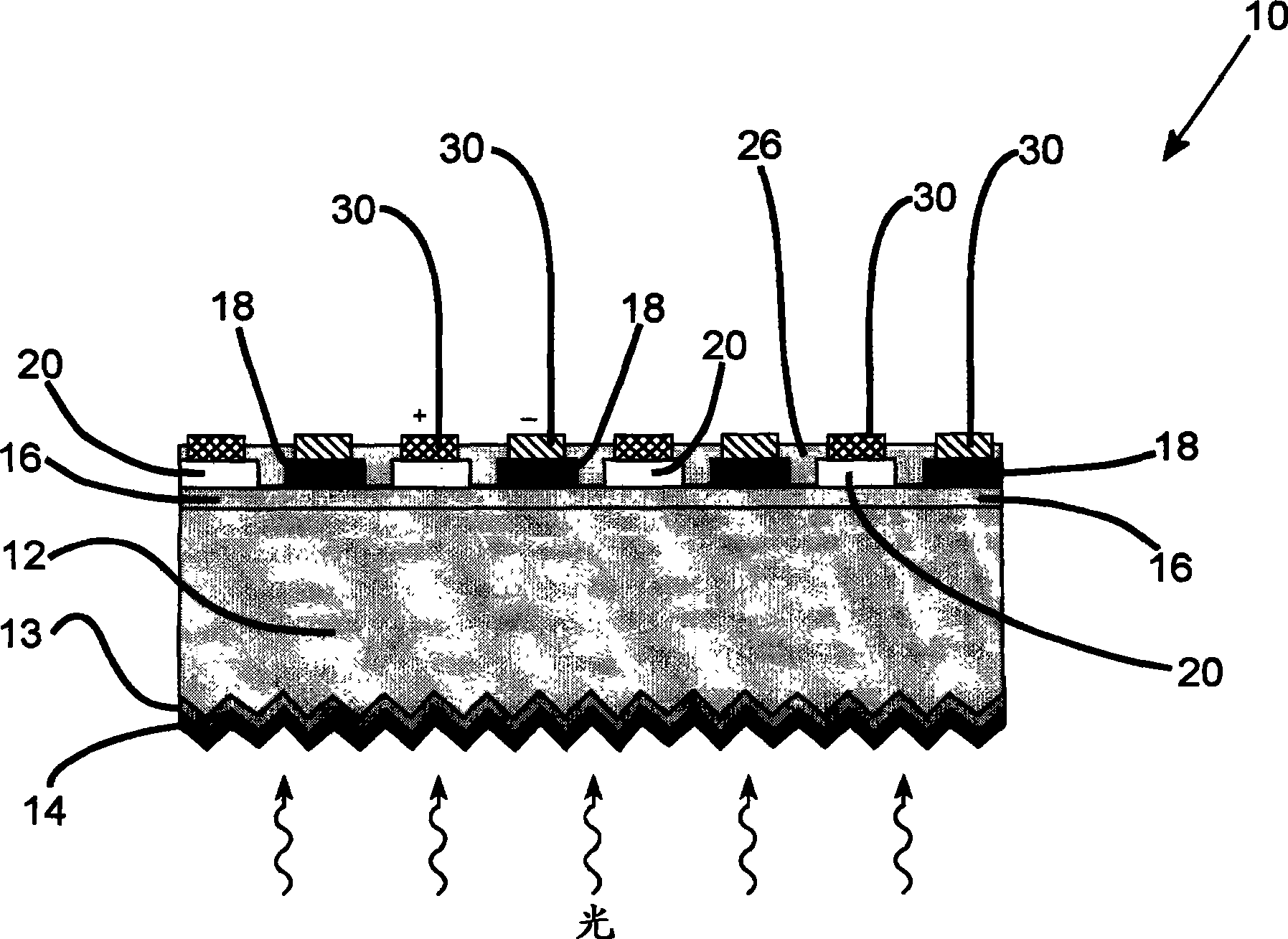

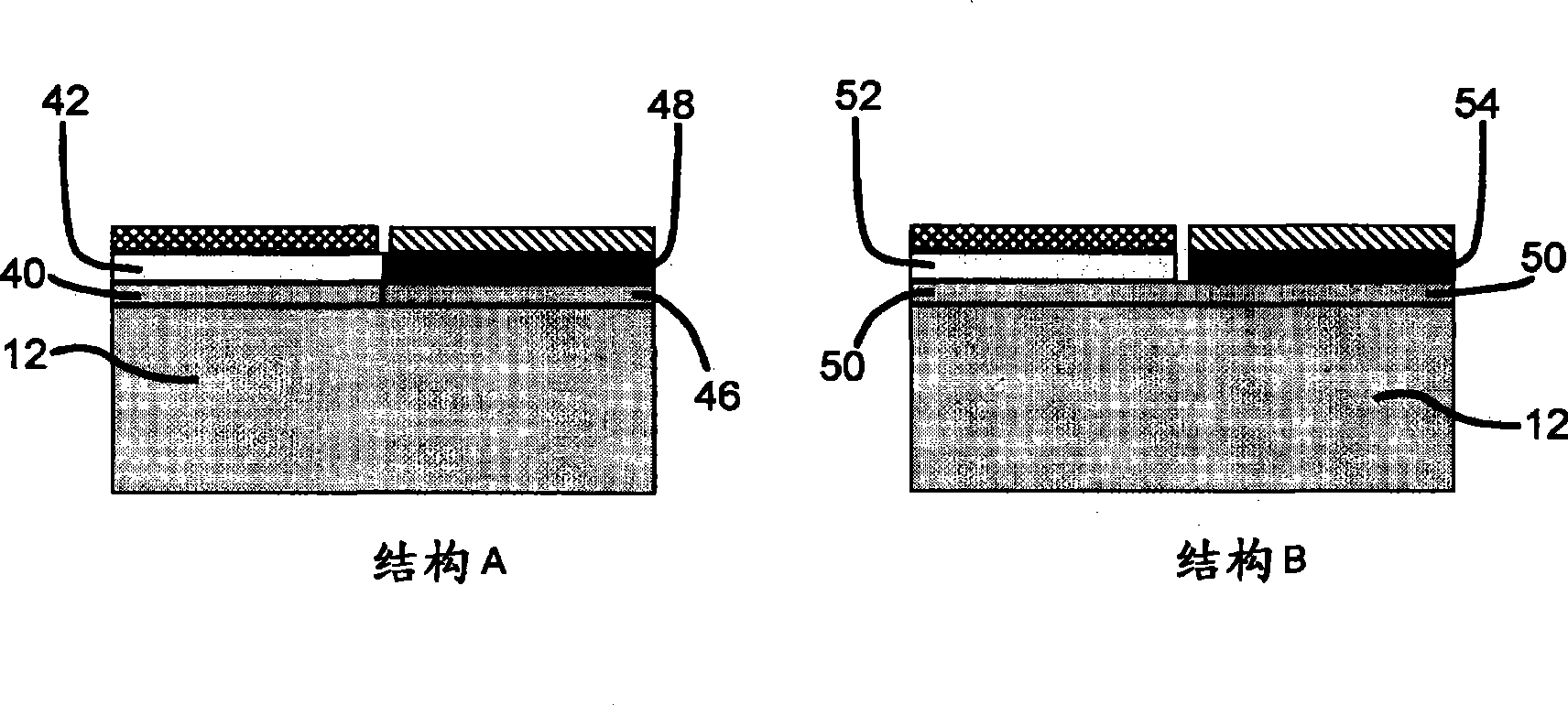

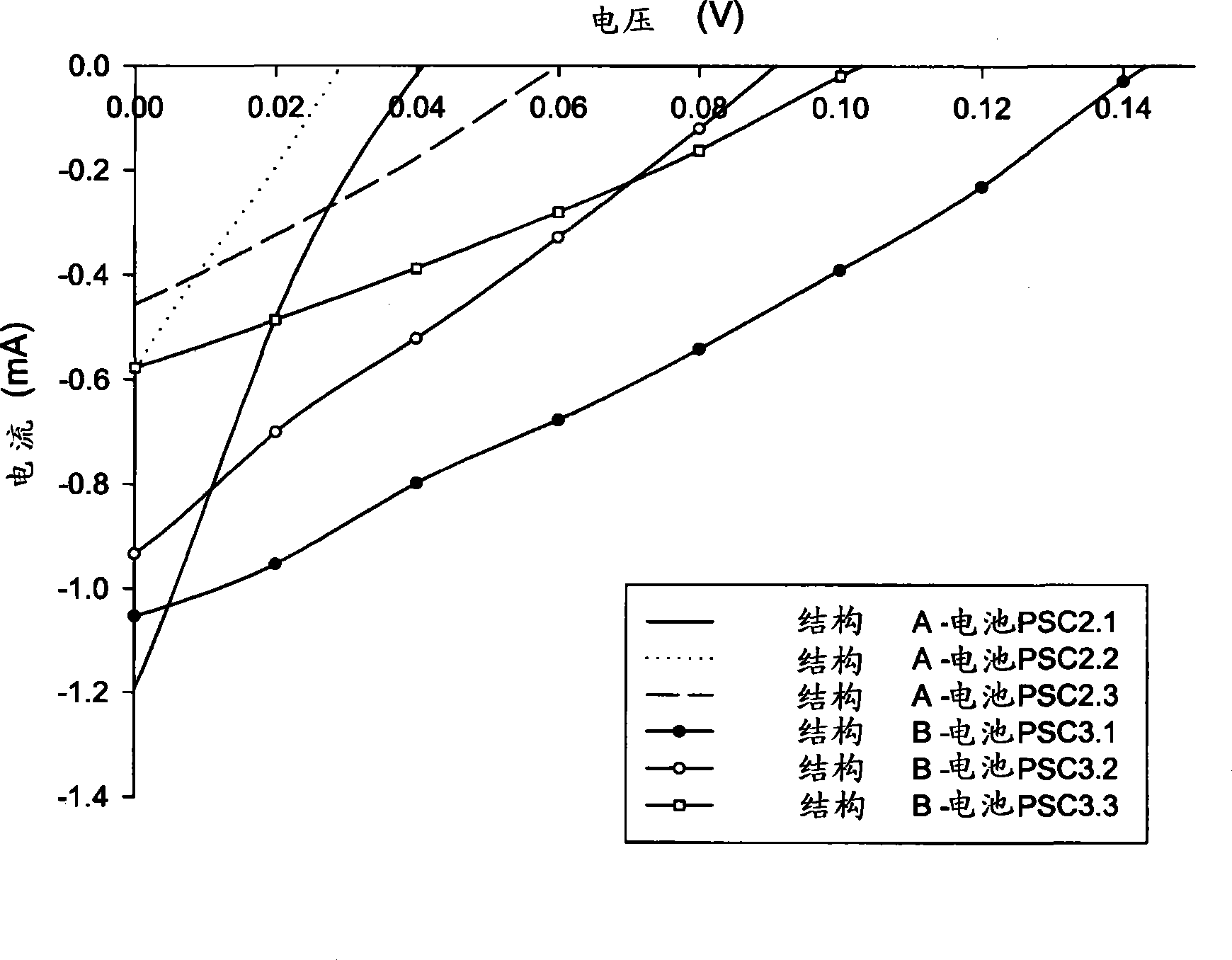

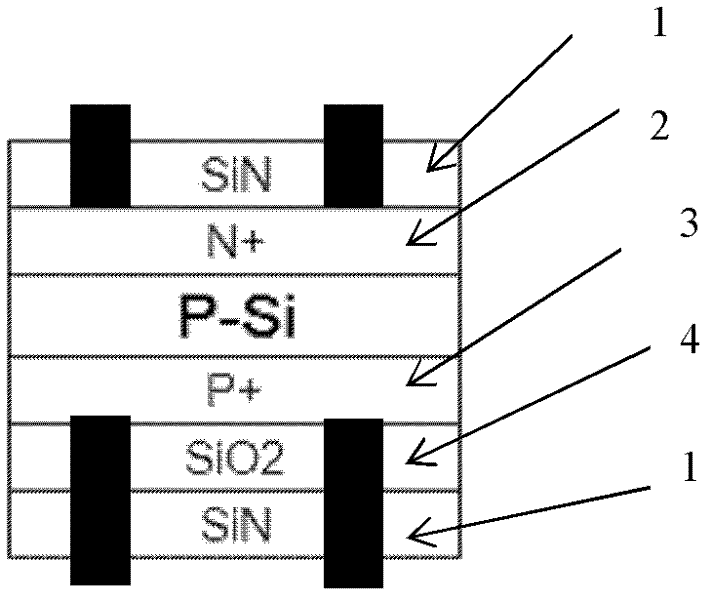

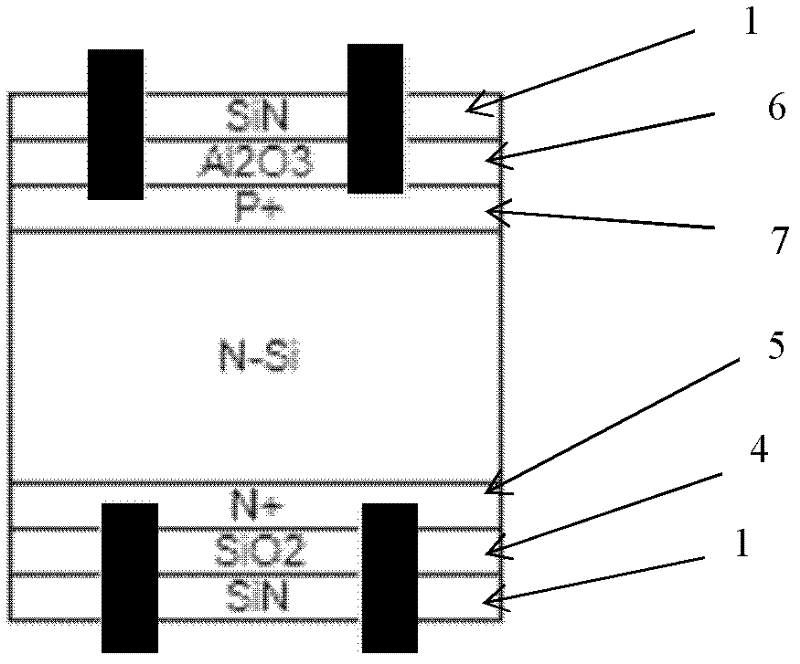

The present invention provides a thin film amorphous silicon-crystalline silicon back heterojunction and back surface field device configuration for a heterojunction solar cell. The configuration is attained by the formation of heterojunctions on the back surface of crystalline silicon at low temperatures. Low temperature fabrication allows for the application of low resolution lithography and / or shadow masking processes to produce the structures. The heterojunctions and interface passivation can be formed through a variety of material compositions and deposition processes, including appropriate surface restructing techniques. The configuration achieves separation of optimization requirements for light absorption and carrier generation at the front surface on which the light is incident, and in the bulk, and charge carrier collection at the back of the device. The shadowing losses are eliminated by positioning the electrical contacts at the back thereby removing them from the path of the incident light. Back contacts need optimization only for maximum charge carrier collection without bothering about shading losses. A range of elements / alloys may be used to effect band-bending. All of the above features result in a very high efficiency solar cell. The open circuit voltage of the back heterojunction device is higher than that of an all-crystalline device. The solar cell configurations are equally amenable to crystalline silicon wafer absorber as well as thin silicon layers formed by using a variety of fabrication processes. The configurations can be used for radiovoltaic and electron-voltaic energy conversion devices.

Owner:KHERANI NAZIR P +1

Surface passivated photovoltaic devices

InactiveUS7375378B2Solid-state devicesPhotovoltaic energy generationSemiconductor materialsBack surface field

A photovoltaic device comprising a photovoltaic cell is provided. The photovoltaic cell includes an emitter layer comprising a crystalline semiconductor material and a lightly doped crystalline substrate disposed adjacent the emitter layer. The lightly doped crystalline substrate and the emitter layer are oppositely doped. Further, the photovoltaic device includes a back surface passivated structure coupled to the photovoltaic cell. The structure includes a highly doped back surface field layer disposed adjacent the lightly doped crystalline substrate. The highly doped back surface field layer includes an amorphous or a microcrystalline semiconductor material, wherein the highly doped back surface field layer and the lightly doped crystalline substrate are similarly doped, and wherein a doping level of the highly doped back surface field layer is higher than a doping level of the lightly doped crystalline substrate. Additionally, the structure may also include an intrinsic back surface passivated layer disposed adjacent the lightly doped crystalline substrate, where the intrinsic back surface passivated layer includes an amorphous or a microcrystalline semiconductor material.

Owner:GENERAL ELECTRIC CO

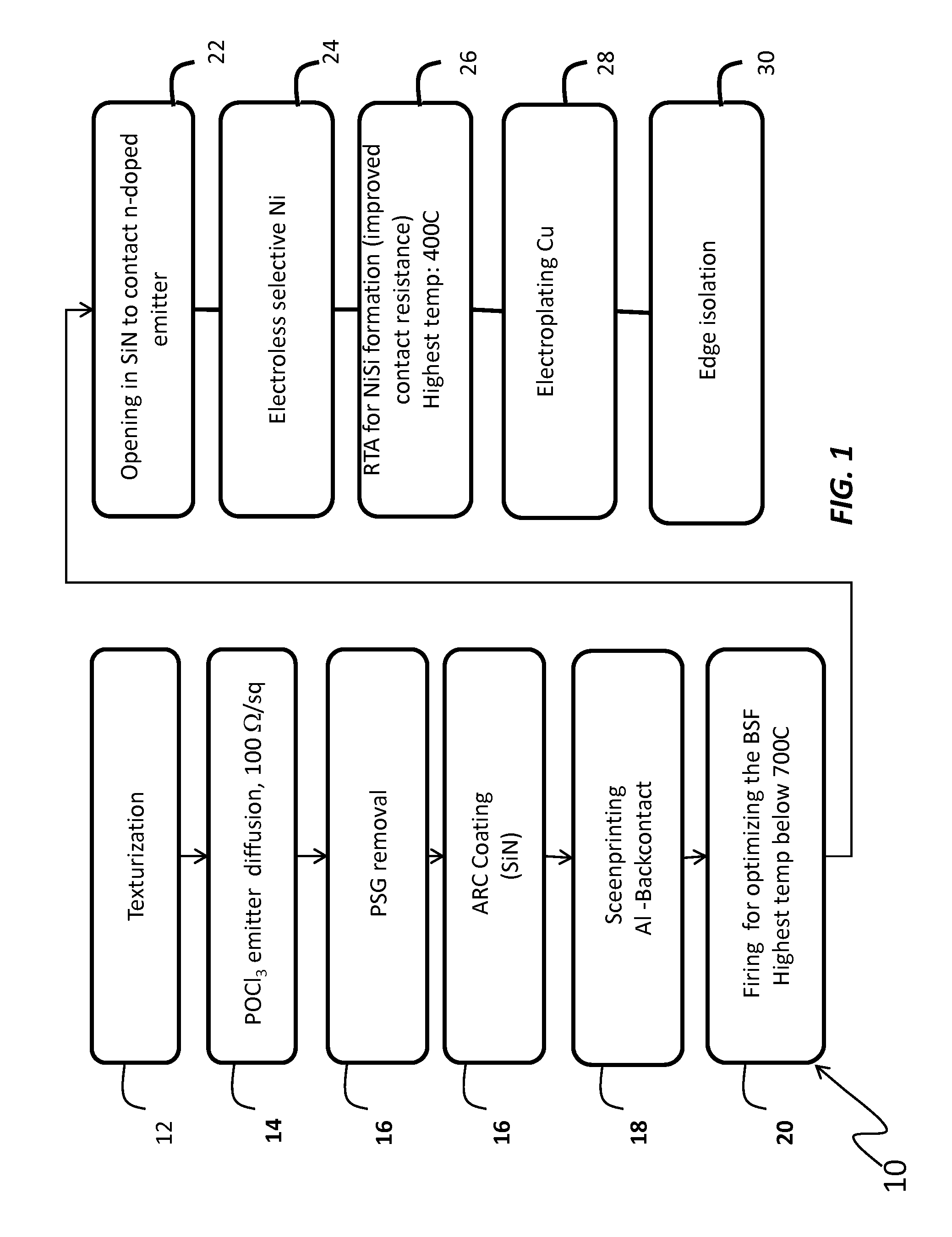

Solar cell and fabrication method using crystalline silicon based on lower grade feedstock materials

InactiveUS20090223549A1Lower resistanceGreat electrical outputPV power plantsFinal product manufactureAnti-reflective coatingElectrical resistance and conductance

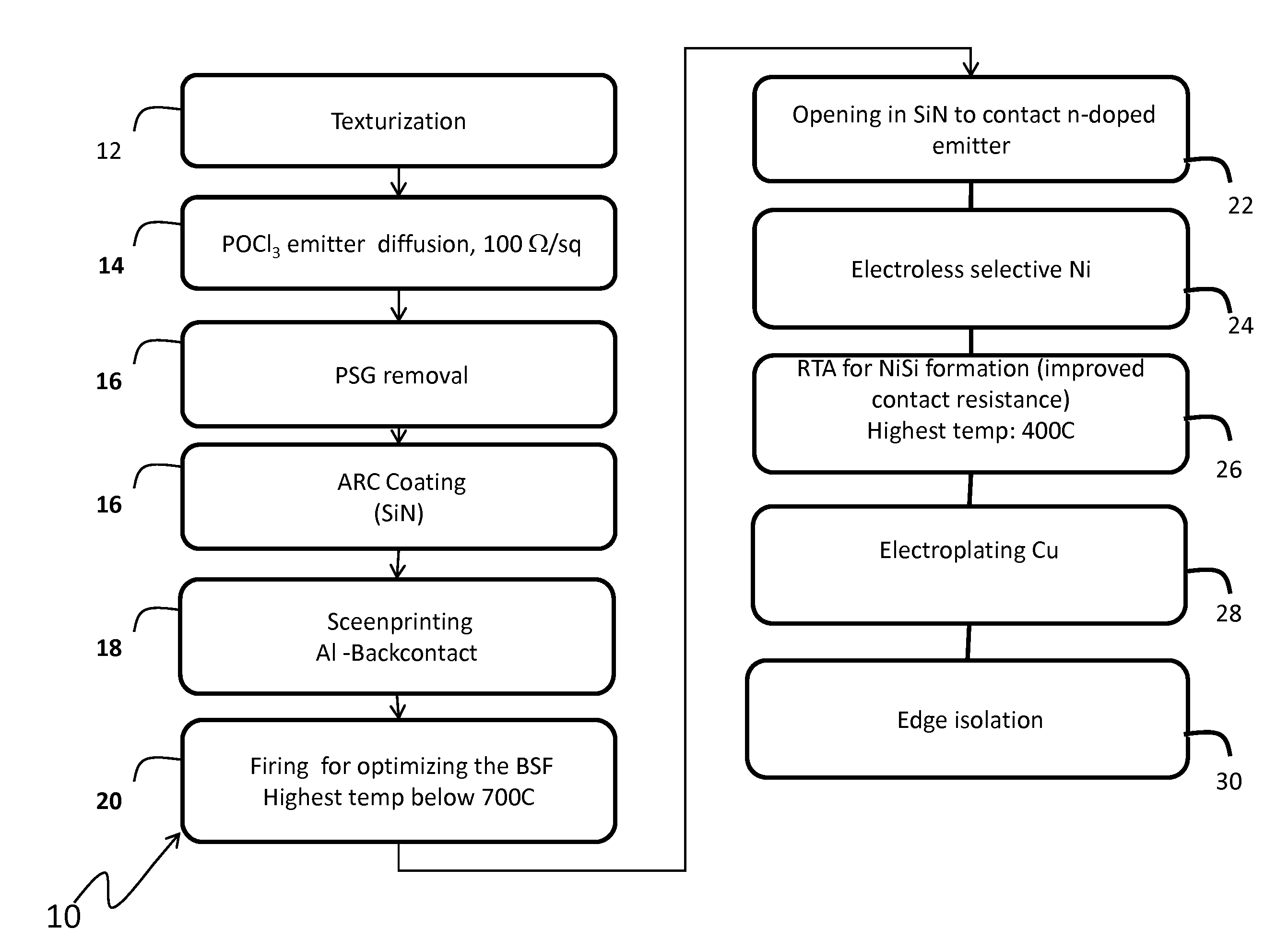

Formation of a solar cell device from upgraded metallurgical grade silicon which has received at least one defect engineering process and including a low contact resistance electrical path. An anti-reflective coating is formed on an emitter layer and back contacts are formed on a back surface of the bulk silicon substrate. This photovoltaic device may be fired to form a back surface field at a temperature sufficiently low to avoid reversal of previous defect engineering processes. The process further forms openings in the anti-reflective coating and a low contact resistance metal layer, such as nickel layer, over the openings in the anti-reflective coating. The process may anneal the low contact resistance metal layer to form n-doped portion and complete an electrically conduct path to the n-doped layer. This low temperature metallization (e.g., <700° C.) supports the use of UMG silicon for the solar device formation without the risk of reversing earlier defect engineering processes.

Owner:SILICOR MATERIALS INC

Process for manufacturing a solar cell

InactiveUS7071018B2Low costFinal product manufactureSemiconductor/solid-state device manufacturingBack surface fieldSilicon solar cell

Process for incorporating a back surface field into a silicon solar cell by depositing a layer of aluminium on the rear surface of the cell, sintering the aluminium at a temperature between 700 and 1000° C., exposing the cell to an atmosphere of a compound of Group V element and diffusing at a temperature of between 950 and 1000°C. so as to dope exposed p-type silicon surfaces with the Group V element. The step of exposing the cell to an atmosphere of a compound of a Group V element is carried separately from the step of sintering the aluminium layer, and subsequent to the step of depositing a layer of aluminium on the rear surface of the cell.

Owner:BP ALTERNATIVE ENERGY INT

Solar cell

InactiveCN101401215APhotovoltaic energy generationSemiconductor devicesHeterojunctionBack surface field

The invention provides a thin film amorphous silicon-crystalline silicon back heterojunction and back surface field device configuration for a heterojunction solar cell. The configuration is attained by the formation of heterojunctions on the back surface of crystalline silicon at low temperatures. Low temperature fabrication allows for the application of low resolution lithography and / or shadow masking processes to produce the structures. The heterojunctions and interface passivation can be formed through a variety of material compositions and deposition processes, including appropriate surface restructing techniques. The configuration achieves separation of optimization requirements for light absorption and carrier generation at the front surface on which the light is incident, and in the bulk, and charge carrier collection at the back of the device. The shadowing losses are eliminated by positioning the electrical contacts at the back thereby removing them from the path of the incident light. Back contacts need optimization only for maximum charge carrier collection without bothering about shading losses. A range of elements / alloys may be used to effect band-bending.

Owner:ARISE TECH CORP

Paste for forming solar battery electrode

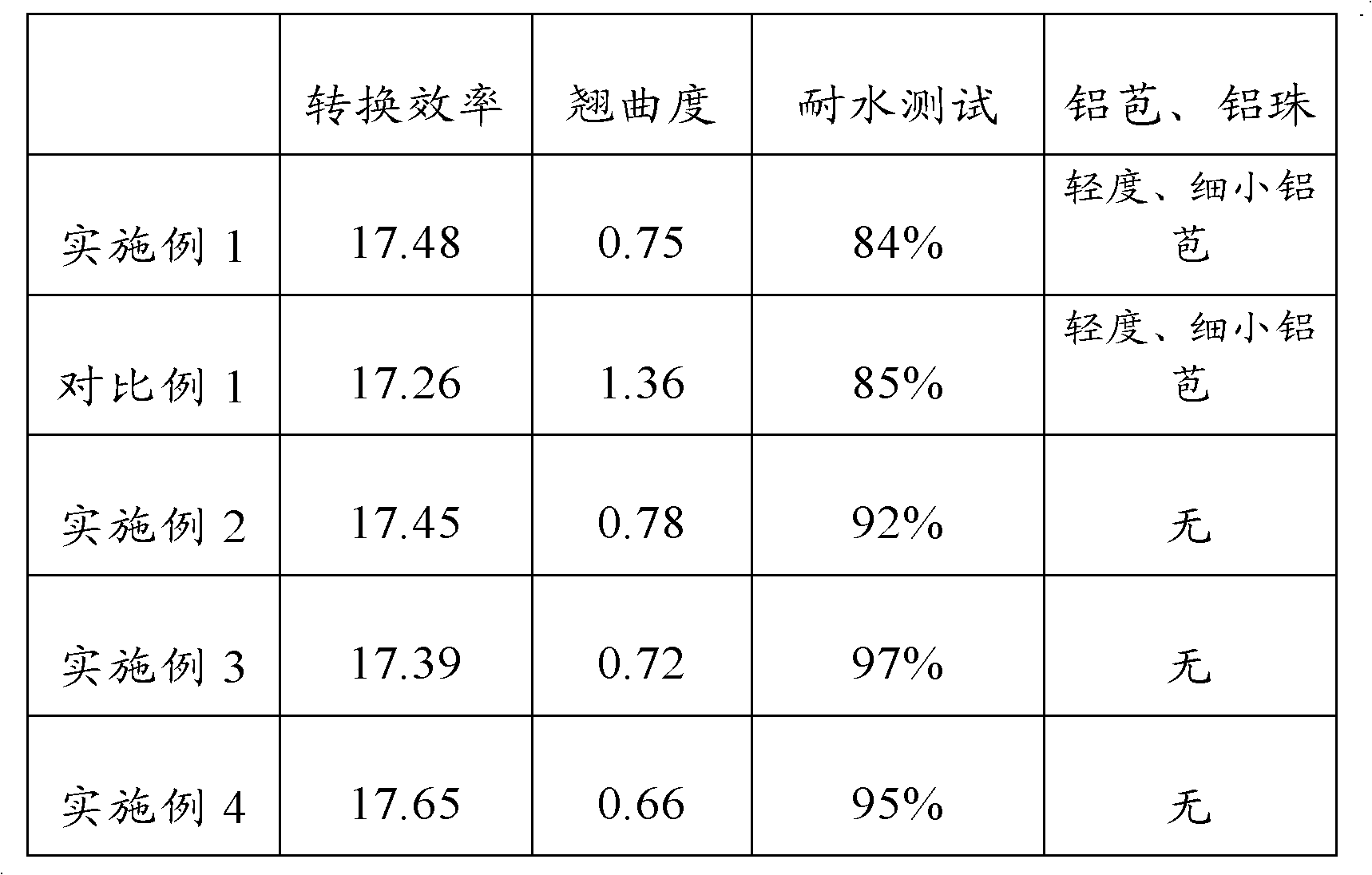

InactiveCN101609847AConversion efficiency is not affectedConversion efficiency impactFinal product manufactureNon-conductive material with dispersed conductive materialElectrical resistance and conductanceBack surface field

The invention discloses paste for forming solar battery electrode, which comprises the following components by mass percent: 65 to 75 percent of aluminum powder, 20 to 30 percent of organic carrier, 0.2 to 6 percent of inorganic glass powder and 0.5 to 1 percent of functional additive. The aluminum powder comprises at least two types, the average particle diameter of one type of the aluminum powder is smaller than 2 micro meters and the mass of the type of the aluminum powder is 1 to 10 percent of that of the aluminum powder. The paste can form back surface field effect required by a solar battery with a silicon substrate, and has the advantages that the electrical conductivity is good, the contact resistance is low, the adhering to the silicon substrate is firm, the silicon substrate is slightly bent, and the open-circuit voltage of the solar battery and the photoelectric conversion efficiency are high.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

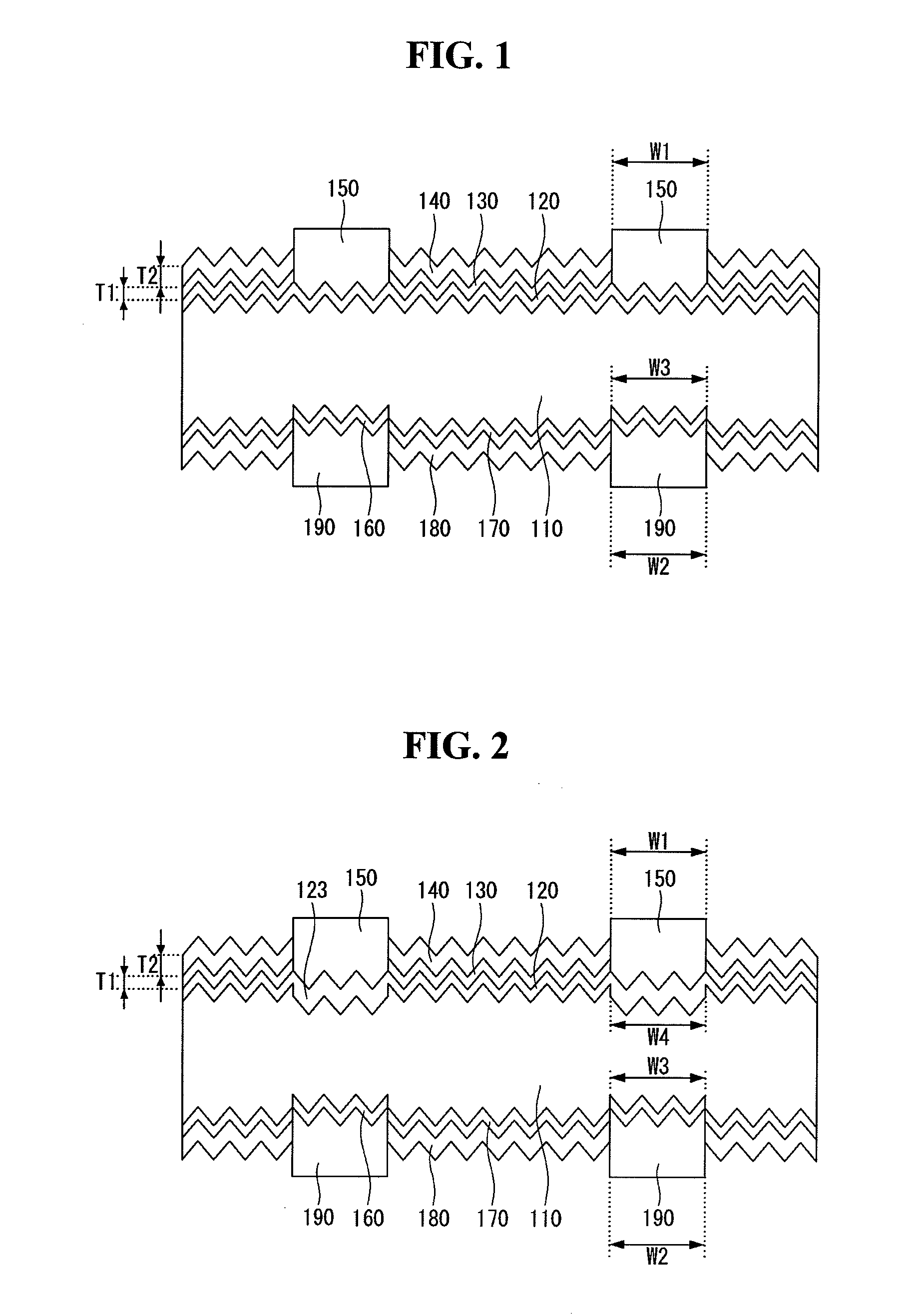

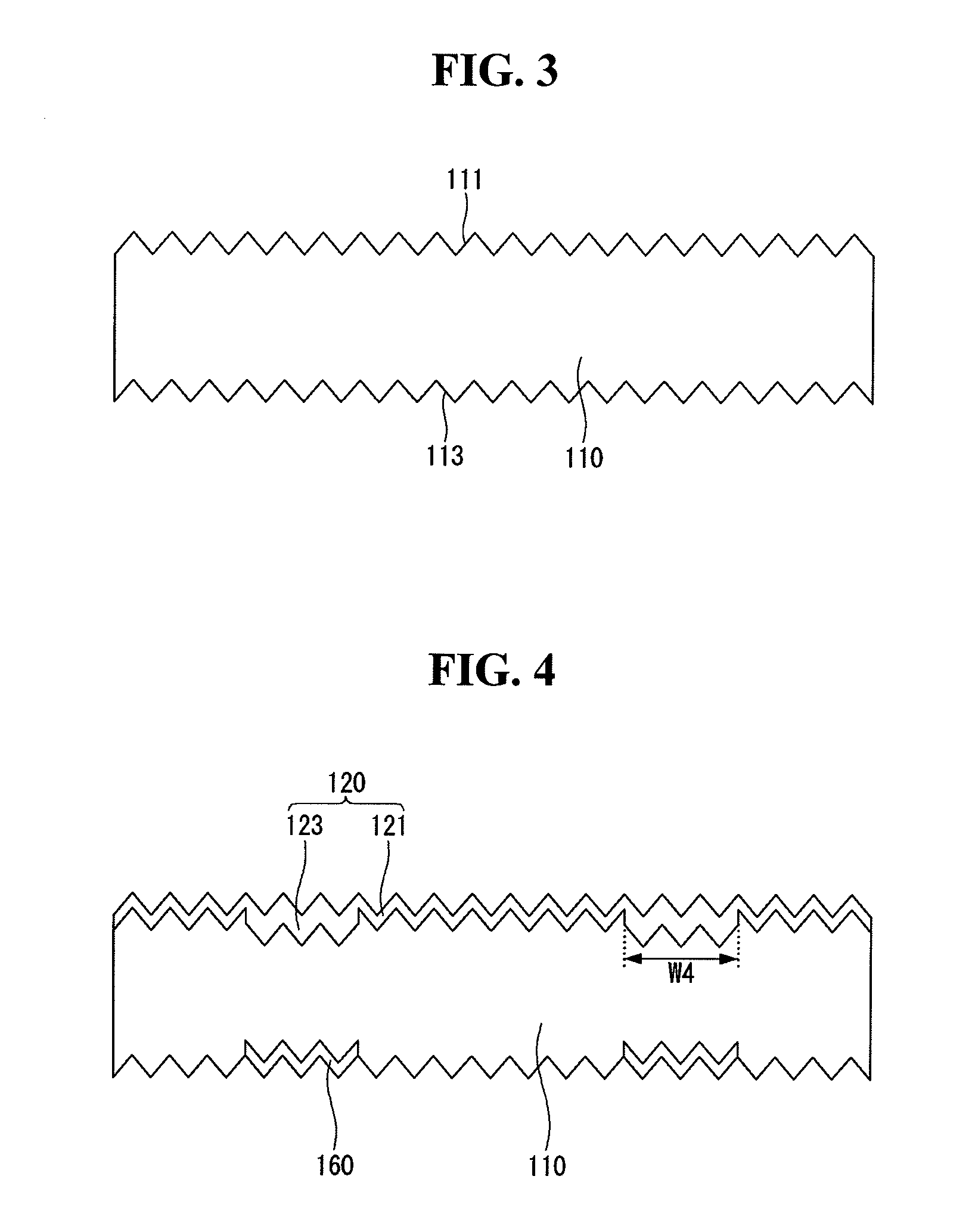

Solar cell and method for manufacturing the same

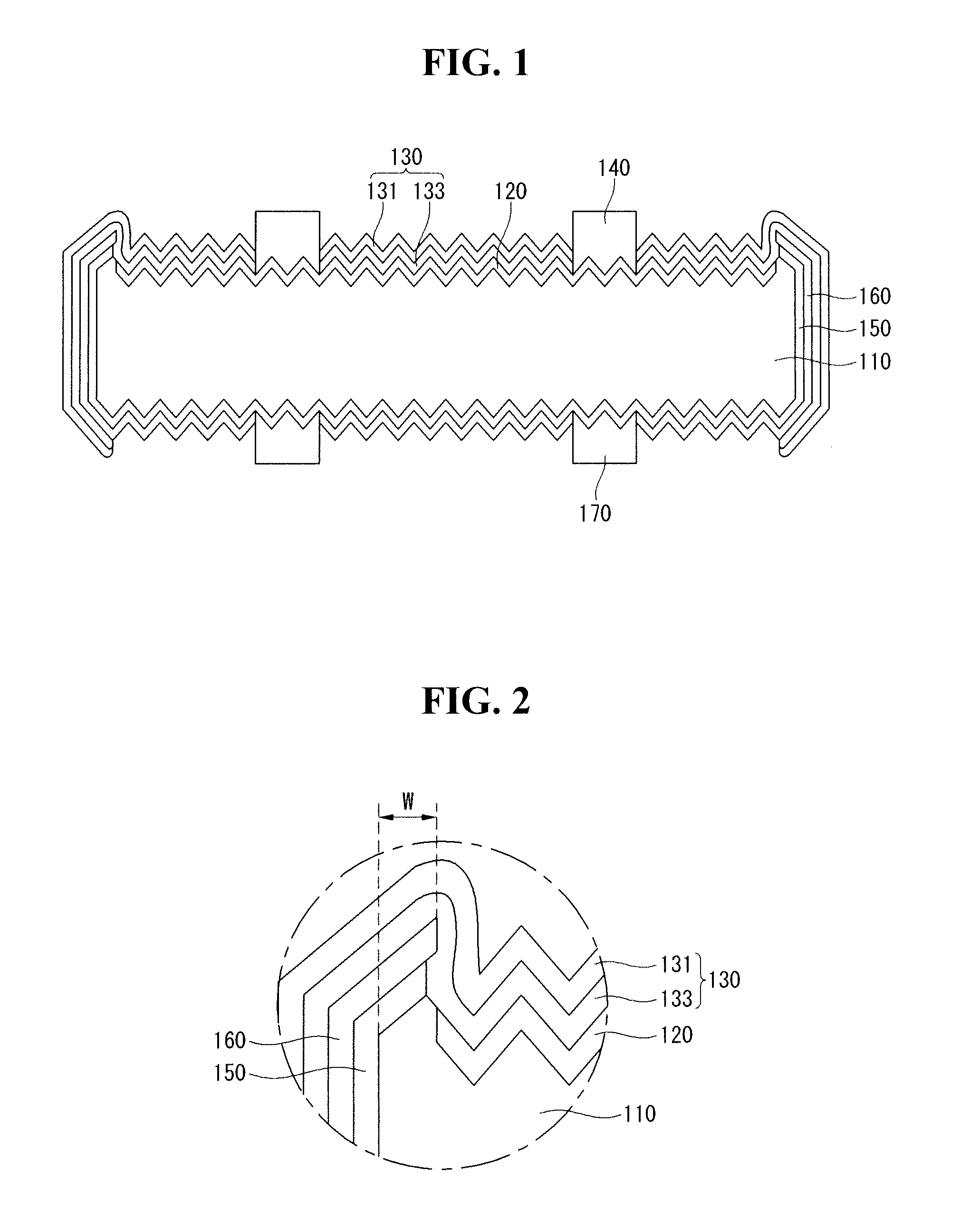

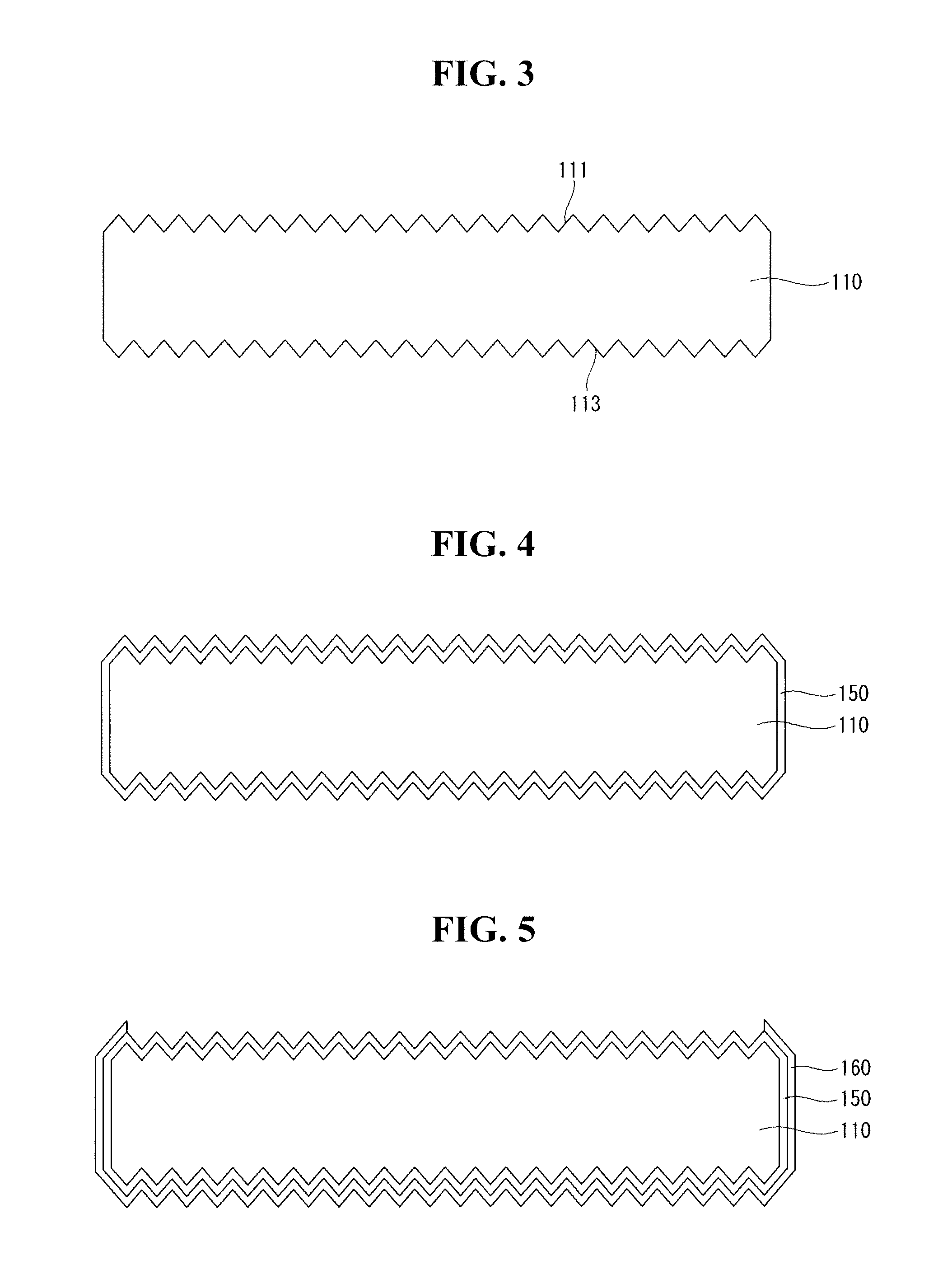

ActiveUS20110100459A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationBack surface fieldPhysics

A solar cell and a method for manufacturing the same are disclosed. The solar cell includes a substrate, an emitter layer at a front surface of the substrate, a first anti-reflection layer on the emitter layer, a back surface field layer at a back surface of the substrate, and a second anti-reflection layer on the back surface field layer. The first anti-reflection layer and the second anti-reflection layer overlap may each other.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

Back surface field aluminium paste for solar cells

ActiveCN102097154AReduce warpageNon-conductive material with dispersed conductive materialSemiconductor devicesAdhesiveBack surface field

The invention relates to a back surface field aluminium paste for solar cells. The aluminium paste comprises the following components in parts by weight: 65-80 parts of aluminium powder, 1-5 parts of inorganic adhesive, 10-30 parts of organic carrier and 1-2 parts of modifier. Sintered films with lower warpage can be obtained through the back surface field aluminium paste.

Owner:长沙族兴新材料股份有限公司

Process for Manufacturing Photovoltaic Cells

InactiveUS20080216893A1Final product manufactureSemiconductor/solid-state device manufacturingDopantBack surface field

A process for making a photovoltaic cell comprising forming a first layer on a front surface of a semiconductor wafer, the wafer comprising a first dopant and the first layer comprising a dopant of a conductivity type opposite the first dopant; depositing a surface coating on the front surface over the first layer; forming grooves in the front surface after depositing the surface coating thereon; doping the grooves with a dopant having a conductivity opposite the first dopant; treating a back surface of the wafer to remove at least substantially all dopant having a conductivity type opposite the first dopant; forming a back surface field; forming a back electrical contact over the back surface; and adding an electrically conductive material to the grooves to form a front electrical contact.

Owner:BP CORP NORTH AMERICA INC +1

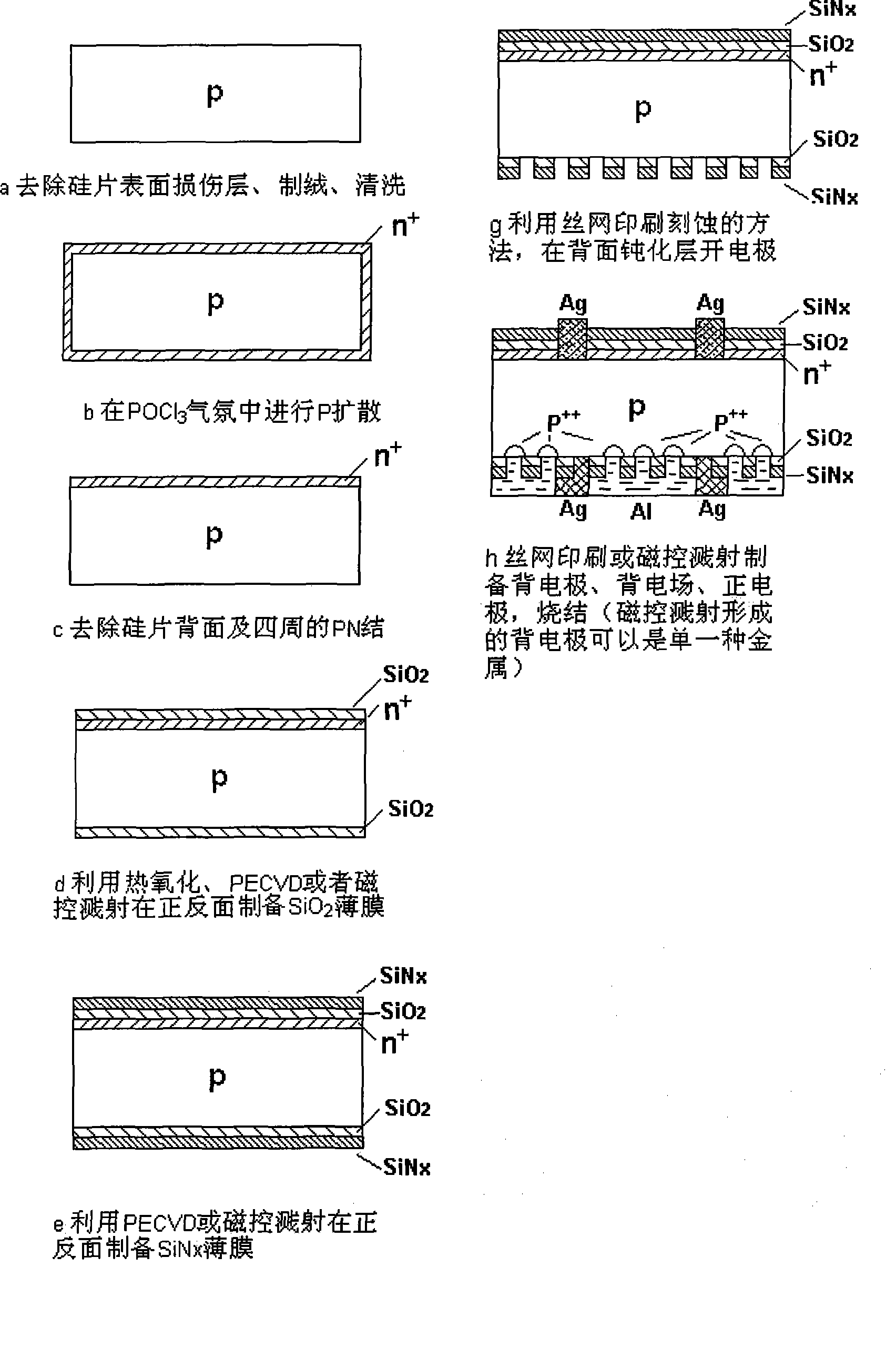

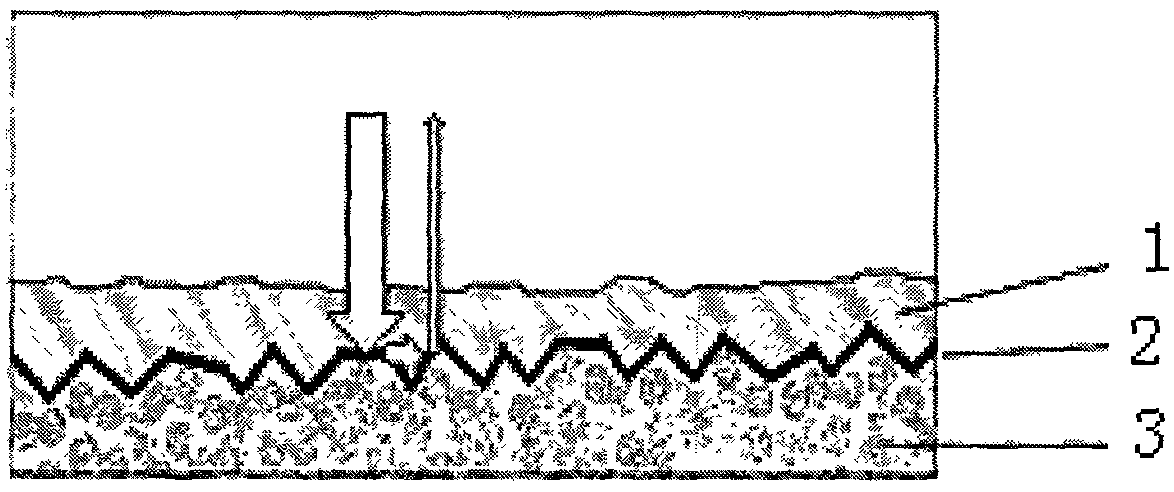

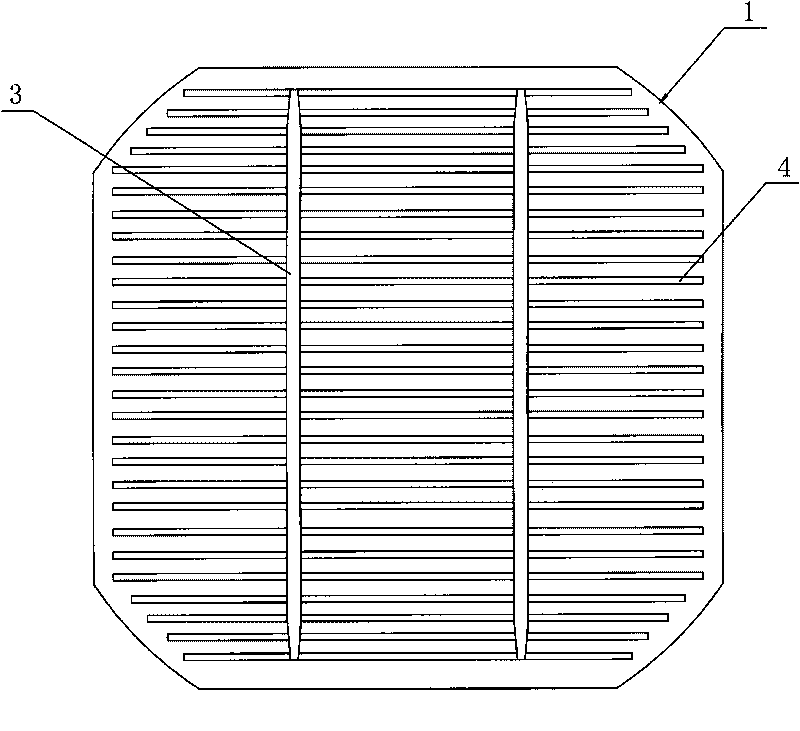

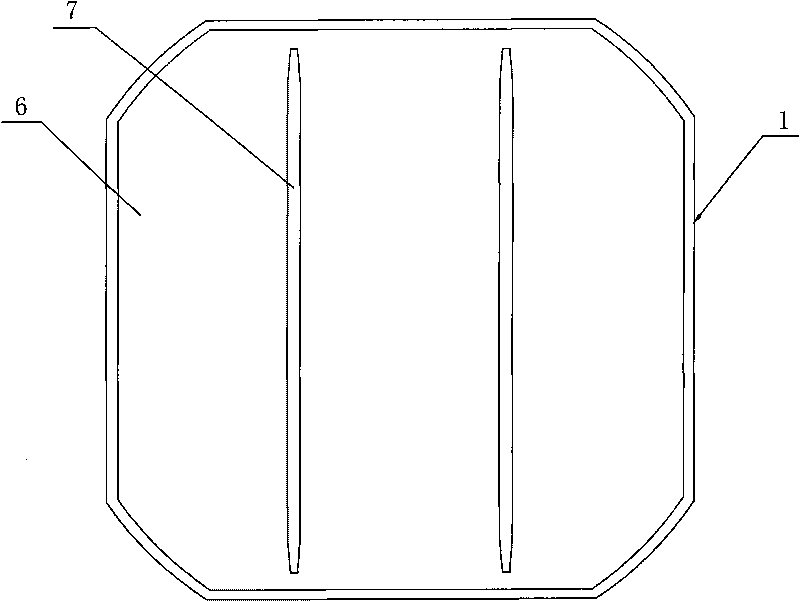

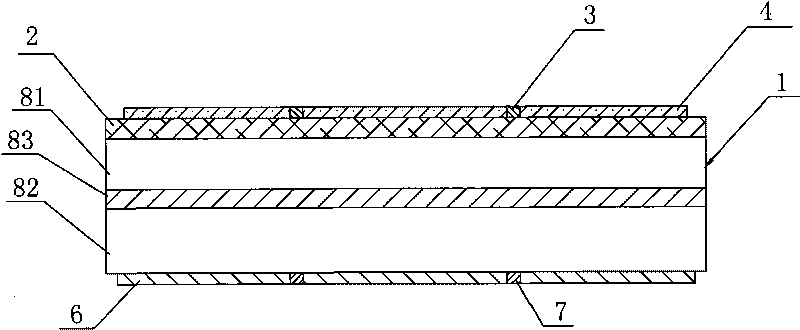

Method for preparing crystalline silicon solar cell with passivation on double surfaces

InactiveCN101447532AImprove long wave responseImprove conversion efficiencyFinal product manufactureSemiconductor devicesScreen printingBack surface field

The invention discloses a method for preparing a crystalline silicon solar cell with passivation on double surfaces. The method comprises the following steps: laminated passivation layers are prepared on the front and the back surfaces of the solar cell; by utilizing a method of screen printing corrosive sizing agent on the laminated passivation layer on the back surface, an electrode window is opened on the laminated passivation layer on the back surface; and then a back electrode is formed by screen printing or sputtering on the electrode window. By utilizing the screen printing corrosive sizing agent method, a structure of passivation on double surfaces of the solar cell is achieved; the structure greatly improves long-wave responses of the solar cell, and increases the conversion efficiency of the solar cell; and meanwhile, as an all-aluminium back surface field is cancelled and a local aluminum back surface field is adopted, bending of the solar cell is reduced and the structure is more suitable for the trend of solar cell thin section. As the method utilizes screen printing technique to replace pholithography and a laser sintering method, production costs are saved. Furthermore, the method is more suitable for mass production.

Owner:上海晶澳太阳能光伏科技有限公司

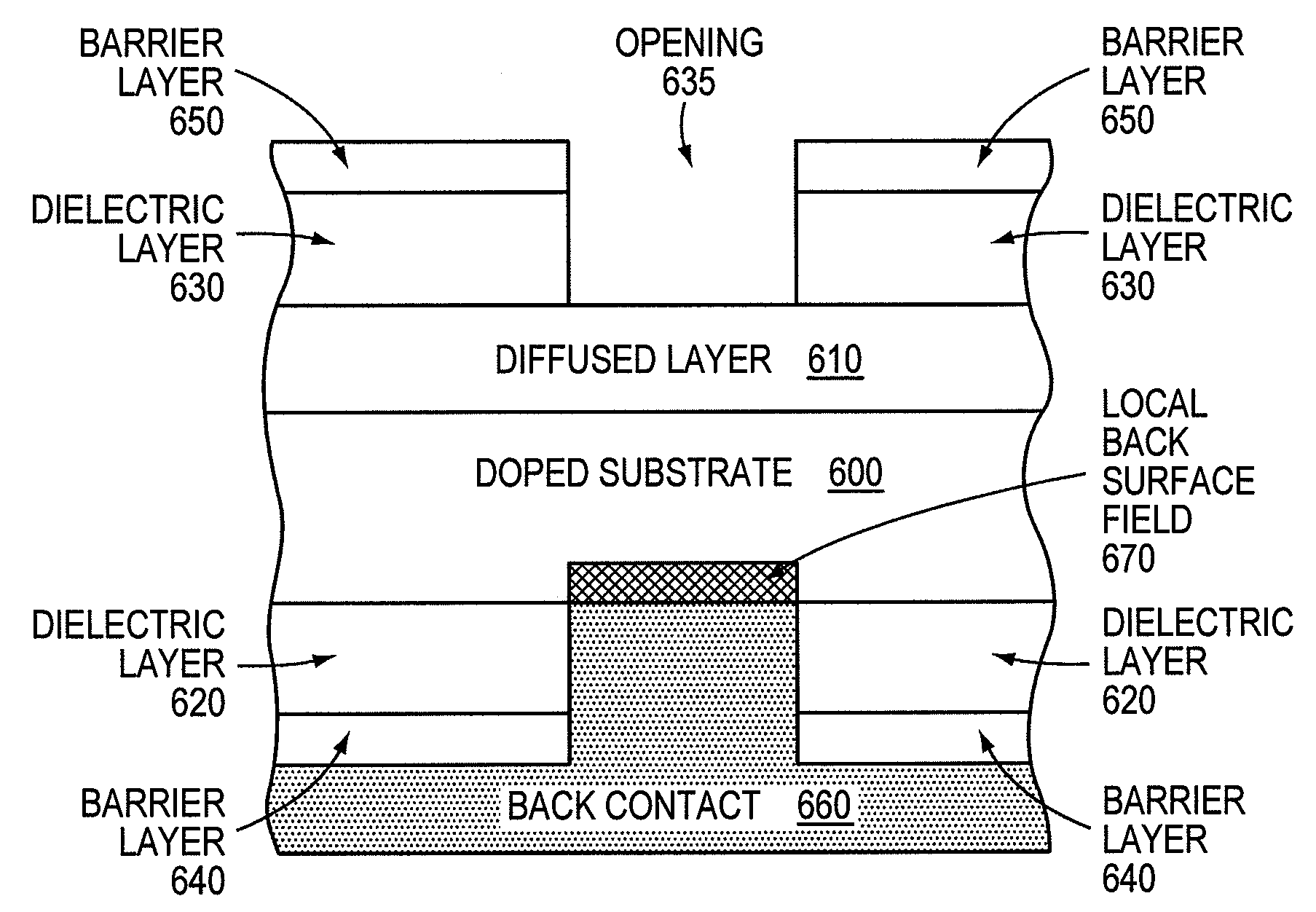

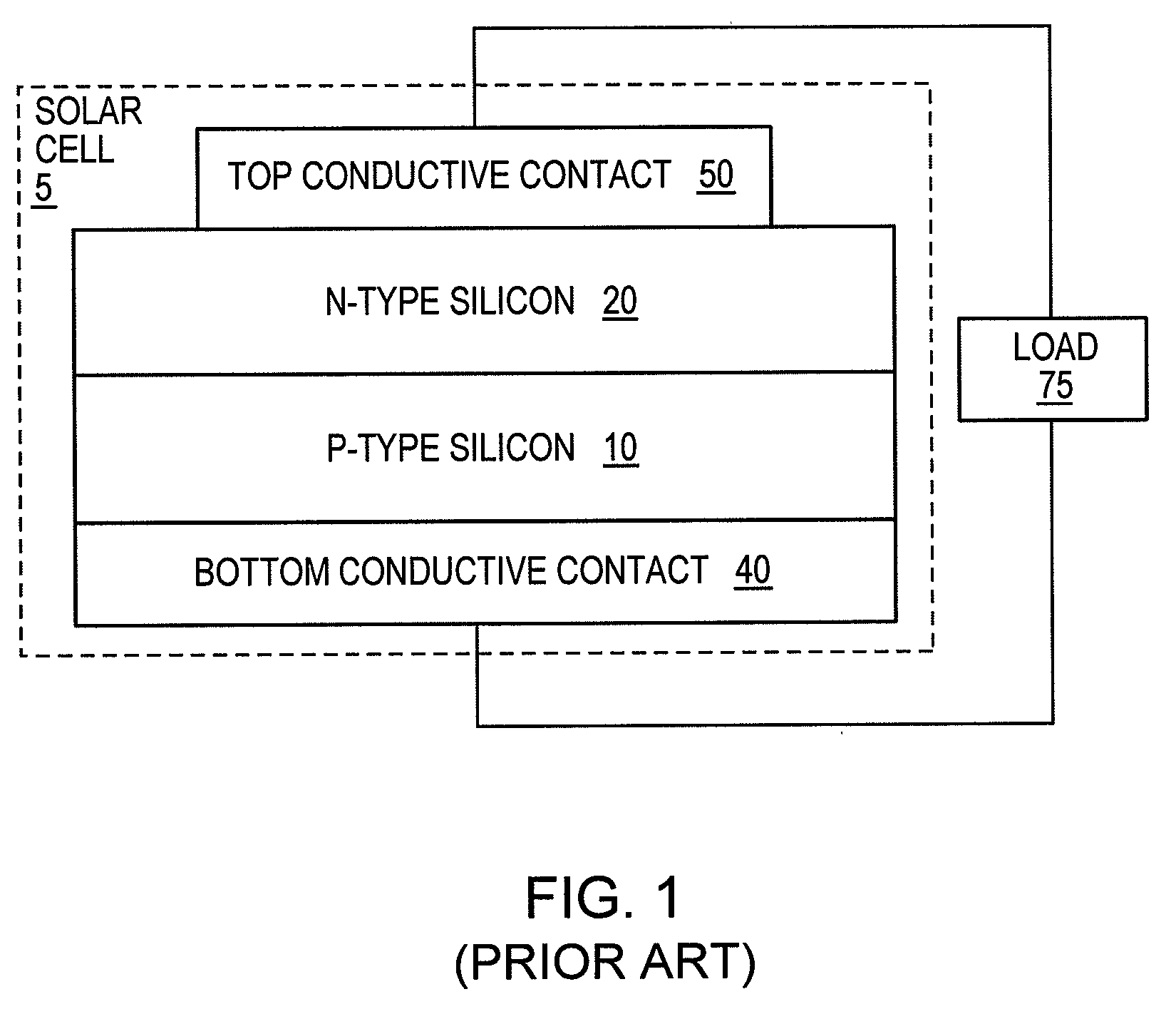

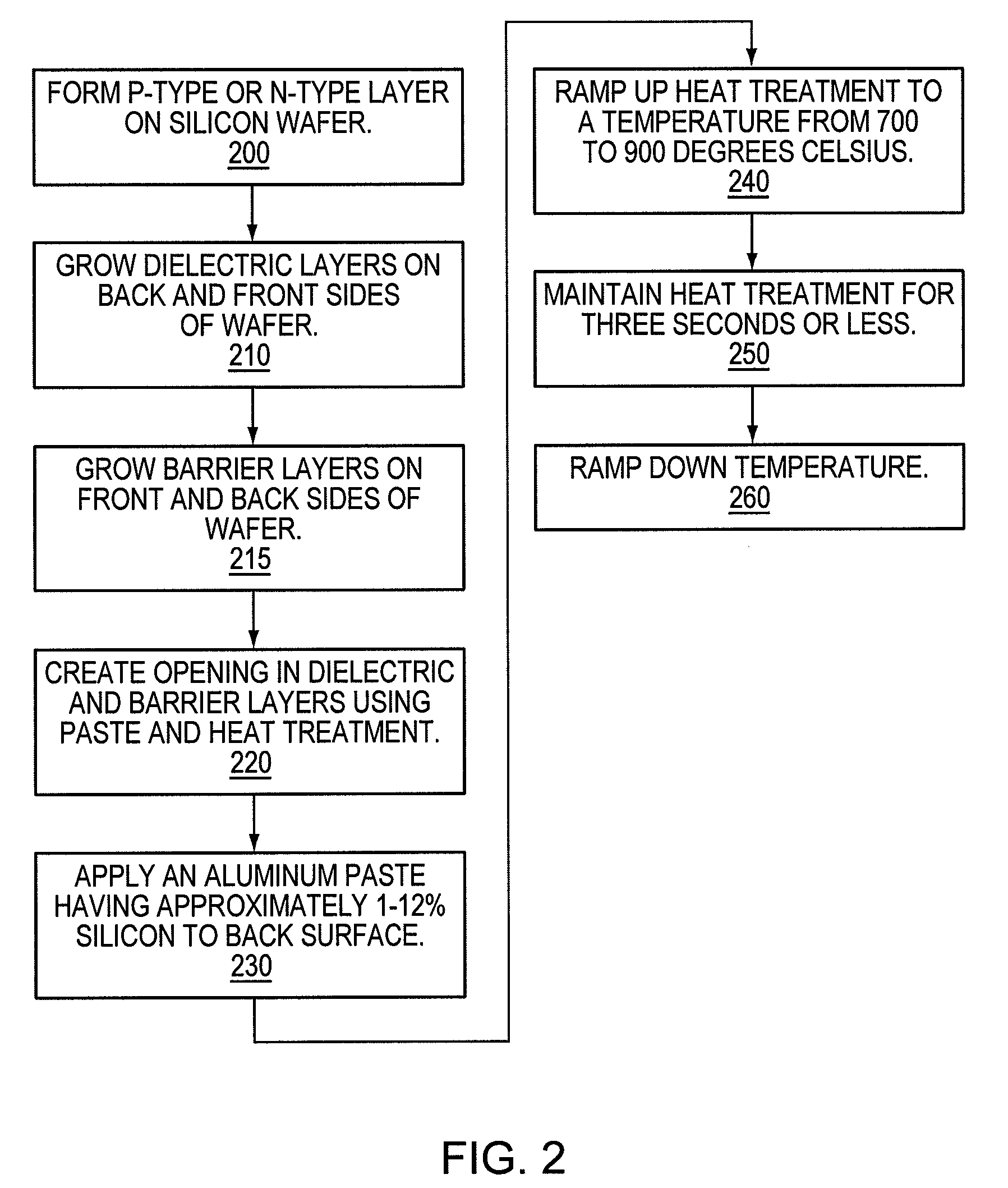

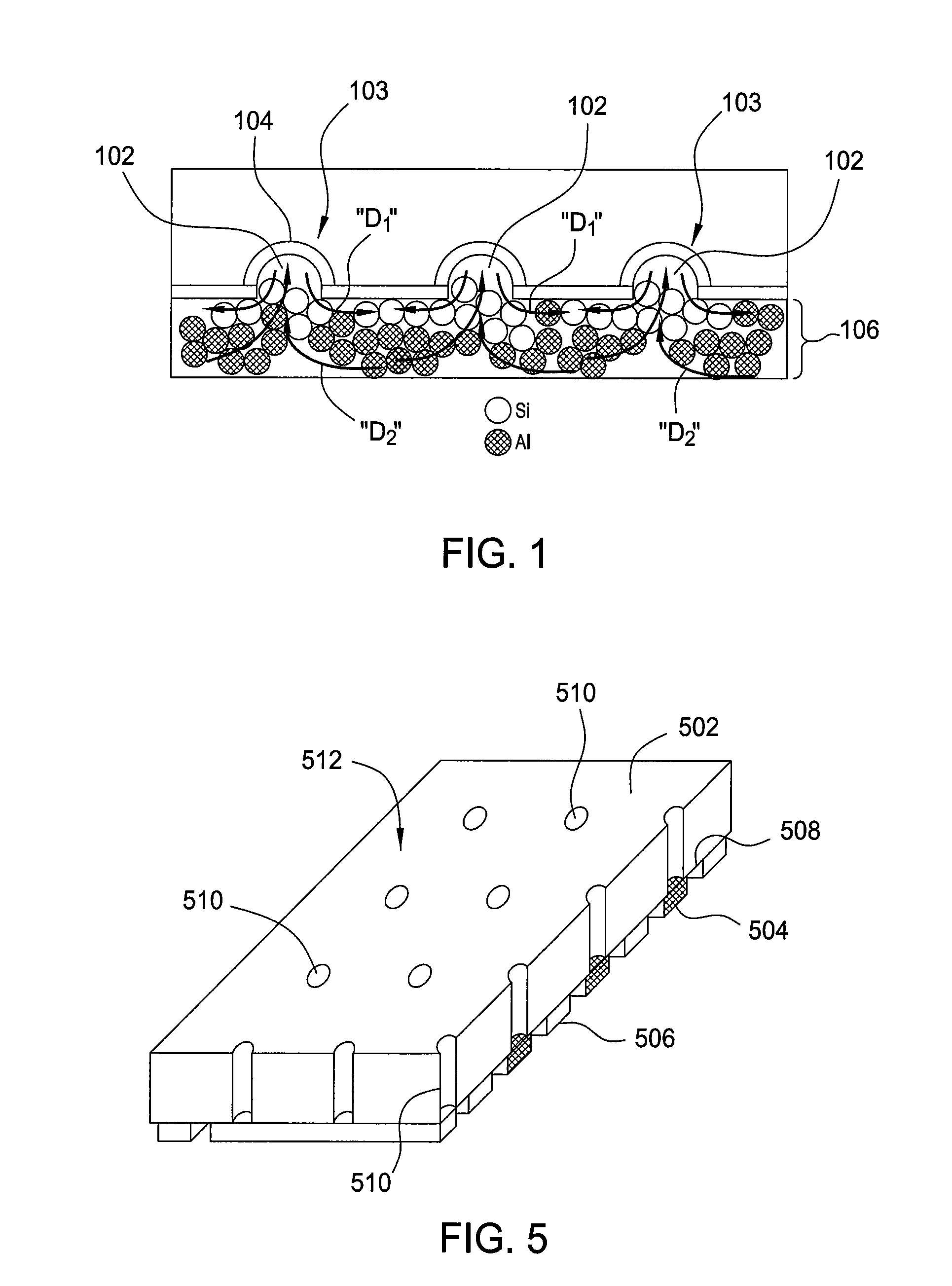

Solar cell having high quality back contact with screen-printed local back surface field

InactiveUS20090025786A1Final product manufacturePhotovoltaic energy generationScreen printingCelsius Degree

A thin silicon solar cell having a back dielectric passivation and rear contact with local back surface field is described. Specifically, the solar cell may be fabricated from a crystalline silicon wafer having a thickness from 50 to 500 micrometers. A barrier layer and a dielectric layer are applied at least to the back surface of the silicon wafer to protect the silicon wafer from deformation when the rear contact is formed. At least one opening is made to the dielectric layer. An aluminum contact that provides a back surface field is formed in the opening and on the dielectric layer. The aluminum contact may be applied by screen printing an aluminum paste having from one to 12 atomic percent silicon and then applying a heat treatment at 750 degrees Celsius.

Owner:GEORGIA TECH RES CORP

High-photoelectric-conversion-efficiency crystalline silicon solar battery aluminum paste and preparation method thereof

InactiveCN102324267AReduce dosageImproved aluminum back fieldNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon alloyBack surface field

The invention relates to a high-photoelectric-conversion-efficiency crystalline silicon solar battery aluminum paste, which consists of the following raw materials by mass percent: 60-70 percent of aluminum powder, 20-35 percent of organic bond, 1-10 percent of aluminum-silicon alloy powder, 0.2-2 percent of glass powder and 0.1 to 1.5 percent of adjuvant, wherein the sum of the mass percent of the raw materials is 100 percent, the content of aluminum contained in the aluminum-silicon alloy powder is 8-15 percent and the average grain size of the aluminum-silicon alloy powder is small than 2mum. The invention additionally provides a preparation method for the crystalline silicon solar battery aluminum paste. After the paste is screen-printed, dried and sintered, an aluminum back surface field is formed on a silicon wafer. The adhesive force of the aluminum back surface field is high, the warping degree of cells is low, the photoelectric conversion efficiency is high, the cost is low and the aluminum paste is nontoxic.

Owner:JIANGSU HOYI TECH

Lead-free Al-back-surface-field (BSF) paste for crystalline silicon solar battery and preparation method thereof

ActiveCN101582462AReduce warpageGood dispersionFinal product manufactureMetal/alloy conductorsScreen printingOhmic contact

The invention provides a lead-free Al-back-surface-field (BSF) paste for a crystalline silicon solar battery and a preparation method thereof. The paste is made of 72-82 parts of aluminium powder, 0.1-2 parts of zirconia powder, 0.1-5 parts of inorganic bonding agent, 15-25 parts of organic bonding agent and 1-3 parts of auxiliary agent. After being processed by screen painting and sintering, the paste forms Al-BSF on a silicon chip, the BSF and the silicon chip form good ohmic contact and have good adhesive attraction; an aluminum film does not fall off, the battery has high transfer efficiency, and a battery piece has low warpage.

Owner:GUANGZHOU RUXING TECH DEV +1

Paste for electrode forming of solar cell

InactiveCN101304049AImprove efficiencyHigh mechanical strengthFinal product manufactureNon-conductive material with dispersed conductive materialBack surface fieldEngineering

The invention provides a sizing agent for forming an electrode of a solar cell. The sizing agent has the following advantages that: the mechanical strength of the electrode and the closing performance with the base material are good, the back surface field (BSF) effect required by the solar cell can be accomplished thoroughly, the bend of the base material after burned can be restrained, the efficiency of the solar cell can be improved, and the sizing agent is more particularly suitable for burning at high temperature / high speed with excellent mass production. The sizing agent for forming an electrode of a solar cell is characterized in that a) 60-75 parts by weight of aluminum power with at least 1.28 g / cc of tap density, b) 1-5 parts by weight of glass powder, and c) 20-38 parts by weight of organic carrier are included.

Owner:DONGJIN SEMICHEM CO LTD

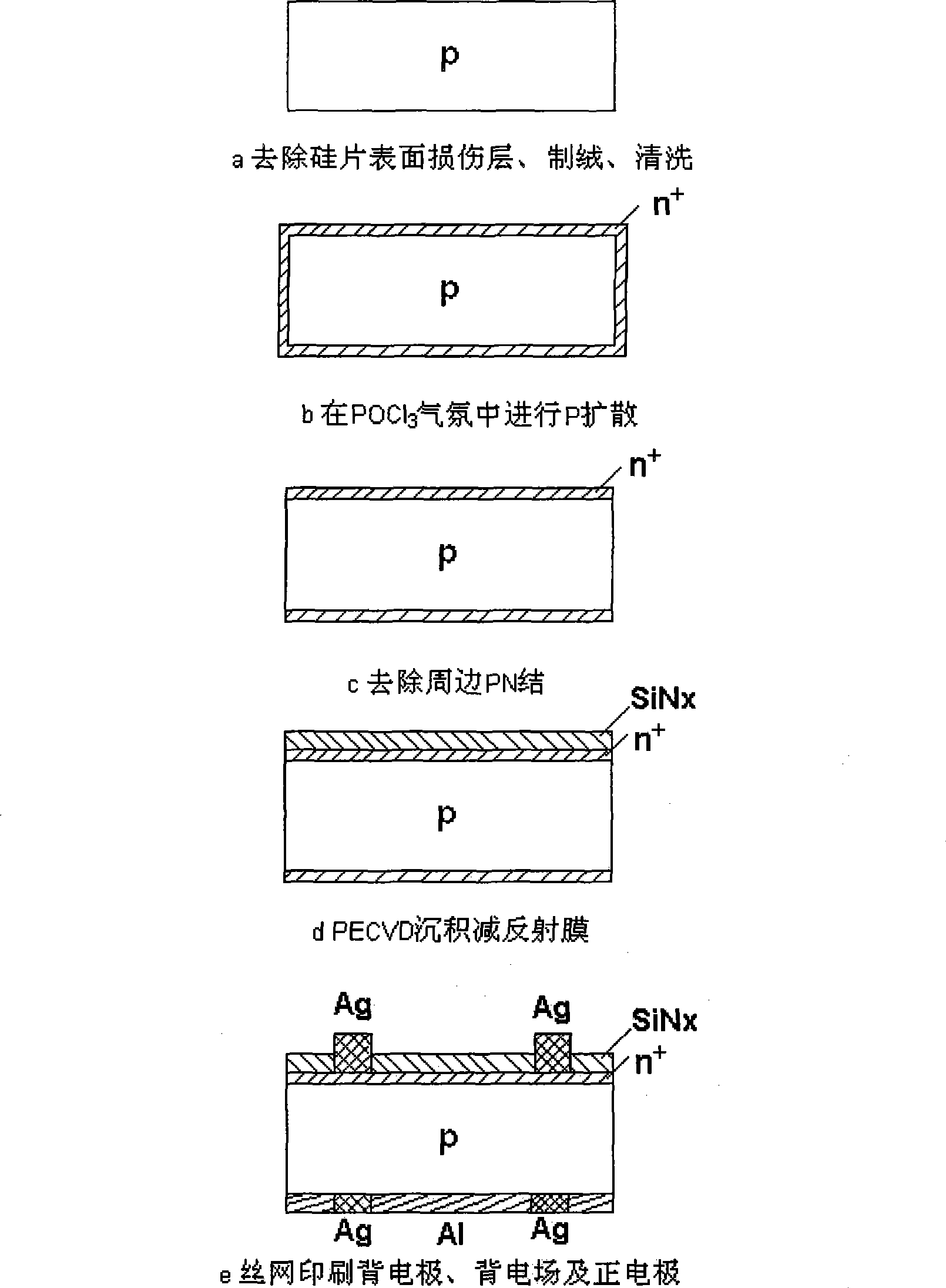

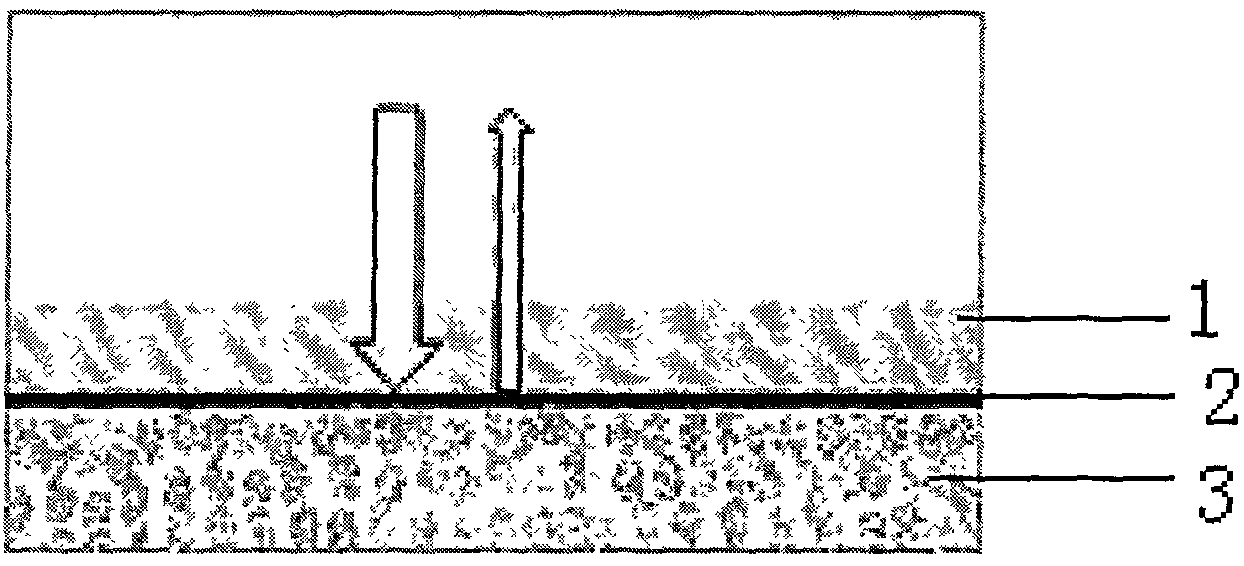

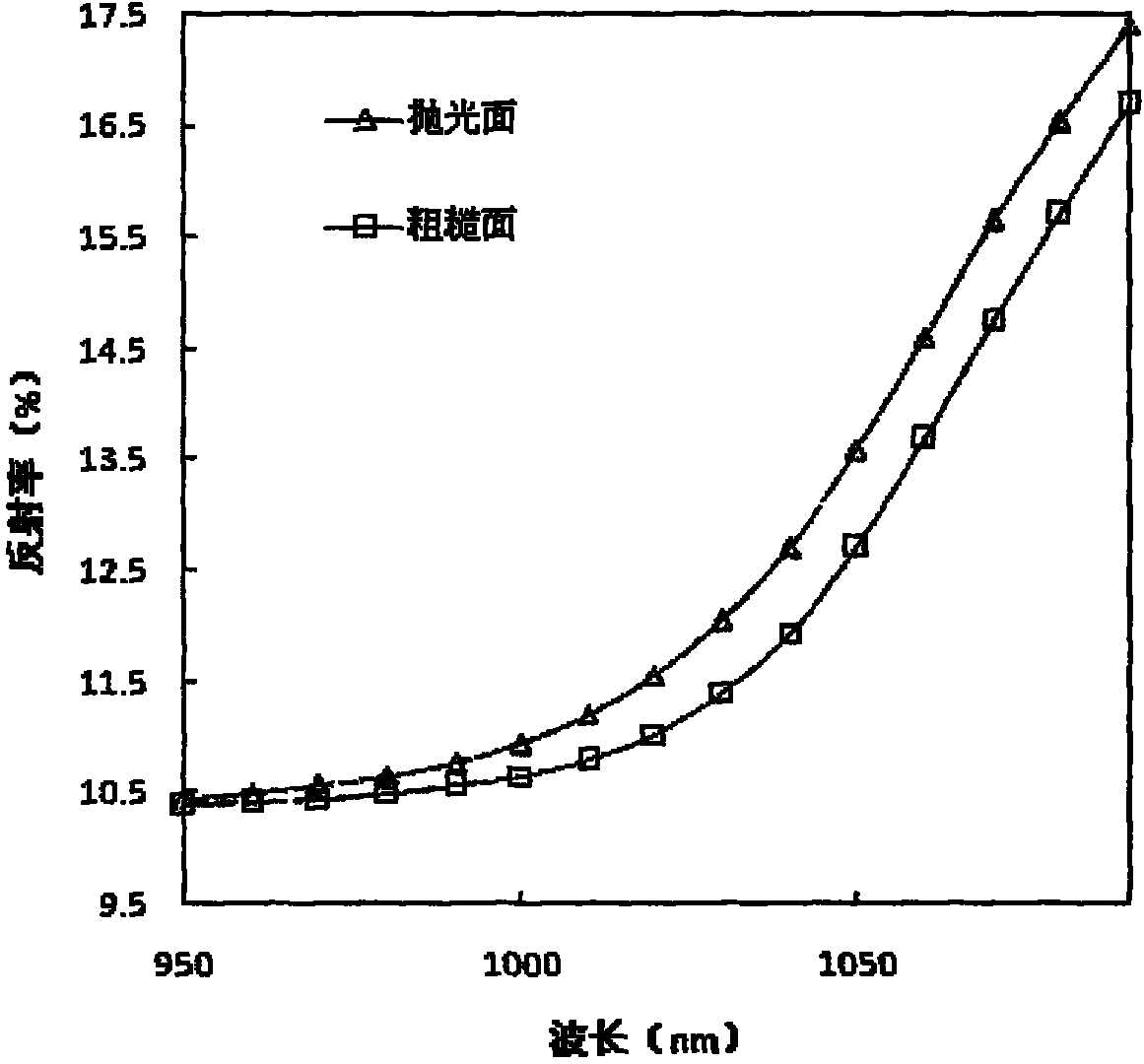

Industrialized production process of crystalline silicon solar battery

ActiveCN101840961AReduce the probability of electric leakageReduce process stepsFinal product manufactureSemiconductor devicesSpectral responseBack surface field

The invention discloses an industrialized production process of a crystalline silicon solar battery, which comprises the following steps of: selecting a silicon chip; performing front surface matte making, phosphorous diffusion, the removal of phosphorosilicate glass formed on the surface during the phosphorous diffusion, and the deposition of silicon nitride on the front surface through PECVD inturn, and then putting an anti-reflecting film protected silicon ship provided with the front surface silicon nitride into heated alkali liquor to perform back polishing so as to remove a diffusion layer on the back surface; and washing and drying the silicon chip, and printing and sintering the silicon chip by adopting a bending-resistant aluminum paste silk screen. The process adopts a chemicalmethod to replace a plasma etching process, realizes non-contact of a matte surface of the silicon chip in the whole production flow, avoids matte surface damages caused by silicon chip friction, so the probability of electric leakage after facade silver paste sintering is reduced; the flat and clean back surface is favorable for the reaction of aluminum and silicon during the sintering to form amore uniform aluminum back surface field; and a polished surface has a stronger reflex action compared with an irregular matte surface, and can increase the absorption of incident light, improve the spectral response of the long-wavelength of a battery chip, and significantly improve a short-circuit current and an open-circuit voltage.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

Solar cell

ActiveUS20110265870A1Improve featuresImprove efficiencyFinal product manufacturePhotovoltaic energy generationBack surface fieldFixed charge

A solar cell includes a substrate of a first conductive type, an emitter layer, of a second conductive type opposite the first conductive type, positioned at one surface of the substrate, a first electrode electrically connected to the emitter layer, a first protective layer positioned on a front surface of the emitter layer where the first electrode is not positioned, a back surface field layer positioned at another surface of the substrate, a second electrode electrically connected to the back surface field layer, and a second protective layer positioned on a back surface of the substrate where the second electrode is not positioned. Each of the first and second protective layers is formed of a material having fixed charges of the first conductive type.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

Process for preparing back point-contact crystalline-silicon solar cells

InactiveCN101540350AReduce manufacturing costEase of mass productionFinal product manufactureSemiconductor devicesSilicon nitrideBack surface field

The invention discloses a process for preparing back point-contact crystalline-silicon solar cells. The process comprises the following steps: coating the back surface of a silicon wafer with a silicon dioxide and silicon nitride compound passivating film; screen-printing a silicon slurry layer with a point-contact pattern on the compound passivating film with silicon slurry; then, etching off the area which is not covered by the silicon slurry layer with a chemical etching solution; further screen-printing an aluminum slurry layer on the back surface of the silicon wafer; allowing the contact surface of the aluminum slurry layer and the silicon slurry layer to form a silicon-aluminum alloy layer by sintering; and finally, allowing the aluminum slurry and the silicon substrate on the back surface of the silicon wafer to form the local ohmic contact and the local aluminum back-surface field. The process can reduce the preparation cost and realize the industrial mass production more easily; and the prepared back point-contact electrode crystalline-silicon solar cell can form good back ohmic contact and local aluminum back-surface field, solve the problem that the resistance increases when the cells are connected in series caused by the point contact to a certain extent and maintain the good back-passivating effect and the optical back-reflecting property.

Owner:SUN YAT SEN UNIV

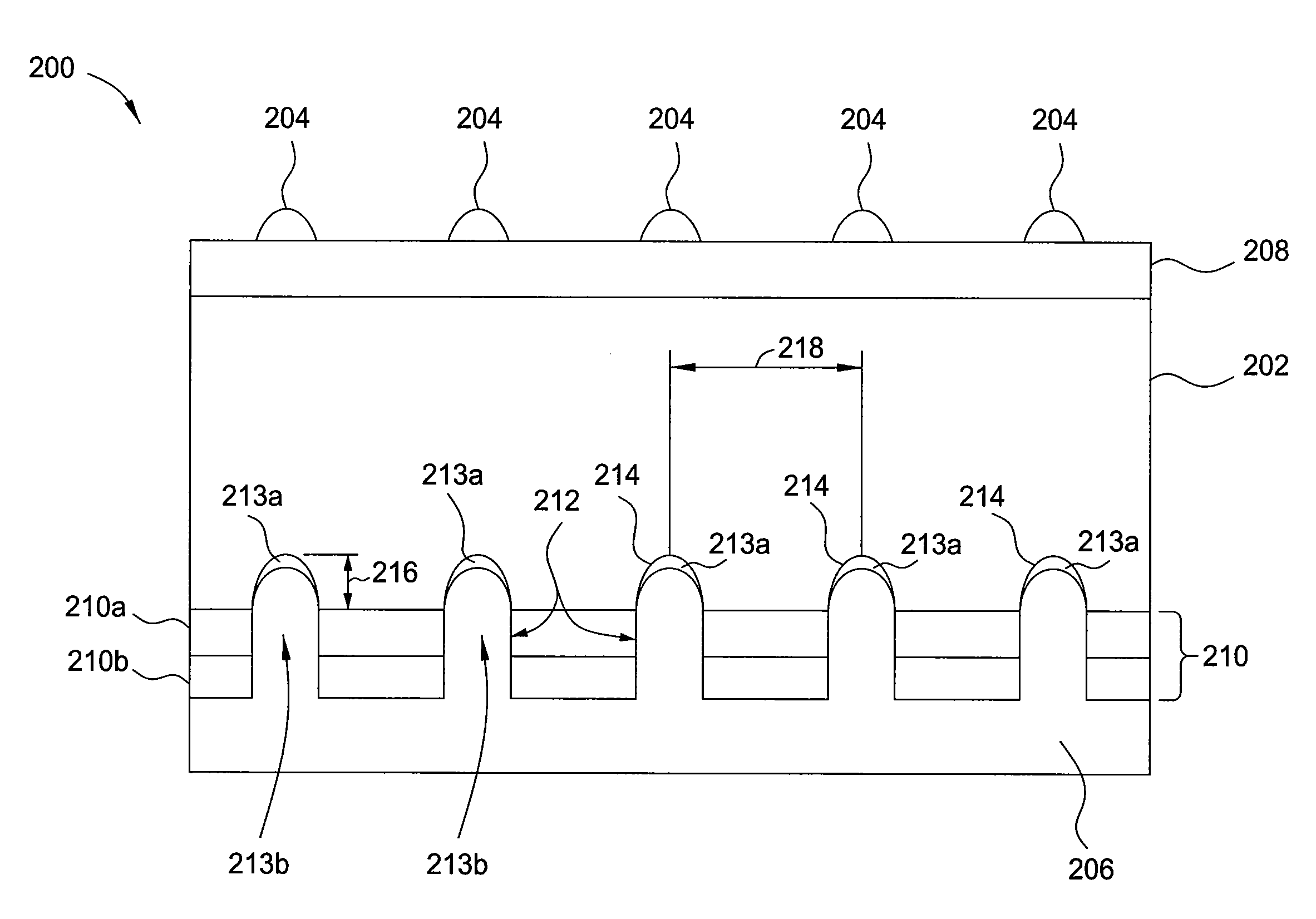

Doped ai paste for local alloyed junction formation with low contact resistance

InactiveUS20130255765A1Reduce carrier recombinationReduces cost-per-wattSemiconductor/solid-state device manufacturingPhotovoltaic energy generationJunction formationCharge carrier

Embodiments of the invention generally relate to solar cells having reduced carrier recombination and methods of forming the same. The solar cells have eutectic local contacts and passivation layers which reduce recombination by facilitating formation of a back surface field (BSF). A patterned aluminum back contact doped with a Group III element is disposed on the passivation layer for removing current form the solar cell. The methods of forming the solar cells include depositing a passivation layer including aluminum oxide and silicon nitride on a back surface of a solar cell, and then forming openings through the passivation layer. An aluminum back contact doped with a Group III element is disposed on the passivation layer in a pattern covering the holes, and thermally processed to form a silicon-aluminum eutectic within the openings.

Owner:APPLIED MATERIALS INC

Silicon solar battery

InactiveCN101710596AIncrease power generation per unit areaReduce shading areaPhotovoltaic energy generationSemiconductor devicesBack surface fieldSlurry

The invention discloses a silicon solar battery which comprises a silicon substrate, wherein a silicon nitride film is deposited on the front surface of the silicon substrate; a group of auxiliary grid lines are arranged on the silicon nitride film; an aluminum-back surface field (Al-BSF) made of aluminum slurry is coated on the back surface of the silicon substrate; a main grid line is arranged on the Al-BSF; a plurality of conducting through holes which penetrate through the silicon substrate are arranged on the silicon substrate; conducting slurry is filled in the conducting through holes; the auxiliary grid lines and the main grid line are respectively connected with two ends of the conducting slurry; and an insulation tank for isolating the Al-BSF from the main grid line is arranged at the periphery of the main grid line. The invention has the advantages that by arranging the main grid line on the back surface of the silicon substrate, arranging the conducting through holes on the silicon substrate and filling the conducting slurry into the conducting through holes, each auxiliary grid line is mutually conducted with the main grid line through the conducting slurry, and the current generated by the battery under the condition of illumination passes through the auxiliary grid lines and then passes through the conducting slurry to be converged onto the main grid line to be derived. In the battery with the structure, as the main grid line for converging current is arranged on the back surface of the silicon substrate, the effective illumination surface of the front surface of the battery is increased.

Owner:SUN EARTH SOLAR POWER

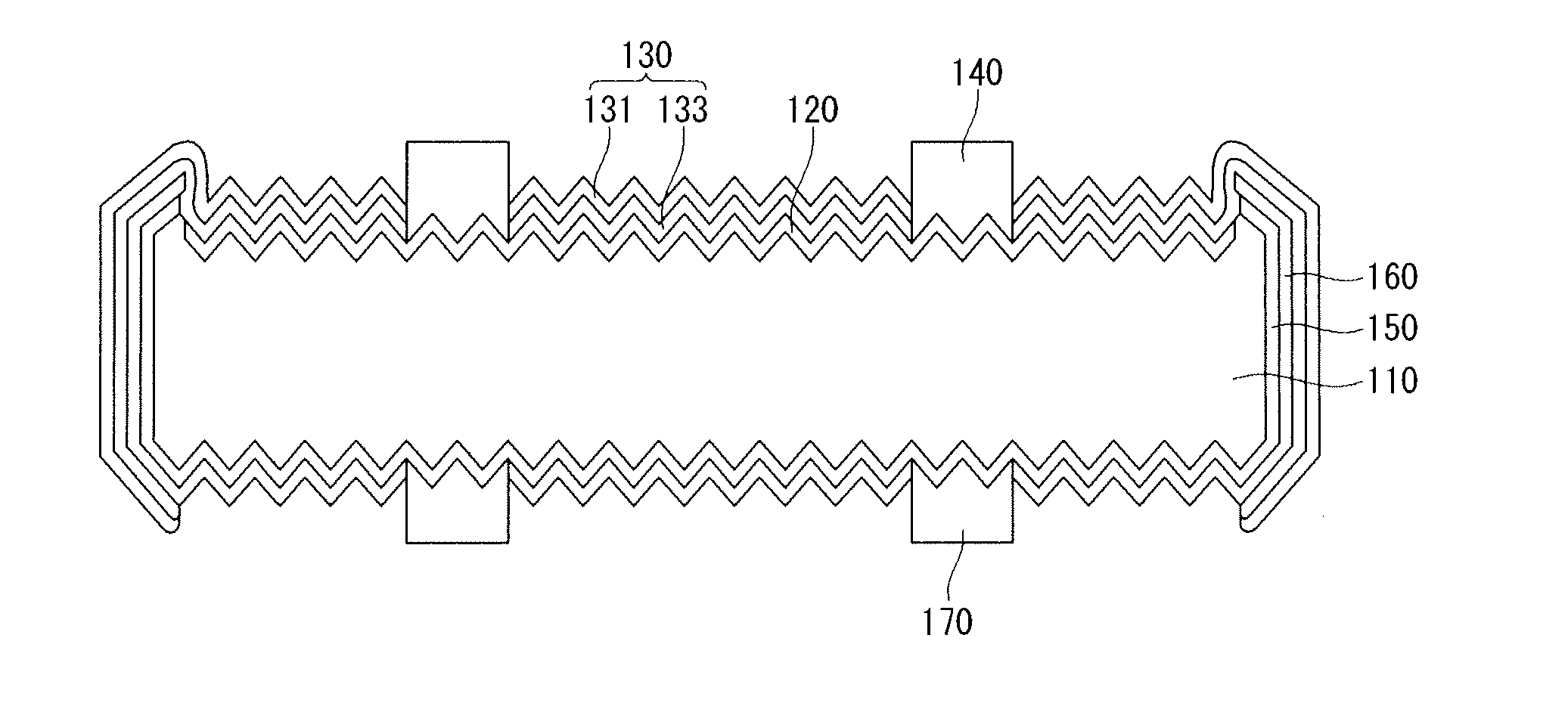

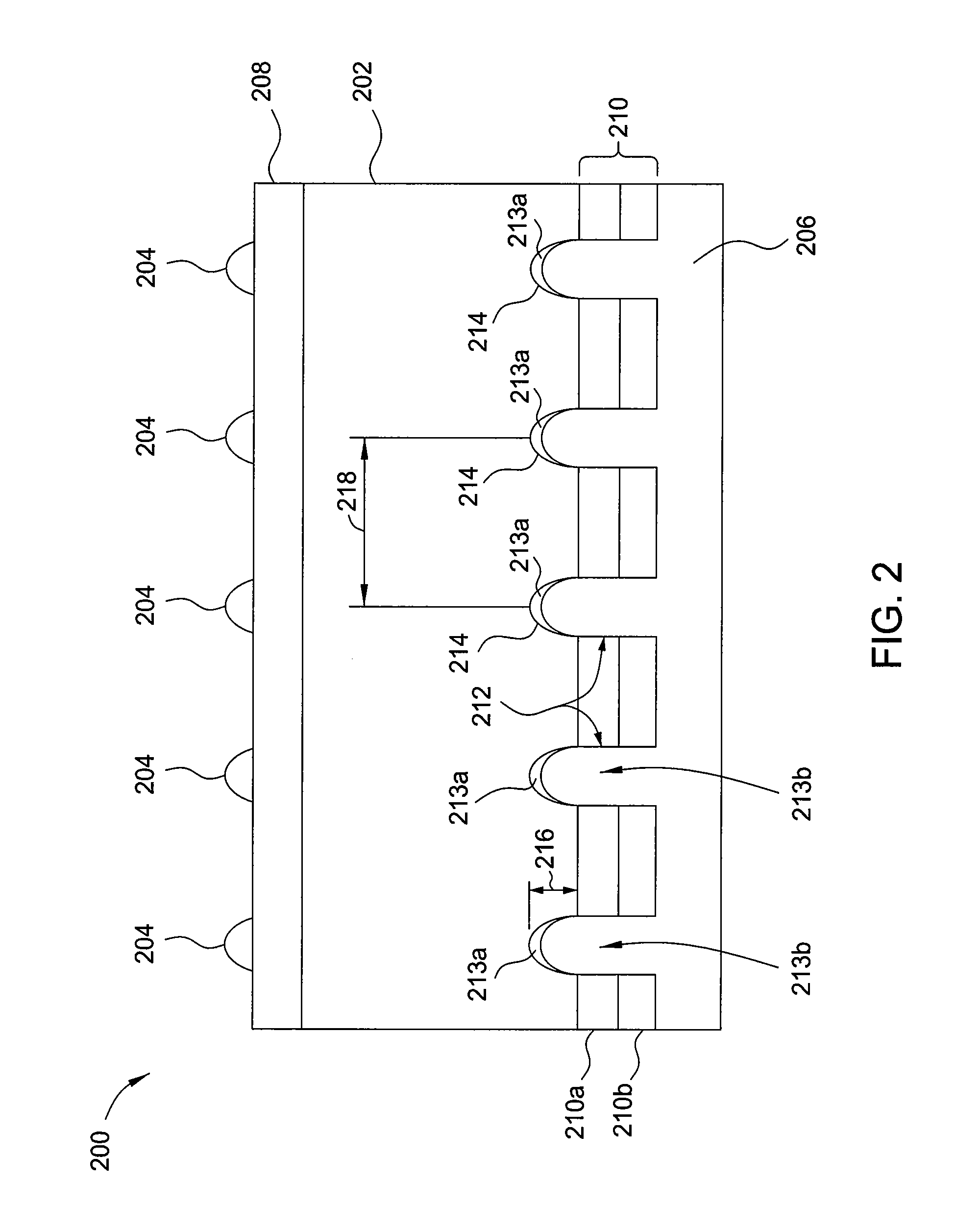

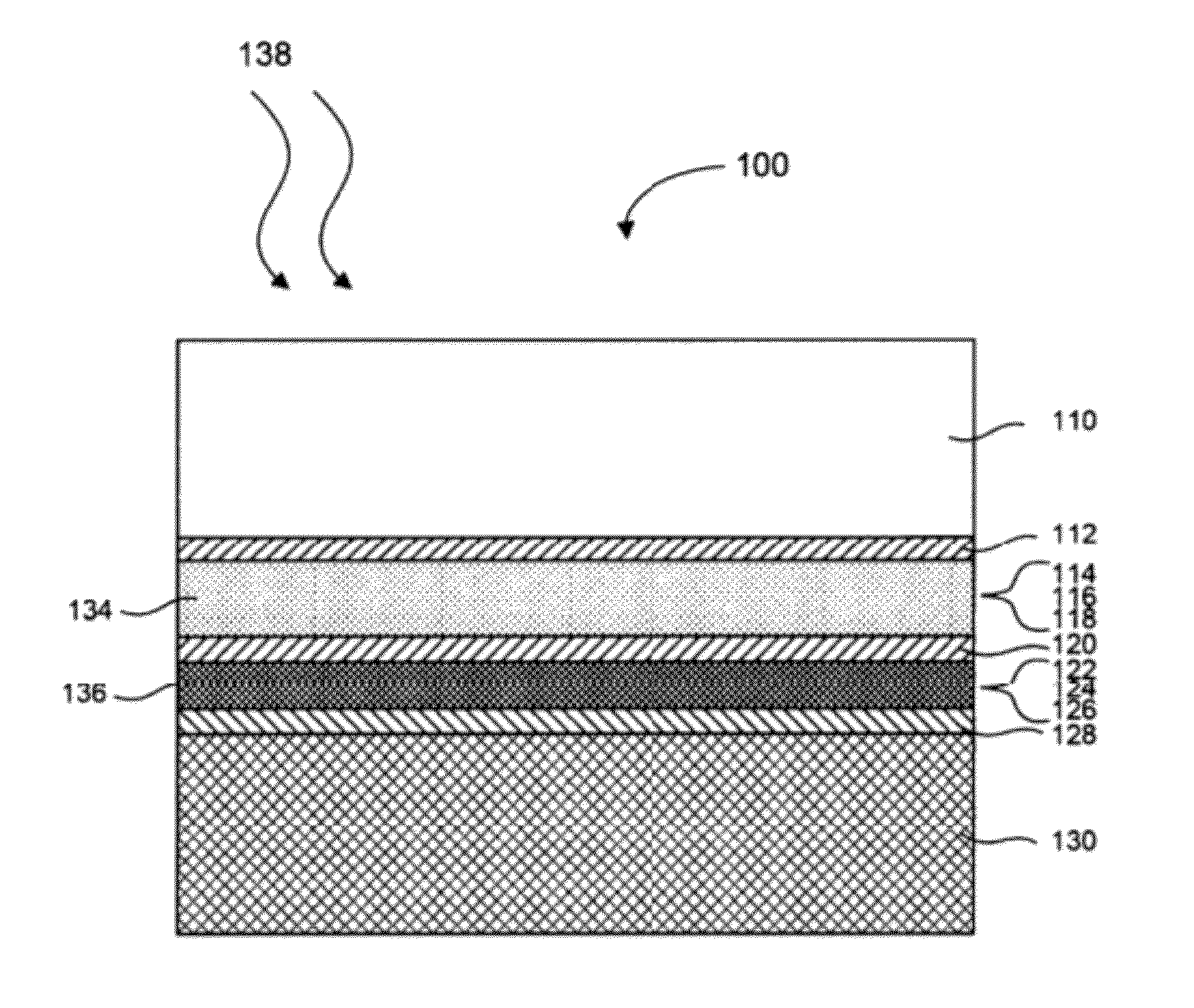

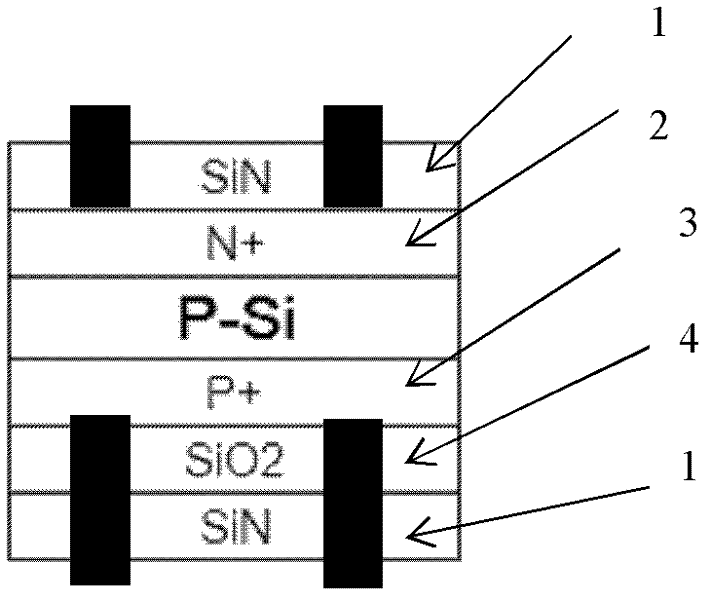

Multi-Junction Semiconductor Photovoltaic Apparatus and Methods

InactiveUS20120291859A1Increase long wavelength light efficiencyImprove quantum efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingBack surface fieldSemiconductor

A photovoltaic device and methods of manufacturing a photovoltaic device are disclosed. A photovoltaic device includes a first photovoltaic cell, a second photovoltaic cell, a semiconductor layer, and a doped layer. The second photovoltaic cell is in electrical communication with the first photovoltaic cell. The semiconductor layer includes a textured portion. The doped layer is configured to create a back surface field, the doped layer disposed between a proximal layer of the second photovoltaic cell and the semiconductor layer.

Owner:SIONYX

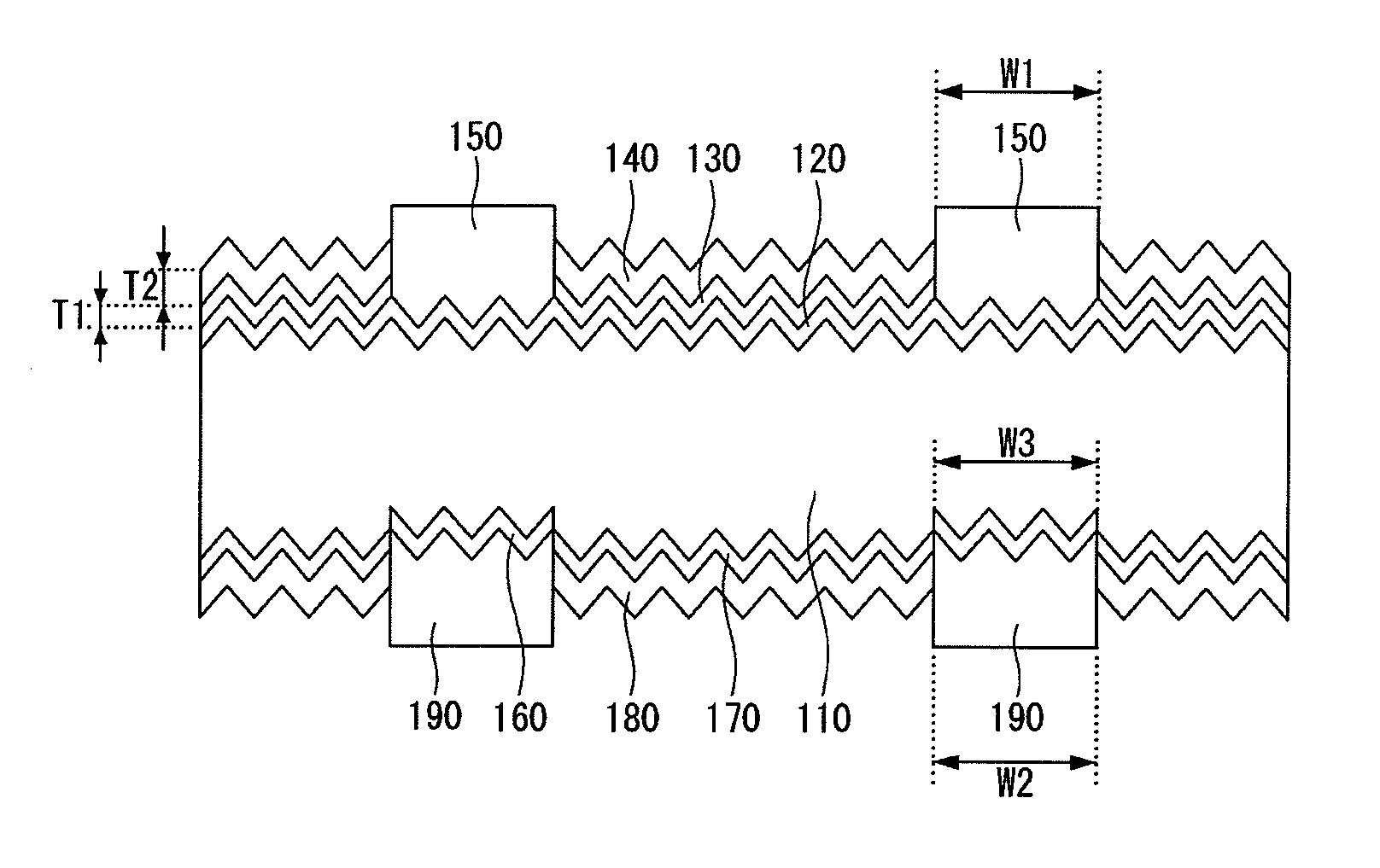

Preparation method and structure of one-film and multipurpose masked texturing solar cell

ActiveCN102403399ASimple processEasy to controlFinal product manufacturePhotovoltaic energy generationBack surface fieldBoron

The invention relates to the technical field of manufacturing of photovoltaic cells, in particular to a preparation method and a structure of a one-film and multipurpose masked texturing solar cell. The preparation method comprises the following steps of: taking a P-type Czochralski monocrystalline silicon as a substrate, manufacturing an SiO2 thin film on a P-type back surface field, taking the SiO2 thin film as a positive alkali solution-textured mask, diffusing a phosphorus source after the completion of texturing, and preparing P-N nodes on the front surface; forbidding to completely remove the SiO2 thin film and an SiNx thin film after the diffusion of the phosphorus source, and retaining the SiO2 thin film of 10-150 nm as a passivation film on the back surface; or taking an N-type Czochralski monocrystalline silicon as a substrate, manufacturing a SiO2 thin film on an N-type back surface field, taking the SiO2 thin film as a positive alkali solution-textured and boron source-diffused mask; and forbidding to completely remove after the diffusion of a phosphorus source, and retaining the SiO2 thin film of 10-150 nm as a passivation film on the back surface. The invention has the beneficial effects that compared with the prior process method, the process is simple, the control is easy, the cost is low, and the photoelectric conversion efficiency is high.

Owner:TRINA SOLAR CO LTD

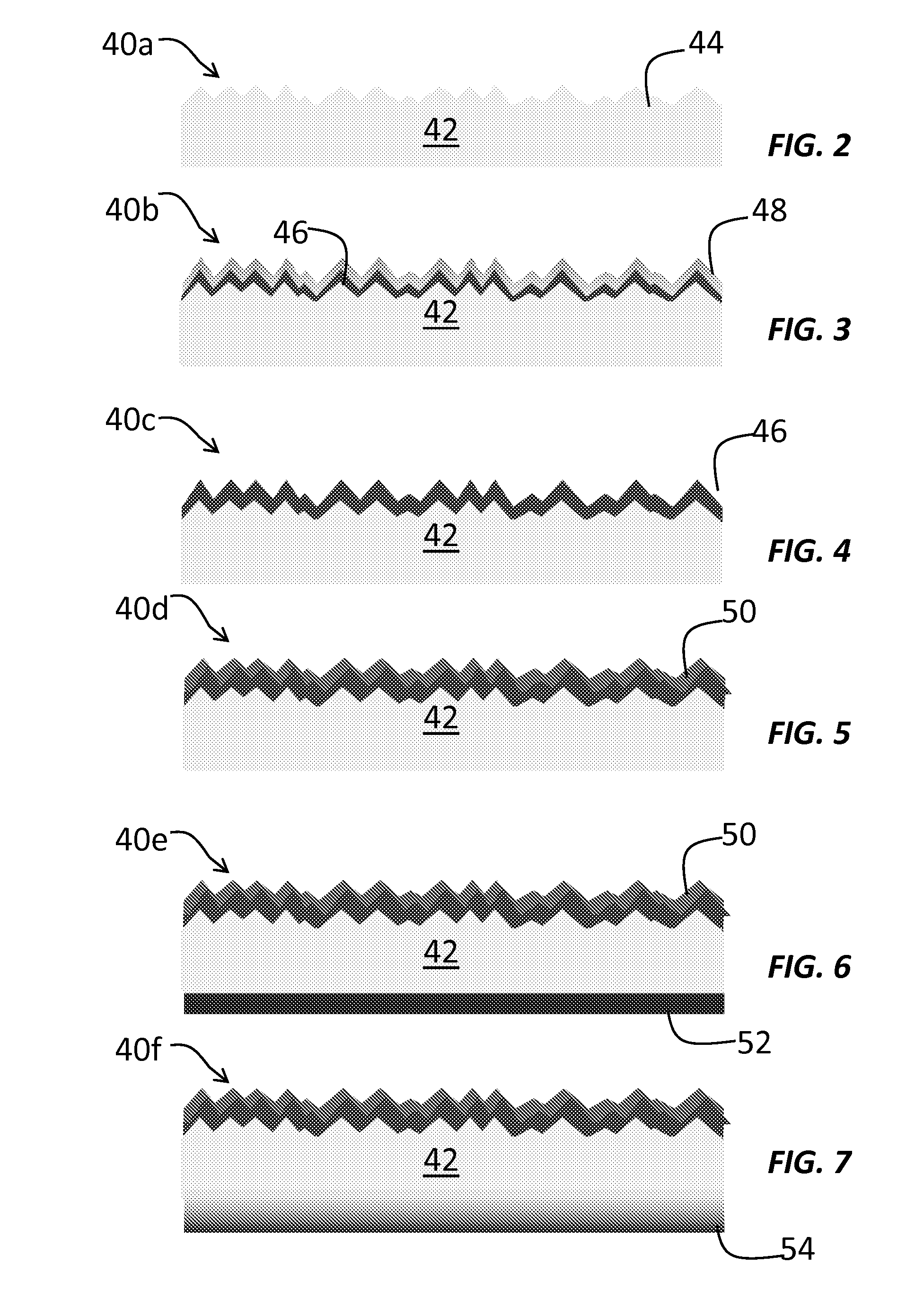

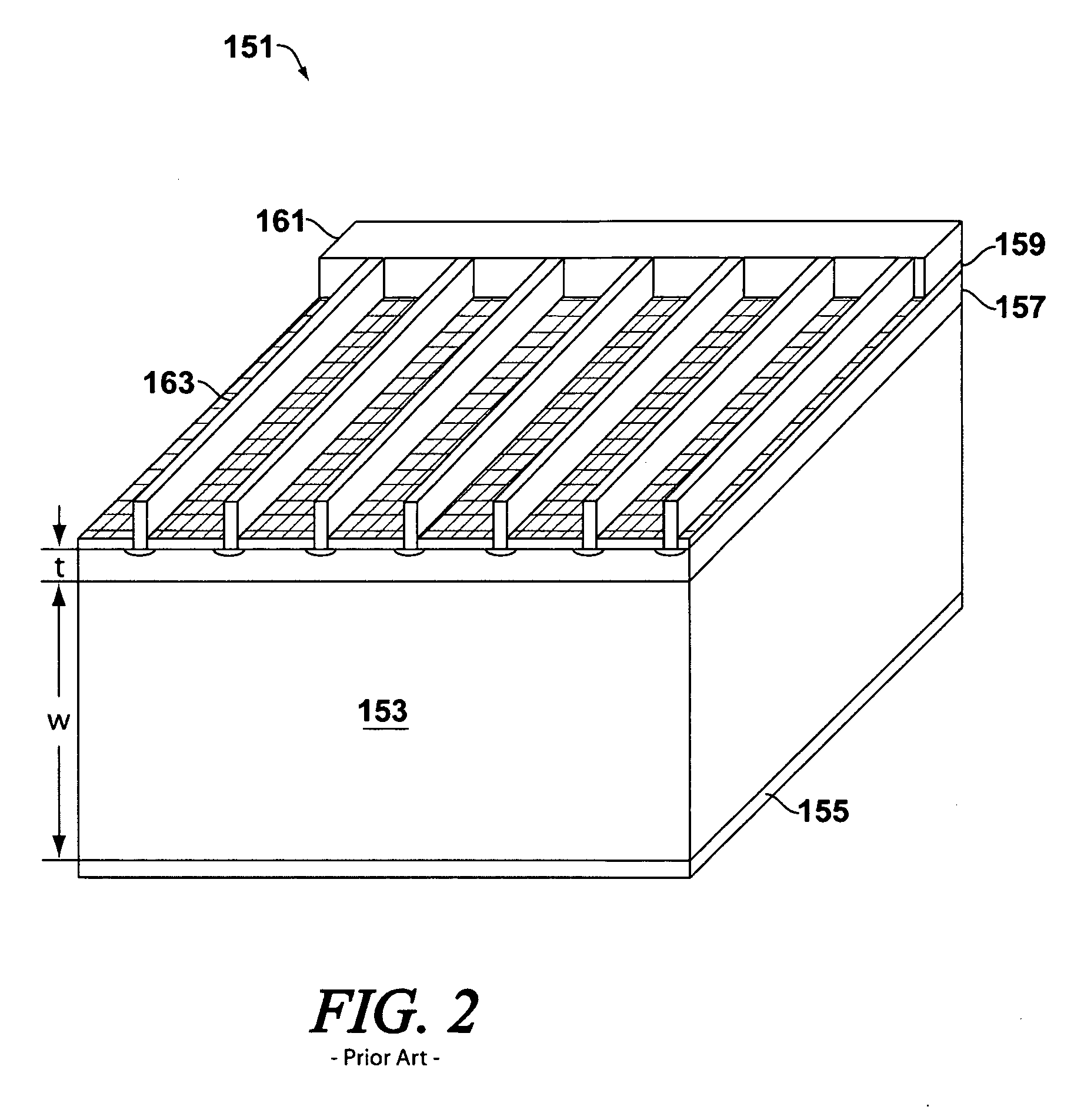

Photovoltaic device having a textured metal silicide layer

A semiconductor device is formed on a low cost substrate 312 onto which is deposited a metal film 314 that serves as an intermediate bonding layer with a transferred film 324 of semiconducting material from a bulk semiconductor substrate 322. The metal film forms an intermetallic compound such as a silicide 316 and functions as a bonding agent between the low cost substrate and the semiconducting substrate, as a back surface field for reflection of minority carriers, and as a textured optical reflector of photons. The silicide also forms a low resistivity back-side ohmic contact with the semiconductor layer. This results in a low cost, flexible, high efficiency, thin film solar cell device.

Owner:WOODSIDE GRP PTE LTD THE

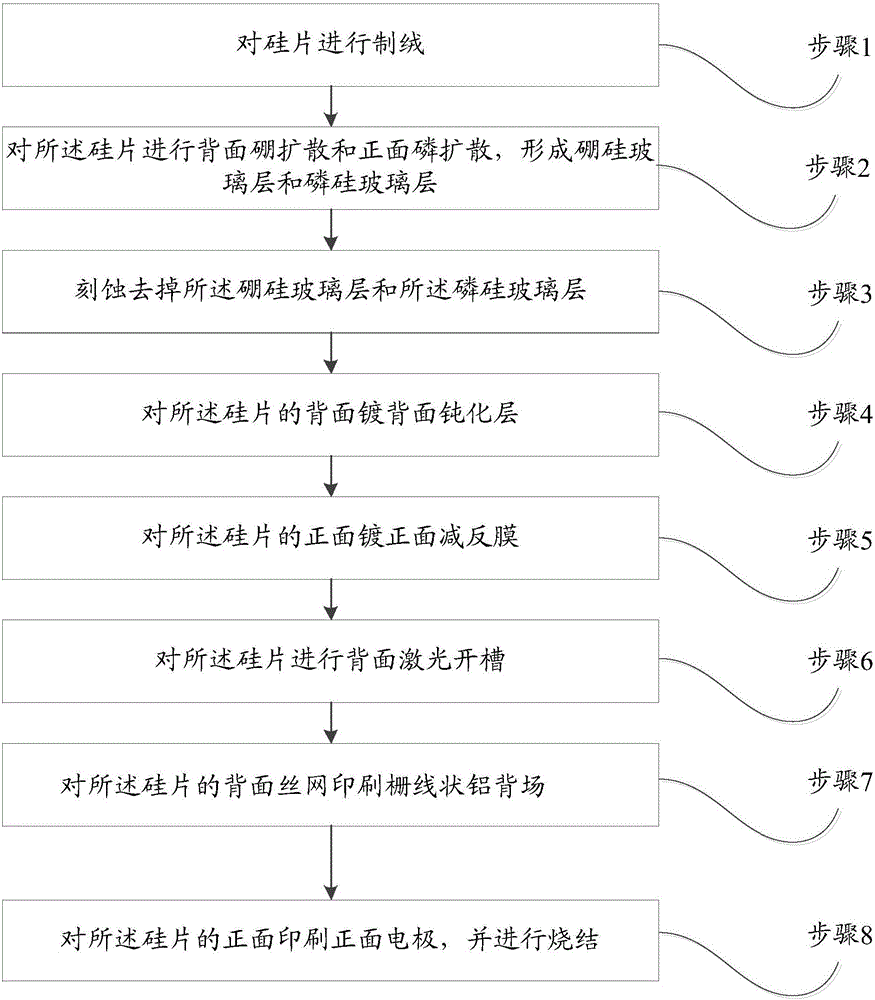

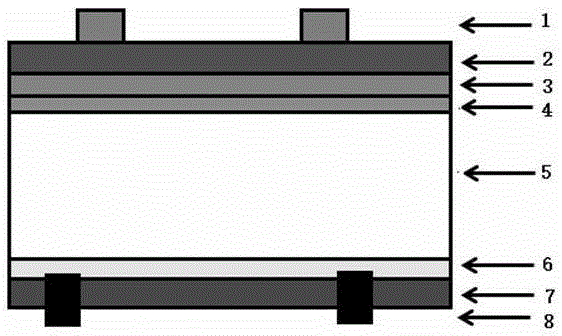

PERC preparation method

InactiveCN106449877AReduce void ratioIncrease powerFinal product manufacturePhotovoltaic energy generationScreen printingBack surface field

The invention discloses a PERC preparation method, which comprises the following steps: 1) carrying out texturing on a silicon wafer; 2) carrying out back-surface boron diffusion and front-surface phosphorus diffusion on the silicon wafer to form a borosilicate glass layer and a phosphorosilicate glass layer; 3) etching the borosilicate glass layer and the phosphorosilicate glass layer; 4) plating a back-surface passivation layer on the back surface of the silicon wafer; 5) plating a front-surface anti-reflection film on the front surface of the silicon wafer; 6) carrying out back-surface laser grooving on the silicon wafer; 7) carrying out grid line aluminum back-surface field silk-screen printing on the back surface of the silicon wafer; and 8) printing a front-surface electrode on the front surface of the silicon wafer and carrying out sintering. By printing a grid line aluminum back-surface field on the back surface, aluminium slurry can be fully extruded and fully fill the whole opening groove body, thereby reducing aluminium silicon cavity proportion, saving aluminium slurry and reducing manufacture cost; and meanwhile, the PERC prepared through double-side diffusion and superposition and printing of the grid line aluminum back-surface field has a double-battery effect, and has a certain power rise for a current novel double-glass assembly.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Crystalline silicon solar cell capable of realizing double-side light entrance and preparation method therefor

ActiveCN105322043AReduce dosageReduce investmentFinal product manufacturePhotovoltaic energy generationBack surface fieldCrystalline silicon

A crystalline silicon solar cell capable of realizing double-side light entrance and a preparation method therefor are disclosed. The crystalline silicon solar cell comprises a metal grid line I, a transparent conductive oxide antireflection conductive layer, a doped silicon based thin film emitting electrode layer, an intrinsic silicon based thin film passivating layer, a crystal silicon wafer, a doped crystalline silicon thin film back surface field layer, a passivating antireflection layer and a metal grid line II. The preparation method comprises the steps of cleaning and texturing firstly, then preparing the doped crystalline silicon thin film back surface field layer, the passivating antireflection layer and the metal grid line II in sequence; then cleaning the surface, of the crystal silicon wafer, where the emitting electrode is positioned, then preparing the intrinsic silicon based thin film passivating layer, the doped silicon based thin film emitting electrode layer, the transparent conductive oxide antireflection conductive layer and the metal grid line I in sequence. The crystalline silicon solar cell has the advantages of capability of realizing double-side light entrance, high open-circuit voltage and good low light effect; the series resistance of the solar cell is further reduced, the consumption of valuable raw materials is reduced, and the cost is reduced; and in addition, the preparation method is suitable for large-scale production, capable of reducing the cost of the production equipment, and is expected to improve the stability and the yield of the products.

Owner:江西昌大高新能源材料技术有限公司

Aluminium paste for preparing crystal silicon solar cell aluminium back surface field and manufacture method thereof

InactiveCN102347094AReduce manufacturing costImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh cellSilicon alloy

The invention relates to an aluminium paste for preparing a crystal silicon solar cell aluminium back surface field and a manufacture method thereof. The paste comprises the following components in percentage by weight: 40-80wt% of aluminium powder, 3-45wt% of aluminium-silicon alloy powder, 0.5-10wt% of lead-free glass powder, 10-26wt% of organic solvent, 2-12wt% of thickening agent and 0.3-6wt% of organic addition agent. The manufacture method for the aluminium paste comprises the following steps: preparing the aluminium-silicon alloy powder; preparing the lead-free glass powder; preparing an organic carrier; proportioning all components; and synthetizing slurry. The aluminium paste has the advantages of reasonable component proportion, simple preparation technology, good adhesive force between the prepared aluminium paste and a solar cell silicon substrate, low slurry production cost, high peeling strength of the aluminium back surface field prepared by sintering, good formation of the aluminium back surface field, small cell sheet flexibility and high cell photoelectric conversion rate, and is suitable for industrial production, and the solar cell photoelectric conversion efficiency can be effectively improved.

Owner:湖南威能新材料科技有限公司

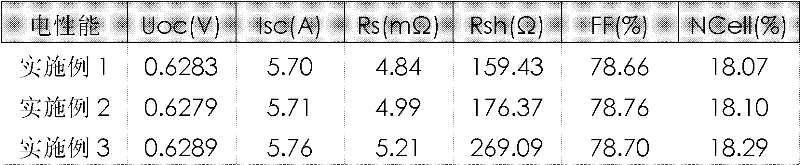

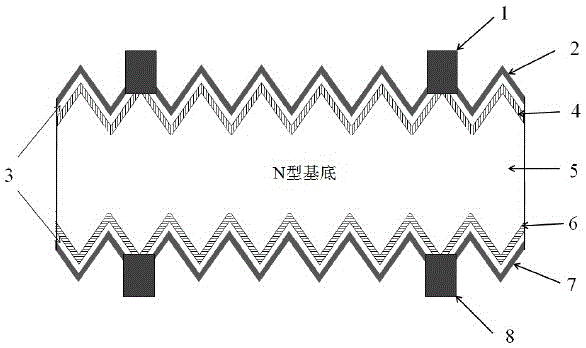

Double-sided N-type crystalline silicon cell and preparation method thereof

InactiveCN105047742AIncrease the open circuit voltageImprove current efficiencyFinal product manufacturePhotovoltaic energy generationChemical solutionBack surface field

The invention discloses a double-sided N-type crystalline silicon cell comprising a front AgAl electrode, a front antireflection film, a boron emitter passivation layer, a boron emitter p+ layer, an N-type silicon wafer, a phosphorus diffusion n+ back surface field layer, a back passivation layer, a back antireflection film, and a back Ag electrode. The front and the back of the cell are textured surfaces, and both sides can receive light and generate electricity. The boron emitter passivation layer and the back passivation layer are prepared at the same time by growing SiO2 layers through thermal oxidation in a low-temperature dry method, which reduces the interface-state density and the rate of interface recombination. A laminated film composed of a borosilicate glass layer and a silicon nitride layer formed in the diffusion process is used as a boron emitter protection layer. Therefore, boron diffusion surface etching and phosphorous diffusion cross contamination caused by chemical solution are prevented effectively, multiple times of etching and mask deposition in the process are reduced, and the technological process is simplified.

Owner:中国东方电气集团有限公司

Environment-friendly crystalline silicon solar-cell back surface field silver-aluminium paste and preparation method thereof

InactiveCN102024856AConducive to import and exportFinal product manufactureSemiconductor devicesAdhesiveHazardous substance

The invention discloses an environment-friendly crystalline silicon solar-cell back surface field silver-aluminium paste and a preparation method thereof. The silver-aluminium paste comprises the following components in percentage by weight: 15-35% of silver powder, 30-70% of aluminium powder, 10-15% of organic carrier, 1-5% of adhesive, 3.5-13% of solvent and 0.5-2% of dispersant. The organic carrier is prepared by dissolving 10-30% of ethyl cellulose resin in 70-90% of organic solvent. In the paste, environment-friendly glass powder without harmful substances is used as the adhesive, and an environment-friendly organic reagent is used as a solvent and a diluter; and thus, the prepared silver-aluminium paste does not contain six substances (Pb, Cd, Hg, Cr(VI), polybrominated diphenyl PBB and polybrominated diphenyl ether PBDE) inhibited by European Union RoHS Instruction, completely conforms to the Instruction 2005 / 84 / EC on phthalic ester in European Union RoHS, realizes environment friendliness in deed, and is beneficial to the import and export of solar cells made in China and raw materials of the cells.

Owner:IRICO

Aluminium paste special for local aluminium back surface field crystalline silicon solar cells and preparation method of aluminium paste

ActiveCN103545013AImprove liquidityAvoid damageFinal product manufactureNon-conductive material with dispersed conductive materialAl powderBack surface field

The invention discloses aluminium paste special for local aluminium back surface field crystalline silicon solar cells. The paste is prepared from, by mass, 70-80 parts of aluminium powder, 0.05-3 parts of inorganic bond, 17-27 parts of organic bond and 1-5 parts of additives in proportion. The invention further discloses a preparation method of the aluminium paste special for the local aluminium back surface field crystalline silicon solar cells. Compared with traditional aluminium paste, the aluminium paste specially applied to the local aluminium back surface field crystalline silicon solar cells has the advantages of good fluidity, small damage to passivating films, good contact with a window, density and uniformity in aluminium coatings, and the like. Average conversion efficiency of mass production of the aluminium paste applied to the local aluminium back surface field crystalline silicon solar cells is more than or equal to 20.0%, and tested aluminium back surface field adhesion tension is more than or equal to 10N via EVA tearing test after the cells are laminated and encapsulated.

Owner:GUANGZHOU RUXING TECH DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com