Patents

Literature

61 results about "Tearing test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

ActiveCN102409224AGuaranteed toughnessSuitable for solderabilityRoll mill control devicesMetal rolling arrangementsHydrogenChemical composition

The invention provides a hot rolled steel plate with excellent low-temperature toughness for a thick submerged pipeline and a production method of the hot rolled steel plate. The hot rolled steel plate comprises the following chemical components by weight percentage: 0.02%-0.07% of C, 0.15%-0.40% of Si, 1.0%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.003% of S, less than or equal to 0.06% of Nb, less than or equal to 0.025% of Ti, less than or equal to 0.06% of V, less than or equal to 0.20% of Mo, less than or equal to 0.25% of Cu, 0.10%-0.30% of Ni, less than orequal to 0.25% of Cr, less than or equal to 0.008% of N, 0.010%-0.040% of Al, more than or equal to 2 of Al / N and the rest Fe and inevitable impurities. According to the steel for the submerged pipeline with the thickness being over 28mm, disclosed by the invention, the transversal and longitudinal bending strength can reach over 480MPa or 510MPa, the transversal and longitudinal tensile strengthcan reach over 560MPa or 600 MPa, the transversal impact toughness at the temperature of 60 DEG below zero is larger than or equal to 400 J, the transversal DWTT (Drop-Weight Tear Test) shearing areaat the temperature of 25 DEG C below zero is larger than or equal to 85%, simultaneously, the corrosion resistant of the steel plate is excellent, and the result of a 96-hour HIC (Hydrogen Induced Cracking) test conforms to the requirements of the standard 0284 of the NACE (National Association of Corrosion Engineers). The hot rolled steel plate is suitable to be as a raw material for manufacturing a pipeline for submerged oil and gas transmission.

Owner:ANGANG STEEL CO LTD

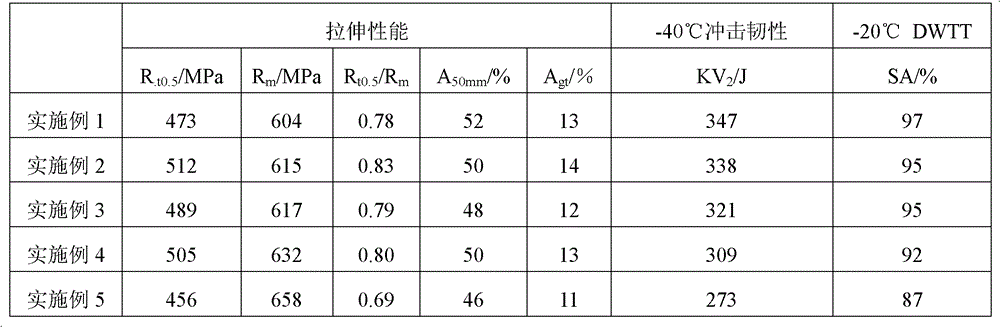

Pipeline steel with a thickness of ≥25mm for deep sea and its production method

ActiveCN102277530ASimple production processAvoid complex production processesDrop weightRoom temperature

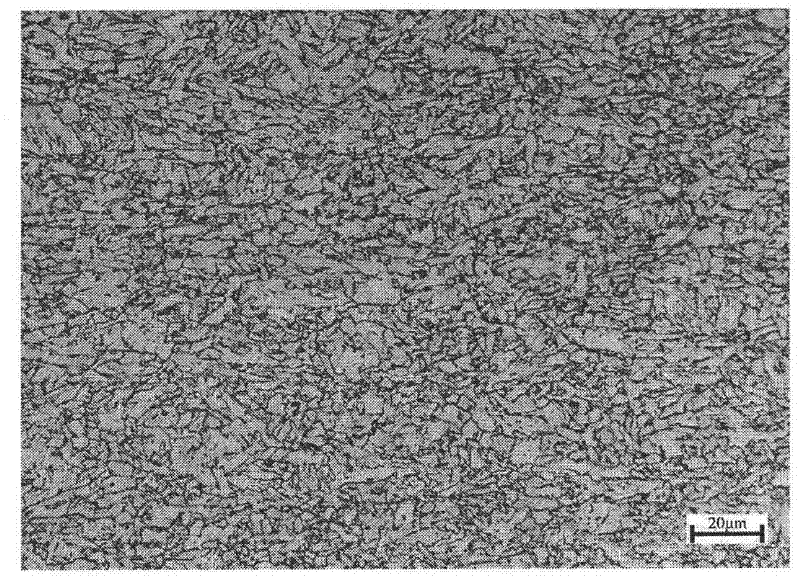

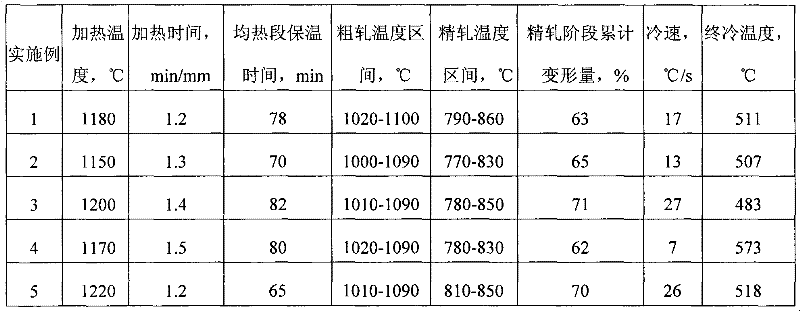

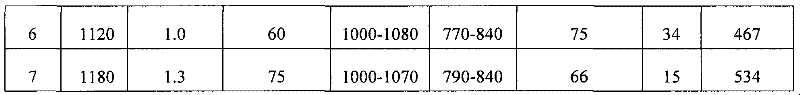

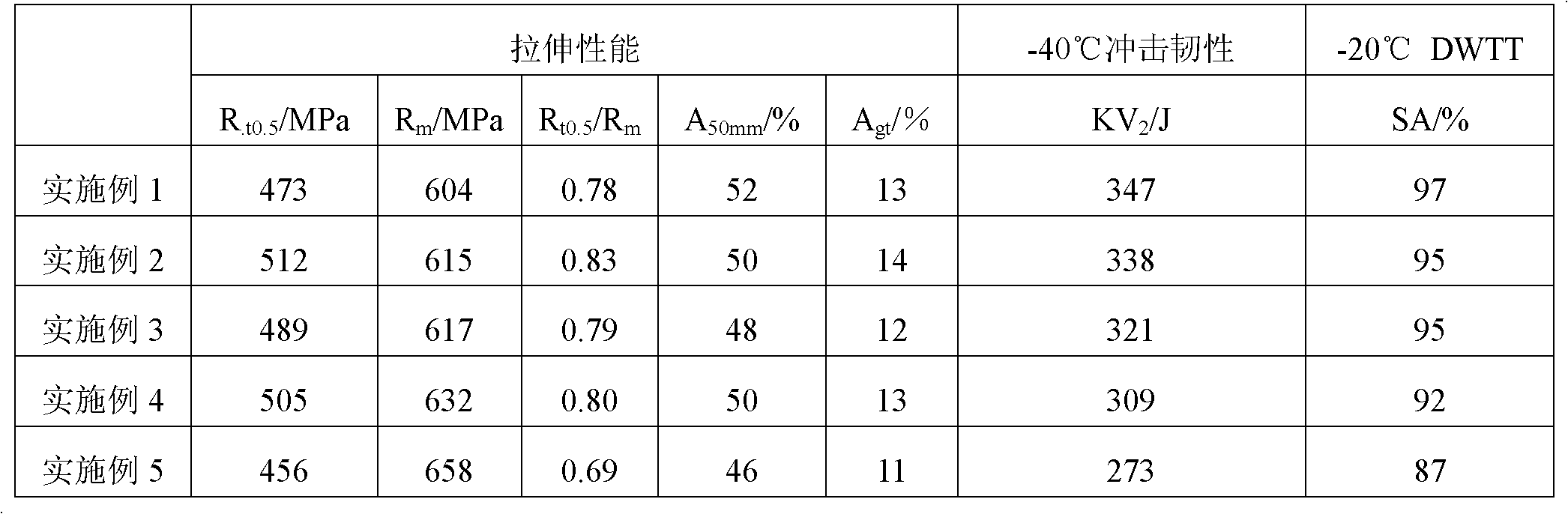

The invention relates to a pipeline steel for deep sea and a production method thereof. The pipeline steel for deep sea comprises the following components in percentage by weight: 0.025-0.080% of C, 0.05-0.50% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.05-0.30% of Mo, 0.03-0.06% of Nb, 0.005-0.025% of Ti, 0.01-0.04% of Al, less than or equal to 0.010% of N and 0.0010-0.0050% of Ca used as main components, and less than or equal to 0.03% of As, less than or equal to 0.01% of Sb, less than or equal to 0.02% of Sn, less than or equal to 0.01%of Pb, less than or equal to 0.01% of Bi and less than or equal to 0.0005% of B used as residual elements. The production method comprises the following production steps: smelting according to clean steel, and carrying out continuous casting to obtain a blank; heating the cast blank; carrying out rough rolling; carrying out fine rolling; relaxing; cooling; relaxing again; straightening; and carrying out air cooling to room temperature. The pipeline steel has simple ingredient and technology, the thickness of the pipeline steel is more than or equal to 25mm, and the pipeline steel is used for deep sea pipelines. The Rt05 of the pipeline steel is more than or equal to 450MPa, Rm is more than or equal to 550MPa, Rt05 / Rm is less than or equal to 0.85, A50mm is more than or equal to 40%, Agt is more than or equal to 10%, -40DEG C KV2 is more than or equal to 200J, and -20DEG C DWTT (Drop-Weight Tear Test) SA is more than or equal to 85%.

Owner:武汉钢铁有限公司

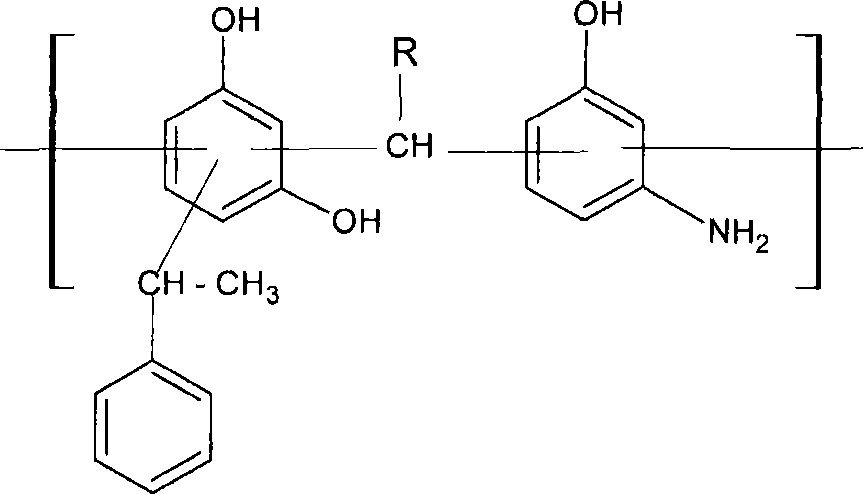

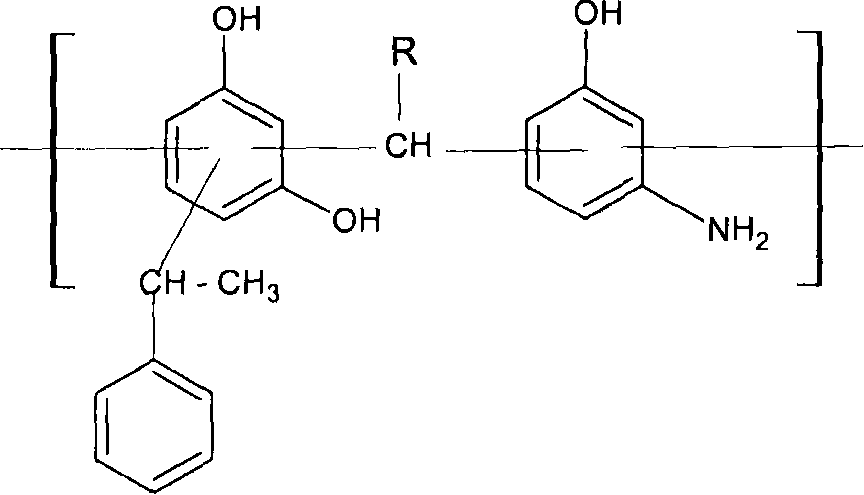

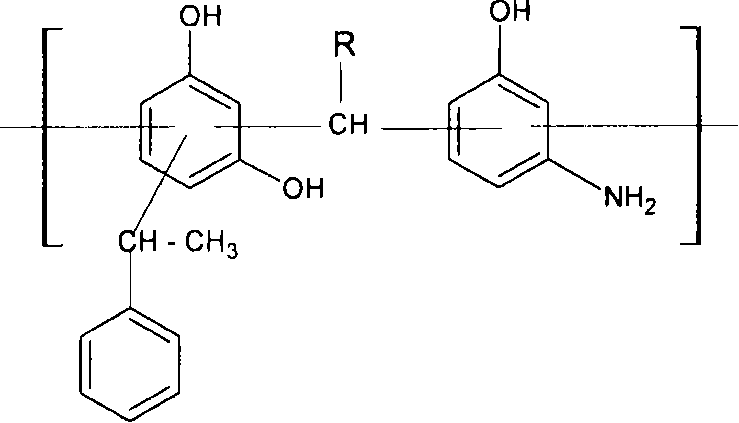

M-aminophenol modified aralkylresorcinol-aldehydes compound resin used for rubber formulation and application

The invention relates to a modified cured rubber compound which comprises (i) the rubber components of natural rubber or synthetic rubber, (ii) methano donator, (iii) aralkyl resorcin-aldehyde resin as the methano acceptor, which is modified by m-aminophenol. The inventive methano acceptor has lower smoke degree than R-80 and higher vulcanizing speed than Penacolite B-20-S. The tension and tearing tests prove that the rubber added with the aralkyl resorcin-aldehyde resin modified by m-aminophenol has better performance than R-80 and B-20-S.

Owner:RACHEM CHINA CO LTD

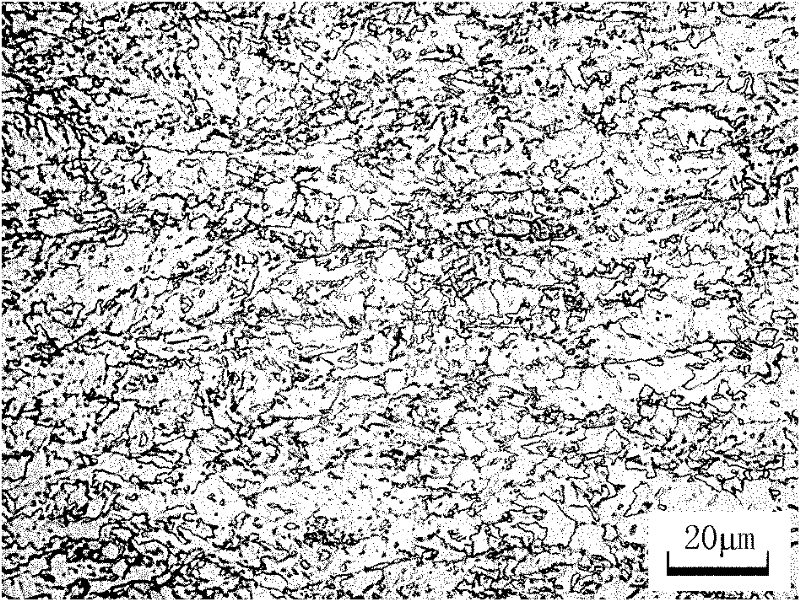

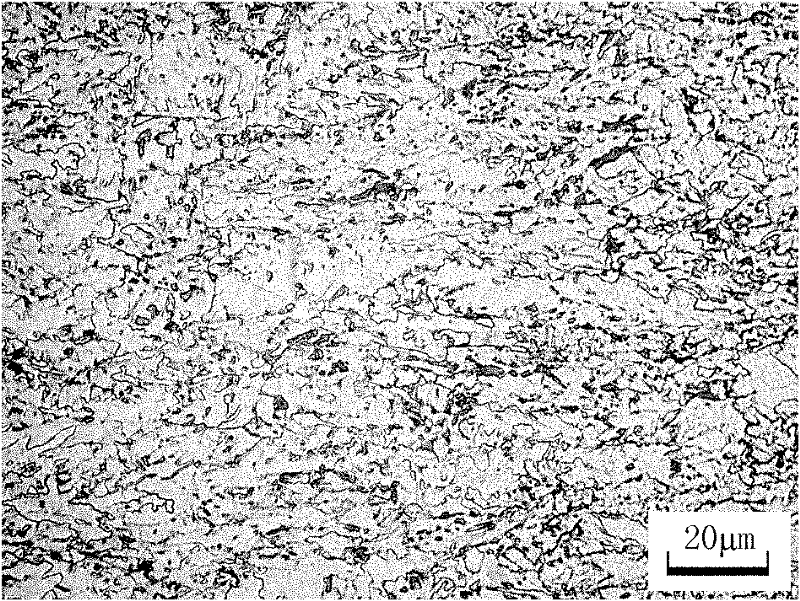

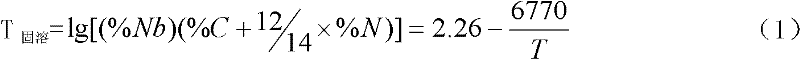

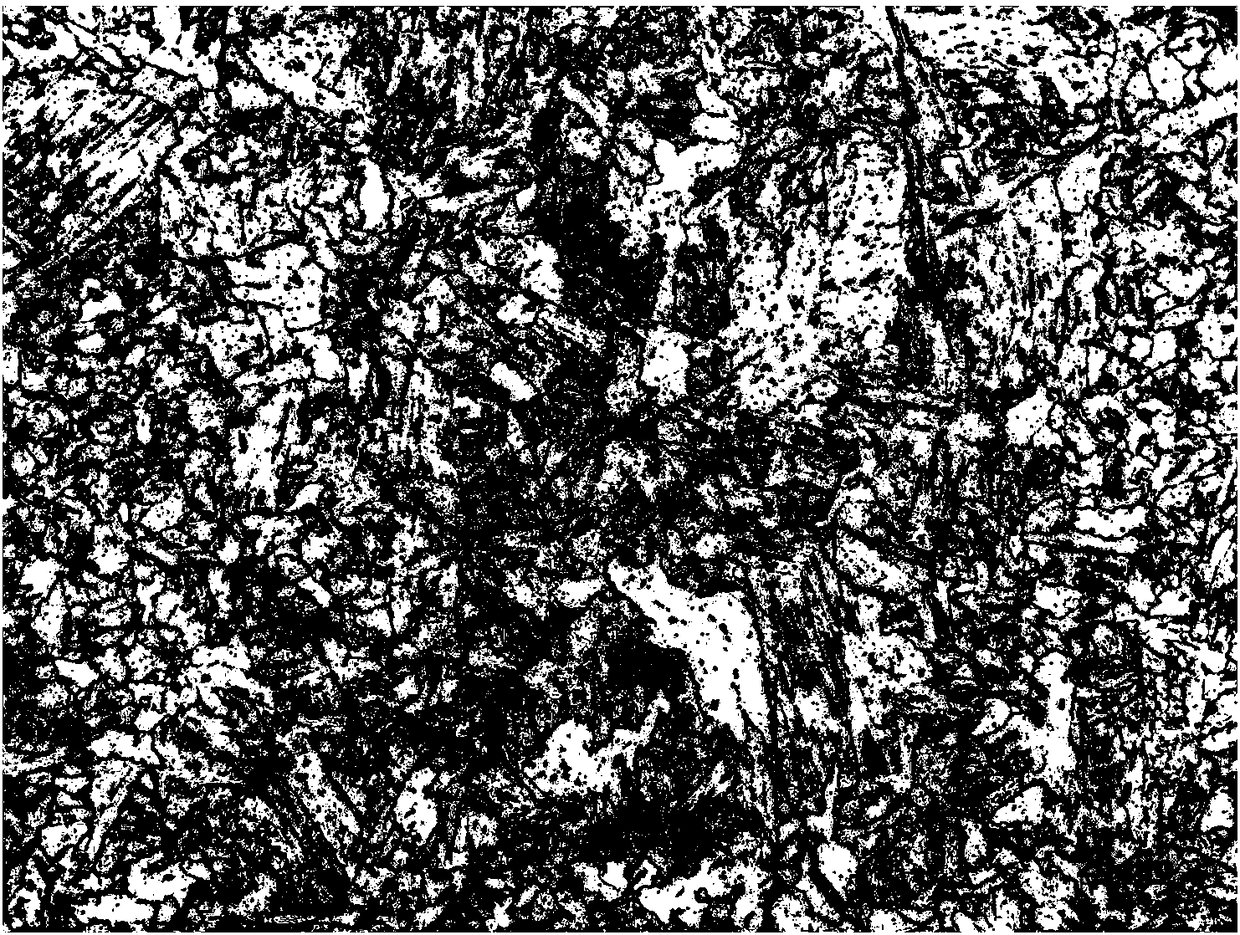

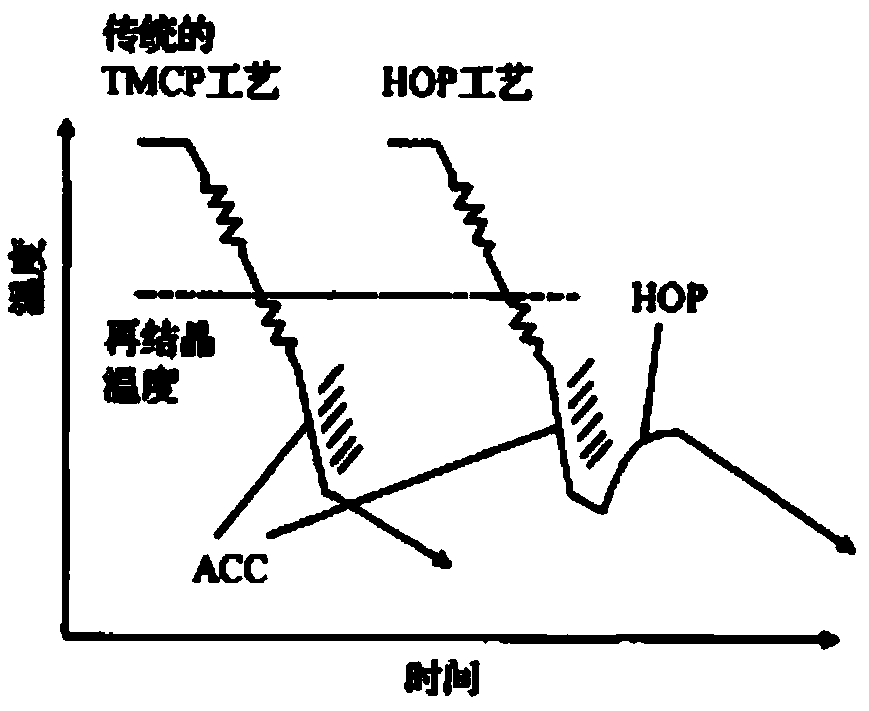

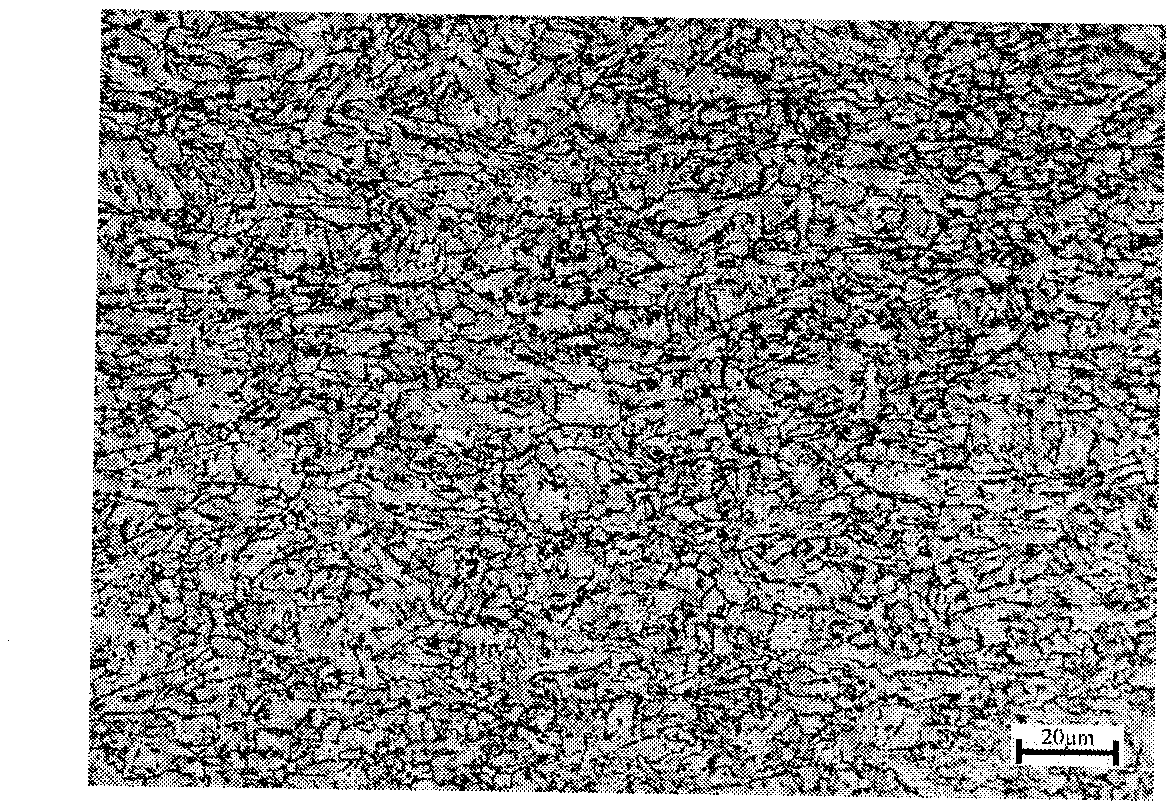

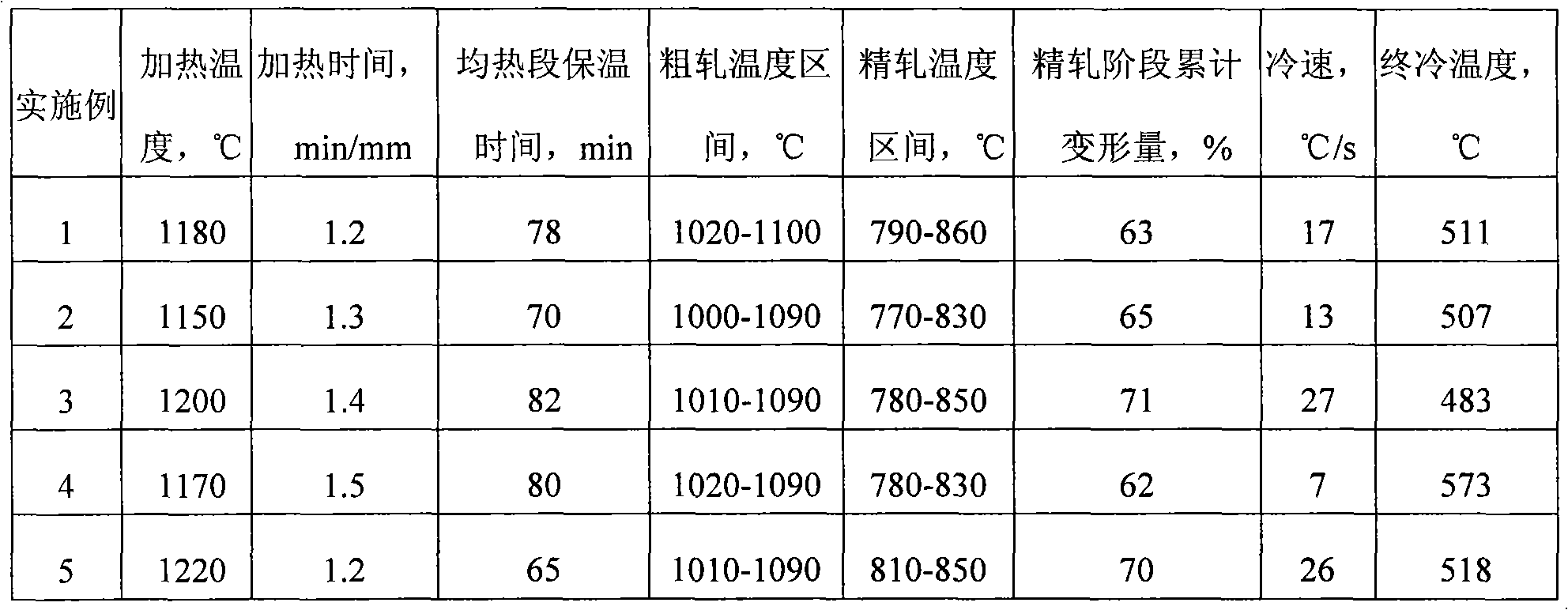

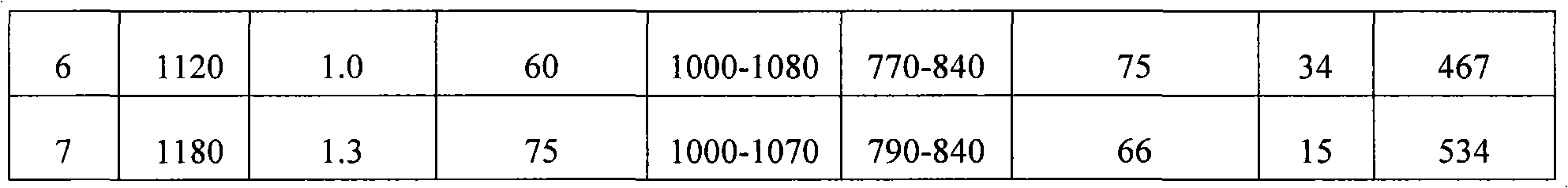

Hot rolling process capable of improving high-grade thick pipeline steel fracture toughness

InactiveCN102172619AIncrease the dislocation densityLower transition temperatureMetal rolling arrangementsDrop weightTemperature difference

The invention provides a hot rolling process capable of improving high-grade thick pipeline steel fracture toughness, sequentially comprising a plate blank reheating section process, a hot rolling section process, a plate reeling section process and a cooling section process, wherein the concrete processing parameters of each process are as follows: in the plate blank reheating section process, the plate blank heating temperature is equal to T solid solution plus 30-80 DEG C, the relation between in-furnace time and blank thickness is that the total in-furnace time is equal to 0.5t plus 30-50min, and the temperature difference of the upper surface and the lower surface after the plate blank is reheated is less than or equal to 30 DEG C; and in the hot rolling section process, the single track down rate in rough rolling is more than or equal to 15%, the accumulated down rate in fine rolling is more than or equal to 70%, and the finished rolling temperature is equal to Ar3 plus 0-60 DEG C, wherein Ar3 is a phase transformation point temperature. By utilizing the hot rolling process provided by the invention, the problem that DWTT (drop weight tear test) control is difficult to carry out on X70 and X80 steel more than 15mm can be effectively solved. The hot rolling process provided by the invention is practical and feasible and produces less loss on a rolling machine, a reeling machine and the like, and the qualifying rate of the DWTT properties of a product can reach up to more than 99%.

Owner:武钢集团有限公司

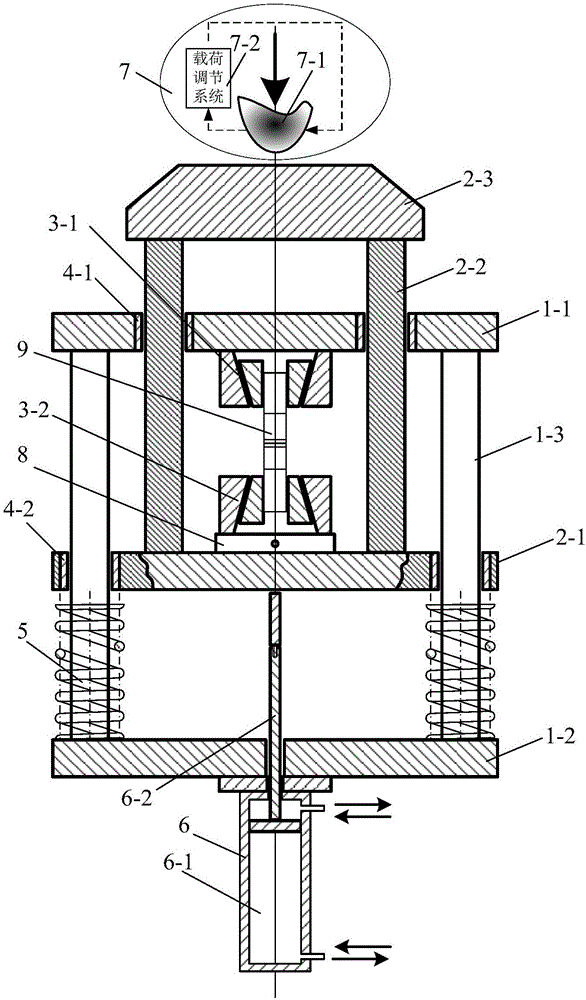

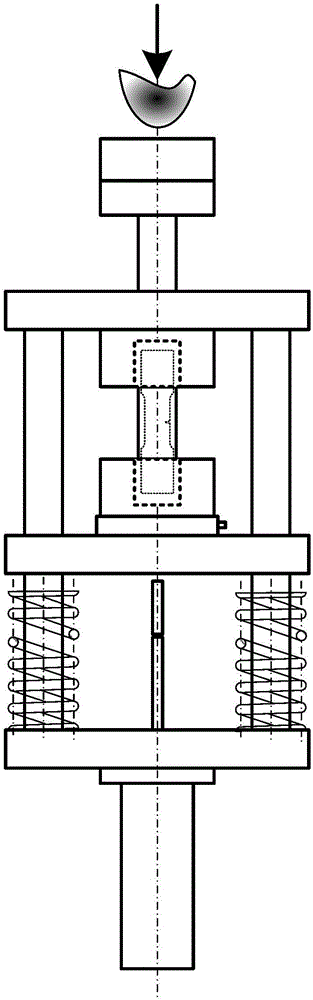

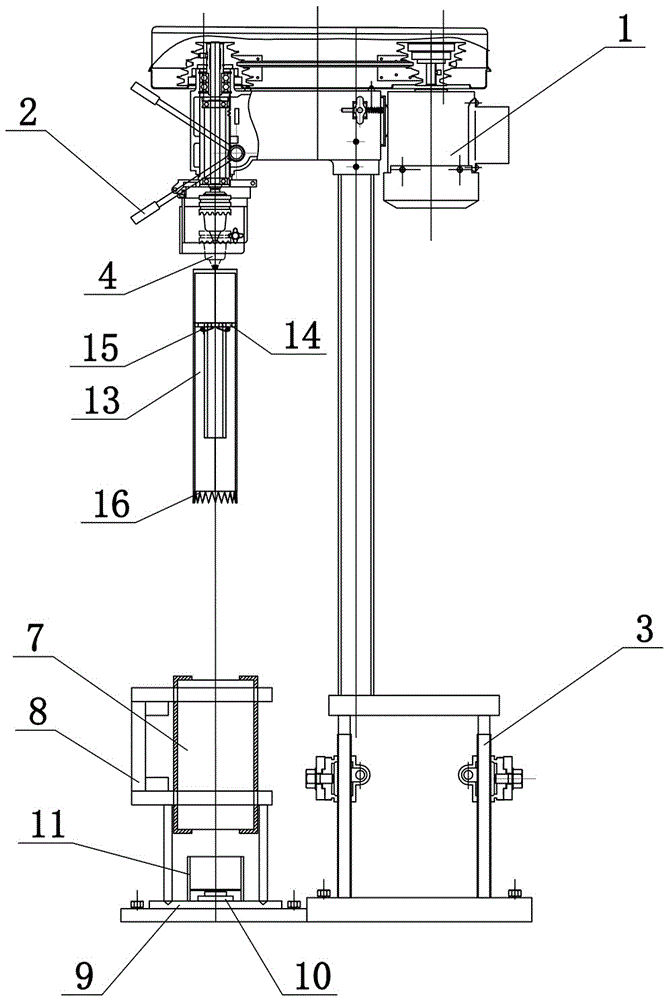

Testing device and testing method capable of simulating pipeline blasting fracture morphology

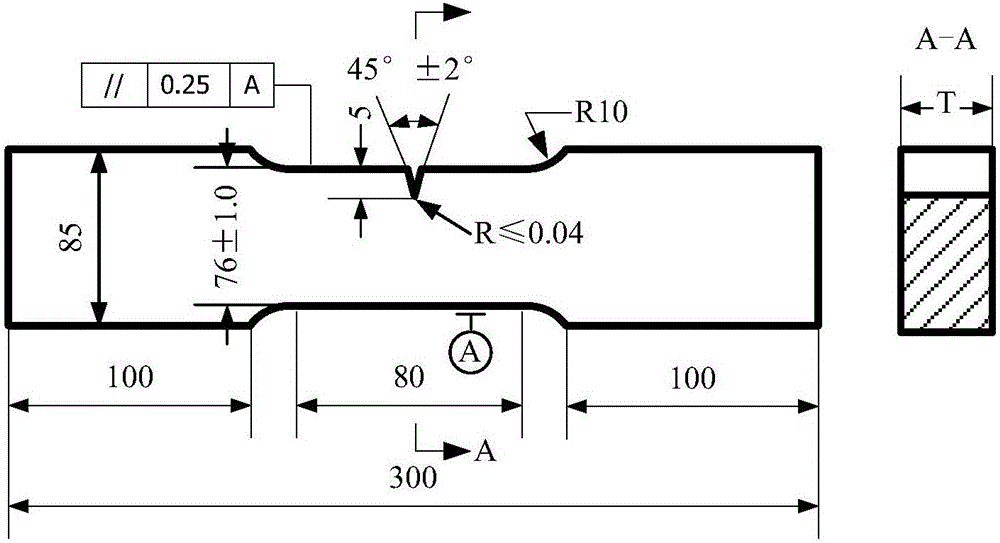

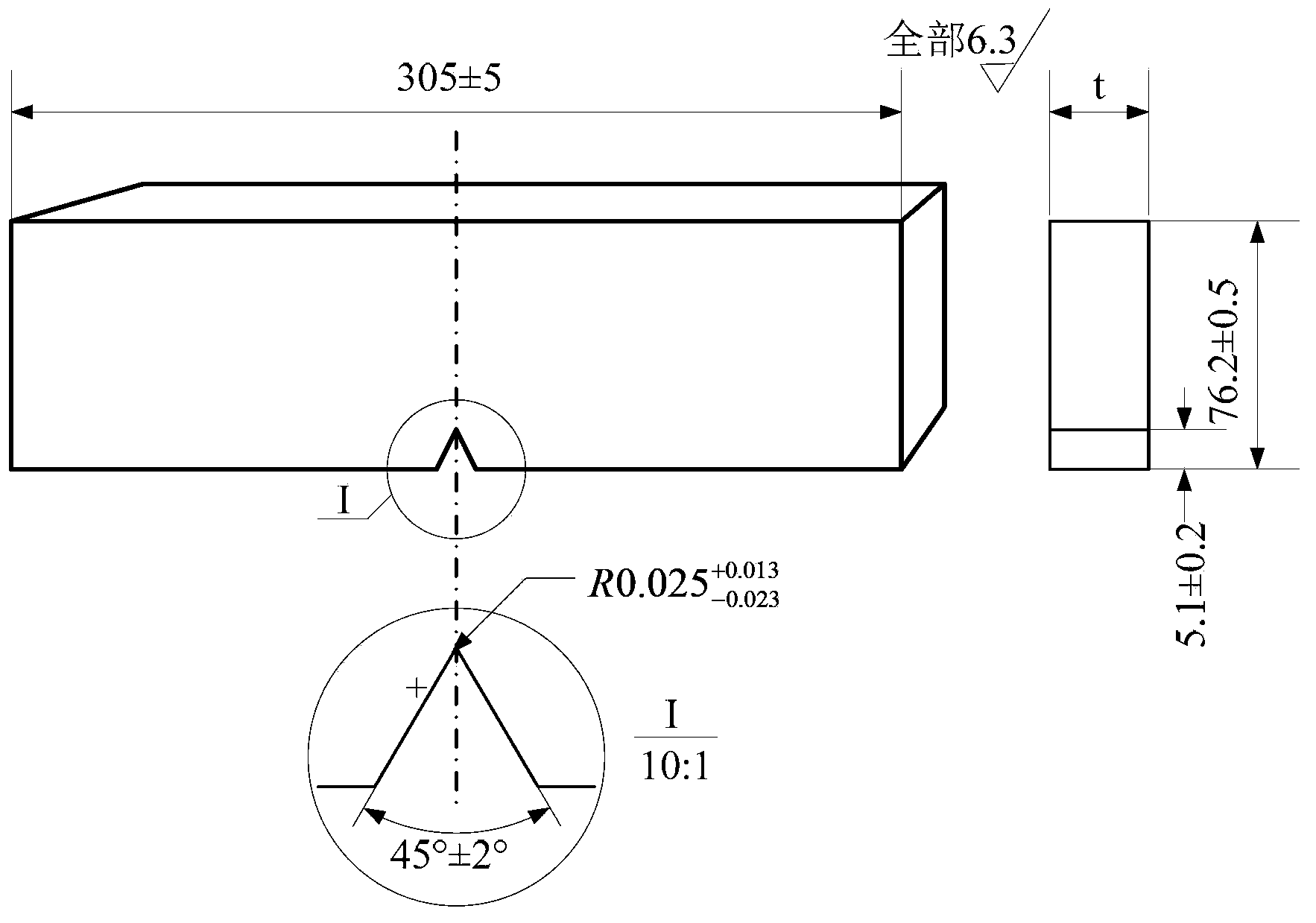

ActiveCN106769546AIncreasing the thicknessHigh strengthMaterial strength using single impulsive forceDrop weightTest sample

The invention discloses a testing device and a testing method capable of simulating pipeline blasting fracture morphology. The testing device comprises a supporting device, a high-speed impact stretching device, a clamping device, a slide bearing, a damping device, an ejecting mechanism, a high-speed loading device and a data collecting system. A machining method is utilized to process a test material into a tensile sample with the length of 300mm and in a dumbbell shape, and a V-shaped notch is formed in the middle of one side of a parallel section of the test sample in the wall thickness direction. The testing device and the testing method have the advantages that the testing results of the testing device can truly reflect facture morphology of a practical engineering pipeline in blasting, the problem of test failure due to the fact that abnormal fracture completely different from entity blasting fraction morphology is generated by directly hammering the test sample in an original drop weight tear test is solved, can be effectively simulated mechanical response of pipelines in blasting / impact load and is beneficial to engineering application and engineering design of the materials.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

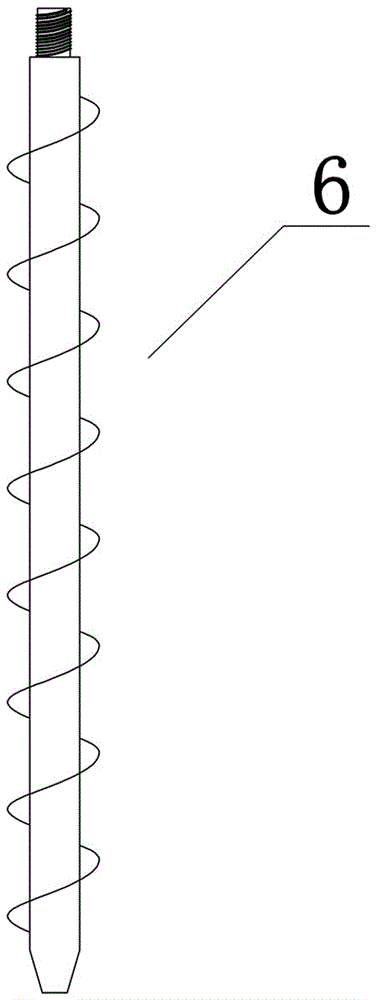

Soft clay hollow cylinder sample preparation instrument and use method

ActiveCN106501055ASimple structureEasy to operatePreparing sample for investigationSoft clayEngineering

The invention discloses a soft clay hollow cylinder sample preparation instrument and a use method. The sample preparation instrument comprises a table type water drilling machine part, a replaceable drill bit part and a sample preparation barrel part; the table type water drilling machine part comprises a water drilling machine, a lifting bracket and a regulating handle; the lifting bracket is arranged at the lower part of the water drilling machine, a tool bit of the replaceable drill bit part is installed on the water drilling machine through an adapter; the sample preparation barrel part is fixed on the lifting bracket, a sample preparation barrel bracket of the sample preparation barrel part is fixed on a bottom turntable, a sample preparation barrel is arranged on the sample preparation barrel bracket, a spent clay barrel is arranged right below the sample preparation barrel, and a turntable motor is connected with the bottom turntable. According to the soft clay hollow cylinder sample preparation instrument and the use method, provided by the invention, the sample preparation instrument is simple in structure, convenient in operation and easy in demolding, and can realize mechanized sample preparation rapidly; the disturbance of the intact clay is reduced, the interior pile collapse of a hollow sample is prevented, the quality of a prepared sample is guaranteed effectively, and a foundation is laid for the torsional tear test of a hollow cylinder.

Owner:ZHEJIANG UNIV CITY COLLEGE +1

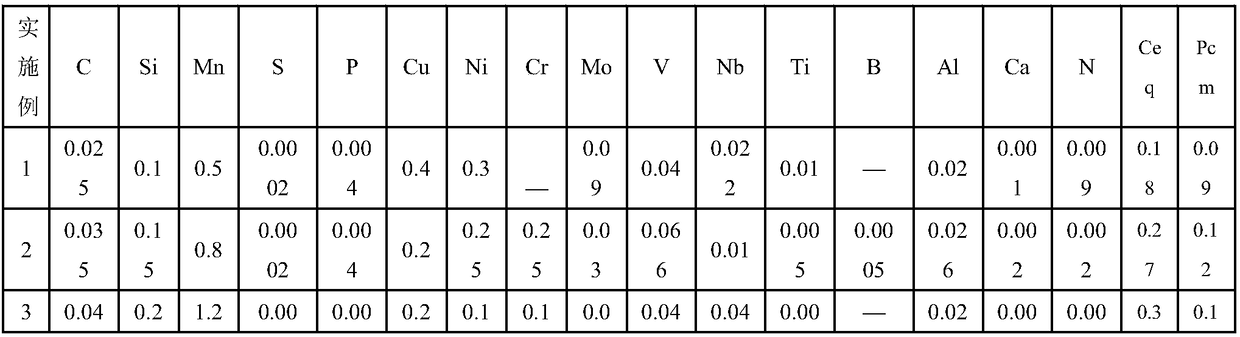

Hardening and tempering type anti-acid pipeline steel and manufacturing method thereof

The invention discloses hardening and tempering type anti-acid pipeline steel which is prepared from the chemical elements in percentage by mass: 0.025 to 0.090 percent of C, 0.1 to 0.5 percent of Si,0.50 to 1.35 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.003 percent of S, 0.01 to 0.09 percent of Mo, 0.01 to 0.06 percent of Nb, 0.005 to 0.02 percent of Ti, 0.001 to 0.006 percent of Ca, 0.02 to 0.045 percent of Al, larger than 0 and smaller than or equal to 0.010 percent of N, and the balance Fe and other inevitable impurities. A microstructure of the hardening and tempering type anti-acid pipeline steel has tempered bainite with the phase proportion being larger than 90 percent, and has the grain size reaching to more than 11 grades. In addition, theinvention further discloses a manufacturing method of the hardening and tempering type anti-acid pipeline steel. The hardening and tempering type pipeline steel provided by the invention has the yieldstrength being 290 to 550MPa, the tensile strength being 415 to 760MPa, the charpy impact work at minus 40 DEG C being higher than 120J, and the shear fracture area percentage under a drop-weight tear test (DWTT) at minus 25 DEG C being larger than 85 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

Large deformation resistant multiphase X100 high-strength steel plate for large diameter pipeline and manufacturing method for steel plate

The invention belongs to the technical field of manufacturing of low-alloy high-strength pipeline steel, and particularly relates to a large deformation resistant multiphase X100 high-strength steel plate for a large diameter pipeline and a manufacturing method for the steel plate. The high-strength steel plate is prepared from the following components by weight percent: 0.04-0.08% of C, 0.15-0.35% of Si, 1.60-2.00% of Mn, less than or equal to 0.008% of P, less than or equal to 0.003% of S, 0.07-0.11% of Nb, 0.015-0.025% of Ti, less than or equal to 0.25% of Mo, less than or equal to 0.35% of Cu, less than or equal to 0.030% of Ni, less than or equal to 0.030% of Cr, and the balance of Fe and unavoidable impurities. The high-strength pipeline steel has the following benefits: the P content maximum value in the component design is 0.010%; the S content maximum value is 0.003%; the steel is purer; the high-niobium component design can significantly improve the crystal refinement and the strength of the steel plate, so that the noble metals such as Mo and Ni of the steel plate are reduced; the cost is lower; the energy saving and environmental protection effects are realized; the high-strength steel plate is suitable for material development direction, and easier to produce and promote. The yield strength of the steel plate is 690-760 MPa; the tensile strength is 870-920 MPa; the uniform ductility is greater than or equal to 10%; the yield ratio is less than or equal to 0.78; the Charpy impact power at -20 DEG C is greater than or equal to 300 J; the drop hammer tearing test shear area at -15 DEG C is greatert than or equal to 85%.

Owner:JIGANG GRP

Tempered high-low-temperature toughness pipeline steel and manufacturing method

InactiveCN105821325AEasy to shapeImprove low temperature toughnessProcess efficiency improvementDrop weightPerformance index

The invention belongs to the field of metal material rolling, and relates to tempered high-low-temperature toughness pipeline steel and a manufacturing method. The steel is characterized by comprising chemical components including, by weight, 0.08-0.11% of C, 0.25-0.45% of Si, 1.60-1.80% of Mn, smaller than or equal to 0.006% of P, smaller than or equal to 0.003% of S, 0.015-0.035% of Nb, 0.010-0.030% of Ti, 0.10-0.30% of Mo, 0.015-0.045% of Alt, 0.010-0.030% of Ce and 0.030-0.050% of V, residual components including, by weight, smaller than or equal to 0.50% of Cu, smaller than or equal to 0.50% of Ni, smaller than or equal to 0.50% of Cr and smaller than or equal to 0.0005% of B, and the balance Fe. The chemical components of the steel meet the equation Pcm=C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5, B is smaller than or equal to 0.24%, and the sum of Nb, V and Ti is smaller than or equal to 0.15%. The finally-obtained produced tempered pipeline steel is fine in texture and excellent in low-temperature performance index charpy impact and drop-weight tear test performance.

Owner:SHANDONG IRON & STEEL CO LTD

Drop weight tear test system and method thereof

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

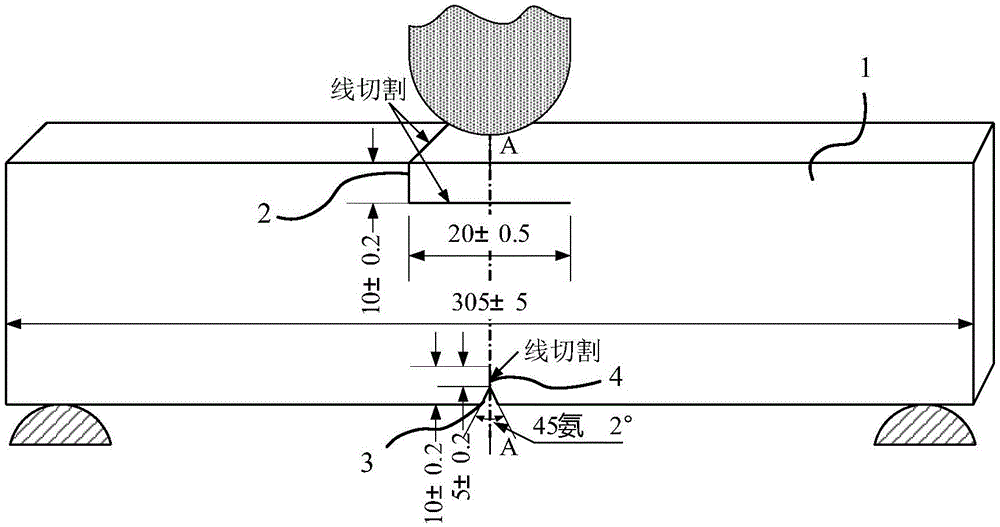

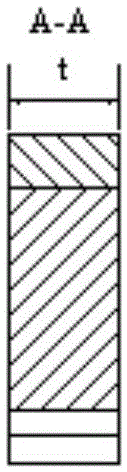

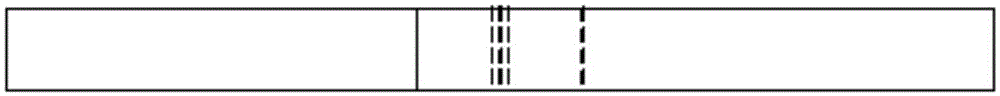

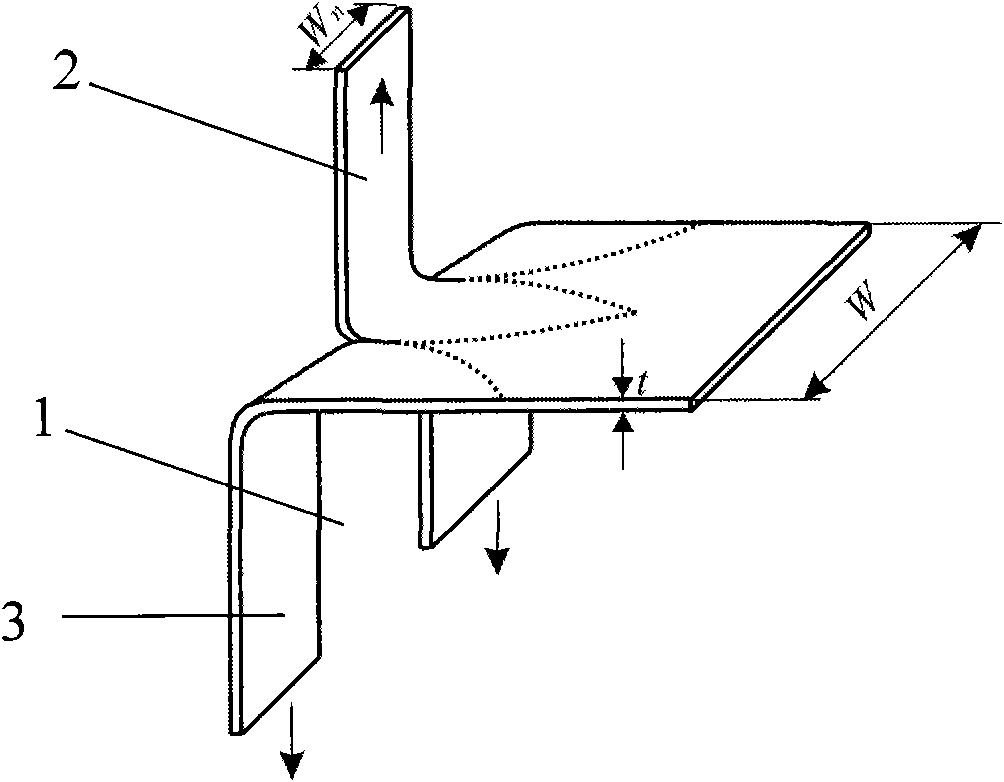

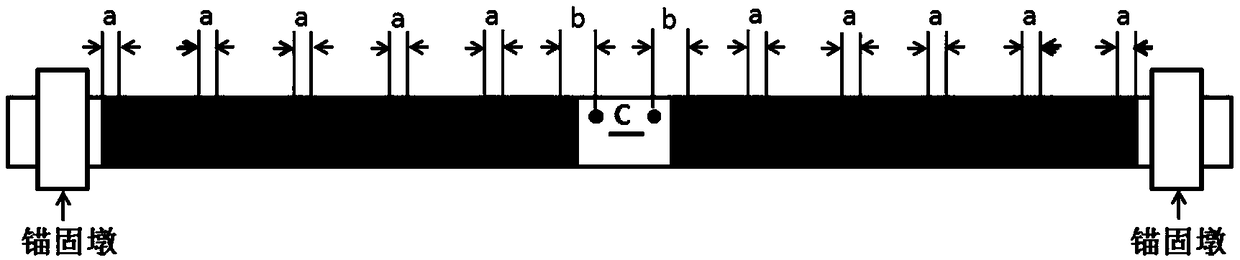

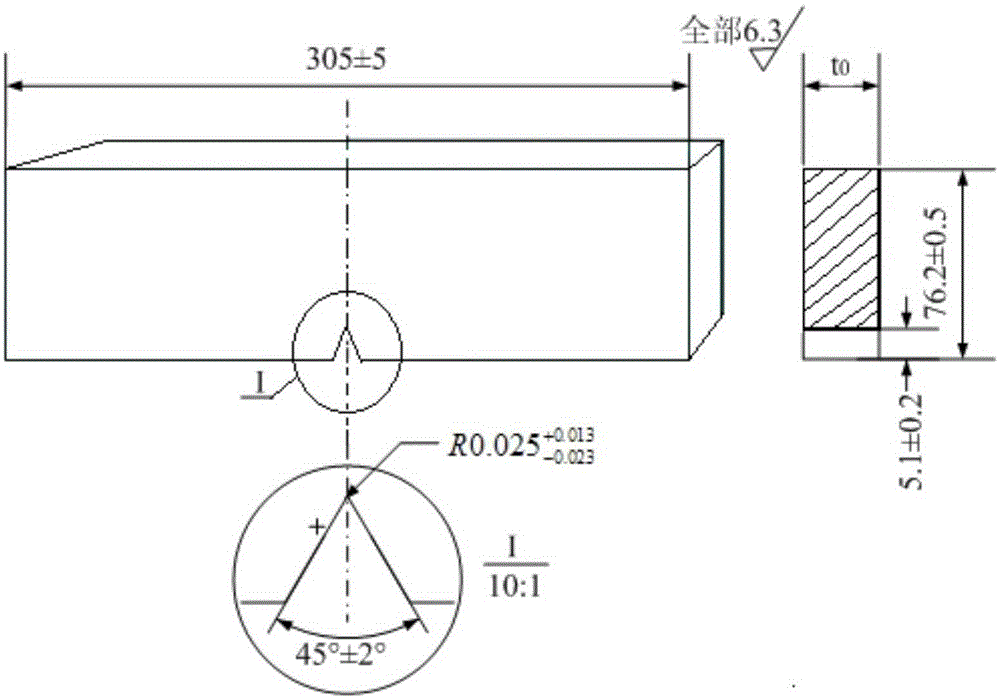

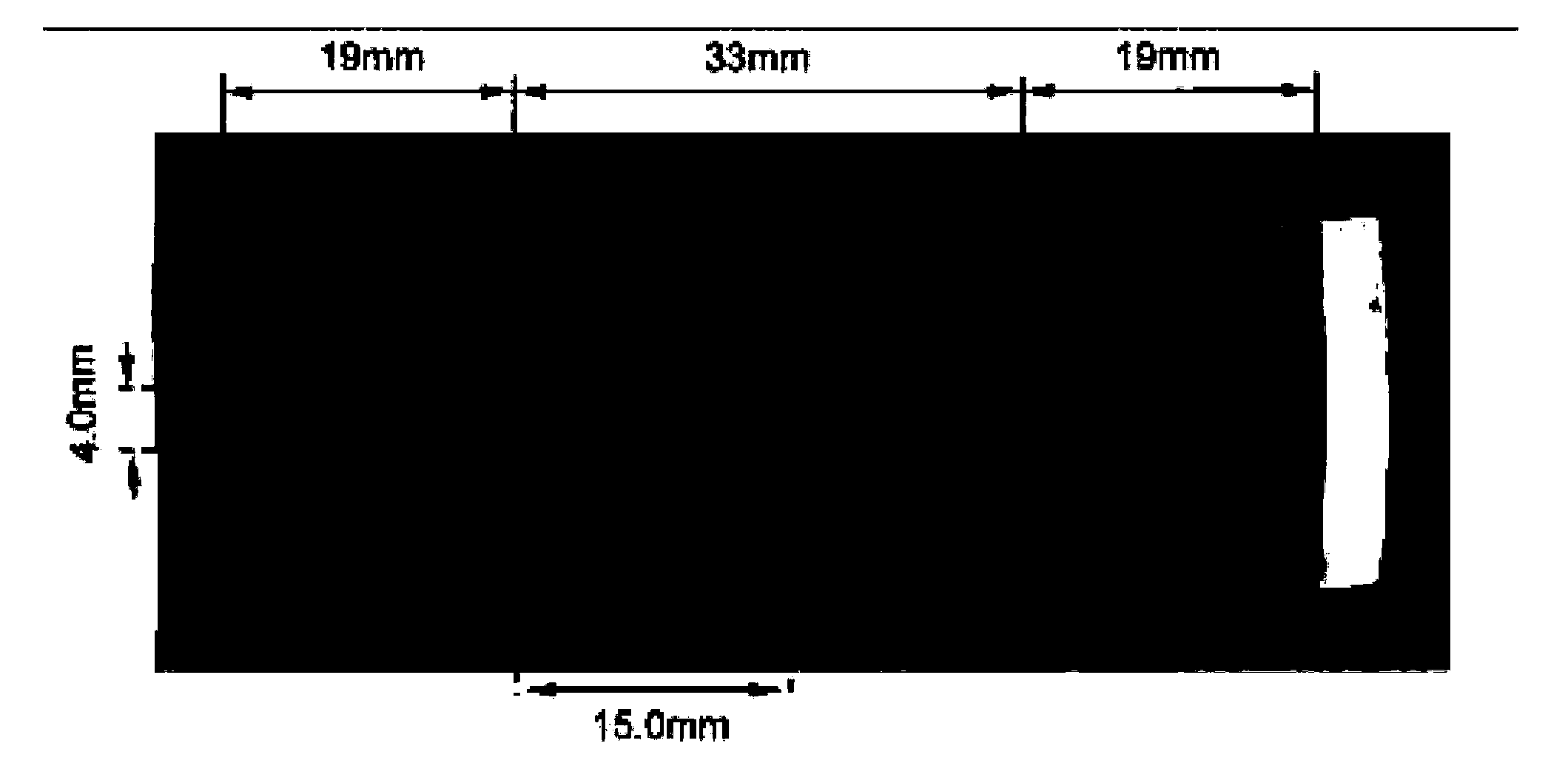

Sample with DWTT (drop weight tear test) abnormal fracture preventing function and method for manufacturing sample

ActiveCN105092335ASmall compression deformationCompression Deformation EliminationPreparing sample for investigationMaterial strength using repeated/pulsating forcesDrop weightElectricity

The invention discloses a sample with a DWTT (drop weight tear test) abnormal fracture preventing function and a method for manufacturing the sample, and belongs to the field of material toughness tests. An L-shaped notch is prefabricated in the middle of a hammering side of a standard sample, and an I-shaped notch is prefabricated in a V-shaped notch root of the standard sample, so that the DWTT sample can be formed. The L-shaped notch and the I-shaped notch are manufactured by the aid of wire-cut electrical discharge machining processes, the depth of the L-shaped notch in the width direction of the sample is 10+ / -0.2mm, and the length of the L-shaped notch along the length of the sample is 20+ / -0.5mm; the depth of the I-shaped notch in the width direction of the sample is 5+ / -0.2mm. The diameters of molybdenum wires for carrying out wire-cut electrical discharge machining on the L-shaped notch and the I-shaped notch need to be smaller than or equal to 0.15mm. The sample and the method have the advantages that crack is easy to start when the DWTT sample is hammered by a heavy hammer, work-hardening of the hammering side can be reduced, DWTT abnormal fracture can be effectively reduced or prevented, test results are similar to actual explosion fracture, and the test cost can be saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

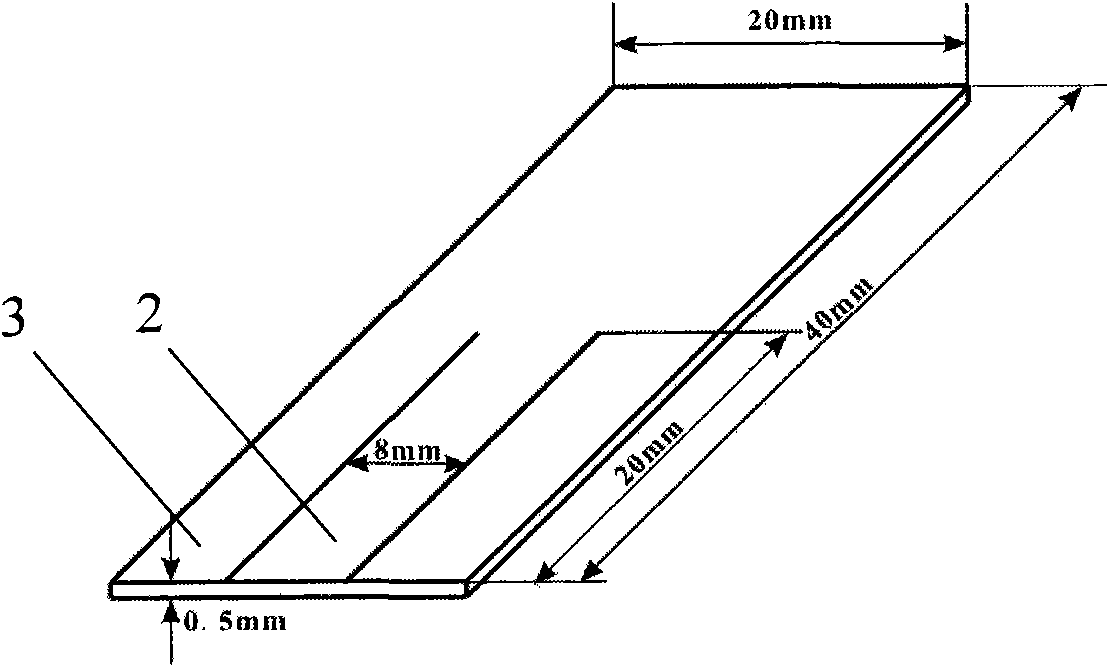

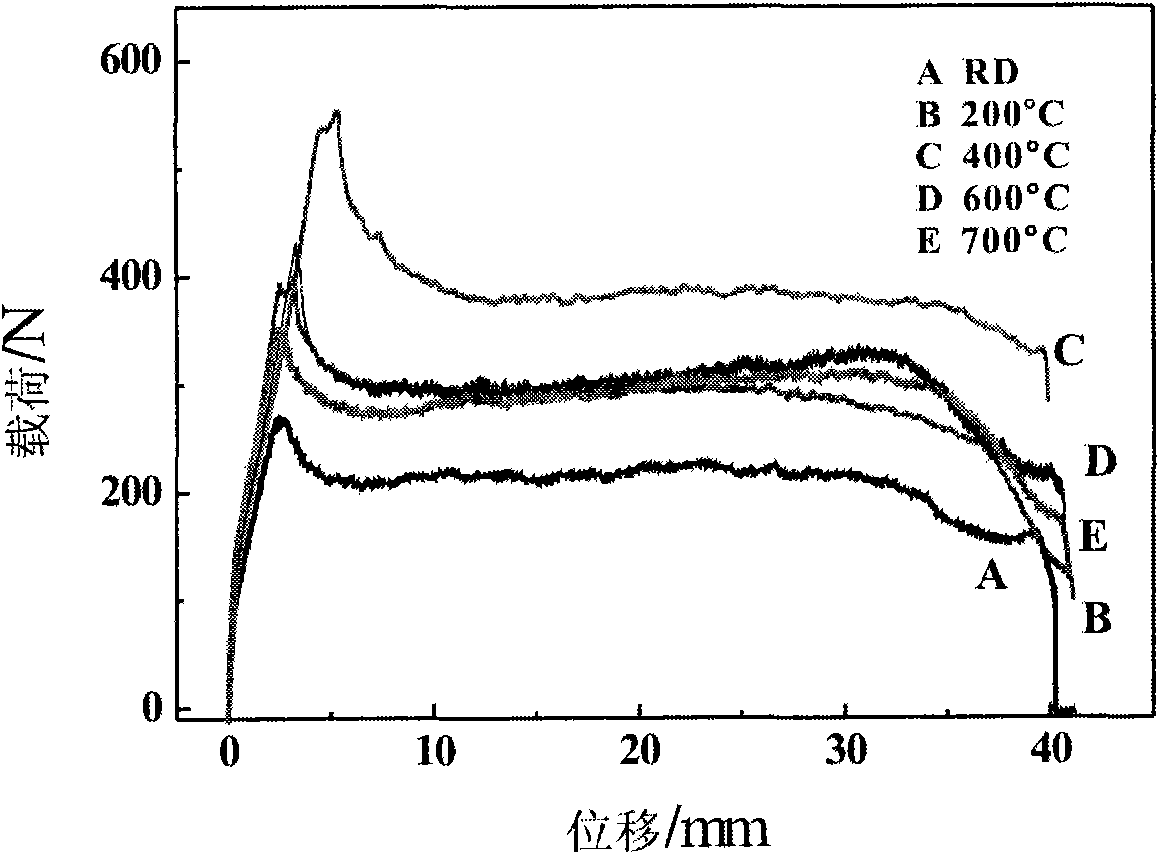

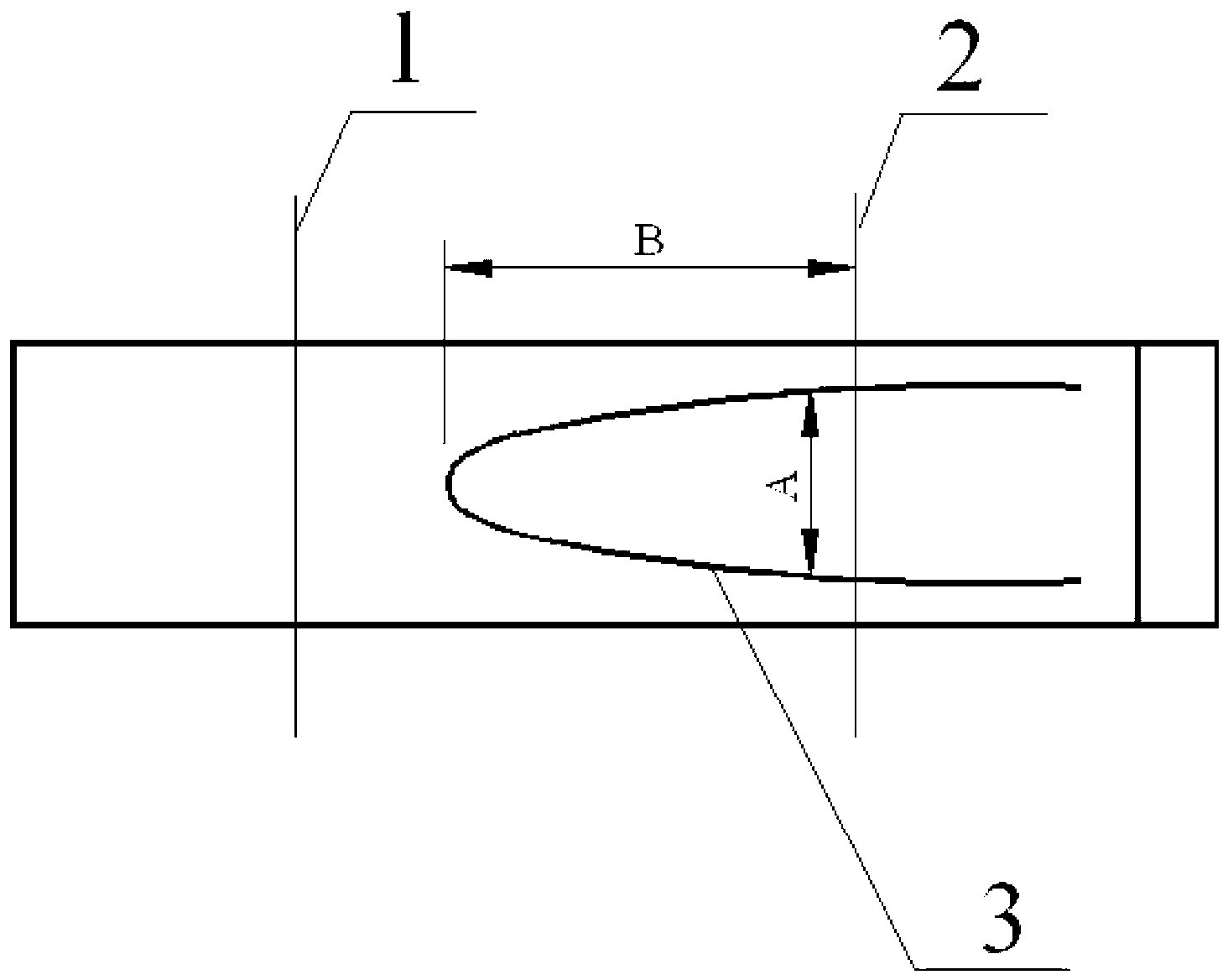

Method for evaluating tearing toughness of ductile metal materials

InactiveCN102374951AExtended stabilityPerfect mechanical propertiesMaterial strength using tensile/compressive forcesCrazingStrength of materials

The invention relates to the field of mechanical property evaluation and characterization of materials, and in particular relates to a method for evaluating the tearing toughness of ductile metal materials. The method is characterized in that through carrying out a tearing test on ductile metal materials by using three-leg trouser-shaped samples, a characteristic that applied loadings in the process of tearing are unchanged is obtained, thereby providing a powerful test basis for the proposition of a tearing toughness concept, thereby obtaining a defined tearing toughness which is shown in a formula as follows: Gamma = FS / 2 t, and used for evaluating the toughness or crack propagation resistance of ductile materials. The tearing test method and the tearing toughness concept provide an effective thought for knowing an inversion relation between the strength and plasticity (toughness) of a material, therefore, a new reference criterion is provided for selecting materials (the strength and plasticity are fitted better) for actual engineering. As for ductile sheet metals, a crack propagation process and a fracture process can be described more accurately by using the tearing toughness, which has a vital significance to the evaluation and characterization of engineering applications and mechanical properties of materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ultralow-temperature, large-diameter and WPHY80-level steel plate special for three-way pipe fitting and production method of steel plate

The invention belongs to the technical field of low-alloy and high-strength pipeline steel and particularly relates to an ultralow-temperature, large-diameter and WPHY80-level steel plate special for a three-way pipe fitting and a production method of the steel plate. The steel plate comprises, by weight percentage, 0.04-0.06% of C, 0.50-0.80% of Si, 1.40-1.80% of Mn, not more than 0.008% of P, not more than 0.002% of S, 0.08-0.12% of Nb, 0.04-0.06% of Ti, 0.30-0.40% of Mo, 0.12-0.20% of Cu, 0.30-0.40% of Ni, not more than 0.50% of Cr, 0.050-0.060% of V, not more than 0.0005% of B, and the balance of iron and inevitable impurities. Under the premise that field production efficiency is increased, the produced steel plate is stable in performance, the steel plate has excellent low-temperature drop weight tear test performance: -25 DEG C SA%>=90% and excellent Charpy impact performance: -60 DEG C Charpy impact energy>=260J, -80 DEG C Charpy impact energy>=210J.

Owner:SHANDONG IRON & STEEL CO LTD

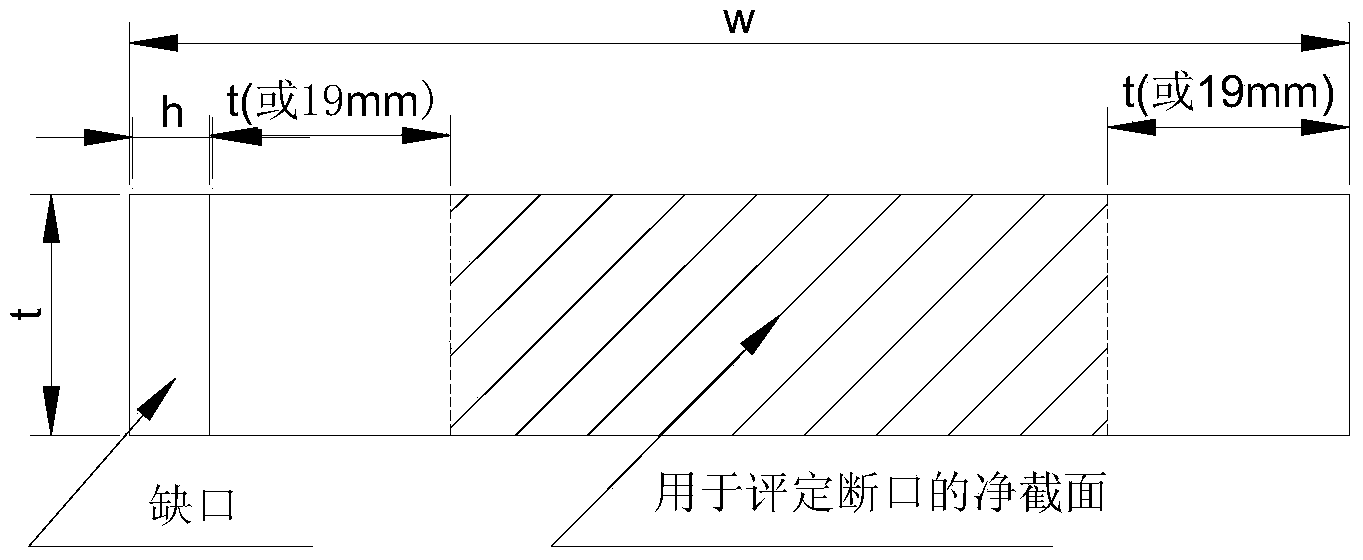

Drop-weight tear test sample fracture shearing area detection method

InactiveCN103486985AGuaranteed accuracyAvoid irregular shear lips, hard to identify issues with hammered side boundariesUsing optical meansDrop weightSample image

The invention provides a drop-weight tear test sample fracture shearing area detection method. After a DWTT sample is shorn, a DWTT sample fracture is shot and imaged through a camera, the area of net sections and the area of brittle fracture regions are calculated through image analysis software, and therefore fracture shearing area percentage is worked out. The method is simple and easy to carry out, none equipment needs purchasing, funding is not needed, the brittle fraction regions, especially small brittle fraction regions facilitating brittle fraction region boundary recognition can be freely amplified in the image analysis software, and therefore accuracy of the area of the brittle fraction regions is guaranteed. Due to the adoption of the method that the thickness of the root portion of a sample image notch is measured in the interface of the image analysis software to determine the amplification factor, accuracy of the area of the net sections can be guaranteed, irregular shear lips are prevented from appearing on the hammered side of the sample after sample shearing, calculation accuracy of the area of the net sections is guaranteed, and accordingly scientific and reliable detection data bases are provided for pipeline steel pipe control and fraction prediction.

Owner:ANGANG STEEL CO LTD

Pipeline steel with thickness more than or equal to 25mm for deep sea and production method thereof

ActiveCN102277530BSimple production processAvoid complex production processesDrop weightRoom temperature

The invention relates to a pipeline steel for deep sea and a production method thereof. The pipeline steel for deep sea comprises the following components in percentage by weight: 0.025-0.080% of C, 0.05-0.50% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.05-0.30% of Mo, 0.03-0.06% of Nb, 0.005-0.025% of Ti, 0.01-0.04% of Al, less than or equal to 0.010% of N and 0.0010-0.0050% of Ca used as main components, and less than or equal to 0.03% of As, less than or equal to 0.01% of Sb, less than or equal to 0.02% of Sn, less than or equal to 0.01%of Pb, less than or equal to 0.01% of Bi and less than or equal to 0.0005% of B used as residual elements. The production method comprises the following production steps: smelting according to clean steel, and carrying out continuous casting to obtain a blank; heating the cast blank; carrying out rough rolling; carrying out fine rolling; relaxing; cooling; relaxing again; straightening; and carrying out air cooling to room temperature. The pipeline steel has simple ingredient and technology, the thickness of the pipeline steel is more than or equal to 25mm, and the pipeline steel is used for deep sea pipelines. The Rt05 of the pipeline steel is more than or equal to 450MPa, Rm is more than or equal to 550MPa, Rt05 / Rm is less than or equal to 0.85, A50mm is more than or equal to 40%, Agt is more than or equal to 10%, -40DEG C KV2 is more than or equal to 200J, and -20DEG C DWTT (Drop-Weight Tear Test) SA is more than or equal to 85%.

Owner:武汉钢铁有限公司

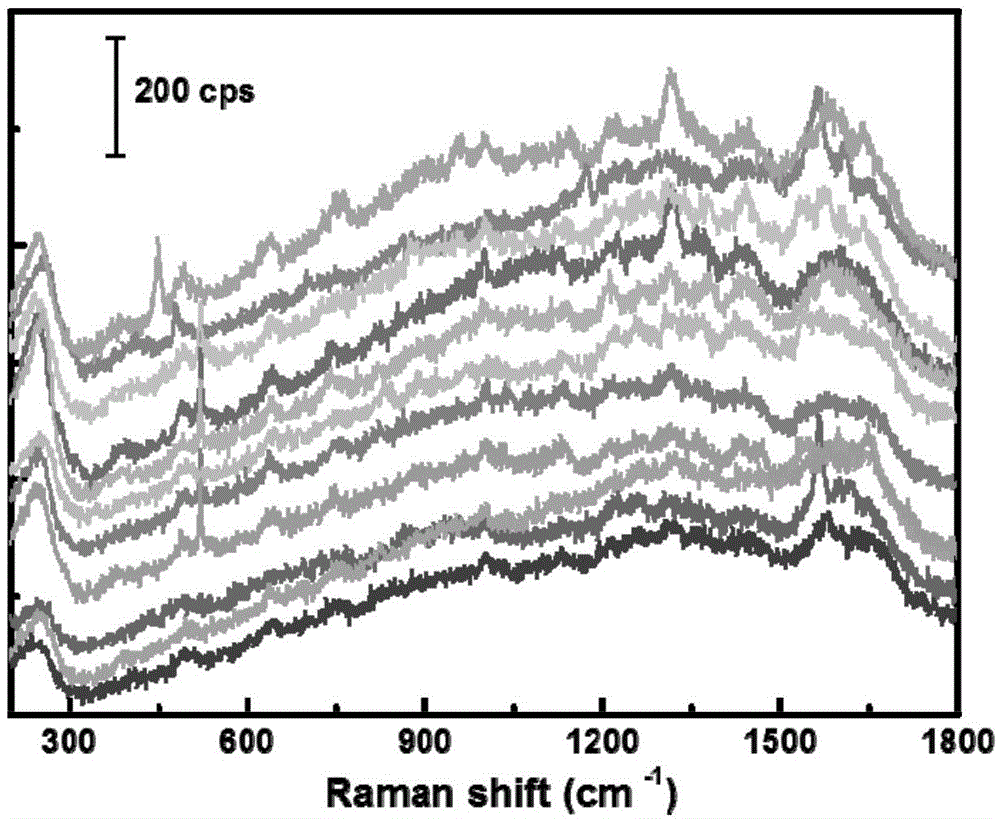

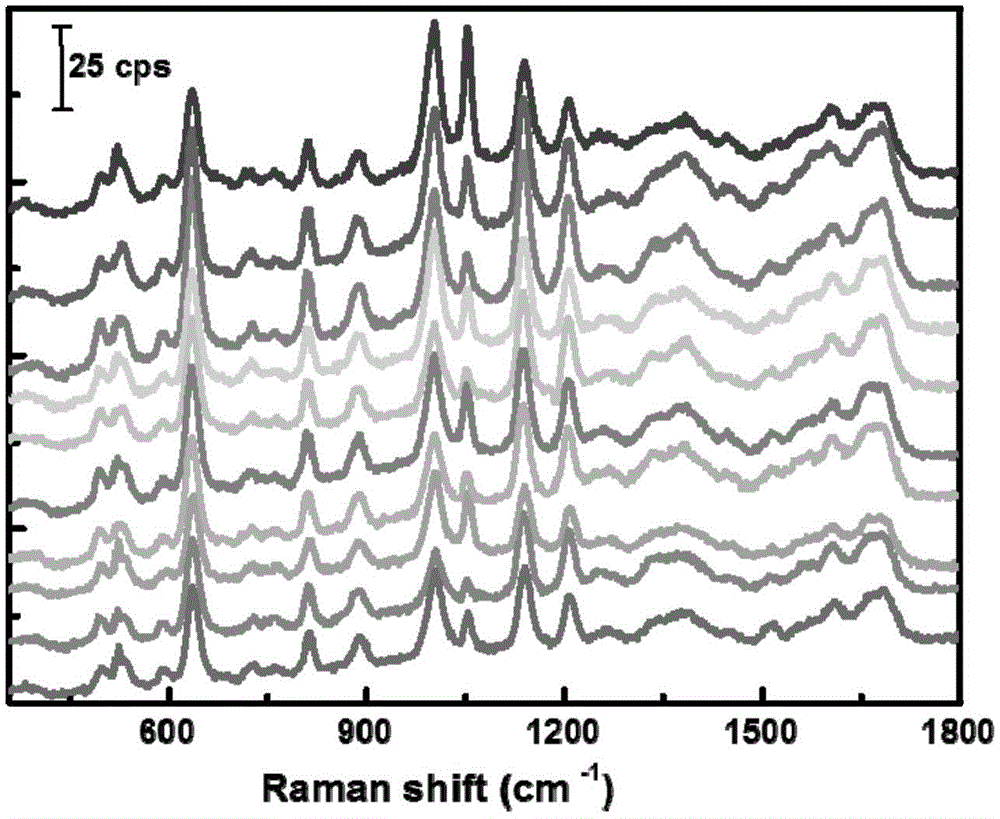

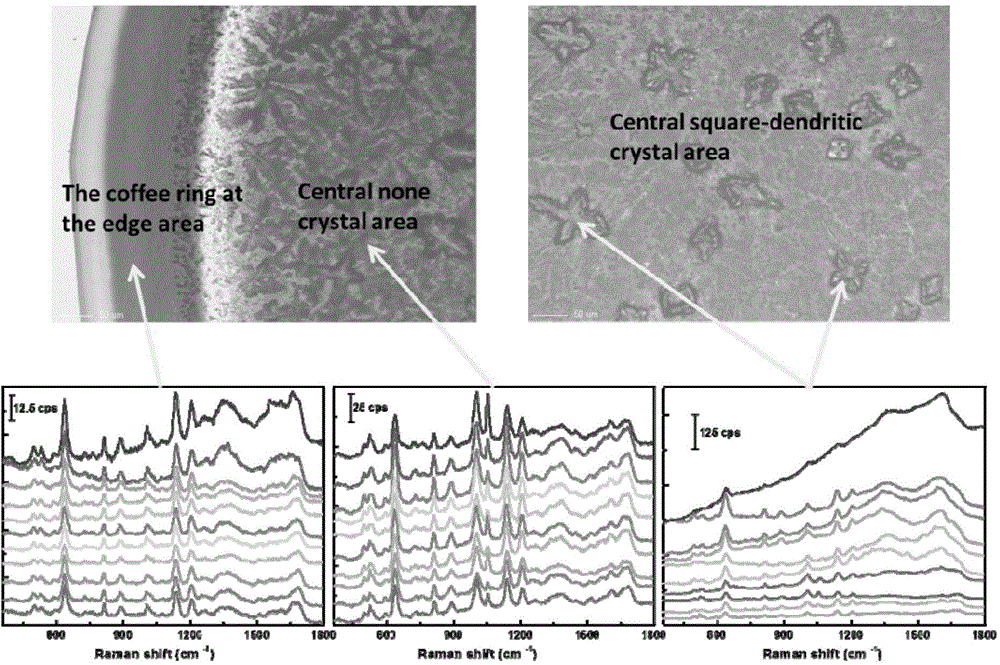

Tear test method based on surface-enhanced raman spectroscopy

The invention discloses a tear test method based on surface-enhanced raman spectroscopy. The tear test method comprises the steps of mixing nano particles and tears, and detecting a tear and particle mixture through a raman spectrometer, thus obtaining a tear component raman spectrogram, wherein the tear and particle mixture can be liquid, semi-liquid or a dried crystal. The invention aims at providing a novel, quick, noninvasive and sensitive method for detection and analysis of the tears.

Owner:XIAMEN UNIV

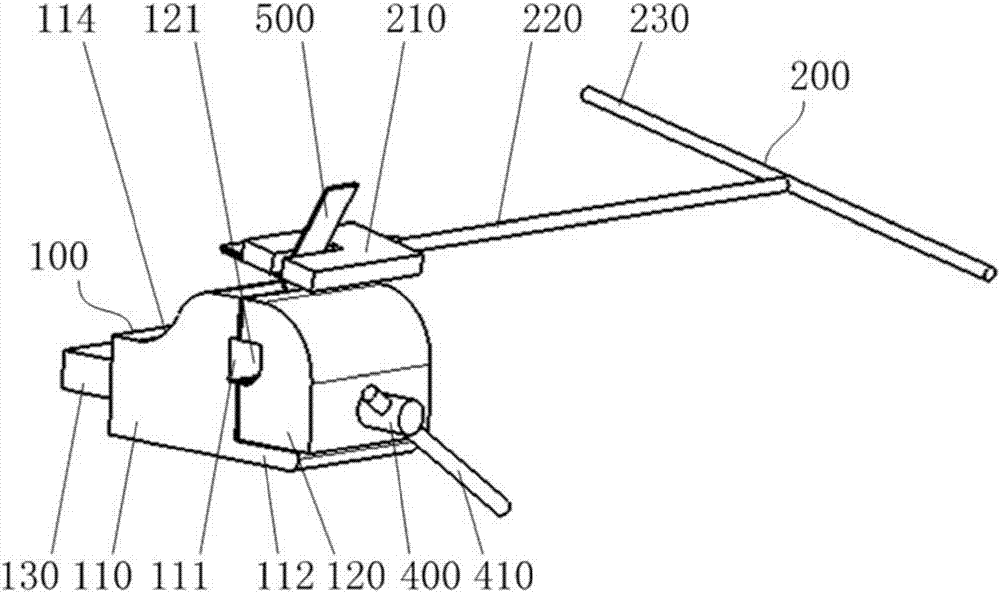

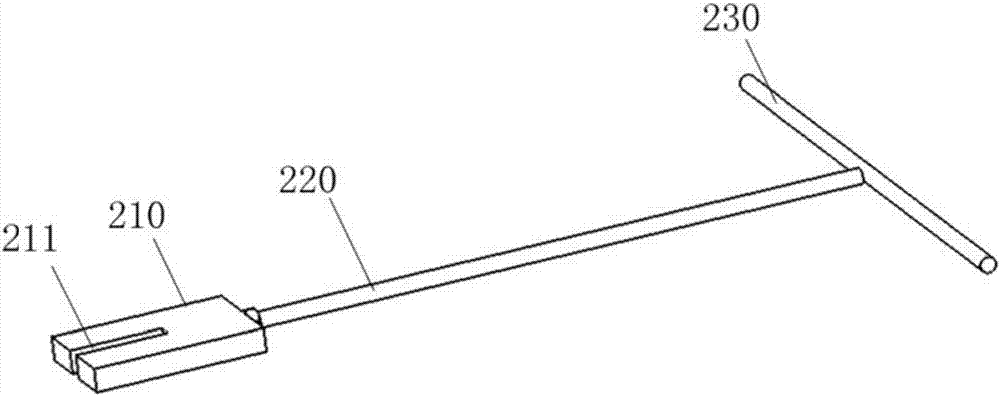

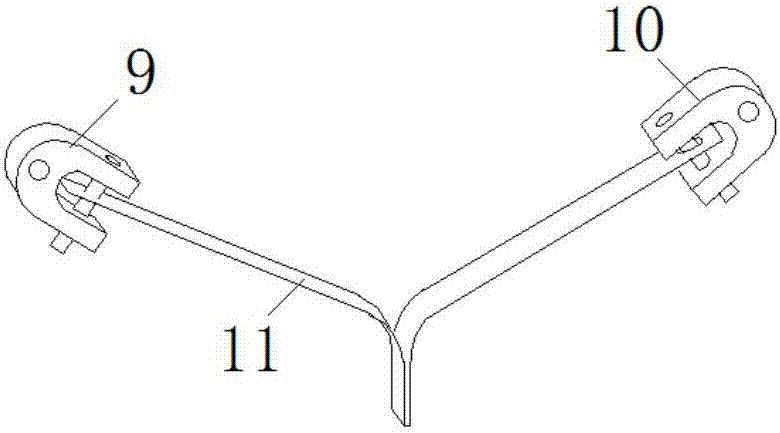

Welding spot test piece tearing test fixture

InactiveCN107219130ATearing achievedAchieve clampingMaterial strength using steady torsional forcesEngineeringTearing test

The invention discloses a welding spot test piece tearing test fixture which comprises a torsional mechanism, a fixed mechanism, a lead screw and a fixed sleeve, wherein the torsional mechanism comprises a clamping plate and an operating rod; a clamping groove is formed in one end of the clamping plate; the other end of the clamping plate is fixedly connected with the operating rod; the fixed mechanism comprises a fixed block and a slide block; the slide block is connected with the fixed block in a sliding manner; a baffle plate is arranged at the lower part of the slide block; a through hole is formed in the baffle plate; a separation blade is fixedly arranged on the lead screw; a long axis segment is arranged at the left end of the separation blade, a short axis segment is arranged at the right end of the separation blade, the long axis segment is in threaded connection with the fixed block and the short axis segment passes through the through hole; the baffle plate is propped against the baffle plate; the fixed sleeve is fixedly connected with the short axis segment; and the fixed sleeve is propped against the baffle plate. According to the welding spot test piece tearing test fixture, clamping and testing of a test piece are achieved, the problem that the test piece is not easy to tear through double hands in the prior art is solved, meanwhile, the fixture is simple and convenient to operate and the work efficiency of the staff is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

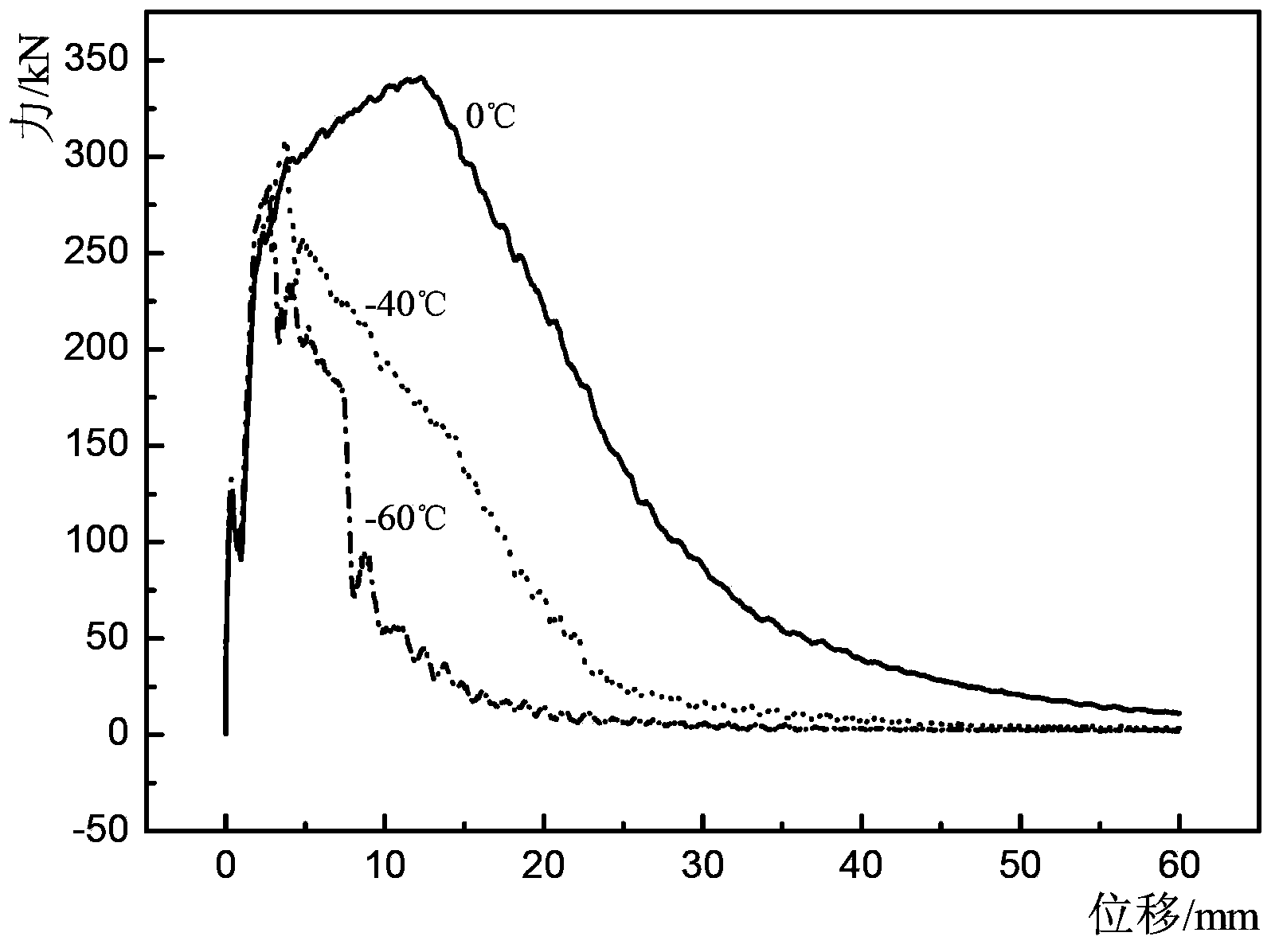

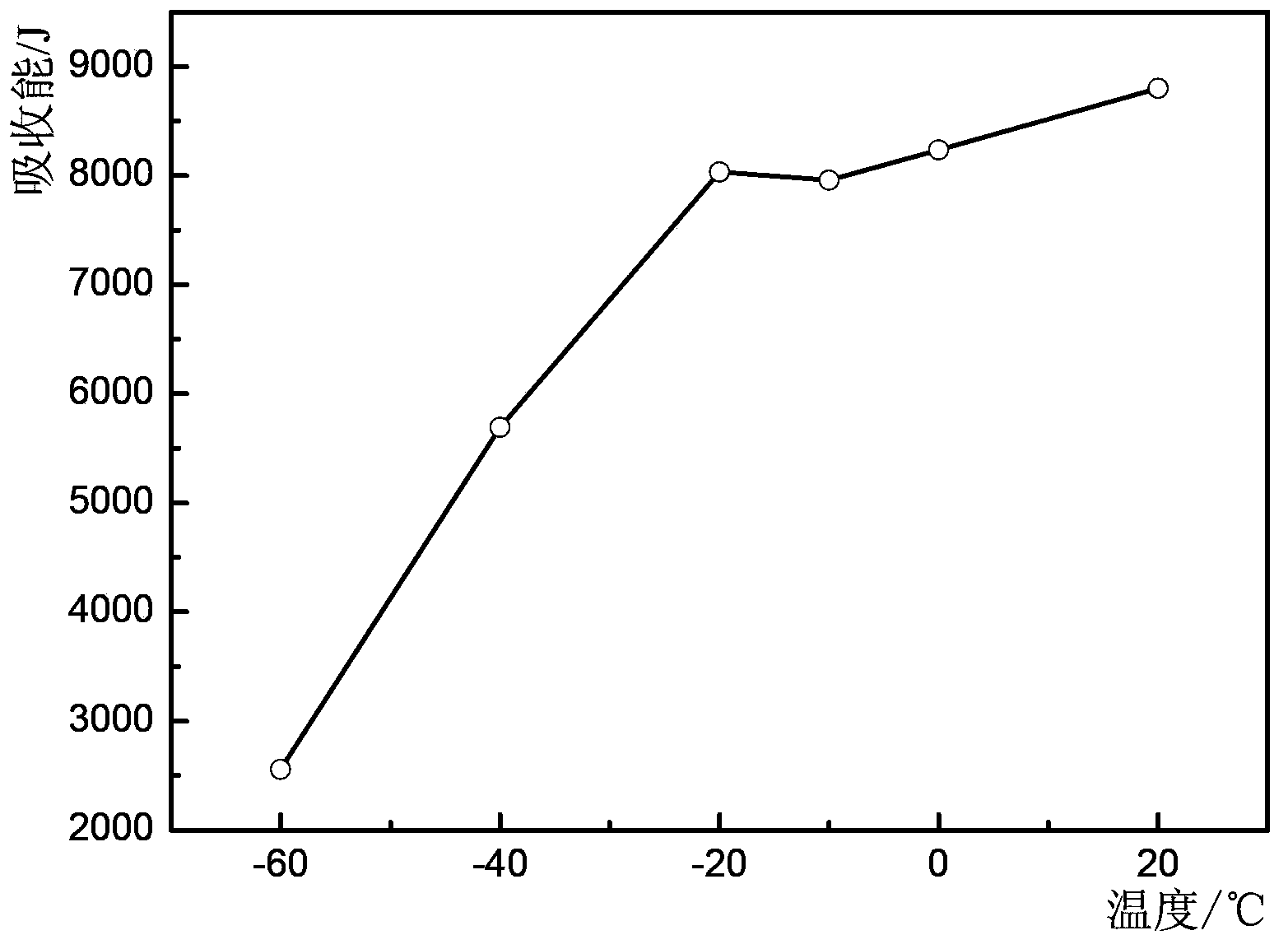

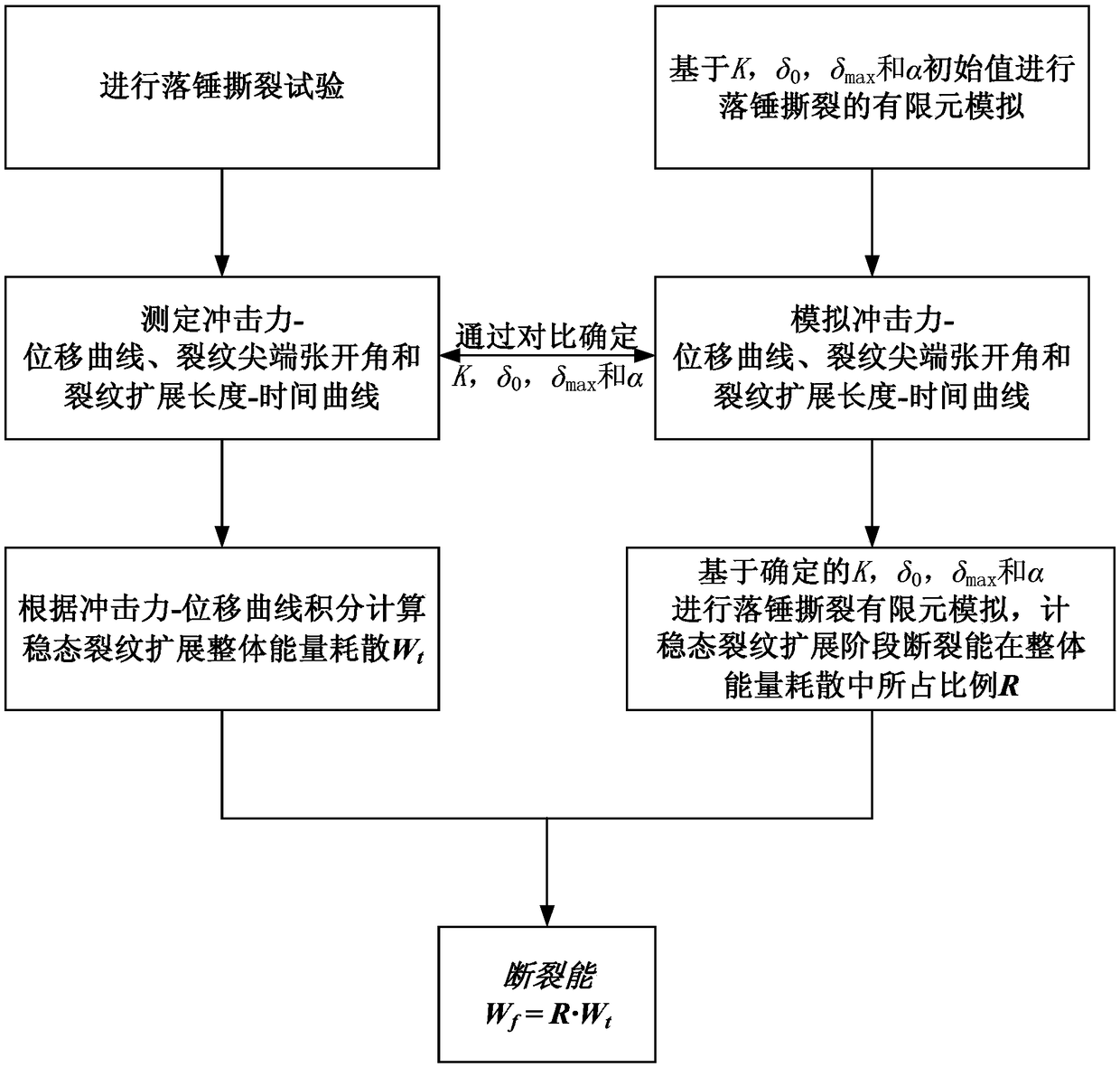

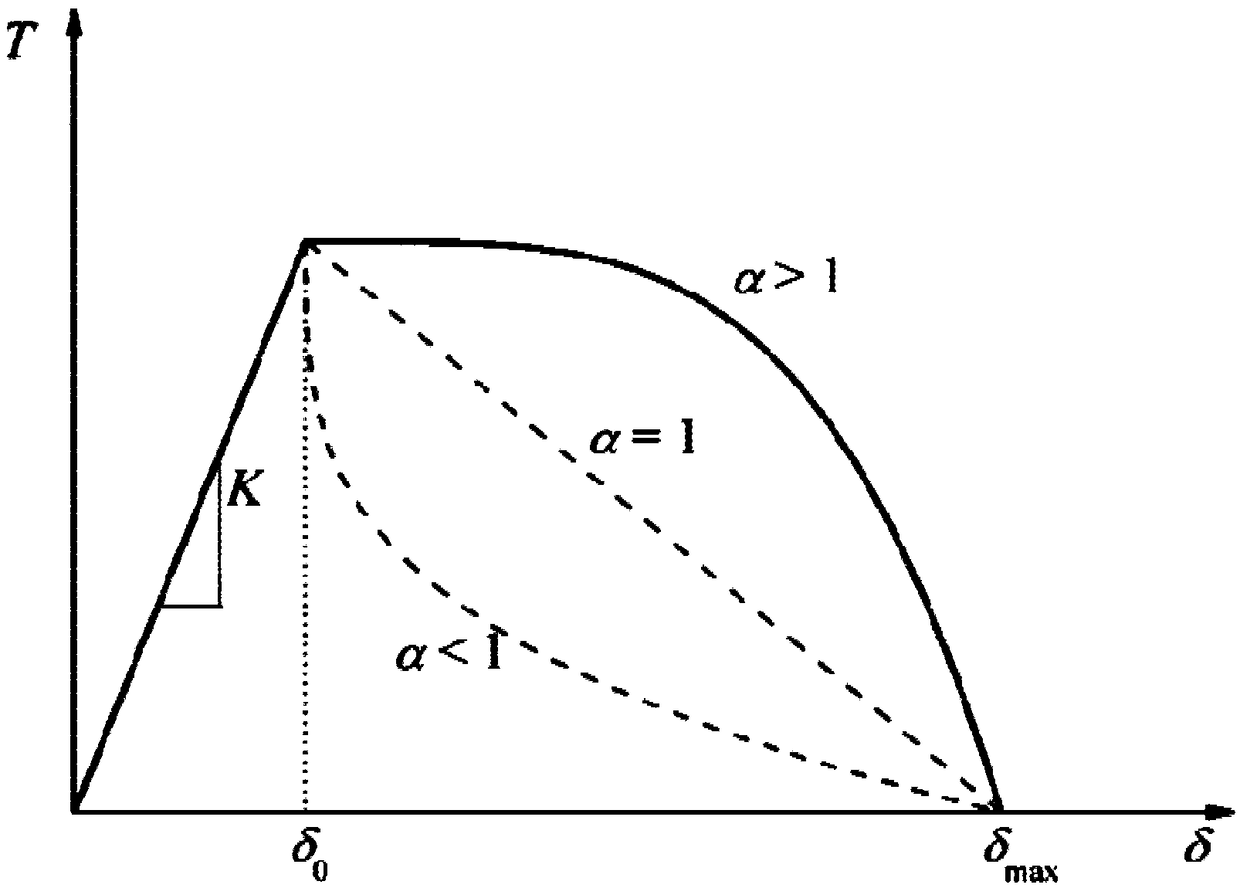

Method for measuring actual fracture energy of drop hammer tearing test material

ActiveCN108918253ASolve the technical problem that the real fracture energy cannot be directly measuredStrength propertiesFinite element methodEngineering

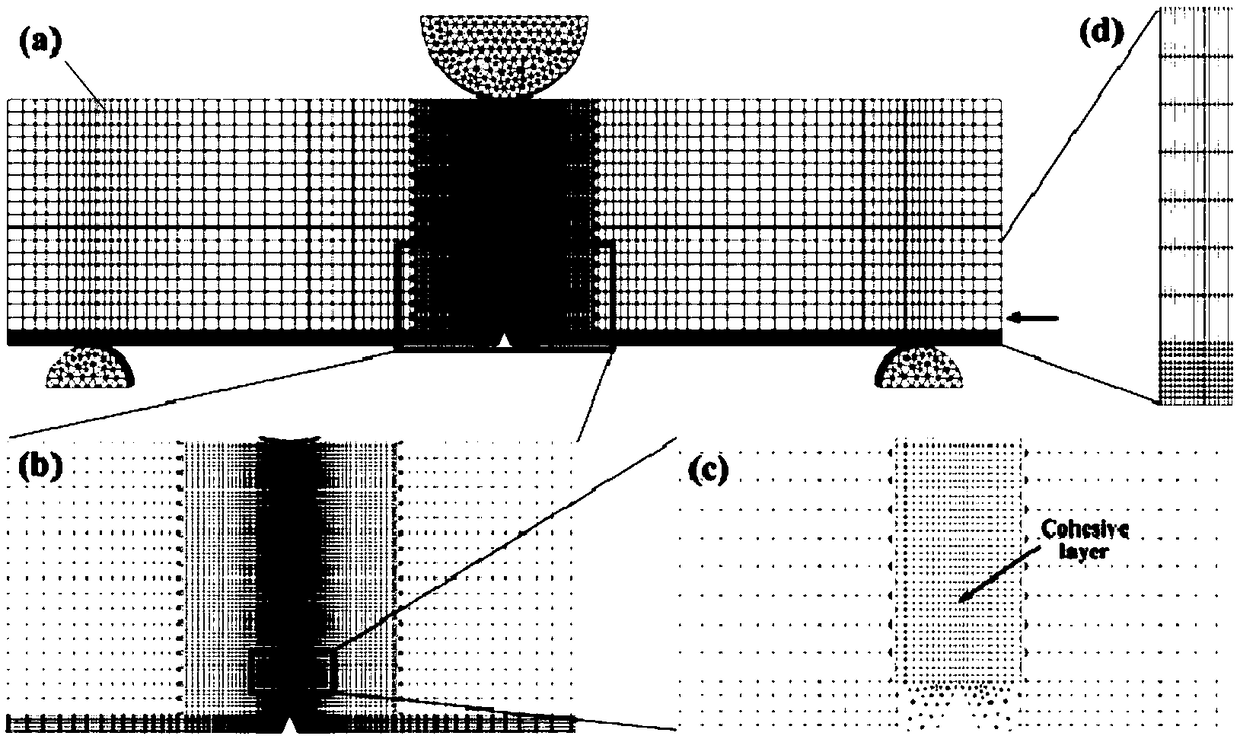

The invention provides a method for measuring the actual fracture energy of a drop hammer tearing test material. An impact force-displacement curve, a crack tip opening angle-crack growth length curveand a crack growth length-time curve measured in a drop hammer tearing test are used for calibrating K, alpha, sigma<0> and delta<max> in a tractive force-separation criterion needed for the method for measuring the real fracture energy of the drop hammer tearing test material, then based on the calibrated K, alpha, sigma<0> and delta<max>, the drop hammer tearing test under impact load is simulated by using a finite element method, based on the simulated results, the total energy dissipation in the drop hammer tearing test is analyzed, the proportion of fracture energy of the steady-state crack growth stage in the total energy dissipation is calculated, the ratio of the fracture energy to the total energy dissipation is obtained, and the ratio is multiplied by the integral results of theobtained impact force-displacement curve by simulation to obtain the actual fracture energy of the material. The method for measuring the actual fracture energy of the drop hammer tearing test material has the advantages of low cost and simple and convenient process.

Owner:无锡洲翔成套焊接设备有限公司

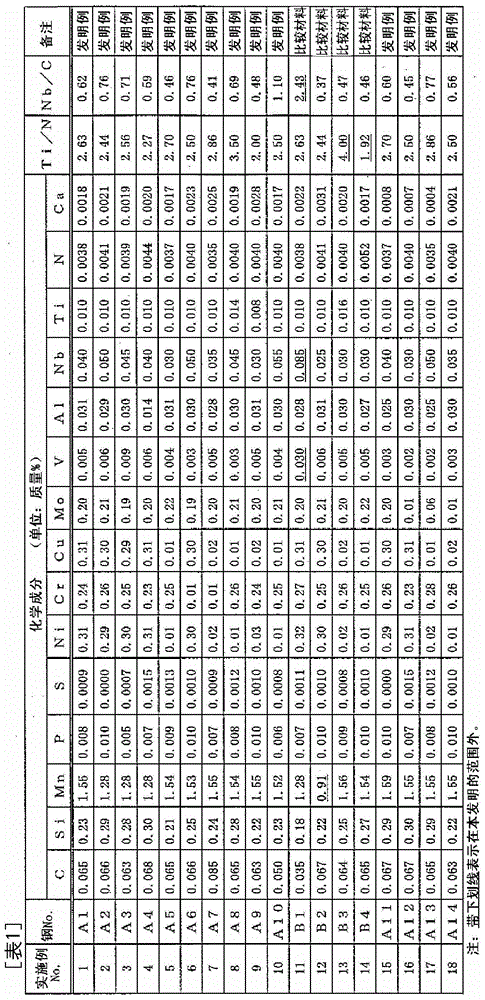

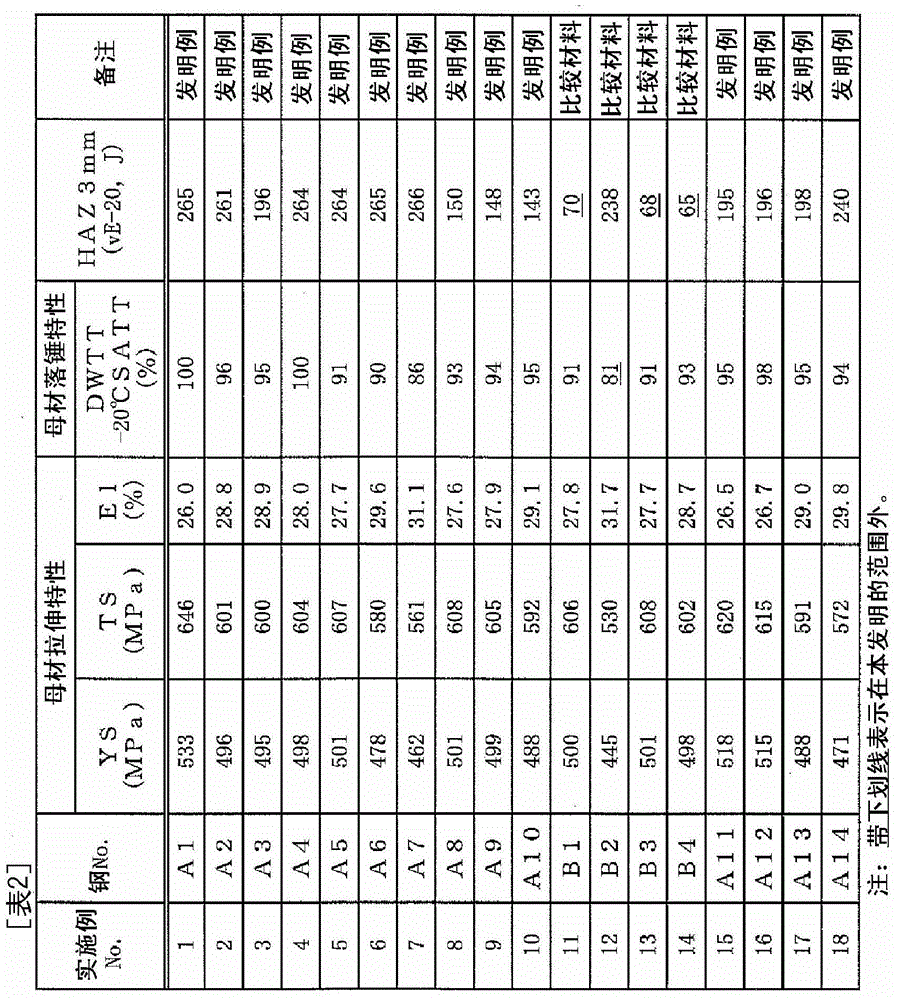

Base metal for high-toughness clad steel plate giving weld with excellent toughness, and process for producing clad steel plate

ActiveCN104080937AImprove low temperature toughnessFurnace typesThin material handlingDrop weightHeat-affected zone

The invention provides a base metal for high-toughness clad steel plates that give welds with excellent toughness. The base metal is characterized by containing, in terms of mass%, 0.030-0.10% of C, 0.10-0.30% of Si, 1.00-1.60% of Mn, up to 0.015% of P, up to 0.003% of S, and less than 0.010% of V and further containing one or more elements selected from 0.05-0.50% of Mo, 0.010-0.060% of Nb, 0.005-0.020% of Ti, up to 0.040% of Al, 0.0010-0.0040% of Ca, and 0.0030-0.0060% of N, with the balance being Fe and unavoidable impurities. The base metal is further characterized by having a percent ductile fracture of 85% or higher in a -20 DEG C drop weight tear test (DWTT) and having a value of vE-20 DEG C, measured at a location 3 mm apart from the heat affected zone (HAZ), of 100 J or more.

Owner:JFE STEEL CORP

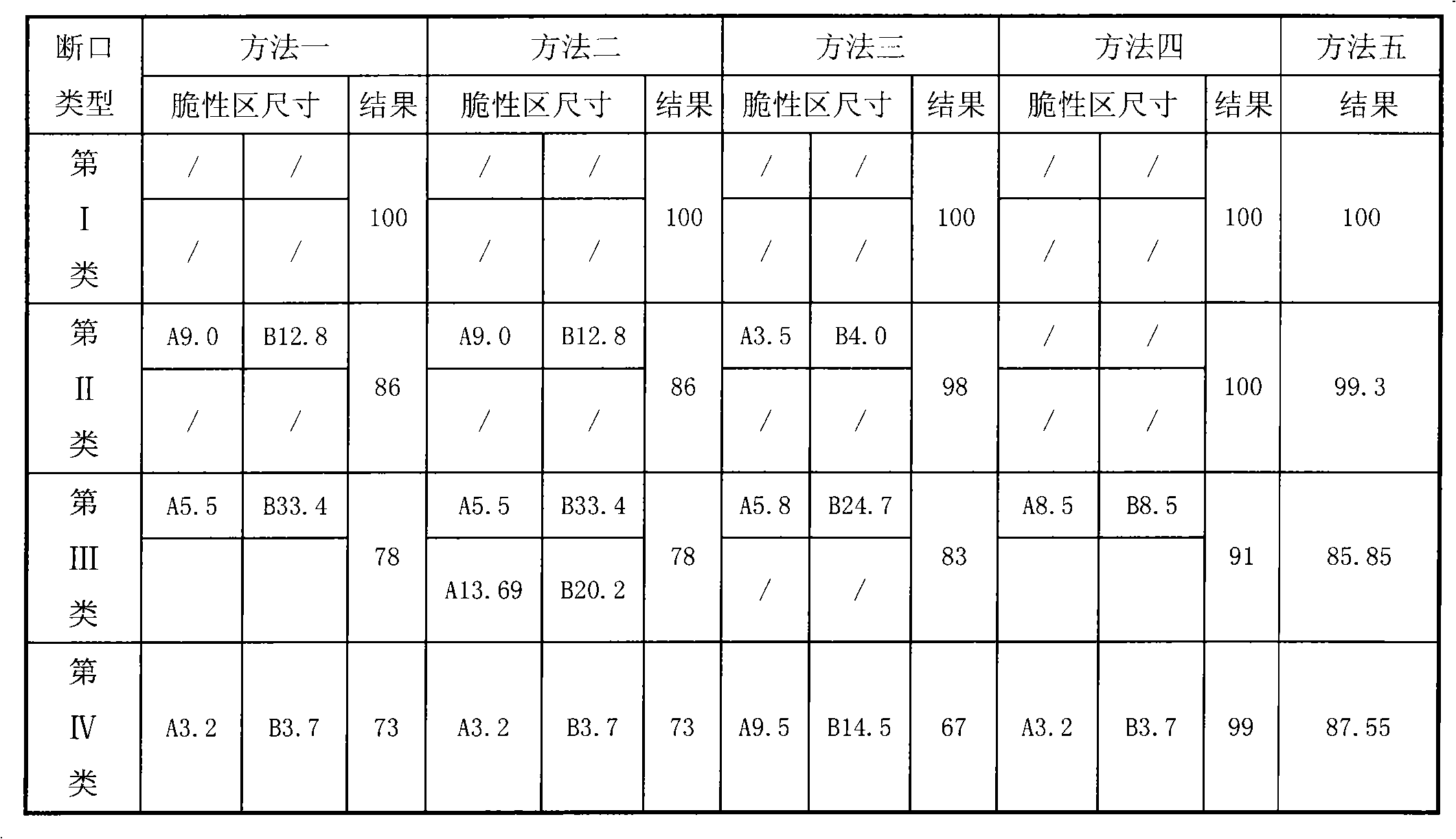

Evaluation method of abnormal fracture in drop weight tear test of steel pipe

ActiveCN102466600AQuality improvementPromote the development of applicationsMaterial strength using repeated/pulsating forcesDrop weightDistribution characteristic

The invention relates to an evaluation method of an abnormal fracture in a drop weight tear test of a steel pipe; according to the distribution characteristics of brittle zones in the abnormal fracture, the abnormal fracture is classified into four types: in a first type of abnormal brittle fracture, the brittle zones are distributed within one 1 wall thickness on a hammering side; in a second type of abnormal brittle fracture, the brittle zones are on the hammering side and are distributed out of one wall thickness; in a third type of abnormal brittle fracture, the brittle zones are distributed in the middle part of fracture ligament, and exceed the centerline of the fracture ligament from the hammering side; and in a fourth type of abnormal brittle fracture, brittle zones appear earlier, and the nearest distance of the zones from the fracture is less than 1 wall thickness. The invention provides the evaluation methods of fracture classification and the abnormal fracture of the drop weight tear test of high-grade large-aperture high-pressure gas transmission pipeline steel and the steel pipe, solves the difficult problem of abnormal fracture evaluation, and meets the needs of quality control and acceptance evaluation of the high-grade pipeline steel and steep pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

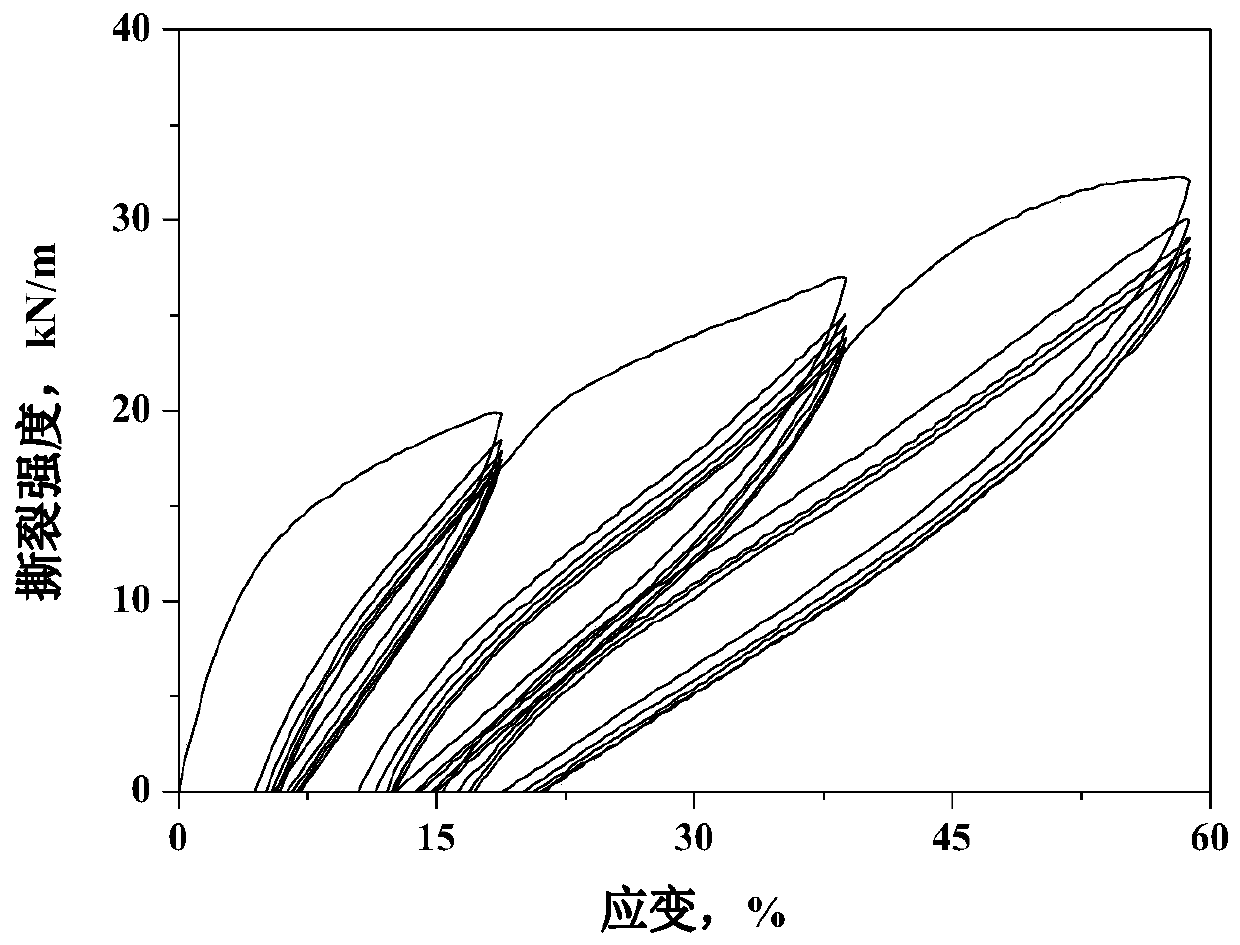

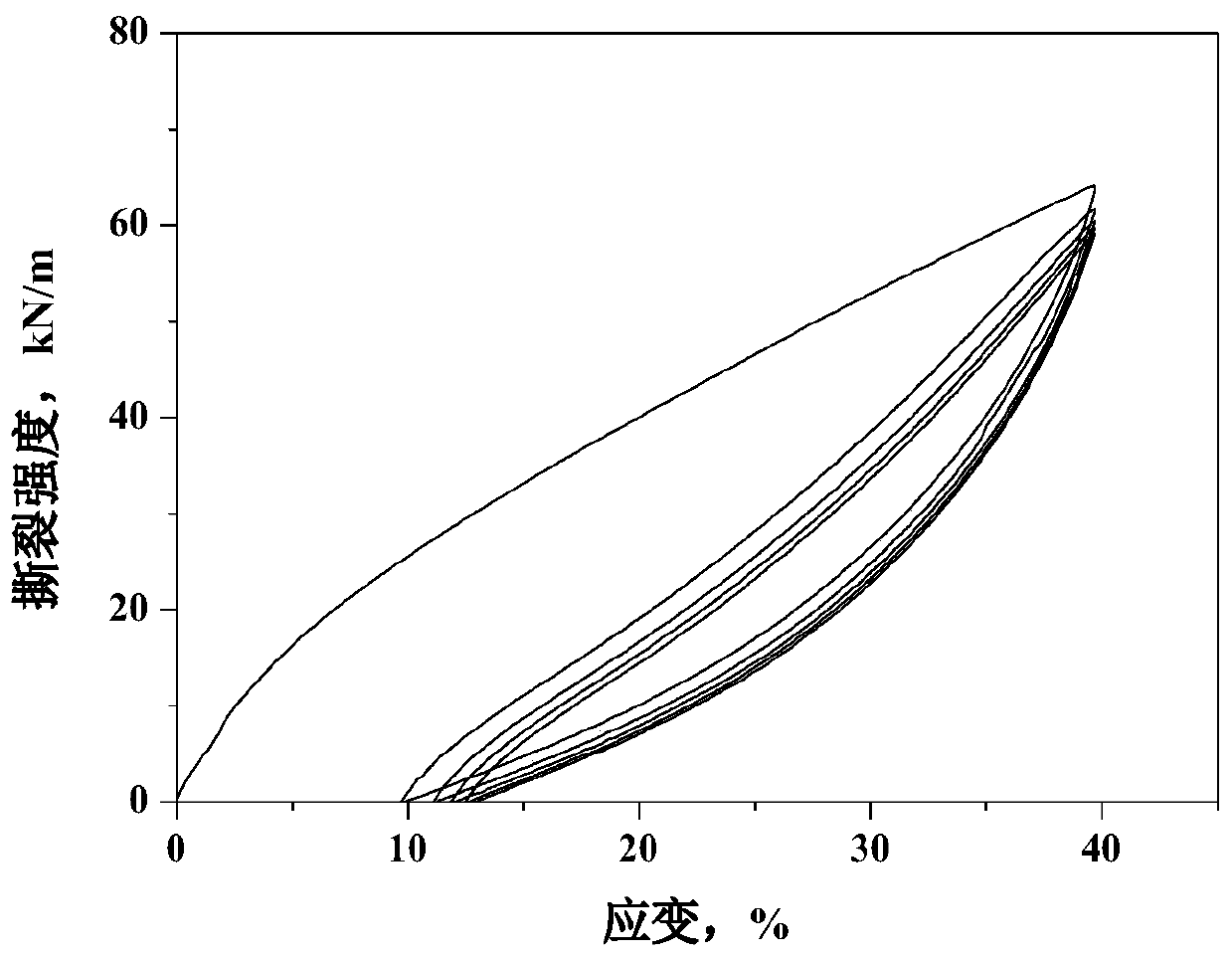

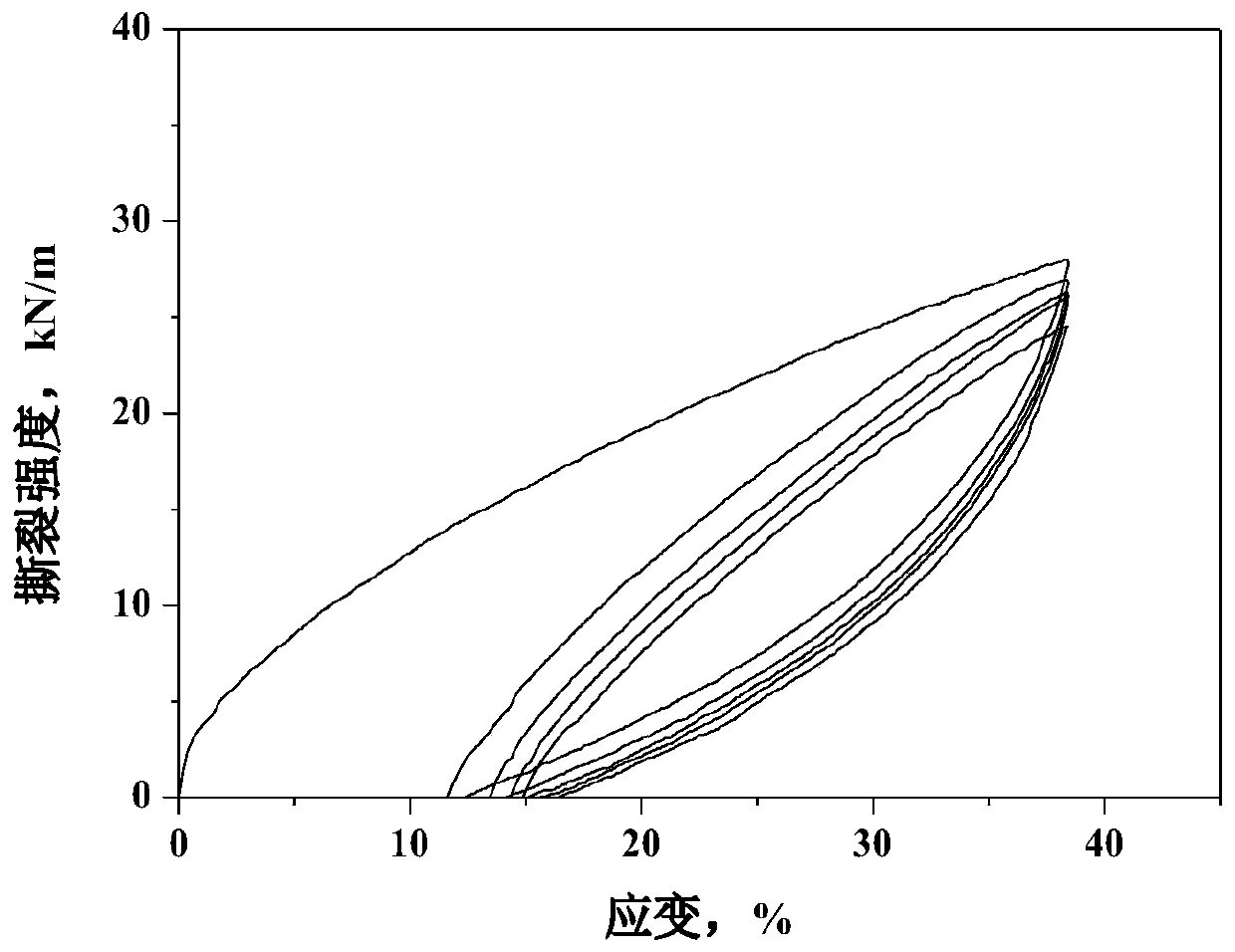

Characterization method for stress softening and instantaneous residual strain in elastomer tearing mode

The invention relates to a characterization method for stress softening and instantaneous residual strain in an elastomer tearing mode, and provides an effective method for evaluating the stress softening and the instantaneous residual strain of an elastomer in a uniaxial cyclic tearing strength-strain test. The quantitative characterization method comprises the steps of: a, subjecting a right-angled tearing test sample to the uniaxial cyclic tearing strength-strain test on a universal material testing machine, and repeatedly and continuously tearing and loosening the test sample at the same speed to obtain a uniaxial cyclic tearing strength-strain curve; b, reading the stress when the sample is stretched to a specific strain in a tearing mode each time from the tearing strength-strain curve, so as to obtain stress softening data; c, and regarding an initial distance between two parallel marked lines of the right-angled tearing sample as l0, regarding an instantaneous distance betweenthe two parallel marked lines as li when the stress is reduced to zero in the uniaxial cyclic tearing strength-strain test period, and calculating the instantaneous residual strain according to a formula shown in description.

Owner:QINGDAO UNIV OF SCI & TECH

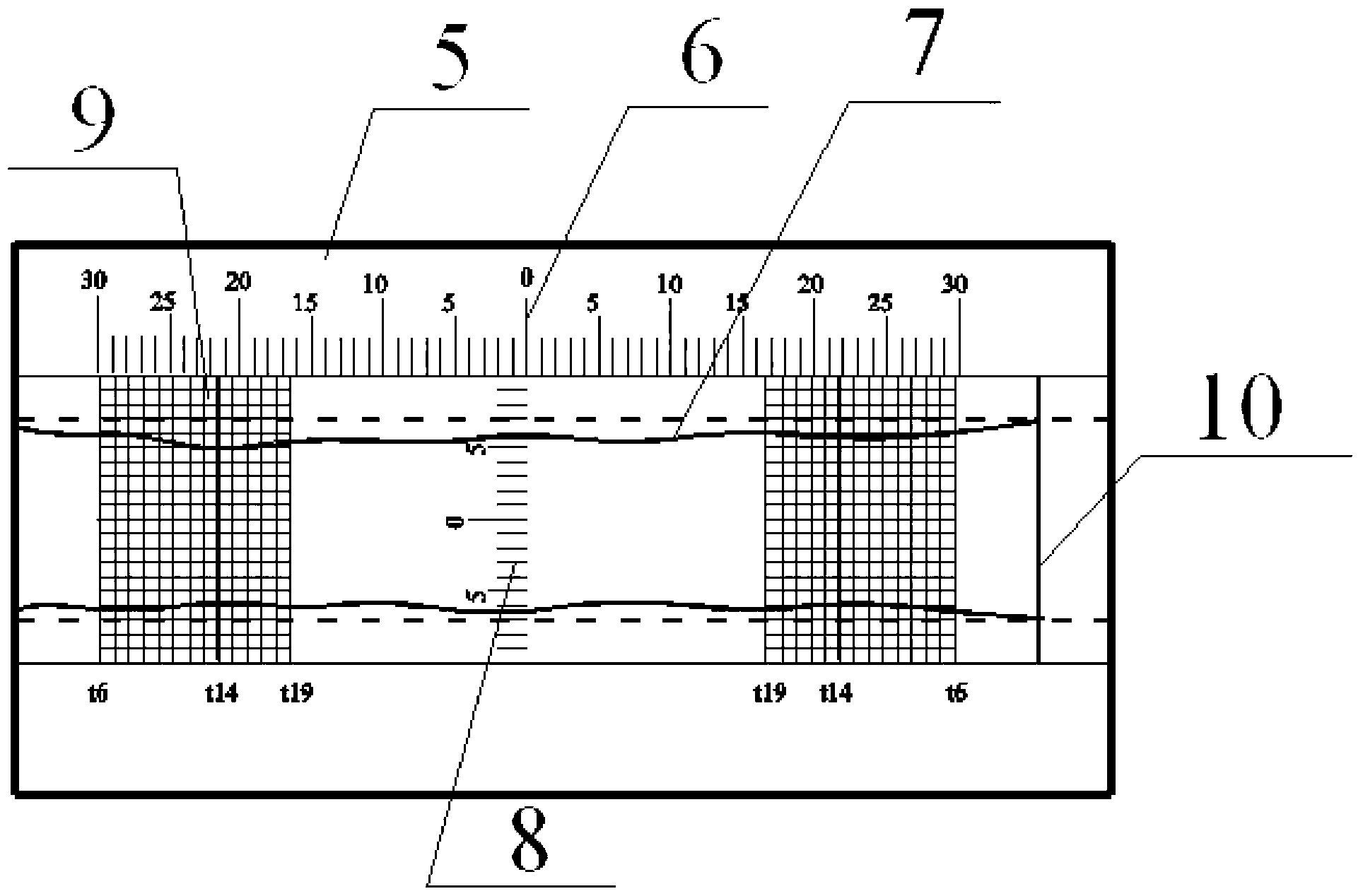

Measuring scale for drop weight tear tests and method for measuring fracture surfaces of drop weight tear test samples

InactiveCN103292649AReasonable designSimple and fast operationMechanical counters/curvatures measurementsRulers for direct readingDrop weightMetallic materials

The invention discloses a measuring scale for drop weight tear tests and a method for measuring fracture surfaces of drop weight tear test samples, and belongs to the technical field of tests for mechanical properties of metal materials. The measuring scale comprises a measuring scale body. Transverse scale marks are drawn on the upper portion of the measuring scale body, longitudinal scale marks are drawn in the middle of the measuring scale body and are perpendicular to the transverse scale marks, and grids are drawn on the lower portions of two sides of the transverse scale marks. The measuring scale and the method have the advantage that various feature sizes of the fracture surfaces of the drop weight tear test samples can be quickly, accurately and directly measured by the measuring scale.

Owner:武汉钢铁有限公司

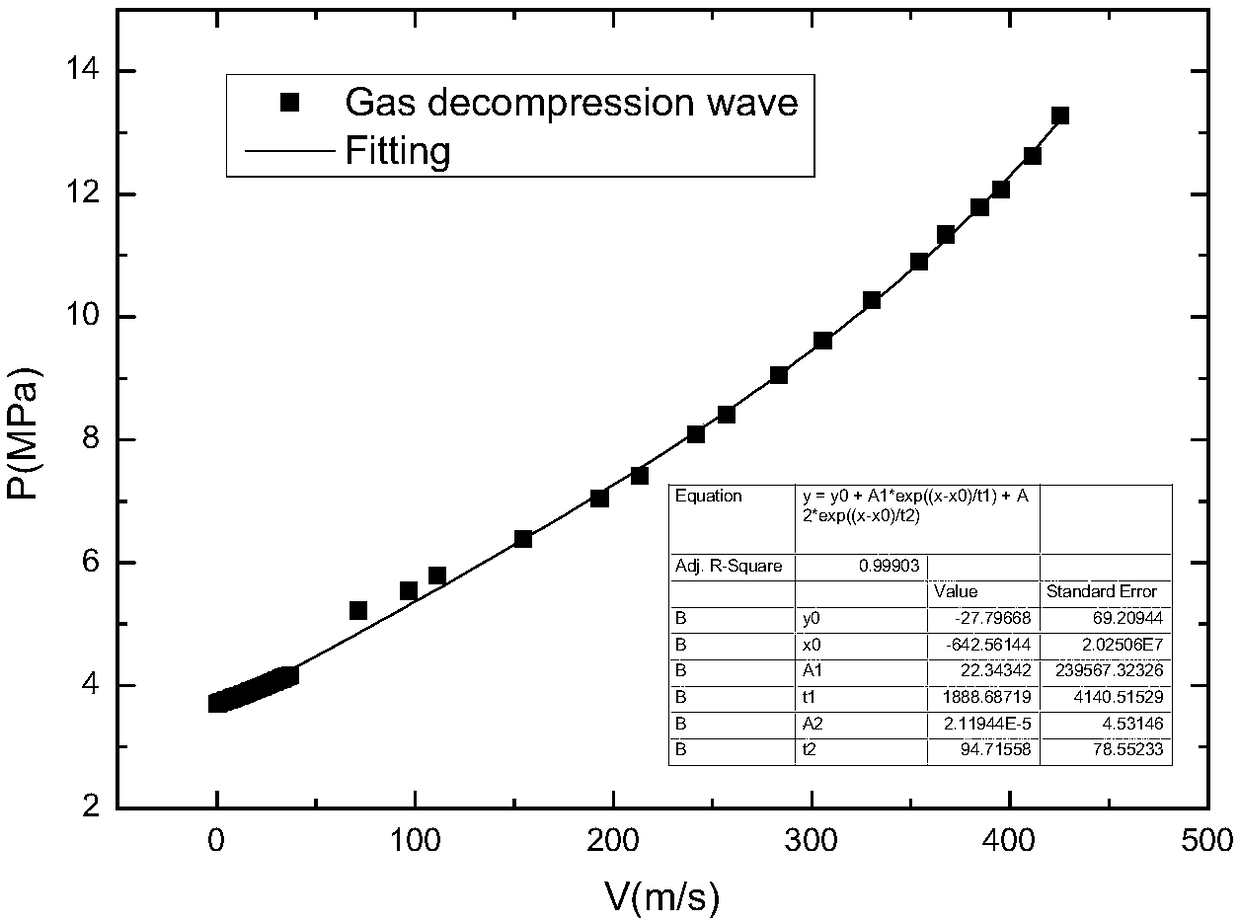

Method of calculating arrested toughness of pipeline by full dimensional bursting test of natural gas pipeline

InactiveCN109187202AThe principle is simpleImprove calculation accuracyMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceDrop weightToughness

The invention discloses a method of calculating arrested toughness of a pipeline by a full dimensional bursting test of a natural gas pipeline. The method comprises the following steps: putting an acquired gas pressure-reduced pressure wave velocity curve of the natural gas pipeline and an acquired pressure-crack expansion velocity cure of the natural gas pipeline in a same coordinate system; thenchanging the energy density Rdwtt of a drop weight tear test, wherein the gas pressure-reduced pressure wave velocity curve of the natural gas pipeline and the acquired pressure-crack expansion velocity cure of the natural gas pipeline are tangent; and calculating the arrested toughness of the pipeline by a full dimensional bursting test of the natural gas pipeline by taking the point of tangencyRdwtt of the gas pressure-reduced pressure wave velocity curve of the natural gas pipeline and the acquired pressure-crack expansion velocity cure of the natural gas pipeline as critical arrested toughness energy density for arrested toughness of the natural gas pipeline. The method can be used for precisely determining the arrested toughness of the natural gas pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A special aluminum paste for partial aluminum back field crystalline silicon solar cells and preparation method thereof

ActiveCN103545013BImprove liquidityAvoid damageFinal product manufactureNon-conductive material with dispersed conductive materialAluminium powderBack surface field

Provided is an aluminium paste dedicated for a local aluminium back surface field crystalline silicon solar cell. The paste is prepared from raw materials matched with the following parts by mass: 70-78 parts of aluminium powder, 0.05-3 parts of inorganic bond, 17-27 parts of organic bond and 1-5 parts of additive. Further provided is a preparation method for the aluminium paste dedicated for a local aluminium back surface field crystalline silicon solar cell. Therefore, compared with the traditional aluminium paste, the aluminium paste is specially applied to a local aluminium back surface field crystalline silicon solar cell, and has the advantages of good flowability, minimal damage to a passive film, good contact with a window, a compact and uniform aluminium film, etc. The average conversion efficiency of volume production for the crystalline silicon solar cell is ≥ 20.0%. After a cell slice is laminated and packaged, and an EVA tear test is performed thereon, the adhering pulling force of the aluminium back surface field is measured as ≥ 10 N.

Owner:GUANGZHOU RUXING TECH DEV +1

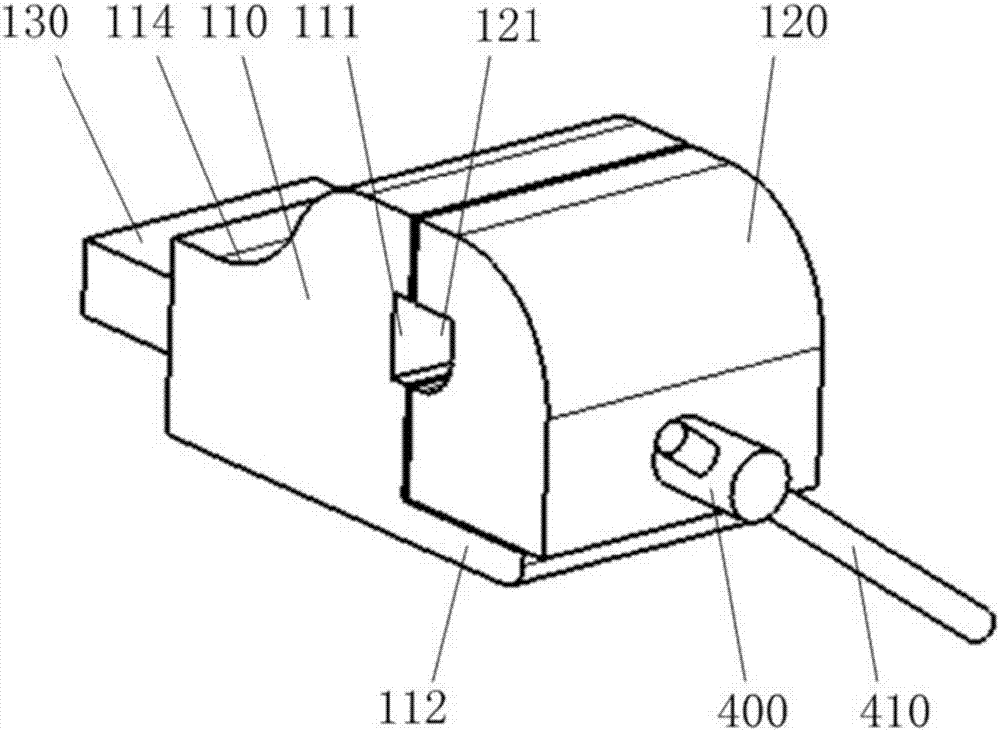

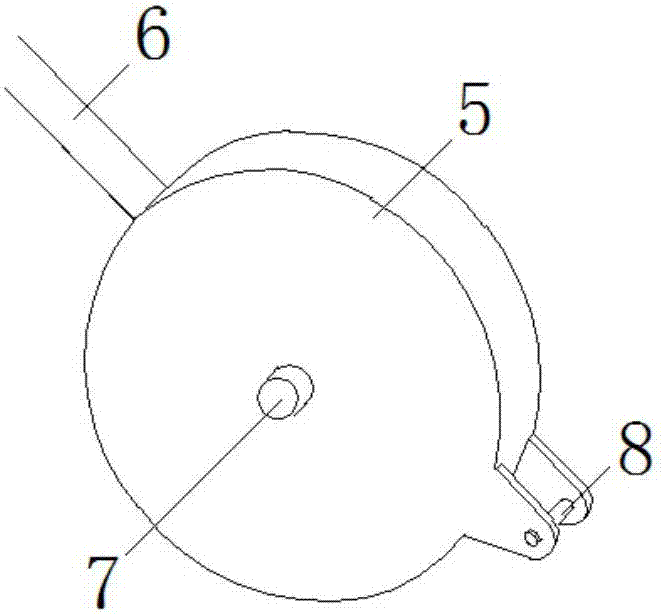

Spot welding test plate tearing test device and test method thereof

InactiveCN107121346AReasonable structural designSimple structureMaterial strength using steady torsional forcesEngineeringSpot welding

The invention discloses a spot welding test plate tearing test device. The spot welding test plate tearing test device comprises a frame mechanism, a tearing action mechanism and a connecting mechanism; the tearing action mechanism comprises a rotary plate and a handle arranged on the rotary plate; the rotary plate is arranged on the frame mechanism through a rotary plate fixing shaft; the connecting mechanism comprises a fixed hinge and a movable hinge which are used for connecting with the two ends of a welding test plate; the fixed hinge is connected with the frame mechanism; and the movable hinge is connected with the rotary plate. A test method comprises the following steps: after test plate welding is completed, an operator separates the open hole ends of two test plate into an angle to connect the outer ends of the test plates with the movable hinge and the fixed hinge correspondingly; the handle is pulled, the welding test plates rotate along with the rotary plate, the opening is enlarged gradually and tearing starts; and when the welding test plates are pulled to the maximal angle, the welding spot or the test plates are torn. The test is simple and convenient to operate, safe and efficient, the welding spot binding force of the two test plates can be roughly quantized, and comparison is facilitated; and the structure is simple and the cost is low.

Owner:CHERY COMML VEHICLE ANHUI

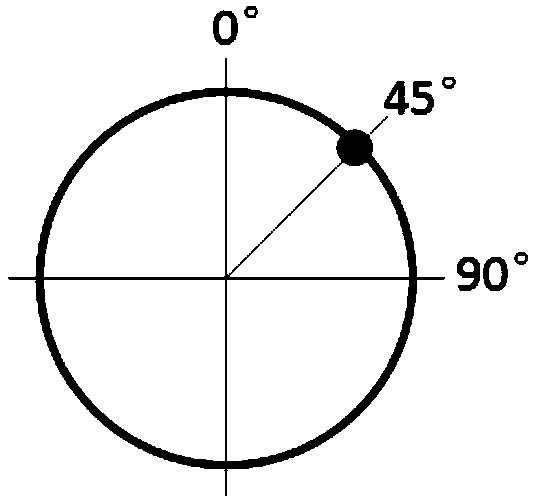

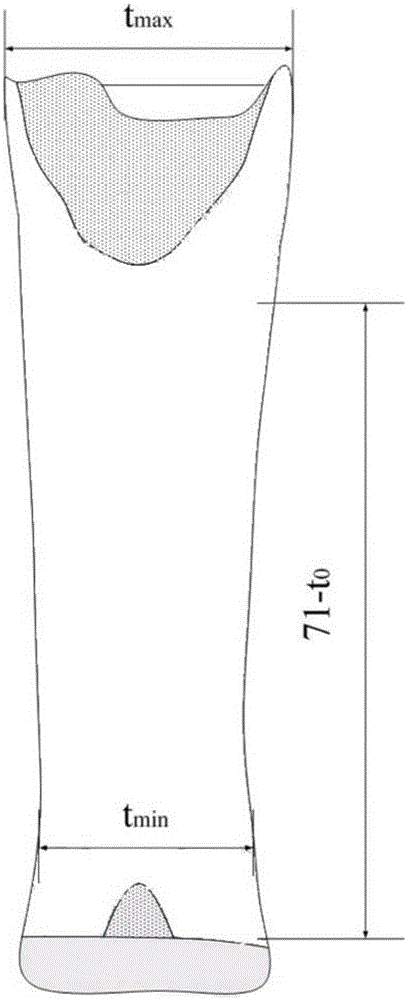

Method for judging plasticity index of material in rapid deformation process through drop-weight tear test (DWTT)

InactiveCN105181490ASolve the problem of how to judge the plasticity indexEasy to useStrength propertiesDrop weightTest sample

The invention discloses a method for judging the plasticity index of a material in the rapid deformation process through a drop-weight tear test (DWTT). The method includes the following steps that S1, the original thickness t0 of a sample to be subjected to the DWTT is acquired first, and the original area S0 of a judgment region which ranges from the root portion of a sample notch to a hammering edge by subtracting the wall thickness t0 of the sample is calculated; S2, the DWTT is carried out, the minimum thickness tmin and the maximum thickness tmax of a fracture of the sample are measured and recorded, and the enveloping area S of the fracture contour line in the region is judged; S3, the plasticity index of the sample in the rapid deformation process is calculated. By the adoption of the method, the problem about how to judge the plasticity index when the material is loaded and cracked at a high speed is solved, and the basis is provided for crack-stopping study of a petroleum and gas pipeline. According to the method, the DWTT method is adopted, the plasticity index of the material in the rapid deformation process is acquired by judging the fracture of the tested sample. The method is convenient to use, and implementation cost is low.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH

Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

ActiveCN102409224BImprove corrosion resistanceRoll mill control devicesMetal rolling arrangementsDrop weightHydrogen

The invention provides a hot rolled steel plate with excellent low-temperature toughness for a thick submerged pipeline and a production method of the hot rolled steel plate. The hot rolled steel plate comprises the following chemical components by weight percentage: 0.02%-0.07% of C, 0.15%-0.40% of Si, 1.0%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.003% of S, less than or equal to 0.06% of Nb, less than or equal to 0.025% of Ti, less than or equal to 0.06% of V, less than or equal to 0.20% of Mo, less than or equal to 0.25% of Cu, 0.10%-0.30% of Ni, less than orequal to 0.25% of Cr, less than or equal to 0.008% of N, 0.010%-0.040% of Al, more than or equal to 2 of Al / N and the rest Fe and inevitable impurities. According to the steel for the submerged pipeline with the thickness being over 28mm, disclosed by the invention, the transversal and longitudinal bending strength can reach over 480MPa or 510MPa, the transversal and longitudinal tensile strengthcan reach over 560MPa or 600 MPa, the transversal impact toughness at the temperature of 60 DEG below zero is larger than or equal to 400 J, the transversal DWTT (Drop-Weight Tear Test) shearing areaat the temperature of 25 DEG C below zero is larger than or equal to 85%, simultaneously, the corrosion resistant of the steel plate is excellent, and the result of a 96-hour HIC (Hydrogen Induced Cracking) test conforms to the requirements of the standard 0284 of the NACE (National Association of Corrosion Engineers). The hot rolled steel plate is suitable to be as a raw material for manufacturing a pipeline for submerged oil and gas transmission.

Owner:ANGANG STEEL CO LTD

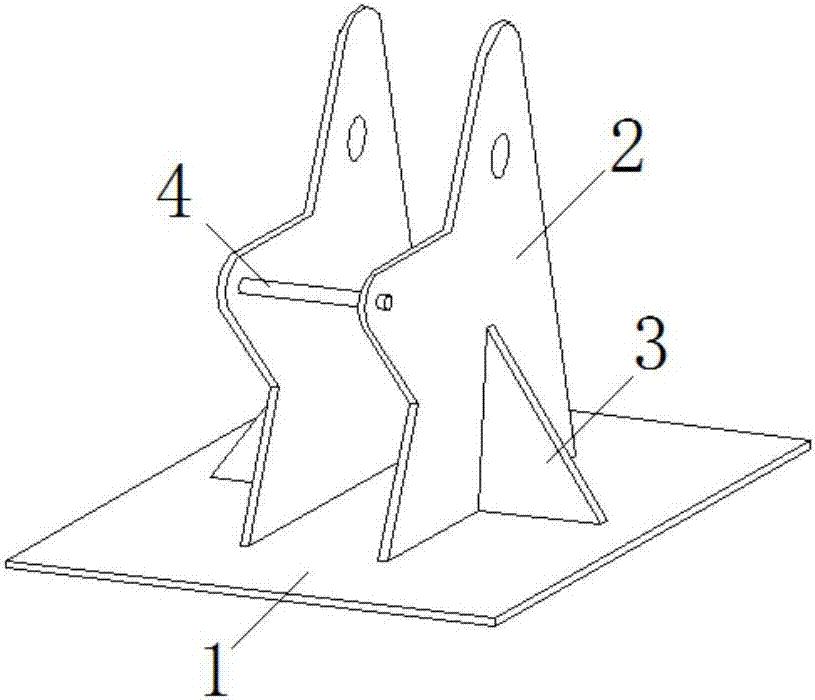

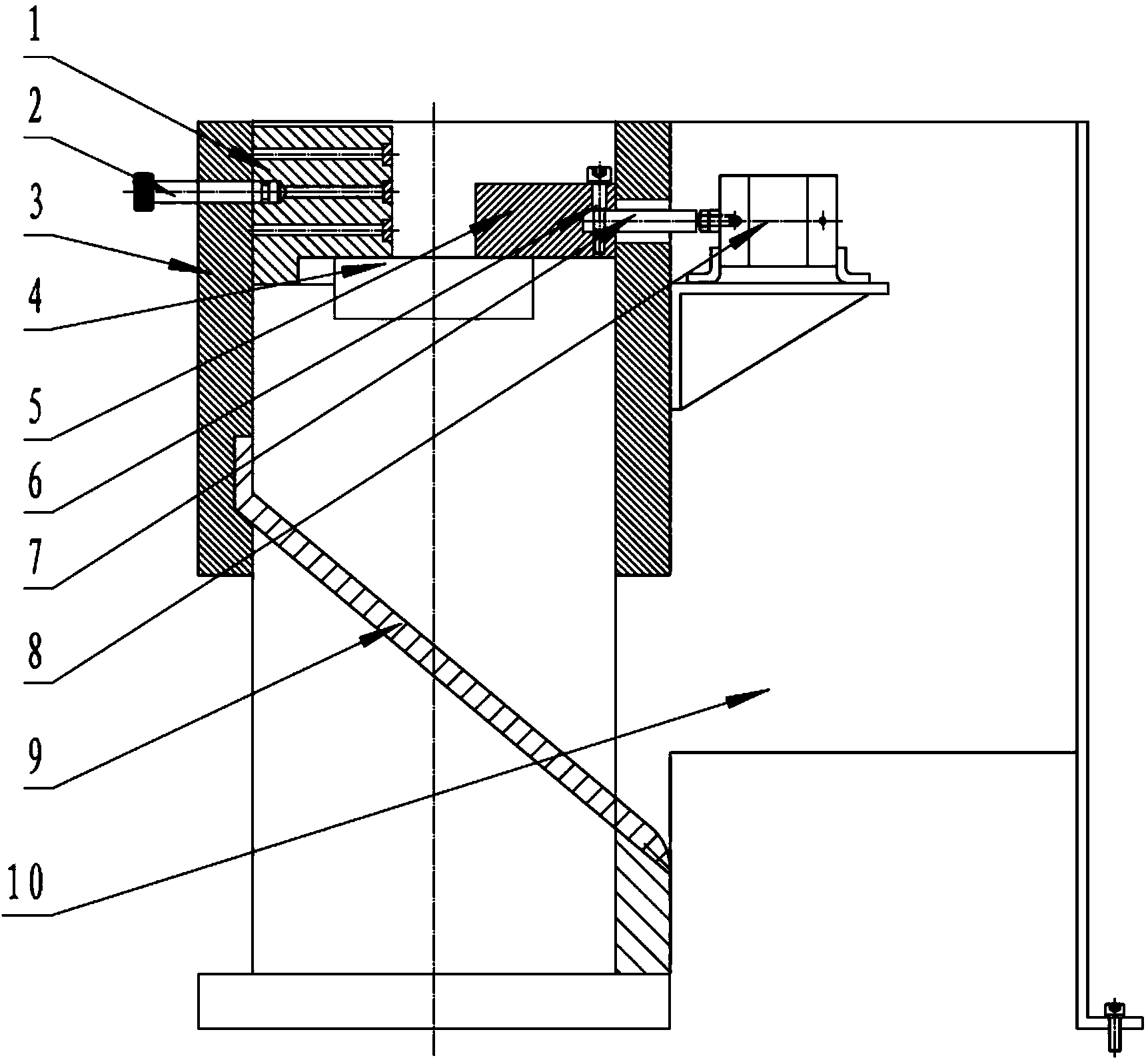

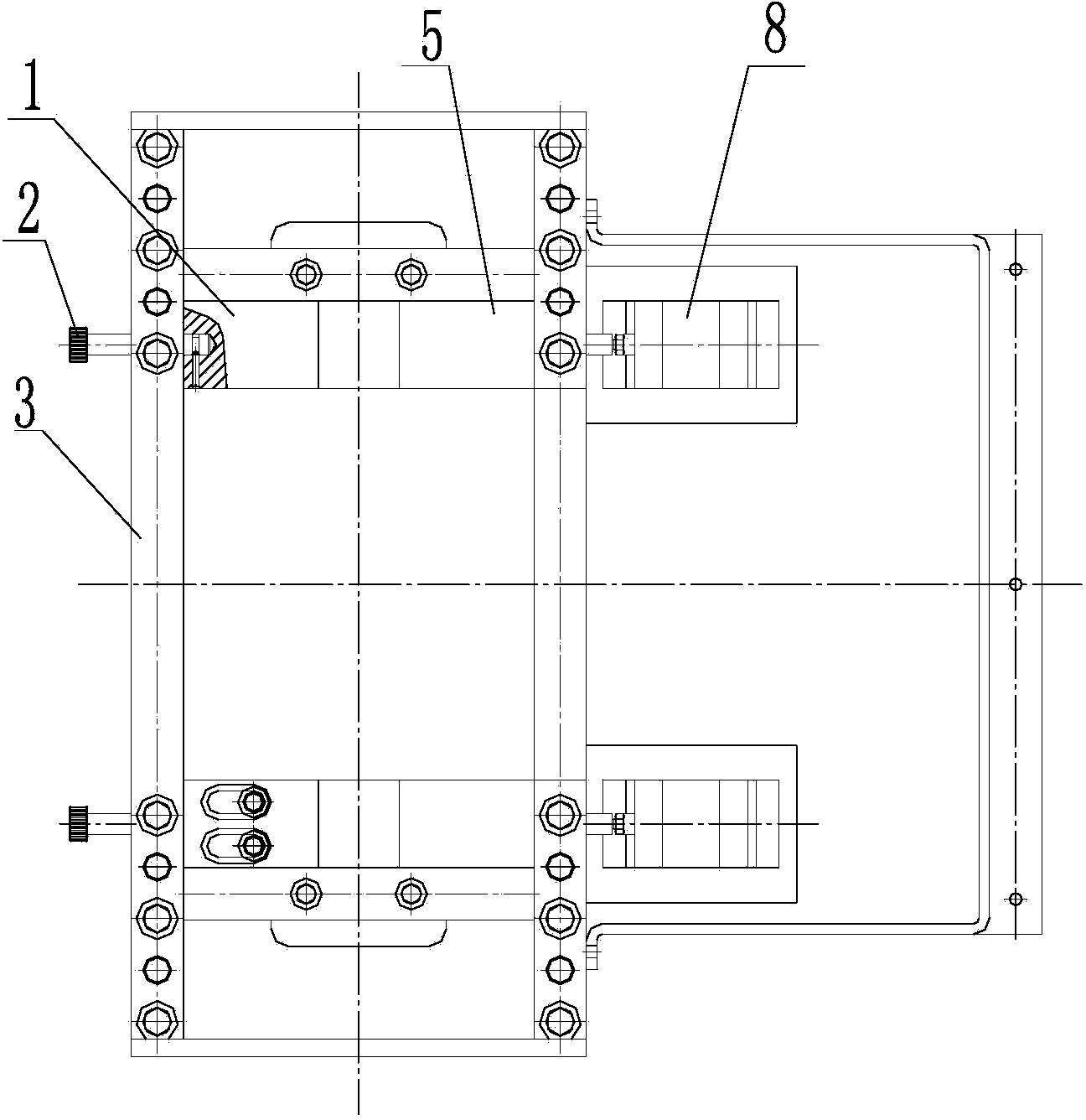

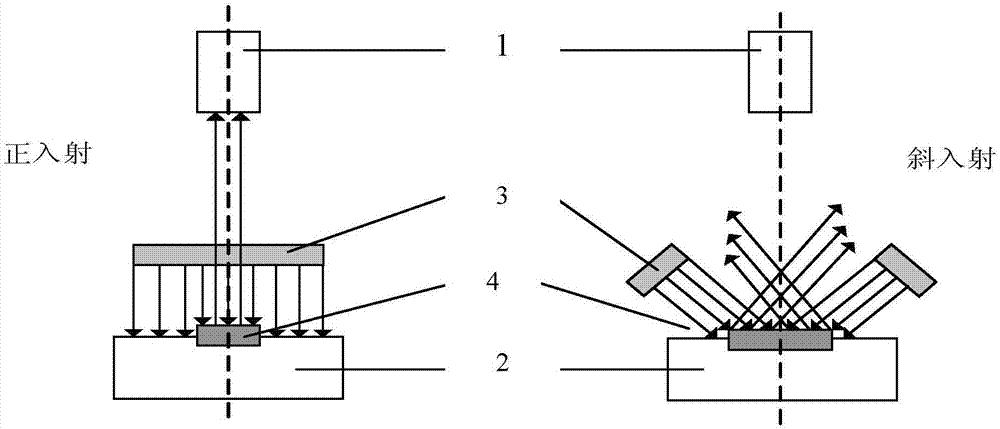

Automatic sample centering device for drop-weight tear test

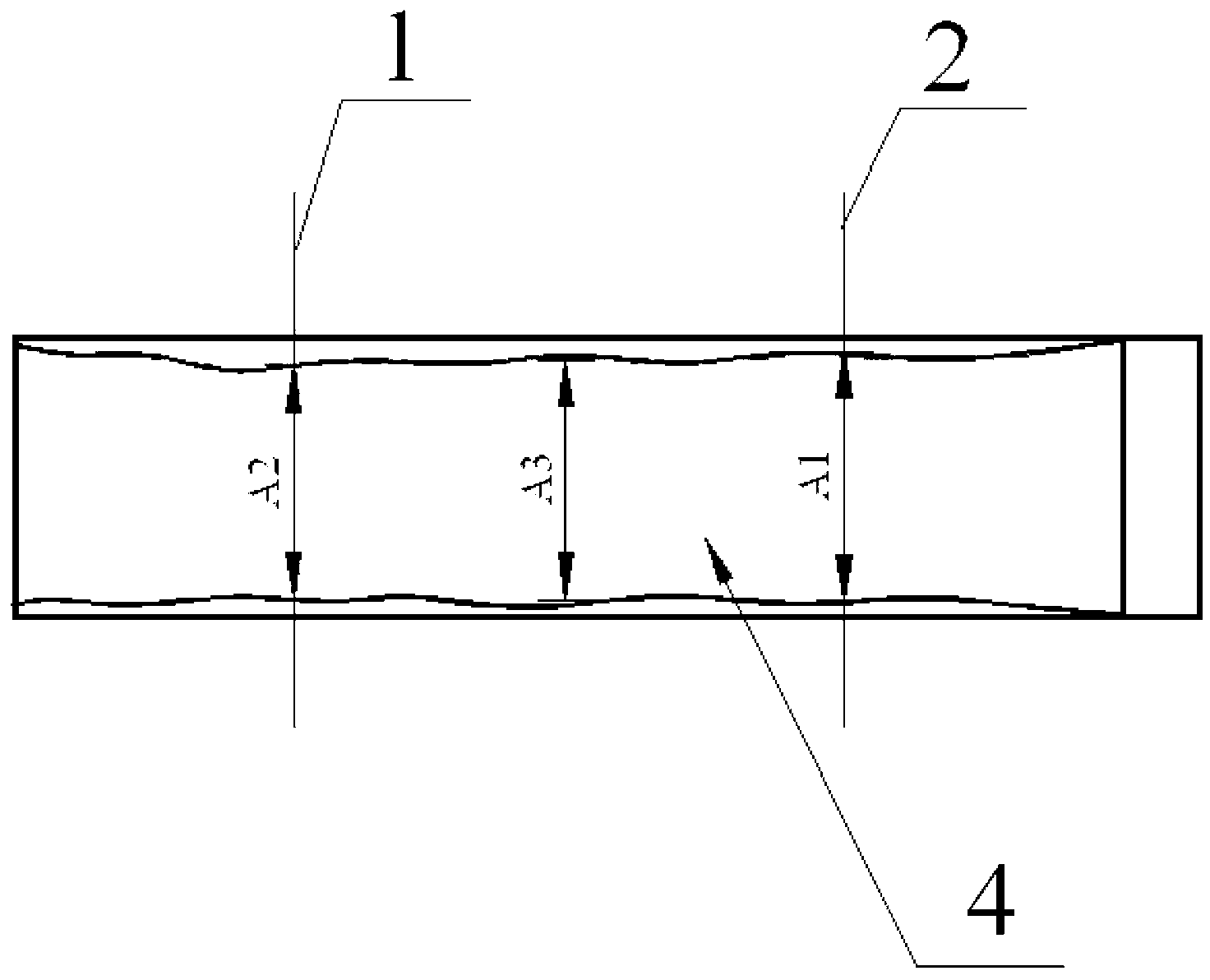

The invention relates to an automatic sample centering device for a drop-weight tear test. The device comprises a testing machine body (A), wherein a sample support (4) and anvil beds (3 and 3') are installed on the testing machine body, and the anvil beds are installed on two sides of the sample support symmetrically; a magnetic backup plate (1) and a centering plate (5) are installed on inner sides of the two anvil beds respectively, and bottoms of the magnetic backup plate and the centering plate are located on the sample support; a through hole (11) is formed in the anvil bed close to the centering plate; one end of the centering plate is fixedly connected with a horizontal push-and-pull shaft (7) which penetrates through the through hole; the other end of the push-and-pull shaft is fixedly connected with a centering cylinder (8) fixedly mounted on the outer side of the anvil bed. According to the automatic sample centering device, no human is involved in the test, and the drop-weight tear test can be finished in 10 s, so that the accuracy of a test result is guaranteed. According to the automatic sample centering device, the magnetic backup plate is arranged, and a sample is driven by the centering cylinder to be adsorbed by the magnetic backup plate, so that the sample is not toppled in the test, and the test can be finished successfully.

Owner:SHANGHAI HUALONG TEST INSTR

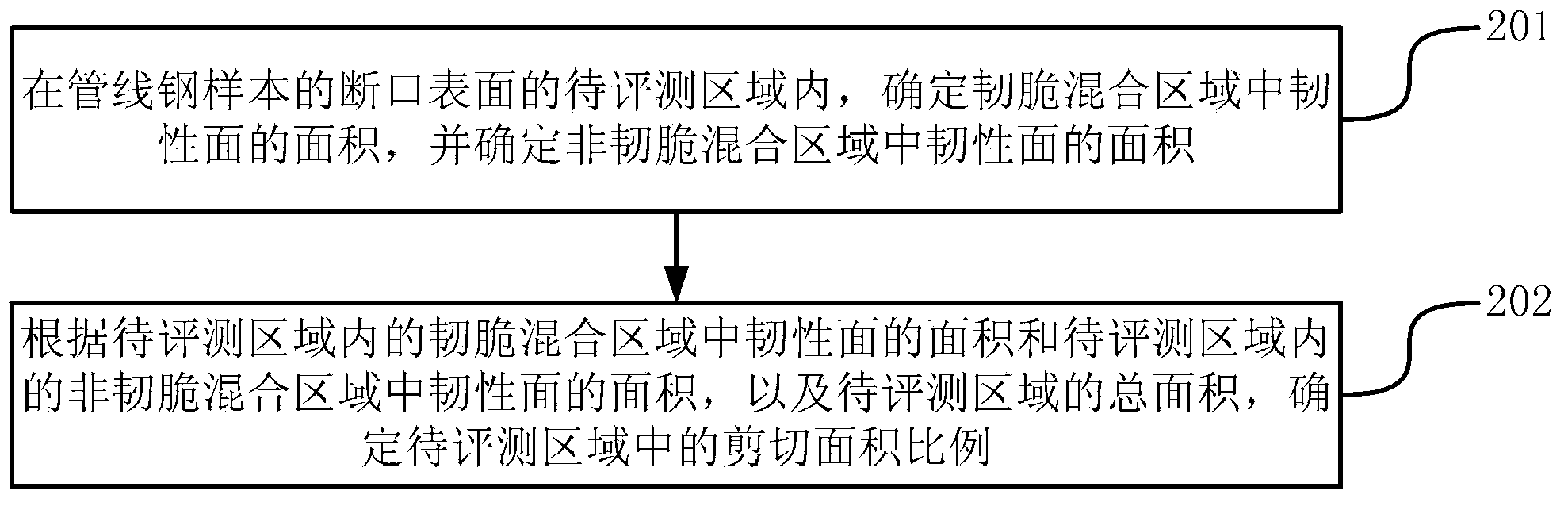

Method and device for determining sample toughness in pipeline steel drop weight tear test

InactiveCN104122136AAccurate shear area ratioImprove accuracyStrength propertiesDrop weightToughness

The invention discloses a method and a device for determining sample toughness in a pipeline steel drop weight tear test, belonging to the field of pipeline steel judgment. The method comprises the following steps: determining the area of a tough surface in a tough-brittle mixing area in a to-be-evaluated area of the fracture surface of a pipeline steel sample, and determining the area of a tough surface in a non-tough-brittle mixing area, wherein the tough-brittle mixing area is a triangular-like area in which the tough surface and the brittle surface are distributed in a stripe shape at intervals; and determining the shear area ratio in the to-be-evaluated area according to the area of the tough surface in the tough-brittle mixing area in the to-be-evaluated area, the area of the tough surface in the non-tough-brittle mixing area in the to-be-evaluated area and the total area of the to-be-evaluated area. With the adoption of the method and the device, the accuracy of the shear area ratio obtained in the pipeline steel drop weight tear test can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

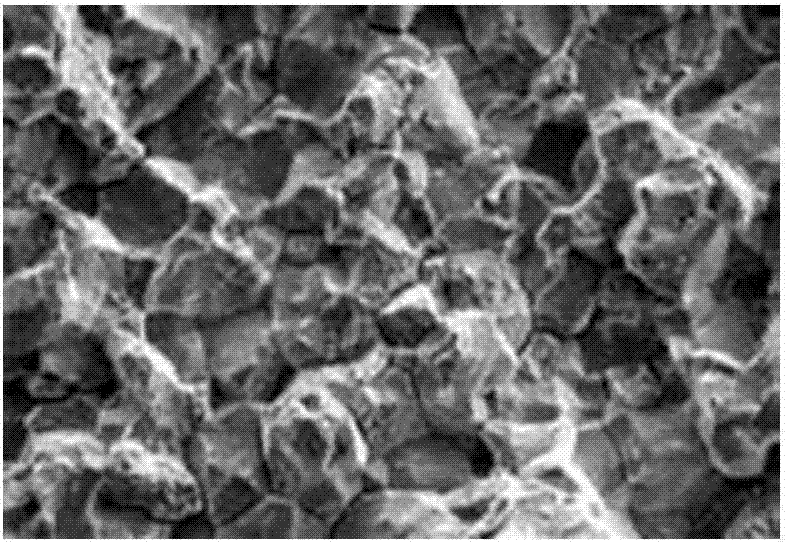

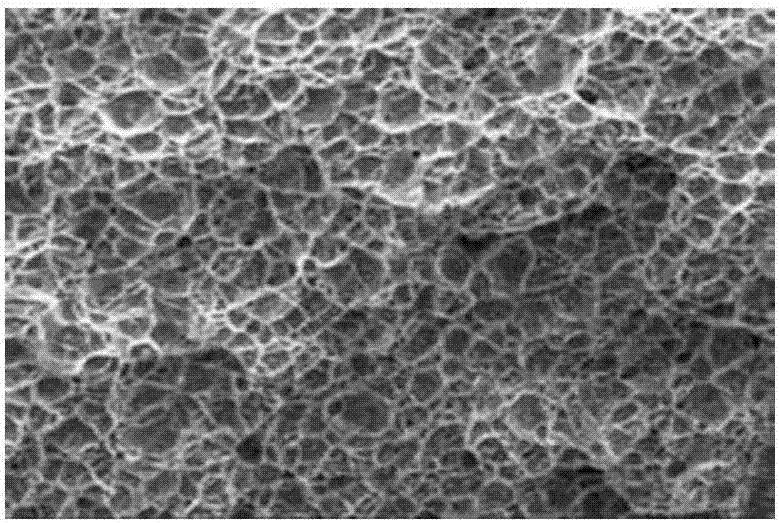

DWTT (Drop Weight Tear Test) specimen fracture imaging method

InactiveCN107014812AEasy to detectEasy to distinguishMaterial analysis by optical meansDrop weightImage resolution

In allusion to the problem of a poor DWTT (Drop Weight Tear Test) fracture imaging effect in the prior art, the invention provides a DWTT specimen fracture imaging method, and belongs to the field of image measurement. A specimen fracture is placed on a moving platform, and a camera is postponed above the specimen fracture. The DWTT specimen fracture imaging method comprises the following steps: adjusting a normal incident light source and an inclined incident light source, irradiating onto the surface of the specimen fracture, and acquiring a preliminary image of the specimen fracture by the camera; segmenting the preliminary image by an image segmenting method to obtain a fracture area; dividing the net section of the fracture area into N parts, controlling the moving platform to move up and down, obtaining focusing evaluation values of the parts respectively, and finding a maximum focusing evaluation value for each part; controlling the moving platform to move up and down, and when the focusing evaluation values of the N parts are high than a% of the respective maximums, stopping movement of the moving platform, and acquiring a focal plane image of the specimen fracture by the camera. By the DWTT specimen fracture imaging method, the imaging depth of field and the imaging resolution are ensured, and a tough fracture area and a brittle fracture area can be effectively distinguished.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com