Pipeline steel with thickness more than or equal to 25mm for deep sea and production method thereof

A pipeline steel and deep-sea technology, which is applied to the deep-sea pipeline steel and its production field, can solve the problems of complicated production process, high production cost, and difficult performance, and achieve the effects of simple production process, reduced production cost, and economical component design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

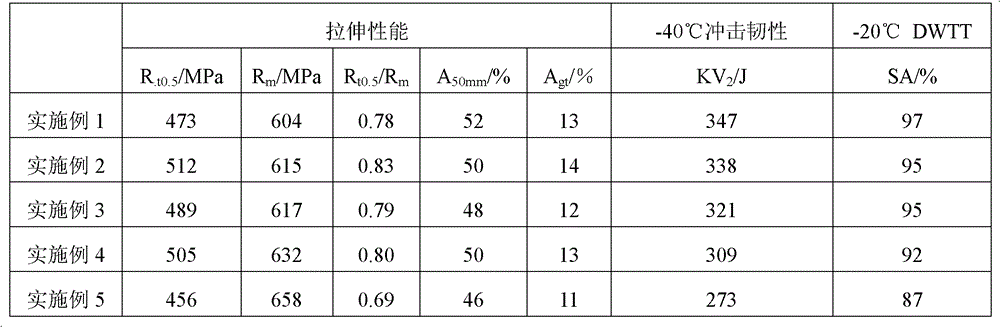

Examples

Embodiment 1

[0044] 28mm thick pipeline steel for deep sea, its composition and weight percentage are: C: 0.025%, Si: 0.50%, Mn: 1.60%, P: 0.014%, S: 0.0020%, Ni: 0.01%, Mo: 0.30% , Cr: 0.05%, Cu: 0.03%, Nb: 0.031%, V: 0.004%, Ti: 0.01%, Al: 0.011%, N: 0.009%, Ca: 0.0034%, the weight percentage of residual element control is: As : 0.008%, Sb: 0.001%, Sn: 0.002%, Pb: 0.001%, Bi: 0.003%, B: 0.0001%, the balance is Fe and other unavoidable impurities;

[0045] Welding cold crack sensitivity coefficient Pcm=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B=0.147%;

[0046] Nb: 0.031% + V: 0.004% + Ti: 0.010% = 0.045%.

[0047] The method for producing 28mm thick pipeline steel for deep sea, the steps:

[0048] 1) Smelting and continuous casting into billets according to the clean steel process;

[0049] 2) Heating the continuous casting slab, and controlling the heating temperature to be 1120-1125°C;

[0050] 3) Carry out rough rolling, control the rolling start temperature at 1075-1180°C, end tem...

Embodiment 2

[0058] 25.4mm thick pipeline steel for deep sea, its composition and weight percentage are: C: 0.040%, Si: 0.32%, Mn: 1.52%, P: 0.012%, S: 0.0025%, Ni: 0.07%, Mo: 0.05 %, Cr: 0.22%, Cu: 0.02%, Nb: 0.040%, V: 0.01%, Ti: 0.007%, Al: 0.021%, N: 0.0070%, Ca: 0.0048%, the weight percentage of residual element control is: As: 0.009%, Sb: 0.001%, Sn: 0.001%, Pb: 0.0007%, Bi: 0.004%, B: 0.0001%, the balance is Fe and other inevitable impurities;

[0059] Welding cold crack sensitivity coefficient Pcm=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B=0.145%.

[0060] Nb: 0.040% + V: 0.01% + Ti: 0.007% = 0.057%.

[0061] The method for producing pipeline steel with a thickness of 25.4mm for deep sea, the steps:

[0062] 1) Smelting and continuous casting into billets according to the clean steel process;

[0063] 2) Heating the continuous casting slab, and controlling the heating temperature to be 1145-1150°C;

[0064] 3) Carry out rough rolling, control the rolling start temperature at 111...

Embodiment 3

[0072] 27mm thick pipeline steel for deep sea, its composition and weight percentage are: C: 0.048%, Si: 0.25%, Mn: 1.37%, P: 0.010%, S: 0.0011%, Ni: 0%, Mo: 0.07% , Cr: 0.28%, Cu: 0.05%, Nb: 0.058%, V: 0.003%, Ti: 0.015%, Al: 0.032%, N: 0.006%, Ca: 0.0025%, the weight percentage of residual element control is: As : 0.008%, Sb: 0.0008%, Sn: 0.0006%, Pb: 0.0009%, Bi: 0.003%, B: 0.0001%, the balance is Fe and other unavoidable impurities;

[0073] Welding cold crack sensitivity coefficient Pcm=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B=0.147%;

[0074] Nb: 0.058% + V: 0.003% + Ti: 0.015% = 0.076%.

[0075] The method for producing 27mm thick pipeline steel for deep sea, the steps:

[0076] 1) Smelting and continuous casting into billets according to the clean steel process;

[0077] 2) Heating the continuous casting slab, and controlling the heating temperature to be 1225-1230°C;

[0078] 3) Carry out rough rolling, control the rolling start temperature to 1165-1170°C, end te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com