Patents

Literature

1888 results about "Procedure Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A process agent is a representative upon whom court papers may be served. In the US, the role is generally a requirement of US State law and is known as a registered agent, a resident agent or statutory agent. However, process agents are utilized in the US by truck drivers, brokers or freight forwarders for similar purposes.

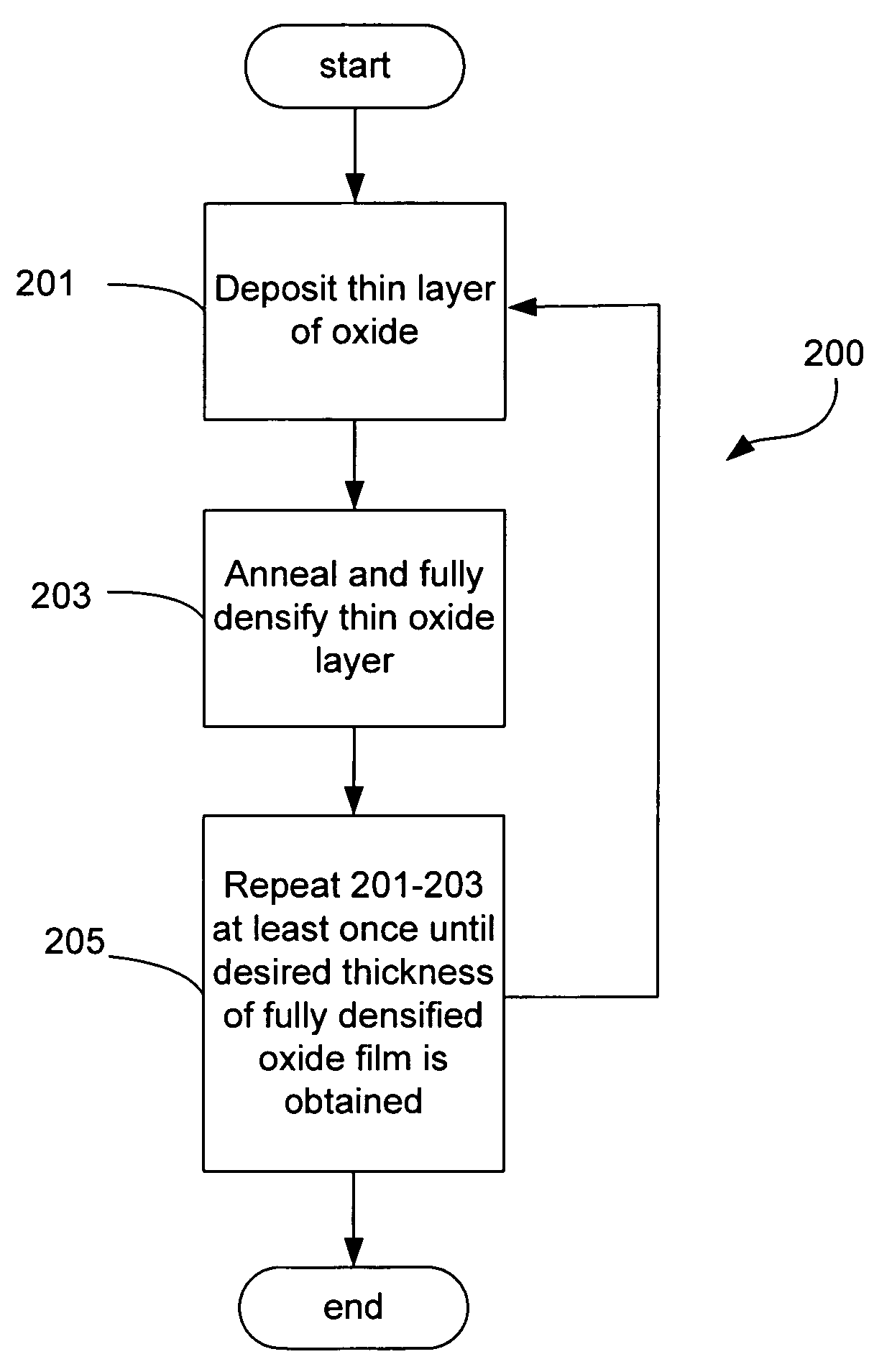

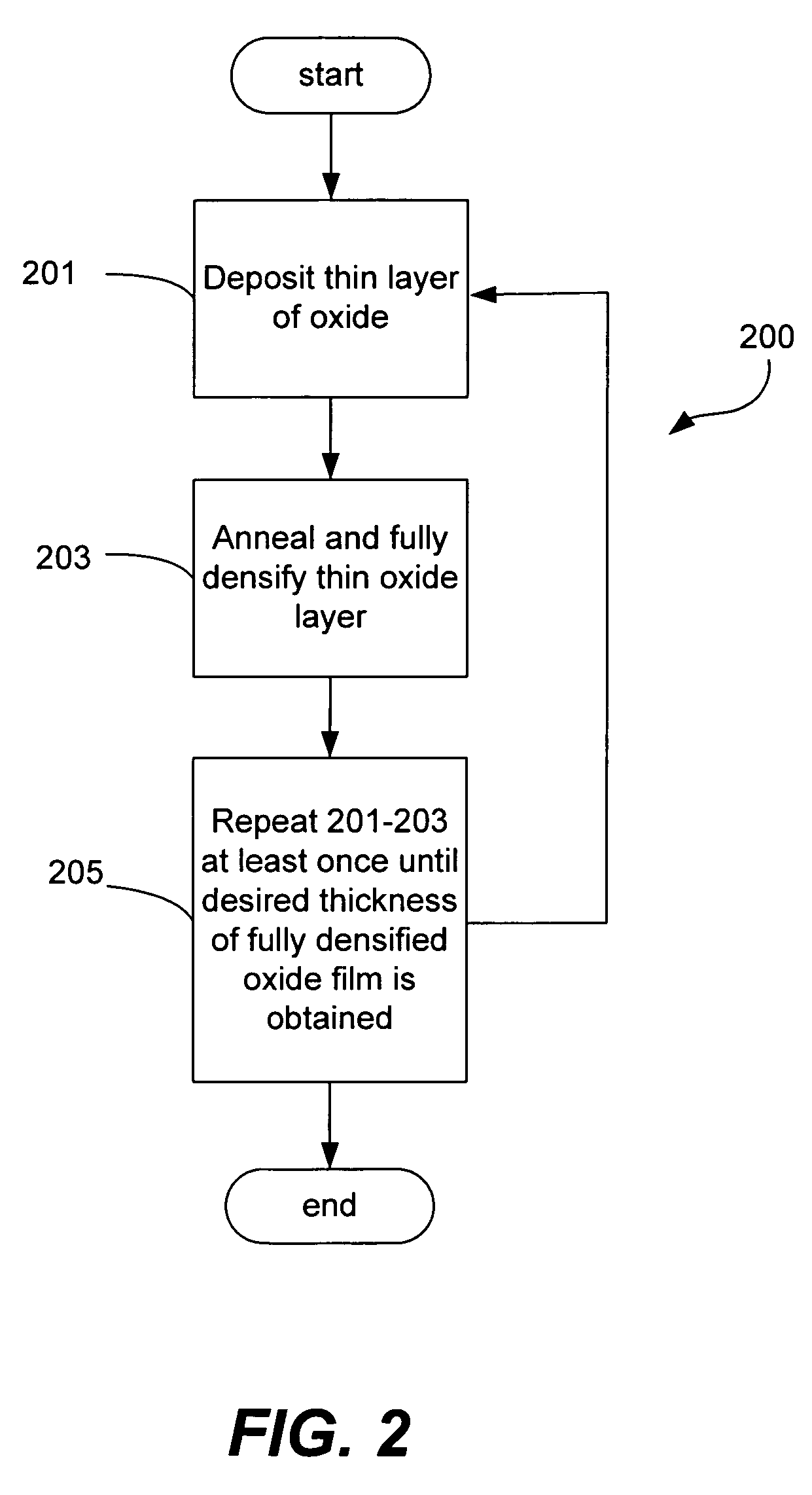

Sequential deposition/anneal film densification method

ActiveUS7790633B1Maintaining film propertyMaintain propertiesSemiconductor/solid-state device manufacturingProcedure AgentsOptoelectronics

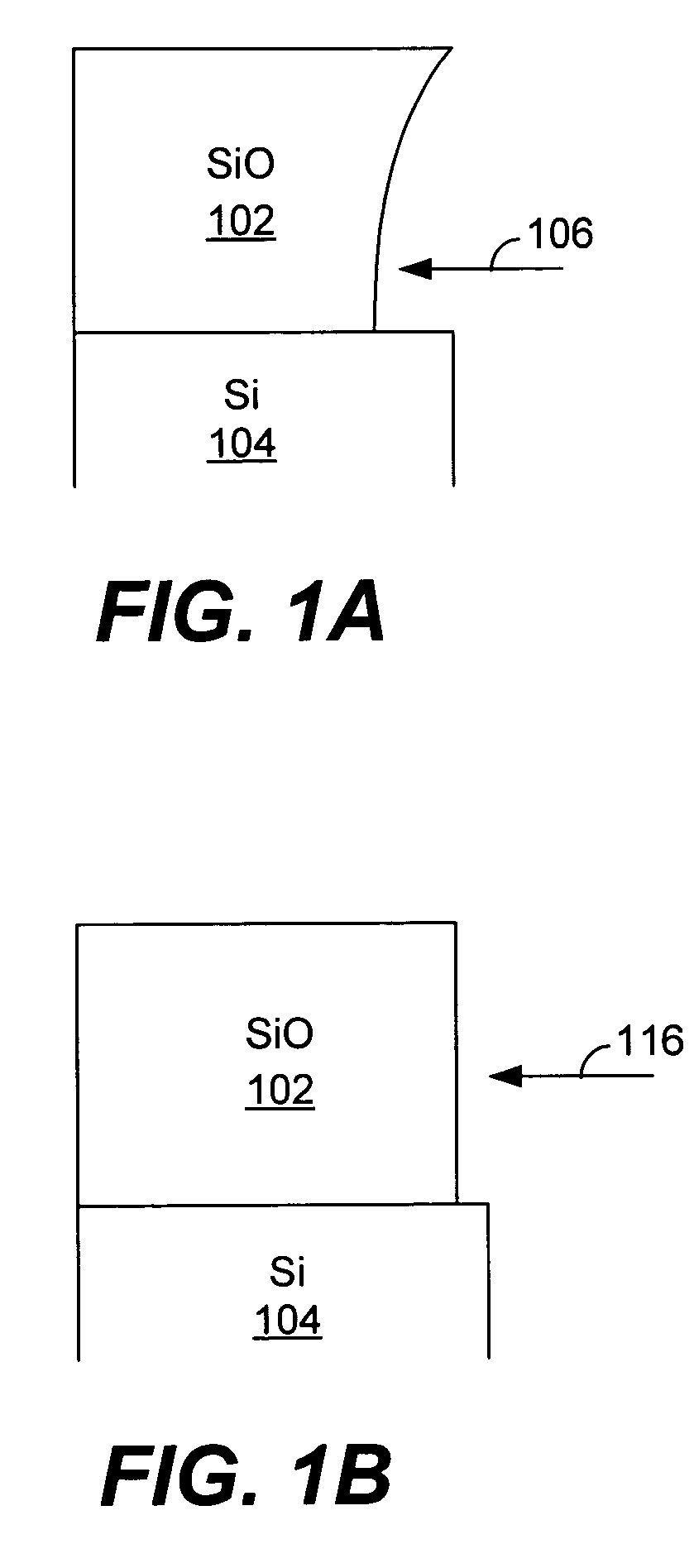

A silicon dioxide-based dielectric layer is formed on a substrate surface by a sequential deposition / anneal technique. The deposited layer thickness is insufficient to prevent substantially complete penetration of annealing process agents into the layer and migration of water out of the layer. The dielectric layer is then annealed, ideally at a moderate temperature, to remove water and thereby fully densify the film. The deposition and anneal processes are then repeated until a desired dielectric film thickness is achieved.

Owner:NOVELLUS SYSTEMS

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

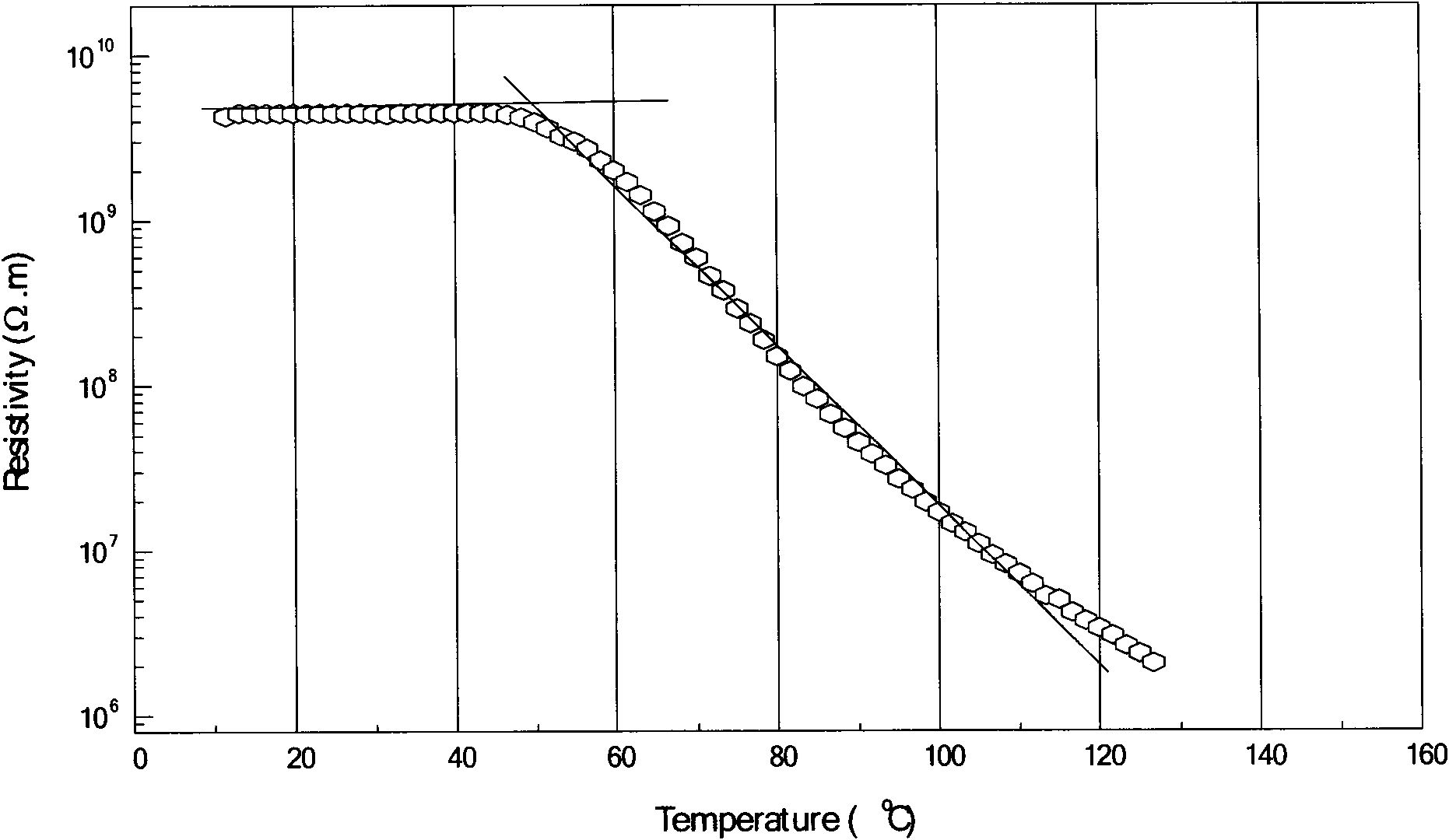

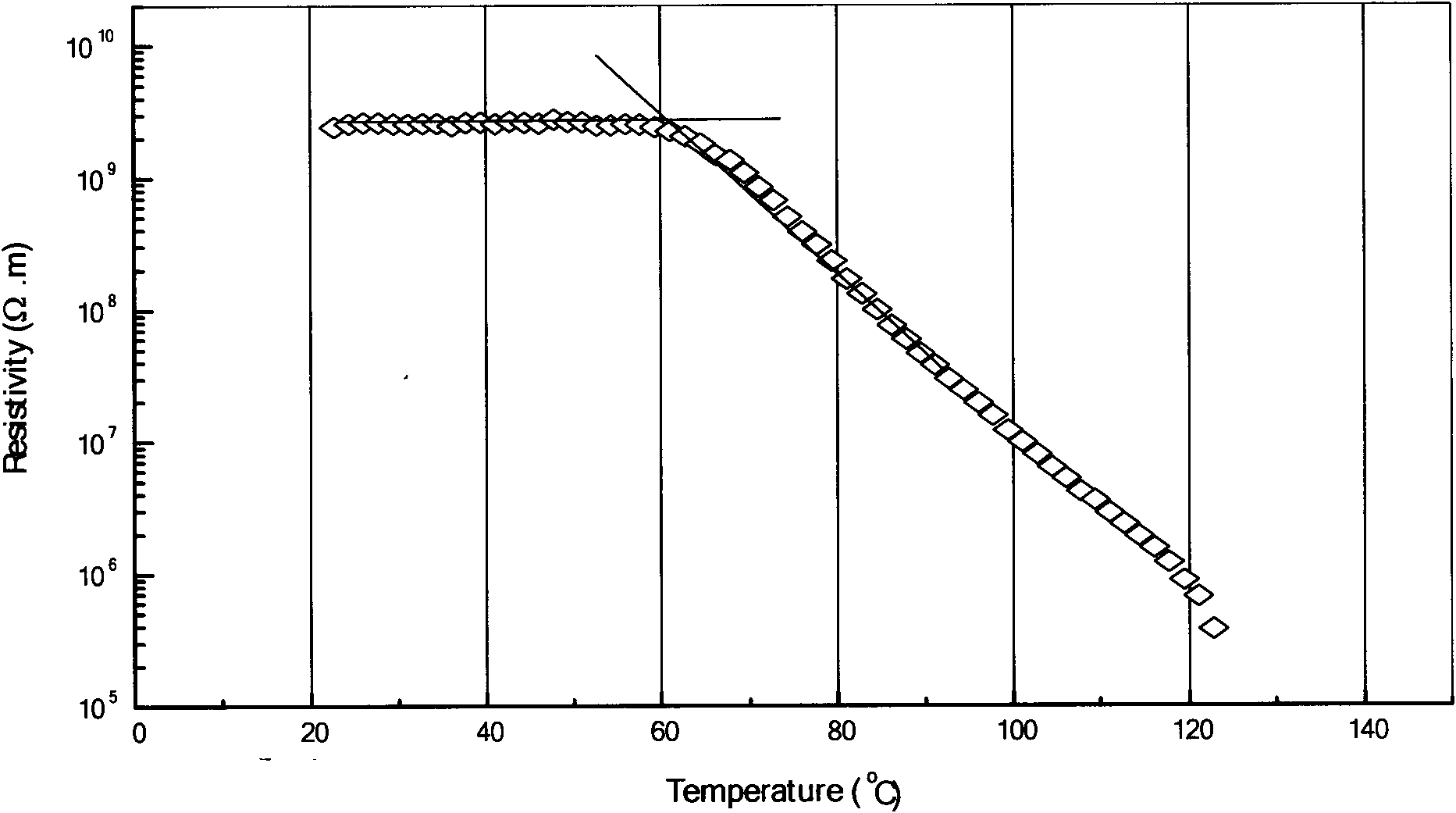

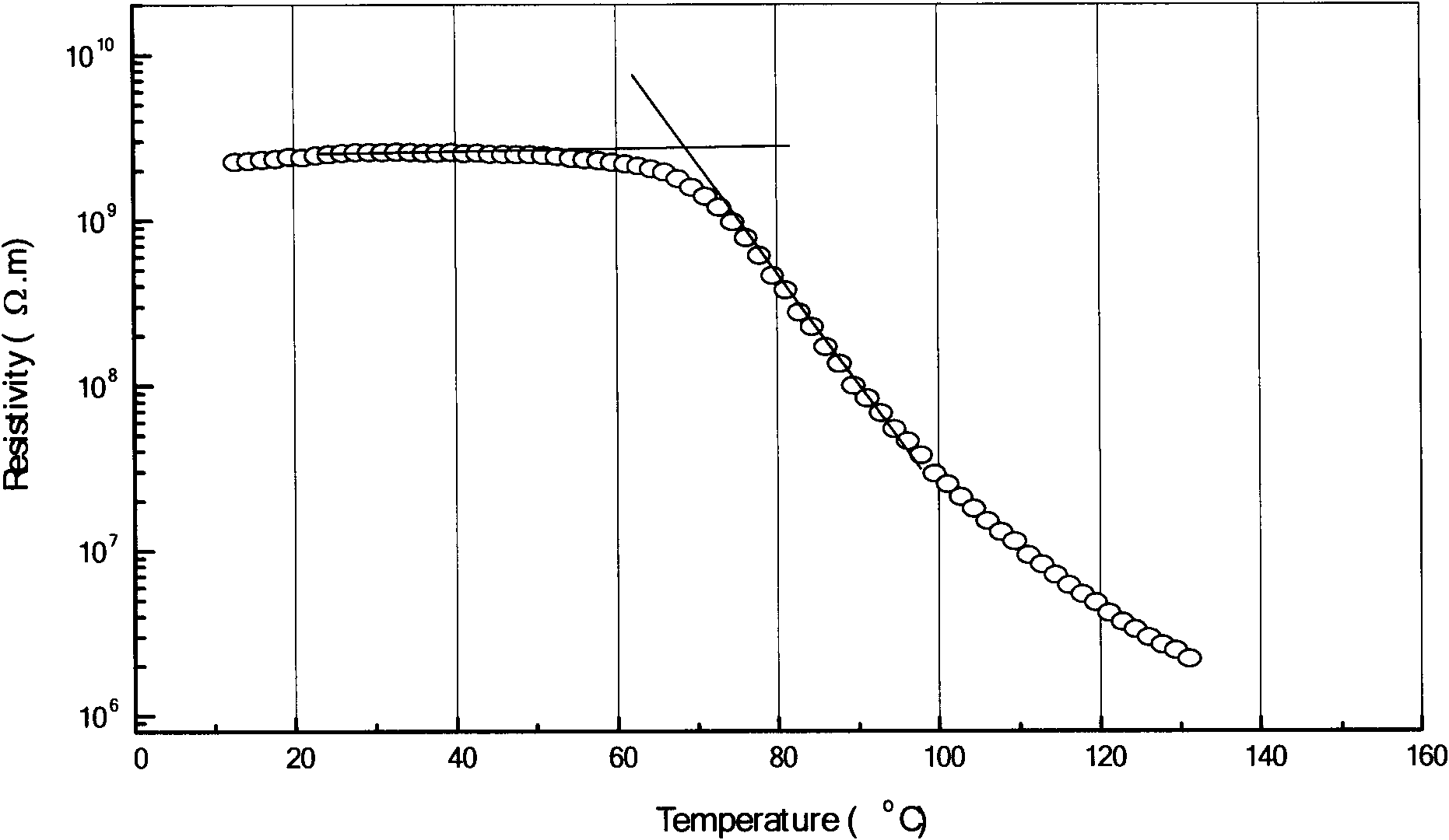

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

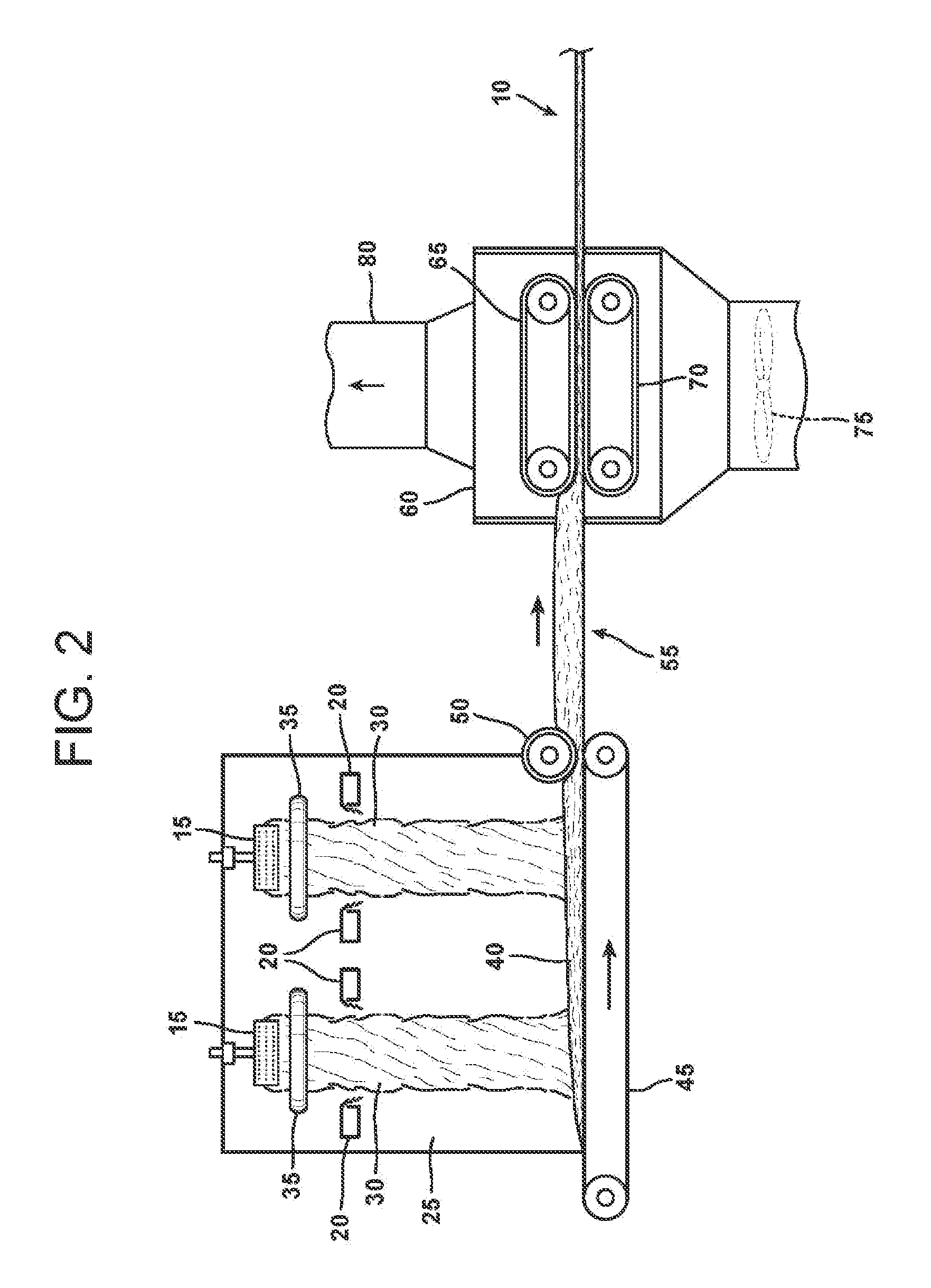

Bio-based binders for insulation and non-woven mats

ActiveUS20110086567A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

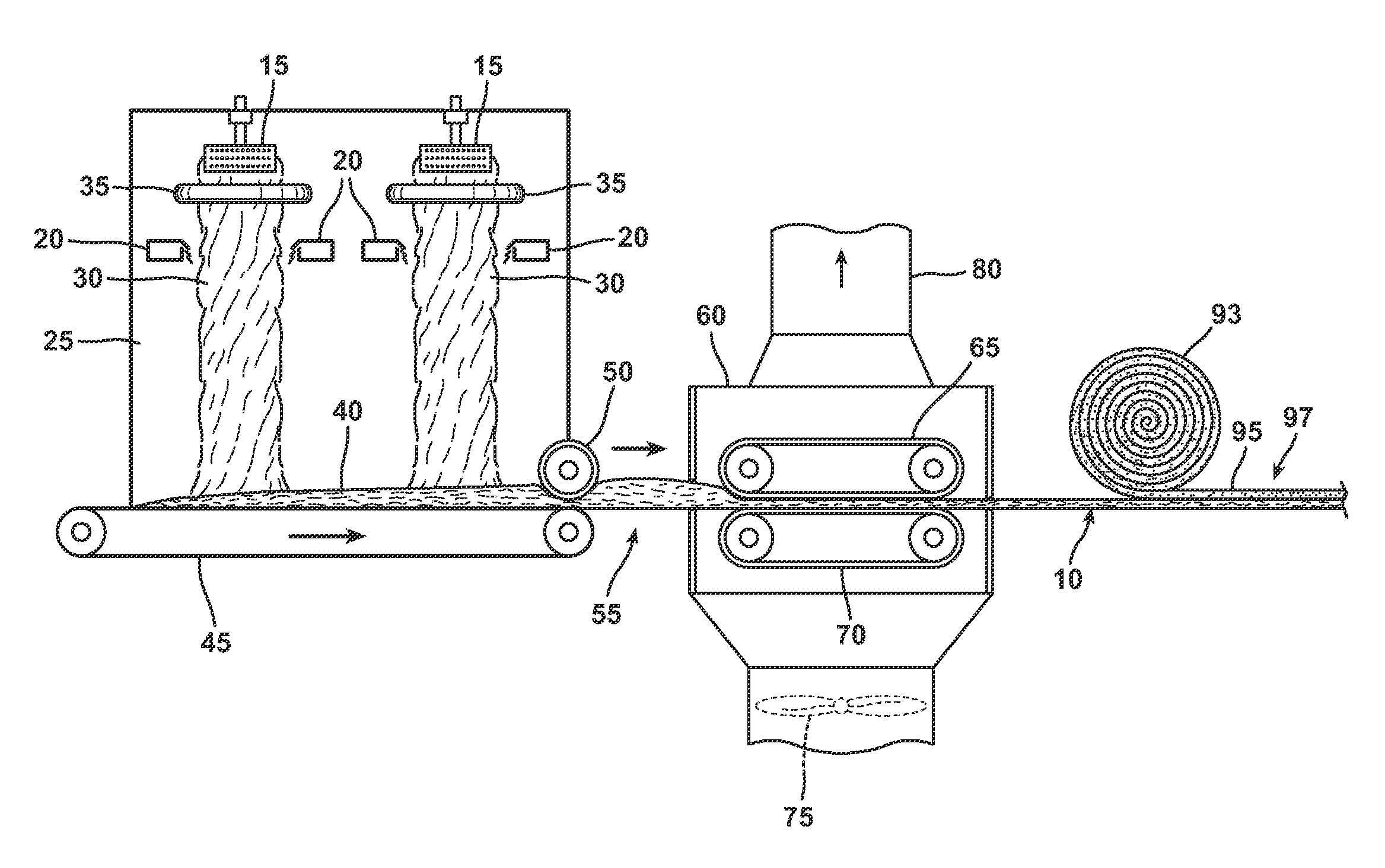

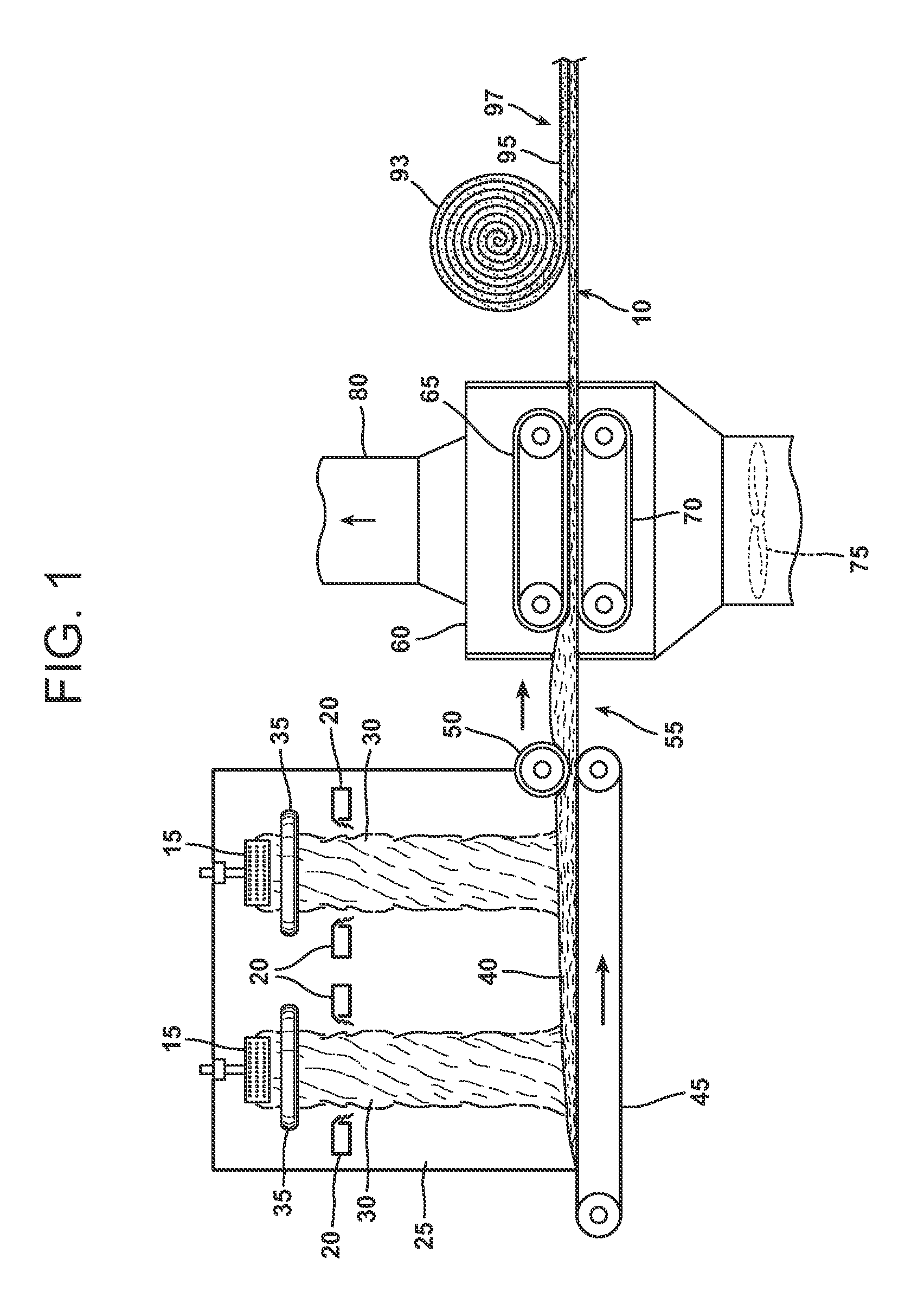

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Process aid for preparing a flowable slurry

A process for preparing a flowable slurry comprising mixing 25-70 wt. % water; an alkaline material selected from the group consisting of chlorosilicon manufacturing byproducts, direct process residue gels, cement kiln dust, and mixtures thereof; and a process aid selected from the group consisting of sucrose, raffinose, lignin, methylglucopyranoside, lactose, fructose, sodium polyphosphate, trehalose and mixtures thereof to form a flowable slurry. This slurry is especially useful in the manufacture of cement.

Owner:DOW CORNING CORP

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

Carbon fiber reinforced composite and preparation thereof

The invention discloses carbon fiber reinforced thermoplastic resin composite material which is composed of the components according to the percentage by weight: carbon fibers with the surface modified accounting for 5 percent to 50 percent, thermoplastic resin accounting for 44 percent to 75 percent, polytetrafluoroethylene accounting for 5 percent to 15 percent and processing auxiliary agent accounting for 1 percent to 5 percent; the carbon fibers with the surface modified is manufactured by processing the carbon fibers in specially mixed acidic solution under the temperature of 40 DEG C to 80 DEG C for 30 minutes to 120 minutes and dried at the temperature of 80 DEG C to 150 DEG C. The invention also discloses the preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fibers of the carbon fiber reinforced thermoplastic resin composite material provided by the invention are dispersed in a state of 3 mm to 5 mm in a resin matrix, the original high intensity of the carbon fibers is maintained to the maximum, so as to ensure the prepared composite material to have high intensity, high modulus, high heat resistant and high wear resistant performances.

Owner:宁波益德新材料有限公司

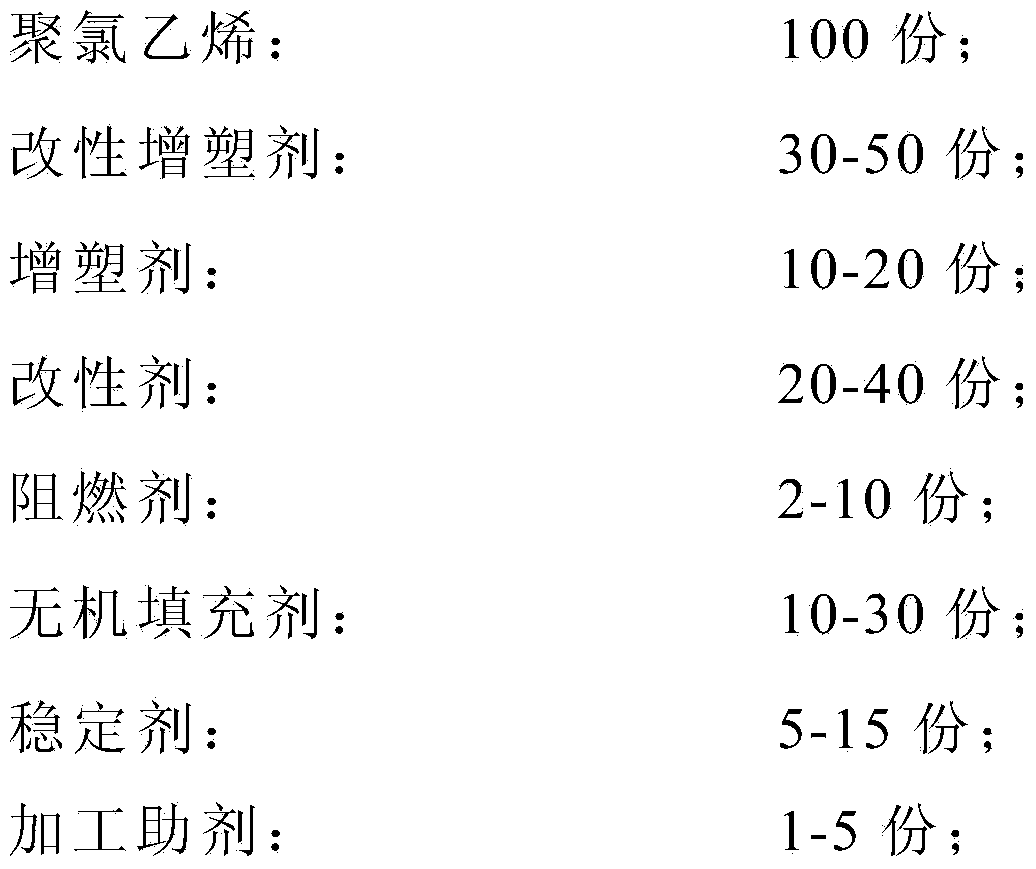

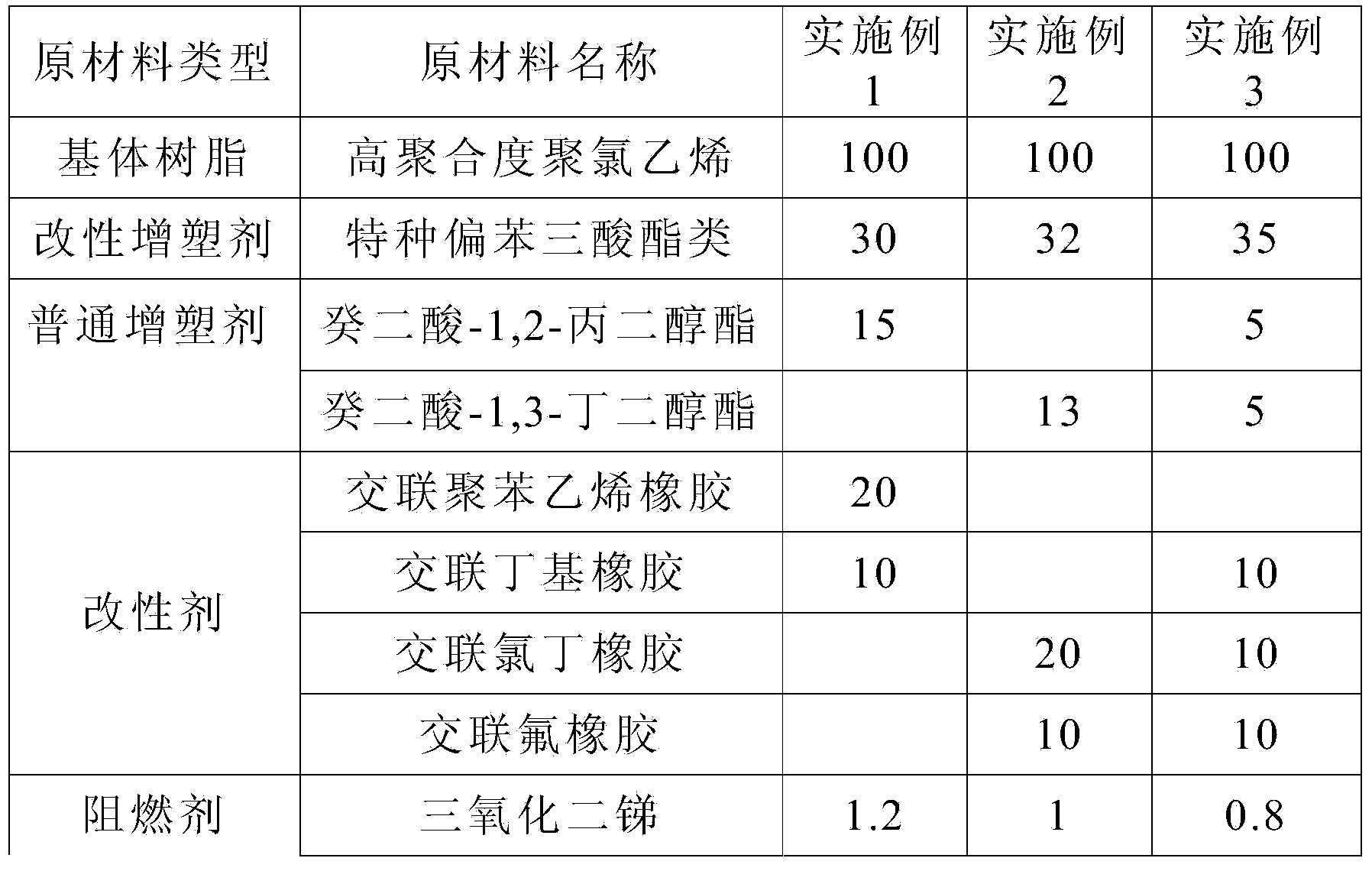

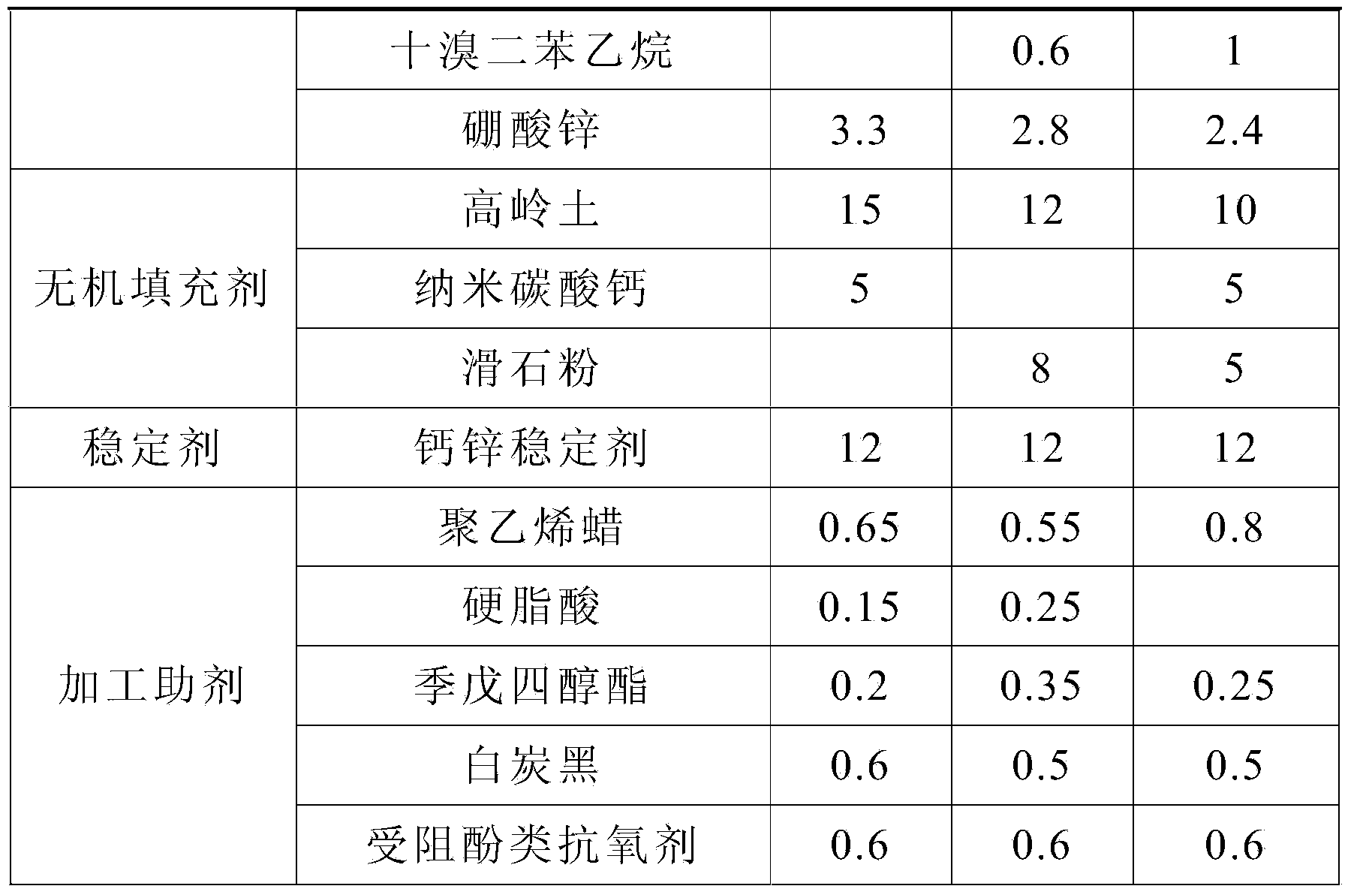

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

Customized implants for bone replacement

InactiveUS20110144752A1Reduce the chance of solidificationLow process temperatureImpression capsAdditive manufacturing apparatusNatural boneCustom made implant

The present invention relates to customized implants for bone replacement that are prepared from poly(ether ketone ketone) or PEKK, and to a computer-based imaging and rapid prototyping (RP)-based manufacturing method for the design and manufacture of these customized implants. The PEKK customized implants made using rapid prototyping demonstrate biomechanical properties similar (if not identical) to that of natural bone even when prepared without the use of processing aids such as carbon black and aluminum powder.

Owner:OXFORD PERFORMANCE MATERIALS

Polyvinyl chloride antistatic dust-proof modified window section bar and producing method thereof

The invention discloses a kind of window PCE shaped material with antistatic and dustproof function and its manufacturing method. It raw materials are composes of PVC resin powder, antistatic agent, impact modifier, stabilizer, filler and processing aid in accordance with the weight ratio of 100:0.2-20:1-10:2-8:5-20:1-10. Then it heats and stirs the raw materials at a temperature of 100 ~ 130deg.C in the high-speed mixer, and then it slowly cools the mixture to room temperature and transfers the materials to the extruder, finally it achieves the shaped material through extrusion molding mold, vacuum cooling, traction and cutting.

Owner:LG HAUSYS TIANJIN

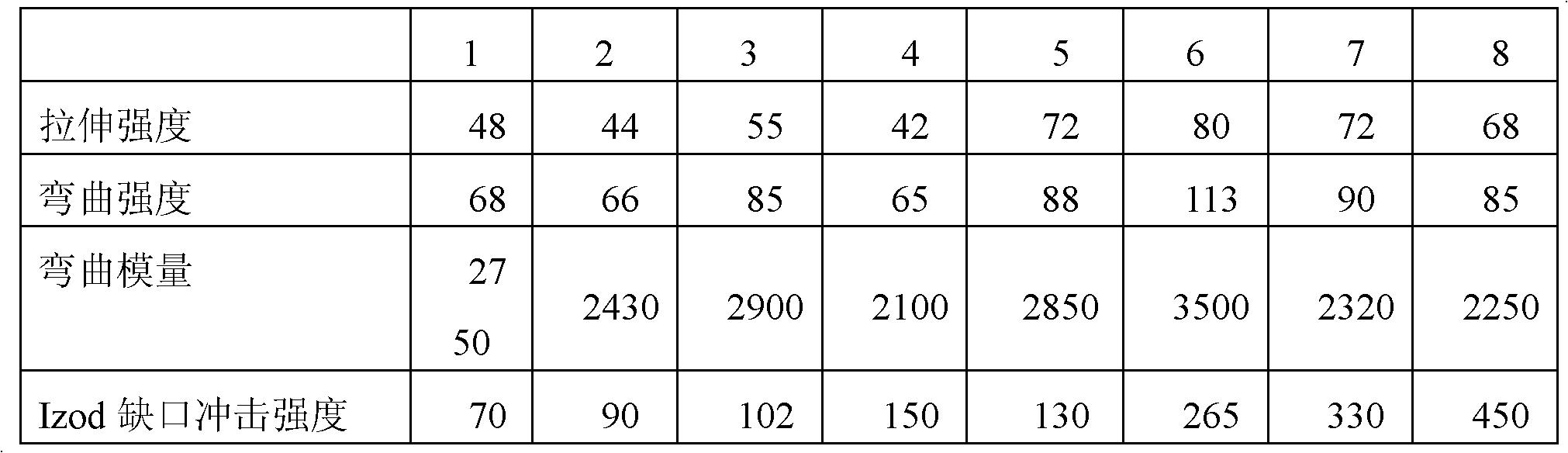

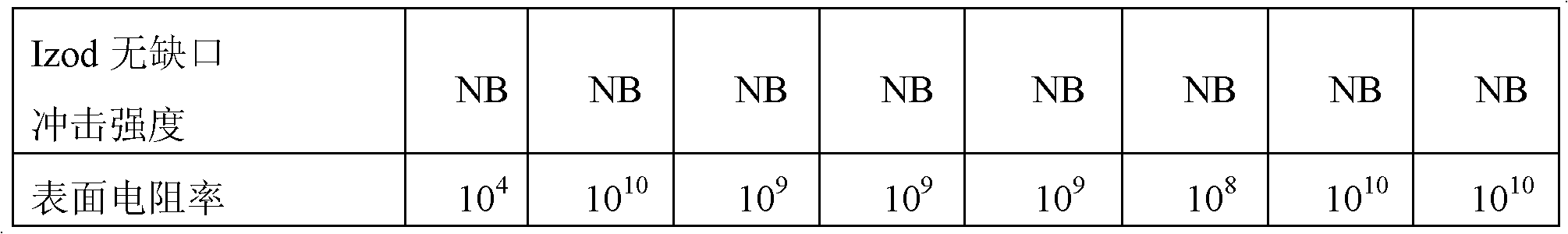

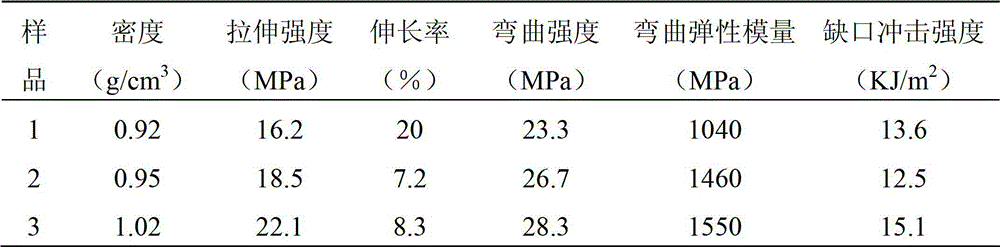

Biodegradable resin composition for modifying toughness and heat resistance and preparation method thereof

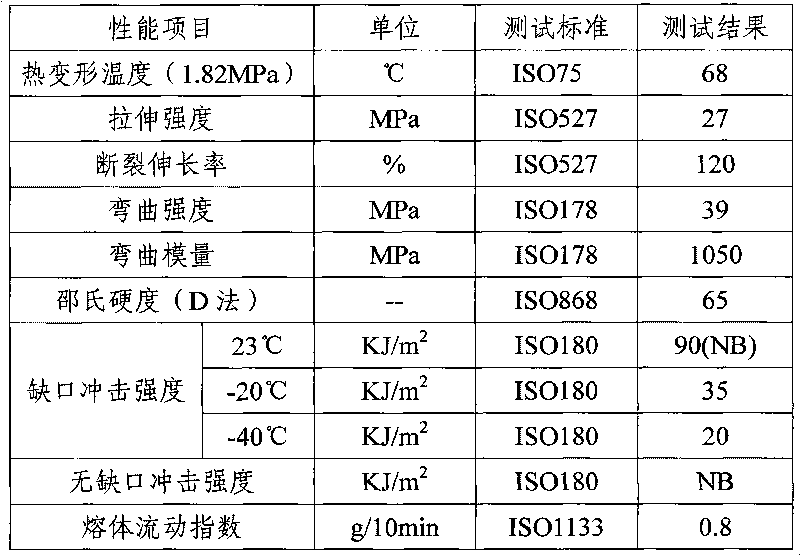

InactiveCN101143962AImprove toughnessImprove heat resistanceHeat deflection temperatureProcedure Agents

The invention provides a biodegradable resin component with toughness and heat resistance improved and a method for preparing the same, wherein the resin component contains 100 parts by mass of biodegradable resin, 1-40 parts by mass of thermoplastic elastomer, and 0.1-30 parts by mass of inorganic additive, and preferentially contains 3-25 parts by mass of flame retardant, 0.1-10 parts by mass of performance reinforcing agent and 0.1-10 parts by mass of processing aid; the resin component is granulated by a double screw extruder after melting mixing, the forming processing cycle of the resin component is short during injection forming, and after treatment for 10 min at 110DGE C, the lzod notched impact strength is higher than 30J / m, and the heat deformation temperature is higher than 90DGE C.

Owner:CHITEC TECH

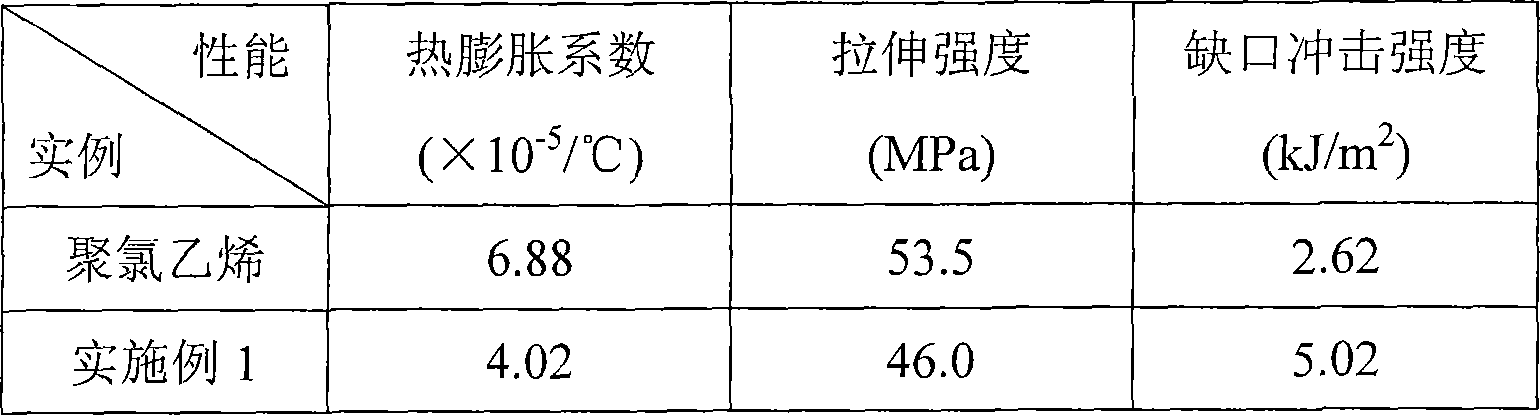

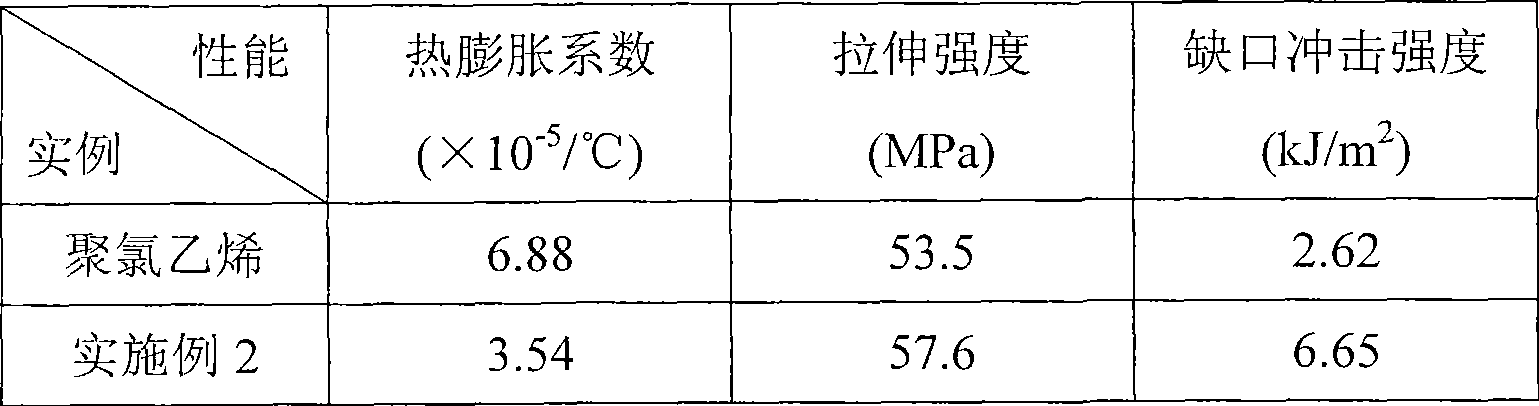

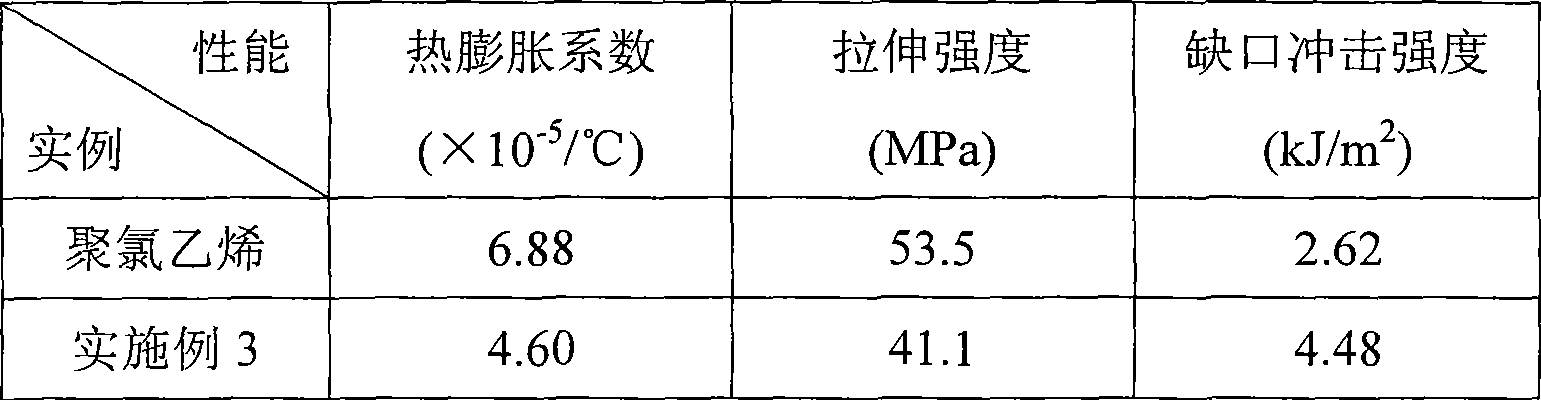

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

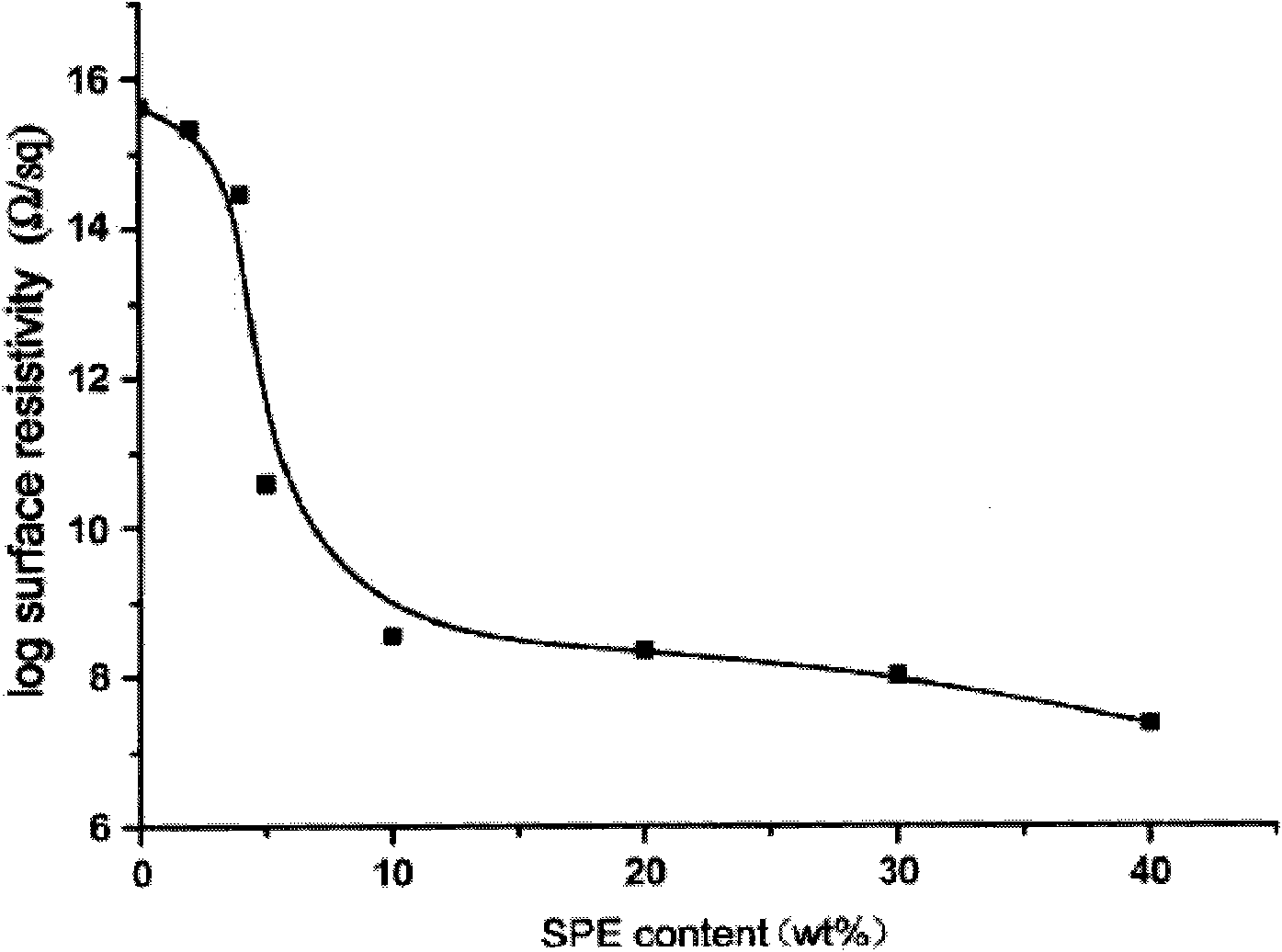

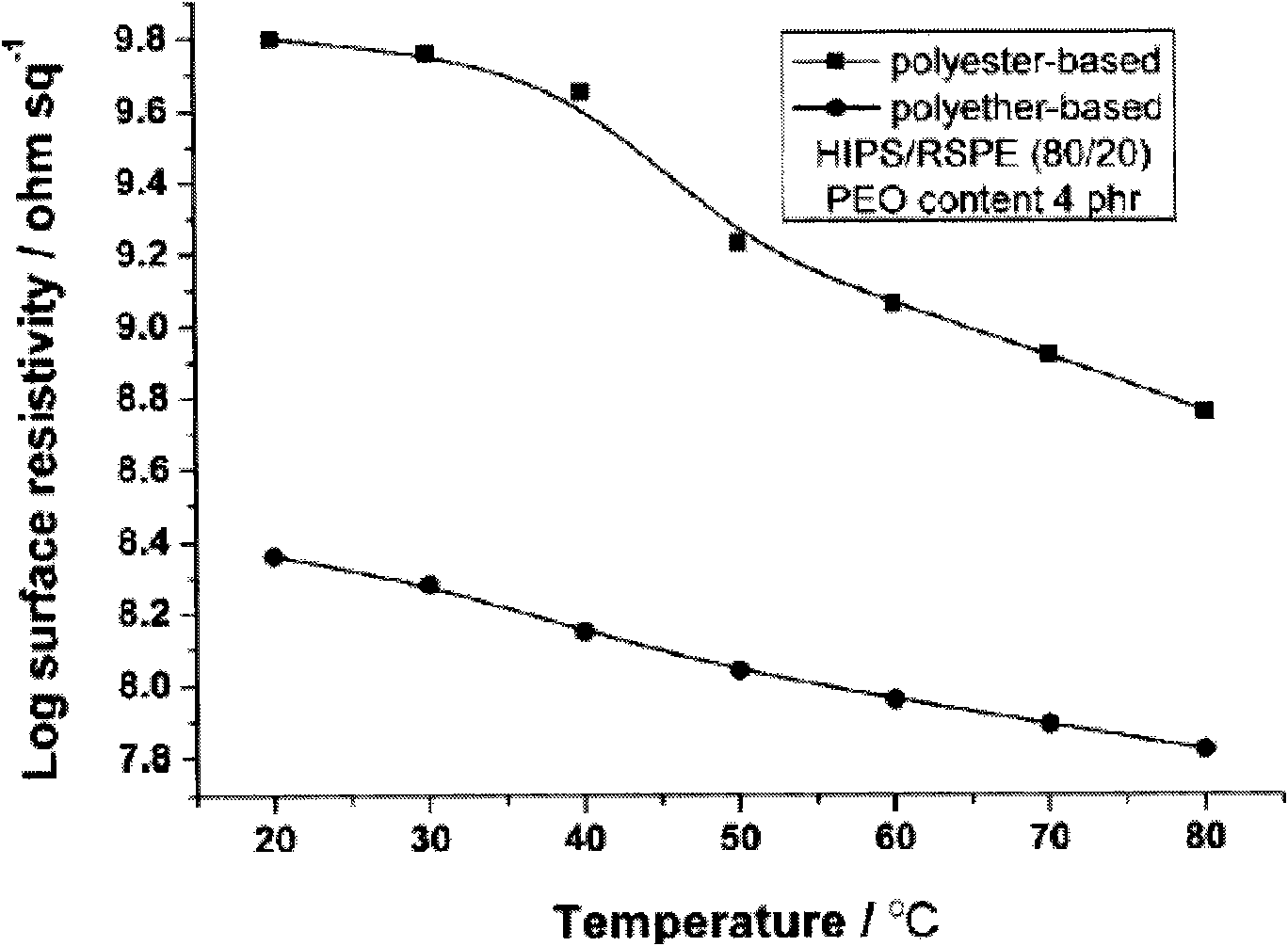

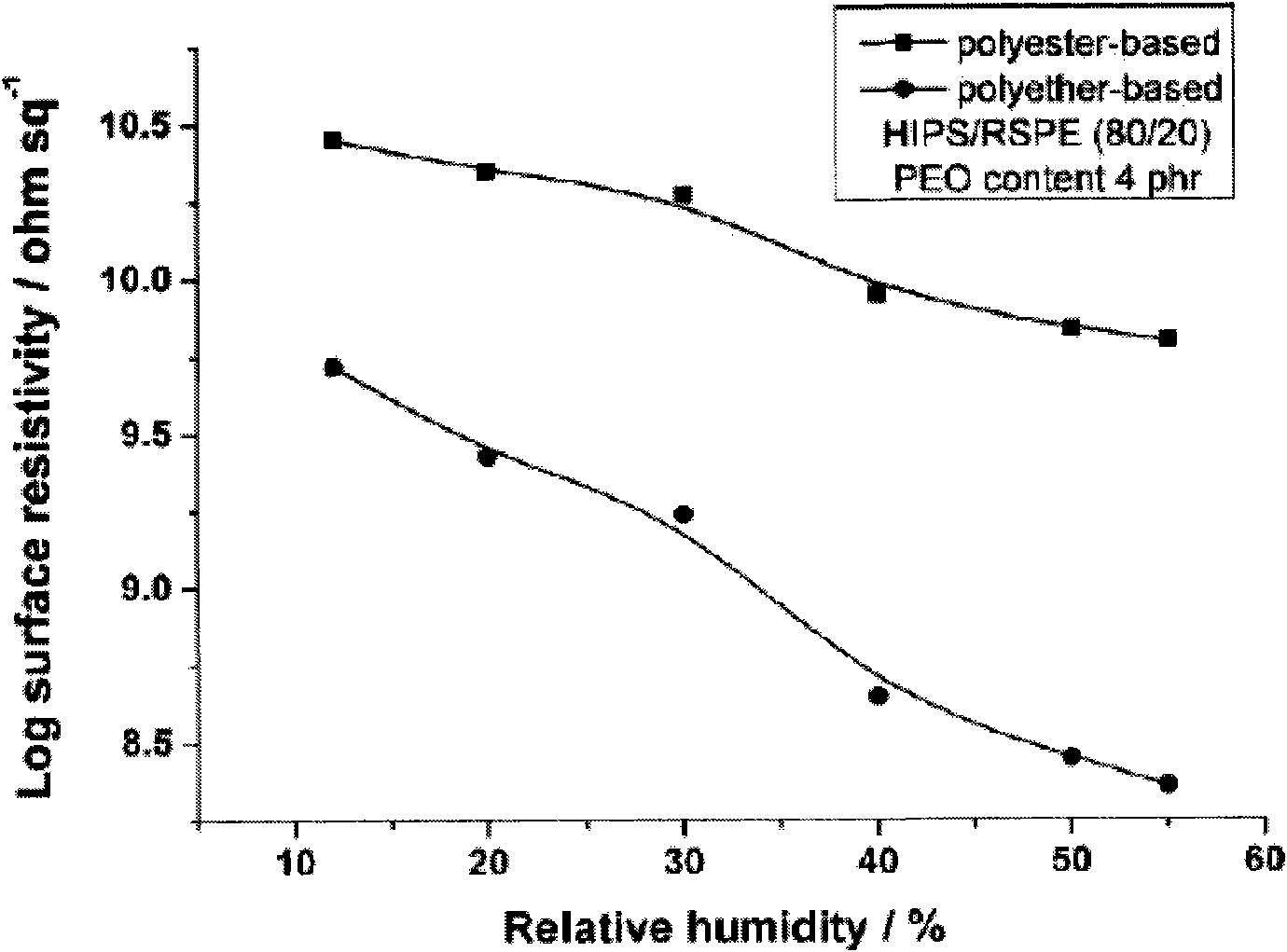

All-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and antistatic composite material

The invention belongs to the field of preparation of macromolecular composite materials and particularly relates to an all-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and an antistatic composite material. The antistatic master batch is prepared by forming of a low-dissociation-energy compounding agent, a processing auxiliary agent and thermoplastic macromolecular resin containing polar groups through macromolecular thermoplastic processing equipment at the temperature of 25-300 DEG C; and the mass ratio of the compounding agent to the thermoplastic macromolecular resin is equal to (1:10)-(1:50). The invention also discloses the antistatic composite material which is obtained after the persistent antistatic master batch and a macromolecular base material are formed through the thermoplastic processing equipment. The antistatic composite material has the characteristics that: 1. the antistatic composite material has light color and dyeability; 2. The master batch of the antistatic composite material and the compounding agent are wider in selection range, low in cost and easy to obtain, and the production process is simple, safe and non-hazardous; and 3. the influence of the ambient environment on the antistatic performance of the antistatic composite material is less, and the antistatic performance is persistent.

Owner:浙江三和塑料有限公司

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

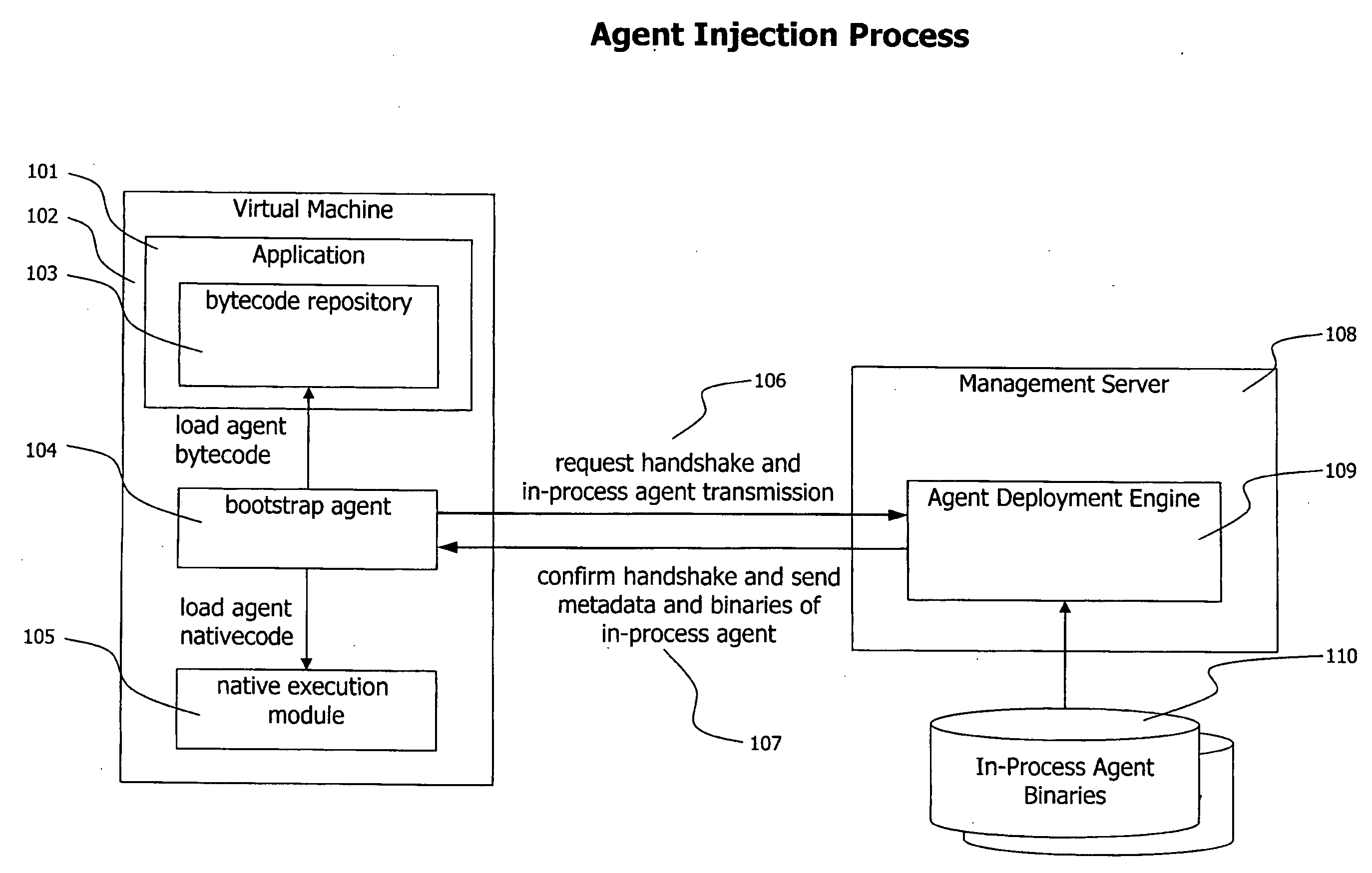

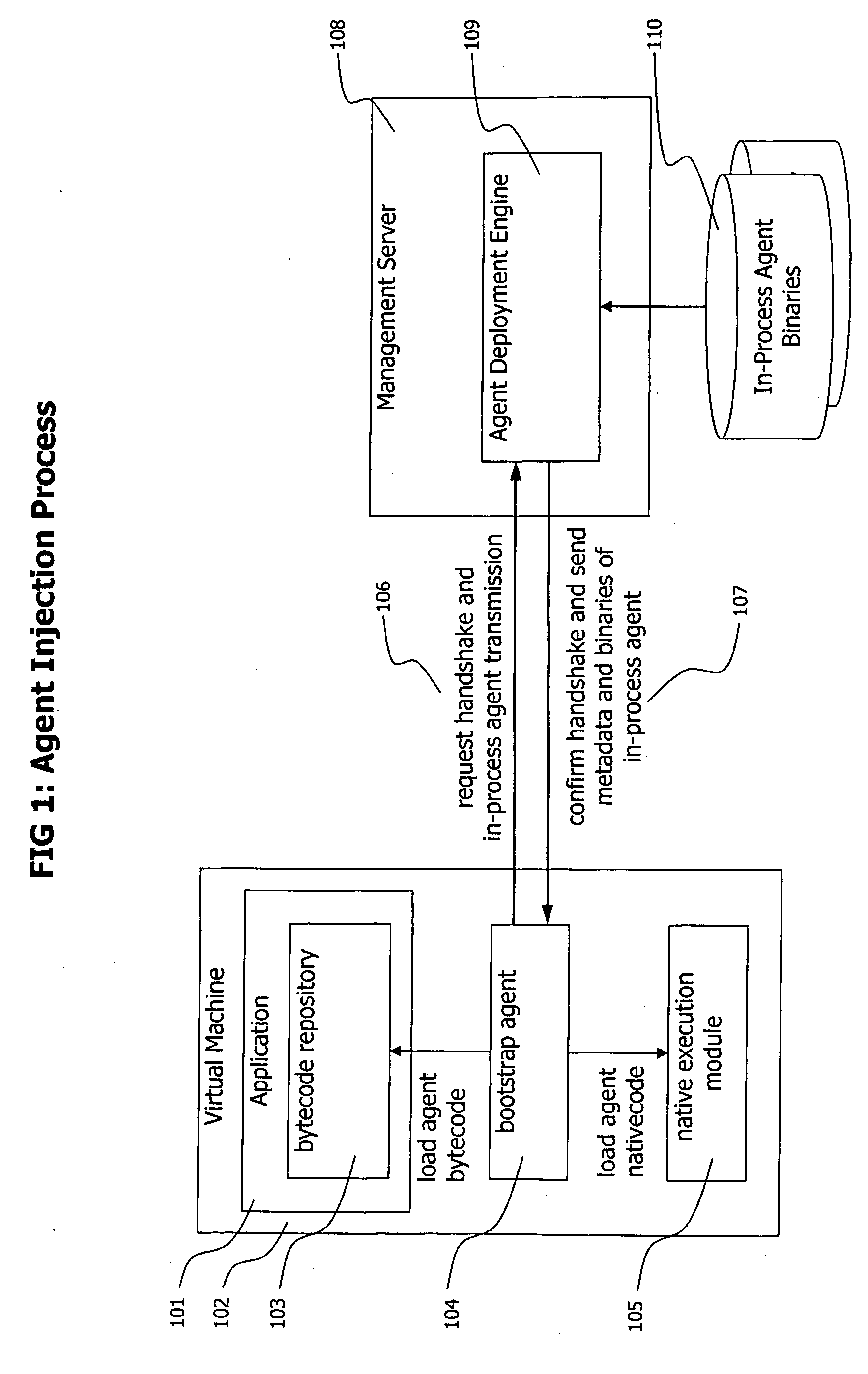

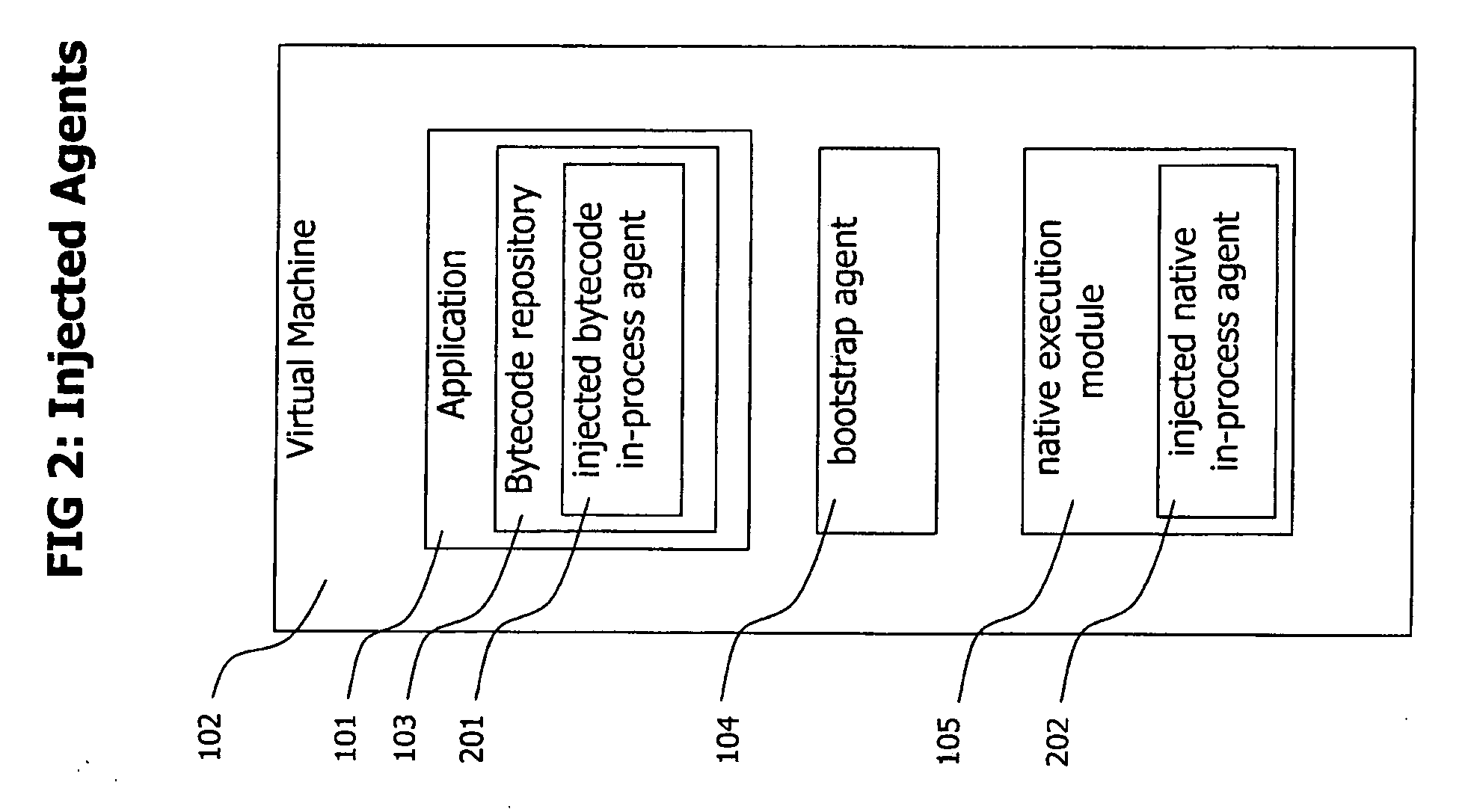

Method and System for Dynamic Remote injection of In-process Agents into Virtual Machine based Applications

A method and system for dynamic and adaptive deployment of in-process agents to virtual machine based applications which may run on remote hosts is provided. A bootstrap agent is injected into the application, using standardized interfaces provided by virtual machine based systems like Sun Microsystems' Java or Microsoft's .NET. Said bootstrap agent establishes a network connection to a management server which provides binaries representing in-process agents in bytecode or native code format. The bootstrap agent sends data identifying its runtime environment to the management server, which determines the matching in-process agent binaries for the runtime environment of the connected agent and sends the selected binaries to the bootstrap agent. The bootstrap agent receives the binaries and installs them to its hosting virtual machine, according to their format (bytecode or native code).

Owner:DYNATRACE

Ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and method for preparing ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from same

ActiveCN102153802AEnhanced cross-linking efficiencyIncreased uniform photocrosslinking depthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention relates to ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and a method for preparing an ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from the same. The method comprises the following steps: adding a metal hydroxide flame retardant, a cationic photoinitiator, a free radical photoinitiator, a multi-functional cross-linking agent, a compound antioxidant, a flame-retardant synergist, a synergistic smoke suppressant and a processing aid to polyethylene or grafted and modified polyethylene and / or ethylene vinyl acetate or grafted and modified copolymer thereof which are used as base materials, compounding, mixing the materials uniformly according to the proportion, granulating, extruding to prepare the ultraviolet-light cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer, and immediately irradiating with a specific ultraviolet-light source to obtain the deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer. The cross-linking equipment used for preparing the novel material by using anovel technology has low investment, and the process is simple and environmental friendly, saves energy, ensures high production efficiency and low cost and good quality of product and can be widely used for producing high-performance special wire and cable products and the like.

Owner:HEILONGJIANG MINGXIANG TECH

Resin material, preparation method and applications of resin material

The invention belongs to the technical field of high-polymer materials and discloses a resin material, a preparation method and applications of the resin material. The resin material disclosed by the invention comprises the following components in parts by weight: 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid. The preparation method for the resin material disclosed by the invention comprises the following steps of: weighing 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid; putting in a high-speed mixing machine and fully mixing; delivering a mixed material into a twin-screw extruder by using a metering material conveying device; fully mixing the material under the shearing actions of screws; performing extrusion, bracing, cooling and grain cutting on a molten blend; and packaging into a finished product. The resin material disclosed by the invention has an anti-static dustproof effect, is excellent in surface effect and can be used for manufacturing card readers or electrical equipment enclosures and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Halogen-free flame retardant antistatic PC/ABS alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant antistatic PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof, belonging to the technical field of alloy materials. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention comprises the following components in parts by weight: 1-30 parts of ABS resin, 40-90 parts of PC resin, 8-20 parts of fire retardant, 1-10 parts of flexibilizer, 0.02-0.5 part of antistatic agent, 0.1-1 part of photo-thermal stabilizing agent and 0.1-1 part of processing agent. The invention also discloses a preparation method of the halogen-free flame retardant antistatic PC / ABS alloy material, which comprises the following steps of: mixing the 1-30 parts of ABS resin, the 40-90 parts of PC resin, the 8-20 parts of fire retardant, the 1-10 parts of flexibilizer, the 0.02-0.5 part of antistatic agent, the 0.1-1 part of photo-thermal stabilizing agent and the 0.1-1 part of processing agent, and then sending to a dual-screw extruder, mixing, extruding, staying, cooling, sized-dicing and obtaining a finished product of the halogen-free flame retardant antistatic PC / ABS alloy material. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention has the advantages of simple process, continuity, high production efficiency and stable quality.

Owner:HEFEI GENIUS NEW MATERIALS

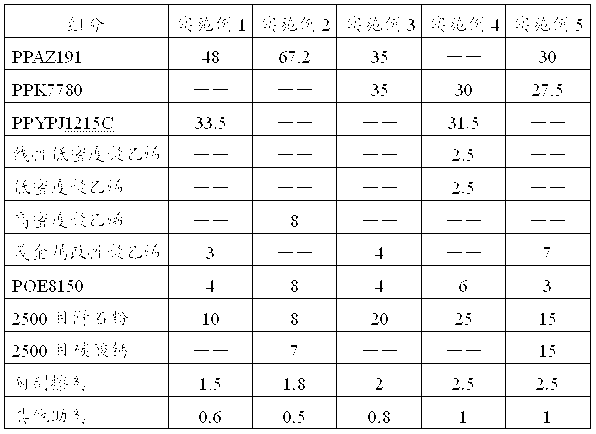

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

Low-luster polypropylene composite material and method for producing the same

InactiveCN101173075AImprove heat aging resistanceImprove performanceElastomerPolypropylene composites

The invention discloses A polypropylene composite material with low luster and a preparation method thereof. The invention is characterized in that the material is formed by following raw materials by weight part: 56.5 to 98 parts of polypropylene, 0.2 to 1.5 parts of heat stabilizer, 0.3 to 1 part of light stabilizer, 0 to 20 parts of elastic bodies, 0.2 to 1 part of processing agent, 0 to 30 parts of inorganic filler, and 0.5 to 5 parts of silicon dioxide. The product of the invention has lower material luster, and the luster for the angle of 60 degrees on a smooth surface is lowered by 10 to 20 degrees than the primary product, thereby satisfying the requirement of low luster for material of people.

Owner:SHANGHAI KINGFA SCI & TECH +1

Strengthening-toughening type antistatic antiflaming master batches and preparation method and application

InactiveCN101838418AImprove antistatic performanceImprove flame retardant performanceAntistatic agentProcedure Agents

The invention discloses strengthening-toughening type antistatic antiflaming master batches and a preparation method and application. The antistatic antiflaming master batches mainly comprise the following components of: a fire retardant, an antistatic agent, a processing aid and a carrier resin. The preparation method comprises the steps of: preparing the components in a formula ratio to obtain a mixture; plasticizing and mixing the mixture by using an internal mixer or a kneading machine first and then pelletizing by using a single screw extrusion machine to obtain the master batches; and or uniformly mixing the components by using a high mixing machine and then pelletizing the mixture by using a reciprocating type single screw extrusion machine to obtain the master batches. The antistatic antiflaming master batches not only have the antistatic and antiflaming function but also have the function of strengthening and toughening. The master batches are mainly used for plastic products, coal mine underground plastic pipes and top meshes which have high requirements on antistatic and antiflaming performance and strengthening and toughening performance, and can be used for gas transport pipelines and various plastic products of the electric appliances.

Owner:SHANXI DAXING NEW MATERIALS TECH

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

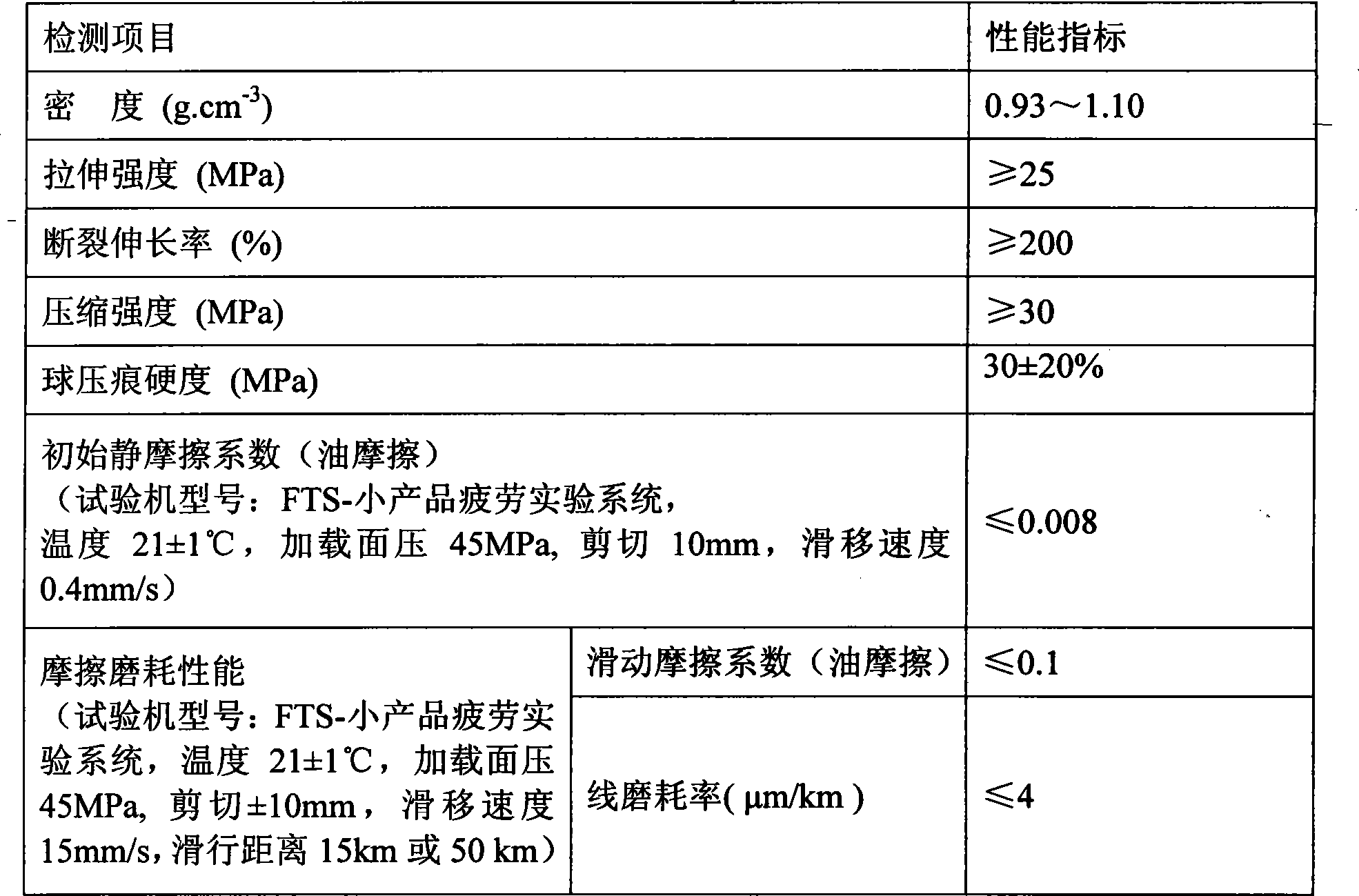

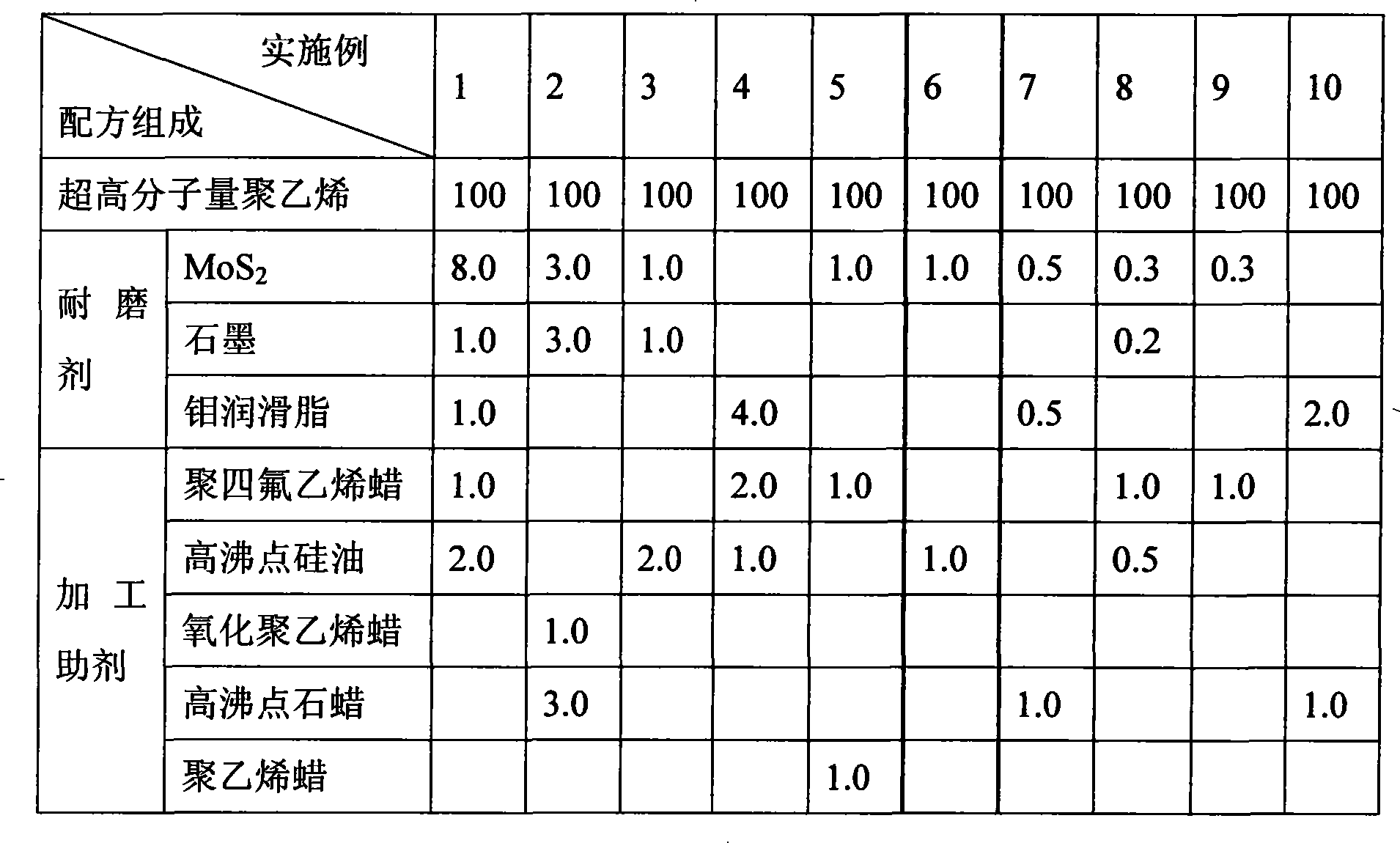

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

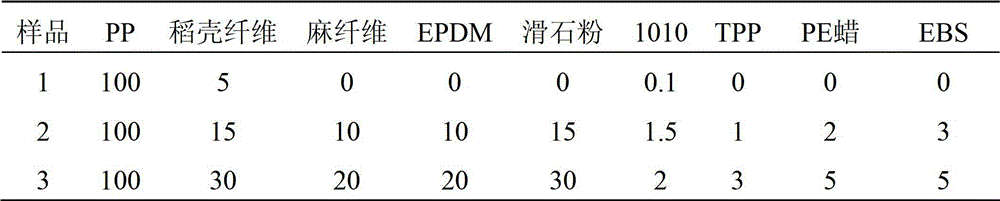

Injecting molding grade natural fiber composite material and preparation method thereof

The invention relates to a natural fiber composite material and a preparation method of the composite material. The composite material comprises the following components in parts by weight: 100 parts of thermoplastic resin, 5-50 parts of natural fiber, 0-20 parts of impact modifier, 0-30 parts of inorganic filler, 0.1-5 parts of anti-aging agent, and 0-10 parts of processing aid. The preparation method of the composite material comprises the steps of adding the natural fiber into an aqueous solution of a saline coupling agent to soak, then drying the natural fiber, mixing the natural fiber with the other processing aids, feeding the mixed material into a double-screw extruder to subject to the melting extrusion, and granulating to obtain the composite material. Compared with the prior art, the preparation method is simple in process and environment-friendly. More importantly, the problems that the composite material, into which a large amount of natural fiber is added, is poor in material mobility, low in intensity of parts, and poor in appearance quality, are solved. The current situation that the natural fiber composite material cannot adapt to the injection moldings of complex structures is changed.

Owner:CHERY AUTOMOBILE CO LTD

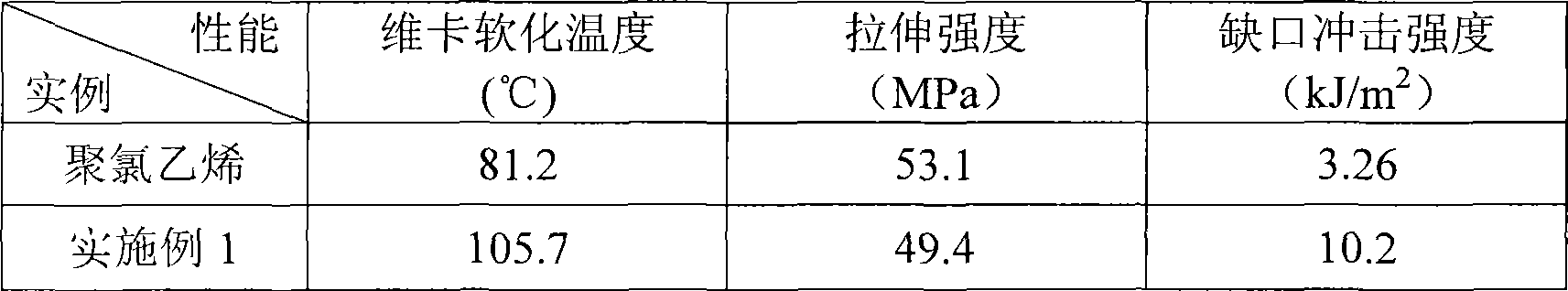

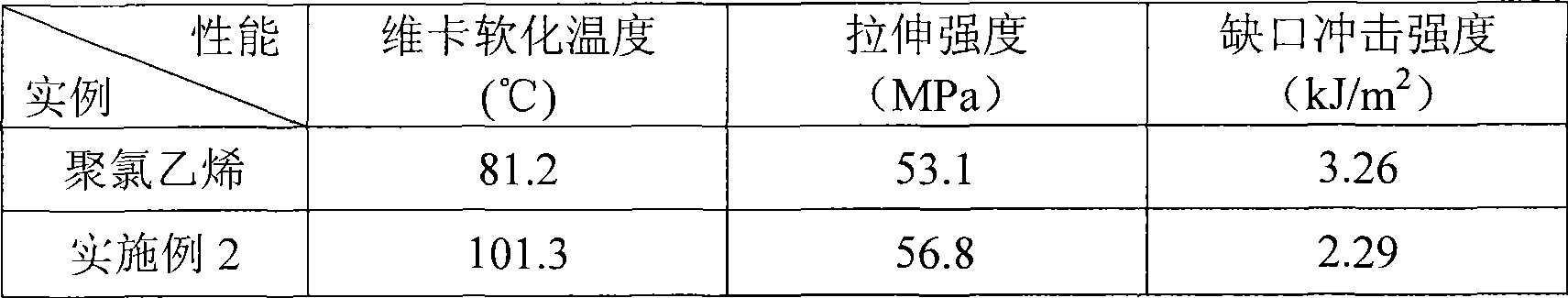

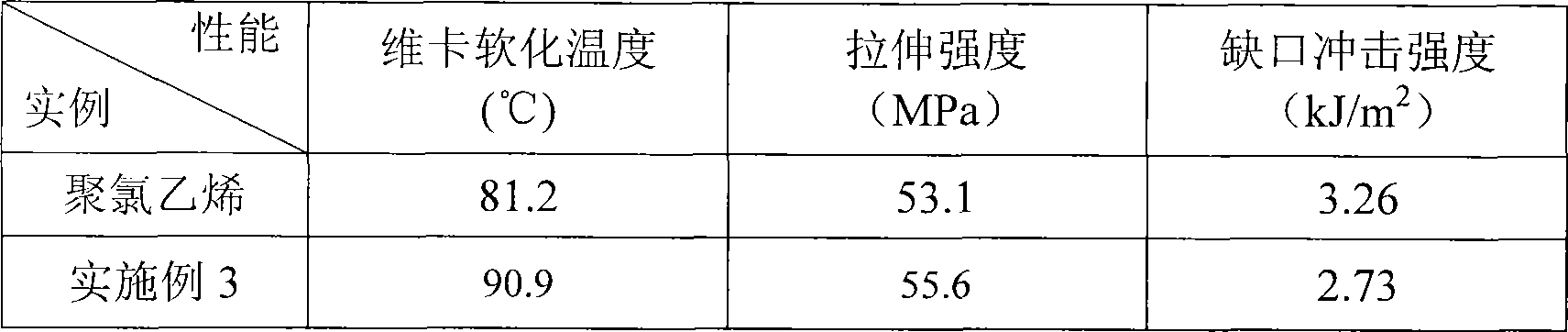

Heat-resistant polyvinyl chloride alloy material and preparation method thereof

The invention provides a heat-resistant polyvinyl chloride alloy material and a preparation method thereof. The alloy material mainly comprises the components of a polyvinyl chloride matrix, a heat-resistant modifying agent, a thermal stabilizer, a lubricating agent, a filler, a shock-resistant modifying agent and a processing agent. The components of the processing agent and the filler in the invention are the processing agent modified by a new method and the organically processed filler, and self plasticisation, toughening and reinforcement of PVC are organically combined by a mechanical chemical reaction, so as to improve the compatibility between the polyvinyl chloride and a heat-resistant resin, to solve the conflict among the increment of heat-resistant quality, the working quality, the strength and the ductility of the polyvinyl chloride, to overcome the problems that the polyvinyl chloride has a low heat-resistant temperature and the working quality of the polyvinyl chloride is poor even though the heat-resistant temperature of the polyvinyl chloride is high, and to prepare the polyvinyl chloride engineering plastic with high heat resistance, high strength, high ductility and excellent working quality. The preparation method of the heat-resistant polyvinyl chloride alloy material in the invention has simple technology, stable quality and high production efficiency, and is easily operated and controlled.

Owner:SICHUAN UNIV

Two-part epoxy-based structural adhesives

A two-part epoxy-based structural adhesive composition comprising a curable epoxy resin, an amine curing agent, a toughening agent, and an oil-displacing agent. The structural adhesive may optionally include reactive liquid modifiers, fillers, secondary curatives, reactive diluents, surfactants, metal salts, pigments and combinations thereof. The structural adhesive may be used to form bonded joints between adherends having clean surfaces, as well as those having surfaces contaminated with hydrocarbon-containing materials, such as oils, processing aids and lubricating agents.

Owner:3M INNOVATIVE PROPERTIES CO

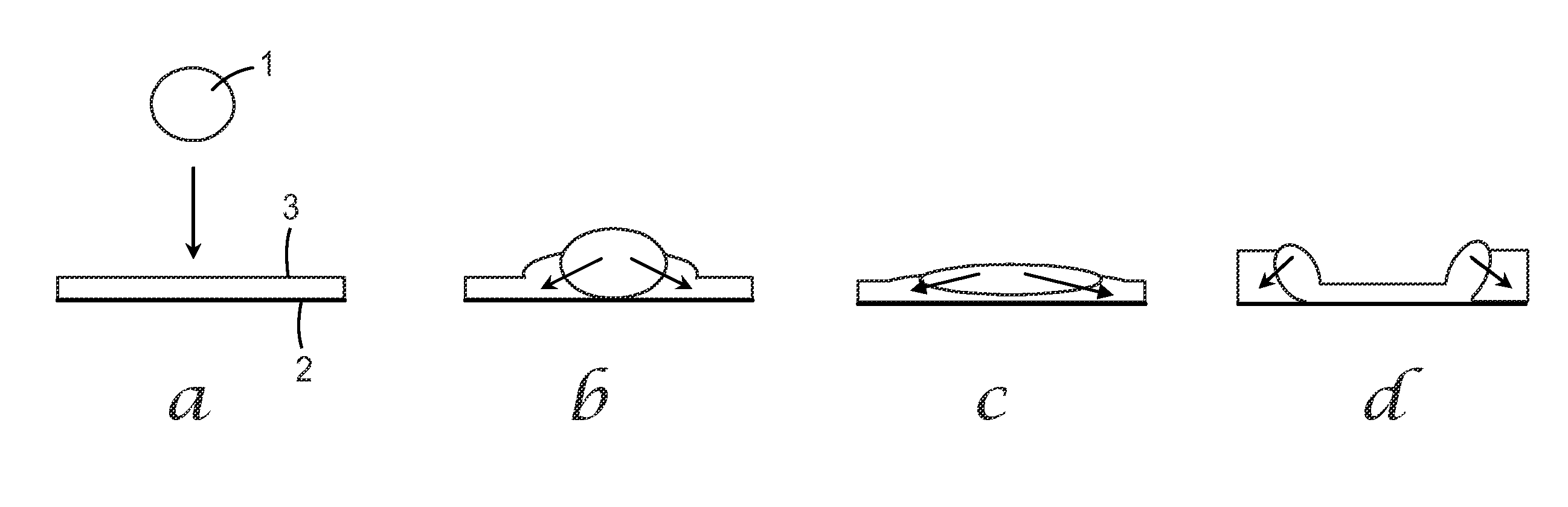

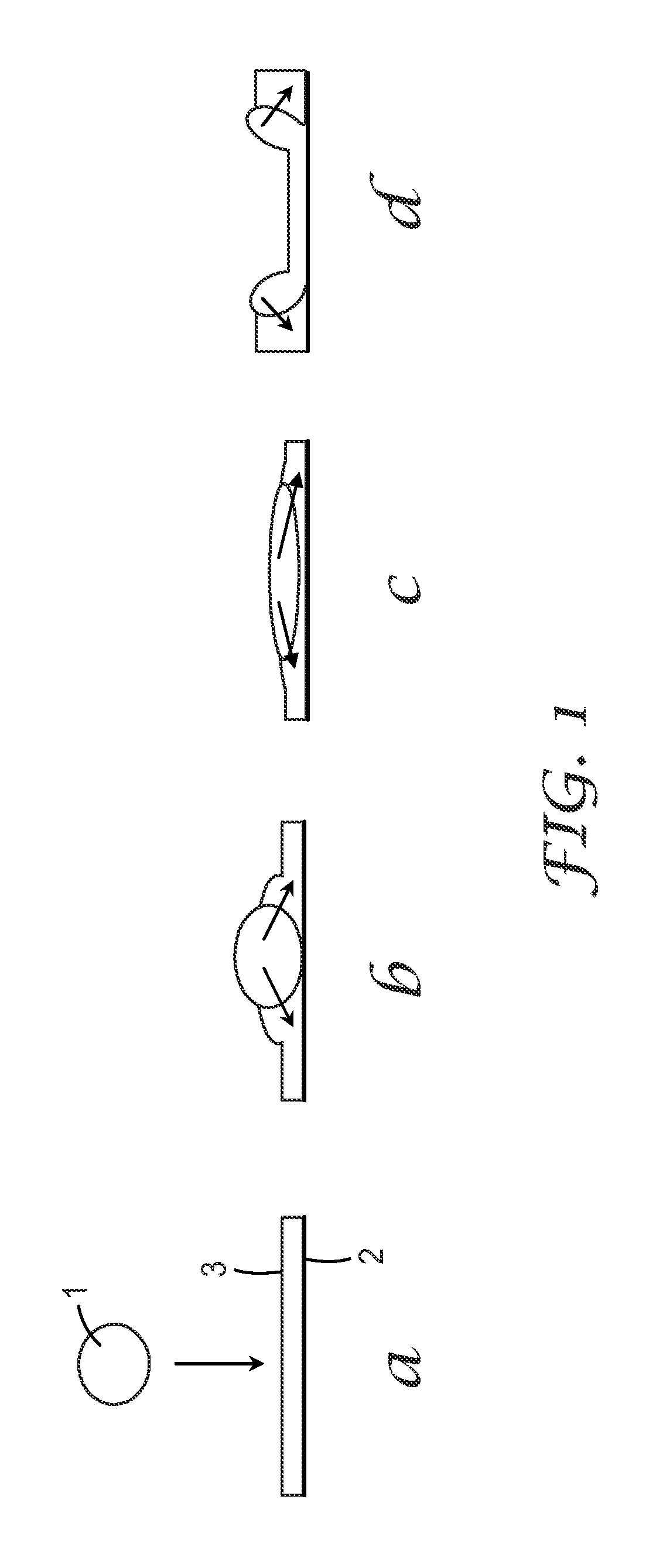

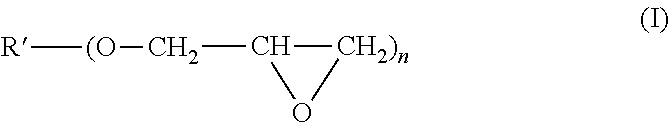

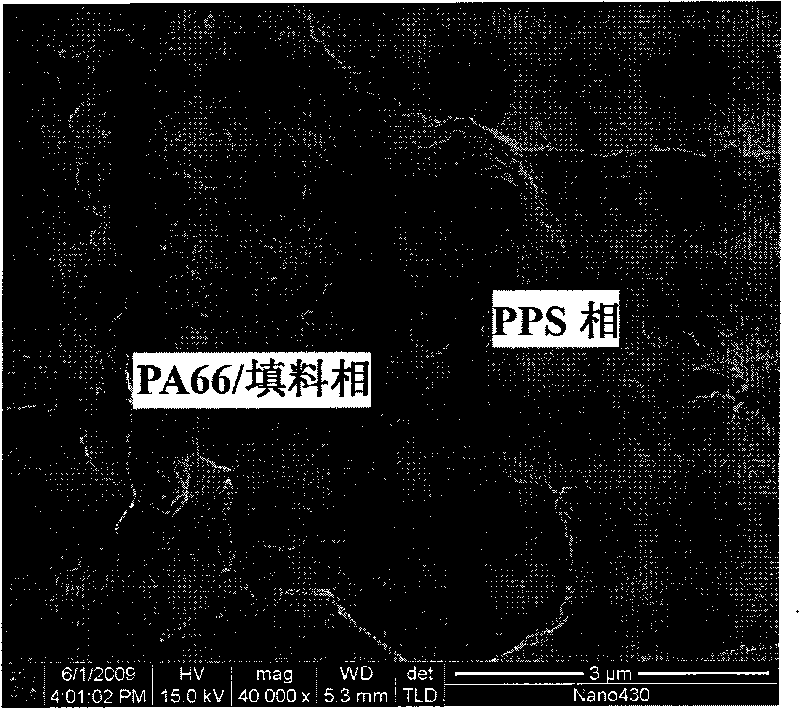

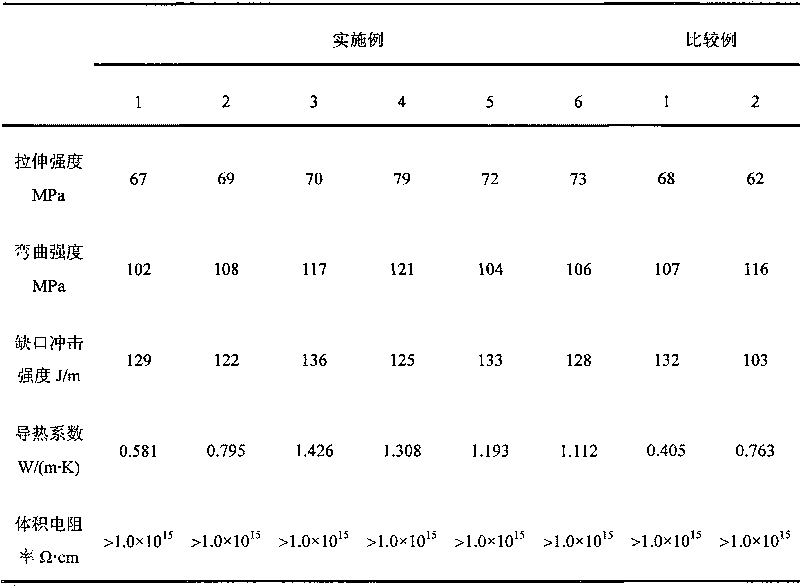

Filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and preparation method thereof

The invention discloses a filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and a preparation method thereof. The blended alloy comprises polyphenyl thioether, polyamide, an inorganic thermal-conducting filler, a surface modifier and processing assistants, wherein the polyamide and the polyphenyl thioether form a bicontinuous phase structure, and the inorganic thermal-conducting filler is distributed in the polyamide phase and forms a continuous thermal-conducting network. The preparation method comprises the following three steps: step 1: carrying out the surface modification on the inorganic thermal-conducting filler by using the surface modifier; step 2: mixing the inorganic thermal-conducting filler, the polyamide and the processing assistants by using a high-speed mixer, and extruding the mixture by using a double screw extruder to obtain the thermal-conducting master batch; and step 3: extruding the thermal-conducting master batch, the polyphenyl thioether and the processing assistants for the second time to make granules. The composite material of the invention has good thermal conduction, electrical insulation, mechanical properties and processability. Under the condition of the same amount of the inorganic thermal-conducting filler, compared with the blended alloy phase in which the continuous phase is not formed, the coefficient of thermal conductivity of the composite material in the invention is obviously enhanced.

Owner:SOUTH CHINA UNIV OF TECH

A kind of stress whitening resistant polypropylene composition and its preparation method

ActiveCN102295808AImprove mechanical propertiesGood resistance to stress whiteningPolymer scienceProcedure Agents

The invention discloses a stress whitening resistant polypropylene composition and a preparation method thereof. The stress-whitening-resistant polypropylene composition comprises the following components calculated by weight percentage: 35%-82% polypropylene resin; 2%-12% compatibilizer; 5%-15% stress-whitening-resistant agent; 10%-40% filler; 0.2%-1.0% antioxidant; 0.2%-1.0% processing aid; the polypropylene resin is a mixture of homopolymerized polypropylene and random copolymerized polypropylene; The whitening agent is a mixture of polyethylene and thermoplastic elastomer; the compatibilizer is a graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The stress-whitening-resistant polypropylene composition of the present invention has both good comprehensive mechanical properties and good stress-whitening resistance, and can be applied to the fields of household appliances, toys, auto parts, electric tools and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Foam control formulations

ActiveUS20150080273A1Lower Level RequirementsInhibition formationDewatering/demulsification with chemical meansDefoamers additionProcedure AgentsWater insoluble

The invention provides a foam control formulation in the form of a microemulsion, the formulation comprising: (a) from S to 70% w / w of primary surfactant, this surfactant having an HLB of from 1 to 12 and / or a cloud point of from 20 to 70° C.; (b) from 2 to 40% w / w of water-insoluble organic carrier liquid; and (c) water. Also provided is the use of this formulation to prevent and / or reduce foam in a fluid system, or as a processing aid to control foam production in a fluid system. The formulation may be used in an aqueous fluid system, such as an oilfield.

Owner:ENERGY SOLUTIONS (US) LLC

Scraping-resistant polypropylene combination with good appearance and manufacturing method and application thereof

The invention discloses a scraping-resistant polypropylene combination with good appearance. The combination comprises the components, by weight, of polypropylene of 57-82 parts, polyethylene of 3-8 parts, flexibilizer of 3-8 parts, mineral filler of 10-30 parts, scraping-resistant agents of 1.5-2.5 parts, and other assistant agents of 0.5-1 part. The invention further discloses a manufacturing method and application of the scraping-resistant polypropylene combination with the good appearance. According to the combination, by adding the polyethylene and the processing agents, phase interface problems of the combination are well improved, current ripple and tiger stripe problems existing in an injection process of the combination are well improved, so that great surface effect of an combination injection molding piece is achieved, and the scraping-resistant agents are added so that surface damage generated by scraping and friction during a using process of the combination injection molding piece is relieved. The requirements on the surface performance of the combination during the injection molding process and the later-stage using process and mechanical performance are considered in an overall mode, the requirements on inner ornaments and outer ornaments of an automobile are met, and good application prospect is achieved.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com