Patents

Literature

486results about How to "Continuous process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

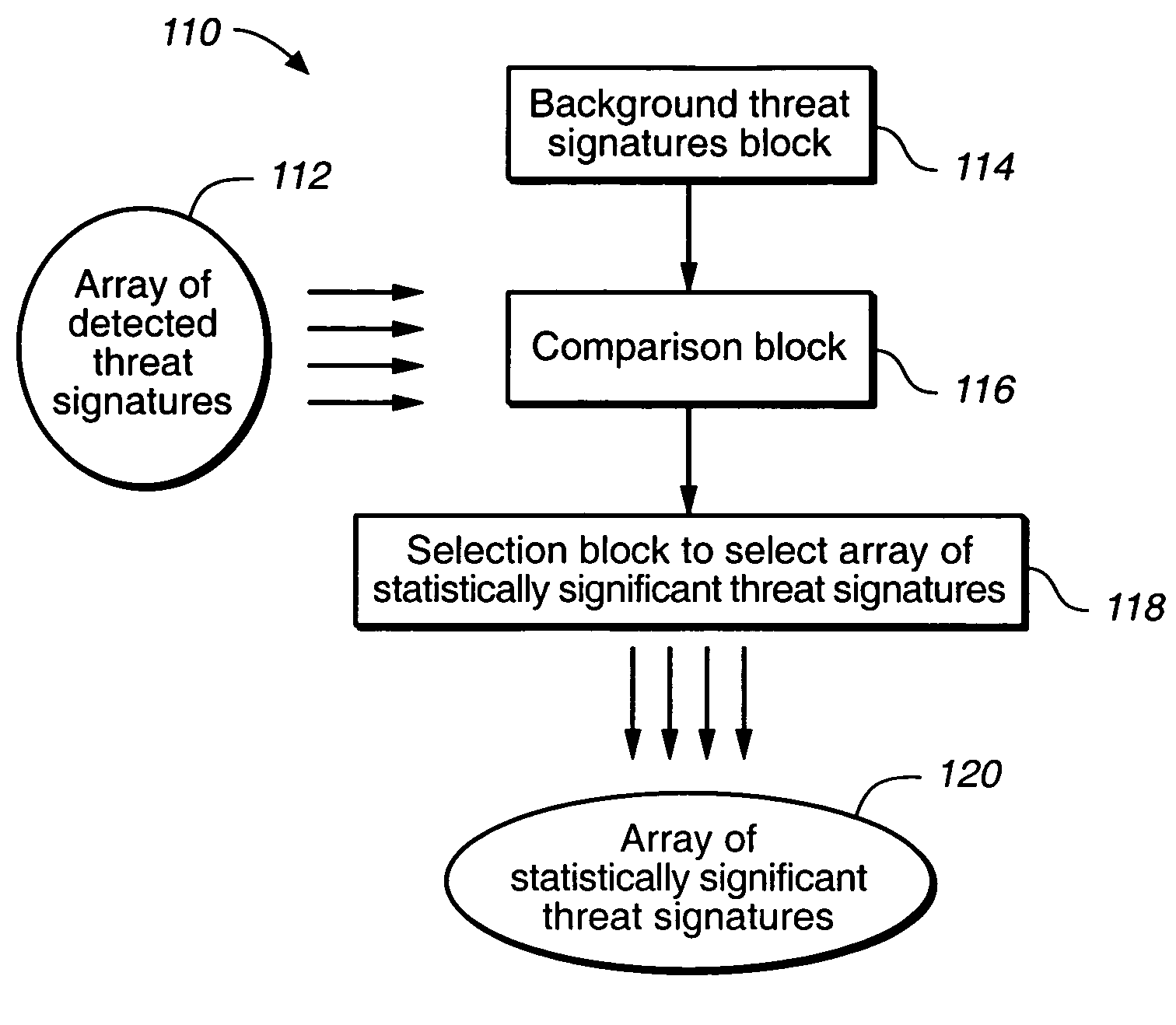

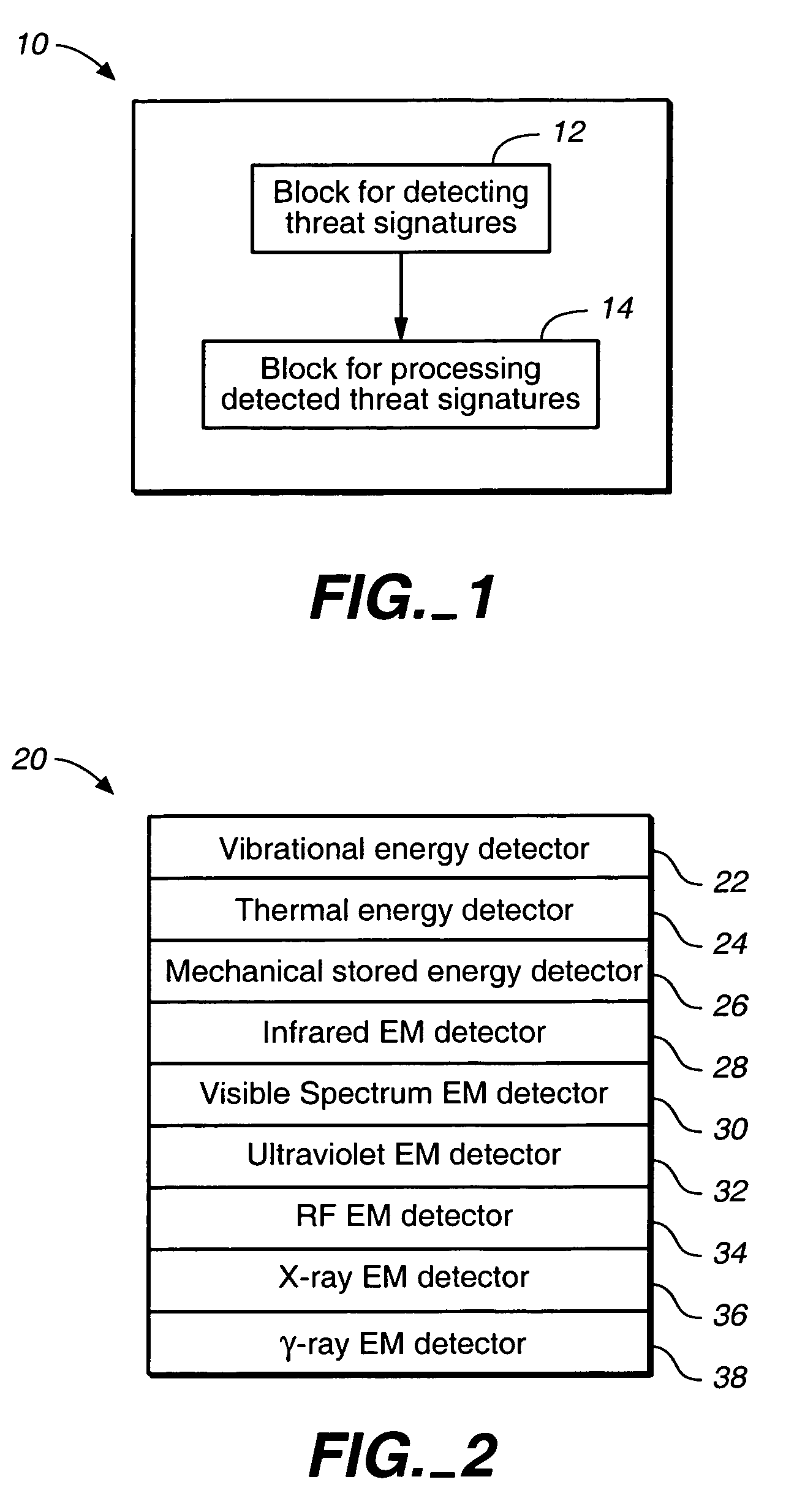

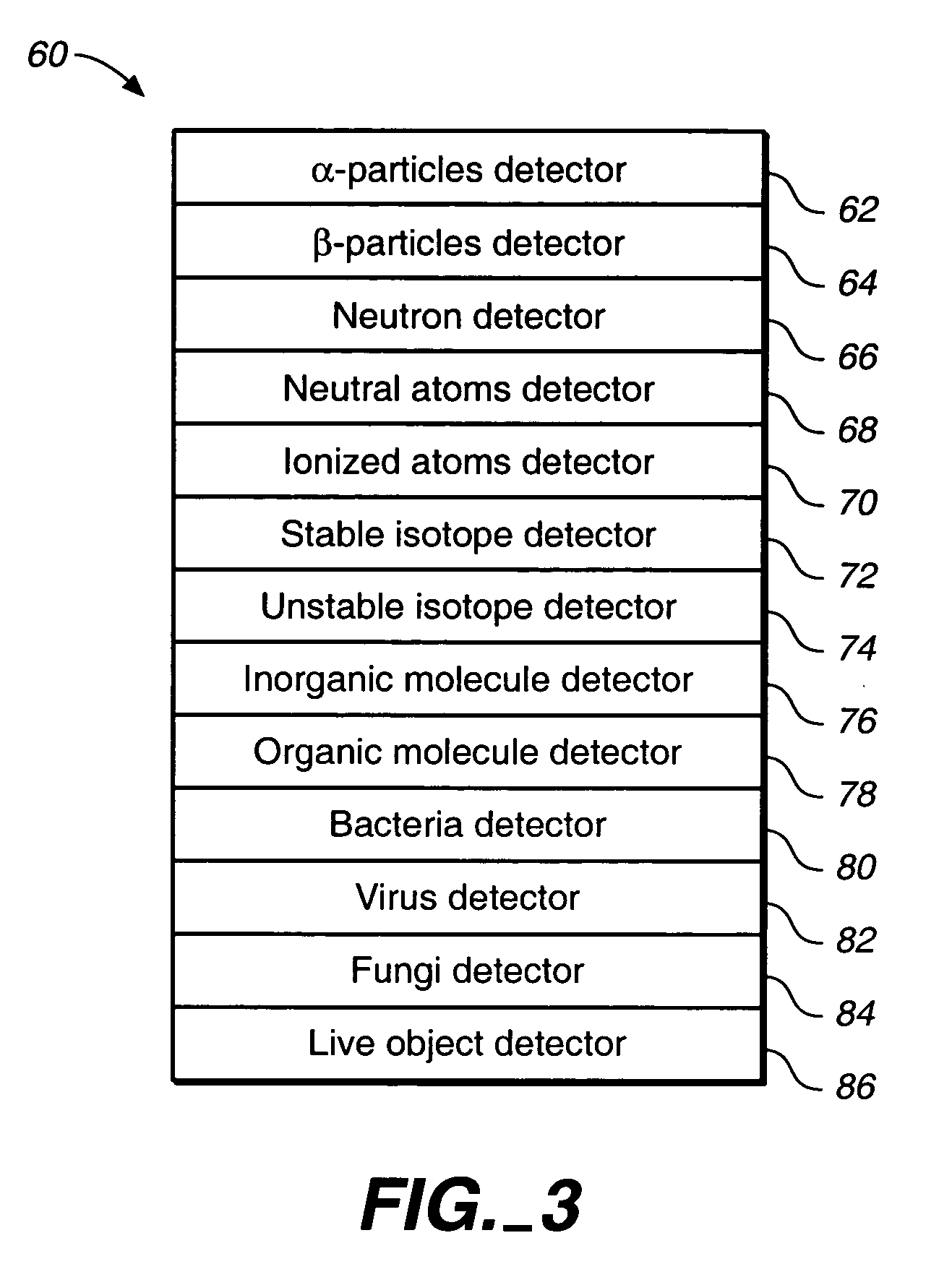

Detection and identification of threats hidden inside cargo shipments

InactiveUS7151447B1Continuous processConversion outside reactor/acceleratorsMaterial analysis by optical meansHomeland securityCargo container

A method for identifying at least one threat to the homeland security. Each threat is either hidden inside at least one cargo container before transit, or is placed inside at least one cargo container while in transit. Each threat while interacting with its surrounding generates a unique threat signature.The method comprises the following steps: (A) detecting at least one threat signature; and (B) processing each detected threat signature to determine a likelihood of at least one threat to become a threat to the homeland security.

Owner:ERUDITE

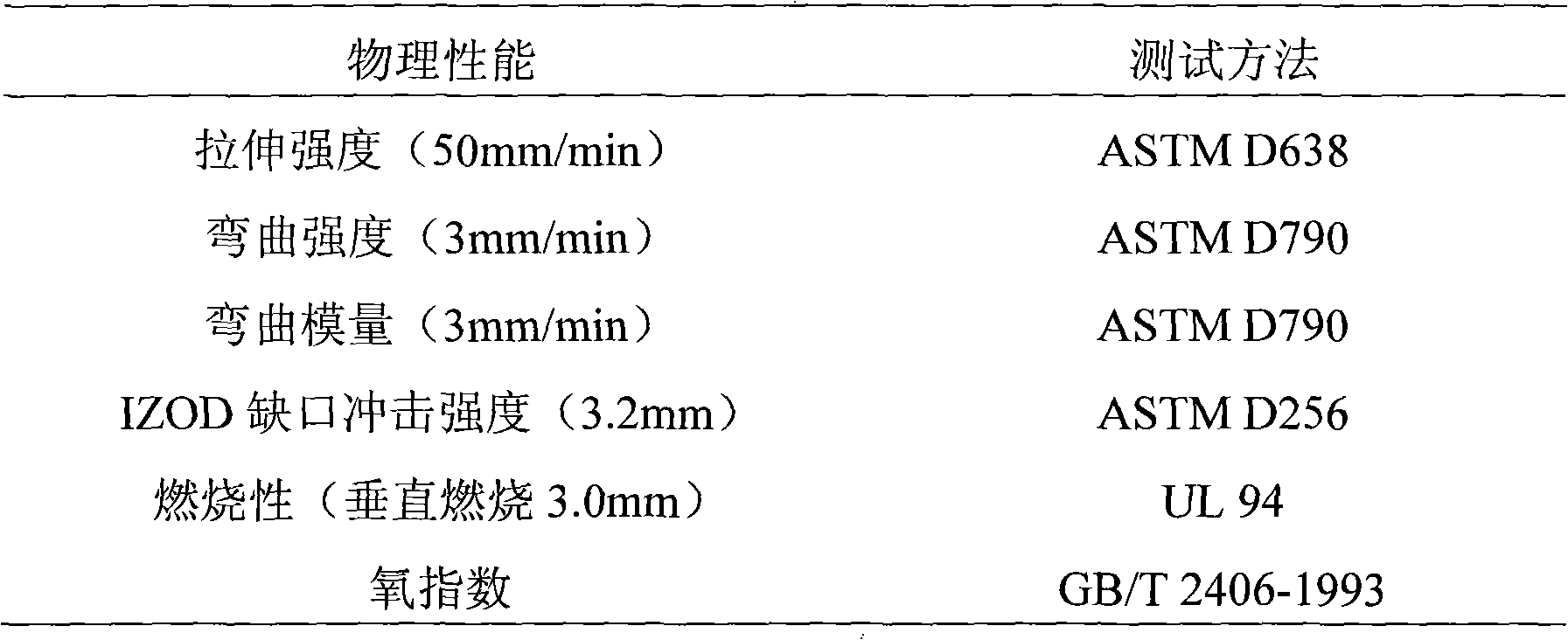

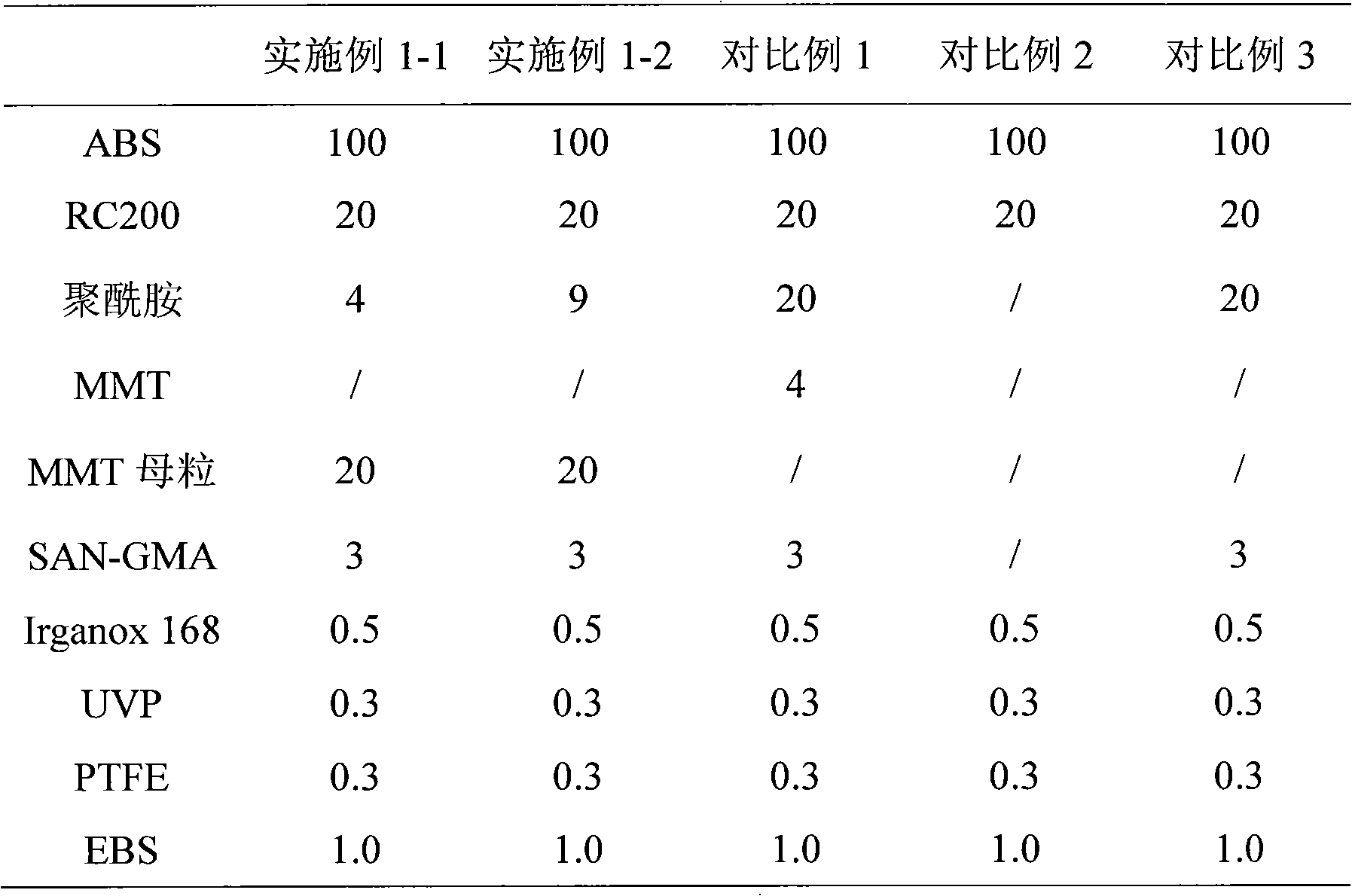

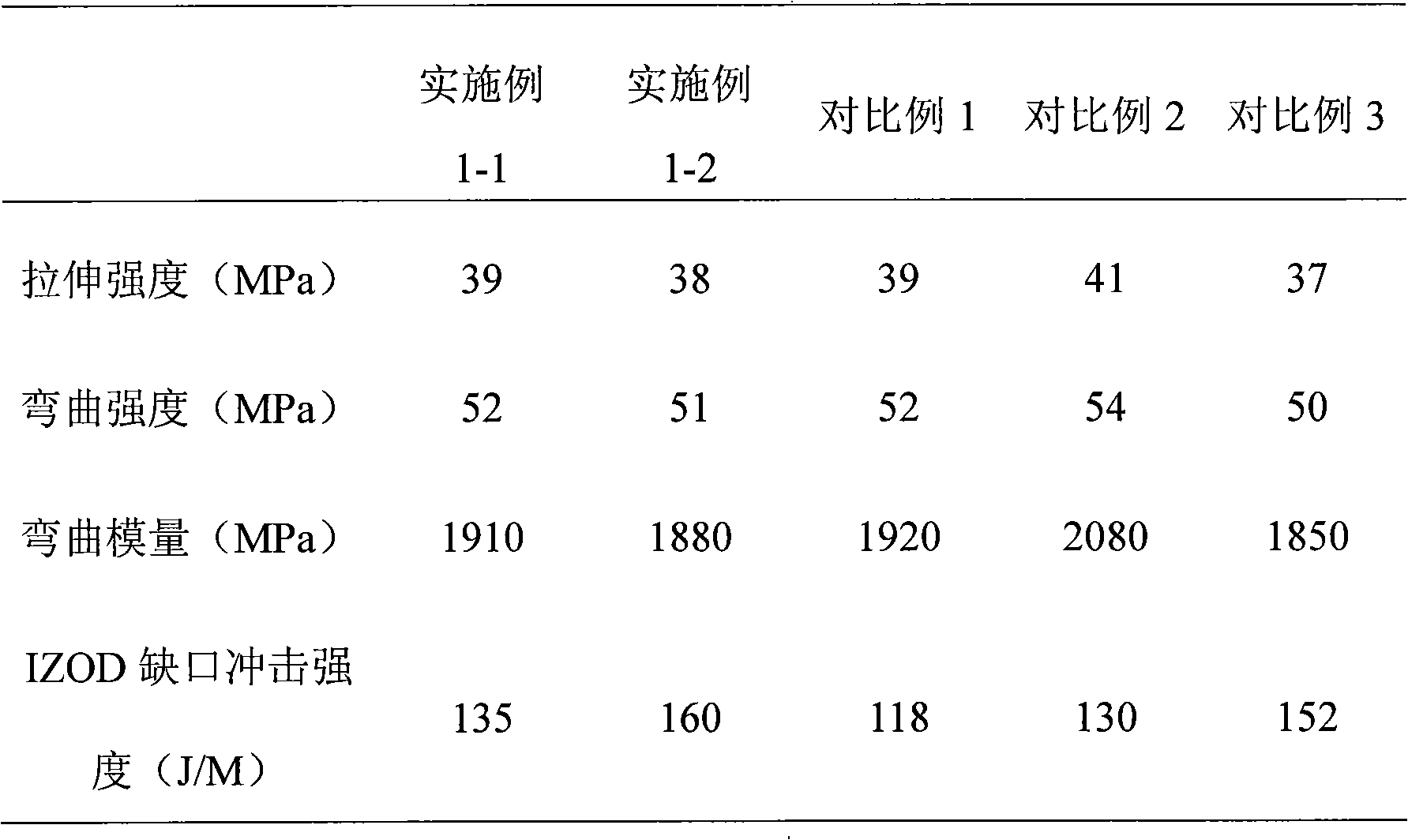

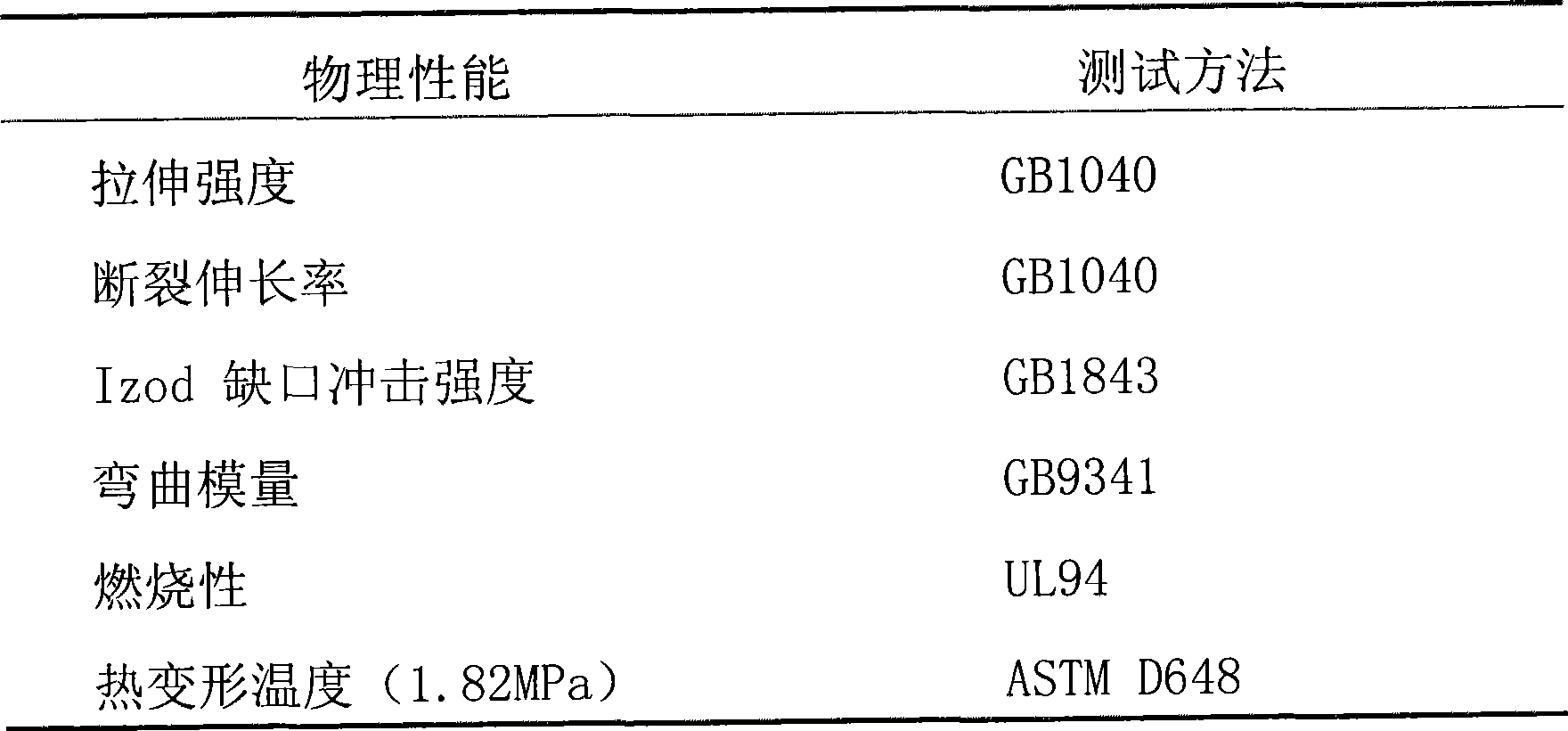

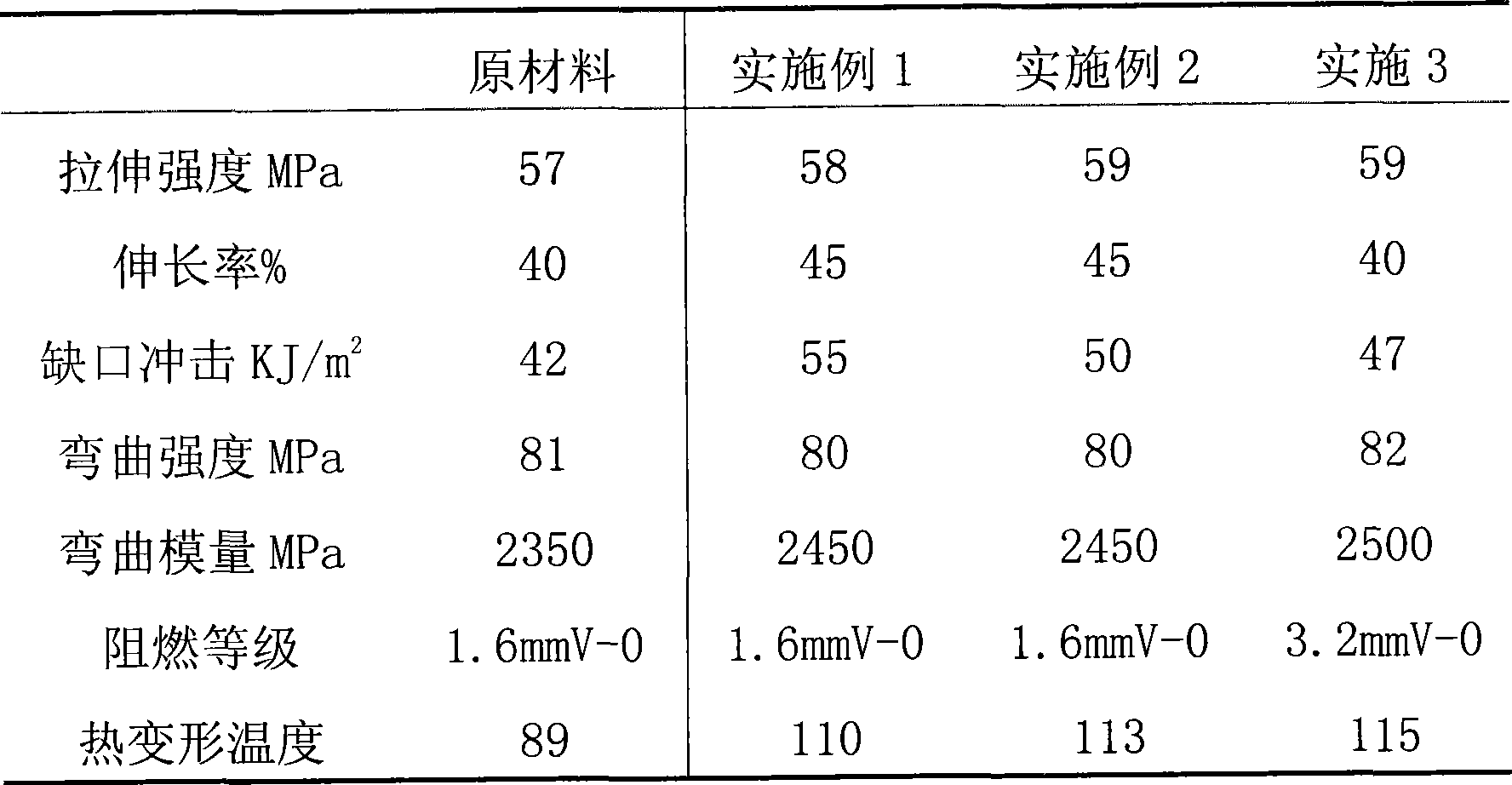

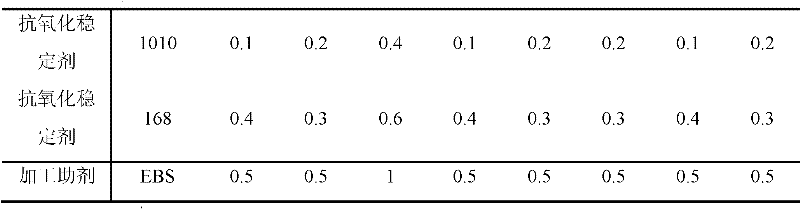

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Heat-proof combustion-resistant ABS resin and its preparation method

The invention discloses a heat resistant flame-proof ABS type resin and its preparing process, wherein the constituents include (by mass portions) ABS type resin 100 parts, flame retardant 2-30 parts, heat-proof modifier 5-20 parts, flexibilizer 1-10 parts, optical-thermal stabilizing agent 0.2-2 parts, and fabrication auxiliary agent 1-5 parts. The resin can substitute engineering plastics to be applied to situations for high requirement of flame-proof and heat resistance properties.

Owner:SHANGHAI KINGFA SCI & TECH +1

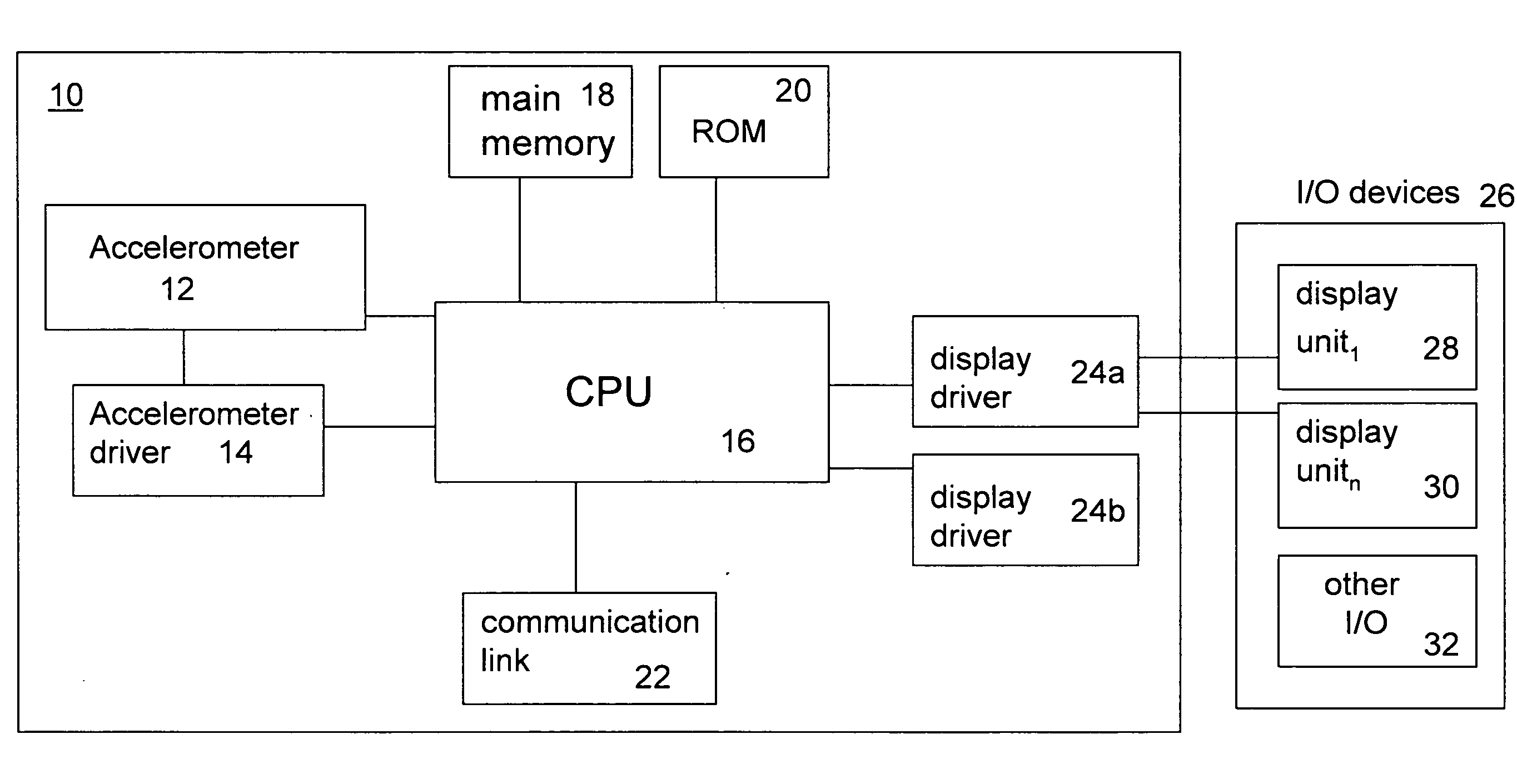

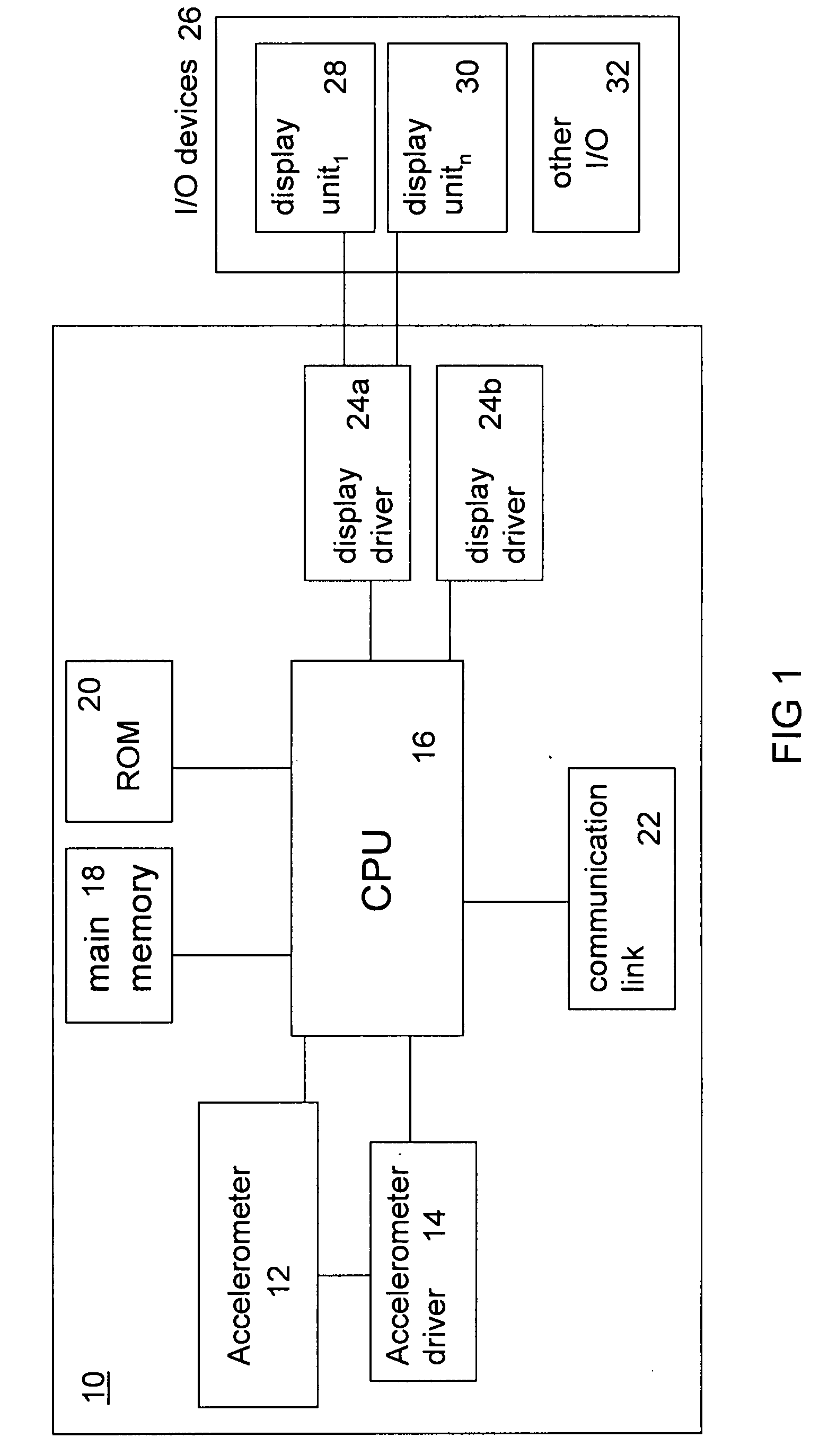

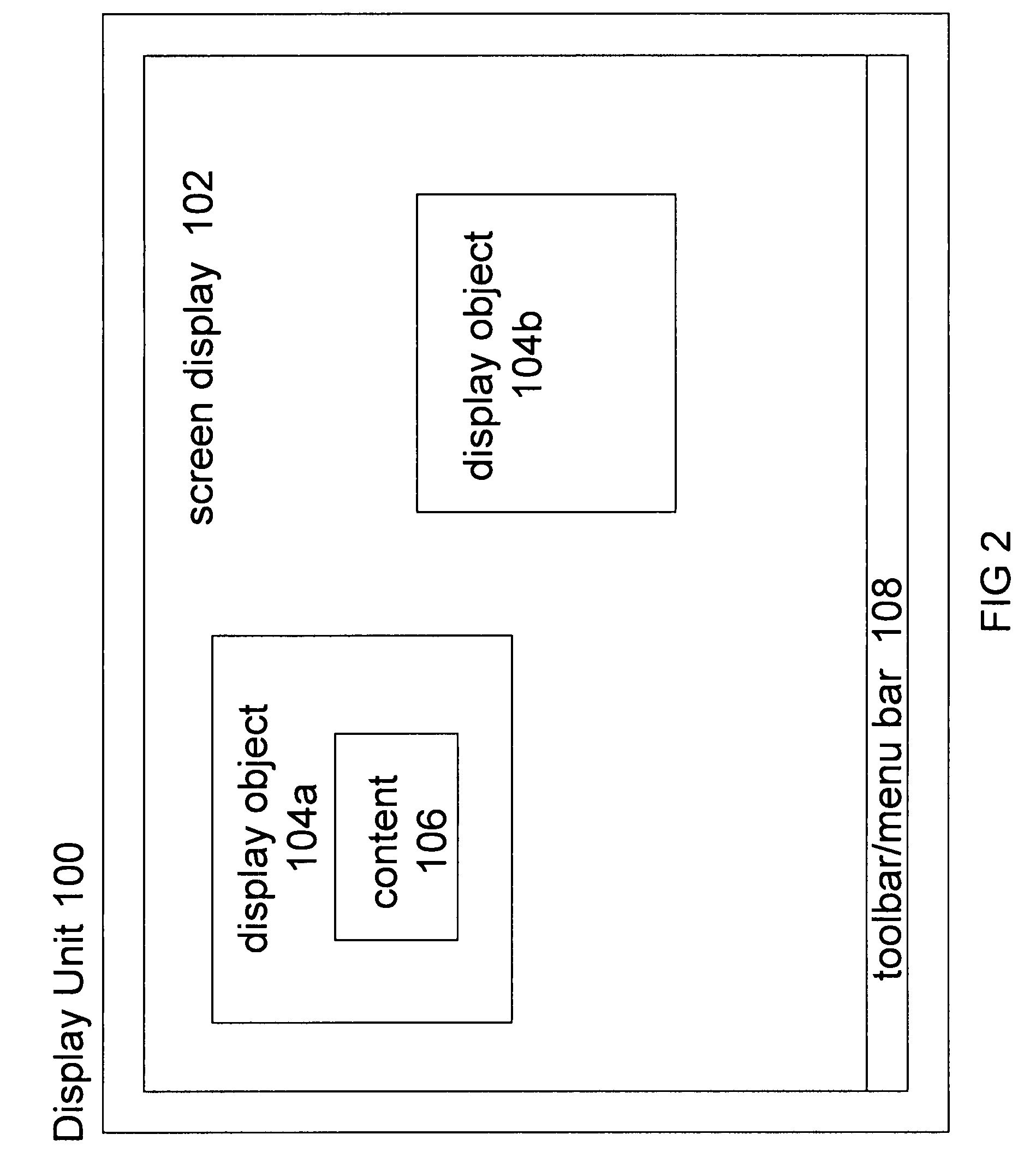

Detecting movement of a computer device to effect movement of selected display objects

InactiveUS20080048980A1Continuous processControl movementCathode-ray tube indicatorsDetails for portable computersAccelerometerControl signal

The systems and methods of the invention relate to providing a computer device, having a display unit, with an accelerometer (or other motion sensor) to detect movement of the computer device (and / or an associated display unit) and generate movement data. An accelerometer driver may receive the generated movement data. The generated movement data may be processed and / or interpreted in order to create one or more control signals. The control signals may be sent to a display driver to control movement of one or more selected display objects on one or more display units. The control signals may control movement of selected display objects on a screen display (or between multiple screen displays) associated with the computer device.

Owner:APPLE INC

Unitary or polybasic aerogel thermal insulation material and preparation method thereof

ActiveCN102584162AGood application effectApplicability is differentThermal insulationSingle component

The invention discloses a unitary or polybasic aerogel thermal insulation material and a preparation method of the material. The method comprises the steps of preparing sol, solidifying sol to form gel, aging and drying, or comprises the steps of preparing sol, preparing a prefabricated body, infiltrating, coagulating sol, aging and drying. The aerogel component in the thermal insulation materialdisclosed by the invention is formed in a unitary or polybasic way, and can be formed by flexibly adjusting a single component, so that the characteristic of aerogel can be given a full play to the greatest extent, the material can be used in different temperature resisting fields, and aerogel formed by different components can be used aiming at the different temperature resisting fields, so thatthe heat insulation effect of the aerogel thermal insulation material can be more high-efficiency. The production and forming method of the unitary or polybasic aerogel thermal insulation material, disclosed by the invention, is a set of technology which is complete, continuous, and low in cost, and can be used in industrial method production, the produced aerogel thermal insulation material withhigh performance is wide in application field, is wide in using temperature, can meet different using requirements of war industry fields, civil fields, heat-protection fields with special requirements, and the like.

Owner:GUANGDONG ALISON HI TECH

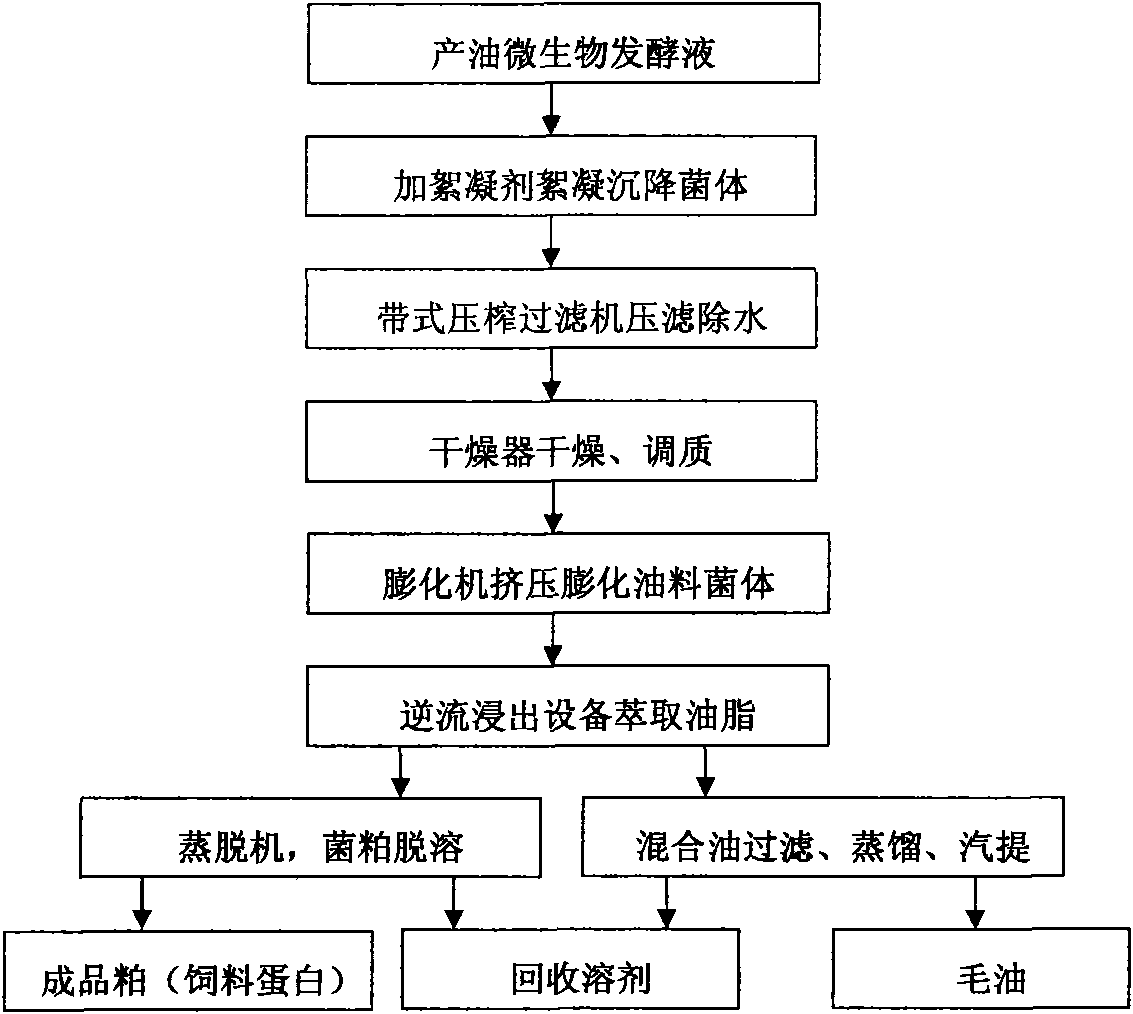

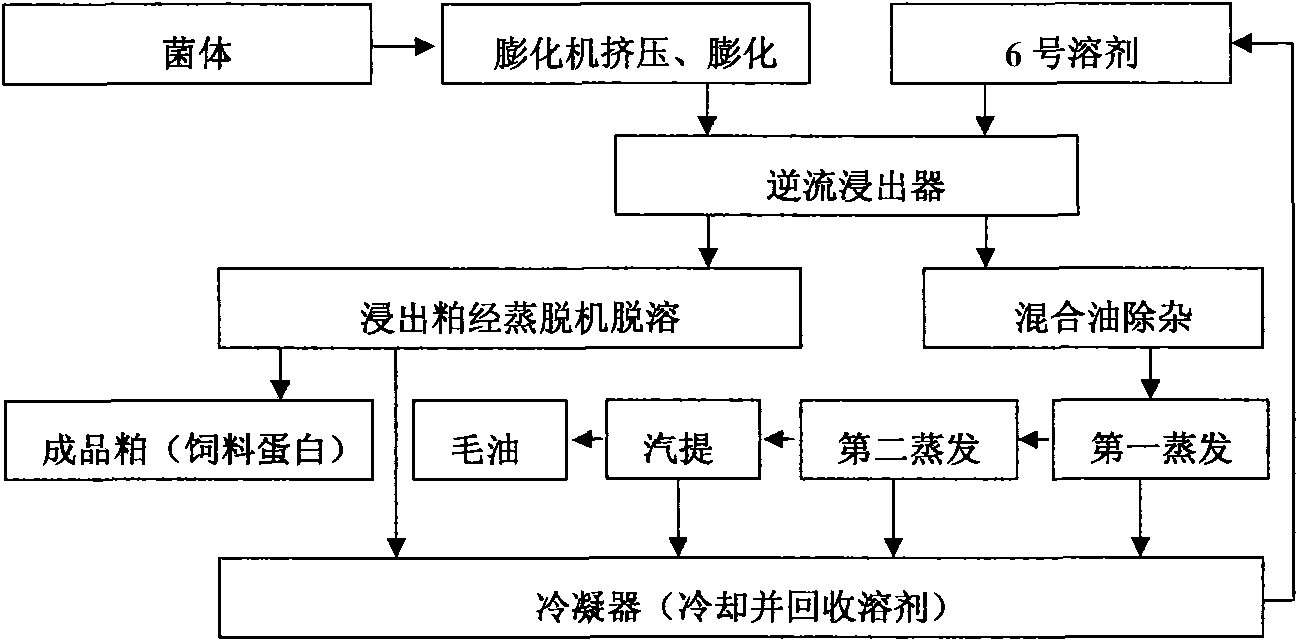

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

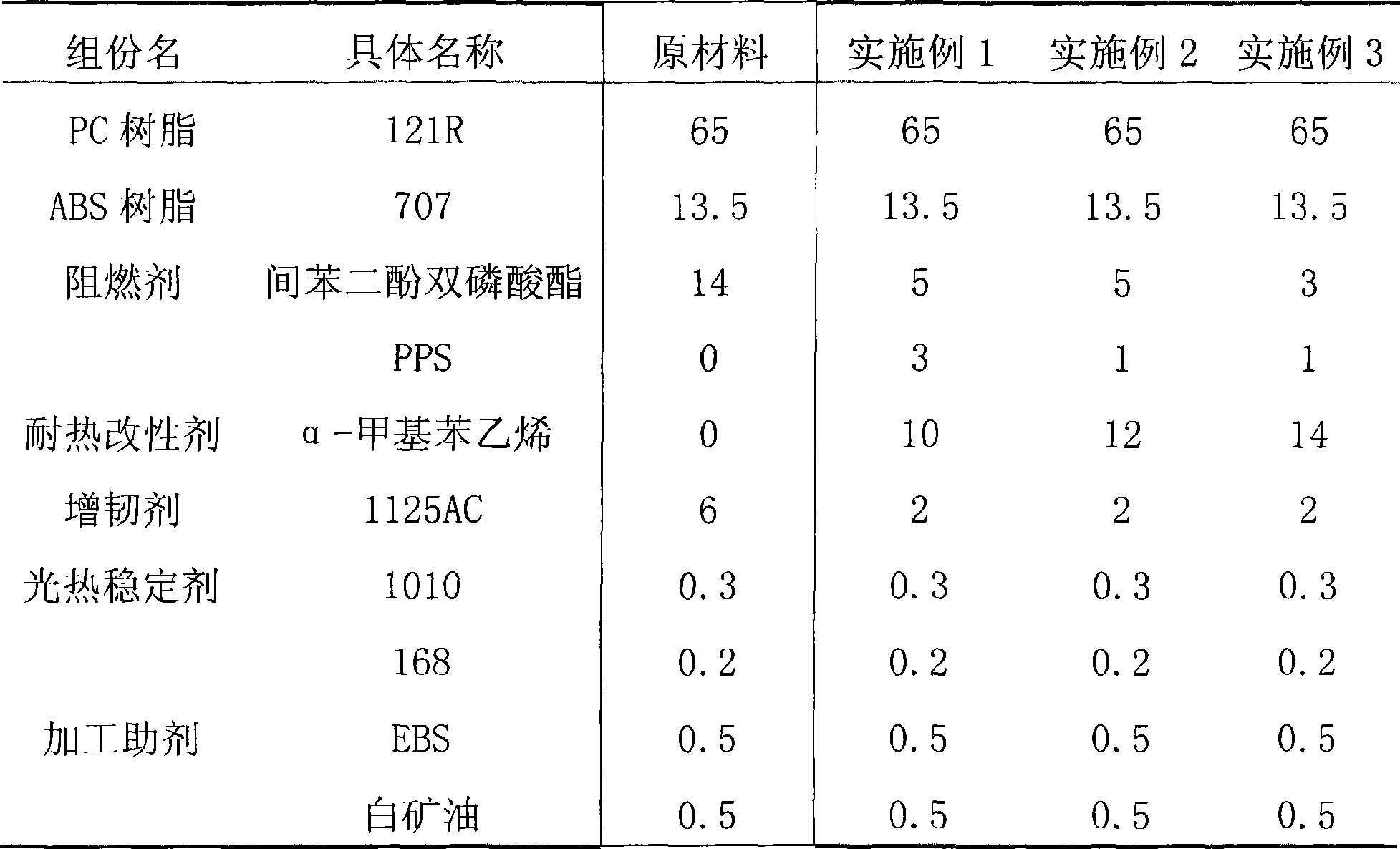

Polycarbonate and acrylic nitrile-butadiene-phenylethylene grafted copolymer heat resisting and flame-retardant alloy

InactiveCN101397396AReduce dosageHigh heat distortion temperatureHeat deflection temperaturePhosphate

The invention relates to an anti-flaming polycarbonate (called PC hereafter) and acrylonitrile-butadiene-styrene graft copolymer (called ABS hereafter) alloy resin, in particular a halogen-free PC and ABS graft copolymer fireproof anti-flaming alloy, and a preparation method thereof. The fireproof anti-flaming alloy comprises the following components as per weight percentage: 53-65 percent of PC, 12-24 percent of ABS resin, 6-18% of flame retardant, 3-12 percent of heat-resistance modifier, 0.6-3 percent of toughener, 0.1-1 percent of optothermal stabilizer and 0.6-3 percent of processing aids, wherein, the flame retardant is the combination of polyphenylene sulfide and organic phosphate flame retardant, and the processing aids include lubricant, coupling agent, antioxidant and processing lubricant aid. The invention uses the mutual matching between the S element contained in the polyphenylene sulfide and the P element contained in the flame retardant to reduce the dosage of the retardant, and improve the heat-resistance and deformation temperature.

Owner:SHANGHAI KINGFA SCI & TECH +1

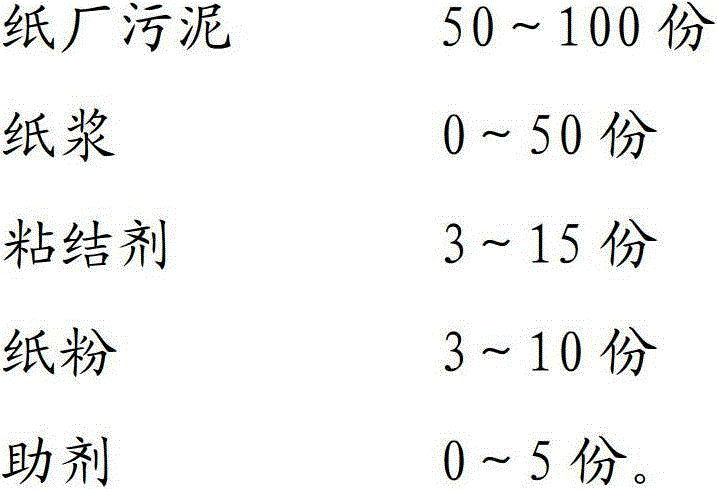

Cat litter for pets and preparation method of cat litter

The invention relates to the technical field of articles for pet garbage cleaning, in particular to cat litter for pets and a preparation method of the cat litter. The cat litter for pets comprises the following ingredients in parts by weight: 50 to 100 parts of paper plant sludge, 0 to 50 parts of paper pulp, 3 to 10 parts of bonding agents, 3 to 5 parts of paper dust and 0 to 5 parts of auxiliary agents, wherein the paper fiber length in the paper pulp is 1.5 to 3mm, and the paper fiber length in the paper dust is 0.5 to 1.5mm. The cat litter for pets has the advantages that the specific gravity is light, the adsorption capacity is high, the caking effect is good, the processing is easy, the environment protection is excellent, and in addition, the cost is low. The flow process of the preparation process of the cat litter is continuous, the time is saved, during the raw material stirring homogenization and granulation, the process is mild, and the operation is easy.

Owner:朱群

Antiscratch resin and preparation method thereof

The invention relates to an antiscratch resin. The antiscratch resin comprises the following components in part by weight: 50 to 90 parts of polymethyl methacrylate (PMMA) resin, 10 to 50 parts of toughening agent, 0.2 to 0.6 part of light stabilizer, 0.2 to 1 part of antioxidant, 0.2 to 2 parts of lubricating agent, 0 to 3 parts of pearl pigment, 0 to 3 parts of metal pigment and 0 to 3 parts of toner. The antiscratch resin is prepared by the following steps of: stirring and mixing all the components in a high-speed mixing machine; conveying the mixture to a double-screw extruder; melting and compounding the materials under conveying, cutting and mixing action of screws; and extruding, bracing, cooling and dicing to obtain the antiscratch resin. The antiscratch resin has high impact strength, high antiscratch property, high heat resistance, various appearance effects and a wide application range, and can avoid spraying completely.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

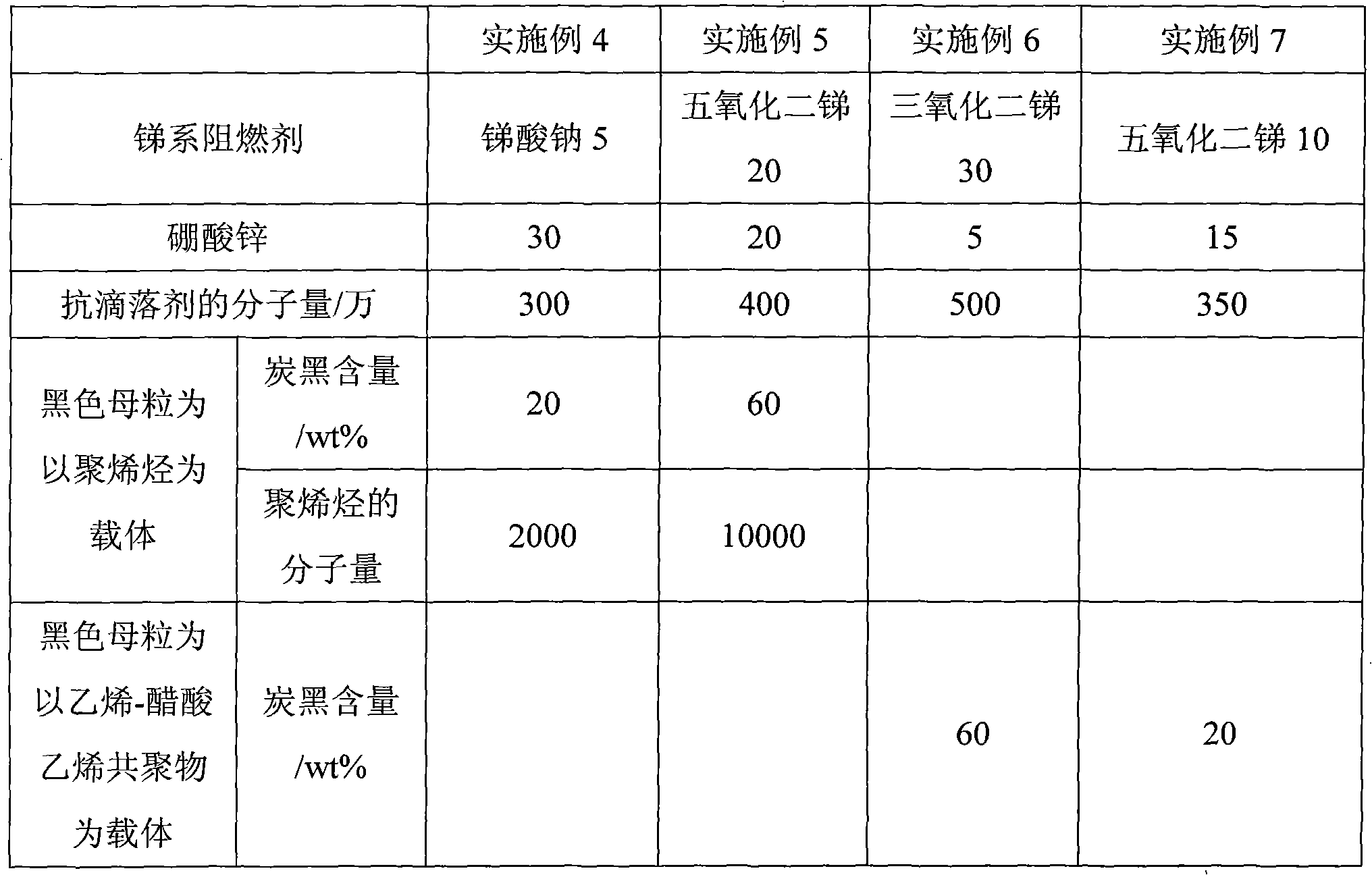

Low-L value inflaming retarding ABS modified resin and preparation method thereof

The invention relates to a low-L value (less than 27) inflaming retarding ABS modified resin and a preparation method thereof. The resin comprises the components with the content (based on parts by weight): 100 parts of ABS resin, 10-25 parts of brominated flame retardant, 20-40 parts of inorganic inflaming retarding master batch, 0.1-0.5 part of anti-dripping agent, 0.2-1 part of antioxidant, 0.1-0.5 part of light stabilizer, 1-3 parts of lubricating agent and 1-4 parts of black master batch. Compared with the prior art, the invention has reasonable technique, overcomes the defect of high L value (namely, low degree of blackness) of the existing inflaming retarding ABS resin, and adopts the novel high-efficiency inflaming retarding synergistic effect technology. The invention leads the resin has higher degree of blackness by reasonably selecting the grain diameter of antimony trioxide, a carbon black lubricating dispersion system and the processing technique of a master batch method on the basis of maintaining the excellent performance of the inflaming retarding ABS resin, and has wide application prospect in the field of the requirement of high degree of blackness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

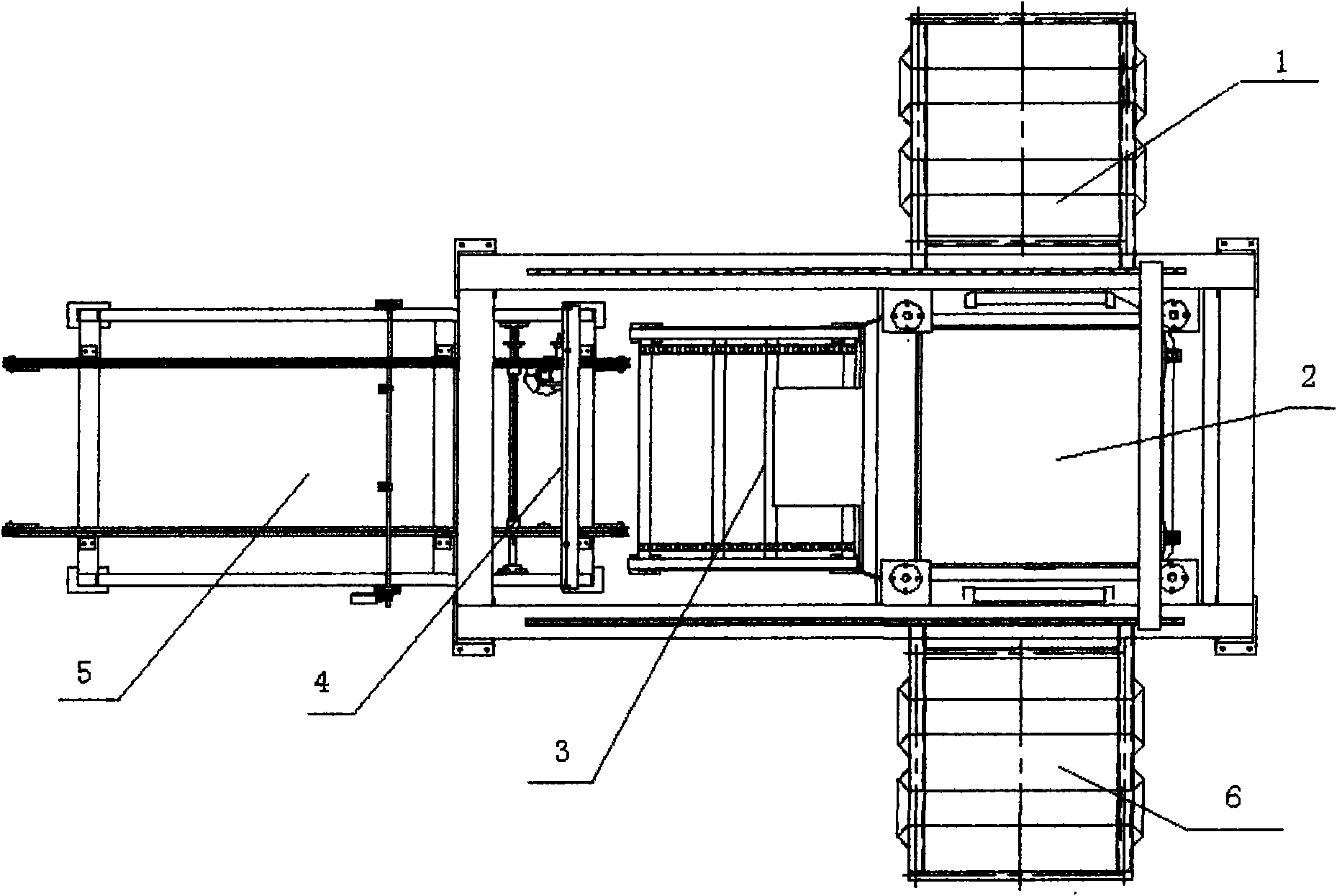

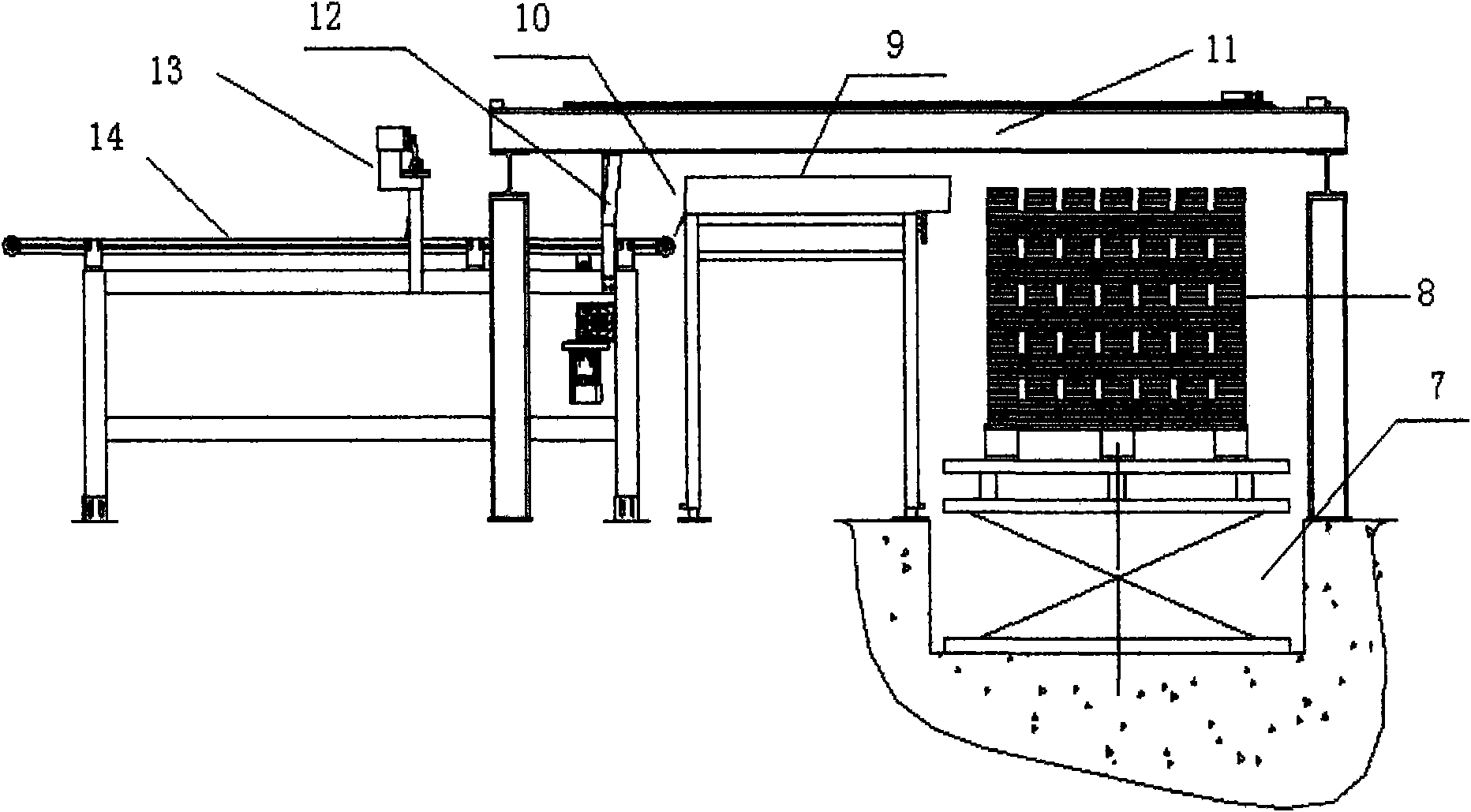

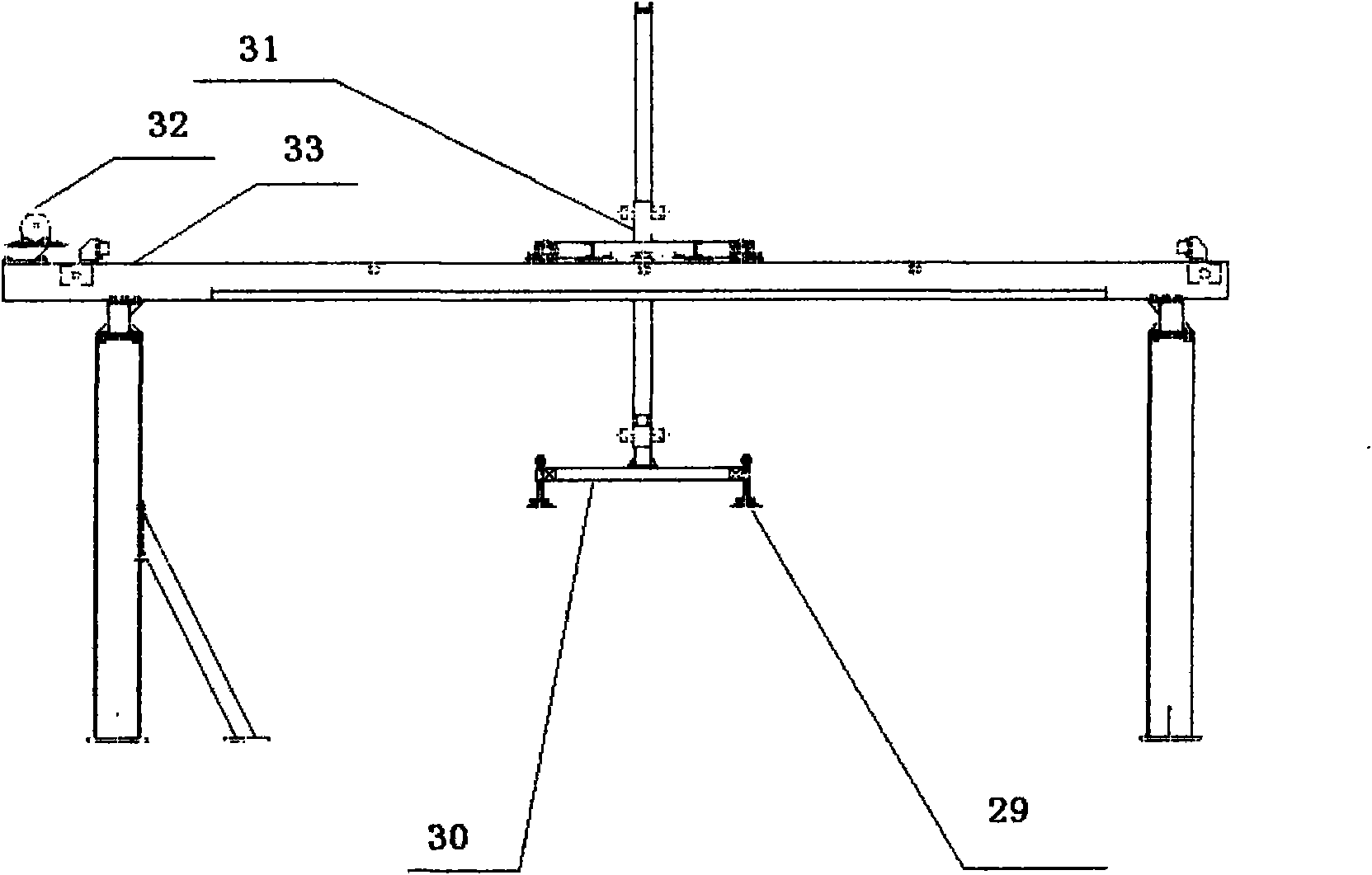

Automatic loading device for plates to be milled and loading material method thereof

InactiveCN101830013AAchieve mechanical propertiesFully automatedWood mortising machinesWood slotting machinesAutomatic controlEngineering

The invention discloses an automatic loading device for plates to be milled, which is suitable for delivering wood floor strips in a production process. The device consists of a feeding and discharging conveyor, a hydraulically lifted steering platform, a plate pusher or a plate absorbing carriage system, a lift-up roller and a turning and conveying mechanism, wherein the feeding and discharging conveyor is used for conveying a tray inside and outside; the hydraulically lifted steering platform is used for lifting the tray and steering the tray at an right angle horizontally; the plate pusher is used for pushing a plate blank onto the lift-up roller; the plate absorbing carriage system absorbs the plate blank and transfers the plate blank to the turning and conveying mechanism; and the turning and conveying mechanism turns the designated plate blank. The invention also discloses an automatic loading method for the plates to be milled, which comprises the following steps of: conveying the tray to the feeding and discharging conveyor; transferring the plate blank (lapped in a single manner) on the top layer onto the lift-up roller by using the plate pusher and conveying the plate blank onto the turning and conveying mechanism; or absorbing the plate blank and transferring the plate blank on the turning and conveying mechanism by using the plate absorbing carriage system; and turning over the designated plate blank by using a turning hook and conveying the designated plate blank into a two-end mill. The automatic loading device and the automatic loading method thereof adopt automatic control, are convenient to operate, reduce labor intensity and save materials.

Owner:苏州伍得人造板设备有限公司

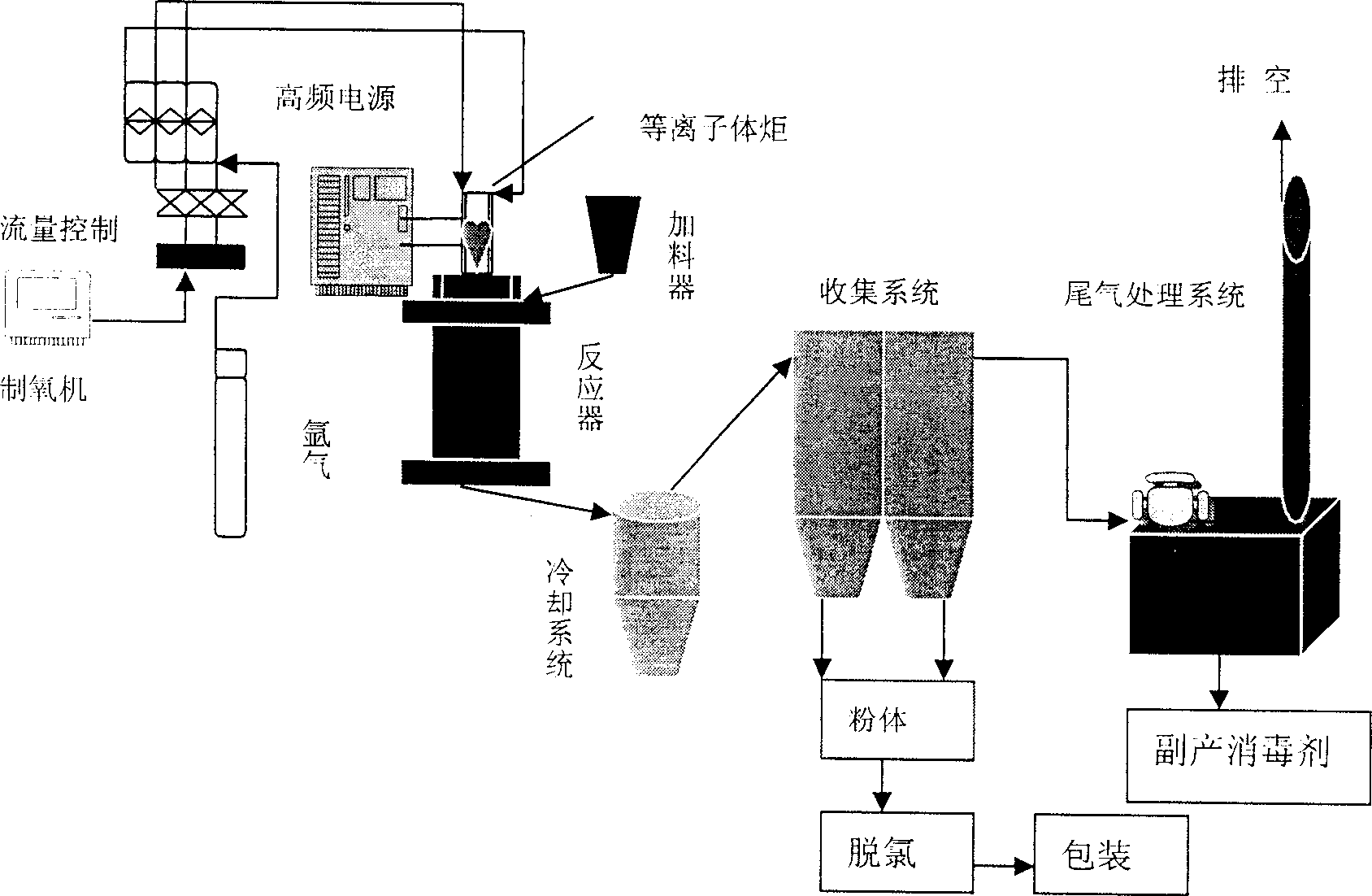

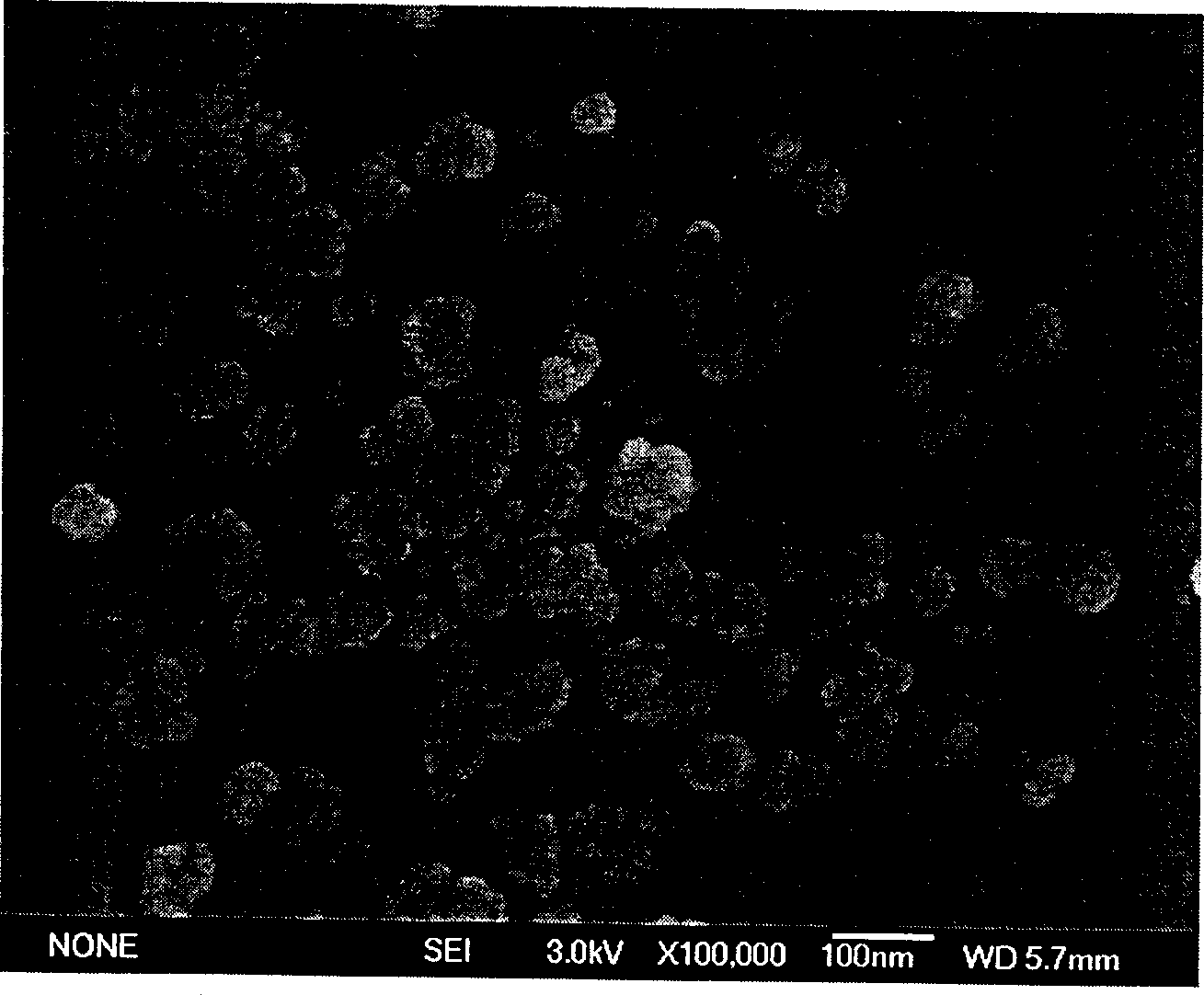

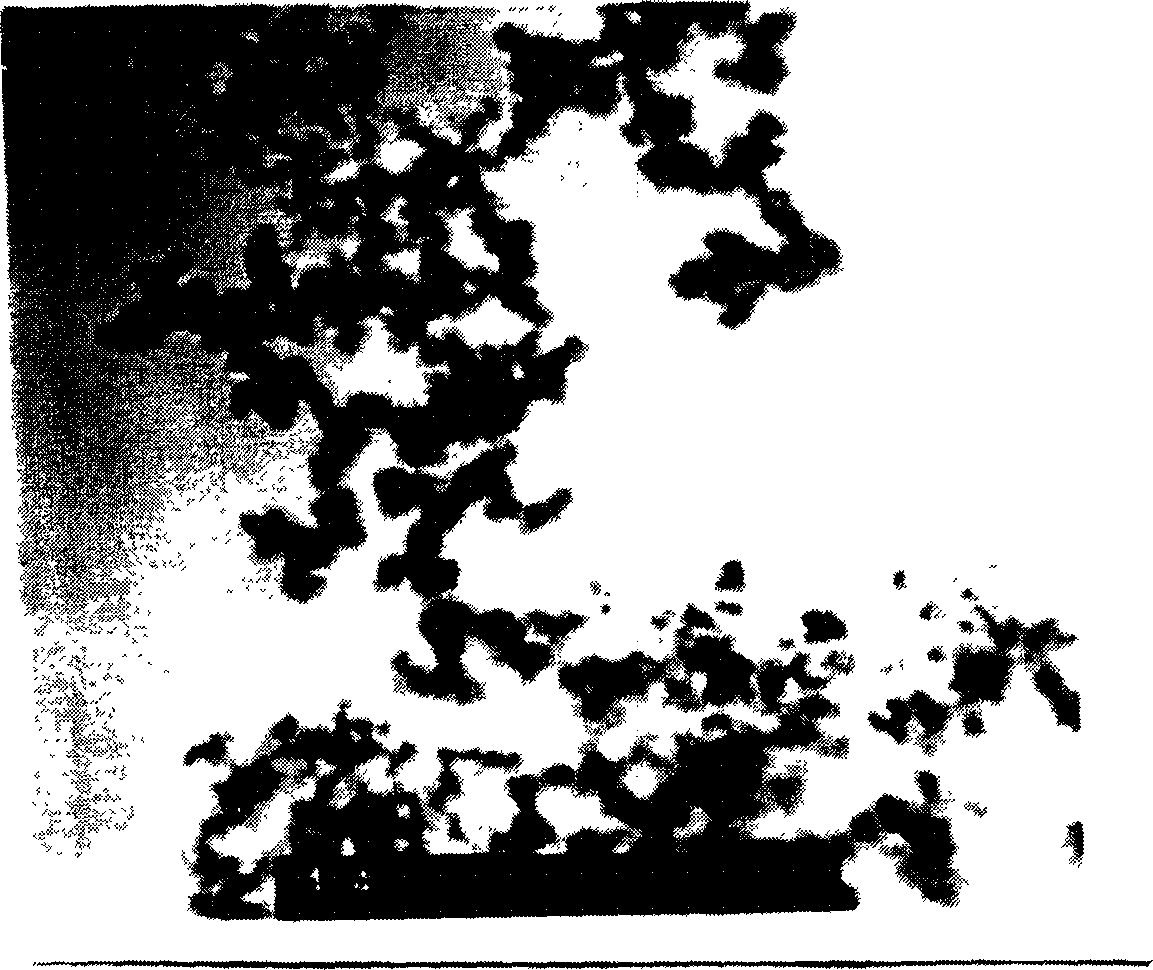

Preparation of high-purity nanometer silicon dioxide

Production of nanometer high-purity silicon dioxide in high-frequency plasma gas-phase oxidizing reactor is carried out by purifying air of oxygen and feeding it into high-frequency plasma generator, generating plasma oxygen at oscillating power 30KW and frequency 3í½4MHz, gasifying SiCl4 at 200í½300íÒC and delivering it plasma chemical reactor, reacting it with oxygen plasma at 1200í½1800íÒC, keeping the reactant in reactor for 0.15í½1s, removing scar with mol ratio of SiCl4 and oxygen: 1:1.2í½2, inducing dried air or N2 gas, quenching silicon dioxide crystal below 300íÒC, collecting powder, removing chlorine, and obtaining nanometer high-purity silicon dioxide. It achieves good dispersity, high output and simple process.

Owner:优美特(北京)环境材料科技股份公司

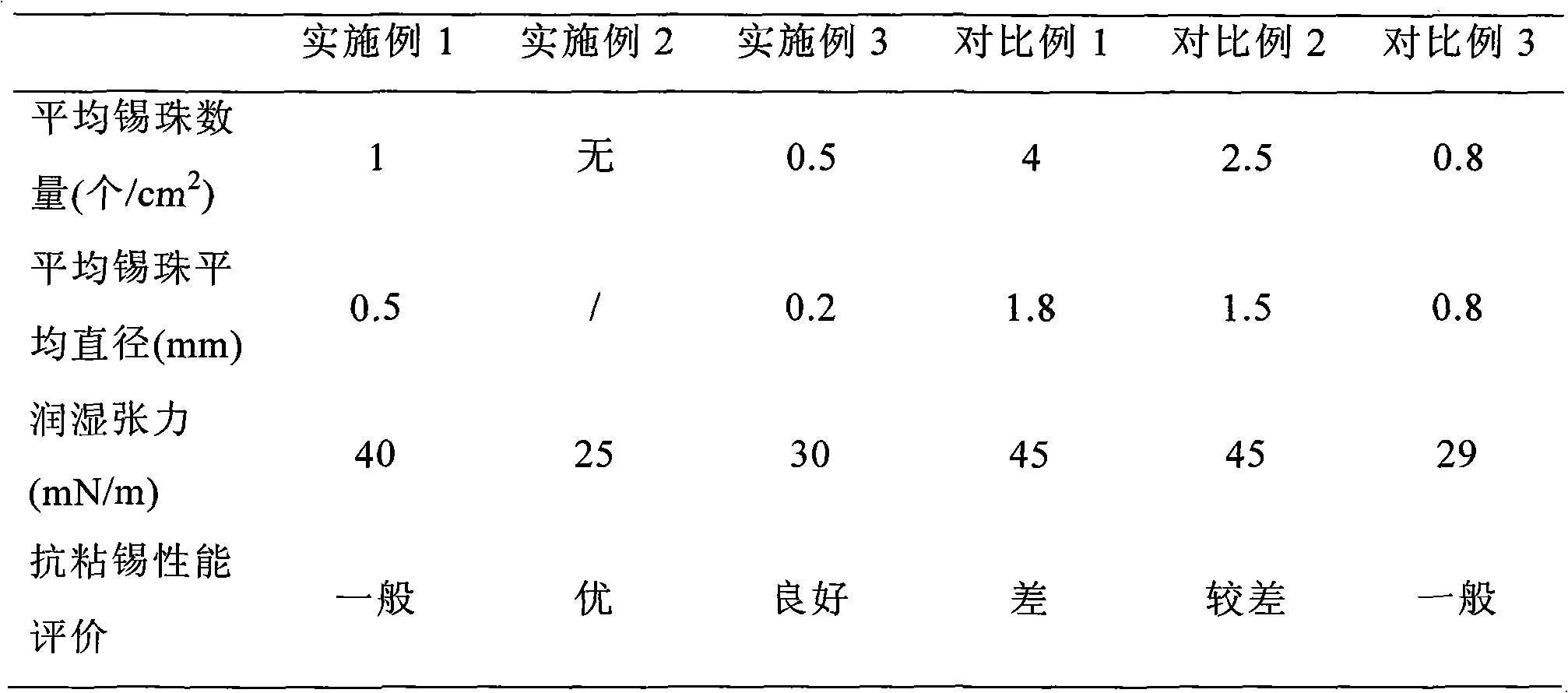

Anti-solder-adhering flame-retardant ABS modified resin and preparation method thereof

The invention relates to an anti-solder-adhering flame-retardant ABS modified resin and a preparation method thereof. The resin comprises the following components in part by weight: 100 parts of ABS resin, 10 to 25 parts of bromic flame retardant, 3 to 8 parts of antimonic flame retardant, 10 to 40 parts of heat-resistant master batch, 0.1 to 0.5 part of anti-dripping agent, 0.5 to 5 parts of active substance with low surface energy, 0.2 to 1 part of antioxidant and 1 to 3 parts of lubricant. The materials are mixed in a high-speed mixer and then sent into a double-screw extruder, and conveyed, sheared and mixed by screws, the materials are melted, compounded, extruded, drawn into bars, cooled and cut into granules, so that the anti-solder-adhering flame-retardant ABS modified resin is obtained. Compared with the prior art, the invention overcomes the defect that solder can easily adhere to the prior flame-retardant ABS resin when diodes are soldered, thus avoiding safety accidents caused by short-circuiting due to the existence of the adhering solder, moreover, the resin is endowed with higher electric safety performance, and the resin has a broad application prospect in the field of electronic devices.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

High-fluidity polyester composition and preparation method

The invention relates to a high-fluidity polyester composition and a preparation method, wherein the composition comprises the following components in parts by weight: 24 to 100 parts of thermoplastic polyester, 0.1 to 5 parts of flow promoter, 0.1 to 1 part of antioxidant, 0 to 15 parts of toughening agent and 0 to 50 parts of inorganic reinforced material, and the preparation method comprises the following steps: uniformly stirring and mixing the thermoplastic polyester, the flow promoter, the toughening agent and the antioxidant according to the proportion through a high-speed mixer, sending into a double-screw extruder through a main feed opening, subsequently adding the inorganic reinforced material into the extruder through a lateral feed opening, extruding and pelletizing to obtain a product. Compared with the prior art, the invention has the advantages of simple and continuous flow, high production efficiency, stable product quality and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

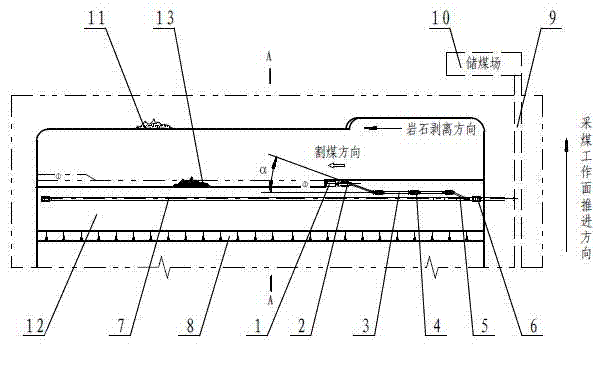

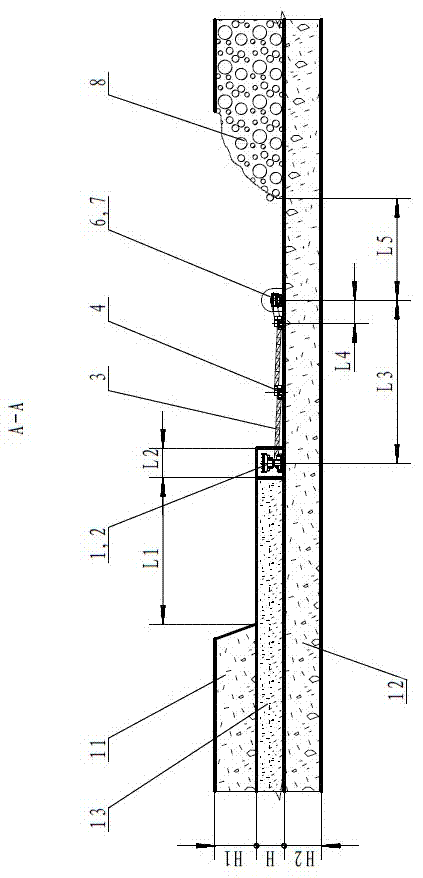

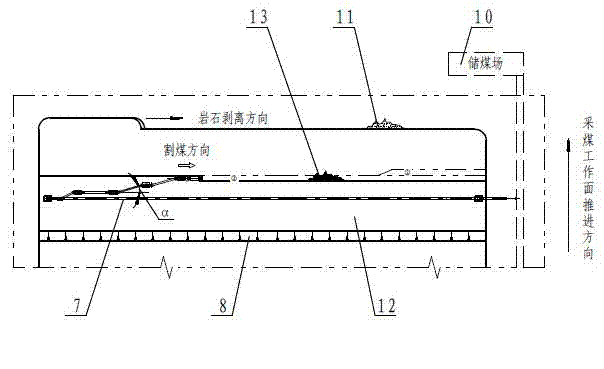

Continuous mining technique for thin coal layer of opencast coal mine

ActiveCN102889084AIdeal continuous coal mining processContinuous processUnderground miningSurface miningBridge typeCrusher

The invention relates to a continuous mining technique for a thin coal layer of an opencast coal mine. Aiming at a stratum condition and a reserve situation of the thin coal layer of the opencast coal mine, a plurality of mining areas are arranged; steps of digging, crushing, transferring, conveying and storing are adopted; an opencast coal mine continuous mining machine, an opencast coal mine traveling type feeding crusher, a long-span bridge type reversed loader, a travelling reversed loader, a short-span bridge type reversed loader, a discharging trolley, a working surface belt conveyer and a machine alley externally-used belt conveyer are integrated; and a production mode combining digging, crushing, conveying, discharging and storing is formed. The coal mining technique is advanced; the devices are scientific and rational; equipment are compact and continuously arranged and are safe, stable and reliable; the mining efficiency is high; multi-stage transferring is realized; coals can be smoothly conveyed; and the continuous mining technique for the thin coal layer of the opencast coal mine is very ideal.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

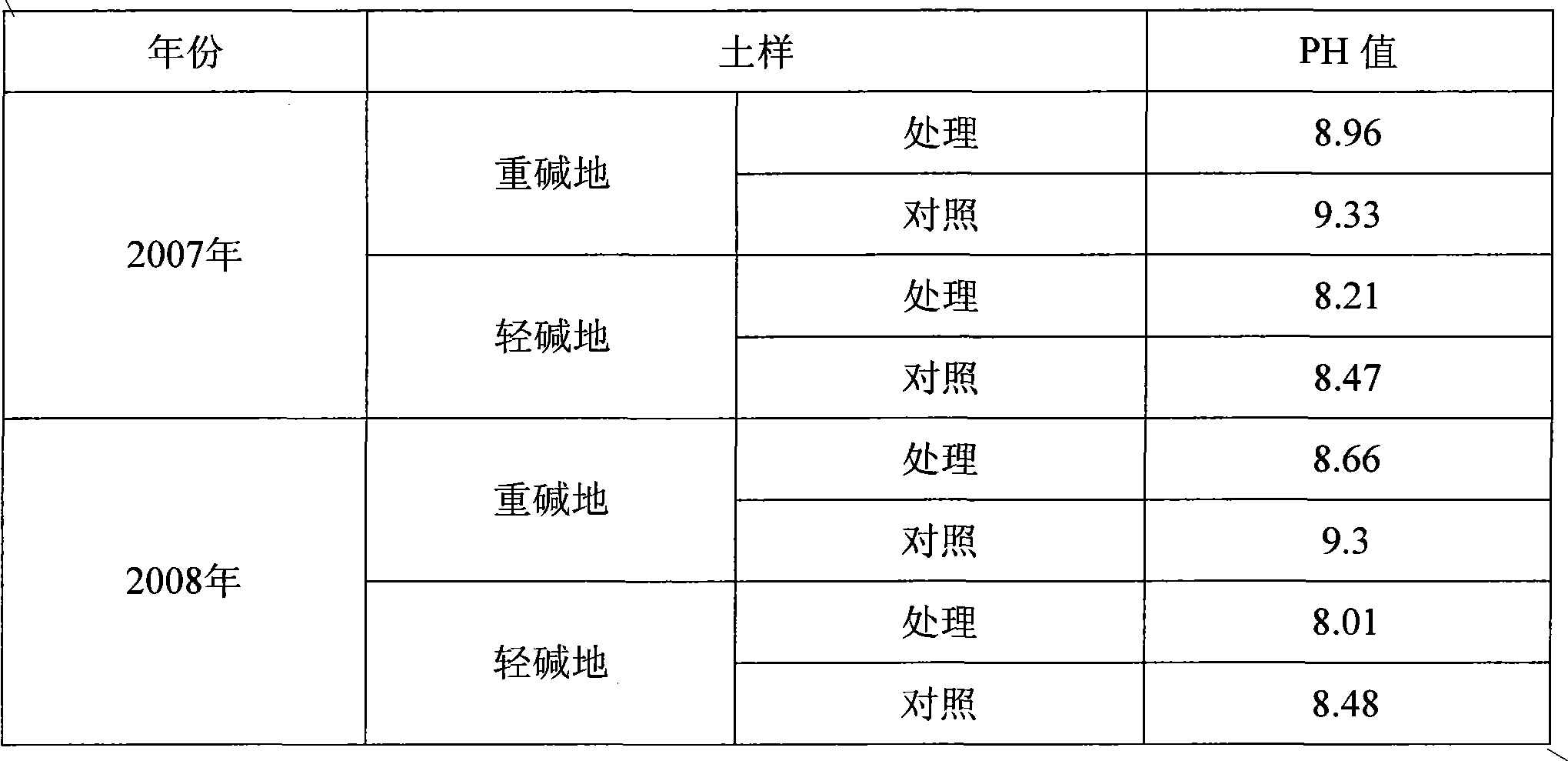

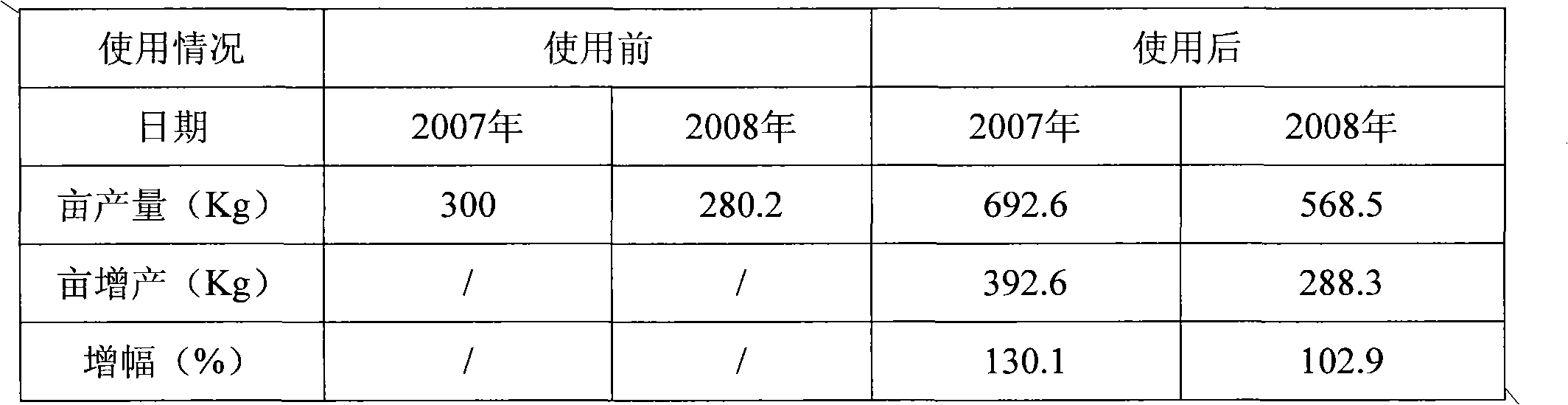

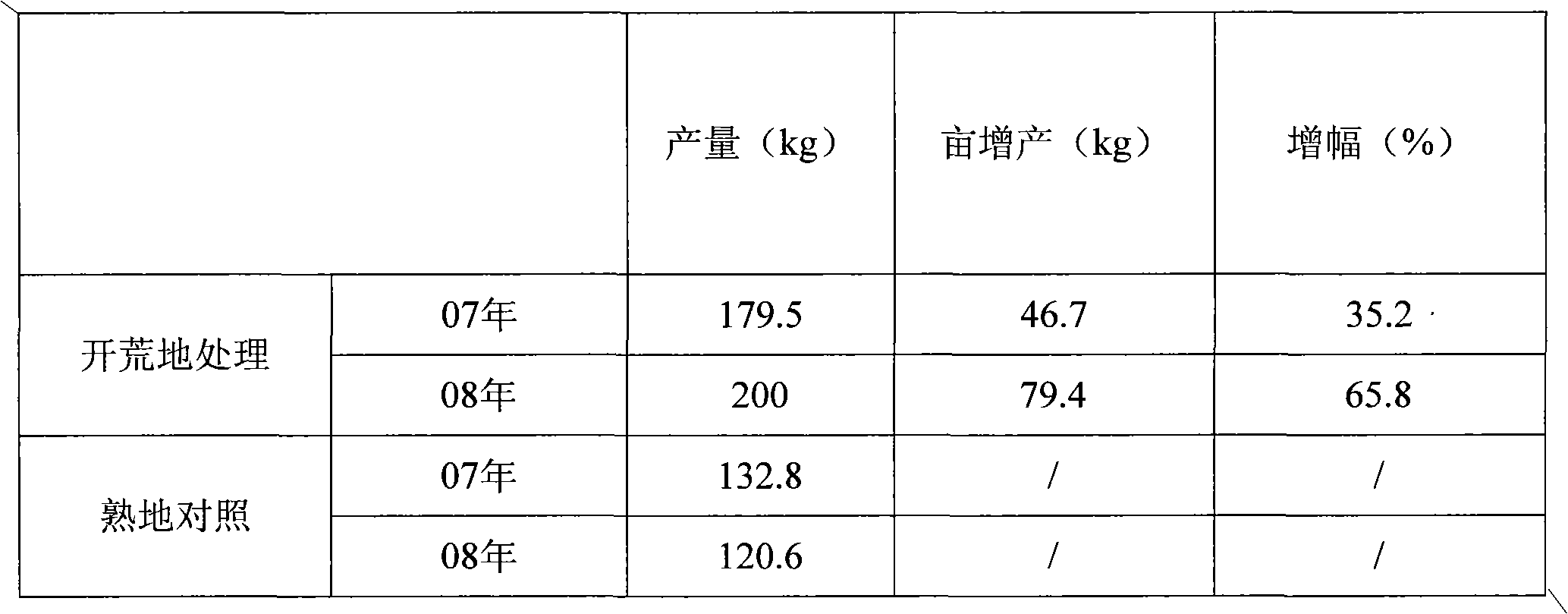

Industrial sludge treatment method and method for preparing various fertilizers by using treated industrial sludge

ActiveCN102010108ARapid precipitationDehydration fastSludge processingMultistage water/sewage treatmentAlkali soilWater insoluble

The invention discloses an industrial sludge treatment method and a method for preparing various fertilizers by using the treated industrial sludge. The industrial sludge treatment method comprises the following steps of: after industrial sludge is diluted, adding a heavy metal ion capturing and precipitating agent DTCR and reacting the agent with heavy metal ions in waste solution so as to generate water-insoluble chelated salt; adding a polyacrylamide flocculating agent to ensure that the chelated salt forms flocculent precipitates; and removing the flocculent precipitates to obtain sludge water, and adding potato water into the sludge water to ferment the sludge. The method for preparing various fertilizers by using the treated industrial sludge comprises the following steps of: preparing a powdery biological bacterial fertilizer by taking the sludge water obtained from the treated sludge as a raw material; and preparing a granular organic fertilizer and a fertilizer for changing saline and alkaline lands into fertile farmlands by taking the powdery biological bacterial fertilizer as a raw material. The industrial sludge treatment method has low cost and does not cause secondary pollution to the environment. The biological bacterial fertilizer and the granular organic fertilizer which are produced by the invention are used in lands of various areas, the yield is improved by 15 to 20 percent; and the fertilizer for improving the saline and alkaline lands has extremely obvious saline and alkaline transformation effect.

Owner:LIAOCHENG JINTAIYANG BIOCHEM

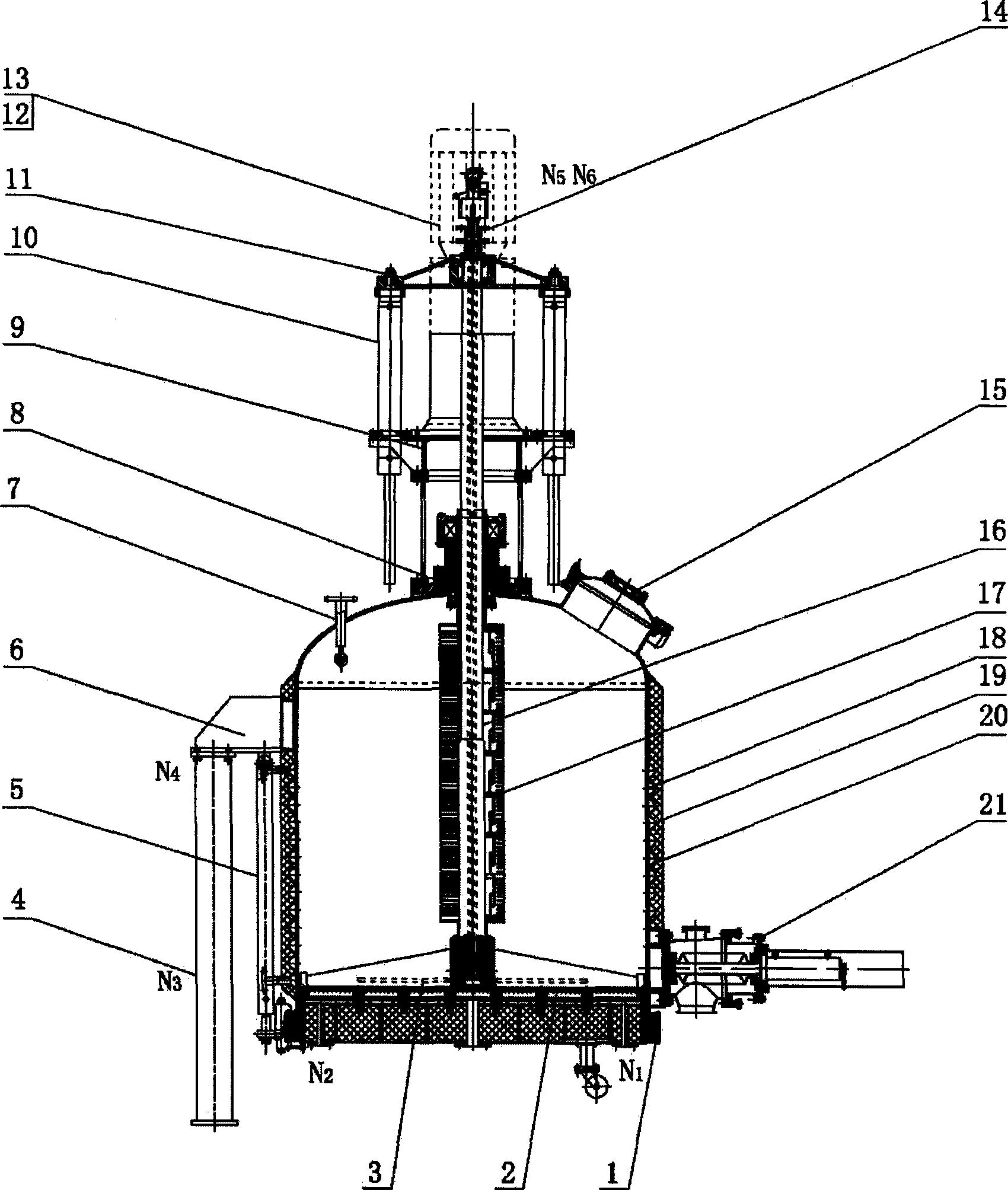

Filtering, cleaning, drying three-in-one device

InactiveCN101455918AReduce labor intensityNo harmStationary filtering element filtersEngineeringInsulation layer

The present invention relates to three-in-one equipment of filtering, washing and drying, which is provided with a pot body, a chassis, a supporting seat, a pot body attachment and an insulation layer. The equipment is characterized in that the pot body is also provided with a stirrer which can be lifted; a coiled pipe type heater is arranged on the side walls of the pot body and the chassis; the bottom of the pot body is provided with a filter disc; and the side at the bottom of the pot body is provided with a hydraulic pressure material outlet device. The equipment can achieve the functions of filtering, washing and drying under airtight environment. At the time of achieving a continuous process, harmful gas can not volatilize so as to not generate harm to operation workers because the equipment is airtight. Material discharge is achieved by back pushing the materials through a stirring blade, and automatic material discharge is achieved through the hydraulic pressure material outlet device. Compared with a manual material outlet device, the equipment greatly reduces labor intensity of workers.

Owner:WUXI ZHANGHUA MEDICAL EQUIP

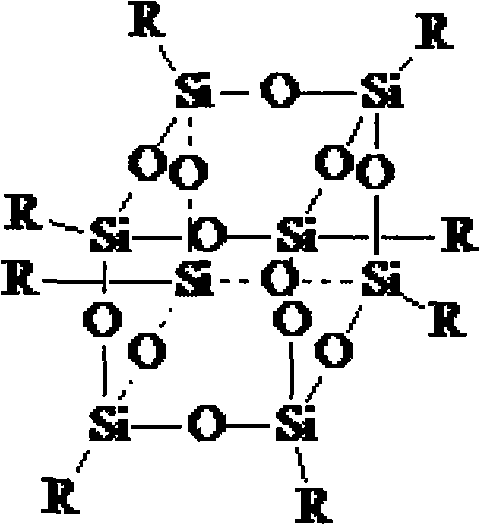

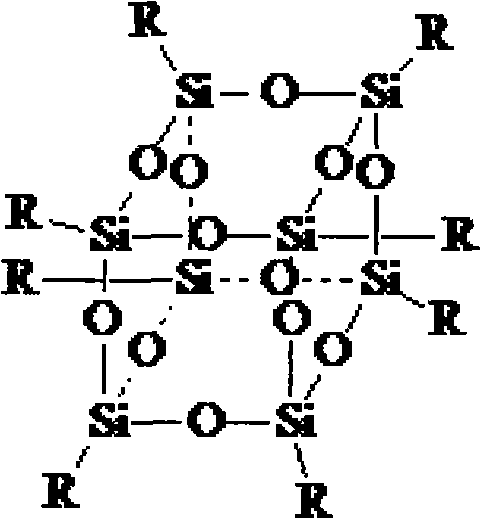

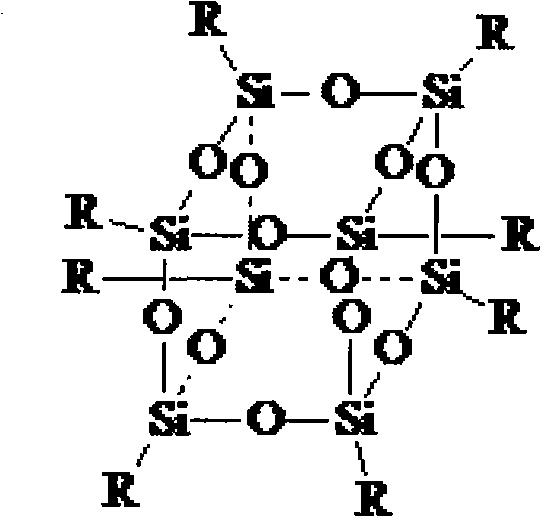

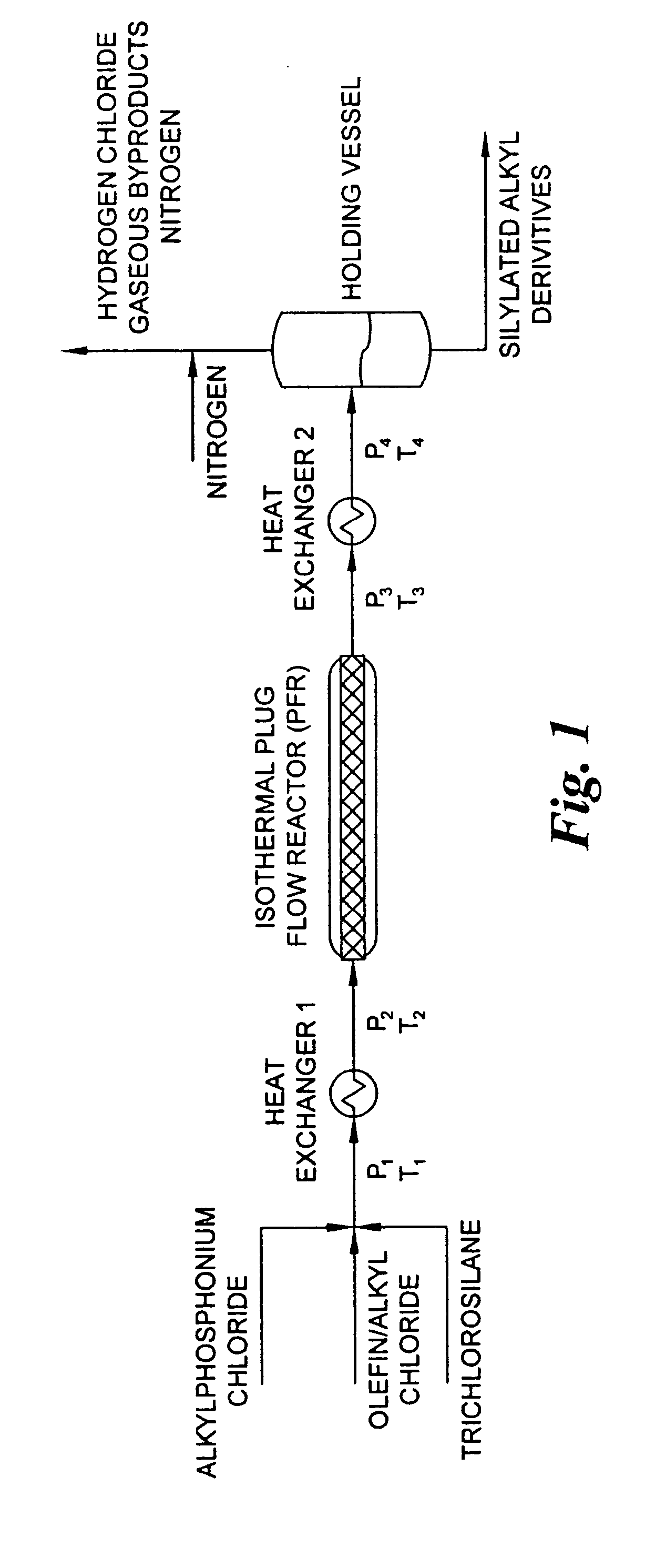

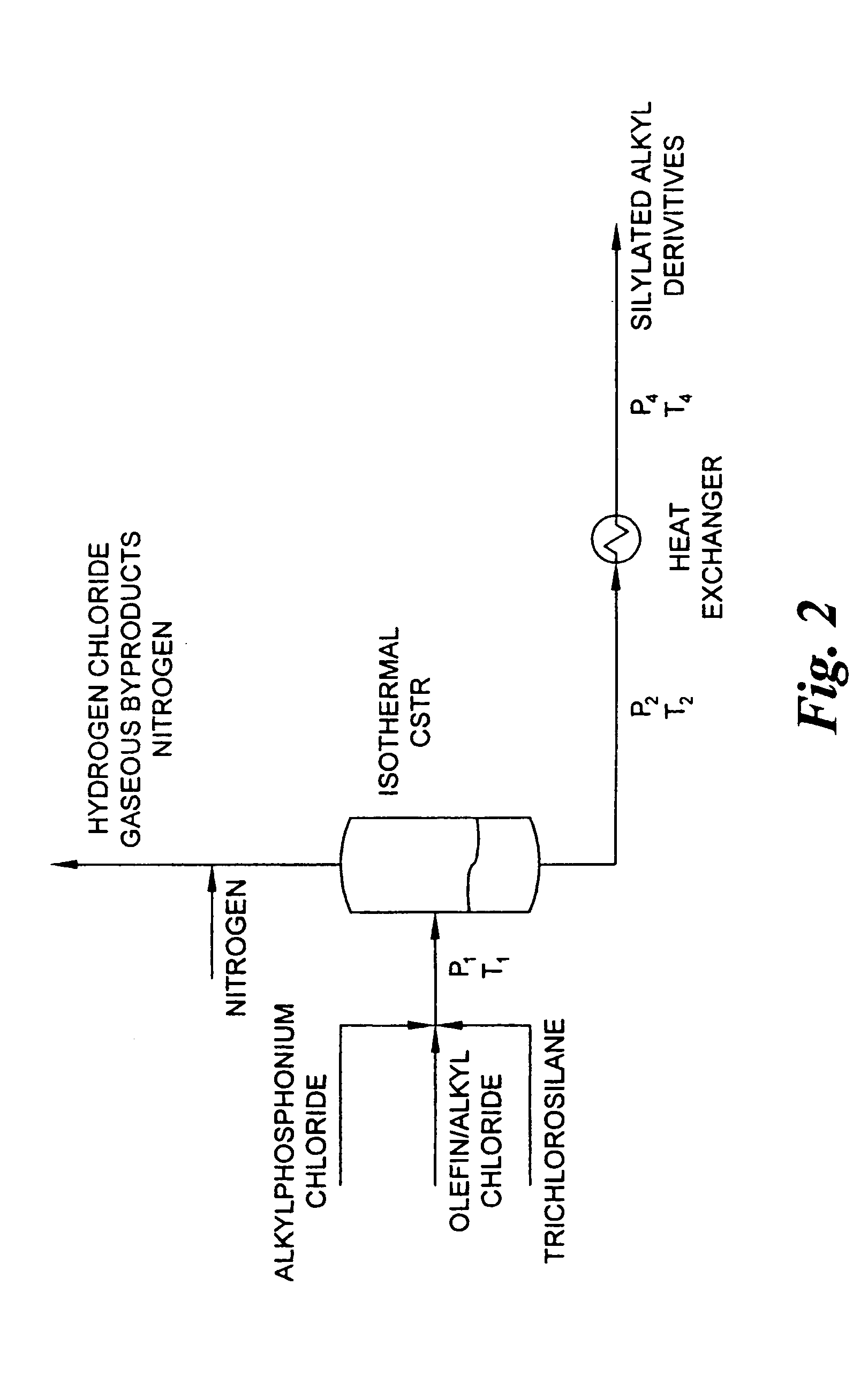

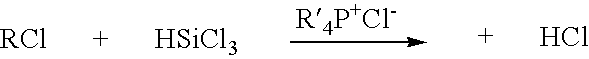

Processes for manufacturing organochlorosilanes and dipodal silanes and silanes made thereby

ActiveUS20050027138A1Continuous processEliminate formationSilicon organic compoundsContinuous useChemistry

Processes are provided for producing organchlorosilanes and dipodal silanes in which an organic halide or alkene or chloralkene is reacted with a hydridochlorosilane in the presence of a quarternary phosphonium salt catalyst by providing sufficient heat to effect a dehydrohalogenative coupling reaction and / or a hydrosilylation reaction and venting the reaction to control reaction pressure and to remove gaseous byproducts from the reaction. The processes are preferably continuous using a catalyst in fluid form at reaction pressures not exceeding about 600 psi. The reactions may be carried out substantially isothermally and / or isobarically, for example in a plug flow reactor or continuous stirred tank reactor. The processes may produce novel silylated compounds including 1,2-bis(trichlorosilyl)decane or 1,2-bis(trimethoxysilyl)decane.

Owner:GELEST

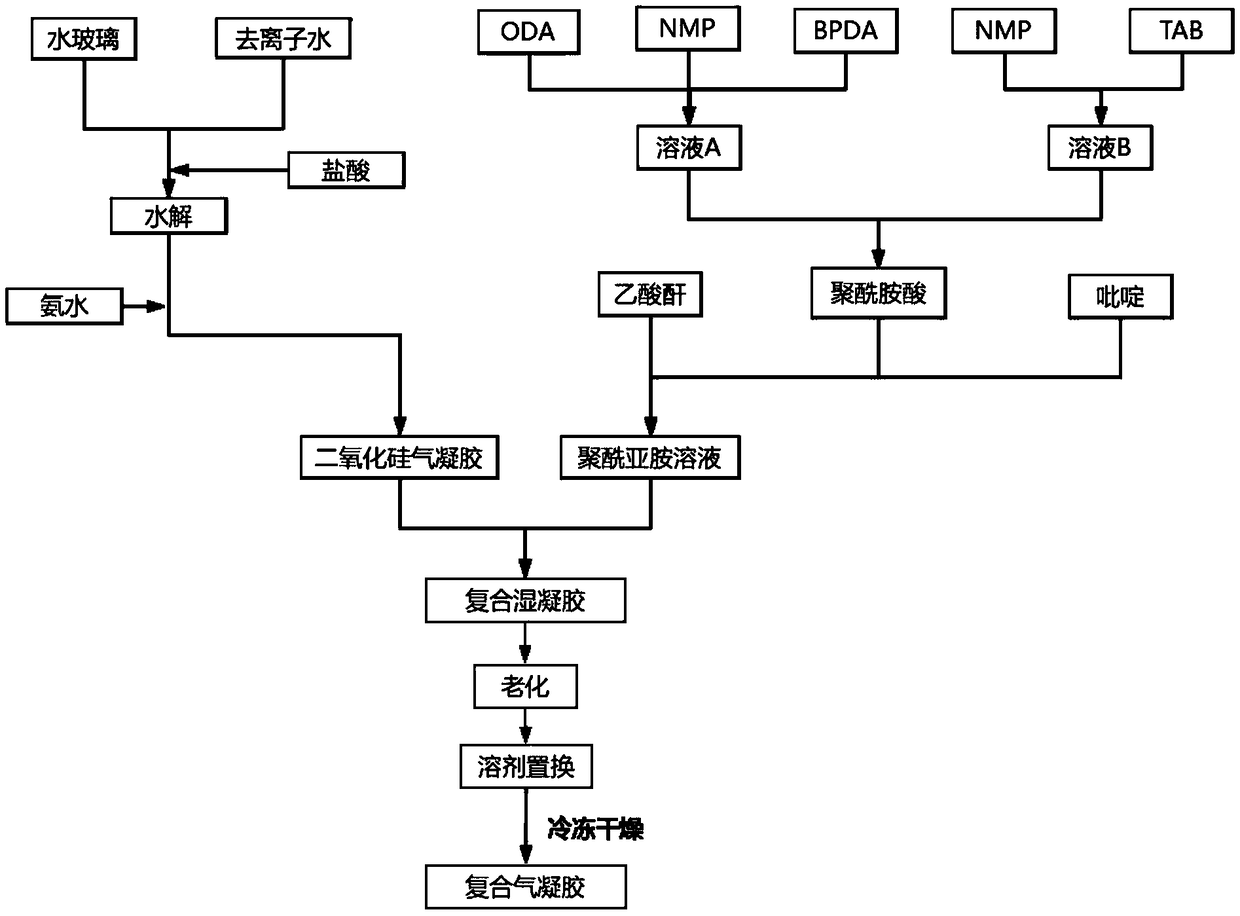

Hydrophobic silicon dioxide/polyimide aerogel composite material and preparation method

ActiveCN108727818AImprove hydrophobicityImprove mechanical propertiesTemperature resistanceSilicon dioxide

The invention provides a hydrophobic silicon dioxide / polyimide aerogel composite material. The hydrophobic silicon dioxide / polyimide aerogel composite material comprises hydrophobic modified silicon dioxide aerogel and polyimide aerogel, wherein the polyimide aerogel is used as a substrate of the composite material, and hydrophobic modified silicon dioxide aerogel fillers are embedded into pores of the polyimide aerogel. According to the hydrophobic silicon dioxide / polyimide aerogel composite material, the silicon dioxide aerogel is added to the polyimide aerogel; the polyimide aerogel is usedas the substrate and a framework of a composite heat insulation material to realize the supporting reinforcing effect, so that the mechanical strength of the composite heat insulation material is improved; and the silicon dioxide aerogel is used as the filler and has the hydrophobic function and outstanding heat insulation performance, so that the heat insulation effect is realized in the composite material. The hydrophobic silicon dioxide / polyimide aerogel composite material comprehensively considers the physical performance and the mechanical performance of the composite heat insulation material and has the advantages of being high in strength, high in high temperature resistance, low in volume weight, low in heat conductivity, and high in waterproofing performance, and meets the requirements on performances of the heat insulation material in actual application.

Owner:UNIV OF SCI & TECH OF CHINA

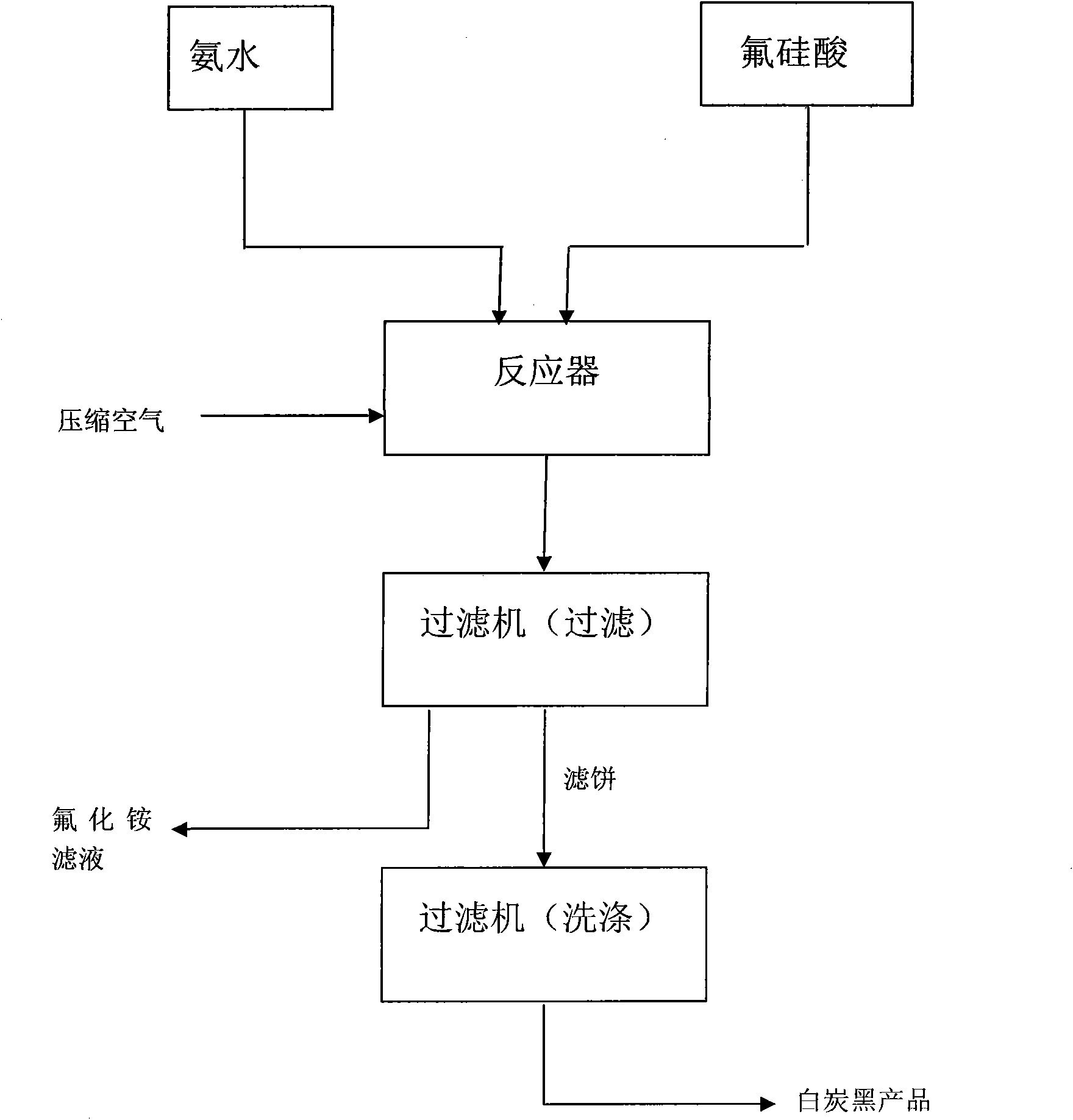

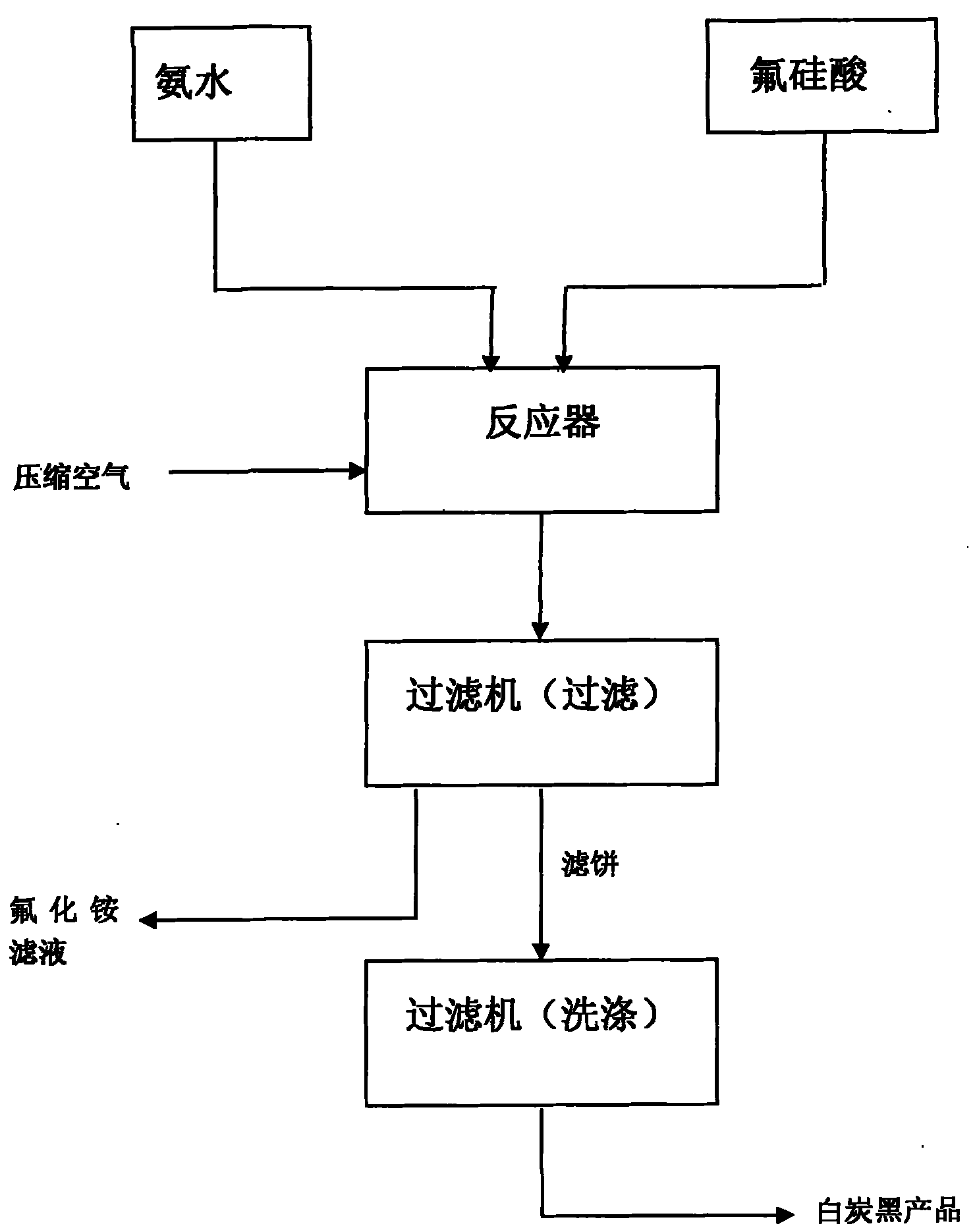

Method for continuously preparing white carbon black and ammonium fluoride by carrying out fluosilicic acid ammoniation

ActiveCN101863482AContinuous processProcess stabilitySilicaAmmonium halidesSal ammoniacHexafluorosilicic acid

The invention discloses a method for continuously preparing white carbon black and ammonium fluoride by carrying out fluosilicic acid ammoniation, which relates to a chemical production method, in particular to a method for preparing the white carbon black and the ammonium fluoride. The method comprises the following steps: (a) at a temperature between minus 5 and 30 DEG C, starting a stirrer and an air compressor, blowing compressed air into an outlet pipe of a reactor by the air compressor and adding fluosilicic acid and ammonia into the reactor simultaneously; (b) when the fluosilicic acid and the ammonia are added to the position of an overflow pipe in the reactor, opening an emptying valve to continuously feed and discharge materials and controlling a PH value of the reaction, wherein the period of the continuous reaction is 24 hours; (c) in the reaction process, filtering the materials discharged by the step (b) to obtain a white carbon black filter cake and filtrate of ammonium fluoride, and washing and drying the white carbon black filter cake to obtain a white carbon black finished product, wherein the filtrate is ammonium fluoride solution; and (d) after performing a reaction for 24 hours in the reactor, emptying the materials, cleaning the reactor to be used next time and producing the white carbon black finished product by using the materials according to the step (c), wherein the ammoniation yield of the process can reach 99.99 percent. The method of the invention effectively overcomes the defects of the existing intermittent technology and has the advantages of continuous, stable and simple process and long operation period.

Owner:YUNNAN YUNTIANHUA +1

Preparation method of hollow fiber nanofiltration membrane

ActiveCN103041713AAvoid the problem that it is difficult to distribute fully and evenly on the surface of the membrane filamentHigh affinitySemi-permeable membranesDouble diffusionSolvent

The invention discloses a preparation method of a hollow fiber nanofiltration membrane, and provides the preparation method of the hollow fiber nanofiltration membrane continuous in technical process, uniform in nanofiltration functional layer and few in deficiencies. The method comprises the following steps of: using polyelectrolyte aqueous alkali as an outer coagulating bath and a mixed liquor of water and a solvent for the coagulating bath as an inner coagulating bath, spinning and forming a hollow fiber nanofiltration membrane spinning and membrane forming system through a hollow spinning nozzle and a double diffusion process, and initially curing and forming a hollow fiber membrane; and adding the initially cured hollow fiber nanofiltration membrane into an aqueous liquor of polyamine, erasing the suspended liquid on the surface, adding the membrane into an organic liquor of polyacyl chloride, and drying and curing the membrane to obtain the hollow fiber nanofiltration membrane. The method provided by the invention is continuous in technical process, uniform and controllable in nanofiltration functional layer and few in defects, and has a wide prospect in the fields of seawater and brackish water desalination, treatment and recovery of sewage and wastewater, preparation of ultrapure water and the like.

Owner:ZHEJIANG JINMO ENVIRONMENT TECH CO LTD

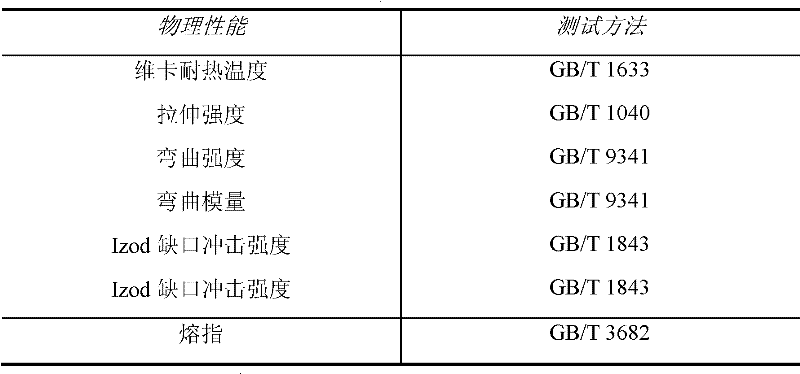

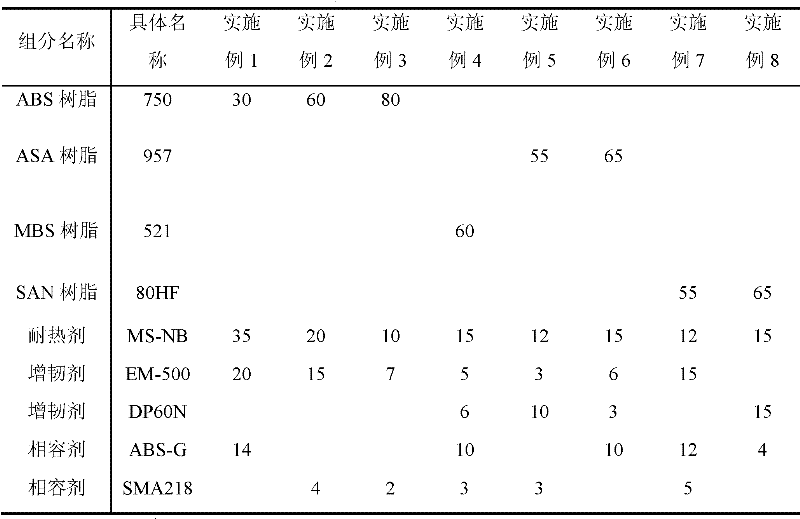

High-heat-resistance high-toughness ABS (acrylonitrile-butadiene-styrene) resin and preparation method thereof

The invention discloses a high-heat-resistance high-toughness ABS (acrylonitrile-butadiene-styrene) resin and a preparation method thereof. The high-heat-resistance high-toughness ABS resin comprises the following components in parts by weight: 30-90 parts of ABS resin, 10-50 parts of heat resisting agent, 5-30 parts of toughener, 5-20 parts of compatilizer, 0.5-1 part of antioxidant assistant and 1 part of processing assistant. The high-heat-resistance high-toughness ABS resin is prepared by a double-screw extrusion technique; the preparation technique has the advantages of simple and continuous process and high production efficiency, can greatly enhance the heat resistance temperature of the ABS, well maintains the toughness of the universal ABS, and can partially be substituted for a PC (polycarbonate) / ABS alloy material.

Owner:滁州格美特科技有限公司

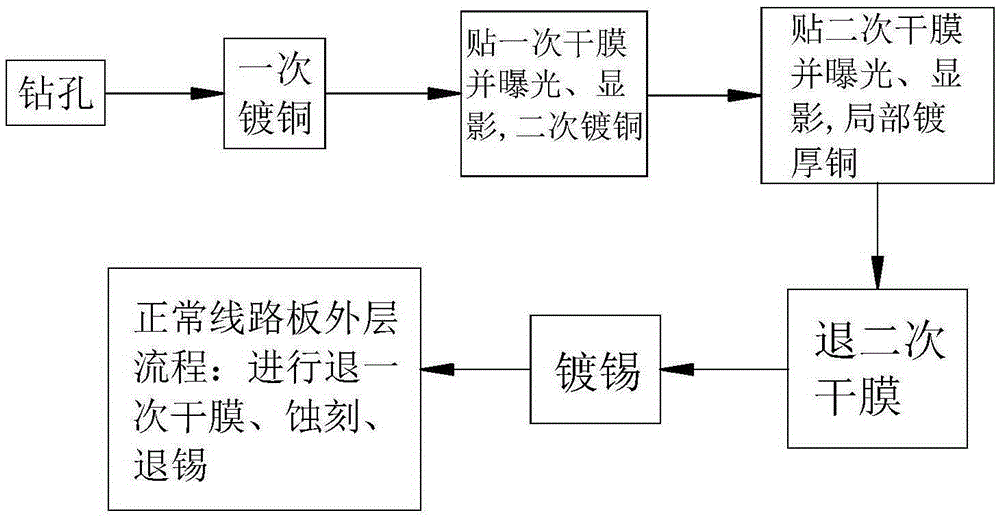

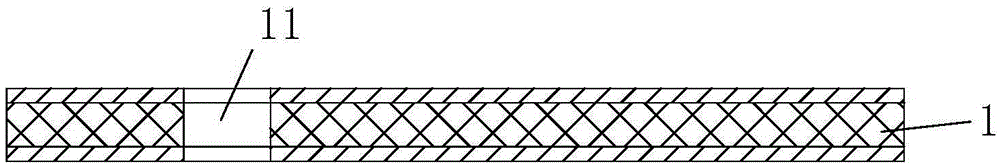

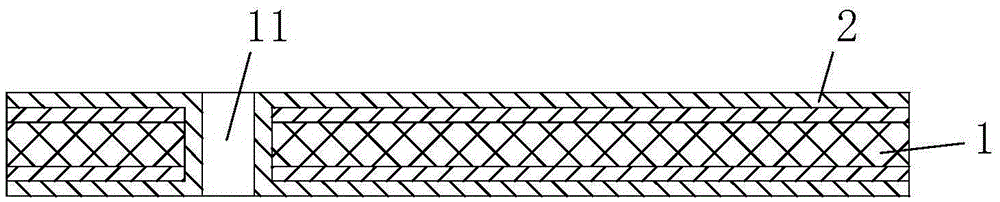

Production method of local-thick copper PCB

InactiveCN105338754AContinuous processSimple processPrinted circuit aspectsConductive pattern reinforcementTinningEtching

The invention relates to technical field of PCBs and particularly relates to a production method of a local-thick copper PCB. The production method comprises the following steps of A, drilling, namely drilling on a circuit board; B, primary copper plating; C, secondary copper plating, namely pasting a primary dry film, exposing, developing, and then, carrying out secondary copper plating treatment on the circuit board; D, local thick copper plating, namely pasting a secondary dry film, exposing, developing, and then, carrying out thick copper plating treatment on the circuit board; E, secondary dry film deplating; F, tin plating; and G, primary dry film deplating, etching and tin deplating treatment. According to the production method, secondary copper plating is carried out through covering a region to be etched by using the primary dry film, and then, the region except for the regions where thick copper is needed to be plated are covered by the secondary dry film, so that the process is continuous, local thick copper plating can be realized favorably through only selecting the dry films with proper thicknesses and controlling proper film deplating parameters, and the process flow is simplified; the films can be pasted on a plane every time, so that the films are firmly pasted, the rate of good products is increased, and the quality of the local-thick copper PCB is improved.

Owner:东莞森玛仕格里菲电路有限公司

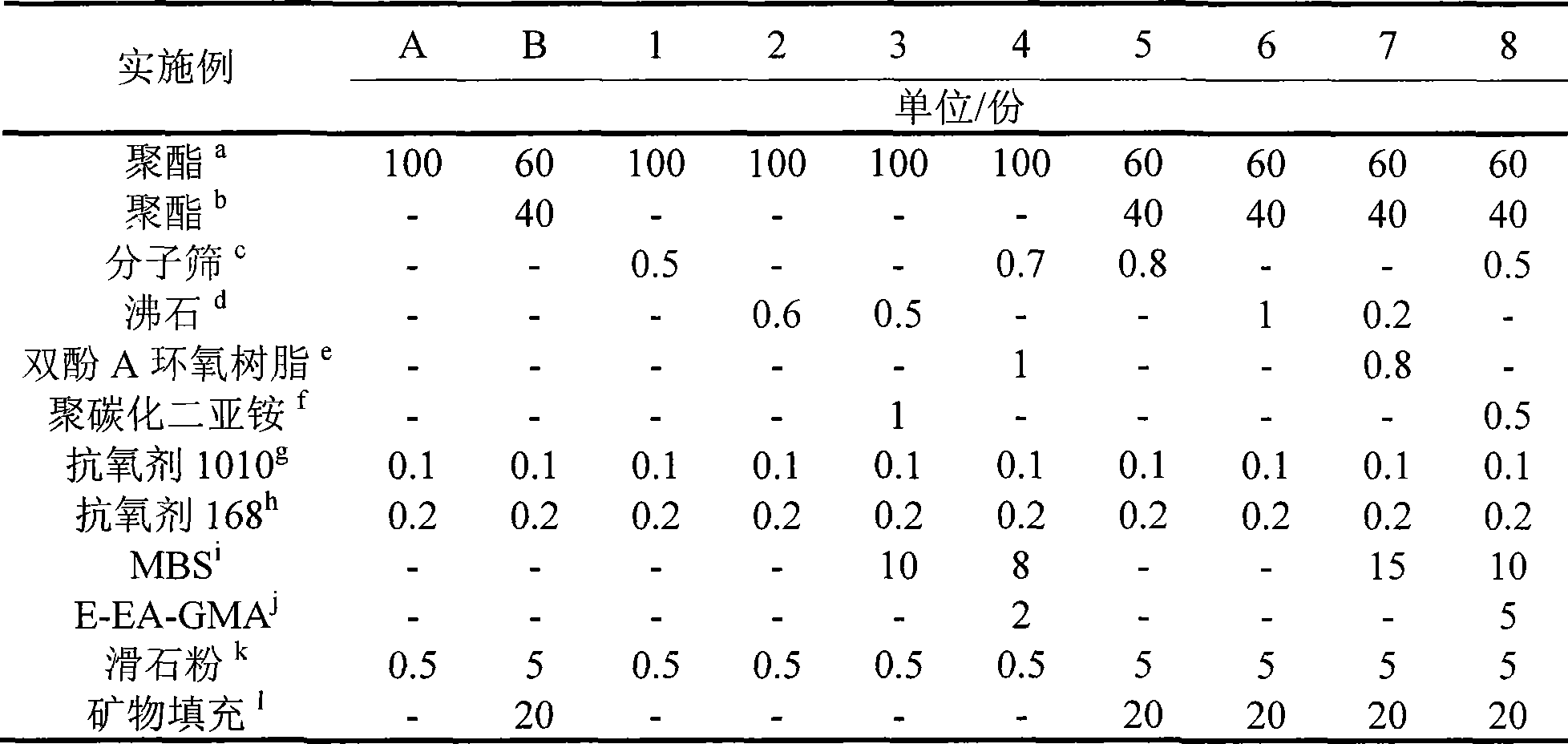

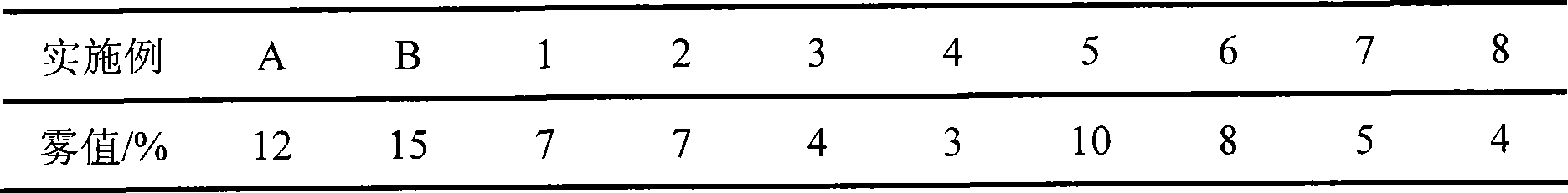

Low fog value polyester composition and preparation thereof

The invention relates to a polyester composition with low fog value and a preparation method thereof. Hypocrystalline thermoplastic polyester, micromolecule absorbent, long lasting stabilizing agent, antioxidizer, nucleating agent and toughener are evenly mixed at the mixture ratio according to the parts by weight, and then stirred by a high-speed mixer; the mixture is transmitted into a double screw extruder by main feeding, and then mineral filling material is added into the extruder from side feeding; finally, granules are extruded, and the product is obtained. The finished piece material of the polyester composition with low fog value can be maintained for 24h at the temperature of 150-185 DEG C, and the light transmission rate of a glass sheet which is fogged is reduced by 0-5%. Furthermore, the preparation operating process is simple and continuous, and has high production efficiency and stable product quality.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Method for producing maleic anhydride through benzene process and absorbing maleic anhydride with solvent

InactiveCN103044368ASimple processNo environmental problemsOrganic chemistryFumaropimaric acidBenzene

The invention discloses a method for producing maleic anhydride through a benzene process. The method comprises the steps of: enabling a maleic anhydride gas and air mixture obtained by oxidizing benzene and air with an oxidizer to pass a solvent absorption tower and be absorbed by a solvent, separating the maleic anhydride from the solvent containing the maleic anhydride through a desorber, enabling the separated coarse maleic anhydride to enter a refining tower and be refined to prepare the maleic anhydride finished product, and regenerating the separated solvent for recycling. According to the method, a non-water recovery technology is adopted, lots of energy consumption for evaporation and dehydration is reduced, the generation of impurities such as fumaric acid is avoided, the recovery rate of the maleic anhydride is increased, the equipment investment is reduced, and the cost is saved.

Owner:WEIFANG YUANLI CHEM

Polyropylene composite material and preparation method thereof

InactiveCN104974418AImprove notched impact strengthHigh strengthPolypropylene compositesPolymer science

The invention discloses a polypropylene composite material and a preparation method thereof, wherein the material includes, by weight, (a) 40-85% of polypropylene resin, (b) 5-30% of a toughening agent, (c) 5-40% of a filling material, (d) 0.1-1% of a composite antioxidant, and (e) 0.1-1% of a processing aid. The preparation method includes the steps of (1) weighing the material according to the weight ratio of 40-85% of the polypropylene resin, 5-30% of the toughening agent, 5-40% of the inorganic material, 0.1-1% of the composite antioxidant, and 0.1-1% of the processing aid; (2) mixing the raw materials in a high-speed mixer uniformly; and (3) performing extrusion in a double-screw extruder to obtain a blended substance. The polypropylene composite material is excellent in anti-impact performance, is high in toughness at normal and low temperatures, is excellent in notch impact strength and is excellent in heat resistance and rigidity.

Owner:SINOPEC YANGZI PETROCHEM +1

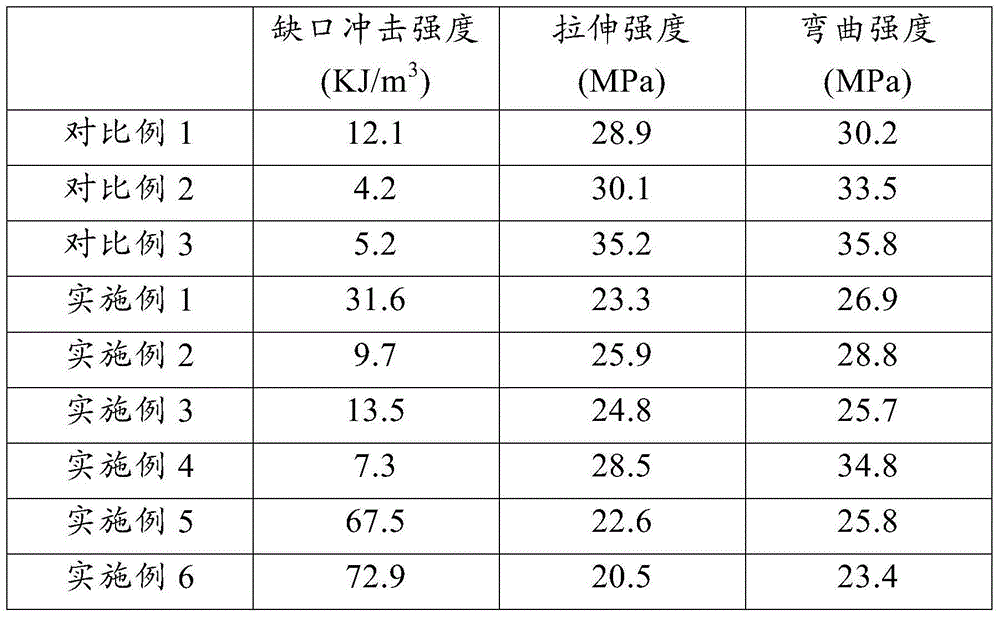

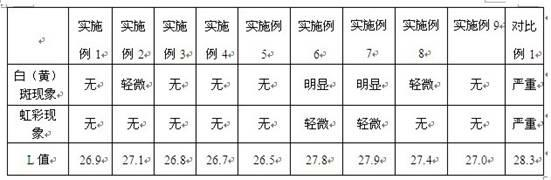

ASA (acrylonitrile-styrene-acrylate) resin with favorable appearance performance and preparation method thereof

The invention discloses an ASA (acrylonitrile-styrene-acrylate) resin with favorable appearance performance and a preparation method thereof. The ASA resin comprises the following components in parts by weight: 10-50 parts of SAN (styrene-acrylonitrile), 50-90 parts of ASA crosslinking-modified graft copolymer, 0.2-0.6 part of light stabilizer, 0.2-1 part of antioxidant and 0.2-2 parts of lubricant. The preparation method comprises the following steps: stirring and mixing the raw materials, and sending the mixture into a double screw extruder; and under the actions of delivering, shearing andmixing of the screws, melting and compounding the material, extruding, drawing, cooling, and granulating to obtain the ASA resin with favorable appearance performance. The invention solves the problems of uneven luster, high tendency to irisation and white spotting, and low coloring power in the existing injection-molding ASA resin, thus has excellent appearance performance, and greatly widens the application range of the ASA resin in the fields of building materials, automobiles, electronic and electrical engineering, outdoor supplies, sports equipment and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

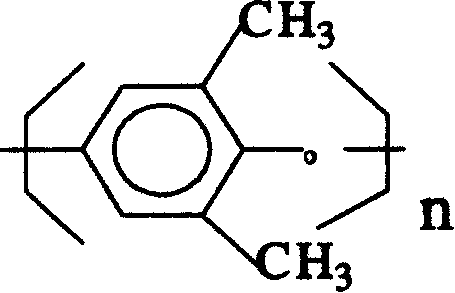

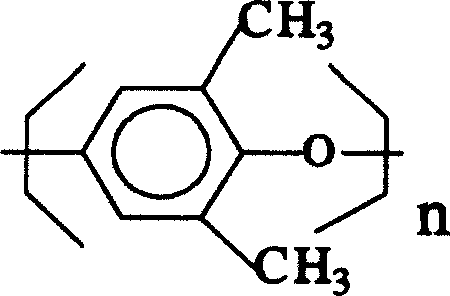

Halogen -free flame-proof ABS resin and its preparing method

The halogen-free flame retardant ABS resin consists of ABS resin 100 weight portions, polyphenylene oxide 2-30 weight portions, phosphonate 5-20 weight portions, epoxy resin 1-10 weight portions, light and heat stabilizer 0.2-2 weight portions and processing assistant 1-5 weight portions. The halogen-free flame retardant ABS resin has the excellent performance of ABS resin maintained, flame retardant property, and the synergistic flame retarding effect of different flame retardant components. The preparation process of the halogen-free flame retardant ABS resin is also disclosed.

Owner:KINGFA SCI & TECH CO LTD +1

Method for compounding functional nanoparticles on surfaces of polymer filaments

ActiveCN103556451ADoes not affect mechanical propertiesRetain mechanical propertiesVegetal fibresFiberPolymer science

The invention relates to a method for compounding functional nanoparticles on surfaces of polymer filaments, belonging to the technical field of new fiber materials. The method comprises the steps of protein-based modification on surfaces of functional nanoparticles, preparation of a blended solution, formation of polymer filaments with surfaces compounded with the blended solution and control of thickness, phase inversion primary formation of the polymer filaments with surfaces compounded with the blended solution and thermosetting formation of the polymer filaments with surfaces compounded with the blended solution, thus obtaining the polymer filaments with surfaces compounded with the functional nanoparticles. In the preparation method, carbon nano tubes, graphene, carbon black, titanium dioxide, zinc dioxide, iron particles, iron oxide, aluminium oxide, silver particles and other nanoparticles can be compounded on the surfaces of the polymer filaments. The polymer filaments after compounding have good mechanical properties and functionality. The preparation method is simple to operate, dispenses with special equipment and achieves industrial production easily.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

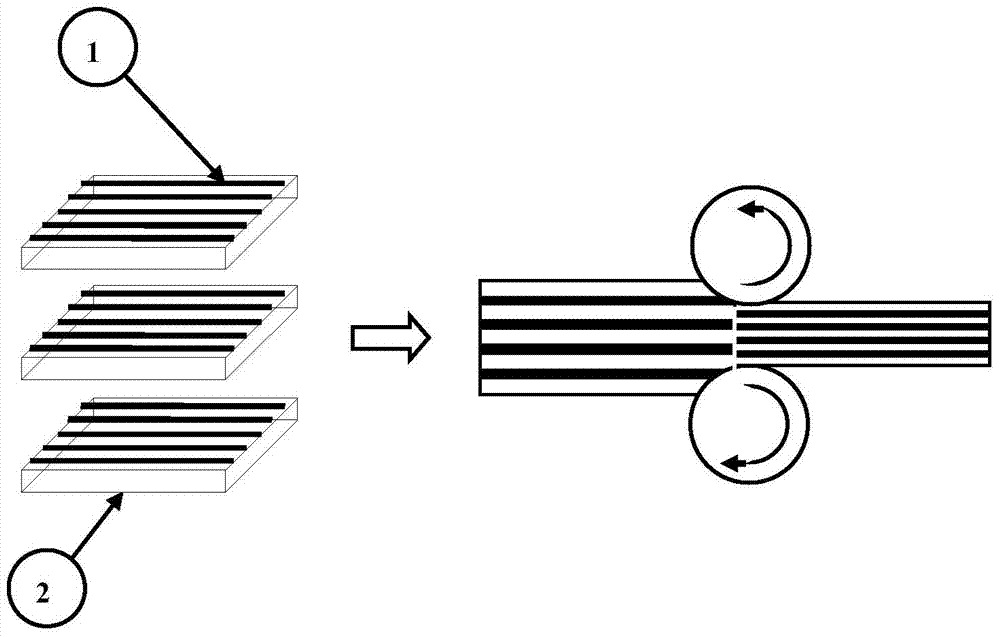

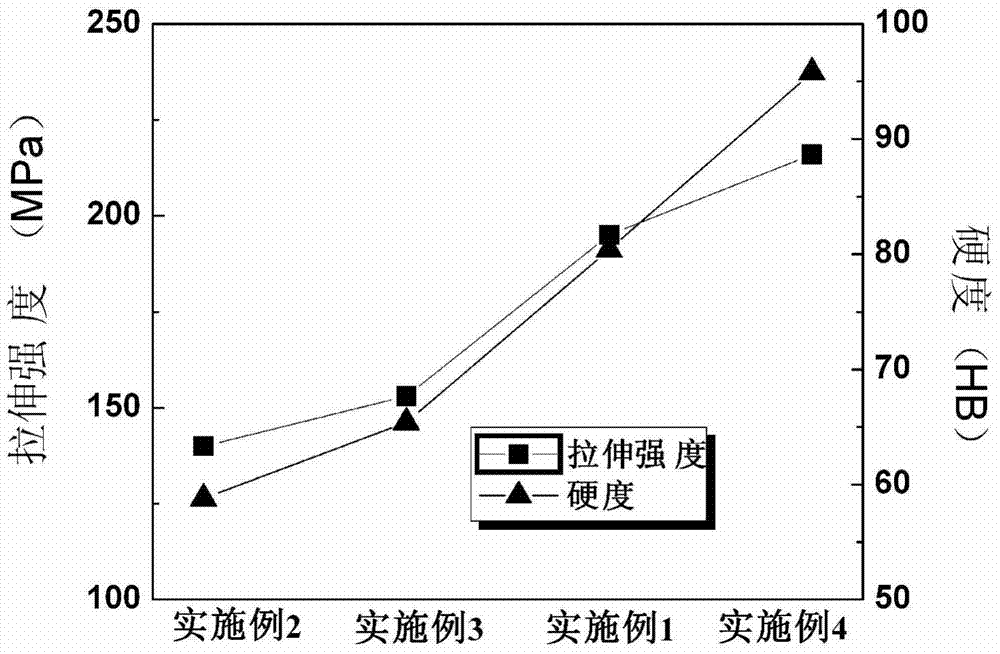

Ordered carbon nano-tube reinforced aluminum matrix composite material and preparation method thereof

ActiveCN103757569ATake full advantage of performanceSignificant mechanical enhancementCarbon nanotubeThin membrane

The present invention discloses an ordered carbon nano-tube reinforced aluminum matrix composite material and a preparation method thereof. The composite material comprises aluminum or an alloy thereof adopted as a matrix material and carbon nano-tubes orderedly dispersed in the matrix material. The method comprises: carrying out cross-lamination on plural ordered carbon nano-tube thin film layers and plural aluminum layers or aluminum alloy layers, and carrying out hot rolling to form the ordered carbon nano-tube reinforced aluminum matrix composite material, wherein the ordered carbon nano-tube thin film layer is formed by the plural orderly-dispersed carbon nano-tubes. According to the present invention, the ordered carbon nano-tube thin film such as the superaligned nano-tube thin film and the like is adopted to carry out lamination and hot rolling with the aluminum foil to prepare the composite material so as to achieve orientation distribution of the carbon nano-tubes in the aluminum matrix, completely provide excellent mechanical property and functional characteristics of the carbon nano-tubes, achieve mechanical enhancement and function modification on the aluminum matrix composite material, combine with the hot rolling molding, and provide important practical application prospects.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com