Patents

Literature

525results about How to "Increase responsiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

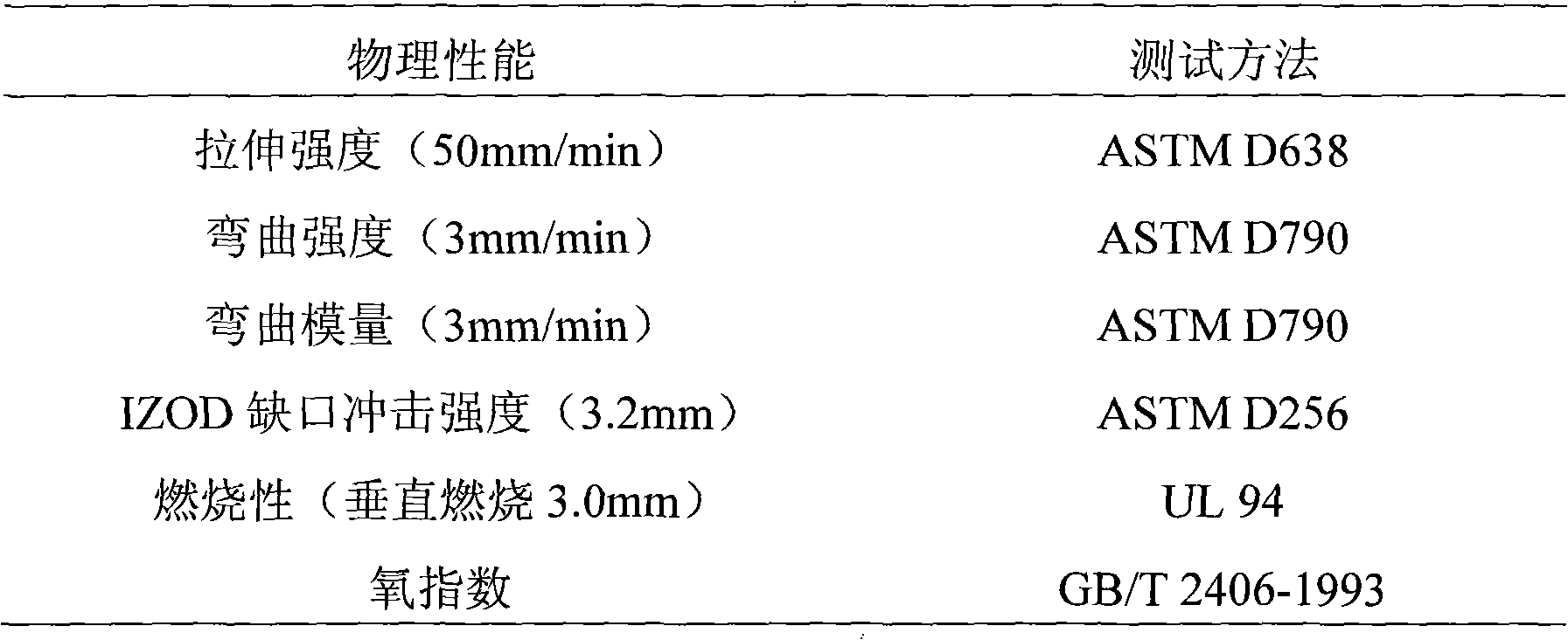

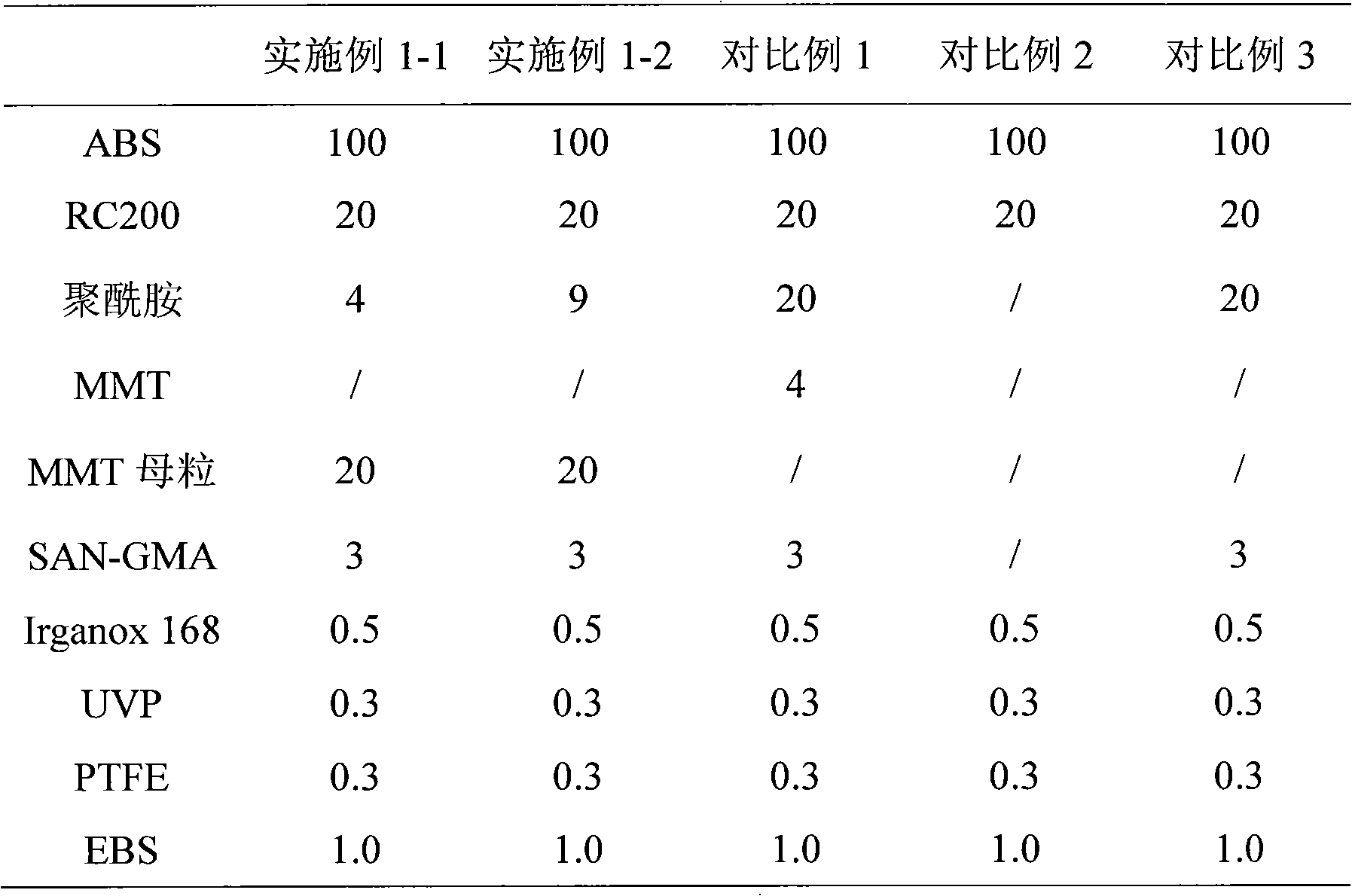

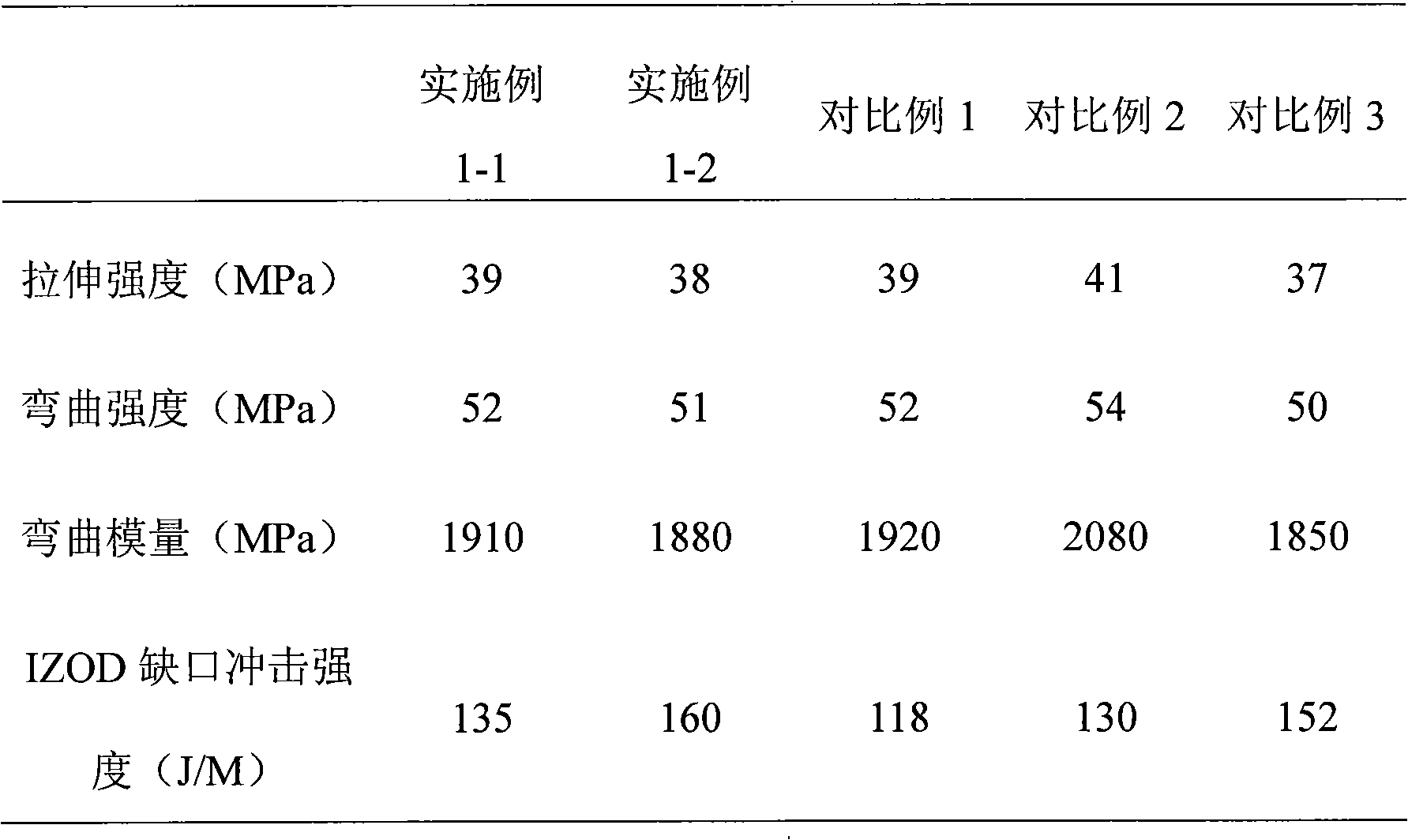

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

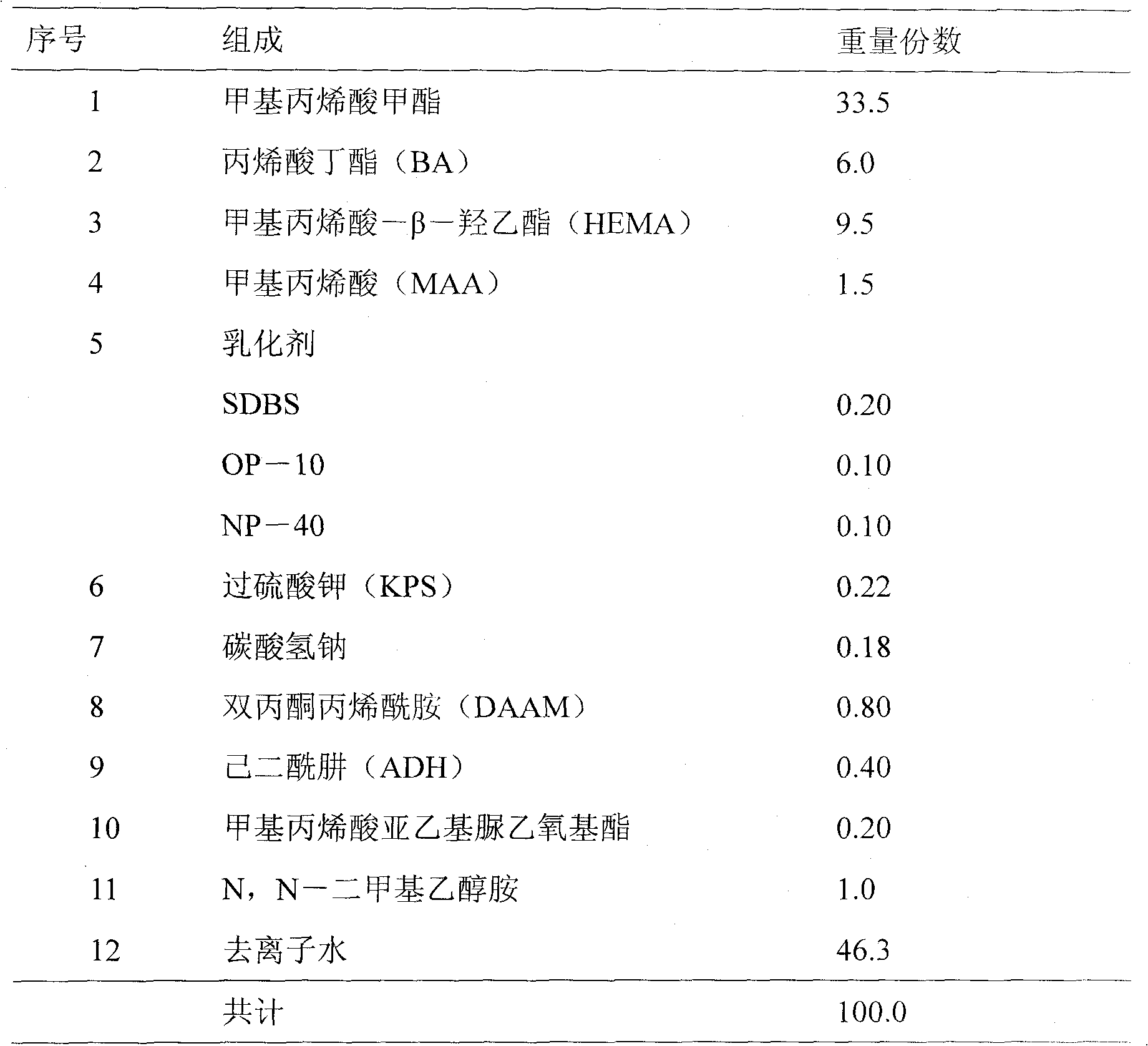

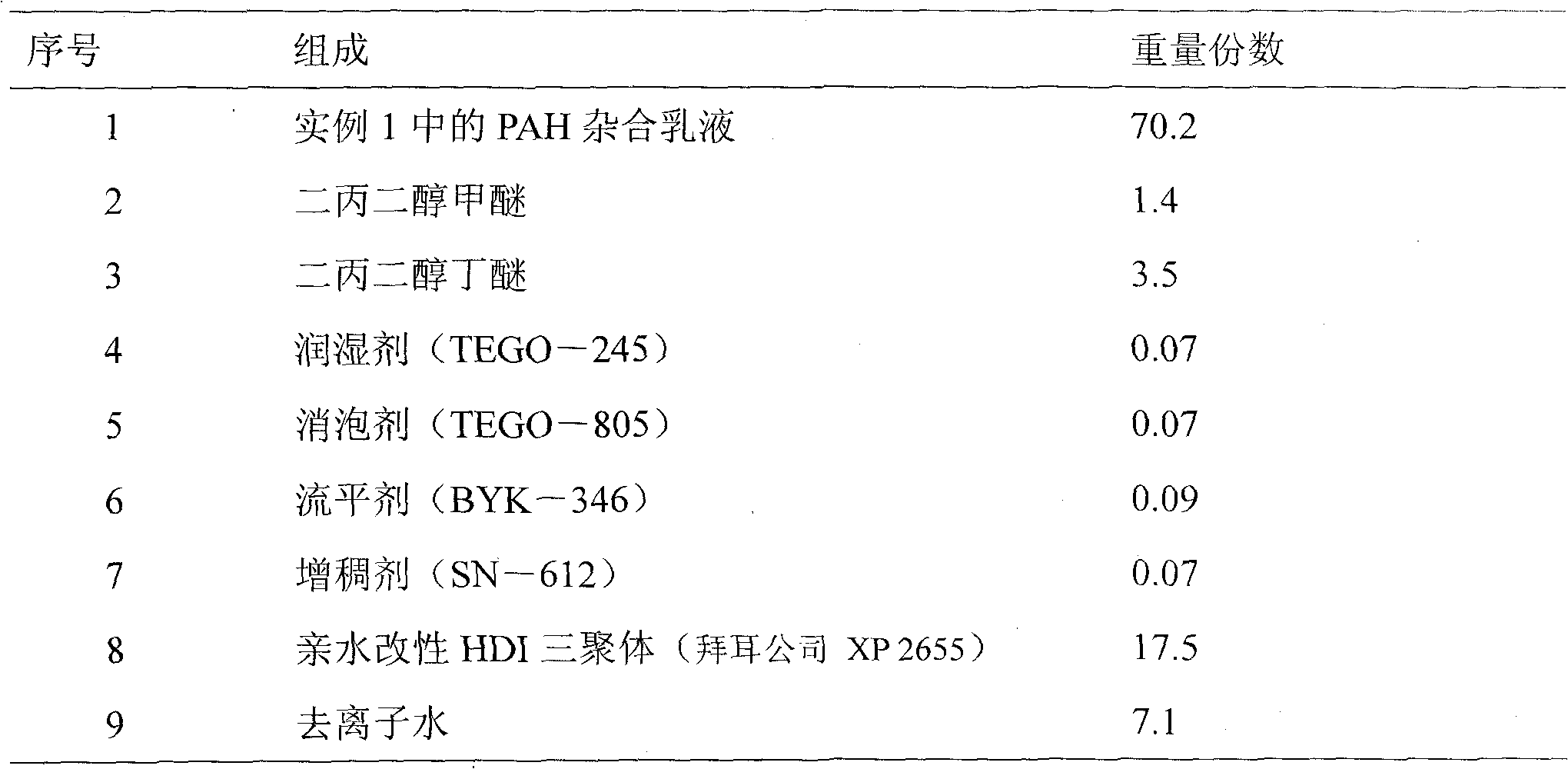

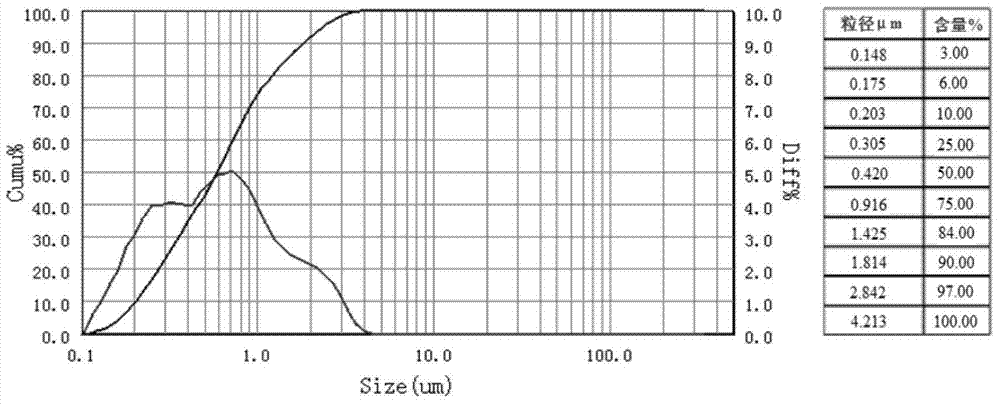

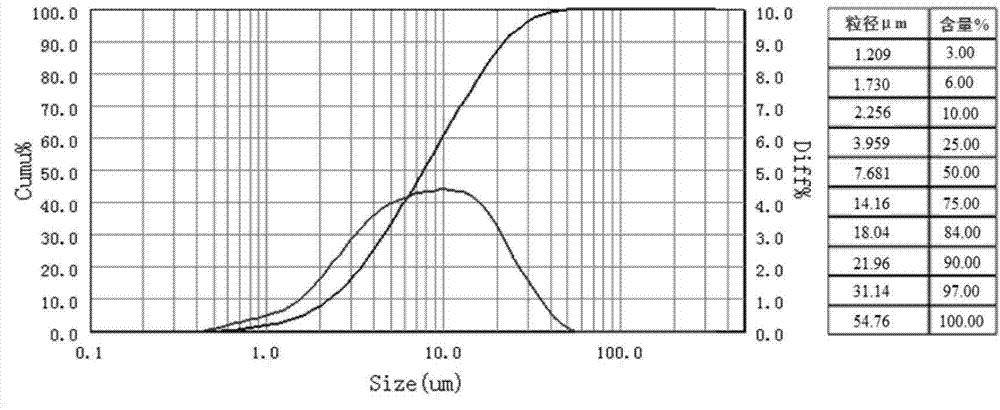

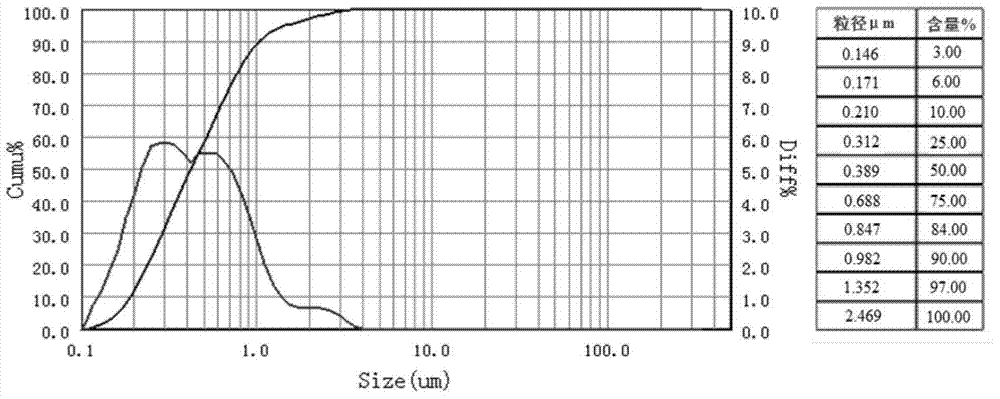

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

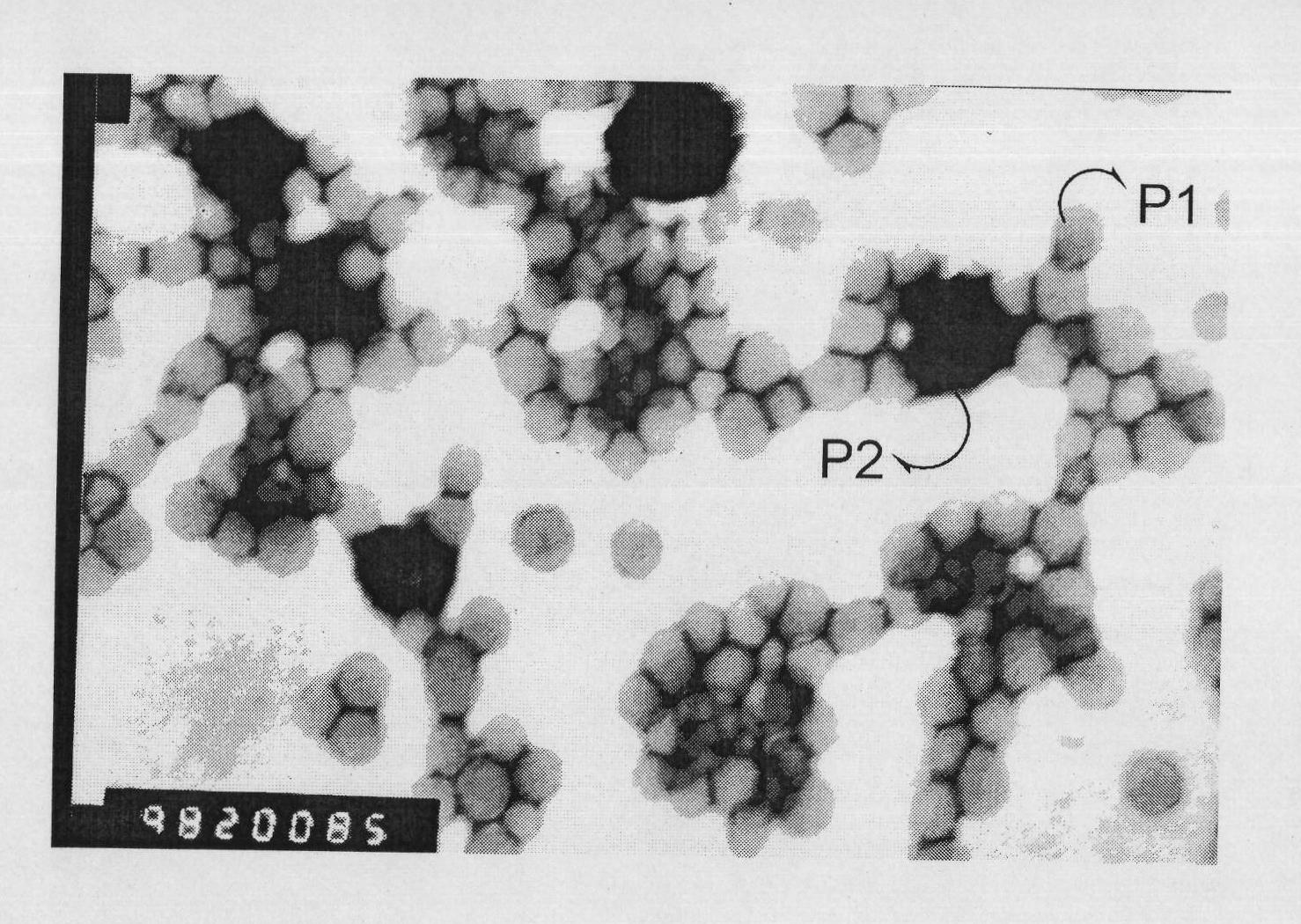

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

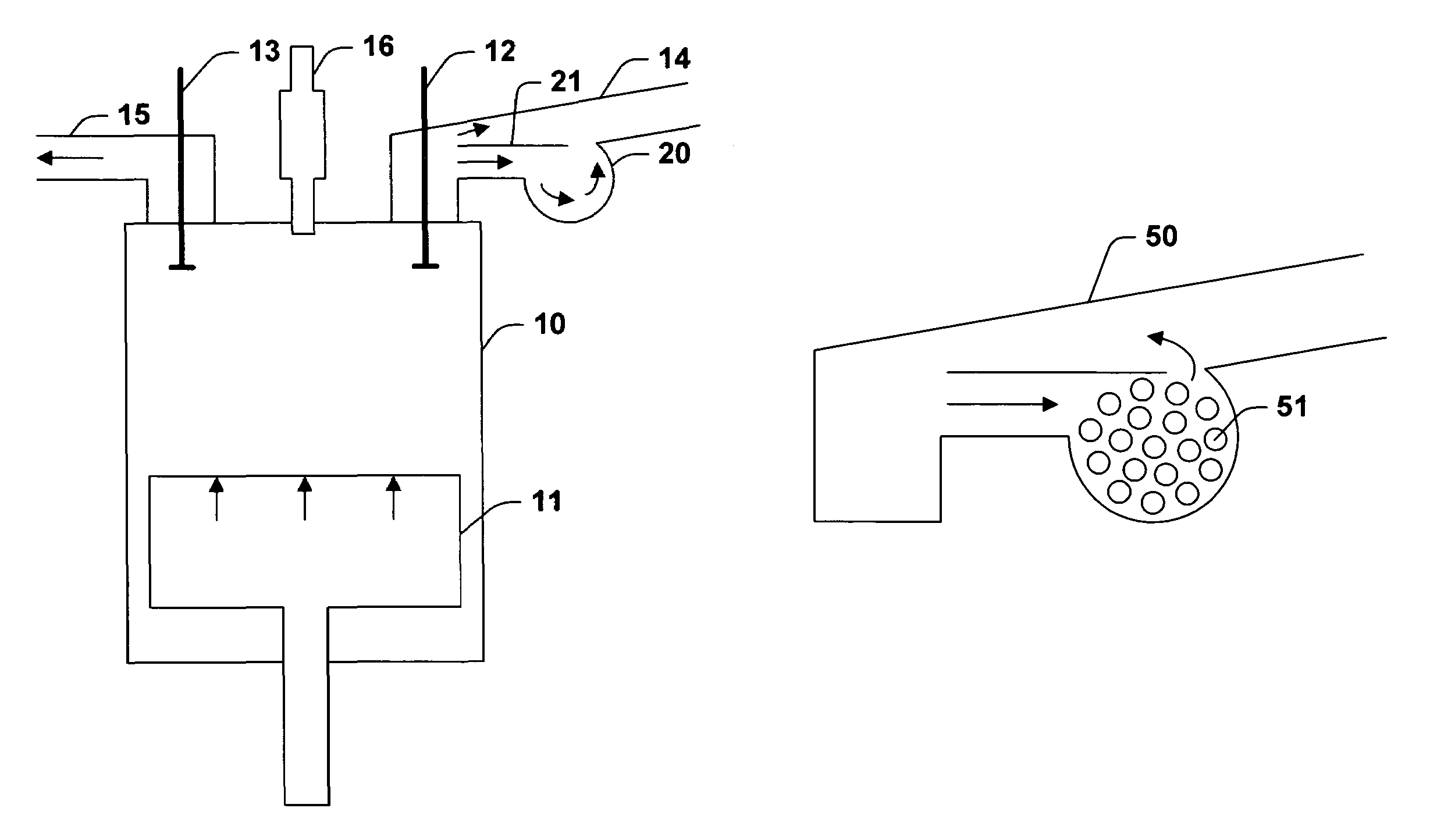

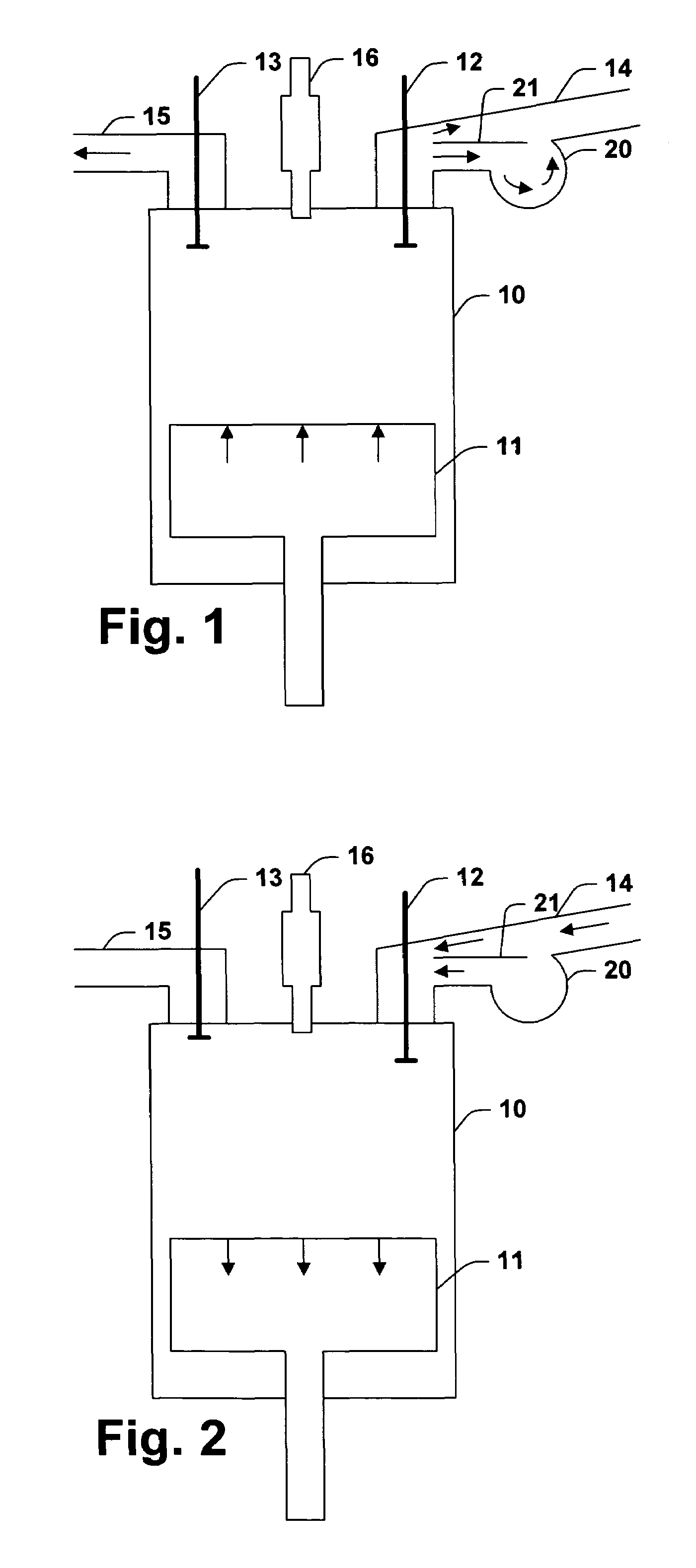

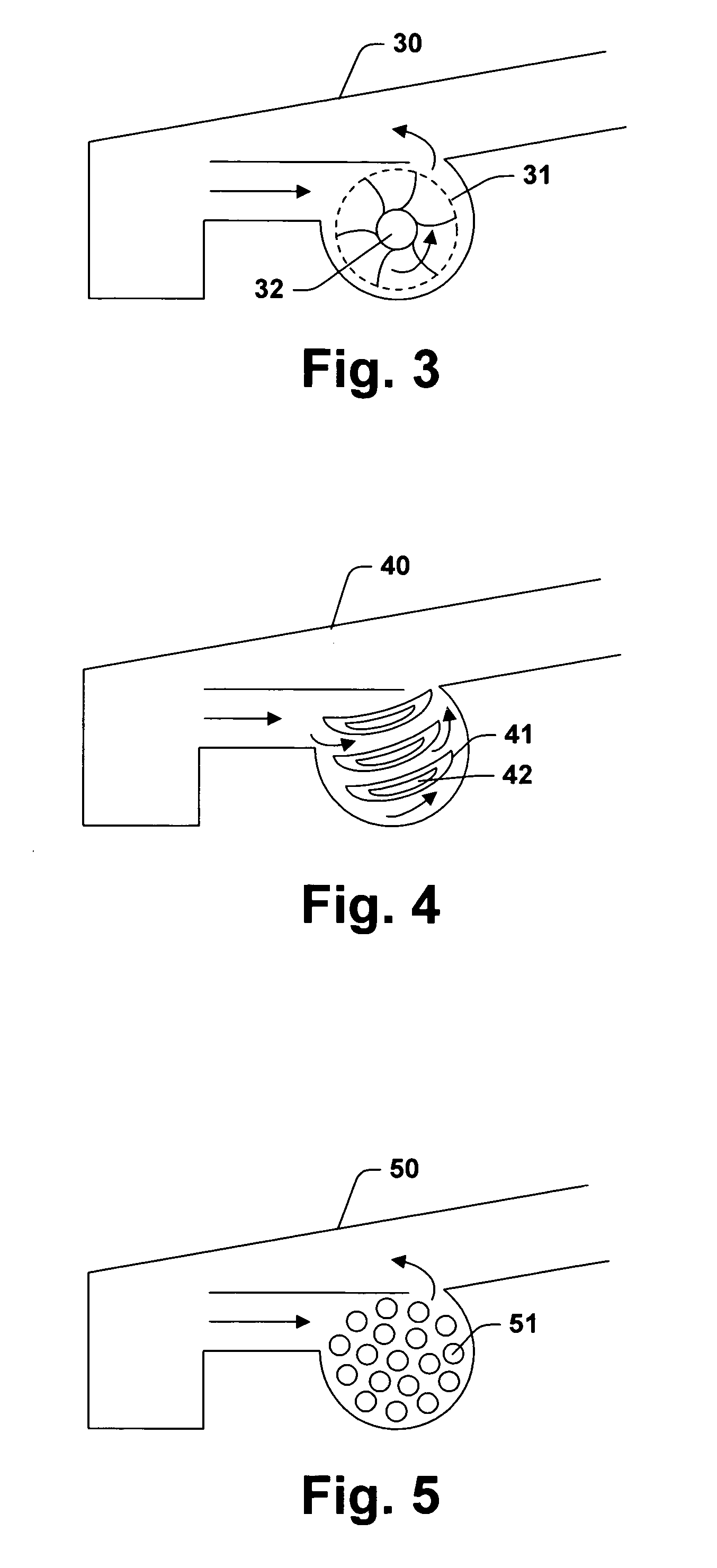

Internal EGR cooler

ActiveUS6932063B1Improve responsivenessIncrease responsivenessInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringHeat exchanger

One aspect of the invention relates to cooled internal EGR. Cooled internal EGR is achieved by selectively admitting exhaust to an intake manifold. A heat exchanger is used to cool the exhaust within the intake manifold. Another aspect of the invention related to an intake manifold adapted for internal EGR cooling. The manifold has a bulge to retain exhaust, whereby the exhaust admitted to the intake side for internal EGR generally does not flow past the intake manifold and significantly heat or foul any upstream portion of the system. The manifold further includes a heat exchanger for cooling the exhaust. A further aspect of the invention relates to a method of reducing the response time of an EGR system. The method comprises providing a temporary increase in an internal EGR rate during a transition from a first to a second external EGR rate.

Owner:EATON INTELLIGENT POWER LIMITED

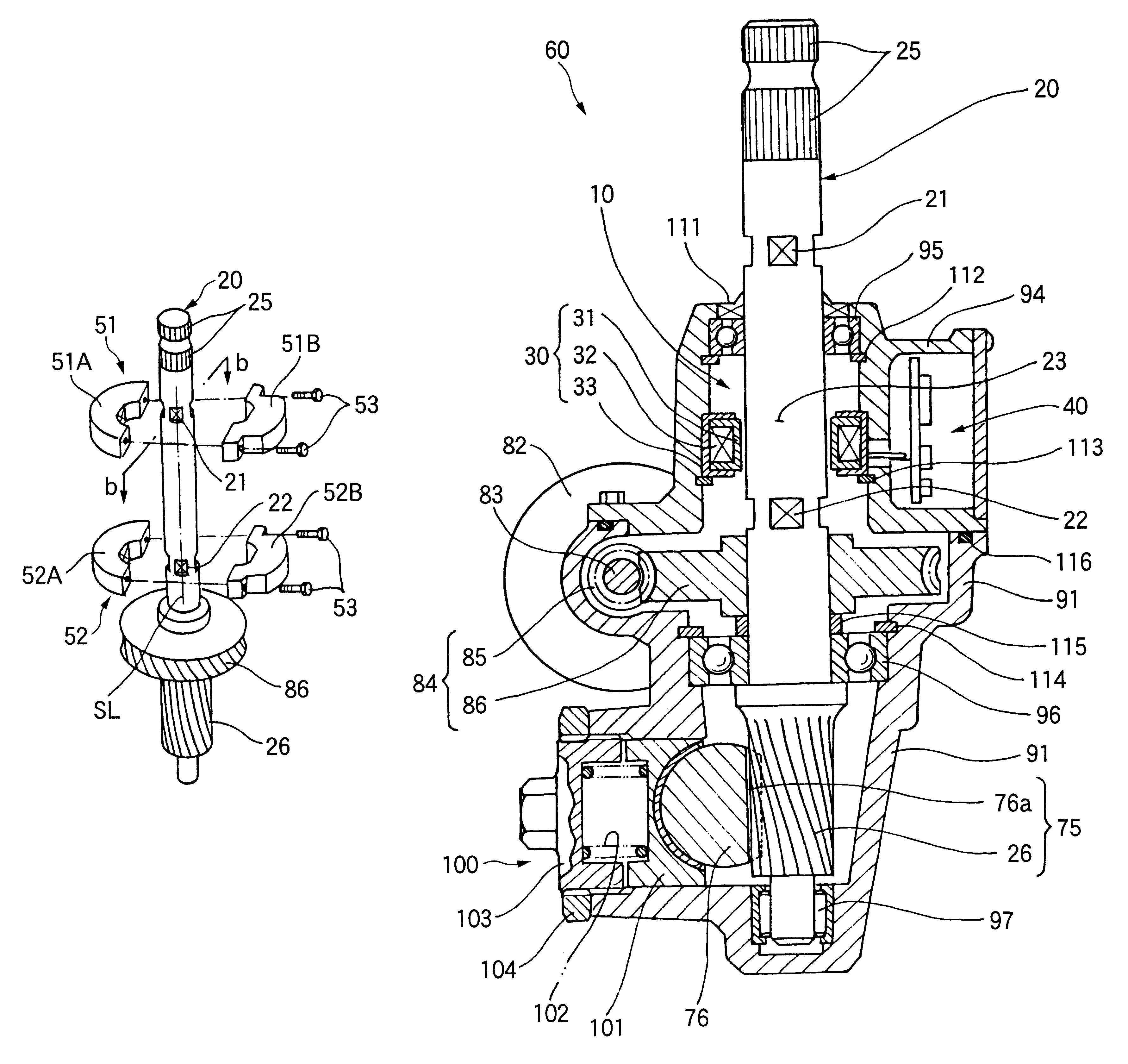

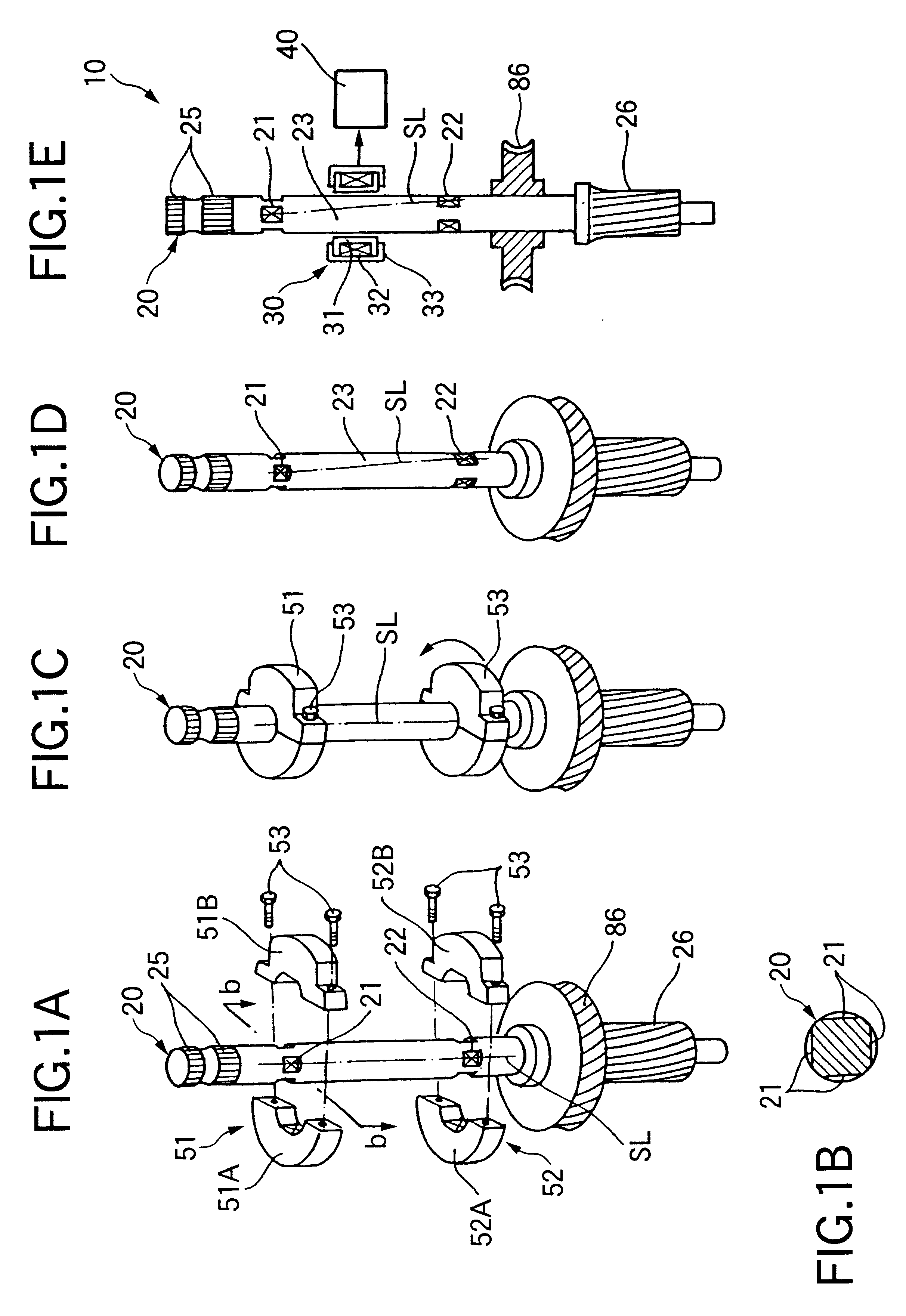

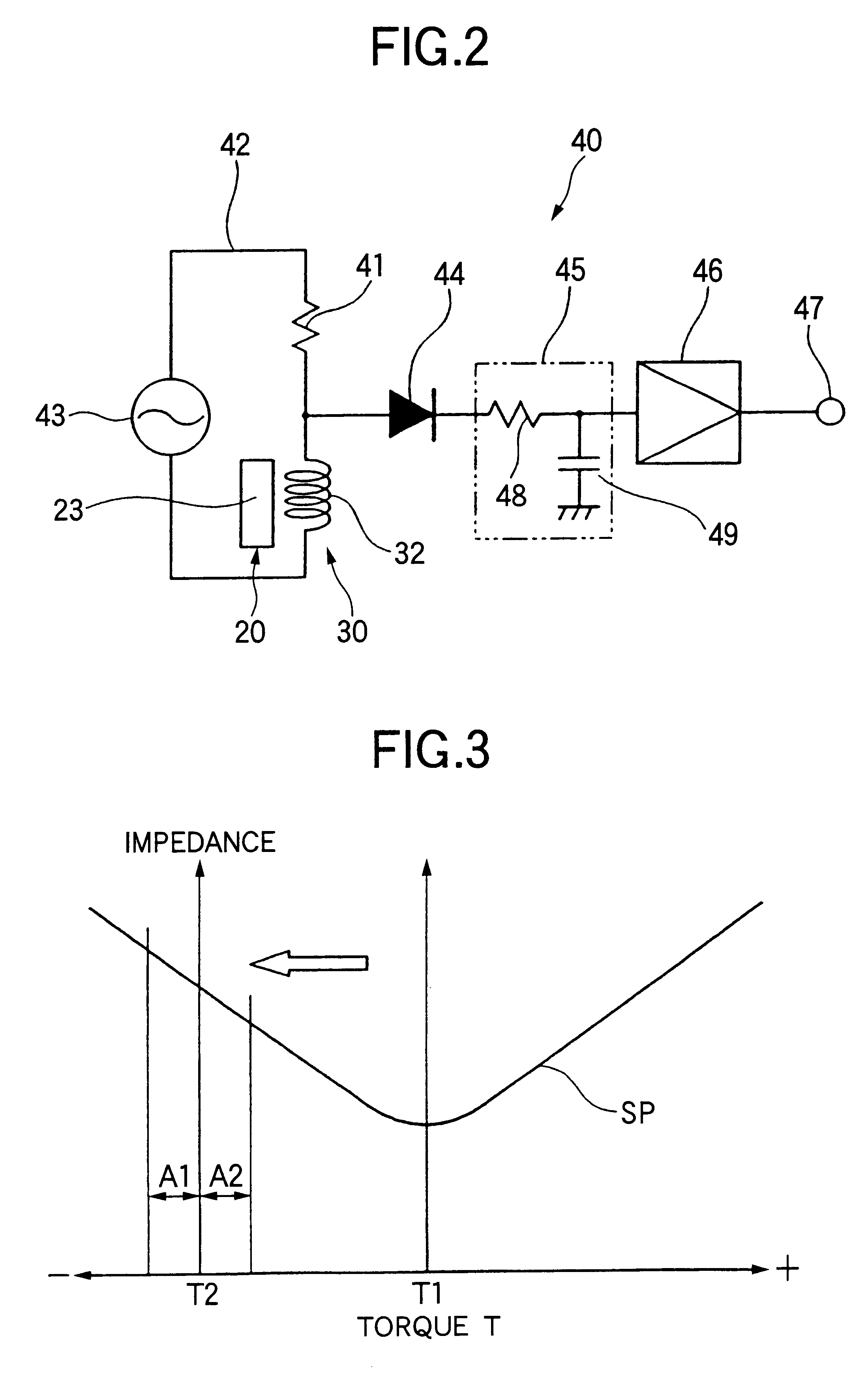

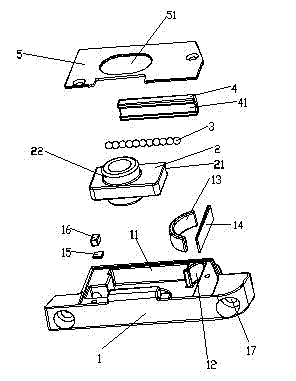

Torque detecting device and electromotive power steering apparatus mounting the torque detecting device thereon

InactiveUS6595074B2Increase responsivenessSteer sense be enhanceSteering linkagesForce measurementPower steeringElectricity

Owner:HONDA MOTOR CO LTD

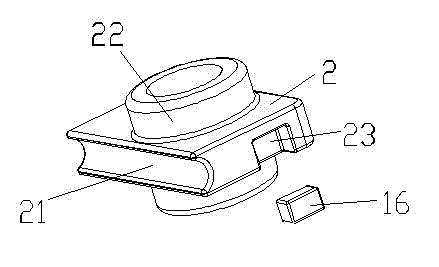

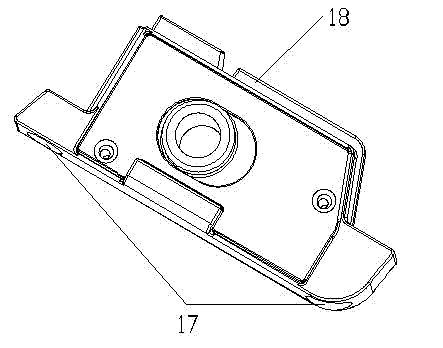

Structure of electric power sensor matched with rear fork of bicycle

InactiveCN102303682AGood magnetic induction effectIncrease responsivenessAxle suspensionsRider propulsionElectric machineHall element

The invention discloses a structure of an electric power sensor matched with a rear fork of a bicycle. The structure is provided with a box body, a Hall element is arranged at one side of the bottom of the box body, a sensor assembly passing through an elongated slot hole at the bottom of the box body and being in a movable state is held in the box body, and a permanent magnet arranged on the sensor assembly is in magnetic induction fit with the Hall element on the box body; a rear axle of the bicycle is limited to move in the elongated slot hole at the bottom of the box body; and by using the magnetic induction change between the permanent magnet fixed relative to the rear axle and the Hall element when the rear axle moves, an electrical signal is output to control stress application rotation of a bicycle motor. The rear fork of the bicycle is fully used as the carrier of the sensor, the whole sensor component is skillfully arranged in the box body, and the box body is arranged on the rear fork of the bicycle, so that the structure has the characteristics of good magnetic induction effect, high response degree and convenience for installation and maintenance.

Owner:WUXI SHANGGE IND DESIGN

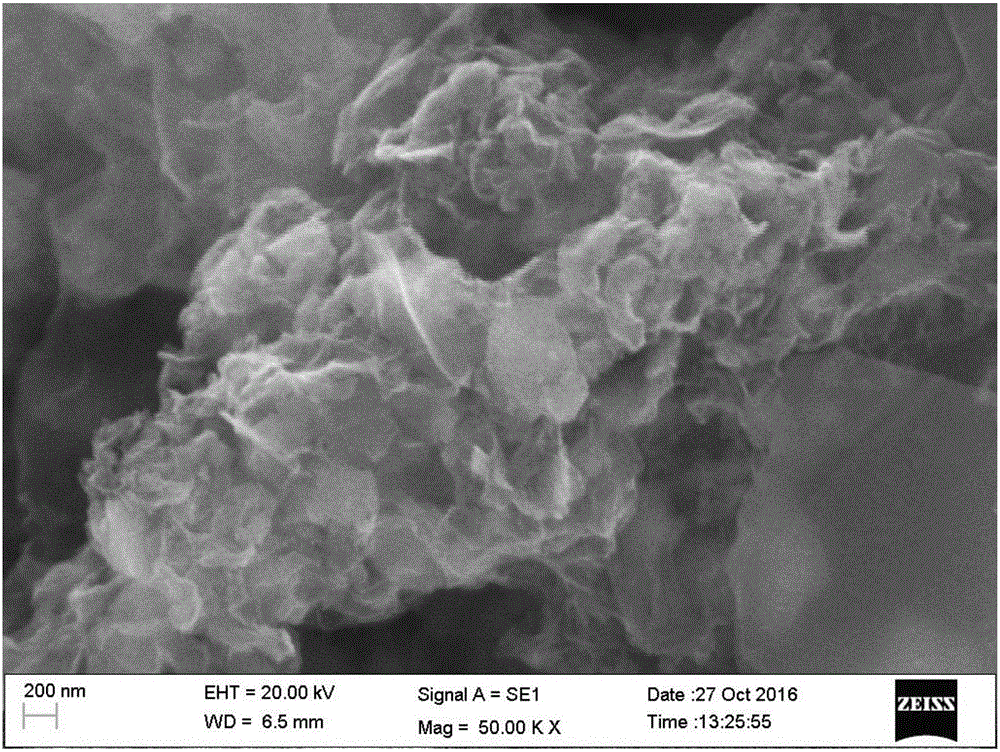

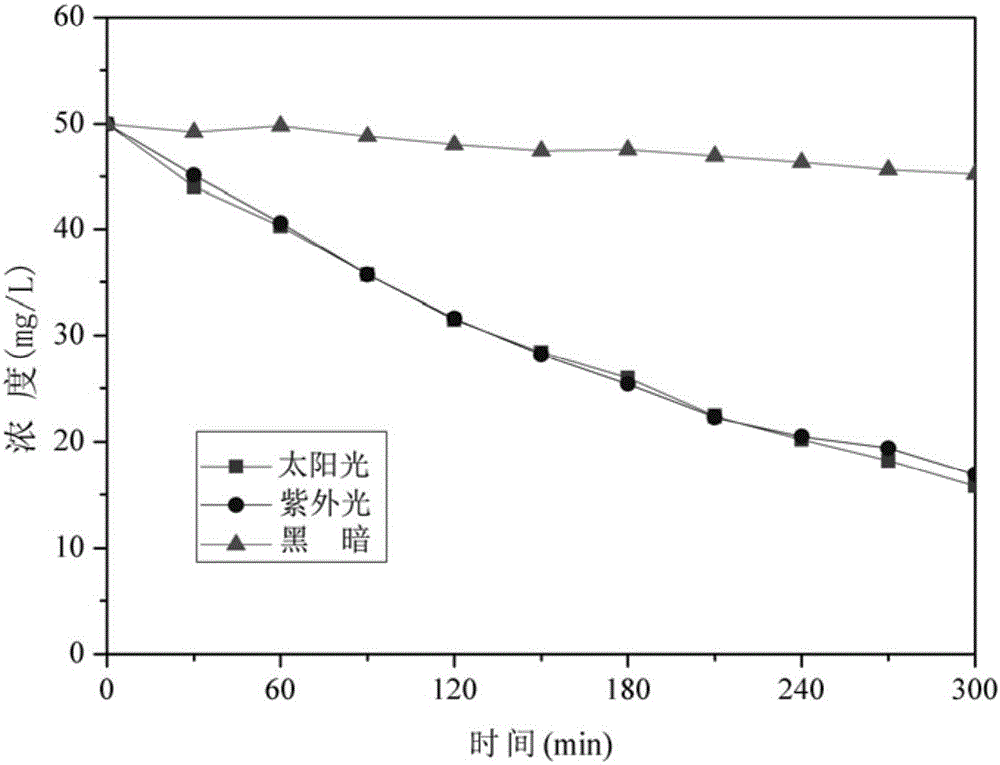

Preparation method of photocatalytic ultrafilter membrane material with visible light activity

InactiveCN106582331AImprove hydrophilicityImprove pollutionSemi-permeable membranesMembranesLight ActivityVacuum pumping

The invention discloses a preparation method of a photocatalytic ultrafilter membrane material with visible light activity. The method comprises the following steps: 1, preparing N-TiO2 powder; 2, preparing N-TiO2 / GO particles; 3, preparing an ultrafilter membrane; and 4, producing an ultrafilter membrane with the surface loaded with N-TiO2 / GO: processing the N-TiO2 / GO particles to prepare an N-TiO2 / GO dispersion, tiling the ultrafilter membrane on a suction filtration device, pouring the N-TiO2 / GO dispersion, carrying out vacuum pumping, and airing the obtained membrane to obtain the ultrafilter membrane with the surface loaded with N-TiO2 / GO. The photocatalytic material with the advantages of visible light activity, hydrophilic property and difficulty in loss of nano-particles is obtained through the preparation method of the photocatalytic ultrafilter membrane material with visible light activity.

Owner:HOHAI UNIV

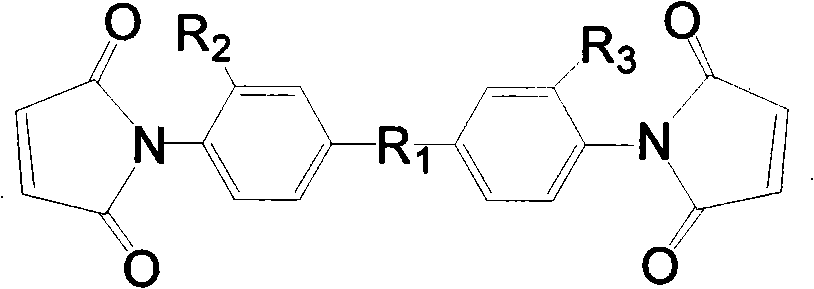

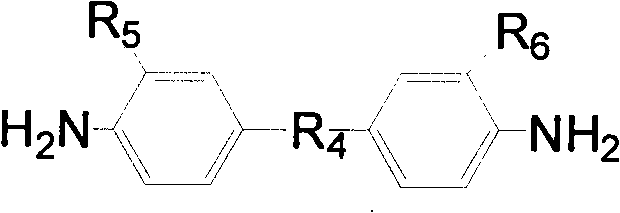

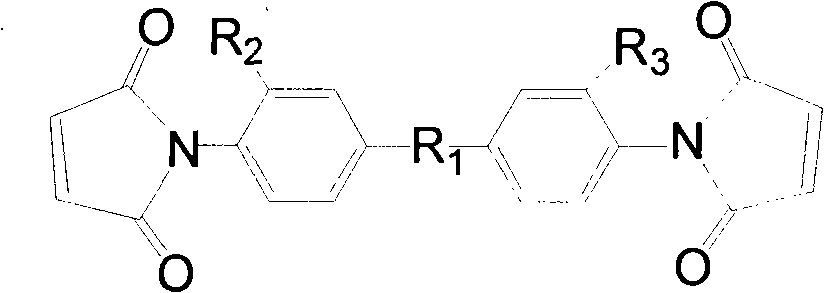

High temperature resistant halogen-free flame-retardant adhesive for flexible copper clad foil substrate and preparation thereof

InactiveCN101323773AImprove solubilityReduce adverse effectsAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesEpoxyChemical reaction

The invention provides a high-temperature resistant halogen-free fire-resistant adhesive used in flexible copper-clad baseplates and a preparation method thereof. The adhesive consists essentially of aromatic amine modified bismaleimide performed polymer, phosphorus epoxy resin, chemigum, phenolic resin, inorganic filler, a curing catalyst and a solvent. The preparation method comprises the steps that: first of all, toluene is taken as the solvent; under the reflow temperature of the toluene, aromatic diamine, aniline and bismaleimide polymerize to obtain a aromatic amine modified bismaleimide performed polymer solution which is then added with the phosphorus epoxy resin and then added with the chemigum, the phenolic resin, the inorganic filler, the curing catalyst and the solvent after chemical reaction or physical mixture so as to form the high-temperature resistant halogen-free fire-resistant adhesive which is used for bonding the polyimide film and copper foil of the flexible copper-clad baseplate; the prepared flexible copper-clad baseplate has excellent heat resistance, flame resistance, dimensional stability and comparatively high peeling strength.

Owner:WUHAN TEXTILE UNIV

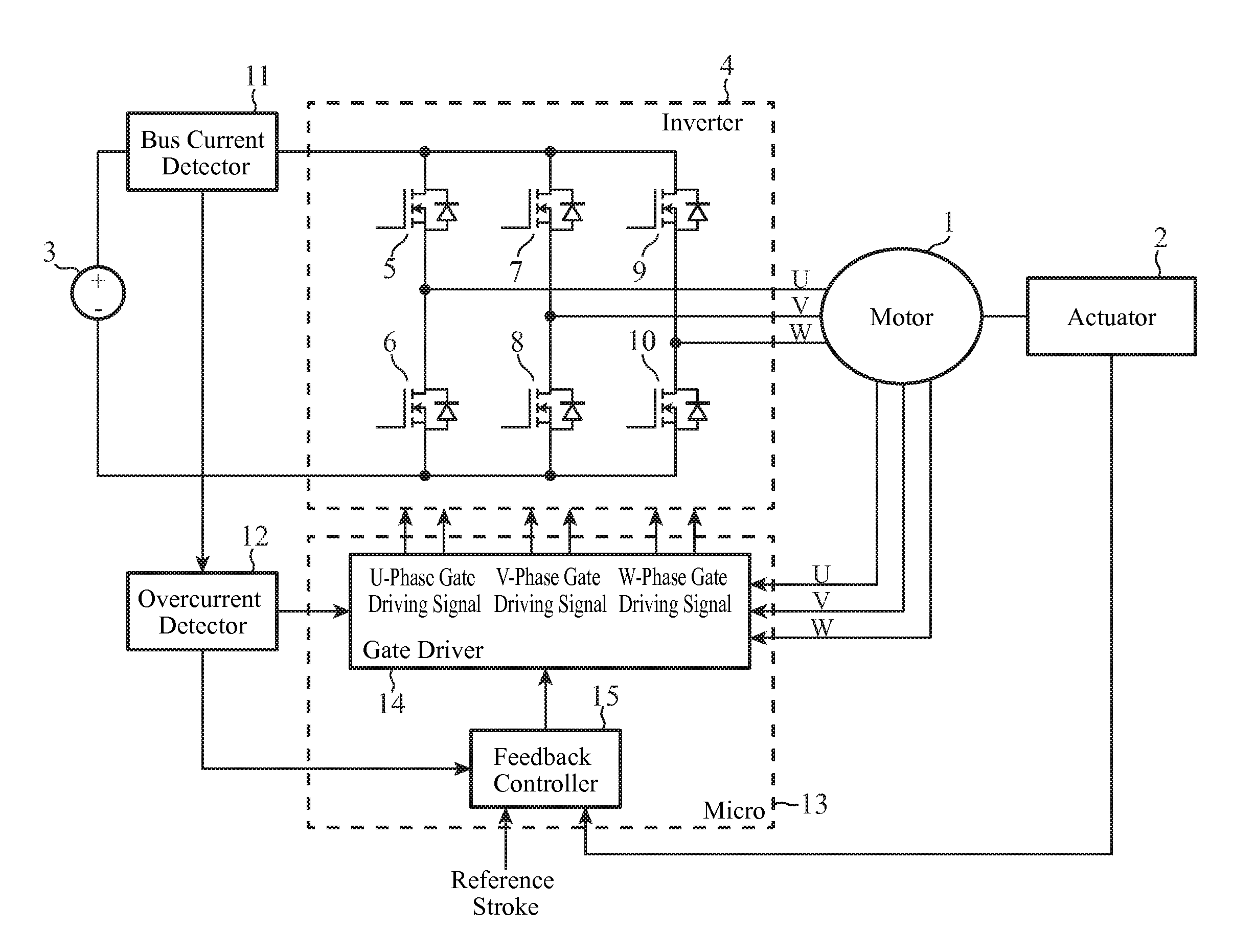

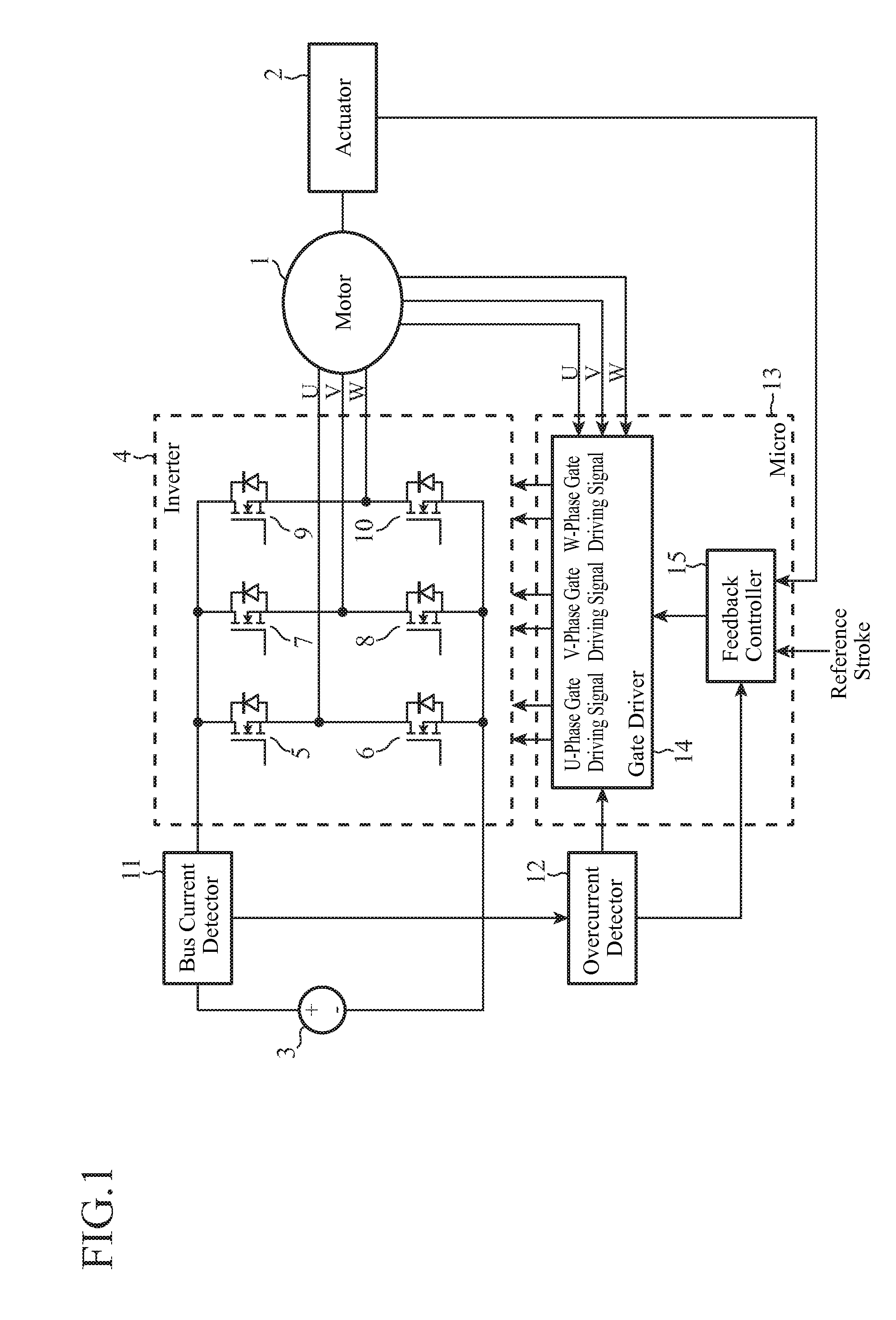

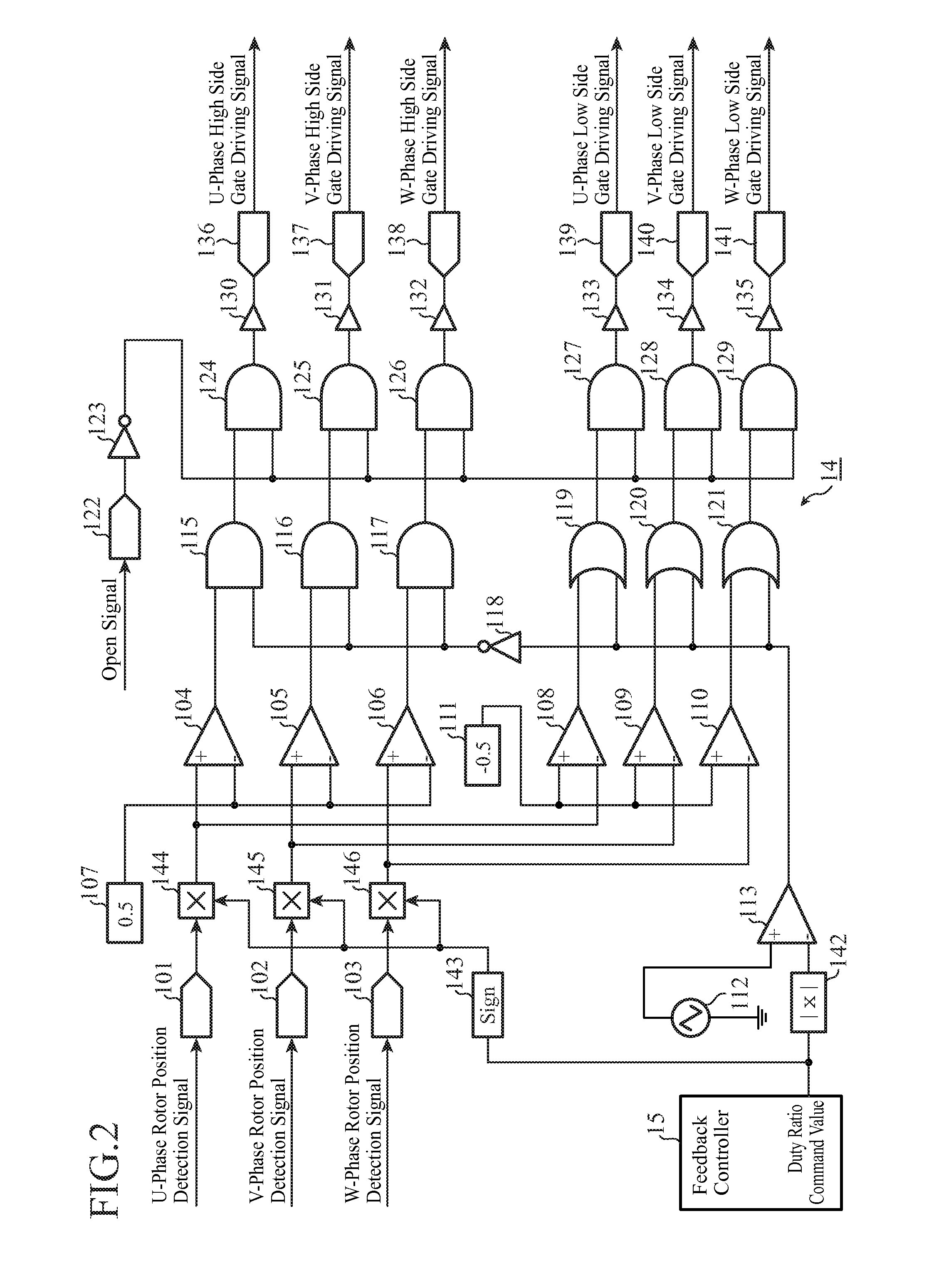

Motor drive

ActiveUS20150303839A1Increase responsivenessCurrent be suppressMotor/generator/converter stoppersAC motor controlGate driverEngineering

If a bus current a bus current detector 11 detects exceeds a current cutoff value, an overcurrent detector 12 supplies a gate driver 14 with an open signal for turning off switching elements 5-10 to break the current to a motor 1. Besides, when the overcurrent detector 12 detects an overcurrent, a feedback controller 15 provides the gate driver 14 with a short-circuit braking instruction to apply short-circuit braking after breaking the power supply, and to restart PWM control from a state in which the short-circuit braking is being applied and the duty ratio command value is reset at 0.

Owner:MITSUBISHI ELECTRIC CORP

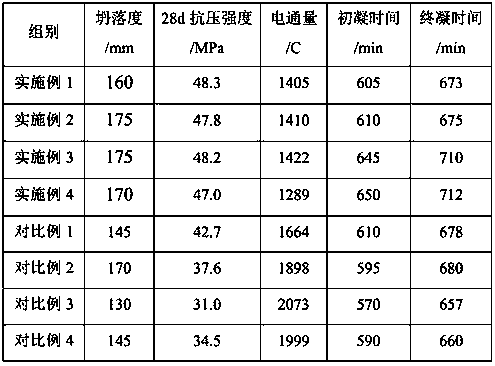

High-strength coral aggregate concrete and preparation method thereof

ActiveCN108218350AReduce hydration temperature riseReduce or avoid temperature cracksMetakaolinSeawater

The invention discloses high-strength coral aggregate concrete which is prepared from the following ingredients in parts by weight: 260-350 parts of low-heat marine Portland cement, 35-50 parts of flyash floating beads, 35-50 parts of mineral powder, 8-16 parts of silica fume, 8-16 parts of metakaolin, 2-6 parts of nano silicon dioxide, 2-6 parts of polyaluminum chloride, 550-679 parts of coral reef sand, 890-1000 parts of coral reef and 180-256 parts of seawater. The high-strength coral aggregate concrete has the advantages that the pelagic engineering construction cost is lowered, and environment-friendly and energy-saving requirements of civil engineering are also met.

Owner:CCCC SECOND HARBOR ENG +2

Method for preparing biodegradable polyurethane foam by liquefied modification of bark powder and lignin

InactiveCN102675581AIncrease the phenolic hydroxyl contentIncrease responsivenessApparent densityPolymer science

The invention relates to a method for preparing biodegradable polyurethane foam by liquefied modification of bark powder and lignin. The method comprises the following steps: 1. adding phenol into alkaline solution, heating, then adding larch bark powder and the lignin, stirring evenly, carrying out reaction adequately, and cooling for use; 2. heating liquefied product, adding formaldehyde and catalyst to obtain methylolated lignin, phenolic hydroxyl lignin and methylolated tannin; 3. mixing above modified product, polyether, a foam homogenizing agent and catalyst according to a certain proportion, and mixing with isocyanate for foaming. The rigid foam material foamed by mixing, provided by the invention, has an apparent density of 0.03-0.05g / cm<3>, compressive strength greater than 0.15MP, thermal conductivity of 0.023W / (M.K), and water absorption of 3%. The method provided by the invention can improve the utilization of lignin, save resources, does not cause environmental pollution, and is high in production efficiency. The foam is good in lame retardant property.

Owner:BEIHUA UNIV

Preparation method of material with tobacco fragrance

The invention discloses a preparation method of a material with tobacco fragrance. The preparation method is characterized by sequentially comprising the following steps: 1, drying and pulverizing tobacco raw materials, then conducting extraction through an ethanol solution, conducting solid-liquid separation, then conducting decompression condensation on filter liquor, and obtaining tobacco extract A; adding a bio-enzyme preparation to obtained filter residues for conducting enzymatic hydrolysis, conducting solid-liquid separation, then conducting decompression condensation on filter liquor, and obtaining tobacco extract B; mixing the exact B, amino compounds and polyalcohol, conducting heating, making the mixture react, and obtaining a tobacco reagent C; 4, mixing the tobacco exact A and the tobacco reagent C in a certain proportion, and obtaining the material with tobacco fragrance. The preparation method of the material with tobacco fragrance is applicable to different varieties of tobacco products, and real, abundant and rich original tobacco fragrance can be supplied to the tobacco products.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

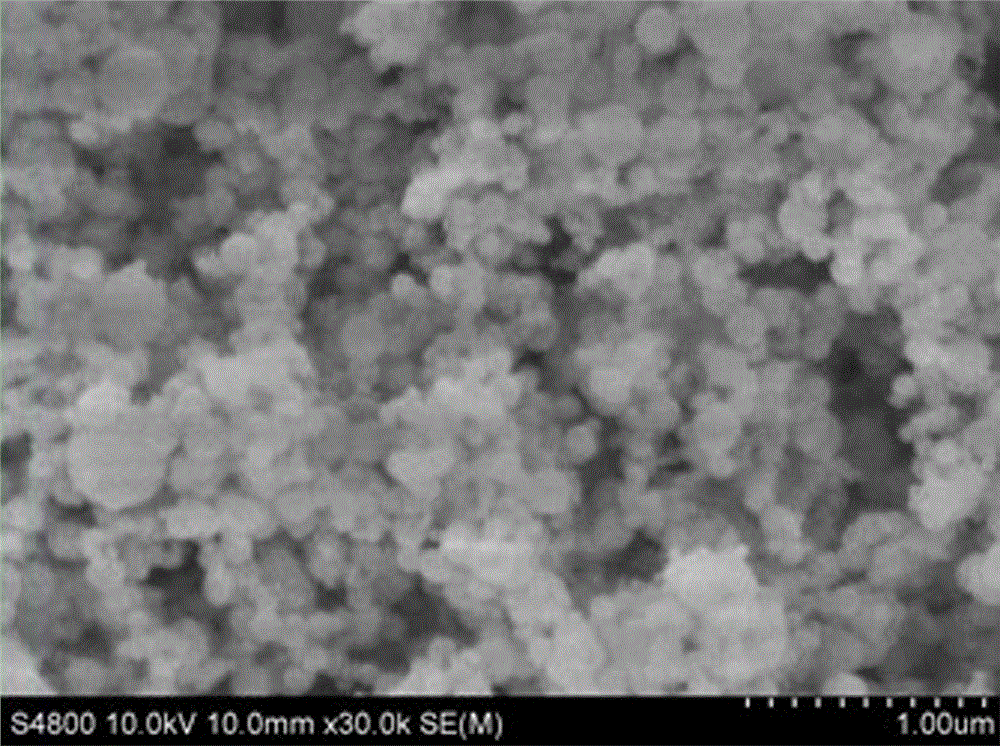

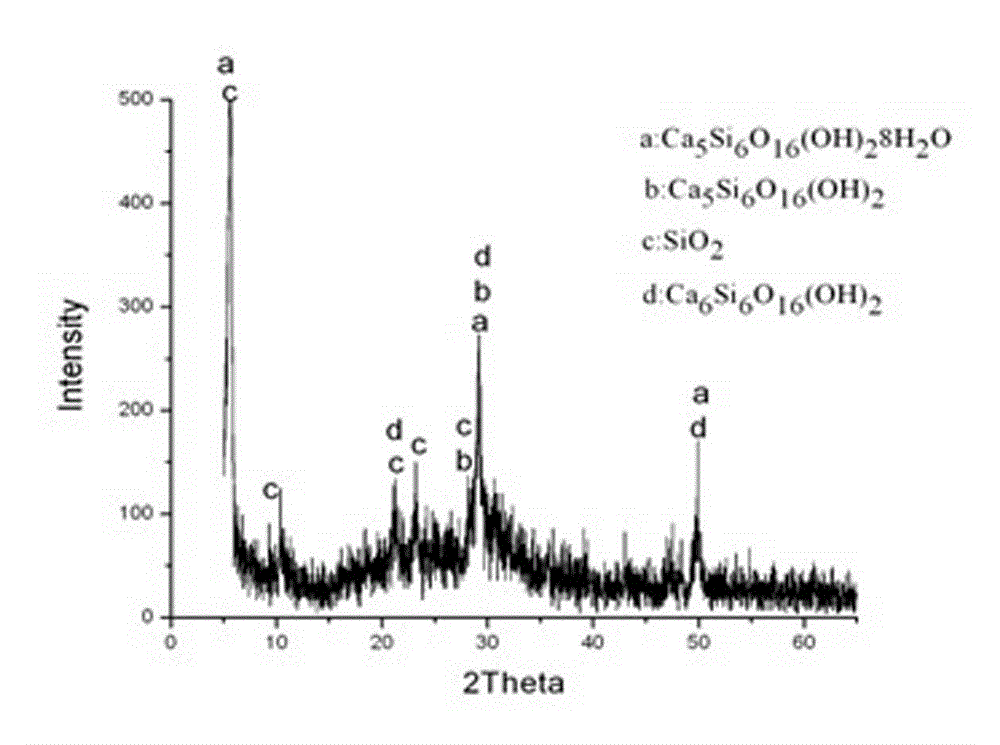

Method for preparing nano hydrated calcium silicate using silican fume as siliceous materials

ActiveCN102718228AWide variety of sourcesLow priceAlkaline-earth metal silicatesNanotechnologyCalcium in biologyCalcium silicate

The invention provides a method for preparing nano hydrated calcium silicate using silican fume as siliceous materials, and solves the problems of slow reaction rate, harsh reaction conditions, low SiO2 reaction degree, low yield, unstable raw material components, and relatively large structure and performance differences of the produced hydrated calcium silicate if current siliceous materials are used as raw materials for the hydrated calcium silicate. The method comprises utilizing the silican fume as siliceous materials and calcium oxide as calcareous materials, with water being added, mixing them in a reaction vessel, and getting the nano hydrated calcium silicate through stirring, hydrothermal reacting, ultrasonic treating, centrifugally separating and vacuum drying. The silican fume used as siliceous materials provided by the invention has advantages of wide source, low price, large specific surface area, strong adsorptivity, mild reaction condition and low impurity content, and thus can be produced into high-purity nano-powder. According to the invention, calcium-silicon ratio, reaction temperature and time can be regulated to control particle sizes of products, thereby obtaining products with excellent performance.

Owner:大同煤矿集团朔州煤电宏力再生工业股份有限公司

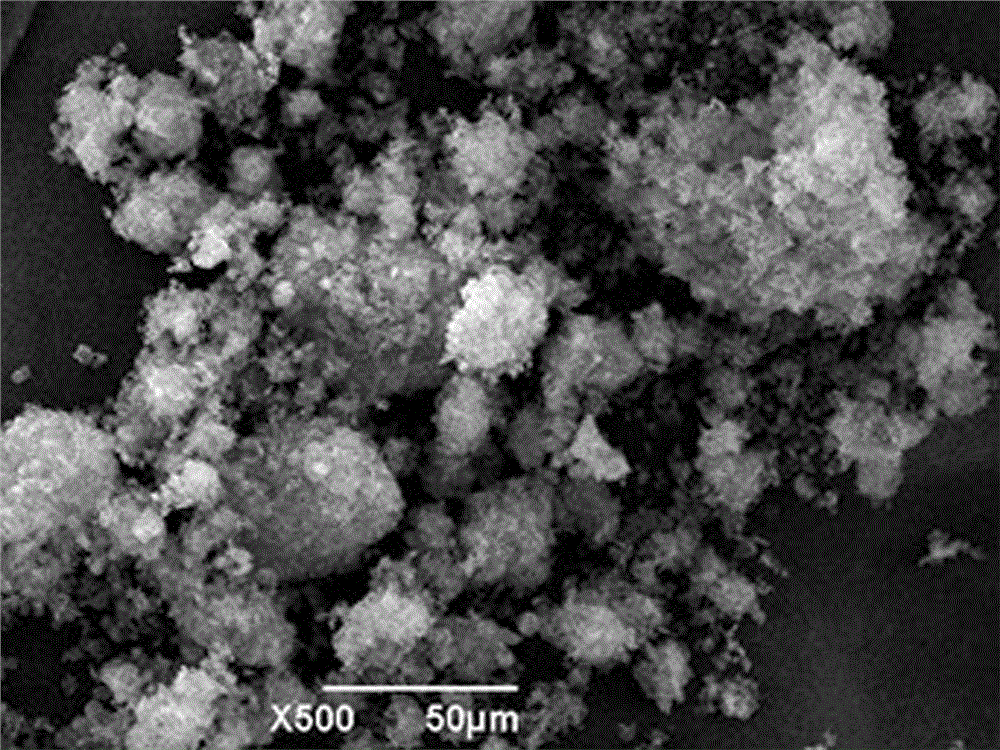

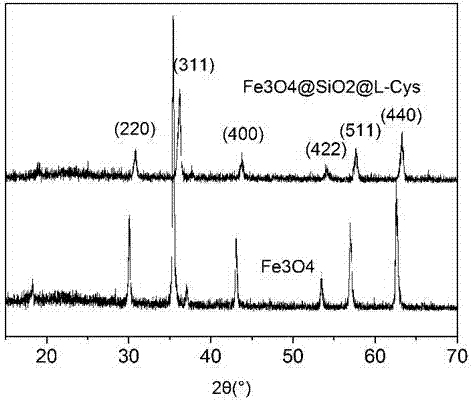

Group enhanced type magnetic nanometer water treatment agent and preparation method and application thereof

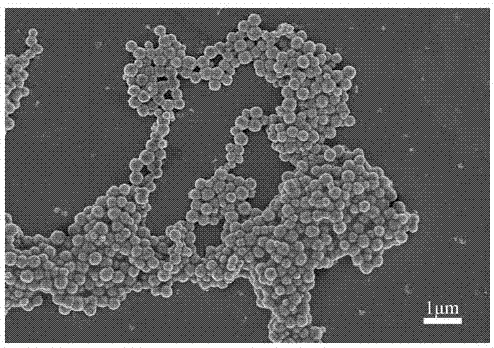

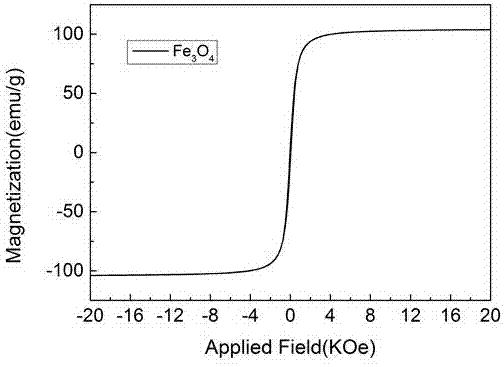

InactiveCN106955672AImprove the magnetic adsorption effectImprove adsorption capacityOther chemical processesWater contaminantsPolyethylene glycolMagnetite Nanoparticles

The invention discloses a group enhanced type magnetic nanometer water treatment agent and a preparation method and application thereof. The preparation method is characterized by comprising the following steps: accurately weighting hexahydrate ferric chloride and anhydrous sodium acetate as reaction raw materials; firstly, dissolving the raw materials into ethylene glycol; then, adding polyethylene glycol to disperse; adding solution into a high-pressure reaction reactor container to react; carrying out magnetic adsorption to obtain Fe3O4 magnetic nanoparticles; taking ethyl orthosilicate as a silicon source to enable silicon dioxide to cover the surface of the Fe3O4 magnetic nanoparticles; taking silane coupling agent as an amino source to graft an -NH2 group to the surface of the silane coupling agent to obtain Fe3O4@SiO2-NH2 magnetic nanoparticles; finally, under a constant temperature, stirring to modify the amino and sulfydryl group of cysteine on the surfaces of the Fe3O4@SiO2-NH2 magnetic nanoparticles to obtain group-enhanced magnetic nanometer water treatment agent Fe3O4-SiO2-NH2-L-Cys. The preparation method has the advantages of simpleness in preparation process operation and easiness in realizing reaction conditions. In addition, the group enhanced type magnetic nanoparticles prepared with the preparation method has the advantages of narrow particle size distribution, good stability, good adsorption function for various heavy metal ions and high adsorption efficiency.

Owner:CHONGQING UNIV

Silicon rubber/polypropylene thermoplastic vulcanizate and preparation method thereof

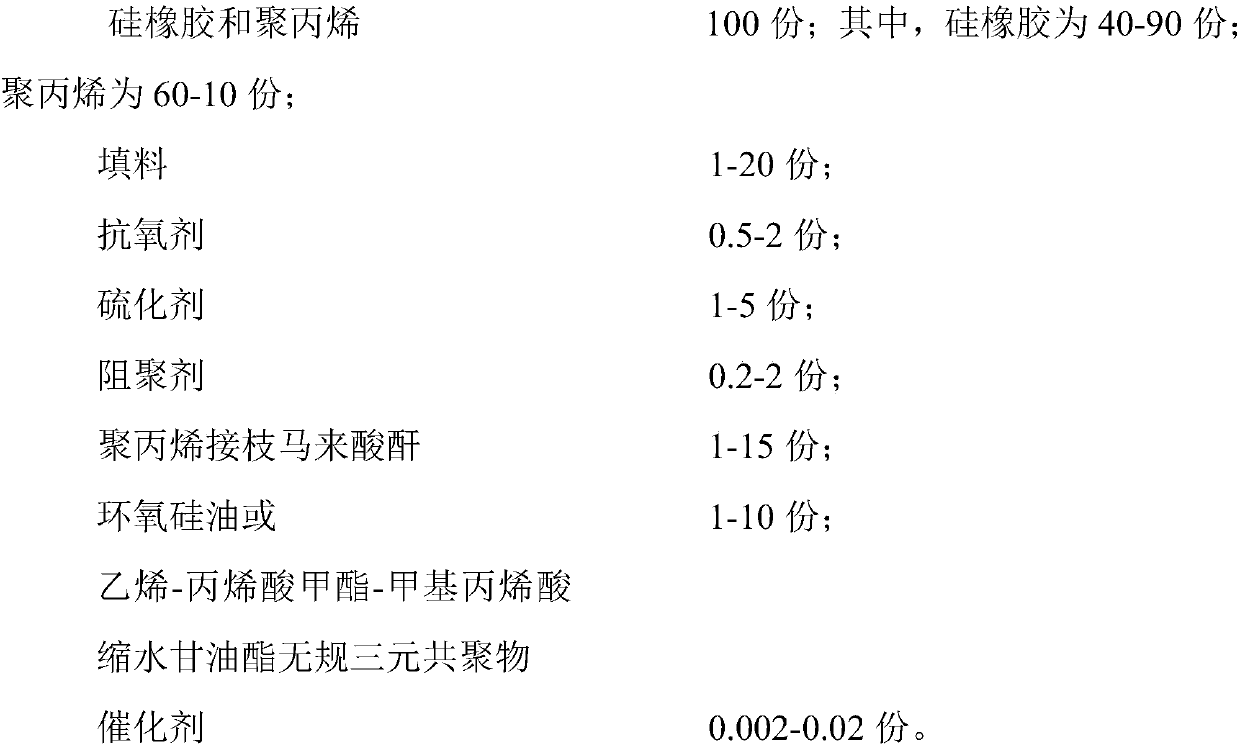

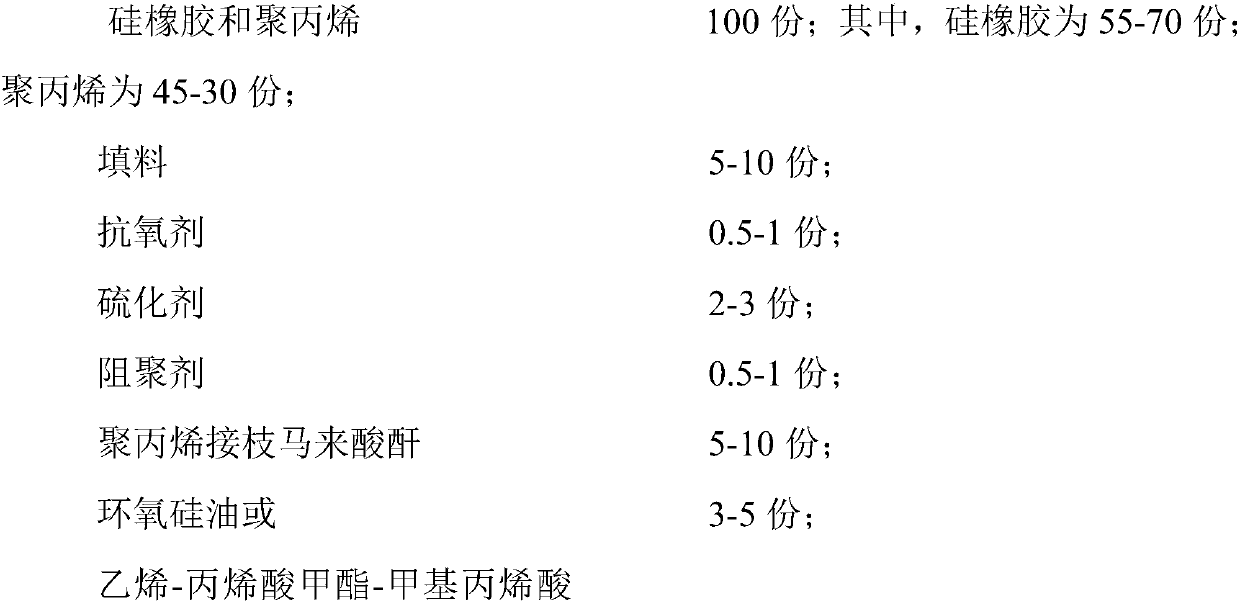

ActiveCN110066519AImprove physical and mechanical propertiesImprove high temperature resistanceGlycidyl methacrylatePolymer science

The invention relates to a silicone rubber / polypropylene thermoplastic vulcanizate and a preparation method thereof. The thermoplastic vulcanizate comprises silicone rubber, polypropylene, a filler, an antioxidant, a vulcanizing agent, a polymerization inhibitor and a compatibilizer, wherein a catalytic reaction product of epoxy silicone oil or ethylene methyl acrylate-glycidyl methacrylate randomterpolymer and polypropylene and grafted maleic anhydride under the action of a catalyst is used as a compatibilizer, the filler is added to the silicone rubber to increase the viscosity of siliconerubber, and the compatibility of the silicone rubber with the polypropylene and the viscosity ratio of the two are improved; through the dynamic vulcanization technology, the prepared thermoplastic vulcanizate has a fine structure, excellent mechanical properties and elasticity, has good high temperature resistance and excellent chemical stability, and can be widely used in automobiles, medical instruments, wearable devices and the like.

Owner:BEIJING UNIV OF CHEM TECH

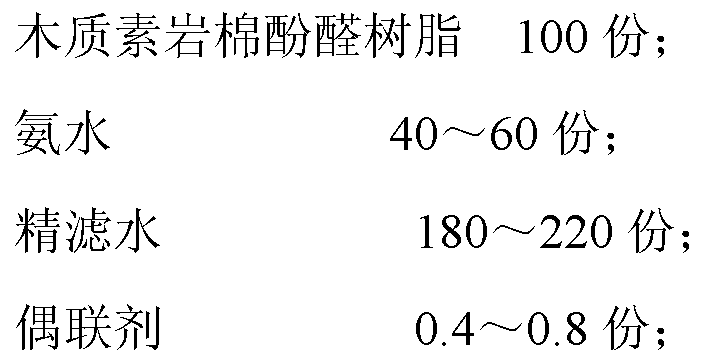

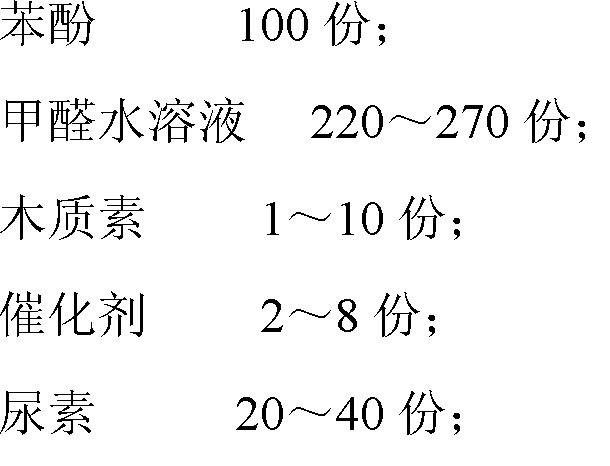

Lignin rock wool phenolic resin binder and its preparation method and use method

InactiveCN103911104AReduce polycondensationReduce contentAldehyde/ketone condensation polymer adhesivesThermal insulationUltimate tensile strength

The invention discloses a lignin rock wool phenolic resin binder and its preparation method and use method. The lignin rock wool phenolic resin binder comprises components A, B and C. The component A comprises, by weight, 100 parts of lignin rock wool phenolic resin, 40-60 parts of ammonia water, 180-220 parts of fine-filtered water and 0.4-0.8 parts of a coupling agent. The component B comprises, by weight, 100 parts of anti-dust oil and 180-220 parts of fine-filtered water. The component C comprises, by weight, 100 parts of a water repellent and 180-220 parts of fine-filtered water. The lignin rock wool phenolic resin binder has long-term storage stability, excellent waterproof performances and bonding performances, realizes high strength and toughness of a rock wool product and can be widely used for production of rock wool thermal-insulation fireproof materials.

Owner:河北东华绿源节能科技有限公司

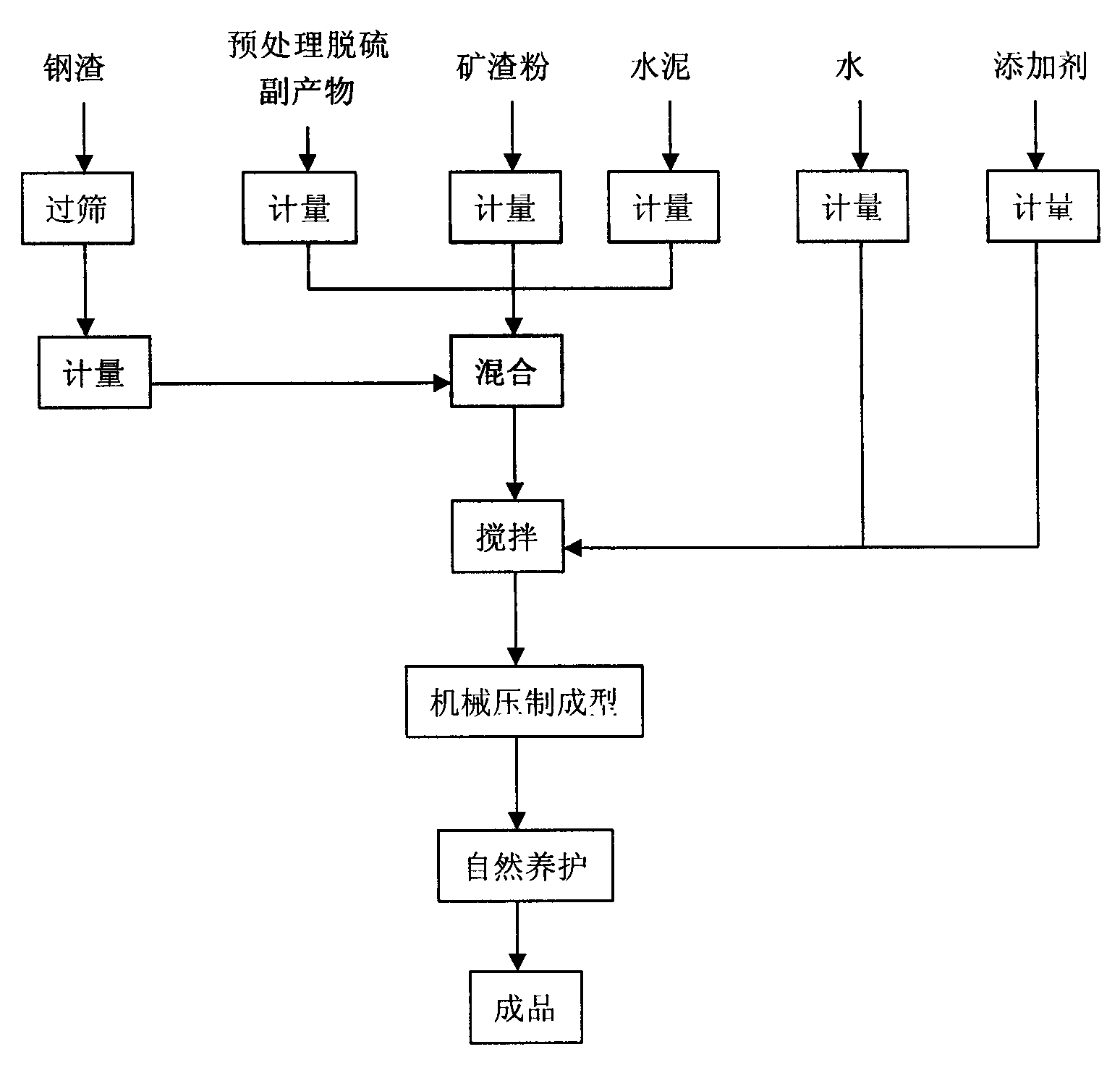

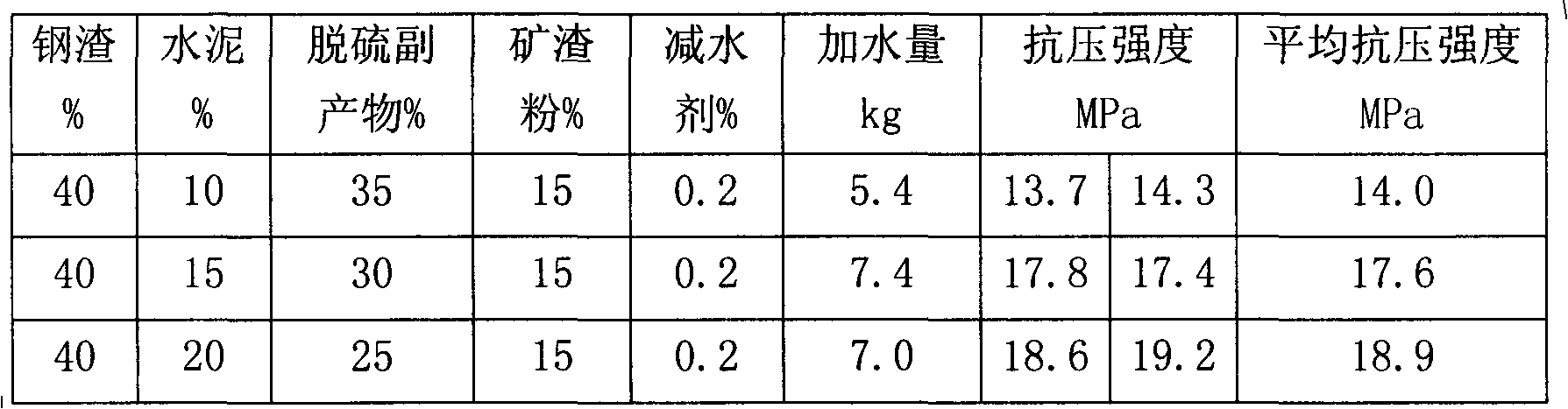

Method for preparing non-fired and non-steamed bricks by using sintering dry desulphurization byproduct

ActiveCN101672081AIncrease responsivenessImprove mechanical propertiesSolid waste managementMixing operation control apparatusWater contentSlag

Owner:SHOUGANG CORPORATION

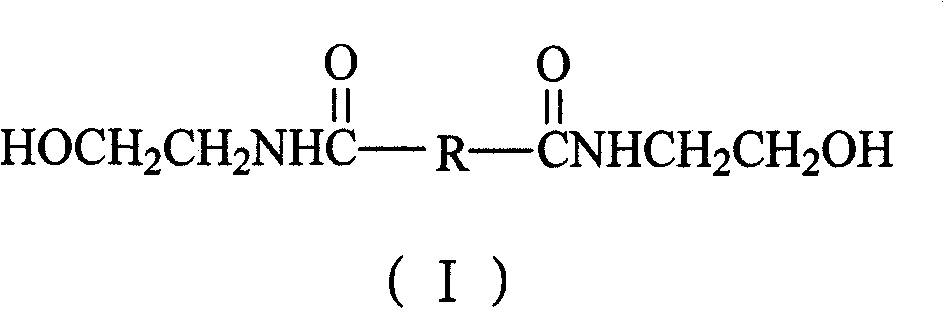

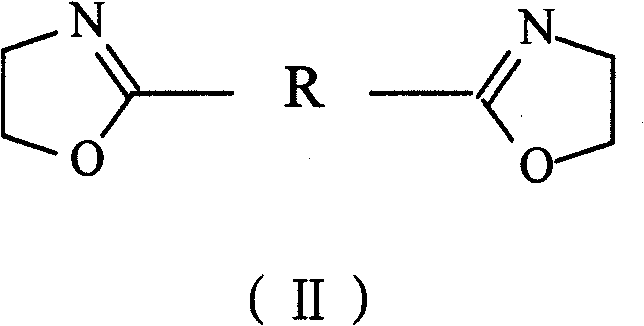

Method for preparing biodegradable polyesteramide through chain extension

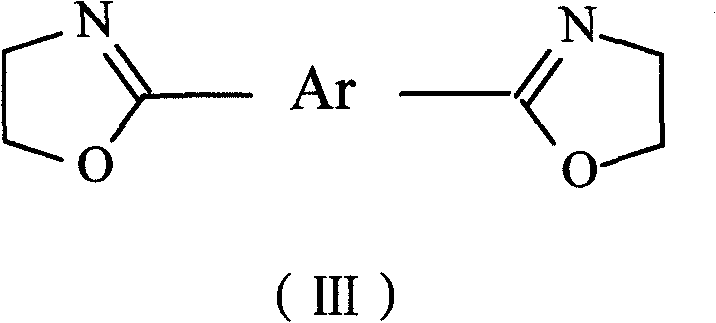

The invention discloses a method for preparing biodegradable polyesteramide through chain extension, and relates to a method for preparing polyesteramide. The prior method for preparing the polyesteramide has the defects of environmental pollution, high requirements on equipment and vacuity, difficult control of material input ratio and the like. The method of the invention comprises the followingsteps: performing melt polycondensation on diamide-diols, dibasic acid and aliphatic diol to prepare polyesteramide prepolymer provided with terminal carboxyl group and terminal hydroxy group structures simultaneously; and performing chain extension with chain extenders of diacyl dilactam and bis-2-oxazoline to prepare the biodegradable polyesteramide of which the limiting viscosity is between 0.42 and 1.05dL / g. The method has low requirement on the vacuity, simplicity and convenience, high efficiency, time conservation, and rich and easily-obtained raw materials, and can prepare polyesteramide with different amide contents to control structures and performance of products by changing the ratio of the diamide-diols to the aliphatic diol to the dibasic acid.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing smectite inorganic gel by mechanochemical modification

InactiveCN104760969AReduce the impact of suspension stabilityNo pollutionSilicon compoundsDispersityWater dispersible

The invention discloses a method for preparing a smectite inorganic gel by mechanochemical modification, which comprises the following steps: adding water into the smectite raw material to prepare a slurry with the concentration of 5-20 wt%, stirring and dispersing uniformly, and pretreating with an ion exchange resin to obtain a pretreated smectite slurry; adding a modifier which is 0.6-1.2 times of smectite CEC, and stirring and dispersing uniformly; feeding the slurry into a wet-process superfine treatment device to perform superfine treatment, thereby obtaining the smectite slurry of which the particle size distribution is D50<=1.0 mu m and D90<=5.0 mu m; and adding an electrolyte which accounts for 0-5 wt% of the smectite into the superfine slurry, and stirring and dispersing uniformly to obtain the target product. The method obviously enhances the water dispersity, suspension stability and thickening property of the smectite, and especially has obvious improvement effects on high-level charged smectite.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Bismuth vanadate composite photo-catalyst co-modified by silver and phosphorous-modified graphite-phase carbon nitride nano-sheets, and preparation method and application of same

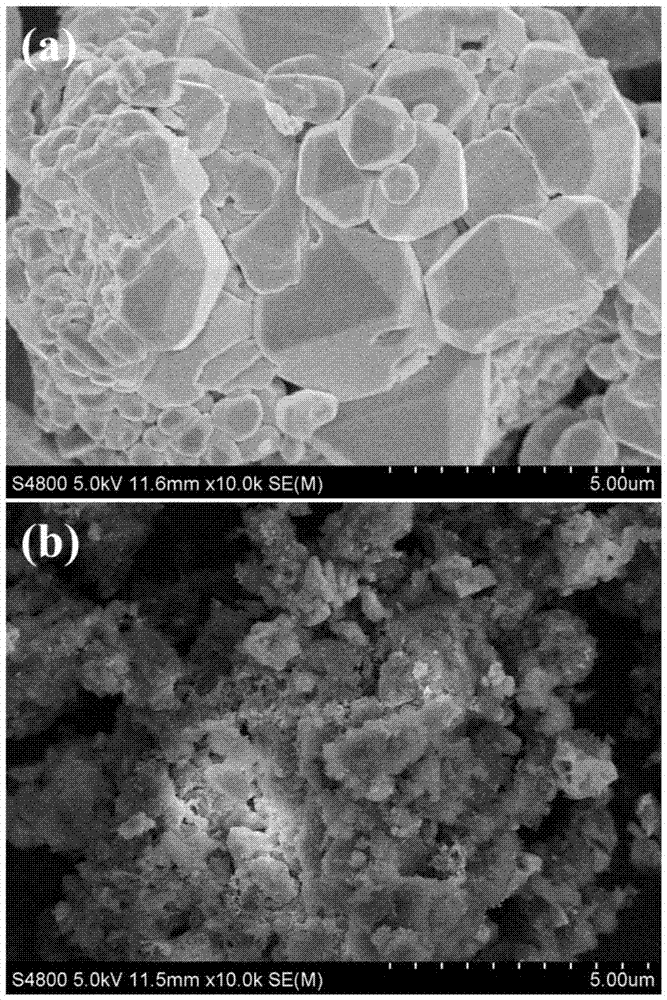

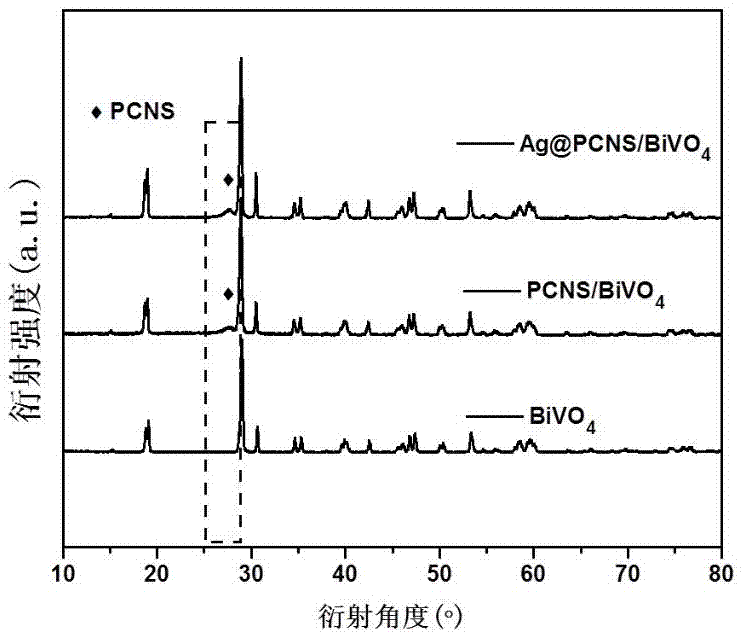

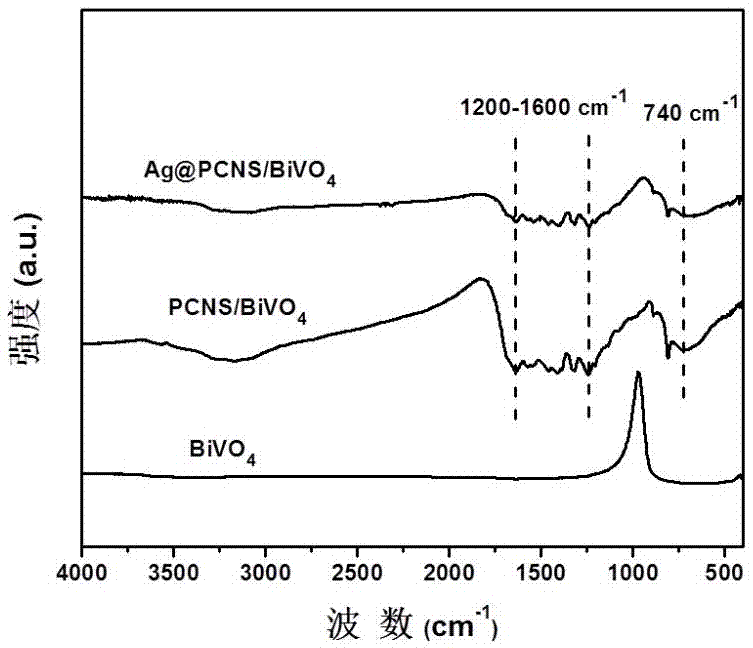

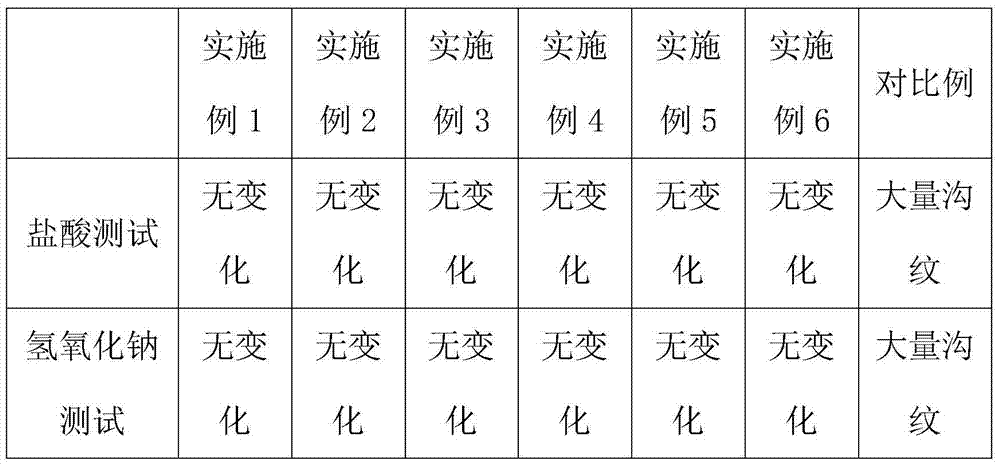

ActiveCN106944118AImprove stabilityEasy to makePhysical/chemical process catalystsWater/sewage treatment by irradiationBismuth vanadateCarbon nitride

The invention discloses a bismuth vanadate composite photo-catalyst co-modified by silver and phosphorous-modified graphite-phase carbon nitride nano-sheets, and a preparation method and an application of same. The composite photo-catalyst includes bismuth vanadate particle, which modifies the surface of phosphorous-modified graphite-phase carbon nitride nano-sheets to form PCNS / BiVO4, and elementary silver modifies the surface of the PCNS / BiVO4. The preparation method includes the steps of: preparing a suspension liquid, preparing the PCNS / BiVO4, and supporting the silver. The composite photo-catalyst has high photo-catalysis activity and good stability. The preparation method is simple in operation and processes and is low in cost. The composite photo-catalyst can be used for treating antibiotics wastewater and has simple application method, low cost, high removal rate on antibiotics, stable photo-catalysis performance, good repeatability, etc.

Owner:HUNAN UNIV

Method for preparing novel polyethylene wood-plastic composite material

The invention discloses a method for preparing a novel polyethylene wood-plastic composite material. The method comprises the following steps: (1) smashing a rape stalk, a cotton stalk and a cotton straw, baking to obtain wood powder, immersing the wood powder in a NaOH solution to perform ultrasonic treatment, taking out, rinsing by deionized water, drying and screening to obtain the alkalified wood powder; (2) mixing polyethylene, maleic anhydride, rare earth oxide and DCP to obtain a rare earth compatilizer; (3) adding phenolic resin and rare earth chloride into a reaction kettle, heating and stirring, heating the reaction solution till boiling, performing reflux reaction, continuously heating, keeping the temperature, stopping heating and reacting to obtain the rare earth phenolic resin; (4) mixing polyethylene, the alkalified wood powder, the compatilizer and the rare earth phenolic resin, moving to an oven, and drying to achieve constant weight to obtain the mixed materials; (5) adding the mixed materials into a conical twin-screw extruder, extruding and granulating to obtain the granules, and baking to obtain the polyethylene wood-plastic composite material.

Owner:江西欧居工程有限公司

Bisphenol A liquid epoxy resin refining method

The invention relates to a bisphenol A liquid epoxy resin refining process. The bisphenol A liquid epoxy resin refining process is characterized by including steps: feeding coarse epoxy resin, NaOH solution and solvent into a reaction kettle, stirring, heating to 60-100 DEG C, reacting for 1-4h, adding NaOH solution and promoter, reacting at 60-100 DEG C for 1-4h, washing with water for three times at 60-100 DEG C after reaction is completed, and subjecting filtrate to reduction vaporization for removing the solvent to obtain high-purity, low-chlorine and low-viscosity bisphenol A liquid epoxy resin. The bisphenol A liquid epoxy resin refining process has the advantages that reaction degree of hydrolysable chlorine on NaOH and coarse resin can be increased by adding the promoter under the low refining alkali condition, adding resolving water during water washing for neutralizing excess alkali can improve the skimming condition and reduce consumption of pure water, little 'three wastes' (waste water, waste gas and waste residues) are generated, production cost is low, products are high in transparency and purity and low in viscosity, and the bisphenol A liquid epoxy resin refining process has high application value.

Owner:CHINA PETROCHEMICAL CORP

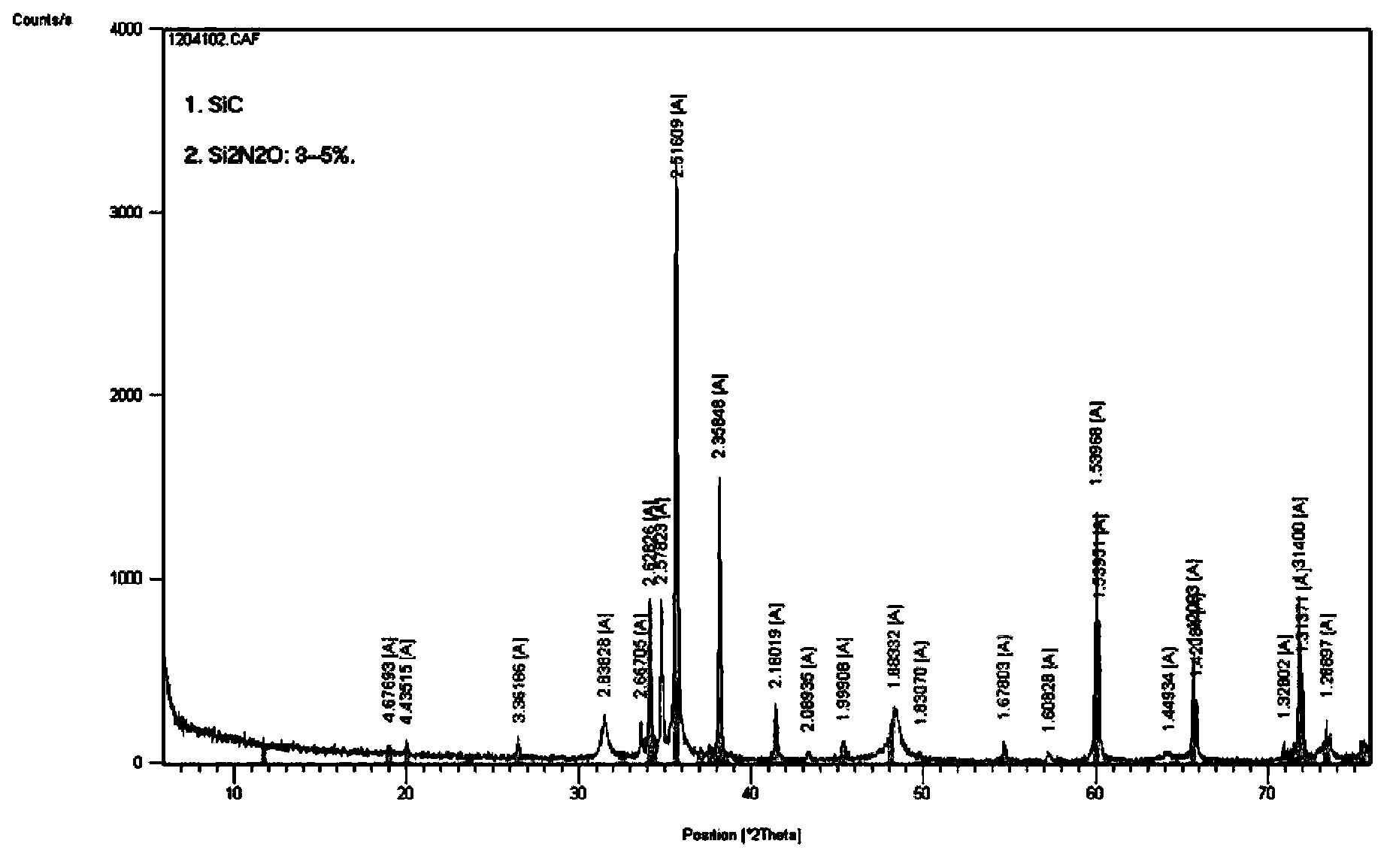

Method for preparing silicon carbide refractory material by taking polycarbosilane as binding agent

The invention discloses a method for preparing a silicon carbide refractory material by taking polycarbosilane as a binding agent. According to the method, a raw material is made up of a silicon carbide precursor, namely, polycarbosilane, as a binding agent, and silicon carbide in grain composition, and the silicon carbide formed through in-situ reaction in the sintering process of polycarbosilane is used as binding phase to ultimately prepare a pure silicon carbide product. The added polycarbosilane plays the role of the binding agent in the pressing process, so that a blank has certain strength, the operability is improved, and meanwhile the polycarbosilane can be converted into silicon carbide in situ in the sintering process, so that the function of binding silicon carbide grains is achieved, and the property of a silicon carbide refractory material product is improved.

Owner:LUOYANG SHENJIA KILN

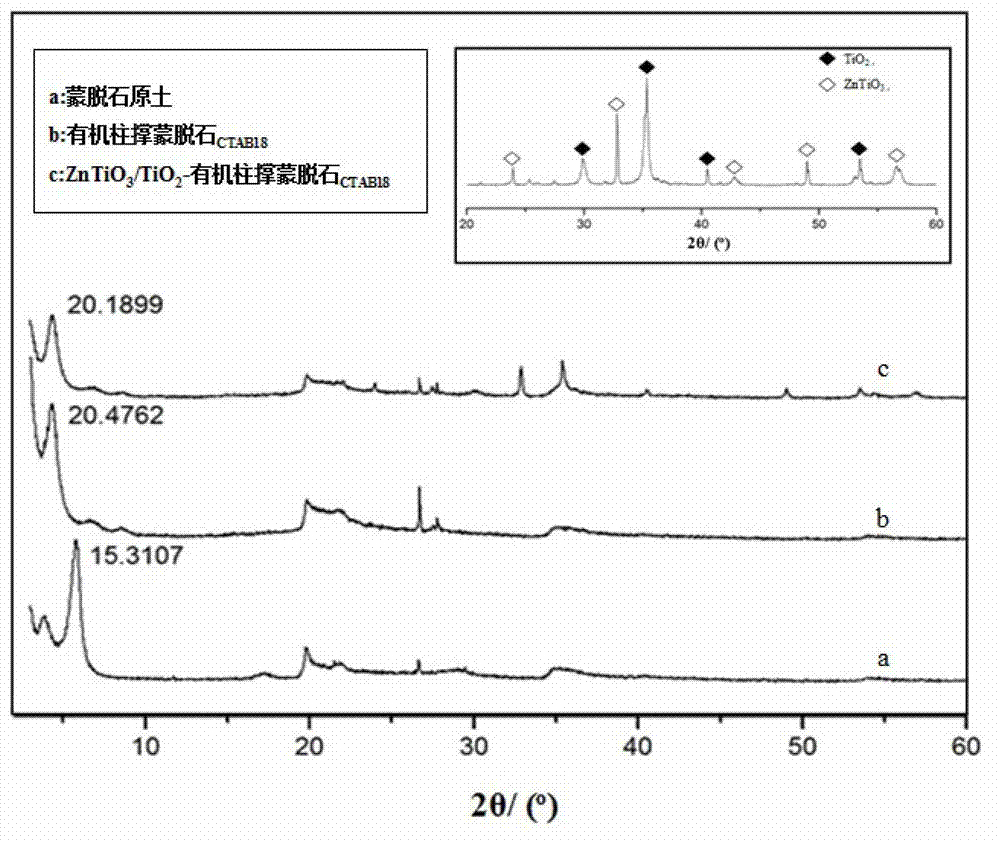

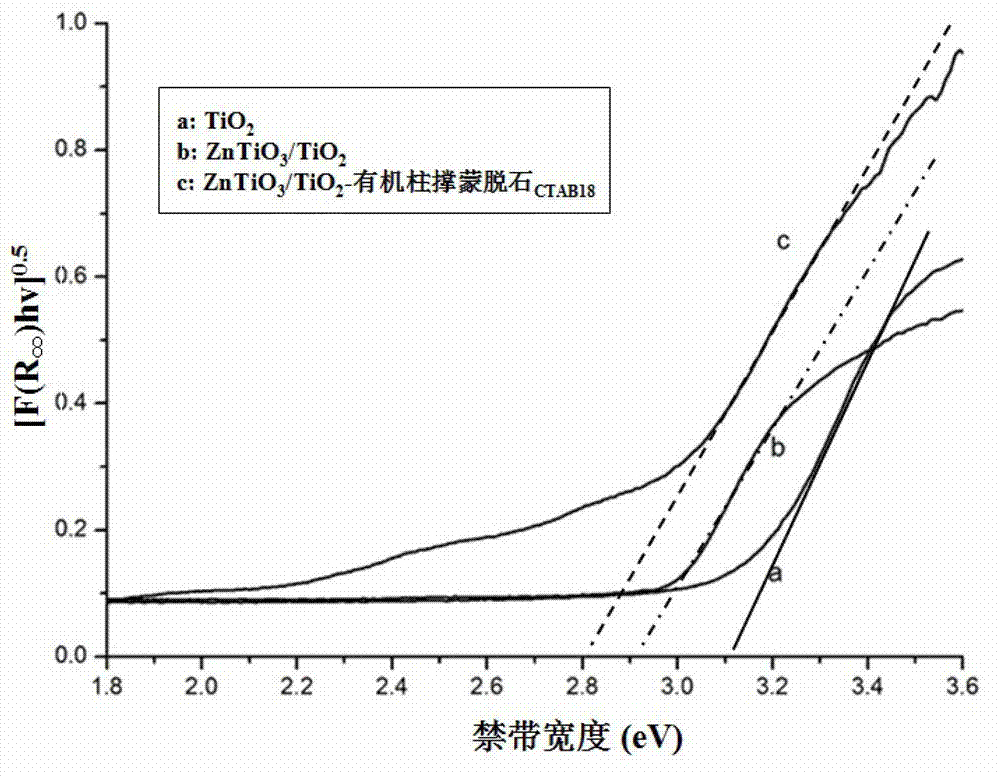

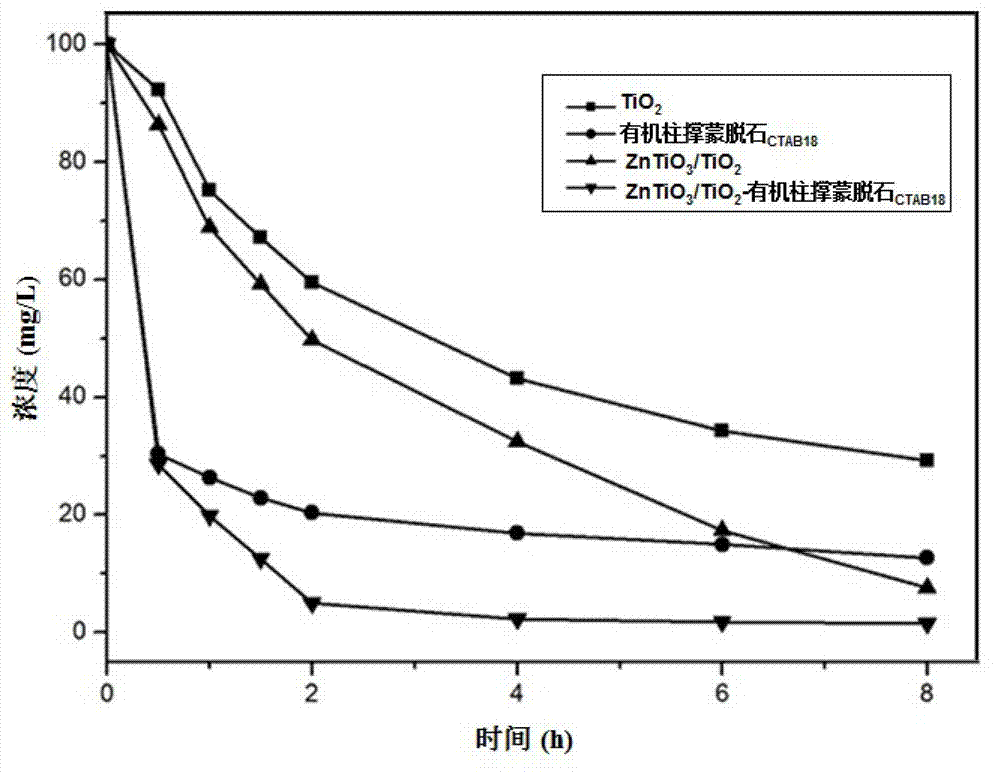

Composite material having visible-light catalytic activity and preparation method thereof

ActiveCN103071477APracticalEasy to operateMetal/metal-oxides/metal-hydroxide catalystsIntercalation reactionSol-gel

The invention discloses a composite material having a visible-light catalytic activity and a preparation method thereof. The composite material having a visible-light catalytic activity is prepared by compounding organic pillared clay and a modified ZnTiO3 / TiO2 material. The organic pillared clay is prepared by an intercalation reaction between an organic pillaring agent and raw clay. The ZnTiO3 / TiO2 material is prepared by a sol-gel method. The ZnTiO3 / TiO2 material and the organic pillared clay are compounded into the ZnTiO3 / TiO2-organic pillared clay composite material having a visible-light catalytic activity. Compared with single TiO2, the ZnTiO3 / TiO2-organic pillared clay composite material has good responsibility in a visible wavelength range. Through utilization of the organic pillared clay as a carrier, adsorption performances of the ZnTiO3 / TiO2-organic pillared clay composite material are improved. The preparation method has the advantages of simple processes, no special equipment, low investment, low cost and popularization convenience.

Owner:SOUTH CHINA UNIV OF TECH

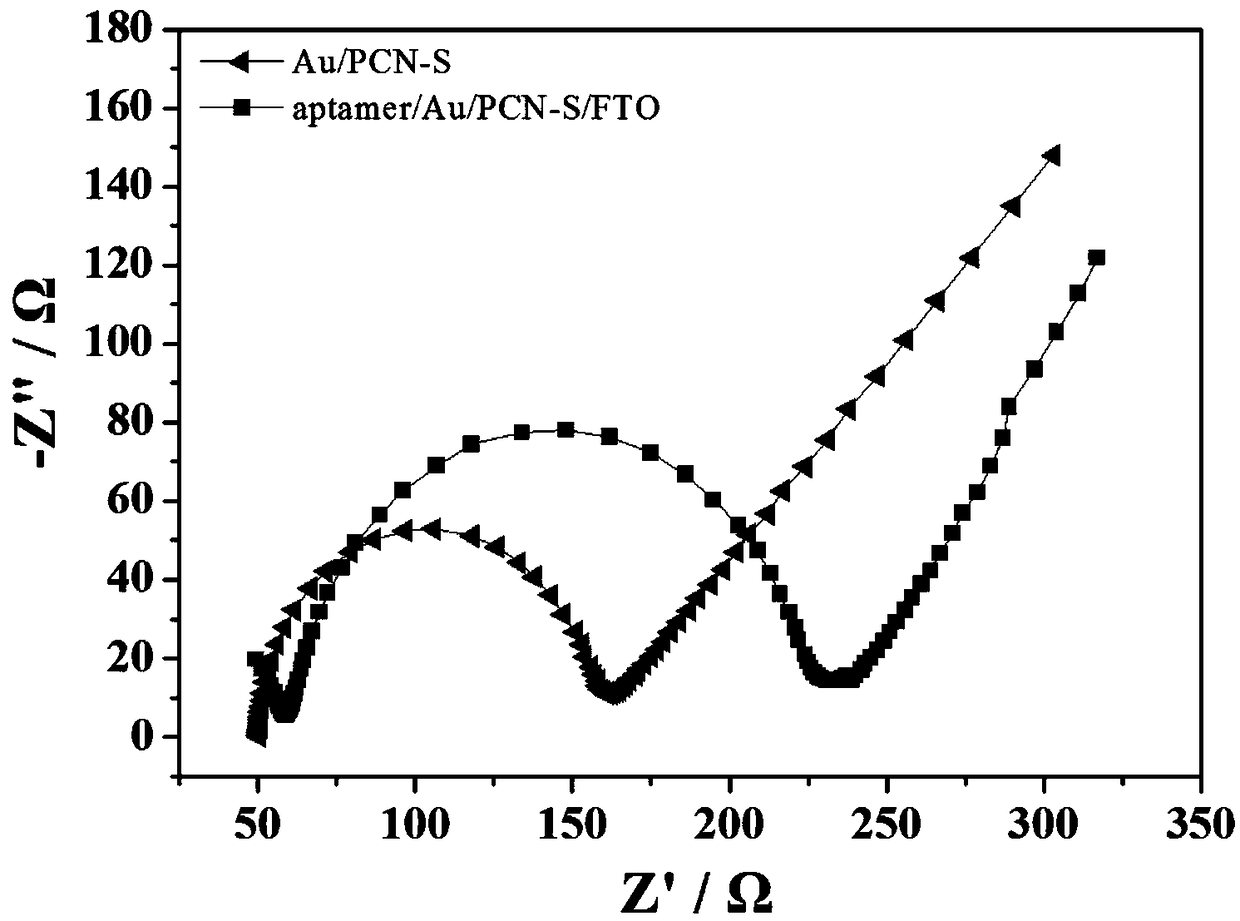

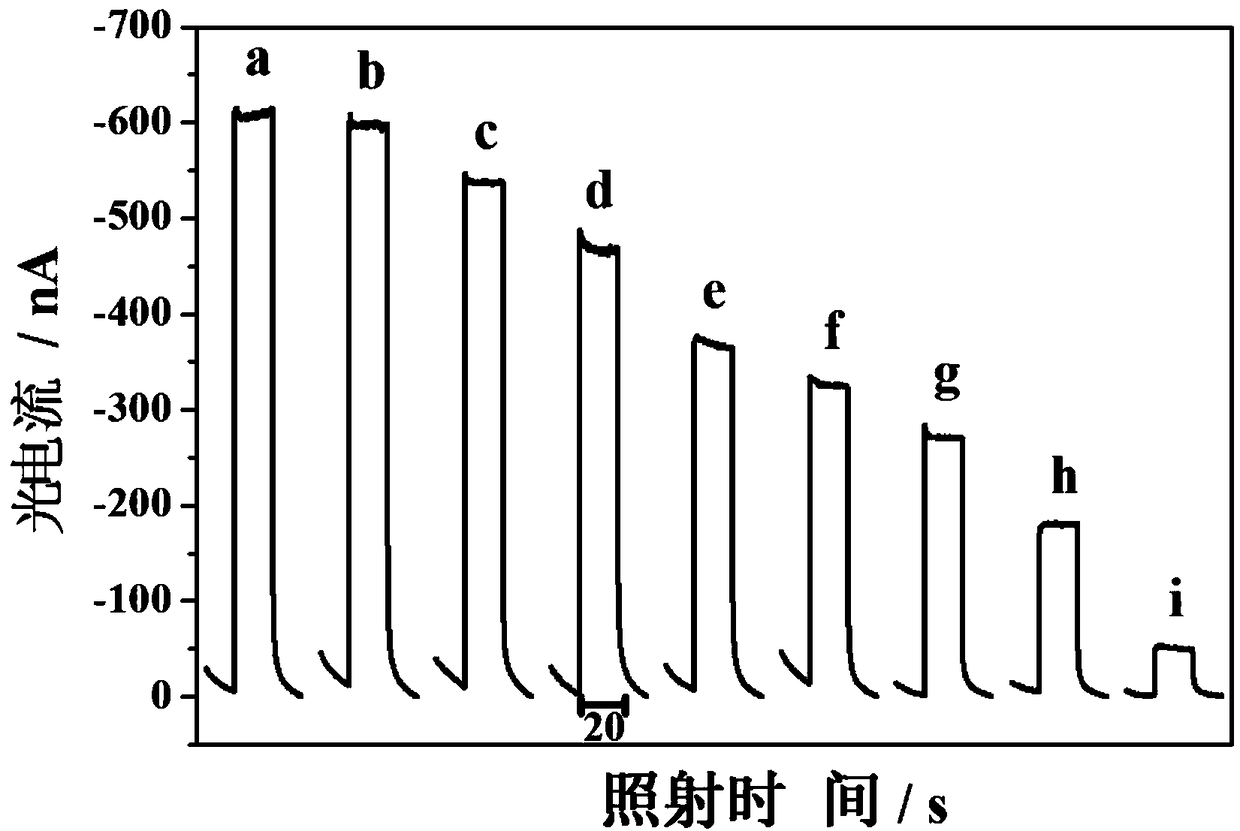

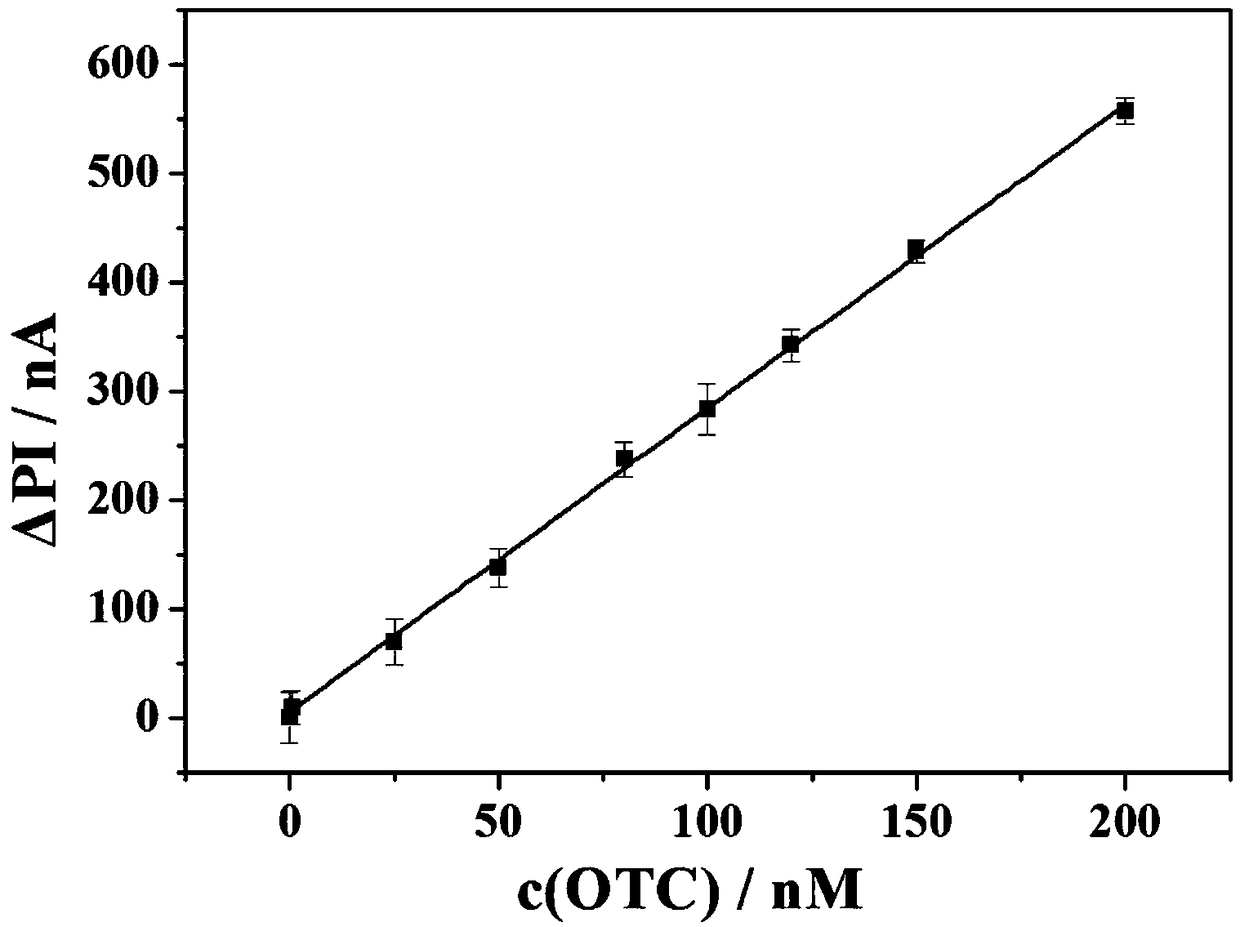

Photoelectrochemical adaptor sensor as well as preparation method and application thereof

ActiveCN108845009AHigh detection sensitivityLarge specific surface areaMaterial electrochemical variablesAnti jammingAntibiotic Y

The invention discloses a photoelectrochemical adaptor sensor as well as a preparation method and application thereof. The photoelectrochemical adaptor sensor comprises a conductive glass electrode, wherein the reacting end surface of the conductive glass electrode is modified with a composite membrane consisting of phosphorus hybridization graphite phase carbon nitride nanosheets loading gold nanoparticles; and a specific adaptor probe is self-assembled on the surface of the membrane. The preparation method of the photoelectrochemical adaptor sensor comprises the following step: modifying thephosphorus hybridization graphite phase carbon nitride nanosheets loading the gold nanoparticles and the specific adaptor probe on the reacting end surface of the conductive glass electrode. The sensor disclosed by the invention has the advantages of high stability, long service life, high anti-jamming capability, wide detection range, low detection limit and the like. The preparation method of the photoelectrochemical adaptor sensor has the advantages of simple technology, convenient operation, safety, low cost, no pollution, high production efficiency and the like. The sensor disclosed by the invention can be widely applied to detecting pollutants (such as antibiotics) in mediums such as a water body and a living body and has the advantages of high utilization rate, wide application range, high application value and the like.

Owner:HUNAN UNIV

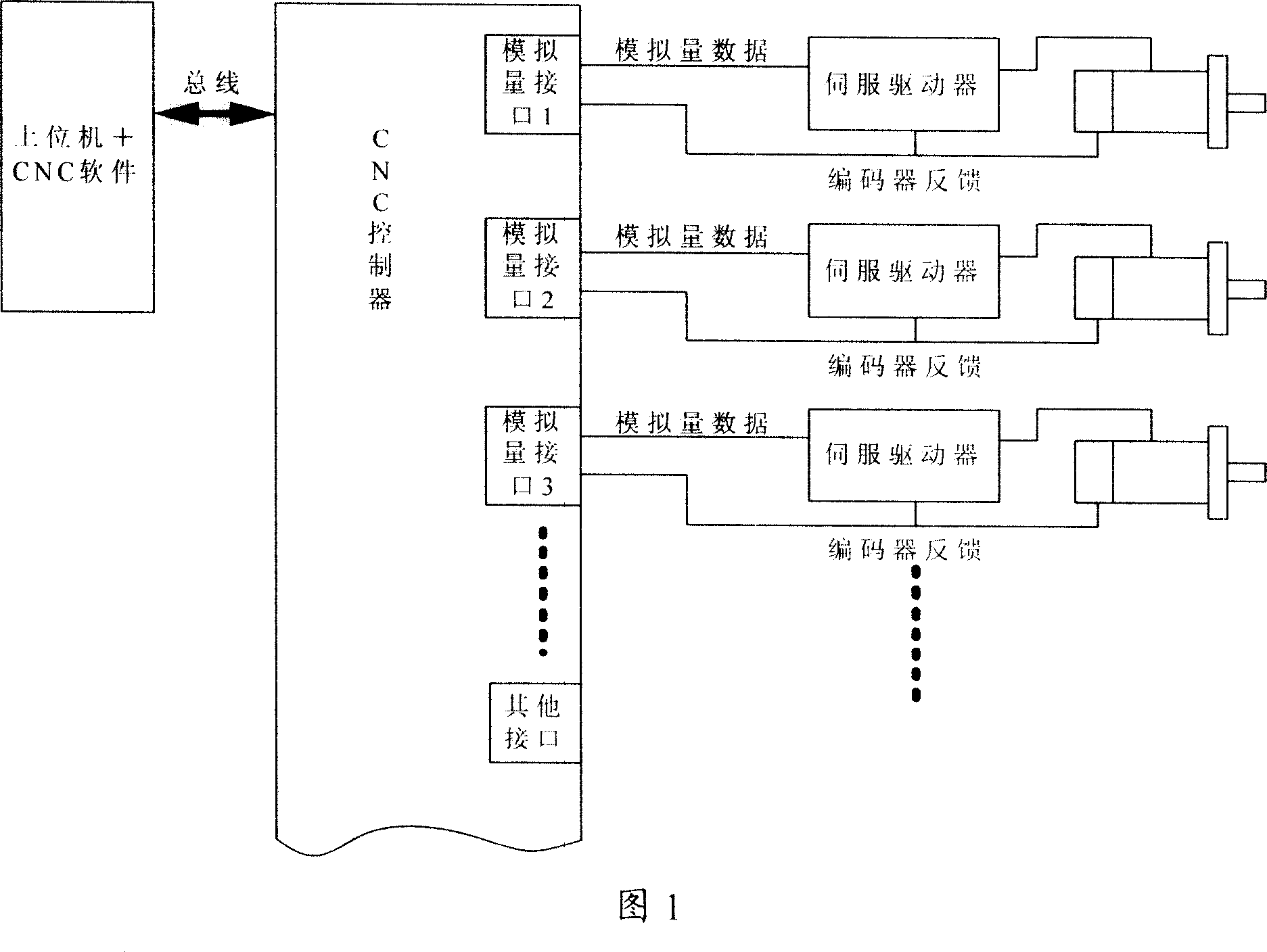

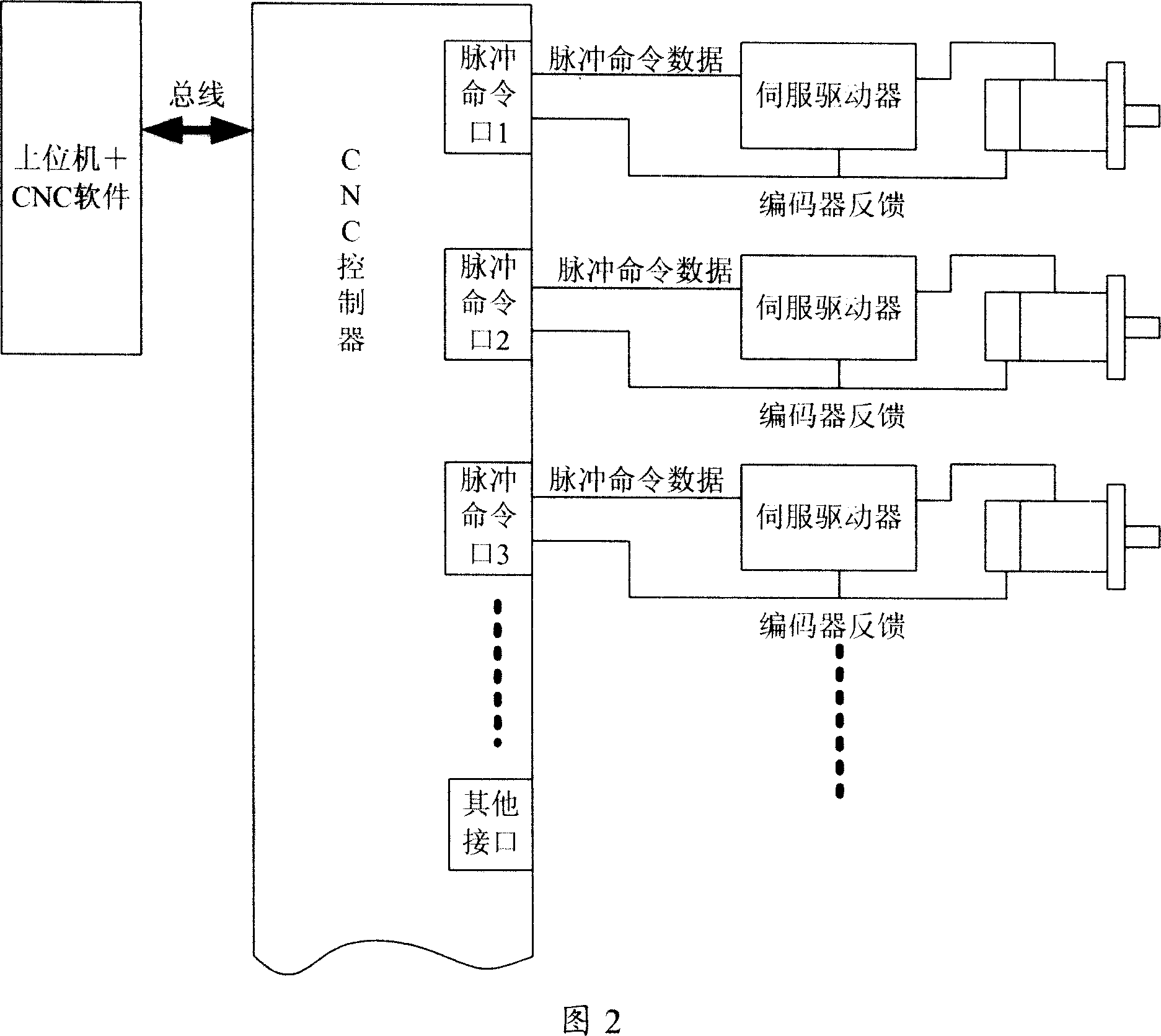

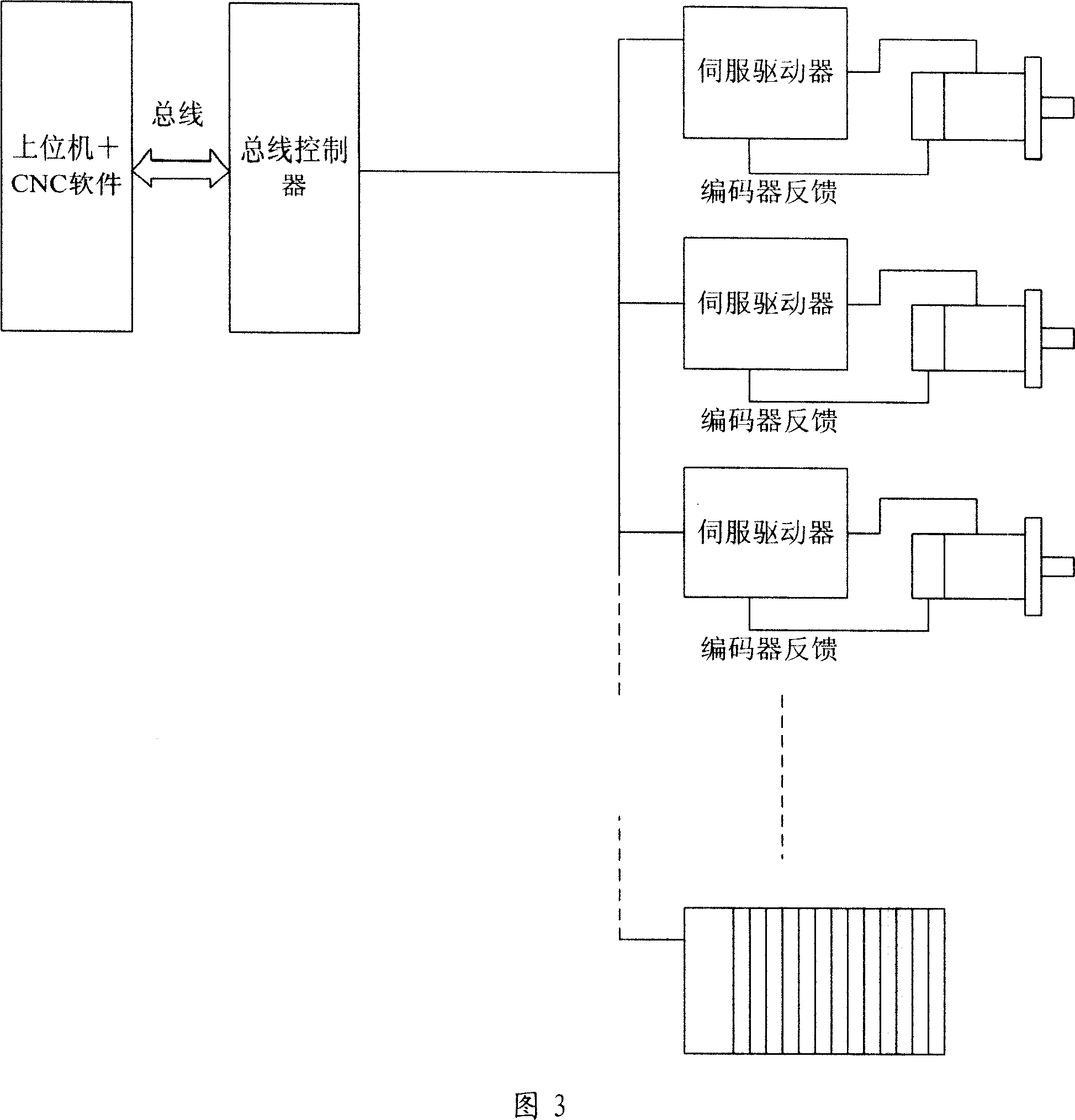

Integrated numerical control system based on full digital ring bus

InactiveCN101013314AReduce unreliabilityStrong scalabilityNumerical controlControl systemClosed loop

The invention discloses an integrated control system based on digital ring bus, including master equipment and slave equipment; the main equipment includes the PC (1) with digital control software and the bus controller unit (2); the slave equipment includes digital bus servo drive (3) and the PLC, and main equipment connecting with 1-24 slave equipments in serial which back to the main equipment thereby constituting a closed loop, and between the main equipment and the slave equipment transmitting data through the link connecting with physical layer and transmission media; among them, the bus controller unit uses integrated method to fix on the motherboard based on X86 architecture, and communicates with the X86CPU on the motherboard. The invention relies on industrial control motherboard to integrate the bus controller, in order to ensure the system stability and reliability.

Owner:DALIAN GUANGYANG SCI & TECH ENG CO LTD

Method for preparing high-purity vinylene carbonate

The present invention relates to a method for preparing high-purity vinylene carbonate. The method comprises the steps of (a) carrying out a chlorination reaction between ethylene carbonate and dry chlorine under the irradiation of ultraviolet light to produce chloroethylene carbonate; (b) dispersing chloroethylene carbonate into methylsilicone oil, then, adding an organic amine, and carrying out an elimination reaction to obtain vinylene carbonate, wherein the mole ratio of chloroethylene carbonate to the organic amine is 1: (1.1-1.5); and (c) refining the products obtained in the step (b) under reduced pressure. Through carrying out the elimination reaction between chloroethylene carbonate and the organic amine in the methylsilicone oil, and controlling the ratio of chloroethylene carbonate to the organic amine, the extent of the reaction can be improved, and the separation of each product can be facilitated, so as to increase the product purity.

Owner:SUZHOU HUAYI NEW ENERGY TECH CO LTD

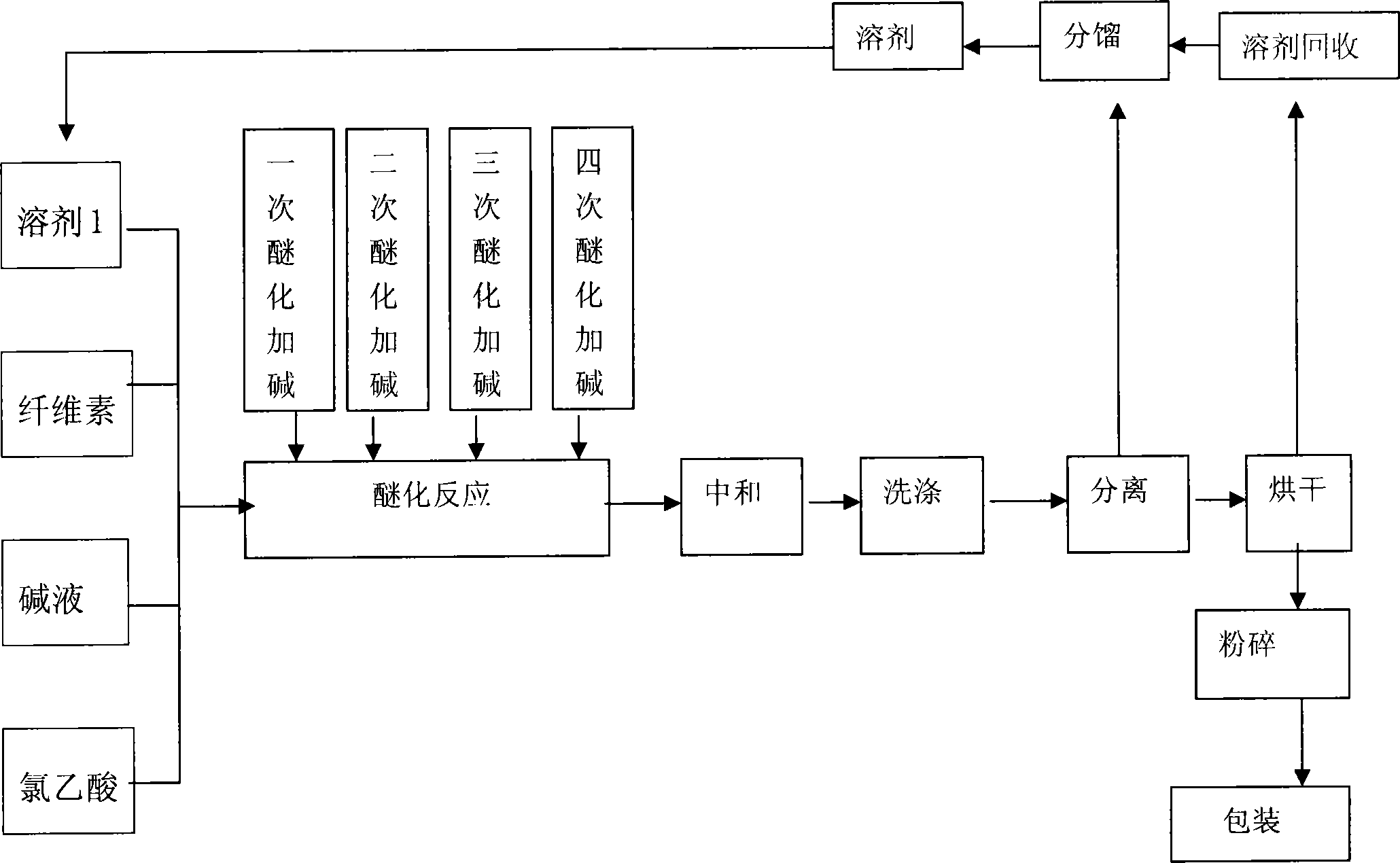

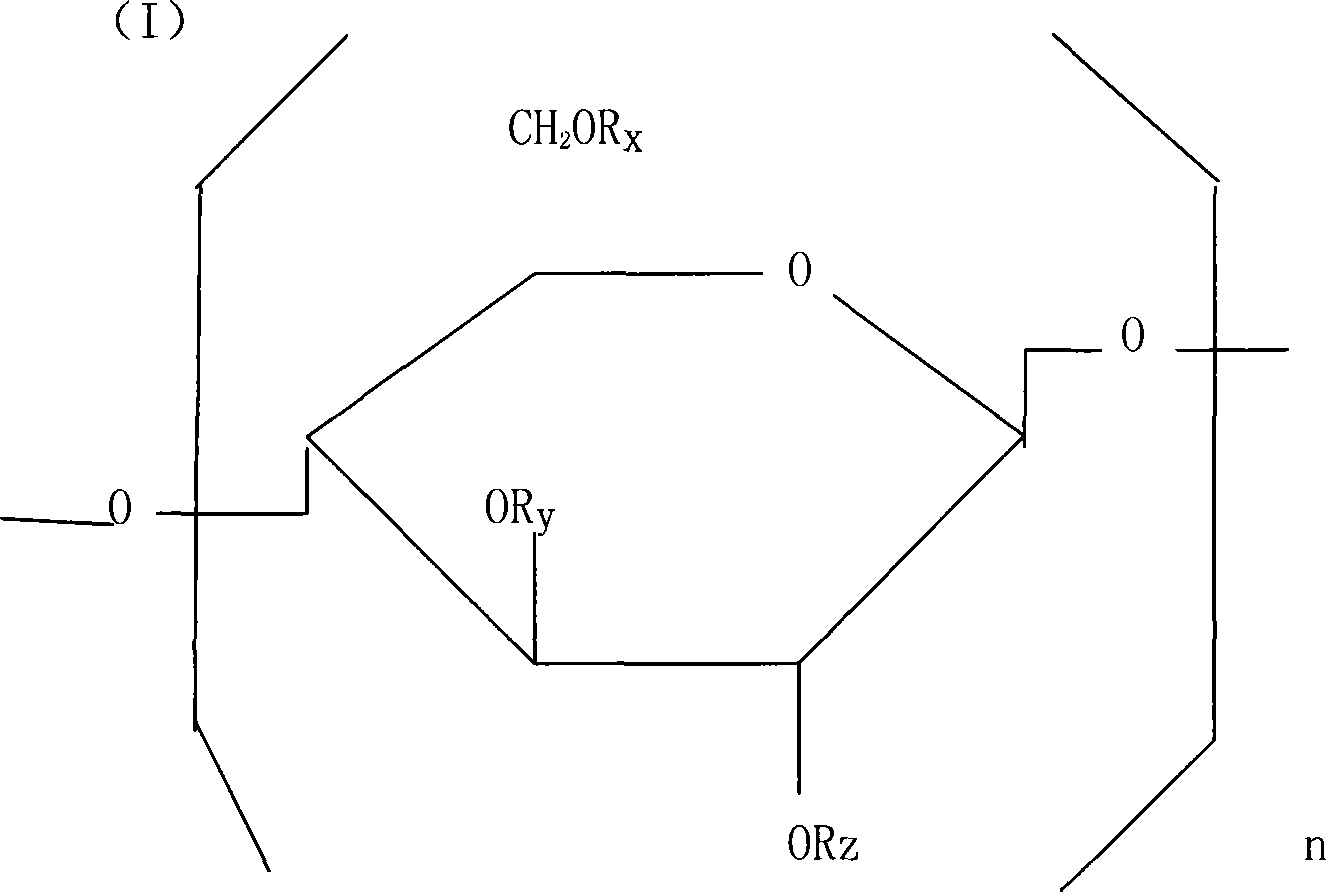

Ultra-high substitution carboxymethyl cellulose sodium and its preparation method and application

InactiveCN101240035ASuper high degree of substitutionHigh degree of substitutionFruit and vegetables preservationDough treatmentCarboxymethyl celluloseCellulose

The invention discloses a extra highly substituting cellulose carboxymethyl sodium, which comprehensively utilize spraying impregnation and high-temp mist agitation. Charging a proportion of alkali and cellulose material sequentially into complex solvent of isopropanol, ethanol and water to carry out invasive quaternization, fractionally spray residual alkali liquid in mist into the reaction system by pressurization under high-temp agitation, charging etherifying agent to execute etherification for four times, and purifying to get final product. The product is high in degree of substitution, whose substituent distribute equally, has characteristics of high viscosity, high content of sodium, high acid-viscosity ratio. Meanwhile, the product has great heat resistance, great pseudoplastic behavior, and excellent suspension stability, prevent generation of gel particles, can have cooperative synergism with other stabilizer. The product is reduced in dosage, with improved taste and prolonged shelf life.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

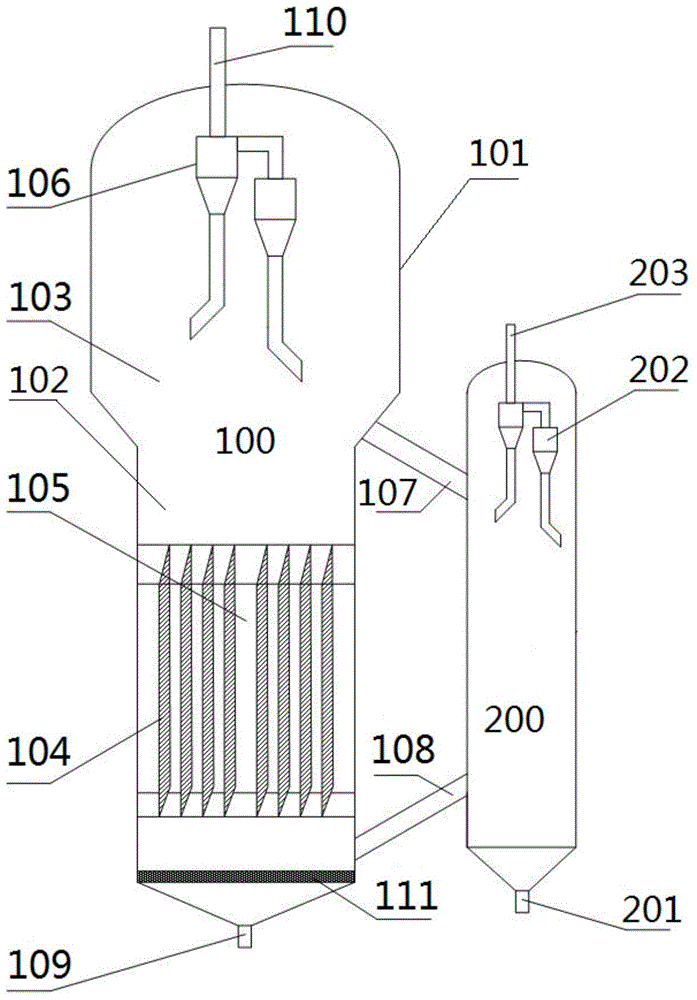

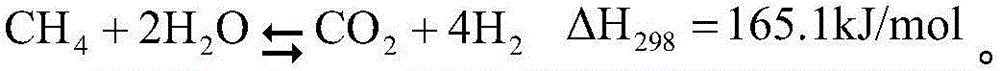

Fluidized bed reactor, fluidized bed reaction apparatus, and methane water-vapour reforming method

ActiveCN104587912AAchieve double catalytic effectIncrease responsivenessHydrogenChemical/physical processesSteam reformingFluidized bed

The invention provides a fluidized bed reactor. A reaction area of the reactor is provided with foam metal plates with catalytic activity, the foam metal plates are longitudinally and / or transversely arranged along the reaction area, the space among the foam metal plates and / or the space between the foam metal plates with the inner wall of the reaction area are / is used to hold a fluidizable particle, and the fluidizable particle can pass through pores on the transversely-arranged foam metal plates. The invention also provides a fluidized bed reaction apparatus which comprises the fluidized bed reactor and a regenerator. The invention also provides a methane water-vapour reforming method using the fluidized bed reaction apparatus, and the foam metal plates have catalytic activity on the methane water-vapour reforming reaction, and at least a part of the fluidizable particle has adsorption effect on carbon dioxide. In the method, the catalyst does not need frequently regenerating along with the adsorbent, when the adsorbent is guaranteed to be always capable of satisfying usage requirements, energy consumption during regeneration is reduced, and senseless reduction of the catalyst activity is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low monomer residue humic acid sodium type super water-absorbed resin and preparation method

The invention relates to a low monomer residue humic acid sodium type super water-absorbed resin and a preparation method, belonging to the technical field of organic high molecular compound. The invention is used for solving the problem that the humic acid sodium type super water-absorbed resin has high monomer residue and is characterized in that the resin comprises matters of the following weight unit: 14-18 of humic acid sodium, 16-17.5 of acrylic acid, 3.8-6.5 of neutralizing agent, 0.23-0.55 of evocating agent, and 0.085-0.15 of cross linker. The product has high humic acid sodium content. The method replaces a conventional heating method with a microwave polymerization method, greatly increases the polymerization reaction yield and reaction degree, and leads the super water-absorbed resin to reach knockdown low monomer residue. Compared with the conventional product produced by the prior art, the multiplying power of the product absorbing de-ionized water is increased by about 40%, the multiplying power of the product absorbing 0.9% of NaCI water solution is increased by about 80%, and the monomer residual quantity is 5-6% of the conventional product, thus greatly increasing use safety.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

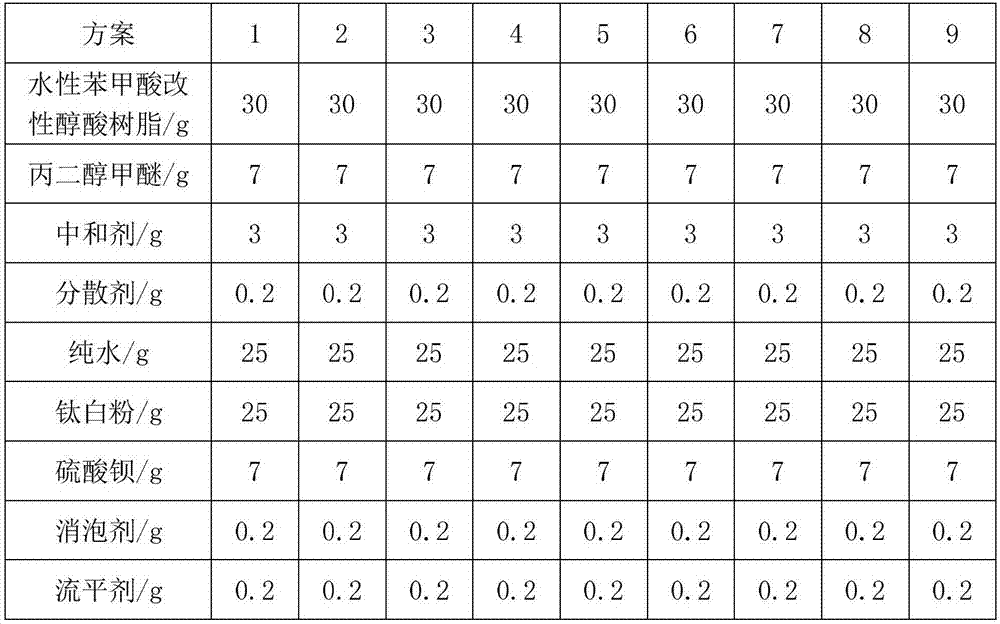

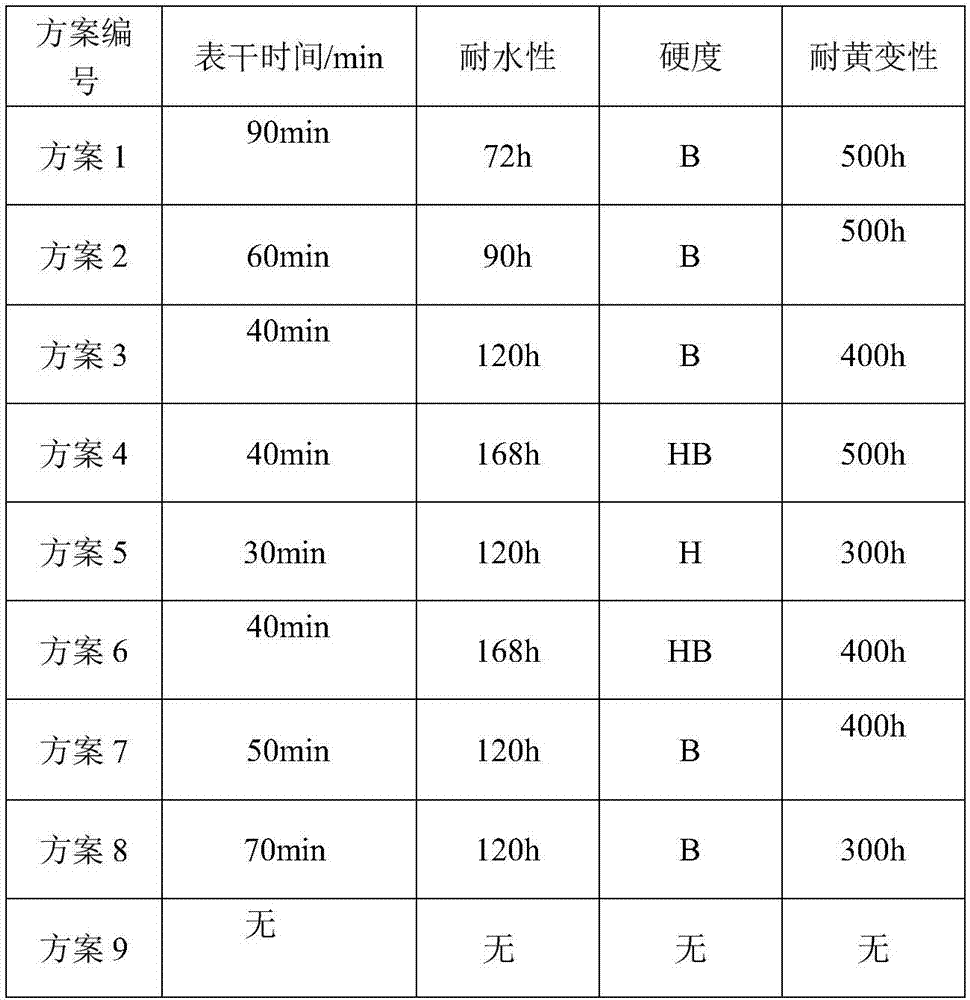

Water-based benzoic acid modified alkyd resin for air-dry paint and preparation method of water-based benzoic acid modified alkyd resin

InactiveCN106978049AFast dry timeImprove water resistanceEmulsion paintsPolyester coatingsWater basedBenzoic acid

The invention provides water-based benzoic acid modified alkyd resin for an air-dry paint and a preparation method of the water-based benzoic acid modified alkyd resin and belongs to the technical field of paints. The water-based benzoic acid modified alkyd resin is prepared from the following raw materials of oleic acid, benzoic acid, polyhydric alcohol, polybasic acid, a catalyst, trimellitic anhydride, ethylene glycol butyl ether and sec-butyl alcohol at the mass ratio of (20-35):(5-20):(20-30):(15-30):(0.01-0.05):(4-10):(8-12):(6-8), wherein the oleic acid is any one or more of soya oil acid, tall oil acid, linoleic acid, linseed oil acid, calophyllum inophyllum oleic acid and dehydrated ricinolic acid. According to the water-based benzoic acid modified alkyd resin for the air-dry paint and the preparation method of the water-based benzoic acid modified alkyd resin, the prepared water-based benzoic acid modified alkyd resin has the beneficial effects of short surface drying time, high hardness and excellent water resistance and yellowing resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com