Patents

Literature

3633results about How to "Improve pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

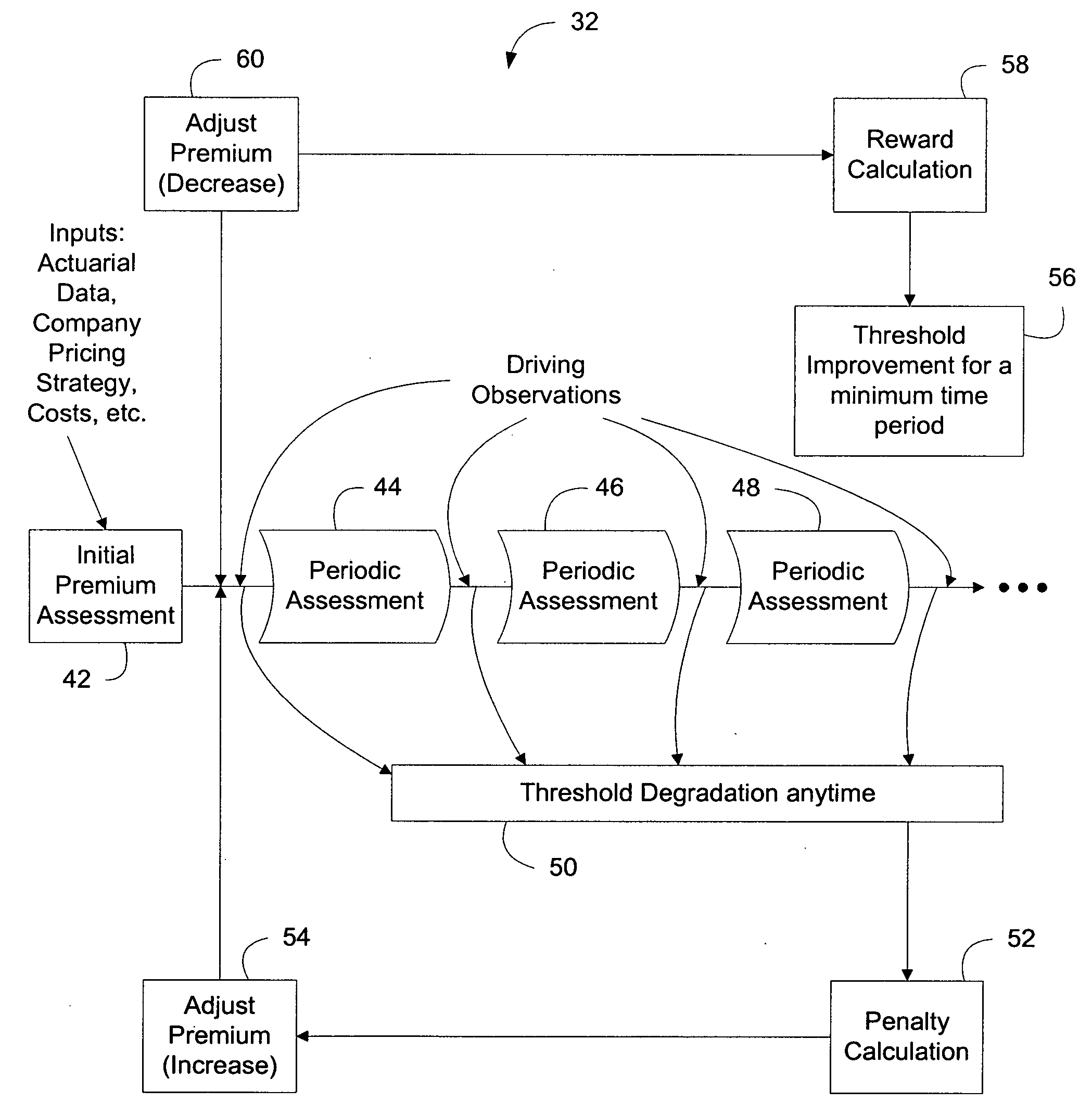

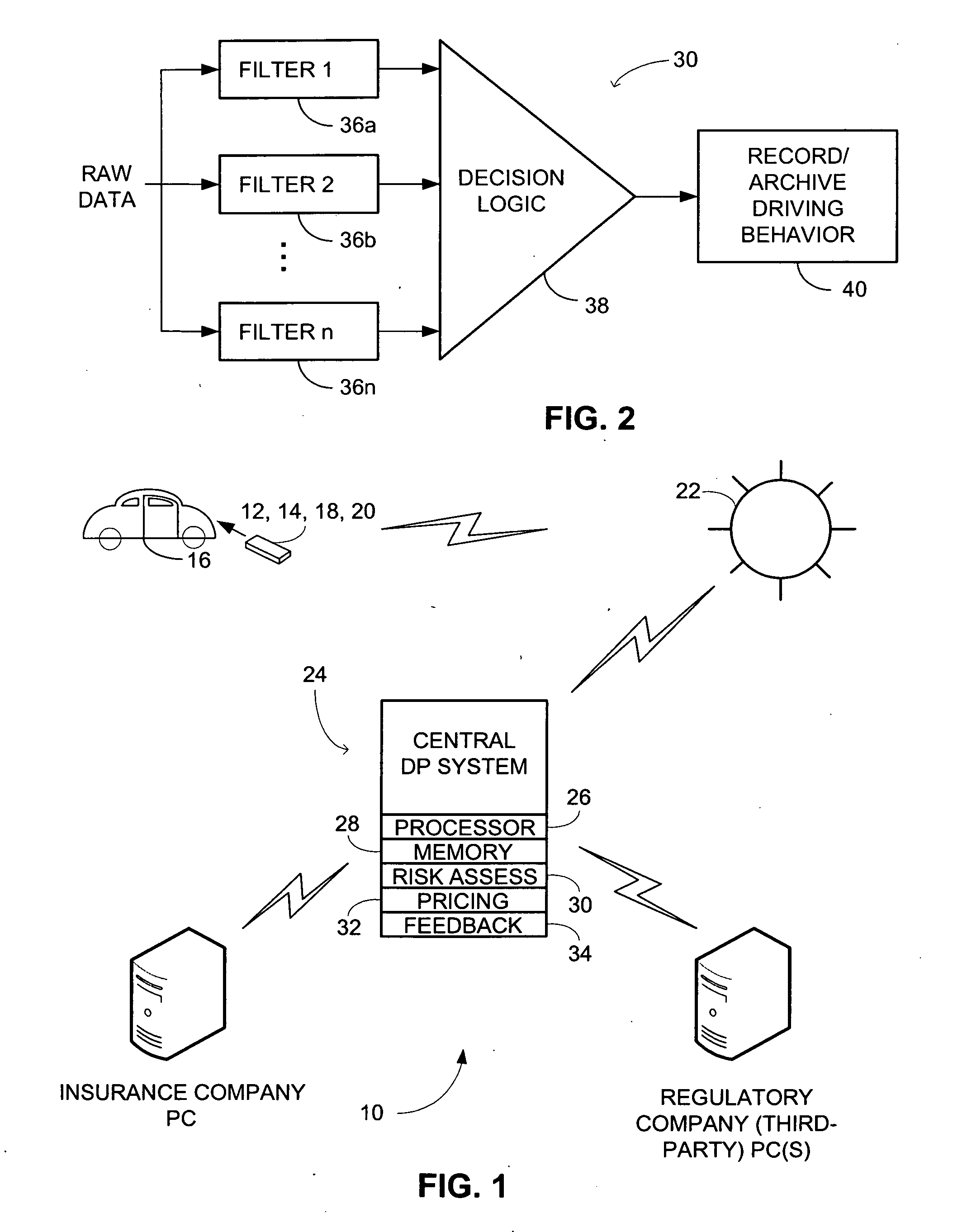

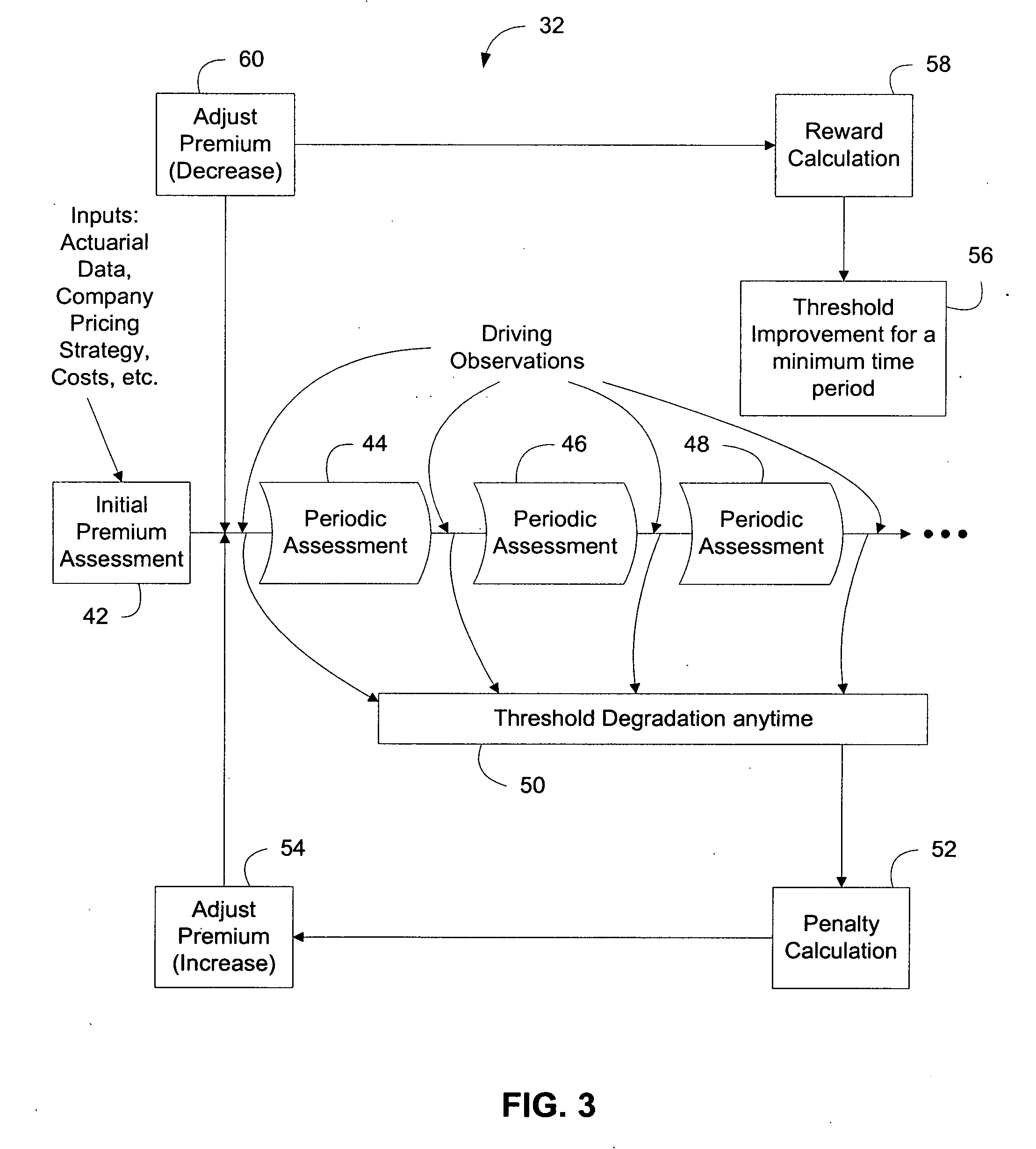

System and method for monitoring driving behavior with feedback

InactiveUS20080243558A1Accelerate emissionsReduce fossil fuel reservesFinanceRegistering/indicating working of vehiclesData processing systemAnalysis data

In accordance with an embodiment of the present invention, a network system for monitoring driving behavior comprises one or more vehicle-mountable motion sensing mechanisms that generate a plurality of data relevant to vehicle moving attitude. The data being indicative of manual or mental risks for a vehicle operator is wirelessly transmittable. The network system also comprises a central data processing system that collects the data transmitted from the motion sensing mechanisms. A risk assessment engine operatively coupled to the central data processing system analyzes the collected data to determine the manual or mental risks. The central data processing system further comprises a feedback engine operable to yield indicia based on the analyzed data that is reportable to the vehicle operator or an authorized data recipient. A reward engine operatively coupled to the feedback engine provides incentives to encourage good or improved driving behavior.

Owner:GUPTE ASH

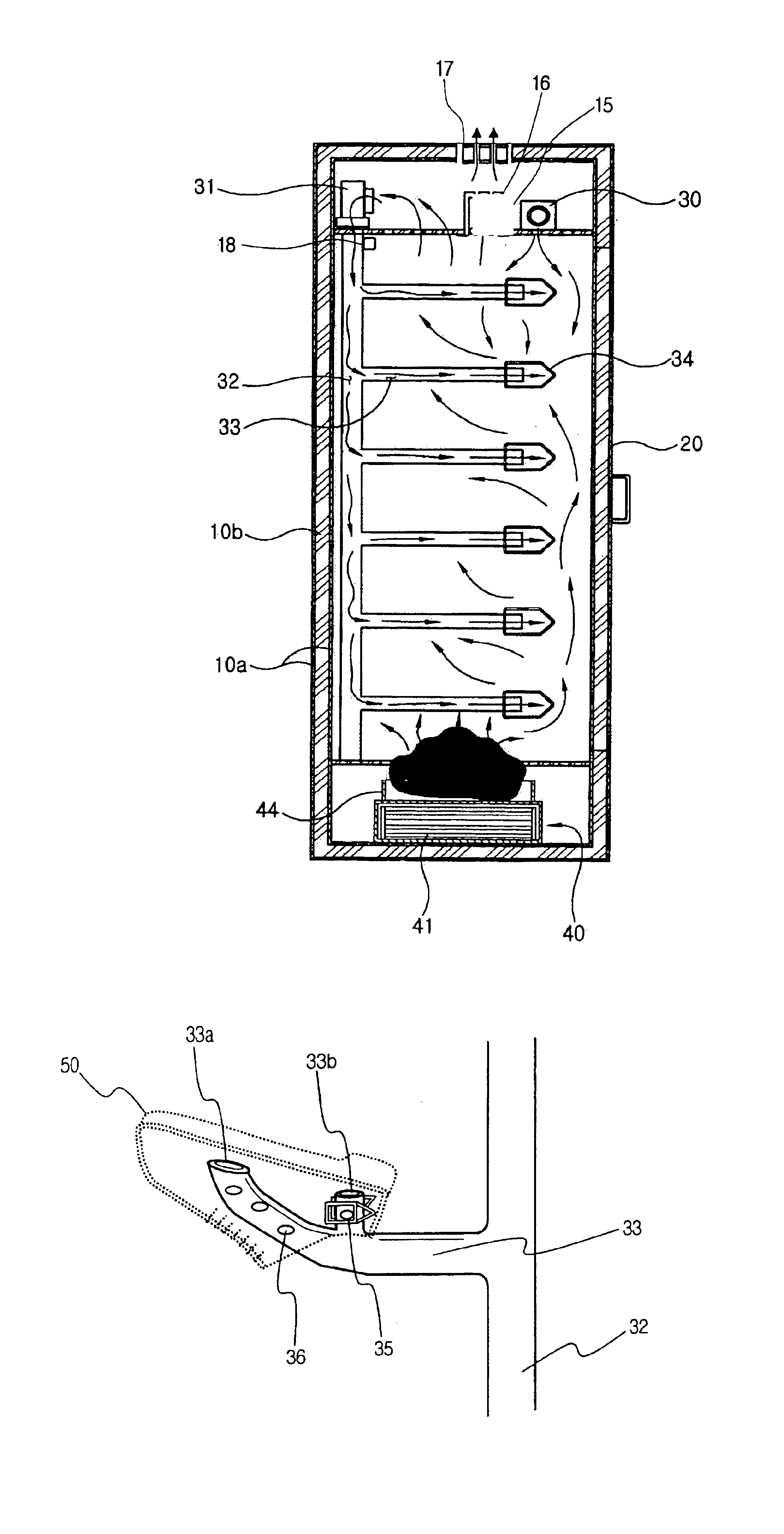

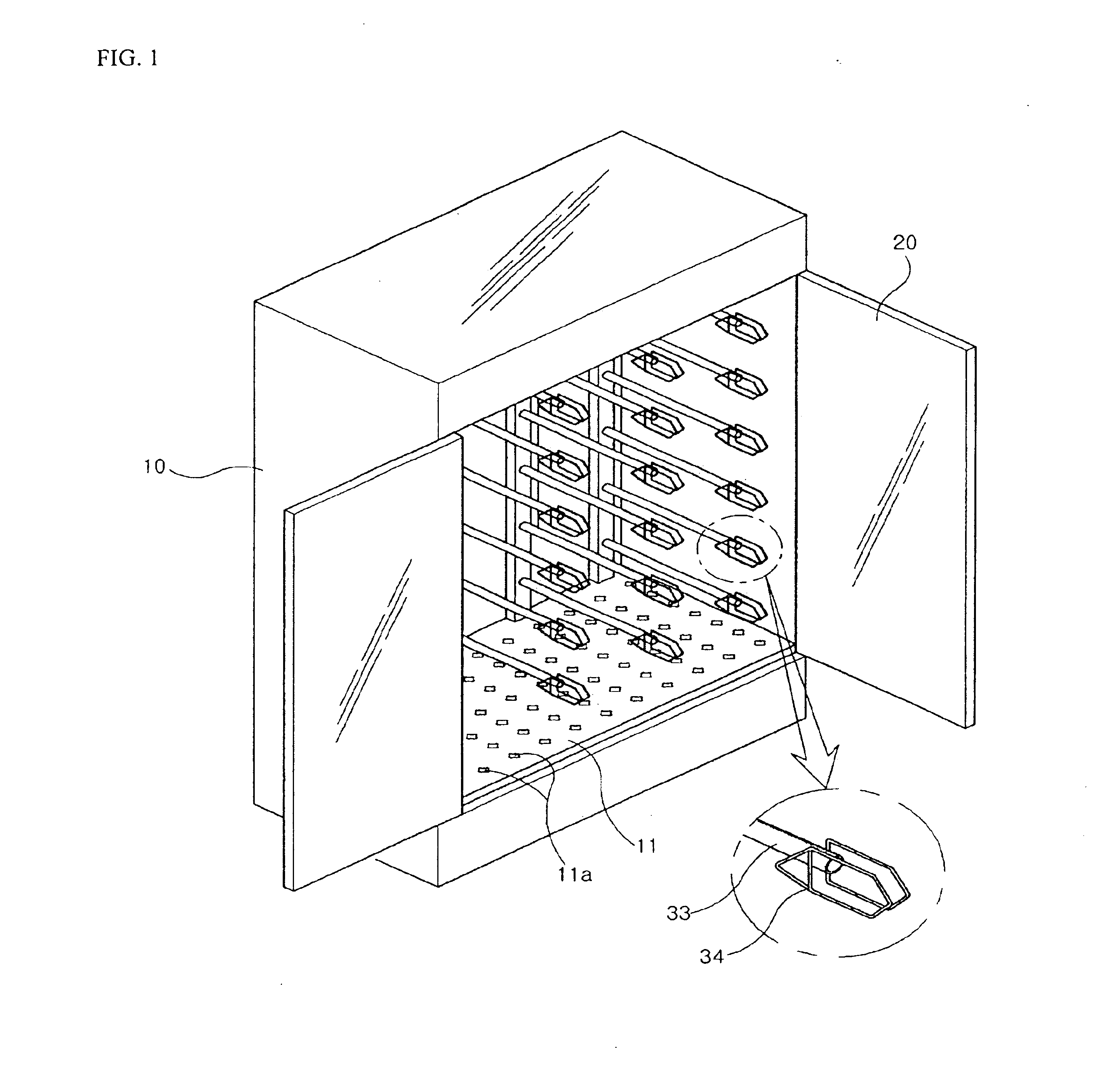

Shoe drying apparatus

InactiveUS6845569B1Short timeReduce maintenanceDrying chambers/containersDrying solid materialsEngineeringHollow core

The present invention provides a new and improved shoe drying apparatus that can dry washed and / or unwashed shoes in a short period of time by circulating ozone-containing air in the airtight interior of the apparatus and also deodorize and sanitize shoes by removing odor and bacteria from the shoes. The shoe drying apparatus comprises a housing having a front door, a first porous plate installed in the bottom interior of the housing, a sanitizing-deodorizing assembly for generating ozone-containing air (“mixed air”), a second porous plate installed in the top interior of the housing, a ventilating fan for dispersing the mixed air into the central interior of the housing, an intake fan for bringing back air present in the upper space of the second plate to the sanitizing-deodorizing assembly, a plurality of hollow main conduits extending vertically from the second plate to the first plate, a plurality of hollow auxiliary conduits extending horizontally from each main conduit, and a shoe-holding member on which a shoe is fixed for drying.

Owner:KIM SOO KIL

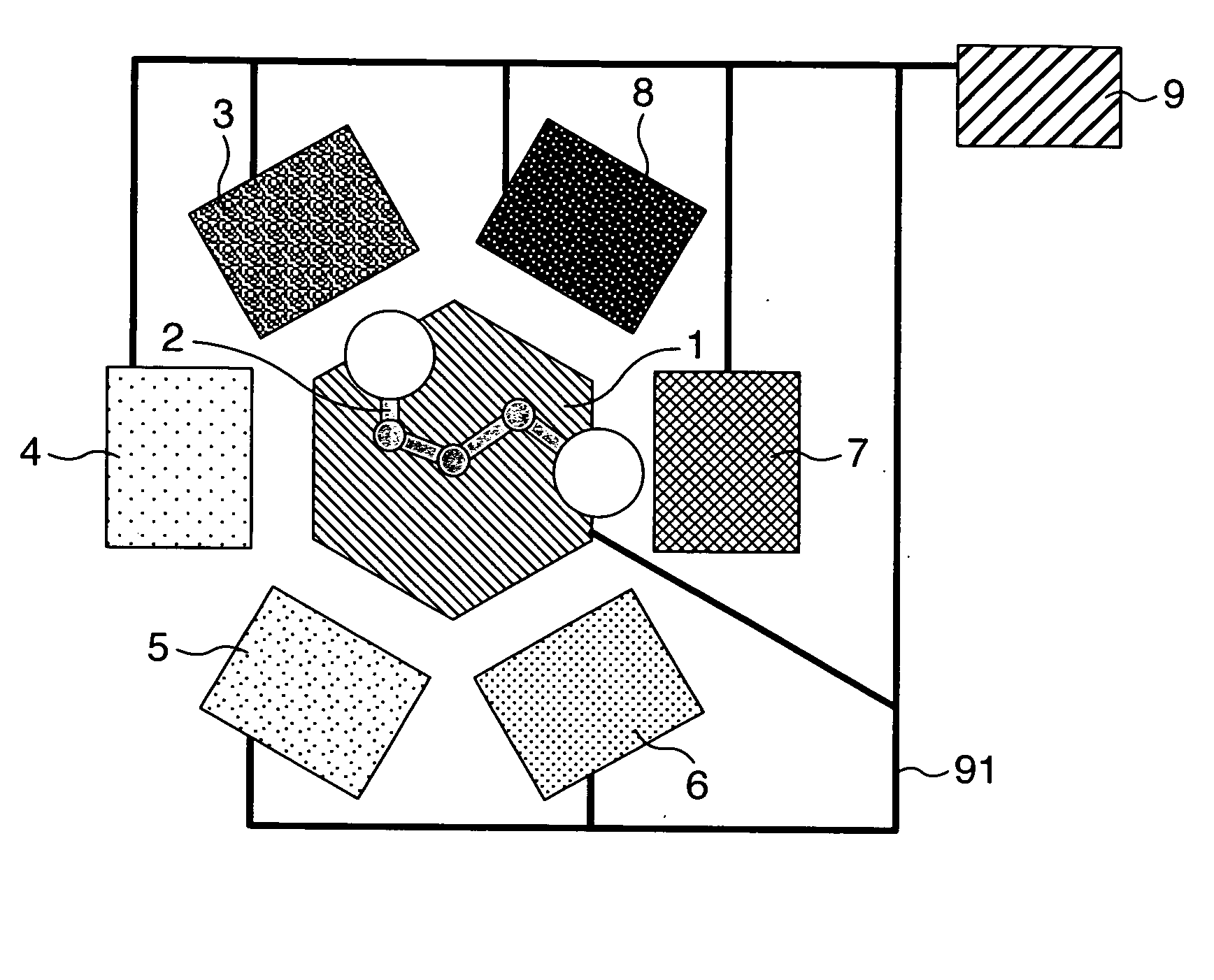

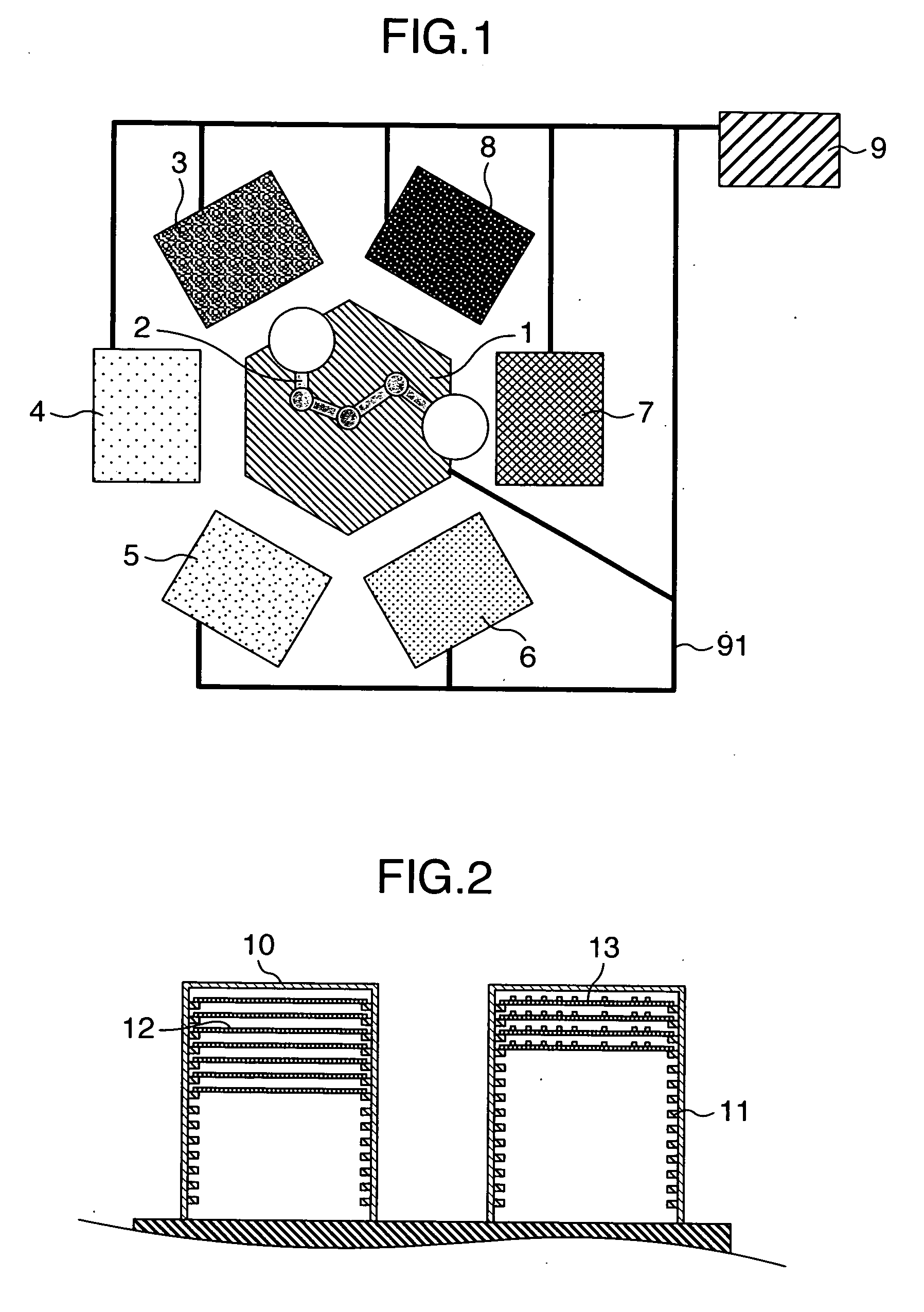

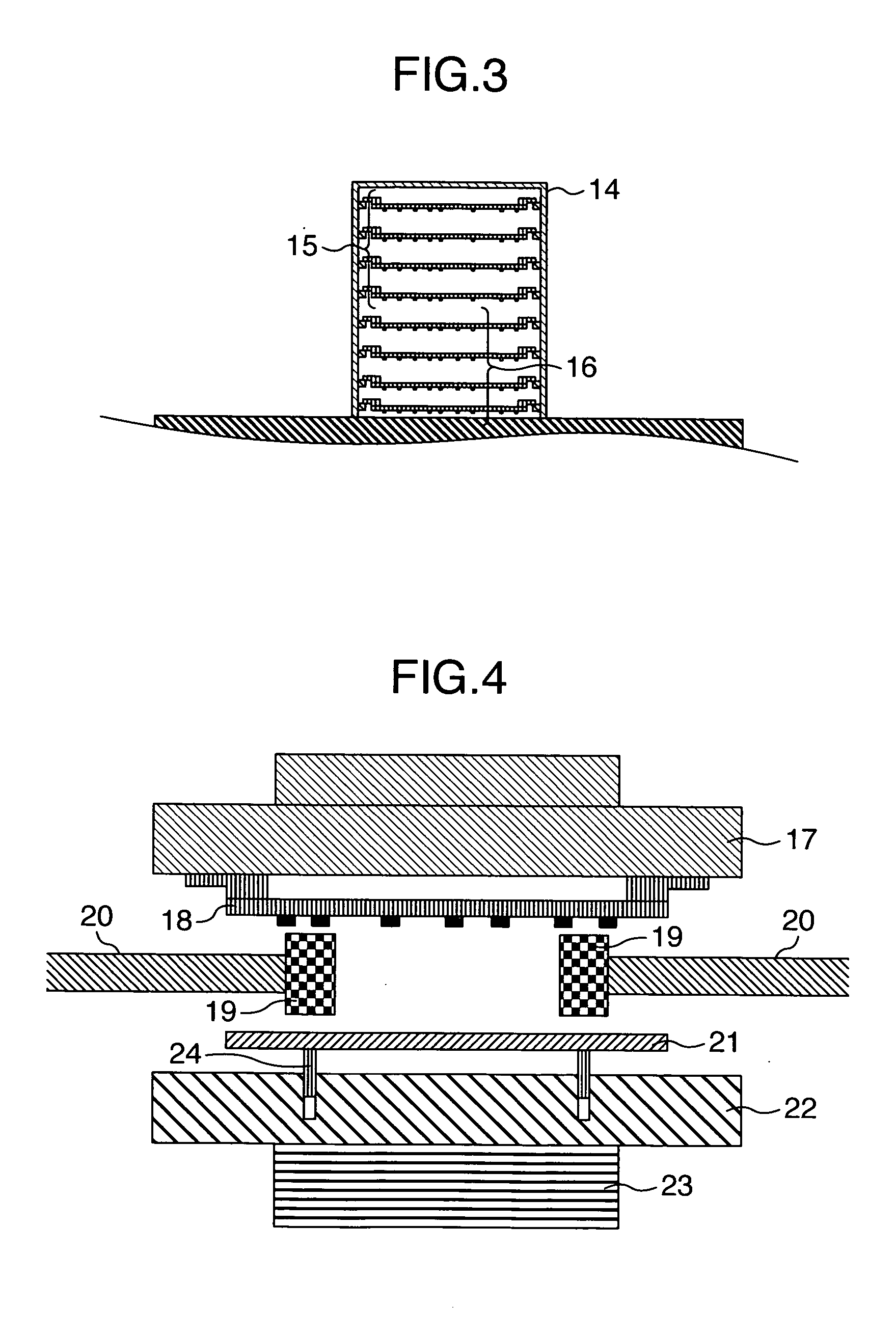

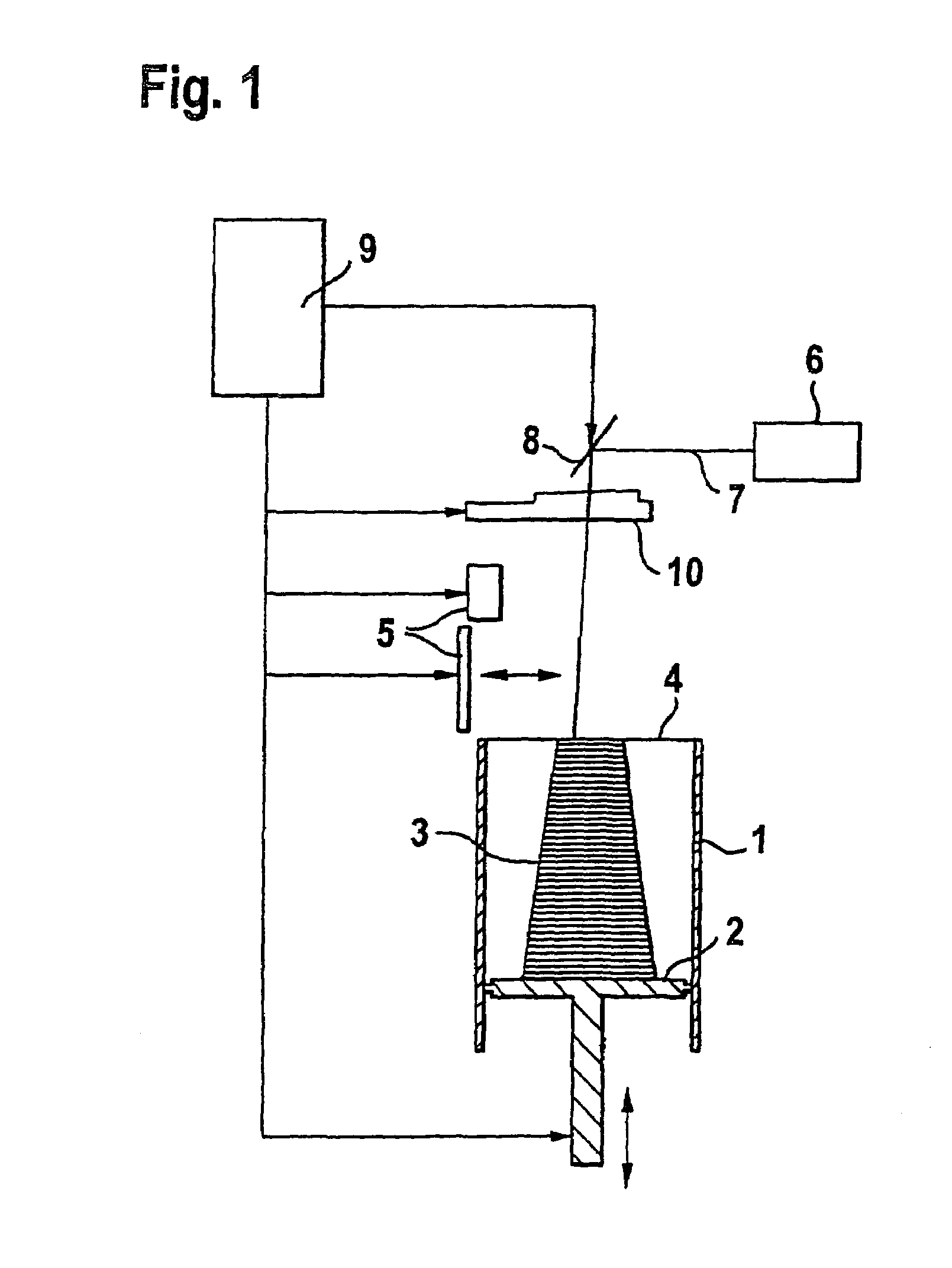

Imprinting machine and imprinting method

InactiveUS20050116370A1Rapid change of pressureIncreased substrate speedNanoinformaticsPhotomechanical apparatusConvex structureNanometer size

An object of the invention is to execute an imprinting process at a higher speed and a higher accuracy, in an imprinting apparatus. In an imprinting apparatus for contacting and pressurizing a mold having a micro concavo-convex structure formed on a surface thereof to a substrate surface in order to form a micro and nanometer size structure on a substrate, a step of pressurizing the mold and the substrate and a step of peeling the mold from the substrate are constituted by independent units, the mold and the substrate are moved in a closely attached state at a time of moving from the pressurizing step to the peeling step, and preferably at least two sets of molds and substrates are processed by the different steps simultaneously or a temporarily overlapped manner.

Owner:HITACHI PLANT TECH LTD

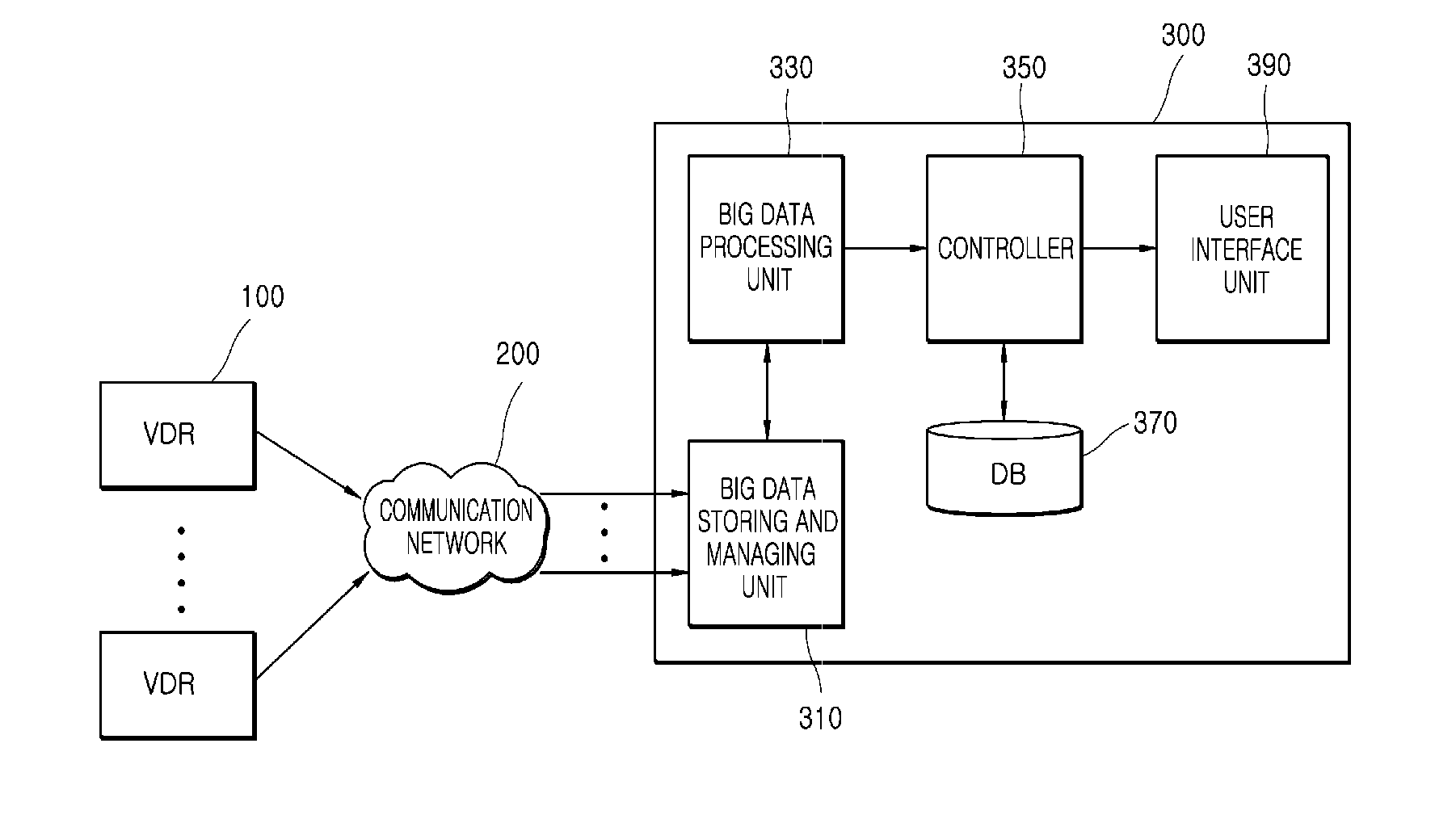

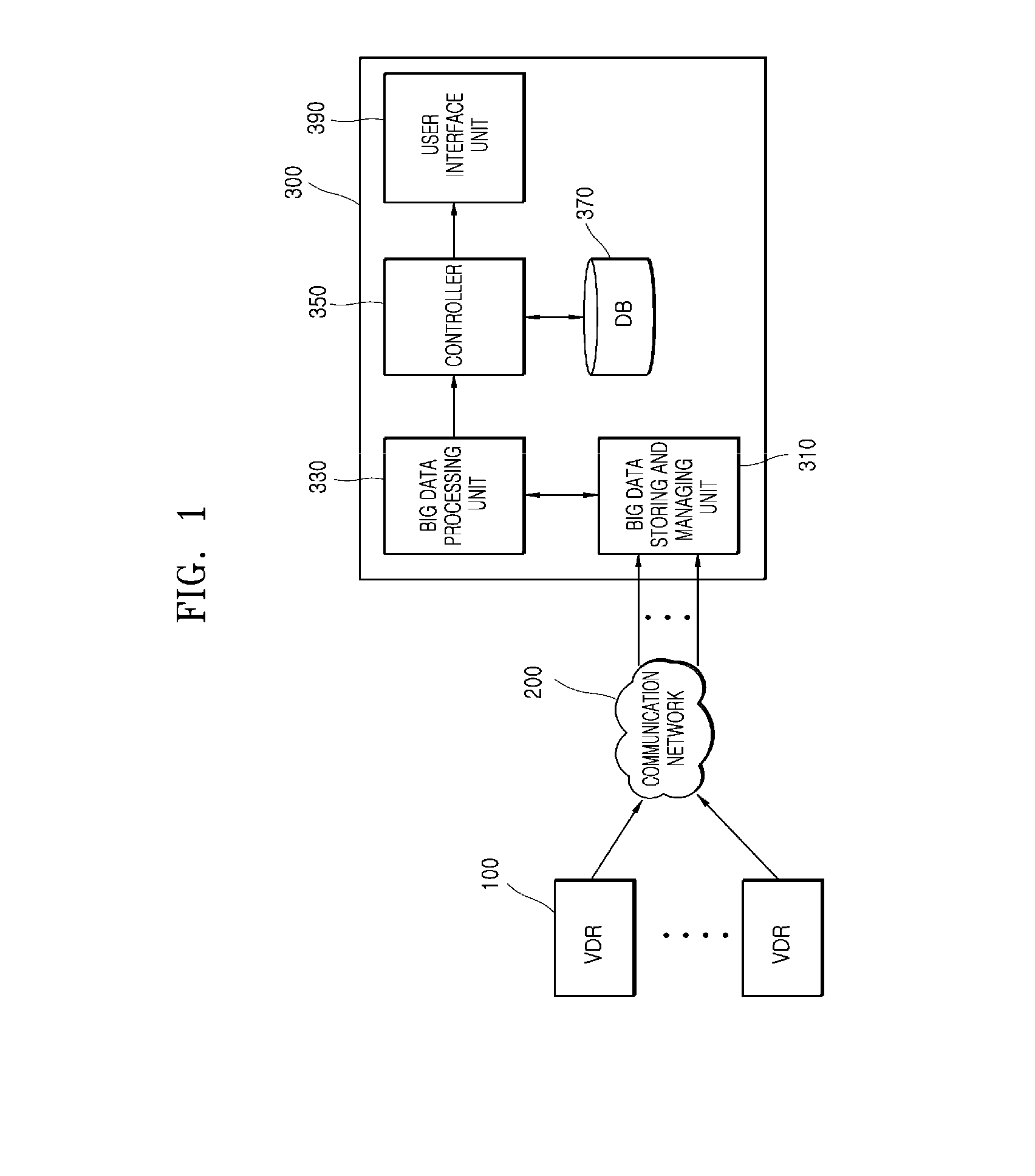

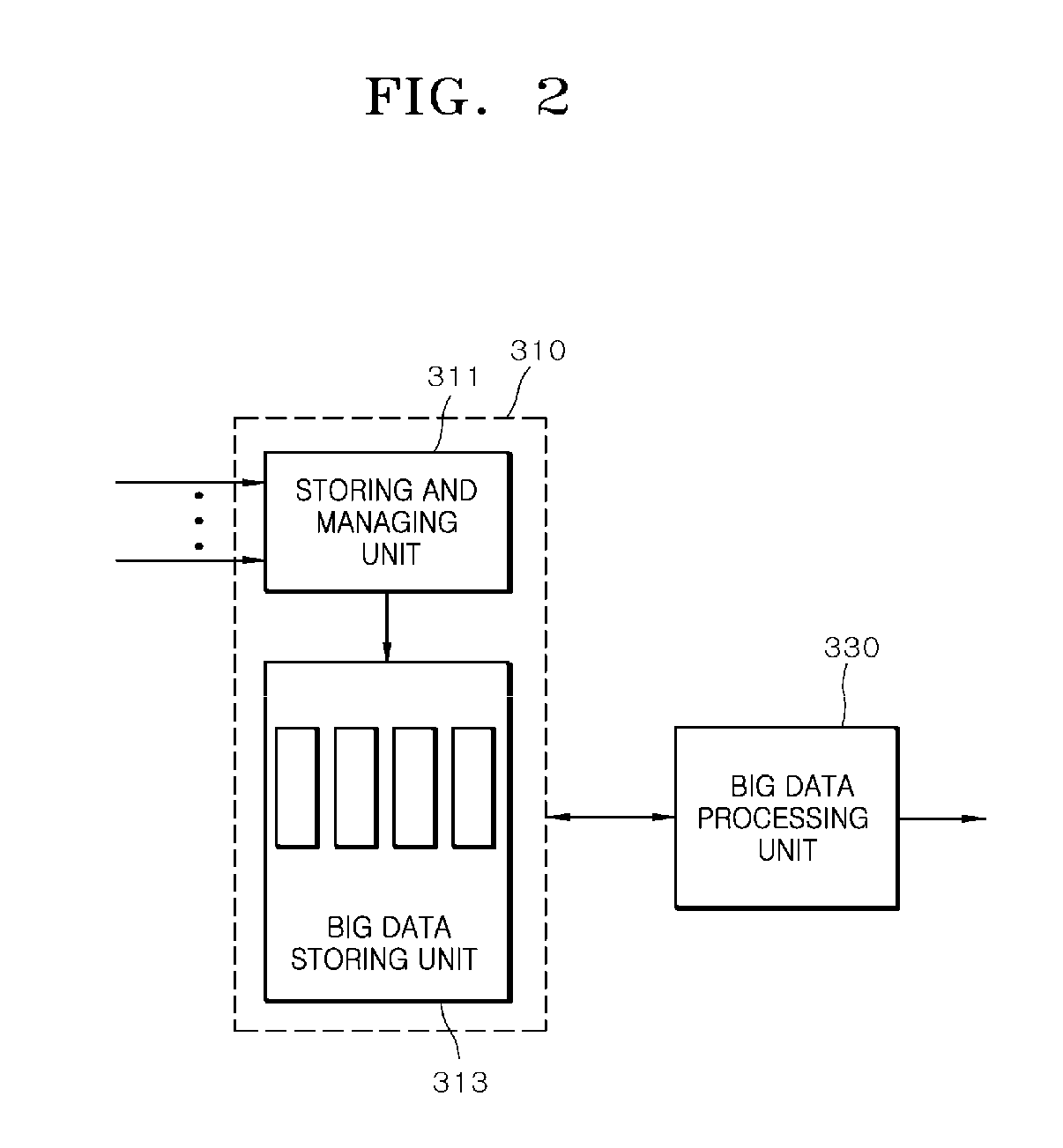

Method of processing and analysing vehicle driving big data and system thereof

ActiveUS20150317844A1Reduce analysisImprove analytical performanceVehicle testingFinanceVehicle drivingAnalysis method

Provided is a method of processing and analyzing vehicle driving big data, the method including: refining vehicle driving data of raw data; acquiring statistical data based on the refined vehicle driving data; and performing mining analysis based on at least one of the refined vehicle driving data and the acquired statistical data.

Owner:KOOKMIN UNIV IND ACAD COOP FOUND

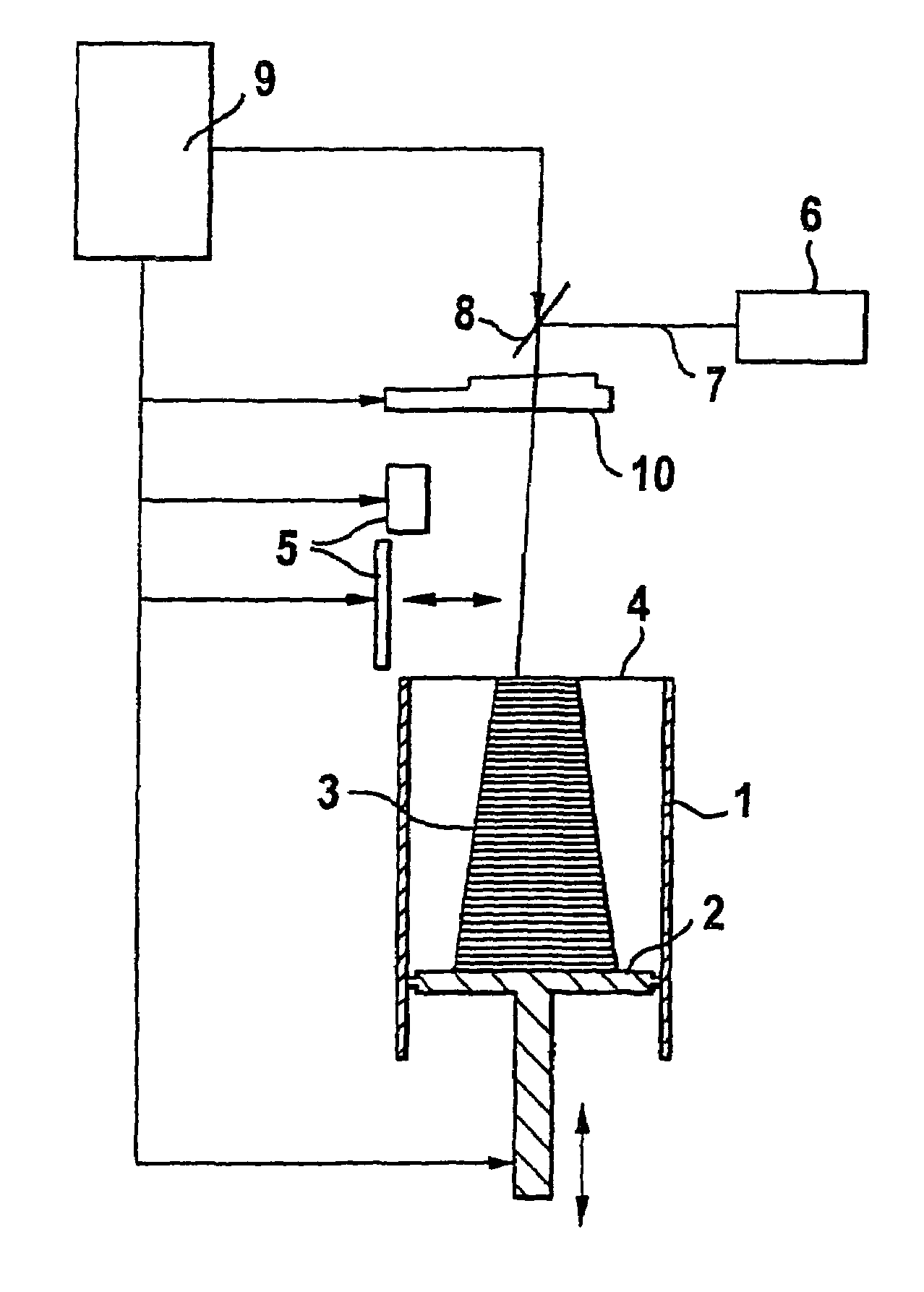

Device for layerwise manufacturing of a three-dimensional object

ActiveUS8075814B2Avoid pollutionEnhanced couplingMouldsConfectioneryEngineeringElectromagnetic radiation

An apparatus for layerwise manufacturing of a three-dimensional object by solidification of a material, which can be solidified via electromagnetic radiation, includes a source for the electromagnetic radiation, a building space for manufacturing the three-dimensional object, a coupling window, for transmitting the electromagnetic radiation into the building space and a heating element for heating the coupling window. By the heating element the temperature of the lens is increased during the building of the three-dimensional object. By the increased temperature the accumulation of contamination on the coupling window is prevented.

Owner:EOS ELECTRO OPTICAL SYST

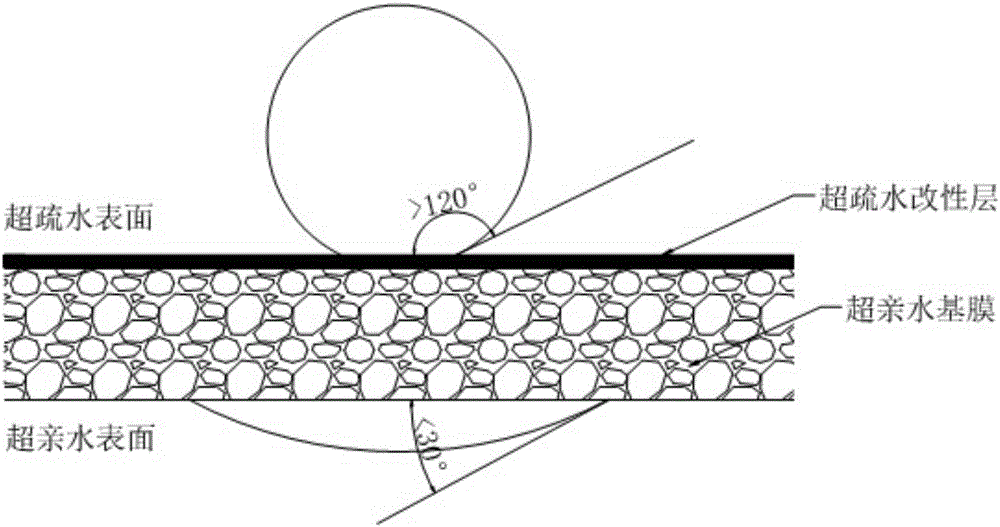

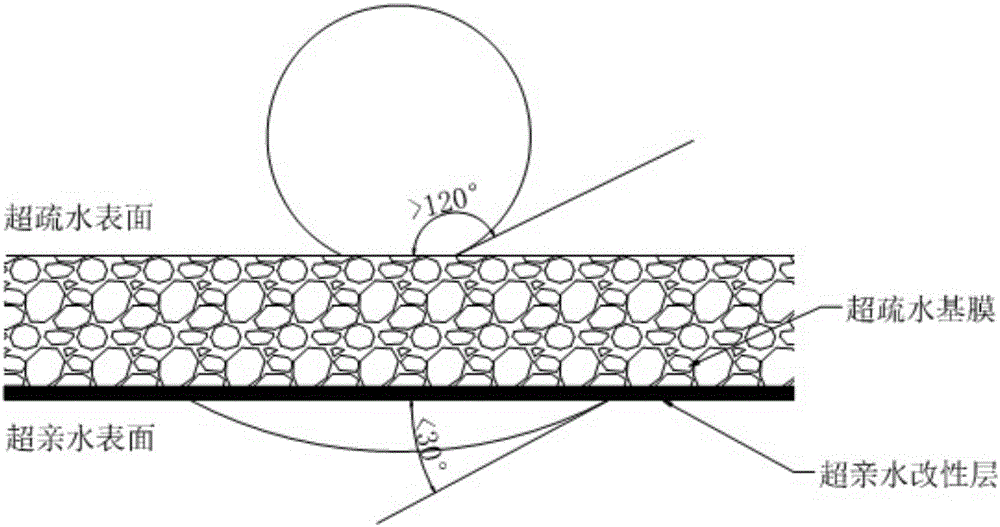

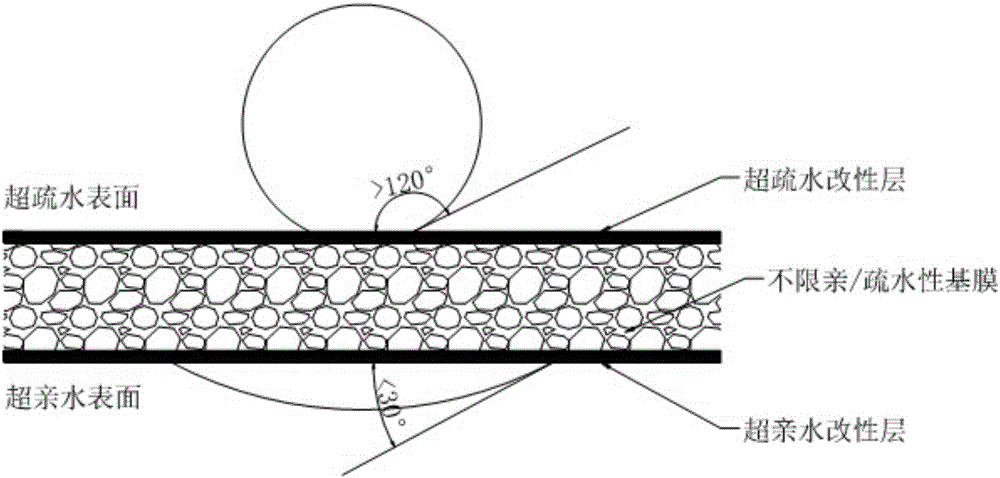

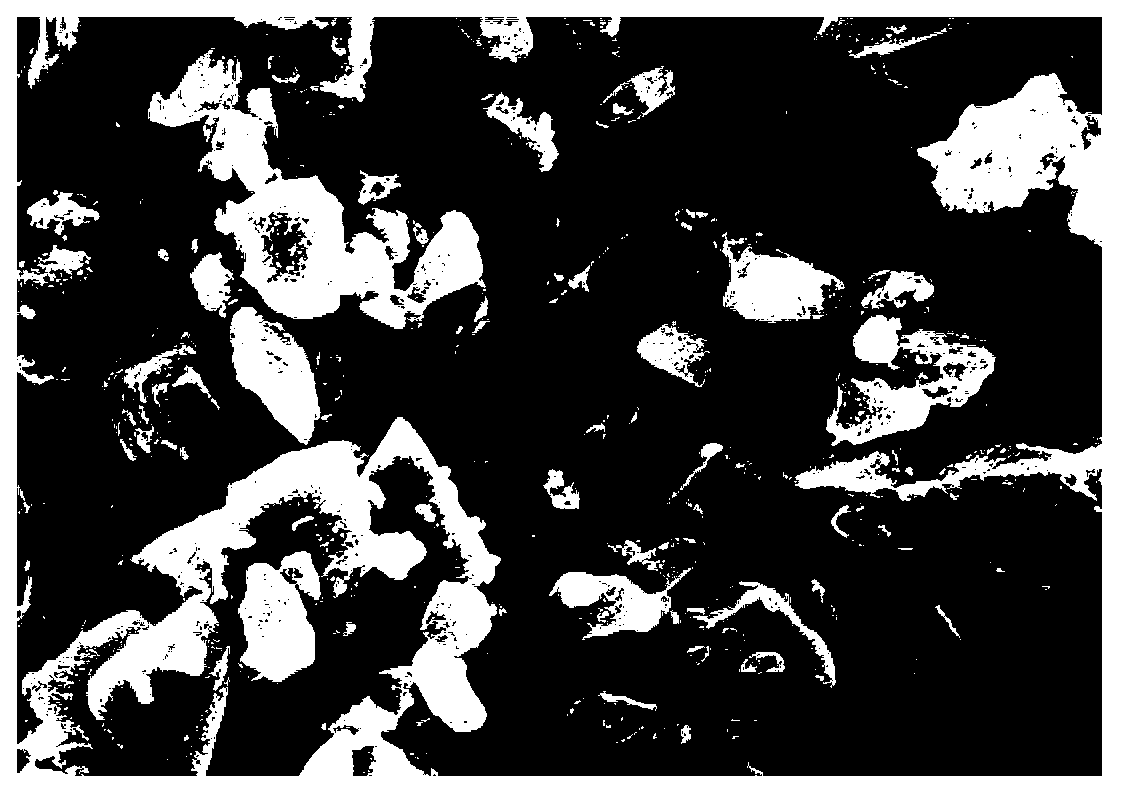

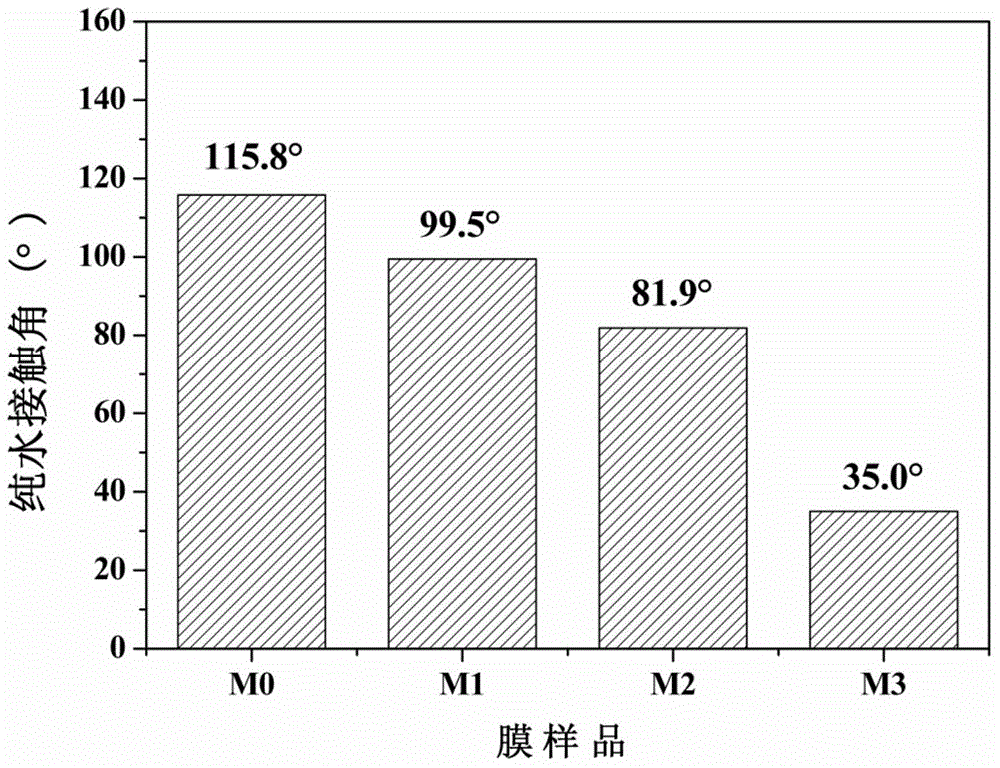

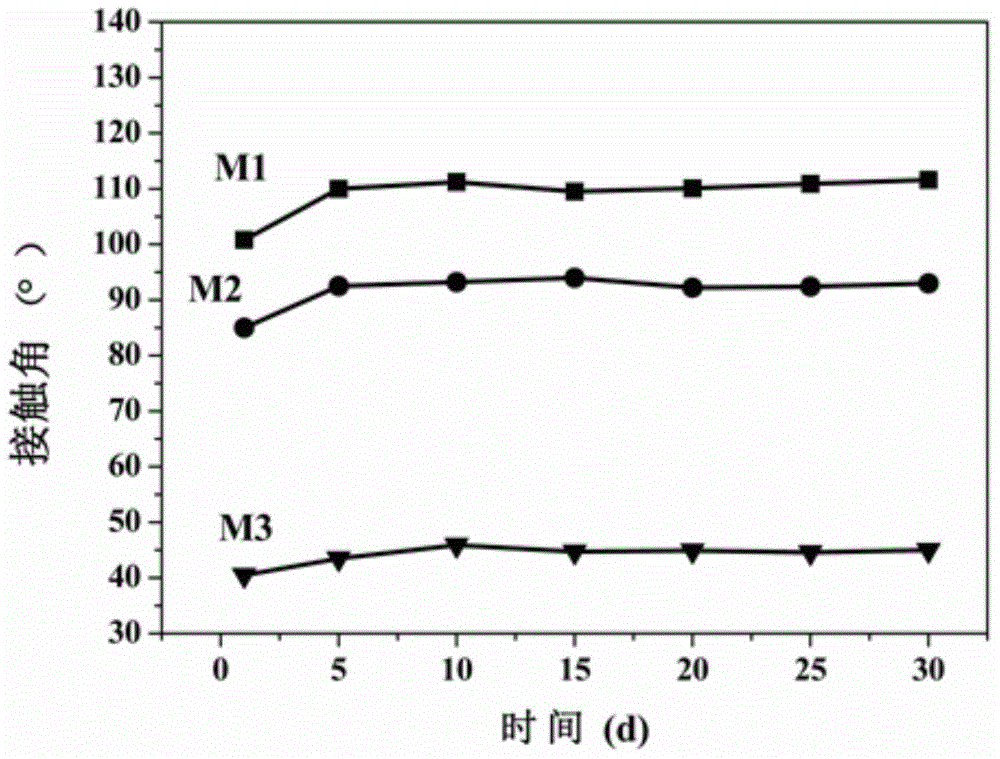

Asymmetric ultra-hydrophilic/hydrophobic dual-property polymer membrane and preparation method thereof

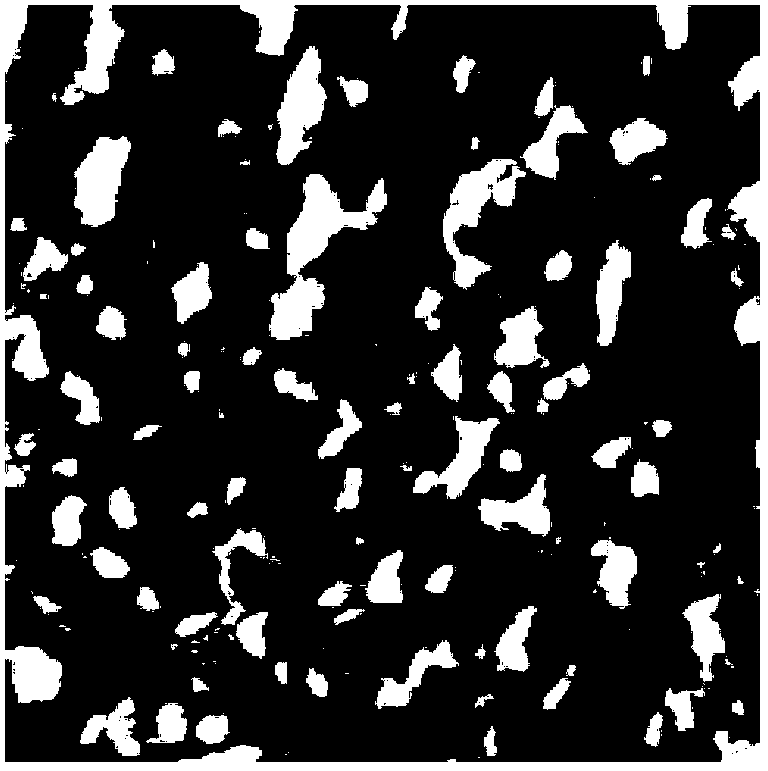

ActiveCN106268355AImprove anti-pollution performanceReduce adhesionMembranesSemi-permeable membranesPore diameterHollow fiber membrane

The invention relates to a membrane separation technique and aims at providing an asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane and a preparation method thereof. According to the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane, a base membrane is a flat sheet membrane or a hollow fiber membrane, one side of the base membrane is a hydrophilic side, the water contact angle of the hydrophilic side is not greater than 30 degrees, the other side of the base membrane is a hydrophobic side, and the water contact angle of the hydrophobic side is not smaller than 120 degrees. The prepared asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane is of the type of the flat sheet membrane or the hollow fiber membrane and belongs to an ultra-micro filter membrane category, and the pore diameter range of the membrane is 0.01-2.0 microns. Therefore, the hydrophilic and hydrophobic properties on double sides are different, one side is hydrophilic, the other side is hydrophobic, and the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane shows asymmetric hydrophilic / hydrophobic properties and is a novel water treatment membrane.

Owner:ZHEJIANG UNIV

Aqueous polyurethane dry process transform-film synthetic leather and manufacturing method thereof

InactiveCN102312378AHeating evenlySave heating energySynthetic resin layered productsTextiles and paperOrganic solventSolvent based

The invention which relates to an aqueous polyurethane dry process transform-film synthetic leather and a manufacturing method thereof belongs to the technical field of synthetic leathers and manufacturing methods thereof. The manufacturing method of the aqueous polyurethane dry process transform-film synthetic leather is characterized in that the manufacturing method comprises the following steps: 1, preparing a base cloth which treats a non-woven fabric as the skeleton; 2, coating a superficial layer, a foaming layer and a bonding layer on release paper to realize the dry process transform-film; 3, carrying out leather-paper separation after the paper-leather separation or slaking; and 4, examining and warehousing. Compared with solvent-based polyurethane, the aqueous polyurethane dry process transform-film synthetic leather has equivalent physical properties, and accords with application demands, environmentally friendly aqueous polyurethane is used, a product (the aqueous polyurethane dry process transform-film synthetic leather) contains no organic solvents which are harmful to environmental protection, a DMF recovery operation which is required in the production process of solvent-based products is reduced, the production process is simplified, and energy saving and environmental protection are realized, so the aqueous polyurethane dry process transform-film synthetic leather which adapts to foreign restrictive requirements on environment friendly polyurethane synthetic leathers and allows the production personnel demand, the damage to the personnel, and the production cost to be reduced has a strong market competitiveness.

Owner:YANTAI LIANCHENG POLYMER MATERIAL

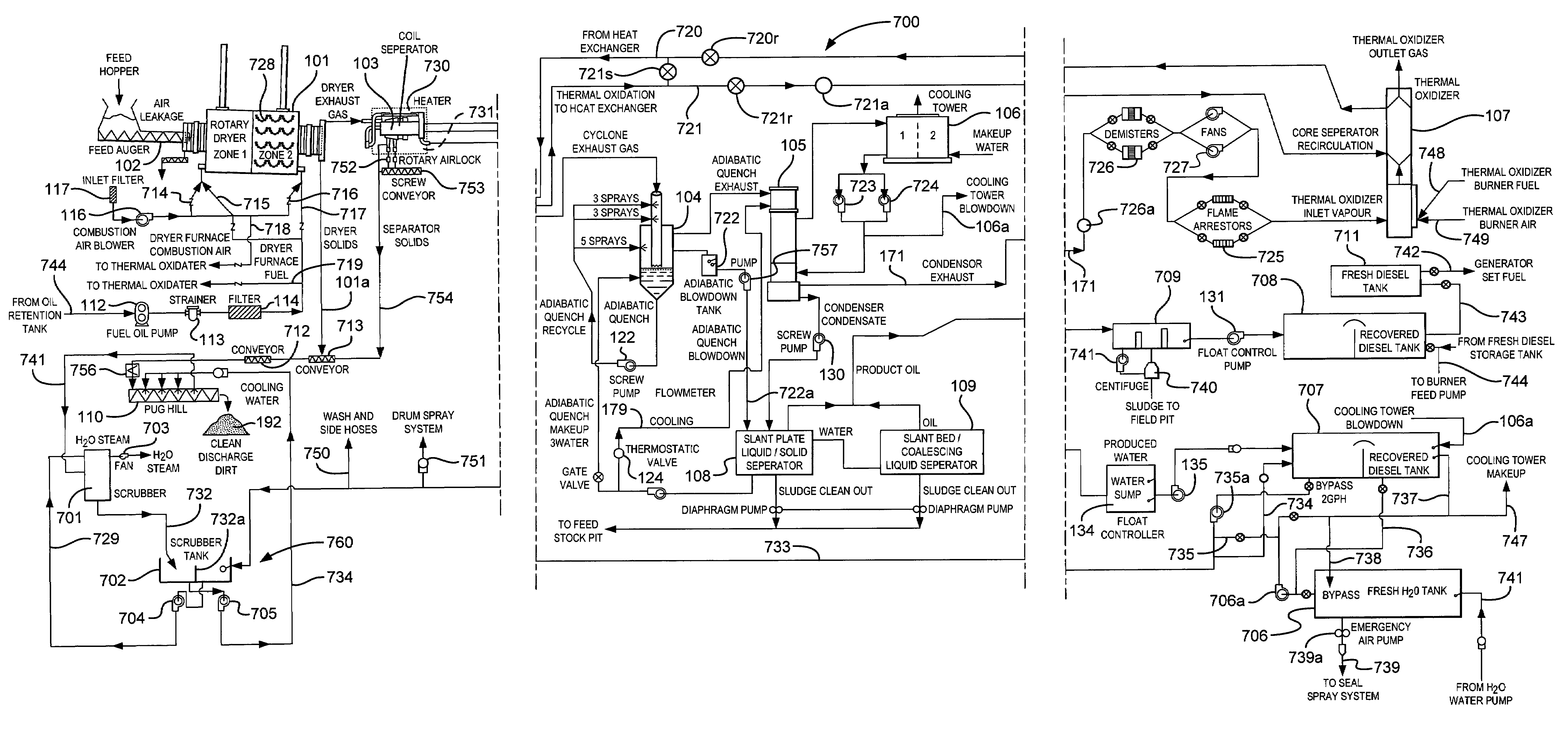

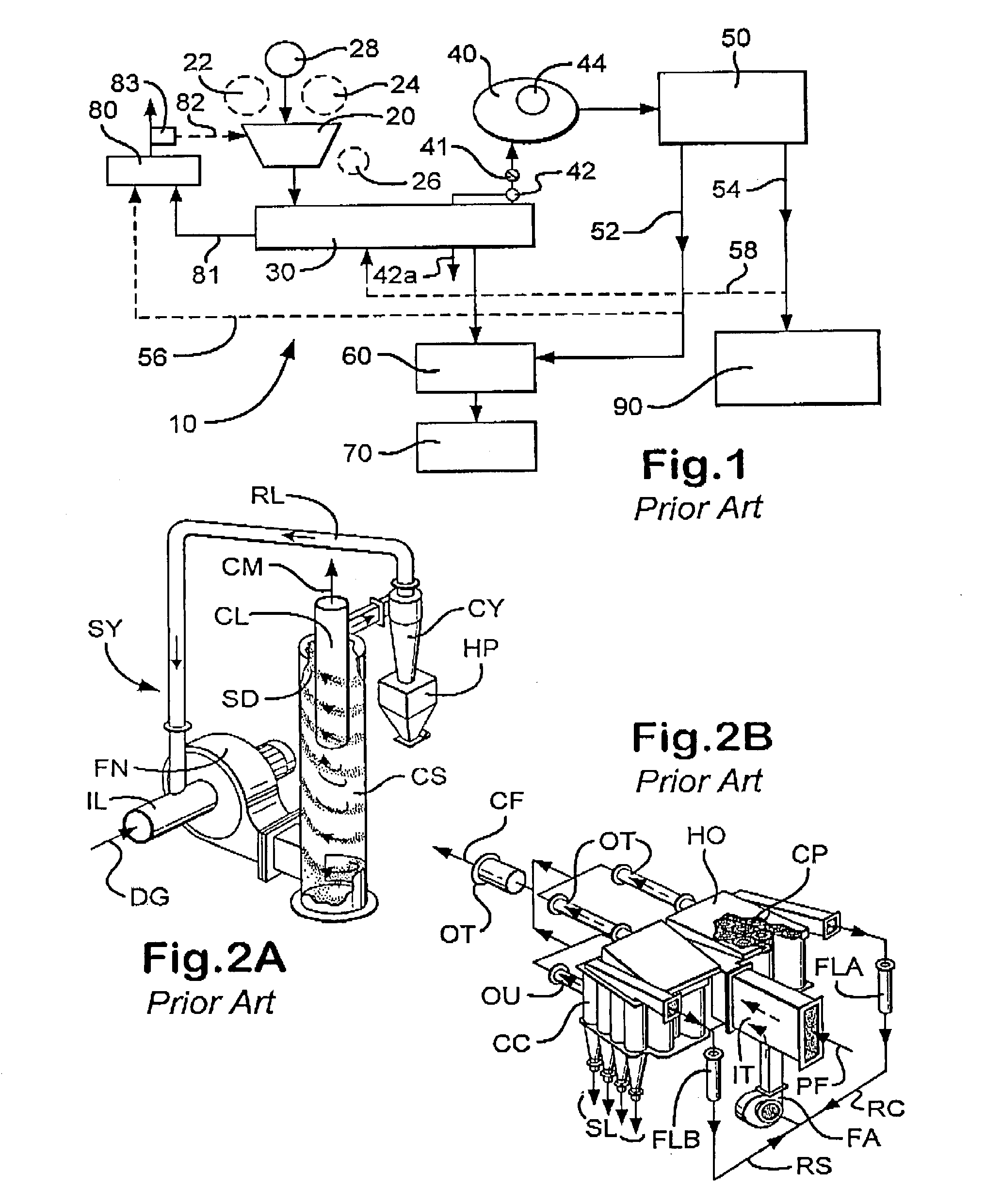

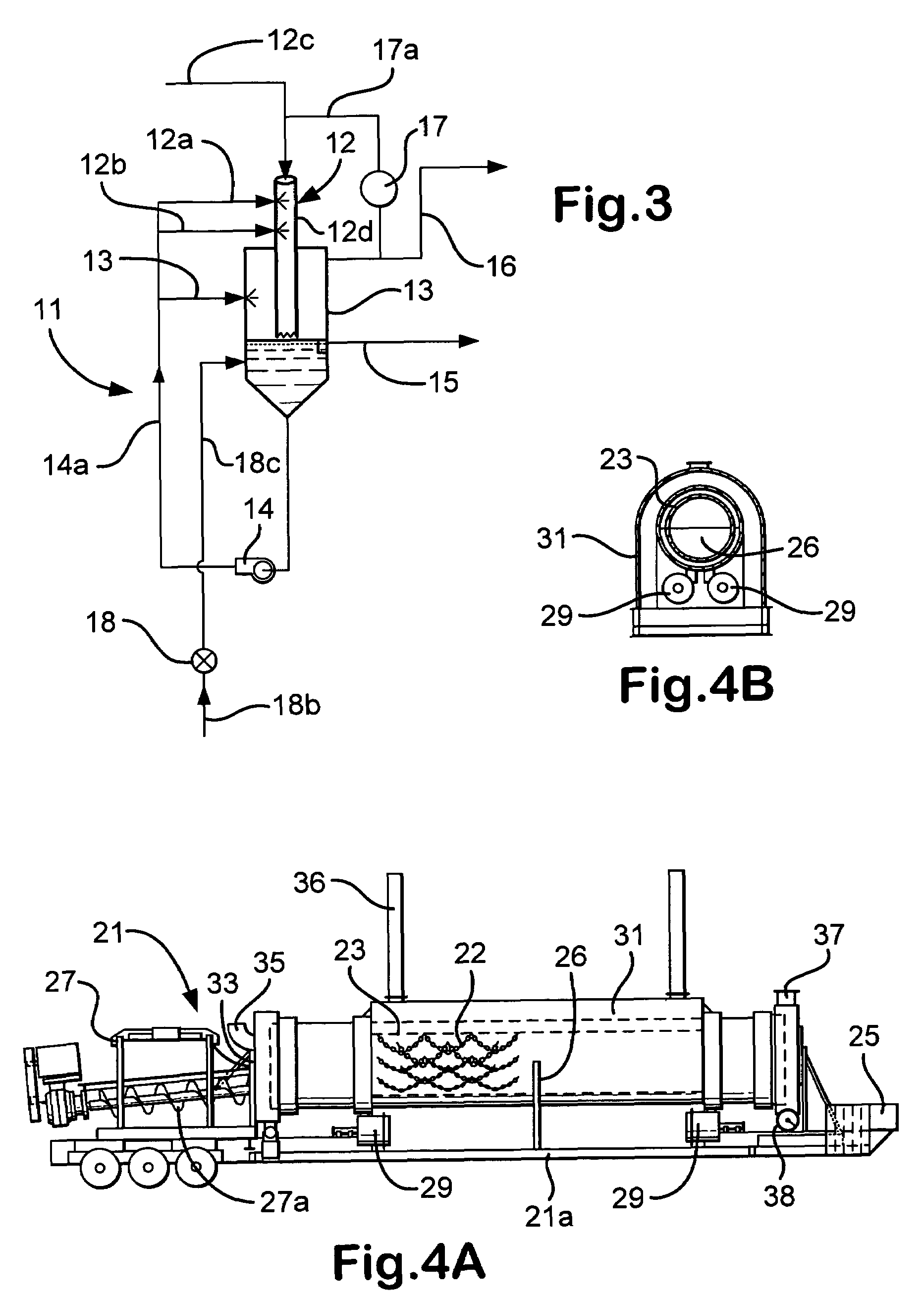

Thermal drill cuttings treatment with weir system

InactiveUS7306057B2Small sizeImprove pollutionWater/sewage treatment by centrifugal separationHollow article cleaningSlurryDrill cuttings

A method for treating material, the material contaminated with contaminants, the method including: introducing material with contaminants to a system for remediation including a thermal treatment system, a quench system, a weir tank system and a condensing system; feeding a slurry of the material to the thermal treatment system and heating the material therein producing heated discharge solids and a discharge stream with liquid and solids therein; optionally, discharging the heated discharge solids and feeding them to a mill system; feeding the discharge stream to a quench system producing a cooled discharge stream which is fed to the weir tank system; the weir tank system having a clean side and a dirty side; the cooled discharge stream fed to the dirty side of the weir tank system, and from the weir tank system producing at least one stream of cleaned liquid and a stream with contaminants therein; and, in one particular aspect, remediating drilled cuttings material using such a method.

Owner:VARCO I P INC

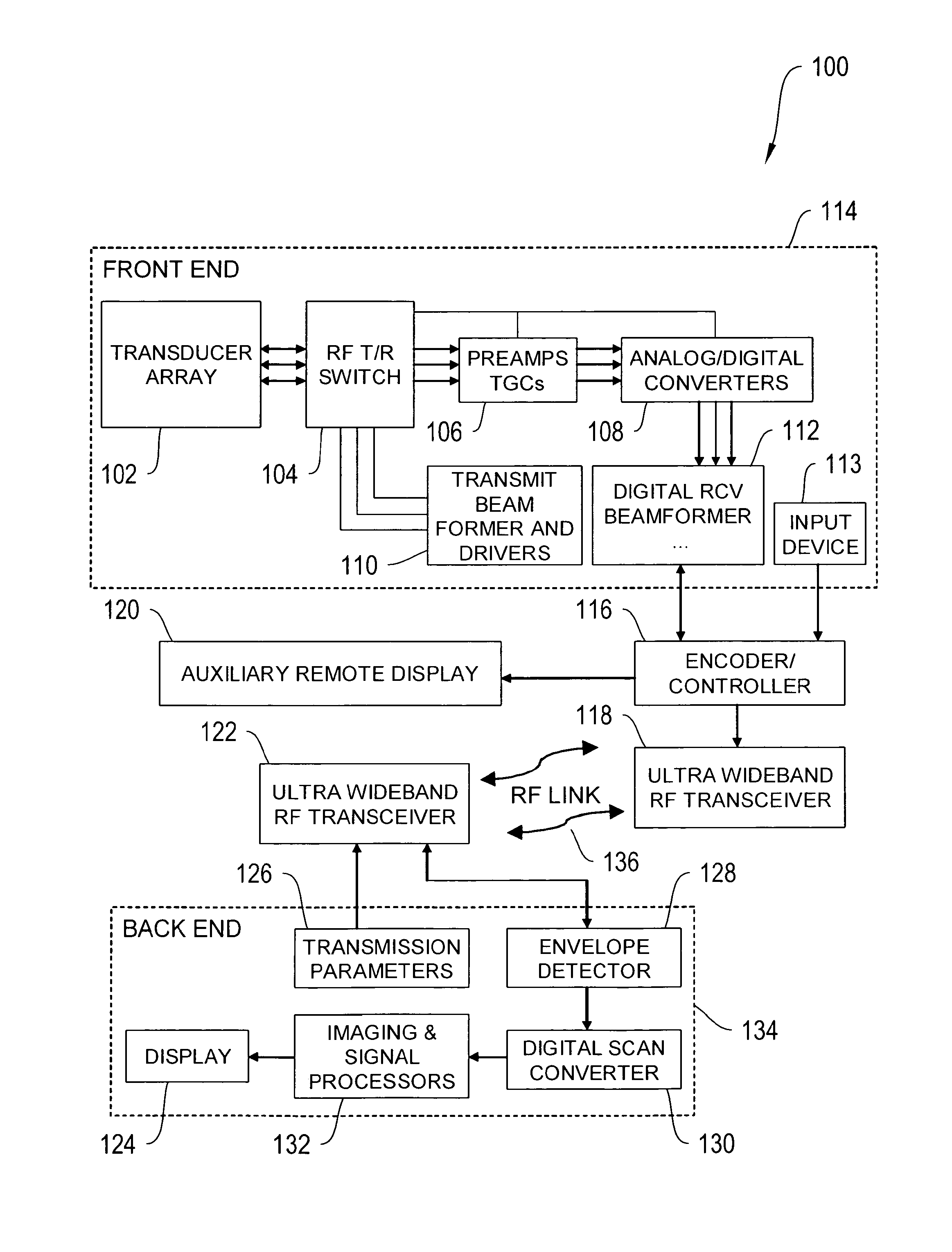

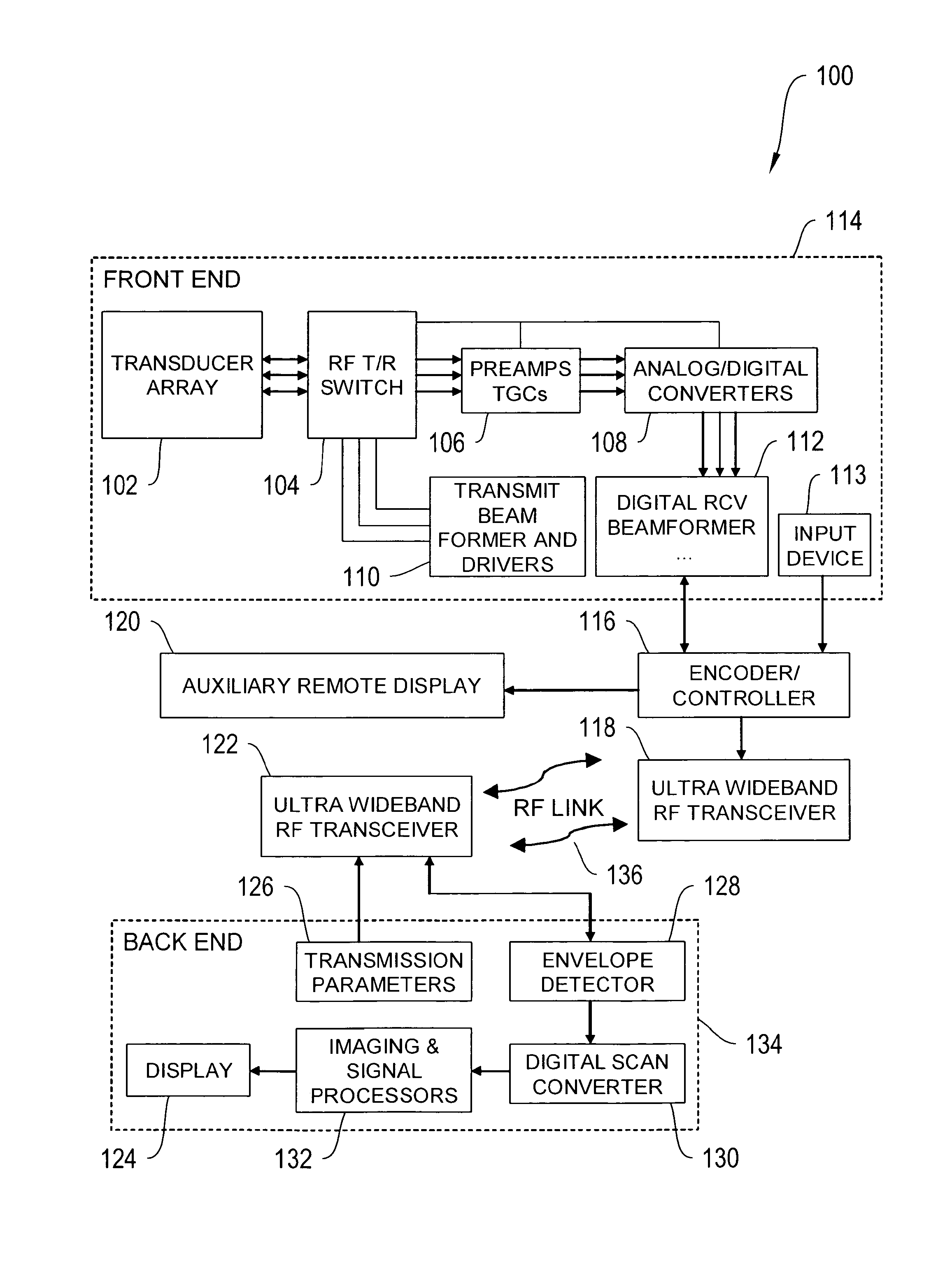

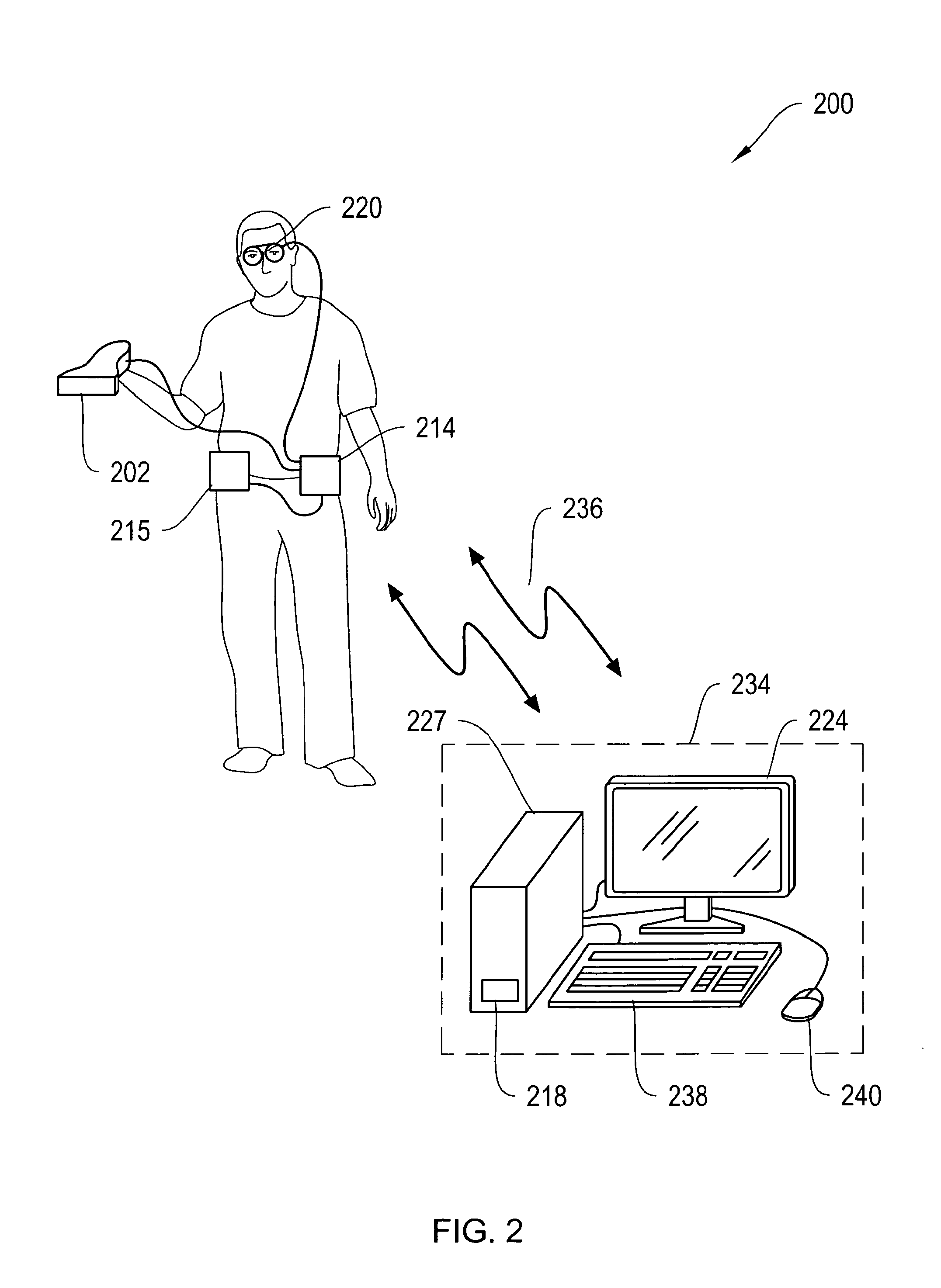

Wireless ultrasound transducer using ultrawideband

InactiveUS20100298711A1Eliminate useEliminate needTelemedicineInfrasonic diagnosticsTransceiverUltrasonic sensor

Ultrasound imaging systems and methods are described that include a cableless front end having a UltraWideBand transceiver and a beamformer that transmit ultrasound data to a back end physically separated from the front end, with the back end having a UltraWideBand transceiver for receiving ultrasound data from the front end UltraWideBand transceiver via a peer-to-peer communication protocol. The back end unit can also receive and transmit commands to and from the front end unit to select an image mode and has a signal processor and scan converter that can convert ultrasound data into image data for display. An input device in the front end allows the operator to selectively display ultrasound data or patient data on an auxiliary worn display or the nearest local display.

Owner:WORCESTER POLYTECHNIC INSTITUTE

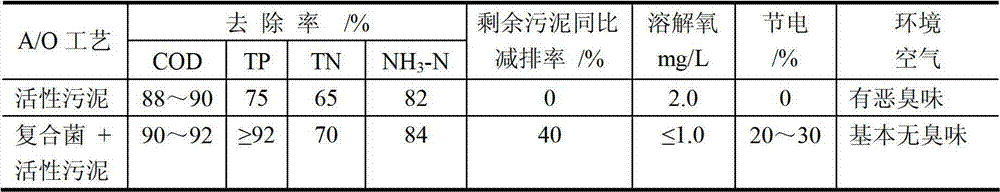

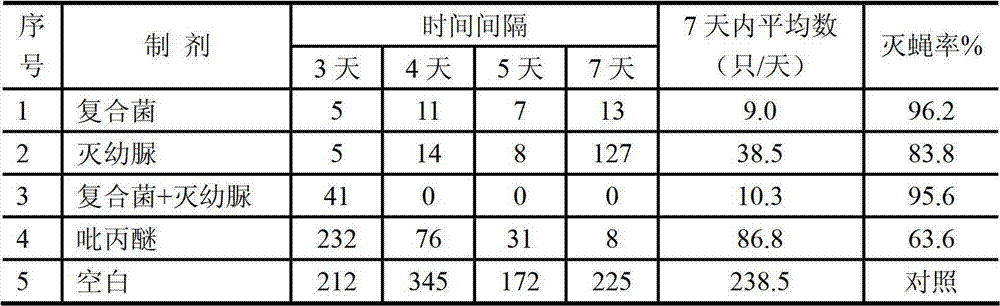

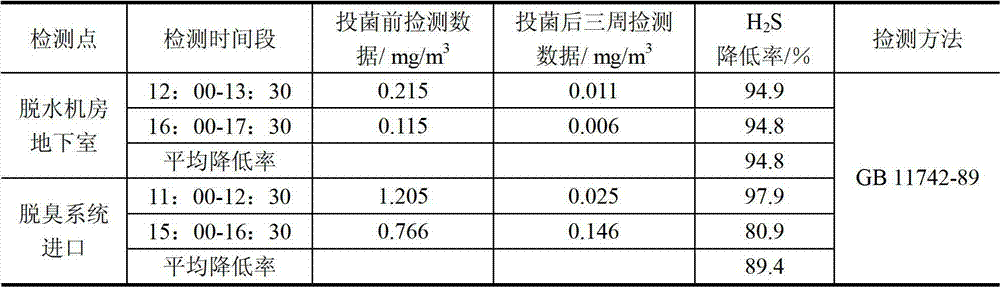

Novel compound microorganism living bacteria agent, method for preparing same and applications

The invention discloses a novel compound microorganism living bacteria agent. The agent comprises probiotics such as pediococcus, saccharomyces, bacillus and the like, wherein the total bacterial quantity is above 107 colony-forming units (cfu) / gram. The invention further discloses a method for preparing the novel compound microorganism living bacteria agent and applications of the novel compound microorganism living bacteria agent in preparation of organic sewage purification additives, deodorization fly dispelling agents, degreasing agents, pipeline blockage removing agents, feed additives and microorganism disease prevention agents. The novel compound microorganism living bacteria agent has the comprehensive effects of high removal rates to ammonia nitrogen, total nitrogen and total phosphorus, small sludge residues, energy saving, environmental friendliness and the like and the characteristics of convenience in use, safety and quickness in function, no secondary pollution, benefits to ecological protection, low treatment cost, good comprehensive profit and the like.

Owner:SHANGHAI ECO WELL BIOSCI

Middle temperature sealant and closing process for aluminum anodized film

ActiveCN101323965AEasily biodegradableReduce pH variationSurface reaction electrolytic coatingNickel saltHeavy metals

The invention discloses a mesophilic sealing agent and a sealing technique of aluminum anodic oxide films and belongs to the technical field of the post sealing processing of the anodic oxide films of aluminum and aluminum alloys. The sealing agent of the invention is an aqueous solution that consists of alkali metals or salts of alkali earth metals, a complexing agent and a pH buffering agent; wherein, the concentration of the alkali metals or the salts of alkali earth metals is 5 to 15 g / L, the concentration of the complexing agent is 10 to 20 g / L,, the concentration of the pH buffering agent is 0 to 10 g / L, and the residual quantity is water; the pH value of the aqueous solution of the sealing agent is maintained between 5 and 6, the aluminum anodic oxide film is sealing processed by the sealing agent, the temperature of the aqueous solution of the sealing agent is 75 to 90 DEG C, and the soaking and sealing time lasts for 20 to 30 minutes. The sealing agent adopts the alkali earth metals or the salts of alkali metals with wide resource and low cost so as to replace heavy metal nickel salts or cobalt salts in the prior art and adopts the organic complexing agent that has biodegradability, low price and simple molecules so as to replace surface activating agents that contain giant molecules and benzene rings in the prior art, and consequently the aluminum anodic oxide film that is sealing processed by the sealing agent obtains excellent anti-pruina property, and the anti-corrosion and anti-pollution properties of the anodic oxide film of aluminum and aluminum alloys are generally improved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Self-cleaning water permeable brick and preparation method thereof

InactiveCN101445340AWide variety of sourcesImprove pollutionSolid waste managementEcological environmentBrick

The invention discloses a self-cleaning water permeable brick comprising a surface material and a base material. The base material is weighed according to weight percentage, comprising 68.4 percent to 77.5 percent of rubble or building rubbish granule or slag, 10 percent to 25 percent of cement, and 5.3 percent to 12 percent of water. The surface material is weighed according to weight percentage, comprising 66.7 percent to 71.8 percent of high-intensity sand, 10.8 percent to 26.5 percent of cement, 3.4 percent to 10.4 percent of water, and 0.1 percent to 1.0 percent of nanometer titanium dioxide. The surface material and the base material are compacted together to form an integrated water permeable brick. The invention further discloses a preparation method of the self-cleaning water permeable brick. The method comprises the following steps: 1) the base material and the surface material are weighed, respectively premixed and then stirred as raw materials for standby application; 2) molding is carried out; 3) steam curing is carried out; and 4) liquid titanium dioxide is sprayed. Road surfacing of the self-cleaning water permeable brick in the invention can reduce water permeable hole plugging and surface pollution, thereby having the effects of road surface temperature decrease and high-efficient sterilization, regaining circulatory system of natural soil air and water, preventing soil pollution and improving ecological environment.

Owner:程卫国

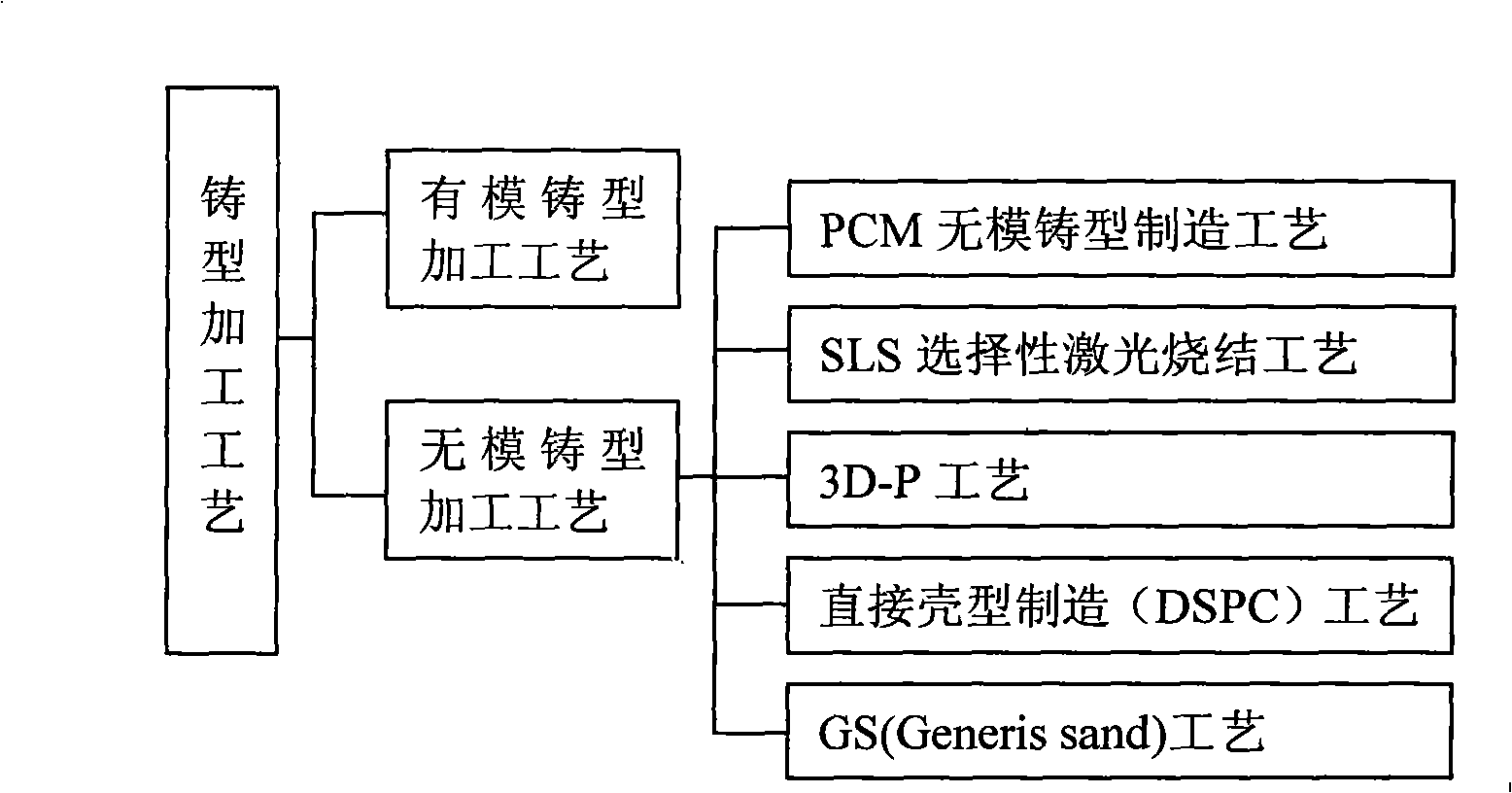

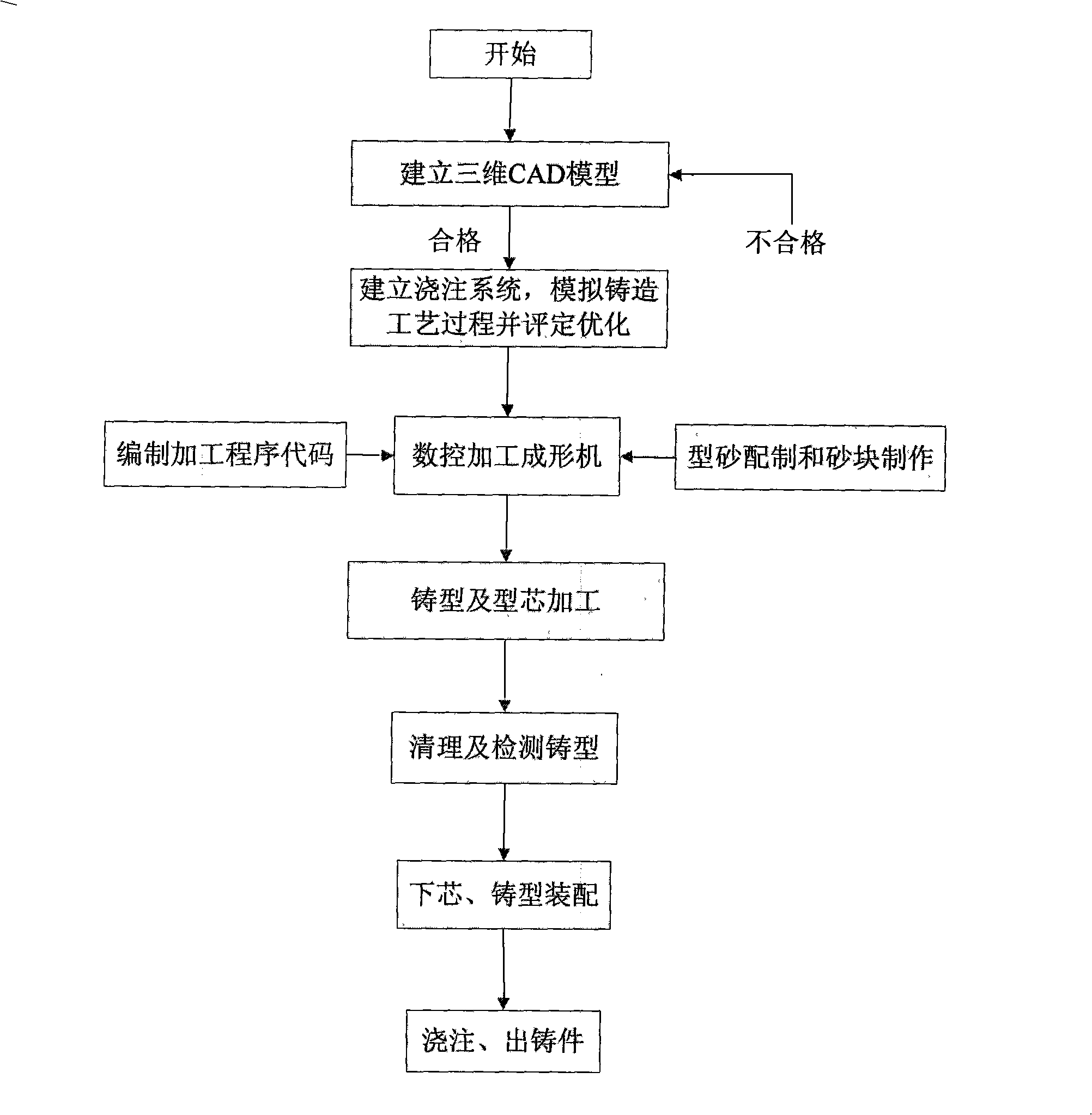

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

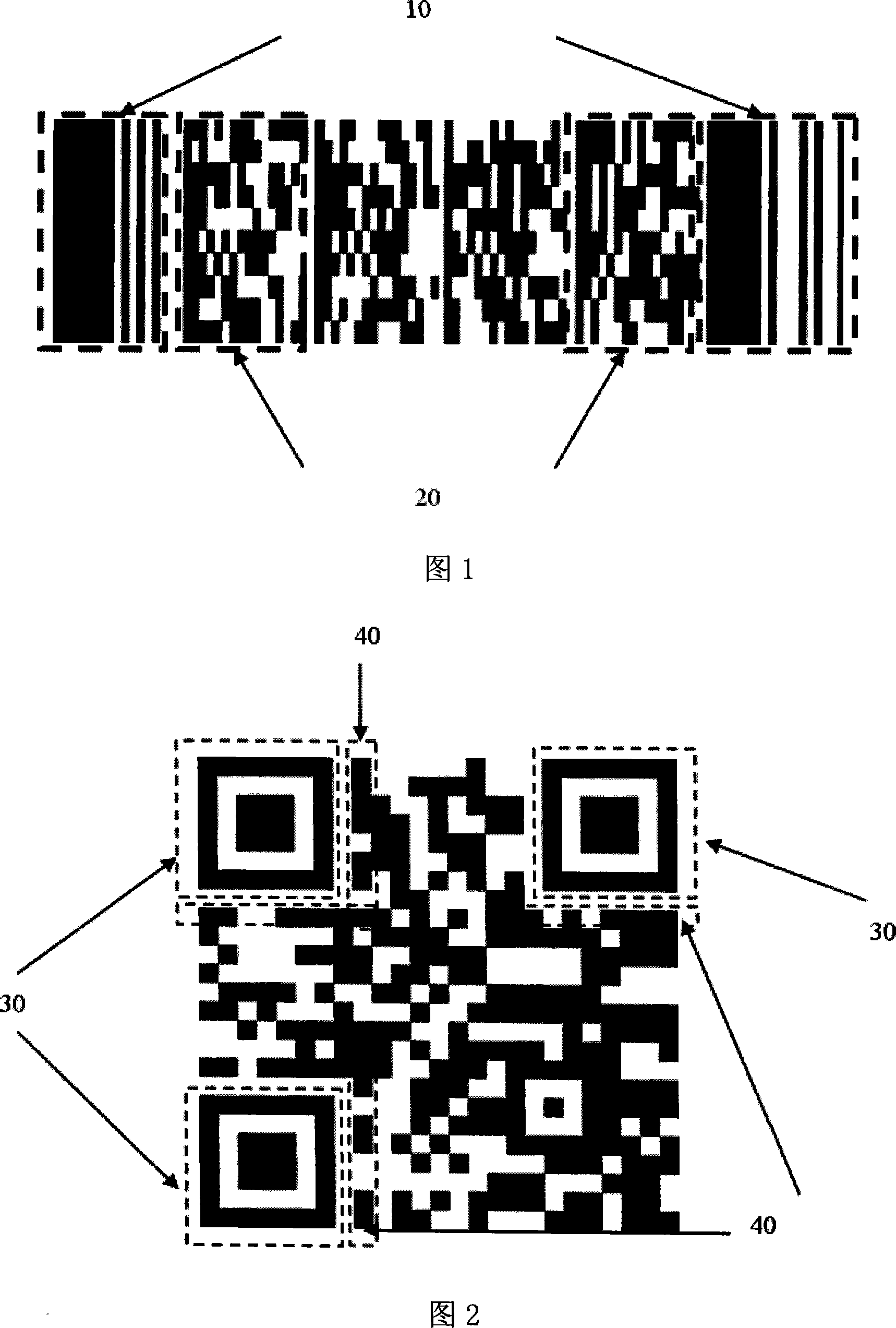

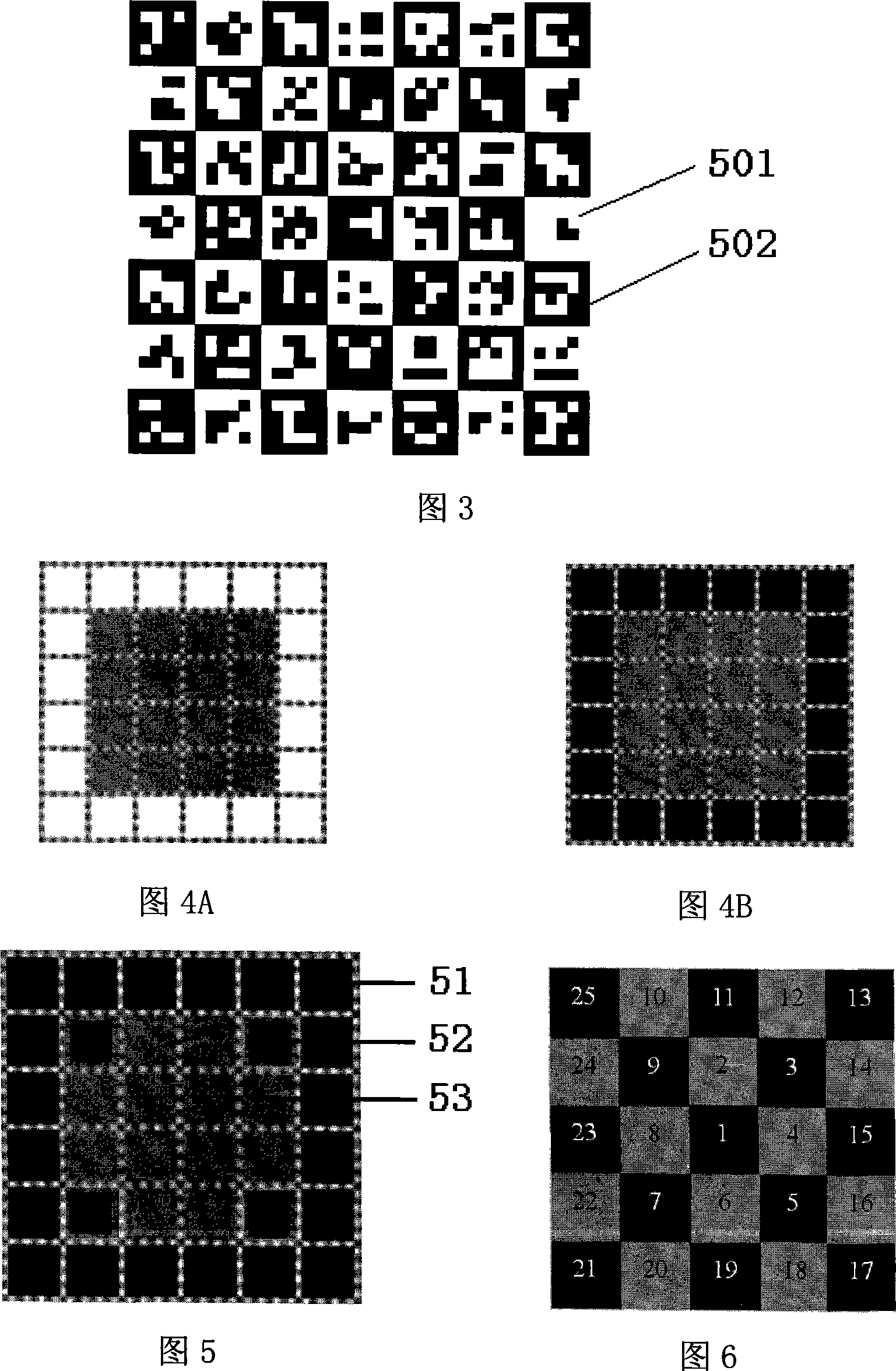

Two-dimension bar code and its coding and decoding method

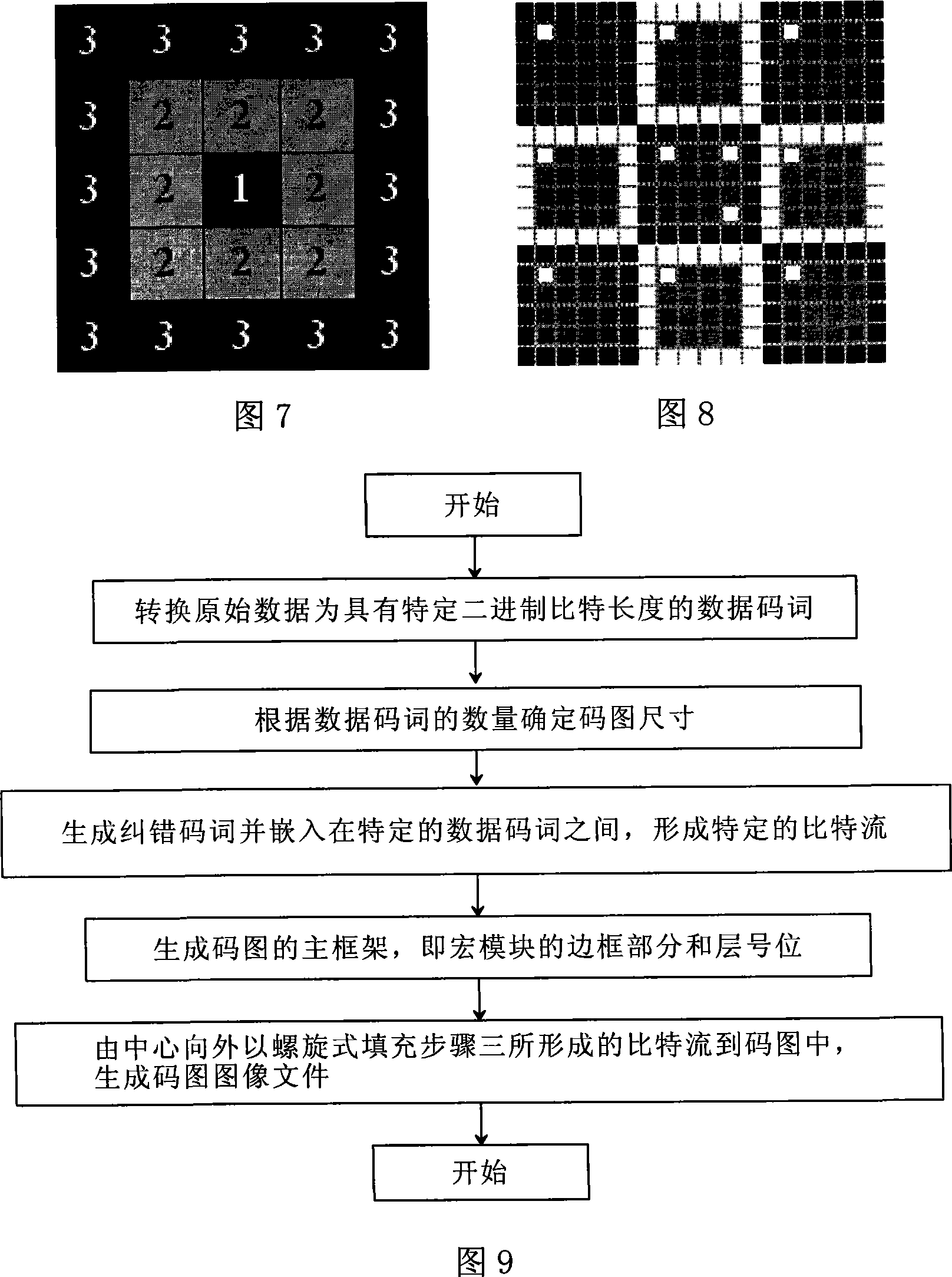

InactiveCN101197004ADirection is easy to determineSmooth decodingRecord carriers used with machinesSensing by electromagnetic radiationProgramming languageError correcting

The present invention discloses a method for coding and decoding two-dimensional bar codes. The coding method comprises a data code word generating step, an error-correcting code word generating step, a main code pattern frame generating step and a code pattern image forming step through code word filling. The decoding method is that: a gray scale image of a code pattern is acquired through a digital photography mode; the gray value distribution of different pixels in the gray scale image is counted; a threshold value is determined; the gray scale image is converted into a binary image and an edge image is acquired; the four-corner coordinate of each macro block in the code pattern and the center coordinate of each unit module inside the macro blocks are calculated; the bit value stored by each unit module is determined so as to acquire a data code word matrix corresponding to the decoded code pattern; the data code word is read according to a correct center macro block and the code pattern direction; RS error-correcting algorithm is used to correct the errors in the code word according to a preset error-correcting grade; the data code word is output and recovered as a binary number.

Owner:SHENZHEN SYSCAN TECHC CO LTD

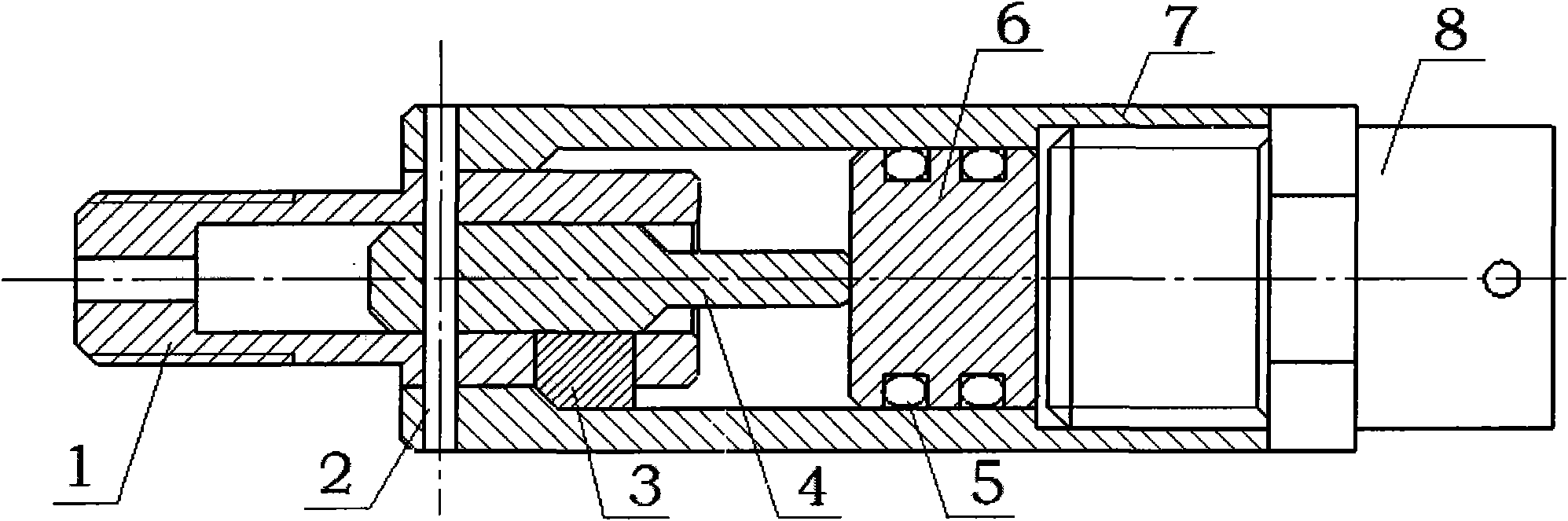

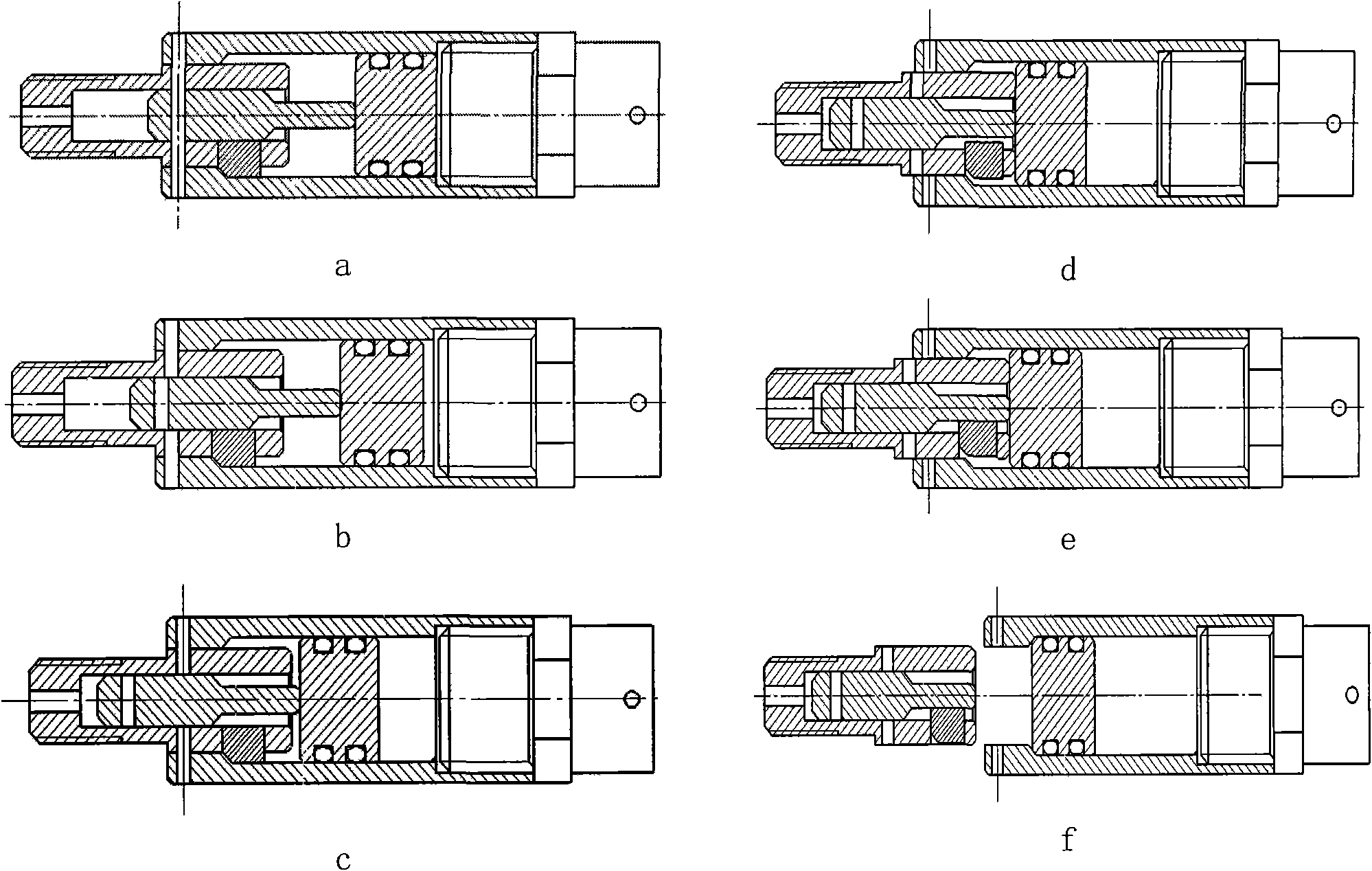

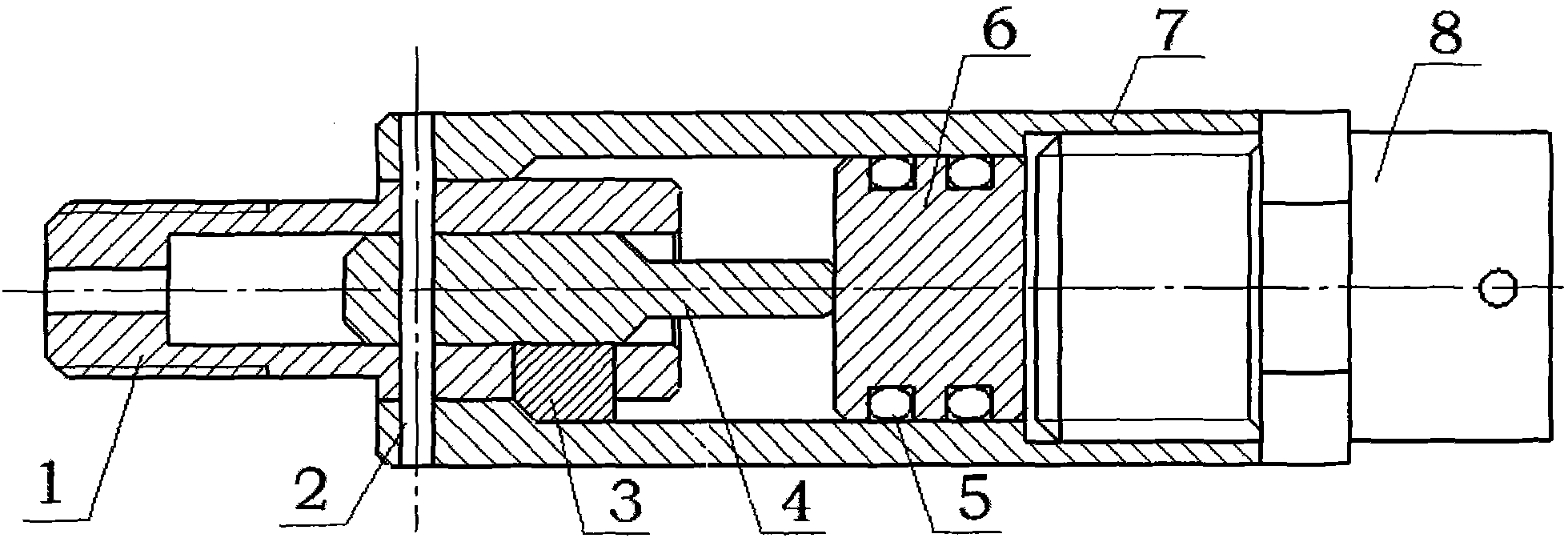

Sealed small low-impact release screw bolt

The invention relates to a sealed small low-impact release screw bolt. The bolt comprises an inner cylinder (1), a shear pin (2), a wedge block (3), a piston (4), a sealing ring (5), a double O-shaped ring sealed baffle (6) and an outer cylinder (7). The bolt is characterized by small size, sealing type, low impact, strong connection and no pollution. Before separated, the two polars of the connected body form strong connection; and when separated, the two polars of the connected body can be safely and fast separated and generate low impact disturbance, thus the bolt is a pyrotechnic connection separating device with good comprehensive performance, and can be directly used in the stage separating systems of the missile and other spacecrafts, also provide beneficial reference for the design of the similar separating mechanism, have good application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

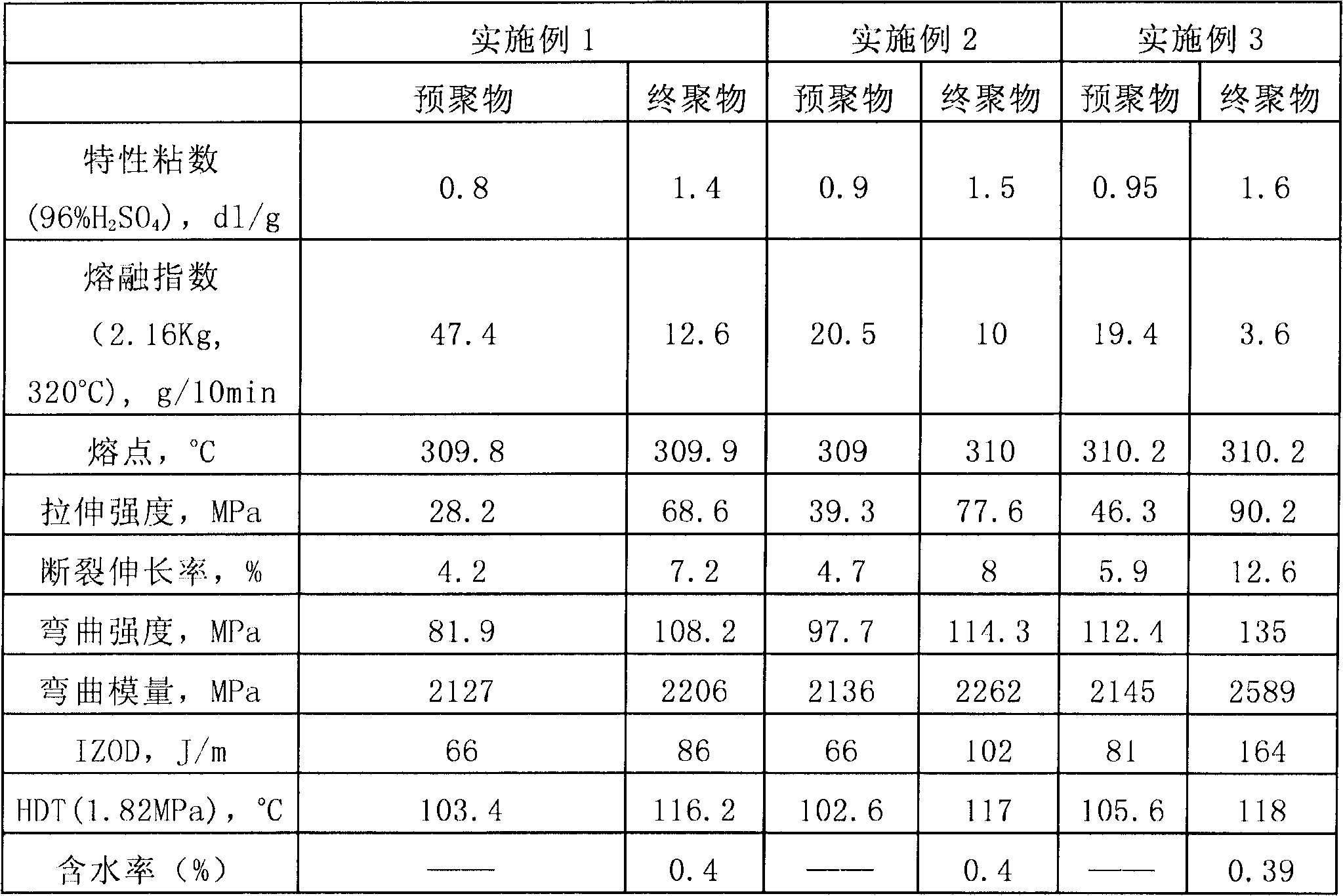

Homopolymer and copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and synthesis method thereof

The invention provides a method for synthesizing a homopolymer and a copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and polymerization products obtained by the method. The method comprises the following steps of: (a) prepolymerizing terephthalic acid and 1,10-decanediamine in a molar ratio of 1:(1.00-1.02) and optional copolymerization components to obtain a prepolymer that the intrinsic viscosity is controlled to be between 0.4 and 1.1dl / g; and (b) performing solid-phase polymerization on the prepolymer in step (a) to obtain the long-carbon-chain semi-aromatic high-temperature-resistant polyamide PA10T or the copolymer thereof, wherein the intrinsic viscosity is controlled to be between 1.2 and 2.6dl / g.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

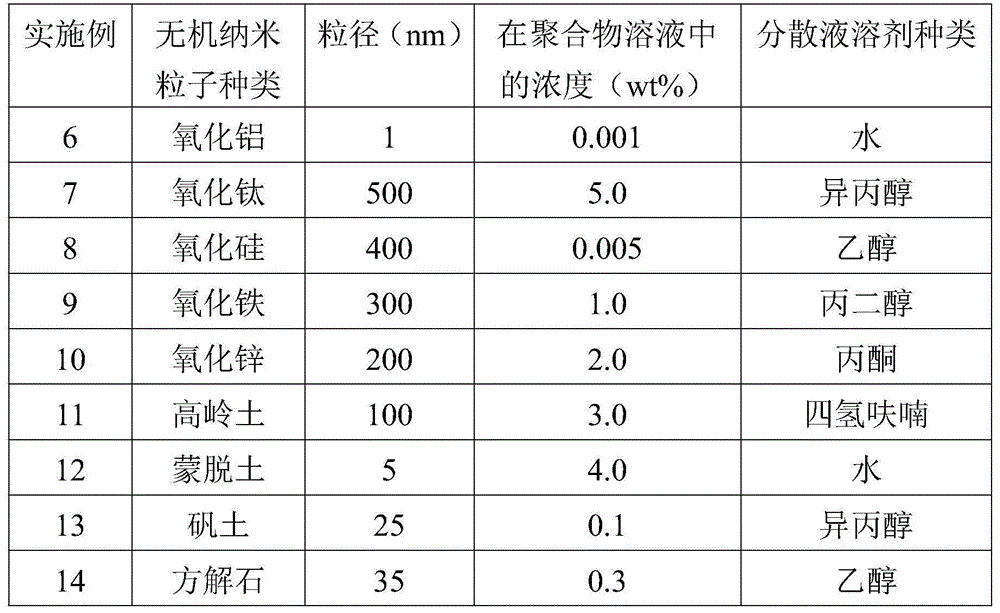

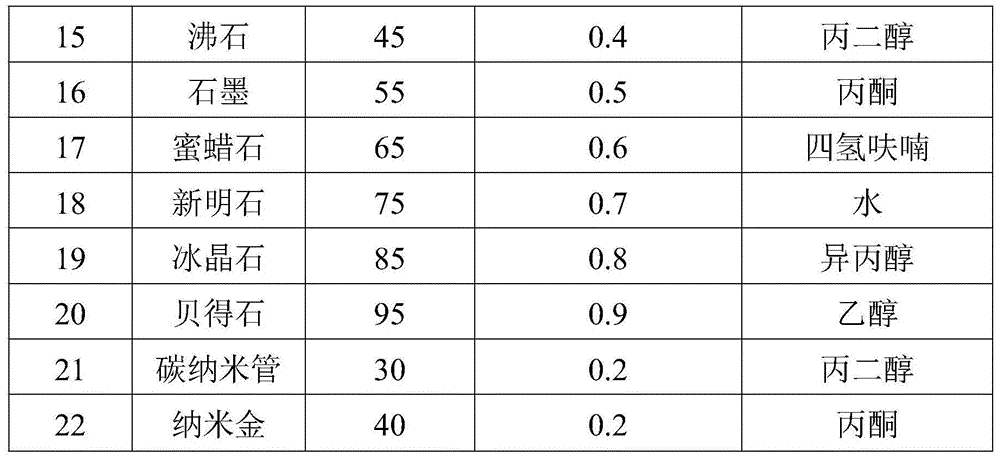

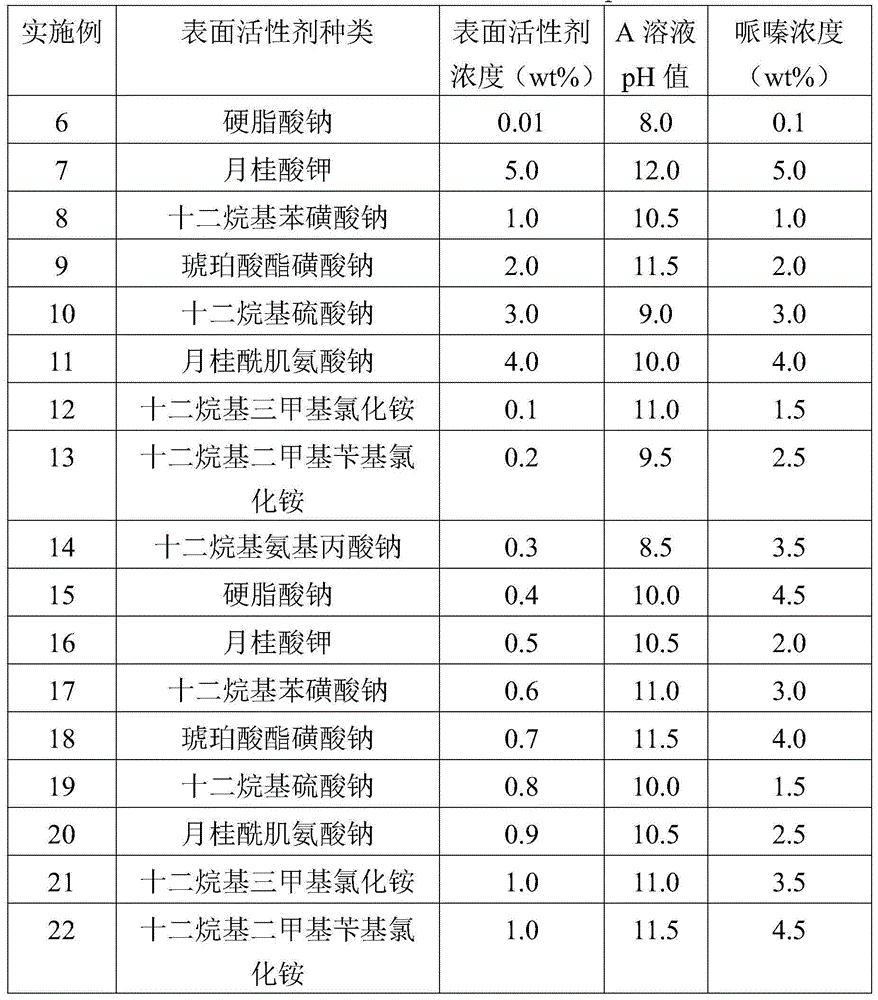

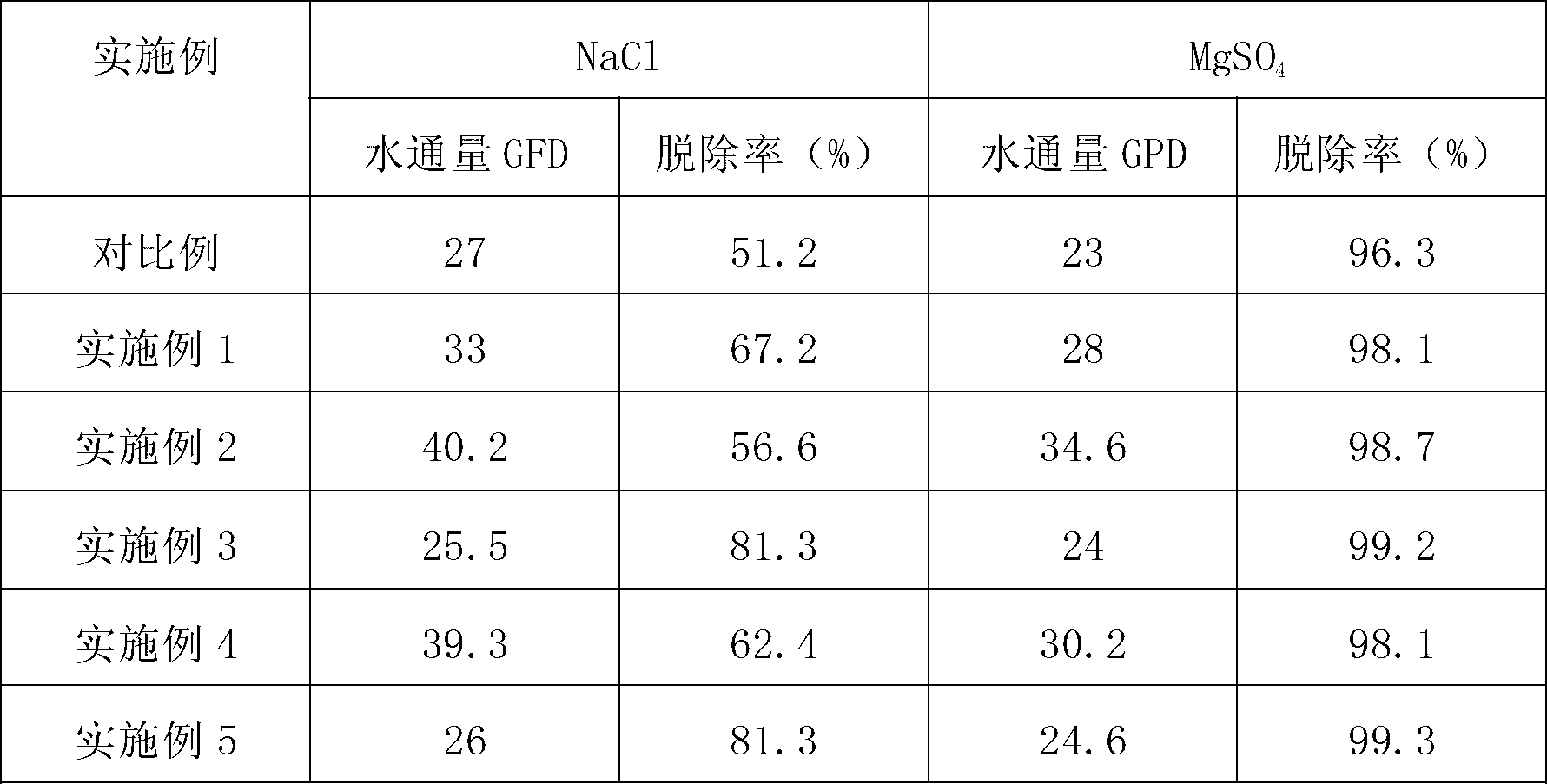

Preparation method of high-throughput anti-pollution composite nanofiltration membrane

ActiveCN104667759AImprove performanceImprove throughputSemi-permeable membranesGlycerolSurface-active agents

The invention discloses a preparation method of a high-throughput anti-pollution composite nanofiltration membrane. The preparation method comprises the following steps: inorganic nanoparticles are uniformly dispersed in a porous polymer supporting layer, a surface active agent is added in solution A, a polyamide layer is prepared on the porous polymer supporting layer through interfacial polymerization, hot water soaking treatment and glycerol moisturization treatment are adopted, and then drying is performed, and thus, the high-throughput anti-pollution composite nanofiltration membrane is prepared. According to the method, the porous supporting layer microstructure is changed by inorganic nano particles, the surface active agent is added in the solution A, and the flux and the antifouling property of the composite nanofiltration membrane are improved. The preparation method is easy, the raw material is cheap, the preparation process is simple and the method has good industrial applicability.

Owner:VONTRON TECH CO LTD

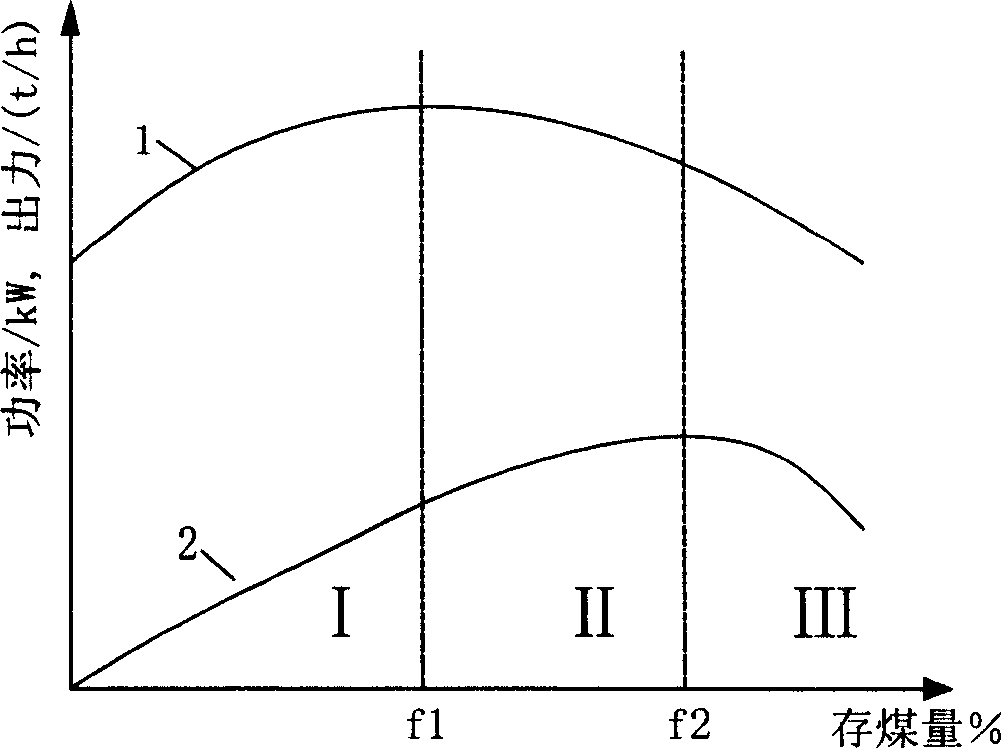

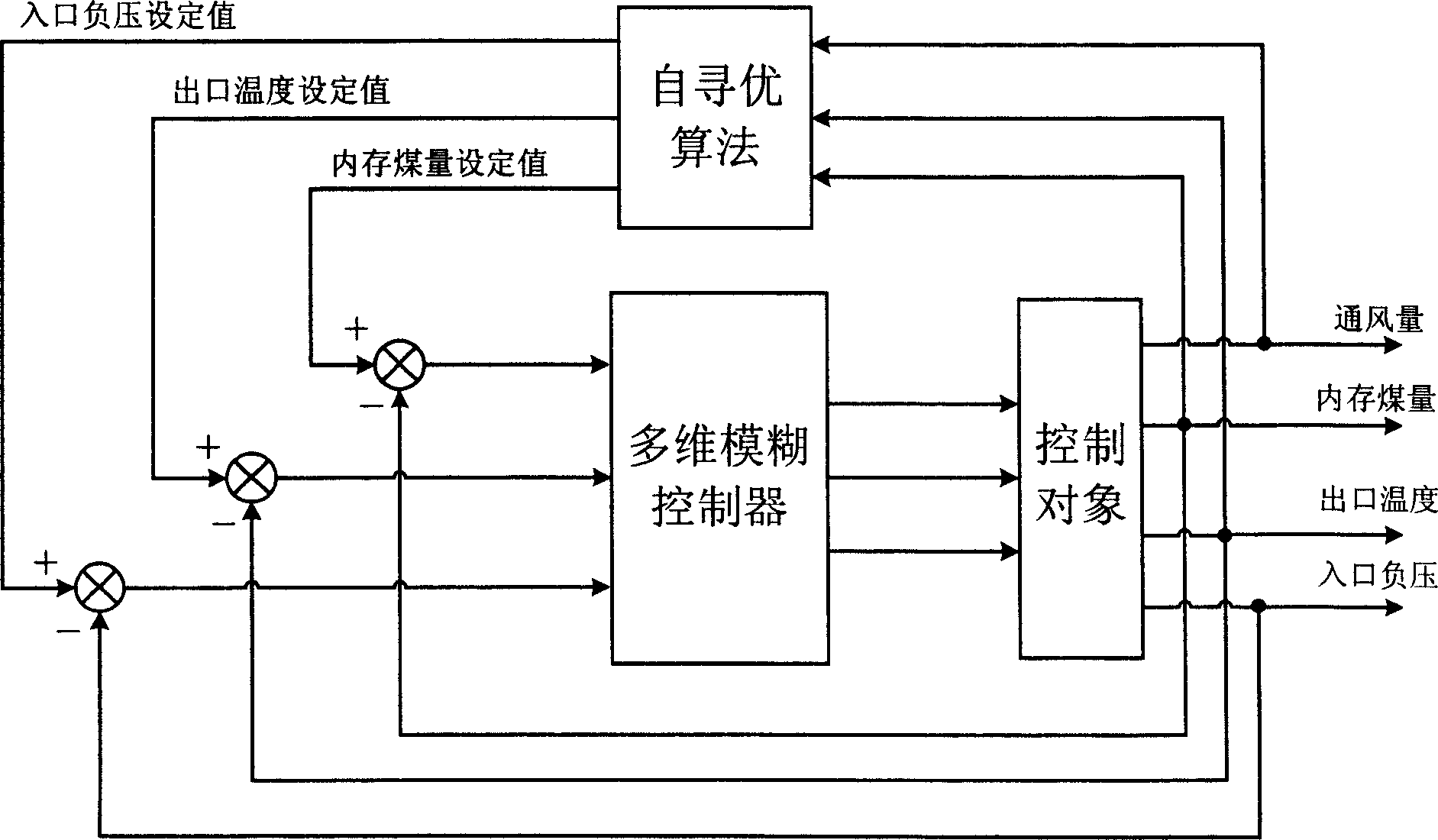

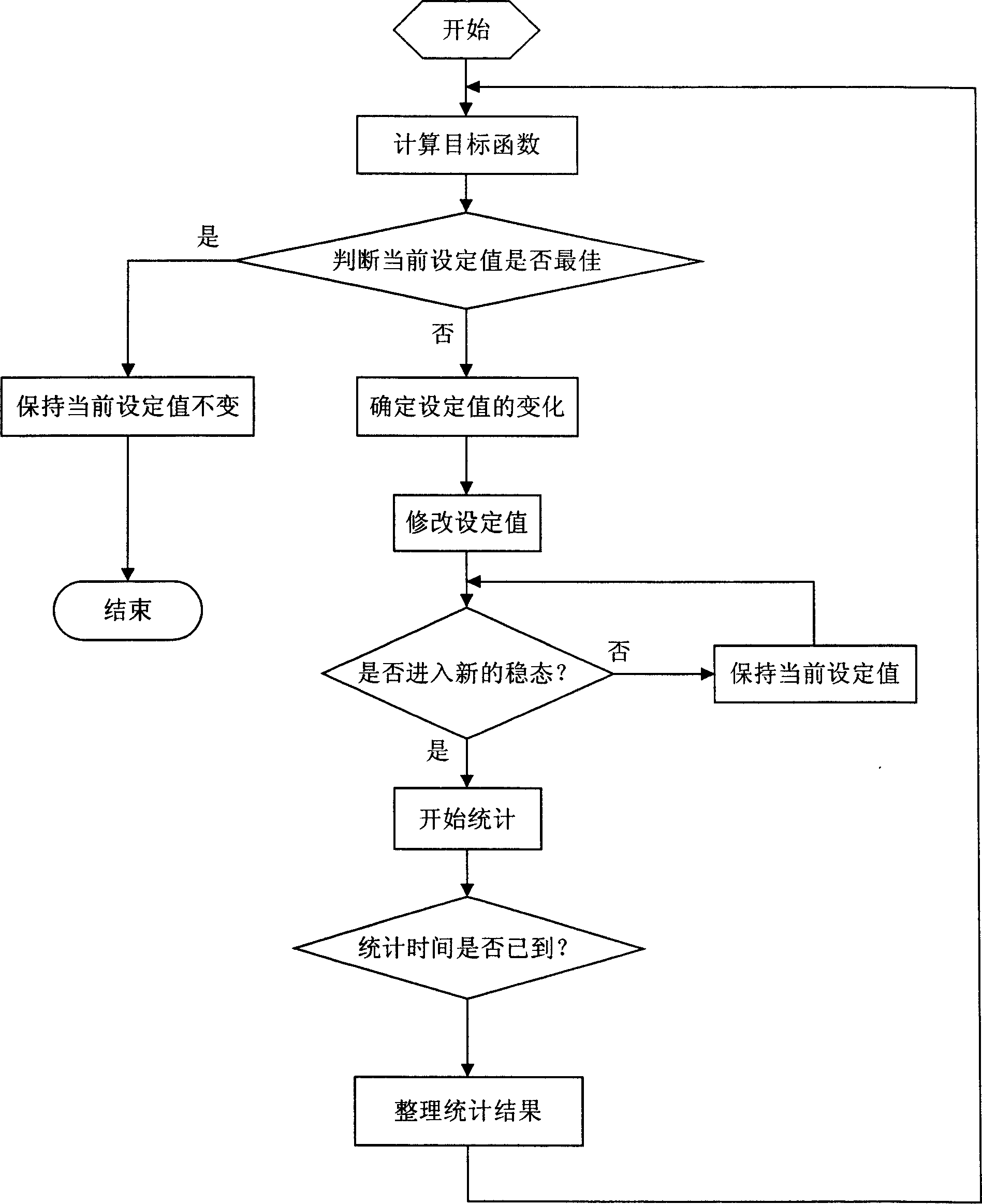

Powder-making system automatic control method for heat engine plant steel ball coal grinding mill

The automatic control method for steel ball coal mill in thermal power plant adopts a double-layer control structure, including an upper layer of self optimizing algorithm and a lower layer of multidimensional fuzzy control algorithm. The self optimizing algorithm finds out the optimal inside coal storage quantity inside the coal mill, the optimal outlet temperature of the coal mill and the optimal inlet negative pressure value of the coal mill as the controlling set values; and the multidimensional fuzzy control algorithm realizes the automatic regulation of the coal feed quantity, the hot air valve opening, and the recirculating air valve opening or the cold air valve opening, so as to ensure the safe and reliable running of the steel ball coal mill system in optimal mode.

Owner:XI AN JIAOTONG UNIV +1

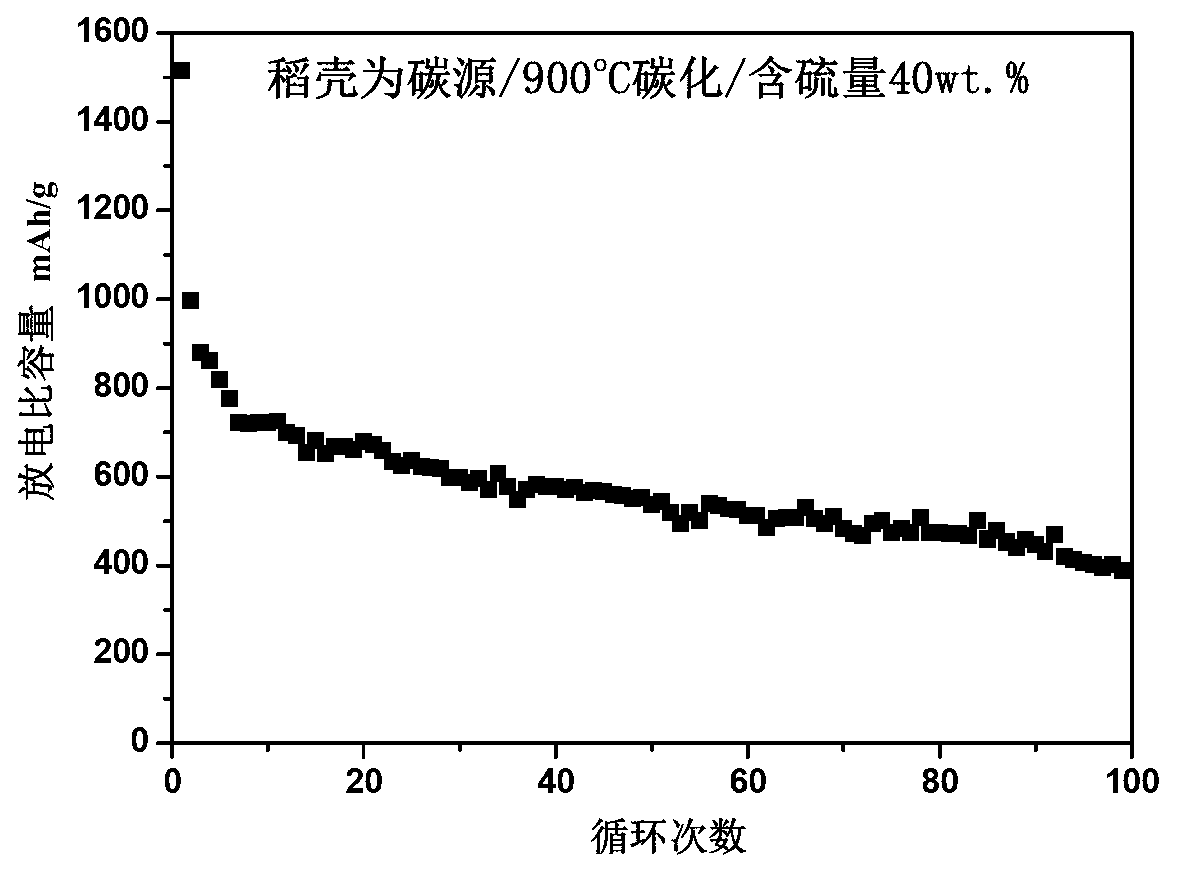

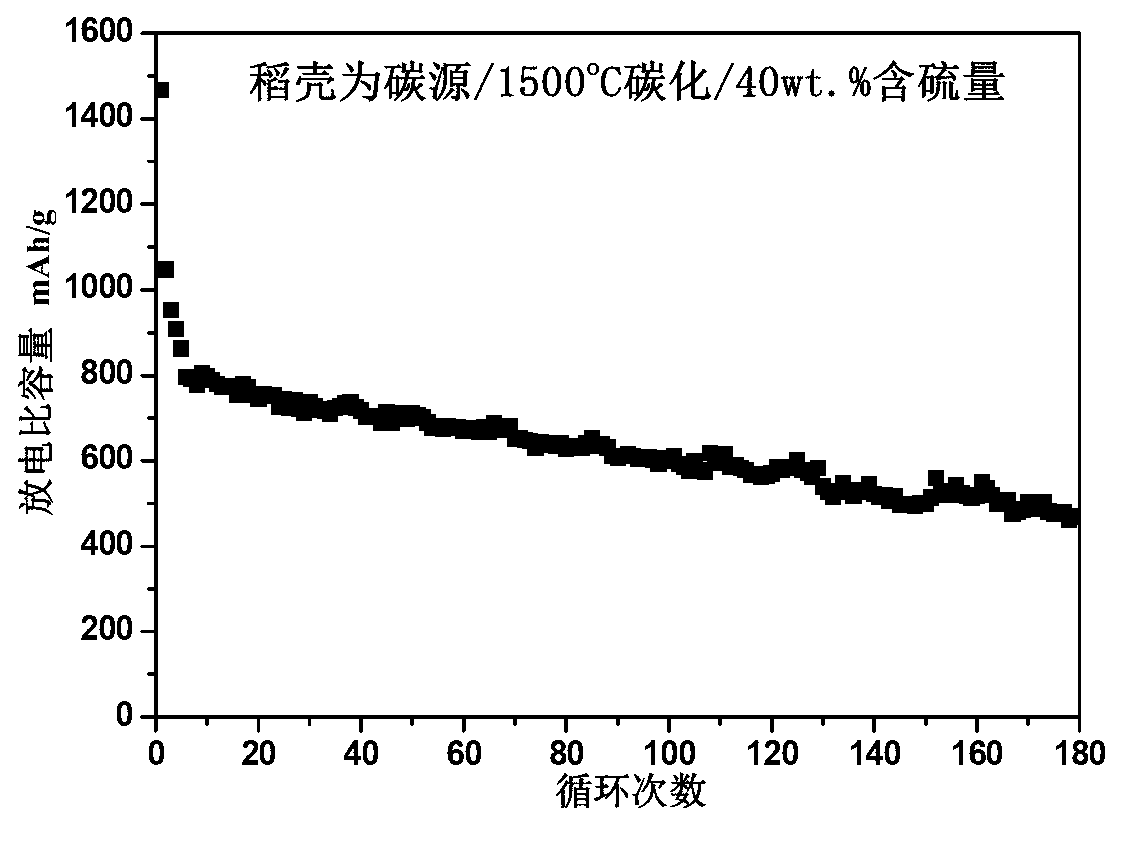

Lithium-sulfur battery sulfur/carbon composite positive electrode material, preparation method and applications thereof

ActiveCN103236560ASimple methodIncrease productivityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesCarbon compositesLithium–sulfur battery

The present invention belongs to the field of lithium ion battery positive electrode materials and lithium ion batteries, and particularly relates to a lithium ion battery positive electrode material and a preparation method thereof, a positive electrode adopting the material, and a lithium ion battery adopting the positive electrode. The lithium-sulfur battery sulfur / carbon composite positive electrode material preparation method comprises: mixing sulfur and carbon through a ball milling method or a stirring method, carrying out heat preservation on the obtained mixture for 0.5-24 h at a temperature of 100-600 DEG C in vacuum, argon or nitrogen atmosphere, and cooling to obtain the sulfur / carbon composite material, wherein a carbon-containing biomass material is adopted as a carbon source, and is subjected to carbonization to obtain the used carbon, the used sulfur is elemental sulfur, and a mass ratio of the sulfur to the carbon in the composite material is (0.4-5):1. With application of the prepared sulfur / carbon composite material as the lithium ion battery positive electrode material, first discharge capacity can be 1300-1600 mAhg<-1>, and capacity after 200 cycles can be 620 mAhg<-1>.

Owner:ZHEJIANG UNIV

Geopolymer grouting material

InactiveCN101712546AImprove early strengthImprove liquiditySolid waste managementCement productionSlagGeopolymer

The invention discloses a geopolymer grouting material, which is prepared from the following components in parts by weight: 10-30 parts of waste concrete powder, 5-15 parts of desulfurization gypsum, 10-20 parts of steel slag powder, 20-40 parts of scoria powder, 3-8 parts of high calcium fly ash, 20-50parts of coal ash and 5-10 parts of alkali-activator. The geopolymer grouting material has the advantages of high early strength, good flowing property, low production cost, and the like; moreover, the geopolymer grouting material has self-hardening property, can react with soil, and enable soil bodies to become a plate-shaped structure, thereby improving the bearing capacity of a soil roadbed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

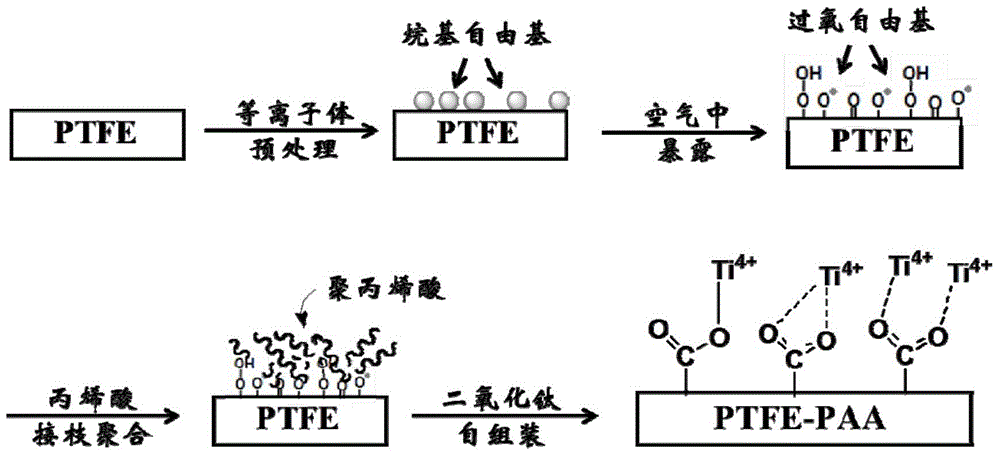

Hydrophilic modification method for polytetrafluoroethylene membrane

ActiveCN104998562AImprove featuresImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGlass sheetVacuum drying

The inveniton provides a hydrophilic modification method for a polytetrafluoroethylene membrane. The method comprises the following steps: step 1, subjecting the polytetrafluoroethylene membrane to plasma treatment under a nitrogen atmosphere, and allowing the surface of the polytetrafluoroethylene membrane to generate relatively-stable free radicals and active sites; step 2, placing the polytetrafluoroethylene membrane into an acylic acid solution and carrying out static impregnation for a period of time, then taking the polytetrafluoroethylene membrane out of the solution and then placing the polytetrafluoroethylene membrane between two glase plates, and carrying out thermochemical polymerization in a vacuum drying oven so as to obtain the polytetrafluoroethylene membrane with the surface grafted with polyacrylic acid; and step 3, subjecting the polytetrafluoroethylene membrane to static impregnation in a titanium dioxide sol for a period of time, and allowing titanium dioxide to be assembled onto the surface of the polytetrafluoroethylene membrane through the coordination effect of metal titanium-ion Ti4+ and a carboxyl group on the polyacrylic acid so as to obtain a hydrophilic modified polytetrafluoroethylene membrane. The hydrophilic modified polytetrafluoroethylene membrane prepared by using the method in the invention retains excellent properties of a conventional polytetrafluoroethylene membrane and greatly improves filter performance, hydrophilic property, pollution resistant property and photocatalytic property of the polytetrafluoroethylene membrane.

Owner:深圳市新纳捷科技有限公司

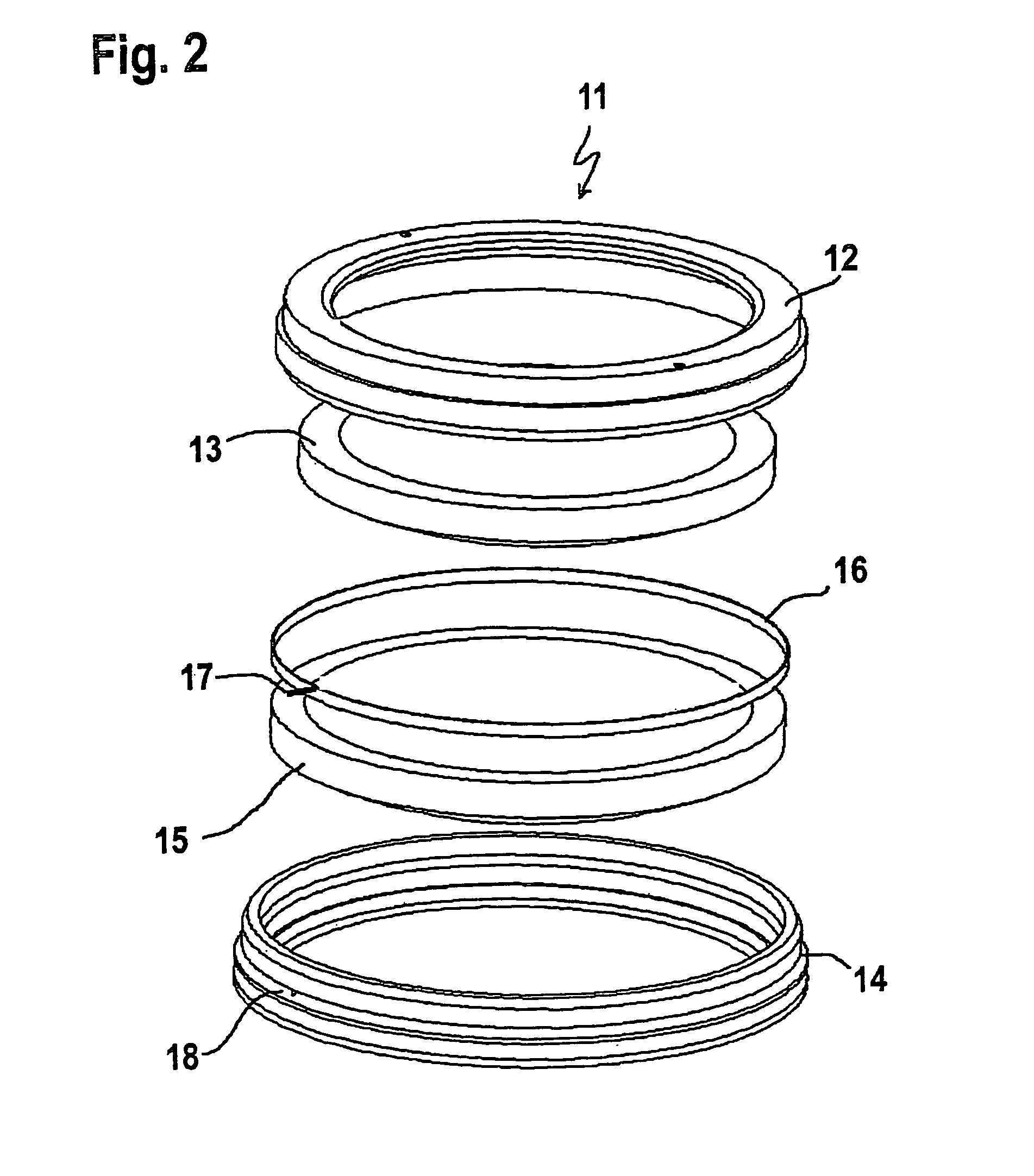

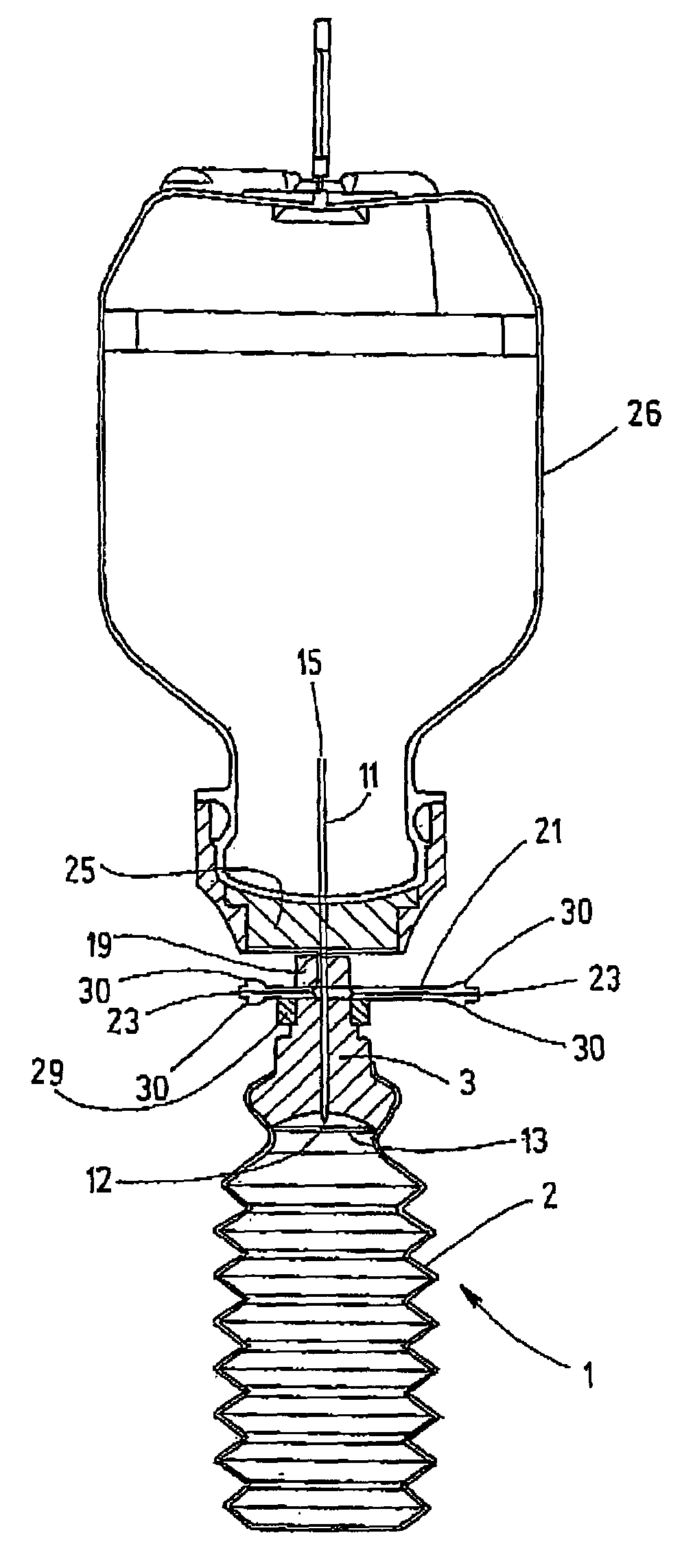

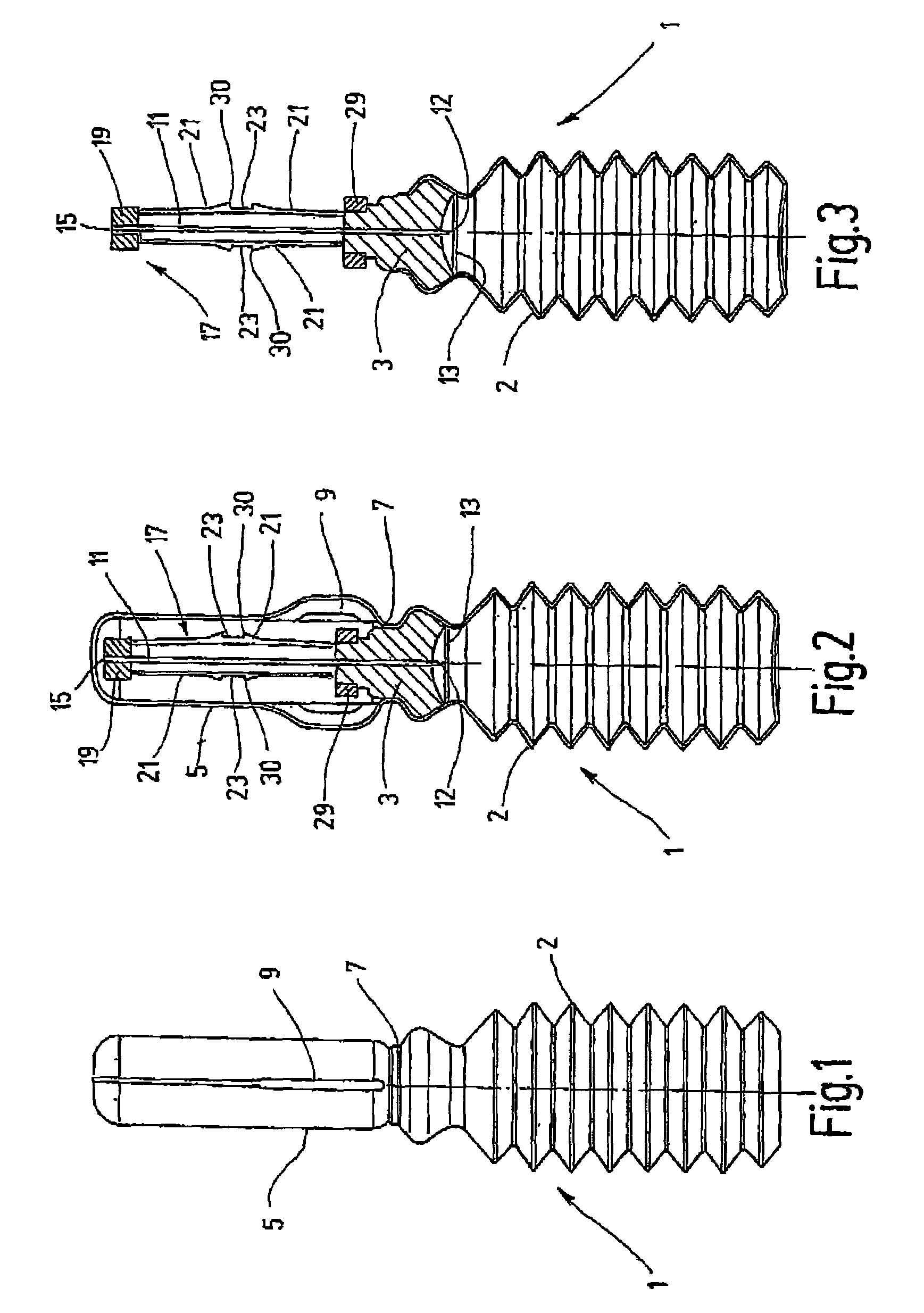

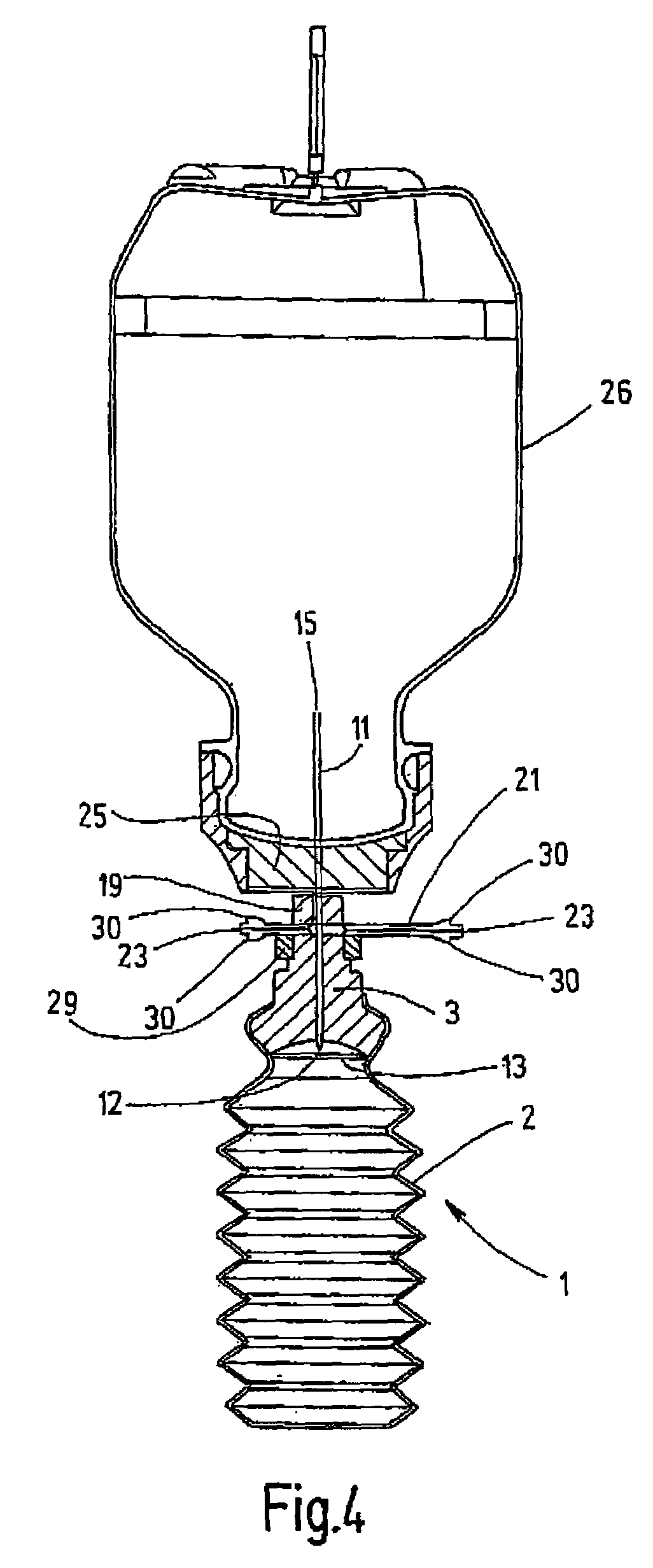

Device for distributing substances

InactiveUS7004213B2Improve securityImprove pollutionAmpoule syringesPharmaceutical containersEngineeringElectrical and Electronics engineering

A device for distributing substances includes distribution container (1) receiving a substance. The container has a closing unit (3) provided with a canula (11) for the substance to be distributed. The outer end (15) of the canula protrudes from the closing unit (3). A safety device (5, 17) can alternate between a protective state in which it covers the outer end (15) of the canula (11), and a user state for the distribution of the substance from the canula (11).

Owner:HANSEN BERND

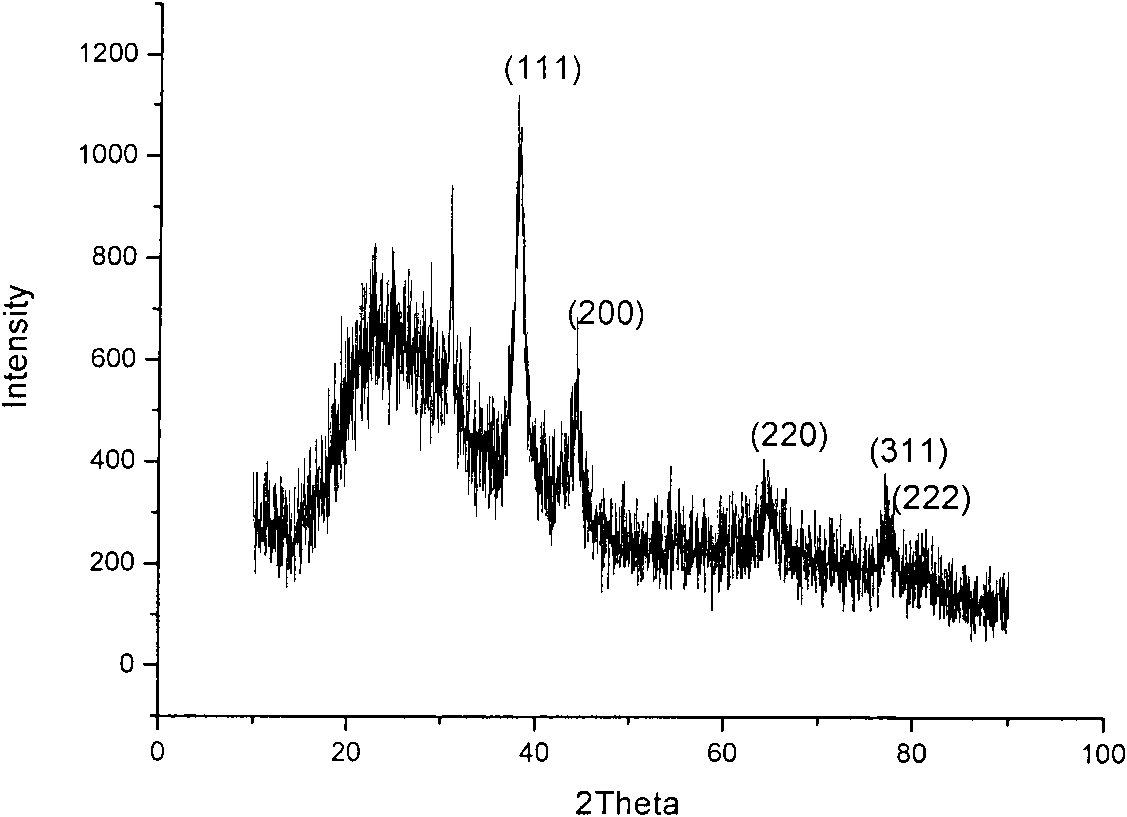

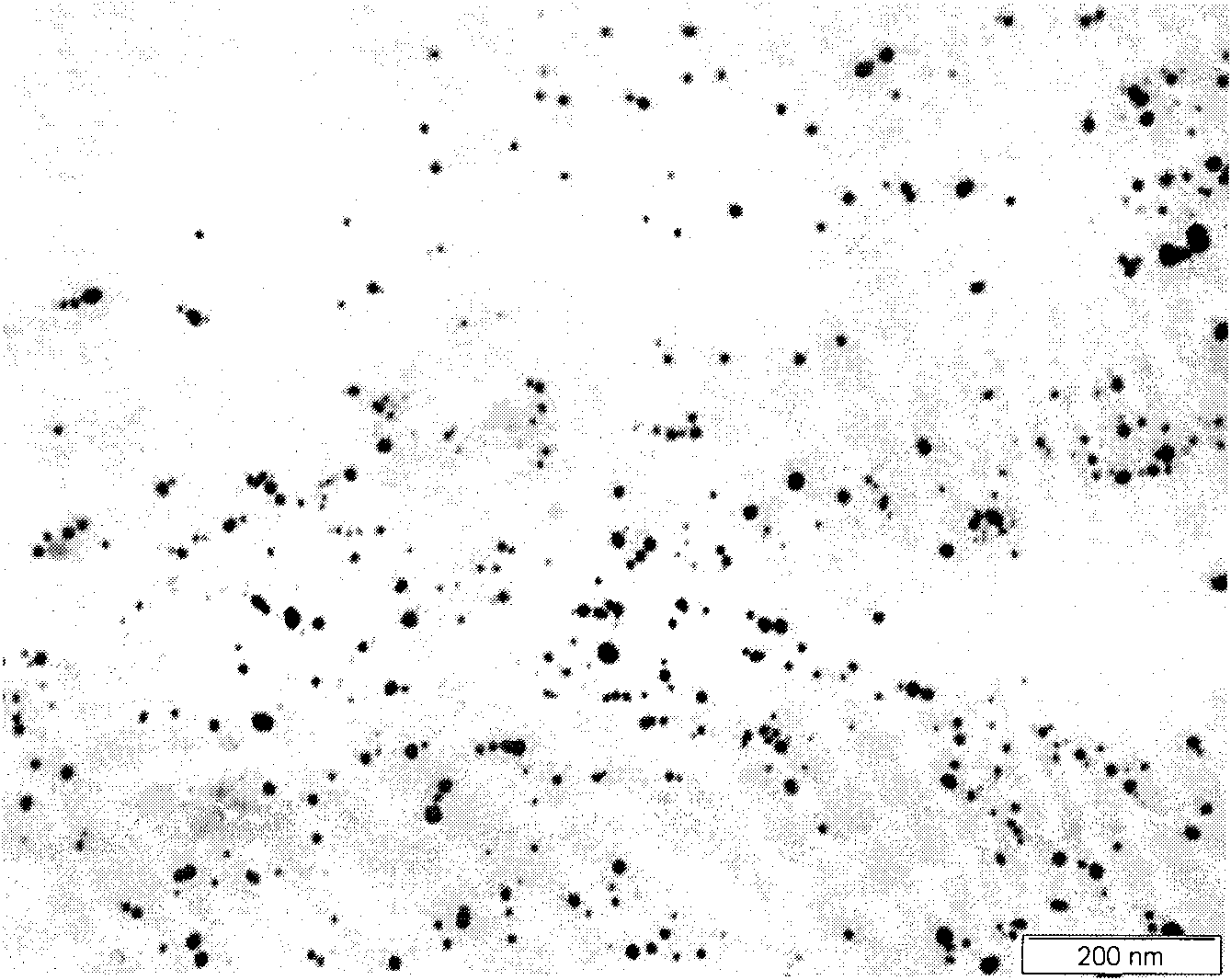

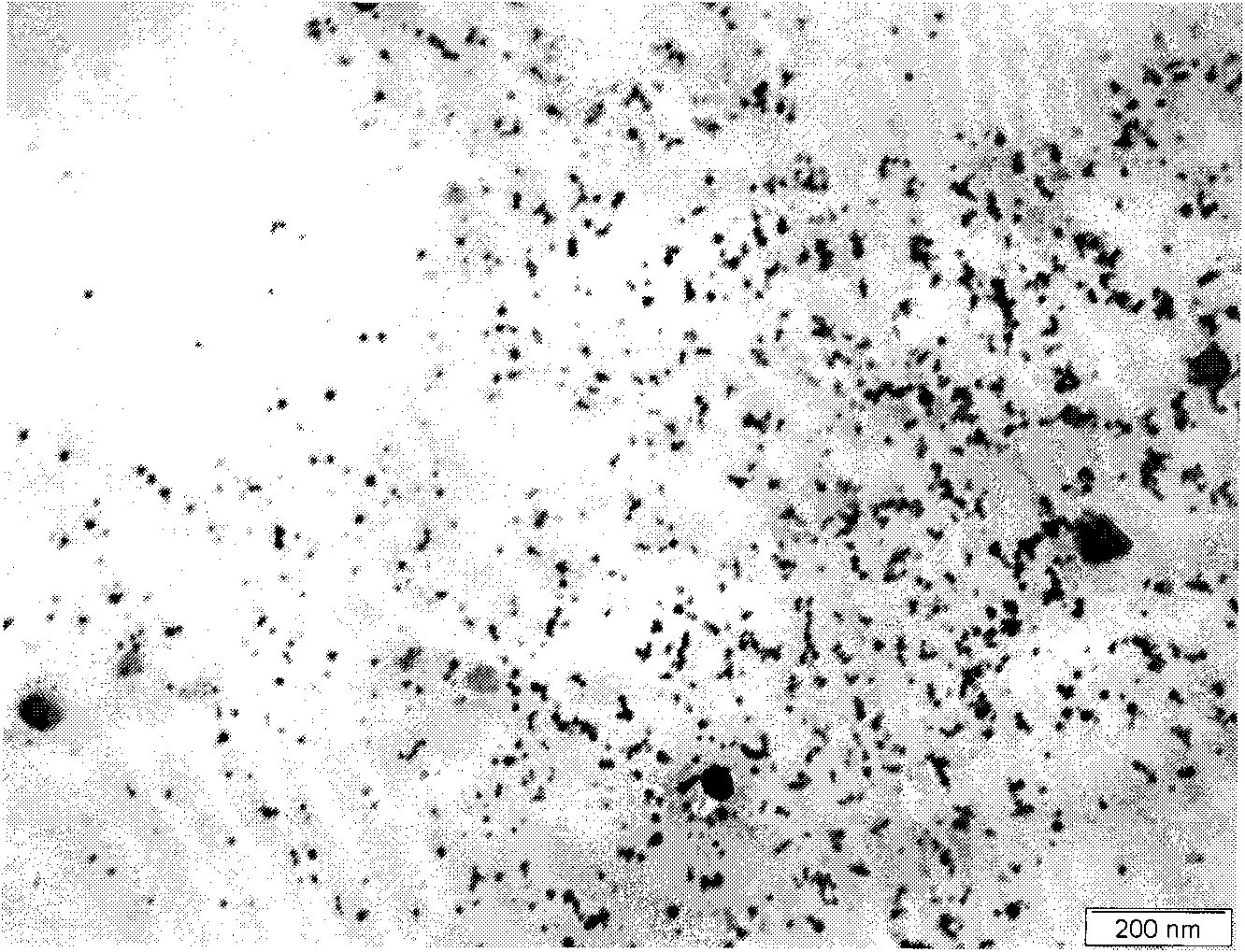

Nanofiltration membrane with nanometer hybridized desalination layer

The invention discloses a nanofiltration membrane with a nanometer hybridized desalination layer. The desalination layer formed through interphase hybridization of an inorganic nanoparticle with a particle size of 1 to 1000 nm and polyamide or polyimide is arranged on a porous supporting layer of the membrane. A preparation method for the nanofiltration membrane mainly comprises the following steps: pre-dispersion of the nanoparticle, preparation of a solution A, preparation of a solution B, interfacial polymerization, surface polishing and roller squeezing, rinsing with deionized water, moisture retention with glycerin and drying, wherein air drying and sulfonation can be carried out after surface polishing and roller squeezing. According to the invention, nanometer hybridization effects of a high polymer nano-material in the nanofiltration membrane are made full use of, so hydrophilic performance, antioxidation performance and anti-pollution performance of the nanofiltration membrane are improved, and the nanofiltration membrane has the advantages of low pollution, great flux and a high removal rate. The preparation method is scientific and reasonable, enables the nanometer composite nanofiltration membrane with a specific nanoparticle and polyamide hybridized desalination layer to be prepared and has higher ion selectivity, low pollution capability and temperature stability.

Owner:VONTRON TECH CO LTD

Nanometer silver collosol, preparation method and application thereof

ActiveCN101633045AImprove the safety of useImprove antibacterial propertiesFibre treatmentLavatory sanitoryAlcoholFatty alcohol

The invention relates to a nanometer silver collosol, a preparation method and an application thereof. The preparation method comprising the following steps: dissolving reductor, alcohol and fatty alcohol in a closed reactor to prepare a mixed dispersion reductor solution; and then carrying out reaction between a silver salt alcohol solution and the mixed dispersion reductor solution for 6-72 hours under the temperature of 35-70 DEG C to obtain the nanometer silver collosol. The nanometer silver collosol has good antibacterial property and is very stable, safe in use and low in production cost, thereby being extensively used for the antibacterial processing of textiles and the antibacterial and deodorizing processing of shoes and having strong market competitiveness.

Owner:CHANGZHOU CHAMGO NANO MATERIALS

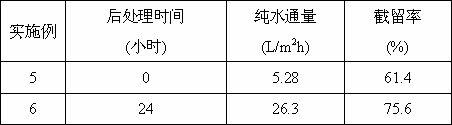

Anti-pollution cyclodextrin-polymer composite nano-filtration membrane and preparation method thereof

InactiveCN102327746AImprove hydrophilicityImprove pollutionSemi-permeable membranesFiltration membraneOil phase

The invention belongs to the technical field of membranes, and particularly provides an anti-pollution cyclodextrin-polymer composite nano-filtration membrane and a preparation method thereof. The cyclodextrin-polymer composite nano-filtration membrane is prepared by compounding a cyclodextrin-containing aromatic polymer functional cortex on a porous support membrane by virtue of an interfacial polymerization method. In the nano-filtration membrane, the porous support membrane is immersed in an oil-phase solution, in a cyclodextrin-containing aqueous-phase solution and in the oil-phase solution; and the cyclodextrin is loaded to the composite membrane functional cortex by virtue of interfacial polymerization, and the structure is stable. The preparation method has a simple operation process and mild reaction conditions; and by virtue of the annular cavity structure of the cyclodextrin and massive hydroxy carried by the cyclodextrin, the water flux, hydrophilicity and pollution resistance of the membrane are improved.

Owner:FUDAN UNIV

Red mud dealkalization method

ActiveCN101423318ALow alkali contentRemarkable effect of sodium removalSludge treatmentSocial benefitsBrick

The invention discloses a dealkalization method for red mud. The method comprises a dilute sulphuric acid dealkalization step and a pressure calcium oxide dealkalization step. Red mud is prepared into slurry and introduced into a grinder to be ground; according to the content of alkaline in the red mud, the slurry is slowly added with required dilute sulphuric acid to be ground, filtered and washed to obtain a filter cake and the content of alkaline in the filter cake is analyzed; according to the analyzed content of alkaline in the filter cake, the filter cake is added with calcium oxide and uniformly mixed to be introduced to a high pressure reaction kettle and heated for reaction, and after reaction, the mixture is cooled, filtered and washed; and the obtained filter cake is dried and content of alkaline in the dried filter cake is analyzed. The invention can use only the pressure calcium oxide method to carry out dealkalization of the red mud. Red mud subjected to dealalization treatment of the method has low alkaline content and can be used more in fields such as concrete production, high quality brick and transformed brickproduction. The method solves the problem of the red mud of severe pollution and achieves remarkable economic and social benefits.

Owner:中国长城铝业有限公司

Dry farm cultivating agent

The dry-land planting agent refers to a kind of droughtresistance crop's nutrient specific to the growth of the plants. The invention is composed of the following components: AU absorber with super strength, carbamide, potassium dihydrogen phosphate, ammonium dibasic phosphate, calcium nitrate, bitter salt, ammonium molybdate, zinc sulfate, manganese sulfate, boracic acid or borax, ferrous sulphate, fulvic acid potassium, disodium edta, fatty alcohol polyethenoxy ether, 6- benzyl aminopurine, melissyl alcohol, potassium naphthylacetic acid, indolebutyric acid, gibberellin, santobrite, potassium sorbate, ketotriazole, penta azole alcohol., thiram, carbendazim, acid brilliant scarlet, humic acid, bluestone, potassium permanganate, potassium chloride, polyethylene glycol, bentonite or water. The invention is featured by sopping, molding moisture, molding fertilizer, withering resistance, disinsection, sterilization, strengthening the effects of the pesticide, accelerating the burgeon of the plants, increasing roots, innocuity, no pollution and low cost.

Owner:王亚玲

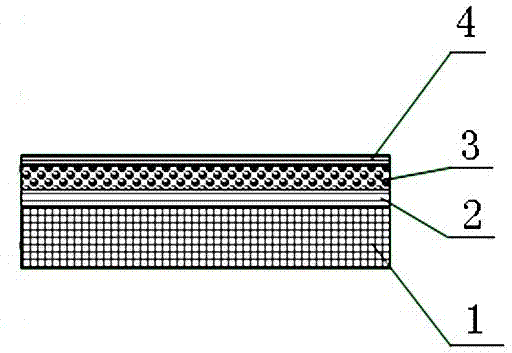

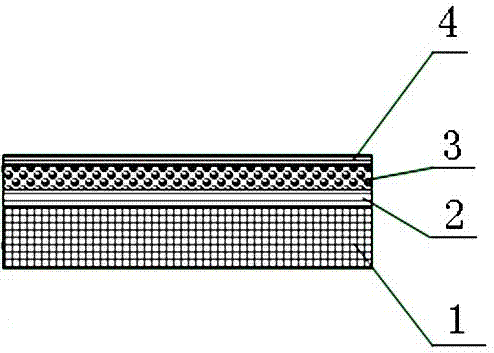

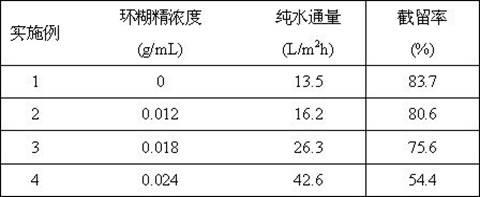

Polyethylene film, packaging composite film and preparation method thereof

InactiveCN104191766AStraight line tearGood linear tearabilitySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene film. The polyethylene film orderly comprises a corona layer, a middle layer and a heat sealing layer; the corona layer is prepared from such raw materials as 45wt%-50wt% of linear low density polyethylene and 50wt%-55wt% of high density polyethylene; the middle layer is prepared from such raw materials as 20wt%-25wt% of low density polyethylene and 75wt%-80wt% of high density polyethylene; the heat sealing layer is prepared from such raw materials as 75wt%-80wt% of metallocene linear low density polyethylene and 20wt%-25wt% of low density polyethylene; the polyethylene film is formed by virtue of co-extrusion blow molding of the raw materials of the corona layer, the middle layer and the heat sealing layer; the blowup ratio of the co-extrusion blow molding is less than 2. The invention also provides a packaging composite film and a preparation method thereof; the packaging composite film comprises the polyethylene film, has excellent straight tear property in addition to good heat sealing strength, and can be applied favorably.

Owner:HUANGSHAN NOVEL

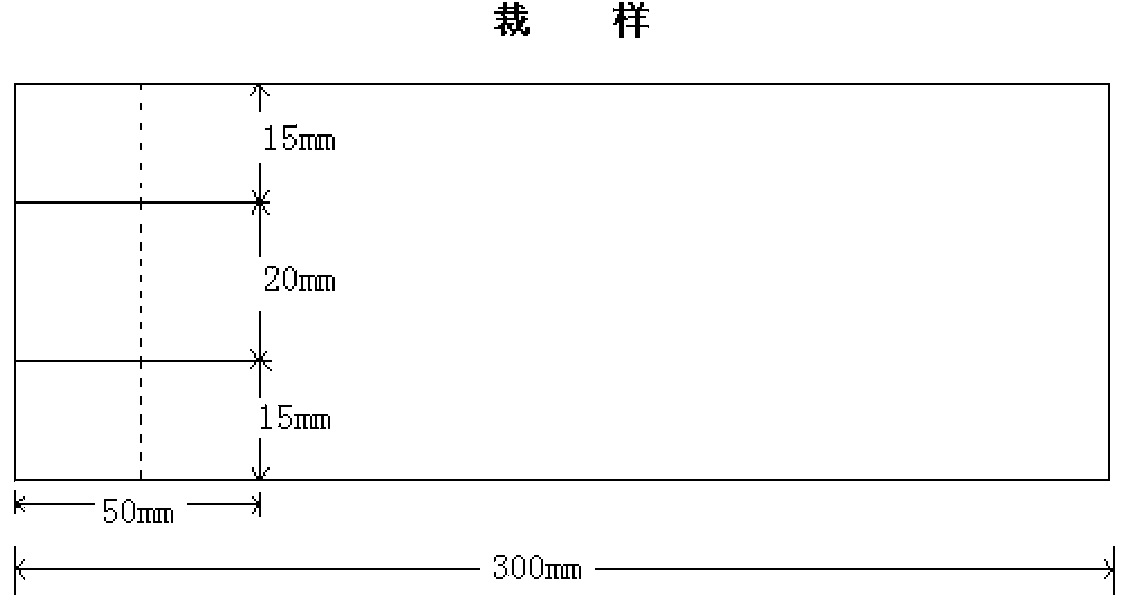

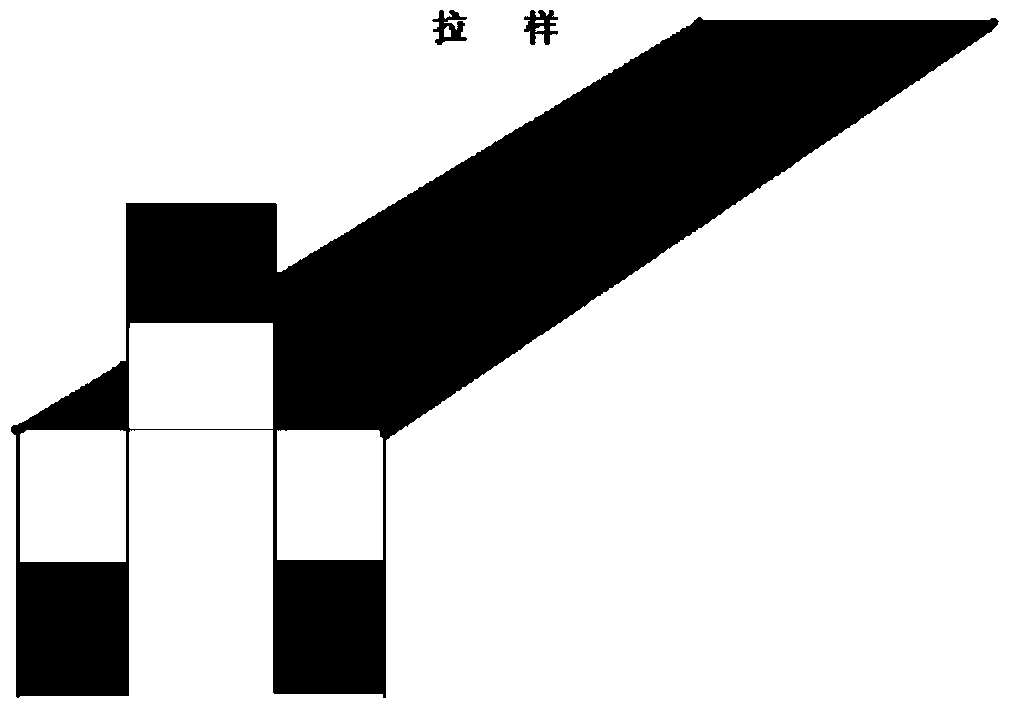

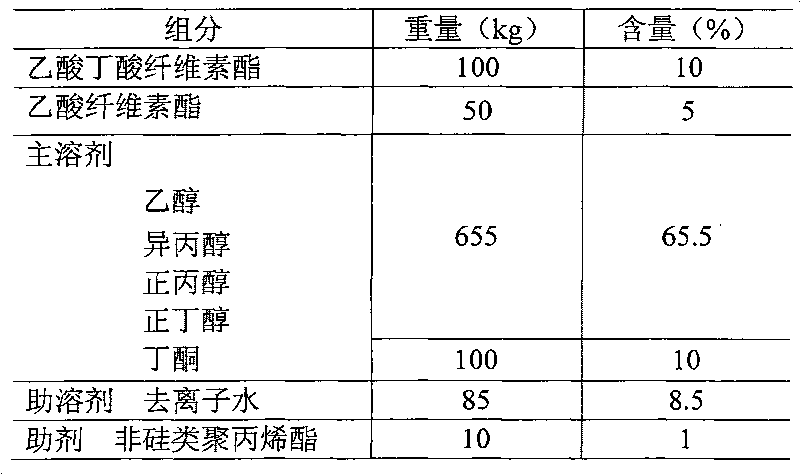

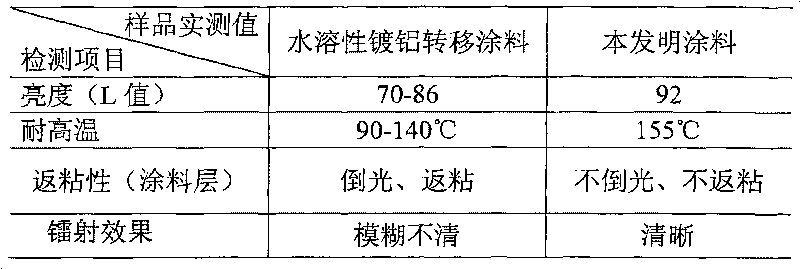

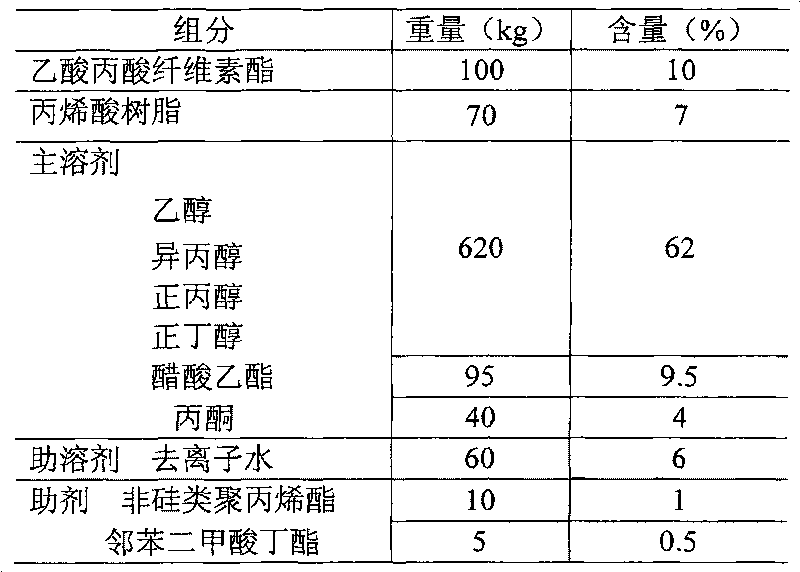

Laser mould pressing alcohol soluble aluminizing transfer paint and preparation method and application thereof

ActiveCN101701117AReduce manufacturing costLow application costPattern printingPaper/cardboardCelluloseAcrylic resin

The invention relates to a laser mould pressing alcohol soluble aluminizing transfer paint and preparation method thereof and application thereof in production of holographic aluminizing transfer paper and common aluminizing transfer paper. The paint comprises the following raw materials (by weight percent): 0-17% of cellulose ester, 0-25% of acrylic resin, 60-73% of main solvent, 3-10% of water and 0-2% of assistant; wherein the cellulose ester and the acrylic resin are film-forming resin, at least one of the two is included, the hydroxyl content of the cellulose ester is 3-8%, Tg value of the cellulose ester is 130-160 DEG C, the acid value of the acrylic resin is 40-60mg KOH / g, and the Tg value of the acrylic resin is 60-160 DEG C; and the content of alcohol solvent in main solvent is at least 70wt%. The main solvent of the paint of the invention is alcohol solvent, contains no solvent harmful to human body and contains appropriate water as assistant, thus eliminating volatilization of harmful solvent in coating process; and the paint dried after coating has favourable water resistance and solvent resistance, and indexes thereof including the laser mould pressing property, high temperature resistance and after-tack in high temperature high humidity environment can meet usage requirement.

Owner:上海绘兰材料科技有限公司

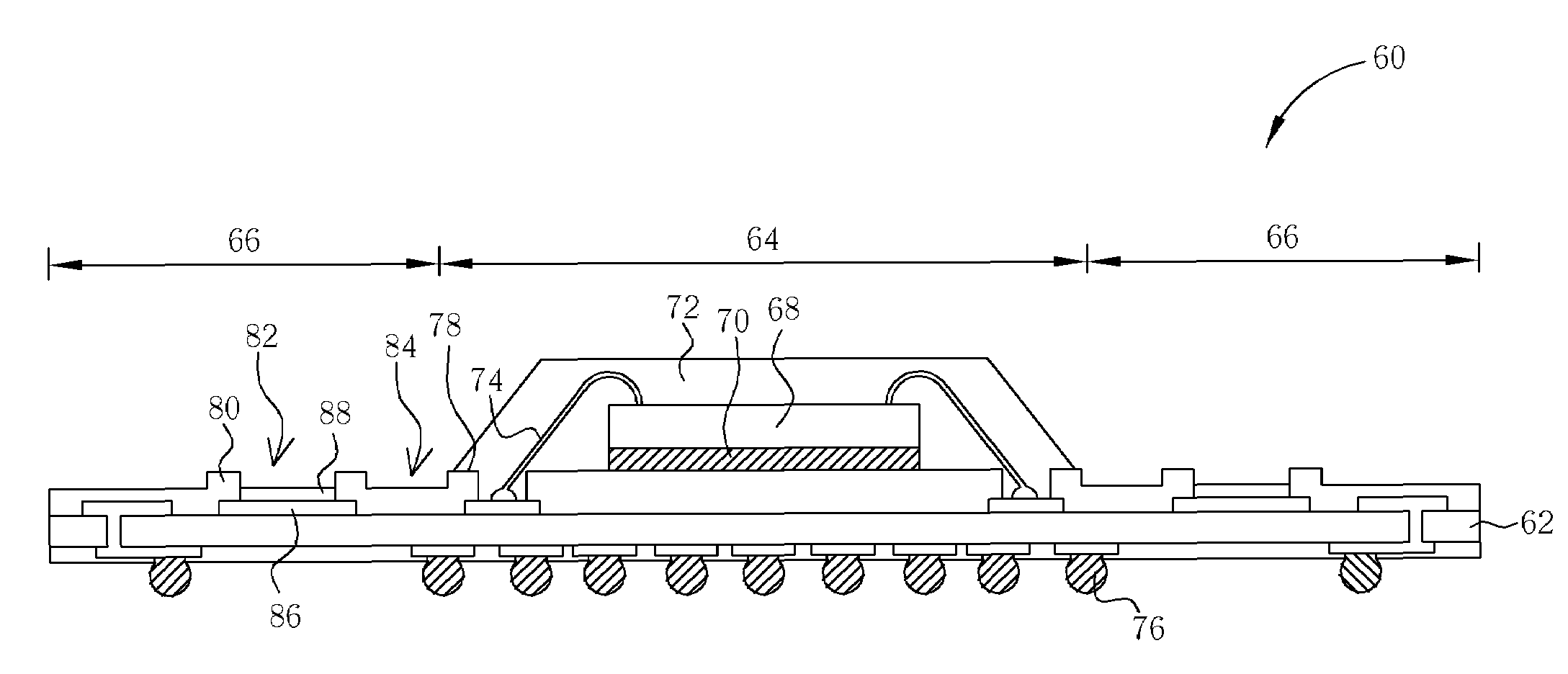

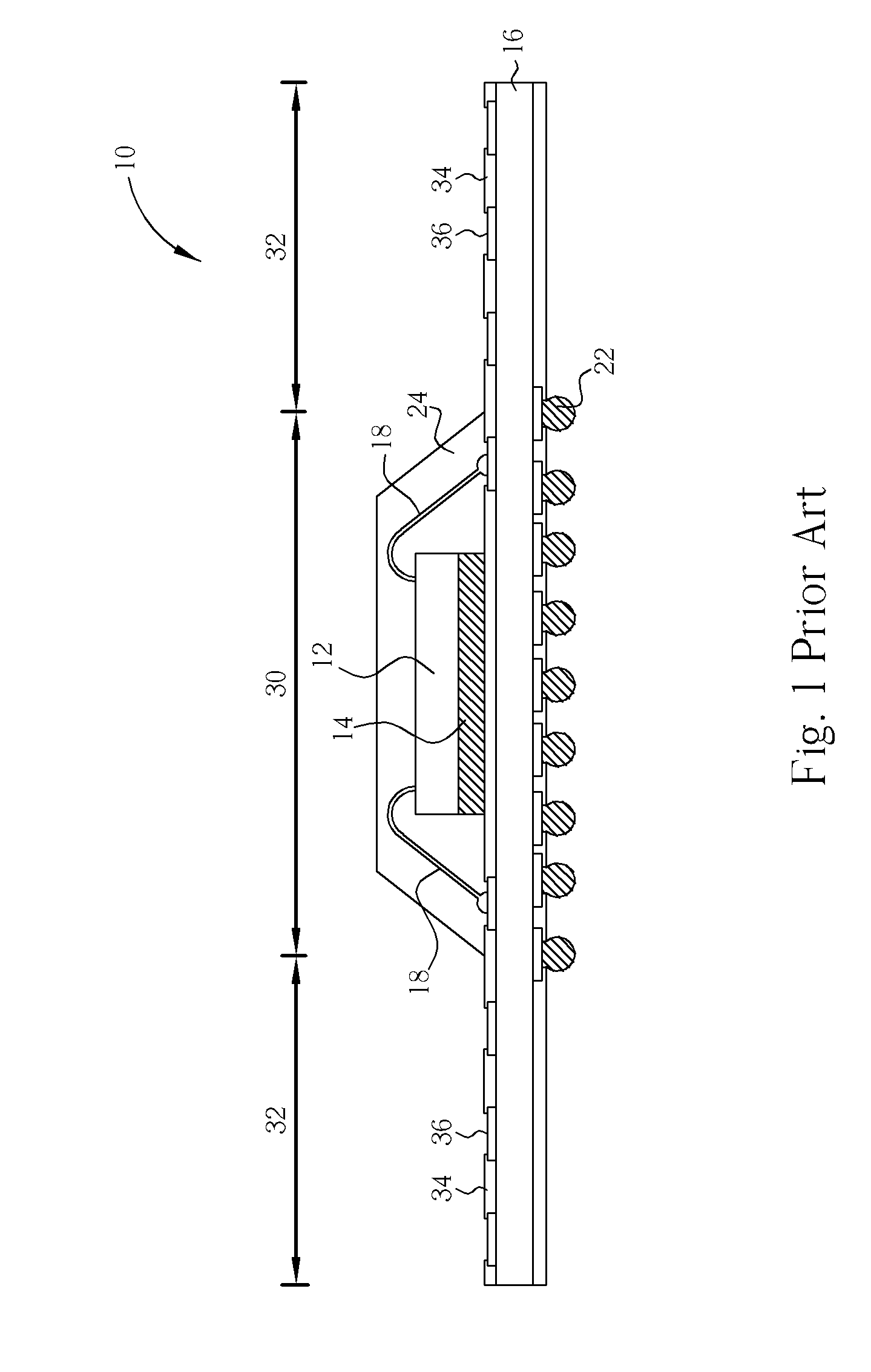

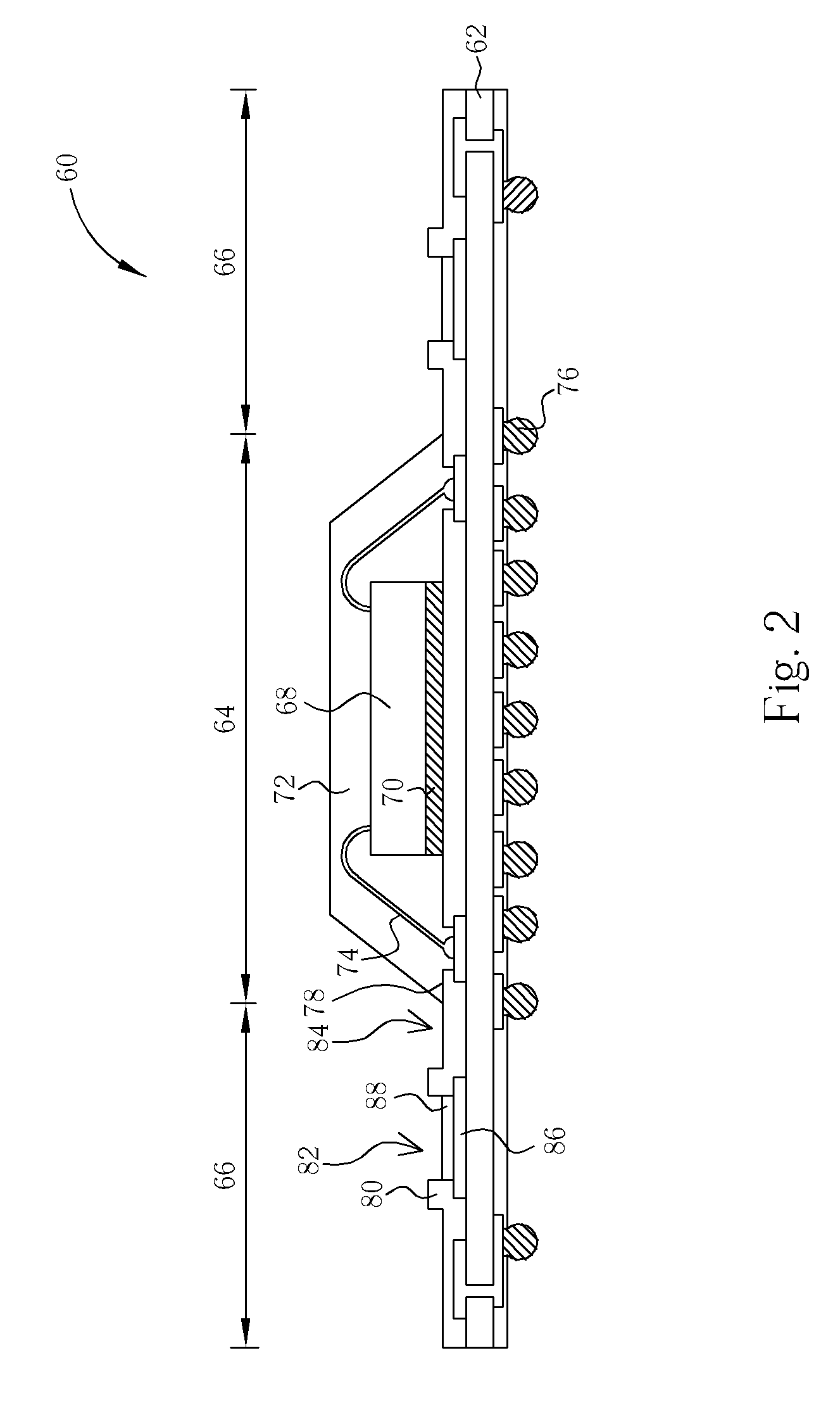

System-in-package structure

ActiveUS7417329B2Improve pollutionImproving yield and stabilitySecond resist patternSemiconductor/solid-state device detailsSolder maskEngineering

A system-in-package structure includes a carrier substrate having a molding area and a periphery area, at least a chip disposed in the molding area, an encapsulation covering the chip and the molding area, a plurality of solder pads disposed in the periphery area, and a solder mask disposed in the periphery area and partially exposing the surface of the solder pads. The solder mask includes at least a void therein.

Owner:ADVANCED SEMICON ENG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com