Polyethylene film, packaging composite film and preparation method thereof

A polyethylene film and composite film technology, applied in the field of packaging materials, can solve the problems of unfavorable applications, the impact of packaging barrier properties and mechanical strength, and the limitations of laser easy-to-tear lines, so as to achieve long-term surface tension value and facilitate compounding Good peeling force and tearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

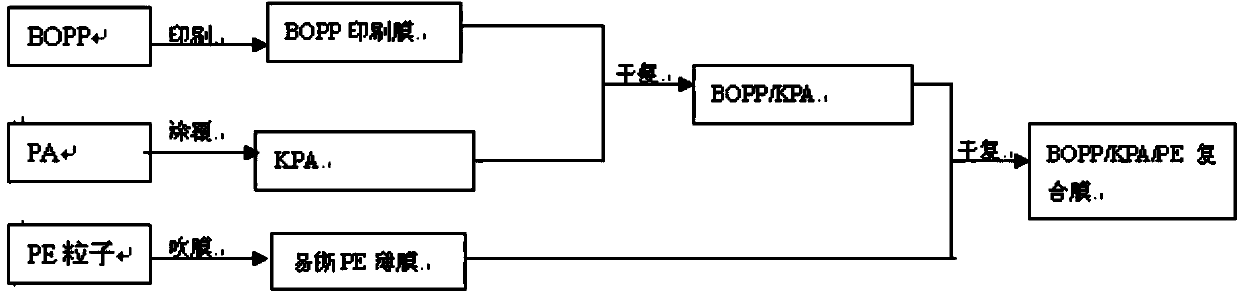

[0052] Correspondingly, the present application also provides a method for preparing the packaging composite film described above, comprising the following steps:

[0053] 1) Composite the polypropylene film and the polyamide film by using the first adhesive to obtain a composite film;

[0054] 2) Composite the polyethylene film and the composite film by using the second adhesive to obtain a packaging composite film.

[0055] see figure 1 , figure 1 The production process flow chart of the packaging composite film provided in the embodiment of this application. In the embodiment of the present application, the first adhesive is used to carry out dry compounding (referred to as dry compounding) of BOPP printing film and KPA film. This is the first compounding (abbreviated as one compounding). BOPP / KPA composite film.

[0056] In the embodiment of the present application, the BOPP printing film is made by printing BOPP, and the KPA film is made by coating K layer with PA. W...

Embodiment 1

[0067] Add the raw materials for the corona layer, the middle layer and the heat-sealing layer respectively into the three barrels of the co-extrusion machine. The formulas of each raw material are as follows:

[0068] Corona layer: 50kg of LLDPE with brand 7042 manufactured by Yangzi Petrochemical and 50kg of HDPE with brand F920;

[0069] Middle layer: 25kg of LDPE with grade 150BW and 75kg of HDPE with grade F920;

[0070] Heat-sealing layer: 25kg Yanshan Petrochemical LDPE with brand 100AC, 75kg mLLDPE with brand SP0510, 1kg silicone slip agent with brand MBSI-002P, 1kg anti-blocking agent with brand AB20LD and 0.2kg with brand 100991-K opening agent.

[0071] Set the first-stage heating temperature of each barrel to 120°C-130°C, the second-stage heating temperature to 130°C-140°C, the third-stage heating temperature to 140°C-150°C, set the die head temperature to 140°C-160°C, and control extrusion The melt pressure is less than 45MPa; the raw material particles in the a...

Embodiment 2

[0074] The difference between this example and Example 1 lies in the raw materials of the corona layer, the intermediate layer and the heat-sealing layer, and the PE film is prepared. The raw material formula of each layer of the present embodiment is as follows:

[0075] Corona layer: 45kg of LLDPE with brand 7042 manufactured by Yangzi Petrochemical and 55kg of HDPE with brand F920;

[0076] Middle layer: 20kg of LDPE with grade 150BW and 80kg of HDPE with grade F920;

[0077] Heat-sealing layer: 80kg Yanshan Petrochemical LDPE with brand 100AC, 20kg mLLDPE with brand SP0510, 1kg silicone slip agent with brand MBSI-002P, 1kg anti-blocking agent with brand AB20LD and 0.2kg with brand 100991-K opening agent.

[0078] The PE film includes a corona layer, an intermediate layer and a heat-sealing layer in sequence, and the thickness ratio of the three layers is 1:1:1, which has good heat-sealing strength and good straight-line tearability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com