Patents

Literature

4130 results about "Plastic packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

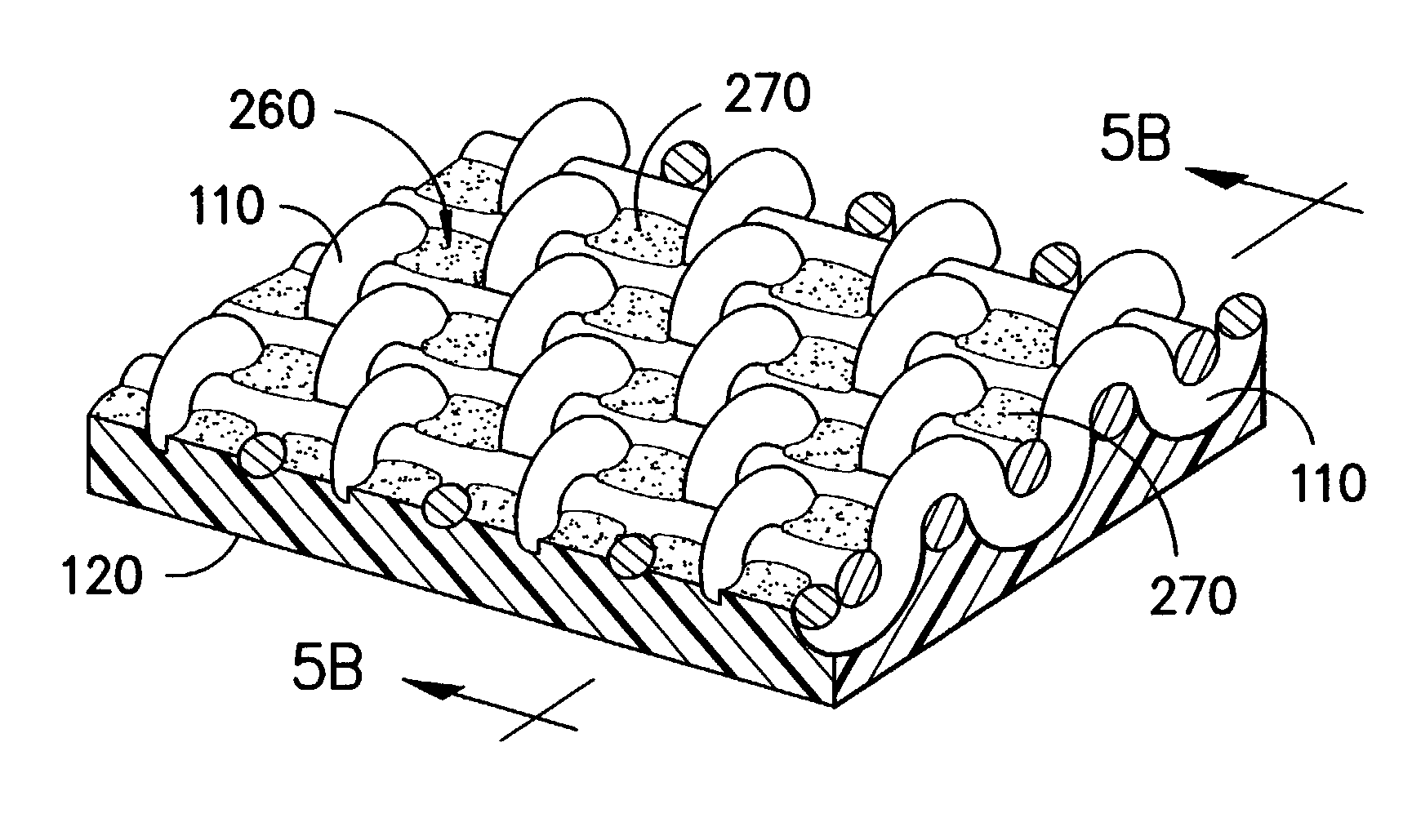

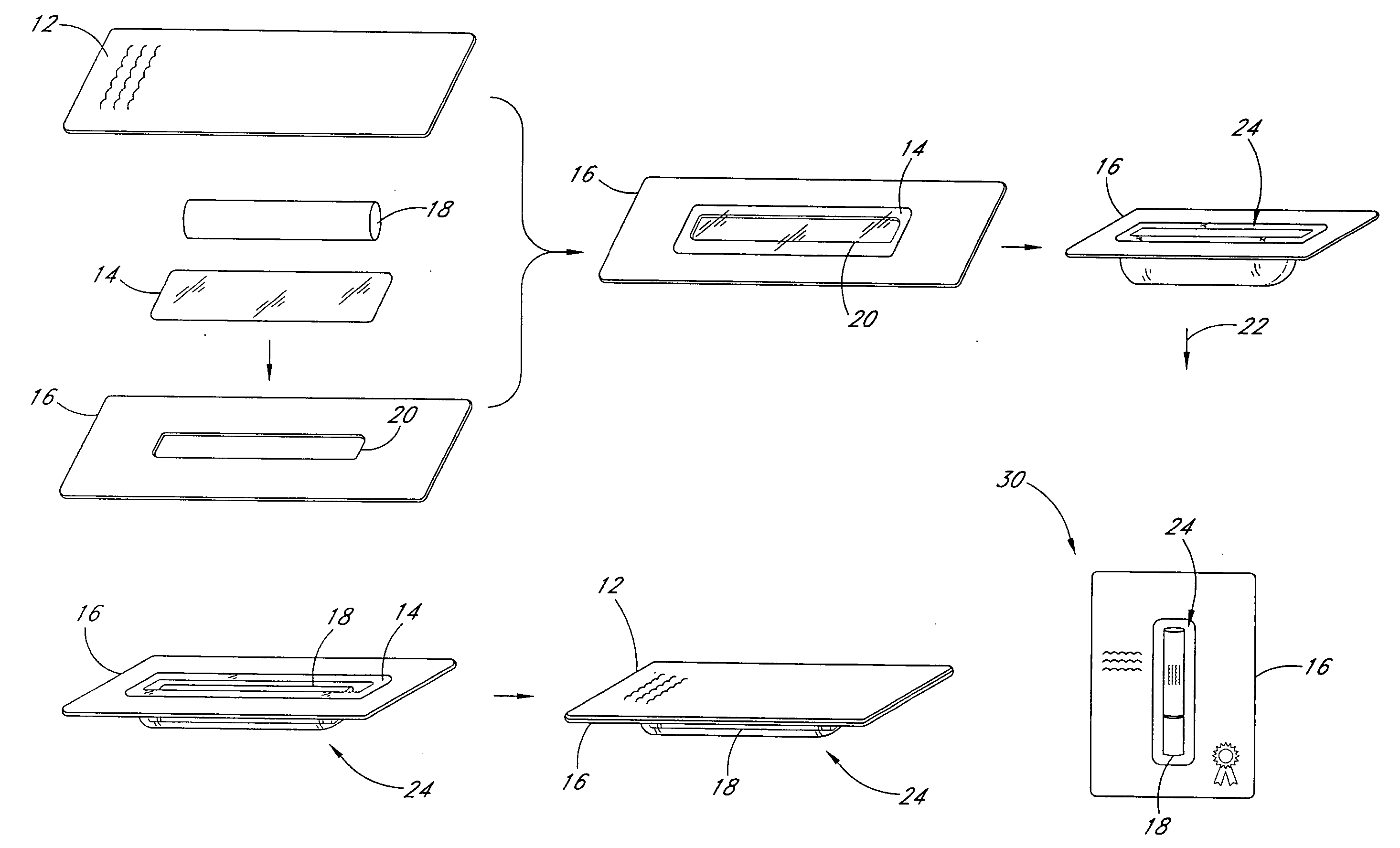

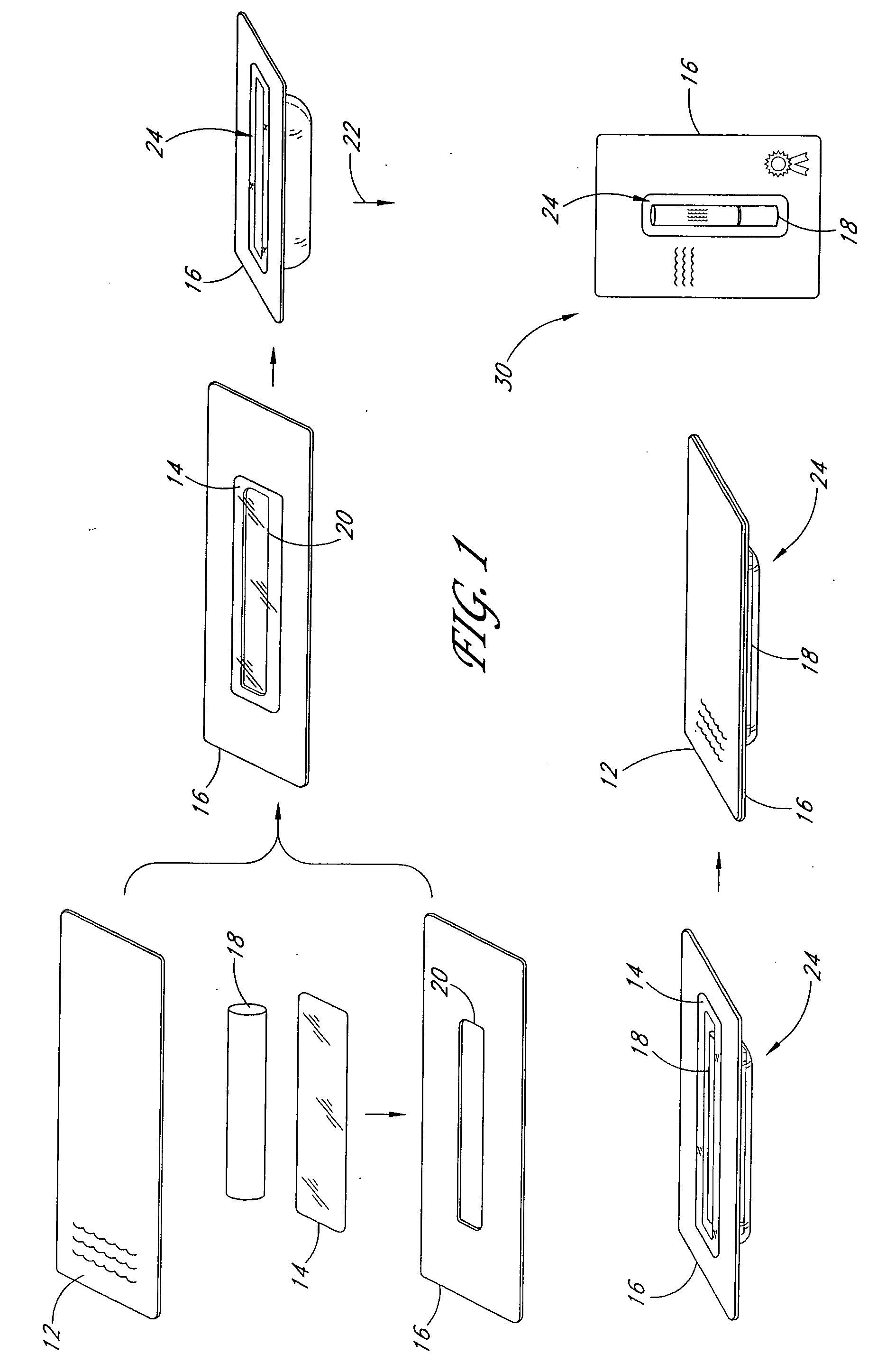

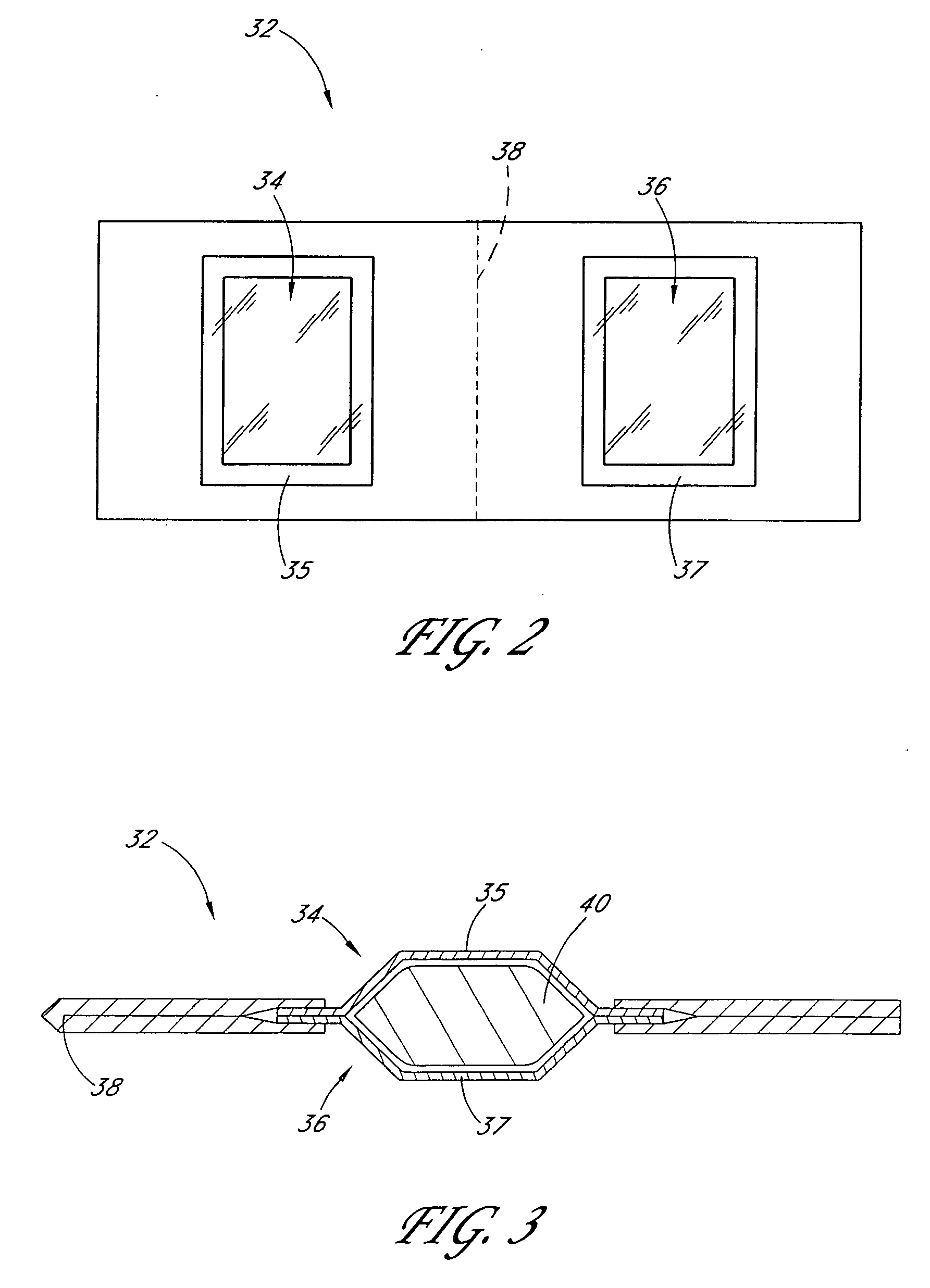

Packaging material and containers formed therefrom

The flexible, reusable packaging container of the present invention is comprised of a packaging material. The packaging material is comprised of one or more layers of coating disposed on one or more layers of textile substrate. The coating layer may be comprised of a stiffening agent for providing support to the packaging container. The stiffening agent may provide a gas and / or liquid impermeable barrier between the contents of the container and the textile substrate. The stiffening agent may also include chemicals which impart antifungal or antibacterial properties to container. The textile substrate typically provides an aesthetically pleasing feel and appearance to the outside of the packaging container, as well as providing functional attributes such as water repellence, stain resistance, and / or anti-static resistance. The resulting packaging container possesses increased strength, puncture resistance, and resistance to de-lamination over the current paper or plastic packaging containers.

Owner:MILLIKEN & CO

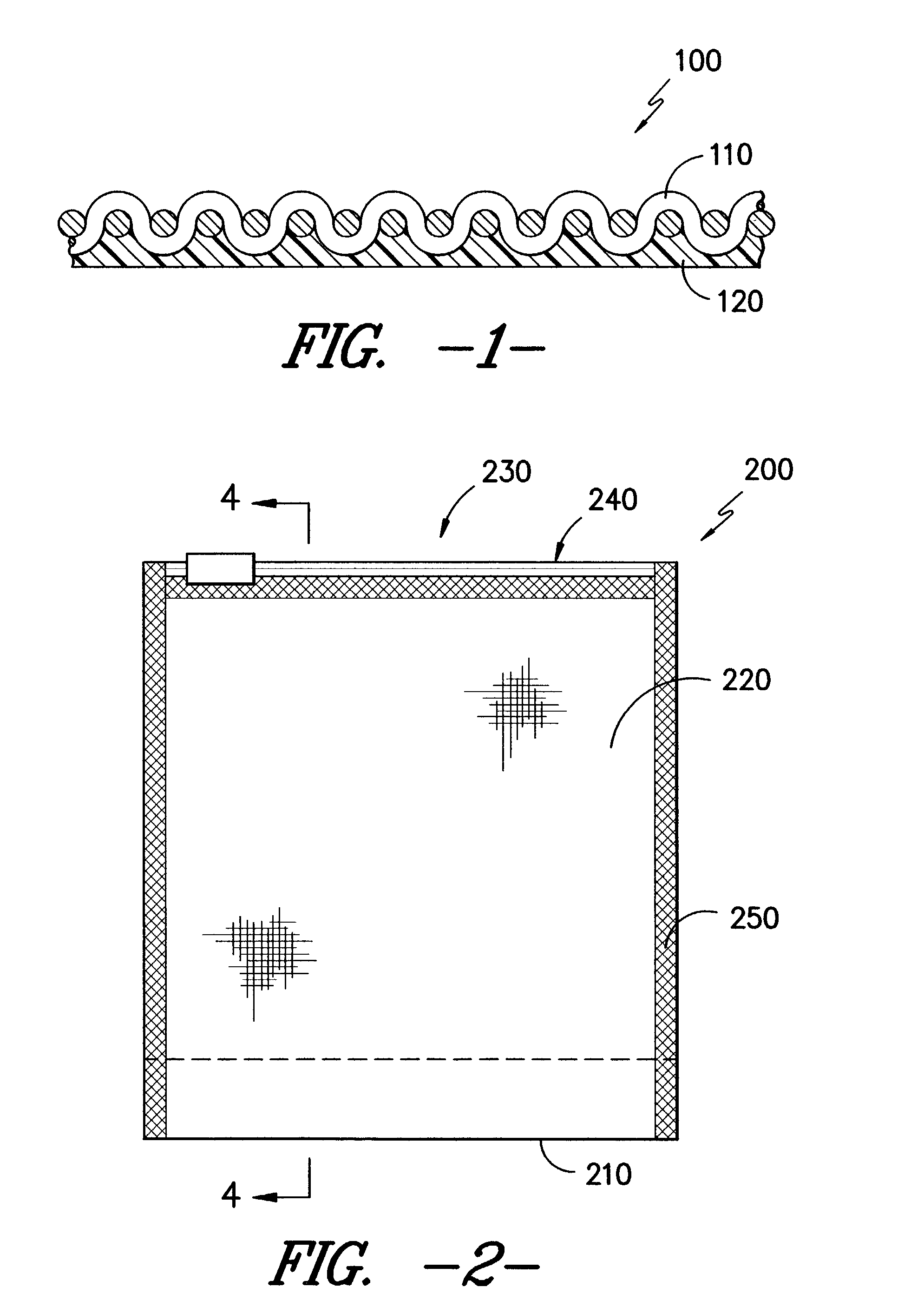

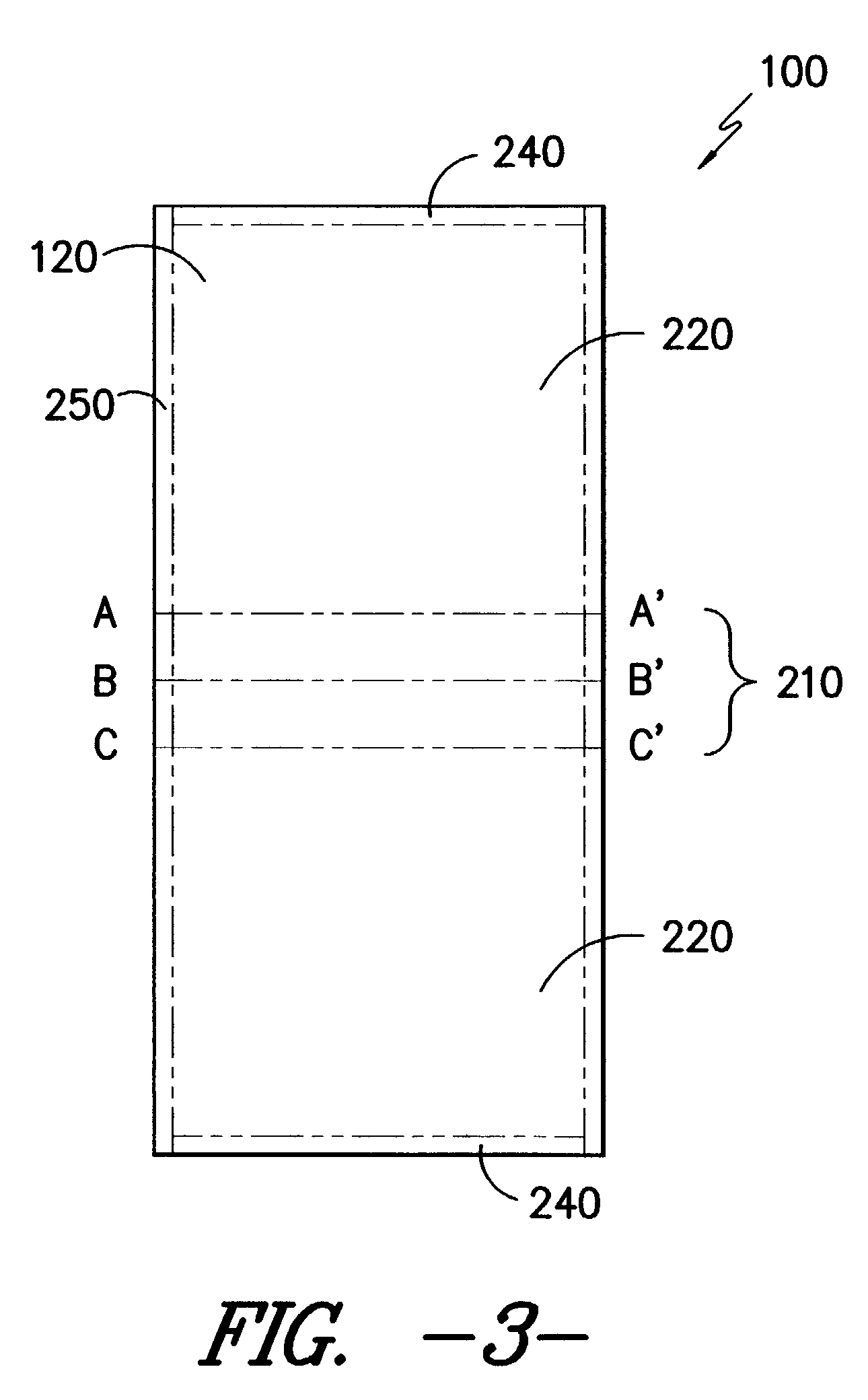

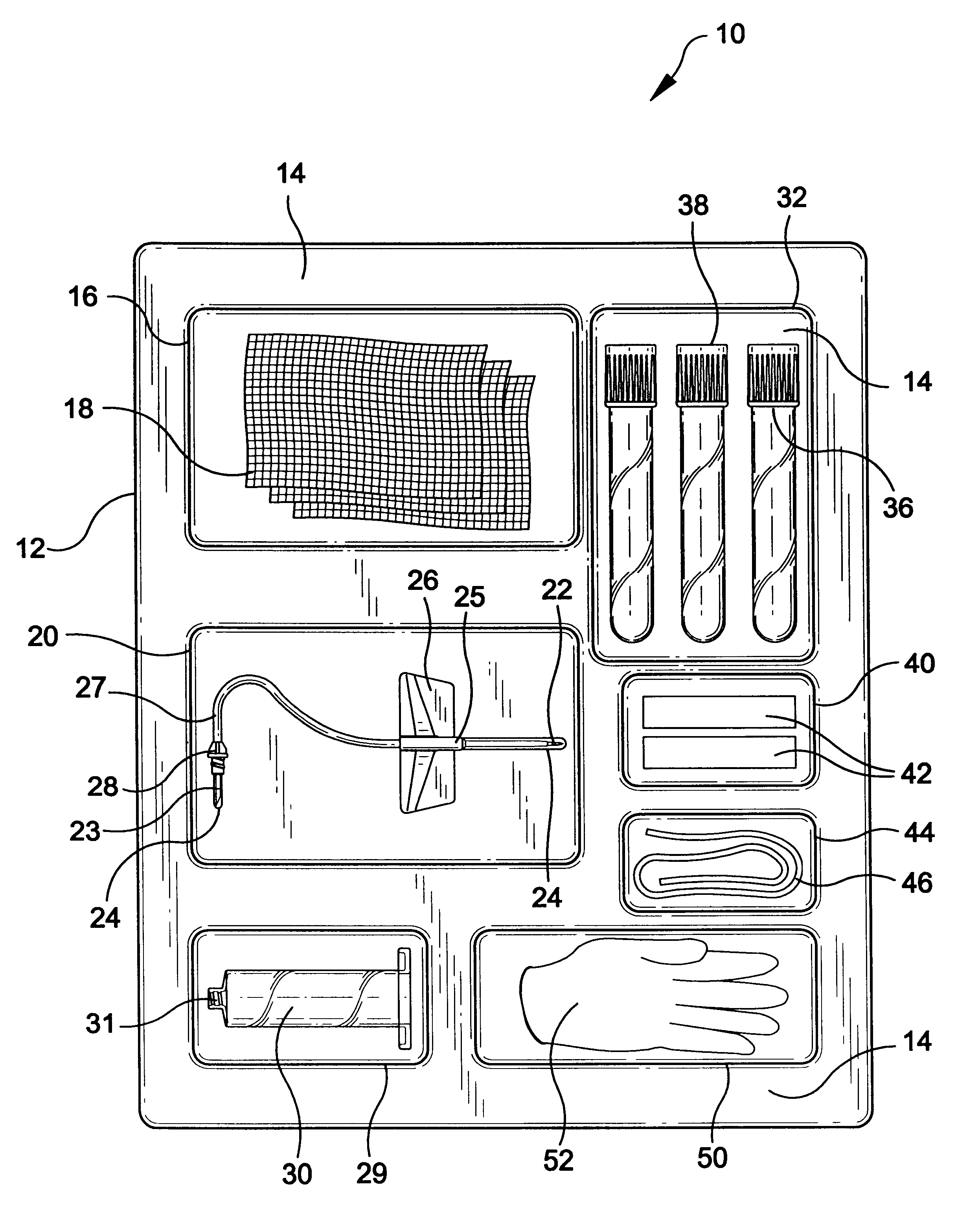

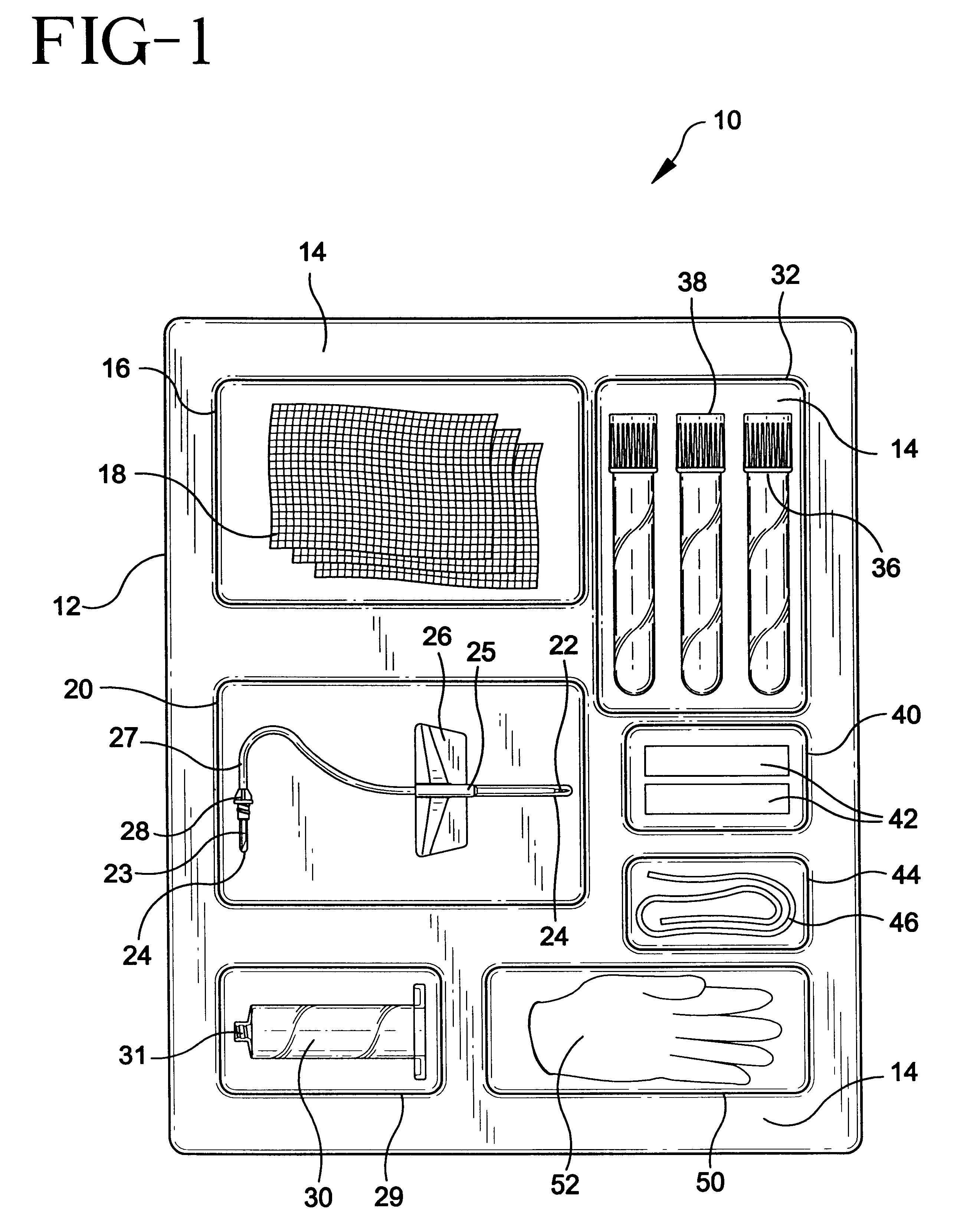

Kit for drawing a blood sample

A kit containing all the materials needed to take a blood sample from a neonatal patient, a pediatric patient, a juvenile patient or an adult patient. The materials are supplied in a plastic package suitable for sterilization.

Owner:BECTON DICKINSON & CO

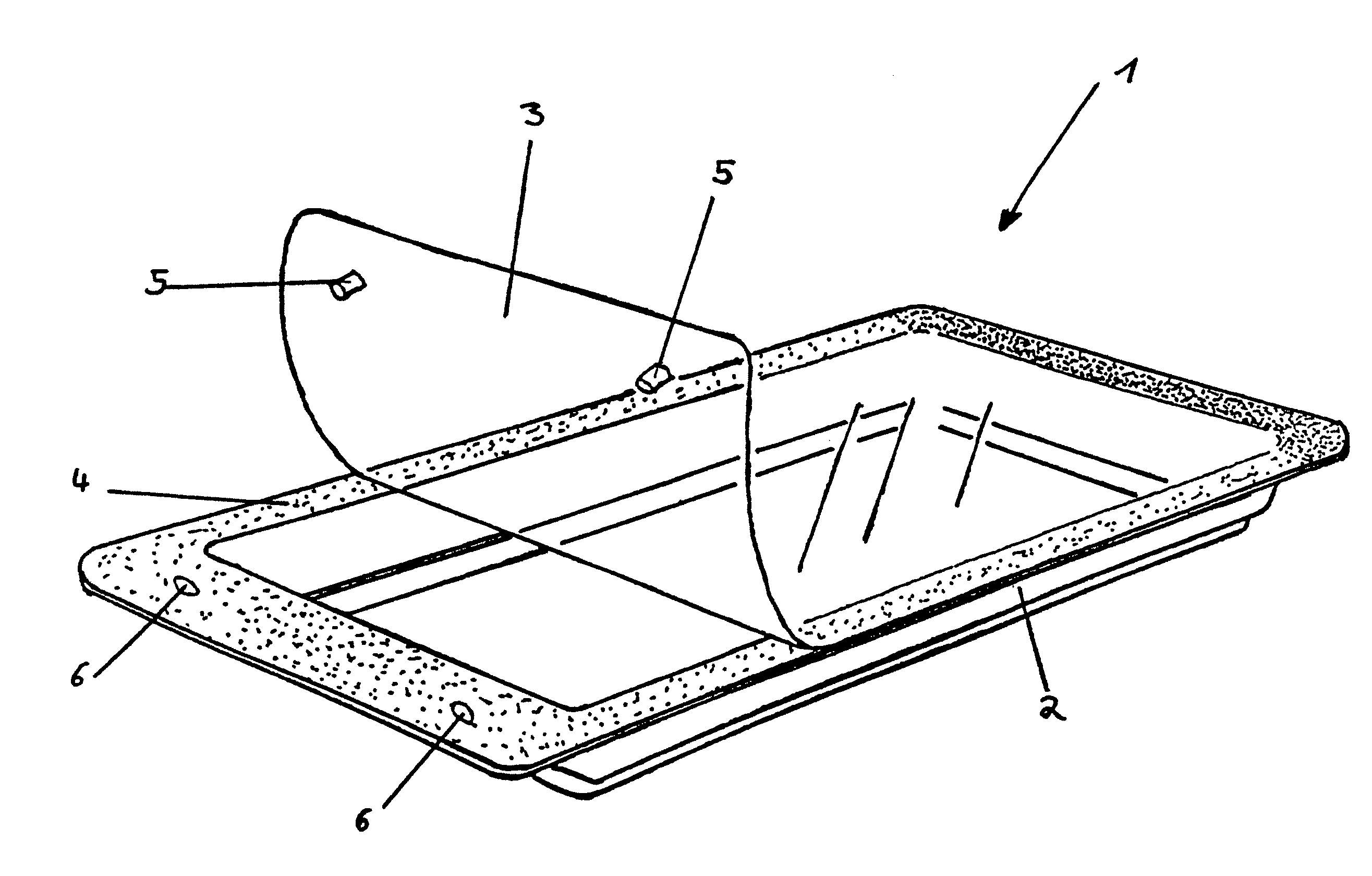

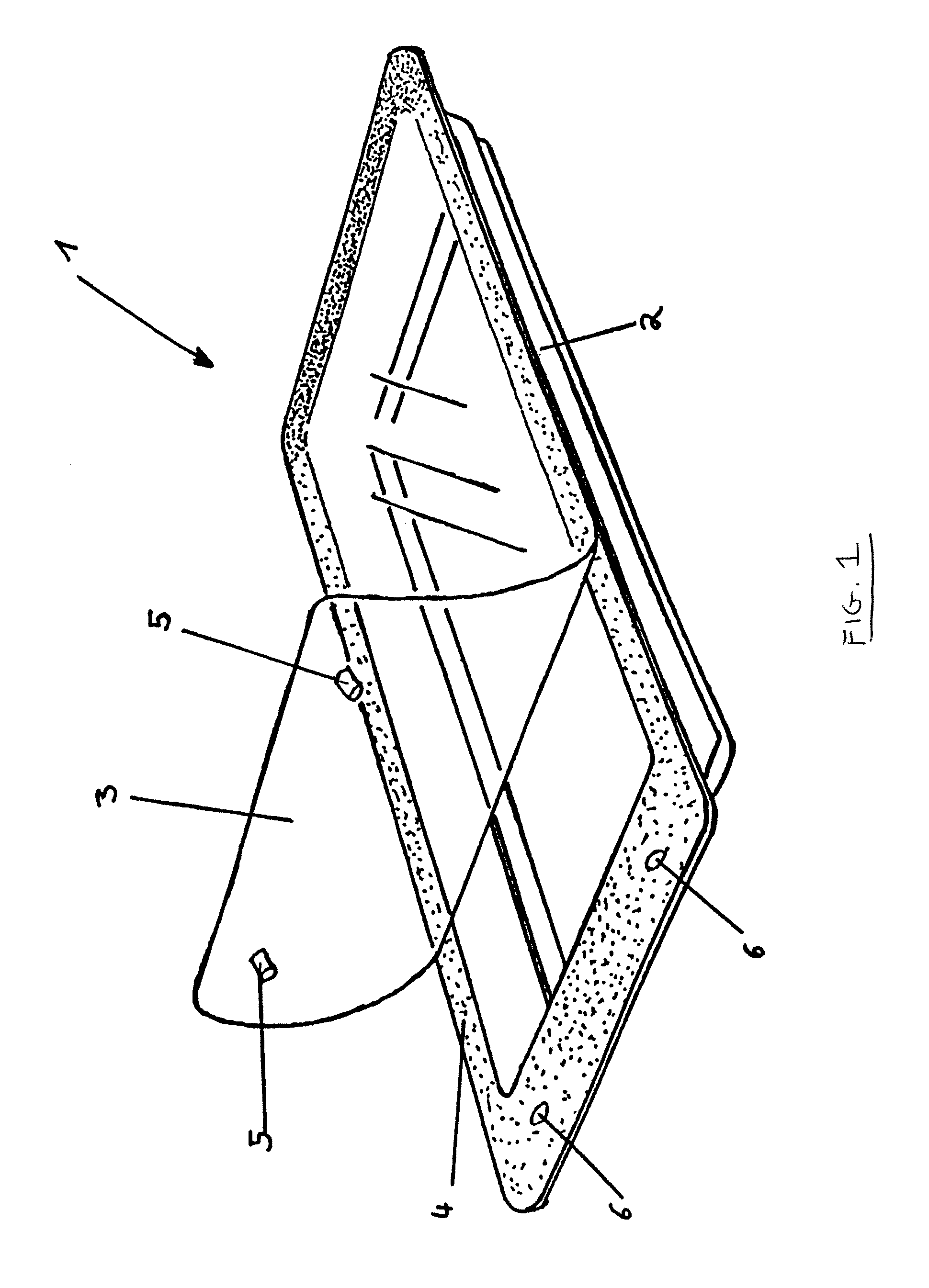

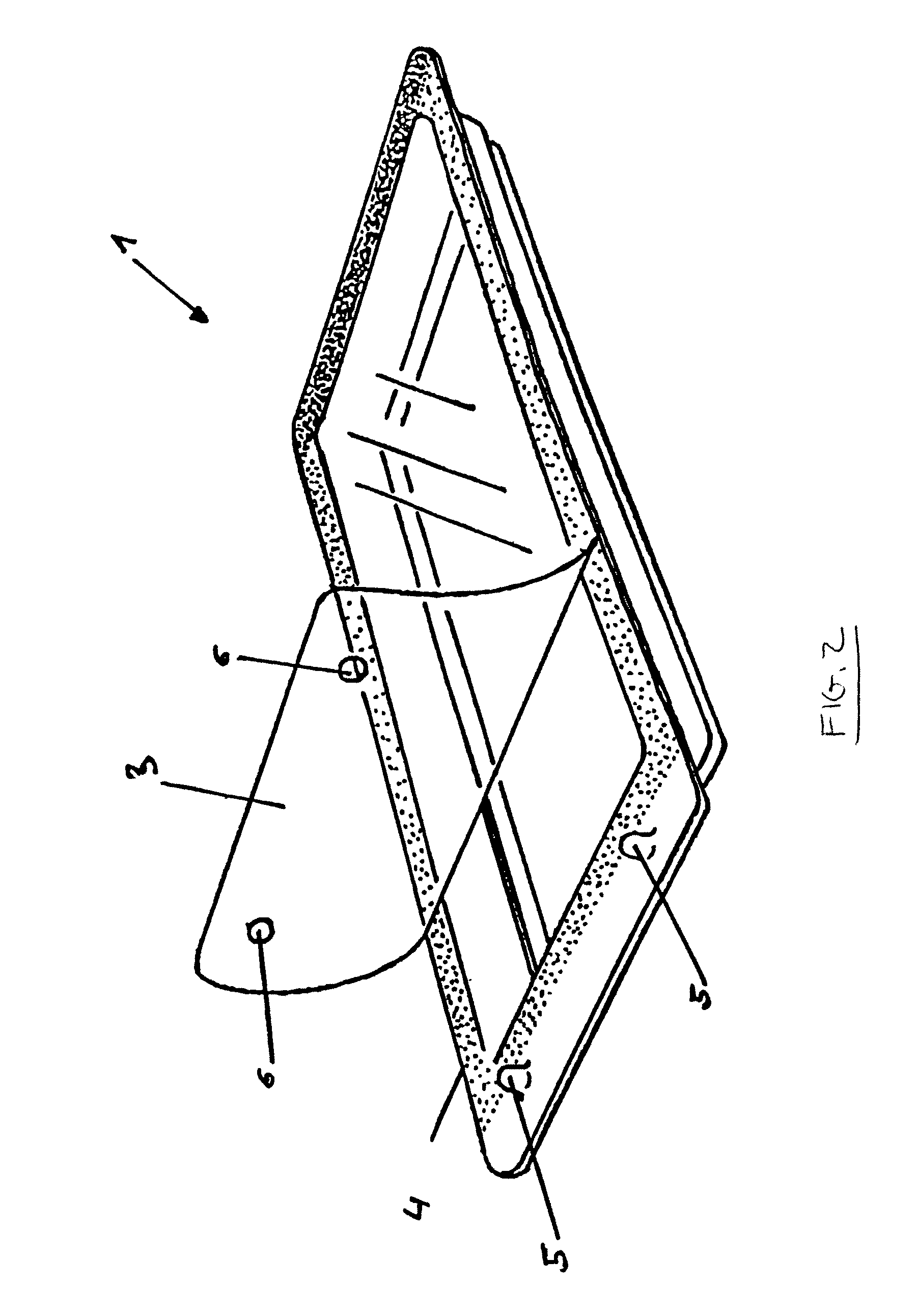

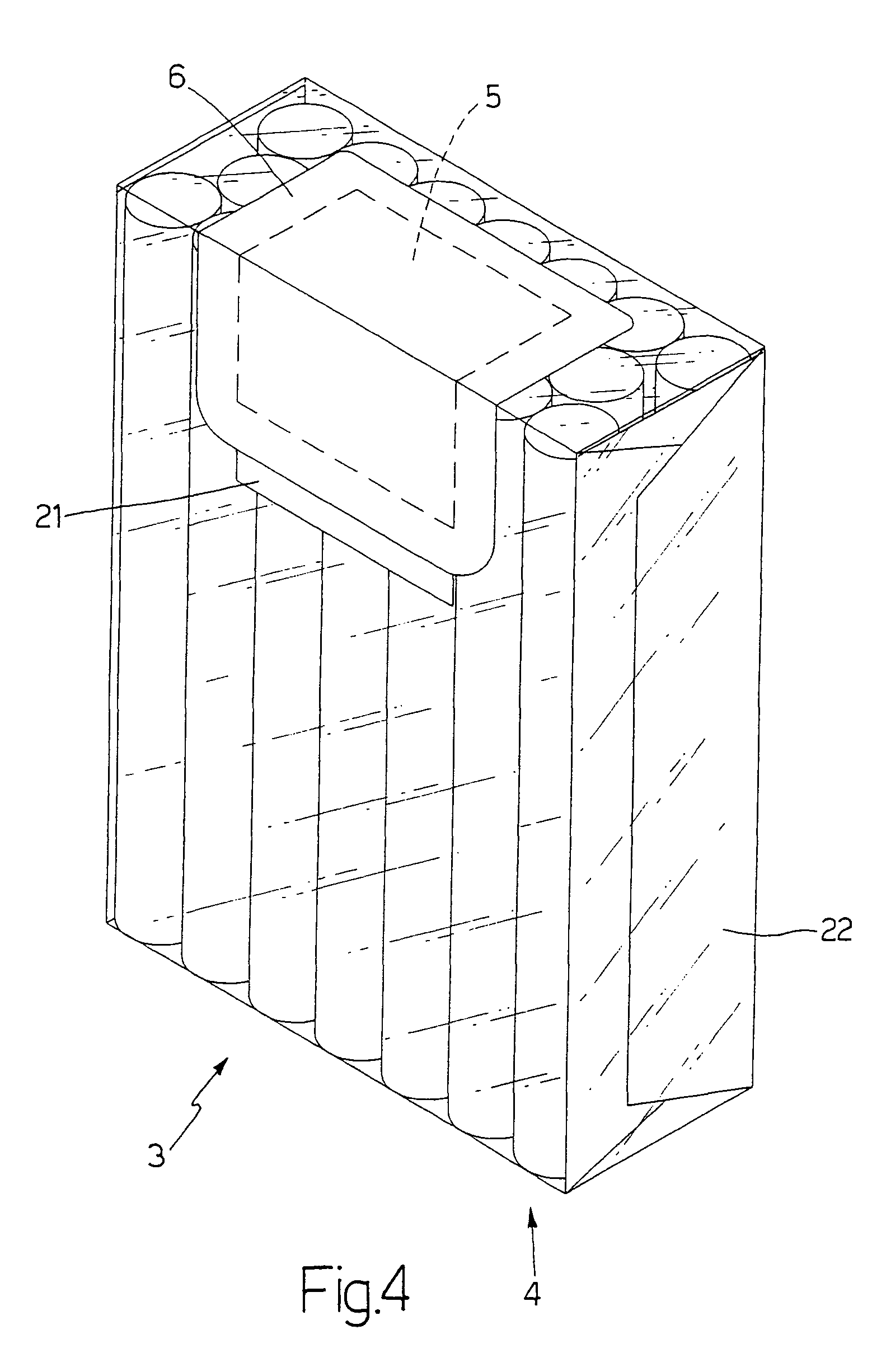

Plastic packaging with at least one welded knob

InactiveUS7322473B2Firmly connectedReadily feltOther accessoriesContainer/bottle contructionPlastic packagingBoundary region

The invention relates to a plastic packaging (1) made from a packaging dish (2) and a cover lid (3). The cover lid (3) is at least partially sealed to the packaging dish (2) in a peelable manner and the cover lid (3), or the packaging dish (2), comprises at least one knob (5) and complementary to the above the packaging dish (2) or the cover lid (3) comprises a recess (6), through which the knob(s) is / are pressed on sealing the plastic packaging (1). At least a partial region of at least one knob is provided with a sealing material (95) or preferably at least one partial region of at least one knob (5) and the boundary region of the complementary recess (7) is connected to a sealing material (9), which on first opening of the packaging (1) is damaged. The invention further relates to methods for the production of said packages.

Owner:CONVENIENCE FOOD SYST WALLAU

Printed packaging

InactiveUS20070051652A1Reduce manufacturing costHigh impact point-of-saleContainer decorationsLevel indicationsCardboardPlastic packaging

High visual impact plastic packaging is described as well as methods for producing such packaging. Printing on multiple surfaces of a package to obtain appealing visual effects is described. Methods of sealing plastic packages are described, including some that use heat sealing techniques. Plasticized or laminated paperboard materials can be used, as well as plastic materials such as recycled and / or recyclable polyurethane.

Owner:ONE SOURCE INDS

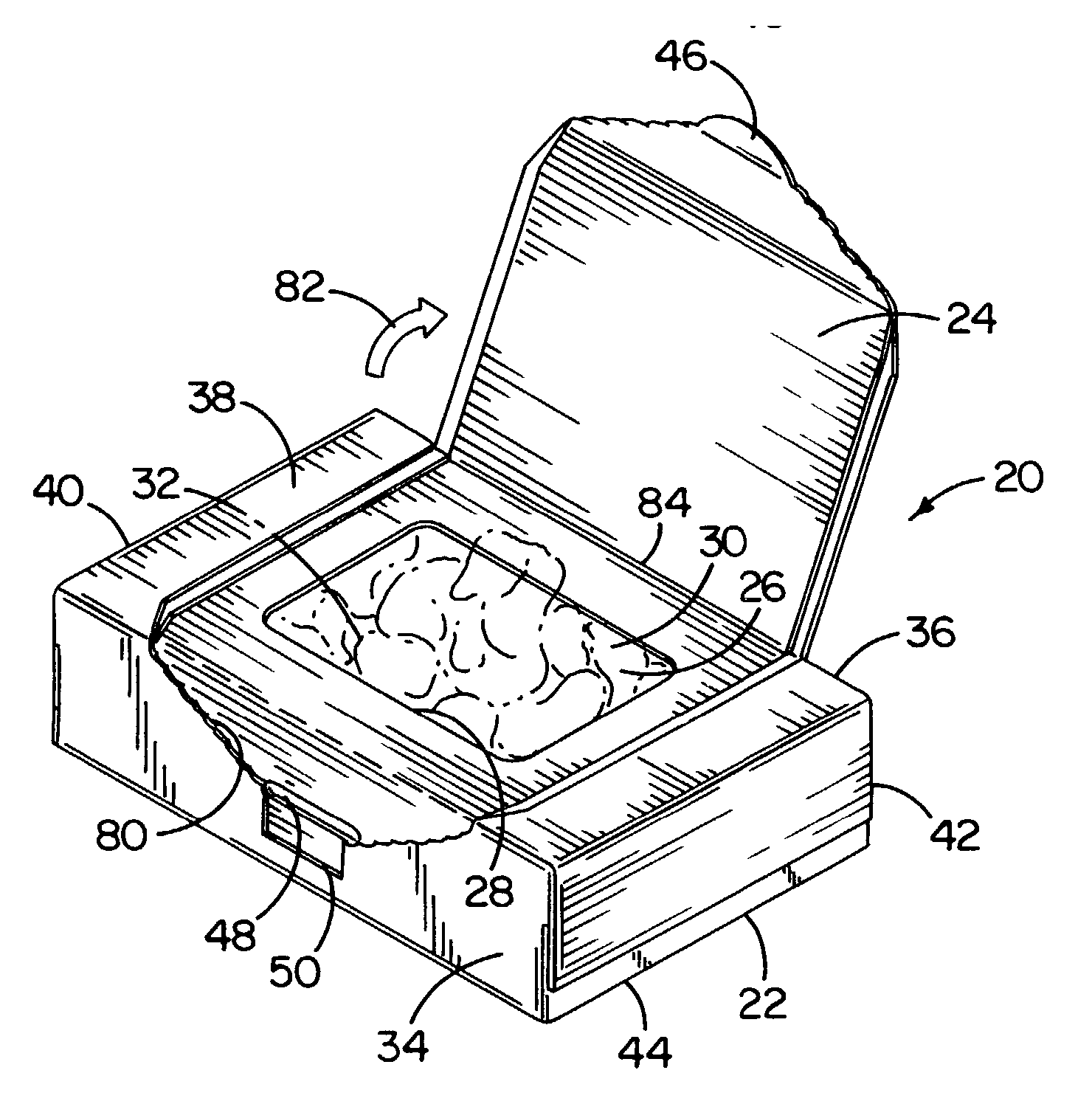

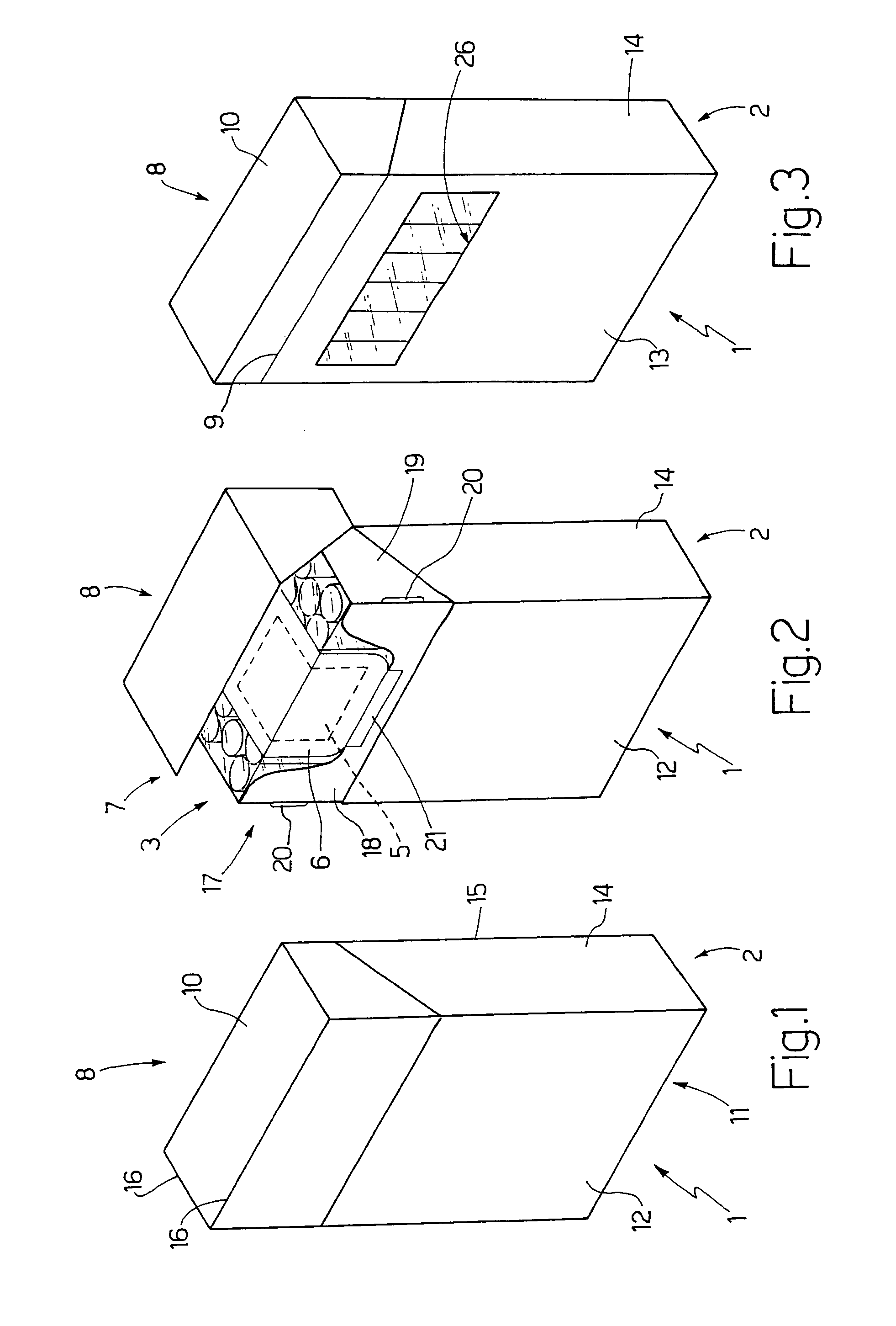

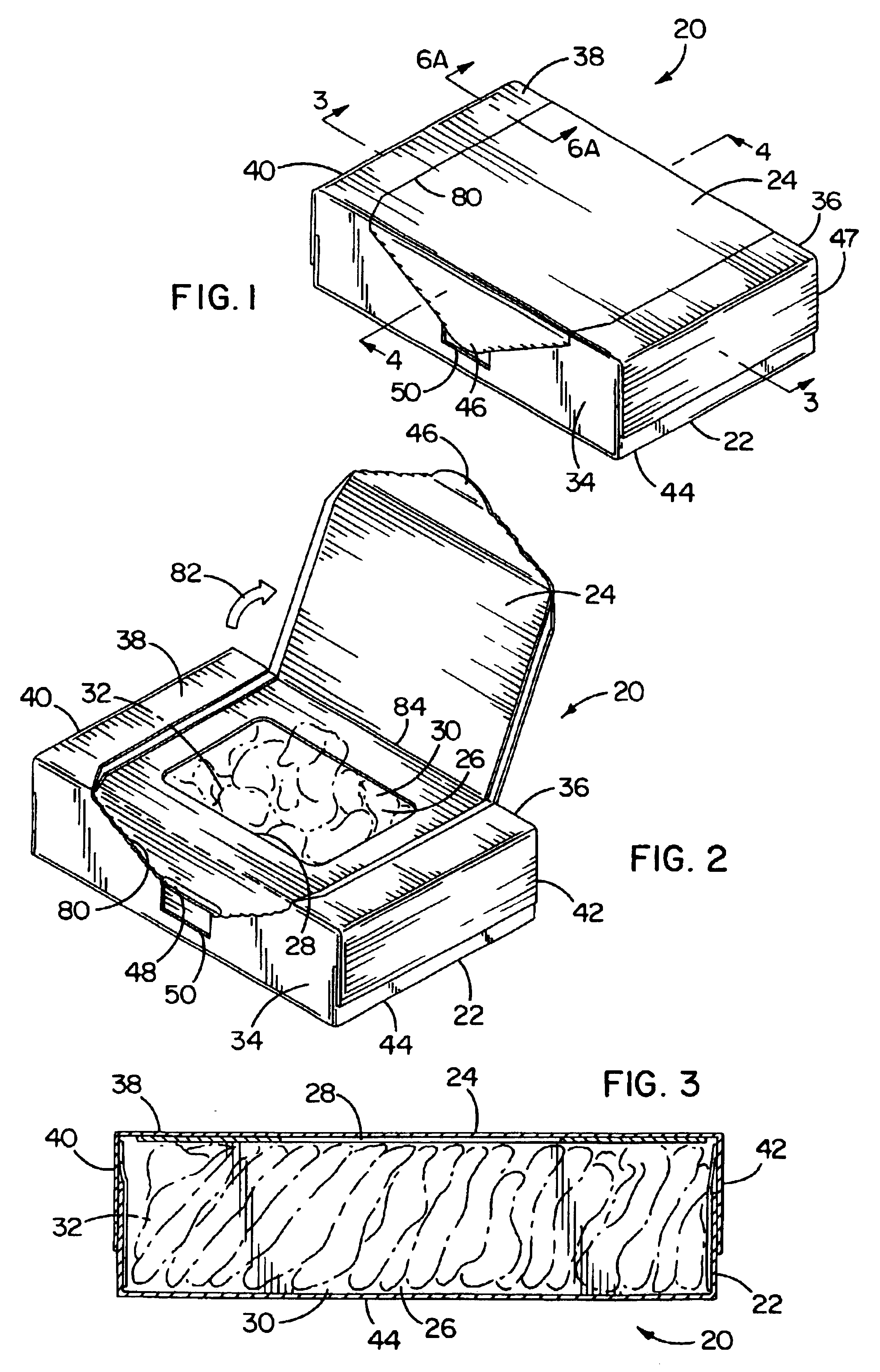

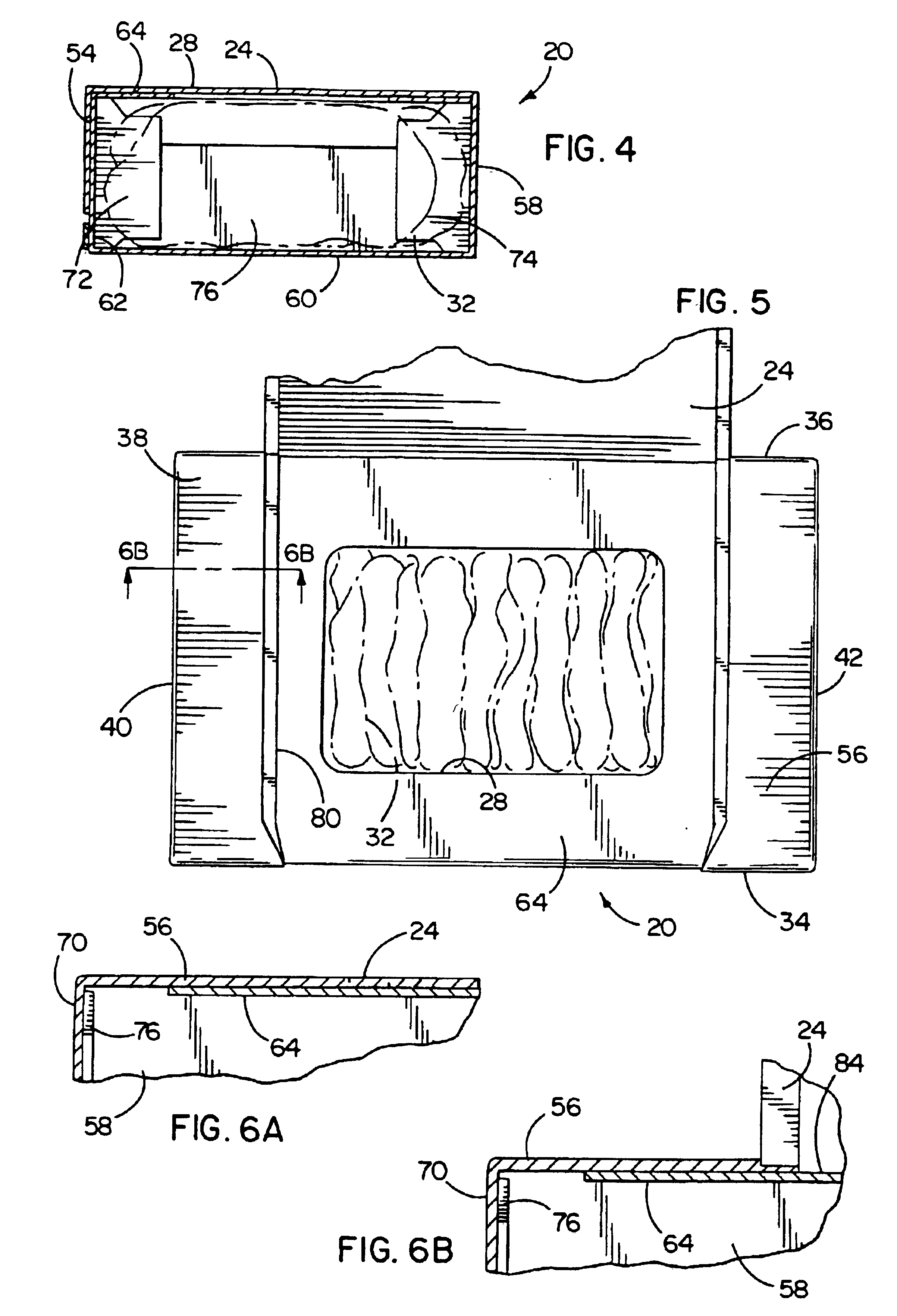

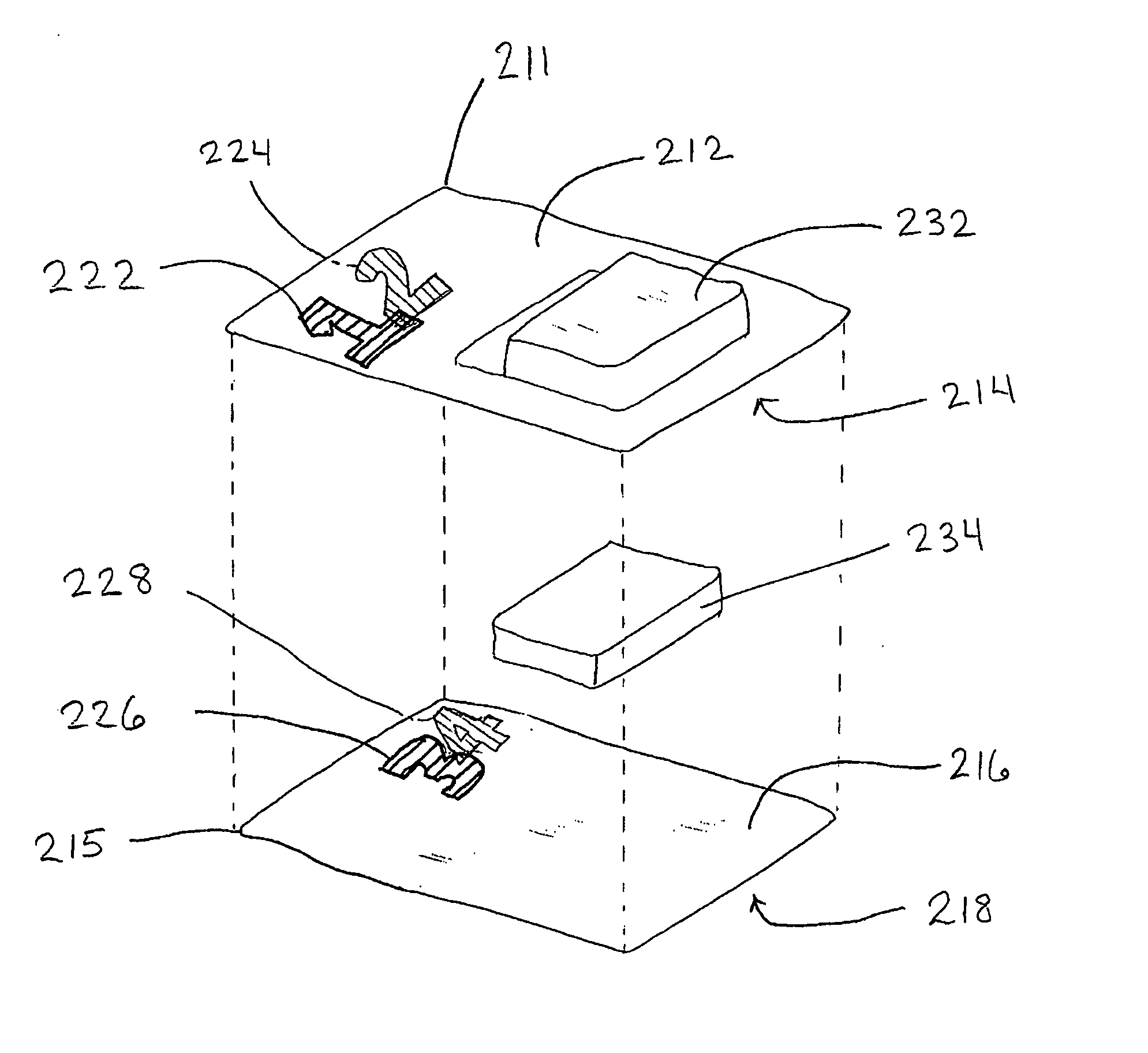

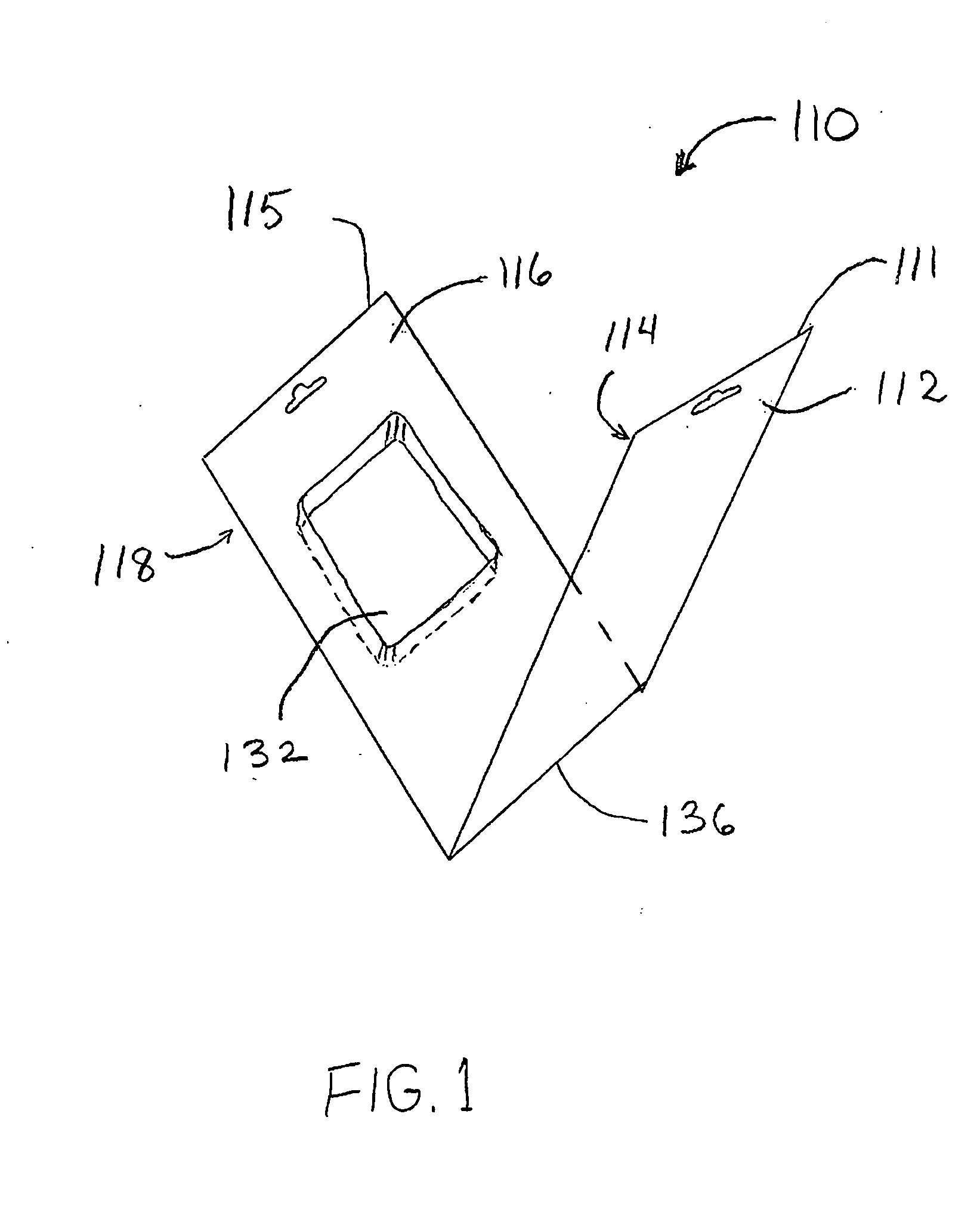

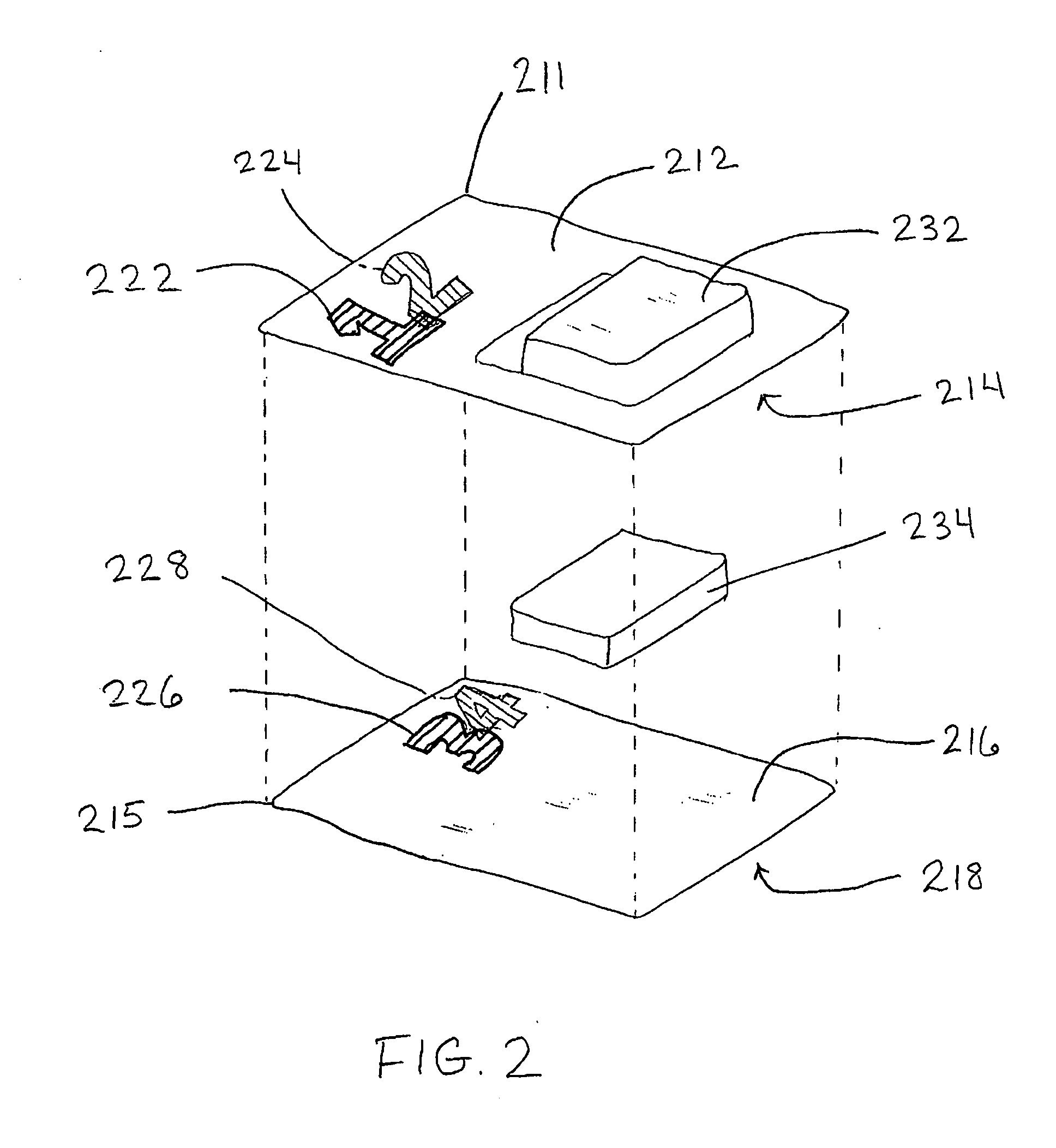

Dispensing container and method for manufacturing same

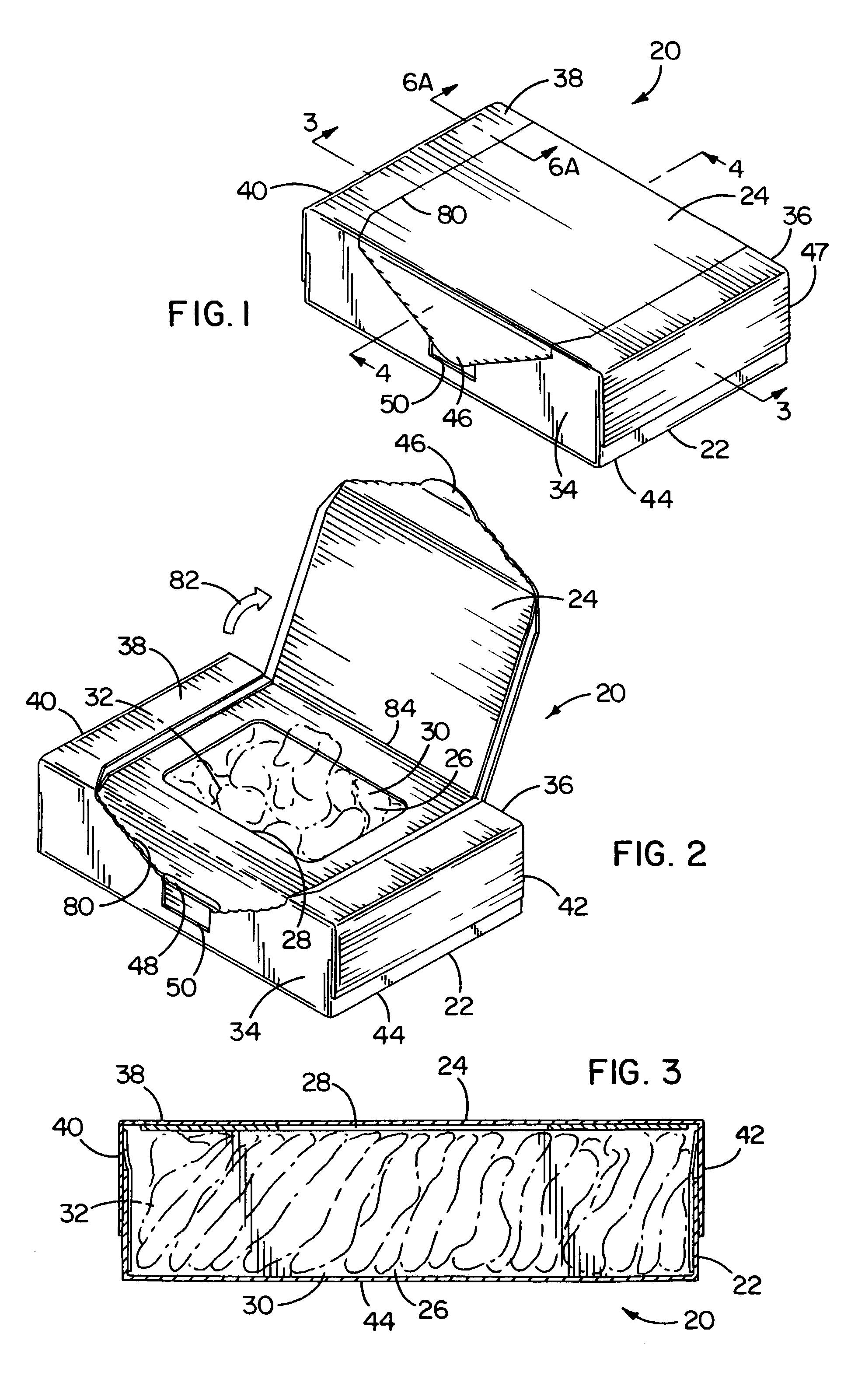

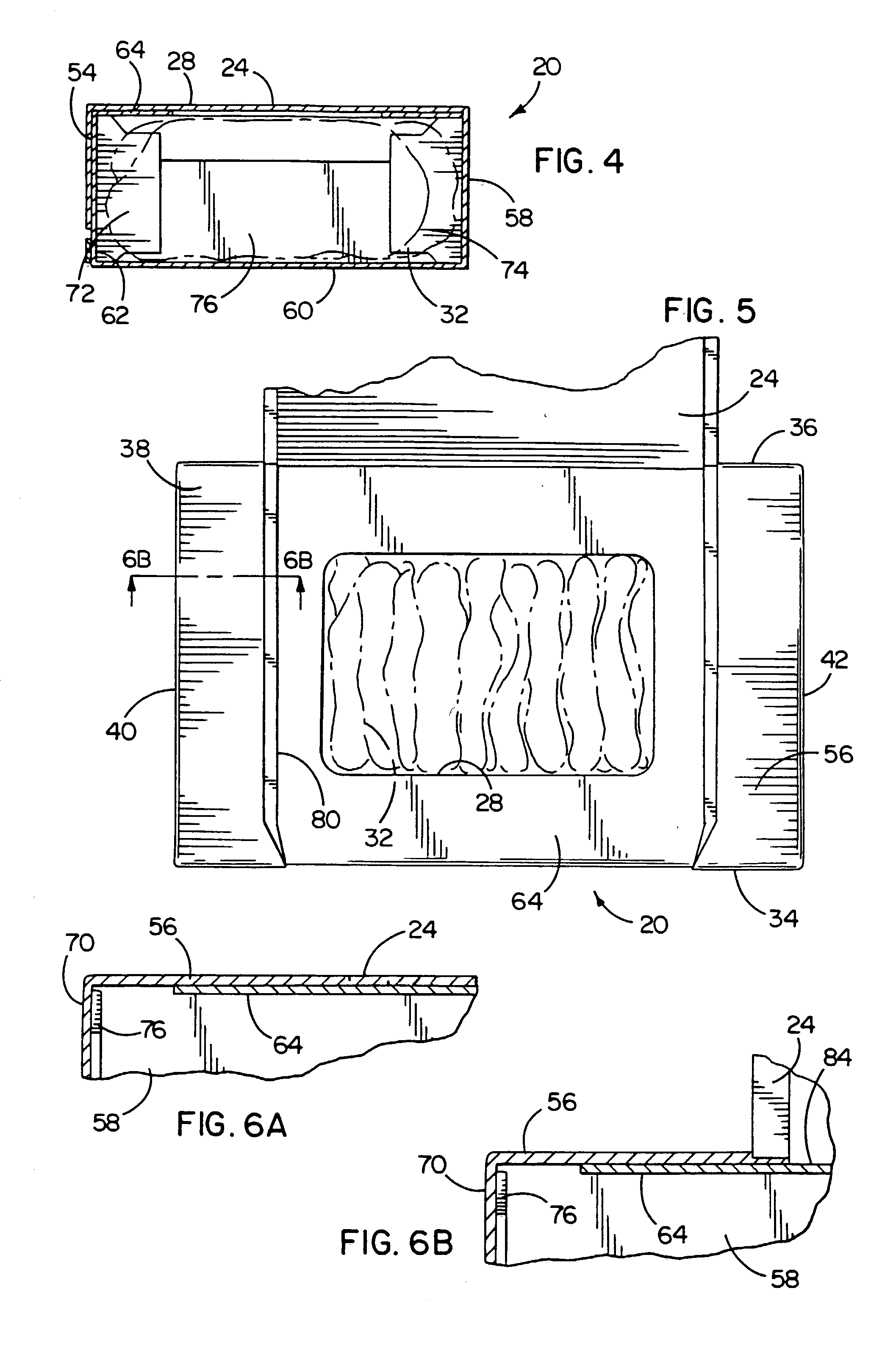

A container for dispensing individual plastic wrap covers and a method of assembling such a container are disclosed. The container may be generally parallelopiped in shape and may include a hinged lid initially secured to the container along a score line. The lid may be torn along the score line and pivoted at the hinge to allow the user to access a smaller opening provided within the container. The smaller opening may be provided within a fifth flap provided integrally with the remainder of the template used to form the container. The opening may be sufficiently large to allow for the plastic wrap covers to be removed, but may be sufficiently small so as to prevent or substantially limit the removal of more than one plastic wrap cover at a time.

Owner:SC JOHNSON & SON INC

Retortable liners and containers

ActiveUS20100006532A1Improve sealingPrevent leakageSynthetic resin layered productsSealingPolyolefinPlastic packaging

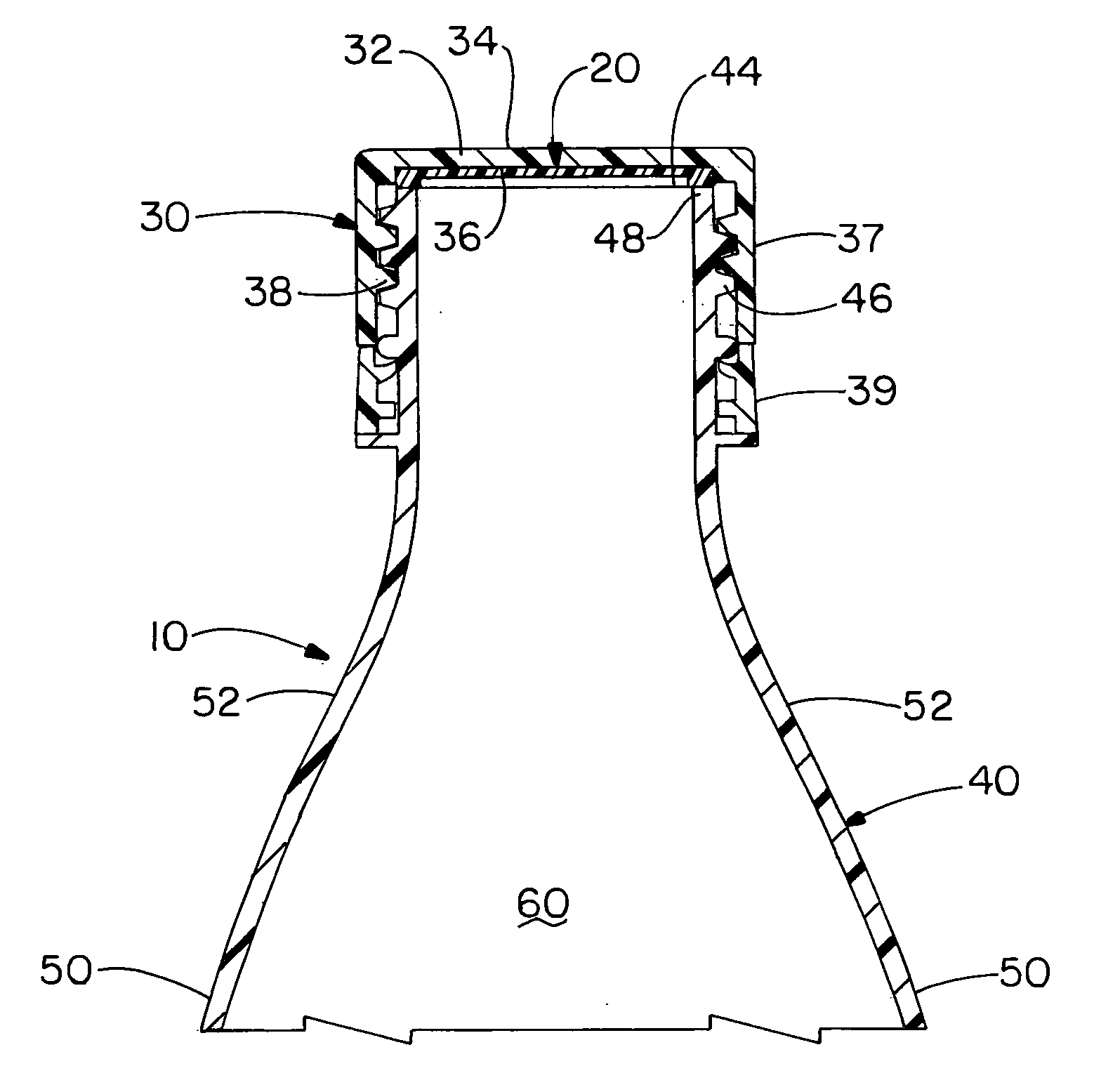

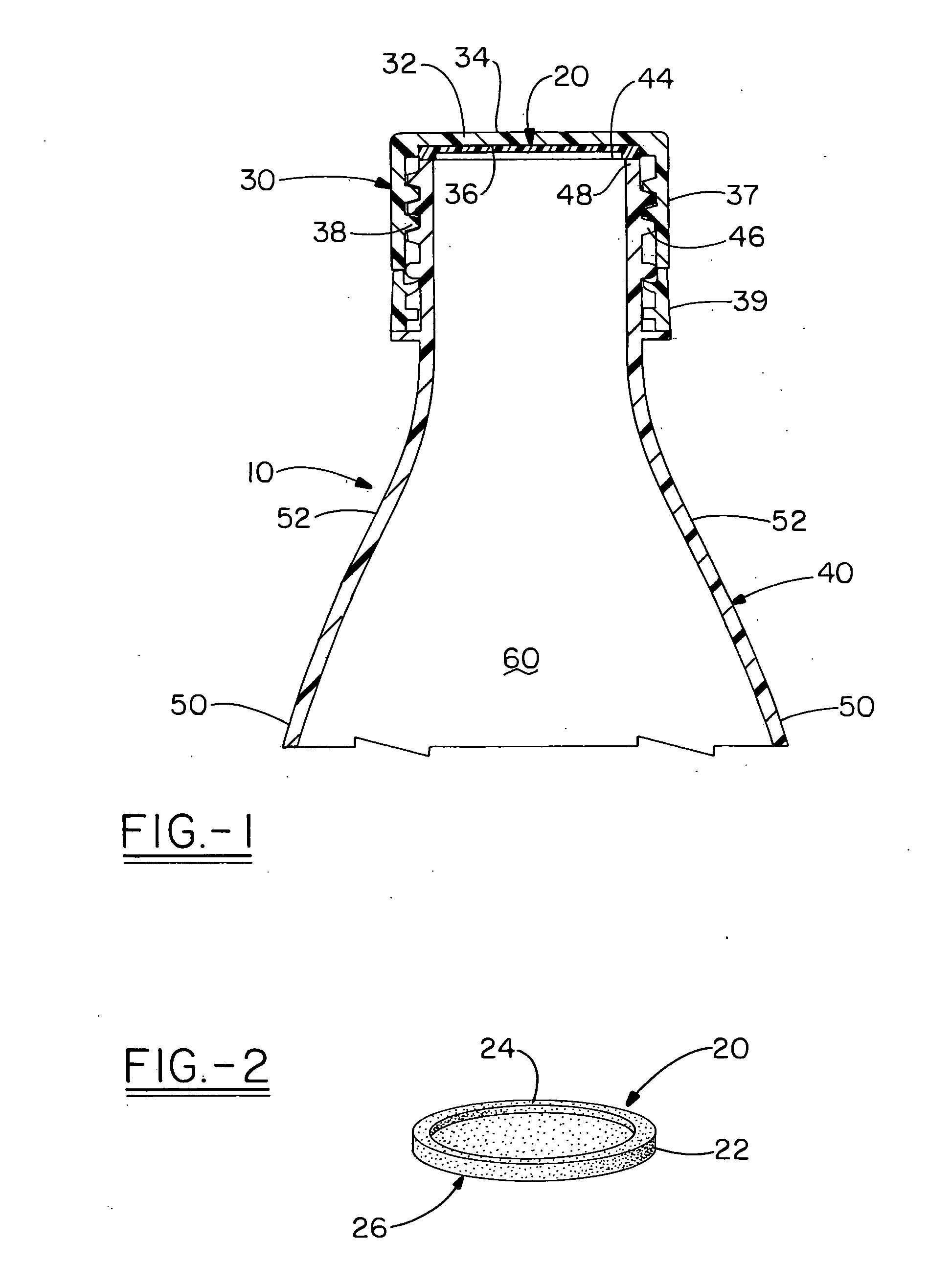

Retort liners and containers including a container body such as a bottle or jar, a closure, and the retort liner, wherein the retort liners exhibit attractive properties such as low compression set under retort conditions, desirable adhesion to a polymeric closure such as a cap or lid, and beneficial oxygen barrier properties. In particular, the retort liners are thermoplastic elastomers formed from compositions including one or more styrenic block copolymers, one or more polyolefins and a softener. In a preferred embodiment, the retortable containers are all plastic packages, wherein the bottle or jar and the closure are thermoplastic compositions and the liner is a thermoplastic elastomer composition.

Owner:TEKNOR APEX

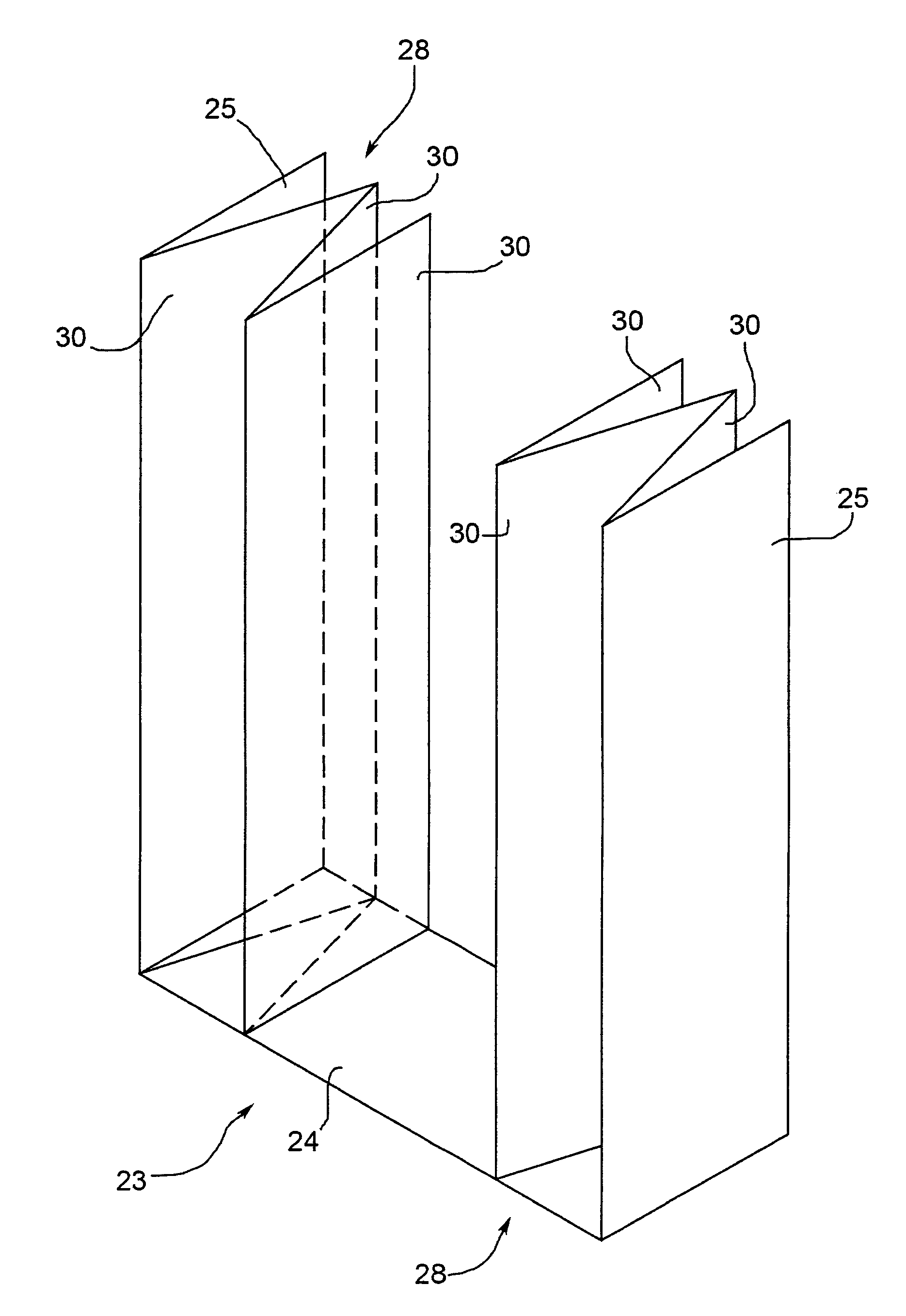

Package of cigarettes

InactiveUS7954635B2Easy and cheap to produceDrawback can be obviatedContainers for flexible articlesCigar manufacturePlastic packagingEngineering

A package of cigarettes having a group (4) of cigarettes; an inner package (3) which encloses the group (4) of cigarettes, is defined by a sheet (22) of transparent, heat-seal plastic packing material folded directly about the group (4) of cigarettes and in direct contact with the cigarettes, and is stabilized by heat sealing; and a U-shaped stiffener (23) of rigid material located inside the inner package (3) and contacting the group (4) of cigarettes.

Owner:GD SPA

Dispensing container and method for manufacturing same

A container for dispensing individual plastic wrap covers and a method of assembling such a container are disclosed. The container may be generally parallelopiped in shape and may include a hinged lid initially secured to the container along a score line. The lid may be torn along the score line and pivoted at the hinge to allow the user to access a smaller opening provided within the container. The smaller opening may be provided within a fifth flap provided integrally with the remainder of the template used to form the container. The opening may be sufficiently large to allow for the plastic wrap covers to be removed, but may be sufficiently small so as to prevent or substantially limit the removal of more than one plastic wrap cover at a time.

Owner:SC JOHNSON & SON INC

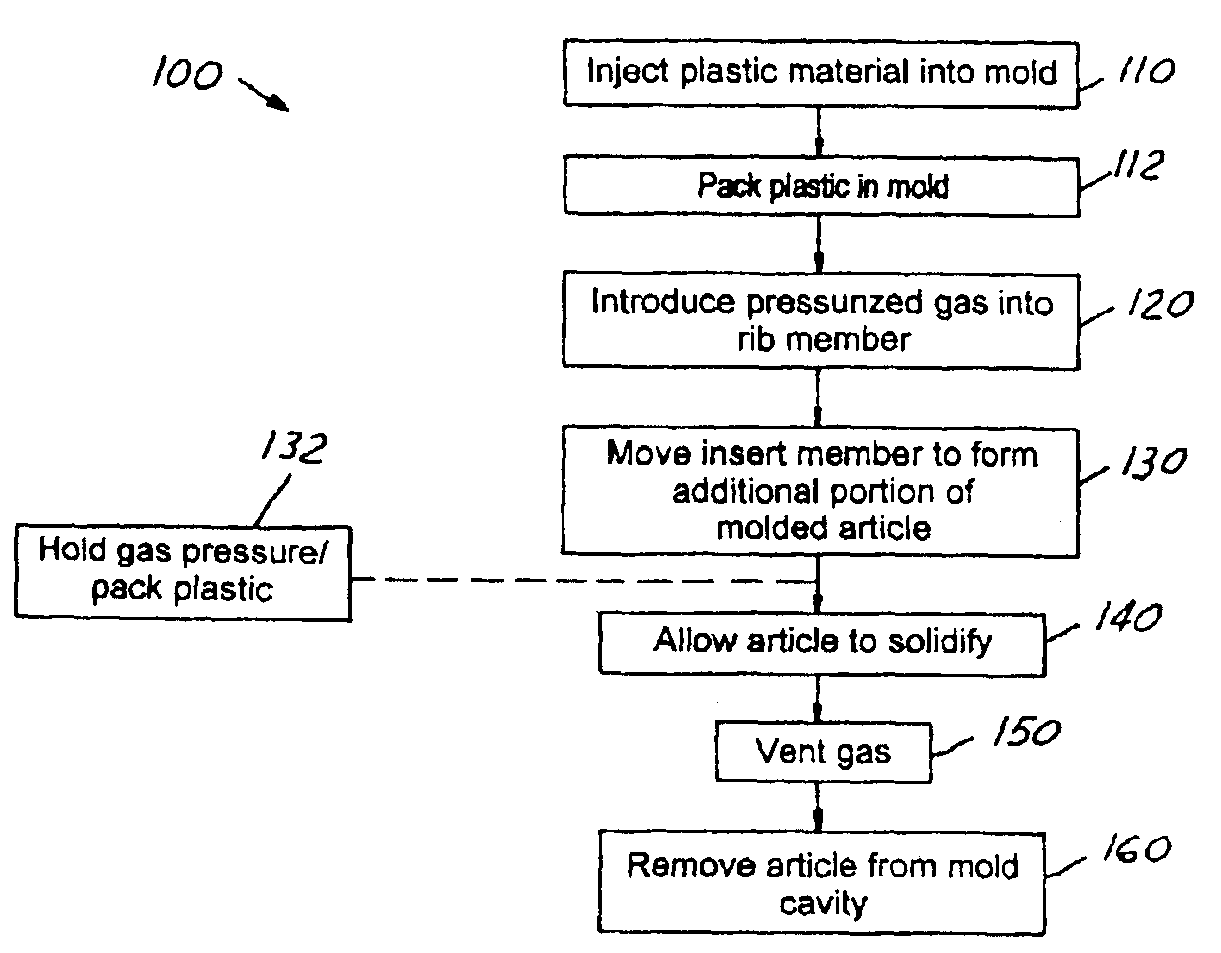

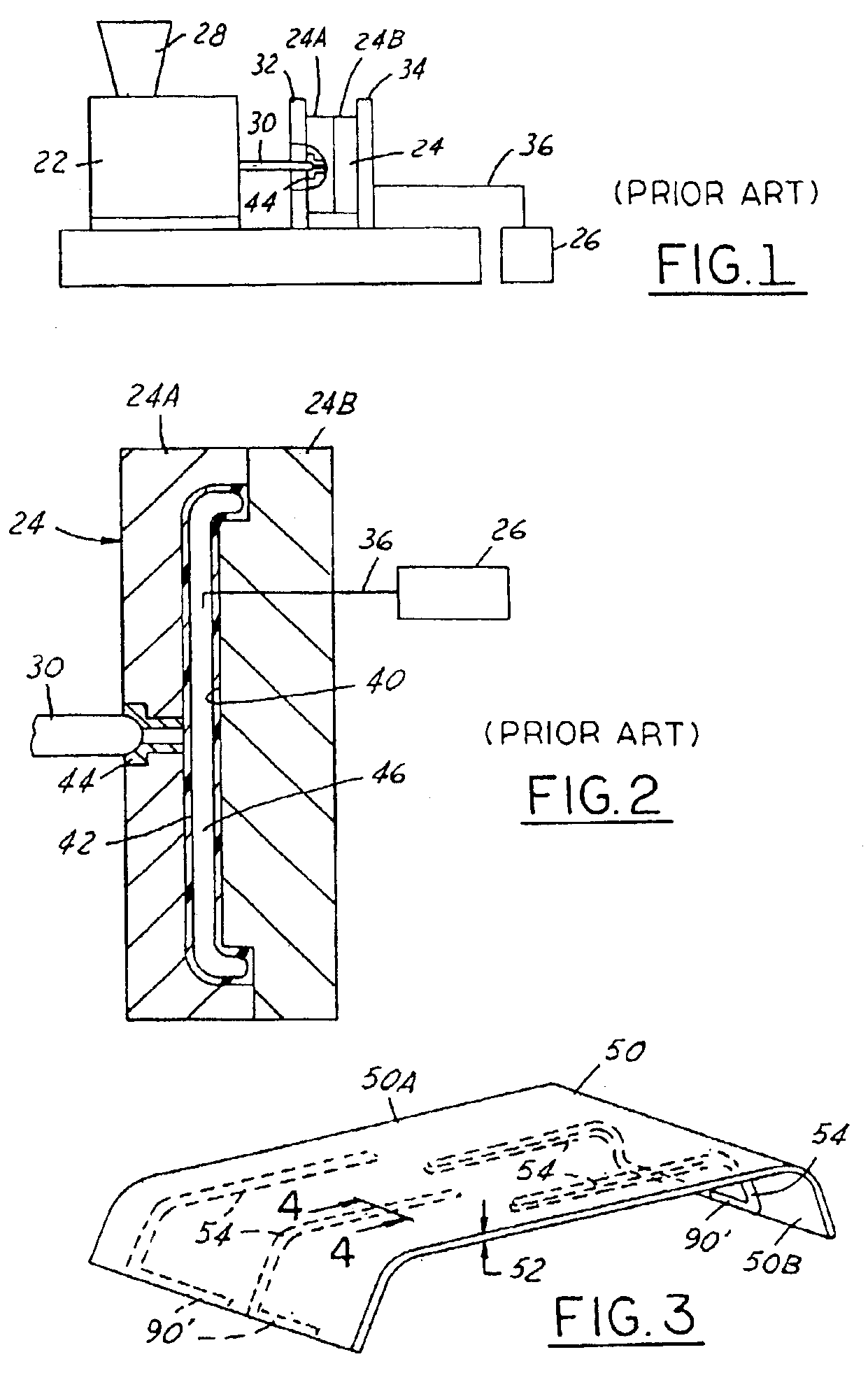

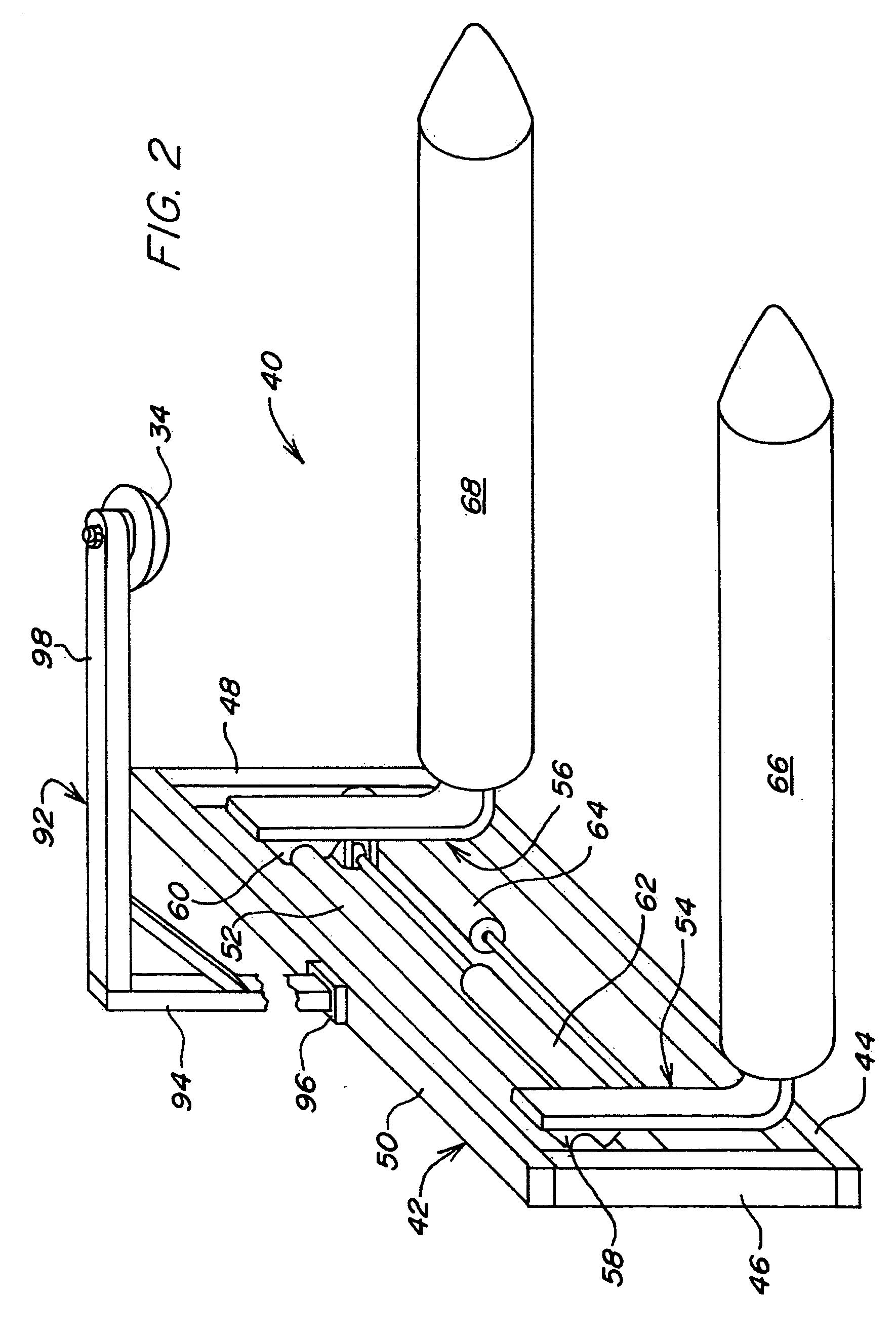

Plastic injection molding with moveable insert members

InactiveUS6939504B2Improve surface propertiesConfectionerySweetmeatsPlastic packagingPlastic injection molding

A method and system for producing hollow rib structures for trim components and panels using gas assisted injection molding. Movable insert members are provided in the mold cavity, particularly at the ends of the structural rib members. After the plastic material is injected into the mold cavity, the plastic is packed in the mold, and the insert members are locked in position. Selectively activatable locking mechanisms are used to lock up the insert members. Thereafter, gas or another fluid is introduced into the rib members in order to provide hollow channels therein. Movement of the insert members provides a recess or groove for placement of the displaced resin from the rib members. The displaced resin material completes the formation of the molded plastic article.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

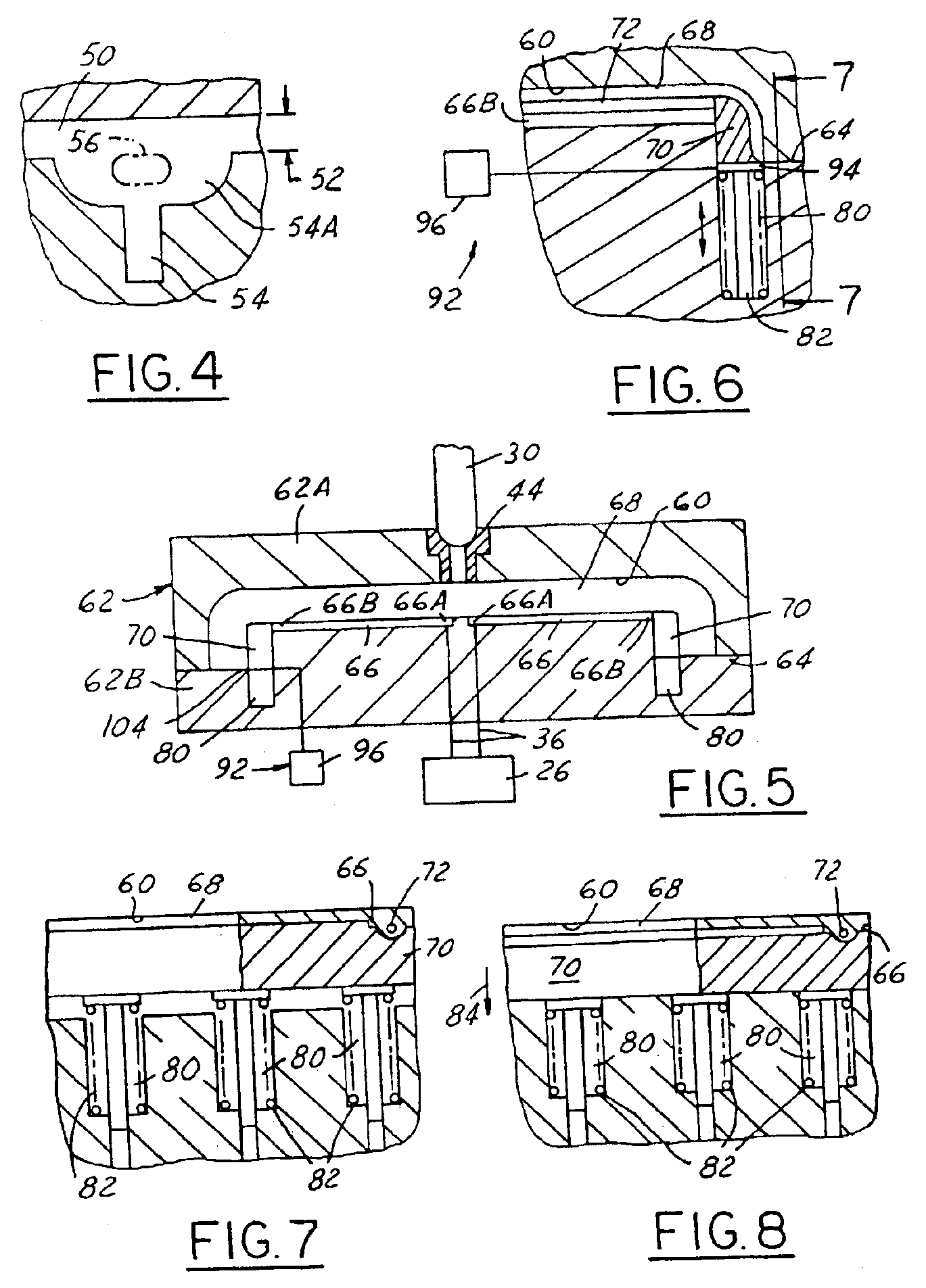

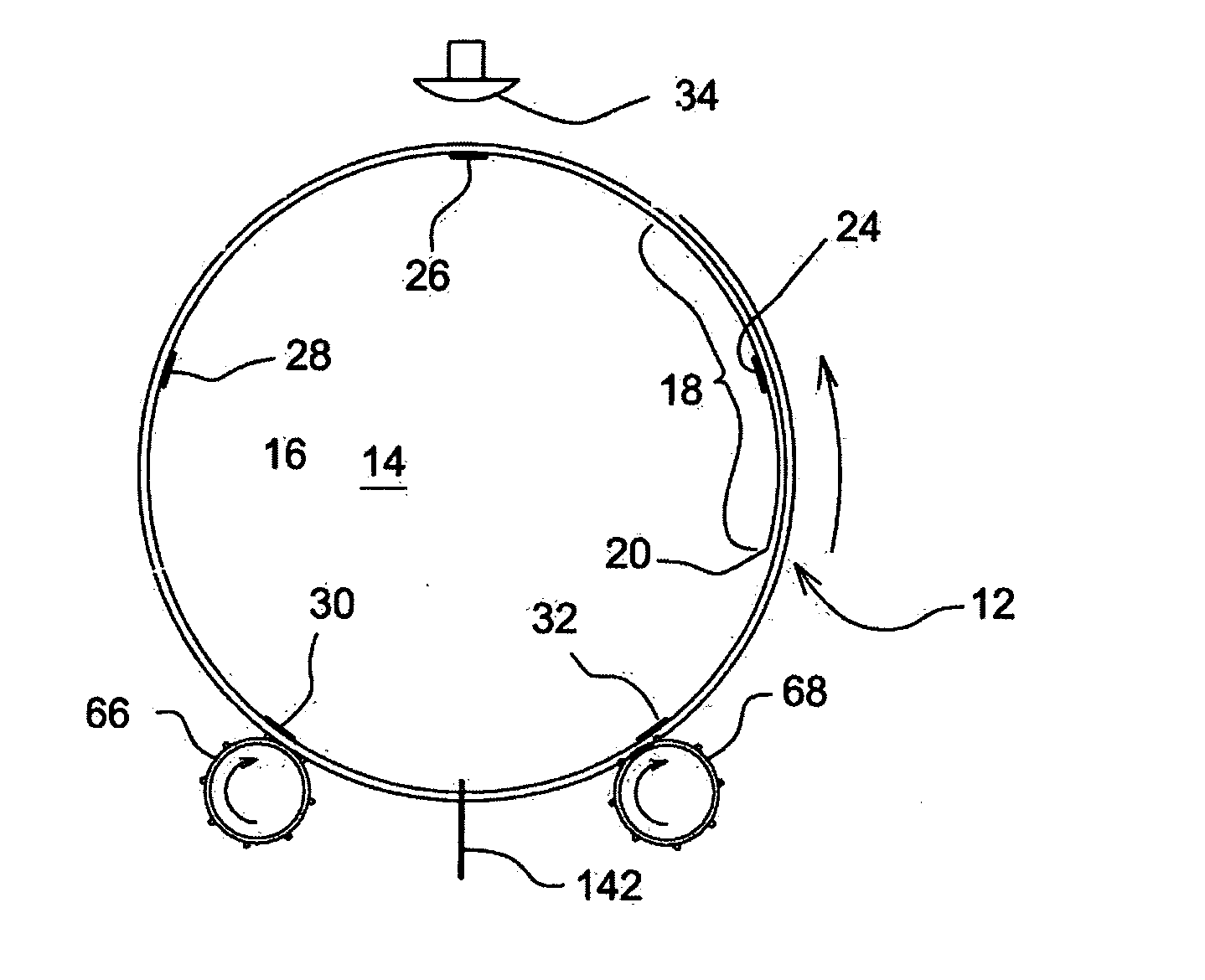

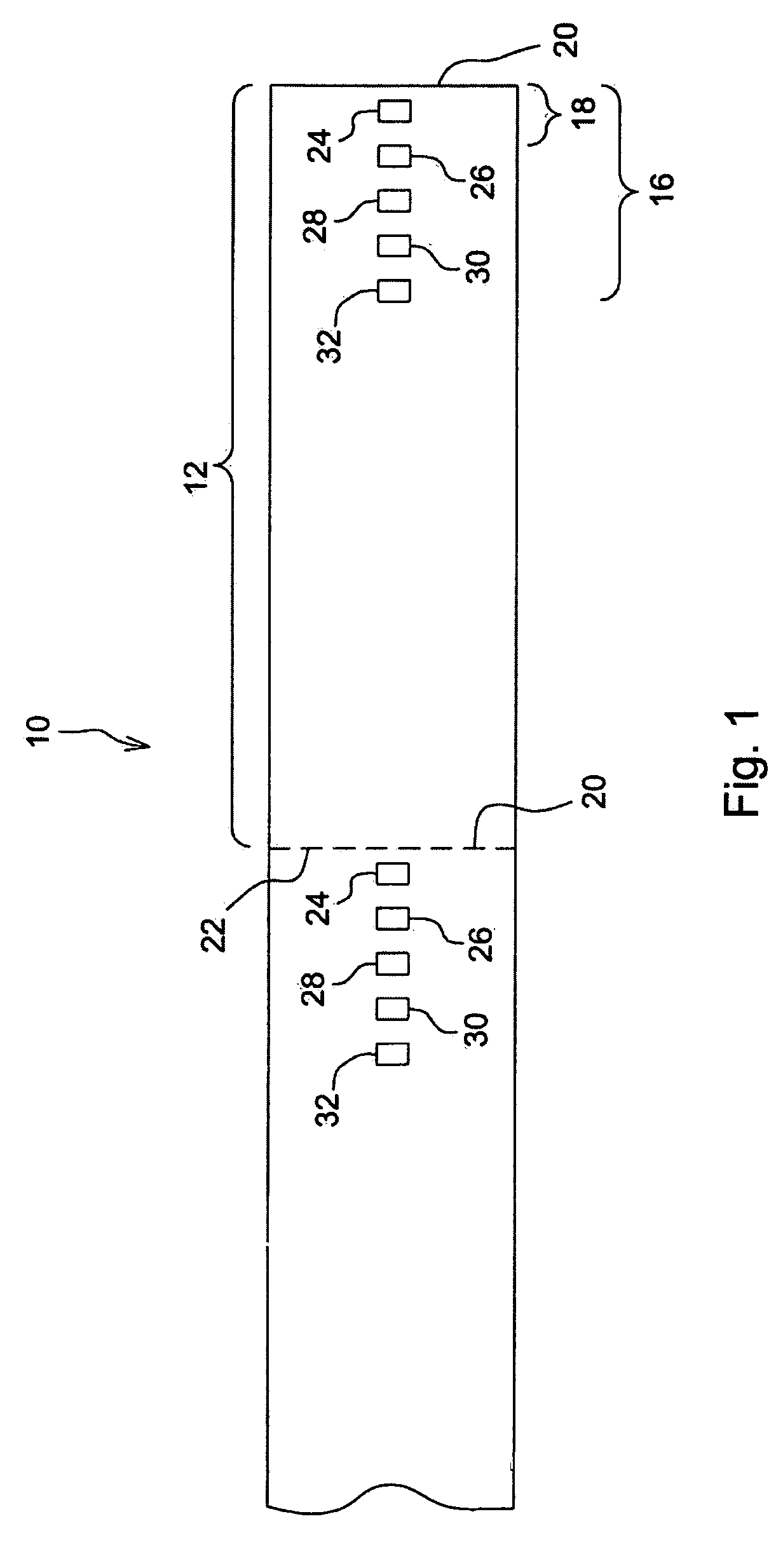

Cotton Module Plastic Wrapping Material And Module Hangler For Optimizing Module Rotation For Wrapping Removal

InactiveUS20100003118A1Avoiding cutting off the loose inner tail of the wrappingMultiplex system selection arrangementsContainers for flexible articlesPlastic packagingComputer module

A supply of plastic wrapping material for wrapping cylindrical modules includes a plurality of end-to-end segments, with each segment being of a length sufficient for enveloping a cylindrical cotton module of a given size with a predetermined number of layers of wrapping. All except an inner tail of an inner layer of wrapping adheres to the following layer. The location within each segment which becomes a loose inner tail when wrapped about a module is provided with a first RFID tag while other RFID tags are provided at equally spaced locations along the inner layer. Each RFID tag is provided with a unique identifier for which may be read by a RFID tag reader carried by a module handling implement having forks rotatable by reversible motors operable for rotating the module for placing the loose inner tail at a desired location relative to a cutting device for slitting the wrapping during wrapping removal. A control arrangement is coupled to the RFID tag reader and uses the information from the tag identifiers to cause the module to be rotated in a direction most suitable for optimizing placement the loose inner tail in the desired location for wrapping removal.

Owner:DEERE & CO

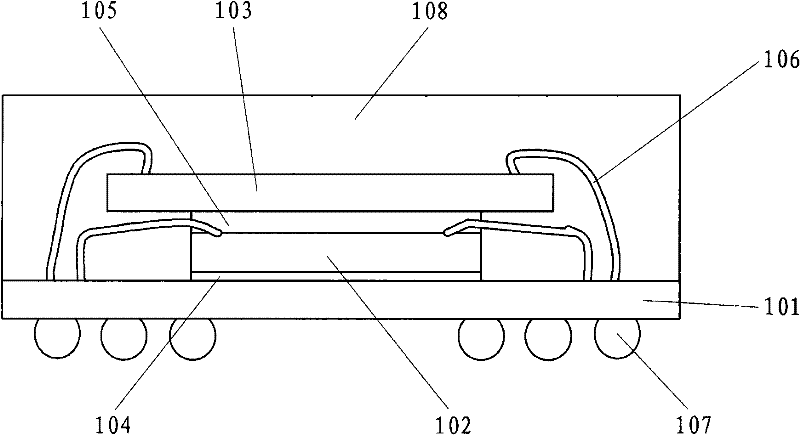

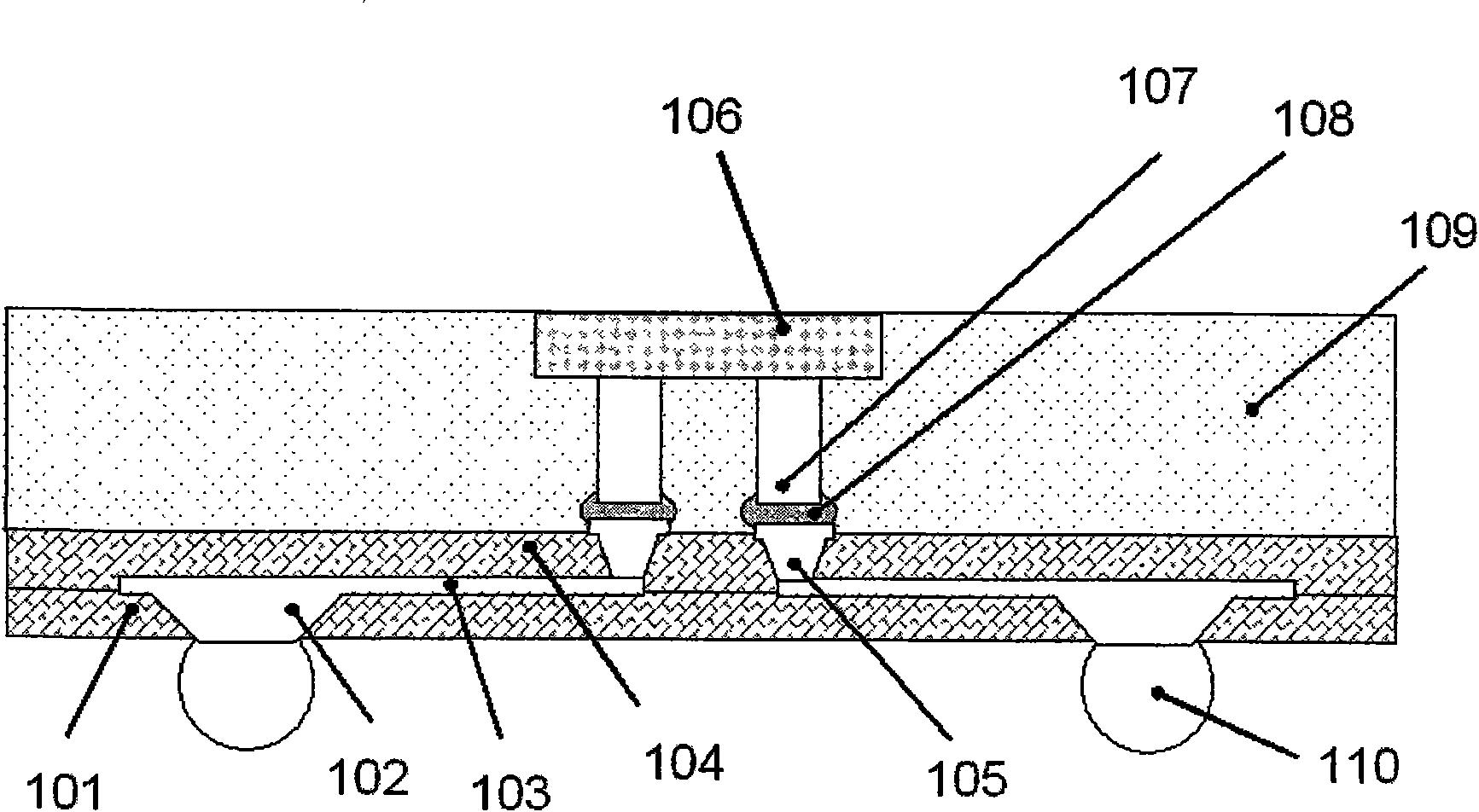

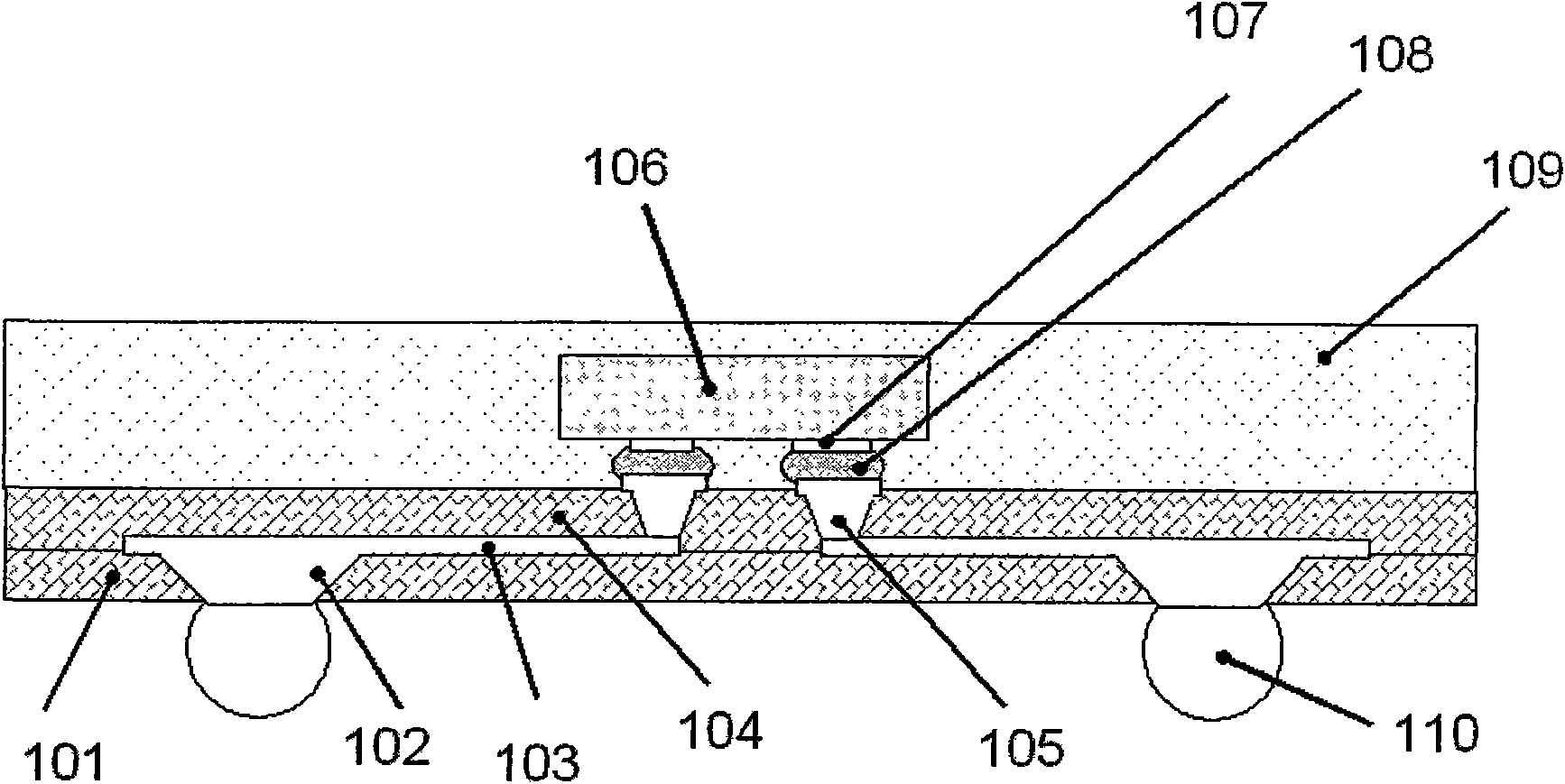

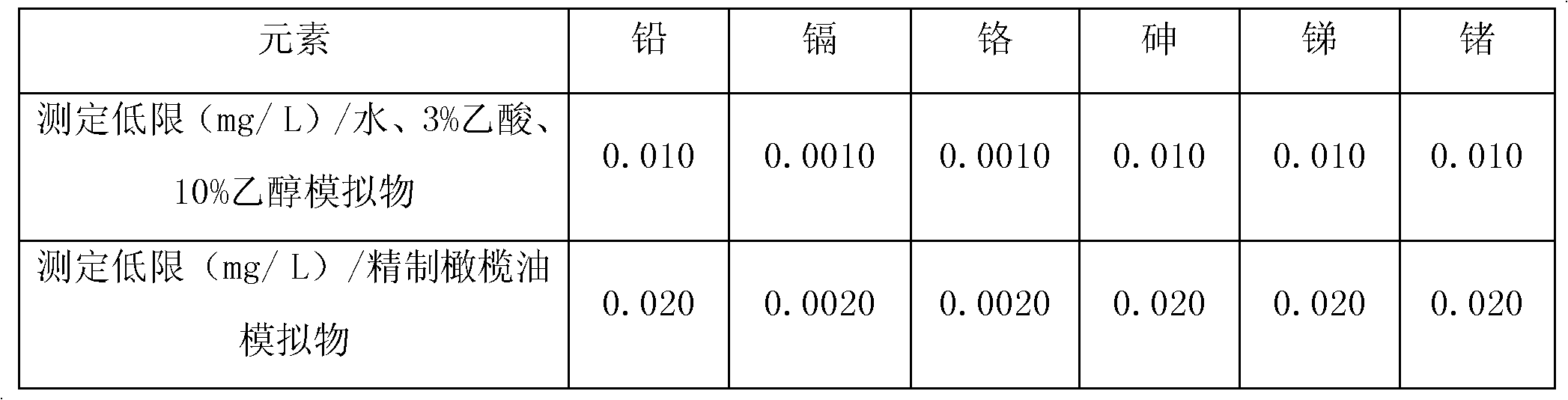

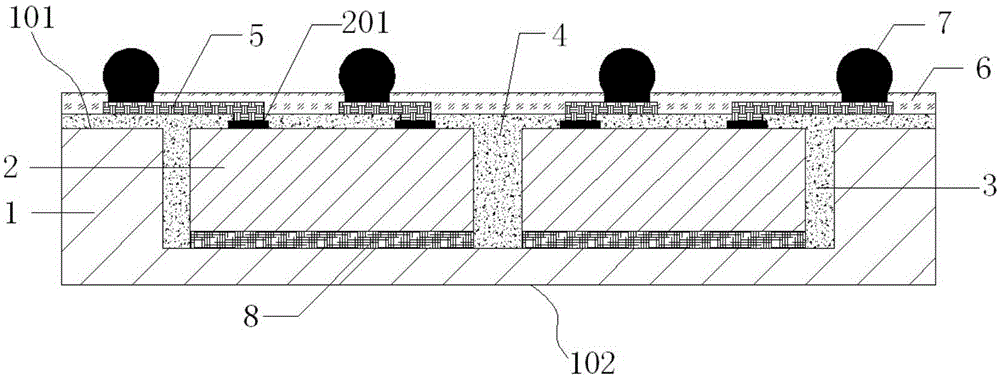

Packaging structure for ball grid array and manufacturing method for same

ActiveCN102456677AReduce generationAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a packaging structure for a multi-chip ball grid array and a manufacturing method for the same, wherein the packaging structure for a ball grid array comprises a substrate; at least two chips fixed on the upper surface of the substrate and the lower surface of the substrate respectively, wherein a signal end is formed on each chip; pad parts disposed on the upper surface and the lower surface of the substrate and provided with through holes penetrating through the substrate in a thickness direction, wherein the pad parts form electric connections with the signal ends via leads; conducting parts which are conducting pins inserted and fixed in the through holes; and plastic packaging parts for protecting the substrate, the conducting parts and the chips. According to the packaging structure for a multi-chip ball grid array and the manufacturing method for the same disclosed by the invention, the generation for a cantilever in a multi-chip packaging can be reduced, the manufacturing technique can be simplified, and a warping phenomenon in structure can be prevented.

Owner:SAMSUNG SEMICON CHINA RES & DEV +1

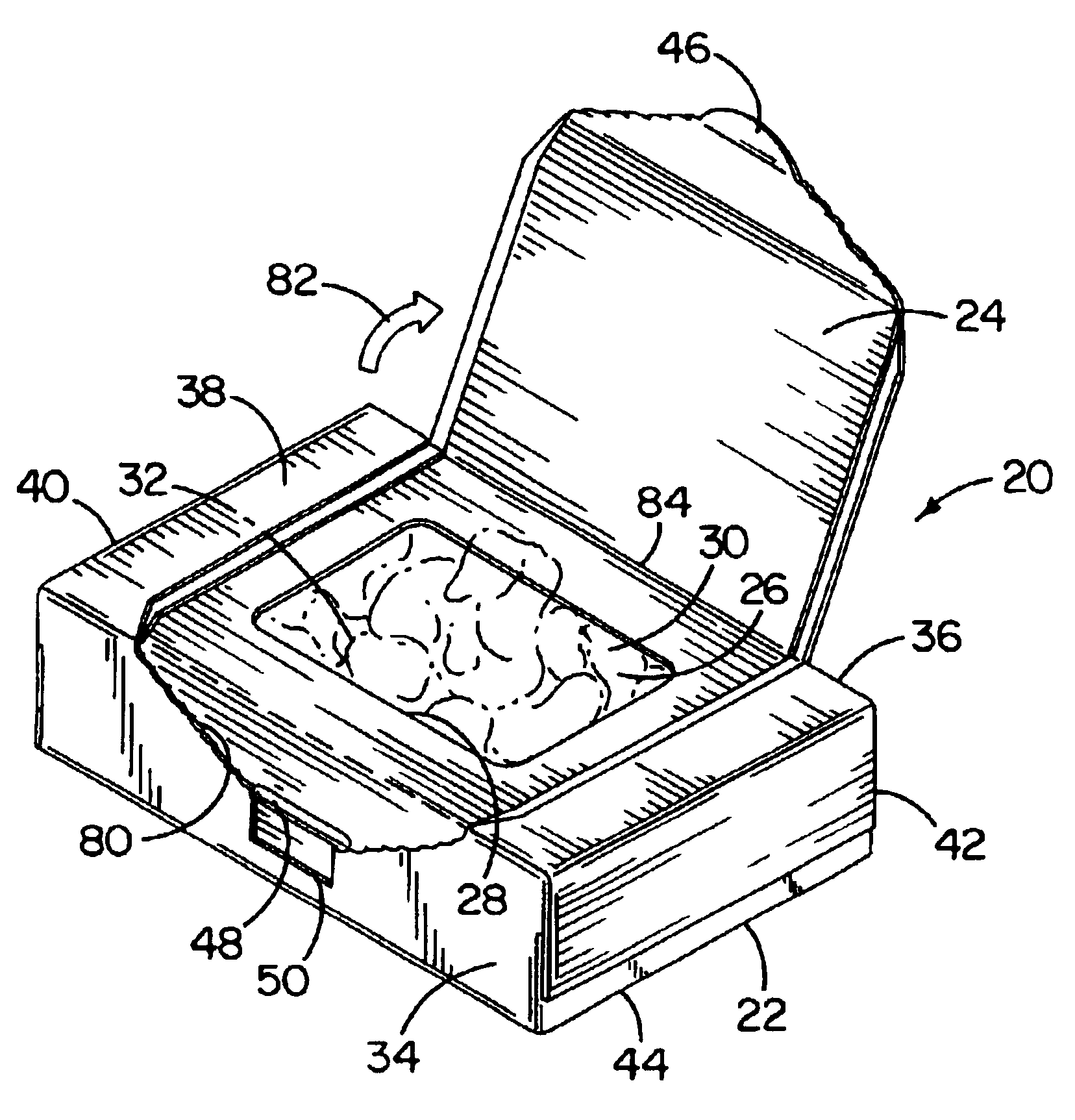

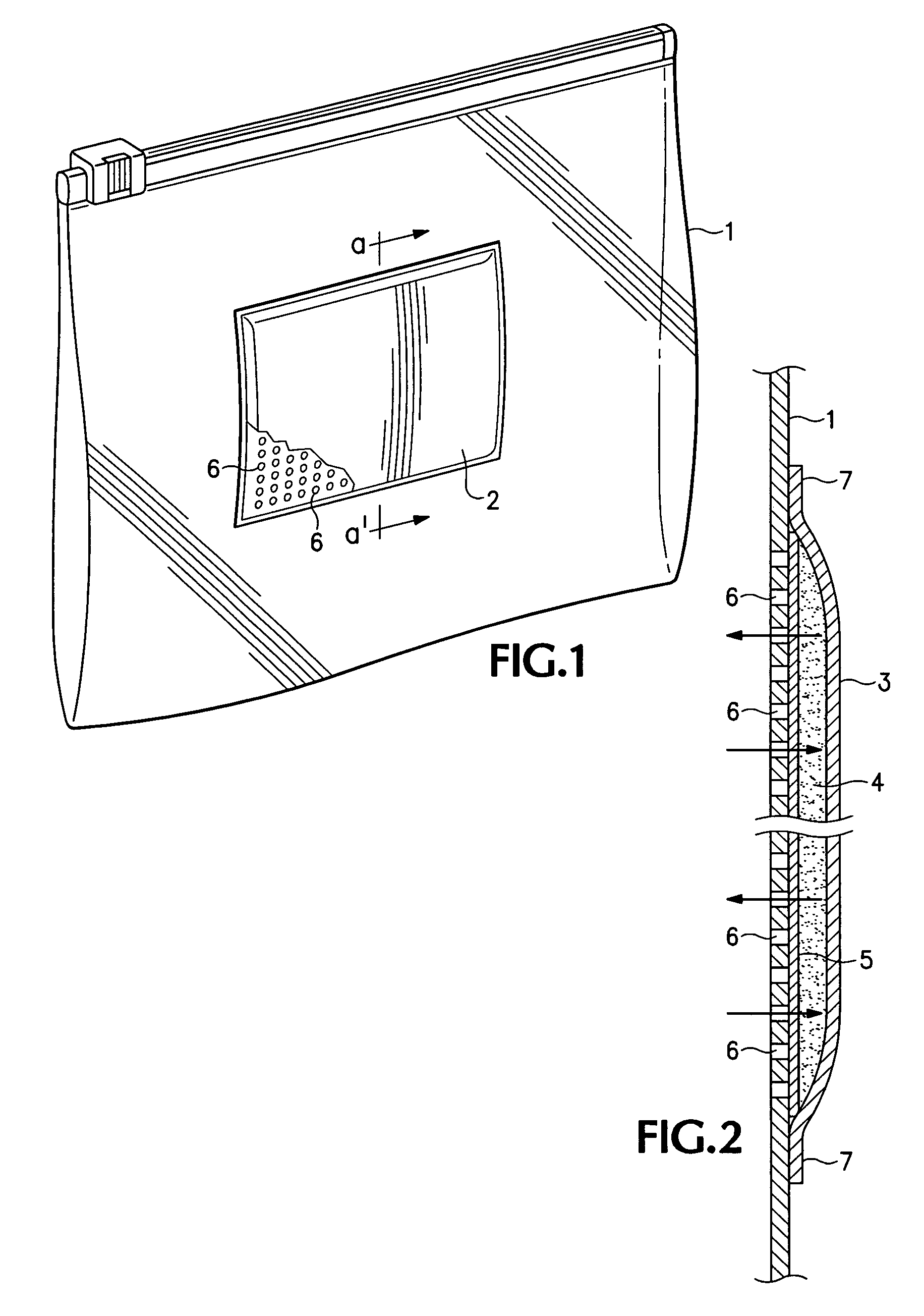

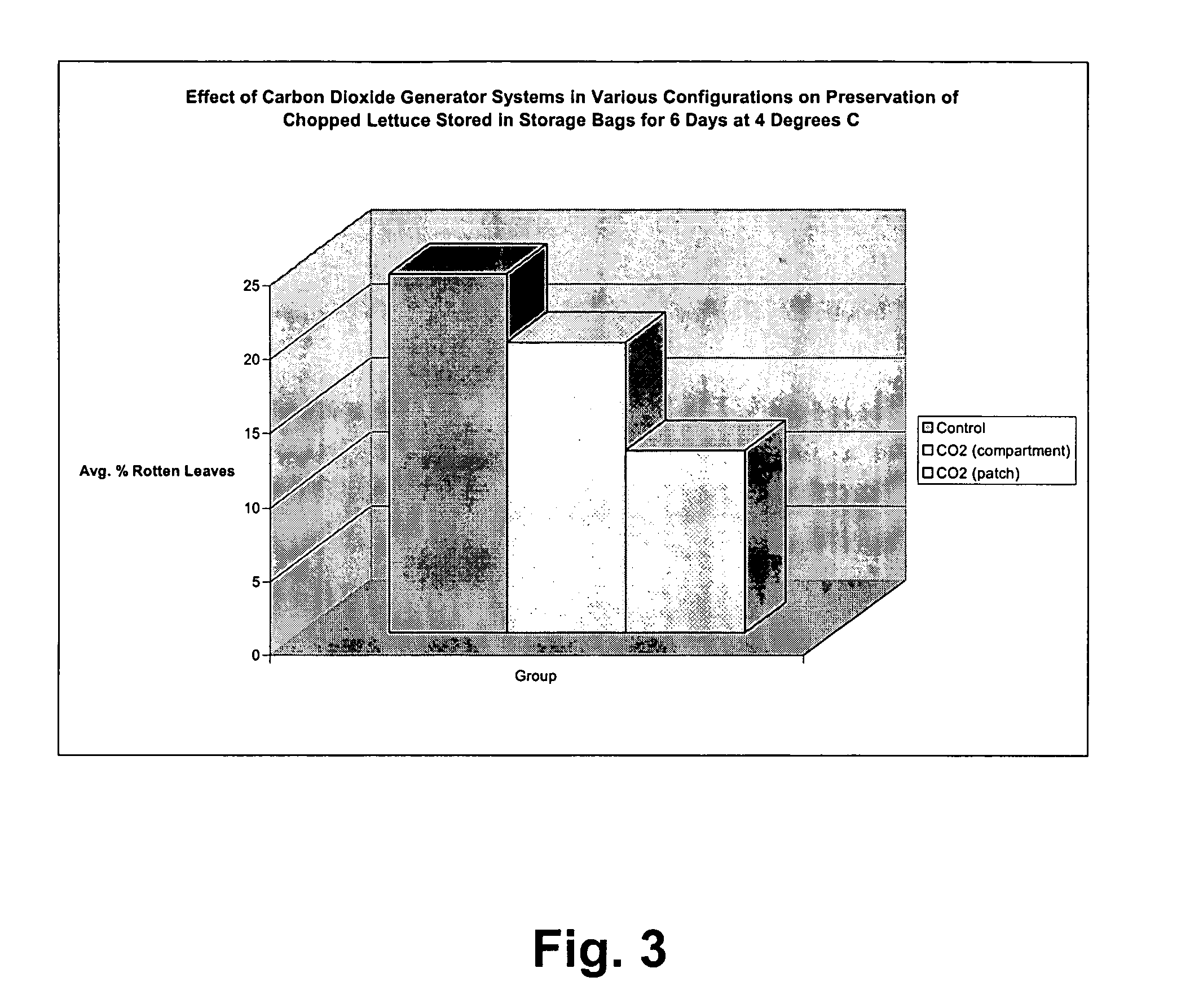

Packaging system for preserving perishable items

A packaging system for preserving perishable items which involves a thermoplastic reclosable bag or container wherein the thermoplastic reclosable bag or container involves sealed means for closing one end of the thermoplastic reclosable bag or container, and an external patch for delivering active packaging materials (e.g., chemicals) into the thermoplastic reclosable bag or container, and means for flowing active packaging materials into the thermoplastic reclosable bag or container from the external patch into the thermoplastic reclosable bag or container. Such packaging can perform a number of functions such as moisture regulation, antimicrobial emission, ethylene scavenging, ethylene emission, antioxidant emission, flavor adsorption and emission, and oxygen and carbon dioxide regulation. The present invention allows the segregation of active compounds in plastic packaging within an external patch that prevents the direct contact of such compounds and the contents of the package but allows the free exchange of liquids and / or gasses between the patch contents and the package interior.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE

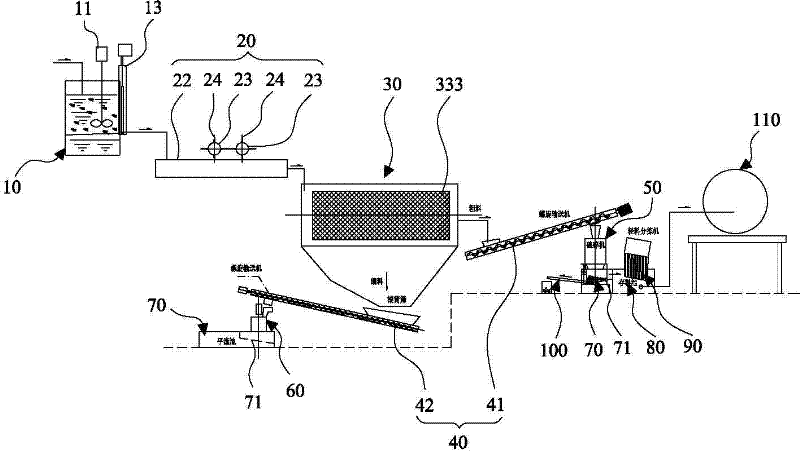

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

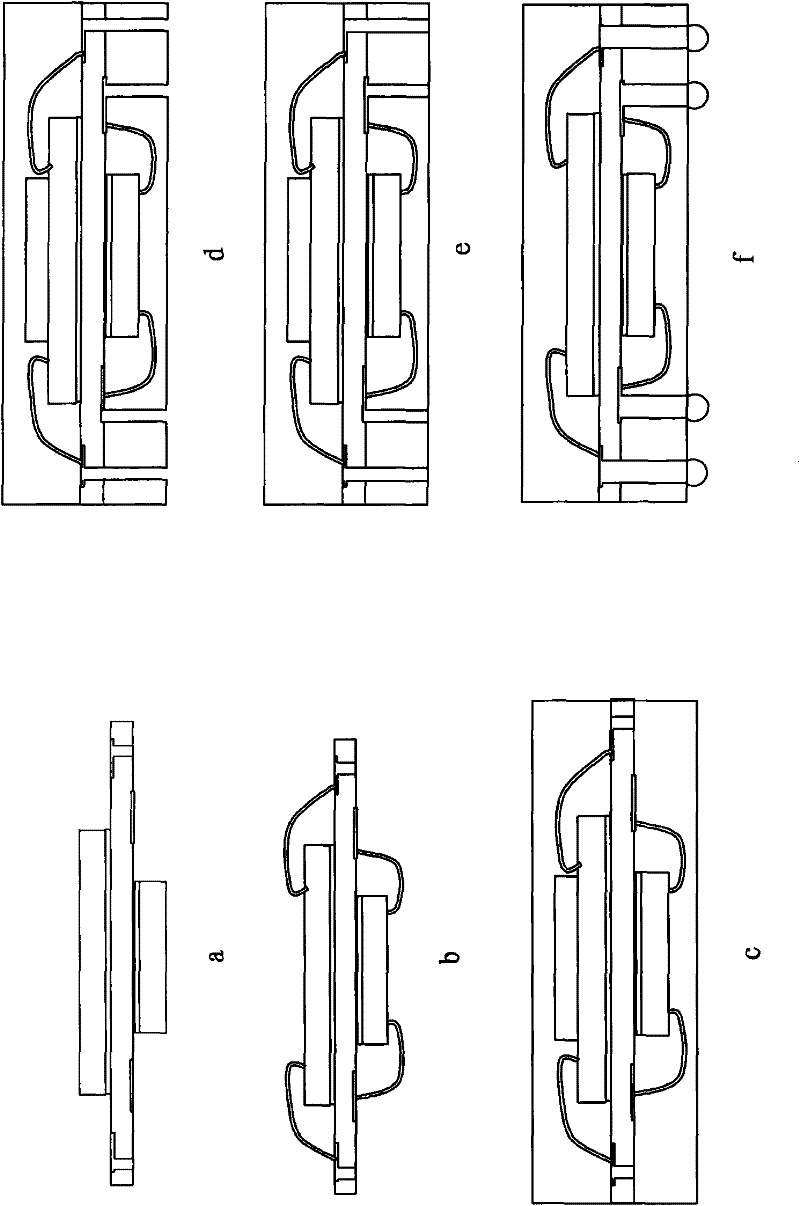

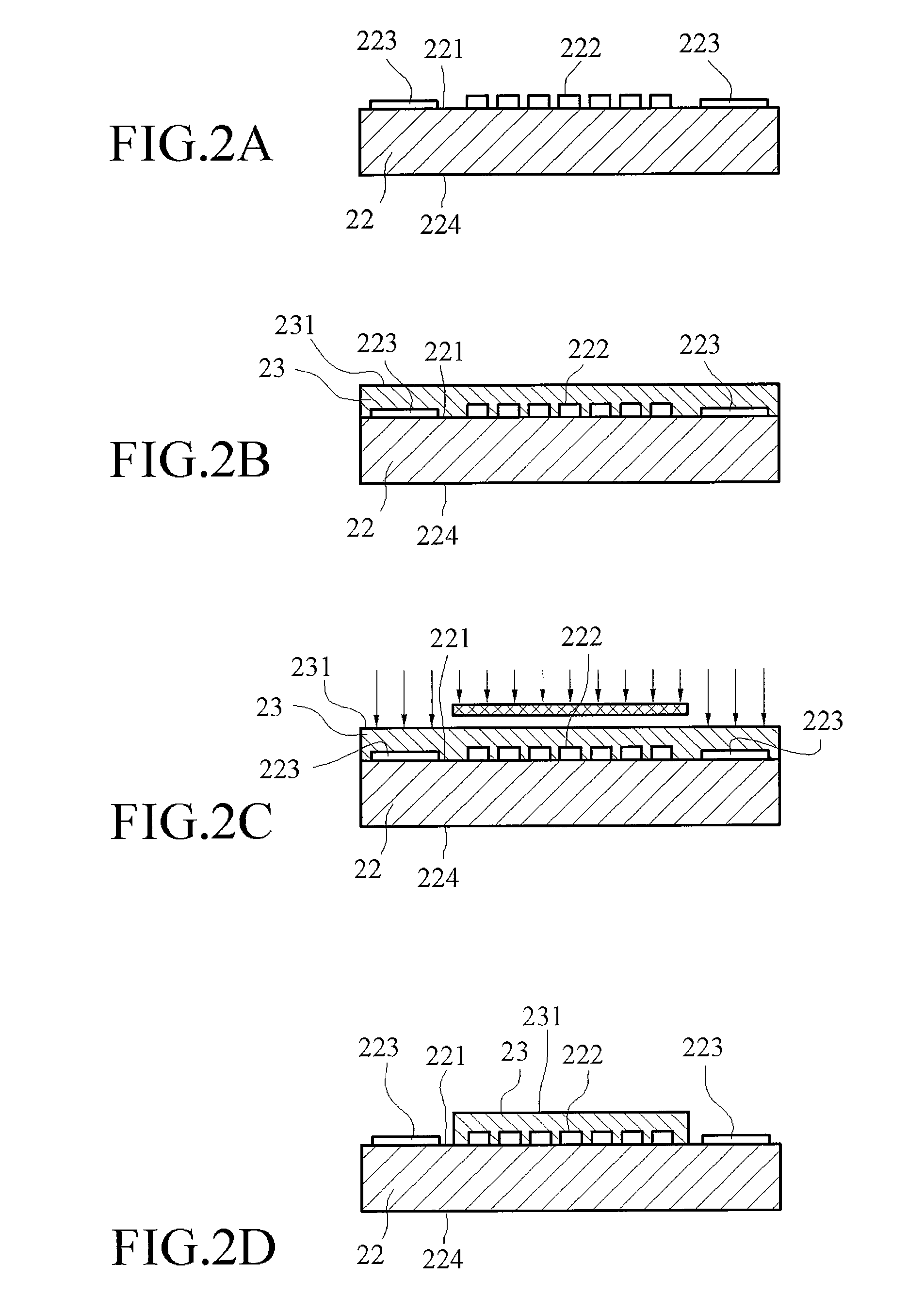

Wafer level fan-out chip packaging method

ActiveCN101604638AAchieve connectionAvoid displacementSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingMetal electrodes

The invention relates to a wafer level fan-out chip packaging method, comprising the following technological processes: a stripping foil and a film dielectric layer I are sequentially covered on the surface of the wafer of a carrier, a photoetching pattern opening I is formed on the film dielectric layer I; a metal electrode and a re-wiring metal routing wire which are connected with a base plate end are arranged on the photoetching pattern opening and the surface thereof, a film dielectric layer II is covered on the surface of the metal electrode, the surface of the re-wiring metal routing wire, and the surface of the film dielectric layer I which are connected with the base plate end, and a photoetching pattern opening II is formed on the film dielectric layer II; a metal electrode connected with a chip end is arranged on the photoetching pattern opening II, after a chip is arranged on the metal electrode connected with the chip end in an inverting way, the injection molding of packaging material and solidification are carried out, so as to form a packaging body with plastic-packaging material; the wafer of the carrier and the stripping foil are separated from the packaging body with plastic-packaging material, so as to form a plastic-packaging wafer; a welding sphere back returns to form a welding ball salient point; cutting is carried out by uniwafers for forming the final structure of the fan-out chip. The method has low cost and a carrying function, and can well solve the problem that the chip is shifted in the technological process.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

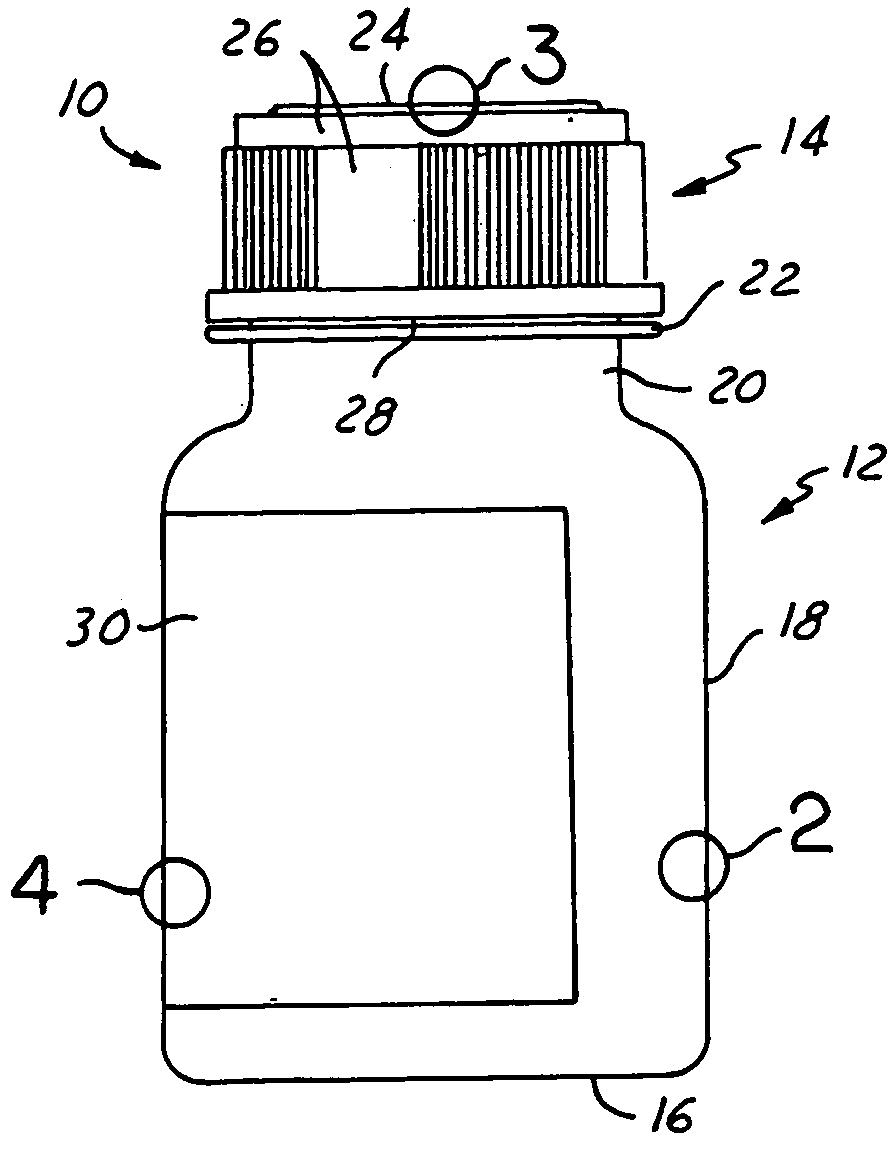

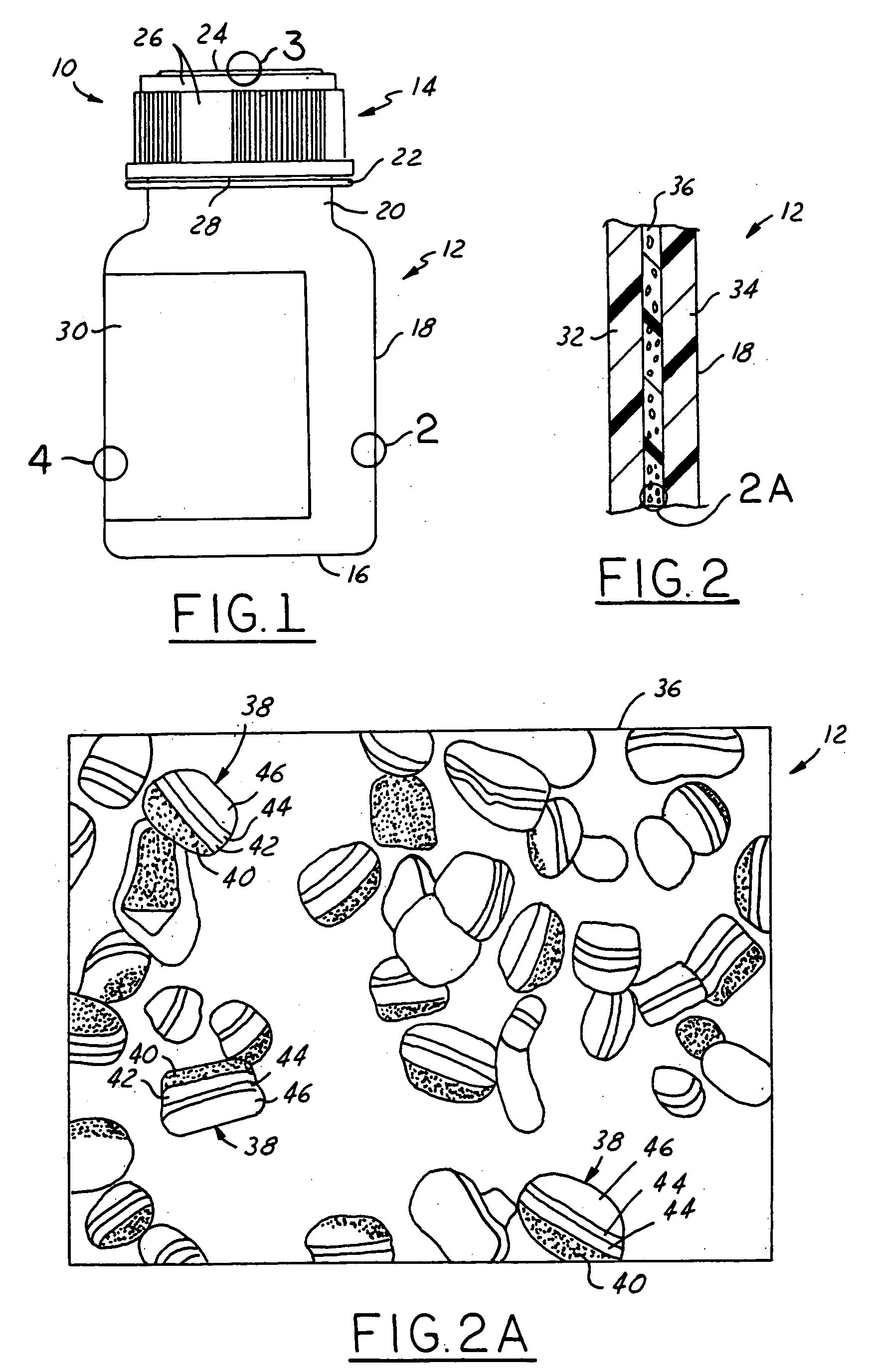

Plastic packaging having embedded micro-particle taggants

An improvement to a package is provided that includes a container having a label secured thereto by an adhesive and a closure secured to the container. The improvement is for identifying the package and includes at least one of the container, the adhesive and the closure having a plurality of micro-particle taggants with multiple colored layers to provide a code for identifying the package.

Owner:OWENS ILLINOIS HEALTHCARE PACKAGING

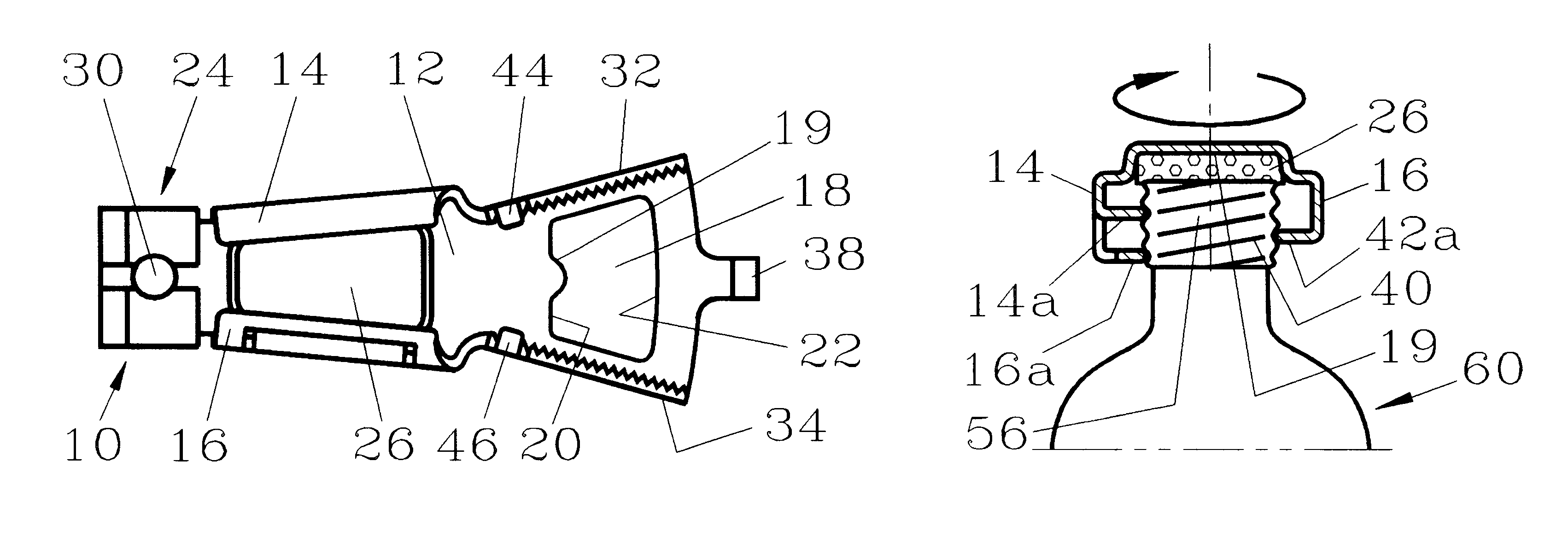

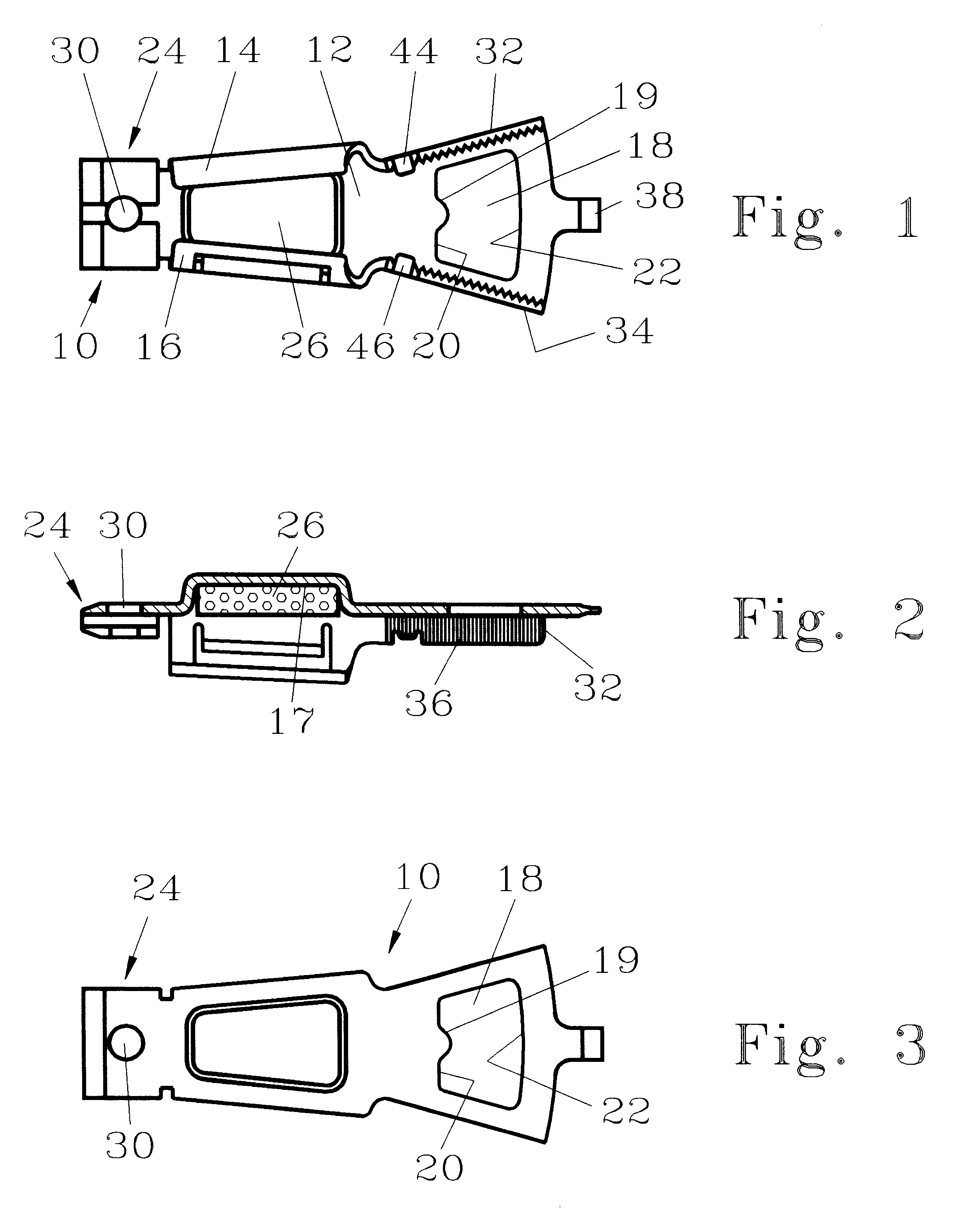

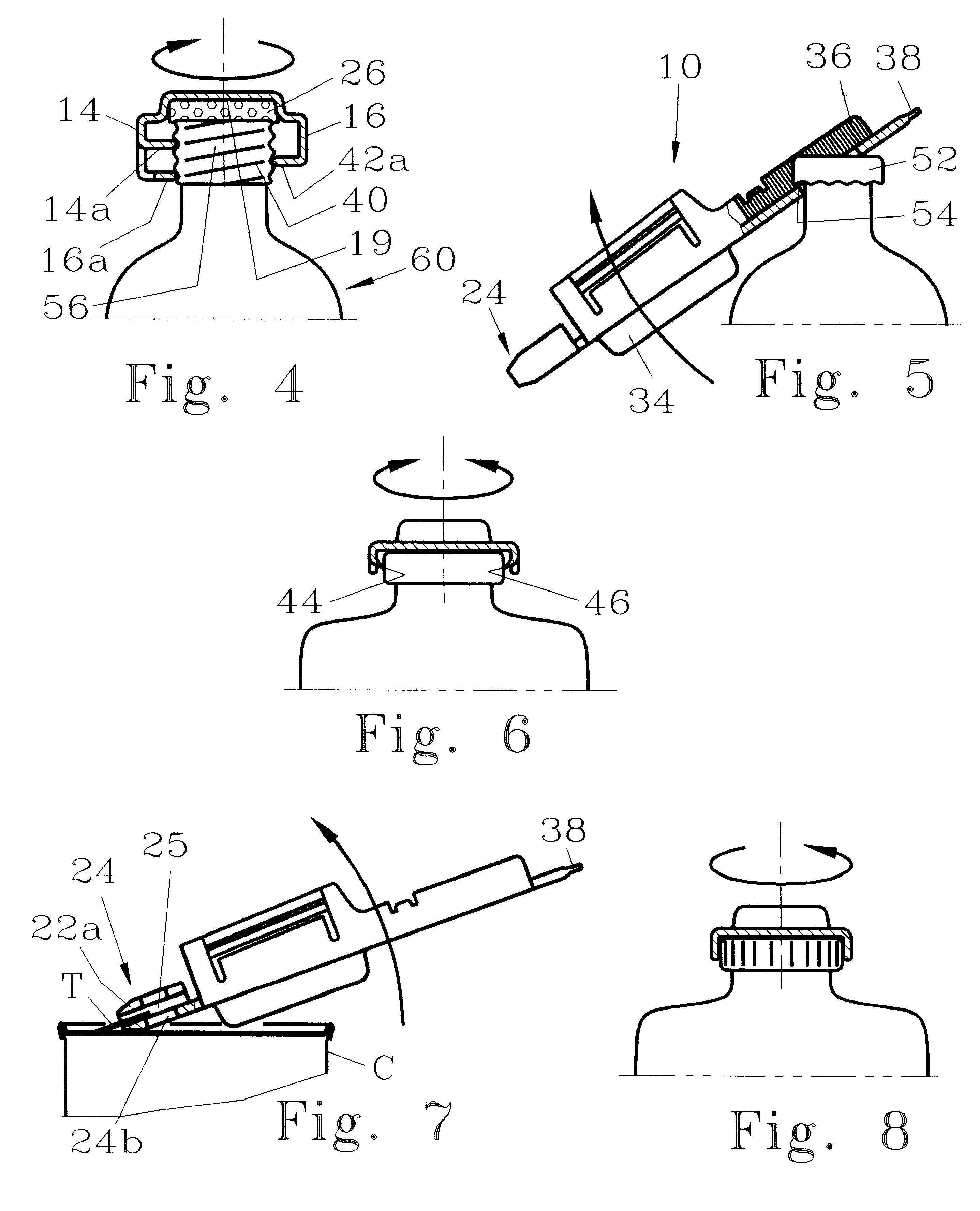

Opener and stopper for crimped and threaded bottle caps

InactiveUS6212721B1Less materialEasy to manufactureCapsPower operated devicesPlastic packagingBottle neck

A combined bottle opener and stopper comprises a metal plate with side edges bent downward and inwardly. Opening is performed with the use of a conventional pry off method. Opened bottles are closed with a rubber pad attached to the bottom of a recess on the inner face of the plate. The opener-stopper has three bent edges which have different heights with the difference corresponding to the pitch of the thread on a threaded bottle neck. For temporary closing the bottle, i.e., with beer or carbonated water, the device is screwed onto the threaded bottle neck as a nut until the rubber pad is tightly pressed to the upper face of the bottle to hermetically close the latter. For closing bottles with nonthreaded bottle necks, the device is moved onto the bottle neck by guiding the convergent bent edges over the neck in a direction transverse to the bottle's axis until the device is fixed tightly on the bottle due to convergence of the bent edges with the rubber pad, thereby to seal the bottle's opening. The device is also provided with sharp edges for cutting plastic wrappings around the bottle neck and with an opener for metal cans openable by pulling up a tongue connected to a scored can cover.

Owner:BORODULIN GERMAN +1

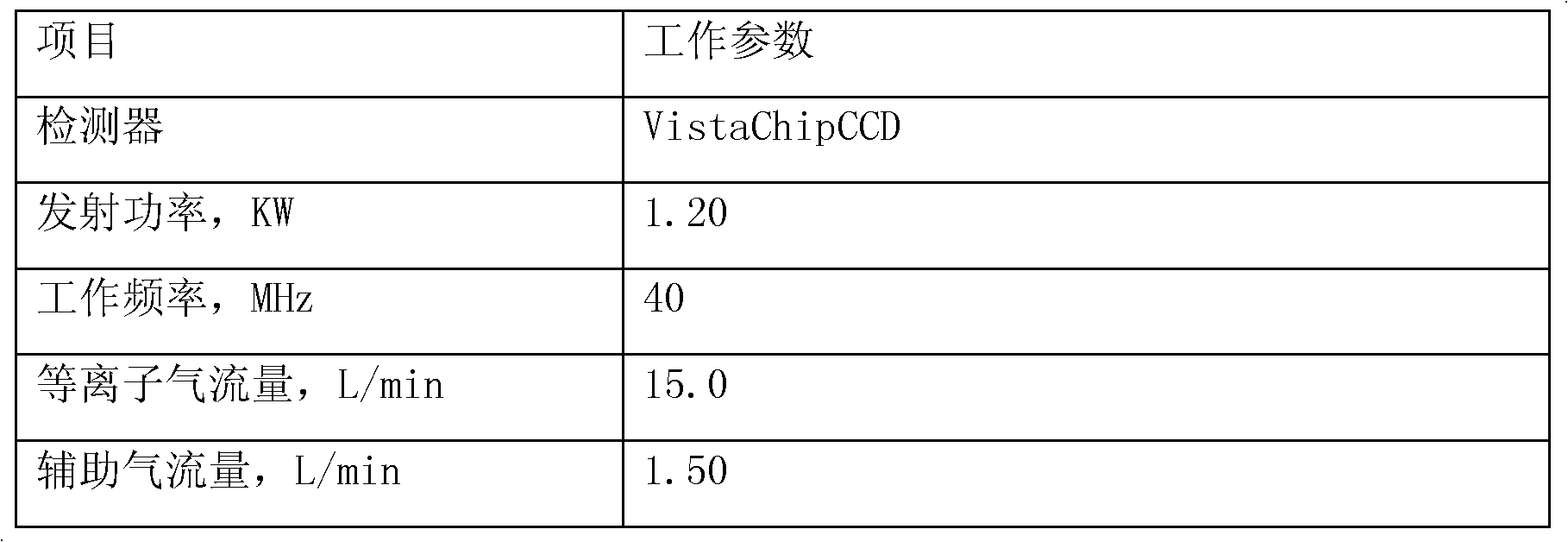

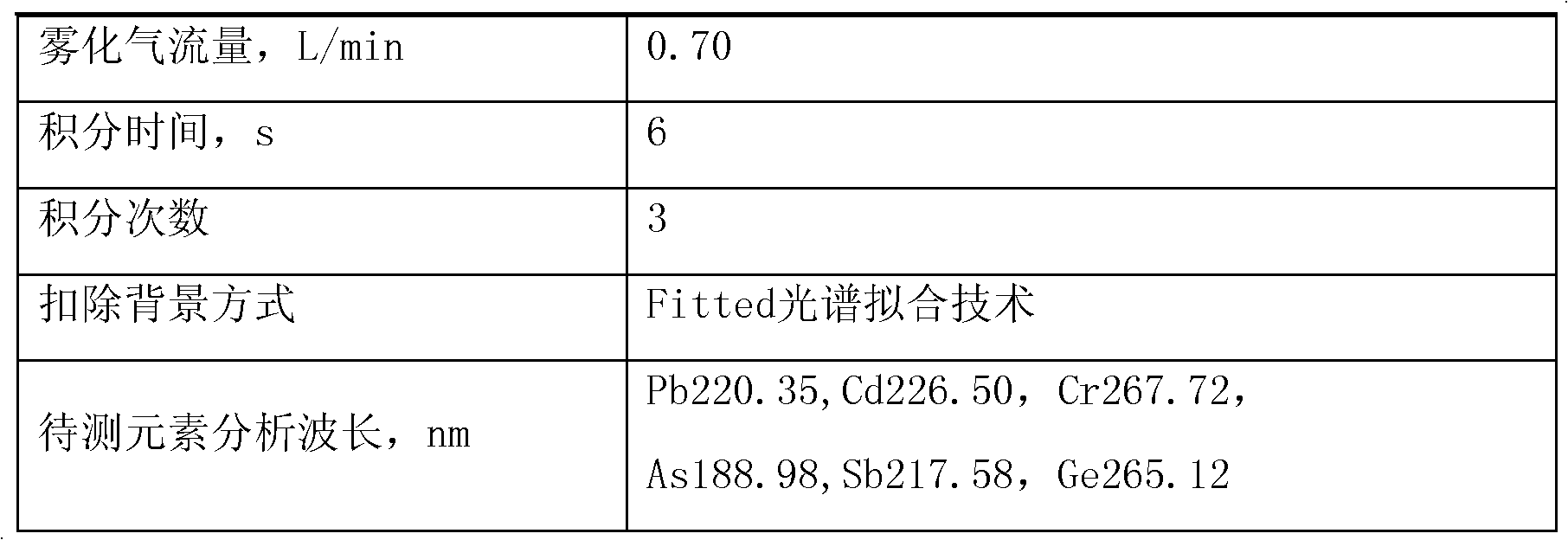

Detection method for simultaneously measuring migrated masses of lead, cadmium, chromium, arsenic, antimony and germanium in plastic packaging container for foods by ICP-AES (inductively coupled plasma emission spectrometry) method

InactiveCN102023155AEfficient determinationEasy to measurePreparing sample for investigationAnalysis by thermal excitationOptical emission spectrometryRadio frequency

The invention relates to a detection method of harmful element migrated masses in a plastic packaging container for foods, in particular to a detection method for simultaneously measuring migrated masses of lead, cadmium, chromium, arsenic, antimony and germanium in a plastic packaging container for foods by an ICP-AES (inductively coupled plasma emission spectrometry) method. The detection method comprises the following steps: 1, carrying out a migration test; 2, carrying out a blank test; and 3, carrying out measurement by an inductively coupled plasma emission spectrometer. The ways of RF (radio frequency) power amplification (for a 3% acetic acid simulacrum test solution), ethanol removal (for a 10% ethanol simulacrum test solution) and microwave digestion (for a delicate olive oil test solution) are used to efficiently, simply and quickly measure the migrated masses of various harmful elements in four simulacrums in the plastic packaging container for the foods simultaneously.

Owner:THE INSPECTION & QUARANTINE TECH CENT ZHEJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

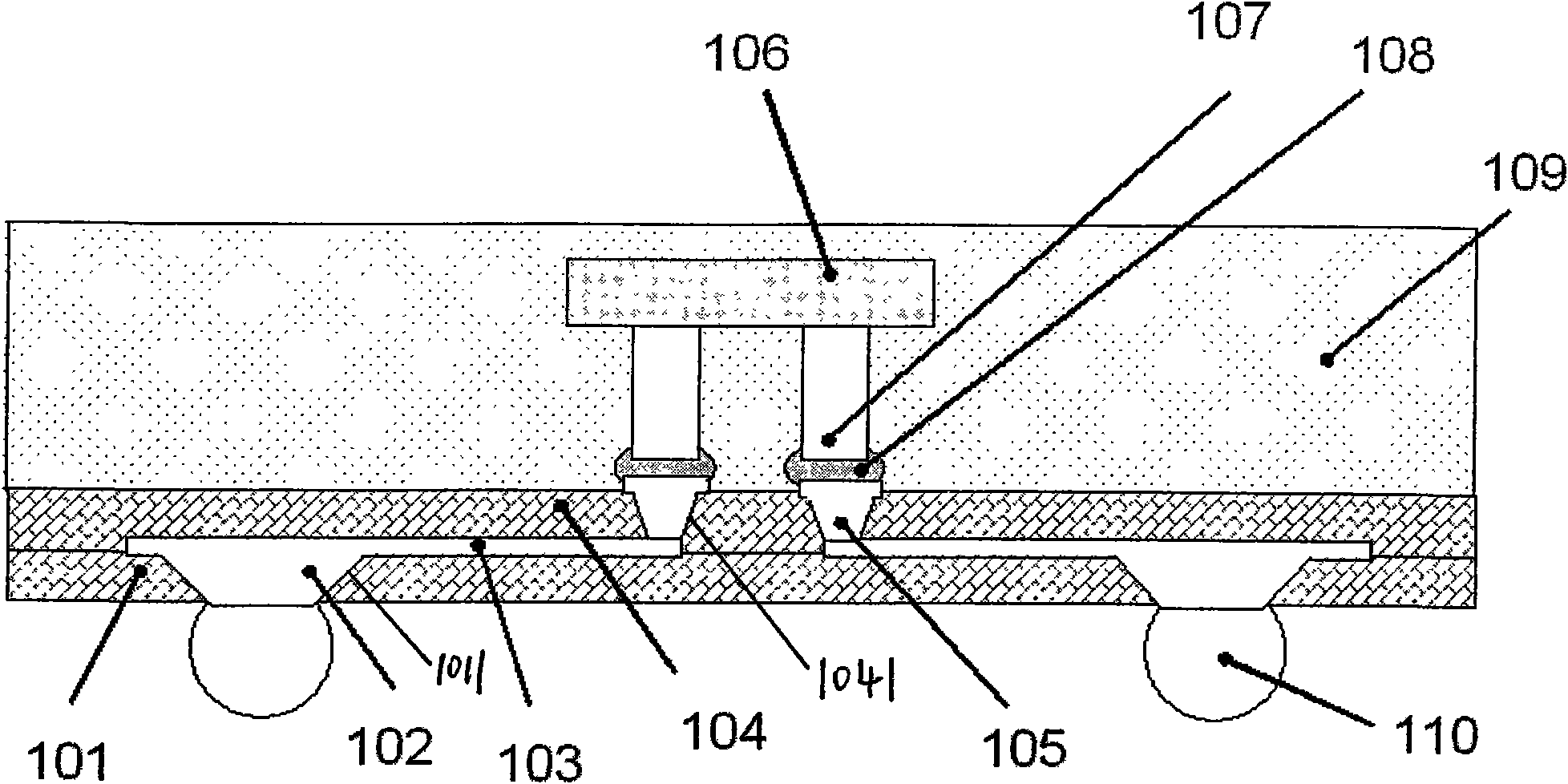

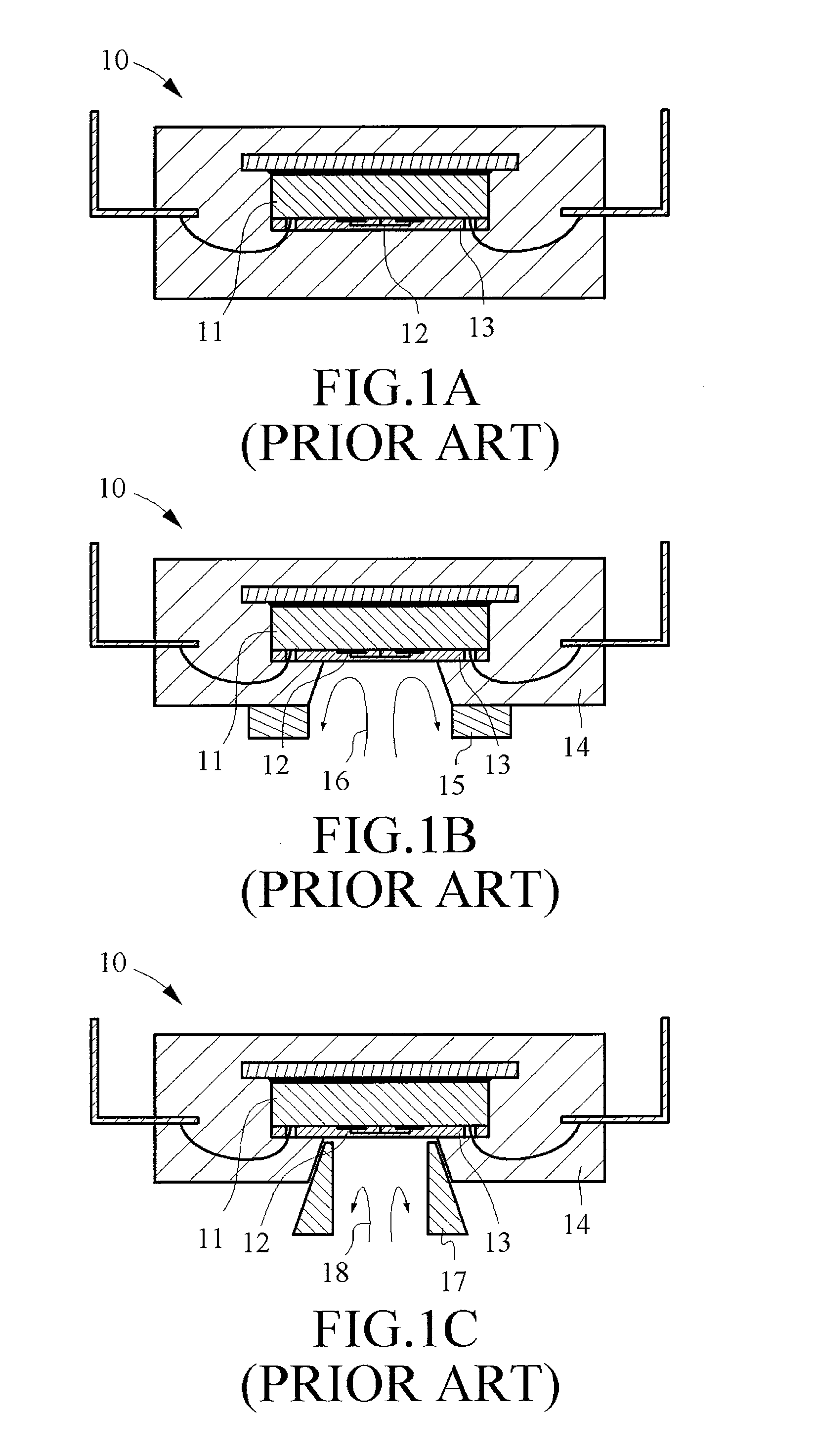

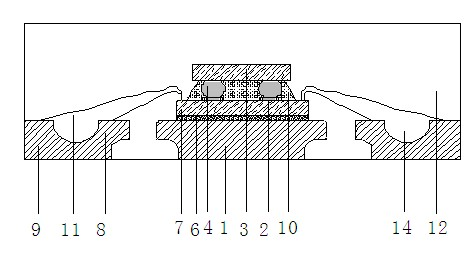

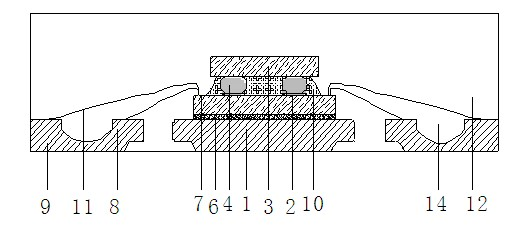

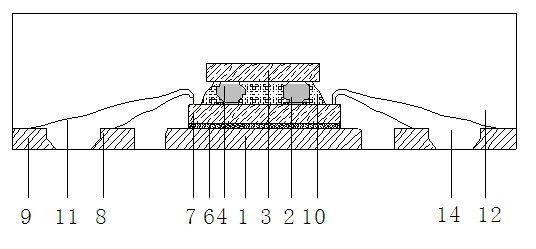

Method for manufacturing plastic packaging of MEMS devices and structure thereof

InactiveUS20070222008A1Simple processImprove yieldSemiconductor/solid-state device detailsFluid pressure measurement by electric/magnetic elementsPlastic packagingSolvent

A plastic packaging of MEMS device and a method therefore are provided. The method includes the steps of: provide a carrier having a surface; provide at least one MEMS device having an active surface with a sensitive area and bonding pads thereon and a back surface; proceed a photoresist process to form a sacrificial layer on the sensitive area; bind and electrically connect the MEMS device to the surface of the carrier; form at least one molding compound, to which the upper surface of the sacrificial layer is exposed. Finally, decompose the sacrificial layer by a solvent to expose the MEMS device on the sensitive area, so as to let the sensitive area contact with ambient atmosphere.

Owner:IND TECH RES INST

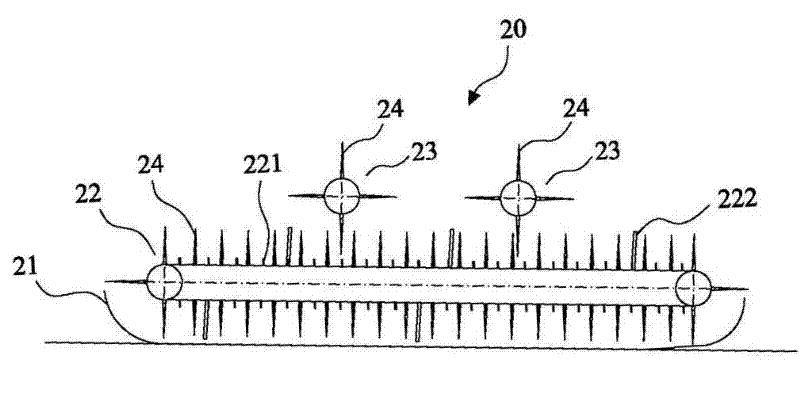

Restaurant-kitchen garbage sorting system

InactiveCN102327890AImprove processing efficiencyAccurate classificationSievingScreeningPlastic packagingProcess engineering

The invention discloses a restaurant-kitchen garbage sorting system. The system orderly comprises a scrubbing oil groove for separating grease from residues, a bag breaking conveyor for tearing a plastic package and a drum screening machine for screening the residues into coarse material and fine material, and a coarse material outlet and a fine material outlet are arranged on the drum screening machine, a coarse material spiral conveyor and a fine material spiral conveyor are respectively arranged corresponding to the coarse material outlet and the fine material outlet, a crusher is arranged at an outlet of the coarse material spiral conveyor, a pulping machine is arranged at an outlet of the fine material spiral conveyor, and a horizontal flow pool for dividing the pulp from the crusher and the pulping machine into light material and heavy material. Therefore, the restaurant-kitchen garbage sorting system can effectively treat the bagged garage without manual operation, and improve the garage processing efficiency; and the garage can be classified so as to be convenient for recycle.

Owner:DONGGUAN CAMDA GENERATOR WORK

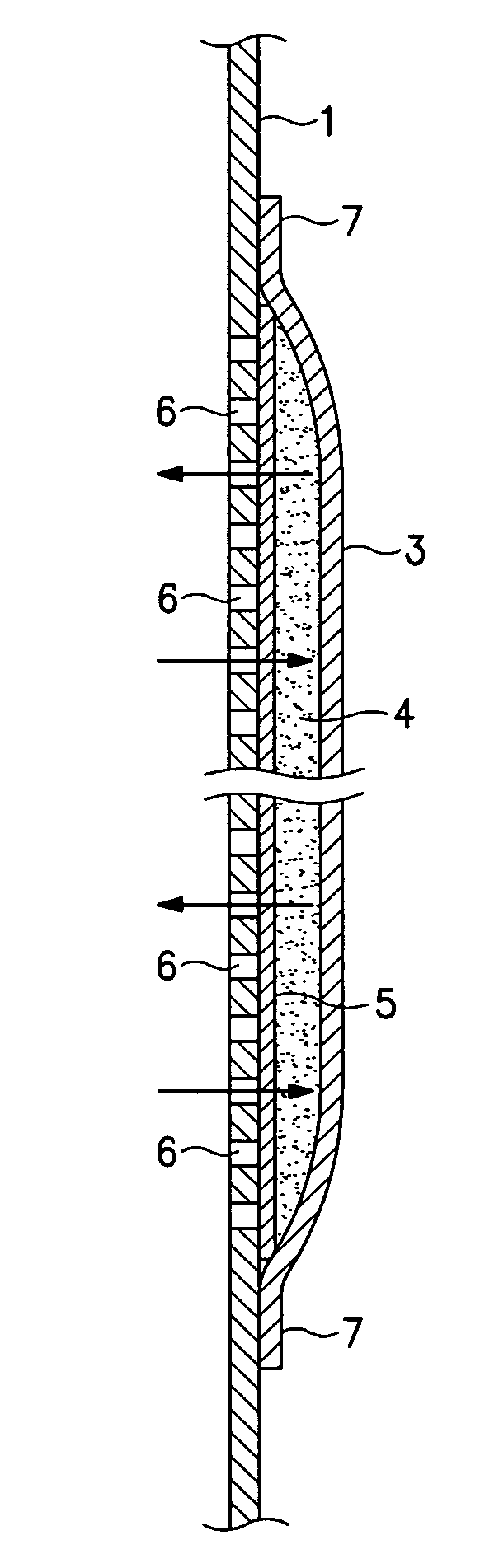

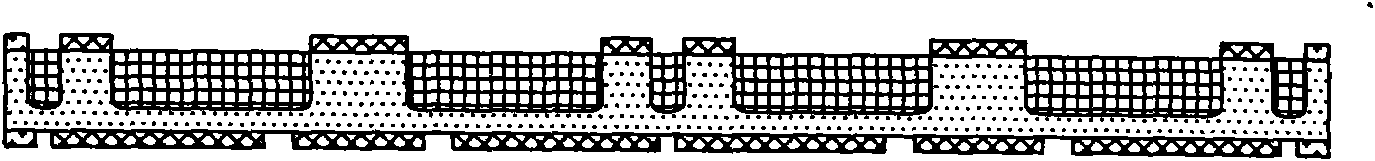

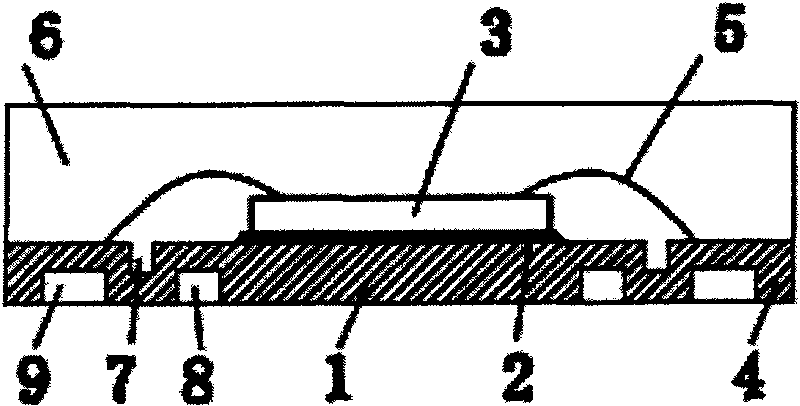

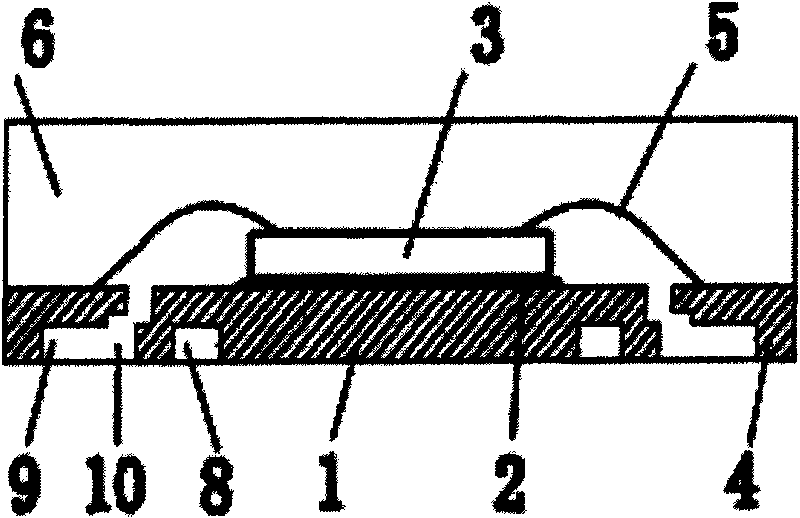

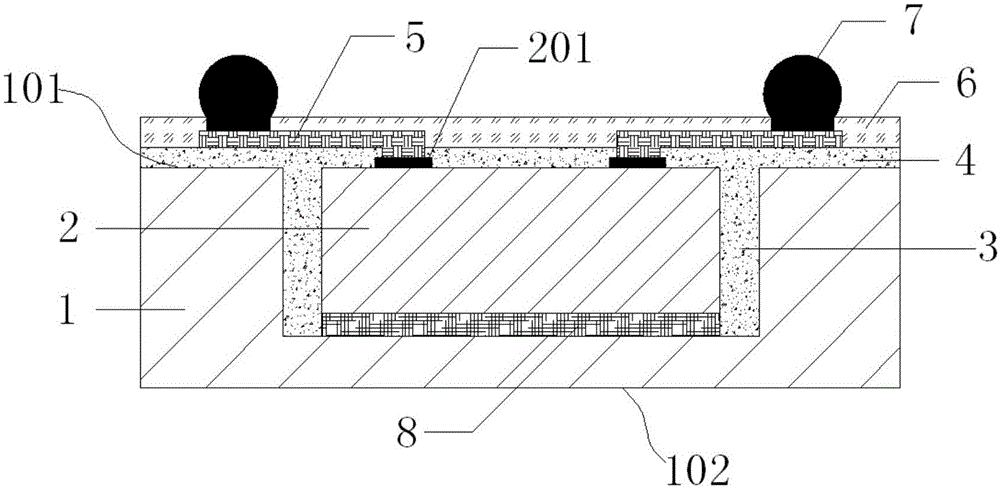

Base island lead frame structure and production method thereof

ActiveCN101814482ALow costRich varietySemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a base island lead frame structure and a production method thereof. The structure comprises a base island (1) and pins (2), wherein a first metal layer (4) is arranged on the front sides of the base island (1) and the pins (2); a second metal layer (5) is arranged on the rear sides of the base island (1) and the pins (2); the front sides of the pins (2) extend to the side of the base island (1) as much as possible; non-filler plastic packaging materials (3) are embedded in the peripheral regions of the pins (2), the region between the base island (1) and the pins (2) and the region between the pin (2) and the pin (2); and the non-filler plastic packaging materials (3) can connect the lower peripheral parts of the pins, the lower parts of the pins (2) and the lower part of the base island (1), as well as the lower part of the pin (2) and the lower part of the pin (2) into a whole and make the size of the back sides of the base island (1) and the pins (2) less than that of the front sides of the base island (1) and the pins (2) so as to form a structure, with a bigger upper part and a smaller lower part, of the base island and the pins. The base island lead frame structure and the production method thereof have the advantages of large restraint capacity of the plastic packaging body and the pins, reduction in cost, energy conservation and carbon reduction and reduction in waste.

Owner:JCET GROUP CO LTD

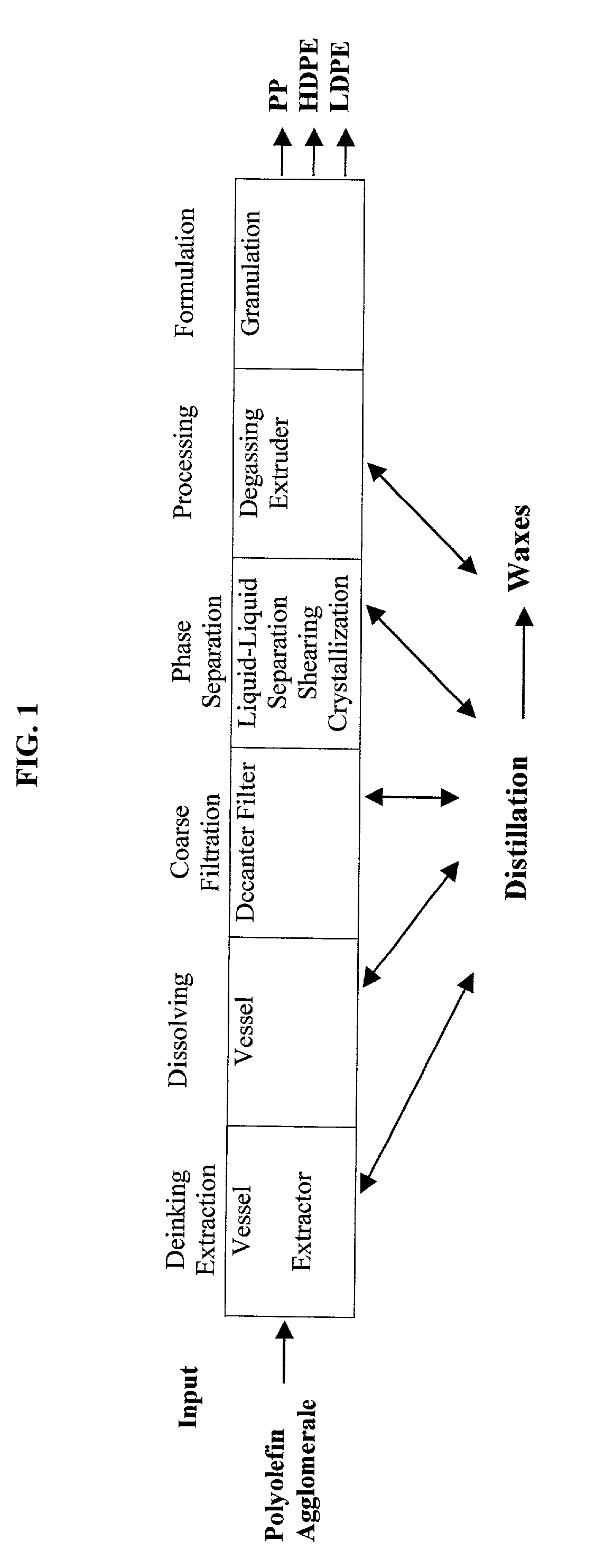

Method for the production of a polypropylene blend

InactiveUS20020128394A1Faster cycle timeMechanical characteristicPlastic recyclingPolymer recoveryOrganic solventPlastic packaging

A method for producing a polypropylene blend from a plastic packaging materials containing high molecular weight polypropylene, other high molecular weight polymers such as polyethylene, low molecular weight polymers and other contaminants. The method includes extraction, solid-liquid separation and liquid-liquid phase separation using various organic solvents. The polypropylene blend has a purity of 95% and has favorable melt flow characteristics, while retaining satisfactory mechanical properties.

Owner:DER GRUNE PUNKT DUALES SYST DEUTLAND

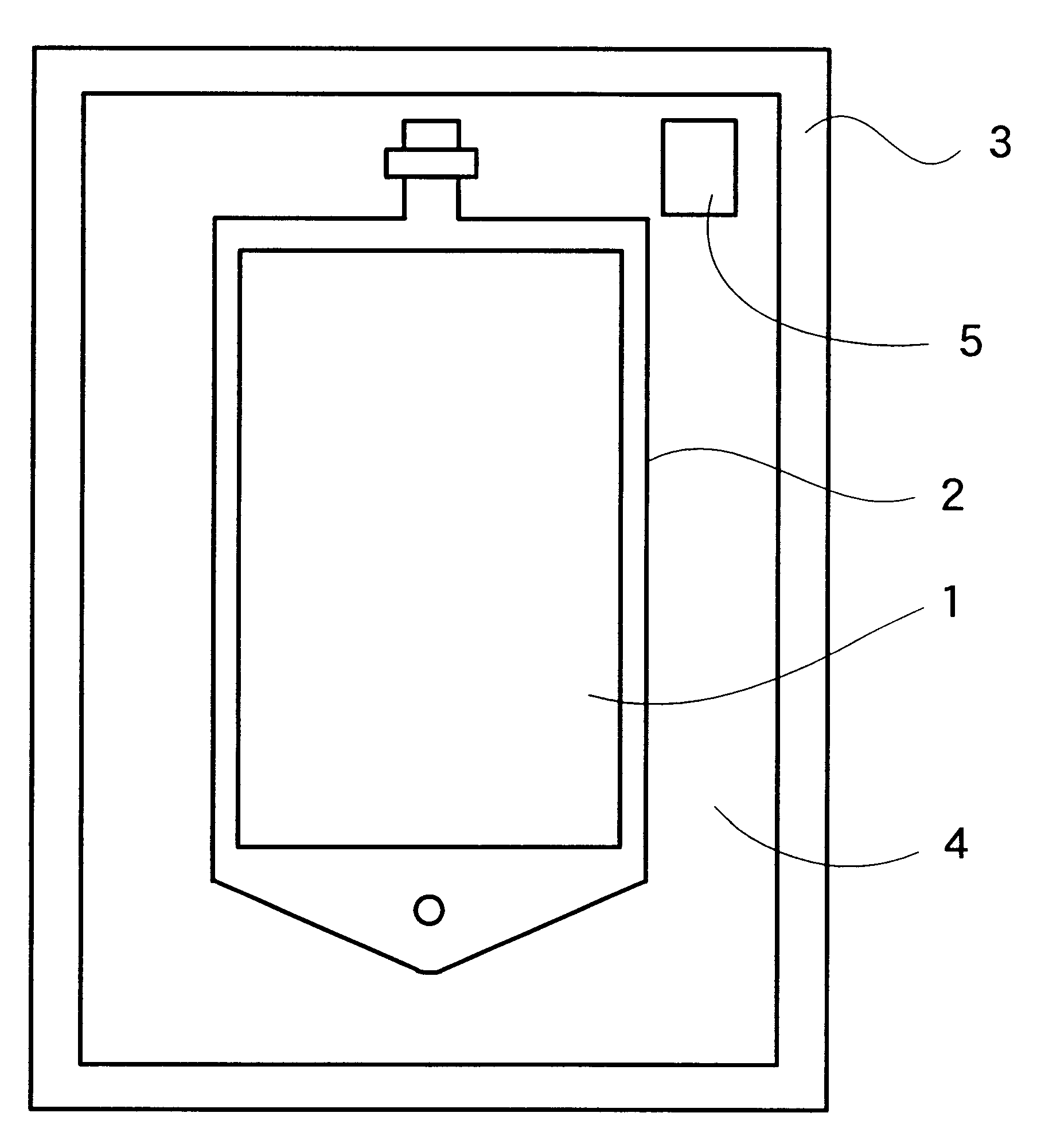

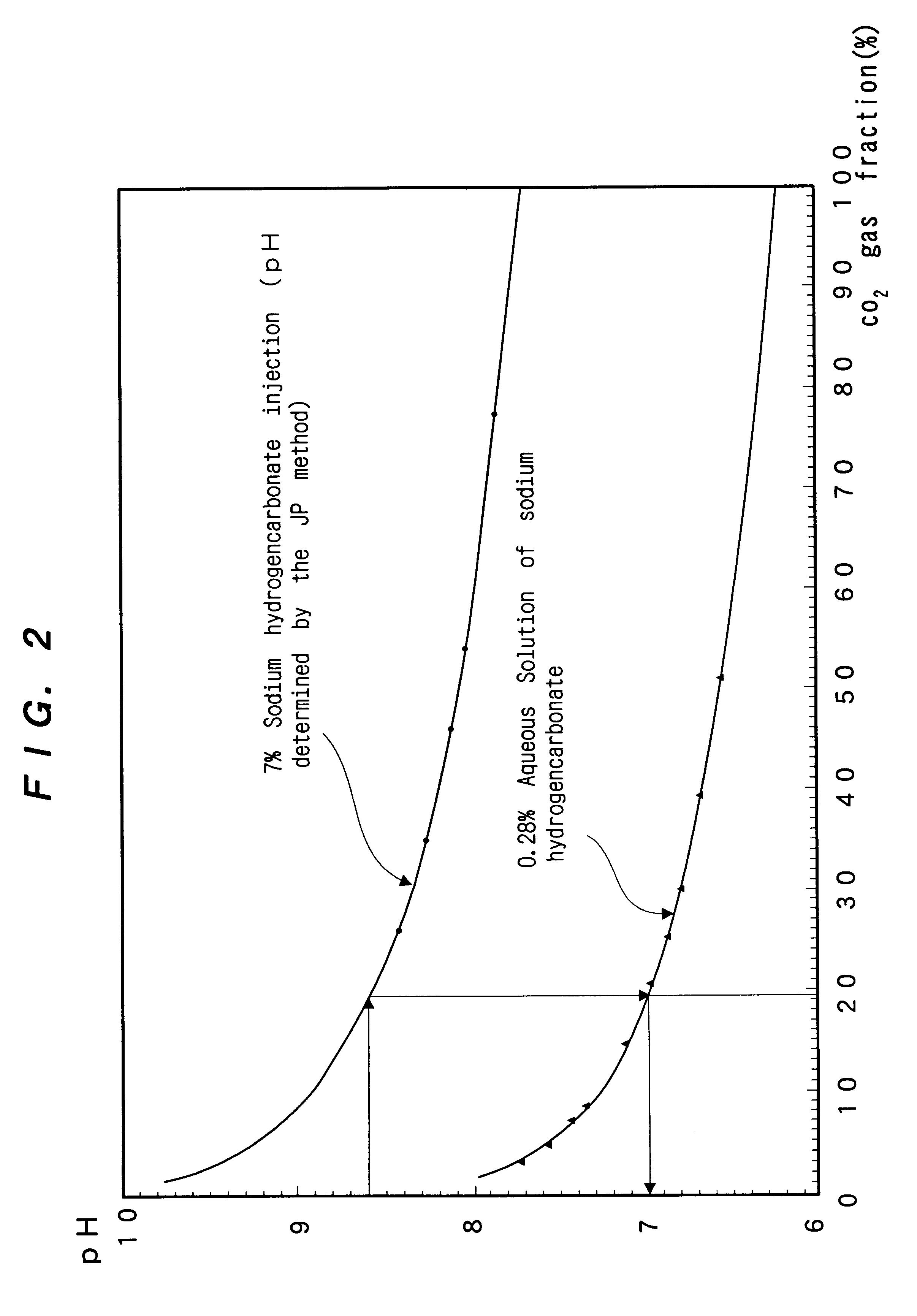

Package for container of liquid medicine containing bicarbonate and pH indicator

InactiveUS6232128B1Dissipation of gas releasedNot easily breakableAnalysis using chemical indicatorsChemical analysis using titrationPlastic packagingEngineering

The invention relates to a bicarbonate-containing medical solution package. The package comprises a gas-permeable plastic container holding a bicarbonate-containing medical solution and a gas-impermeable plastic packaging member containing the gas-permeable plastic container. A carbon-dioxide atmosphere is established in the space between the container and packaging member. In addition, a pH indicating device is contained within the space between the container and packaging member. The pH indicating device is a gas-permeable plastic packet containing a bicarbonate-containing fluid (similar to the medical solution) and a pH indicator. The pH indicator undergoes a change in color in response to a change in pH of the fluid. Use of this package allows the easy monitoring of a change in pH and consequent aging of the medical solution due to prolonged storage or damage to the outer packaging member.

Owner:OTSUKA PHARM FAB INC

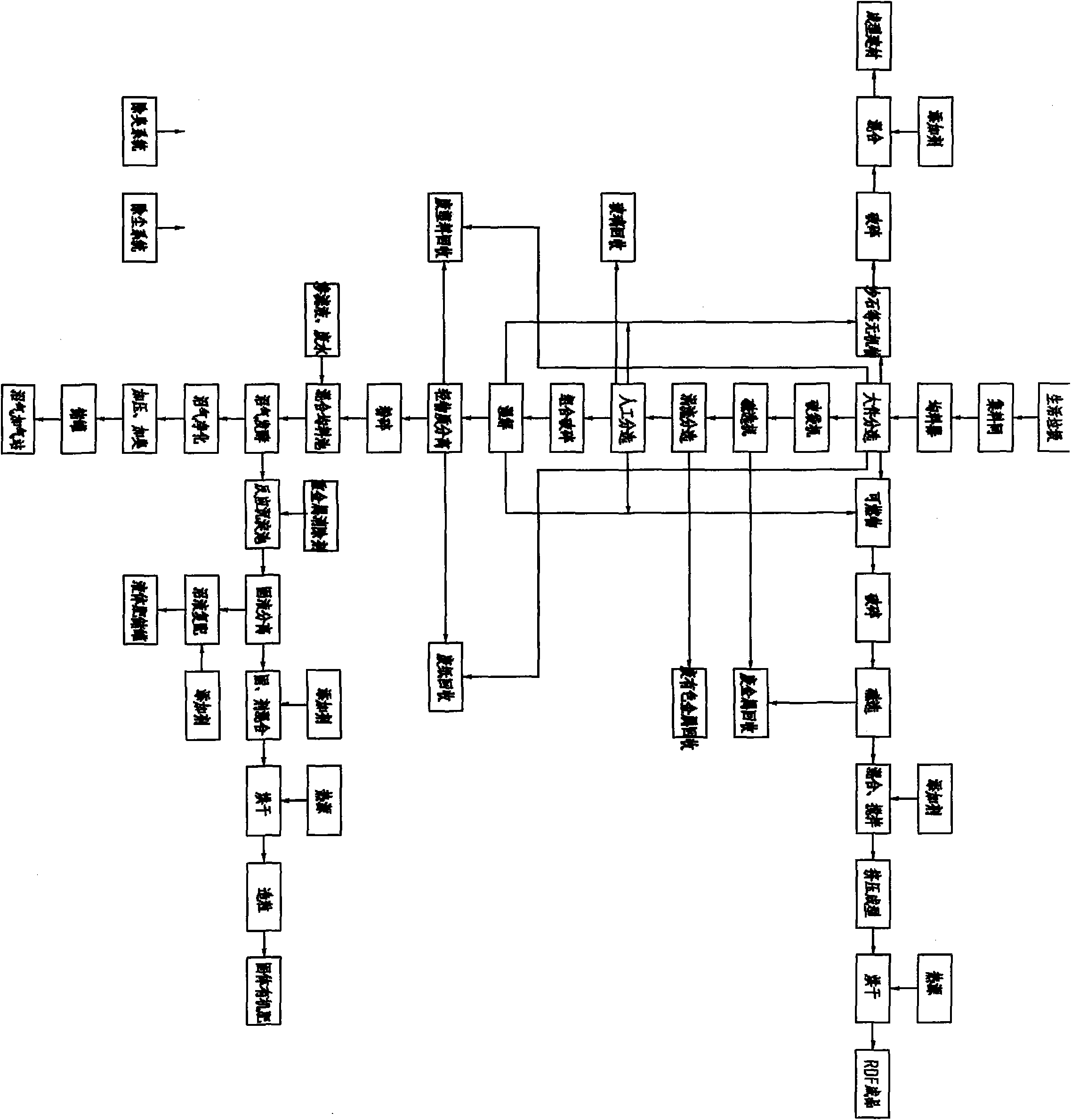

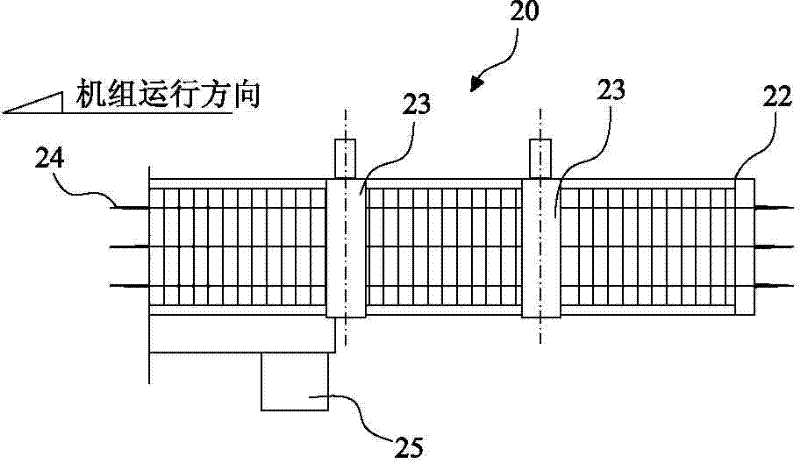

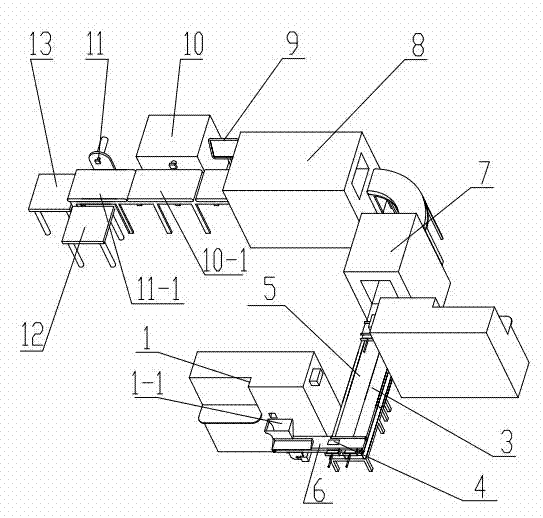

Full-automatic paper money clearing and packaging assembly line

ActiveCN102730227AAdjust the tightnessAnti-breakagePackaging automatic controlManagement unitPlastic packaging

The invention provides a full-automatic paper money clearing and packaging assembly line, structurally comprising a clearing and binding machine, a paper money sorting and transmitting mechanism, a stacking and wrapping machine, a paper money plastic packaging machine, a follow-up detecting and tidying mechanism, transmission belts and assorted sensors, wherein the clearing and binding machine, the paper money sorting and transmitting mechanism, the stacking and wrapping machine, the paper money plastic packaging machine and the follow-up detecting and tidying mechanism are sequentially arranged according to a technique flow order and are controlled by a main control management unit; and the transmission belts and the assorted sensors are arranged among the mechanisms. According to the main points, the paper money sorting and transmitting mechanism between the clearing and binding machine and the staking and wrapping machine refers to a sorting and transmitting channel formed by a middle transmission belt and parallel-connected double-channel transmission belts through bridge type connection. With the adoption of the automatic assembly line, paper money returned back to a bank can be automatically distinguished into ATM (Automatic Teller Machine) currency, circulation currency and damaged currency through a clearing and binding module according to a condition of the paper money, and then be automatically cleared up, boxed and put in storage through stamping, sorting, stacking, binding, labeling and plastically packaging without manual intervention, so that the high automation and the high production efficiency can be realized.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

Printed plastic packaging

InactiveUS20060151350A1Reduce manufacturing costHighly attractiveContainer decorationsLevel indicationsPlastic packagingAdhesive

A premium plastic package is provided as well as a method for producing such a package. Printing on multiple surfaces of a package to obtain appealing visual effects is described. Methods of sealing plastic packages are described, including some that use ultraviolet light to activate an adhesive. Plastic materials that can be used include recycled and / or recyclable polyurethane.

Owner:ONE SOURCE INDS

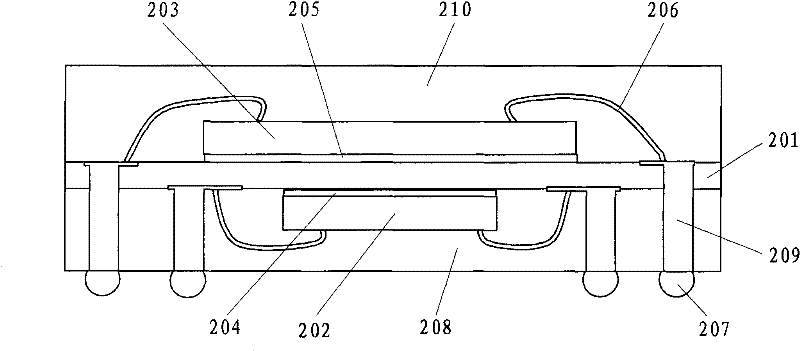

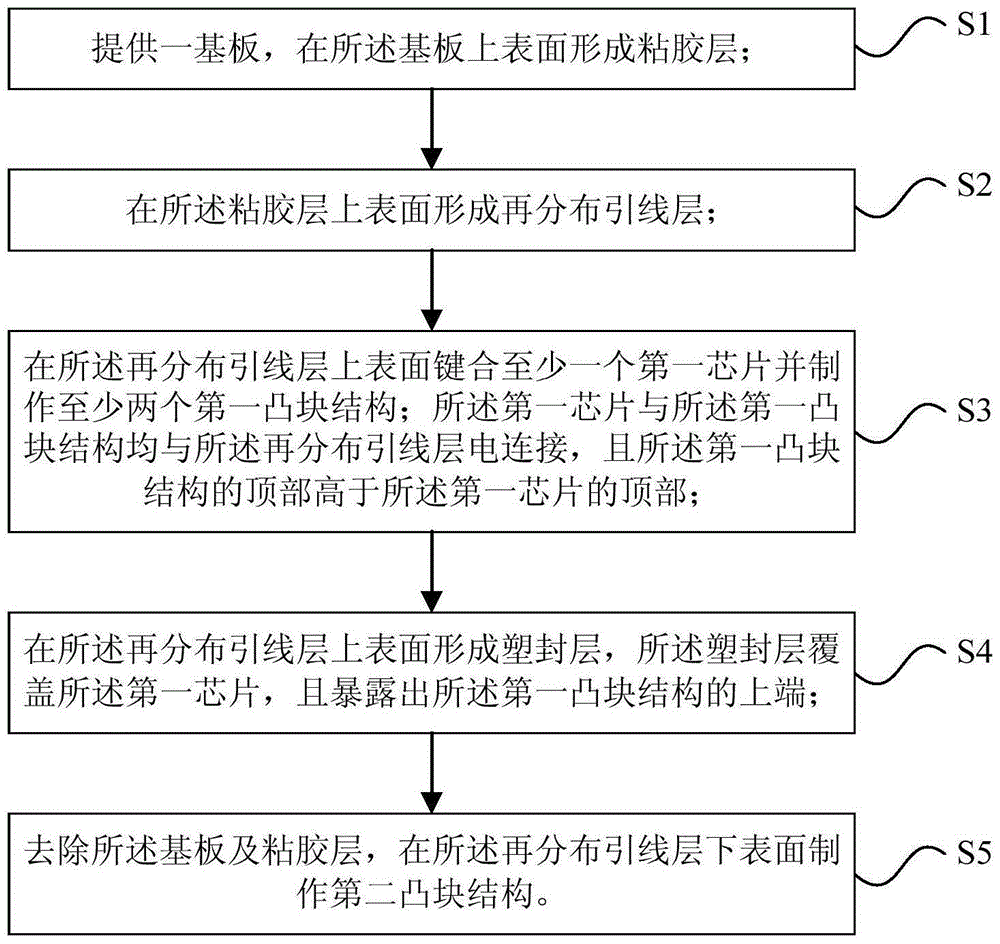

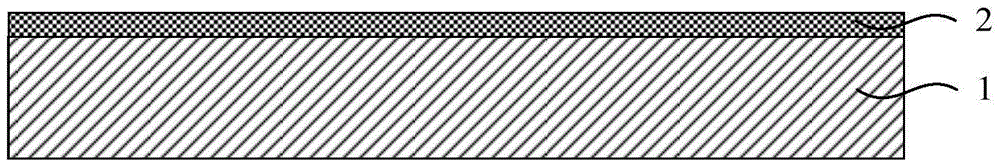

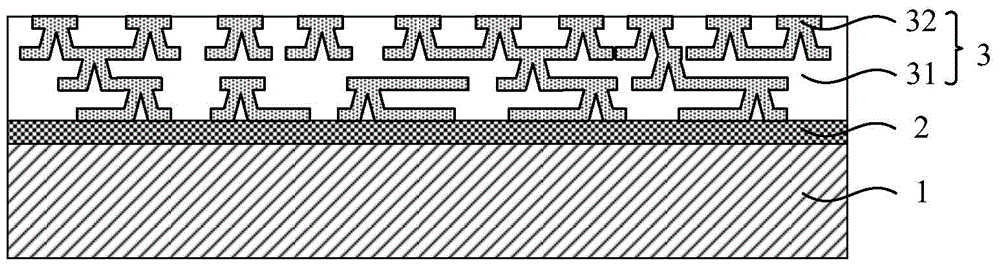

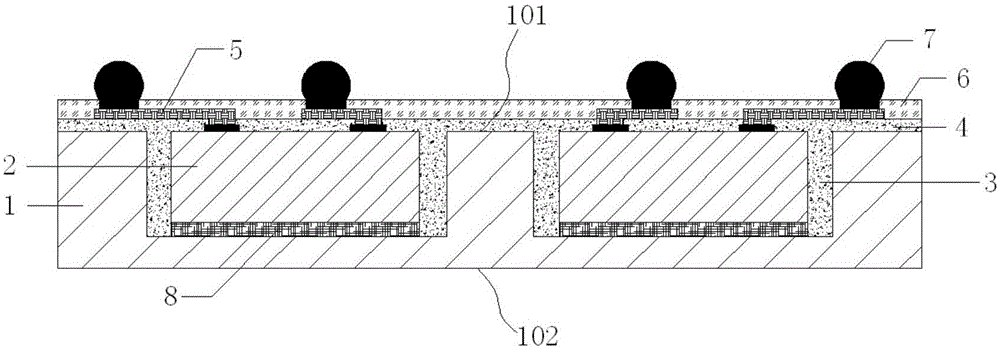

Fan-out type packaging structure and manufacturing method thereof

ActiveCN105225965AAvoid offsetAvoid damageSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention provides a fan-out type packaging structure and a manufacturing method thereof. The method includes the steps of: S1. providing a substrate, and forming an adhesive layer on an upper surface of the substrate; S2. forming a redistribution lead layer on an upper surface of the adhesive layer; S3. bonding at least one first chip and manufacturing at least two first lug structures on an upper surface of the redistribution lead layer, wherein the first chips and the first lug structures are electrically connected with the redistribution lead layer, and the tops of the first lug structures are higher than the tops of the first chips; S4. forming a plastic packaging layer on the upper surface of the redistribution lead layer, the plastic packaging layer covering the first chips and exposing upper ends of the first lug structures; and S5. removing the substrate and the adhesive layer, and manufacturing second lug structures on a lower surface of the redistribution lead layer. The manufacturing method of the fan-out type packaging structure can reduce offset between the chips and the redistribution lead layer, thereby improving the yield; and a packaging process is relatively simple, and product cost can be reduced.

Owner:SJ SEMICON JIANGYIN CORP

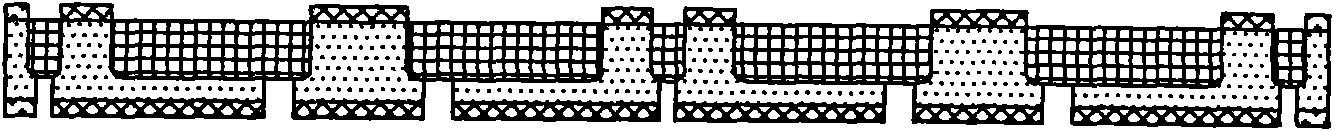

Small-carrier flat-four-side pin-less packaging part and preparation method thereof

ActiveCN101697348ASaving wire costSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a small-carrier flat-four-side pin-less packaging part, which comprises a lead frame carrier, a bonding sheet adhesive, an IC chip, a soldering-pan on the IC chip, a bonding line and a plastic-packaged body. The packaging part is characterized in that: before cutting separation, all inner pins extend inwards to connect with the carrier; a groove is formed between the carrier and the inner pins; the bottom parts of the inner pins are provided with grooves, and the backside of the carrier is provided with a circle of anti-flash groove. The packaging part is processed and produced through the process steps of thinning, scribing, chip loading, press welding, plastic packaging, electroplating, cutting and the like. The small-carrier flat-four-side pin-less packaging part has the characteristics that the carrier is reduced, the inner pins extend inwards to connect with the carrier before the cutting separation, the connection part of the inner pins and the carrier is provided with a 0.10 mm pit, the pin length outside the pit is 1 mm longer than that of a common QFN pin, and the lower part of the carrier is provided with a circle of the anti-flash groove which can prevent flashes from continuously dispersing towards the backside of the carrier.

Owner:TIANSHUI HUATIAN TECH

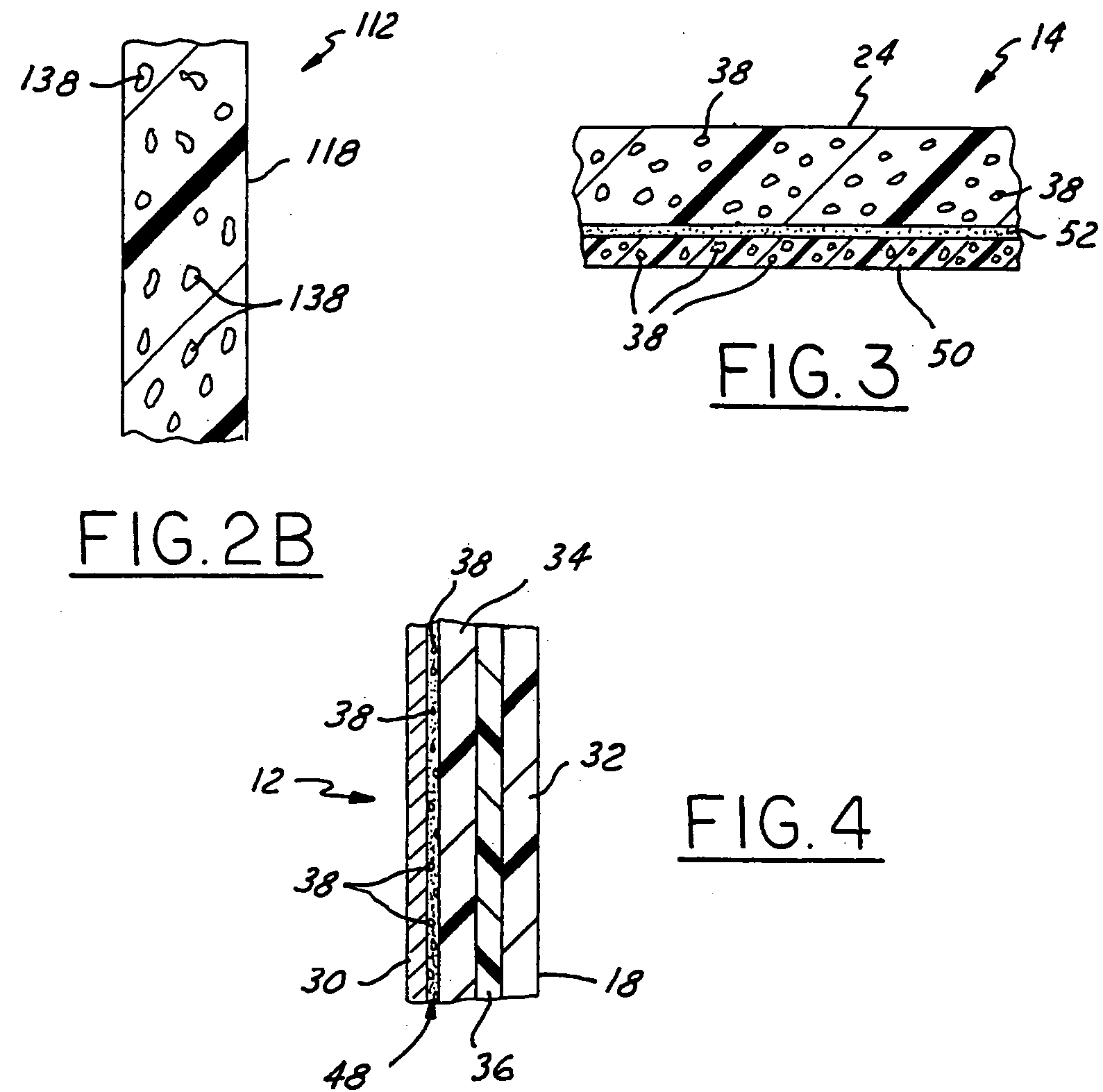

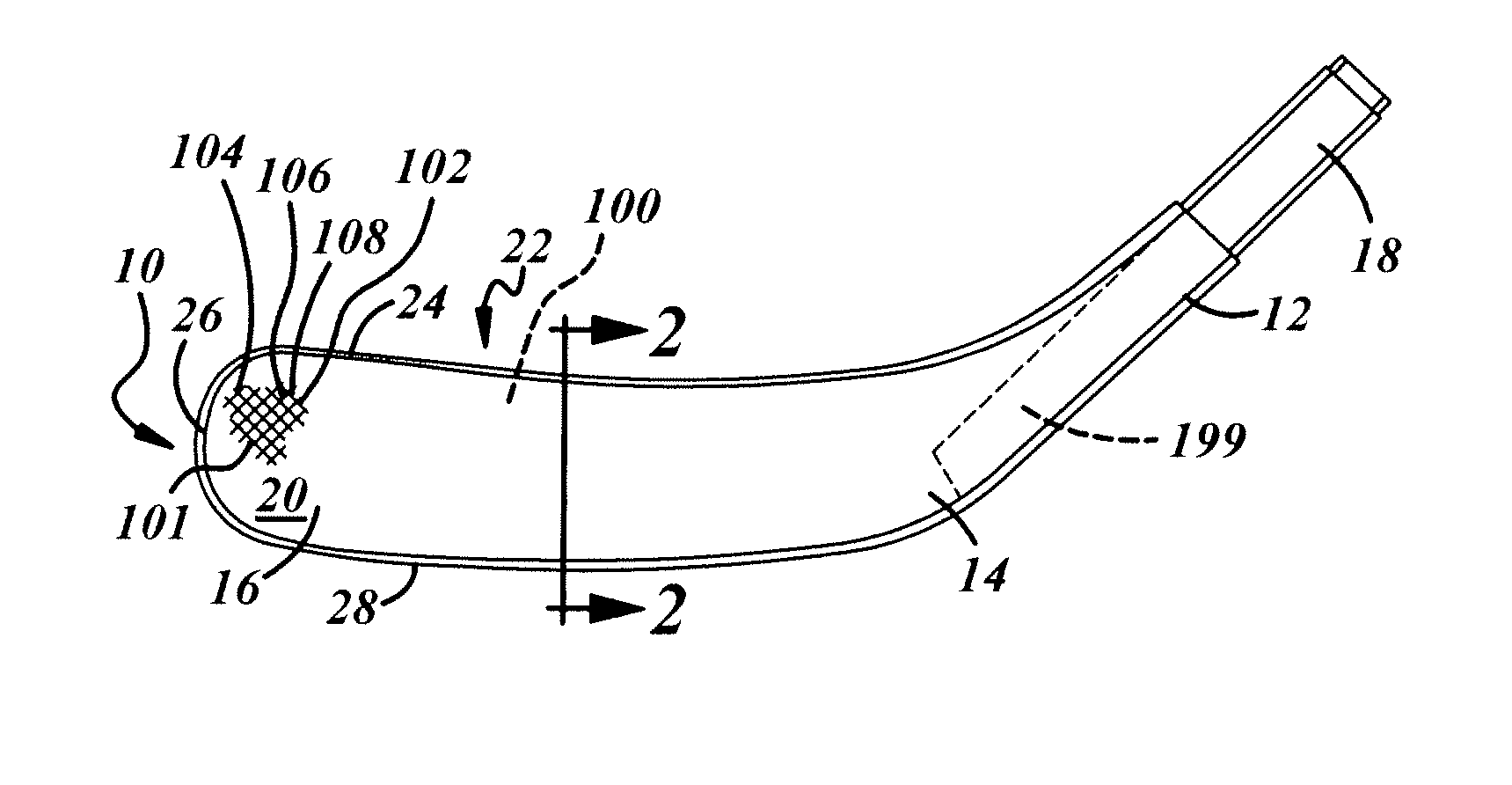

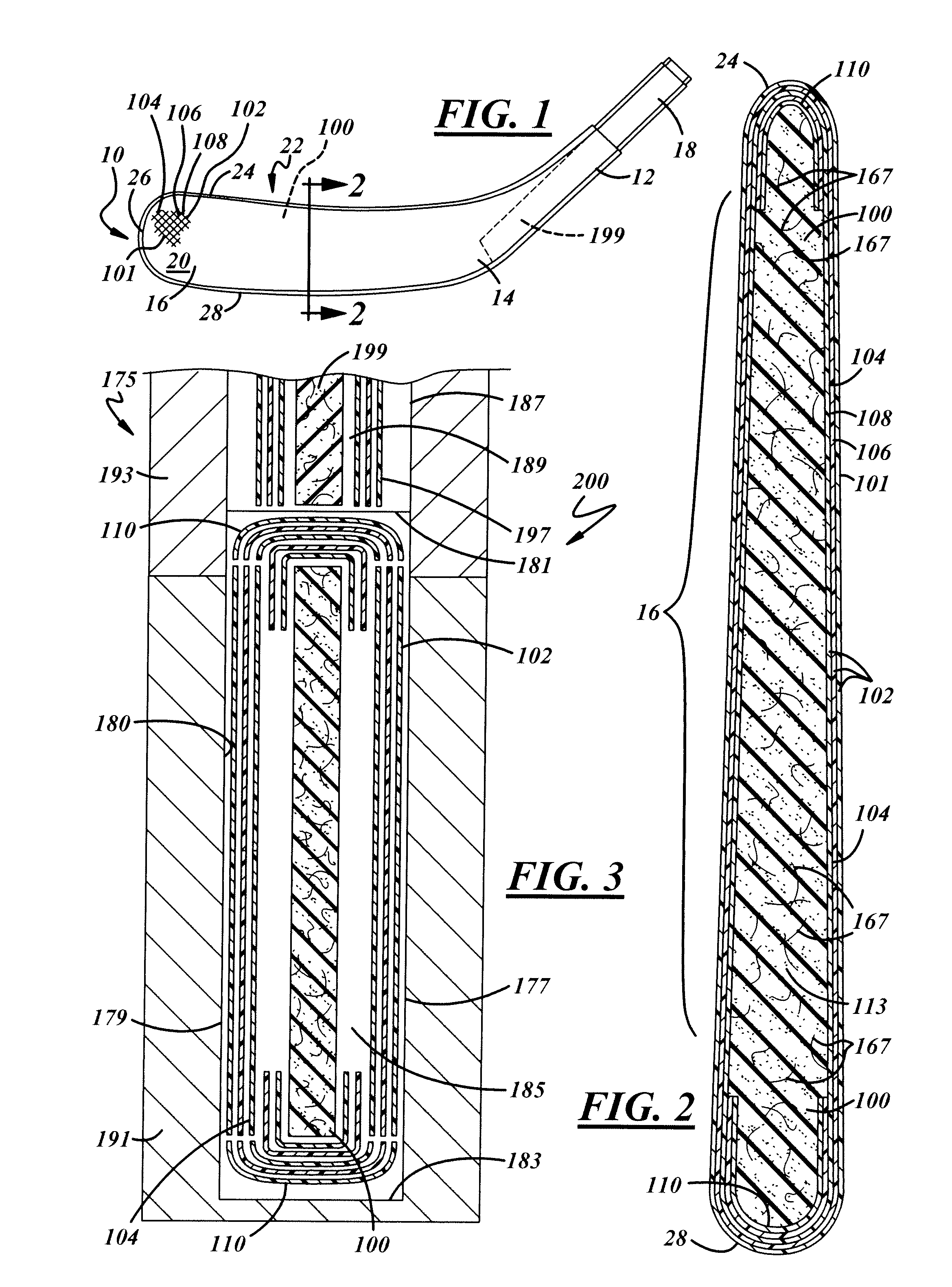

Hockey Stick Blade Having Fiber-Reinforced High Density Foam Core

InactiveUS20090149284A1Improve responsePreventing “ flutter ”Racket sportsHigh densityPlastic packaging

A composite hockey stick blade including a fiber reinforced, high-density foam polymeric core material overlaid with a plastic wrap. The fiber reinforcement material, in the form of a plurality of milled or long fibers, provides increased toughness and stiffness of the high density polymeric foam core material. The hockey stick blade may be utilized as a replacement blade for a two-piece hockey stick, or may be a portion of a one-piece hockey stick.

Owner:WARRIOR SPORTS INC

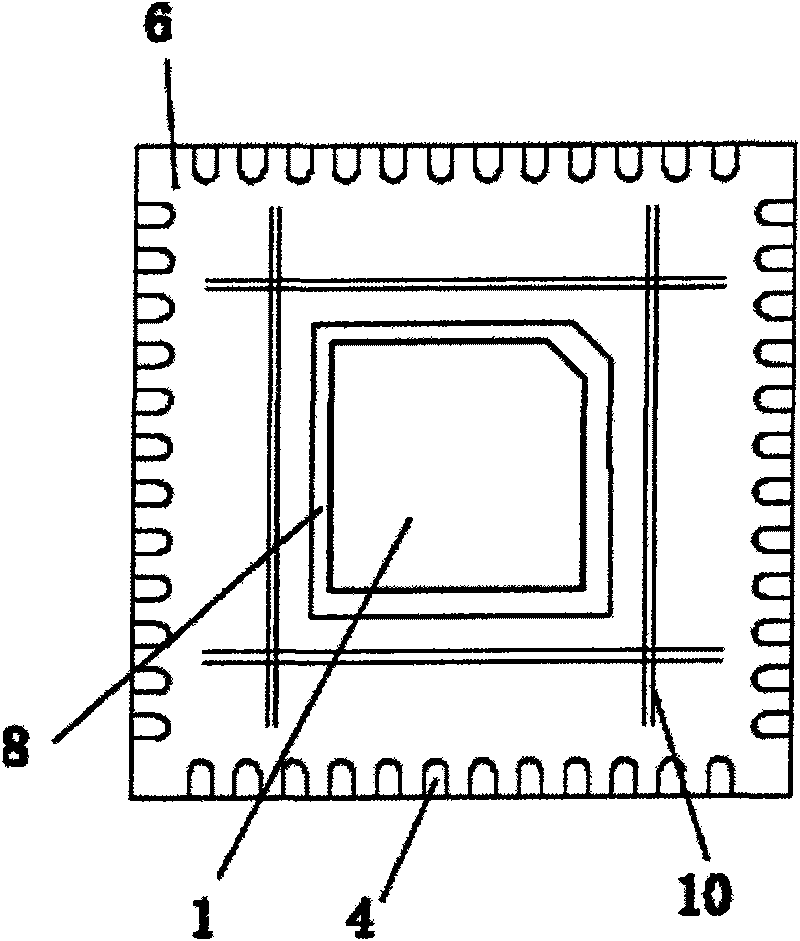

Multi-ring-arranged double-integrated circuit (IC) chip packaging piece and production method thereof

ActiveCN102222657AShort heat conduction heat conduction distanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

The invention discloses a multi-ring-arranged double-integrated circuit (IC) chip packaging piece and a production method thereof. The multi-ring-arranged double-IC chip packaging piece comprises a multi-ring quad flat no (QFN) lead frame with a carrier, an internal pin, IC chips and a plastic package body. The production method comprises the following steps of: thinning; scribing; adding the chips primarily; performing pressure welding; inversely adding the chips secondarily; filling the bottom and solidifying; performing plastic packaging and post solidifying; printing; separating pins; electroplating; separating products; testing the products; packing; and warehousing. Compared with a single-row lead frame with the same area as the multi-ring QFN lead frame, the multi-ring QFN lead frame increases the pins by over 40 percent, so that the requirements of high density and multiple input / output (I / O) packages are met; the chips are inversely added, so that the packaging piece has a small number of short welding lines, a short heat conduction distance and high radiation capacity; through the inverse addition of the chips, the capacitance and the inductance between protruding points and the pins are far lower than those of the welding lines between a chip welding disc and the pins, so that the influence on high frequency application is reduced; and the thickness of a QFN can be reduced to be below 0.5mm, so that the intersection and the open circuit of the welding lines are avoided and testing qualified rate and testing reliability are improved.

Owner:TIANSHUI HUATIAN TECH +1

Degradable plastic packaging bag

InactiveCN104927318AHigh tensile strengthLow moisture permeabilityFlexible coversWrappersArray data structurePolyvinyl alcohol

The present invention belongs to the field of plastic products, and particularly relates to a biodegradable plastic packaging bag which is characterized by comprising the following components by weight: 5-15 parts of ethyl cellulose, 10-20 parts of polyethylene, 15-30 parts of modified starch, 15-30 parts of corn starch, 15-30 parts of sweet potato starch, 20-40 parts of polylactic acid, 2-10 parts of calcium carbonate powder, 1-5 parts of a lubricant, 1-5 parts of a plasticizer, 1-3 parts of a toughening agent, 1-10 parts of a degradation accelerator, 1-5 parts of polyvinyl alcohol, 2-5parts of chitosan, 1-5 parts of a compatibilizing agent and 2-6 parts of polycaprolactone. The biodegradable plastic packaging bag begins to thin, lose in weight, reduce in strength, then gradually splits into fragments after being exposed to the environment for two months, when these fragments are buried in garbage or soil, the degradation effect is very obvious; by addition of the plasticizer and the calcium carbonate powder, the added ingredients may enhance the tensile strength of the plastic packing tape, reduce the air and moisture permeability, and maintain the original characteristics of the plastic packaging bag.

Owner:TIANJIN YOUZHI TECH CO LTD

Embedded silicon substrate fan-out type packaging structure and manufacturing method thereof

InactiveCN105023900AImprove cooling effectAvoid offsetSemiconductor/solid-state device detailsSolid-state devicesSilicon matrixPolymer adhesive

The invention discloses an embedded silicon substrate fan-out type packaging structure and a manufacturing method thereof. A silicon matrix is adopted to replace molding material to act as a fan-out matrix, and fine wiring can be manufactured by fully utilizing the advantages of the silicon matrix. Holes, grooves and other structures can be accurately etched by utilizing a mature silicon etching technology. Chips are embedded in the grooves on the silicon matrix, the gaps between the chips and the side walls of the grooves are filled by polymer glue and partial welded balls are welded at the surface of the silicon matrix in a fan-out way so that packaging reliability can be enhanced, the technology is simple and cost is low. The silicon matrix has great heat radiation and lower warping so that enhancement of packaging heat radiation is facilitated, adverse warping can be overcome and smaller wiring line width can be acquired, and thus the structure is suitable for high-density packaging. `Wafer plastic packaging and the de-bonding technology can be eliminated as for the aspect of technology so that technology difficulty can be reduced, and thus cost can be substantially reduced and yield rate can be enhanced.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com