Patents

Literature

27766 results about "Paper sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

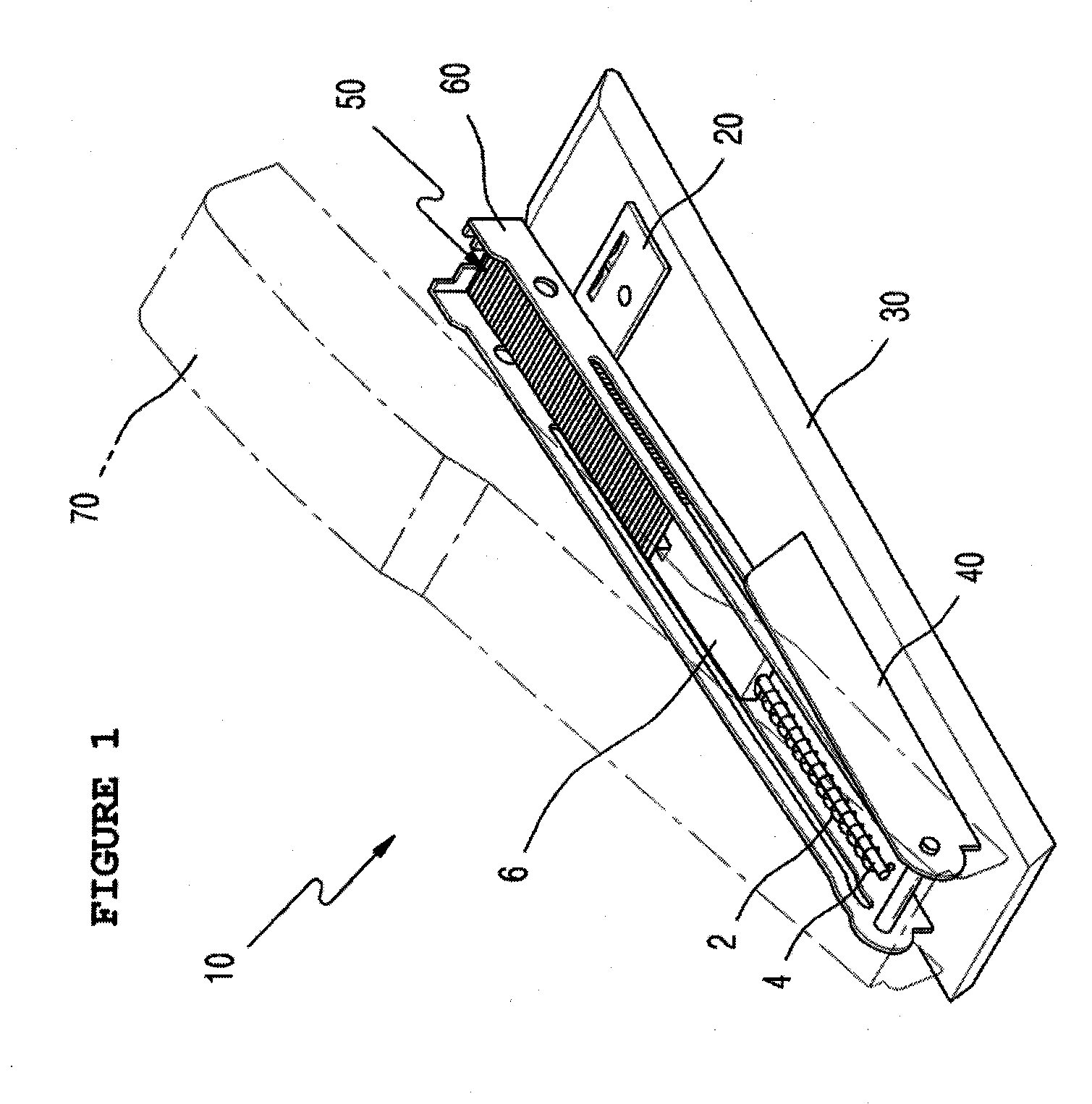

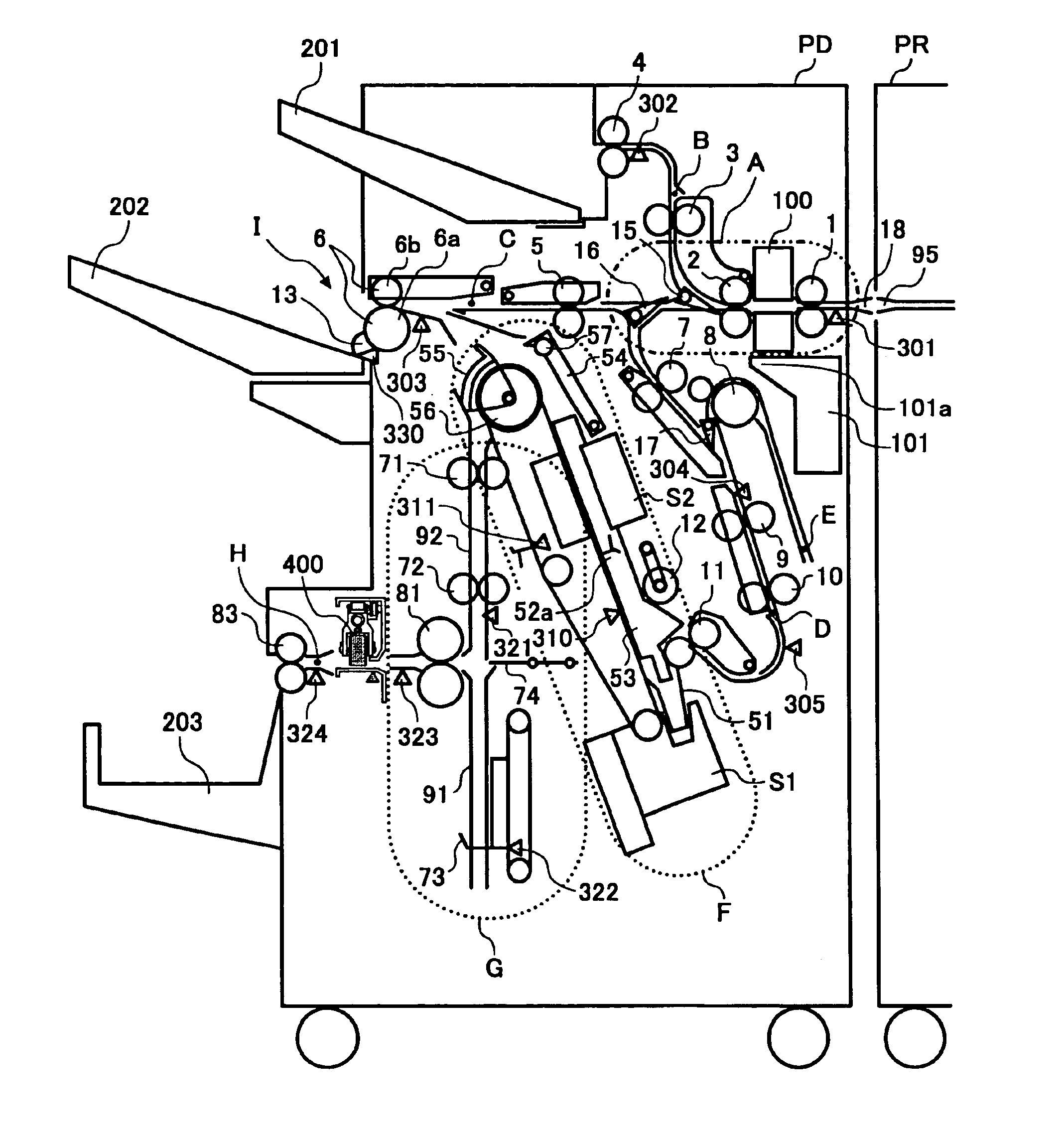

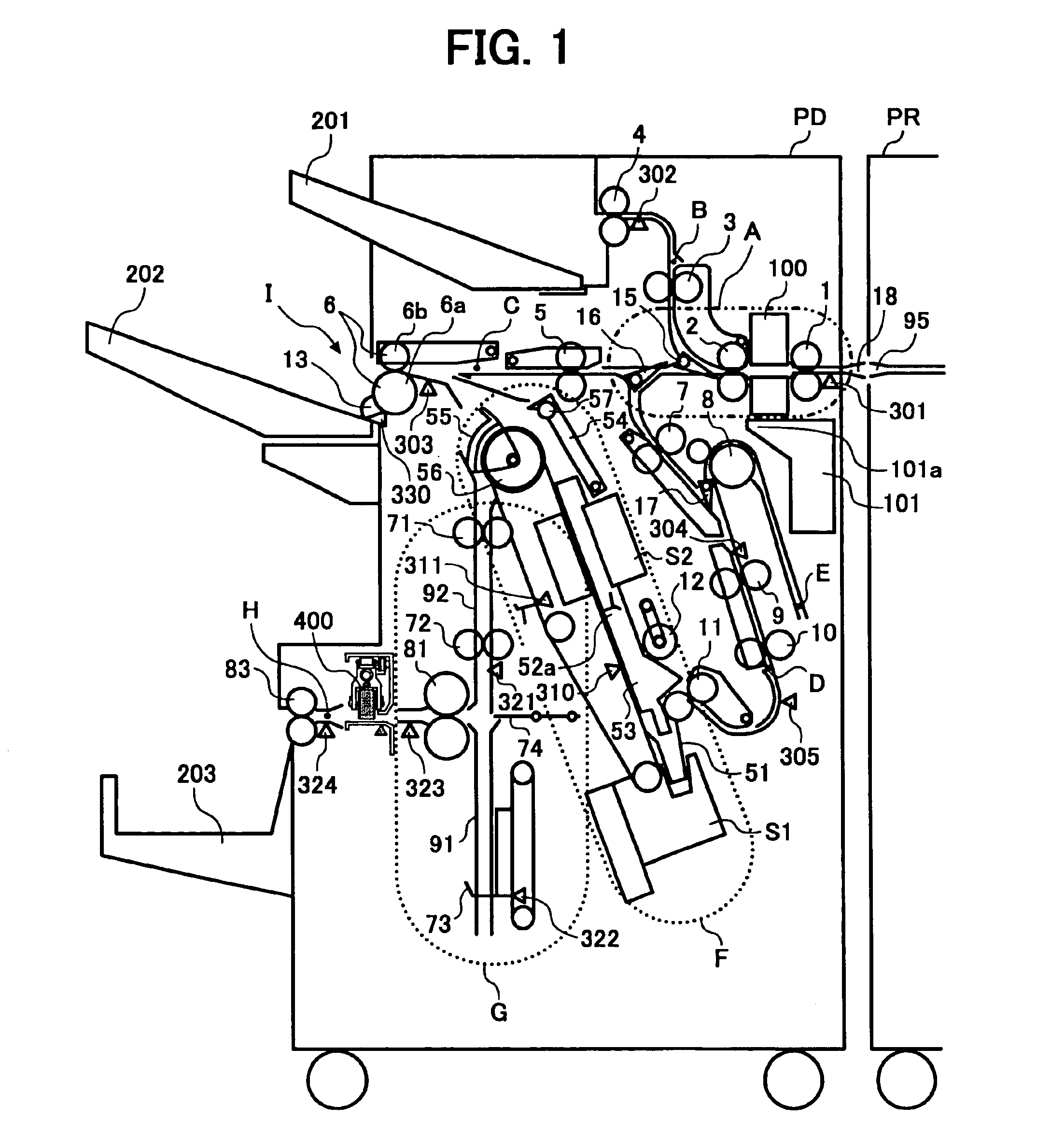

Sheet finisher having an angularly movable stapler and image forming system including the same

InactiveUS7207556B2Simple configurationReduce driving loadStapling toolsElectrographic process apparatusEngineeringPaper sheet

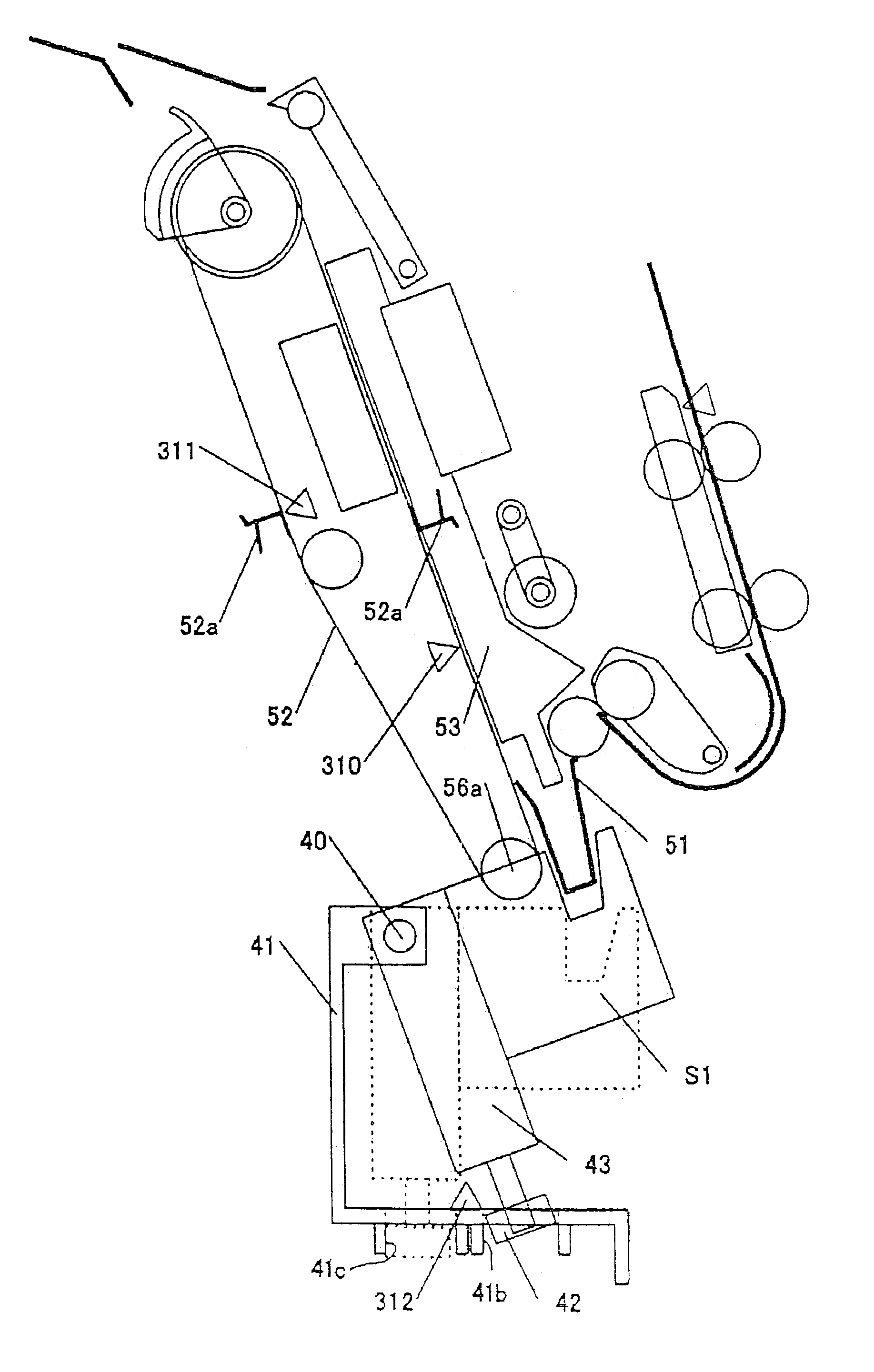

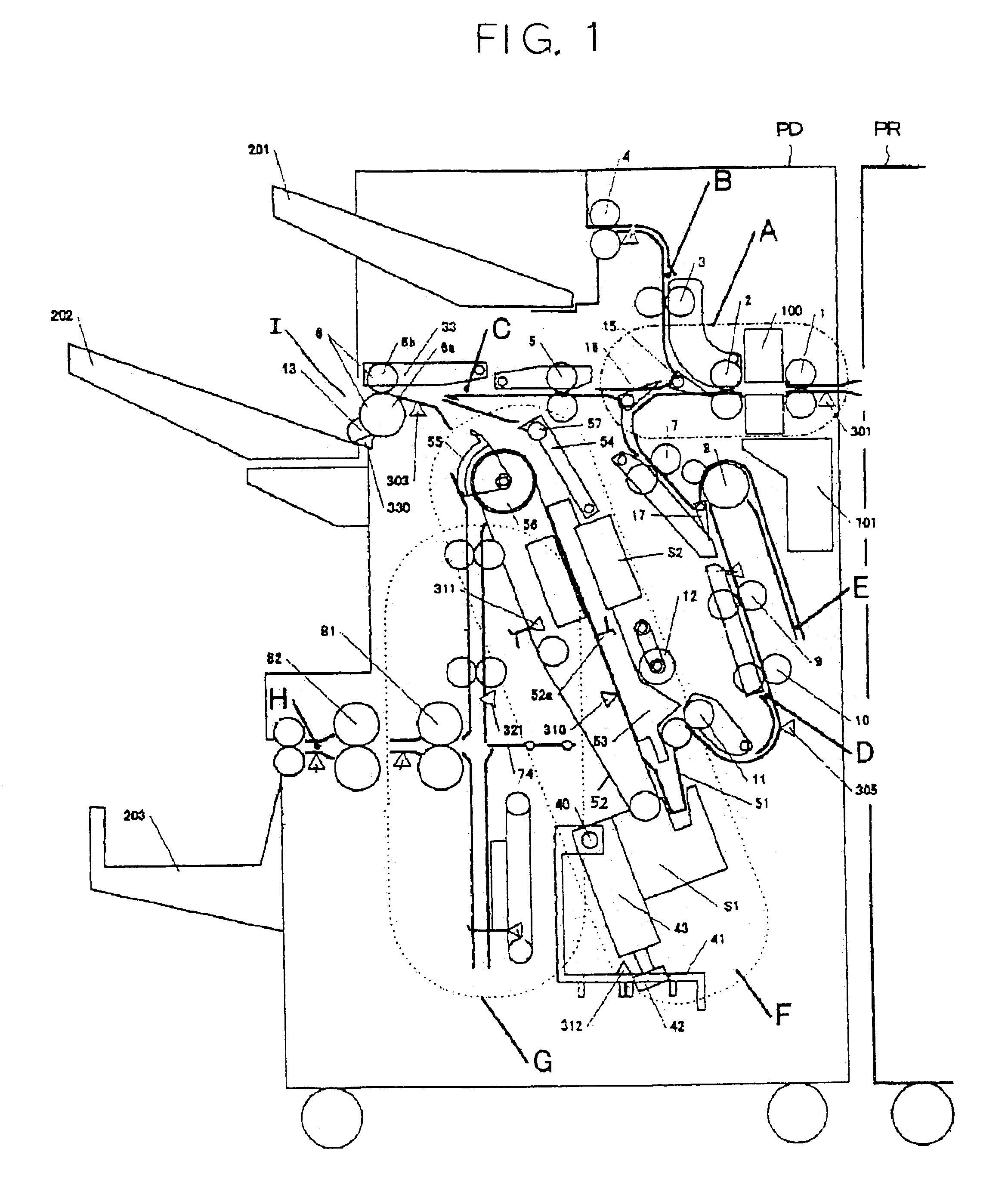

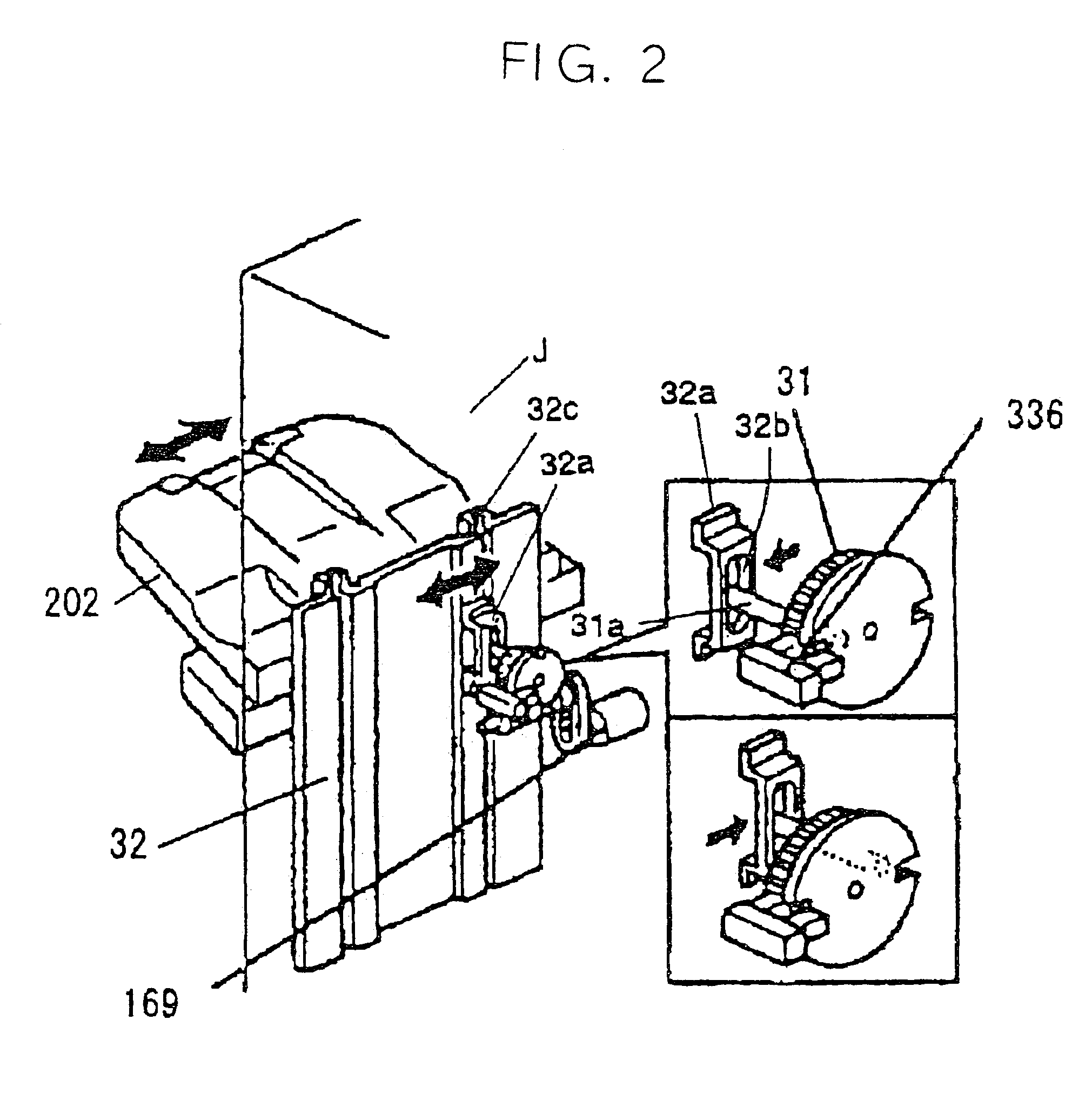

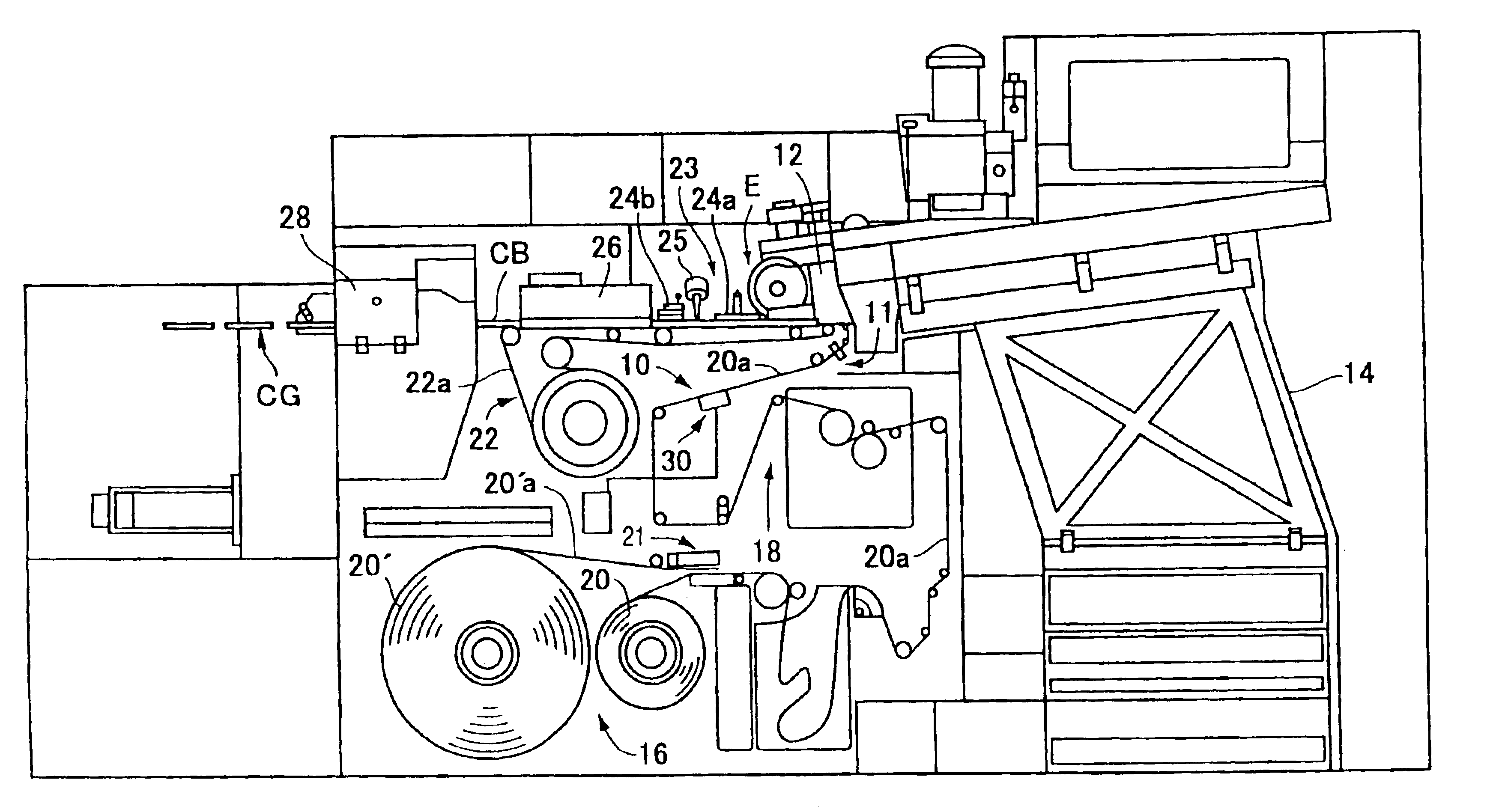

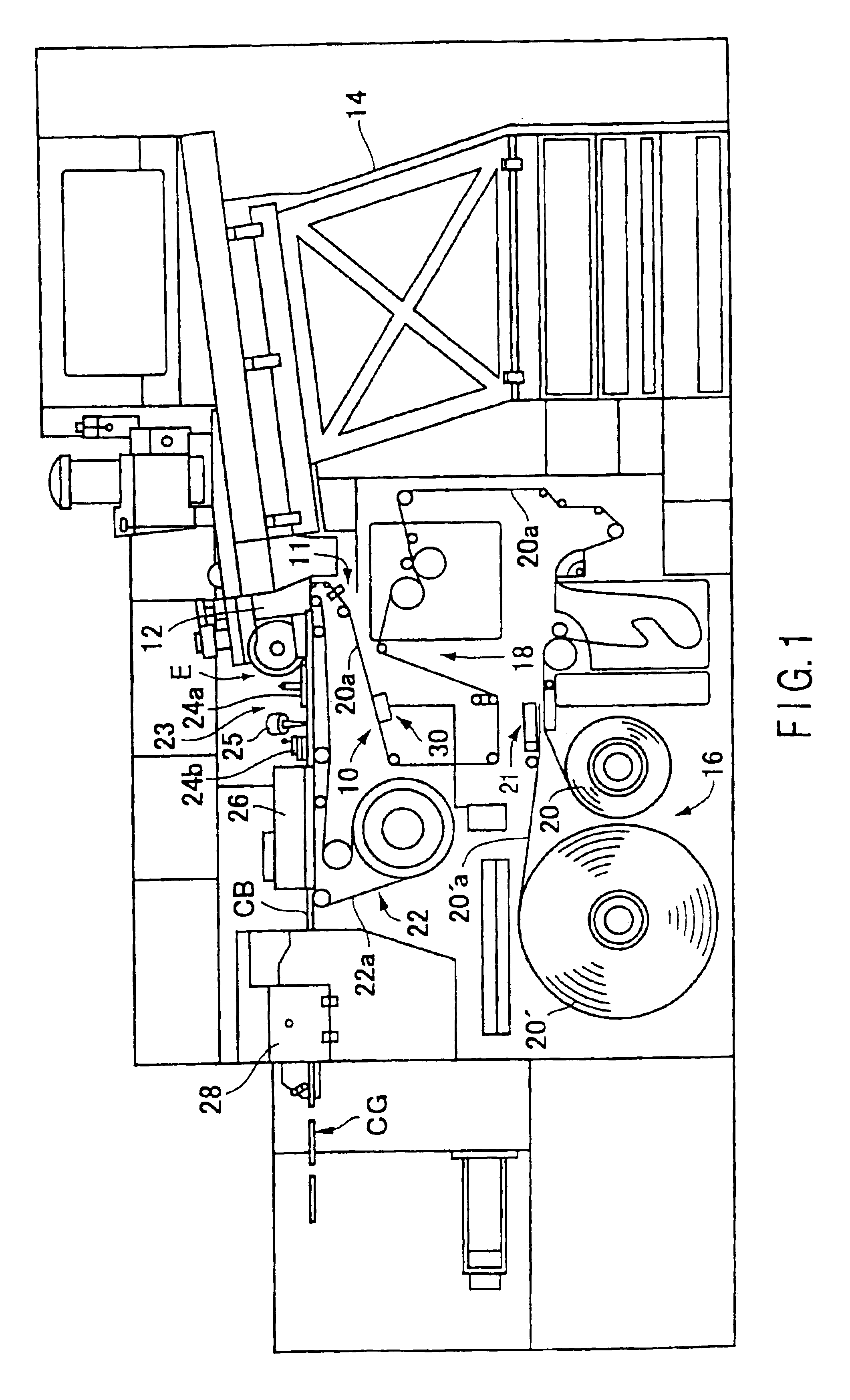

A sheet finisher for executing preselected processing with a sheet introduced thereinto from an image forming apparatus and then discharging the sheet is disclosed. The sheet finisher includes a stacking device configured to temporarily stack sheets sequentially delivered thereto. Jogger fences jog each sheet within the stacking device. A stapler staples the sheet stack jogged in the stacking device. The stapler is supported by a guide shaft such it is movable along the guide shaft in a direction perpendicular to the direction of sheet conveyance and angularly movable in a direction perpendicular to the direction of guide.

Owner:RICOH KK

Structure of staple magazine having permanent magnet

The present invention uses the principle in which staples made of iron are attracted in a direction in which magnetic attraction force is generated. Using this principle, a permanent magnet is provided on a front wall of a staple magazine, so that a staple cartridge is attracted towards an ejection slot of the staple magazine by the magnetic attraction force of the permanent magnet. When a handle having a punching blade is pushed, the frontmost staple in the staple cartridge, which is aligned with the ejection slot, is ejected by the punching blade to staple paper sheets. After the frontmost staple is ejected, the staple cartridge is automatically moved to and brought into close contact with the front wall of the staple magazine such that a subsequent staple, which is in a frontmost position, is aligned with the ejection slot to prepare for a subsequent stapling operation.

Owner:UHM HYUN DUK

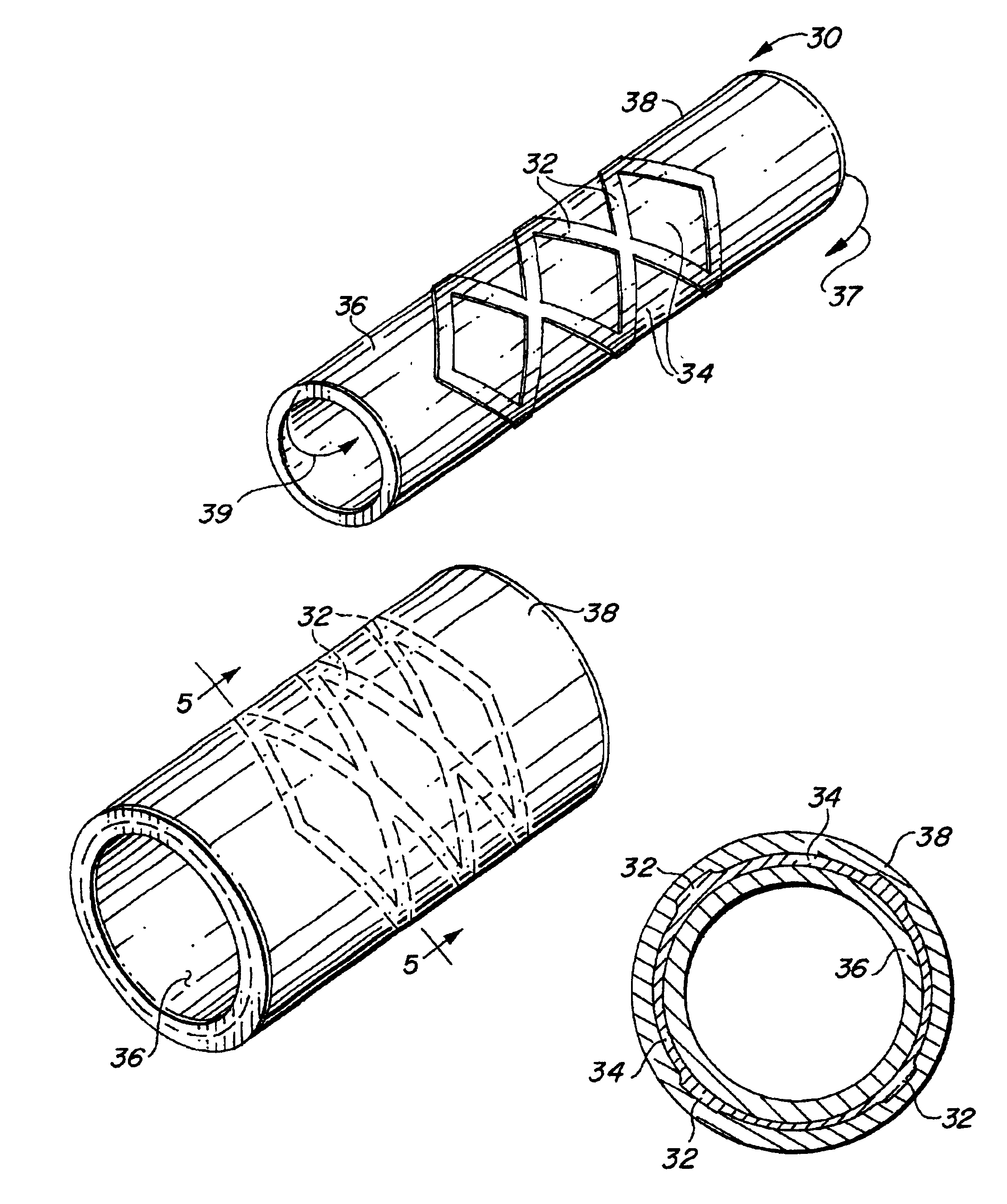

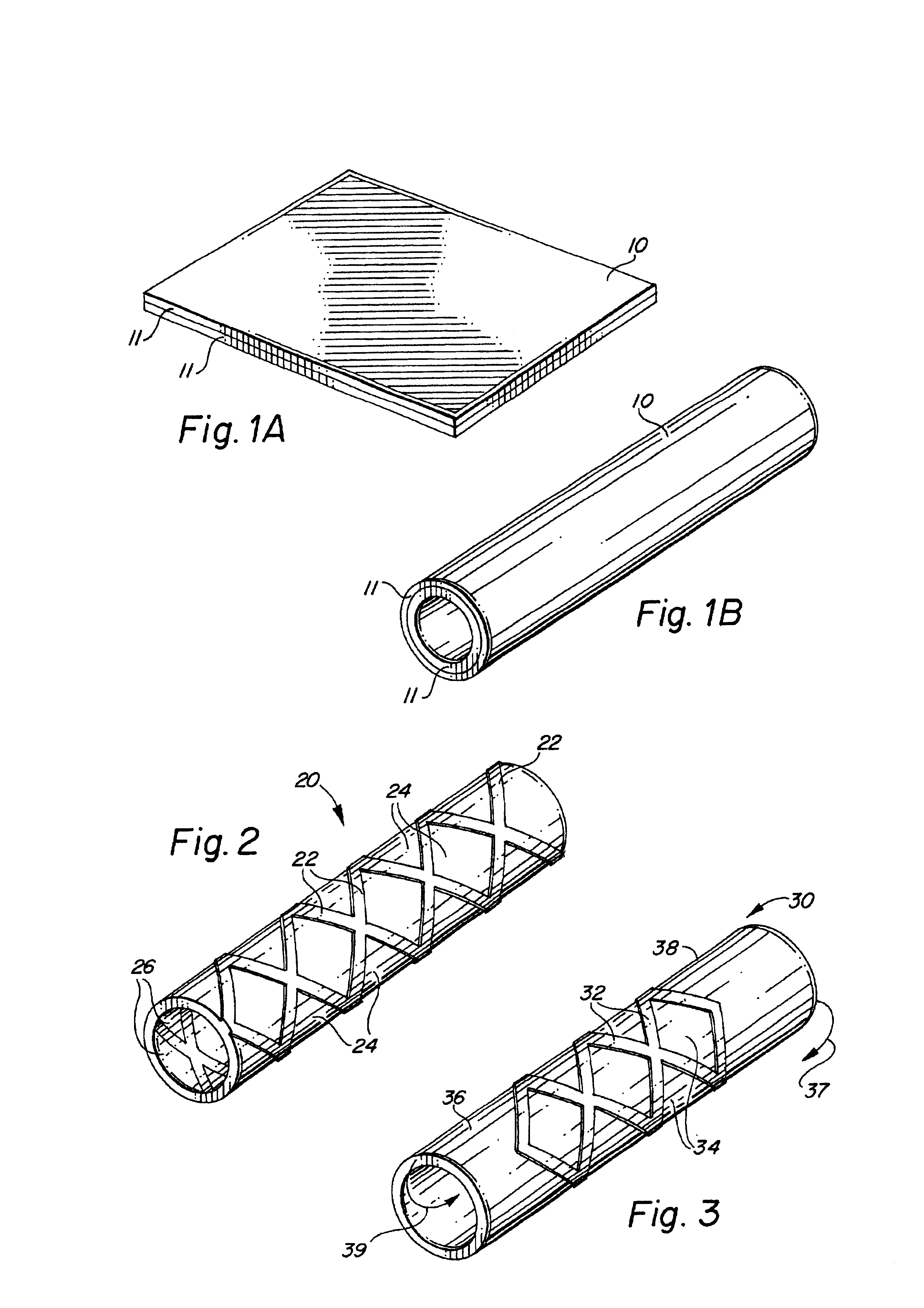

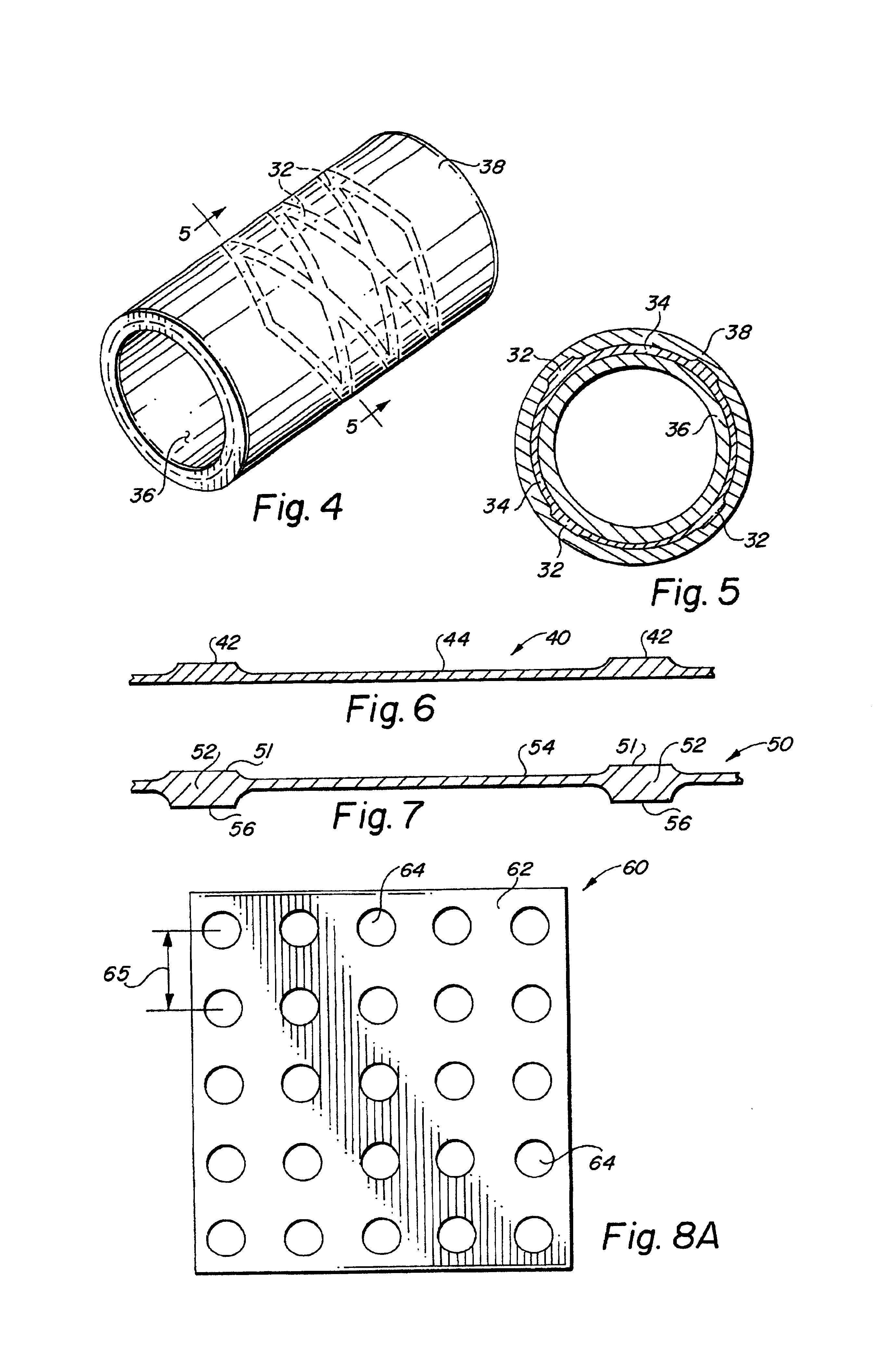

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

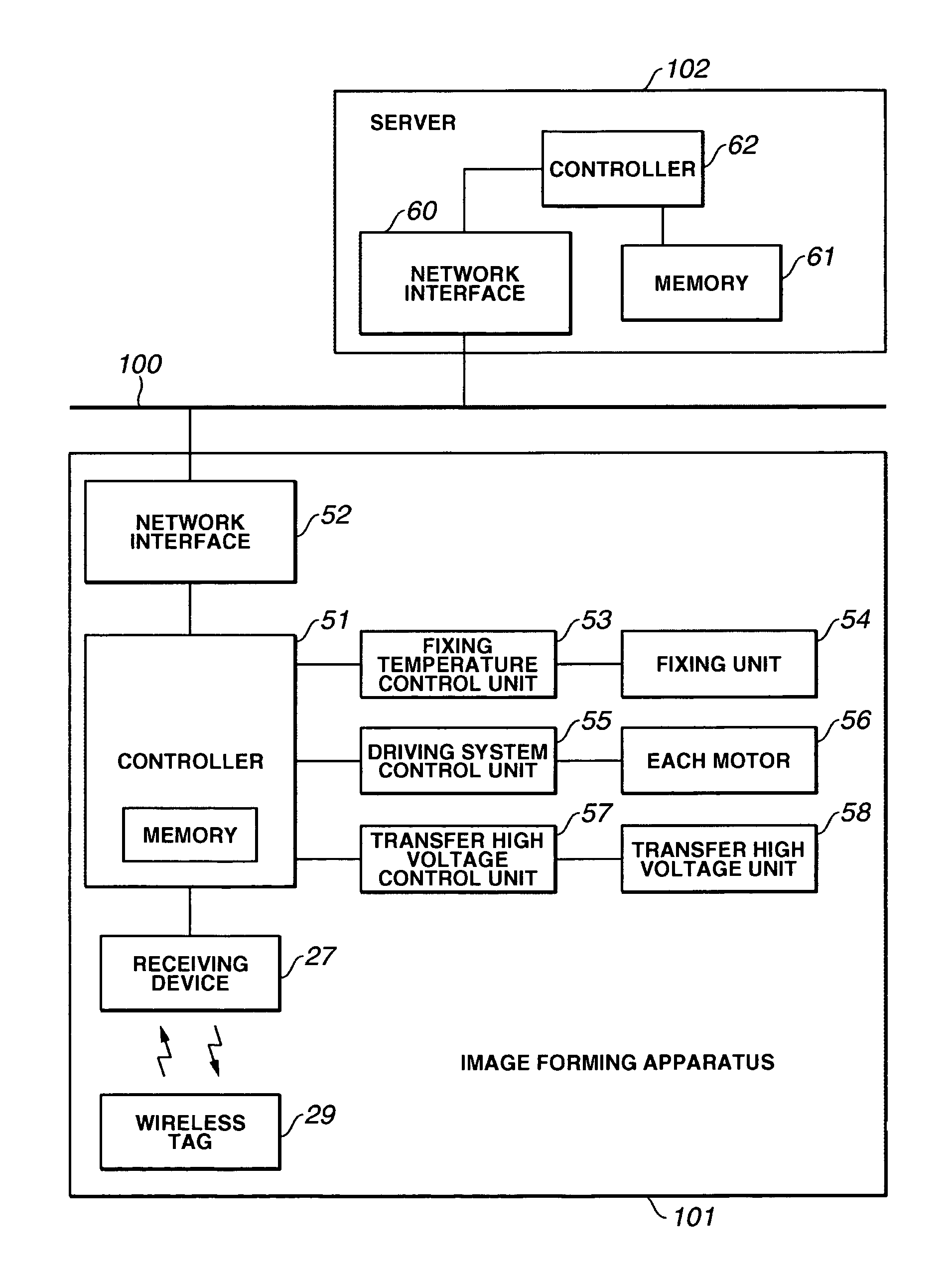

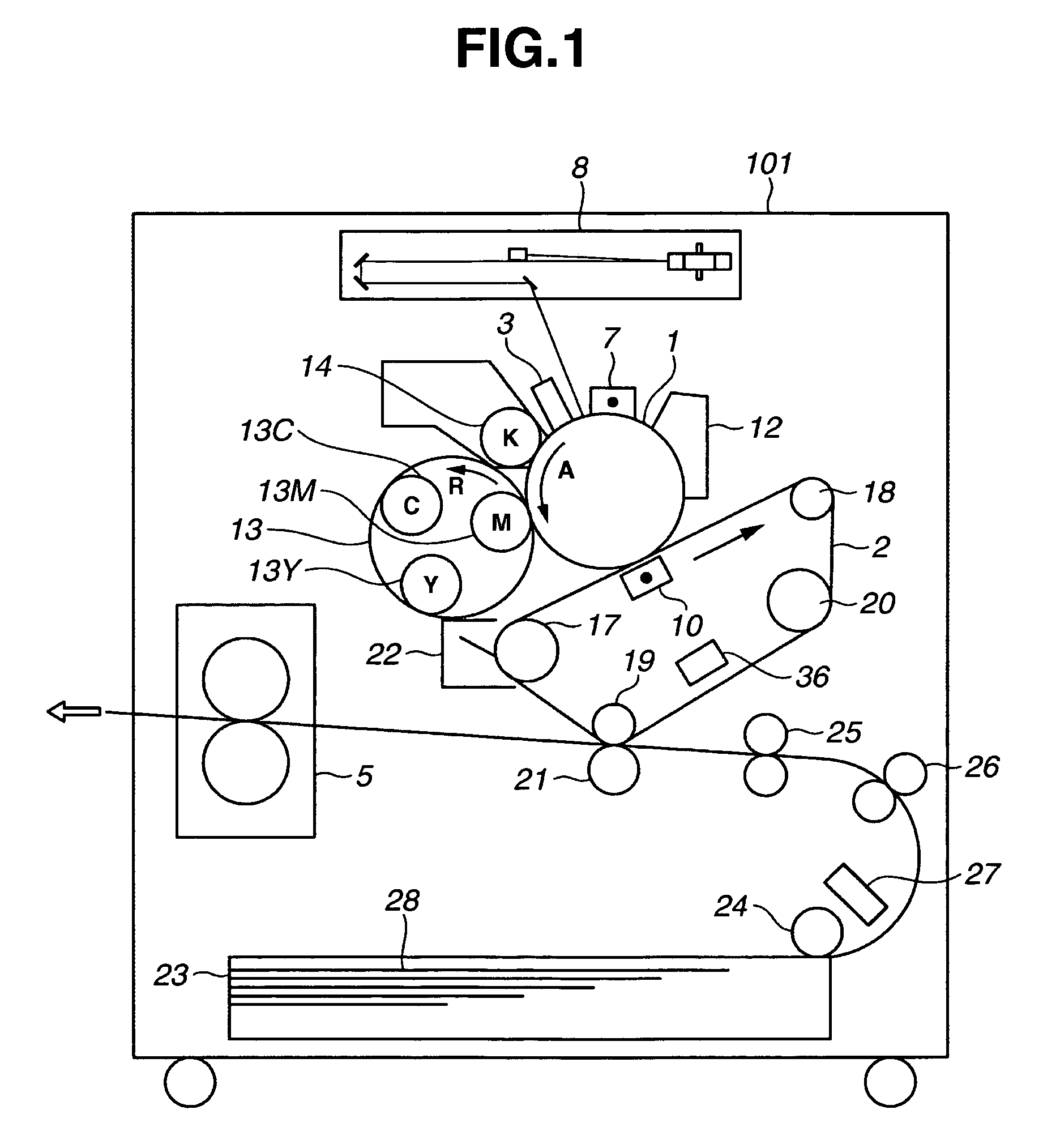

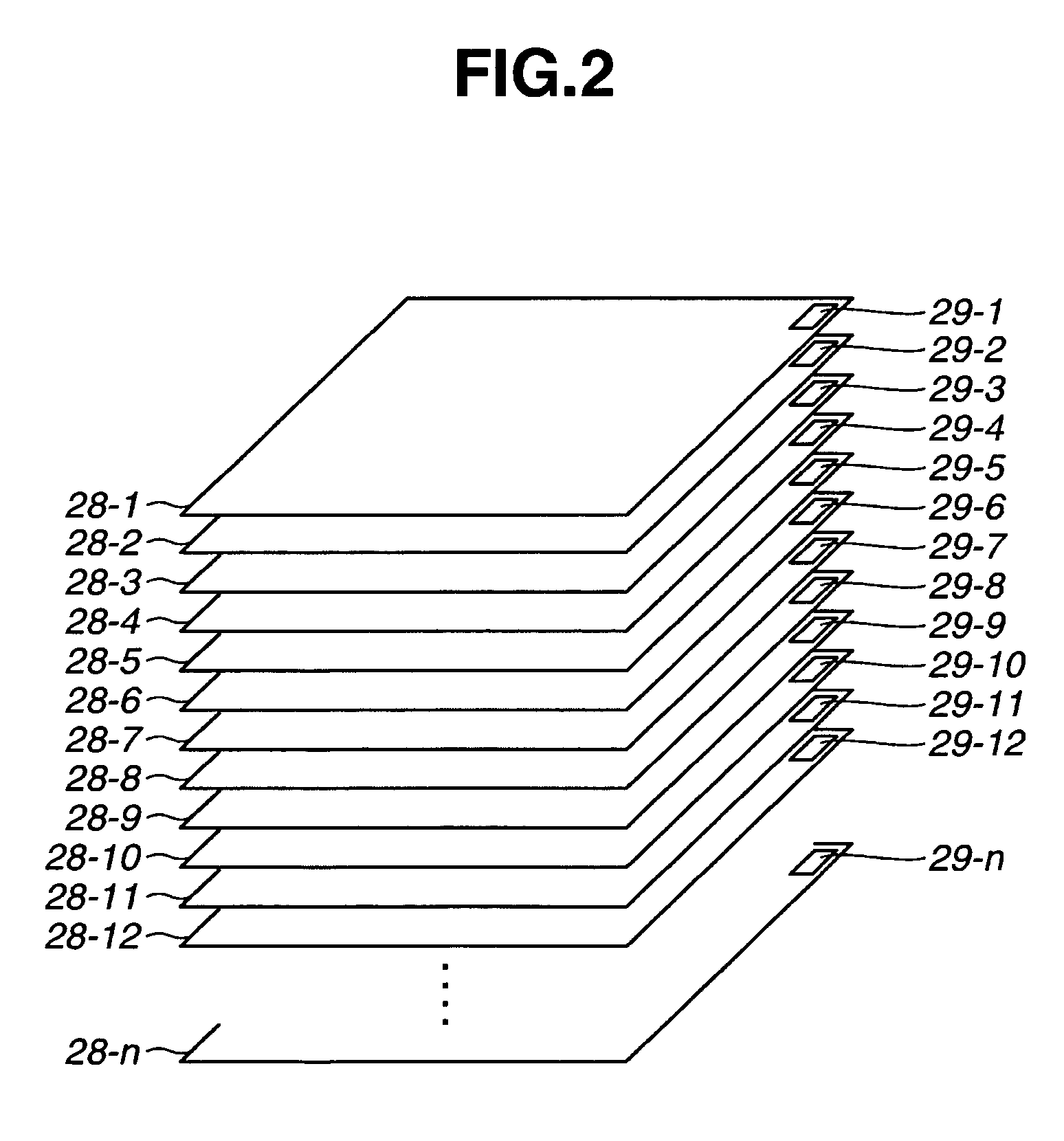

Image forming apparatus, image forming system, and control program thereof to manage printing sheet communications

InactiveUS7957020B2Digitally marking record carriersDigital computer detailsInformation controlImage formation

An image forming apparatus is provided, in carrying out an image forming operation using a paper sheet, that uses a sheet containing a wireless tag that stores an address storing control information for performing an optimum image forming. The image forming apparatus obtains the address from the wireless tag using a receiving device, and obtains control information from a server via a network based on the obtained address. The image forming apparatus controls an image forming condition based on the control information, and carries out the image forming under image forming conditions optimum for the sheet.

Owner:CANON KK

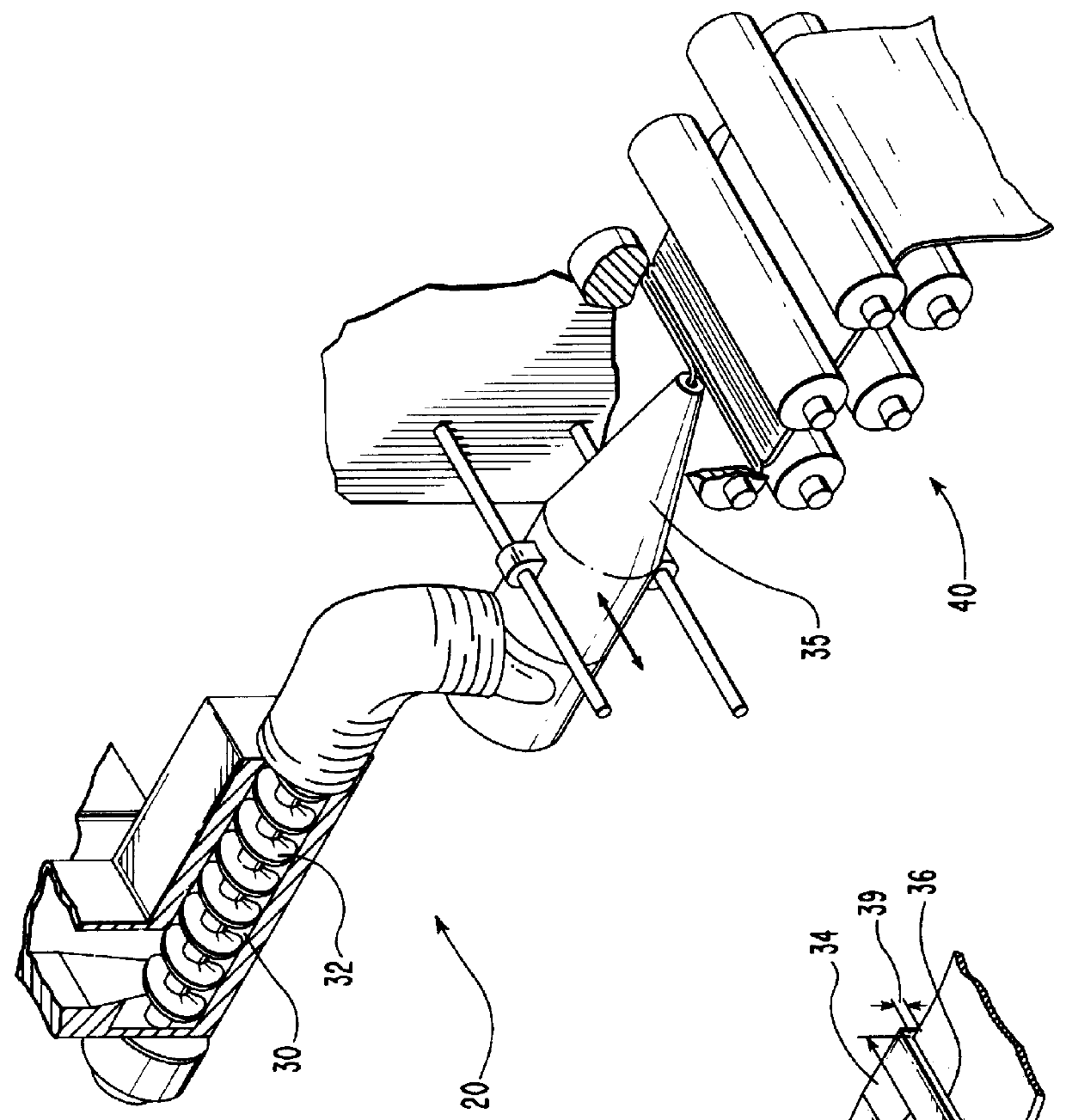

Method of manufacturing cigarette suppressing spread of burn and apparatus for manufacturing cigarette suppressing spread of burn

InactiveUS6904917B2Easy to changeCigar manufactureCigarette manufacturePulp and paper industryEngineering

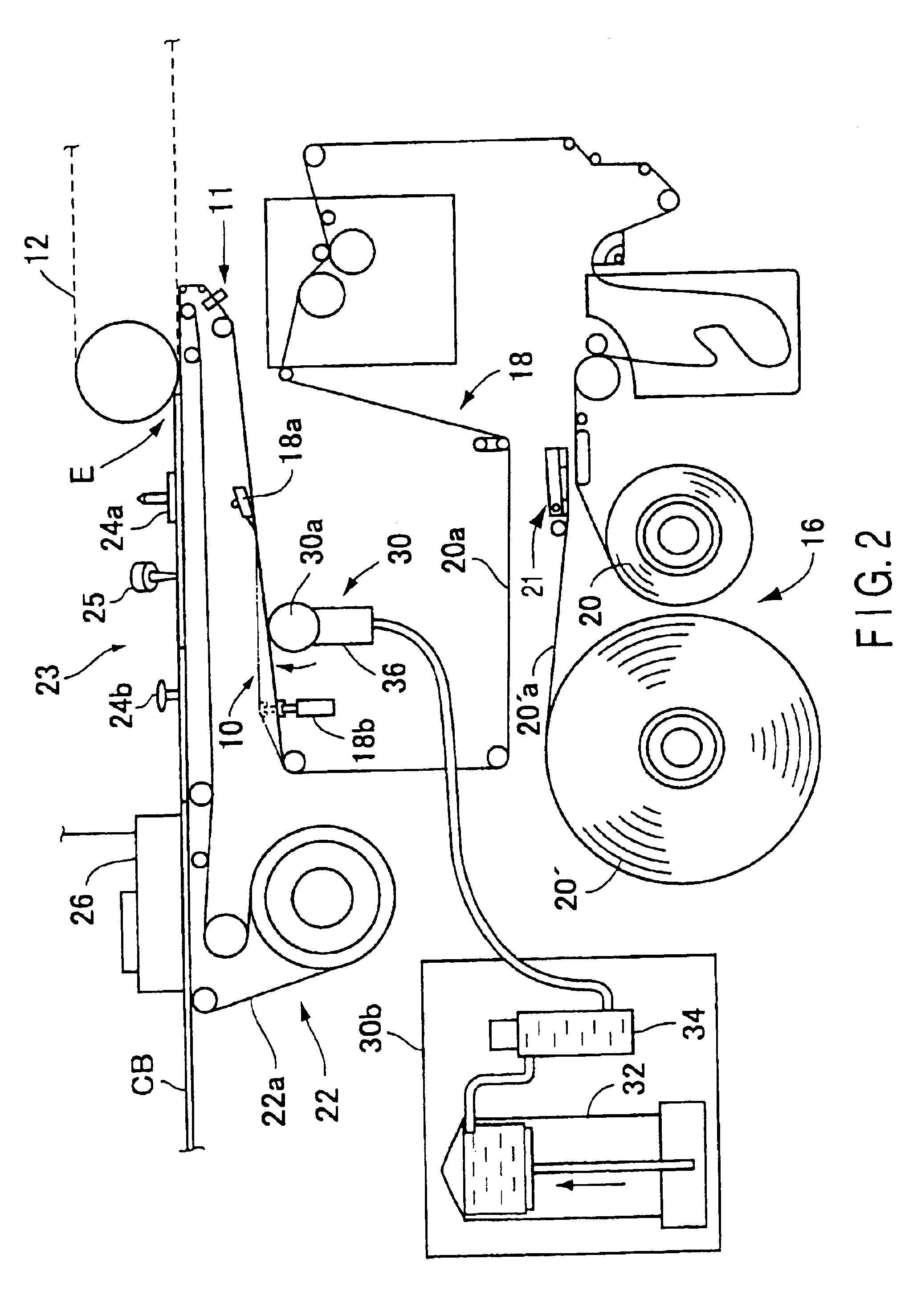

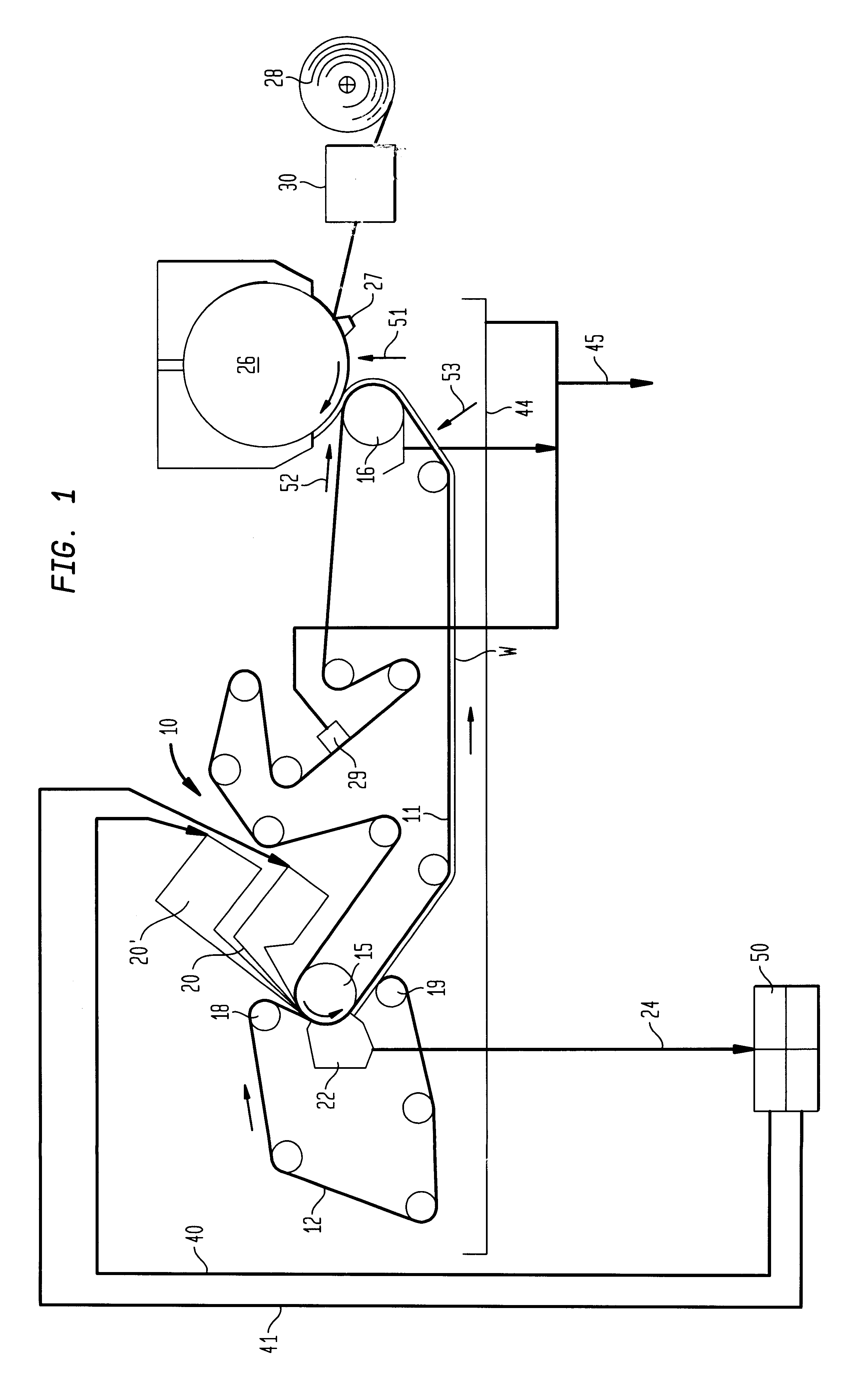

An apparatus includes a unit which forms burn control agent coated regions on a web of a wrapping paper transferred by a wrapping paper transfer unit at a plurality of positions separated from each other in the longitudinal or in the width direction of the web, a unit which supplies chopped tobacco leaves to the wrapping paper after formation of the coated regions, a roll-up unit which rolls up the wrapping paper on which the chopped tobacco leaves are supplied, and a cigarette cutting unit which cuts the rolled-up wrapping paper together with the chopped tobacco leaves in a predetermined length of the cigarette in the longitudinal direction thereof.

Owner:JAPAN TOBACCO INC

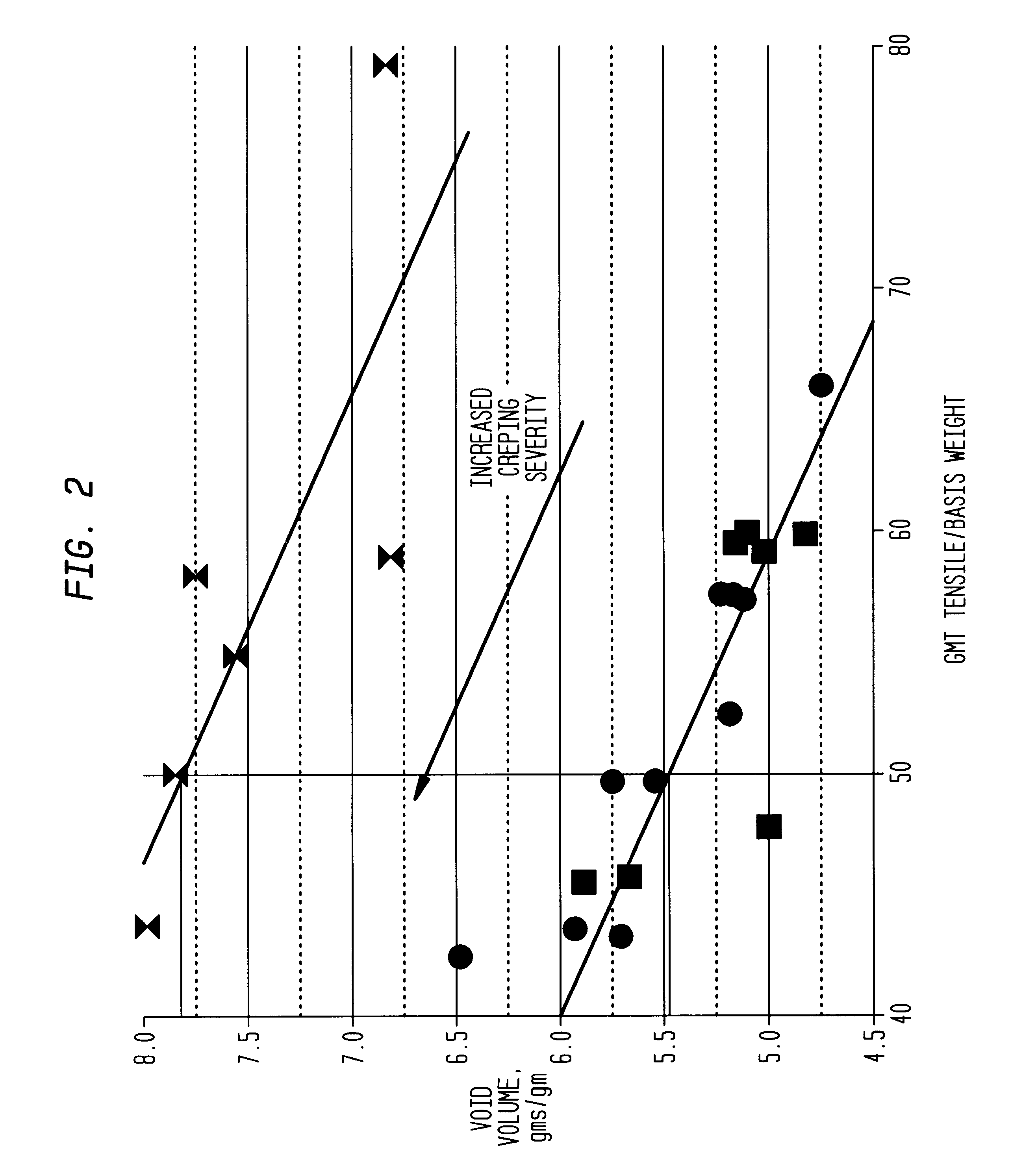

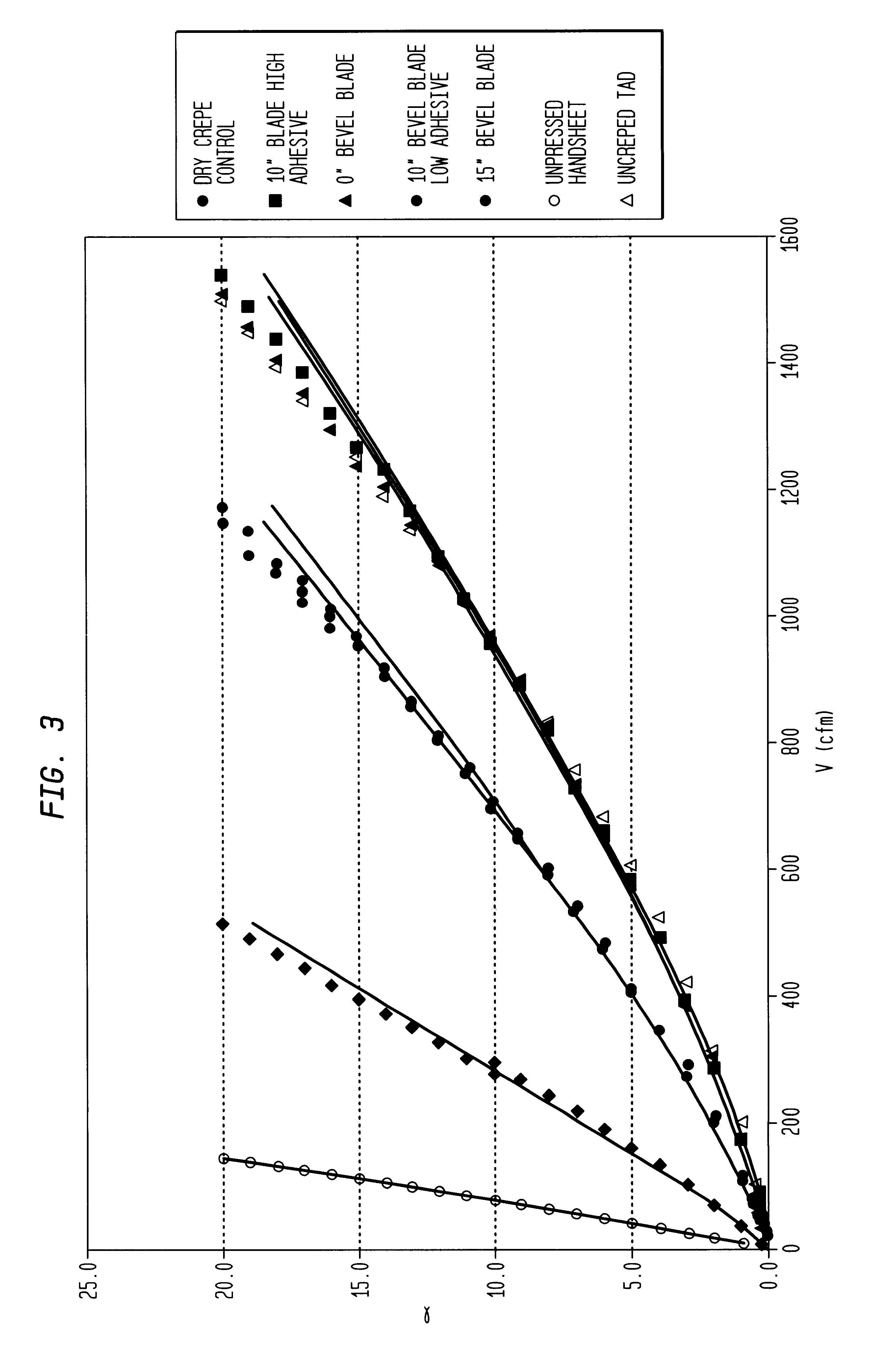

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

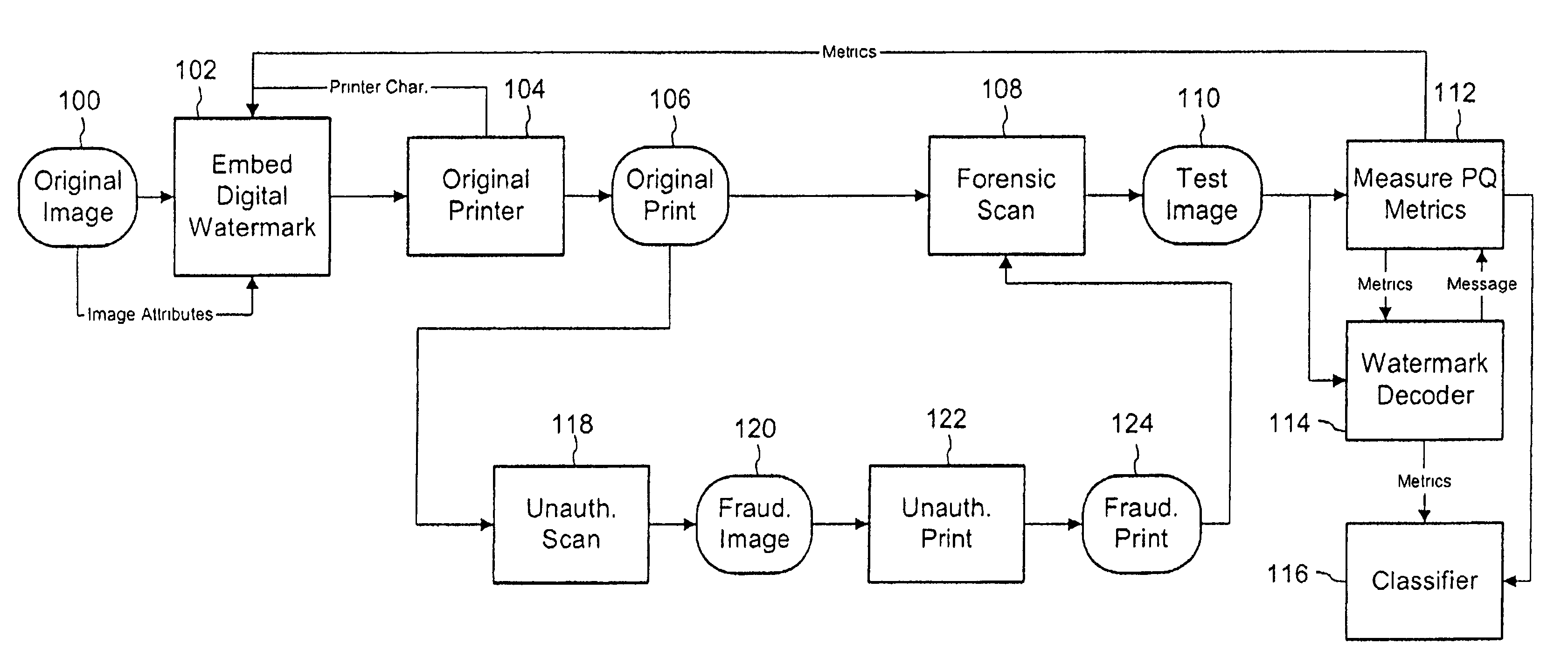

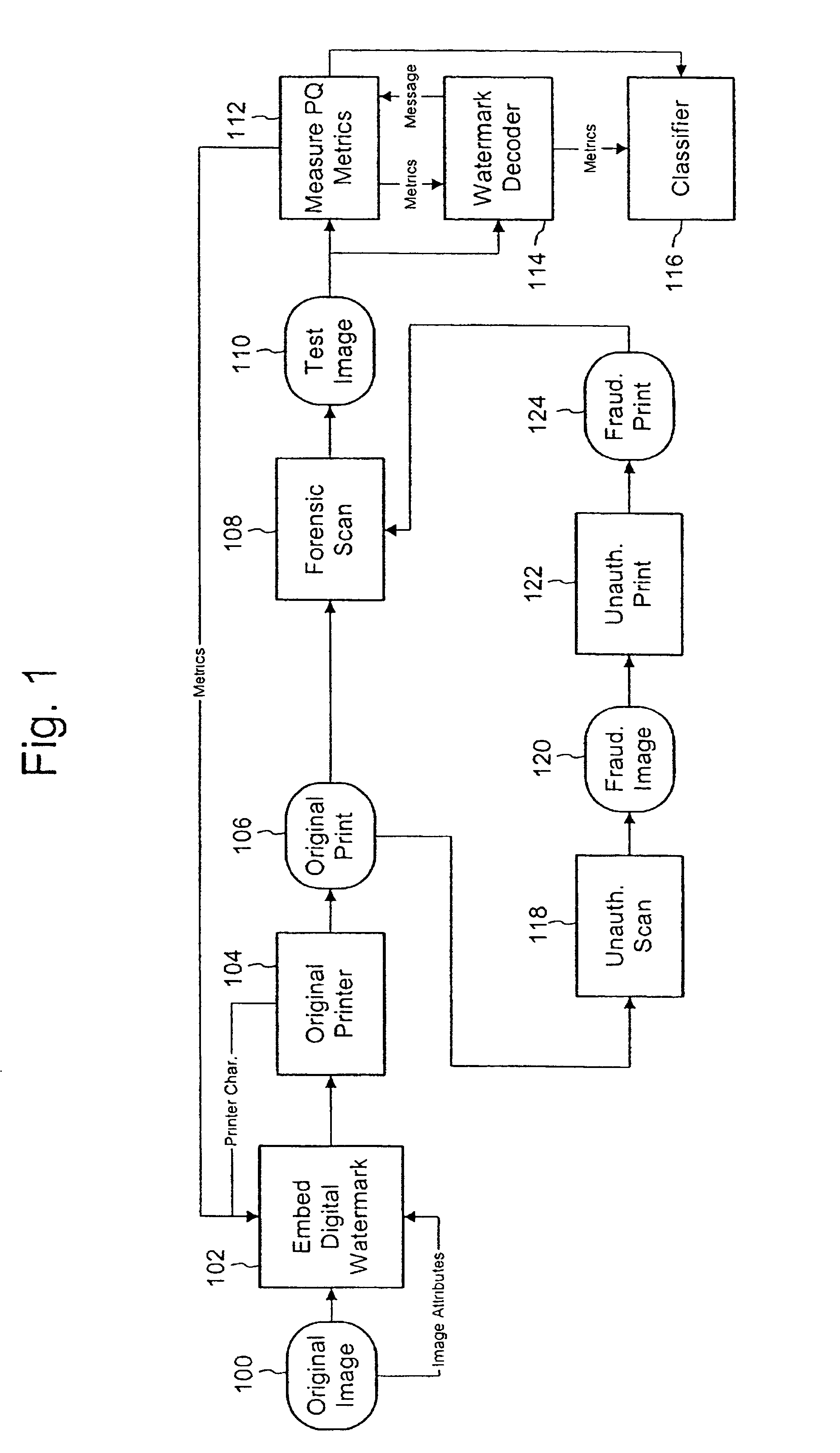

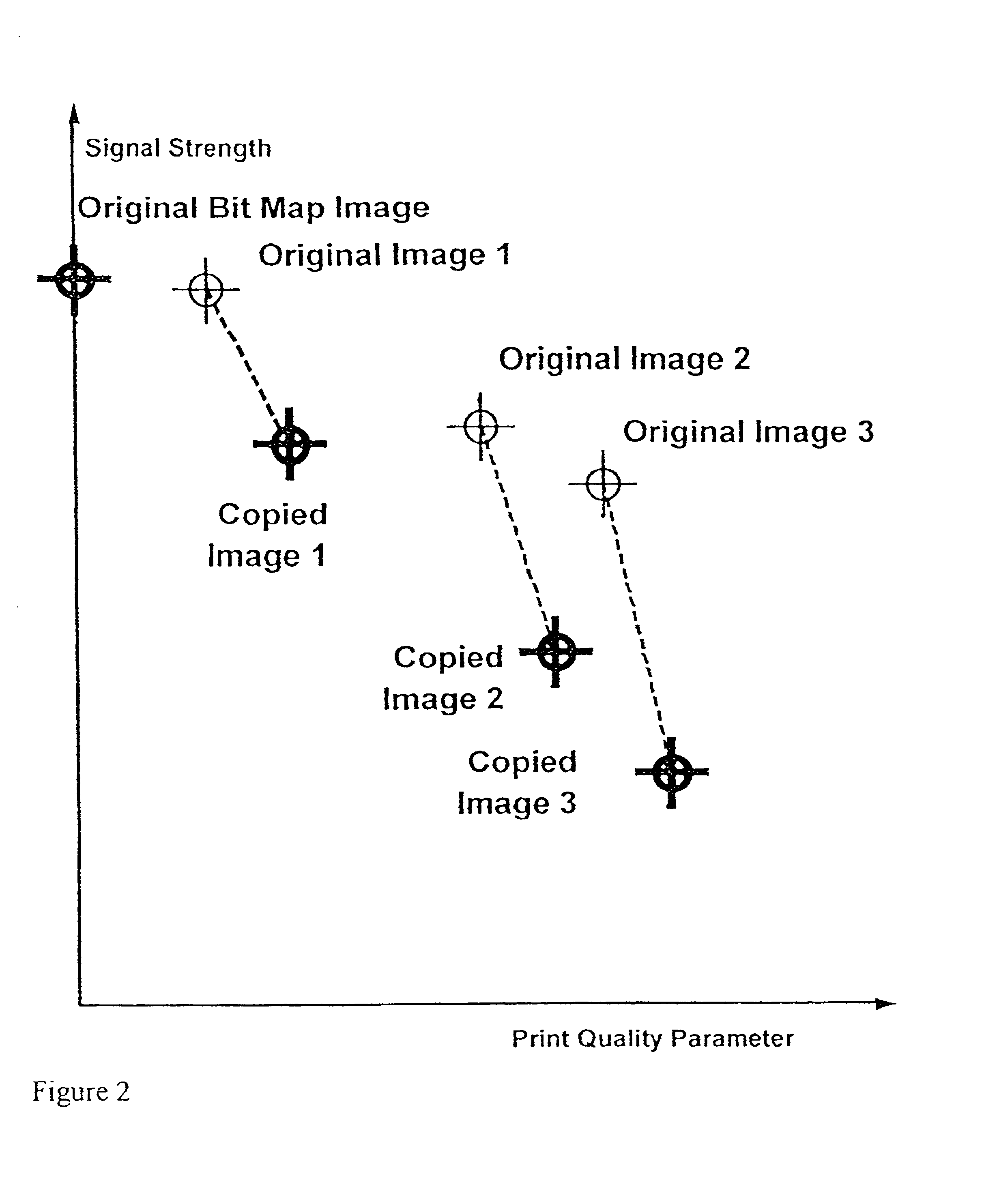

Authenticating printed objects using digital watermarks associated with multidimensional quality metrics

InactiveUS7054461B2Character and pattern recognitionImage data processing detailsPattern recognitionComputer vision

The disclosure describes an authentication system and related methods for authenticating printed objects. The system uses an information-based metric along with one or more print quality metrics to provide accurate detection or classification of a counterfeit printed object. The print quality metric evaluates attributes of a subject image associated with the original printer, ink or paper to detect degradation of those operations due to copying operations like an image scanning and halftone printing subsequent to the original printing of the object. The information-based metric measures message symbol errors in an optically readable code, such as a digital watermark.

Owner:PITNEY BOWES INC +1

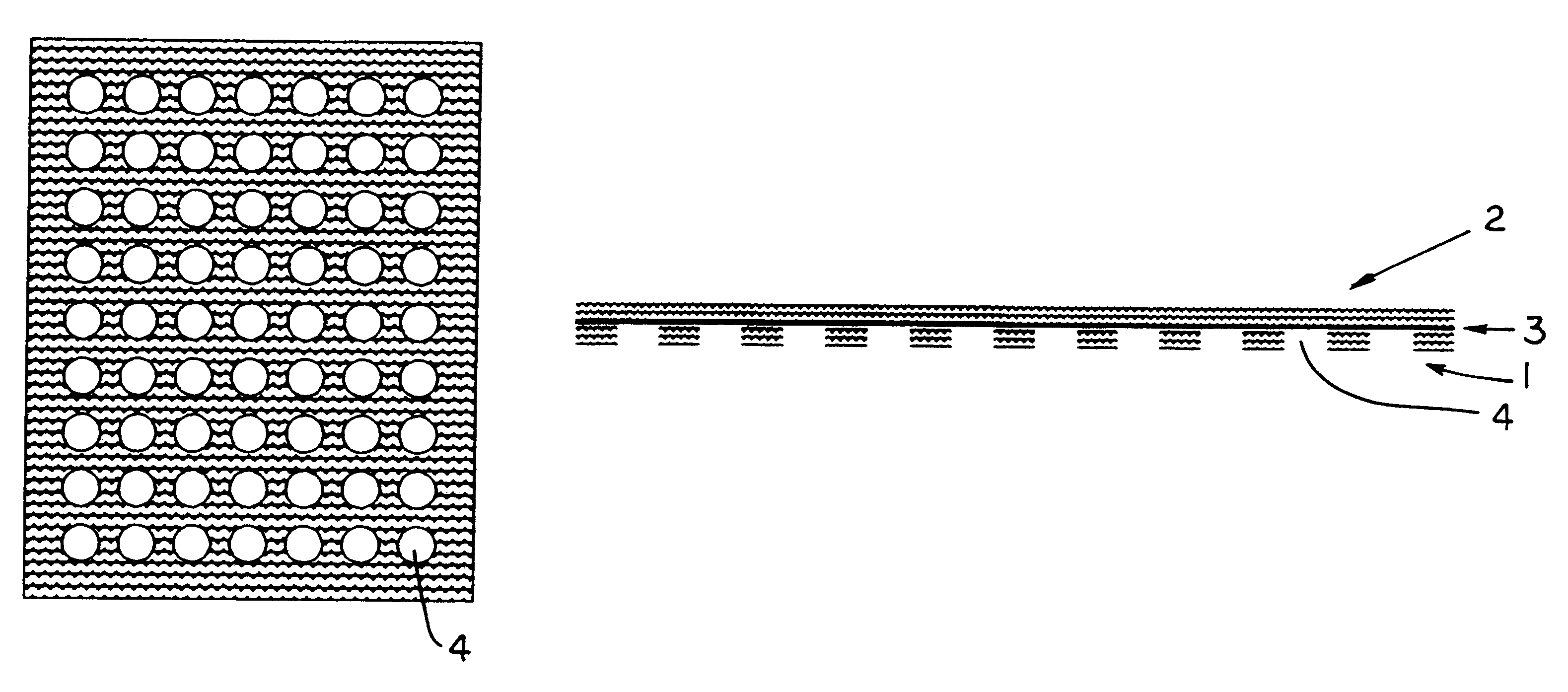

Cleaning sheet with particle retaining cavities

Owner:SC JOHNSON & SON INC

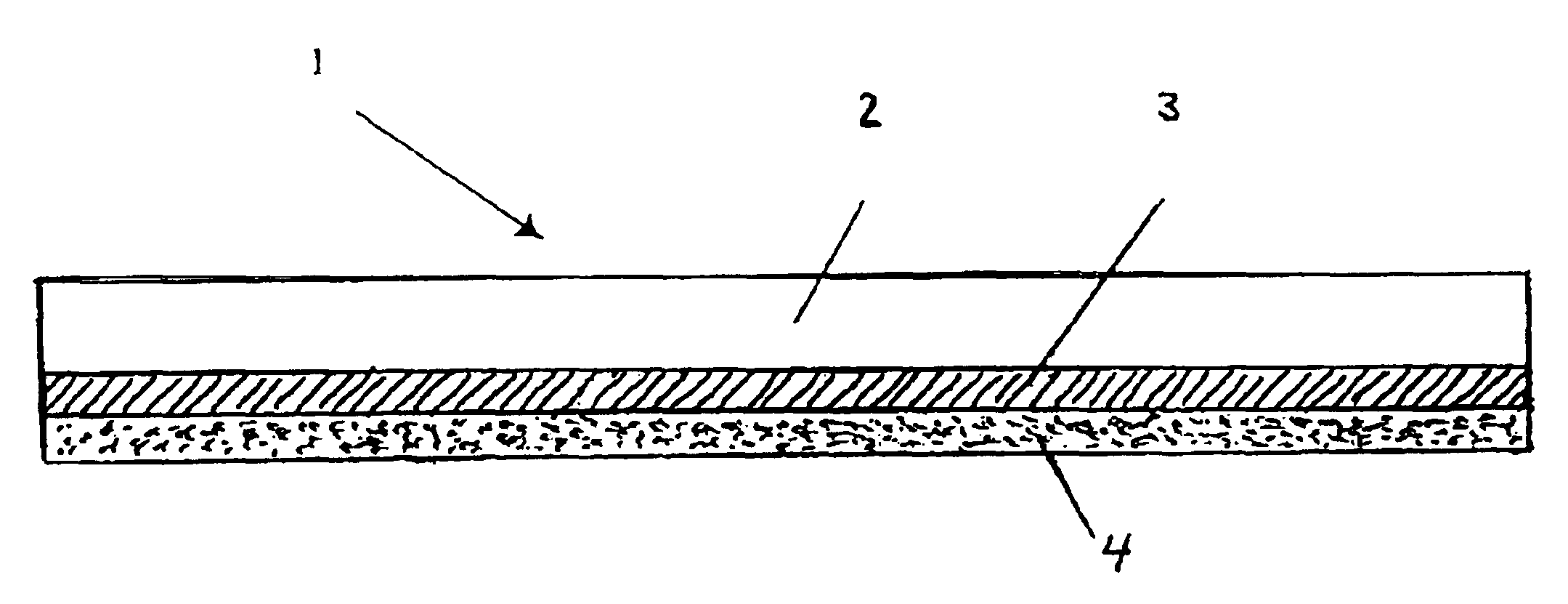

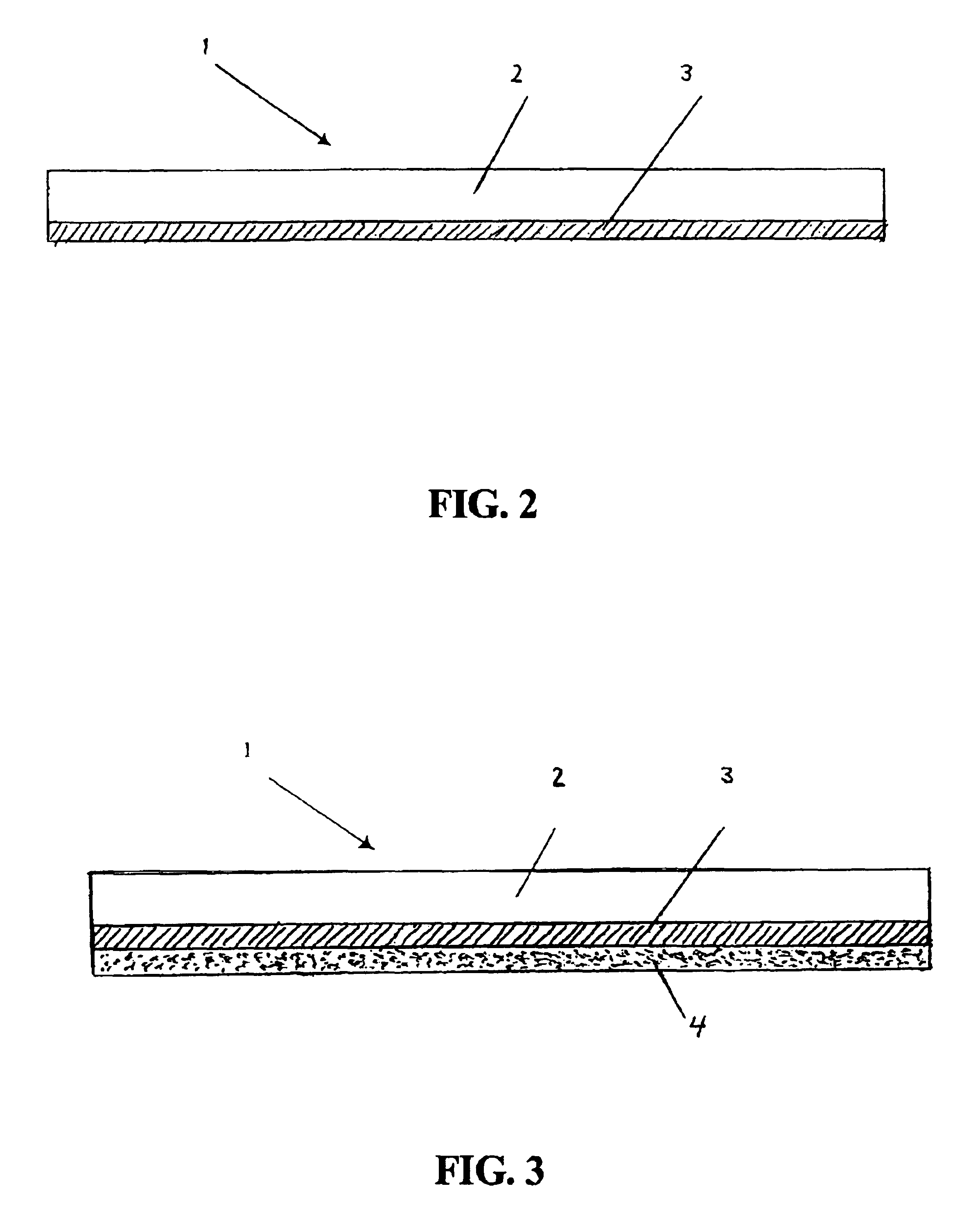

Composite roofing members having improved dimensional stability and related methods

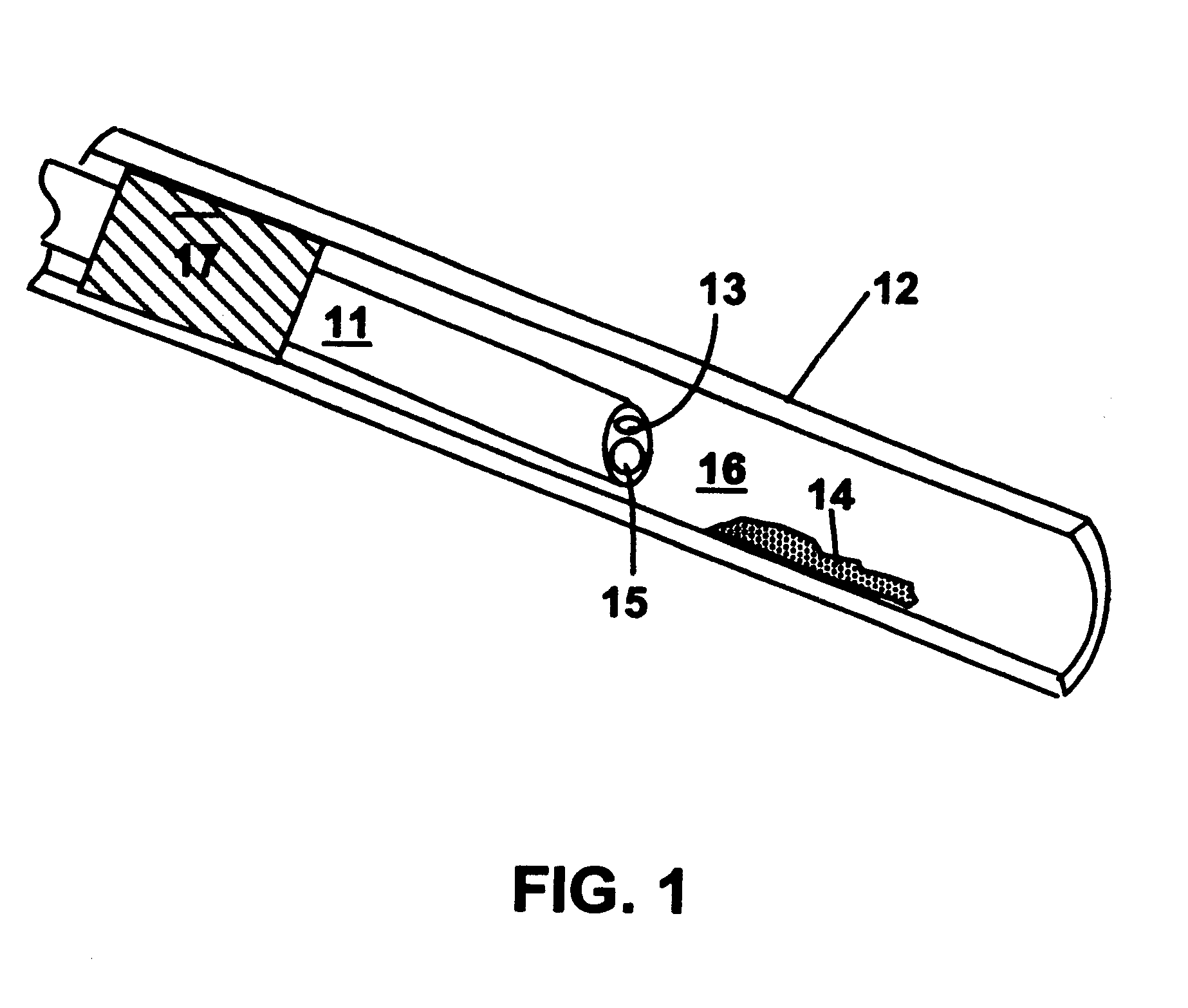

InactiveUS6044604AGood baseRoof covering using slabs/sheetsConstruction materialGlass fiberPolymer science

A composite recovery board (10) containing a foam core (11) of polyisocyanurate, polyurethane materials or mixtures thereof; a facer (15), applied to one major surface (13) of the foam core, where the facer includes polymer materials, reinforced polymer materials, cellulosic materials, paper, aluminum foil or trilaminates thereof, wherein the reinforced polymer material and the cellulosic material are reinforced with glass strands, glass fibers, or mixtures thereof; and, gypsum board (14), applied to the opposite major surface (12) of the foam core. A method of reroofing a roof by applying composite recovery boards of the present invention to a roof deck; and, applying a weather protective layer over the recovery boards. A continuous method of making a composite recovery board by feeding gypsum board (14) into a laminator assembly (21); depositing a foamable polymer liquid (36) onto the gypsum board; feeding a facer material (15) into the laminator assembly above the foamable polymer liquid; allowing the polymer liquid to rise between the gypsum board and facer material forming polymer foam of a pre-determined thickness; curing the polymer foam under heat (44) to create the composite board; and cutting the composite board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

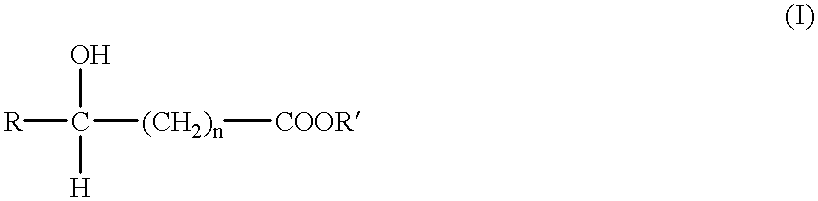

Treated filler or pigment containing natural carbonate

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

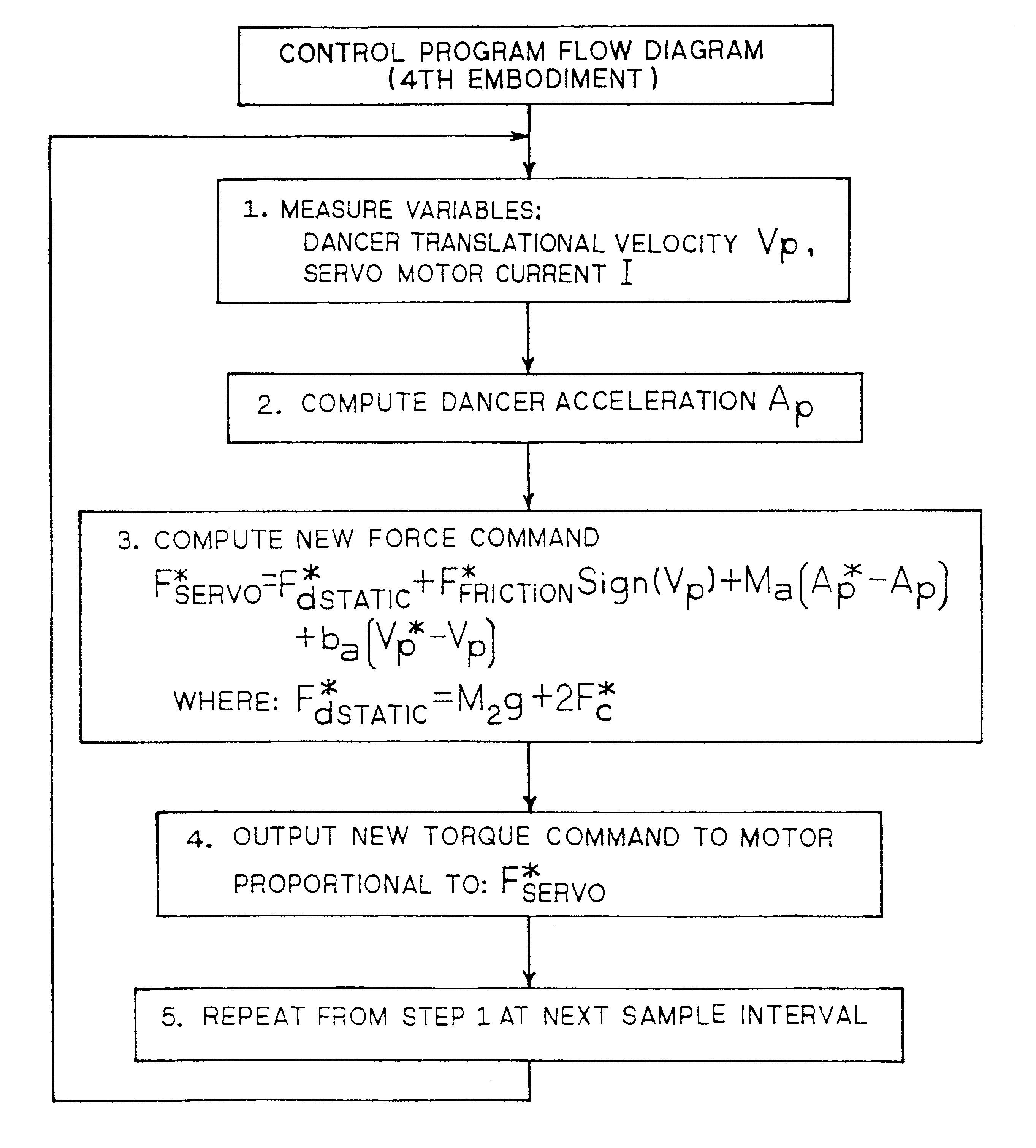

Method and apparatus for controlling web tension by actively controlling velocity and acceleration of a dancer roll

InactiveUS6314333B1The result is accurateAutomatic control devicesPrecision positioning equipmentControl systemEngineering

This invention pertains to processing continuous webs such as paper, film, composites, and the like, in dynamic continuous processing operations. More particularly, it relates to controlling tension in such continuous webs during the processing operation. Tension is controlled in a dancer control system by connecting a corresponding dancer roll to an actuator apparatus or the like, sensing variables such as position, tension, velocity, and acceleration parameters related to the web and the dancer roll, and providing active force commands, in response to the sensed variables, to cause translational movement, generally including a target acceleration, in the dancer roll to control tension disturbances in the web. In some applications of the invention, the dancer control system is used to attenuate tension disturbances. In other applications of the invention, the dancer control system is used to create tension disturbances.

Owner:KIMBERLY-CLARK WORLDWIDE INC

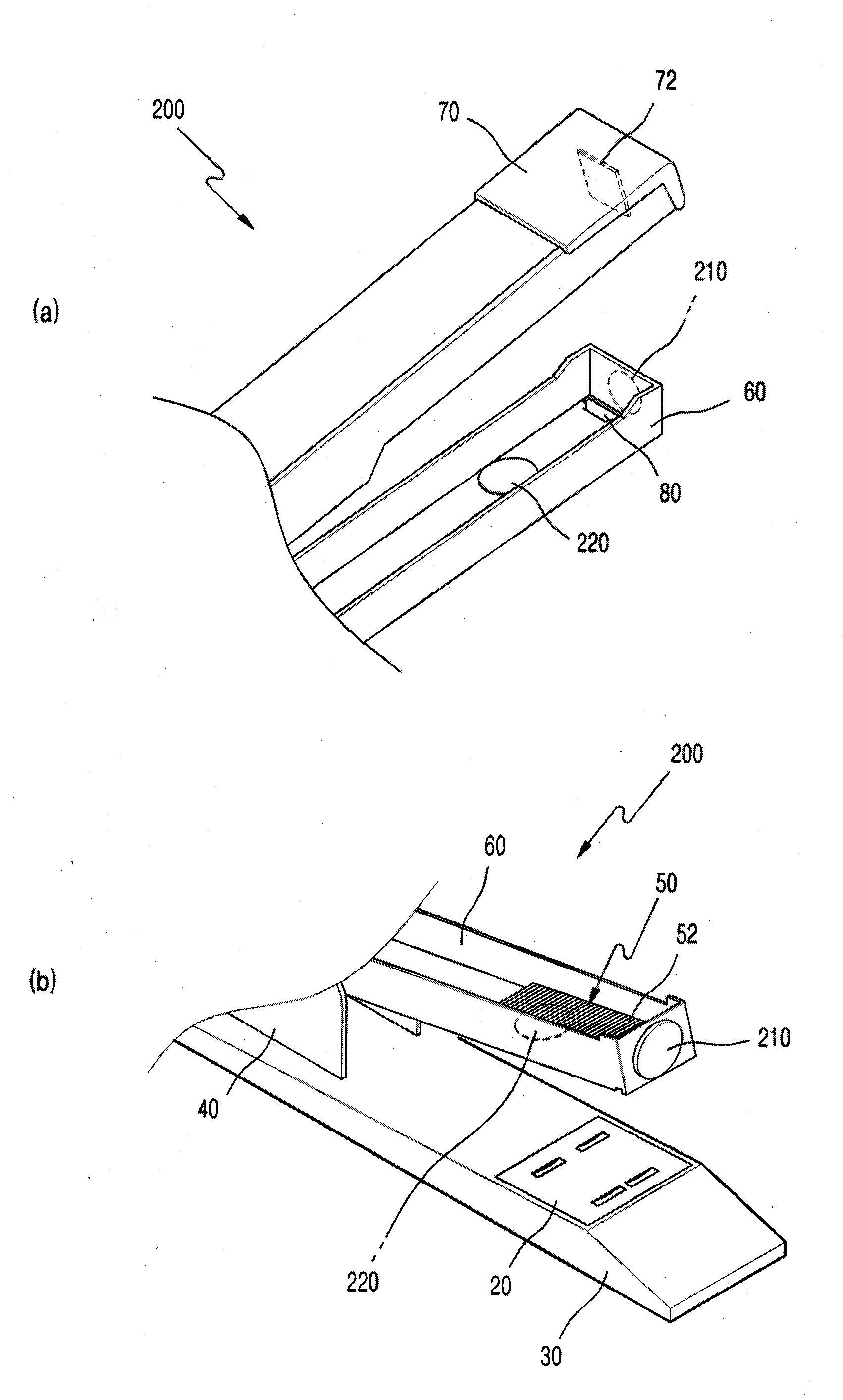

Cassette for holding ink ribbon and print paper therein and printer incorporating the cassette therein

An ink ribbon-print paper cassette is used in a thermal printer. A paper tray accommodates a stack of single sheets of print paper. The paper tray has an opening through which the print paper is fed into a paper path on a sheet-by-sheet basis. An ink ribbon for thermal printing runs over a thermal head located adjacent the paper tray. A housing accommodates the paper tray, thermal head, and ink ribbon therein. When the cassette is loaded into the thermal printer, the outer surface of the cassette and an inner wall of the thermal printer cooperate to form a paper path therebetween through which each of the sheets of print paper is advanced from the paper tray to the thermal head.

Owner:OKI DATA CORP

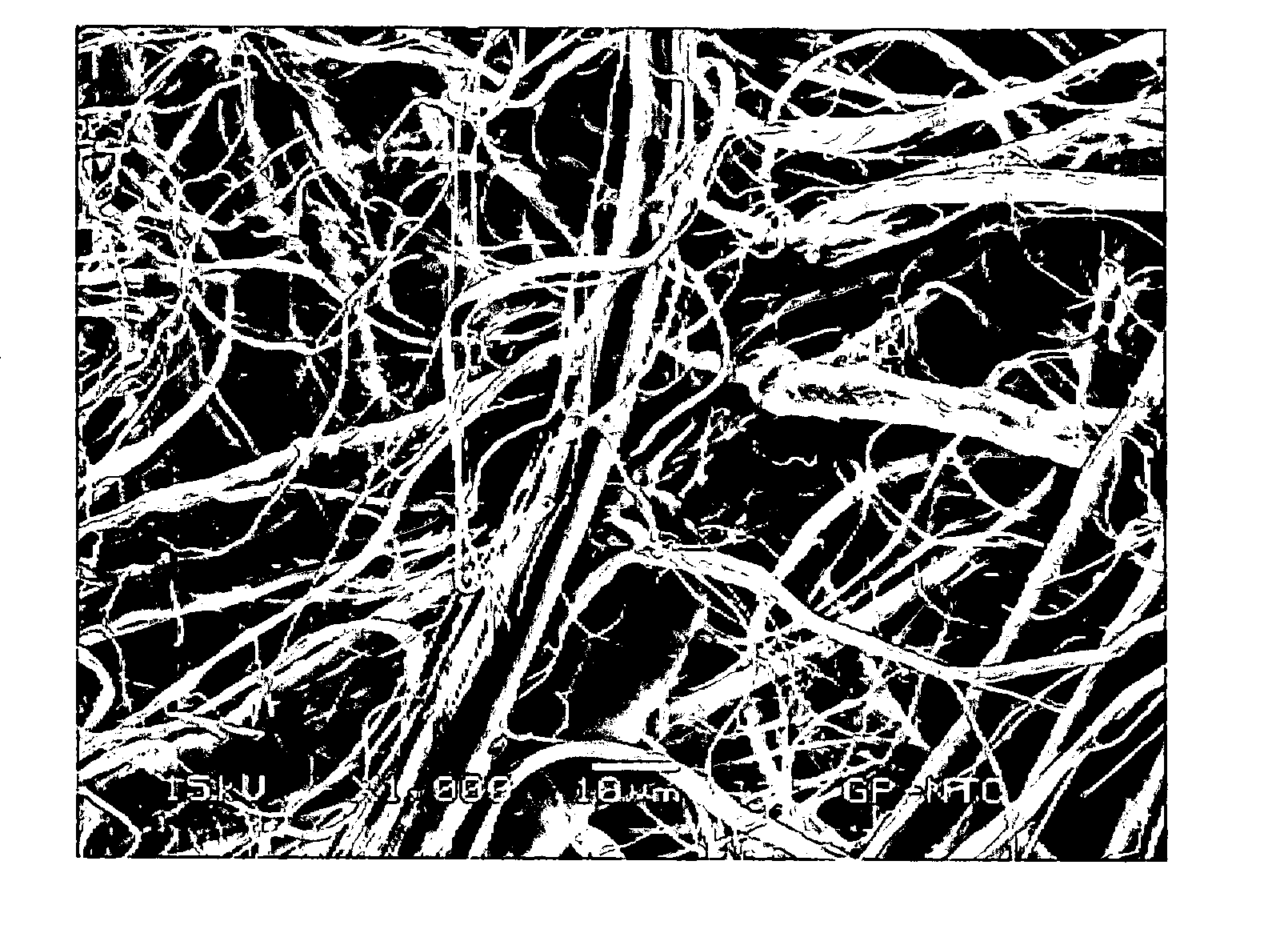

Absorbent sheet having regenerated cellulose microfiber network

ActiveUS20070224419A1High wet/dry tensile ratioImprove consistencyNon-fibrous pulp additionPaper after-treatmentPolymer sciencePapermaking

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

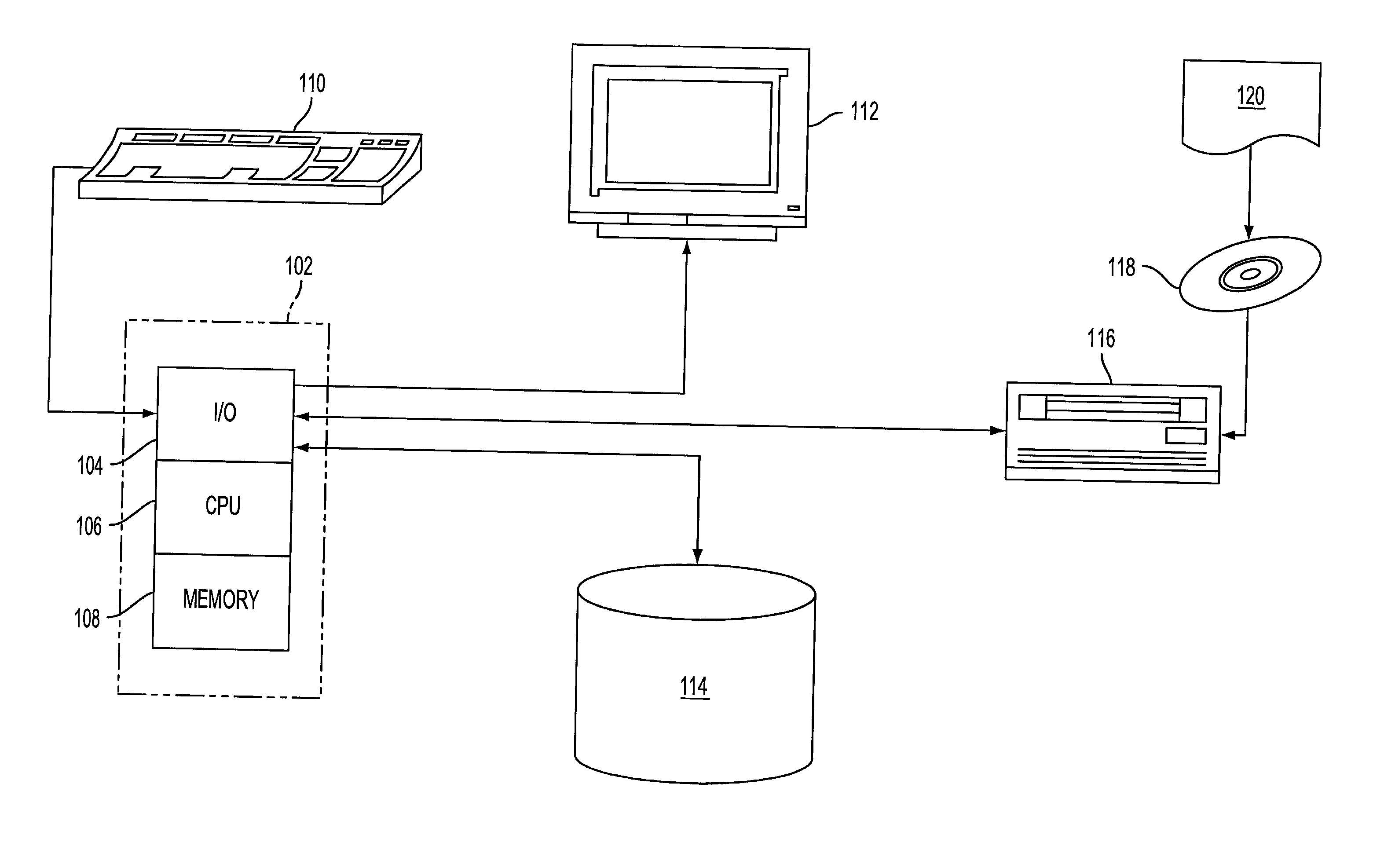

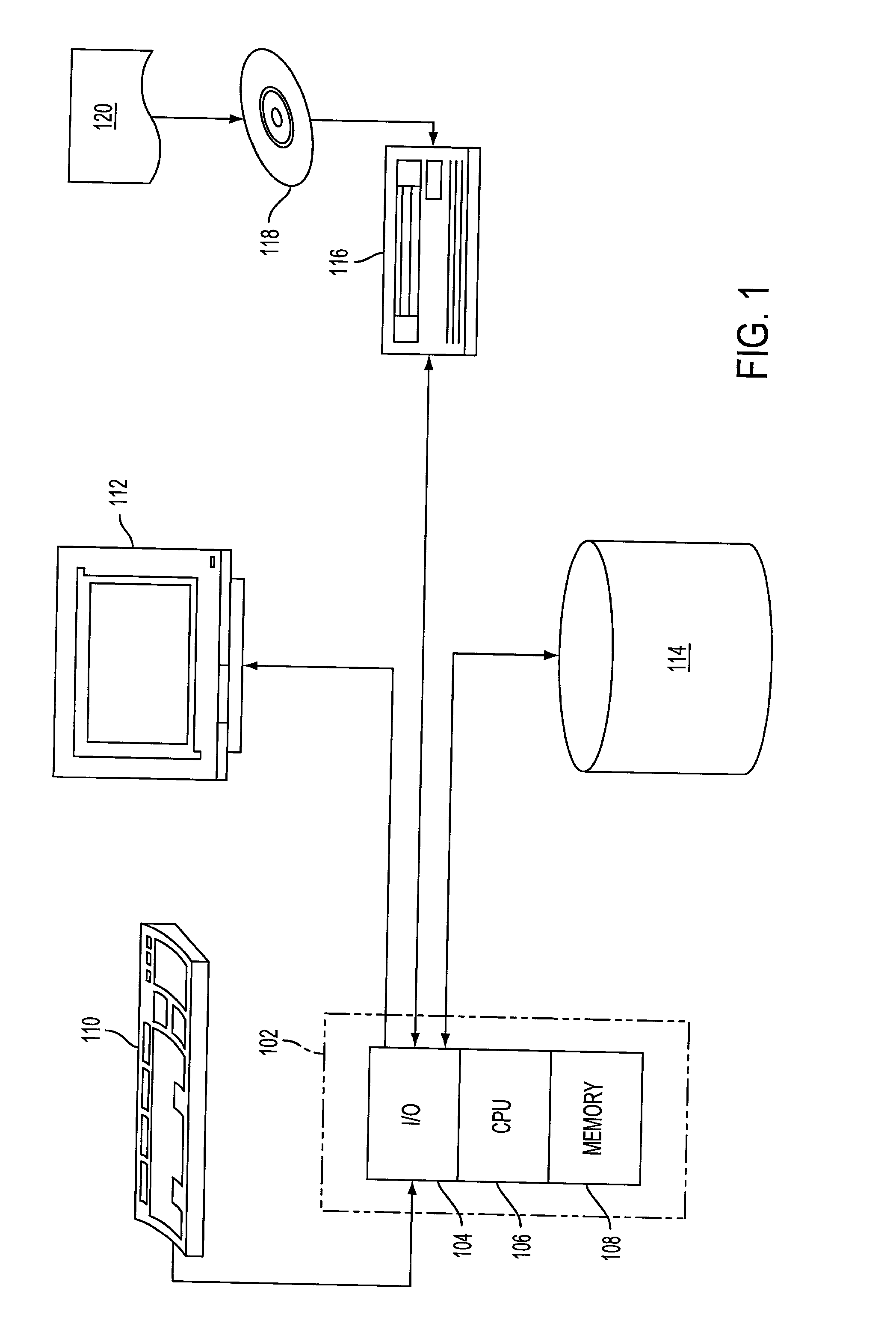

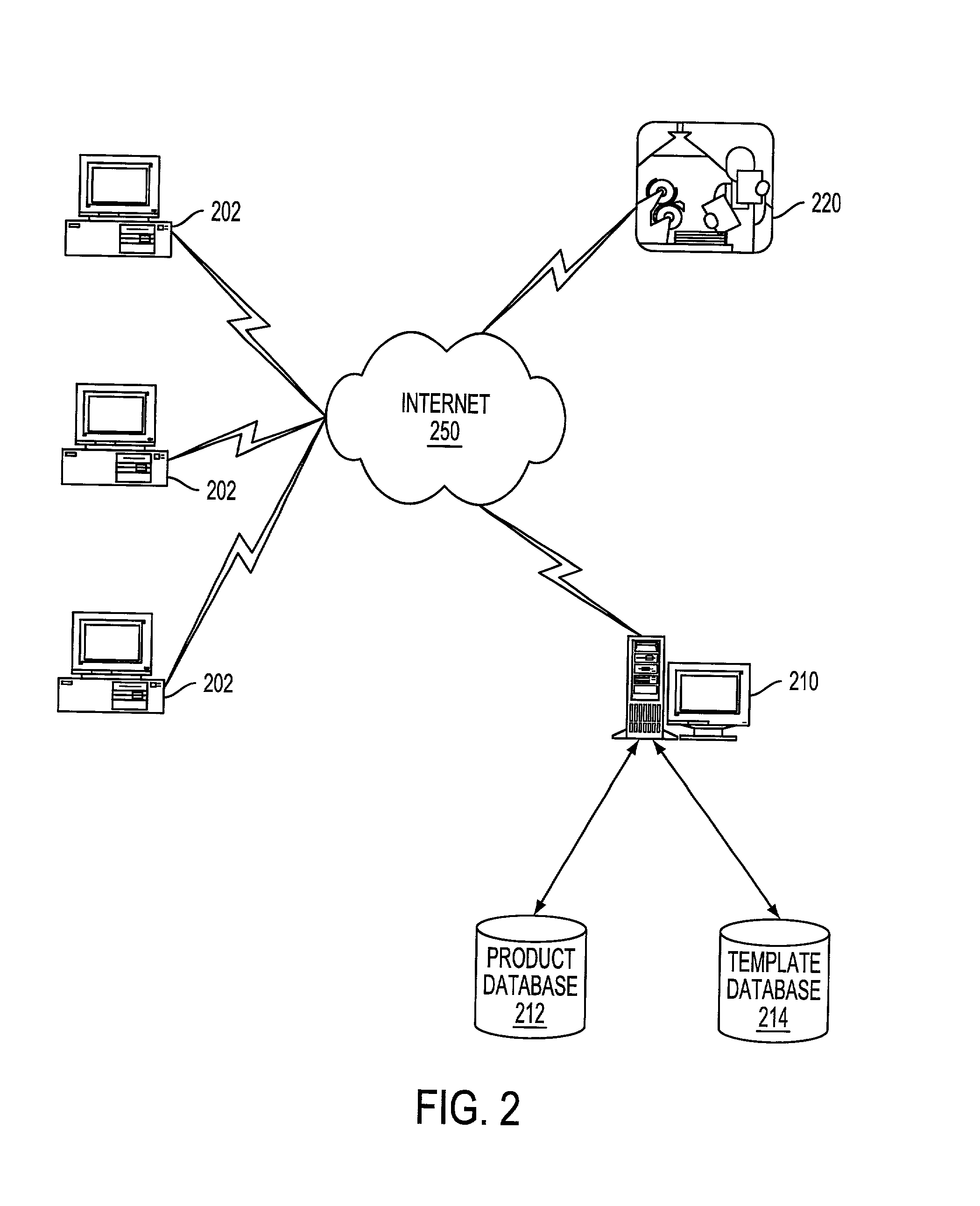

System and method for computer-created advertisements

ActiveUS20020036654A1Quickly and efficiently createAdvertisementsCathode-ray tube indicatorsPaymentComputerized system

The invention relates to a computerized method for a user to create an advertisement by displaying a plurality of advertising formats for selection by a user; displaying a template corresponding to a selected advertising format; displaying a plurality of product references for selection by the user; displaying on the template a selected product reference to create a proposed advertisement; and creating a preview of the proposed advertisement, all of which may be implemented using the Internet. The invention further relates to a computerized system for creating an advertisement that comprises a template database for storing advertising formats; a product database for storing product references; and a computer to access the databases. Preferably, the user has a network interface such as Internet access that permits access via a remote location, software to permit a user to specify specifications such as quantity, printing information, ship date, paper type, pricing information, and payment information, and may be configured to receive images and text for new products.

Owner:ECOMSYST

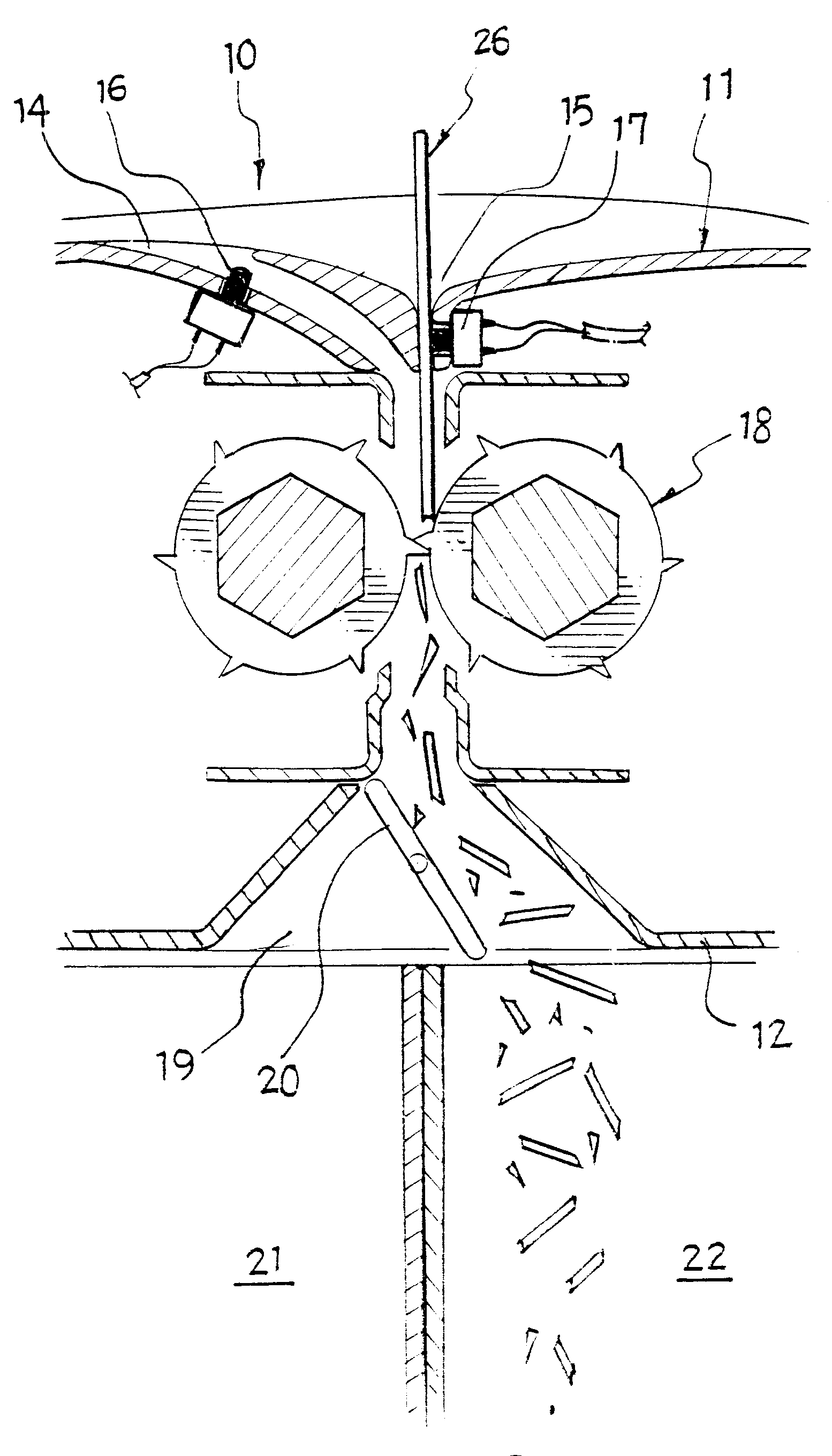

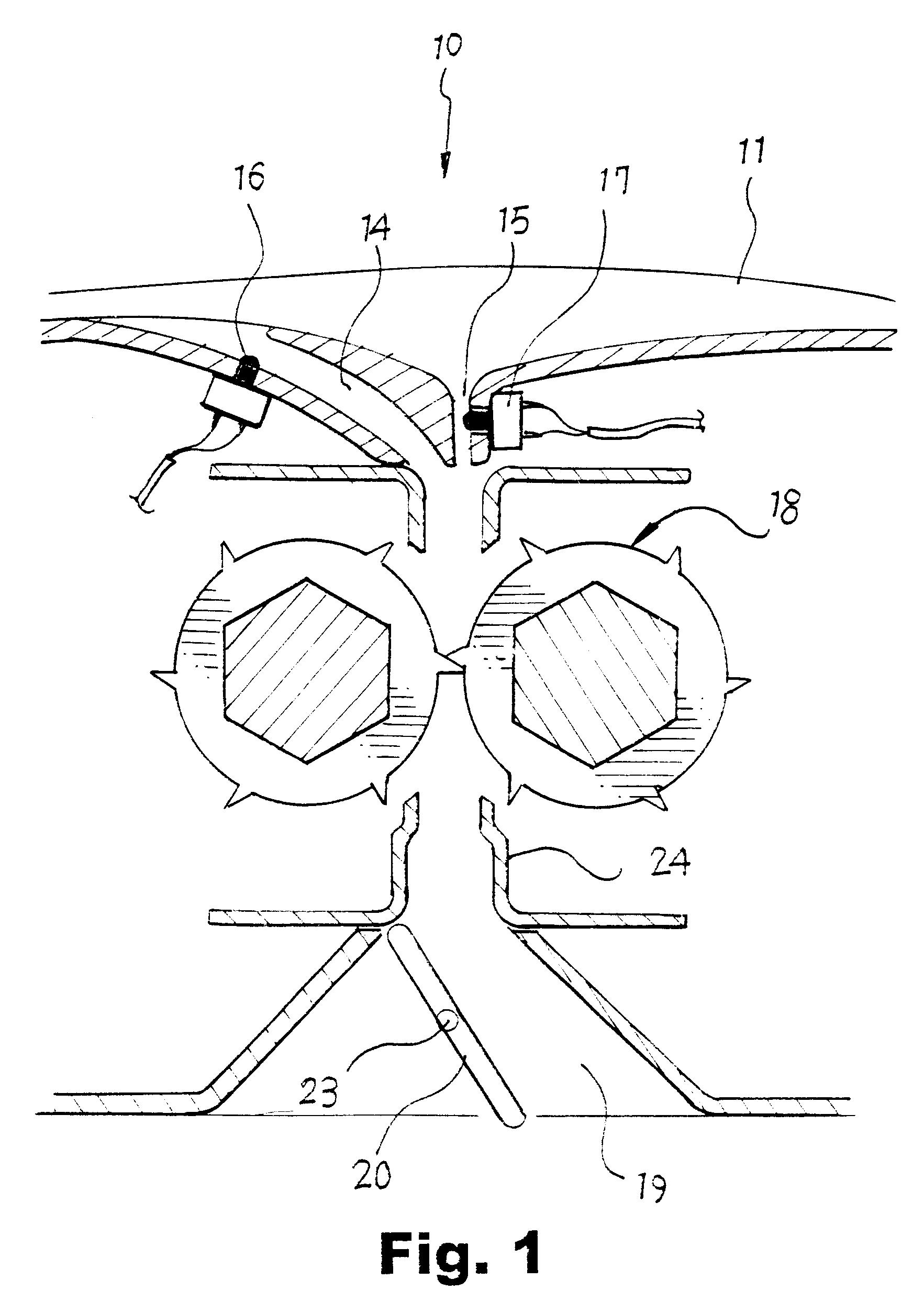

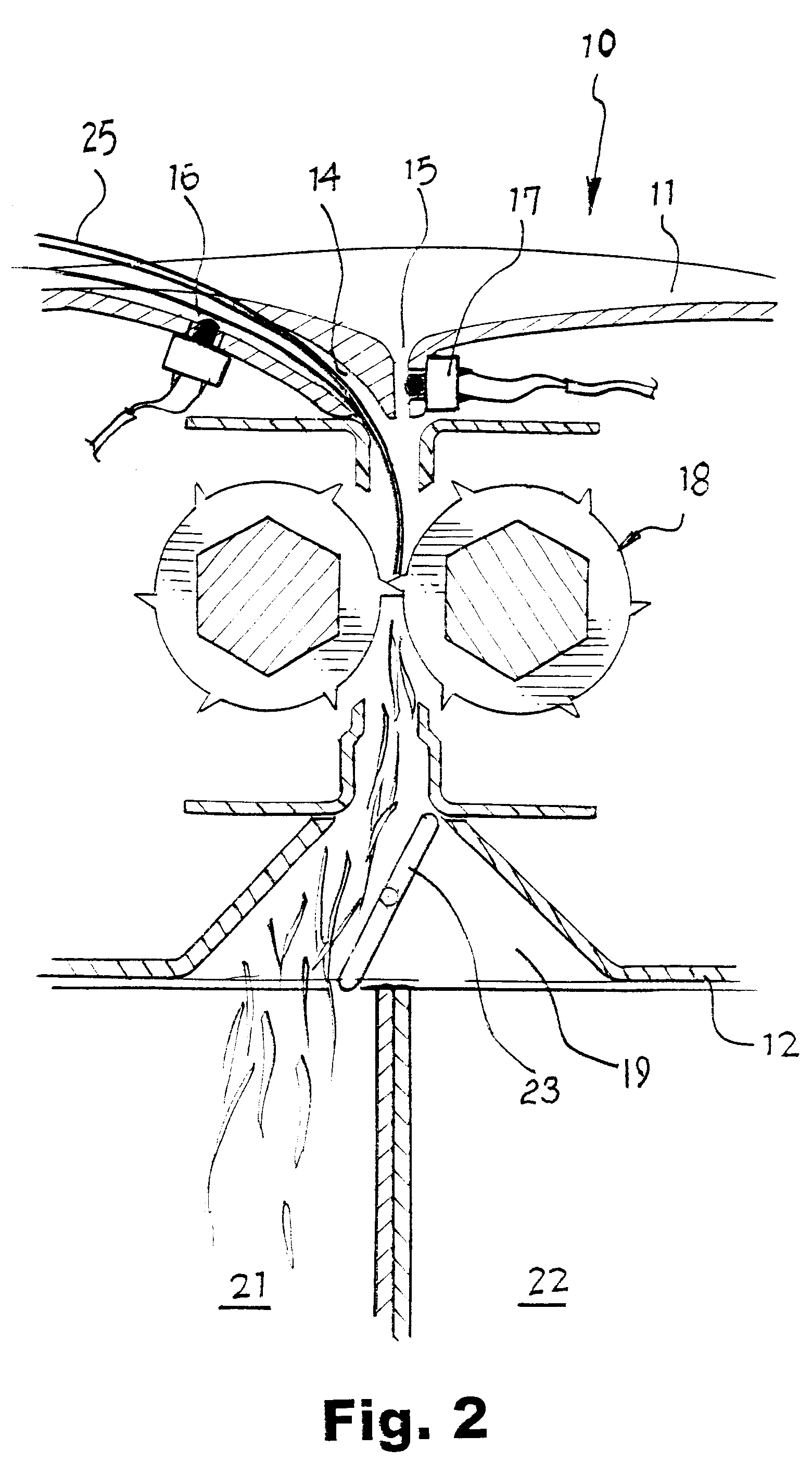

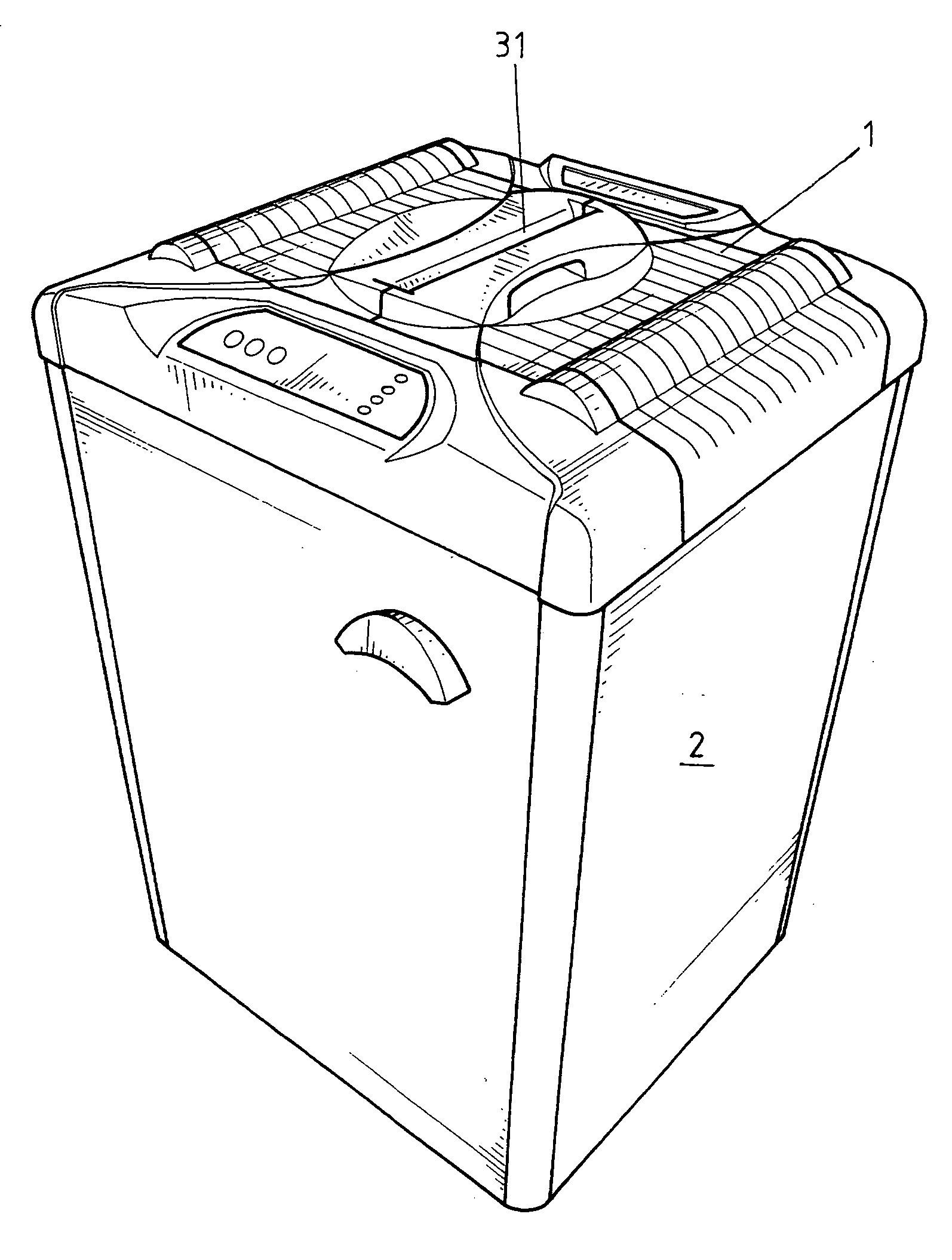

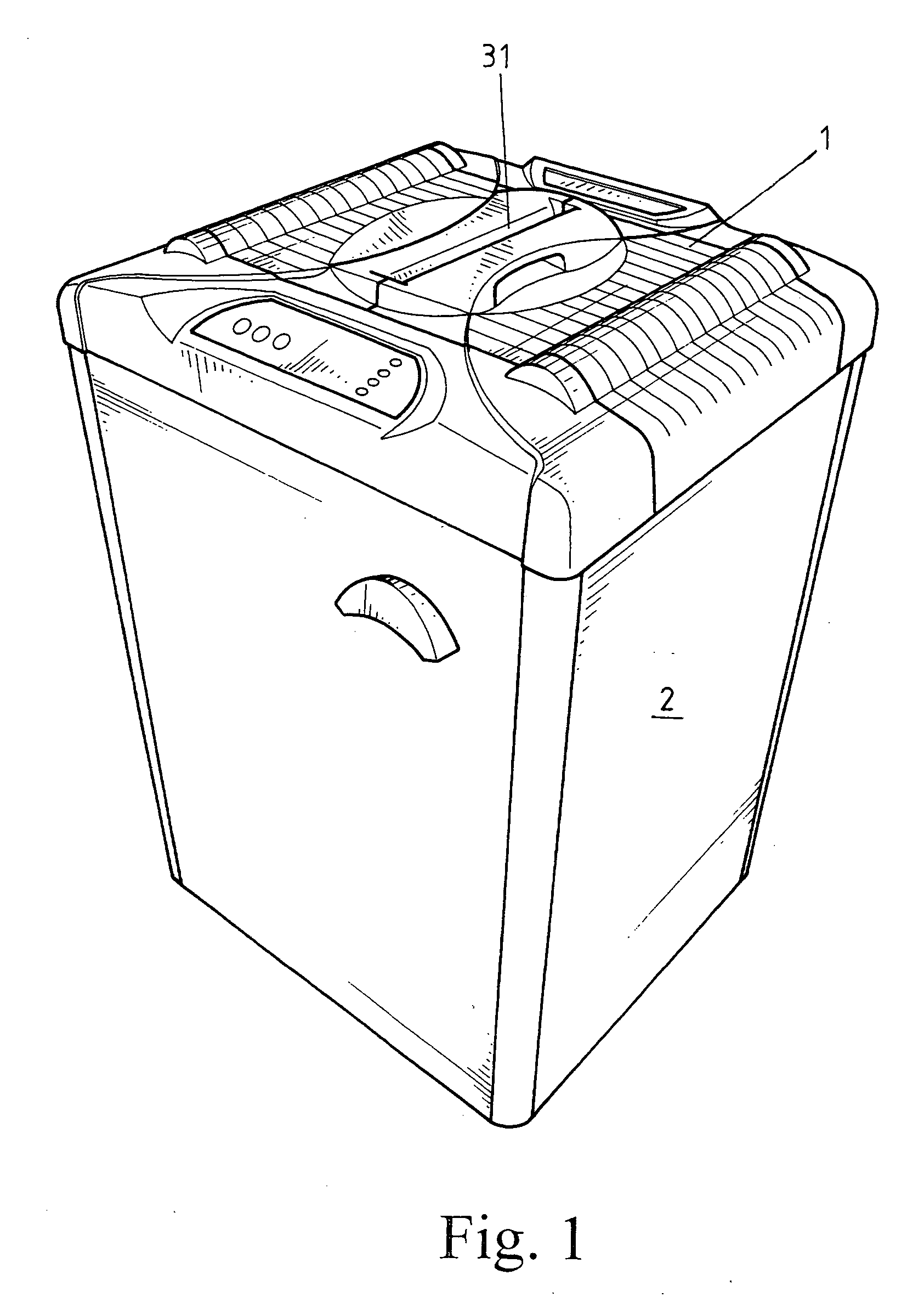

Dual-functional medium shredding machine structure

This invention is related to a dual-functional medium shredding machine structure, specifically designed for shredding or destroying paper printed with data to be destroyed, optical discs containing data to be destroyed, or expired credit cards. This invention mainly implements a pair of shredding roller blades with sharp teeth as shredding means, and is characterized by providing separate feeding inports, including a paper inport for feeding paper in an inclined orientation, and a disc inport for feeding discs in a vertical orientation, wherein the inports are each led to the same shredding roller blades such that, regardless of the type of substance being fed by the user, the paper or the discs can both be shredded by the shredding roller blades, and the shredded scraps are dispensed to separate collectors through an identical exit by means of an auto-revolving switch plate; and a touch switch at each of the inports such that, while feeding the paper or the discs, the touch switch activates the shredding roller blades to perform shredding task, and drives the switch plate so as to dispense shredded scraps of different substance into different collectors.

Owner:MICHILIN PROSPERITY

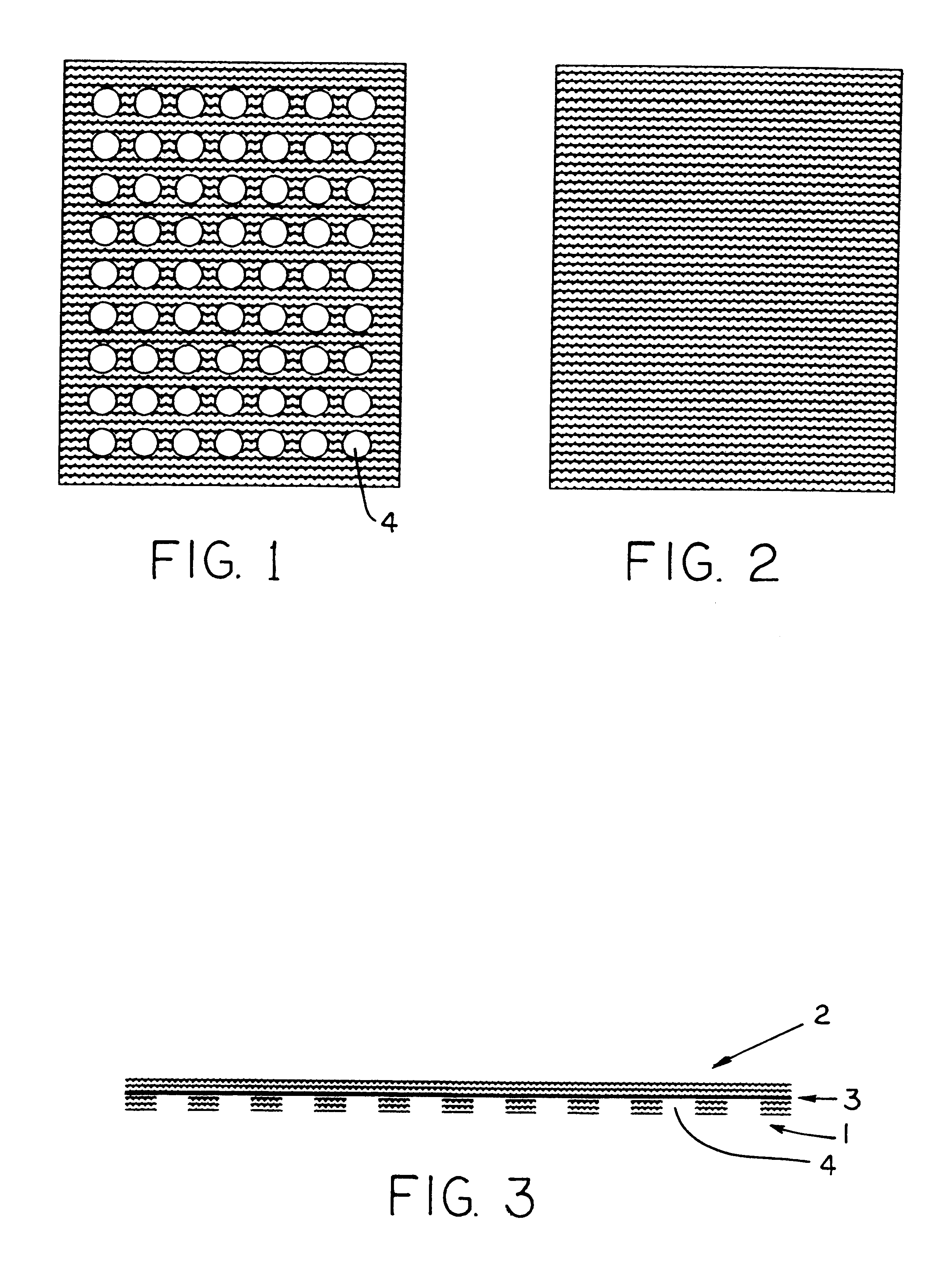

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

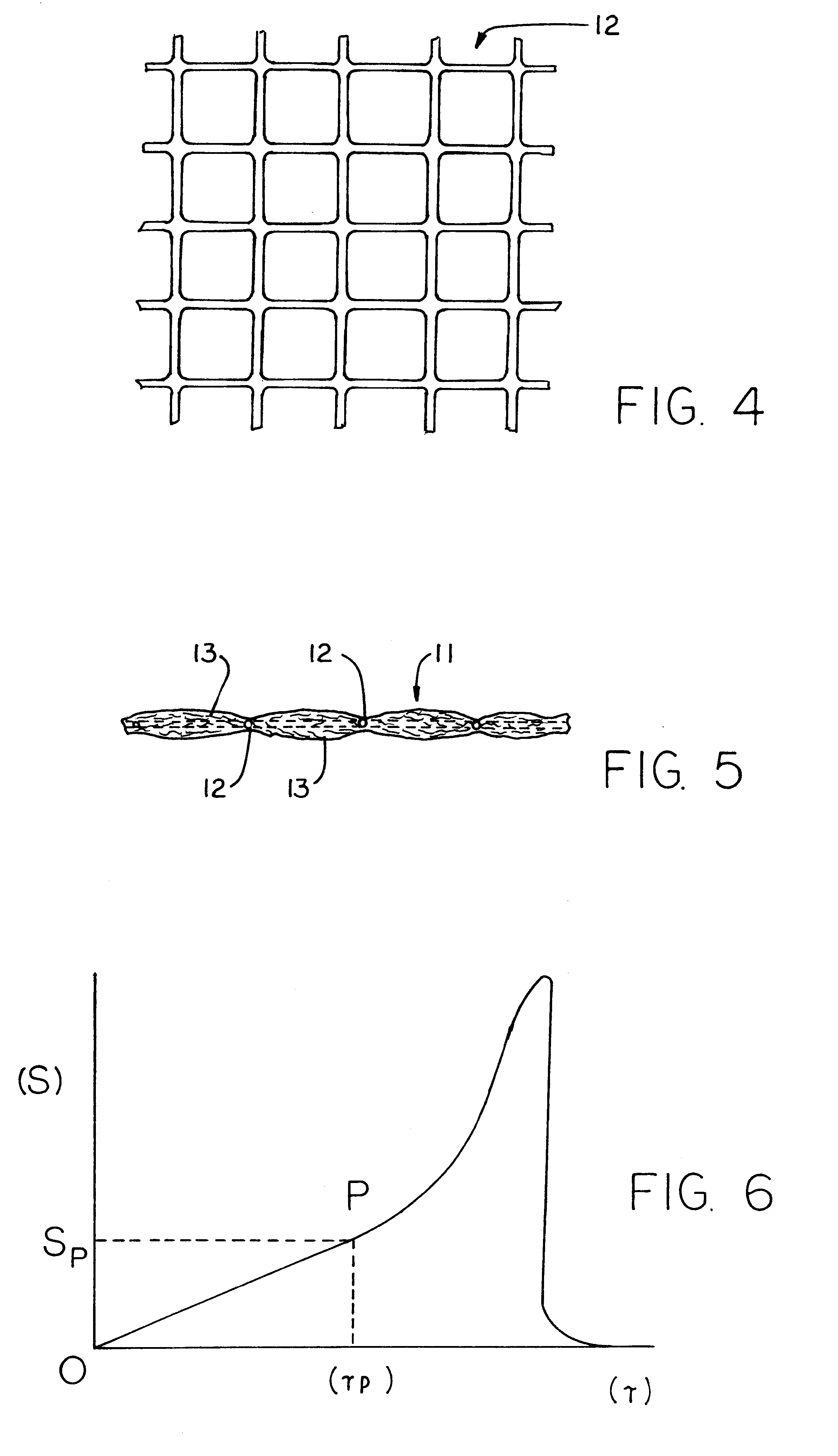

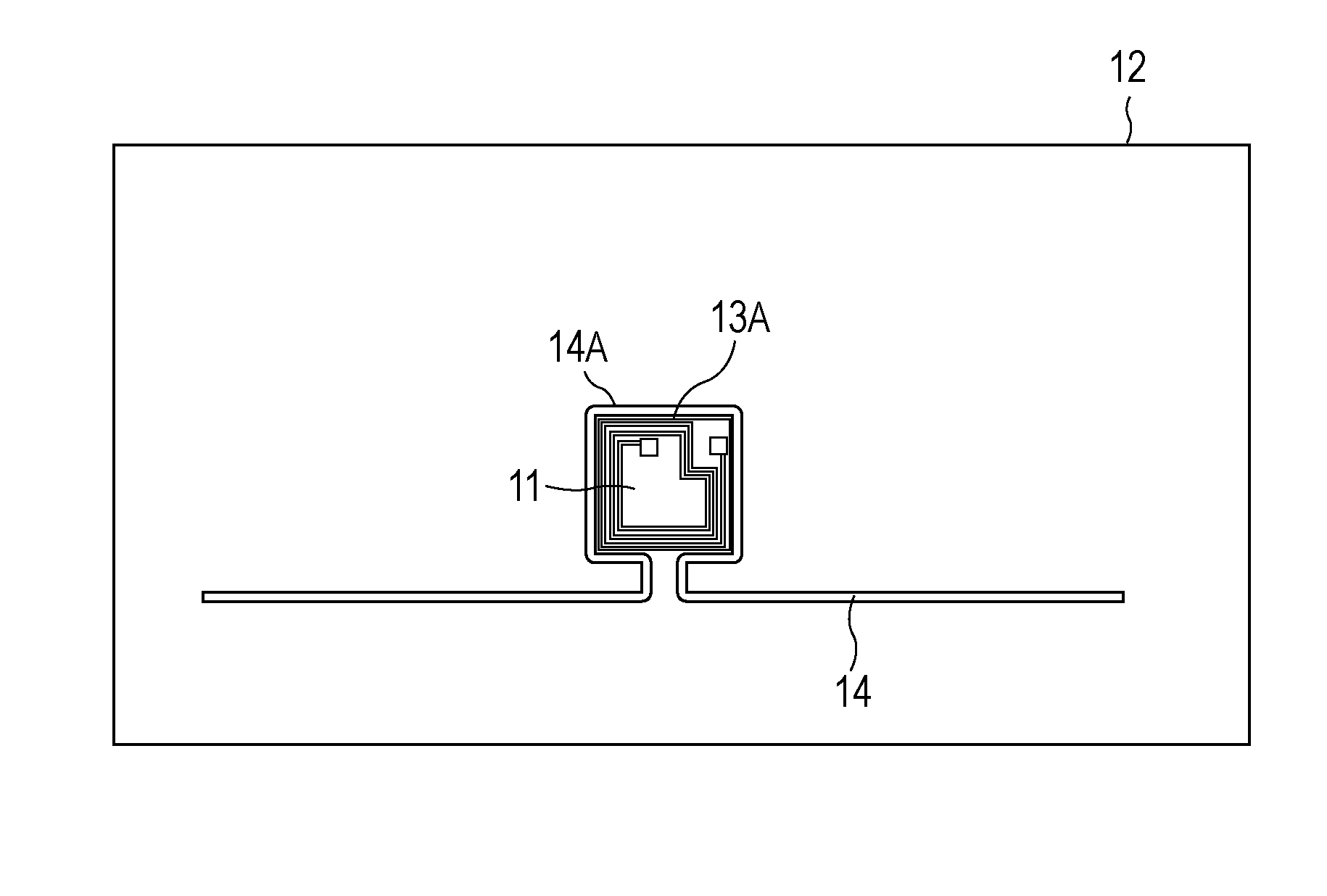

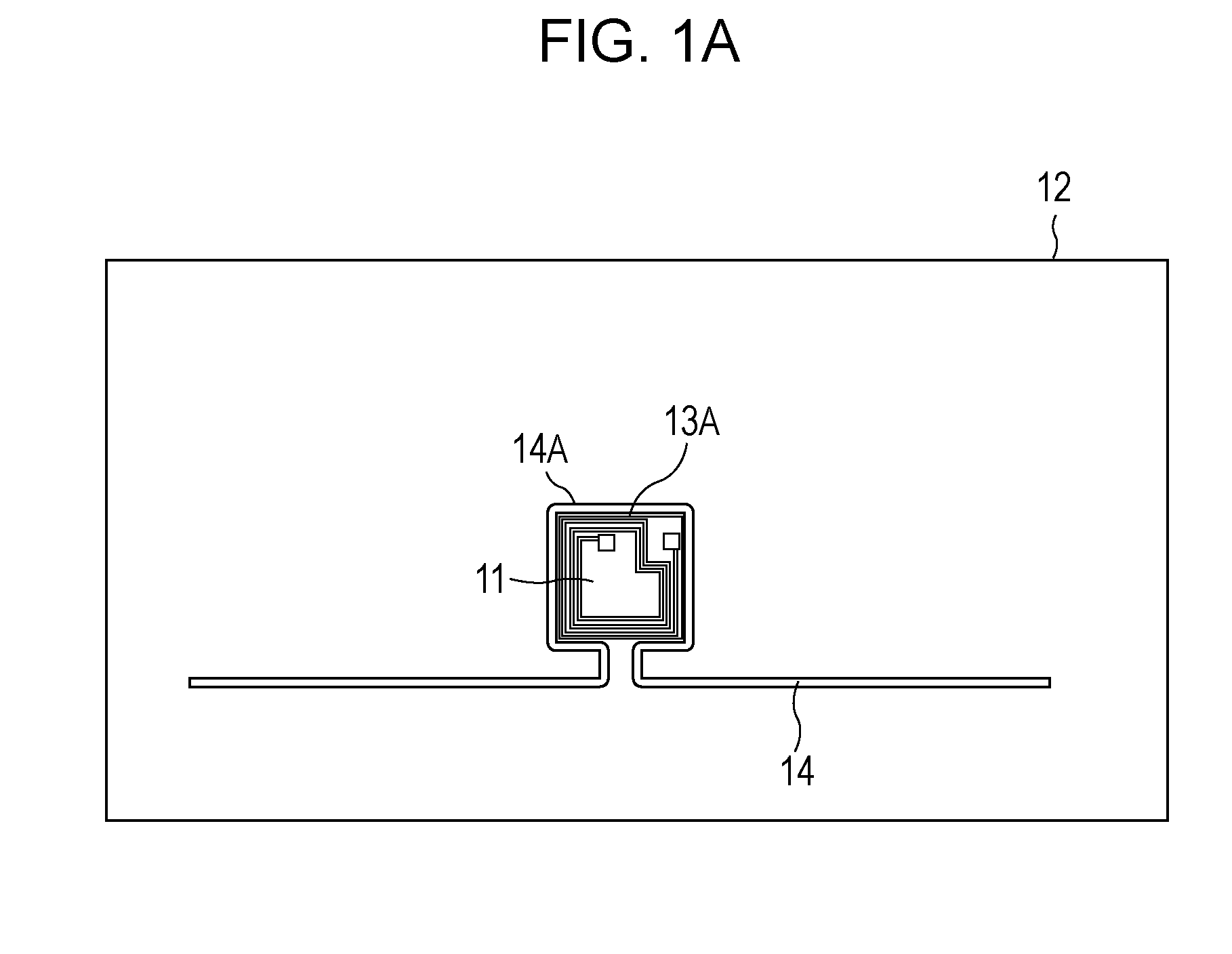

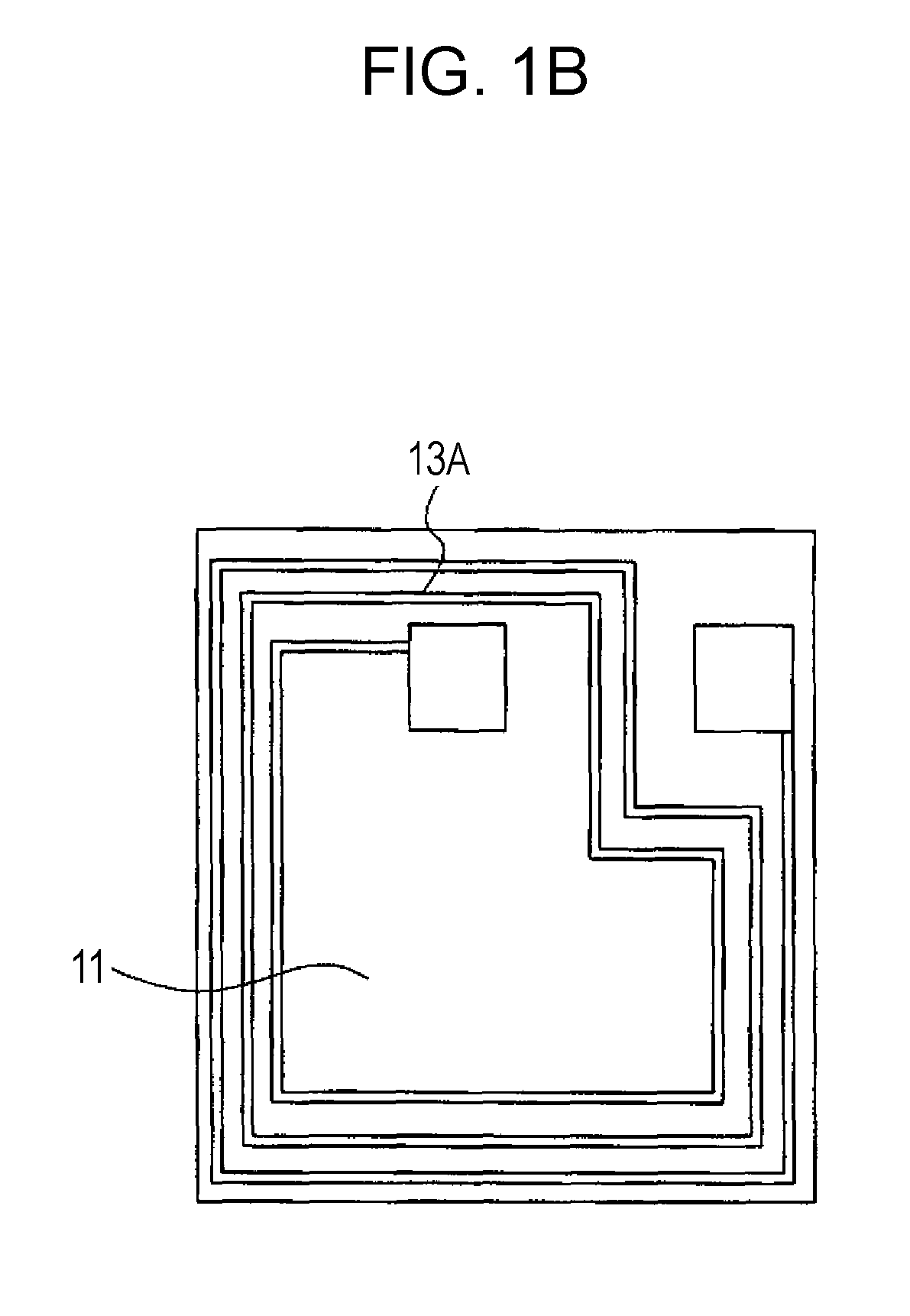

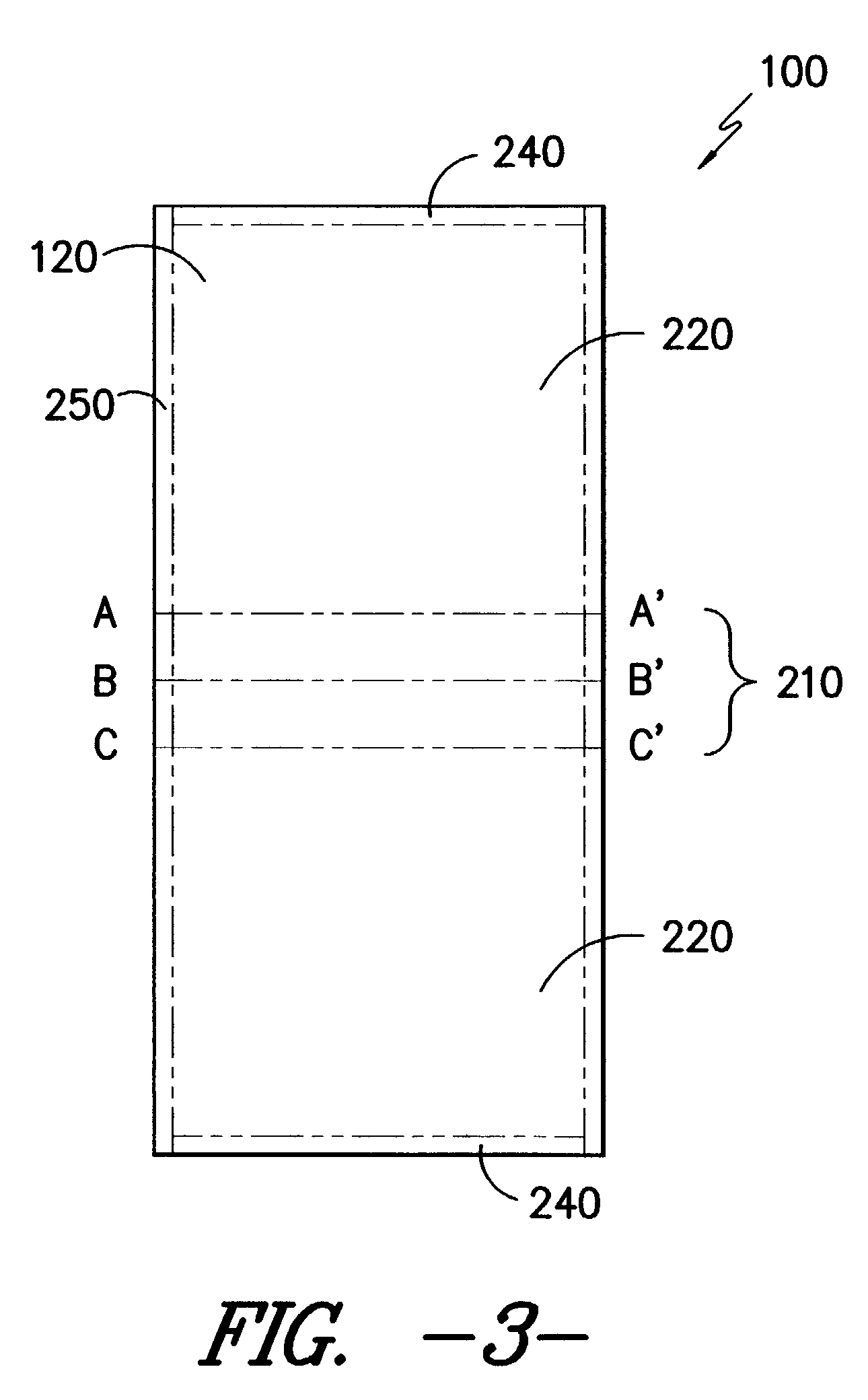

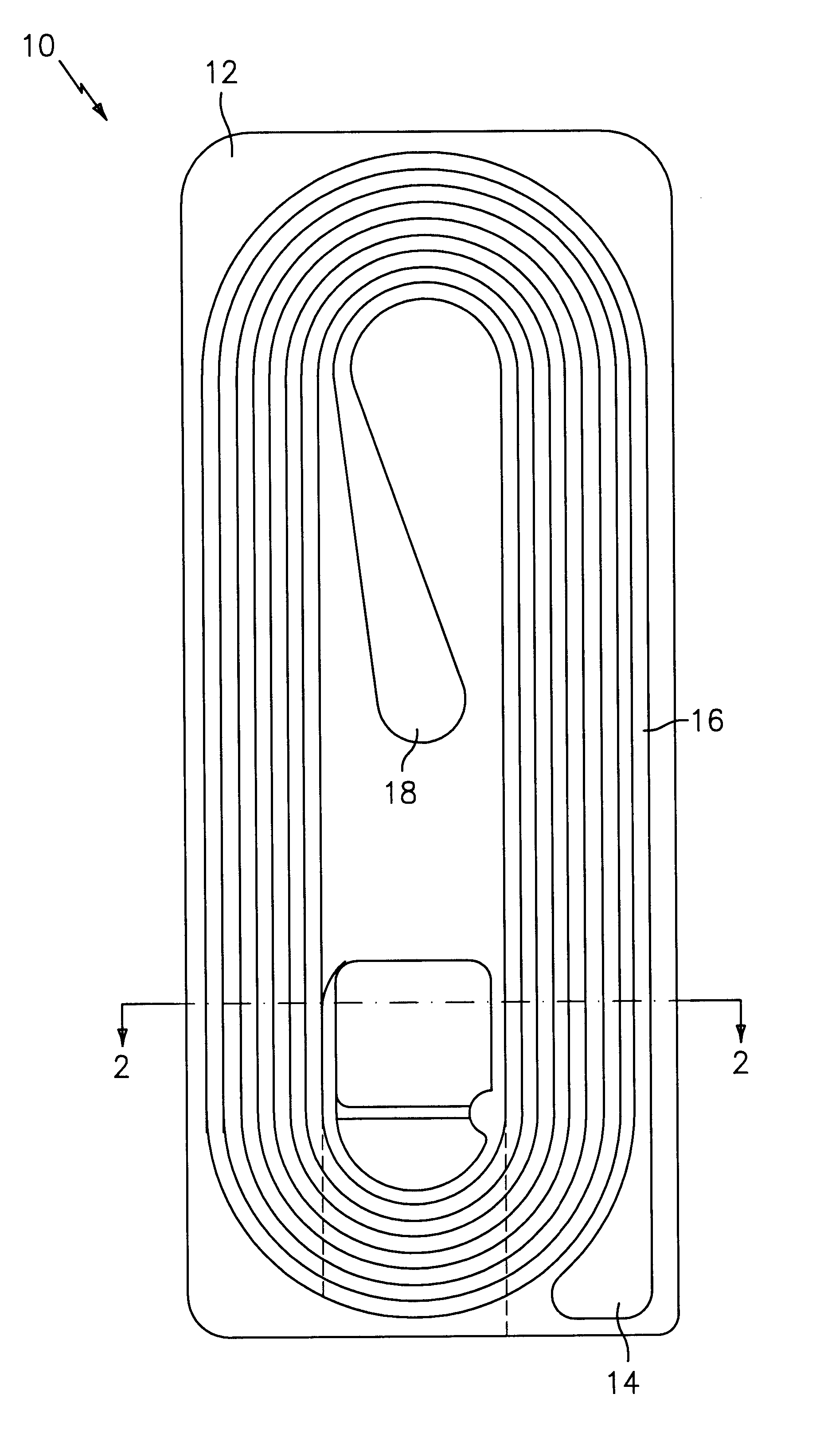

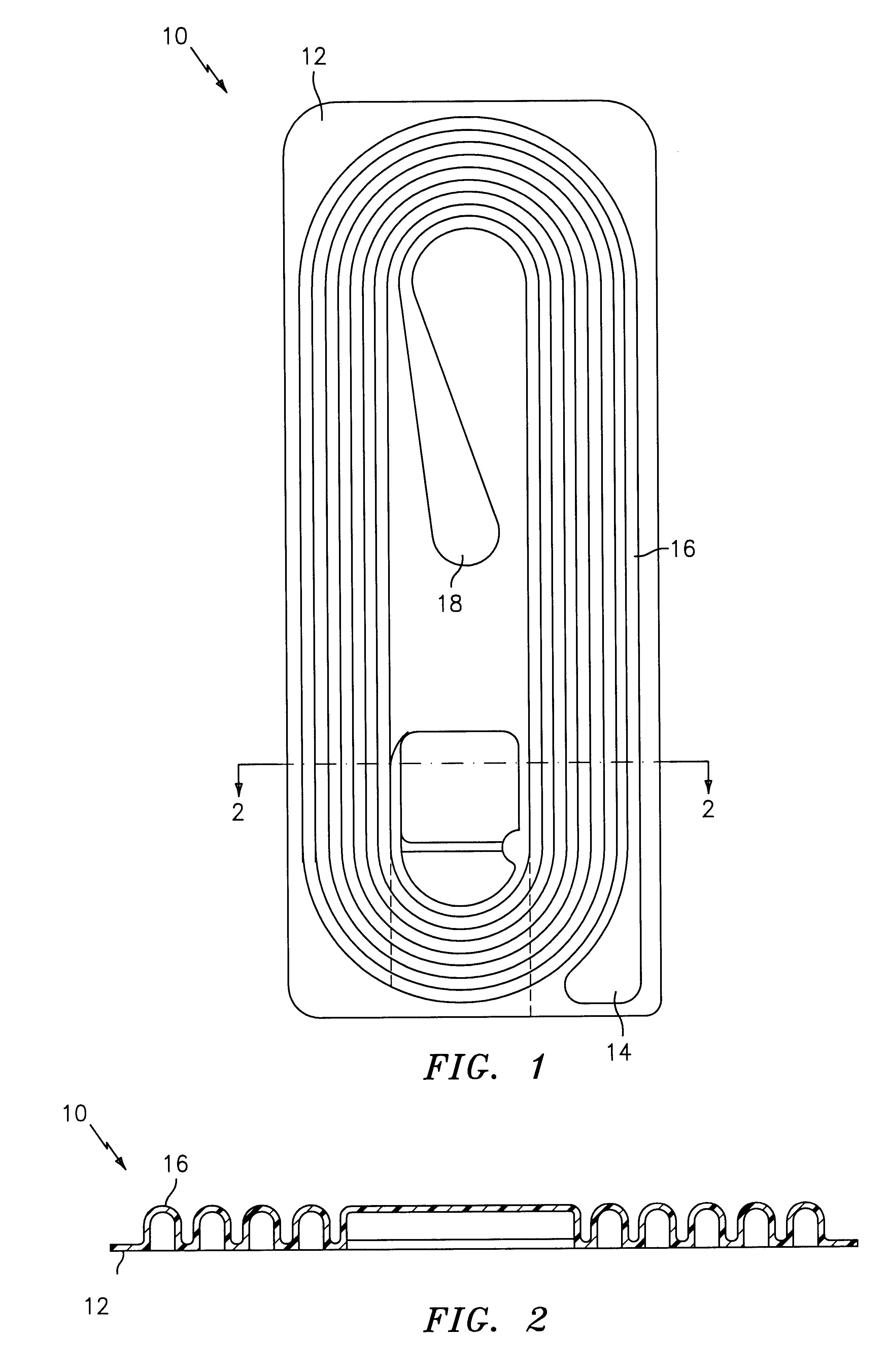

Base sheet

InactiveUS20110063184A1Near-field transmissionRadiating elements structural formsElectrical conductorEngineering

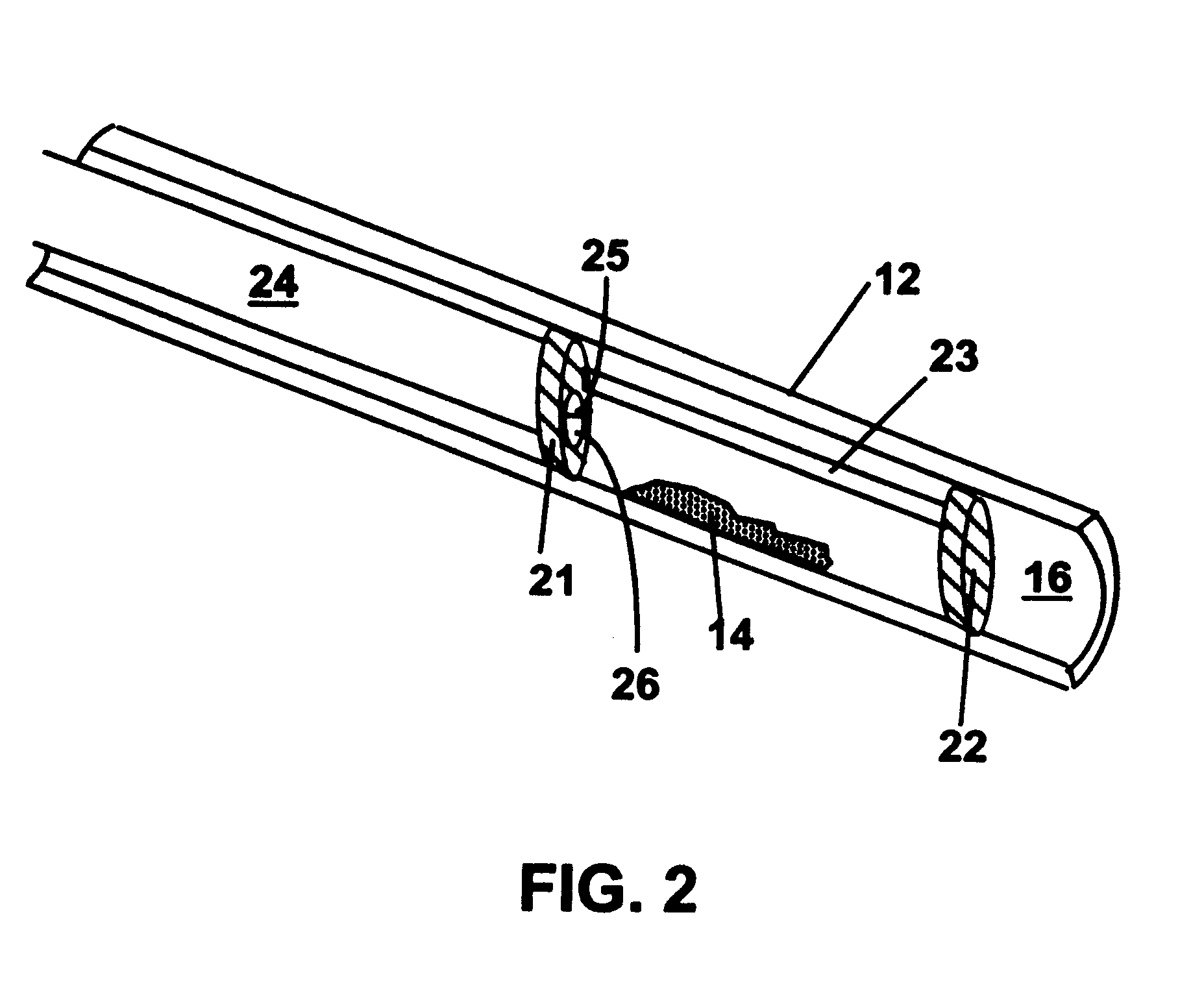

A base sheet 12 has a structure that stably couples a particular chip measuring 1 mm or less on paper with an antenna line by only disposing the chip and antenna line in such a manner that the chip and antenna line are close to each other, without electrically bringing the chip and antenna line into contact with each other. The base sheet 12 includes a chip 11 having a spiral coil 13 with at least one turn disposed on a surface of the chip, or inside the chip and near the surface thereof and an antenna line 14 having a conductor part 14A orbiting around the coil 13A of the chip 11 or directly over or directly below the coil 13A so that the conductor part is magnetically coupled with the coil 13A. This base sheet has a structure that stably couples even a chip measuring 1 mm or less on paper or the like with an antenna line by only disposing the chip and antenna line in such a manner that the chip and antenna line are close to each other, without physically bringing the chip and antenna line into contact with each other.

Owner:PHILTECH

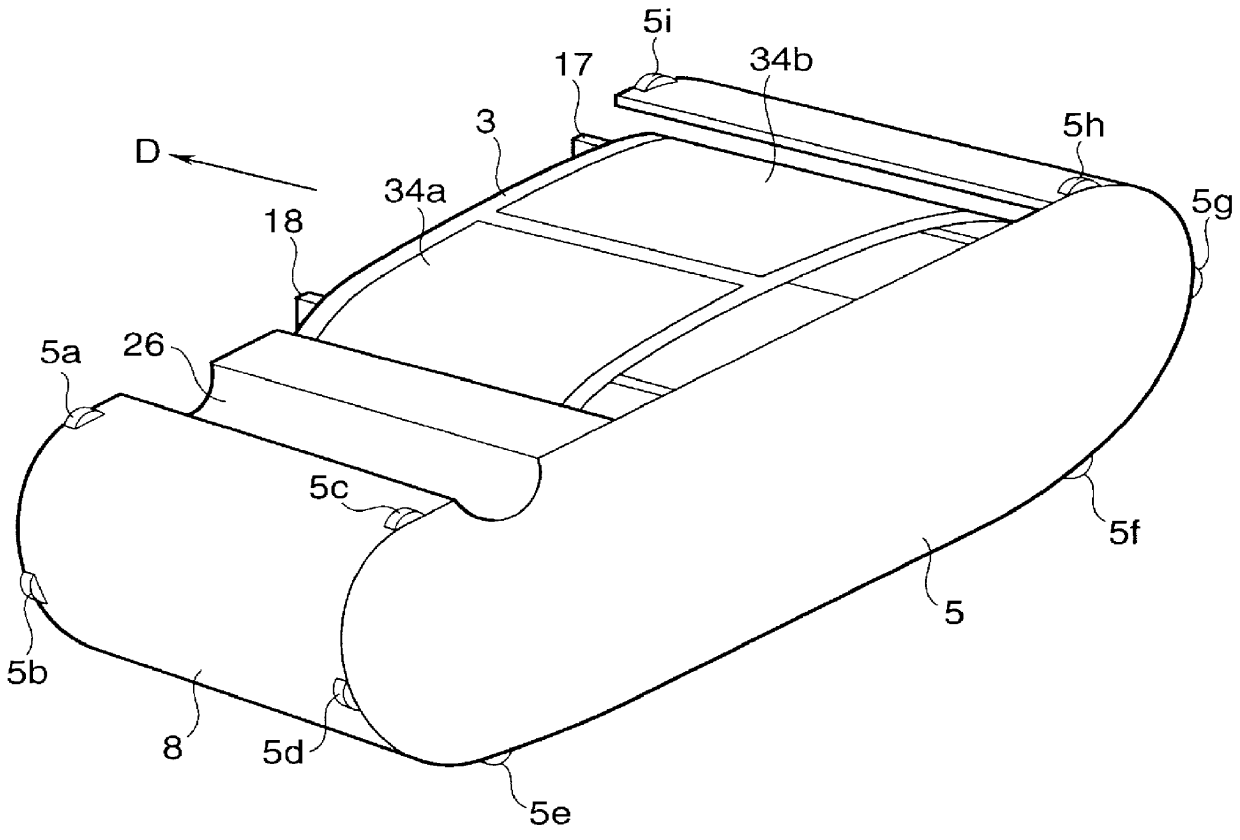

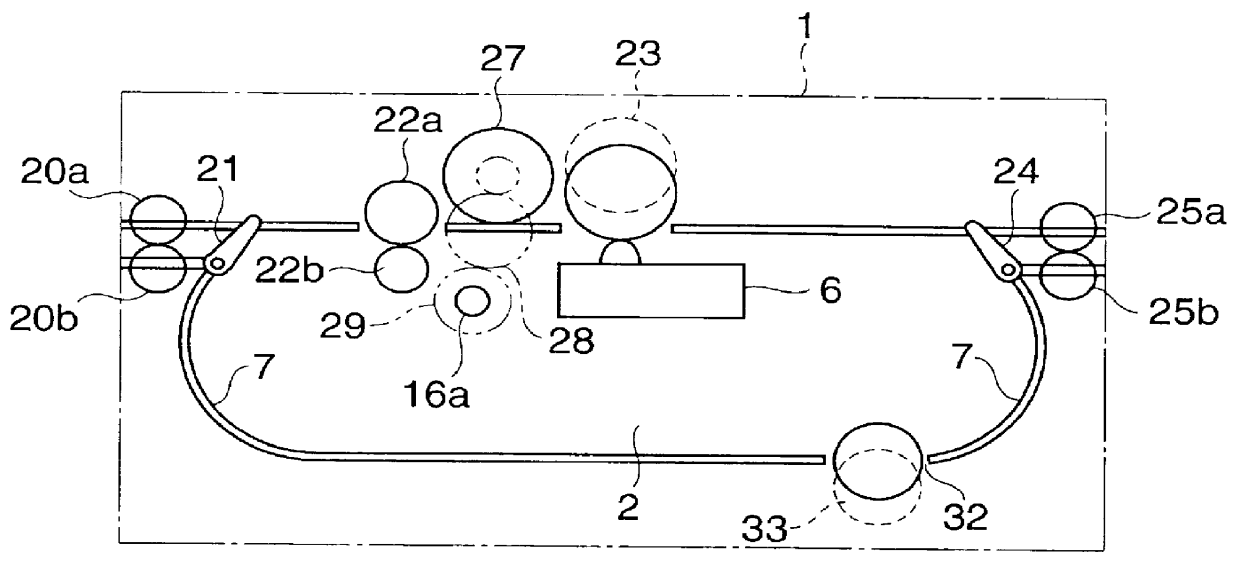

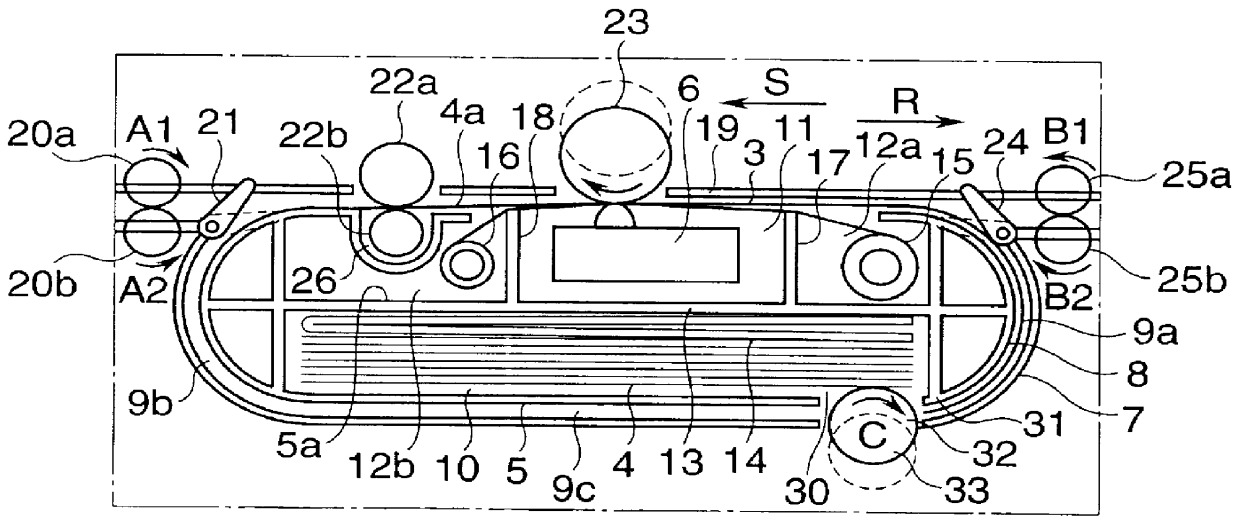

Sheet finisher and image forming system using the same

InactiveUS6905118B2Neatly foldedReduce frictionMechanical working/deformationFolding thin materialsImage formationEngineering

A sheet finisher of the present invention is included in an image forming system and folds a stack of sheets sequentially transferred from an image forming apparatus thereto. The sheet finisher includes a fold roller pair for holding the stack of sheets being conveyed via a nip thereof. A reinforce roller reinforces the fold of the folded sheet stack in cooperation with a guide plate. A drive mechanism causes the reinforce roller to move in a direction perpendicular to a direction of sheet conveyance. A shock absorbing member is located at a position where the reinforce roller and guide plate contact each other.

Owner:RICOH KK

Security paper

InactiveUS6159585AAvoid the needLow compositionNon-fibrous pulp additionNatural cellulose pulp/paperOrganic solventChemical separation

A security paper indicates exposure to a solvent by a solvent resistant color signal. A metal mordant dye first co-reactant and a mordant dye second co-reactant form an organic solvent-insoluble colored reaction product when the paper is washed with an organic solvent. The metal mordant dye first co-reactant and a mordant dye second co-reactant are chemically isolated from each other so as to prevent the coordinate covalent bond from forming until the paper is washed with an organic solvent. The chemical isolation can be effected by encapsulation or other physical separation of the co-reactants. The organic solvent-insoluble colored reaction product, once formed, remains entrapped in the web when the paper is washed with an organic solvent. The chemical isolation prevents the organic solvent-insoluble colored reaction product from forming upon the application of pressure alone to the paper.

Owner:DOMTAR +1

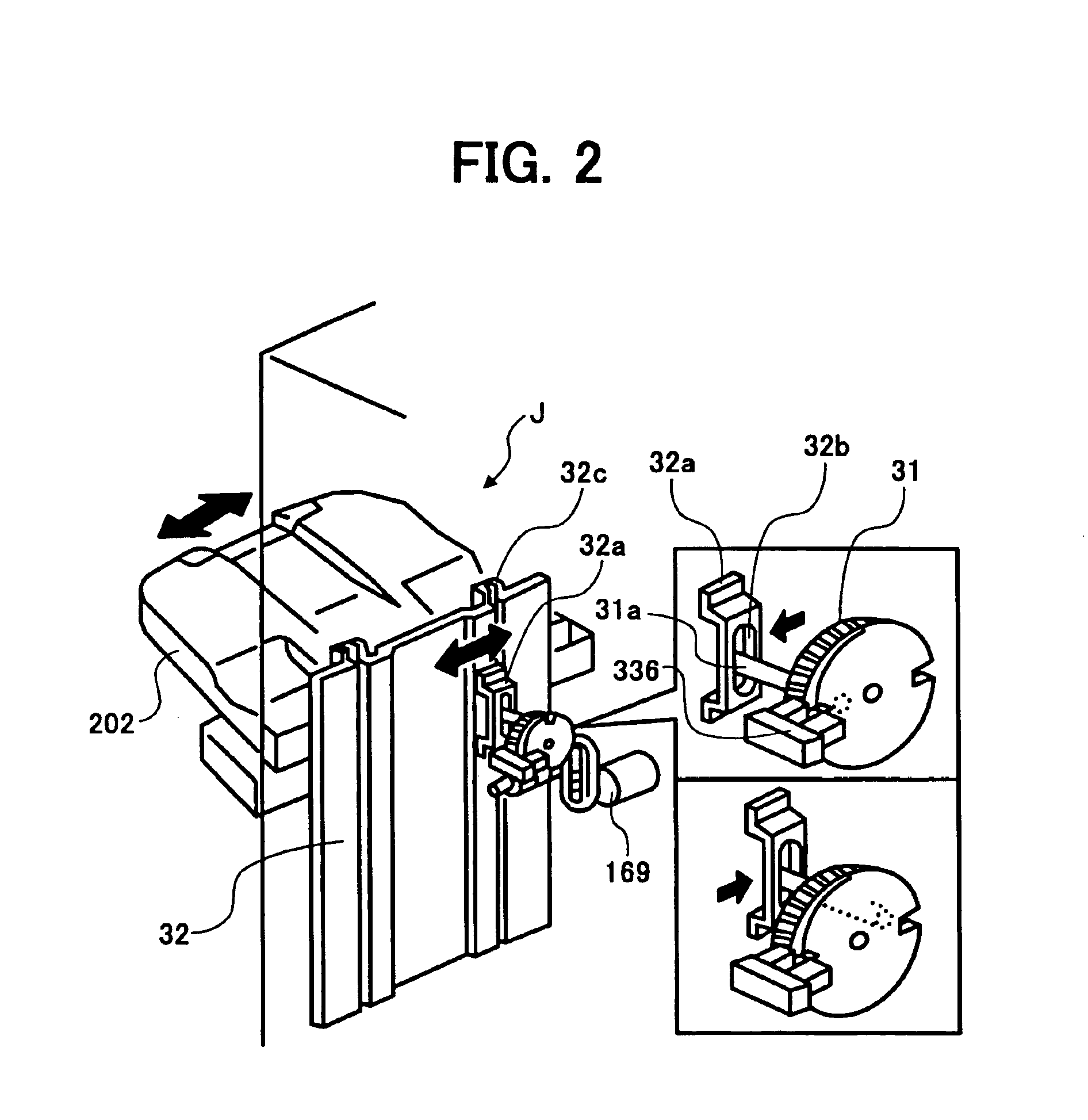

Kits for use in the treatment of vascular calcified lesions

Kits for use in the treatment of vascular calcified lesions are provided. The subject kits include at least one of: (a) a fluid delivery means for conveying fluid to and from a vascular site; and (b) a dissolution fluid for at least partially dissolving the target lesion. In many embodiments, the kits include both of these components. The subject kits further include instructions for treating vascular calcified lesions with the contents of the kit, where the instructions are typically recorded on a recording medium, e.g. printed on a substrate, such as paper.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Packaging material and containers formed therefrom

The flexible, reusable packaging container of the present invention is comprised of a packaging material. The packaging material is comprised of one or more layers of coating disposed on one or more layers of textile substrate. The coating layer may be comprised of a stiffening agent for providing support to the packaging container. The stiffening agent may provide a gas and / or liquid impermeable barrier between the contents of the container and the textile substrate. The stiffening agent may also include chemicals which impart antifungal or antibacterial properties to container. The textile substrate typically provides an aesthetically pleasing feel and appearance to the outside of the packaging container, as well as providing functional attributes such as water repellence, stain resistance, and / or anti-static resistance. The resulting packaging container possesses increased strength, puncture resistance, and resistance to de-lamination over the current paper or plastic packaging containers.

Owner:MILLIKEN & CO

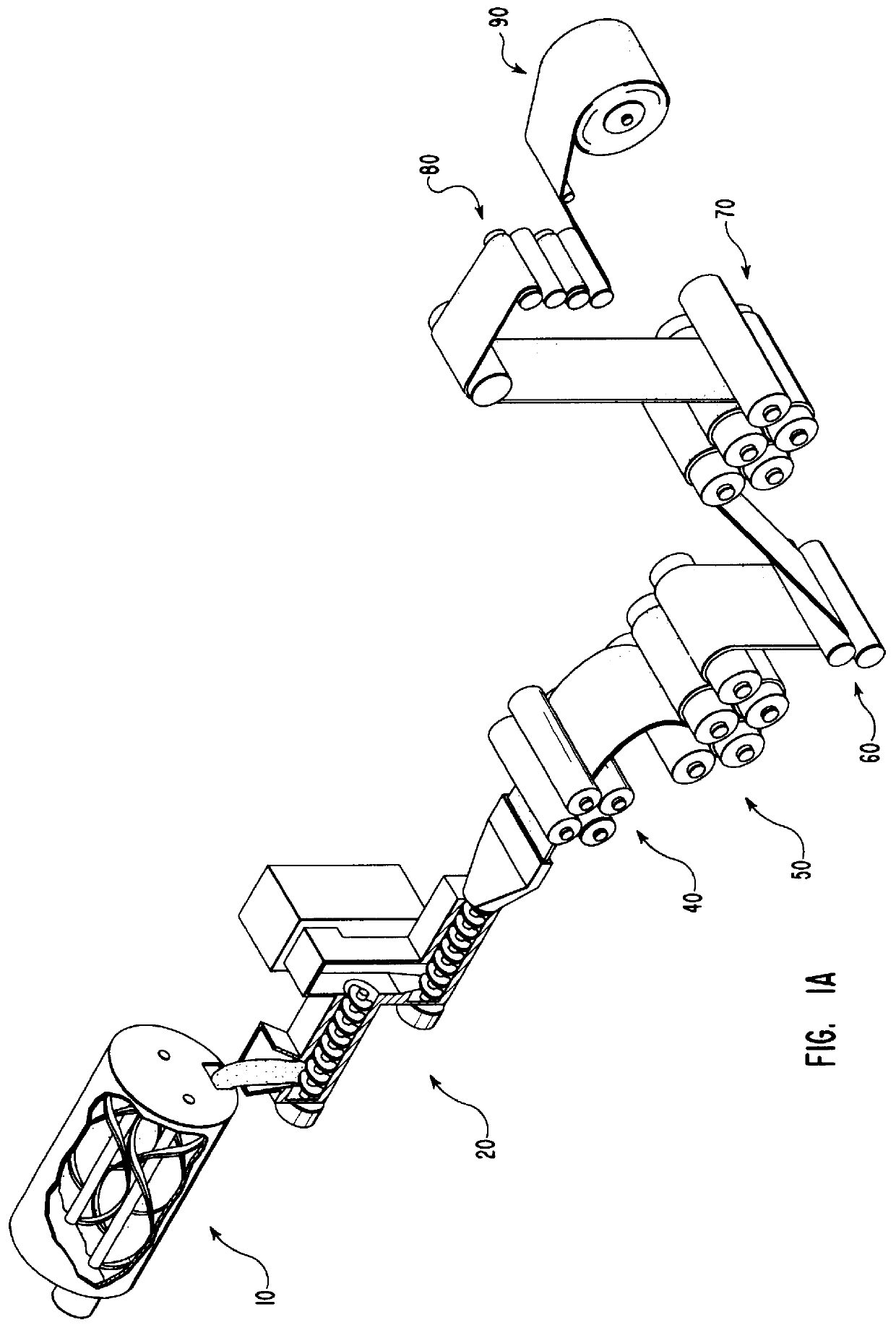

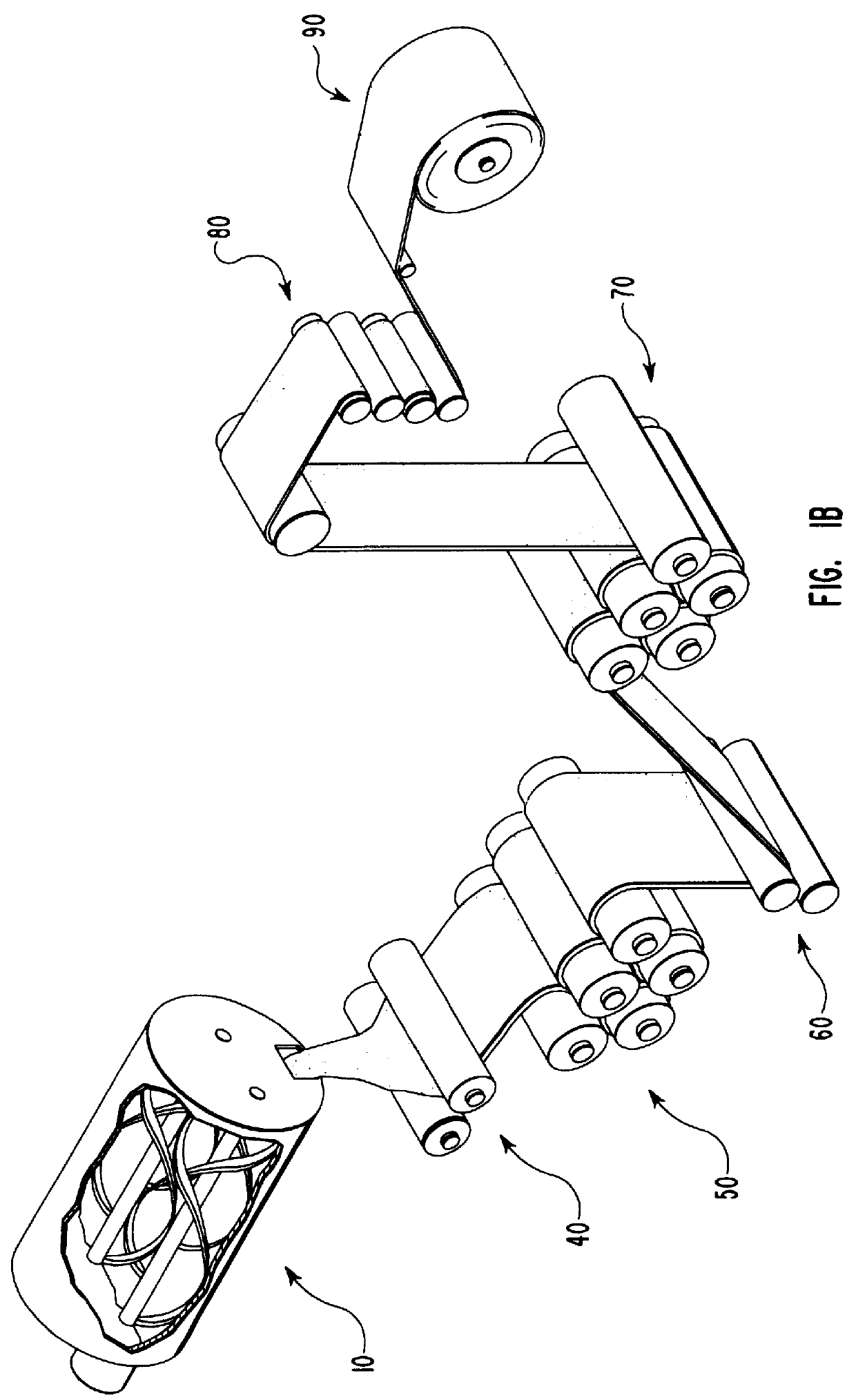

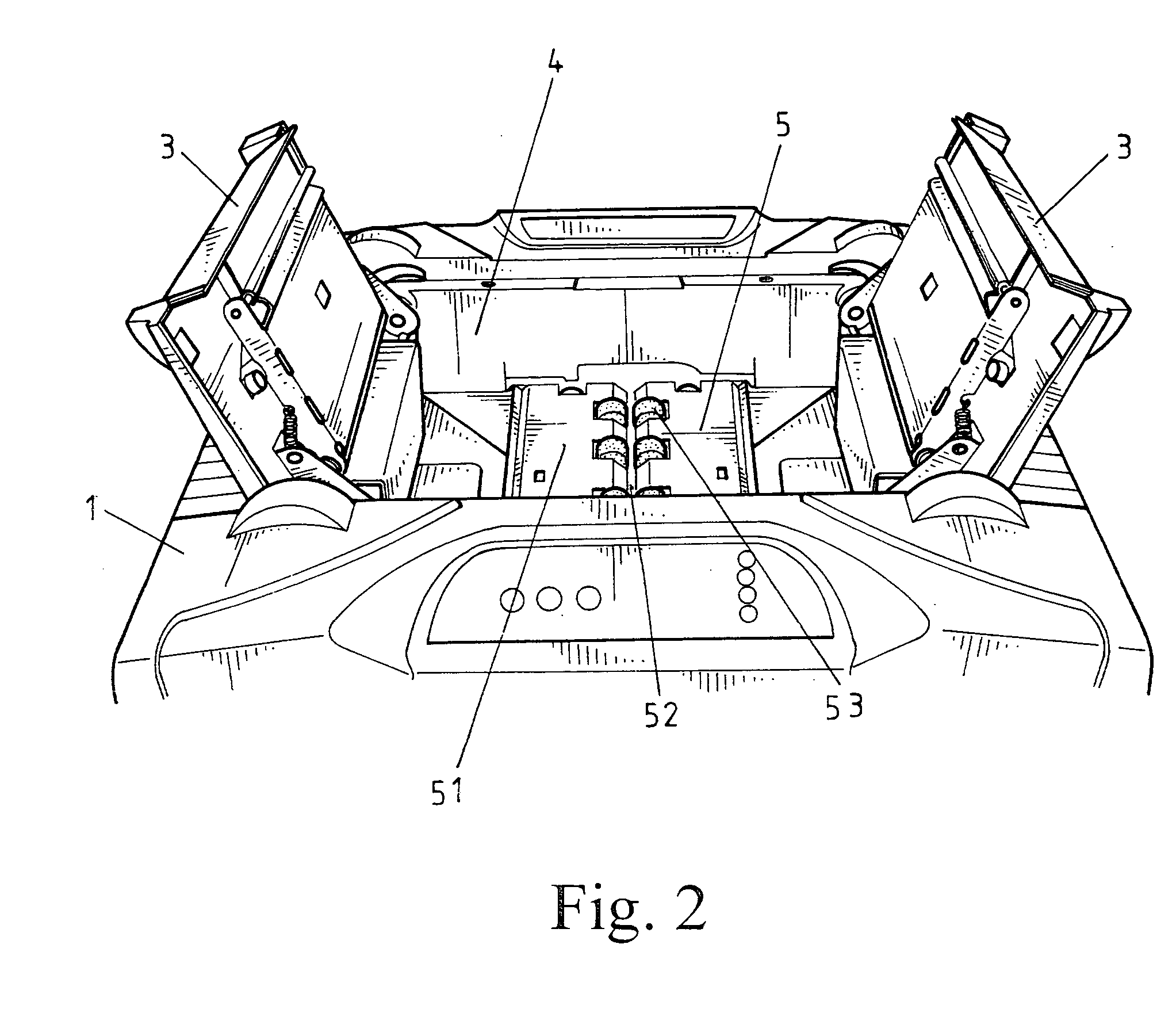

Auto-feed buit-in a paper shredder

InactiveUS20050274836A1Reduce spacingLow costCocoaGrain treatmentsPulp and paper industryPaper sheet

Disclosed is an auto-feed buit-in a paper shredder, including a pair of bisecting lids that are each provided at an inside thereof with a paper press, a paper receiving compartment, an auto-feed, and a paper shredding device located exactly below the auto-feed, wherein the auto-feed includes a paper tray, a paper inlet and two roller assemblies; the paper inlet and the paper shredding device located therebelow are aligned along an identical central axis; the two roller assemblies are provided at opposing sides of the paper inlet in parallel and project into the paper tray, whereby after placing a pile of paper into the paper receiving compartment to be supported by the paper tray, and closing the bisecting lids, the paper presses provided at the insides of the lids would apply a force against the pile of paper, such that a bottommost paper of the pile of paper would be folded in half by the two rollers rotating towards each other and then fed into the paper inlet to be subsequently shredded by the paper shredding device located below the paper inlet.

Owner:MICHILIN PROSPERITY

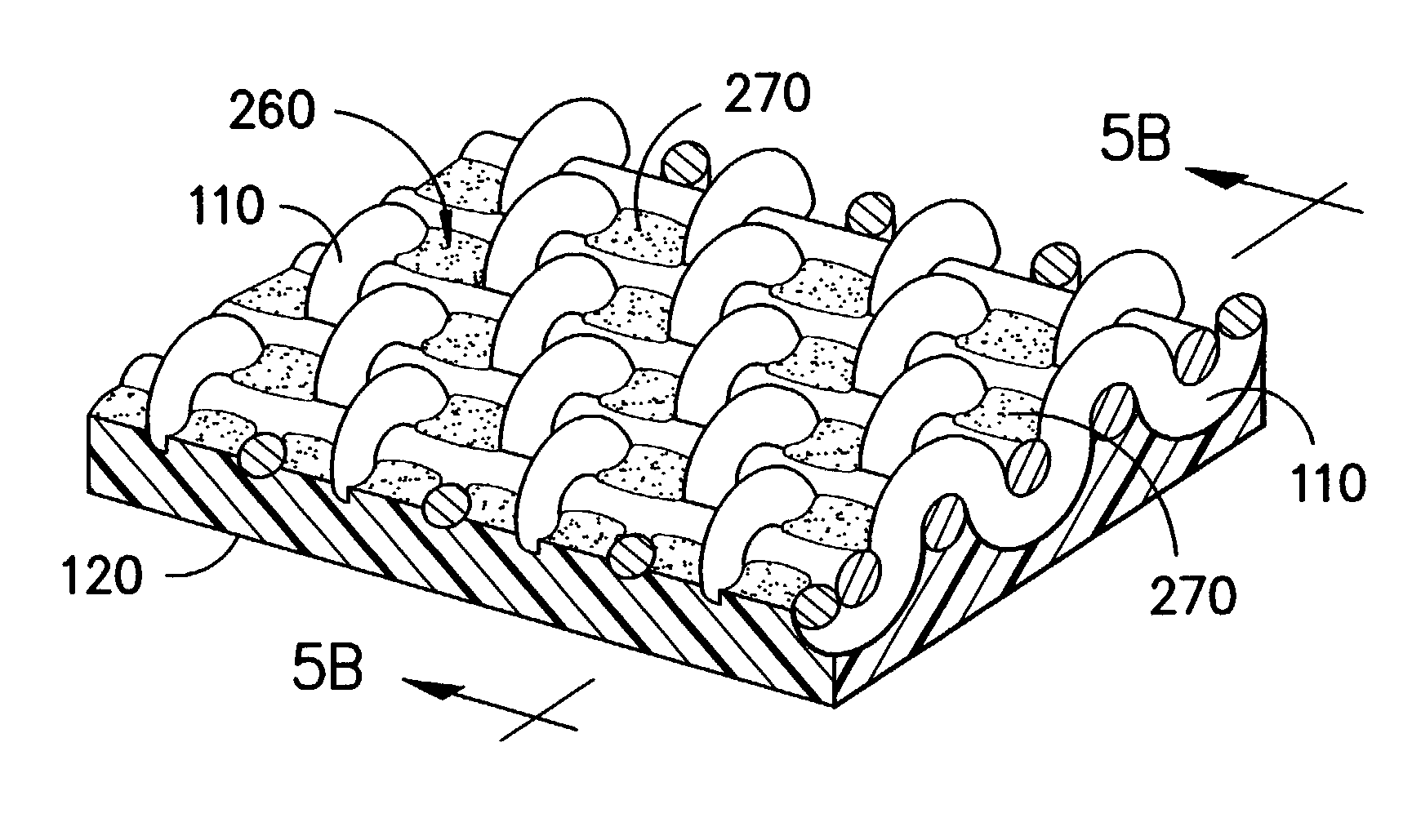

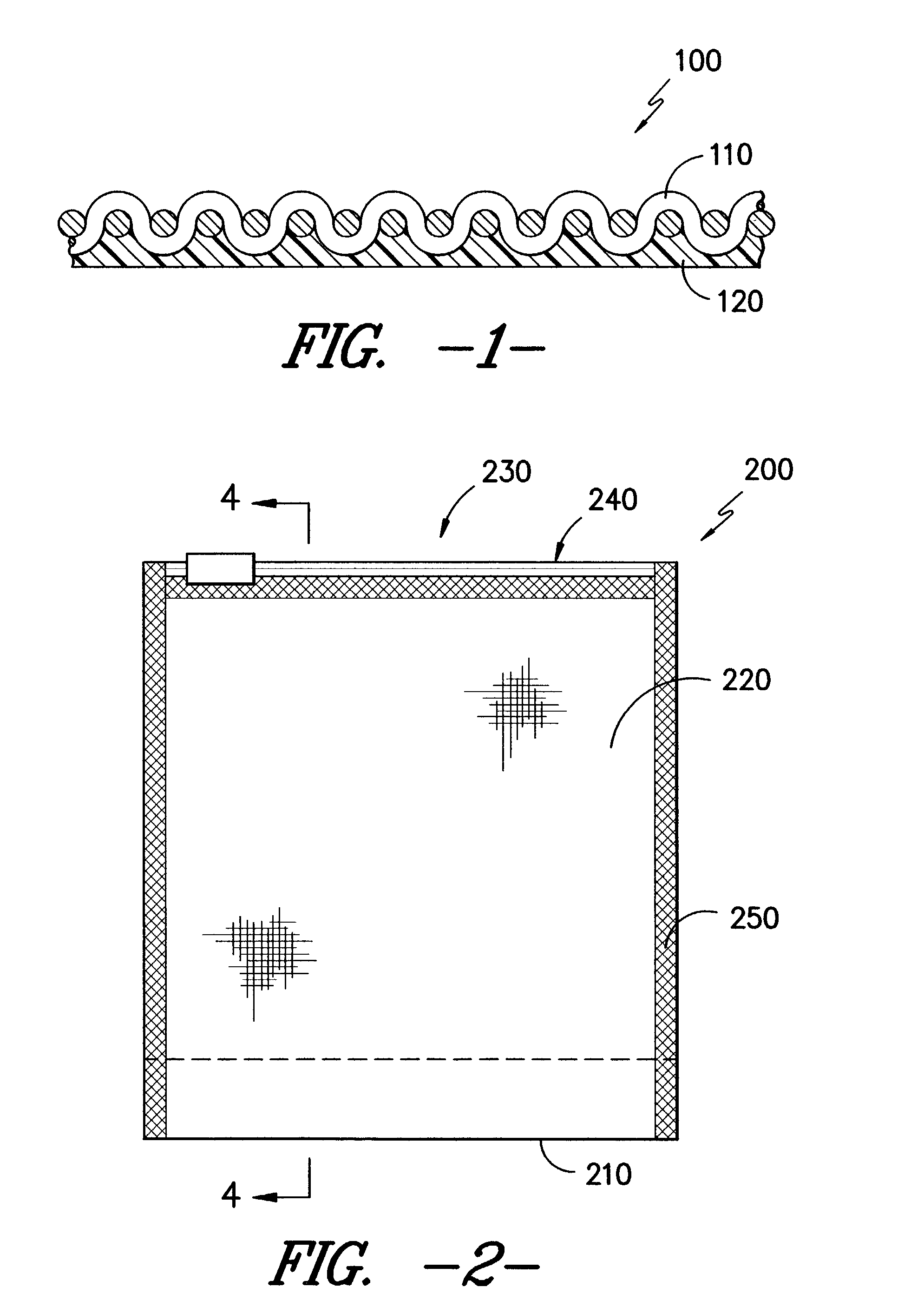

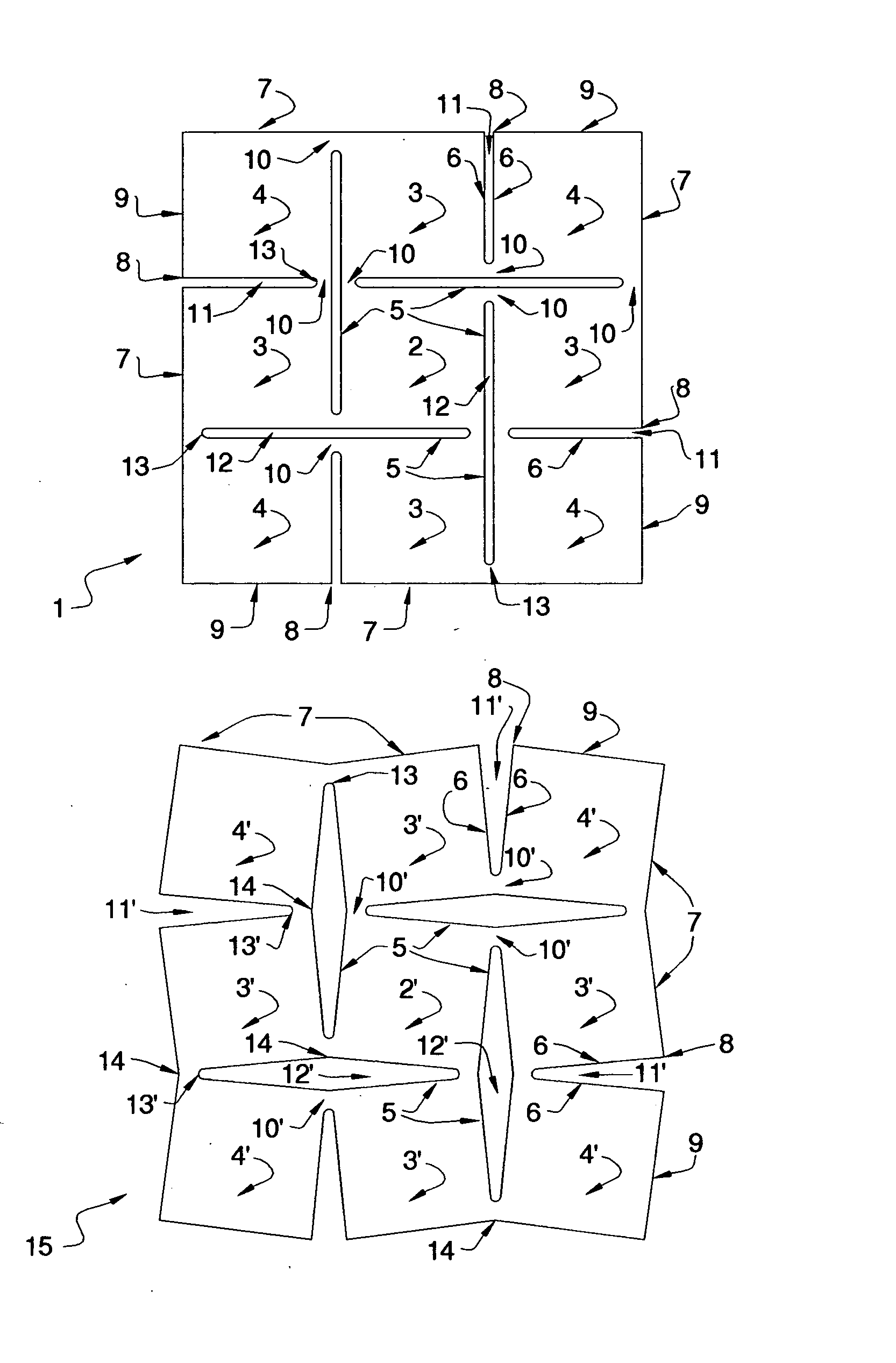

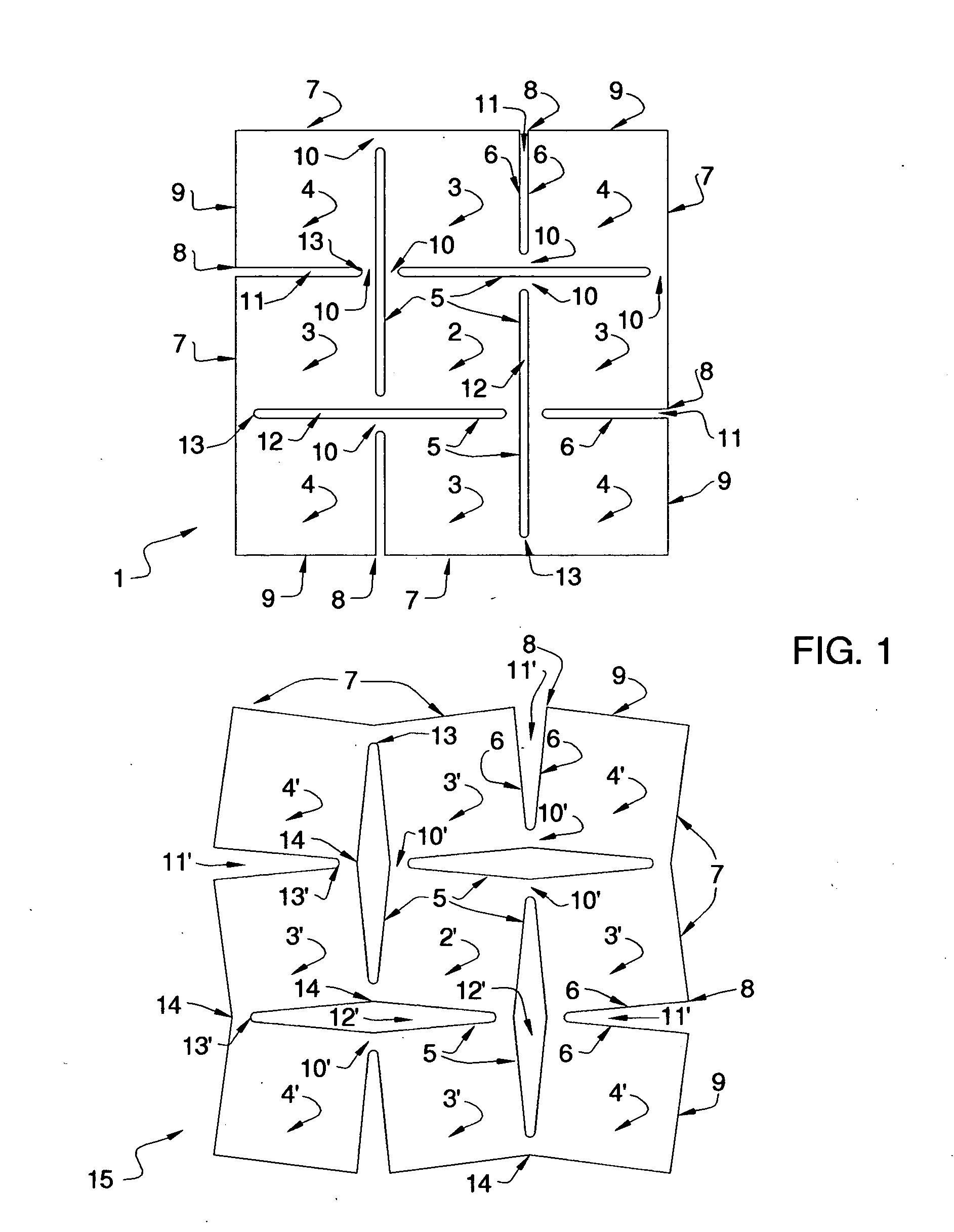

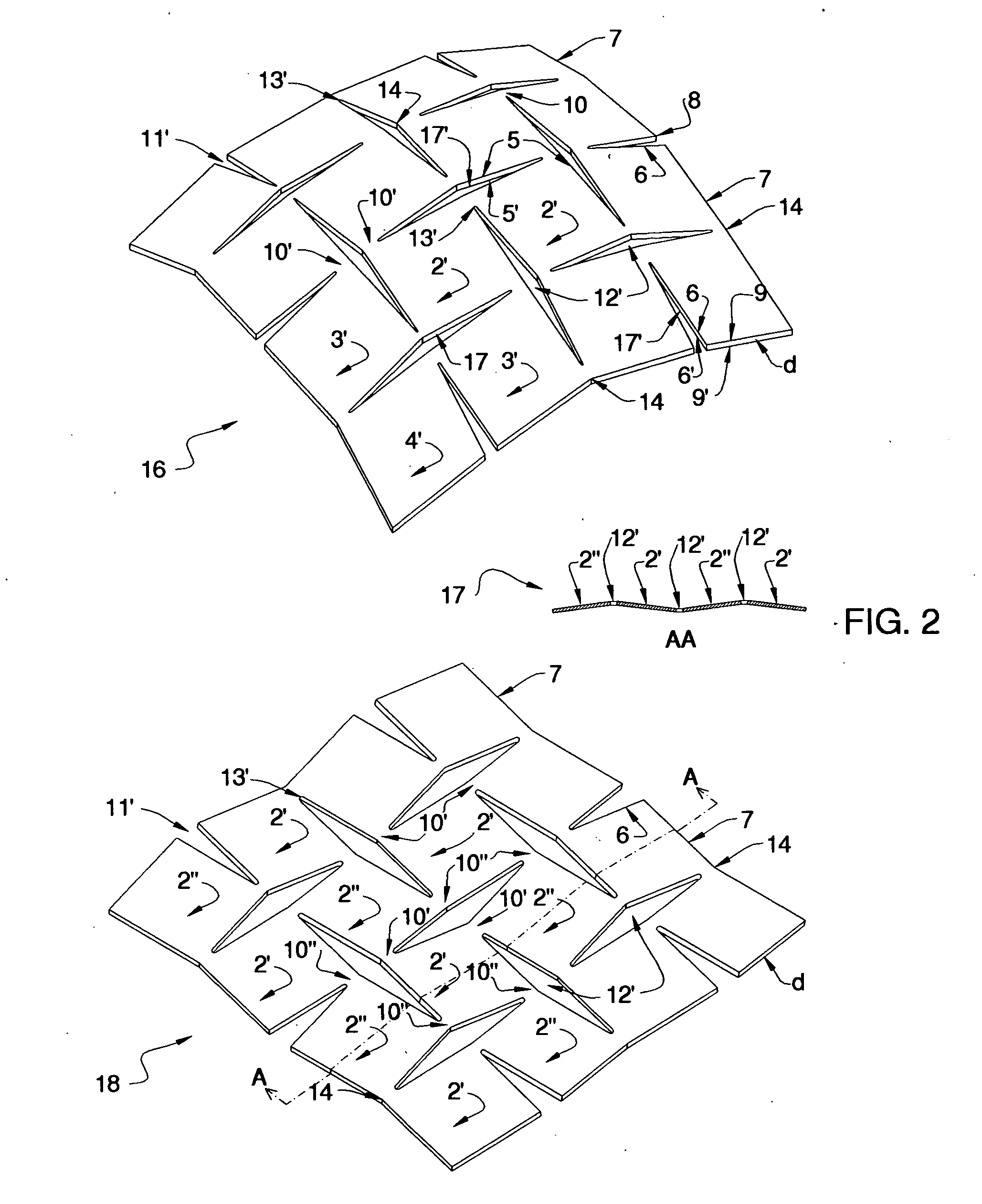

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

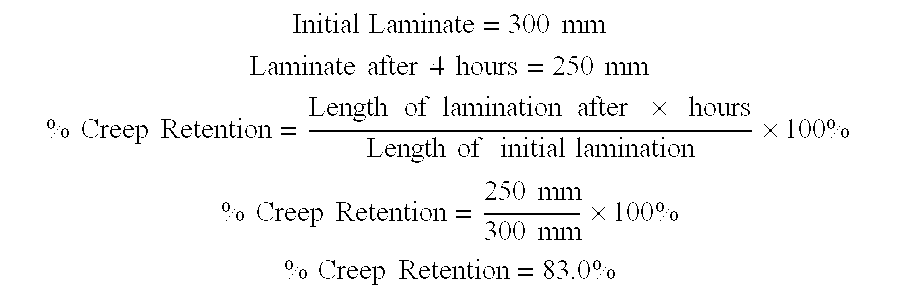

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

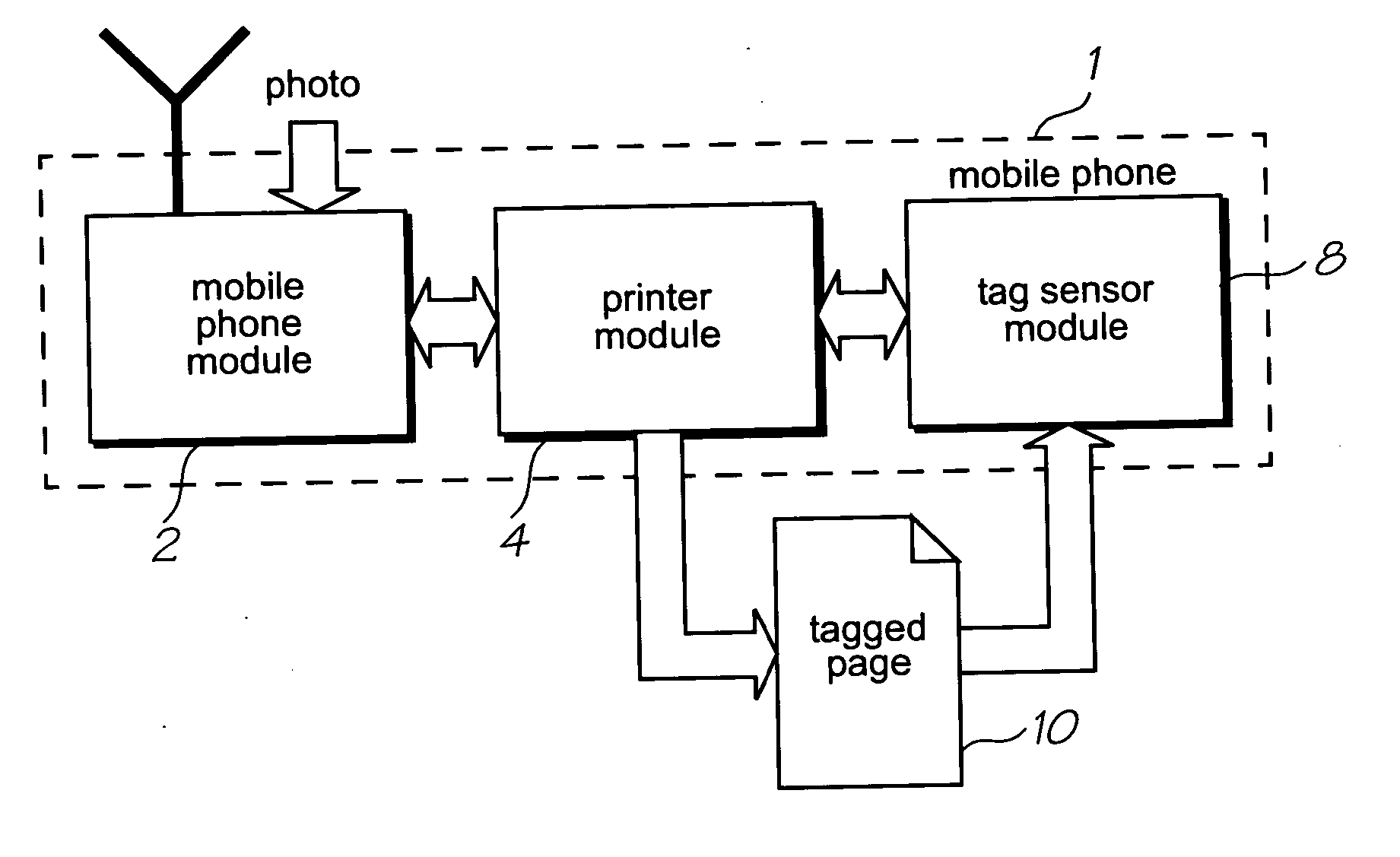

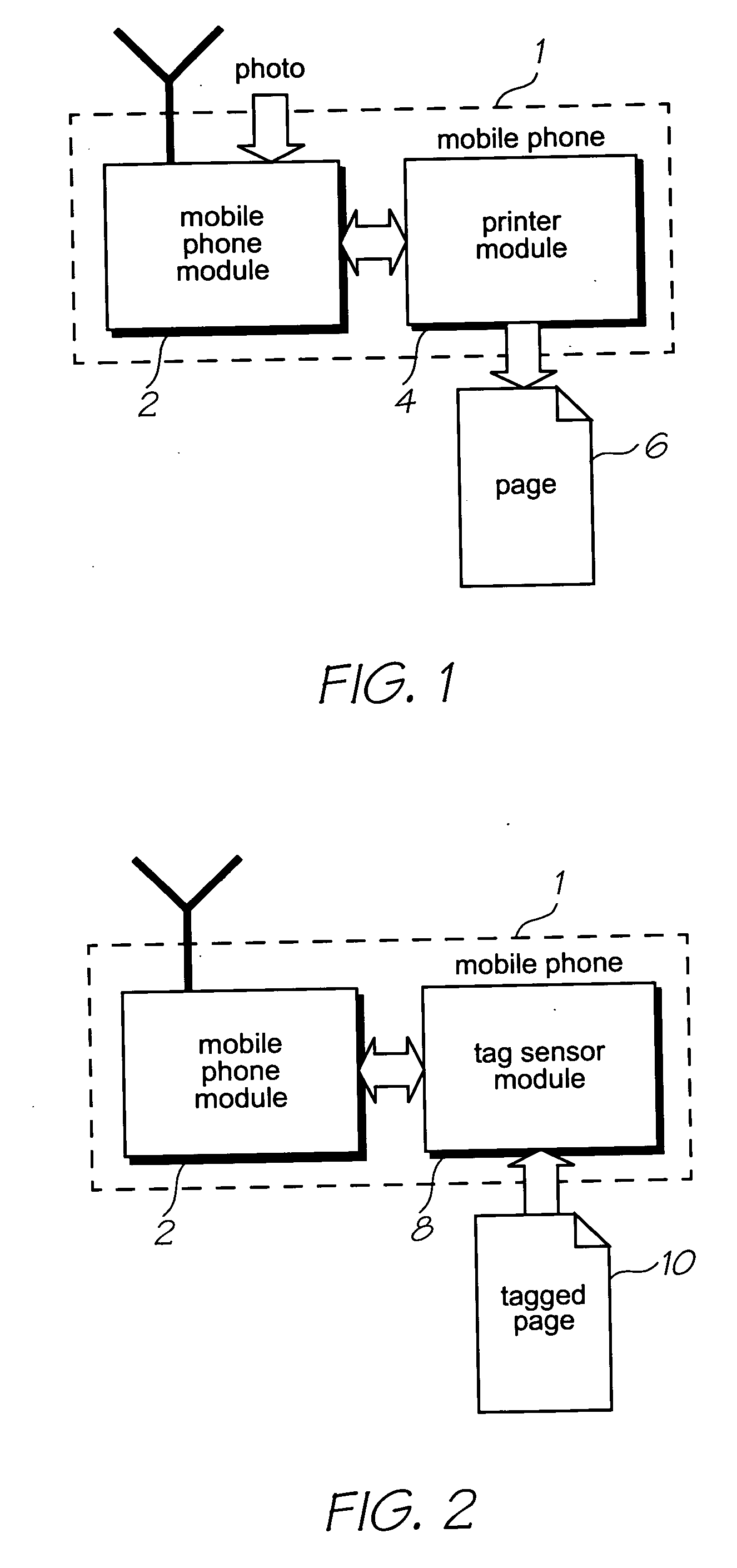

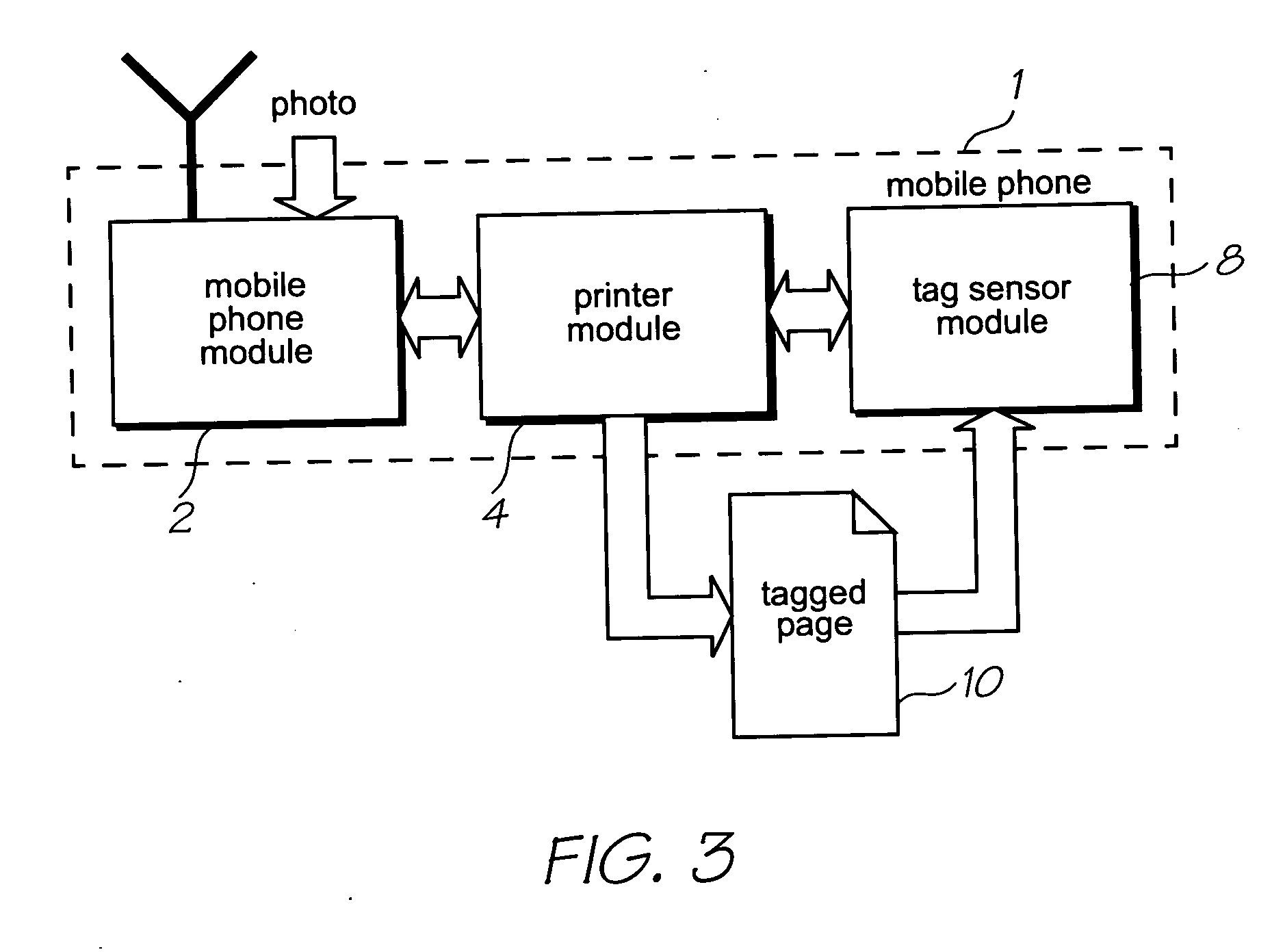

Mobile telecommunication device with a printhead and media sheet position sensor

InactiveUS20060250469A1Increase contact frictionWell formedTypewritersOther printing apparatusEngineeringPosition sensor

A mobile telecommunications device comprising: an inkjet printhead for printing to a media substrate; a media feed assembly for feeding the media past the printhead; a print engine controller for operatively controlling the printhead; and, a position sensor for providing the print engine controller with a signal indicative of the position of the media substrate relative to the printhead; such that, the print engine controller differentiates the signal to derive the speed of the media substrate relative to the printhead and adjusts the operation of the printhead in response to variations in the speed.

Owner:SILVERBROOK RES PTY LTD

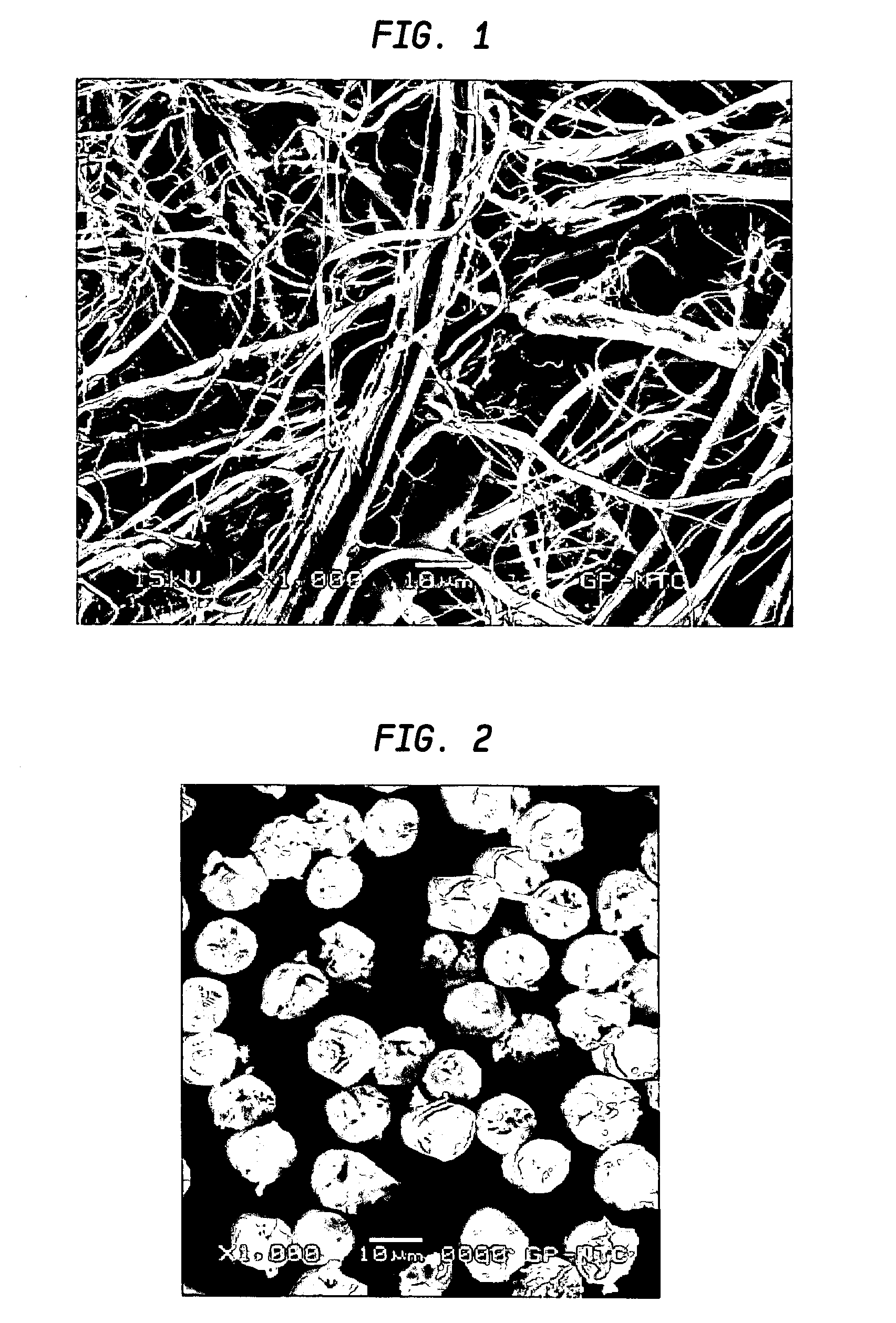

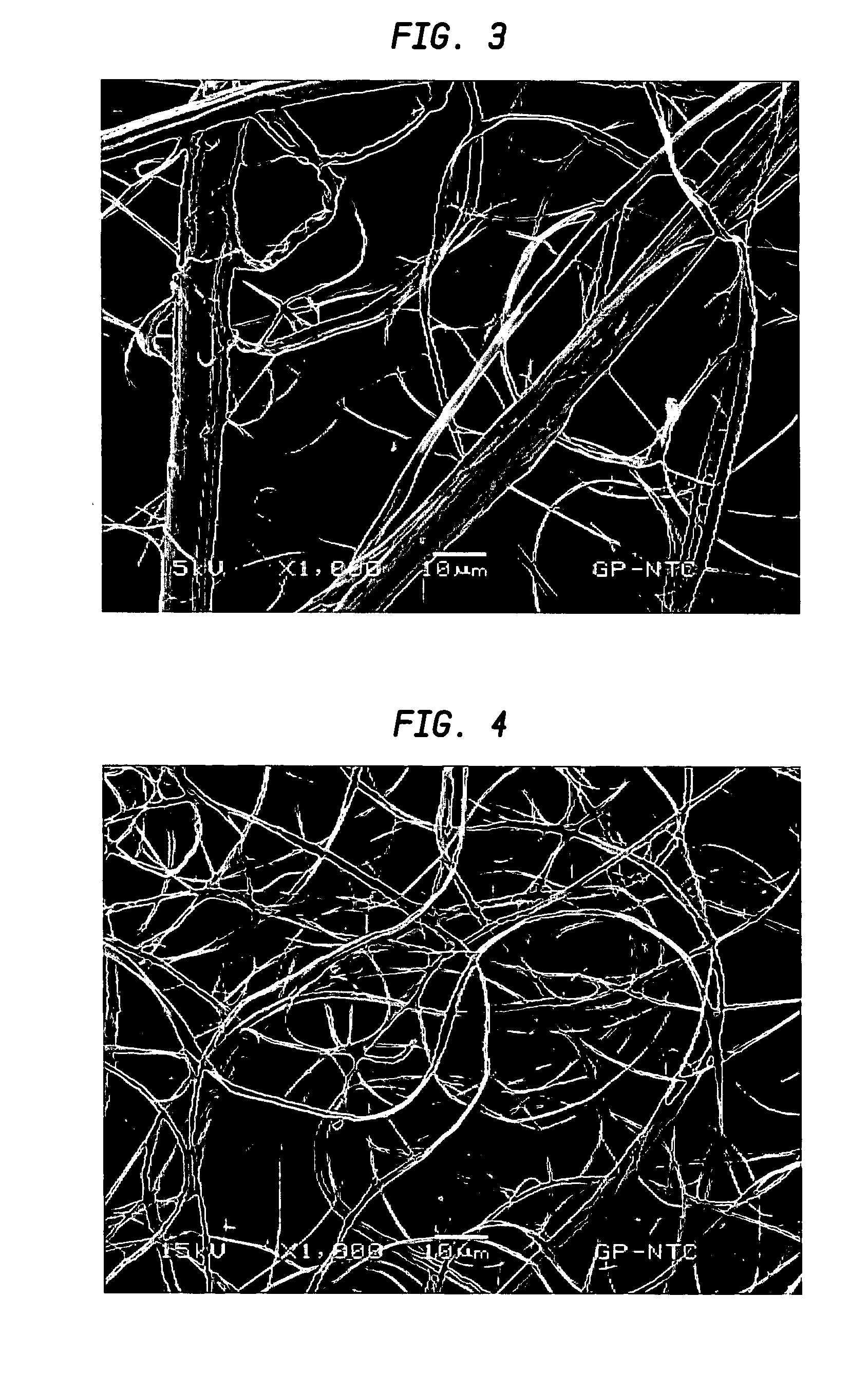

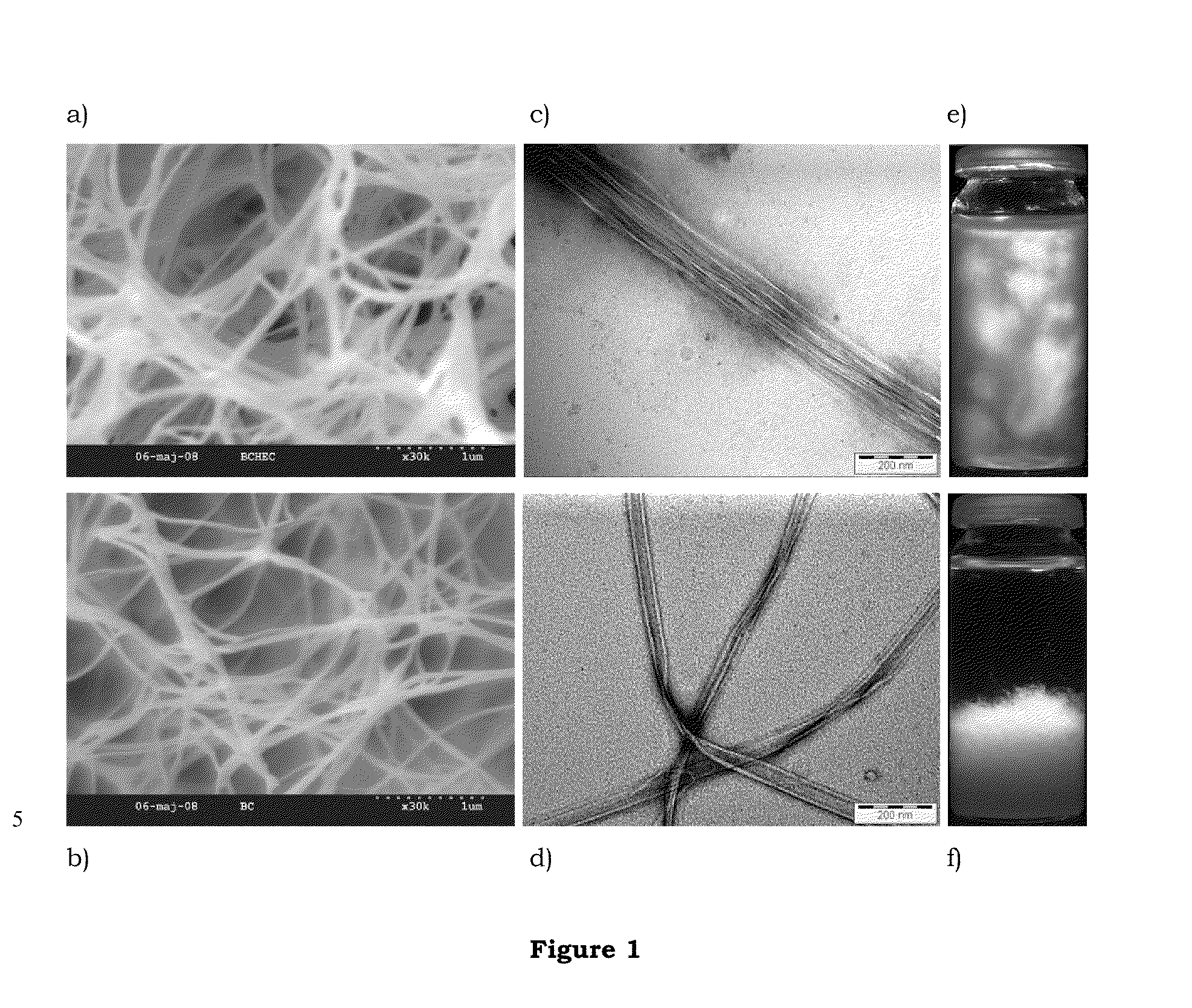

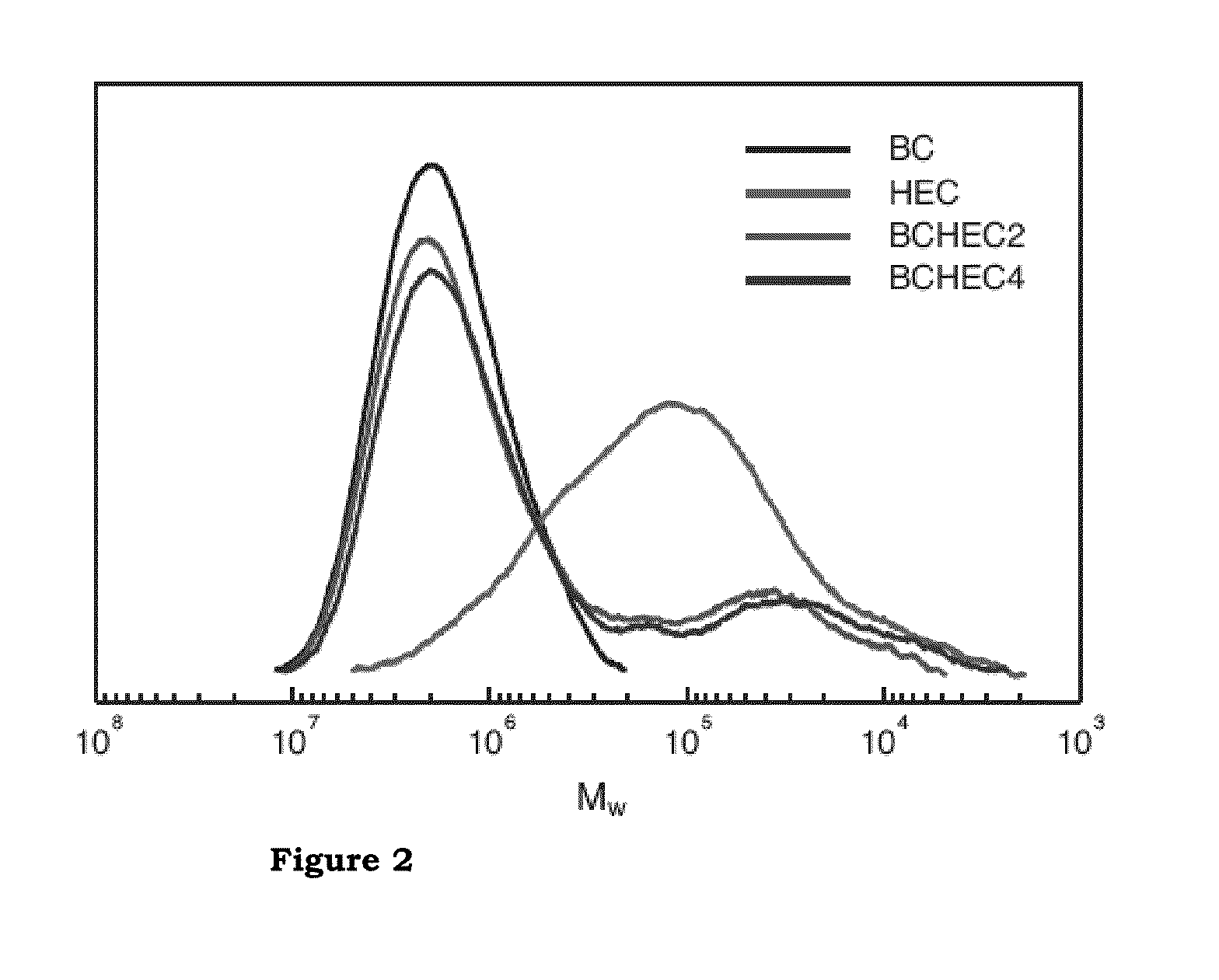

Method of producing and the use of microfibrillated paper

InactiveUS20100065236A1Non-fibrous pulp additionPulp properties modificationChemical structureEngineering

The present invention relates to a method of producing a cellulose based paper, the paper itself and the use thereof where the paper exhibits enhanced mechanical properties. The method involves providing a suspension of well dispersed modified cellulose at a low concentration. The properties and the chemical structure of the paper make it suitable for in vivo applications such as implant material.

Owner:SWETREE TECHOLOGIES AB

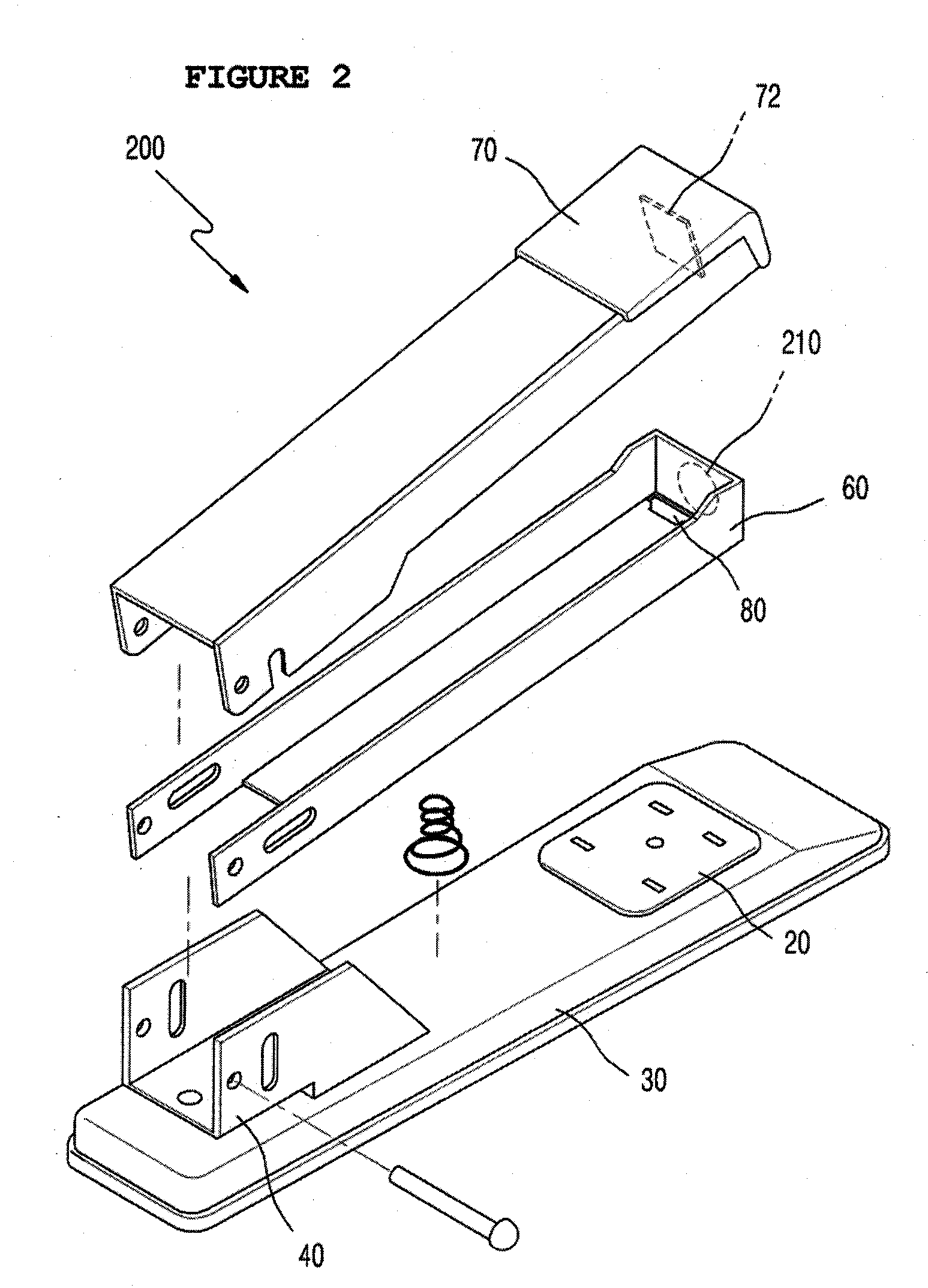

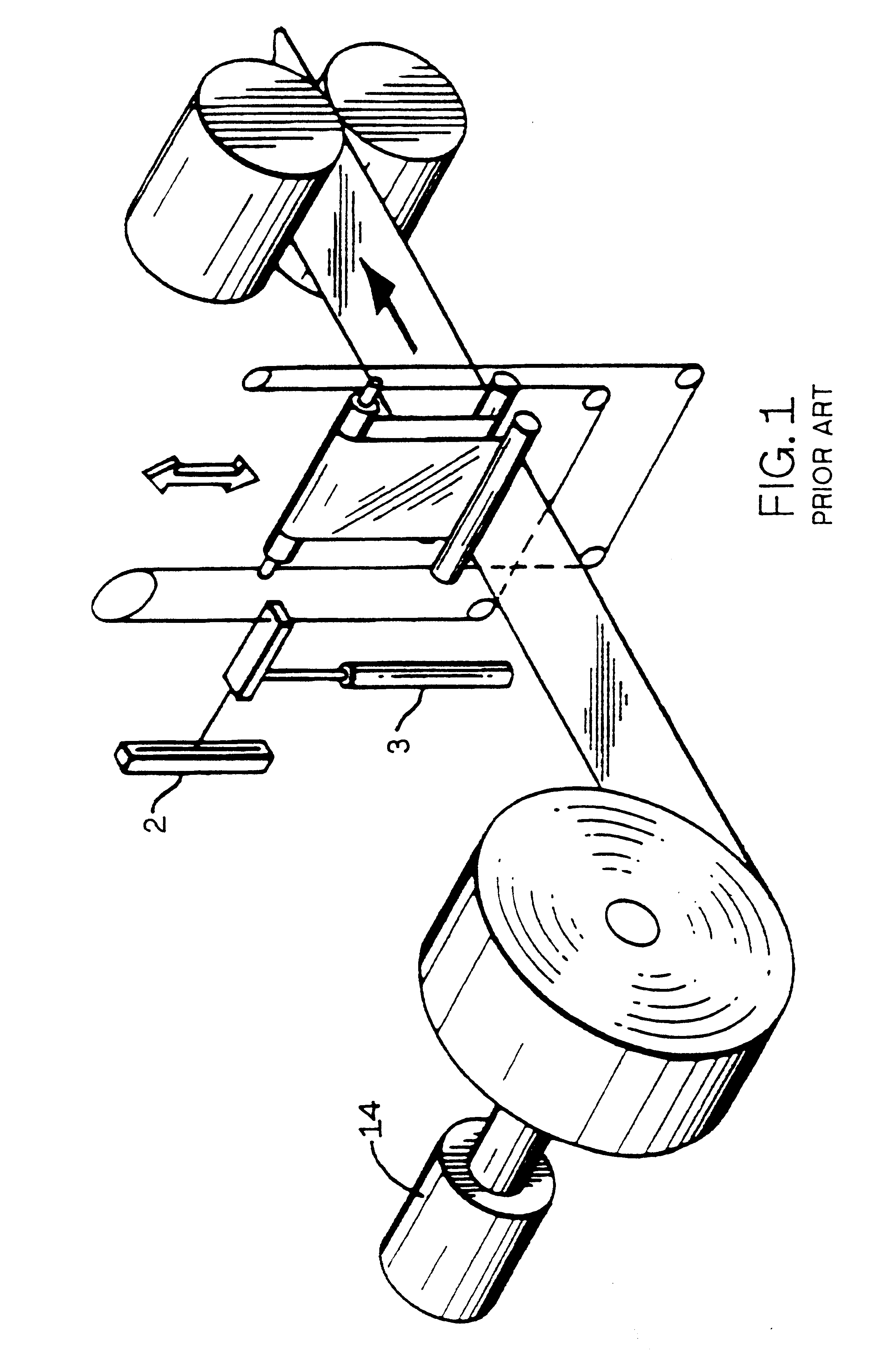

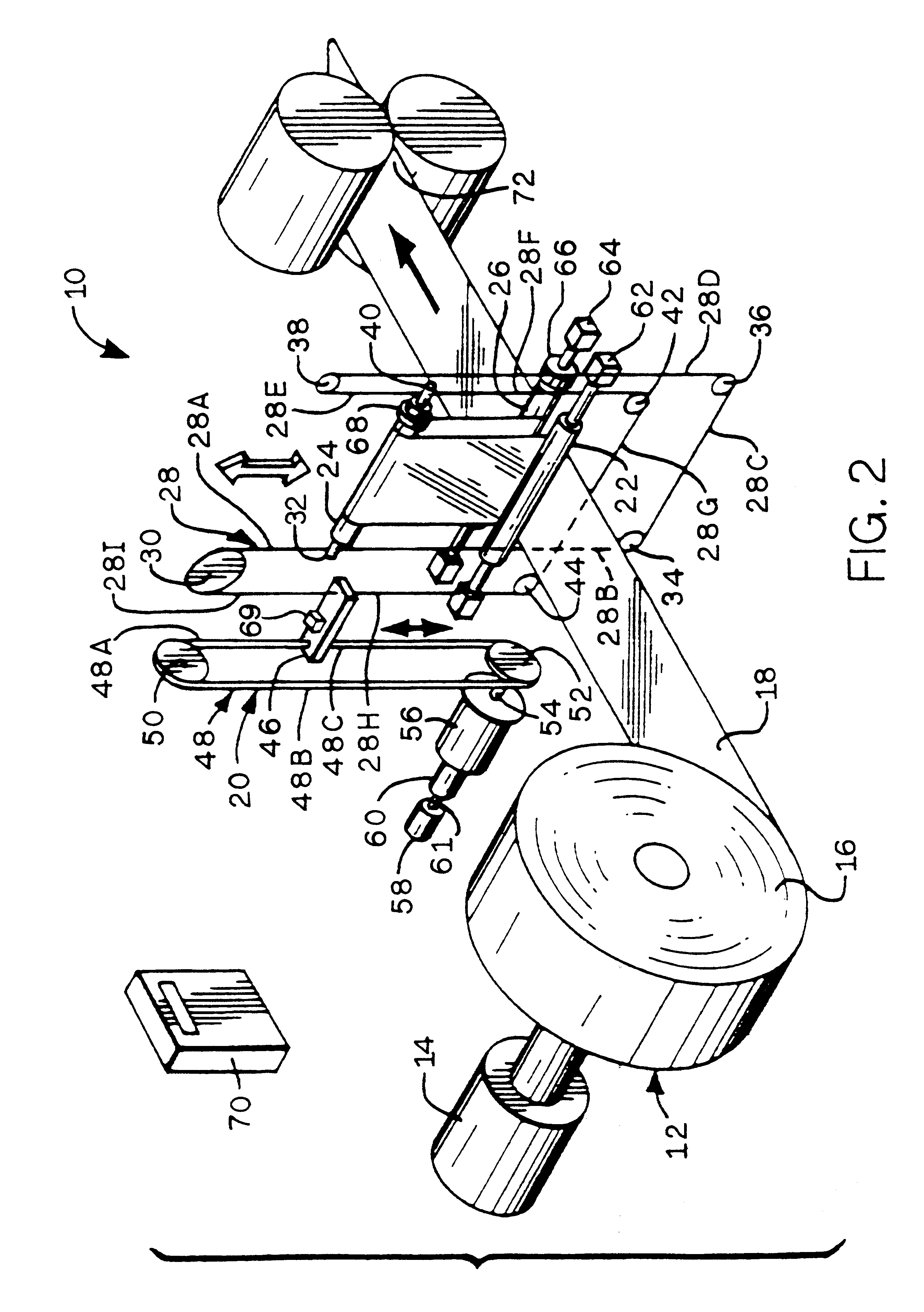

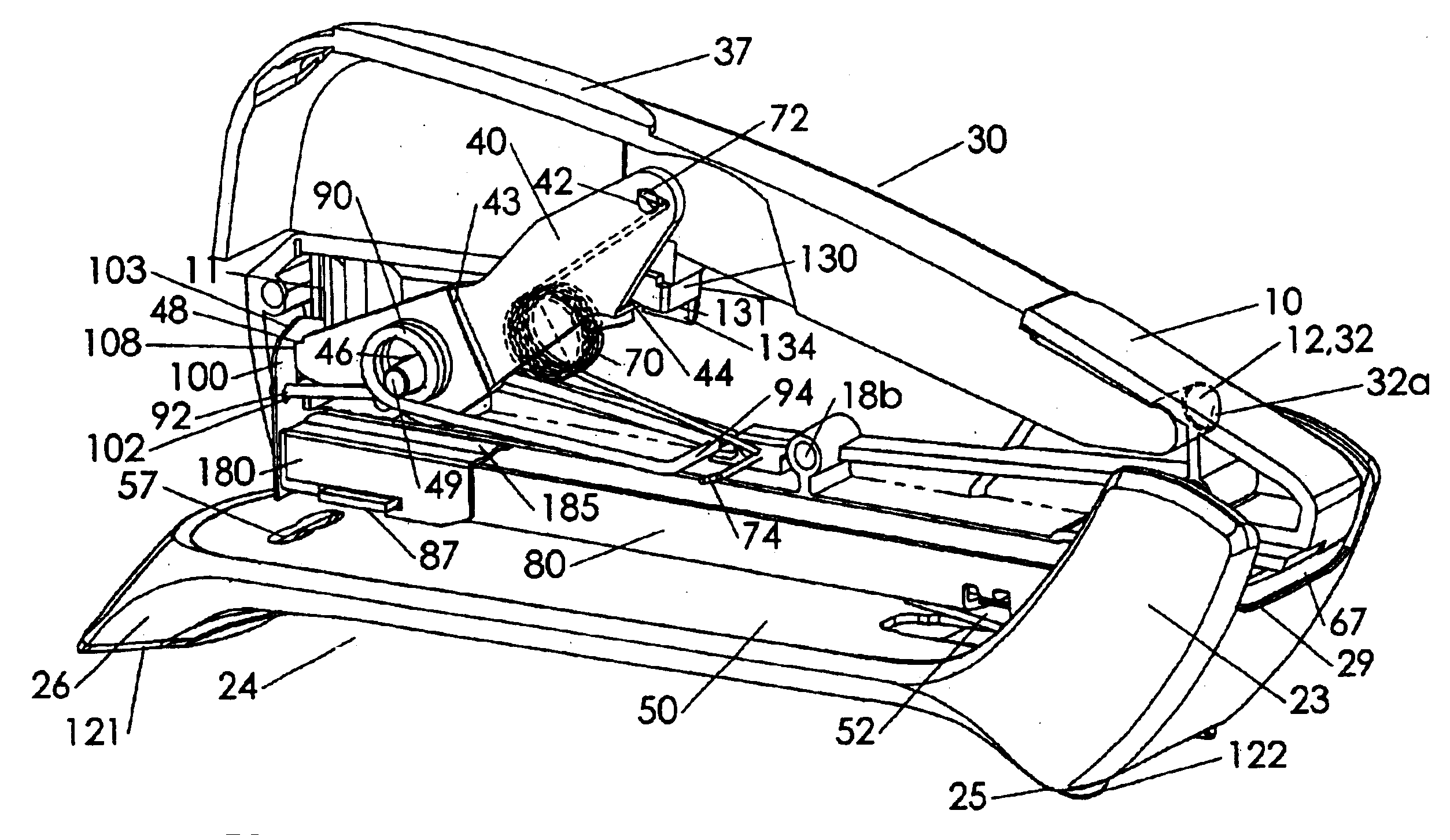

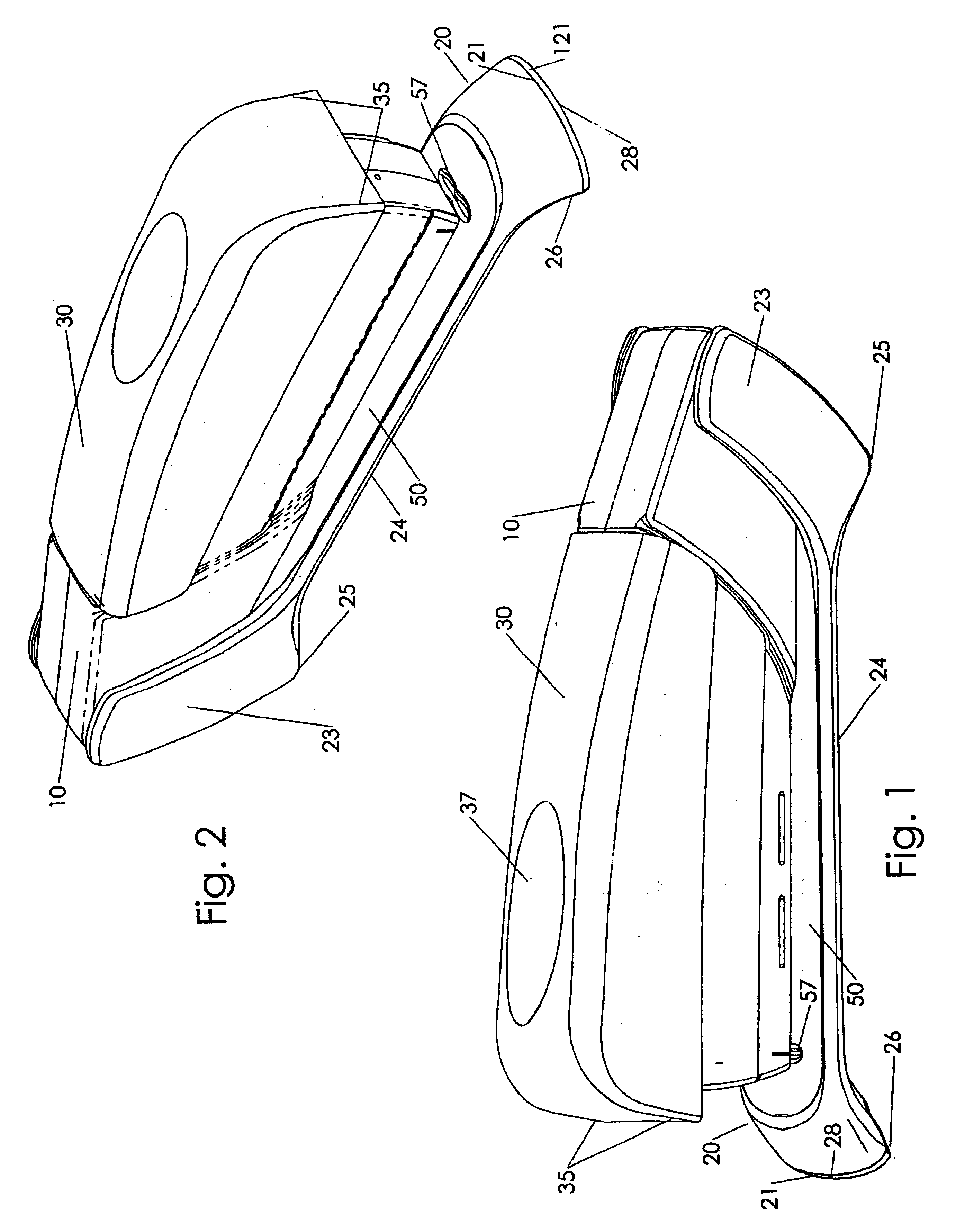

Spring energized desktop stapler

InactiveUS6918525B2Avoid high forceEasy to useStapling toolsNailing toolsEngineeringHorizontal and vertical

A desktop stapler uses a spring to store energy to install staples by impact blow. The force required to fasten papers together is reduced. A very compact mechanism is used, including a dual coil power spring with a nested lever. A multi function base provides a sloped front all the way to down to a desk top surface to guide paper sheets atop the base, easy access for lifting the stapler off a desk, horizontal or vertical resting positions, and integrated soft grip under-surface. The base surrounds the rear of the stapler body to provide a smooth exterior so that the device is natural to use both horizontally and vertically. A simple re-set spring provides a smooth re-set action as the handle is raised. A staple track includes enlargement features to fit a larger staple pusher spring.

Owner:WORKTOOLS

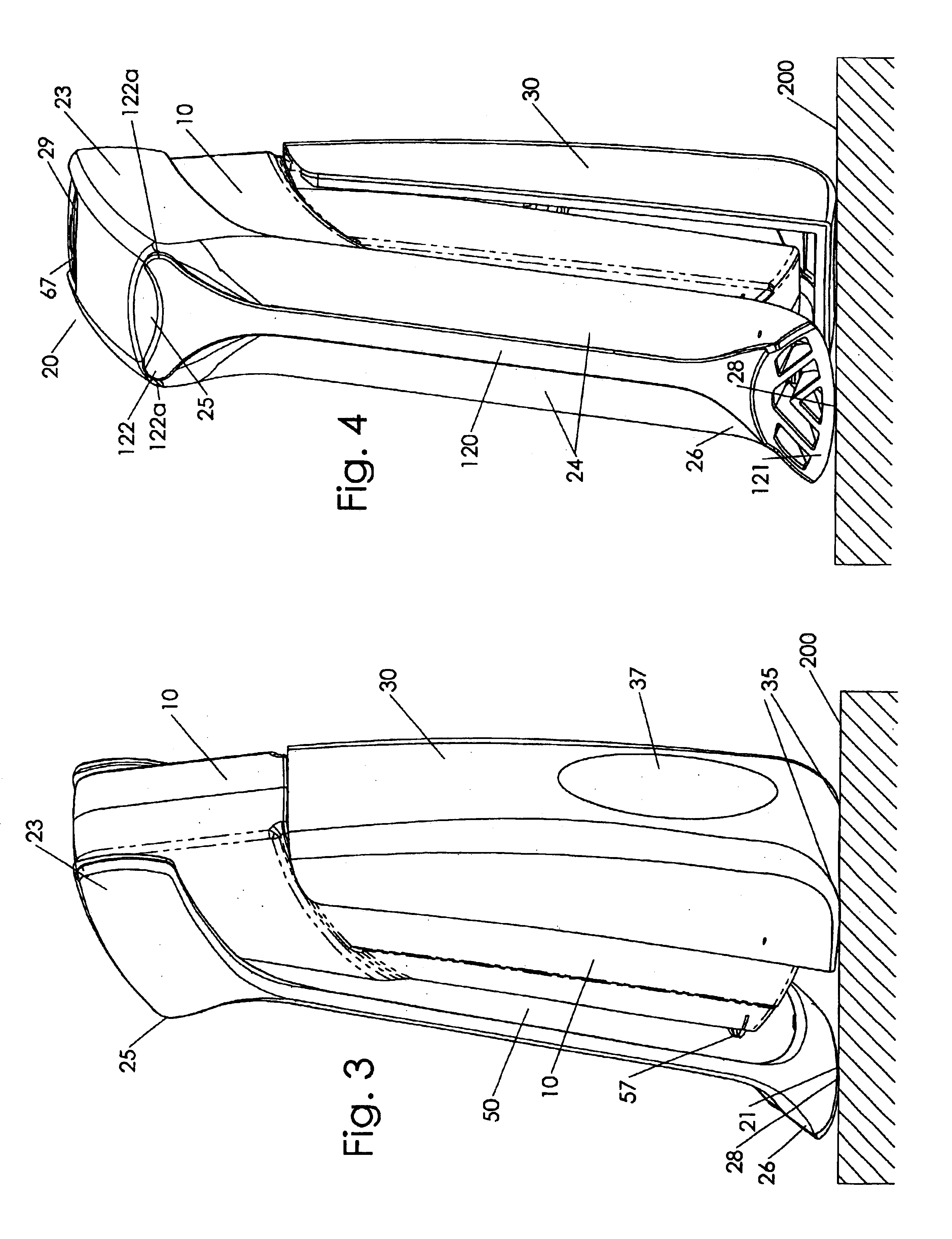

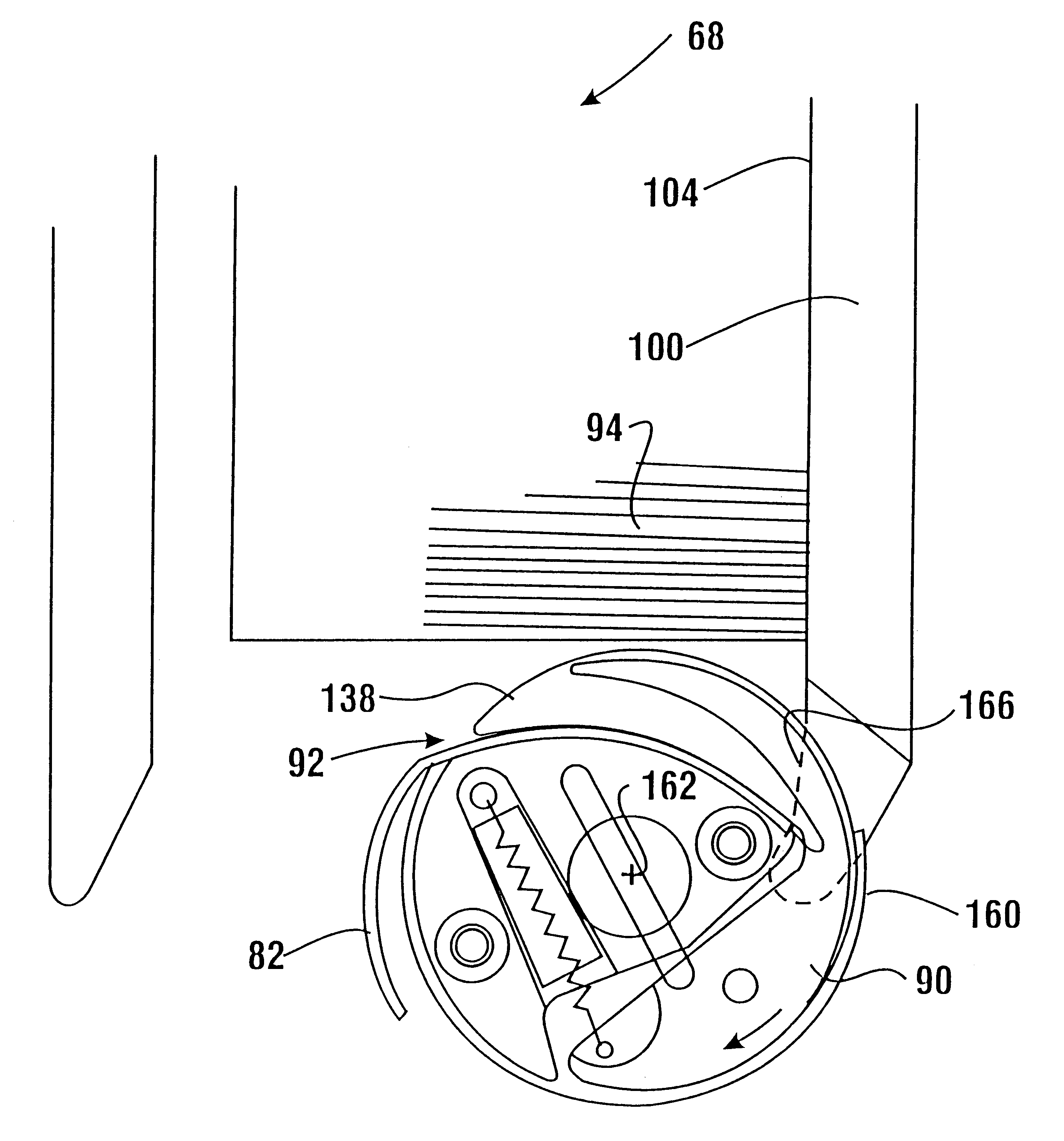

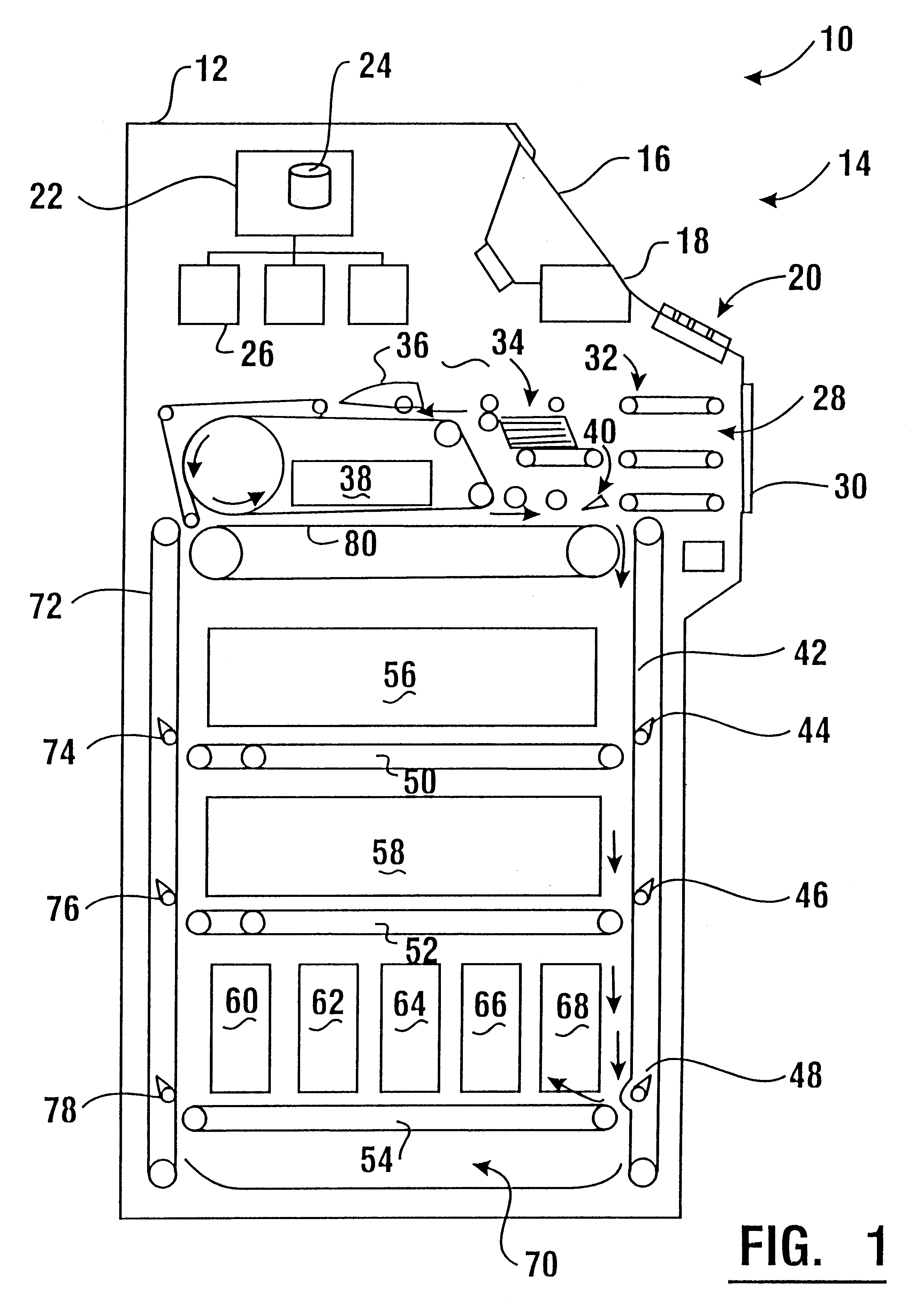

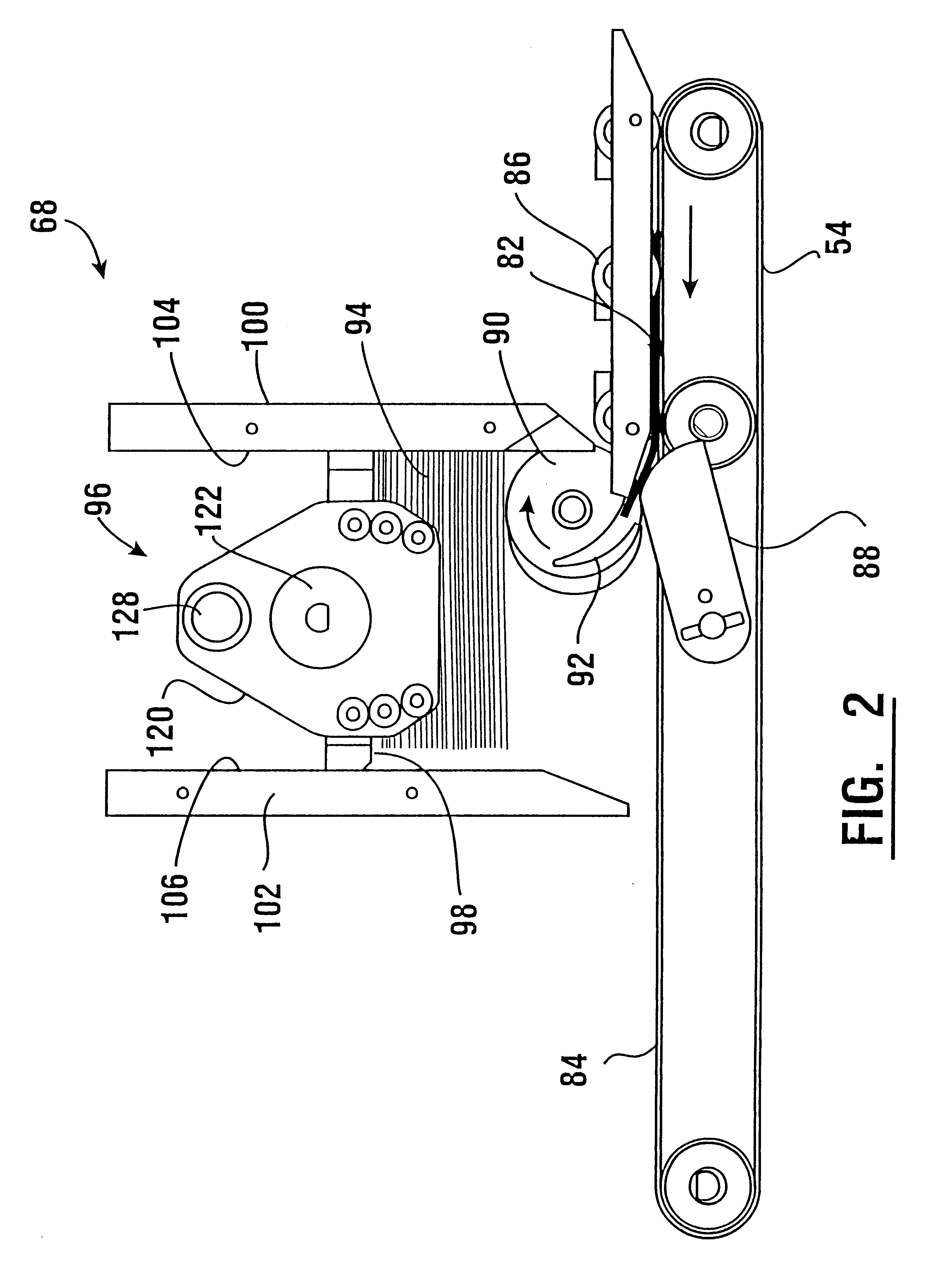

Media storage system for automated banking machine

InactiveUS6302393B1Increase speedStacks sheets reliablyCoin/currency accepting devicesPile receiversEngineeringMechanical engineering

A media storage system for an automated banking machine (10) includes a rotating flipper member (90, 178, 222) which is rotationally movable to engage sheets. A moveable gripper member (138, 182, 226) is movably mounted relative to the flipper member. The flipper member further includes an arcuately extending slot (92, 180, 232). A sheet extending in the slot is held in fixed engagement with the flipper member by the gripper member. Rotation of the flipper member to a releasing position causes the sheet to be engaged with a stop surface (160, 188, 284) as the gripper member moves to release the sheet. Sheets released by the flipper member are positioned in a stack (94, 184, 234). In alternative embodiments a flipper member (178, 222) includes a picker portion (202, 278). The picker portion is selectively operated to remove sheets from the stack for delivery to a user of the machine.

Owner:DIEBOLD NIXDORF

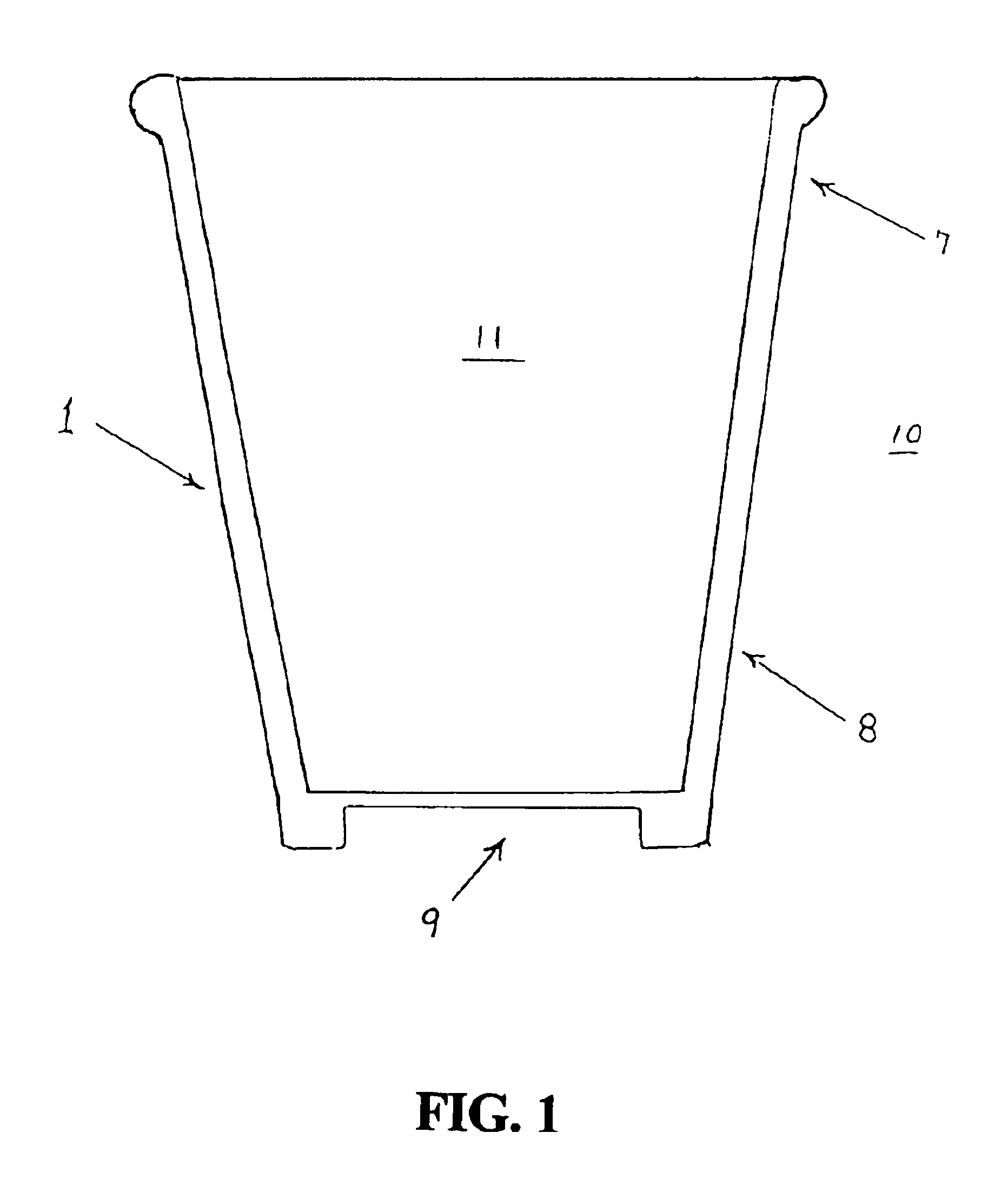

Insulated beverage or food container

InactiveUS6852381B2Reduce energy transferImprove functionalityWrappers shrinkageRefuse receptaclesEnergy transferEngineering

An insulating beverage or food container or sleeve is produced with a foam layer disposed on an inner surface of a paper stock. A polymer shrink film layer is arranged in a position along an inside surface of the beverage container. The foam layer is sandwiched between the polymer shrink film layer and the paper stock and decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the container for an extended period of time without causing user discomfort or pain. The polymer shrink film layer is produced from a shrink film polymer having a percent shrink in the range of 30% or less, and more particularly a percent shrink range of 5 to 10%.

Owner:APPVION LLC

Packaged synthetic absorbable surgical elements

InactiveUS6260699B1Improved out of package handling characteristicImproving out of package flexibility and handSuture equipmentsBiocideGlycerolAbsorbable suture

Synthetic absorbable sutures are filled with a stabilizing agent, preferably a mixture of glycerol and calcium lactate, and inserted into a retainer having a narrow convoluted passageway. The retainer is inserted into an open foil pouch with a package stabilizing element such as a paper sheet filled with stabilizing agent. The package containing the suture, retainer and package stabilizing element is sterilized, aerated, equilibrated to a relatively high moisture level, and sealed. Long lengths of suture and doubled-over and tripled-over suture may be withdrawn from the retainer with low force without damaging the suture. Bends and kinks in the suture are prevented so as to provide a synthetic absorbable suture having highly desirable out of package hand and feel. The suture an removed from the package exhibits improved tissue drag characteristics.

Owner:UNITED STATES SURGICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com