Patents

Literature

335 results about "Special property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

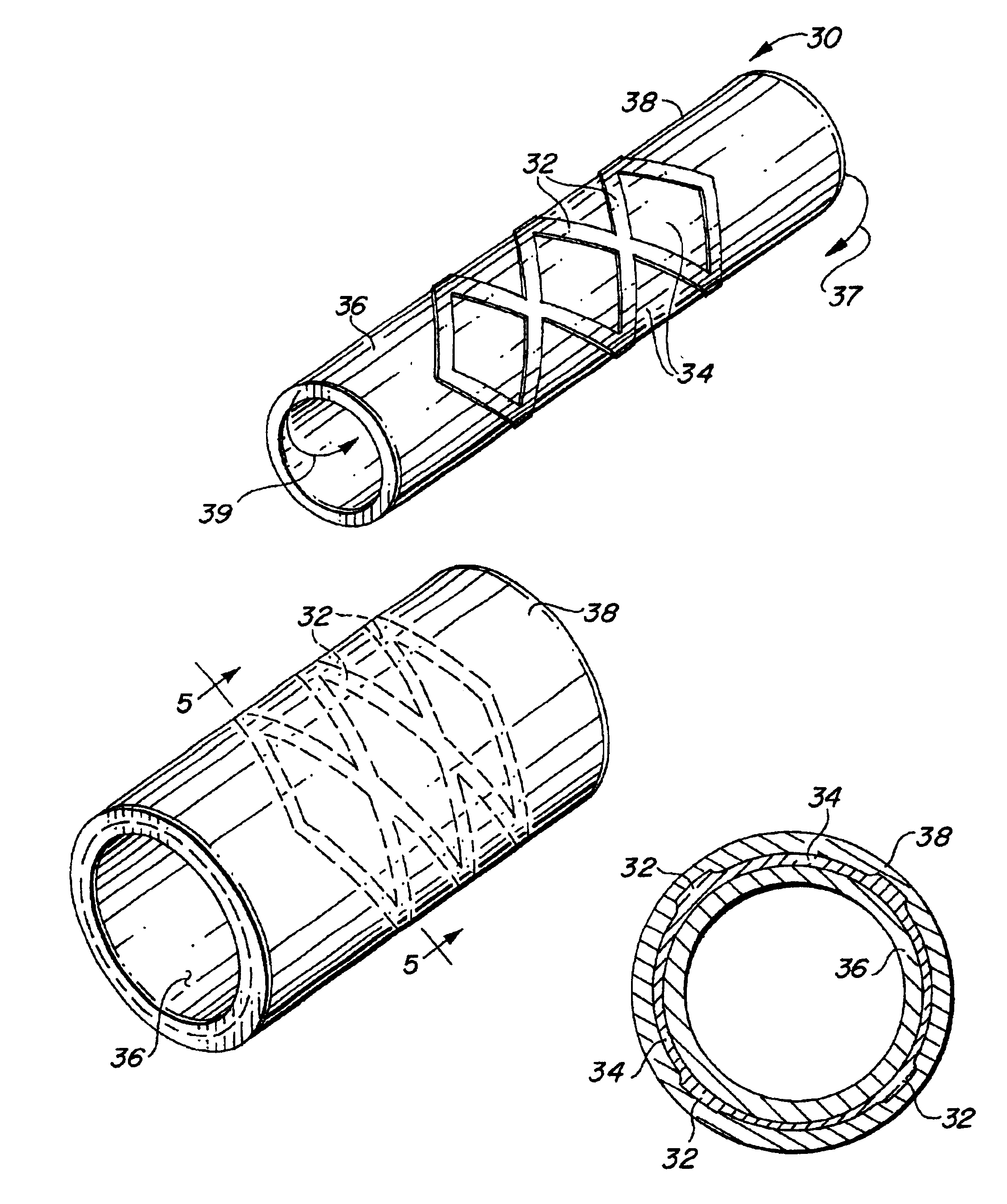

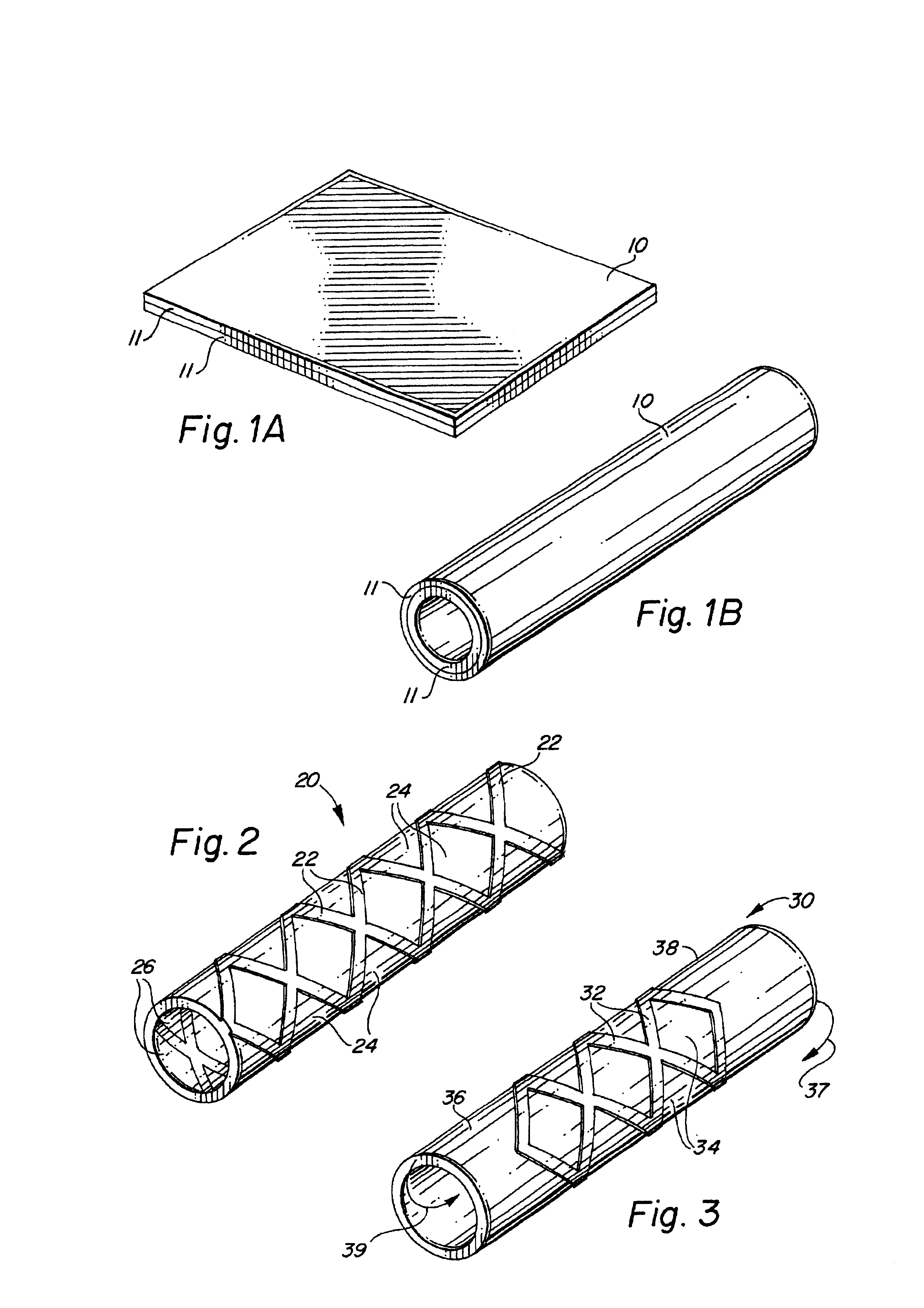

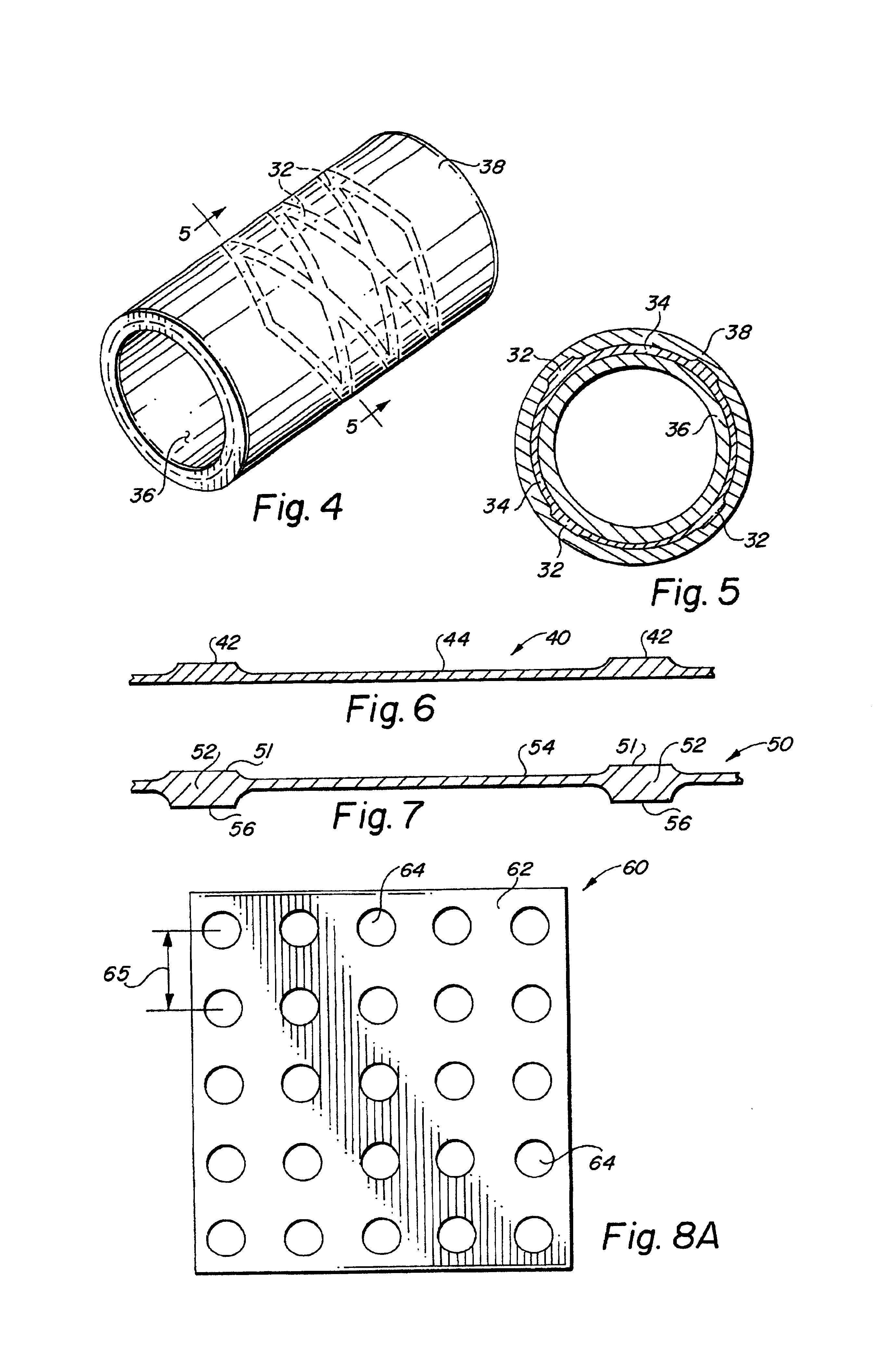

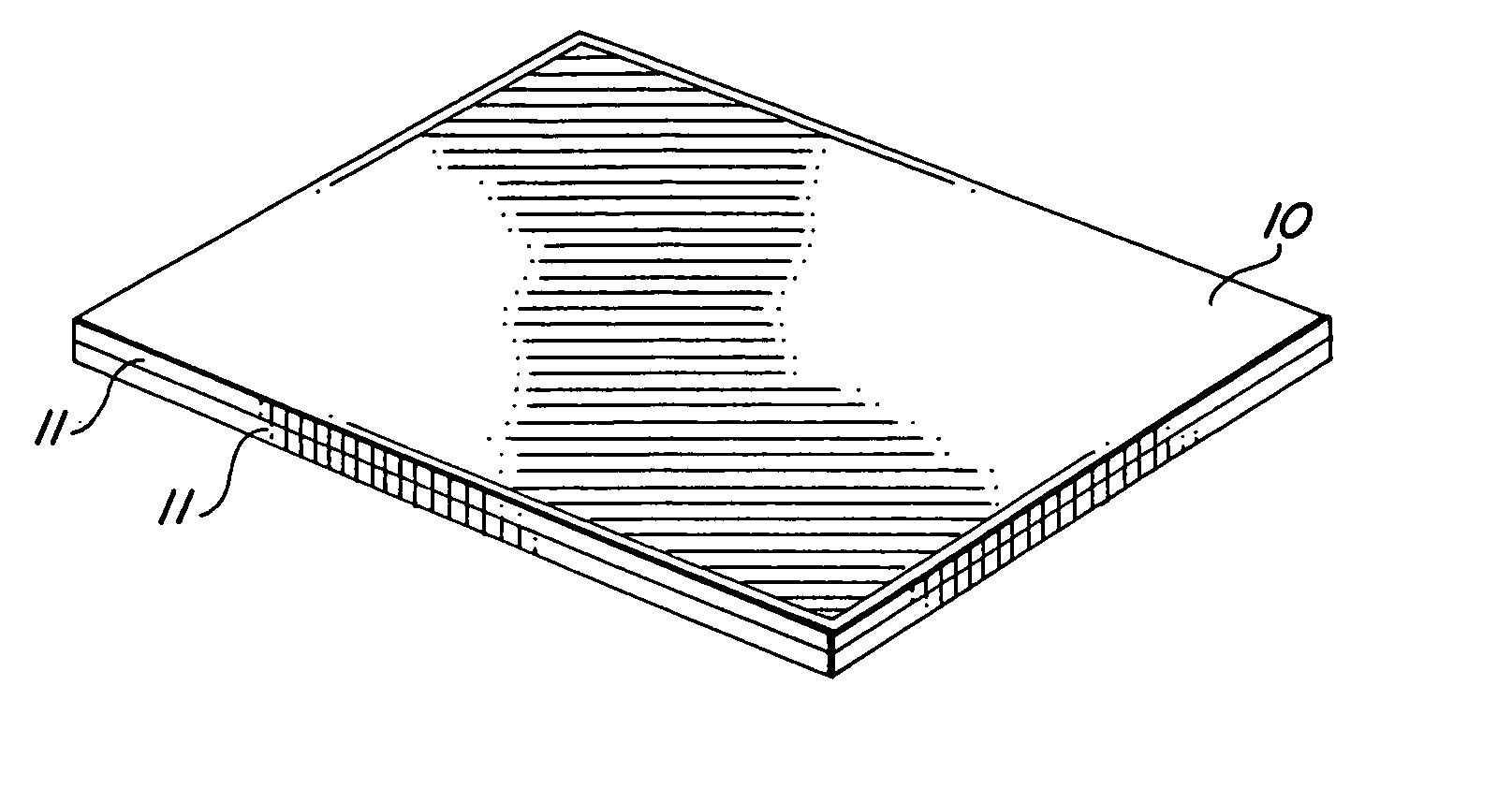

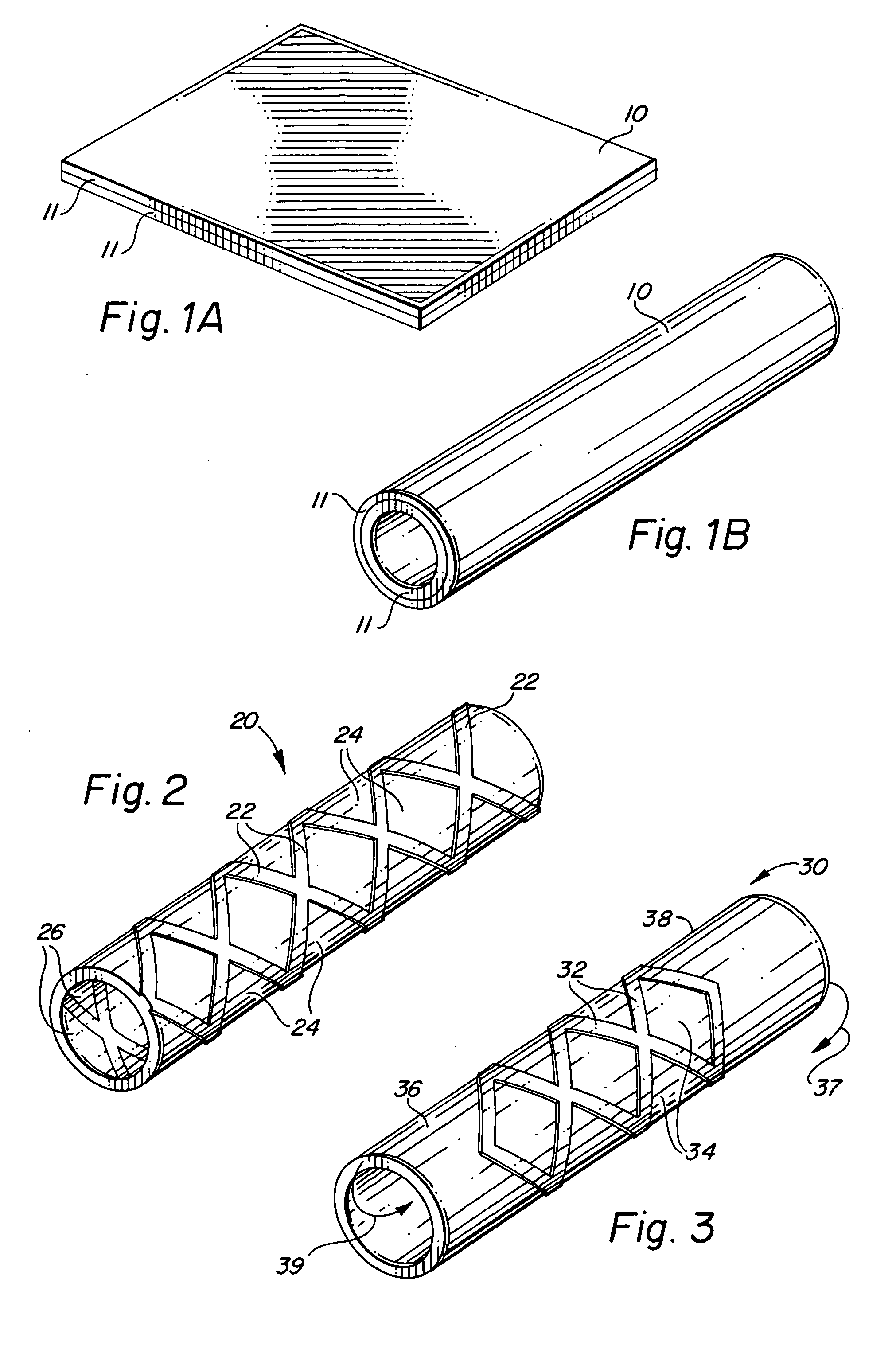

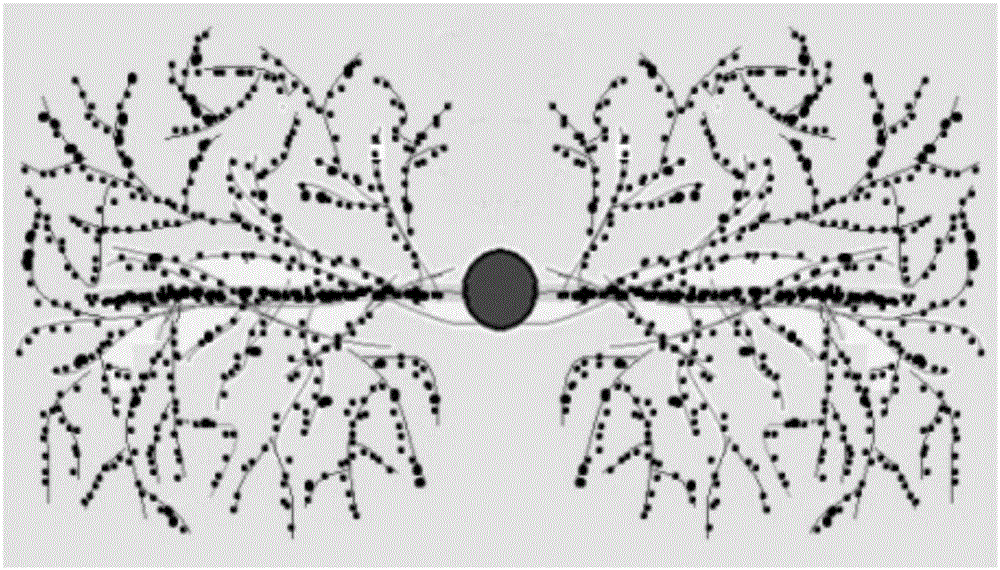

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

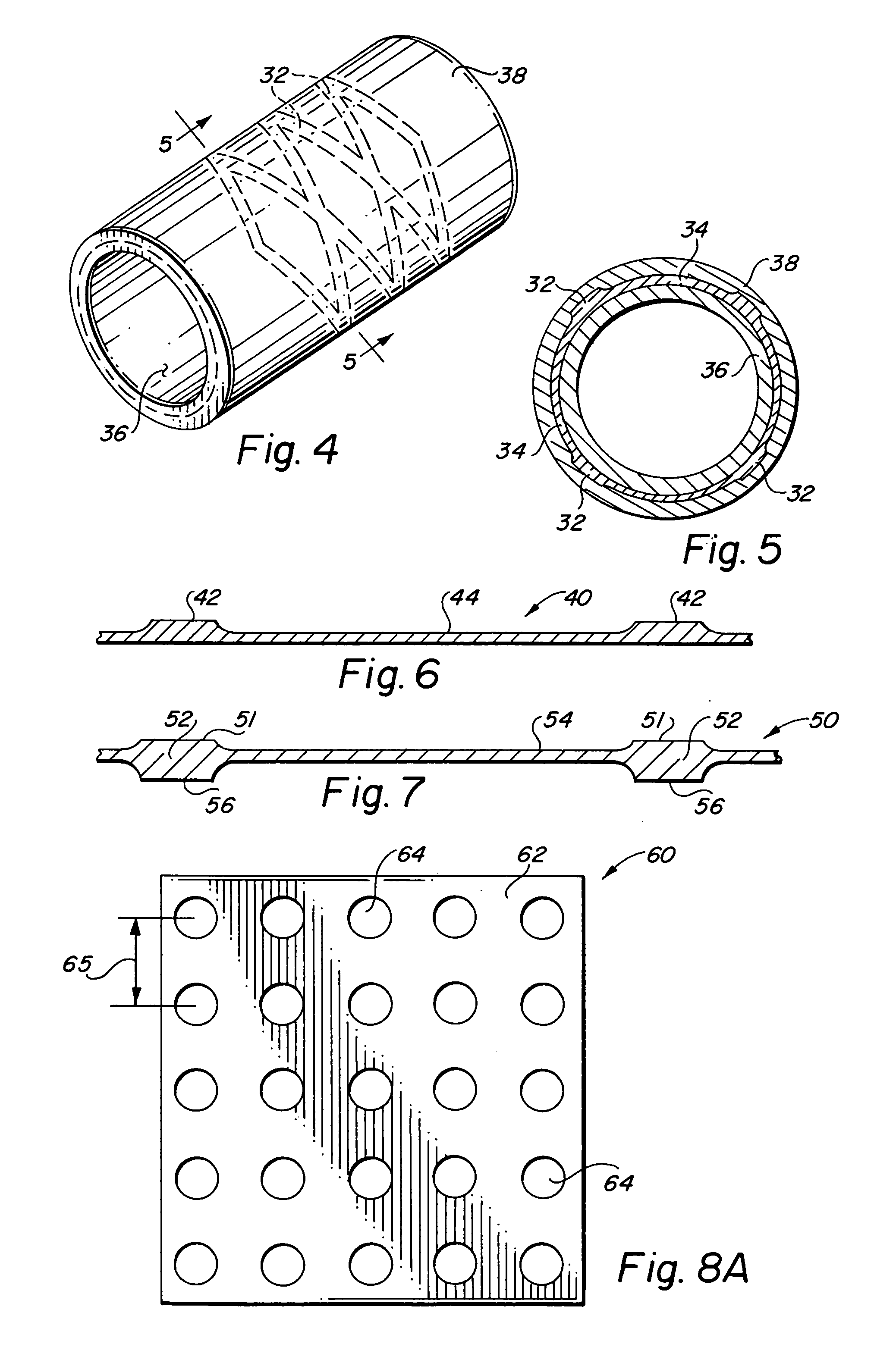

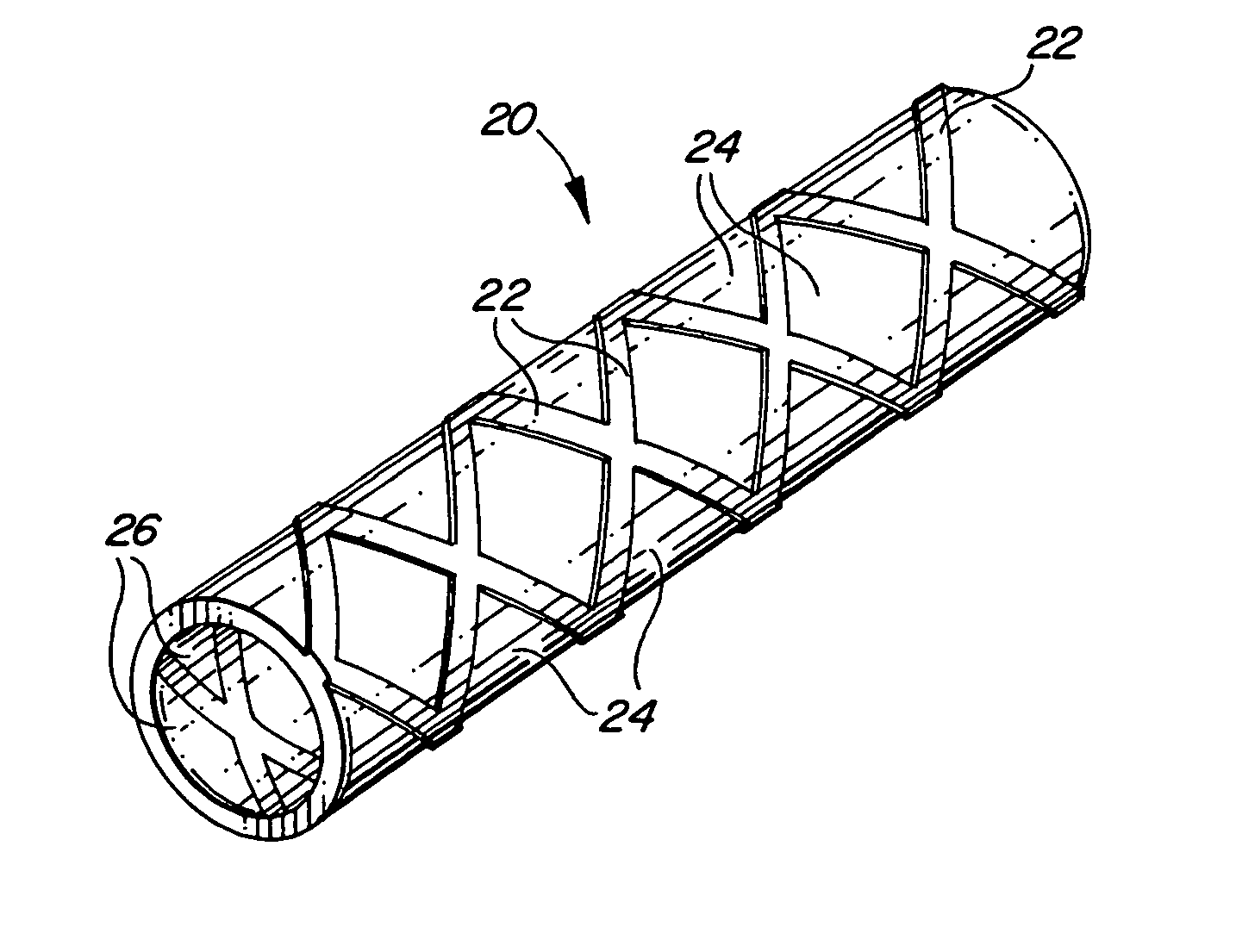

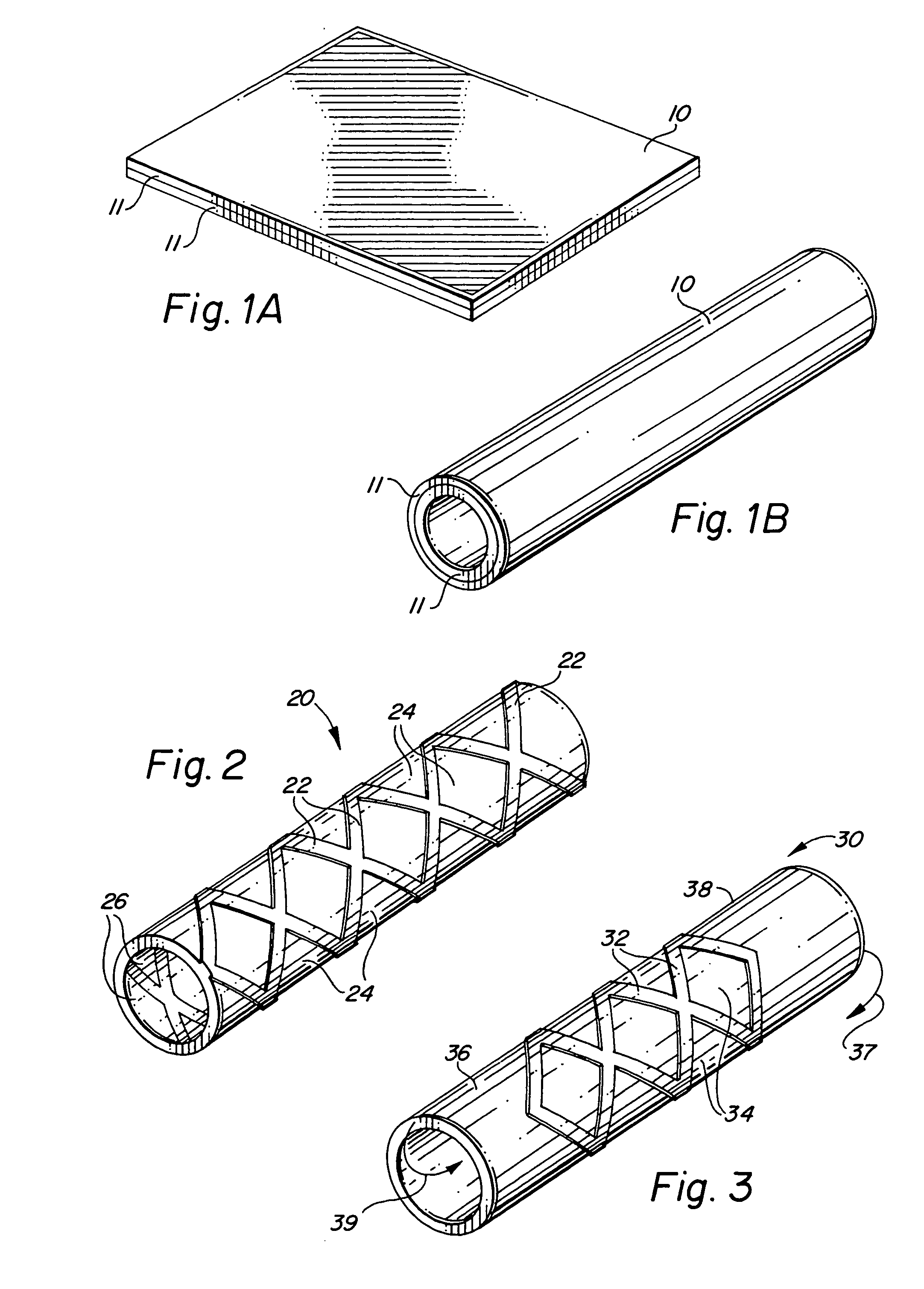

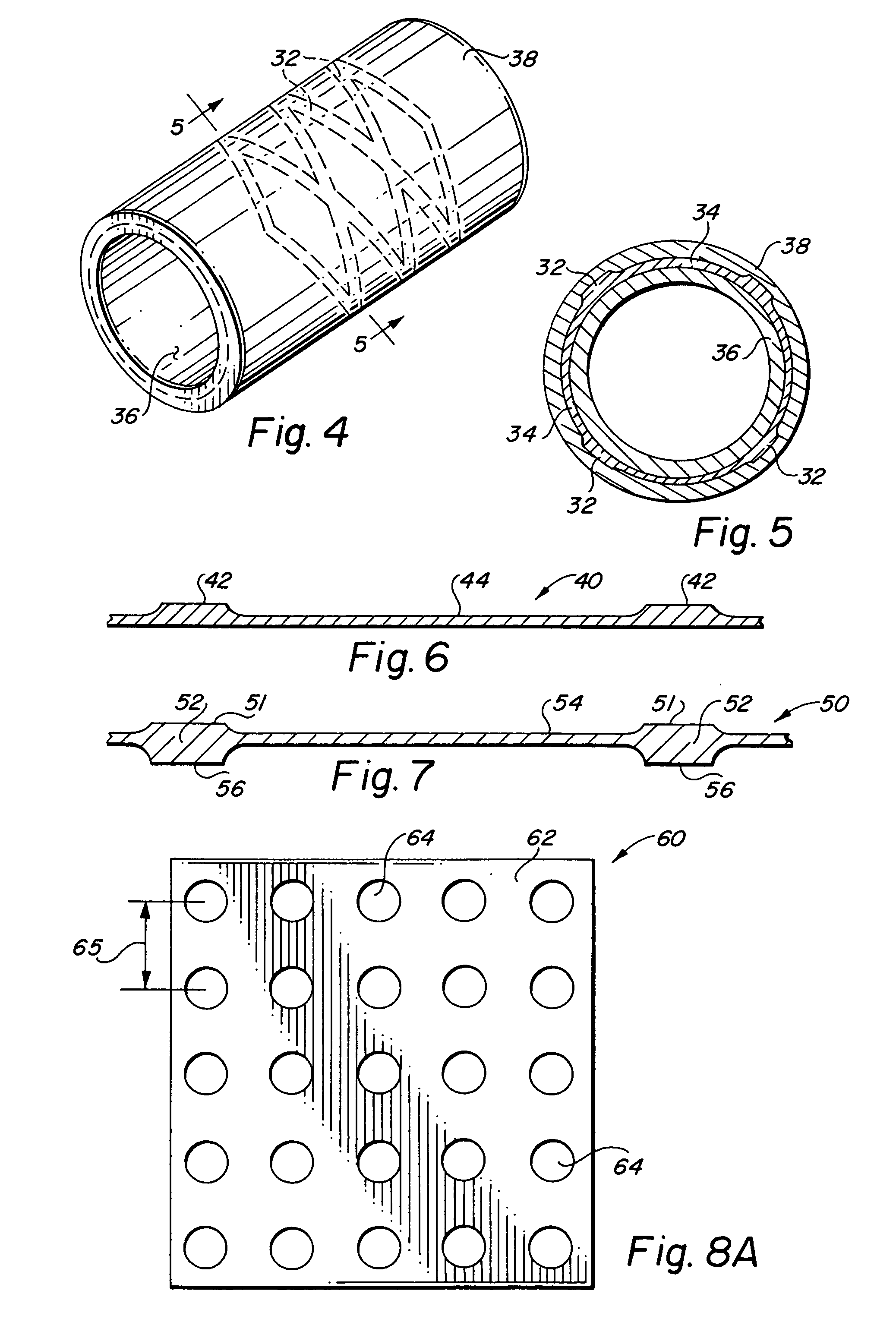

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

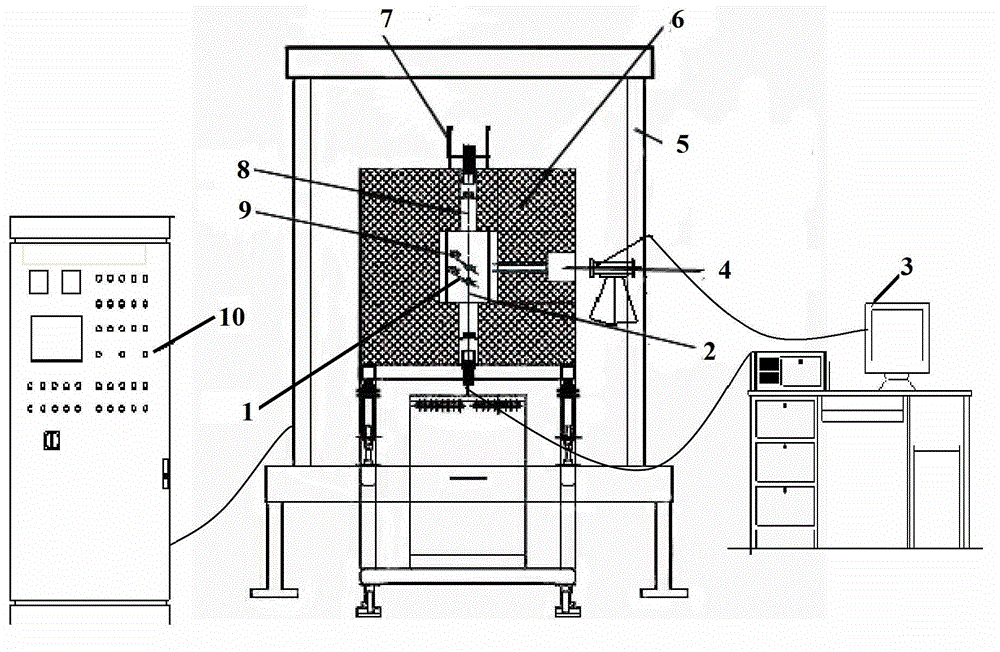

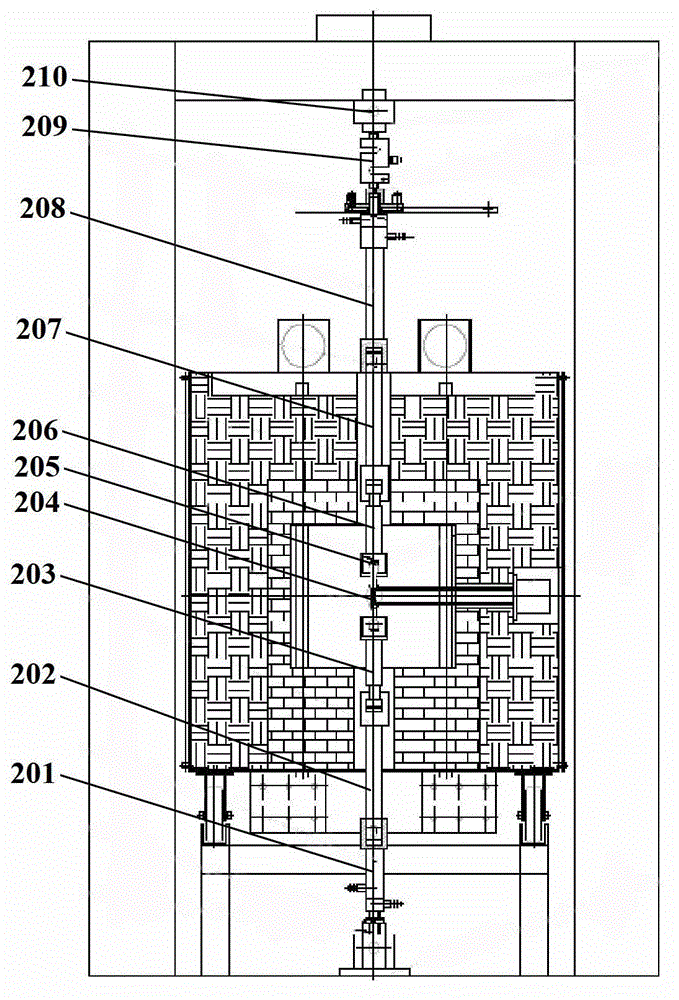

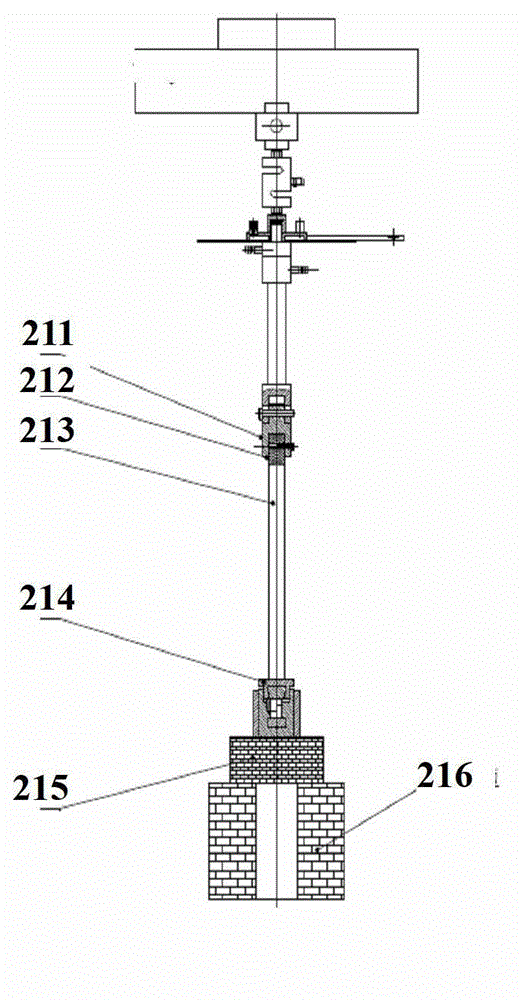

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

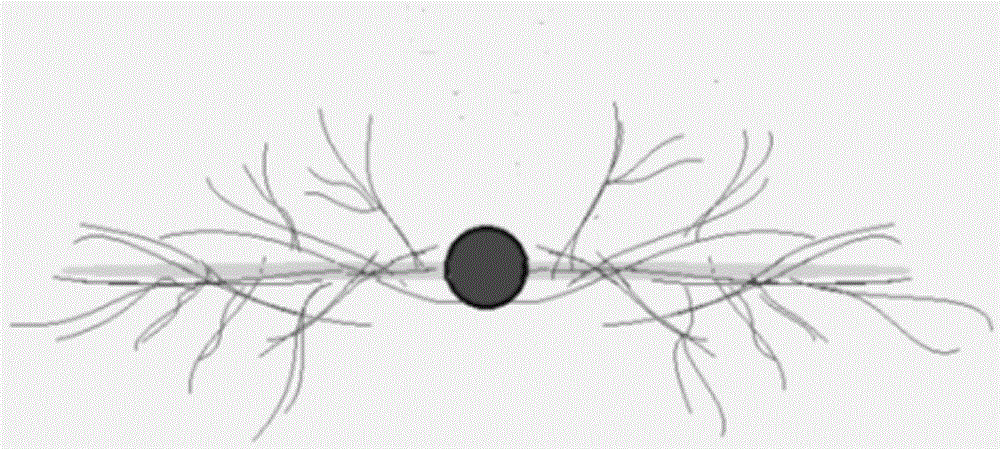

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

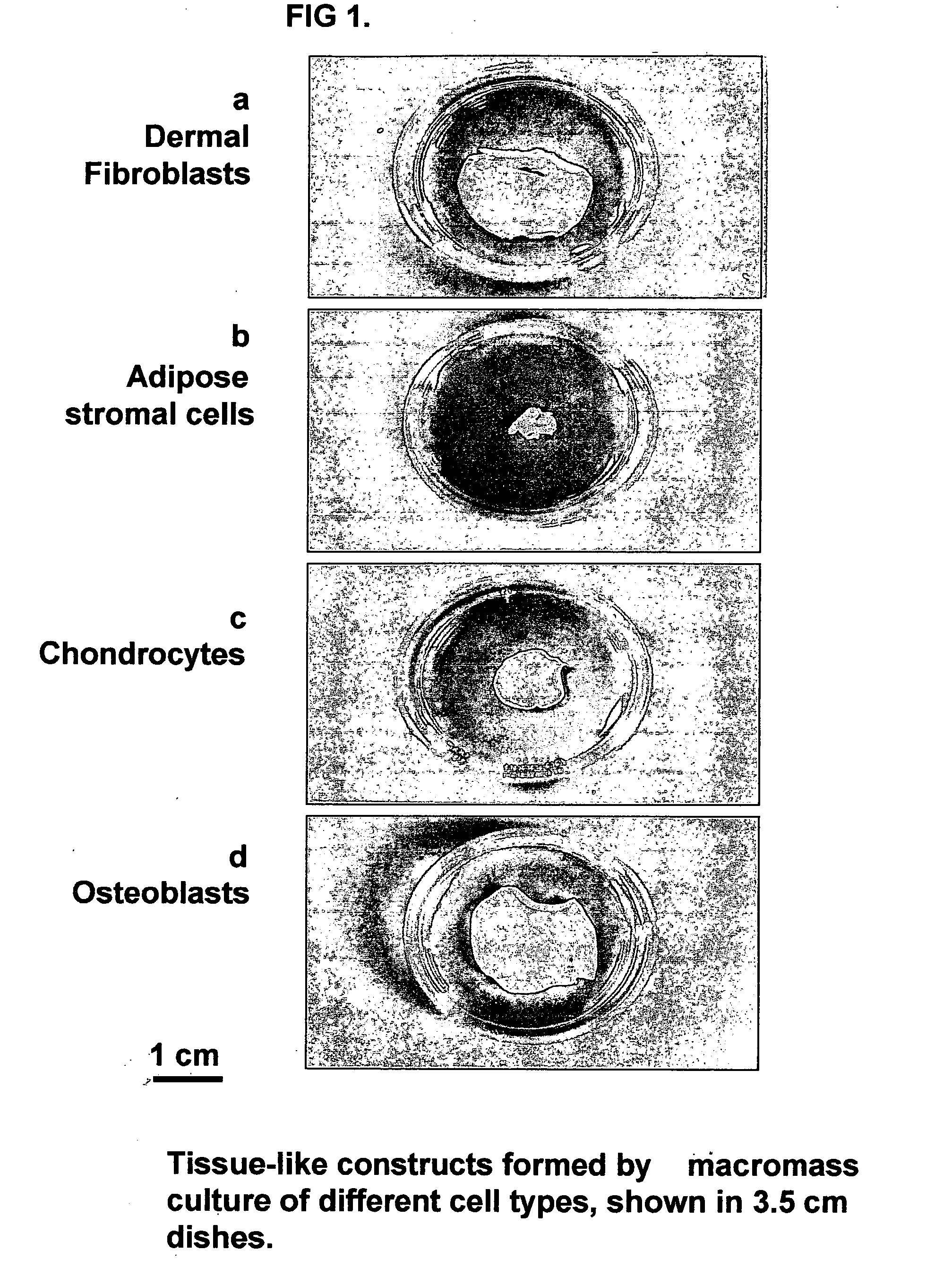

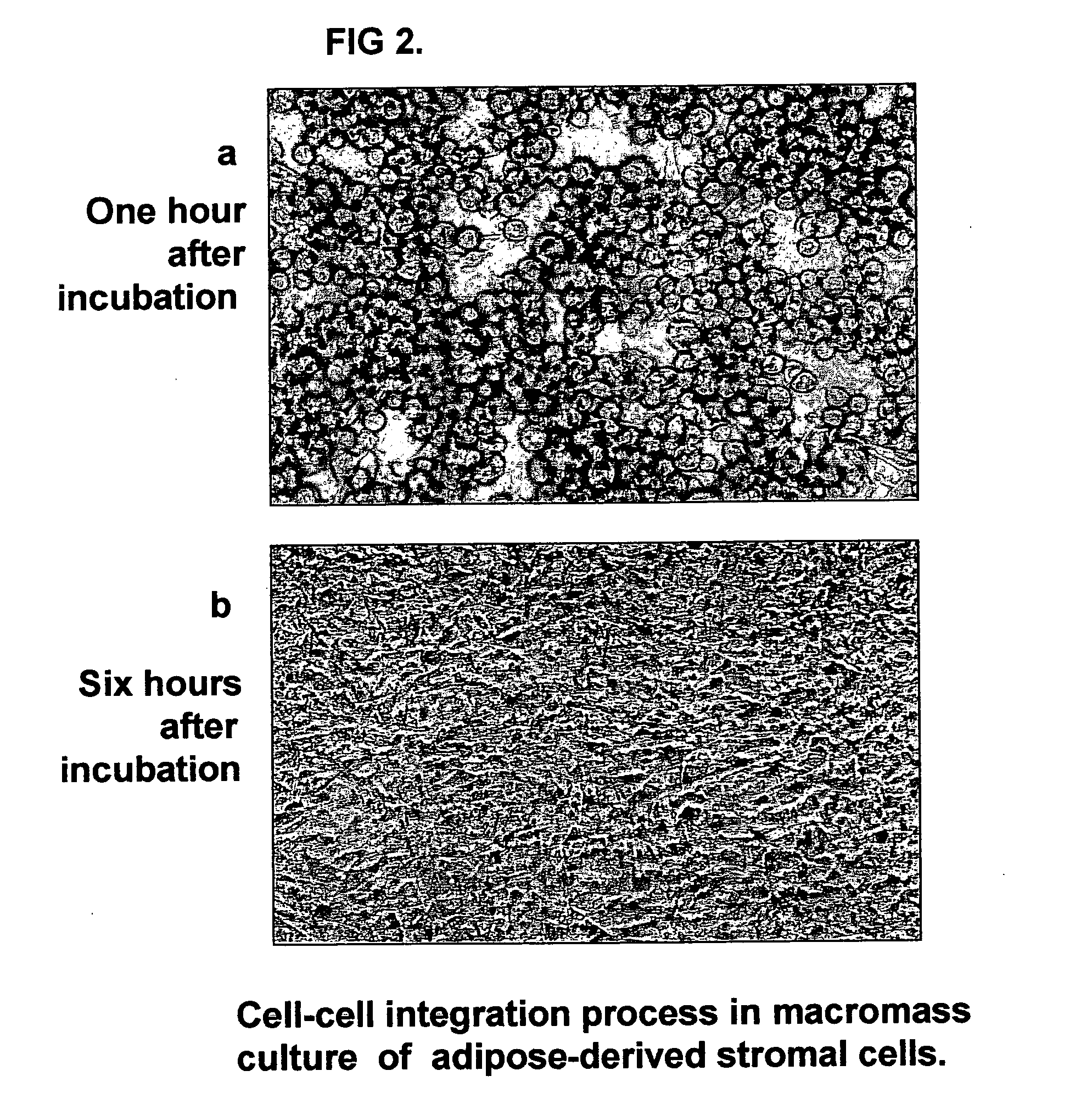

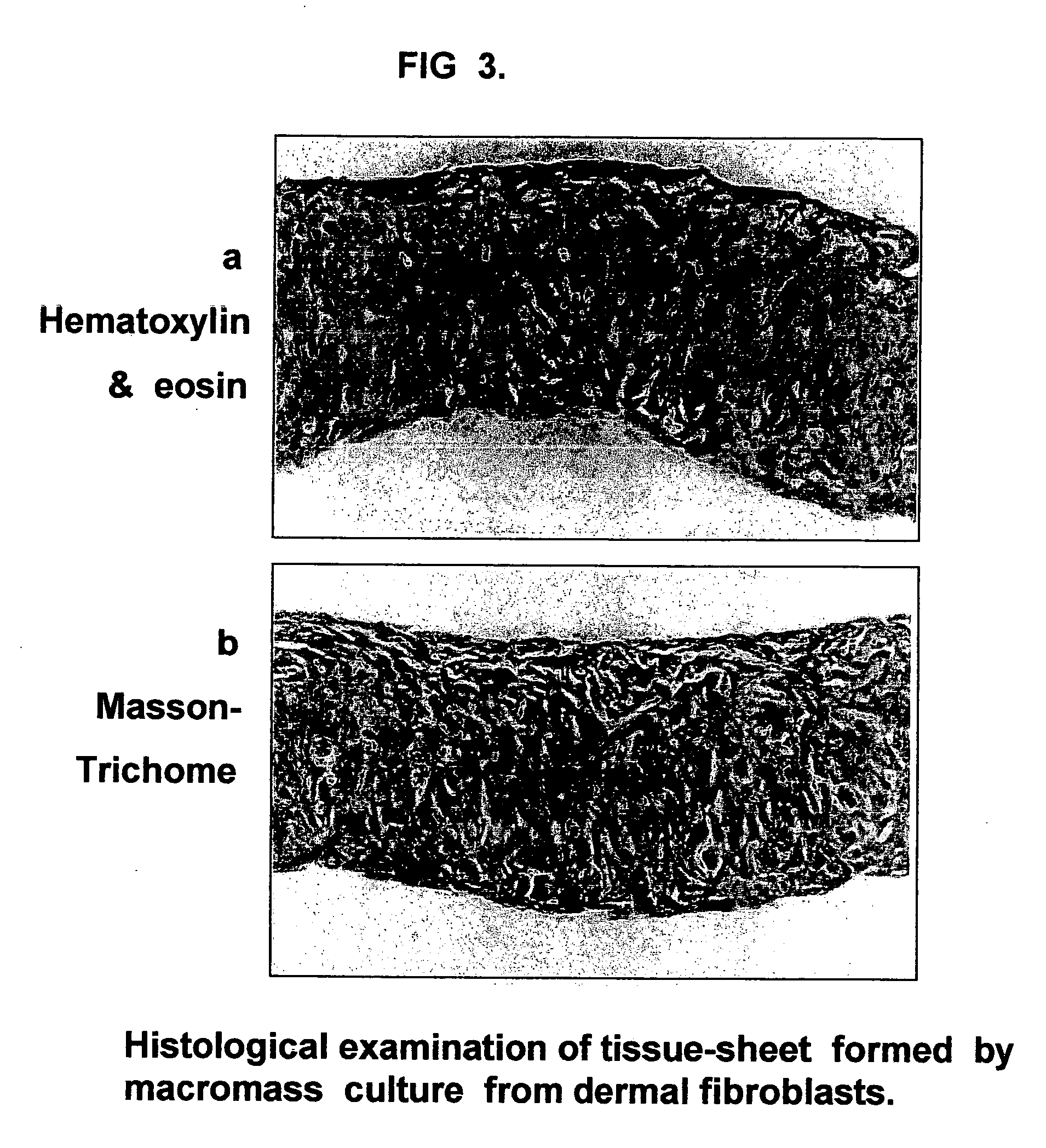

Tissue-like organization of cells and macroscopic tissue-like constructs, generated by macromass culture of cells, and the method of macromass culture

InactiveUS20040082063A1Sectioned easilySmall sizeEpidermal cells/skin cellsMammal material medical ingredientsHigh cellFiber

Three-dimensional tissue-like organization of cells by high cell-seeding-density culture termed as macromass culture is described. By macromass culture, cells can be made to organize themselves into a tissue-like form without the aid of a scaffold and three-dimensional macroscopic tissue-like constructs can be made wholly from cells. Tissue-like organization and macroscopic tissue-like constructs can be generated from fibroblastic cells of mesenchymal origin (at least), which can be either differentiated cells or multipotent adult stem cells. In this work, tissue-like organization and macroscopic tissue-like constructs have been generated from dermal fibroblasts, adipose stromal cells-derived osteogenic cells, chondrocytes, and from osteoblasts. The factor causing macroscopic tissue formation is large scale culture at high cell seeding density per unit area or three-dimensional space, that is, macromass culture done on a large scale. No scaffold or extraneous matrix is used for tissue generation, the tissues are of completely cellular origin. No other agents (except high cell-seeding-density) that aid in tissue formation such as tissue-inducing chemicals, tissue-inducing growth factors, substratum with special properties, rotational culture, etc, are employed for tissue formation. These tissue-like masses have the potential for use as tissue replacements in the human body. Tissue-like organization by high cell-seeding-density macromass culture can also be generated at the microscopic level.

Owner:RELIANCE LIFE SCI PVT

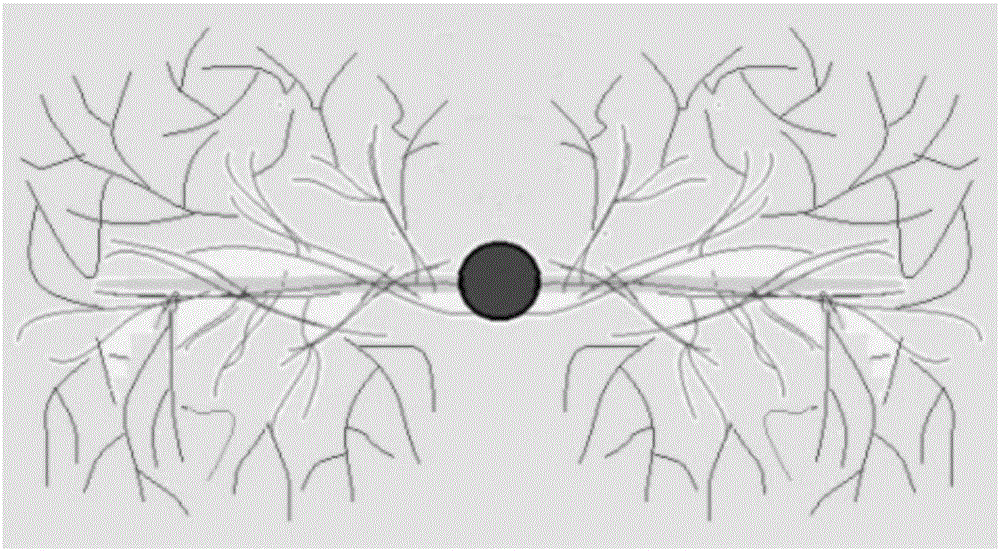

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

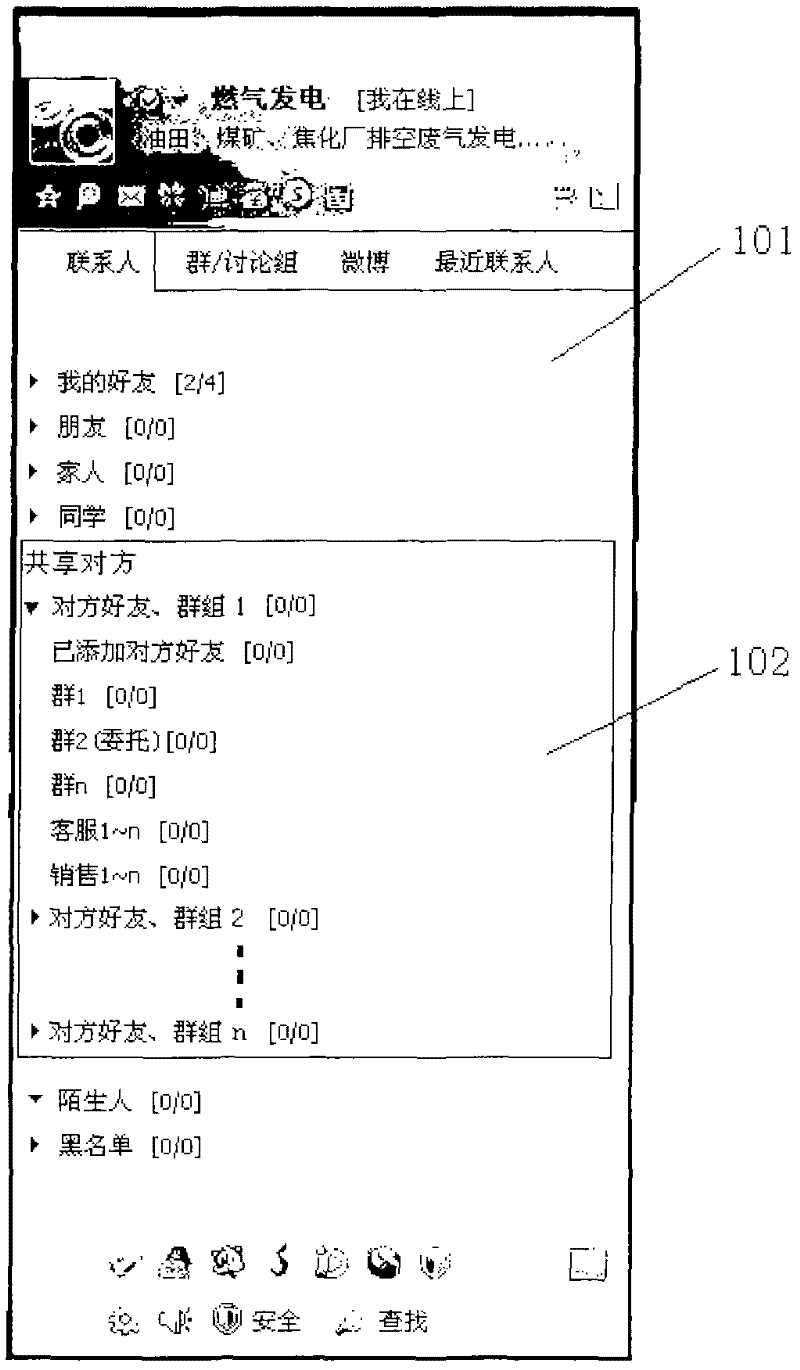

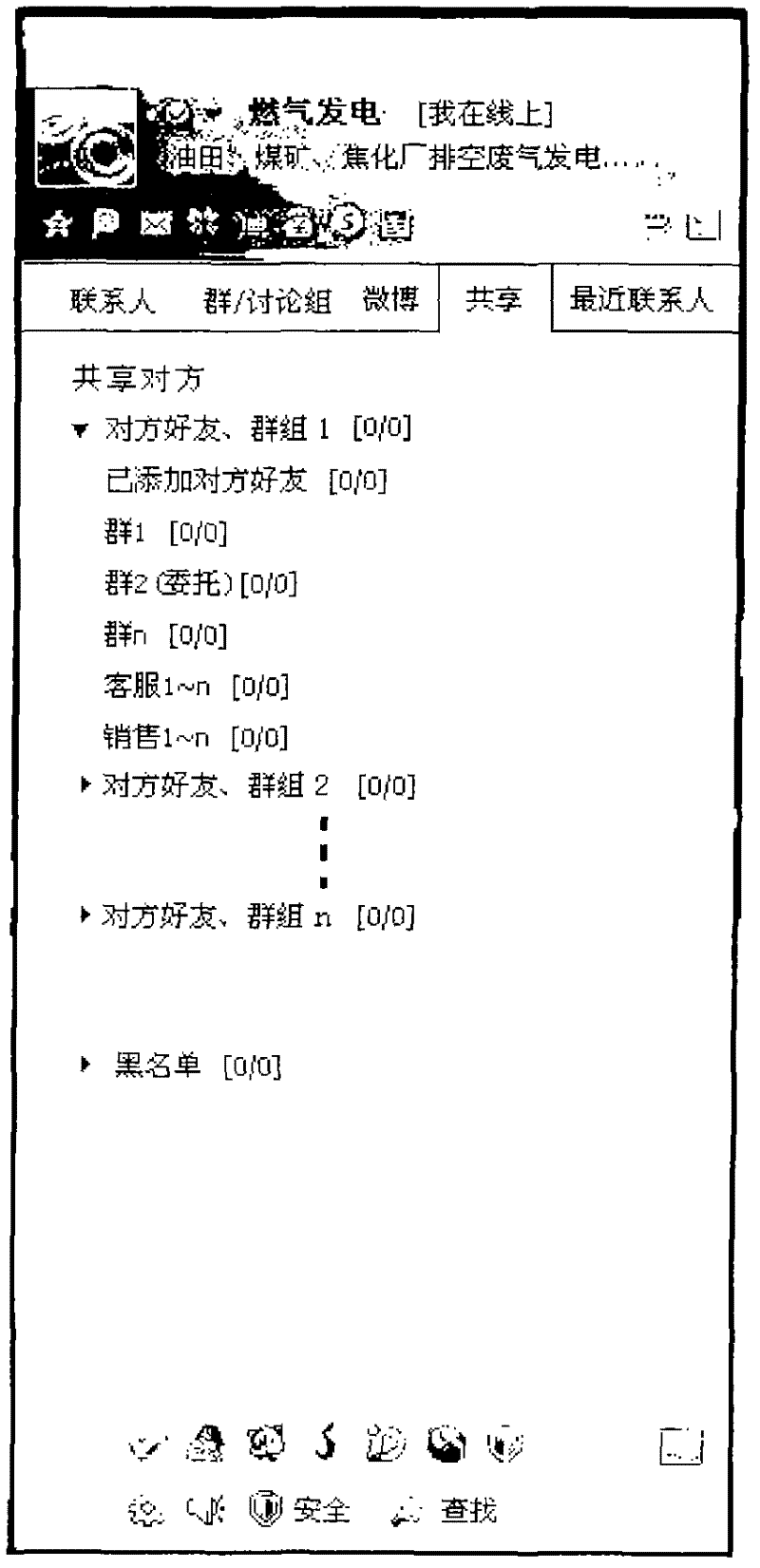

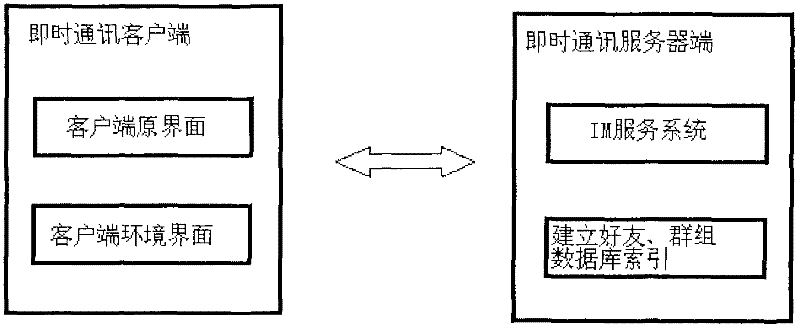

Method and system for sharing of friends and groups in instant messaging

The invention relates to the fields of instant messaging, software service mode, networks and the like, and particularly relates to an application service mode of a method and a system for sharing of friends and groups in instant messaging. The method and the system for sharing of the friends and the groups in the instant messaging are characterized in that a friend database and a group database of a user are established at an instant messaging server end, a corresponding database retrieval index is established in the database, a retrieval index interactive interface is arranged in a searcher client, or on a webpage of a searched person, or in a personal space of the searched person, or on a webpage provided by an instant messaging service provider, and retrieval buttons are arranged on the retrieval index function interactive interface, and are used for providing a retrieval dialog box and retrieval display. The beneficial effects are that one party in the instant messaging can share the selected friends and groups with another party, the friend database with a special property is established so as to be convenient to establish a common topic group, and a self group can be relegated to a friend database environment of the another party by sharing so as to utilize the topic advantages of the another party to develop the self group.

Owner:福建爱特点信息科技有限公司

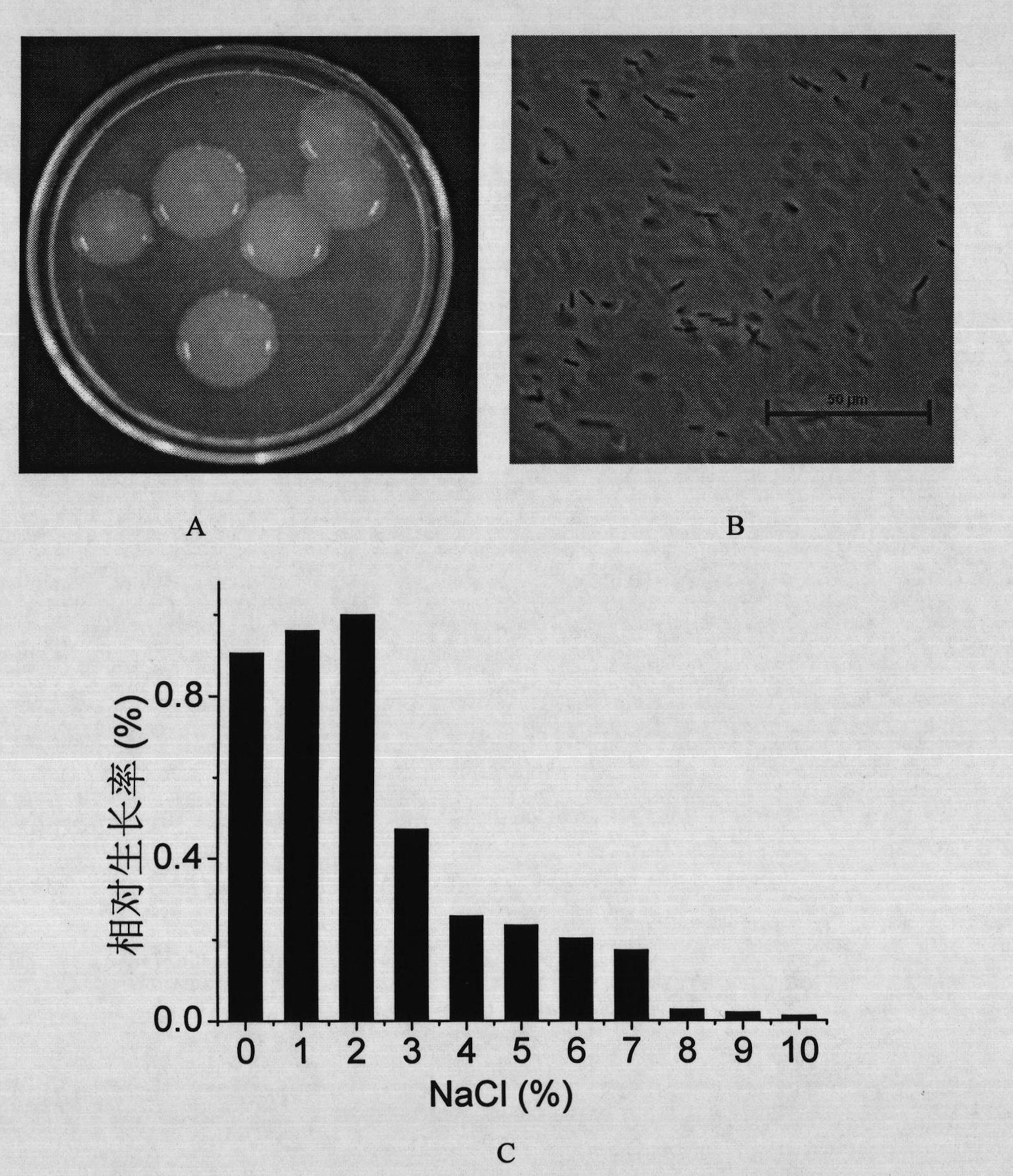

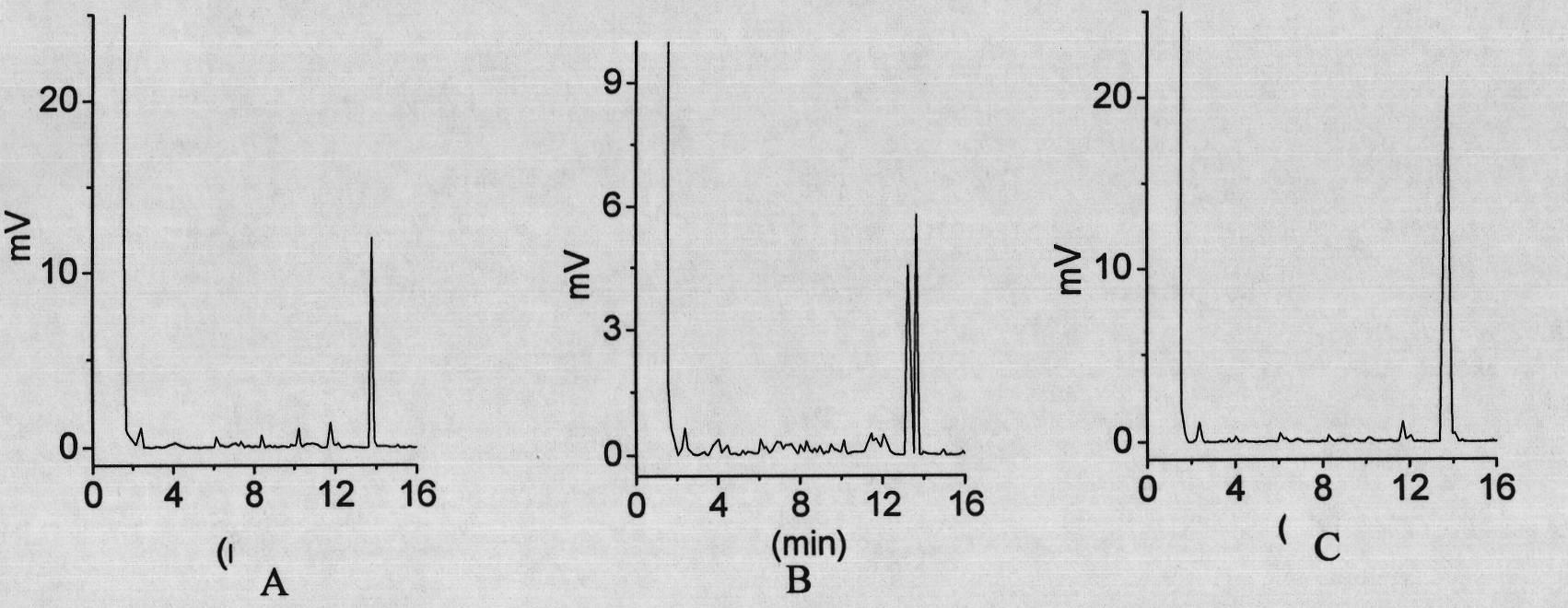

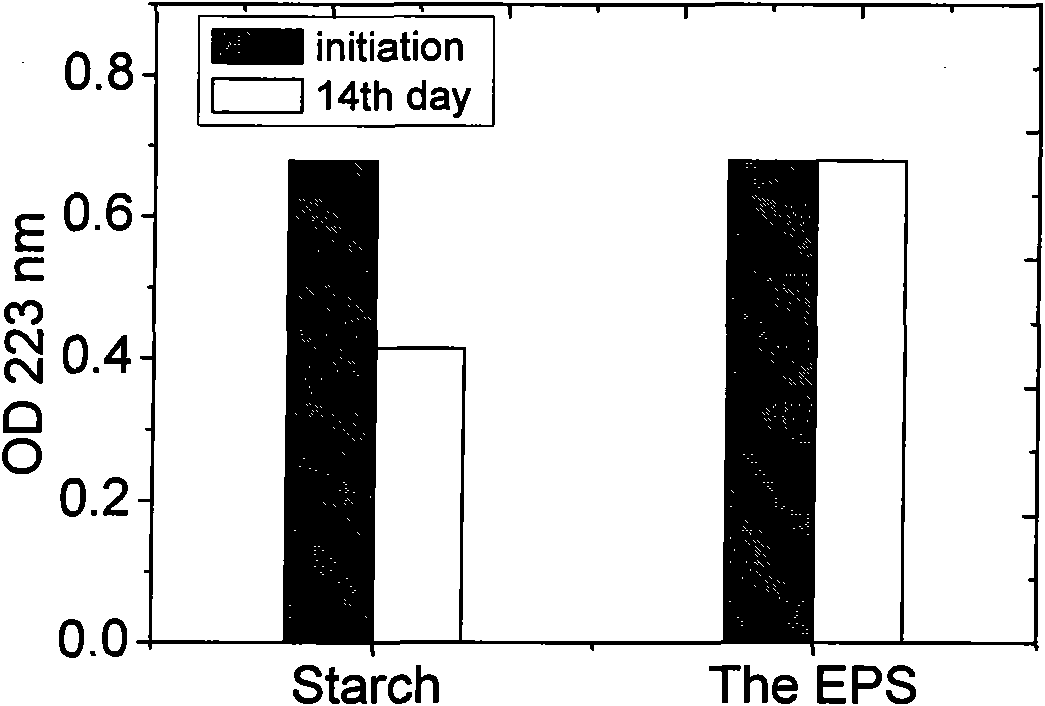

Agrobacterium ZX09, water-soluble beta-glucan prepared from Agrobacterium ZX09 and preparation method thereof and application on reducing blood sugar

ActiveCN101935623AEasy to operateSimple processOrganic active ingredientsBacteriaBeta-glucanMicrobiology

The invention discloses Agrobacterium ZX09, water-soluble beta-glucan prepared from the Agrobacterium ZX09 and the preparation method thereof and the application on reducing blood sugar, wherein the bacterial strain of the Agrobacterium ZX09 is obtained by separating saline soil from Dongying city in Shandong province; the bacterial strain is Agrobacterium sp. and is collected in China Center for Type Culture Collection (CCTCC) on January 21st, 2010; and the collection number is CCTCC NO:M2010020. The structure general formula of the water-soluble beta-glucan prepared from the Agrobacterium ZX09 is as follows: ->(3)-beta-D-Glup-(1->3)-[beta-D-Glup-(1->3)-beta-D-Glup-]3-alpha-D-Glup-(1->3)-alpha-D-Glup-(1)n->, and n in the structural formula is from 100 to 200. The bacterial strain has the advantages of novelty, special properties, salt resistant growth, no pigment secretion in the process of growth, simple and convenient cultivation operation, simple technology, total synthetic media, definite components and low cost, and is suitable for industrial production.

Owner:SICHUAN HETAI SYNLIGHT BIOTECH LTD

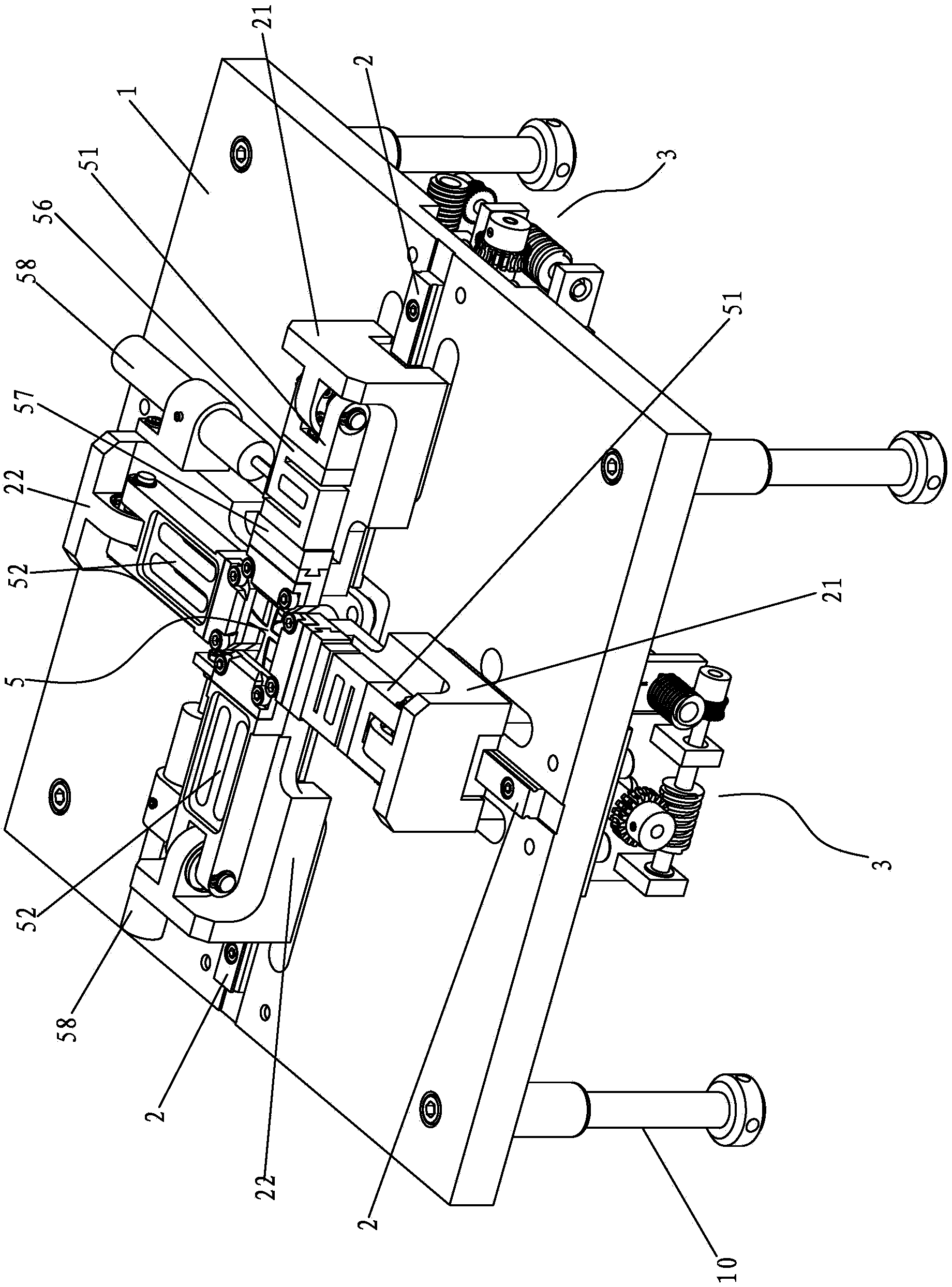

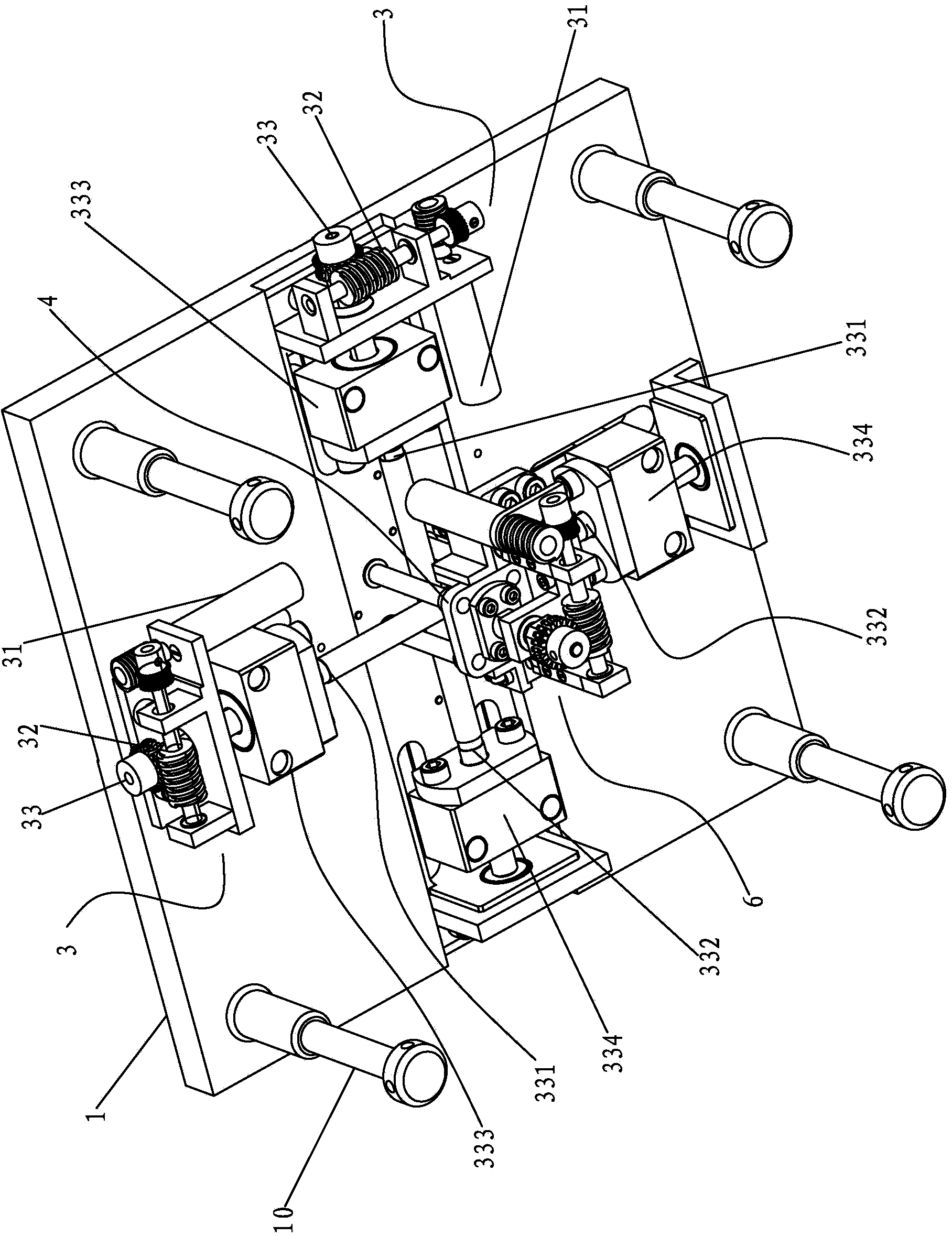

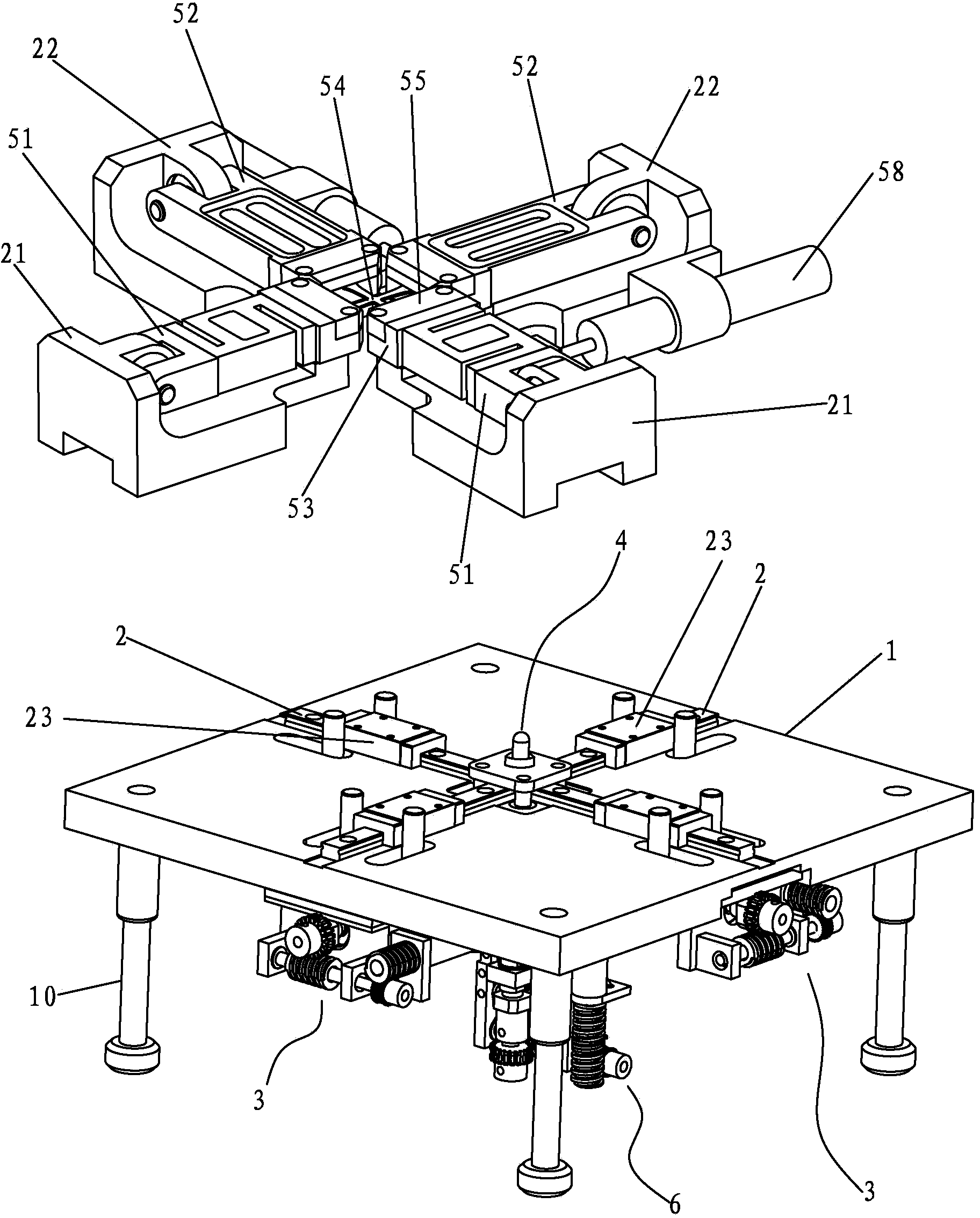

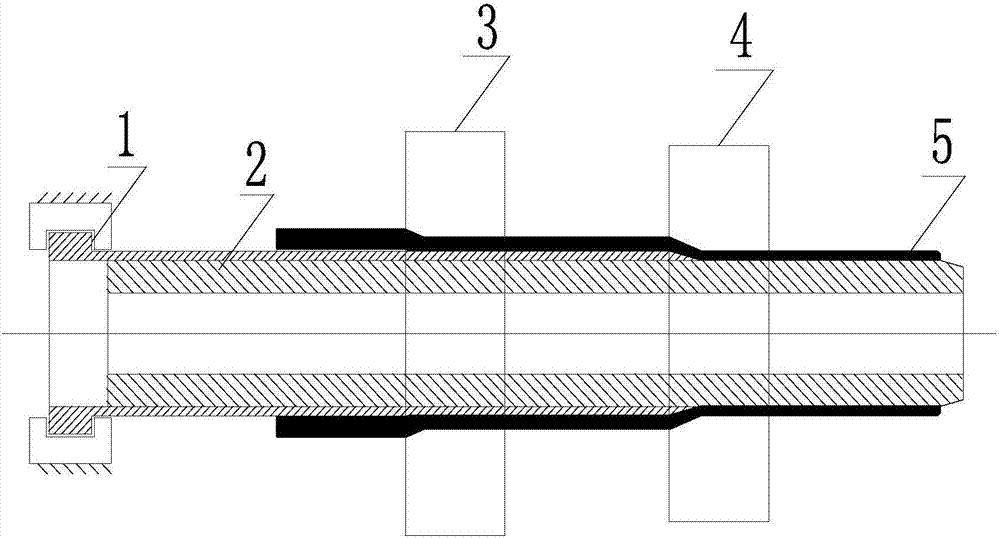

Testing device for mechanical property of material

InactiveCN103487315AFacilitate in-depth researchCompact structureStrength propertiesStress levelStrength of materials

The invention discloses a testing device for a mechanical property of a material. Slide rails vertical to each other are arranged on a working platform along the X axis and the Y axis; a first drawing seat and a second drawing seat for drawing a test piece are arranged on the slide rails along the X-axis direction and / or the Y-axis direction; a clamping device is arranged between the first drawing seat and the second drawing seat; a bending mechanism for applying bending load to the test piece along a Z direction is arranged below the clamping device; a tensile load is applied to the test piece through a control tensile load driving device; a bending load is applied to the test piece through a control bending load driving device; the testing on the mechanical property of the material in a biaxial drawing and bending composite load mode can be realized on the test piece; the provided composite load mode conforms to the stress level of the test piece under the actual working condition. Meanwhile, pure tensile test and pure three-point bending test can also be performed; biaxial drawing load and three-point bending load can be loaded independently or loaded in sequence; the testing device has the characteristics of compact structure and high compound degree.

Owner:JILIN UNIV

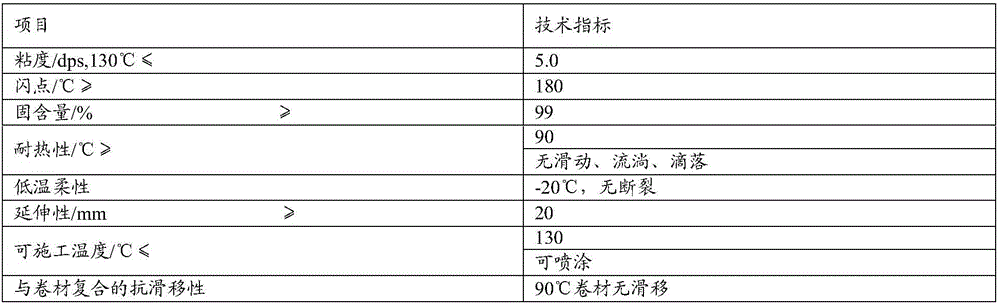

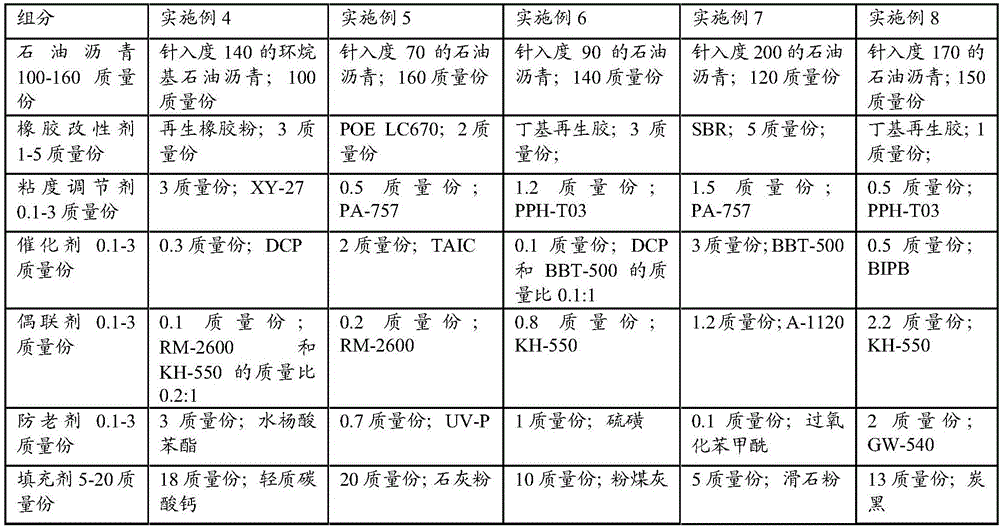

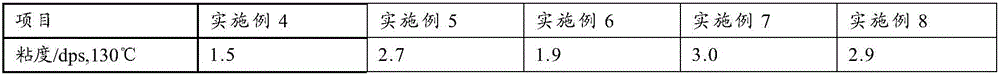

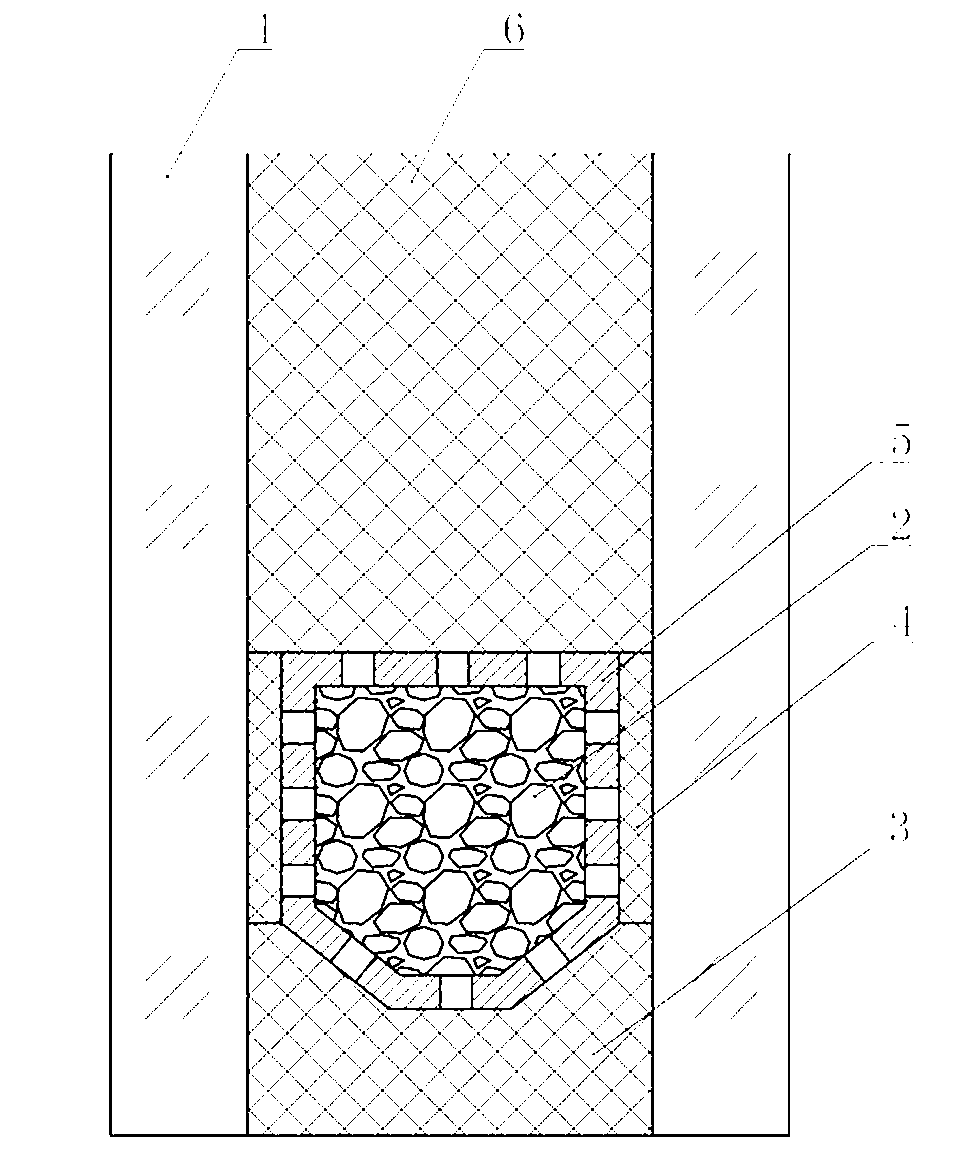

Non-curable rubber asphalt waterproof coating and preparation method and composite waterproof roll material thereof

ActiveCN105885693AImprove heat resistanceLow viscosityFireproof paintsConjugated diene hydrocarbon coatingsBituminous waterproofingElastic plastic

The invention provides a non-curable rubber asphalt waterproof coating and a preparation method and a composite waterproof roll material thereof. The non-curable rubber asphalt waterproof coating is prepared from, by mass, 100-160 parts of petroleum asphalt, 1-5 parts of rubber modifier, 0.1-3 parts of viscosity regulator and 0.1-3 parts of a catalyst. The chemical crosslinking reaction of the petroleum asphalt and the rubber modifier is achieved by adding the viscosity regulator and the catalyst in the petroleum asphalt and the rubber modifier of the non-curable rubber asphalt waterproof coating, so that the non-curable rubber asphalt waterproof coating has high heat resistance (greater than or equal to 90 DEG C) and low viscosity (smaller than or equal to 5.0 dps), can be sprayed or scraped at the low temperature (sprayable at the temperature of 130 DEG C) and also has energy saving and consumption reducing properties and other special properties on the basis that the common properties of an elastic-plastic paste body are kept within the service life, the comprehensive performance of the non-curable rubber asphalt waterproof coating is improved, and the service life of the non-curable rubber asphalt waterproof coating is prolonged.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +1

Transparent-aerogel vacuum glass and manufacturing method thereof

ActiveCN102839893ALow thermal conductivityHigh strengthClimate change adaptationWindows/door improvementRubber ringDesiccant

The invention provides transparent-aerogel vacuum glass and a manufacturing method of the vacuum glass. The transparent-aerogel vacuum glass comprises glass panes, desiccating agent aluminum bars and a sealing rubber ring. The desiccating agent aluminum bars are arranged inside the periphery between the two glass panes, the sealing rubber ring is used to seal the outside of each of the desiccating agent aluminum bars, a hollow interlayer is formed between the two glass panes, and then the hollow interlayer is vacuumized. The transparent-aerogel vacuum glass is characterized in that transparent aerogel is placed inside the hollow interlayer. The transparent-aerogel vacuum glass has the advantages that since thermal conductivity coefficient of the aerogel is quite low, by matching of the aerogel and special properties of a piece of vacuum glass, the requirement of energy conservation can be met; and since the aerogel is high in strength, and external pressure bearing capacity is large, whole strength of the transparent-aerogel vacuum glass is greatly enhanced, and the transparent-aerogel vacuum glass is not prone to break.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Preparation method of carbon/carbon composite material with high heat conductivity

The invention provides a preparation method of a carbon / carbon composite material with high heat conductivity. The preparation method comprises the steps: adopting an intermediate-phase asphalt-basedcarbon fiber with special property to carry out weaving, obtaining a three-dimensional preform, and carrying out densification and final graphitizing treatment, to obtain the carbon / carbon composite material with high heat conductivity. The preparation method comprises the following specific steps: (1) selecting the carbon / carbon composite material with low modulus, intermediate strength, high elongation at break, better weaving processability and high heat conductivity potential to carry out weaving, so as to obtain the three-dimensional preform; (2) introducing a carbon source into the three-dimensional preform to carry out densification so as to obtain the carbon / carbon composite material; (3) carrying out graphitizing treatment on the carbon / carbon composite material so as to obtain the carbon / carbon composite material with high heat conductivity.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

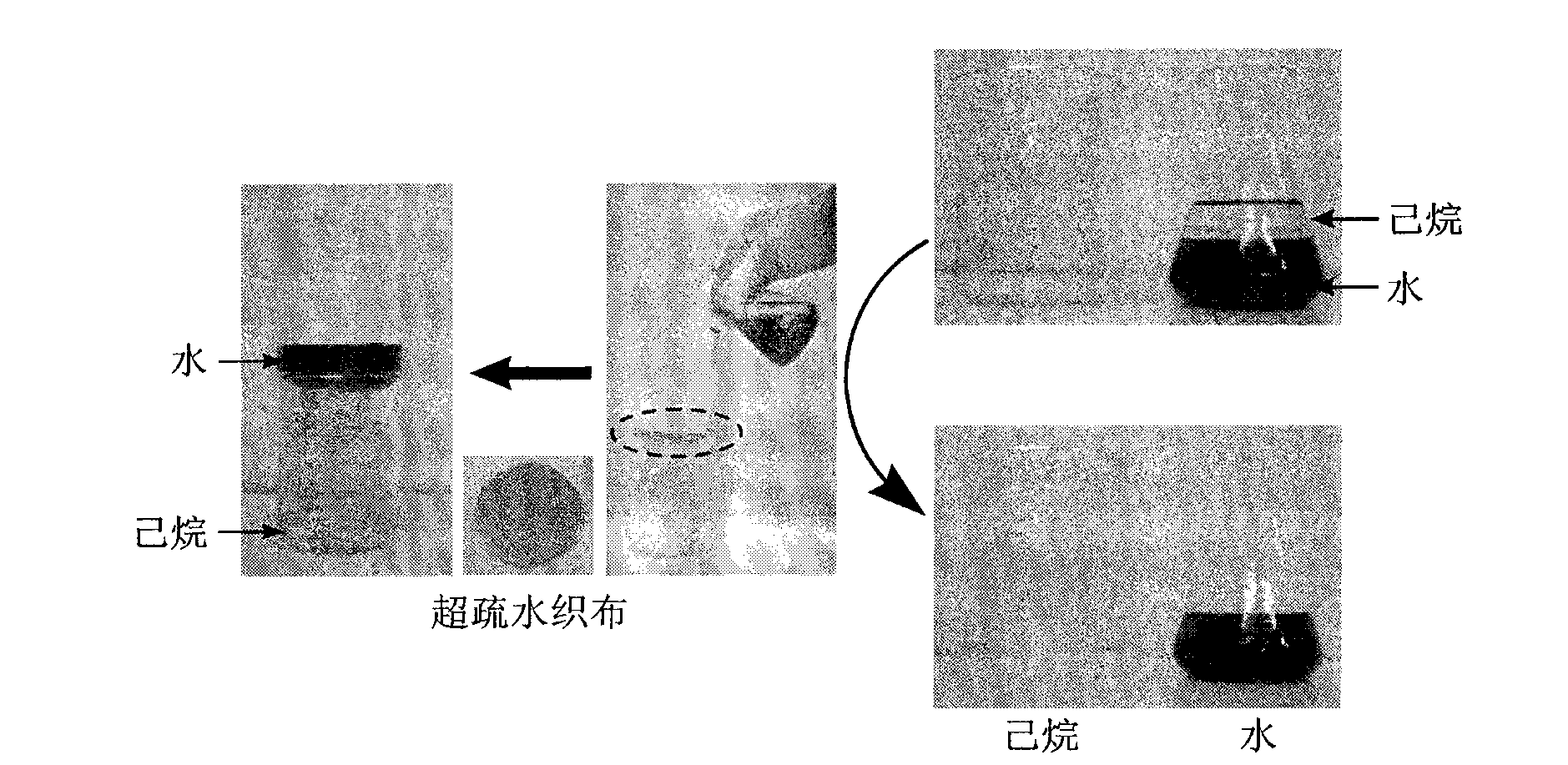

Preparation method of superhydrophobic woven fabric for oil-water separation

ActiveCN103173998ASimple processEasy to operateFibre treatmentFiltration separationOil waterTemperature resistance

The invention discloses a preparation method of superhydrophobic woven fabric for oil-water separation. According to the preparation method disclosed by the invention, transition metal nanoparticles are modified on the surface of woven fabric, the obtained woven fabric has special properties endowed by a transition metal, for example, the superhydrophobic woven fabric modified by Fe3O4 has magnetism, the superhydrophobic woven fabric modified by Ag has good antibacterial performance and excellent superhydrophobic property, the contact angle with water is larger than 150 degrees, the rolling angle is smaller than 10 degrees, and the superhydrophobic woven fabric has high temperature resistance, washing resistance and permanent superhydrophobic property, and can be successfully applied to oil-water separation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

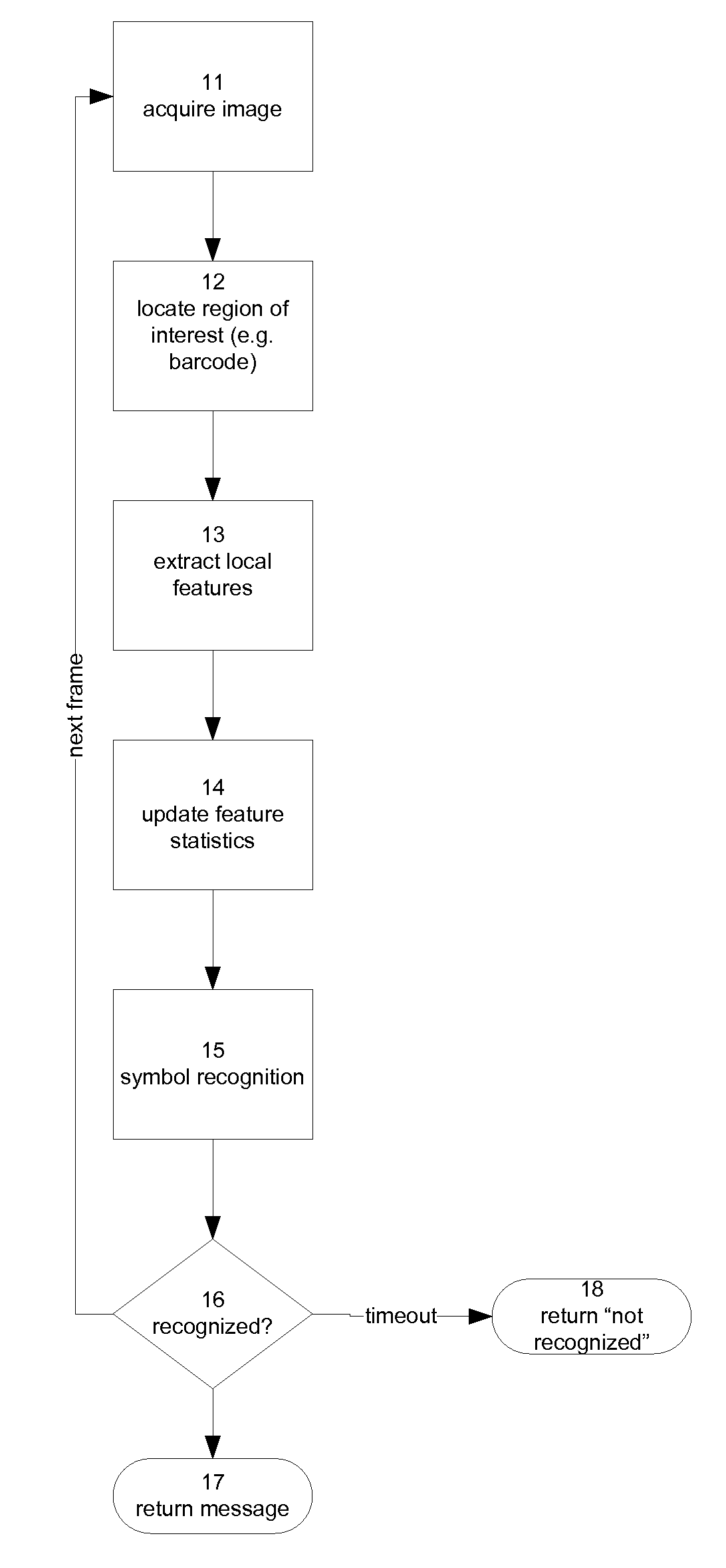

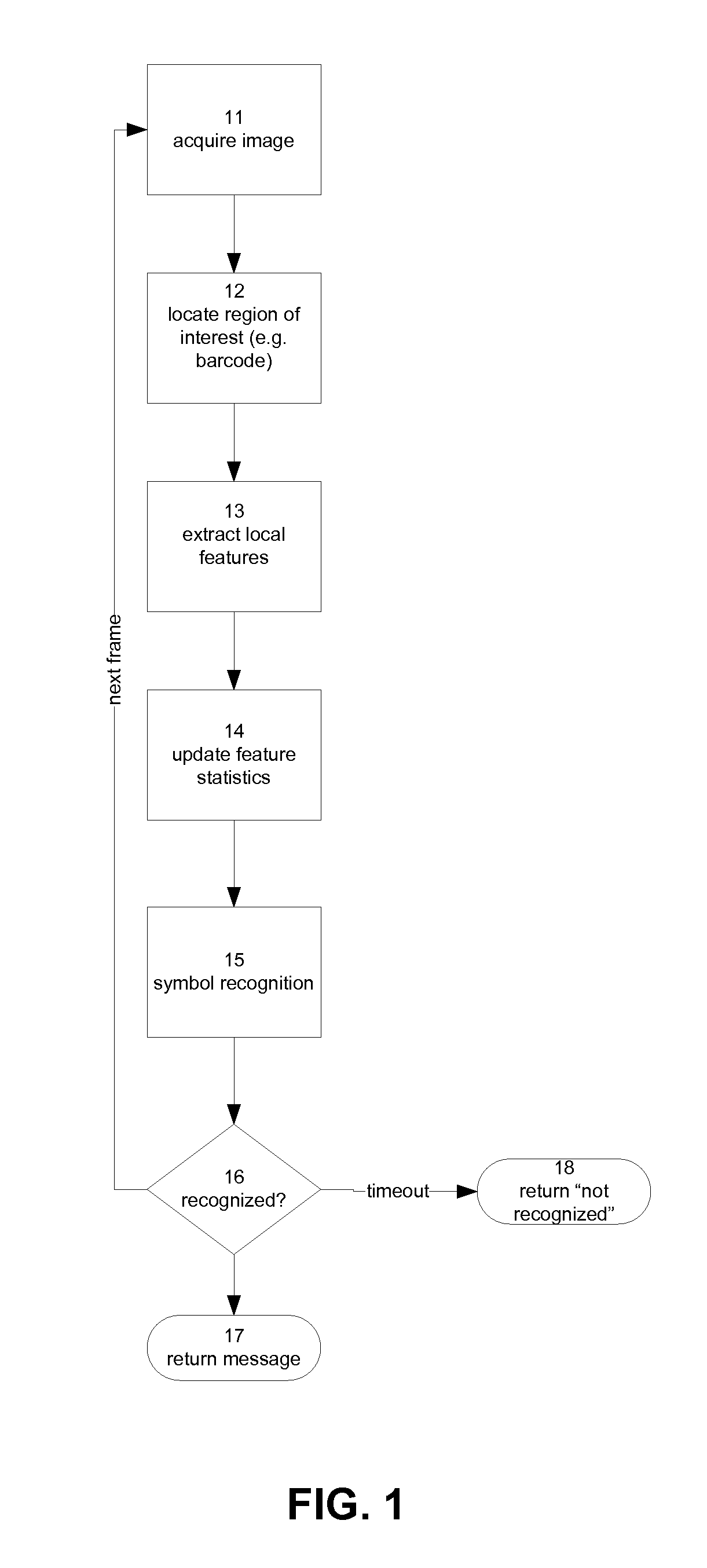

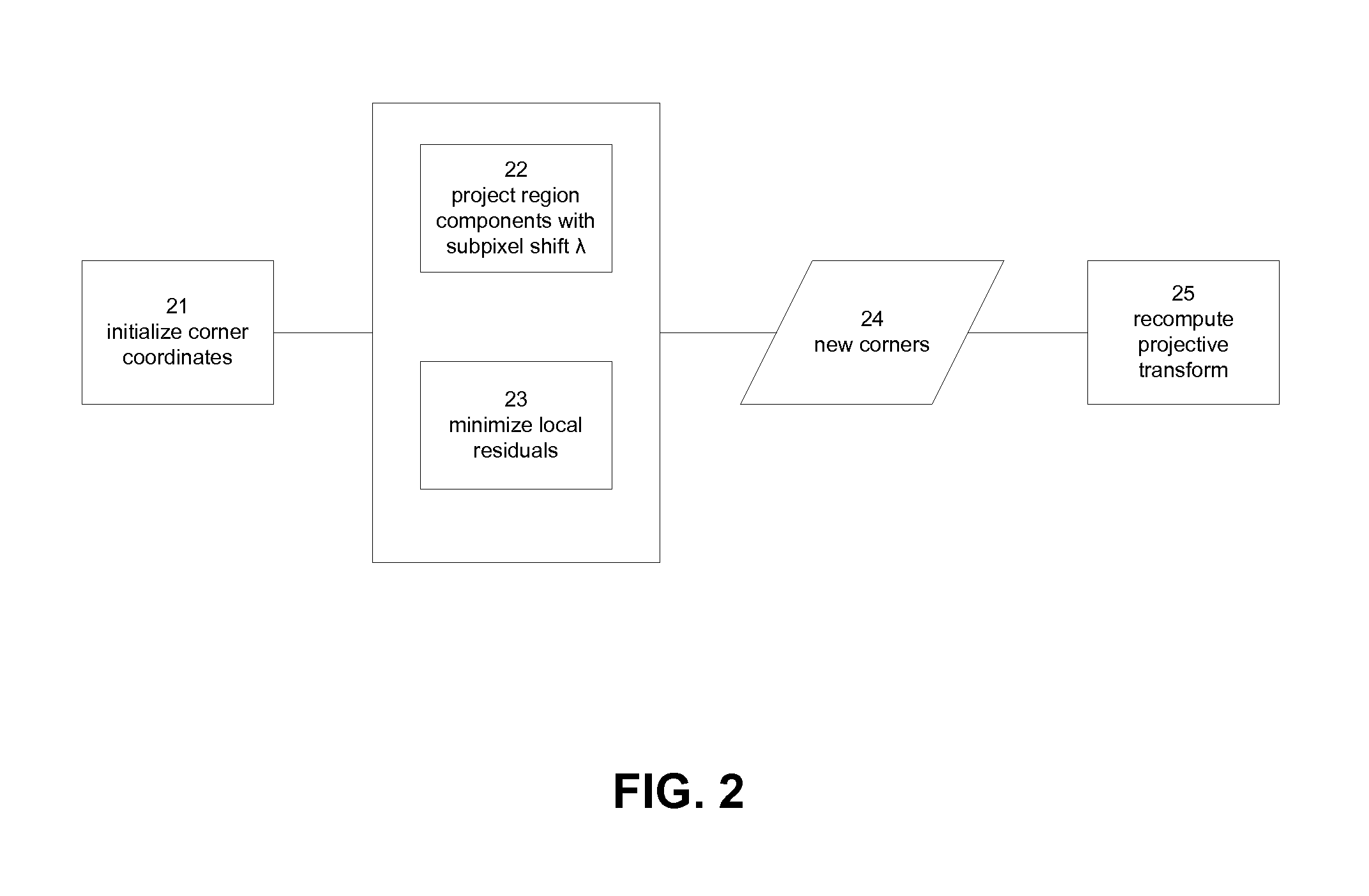

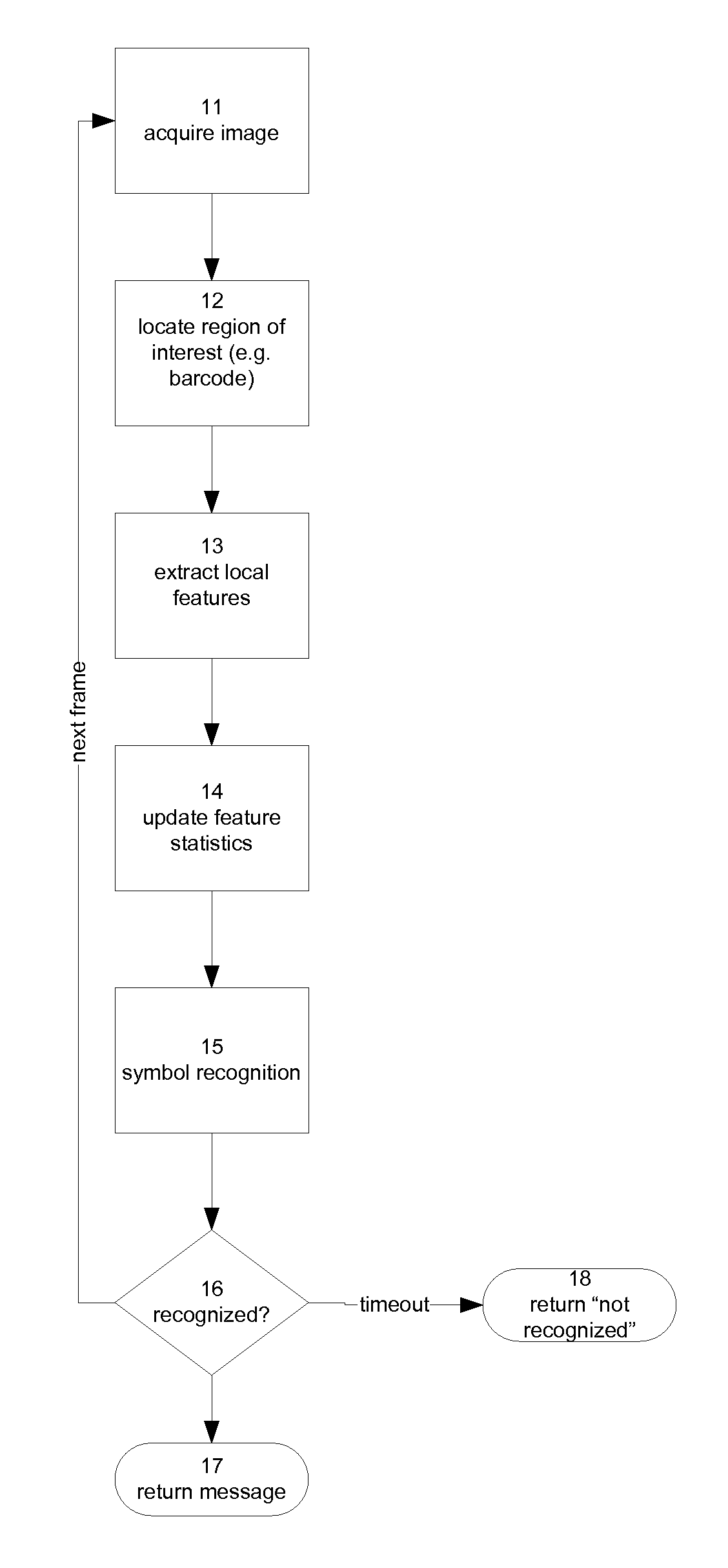

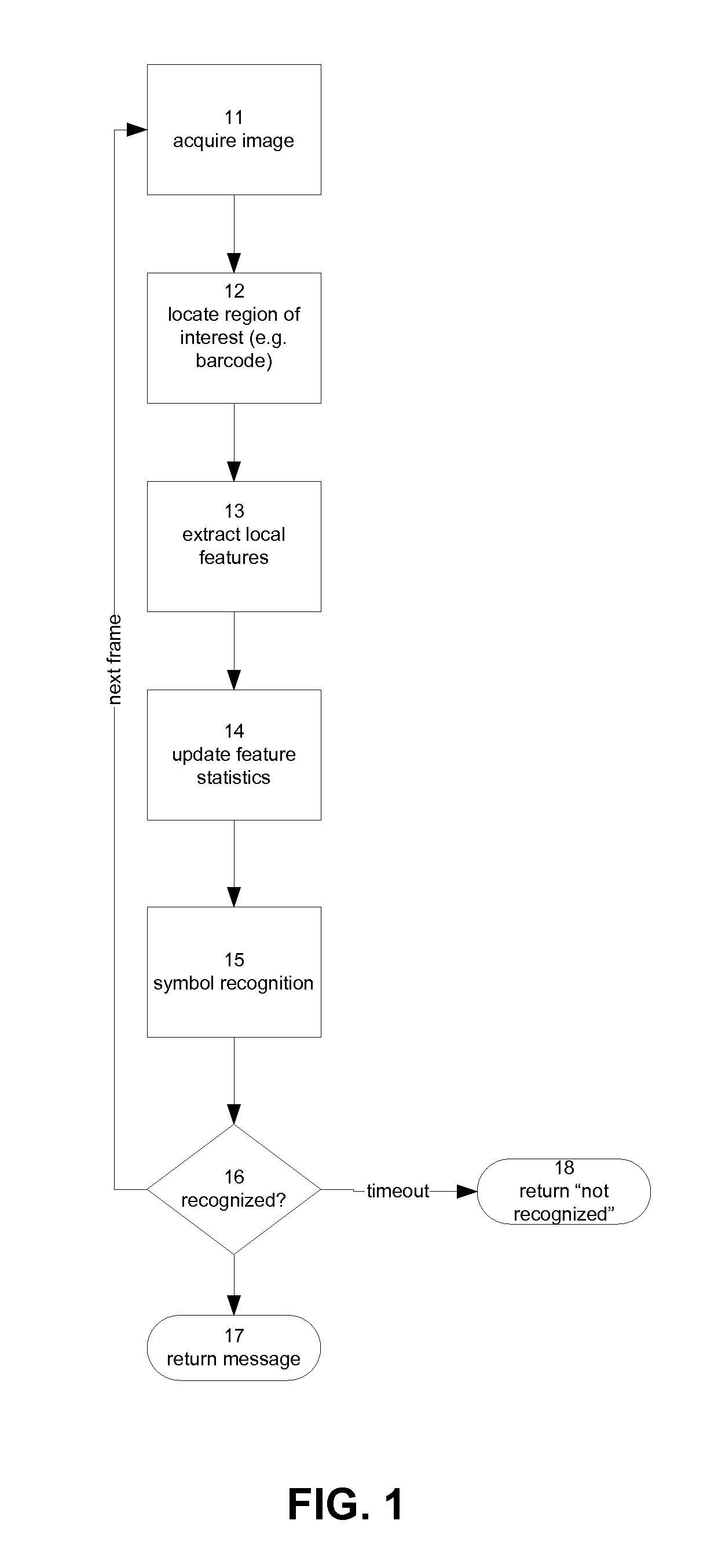

System And Method For Recovering Image Detail From Multiple Image Frames In Real-Time

InactiveUS20070242883A1Guaranteed uptimeHigh resolutionImage enhancementGeometric image transformationMultiple frameImage resolution

This invention describes an efficient super-resolution method for image enhancement that leverages prior knowledge about the specific task for which detail information is recovered. The particular case of barcode scanning is considered. The barcode localization and decoding algorithm of the present invention employs a subpixel-accurate search algorithm which allows for estimating barcode bit values at a higher resolution than that available in the image data itself. It thus allows for the synthesis of image detail from multiple frames with the result containing more detail than any of the input frames. For efficiency, it leverages special properties of the quadrilateral target object as well as prior knowledge about constant patterns in the barcodes of interest. This allows for real-time software implementations on portable devices such as camera-equipped cell phones where super-resolution helps to overcome some of the typical camera resolution and processing power constraints.

Owner:SCANBUY

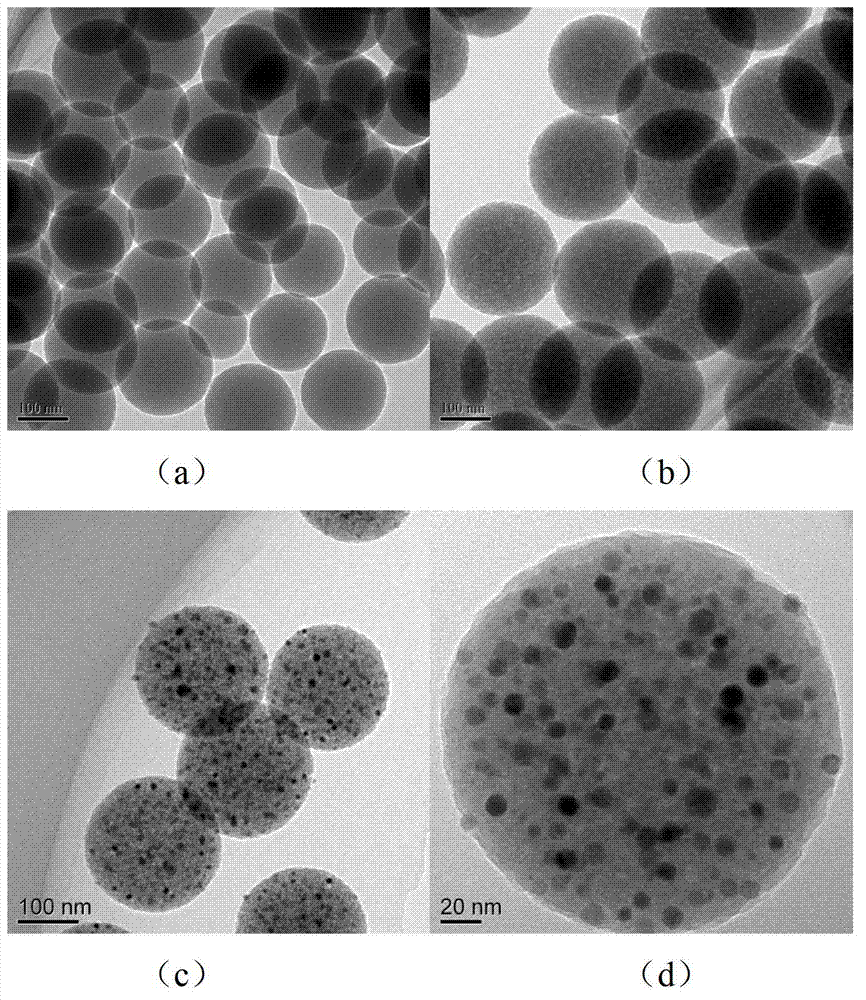

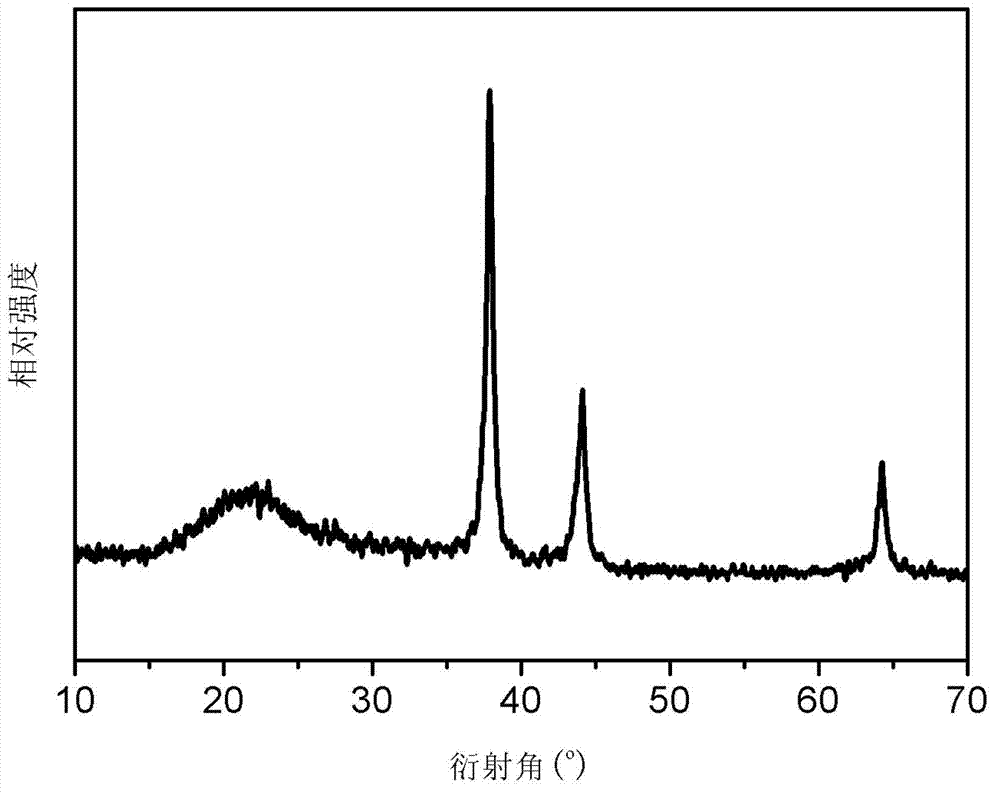

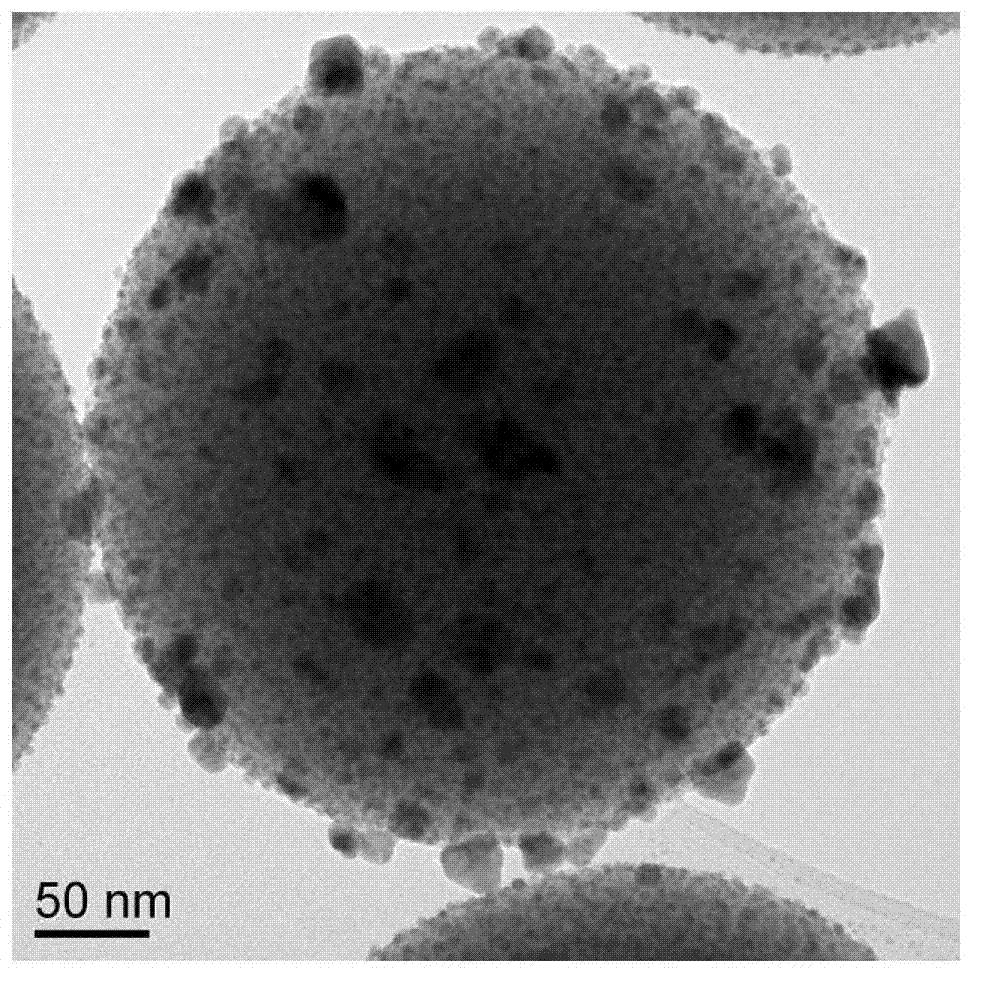

Method for preparing silver-carried silica microsphere functional materials

InactiveCN102764617ANo pollution in the processEasy to operateMicroballoon preparationMicrocapsule preparationSilica particleEtching

The invention discloses a method for preparing silver-carried silica microsphere functional materials. Monodisperse uniform spherical composite metallic silver-carried silica functional particles are prepared by chemical etching and metal salt pyrolysis methods, the particles are formed by uniformly loading nanometer metallic silver with the grain diameter of 5-50nm on the monodisperse multihole silica particles used as inner cores, so that the original silica particles have the special properties of nanometer silver particles. The particle obtained by the method has high purity and good monodispersity, the size of a product can be controlled by reaction conditions, and the method has wide application prospects. The method for preparing the silver-carried silica microsphere functional materials disclosed by the invention has a simple process and is environment-friendly, raw materials and equipment are cheap and are easy to obtain, and the cost is low. The synthesis time is short, the efficient is high, and the method has great industrial production prospects.

Owner:SHAANXI UNIV OF SCI & TECH

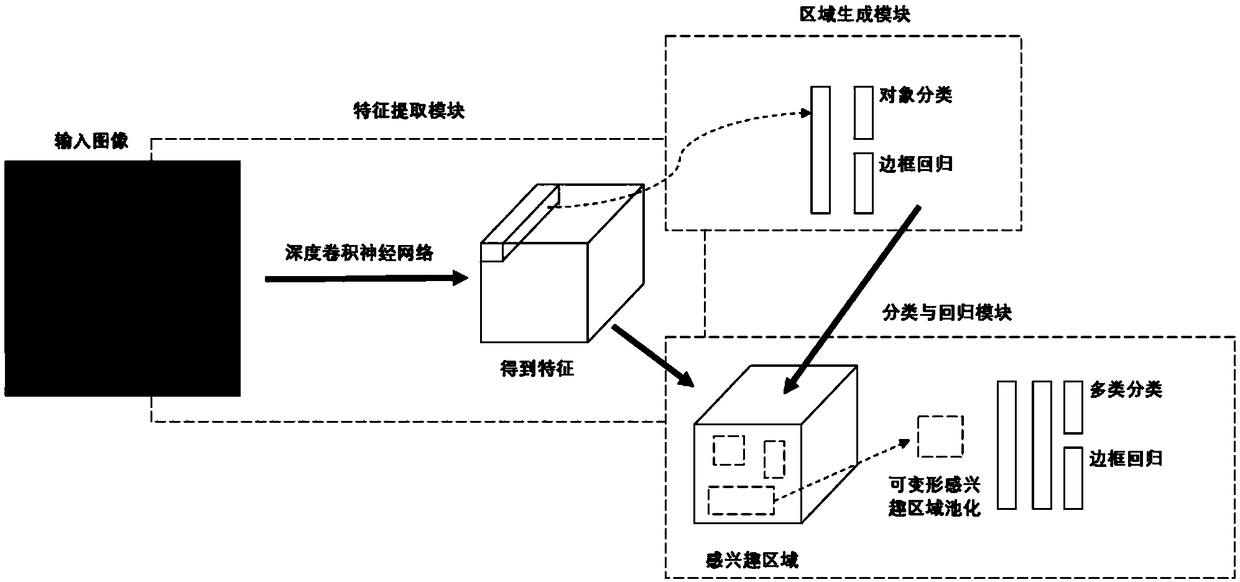

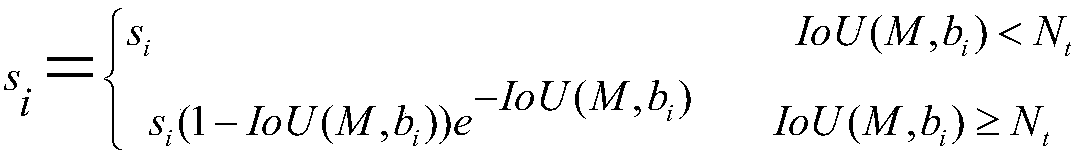

Ship detection method based on deformable fast convolution neural network

ActiveCN109299688ASpeed up object detectionDetection speedCharacter and pattern recognitionImaging processingTraining phase

The invention relates to a ship detection method based on a deformable fast convolution neural network, which relates to image processing. Detection methods include model training phase and ship detection phase. It can be used in the civil field instead of detecting ships in specific ports, harbors and sea areas in real time, and can be used in video surveillance or ship detection in images, and can also be used in ship detection and monitoring of military ports, so as to discover military intelligence as early as possible, provide operational basis for our military command, and grasp the initiative of the battlefield. By improving the end-to-end method Faster R-CNN considering speed and accuracy, according to the special property of ship target, is the key to the improvement of Faster R-CNN Foundation Network, RoI-wise subnetwork and loss function are modified to obtain the model structure of the deformable fast convolution neural network. The experimental results show that the proposed network is more efficient than the original Faster R-CNN method has better detection speed and accuracy.

Owner:XIAMEN UNIV

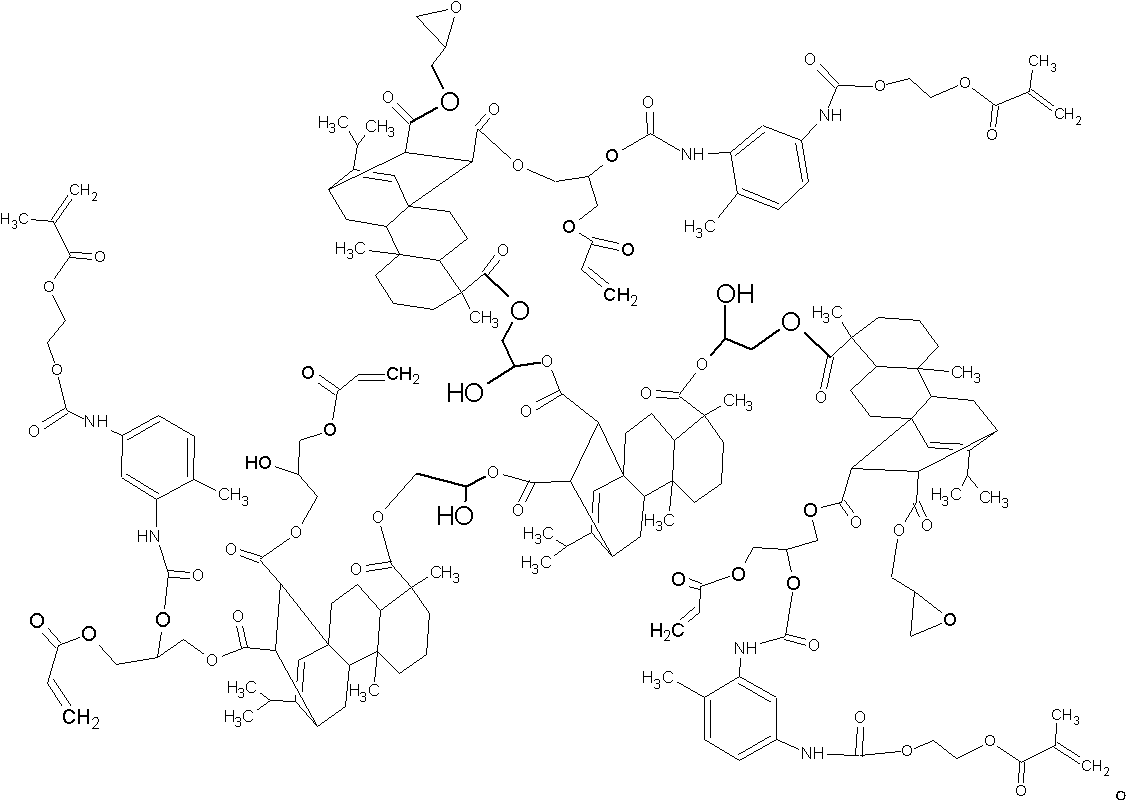

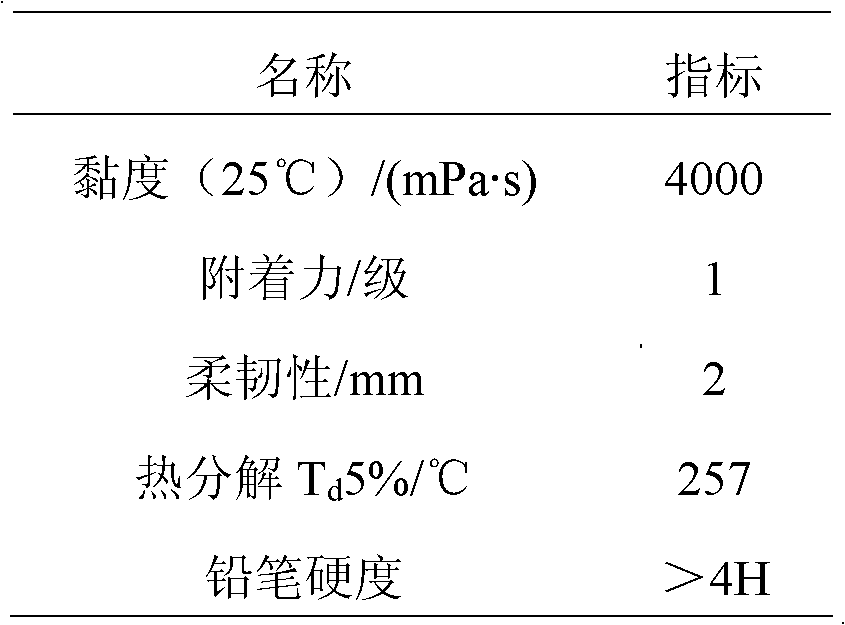

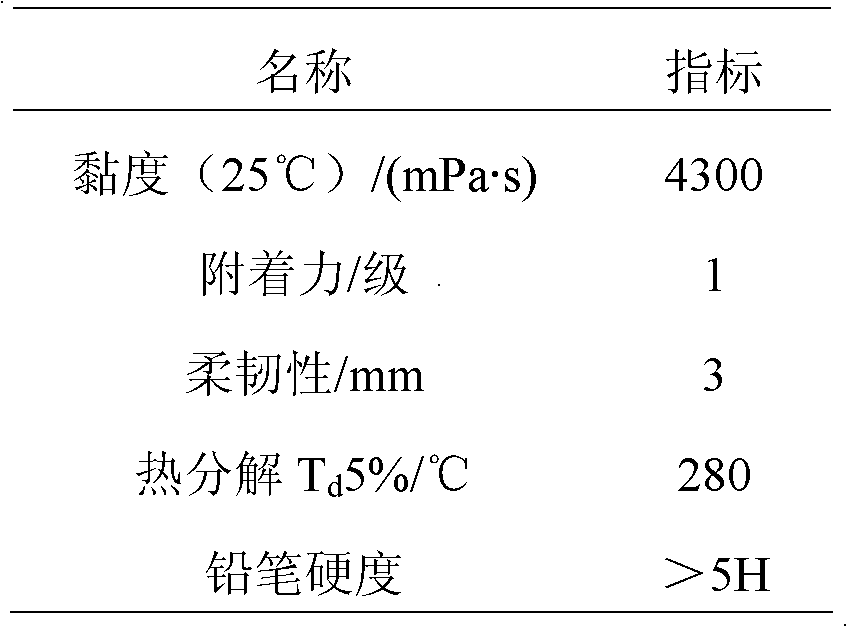

Method for preparing ultraviolet (UV)-curable polyisocyanate modified superbranched epoxy acrylate

ActiveCN102234268ALow viscosityGood alkali resistanceOrganic chemistryCoatingsEpoxyMaleopimaric acid

The invention relates to a method for preparing an ultraviolet(UV)-curable polyisocyanate modified superbranched epoxy acrylate, which comprises the following steps of: heating maleopimaric acid tri glycidyl ester, maleopimaric acid and a catalyst for esterification reaction to obtain rosin-based superbranched resin; cooling, and adding epoxy chloropropane, water and a catalyst for reaction to obtain superbranched epoxy resin; adding crylic acid, a catalyst and a polymerization inhibitor for reaction to obtain superbranched epoxy acrylic resin; and reacting the superbranched epoxy acrylic resin with ethylene glycol methacrylate terminated para toluene diisocyanate, a catalyst and a polymerization inhibitor to obtain the final product. Compared with the prior art, the method has the advantages that: rosinyl is introduced into superbranched polyester, and the hardness, strength and other special properties of the resin are improved and the curing speed is improved by utilizing the special rigid condensed ring structure of the rosin. The cured product has higher ultraviolet resistance; and by adjusting the using amount of raw materials, superbranched polyester for ultraviolet-curable coatings meeting different coating requirements can be prepared.

Owner:江苏金隆新材料有限公司

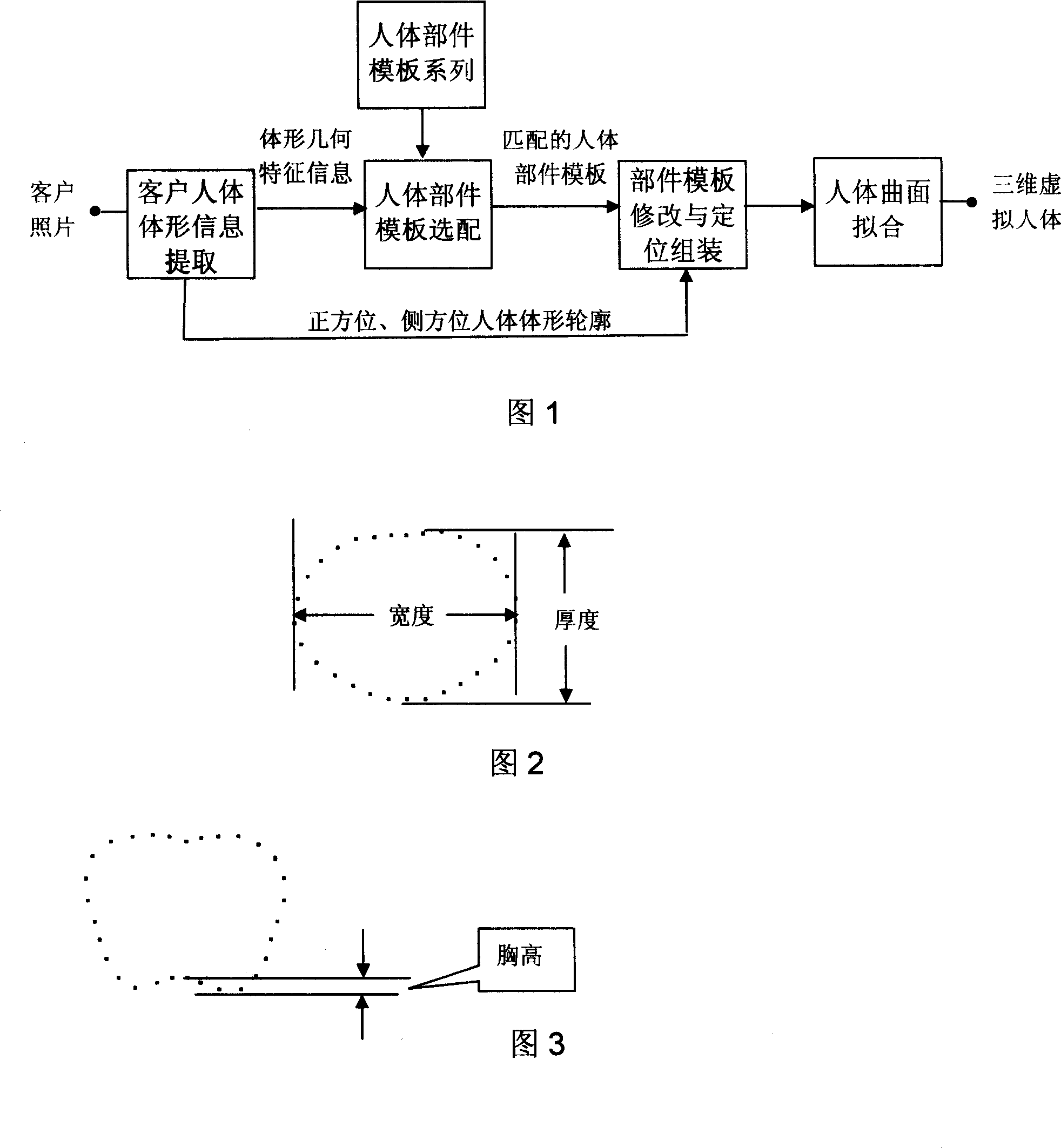

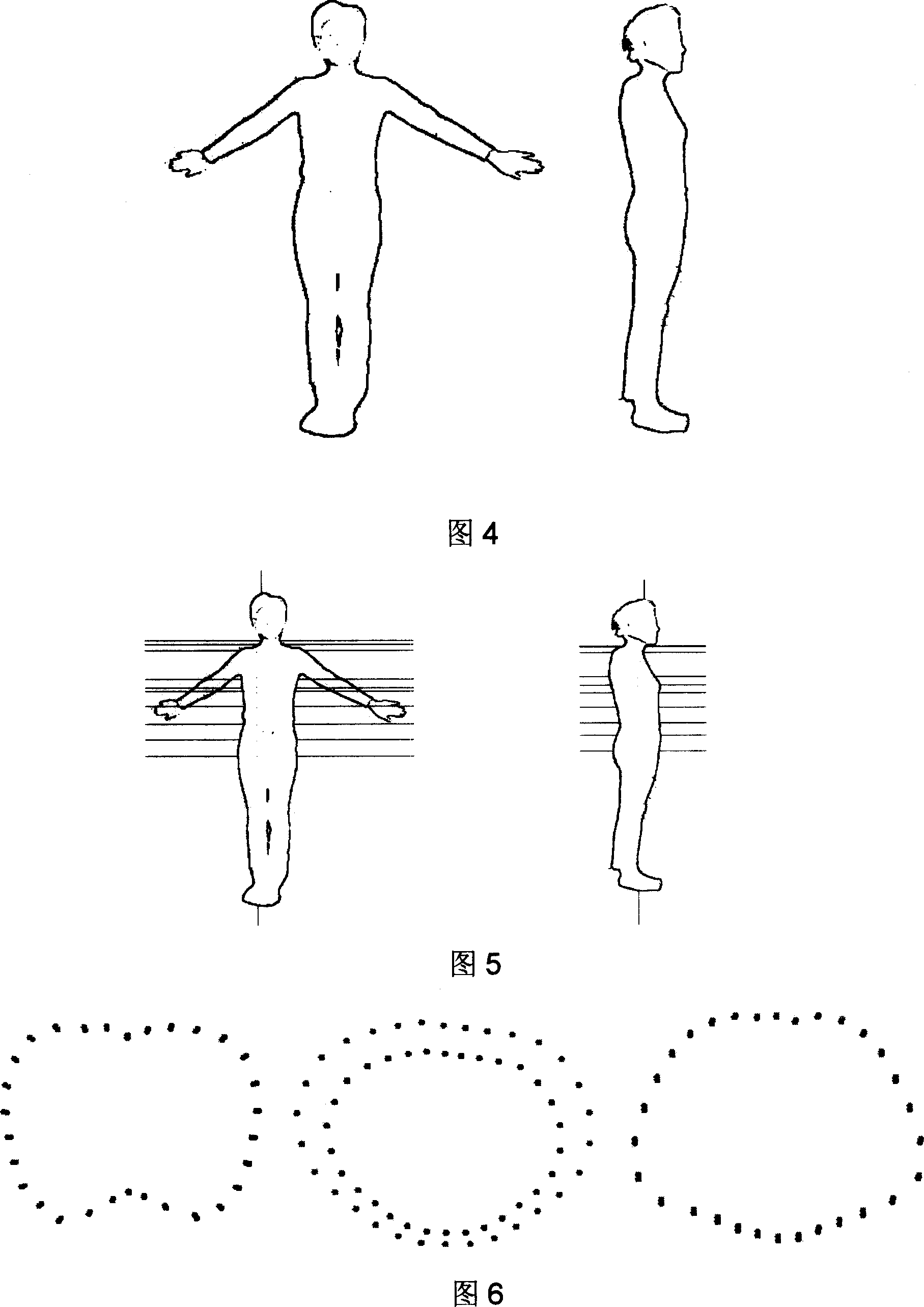

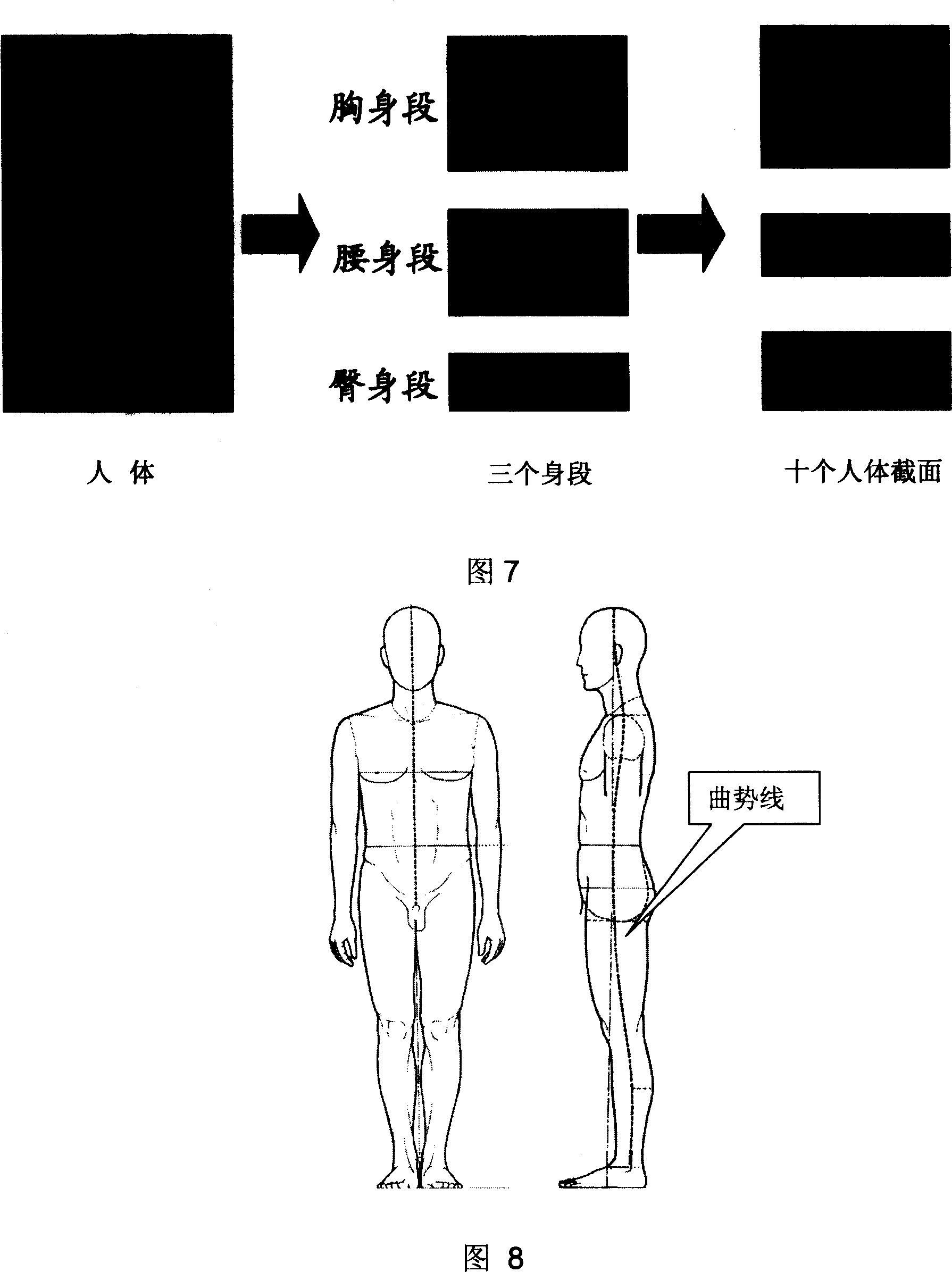

Method for automatically forming 3D virtual human body based on human component template and body profile

This invention relates to one three-dimensional virtual body automatic generation method based on body part module and outline, which comprises the following steps: according to frame special property cutting the body into three sections for breast section, waist section, bug section; on this base, analyzing each section into one set of relative key sections to reflect the geometry shapes of sections as body parts; any one 3D virtual body forming can be as body module to modify and resemble the body outline.

Owner:DONGHUA UNIV

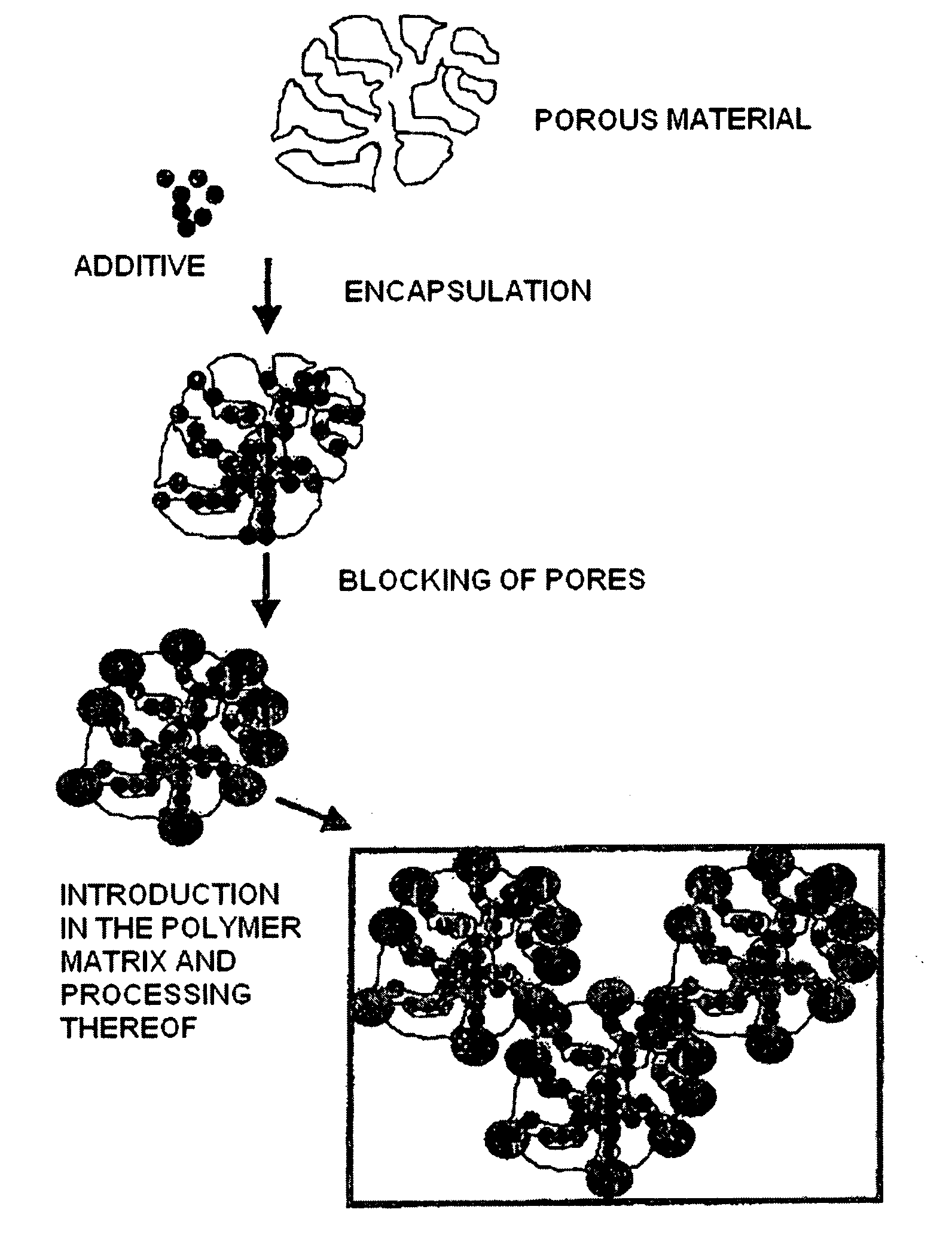

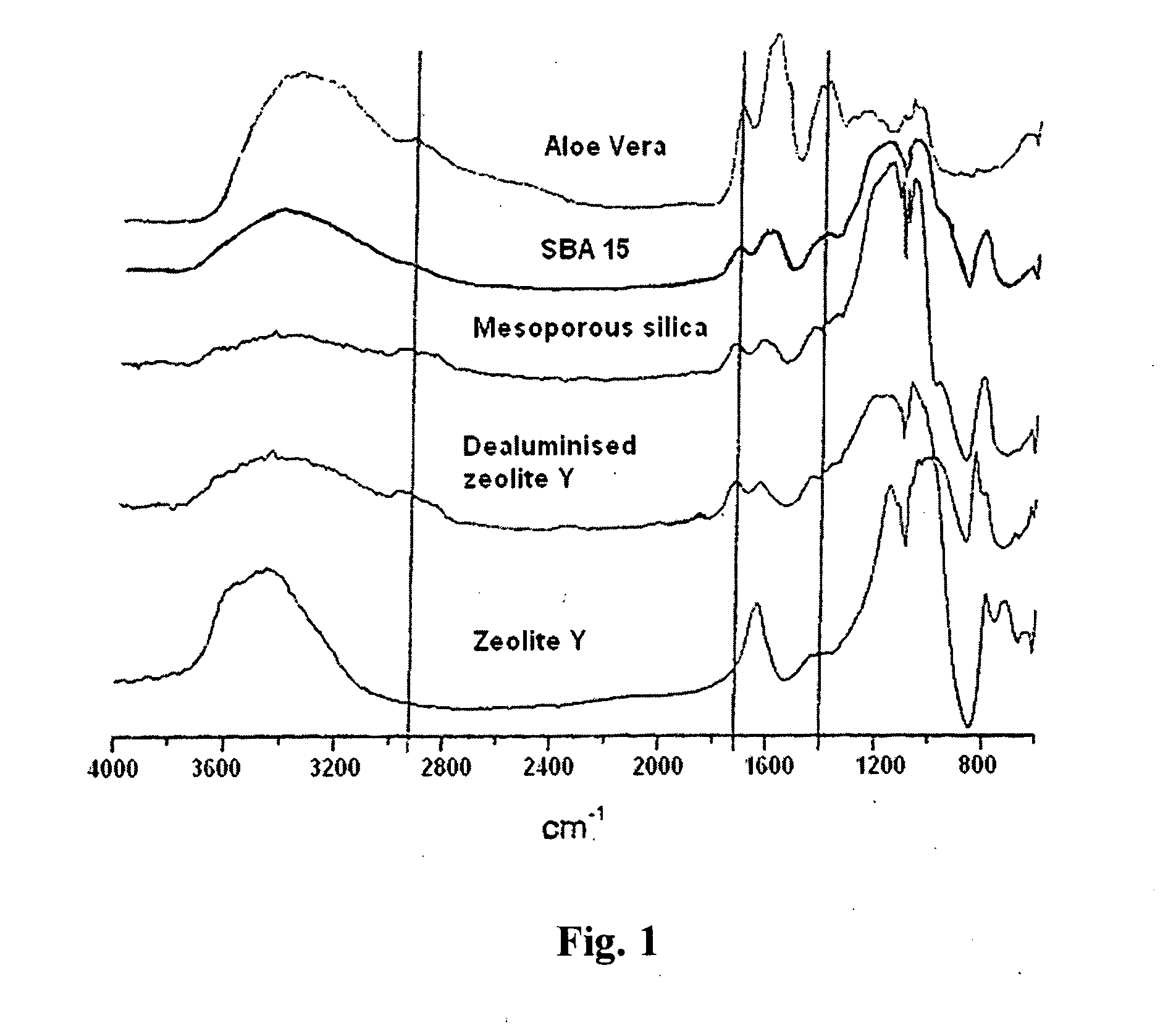

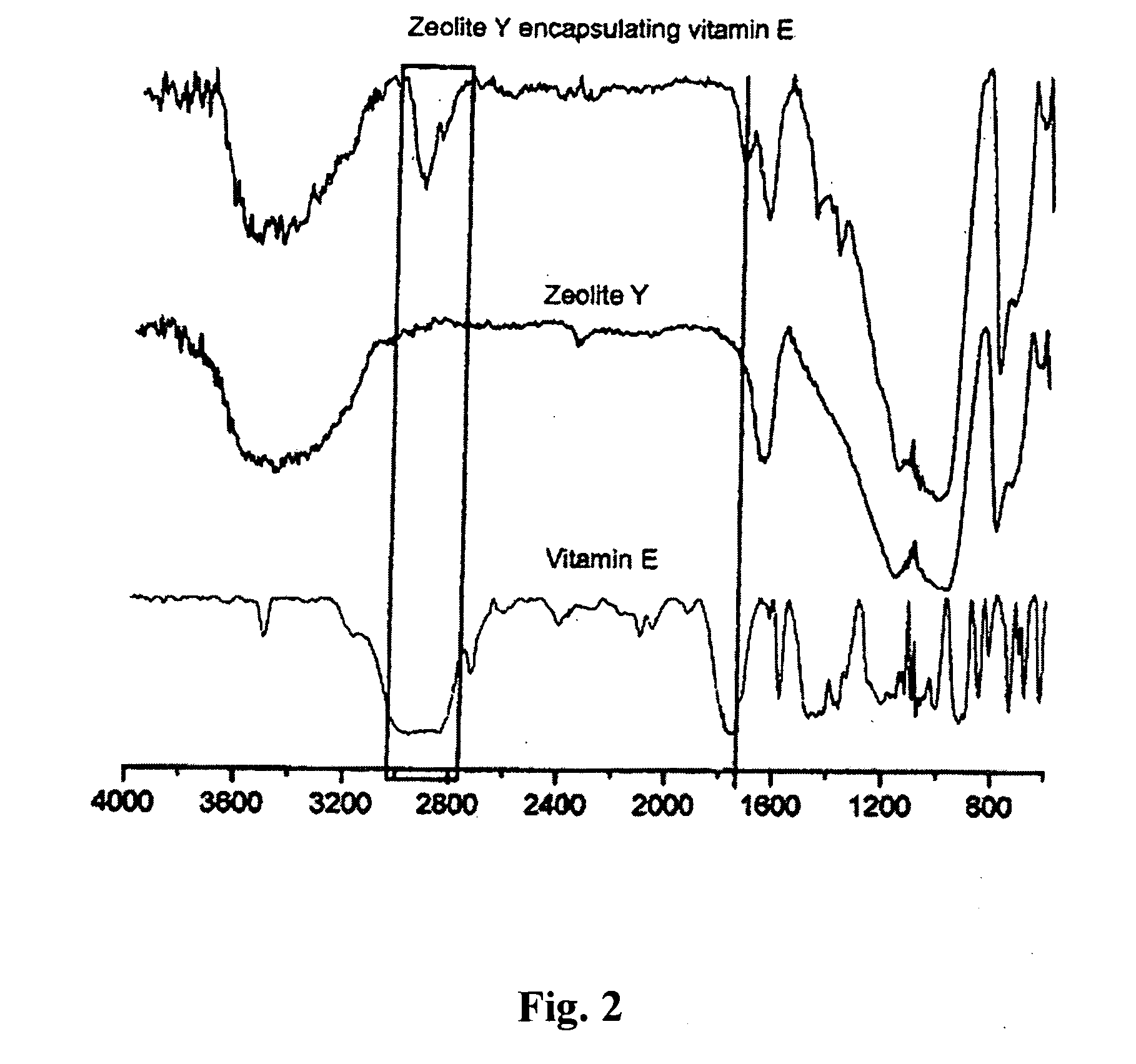

Process for the additivation of synthetic fibres, artificial fibres and polymers with special properties

ActiveUS20080128941A1Narrow distributionSolve insufficient capacityFilament/thread formingArtifical filament manufacturePolymer scienceInorganic materials

A process for the additivation of synthetic fibres, artificial fibres and polymers conferring special properties to them, the process comprising the following steps: the encapsulation of an additive in the pores of a porous material; the incorporation of particles of the porous material (capsules) into the polymer matrix of the fibre; and spinning of the fibre; the capsule withstanding the temperatures and other conditions of the different manufacturing processes which the fibres might undergo and the introduction of the additive into the polymer matrix thereof, characterised in that the porous material is a metal oxide, a zeolite, an aluminophosphate, clay, a carbon material, a hybrid organic-inorganic material or a porous polymer. The invention is an improvement in the additivation process of fibres and polymers in terms of the nature of the capsules used, the increase in the storage capacity of additives thereof, the process of incorporating the capsules into the polymer matrix of the fibres and the fact that the present invention refers to an industrial process.

Owner:MINERA CATALANO ARAGONESA

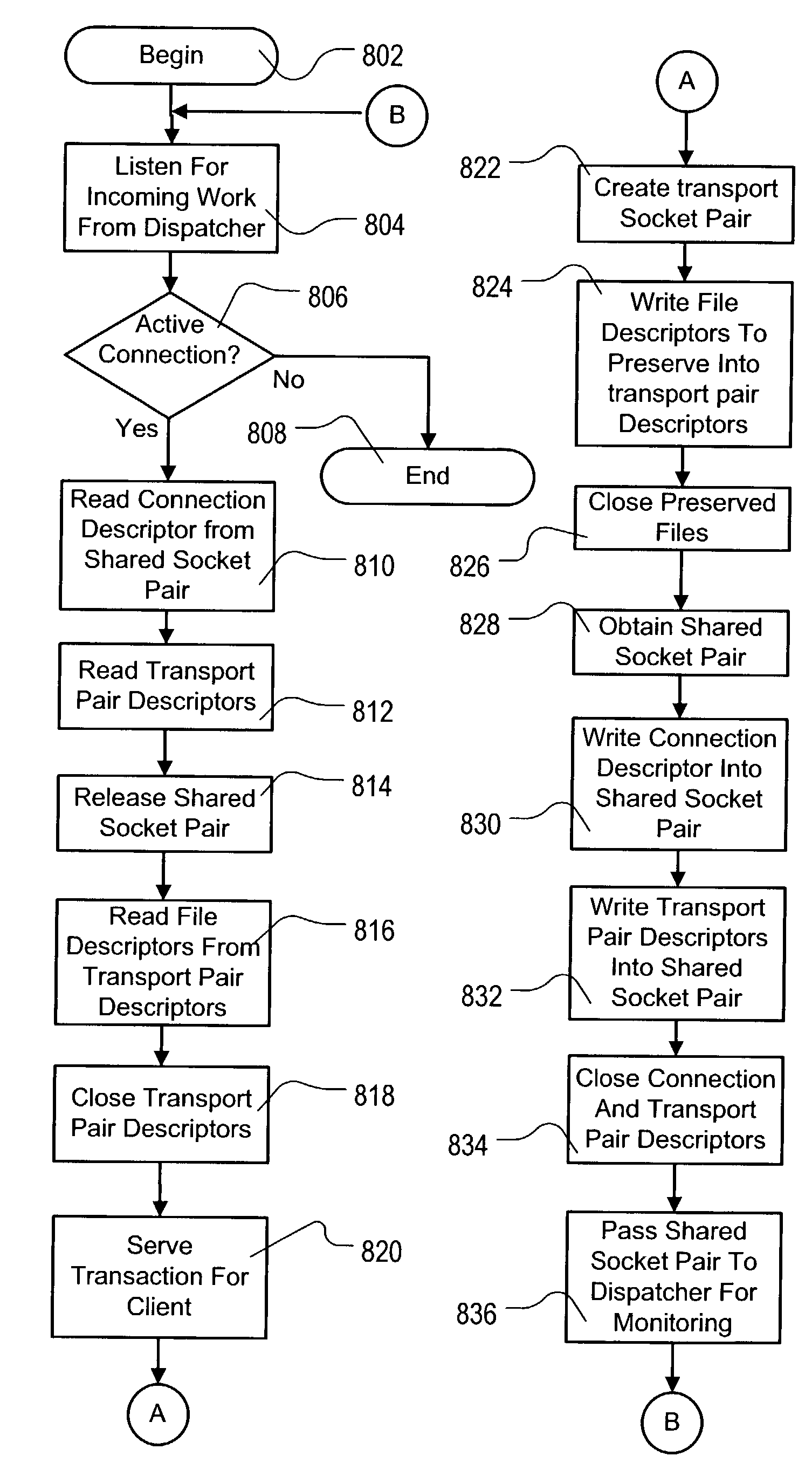

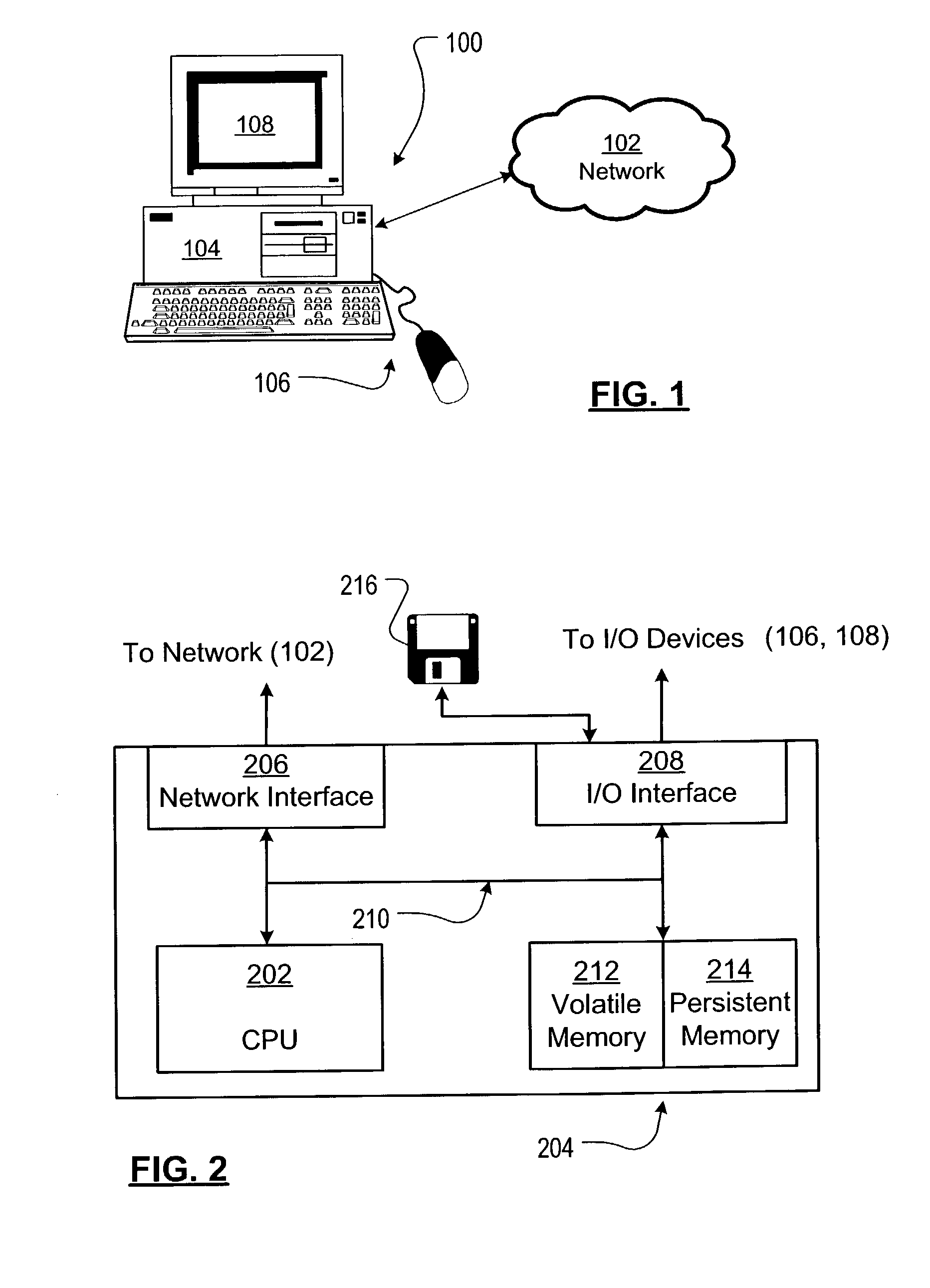

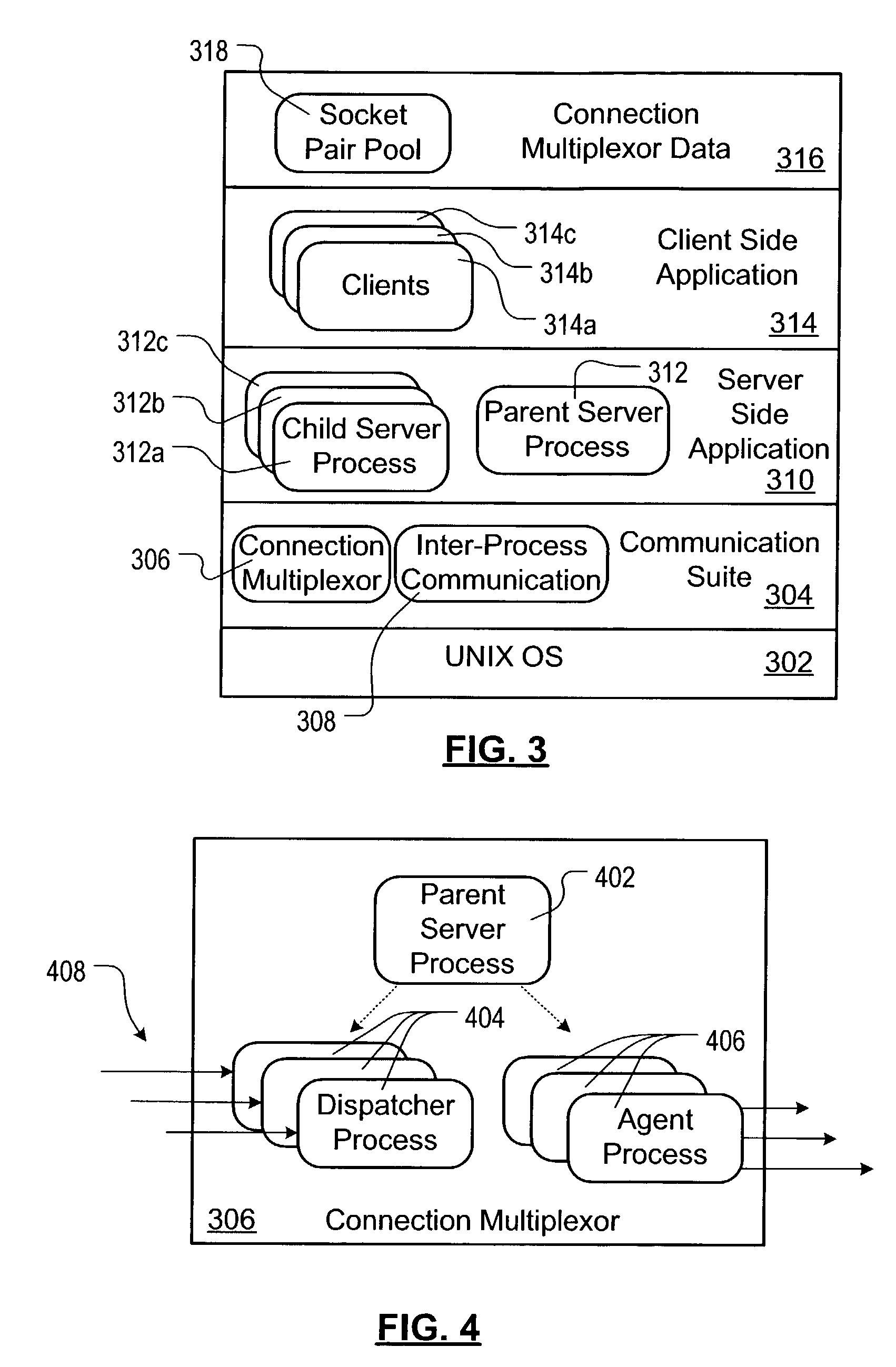

Method and system for optimizing file table usage

InactiveUS7373647B2Easy to useMultiprogramming arrangementsSpecific program execution arrangementsUnix domain socketOperational system

An operating system directed to using special properties of a common inter-process communications mechanism (IPC), namely UNIX domain socket-pairs or stream-pipes alternatively as a storage medium for file-descriptors of UNIX processes. When a file-descriptor is written into a socket-pair, and closed in the UNIX process, the file remains open, but occupies no space in the process' file-table. The file-descriptor may later be read out of the socket-pair to reestablish it in the file-table, and access it. This property is implemented in an IPC mechanism of UNIX operating system whereby a process such as a dispatcher may manage more connections and processes than its file-table size allow. This provides scalability improvements of the UNIX operating system.

Owner:IBM CORP

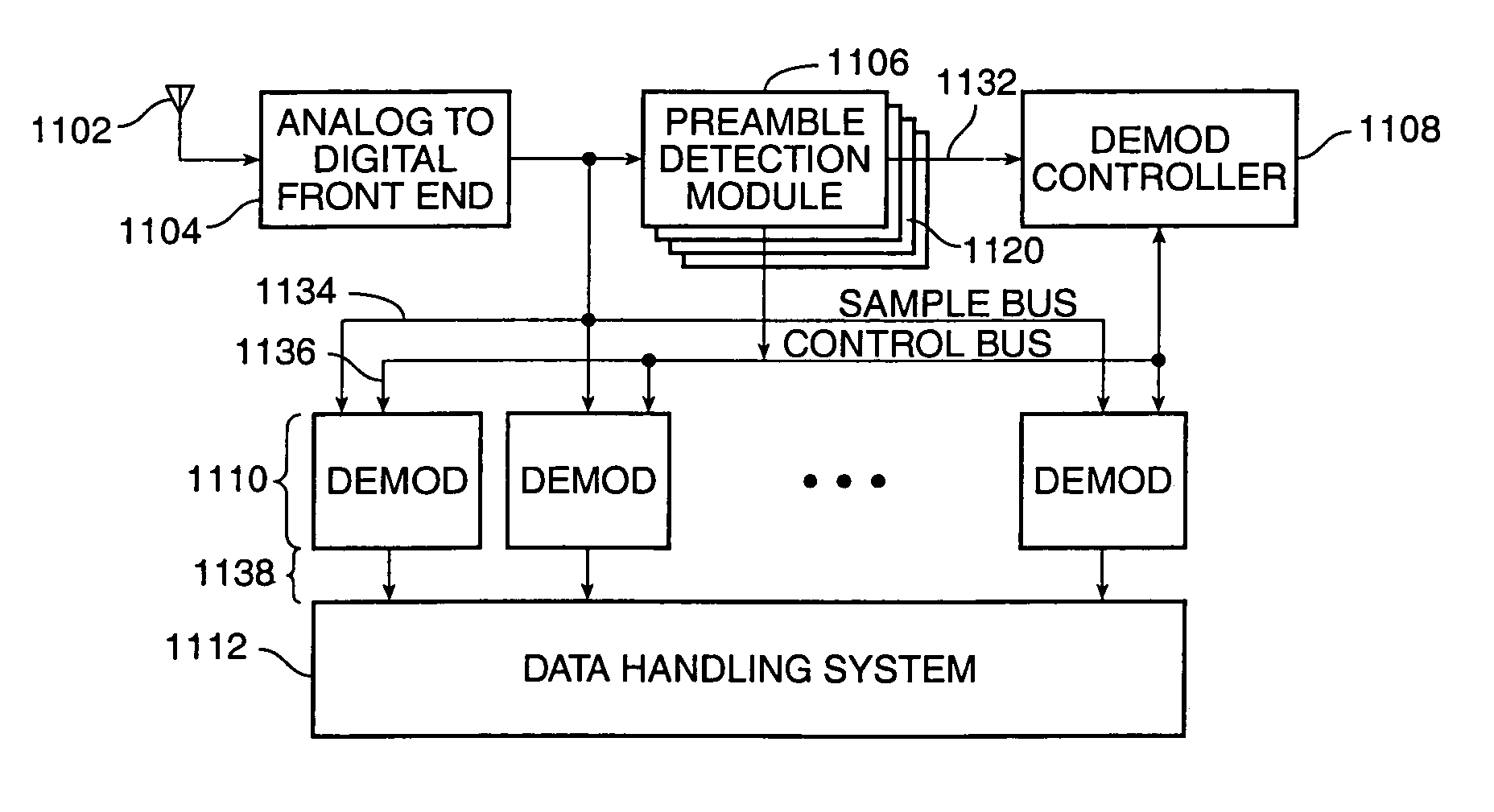

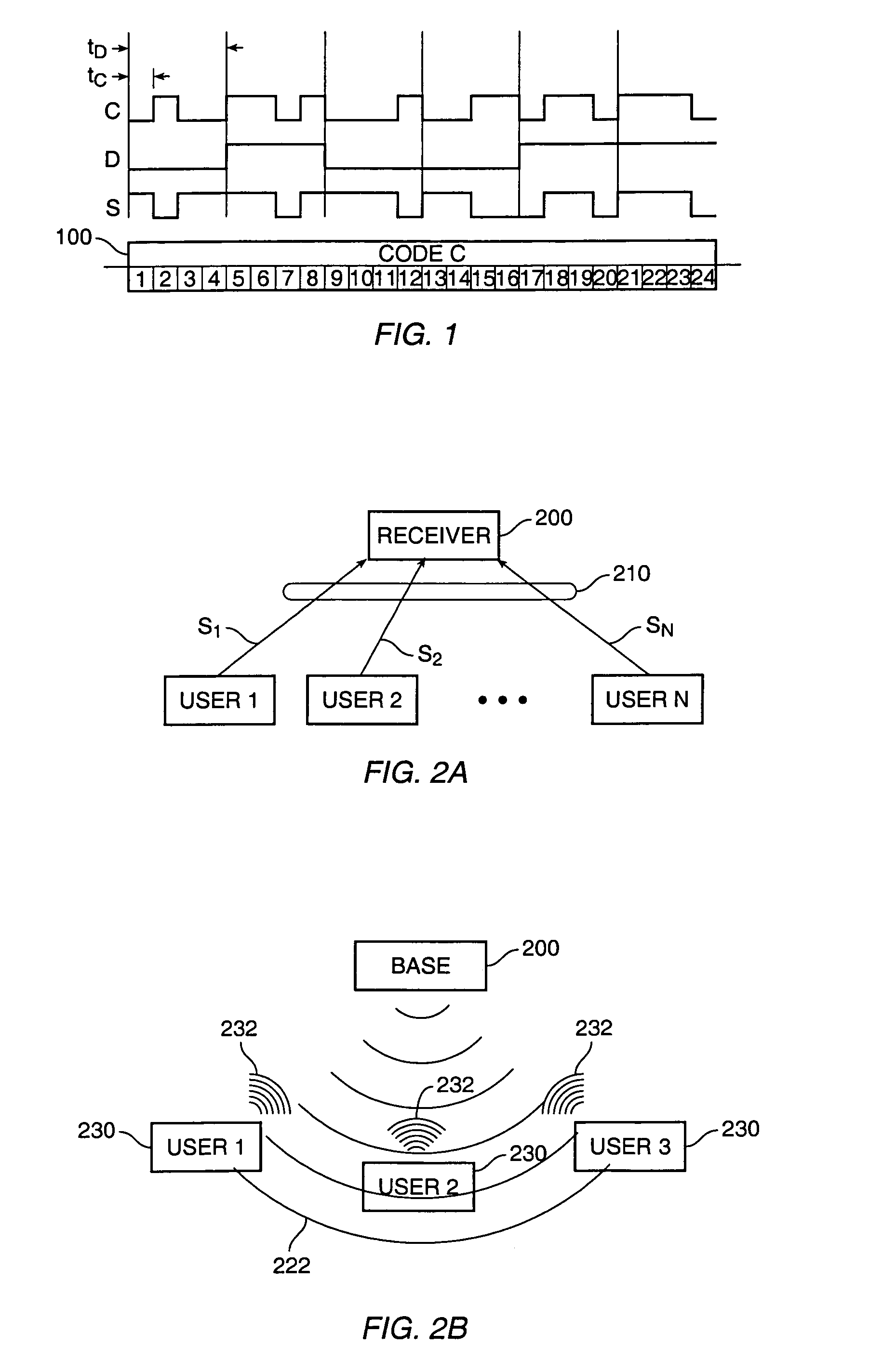

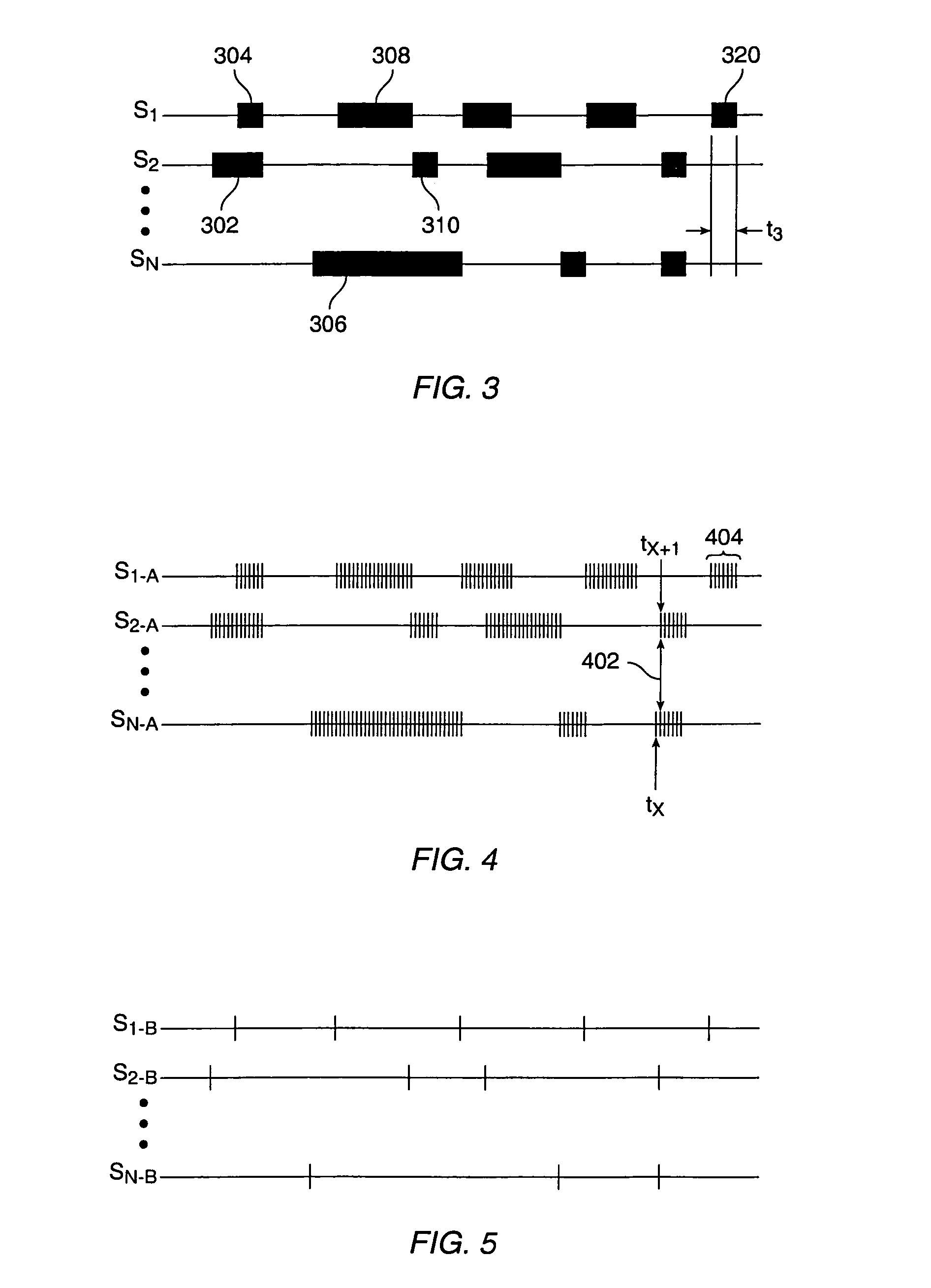

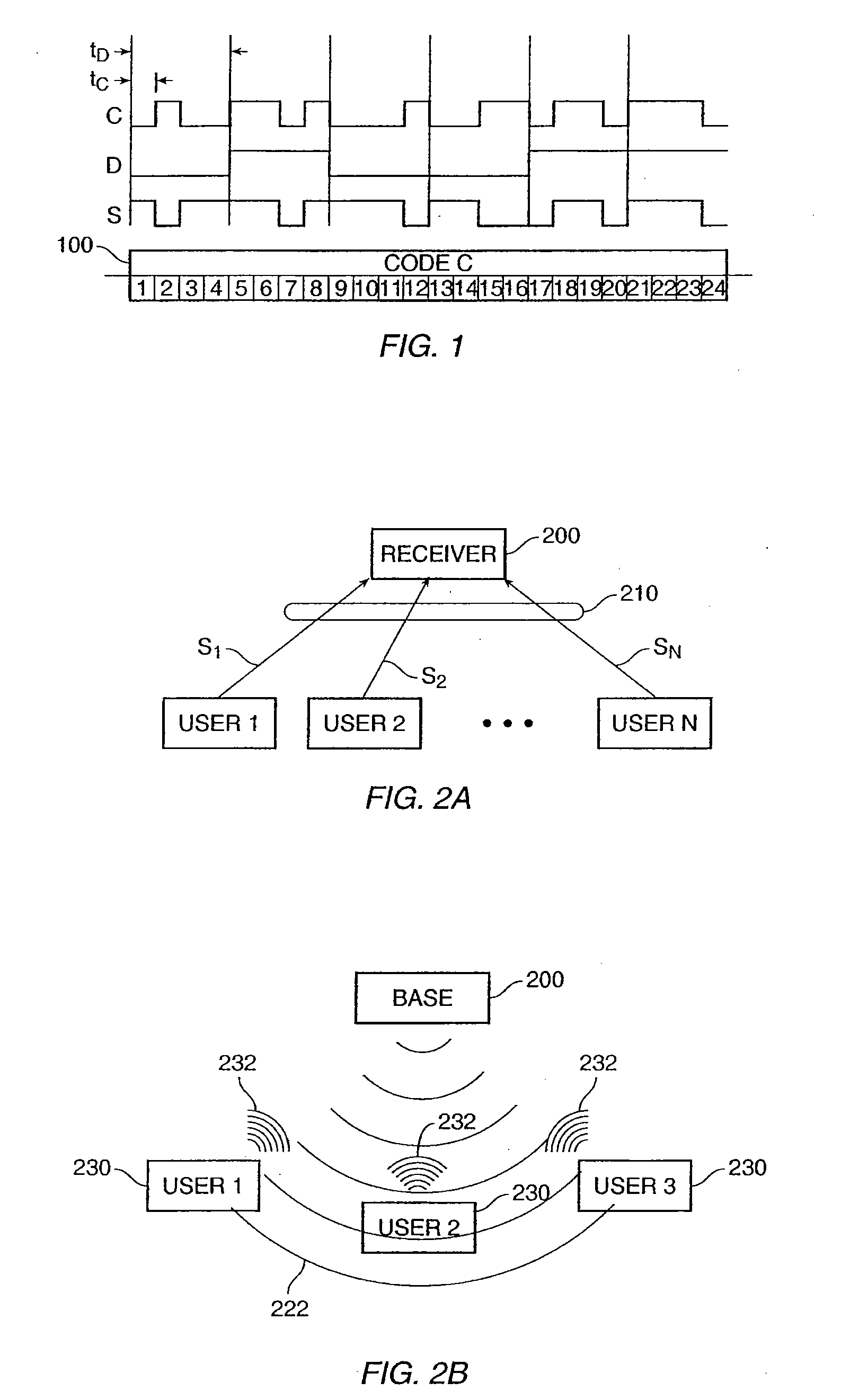

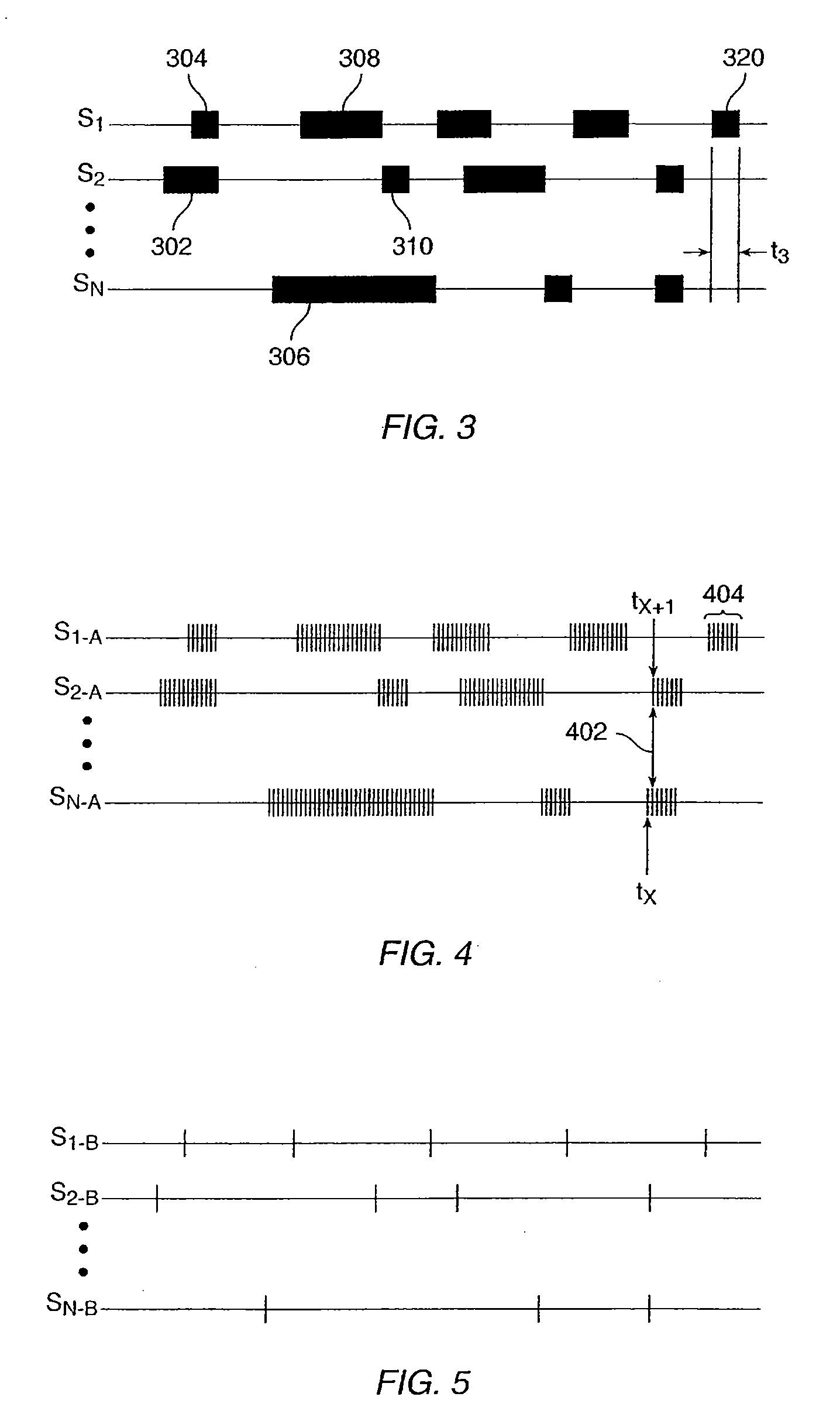

Method and apparatus for multiple access over a communication channel

InactiveUS7065125B1Improve performanceEfficiently receiving signalSynchronisation signal speed/phase controlRadio transmission for post communicationDirect-sequence spread spectrumMulti access

This invention is a multiple access communication technique by which a multitude of transmitters communicate with receivers using direct sequence spread spectrum signaling. The direct sequence codes are reused by a large number of simultaneous transmitters, so the system is named Code Reuse Multiple Access (“CRMA”). This reuse method requires only a small number of codes relative to the number of simultaneous transmitters, and can use as few as one code for all the users. The direct sequence codes are not required to have special properties such as maximal length. The lengths of the spreading codes employed are not necessarily related to the bit or symbol interval. CRMA can be implemented on a Paired Carrier Multiple Access (“PCMA”) system with or without a novel receiver structure which is also described.

Owner:VIASAT INC

Process for preparing a composite adsorption material capable of simultaneously absorbing heavy metal ions and volatile organic substances in waste gas

ActiveCN104437358AImprove adsorption capacityGood specific adsorption performanceOther chemical processesDispersed particle separationCarbon nanotubePhysical chemistry

The invention discloses a process for preparing a composite adsorption material capable of simultaneously absorbing heavy metal ions and volatile organic substances in waste gas. The process comprises the following steps: (1) pretreatment of carbon nanometer pipes; (2) preparation of calcium chloride; (3) loading of calcium chloride; and (4) preparation of composite adsorption material, namely obtaining of the graphene-calcium chloride-carbon nanometer pipe composite adsorption material. According to the process for preparing the composite adsorption material capable of simultaneously absorbing heavy metal ions and volatile organic substances in waste gas, the high-adsorption-capacity composite adsorption material capable of simultaneously absorbing heavy metal ions and volatile organic substances in waste gas, which has the characteristics of nanometer structure, stable properties, large specific surface area and special property of adsorbing heavy metals by calcium chloride, is obtained, can be used for treatment of waste gas with high toxicity, low concentration and high fluidity, and has the advantages of short adsorption time and high adsorption efficiency.

Owner:深圳市富可森环保科技股份有限公司

Medicinal sustained-release and hemostatic composition and preparation method thereof

InactiveCN101837143ARelease stabilityRapid hemostasisAbsorbent padsBandagesSocial benefitsHemostatic function

The invention discloses a medicinal sustained-release and hemostatic composition and a preparation method thereof, which belong to the technical field of novel hemostatic materials. The medicinal sustained-release and hemostatic composition comprises the composition of a medicament-loaded chitosan microsphere, chitosan and hyaluronic acid, wherein the medicament-loaded chitosan microsphere comprises medicinal grade chitosan and medicinal grade tranexamic acid. The novel hemostatic composition is prepared by using chitosan and the hyaluronic acid as a main hemostatic matrix, combining chitosan medicament sustained-release microsphere composite medicament, namely tranexamic acid, utilizing the special property of the chitosan with a hemostatic function and a medicament sustained-release function, and adopting the composition of the hyaluronic acid with good hemostatic function and high biocompatibility and the chitosan as the main matrix. The novel hemostatic composition has the advantages of stopping bleeding rapidly and releasing medicament / factors continuously and stably in a certain time, along with great economic and social benefits.

Owner:北京博恩康生物科技有限公司

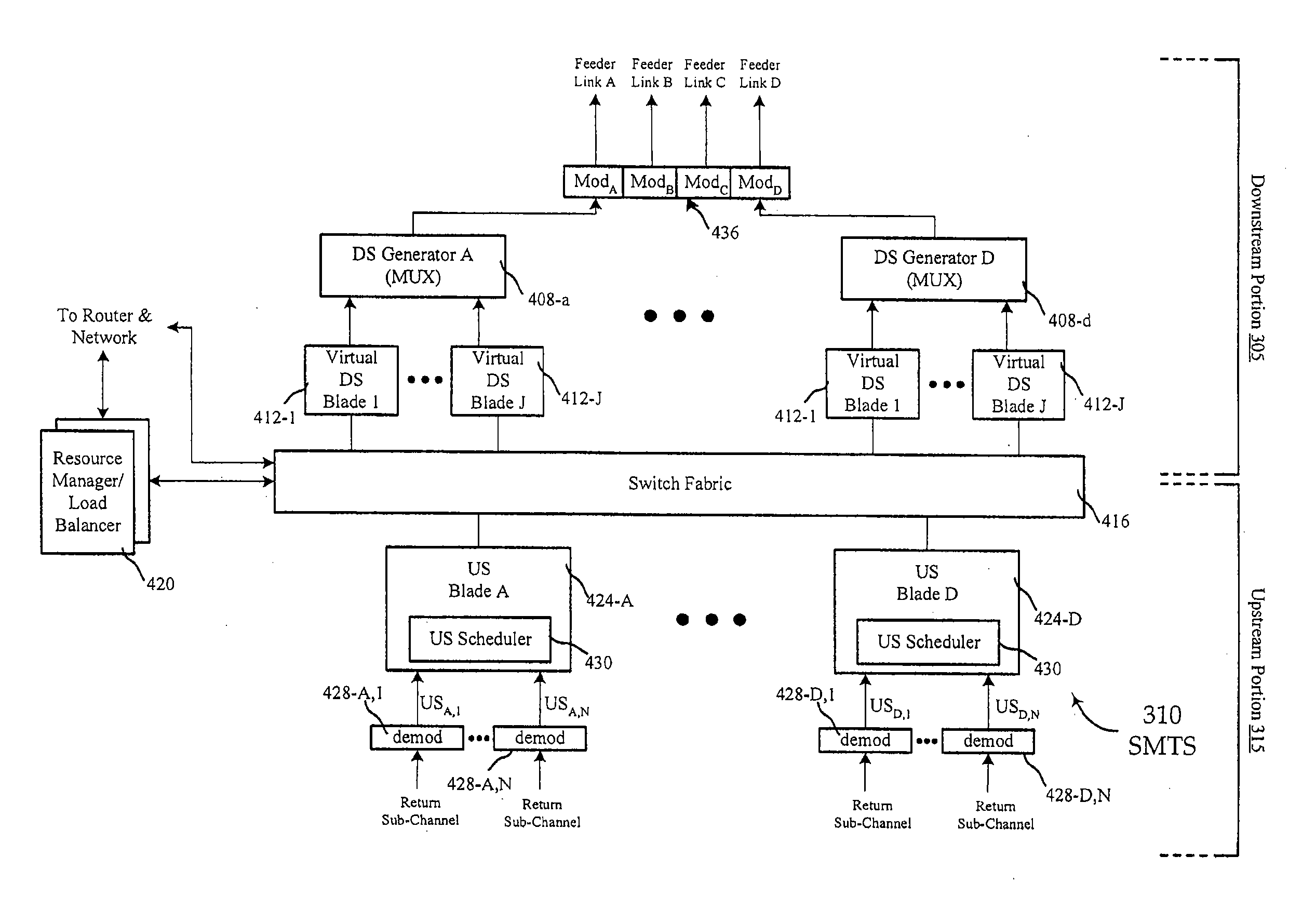

Code Reuse Multiple Access For Satellite Return Link

InactiveUS20070127553A1Improve performanceEfficient processingOrthogonal multiplexTransmissionDirect-sequence spread spectrumComputer science

This invention is a multiple access communication technique by which a multitude of transmitters communicate with receivers using direct sequence spread spectrum signaling. The direct sequence codes are reused by a large number of simultaneous transmitters, so the system is named Code Reuse Multiple Access (“CRMA”). This reuse method requires only a small number of codes relative to the number of simultaneous transmitters, and can use as few as one code for all the users. The direct sequence codes are not required to have special properties such as maximal length. The lengths of the spreading codes employed are not necessarily related to the bit or symbol interval. CRMA can be implemented on a Paired Carrier Multiple Access (“PCMA”) system with or without a novel receiver structure which is also described. In an environment having virtual channels, a clock is derived from the received signal in the uplink by sampling the signal to detect symbol edges.

Owner:VIASAT INC

System and method for recovering image detail from multiple image frames in real-time

InactiveUS8150163B2Guaranteed uptimeEfficient subpixel-accurate search algorithmImage enhancementGeometric image transformationImage resolutionMultiple frame

This invention describes an efficient super-resolution method for image enhancement that leverages prior knowledge about the specific task for which detail information is recovered. The particular case of barcode scanning is considered. The barcode localization and decoding algorithm of the present invention employs a subpixel-accurate search algorithm which allows for estimating barcode bit values at a higher resolution than that available in the image data itself. It thus allows for the synthesis of image detail from multiple frames with the result containing more detail than any of the input frames. For efficiency, it leverages special properties of the quadrilateral target object as well as prior knowledge about constant patterns in the barcodes of interest. This allows for real-time software implementations on portable devices such as camera-equipped cell phones where super-resolution helps to overcome some of the typical camera resolution and processing power constraints.

Owner:SCANBUY

Method for preparing composite board by waste thermosetting foamed plastics

The invention provides a method for preparing a composite board by waste thermosetting foamed plastics, which prepares the composite board through preheating, hot press molding, low-temperature forming and physical change and phase change among materials under high temperature without adhesive, has no solvent and formaldehyde and is safe and environmental-friendly. The composite board can replace a high-density board, has good processing and using property, and special properties, i.e. water resistance, inflaming retarding, corrosion resistance, and the like, which is incomparable from common boards and extensive application prospect.

Owner:TIANJIN UNIV

Carbon dioxide-anti-drag water compound fracturing method

InactiveCN105888641ALow flow resistanceInhibit swellingFluid removalDrilling compositionCompound fracturesFracturing fluid

The invention provides a carbon dioxide-anti-drag water compound fracturing method which comprises the following steps of: injecting liquid carbon dioxide fracturing fluid into a stratum; after a period of time, stopping injecting the liquid carbon dioxide fracturing fluid, and then injecting anti-drag water fracturing fluid not added with a propping agent; and after a period of time, stopping injecting the anti-drag water fracturing fluid not added with the propping agent, then injecting anti-drag water compound fracturing fluid carrying the propping agent, and stopping after a period of time. According to the method, different system fracturing fluids are adopted in different injection phases, and special properties of different fracturing fluids are reasonably utilized, so that the effect of enlarging crack network scale, communicating stratum primary fractures, enhancing fracture efficiency, improving the seepage environment of the stratum and improving the reservoir yield; a carbon dioxide-anti-drag water compound fracturing process is applied to a low percolation oil and gas reservoir, so that the per-well yield can be improved, and the problem that traditional fracturing process for low percolation oil and gas reservoirs is poor in productivity improvement effect.

Owner:BEIJING NIUHE RUICHEN ENERGY TECH CO LTD

Method for hot rolling of large-opening-diameter titanium and titanium alloy thin-wall seamless pipe through jacket core bar

ActiveCN107052076AReduce manufacturing costQuality improvementMetal rolling arrangementsTitanium alloyMechanical property

The invention discloses a method for hot rolling of a large-opening-diameter titanium and titanium alloy thin-wall seamless pipe through a jacket core bar. According to the method, a vacuum self-consuming arc furnace is used for secondary smelting to form a casting ingot; the casting ingot is subject to two-heating-number forging to form the bar; scaling machining is carried out; three-roller (or two-roller) skew rolling punching is used for making a seamless pipe blank; for pipe materials with the special property needs, the pipe blank subject to sand blasting, acid pickling, polishing and grinding and the like is subject to further cold rolling and other deep machining, a finished product pipe with the more excellent property is obtained, the pipe is subject to acid pickling treatment, and the large-opening-diameter thin-wall seamless pipe is obtained; finally, the finished product pipe is subject to vacuum annealing treatment and polishing fixed-size packaging. The large-opening-diameter thin-wall titanium and alloy seamless pipe manufactured through the method is excellent in mechanical property, the method is mainly used for fields of pressure containers, industrial pipelines, condensers, well drilling parts and the like in the industries of petroleum, chemical engineering, ocean and the like, and the needs of the anti-corrosion pipe can be met.

Owner:安徽宝泰特种材料有限公司

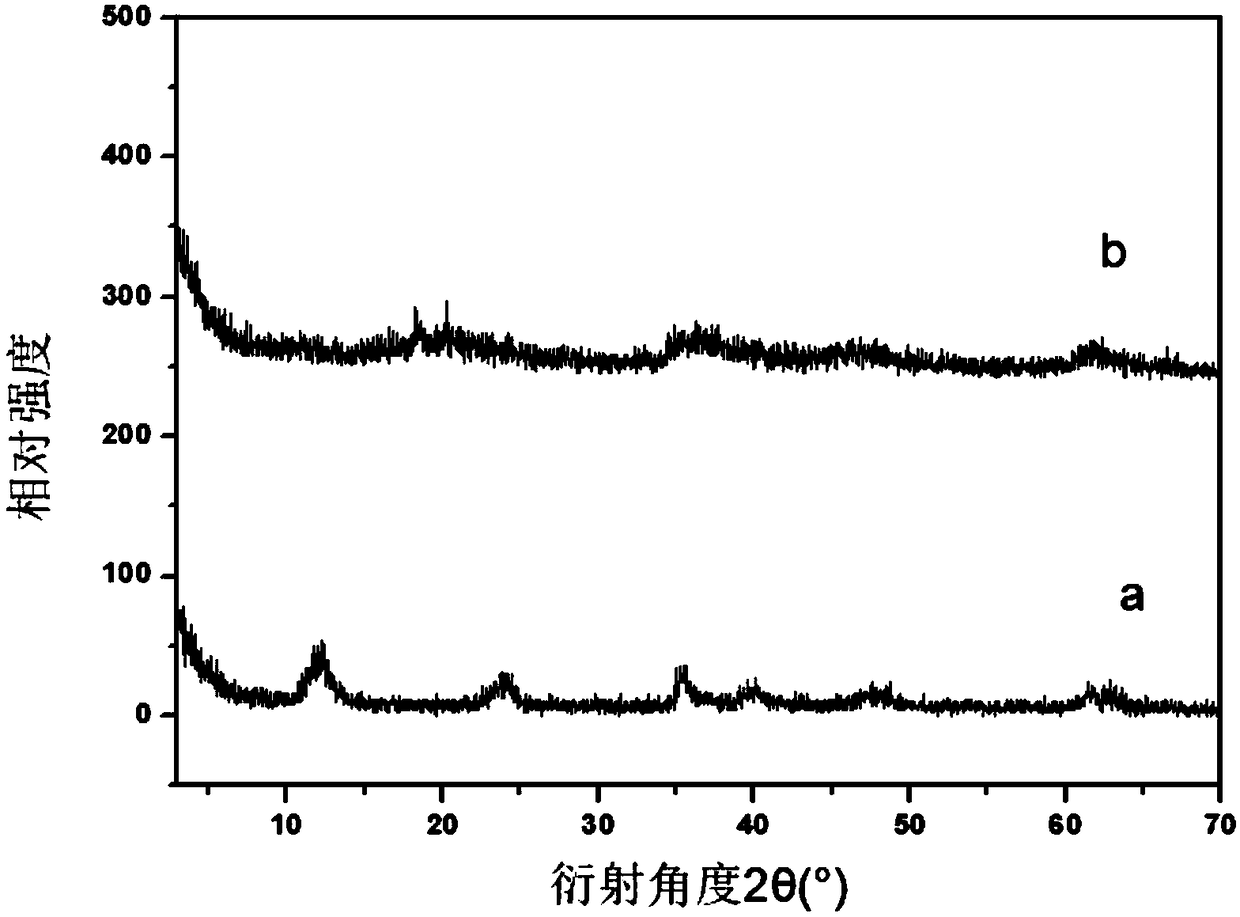

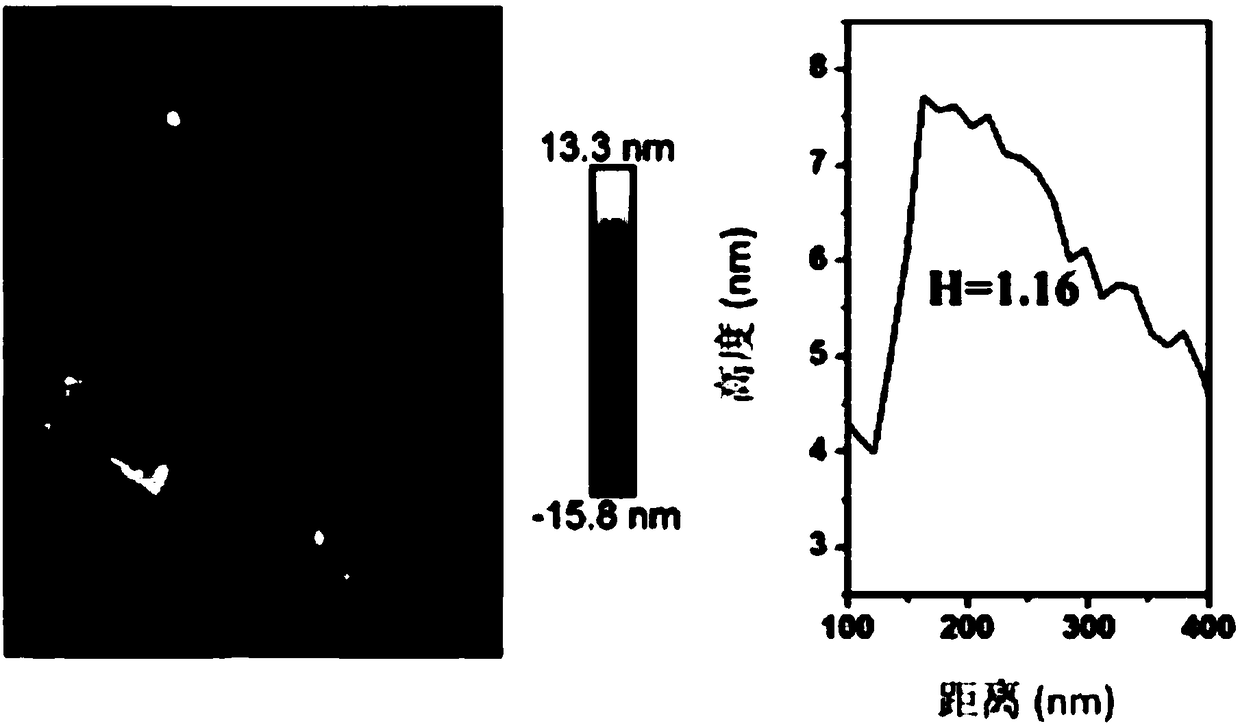

Ultrathin Ti-based LDHs composite photocatalyst for photoreduction of CO2 and preparation method thereof

ActiveCN108554439ABroaden the photoresponse rangeImprove stabilityMaterial nanotechnologyGas treatmentLight excitationBULK ACTIVE INGREDIENT

The invention provides an ultrathin Ti-based LDHs composite photocatalyst for photoreduction of CO2 and a preparation method thereof. The method in the invention comprises the following steps: introducing Ti element with photoactivity into an LDHs laminate, peeling to obtain an ultrathin Ti-based LDHs nano-chip of which the active ingredient Ti is highly dispersed and the accessibility is enhanced, and compounding with a carrier with special property, thereby realizing response of the catalyst in a visible range. The catalyst is represented as U-TiM1M2 / LDHs / S, wherein U-TiM1M2 / LDHs is the ultrathin Ti-based LDHs nano-chip and has an average thickness of 1-2nm, and S is a carrier with visible light absorption ability. The catalyst has visible light responsiveness, and has high activity andstability in a photocatalytic reduction CO2 system. The composite catalyst has excellent catalytic activity in the photocatalytic reduction CO2 system under visible light excitation, has catalytic performance close to that of a supported noble metal catalyst, and provides a novel pathway for preparation of low-cost high-efficiency photocatalysts.

Owner:BEIJING UNIV OF CHEM TECH

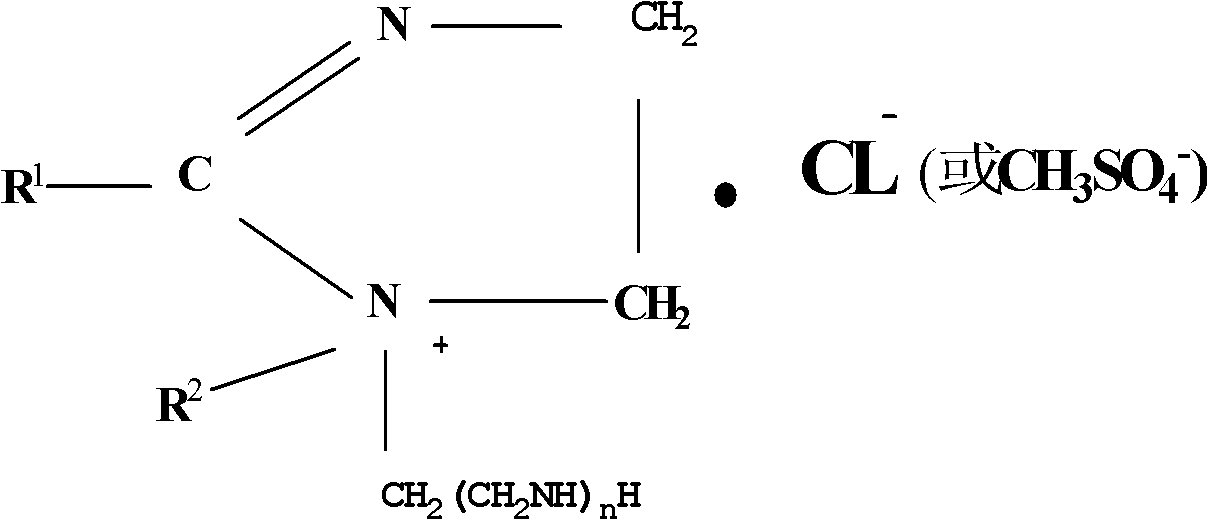

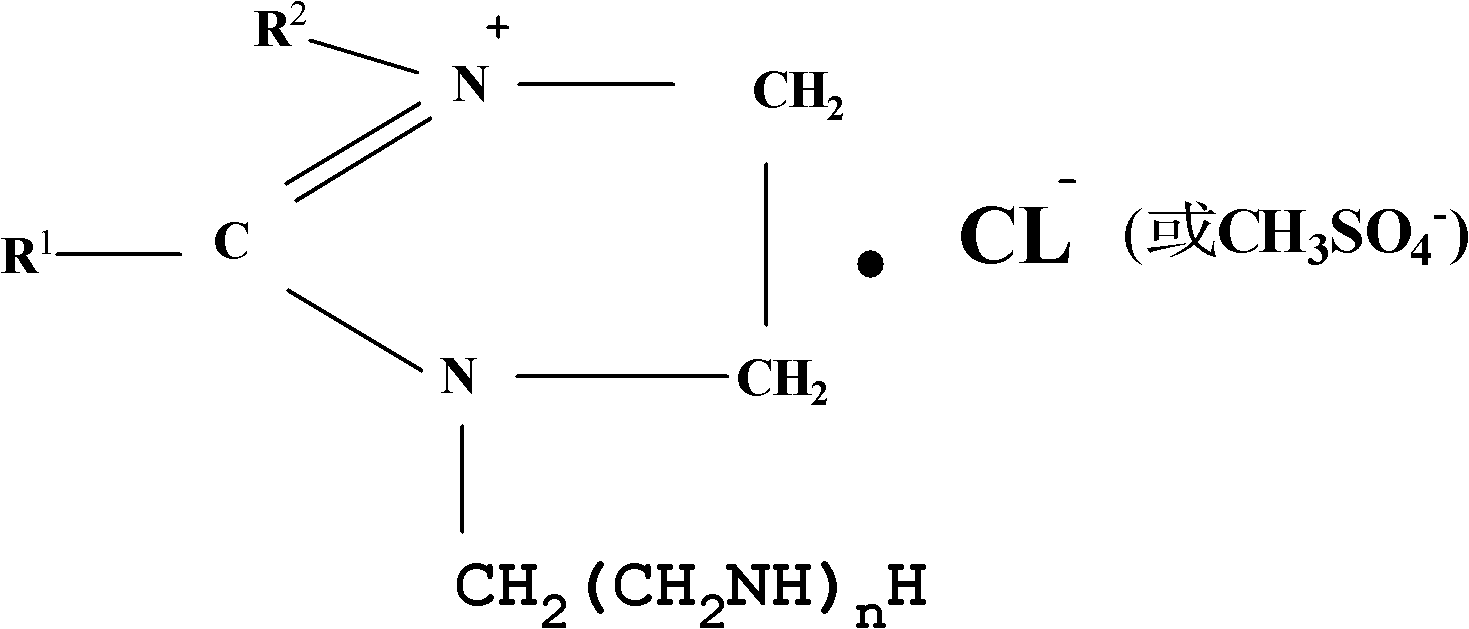

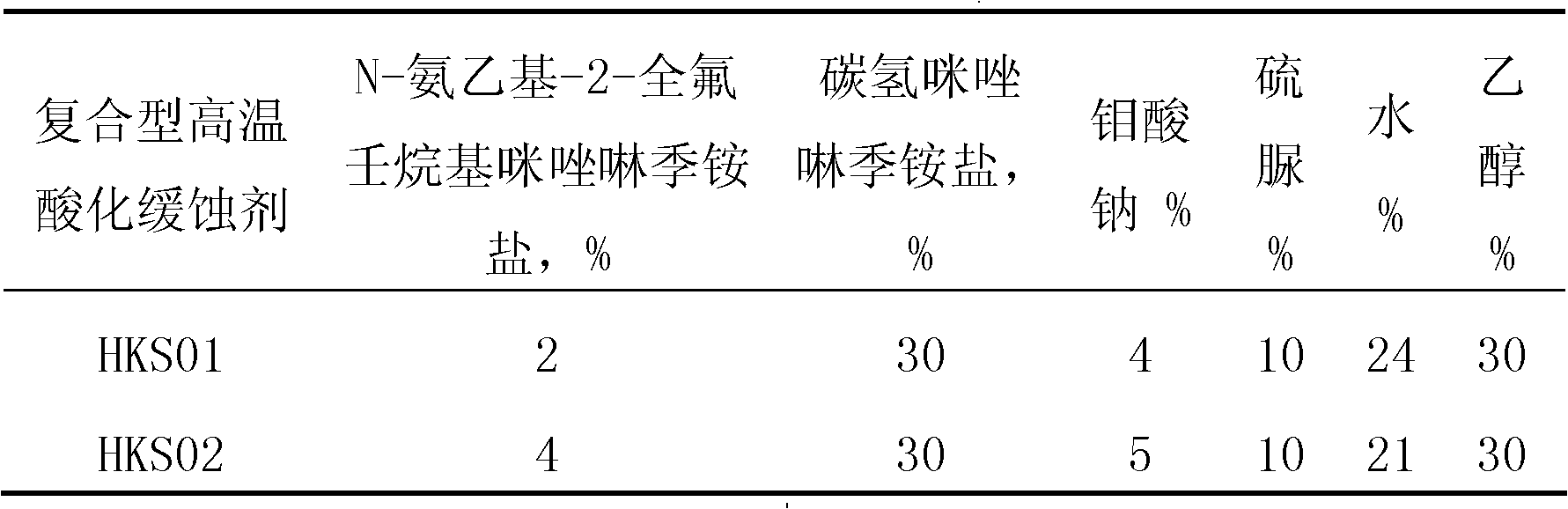

High-temperature acidification corrosion inhibitor and preparation method thereof

ActiveCN102071005AEfficient corrosion inhibitionWide range of high temperature resistanceDrilling compositionSolubilityThiourea

The invention relates to a high-temperature acidification corrosion inhibitor and a preparation method thereof. The high-temperature acidification corrosion inhibitor is prepared from the following components in parts by weight: 1-5 parts of N-alkylamino-2-perfluoroalkyl imidazoline quaternary ammonium salt, 30-50 parts of hydrocarbon imidazoline quaternary ammonium salt, 0-5 parts of sodium molybdate, 5-15 parts of thiocarbamide, 20-30 parts of ethanol and 10-20 parts of water. The preparation method comprises the following steps: adding the raw materials into a reaction kettle in turn, and stirring at 20-80 DEG C for 10-30 minutes to obtain the high-temperature acidification corrosion inhibitor. As the high-temperature acidification corrosion inhibitor contains the N-alkylamino-2-perfluoroalkyl imidazoline quaternary ammonium salt with special properties, compared with the conventional acidification corrosion inhibitor, the high-temperature acidification corrosion inhibitor providedby the invention has the advantages of low addition amount, good water solubility, strong temperature resistance, high corrosion inhibition rate and the like. When being used under acidification conditions at 150-200 DEG C, the high-temperature acidification corrosion inhibitor still has good corrosion inhibition effect and compatibility. The invention has the advantages of high corrosion-inhibition efficiency, low toxicity, environmental protection, high temperature resistance, wide application systems and the like, and can be used as the component of a high-temperature acidification liquid corrosion inhibitor.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

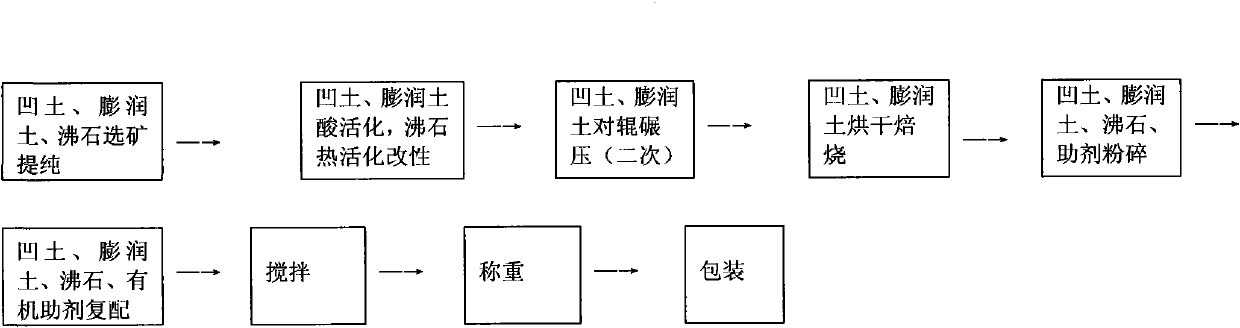

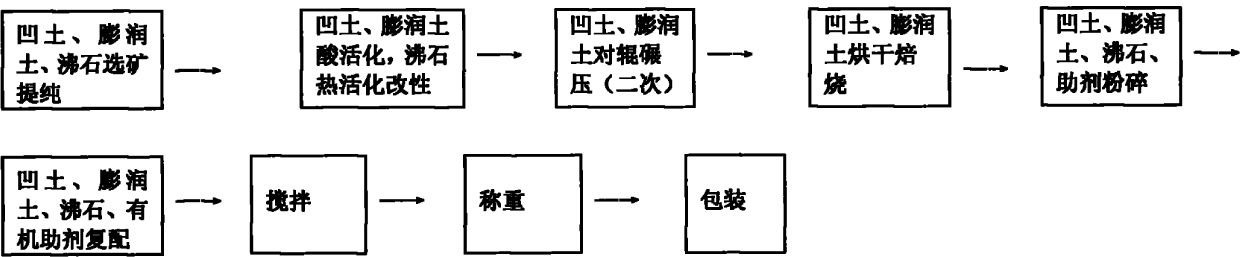

Composite efficient cyanobacteria-eutrophication water treatment agent

InactiveCN102371145AFatty/oily/floating substances removal devicesOther chemical processesSites treatmentSodium Bentonite

The invention relates to an attapulgite clay composite cyanobacteria-eutrophication water treatment agent, which is a special sewage treatment agent in the fields of environmental protection and environmental treatment. According to the present invention, attapulgite clay, bentonite and natural zeolite are subjected to activation and modification and other high-tech deep processing, and are scientifically compounded with organic reagents to prepare the attapulgite clay composite cyanobacteria-eutrophication water treatment agent, which centralizes special properties of a plurality of minerals and organic additives; the treatment agent is mainly used for cyanobacteria outbreak emergency treatments of lakes, reservoirs, rivers, landscape water and the like, and eutrophication long-term treatments; the treatment agent is an innovative method for ecological restoration and resource; the treatment agent further can be used for heavy metal contaminated water treatments, wherein the heavy metals comprise arsenic, lead and the like; the treatment agent is adopted in the cyanobacteria outbreak in Tai lake of Jiangsu, Chao lake of Anhui and the like, cyanobacteria-eutrophication water multiple sampling and field treatment tests, the results show that: the treatment agent has characteristics of good treatment effect, convenient operation and low cost; the treatment agent can be adopted as the emergency agent and the long-term agent, and can treat both manifestation and root cause; the pumped sludge can be adopted as high-quality green fertilizer, such that the waste is changed into wealth so as to realize the ecological restoration and the resource recycling economy.

Owner:周济元 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com