Patents

Literature

1117 results about "Elastic plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

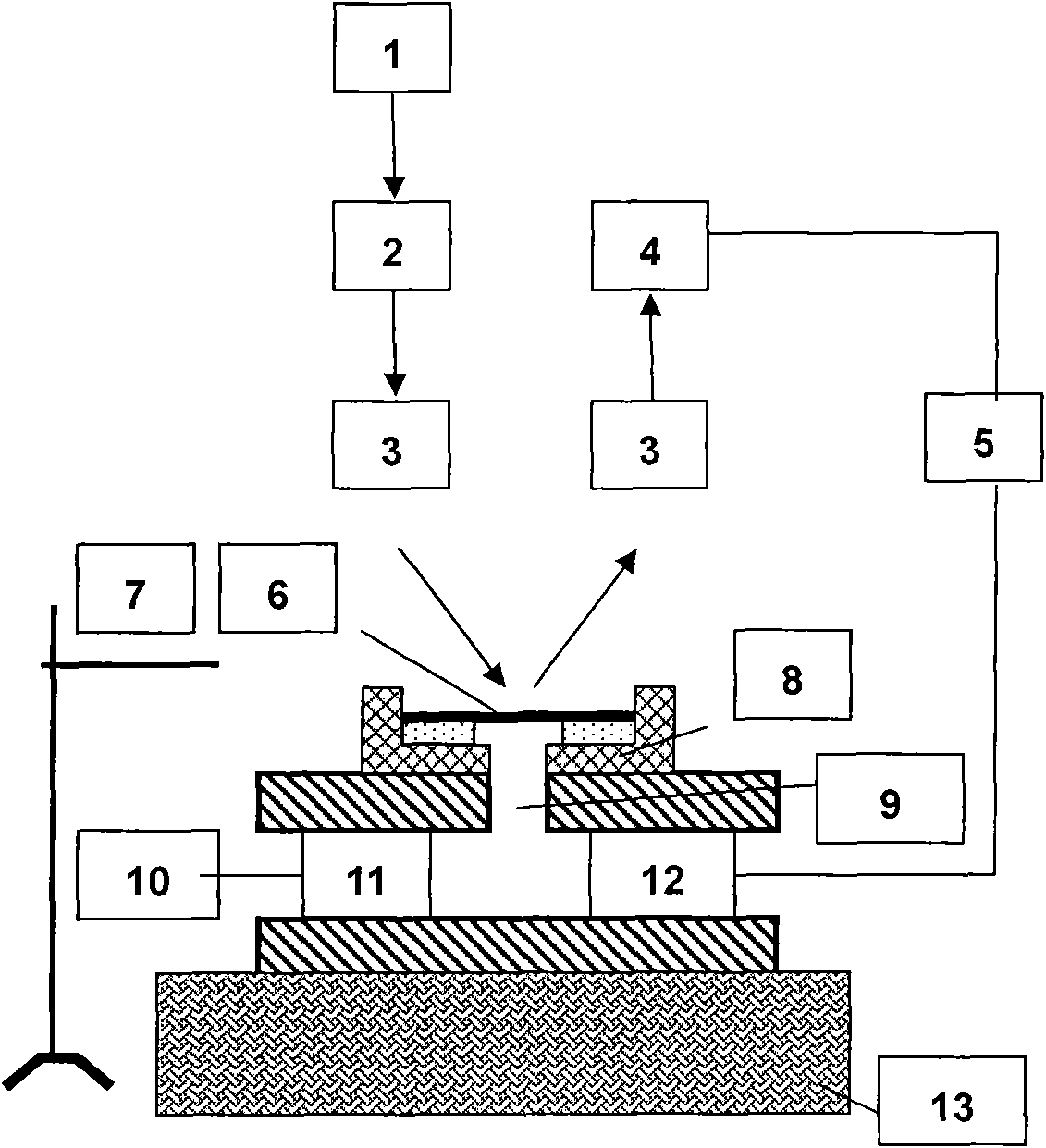

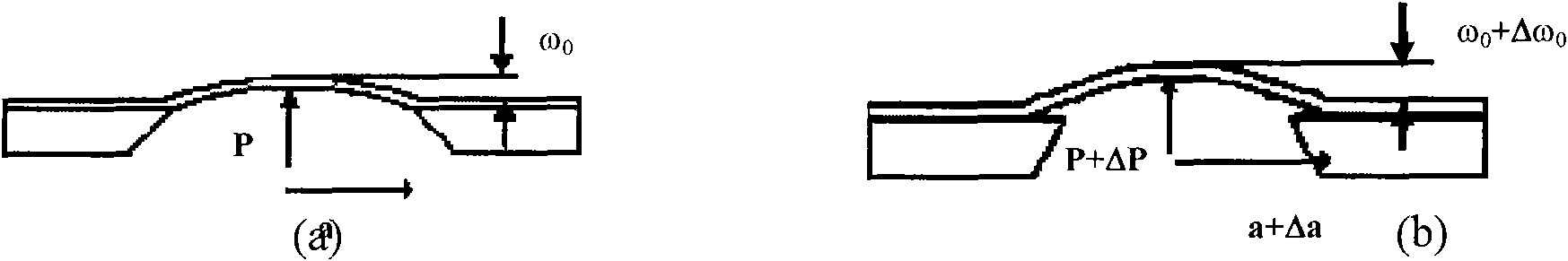

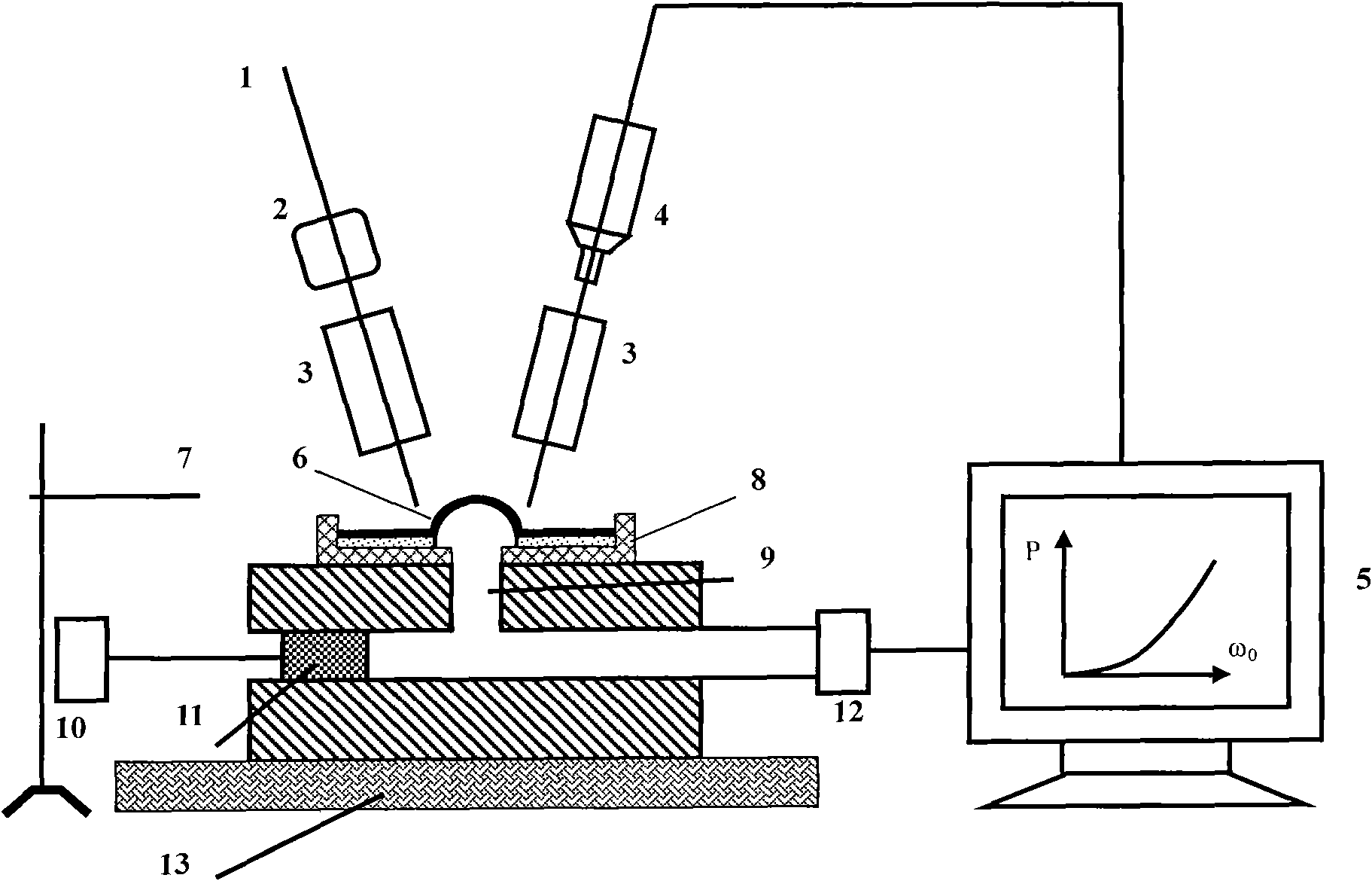

Device for detecting mechanical property of multifunctional film

ActiveCN101788427AHigh measurement accuracyMeasuring field of view can be adjustedMaterial strength using tensile/compressive forcesUsing optical meansElastic plasticSpeckle correlation

The invention discloses a device for detecting the mechanical property of a multifunctional film, comprising a sample stage, a loading mechanism for applying pressure on a film sample, a measuring mechanism for detecting the pressure applied on the film sample and deformation and a computer. The invention uses a digital speckle correlation method (DSCM) to measure film deformation, and combines two mechanical test methods of a bubbling method and a modified layer removal method, thus conveniently, rapidly and accurately measuring a pressure-deformation curve or a corrosion thickness-deformation curve; and mechanical properties of a film and a coating are extracted in terms of a corresponding theoretical model, thus being suitable for detecting the mechanical properties of tool films, decorative films, polymeric films and films of other types in various elastic-plastic systems.

Owner:XIANGTAN UNIV

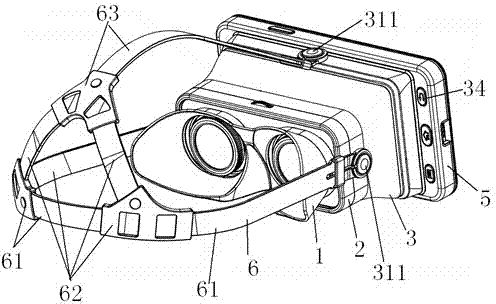

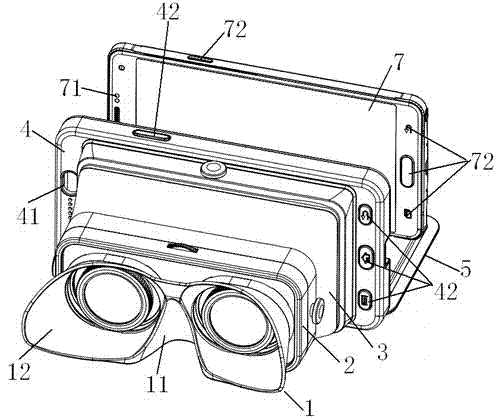

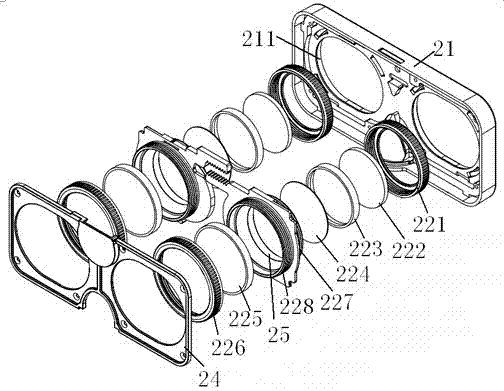

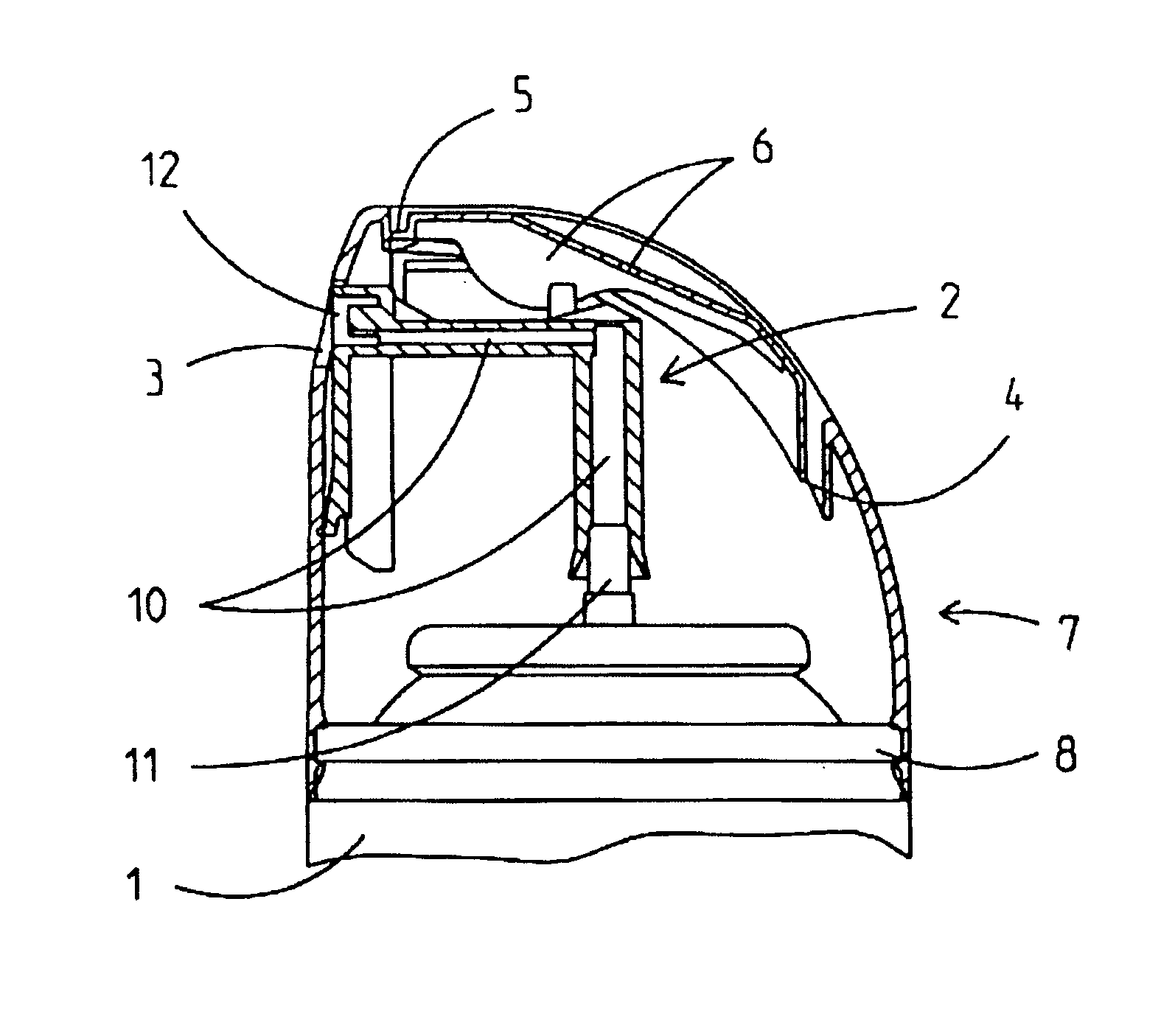

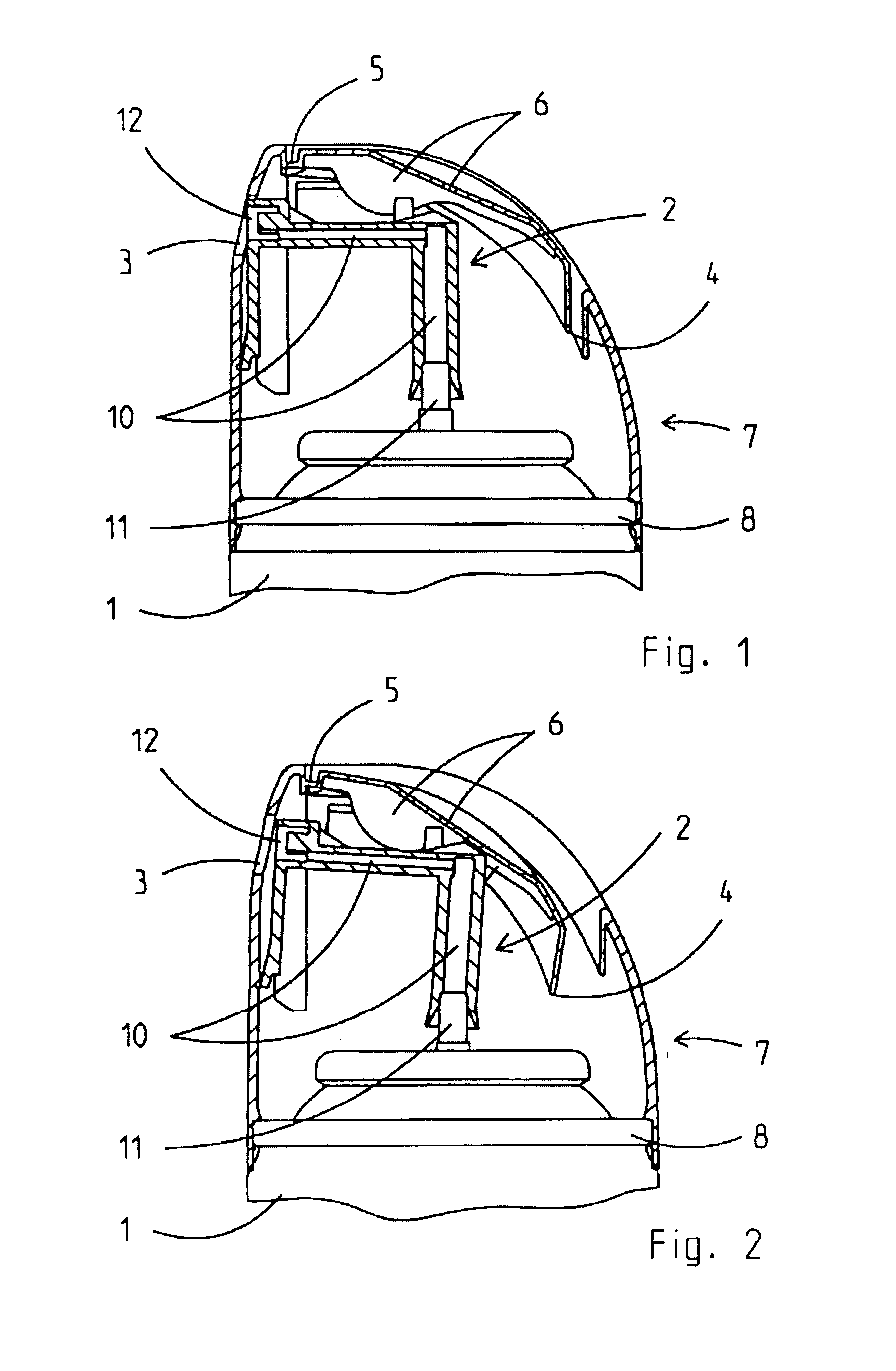

Virtual reality glasses

InactiveCN104849864AEasy to store and carryEasy to adjust and wearInput/output for user-computer interactionGraph readingUses eyeglassesEyepiece

The invention discloses a pair of virtual reality glasses comprising a glasses body and a head band. The glasses body comprises an eyeshade, an optical amplification eyepiece system connected with the eyeshade, a foldable connecting sleeve, a terminal placing box used for accommodating a terminal, and a rear cover connected with the terminal placing box. The foldable connecting sleeve is made of flexible and elastic plastic cement. The optical amplification eyepiece system is provided with an eye disease eyeglass installation part. The terminal placing box is provided with a gesture sensing window which corresponds to a gesture sensor of a display terminal in position. The head band includes a right side band arranged at the right end of the glasses body, a left side band arranged at the left end of the glasses body, and an upper top band arranged at the upper end of the glasses body. The pair of virtual reality glasses is easy to store and carry and convenient to wear and adjust. The pressure of the virtual reality glasses on the head is reduced, operation control on the display terminal of the virtual reality glasses can be performed with gestures and buttons, and patients with eye diseases can view a full and clear virtual reality picture with eyes just like normal people.

Owner:FOSHAN U TEK ELECTRONICS SCI & TECH CO LTD

Adjustable audio headphone

Provided is an adjustable audio headphone, including a headphone body, a damping object and a pressing mechanism. The headphone body includes a headphone shell, which forms a sound cavity in inside thereof and a receiving chamber on one end thereof. A bottom surface of the receiving chamber forms a through hole communicated with the sound cavity. The damping object is made of compressible material such as sponge, elastic plastic, textile and so on and. The damping object is placed into the receiving chamber of the headphone shell. The pressing mechanism is mounted on the headphone shell and is capable of pressing the damping object. The adjustable audio headphone of the present invention can compress the damping object to change the density of the damping object by employing the pressing mechanism, thereby varying the pressure of the sound cavity and realizing the object of adjusting the audio thereof.

Owner:CHENG UEI PRECISION IND CO LTD

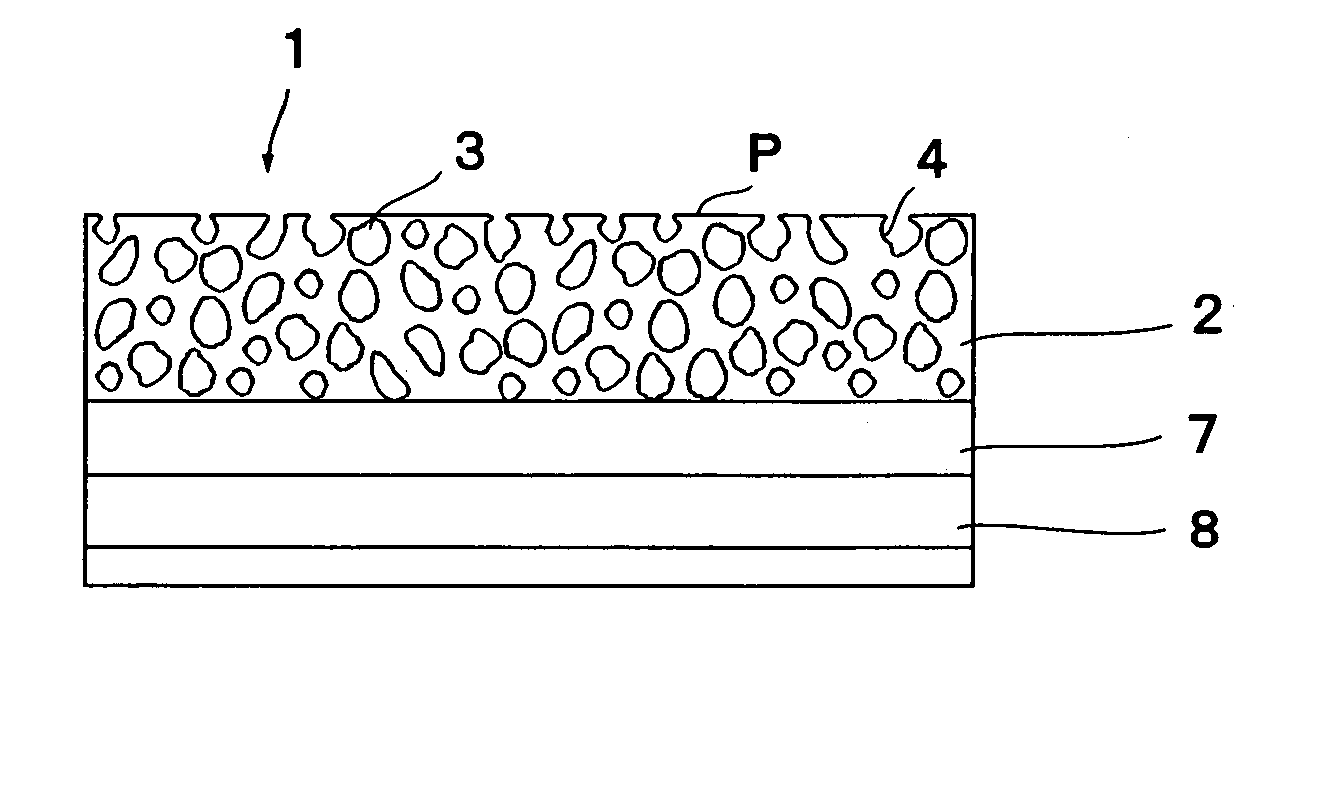

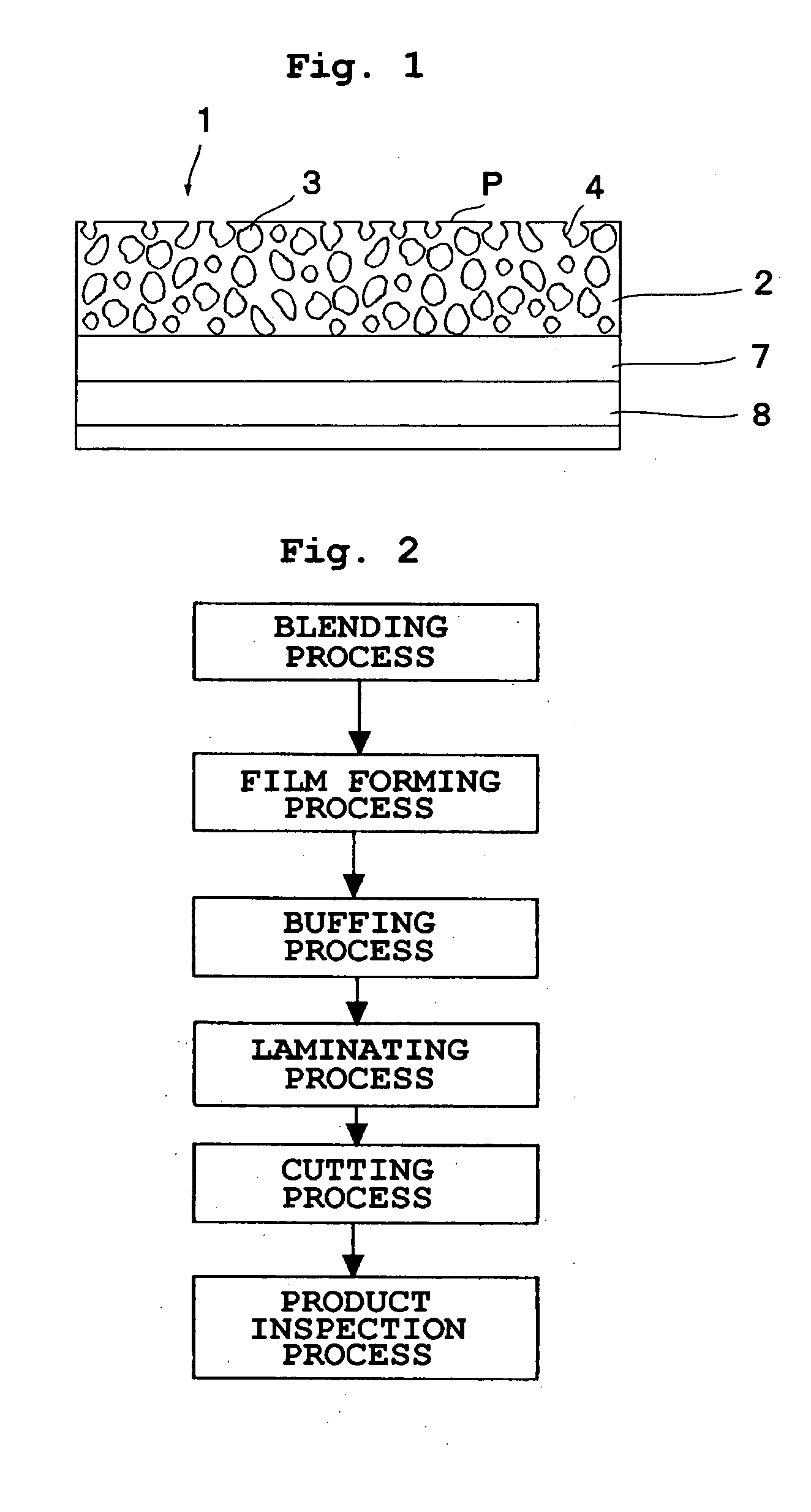

Polishing sheet and manufacturing method of elastic plastic foam sheet

InactiveUS20050112354A1Semiconductor/solid-state device manufacturingPretreated surfacesSurface layerEngineering

A polishing sheet which can improve waviness at a face of a material to be polished and which has a long life is provided. The polishing pad 1 has a polyurethane sheet 2 made of polyurethane resin. The polyurethane sheet 2 has a polishing layer which is disposed inside a surface layer and which is allowed to wear away by polishing and whose thickness is larger than a thickness of the surface layer. The polishing layer has an approximately uniform foam structure in a direction of the thickness of the polishing sheet 2 by being formed foams whose space volume is larger than that of foams formed at the surface layer and which are communicated so as to form a network by continuous holes whose diameter is smaller than that of the space volume of the foams formed at the polishing layer.

Owner:FUJIBO HLDG

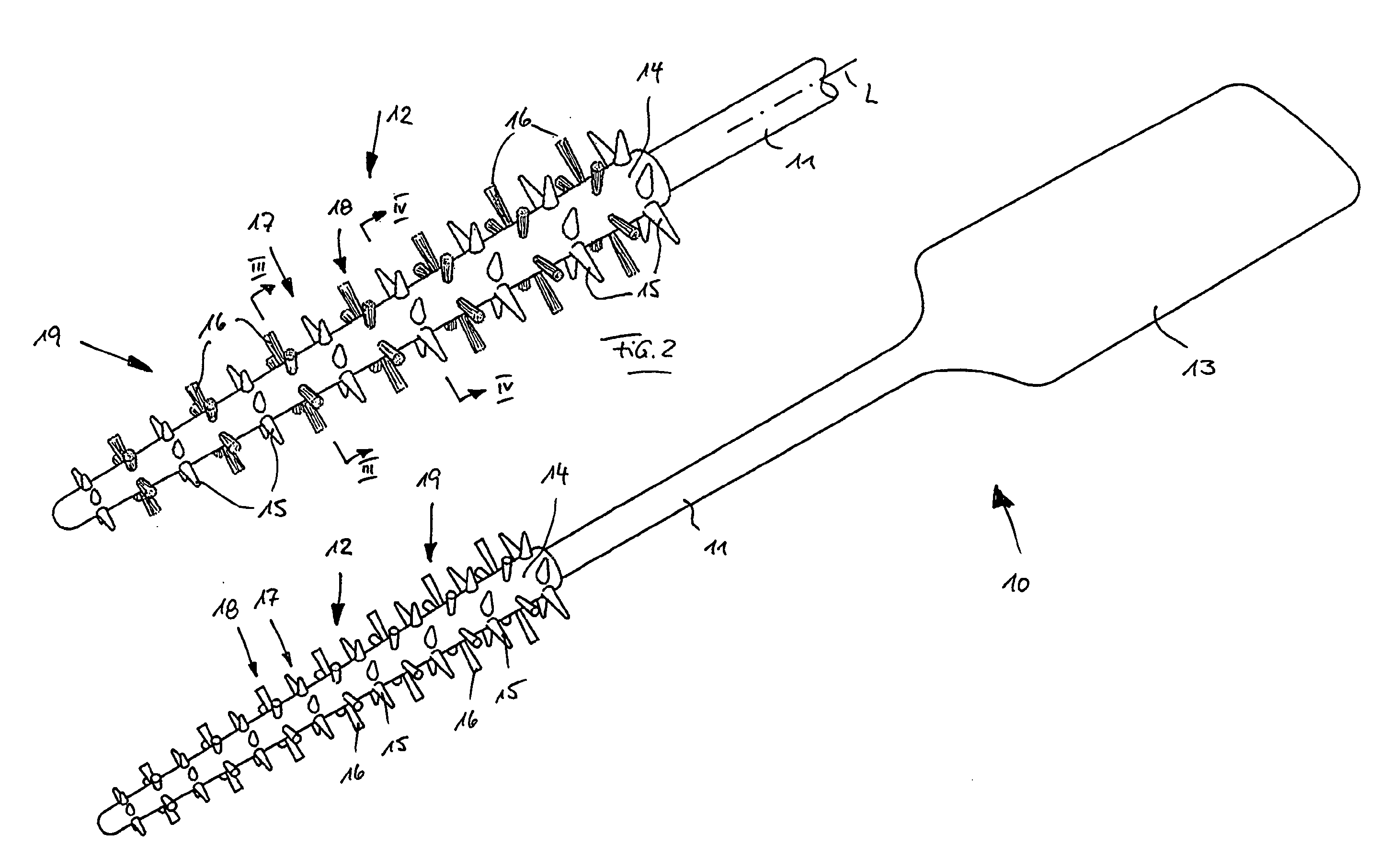

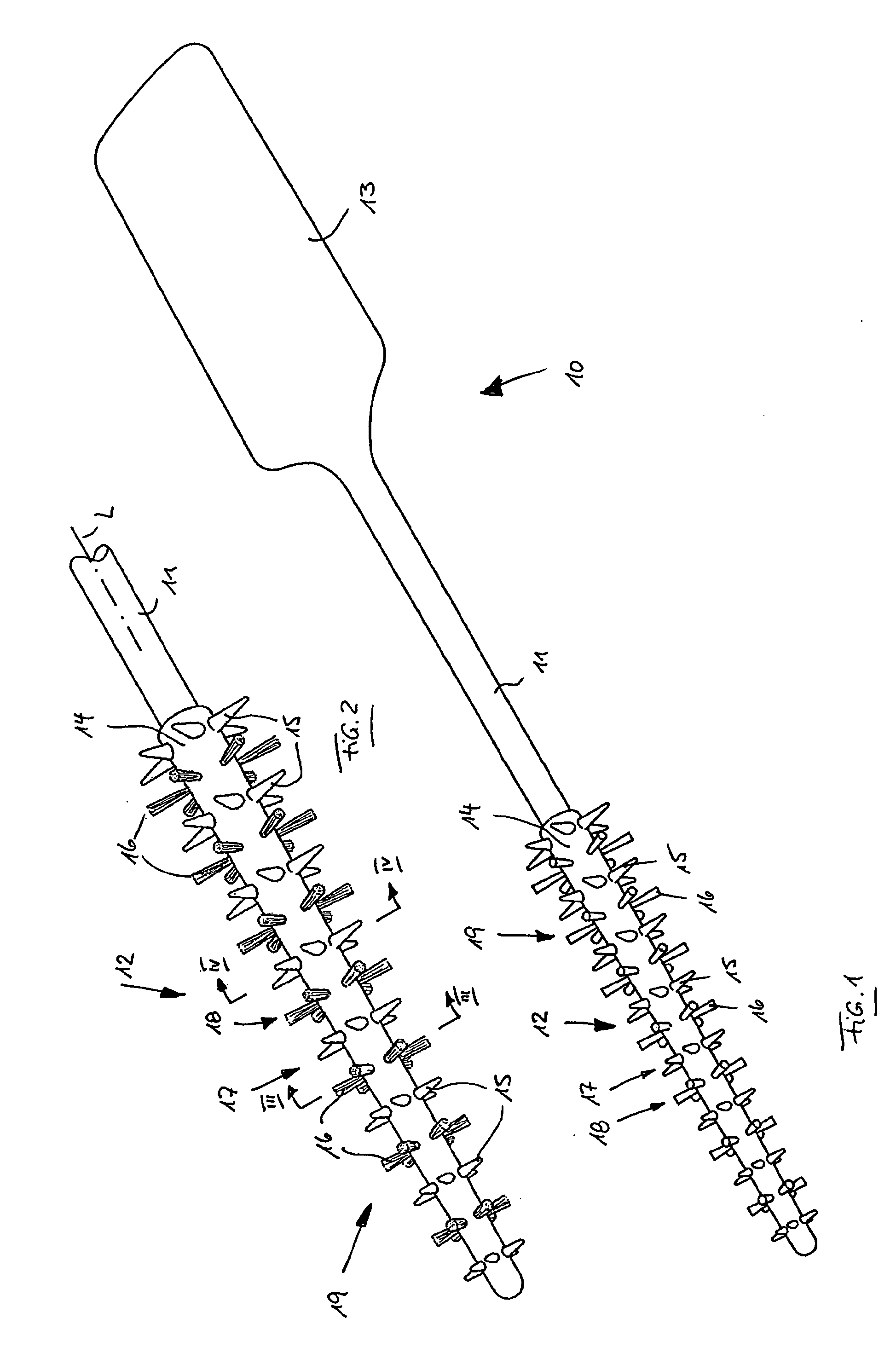

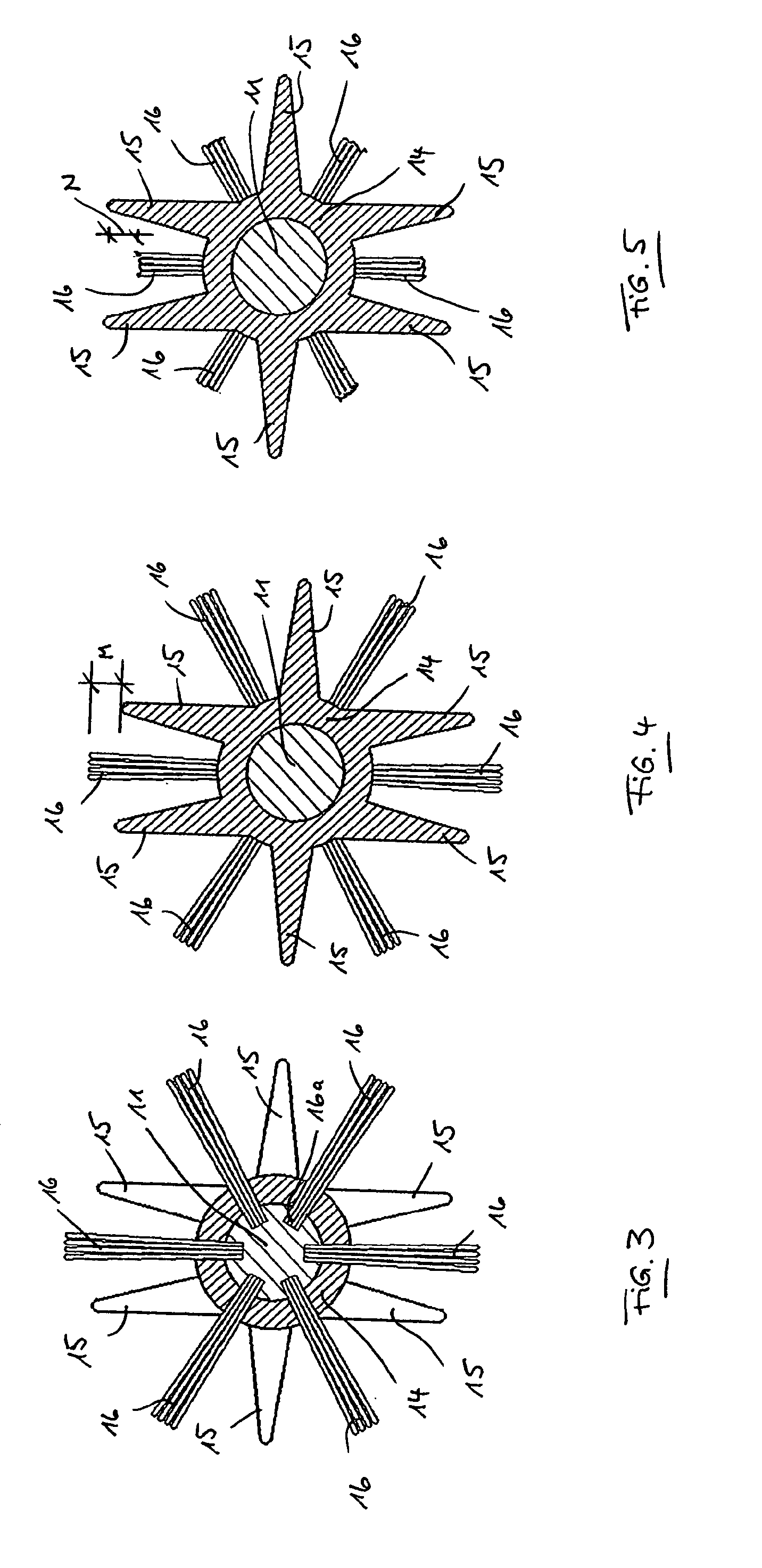

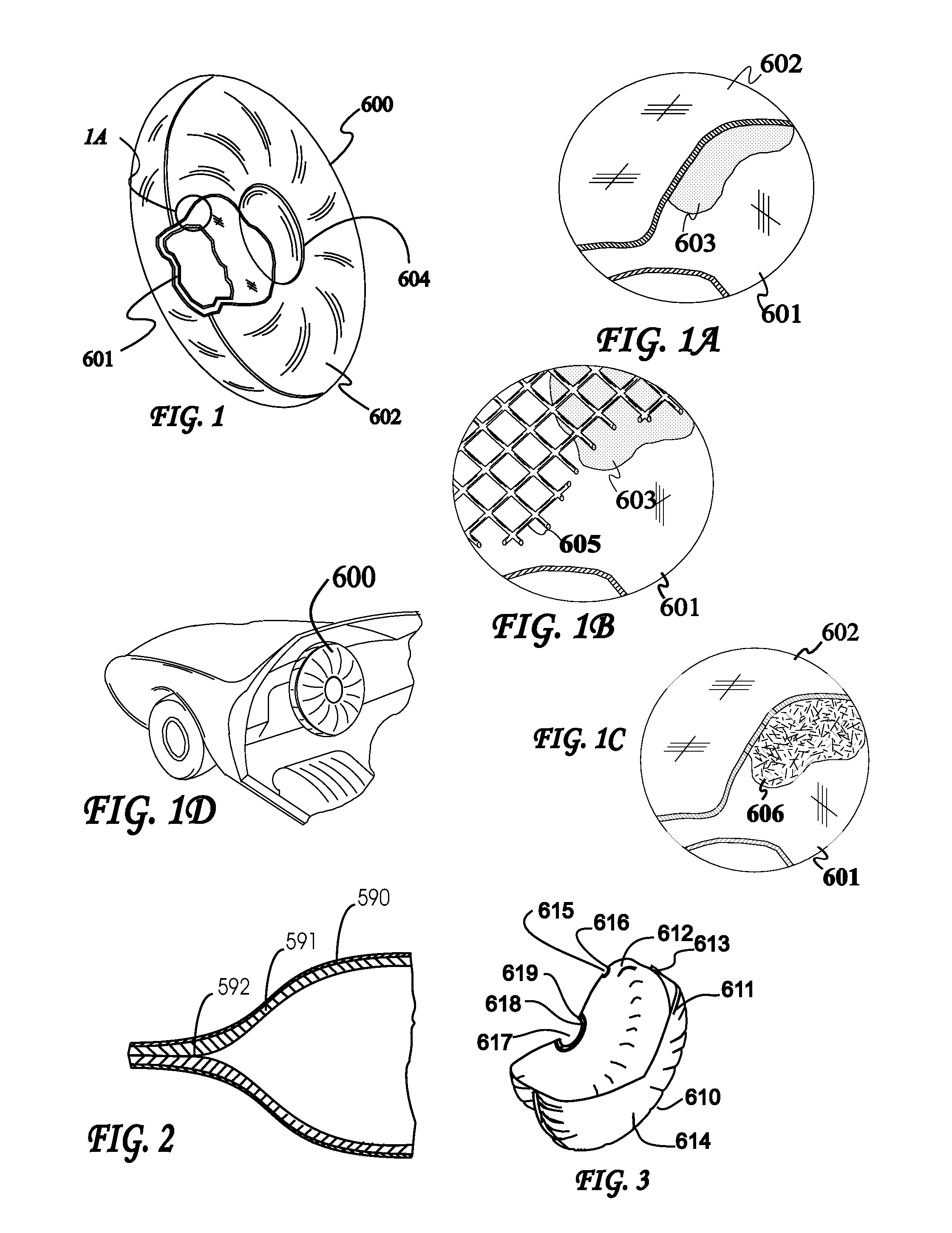

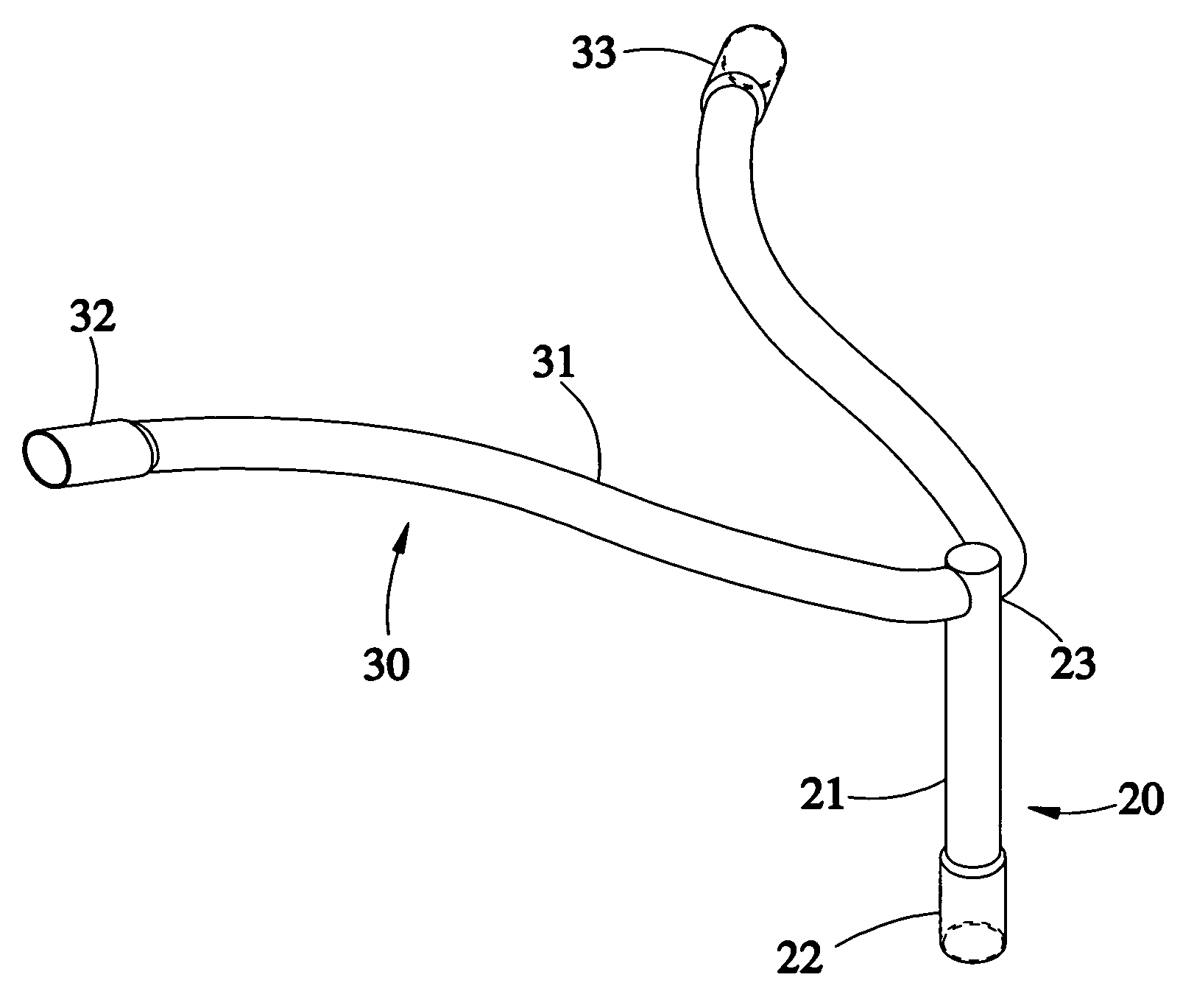

Interdental cleaner

An interdental cleaner with a rod-like support which has a cleaning device in an axial end region. The cleaning device includes a cover on the support made of a soft-elastic plastic, and structuring is formed on the outside of the cover having a plurality of fingers protruding with radial components from the cover, which fingers are made of the same material as the cover and are connected as one piece thereto. The structuring additionally has a bristle edging with a plurality of bristle bundles protruding with radial components from the cover and / or individual bristles which are each formed from pre-produced bristles embedded in the cover and / or in the support.

Owner:INTERBROS

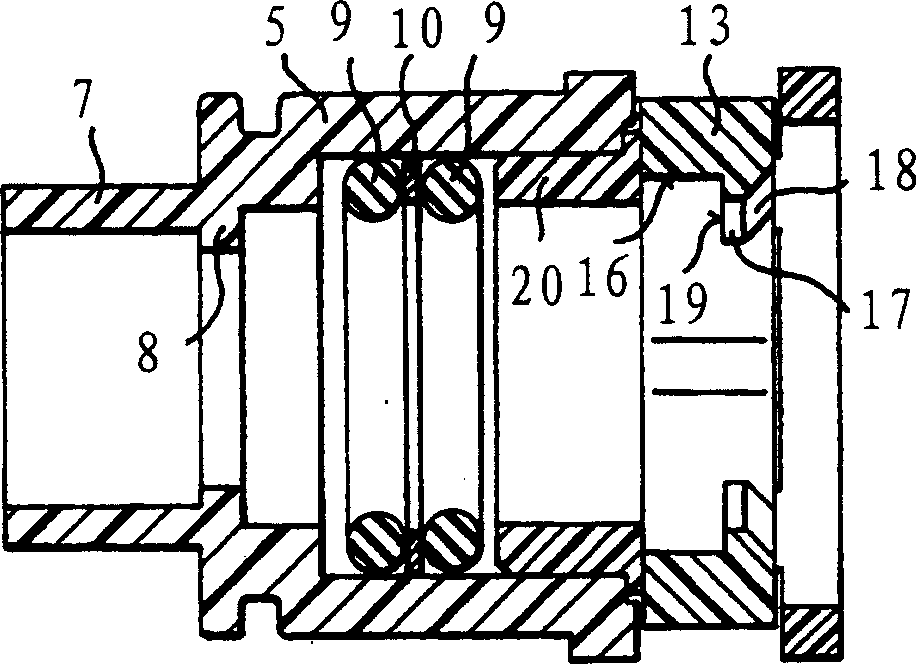

Loosening able plug in type joint in use for inserting to tubular insertion piece with peripheric capped edge

A plug in connector of releasable type used for inserting into tubular plug in piece with fender consists of cylindrical plug in cavity and locking ring prepared from hard and elastic plastics. It is featured as making lock ridge to be arc form towards inside, pushing and opening edge of arc form when plug in piece is pushed in connector then clocking plug in piece in connector and engaging arc edge together behind fender, using a pair of V form elastic arm to connect tail ends of lock ridge edge to each other for using said arm to push it up to unlocked position in order to draw off plug in piece from connector.

Owner:ARAYMOND PRECISION EQUIP ZHENJIANG CO LTD

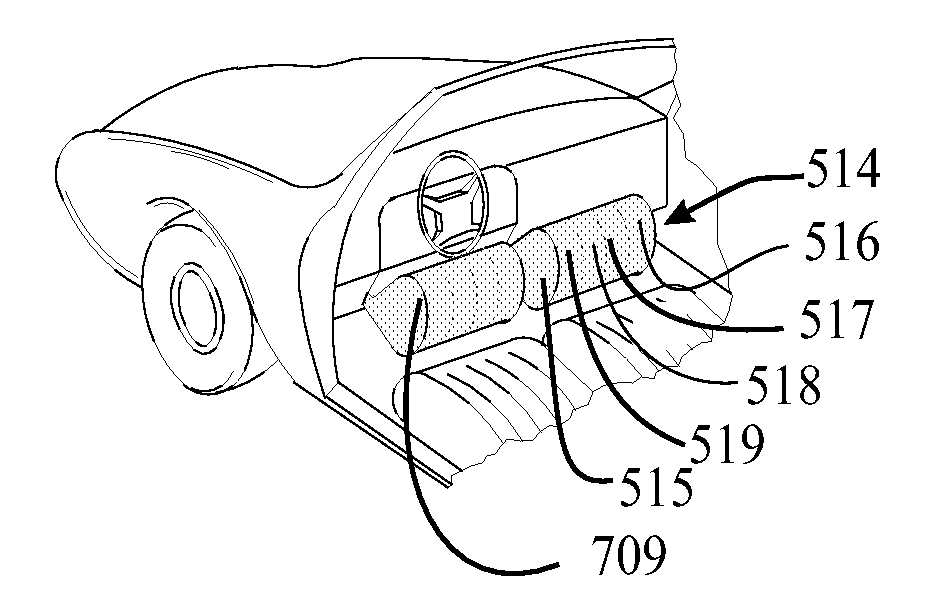

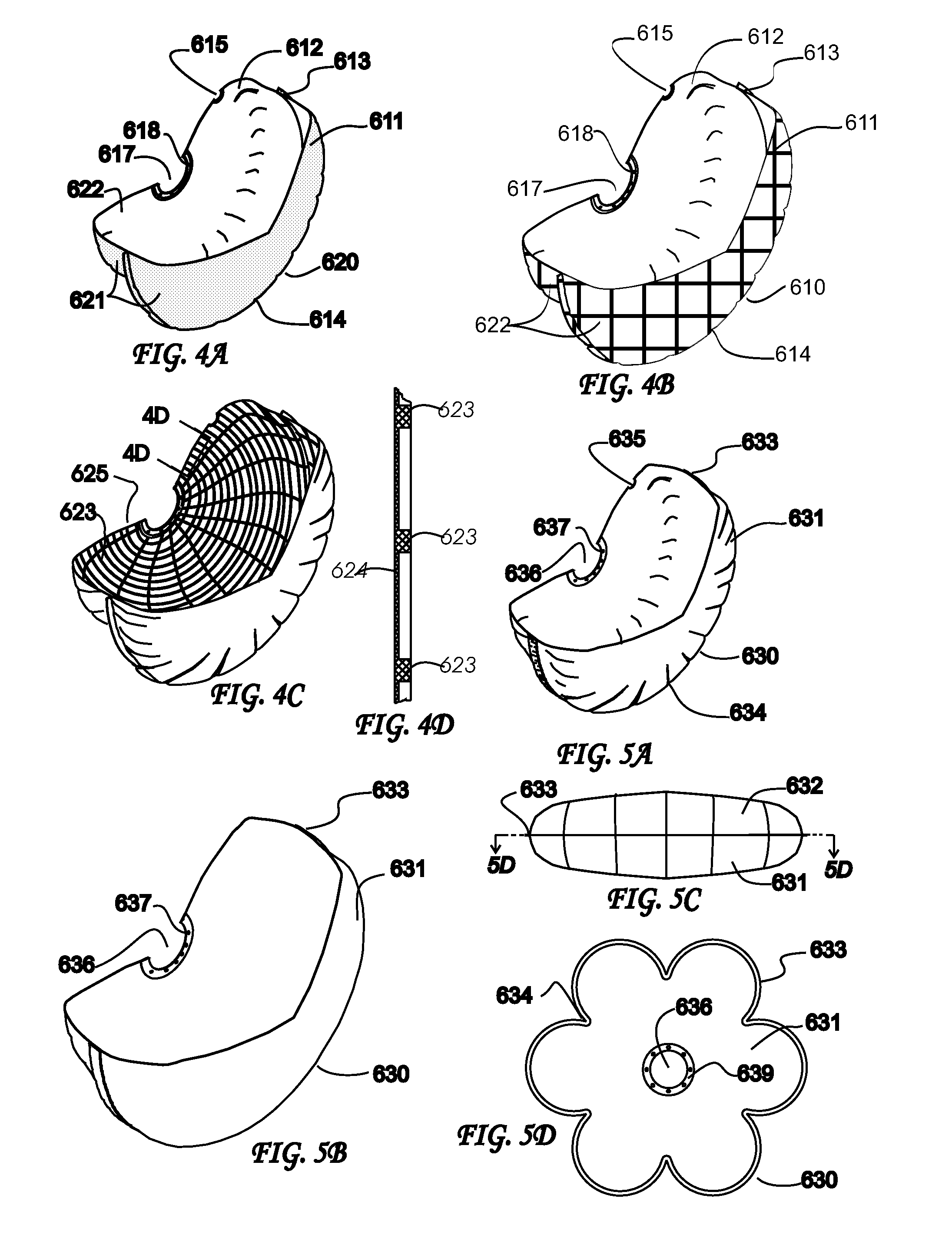

Knee Airbags Including Film

InactiveUS20080147278A1Digital data processing detailsPedestrian/occupant safety arrangementElastic plasticPlastic film

Vehicle with a knee protection airbag having a storage position and a deployed position. The airbag includes at least one cell constructed from reinforced elastic film and an inflator for inflating the airbag from the storage position to the deployed position. The airbag is arranged to substantially fill a space between the knees and lower extremities of the occupant when seated on the front seat and the instrument panel in the deployed position such that the airbag cushions only the knees and lower extremities of the occupant. Alternatively, the airbag includes at least one cell constructed from a laminate of a first elastic film and a second inelastic film. Alternatively, the airbag is a composite airbag having at least one layer of inelastic plastic film attached to a second layer of a more elastic plastic film, the second layer serves to blunt the propagation of a tear.

Owner:AMERICAN VEHICULAR SCI

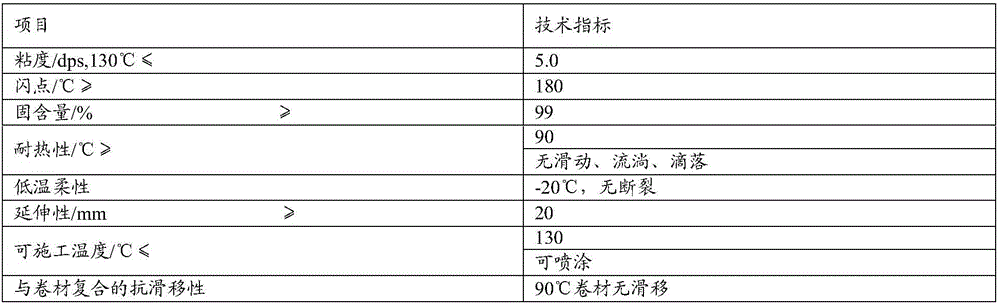

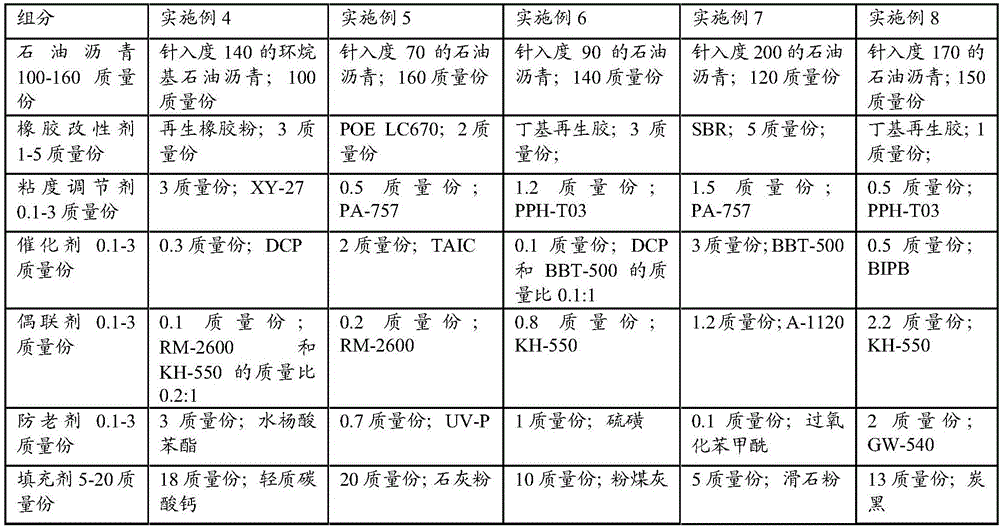

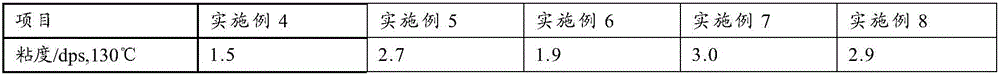

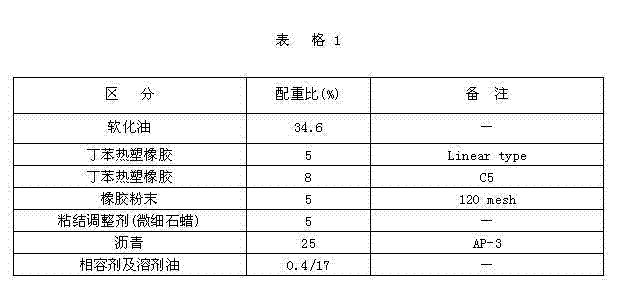

Non-curable rubber asphalt waterproof coating and preparation method and composite waterproof roll material thereof

ActiveCN105885693AImprove heat resistanceLow viscosityFireproof paintsConjugated diene hydrocarbon coatingsBituminous waterproofingElastic plastic

The invention provides a non-curable rubber asphalt waterproof coating and a preparation method and a composite waterproof roll material thereof. The non-curable rubber asphalt waterproof coating is prepared from, by mass, 100-160 parts of petroleum asphalt, 1-5 parts of rubber modifier, 0.1-3 parts of viscosity regulator and 0.1-3 parts of a catalyst. The chemical crosslinking reaction of the petroleum asphalt and the rubber modifier is achieved by adding the viscosity regulator and the catalyst in the petroleum asphalt and the rubber modifier of the non-curable rubber asphalt waterproof coating, so that the non-curable rubber asphalt waterproof coating has high heat resistance (greater than or equal to 90 DEG C) and low viscosity (smaller than or equal to 5.0 dps), can be sprayed or scraped at the low temperature (sprayable at the temperature of 130 DEG C) and also has energy saving and consumption reducing properties and other special properties on the basis that the common properties of an elastic-plastic paste body are kept within the service life, the comprehensive performance of the non-curable rubber asphalt waterproof coating is improved, and the service life of the non-curable rubber asphalt waterproof coating is prolonged.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +1

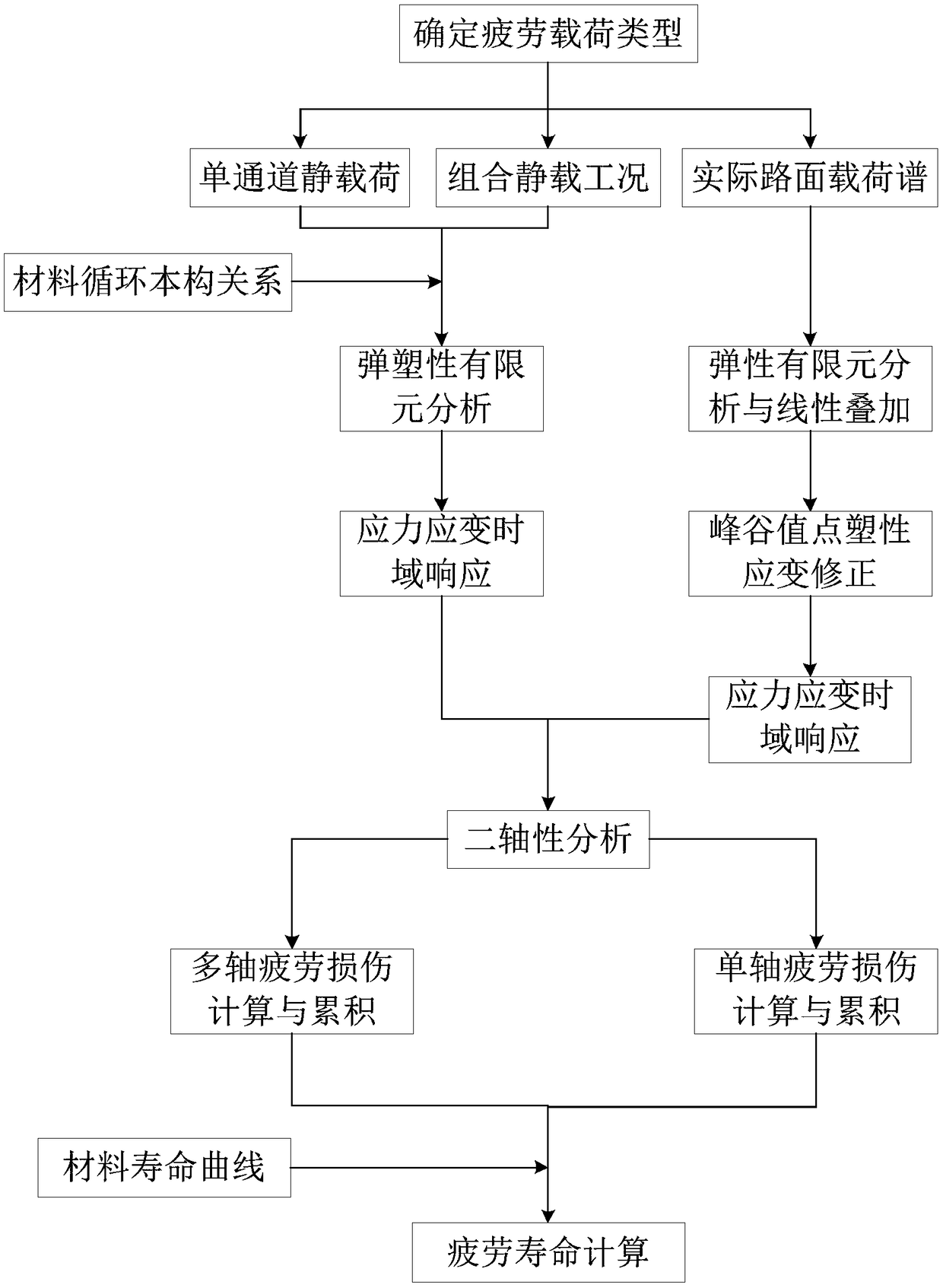

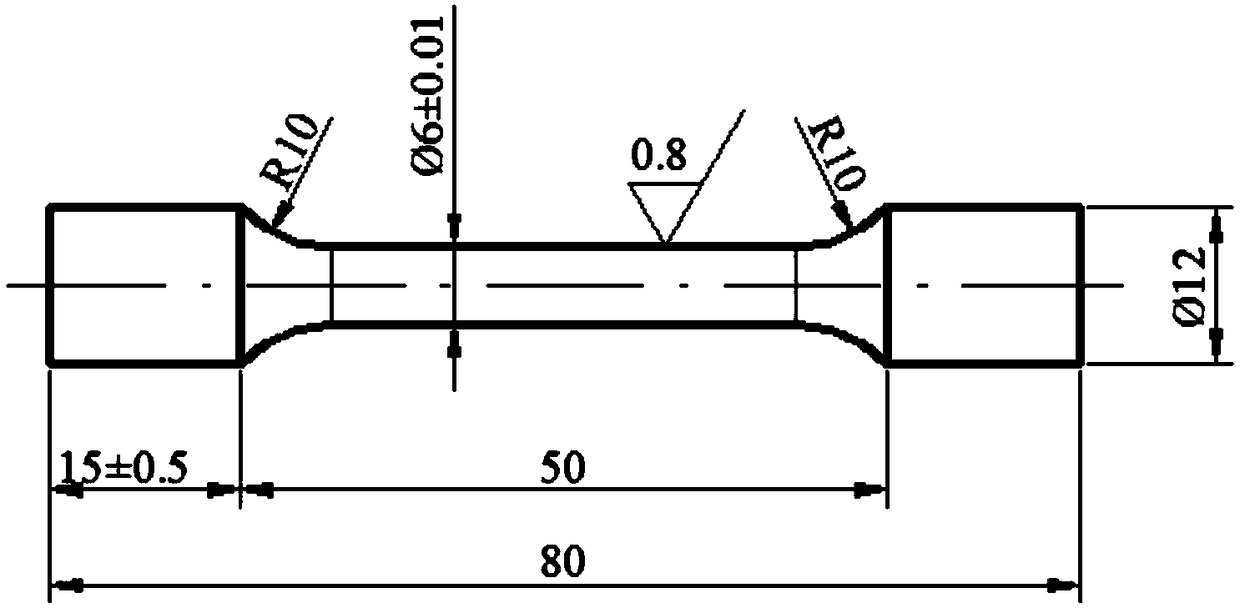

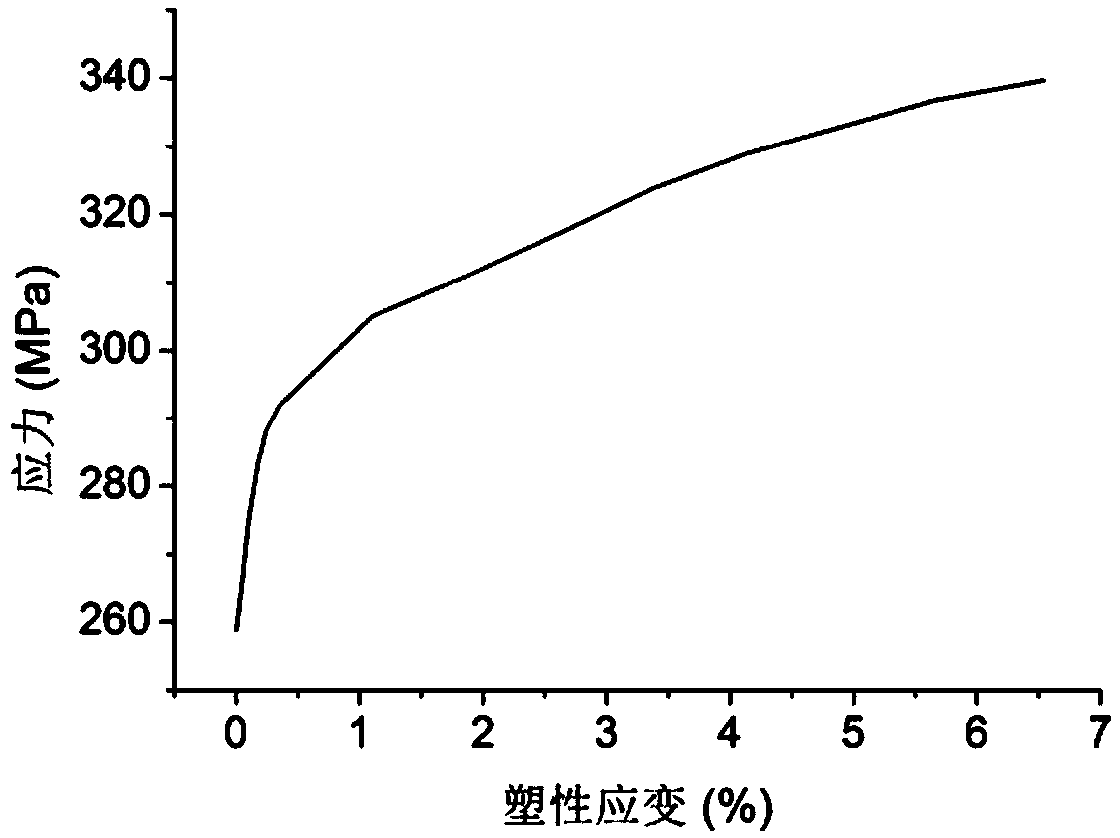

A method for analyzing fatigue life of steering knuckle

ActiveCN109214078ATime-consuming to solveAccurate fatigue analysis resultsGeometric CADSustainable transportationFatigue loadingProblem of time

The invention discloses a method for analyzing the fatigue life of a steering knuckle, comprising the following steps: 1) obtaining the fatigue load of the steering knuckle; 2) carrying out uniaxial tensile material test on the use material; 3) if the fatigue load is under the static load condition, the elastic-plastic finite element analysis method is adopted to solve the problem; or, if it is the actual pavement load spectrum, the elastic-plastic finite element analysis is carried out on the points exceeding the yield strength by elastic finite element method and linear superposition method,and the modified stress-strain results are obtained. 4) analyzing the biaxiality of the obtained stress response in time domain to determine the load state of the steering knuckle; 5) calculating thedamage accumulation and life of steering knuckle. The present invention solves the problem of time-consuming finite element solution under the input of actual pavement load spectrum, at the same time, the stress and strain of the material entering the plastic phase are considered, so that the result is more accurate, and fatigue analysis is carried out by combining the static load condition or the single channel static load condition, and more references are provided in the design phase.

Owner:SOUTH CHINA UNIV OF TECH

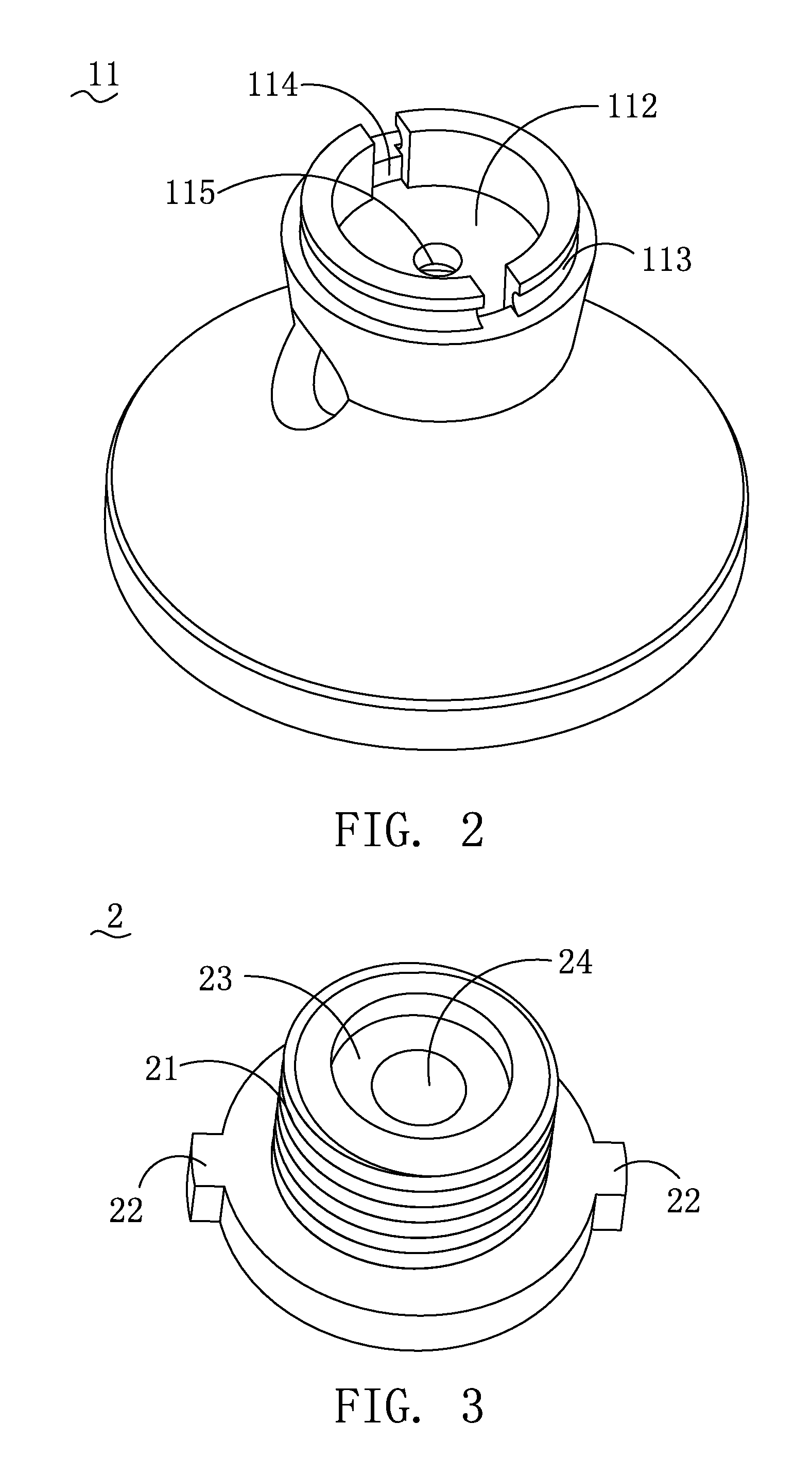

Cap with an angled spray channel for an aerosol container or a spray container

InactiveUS20070290007A1Reduce vibrationProcess economyDispensing apparatusSpray nozzlesElastic plasticMechanical engineering

In order to achieve a comfortable level of spray noise using a cap having a button and an angled spray channel, it is suggested that the spray channel be manufactured in one piece from elastic plastic, e.g., from TPE or TPU.

Owner:THE PROCTER & GAMBLE COMPANY

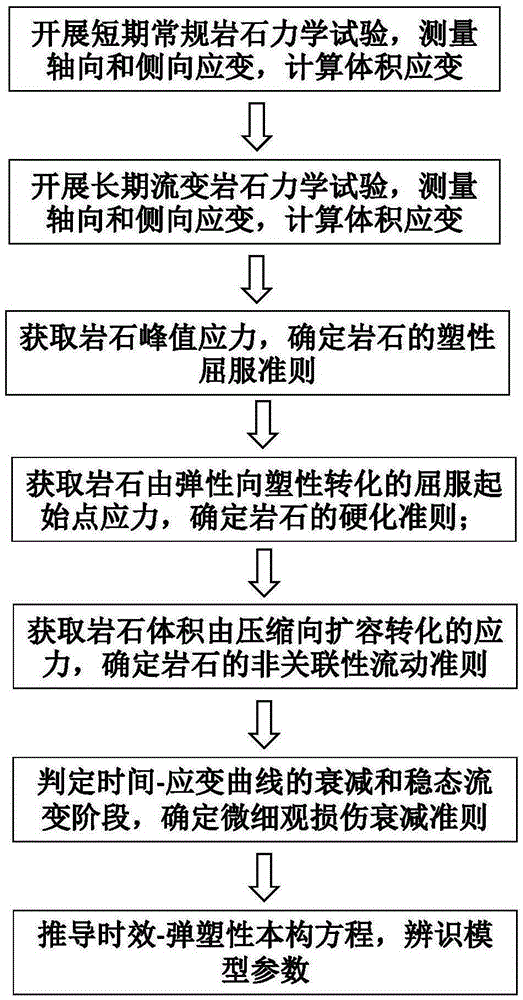

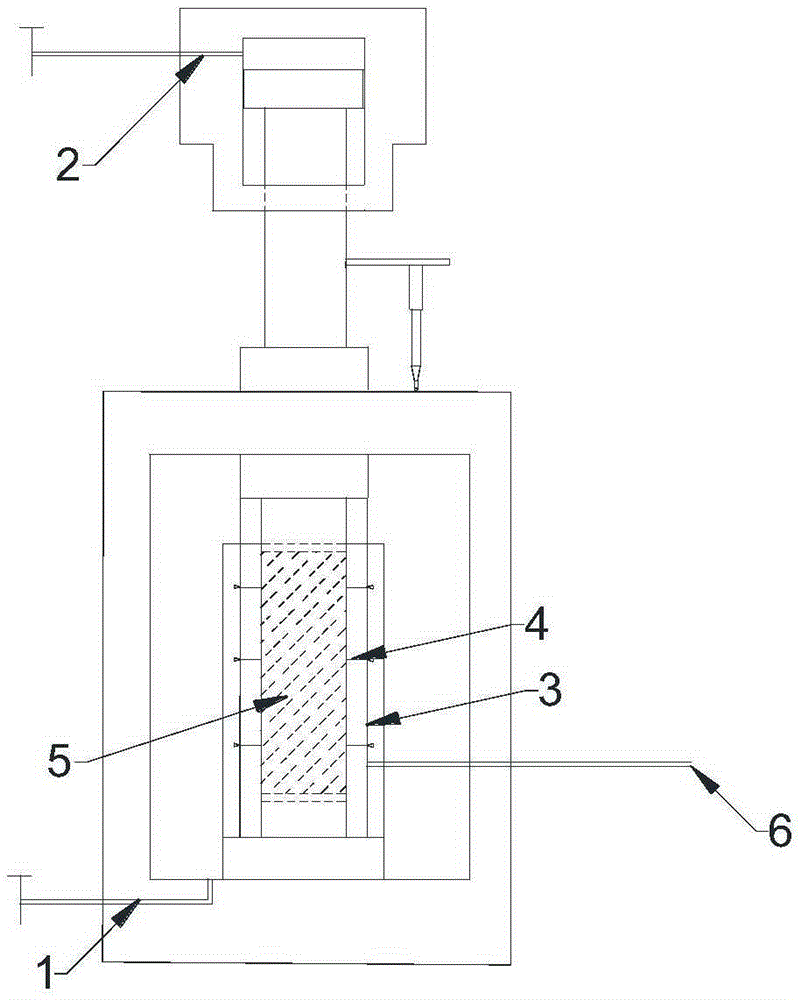

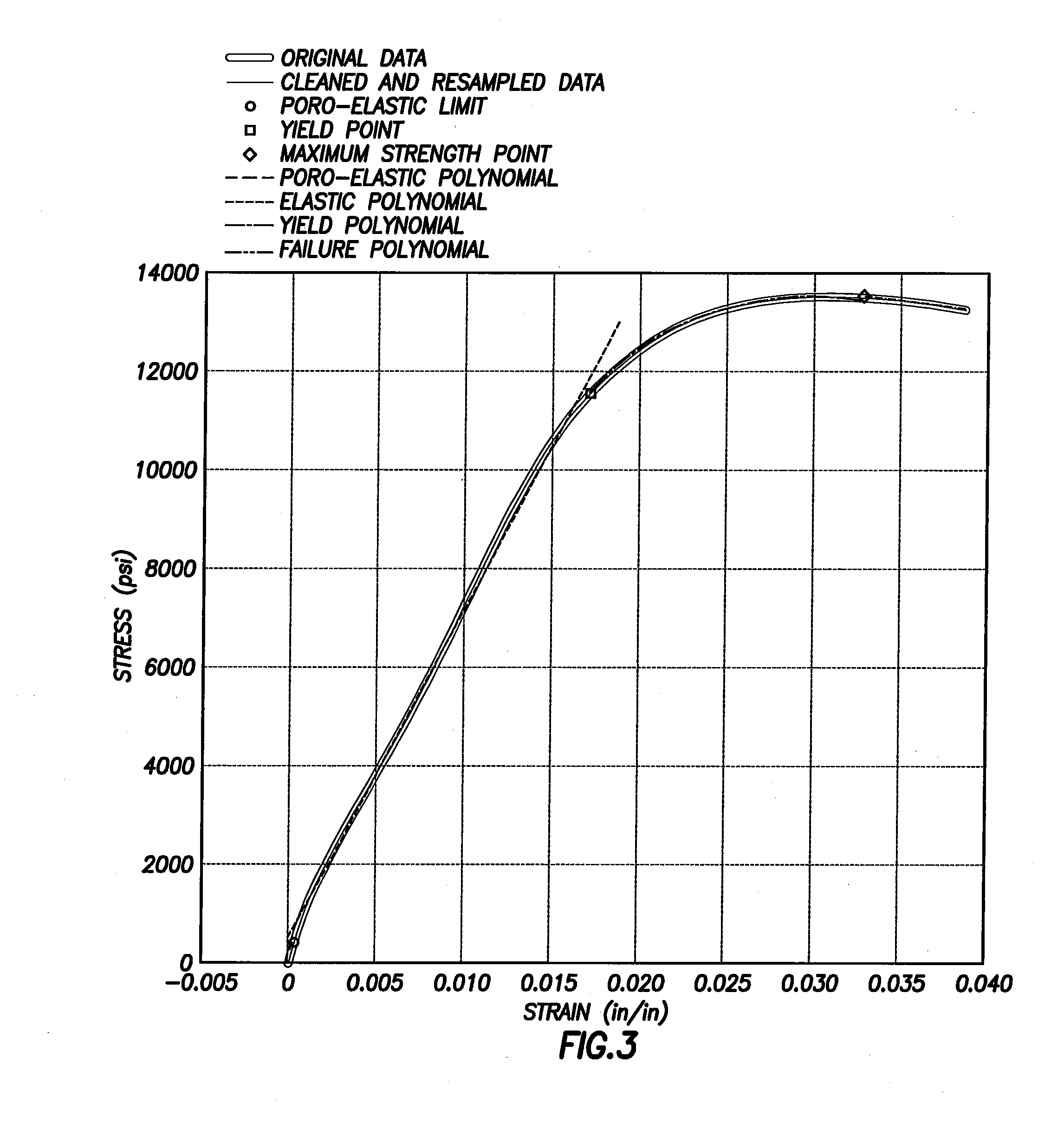

Method for establishing rock material ageing and elastic-plastic mechanics constitutive model

InactiveCN105259035AImprove accuracyWide applicabilityMaterial strength using tensile/compressive forcesUltrasound attenuationDynamic balance

The invention discloses a method for establishing a rock material ageing and elastic-plastic mechanics constitutive model. The method includes the steps that the triaxial short-long term test result of rock is used as the basis first, and the volumetric strains of a rock test piece under different test conditions are calculated; by drawing a stress-axial and lateral strain relation curve and a stress-volumetric strain relation curve, the yield criterion, the non-associated flow rule and the hardening criterion of the rock are determined, and an elastic-plastic mechanics model is established; then by combining material micro and fine damage attenuation ageing evolution dynamic equilibrium, the micro and fine ageing damage rule of the rock is determined, the model is popularized, a relation matrix of strain increment and stress increment at the ageing-elasticoplastic deformation stage is established, and accordingly the rock material ageing and elastic-plastic mechanics constitutive model is obtained. According to the model, the mechanics significance is definite, the expression is unique, the number of parameters is small and can be obtained based on the test results, hence, solving uniqueness and accuracy are guaranteed, and wide applicability and expansibility are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Elastic plastics blended antioxidation modified bituminous water-proof coiled material

InactiveCN1354203AGood low temperature flexibilityImprove high temperature resistanceOther chemical processesBuilding insulationsBituminous waterproofingThermoplastic elastomer

The present invention relates to a modified water-proofing asphalt roll material (called SA roll material for short), and is characterized by that in the raw material formula of asphalt 4-15% of thermoplastic elastomer polystyrene-butadiene-styrene block copolymer (SBS), 3-12% of atactic polypropylene (APP), 1-8% of light shielding agent, 0.05-3% of antioxidant, 0.05-3% of light stabilizer and 0.05-3% of UV absorbing agent. Said water-proofing roll material possesses low-temp. resistance, high-temp. resistance. UV-resisting property and good ageing resistance.

Owner:CHONGQING CITY NEW TYPE WATER PROOFING MATERIAL

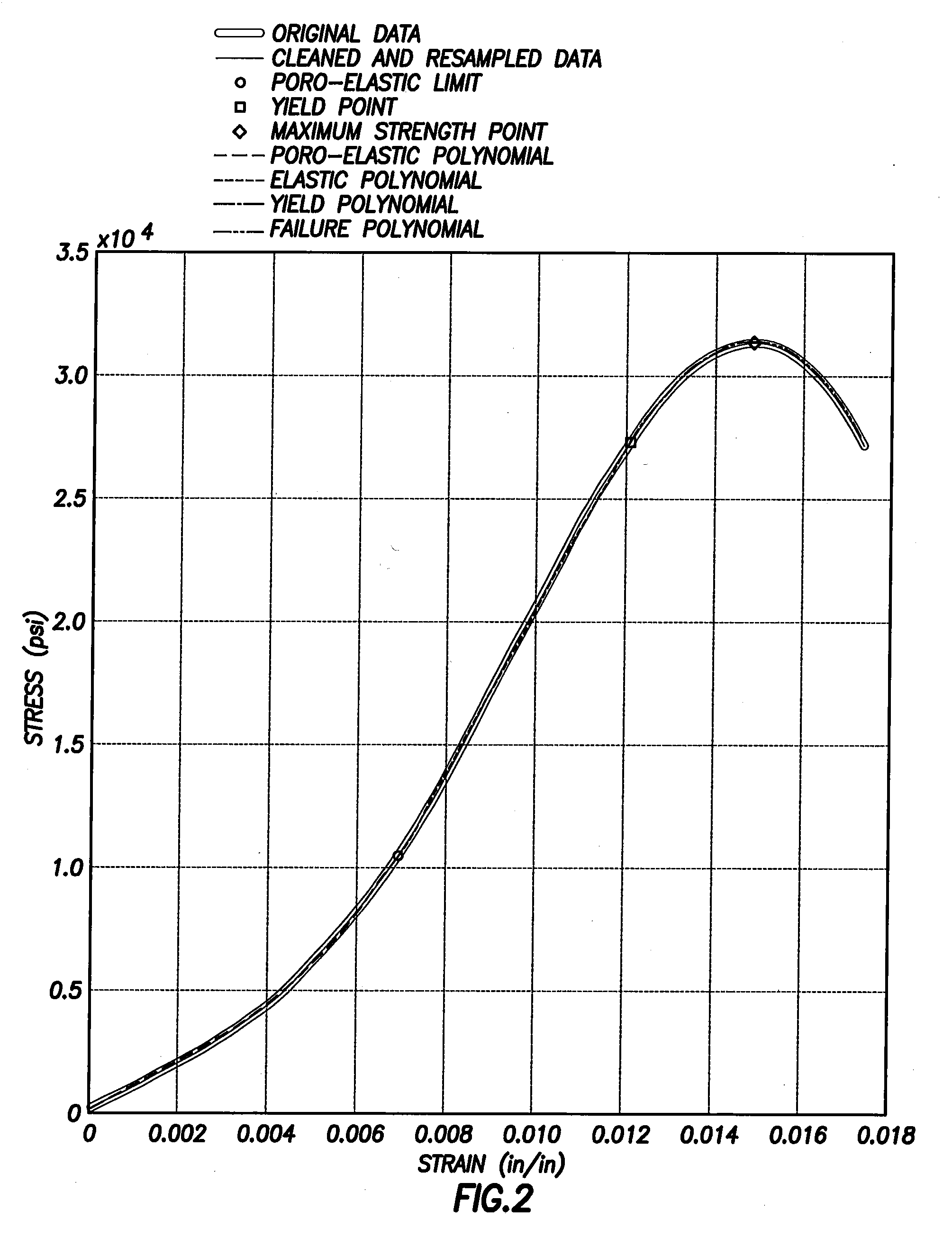

Method of establishing elastic-plastic mechanical constitutive model made of rock material

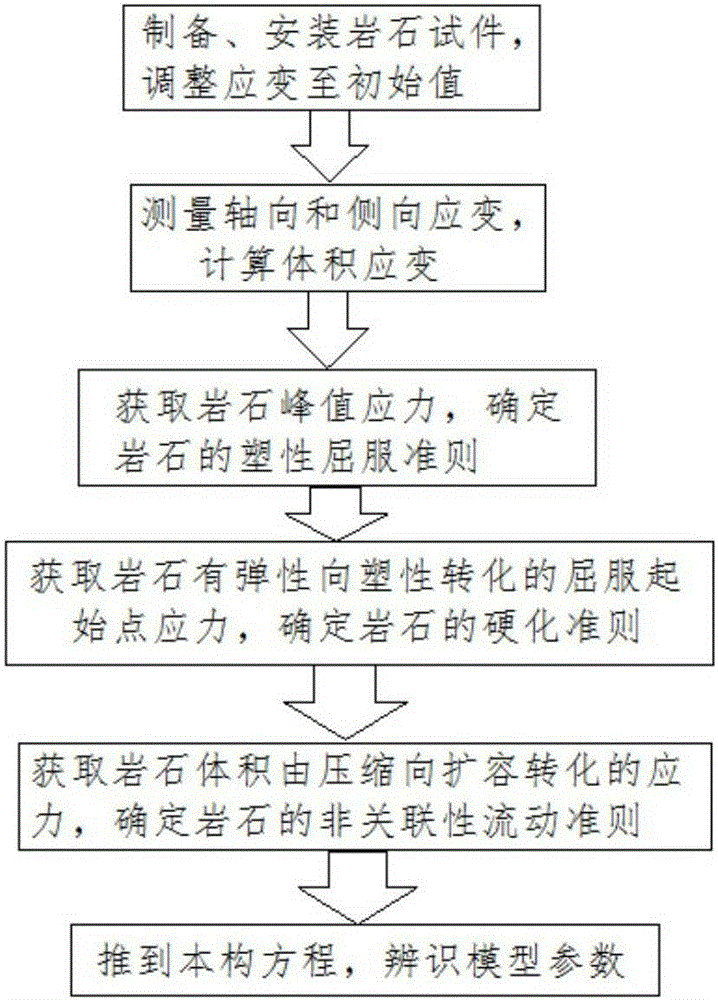

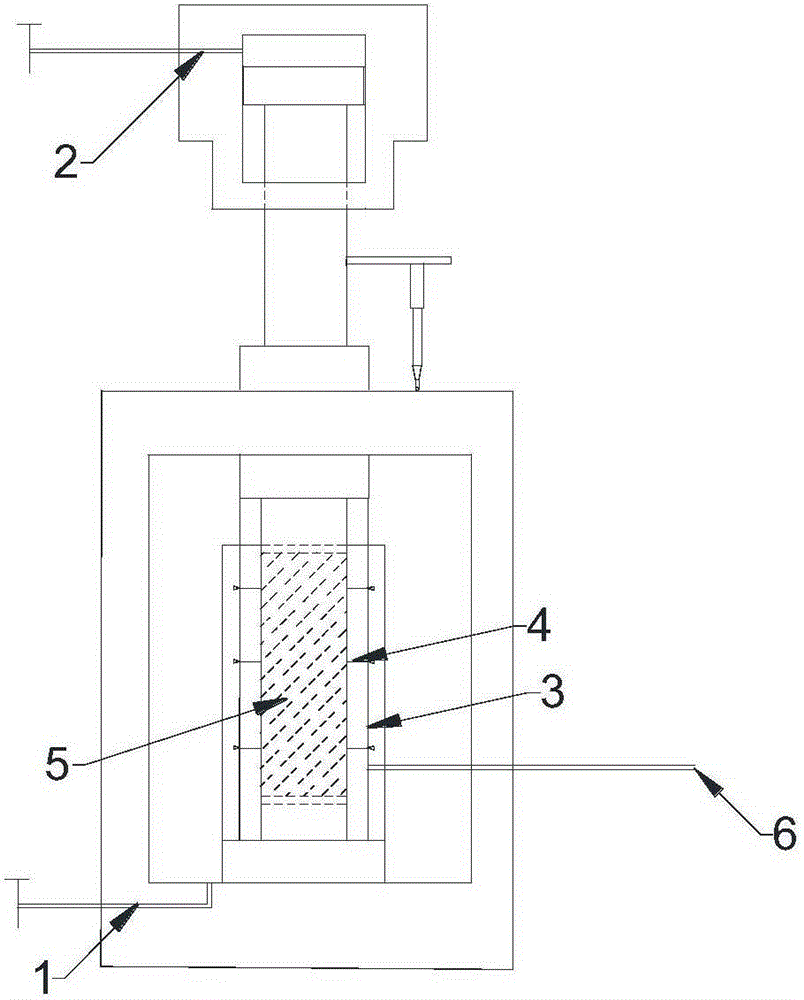

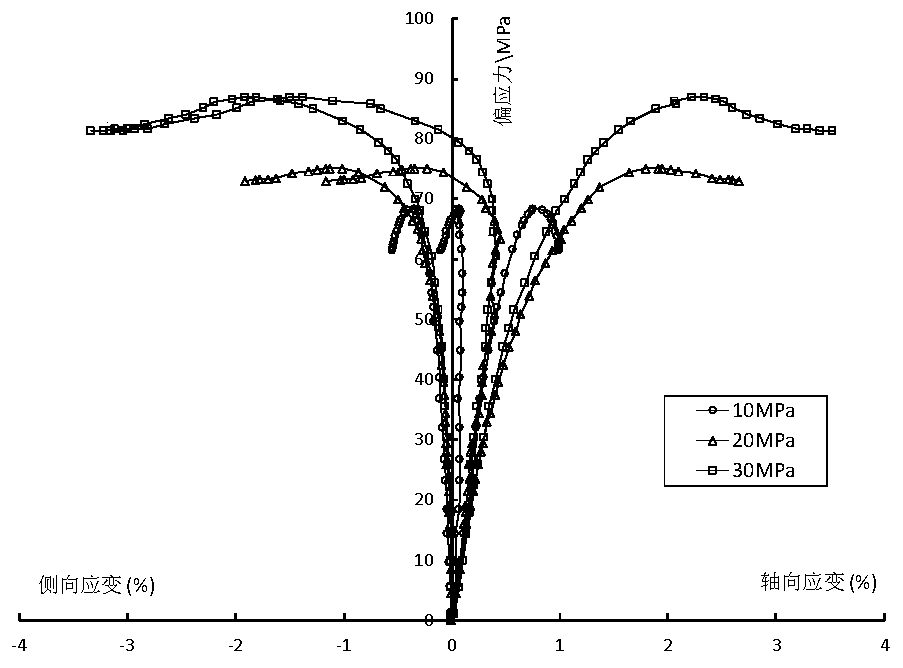

InactiveCN105181435AImprove accuracyWide applicabilityMaterial strength using tensile/compressive forcesStress–strain curveElastic plastic

The invention discloses a method of establishing an elastic-plastic mechanical constitutive model made of a rock material. The method comprises the following steps: measuring and recording variation values of axial and lateral strains of a rock specimen along with the stress, and calculating a volumetric strain of the rock specimen; drawing a stress-axial / lateral strain relation curve according to recorded full-course axial and lateral strain changes of the rock specimen, and respectively determining a yield failure rule and a hardening rule of the rock material of the specimen; drawing a stress-volumetric strain relation curve according to the calculated volumetric strain of the rock specimen to determine a non-relevant flow rule of the rock material of the specimen; determining the constitutive model by using a thermodynamic elastic-plastic theory in combination with the stress-strain curve, peak stress, yield initial stress and boundary strength of rock. The method disclosed by the invention comprehensively considers the yield rule, the non-relevant flow rule and the hardening rule of the rock material, favorably reflects the elastic-plastic mechanical behavior of the rock material and ensures the uniqueness and the accuracy of the constitutive model.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

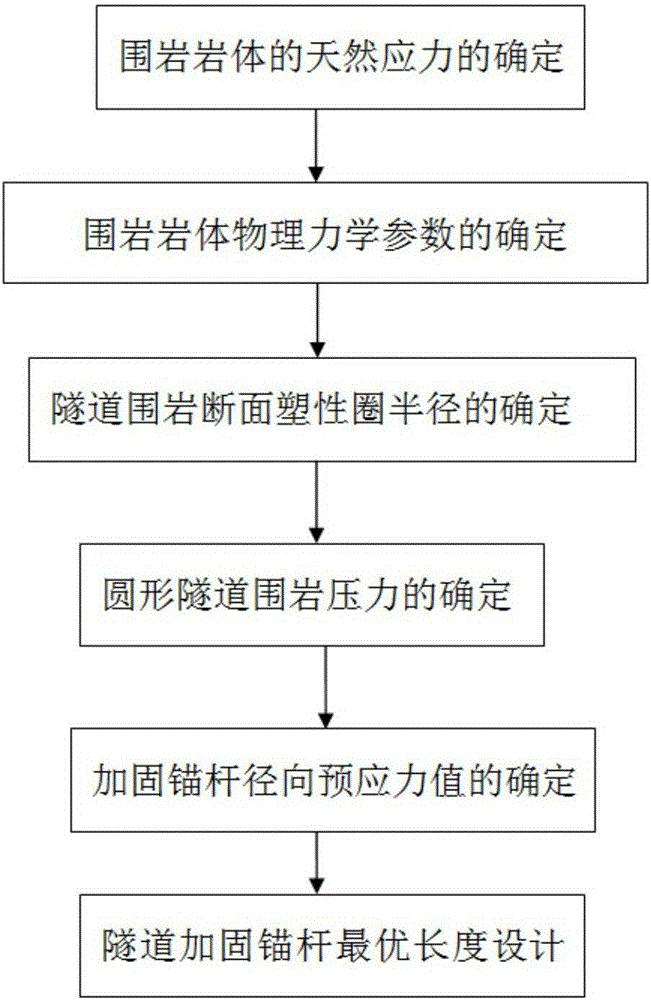

Determination method of tunnel surrounding rock prestressing force reinforcing anchor rod length and radial prestressing force values

The invention discloses a determination method of tunnel surrounding rock prestressing force reinforcing anchor rod length and radial prestressing force values. According to the surrounding rock elastic-plastic theory and the plastic zone distribution regulation, and, on the basis that a tunnel plastic ring radius R and a surrounding rock pressure force are comprehensively determined, the minimum length value and a radial minimum prestressing force value of a tunnel surrounding rock reinforcing anchor rod are determined. The determination method advantageous in that, according to the surrounding rock elastic-plastic theory and the plastic zone distribution regulation, and, on the basis that the tunnel plastic ring radius R and the surrounding rock pressure force are comprehensively determined, the minimum length value and the radial minimum prestressing force value of the tunnel surrounding rock reinforcing anchor rod are determined, the calculation process is relative clear and concise, and a measured result is high in accuracy and accurate, has a small error compared with the actual and can guide the practice well.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

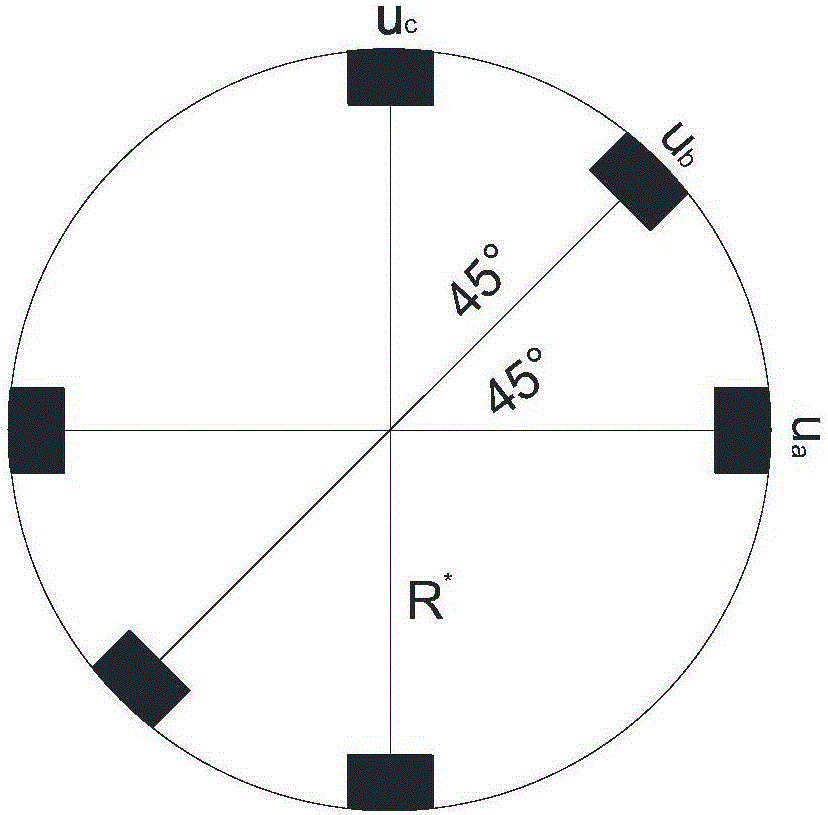

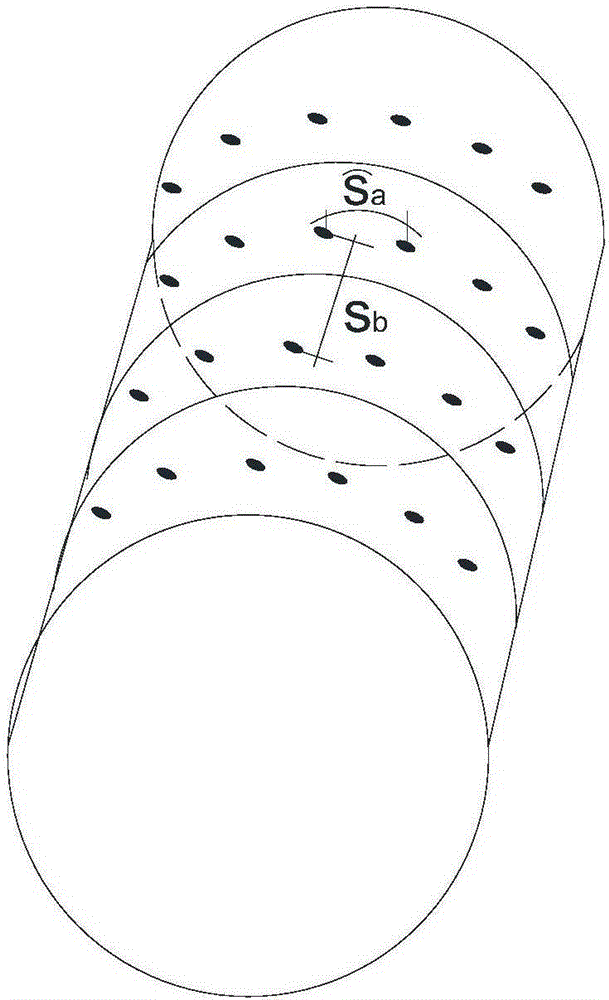

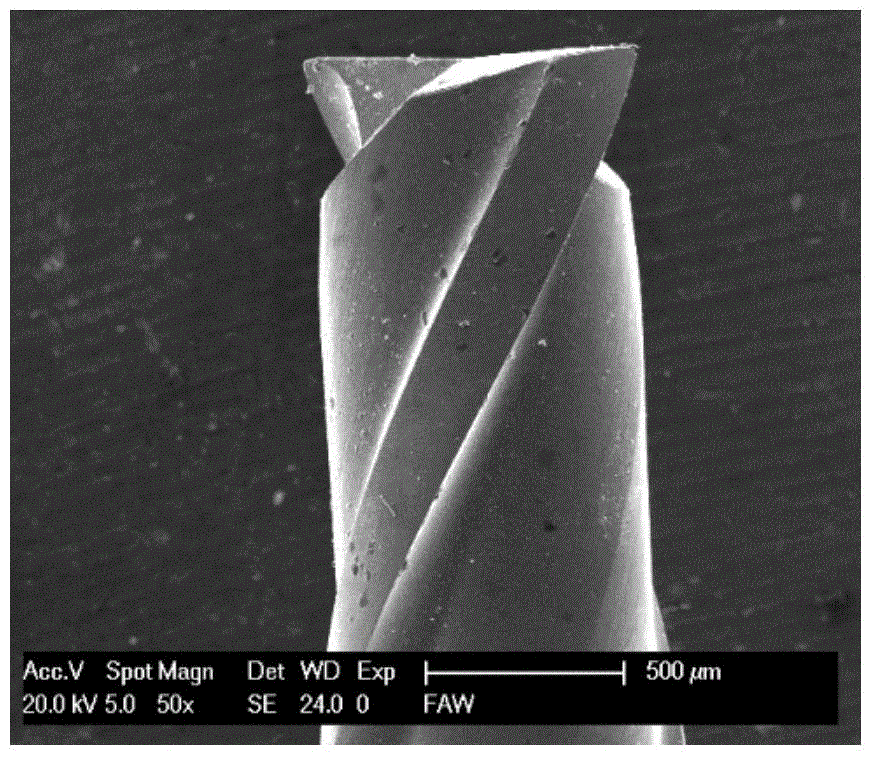

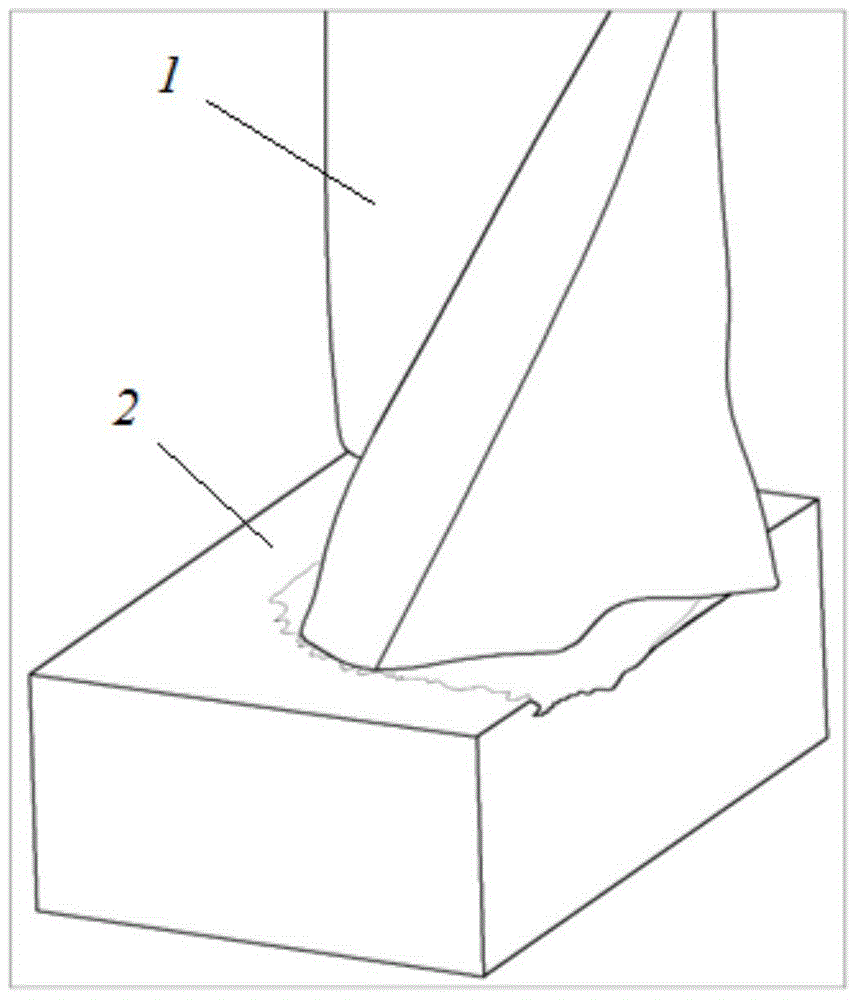

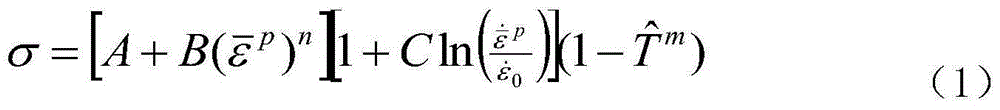

Simulation method for residual stress prediction of micro-milling nickel-based superalloy

ActiveCN105117547AEasy to predictAchieve forecastSpecial data processing applicationsMilling cutterScanning electron microscope

The invention provides a simulation method for residual stress prediction of micro-milling nickel-based superalloy, belongs to the field of finite element simulation cutting, and relates to a finite element simulation method for residual stress prediction analysis in the cutting processing process of difficult-to-process materials of the nickel-based superalloy. According to the simulation method, the finite element simulation method is used; the elastic-plastic constitutive relationship of materials is considered; and a Johnson-Cook fracture failure criterion is used for judging the failure, so that residual stress prediction values under different cutting parameters can be obtained. A micro-milling cutter for experiments is shot into a picture through a scanning electron microscope; the picture is drawn into a micro-milling cutter solid model through software; a three-dimensional processed workpiece model is built; and the model is subjected to lattice division. The method has the advantages that the surface residual stress can be measured, and the residual stress in the depth direction can also be measured, so that the problem of measurement difficulty of the residual stress in the depth direction in the measurement process is solved. The cost is reduced, and the labor is saved. In a prediction model, the cutting parameters are variable; and the prediction on the surface residual stress of the difficult-to-process materials is effectively realized.

Owner:DALIAN UNIV OF TECH

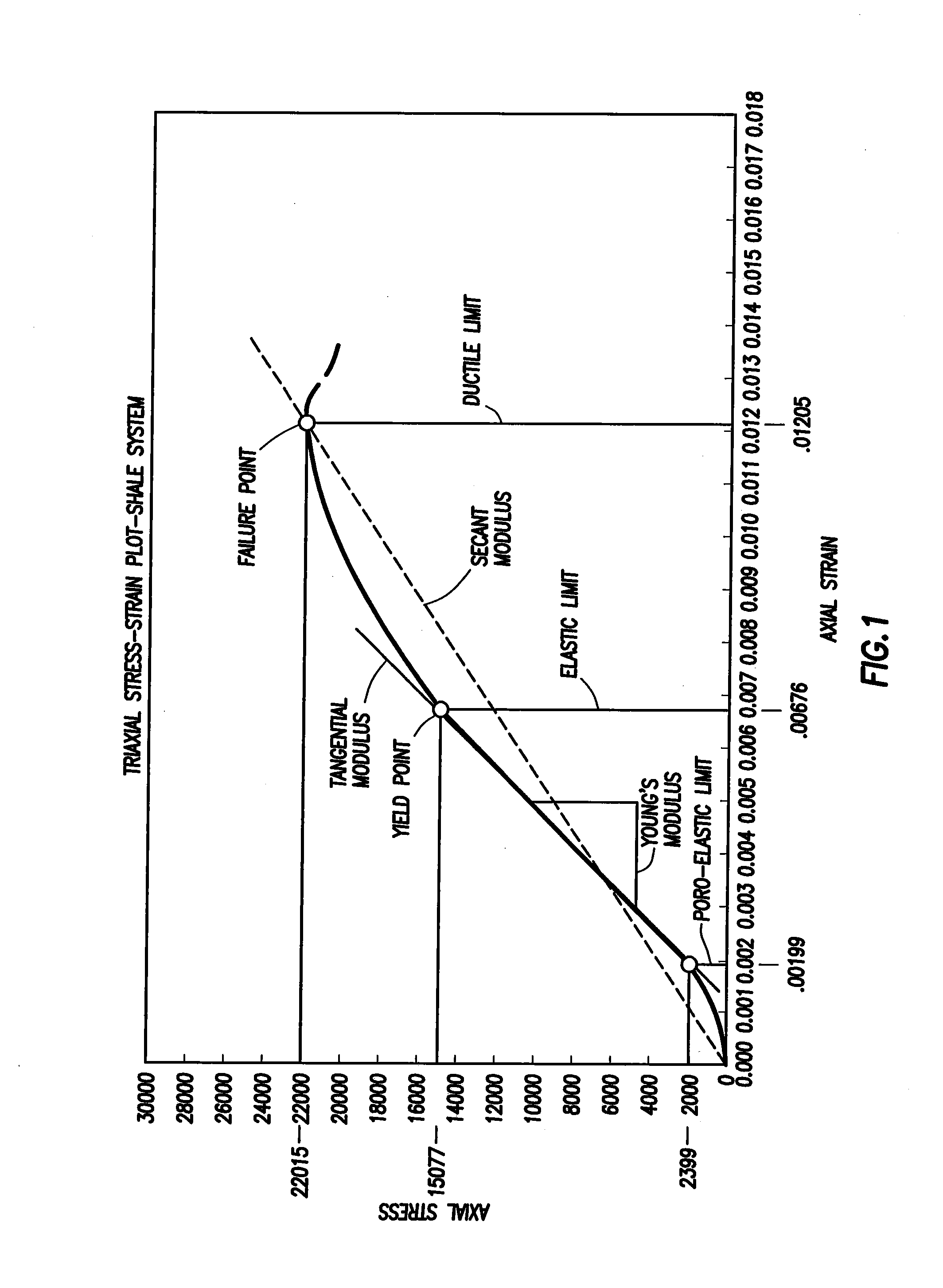

Integrating rock ductility with fracture propagation mechanics for hydraulic fracture design

InactiveUS20140352949A1Significant plasticitySignificant ductilitySurveyConstructionsGeomorphologyLinear region

The invention relates to the calculation of parameters to inform hydraulic stimulation of non-conventional hydrocarbon-bearing rock formations, such as shales. Unlike conventional formations, non-conventional formations tend to display elastic-plastic behavior and have stress-strain characteristics which with substantial non-linear regions. A parameter which has been termed Elastic Index (EI) is proposed, together with a demonstration of how this parameter, when coupled with principles of fracture mechanics, may be used to extract meaningful calculated or estimated values for e.g.; total required volume of fracturing fluid; treating pressure; fracturing fluid viscosity; proppant size; and proppant concentration.

Owner:CONOCOPHILLIPS CO

Uncured polyurethane waterproofing coating and preparation method thereof

ActiveCN103923565AGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses an uncured polyurethane waterproofing coating and a preparation method thereof, belonging to the technical field of polyurethane waterproofing coatings. The uncured polyurethane waterproofing coating is prepared from the following raw materials in percentage by weight: 13-20% of prepolymer, 30-65% of asphalt, 1.0-1.5% of latent curing agent, 3-15% of compatilizer, 2-9% of thermoplastic elastomer and 0-3% of powder stuffing, wherein prepolymer is a substance synthesized by reaction between polyether and isocyanate. The uncured polyurethane waterproofing coating mainly aims to improve the material proportion and polymerization process of polyurethane, and the problem that a hot-melted asphalt material is needed to be heated by using a machine is solved; the uncured polyurethane waterproofing coating is convenient in construction and good in flowability; the viscosity of the constructed material can be automatically enhanced, so that the constructed material can become an elastic plastic body and a favorable waterproofing layer without internal stresses; in addition, the uncured polyurethane waterproofing coating can be well bonded with a coiled material and can be compounded to be waterproof so as to form a waterproofing layer capable of overcoming tension fracture caused by basement layer cracking and preventing puncturing; the uncured polyurethane waterproofing coating is simple and convenient in process, rapid in construction, free of maintenance, high in working efficiency and capable of becoming the development direction of building waterproofing in the further.

Owner:浙江鲁班建材科技股份有限公司

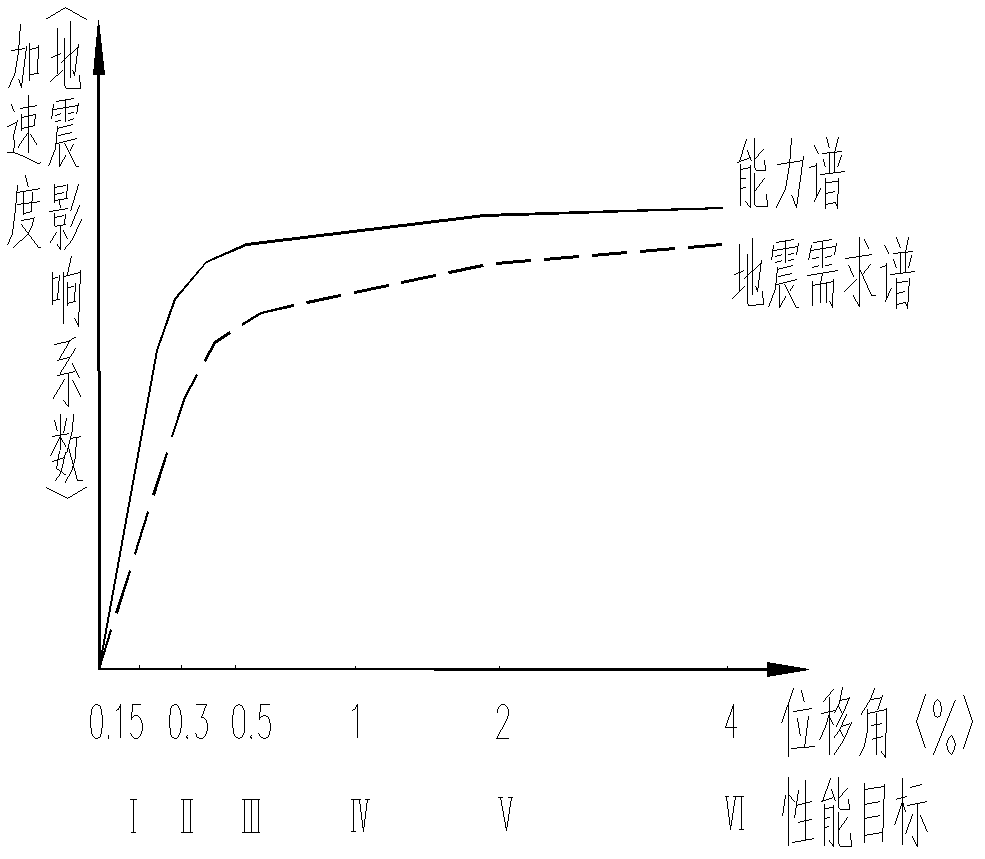

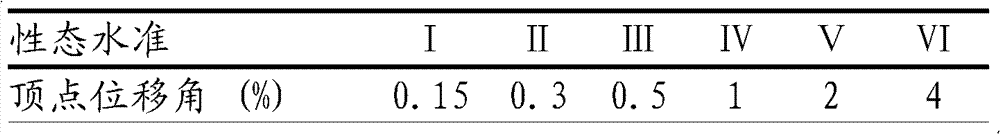

Multi-objective performance-based aseismic design method of engineering structure

ActiveCN102787676AAssessing the Seismic Capacity of StructuresSeismic data acquisitionProtective buildings/sheltersElastic plasticCapacity spectrum

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

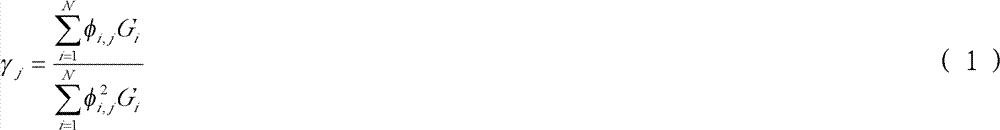

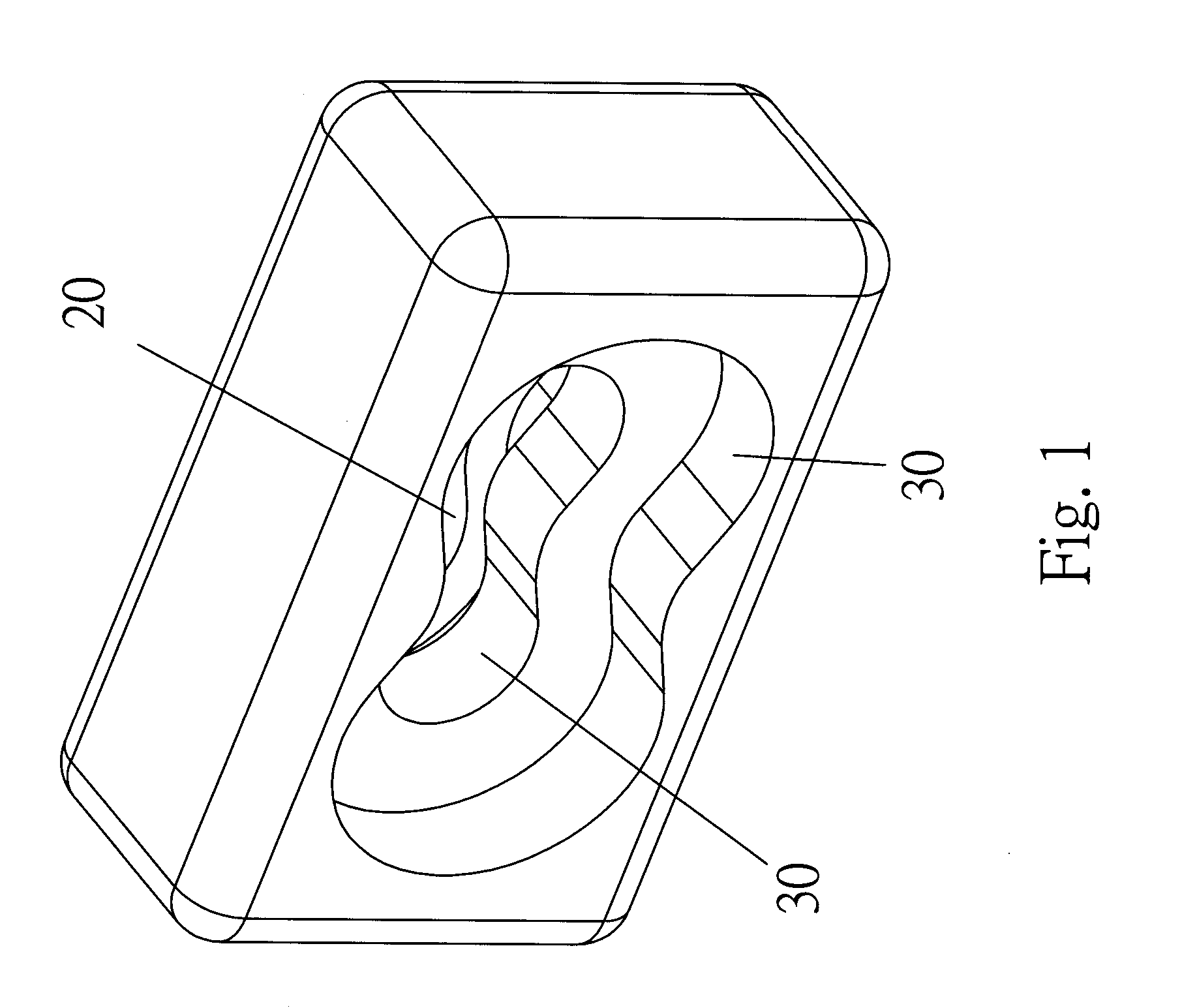

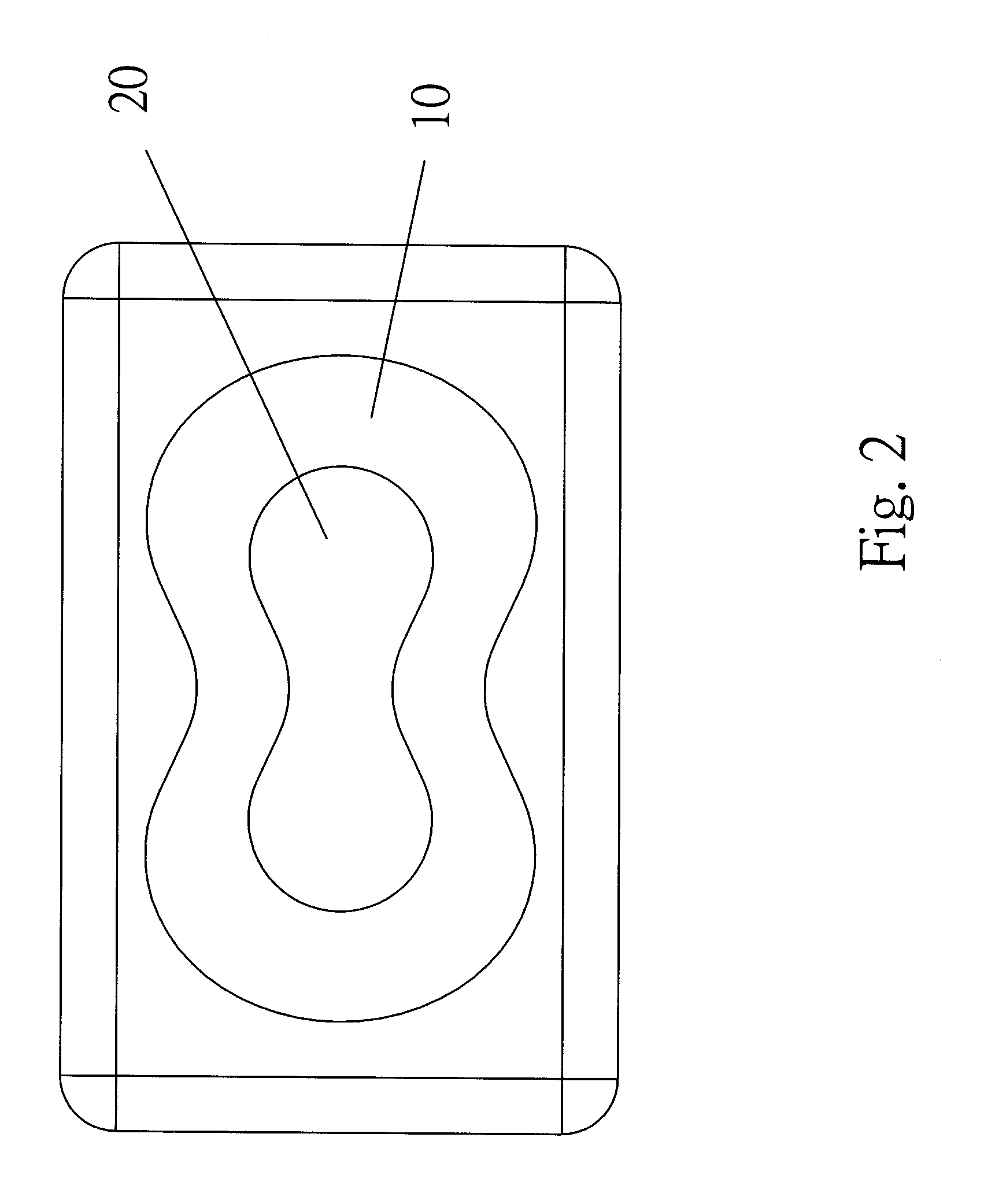

Multi-functional yoga brick

A multi-functional yoga brick comprises a multi-sectional holding portion at a middle section thereof. The holding portion has a shape of “8”, or a round shape or an elliptical shape. The holding portion has a through hole or no through hole. The holding portion has a plurality of layers. The multi-functional yoga brick is an elastic body. The multi-functional yoga brick is made of elastic plastics or rubber or injected plastic material. The user has a better balance in exercise and can support effectively so as to expand the body.

Owner:HSU CHUN CHI

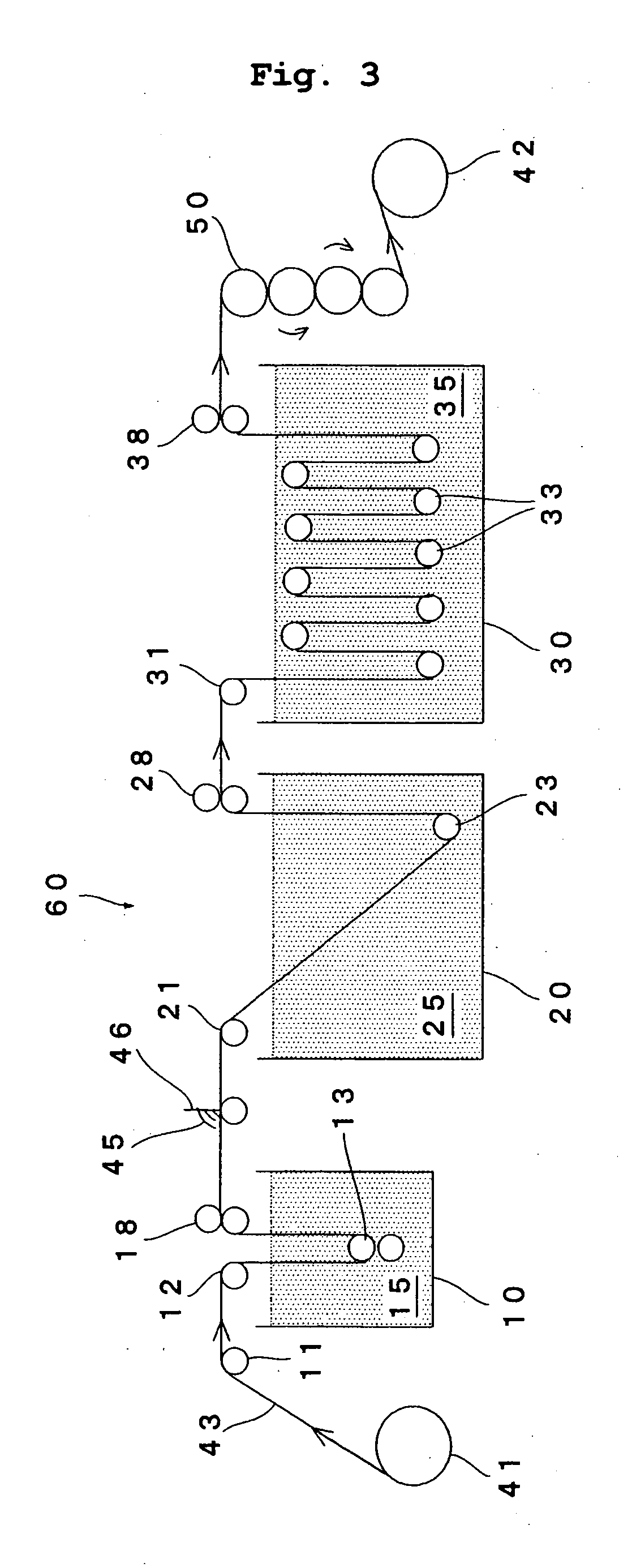

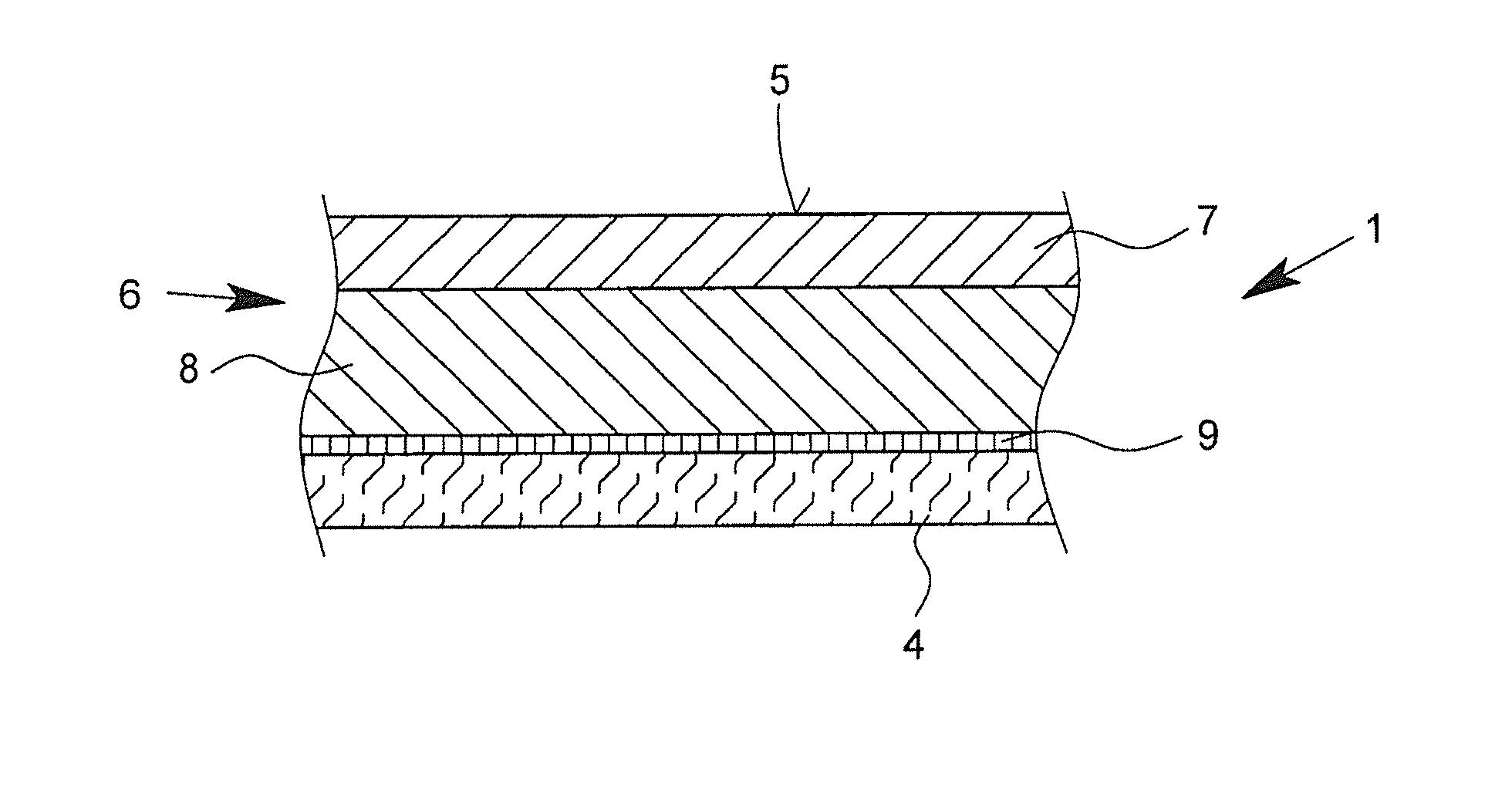

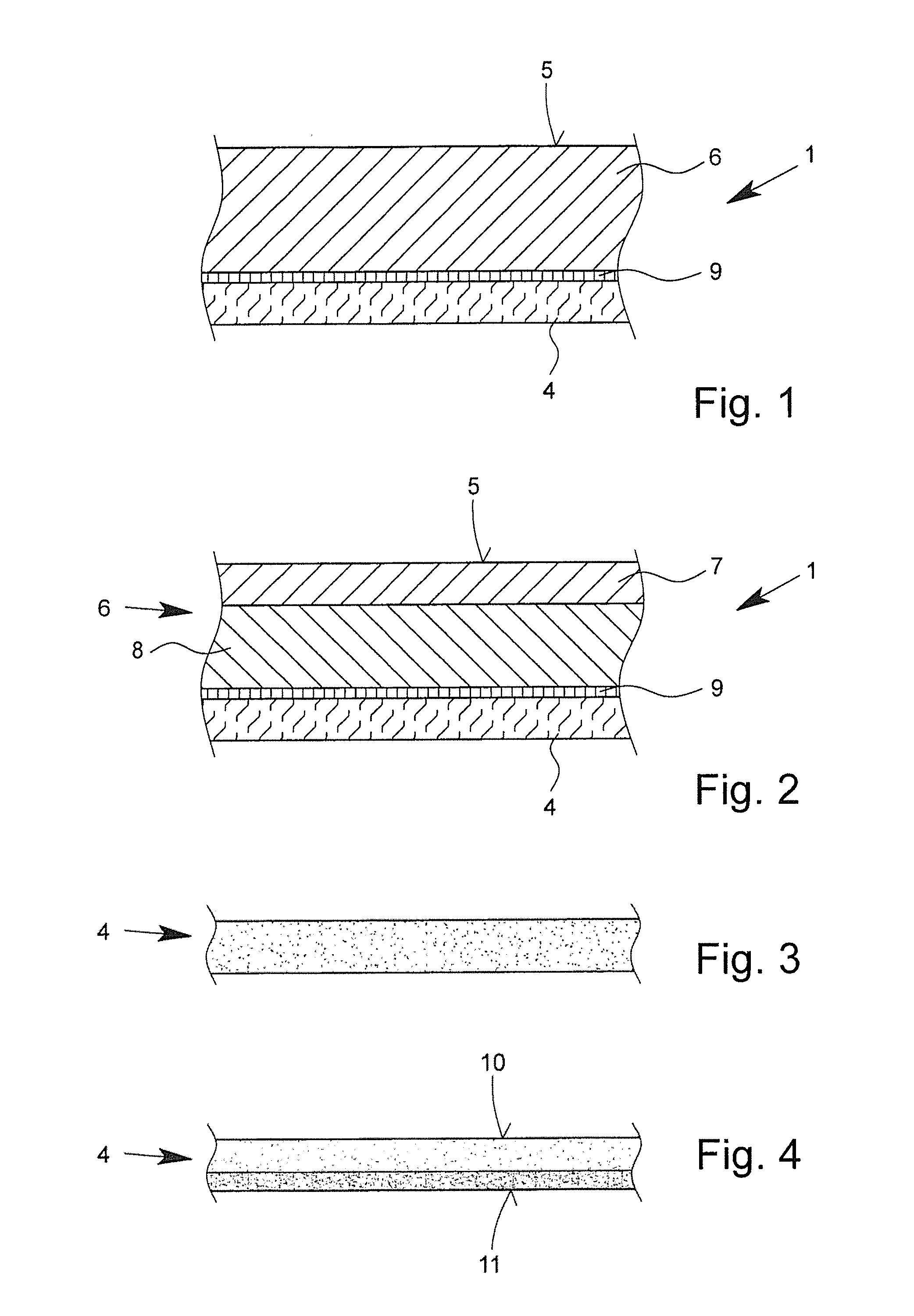

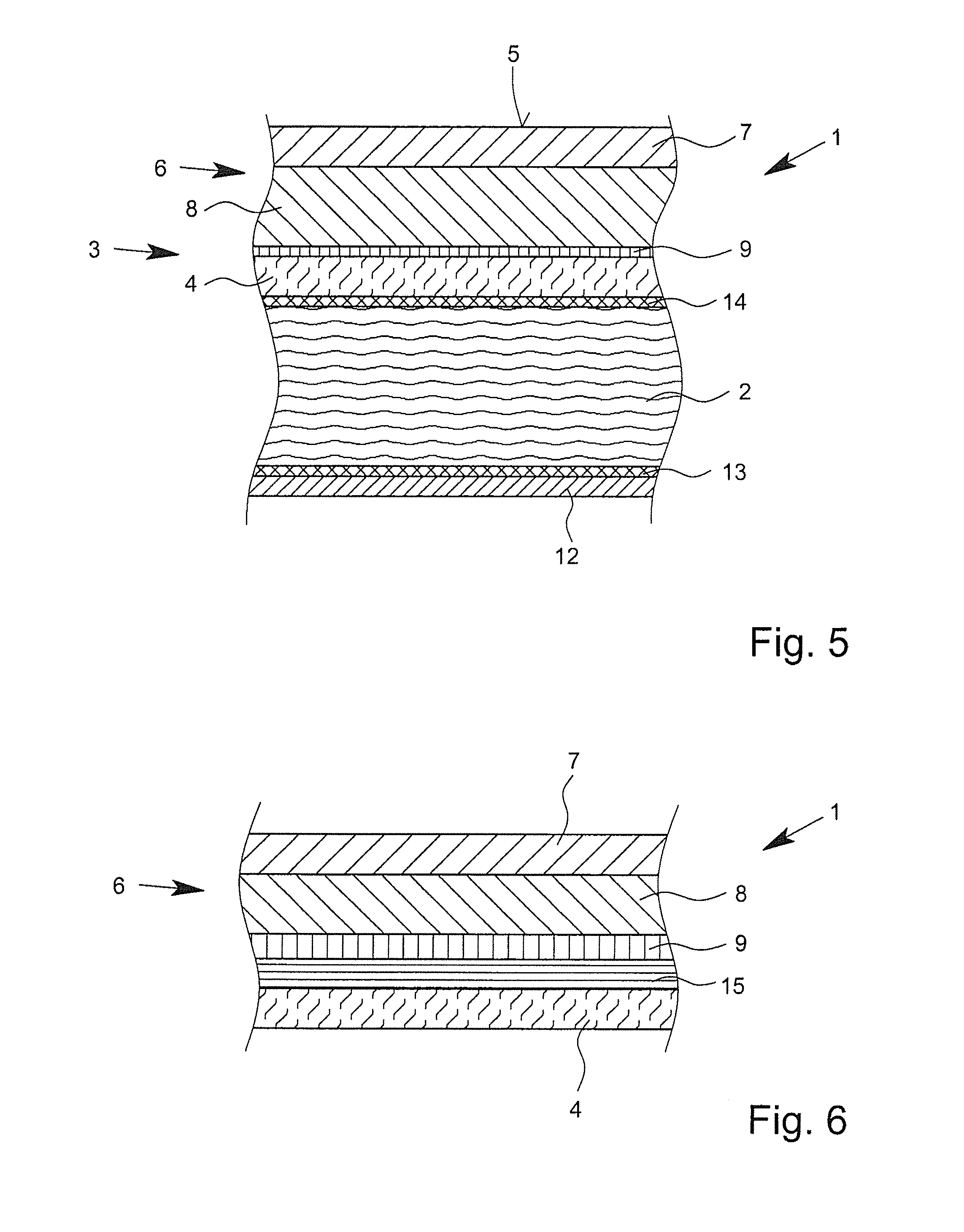

Cover layer with outside film layer of an elastic plastic

InactiveUS20140170359A1Improve propertiesIncreased composite adhesionCovering/liningsFilm/foil adhesivesElastic plasticEngineering

A cover layer (1) for a panel (3) which has a panel base body (2), such as a floor covering panel, wall panel or ceiling sheathing panel and / or furniture component panel, building panel, covering panel or dry finish panel and / or as a facade element, panel element or board element, trimming plate or the like, the cover layer (1) having a paper layer (4) and a film layer (6) of elastic plastic which forms the outside (5) of the cover layer (1). The paper layer (4) is made as a preimpregnate which has already been partially impregnated during paper manufacture or as paper, especially decorative paper, which has been partially impregnated after paper manufacture and before joining to the paper layer (4).

Owner:HUS WERKE HULS +1

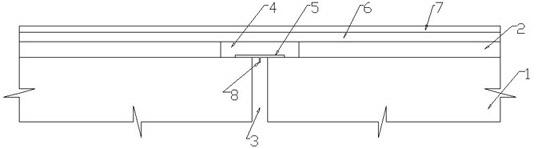

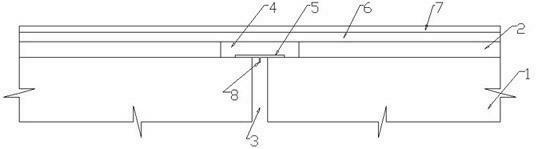

Seamless bridge deck expansion joint structure for road engineering and construction process of seamless bridge deck expansion joint structure

ActiveCN102660922AImprove structural safetyAppropriate costBridge structural detailsBridge erection/assemblyRoad engineeringBridge deck

The invention discloses a seamless bridge deck expansion joint structure for road engineering and a construction process of the seamless bridge deck expansion joint structure. The seamless bridge deck expansion joint structure for the road engineering comprises a bridge body and an expansion join, wherein concrete paving layers are arranged on the bridge body; a preserved notch is formed between two adjacent concrete paving layers; a clearance is reserved between two adjacent bridge bodies or between the bridge body and a bridge abutment; the seamless bridge deck expansion joint structure further comprises an elastic-plastic body and a backing plate; the backing plate is positioned on the bottom surface of the preserved notch for closing the clearance; the backing plate is arranged below the elastic-plastic body; the elastic-plastic body is positioned in the preserved notch for forming an elastic-plastic body expansion joint; and asphalt concrete layers are paved on the concrete paving layers and the elastic-plastic body expansion joint in a penetrating way. According to the seamless bridge deck expansion joint structure disclosed by the invention, a real seamless bridge deck can be formed; and the seamless bridge deck expansion joint structure has the advantages of higher structural safety, greater convenience in construction and convenience in replacement.

Owner:SICHUAN EXPRESSWAY COMPANY

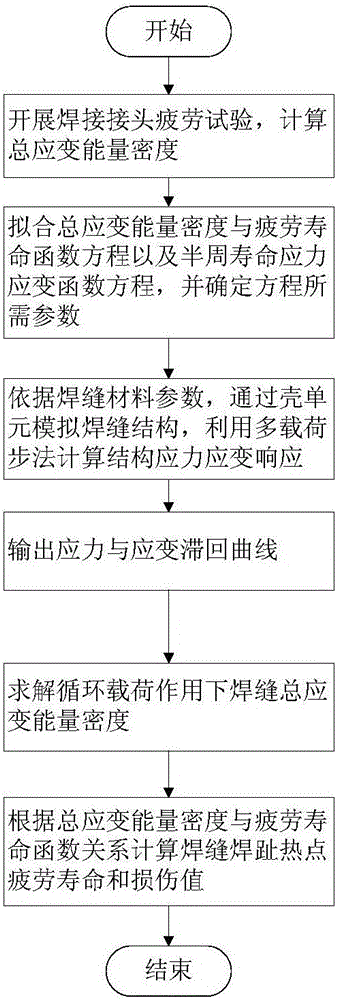

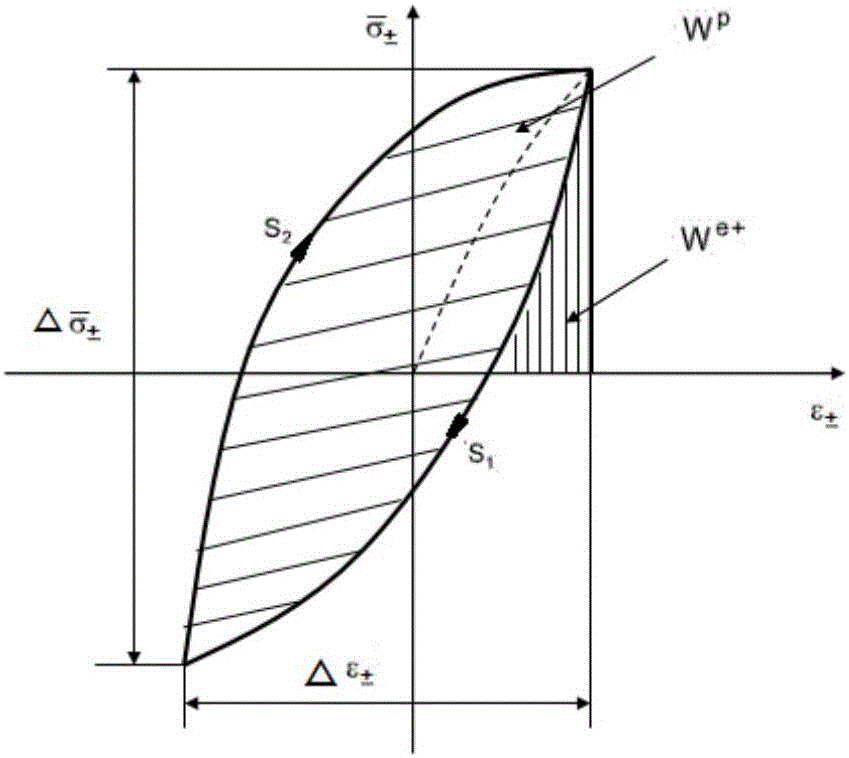

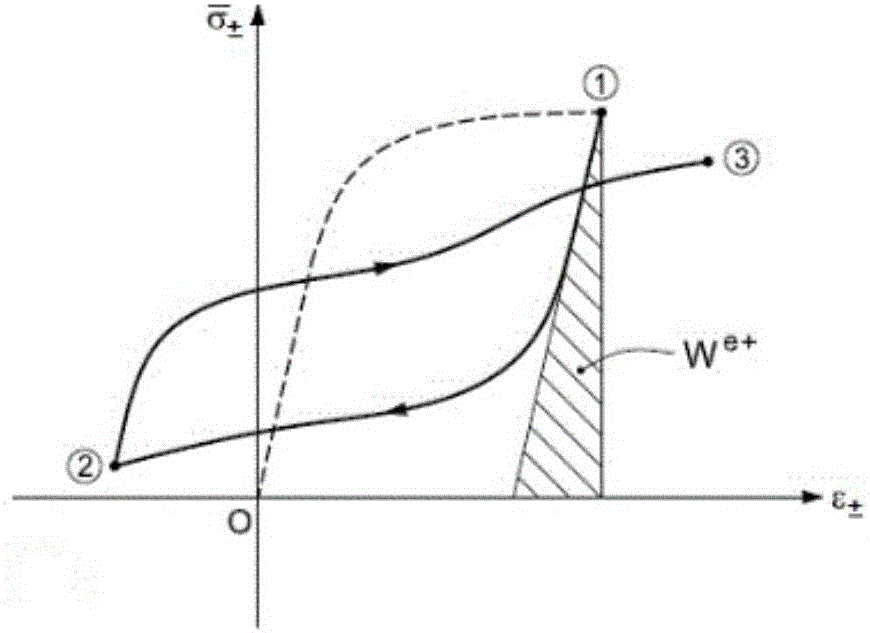

Weld seam fatigue life calculation method based on total strain energy density

ActiveCN106354898AImprove the accuracy of fatigue life calculationAvoid sureDesign optimisation/simulationSpecial data processing applicationsFatigue IntensityFatigue damage

The invention discloses a weld seam fatigue life calculation method based on total strain energy density. The method mainly comprises the steps that 1, the weld-seam total strain energy density, a life function equation and a fatigue strength coefficient, a fatigue strength index, a cyclic strengthening coefficient and a cyclic strain hardening index which are needed by half-cycle life stress and a strain function equation are acquired through a welded joint fatigue test; 2, the weld seam structure is simulated through a shell unit module, the stress-strain response of the weld seam structure under the cyclic load action is calculated through a multi-load step method, and a stress-strain hysteretic curve is output; 3, the total strain energy density is calculated according to the stress-strain response, and the hot point fatigue life and a damage value of a weld toe of the weld seam are calculated by combining the energy density with the life function equation. According to the method, contribution of elastic-plastic stress and strain to the fatigue damage is comprehensively taken into account, scalar quantities are taken as damage parameters, the position and direction problems related to vectors are effectively avoided, the calculation precision is improved, and the time is saved.

Owner:HUNAN UNIV OF TECH

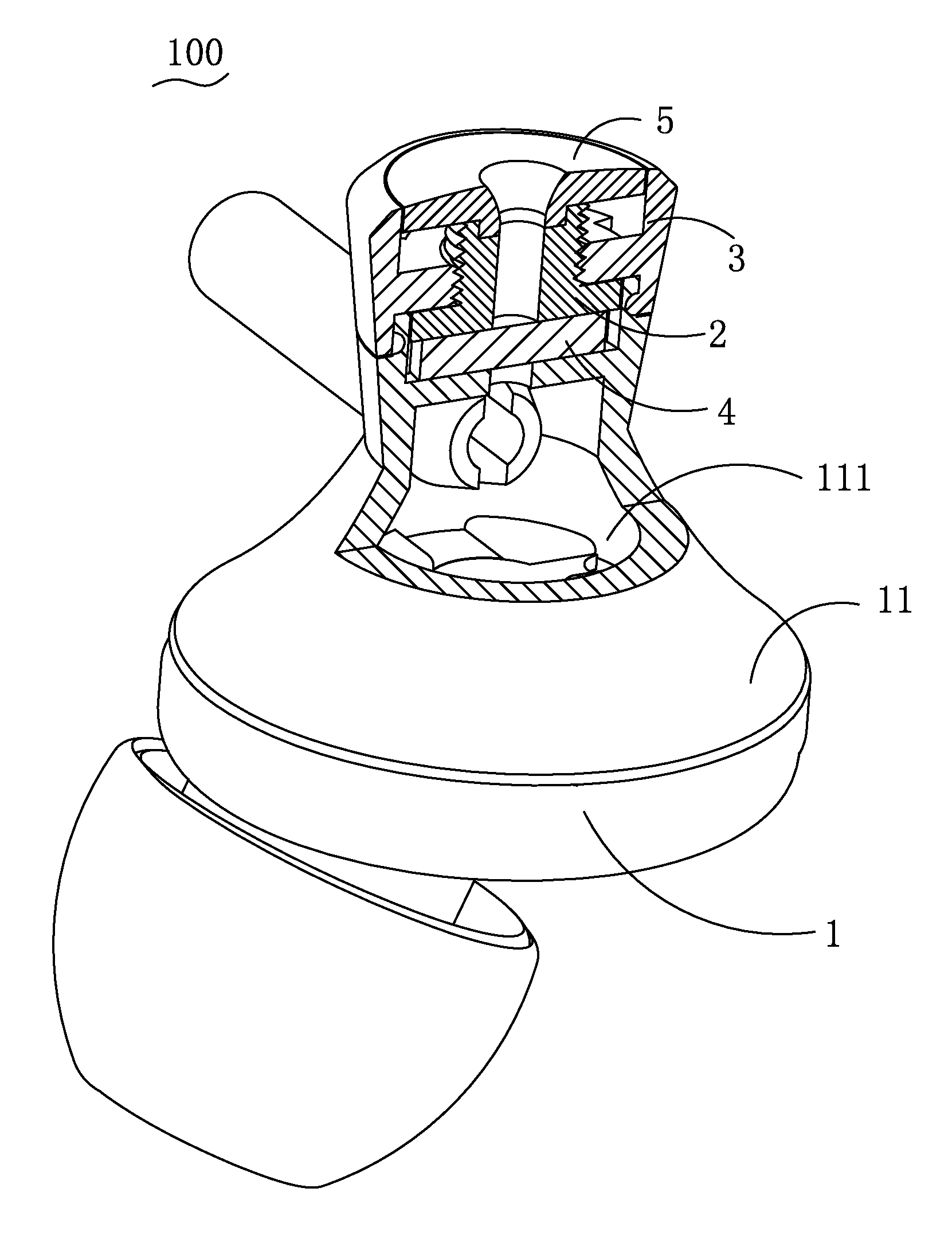

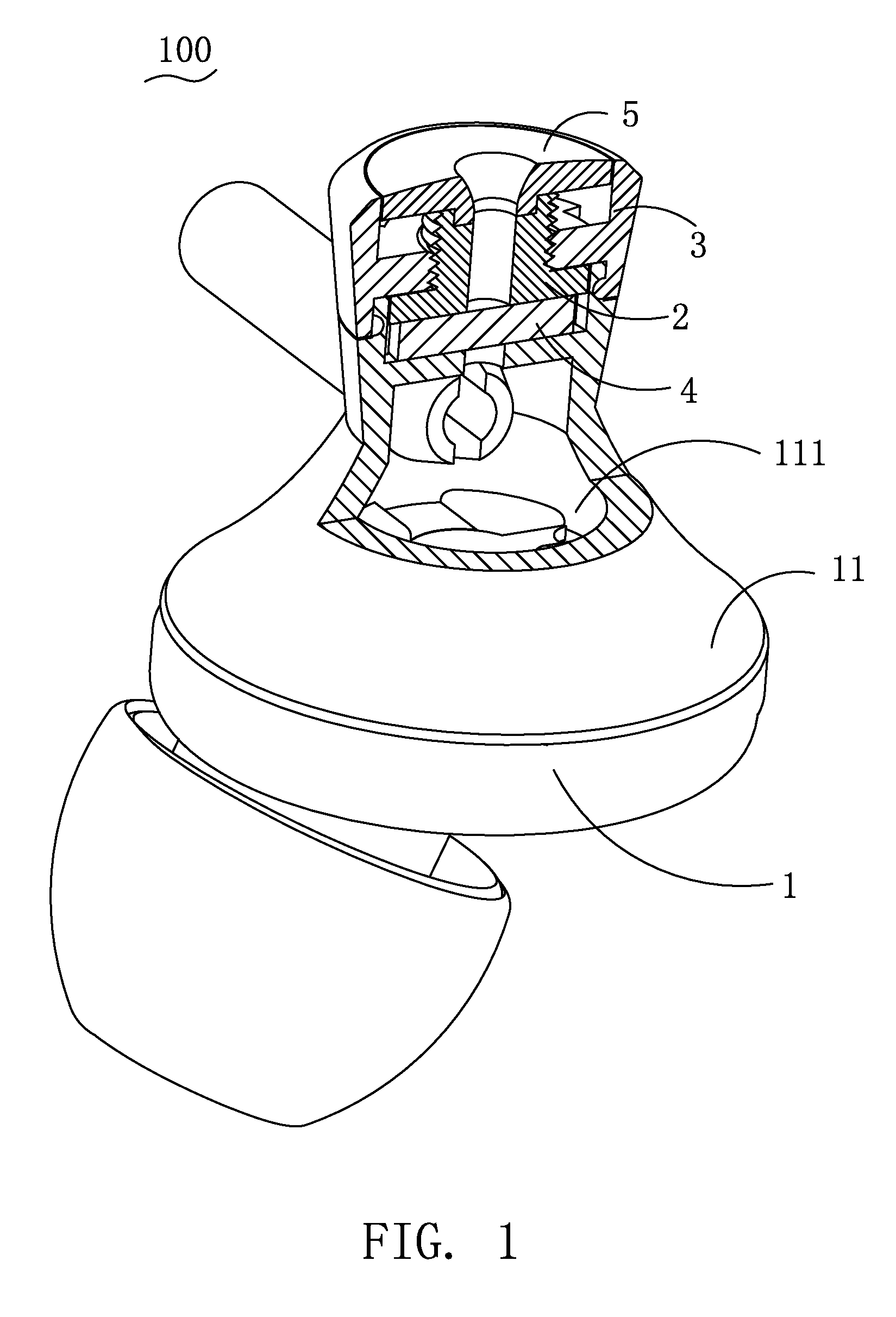

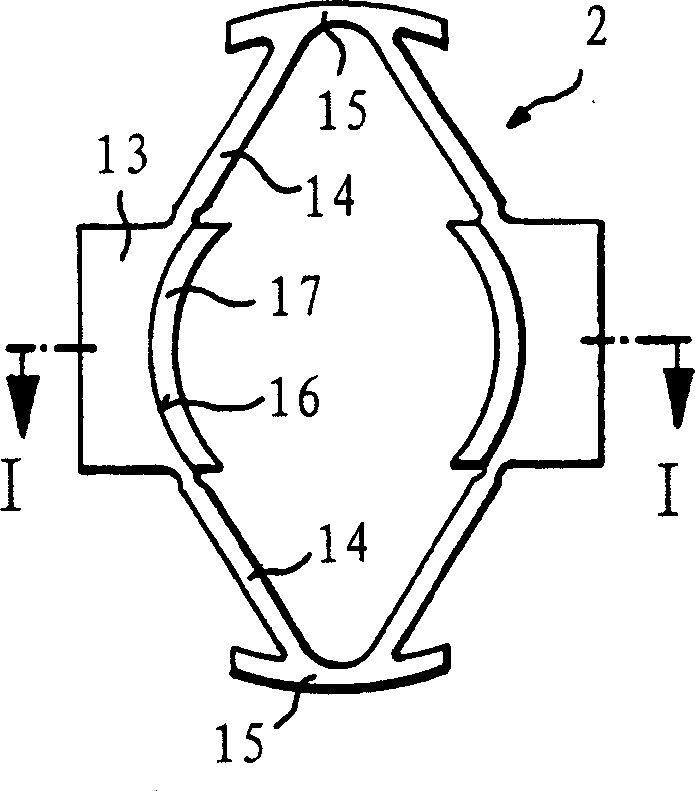

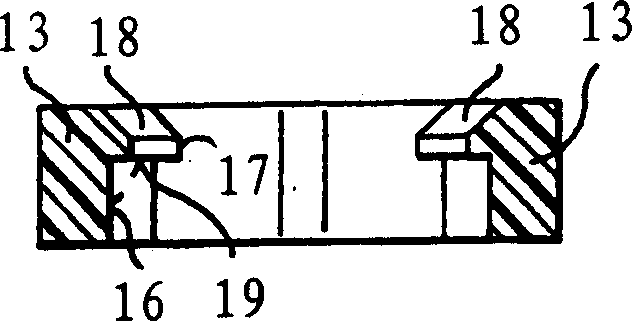

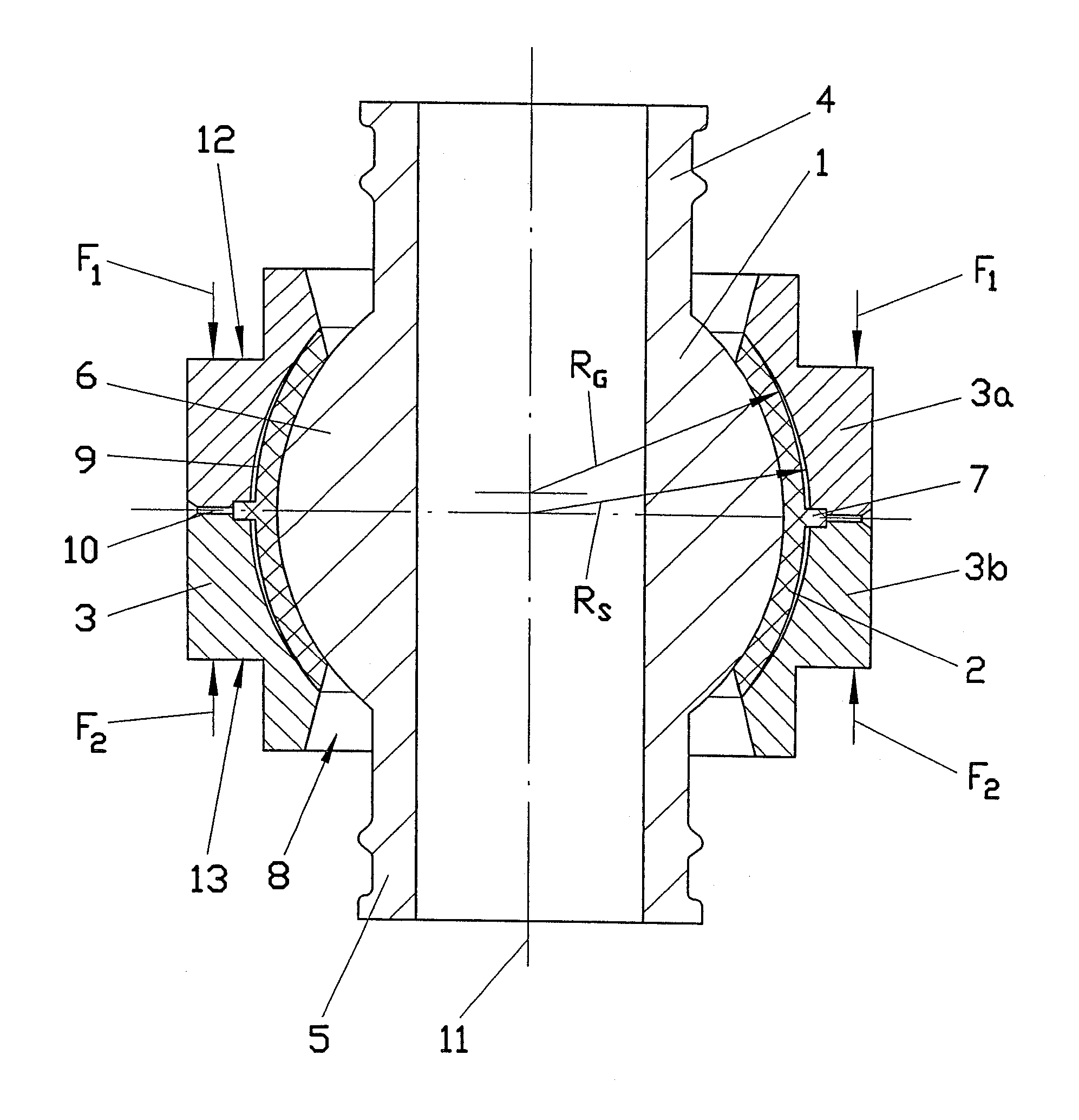

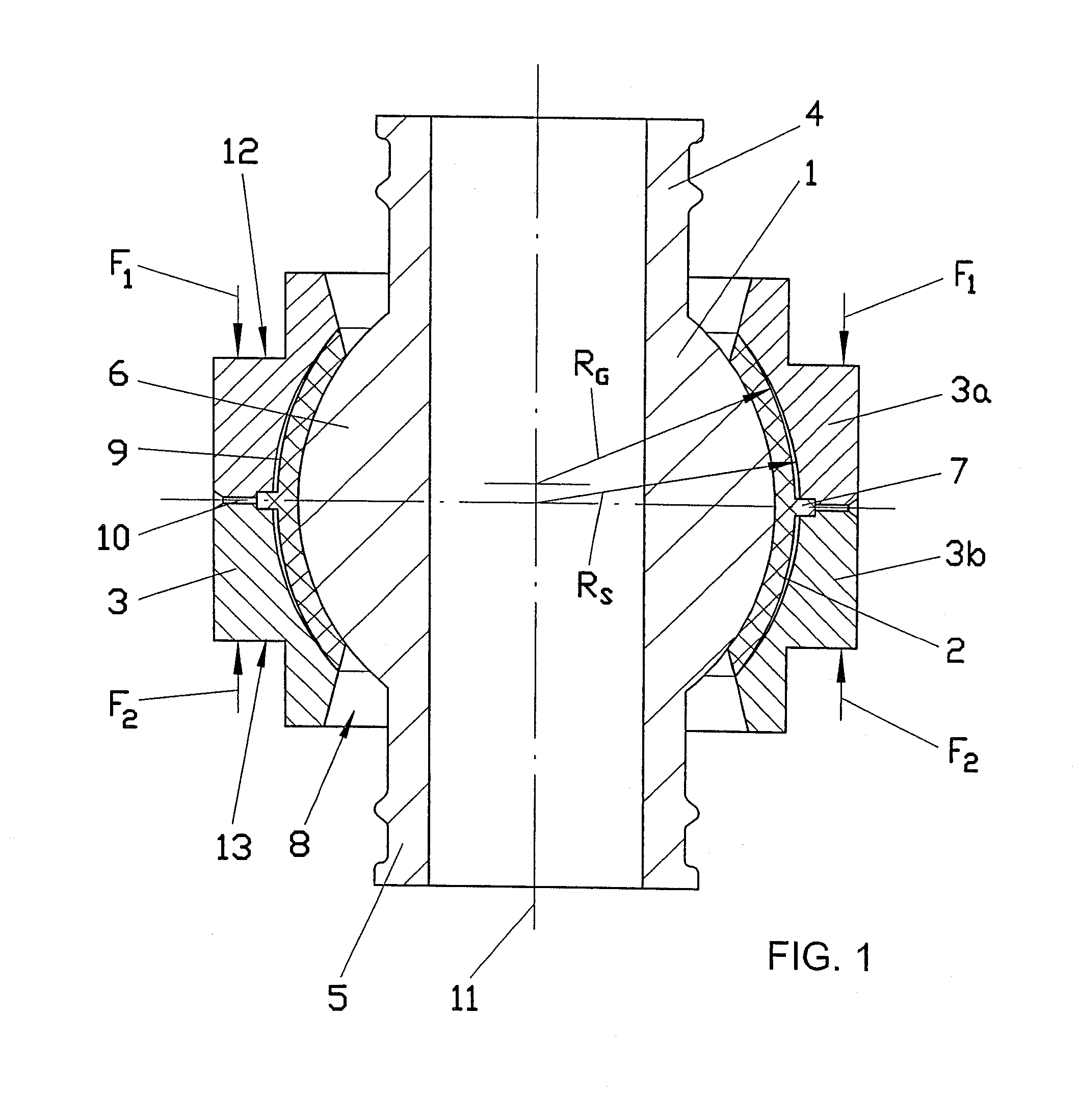

Ball sleeve joint and process for manufacturing same

ActiveUS8282305B2Extended service lifeReduce manufacturing costRolling contact bearingsCouplings for rigid shaftsEngineeringElastic plastic

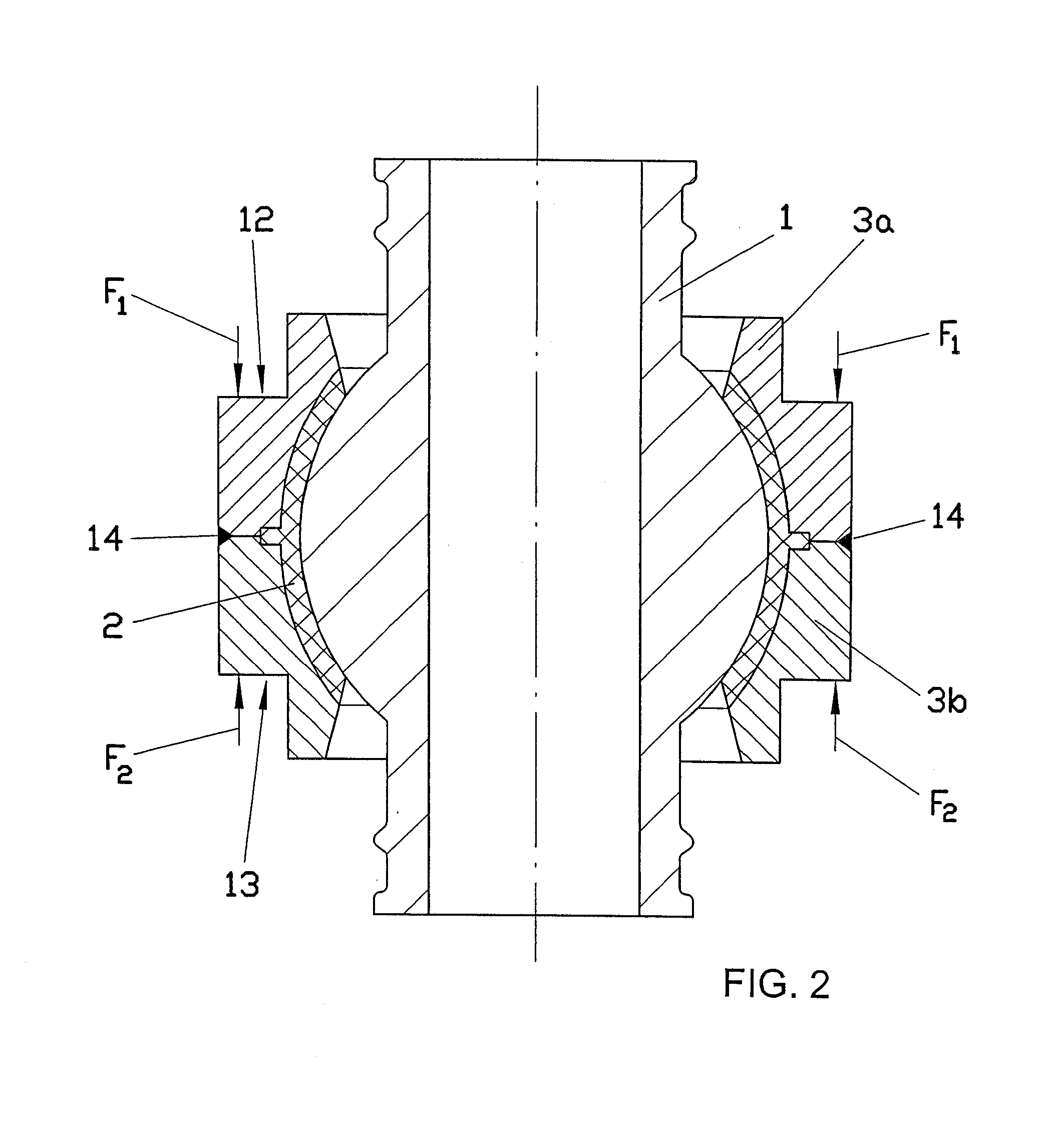

A ball sleeve joint is provided, especially for chassis assembly units and steering assembly units of motor vehicles. The ball sleeve joint includes a joint housing with two housing halves and a ball sleeve provided with a rounded bearing surface. The bearing surface is accommodated in a joint housing, which is manufactured from an elastic plastic and is fixed in a recess of the joint housing, as well as a process for manufacturing such a ball sleeve joint. The two housing halves (3a, 3b) are pressed together with defined pressing forces during the mounting of the ball sleeve joint (1) in the direction of the longitudinal axis of the ball sleeve joint (1). The two housing parts are held in the installed position predetermined by the pressing forces by means of at least one connection (14) in substance between the housing parts (3a, 3b).

Owner:ZF FRIEDRICHSHAFEN AG

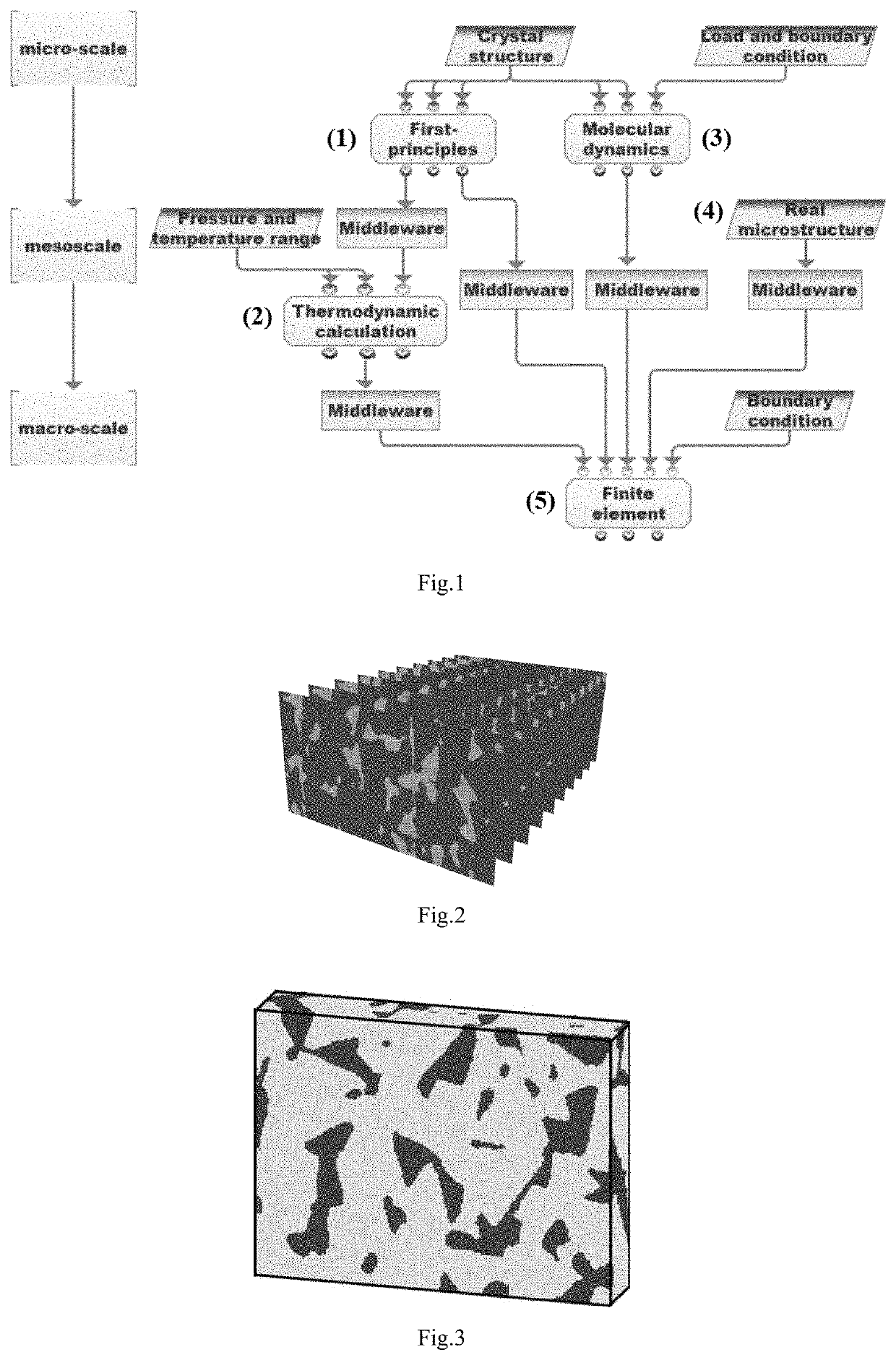

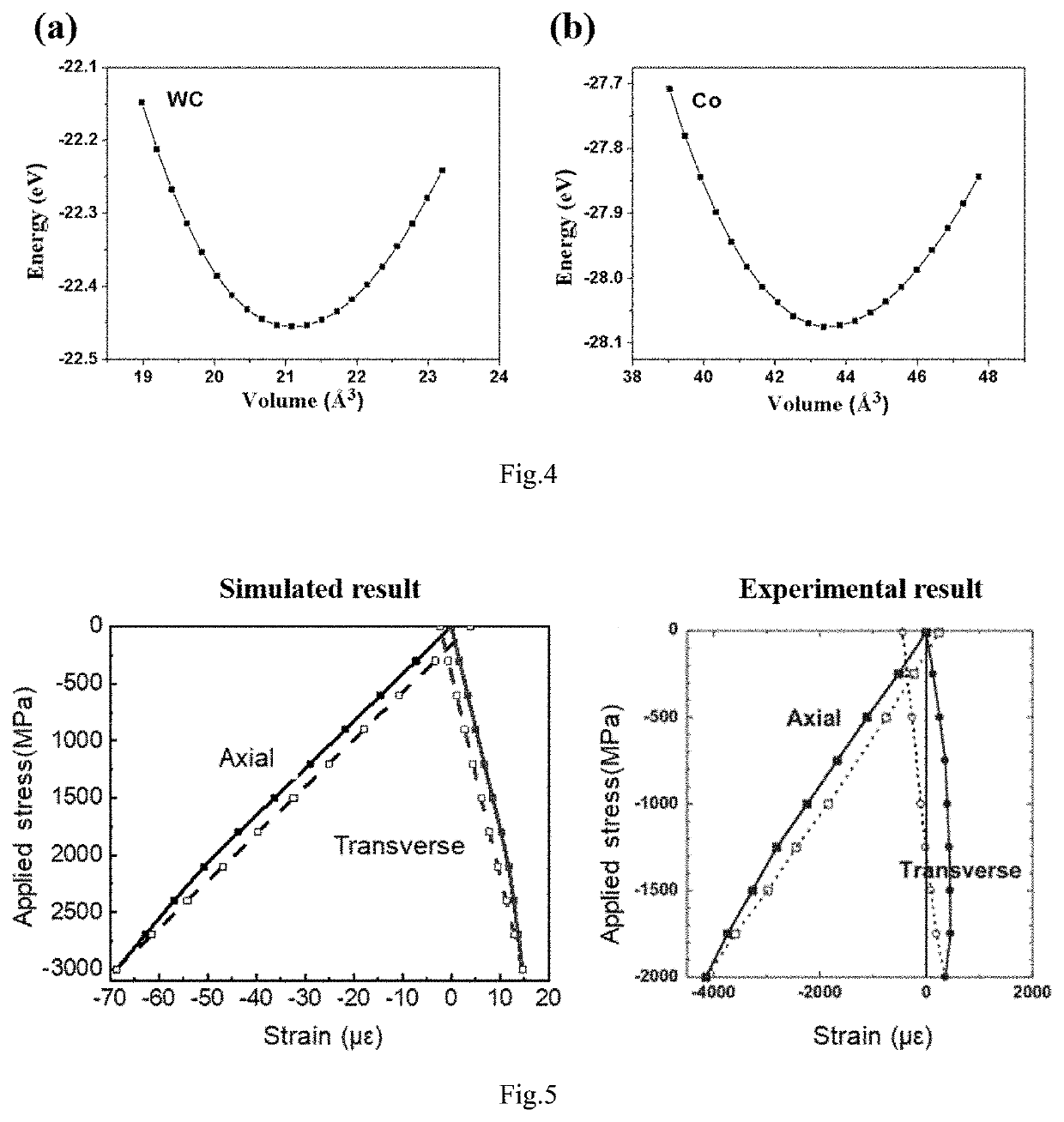

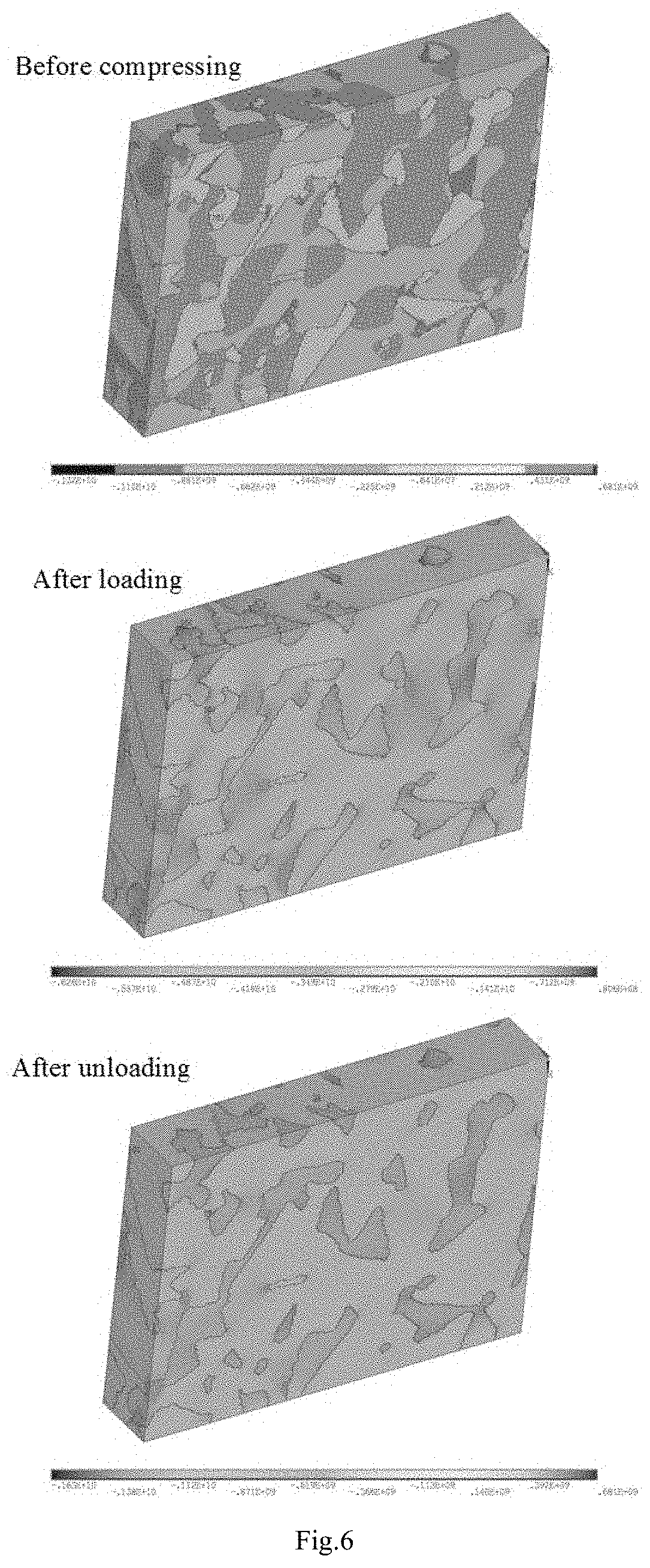

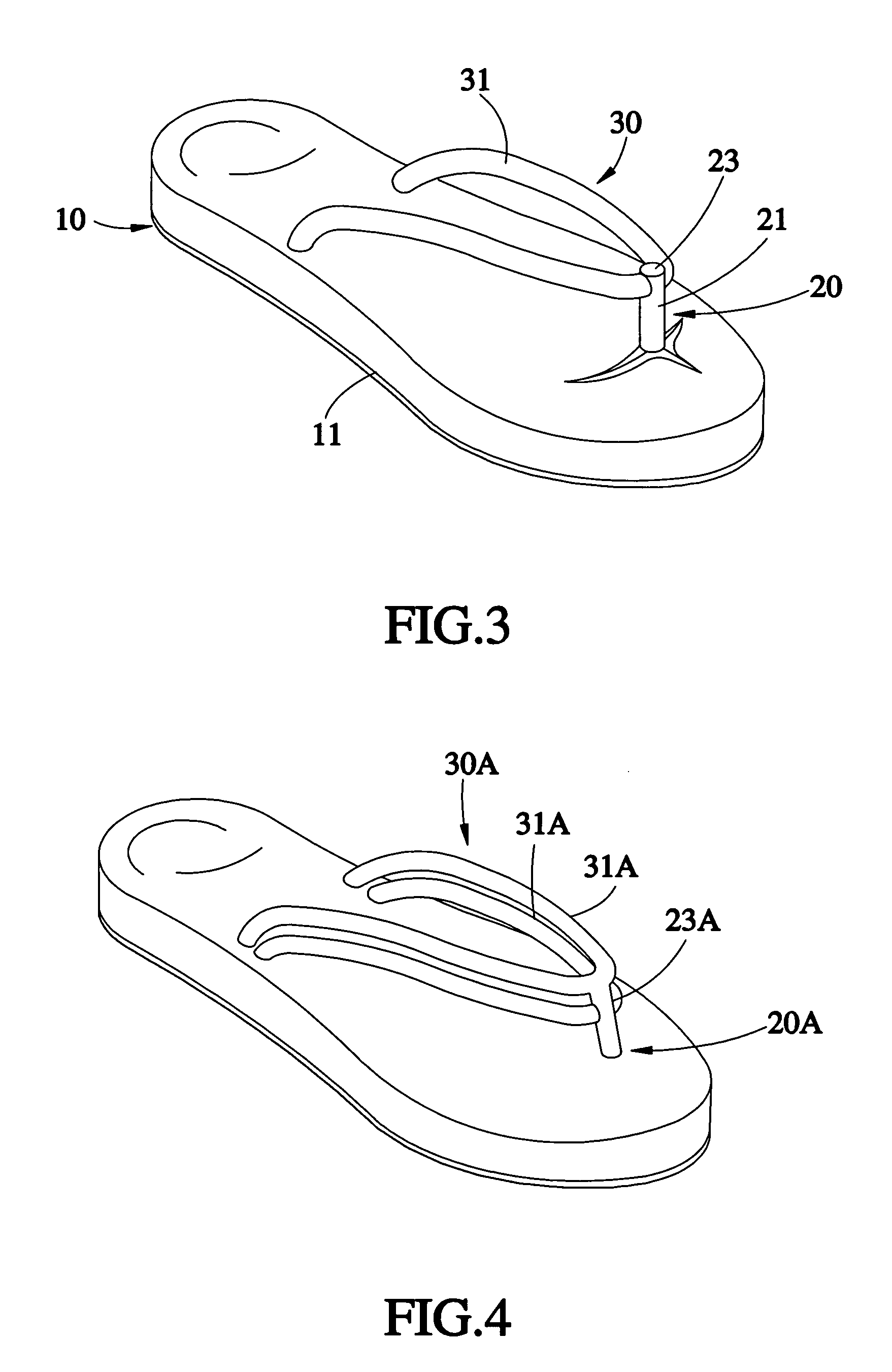

Multi-scale method for simulating mechanical behaviors of multiphase composite materials

PendingUS20210118530A1Plasticity of hard and brittle ceramic phase is negligibleWay accurateChemical property predictionDesign optimisation/simulationMicro structureMacroscopic scale

A computer simulation analysis method suitable for describing the mechanical behavior of multiphase composites based on the real microstructure of materials relates to a multidisciplinary field such as computational material science, simulation and high throughput calculation. Through the first-principles calculation under nano scale, the molecular dynamics simulation under micro scale, and the thermodynamic calculation under mesoscopic scale, various physical parameters needed for the finite element simulation under macro scale can be obtained, including the elastic and plastic physical parameters of each phase in the composite at different temperature and different grain sizes. Focused ion beam experiment and image processing are adopted to obtain real material microstructure. Through the parameter coupling and parameter transfer among the calculated results of various scales, combining the microstructure of the material, stress-strain relationship, stress distribution and its evolution law, plastic deformation and other mechanical behaviors of the multiphase composites under complex stress and different temperature can be simulated.

Owner:BEIJING UNIVERSITRY OF TECH

Method for constructing elastic-plastic-damage coupling mechanical constitutive model of rock material

PendingCN110705165AImprove accuracyWide applicabilityMaterial strength using tensile/compressive forcesDesign optimisation/simulationMechanical modelsElastic plastic

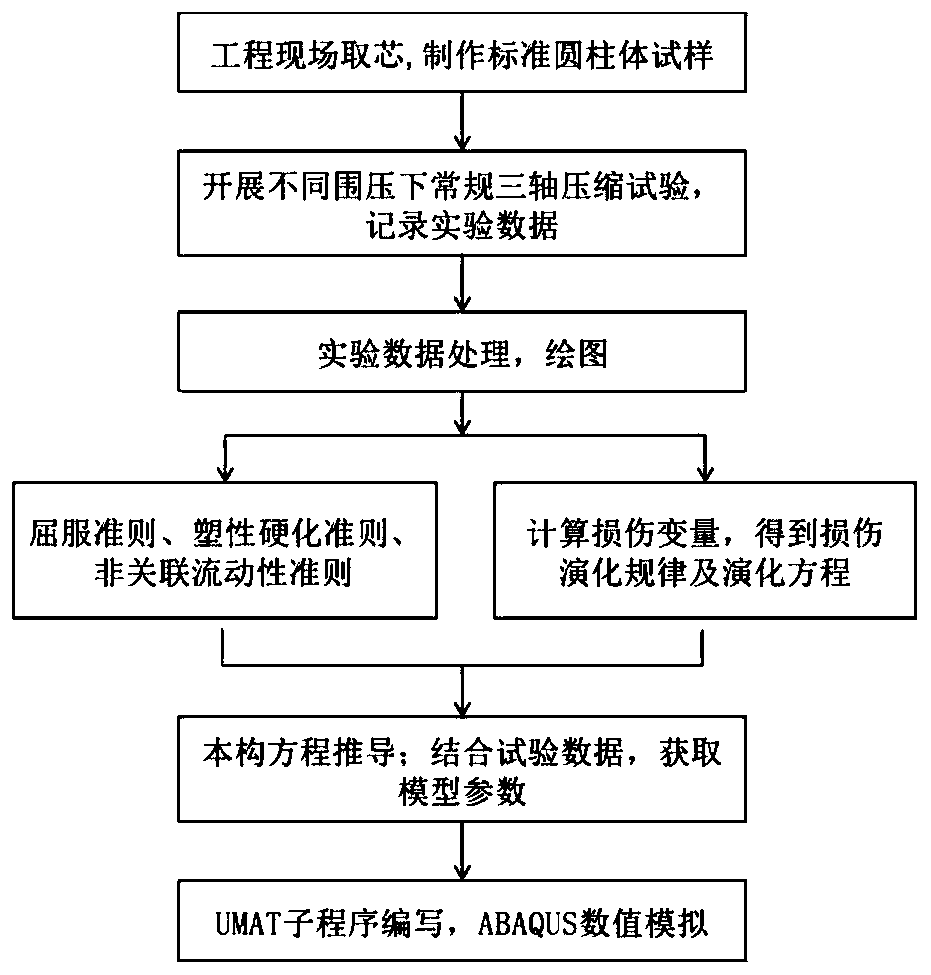

The invention discloses a method for constructing an elastoplasticity-damage coupling mechanical constitutive model of a rock material. The method comprises the following steps of obtaining the rock material on an engineering site, and manufacturing a standard cylinder sample; carrying out conventional triaxial compression mechanical tests under different confining pressures; obtaining a rock yield criterion, a plastic hardening criterion and a non-associated fluidity rule in combination with a test result; calculating a rock damage variable according to the stress-strain curve, and obtaininga rock damage evolution equation according to a damage variable-axial strain evolution rule; deriving a constitutive equation based on an elastic-plastic mechanics theory and an irreversible thermodynamic damage constitutive theory; combining the test data to obtain model parameters; writing the mechanical model into a UMAT subprogram, embedding the UMAT subprogram into ABAQUS finite element software, and carrying out triaxial test numerical simulation, so as to verify and improve the model. The method is clear in mechanical significance, simple in parameter acquisition, wide in application range and relatively high in accuracy.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

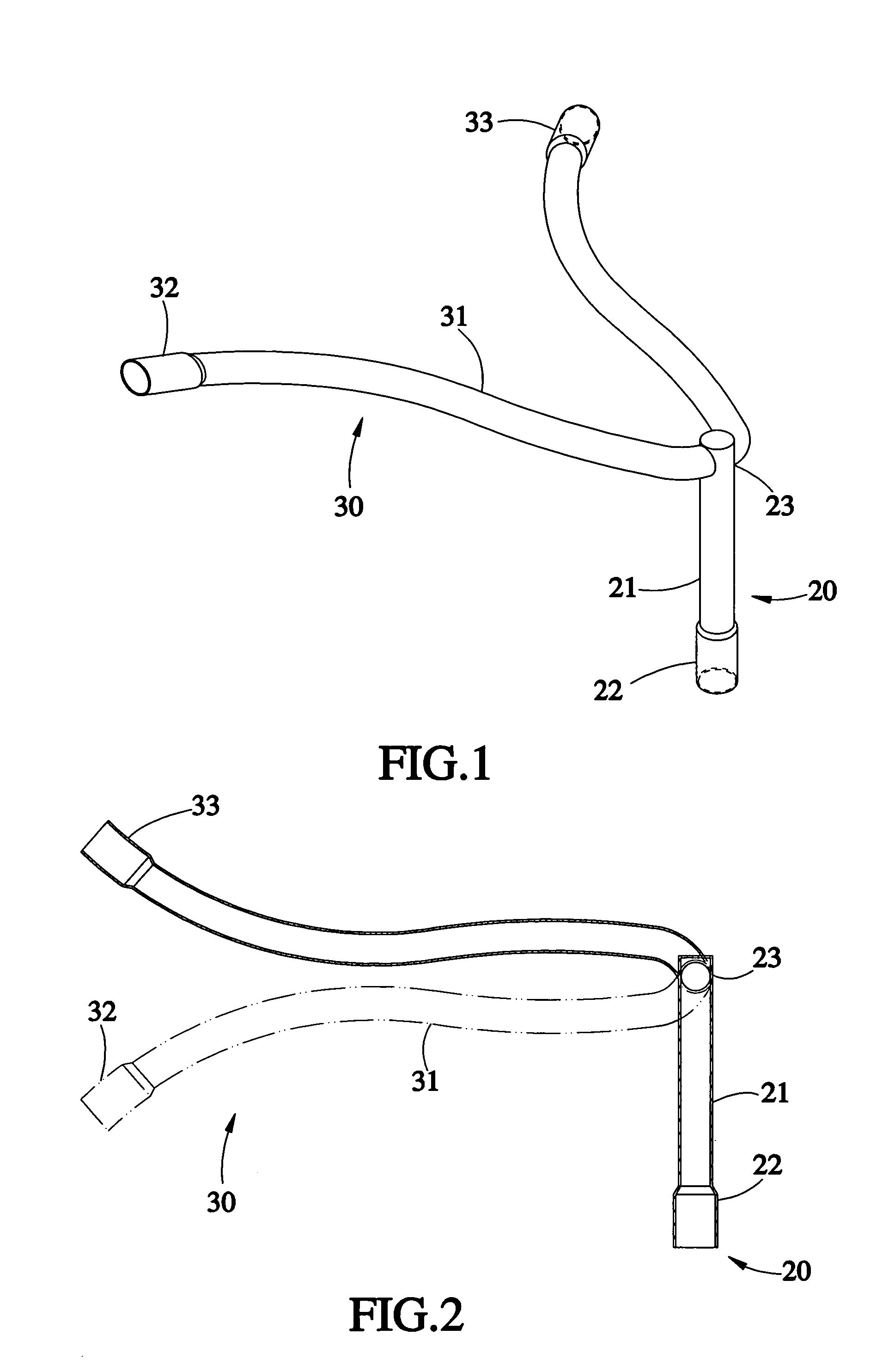

Footwear with improved straps

Owner:PAN KUNG SHENG

Multi-scale simulation method for mechanical behaviors of multi-phase composite material

ActiveCN110210103AImprove continuityRealize simulationChemical property predictionDesign optimisation/simulationMacroscopic scaleFirst principle

Owner:BEIJING UNIV OF TECH

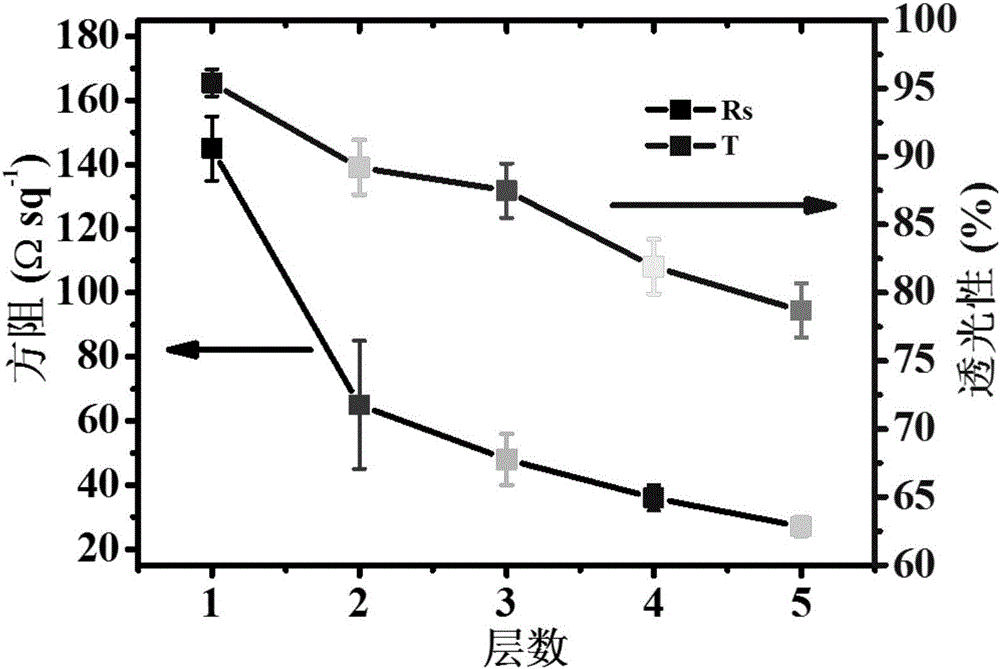

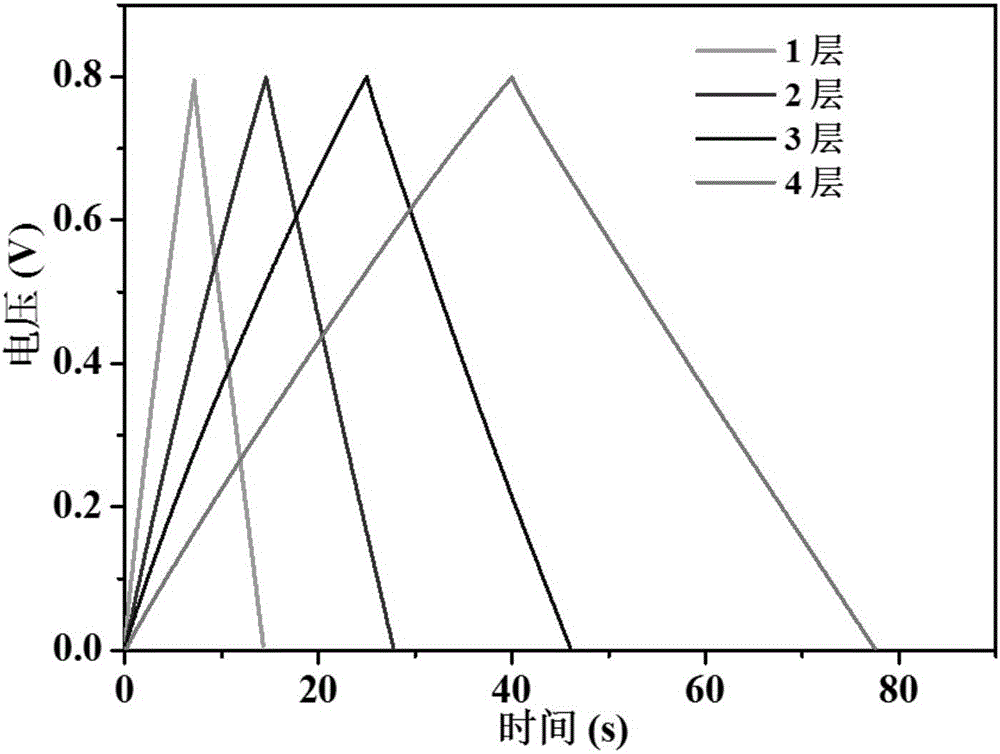

Flexible transparent thin-film electrode and manufacturing method thereof

ActiveCN105914047AReduce surface tensionImprove wettabilityHybrid capacitor electrodesHybrid/EDL manufactureSulfonateScreen printing

The invention discloses a flexible transparent thin-film electrode and a manufacturing method thereof. The structure of the electrode is characterized in that a poly (3,4-ethylenedioxythiophene) : poly (styrene sulfonate) (PEDOT:PSSY) stretchable substrate is employed. The substrate is made from a high-elasticity stretchable plastic material like a PVA material, a PDMS material, a PUA material, or a hydrogel. In addition, the manufacturing method comprises: a PEDOT:PSSY solution is deposited on an elastic plastic substrate by means of spinning, spraying, silk-screen printing or ink-jet printing. Therefore, the manufactured transparent electrode has excellent integrated performances including high transparency, high electrical conductivity, excellent electrochemical performance, high flexibility like random bending or warping, surface smoothness, and high chemical stability and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

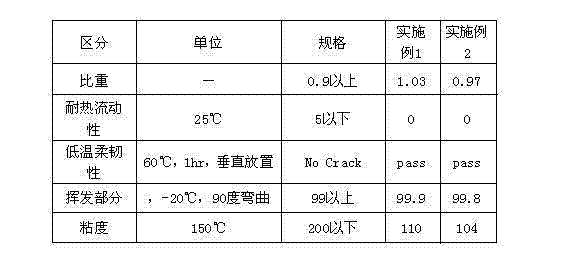

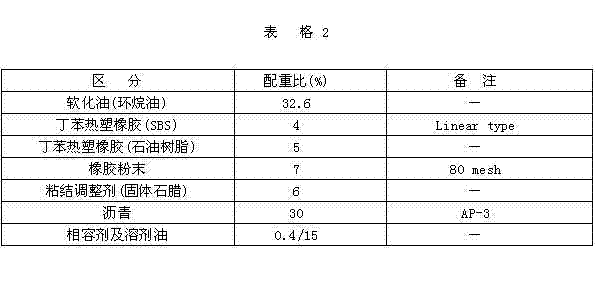

High-solid-content solvent type non-curing rubber asphalt waterproof paint and preparation method thereof

ActiveCN103666261AEasy constructionGood heat resistance and fluidityNatural resin coatingsUnspecified rubber coatingsBituminous waterproofingHeat resistance

The invention discloses a high-solid-content solvent type non-curing rubber asphalt waterproof paint which is prepared by mixing the following ingredients in weight percentage: 20-65 percent of softening oil, 3-20 percent of thermoplastic styrene butadiene rubber, 5-25 percent of rubber powder, 3-20 percent of a bonding modifier, 13-58 percent of asphalt, 10-30 percent of solvent oil and 0.3-1.0 percent of a compatilizer. The waterproof paint can be used under the construction condition of below 30-50 DEG C, the construction is simple, and the high-temperature heat resistance in summer and the low-temperature elasticity in winter are high. The waterproof paint has high heat-resistant liquidity, always keeps in an elastic-plastic colloidal state in the entire service life, is suitable for any forms of underlayer base surfaces, and can cut down the engineering time substantially. The invention further discloses a preparation method of the high-solid-content solvent type non-curing rubber asphalt waterproof paint.

Owner:李崇

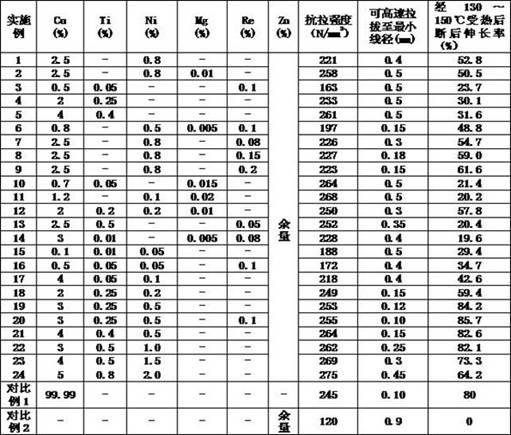

High Strength Zinc Alloy

The invention discloses a high-strength zinc alloy that can be drawn into thin wires at high speed, which contains 0.1%-5% copper, 0.01%-0.8% titanium or / and 0.05%-2% nickel by weight. The balance is zinc and other unavoidable impurities, and the content of impurities in the whole alloy is not more than 0.05% by weight. The product of the present invention has high strength, which can reach or even exceed the index of T2 and T3 soft (M) pure copper wires; it has good cold plastic processing performance, such as drawing wires with thinner wire diameters by high-speed drawing process , the thinnest wire diameter can reach φ0.1mm, the processing technology is simple, and it can realize industrial continuous production; it has a high working temperature; it has good corrosion resistance, small intergranular corrosion tendency, and high dimensional stability. Therefore, the present invention can replace the fine-diameter copper alloy wires used in domestic metal elastic plastic tiles, braided wires for coaxial cable shielding, and spring wires.

Owner:铜陵森泰金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com