High-solid-content solvent type non-curing rubber asphalt waterproof paint and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied to asphalt coatings, unspecified rubber coatings, natural resin coatings, etc. Found damage points and repair, good extensibility and flexibility, the effect of reducing engineering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

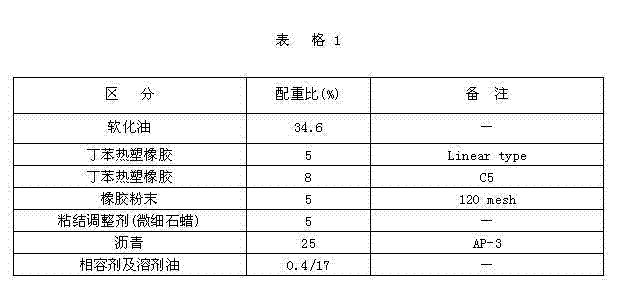

Embodiment 1

[0028] A high solid content solvent-based non-curing rubber asphalt waterproof coating, its composition is as shown in Table 1:

[0029]

[0030] The softening oil is mineral oil or vegetable oil, and the mineral oil is aromatic oil or naphthenic oil; the vegetable oil is linseed oil, soybean oil, castor oil or rapeseed oil.

[0031] The styrene-butadiene thermoplastic rubber is composed of rubber, thermoplastic elastomer or two mixtures, including SBS, SBR, EVA, PE, petroleum resin (c5, c9, c5~c9), natural resin, coumarone resin .

[0032] The particle size of rubber powder is between 30 and 120 mesh.

[0033] The bonding regulator is solid paraffin wax, fine paraffin wax, polyethylene wax, polypropylene wax, amine wax, dioctyl phthalate or dibutyl phthalate.

[0034] The asphalt is straight-run asphalt, blown asphalt or hard asphalt.

[0035] The solvent oil is 70# fragrant flower solvent oil, 90# petroleum ether, 120# rubber solvent oil, 190# detergent oil, 200# paint...

Embodiment 2

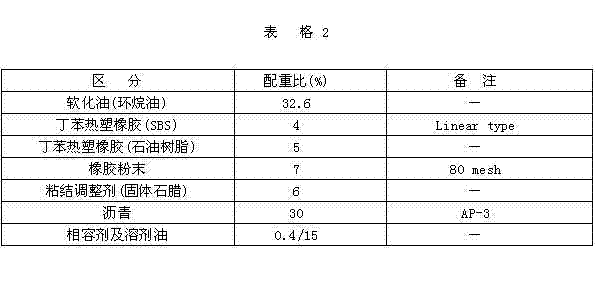

[0042] A high solid content solvent-based non-curing rubber asphalt waterproof coating, its composition is as shown in Table 2:

[0043]

[0044] The preparation method of above-mentioned high solid content solvent type non-curing rubber asphalt waterproof coating comprises the following steps:

[0045] a. Stir for the first time: Add styrene-butadiene thermoplastic rubber and asphalt to the softened oil at 160~200°C, and stir evenly;

[0046] b. The second stirring: add rubber powder and bonding modifier to the material after the first stirring, and stir evenly;

[0047] c. The third stirring: Add solvent oil and compatibilizer to the material after the second stirring, and stir evenly at 120~160°C.

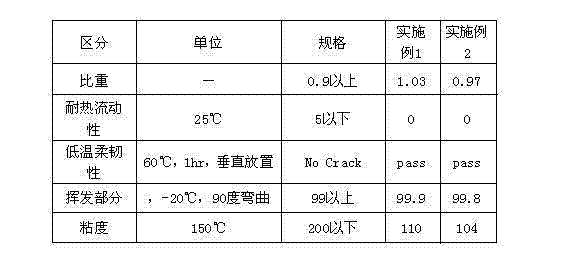

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com