Patents

Literature

11558results about "Forms/shuttering/falseworks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

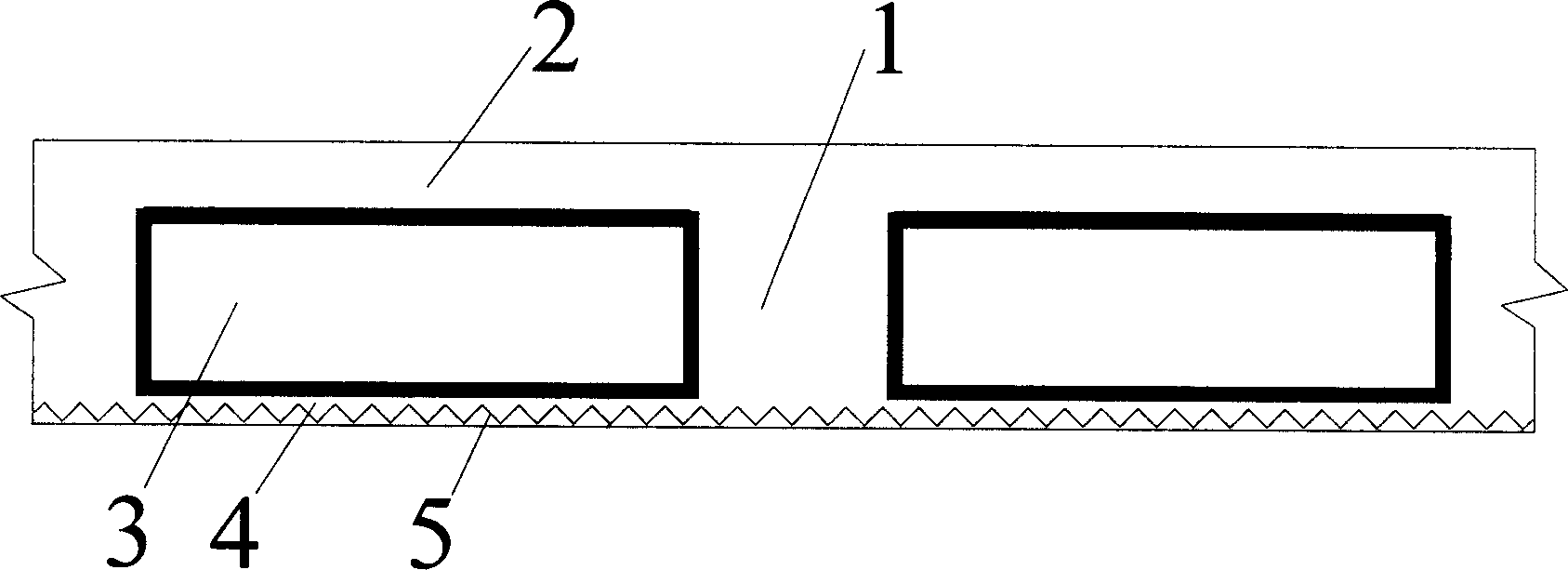

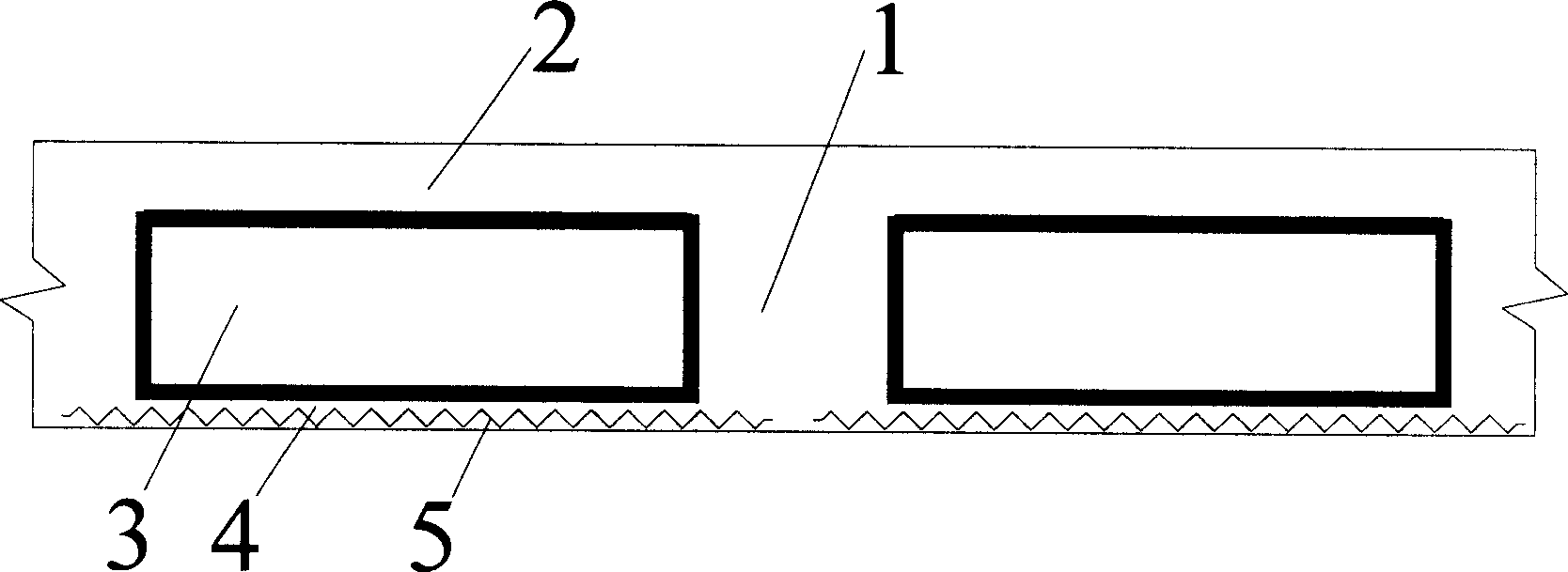

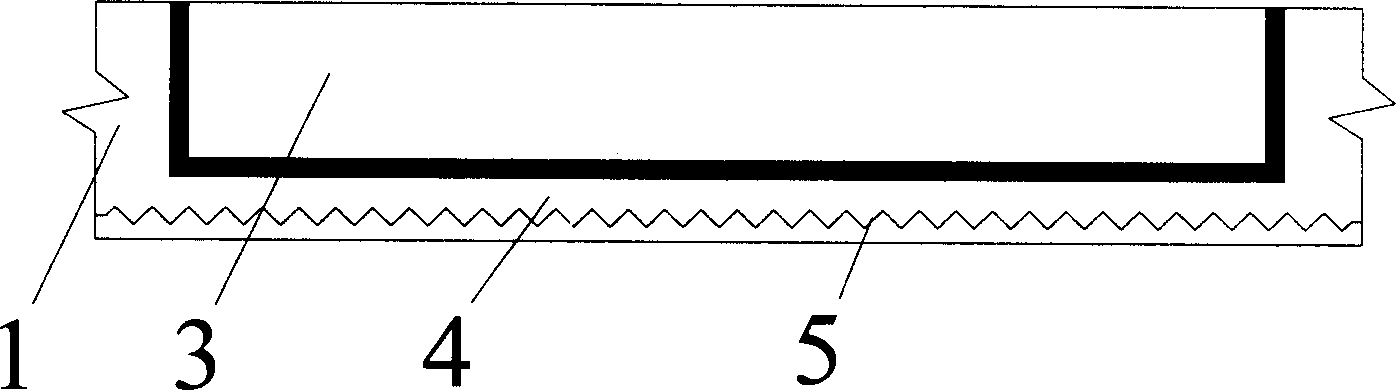

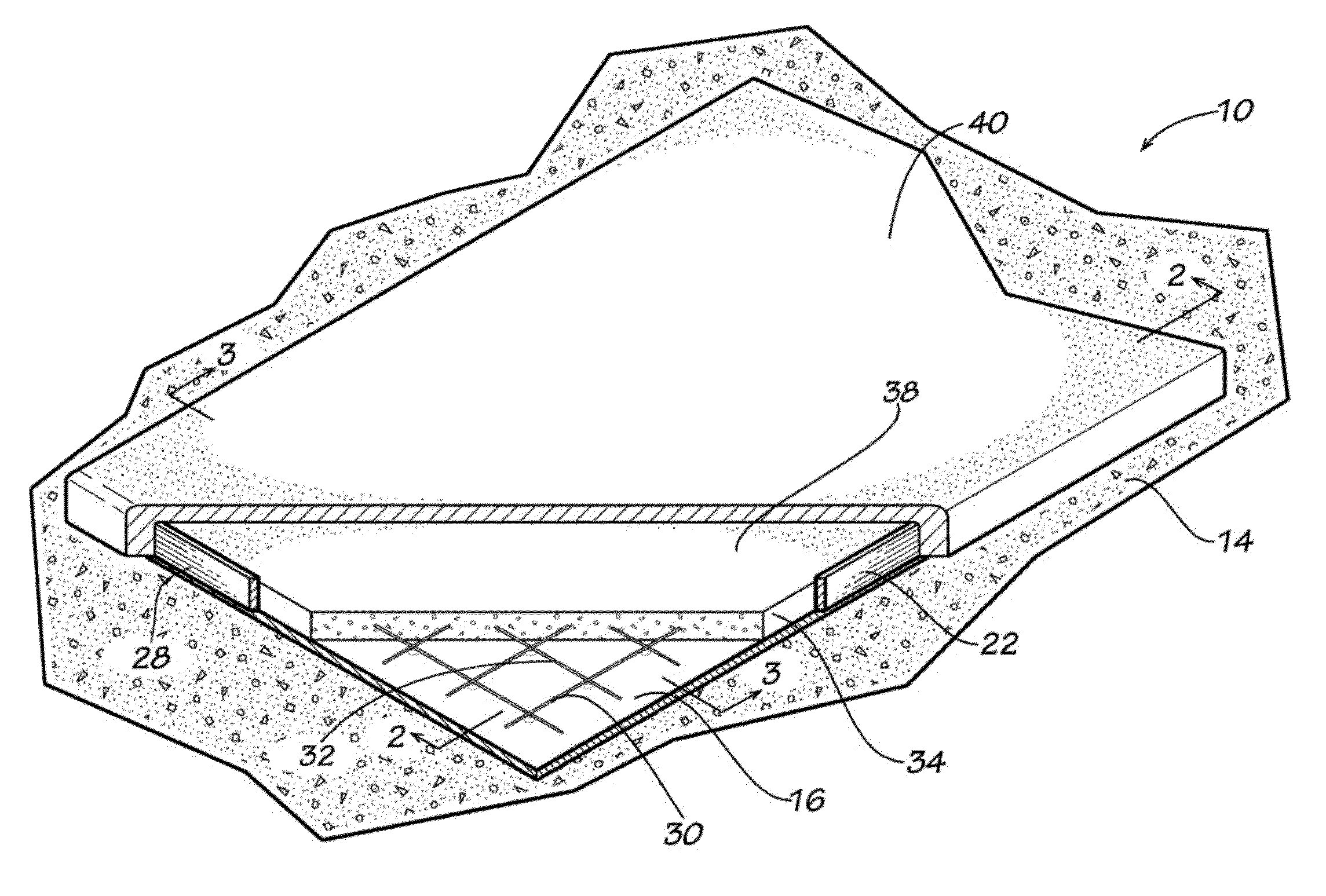

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

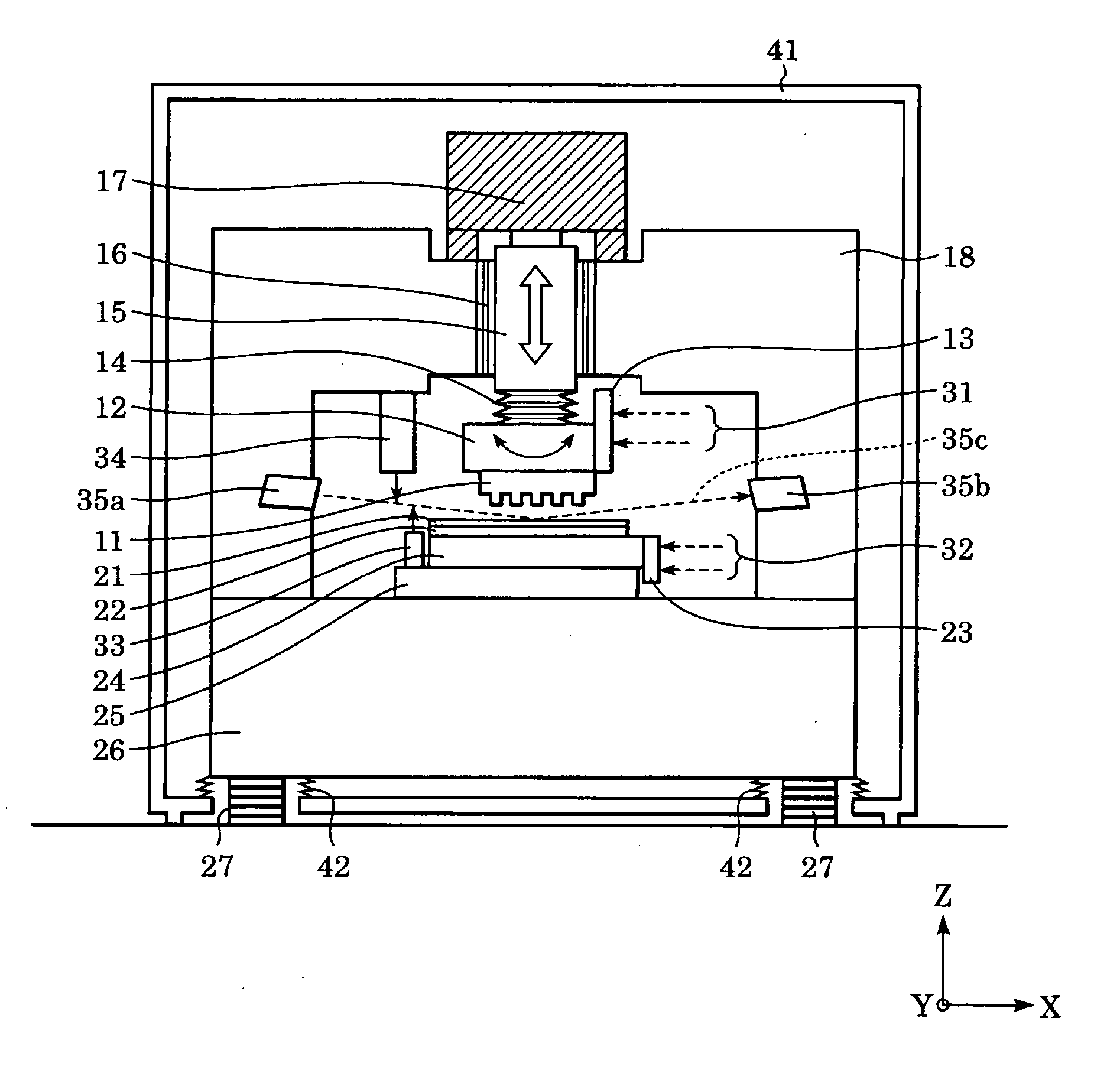

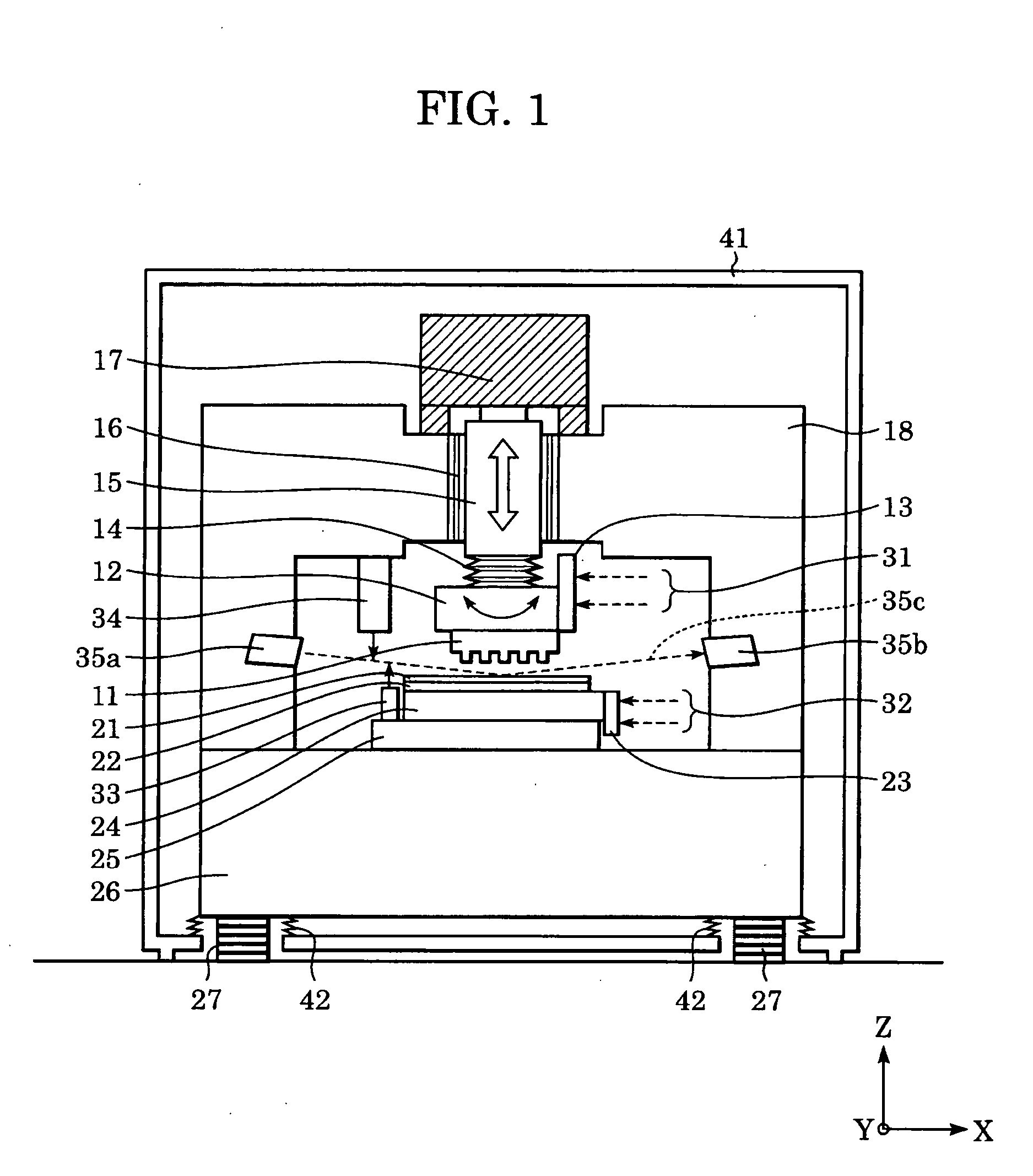

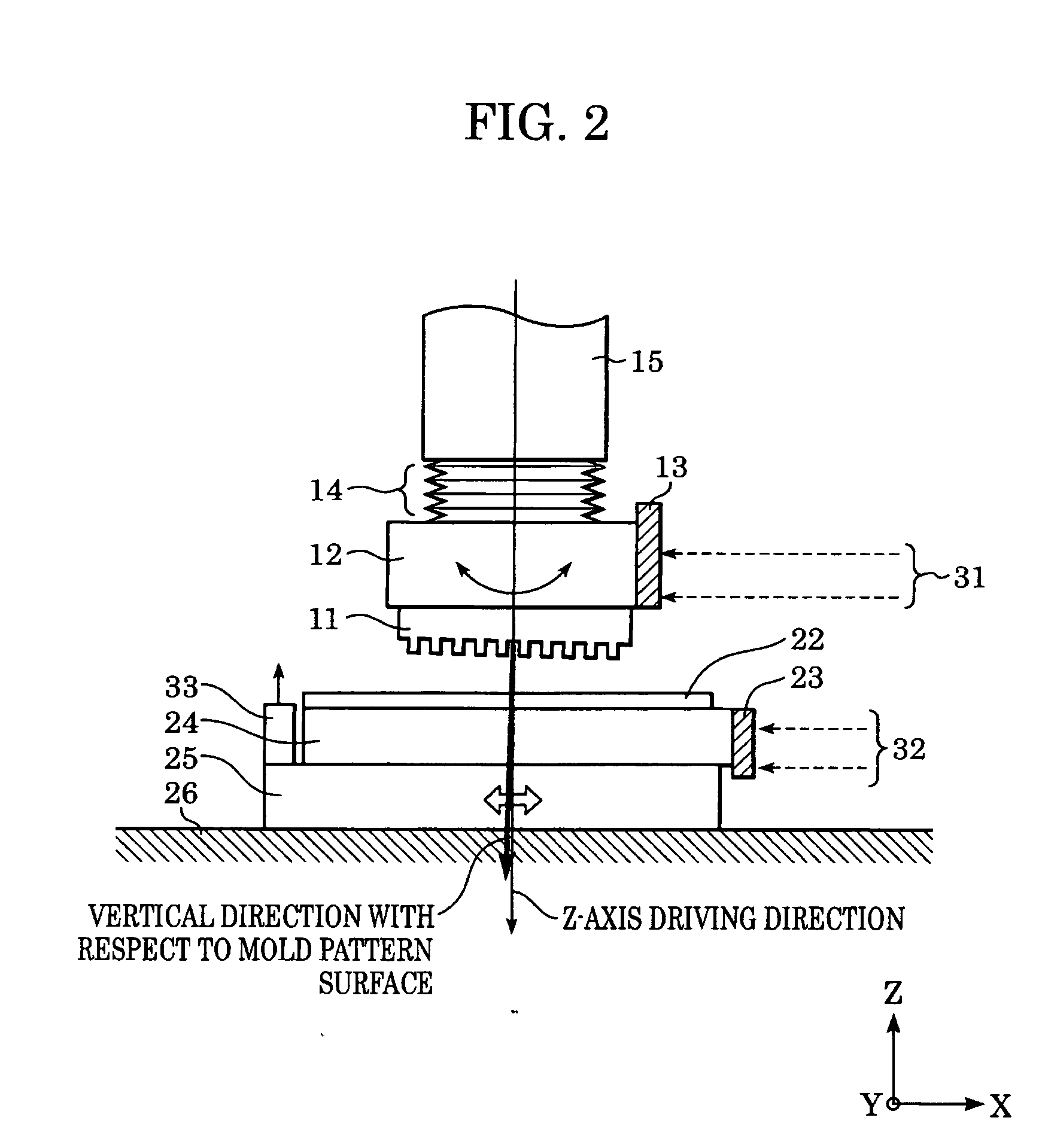

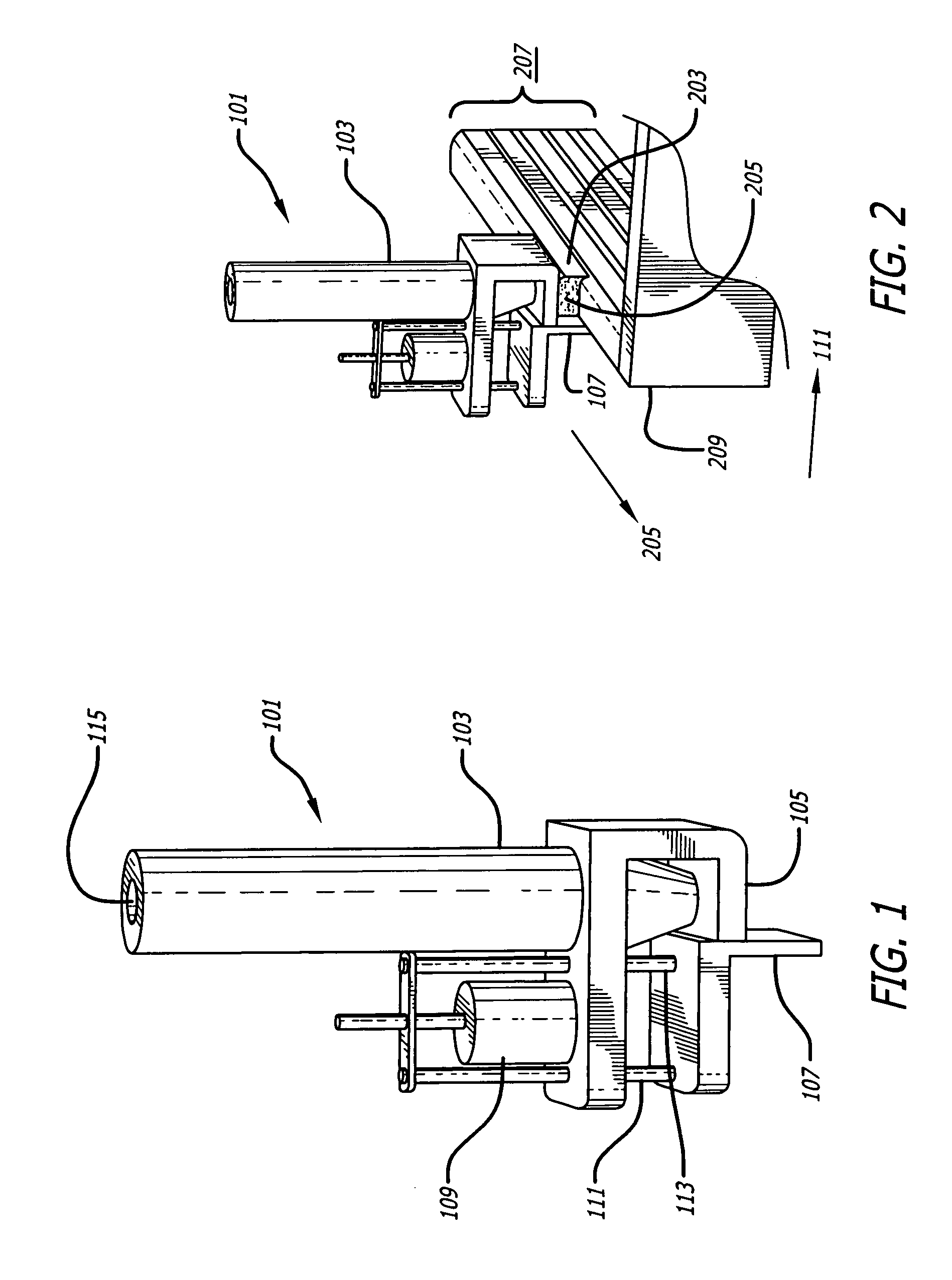

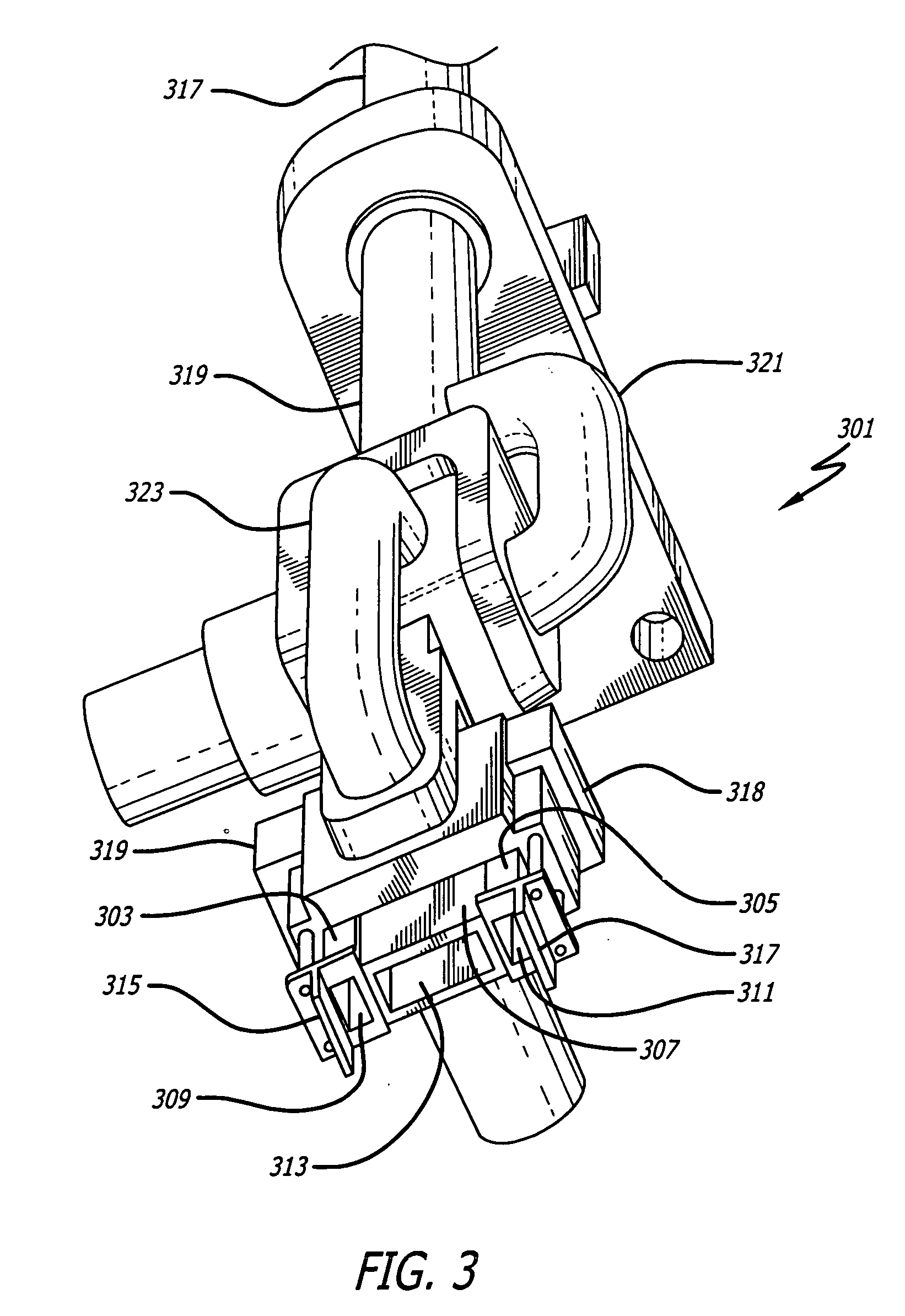

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

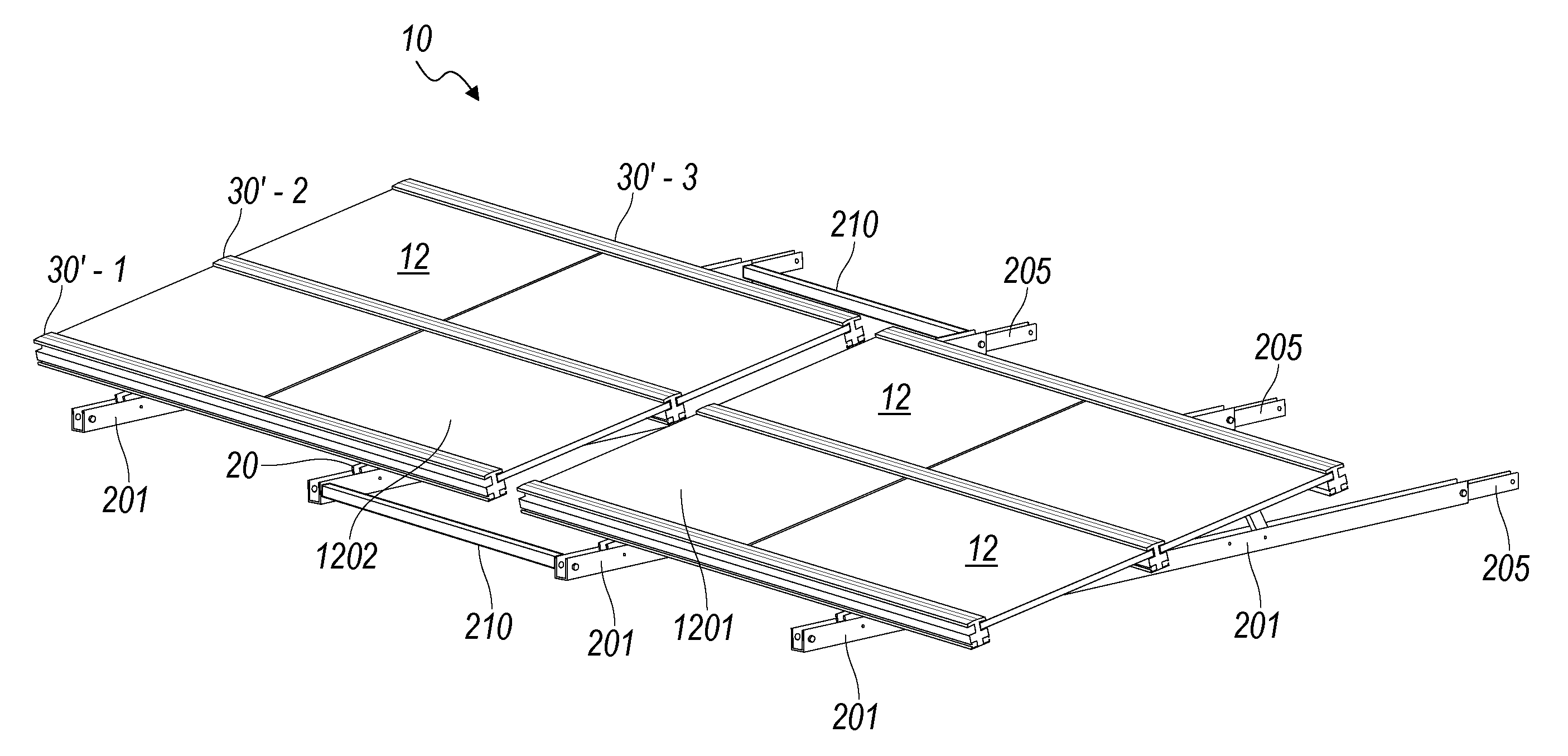

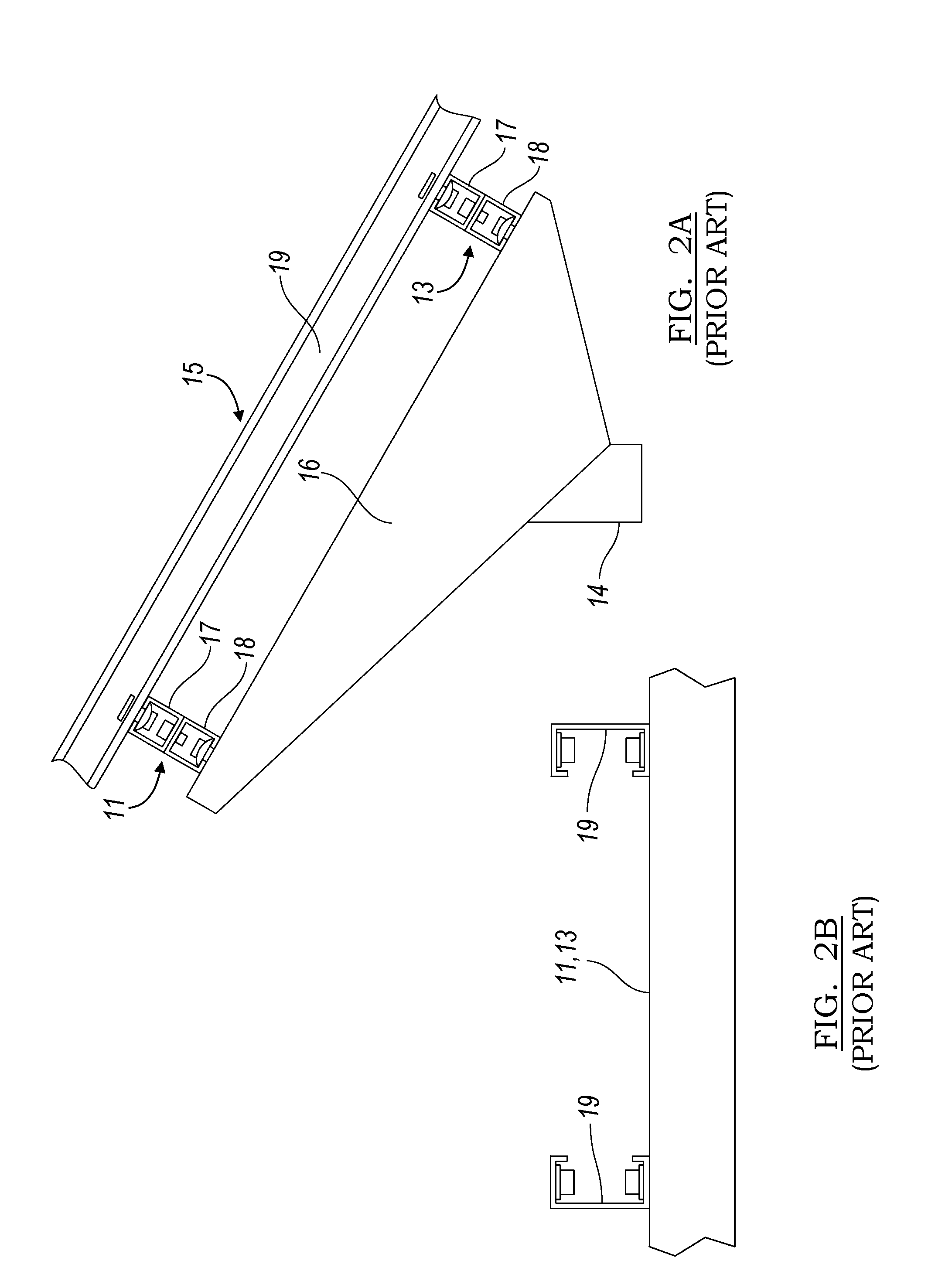

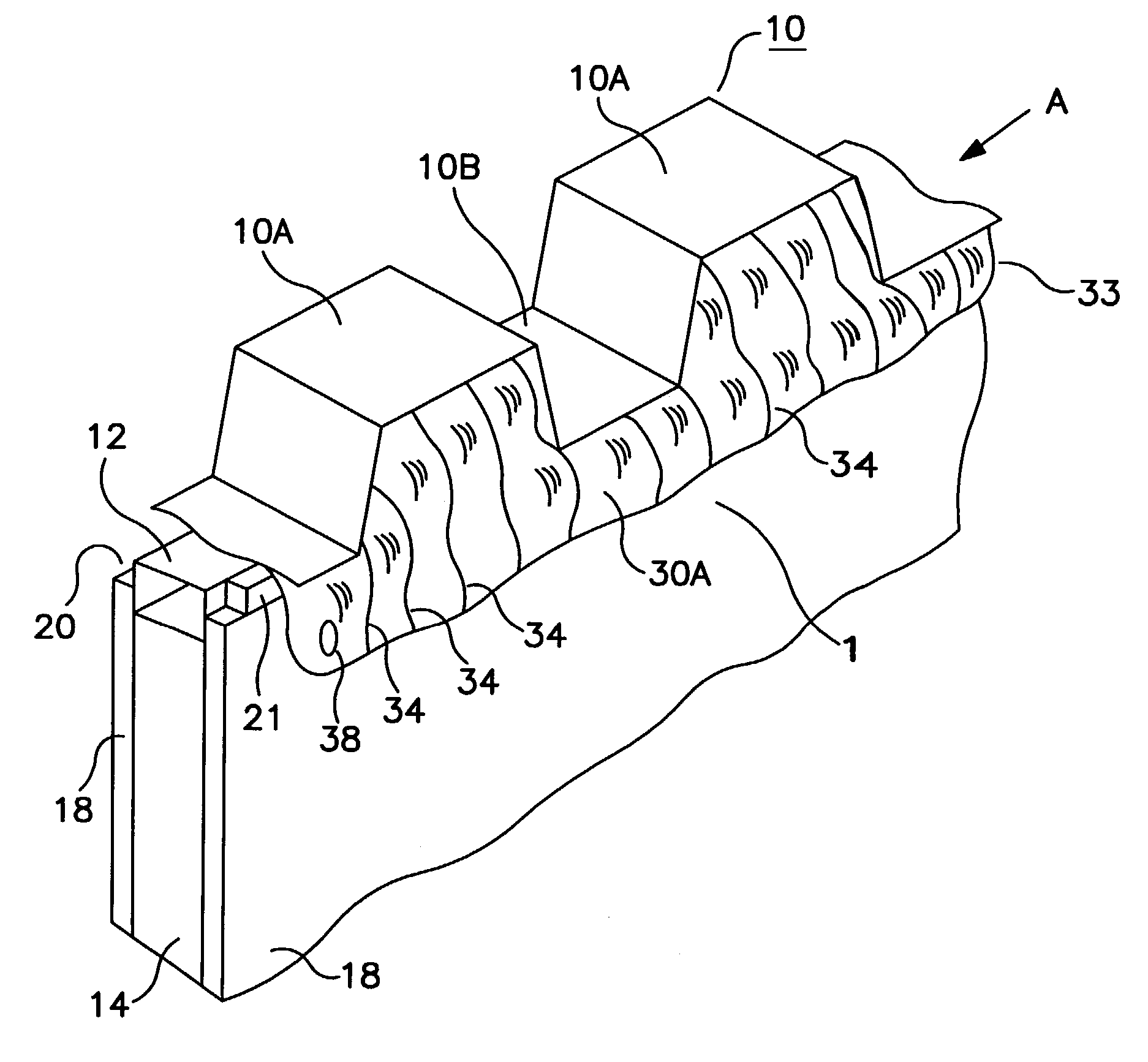

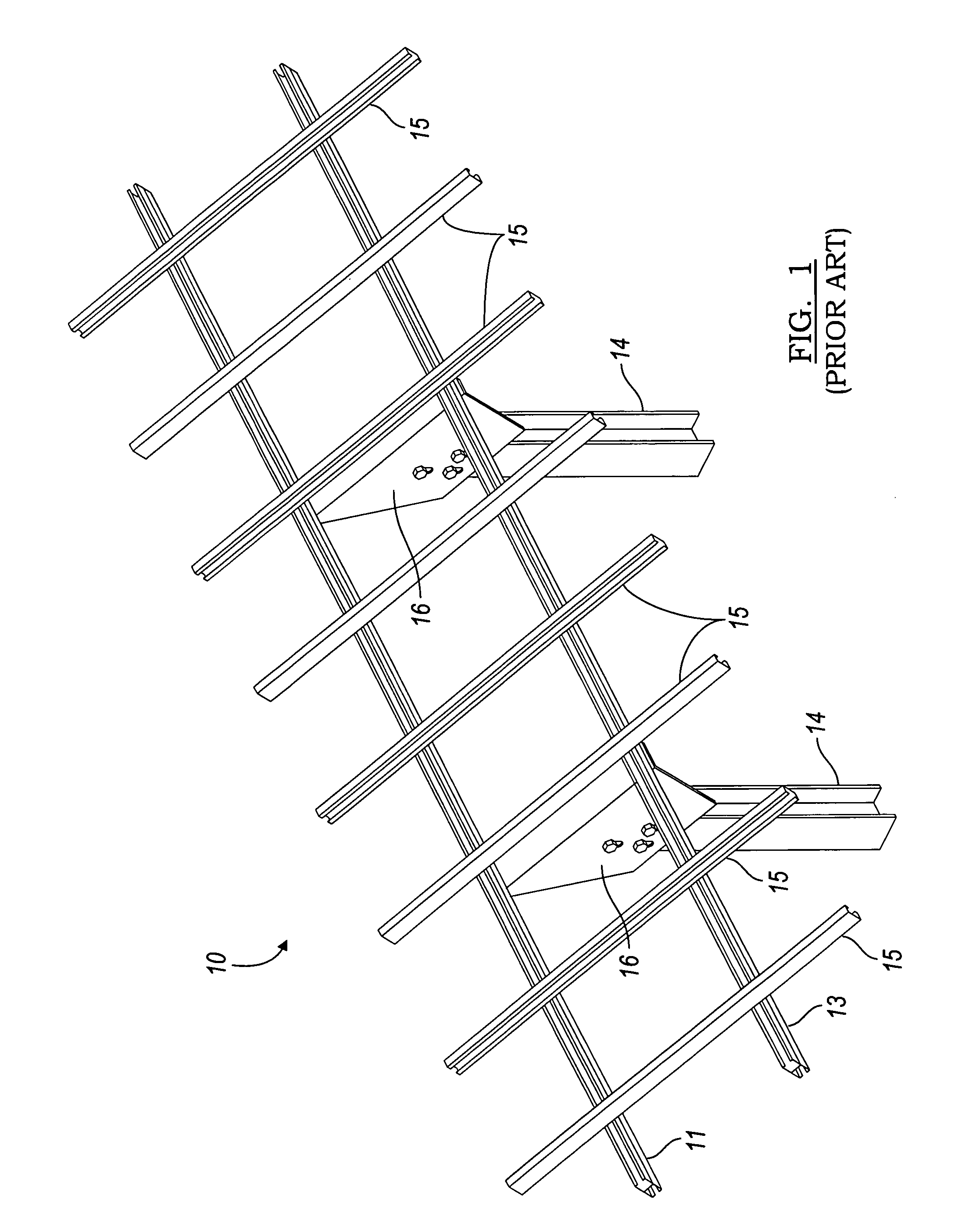

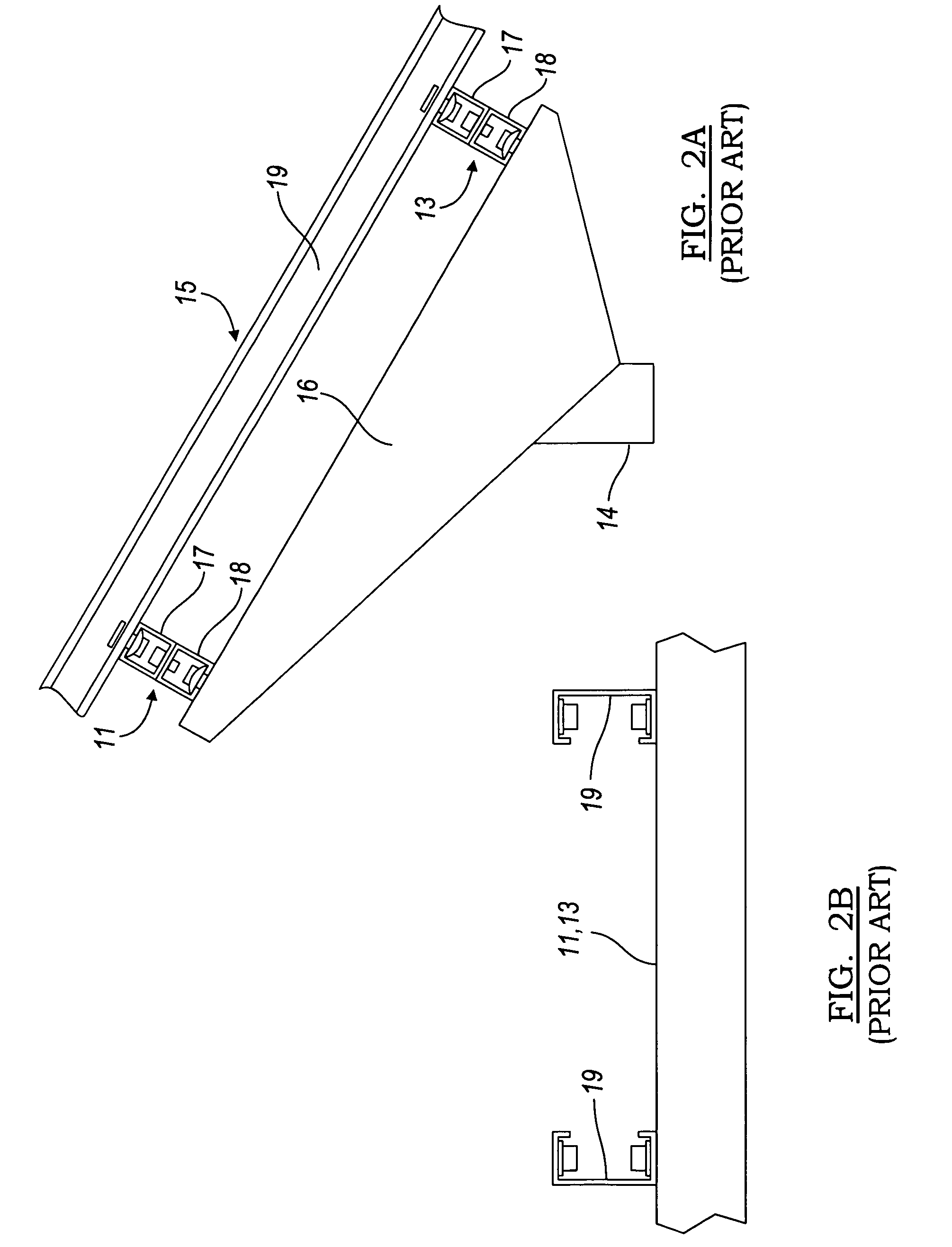

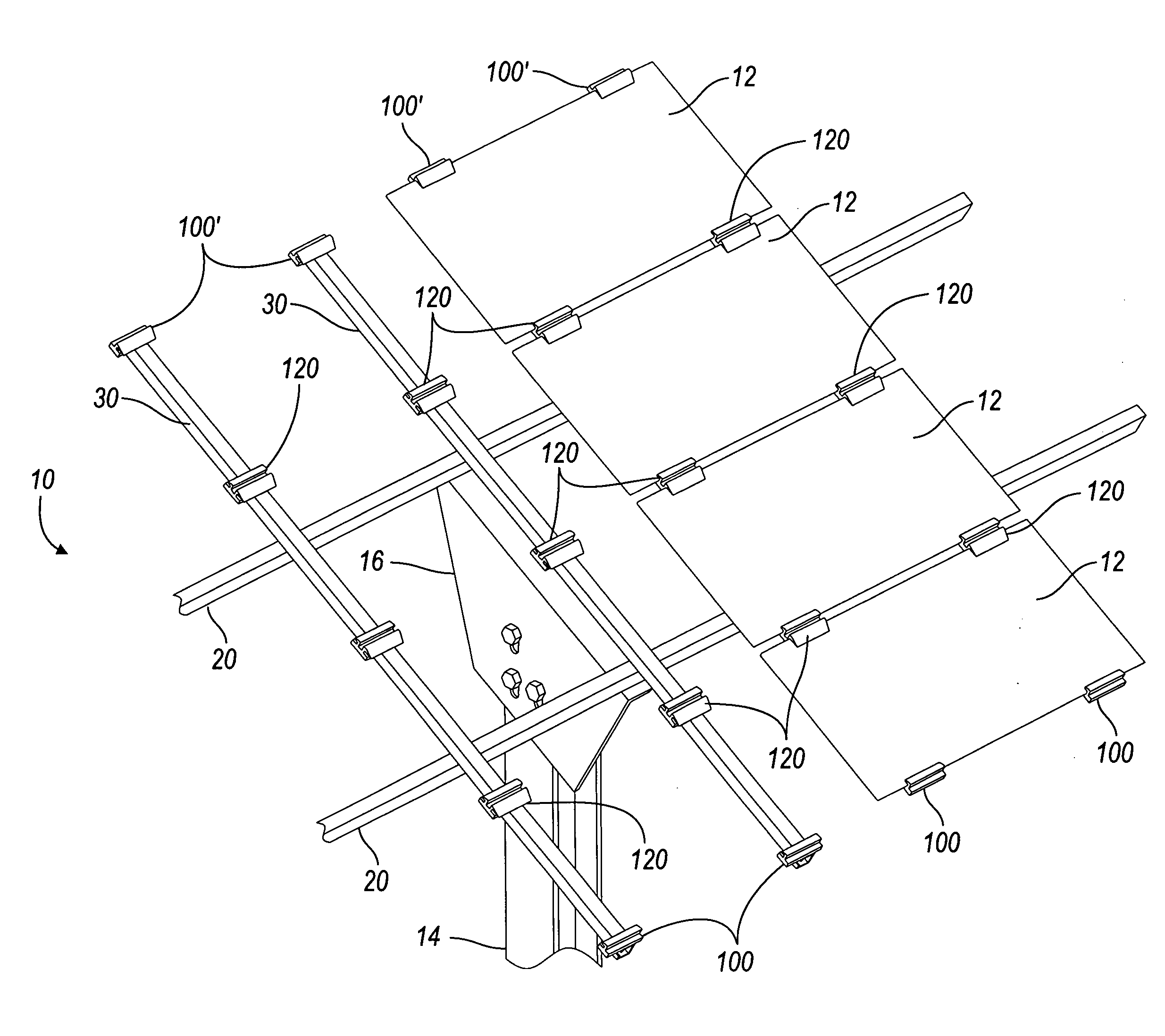

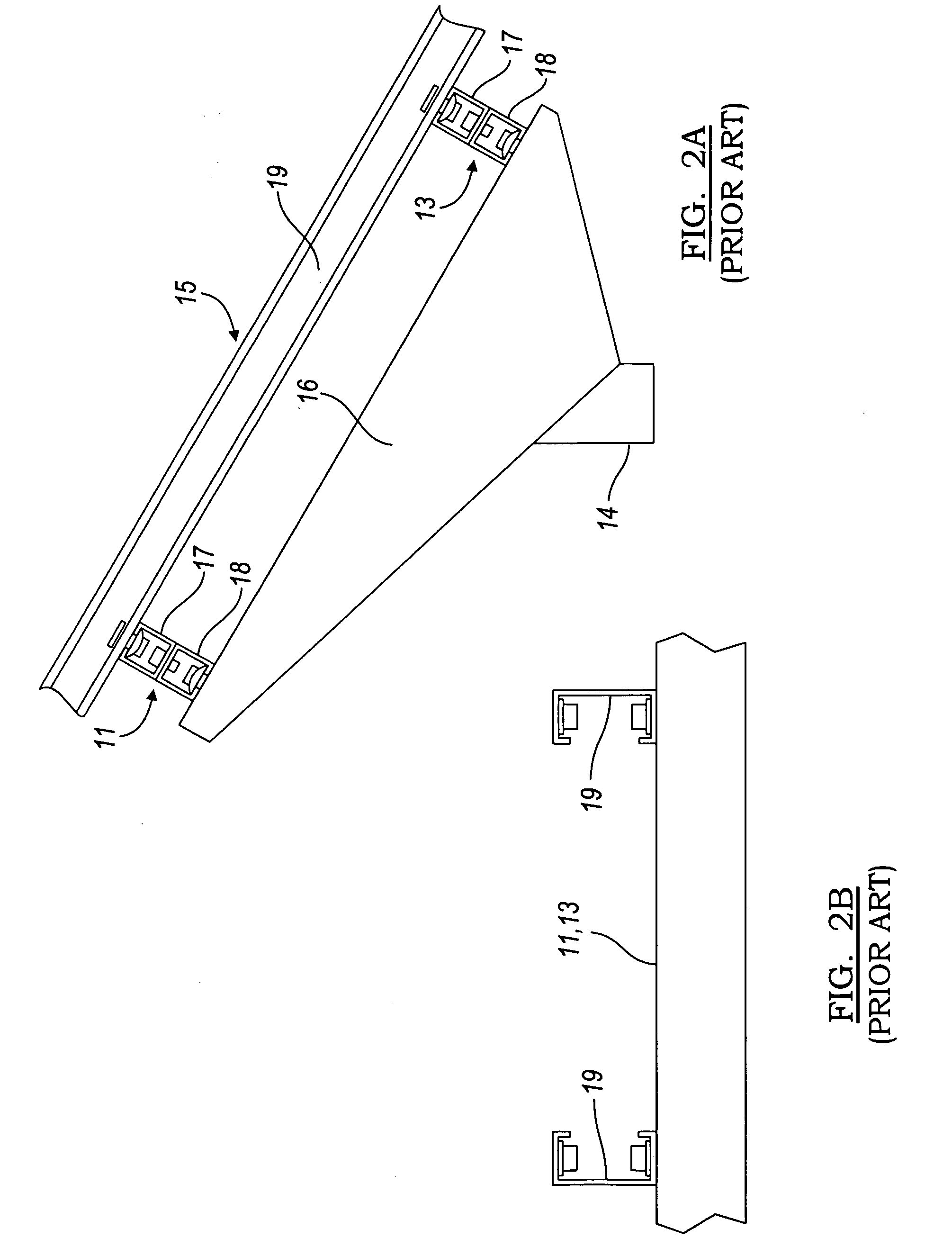

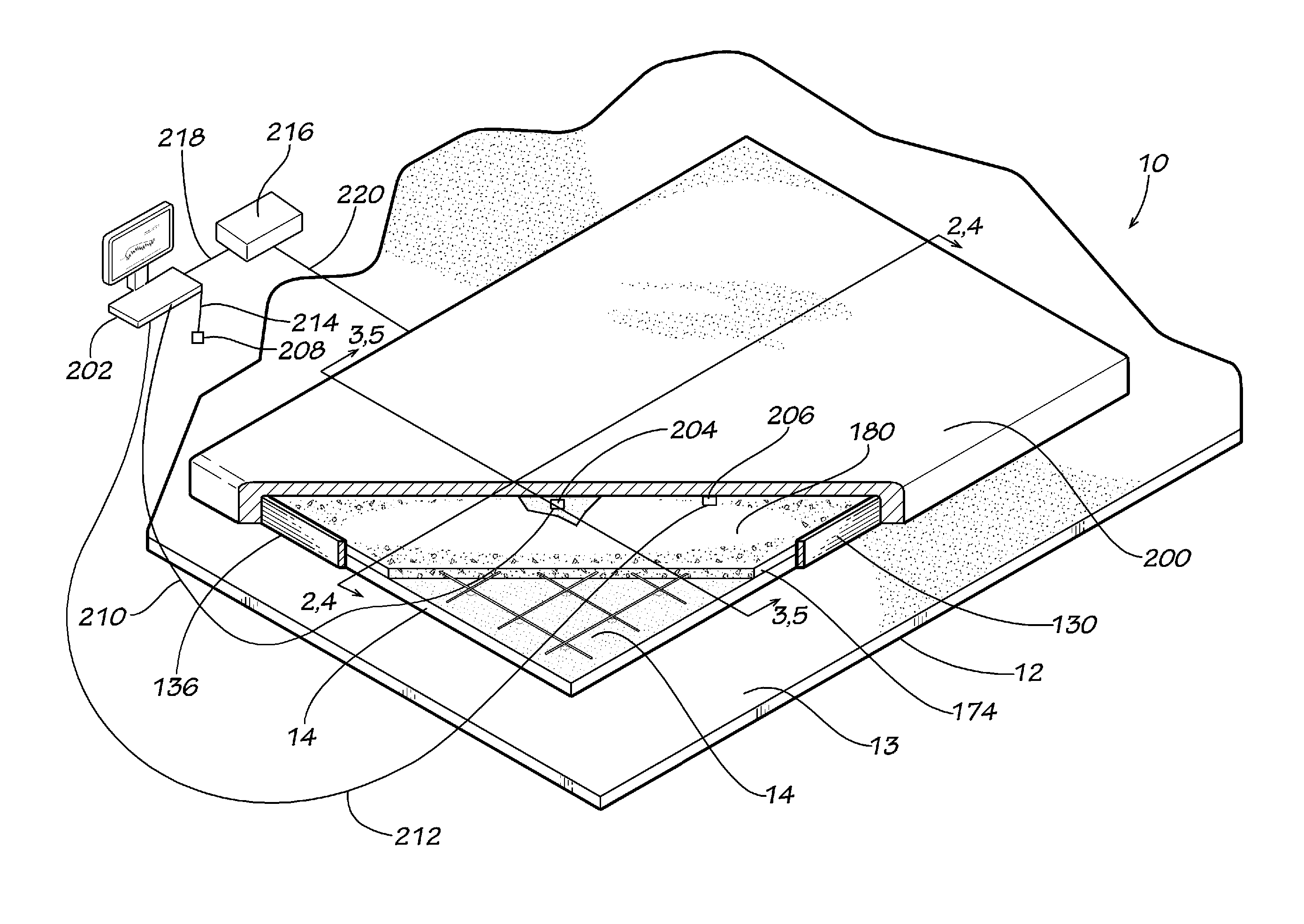

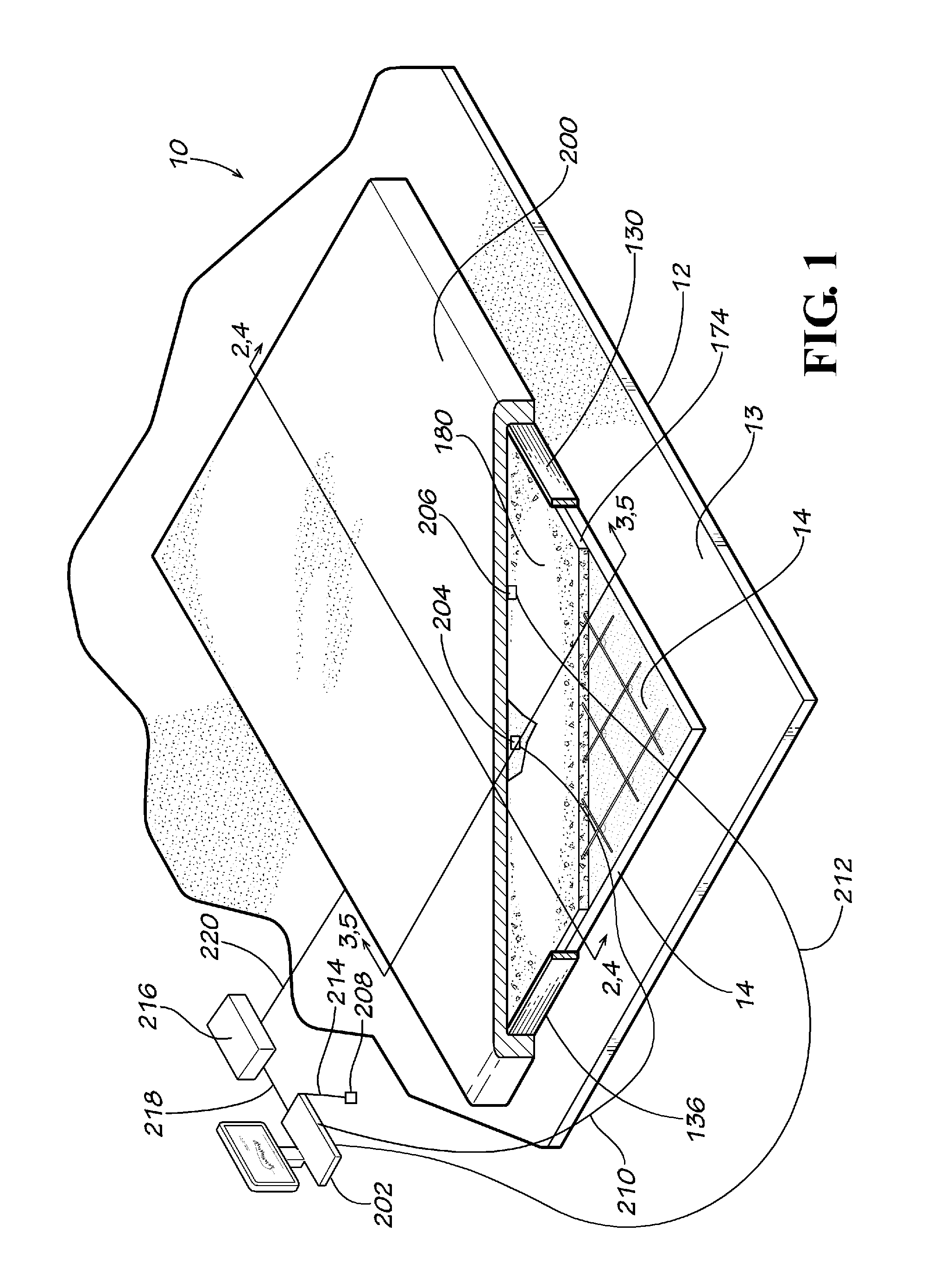

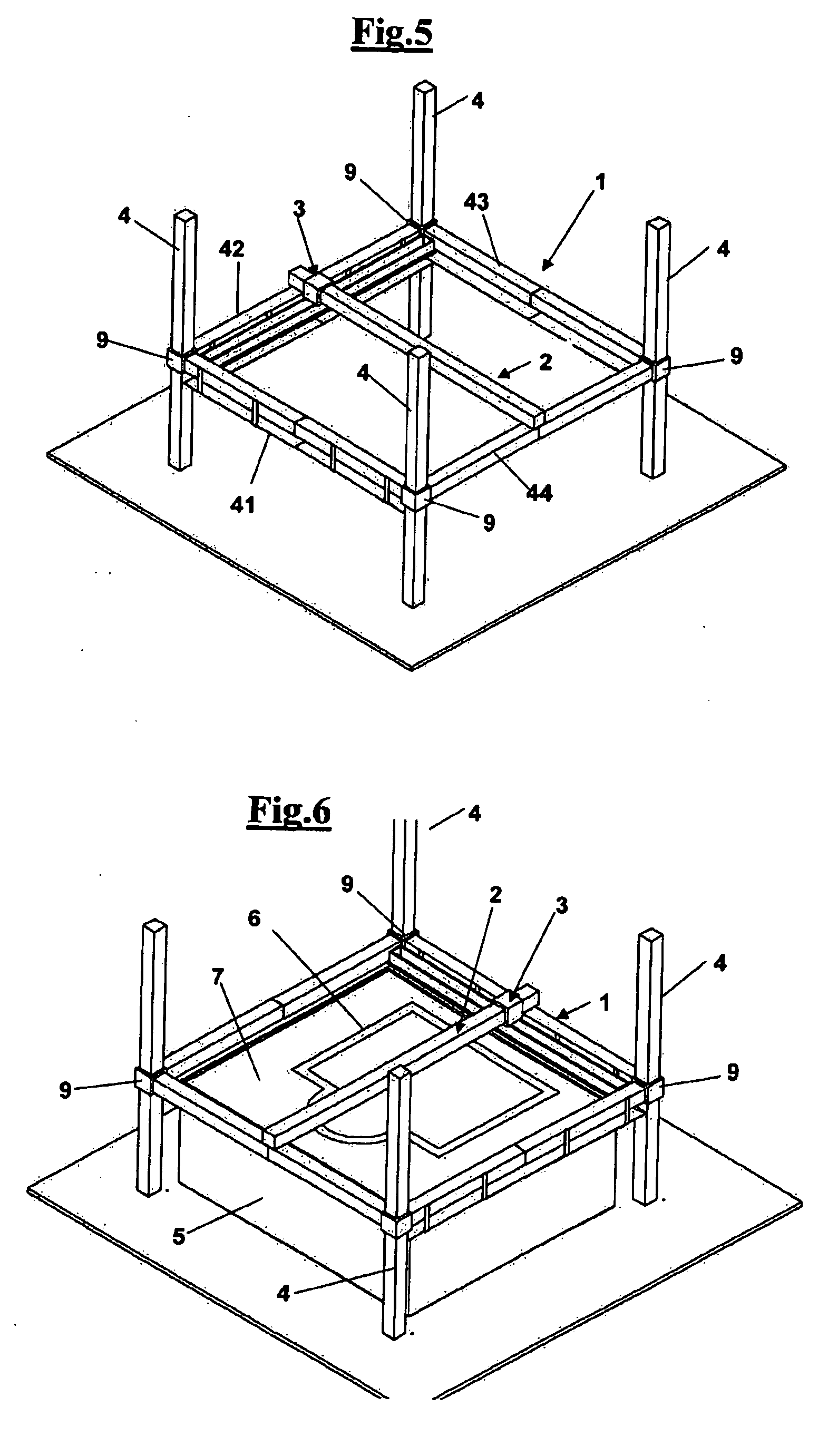

Support System for Solar Panels

ActiveUS20100236183A1Easy to deployEasy to removePhotovoltaic supportsSolar heating energySupporting systemBraced frame

Precise parameters are maintained in a support system for solar panels or other panel-like structures through use of a collapsible folding, support frame which is preassembled to precise tolerances at a convenient staging site before being collapsed for shipment. Installation on flat roofs is also facilitated through the use of a roof interface frame which rotatably supports the panel support frame of the support system and folds along with it at the assembly, staging site.

Owner:NORTHERN STATES METALS

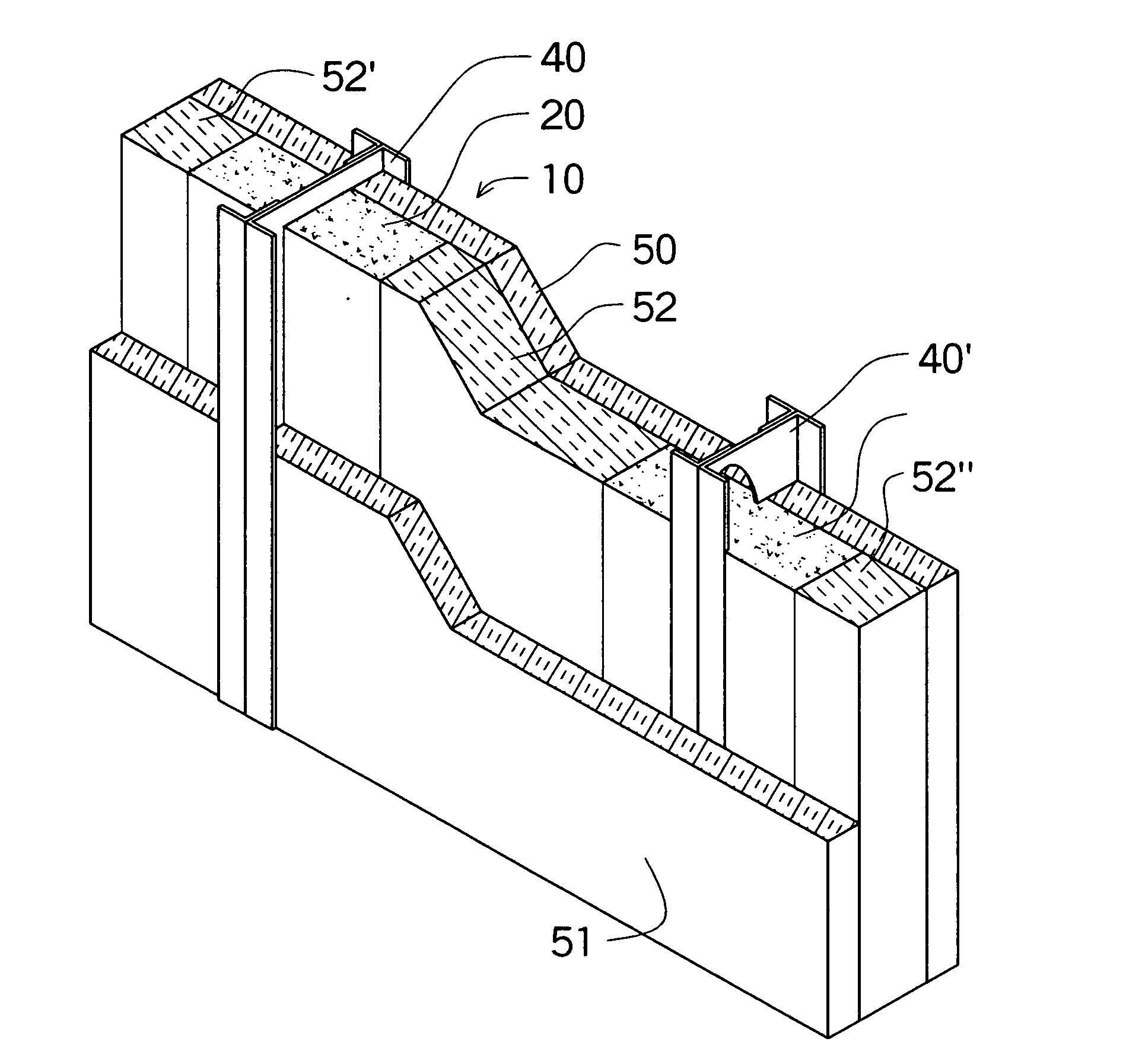

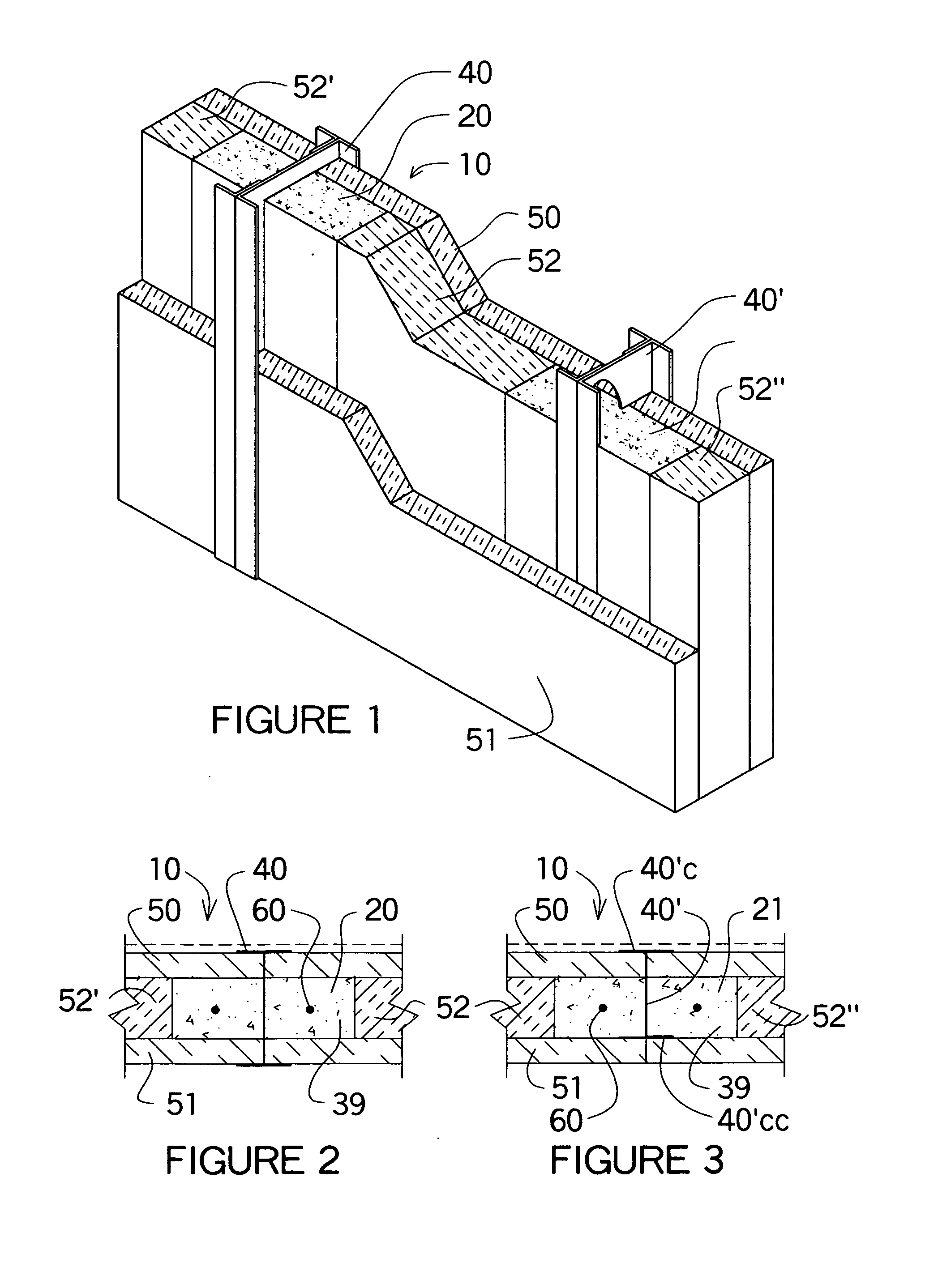

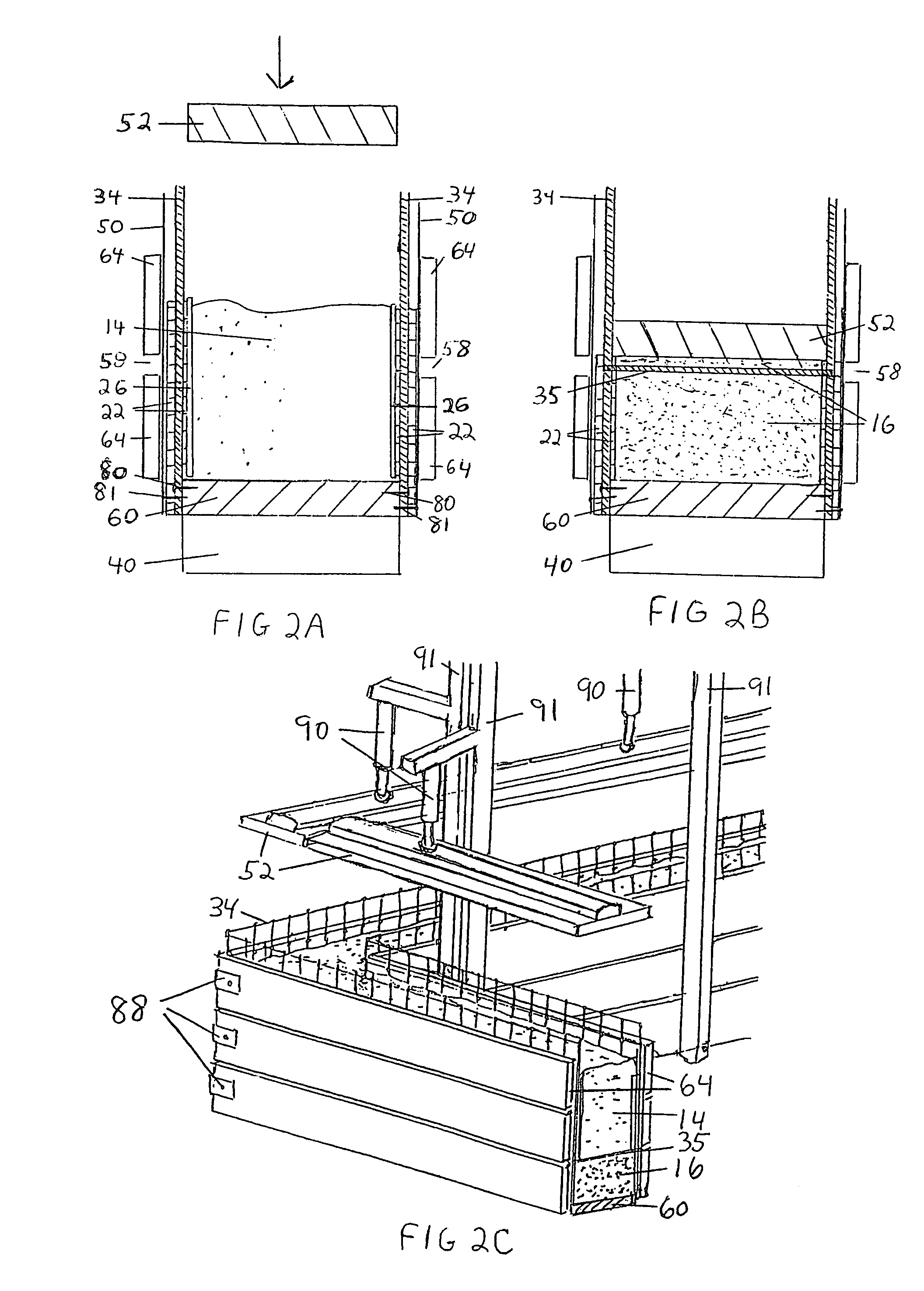

In situ molded thermal barriers

InactiveUS7043880B2Improve fire resistanceExcellent sealing abilityWallsPipesSlurryMaterials science

The invention provides methods, systems, and devices for installing thermal barriers in openings or gaps in or between structures such as walls, ceilings, and floors. At least one thermal barrier molding bag is positioned in the hole or gap, and a flowable firestop material that is operative to cure or harden, such as a hydratable cementitious slurry, is introduced into the bag to mold a barrier in the hole or gap.

Owner:GCP APPL TECH INC

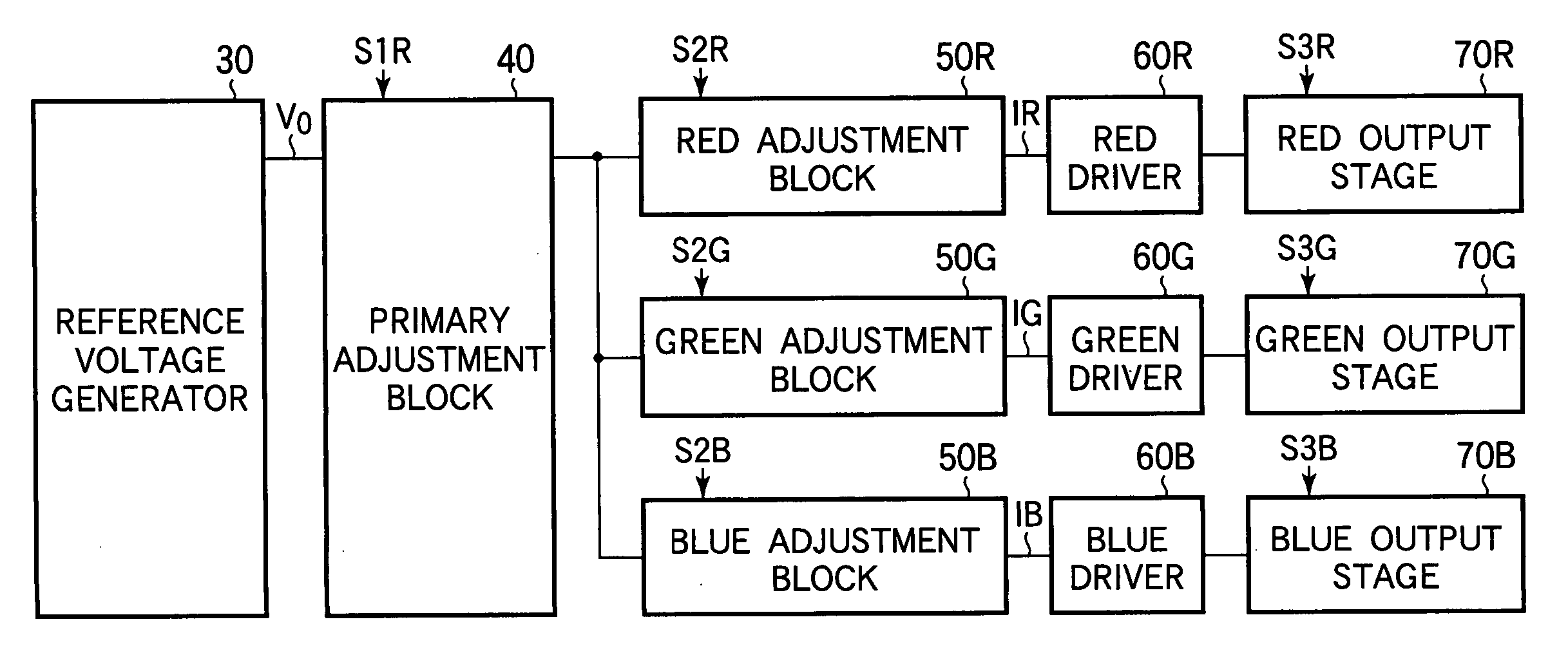

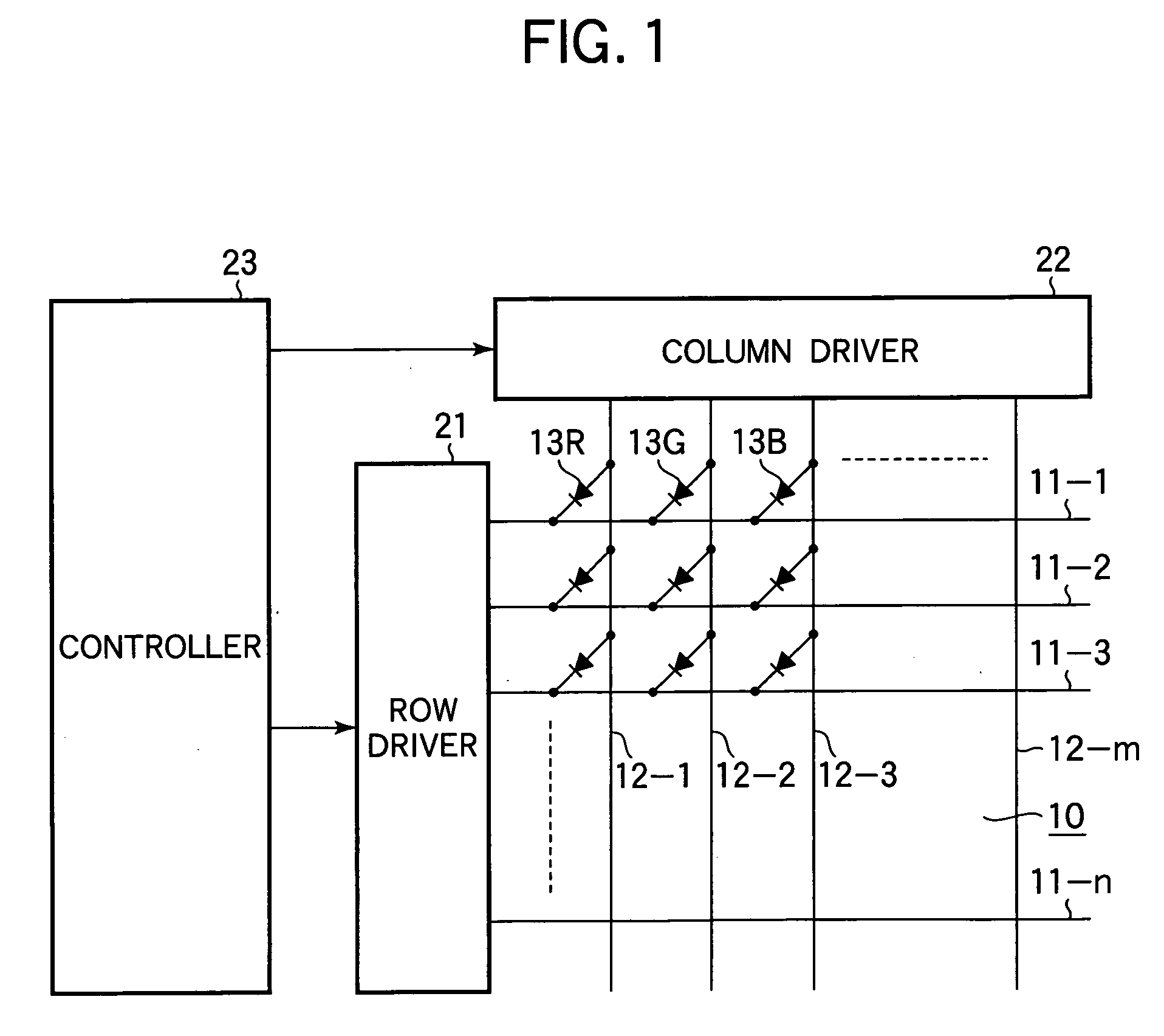

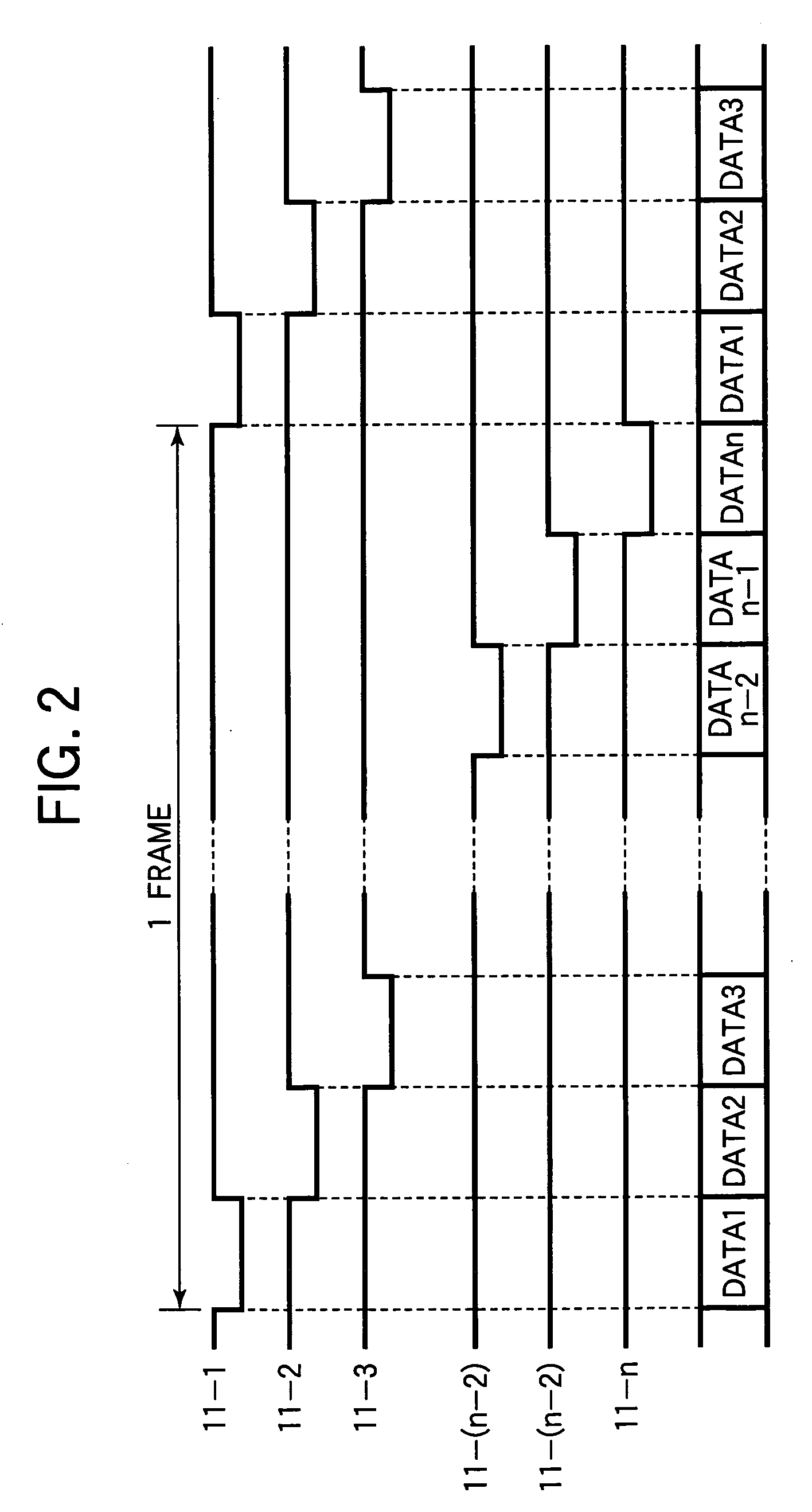

Color balancing circuit for a display panel

InactiveUS20060023002A1Effective balanceSewerage structuresElectrical apparatusDriving currentEngineering

A color balancing circuit for a flat panel display such as an electroluminescent display generates a primary current that can be varied to adjust the overall brightness of the display. Three currents related to the primary current by selectable ratios are generated, by current mirror circuits, for example; the ratios can be individually varied to adjust the color balance. Driving currents are generated from the three adjusted currents, by mirroring the adjusted currents, for example, and are used to drive display elements that emit light in the three primary colors. Image brightness and color balance can accordingly be adjusted separately, even though both are adjusted by adjusting the driving current. Circuit size is reduced in that the same primary current is used for all three primary colors.

Owner:LAPIS SEMICON CO LTD

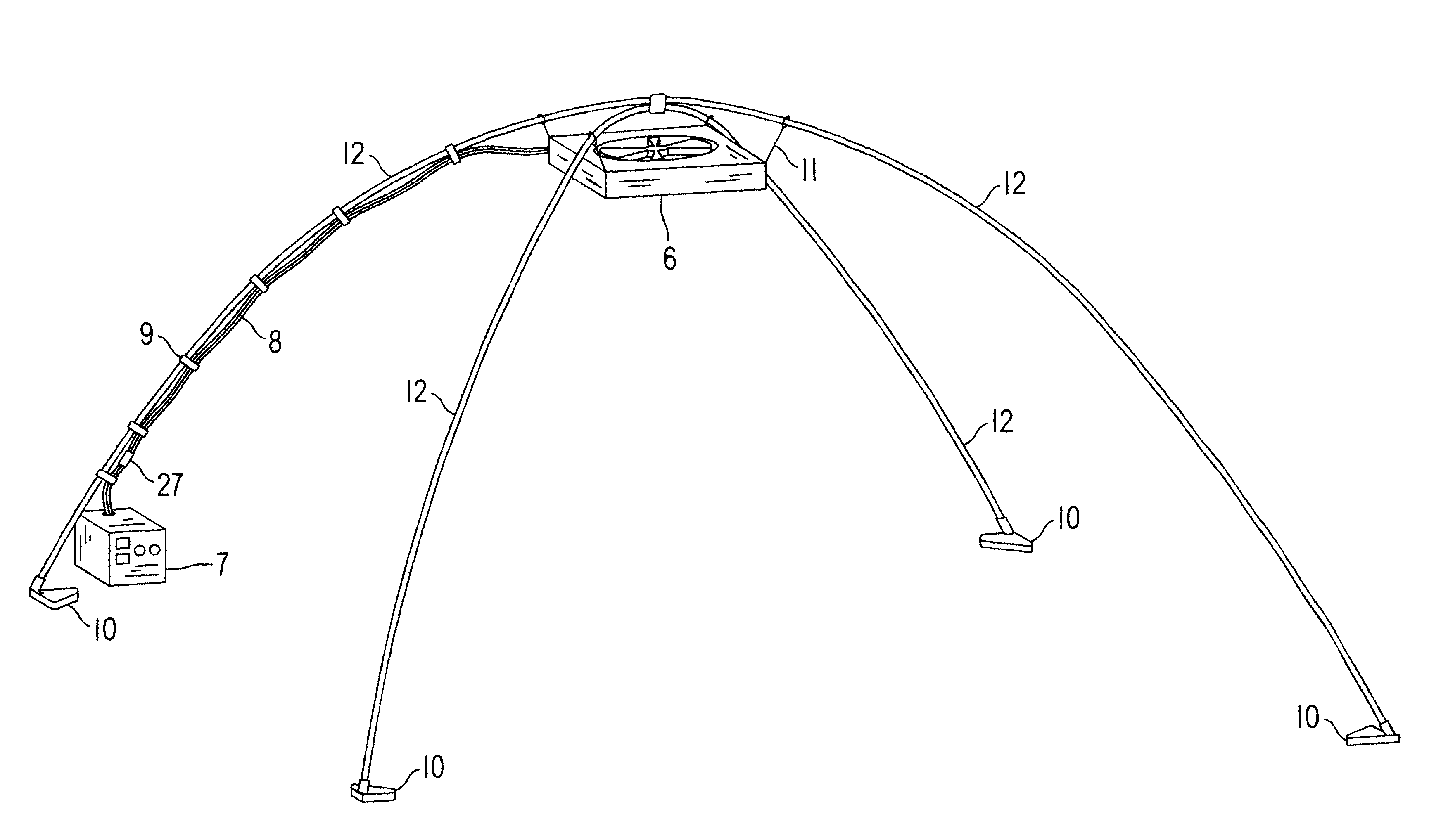

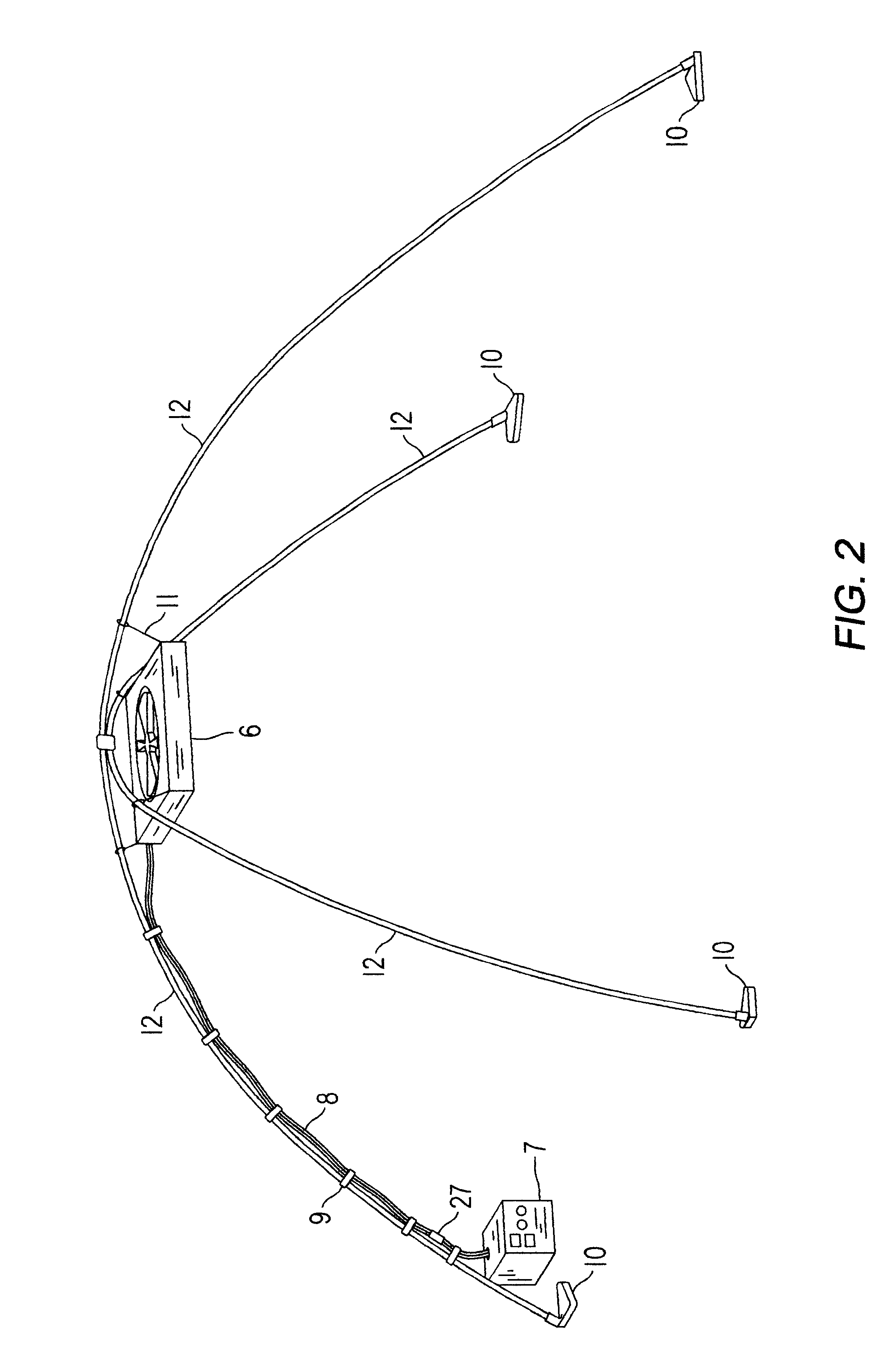

Portable camping tent structure with built-in overhead electric fan and power source

An electric fan with mounted light (6) mounted overhead within a square dome camping tent (1). The fan / light unit is supported by a series of fiberglass poles (12), and pole footings (10). The fan / light unit is powered by a portable power supply and control unit (7) which contains power switches (23), an updraft / downdraft switch (24), an accessory plug (25), and a charger plug (27).

Owner:JENNINGS HARRY G

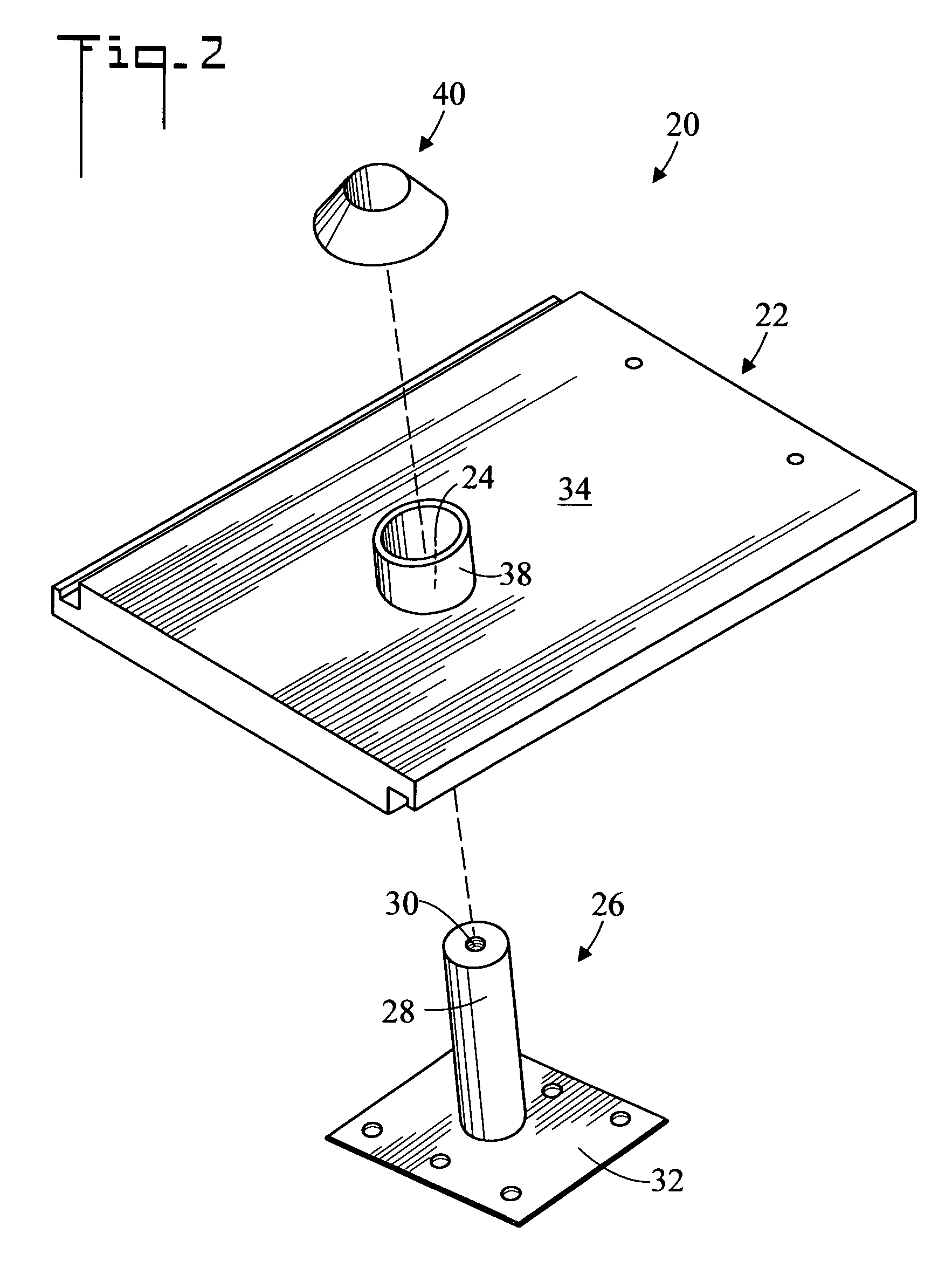

Method for installing a stanchion on a tile roof and system therefor

A method and apparatus for installing a stanchion on a tile roof includes a tile which has an aperture and a stanchion which fits through the aperture. An existing roof tile is removed and the stanchion is connected to the roof sheathing at the place of removal. The tile is then placed over the stanchion so that the stanchion project through the aperture. In an embodiment of the invention, a sleeve surrounds the aperture and a seal provides a weather proof seal between the stanchion and the sleeve.

Owner:WENCON DEV INC

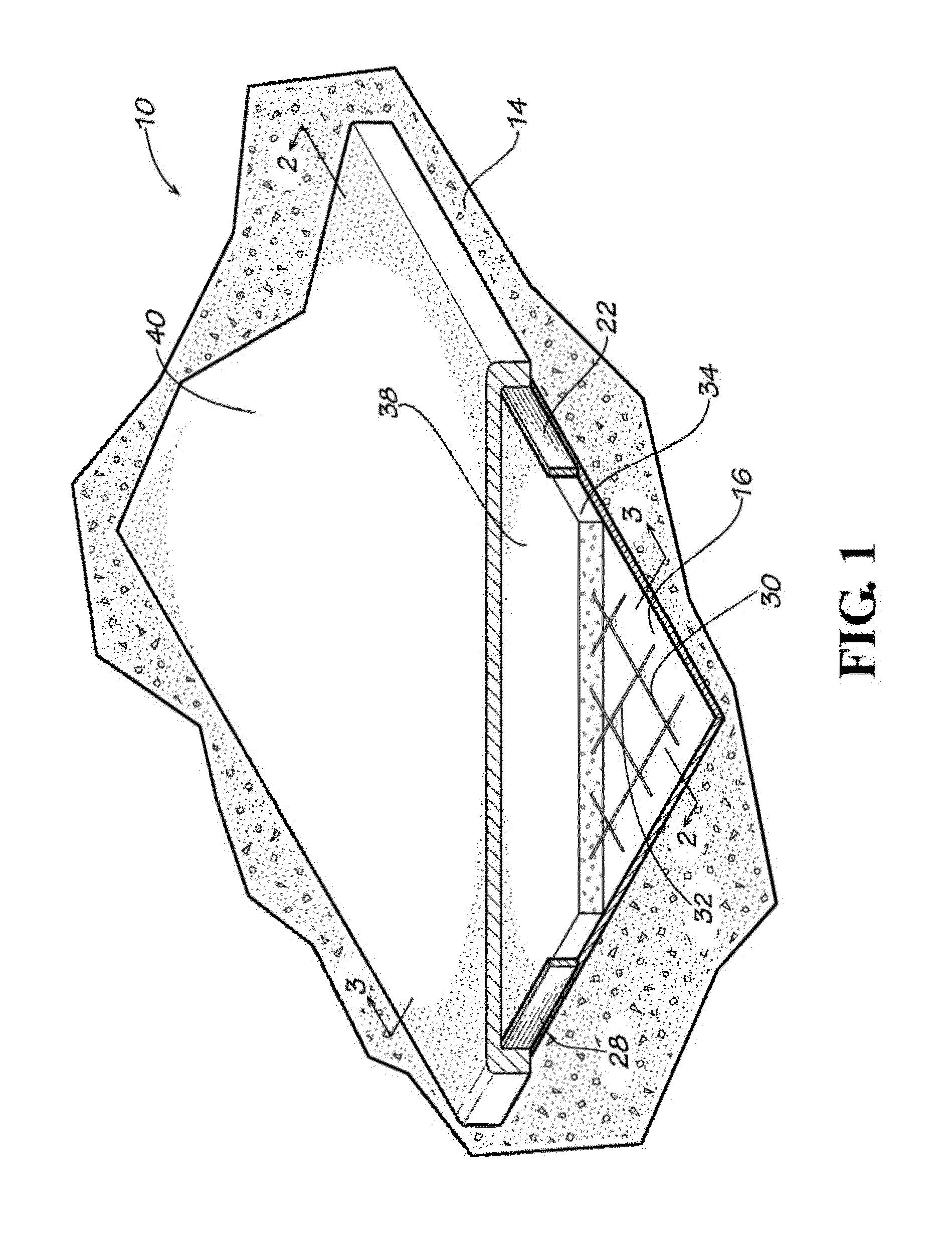

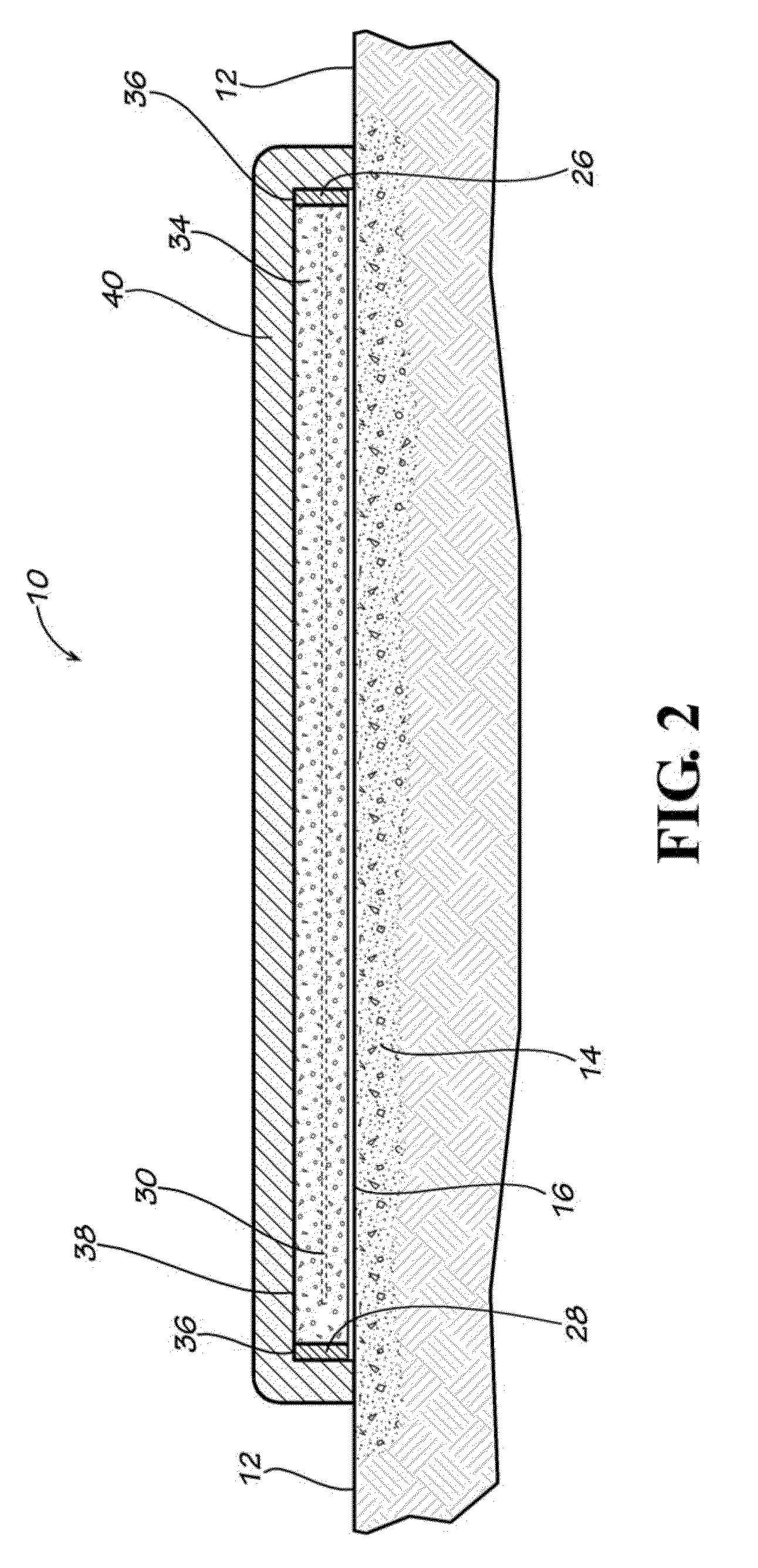

Insulated concrete form and method of using same

InactiveUS20130074432A1Retain heatEasy and inexpensive attachmentCeilingsConstruction materialInsulating concrete formFlange

Owner:CIUPERCA ROMEO ILARIAN

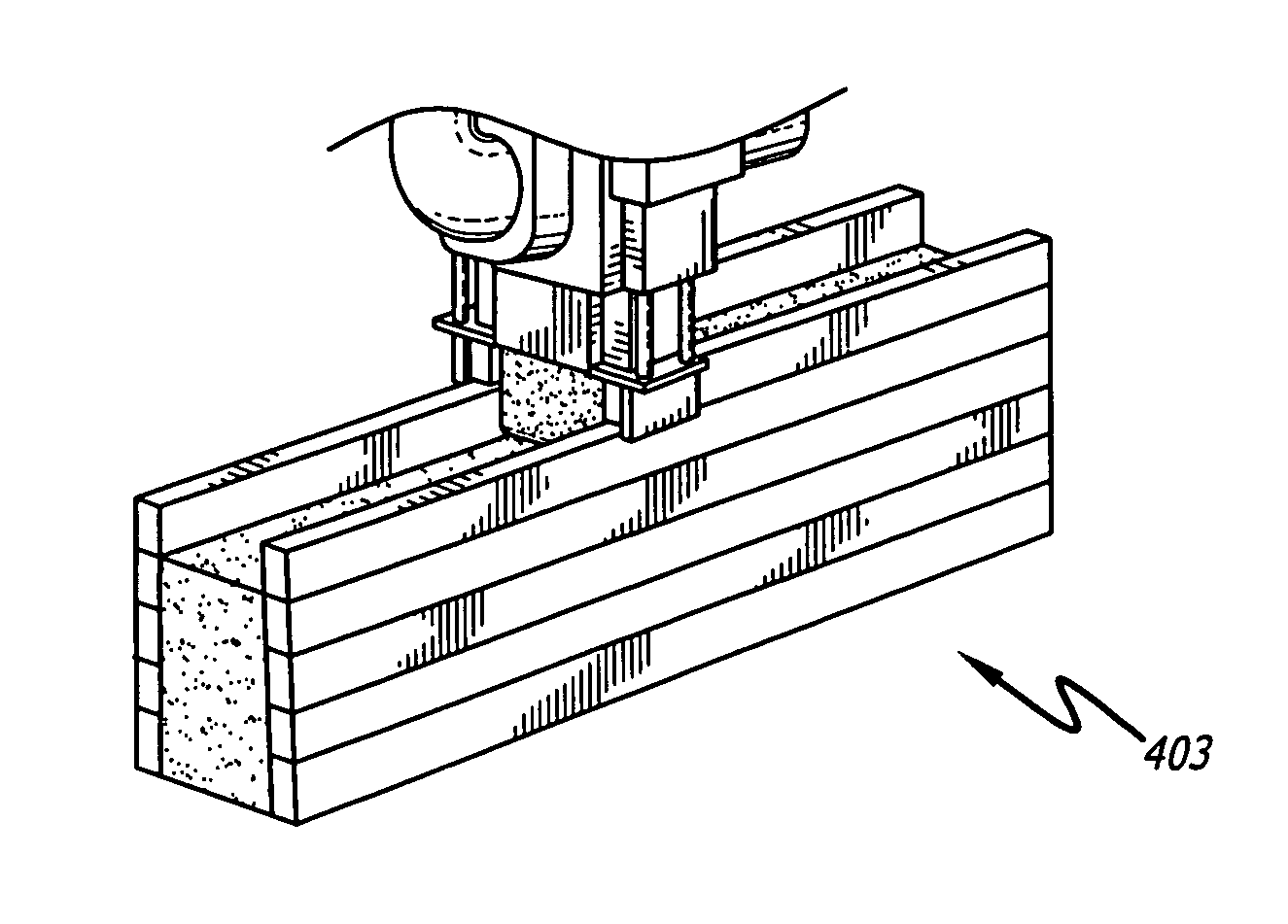

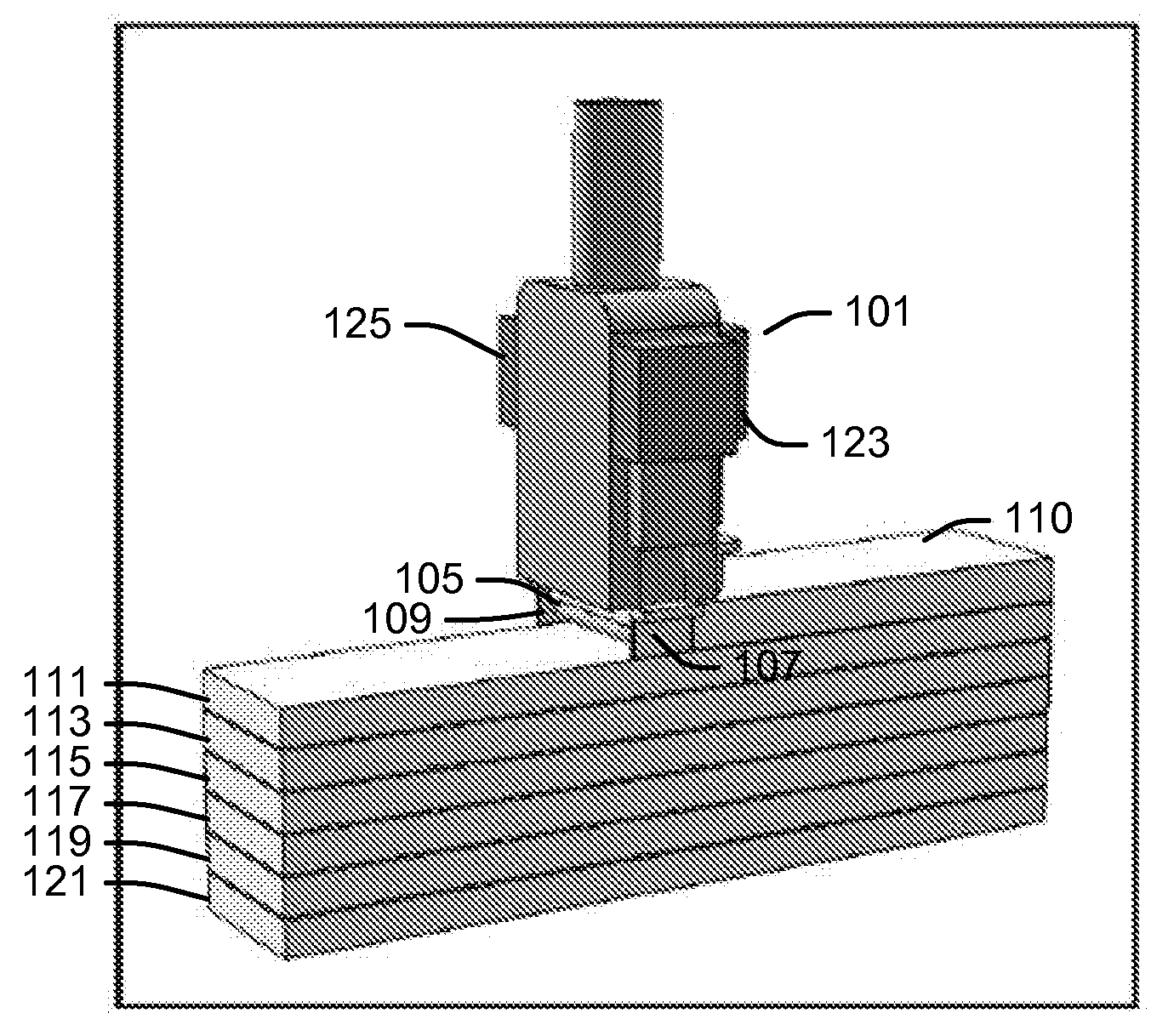

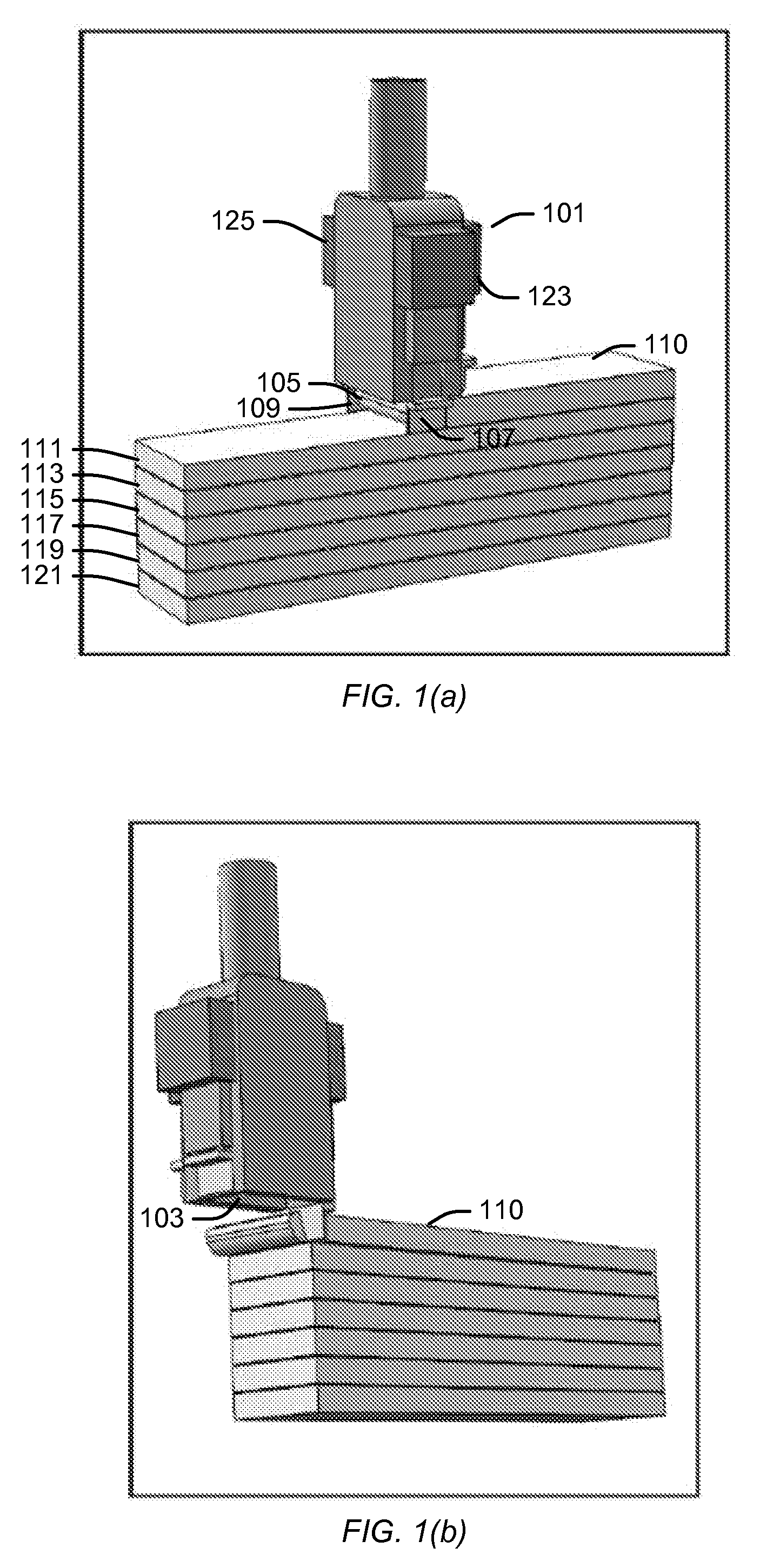

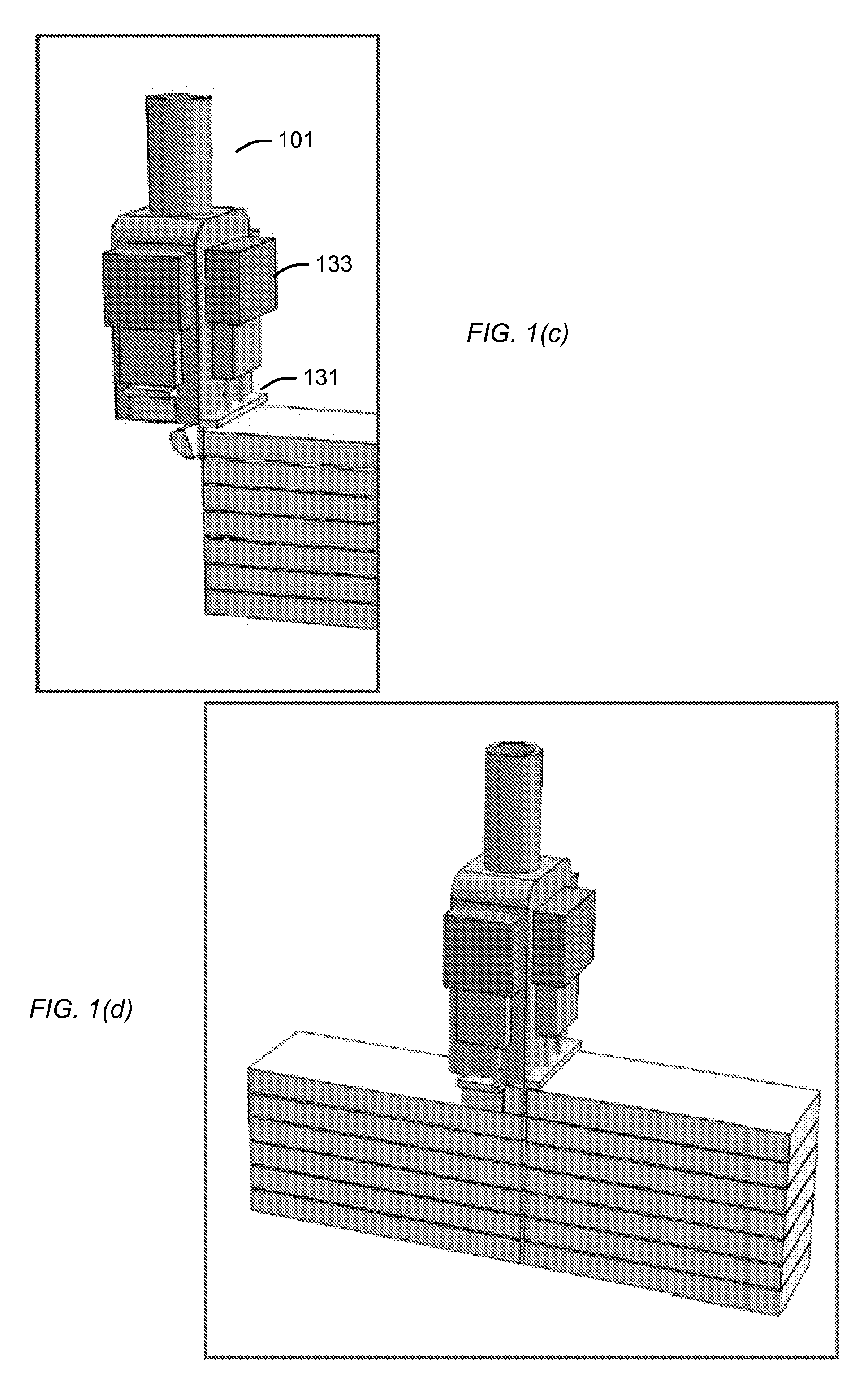

Multi-nozzle assembly for extrusion of wall

A multi-nozzle assembly may include a first nozzle configured to extrude material through a first outlet; a second nozzle configured to extrude material through a second outlet; and a third nozzle configured to extrude material through a third outlet, the third outlet being between the first and second outlets. Related construction processes and wall structures are also disclosed.

Owner:UNIV OF SOUTHERN CALIFORNIA

Multi-nozzle assembly for extrusion of wall

A multi-nozzle assembly may include a first nozzle configured to extrude material through a first outlet; a second nozzle configured to extrude material through a second outlet; and a third nozzle configured to extrude material through a third outlet, the third outlet being between the first and second outlets. Related construction processes and wall structures are also disclosed.

Owner:UNIV OF SOUTHERN CALIFORNIA

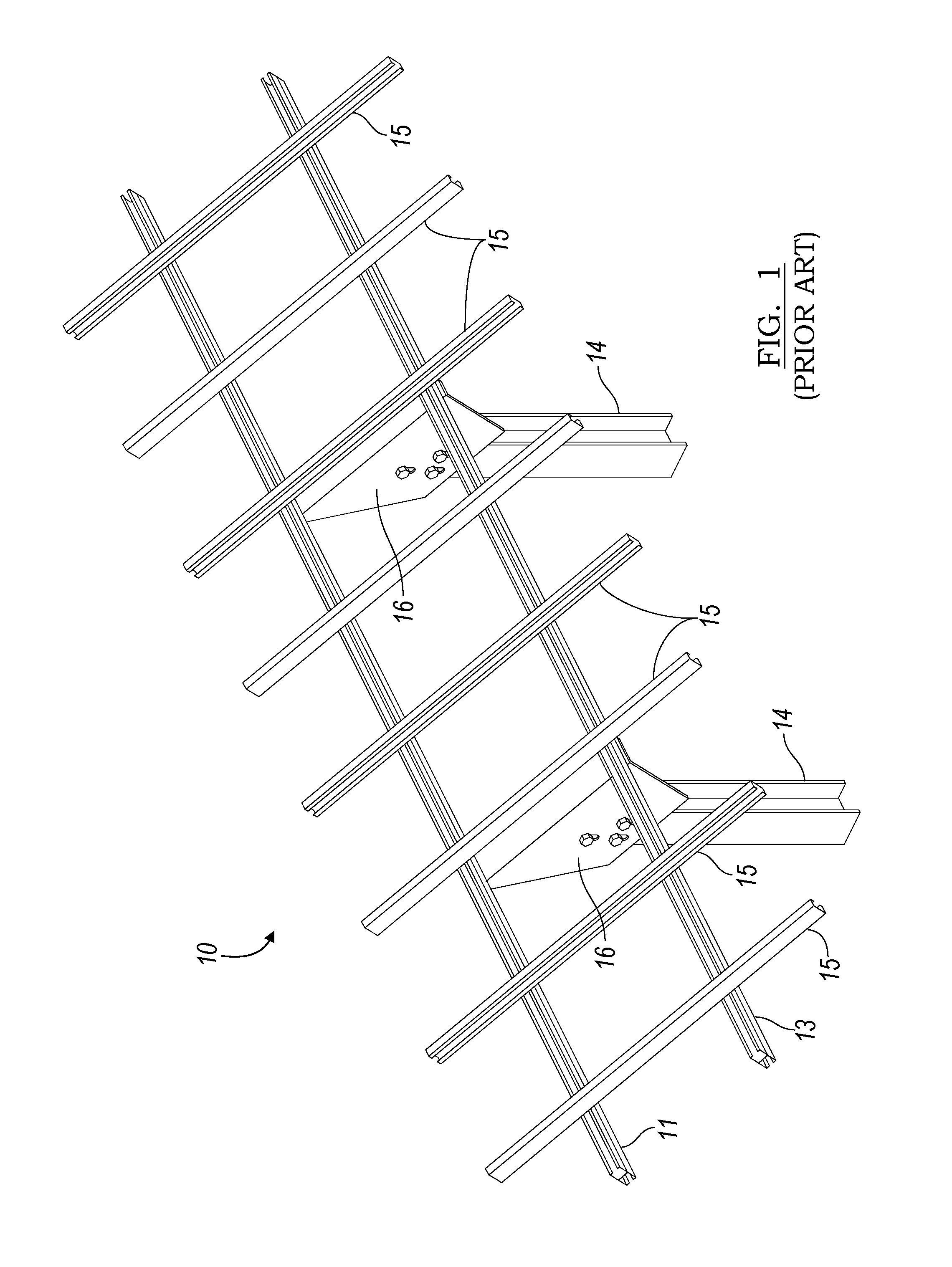

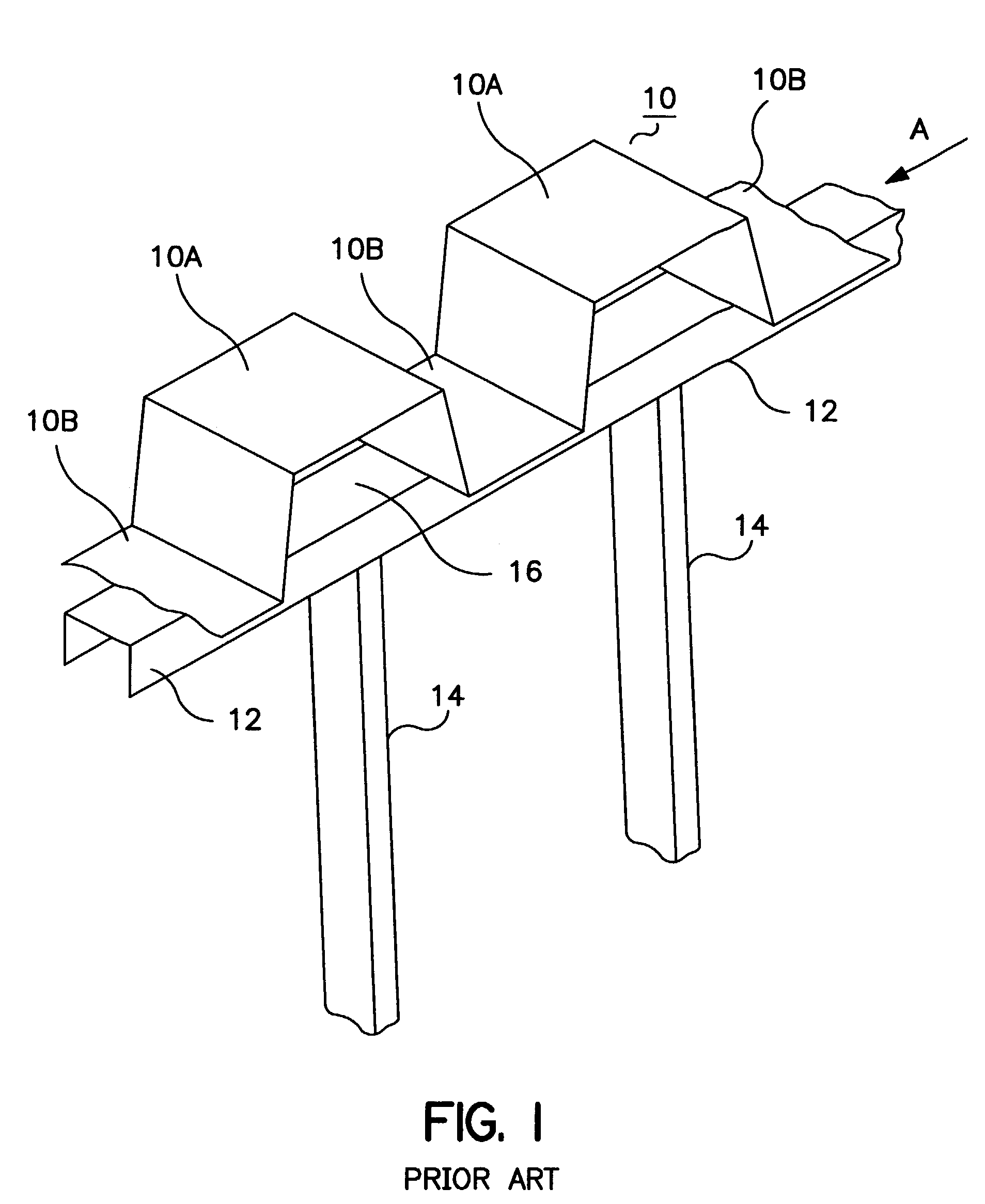

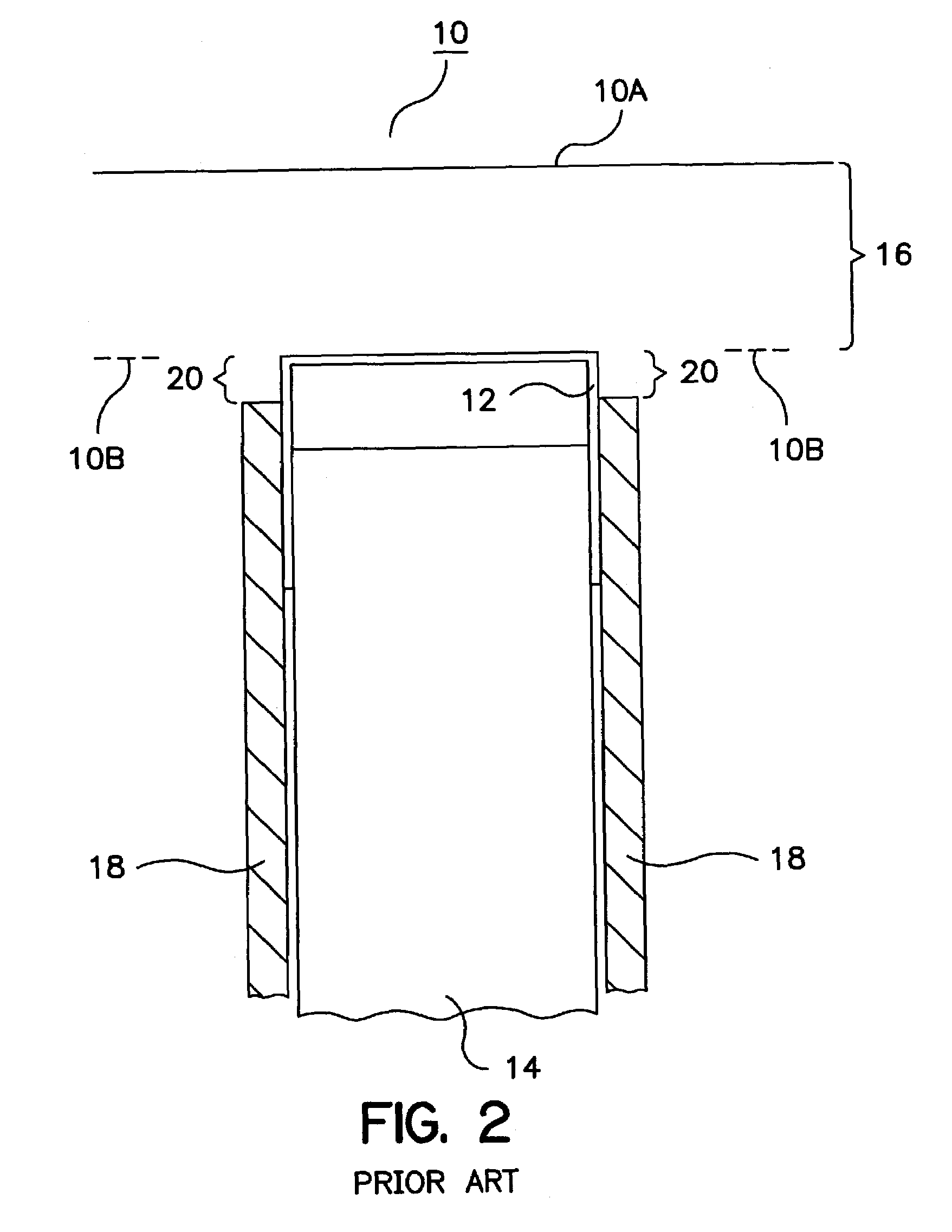

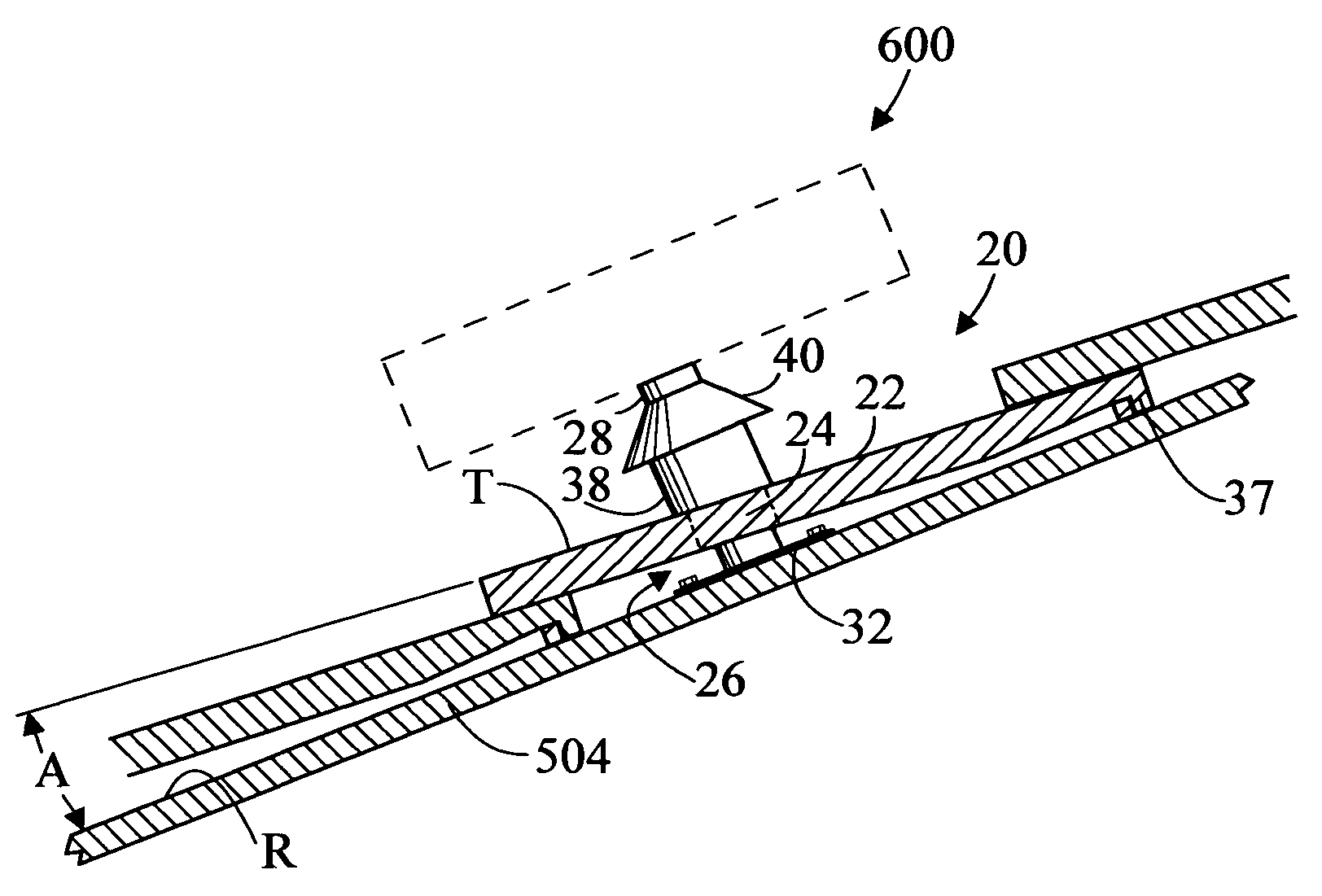

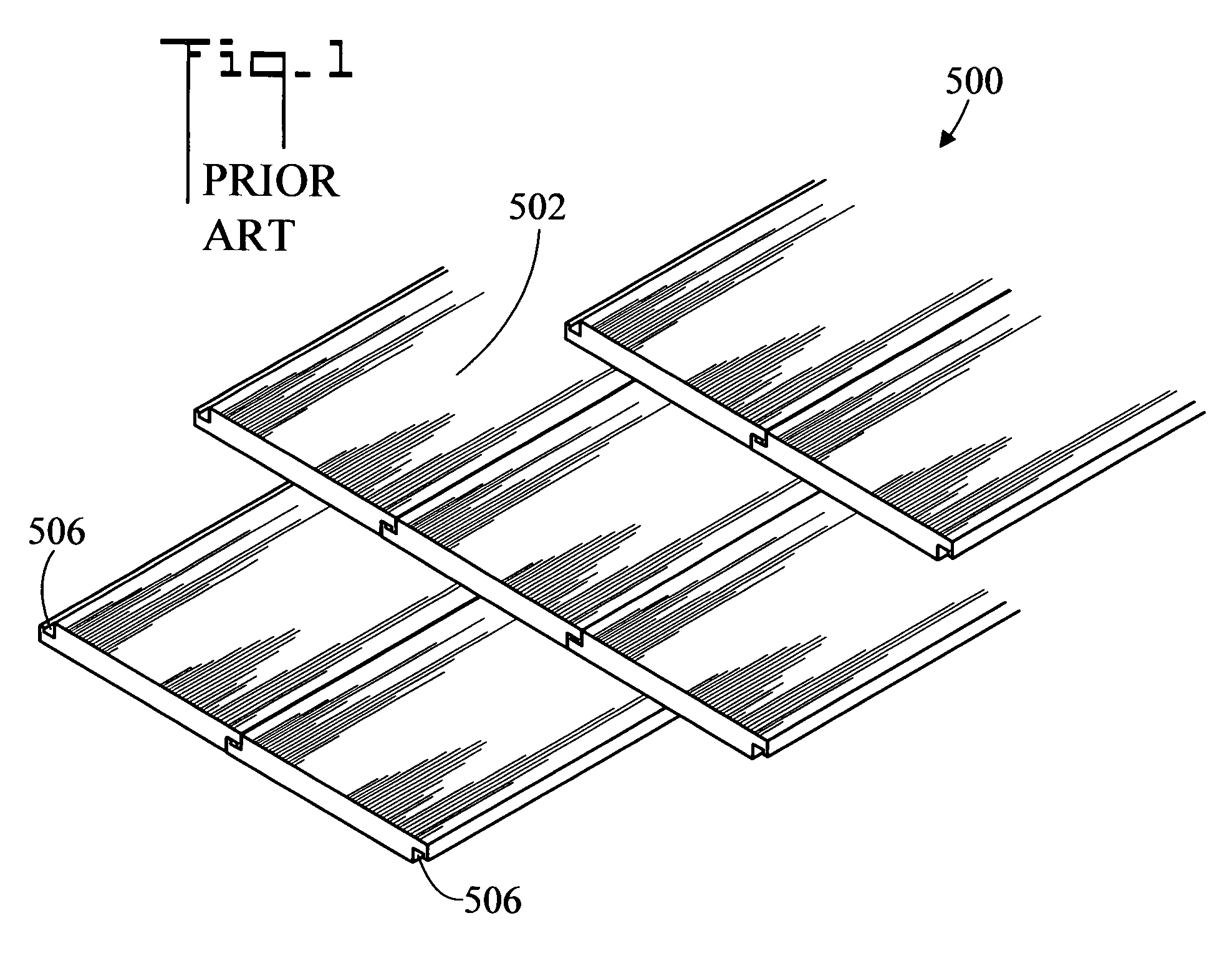

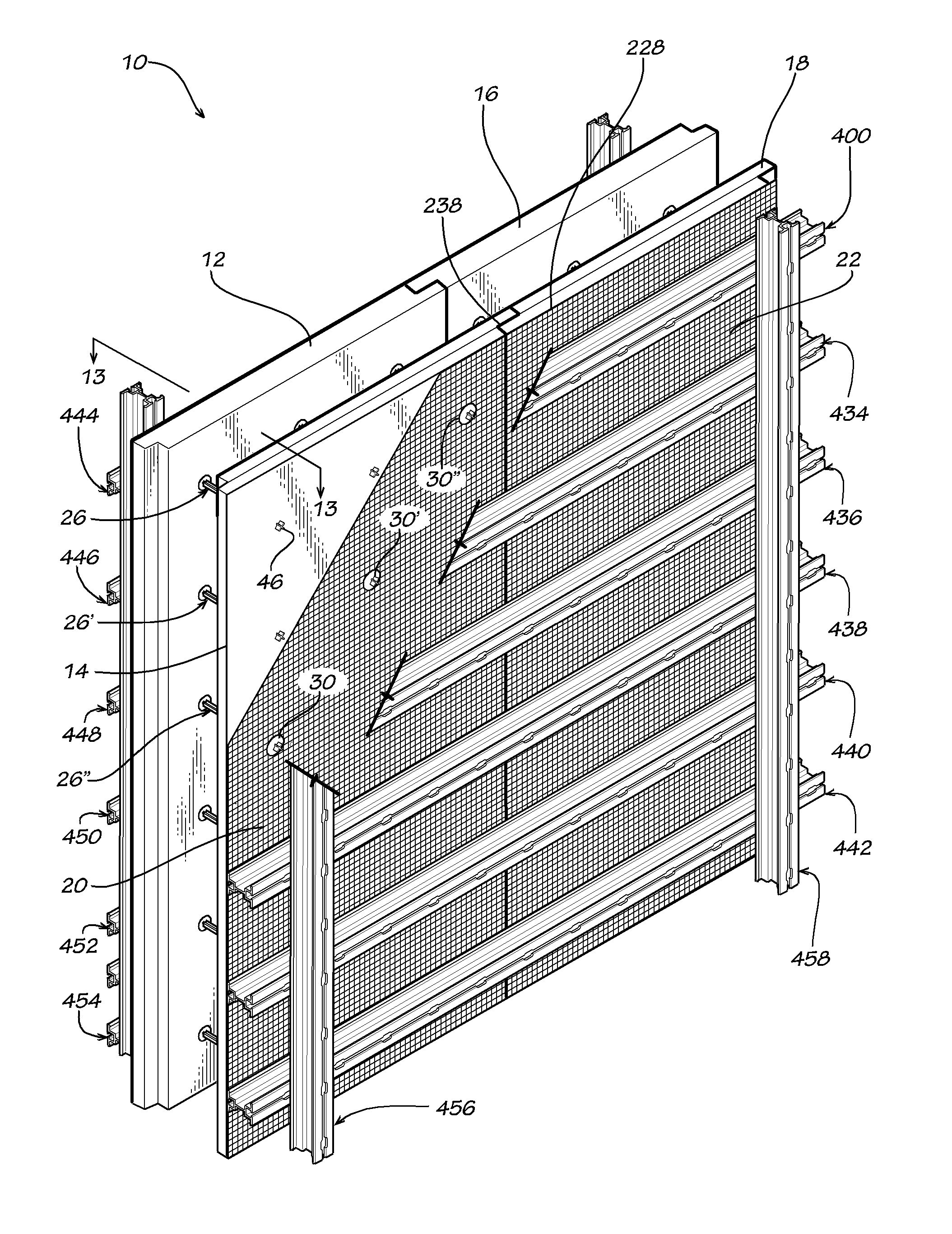

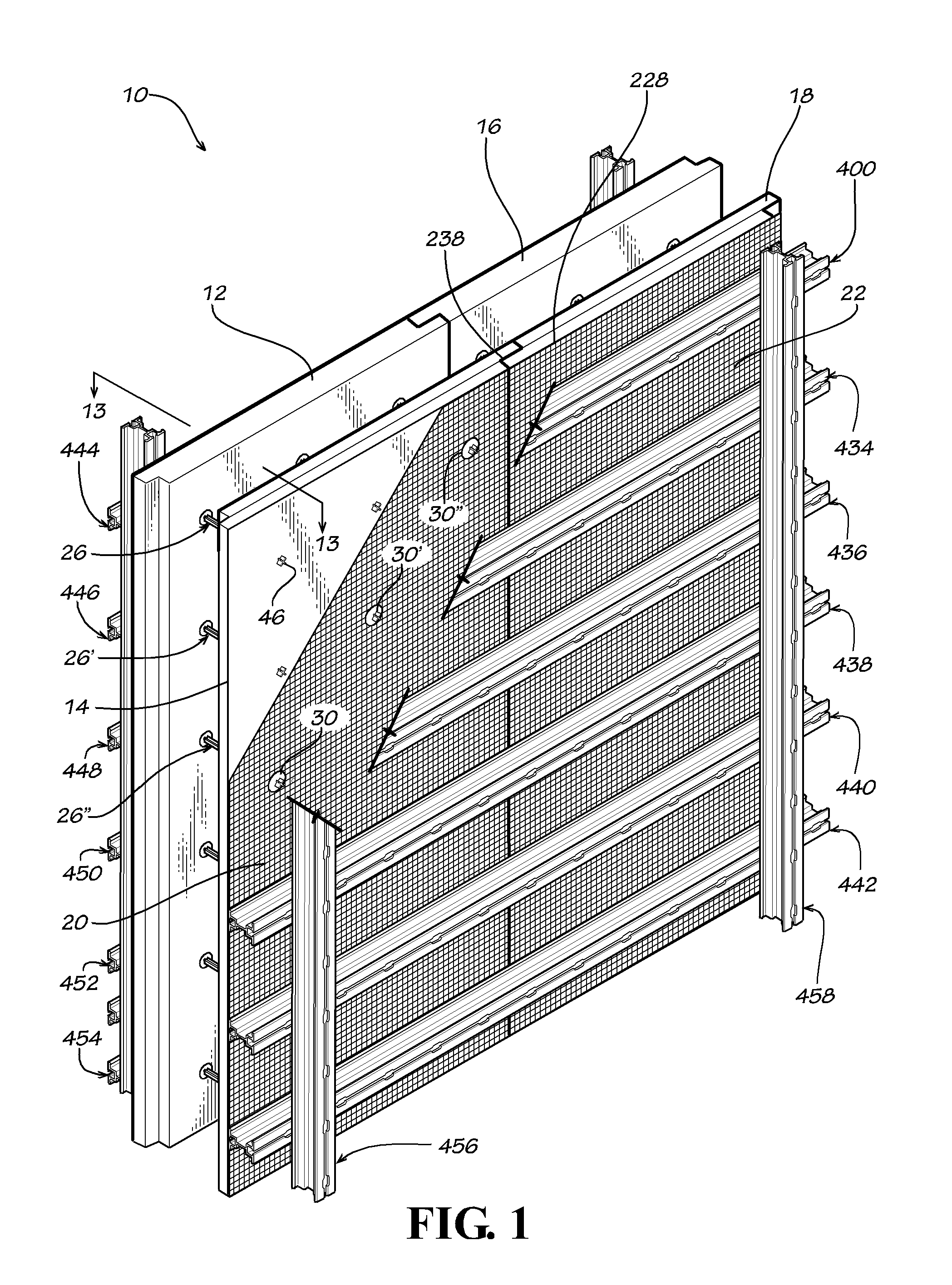

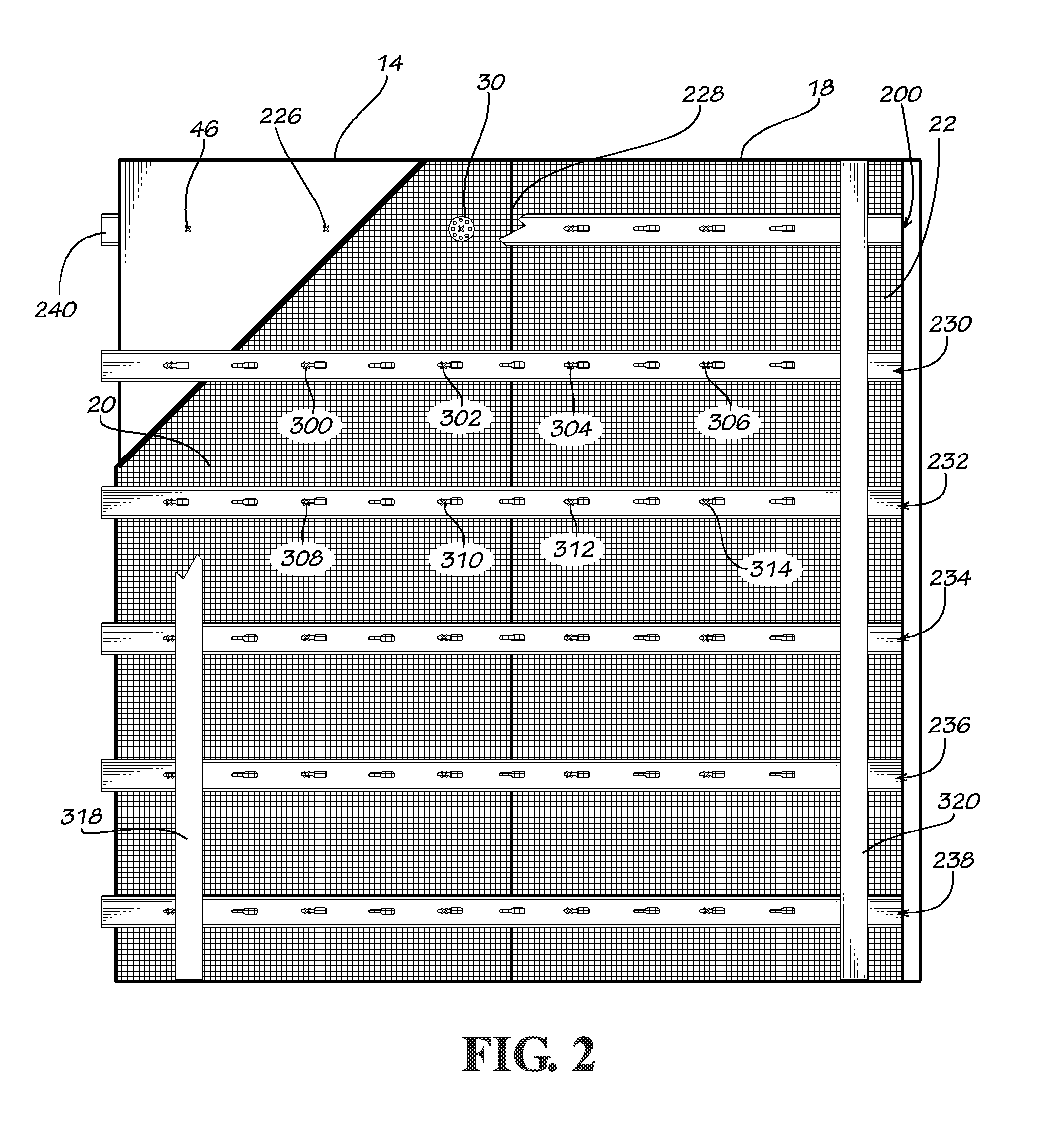

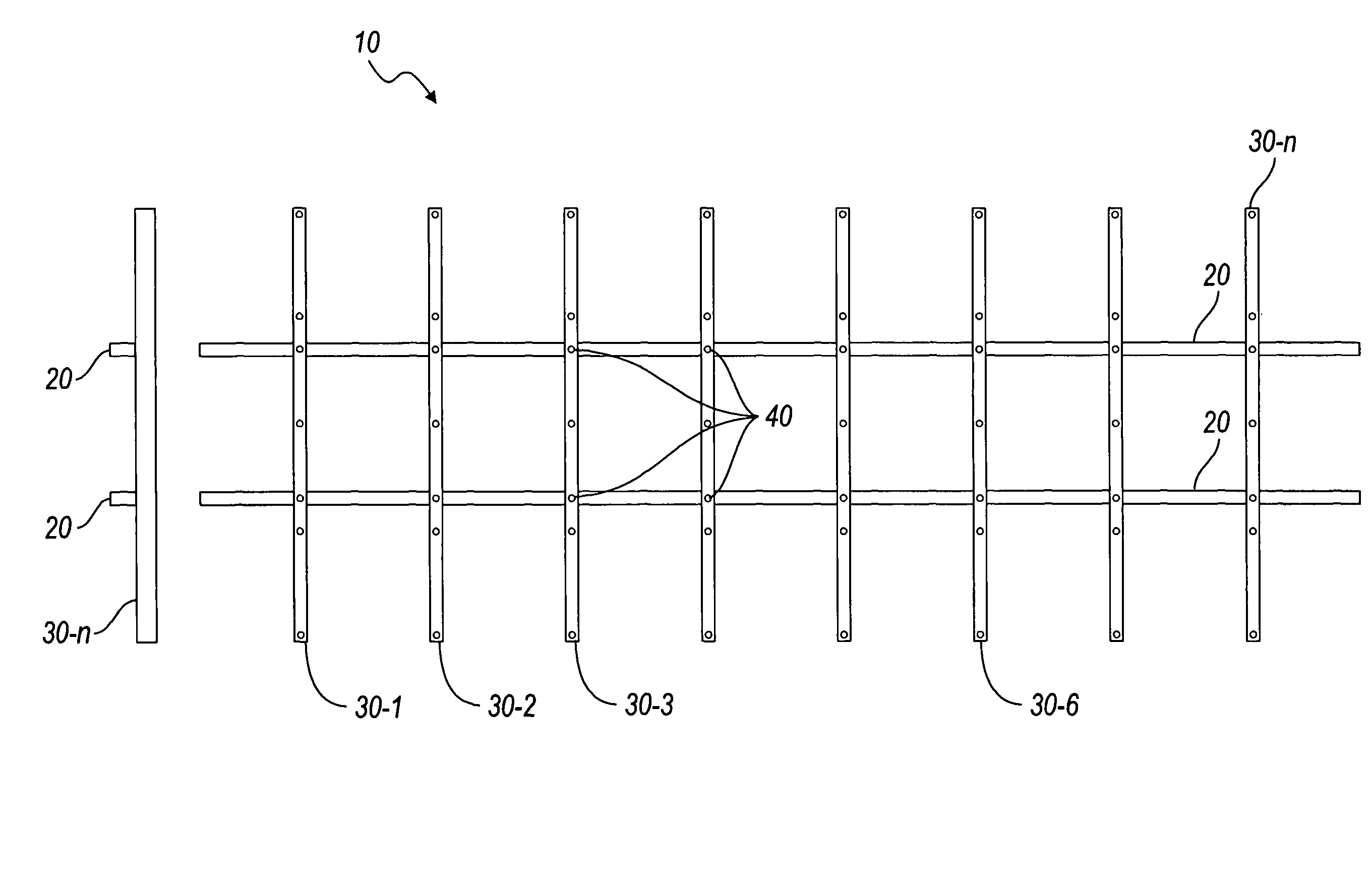

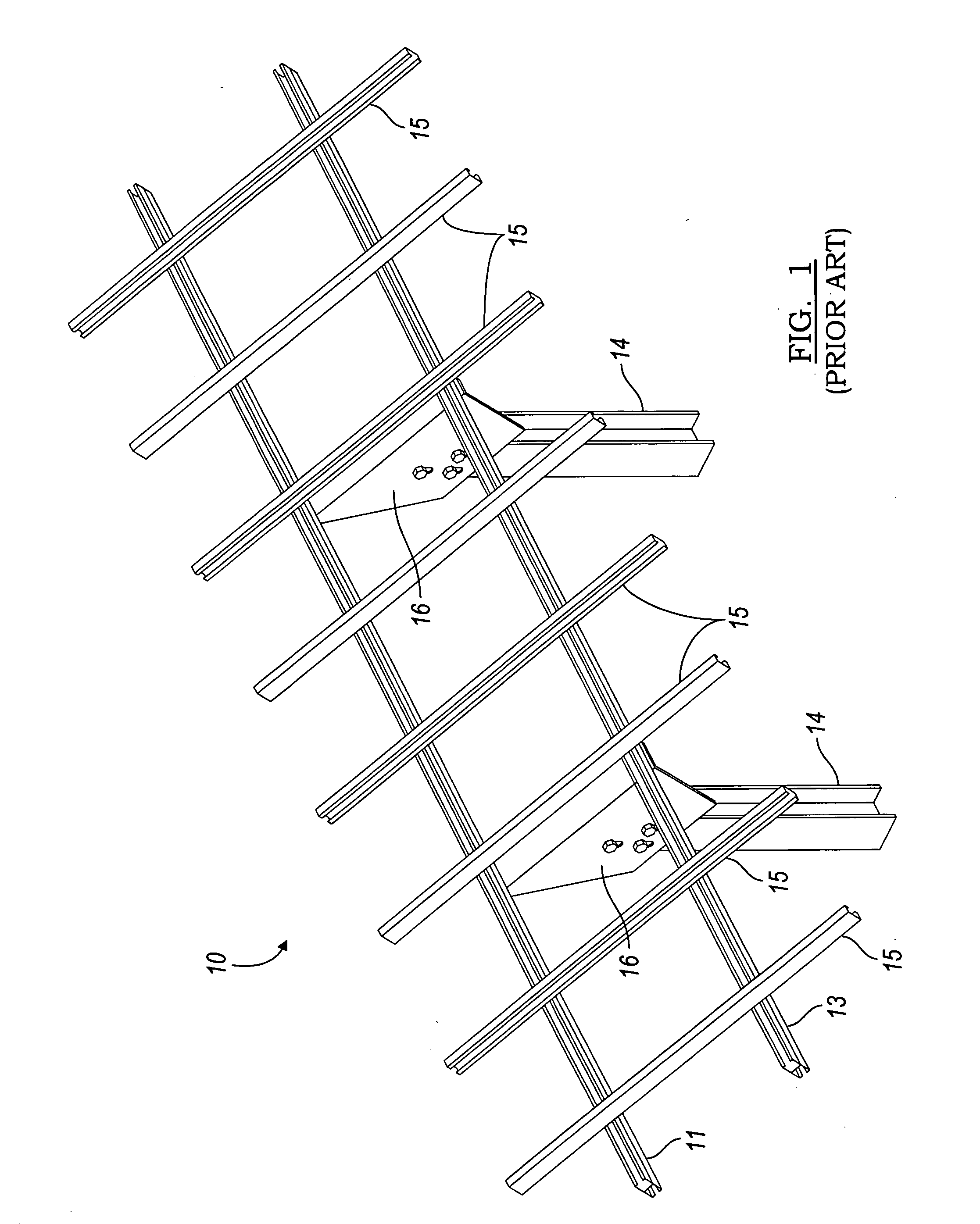

Support system for solar panels

ActiveUS8316590B2Easy to foldReduce spacingPhotovoltaic supportsSolar heating energyRow and column spacesSupporting system

An array of photovoltaic panels is supported in rows and columns spaced from one another using a foldable bi-directional span of support members. The support members include a plurality of support joists and support rails braced at an incline. Each support rail is tubular and generally rectangular, having a lower wall section with a T-slot channel for acceptance of the head of a bolt for adjustable attachment with the support joist. Also, the support rail may have a C-slot channel for retaining electrical wires. Clips are used to secure each panel to upper wall portions of underlying support rails. Each clip has a generally U-shaped gasket and is retained to a corresponding support rail through a threaded hole in a top wall of the support rail that receives a bolt or similar threaded fastener.

Owner:NORTHERN STATES METALS

Support system for solar panels

ActiveUS20100237028A1Easy to foldReduce spacingPhotovoltaic supportsSolar heating energySupporting systemRow and column spaces

An array of photovoltaic panels is supported in rows and columns spaced from one another using a foldable bi-directional span of support members. The support members include a plurality of support joists and support rails braced at an incline. Each support rail is tubular and generally rectangular, having a lower wall section with a T-slot channel for acceptance of the head of a bolt for adjustable attachment with the support joist. Also, the support rail may have a C-slot channel for retaining electrical wires. Clips are used to secure each panel to upper wall portions of underlying support rails. Each clip has a generally U-shaped gasket and is retained to a corresponding support rail through a threaded hole in a top wall of the support rail that receives a bolt or similar threaded fastener.

Owner:NORTHERN STATES METALS

Method of reinforced cementitious constrauction by high speed extrusion printing and apparatus for using same

ActiveUS20180071949A1Low costAdditive manufacturing apparatusConstruction materialReinforced concreteBrick

The present invention relates to methods and apparatuses for an automated reinforced concrete construction system for onsite slip-form molding and casting a variety of cementitious mixes in a cast in place leave in place externally moldable flexible reinforced containment sleeve providing a wide variety of interchangeable full-scale molding configurations simultaneously optimizing a wide variety of cementitious mix curing characteristics, further having optional internal reinforcement net(s), for layer wise interlocking additive printed brick deposition providing improved slip-form mold casting of a wide variety of reinforced concrete structures; the present invention further includes a variety of operating platforms suitable for on and offsite construction as disclosed herein.

Owner:ARMATRON SYST LLC

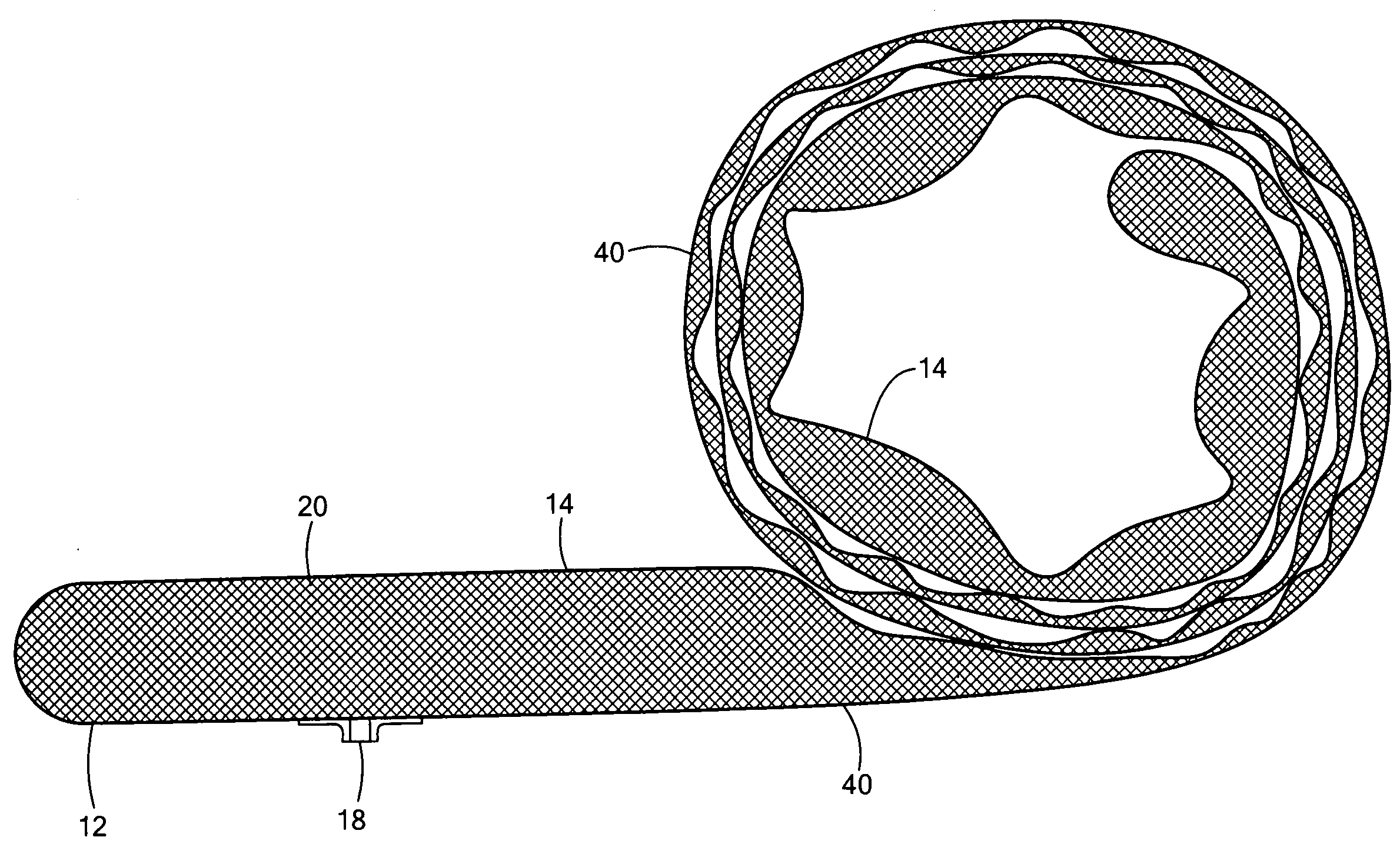

Roll-up inflatable beam structure

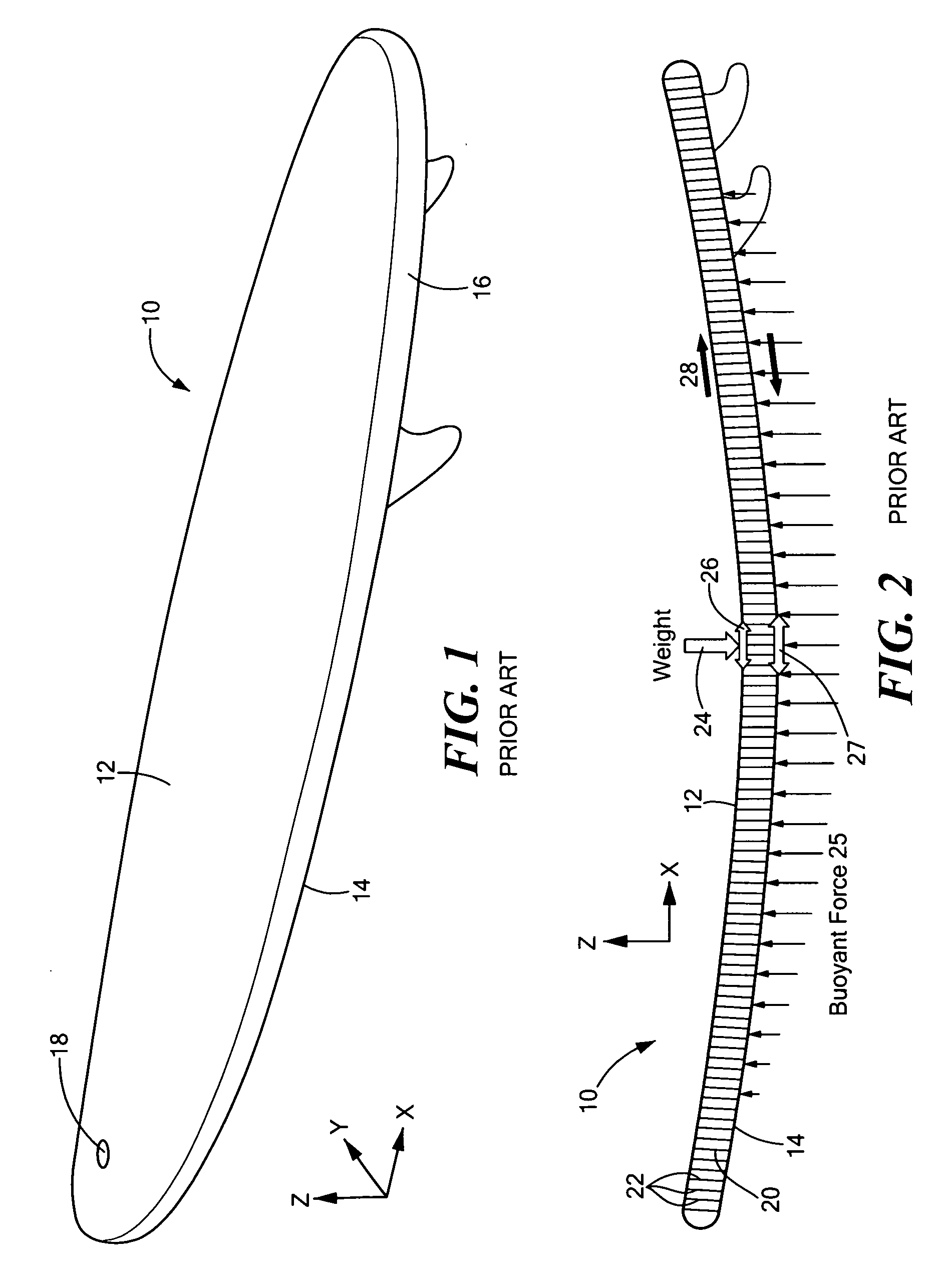

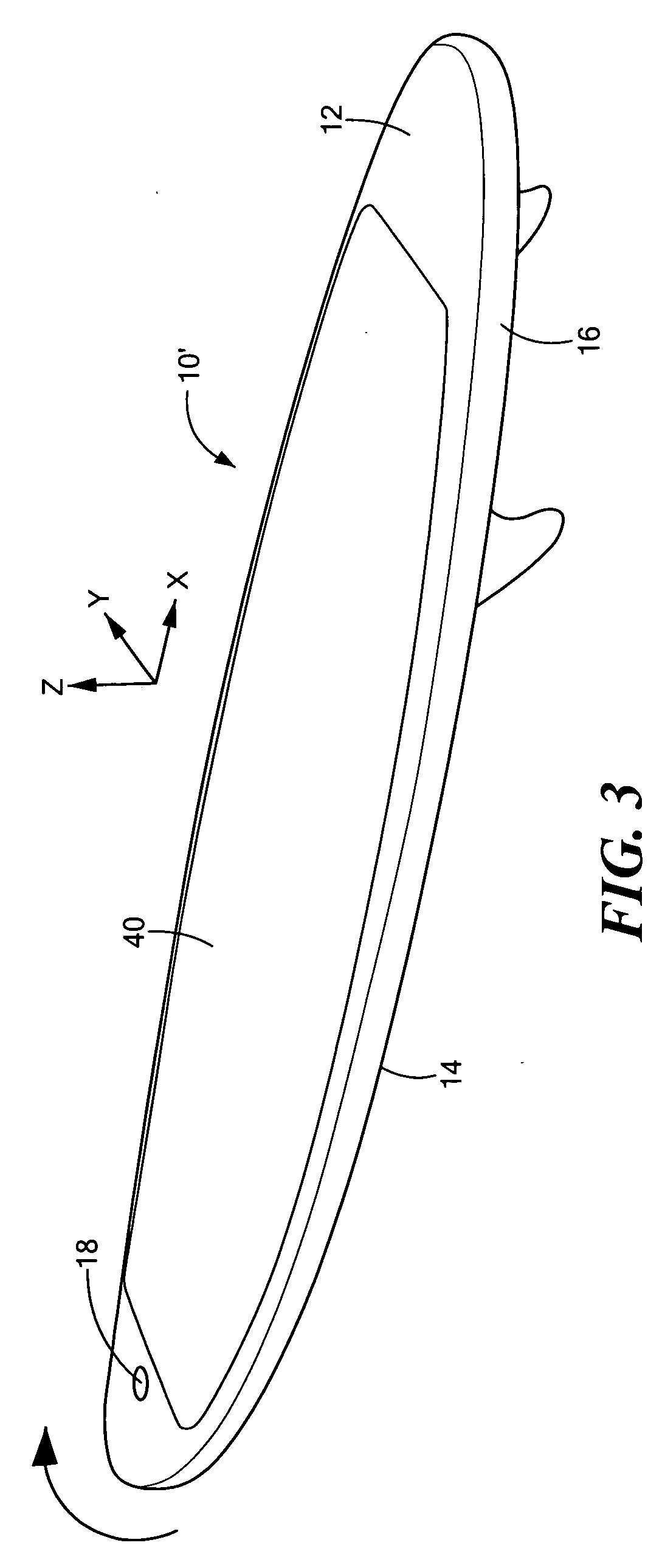

InactiveUS20090049757A1Strong and stable structureGood withstands buckling loadWaterborne vesselsWater sport boardsNuclear engineeringGas pressure

A sandwich beam including in one example first and second spaced walls, a core configured to maintain a predetermined spacing between the walls when the core is filled with pressurized gas and to resist shear when the beam is loaded in bending and a port for filling the core with gas biasing both walls in tension. The tension tends to increase in the second wall and decrease and cause a compression load in the first wall in response to a sufficiently large applied bending load. A compression element is fixed only with respect to the first wall and is configured (a) to support the compression load so that the beam is stronger at a given gas pressure and (b) to flex sufficiently to allow the beam to be rolled up when the gas is emptied from the core via the port.

Owner:FOSTER-MILLER

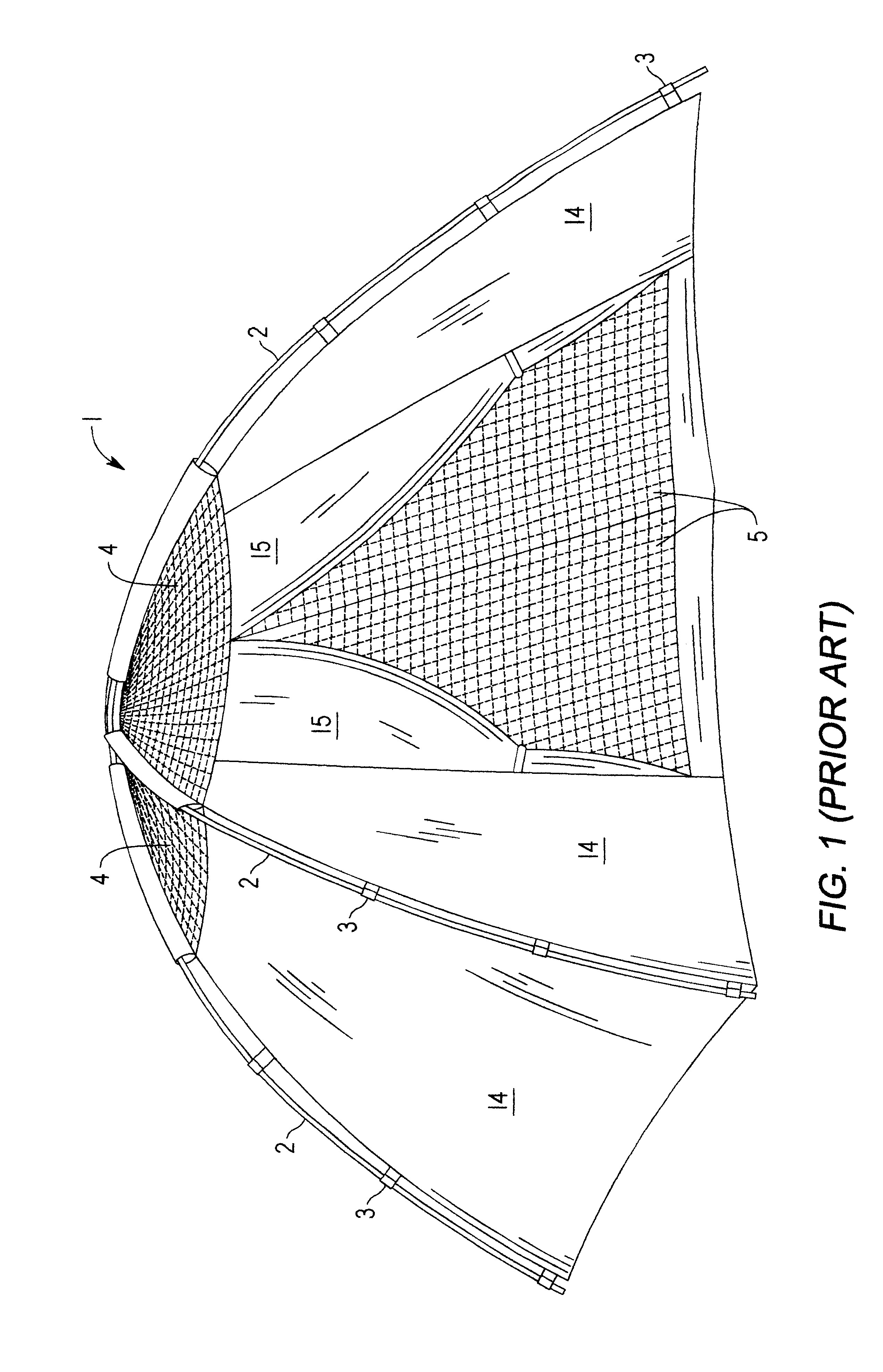

Inflatable fresnel lens solar concentrator for space power

InactiveUS6111190AImprove toleranceReduce quality problemsSolar heating energyCosmonautic vehiclesSpace powerEngineering

A novel, high-efficiency, extremely light-weight, inflatable refractive solar concentrator for space power is described. It consists of a flexible Fresnel lens, flexible sides, and a back surface, together enclosing a volume of space which can be filled with low pressure gas to deploy the concentrator on orbit. The back surface supports the energy receiver / converter located in the focal region of the Fresnel lens. The back surface can also serve as the waste heat radiator. Prior to deployment, the deflated flexible lens and sides are folded against the back surface to form a flat, low-volume package for efficient launch into space. The inflatable concentrator can be configured to provide either a line focus or a point focus of sunlight. The new inflatable concentrator approach will provide significant advantages over the prior art in two different space power areas: photovoltaic concentrator arrays and high-temperature solar thermal conversion systems. Photovoltaic concentrator arrays using the new inflatable lens will be much lighter than prior space concentrator arrays. In addition, for photovoltaic concentrator arrays, the new inflatable lens will eliminate the need for a fragile glass superstrate to support the lens, substantially improving robustness of the lens. Solar thermal concentrator arrays using the new inflatable lens will be much lighter than prior art space concentrators which used parabolic mirrors. In addition, for solar thermal applications in space, the new inflatable lens will eliminate the need for high surface accuracy, which has been a significant problem for prior art concentrators.

Owner:ENTECH INC +1

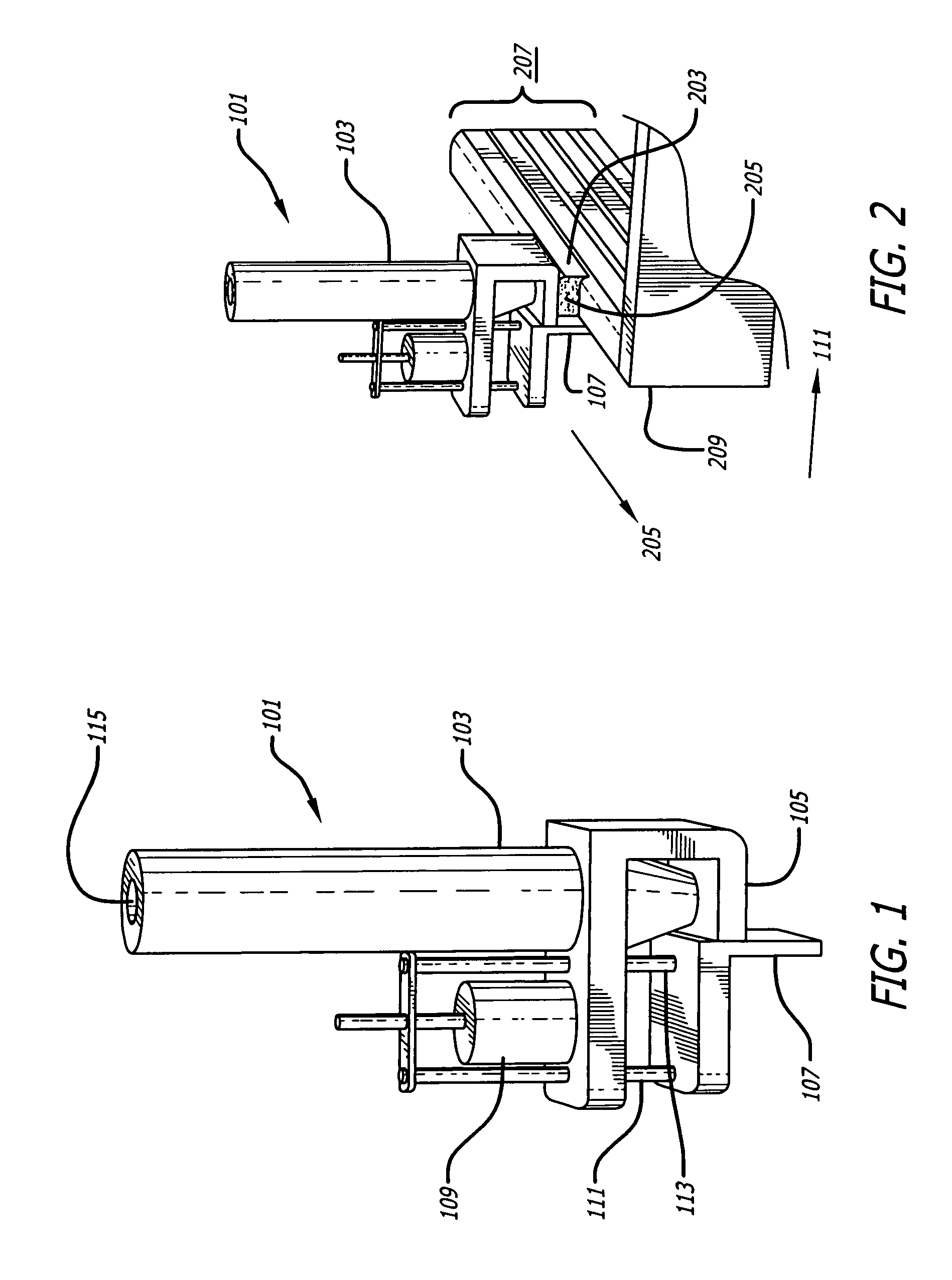

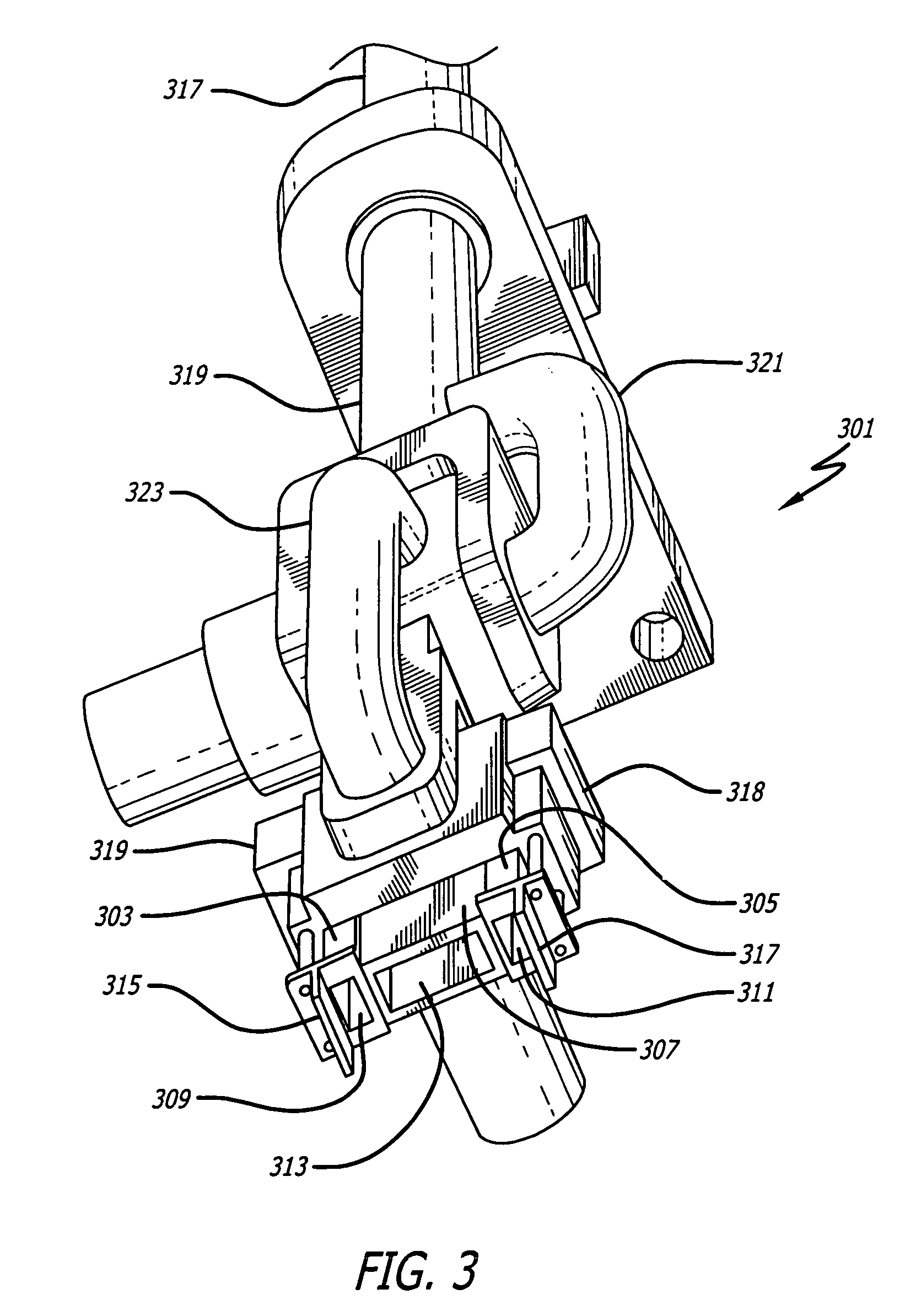

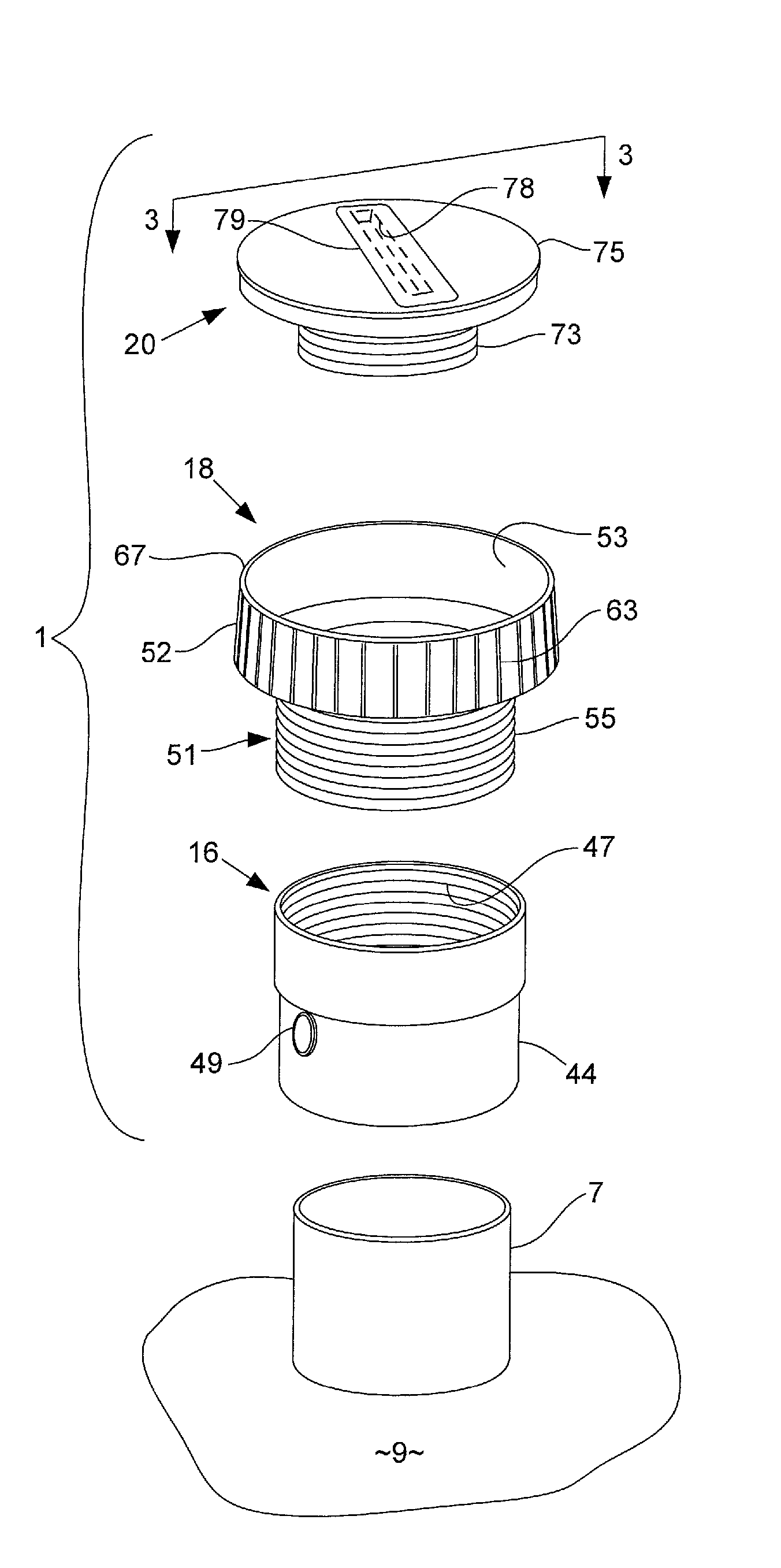

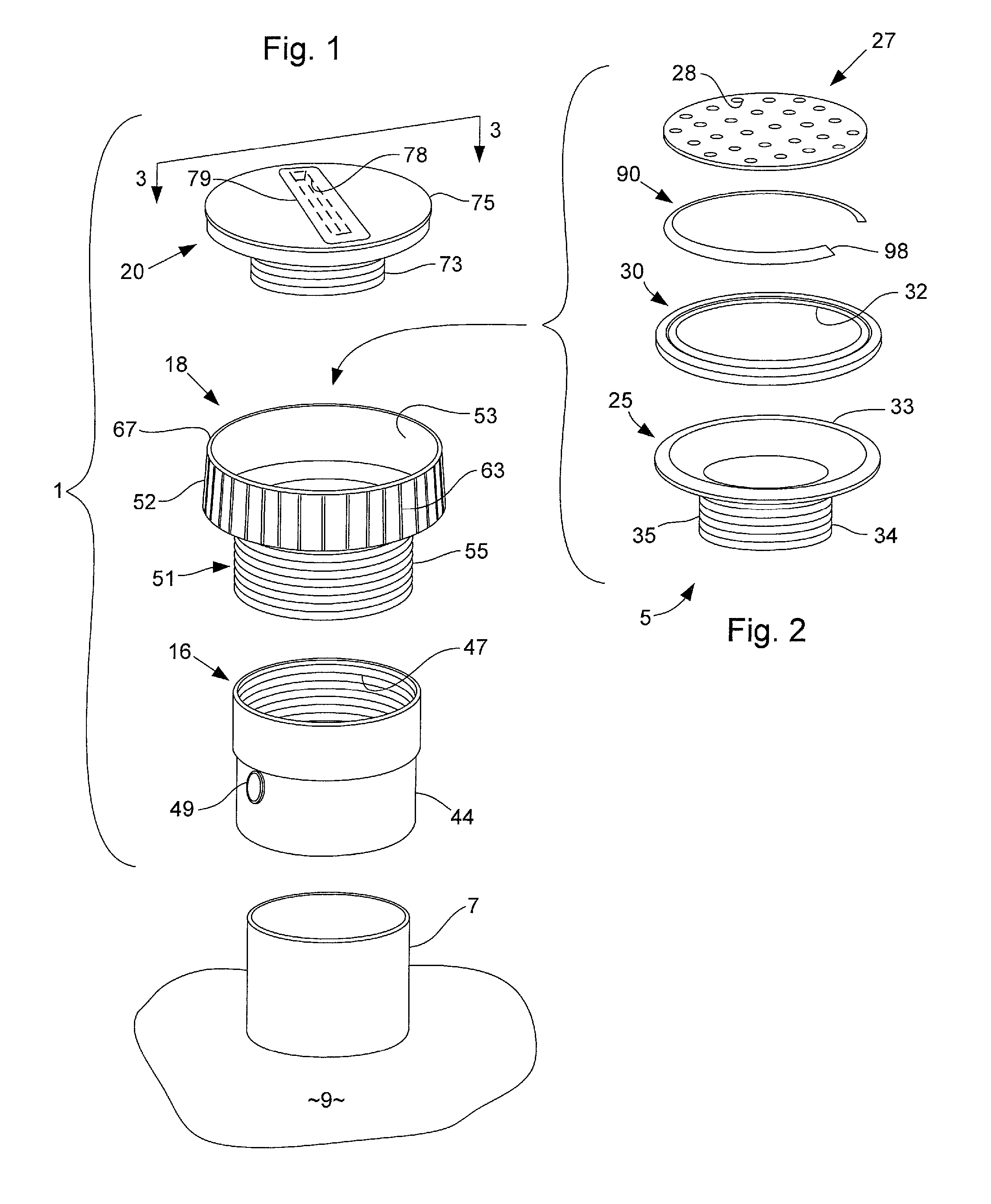

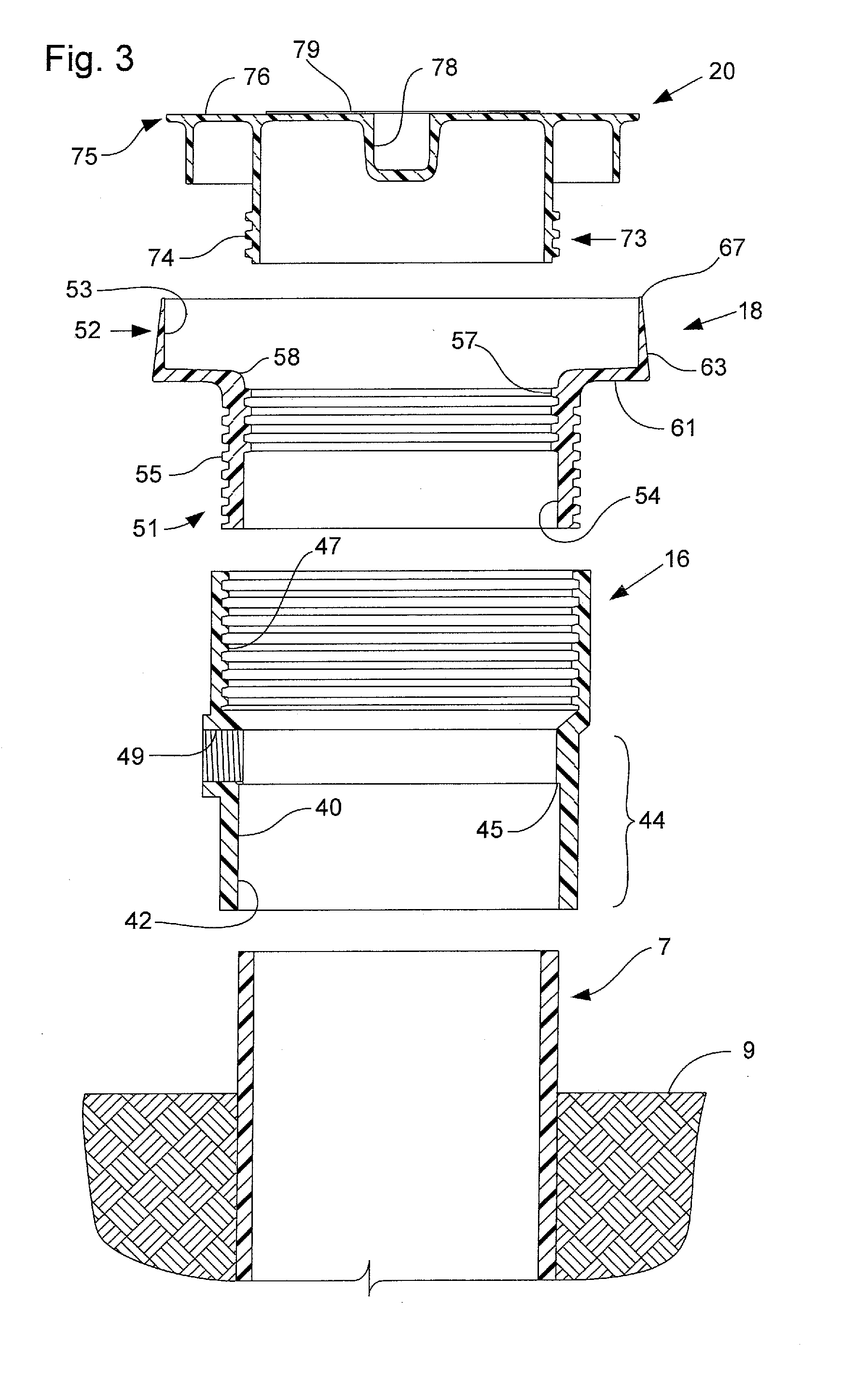

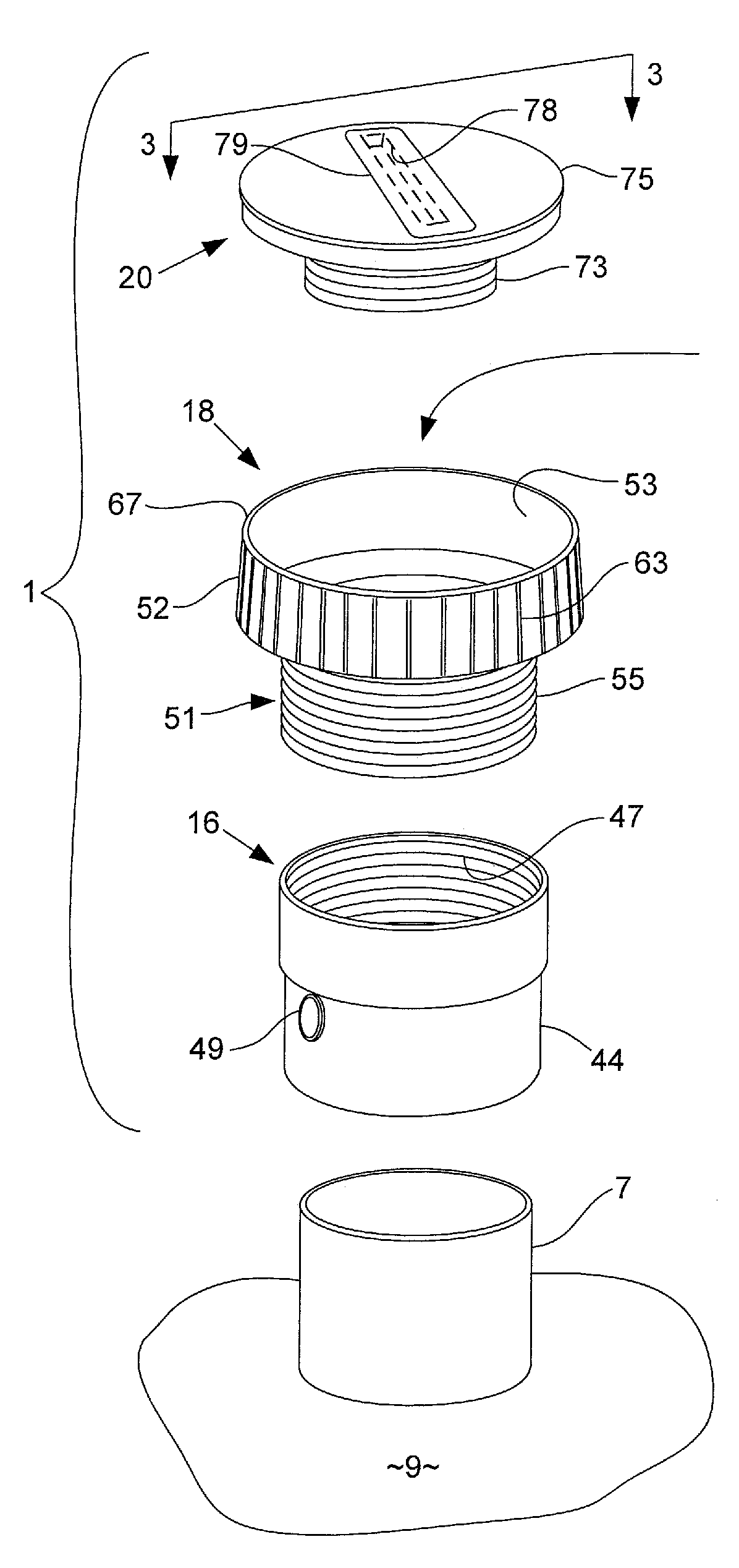

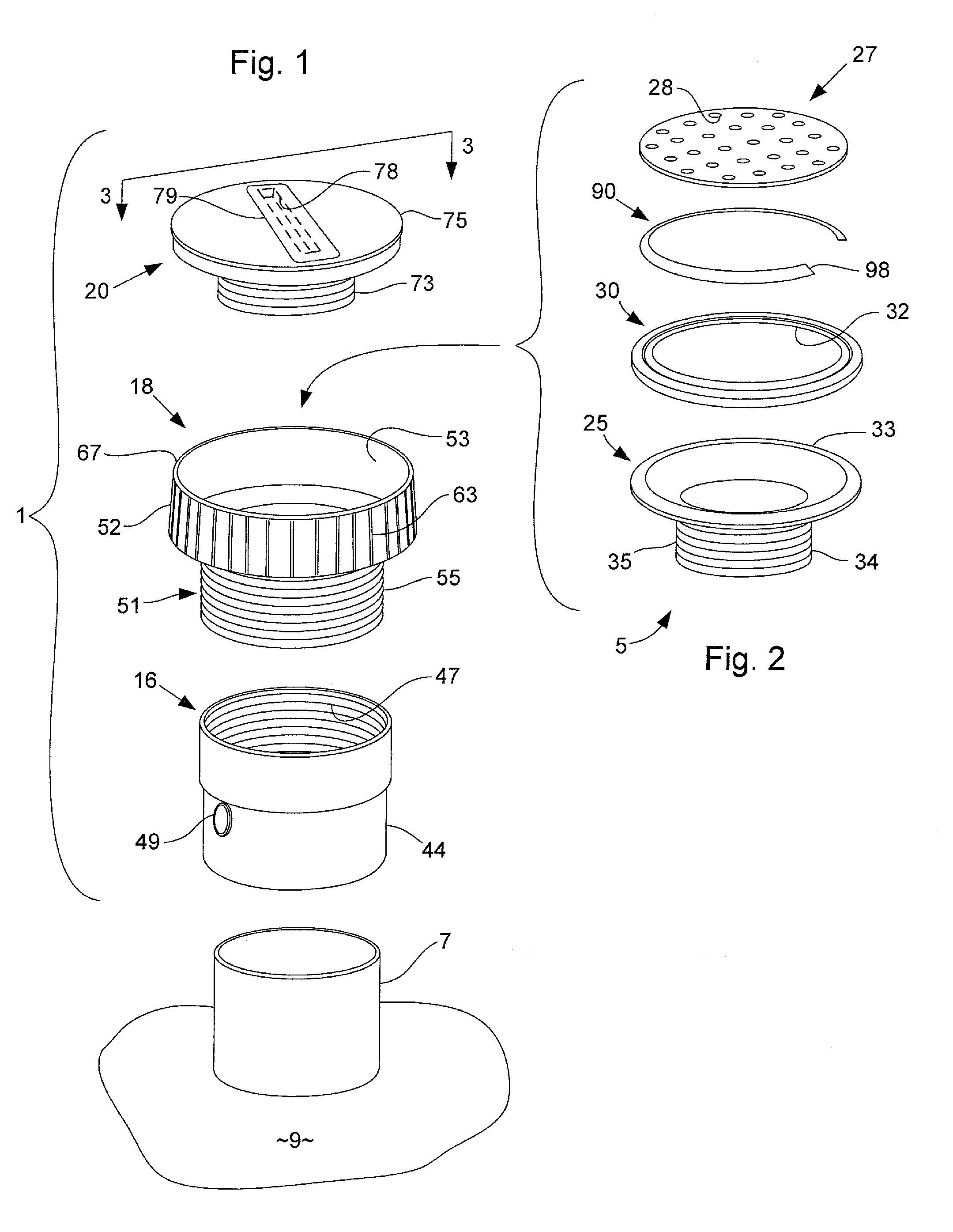

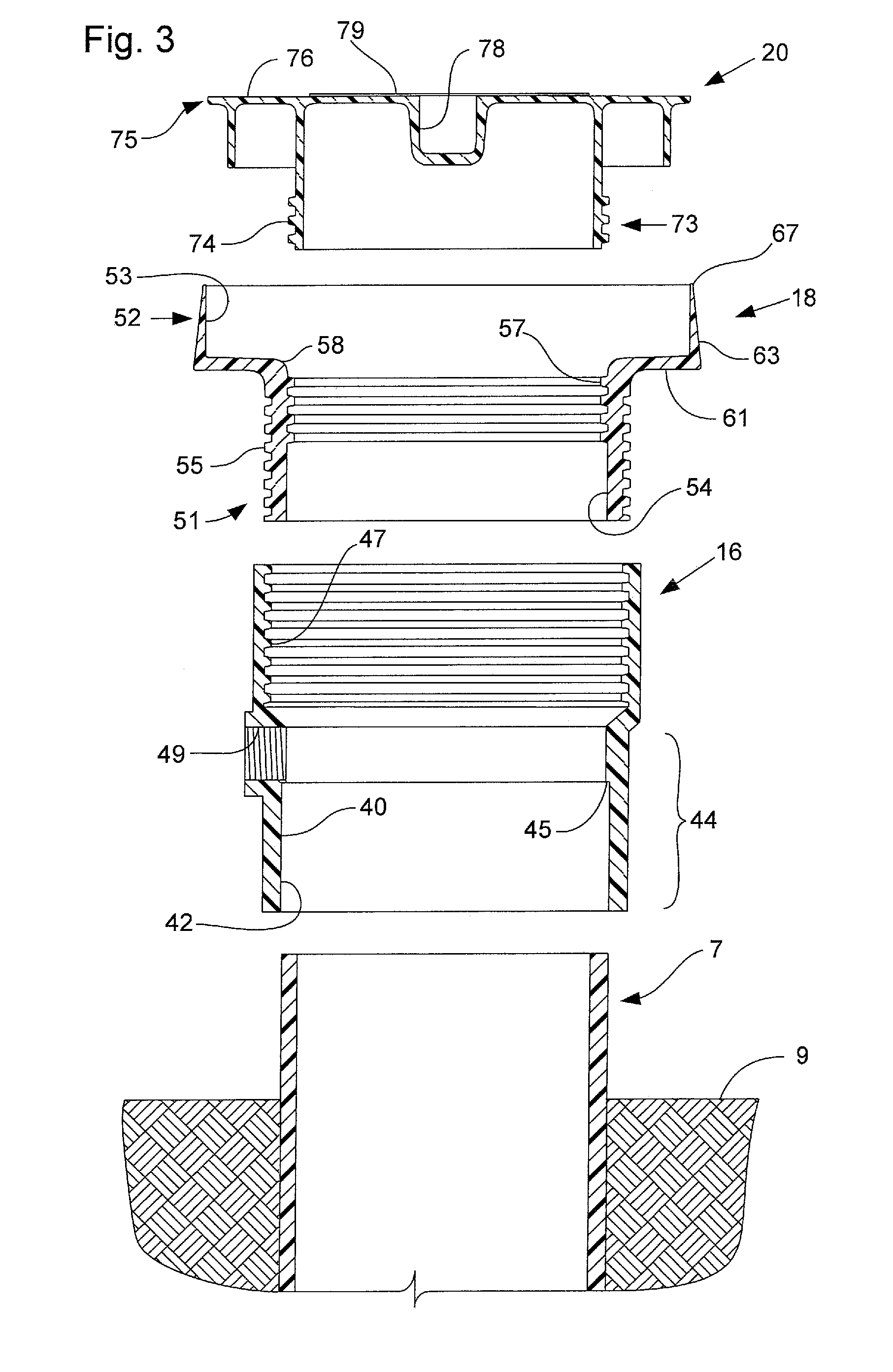

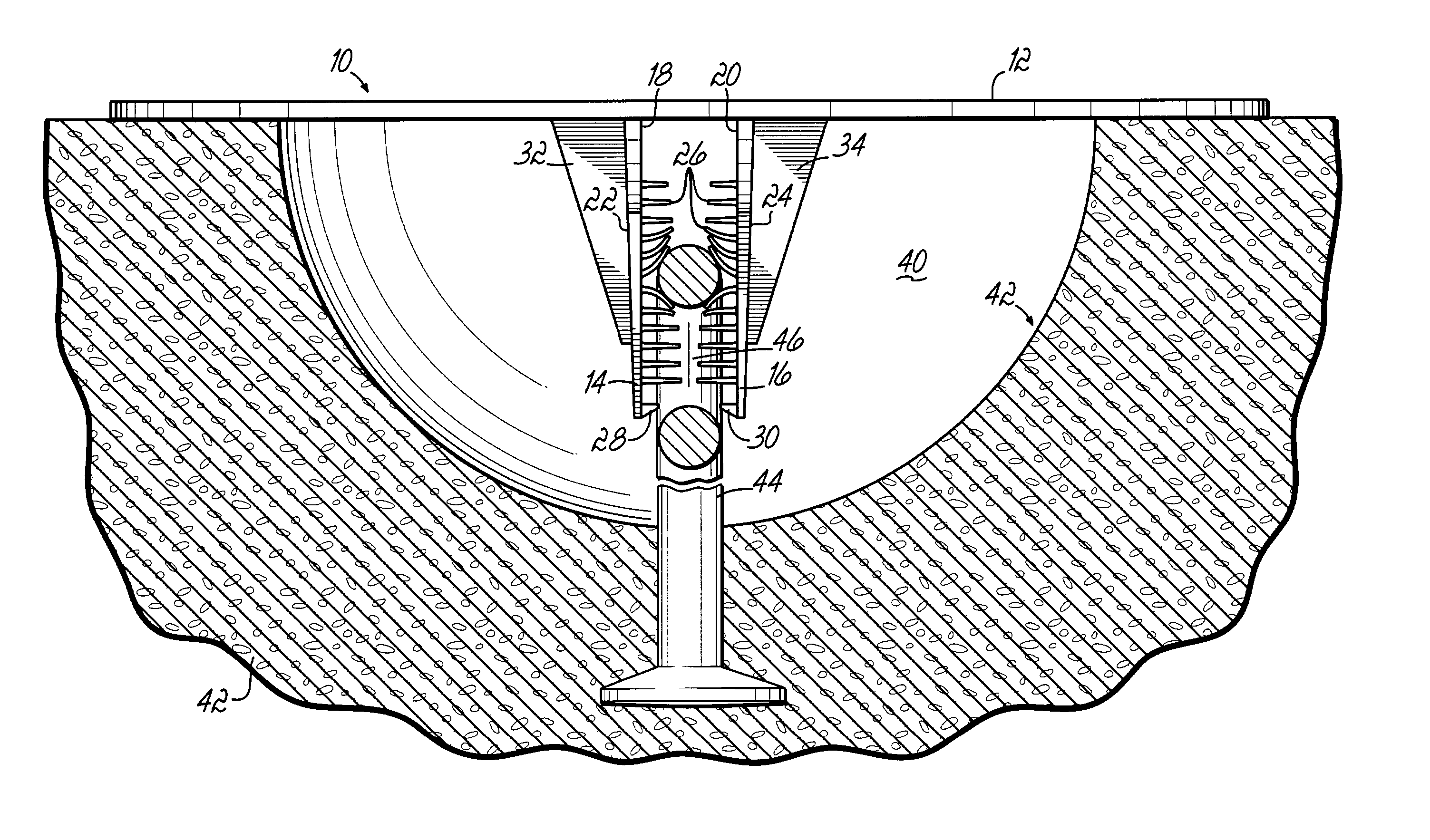

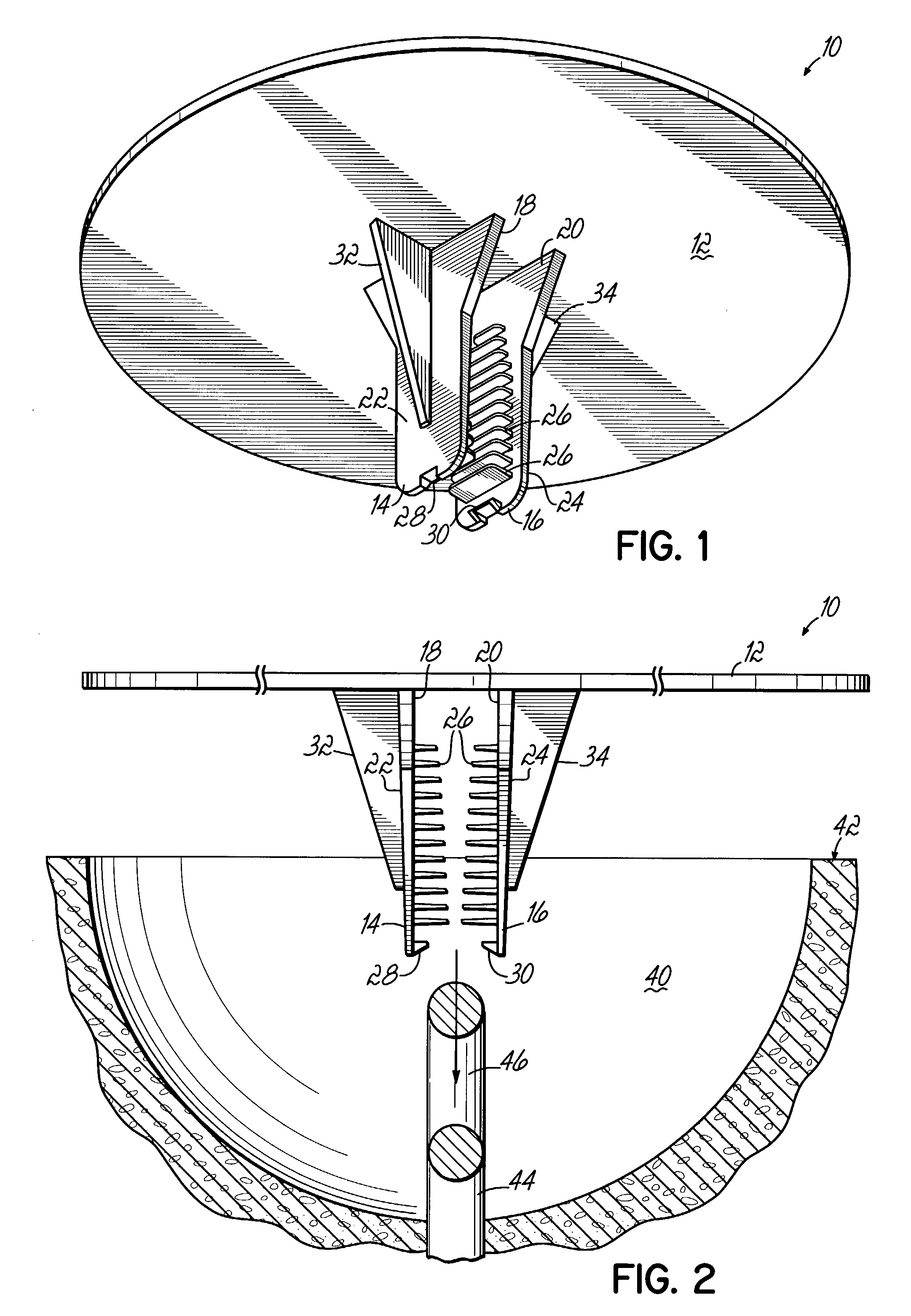

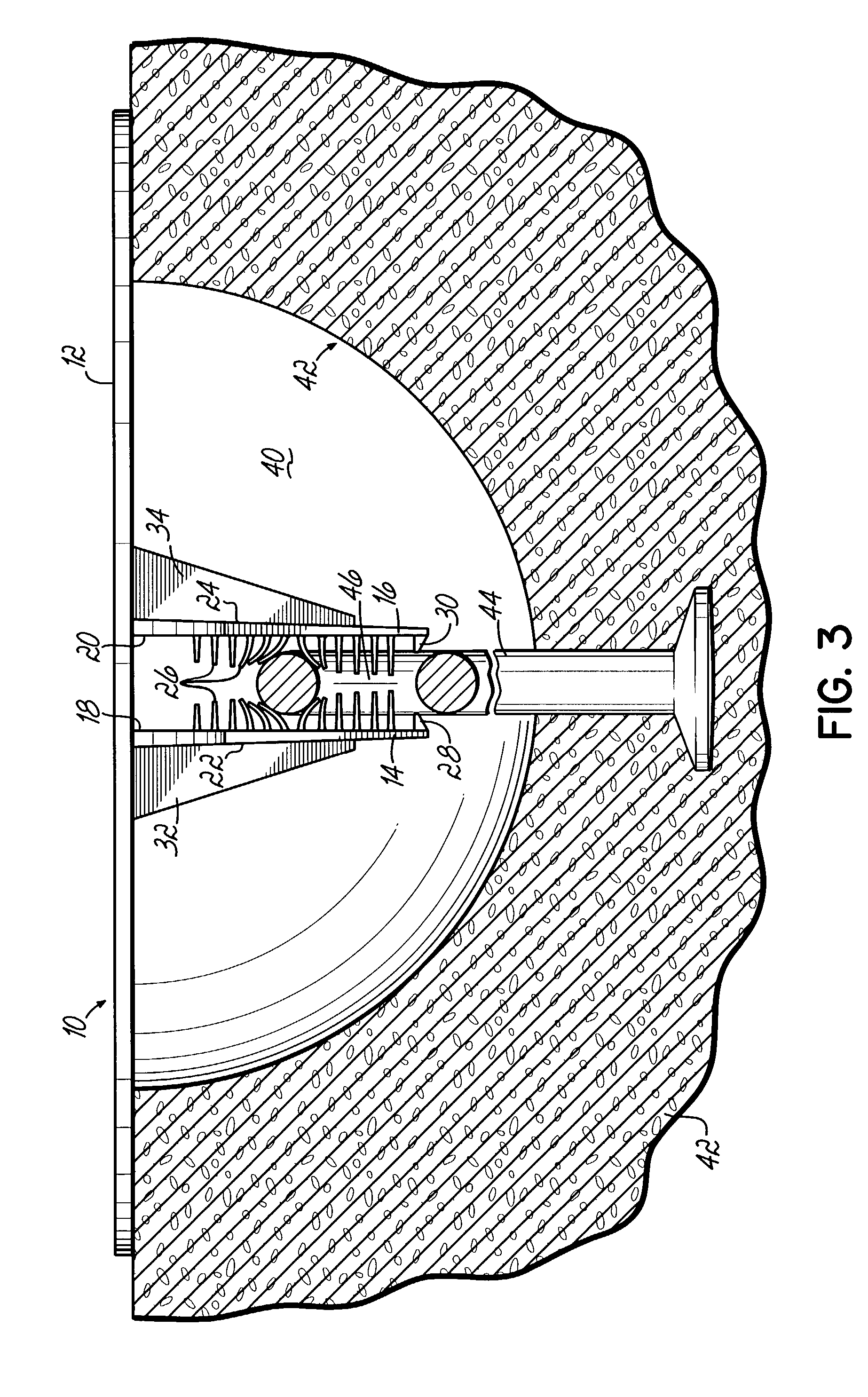

Floor drain installation system

A floor drain installation system includes an adaptor attached to a drain pipe projecting from the ground, a coring sleeve having a bowl-shaped upper end attached to or integral with the adaptor, and a coring plug received within the bowl of the receiver to close off the drain pipe during pouring of a concrete floor and to create a space for subsequent reception of a drain head and grate.

Owner:SIOUX CHIEF MFG

Floor drain installation system

A floor drain installation system includes an adaptor attached to a drain pipe projecting from the ground, a coring sleeve having a bowl-shaped upper end attached to or integral with the adaptor, and a coring plug received within the bowl of the receiver to close off the drain pipe during pouring of a concrete floor and to create a space for subsequent reception of a drain head and grate.

Owner:SIOUX CHIEF MFG

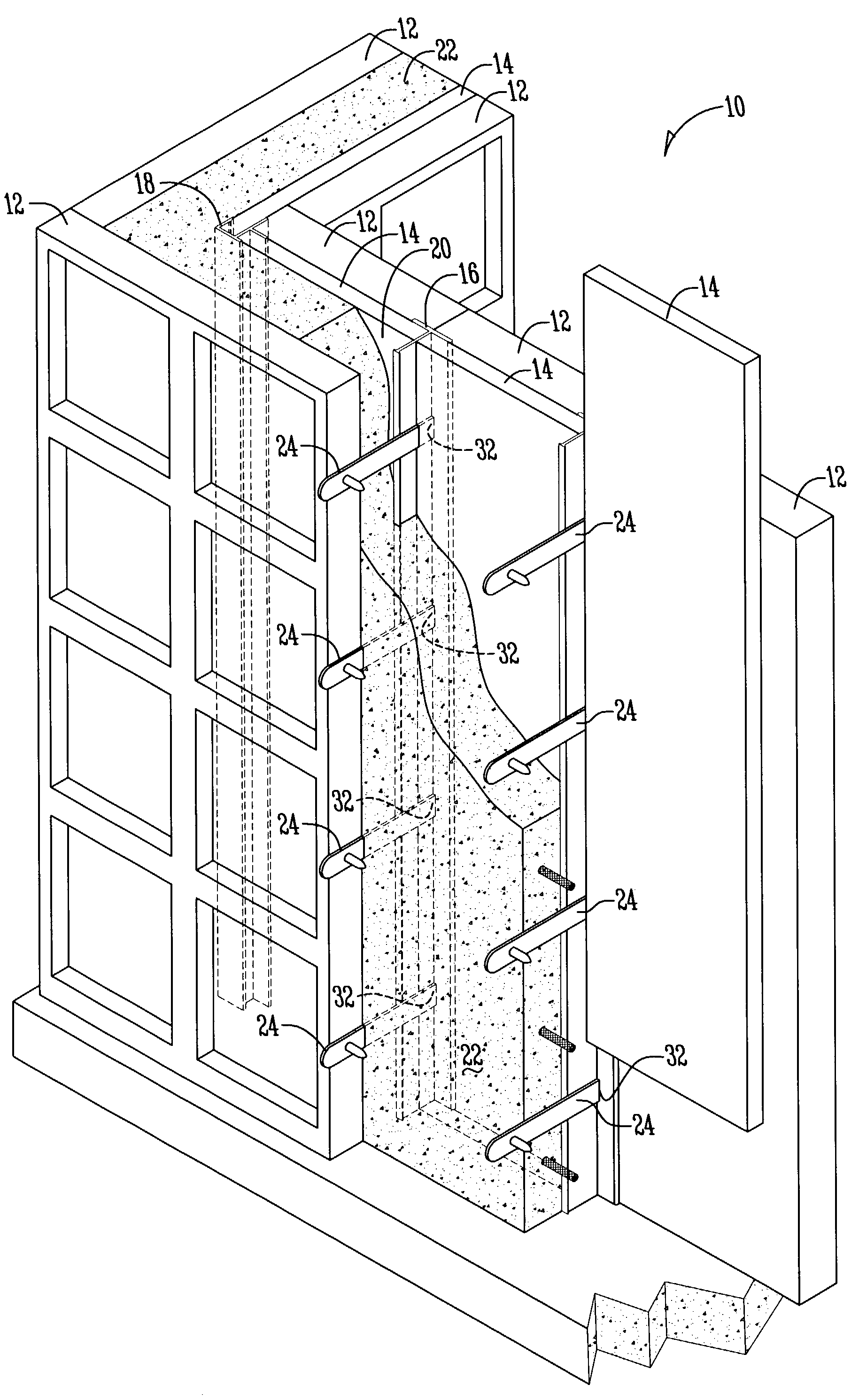

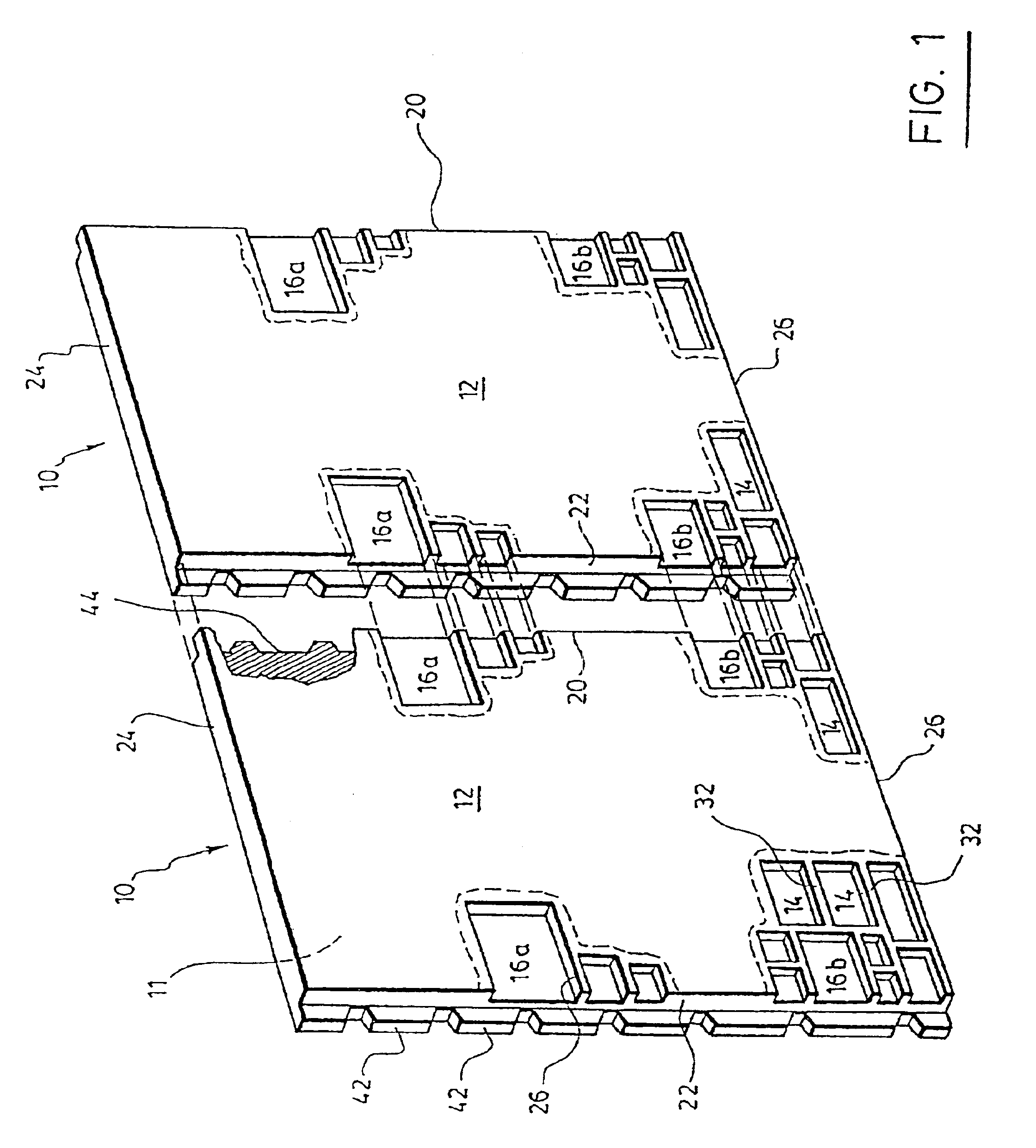

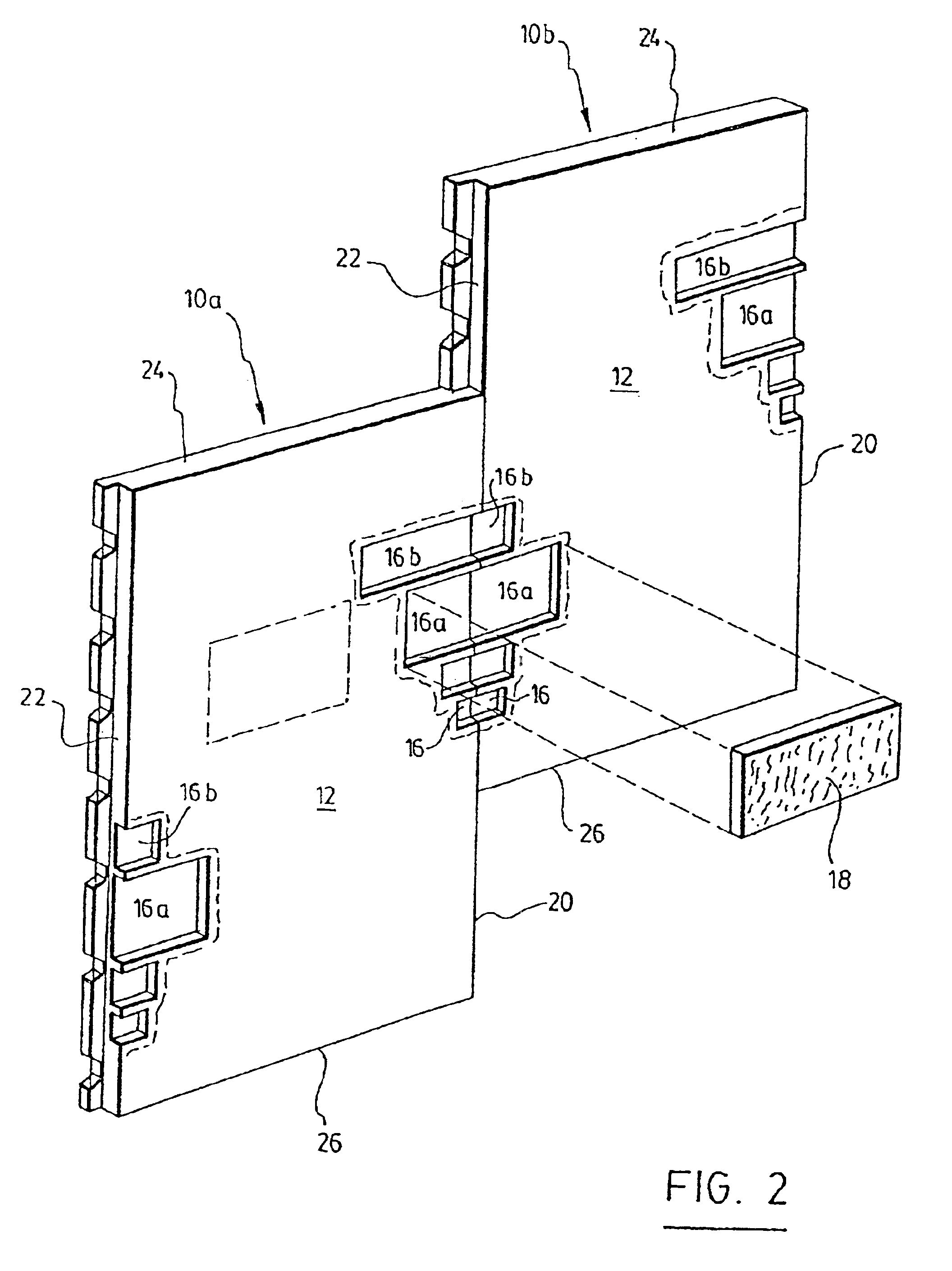

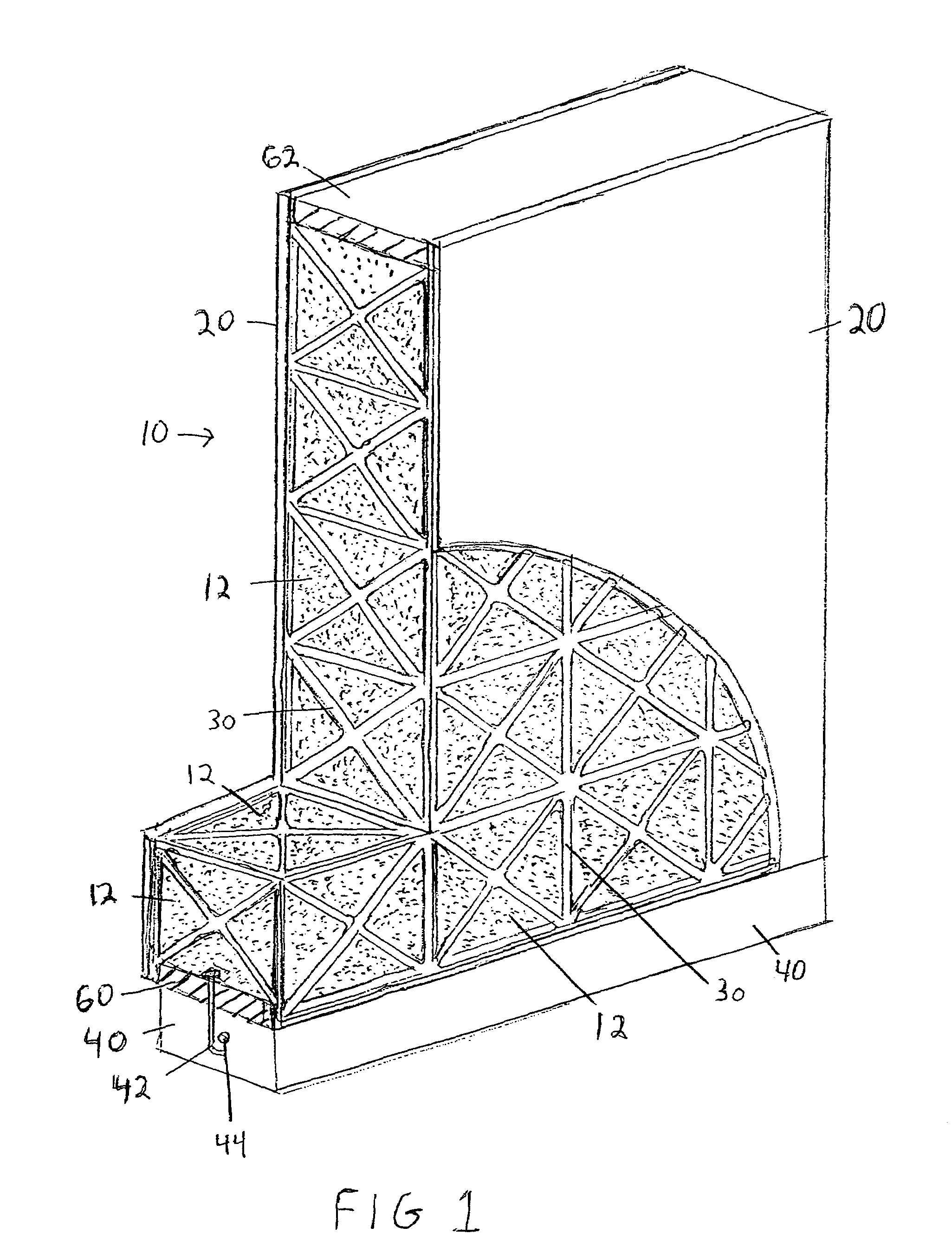

Building construction using structural insulating core

InactiveUS20100058700A1Easy to fixEasy to placeCeilingsWallsConcrete beamsStructural insulated panel

The present invention relates to an improved wall system where a wall form mold has a structural insulated core assembled to form a structural insulated panel (SIP) to form a concrete beam and concrete column to be poured anywhere within the wall as well as between building modules when placed together and erected vertically. The interlocking wall molds interlock within the wall as well as between panels and modules. The wall panels allow concrete columns and beams to be formed with an ICF in any size and shape. The structural insulated core consists of interlocking foam spacers and support channels which can be glued or screwed together to form an independent wall or as part of a precast wall with columns and beams integrated within the wall panels. Expanded and insulating flanges within the wall forming mold separates the wall forming structure from the wall surfaces.

Owner:LEBLANG DENNIS WILLIAM

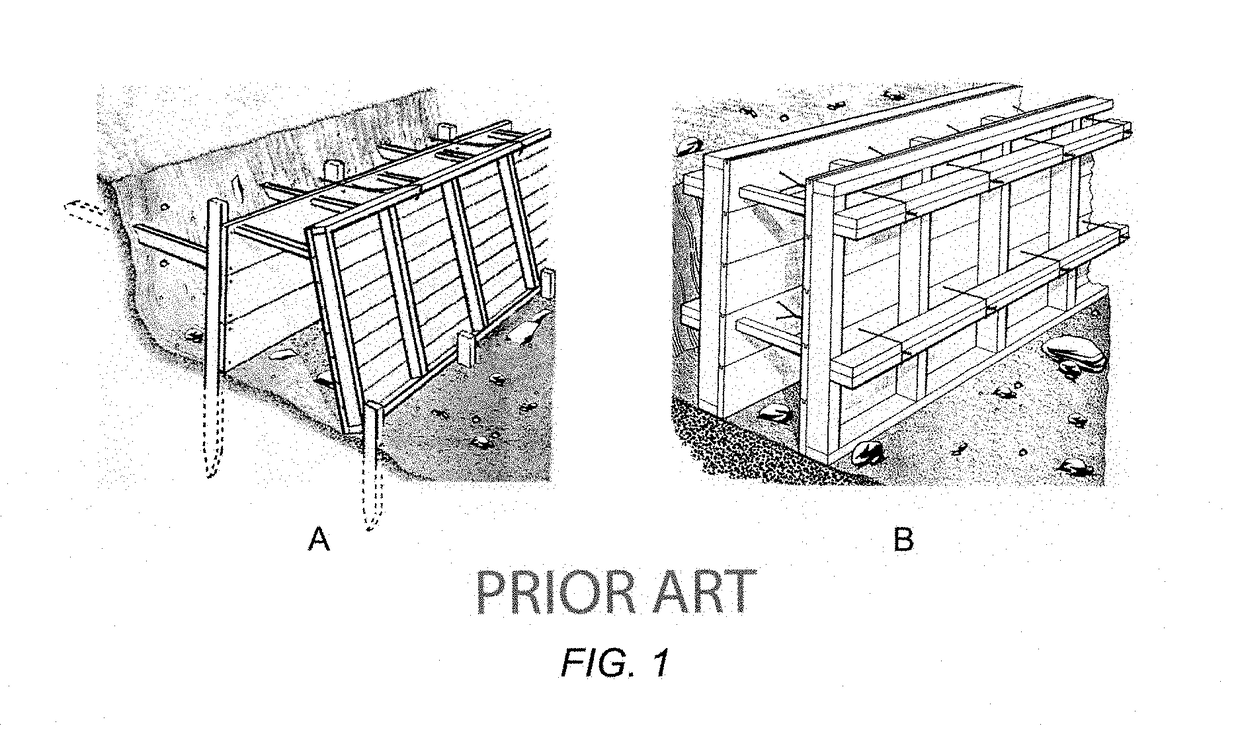

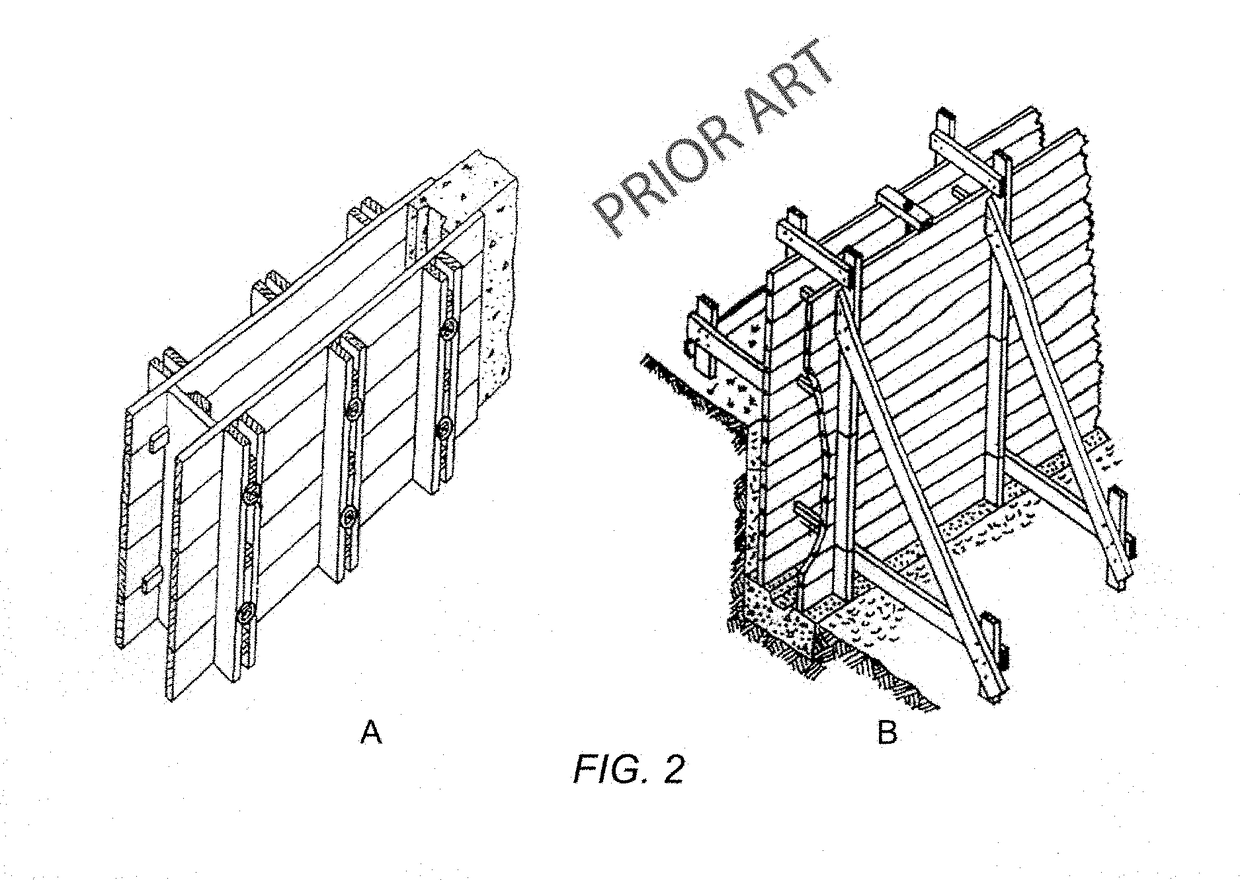

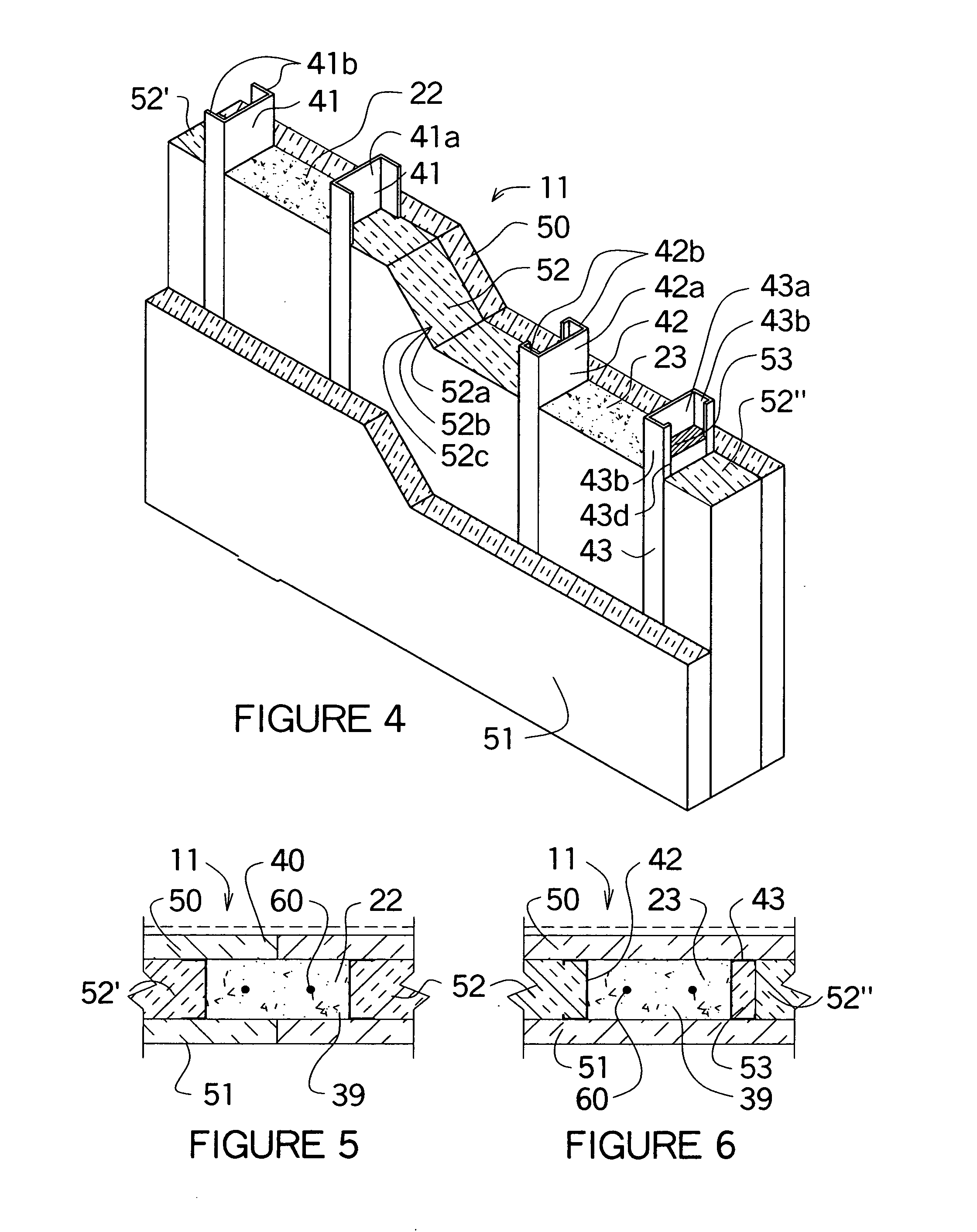

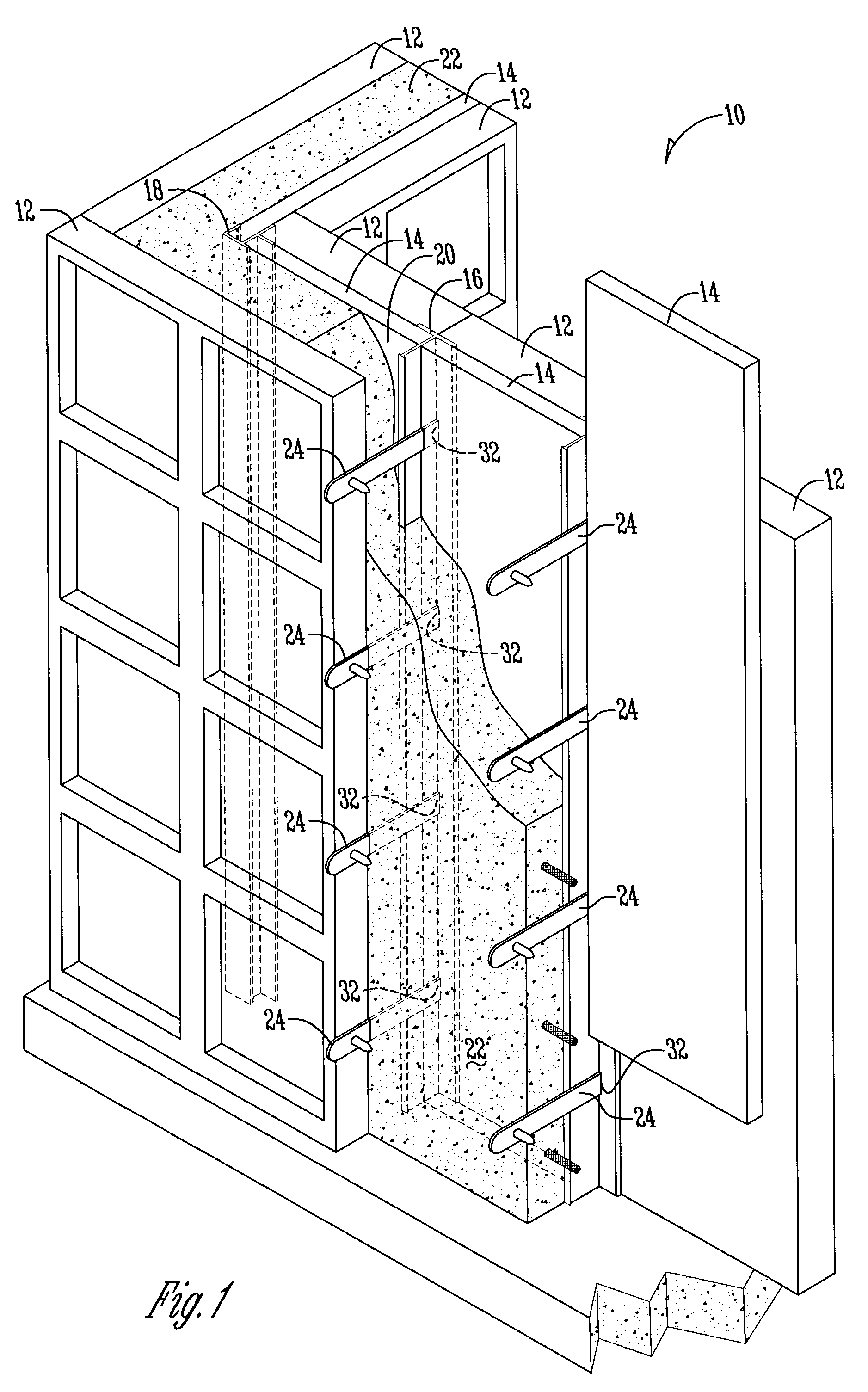

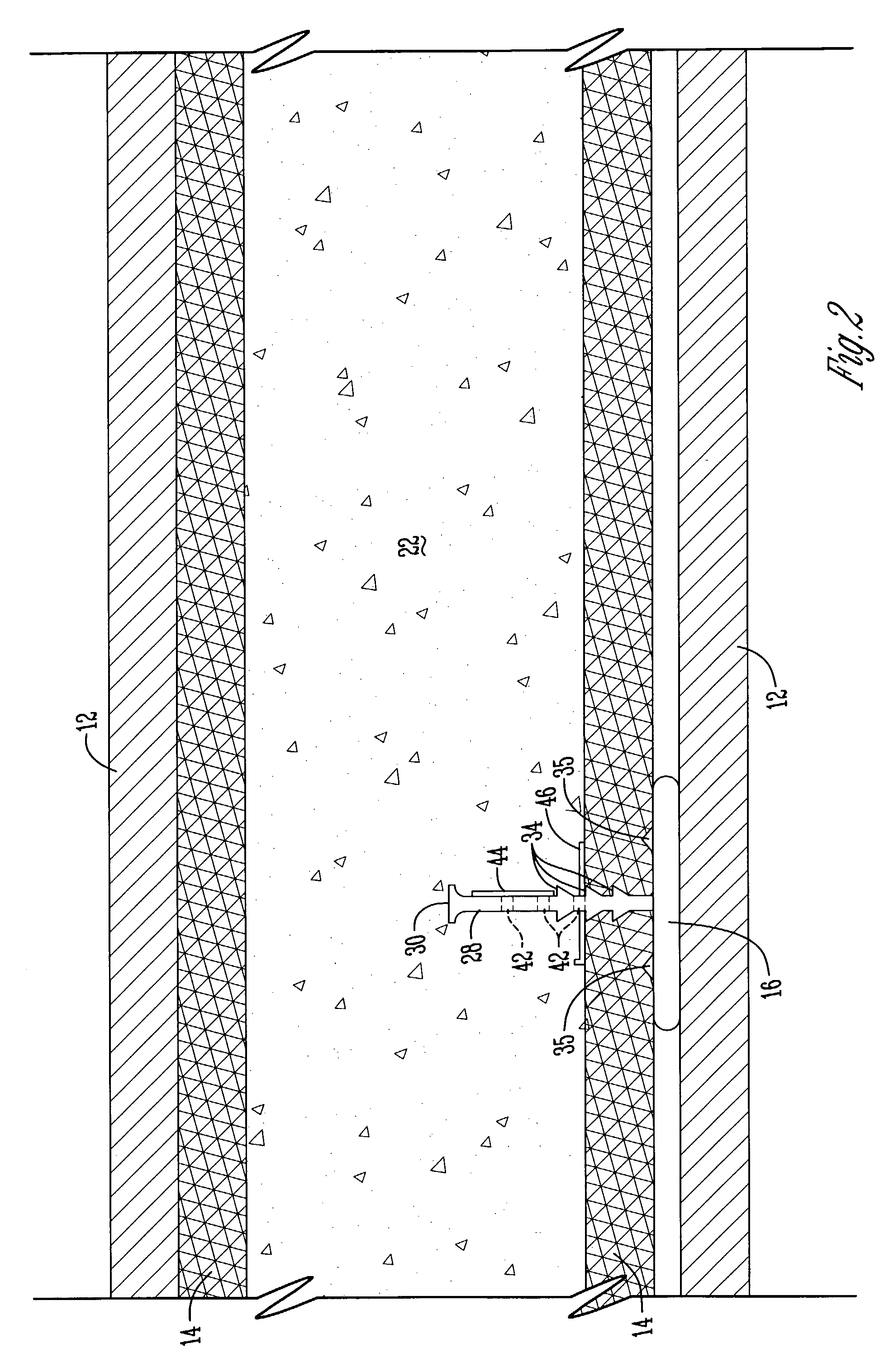

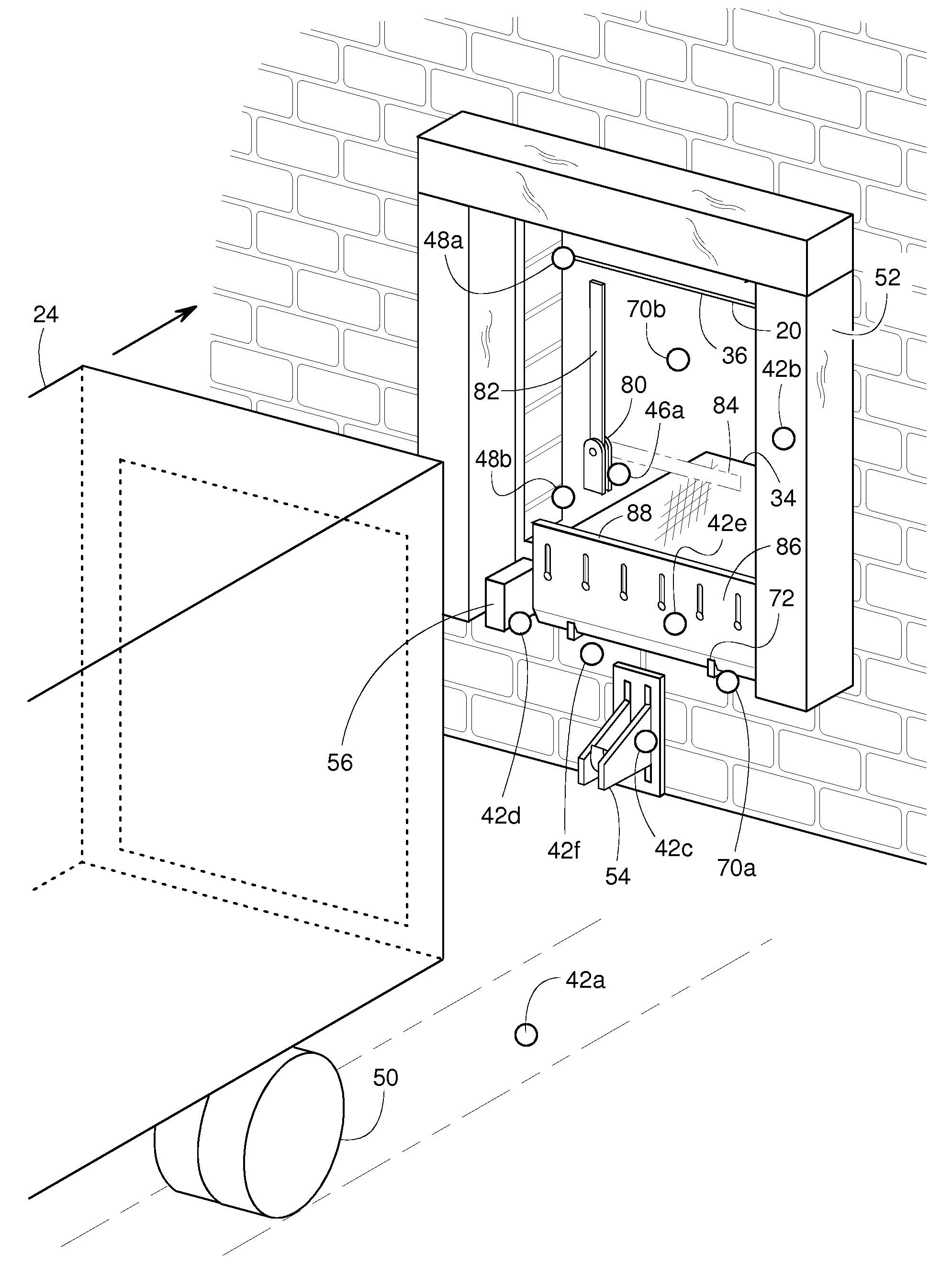

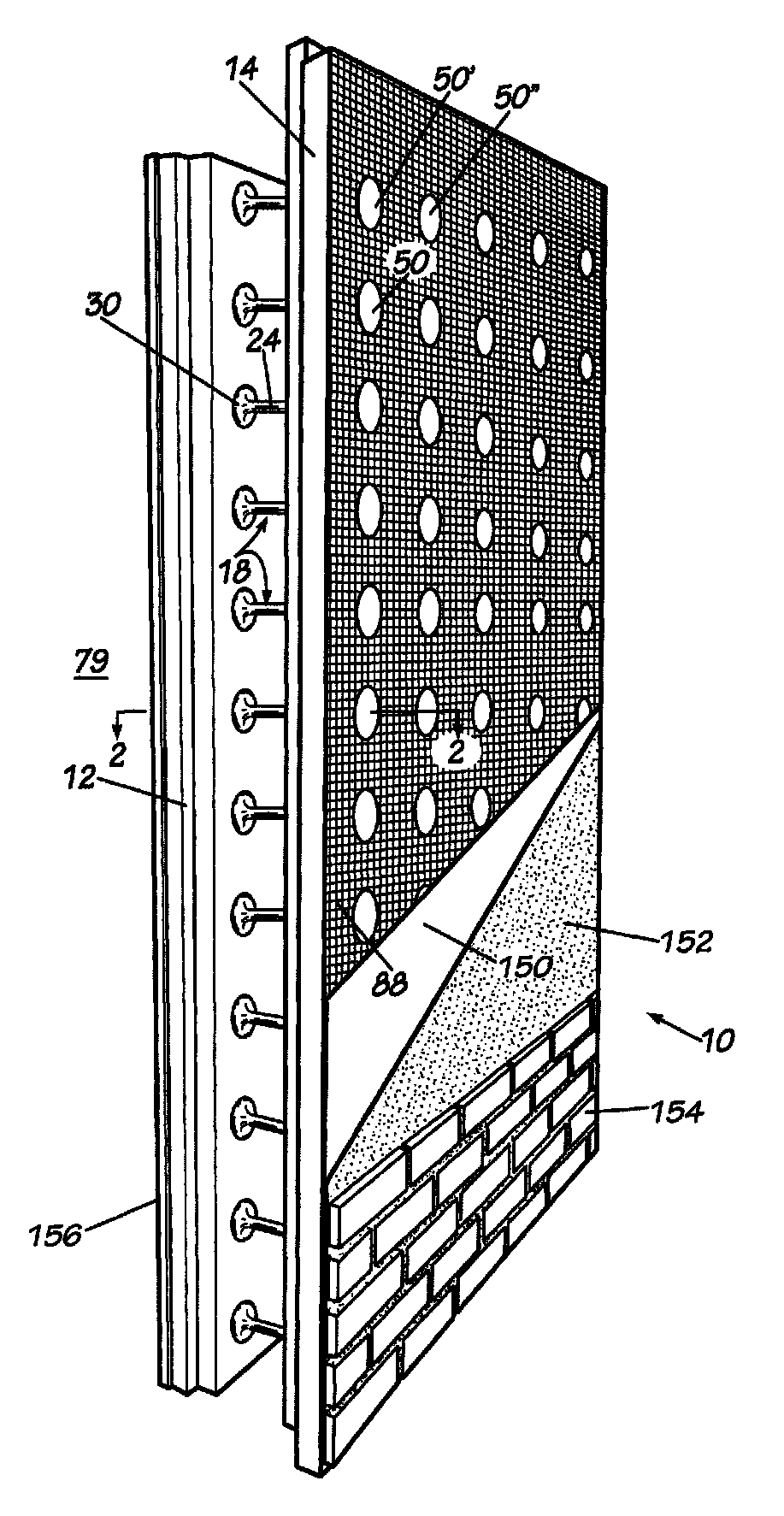

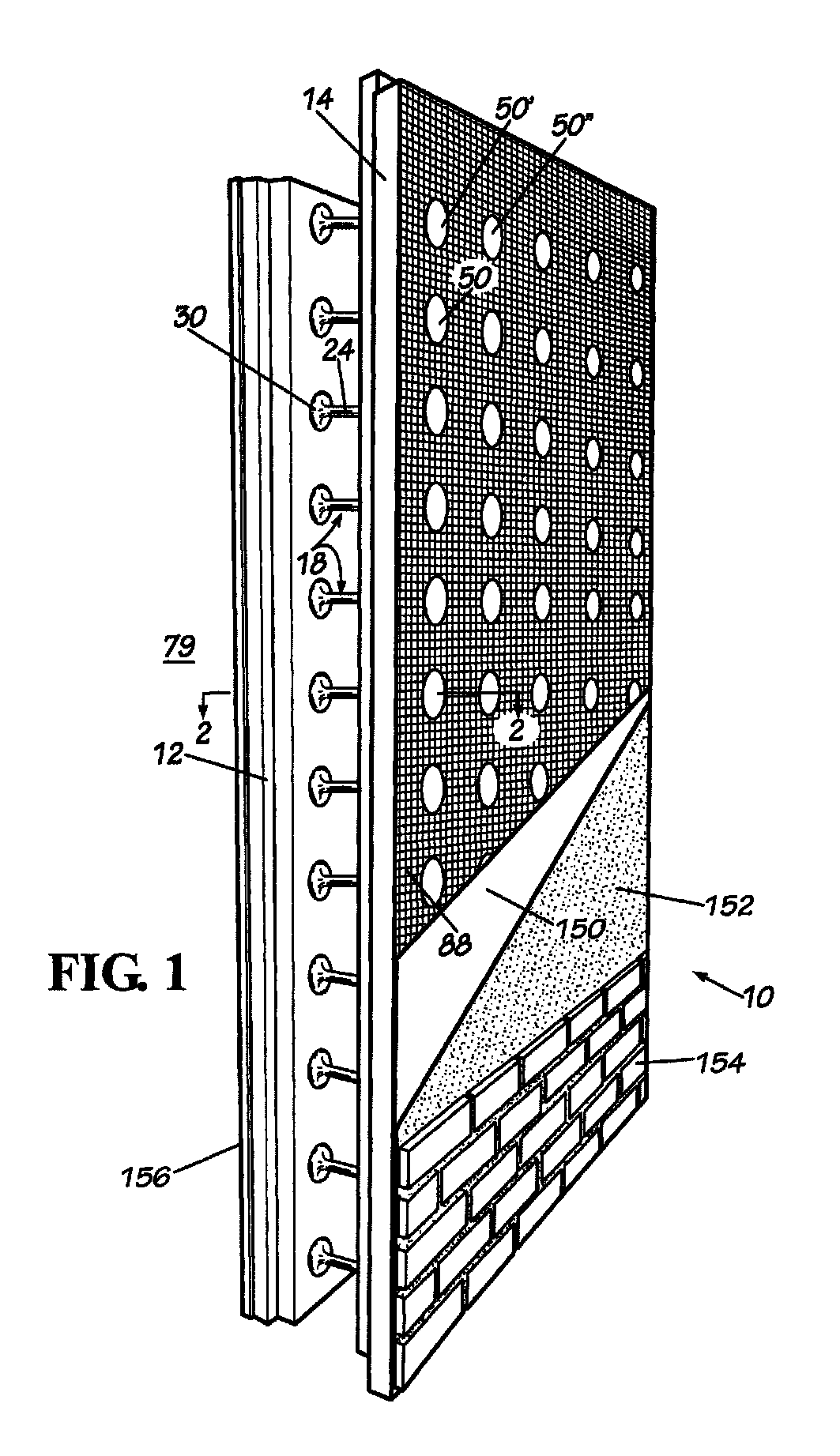

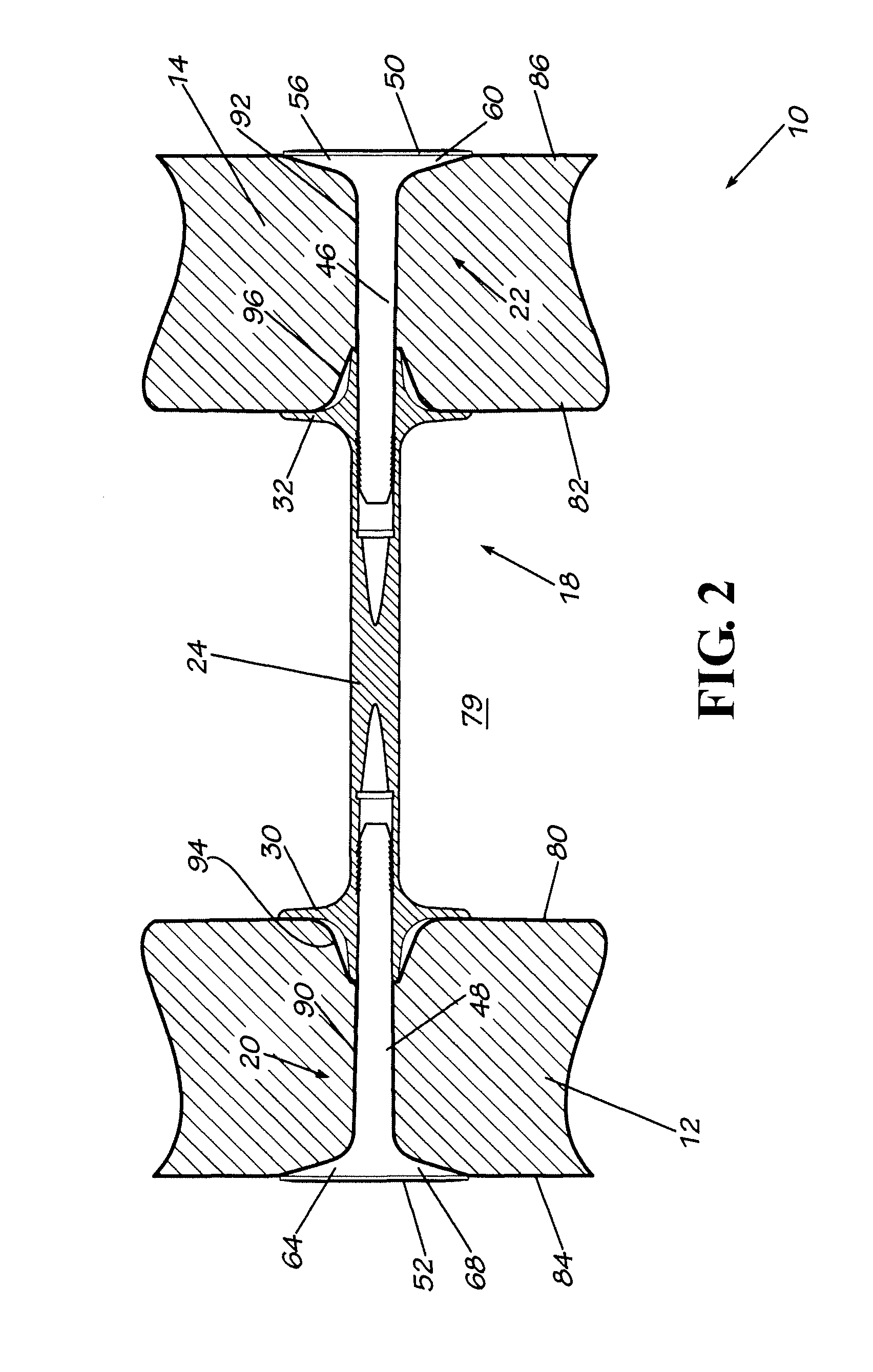

Insulated concrete wall system and method of making same

A method and system for installing an insulated concrete wall includes insulation panels placed in an upright manner. Generally T-shaped wall studs are placed next to the insulation panels such that the front section of the wall stud is on the outside of the insulation panels and an anchoring section of the wall stud extends beyond the insulation panels into the gap into which concrete will later be poured. Concrete pouring forms are placed so as to render the gap into which concrete will be poured a desired thickness. The wall stud may also include slots for receiving cross-ties that secure the concrete pouring forms in proper position and retaining nubs that prevent the insulation panels from floating when concrete is poured. Concrete is then poured into the gap, surrounding the anchoring section the T-shaped wall stud.

Owner:BURGETT FERRALL

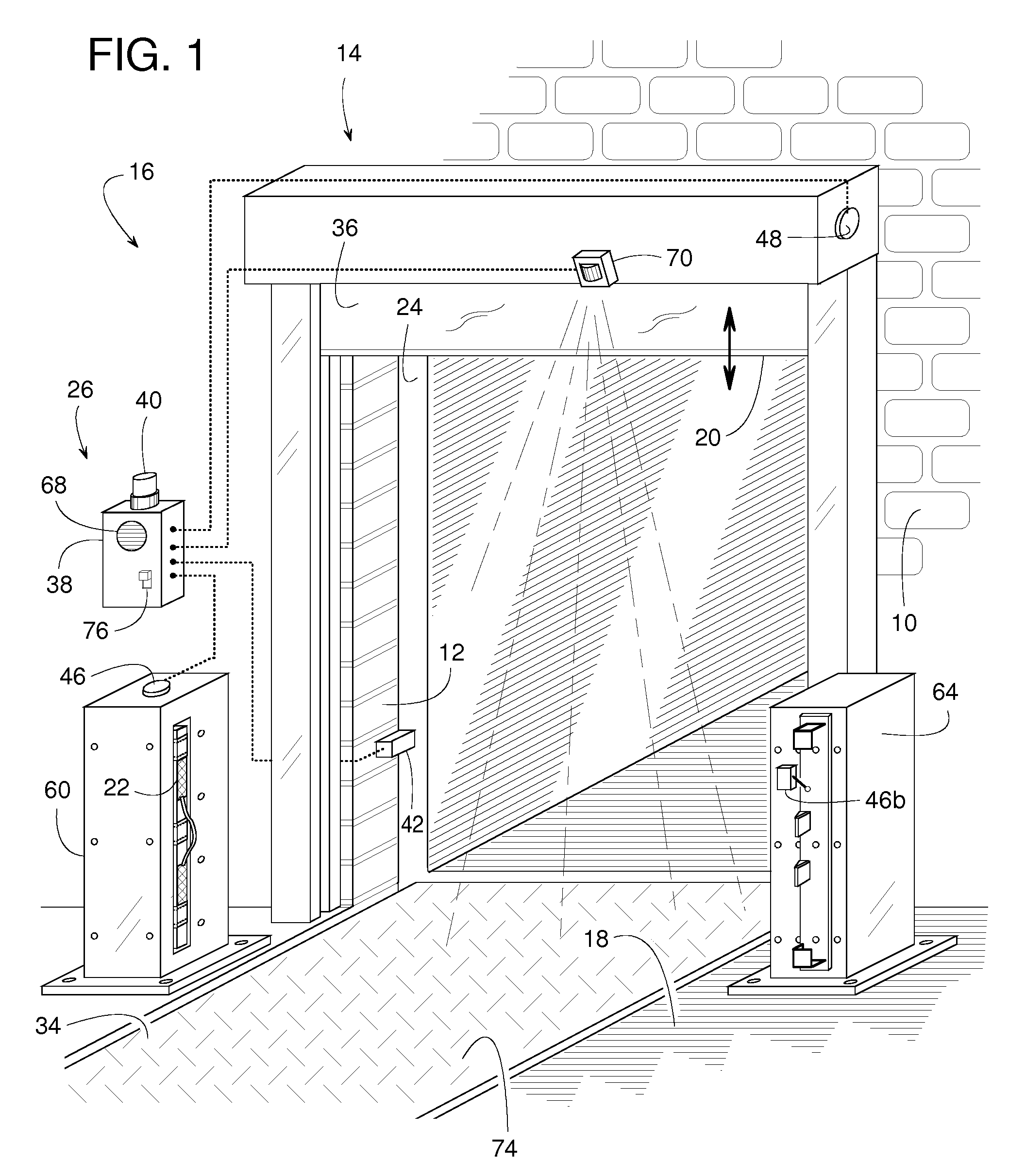

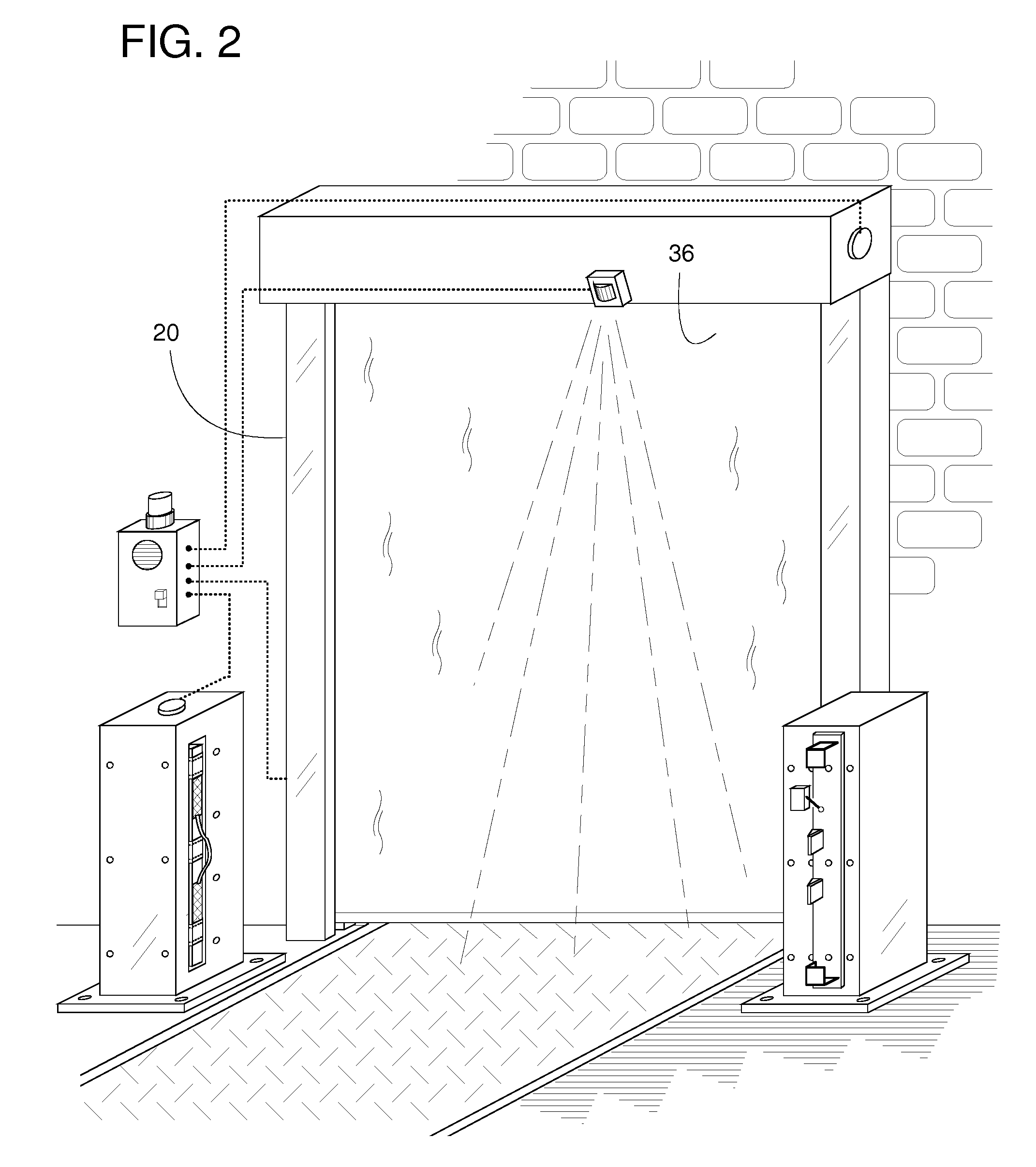

Alarm system for a loading dock

A safety system for a truck loading dock with an elevated platform provides an alarm that warns of a hazard at the loading dock such as a forklift operating inside the truck or a falling hazard that may exist due to the dock door being open while a truck is not present at the dock. In cases where a dock's open doorway is protected by a barrier that can be opened or closed, the alarm can be de-activated by closing the barrier. In some embodiments, the safety system includes a remote body sensor that detects when someone or something is near the doorway. In response to the body sensor, a second, more pronounced alarm can warn of more imminent danger where someone on the platform may be too close to an open doorway when a truck is not present.

Owner:RITE HITE HLDG CORP

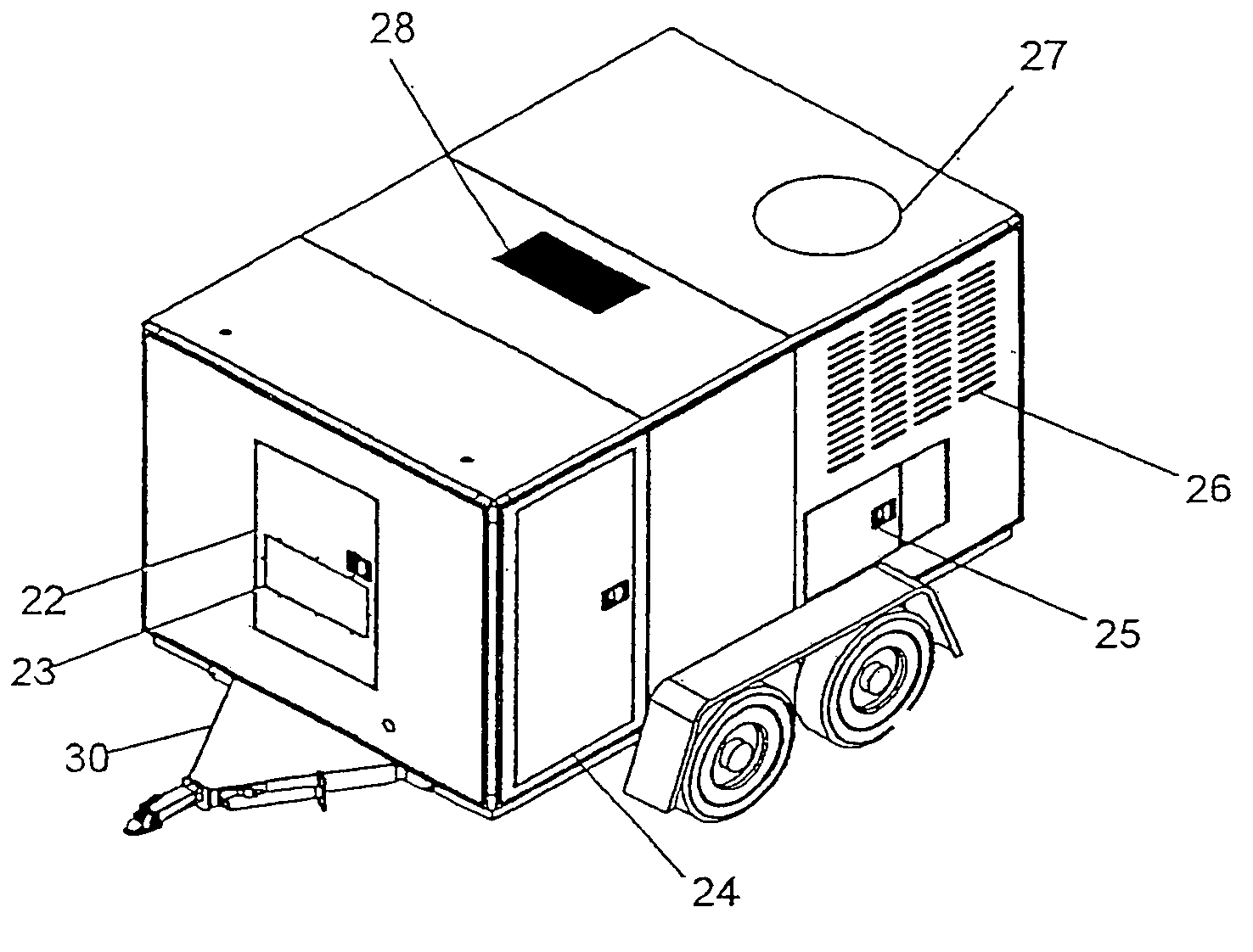

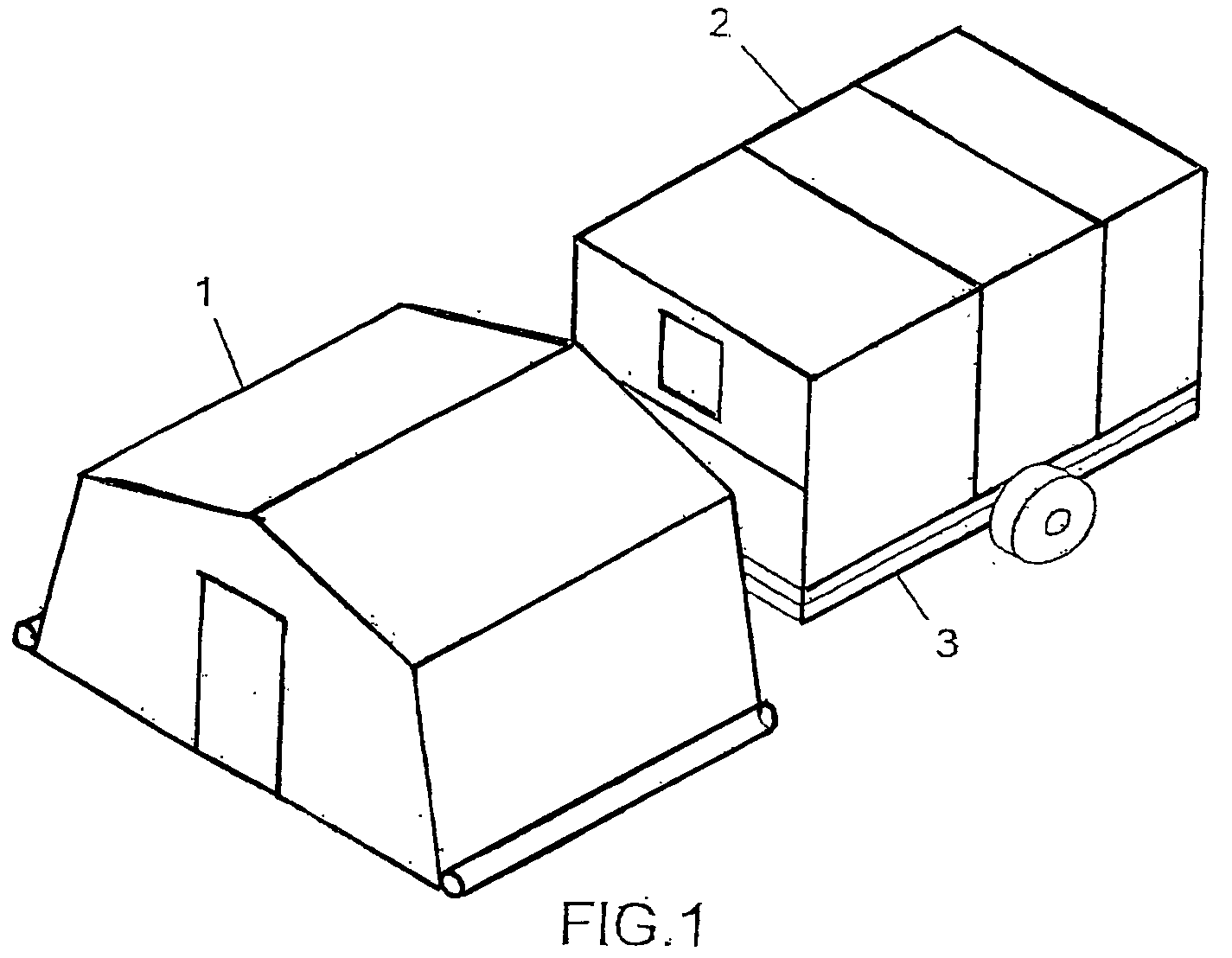

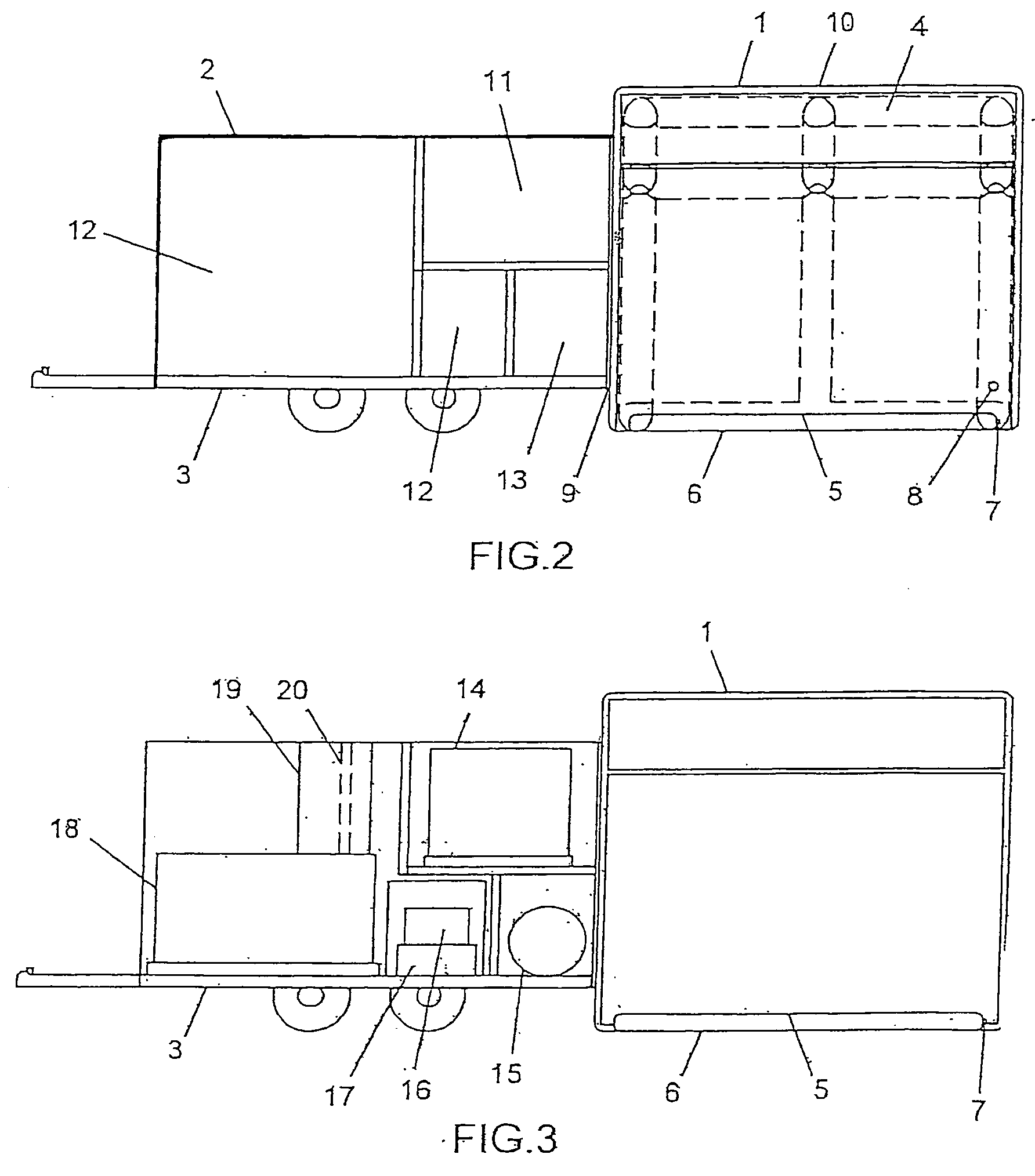

Inner supported climate controlled single trailer shelter

InactiveUS20060055193A1Increase pressureFirmly connectedTents/canopiesForms/shuttering/falseworksTruckWater storage tank

A portable climate controlled air shelter system on a transport device such as a trailer, truck bed or ISO container box with all sub-systems integral to the transport device where the sub systems include an inflatable air shelter with inflation / deflation blower, electrical power generator and fuel system pre-wired to all other sub systems, heating ventilation and air conditioning unit, air filtration, inflation / deflation blower, water management system, external lighting, central control panel for single point monitoring and control of the air shelter system and physical storage. Also provided are compressed air tanks for inflation of the air shelter as well as water ballast tubes that mechanically attach to the air shelter to provide stability in winds and on uneven ground. The water management system includes a water storage tank and pump for filling and emptying the water ballast tubes. The air shelter system also has transfer switch to allow the system to run on external “house power”.

Owner:COLBORNE BRUCE J

Extruded Wall with Rib-Like Interior

A nozzle for extruding a surface may include a first outlet configured to controllably extrude a first extrudate of unhardened material, a second outlet configured to controllably extrude a second extrudate of unhardened material that is separated from the first extrudate, a third outlet configured to extrude a third extrudate of unhardened material between the first and the second extrudates, and a controller. The third outlet may have a width that is substantially less than the distance between the first and second extrudates. The controller may be configured to cause the third extrudate to repeatedly traverse between the first and second extrudates and / or to cause the third extrudate to leave a plurality of substantial and separated spaces between the first and second extrudates.

Owner:UNIV OF SOUTHERN CALIFORNIA

Panel, a kit and a method for forming a masonry wall

Owner:LES MATERIAUX DE CONSTR OLDCASTLE CANADA

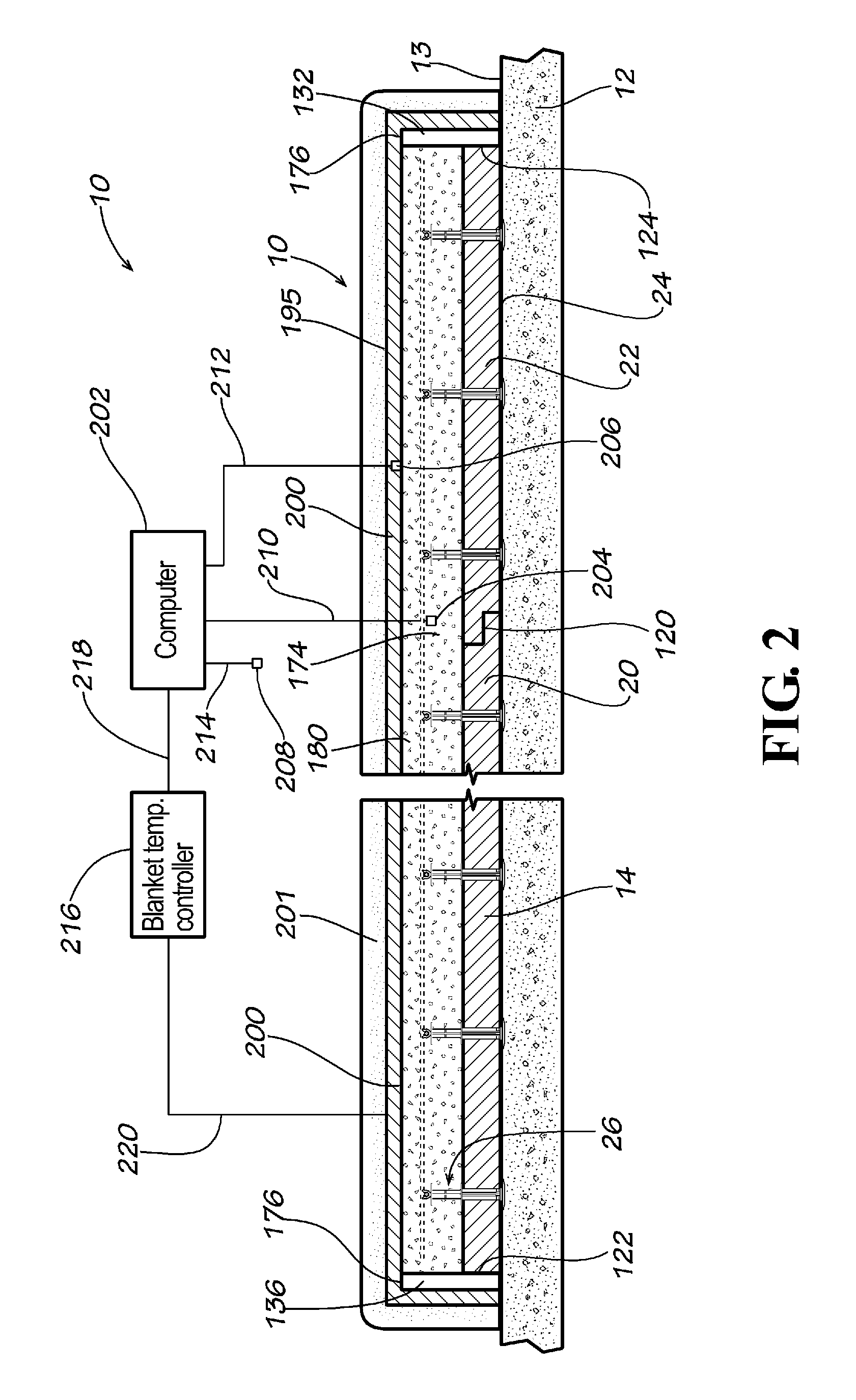

Method for electronic temperature controlled curing of concrete and accelerating concrete maturity or equivalent age of concrete structures and objects

ActiveUS8532815B1Selective heatingSolid waste managementResistance/reactance/impedenceElectronic temperatureMaterials science

Owner:CIUPERCA ROMEO ILARIAN

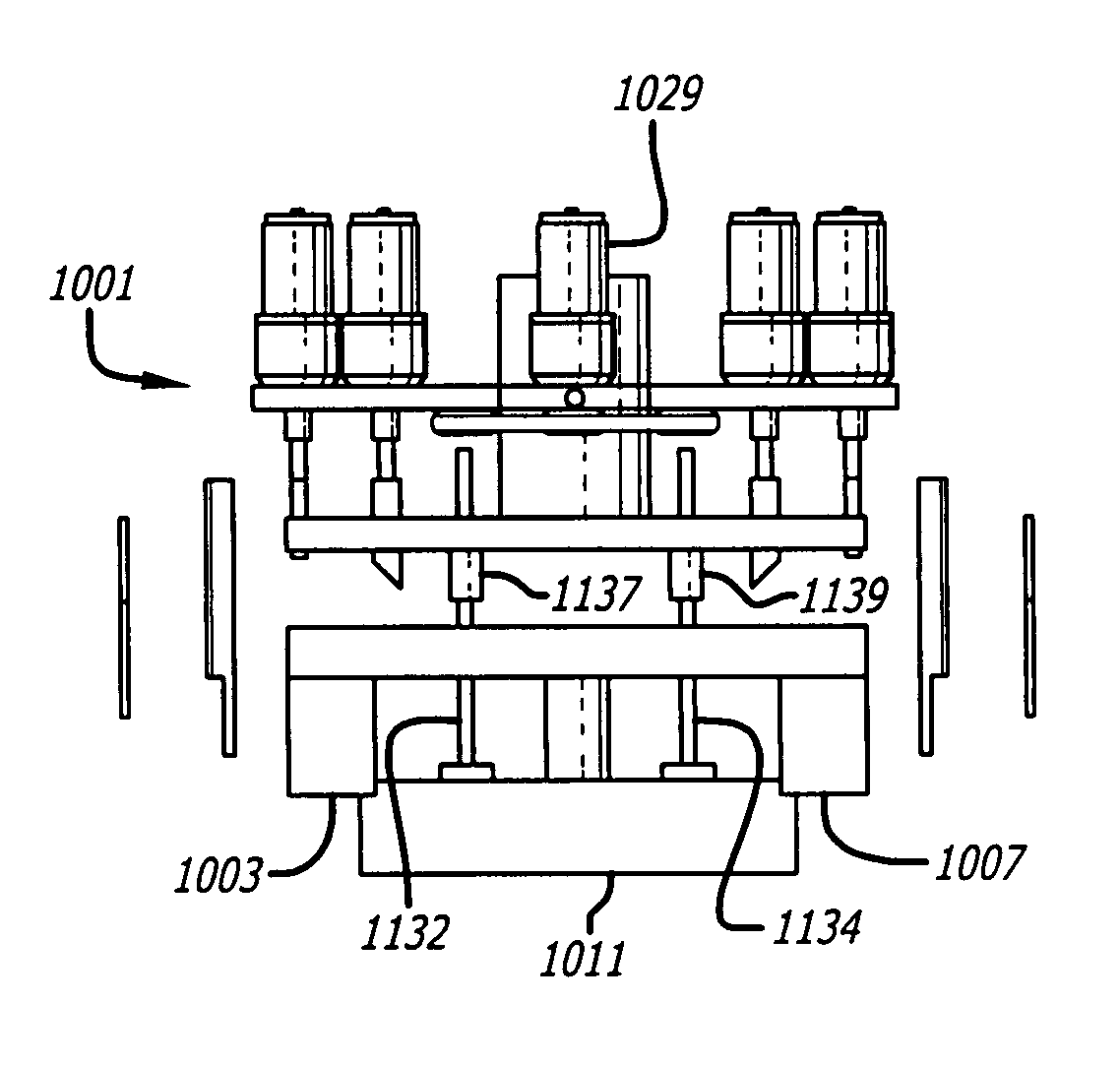

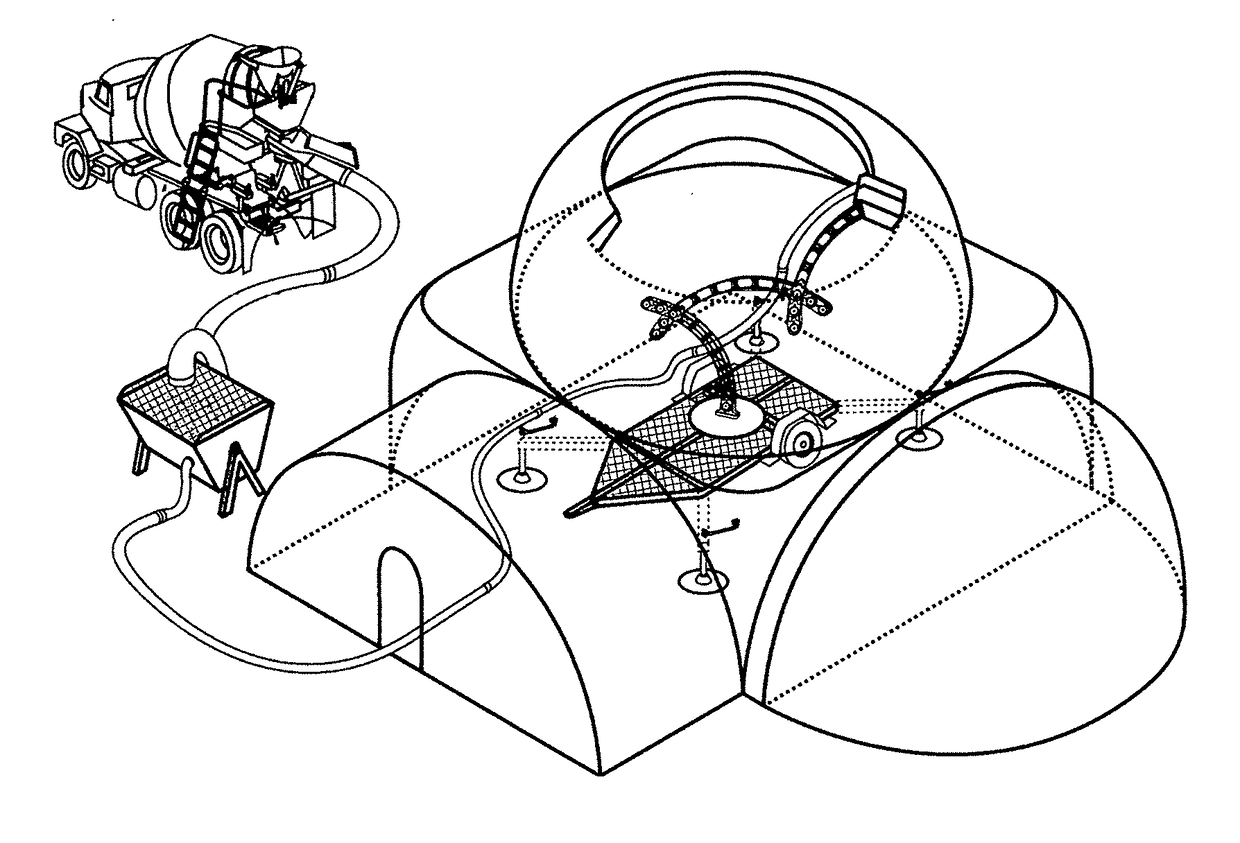

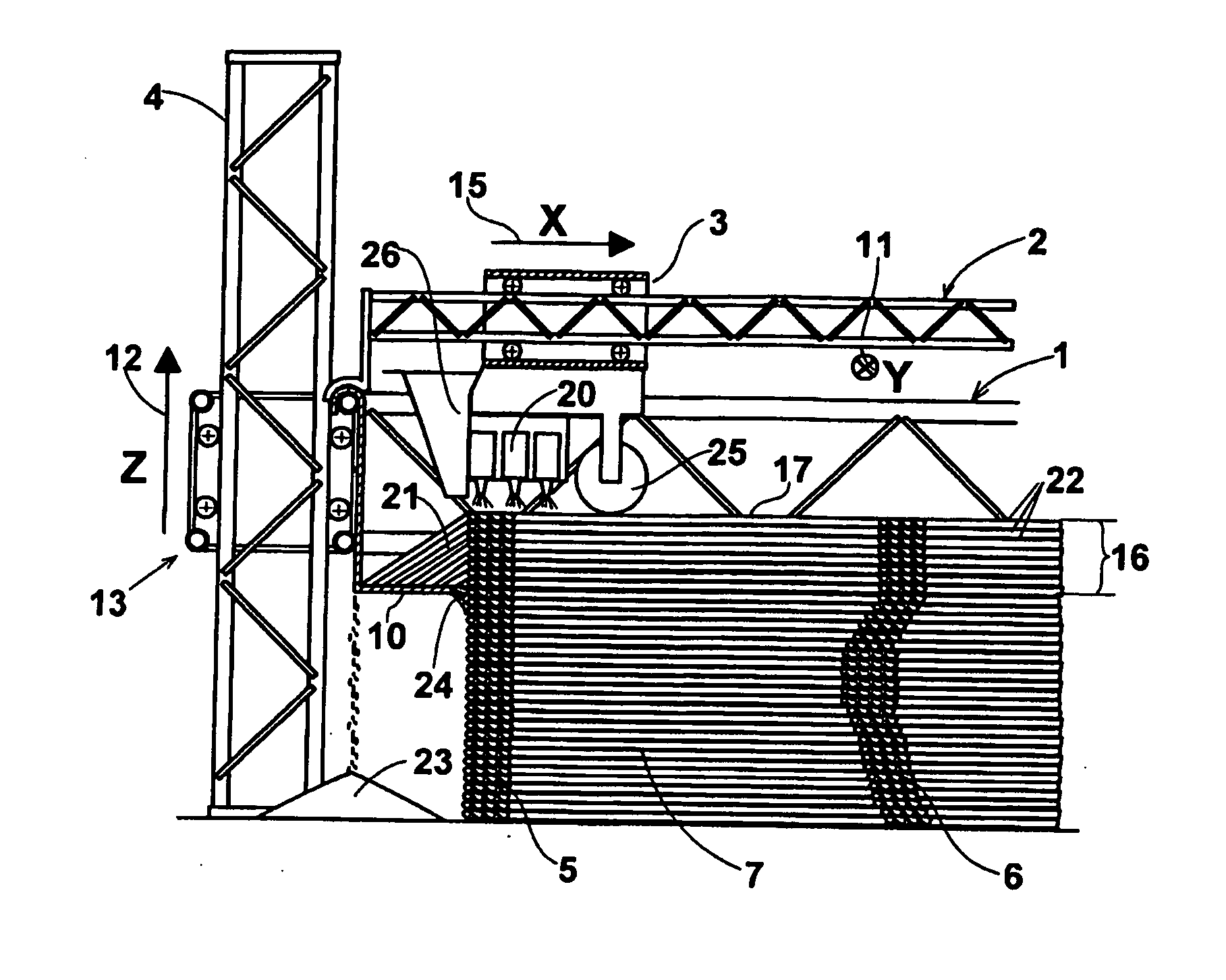

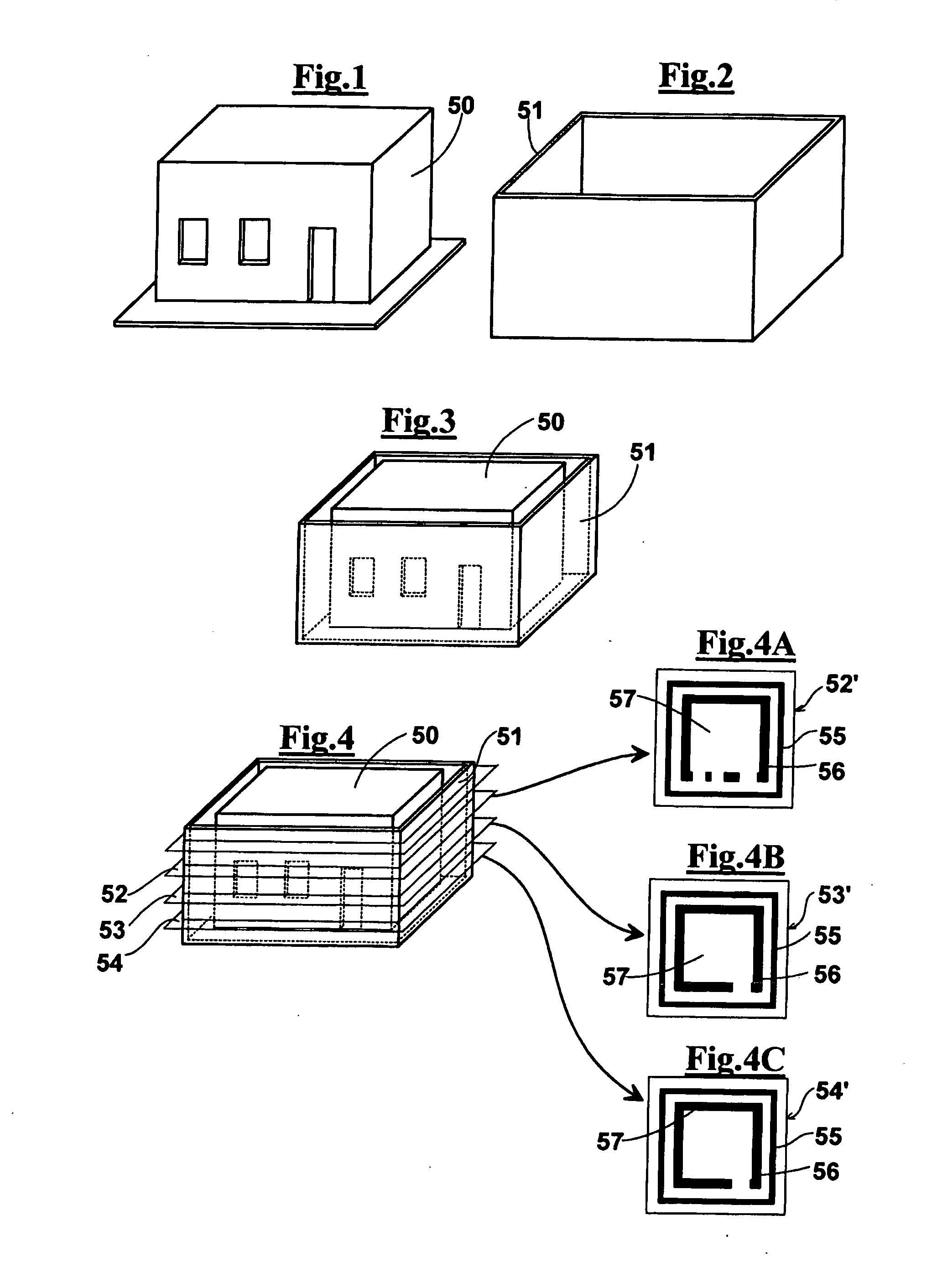

Method for automatically producing a conglomerate structure and apparatus therefor

InactiveUS20100207288A1Improve efficiencyReduce decreaseAdditive manufacturing apparatusMouldsSection planeEngineering

A method and an apparatus for automatically making conglomerated structures (6). The method comprises a) modelling a building structure and a containing shell about the structure by a computer using a CAD software thus obtaining a file; b) extracting sections of modelled structure and of modelled containing shell, by means of horizontal planes spaced apart of a predetermined pitch, such that a plurality of section planes is generated, said planes being sorted from below towards above with respect to the model of the structure and of the model of the shell; c) depositing by a moving unit (3) on a ground a bottom-to-top plurality of layers of granular material (22) alternate to a binding material liquid sprayed on the layers at filled areas corresponding to filled portions of the of the structure and of the containing shell, according to a predetermined path; d) vertically raising the moving unit (3) according to a pitch between a deposited layer and the following layer; e) repeating the step of depositing granulating material and repeating the step of spraying the binding material on a granulated material at filled areas of the structure and of the shell as many times as the planar cross sections into which said structure and the containing shell have been divided, each of said times for a different and consecutive section plane until the last layer (17) is complete; f) demolishing the containing shell (5) and removing unbound granular material (7) accumulated in the shell (5), thus releasing a conglomerate structure (6) that reproduces accurately said modelled structure. The apparatus comprises a horizontal frame (1), a bridge (2) sliding on guide on the horizontal frame (1), a moving unit (3) sliding along the bridge (2) or integral to the bridge (29) and have a spraying head (20). The horizontal frame (1) is moved along uprights (4) by a step actuator. The apparatus comprises a plurality of “skirts” (10) that surround the containing shell (5) and are integral to the horizontal frame (1). Such skirts scrape the outer surface of the containing shell (5) collecting the granular material (21) deposited out of the shell (5). Such skirts (10) can comprise an brush-like edge (20) suitable for externally sweeping the containing shell (5).

Owner:DINI ENRICO

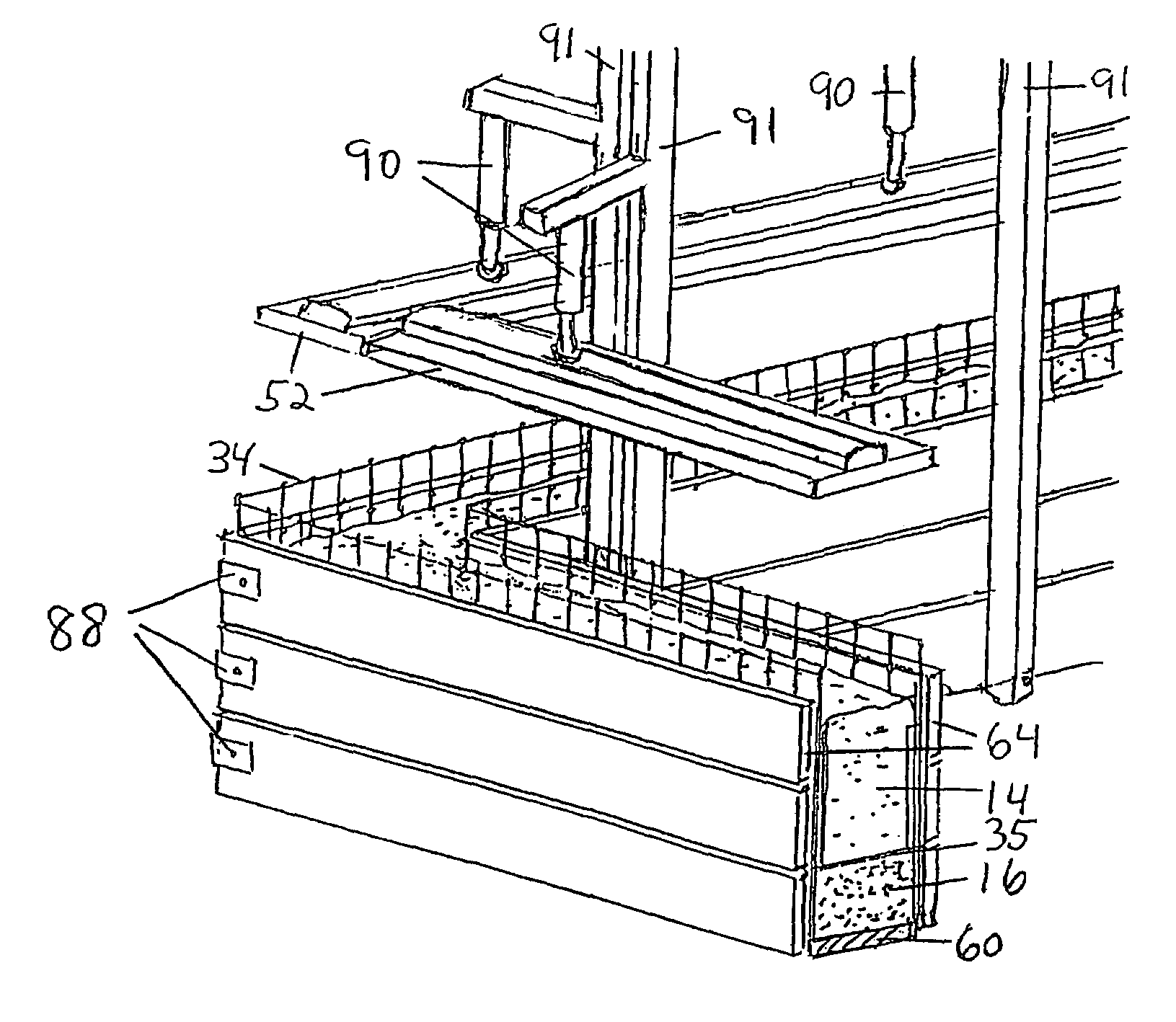

Reinforced insulated concrete form

Owner:CIUPERCA ROMEO ILARIAN

Methods of making concrete runways, roads, highways and slabs on grade

InactiveUS8636941B1Fast curingPromote maturityPaving reinforcementsIn situ pavingsMaterials scienceRunway

The invention comprises a method of forming a slab on grade. The method comprises placing a first layer of insulating material horizontally on the ground and placing plastic concrete for a slab on grade on the first layer of insulating material. The plastic concrete is then formed into a desired shape having a top and sides. A second layer of insulating material is placed on the top of the plastic concrete and the first and second layers of insulating material are left in place until the concrete is at least partially cured. The second layer of insulating material is then removed. The product made by the method is also disclosed. A slab on grade is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

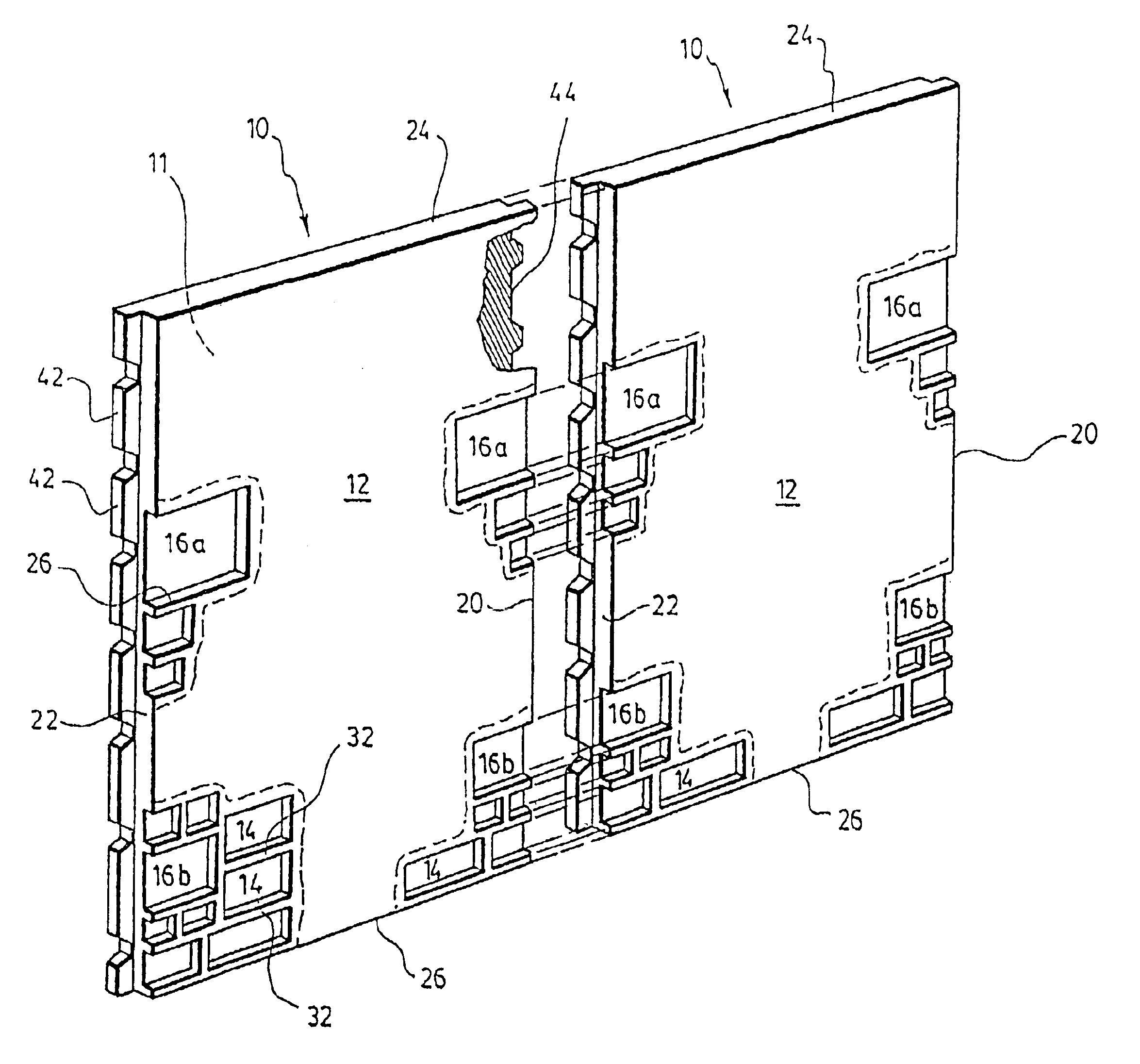

Method of building

This is an improved method of building with fibrous material though other materials can be substituted. A binding secures fibrous material to form a wall assembly (10). Wall surfacing (20) can be included in the binding and forming process, reducing the labor required to apply it. Other building features and components can also be included in the binding and forming process such as electrical wiring, furring strips, windows, doors and structural reinforcing. This method vastly reduces the difficulties encountered when installing these components. The versatility of the method also allows for attributes such as flat wall surfaces and variable wall thicknesses, which are difficult to achieve using baled fiber.

Owner:HAGAMAN HARRY EDWARD

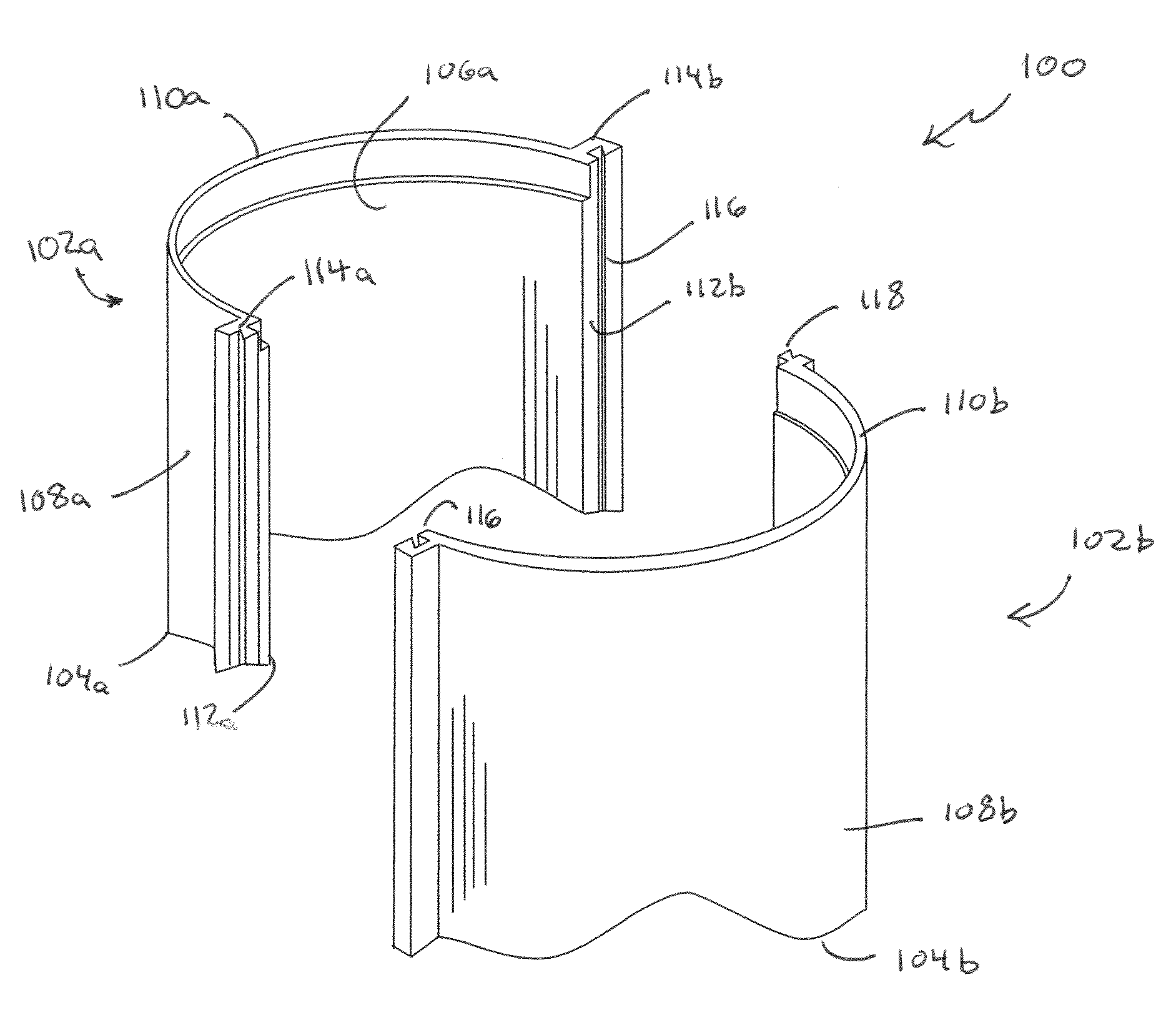

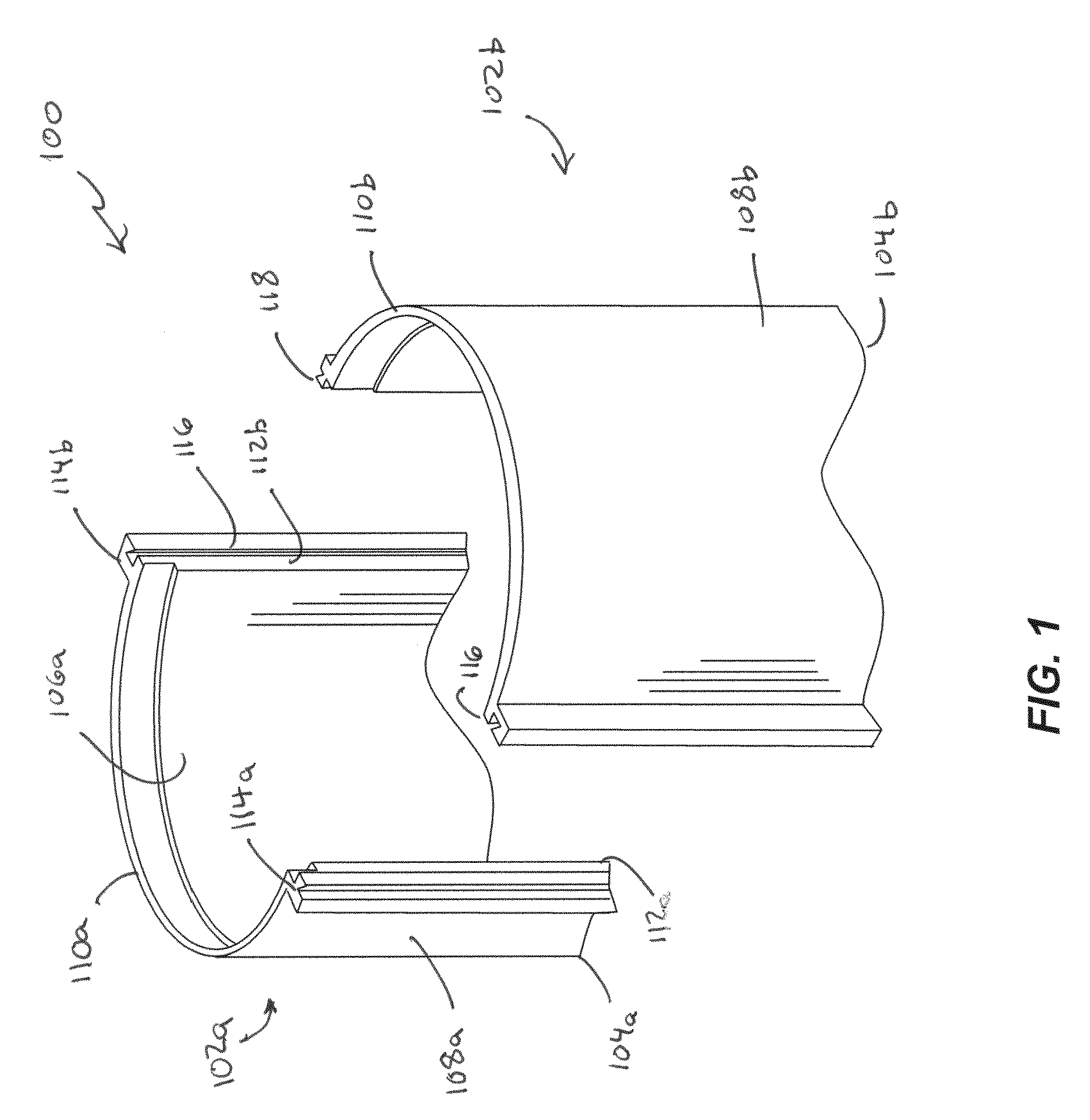

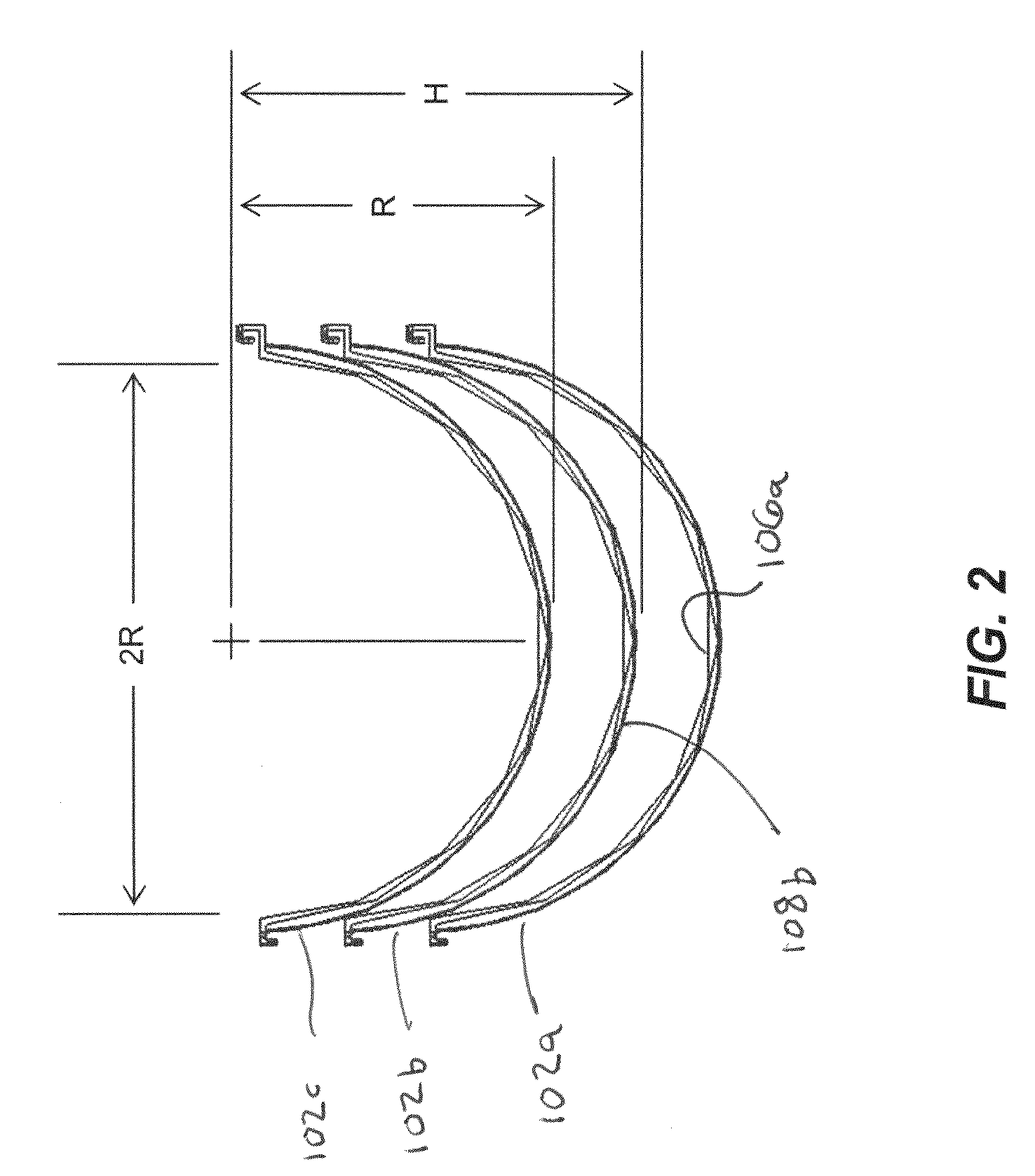

Concrete column forming assembly

Methods and apparatus providing a column forming assembly formable from multiple column forming sub-assemblies that are stackable providing a compact storage or transport configuration. A column forming structure is formed from multiple elongated wall sections configured for interlocking engagement with each other to form a hollow, open ended structure adapted to accept a settable substance, such as concrete or plaster. The multiple elongated wall sections are stackable and can be stored to shipped to a job site in a condensed or nested configuration. The nested configuration reduces empty or hollow spaces provided by assembled forms. In some embodiments, the forms can be disassembled after use for transport from the jobsite, storage, and later reuse. The column forming assembly can be combined with one or more column-end forms and with thin-walled column forming inserts.

Owner:SOUNDFOOTINGS

Cover for a concrete construction

ActiveUS7222460B2Reduce the overall heightEasy and secure fixingRoof covering using tiles/slatesBuilding repairsEngineeringBuilding construction

Owner:DAYTON SUPERIOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com