Patents

Literature

125results about How to "High precision alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

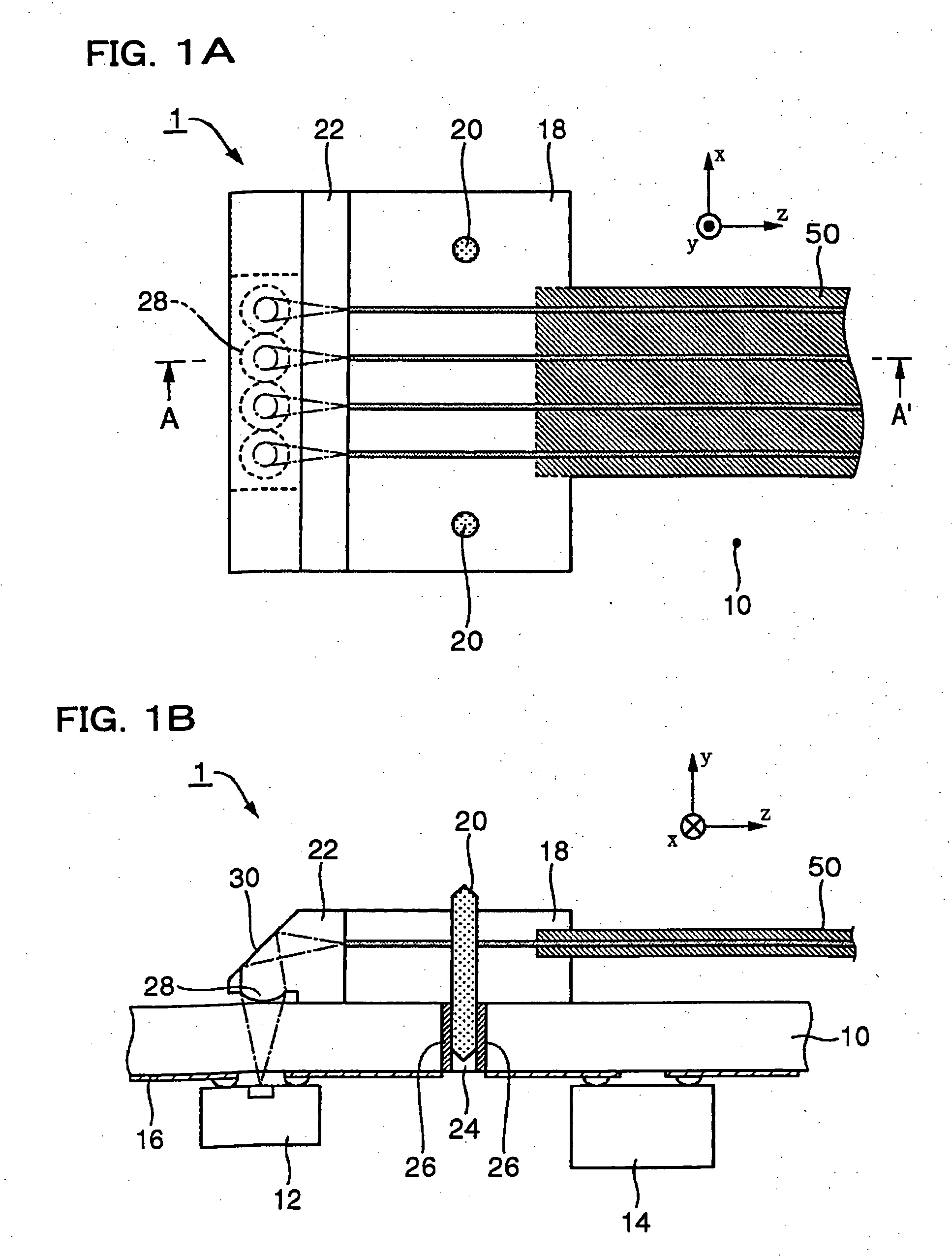

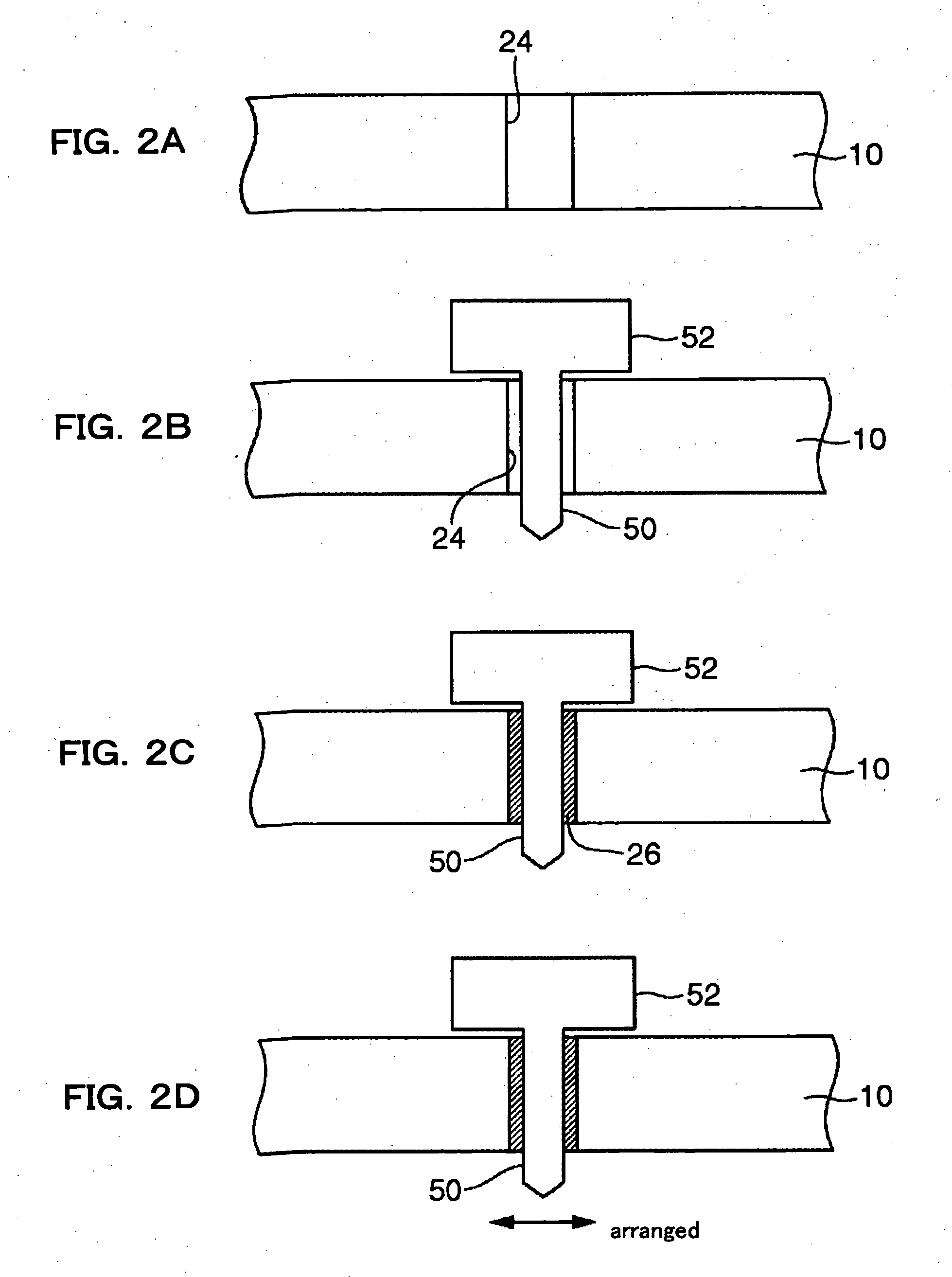

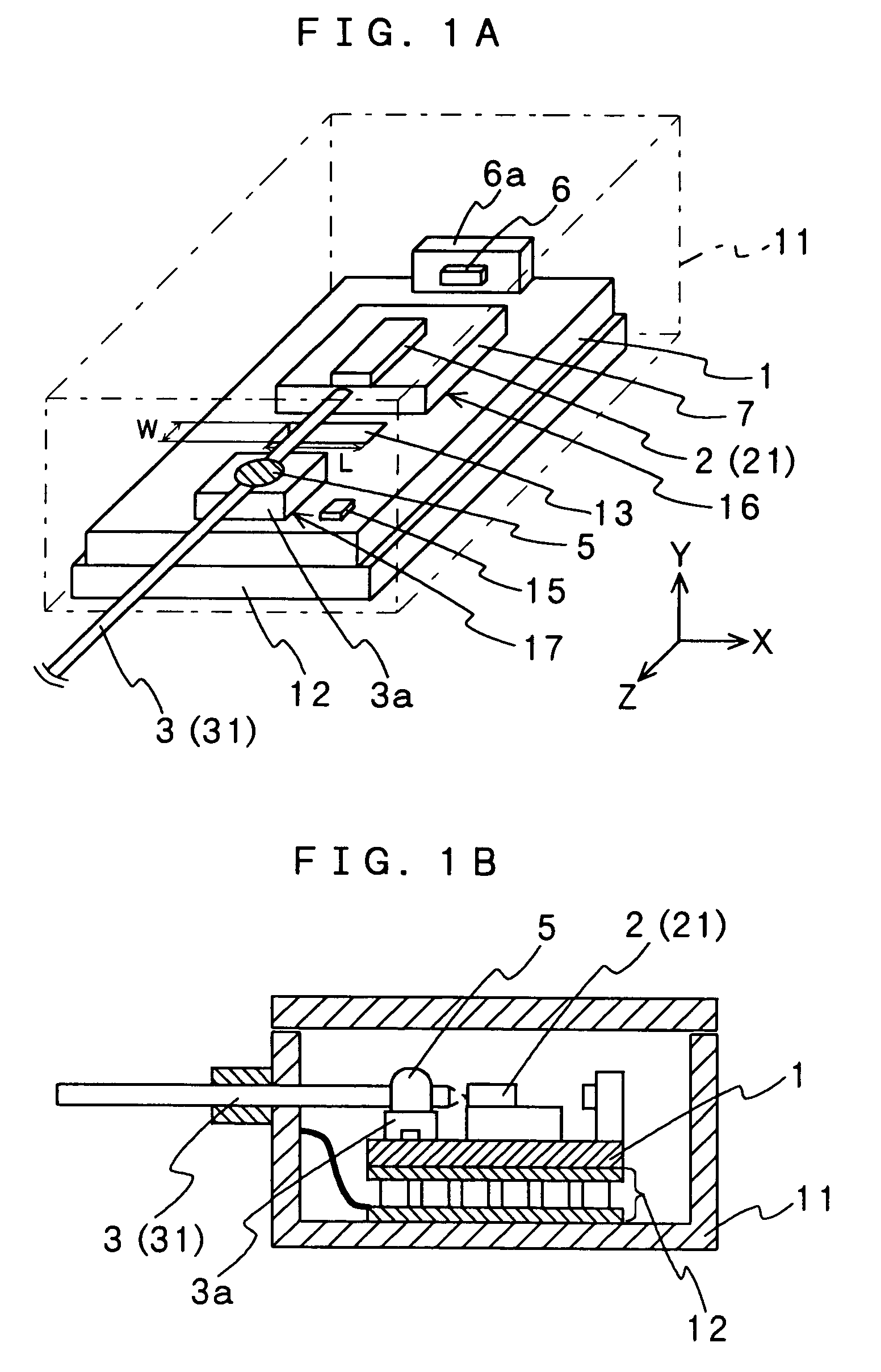

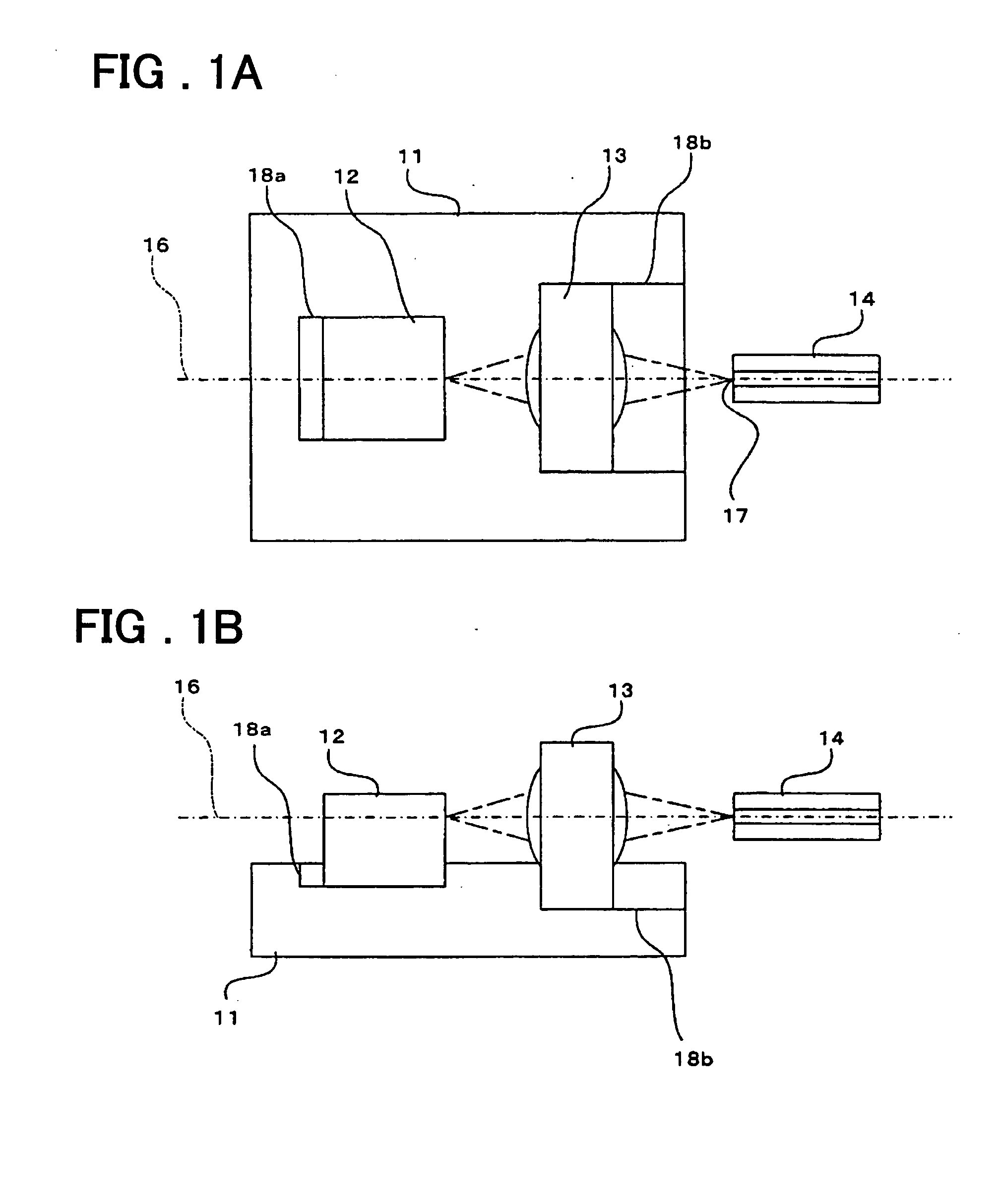

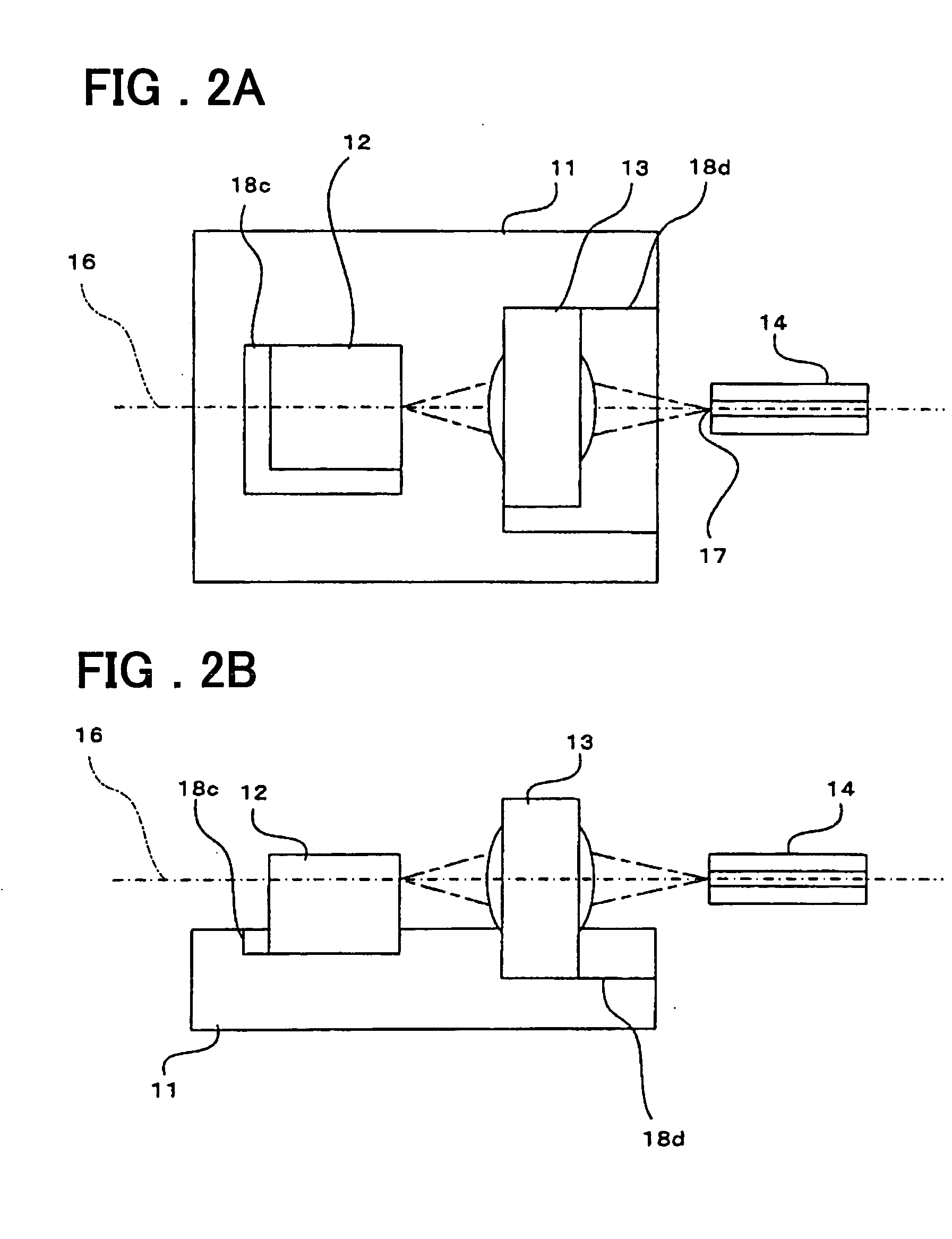

Optical module and method of manufacturing the same, and hybrid integrated circuit, hybrid circuit board, electronic apparatus, opto-electricity mixed device, and method of manufacturing the same

InactiveUS20040234210A1High precisionImprove accuracyPrinted circuit detailsCoupling light guidesElectricityOptical Module

To provide a technology, which enable carrying out an optical position alignment precisely and easily in apparatus and the like used in optical communication, a method of manufacturing an optical module includes forming a guide pin in either a transparent substrate or an optical transmission line support member; forming a guide hole, in which the guide pin is to be inserted, to the other one of the transparent substrate and the optical transmission line support member such that the diameter of the guide hole is made larger as compared with the diameter of the hole; arranging a jig having a protruding portion, of which diameter is substantially the same as the diameter of the guide pin, over the transparent substrate such that the protruding portion is being inserted into the guide hole; filling the gap between the protruding portion and the guide hole with a filler material, which is cured by carrying out a predetermined processing; adjusting a position of the jig; curing the filler material, which is filled in the gap between the protruding portion and the guide pin; and pulling out the protruding portion from the guide hole.

Owner:SEIKO EPSON CORP

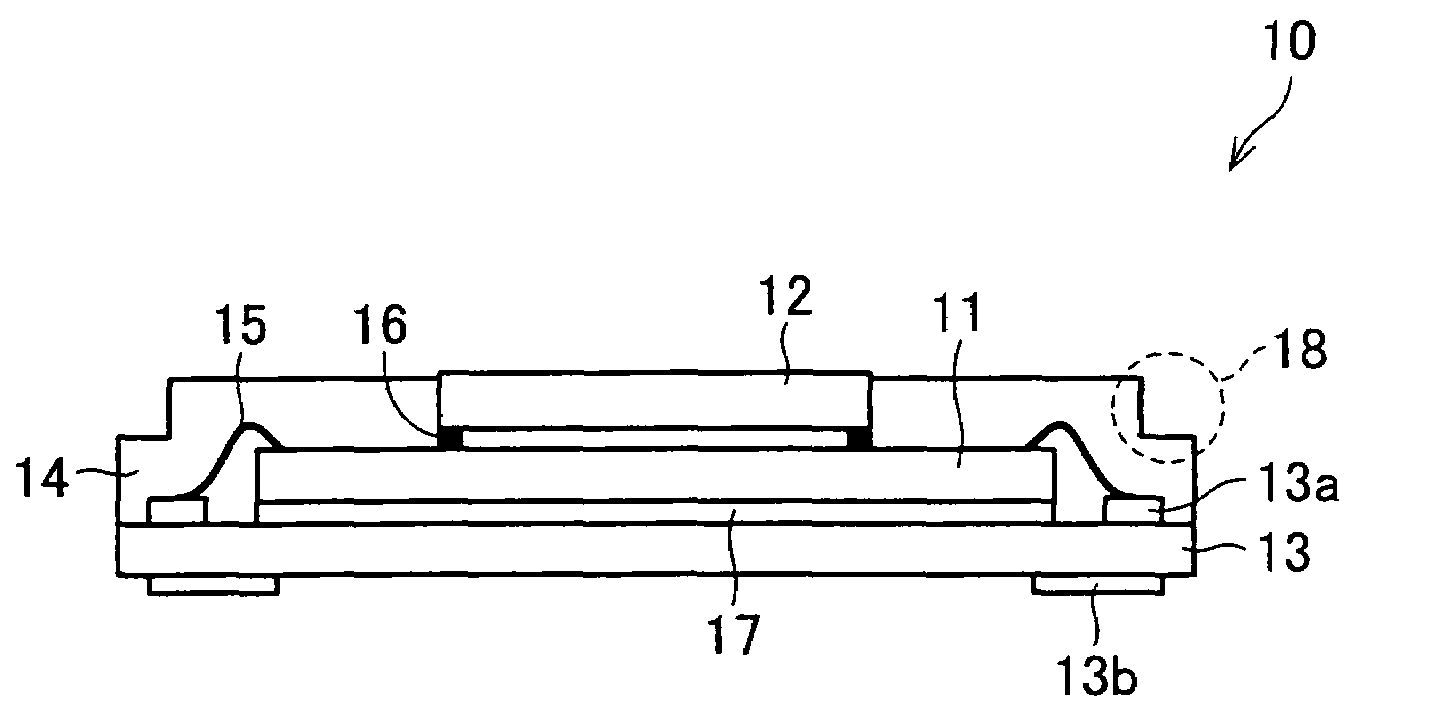

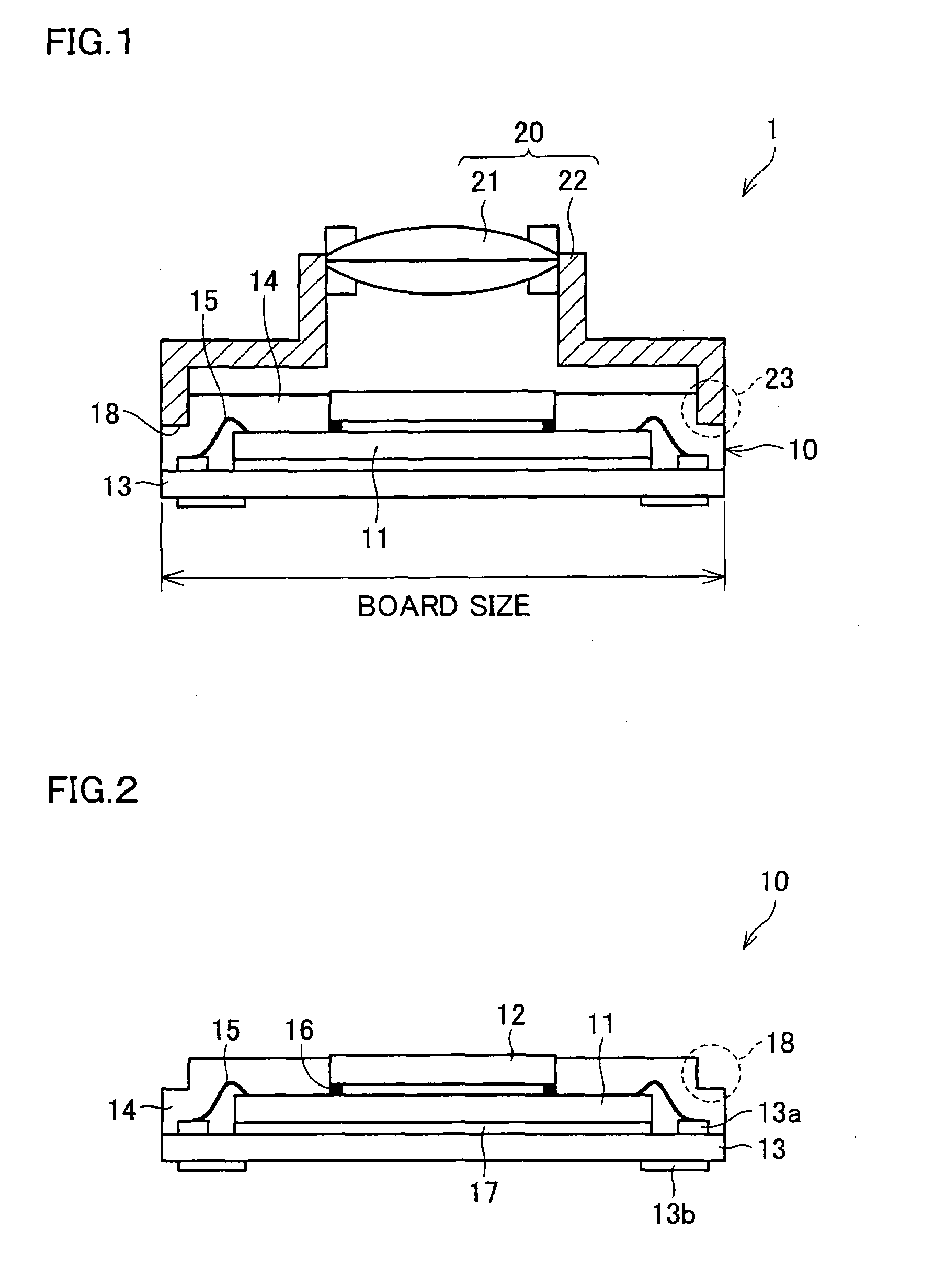

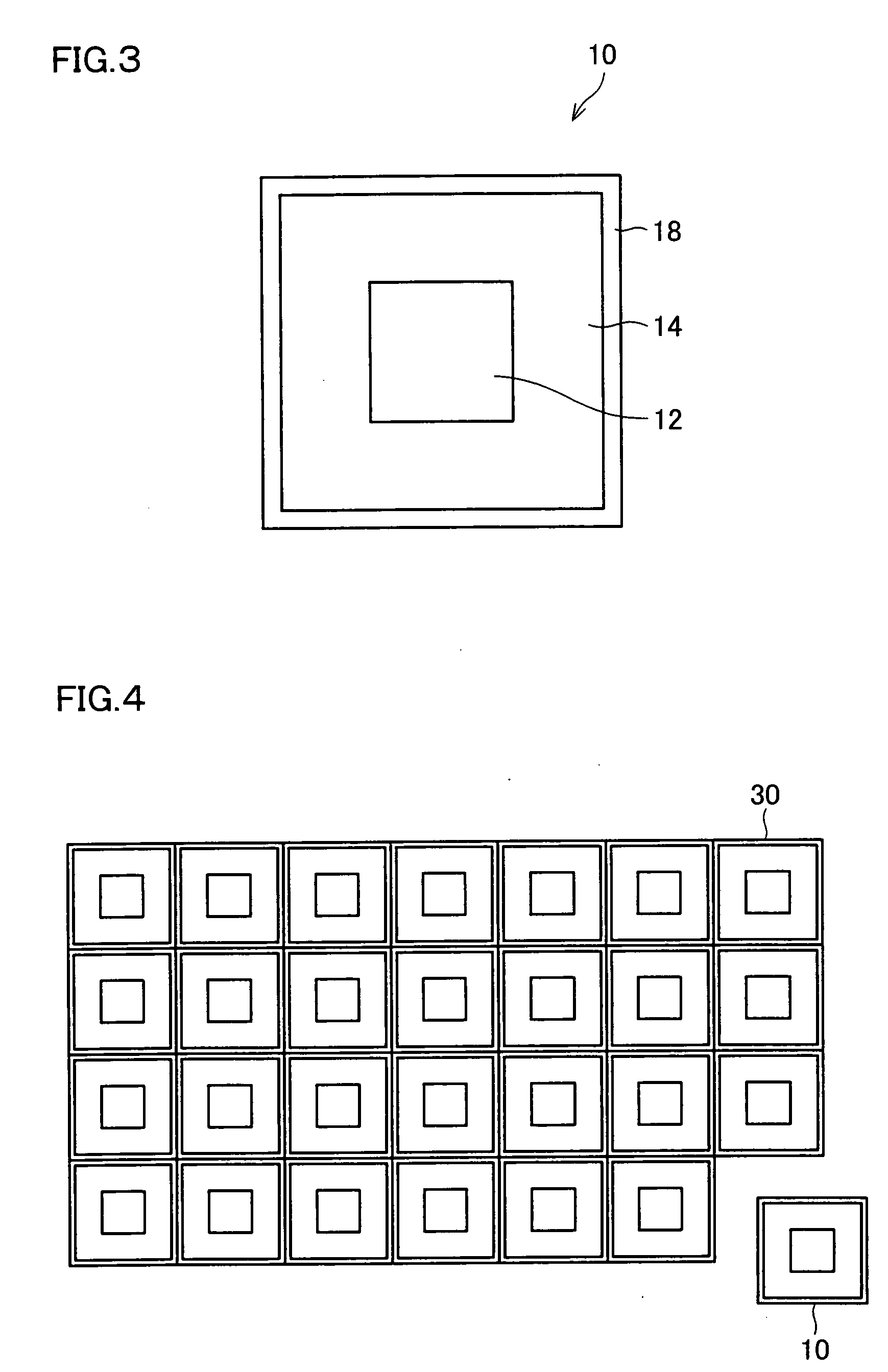

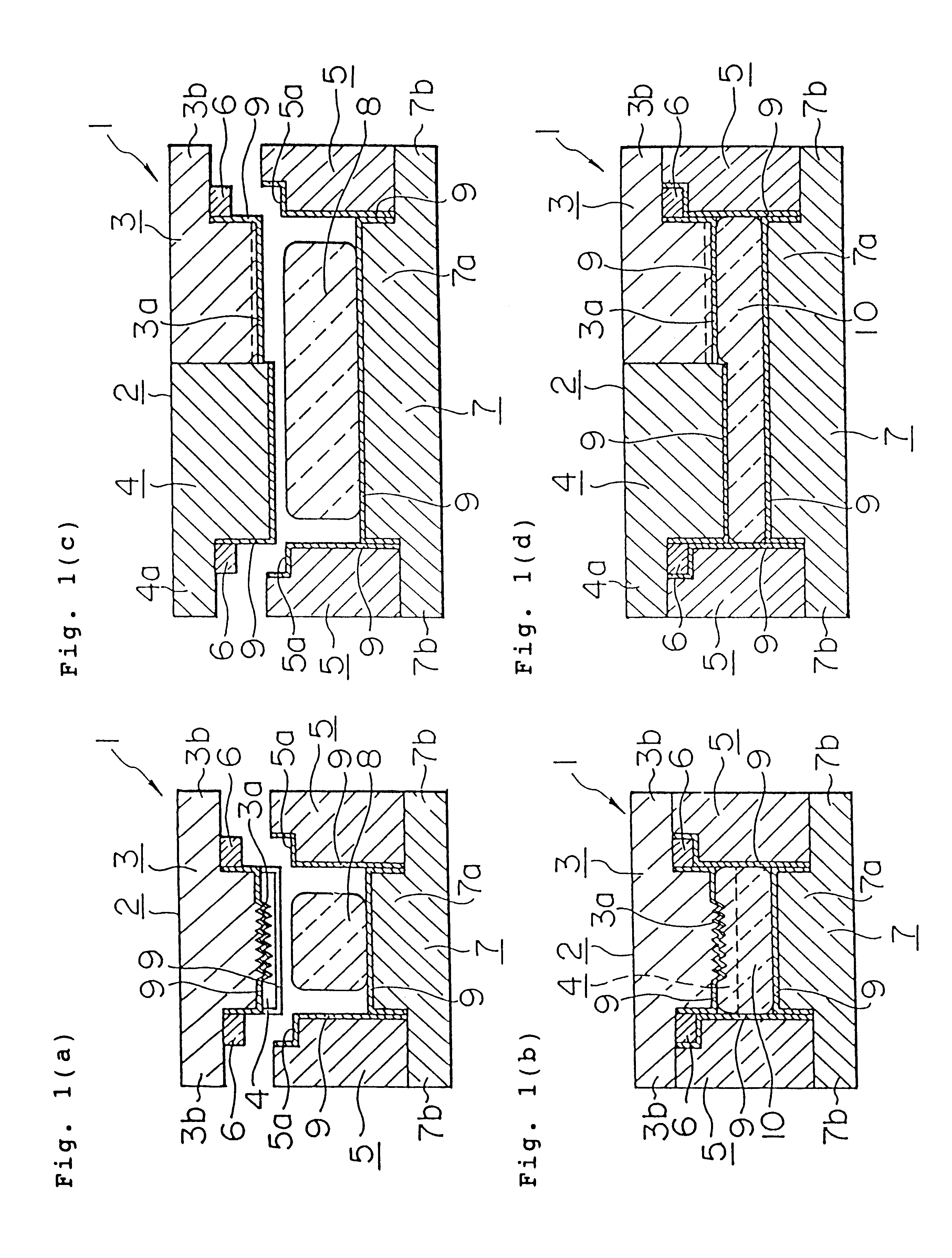

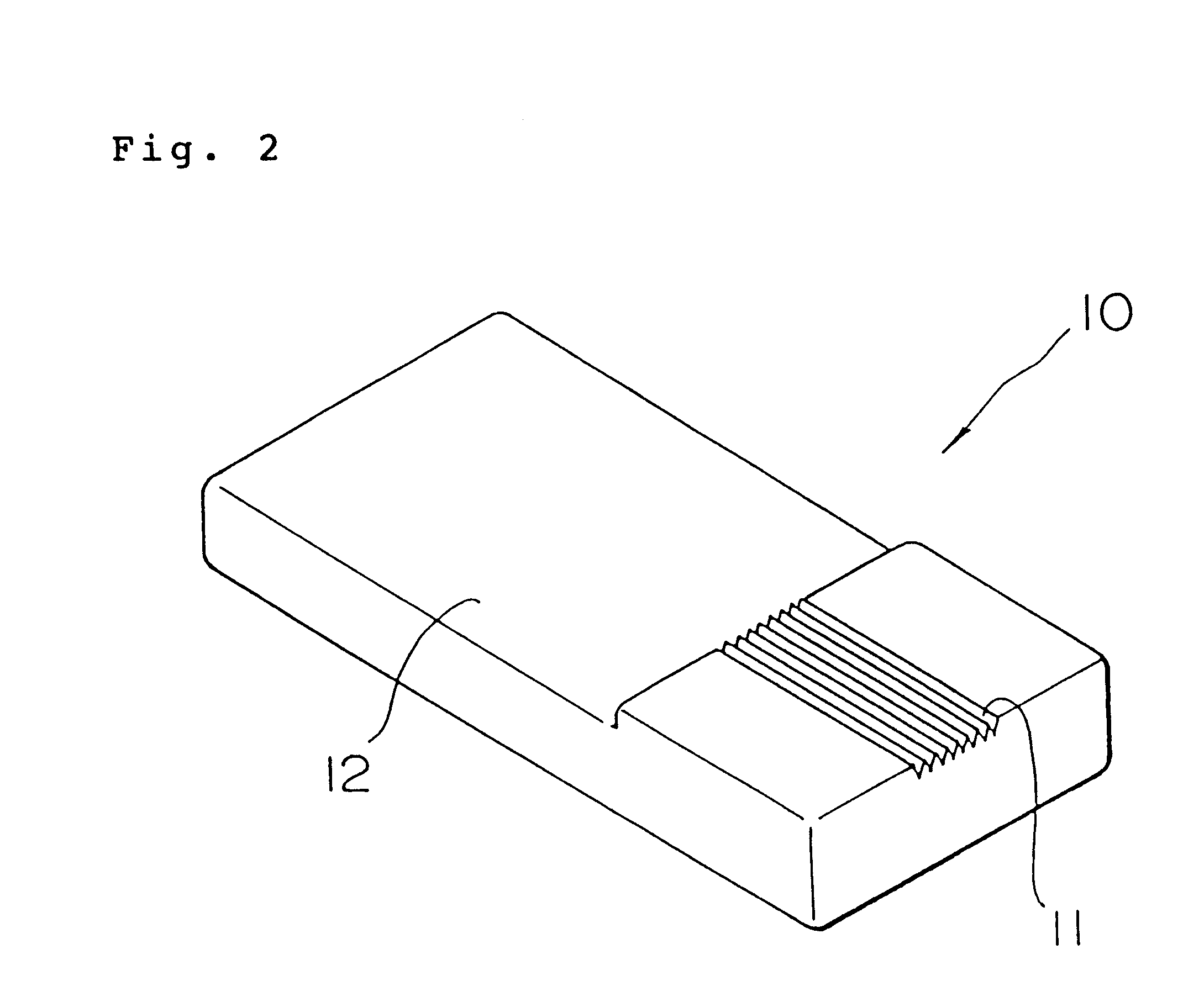

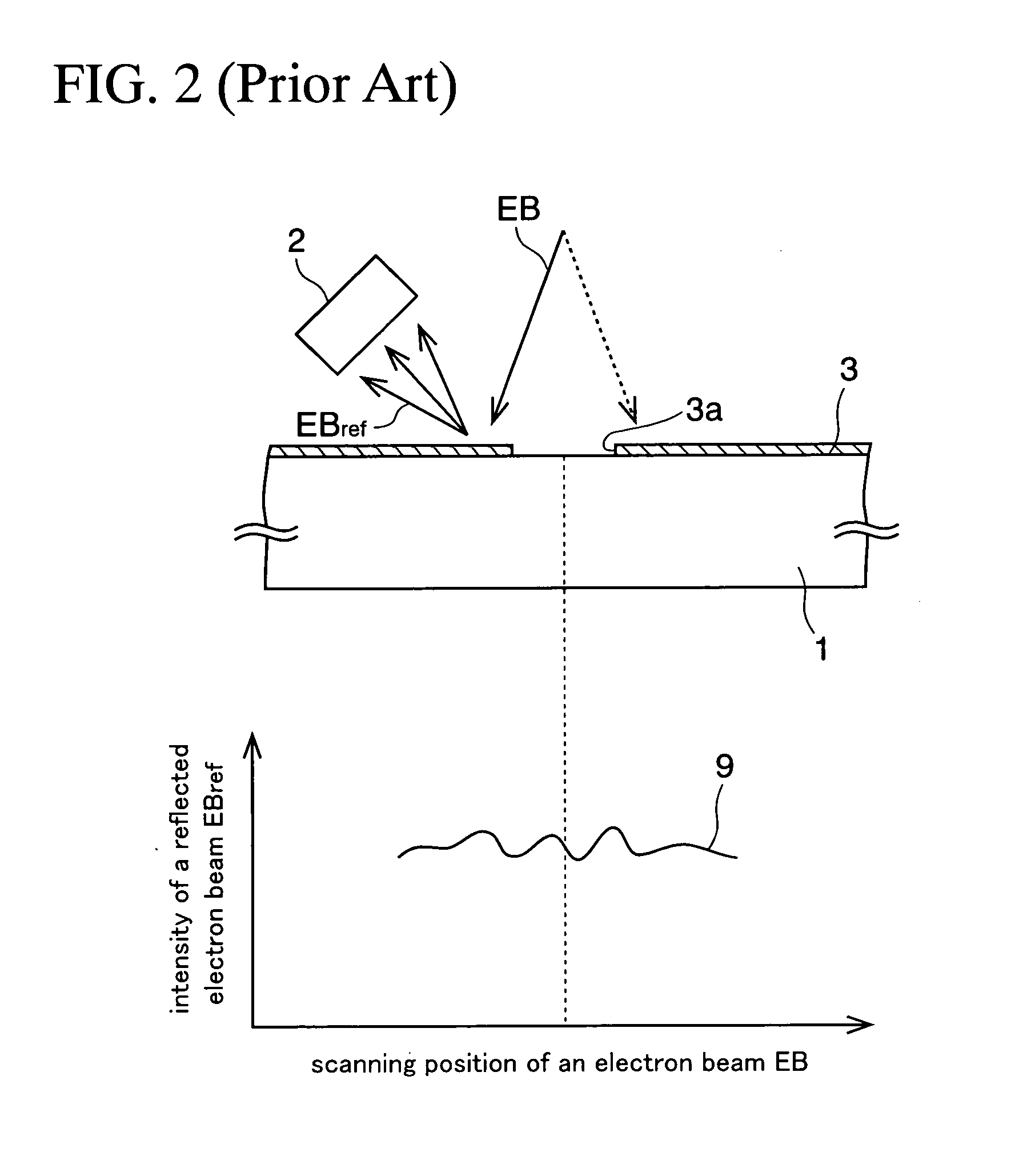

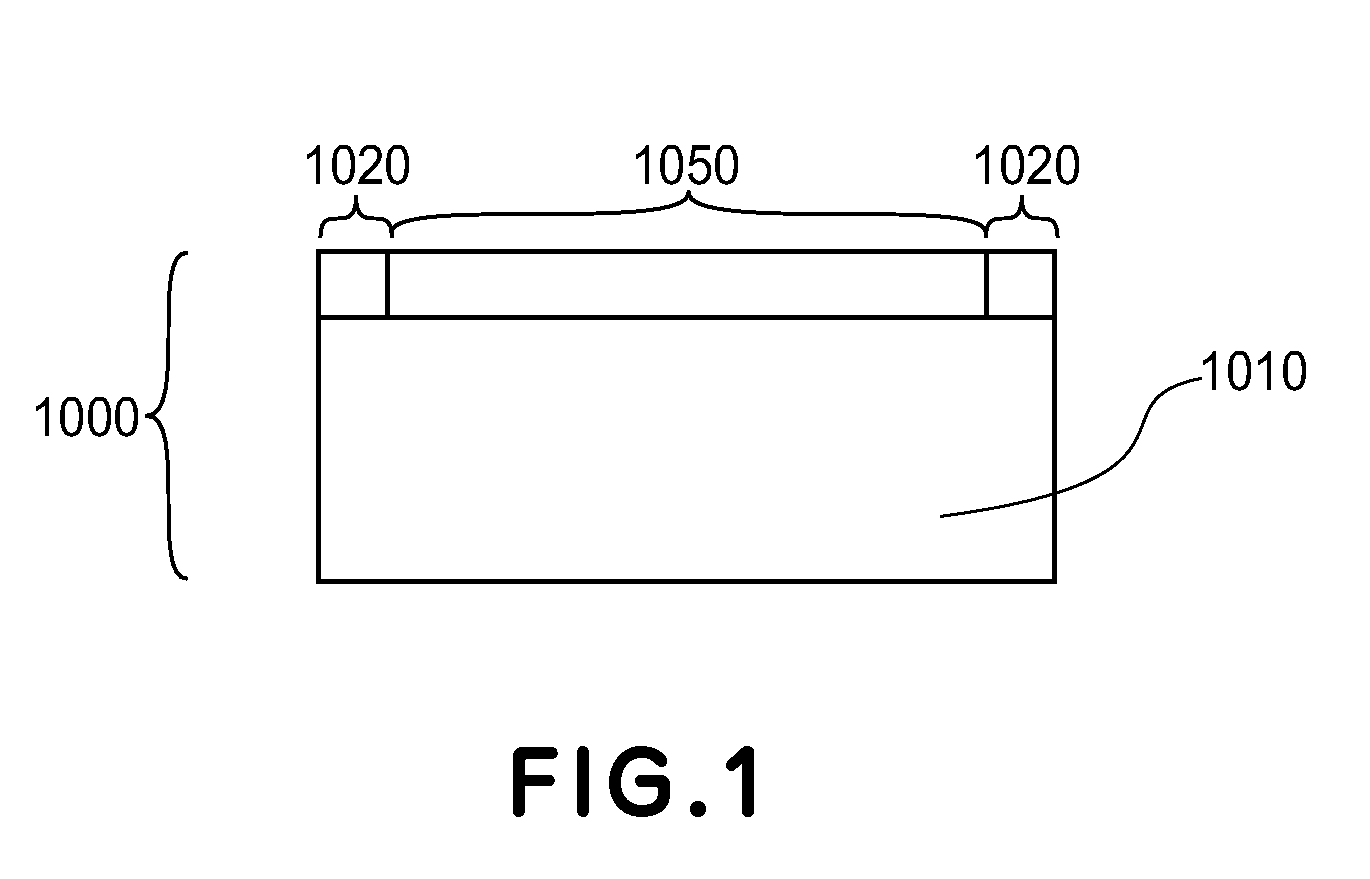

Semiconductor Package, Method for Manufacturing the Same, Semiconductor Module, and Electronic Device

InactiveUS20090256229A1Worsens function of cameraImprove accuracySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageCamera module

In a camera module (1) of the present invention, a lens member (20) is attached to a semiconductor package (10). The semiconductor package (10) includes: an image sensor (11) mounted on a wiring board (13); and a wire 15 through which the wiring board (13) is electrically connected to the image sensor (11). The image sensor (11) and the wire 15 are sealed with mold resin (14). A step (18) is formed around the perimeter of the surface of the mold resin (14), and the semiconductor package (10) and the lens member (20) are joined by fitting the step (18) and a projection (23) of a lens holder (22). With this arrangement, it is possible to realize a small semiconductor module that allows for highly precise alignment between the semiconductor package and a mounting component to which the semiconductor package is joined.

Owner:SHARP KK

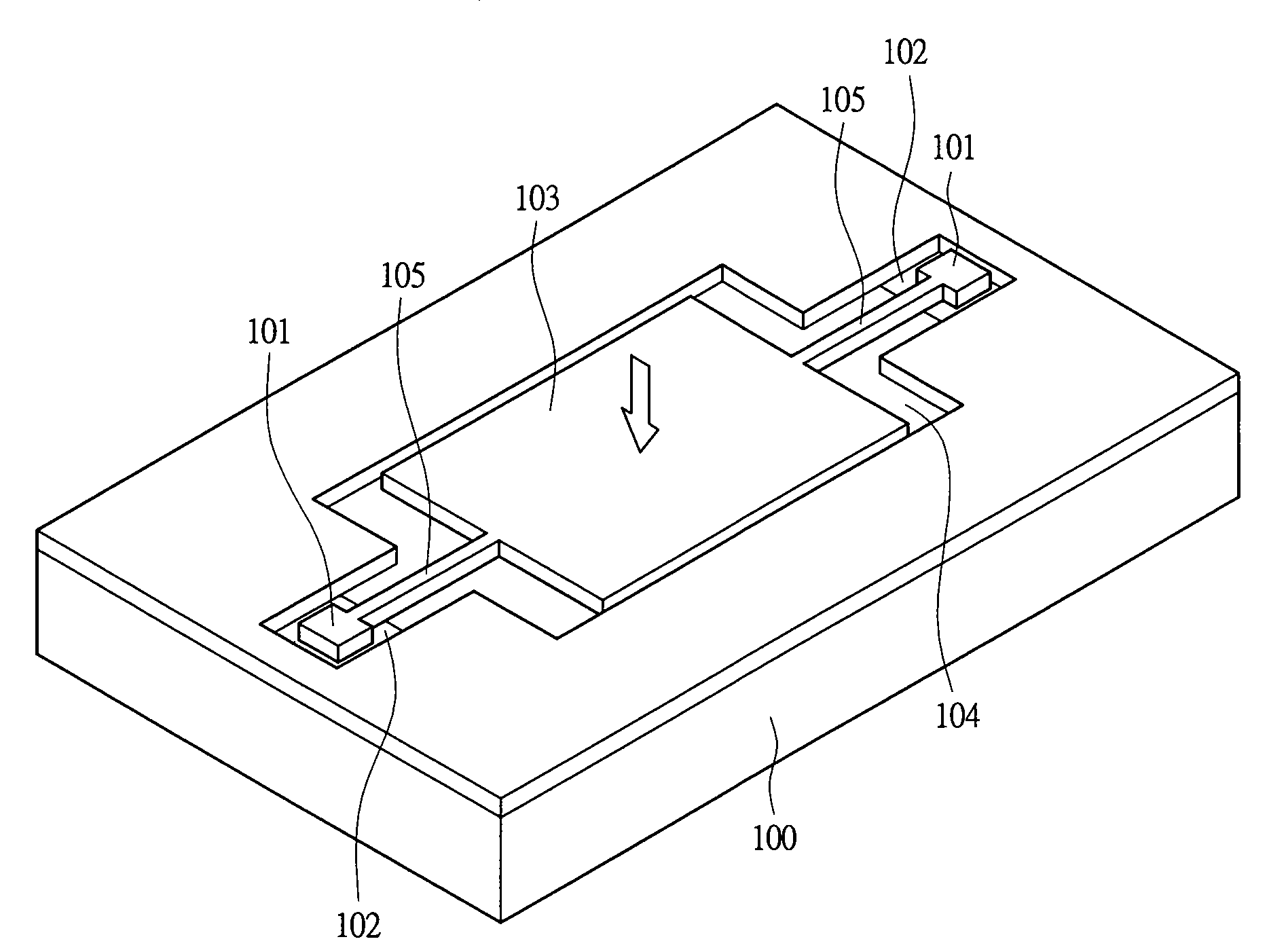

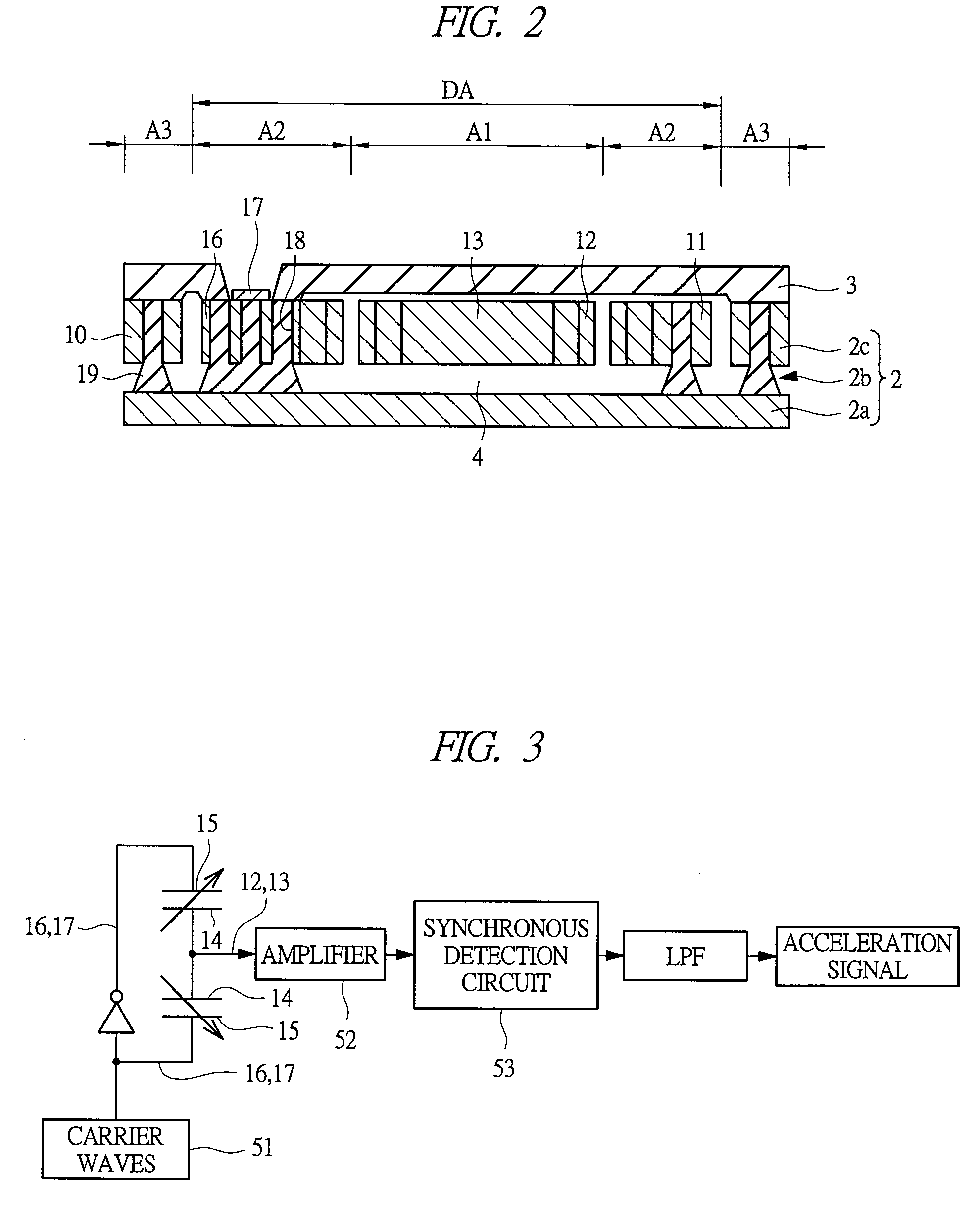

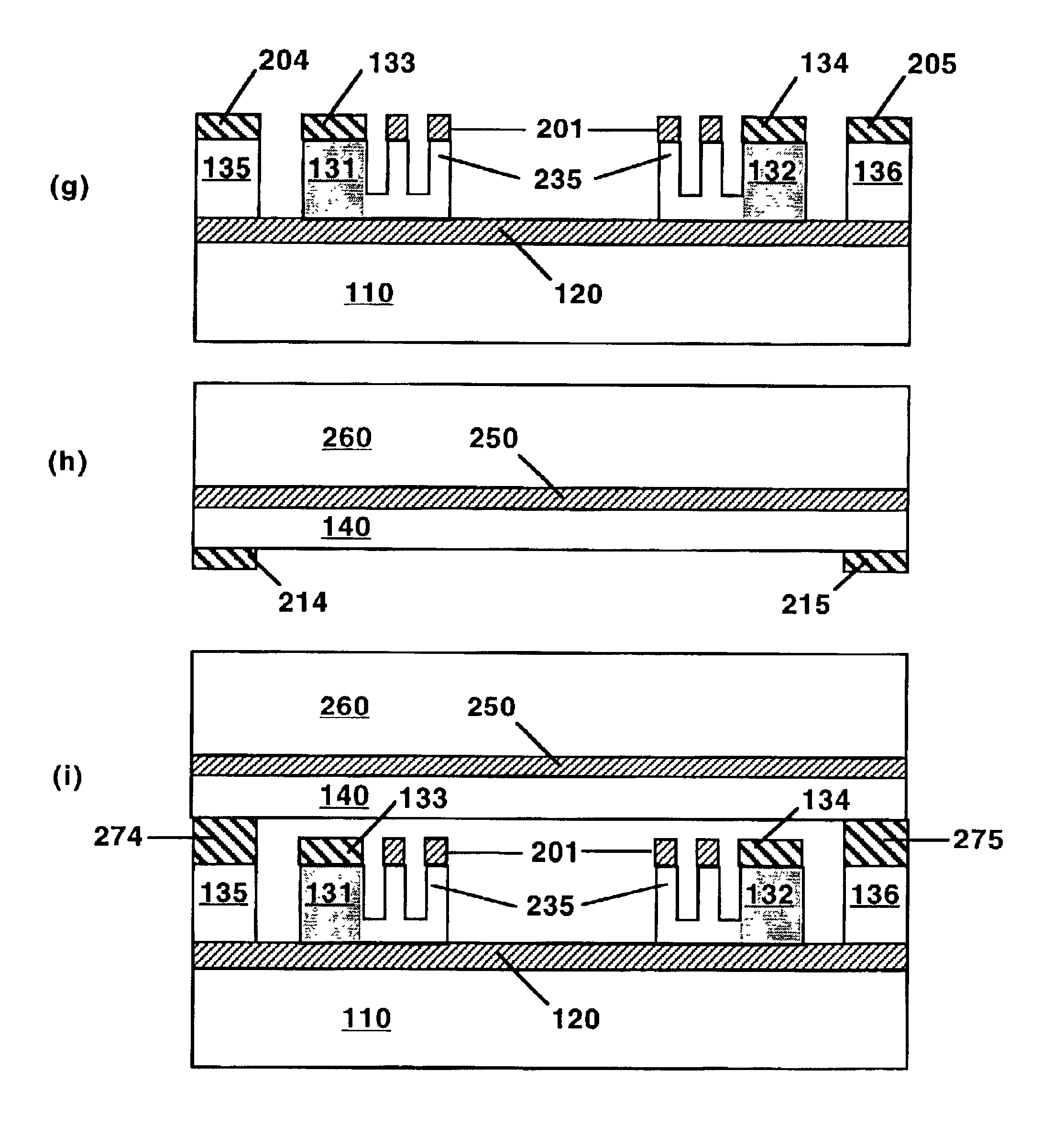

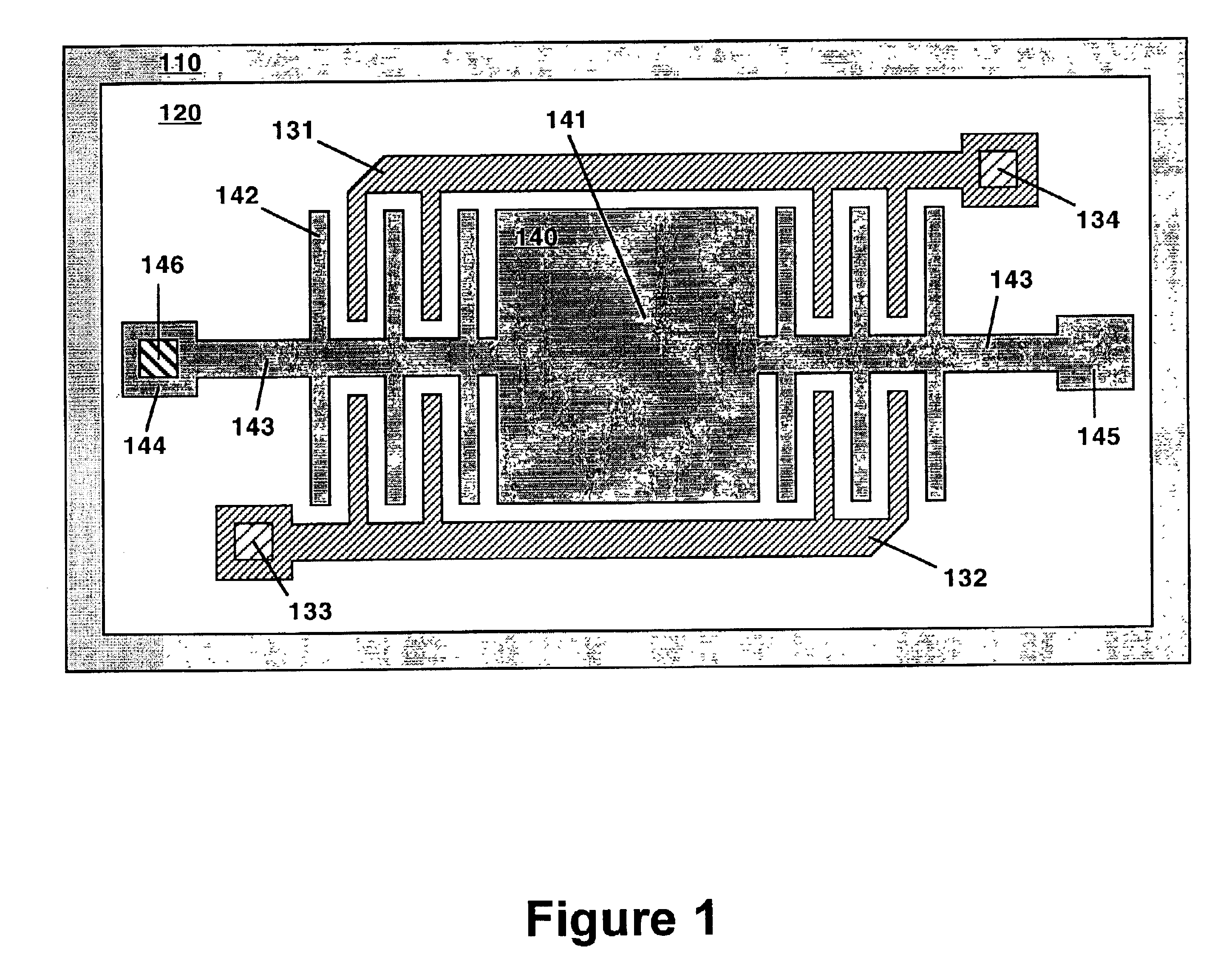

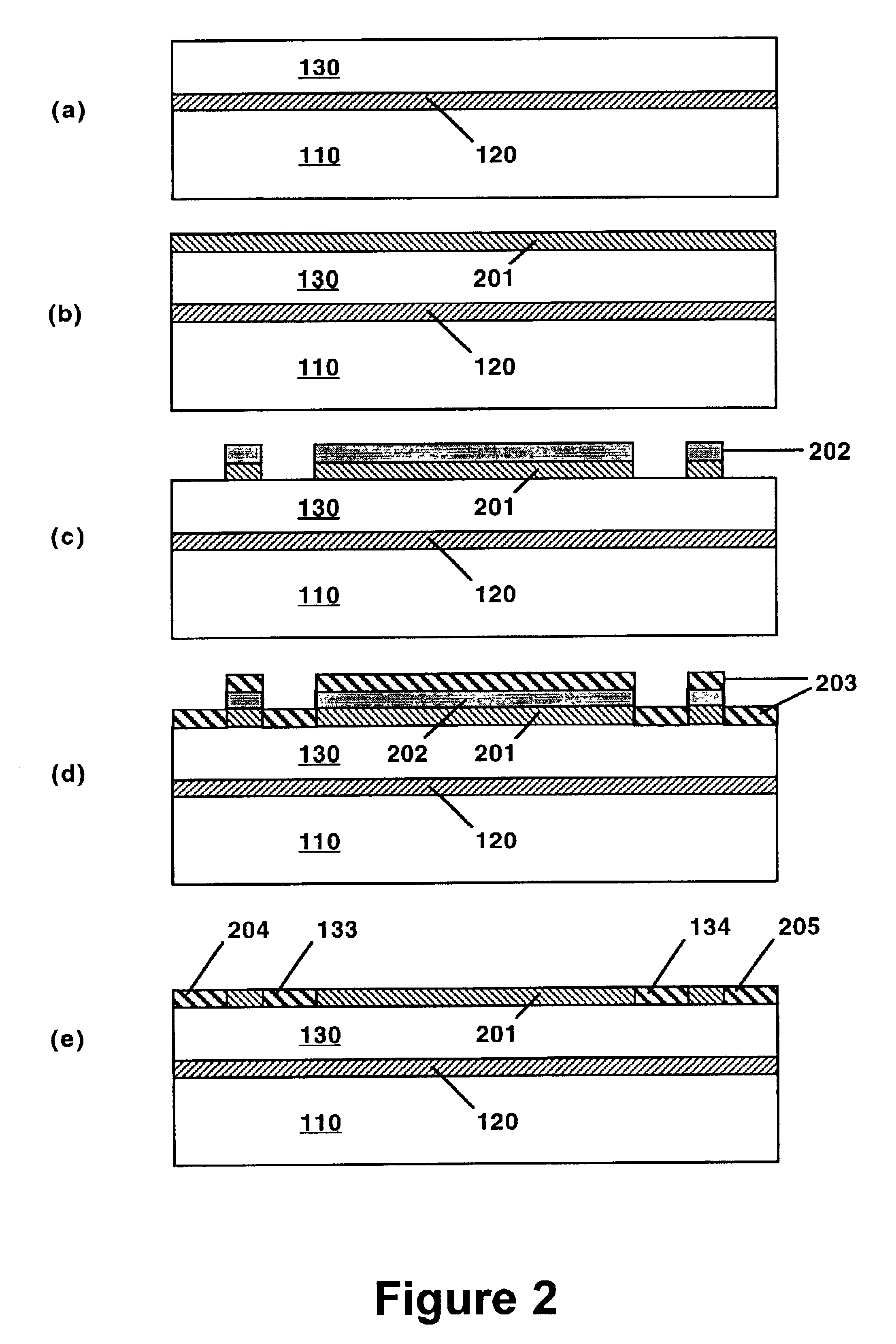

Method of manufacturing micro electro mechanical systems device

InactiveUS20090017579A1Processing requirementHigh precision alignmentAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesAngular velocityEngineering

Provided is a MEMS device which is robust to the misalignment and does not require the double-side wafer processing in the manufacture of a MEMS device such as an angular velocity sensor, an acceleration sensor, a combined sensor or a micromirror. After preparing a substrate having a space therein, holes are formed in a device layer at positions where fixed components such as a fixing portion, a terminal portion and a base that are fixed to a supporting substrate are to be formed, and the holes are filled with a fixing material so that the fixing material reaches the supporting substrate, thereby fixing the device layer around the holes to the supporting substrate.

Owner:HITACHI LTD

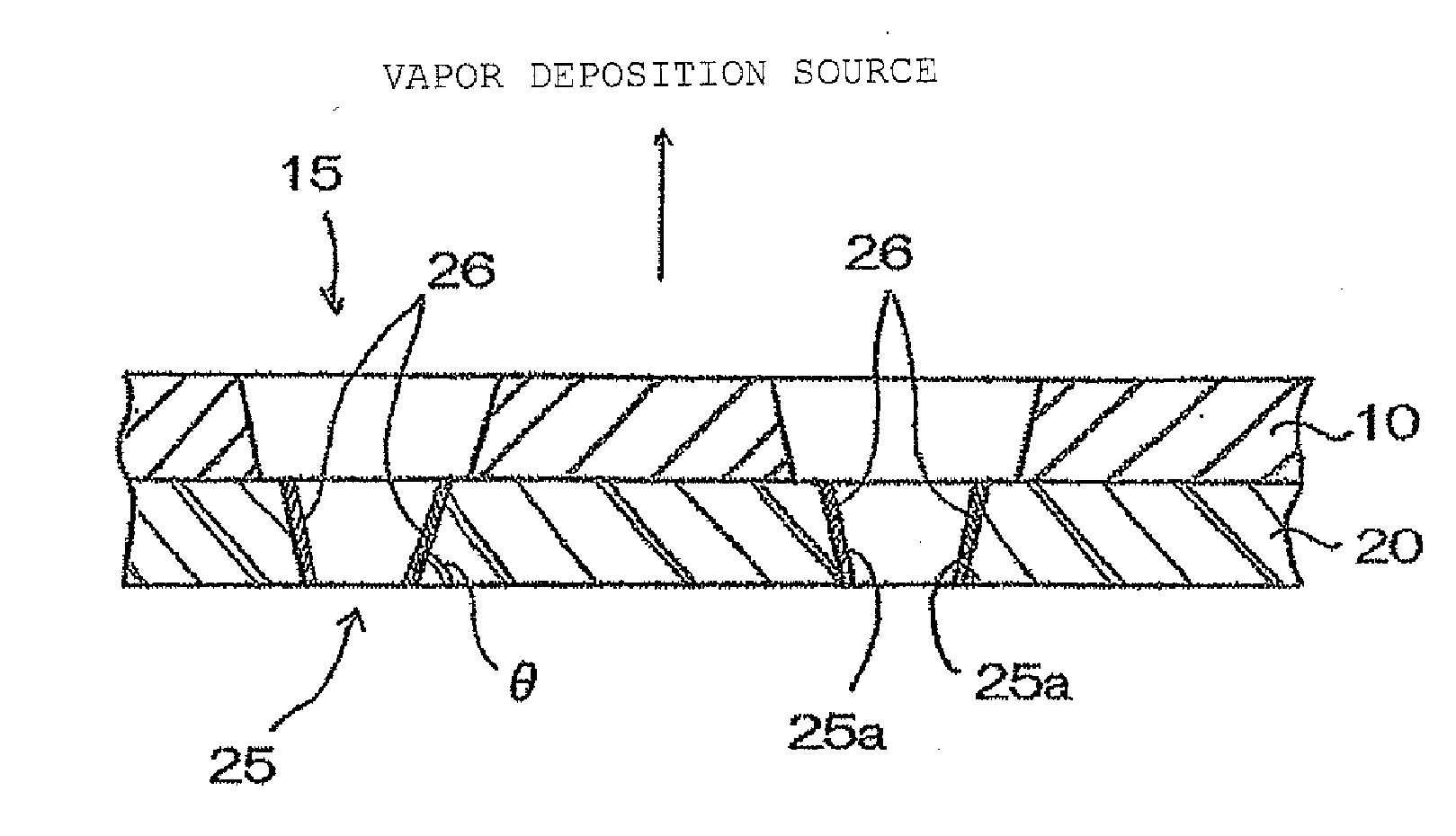

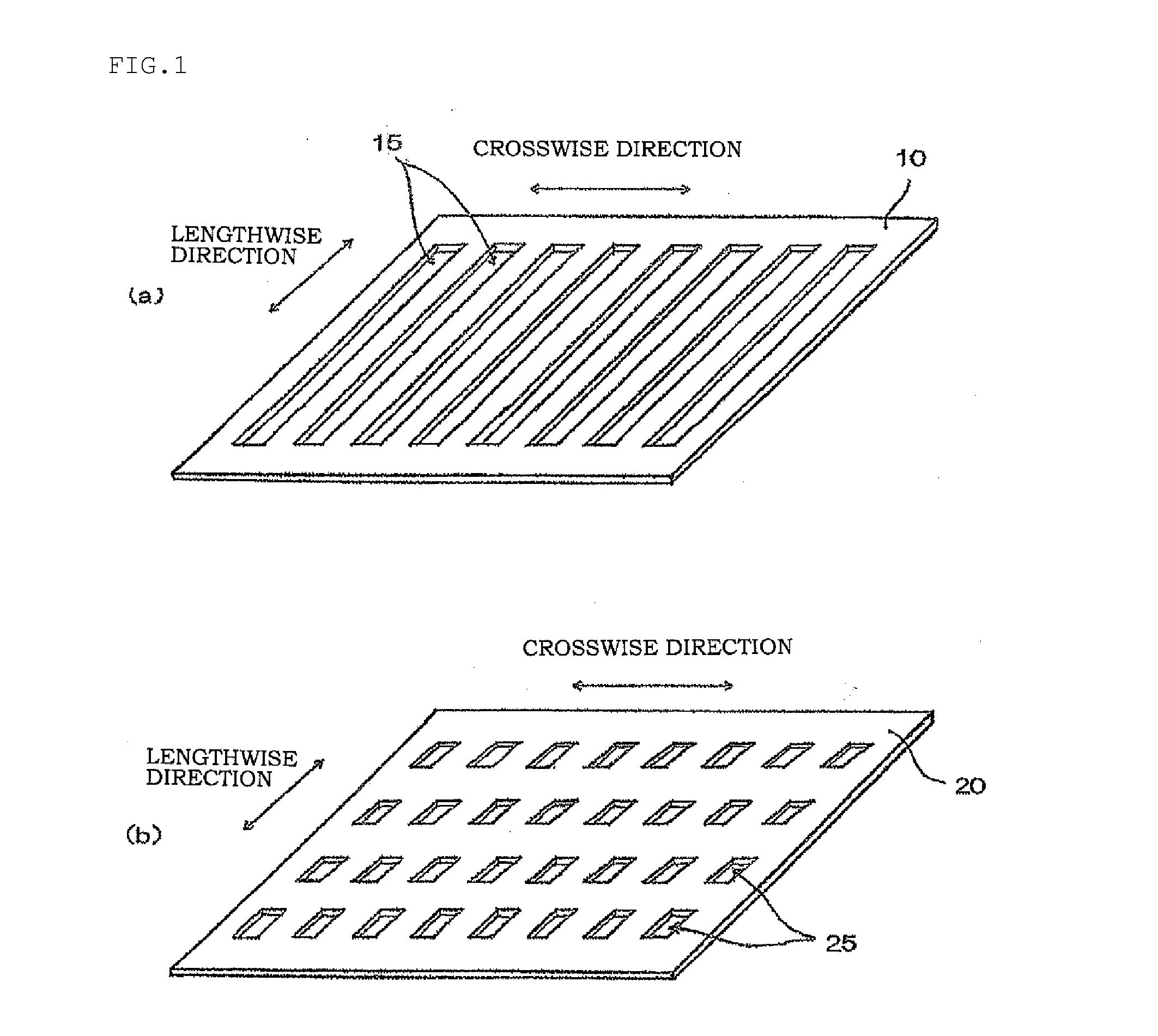

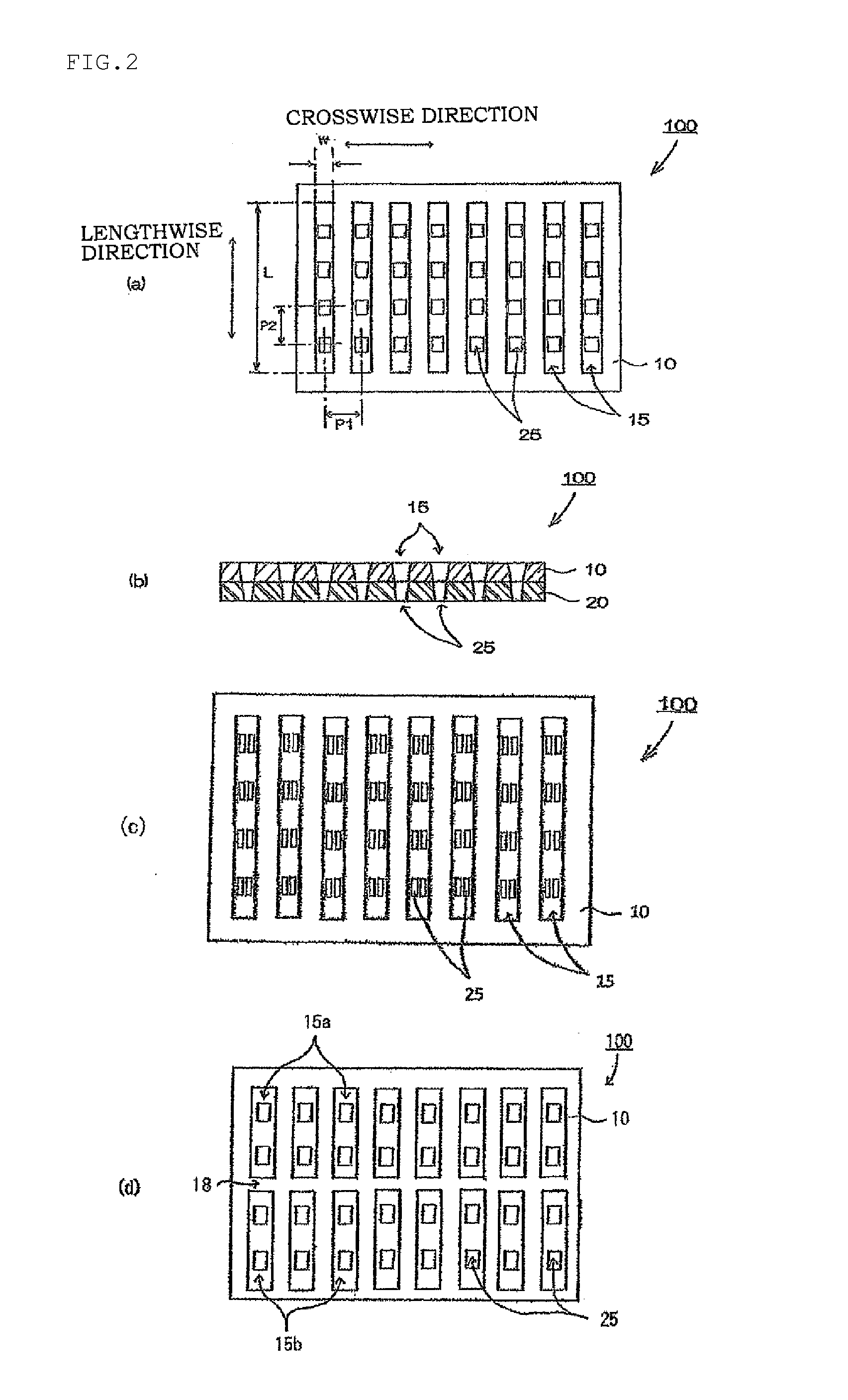

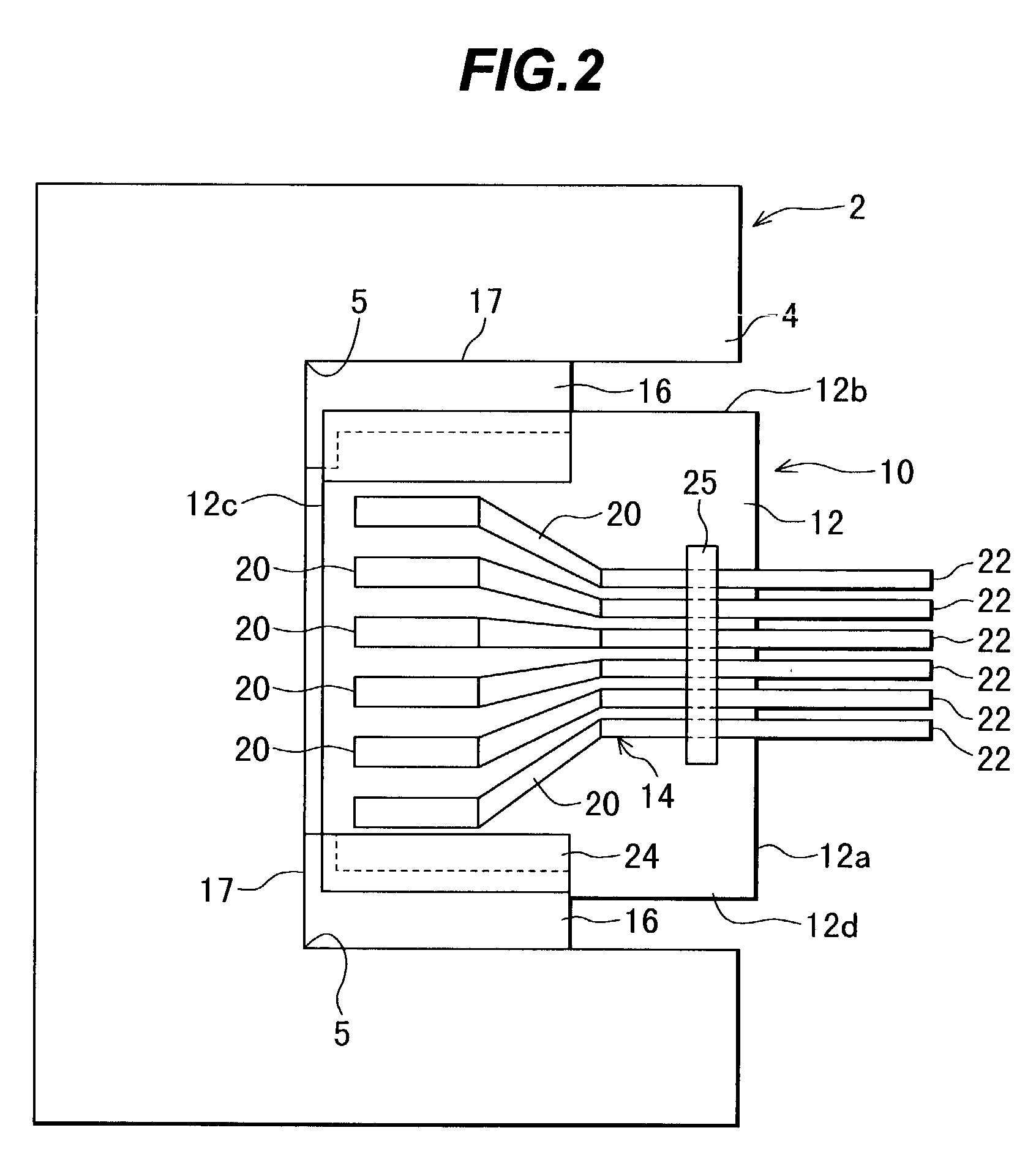

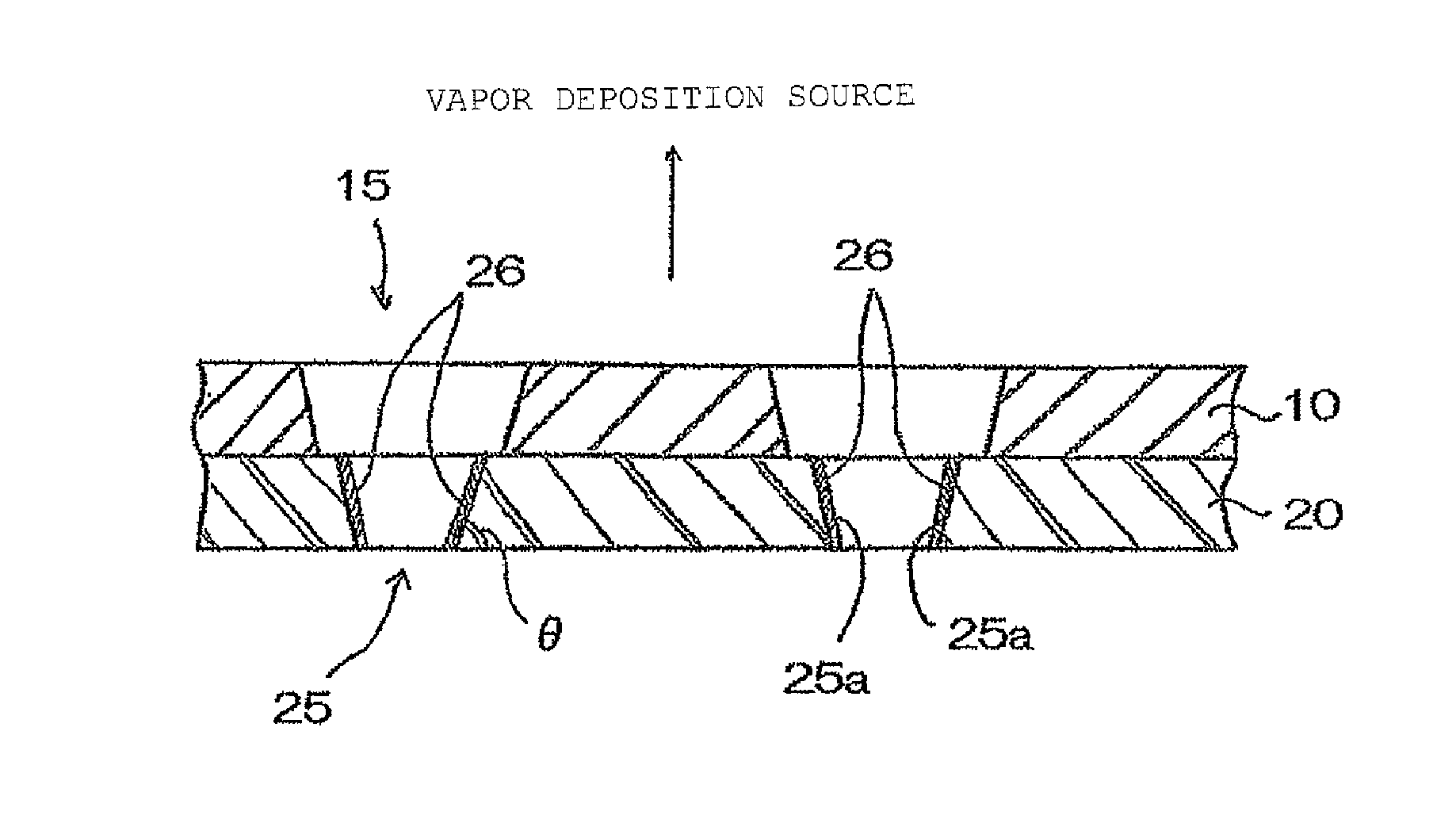

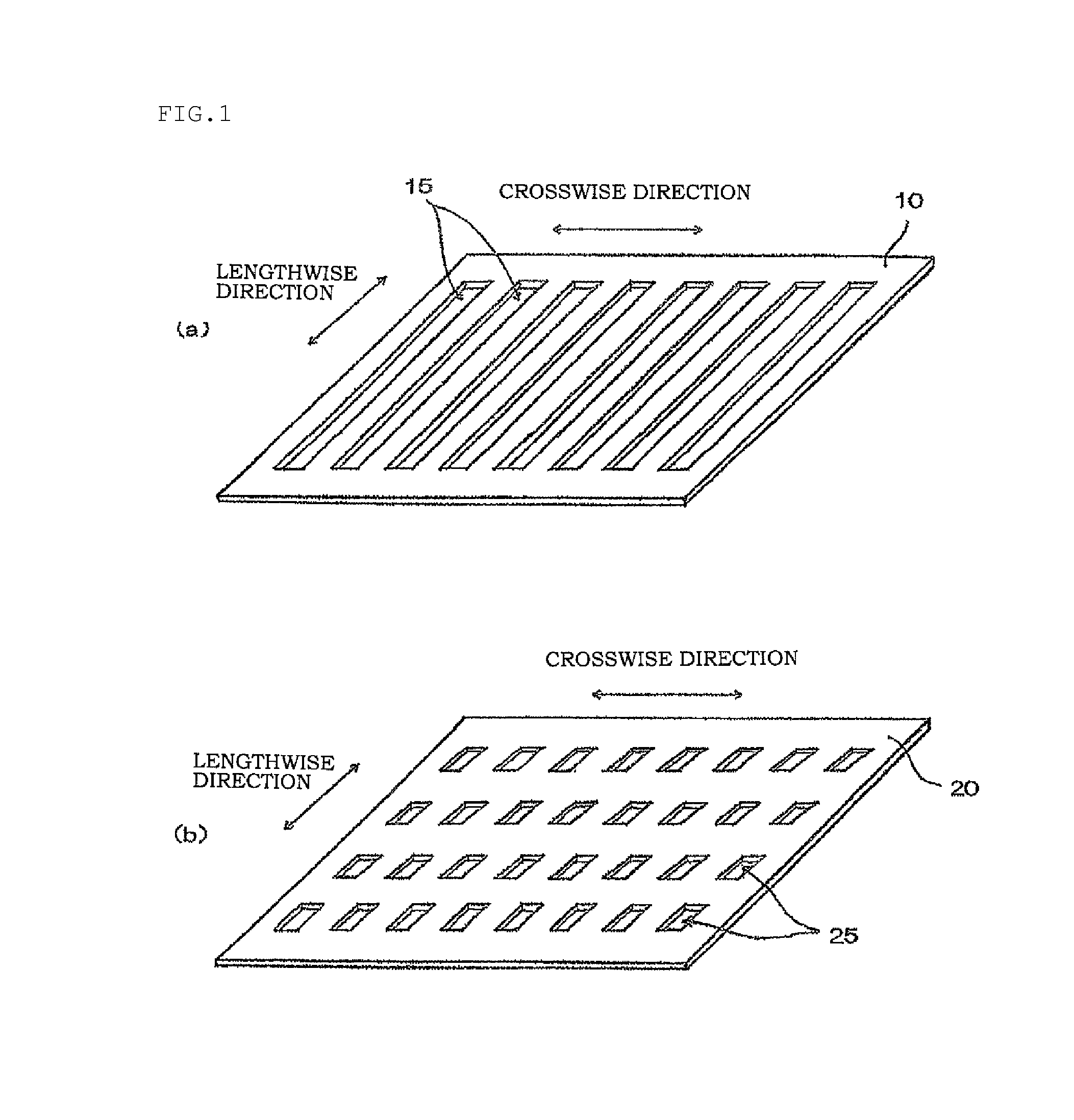

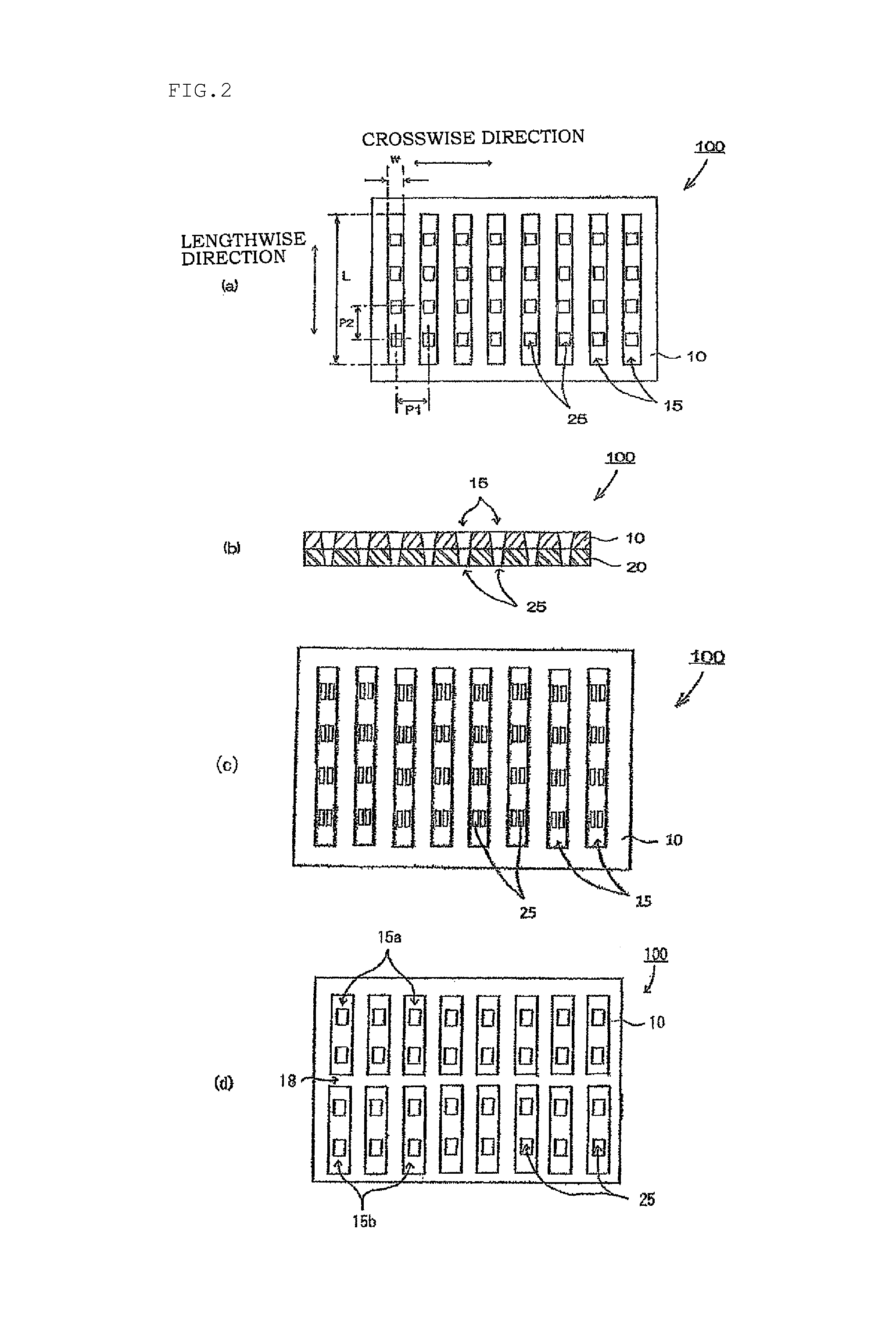

Vapor deposition mask, method for producing vapor deposition mask device and method for producing organic semiconductor element

ActiveUS20150037928A1Enhancement in definitionReduce weightLiquid surface applicatorsSpraying apparatusGas phaseOrganic semiconductor

A method for producing a vapor deposition mask capable of satisfying both enhancement in definition and reduction in weight even when a size is increased, a method for producing a vapor deposition mask device capable of aligning the vapor deposition mask to a frame with high precision, and a method for producing an organic semiconductor element capable of producing an organic semiconductor element with high definition are provided. A metal mask provided with a slit, and a resin mask that is positioned on a front surface of the metal mask and has openings corresponding to a pattern to be produced by vapor deposition arranged by lengthwise and crosswise in a plurality of rows, are stacked.

Owner:DAI NIPPON PRINTING CO LTD

Process for high yield fabrication of MEMS devices

ActiveUS6872319B2Thickness minimizationExceptionally precise layer to layer alignmentSemi-permeable membranesPrecision positioning equipmentEngineeringSilicon

A MEMS fabrication process eliminates through-wafer etching, minimizes the thickness of silicon device layers and the required etch times, provides exceptionally precise layer to layer alignment, does not require a wet etch to release the moveable device structure, employs a supporting substrate having no device features on one side, and utilizes low-temperature metal-metal bonding which is relatively insensitive to environmental particulates. This process provided almost 100% yield of scanning micromirror devices exhibiting scanning over a 12° optical range and a mechanical angle of ±3° at a high resonant frequency of 2.5 kHz with an operating voltage of only 20 VDC.

Owner:TELEDYNE SCI & IMAGING

Optical fiber fixing member and method for manufacturing the same

InactiveUS6240235B1Easy alignmentImprove accuracyGlass pressing apparatusCoupling light guidesEngineeringMachining

The optical fiber fixing member made of glass, especially optical fiber guide block, is conventionally produced by a mechanical processing. However, the mechanical processing has problems that a production cost becomes high and mass-production is difficult. The problems above can be solved by the present invention providing a method for producing an optical fiber fixing member comprising: disposing a glass shaping preform whose plane view resembles to the plane view of the molded article and whose faces to be positioned in the pressurizing direction during press-molding assumes planes or outwardly convex curved surfaces, in a mold having a cavity of a given shape; and heating the glass shaping preform up to a temperature at which the glass shaping preform can be mold-shaping and thereby press-molding it into a molded article having at least one edge formed of a free surface.

Owner:HOYA CORP +1

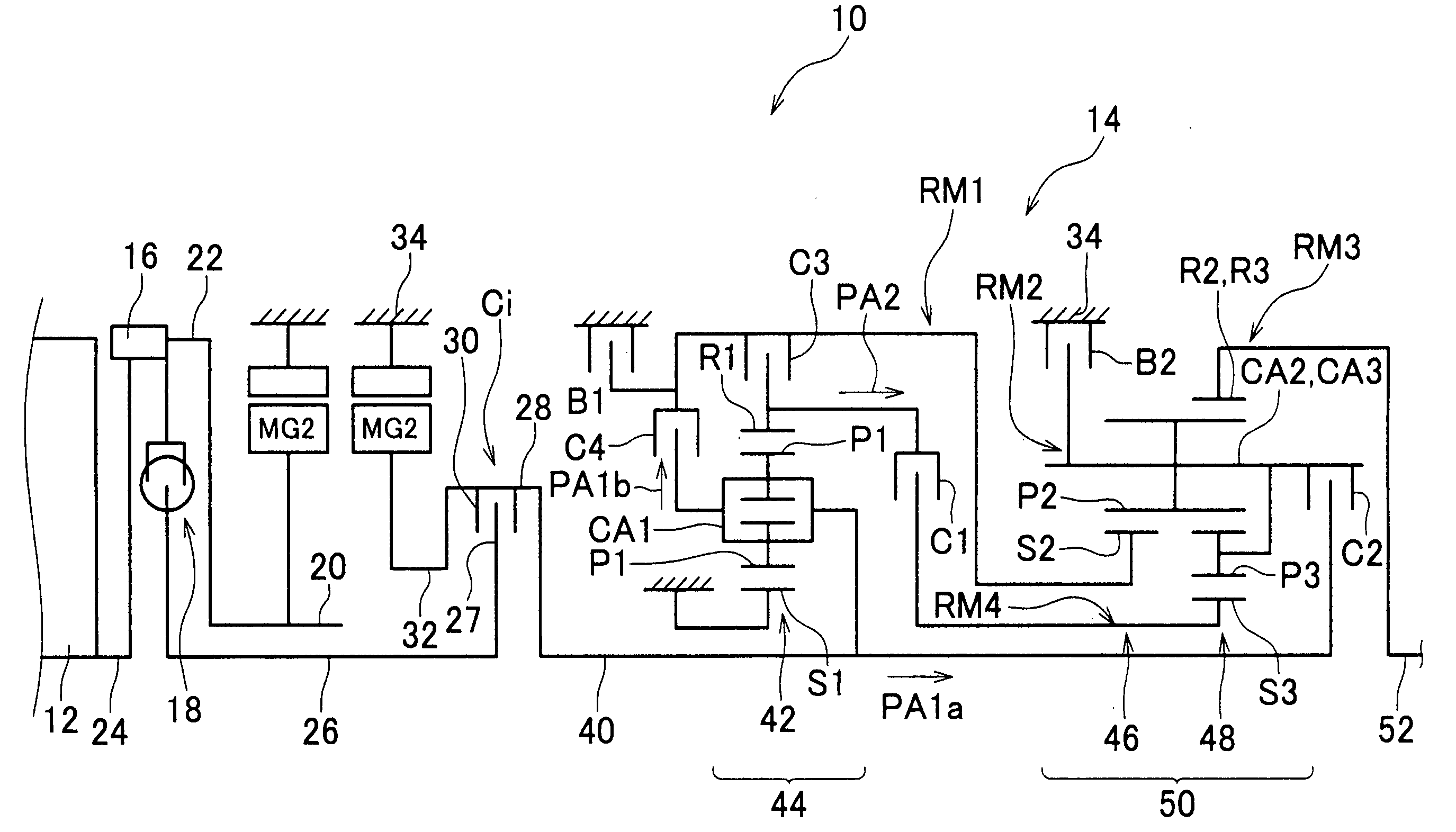

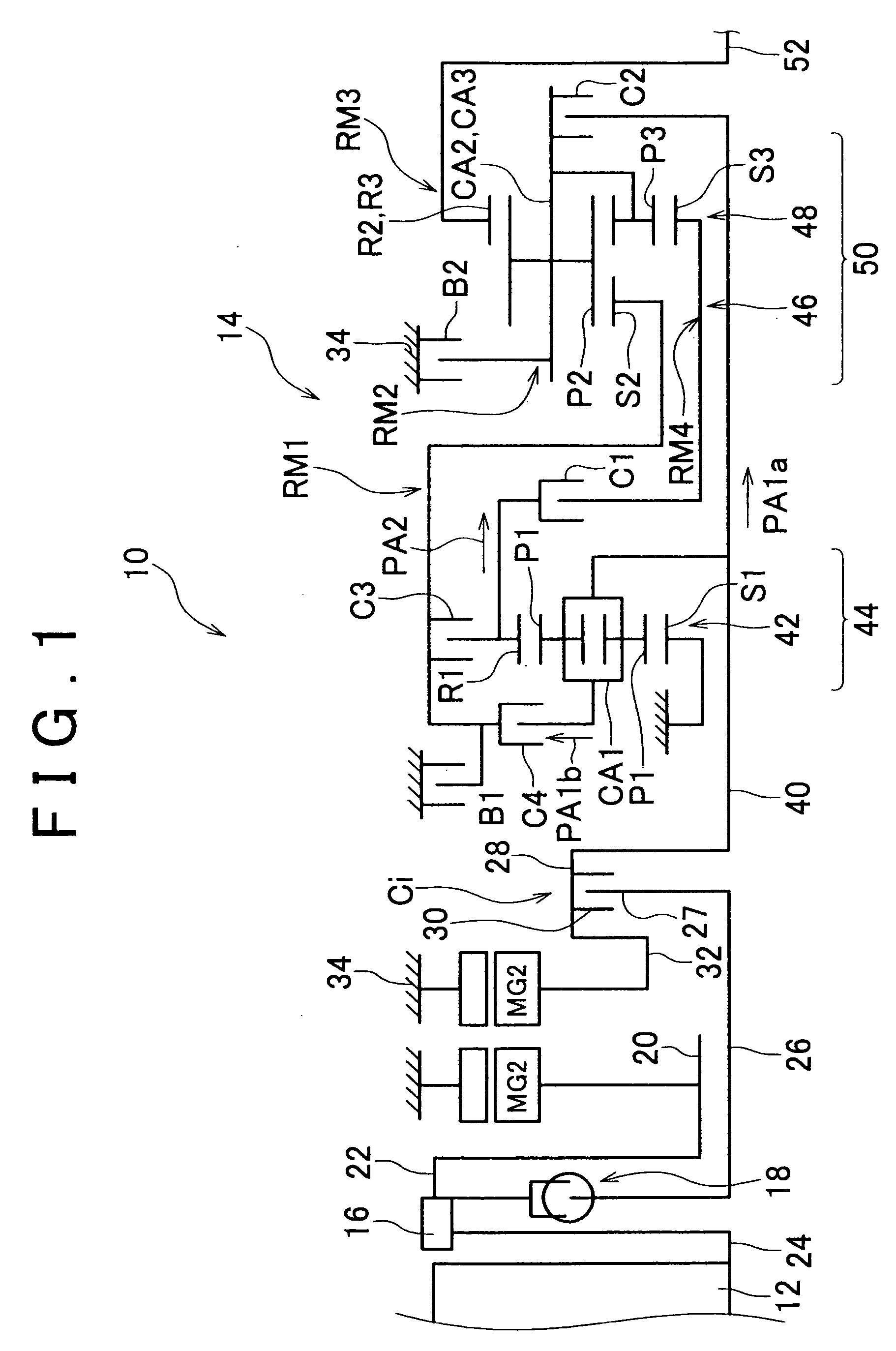

Vehicle driving apparatus

InactiveUS20060108162A1High precisionHigh-precision alignmentGas pressure propulsion mountingToothed gearingsStatorEngineering

A rotor shaft of a first electric motor is connected to a crankshaft of the engine by being fit to a transmitting member that is coupled to the crankshaft. The stator and rotor shaft of the first electric motor are supported by a case housing the first electric motor.

Owner:TOYOTA JIDOSHA KK

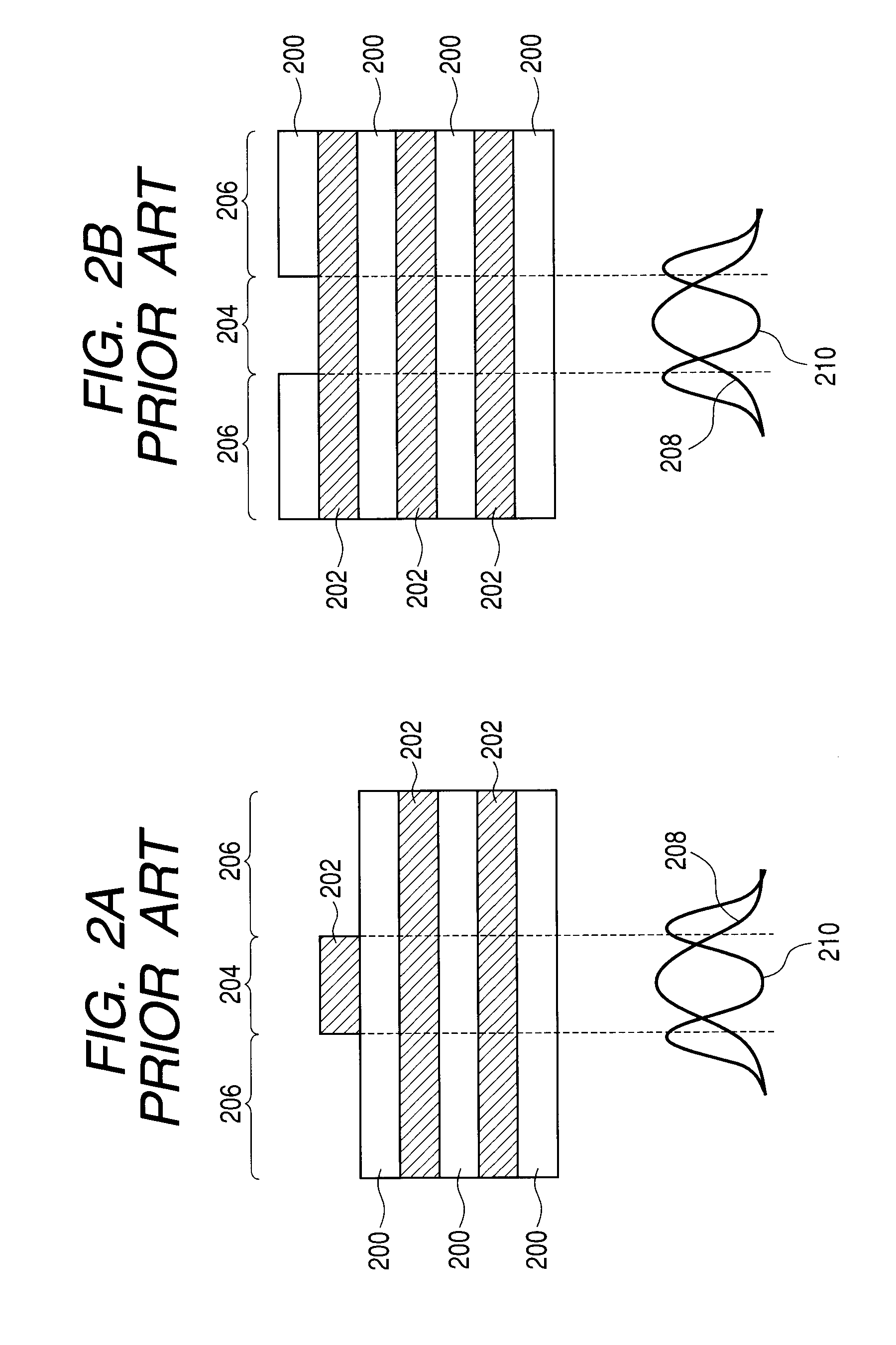

Light beam scanning display

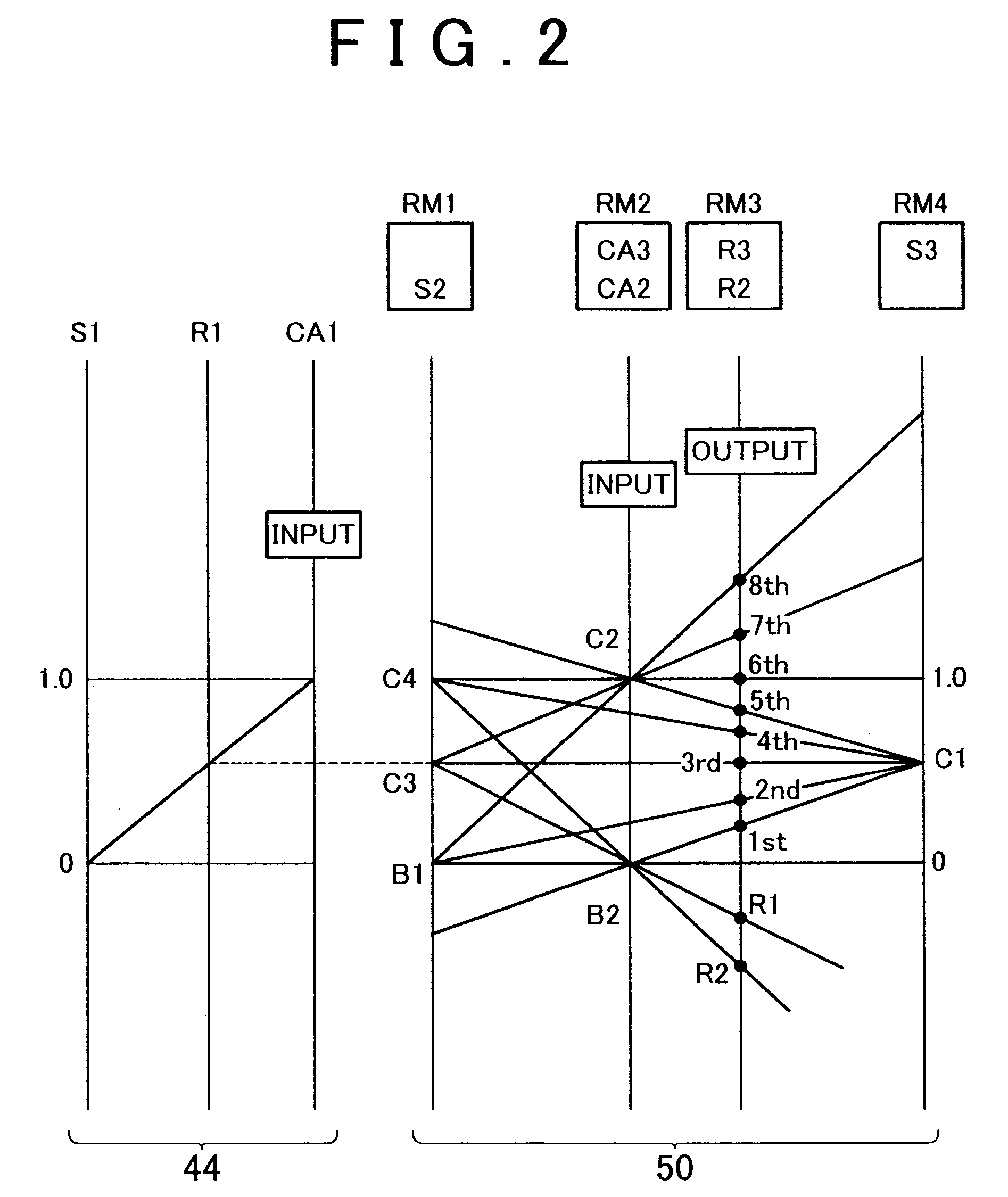

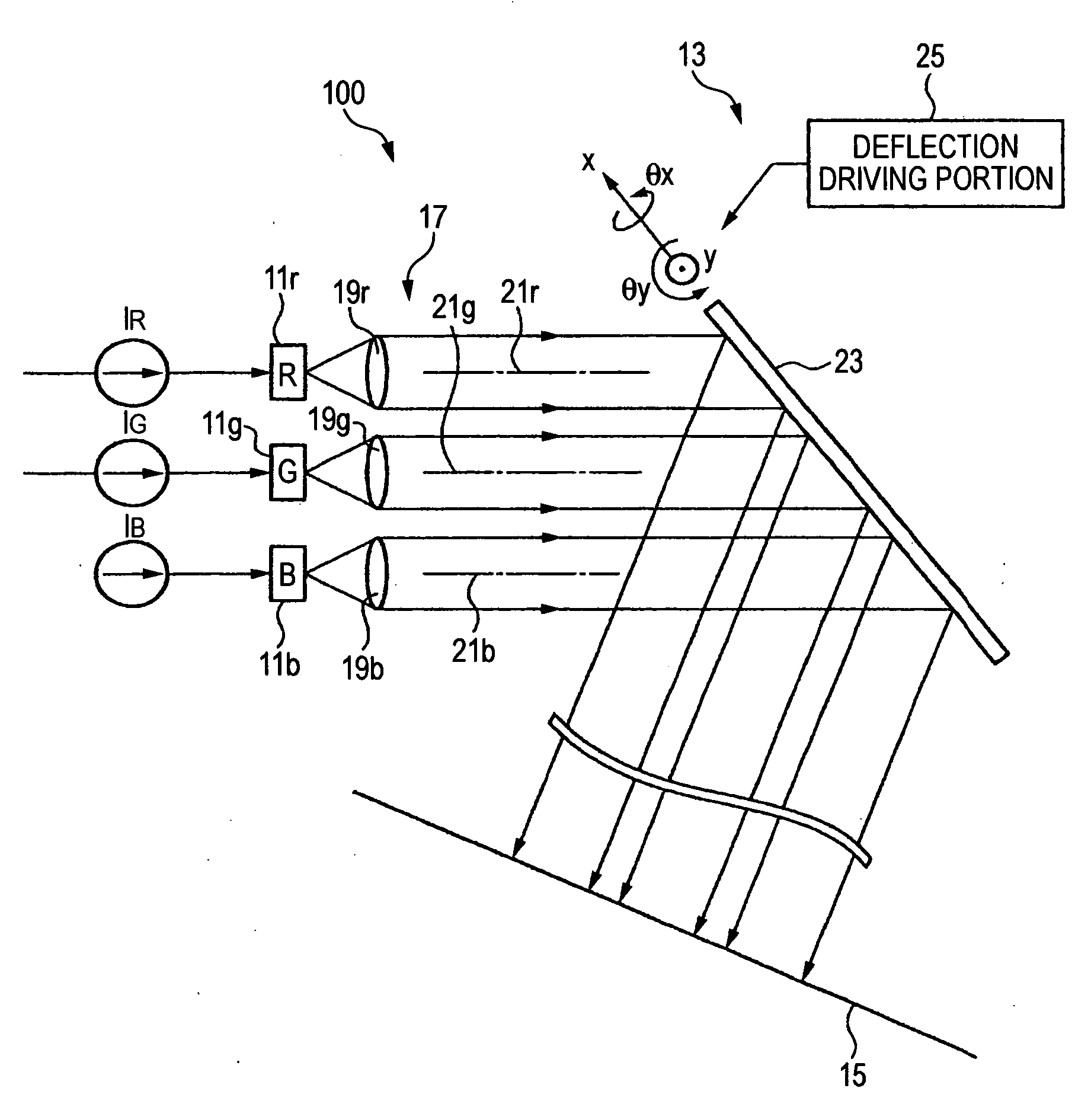

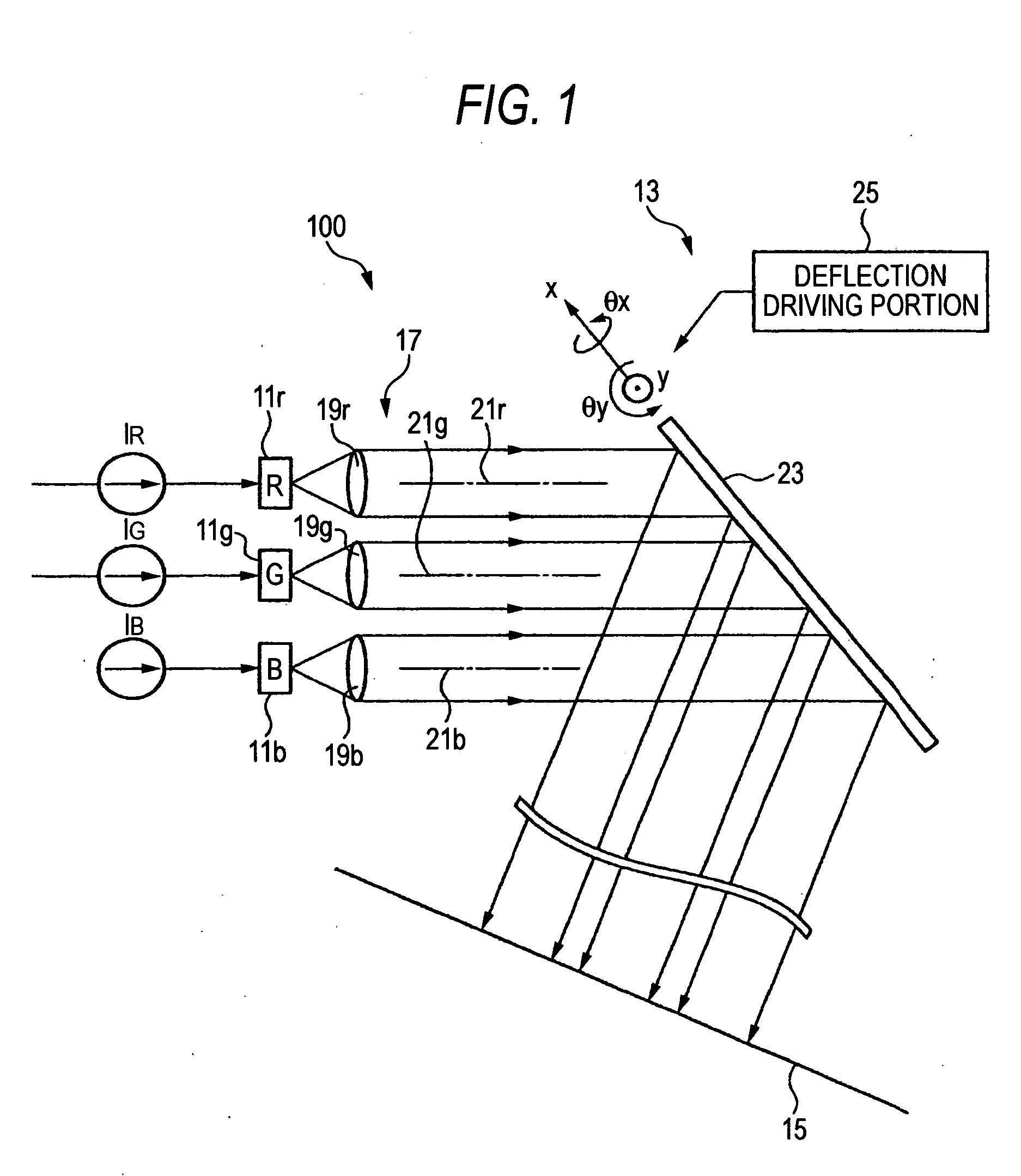

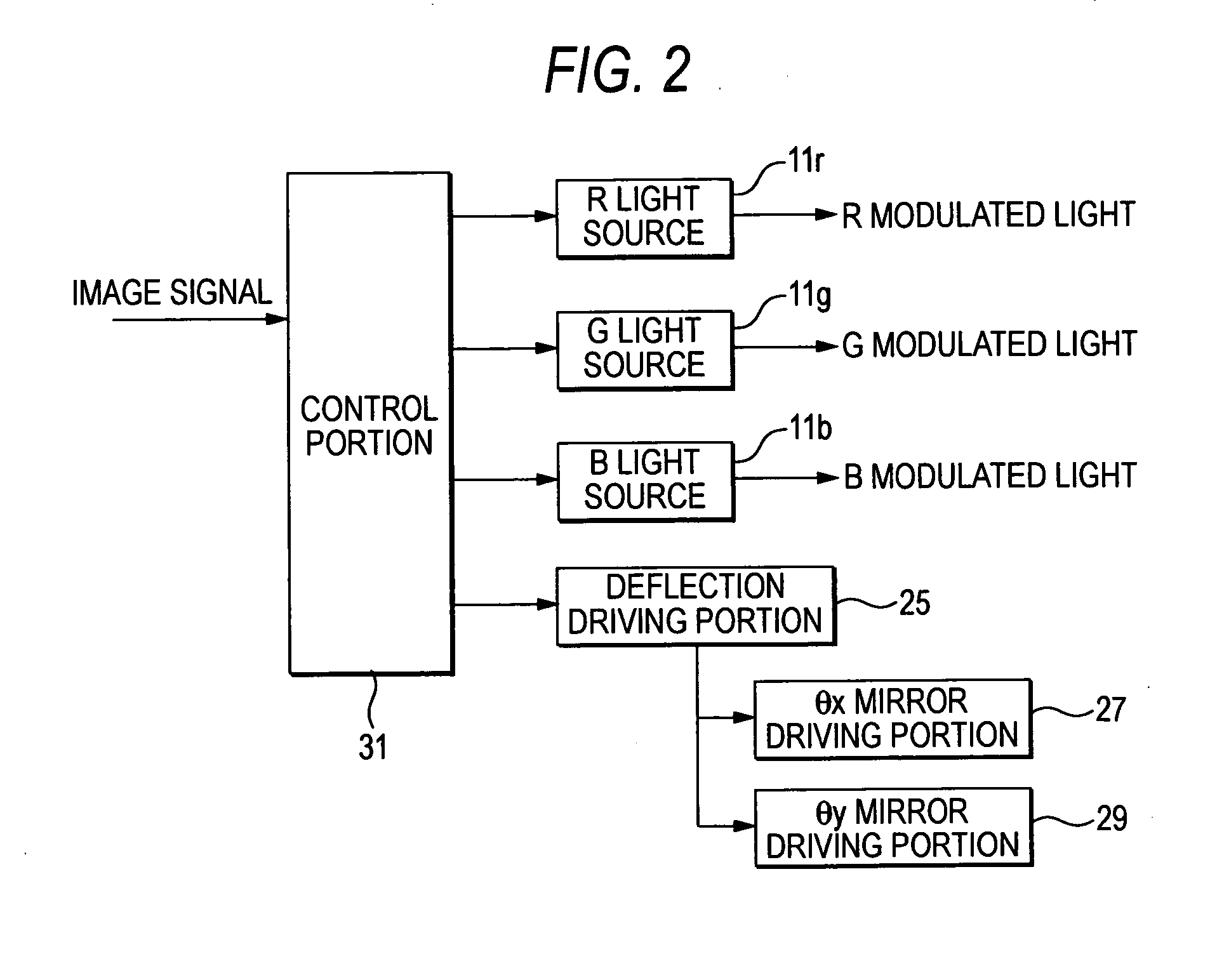

InactiveUS20060138239A1Increase degree of freedomIncrease designProjectorsColor television detailsOptical pathImage based

A light beam scanning display for displaying an image on a drawing screen by modulating laser beams from three primary color light sources, the three primary color light sources being arranged in close vicinity to each other, based on image data respectively and then scanning the laser beams, the light beam scanning display comprising: a parallelizing section that parallelizes respective laser beams; wherein the laser beams being parallelized by the parallelizing section to form one pixel of a drawn image on the drawing screen via different optical paths such that optical axes of the laser beams do not overlap with each other.

Owner:FUJIFILM HLDG CORP +1

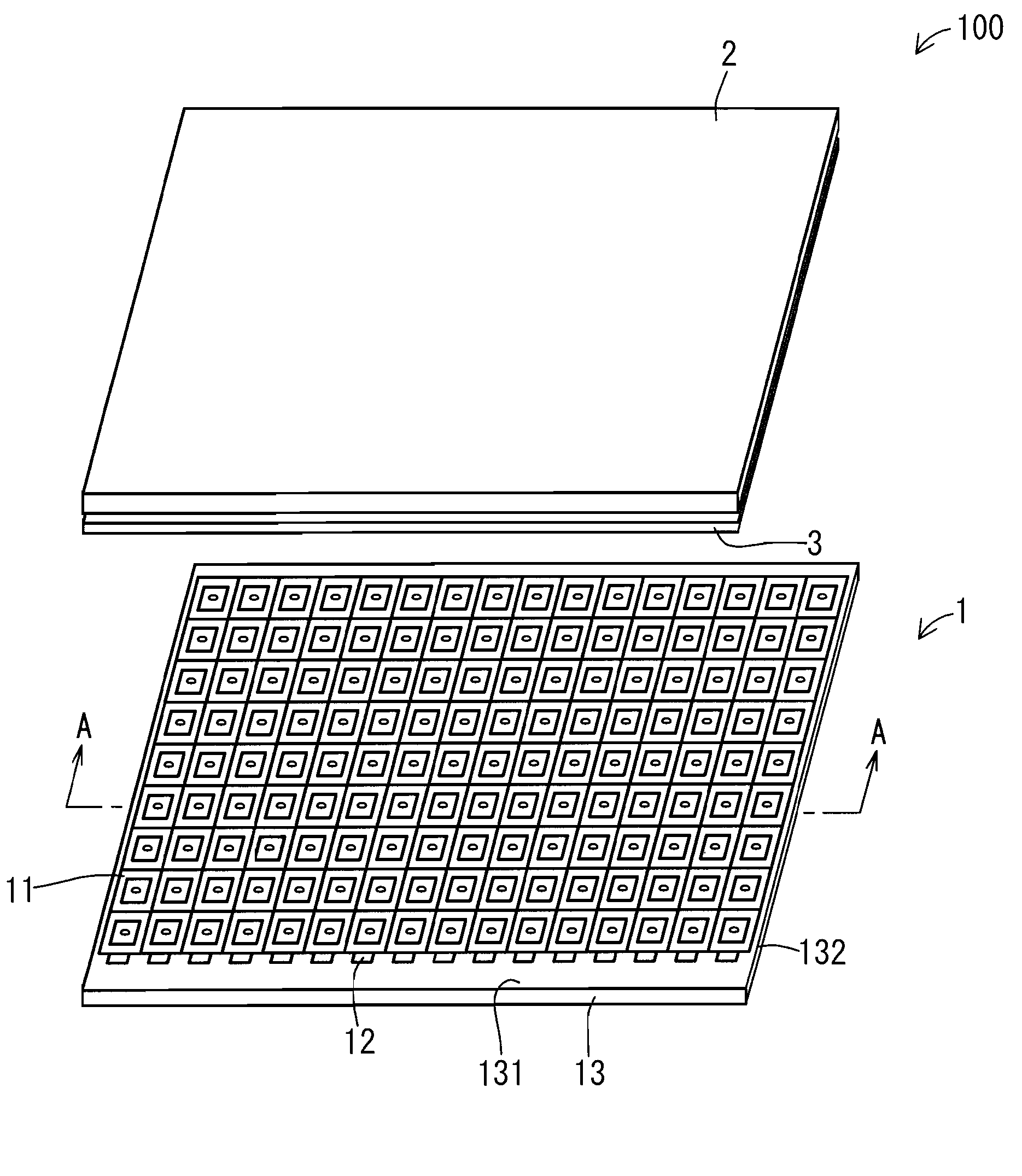

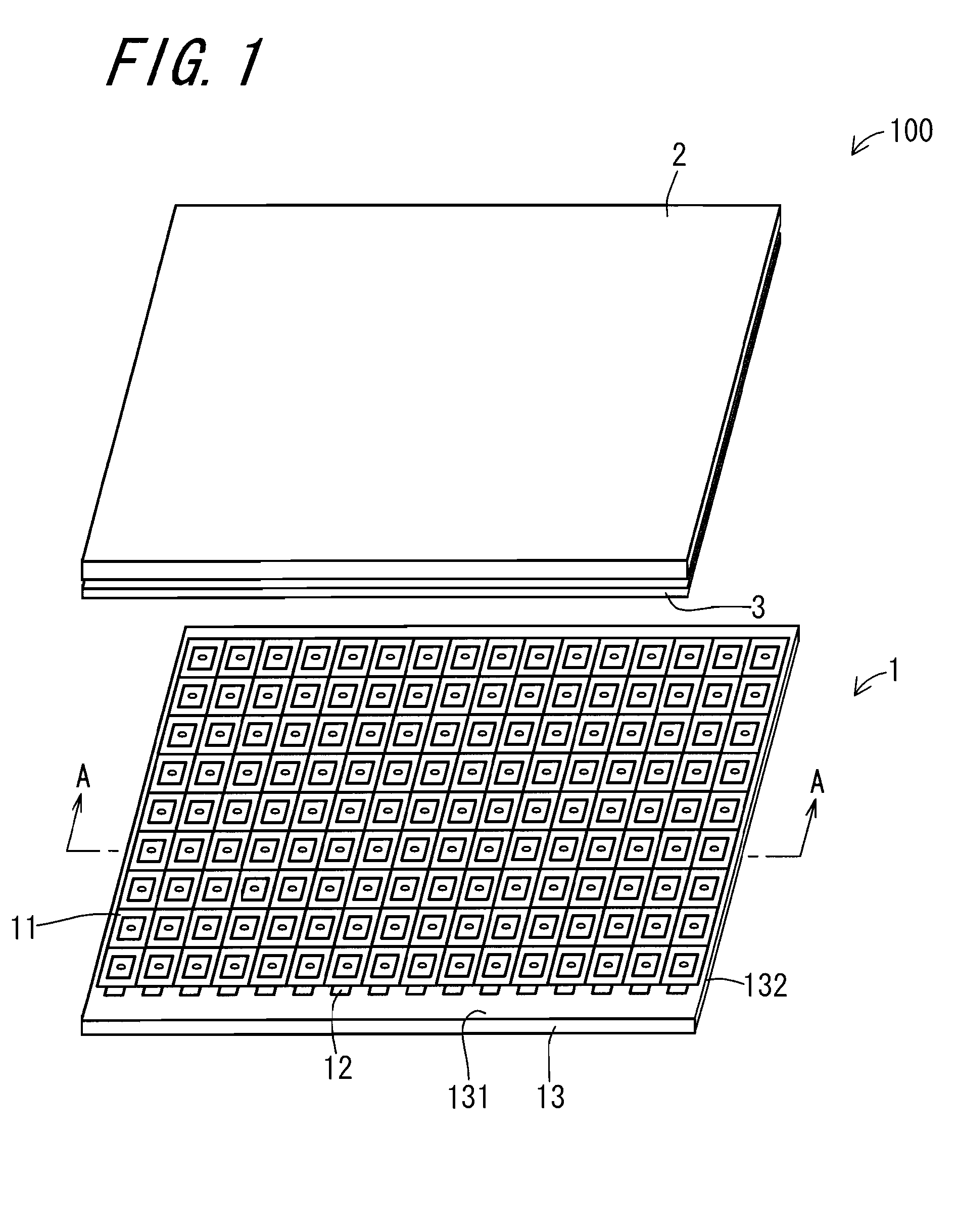

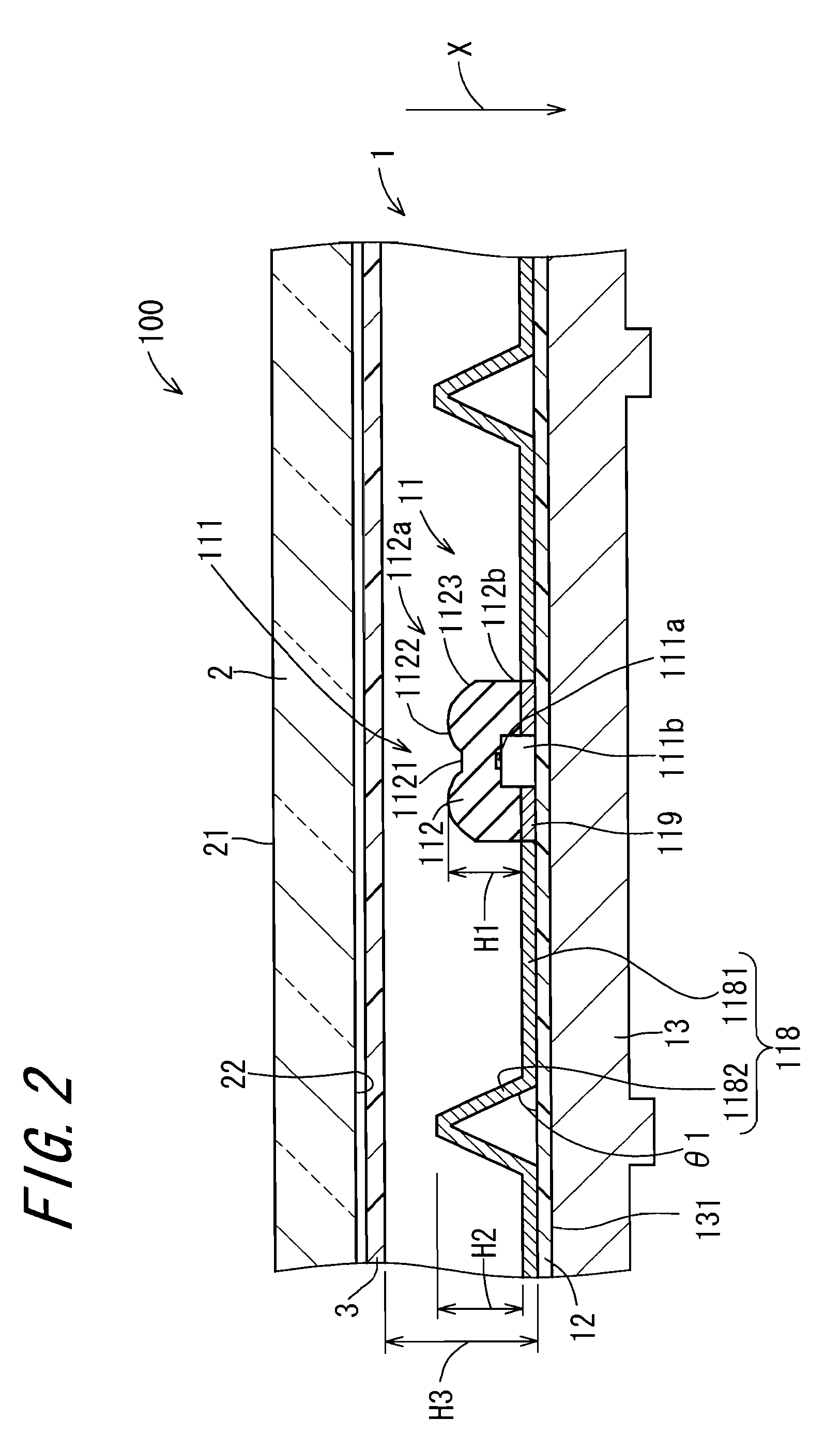

Light-emitting device, illuminating apparatus, and display apparatus

InactiveUS20140376219A1High precision alignmentImprove accuracyNon-electric lightingPoint-like light sourceEngineeringLight emitting device

The invention provides a light-emitting device which is capable of applying light to a display panel with uniformity in brightness and can be made lower in profile. A light-emitting device (11) includes an LED chip (111a), a base support (111b) which supports the LED chip (111a), and a lens (112) disposed in contact with the LED chip (111a) so as to cover the LED chip (111a) and the base support (111b). The lens (112) has first curved sections (1122) which reflect light that has reached a top surface (112a) so that the reflected light is emitted from a side surface (112b), and second curved sections (1123) which refract light that has reached the top surface (112a) to outside so that the refracted light is emitted from the top surface (112a).

Owner:SHARP KK

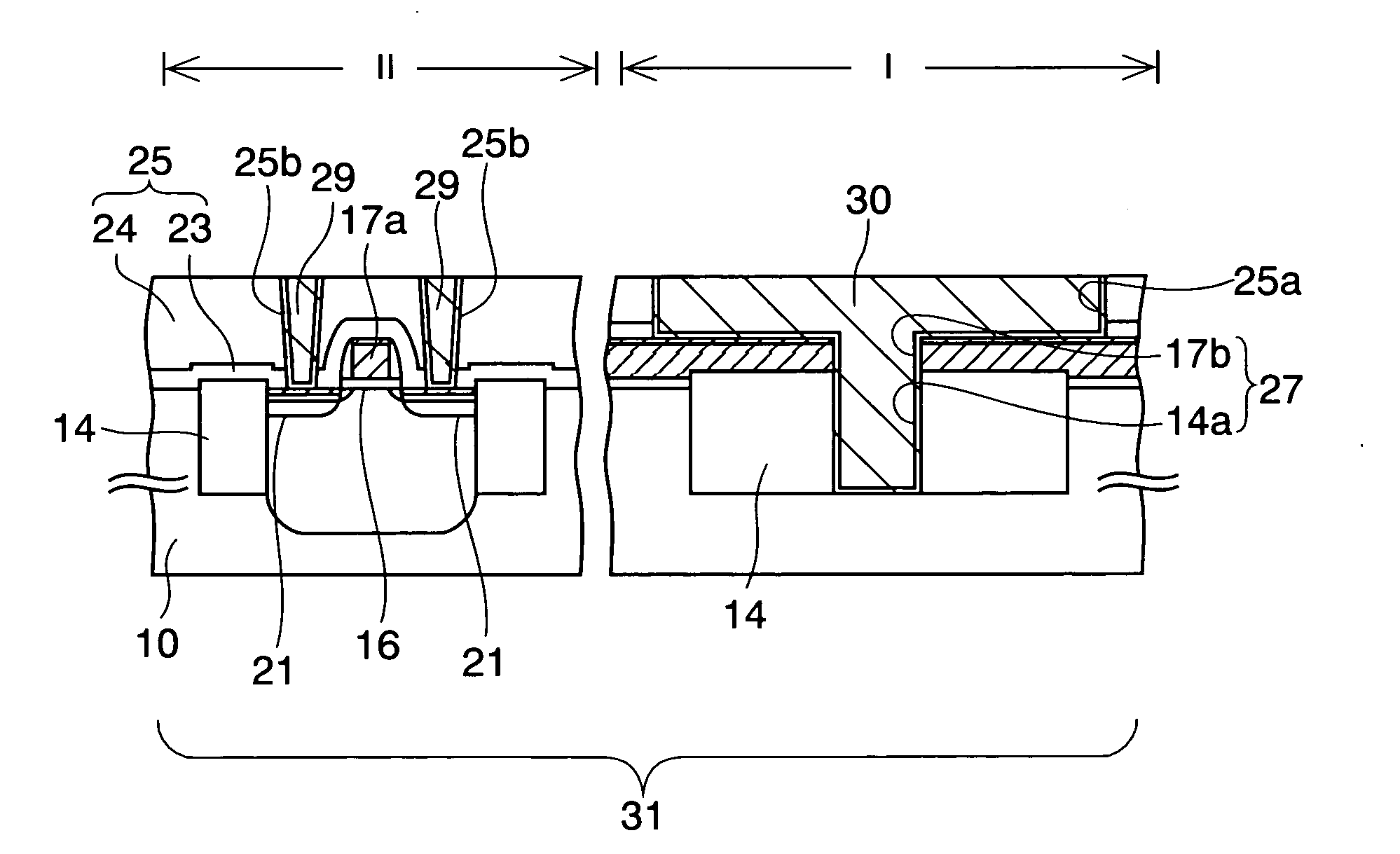

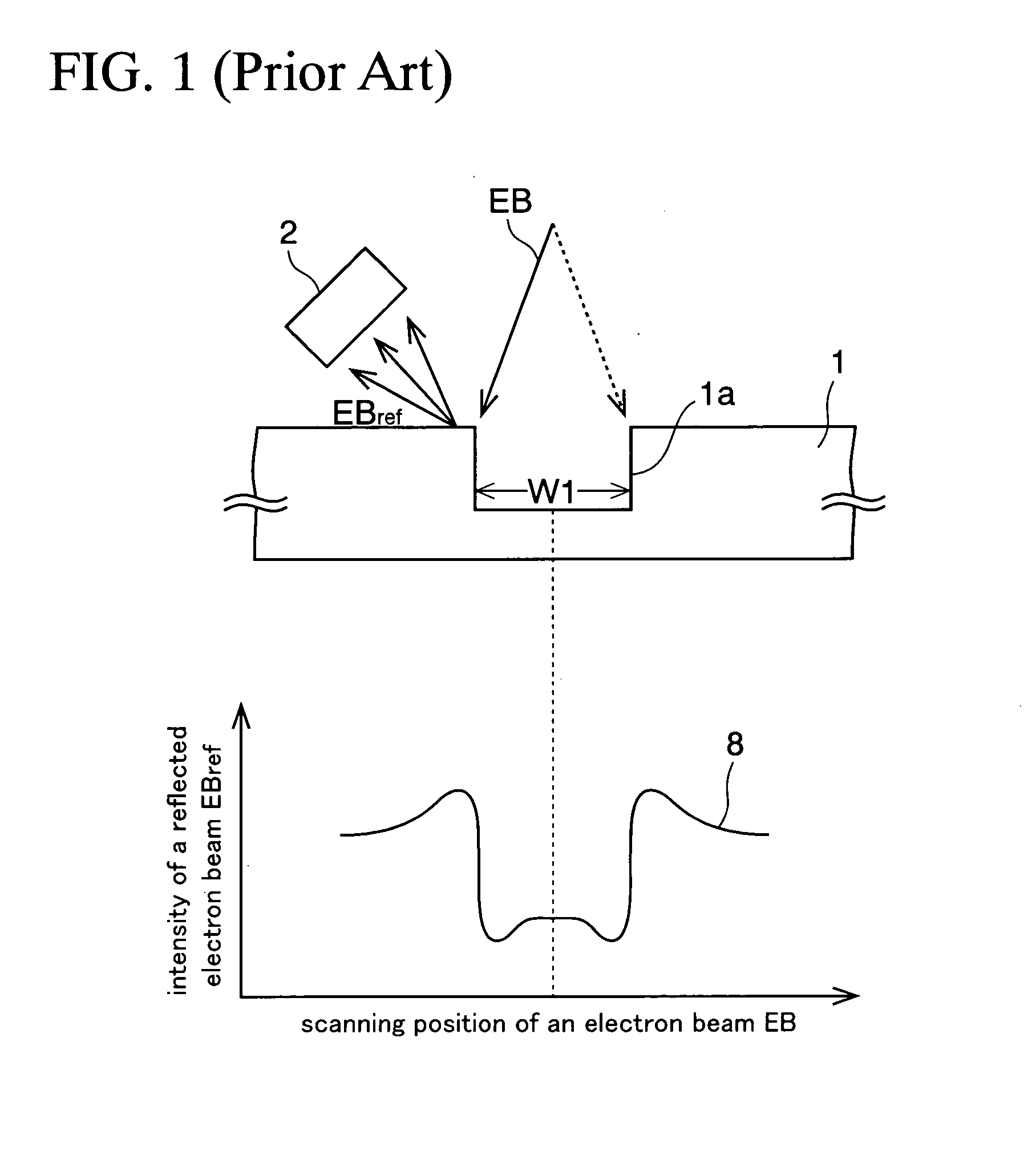

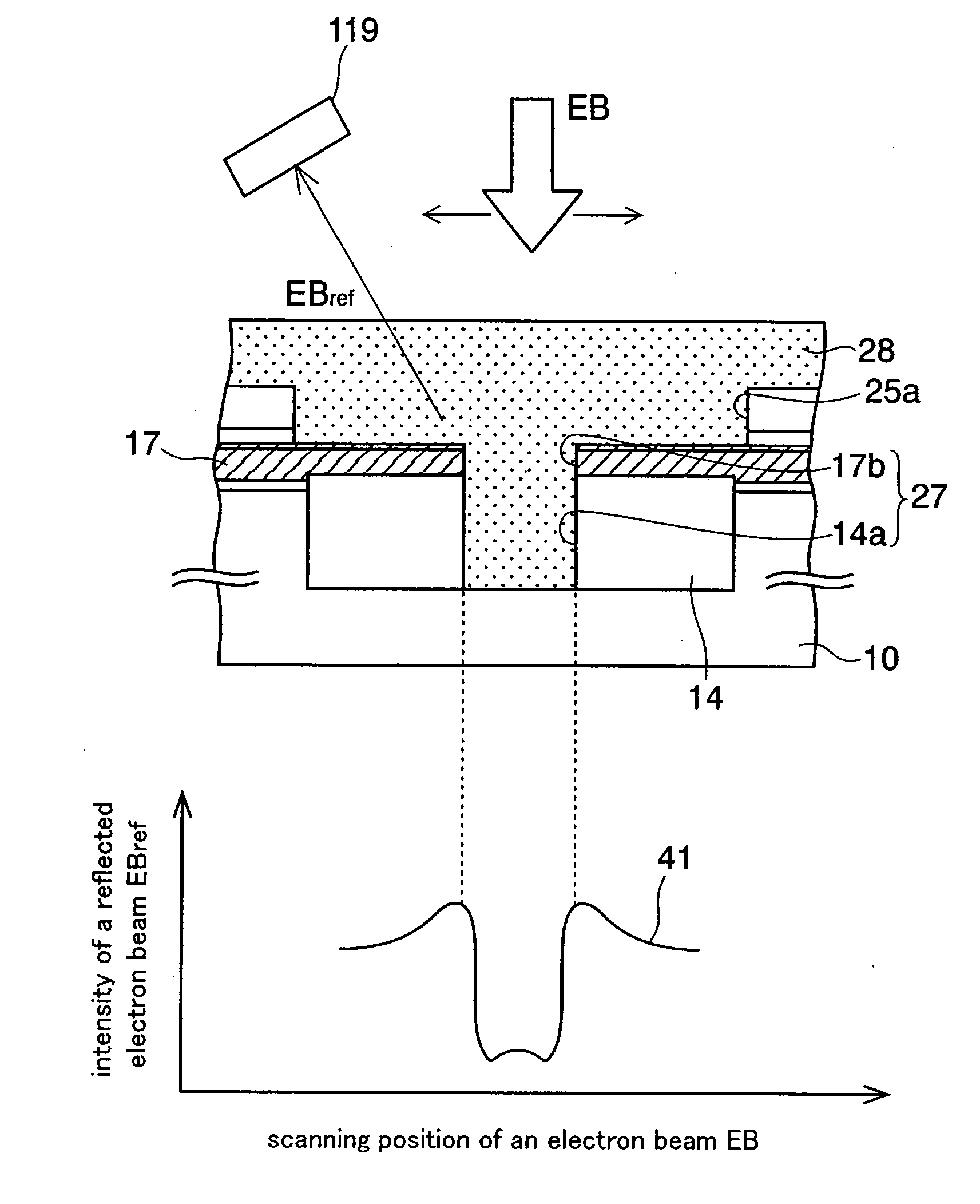

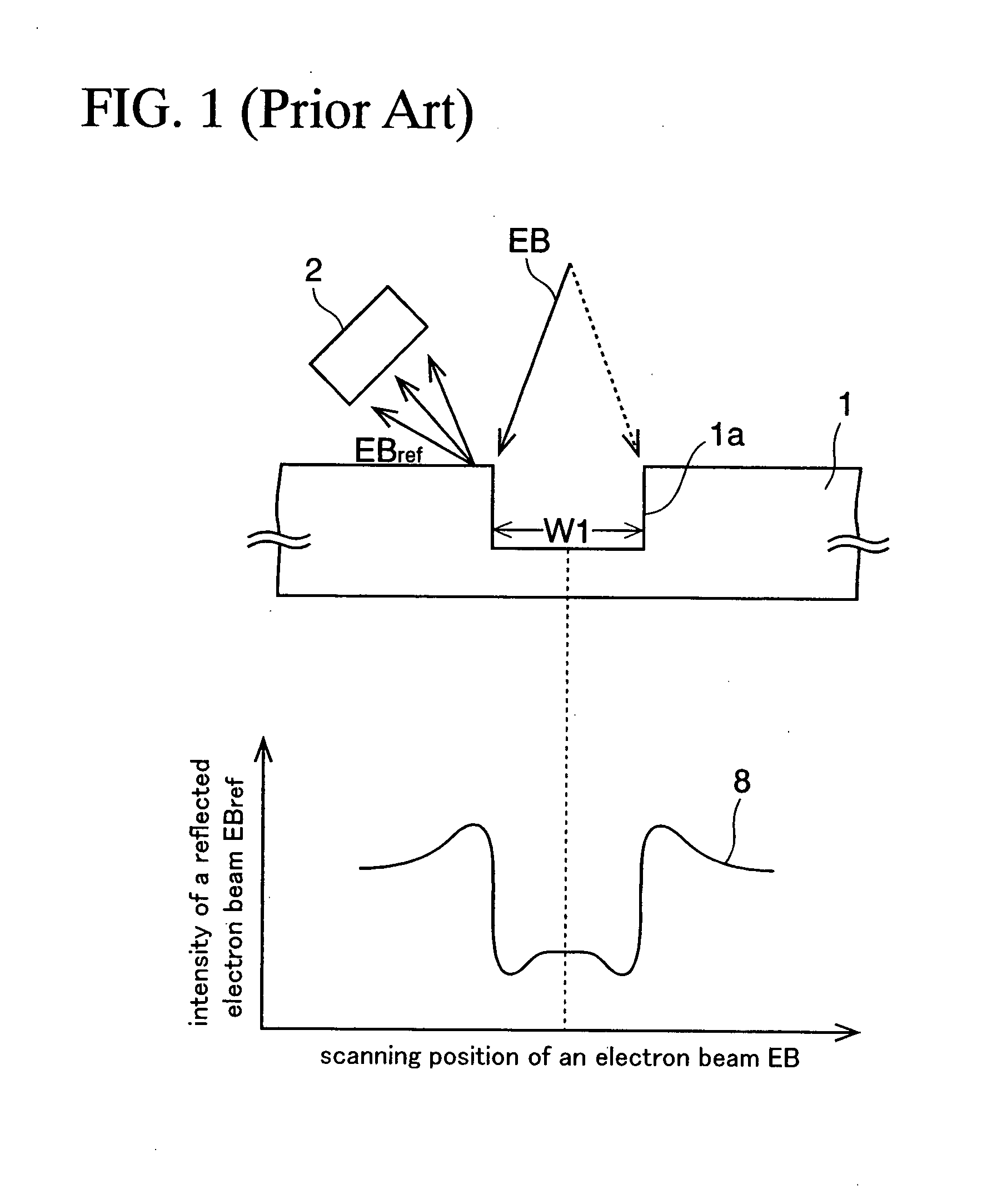

Semiconductor Wafer, Semiconductor Device, And Method Of Manufacturing Semiconductor Device

InactiveUS20060103035A1Improve accuracyReduce distanceElectric discharge tubesSemiconductor/solid-state device detailsResistEngineering

Disclosed are a semiconductor wafer, a semiconductor device, and a method of manufacturing the semiconductor device, which are capable of easily carrying out an alignment between a semiconductor substrate and an electron beam exposure apparatus. There is provided a method including steps of: forming an interlayer insulating film 25 on a gate electrode 17a and a conductive film 17, as well as in a first opening 17b; forming in the interlayer insulating film 25 a second opening 25a including the first opening 17b; forming a hole 14a in an element isolation insulating film 14 under the first opening 17b; by use of the first opening 17b and the hole 14a as an alignment mark 27 used for the alignment in a state where a resist 28 is applied, measuring an intensity of a reflected electron EBref from the alignment mark 27, thus aligning the electron beam exposure apparatus with the semiconductor substrate 10; exposing with an electron beam EB the resist 28 existing in a hole formation region of a first region I; and developing the resist 28 to make a resist pattern 28e.

Owner:FUJITSU SEMICON LTD

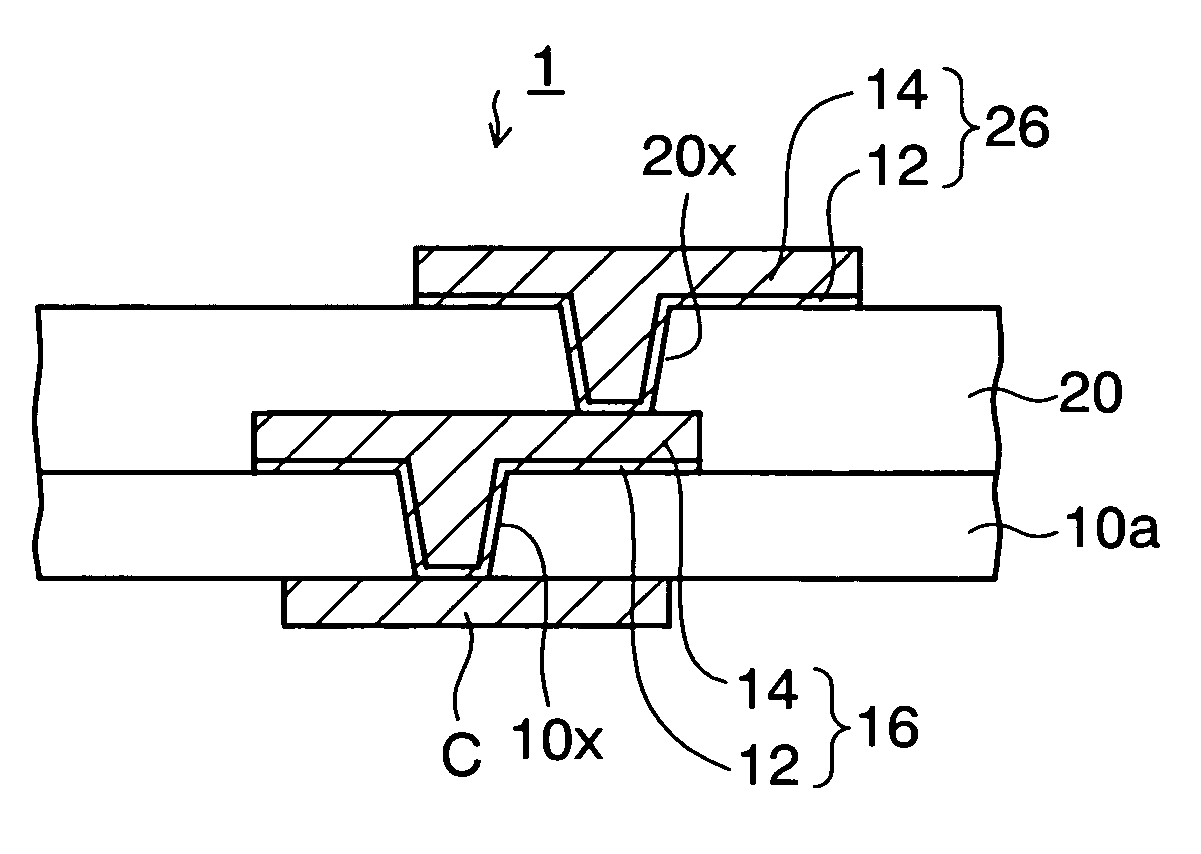

Method of manufacturing flexible wiring substrate and method of manufacturing electronic component mounting structure

InactiveUS20070141757A1Improve reliabilityEasy to operatePrinted circuit assemblingSemiconductor/solid-state device detailsBand shapeEngineering

A method of manufacturing a flexible wiring substrate of the present invention includes the steps of preparing a tape-like substrate composed of a resin layer and a reinforcing metal layer provided on its lower surface, then forming a via hole whose depth reaches the reinforcing metal layer by processing the resin layer of the tape-like substrate by the laser, and then forming a wiring pattern which is connected to the reinforcing metal layer through the via hole on the resin layer by the semi-additive process, wherein the reinforcing metal layer is patterned to constitute a connection pad connected to the wiring pattern or is removed.

Owner:SHINKO ELECTRIC IND CO LTD

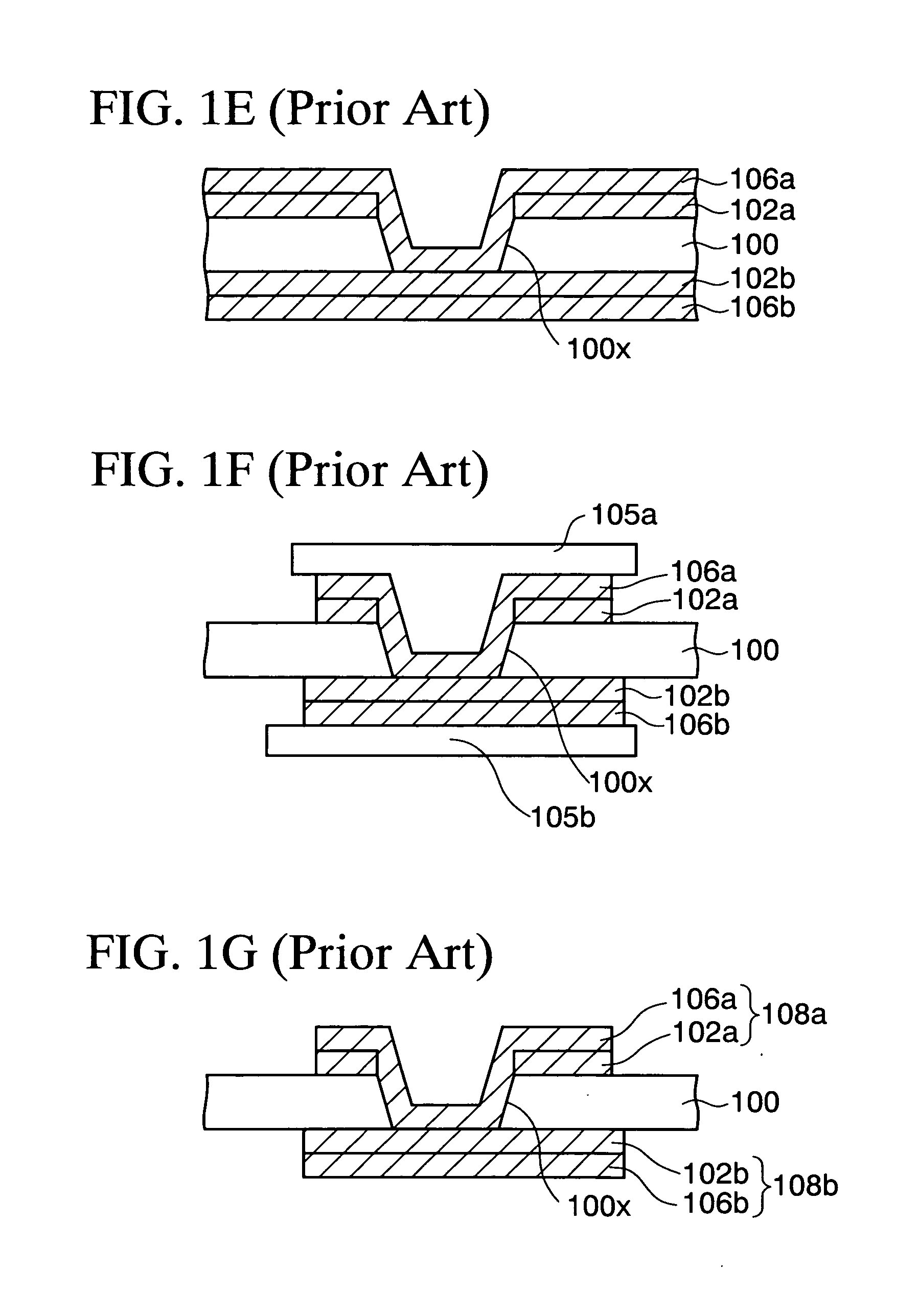

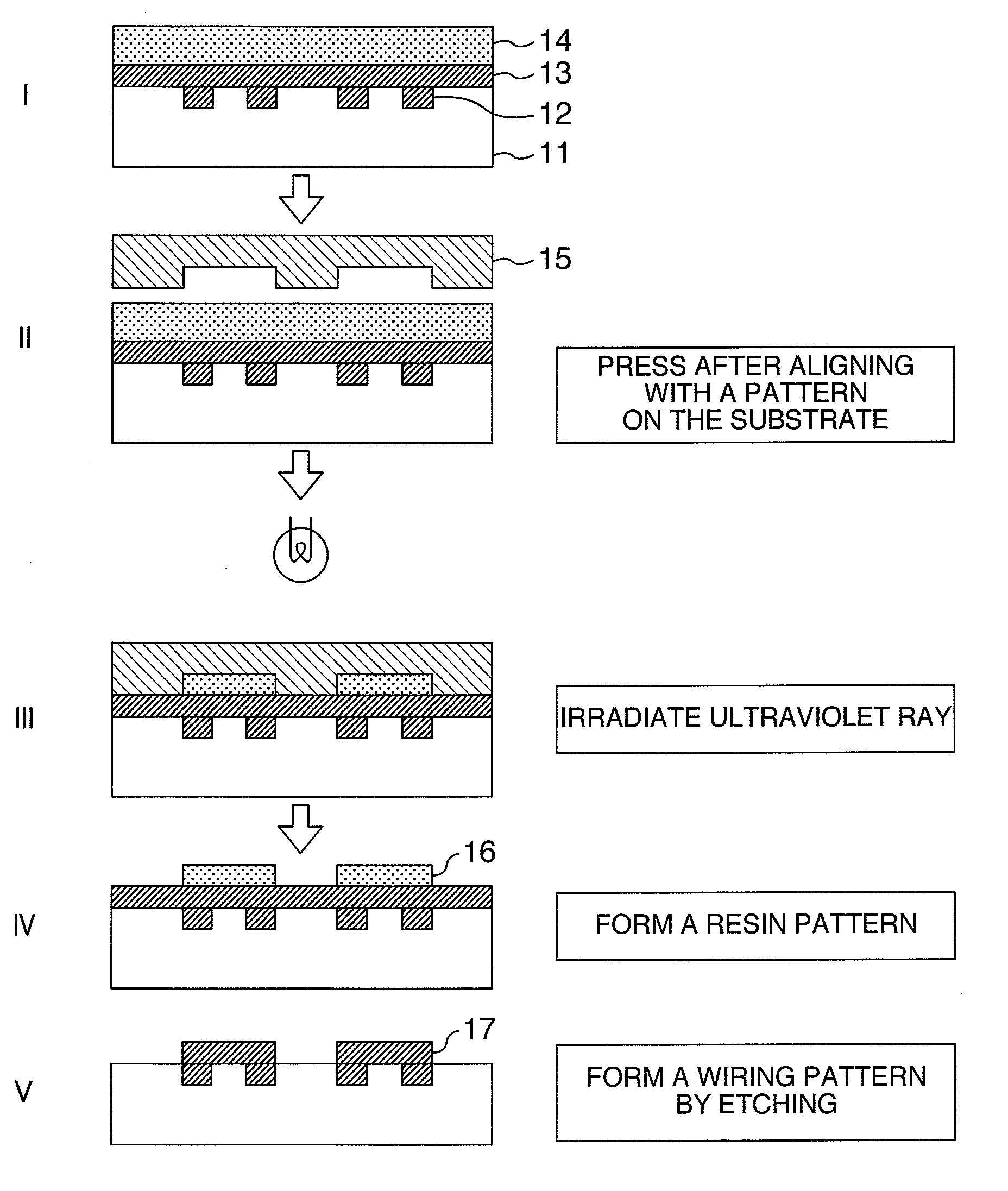

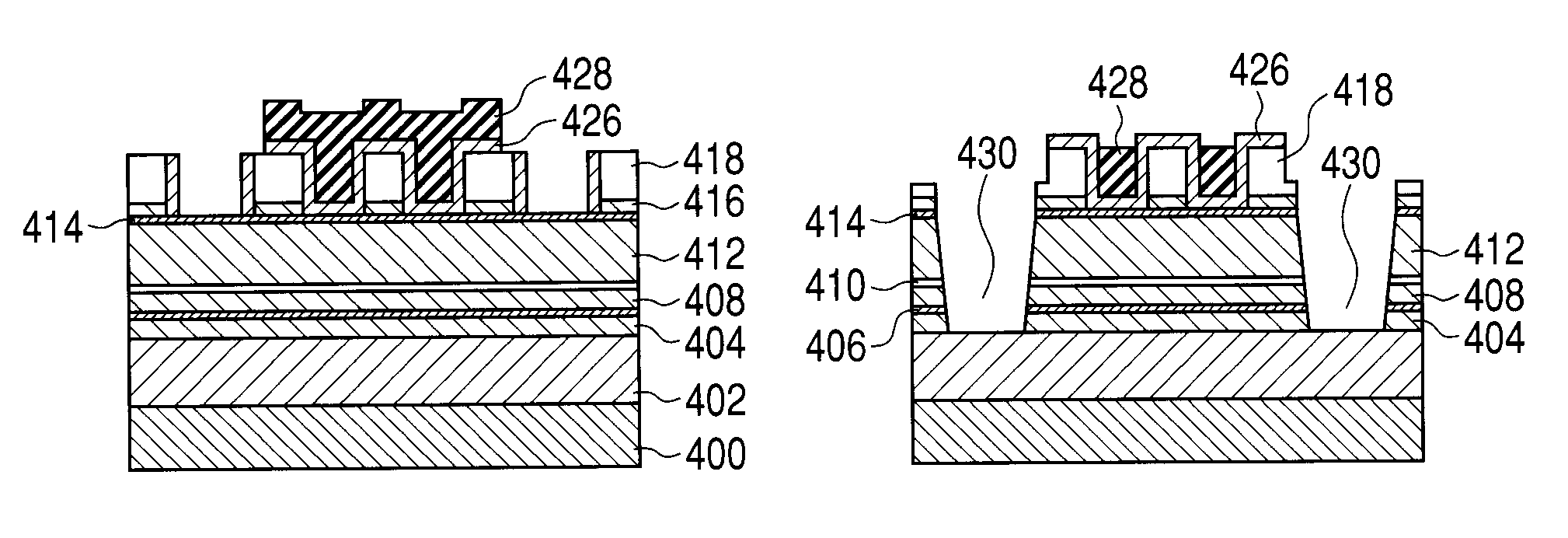

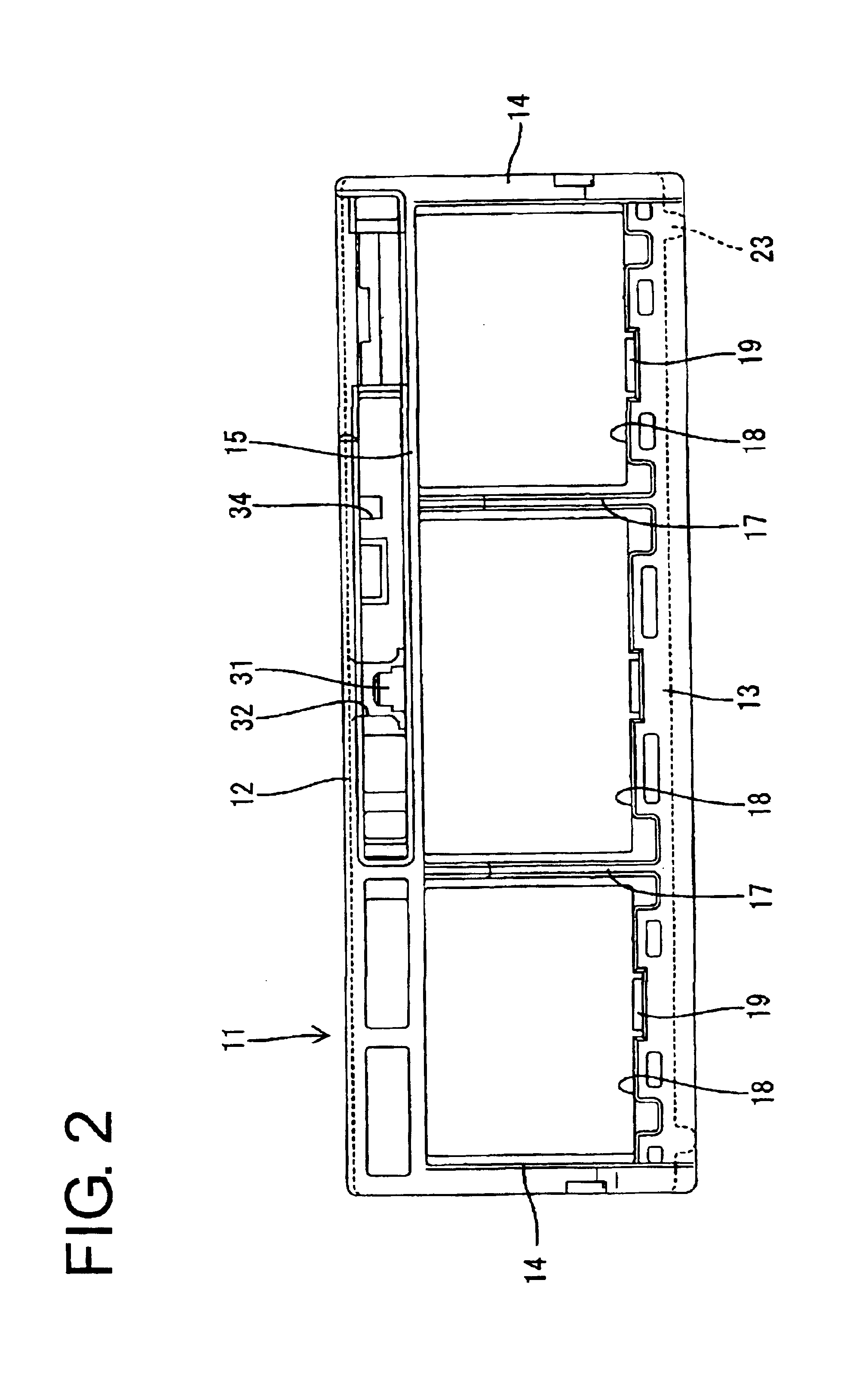

Pattern forming method and its mold

InactiveUS20070164458A1Precise alignmentHigh precision alignmentSemiconductor/solid-state device detailsNanoinformaticsShape formationMaterials science

Owner:HITACHI LTD

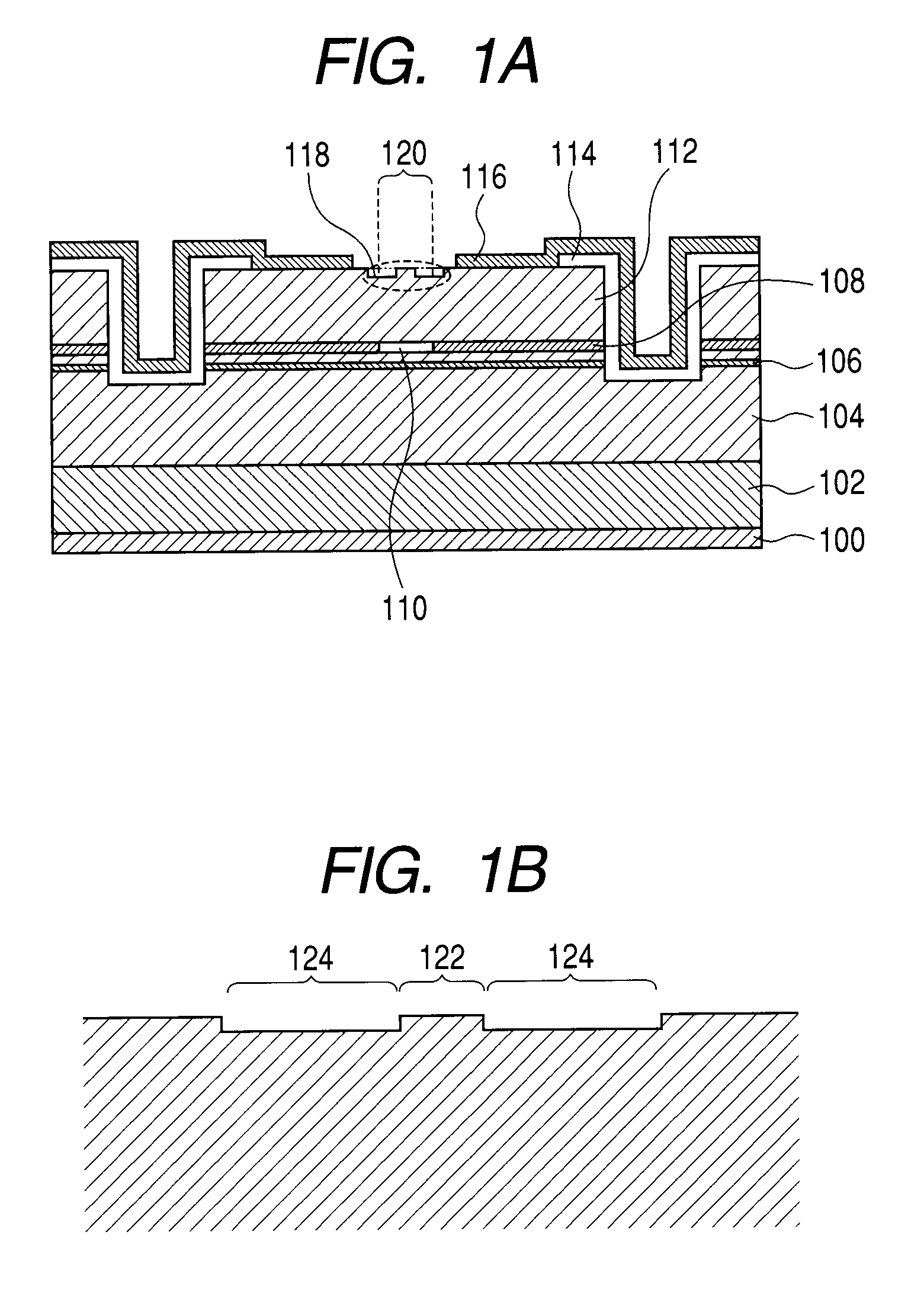

Process for producing surface emitting laser, process for producing surface emitting laser array, and optical apparatus including surface emitting laser array produced by the process

InactiveUS7807485B2Improve accuracyHigh precision alignmentLaser detailsLaser optical resonator constructionLaser arrayOptoelectronics

Owner:CANON KK

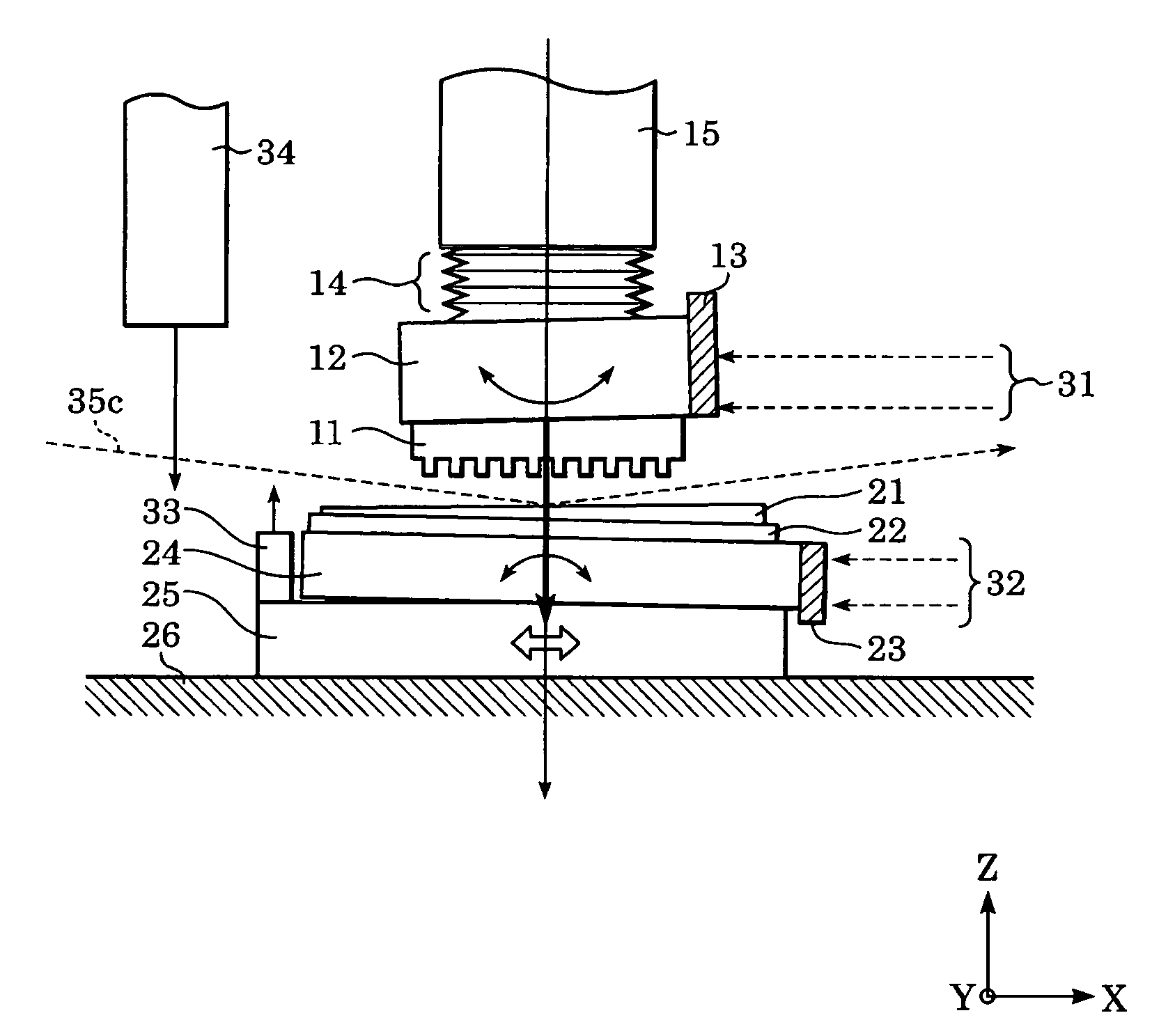

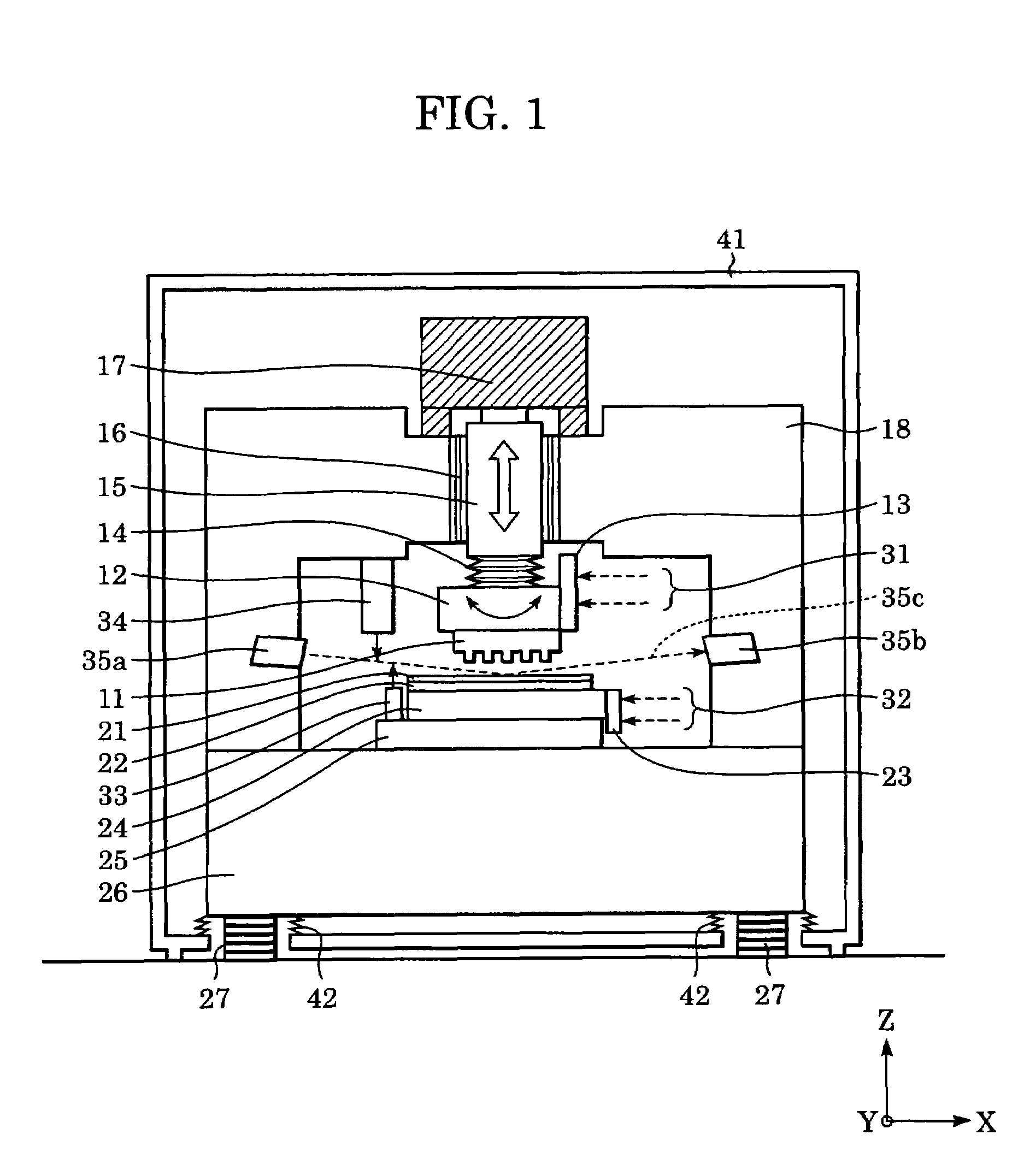

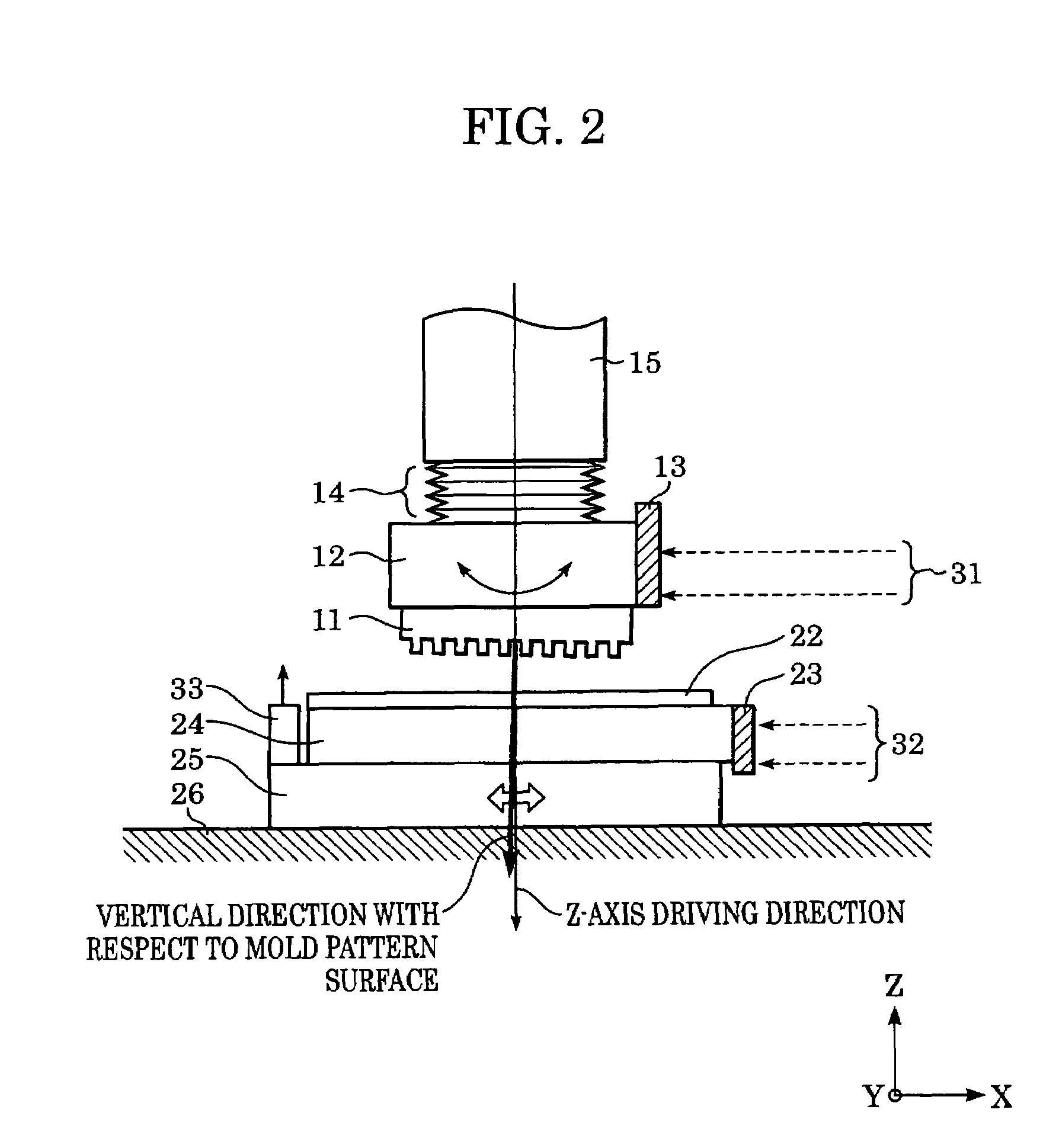

Imprint apparatus and imprint method

InactiveUS20080073604A1High precision alignmentNanoinformaticsPhotomechanical apparatusObservation pointEngineering

An imprint apparatus, comprising a first holder for holding a mold having an imprint pattern; a second holder for holding a workpiece to which the imprint pattern is transferred; a first illumination system for irradiating a mark for determining a position of the mold and a mark for determining a position of the workpiece with light; a first and second optical systems for imaging the marks for the mold and workpiece at a first and second observation points respectively; an imaging optical system; a first and second image pick-up devices for observing the marks for the mold and workpiece respectively; and at least one of a first drive mechanism for moving the first image pick-up device while following movement of the first observation point and a second drive mechanism for moving the second image pick-up device while following movement of the second observation point.

Owner:CANON KK

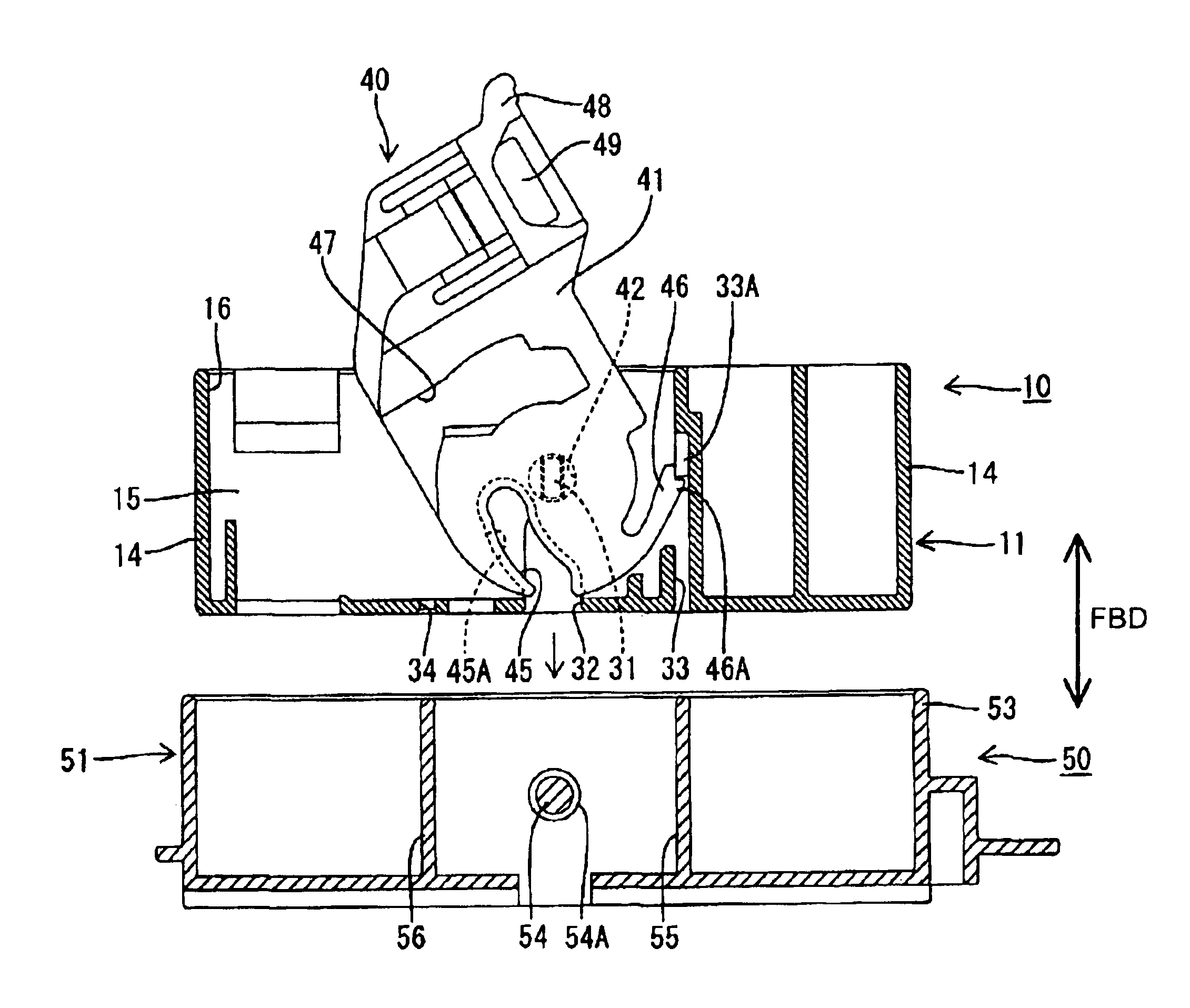

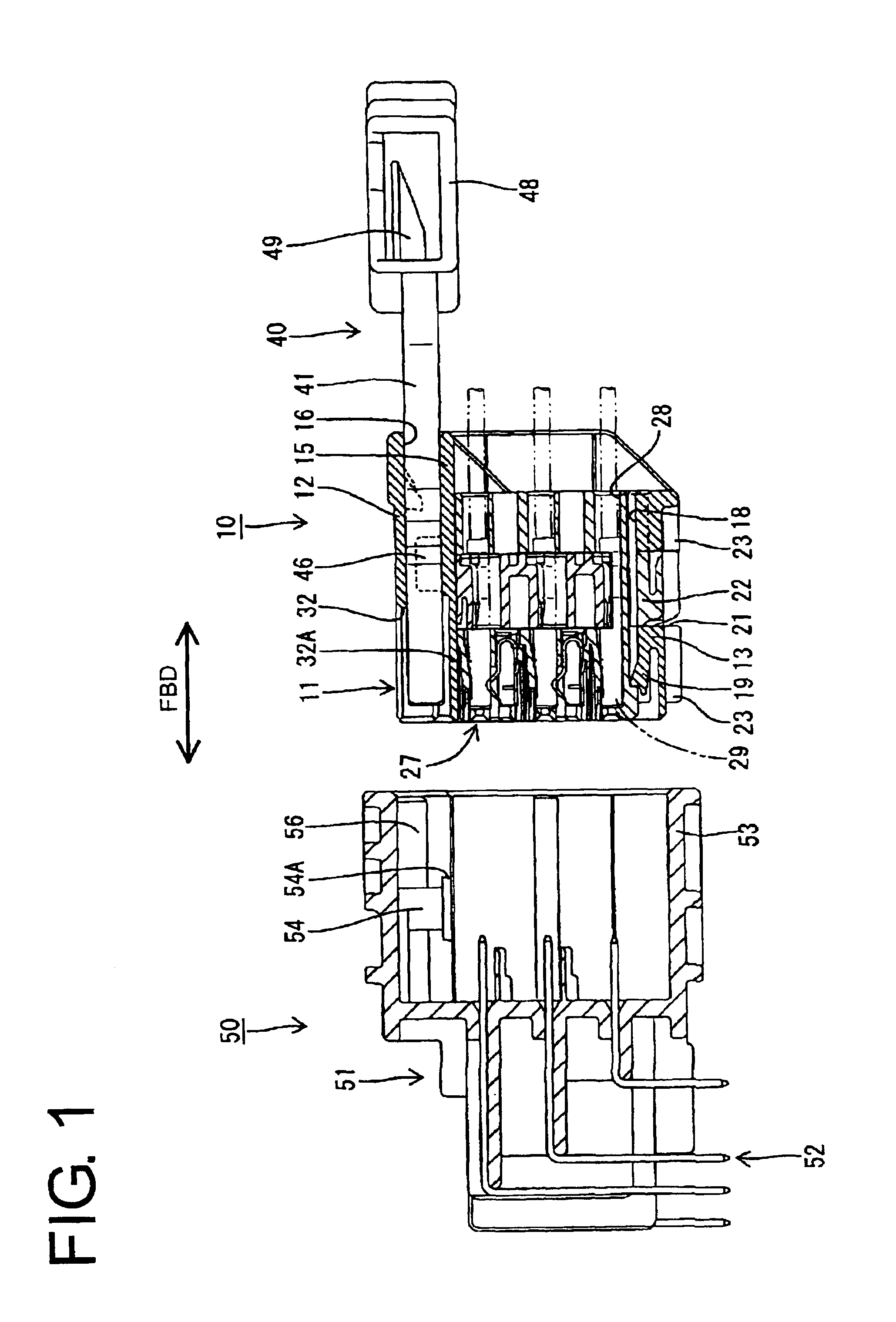

Connector

ActiveUS6942504B2High precision alignmentReduce in quantityEngagement/disengagement of coupling partsSingle plateEngineering

A female connector (10) has a lever (40) in the form of a single plate. The lever (40) is locked at an initial position by a resilient lock (46) before a connecting operation with a male connector (50). An unlocking rib (55) projects from the ceiling surface of a receptacle (53) of the male housing (50) near one side for canceling the locked state of the resilient lock (46) during the connecting operation. An insertion preventing rib (56) projects from the inner surface of the receptacle (53) at a side opposite the unlocking rib (55), and an escape groove (47) for receiving the insertion preventing rib (56) is formed in the upper surface of the lever (40). Thus, the female connector (10) can be prevented from being inserted in a wrong posture.

Owner:SUMITOMO WIRING SYST LTD

Pattern forming apparatus

InactiveUS7658601B2High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceEngineering

Owner:CANON KK

Apparatus for generating dental data for manufacturing an aligner and method of manufacturing clear aligner using the apparatus

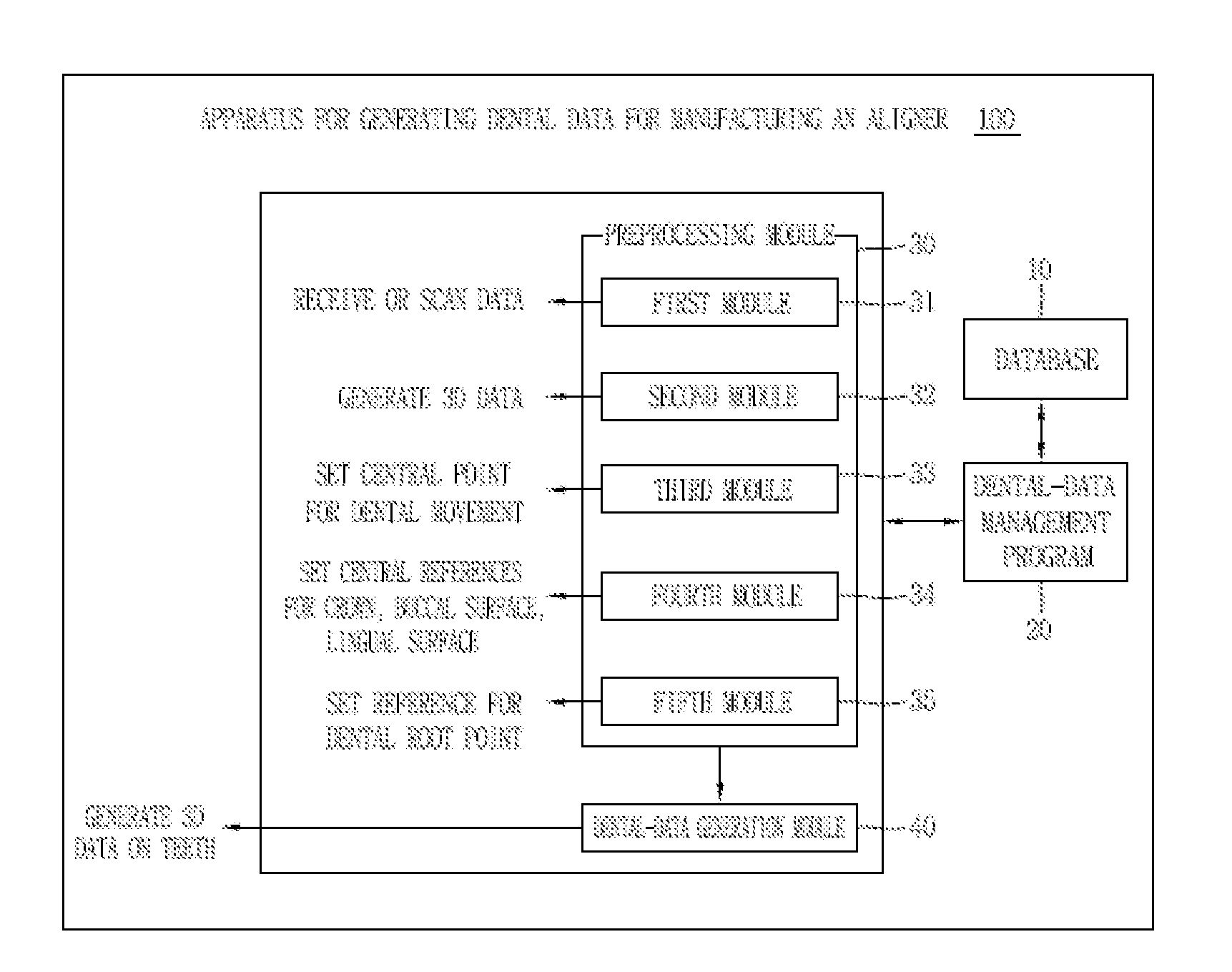

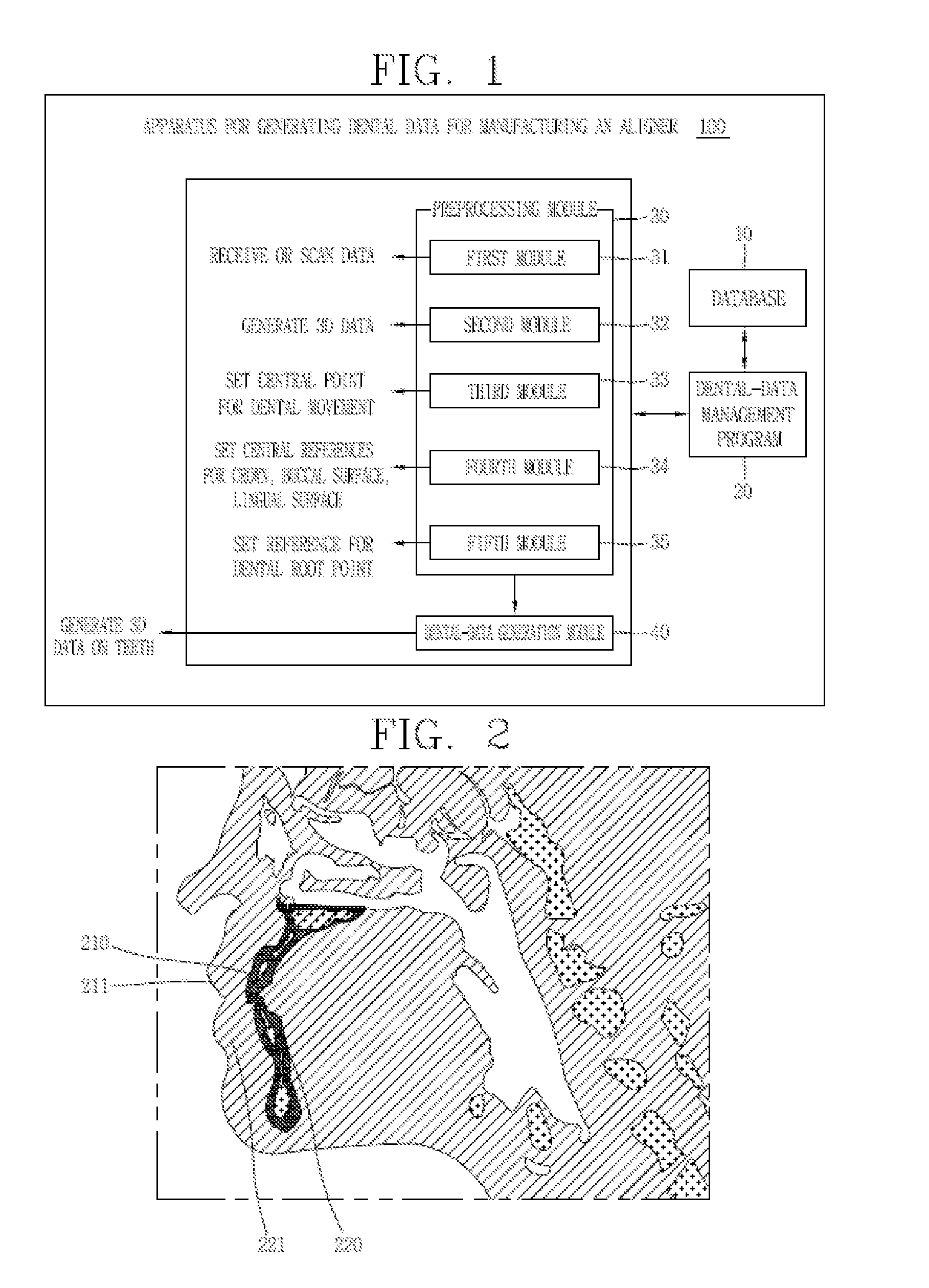

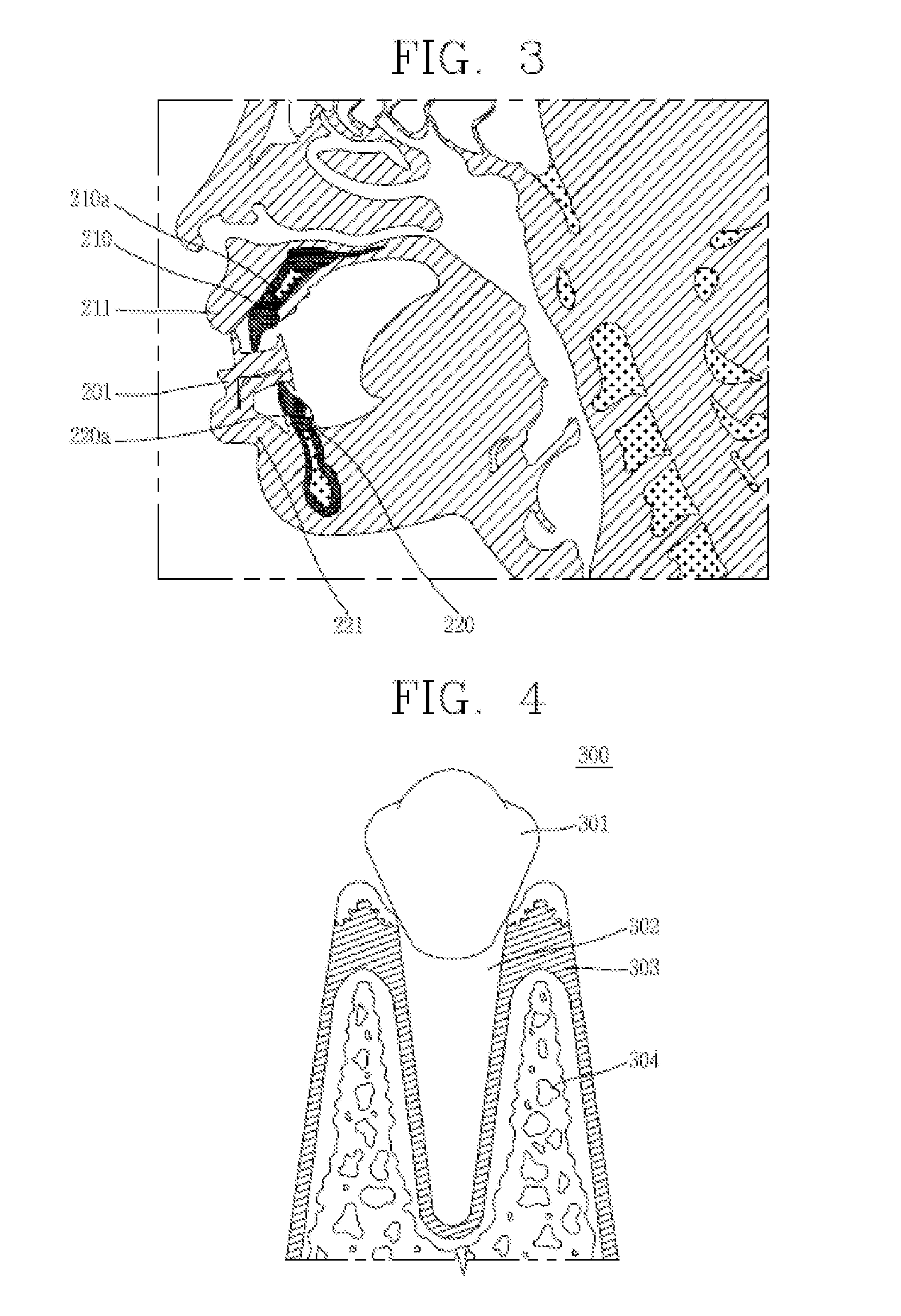

ActiveUS20160120617A1Improve accuracyHigh precision alignmentAdditive manufacturing apparatusImpression capsLingual surfaceEngineering

Provided is an apparatus for generating dental data for manufacturing an aligner, the apparatus including: a dental-data generation unit, in which the dental-data generation unit includes a preprocessing module includes a first module that receives data on a current state of the teeth of the patient from a scanner that scans the current state of the teeth of the patient, a second module that generates a state of the teeth of the patient and the vicinity of the teeth as 3D data, based on the data received from the scanner, a third module that sets a central point for dental movement in the 3D data, a fourth module that sets each central reference for a crown, a buccal surface, and a lingual surface of the tooth in the 3D data, and a fifth module that sets a reference for a dental root point in the 3D data.

Owner:JINKYUN LEE

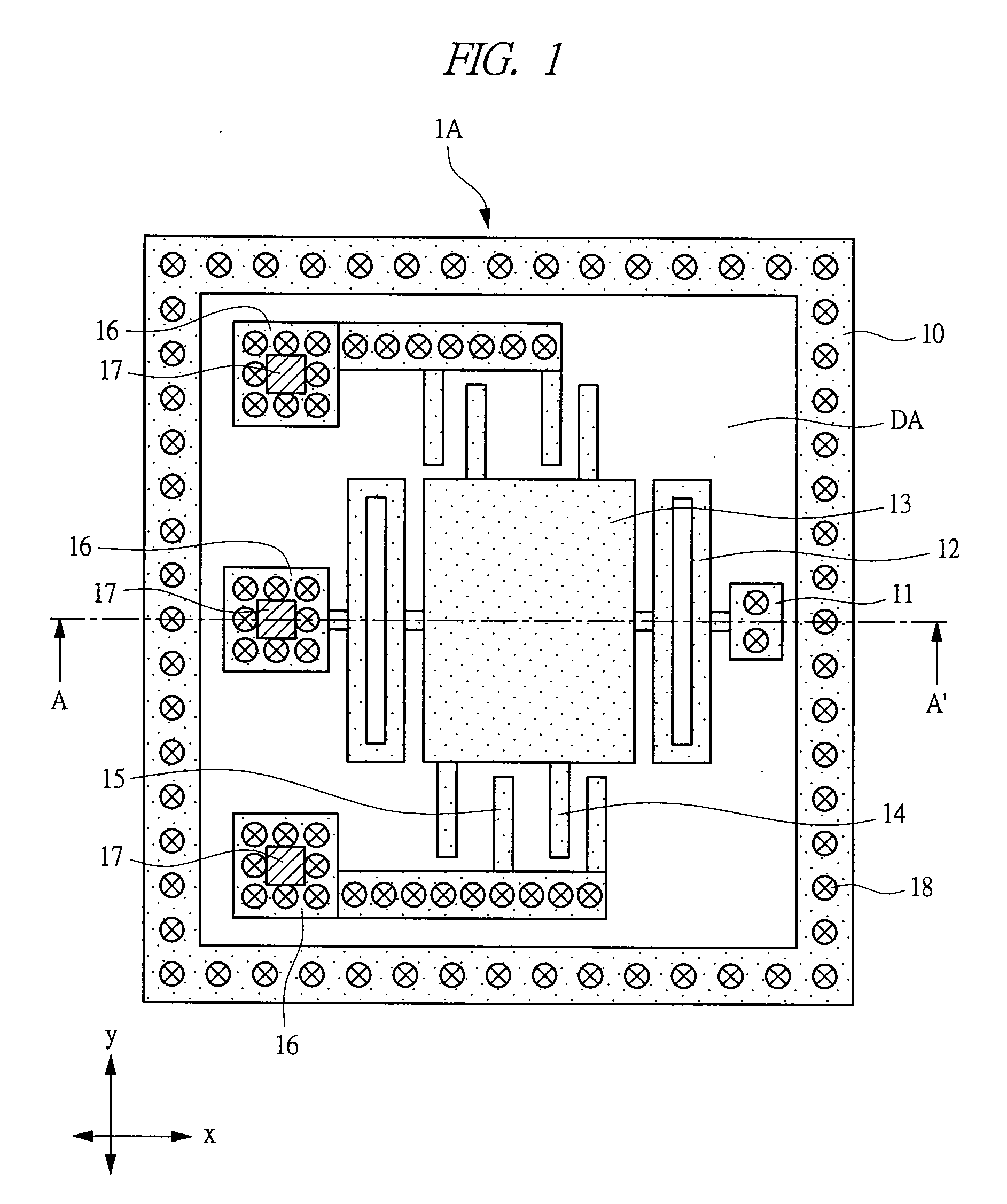

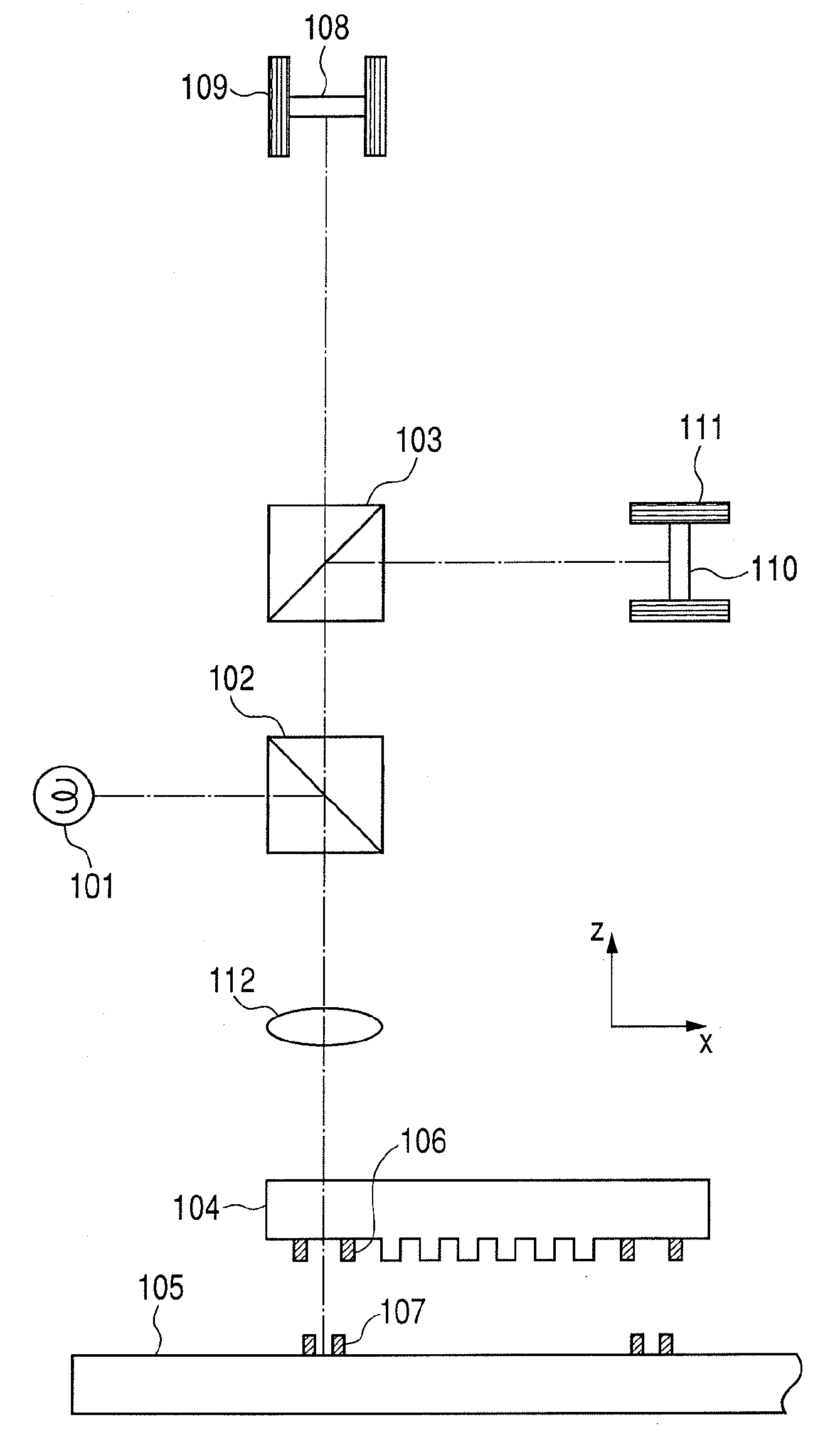

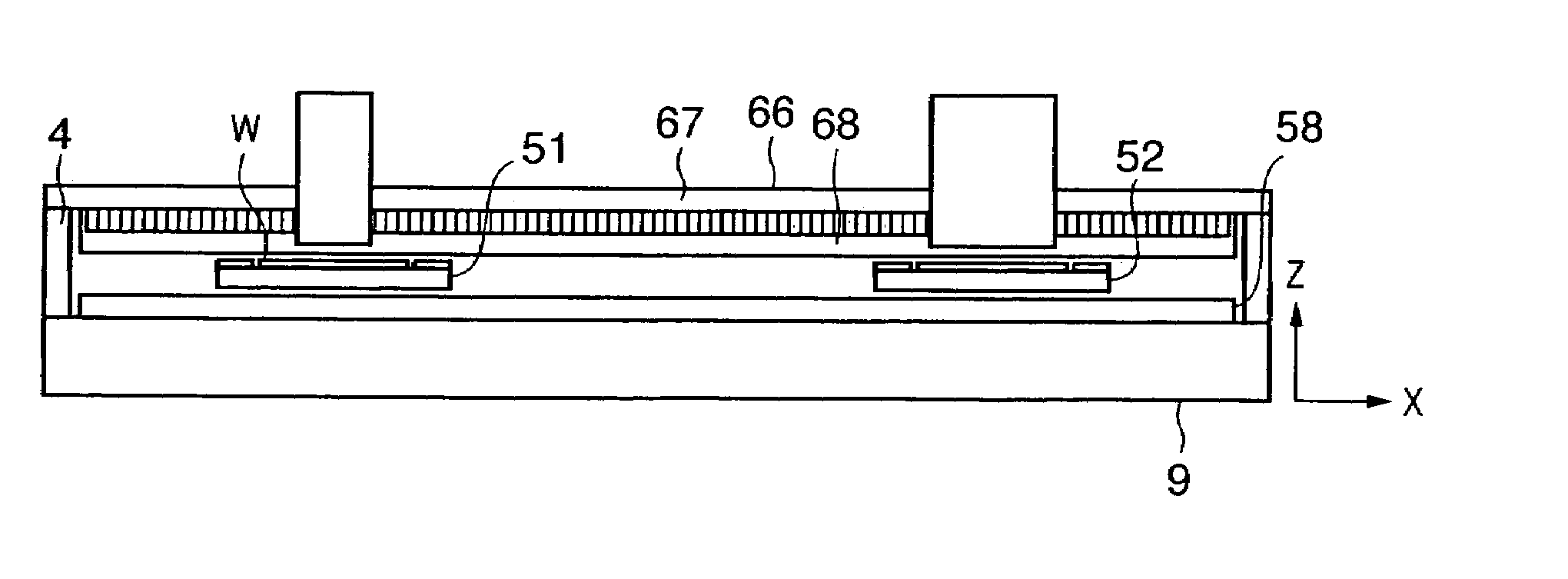

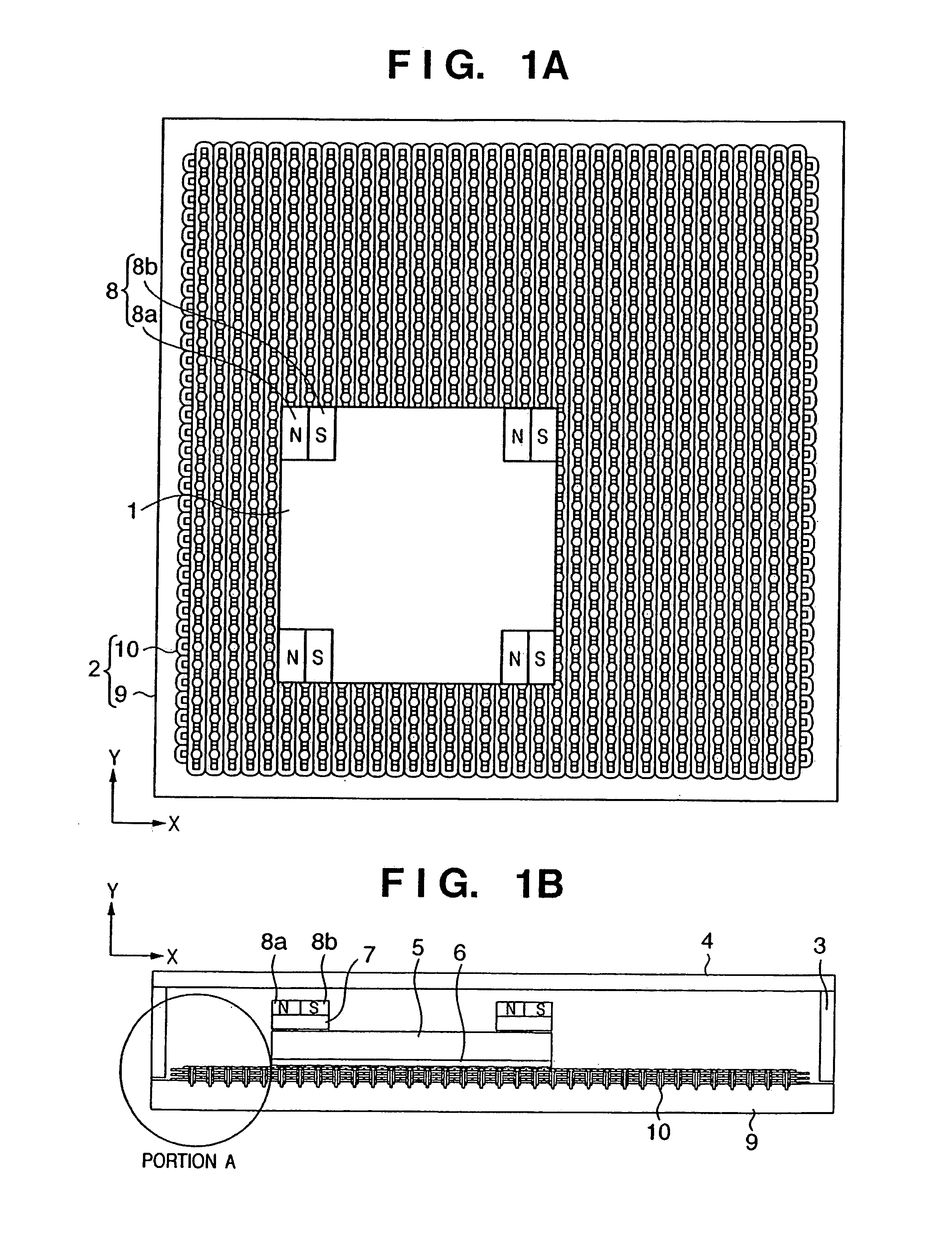

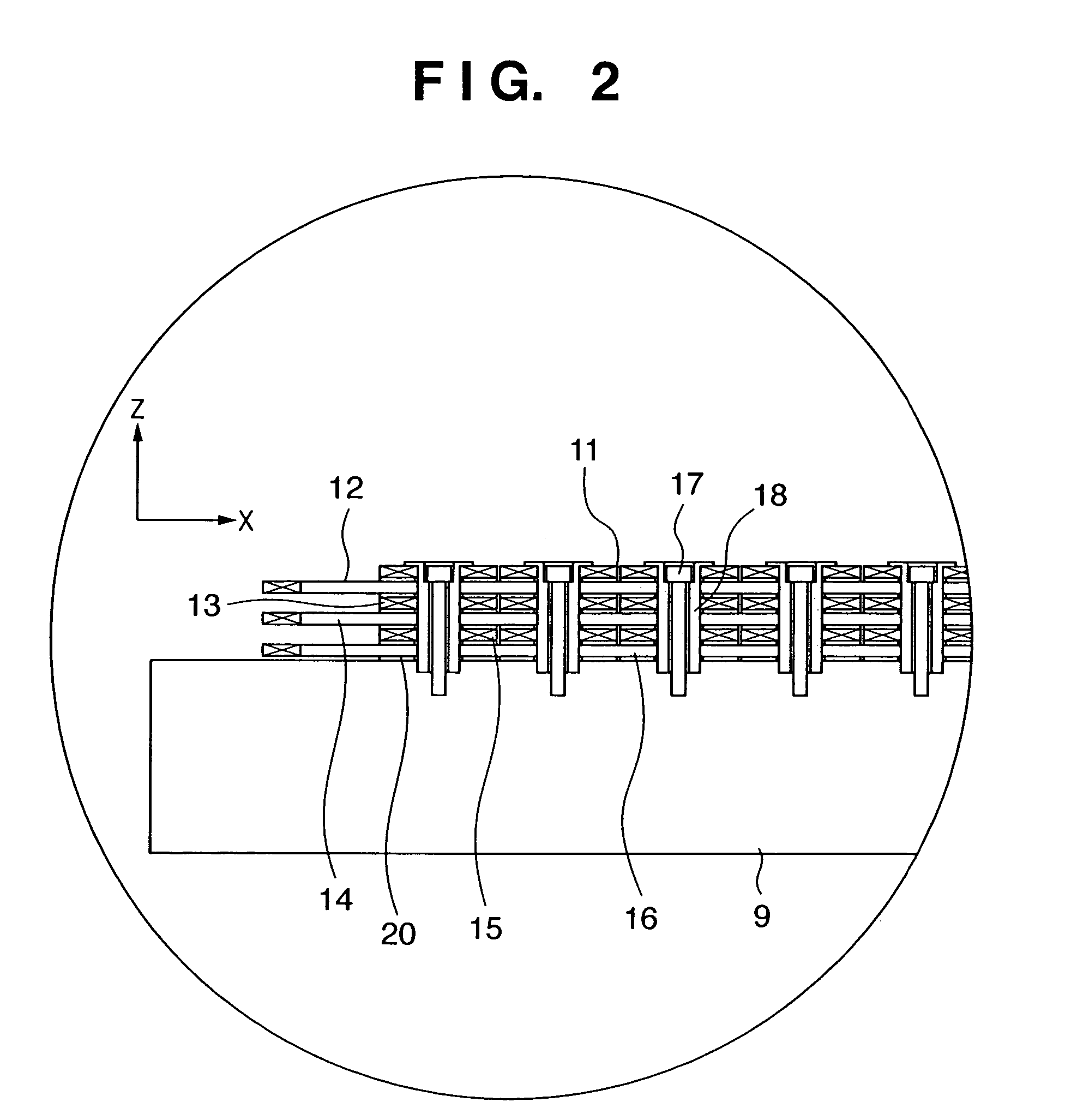

Aligning apparatus, exposure apparatus, and device manufacturing method

An aligning apparatus includes a moving member, a magnetic member arranged vertically above the moving member, a stator unit which is arranged vertically below the moving member and has a plurality of coreless coils, a first magnet unit which is provided to the moving member and generates a force with the magnetic member, and a second magnet unit which is provided to the moving member and generates a force with the stator unit. The aligning apparatus has no coils between the magnetic member and the moving member.

Owner:CANON KK

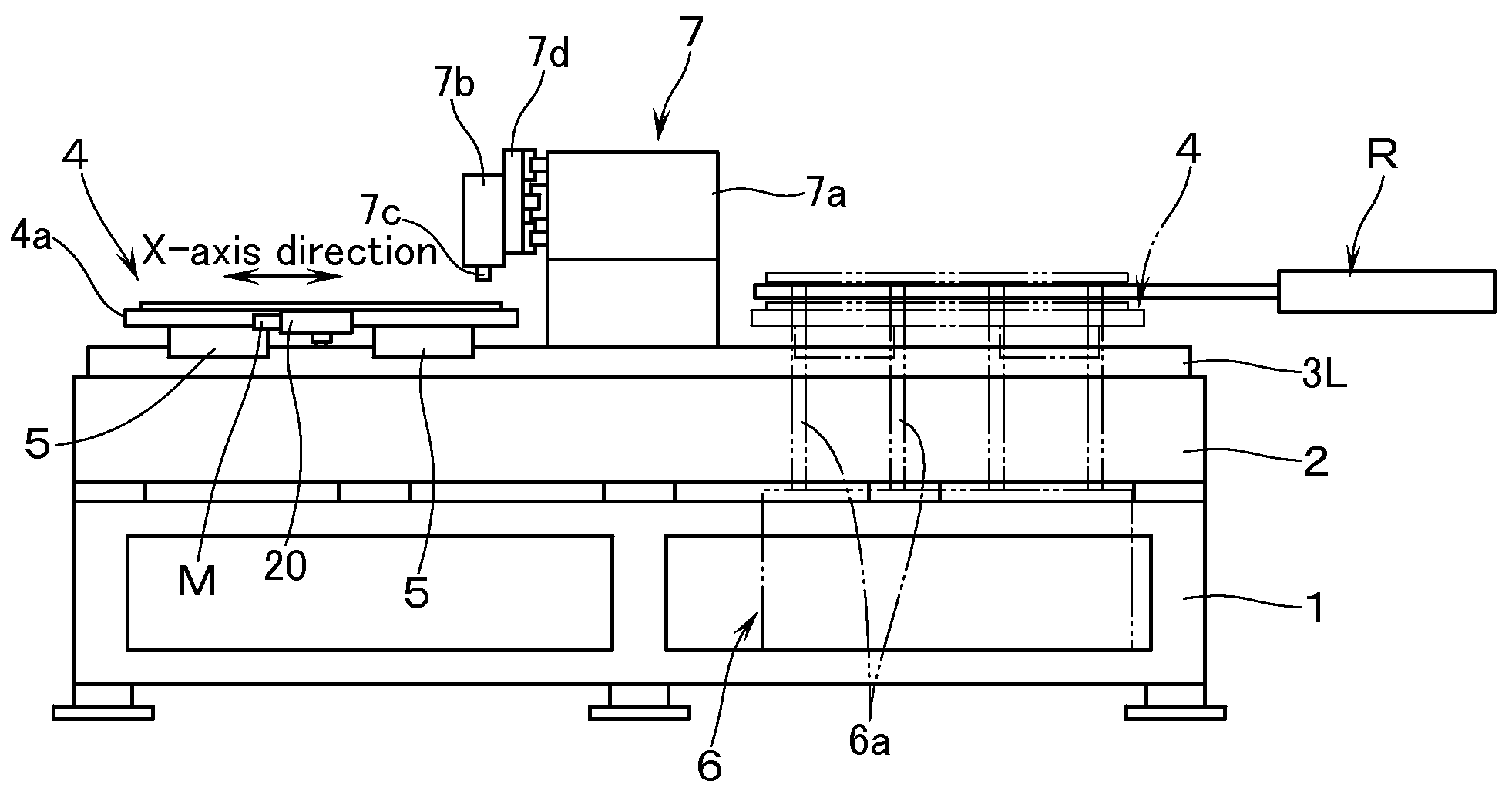

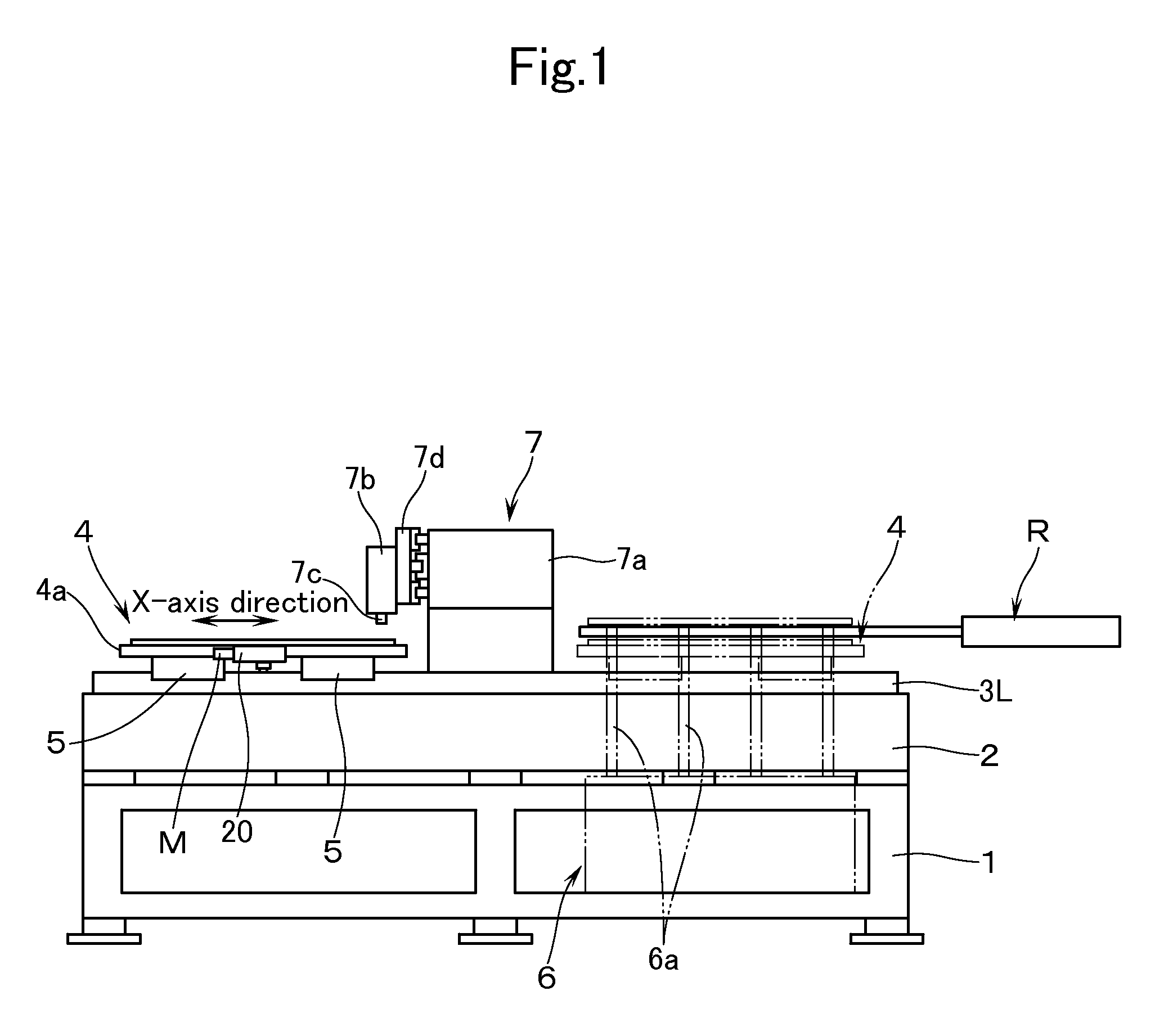

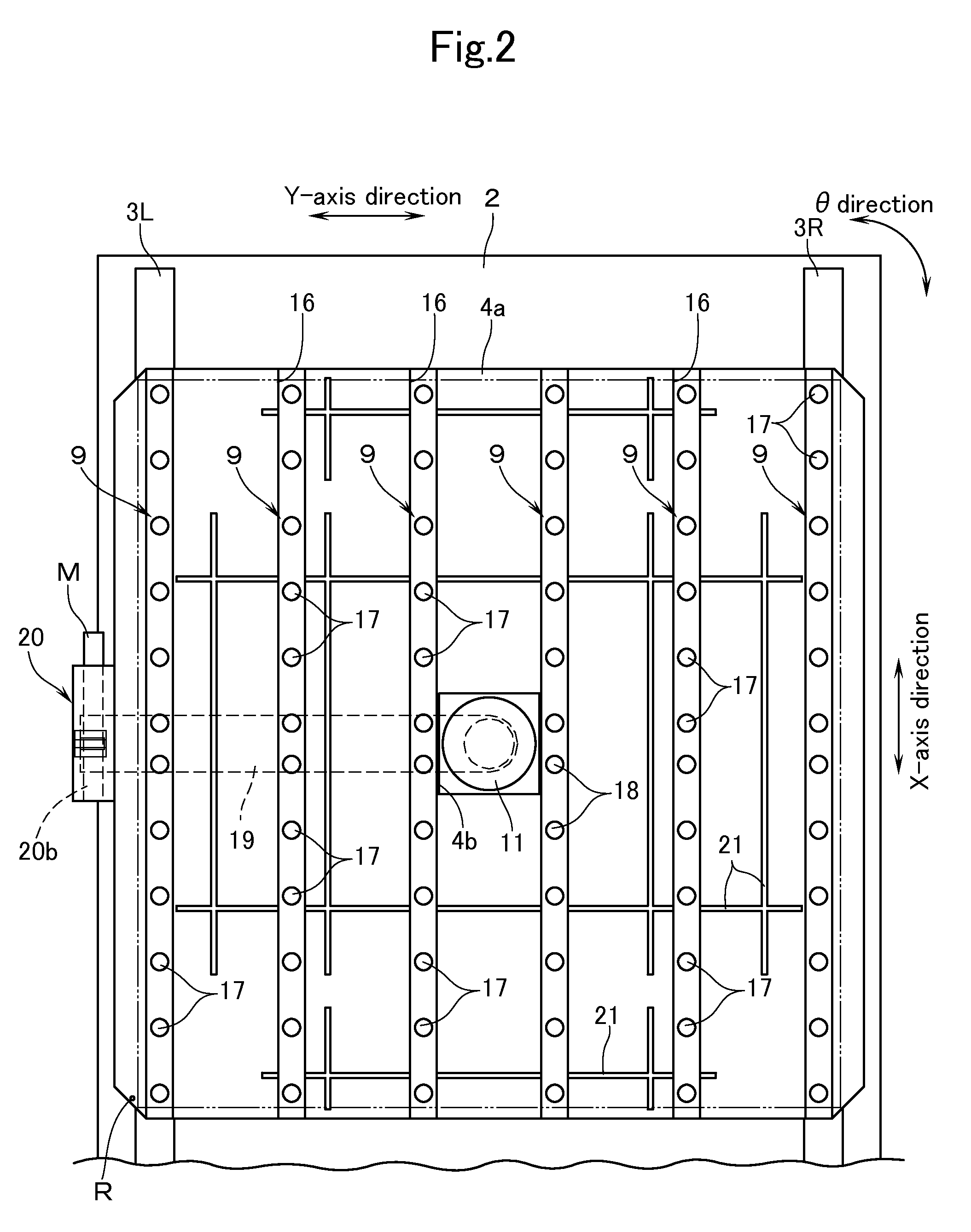

Stage equipped with alignment function, processing apparatus having the stage equipped with alignment function, and method of aligning substrate

InactiveUS20110062641A1High precision alignmentReduce alignment timeConveyorsSemiconductor/solid-state device manufacturingEngineeringGas supply

There is provided an inexpensive stage which is equipped with an alignment function and is capable of easily performing high-accuracy alignment especially in a θ direction even in case an object to be processed is large in weight. The stage equipped with an alignment function has a stage main body for holding a substrate while leaving a processing surface thereof open to access. The stage is provided with: a suction means capable of sucking that surface of the substrate which lies opposite to the processing surface; a gas supply means for supplying a gas to such a region of the substrate as is other than a portion sucked by the suction means; and a drive means to give a rotating force to the suction means so that the substrate can be rotated on the same plane by causing the suction means to serve as the center of rotation.

Owner:ULVAC INC

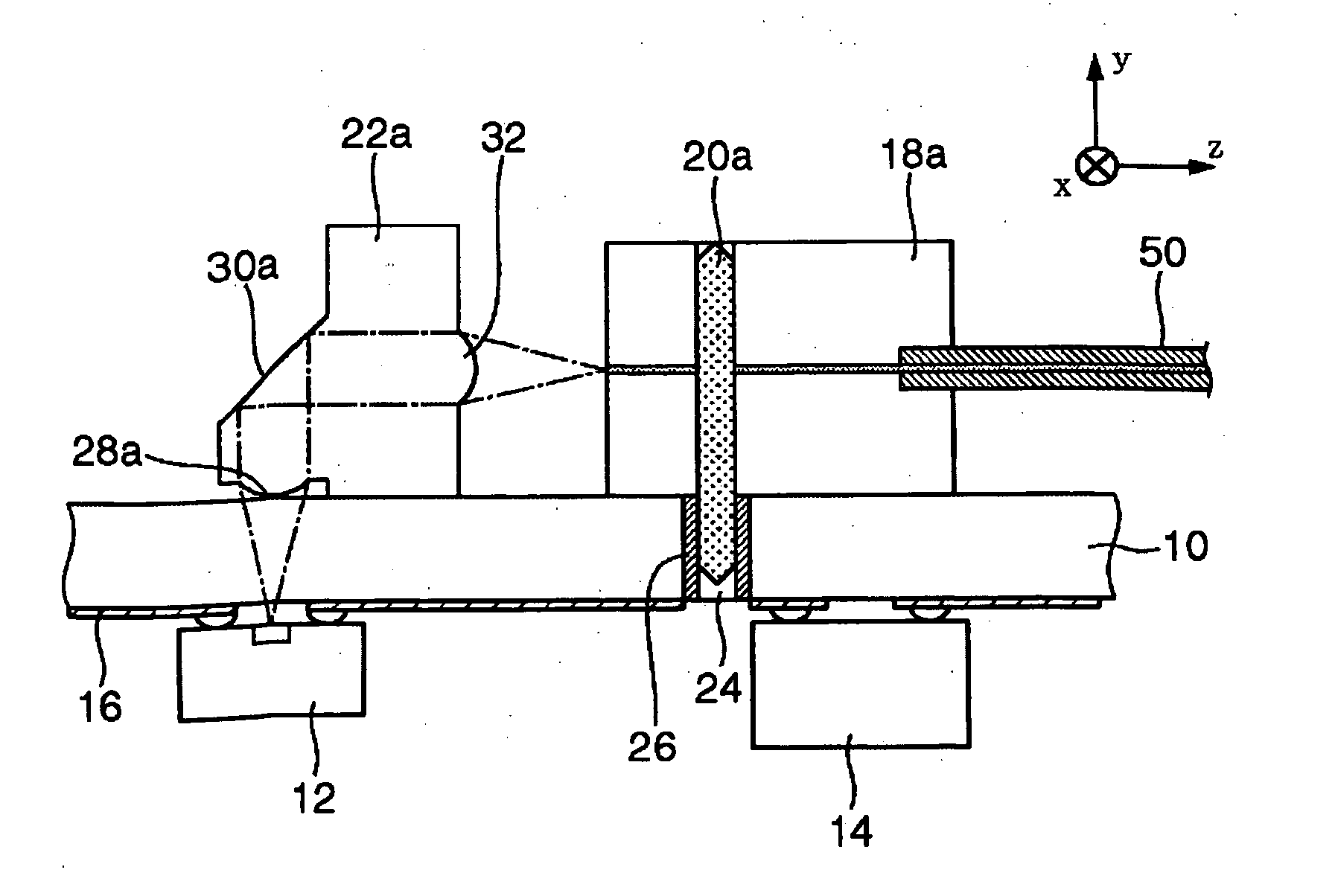

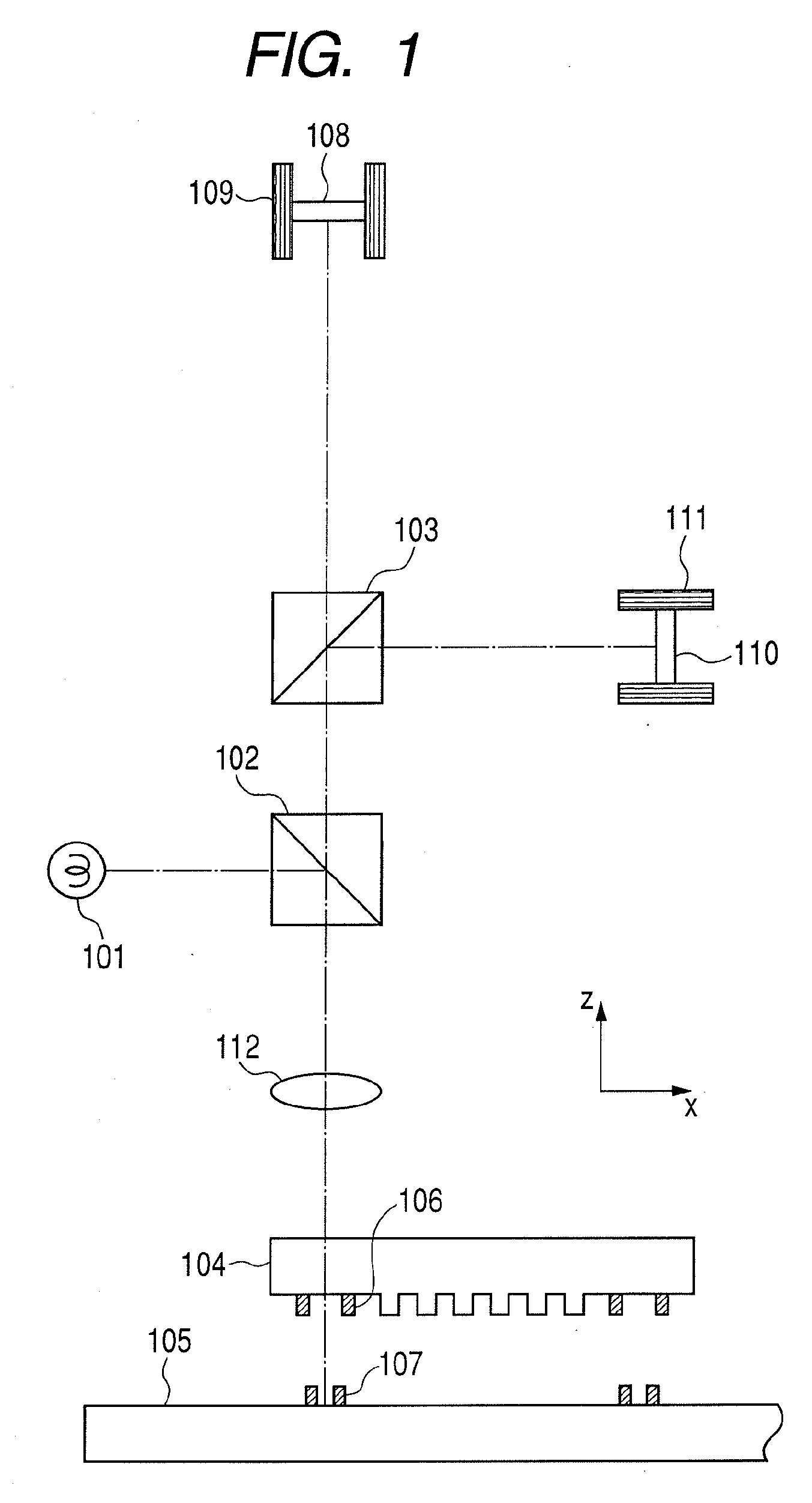

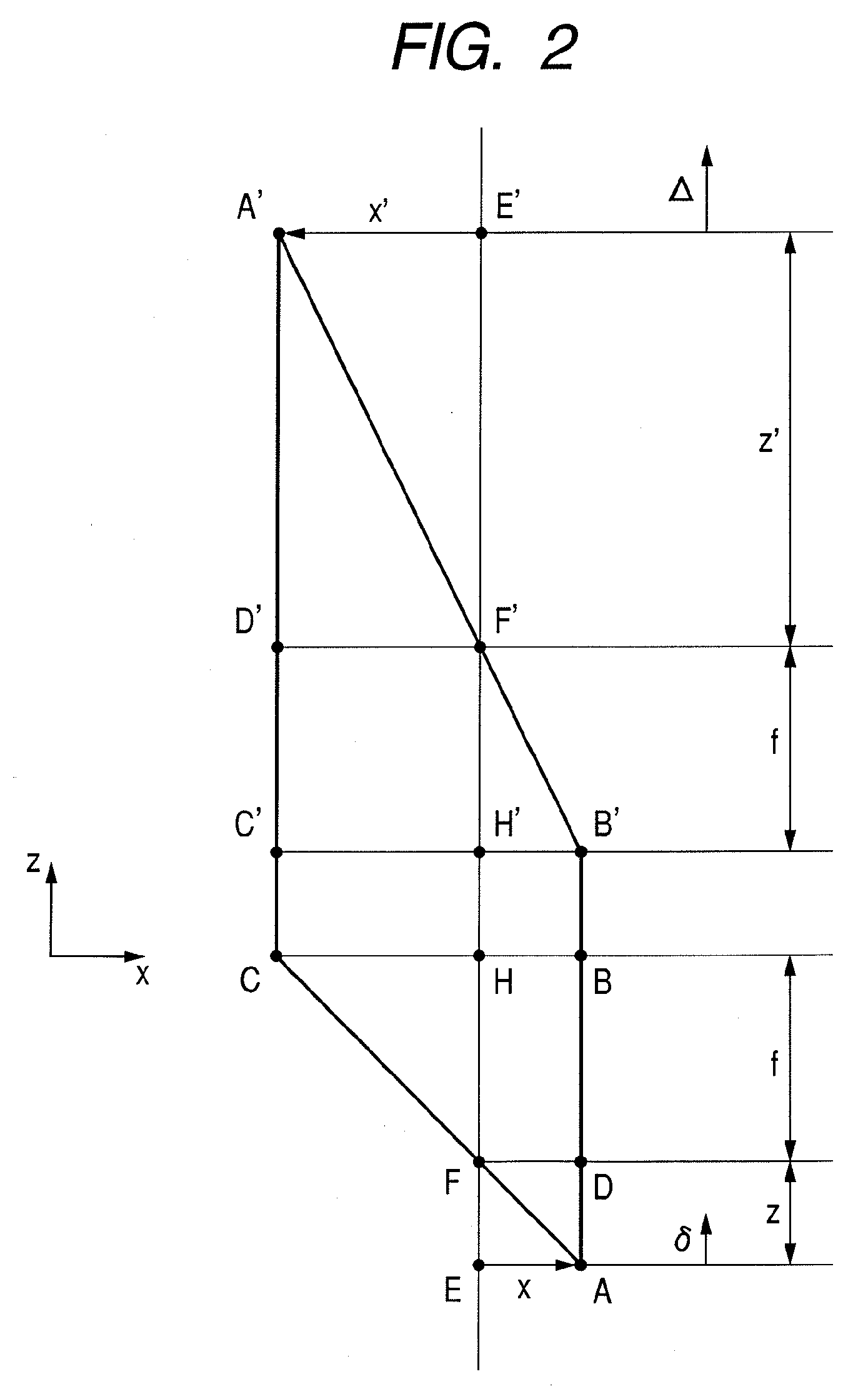

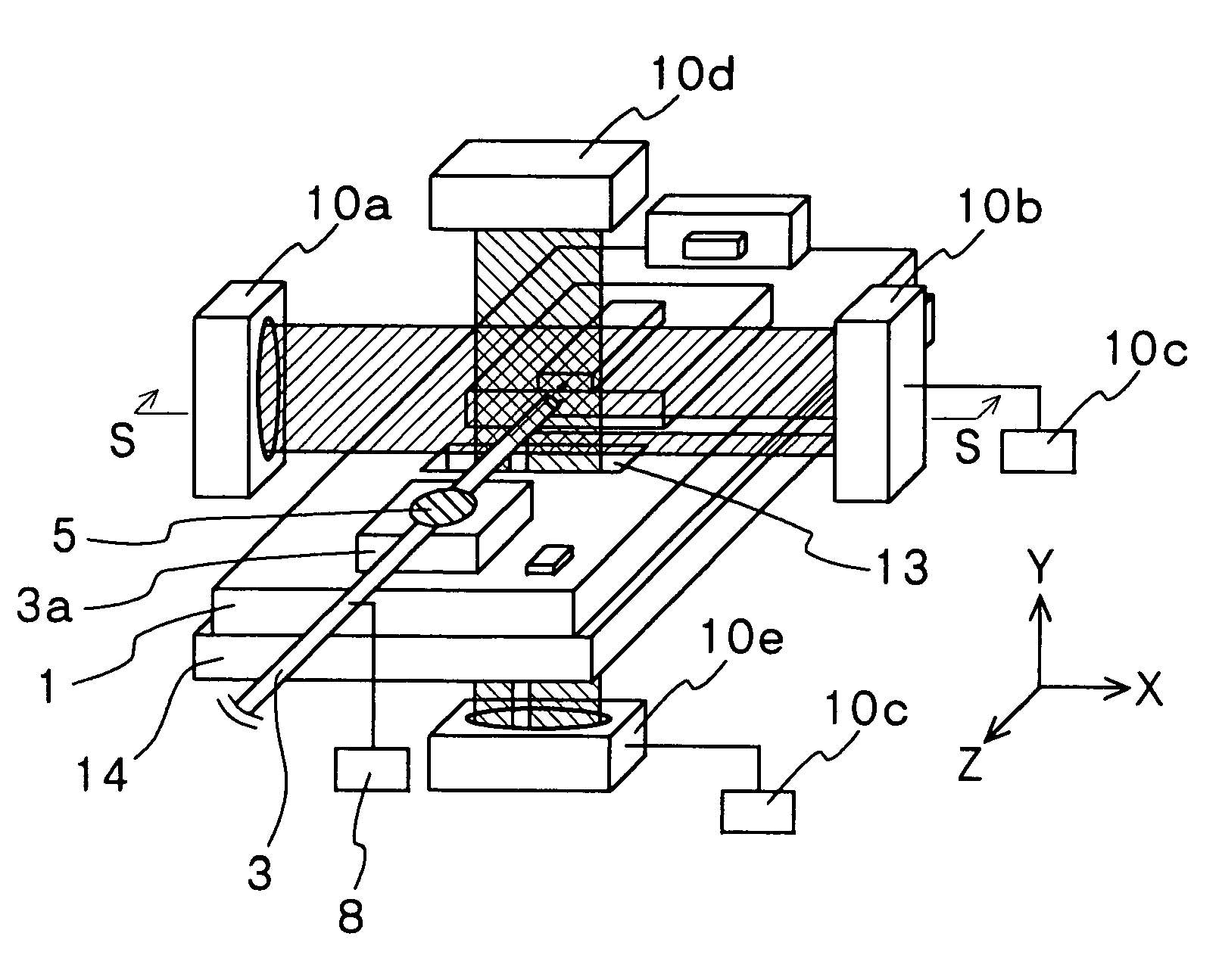

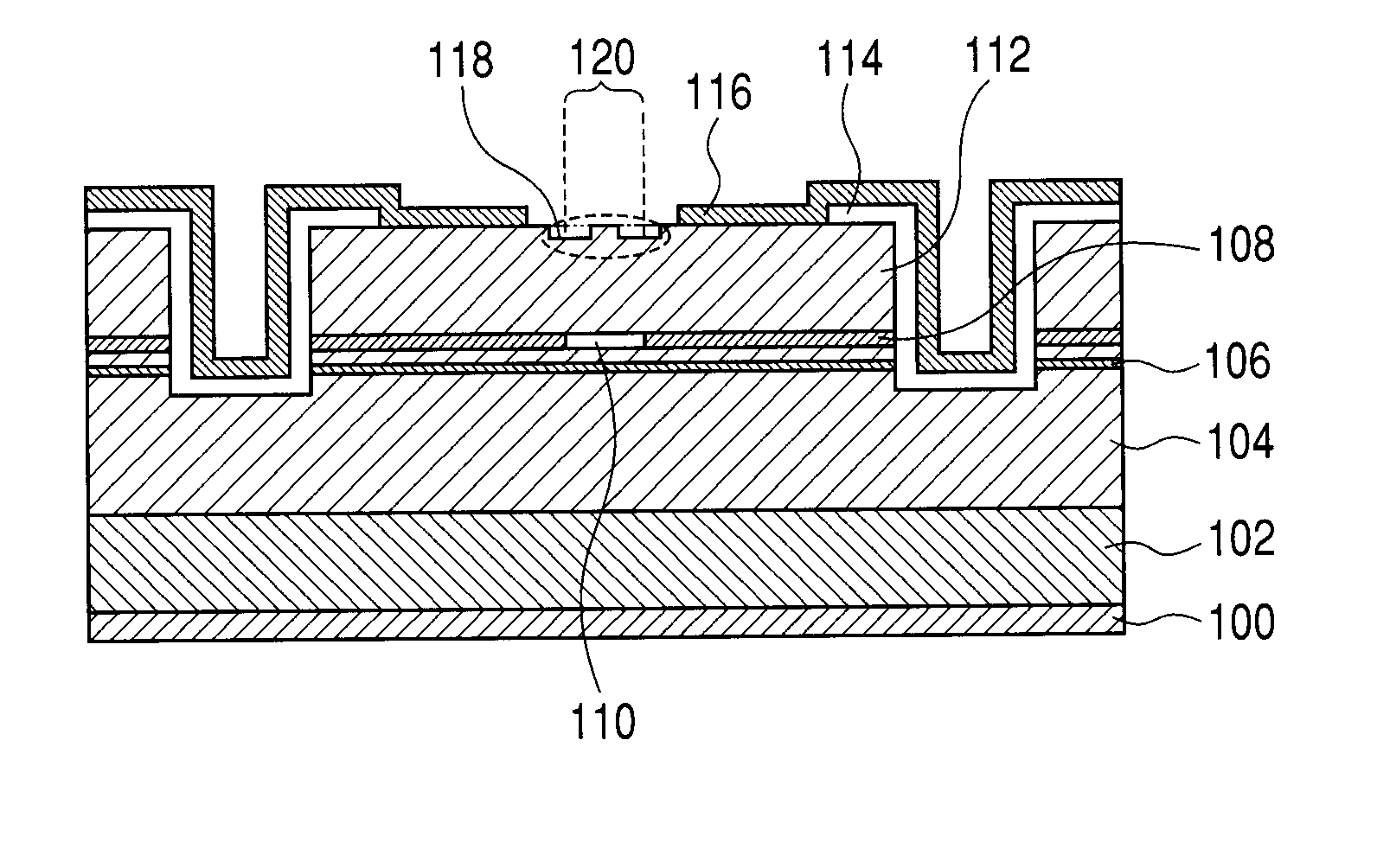

Optical module and method for manufacturing the same

InactiveUS7376312B2High positioning accuracyCoupling efficiency is improvedCoupling light guidesOptical waveguide light guideOptical ModuleCoupling

An optical element and an optical transmission member are fixedly secured onto a substrate so as to be coupled to each other. In this substrate, a through hole is formed between an optical element secured portion and an optical transmission member secured portion. In an attempt to assemble these optical transmission member and optical element so as to make the coupling at an optimal position, first, the position of the optical transmission member is adjusted to an optimal position, and after measuring the position by a laser micrometer, the optical transmission member is fixedly secured thereto by using a soldering material. Thus, measurements are again carried out by the laser micrometer to detect an amount of deviation from the measured value before the securing process, and the secured portion is again fused so that the optical transmission member is shifted based on the amount of deviation, and again fixedly secured thereon.

Owner:ROHM CO LTD

Process for producing surface emitting laser, process for producing surface emitting laser array, and optical apparatus including surface emitting laser array produced by the process

InactiveUS20100029030A1Decrease damage to surfaceReduce harmLaser detailsLaser optical resonator constructionCurrent limitingLaser array

Provided is a process for producing a surface emitting laser including a surface relief structure provided on laminated semiconductor layers, including the steps of transferring, to a first dielectric film, a first pattern for defining a mesa structure and a second pattern for defining the surface relief structure in the same process; and forming a second dielectric film on the first dielectric film and a surface of the laminated semiconductor layers to which the first pattern and the second pattern have been transferred. Accordingly, a center position of the surface relief structure can be aligned with a center position of a current confinement structure at high precision.

Owner:CANON KK

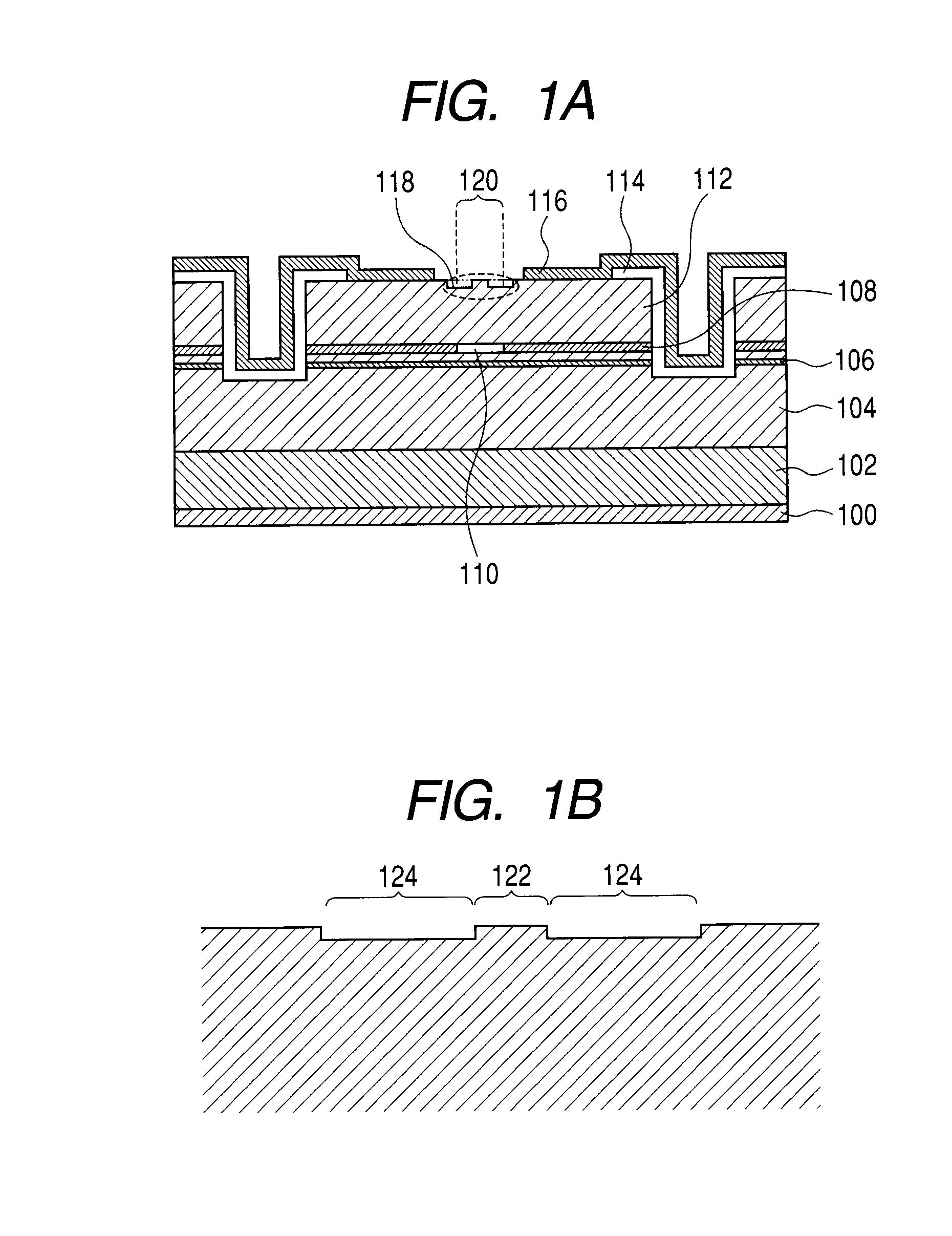

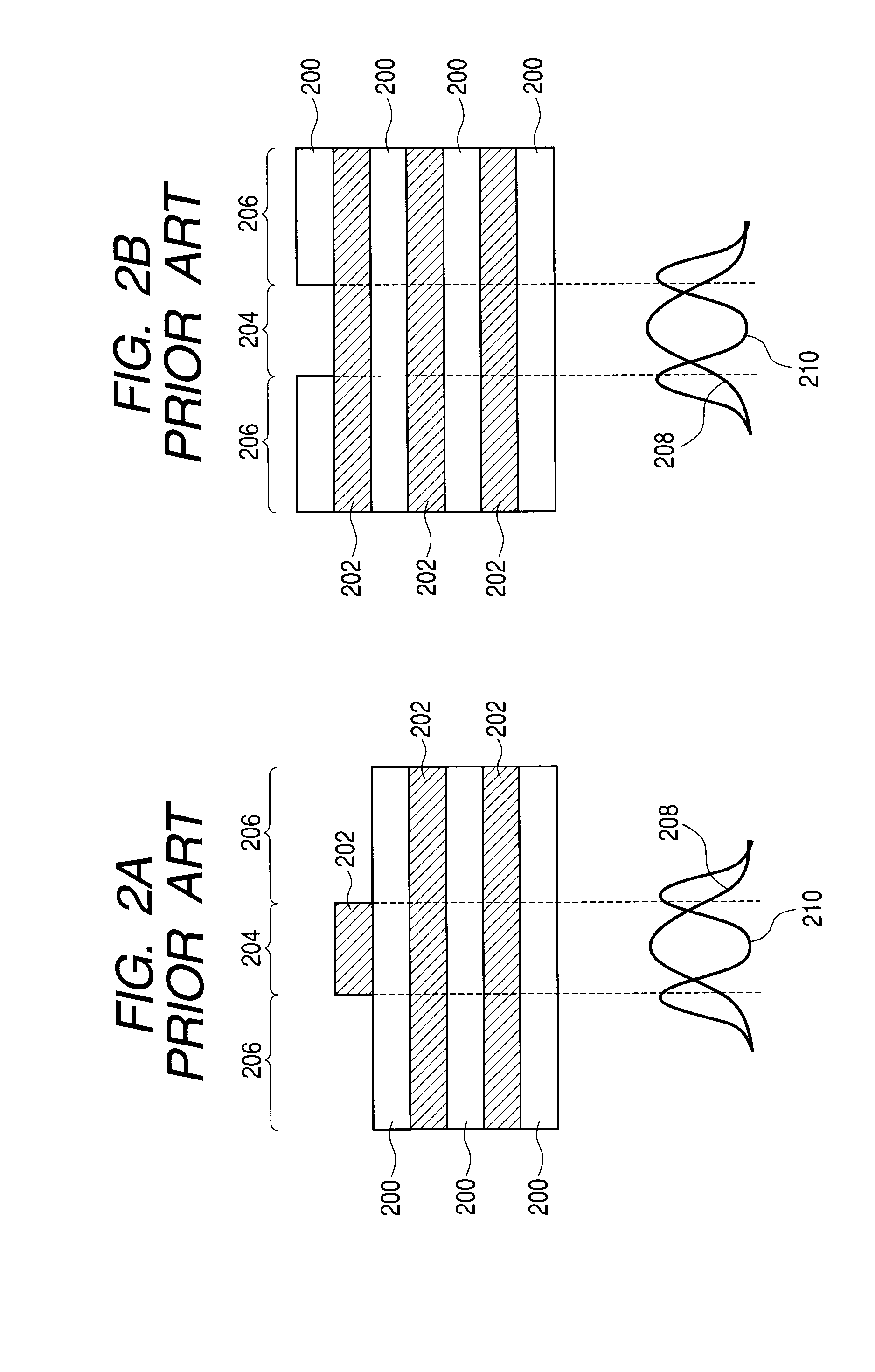

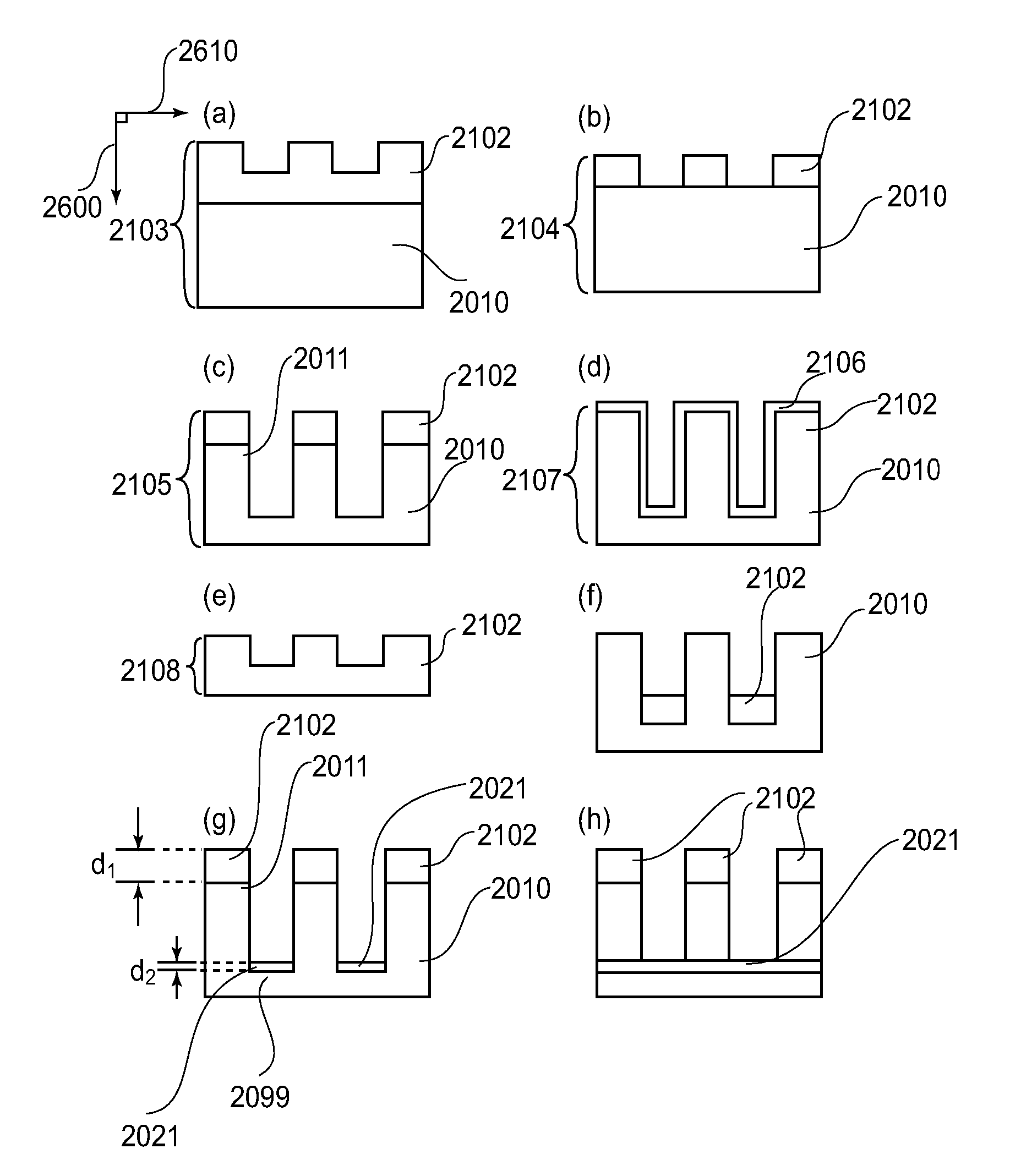

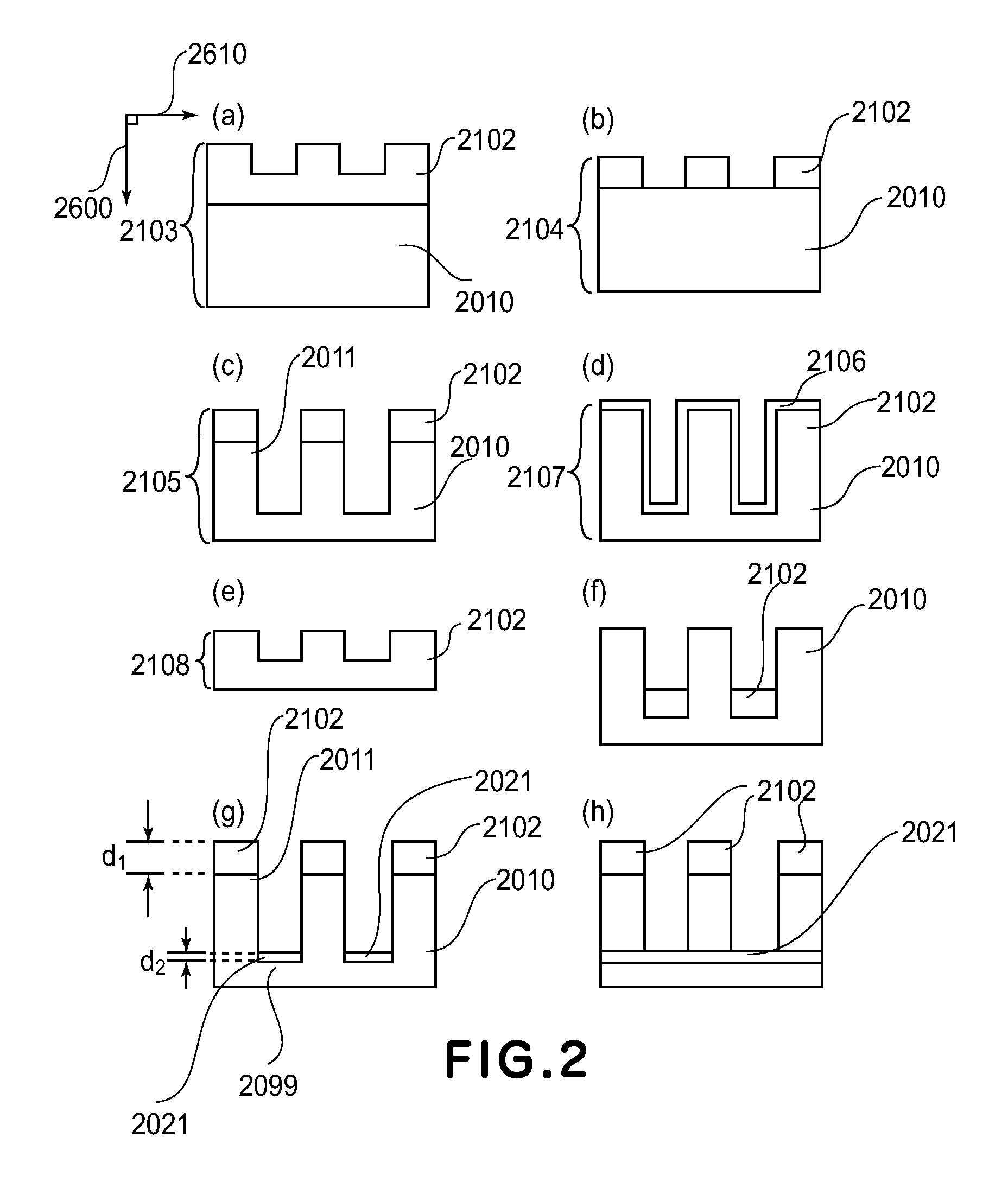

Mold, imprint method, and process for producing chip

InactiveUS7510388B2High precision alignmentConfectioneryNanoinformaticsUltraviolet lightsRefractive index

A mold capable of effecting alignment of the mold and the member to be processed with high accuracy even in such a state that a photocurable resin material is disposed between the mold and the member to be processed is constituted by a substrate 2010 formed of a first material and an alignment mark 2102 formed of a second material different from the first material. The first material and the second material have transmittivities to light in a part of an ultraviolet wavelength range of the ultraviolet light. The second material has a refractive index of not less than 1.7.

Owner:CANON KK

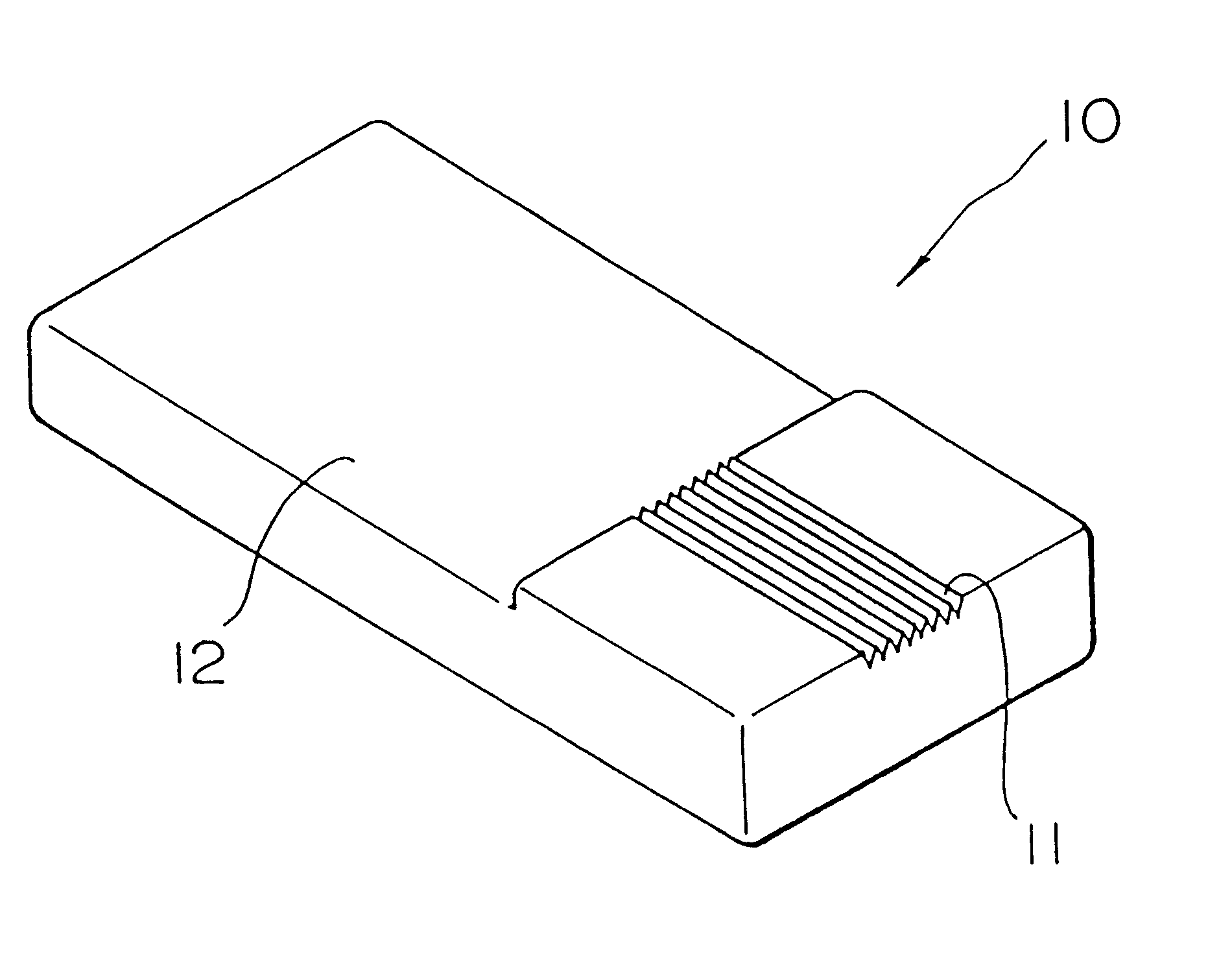

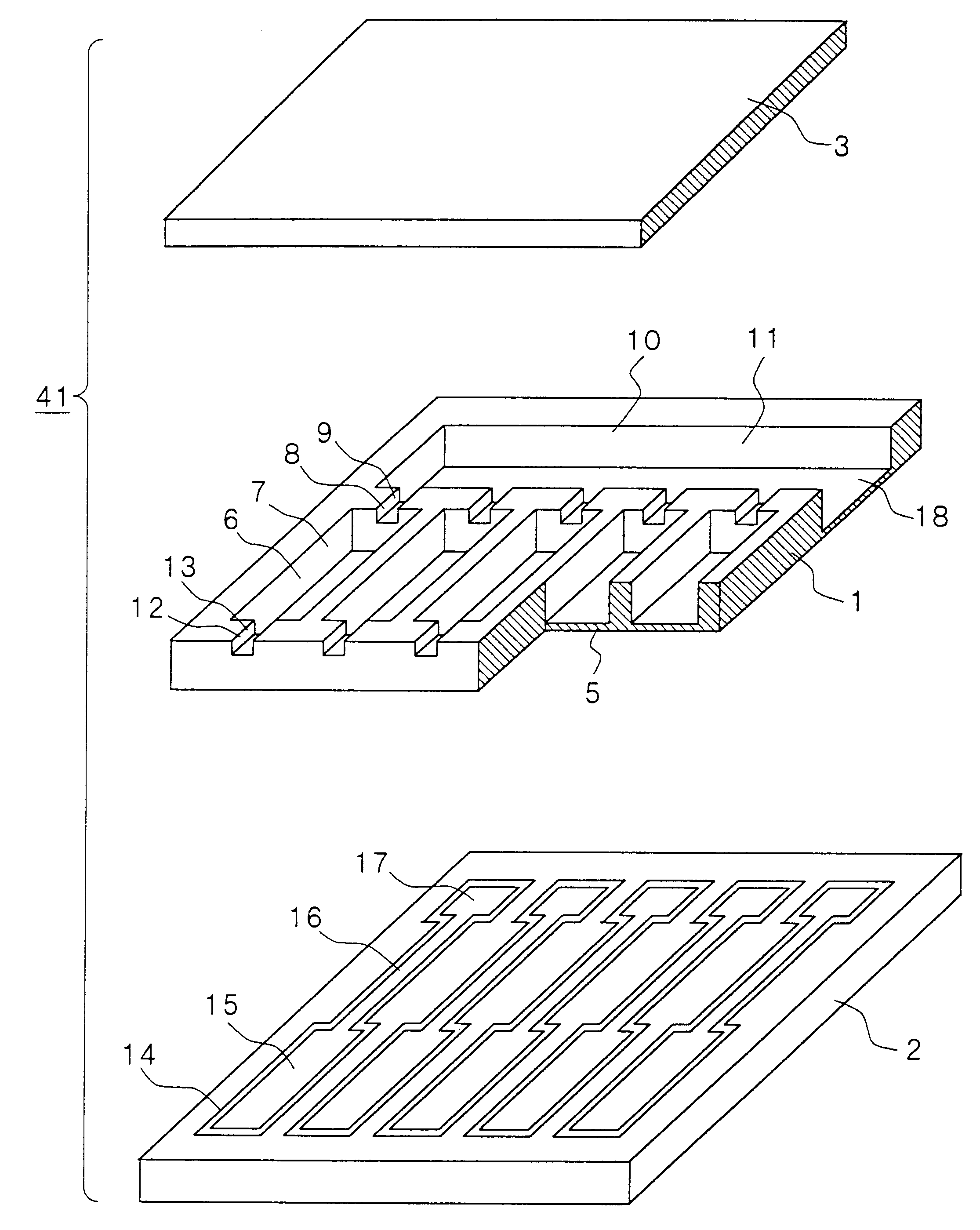

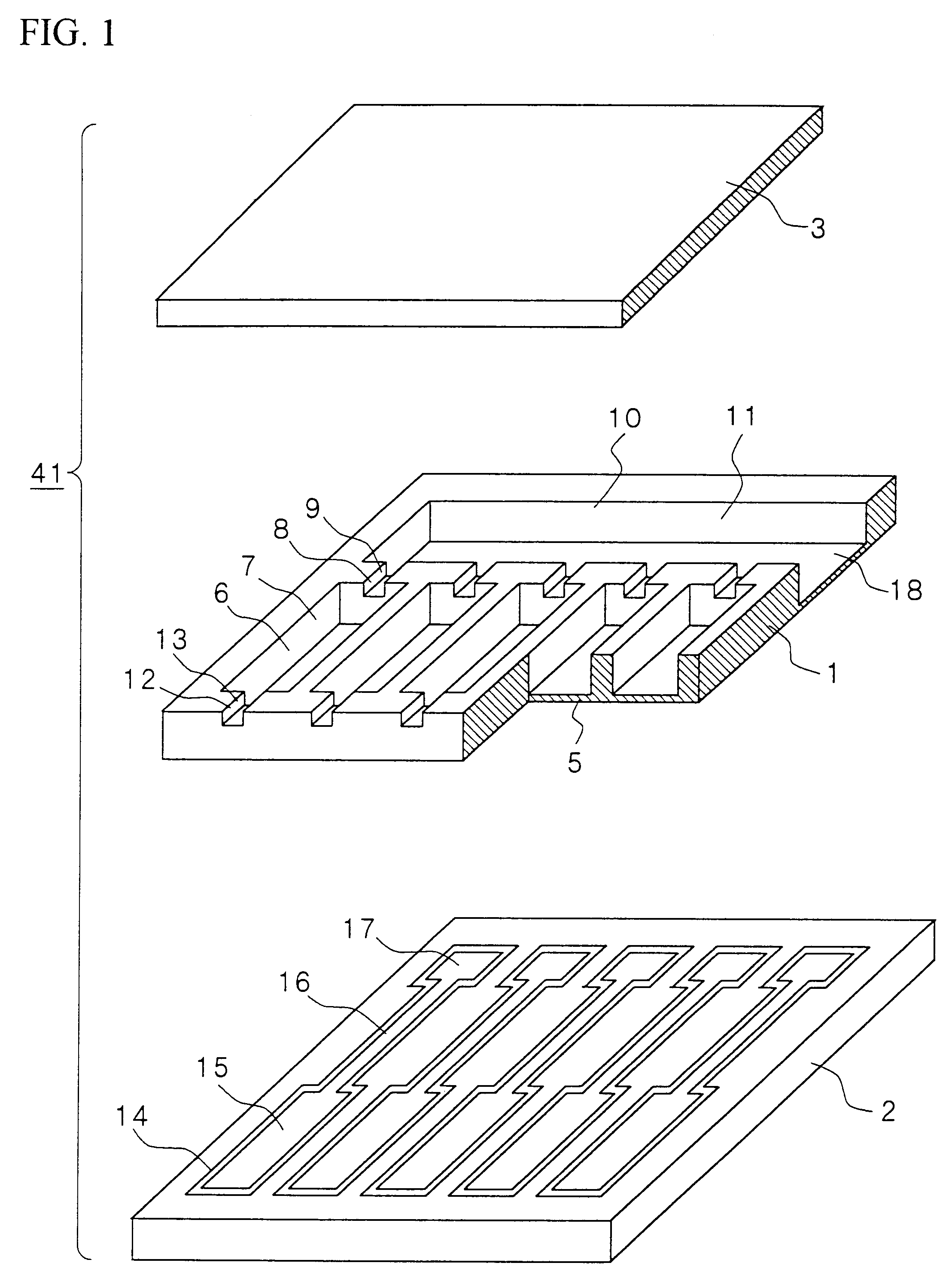

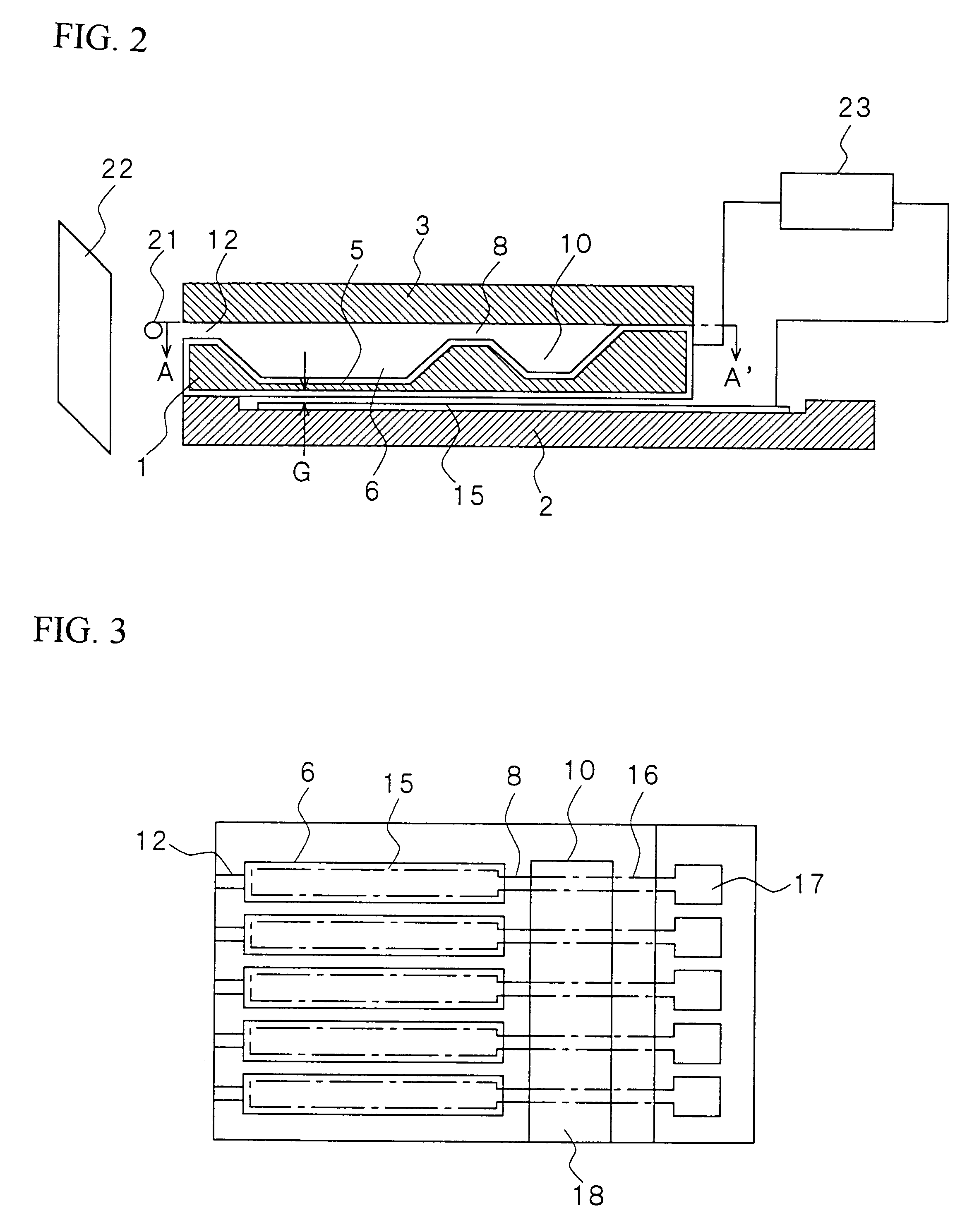

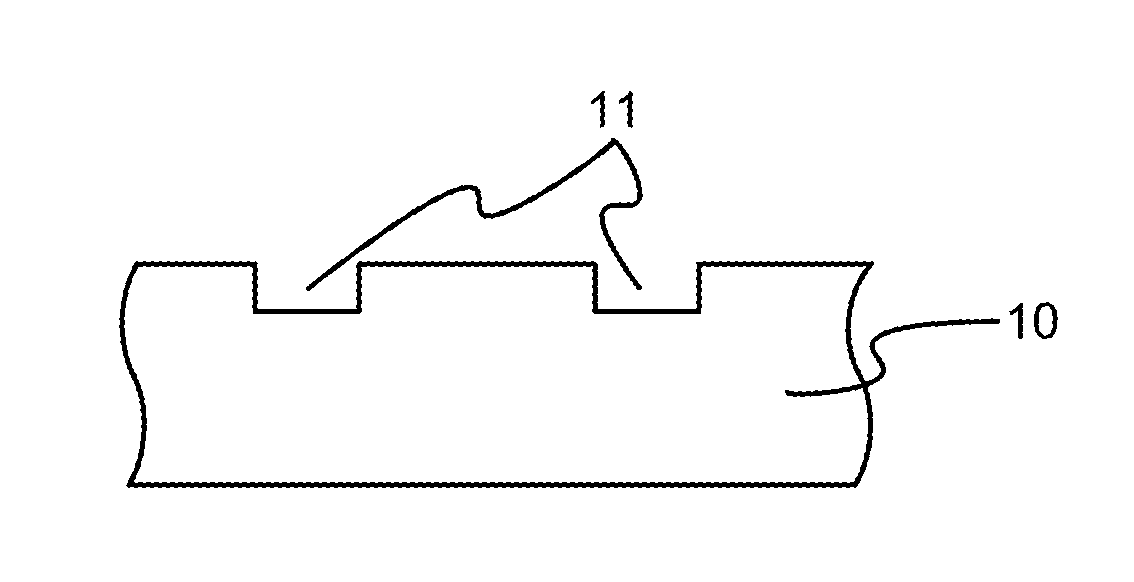

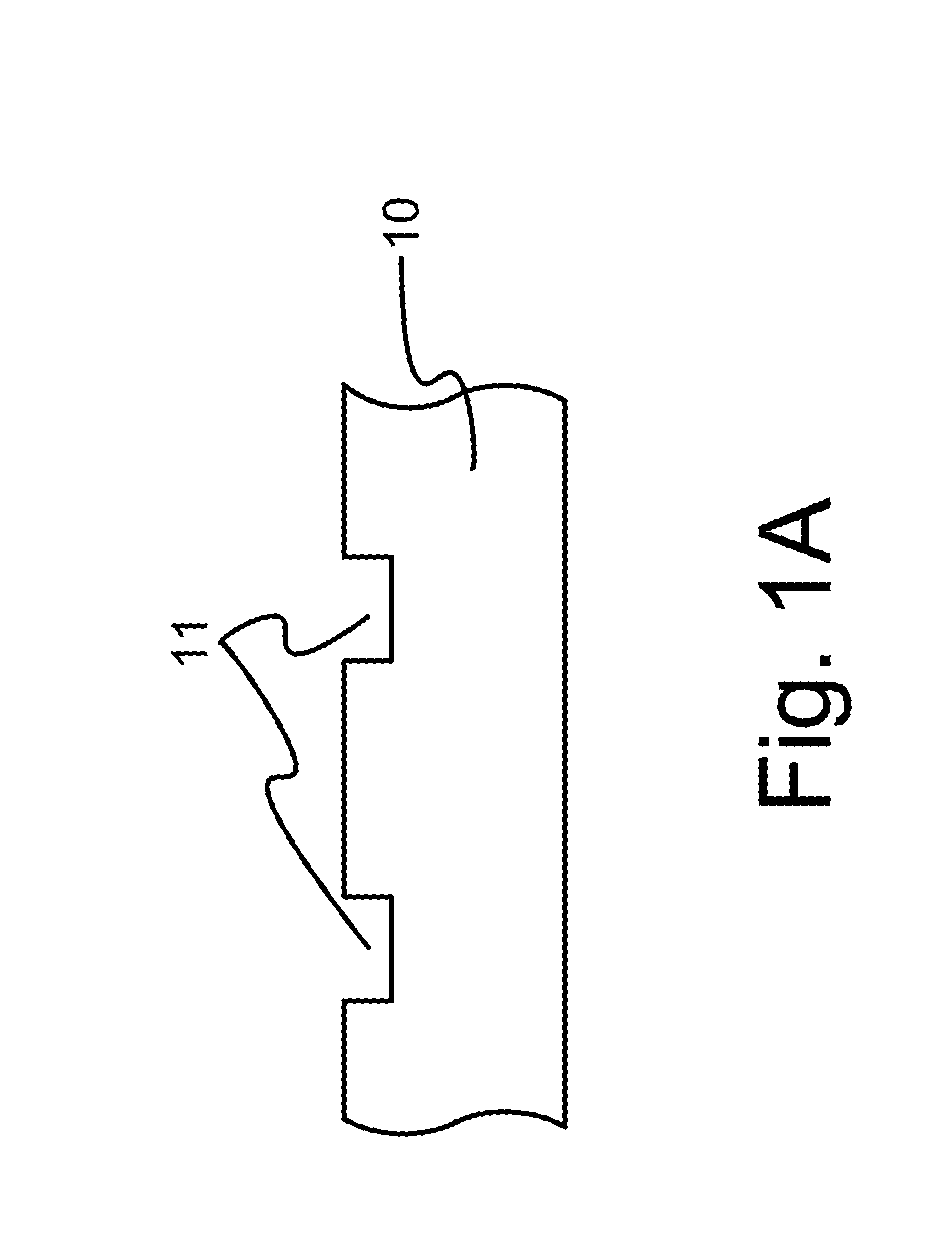

Ink jet head, manufacturing method therefor, and ink jet recording apparatus

An ink jet head in which a multi-nozzle structure is attained, and highly accurate alignment of ink jet head chips is realized, a method for manufacturing the ink jet head, and a recording apparatus on which the ink jet head is mounted. Guide protrusions (141) for alignment of ink jet head chips (41) are formed in an ink jet head chip bonded surface (134) of a nozzle plate (133), the ink jet head chips (41) are aligned by inserting the guide protrusions (141) of the nozzle plate (133) into guide grooves (51) of nozzle surfaces (42) of the ink jet head chips (41), and the nozzle plate (133) and the respective ink jet head chips (41) are bonded with each other by a bonding agent.

Owner:SEIKO EPSON CORP

Semiconductor wafer, semiconductor device, and method of manufacturing semiconductor device

InactiveUS20070222089A1Easy positioningImprove accuracyElectric discharge tubesSemiconductor/solid-state device detailsResistEngineering

Disclosed are a semiconductor wafer, a semiconductor device, and a method of manufacturing the semiconductor device, which are capable of easily carrying out an alignment between a semiconductor substrate and an electron beam exposure apparatus. There is provided a method including steps of: forming an interlayer insulating film 25 on a gate electrode 17a and a conductive film 17, as well as in a first opening 17b; forming in the interlayer insulating film 25 a second opening 25a including the first opening 17b; forming a hole 14a in an element isolation insulating film 14 under the first opening 17b; by use of the first opening 17b and the hole 14a as an alignment mark 27 used for the alignment in a state where a resist 28 is applied, measuring an intensity of a reflected electron EBref from the alignment mark 27, thus aligning the electron beam exposure apparatus with the semiconductor substrate 10; exposing with an electron beam EB the resist 28 existing in a hole formation region of a first region I; and developing the resist 28 to make a resist pattern 28e.

Owner:FUJITSU MICROELECTRONICS LTD

Solar Cell Having Selective Emitter

InactiveUS20140073081A1Increasing the thicknessReduce resistanceFinal product manufactureSemiconductor/solid-state device manufacturingEtchingSingle crystal

The present invention provides a solar cell having a selective emitter structure on a doped silicon substrate. The silicon substrate is mono-crystalline or multi-crystalline. A plurality of trenches are formed at the illuminated side of the silicon substrate. After one-time diffusion doping, the silicon substrate is processed through selective etching. The region outside the trenches obtains a lower doping concentration, while the region of the trenches remains to be highly doped. Thus, a selective emitter structure is formed.

Owner:NATIONAL TSING HUA UNIVERSITY

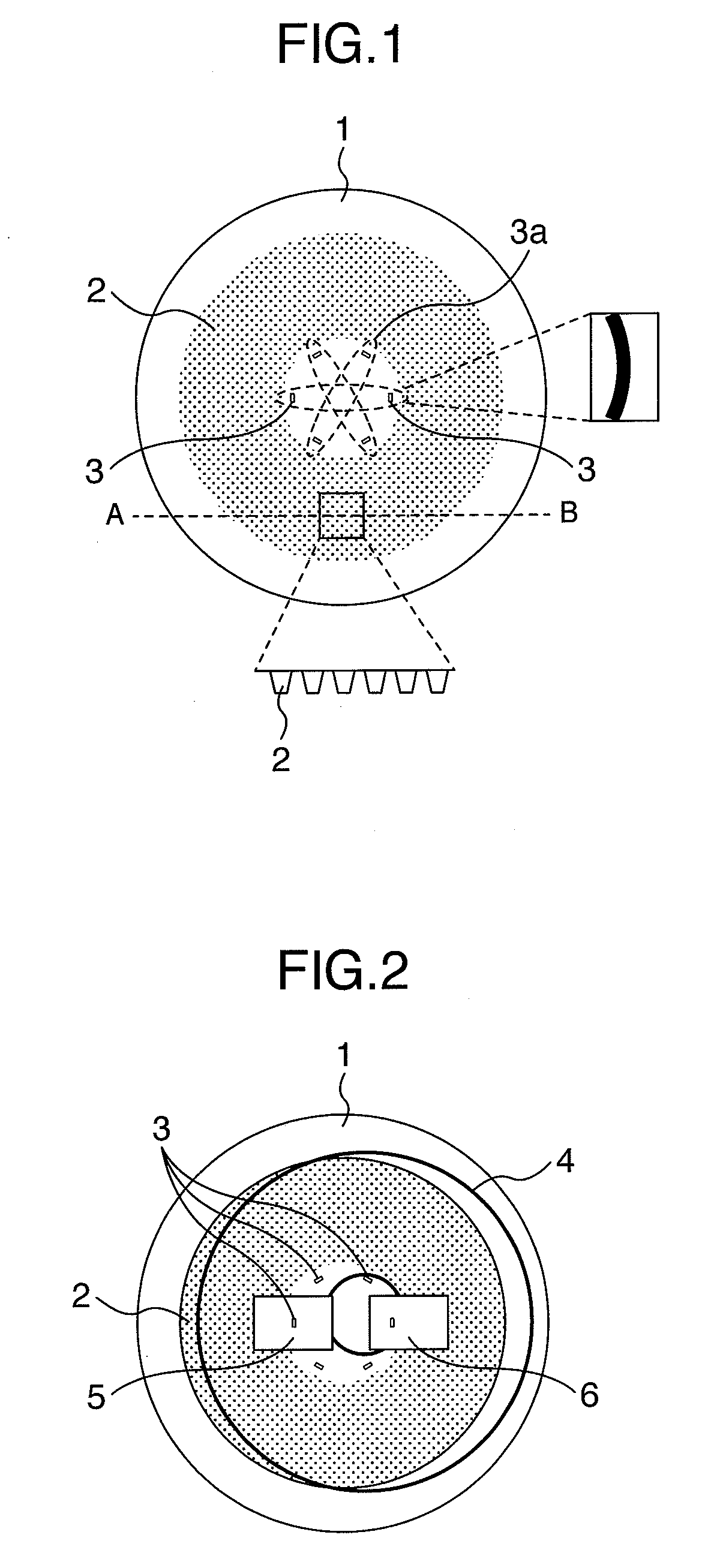

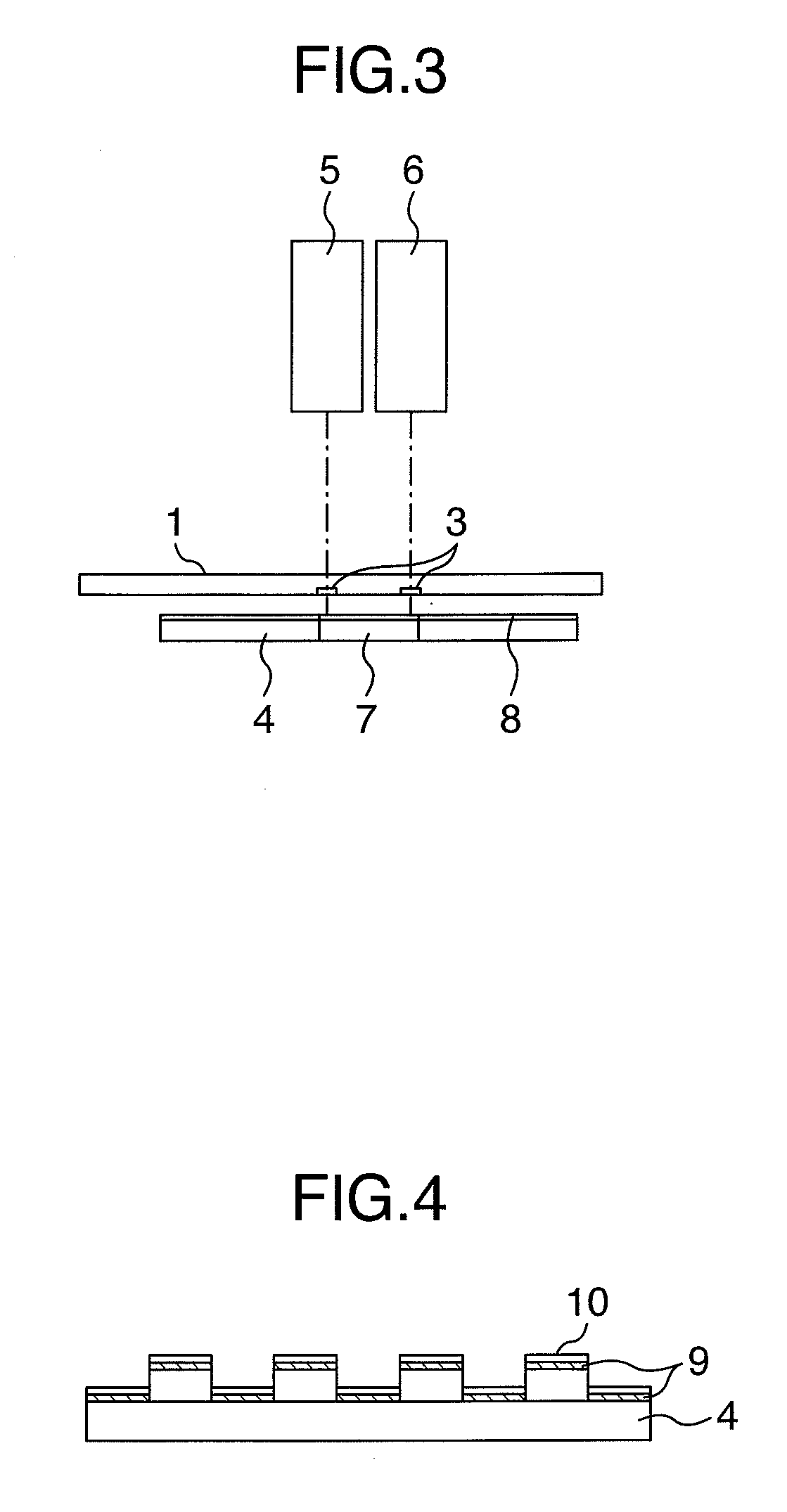

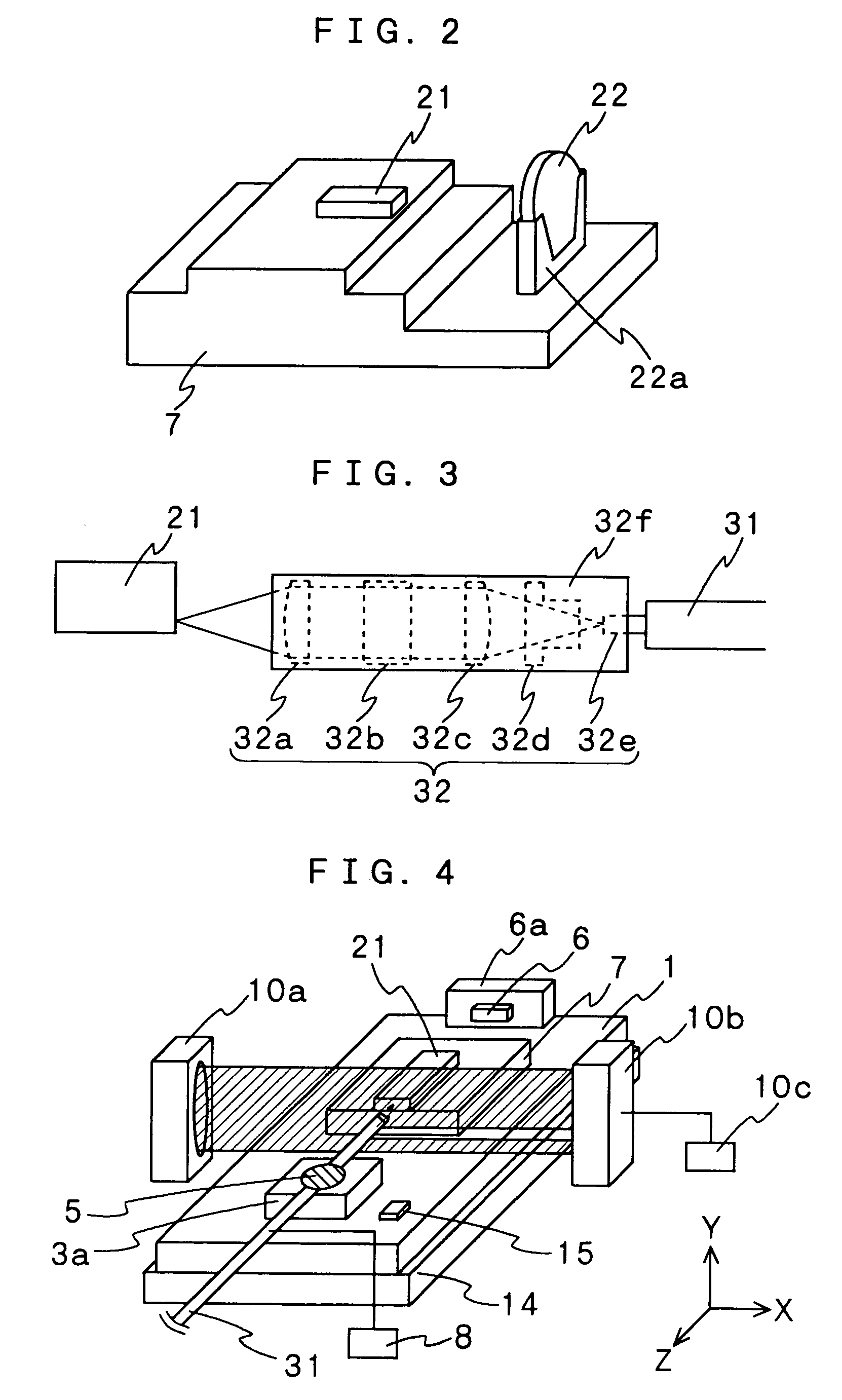

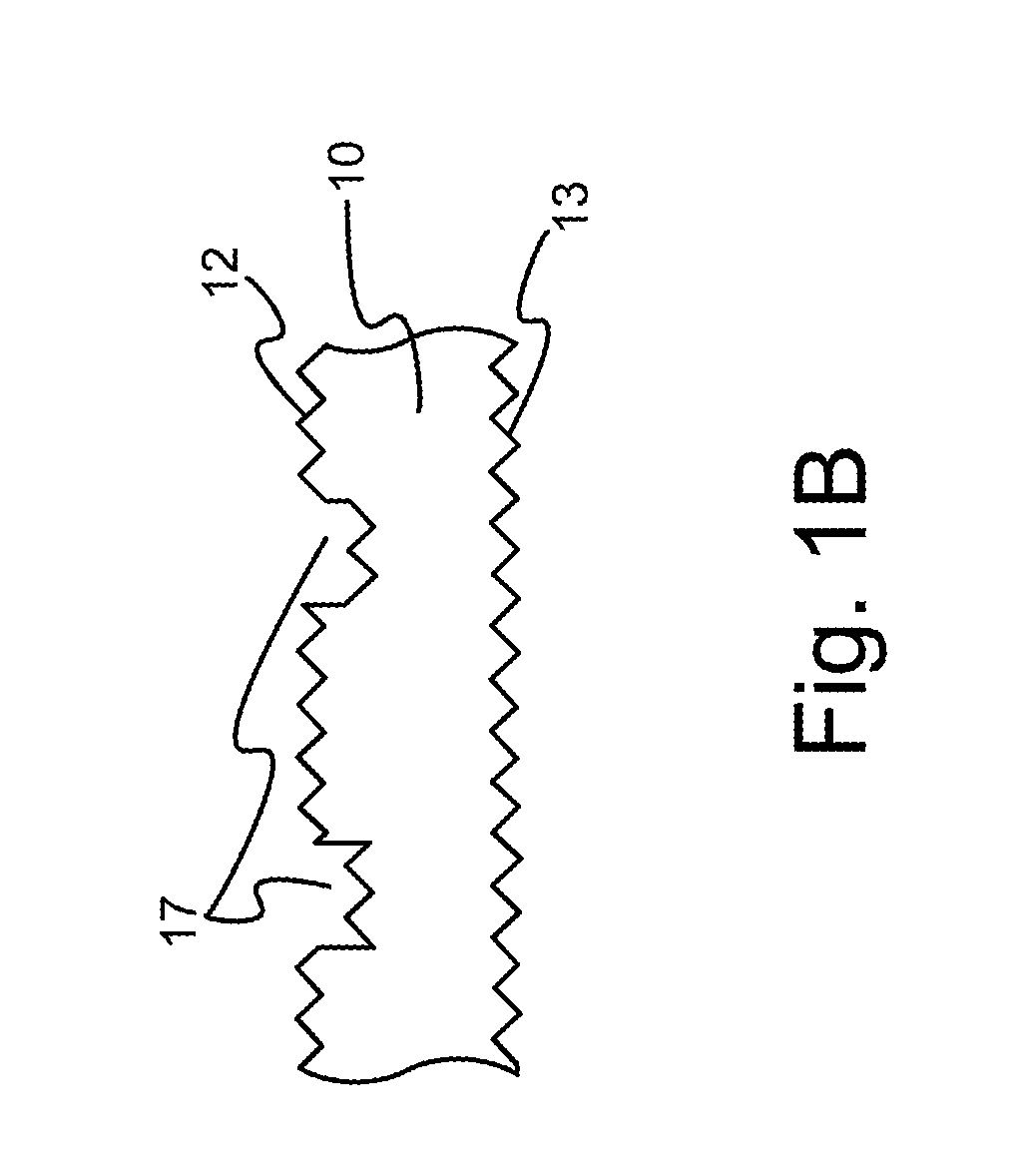

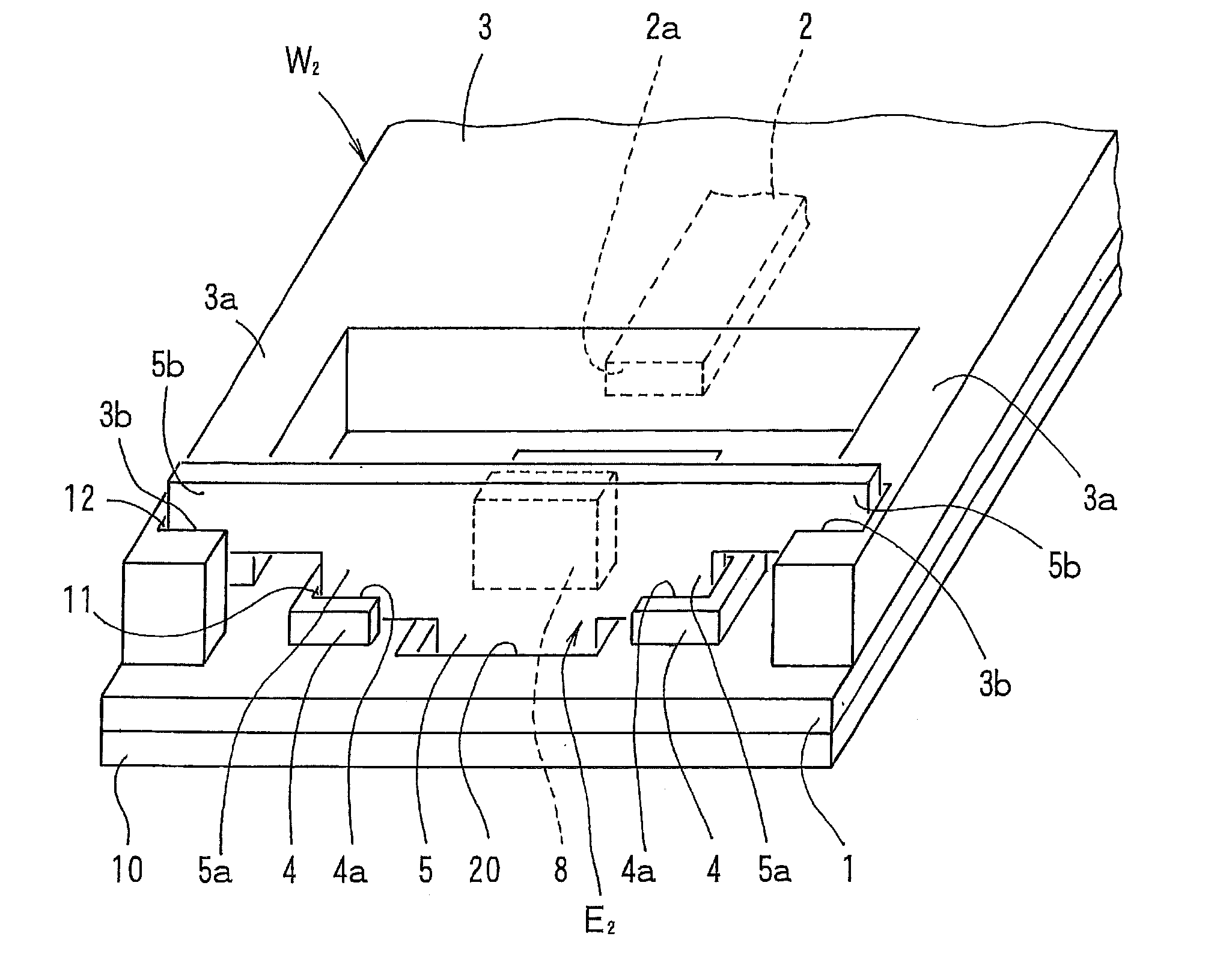

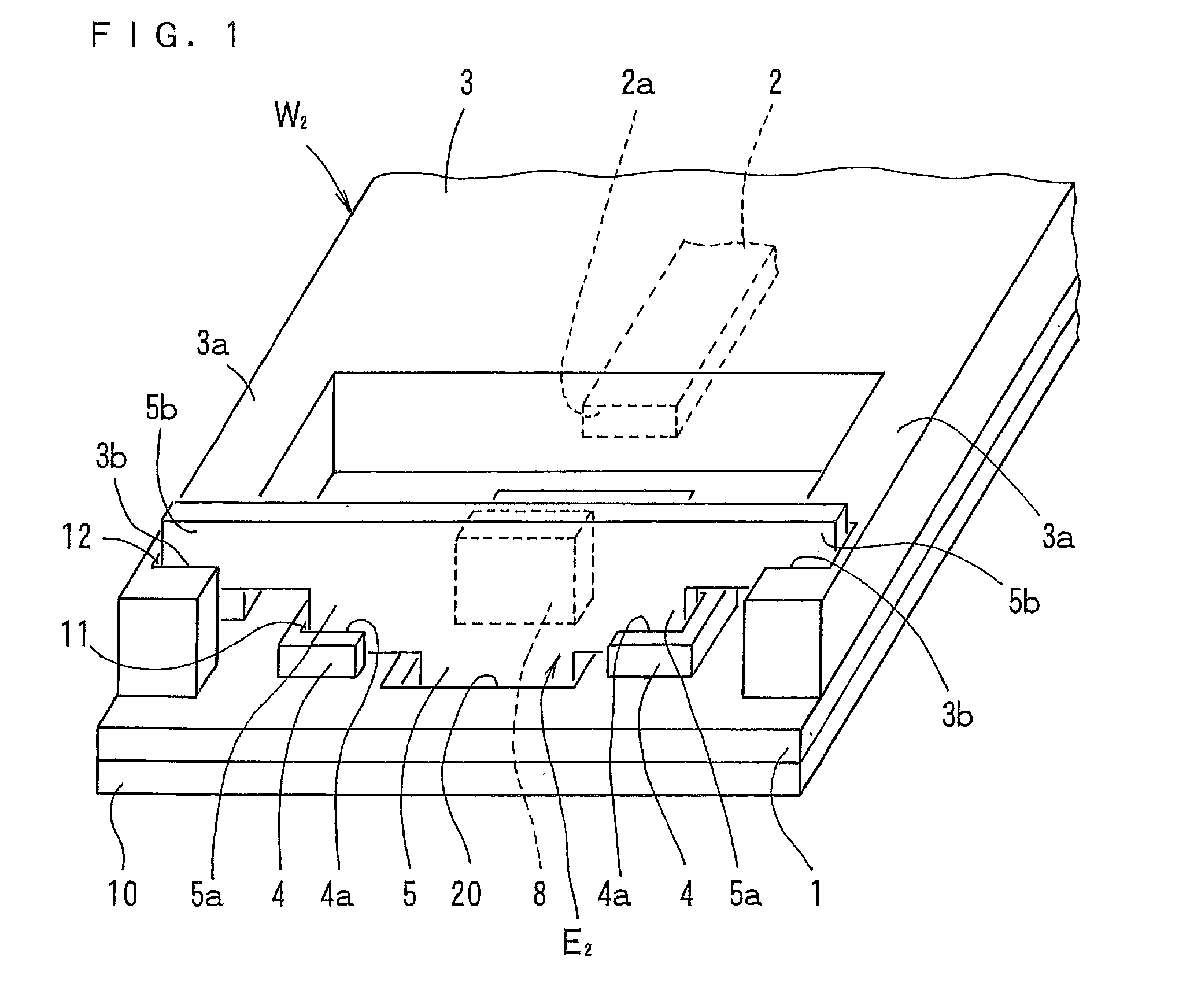

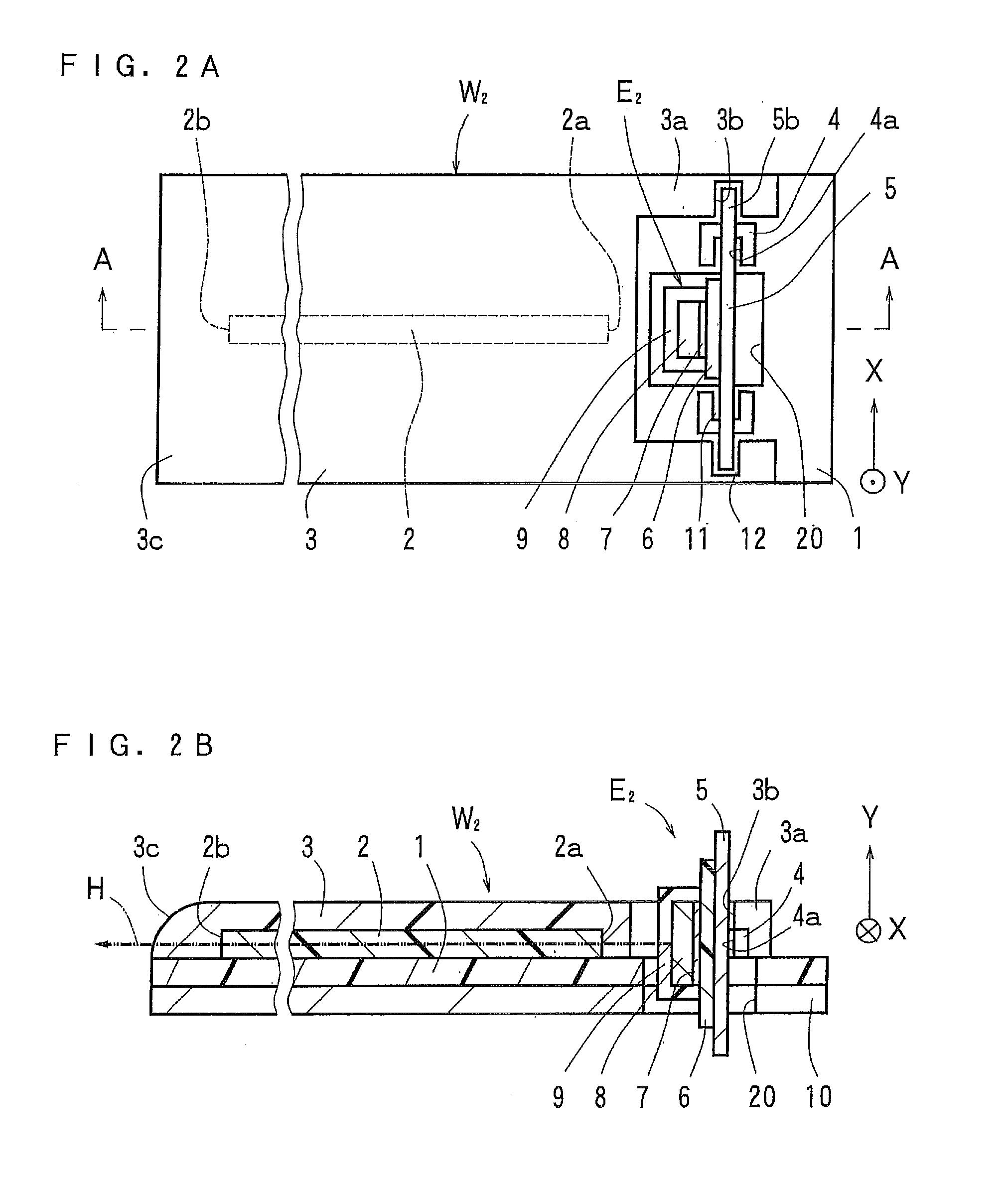

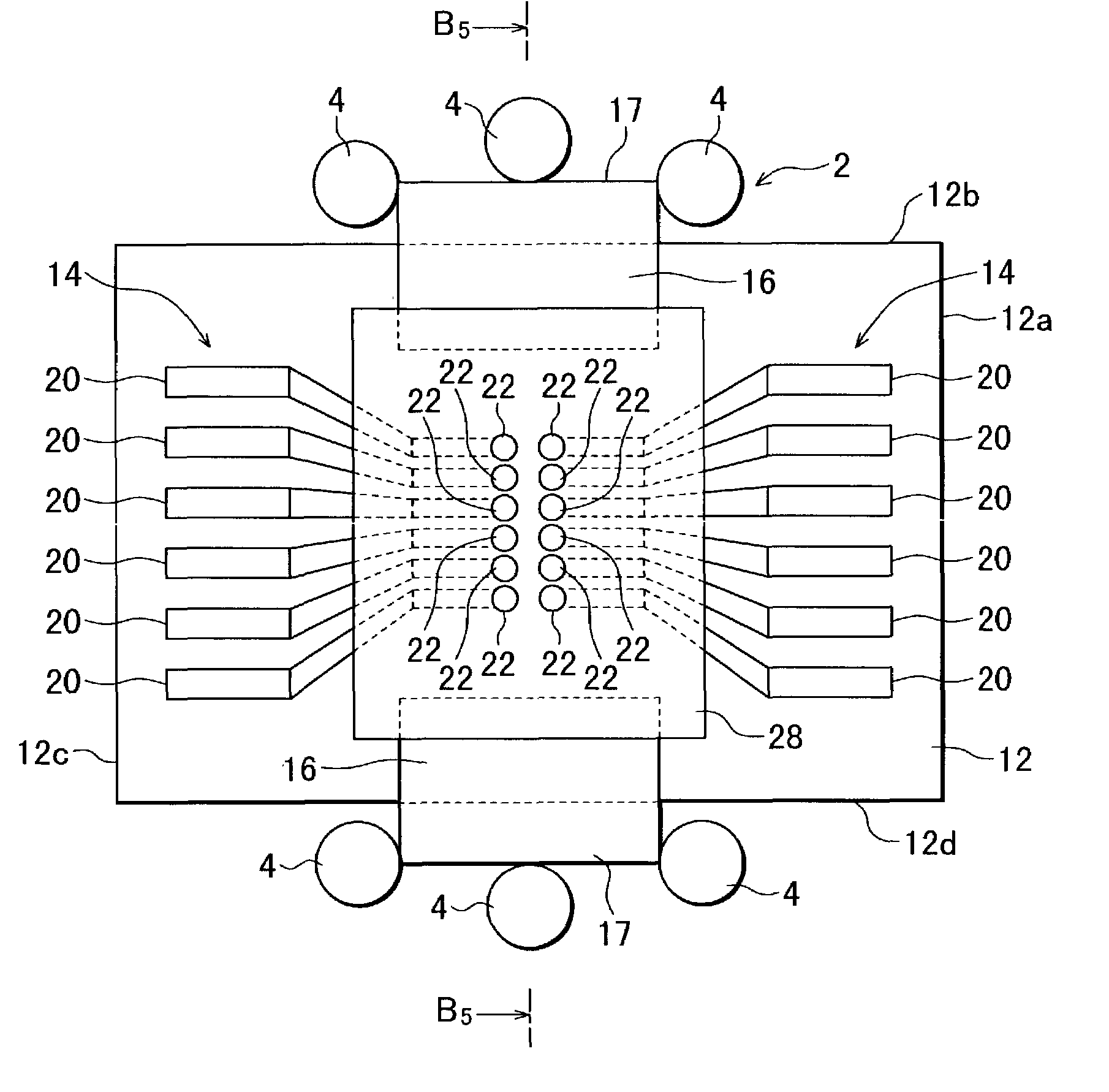

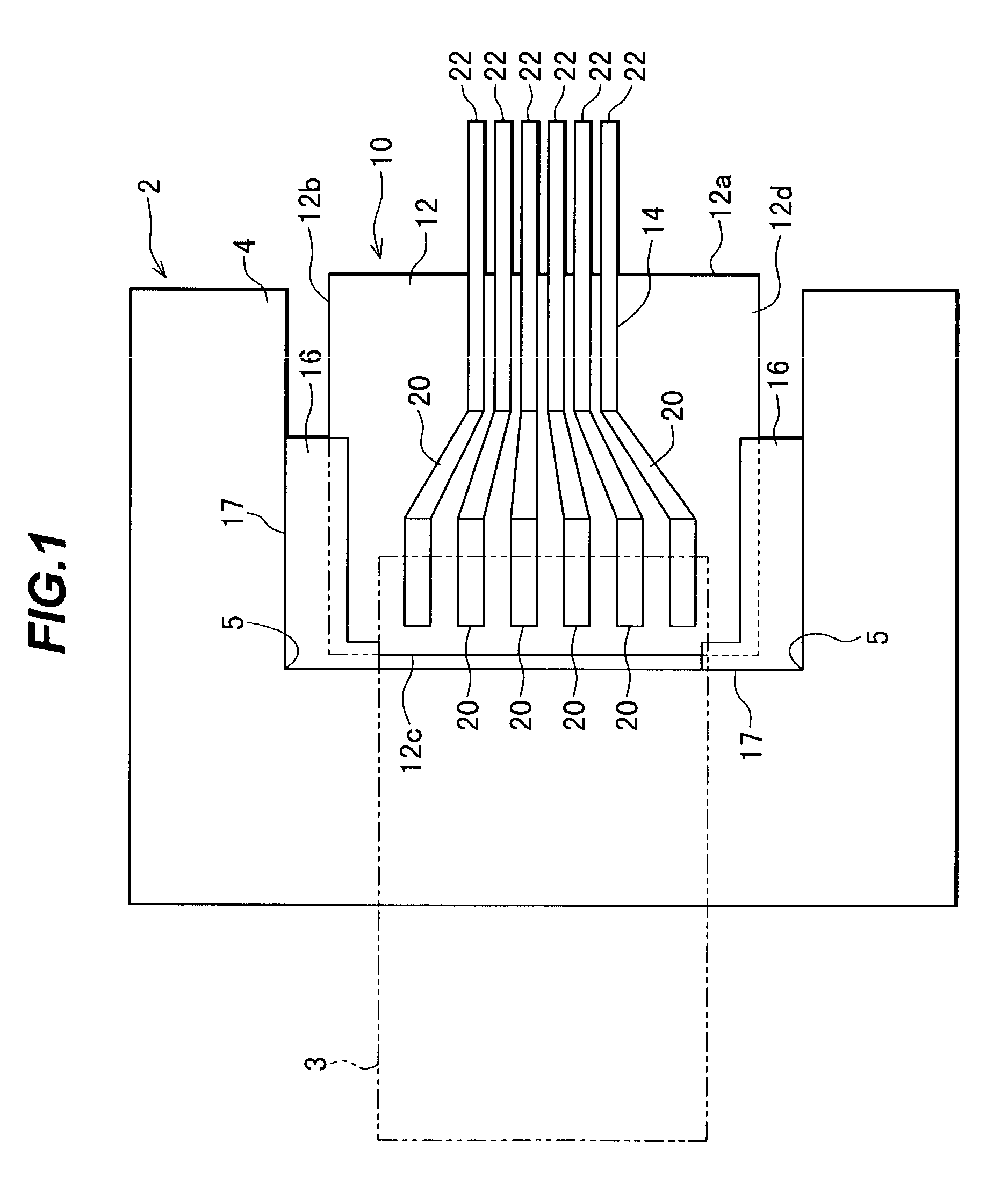

Method of manufacturing optical sensor module and optical sensor module obtained thereby

InactiveUS20110085758A1Simple structureHigh precision alignmentCladded optical fibreOptical articlesOptical ModuleEngineering

A method of manufacturing an optical sensor module which eliminates the need for the operation of alignment between a core in an optical waveguide section and an optical element in a substrate section and which achieves improvement in alignment accuracy and reduction in costs, and an optical sensor module obtained thereby. An optical waveguide section W2 including protruding portions 4 for the positioning of a substrate section and groove portions 3b for fitting engagement with the substrate section, and a substrate section E2 including positioning plate portions 5a to be positioned in the protruding portions 4 and fitting plate portions 5b for fitting engagement with the groove portions 3b are individually produced.

Owner:NITTO DENKO CORP

Probe unit and its manufacture

InactiveUS6998857B2Precise positioningImprove accuracyElectrical measurement instrument detailsElectrical testingLithographic artistBiomedical engineering

A probe unit to be fixed to a probe device for testing functions of a test body. The probe unit includes: a substrate; probe pins formed on the substrate by lithography, the probe pins having distal ends protruded from the substrate and being made in contact with electrodes of the test body; and a positioning member formed on the substrate by lithography at a predetermined position relative to the probe pins, the positioning means abutting upon a member for positioning the substrate relative to the probe device.

Owner:YAMAICHI ELECTRONICS

Vapor deposition mask, method for producing vapor deposition mask device and method for producing organic semiconductor element

ActiveUS9108216B2Enhancement in definitionReduce weightLiquid surface applicatorsSpraying apparatusGas phaseOrganic semiconductor

A method for producing a vapor deposition mask capable of satisfying both enhancement in definition and reduction in weight even when a size is increased, a method for producing a vapor deposition mask device capable of aligning the vapor deposition mask to a frame with high precision, and a method for producing an organic semiconductor element capable of producing an organic semiconductor element with high definition are provided. A metal mask provided with a slit, and a resin mask that is positioned on a front surface of the metal mask and has openings corresponding to a pattern to be produced by vapor deposition arranged by lengthwise and crosswise in a plurality of rows, are stacked.

Owner:DAI NIPPON PRINTING CO LTD

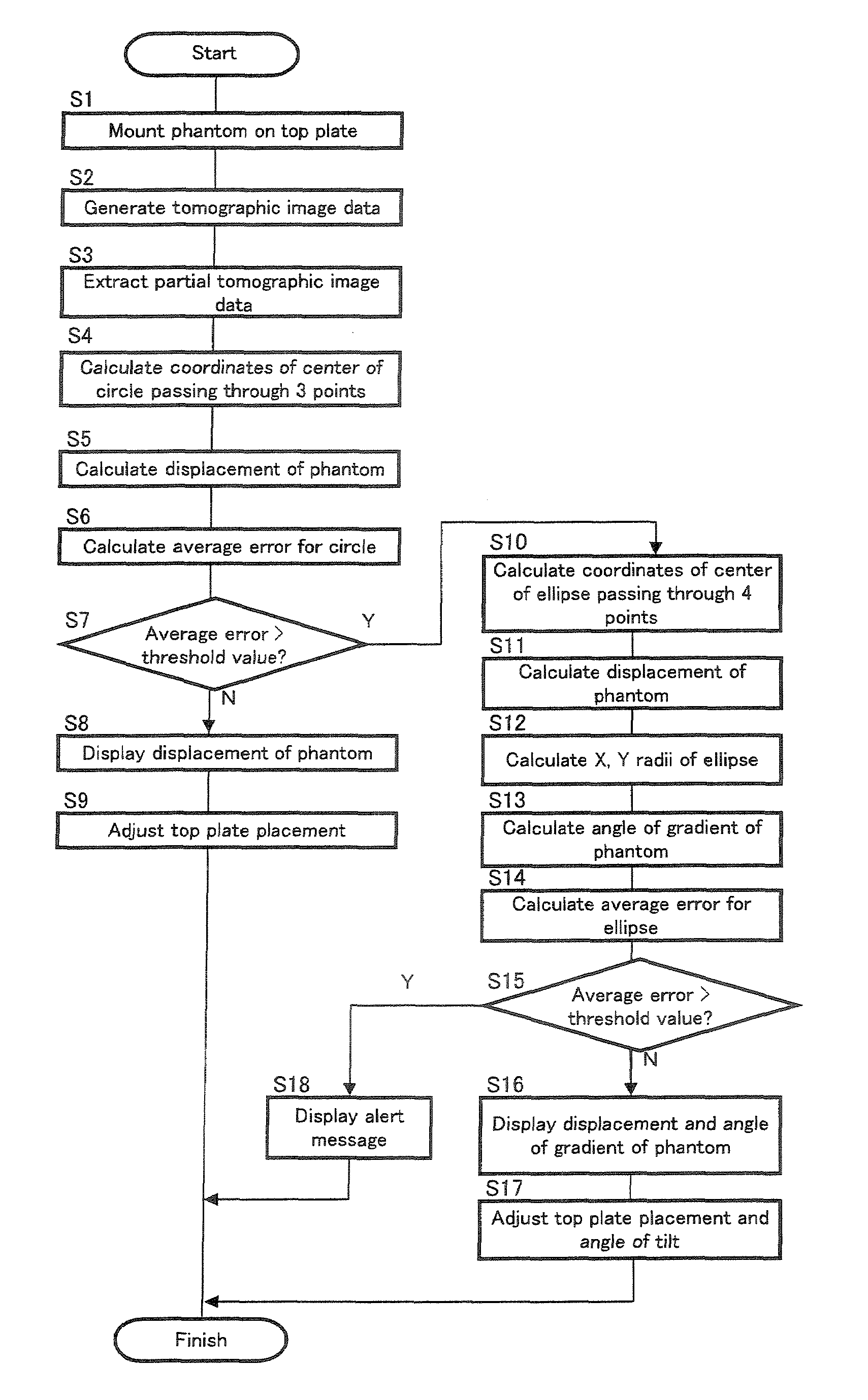

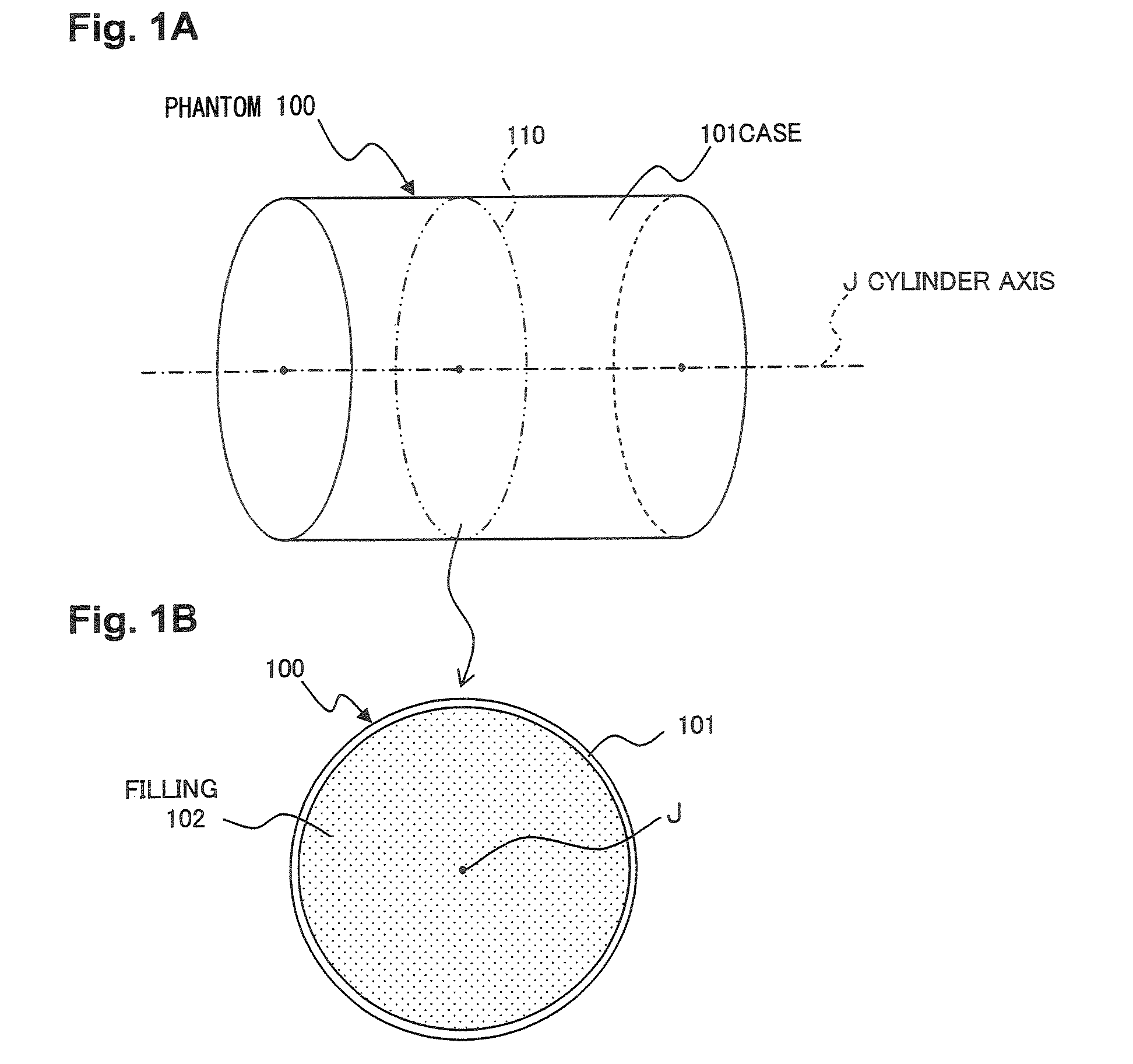

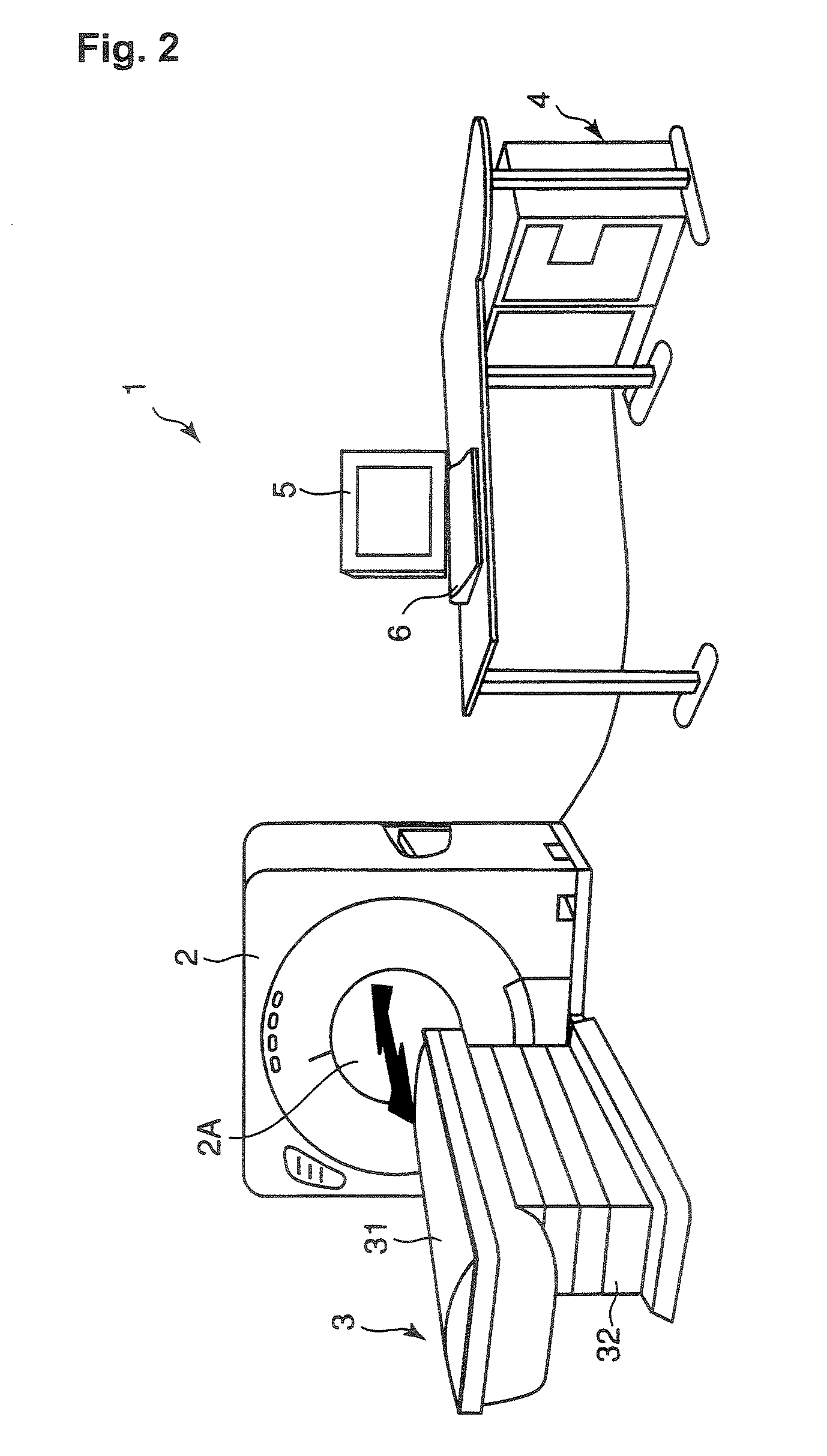

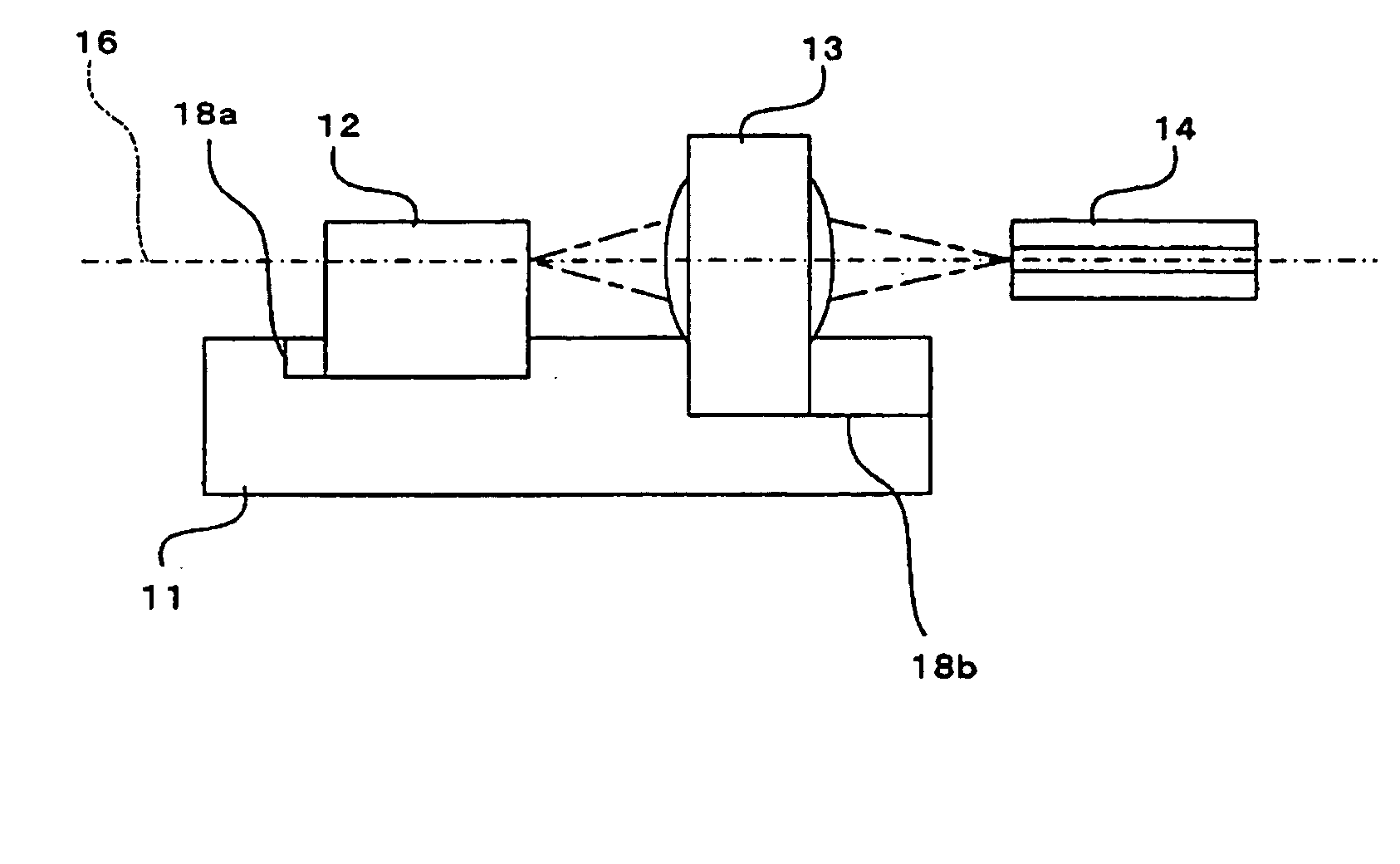

X-ray CT apparatus, method of aligning phantom, and phantom retaining tool

ActiveUS7866884B2Quick alignmentImprove accuracyMaterial analysis using wave/particle radiationRadiation/particle handlingSoft x rayX-ray

The present invention comprises a top plate 31 for placing a cylindrical phantom 100, an X-ray tube 22 that generates X-rays, an X-ray detector 23 that detects X-rays transmitted through the phantom 100 placed on a top plate 31, a supporting body drive part 25 that rotates the X-ray tube 22 and X-ray detector 23, a tomographic image data generating part 60 that generates tomographic image data on the phantom 100 based on a results of detecting X-rays by the X-ray detector 23, a calculation processing part 80 that calculates displacement of the cylinder axis J of the phantom 100 relative to the center of rotation (center of scan) by the supporting body drive part 25, based on the tomographic image data, and the angle of gradient of the cylinder axis J relative to the normal direction (direction of slice) of the rotation plane of said rotation, and a monitor 5 that displays the calculated results.

Owner:TOSHIBA MEDICAL SYST CORP

Optical semiconductor device and method of manufacturing same

InactiveUS20050069261A1Improve accuracySimplify workLaser detailsCoupling light guidesOptical axisDevice material

An optical semiconductor device includes a substrate and a plurality of optical parts mounted thereon. Guide grooves are formed in the substrate at the mounting positions of the optical parts. Each guide groove has first side surfaces, which are substantially orthogonal to the direction of the optical axis, second side surfaces, which are substantially parallel to the direction of the optical axis and substantially perpendicular to the surface of the substrate, and a bottom surface substantially parallel to the surface of the substrate. Each guide groove has a size and a depth that allow at least a bottom portion of the corresponding optical part to be received therein. The corresponding optical part is accommodated in each guide groove in abutting contact with the first side surfaces of the guide groove, whereby the optical parts are aligned with one another along the direction of the optical axis.

Owner:NEC ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com