Patents

Literature

8797results about "Mechanical working/deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

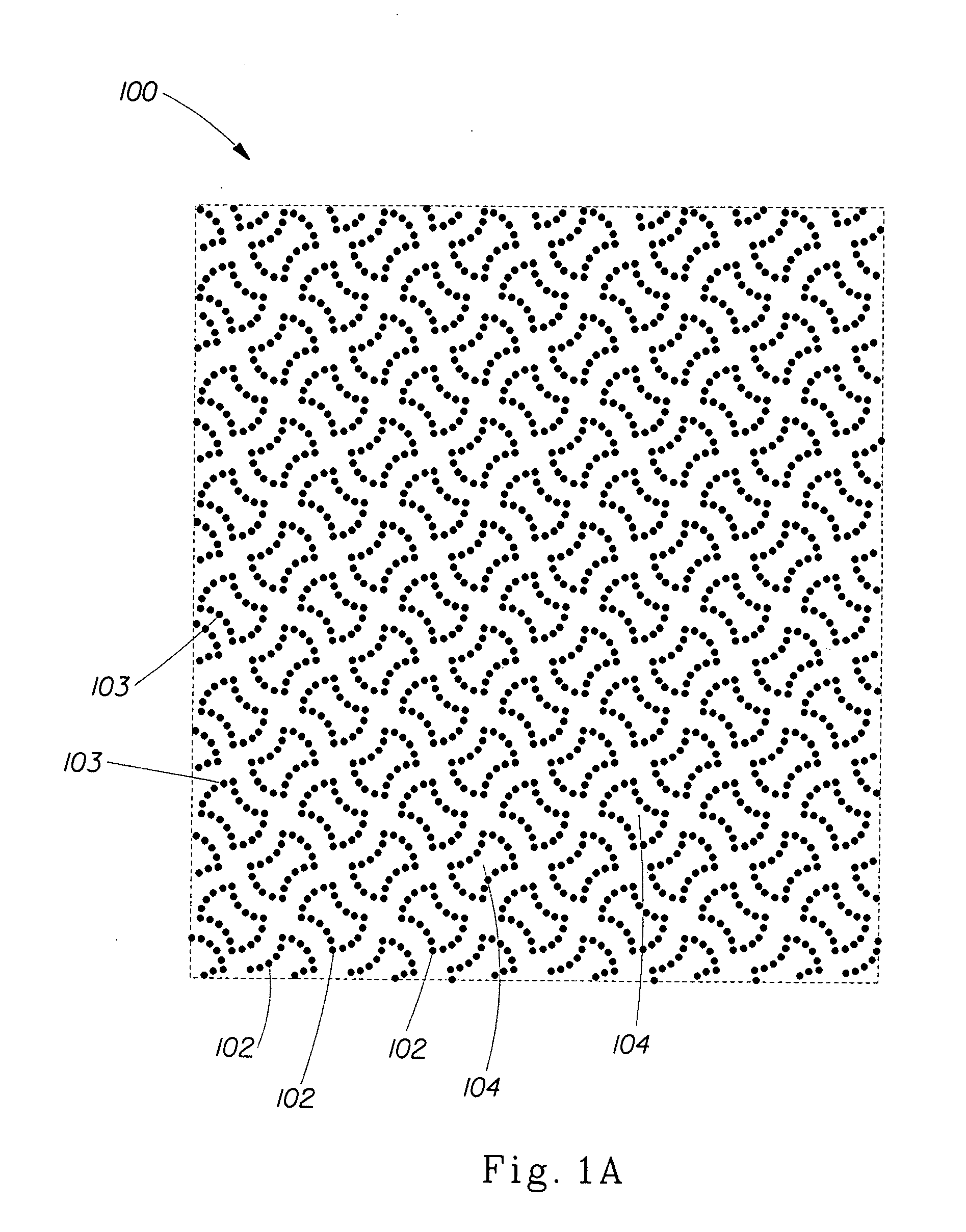

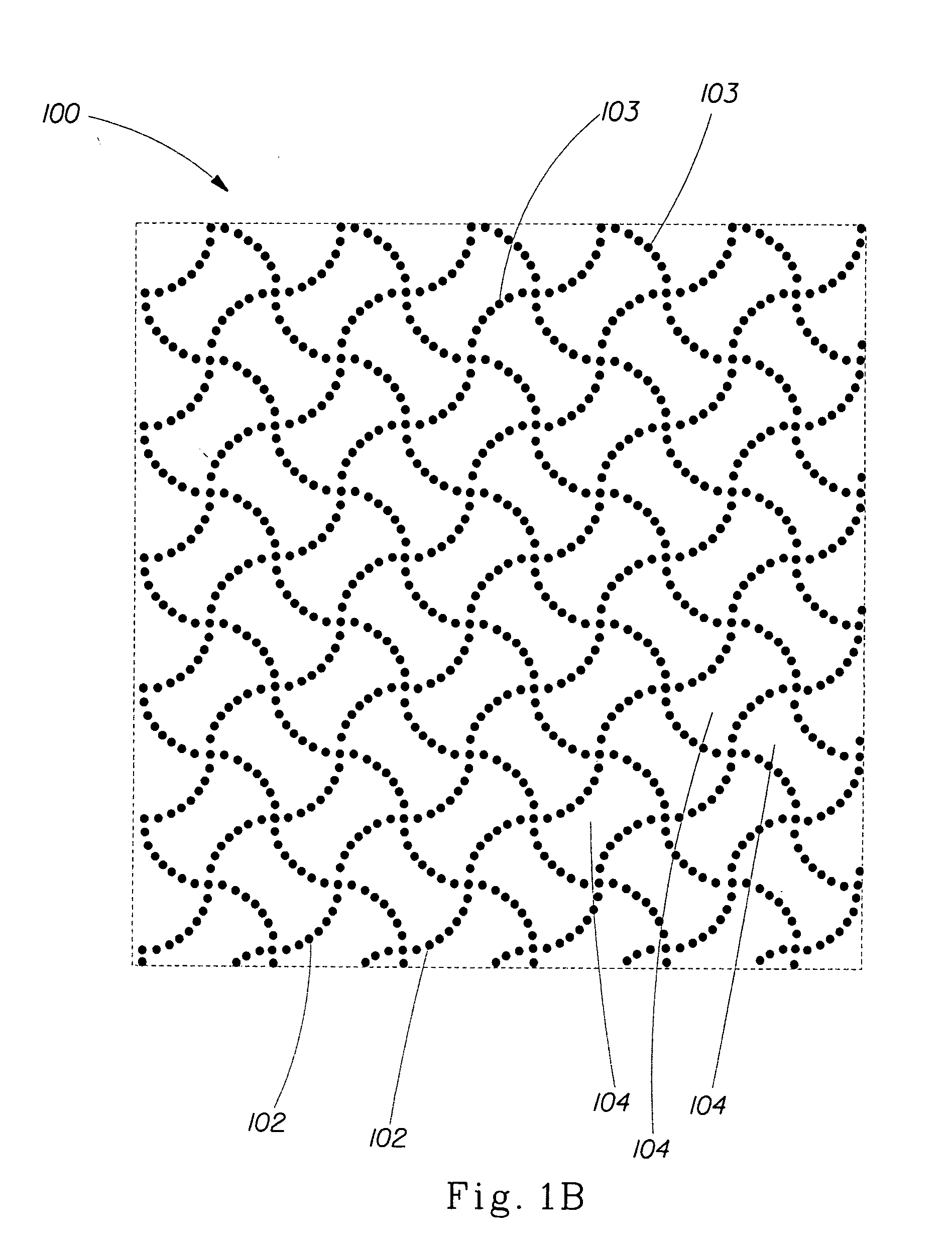

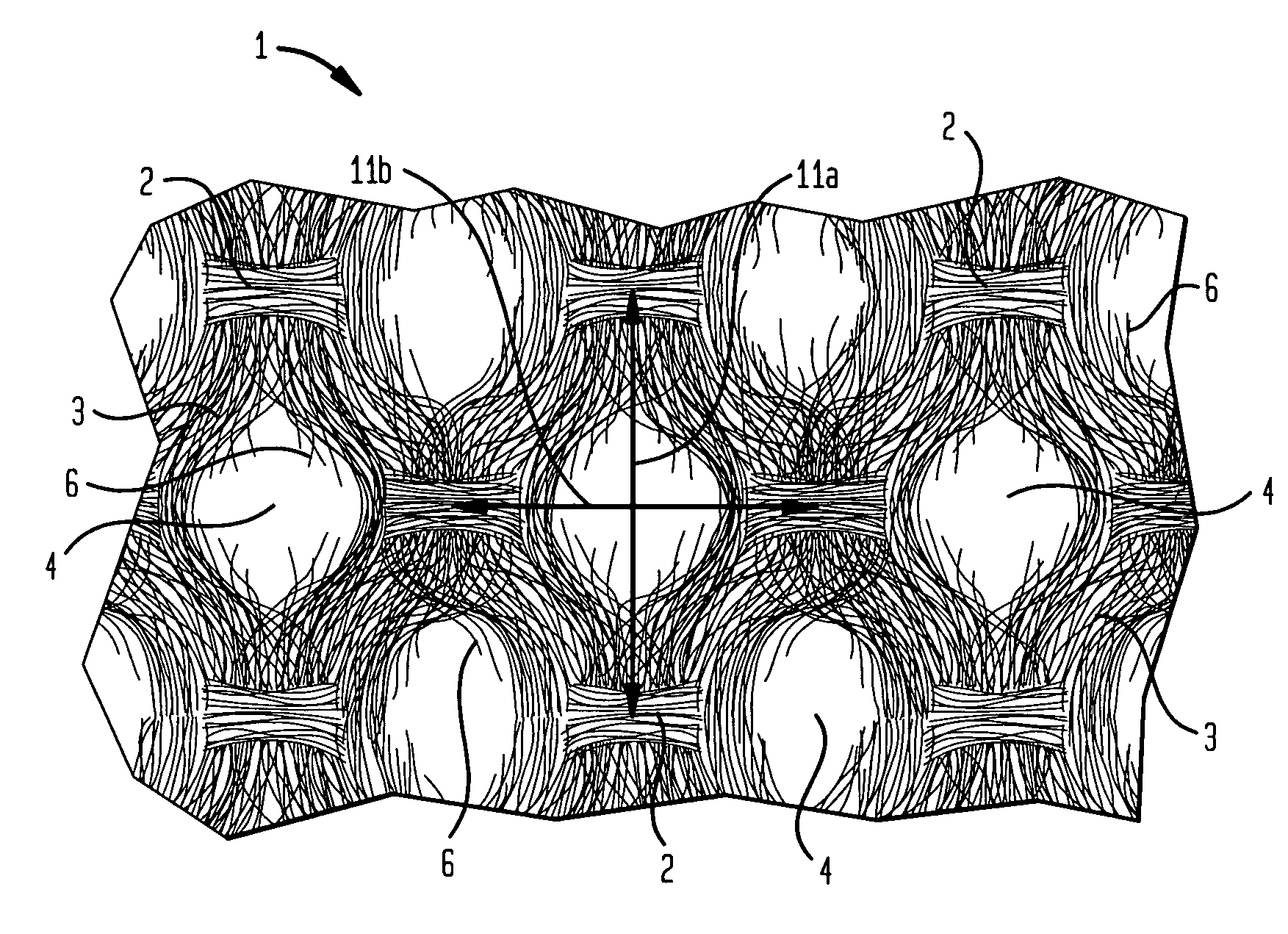

Process for making unitary fibrous structure comprising randomly distributed cellulosic fibers and non-randomly distributed synthetic fibers

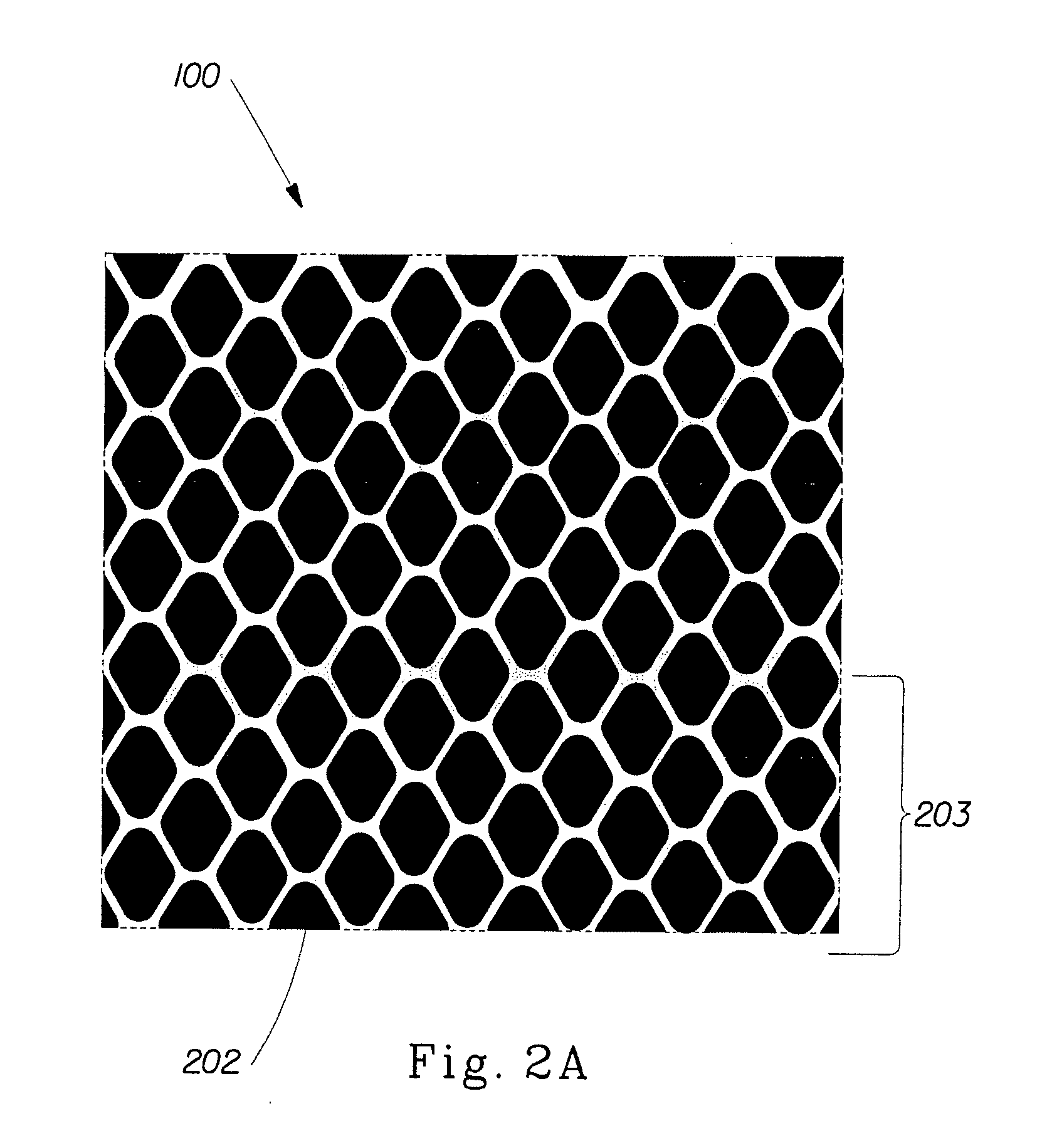

InactiveUS7067038B2High densityNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceRepeat pattern

Owner:THE PROCTER & GAMBLE COMPANY

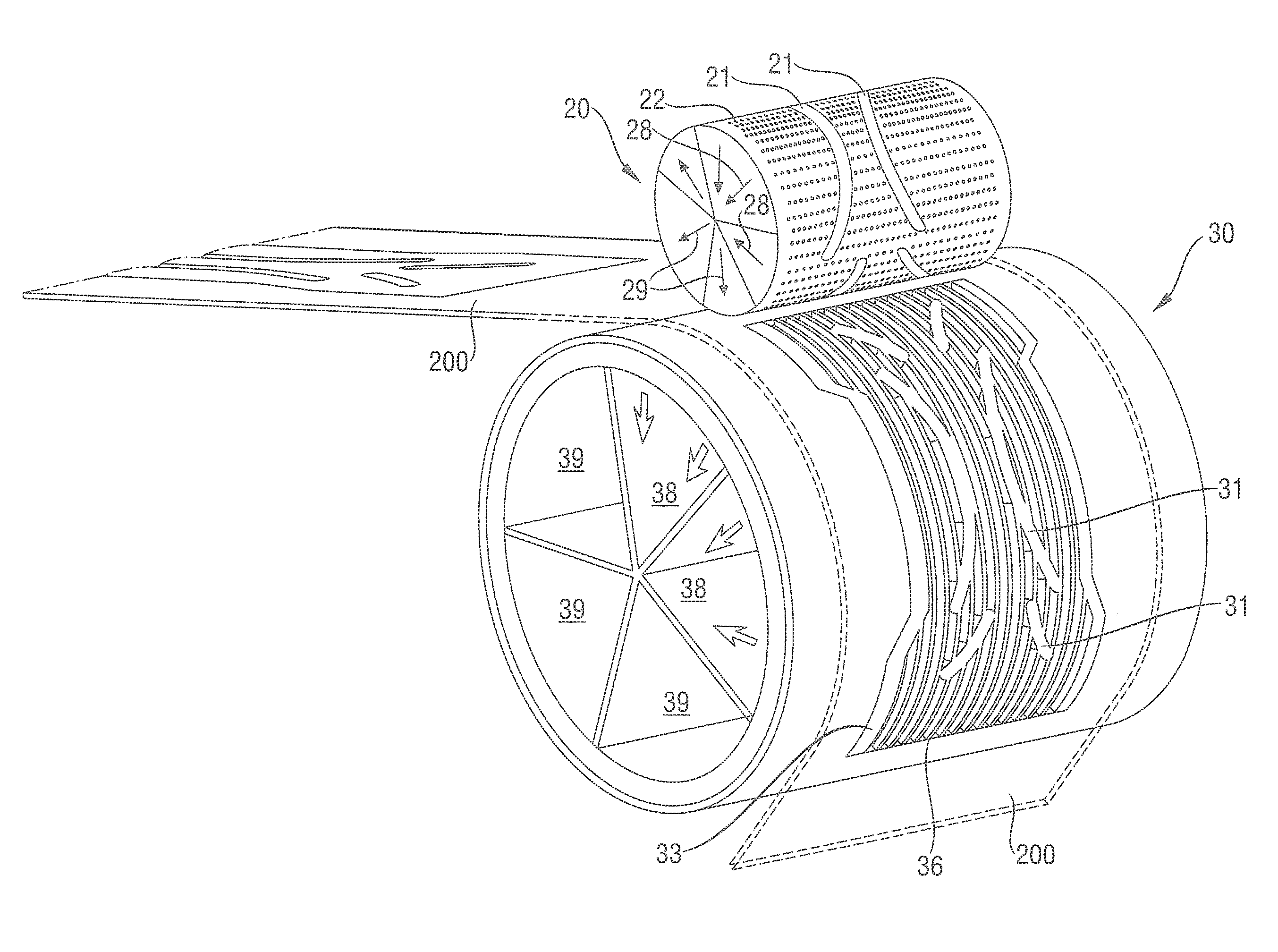

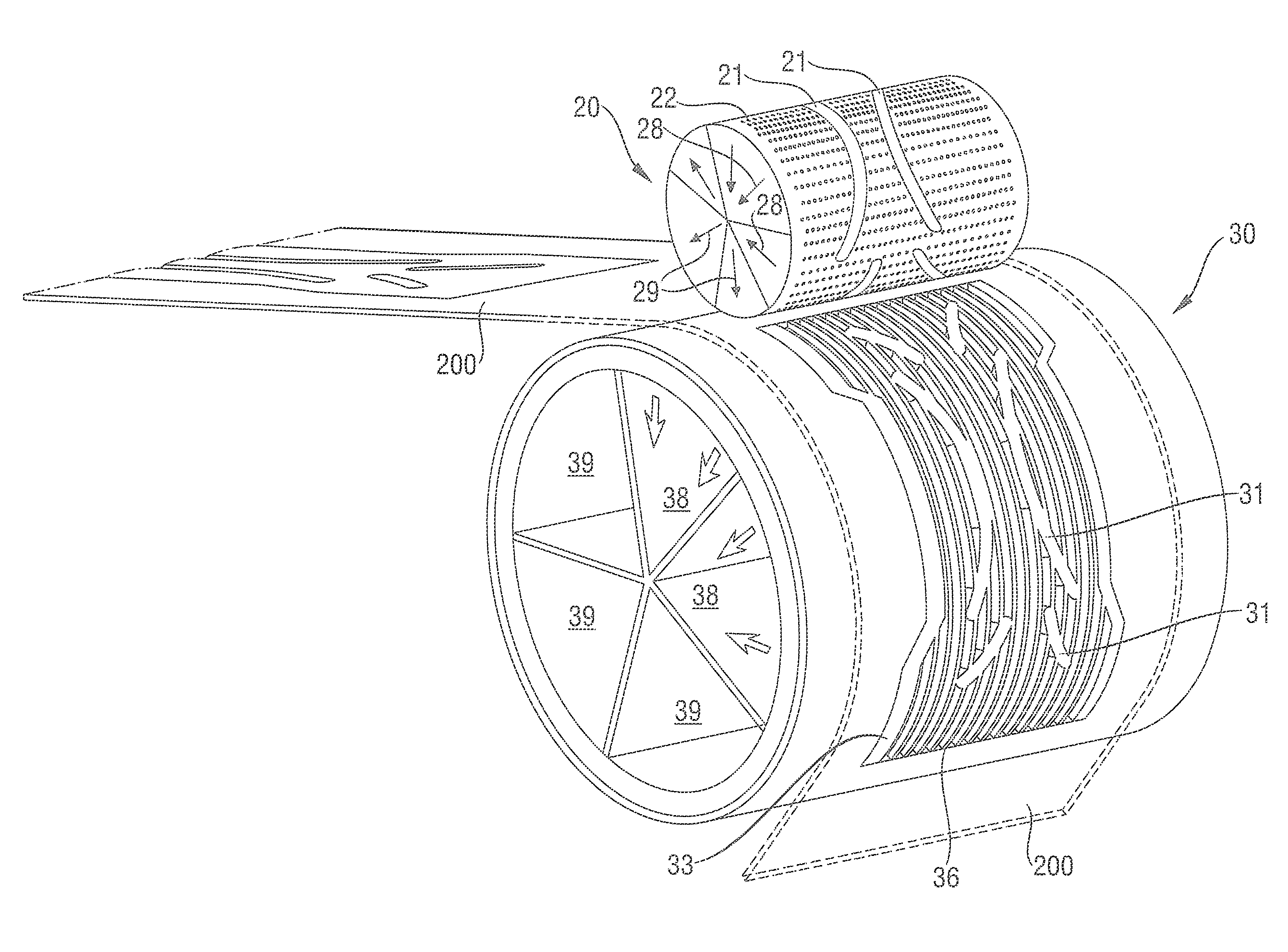

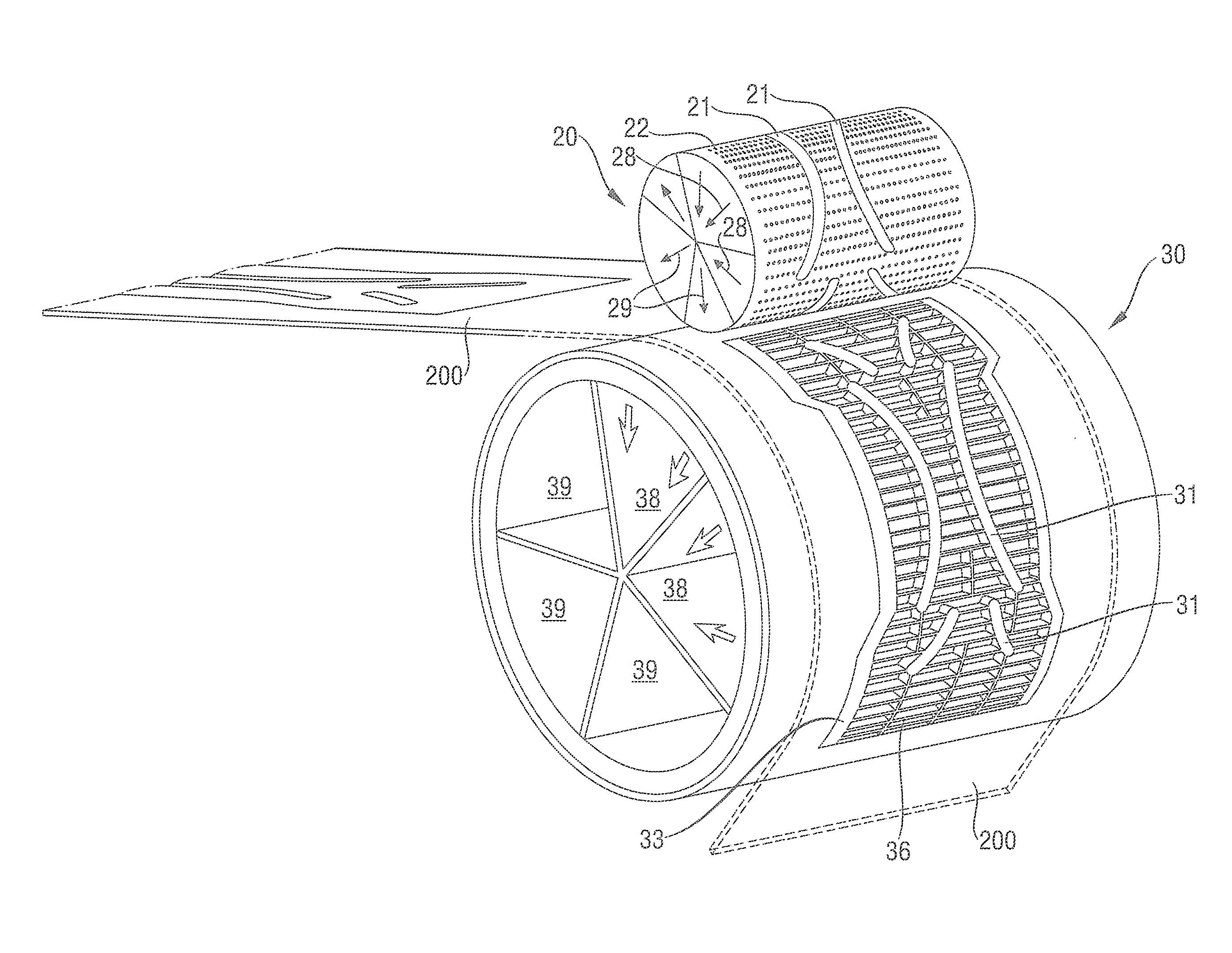

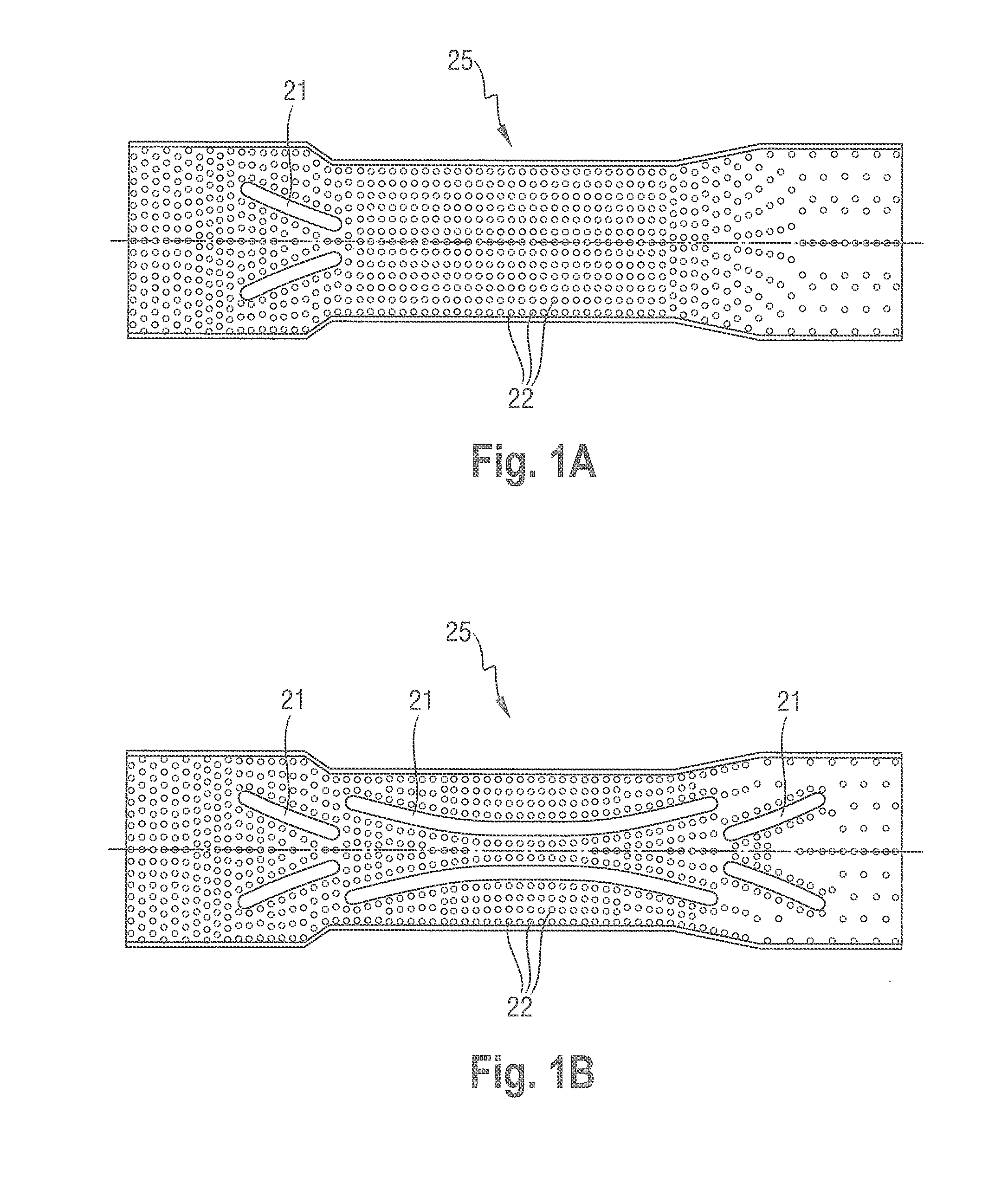

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

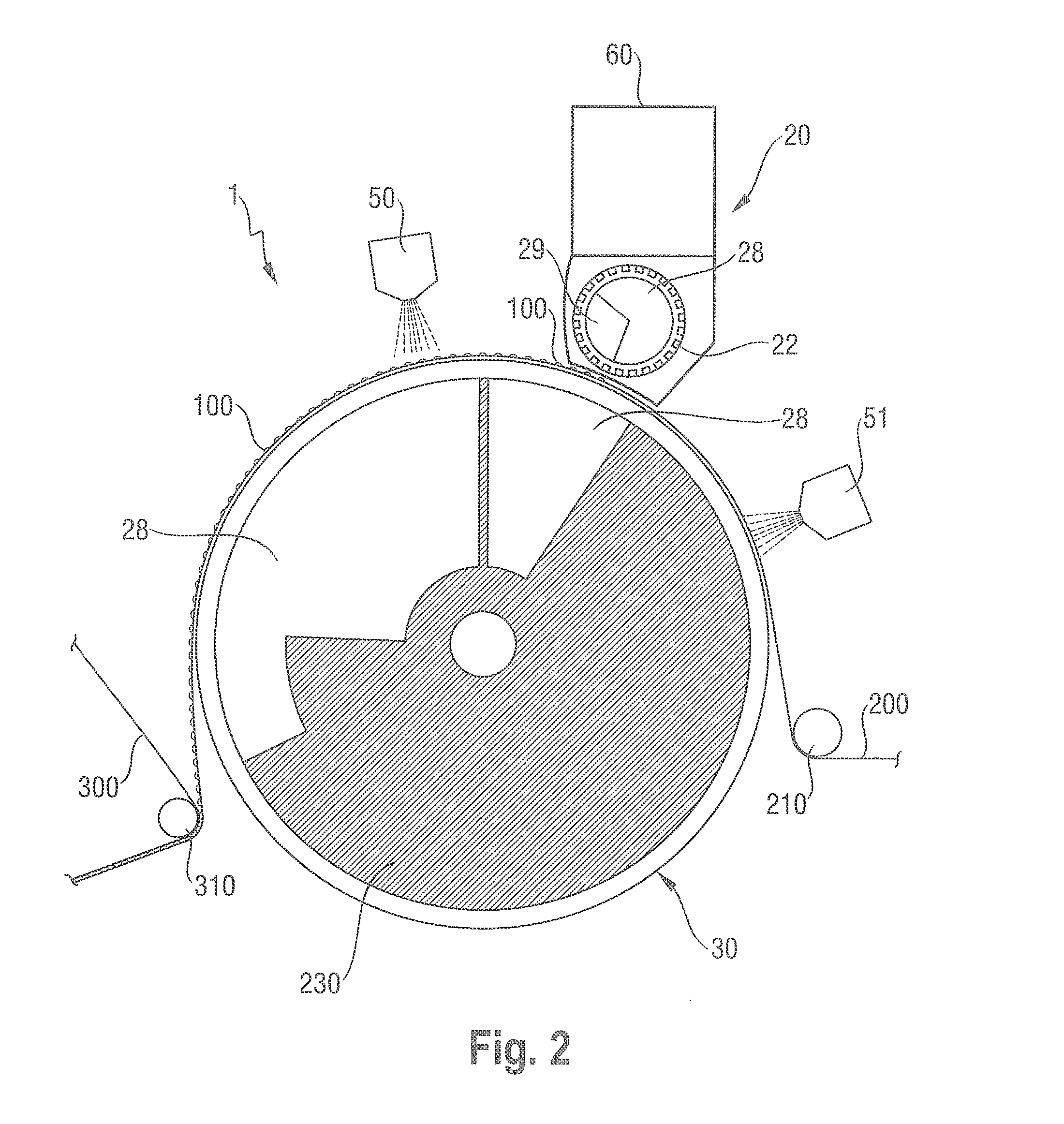

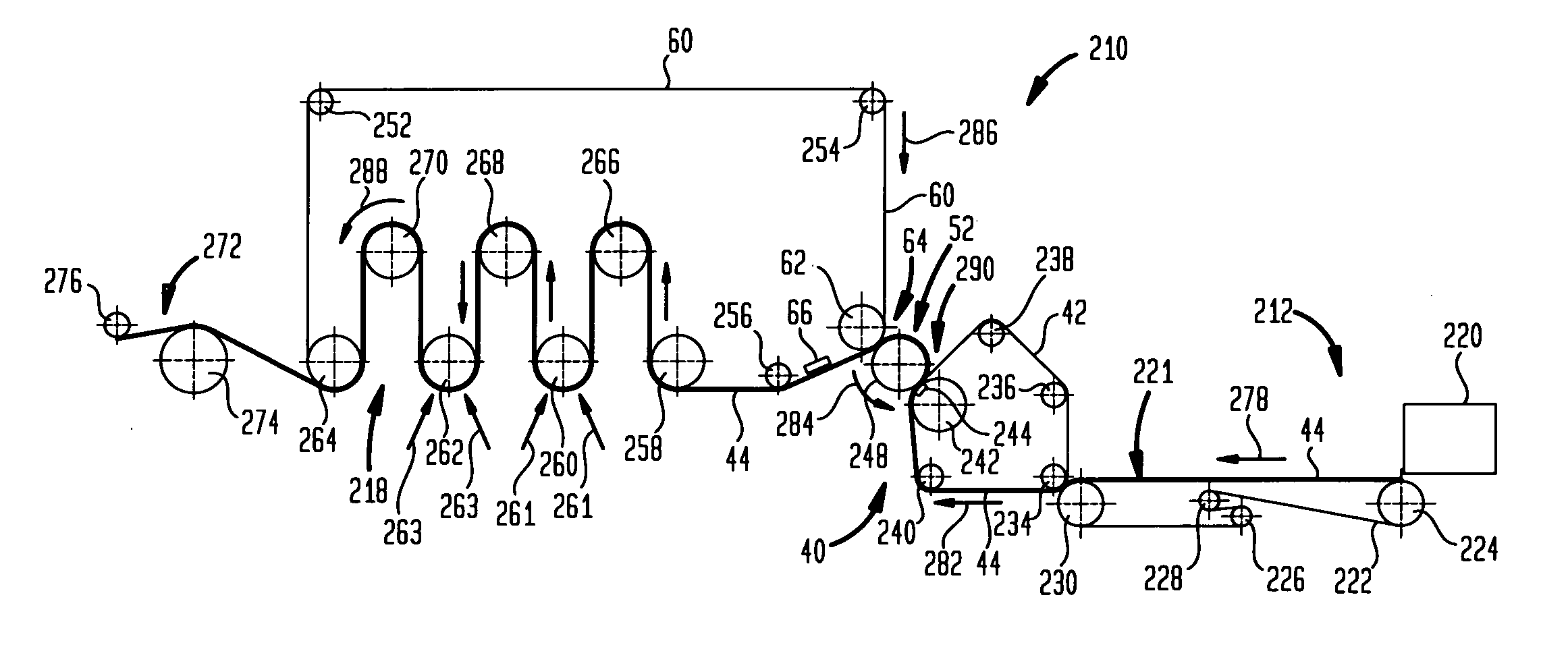

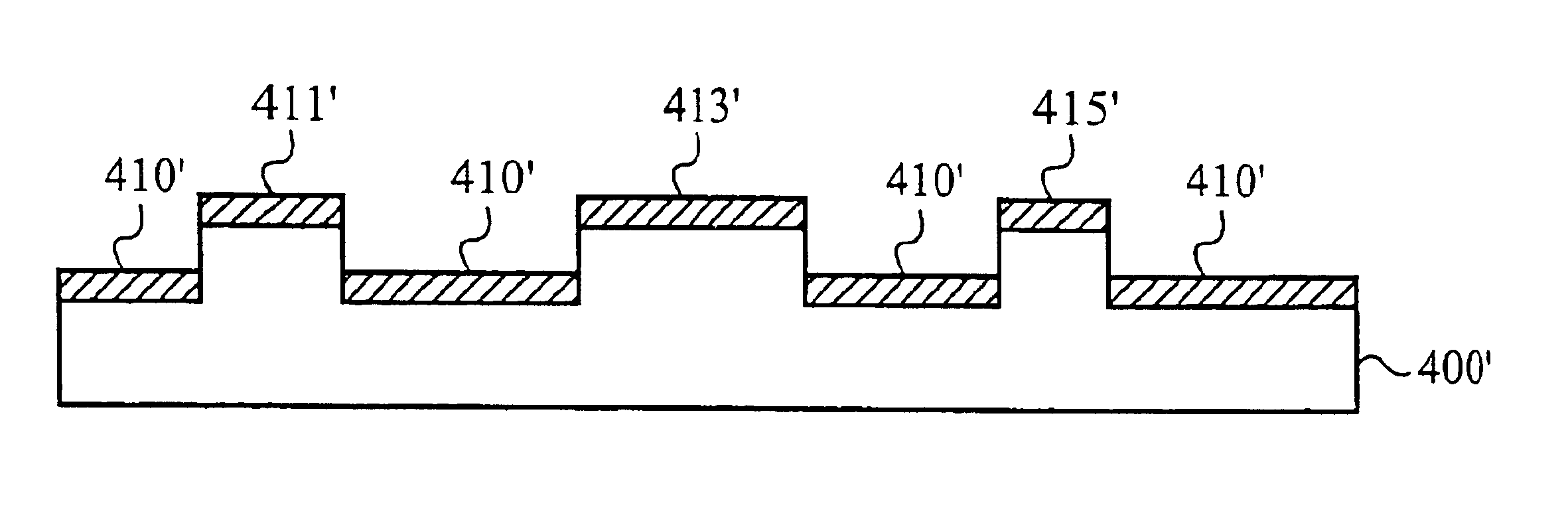

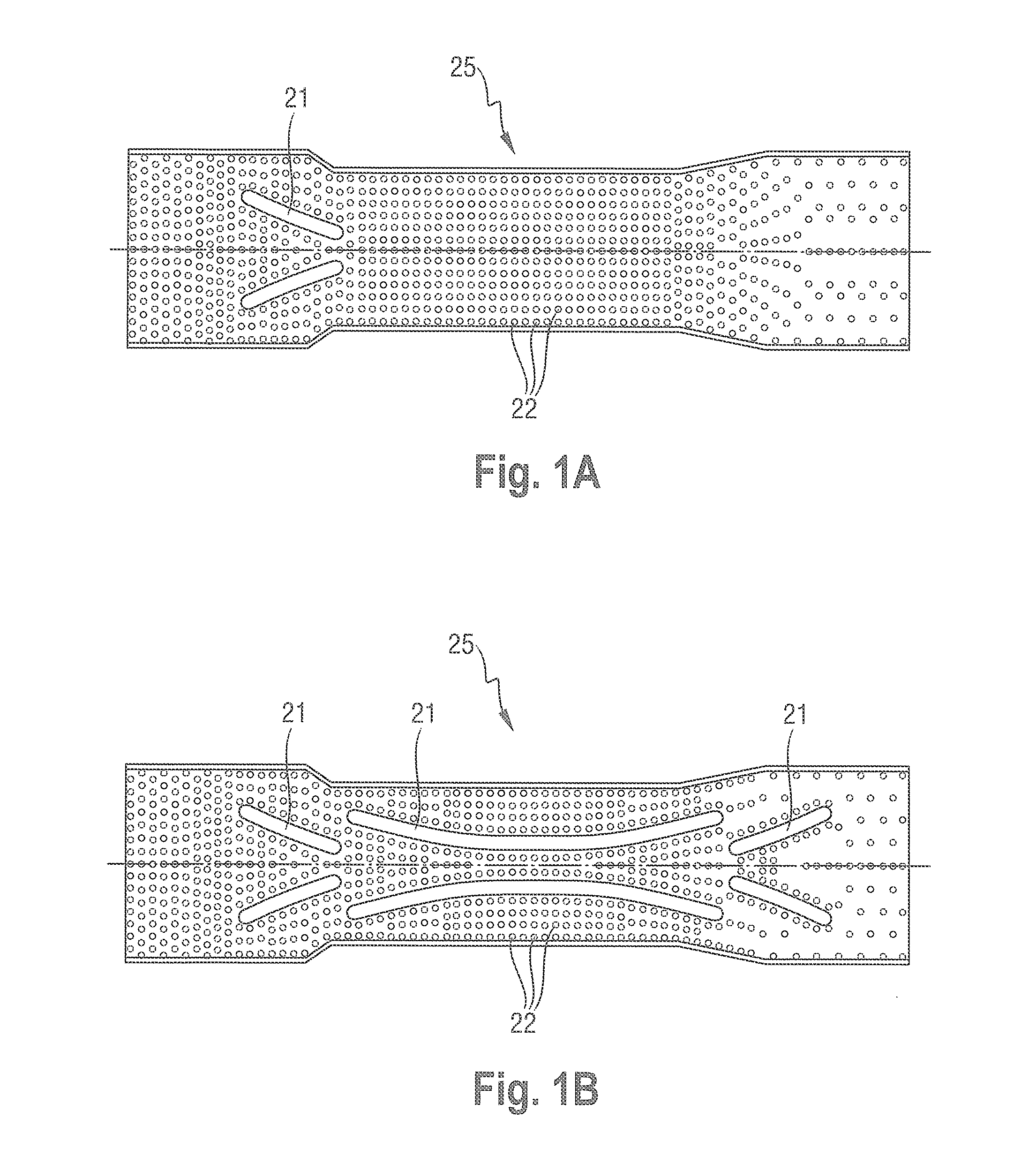

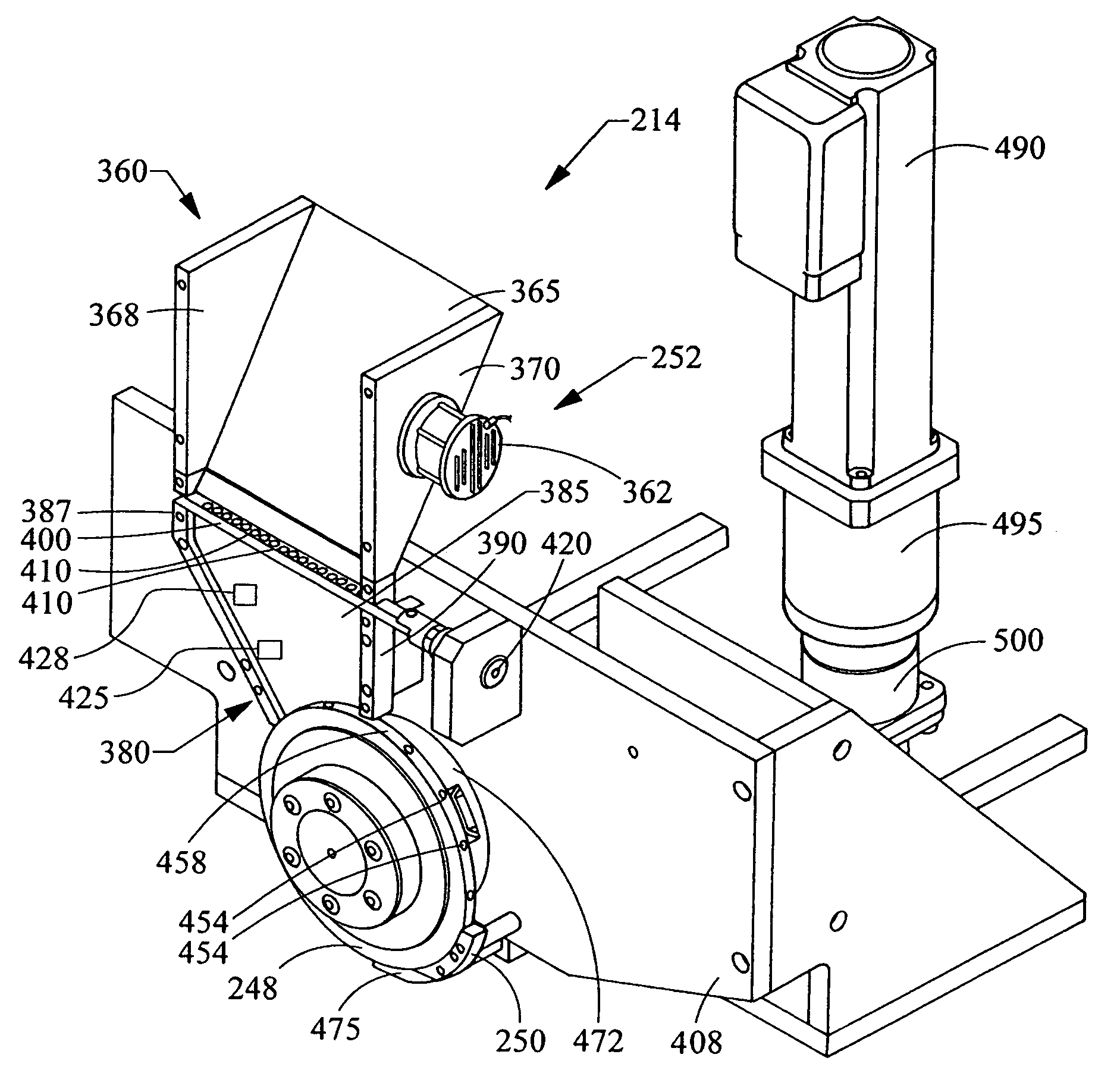

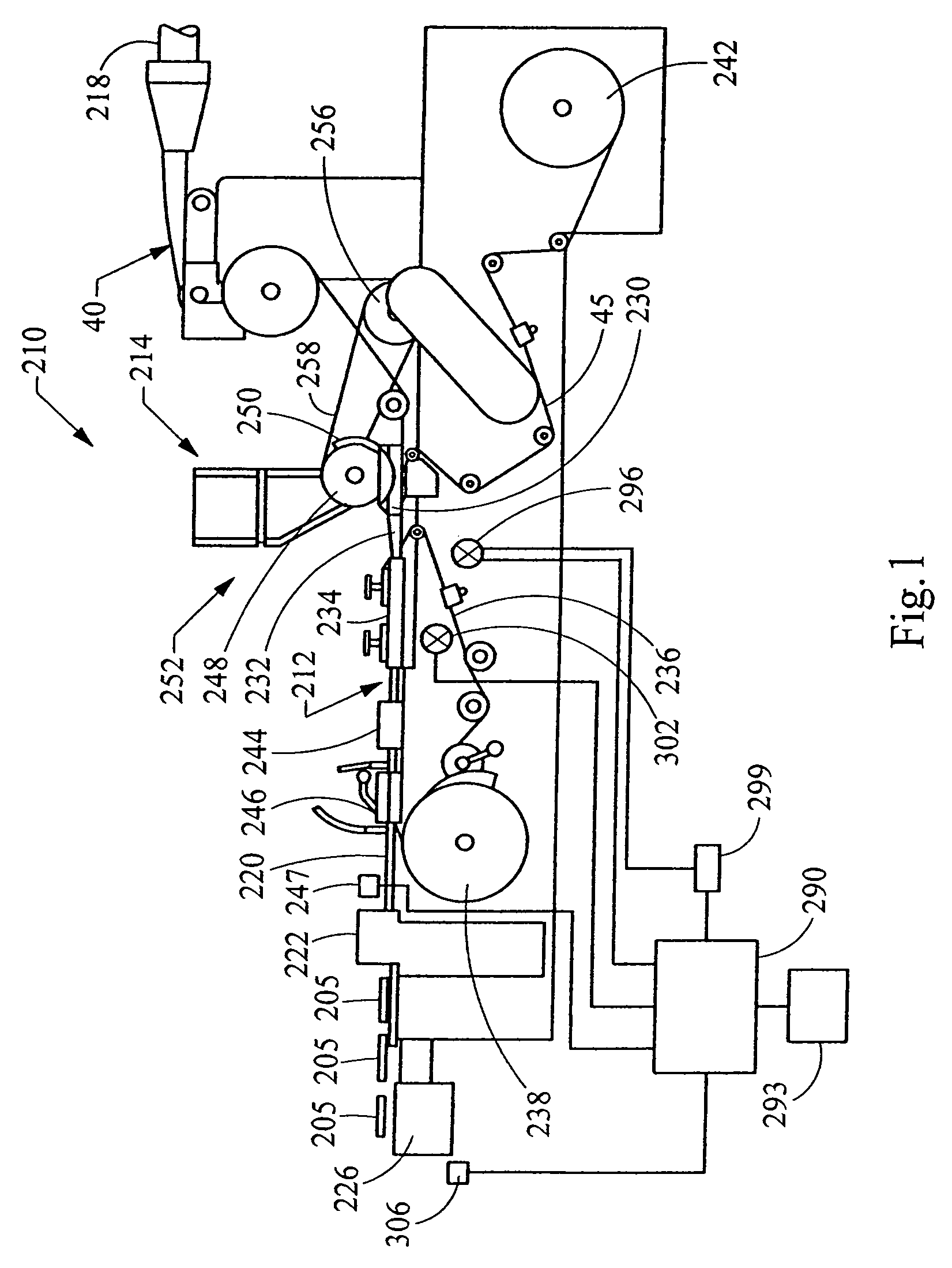

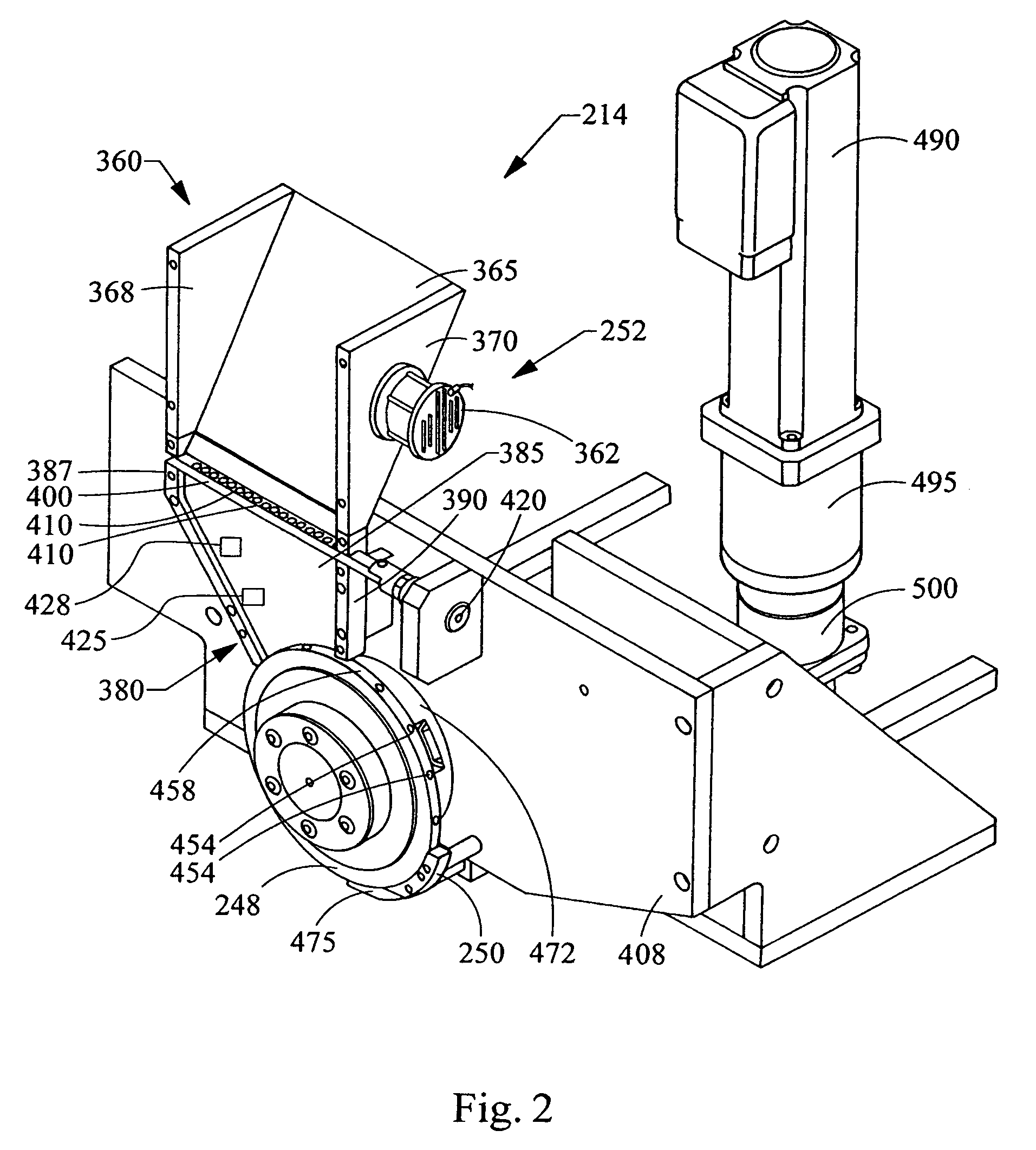

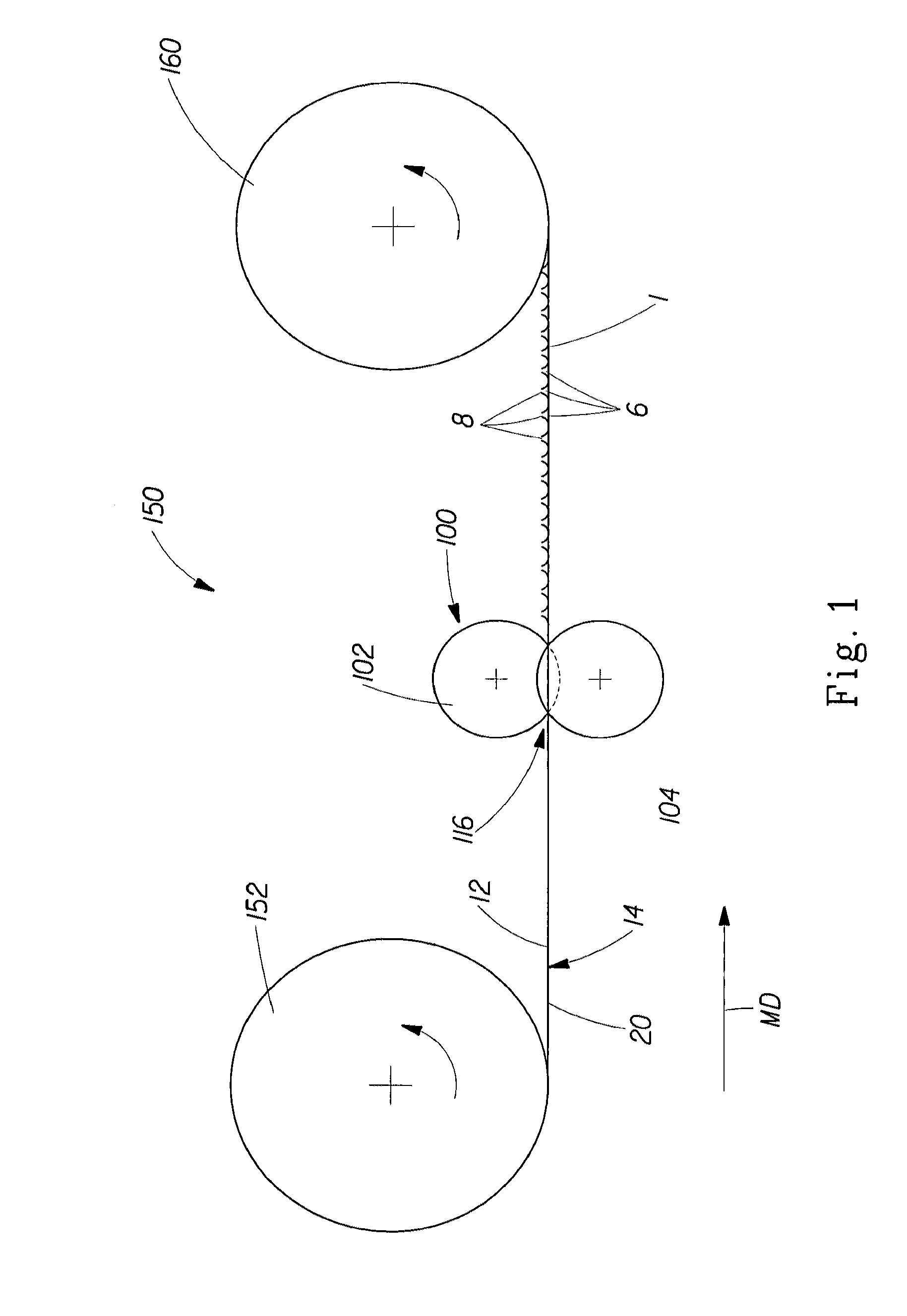

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

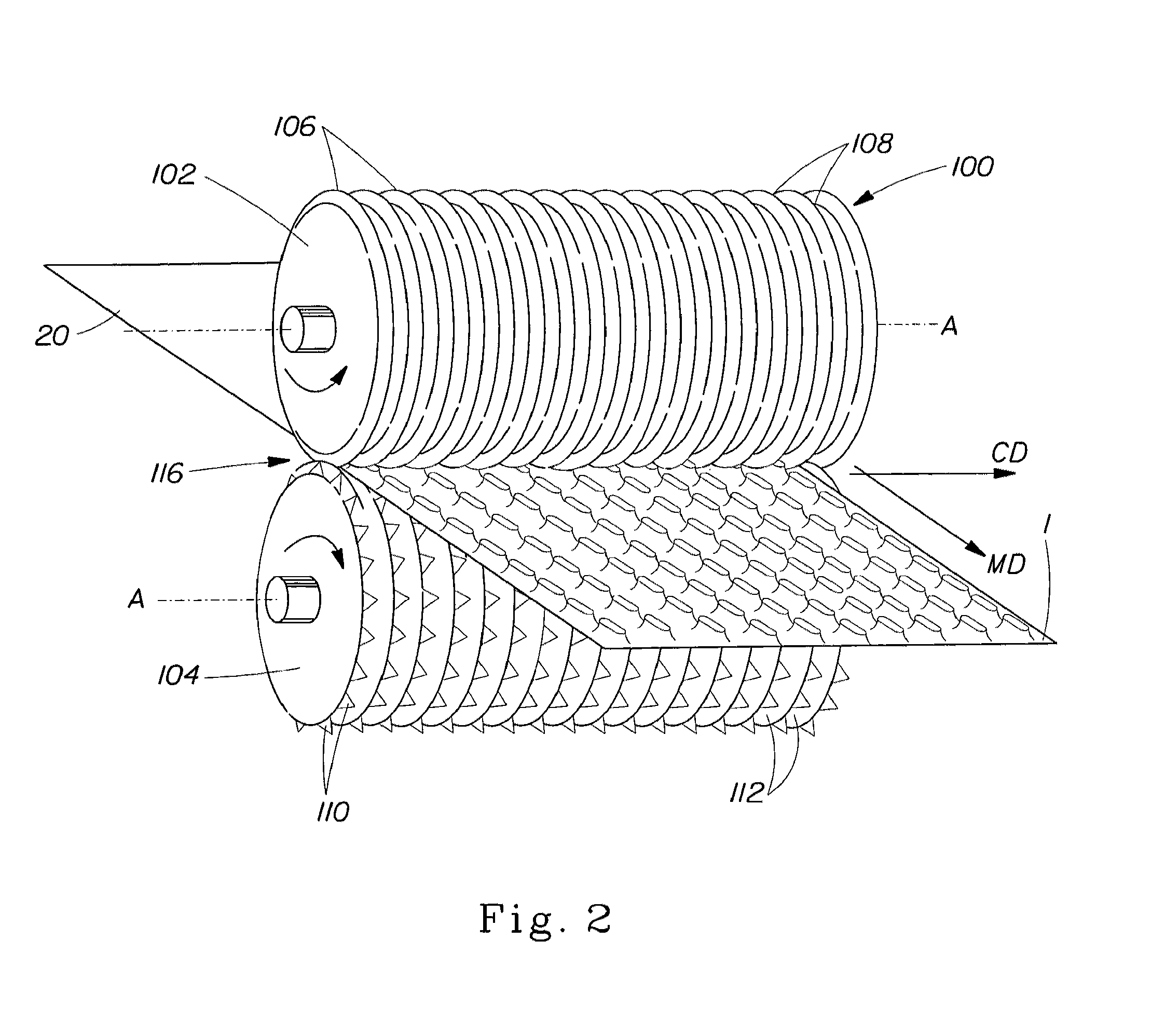

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

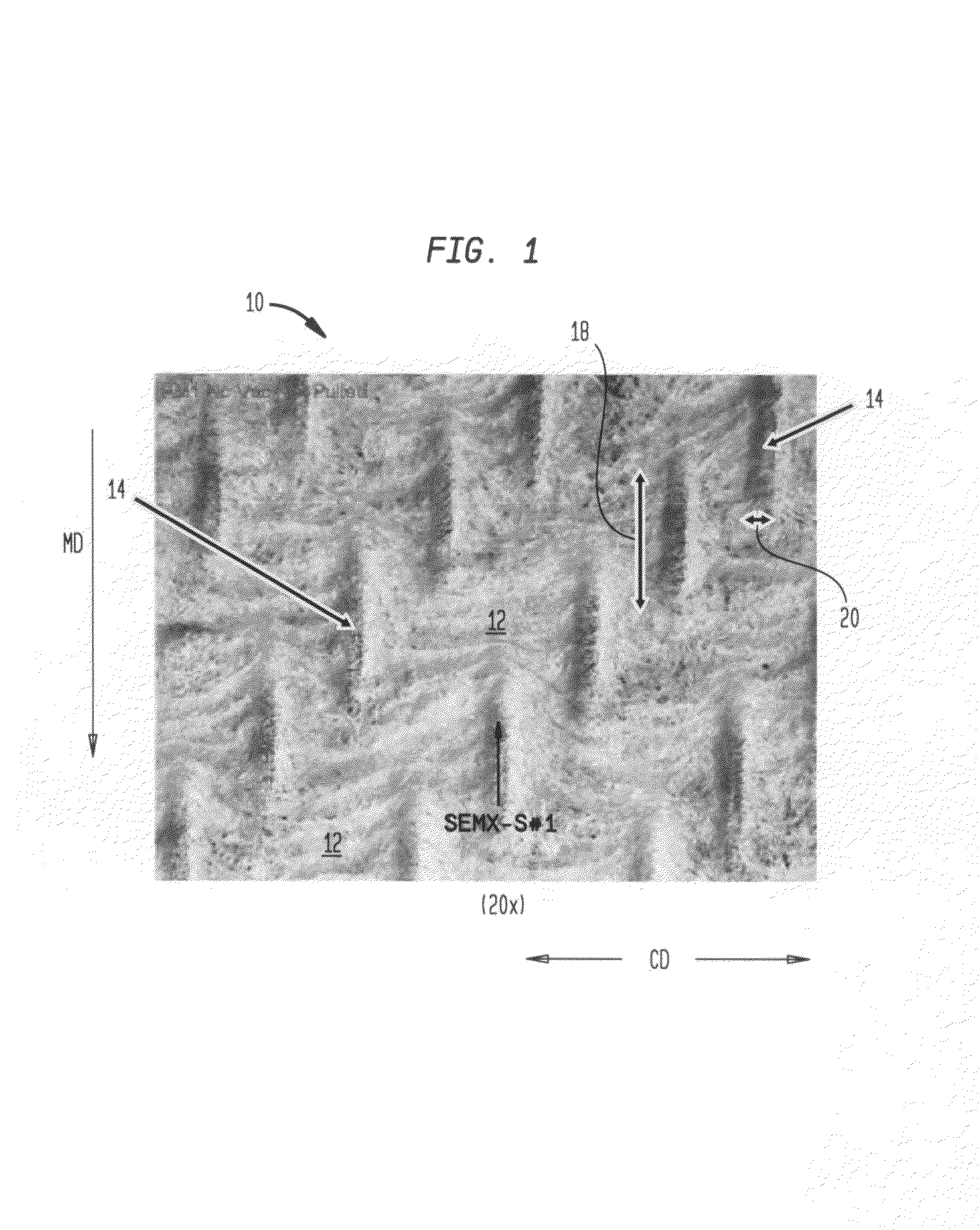

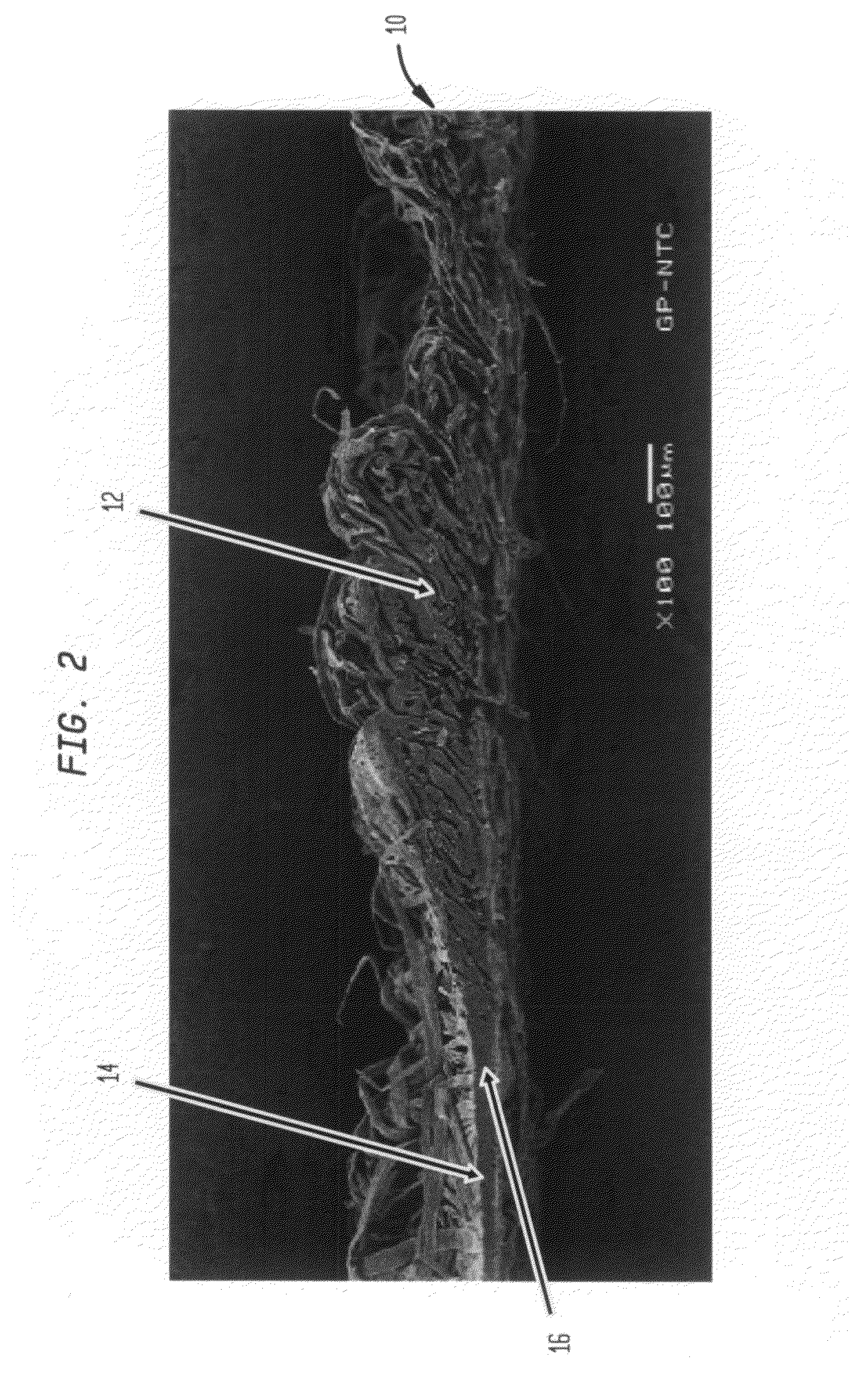

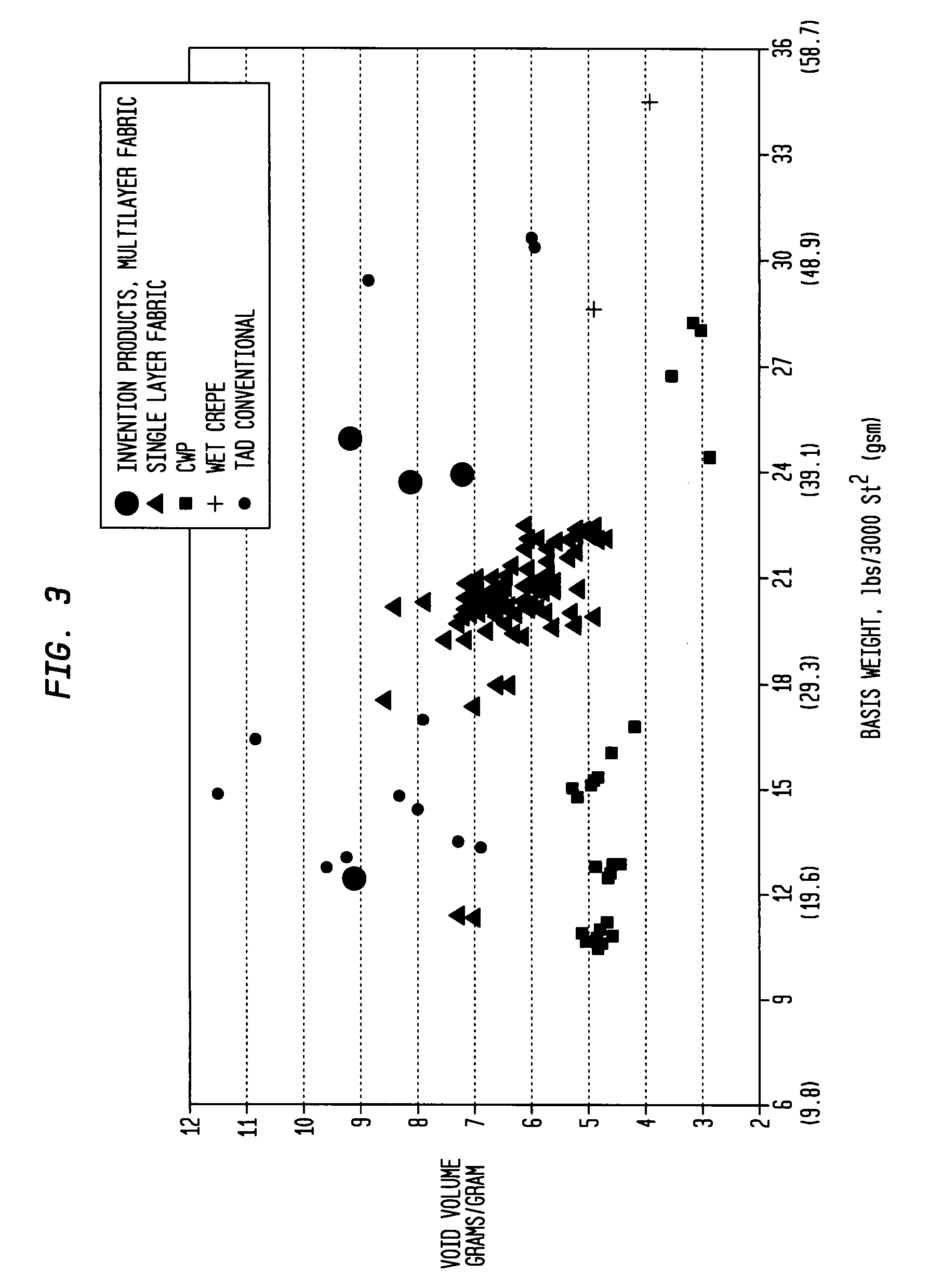

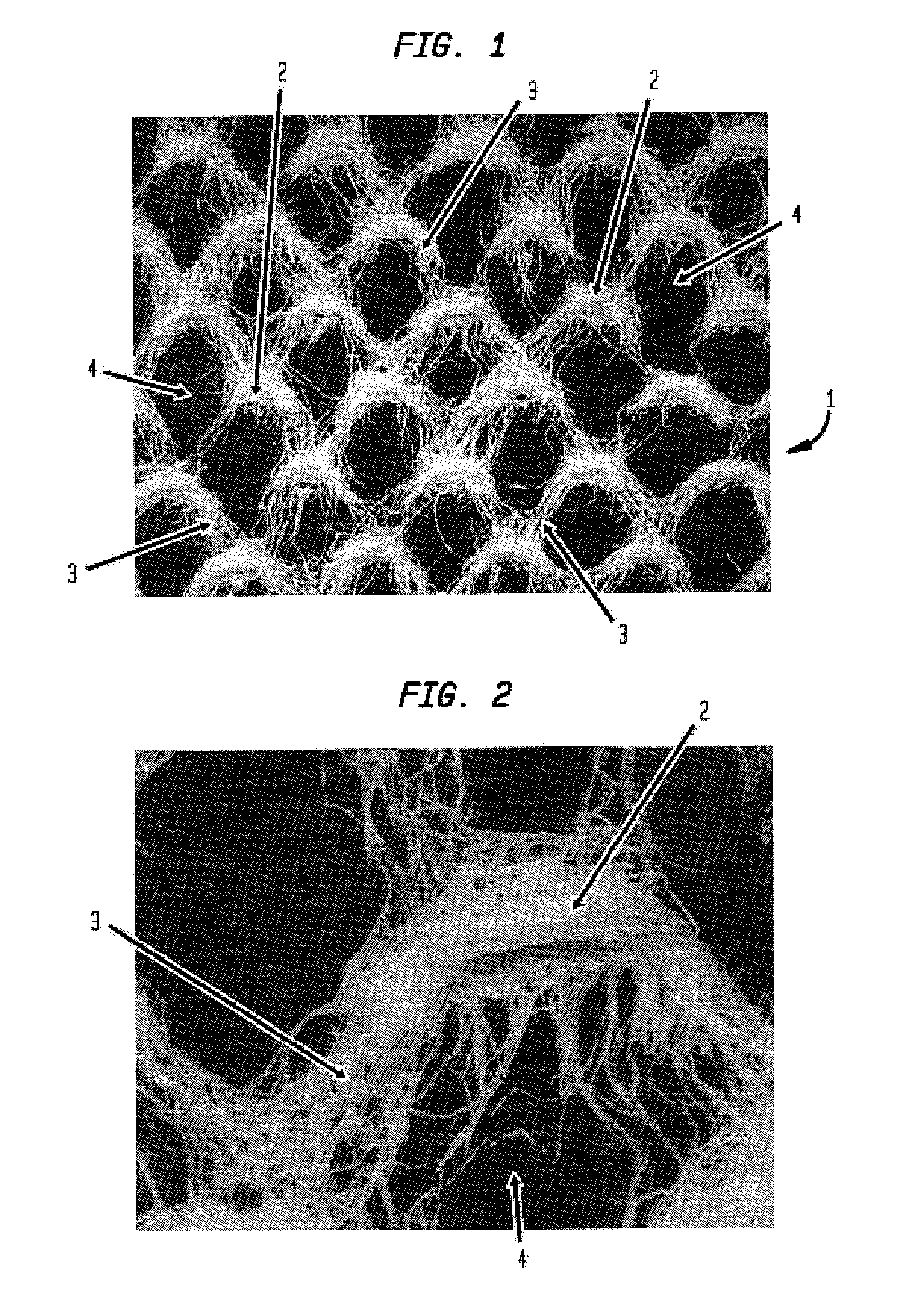

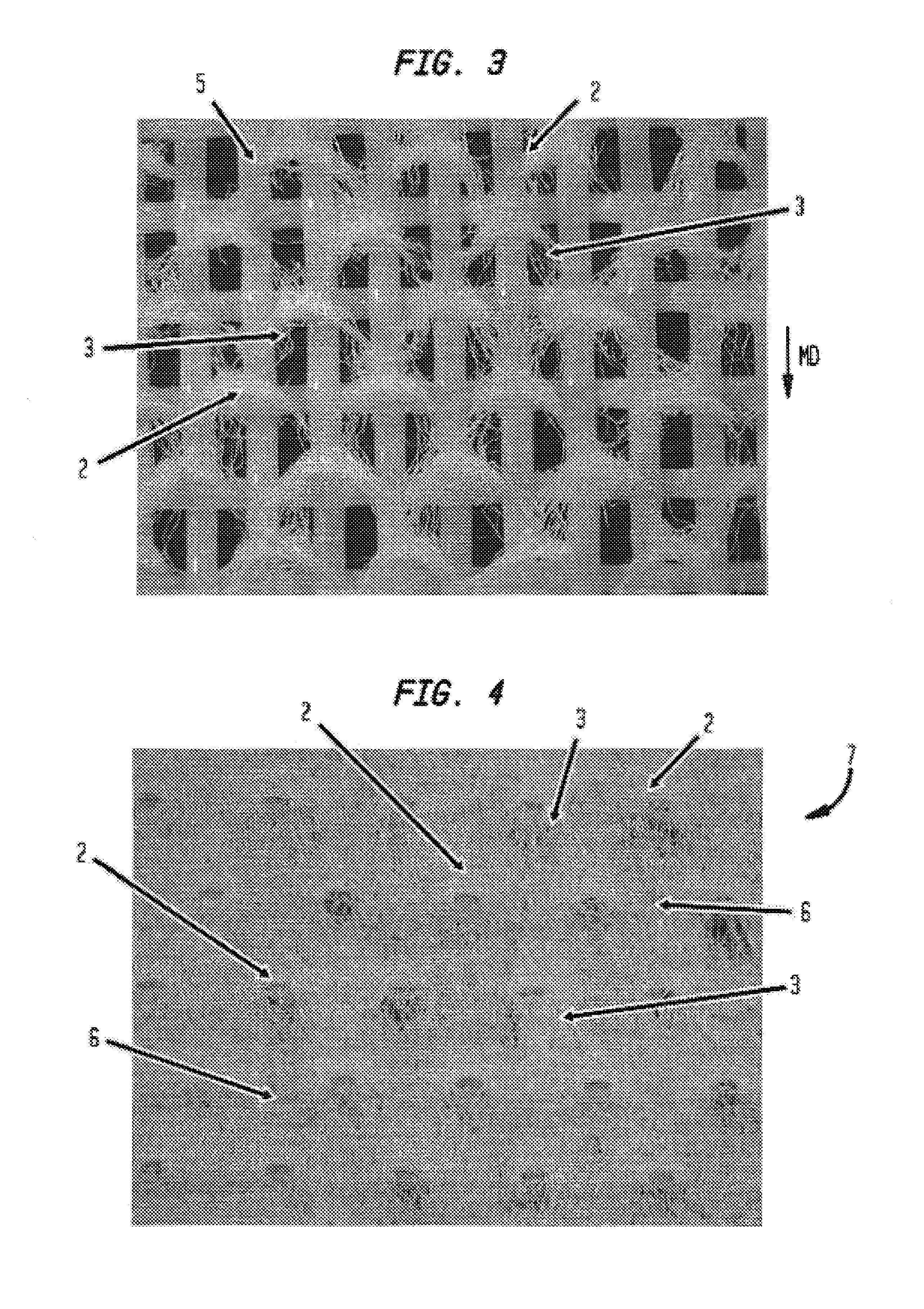

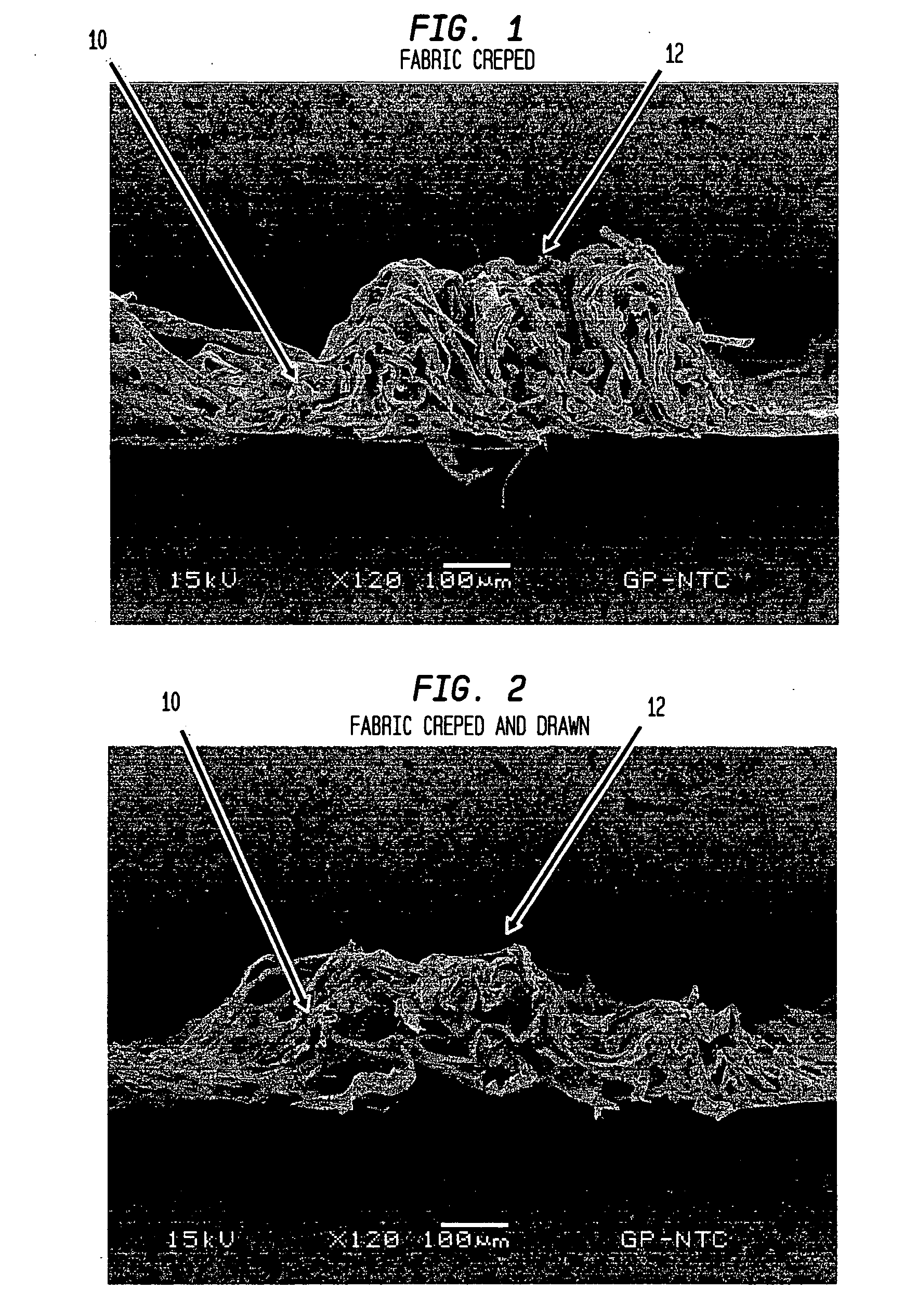

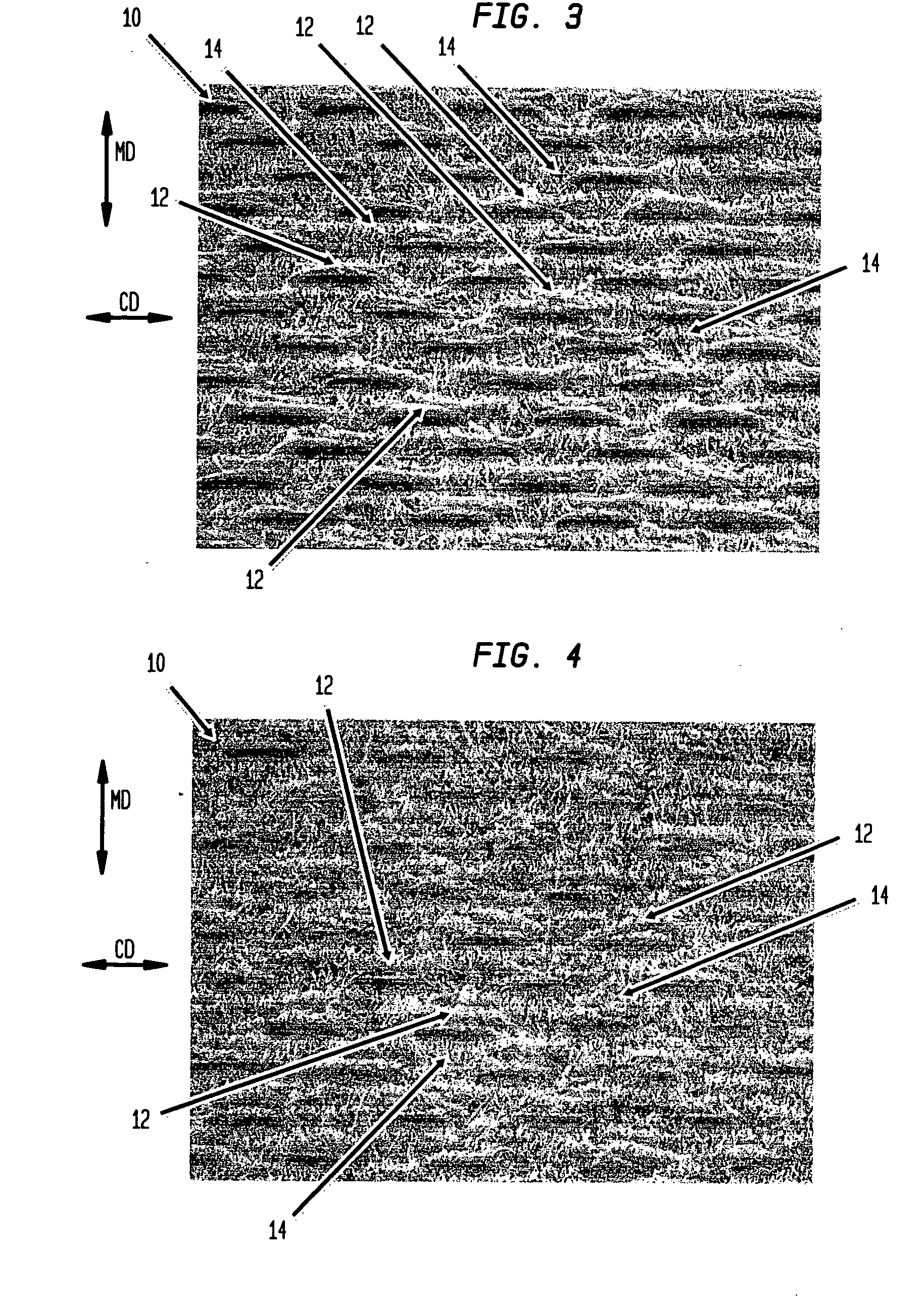

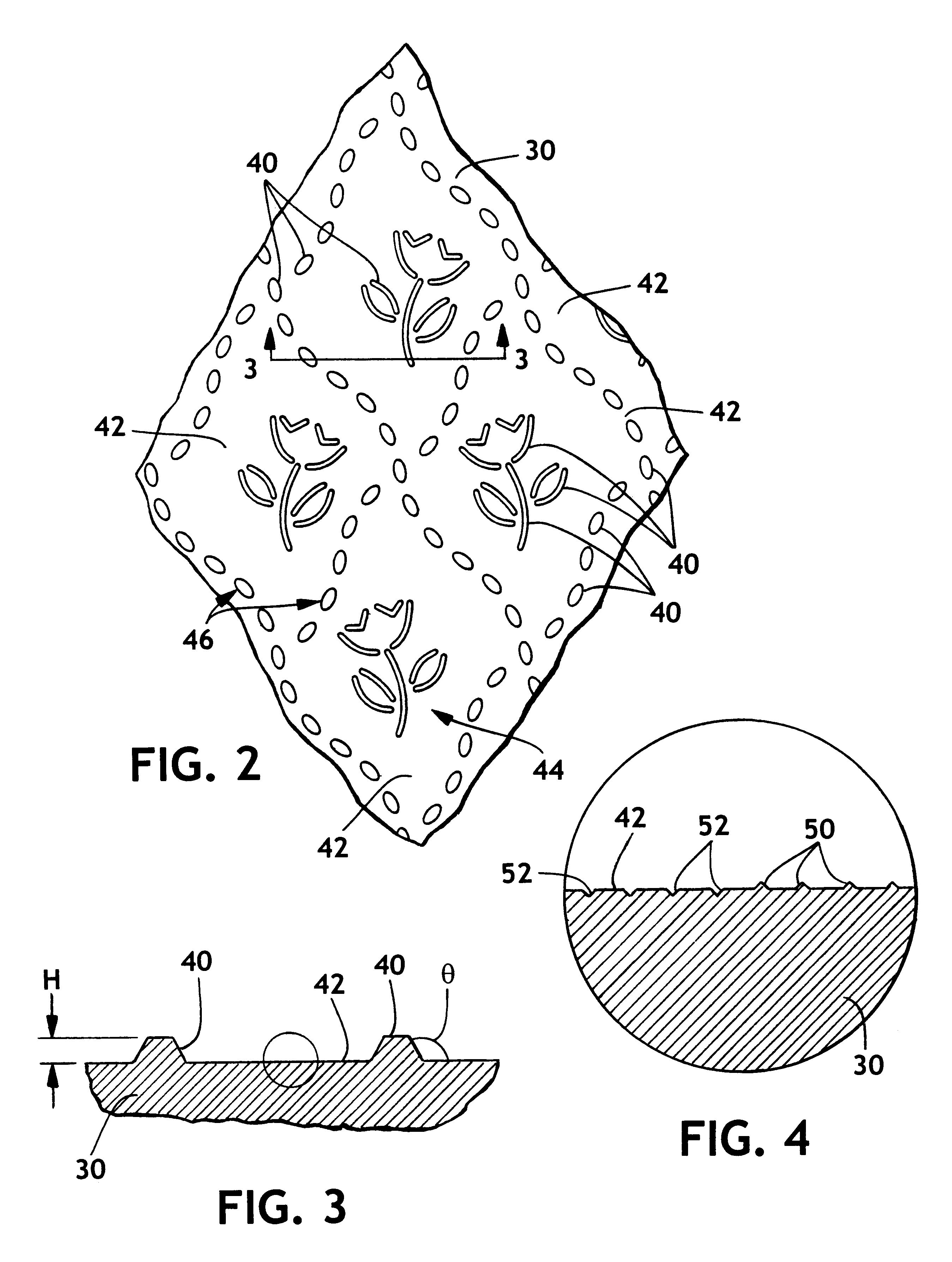

Fabric creped absorbent sheet with variable local basis weight

InactiveUS7494563B2Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

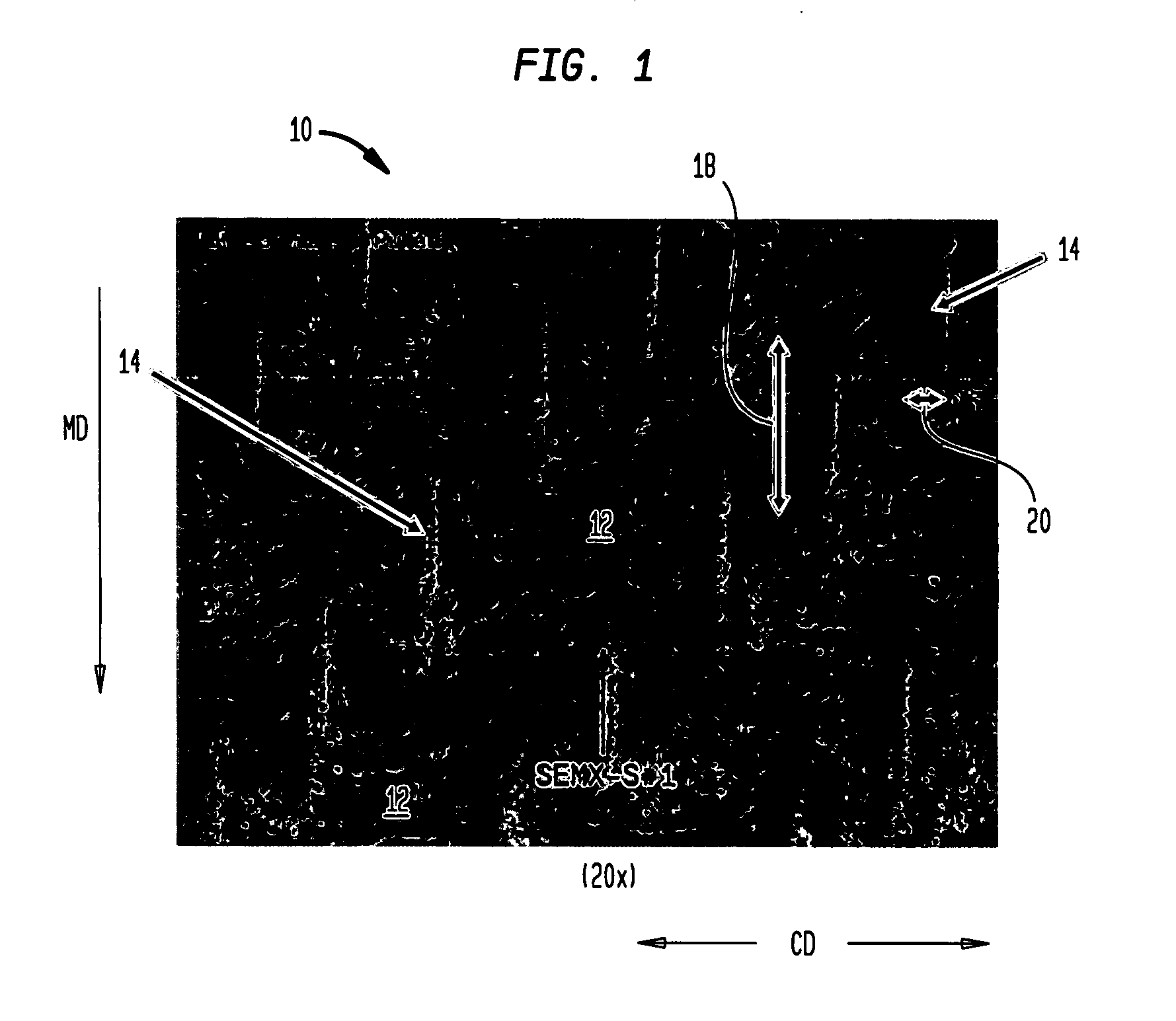

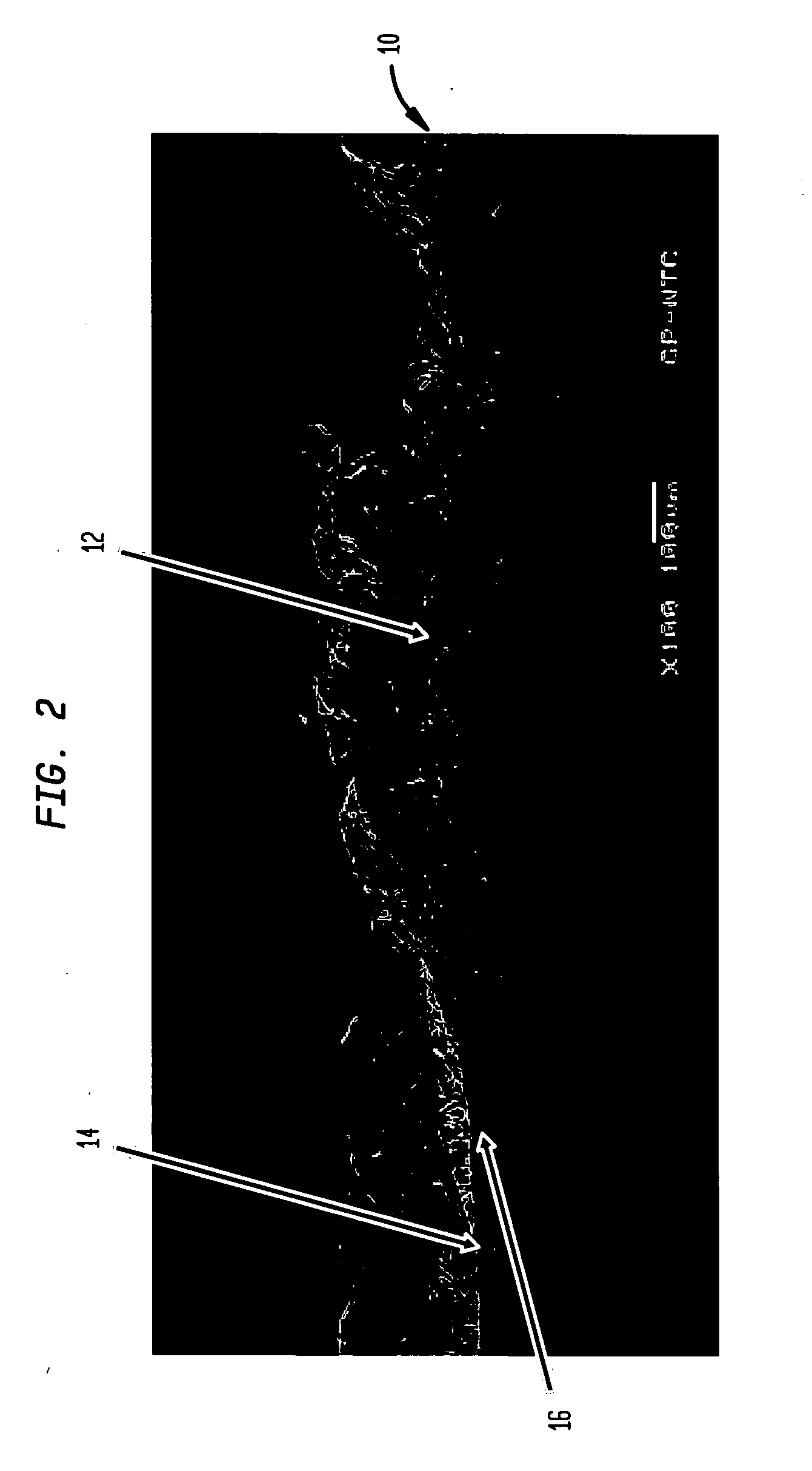

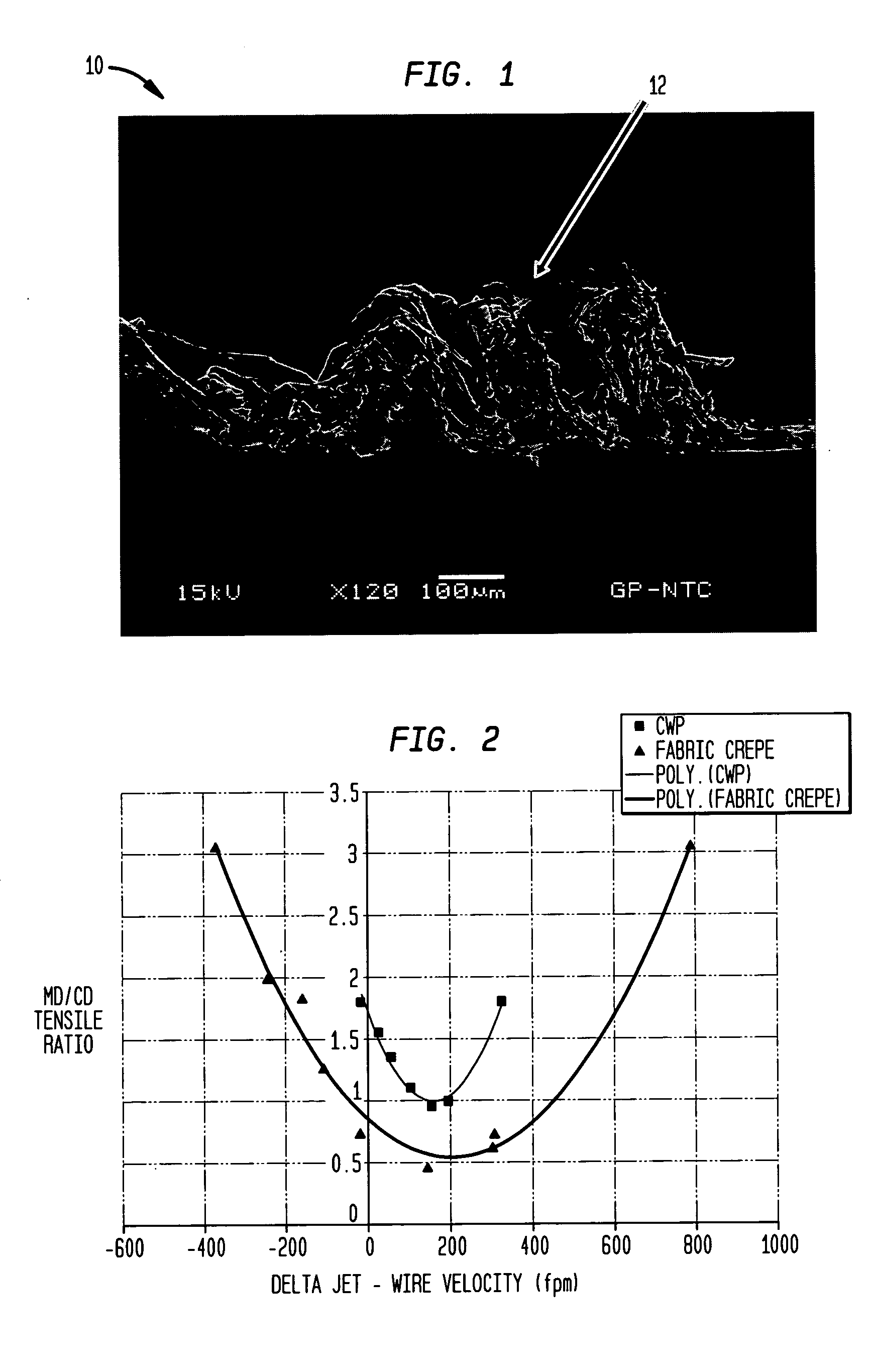

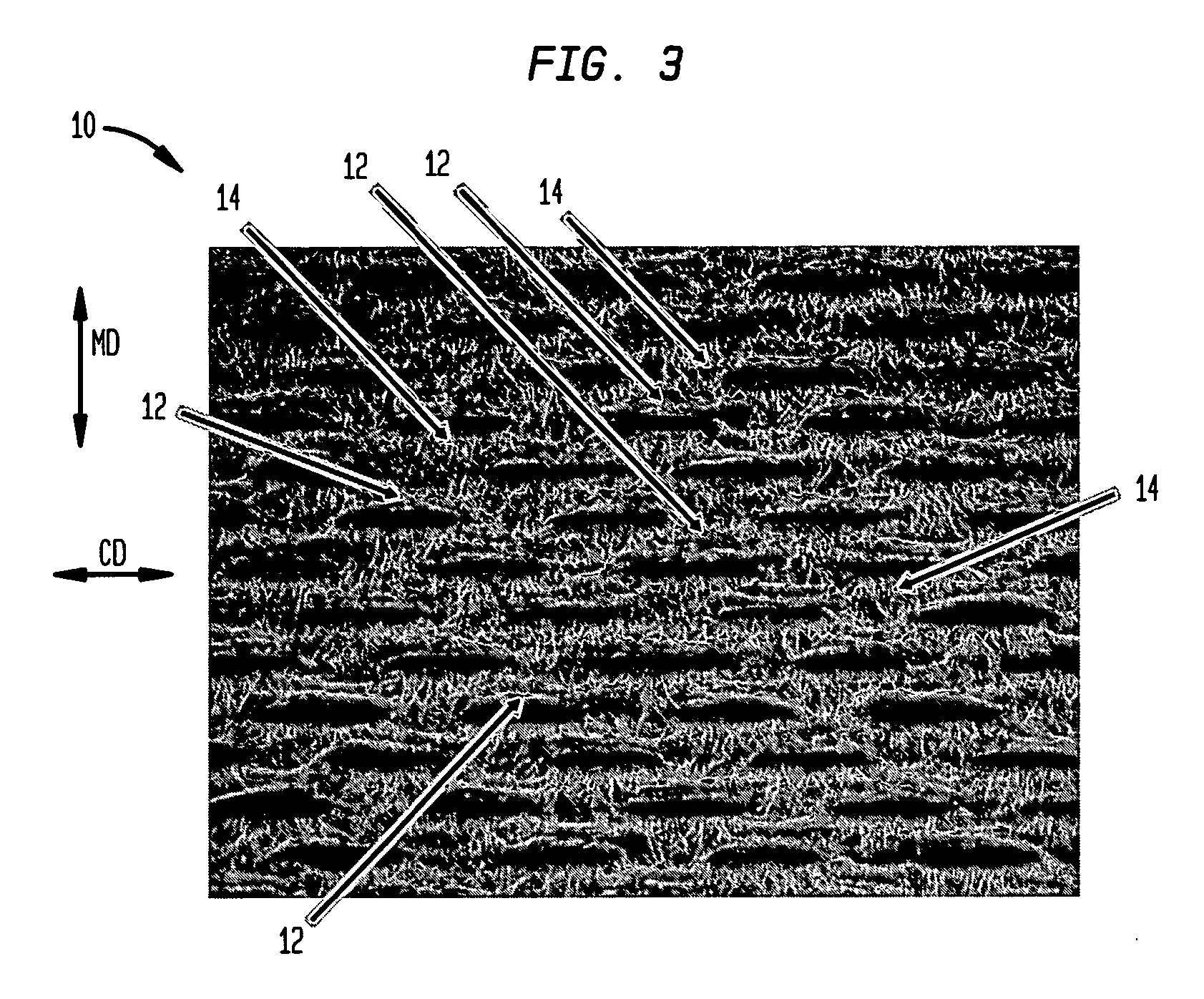

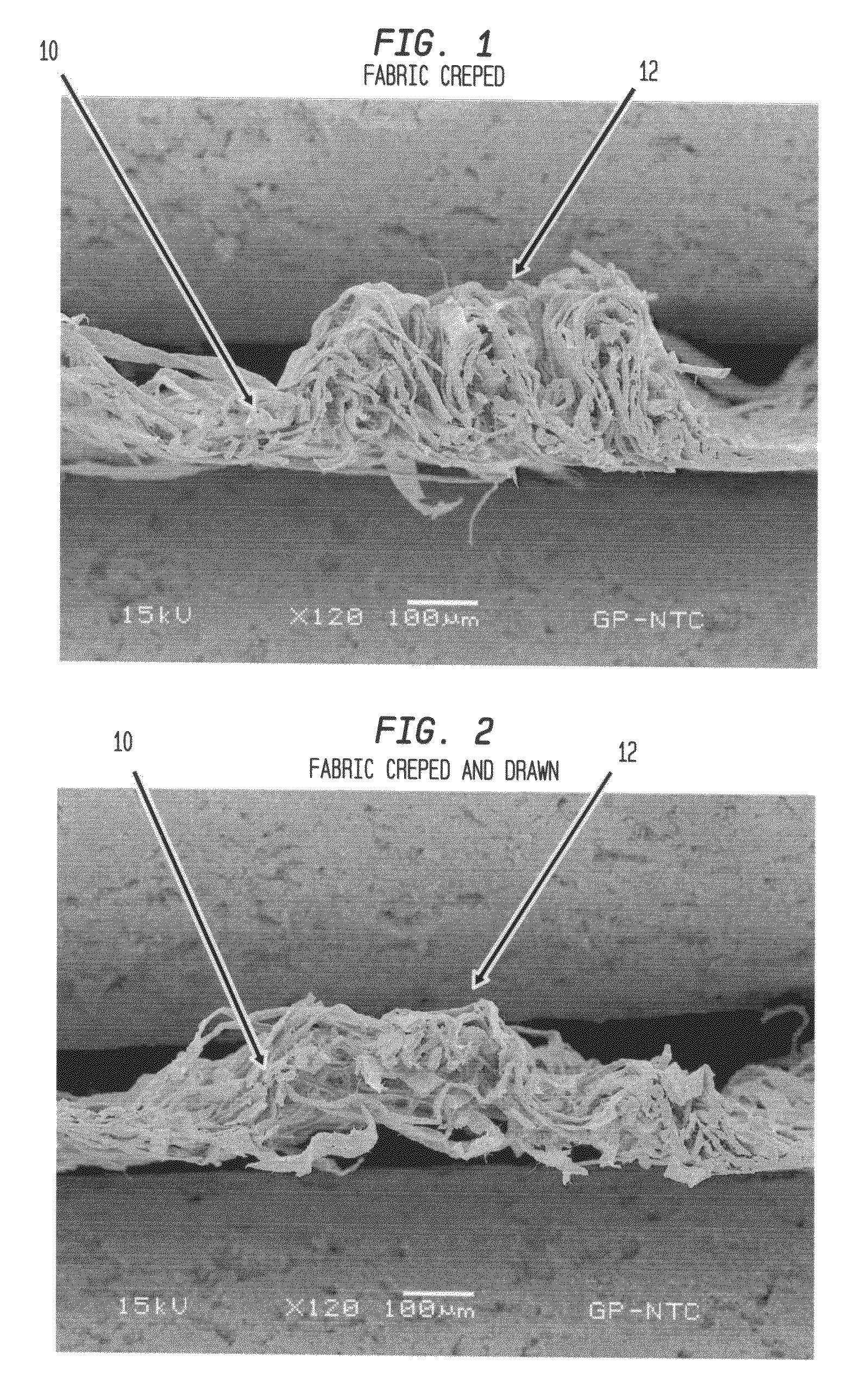

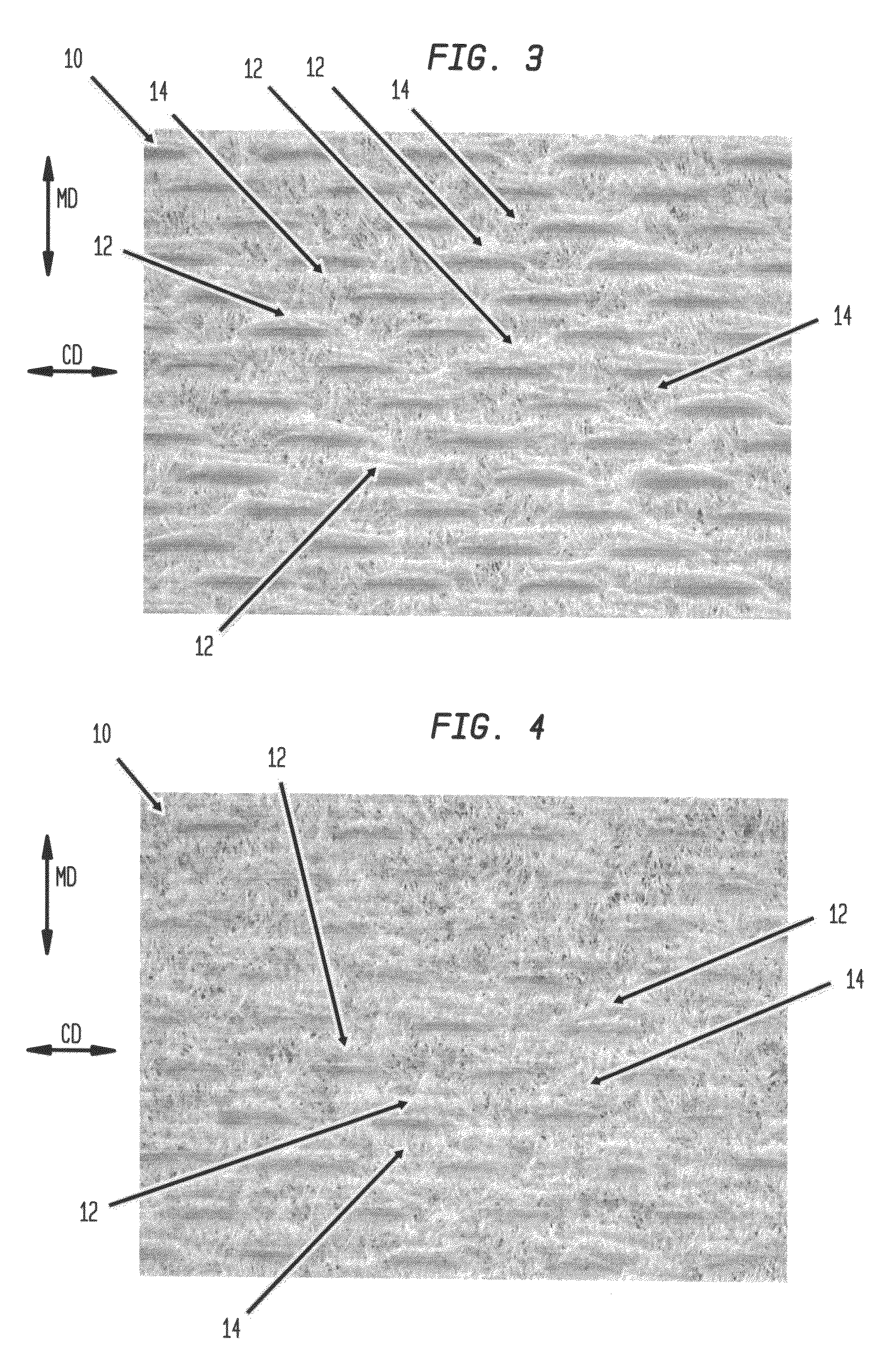

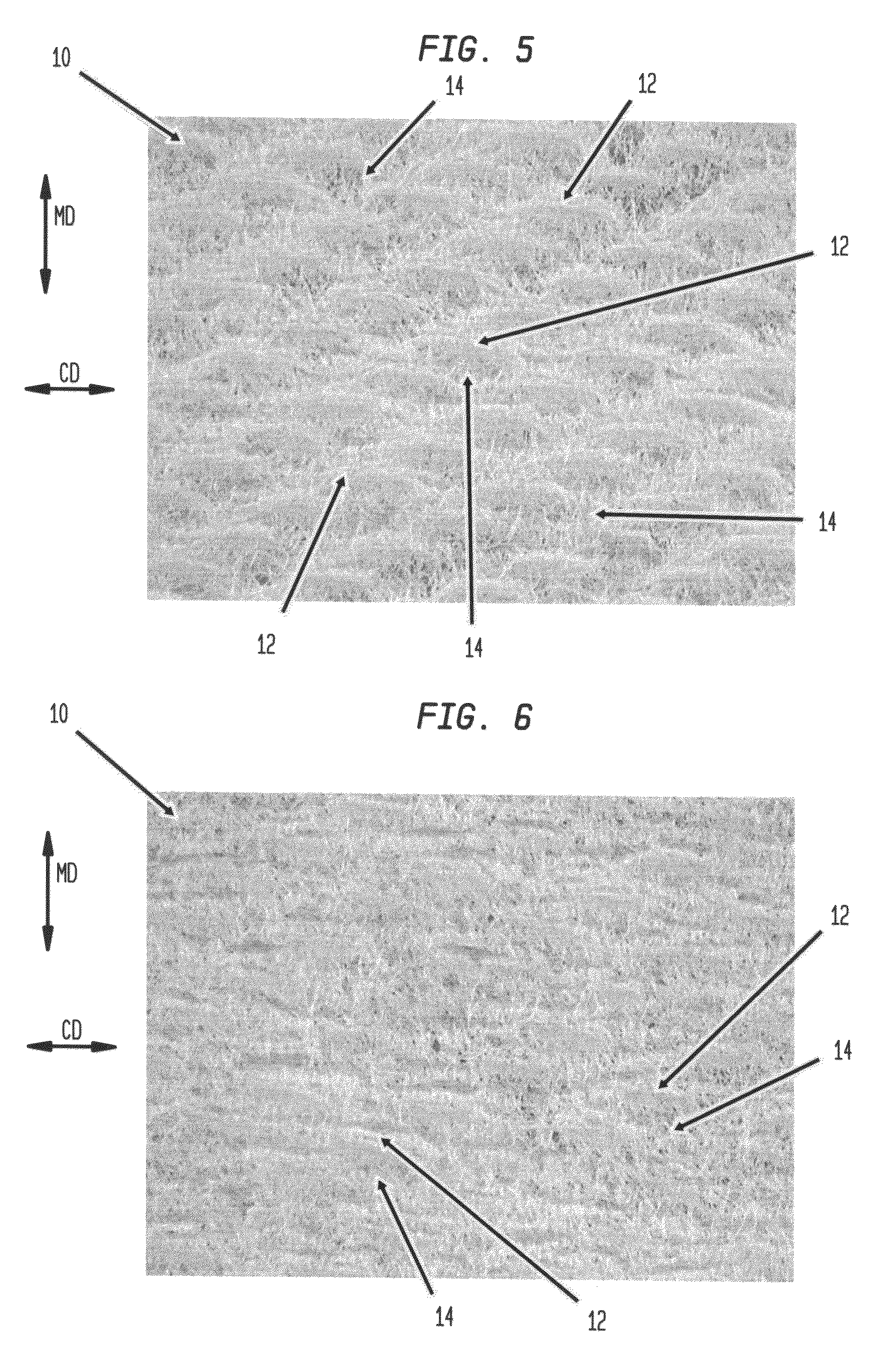

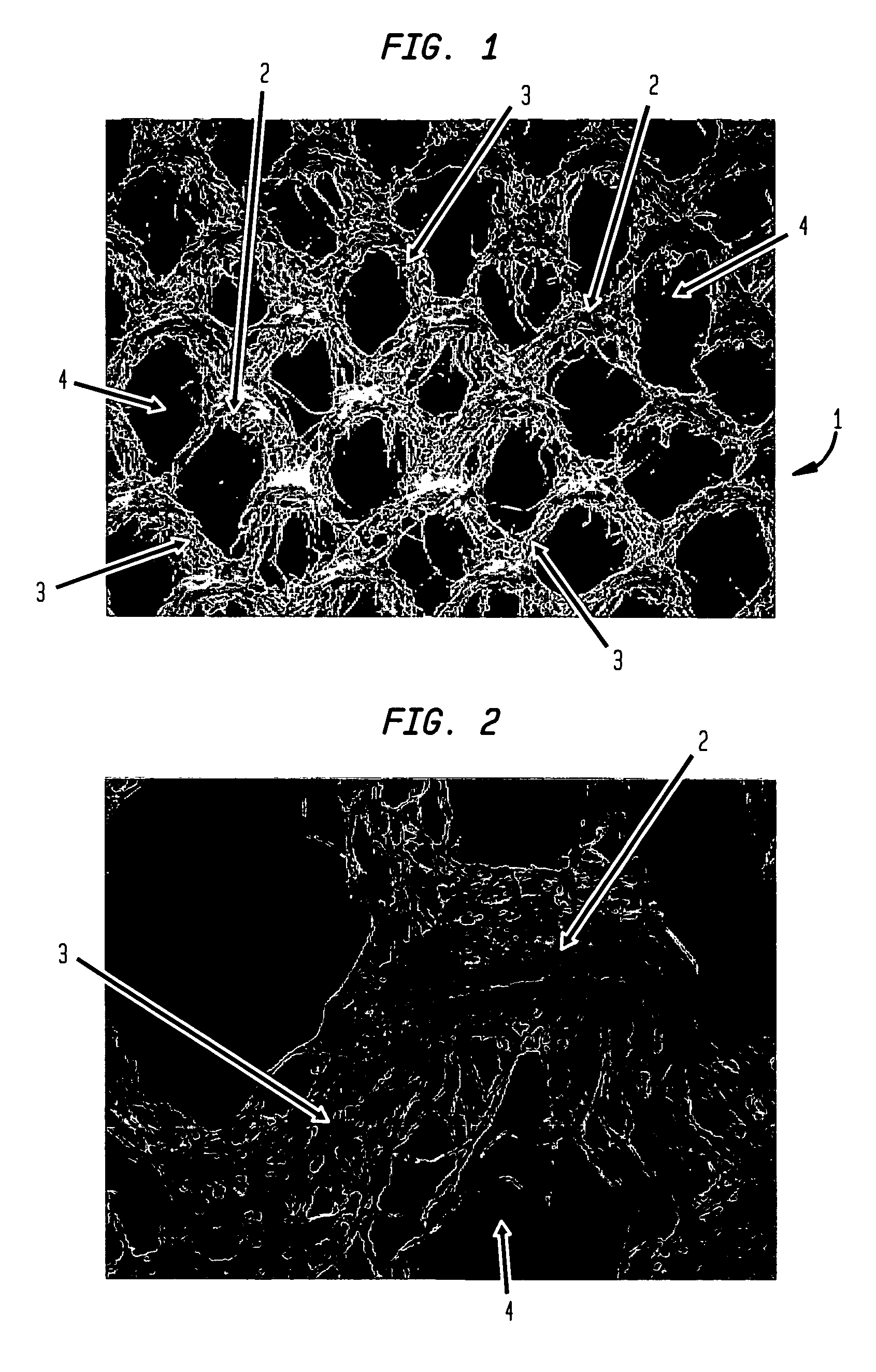

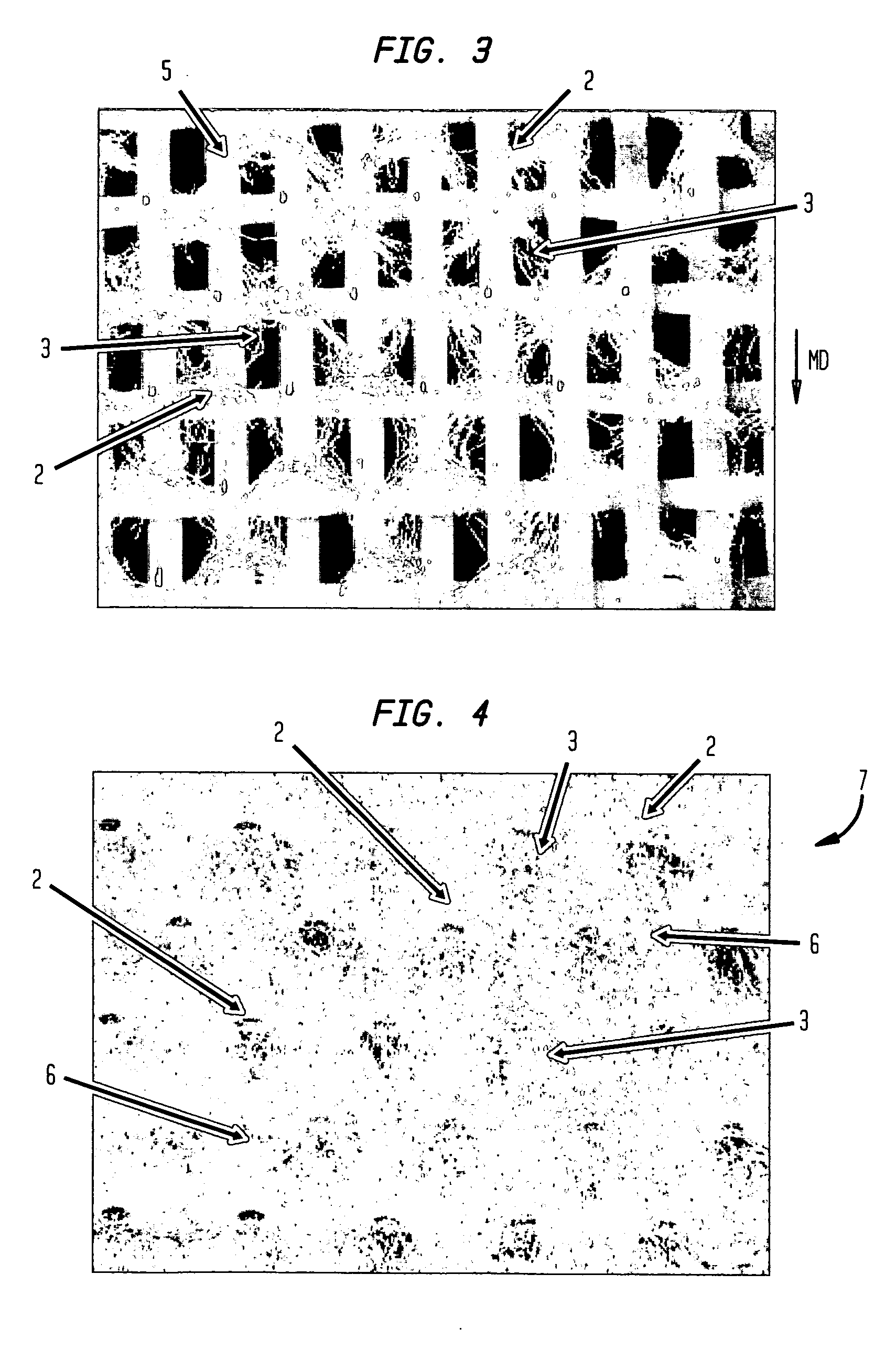

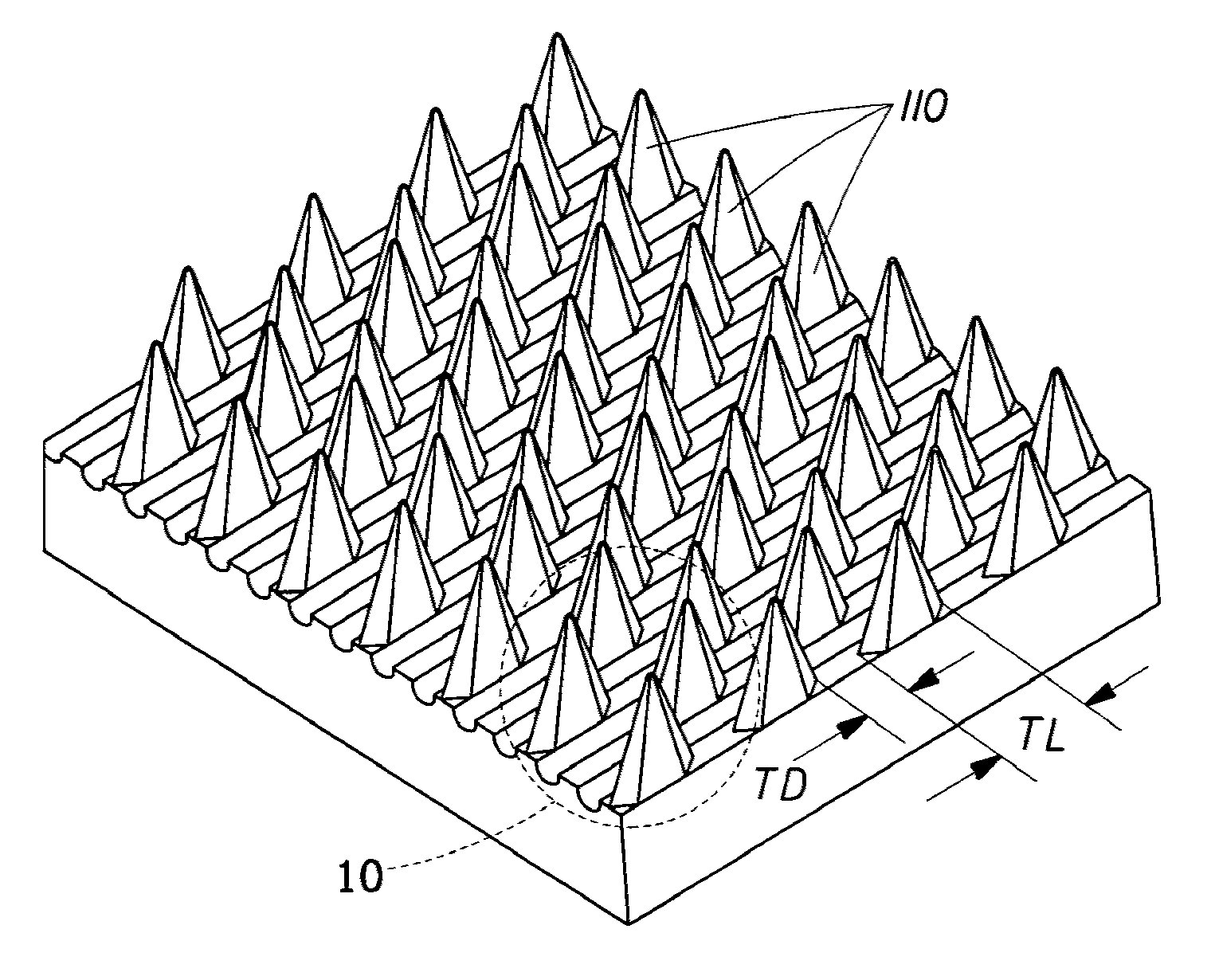

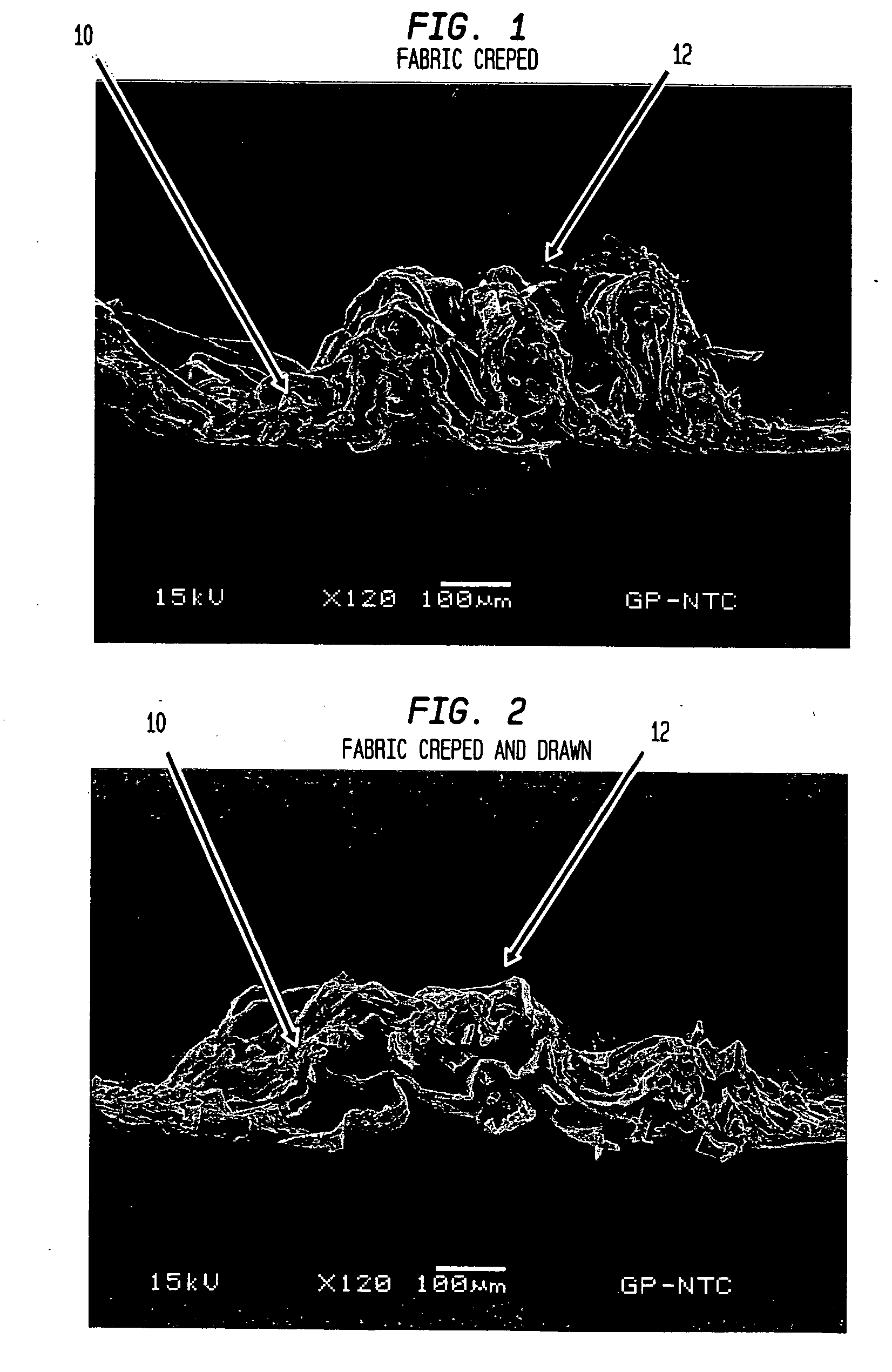

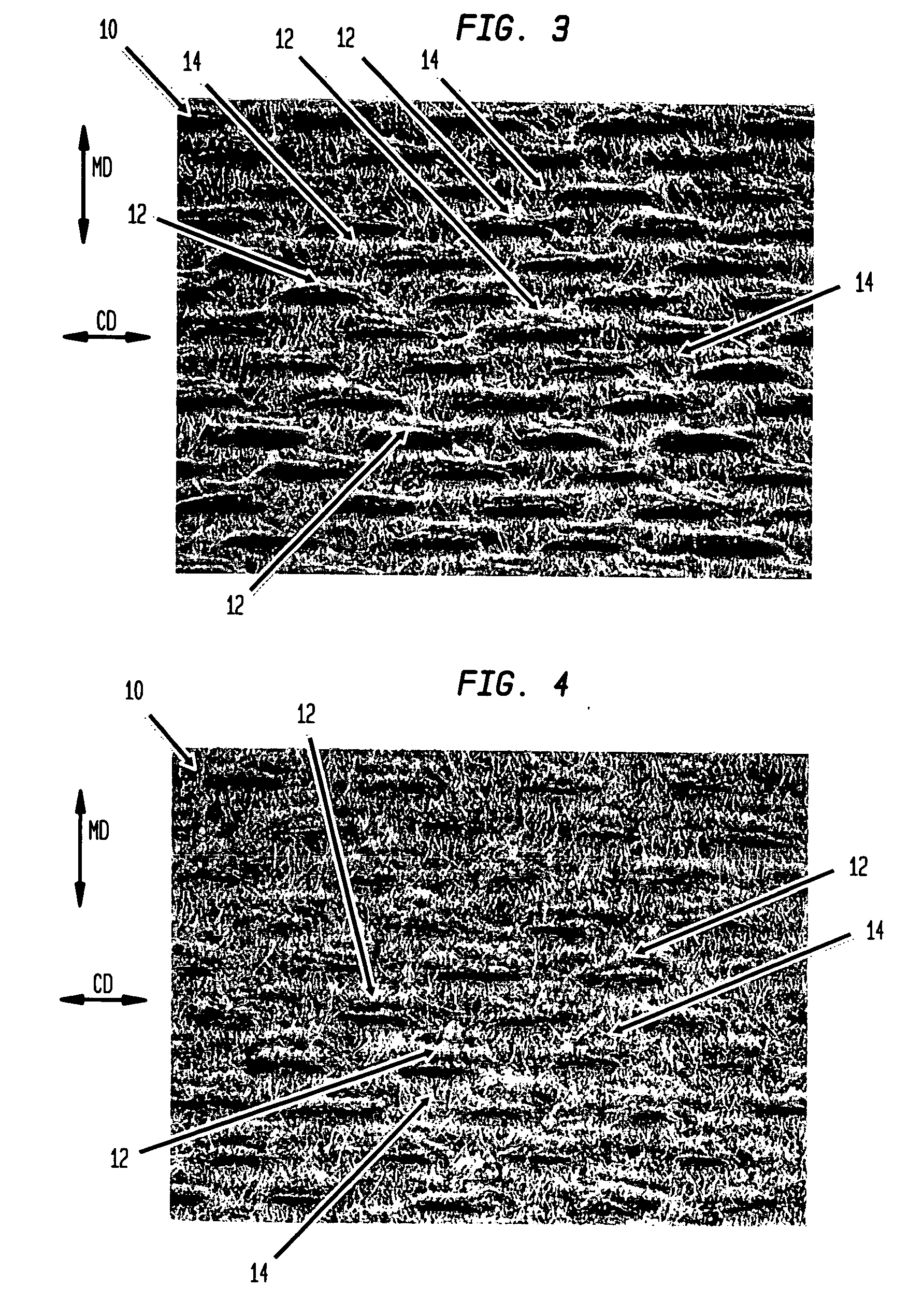

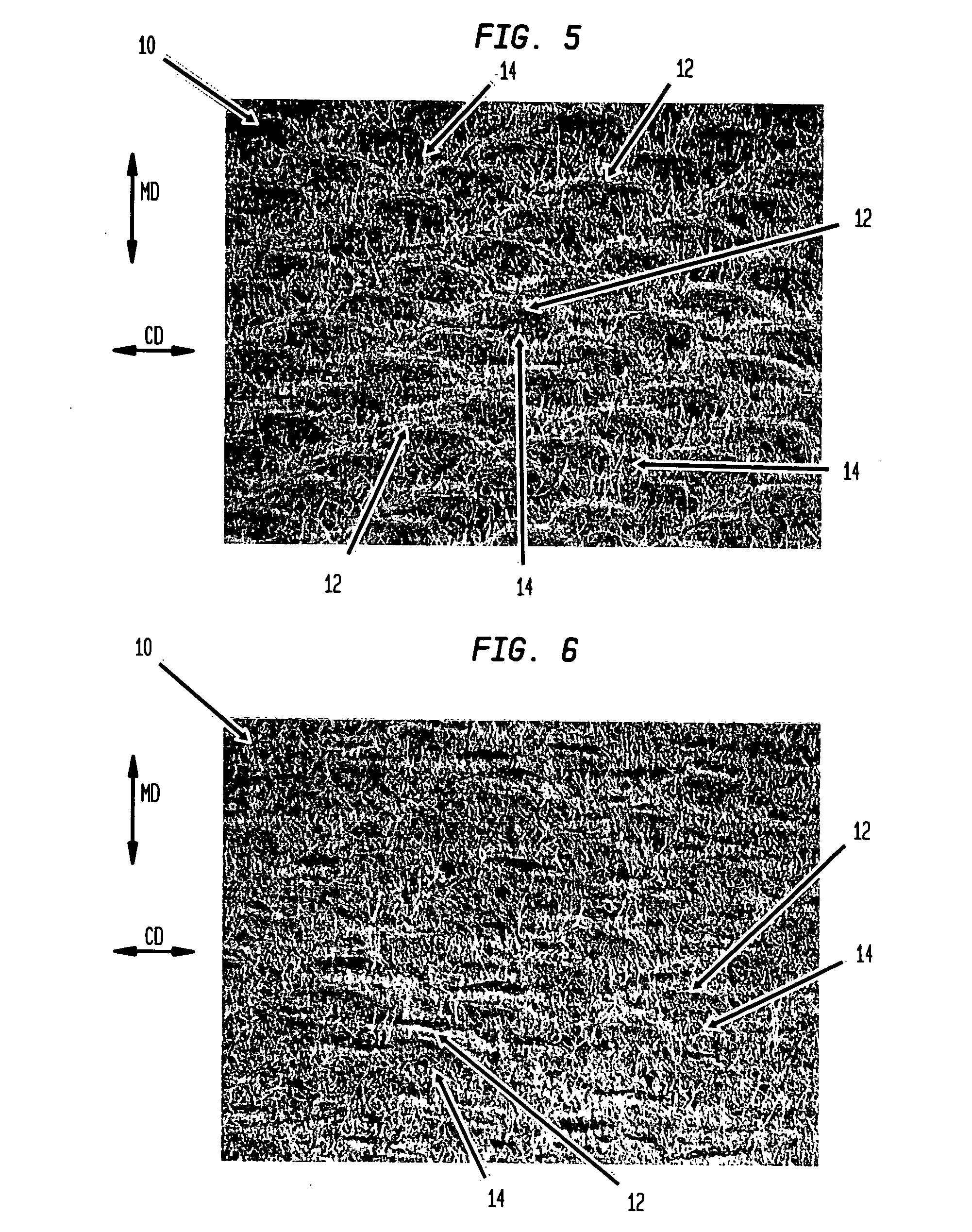

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

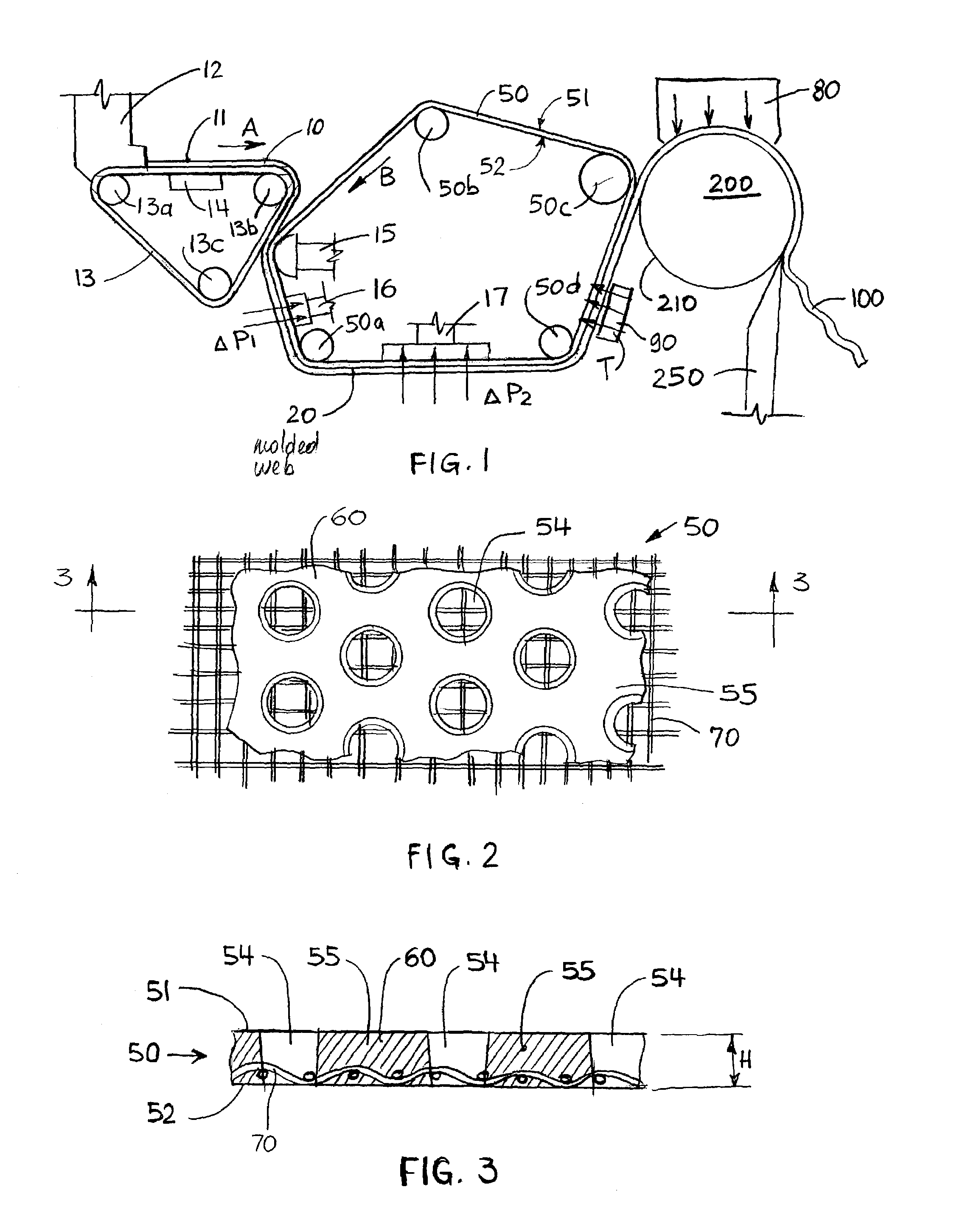

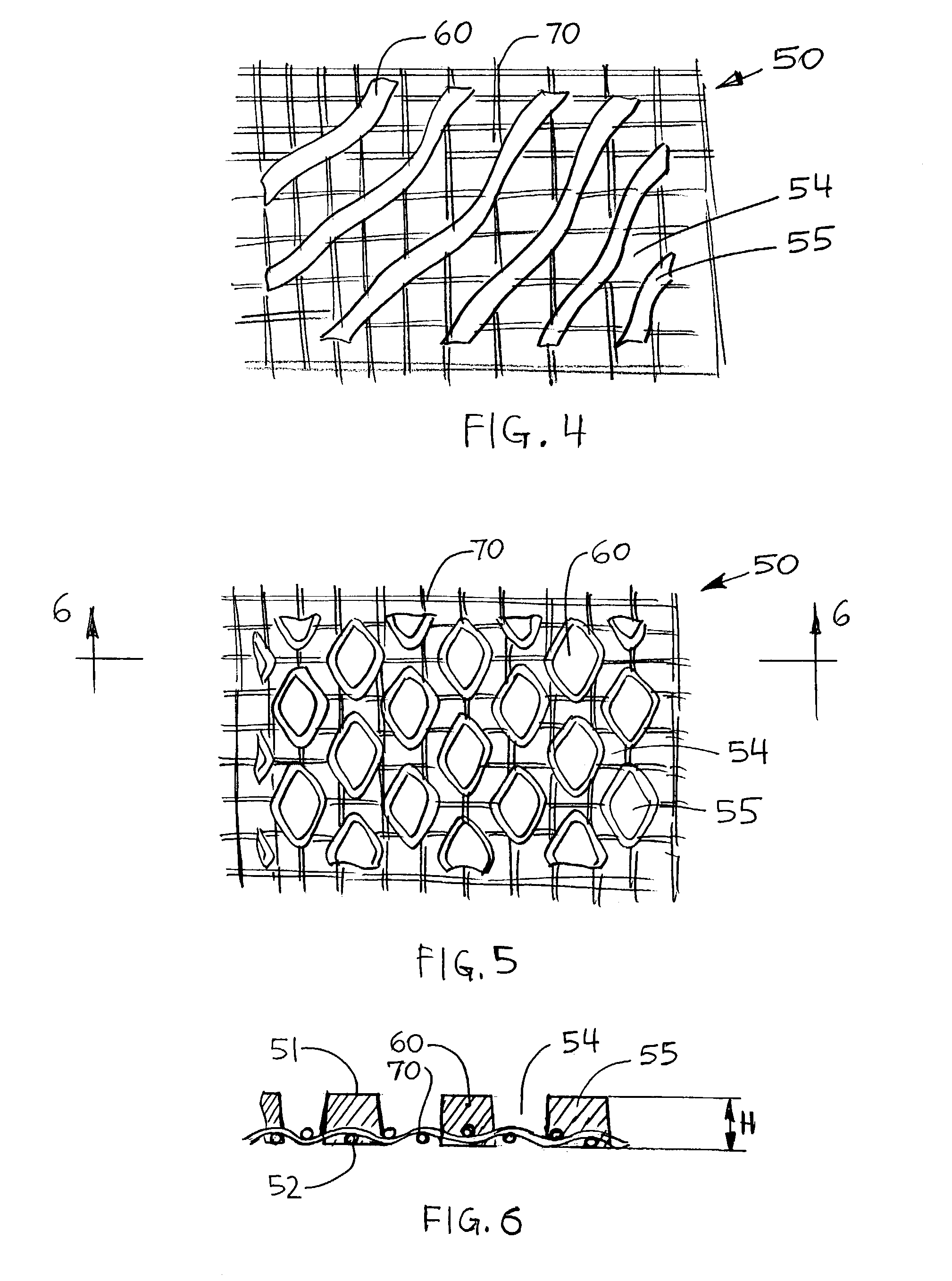

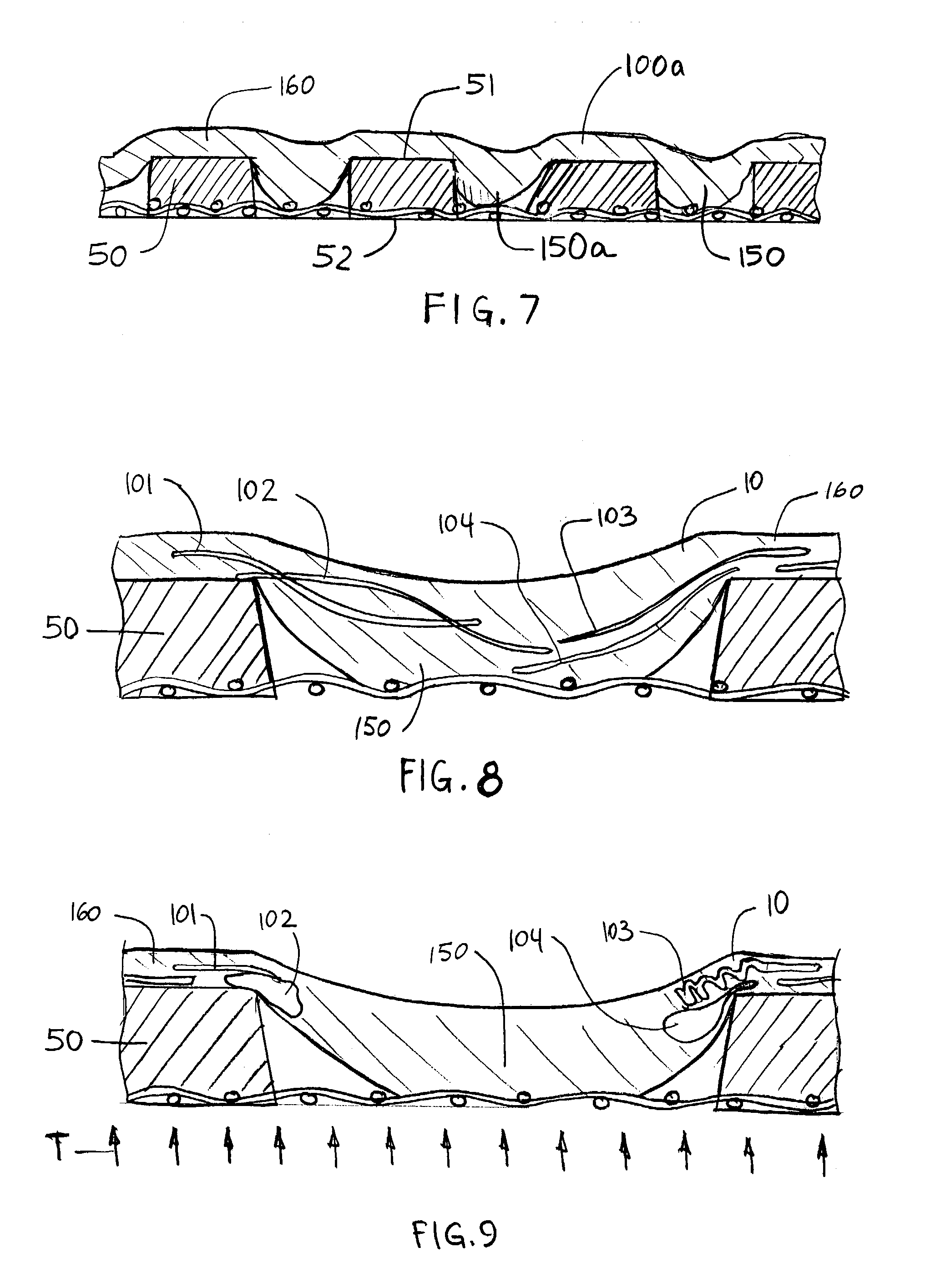

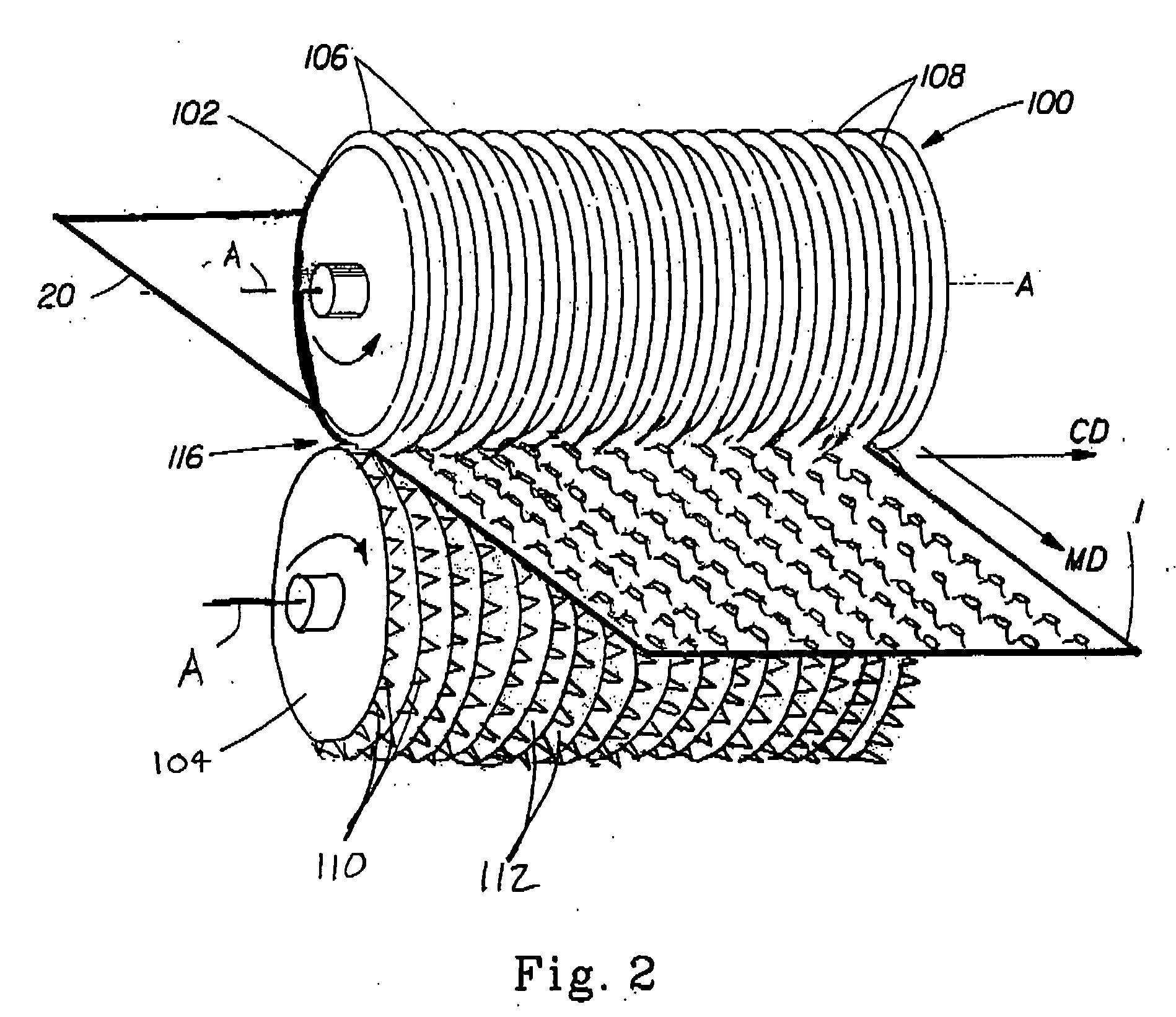

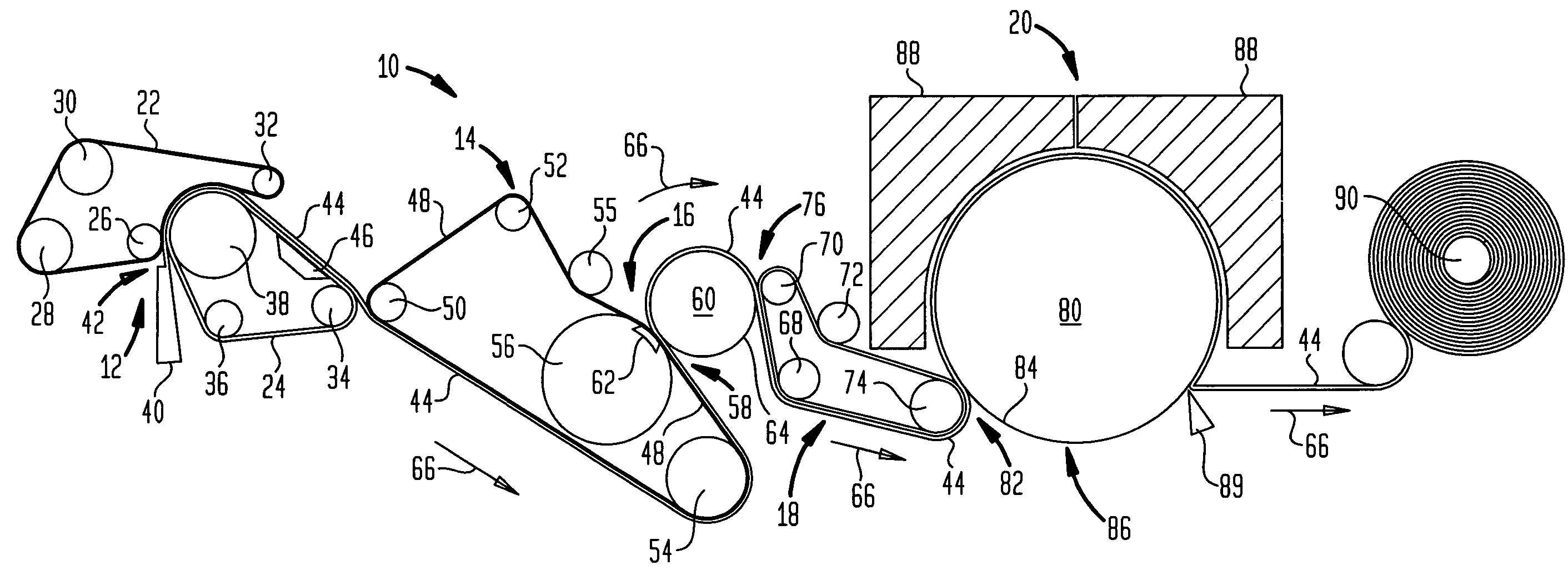

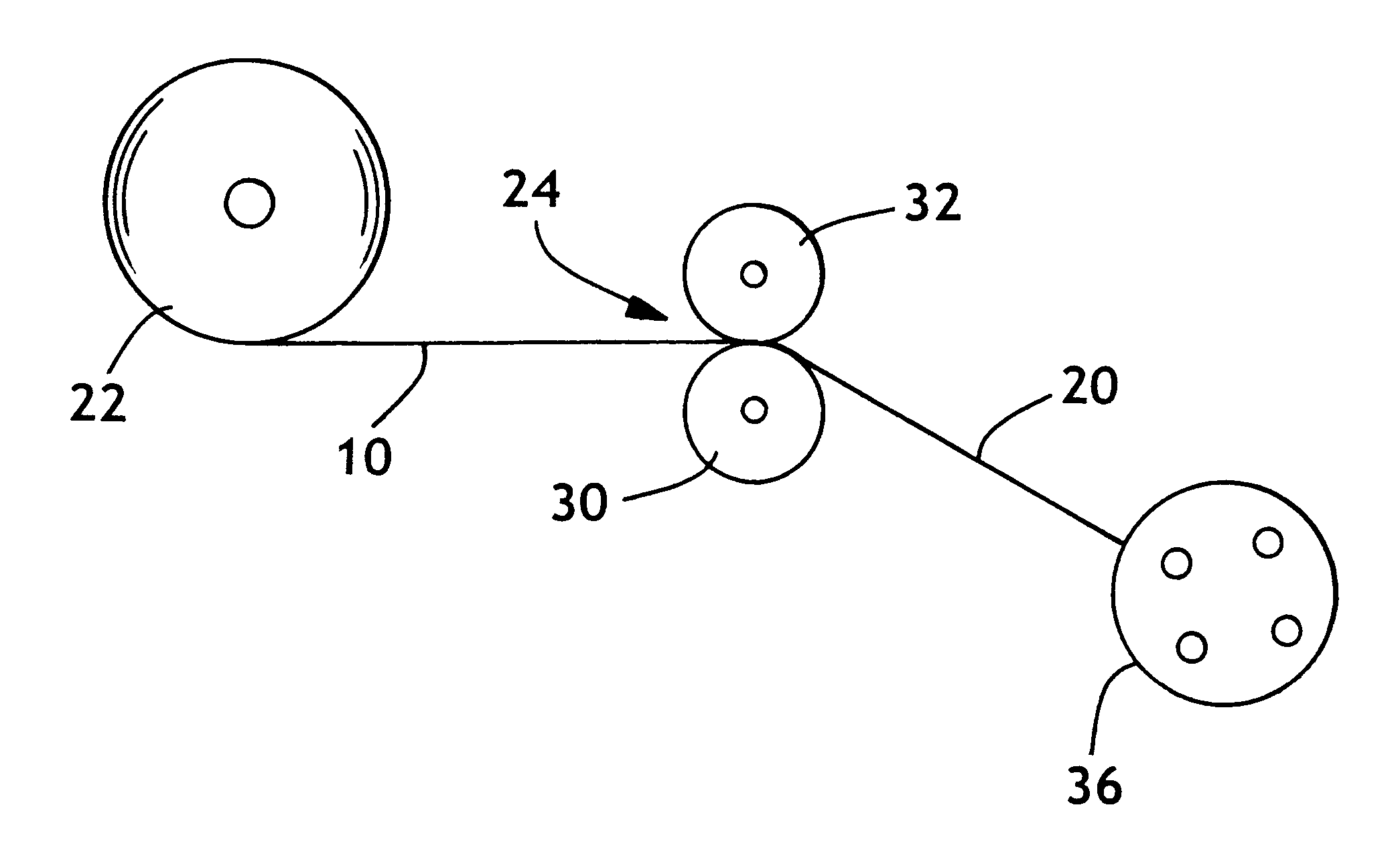

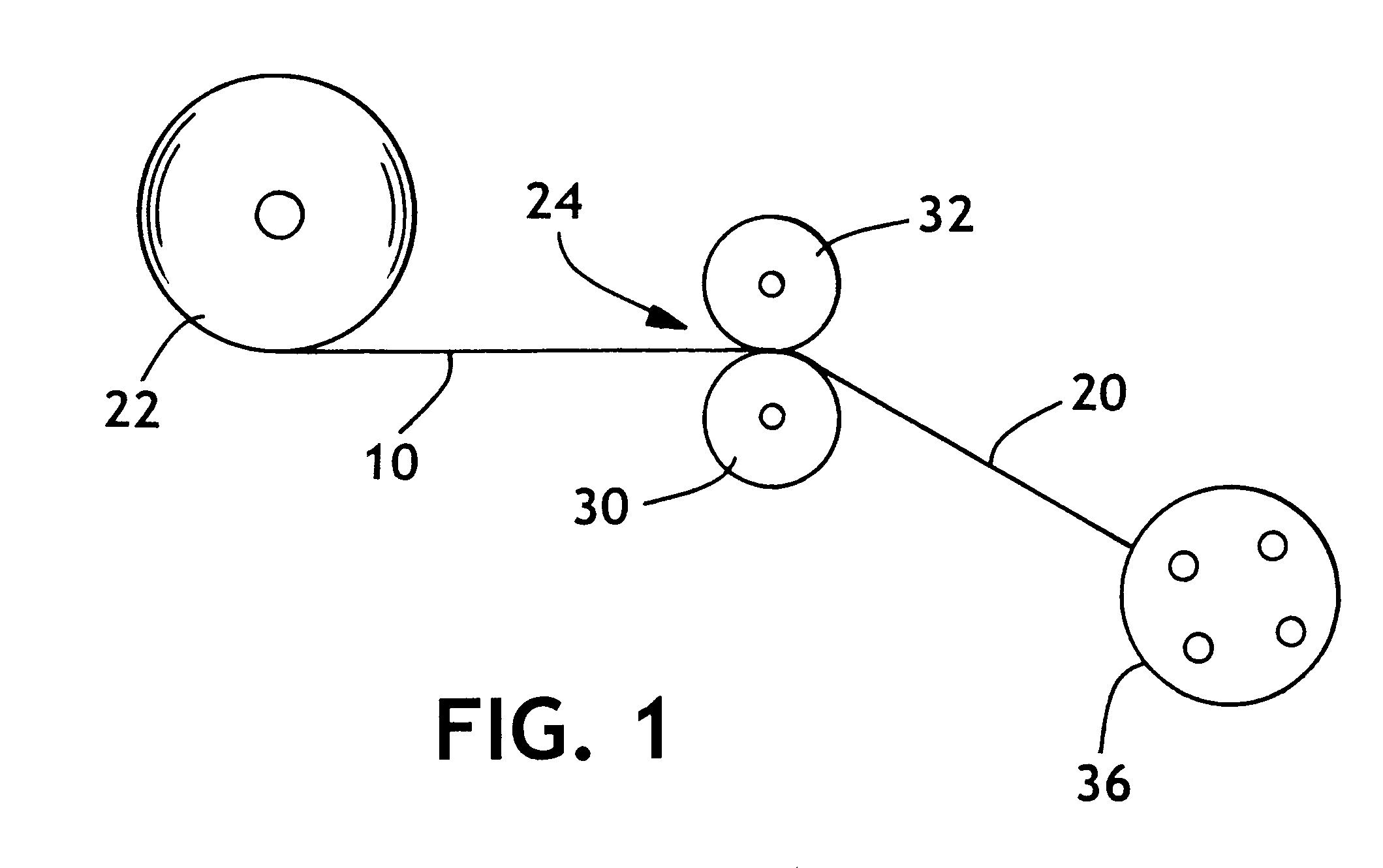

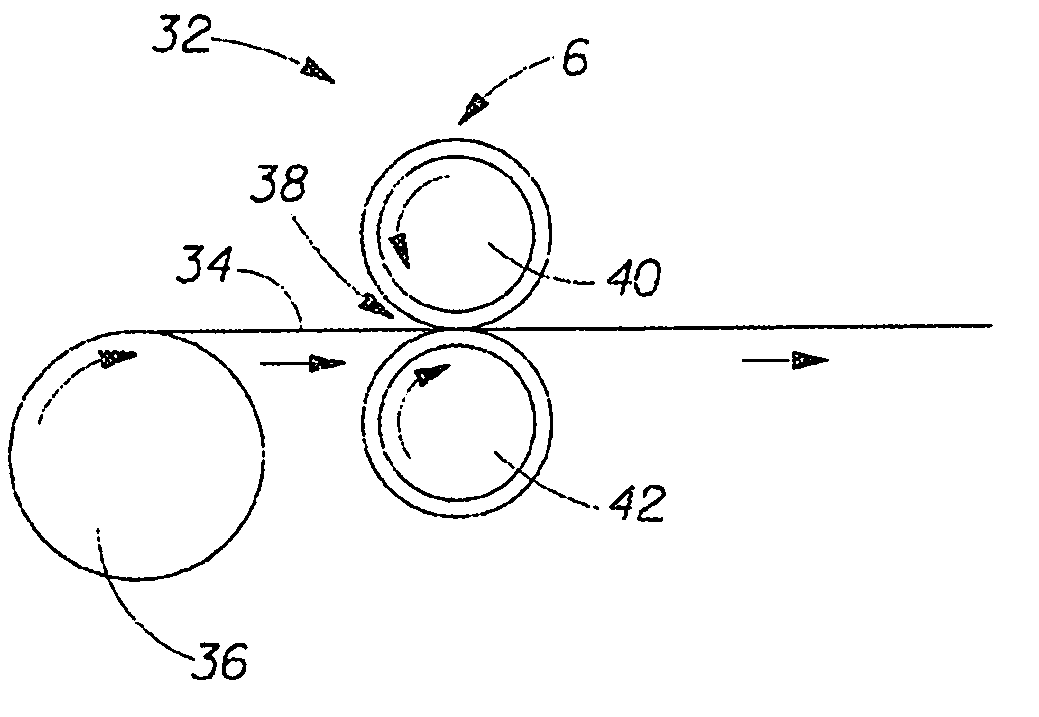

Fabric crepe process for making absorbent sheet

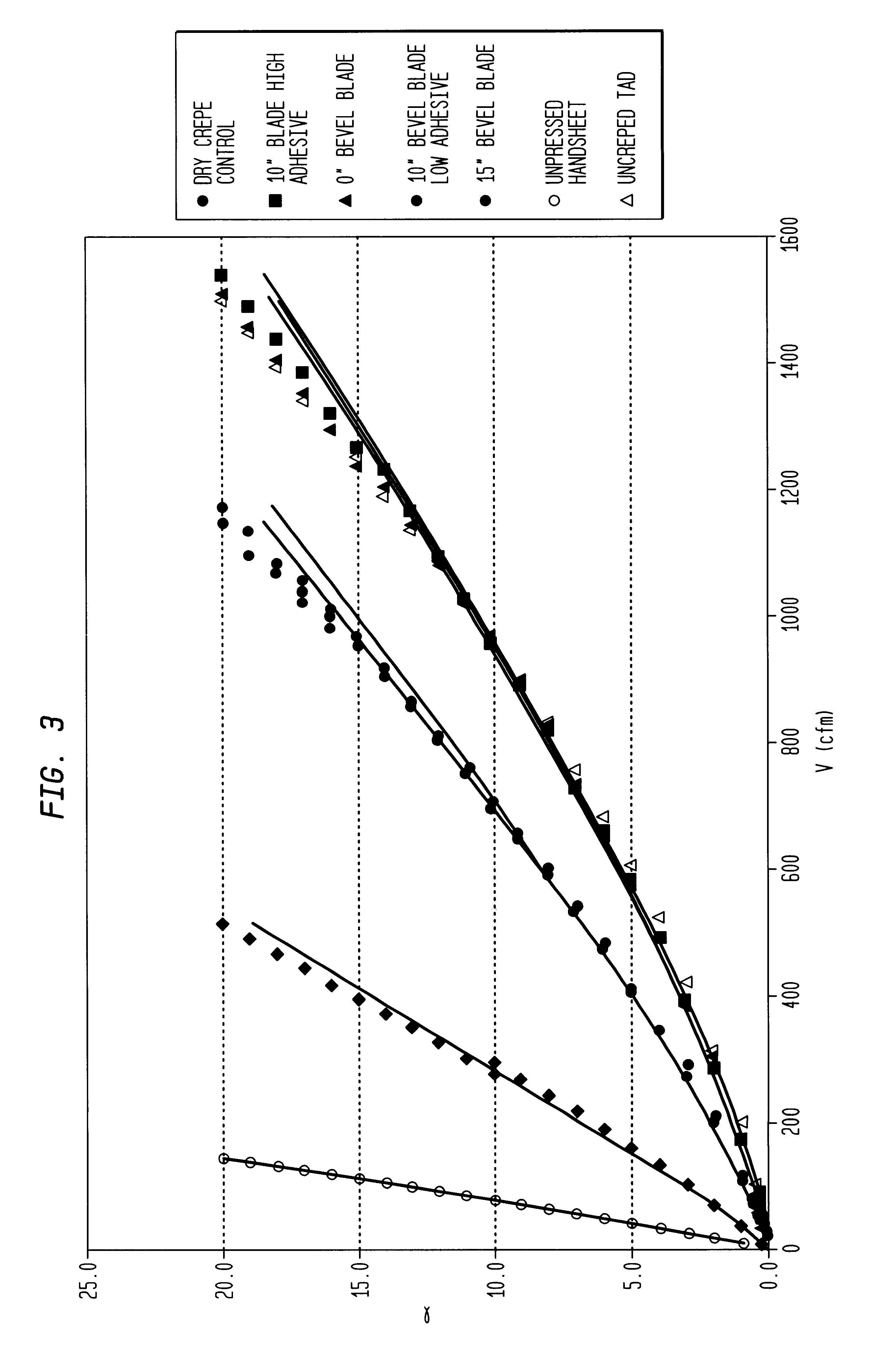

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

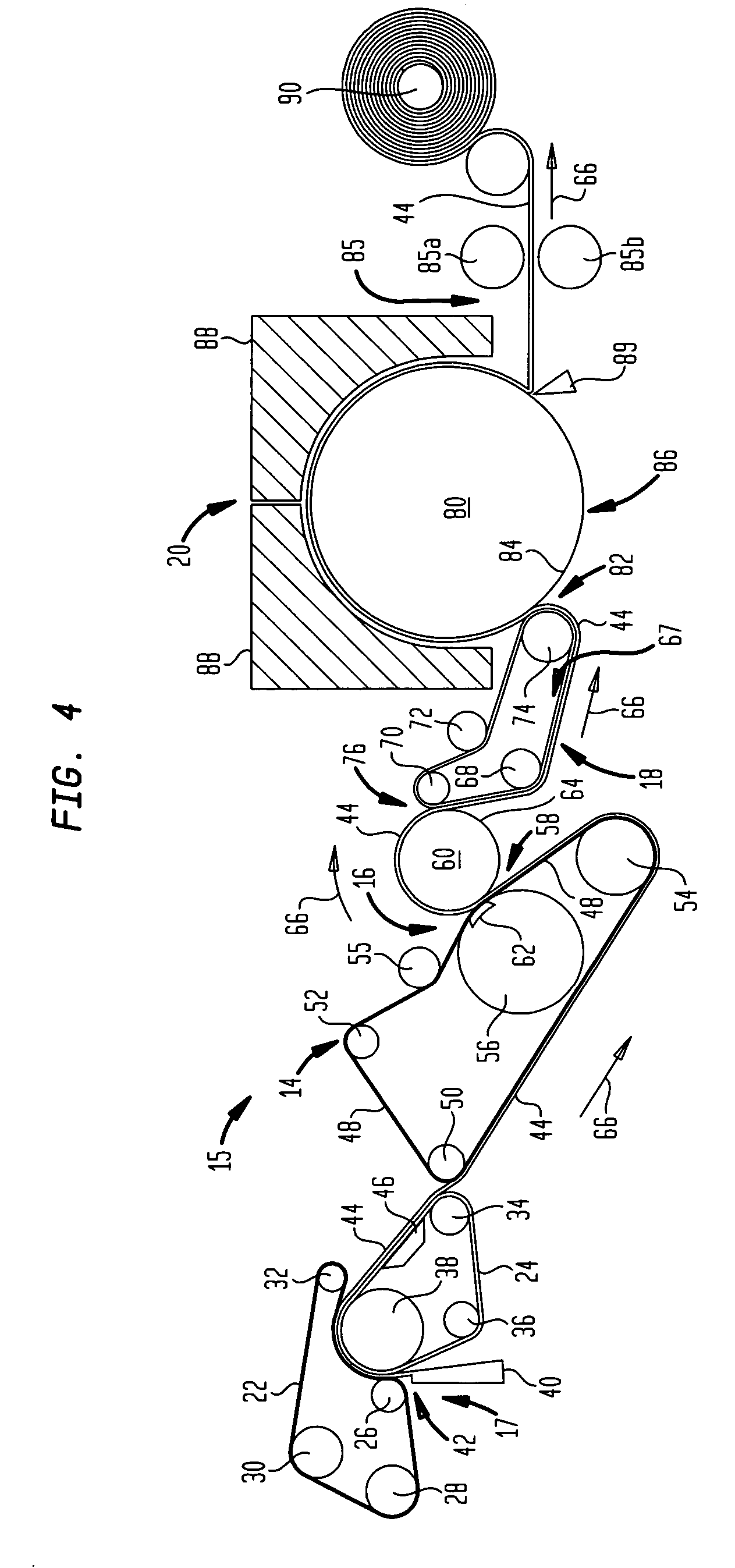

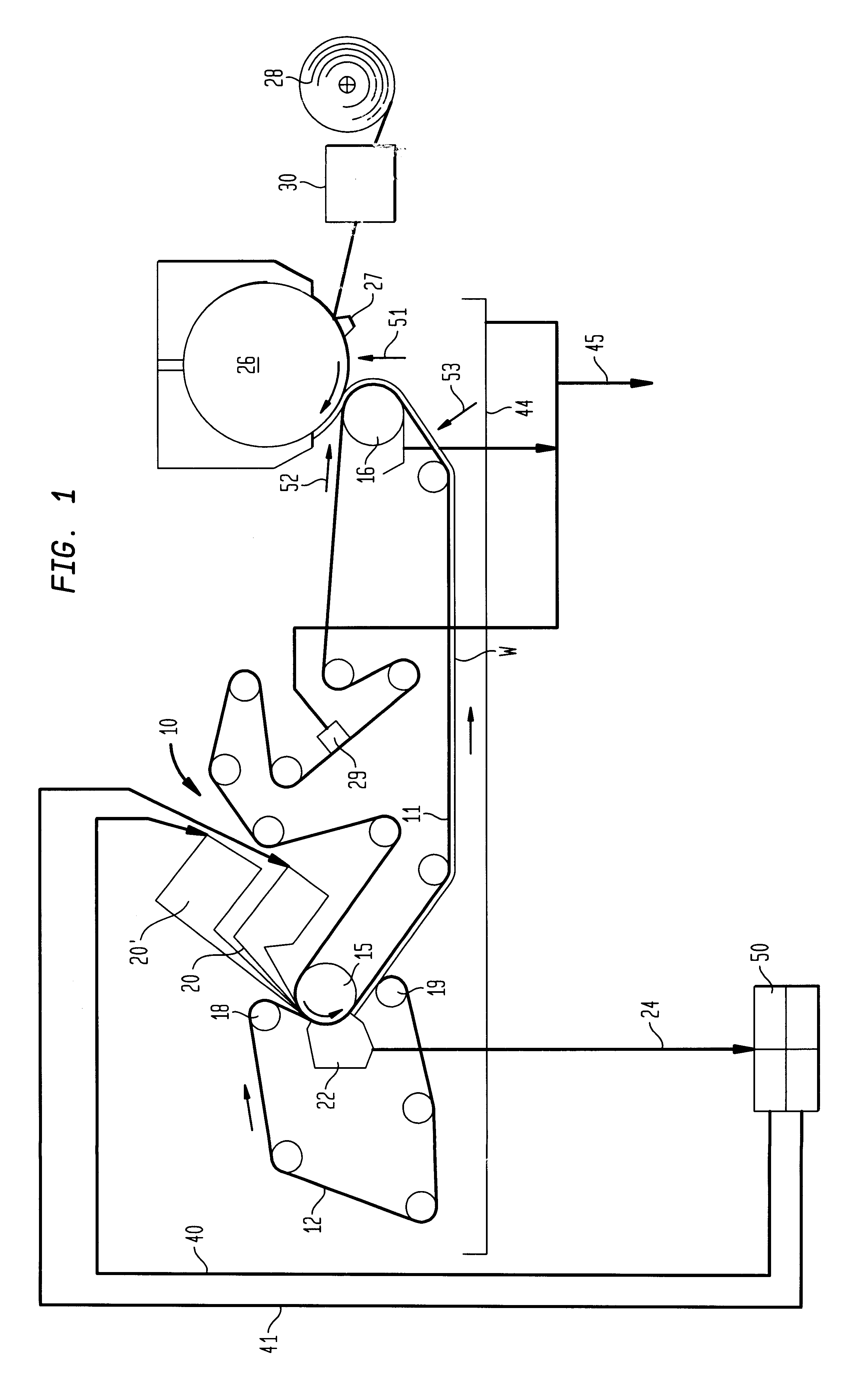

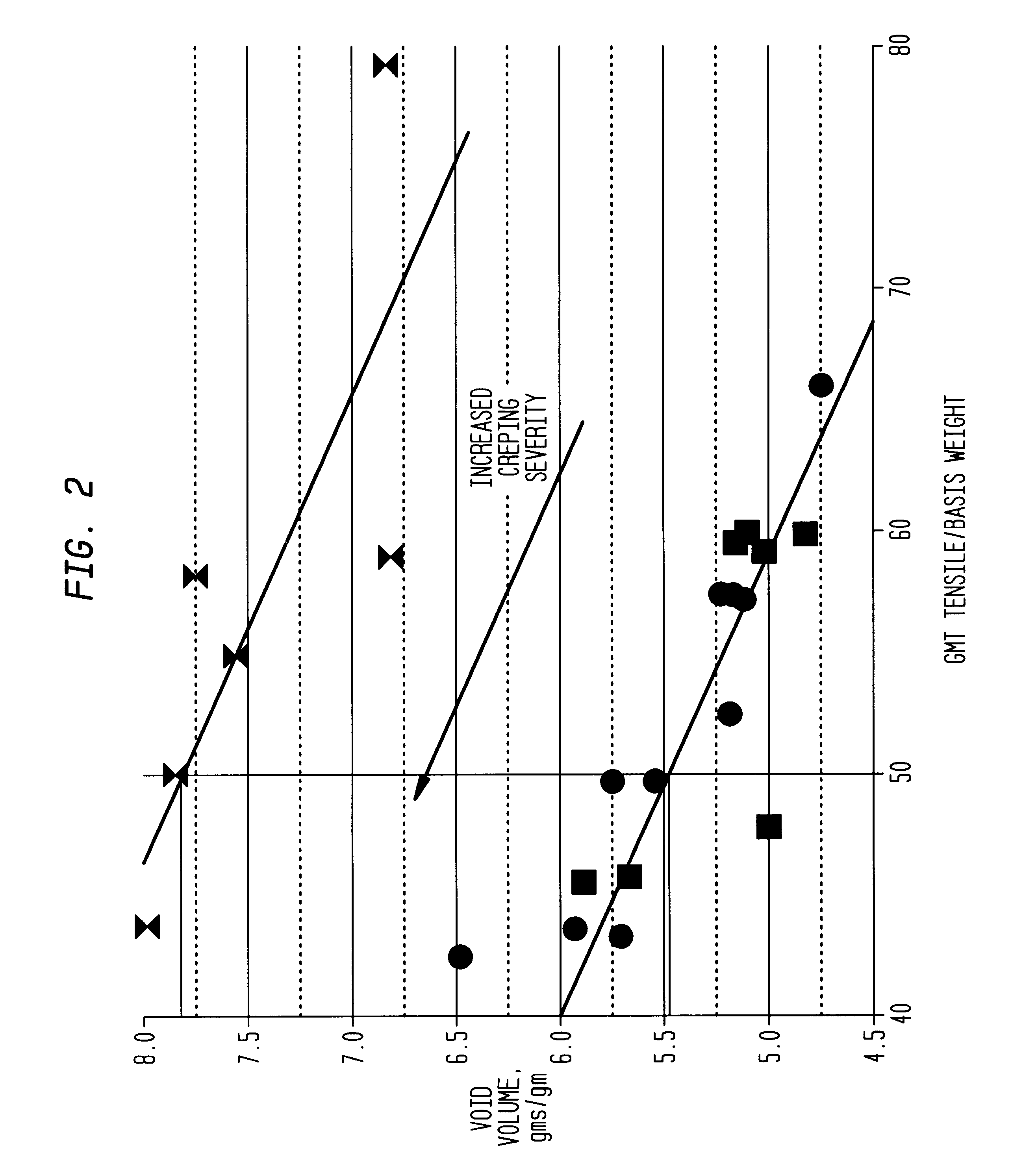

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

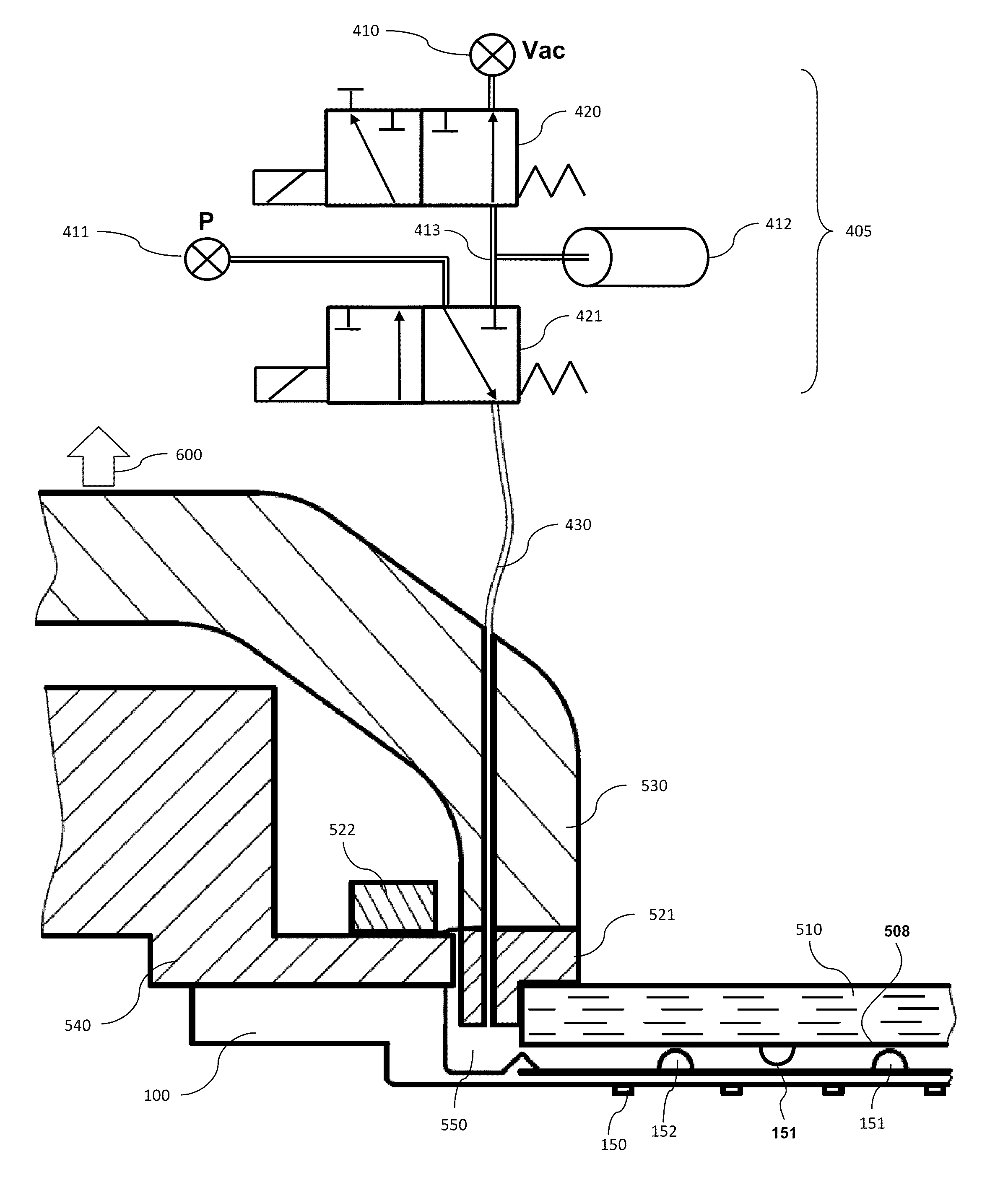

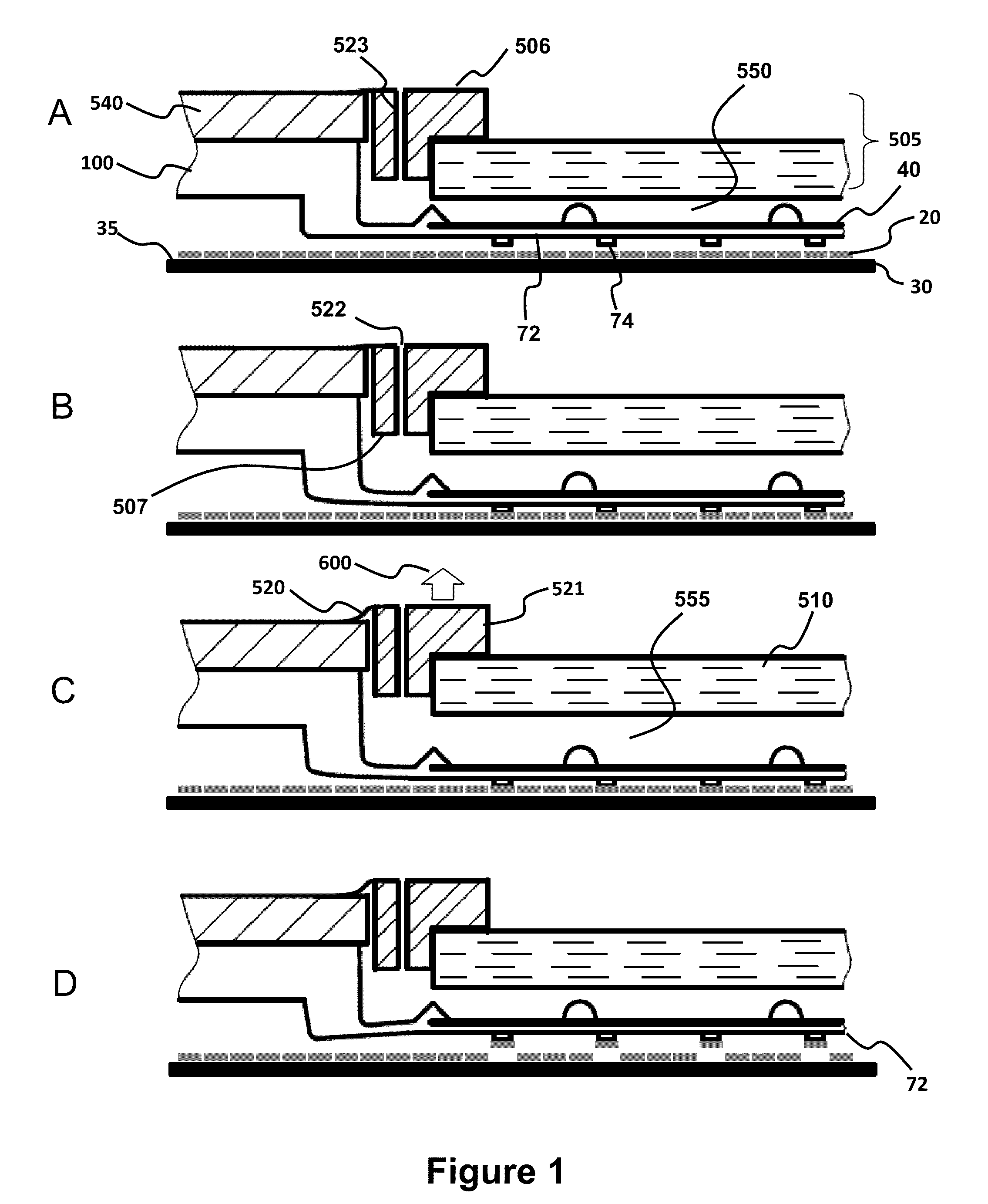

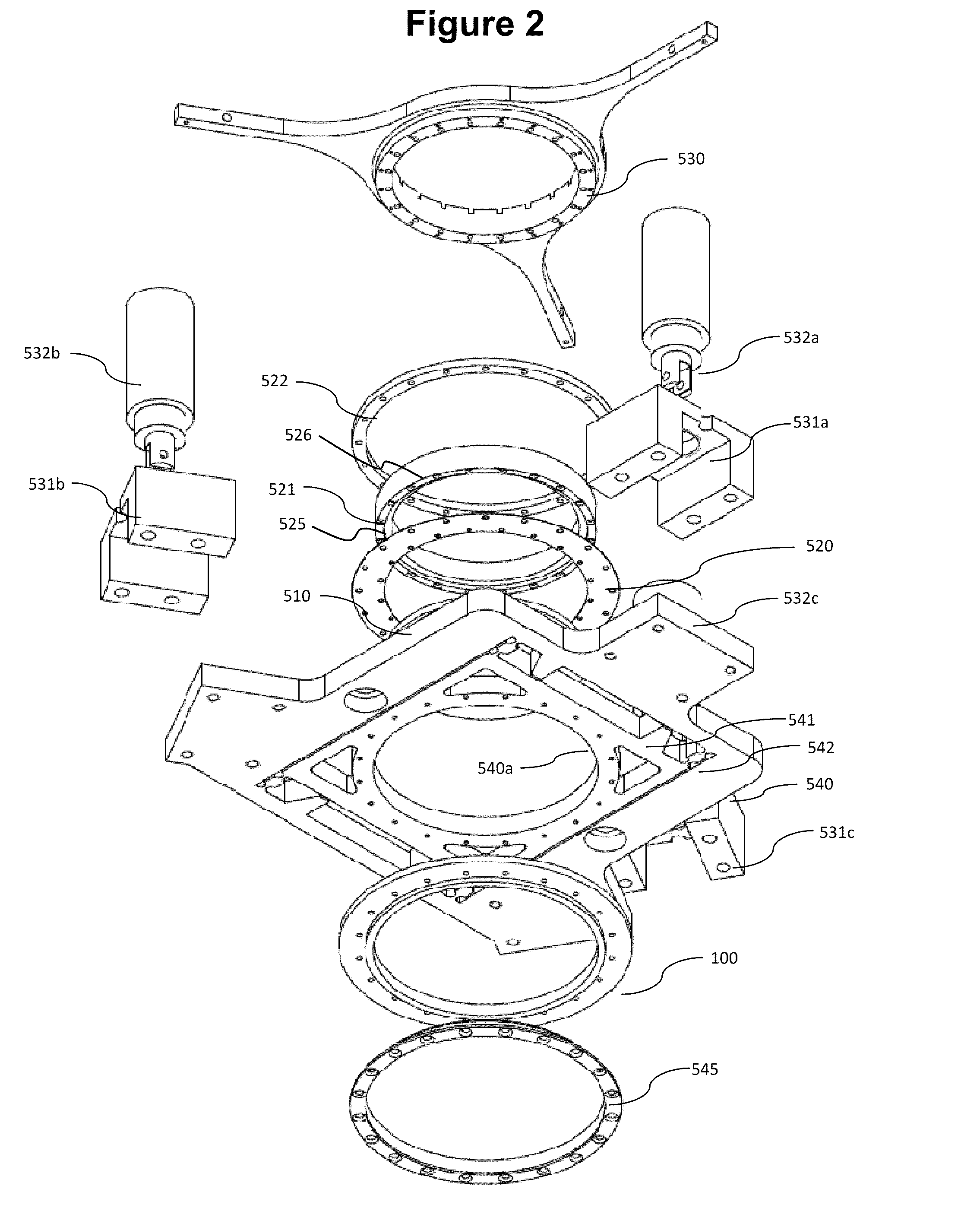

Method and Apparatus for Making Absorbent Structures with Absorbent Material

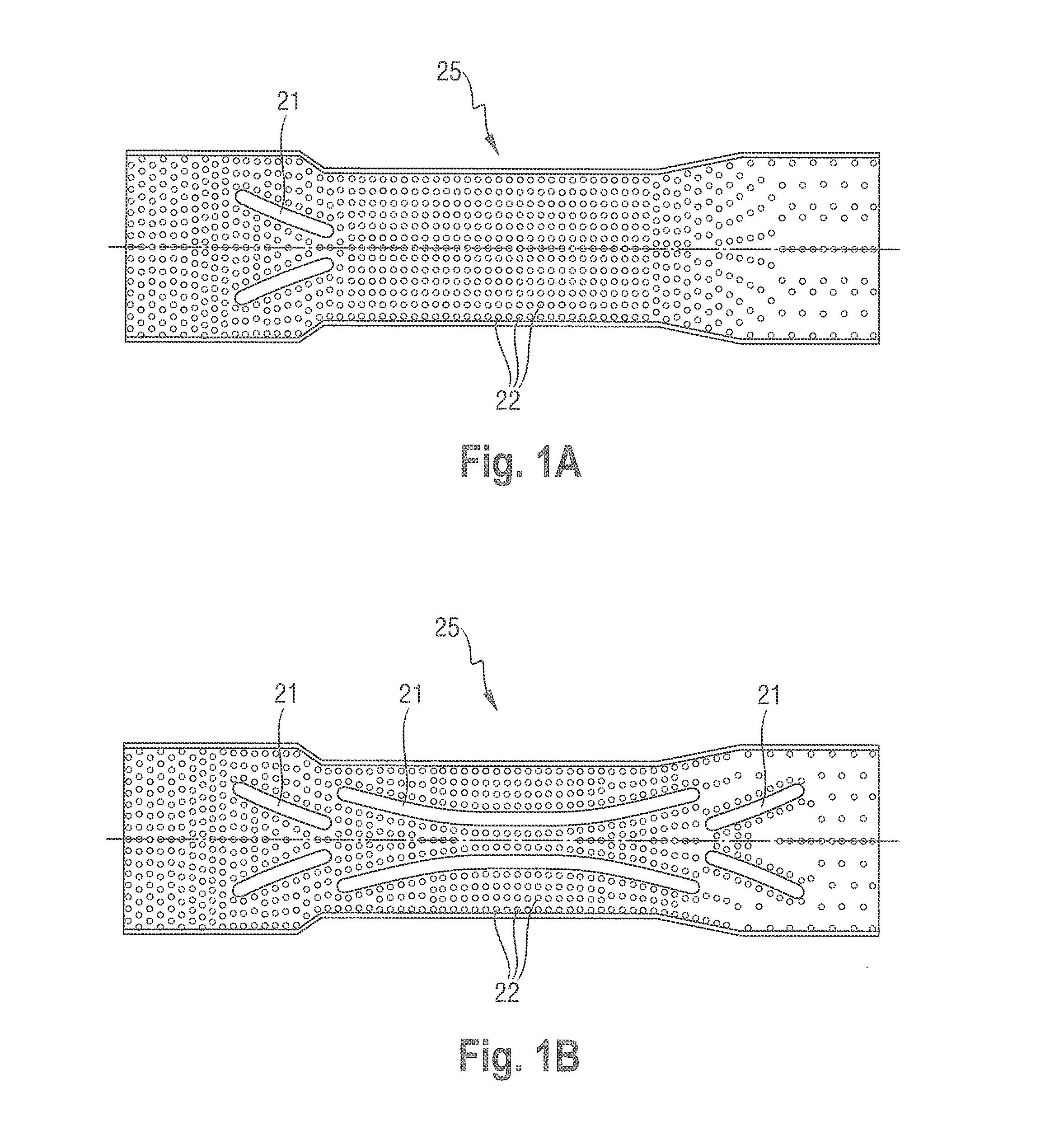

Apparatus and method for producing absorbent structures with absorbent layers with channel(s) without absorbent material, using a first moving endless surface with specific raised strip(s) and a second moving endless surface with specific mating strip(s).

Owner:THE PROCTER & GAMBLE COMPANY

Fabric creped absorbent sheet with variable local basis weight

InactiveUS20080029235A1Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

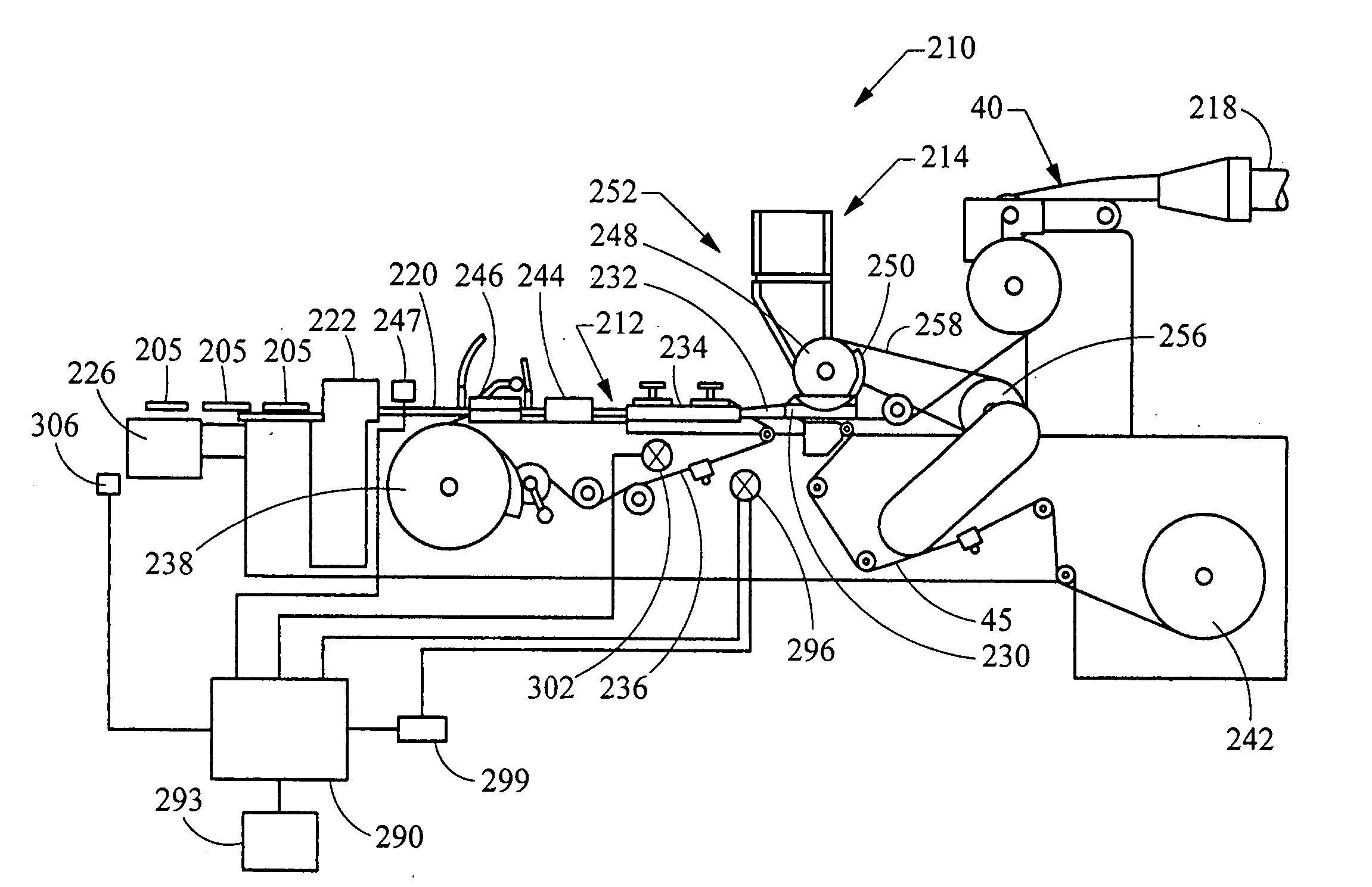

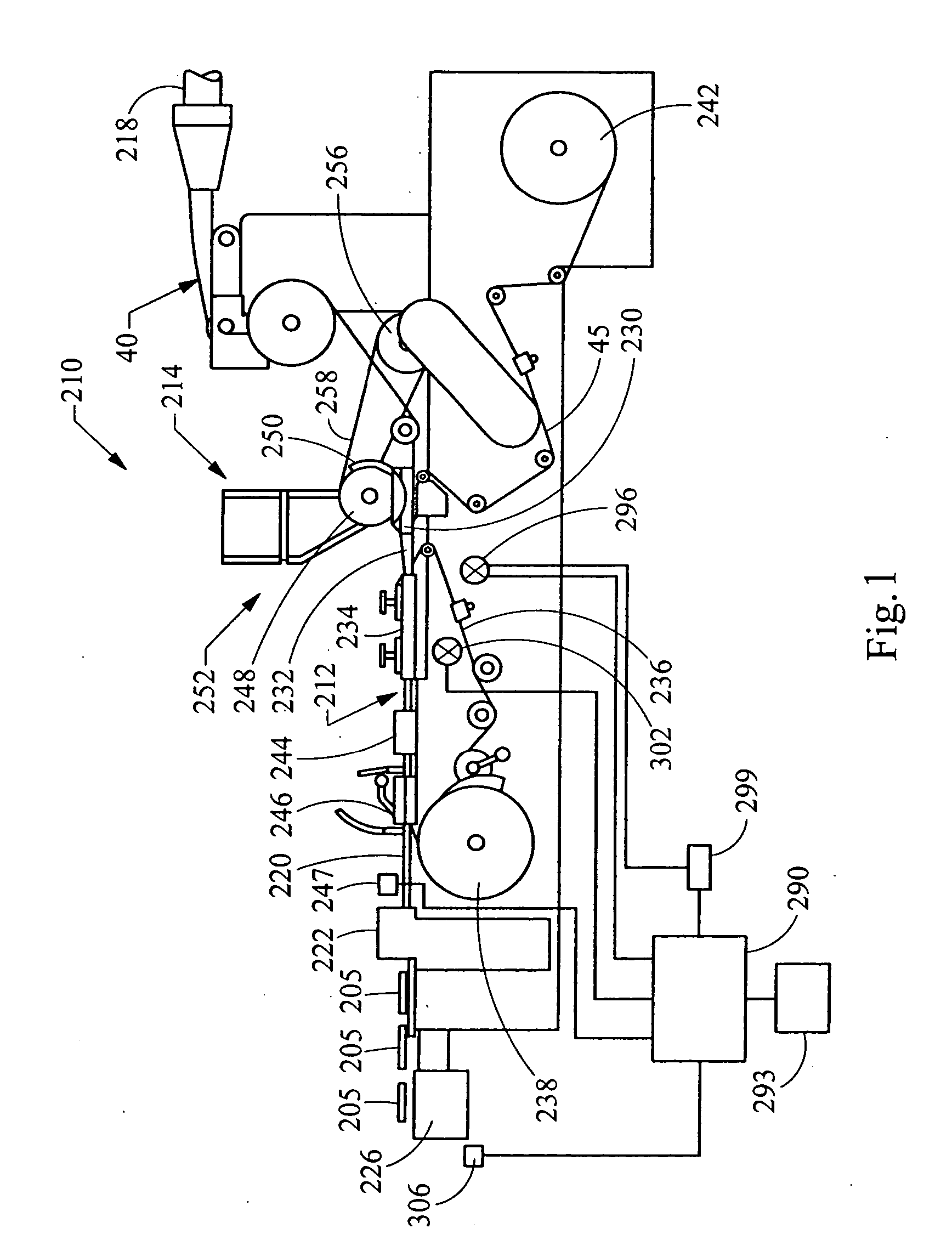

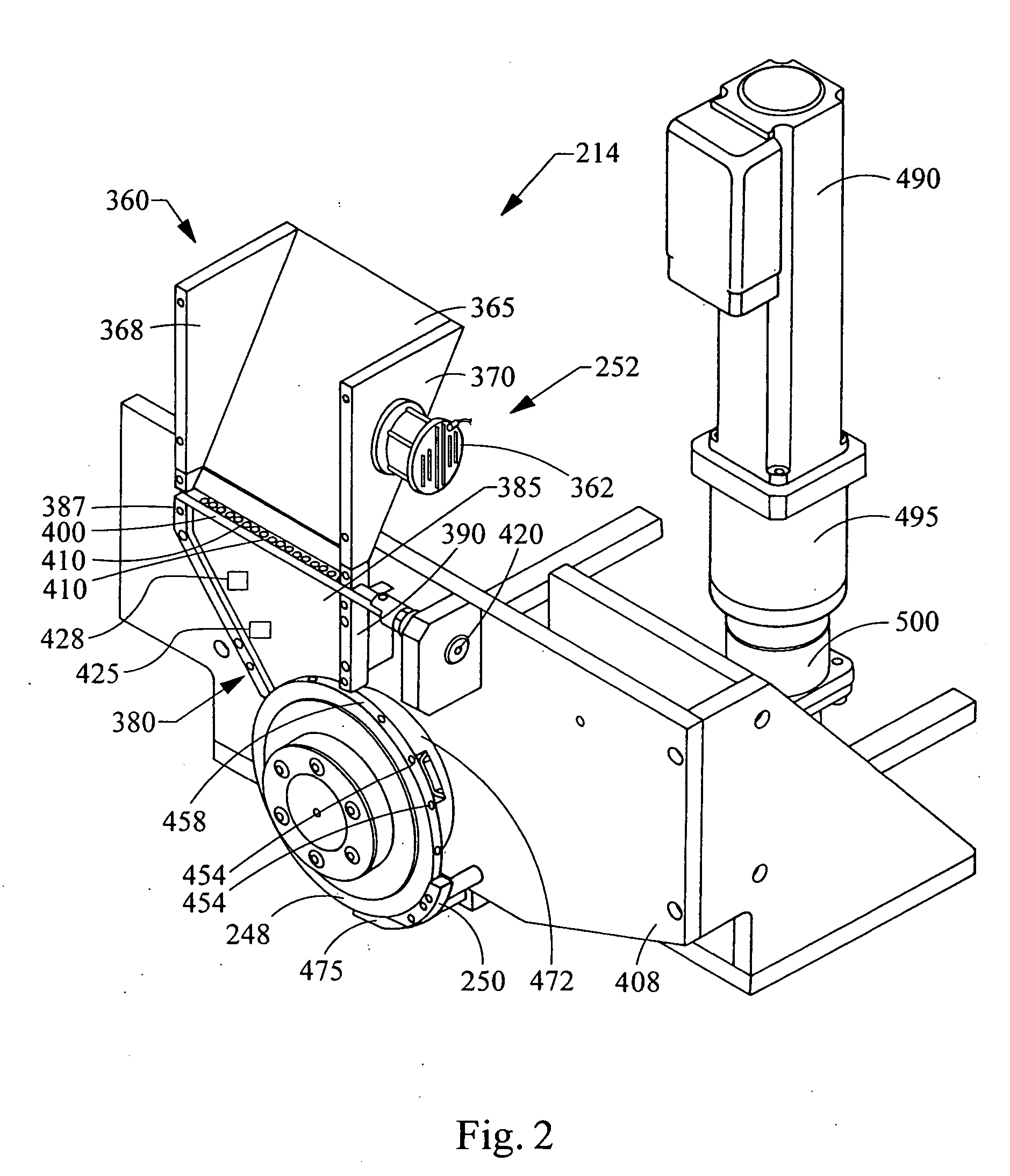

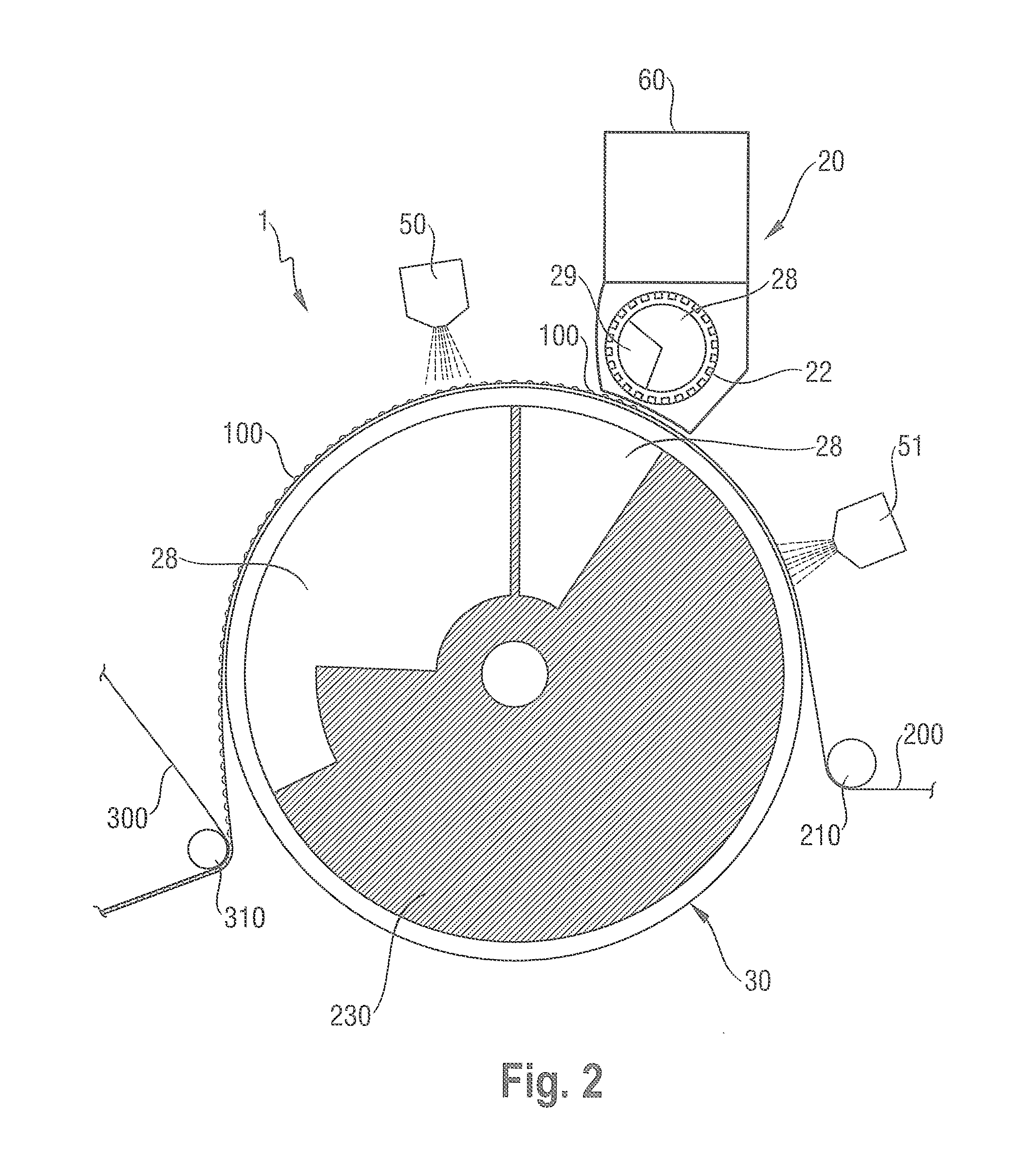

Equipment for insertion of objects into smoking articles

ActiveUS20070068540A1Sufficient shapeSufficient sizeMechanical working/deformationPaper/cardboard articlesEngineeringSpace object

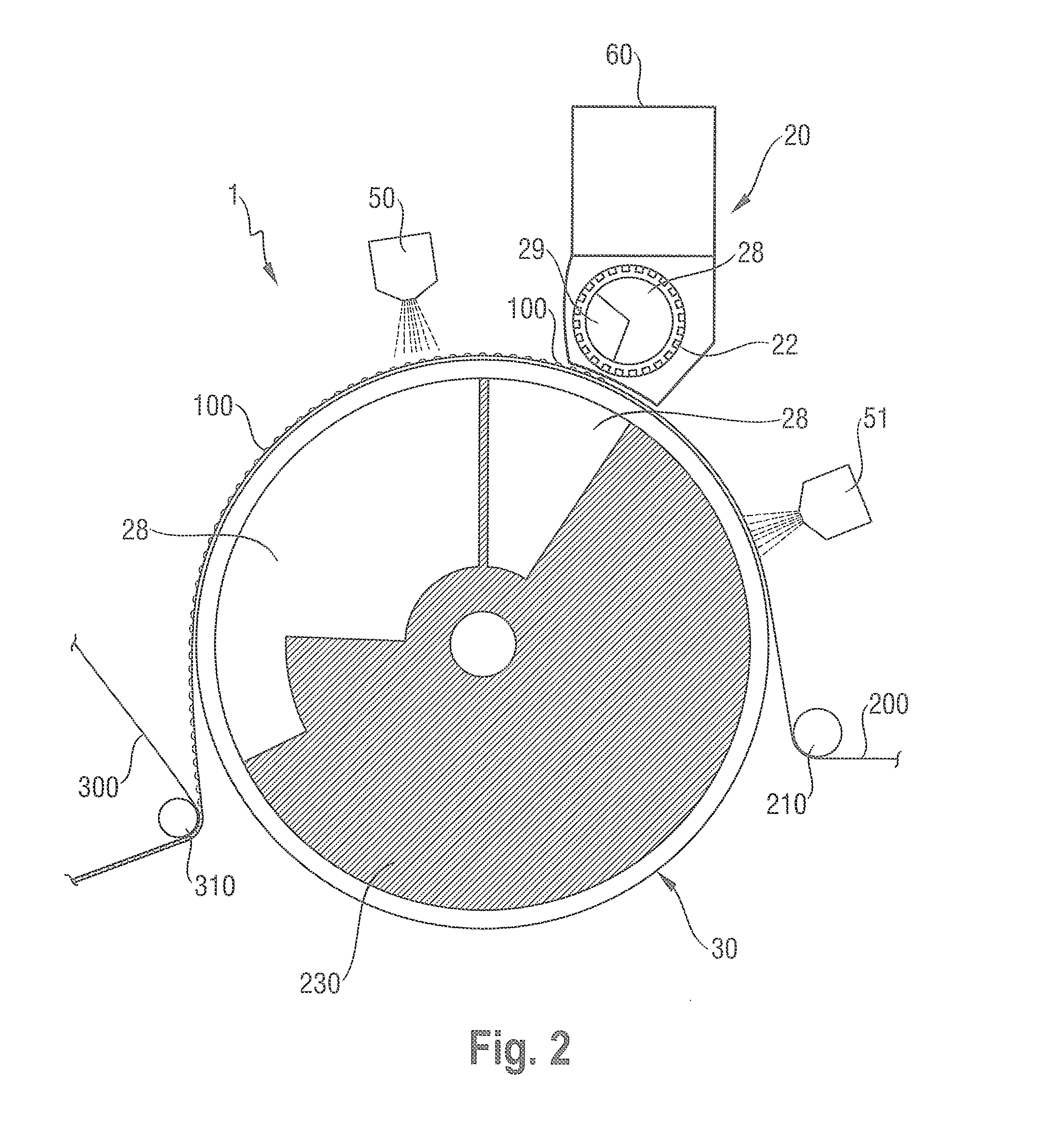

Apparatus incorporating a filter tow processing unit adapted to supply filter tow to a continuous rod forming unit includes an object insertion unit that positions objects within the filter tow to manufacture a filter rod containing objects positioned at predetermined intervals. The apparatus also includes an upper hopper that acts as a reservoir for a plurality of objects, and provides for supply of objects to a lower hopper. The lower hopper is shaped so that objects are stacked therein. The bottom of the lower hopper is shaped so as to cooperate with a portion of upper region of a rotating wheel. The peripheral face of the rotating wheel incorporates a plurality of spaced pockets, each pocket being of sufficient shape and size to accommodate one object. Objects within the lower hopper are aligned in a single line along a portion of the peripheral face in the upper region of the rotating wheel. Each object then is positioned at predetermined intervals within a continuous supply of filter material. Then, the filter material is formed into a continuous rod having individual objects positioned at predetermined spaced intervals within that rod. The continuous rod then is subdivided at predetermined intervals so as to form a plurality of filter rods (e.g., four-up filter rods containing four spaced objects).

Owner:R J REYNOLDS TOBACCO COMPANY

Contact print methods

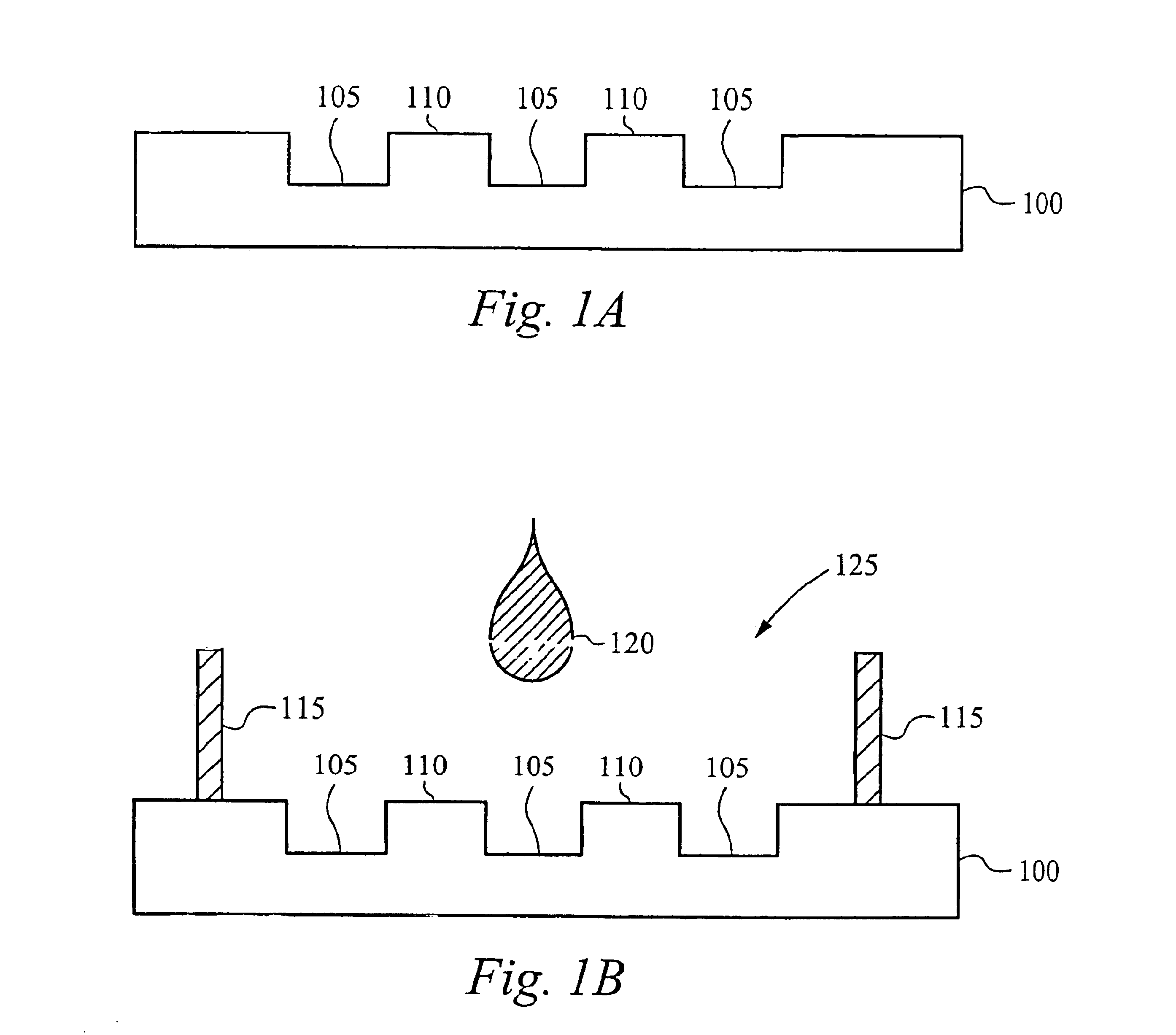

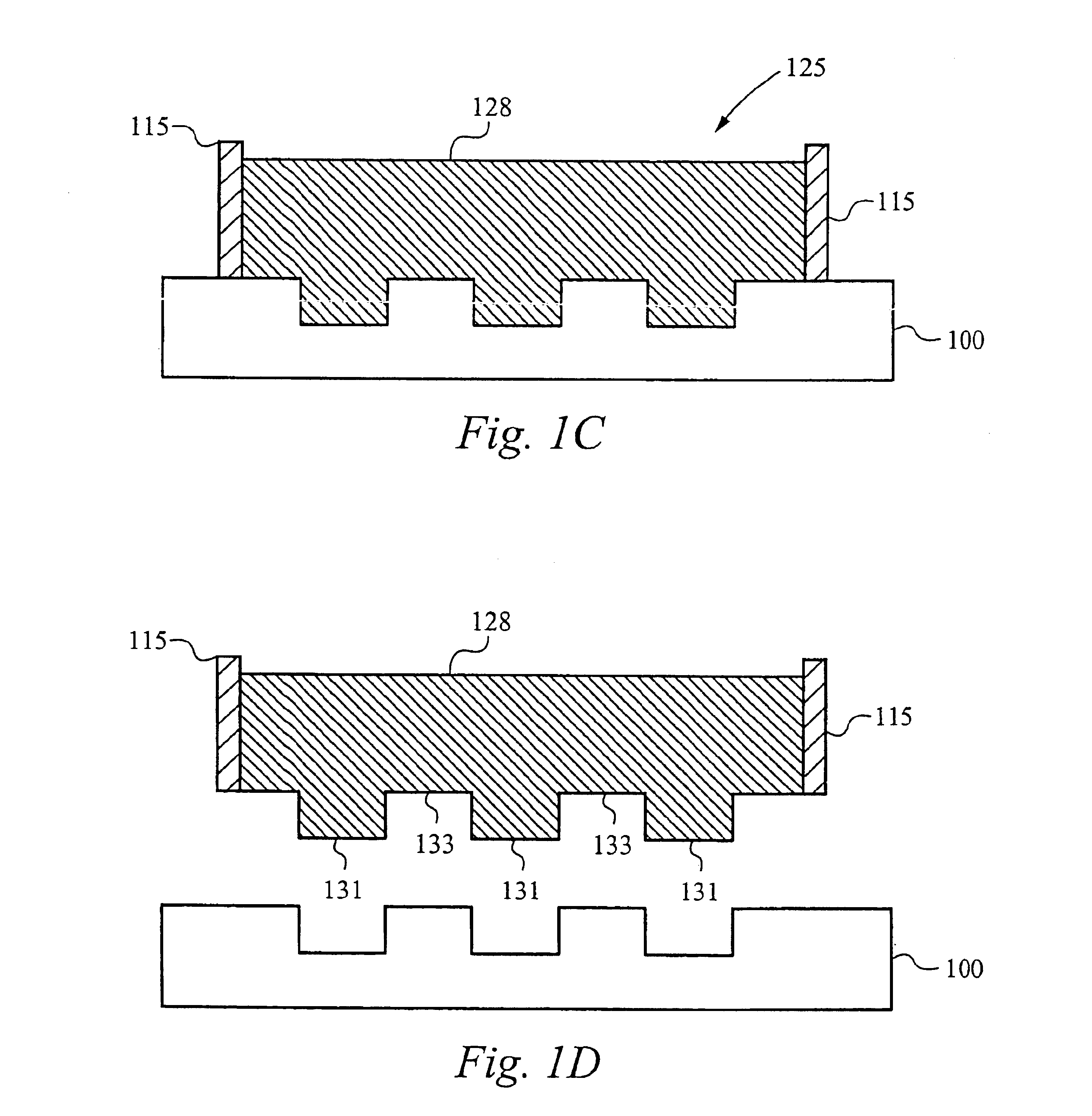

InactiveUS6957608B1High definitionImprove printing effectMechanical working/deformationSolid-state devicesContact printSolvent

A method of and device for controlled printing using liquid embossing techniques is disclosed. In accordance with the embodiments of the invention a stamp comprises a differentiated embossing surface with protruding and recessed surfaces to enhance the ability of the stamp to selectively displace liquid ink from a print surface and / or remove solvent from the liquid in a soft curing process. A stamp with differentiated surfaces is fabricated by selectively coating, or otherwise treating the protruding features, the recessed features, or a combination thereof, such that the surface energies and / or wettability of the protruding surfaces and the recessed surfaces are differentiated.

Owner:KOVIO

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

ActiveUS20050241786A1The implementation process is simpleNatural cellulose pulp/paperMechanical working/deformationMedicineCellulose fiber

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

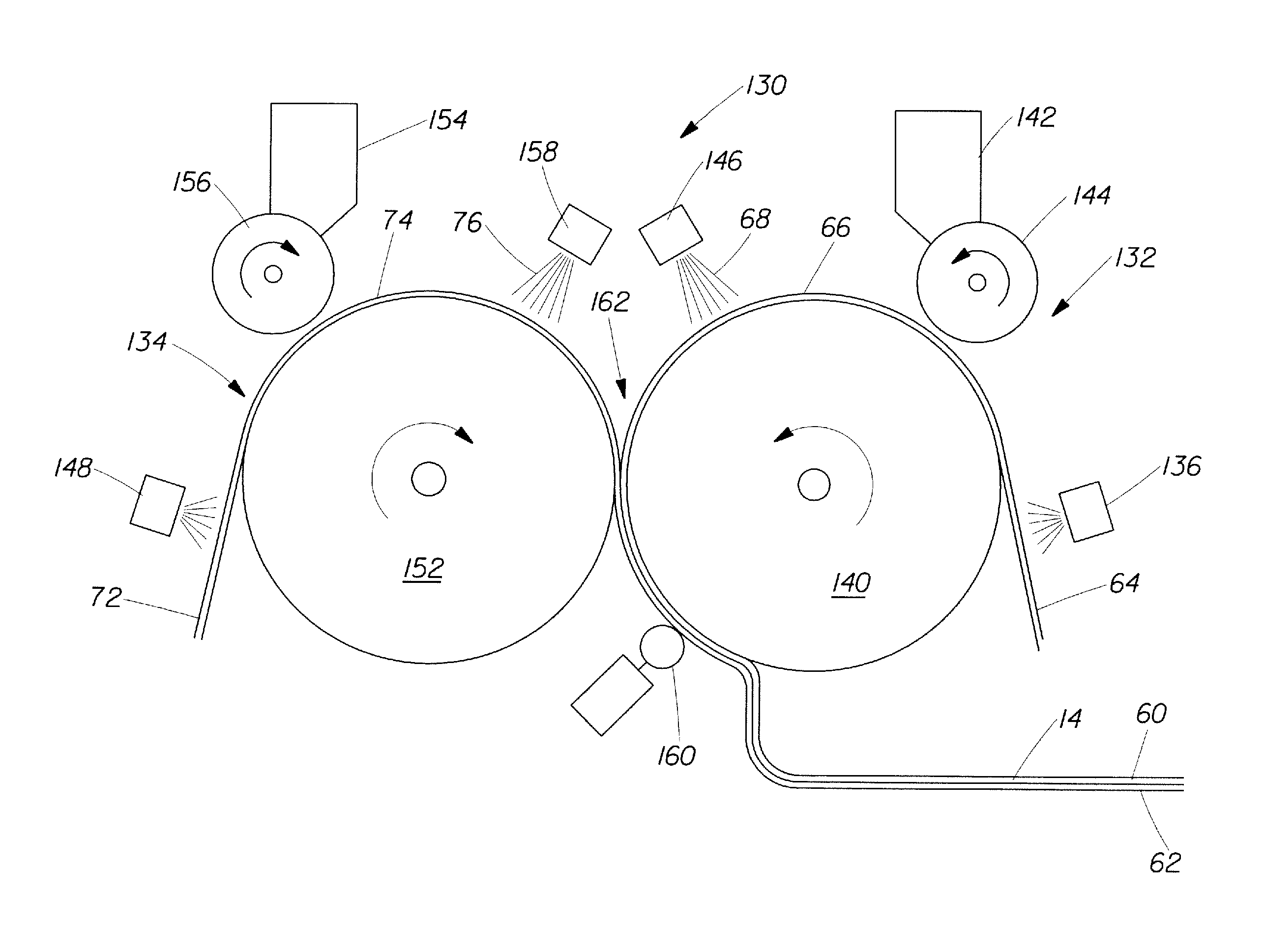

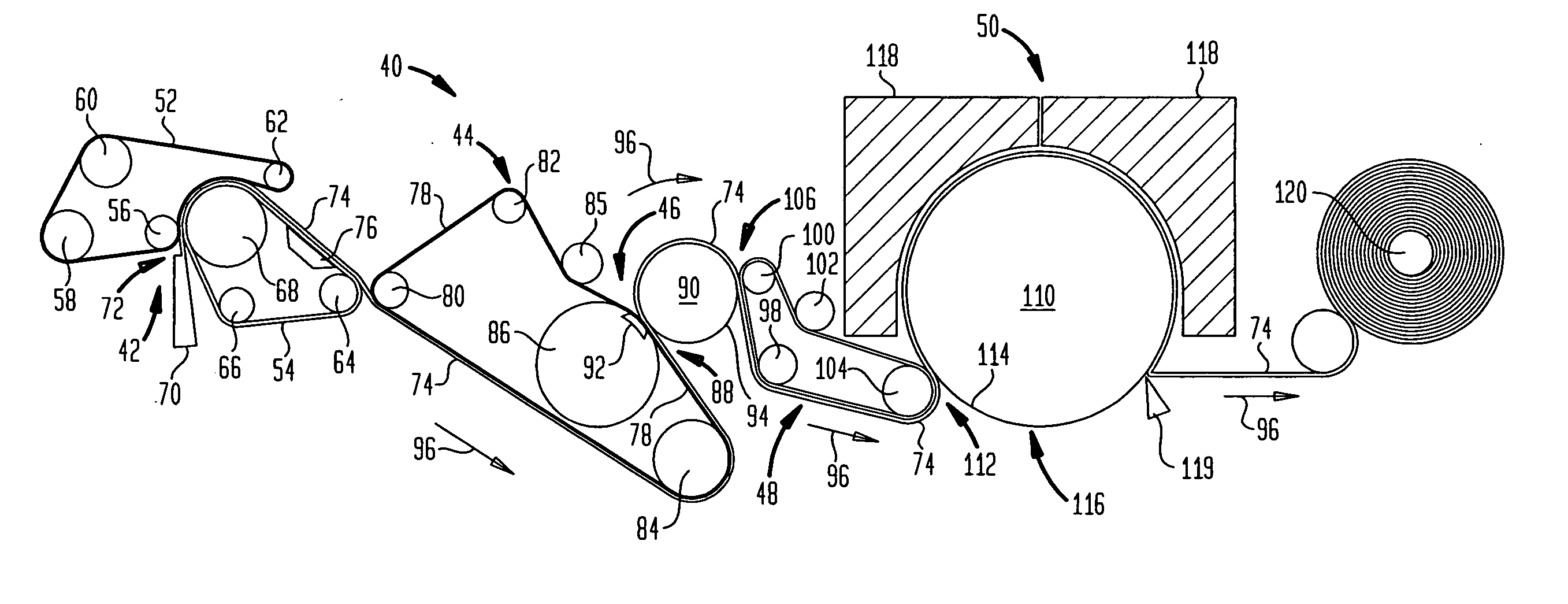

Fabric crepe/draw process for producing absorbent sheet

ActiveUS20050217814A1Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingFiberPapermaking

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

Paper tissue having enhanced softness

InactiveUS6344111B1Increase softnessMaintain tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

A novel paper article, a method of making a paper product, and an embossing roll are disclosed for providing a paper surface region having a minority of fiber to fiber bonds broken in the paper surface region to a depth less than about 0.02 mm from the paper surface. In one aspect, the roughened embossing roll includes protuberances or depressions sized at less than about 0.1 mm. In one aspect, the roughened embossing roll includes protuberances or depressions adapted to produce paper product surface deformations in the paper surface, wherein the paper product surface deformations are invisible to an unaided human eye. The present invention provides a paper product having higher perceived softness while maintaining tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method and apparatus for making absorbent structures with absorbent material

Owner:PROCTER & GAMBLE CO

Fabric crepe/draw process for producing absorbent sheet

ActiveUS7789995B2Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingCelluloseFiber

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

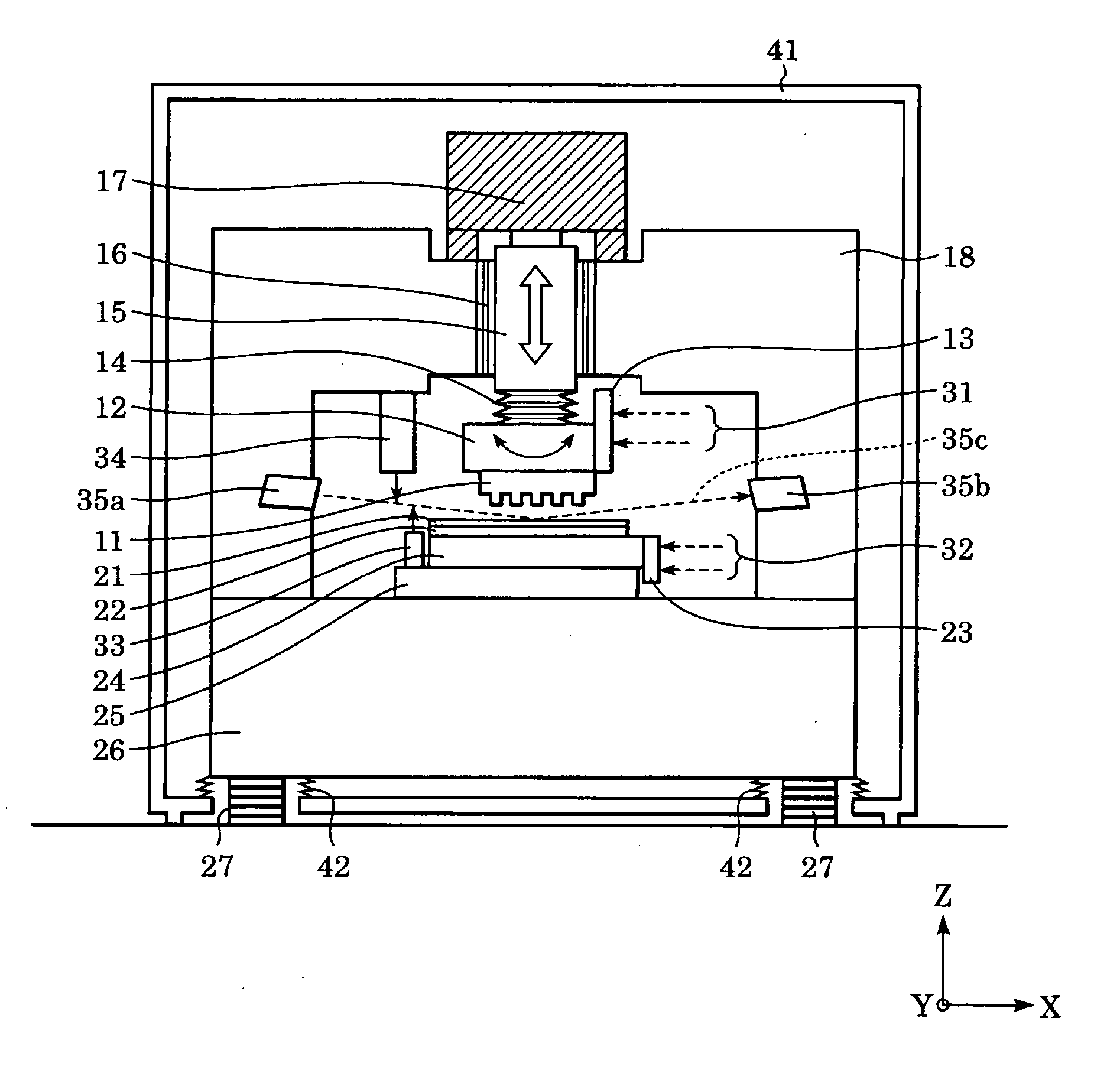

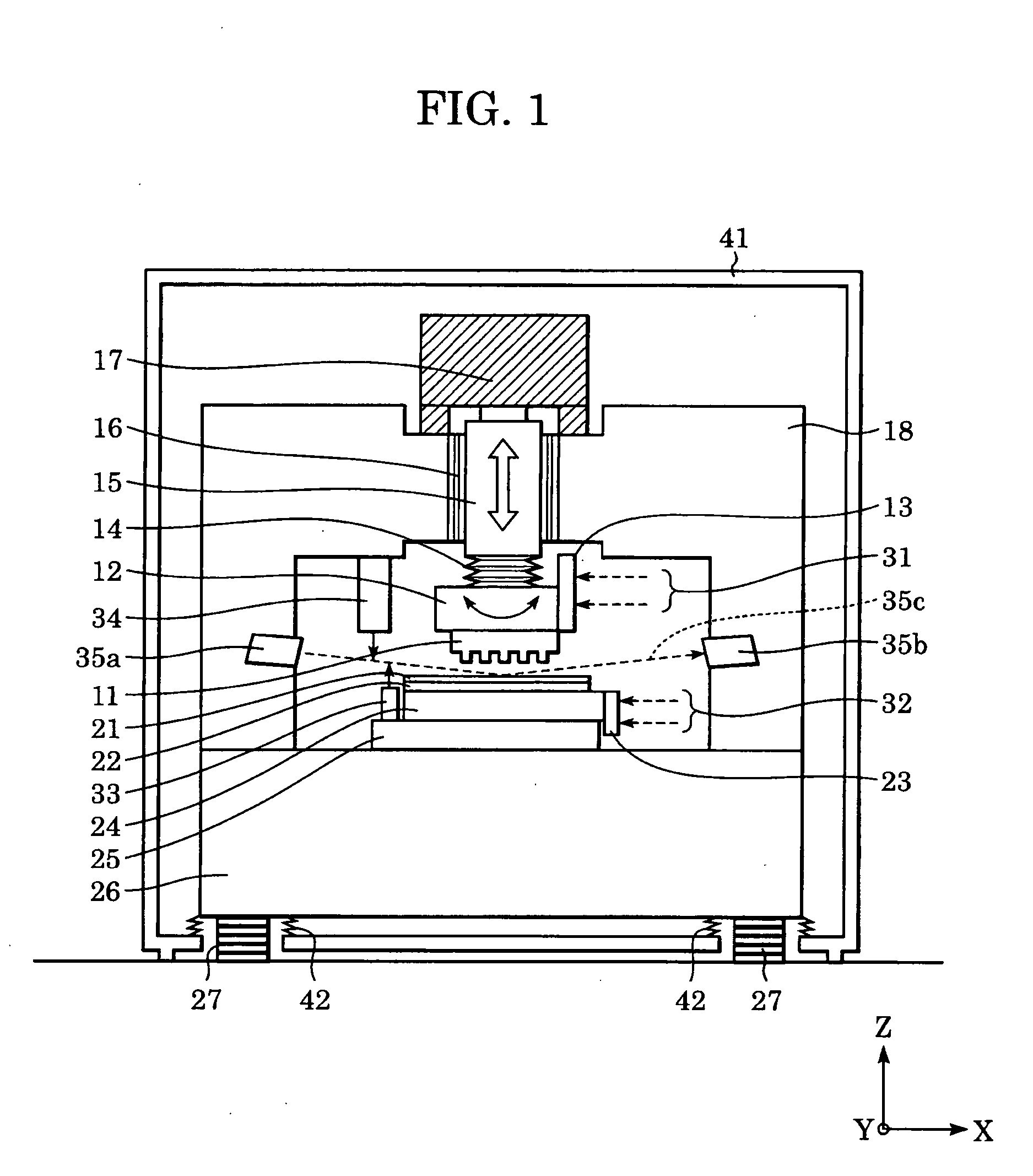

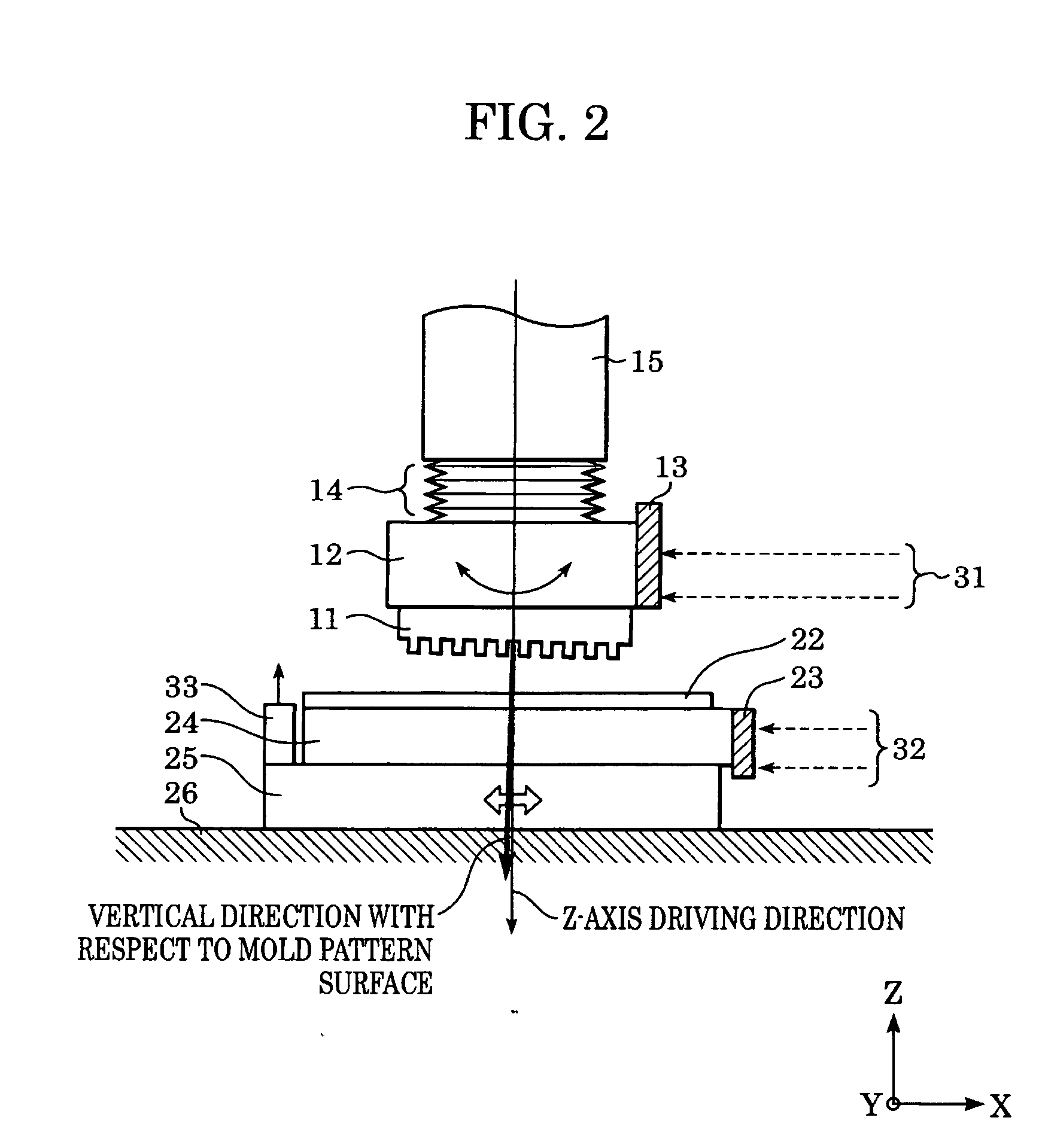

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

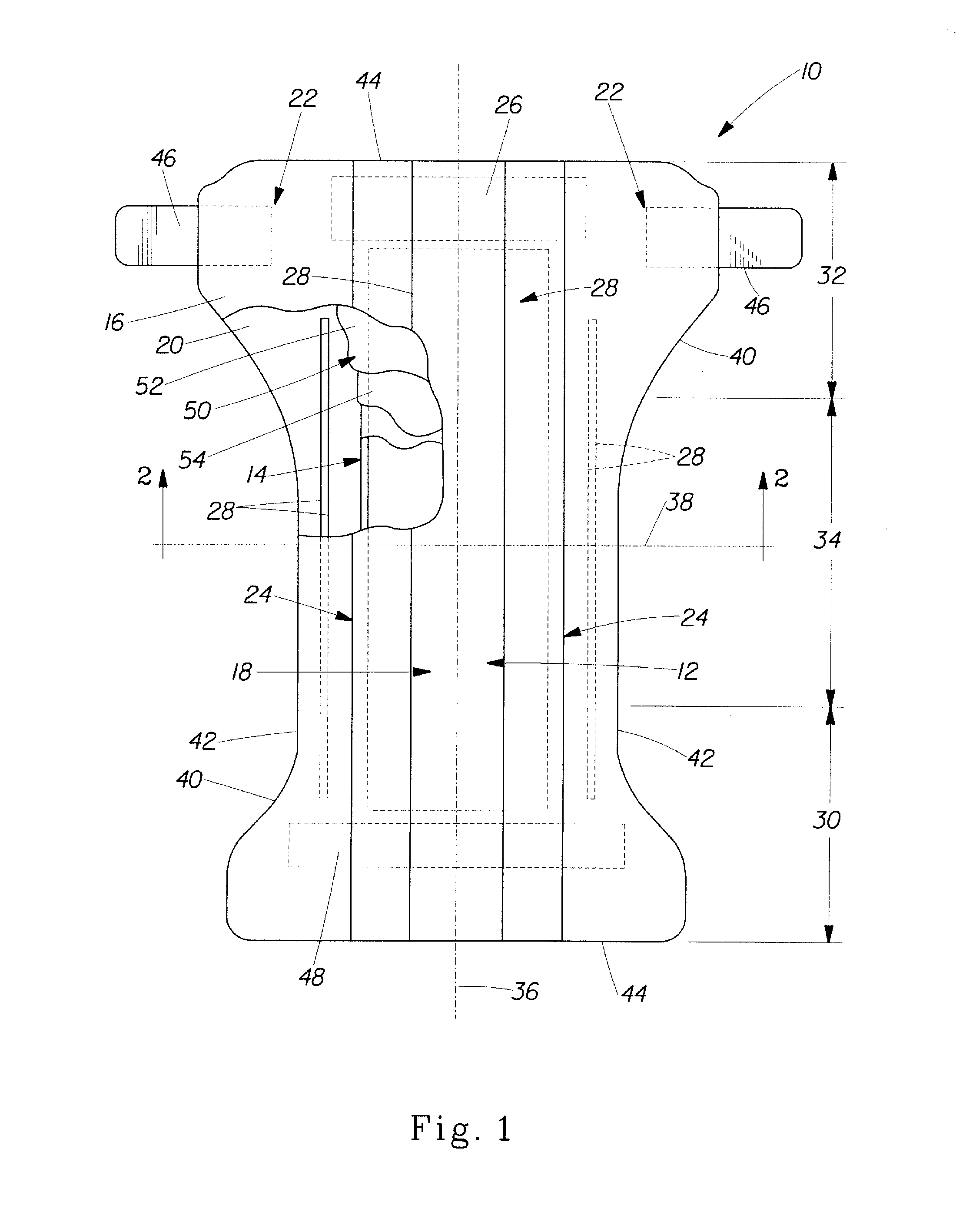

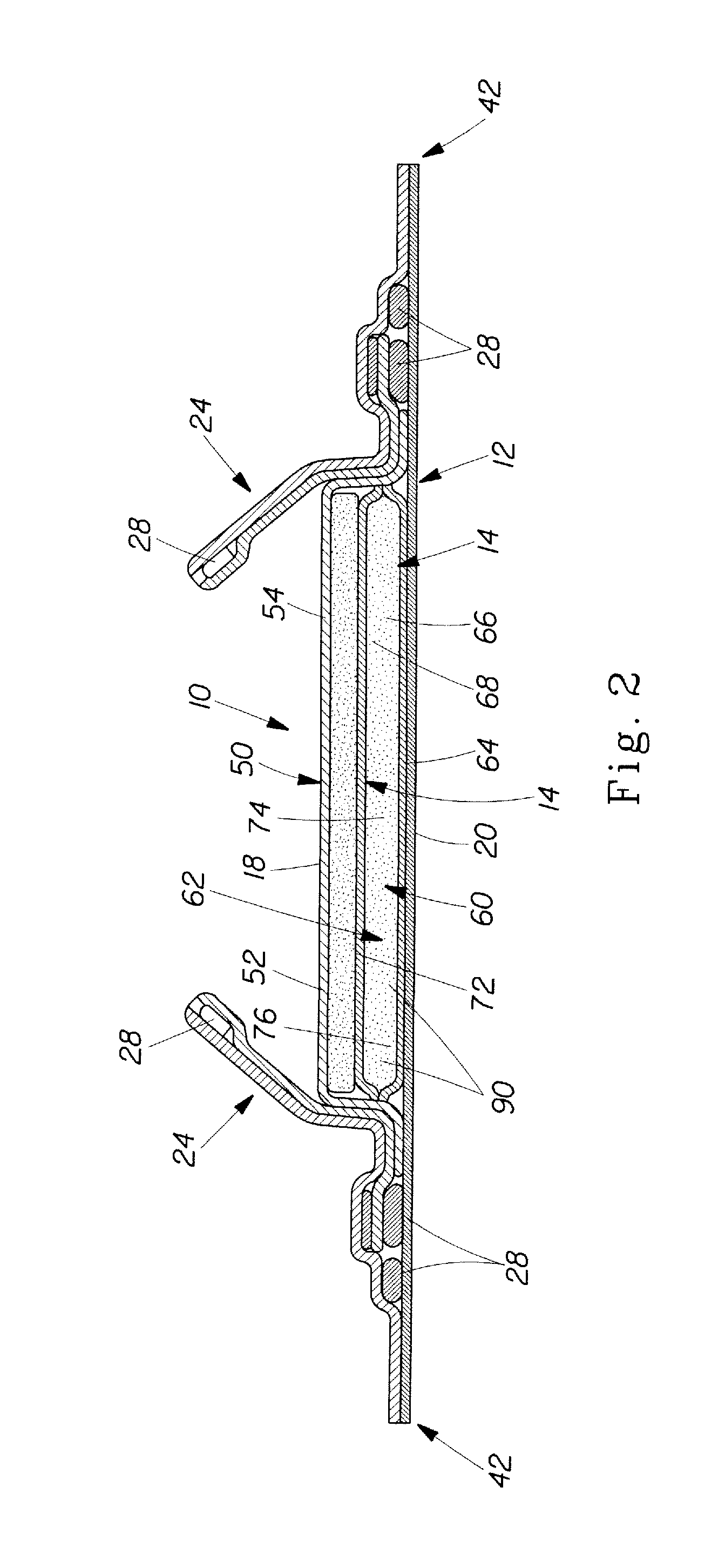

Absorbent core for disposable absorbent article

InactiveUS7935207B2Mechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

A method of making an absorbent core for use in an absorbent article. The method comprising the steps of:a. providing a first absorbent fibrous web material;b. providing a second absorbent fibrous web material;c. providing a pair of rolls forming a nip through which the first and second absorbent fibrous web materials can be processed, the pair of rolls being selected from the processes consisting of, ring rolling, SELF, micro-SELF, and rotary knife aperturing;d. deforming portions of the first absorbent fibrous web material by processing through the pair of rolls;e. deforming portions of the second absorbent fibrous web material by processing through the pair of rolls; andf. combining the first and second absorbent fibrous web materials to form the absorbent core.

Owner:PROCTER & GAMBLE CO

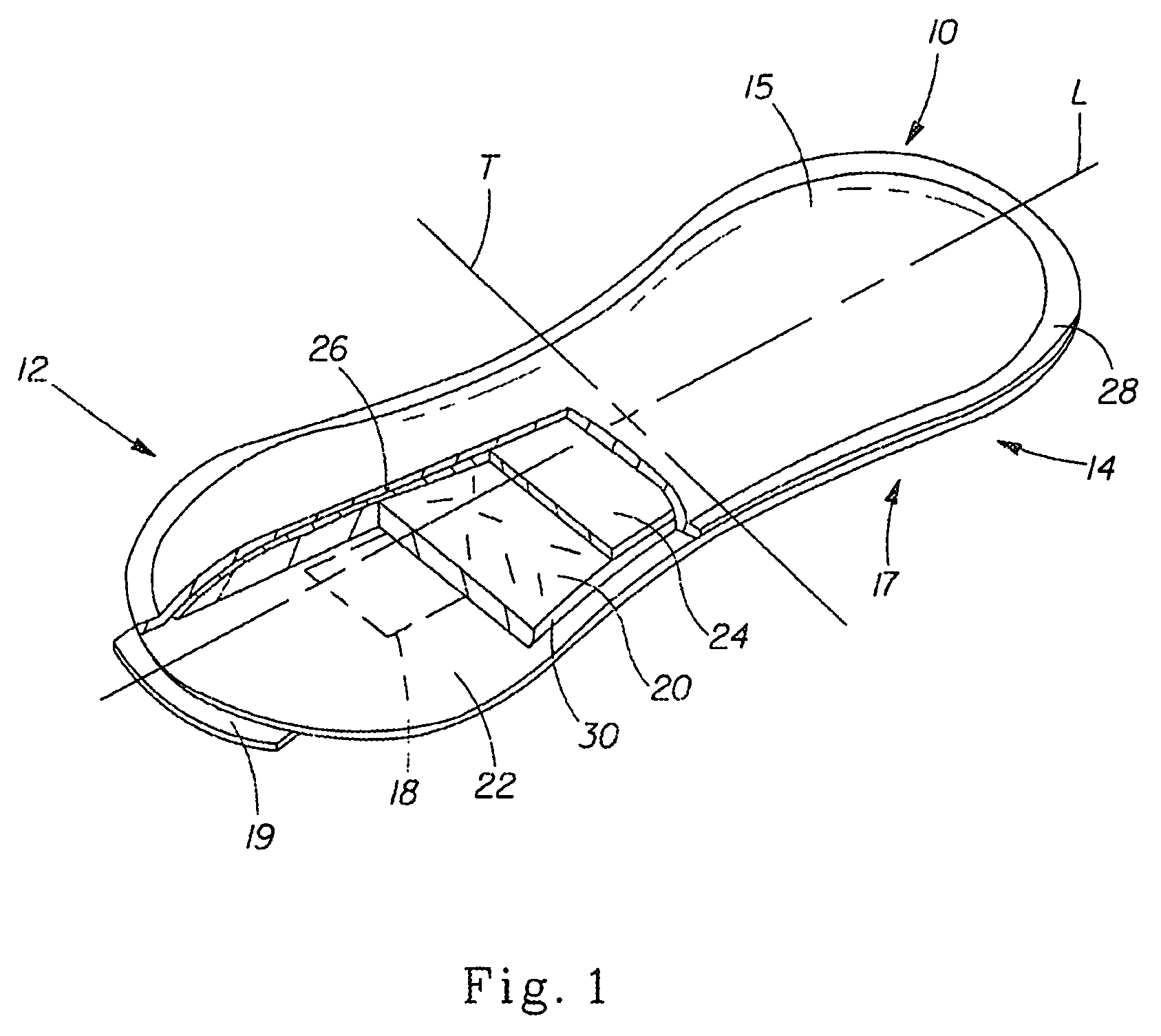

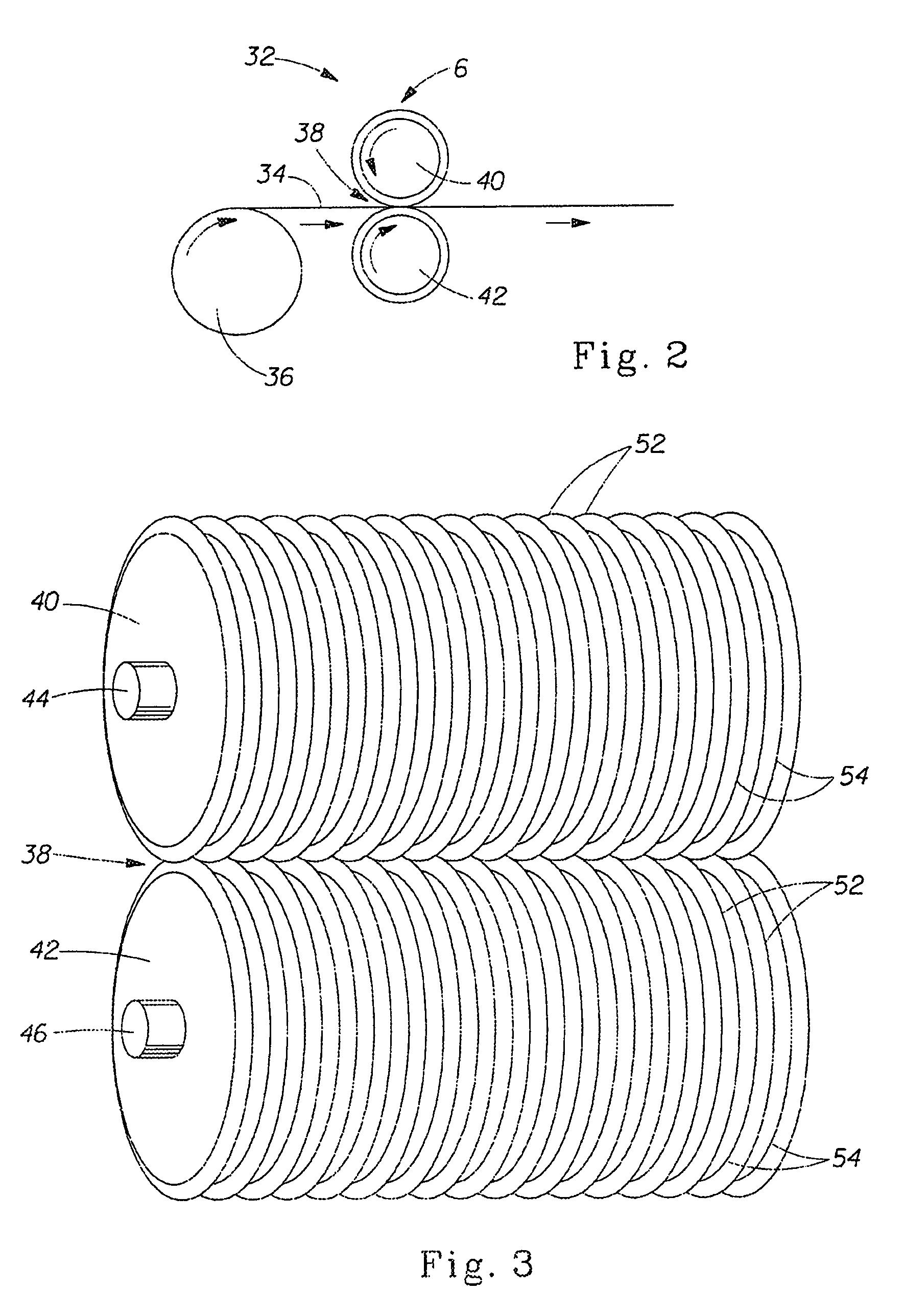

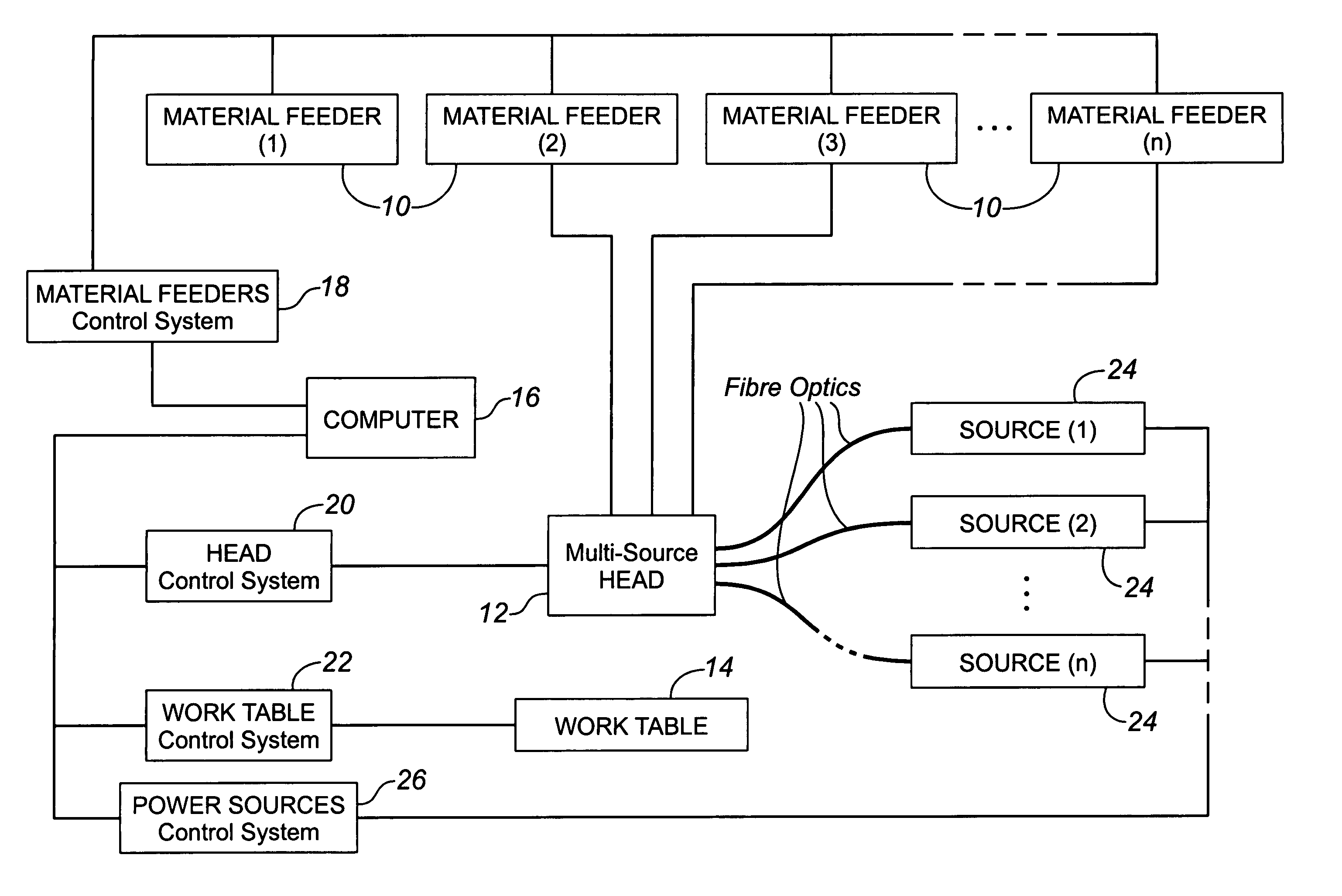

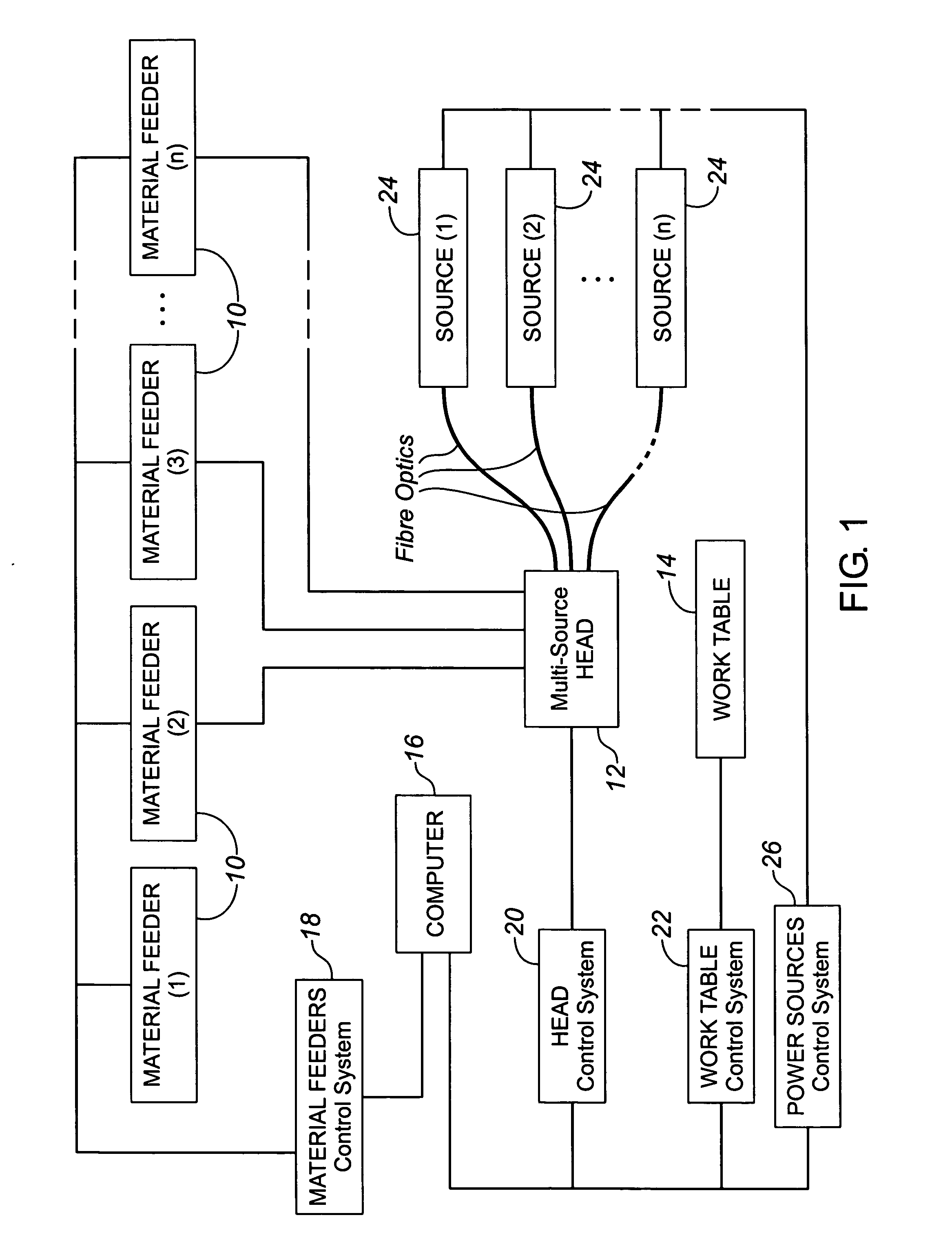

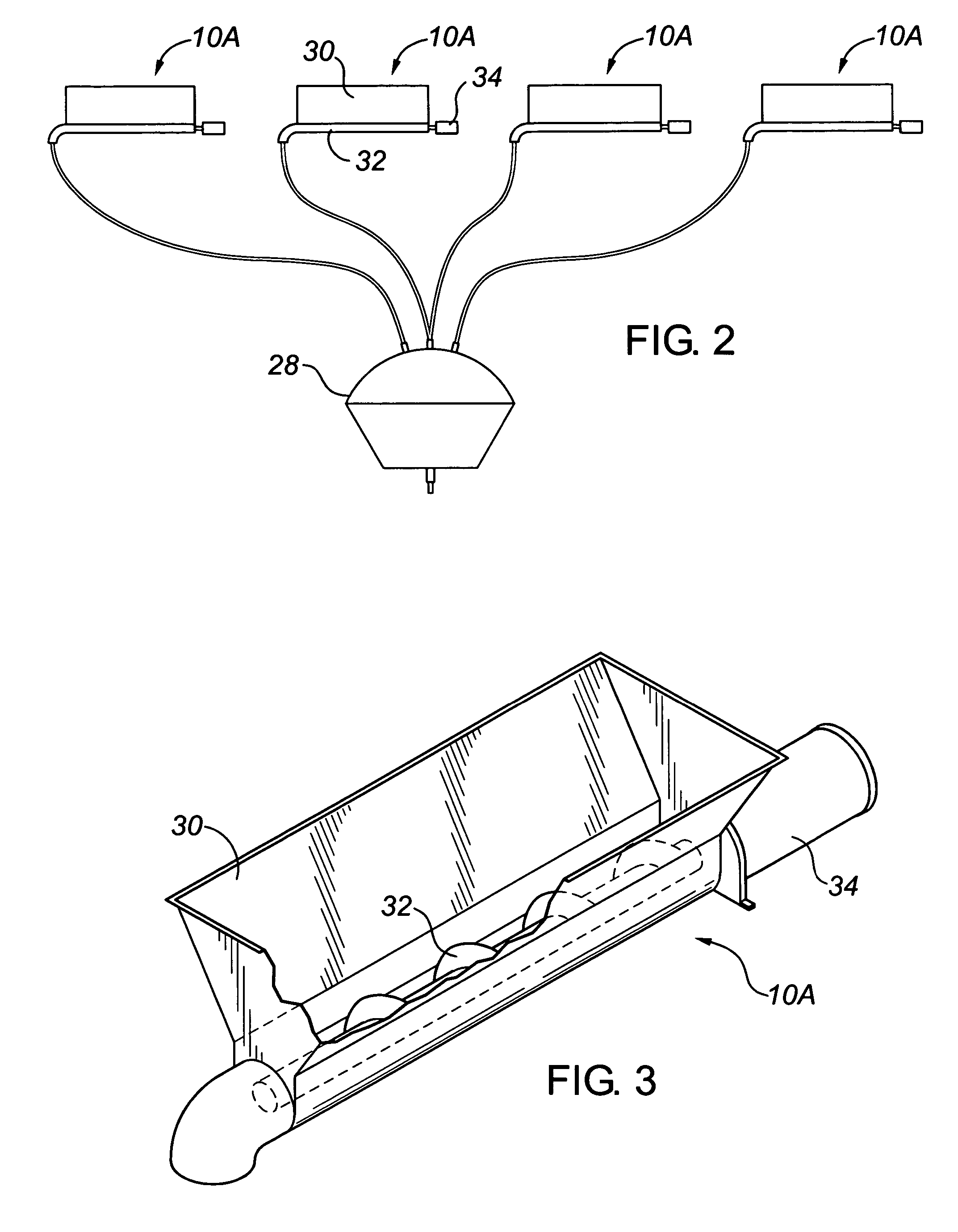

Multisource and multimaterial freeform fabrication

InactiveUS20050104257A1Liquid surface applicatorsMechanical working/deformationControl systemEngineering

An apparatus for forming freeform solid articles includes a head unit having a plurality of arc-shaped support arms. The support arms mount material feeders and power sources which are directed at a work table. The material feeders, power sources and movement of the head unit and work table are controlled by a computerized control system.

Owner:UNIV TECH INT

Embossed multi-ply fibrous structure product

A multi-ply fibrous structure product having two or more plies of fibrous structure where at least one of the plies has a plurality of domes formed during the papermaking process and there are from about 10 to about 1000 domes per square inch of the product. At least one of the plies of the multi-ply fibrous structure has a plurality of embossments thereon with a total embossment area of from about 3% to about 15%. The embossments may be arranged such that they define non-geometric foreground patterns of unembossed cells.

Owner:THE PROCTER & GAMBLE COMPANY

Soft tissue having temporary wet strength

Disclosed is a soft, low density paper product made using papermaking fibers and a cationic temporary wet strength resin. Such paper products have a density less than about 0.6 grams per cubic centimeter, a basis weight is between about 10 and about 65 grams per square meter, a dry strength less than about 500 grams per inch (197 grams per centimeter), a ratio of an initial wet strength to the dry strength greater than about 0.15:1, and a ratio of a thirty minute wet strength to the initial wet strength less than about 0.4. Methods for producing such paper products are also disclosed. The paper products may be produced either as homogeneous structures or as multi-layered structures and may be either creped or uncreped.

Owner:THE PROCTER & GAMBLE COMPANY

Equipment for insertion of objects into smoking articles

ActiveUS7479098B2Sufficient shapeSufficient sizeMechanical working/deformationPaper/cardboard articlesSpace objectEngineering

Apparatus incorporating a filter tow processing unit adapted to supply filter tow to a continuous rod forming unit includes an object insertion unit that positions objects within the filter tow to manufacture a filter rod containing objects positioned at predetermined intervals. The apparatus also includes an upper hopper that acts as a reservoir for a plurality of objects, and provides for supply of objects to a lower hopper. The lower hopper is shaped so that objects are stacked therein. The bottom of the lower hopper is shaped so as to cooperate with a portion of upper region of a rotating wheel. The peripheral face of the rotating wheel incorporates a plurality of spaced pockets, each pocket being of sufficient shape and size to accommodate one object. Objects within the lower hopper are aligned in a single line along a portion of the peripheral face in the upper region of the rotating wheel. Each object then is positioned at predetermined intervals within a continuous supply of filter material. Then, the filter material is formed into a continuous rod having individual objects positioned at predetermined spaced intervals within that rod. The continuous rod then is subdivided at predetermined intervals so as to form a plurality of filter rods (e.g., four-up filter rods containing four spaced objects).

Owner:R J REYNOLDS TOBACCO COMPANY

Use Of A Surface-Reacted Calcium Carbonate In Tissue Paper, Process To Prepare A Tissue Paper Product Of Improved Softness, And Resulting Improved Softness Tissue Paper Products

ActiveUS20120031576A1Good flexibilityNatural cellulose pulp/paperCoatings with pigmentsSurface responseTissue paper

The present invention related to the use of a surface-reacted natural calcium carbonate as filler in tissue paper products, to a process to prepare tissue paper products, and to a tissue paper product featuring an improved softness, wherein said surface-reacted natural calcium carbonate is the reaction product of a natural calcium carbonate with an acid and carbon dioxide, which is formed in situ by the acid treatment and / or supplied externally.

Owner:OMYA INT AG

Method and Apparatus for Making Absorbent Structures with Absorbent Material

ActiveUS20140027066A1Mechanical working/deformationNon-adhesive dressingsAbsorbent materialMechanical engineering

Apparatus and method for producing absorbent structures with absorbent layers with channel(s) without absorbent material, using a first moving endless surface with specific raised strip(s) and a second moving endless surface with specific mating strip(s).

Owner:PROCTER & GAMBLE CO

Vacuum coupled tool apparatus for dry transfer printing semiconductor elements

InactiveUS8261660B2Improvement in printing yield and placement accuracy and fidelityReduce pressureMechanical working/deformationDecorative surface effectsEngineeringThin glass

Owner:X DISPLAY CO TECH LTD

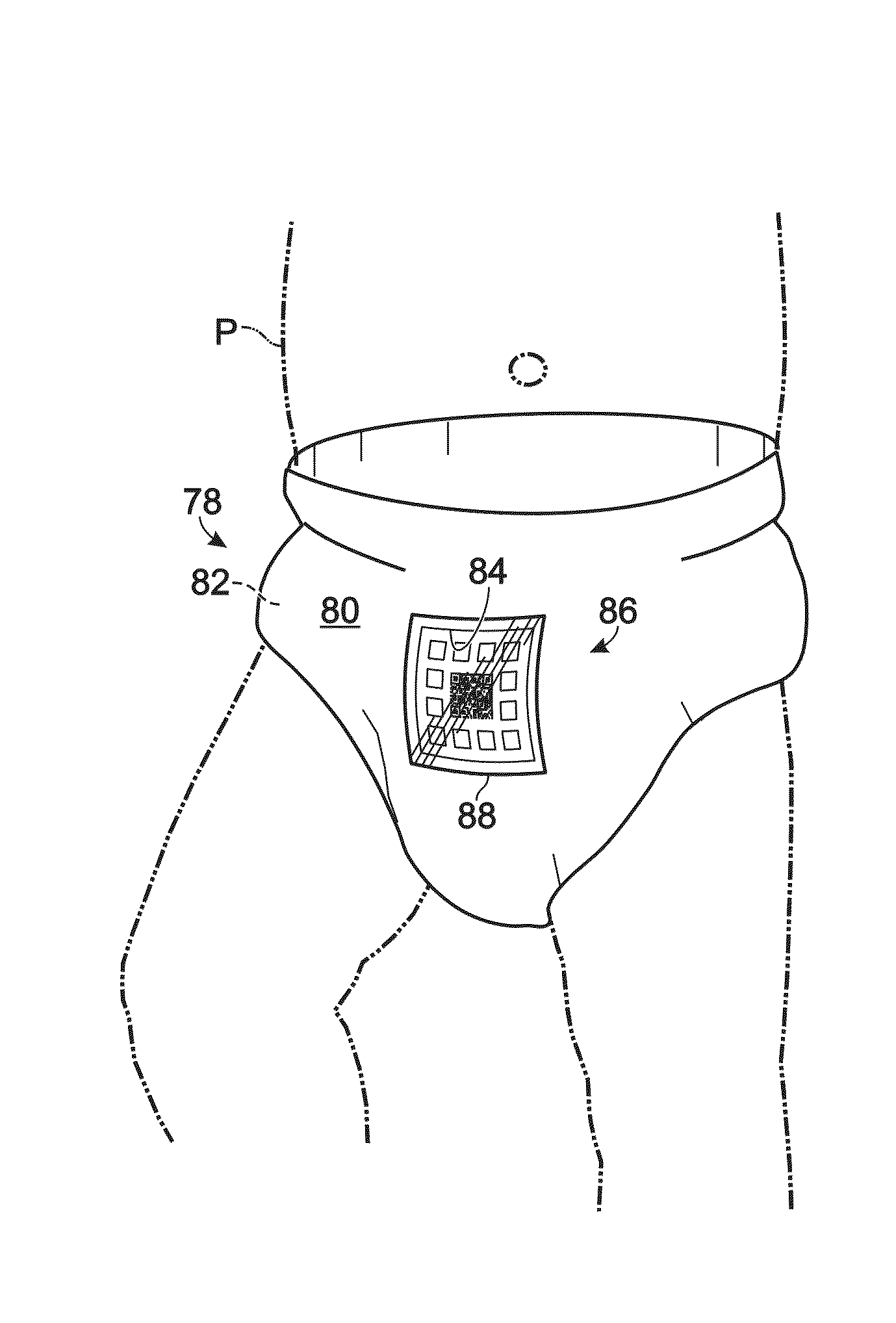

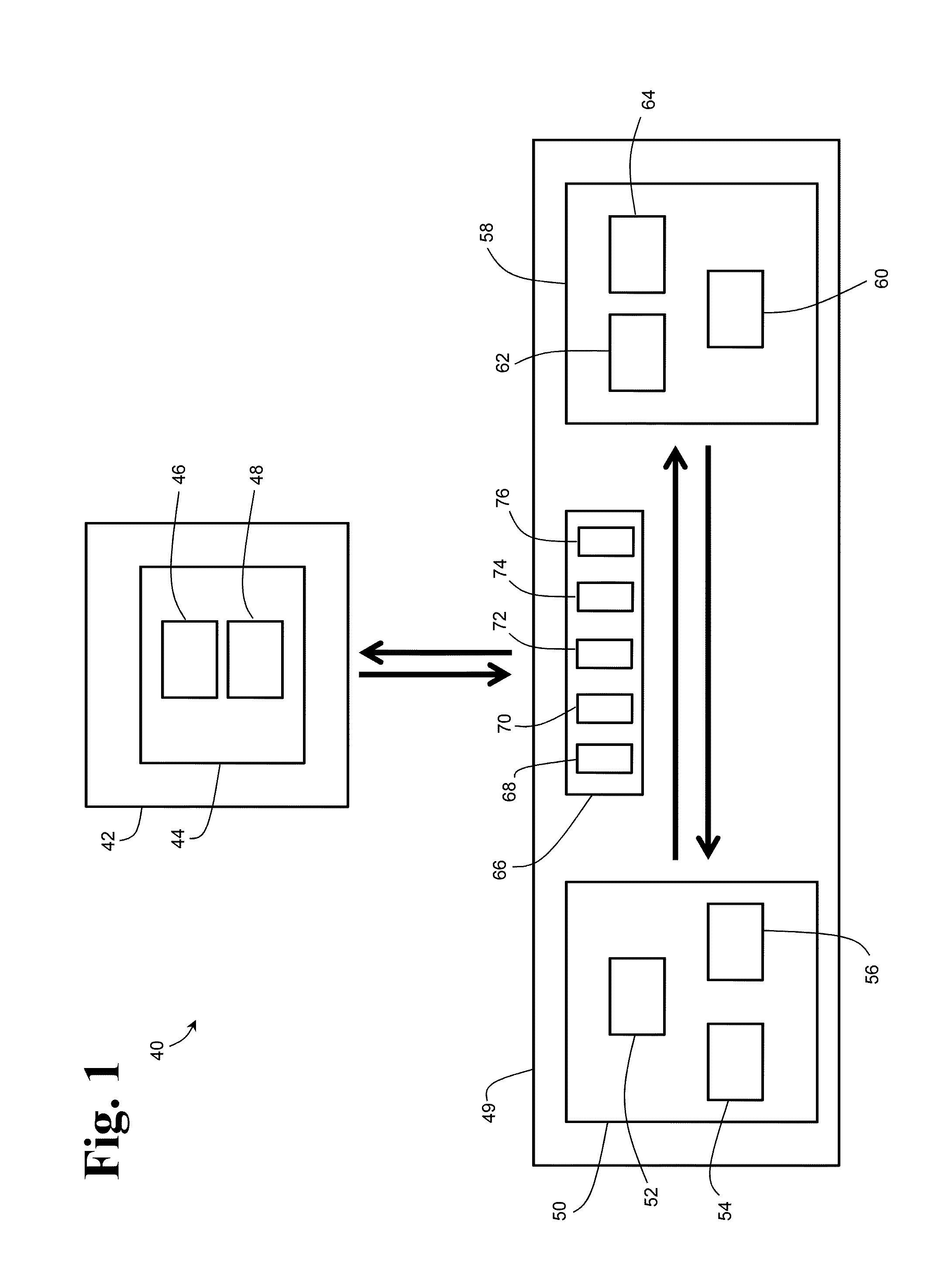

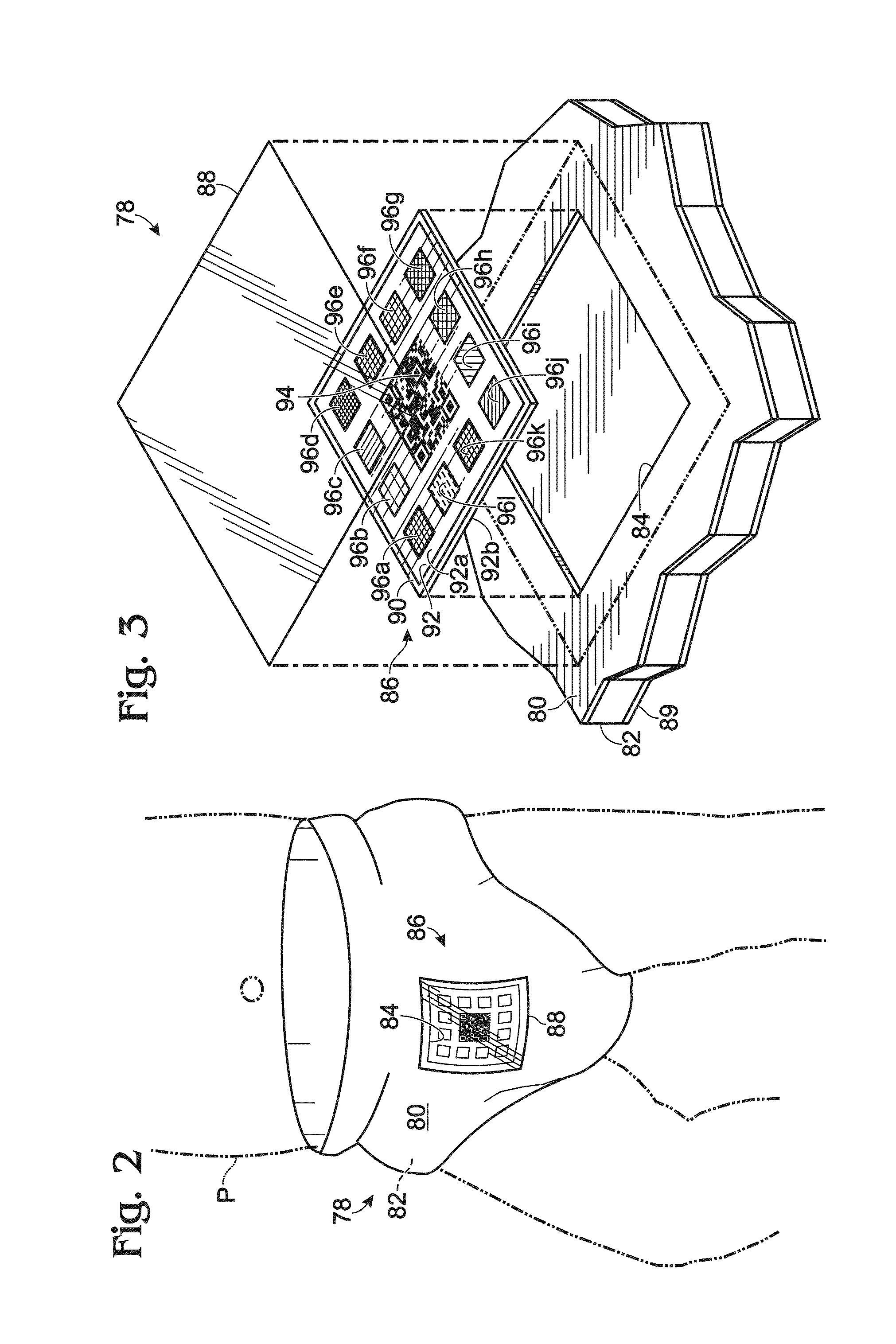

Health diagnostic systems and methods

A health monitoring system, and methods of use and manufacture thereof are disclosed. The health monitoring system may include a computing system and a diagnostic test coupled to a diaper. The diagnostic test may include one or more sensors configured to produce a visual indication of one or more analytes contained in a sample produced by a subject. The diagnostic test may include a machine-readable code. The computing system may be configured to read the machine-readable code to allow an application running on the computing system to automatically perform at least one task related to a production of a data point based on the visual indication. The health monitoring system may aid in identifying a potential abnormal health condition of the subject by providing automatic longitudinal analysis of analytes contained in samples produced by the subject over a period of time.

Owner:ANAVAH HEALTH LLC

Multi-ply paper towel with absorbent core

ActiveUS7662257B2VariationImprove performanceNon-fibrous pulp additionNatural cellulose pulp/paperCellulosePaper towel

A multi-ply absorbent sheet of cellulosic fiber with continuous outer surfaces is provided an absorbent core between the outer surfaces. The absorbent core includes a non-woven fiber network having: (i) a plurality of pileated fiber enriched of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking whose fiber orientation is biased along the direction between pileated interconnected thereby, and (iii) a plurality of fiber-deprived cellules between the fiber enriched and linking regions, also being characterized by a local basis weight lower than the fiber enriched regions. The cellules provide a sponge-like internal structure of low fiber density regions.

Owner:GPCP IP HLDG LLC

Method and apparatus for making an apertured web

Owner:PROCTER & GAMBLE CO

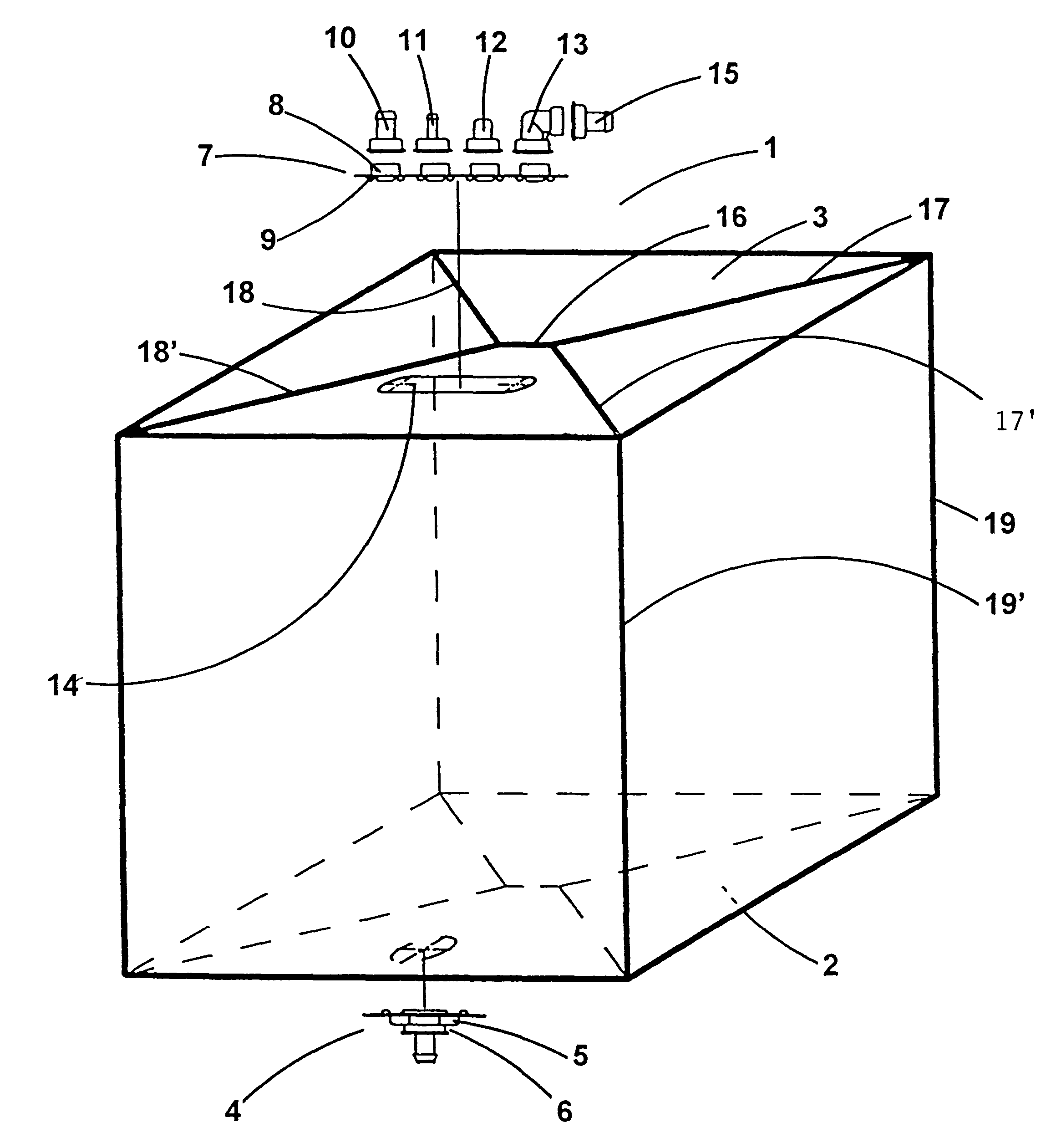

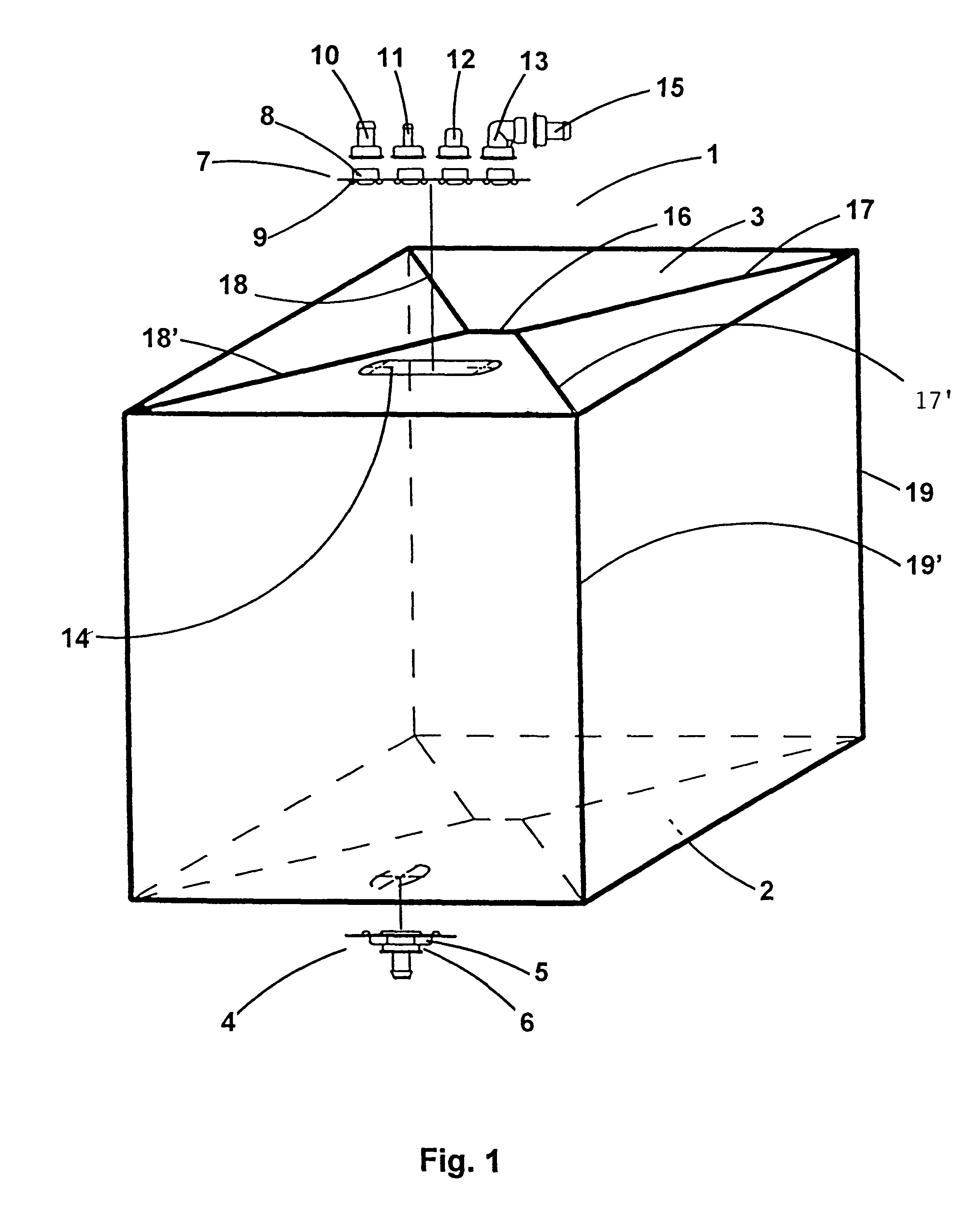

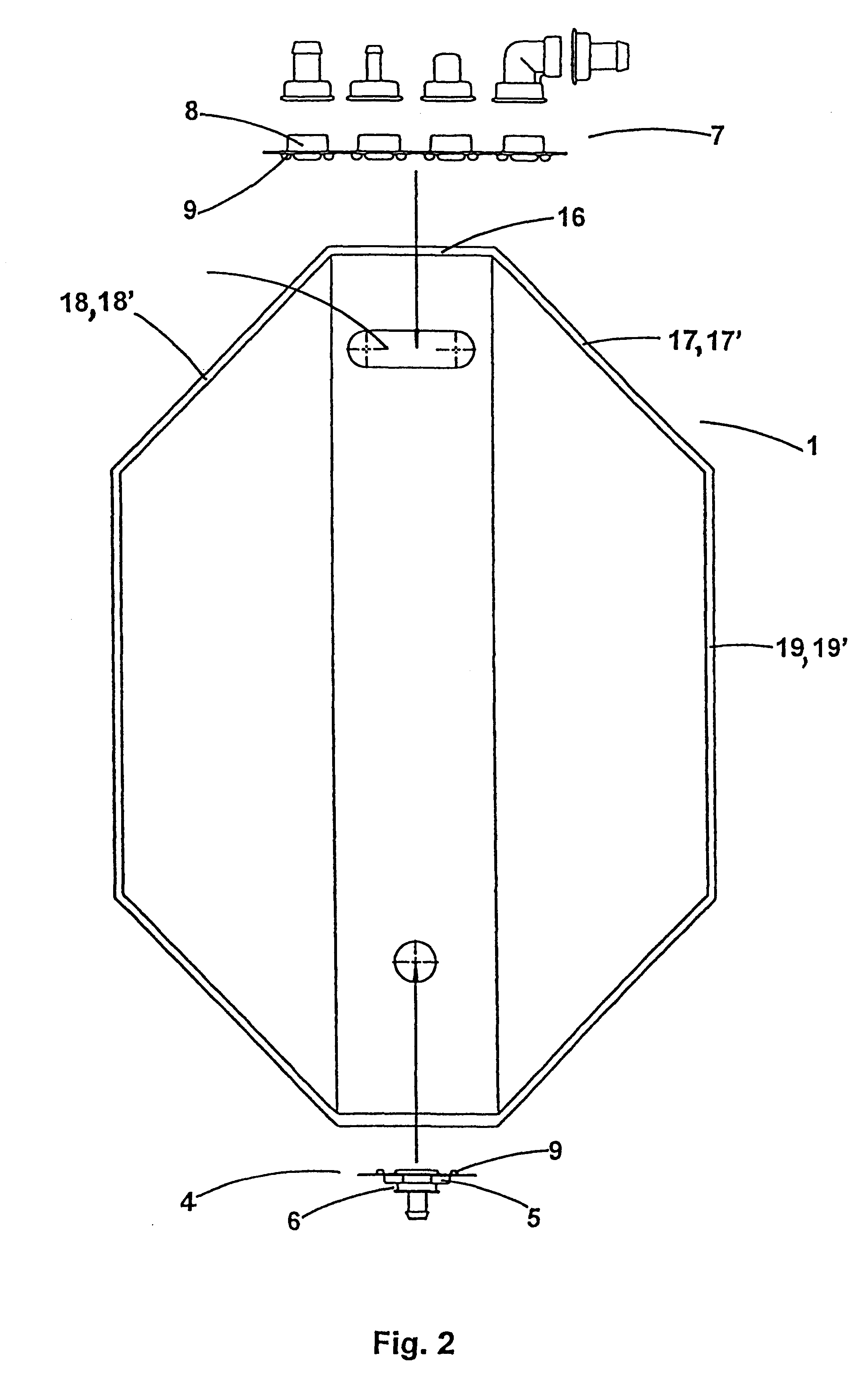

Sachets for bio-pharmaceutical fluid products

InactiveUS6186932B1Easily customizedImprove convenienceBioreactor/fermenter combinationsEnvelopes/bags making machineryPlastic materialsEngineering

A flexible sachet for transporting bio-pharmaceutical liquids with a volume of 50 liters or more, of the bellows type, assumes when filled a substantially parallelepiped shape. It comprises a bottom wall, a top wall and four lateral walls. It is made of a single laminated film with three or more layers, the innermost layer being a plastics material layer that can be heat welded and is biocompatible with the media transported. A method of manufacturing the sachet is also disclosed.

Owner:SARTORIUS STEDIM FMT SAS

Fabric crepe and in fabric drying process for producing absorbent sheet

ActiveUS20050241787A1Decrease sidednessReduced areaNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberPulp and paper industry

A method of making a cellulosic web includes: forming a nascent web from a papermaking furnish, the nascent web having a generally random distribution of papermaking fiber; b) transferring the web having a generally random distribution of papermaking fiber to a translating transfer surface moving at a first speed; drying the web to a consistency of from about 30 to about 60 percent including compactively dewatering the web prior to or concurrently with transfer to the transfer surface; fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a creping fabric with a patterned creping surface, the fabric creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric such that the web has a plurality of fiber-enriched regions arranged in a pattern corresponding to the patterned creping surface of the fabric, optionally drying the wet web while it is held in the creping fabric. Preferably, the formed web is characterized in that its void volume increases upon drawing.

Owner:GPCP IP HLDG LLC

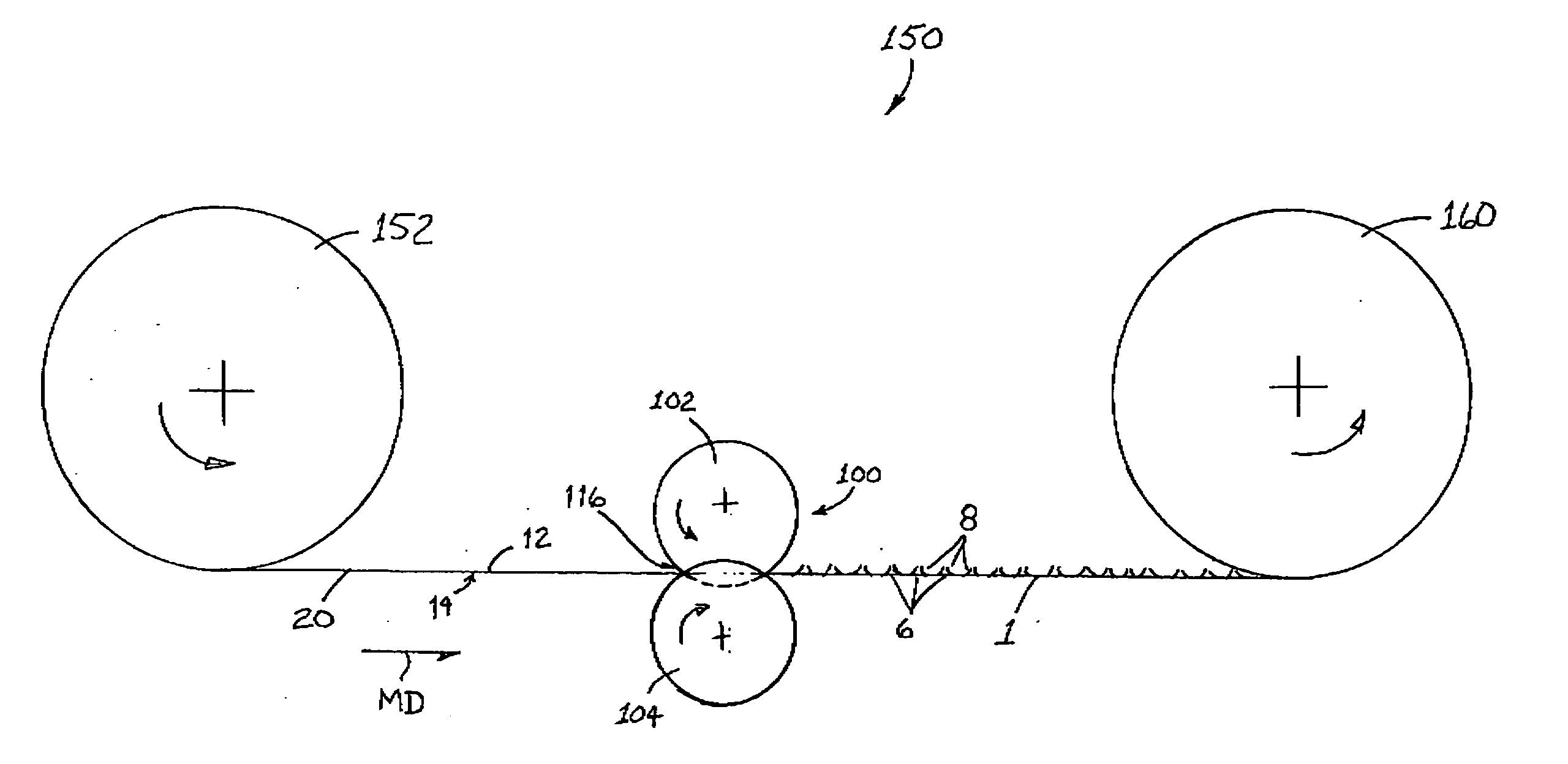

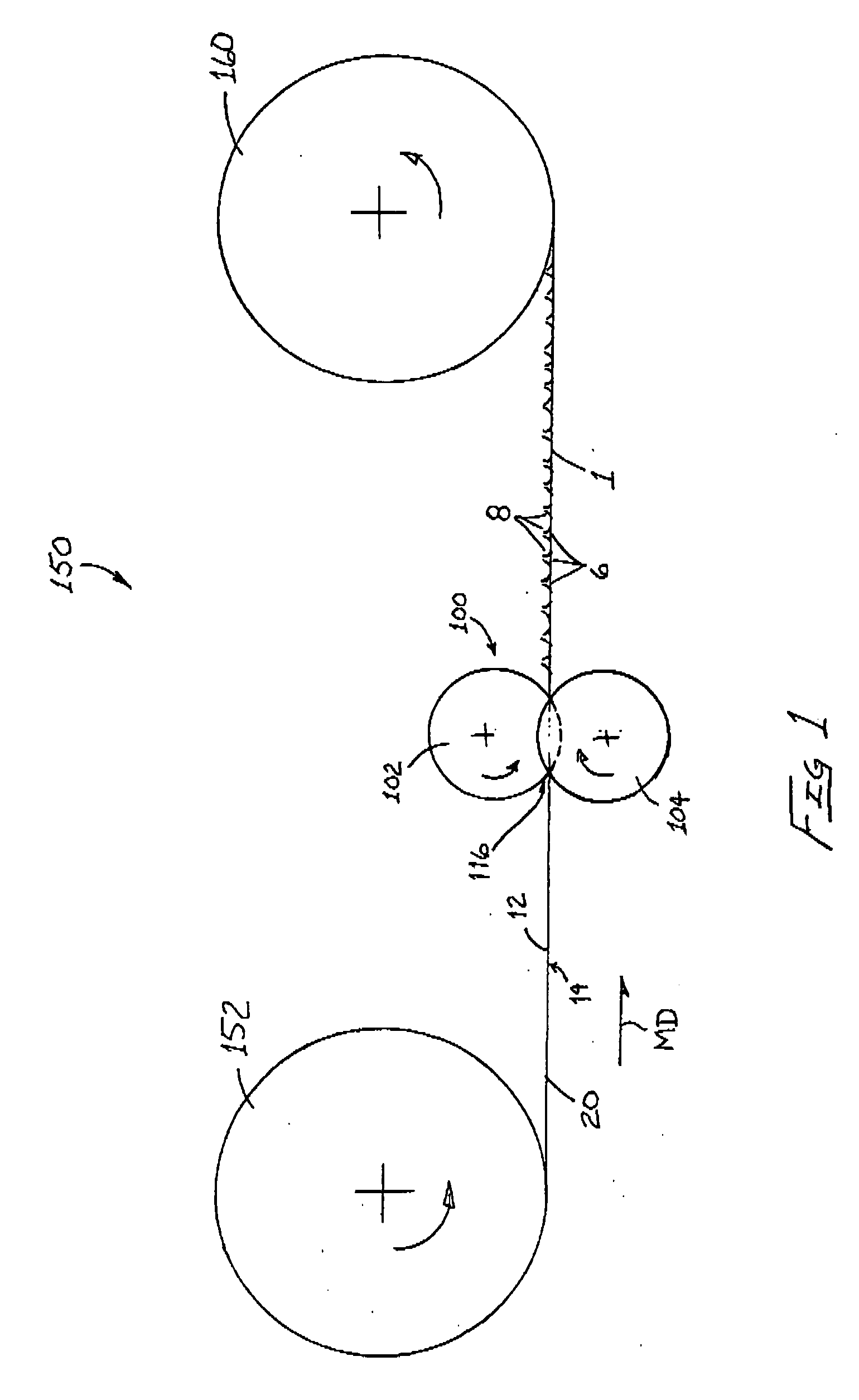

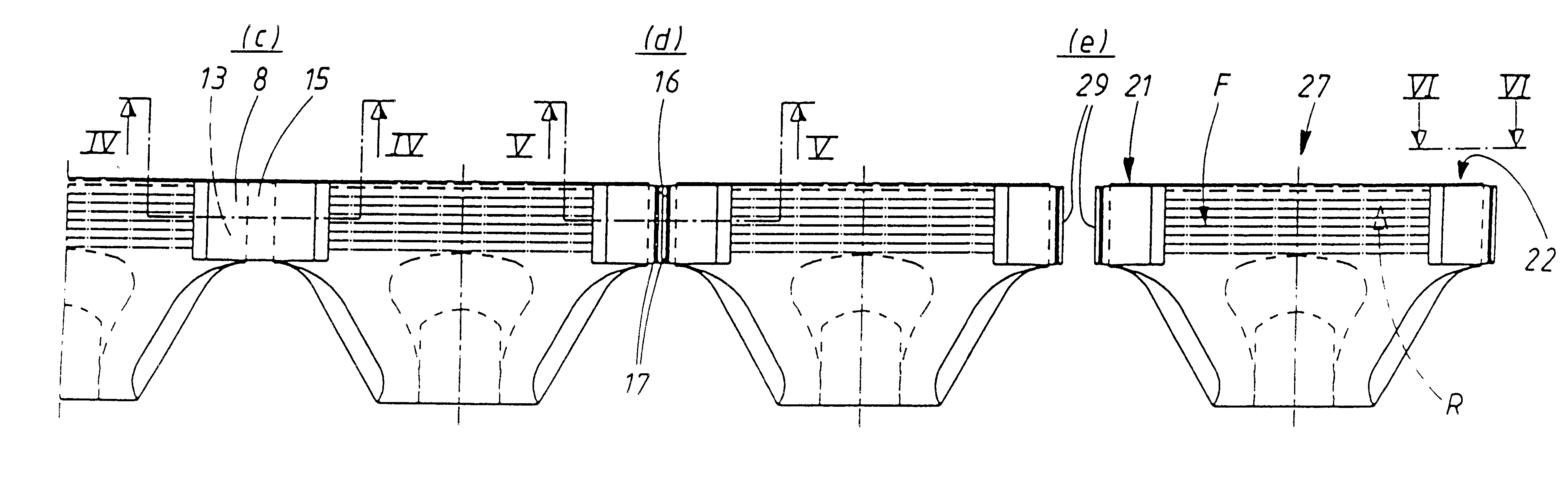

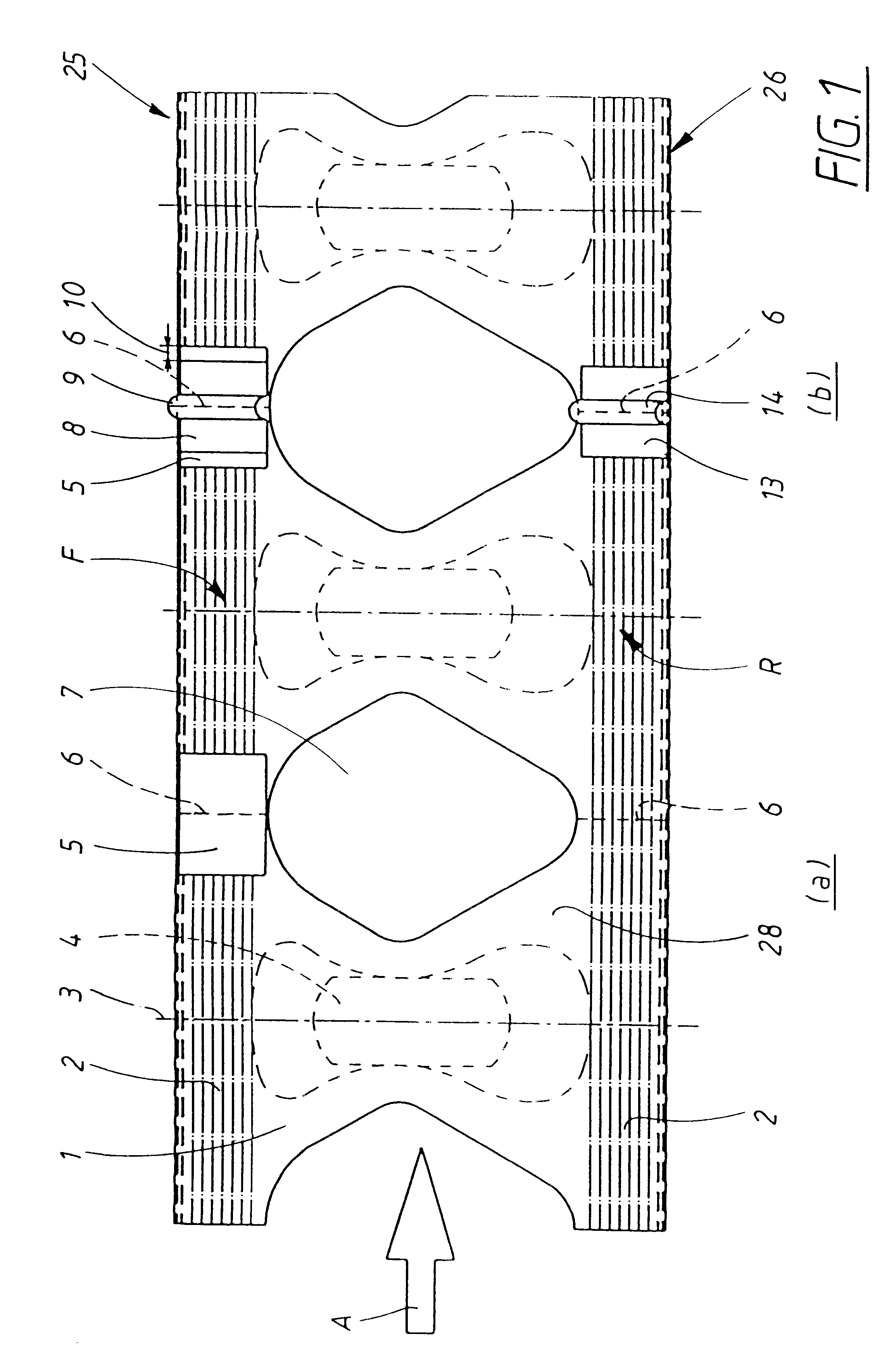

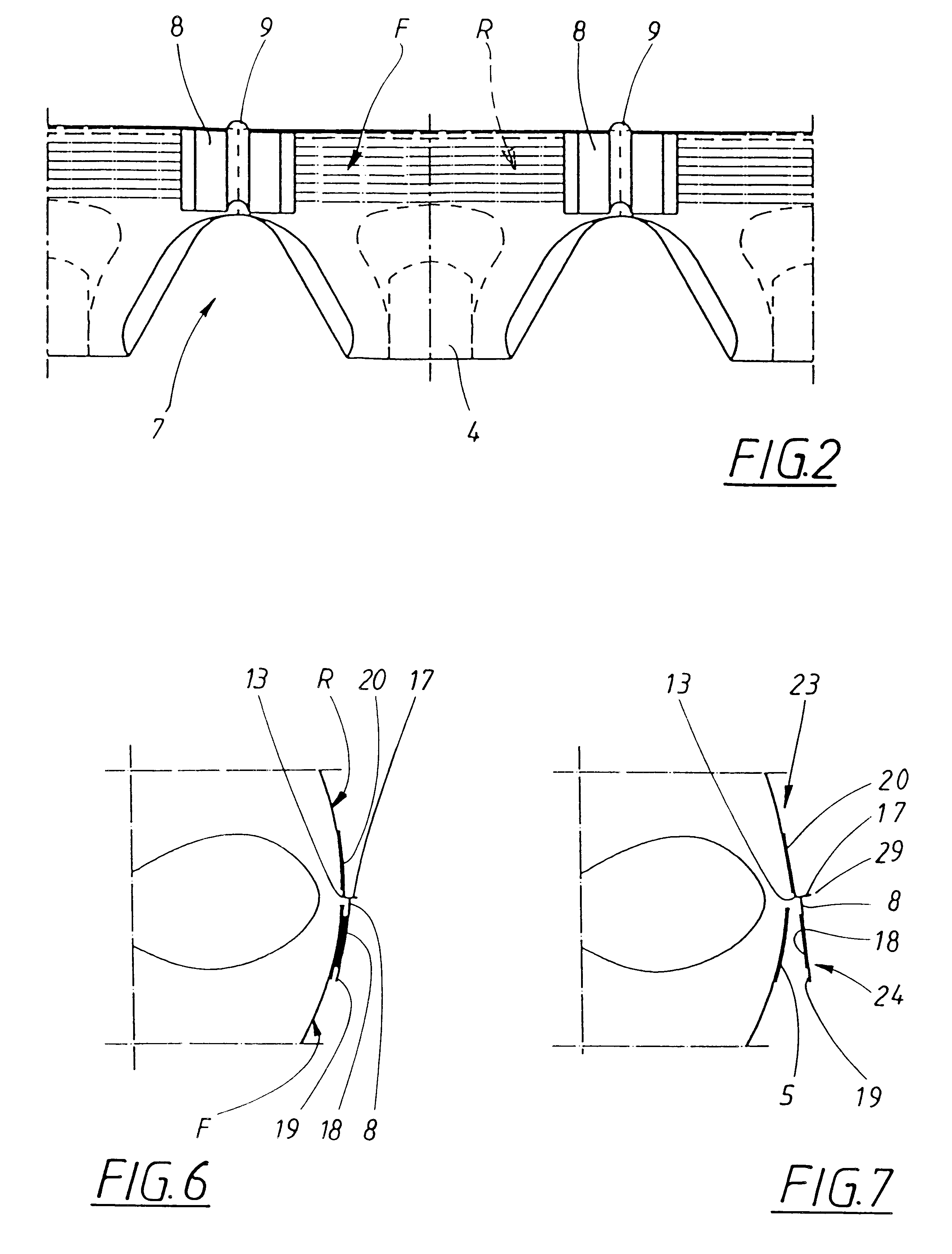

Method of producing reclosable absorbent garments and absorbent garments obtained thereby

InactiveUS6328725B2Avoid separationMechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

The invention relates to a method of producing reclosable absorbent garments, in particular absorbent pants, and to the absorbent garments obtainable by said method. Starting from a continuous web (1) of absorbent articles attached side-by-side and with a line of weakening (6) arranged between adjacent articles, a first strip (8) comprising releasably attachable material is applied across the line (6) at one edge (25) of the web. A second strip of flexible material is also applied across the line (6) at the other edge (26) of the web. The web is then folded longitudinally to form a series of closed, joined adjacent articles. The adjacent articles are then partially separated at said line (6) but without rupturing said strips (8, 13), so as to provide a free zone (15) between said strips (8, 13) and the adjacent separated edges of each article. The strips (8, 13) are then joined together across the free zone (15) to form a plurality of joined garments. The strips (8, 13) may then be severed so as to form individual garments (27) of the reclosable type, or may remain unsevered and be foreseen with a line of weakening for later separation. Due to the particular method and product features of the invention, an in-line process for making closed, reclosable absorbent garments is achieved.

Owner:SCA HYGIENE PROD AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com