Patents

Literature

6620 results about "Machine press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A forming press, commonly shortened to press, is a machine tool that changes the shape of a workpiece by the application of pressure. The operator of a forming press is known as a press-tool setter, often shortened to toolsetter.

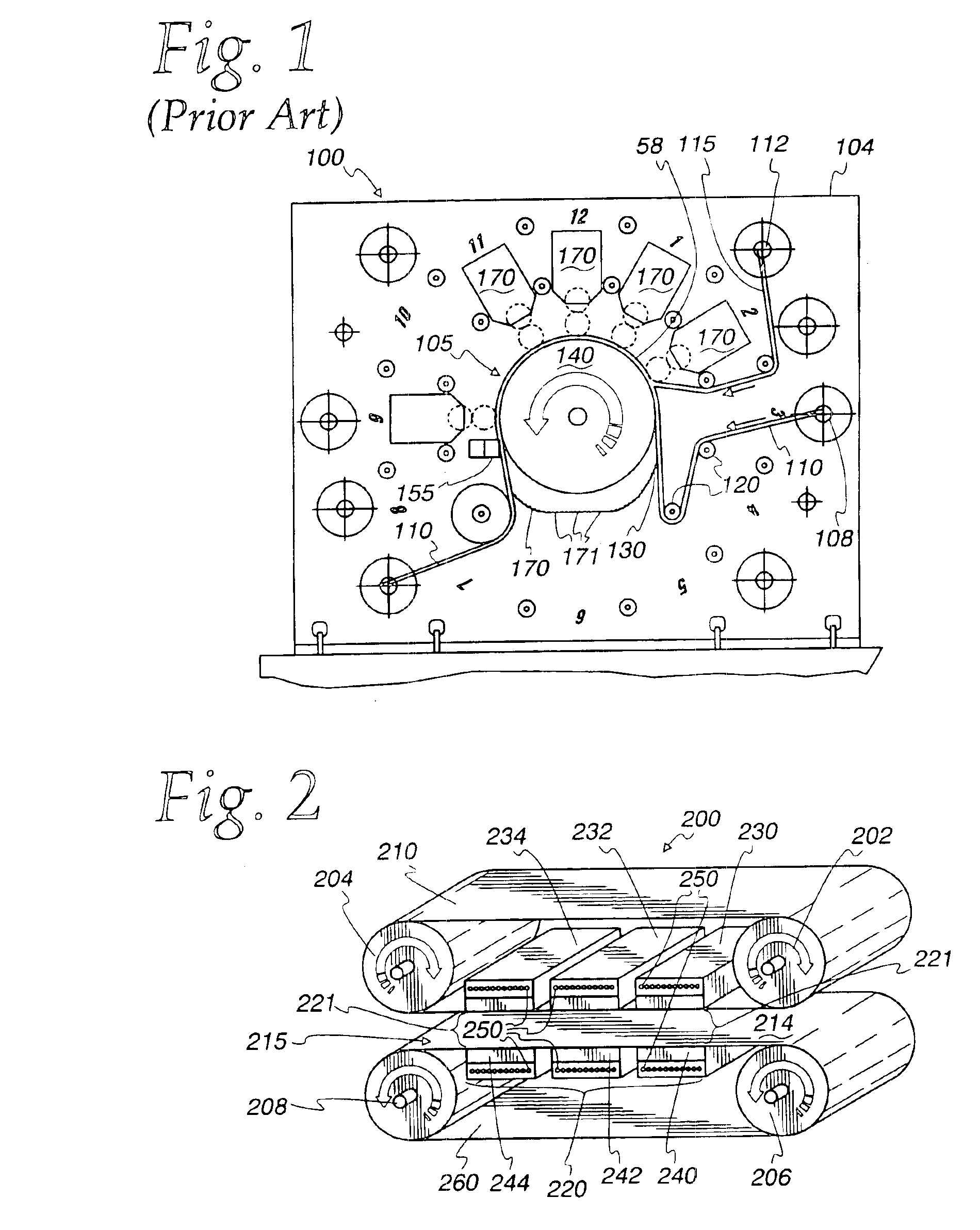

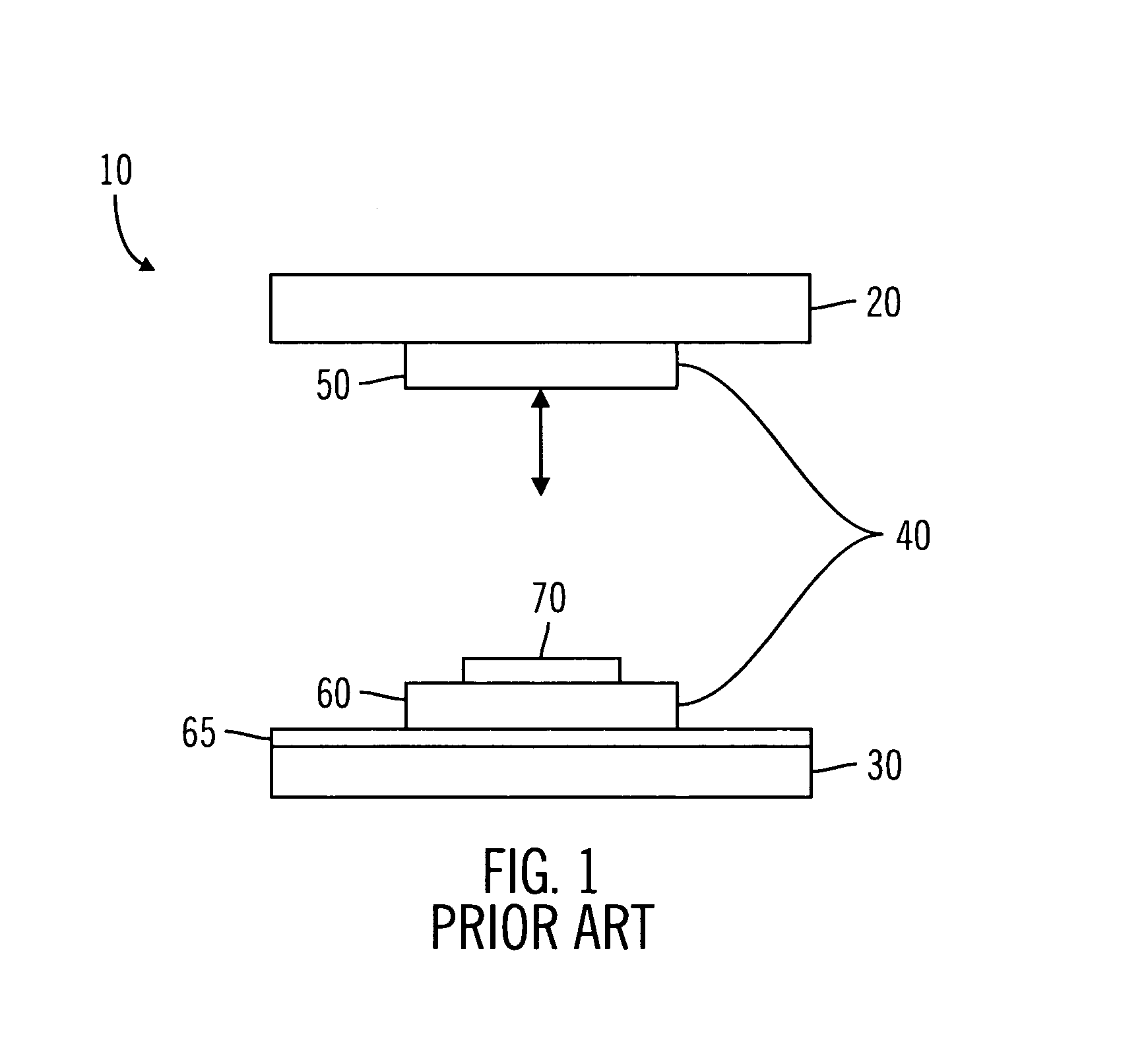

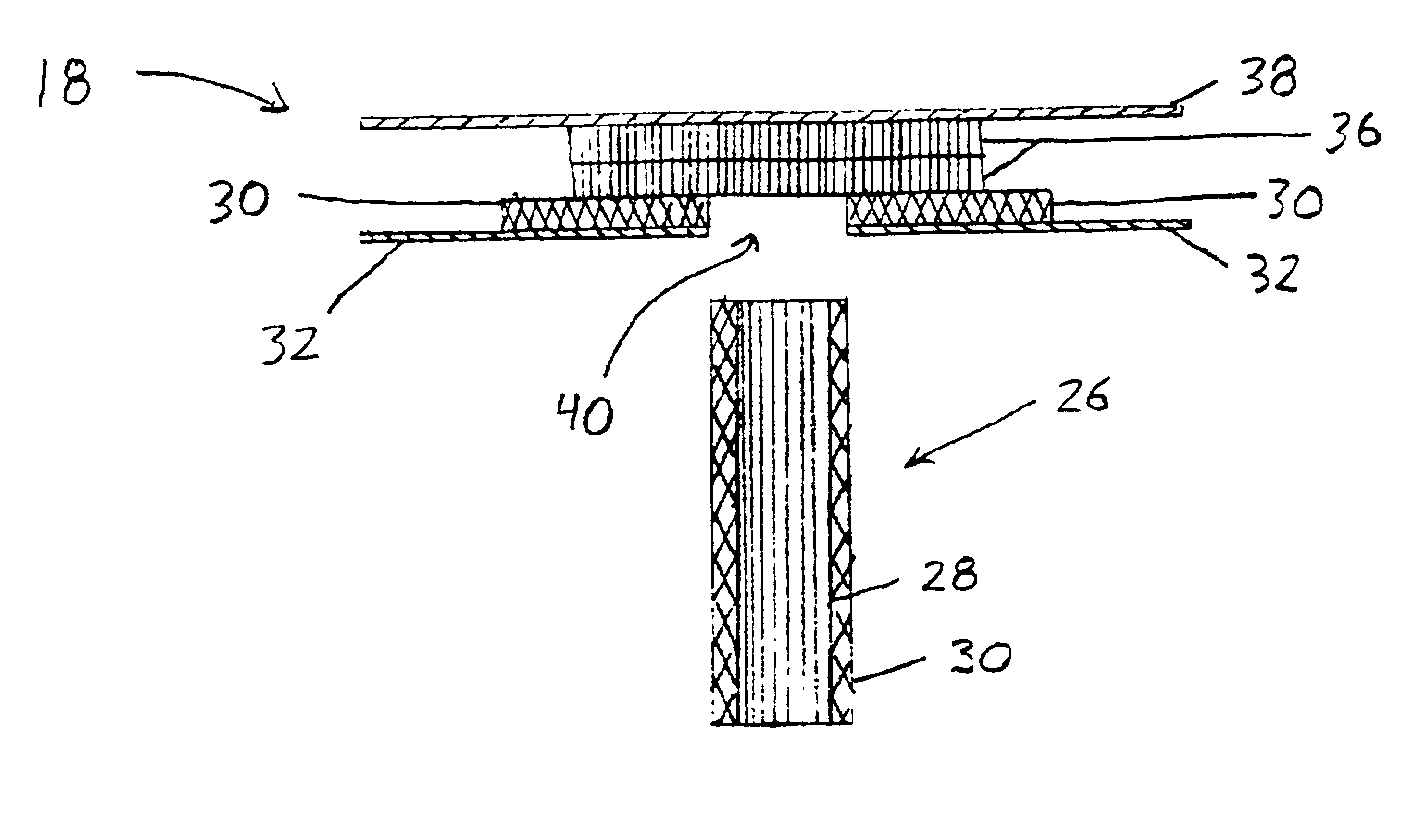

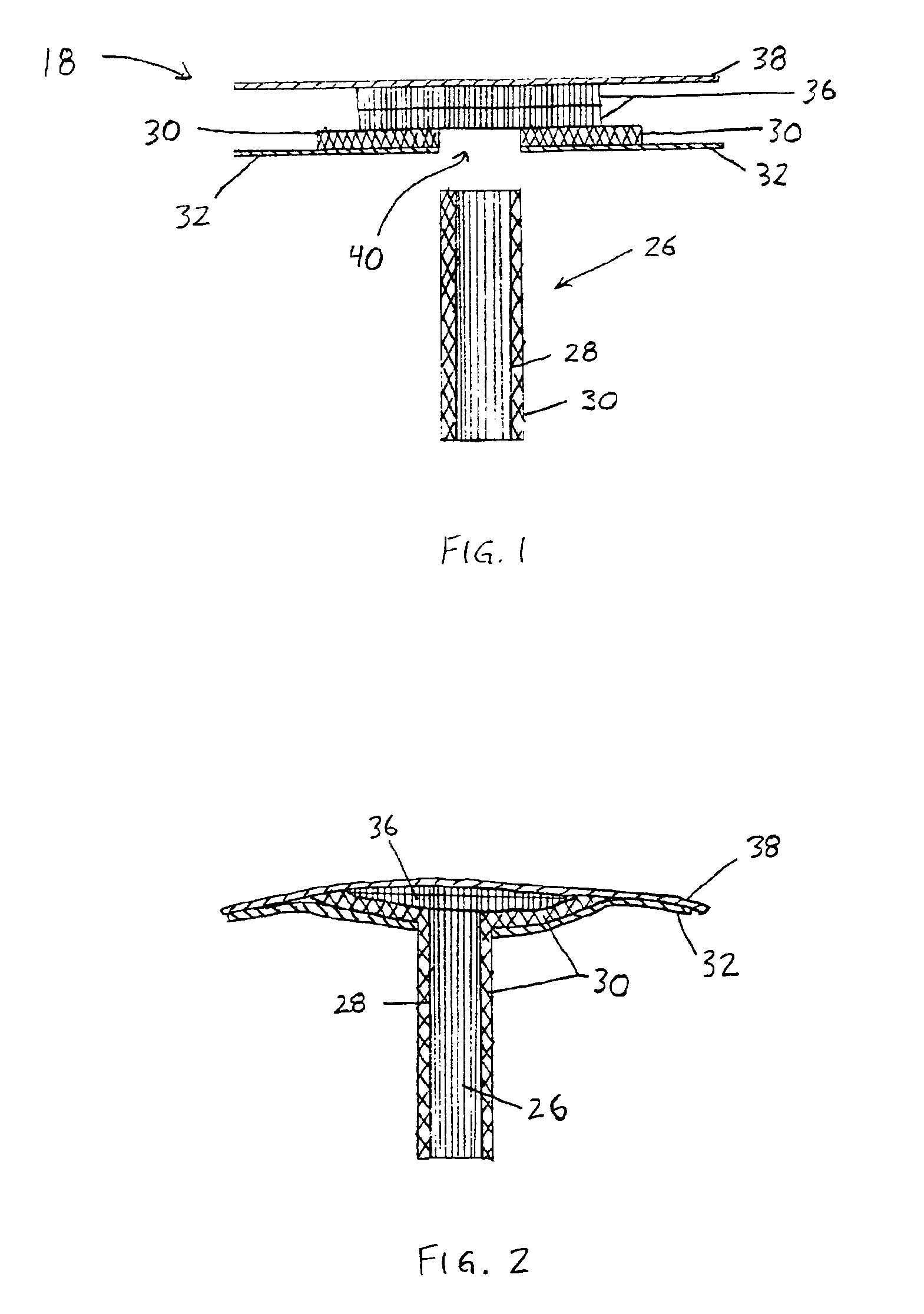

Tissue press and system

InactiveUS6132472AReduce retentionReduce capacitySuture equipmentsInternal osteosythesisTissue GraftEngineering

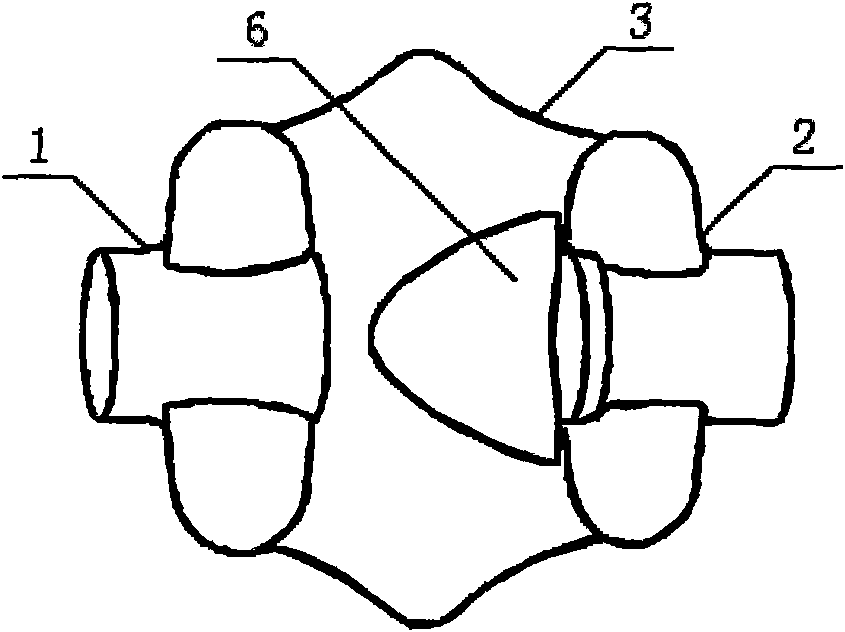

A tissue press and method for shaping or compressing a piece of tissue comprises first and second members movable relative to each other. A first forming element of a predetermined shape is selectively engageable on the first member. A second forming element of predetermined shape is selectively engageable on the second member. The first and second forming elements are positionable on opposite sides of the piece of tissue. The first and second members are relatively movable between a first spaced apart condition and a second condition in which the piece of tissue is held between the first and second forming elements. Means are preferably provided for monitoring and controlling the amount of pressure applied to the piece of tissue, in order to maintain the tissue in a viable living condition. Means may also be provided for draining off fluid from compressed tissue, so that the tissue can be implanted in a compressed state and imbibe fluid from the host site. A retainer, which may be expandable, can be used to maintain the tissue graft in a compressed condition.

Owner:BONUTTI 2003 TRUST A THE +1

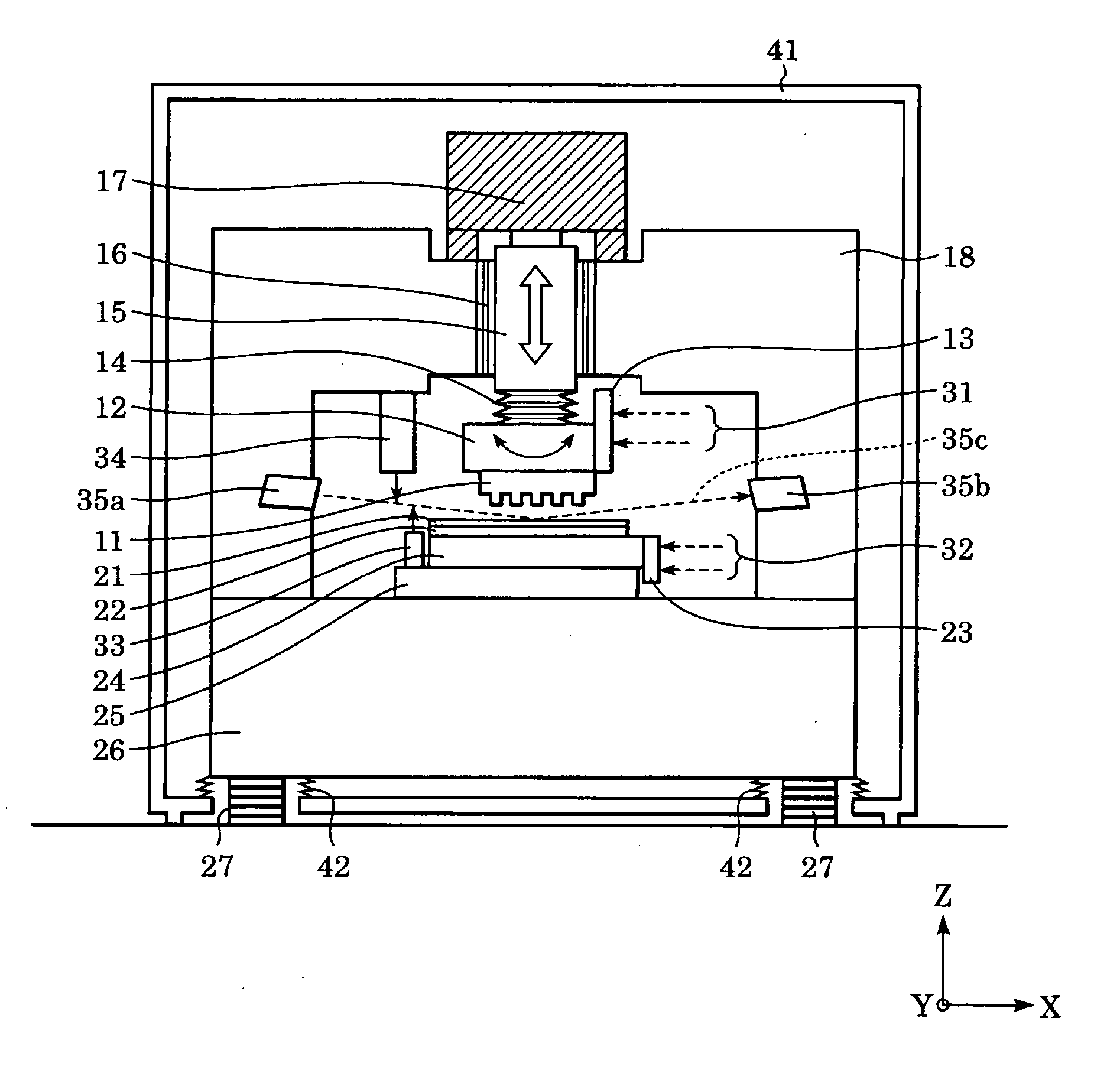

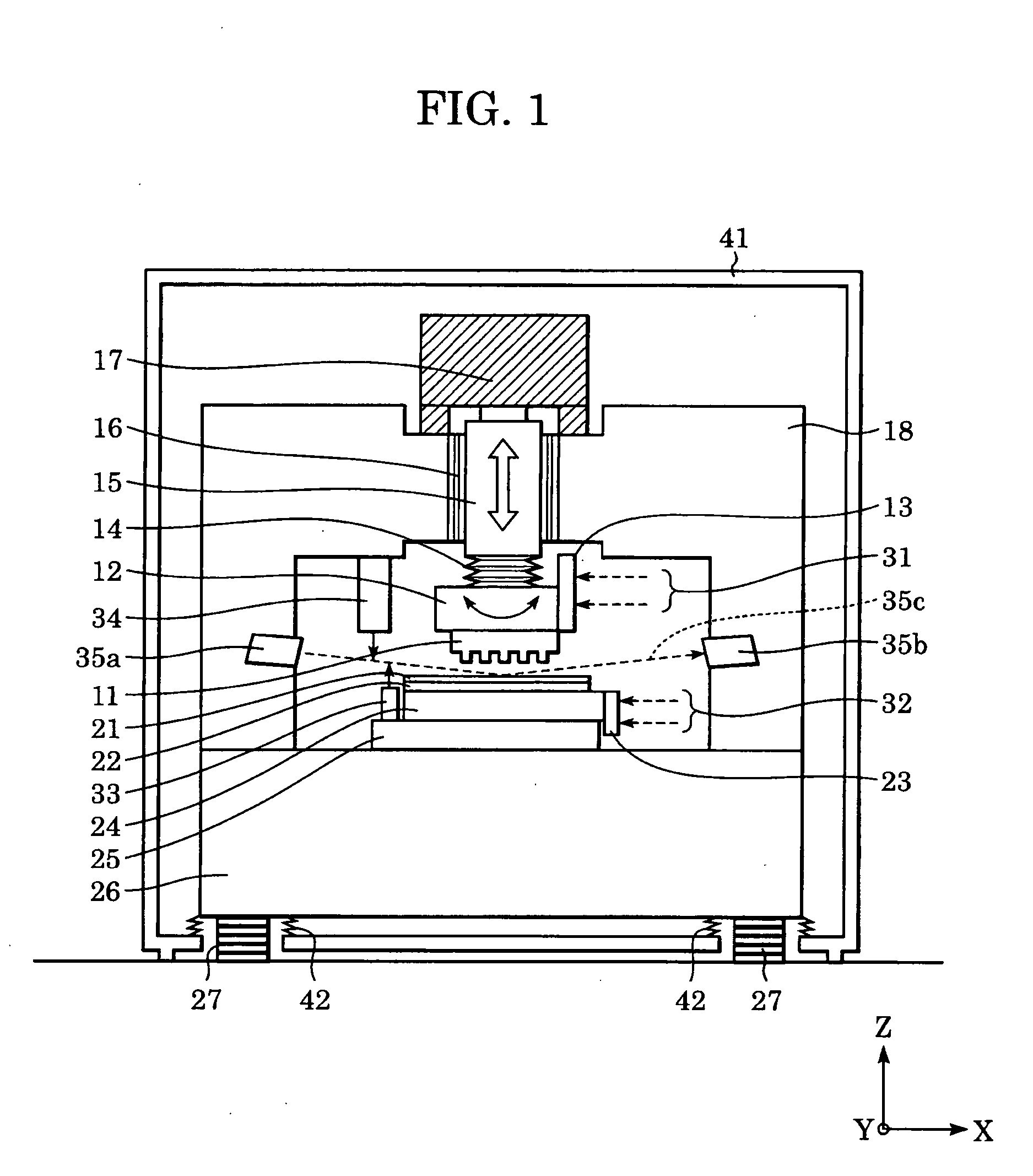

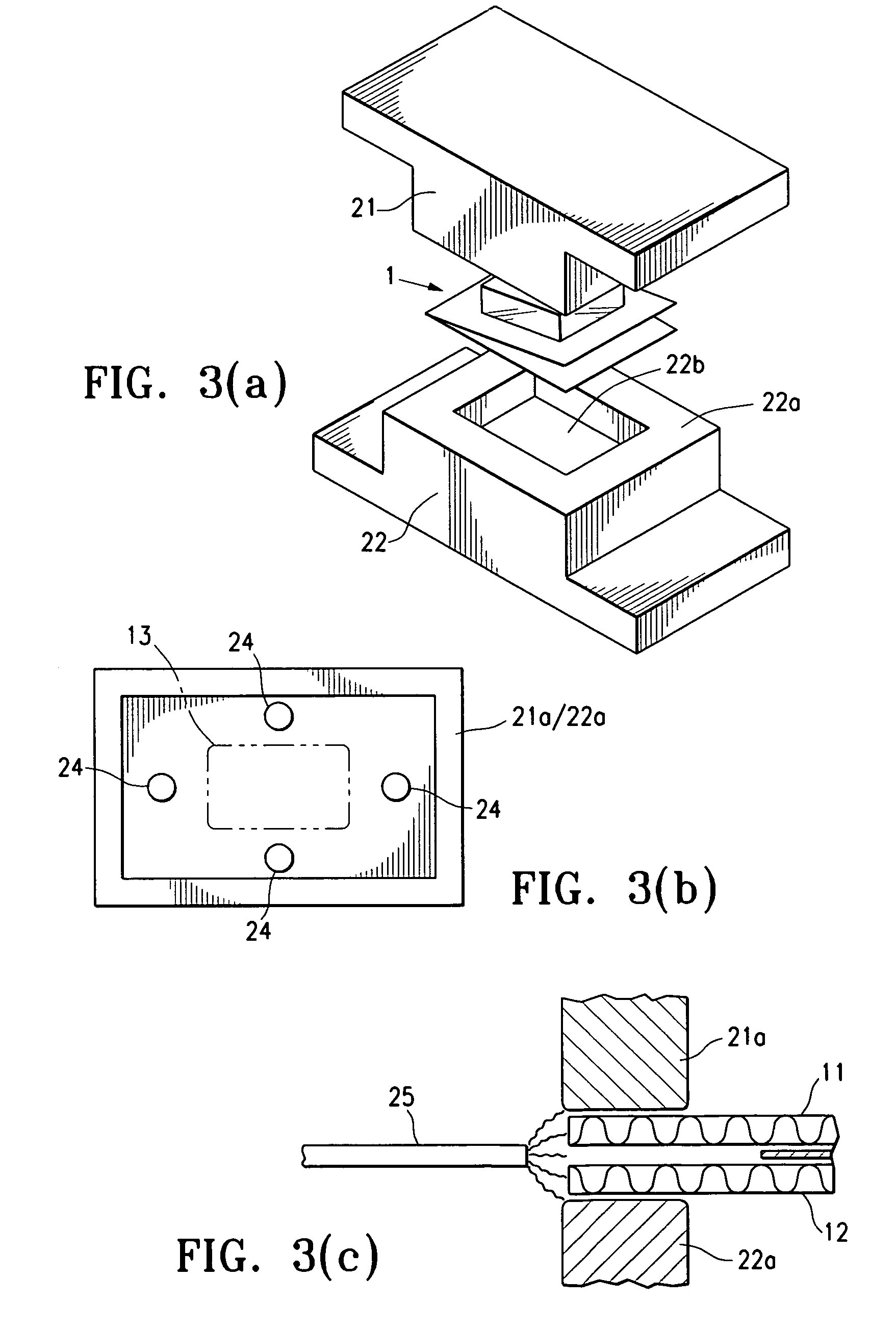

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

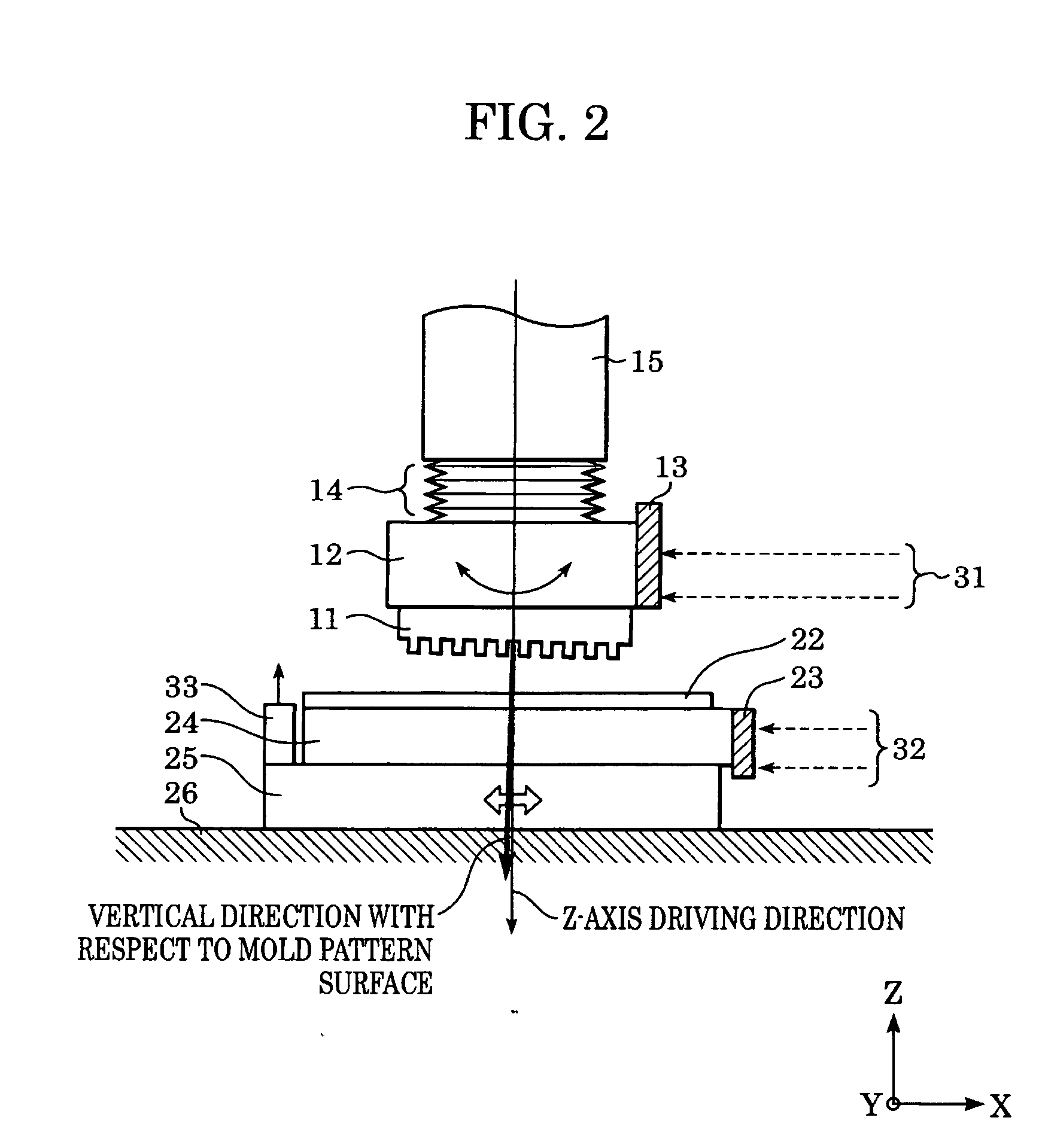

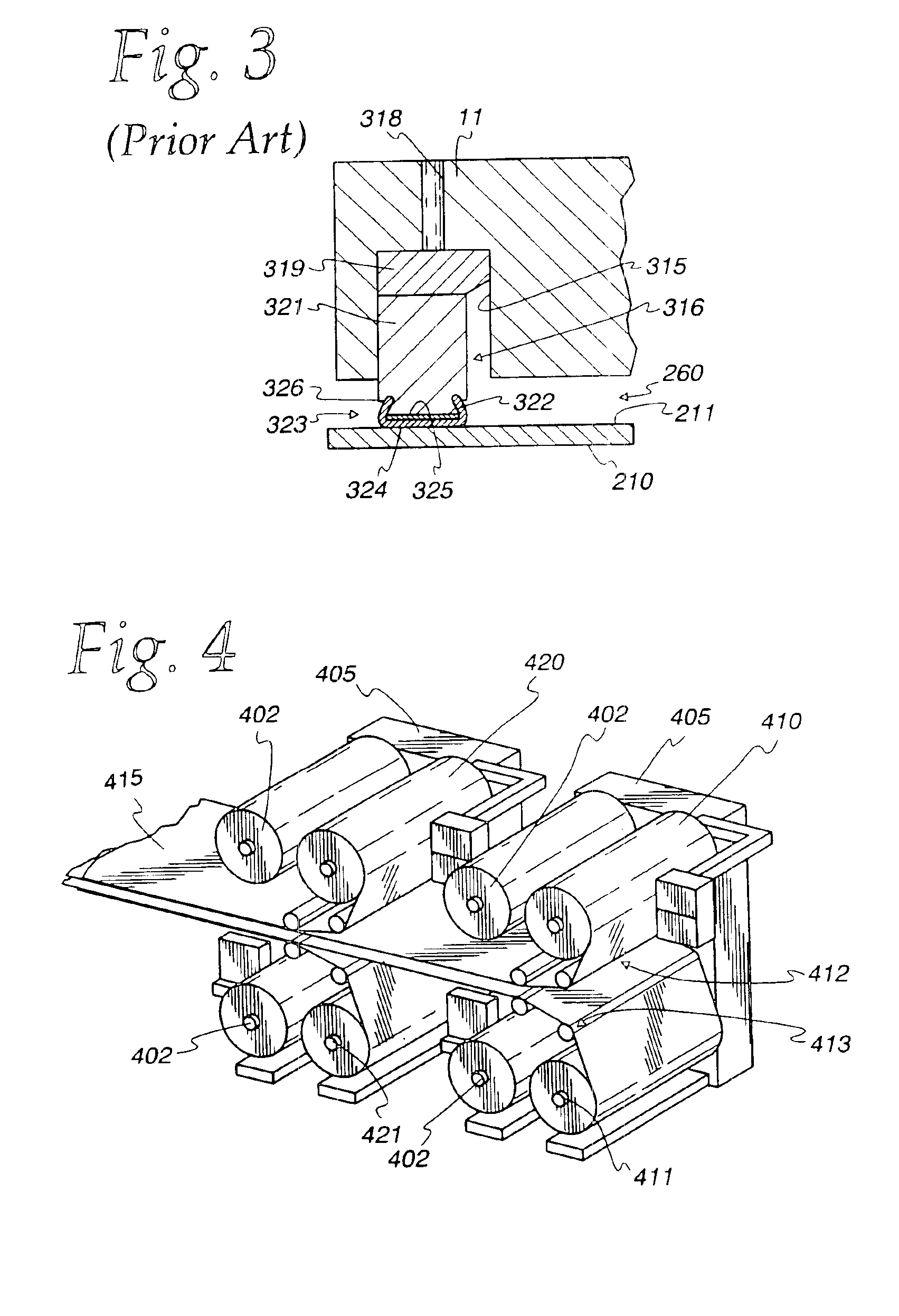

Process and apparatus for embossing precise microstructures and embossing tool for making same

InactiveUS6908295B2Maintain pressureReduce frictionConfectionerySolid-state devicesEngineeringPlastic property

A process and apparatus for embossing thermoplastic products having precise microstructured surfaces including using a continuous press having upper and lower belts with the embossing pattern(s); feeding thermoplastic material through the press where heat and pressure are applied to form the embossed pressure microstructure, and cooling the embossed material, all while maintaining pressure. A continuous embossing tool is provided by welding segments together, the welds including interface material at the weld joint which is of a different material than the segment material to increase the tensile strength.

Owner:AVERY DENNISON CORP

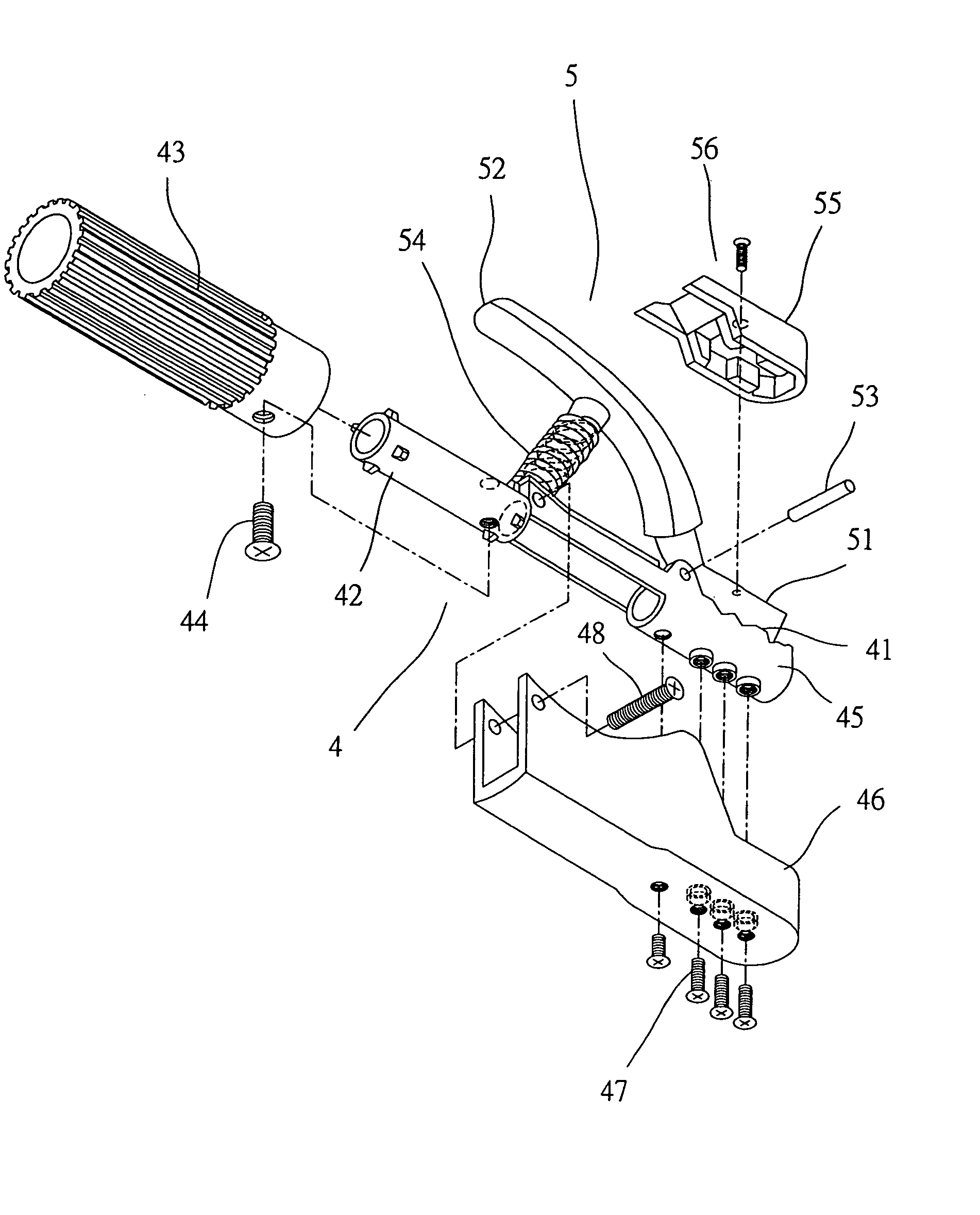

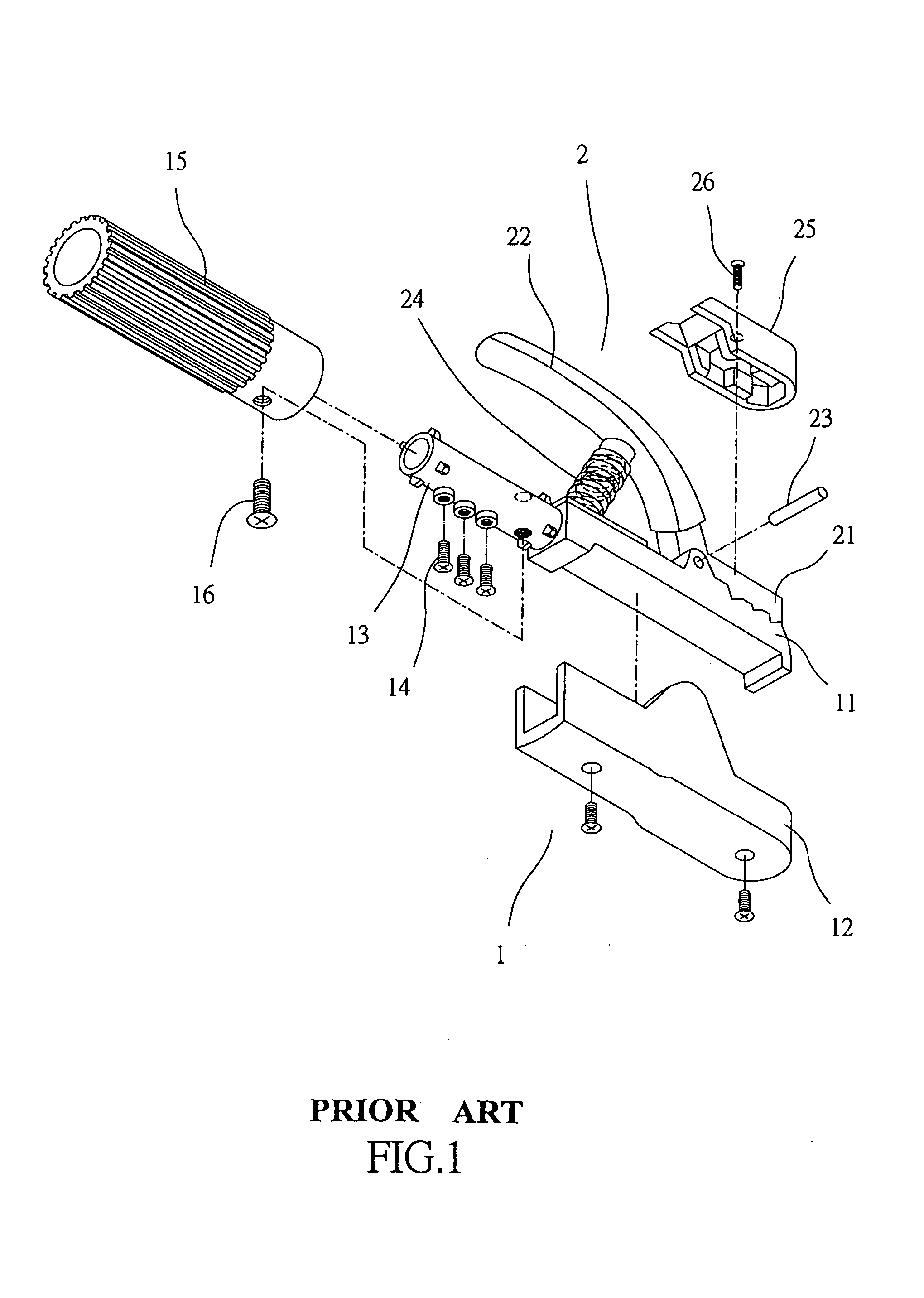

Electrode holder

InactiveUS20050189336A1Achieve normal workElectric discharge heatingWelding/cutting auxillary devicesEngineeringMachine press

An electrode holder comprised of a press and a clamp has at the bottom of the clamp adapted with a cylindrical base to allow one end of an electrode lead to pass through; the lead end being fastened in place by a bolt in conjunction with a protection pad covering up the cylindrical base so that in the course of welding, the point of heat conduction being kept farthest as from the hand gripping the holder to achieve working comfort.

Owner:KU JU CHING

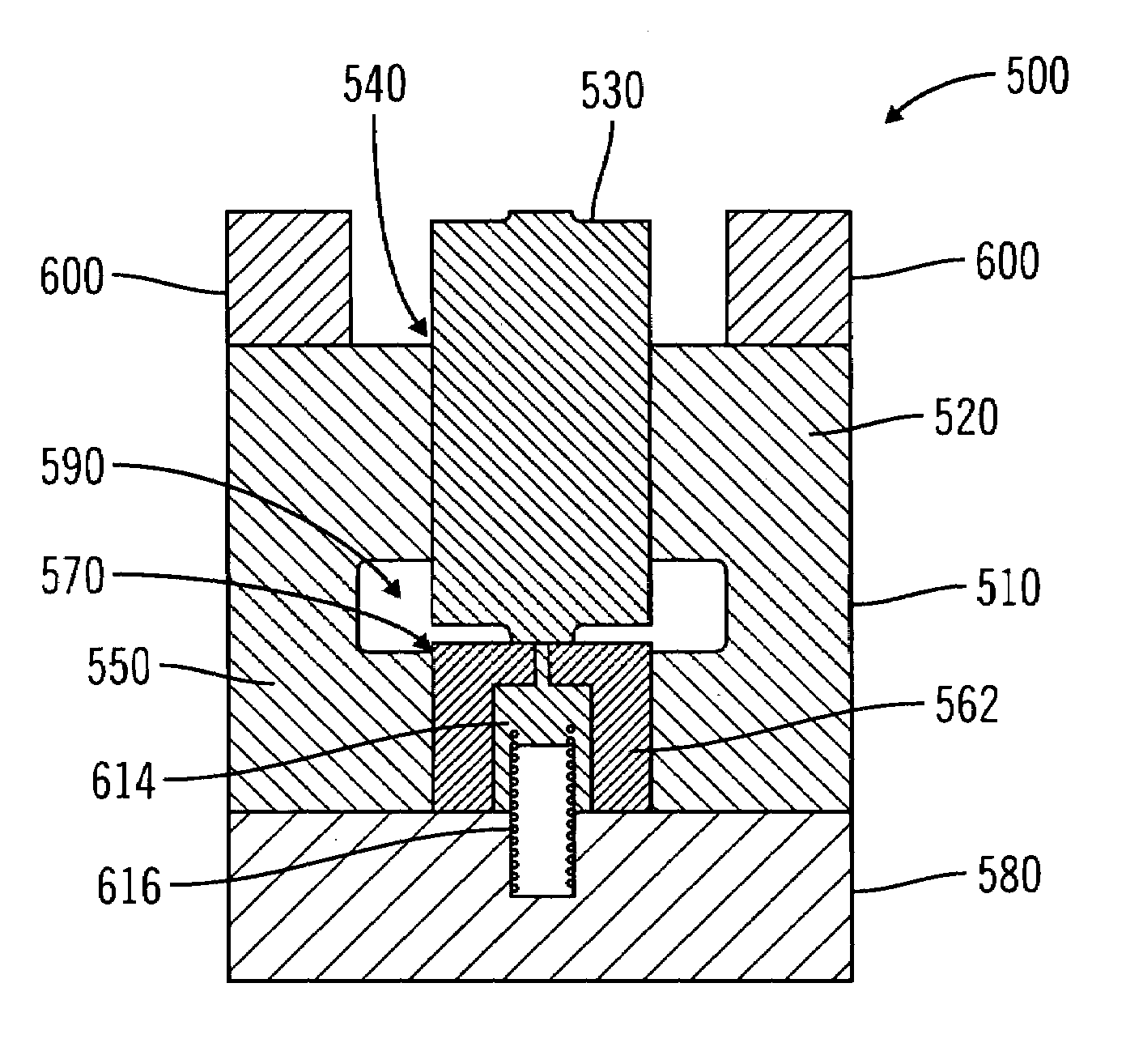

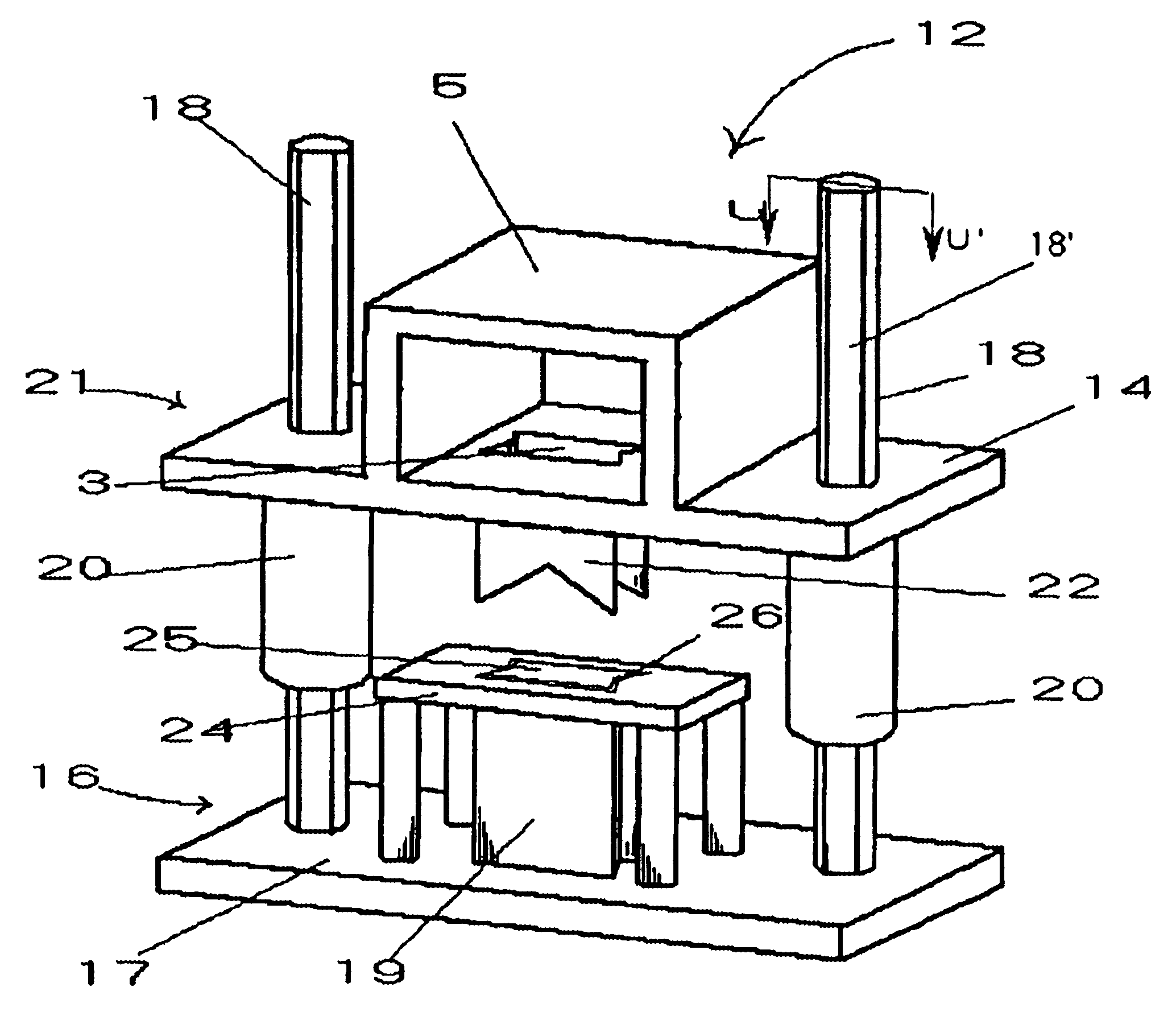

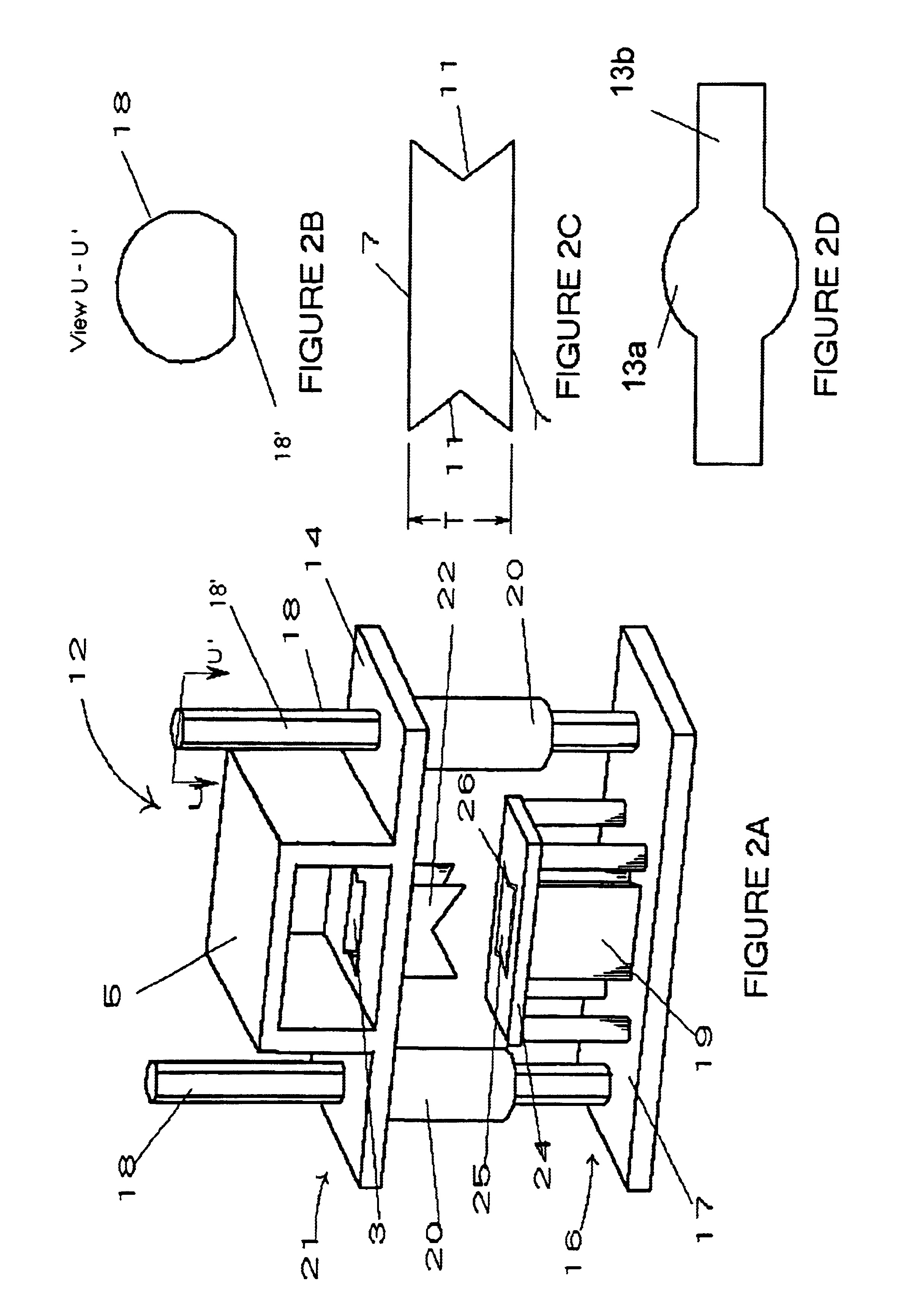

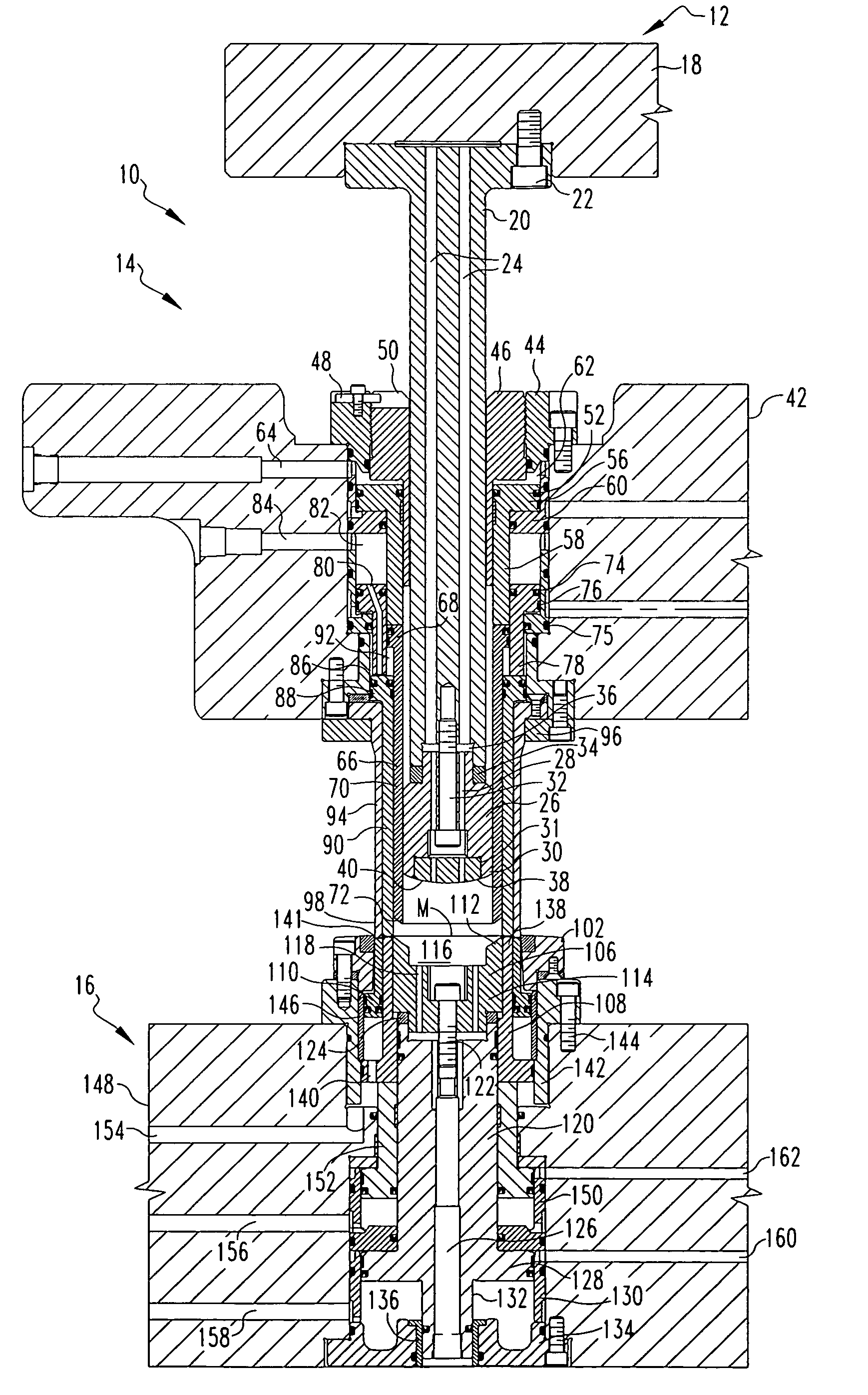

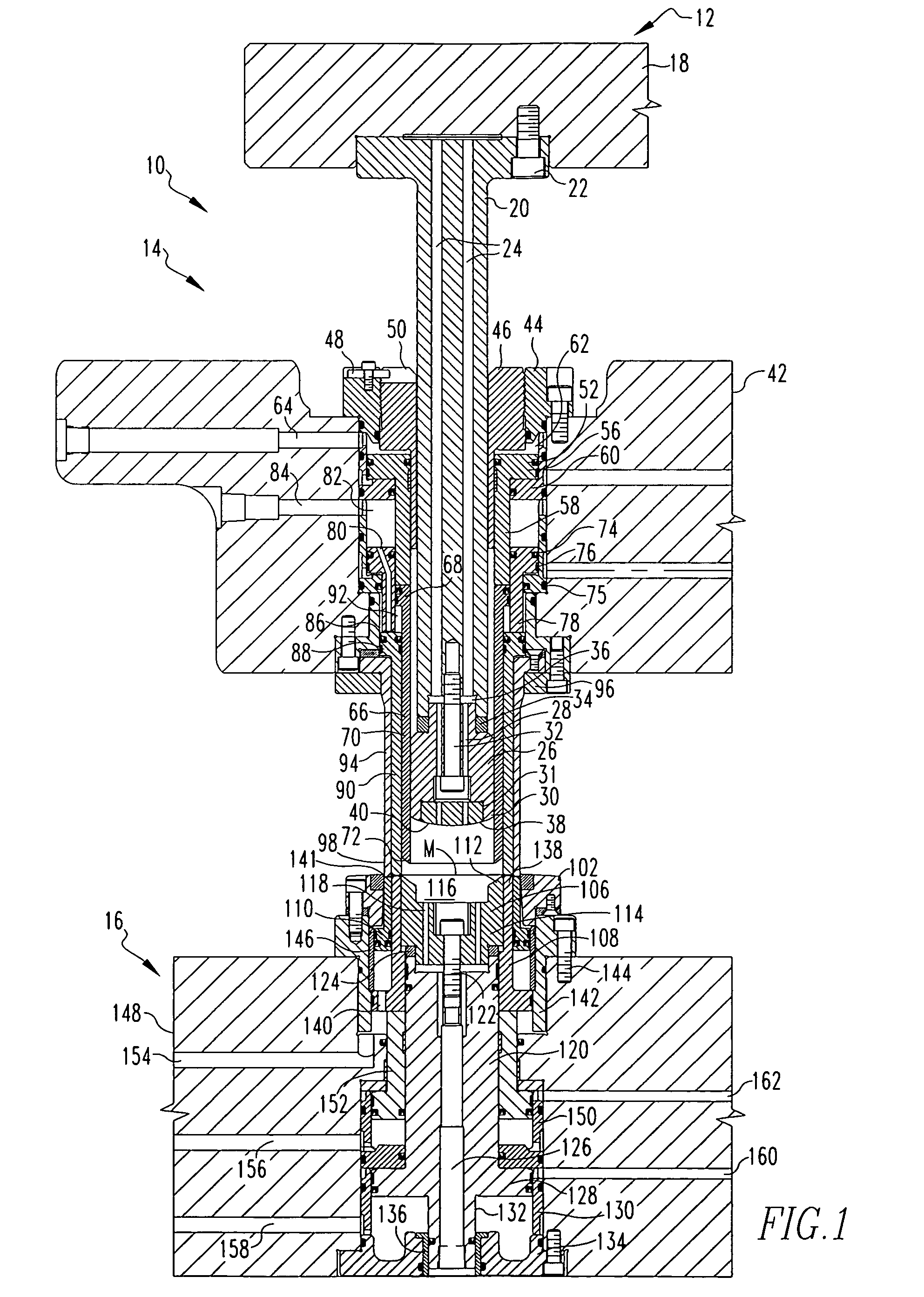

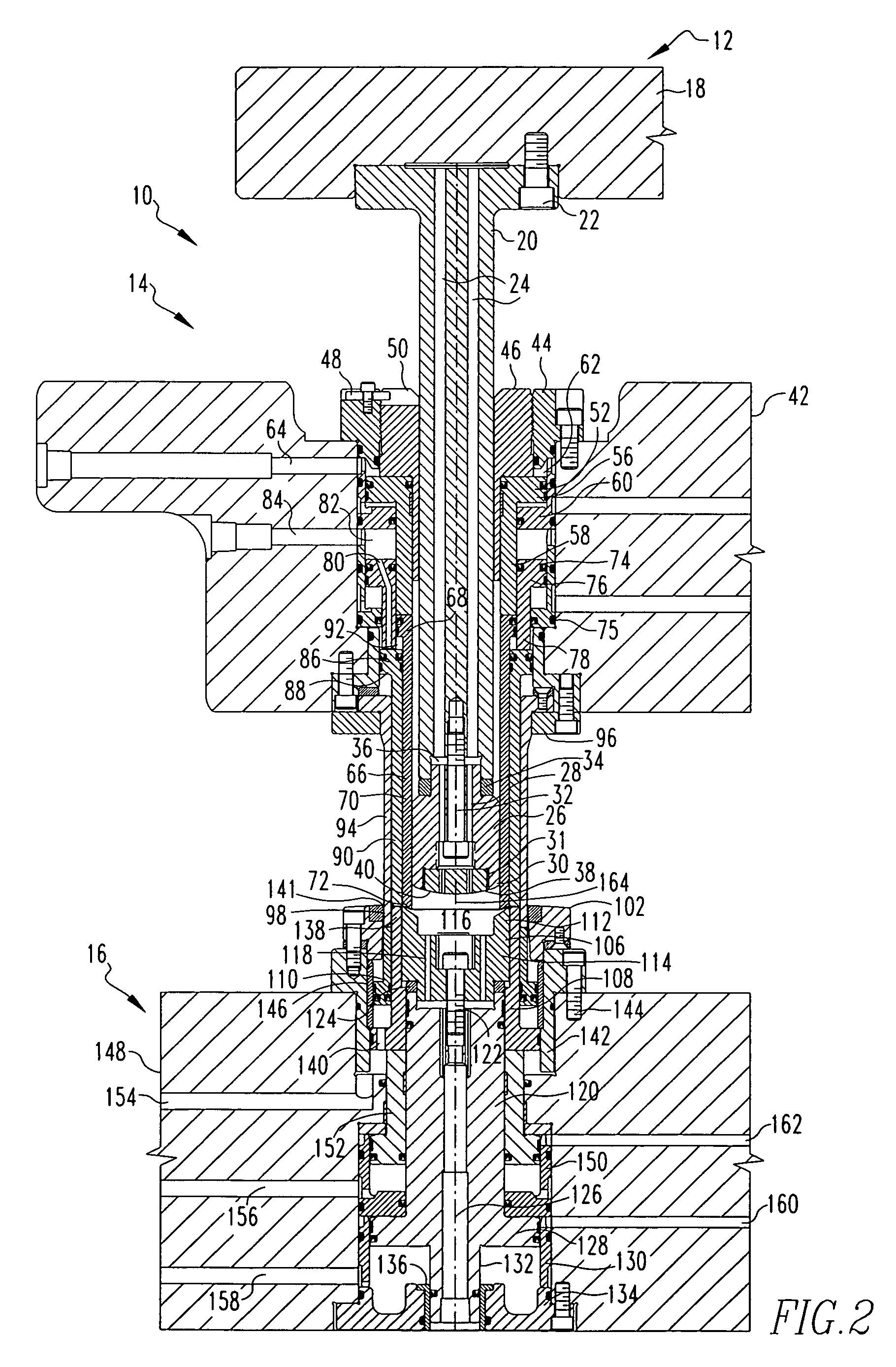

Stamping system for manufacturing high tolerance parts

ActiveUS7343770B2Minimize the numberTight toleranceShaping toolsPerforating toolsMachine pressStamping press

A system and process for stamping parts having tolerances below 1000 nanometers. The inventive system and process is particularly suited for producing optoelectronic parts. The system includes a stamping press and one or a progression of stamping stations for supporting a punch and die. The stamping stations are designed to maintain substantial alignment of the punch and die with minimal moving components. The stamping station includes a shaft for rigidly guiding the punch to the die. The stamping press is capable of providing the punch with the necessary force to perform the stamping operations. The system includes an interface system for interfacing the force of the press with the punch, while simultaneously structurally decoupling the press from the punch. The system also includes a locating sub-plate, for locating the stamping station in alignment relative to each other, and means for in-line machine stock material before entry into the stamping stations.

Owner:SENKO ADVANCED COMPONENTS

Patch plug

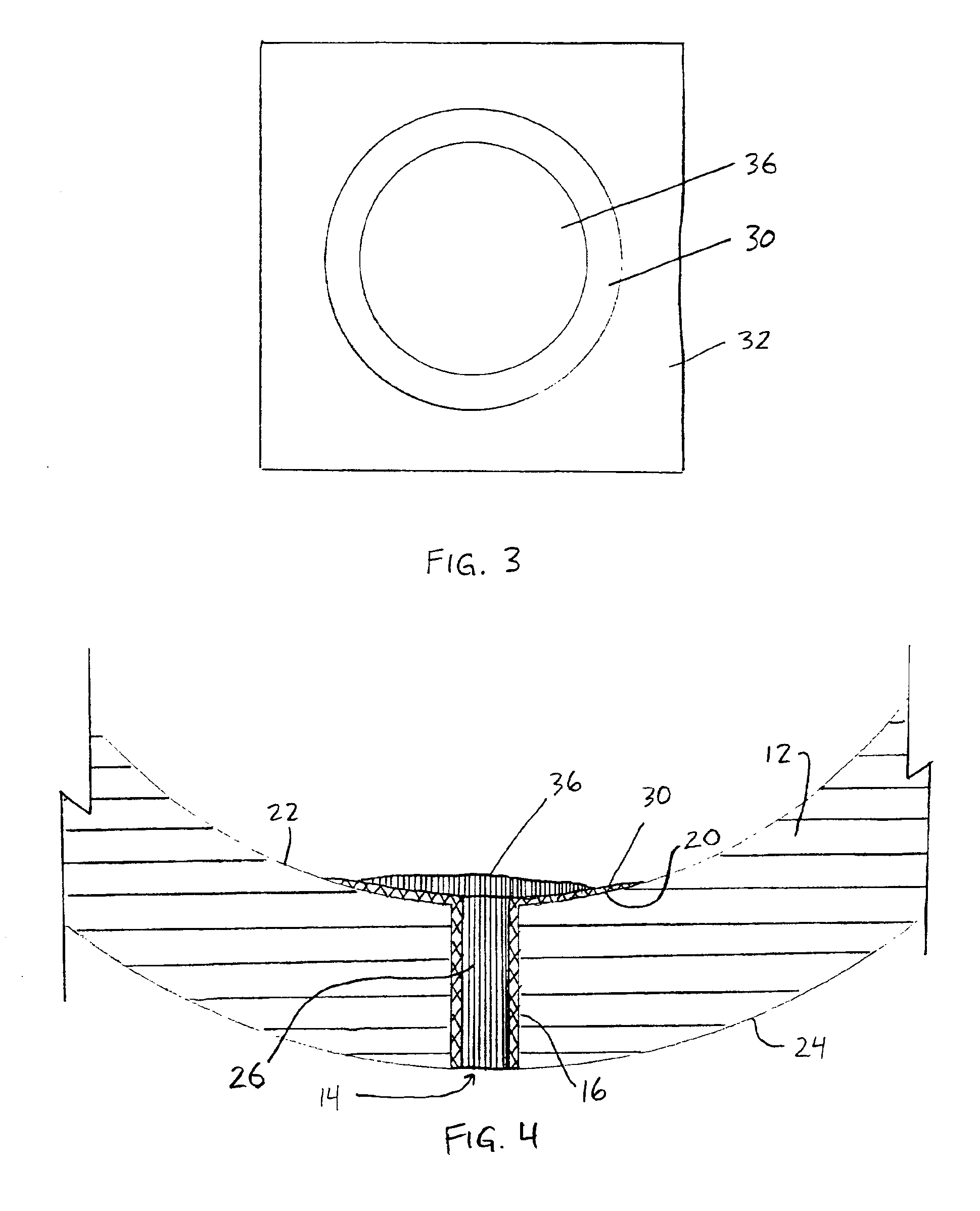

A patch plug is provided that has a coating continuous over both the patch and plug portions, providing a strong and continuous seal to prevent seal failure and water and air introduction. The patch and plug portions may be formed separately, each with a coating element, and fused together in a press which bonds the coatings of the patch and plug portions together to form a single, continuous coating. Means known in the art, for example rubber cement, can also be employed to further ensure a firm seal between the patch plug and the tire. Methods of manufacturing and using the patch plug are also taught herein.

Owner:4254563 MANITOBA

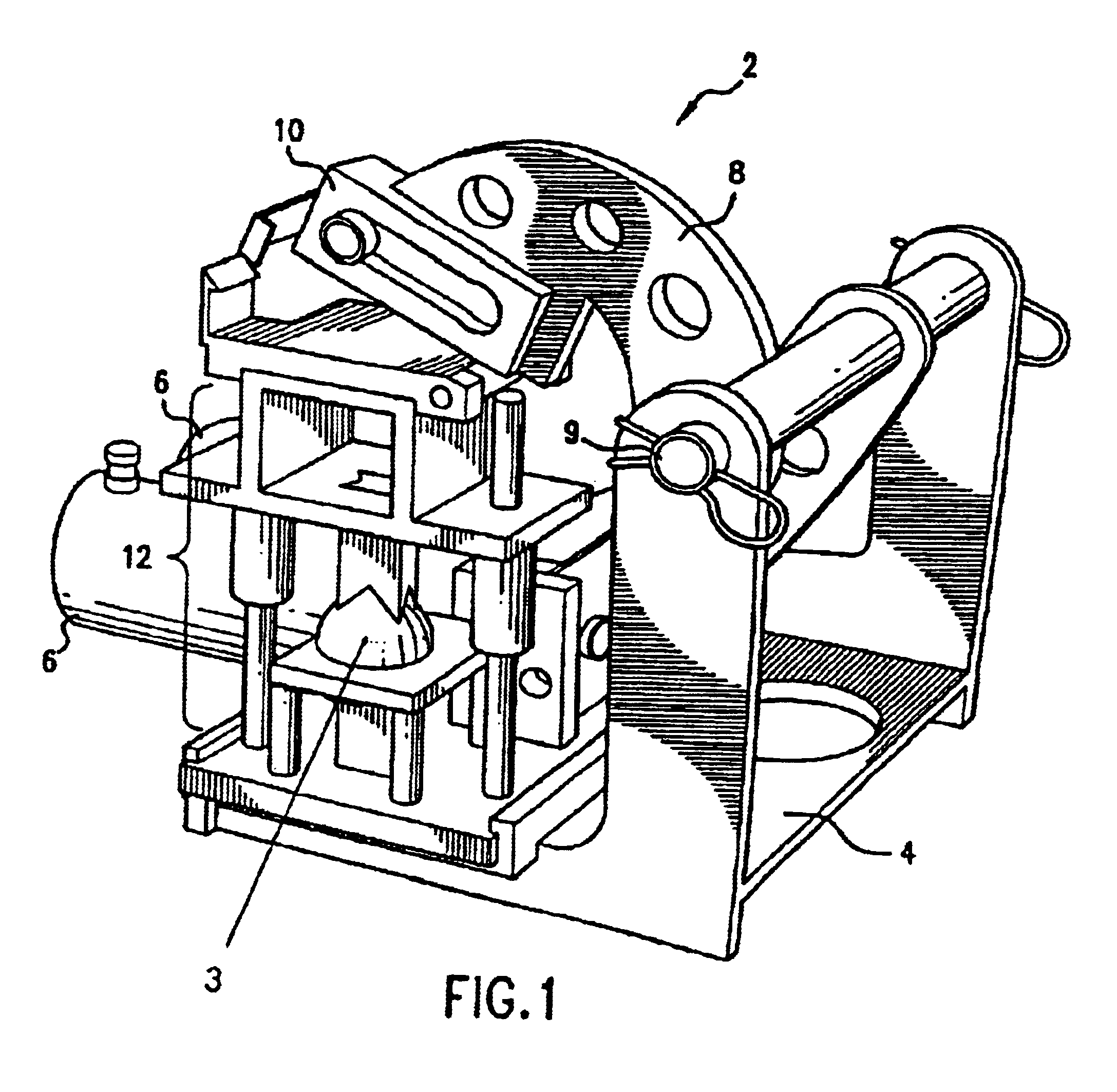

Allograft implant cutting machine

The present invention is an apparatus for cutting allograft bone implants from donor bone. Die sets of standard sizes are installed in a press. Donor bone is then placed in position between the upper and the lower parts of a matched cutting set comprising a hollow cylindrical cutting blade, a mandrel, and a table which establishes a gap around the mandrel which guides the blade. After the bone to be shaped has been properly placed, a shaped cutting blade is driven through the donor bone, producing a precisely shaped allograft implant. The invention provides for rapid change out of blades, rapid cleaning, and easy maintenance.

Owner:ALPHATEC SPINE INC

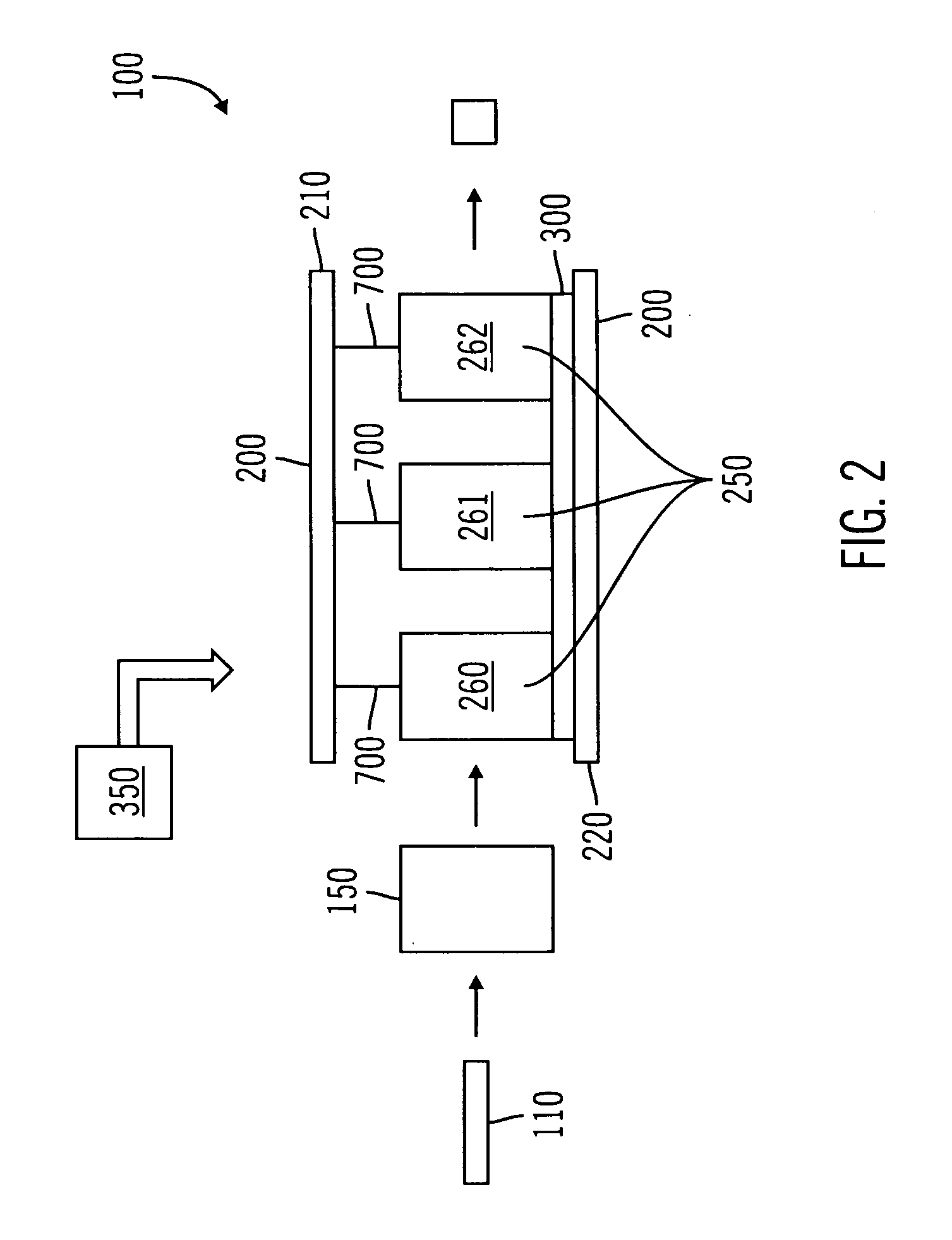

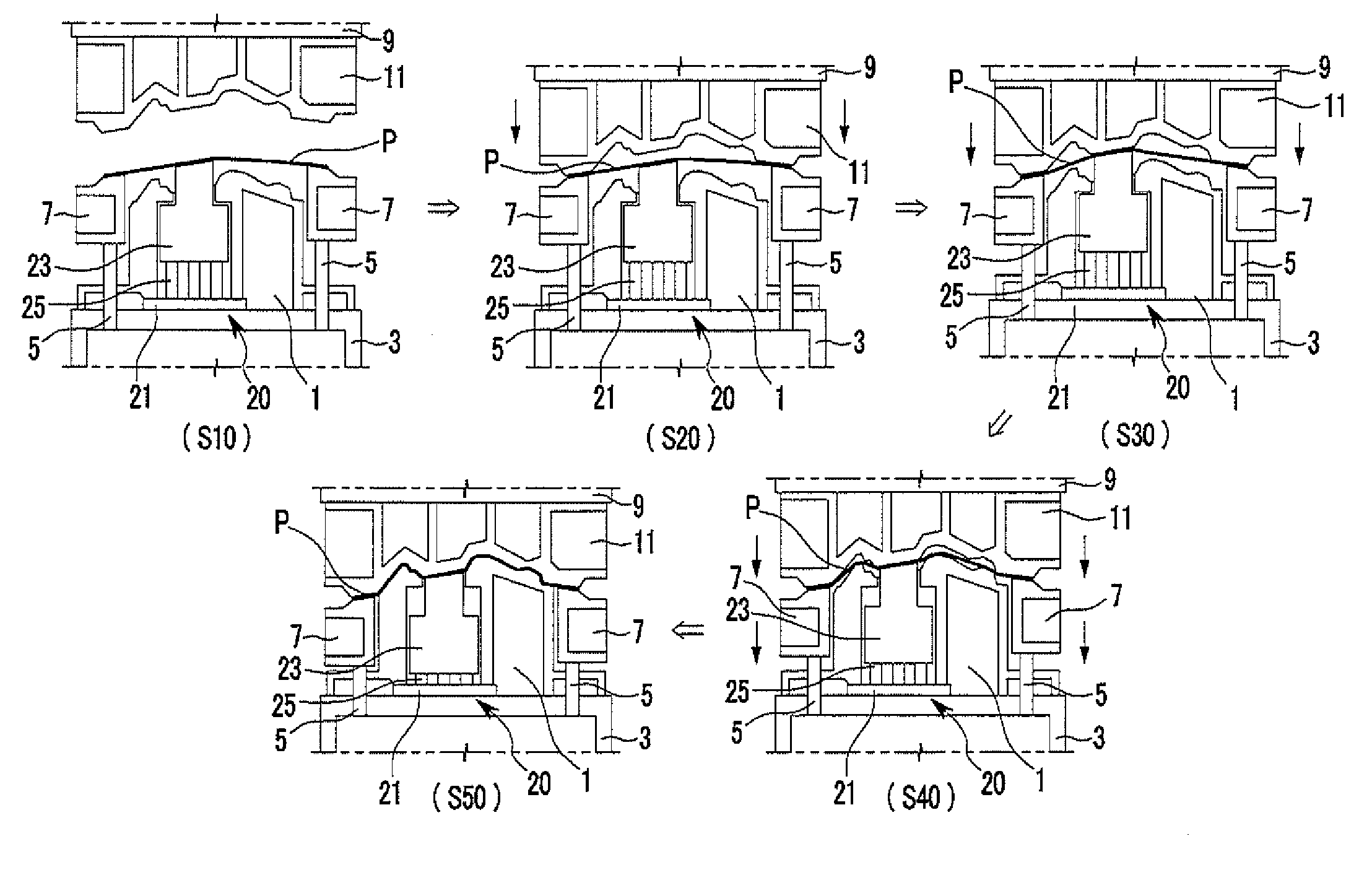

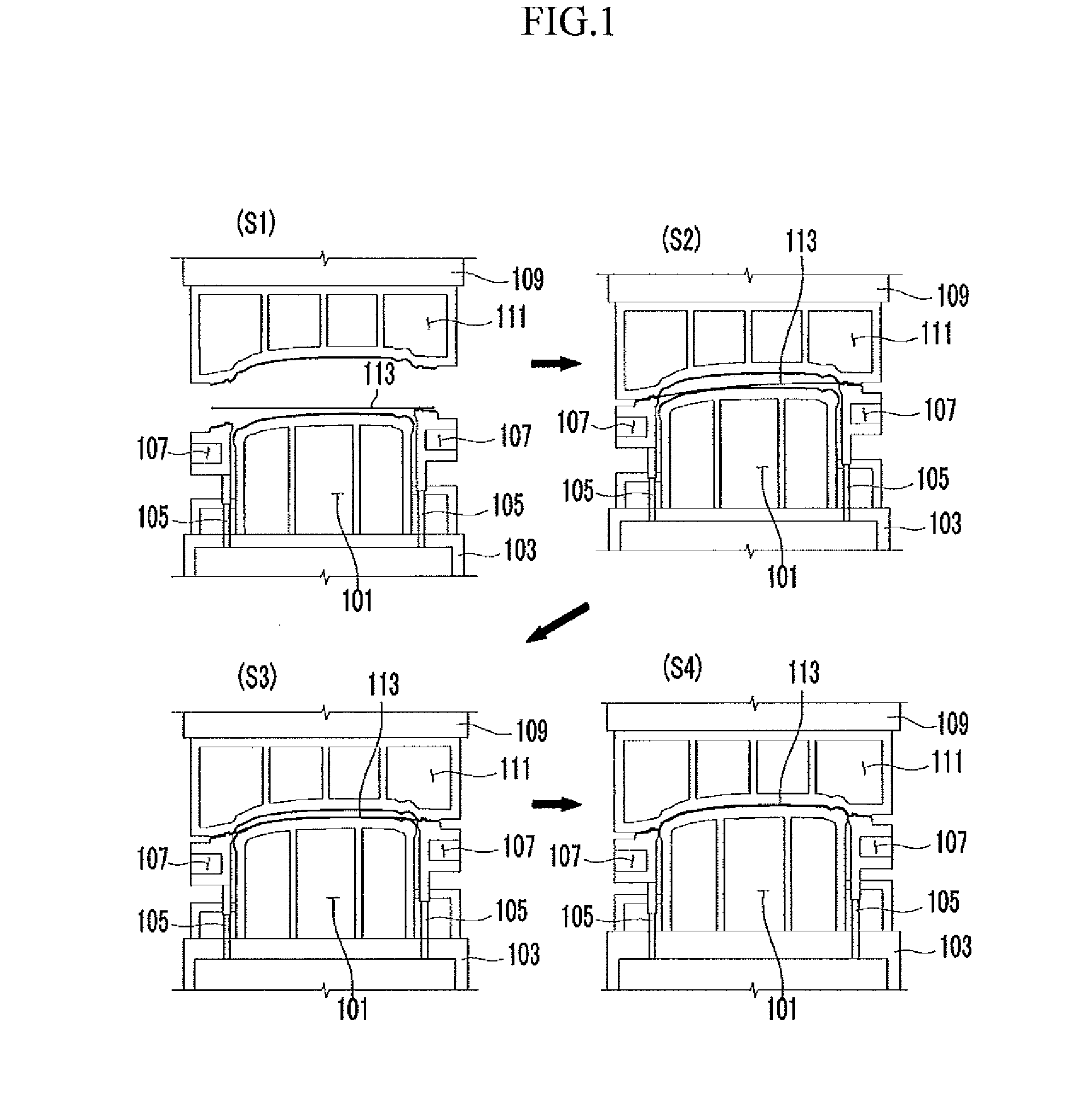

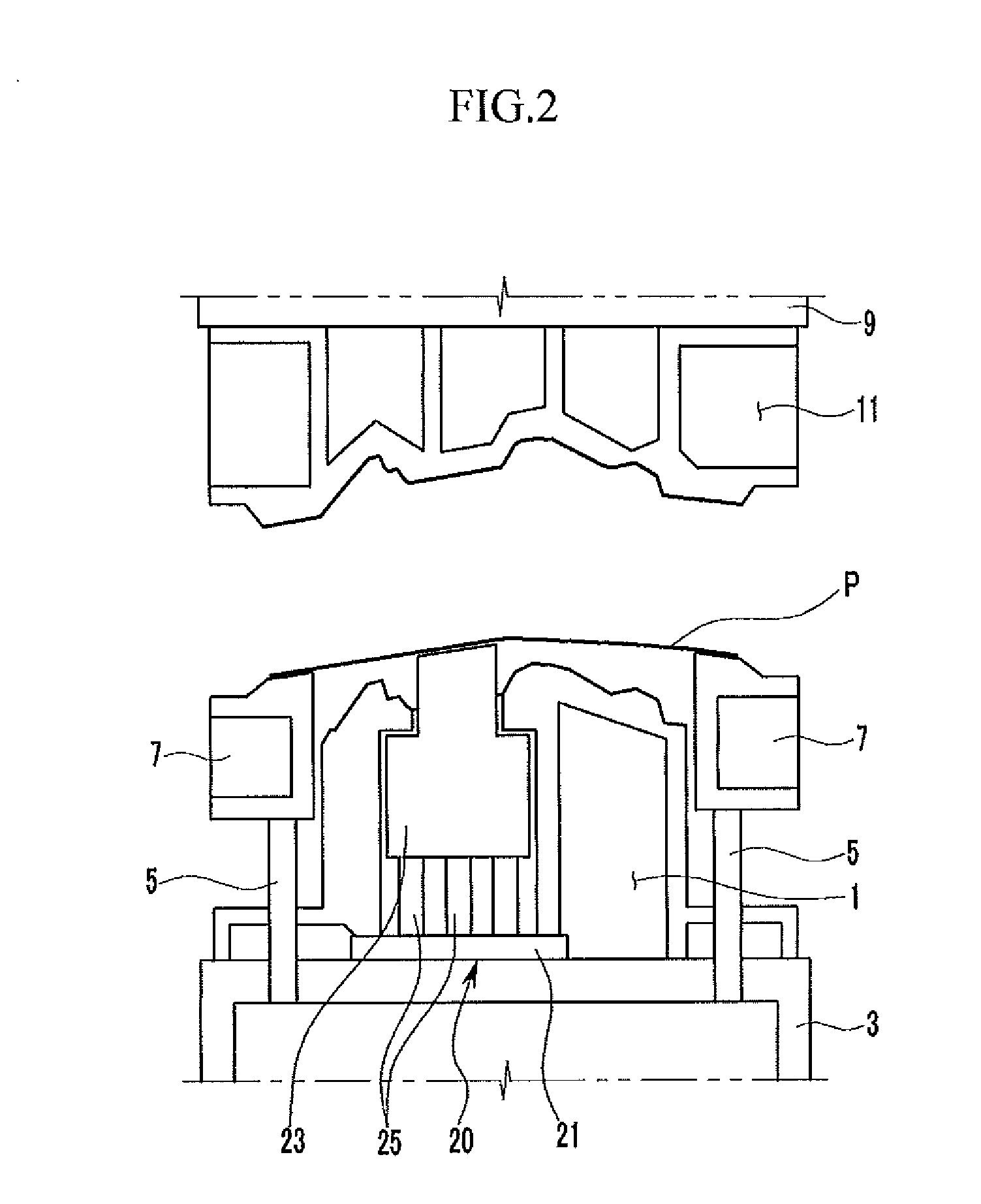

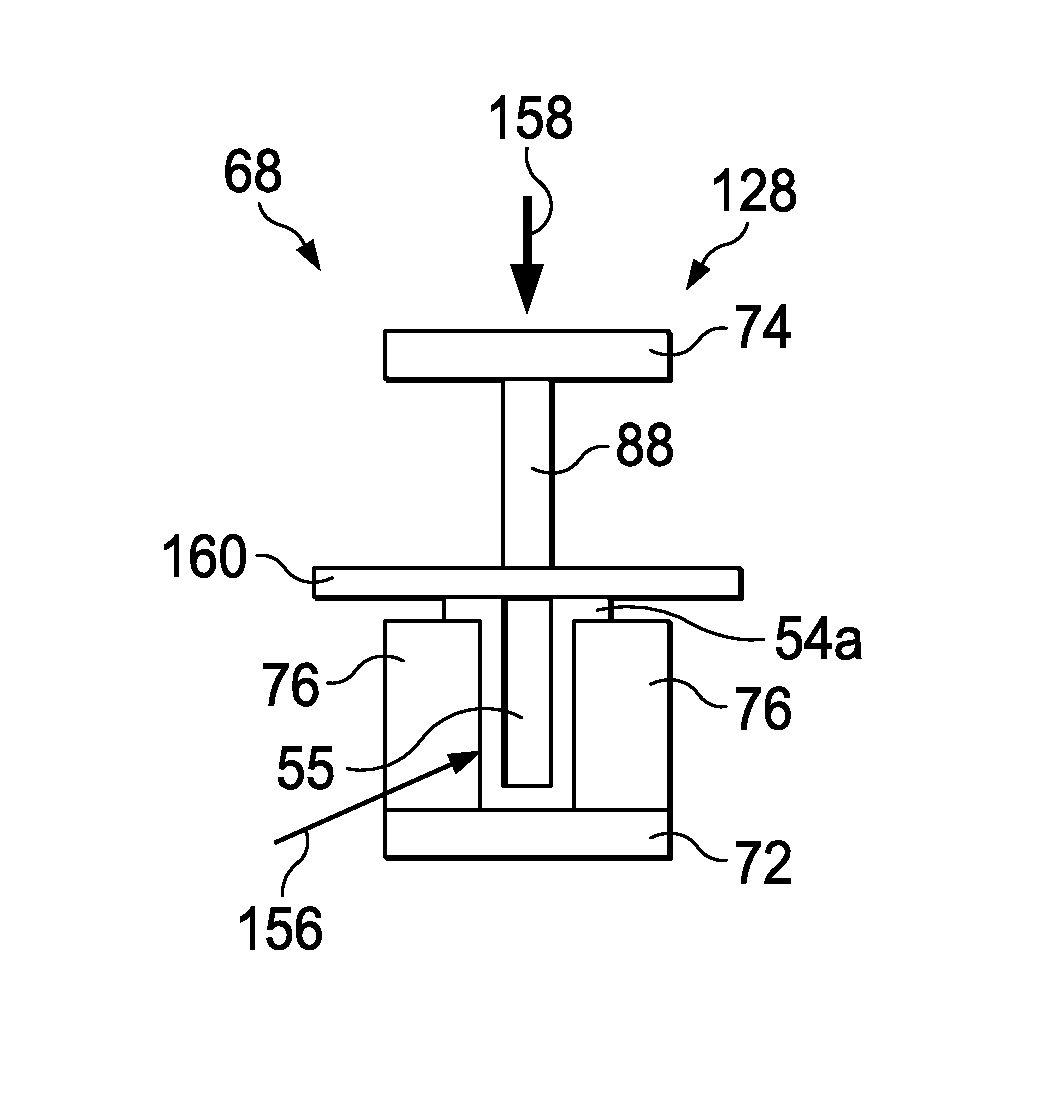

Press system

InactiveUS20120137749A1Good moldabilityImprove marketabilityShaping toolsForging/hammering/pressing machinesEngineeringCushion

Disclosed is a press system having advantages of preventing a molded product panel from bursting or being torn due to a difference in molding depth caused by a protrusion shape to improve the moldability and marketability of the product panel when press molding is performed on a material panel. An illustrative press system comprises: a lower die punch provided on a bolster and having a lower surface shape of a product panel; a blank holder provided on the outside of the lower die punch and mounted on the bolster through cushion pins; an upper die having an upper surface shape of the product panel, mounted on the slider, and pressing a material panel together with the lower die punch to mold the product panel; and a sub blank holder unit provided inside the lower die punch by performing the molding while holding a portion of the material panel to be molded into a protrusion shape together with the upper die such that a difference in molding depth is compensated when molding is performed.

Owner:HYUNDAI MOTOR CO LTD

Press and method of manufacturing a can end

An apparatus and method for forming a can end having an annular ridge and a central panel and a can body with a can bottom is provided that exhibits reduced wrinkling in the material used to form the can end and can body. The method of the invention uses a two step doming process wherein material is first drawn or stretched and then held by a punch core ring and then further drawn, stretched or domed and then held by a punch core. The apparatus and method of the invention also include a lower piston located above an upper pressure sleeve and radially outward from a punch core ring wherein the lower piston has a bore and the lower piston, punch core ring and upper pressure sleeve define a gap to which pressurized gas may be supplied through the bore to selectively axially actuate the punch core ring.

Owner:STOLLE MACHINERY

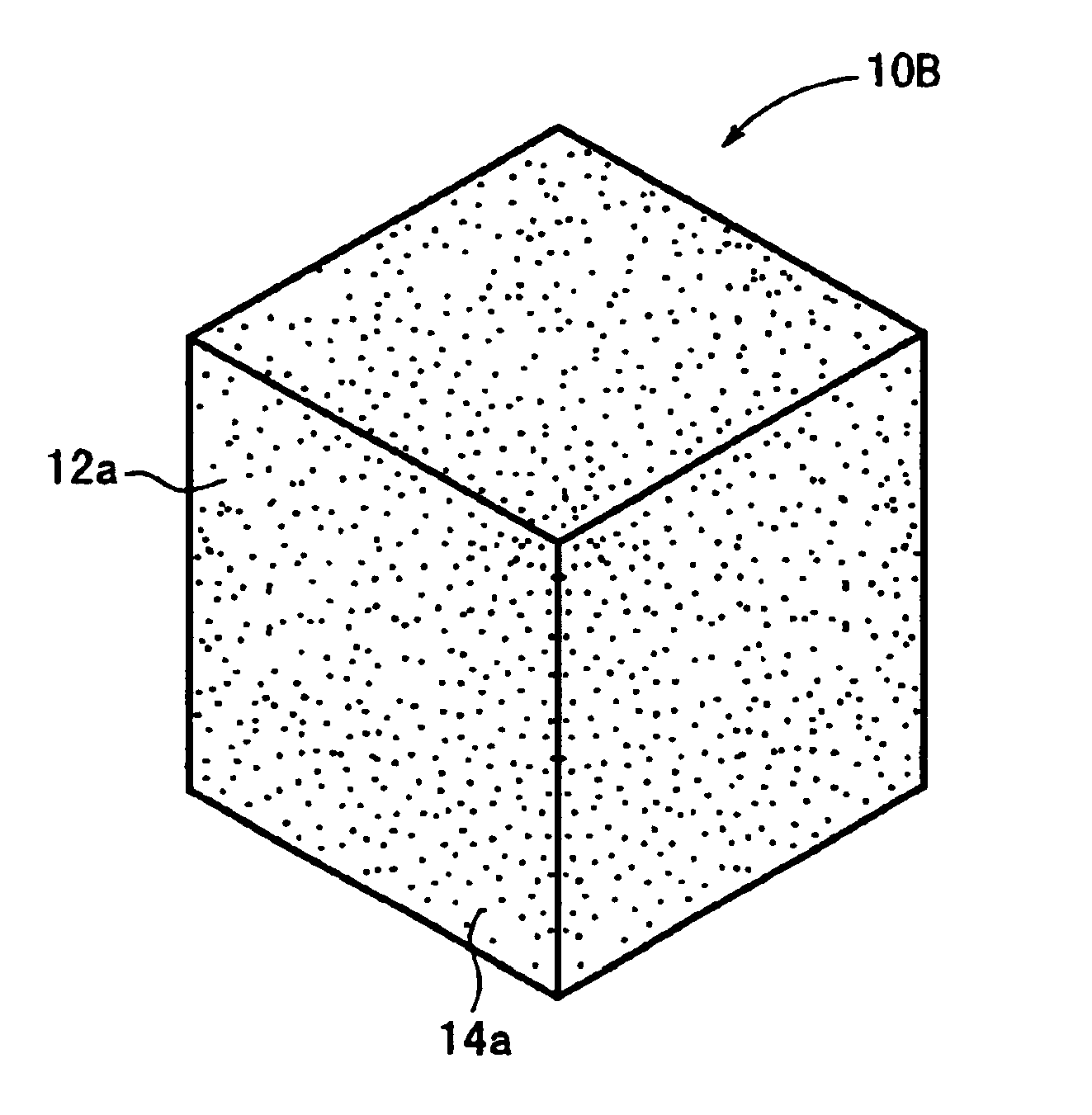

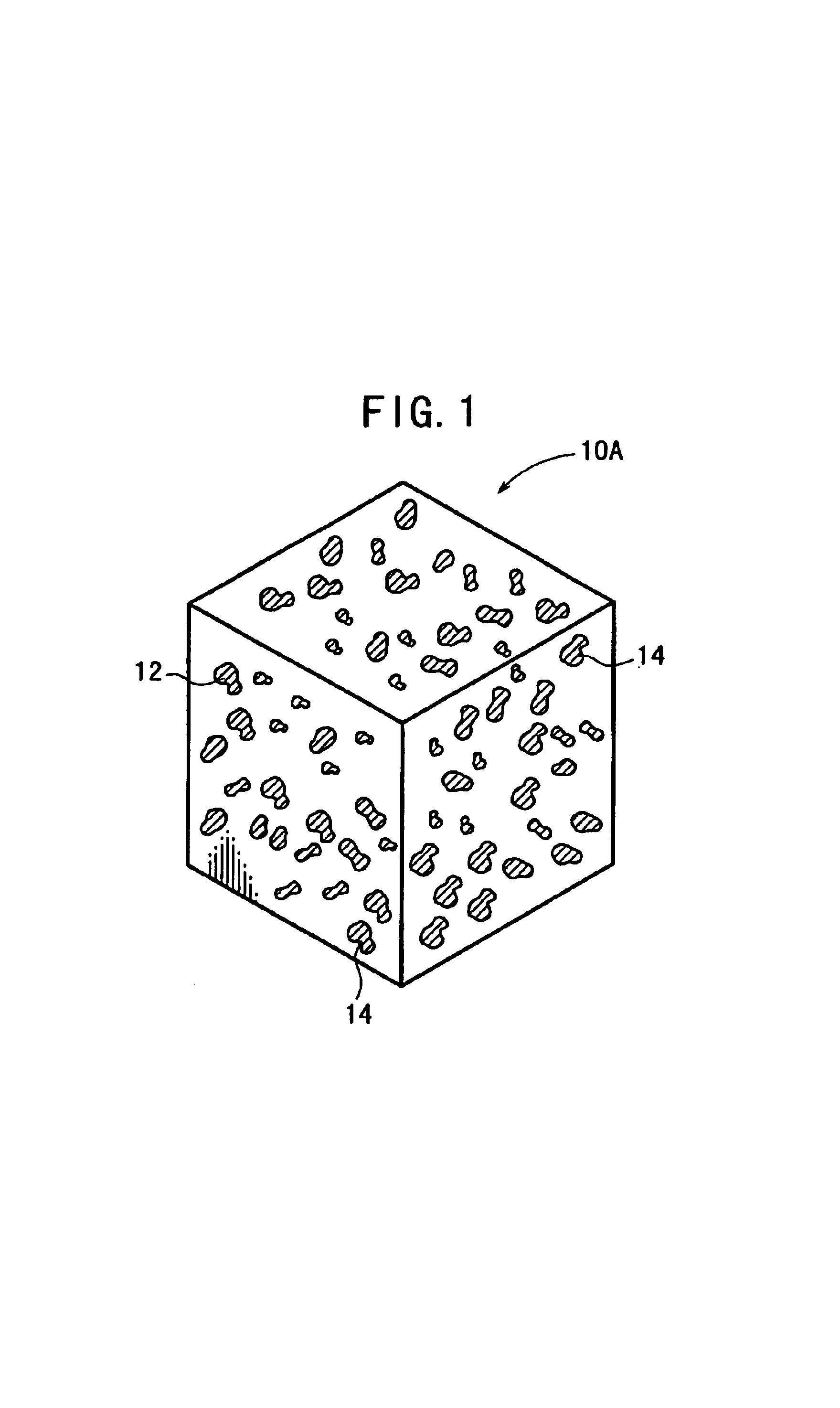

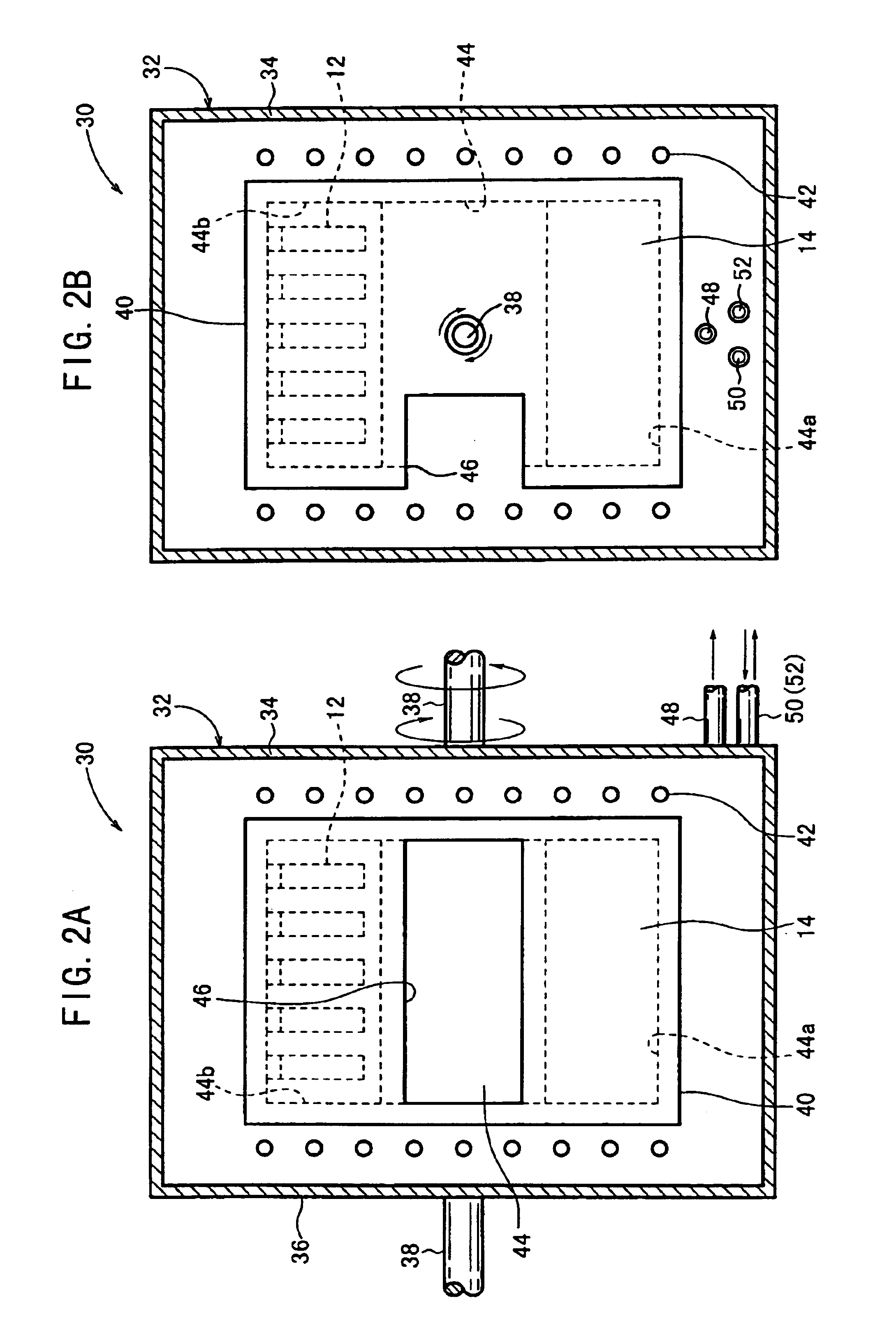

Heat sink material and method of manufacturing the heat sink material

InactiveUS6933531B1Easy to manufactureImprove productivitySemiconductor/solid-state device detailsSolid-state devicesGraphiteMolten metal

Graphite is placed in a case, and the case is set in a furnace. The interior of the furnace is subjected to sintering to produce a porous sintered member of graphite. After that, the case with the porous sintered member therein is taken out of the furnace, and is set in a recess of a press machine. Subsequently, molten metal of metal is poured into the case, and then a punch is inserted into the recess to forcibly press the molten metal in the case downwardly. Open pores of the porous sintered member are infiltrated with the molten metal of the metal by the pressing treatment with the punch.

Owner:NGK INSULATORS LTD

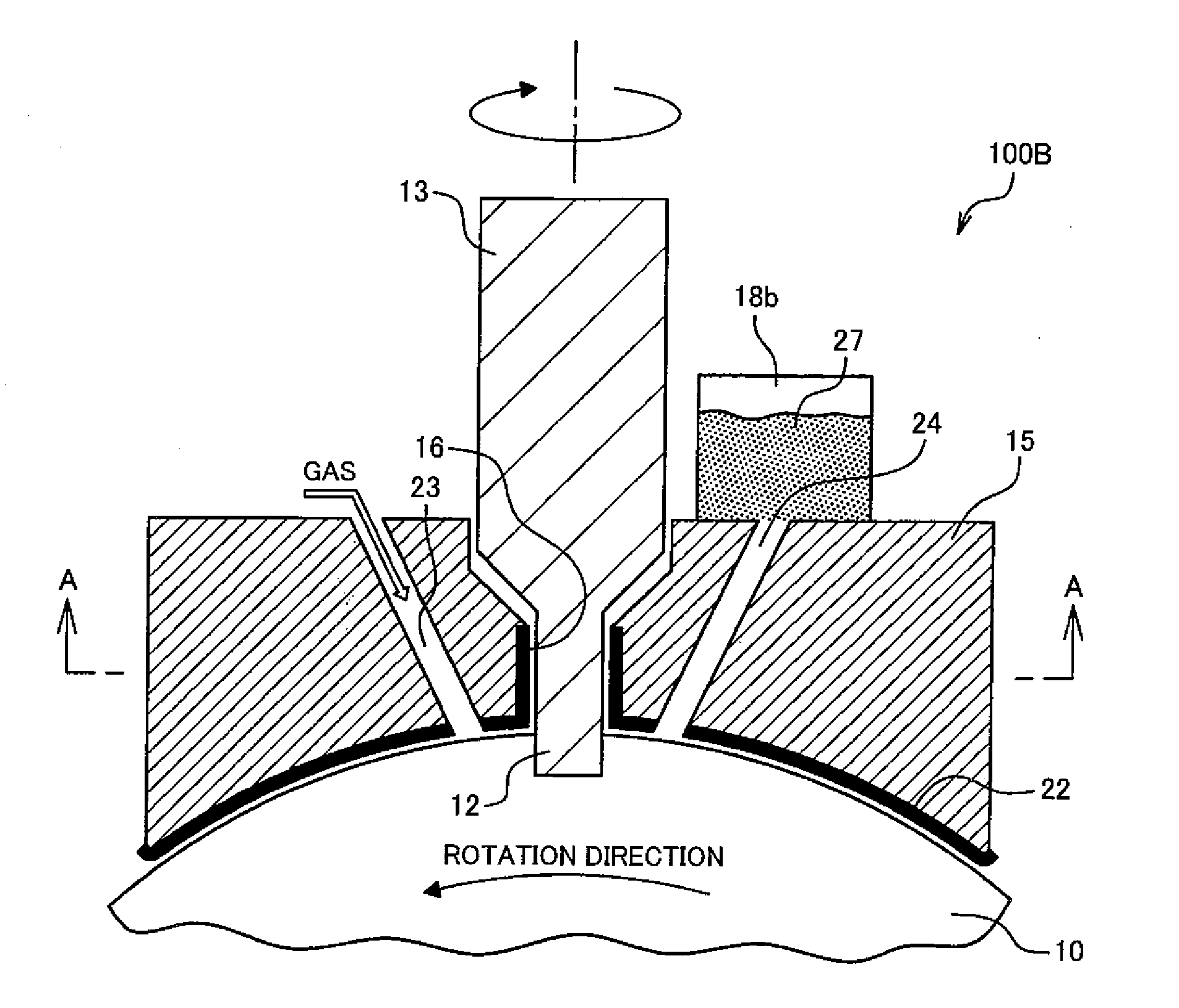

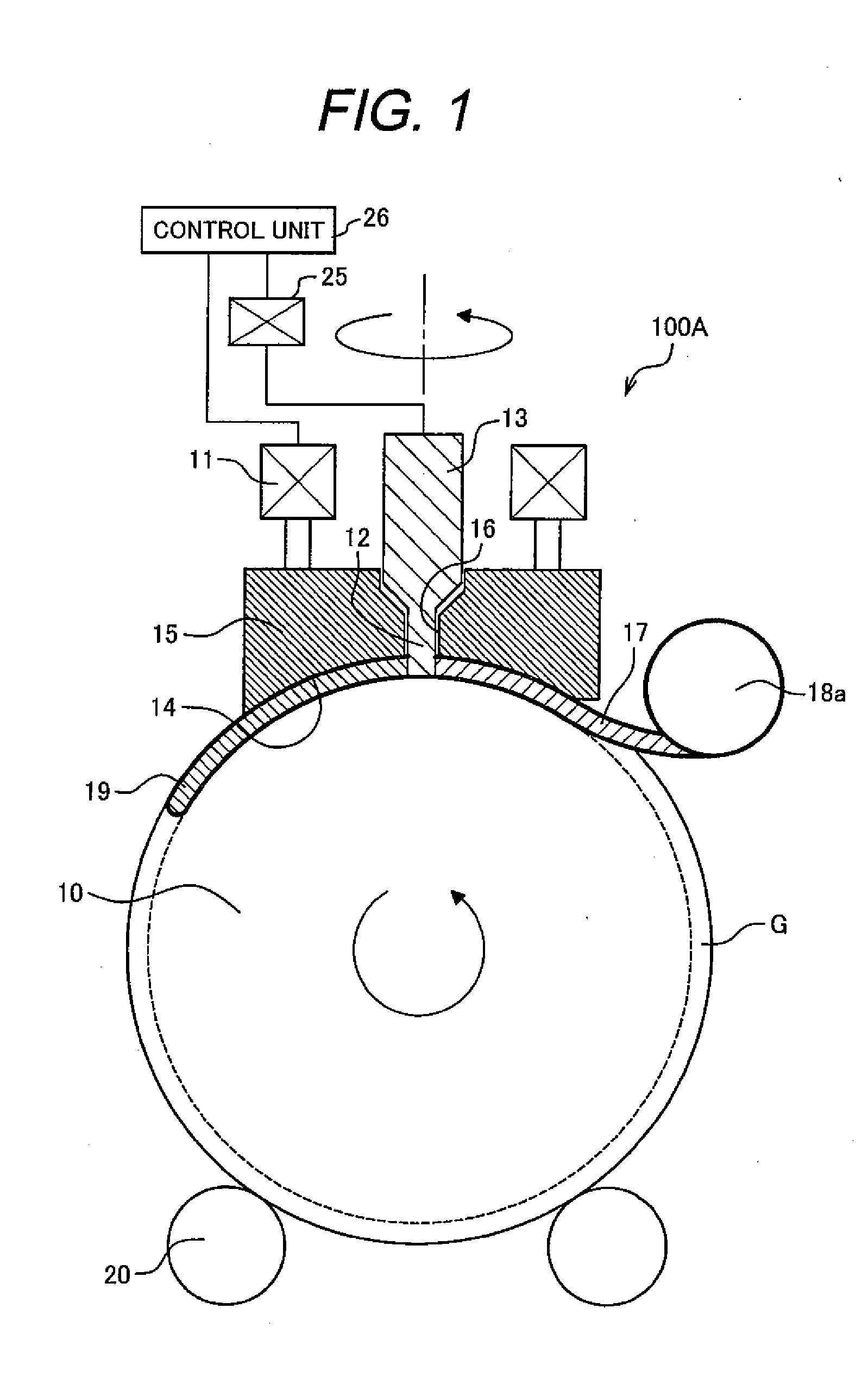

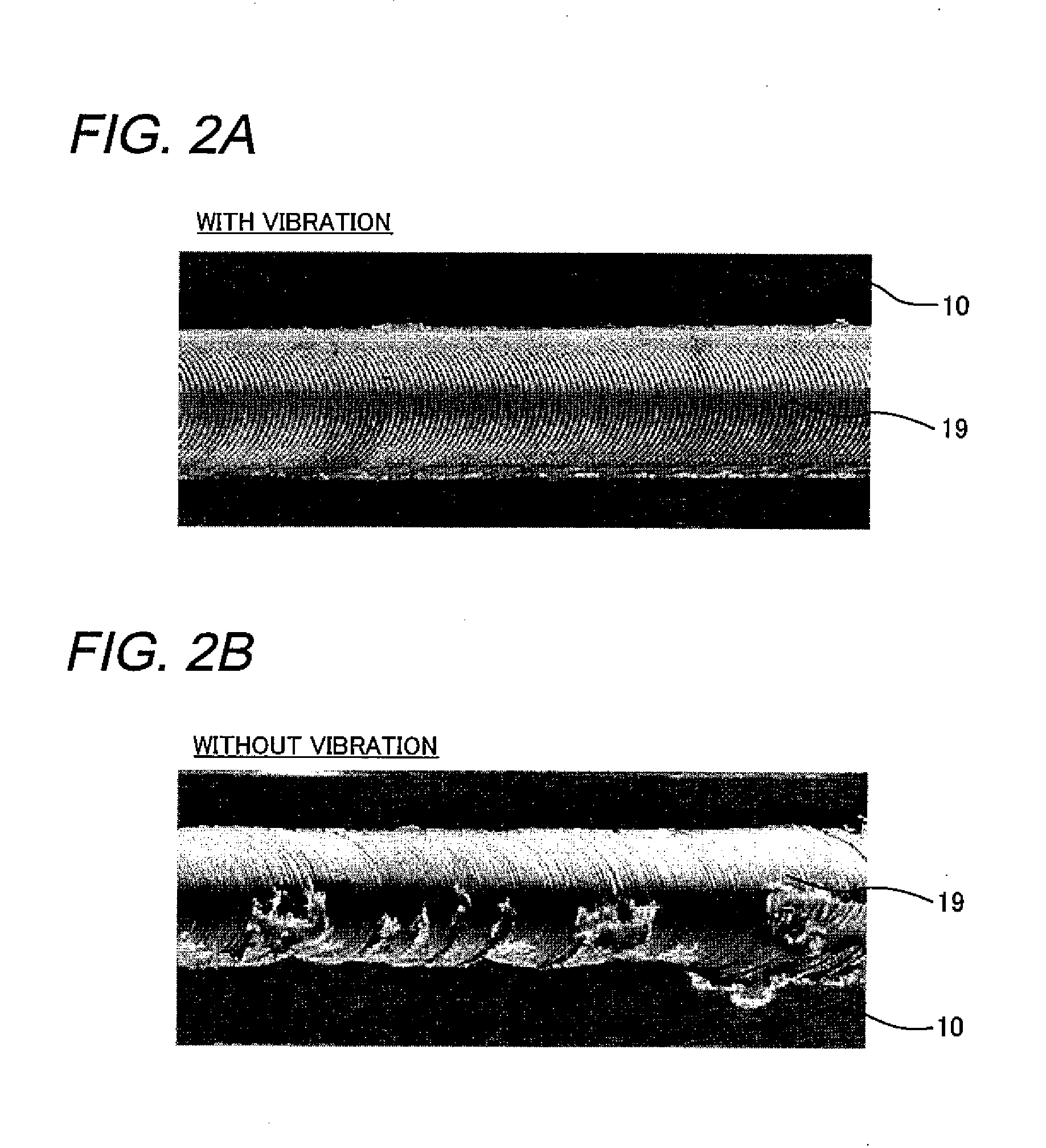

Apparatus for friction stir and friction stir processing

InactiveUS20090152328A1InhibitionWelding/cutting auxillary devicesPistonsEngineeringFriction stir processing

An apparatus for a friction stir and a friction stir processing of the present invention suppress an occurrence of a surface defect in an area processed by the friction stir. The apparatus for the friction stir includes a tool having a columnar tip-side part, a rotating unit for rotating the tool on a central axis, a first pressing unit for pressing a tip of the tool rotated by the rotating unit against a work, a jig having a tool insertion hole into which the tip-side part of the tool is inserted so that the tip-side part of the tool is encircled around the jig, a second pressing unit for slidably pressing the jig against the work, and a press control unit for controlling the first pressing unit so that the tip-side part of the tool is gradually pulled out of the work by the first pressing unit while moving the tool and the jig relative to the work, in a state that the tool is rotated by the rotating unit and the tip of the tool has been sunk into the work to a predetermined depth by the first pressing unit.

Owner:HITACHI LTD

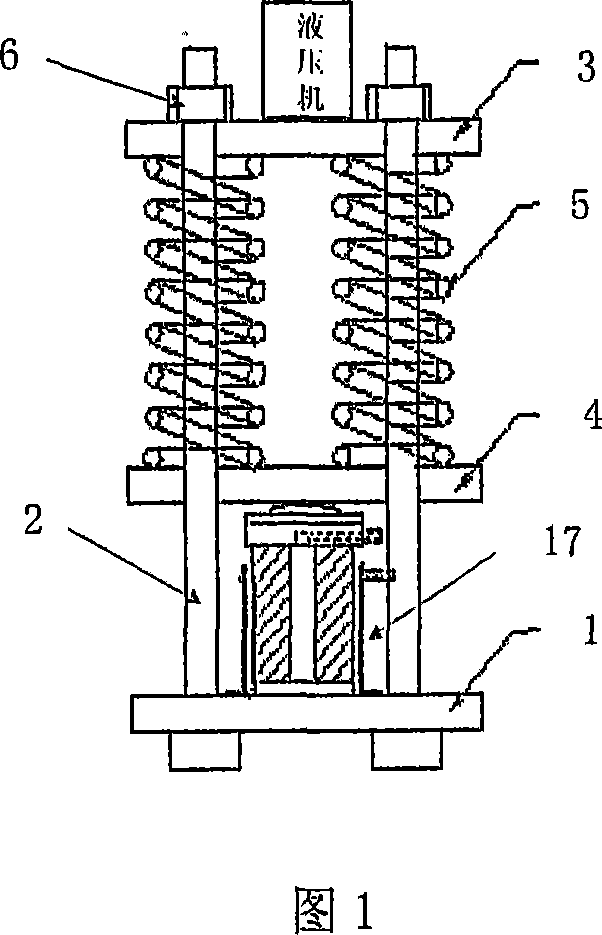

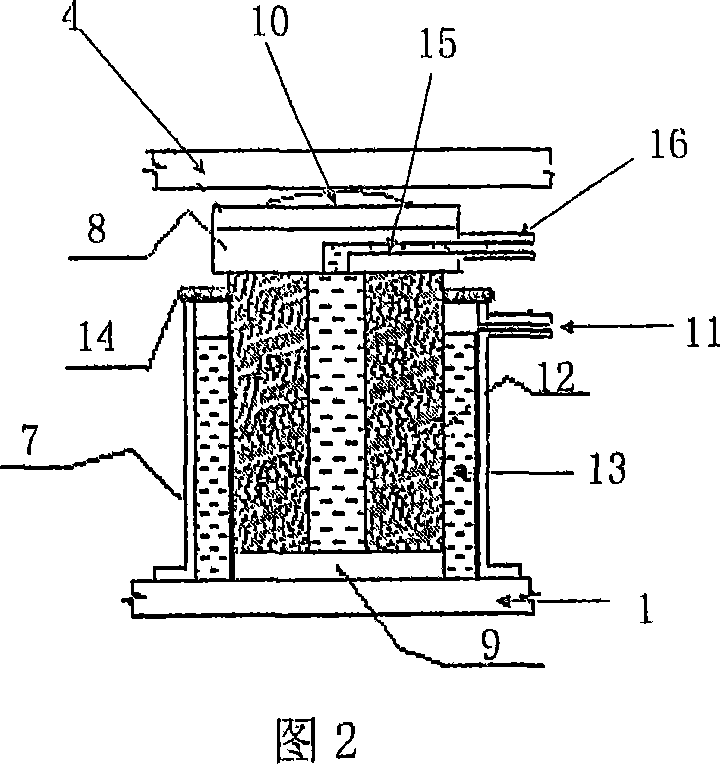

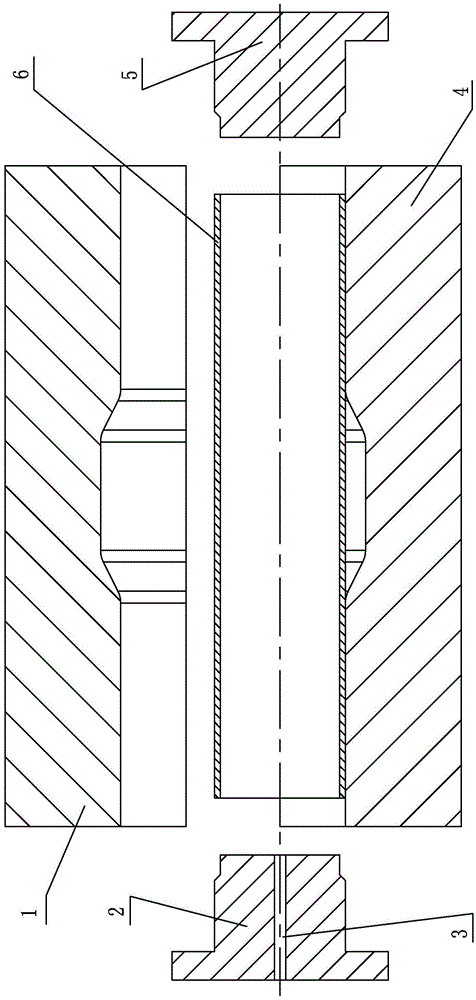

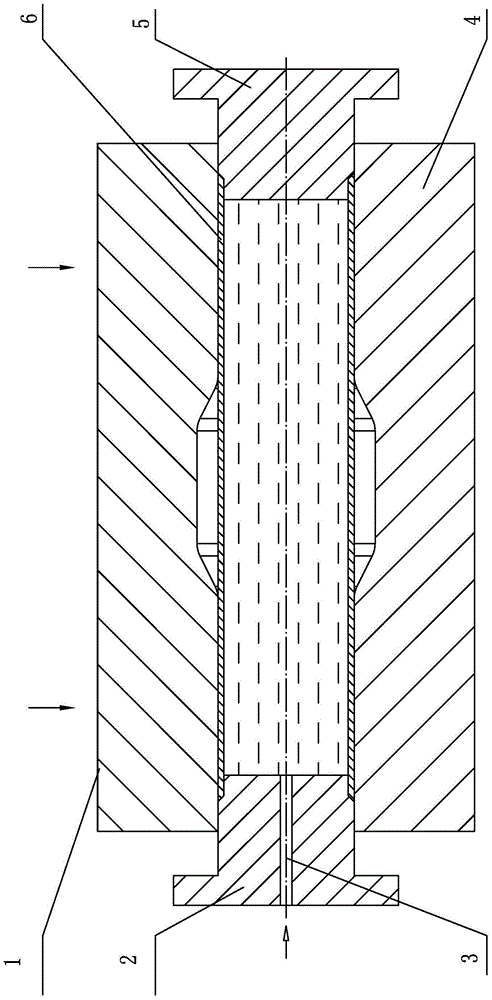

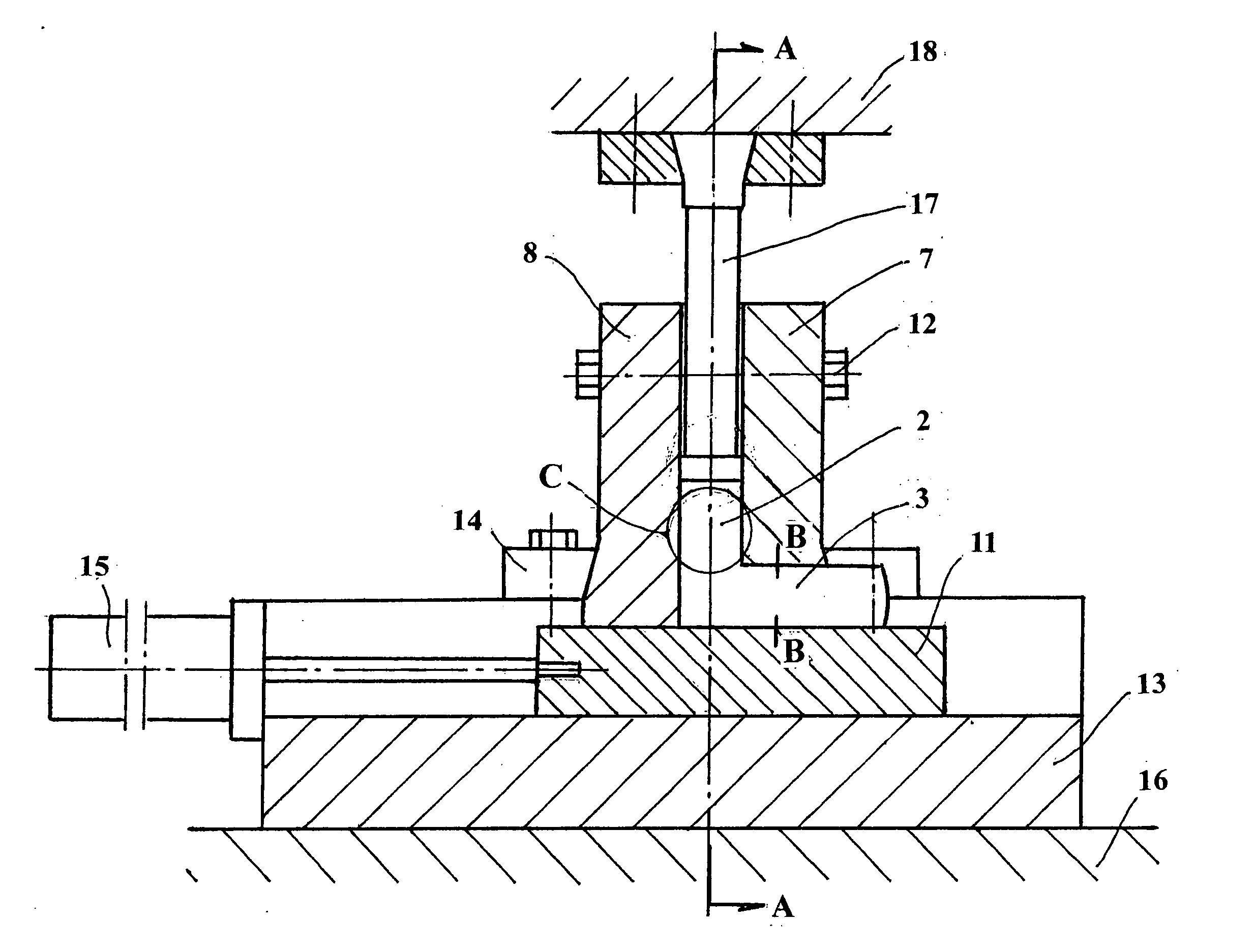

Apparatus and method for testing cement concrete penetration performance under loading action

InactiveCN101074912ASolve the problem that the continuous stability of the load cannot be guaranteedSurface/boundary effectPermeability/surface area analysisGraduated cylinderSheet steel

A device used for testing permeation performance of hydraulic engineering concrete under load action is prepared forming pressurizing unit by steel chassis, steel plate, steel vertical column, spring, nut and bolt; forming test-piece chamber by sleeve, up-pressing steel plate, down-pressing steel plate, ball base and concrete test-piece. Its testing method is also disclosed.

Owner:HOHAI UNIV

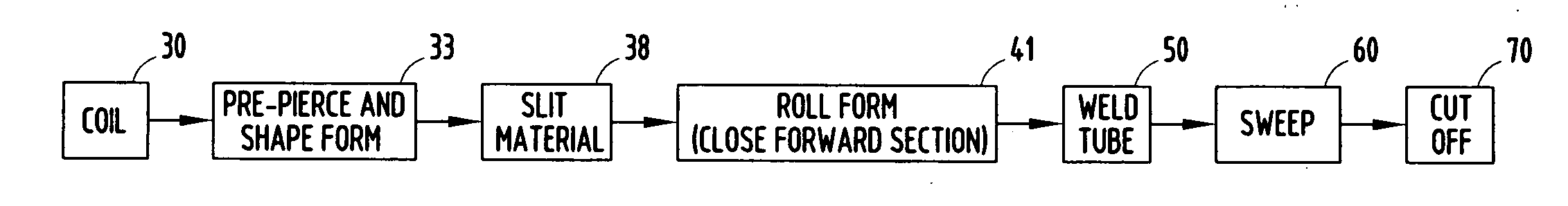

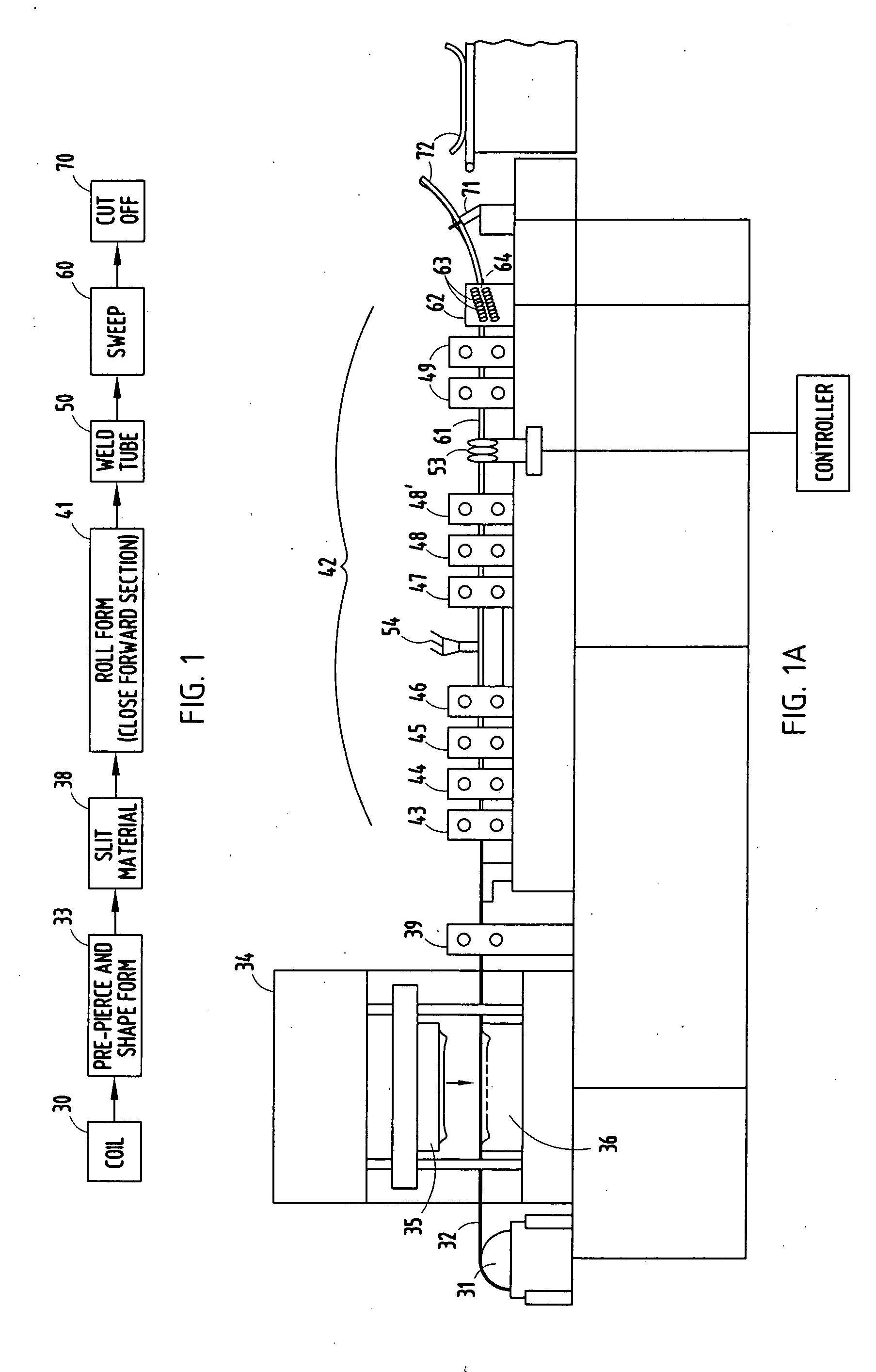

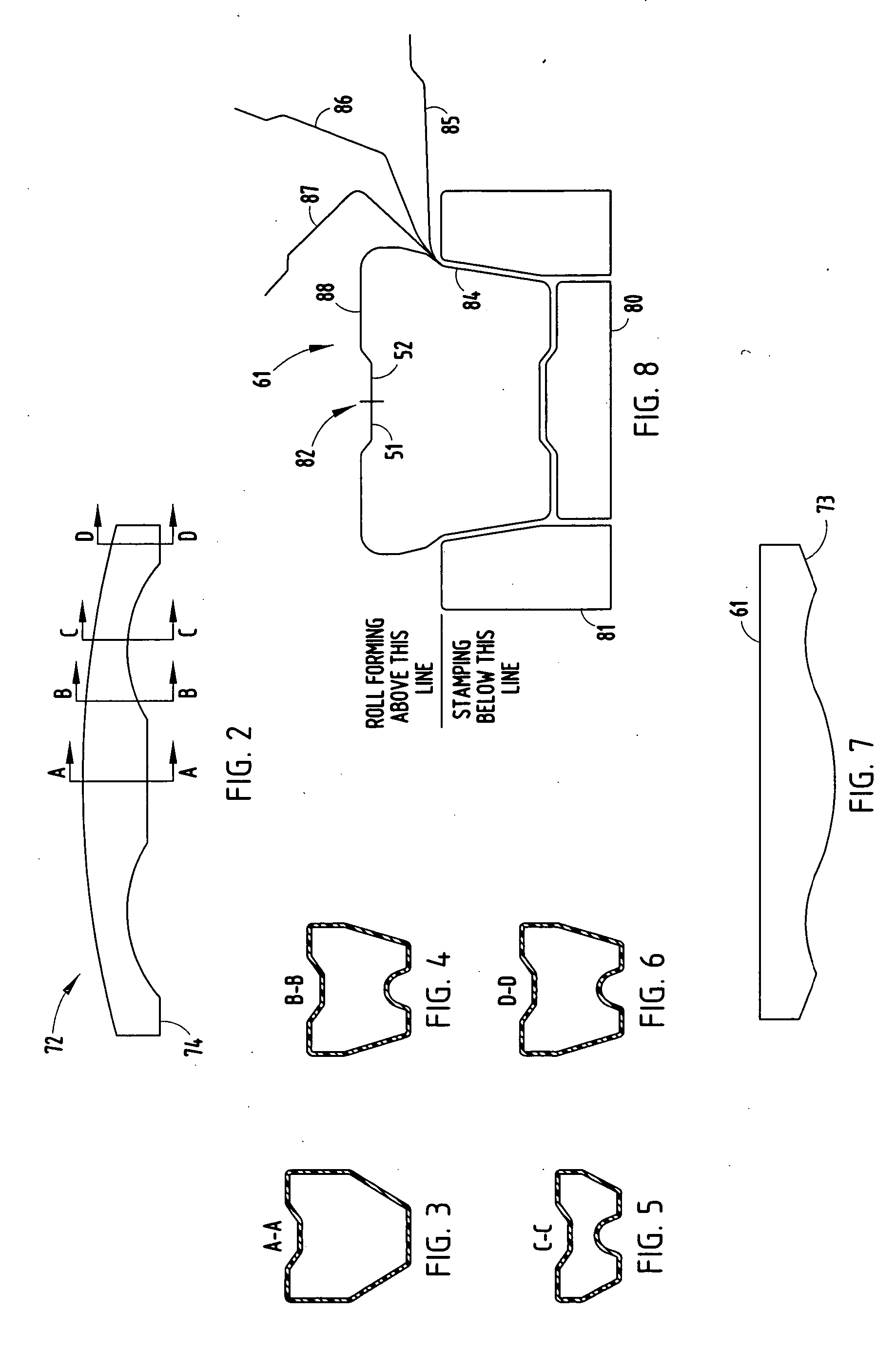

Continuous process of roll-forming stamped sheet

An apparatus includes a press with dies configured to deform a strip of material by drawing material primarily from a width direction, a slitter set to cut the deformed strip to a uniform desired width dimension, and a roll-former with rolls configured to shape linear portions of the deformed and now uniform-width strip into a continuous beam. The apparatus further includes a welder for welding abutting edges of the sheet together to form a permanent tube, a sweep station for imparting a longitudinal shape to the continuous beam, and a cut-off for cutting the continuous beam into segments useful as vehicle bumper beams. A controller controls timing of various components. The beam segments are optimized in specific regions for local strength and minimized weight, and features can be incorporated into the beam segments such as coplanar mounting surfaces.

Owner:SHAPE CORP

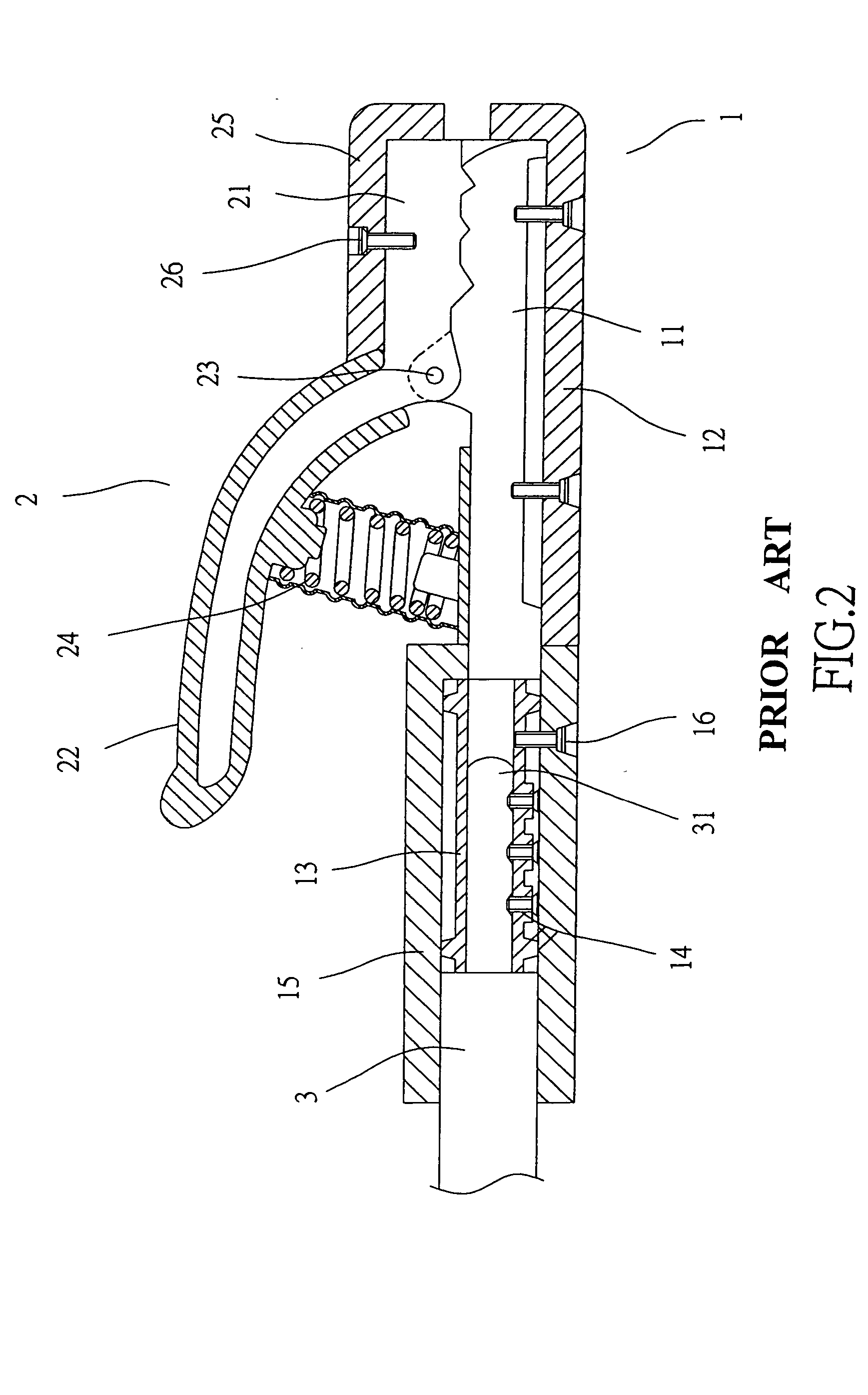

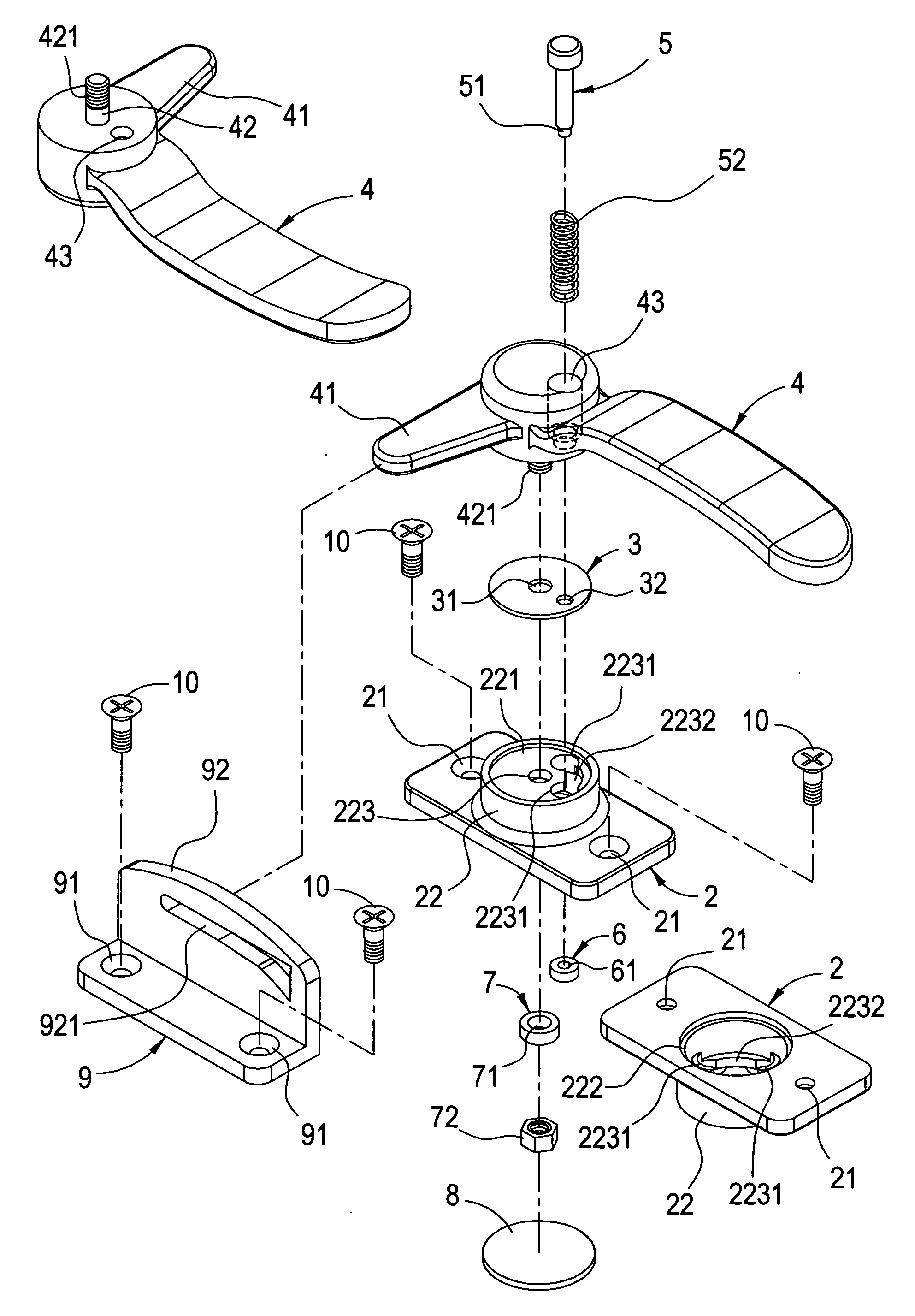

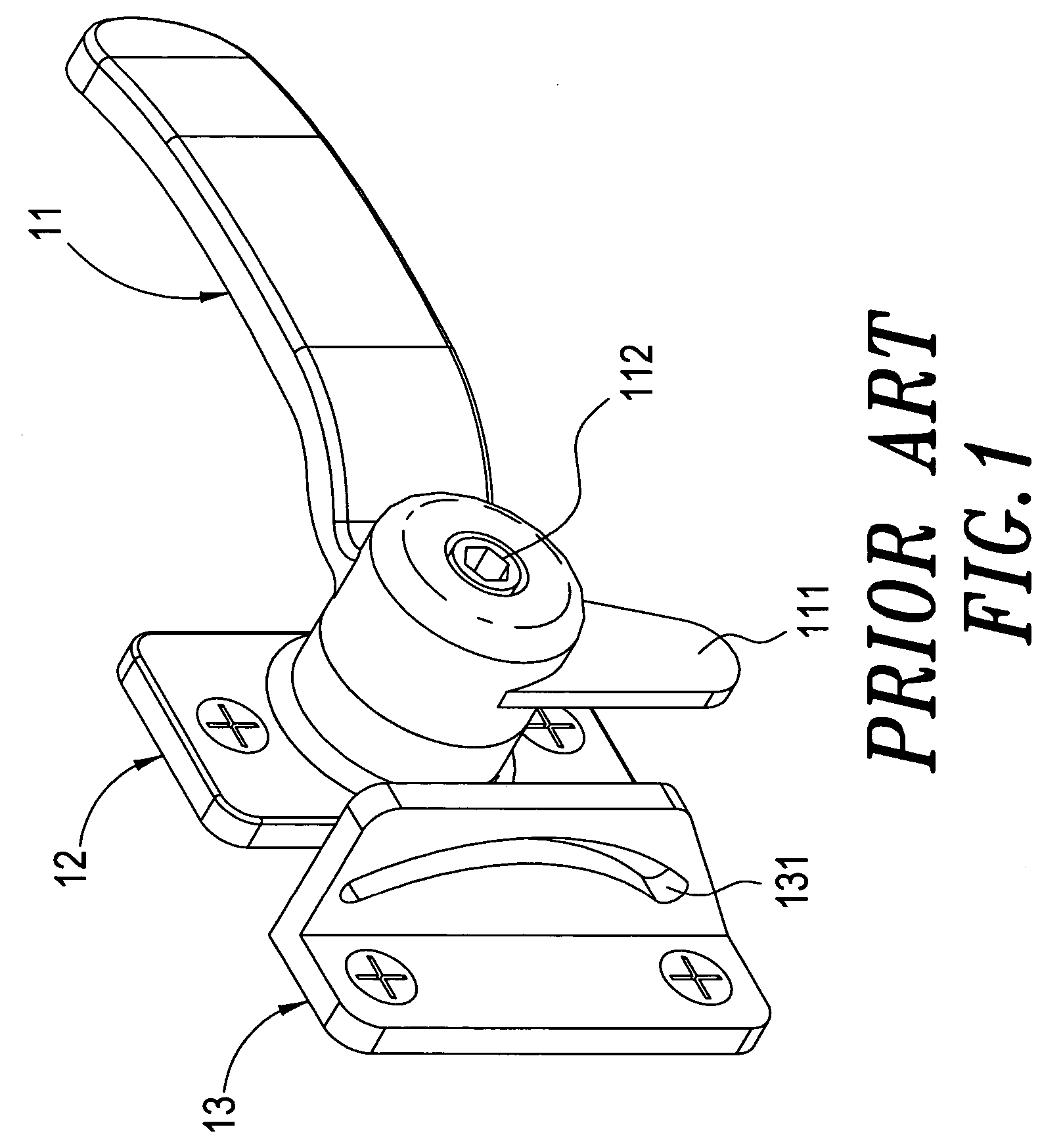

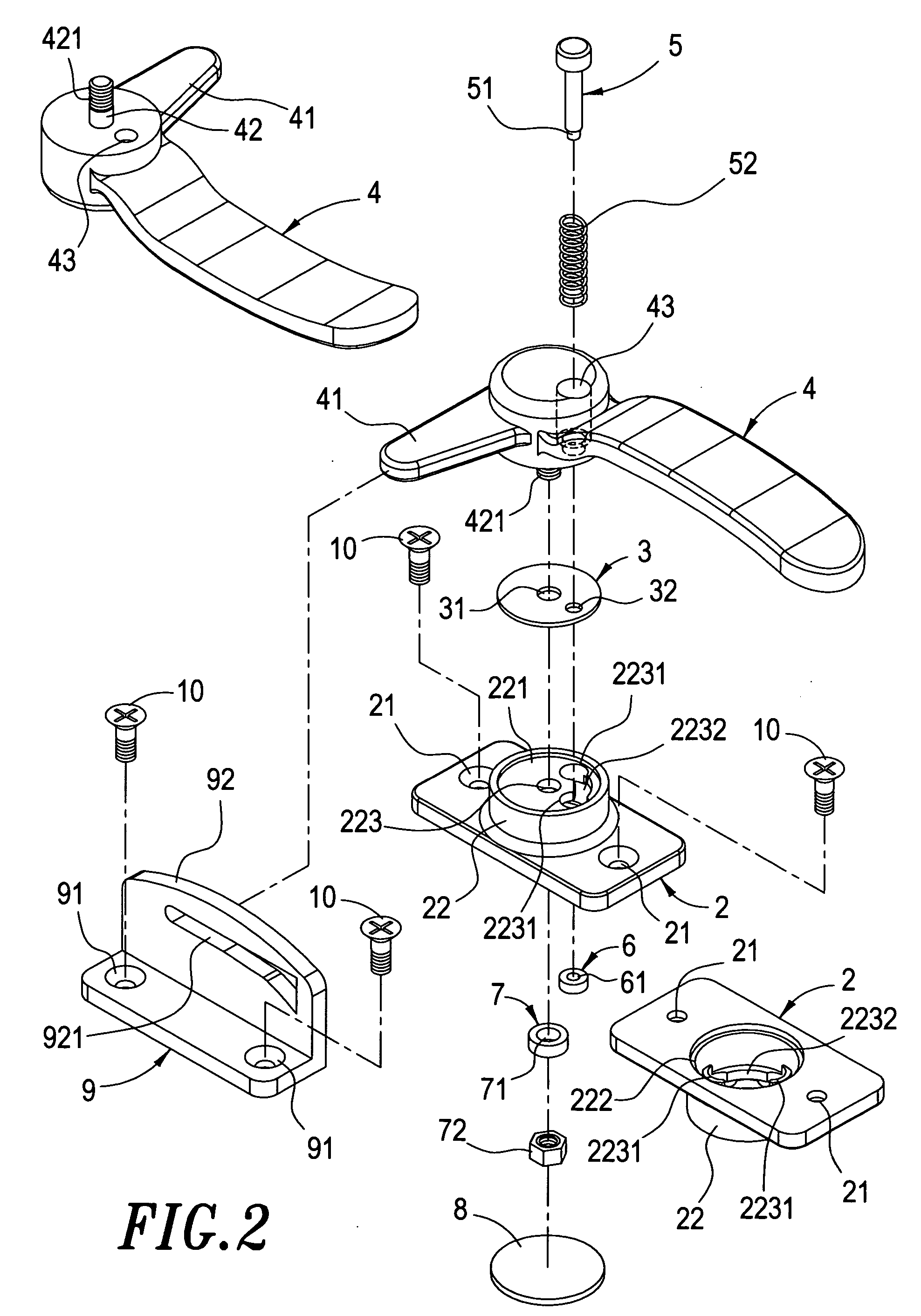

Water gate locker

InactiveUS7100951B2Precise positioningSimple structureKeyhole guardsConstruction fastening devicesEngineeringMachine press

A water gate locker comprises a locker body, a bracket, a fastener-seat, a press-bolt, a position-ring, a nut. A position-slice is extended from one side of the locker body and a turning-axle is extended downward from the bottom of the locker body, and a thread is provided at the front end of the turning-axle, and a hole, with the upper portion larger than the lower, is provided on the locker body, and is penetrated through by a press-bolt, a screw-hole is provided at each side of the bracket, and a protrudent-cylinder is protruded upward from the middle of bracket, and an axle-hole is penetrated through the protrudent-cylinder, and two fastener-portions are penetrated beside the axle-hole, and a runner in an arc form with smaller diameter is penetrated between the two fastener-portions, a screw-hole is provided at each side of the fastener-seat, and a position-plate is extended upward from a side of the fastener-seat, and a position-runner is provided on a suitable portion of the position-plate, the turning-axle of the locker body is fitted in the axle-hole of the protrudent-cylinder of the bracket, and the locker body is integrated with the bracket via a nut, and the bottom end of the press-bolt is protruded from the runner of the protrudent-cylinder, and then a position-ring is combined with the bottom end of the press-bolt. Accordingly, the water gate locker according to the present invention is formed.

Owner:TYRONE MARINE HARDWARE

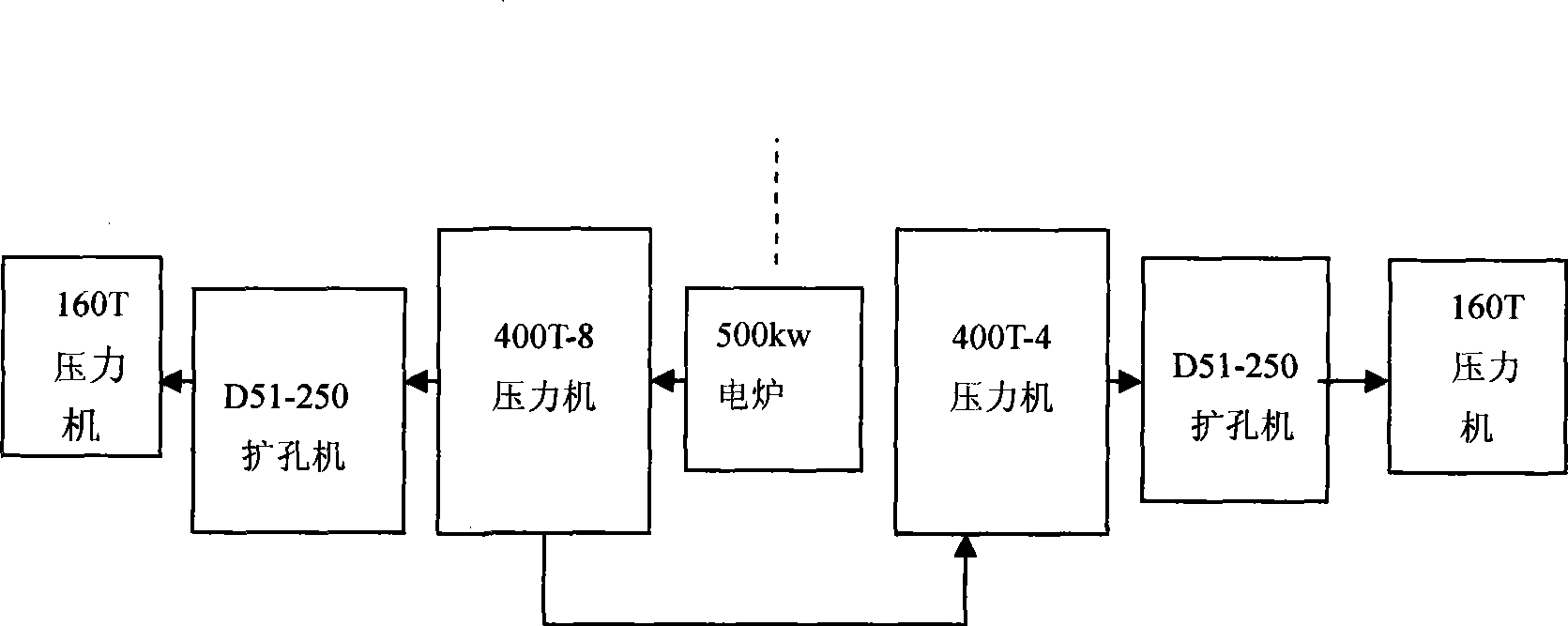

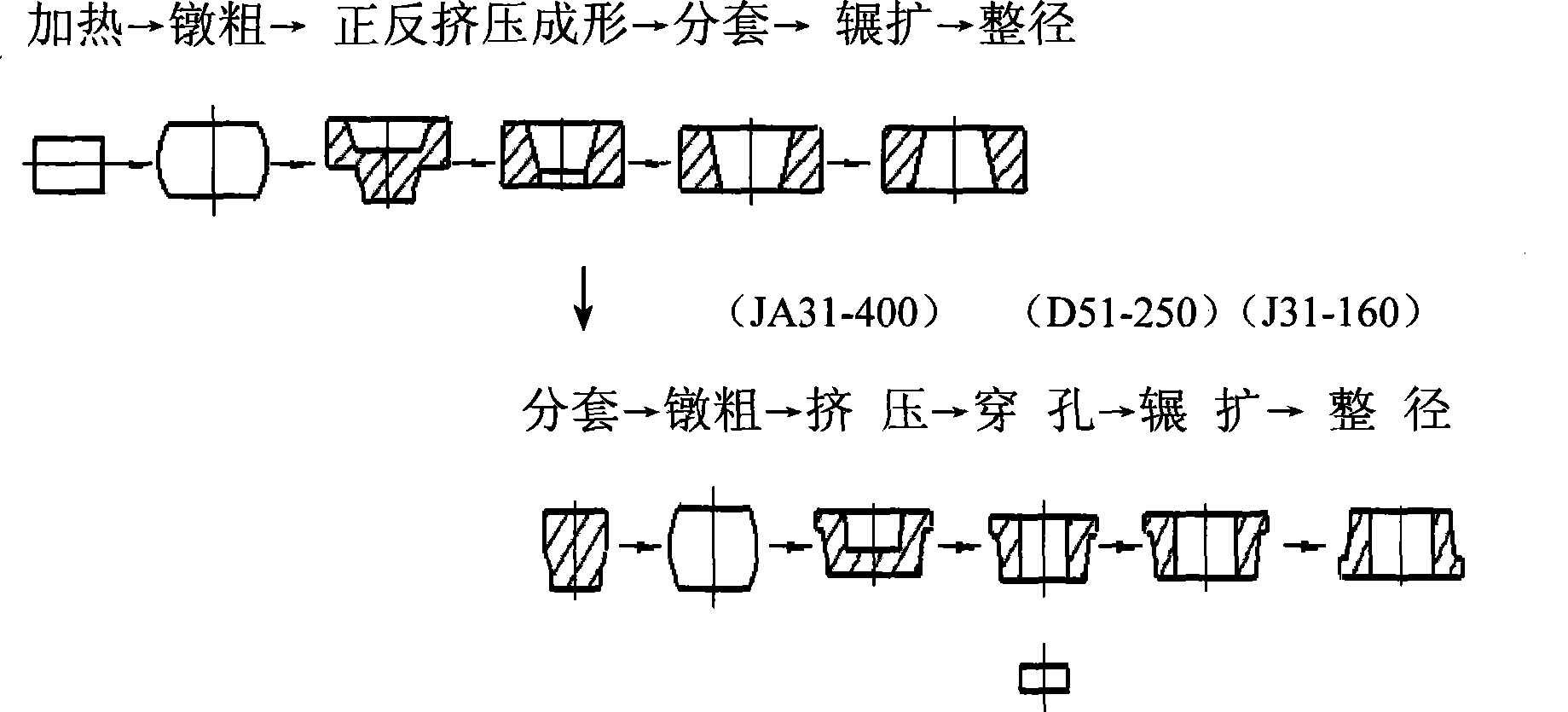

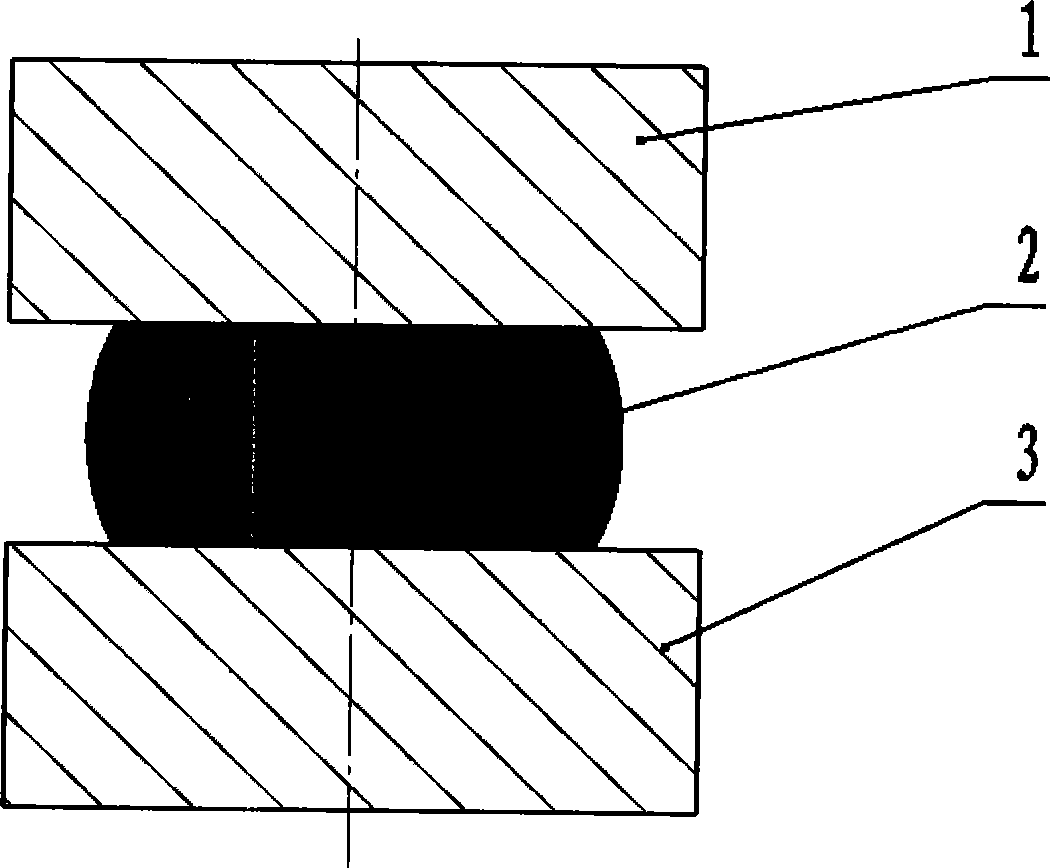

Tapered roller bearing ring double extension-sleeve forging technique

ActiveCN101417379AReduce labor intensityIncrease profitMetal rollingHigh volume manufacturingDouble diffusion

The invention relates to a double diffusion intussusception forge technique of a bearing ring of a tapered roller, belongs to the technical field of forging of the bearing ring of the tapered roller and mainly aims at solving the problems that the existing ring forging technique is not suitable for various bearing rings of the large and medium size tapered rollers. The technique is mainly characterized in that: (1) a GCr15 steel material section is heated to 1050 DEG C on a medium frequency induction furnace, then upset on a press, extruded backward and forward, formed, sheathed respectively and is separated into an outer sleeve and an inner sleeve or a small outer sleeve blank; (2) the outer sleeve blank is ring-rolled on a ring rolling machine, then reeled on the press and cooled into an outer sleeve forged parts of a bearing; and (3) the inner sleeve or the small outer sleeve blank is placed on the press, upset again, extruded and punched and then a ring part is obtained which is ring-rolled on the ring rolling machine, then an inner sleeve hot forged part after being ring-rolled is reeled on the press and then cooled to obtain the inner sleeve forged part of the bearing. The technique is mainly used for manufacturing the inner and outer ring forged parts of the bearing of the large and medium size tapered roller with various types, small batch or large batch.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

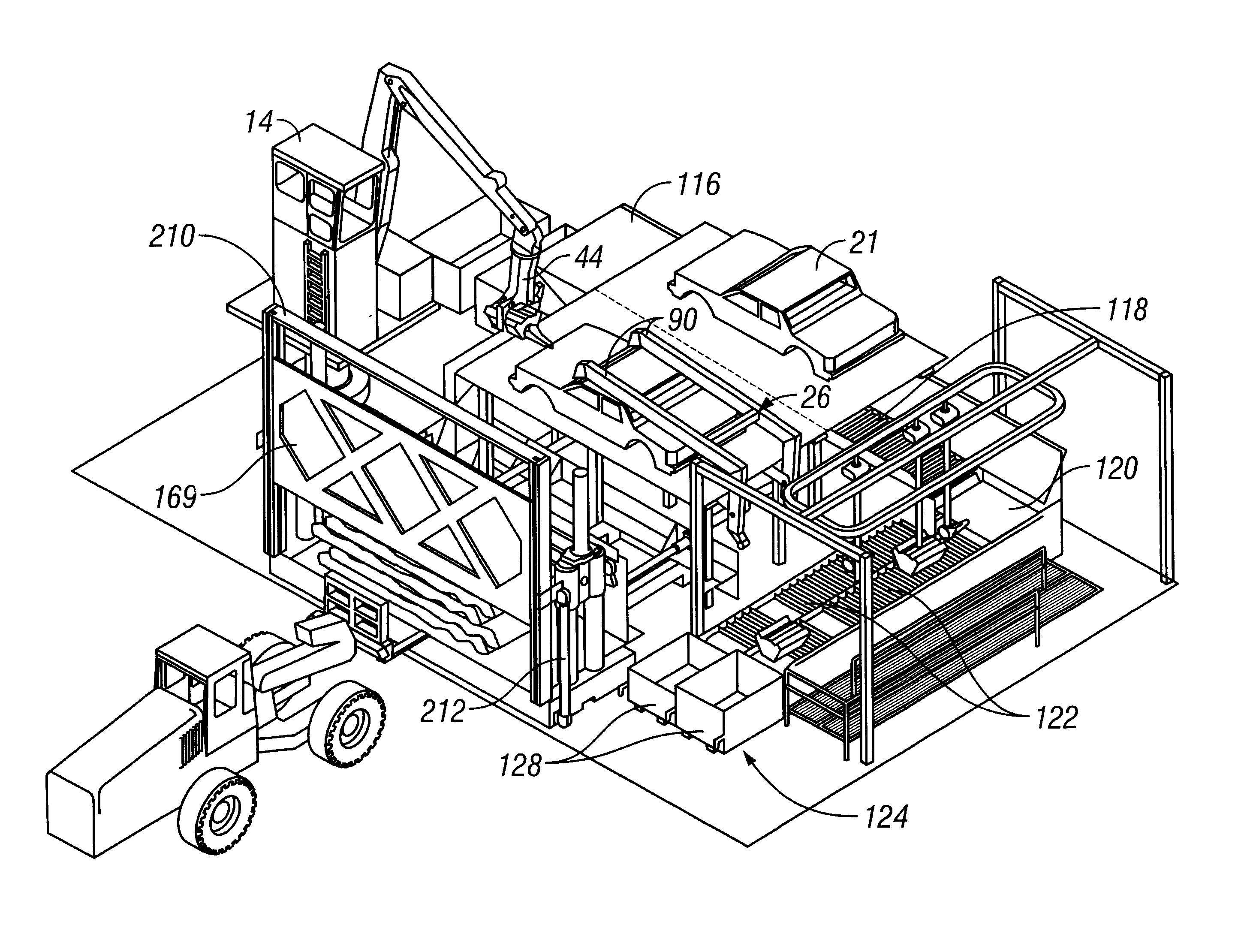

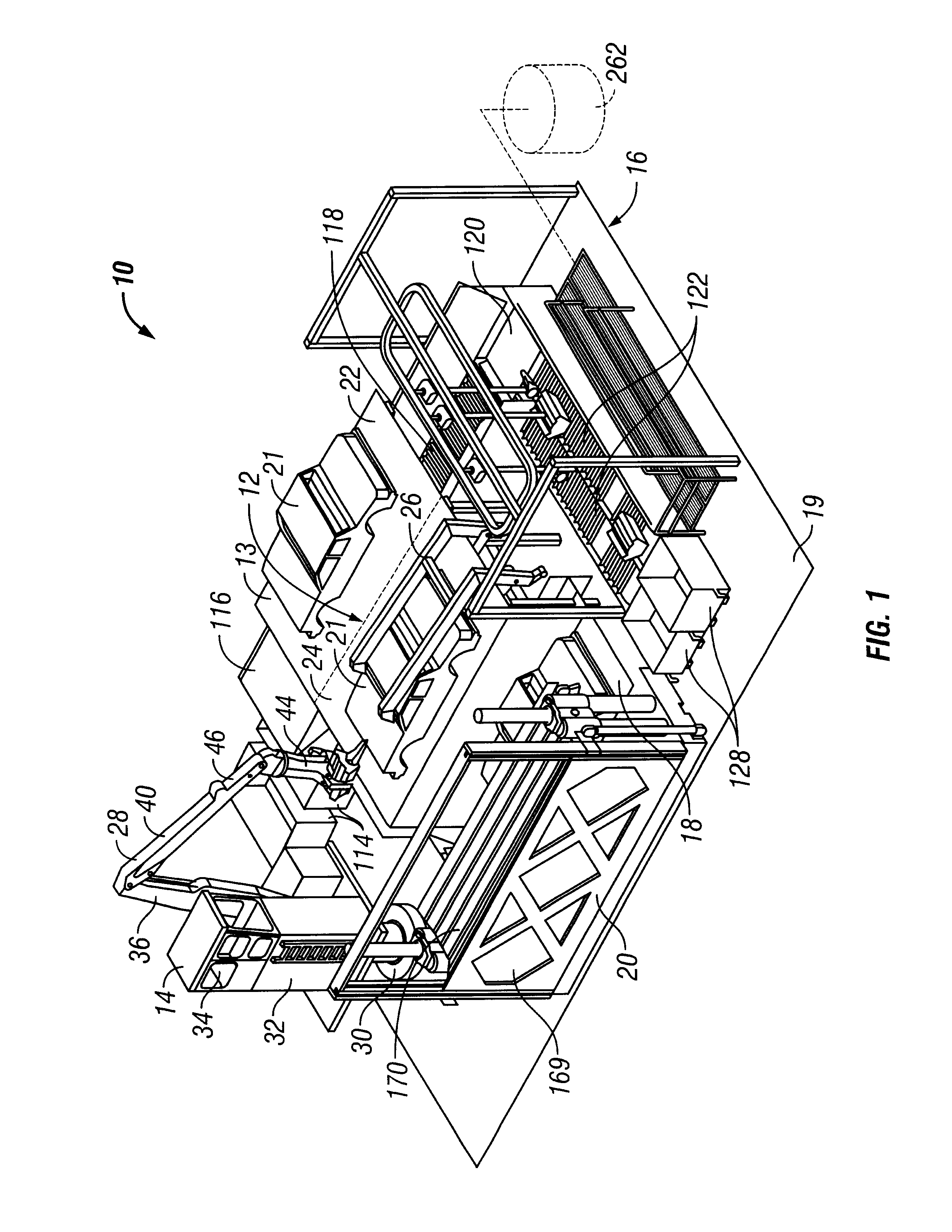

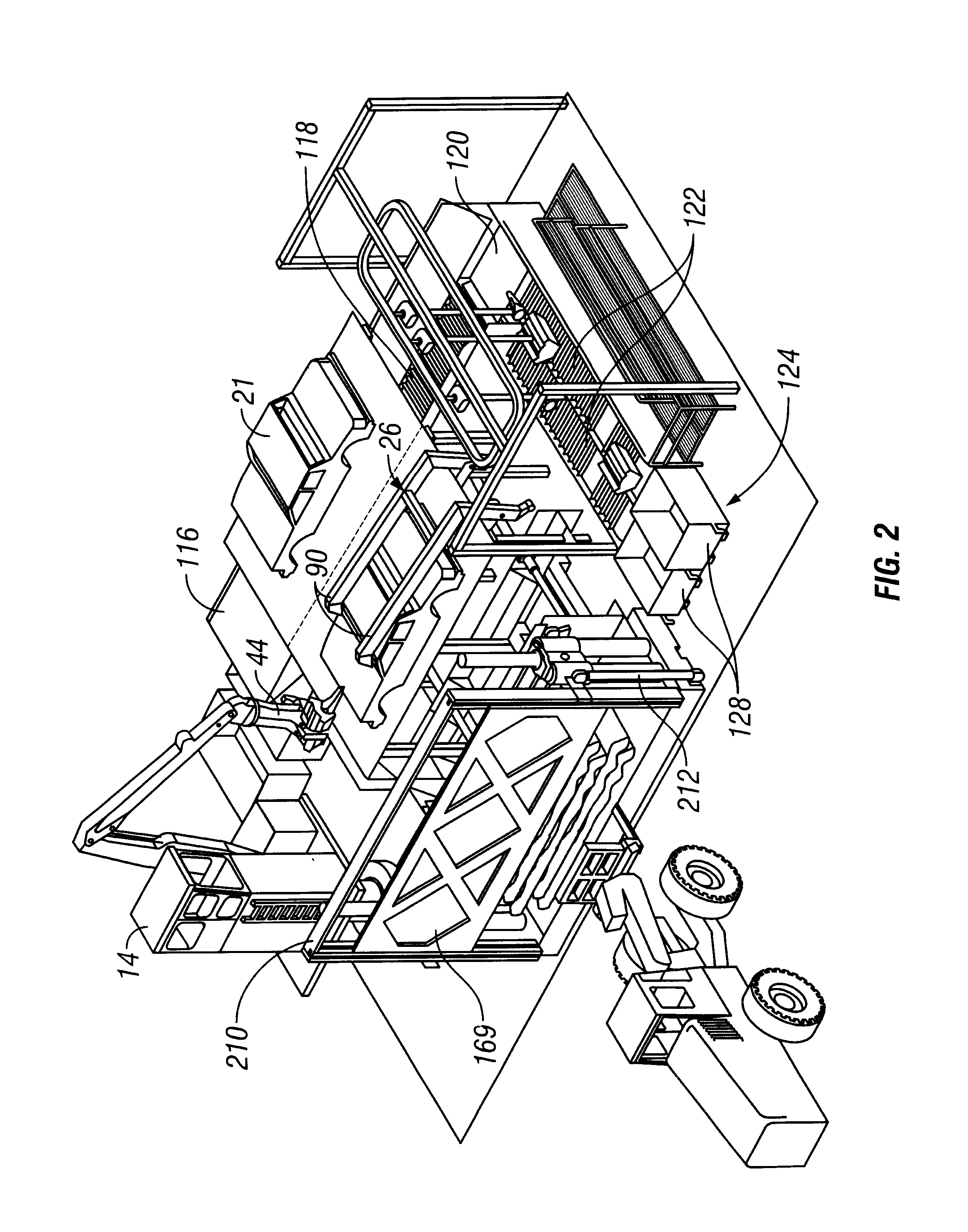

Vehicle recycling system and method

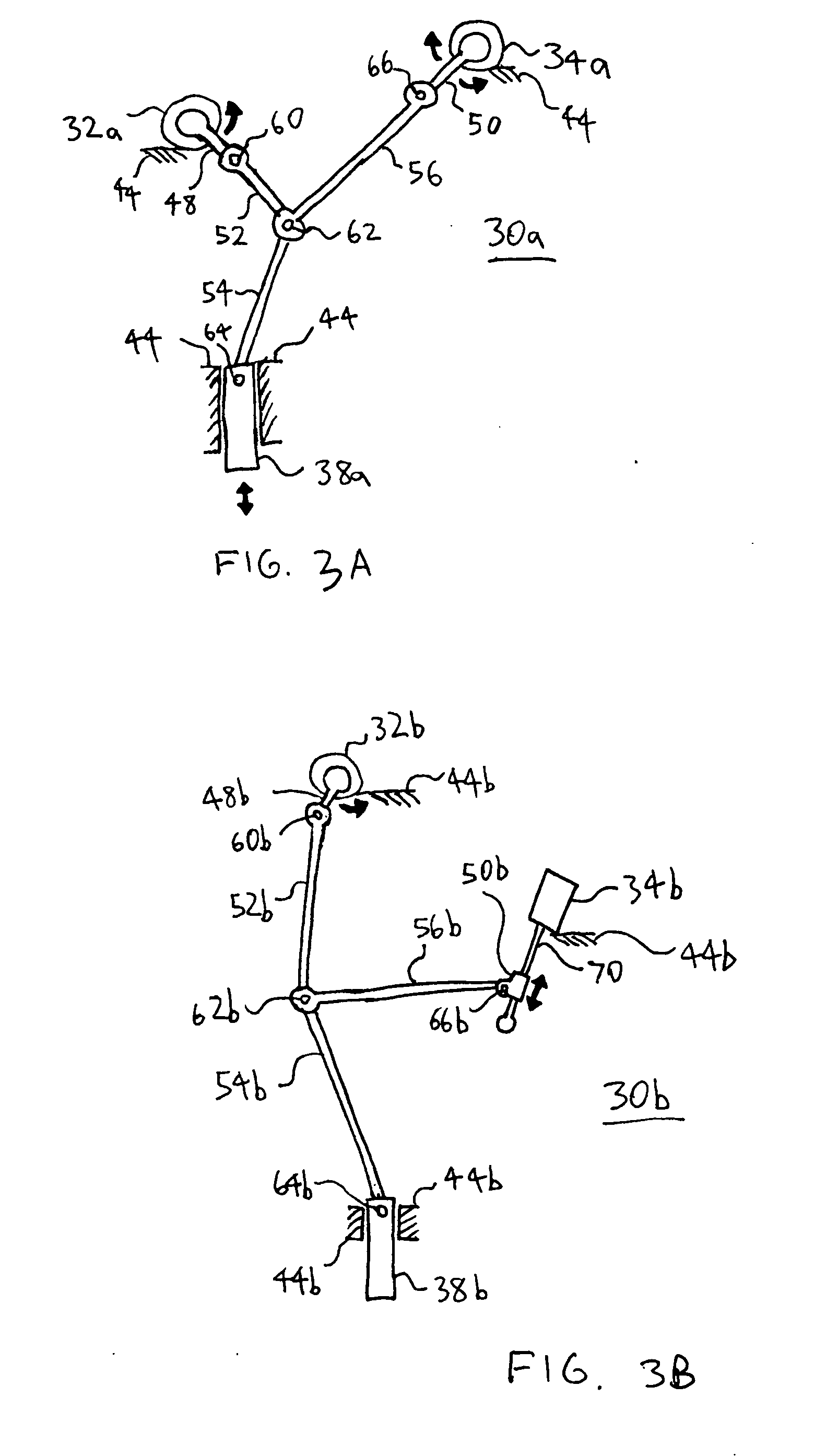

A vehicle recycling system includes an hold-down mechanism, a crane having an engine puller, a component disassembly station, a feed press, and a material press, all of which are housed within a building. A vehicle is placed onto a hold-down table where it is held in place by the hold-down mechanism while the engine and other valuable components are removed using the crane. Components not requiring further processing are placed into bins. Components requiring further disassembly are fed to the component disassembly where they are further disassembled and placed in bins. Once the high value components are removed, the crane loads the vehicle onto the feed press. The feed press then moves the vehicle onto the material press where it is compressed by the press. The back wall of the press is then raised so the crushed vehicle can be removed.

Owner:JON MFG

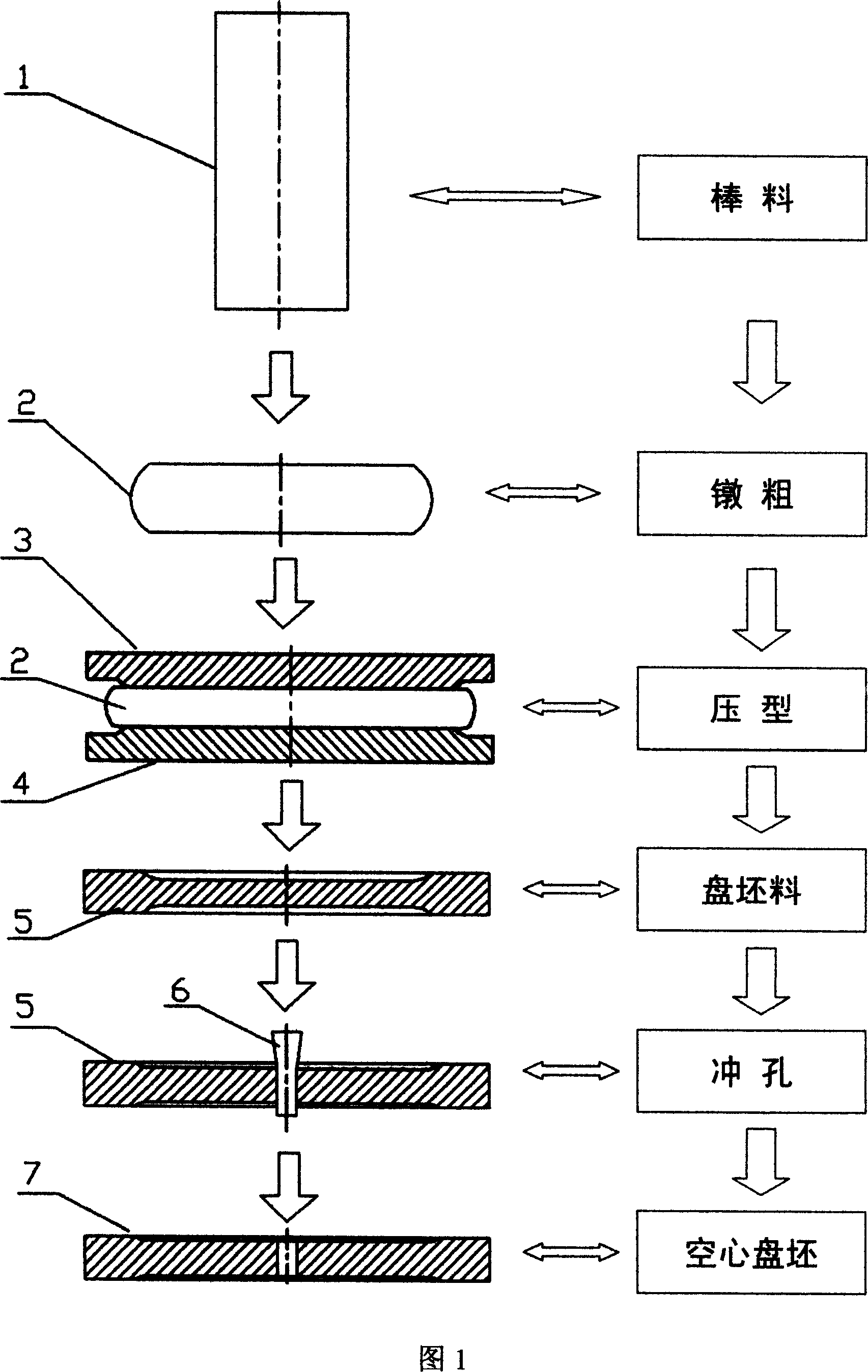

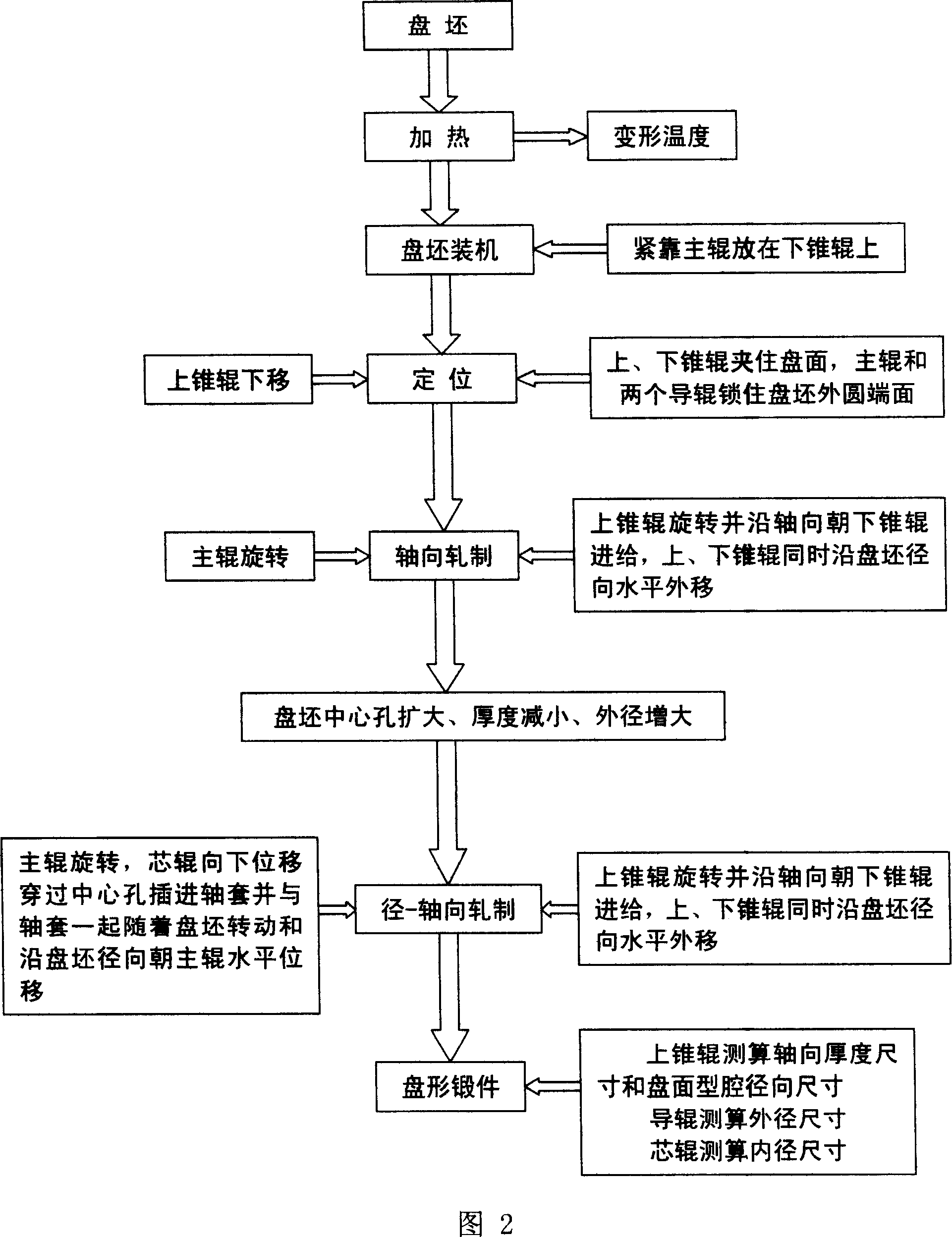

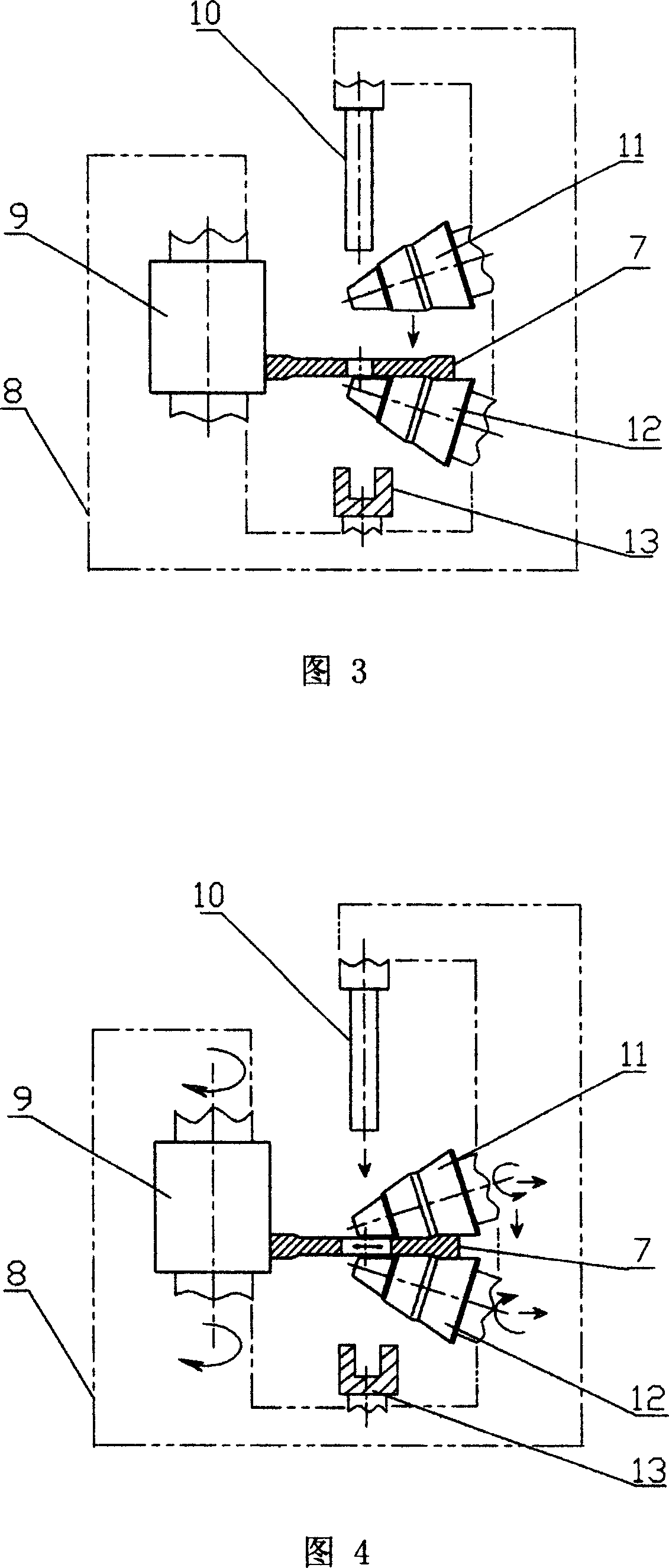

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

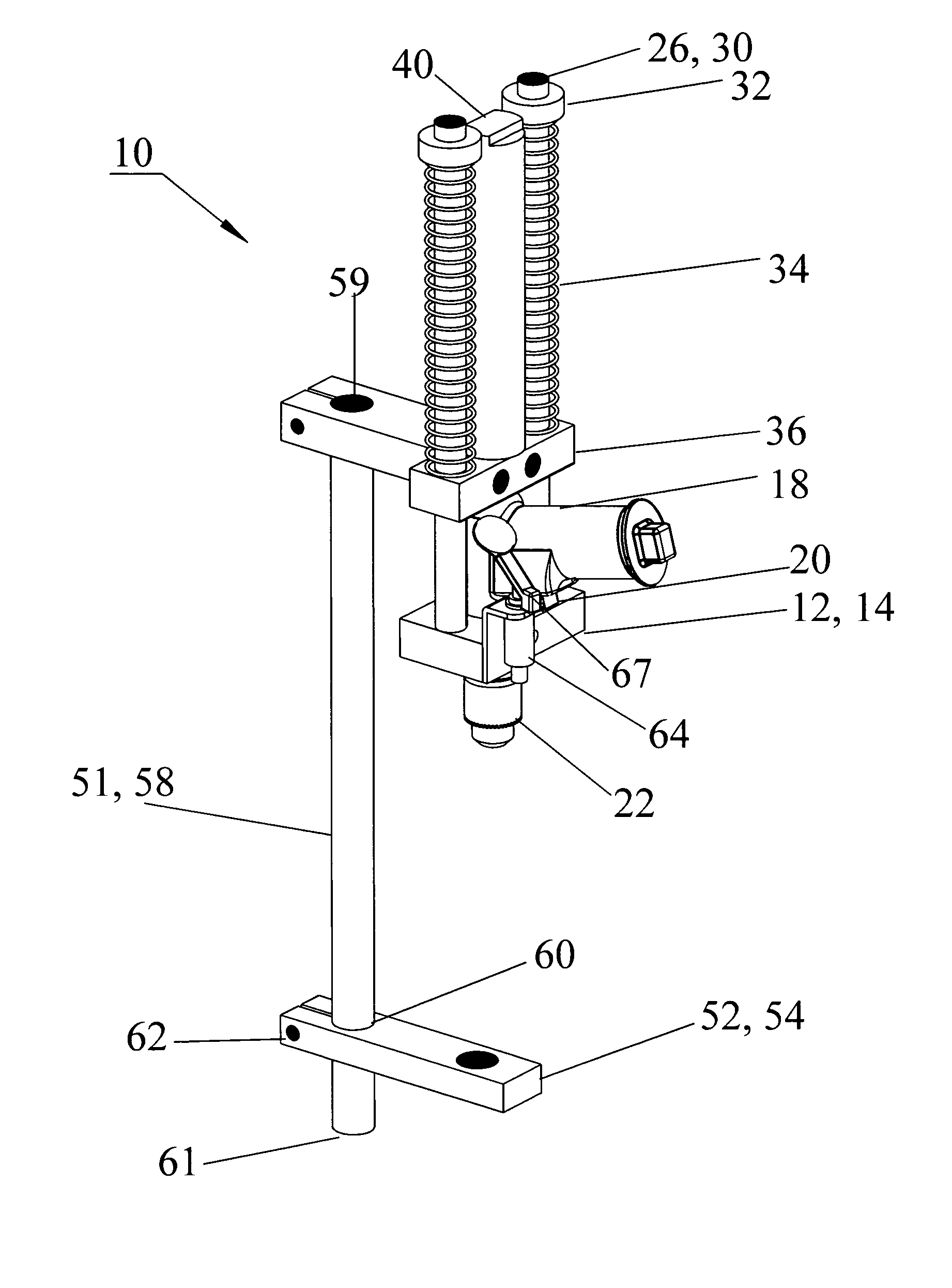

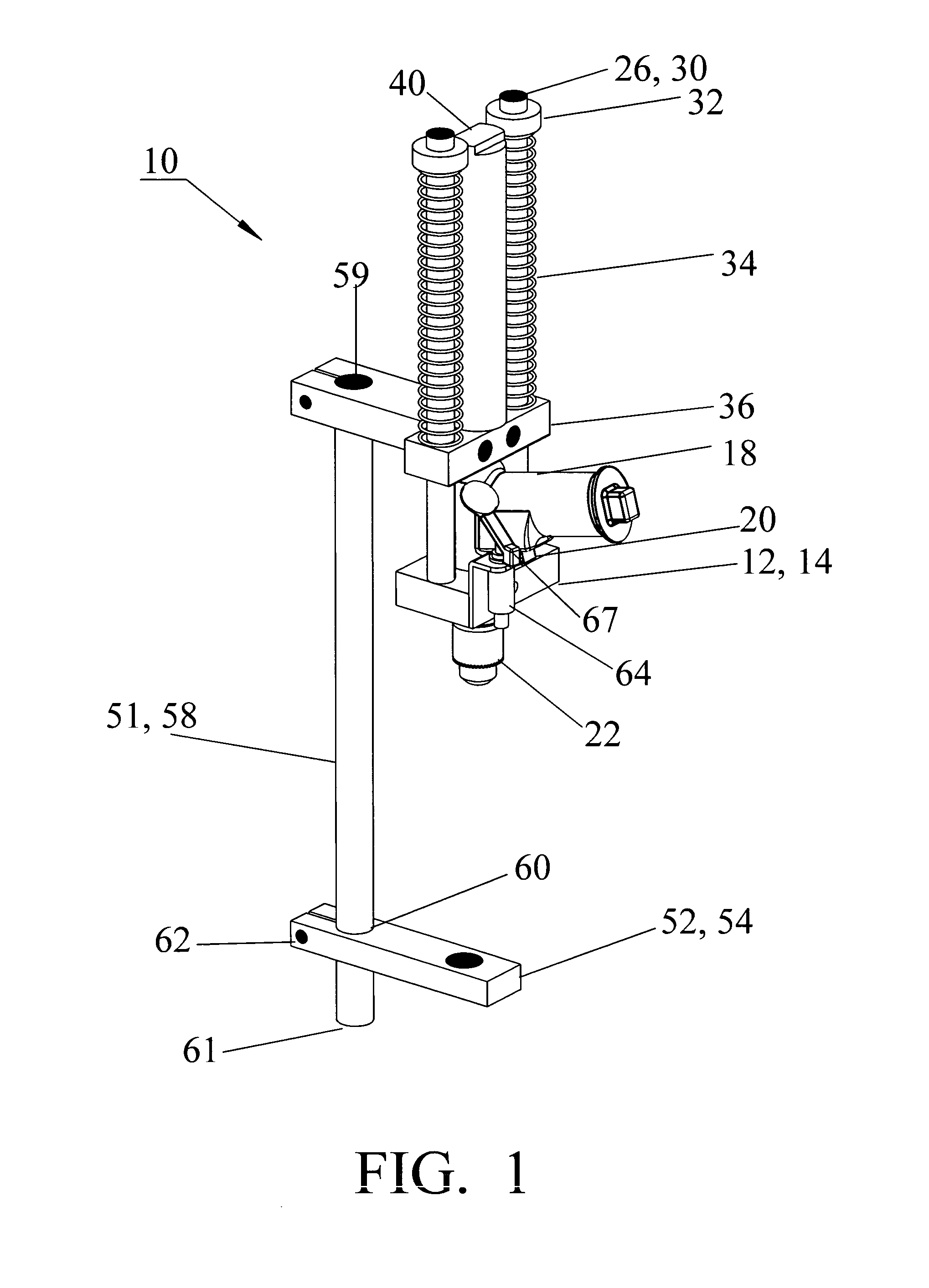

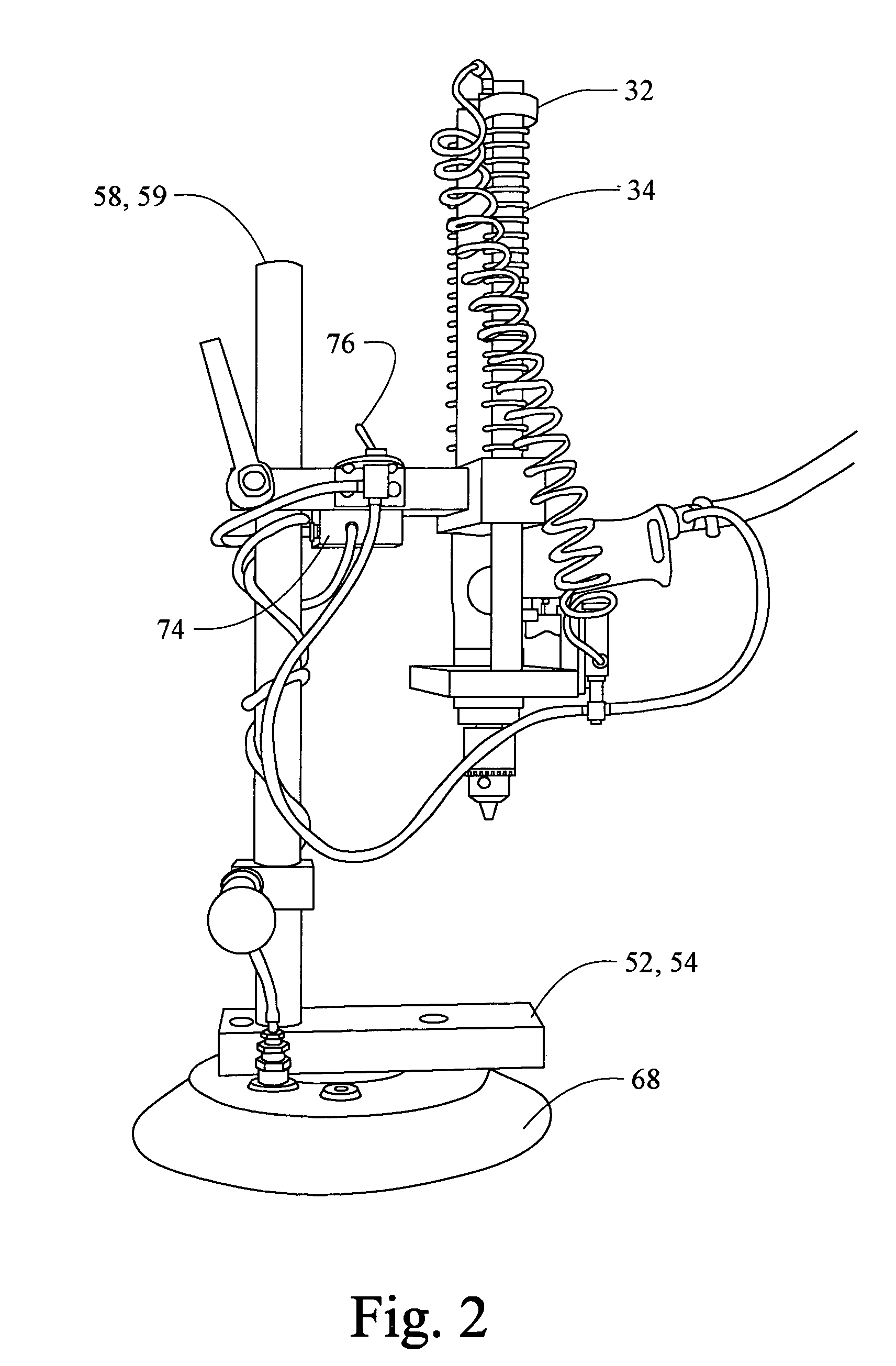

Power assisted drill press

InactiveUS7108459B1Quick and easy securingEasily suppliedDrilling/boring measurement devicesThread cutting machinesEngineeringVariable pressure

A power assisted drill press having a feed cylinder fed by a variable pressure regulator which allows a user to controllably feed a bit and work material together while activating a drill motor to rotate the bit. An embodiment of the power assisted drill press utilizes a suction cup and venturi system for attachment of the press to a surface work material. The drill press uniquely allows a person to variably activate the feed cylinder and also activate the drill motor with a single hand.

Owner:MUELLER THOMAS L MUELLER TOD BEVERLY H & MUELLER JOSEPH E

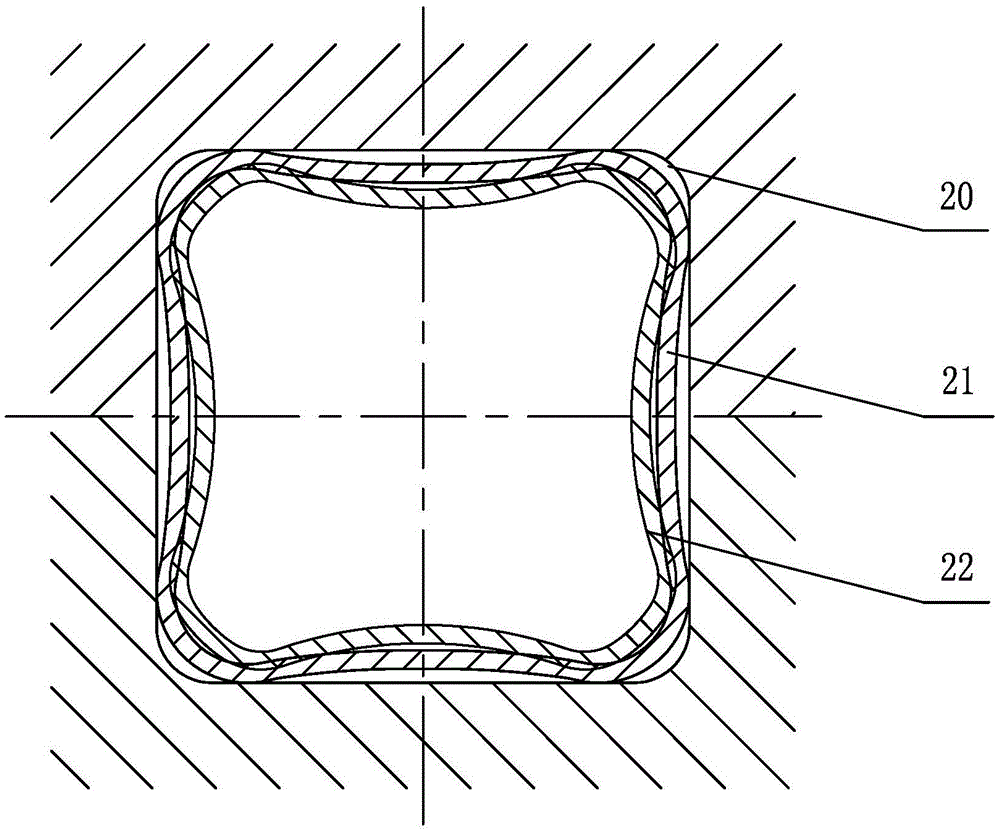

Charging pressing forming method for variable-cross-section special-shaped pipe

The invention discloses a charging pressing forming method for a variable-cross-section special-shaped pipe, and relates to a forming manufacturing method of a metal pipe. The problems that an existing low-internal-pressure forming technology only can form a pipe with the unchangeable section perimeter, and meanwhile, in the internal-high-pressure forming process of an advanced high-strength steel variable-cross-section pipe, the pressure is high, springback is large, and a mold is seriously worn are solved. The forming method comprises the steps that firstly, an upper expansion mold and a lower expansion mold are assembled on a pressure machine; secondly, the upper expansion mold descends to perform mold assembly, a pipe blank is subject to charging, and the pipe blank expands until the pipe blank is attached to the mold; thirdly, the internal pressure of the pipe blank is relieved; fourthly, an upper pressing block and a lower pressing mold are assembled on a pressure machine; fifthly, the upper pressing block descends to perform mold assembly; sixthly, under the joint action of mechanical pressure of the mold and hydraulic pressure of an inner cavity of a variable-cross-section round pipe, mold attaching is carried out, the variable-cross-section round pipe is formed into the variable-cross-section special-shaped pipe, and the forming process is finished; and seventhly, the internal pressure of the variable-cross-section special-shaped pipe is relieved, and the variable-cross-section special-shaped pipe is cut, so that the variable-cross-section special-shaped pipe meeting the design requirement is obtained. The method is used for forming the variable-cross-section special-shaped pipe.

Owner:HARBIN INST OF TECH

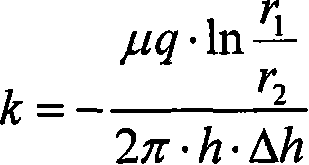

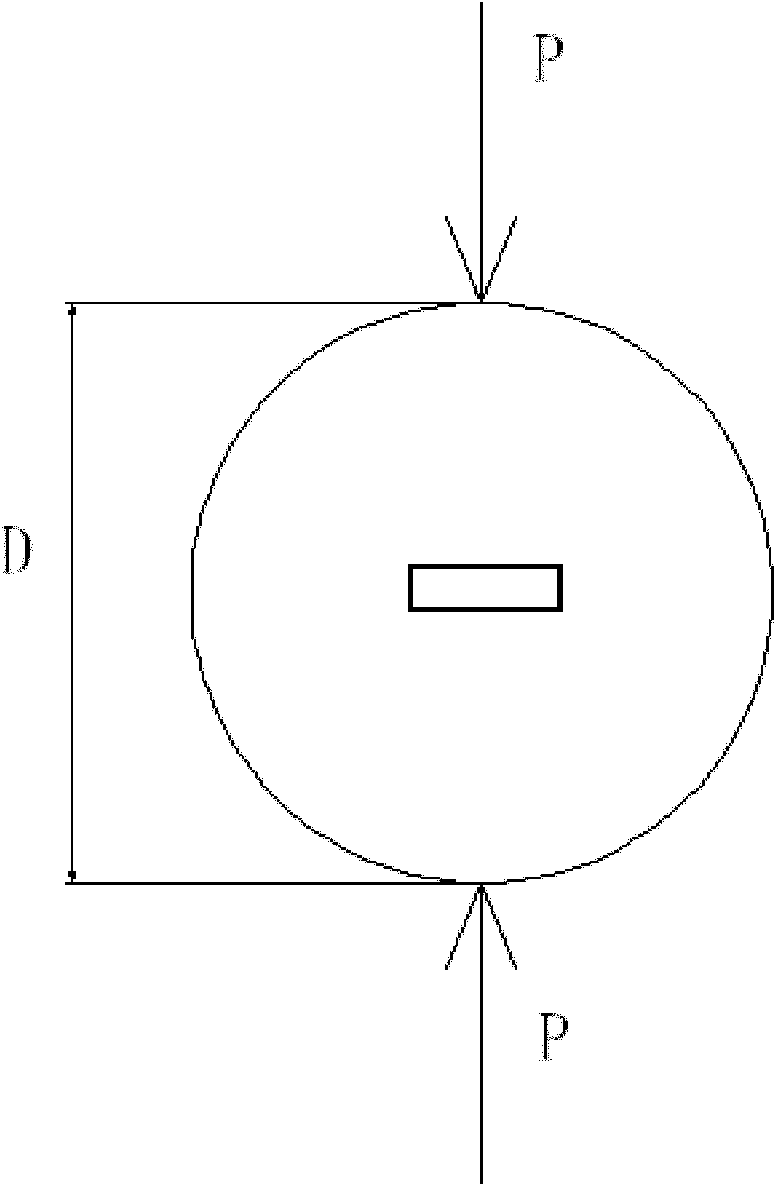

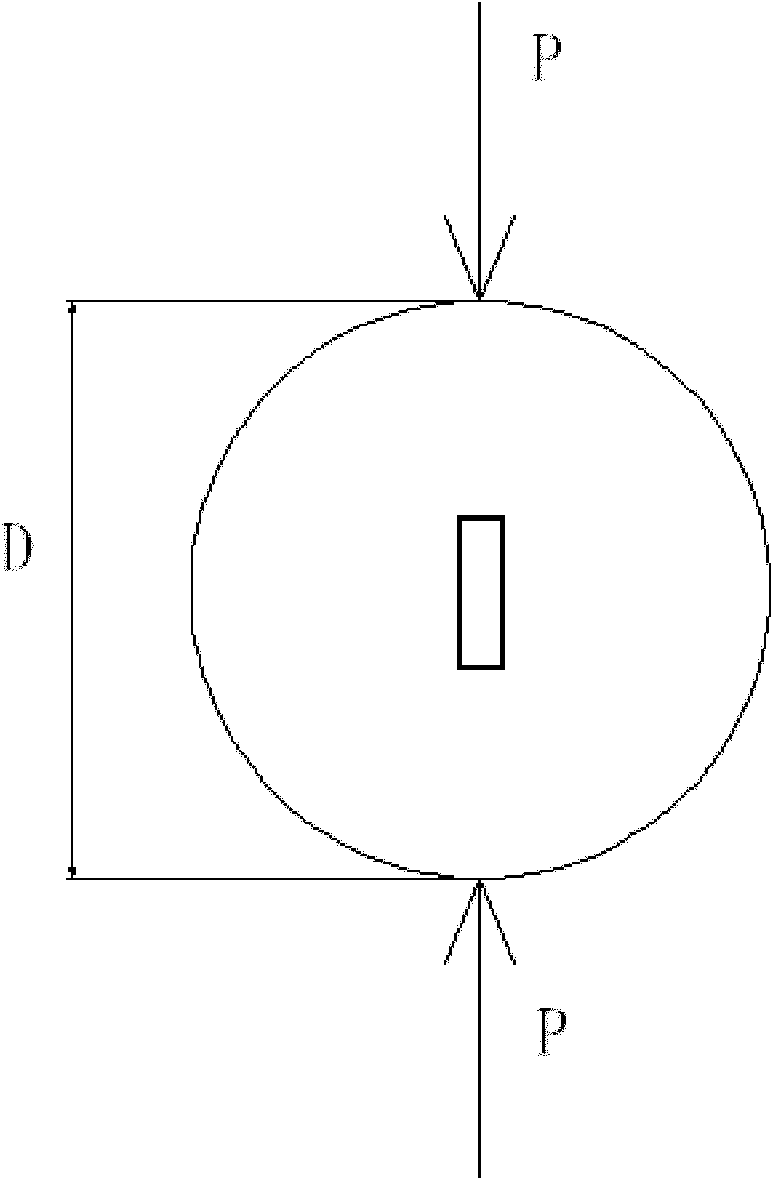

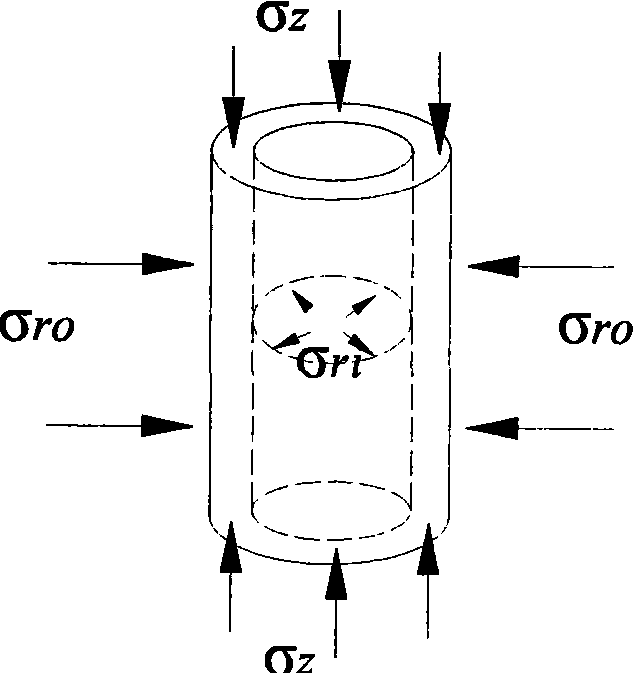

Brazilian split method for measuring elastic parameter of rock under extension condition

InactiveCN102183410AGain tensile strengthGet elastic parametersMaterial strength using tensile/compressive forcesCircular discStress conditions

The invention discloses a Brazilian split method for measuring an elastic parameter of a rock under an extension condition, which comprises the steps of: A. horizontally putting a machined disc-shaped sample between the load bearing plates of a press machine by using a Brazilian disc split method, placing a hard steel wire respectively between the upper load bearing plate and the sample and between the lower load bearing plate and the sample, arranging a filler strip perpendicular to the symmetrical surfaces of the sample, and applying pressure on the upper load bearing plate and the lower load bearing plate to make the sample generate tension perpendicular to the action directions of an upper load and a lower load; B. carrying out analysis by using the Hooke's law in classical elasticity mechanics by combining specific conditions of the Brazilian split method; C. analyzing the stress condition of the rock and the measurement principle in the Brazilian disc split method; and D. obtaining the strain in the stress direction according to the Hooke's law from the stress condition sigma3=0, measuring epsilon1 and epsilon2, obtaining the elastic parameter of the rock sample, and arranging a strain gauge in the center position of the rock sample for measurement of epsilon1 and epsilon2. The method has the advantages of easiness for operation and use, clear principle, low material consumption, and the like. The method is suitable for wide popularization and application.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

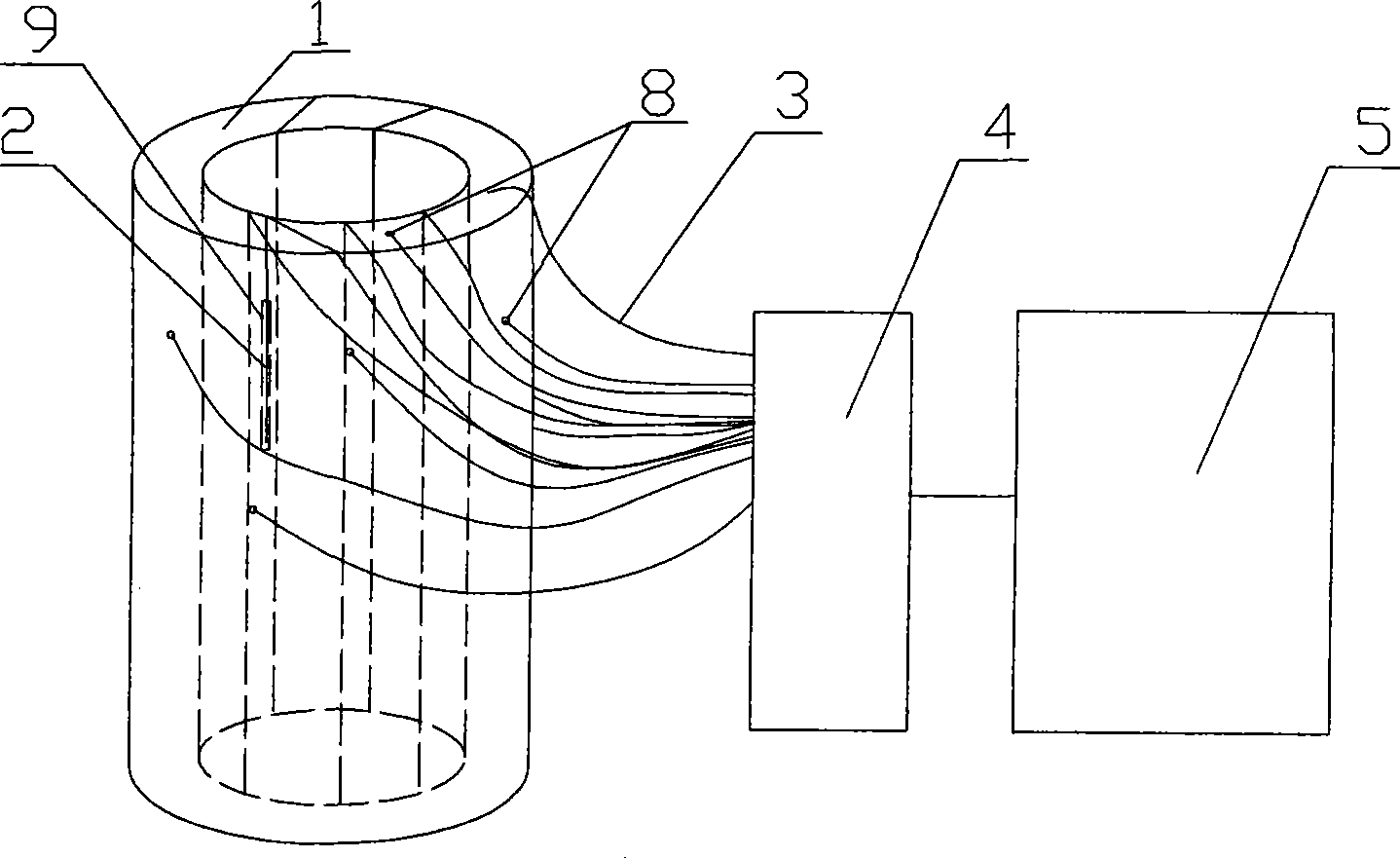

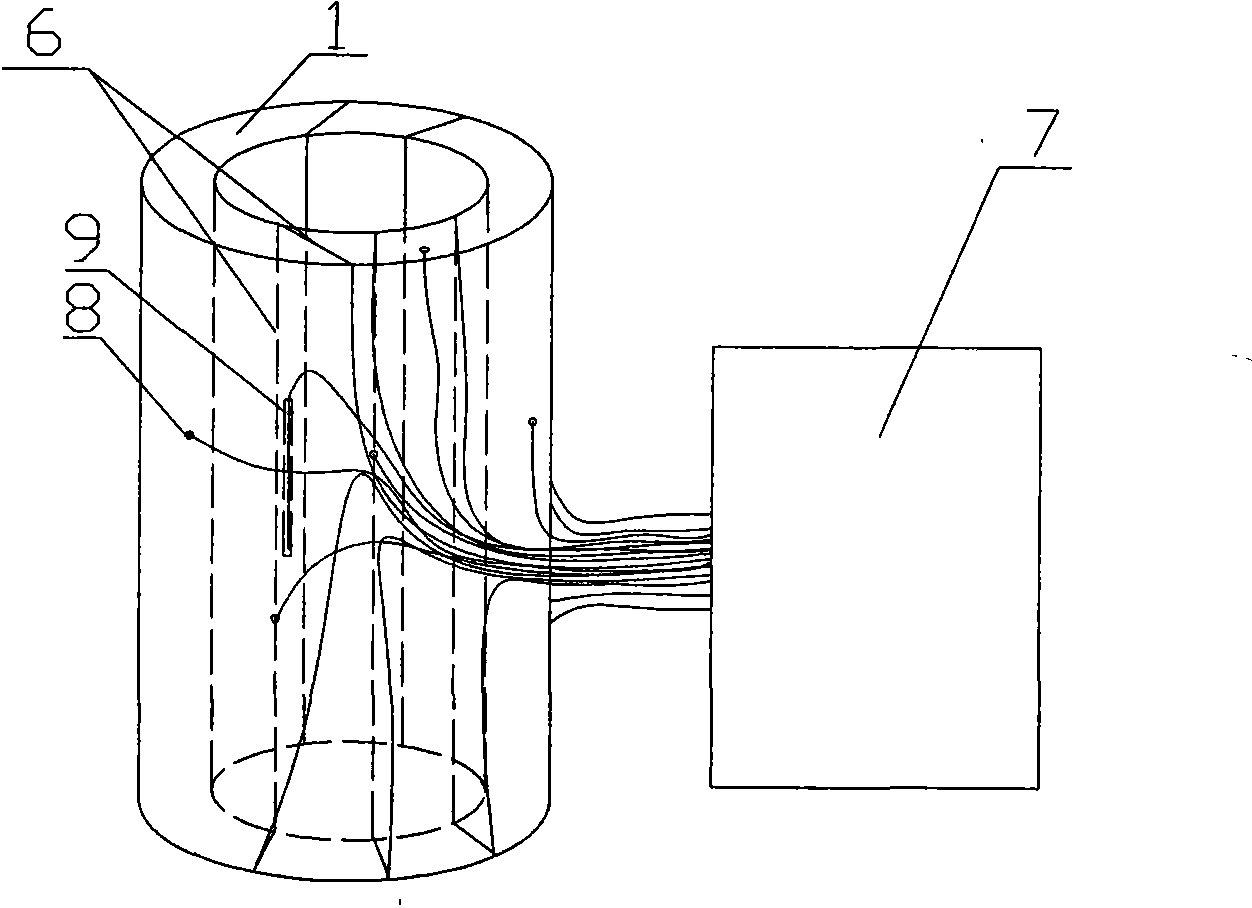

Rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing

InactiveCN101520317AIncrease space positionMaterial strength using tensile/compressive forcesUsing optical meansFiber strainInstability

The invention relates to a rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing, which comprises a testing piece, wherein the testing piece is laid with a fiber sensor encapsulated with a plurality of testing strains; the fiber sensor is connected with a signal demodulation processing device through a connecting fiber; and demodulated data signals can build three-dimensional testing data of the testing piece and can form a three-dimensional dynamic strain field of the testing piece after interpolation. The system can effectively lay out the fiber sensor inside and on the surface of the real rock testing piece under the pressure of a three-axis presser, enters the rock inside to detect the rock dynamic strain under the premise of not influencing the rock structure and the stress, and can really test the rock dynamic cracking process to obtain the crack initial and expended spatial positions inside the testing piece. The system continuously monitors the generation and expansion of tiny cracks inside brittle materials under the loading action in real time at the same time, and can be widely applied to researching cracking instability mechanisms of materials, such as rocks, concrete and the like.

Owner:SHANDONG UNIV

Middle-duty and heavy-duty automobile knuckle stamp forging extruding compound technology

ActiveCN101607294AShort preparation cycleIncrease profitForging/hammering/pressing machinesProduction rateHeavy duty

A middle-duty and heavy-duty automobile knuckle stamp forging extruding compound technology overcomes the disadvantages of low material utilization and large device investment of the traditional production technology, utilizes flexibility of preforming by a stamping hammer and structure characteristic of a press extrusion die and adopts stamping hammer production technology and press extrusion compound technology. The main technical scheme includes a series of technical measures of vertically splitting of blank material by mould with V-shaped cutting edge and locally enclosed structure, preforging of cavity damping stripe, finish forging of locally enclosed structure, hot extrusion forming of steering space and the like, parameter requirements and corresponding moulds and devices. The invention has the characteristics that device investment of stamping hammer production technology is small, structure is simple, and equipment manufacturing period is short; production technological flow is reasonable and processing is easy; and the invention also has the characteristics that product quality is good and productivity is high; and material utilization is obviously higher than that of any original knuckle processing technology and production cost is greatly reduced.

Owner:HUBEI TRI RING FORGING

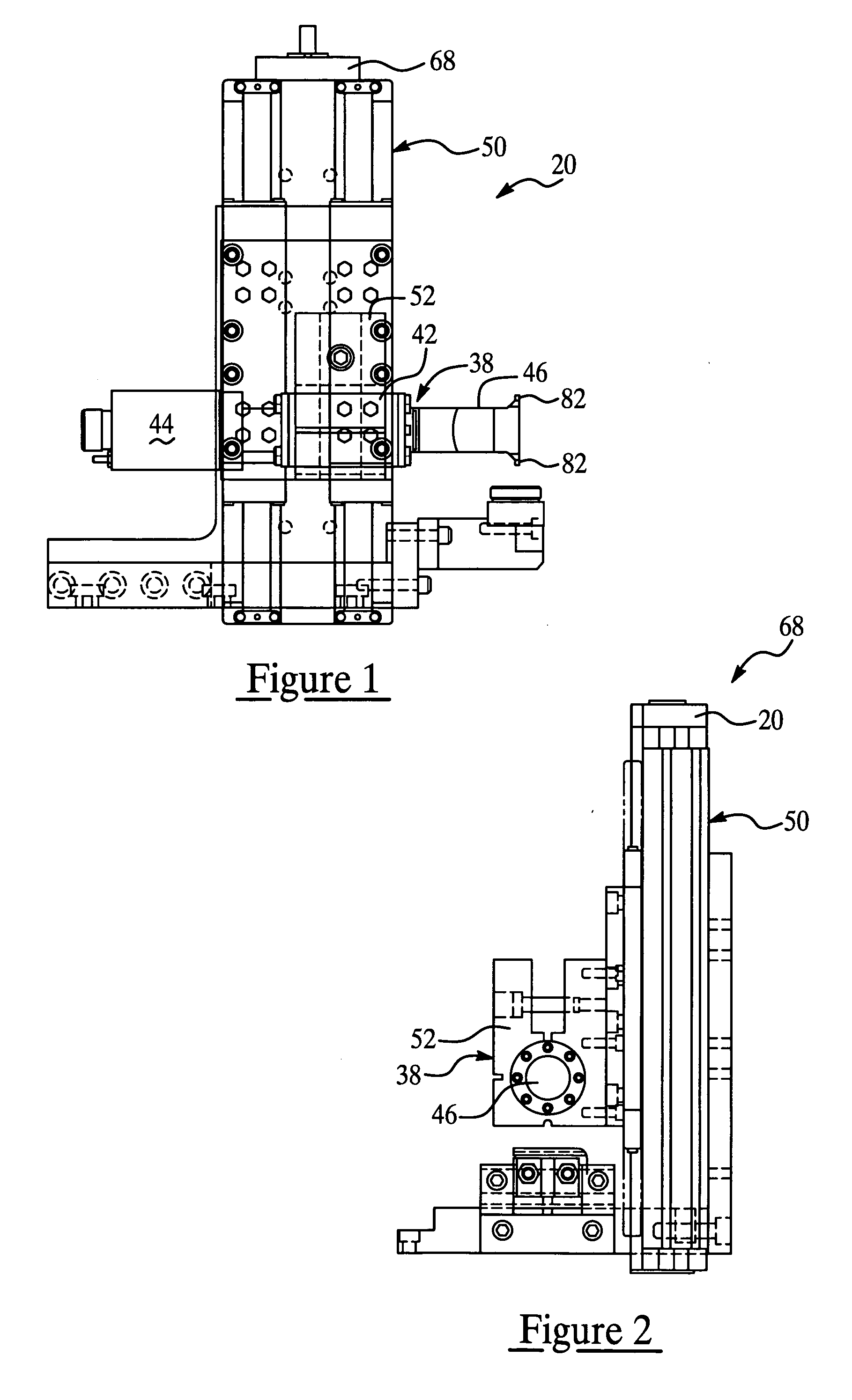

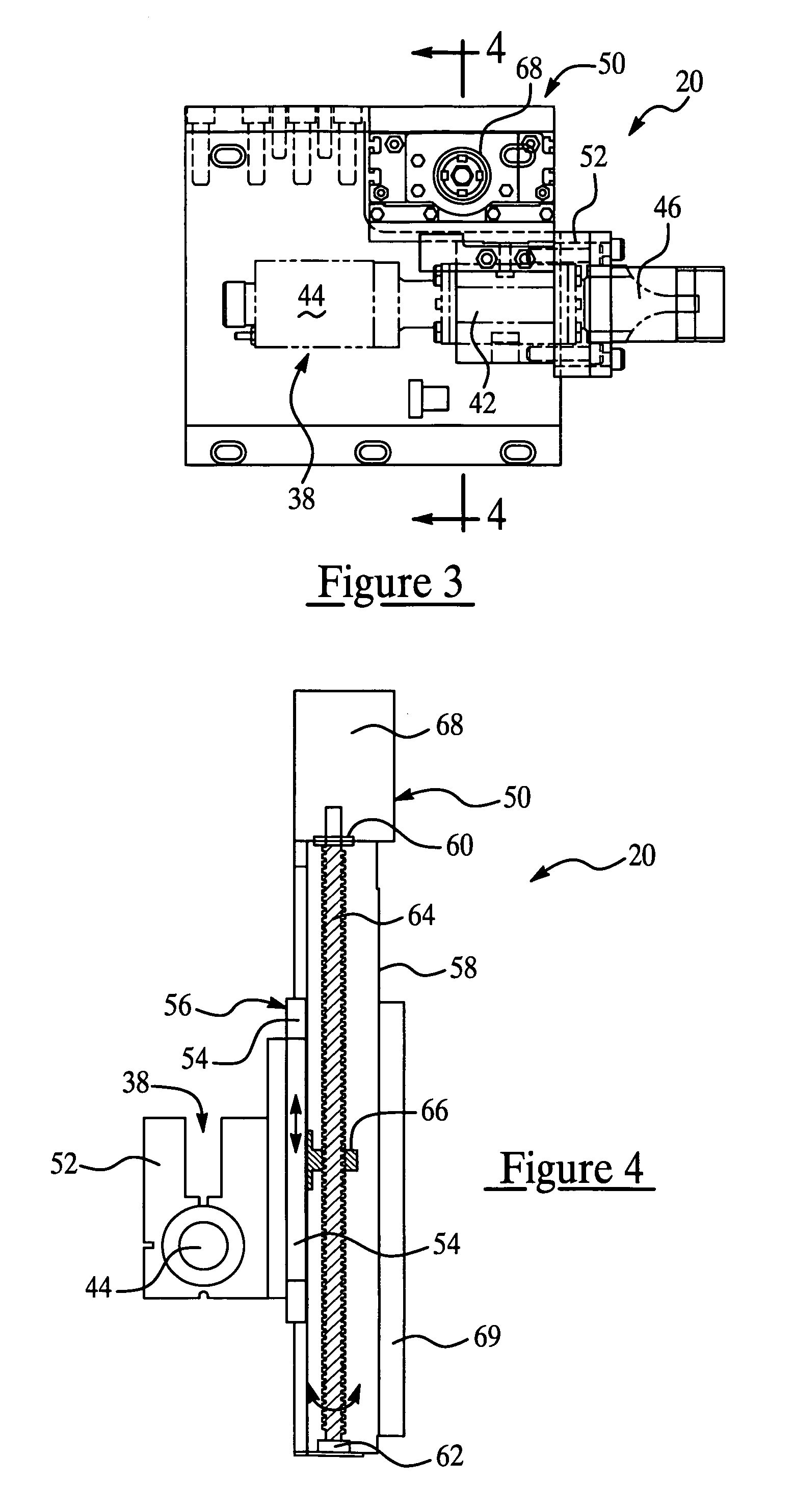

Mechanical press with controllable mechanism

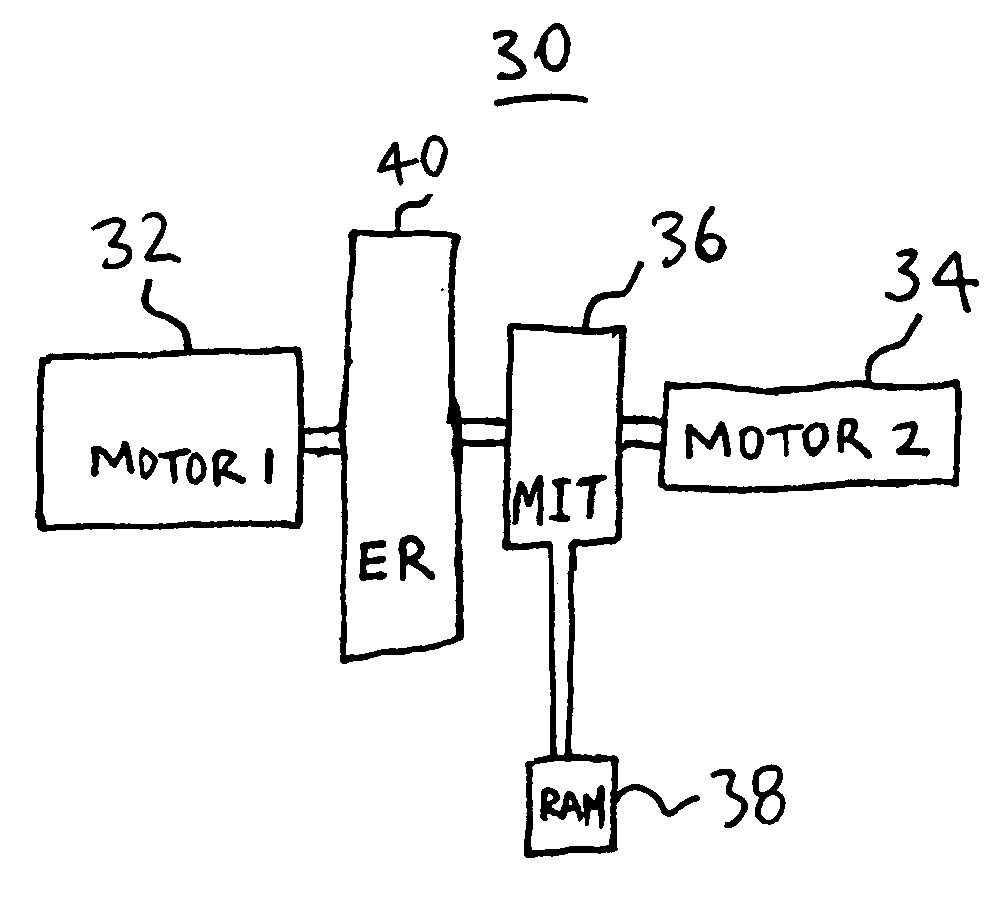

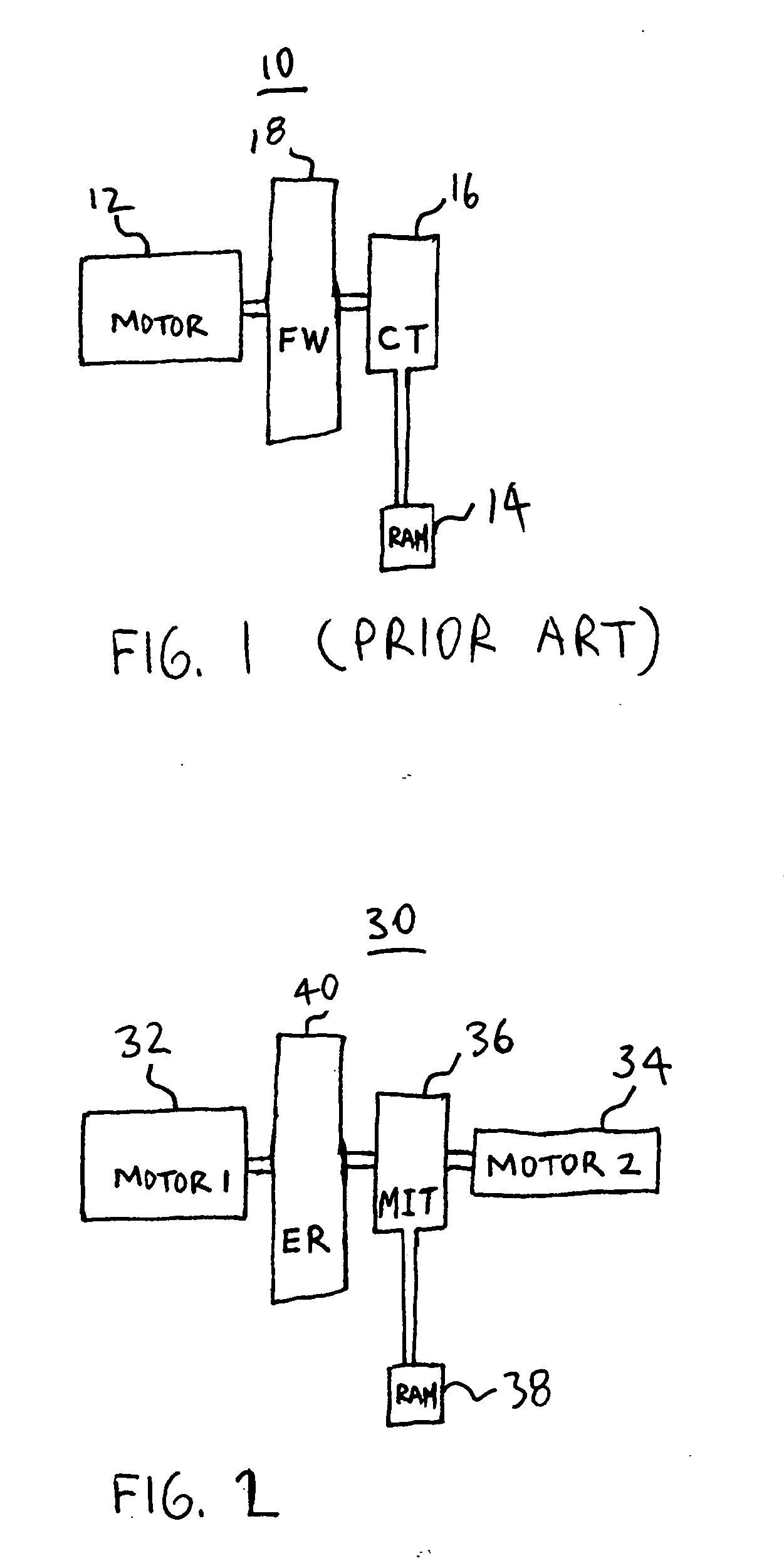

According to an embodiment of the invention, a mechanical press includes a transmission that comprises a first transmission and a second transmission coupled to the first transmission. The first transmission is for receiving mechanical movement from a first motor and to transmit mechanical movement to a ram. The second transmission is for modifying configuration of the first transmission in response to mechanical movement received from a second motor, and a profile of movement of the ram over a pressing cycle is affected by a profile of movement from the second motor over the pressing cycle.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

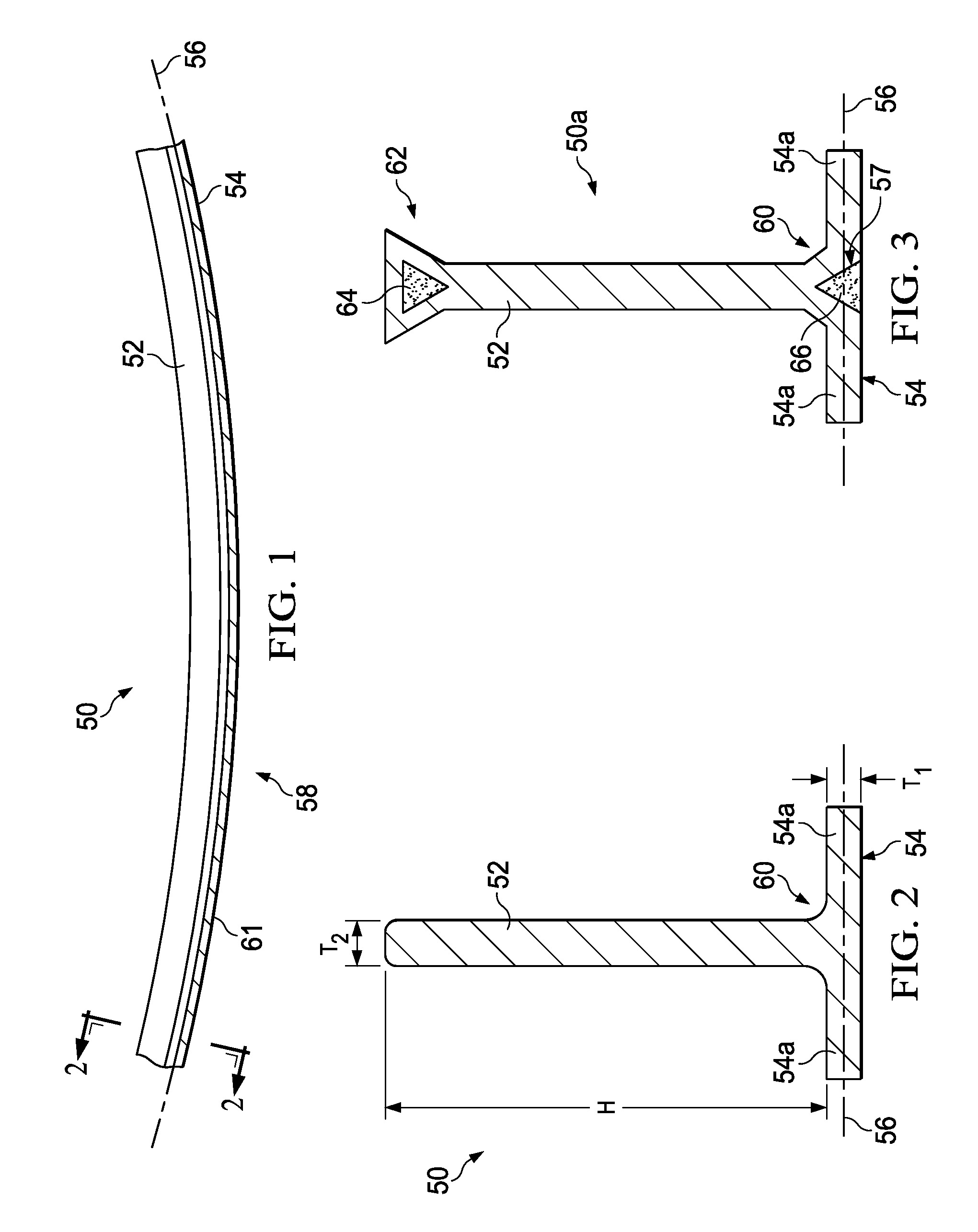

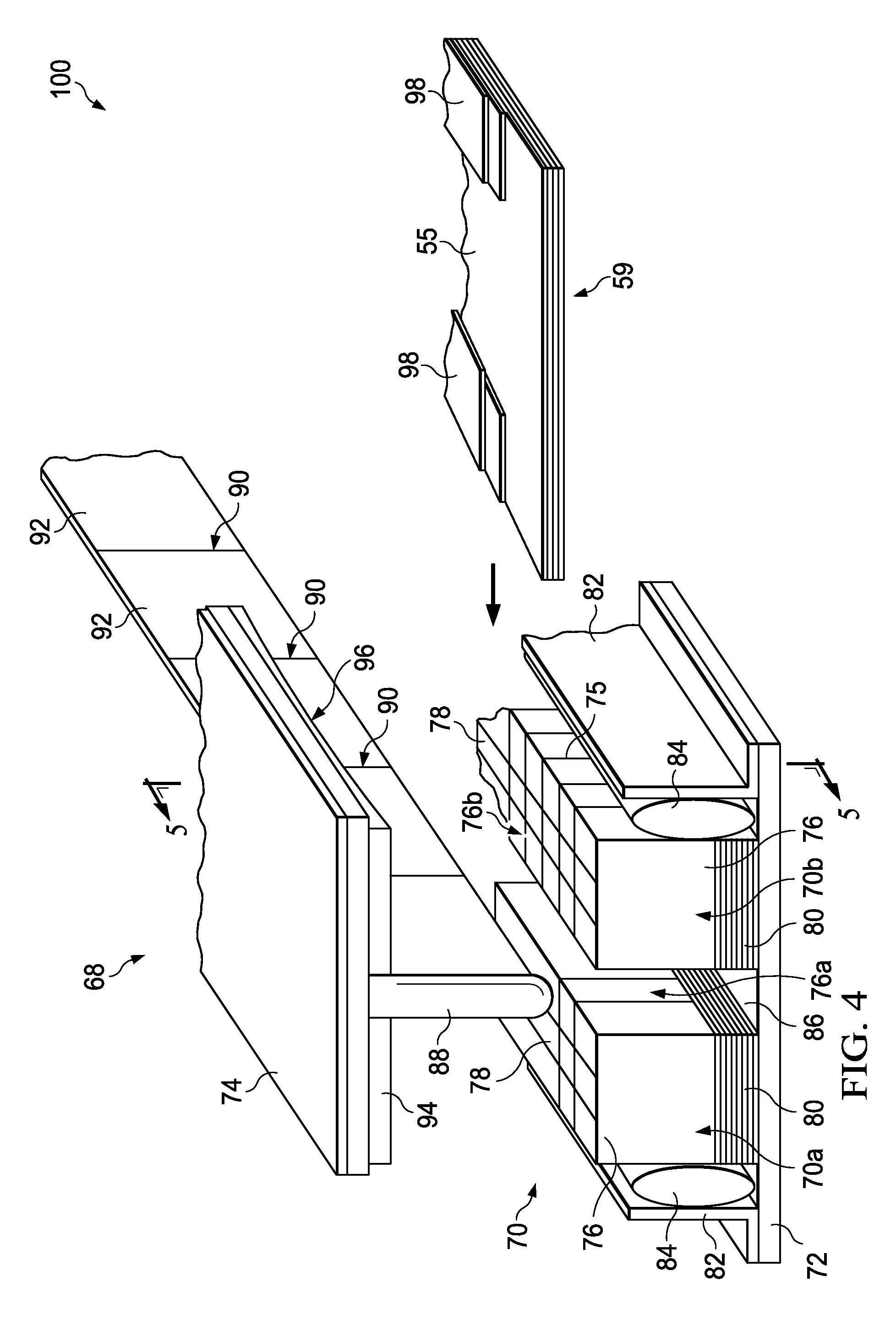

Method and apparatus for fabricating variable gauge, contoured composite stiffeners

ActiveUS8465613B2Low costShorten the timeMechanical working/deformationMetal-working apparatusEngineeringComposite blade

Tooling apparatus for forming a composite charge into a contoured composite blade stringer includes an elongate punch and an elongate die flexible along their lengths. The charge is press formed by using the punch to drive the charge into the die. The punch and the die are mounted between a pair of flexible plates. A press coupled with the plates contours the charge by bending the plates into a desired contour.

Owner:THE BOEING CO

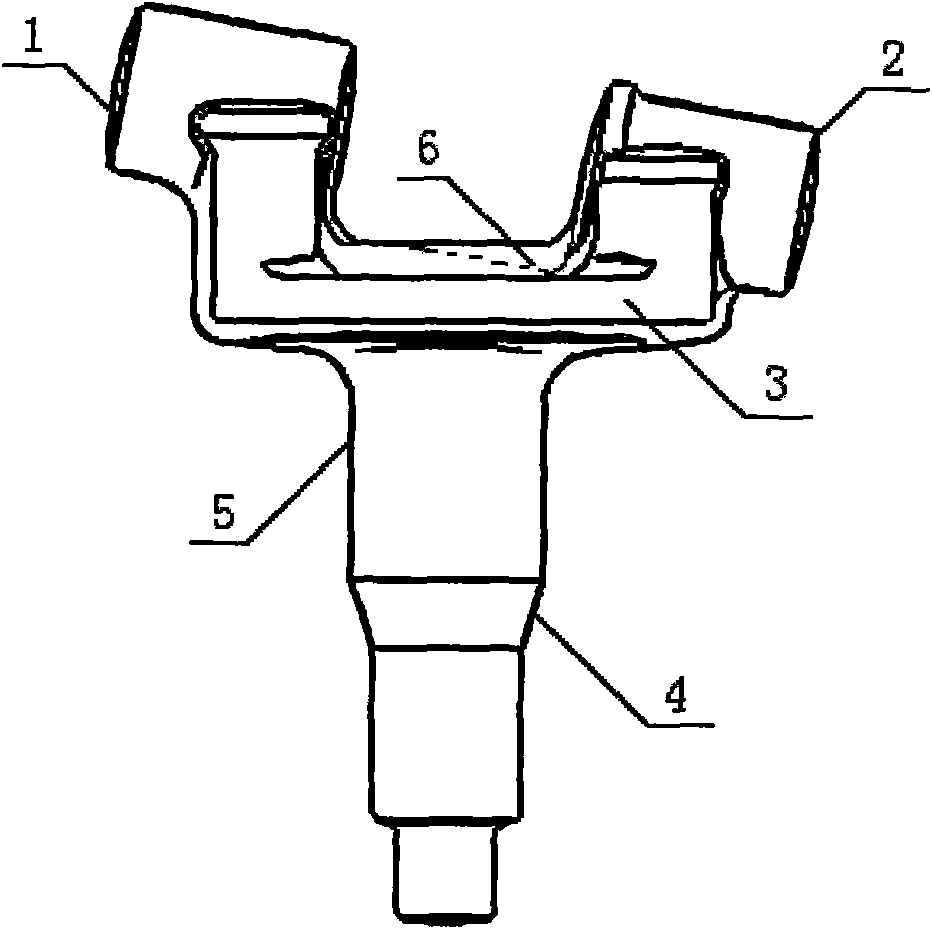

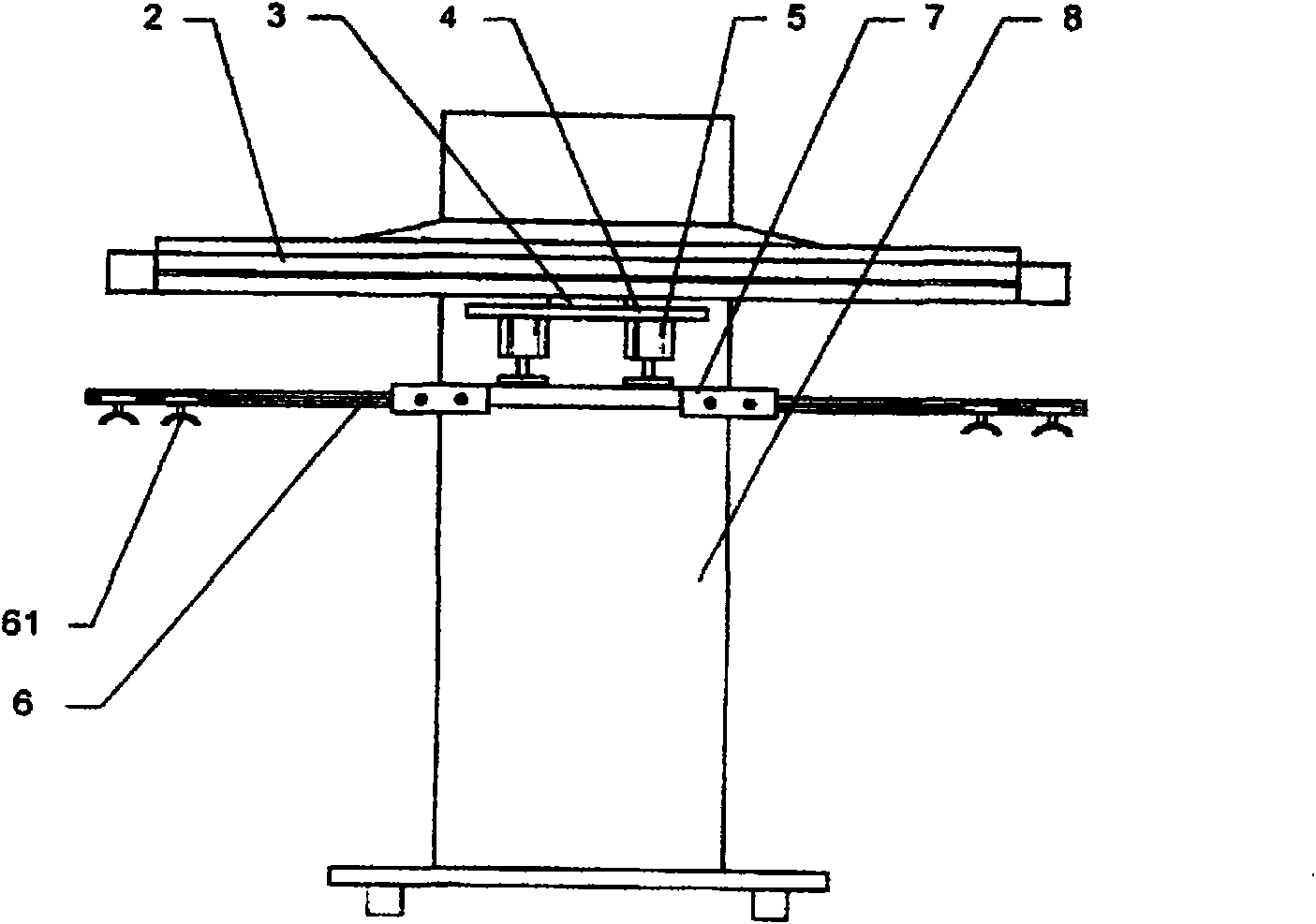

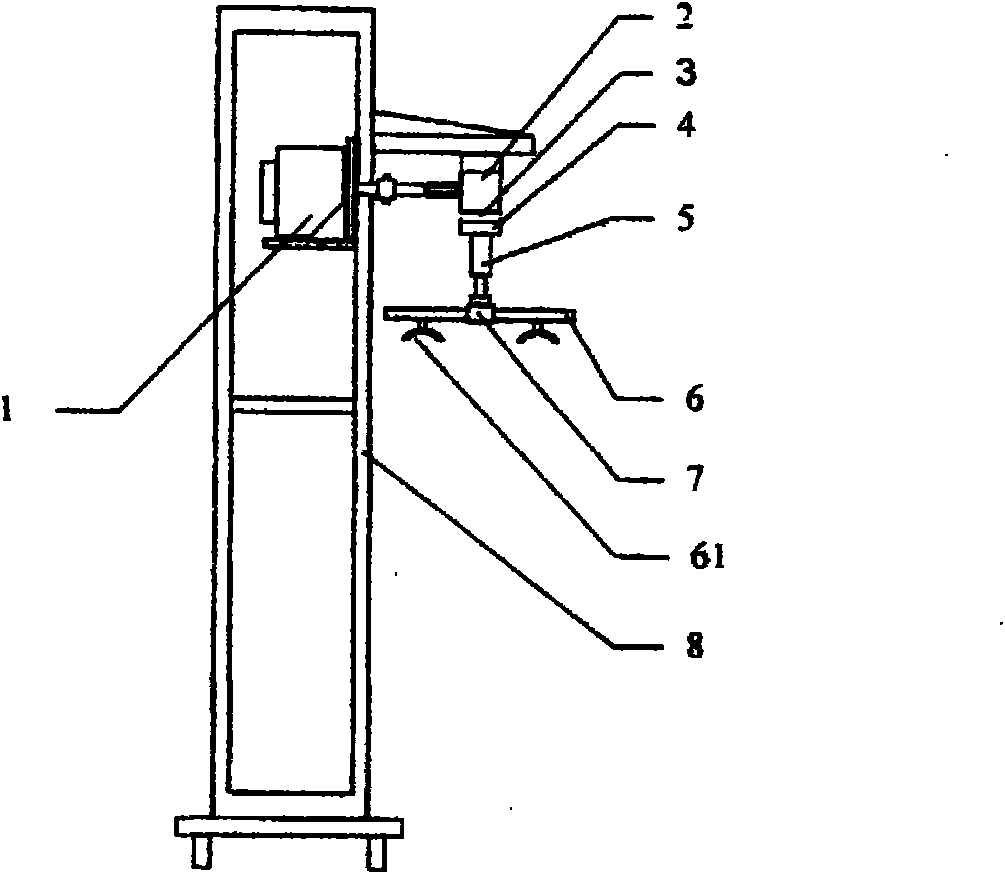

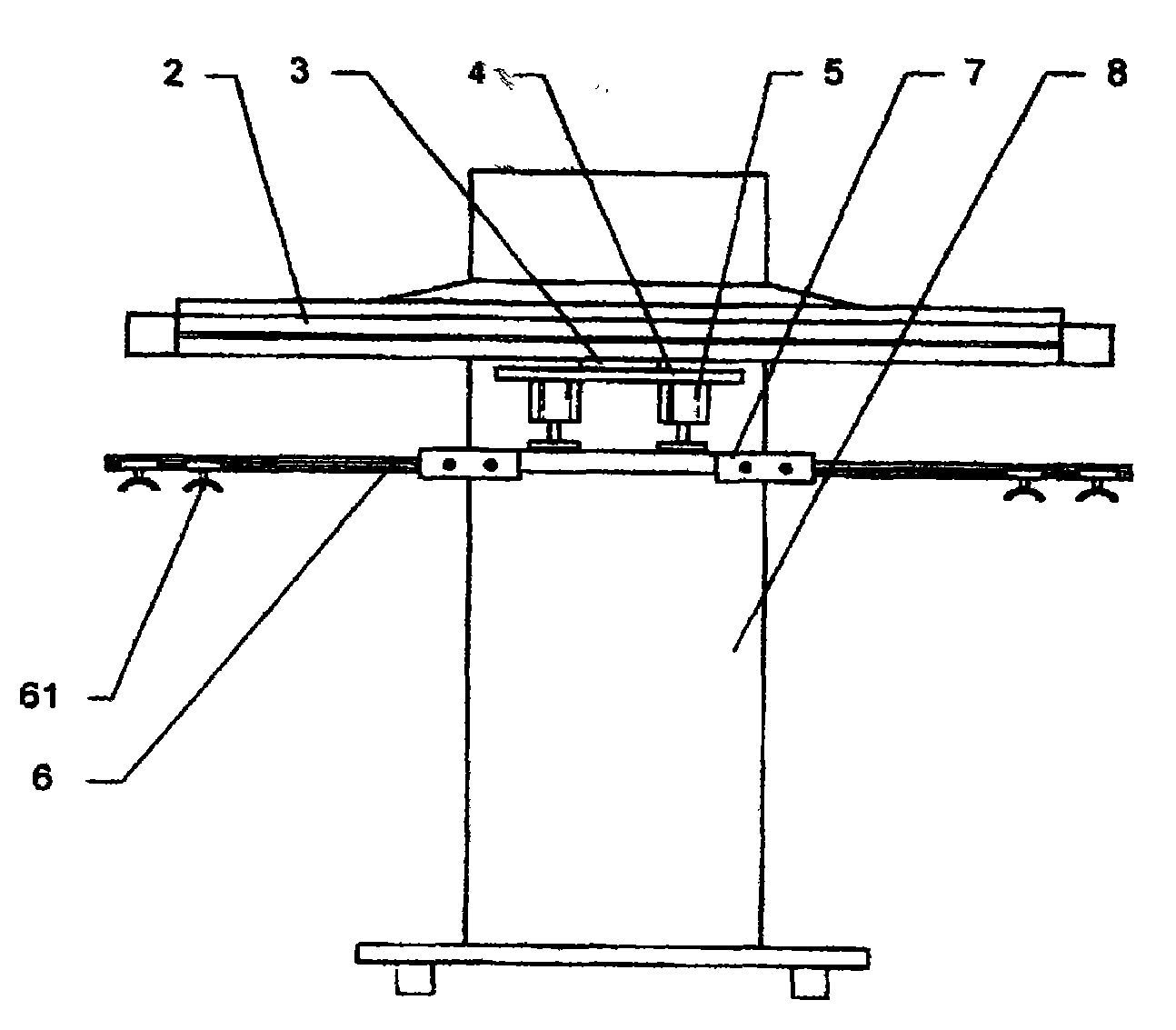

Mechanical hand for stamping and automatic loading and unloading

InactiveCN101987339AMeet stamping productionFlexibleProgramme-controlled manipulatorStripping-off devicesTime controlManipulator

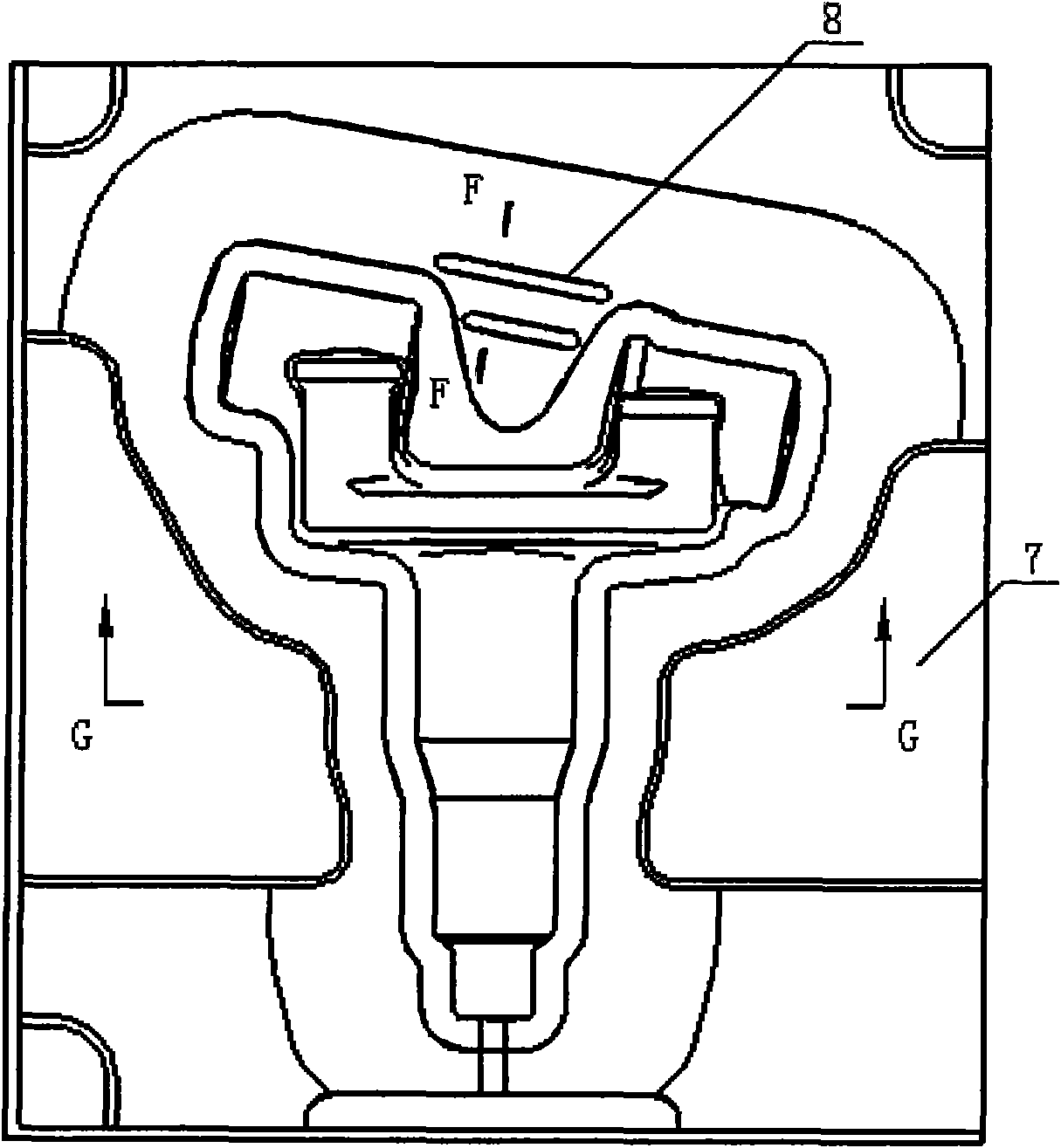

The invention discloses a mechanical hand for stamping and automatic loading and unloading, which is independently placed beside a press machine and comprises a servo motor (1), a linear guide rail (2), a sliding block (3), an air cylinder (5), end pickers (6) and a stand (8), wherein the servo motor (1) controlled by a controller is installed on the stand (8), and on one side of the stand (8), the servo motor (11) is engaged with a belt pulley of the linear guide rail (2) through a belt pulley of a synchronous belt; the sliding block (3) is fixedly installed on the synchronous belt of the linear guide rail (2), and the lower part of the sliding block (3) is fixedly connected with the air cylinder (5) through a support plate (4); a support seat (7) is located below the air cylinder (5), and the end pickers (6) are arranged on both sides of the support seat (7). Because the end pickers in the invention are removable, the position of a vacuum chuck is adjustable and the controller is in real-time control, the stamping production of different products and different press machines can be met, and the mechanical hand has flexibility.

Owner:孟津县平乐新兴铸造厂

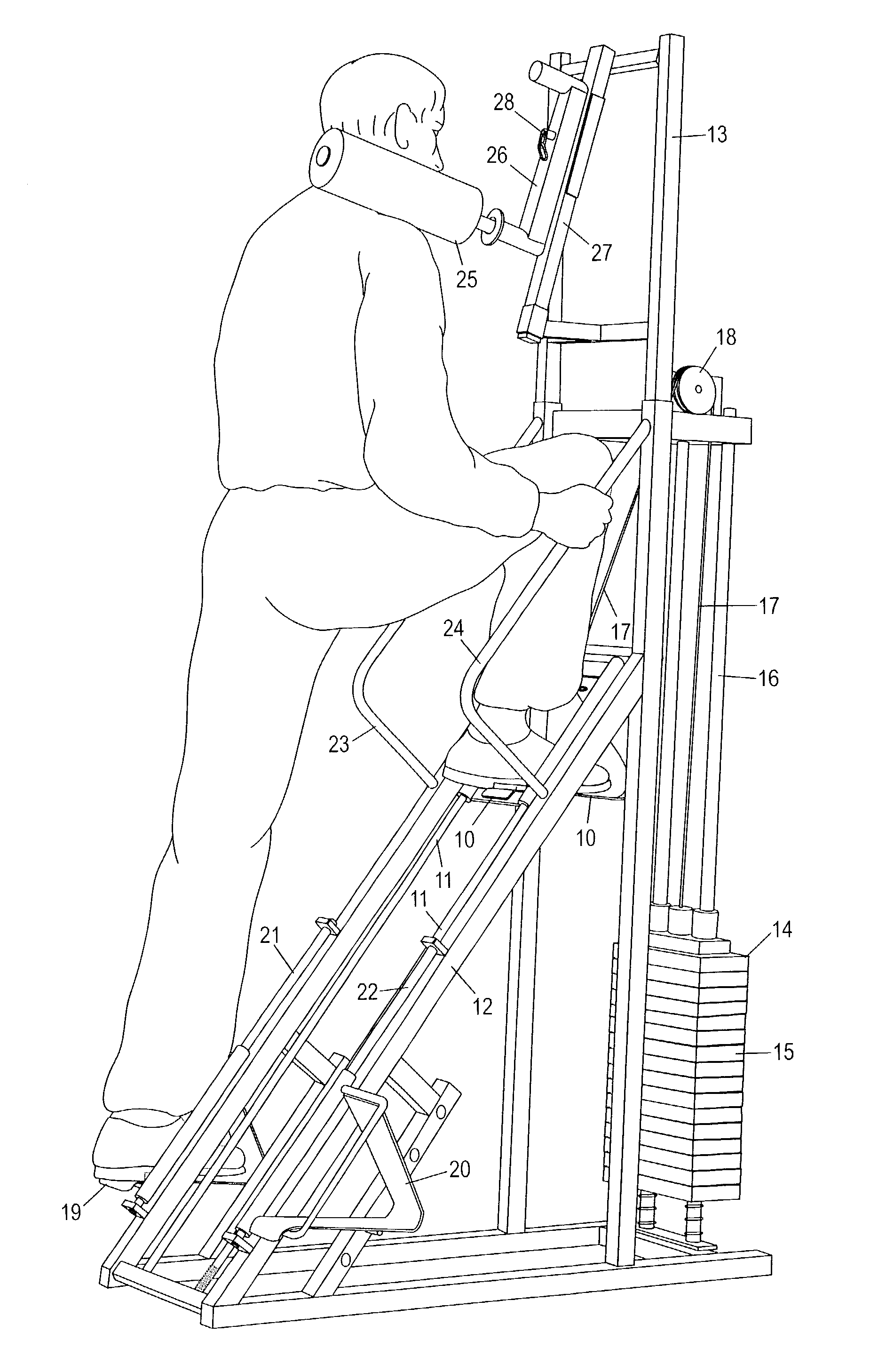

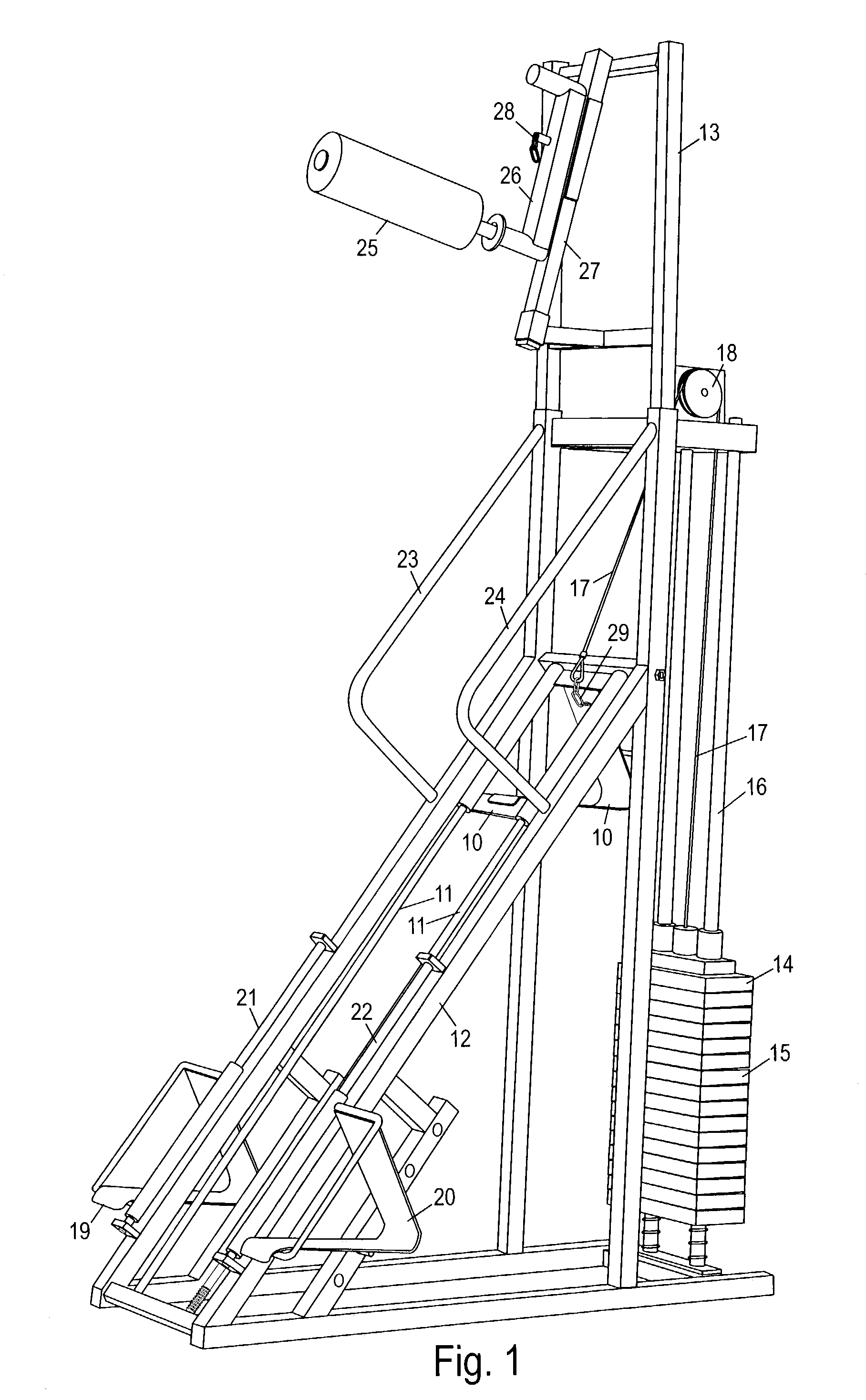

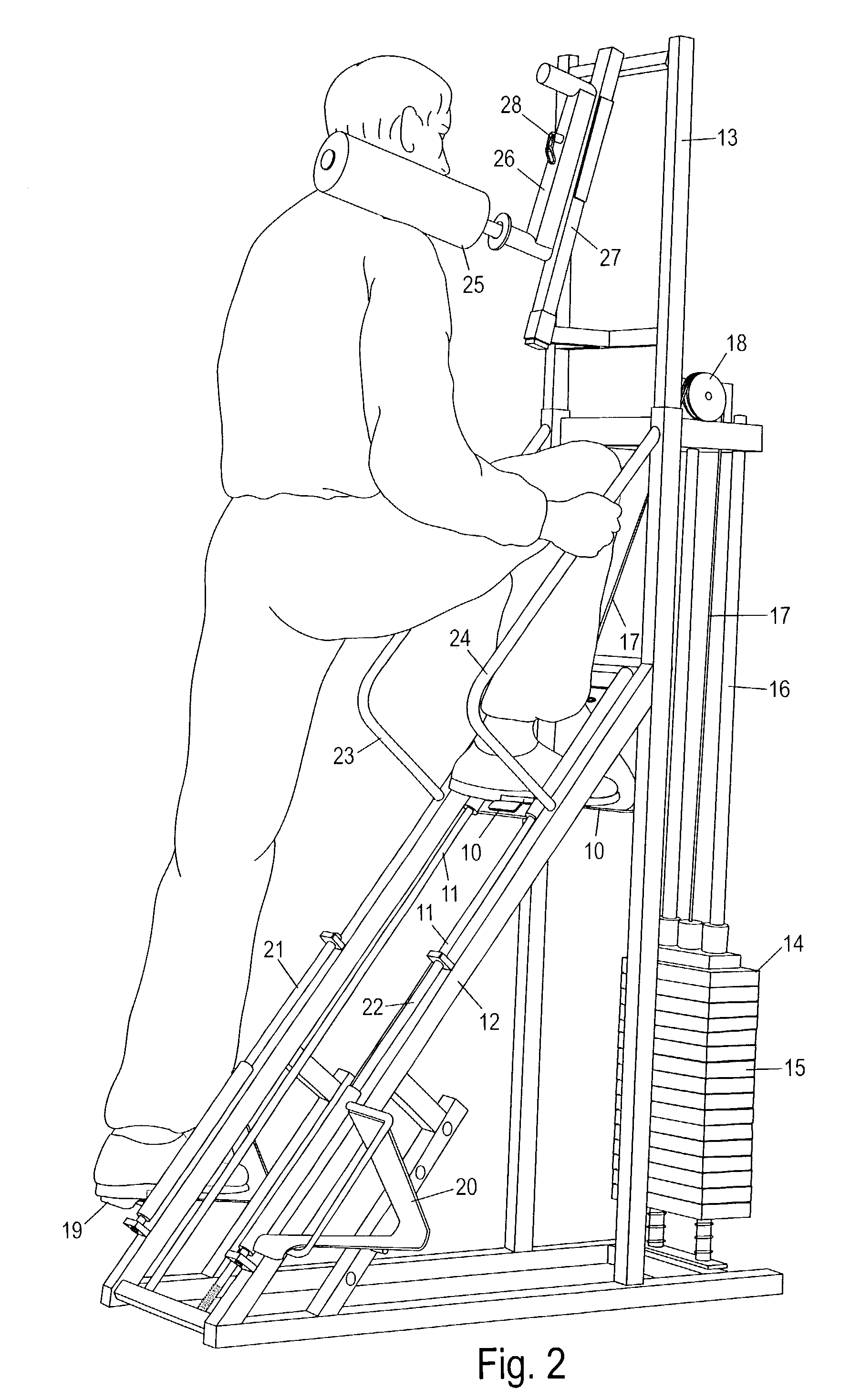

Standing single leg press exercise machine

A standing single leg press exercise machine is comprised of a single movable step arranged to move up and down along an inclined path for exercising only one leg at a time. A resistance mechanism is connected to the movable step for providing resistance to movement. Two stationary steps are positioned on either side of the bottom position of the movable step. Hand rails are also positioned on either side of movable step. A shoulder pad is positioned above the movable step. A method for using the leg press is comprised of standing on one of the stationary steps with a stationary leg, and repeatedly operating the movable step up and down with an active leg. The active leg is exercised until it is tired, and the legs are switched to exercise the previously stationary leg while the previously active leg is rested.

Owner:ADAMS FREDERICK R

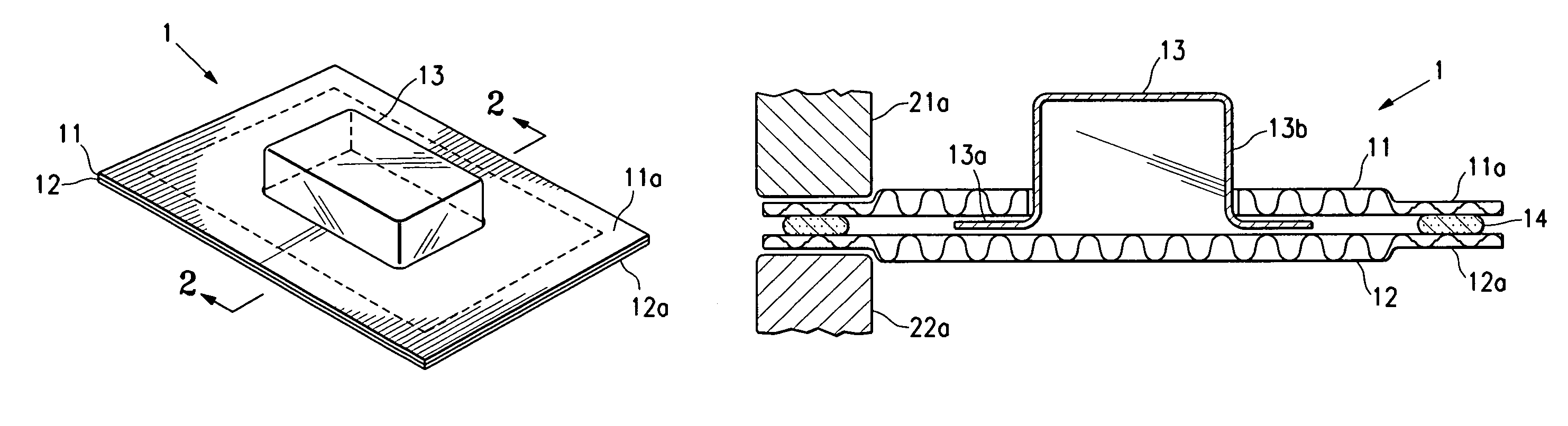

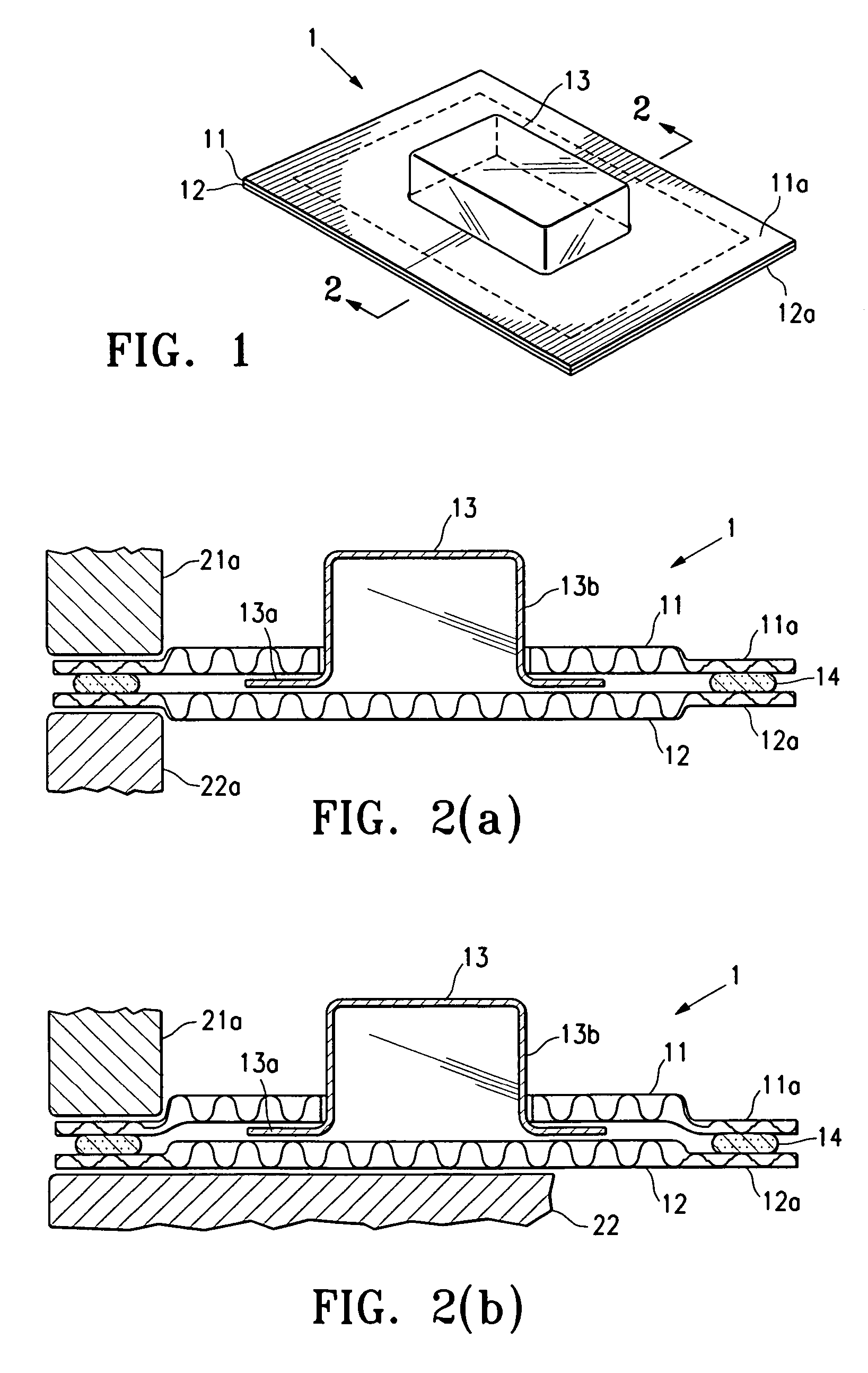

Display pack and packaging method and apparatus

A display pack for a consumer product is made of two sheets of corrugated cardboard and a clear plastic container with a flat insertion portion sandwiched between the cardboard sheets. The two cardboard sheets are adhered together in a peripheral area of the package by a heat-sensitive adhesive, and the corrugations of the cardboard sheets are crushed and flattened in the peripheral area. To seal the package, the peripheral area of the two cardboard sheets is subject to sufficient pressure to crush the corrugations inside the cardboard sheets and flatten them in that area. Heat is applied to the outer side of the cardboard sheets in the peripheral area and conducted to the adhesive material between the two sheets to activate the adhesive material. A sealer machine with a heated sealing press or parallel sets of heated rollers may be used to carry out the sealing process.

Owner:WINTERBORNE

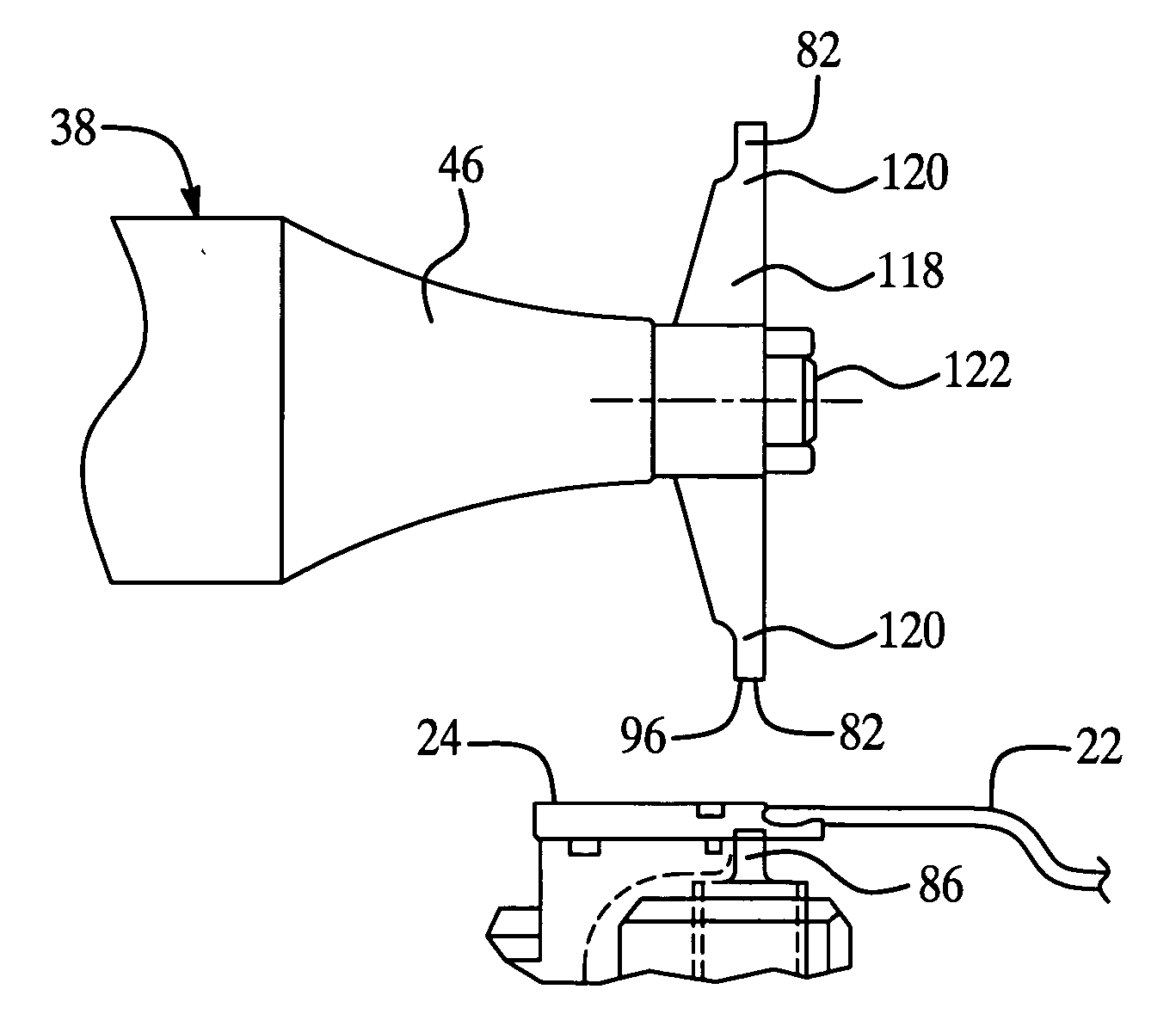

Ultrasonic welding system

InactiveUS20070068991A1Highly versatileRobust systemElectrically conductive connectionsWelding/cutting auxillary devicesUltrasonic weldingTransducer

The present invention is an ultrasonic welding system having an ultrasonic welder integrated with a servo press for galling and ultrasonic welding of a first workpiece to a second workpiece. The first and second workpieces are substantially disposed between a confronting tip and stationary anvil of the ultrasonic welder. Prior to welding, the servo press preferably quickly moves the tip toward and generally against the first workpiece. During welding, a variable speed motor of the servo press preferably slowly moves the tip toward the anvil compressing the workpieces together while a transducer of the ultrasonic welder transmits mechanical vibration to the tip for welding the workpieces together.

Owner:DELPHI TECH INC

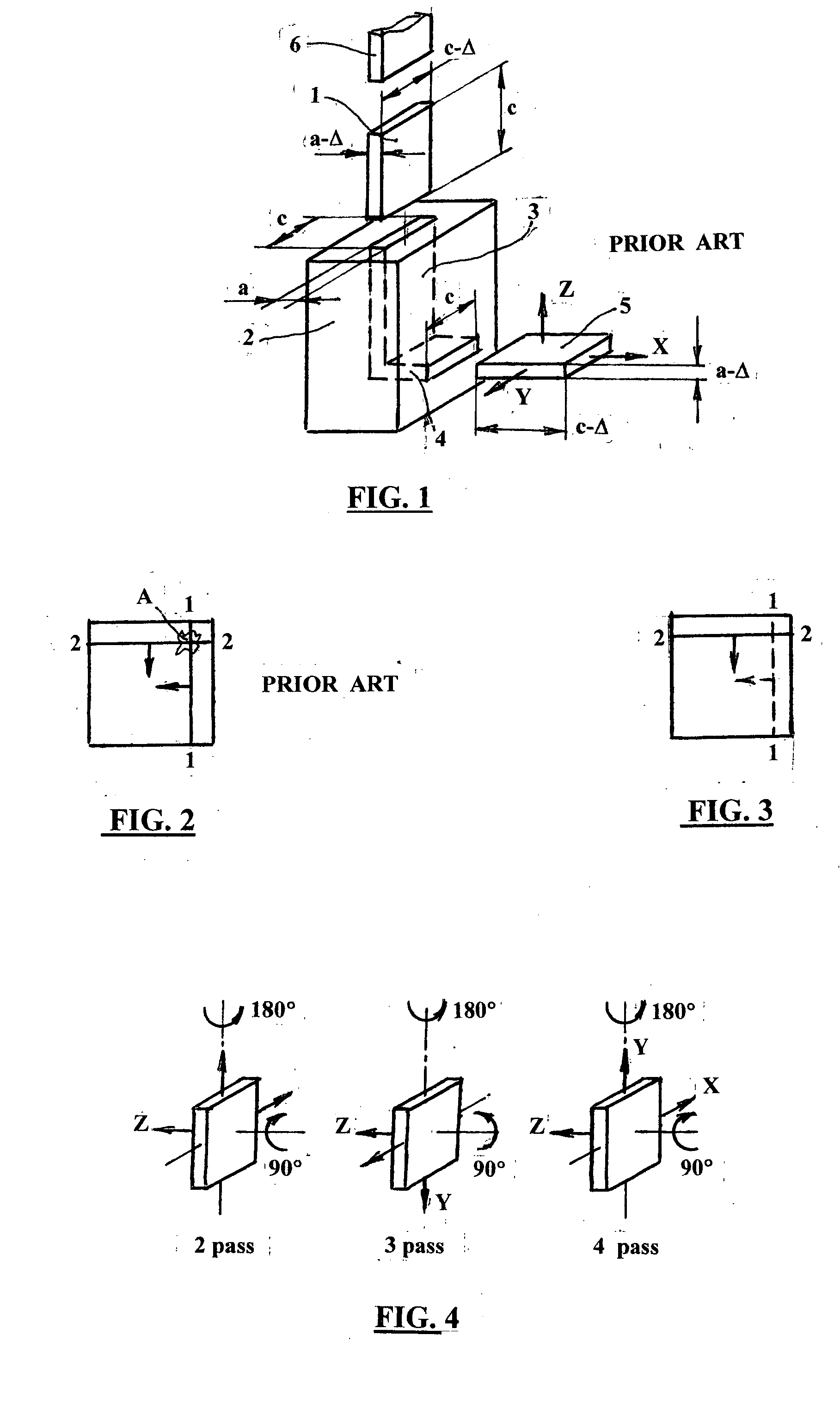

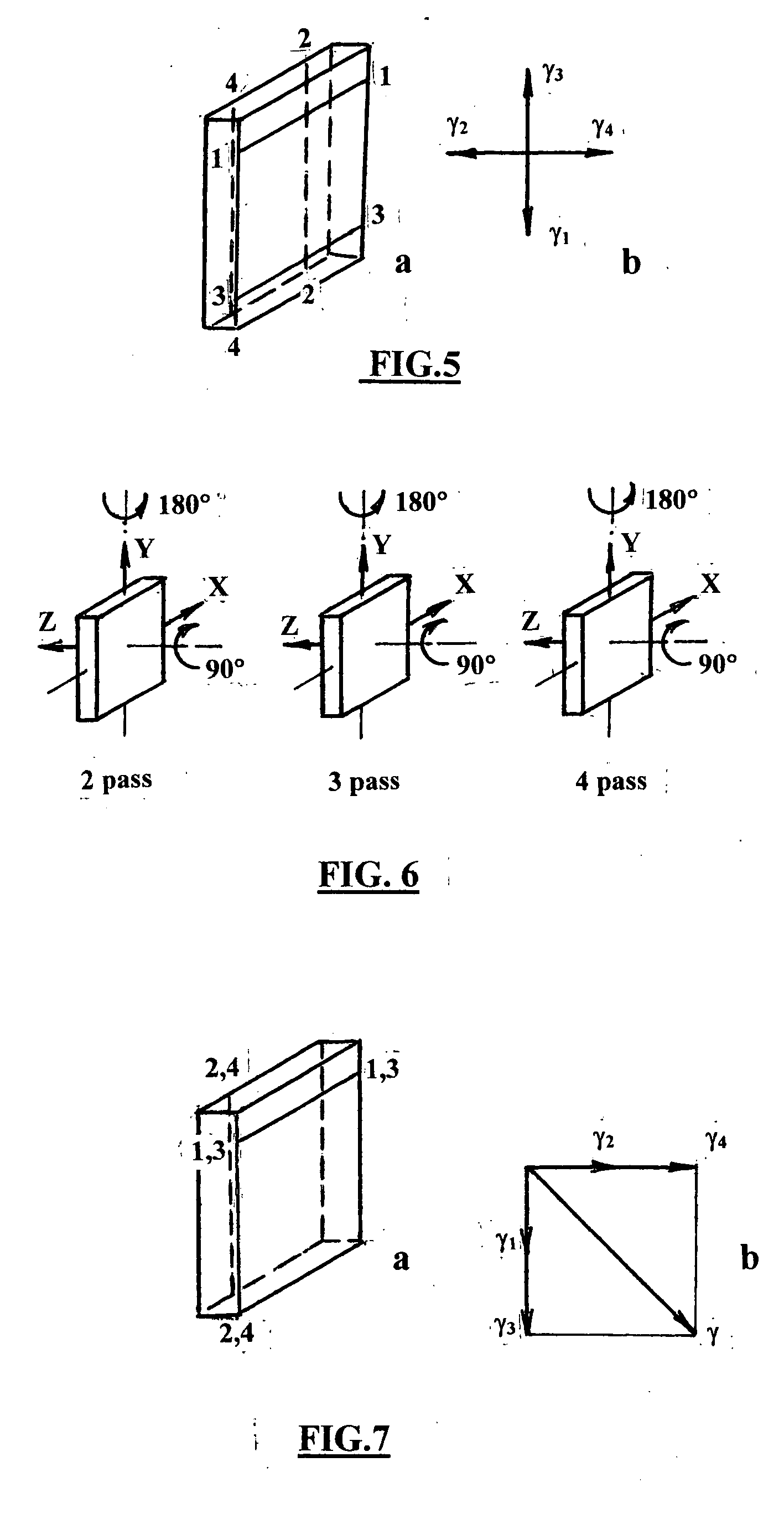

Method and apparatus for equal channel angular extrusion of flat billets

InactiveUS20050016243A1Reliable billet ejectionReduce pressureWork treatment devicesMetal rolling arrangementsCost effectivenessControl system

The invention comprises a method and apparatus for equal channel angular extrusion (ECAE) of flat billets to control material structure and properties. The improvements of the method include the special systems of billet orientations, billet lubrication, billet ejection from dies, and a press / die control system those eliminate surface cracks, flashes and billet reshaping or deburring between passes. Therefore, multi-pass ECAE becomes a cost-effective industrial operation and may be applied to large billets.

Owner:ENGINEERED PERFORMANCE MATERIALS

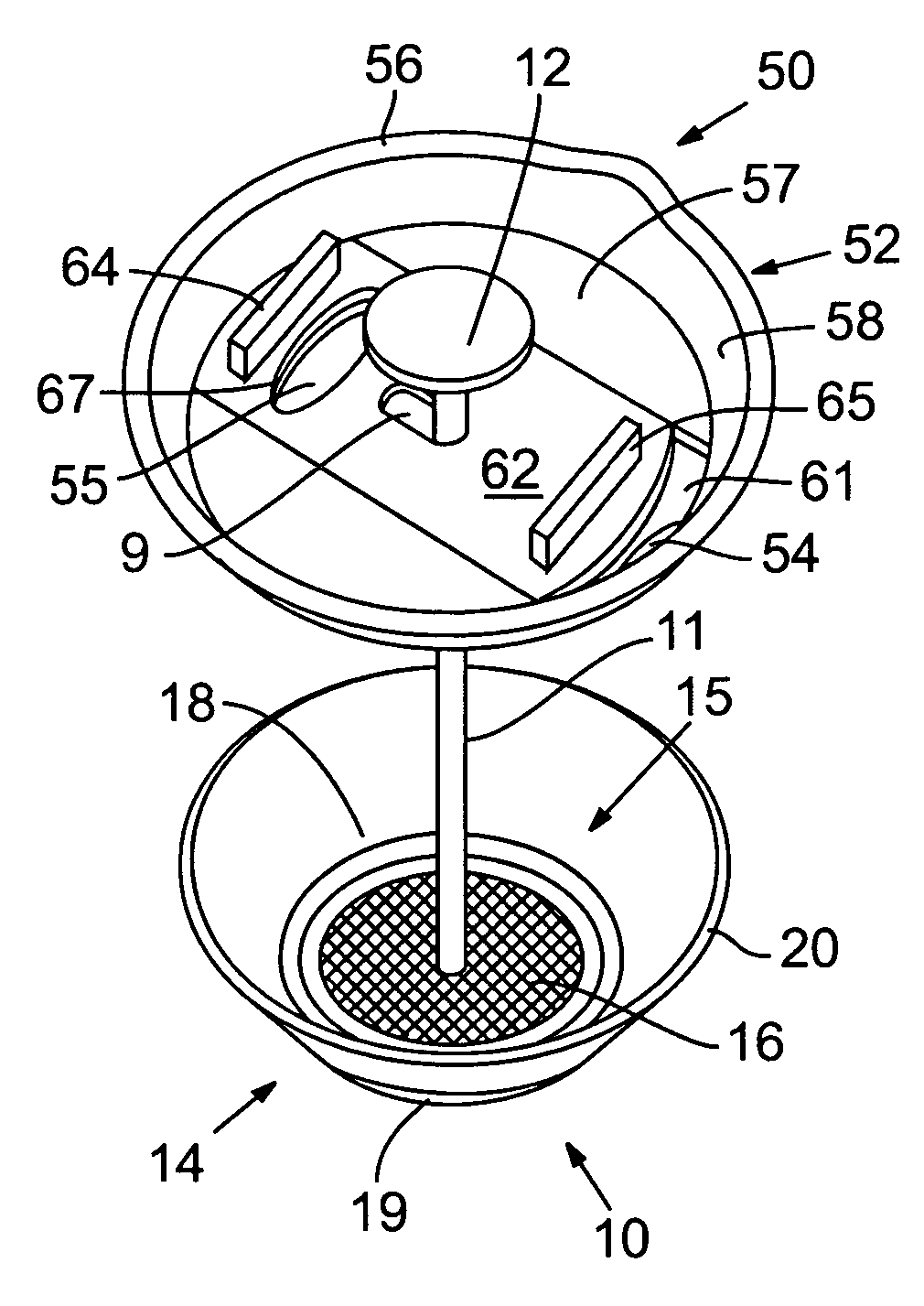

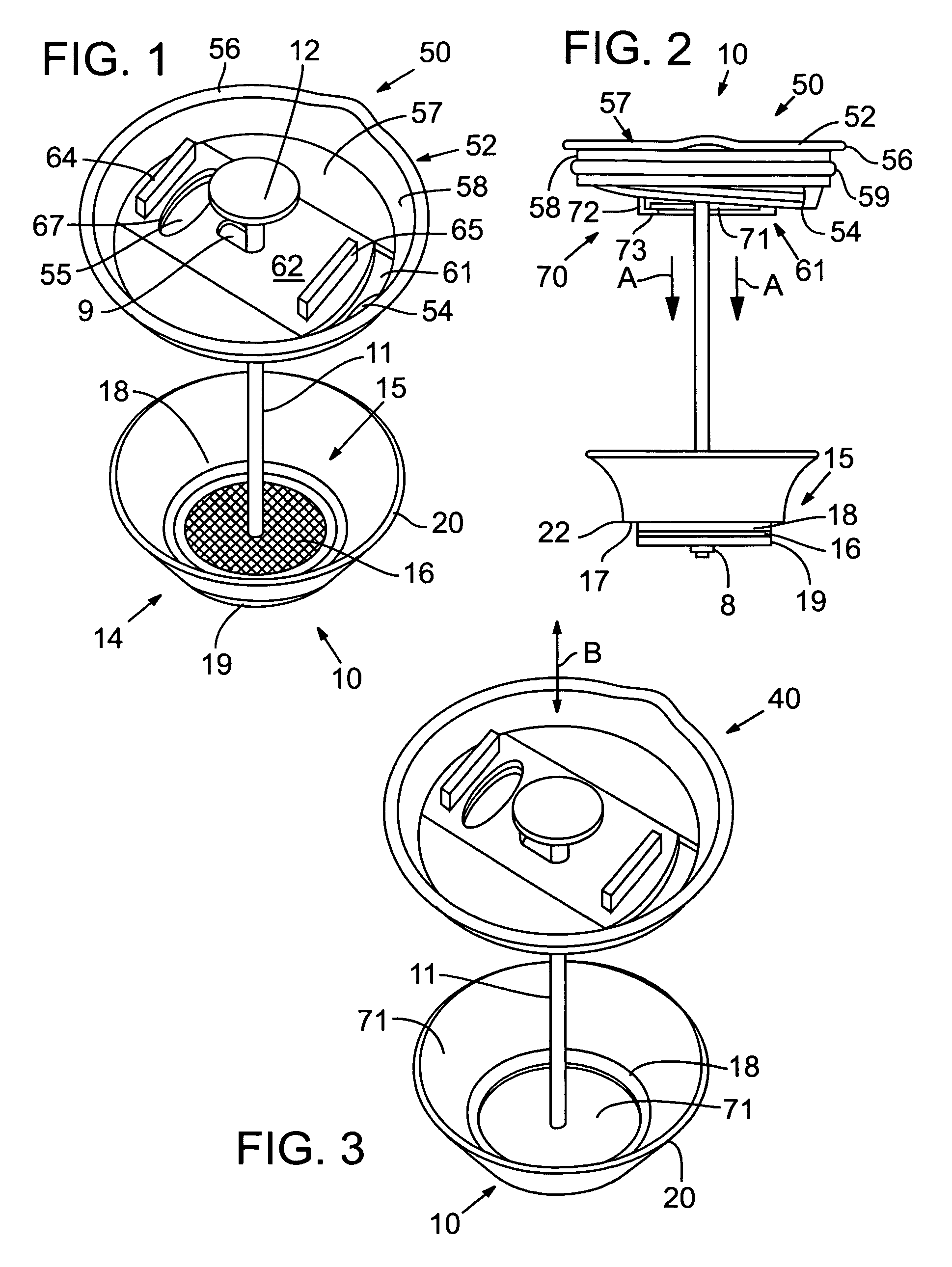

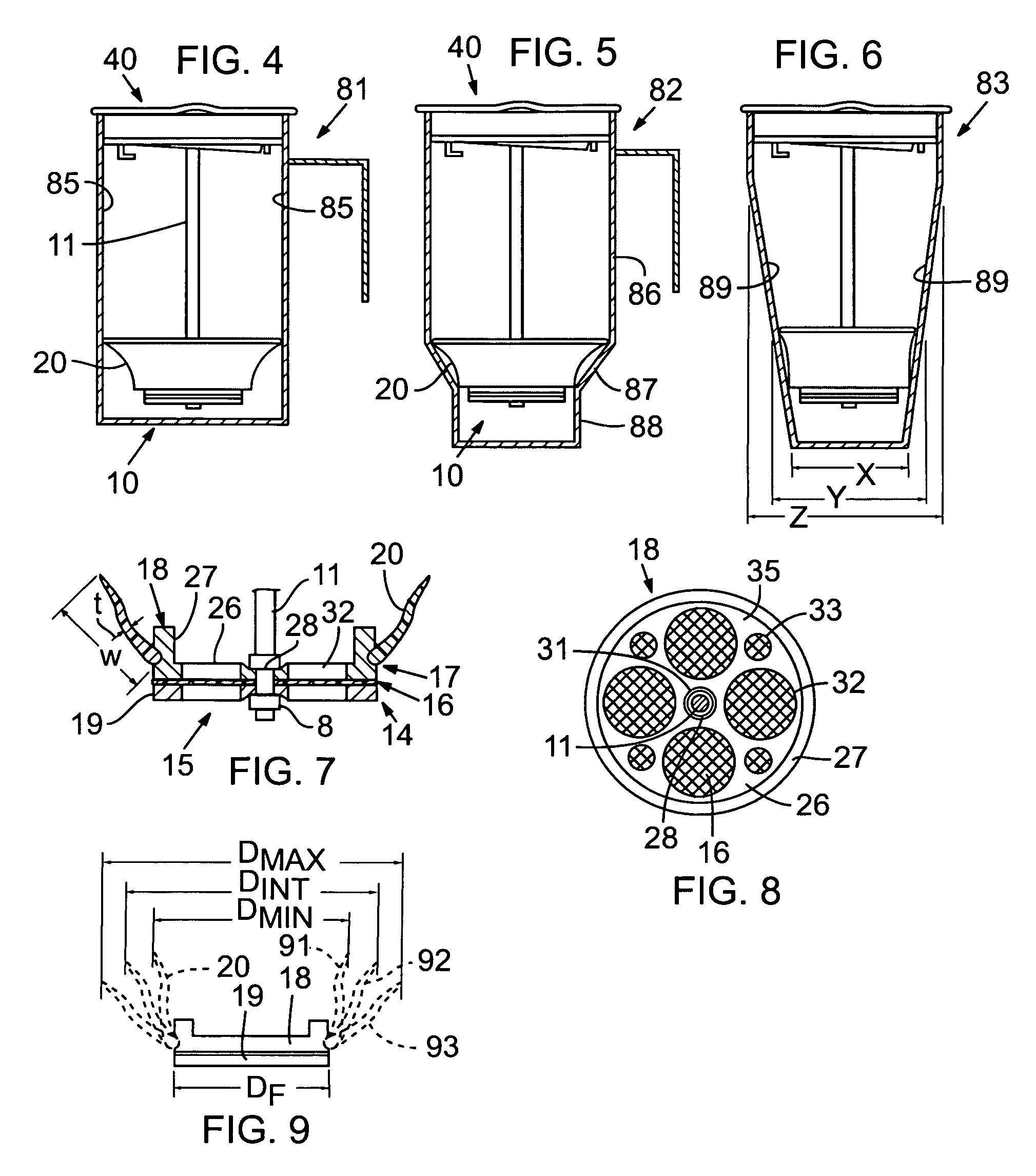

Plunger and lid apparatus for a beverage press and a beverage press having same

A plunger device for use with a beverage press having a screen for filtering fines from an infused beverage. A flexible seal is provided that is compressible to function properly in different sized containers. The seal may be made of a material such as rubber or rubberized plastics or the like and may have a width that is greater than its thickness. Various seal embodiments including ascending, descending and non-circular embodiments are disclosed. Brew control and multiple access openings are also disclosed.

Owner:PACIFIC CORNETTA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com