Patents

Literature

1618results about How to "Avoid lifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

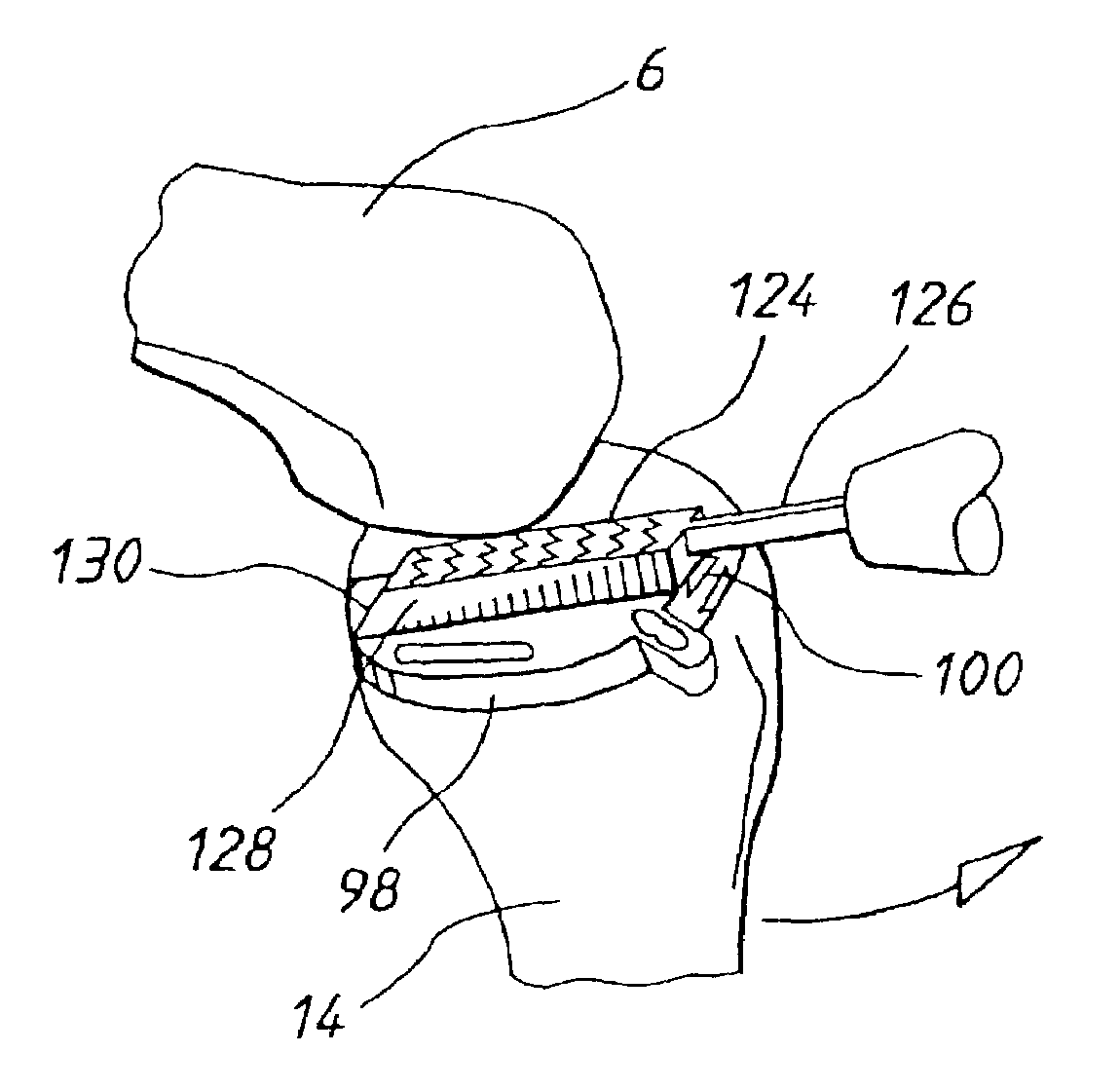

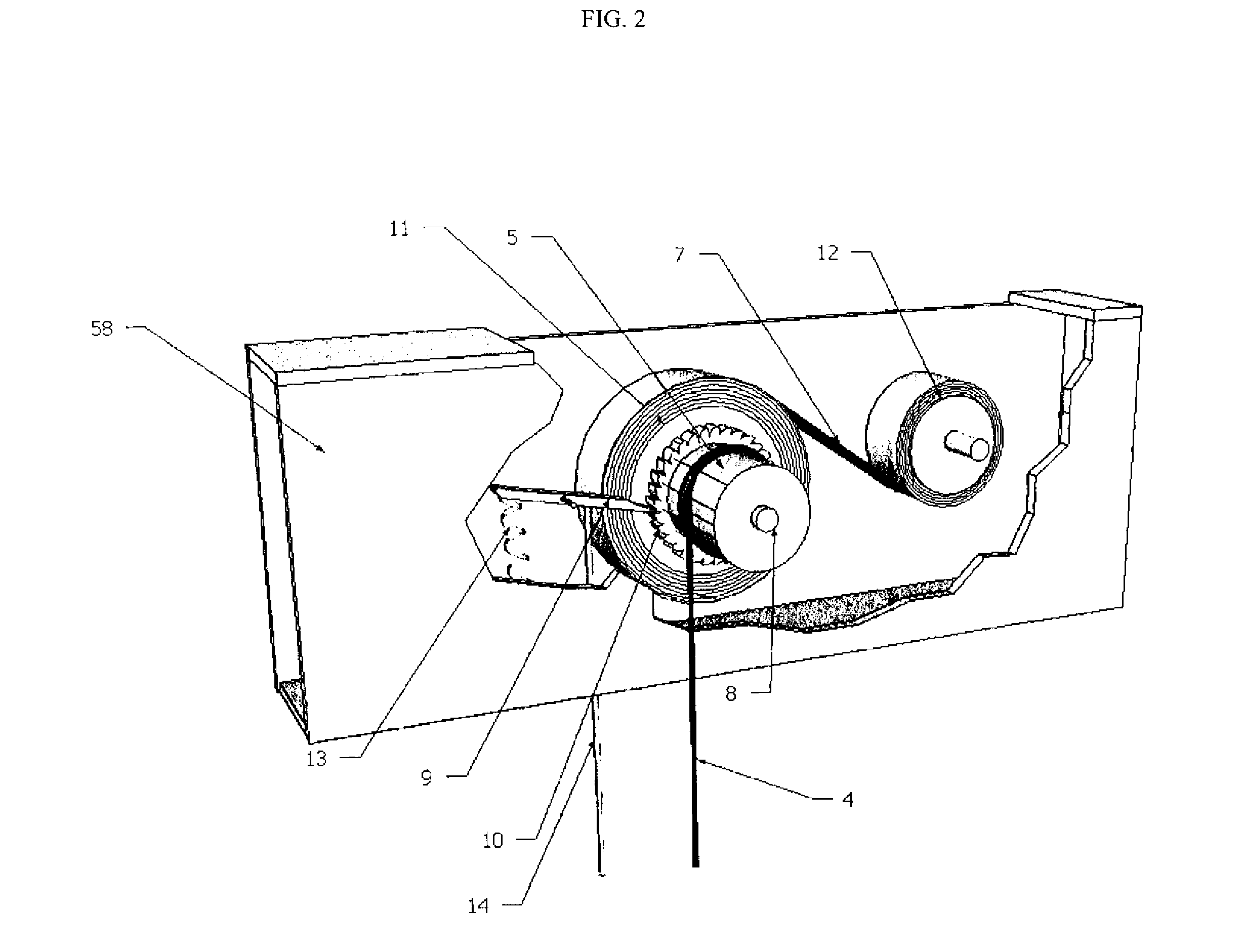

Apparatus for use in arthroplasty of the knees

InactiveUS6969393B2Easy to guideAvoid liftingJoint implantsNon-surgical orthopedic devicesTibiaKnee Joint

A cutting device for being inserted into a knee joint between the tibia and the femur, wherein the cutting device is adapted for resecting bone from the femur to a desired depth in a path of travel of the tibia when located in the knee joint and operated as the tibia is moved through an arc of motion about the femur between backward and forward positions. A cutting device is also disclosed for being inserted into a knee joint between the tibia and the femur for resecting bone from the tibia to a desired depth to form a recess in a condyle of the tibia for reception of a tibial implant, comprising a body being located between the tibia and the femur, a cutter for resecting the bone from the tibia to form the recess and a drive mechanism for driving the cutter to resect the bone and being arranged in the body, wherein the cutter is mounted on the body and protrudes therefrom for resecting the bone from the tibia.

Owner:SMITH & NEPHEW INC

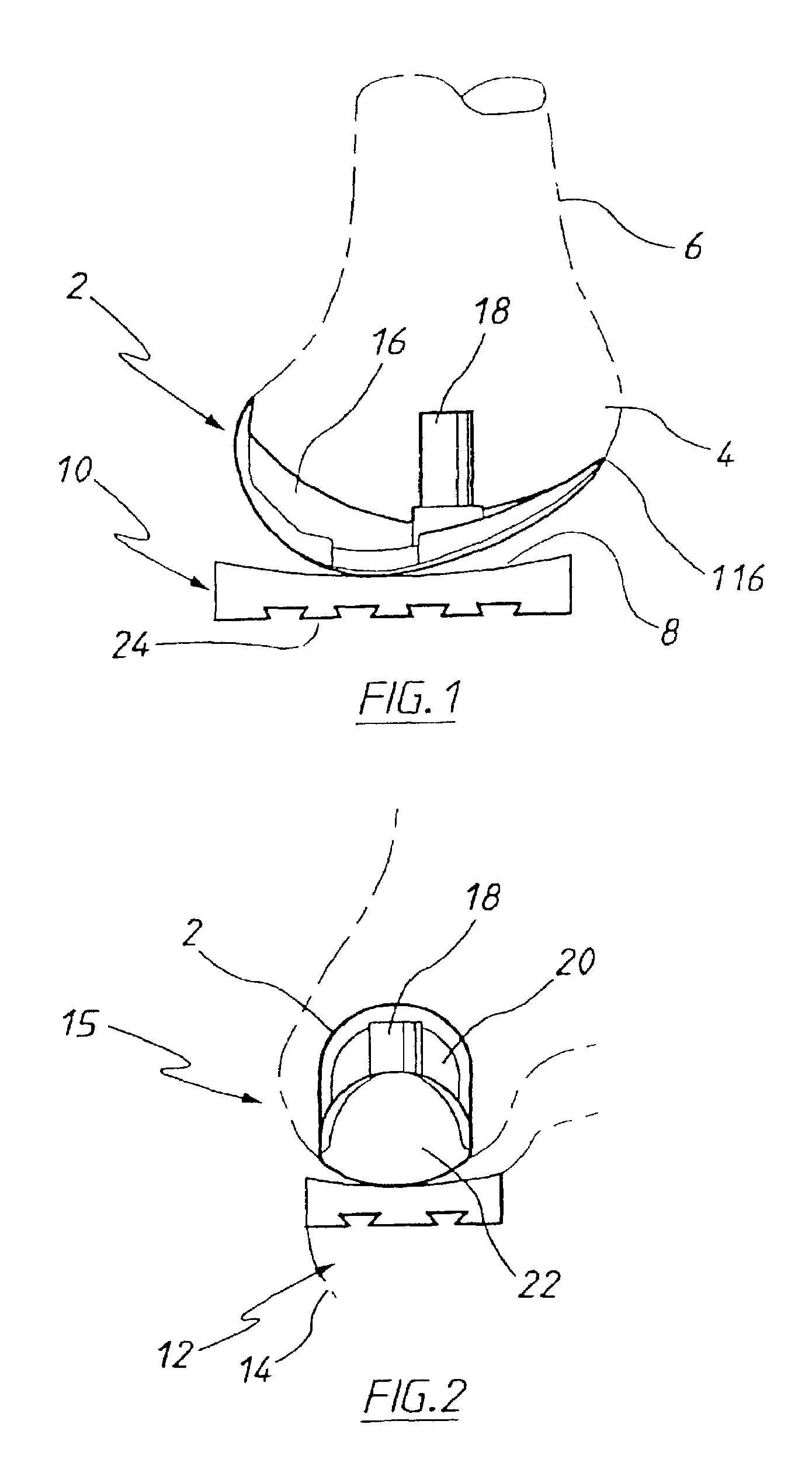

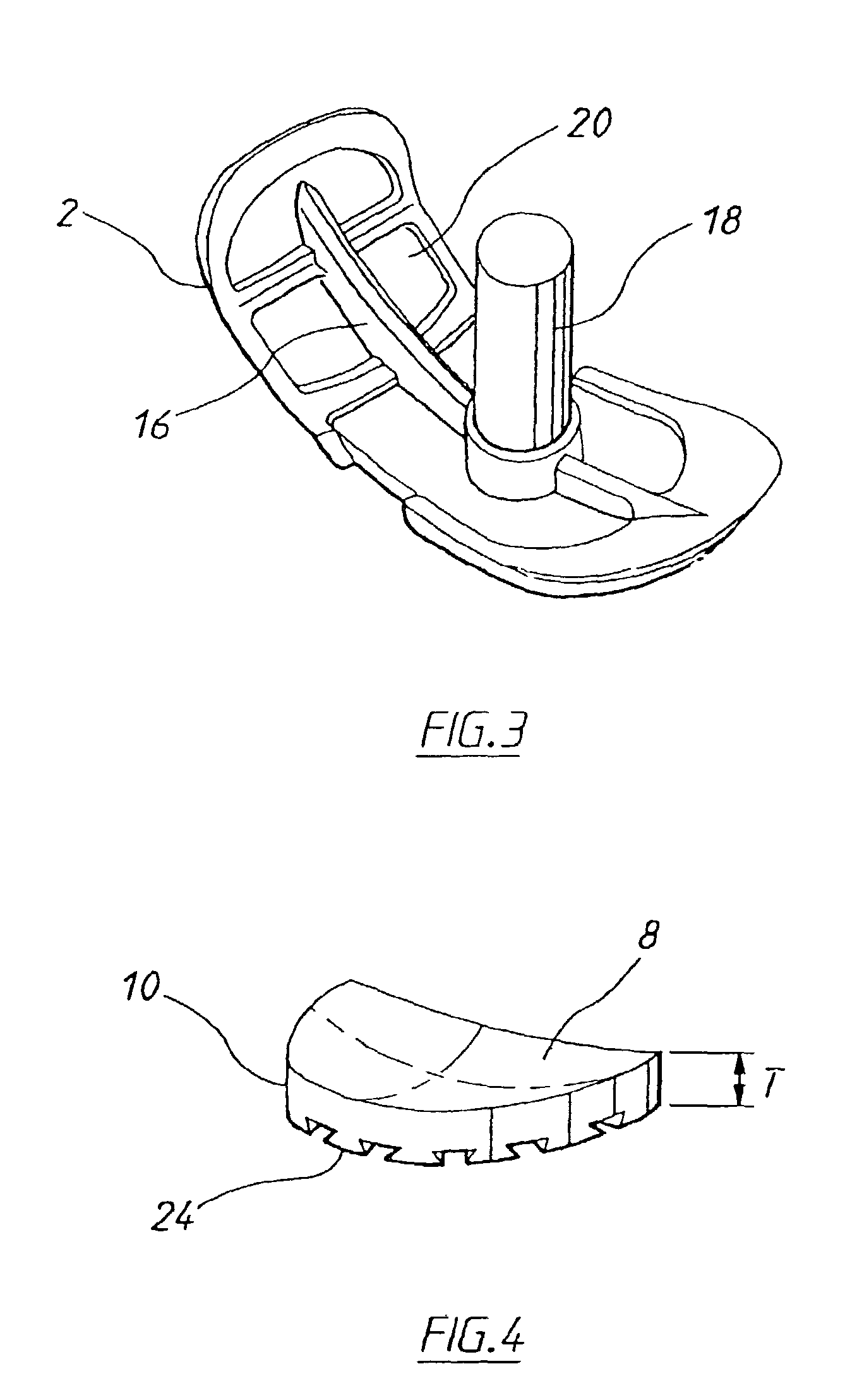

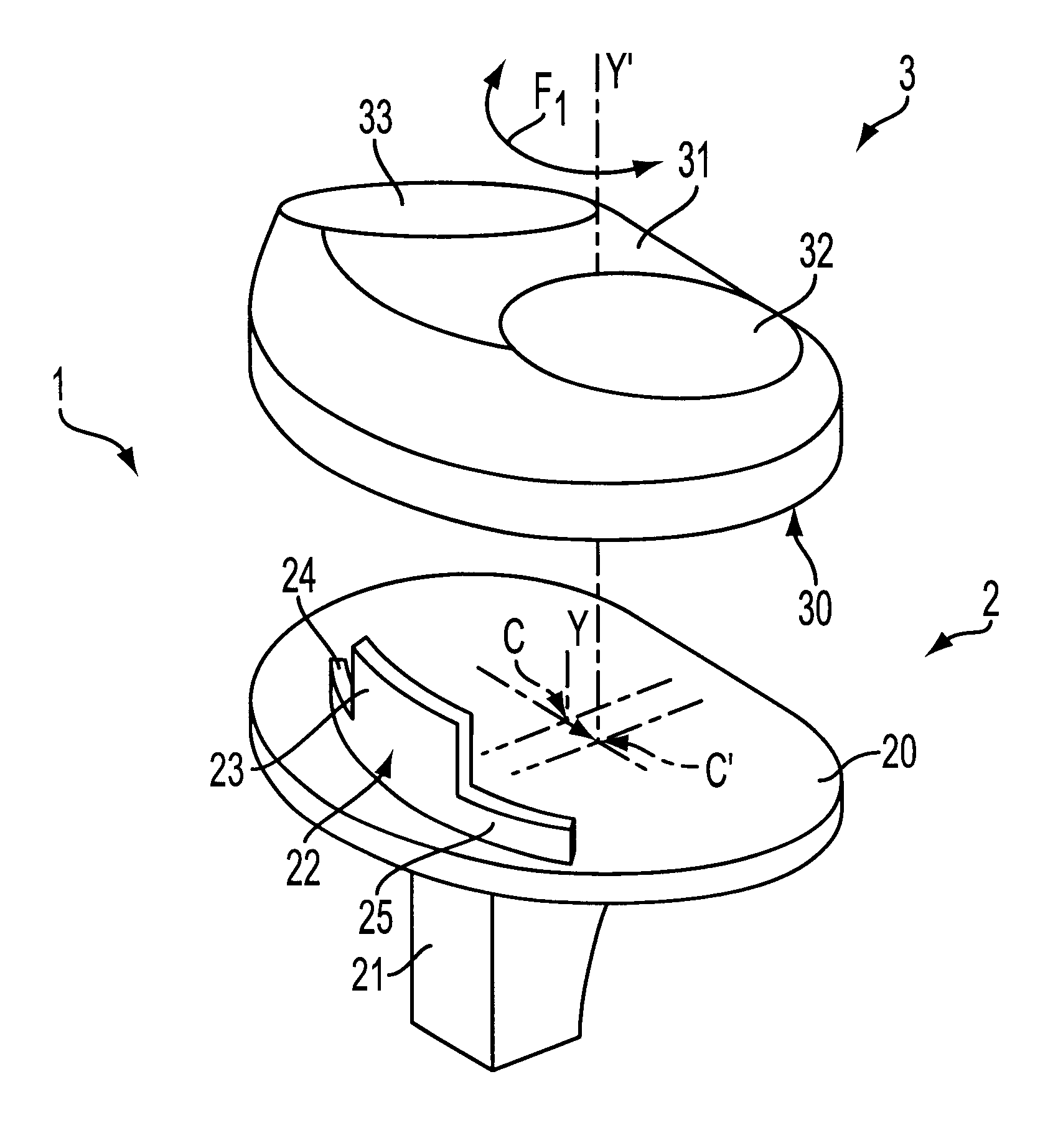

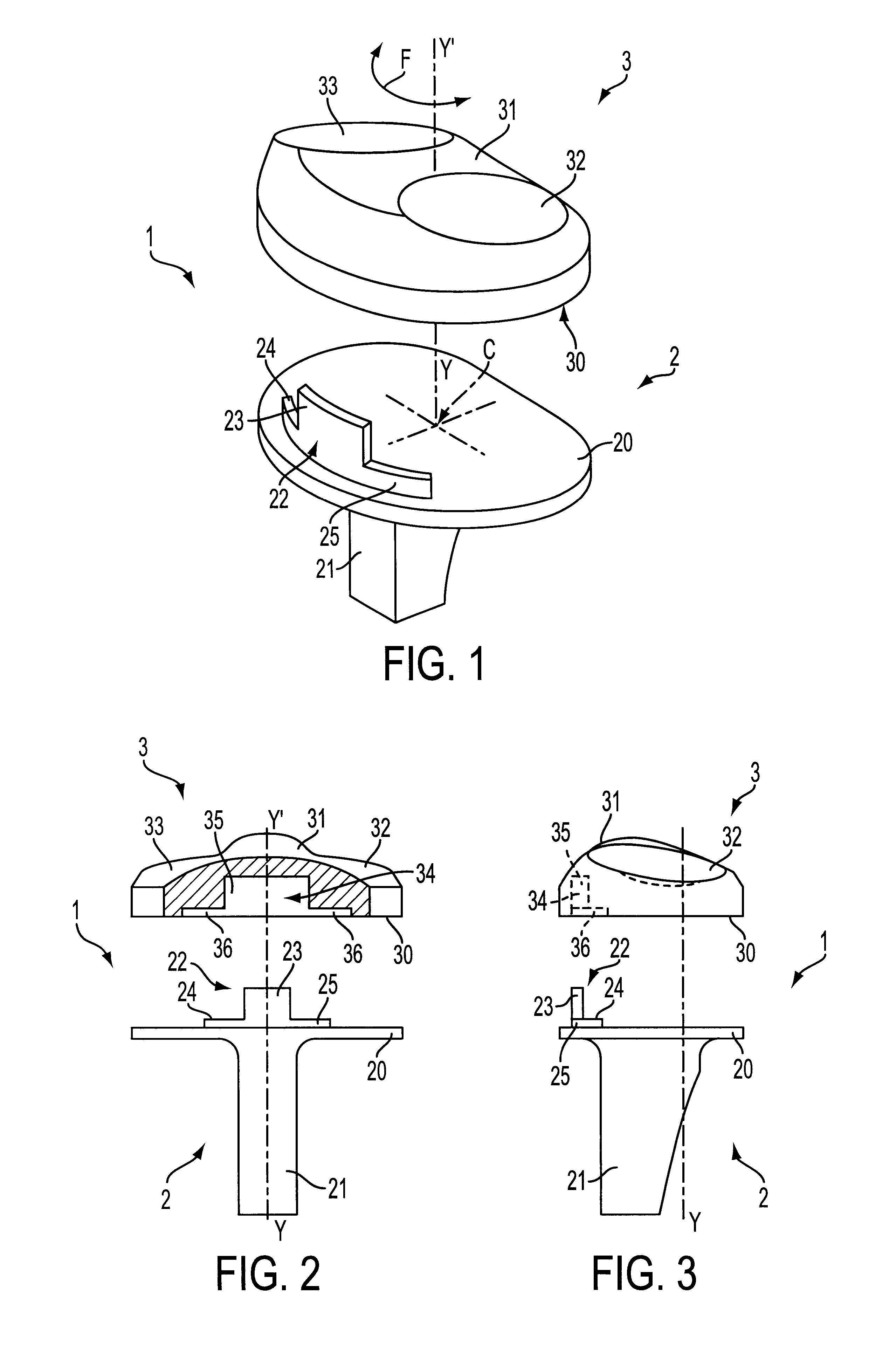

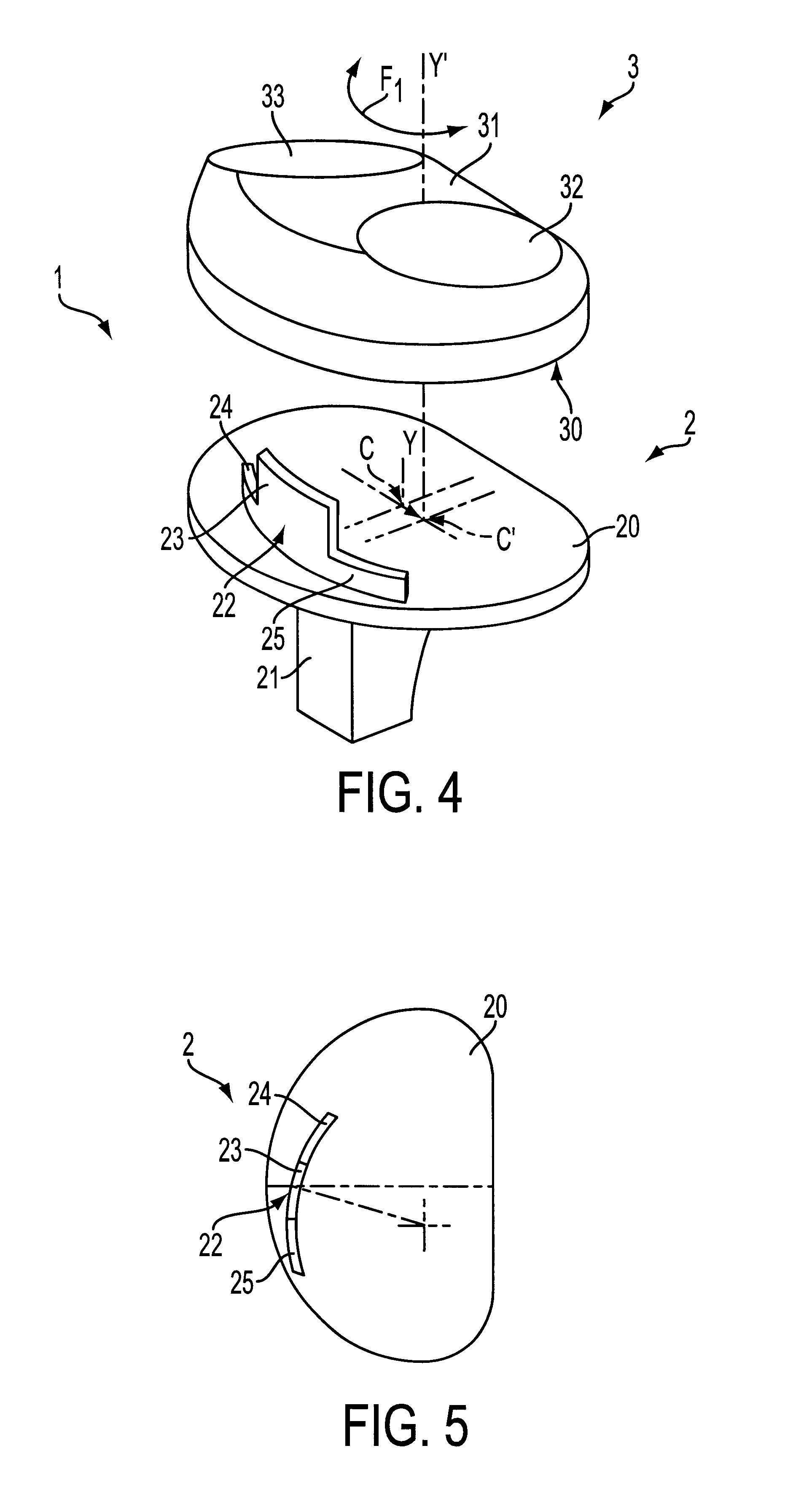

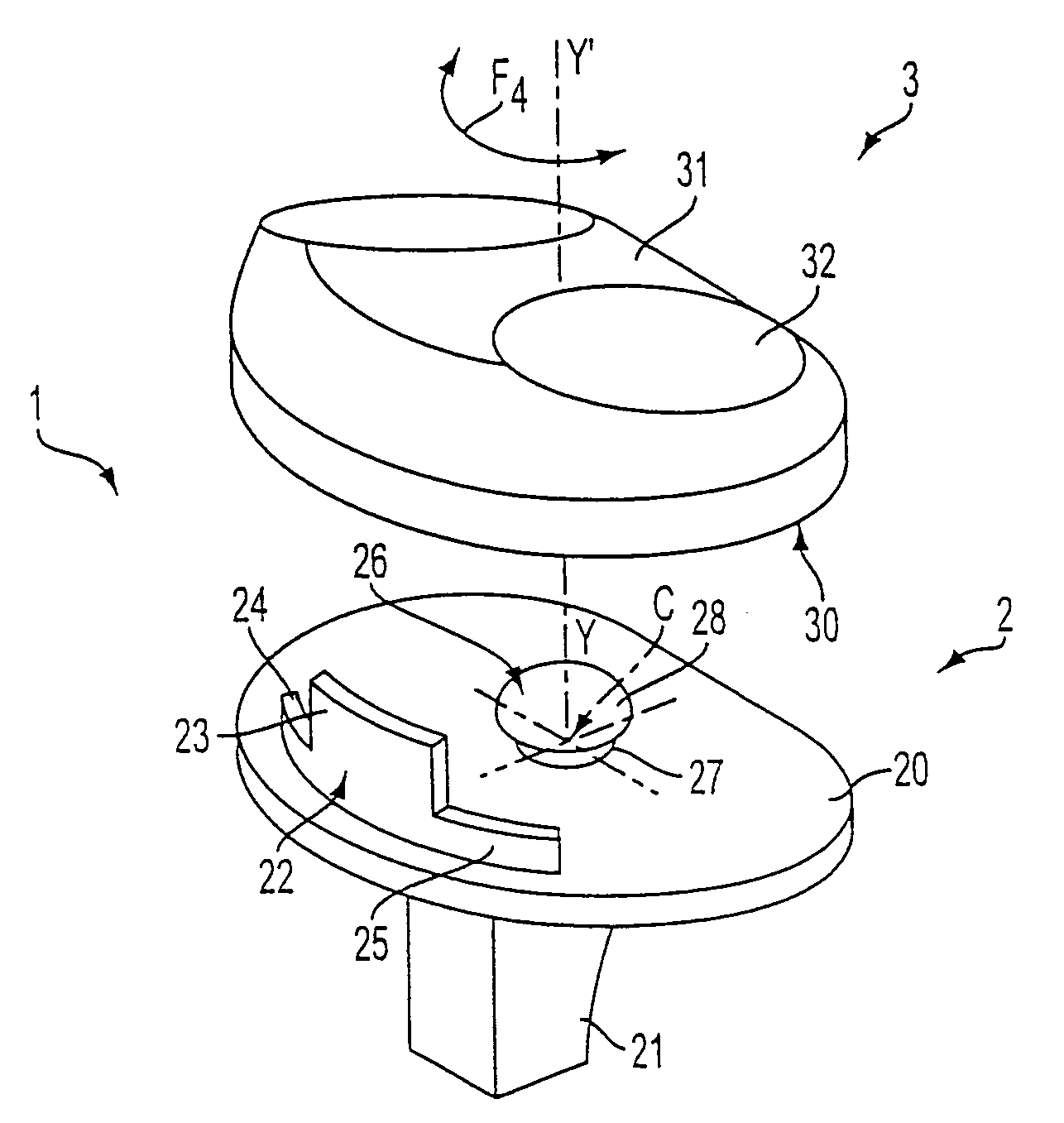

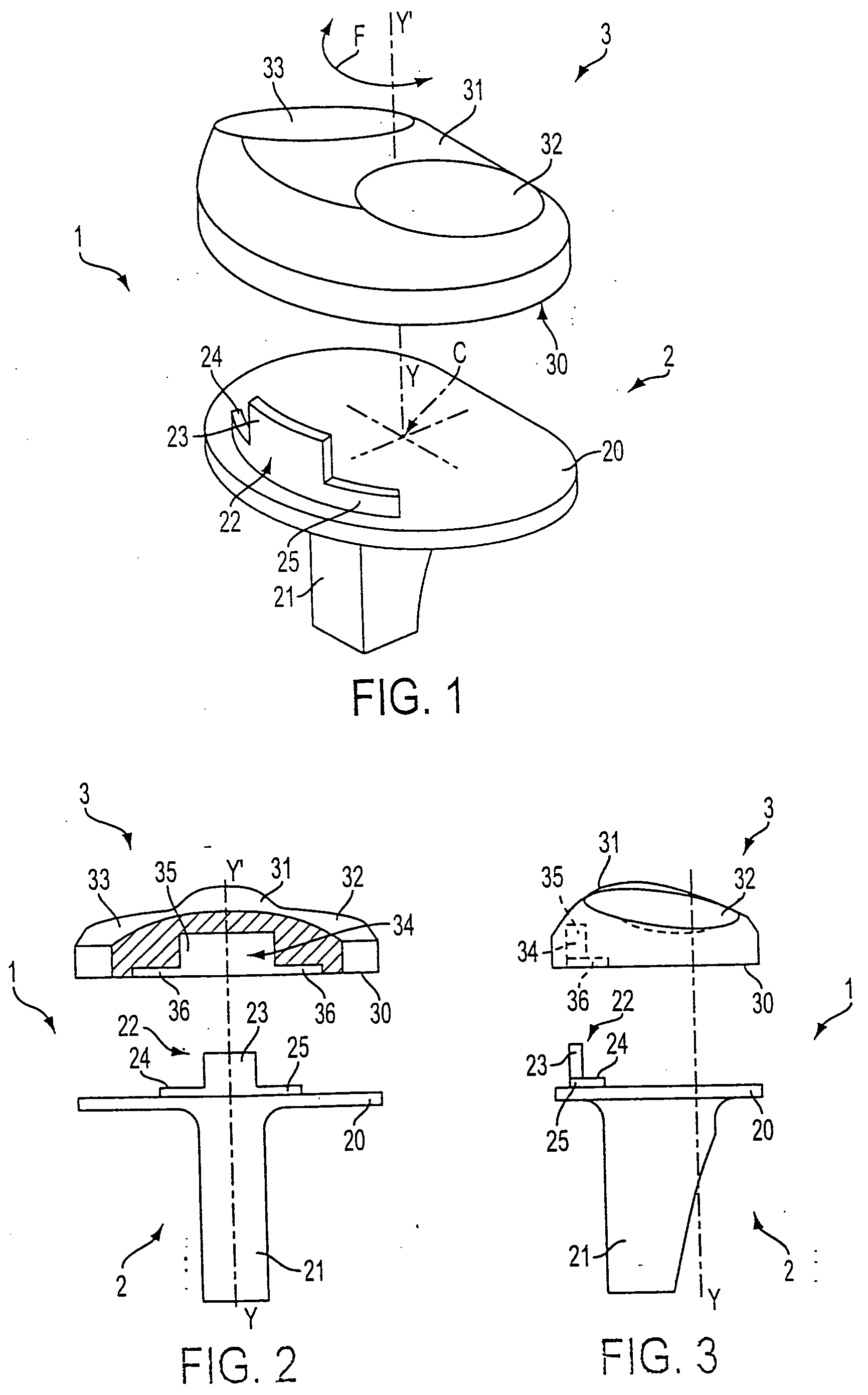

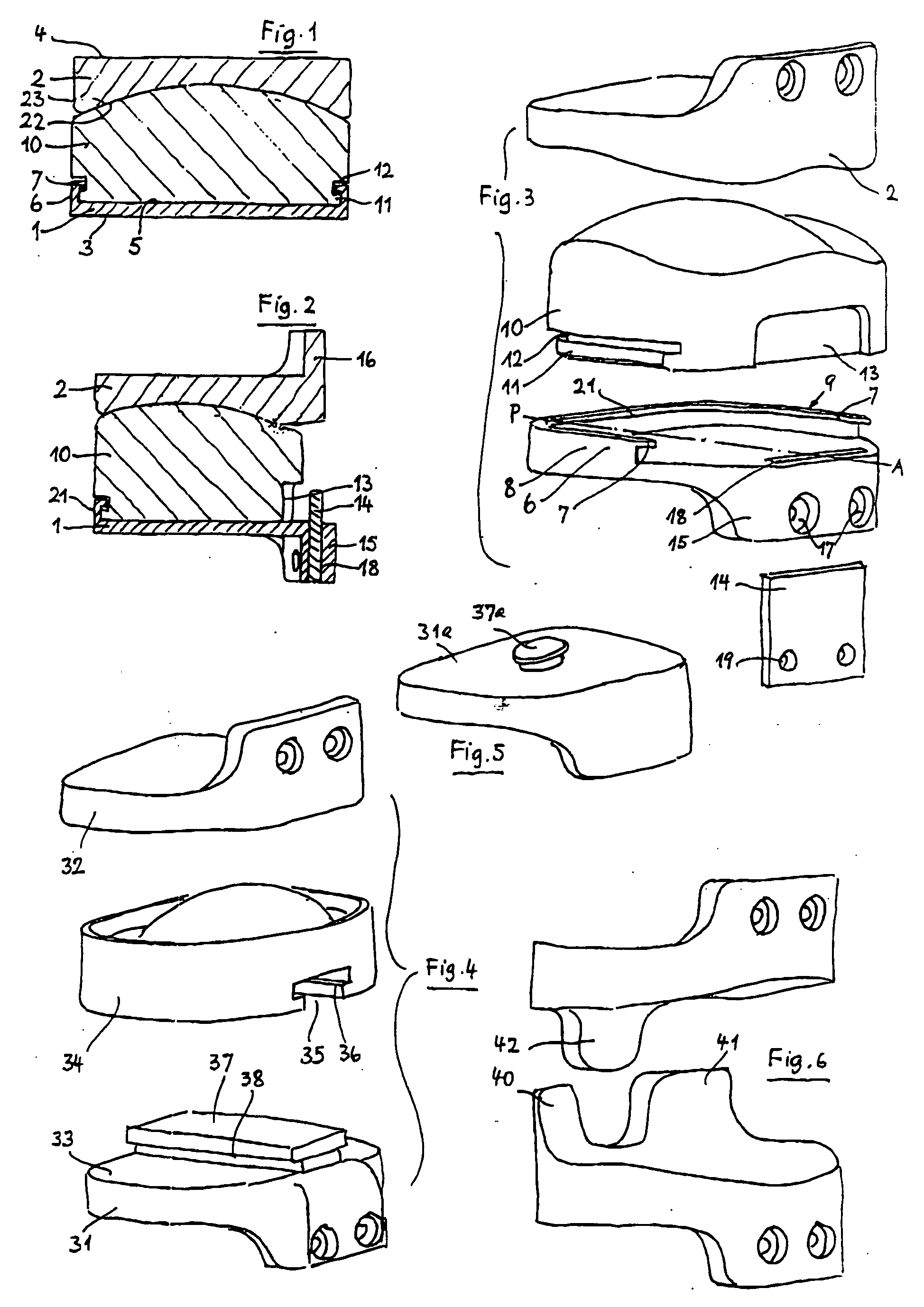

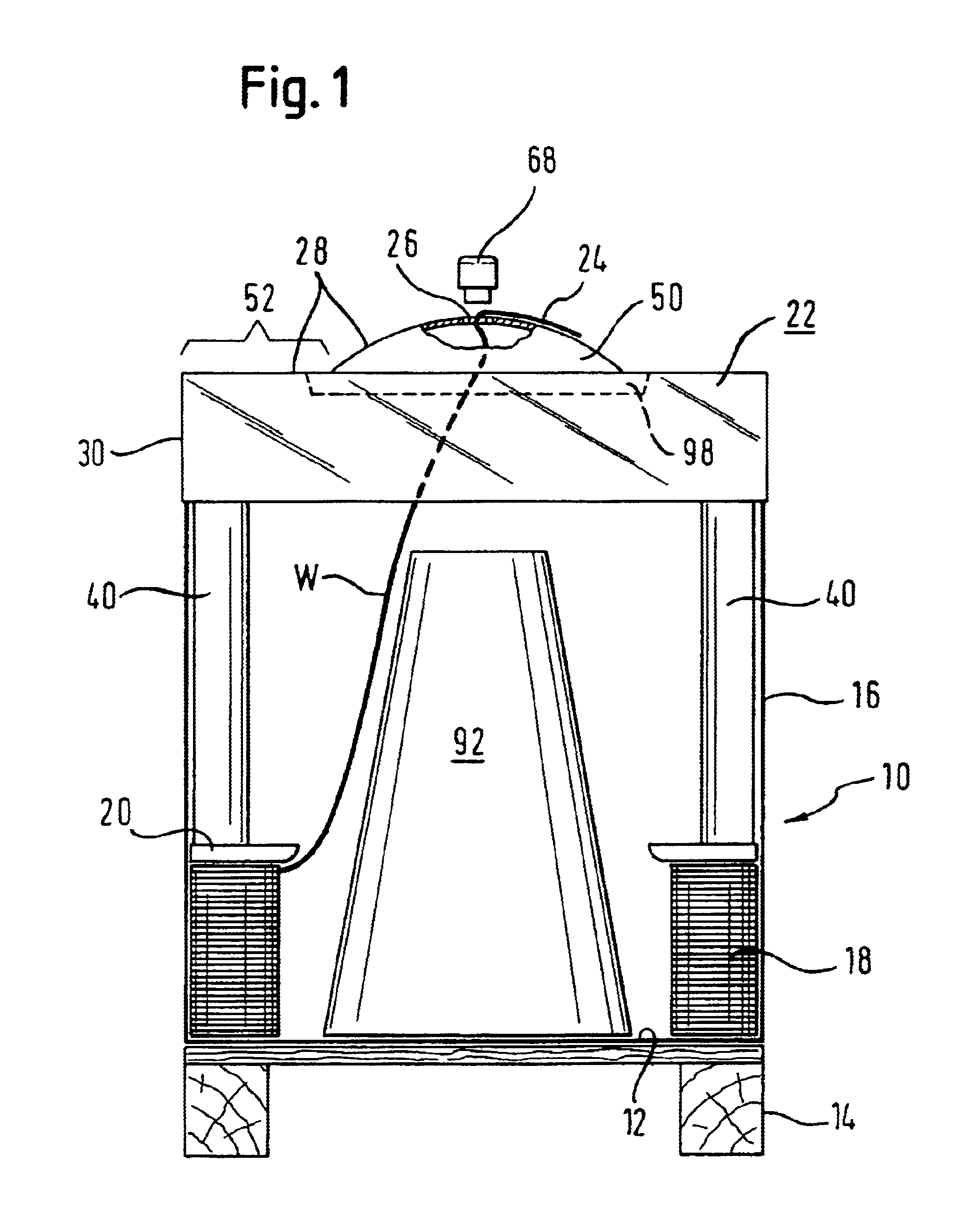

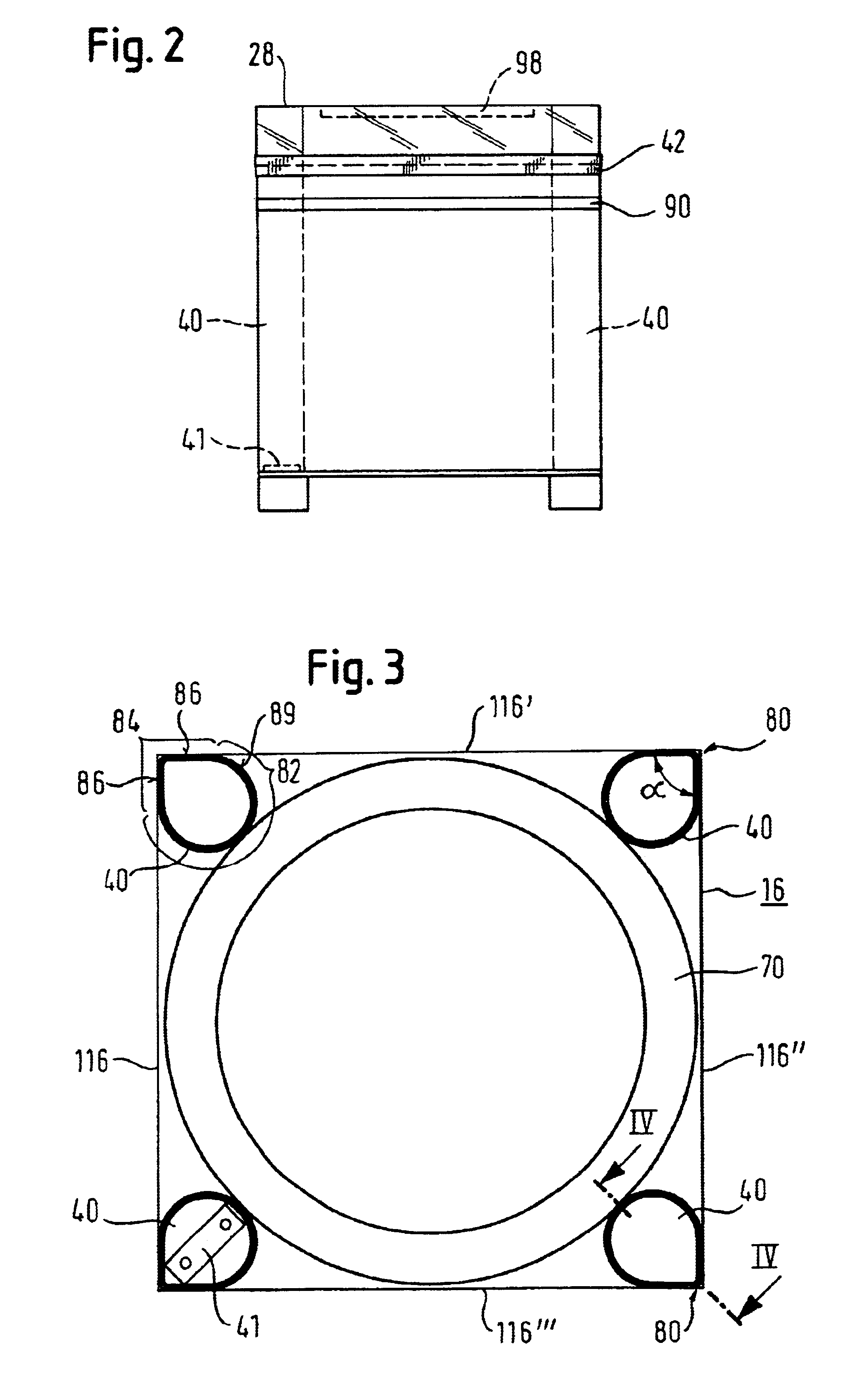

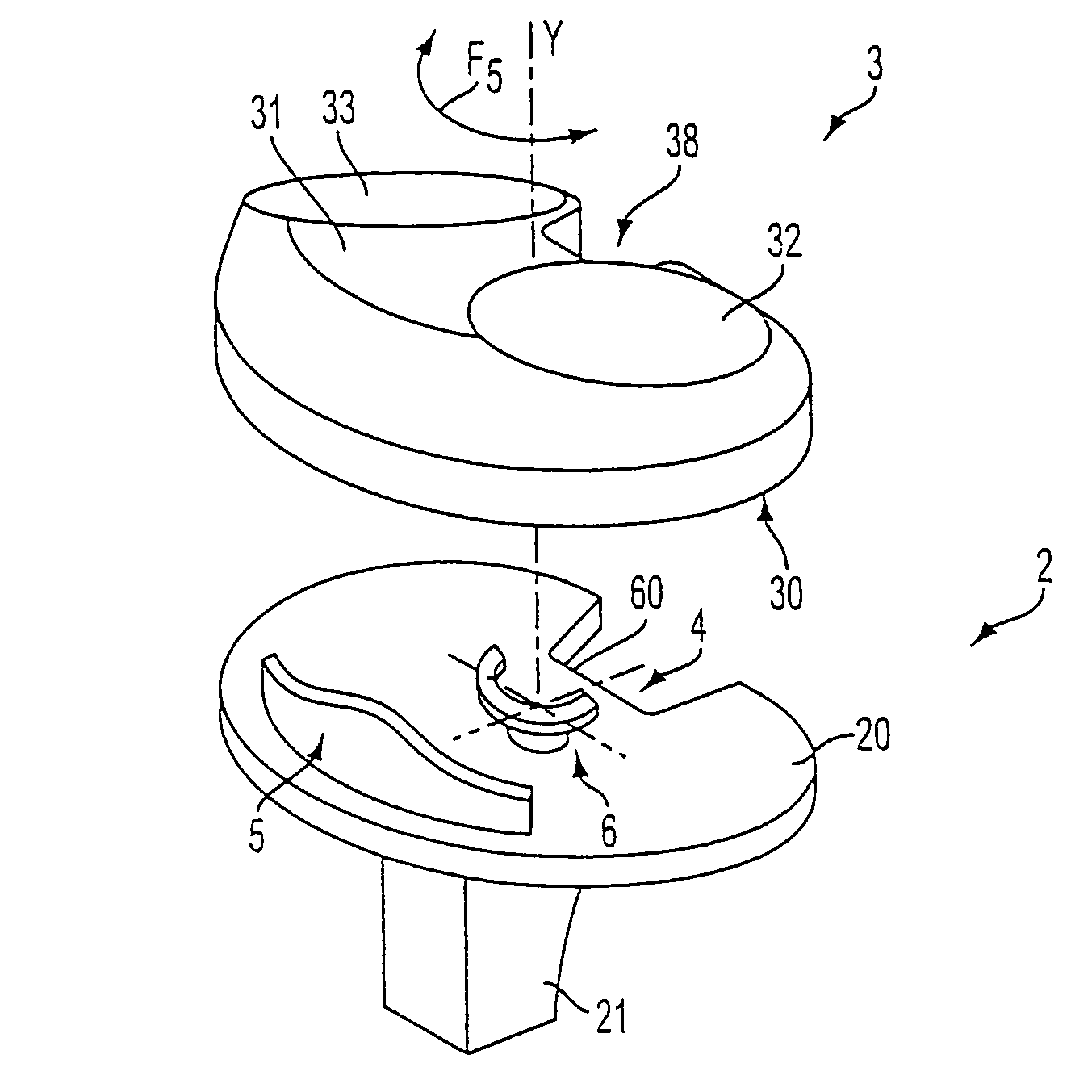

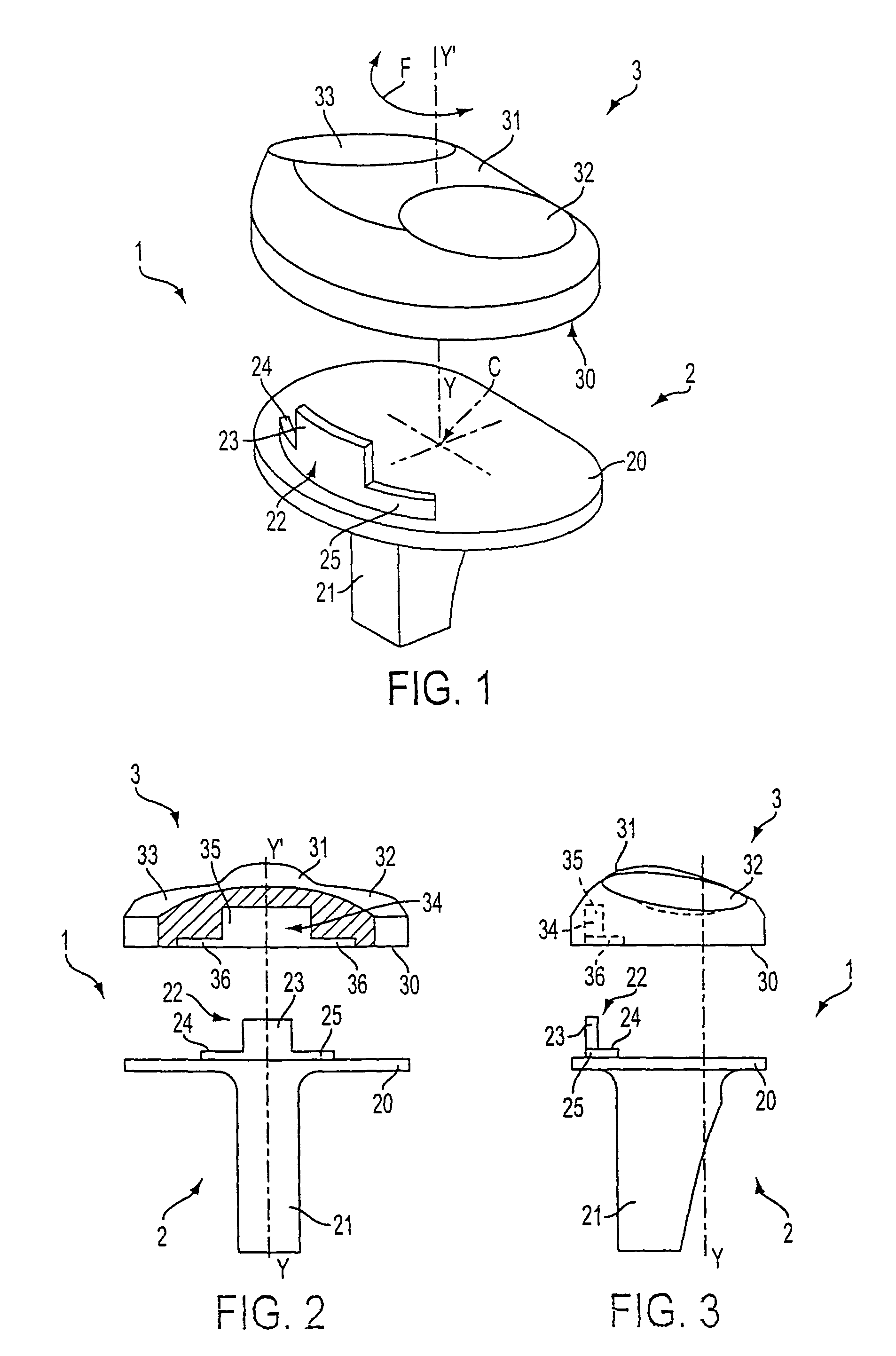

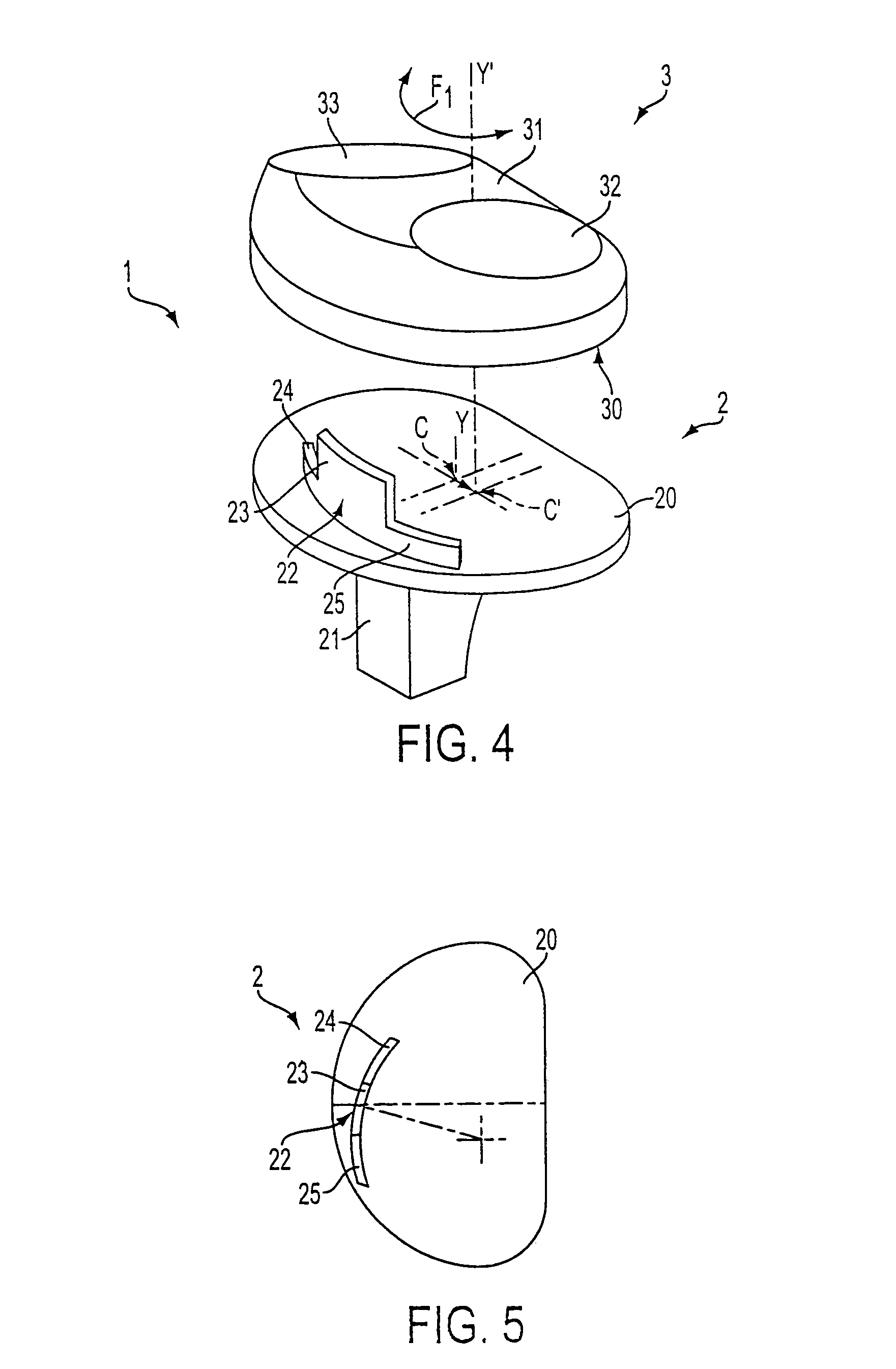

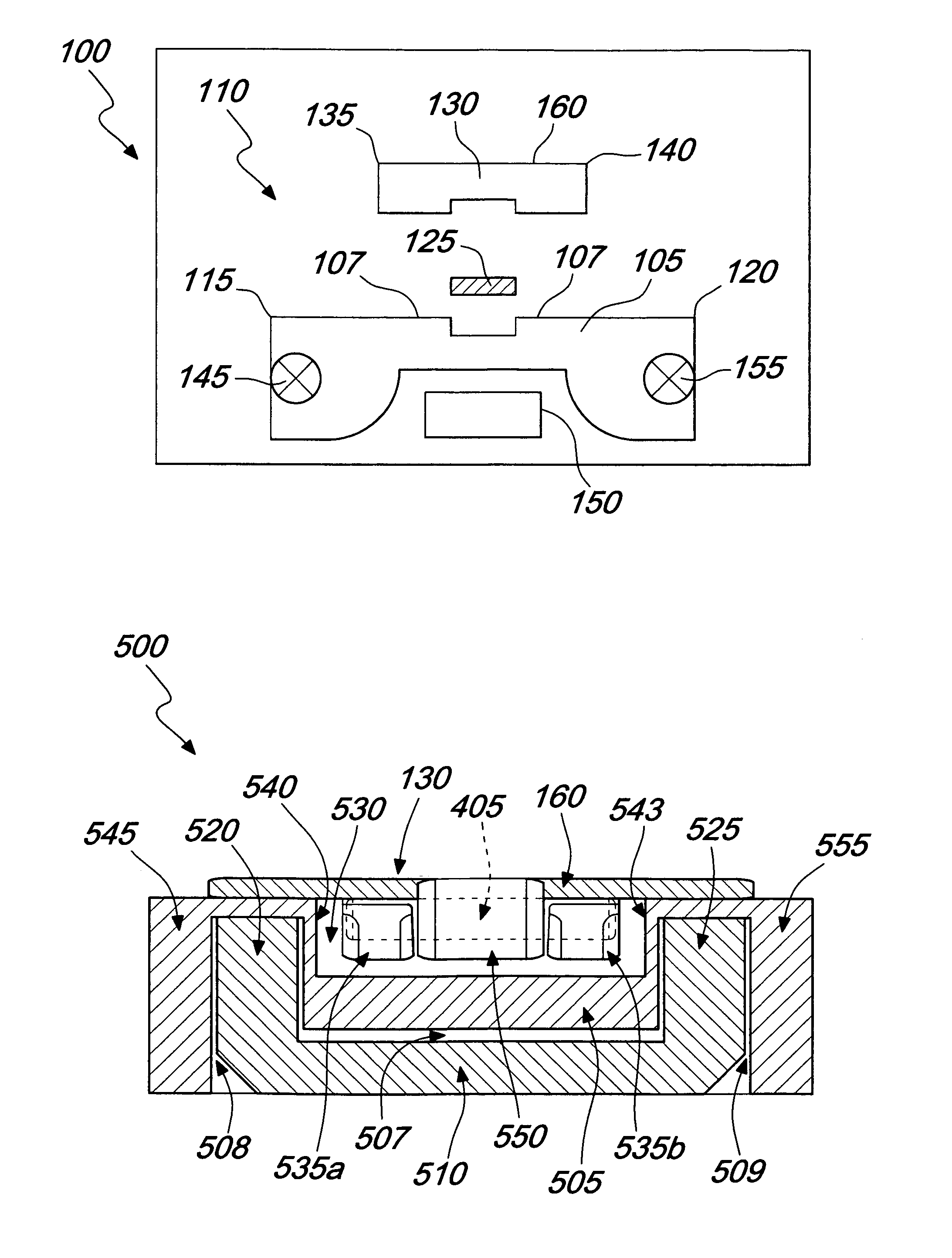

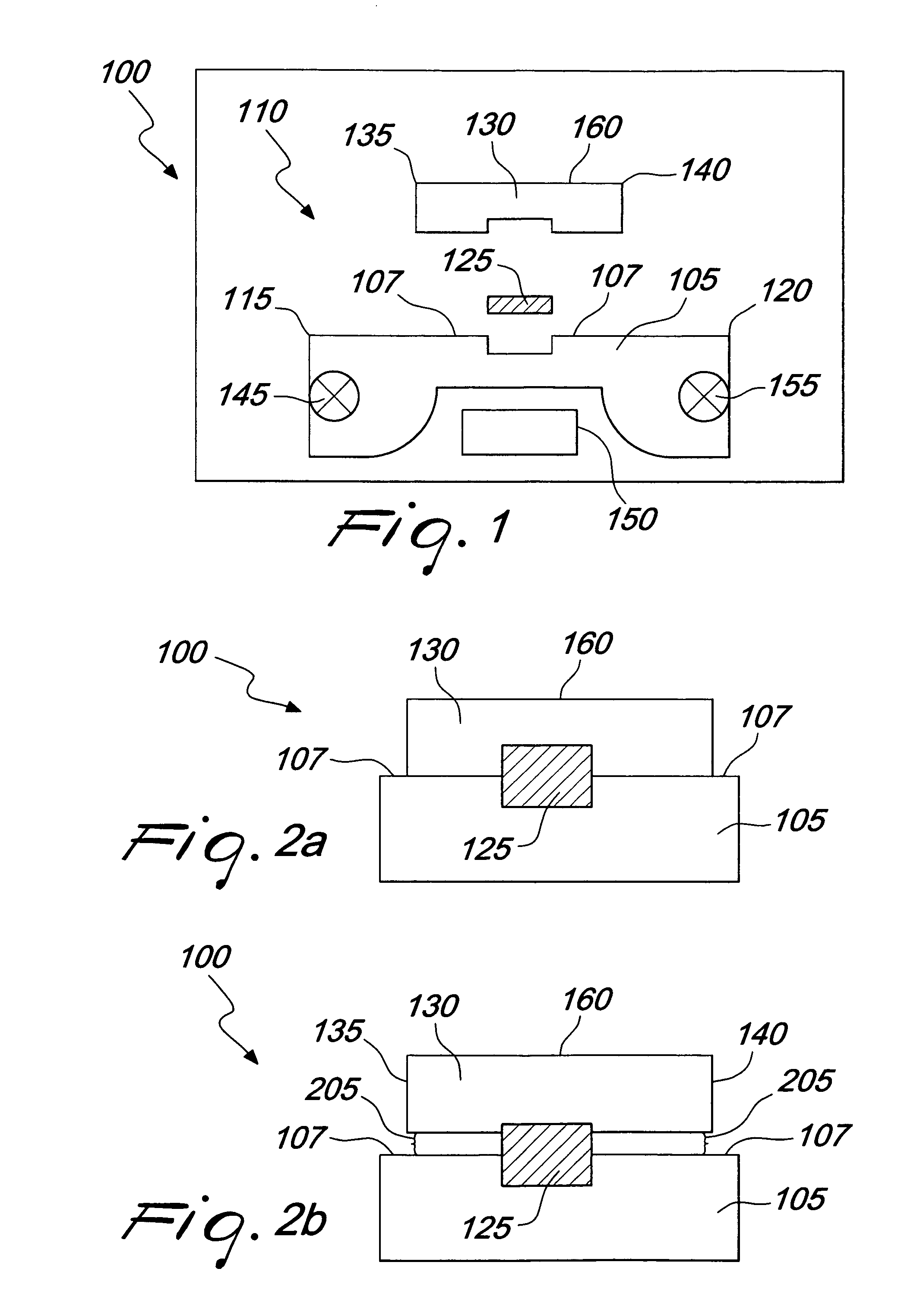

Knee prosthesis with a rotational plate

Knee prosthesis comprising a metal base secured to an anchoring rod for fixing it into a tibia of a patient. A plastic tibia plate is freely slidable over the base. The metal base and the tibia plate are equipped with a guide mechanism defining a center of rotation offset from that of a tibia bone axis, so as to allow the plate to slide in rotation over the base. The guide mechanism is positioned a given distance from the center of rotation. The metal base comprises an upstand in the shape of an arc of a circle having a central part secured to lateral edges which are shorter than the central part. The tibia plate comprises, on a lower face thereof, a housing in the shape of an arc of a circle.

Owner:CORIN

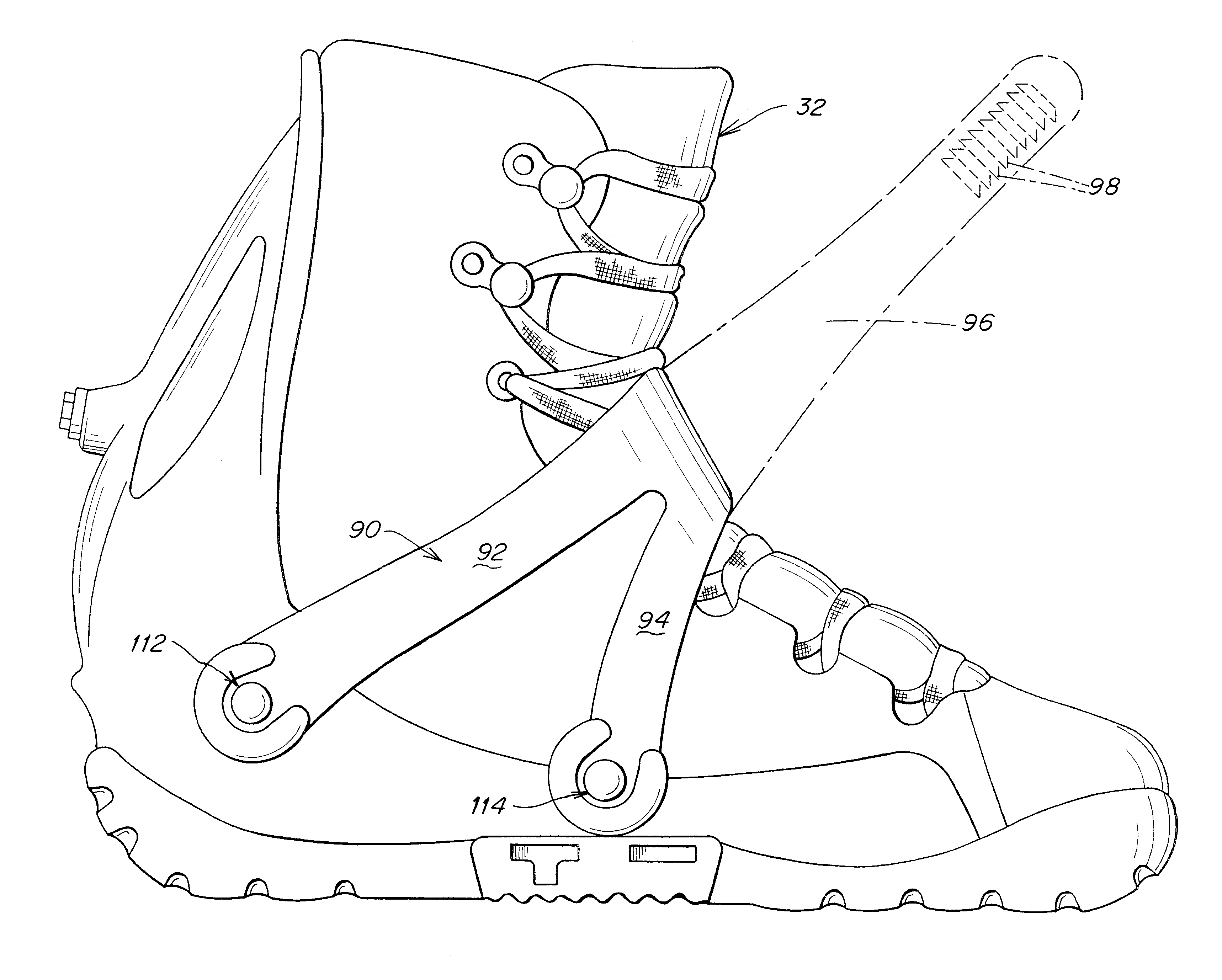

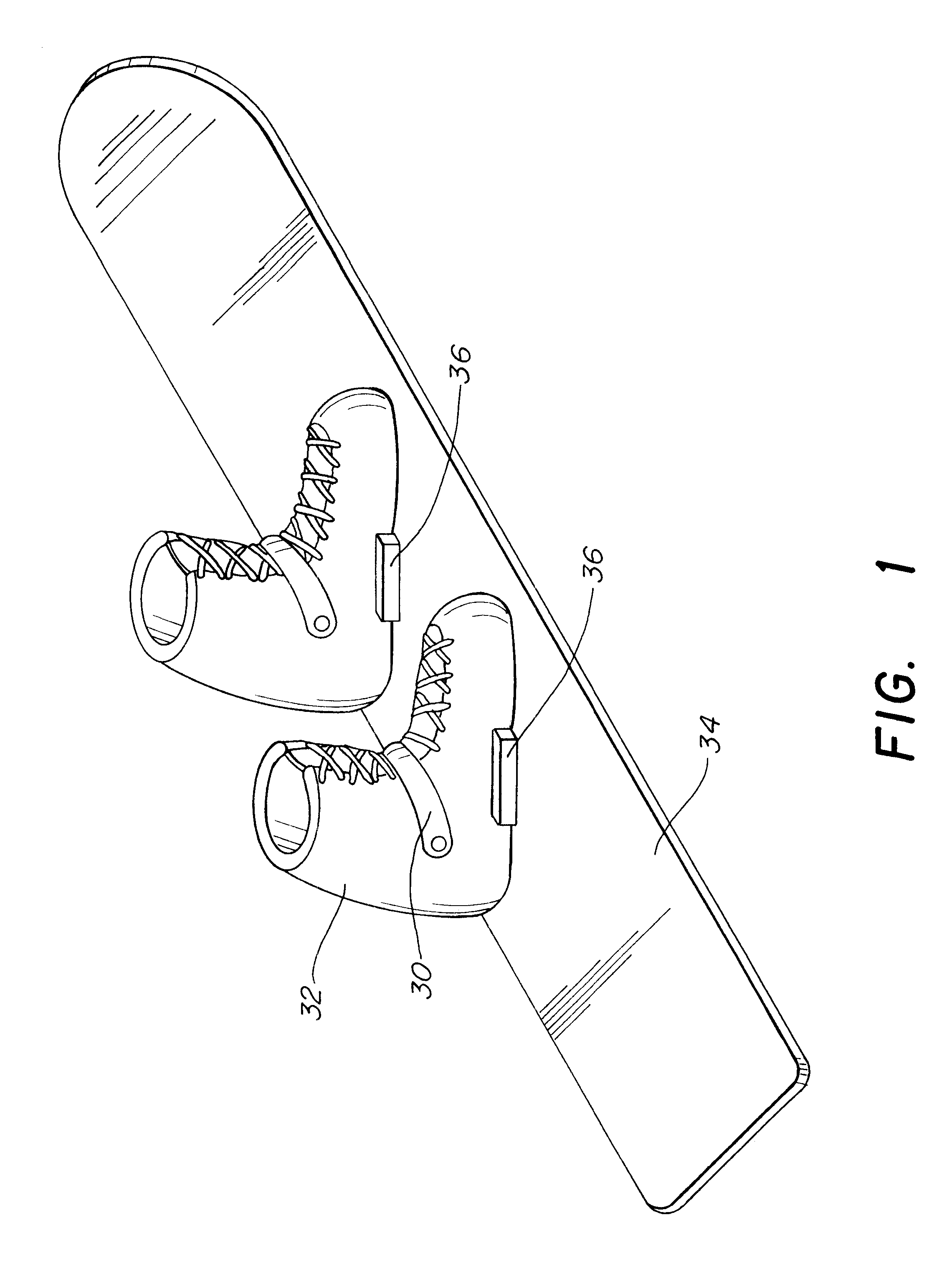

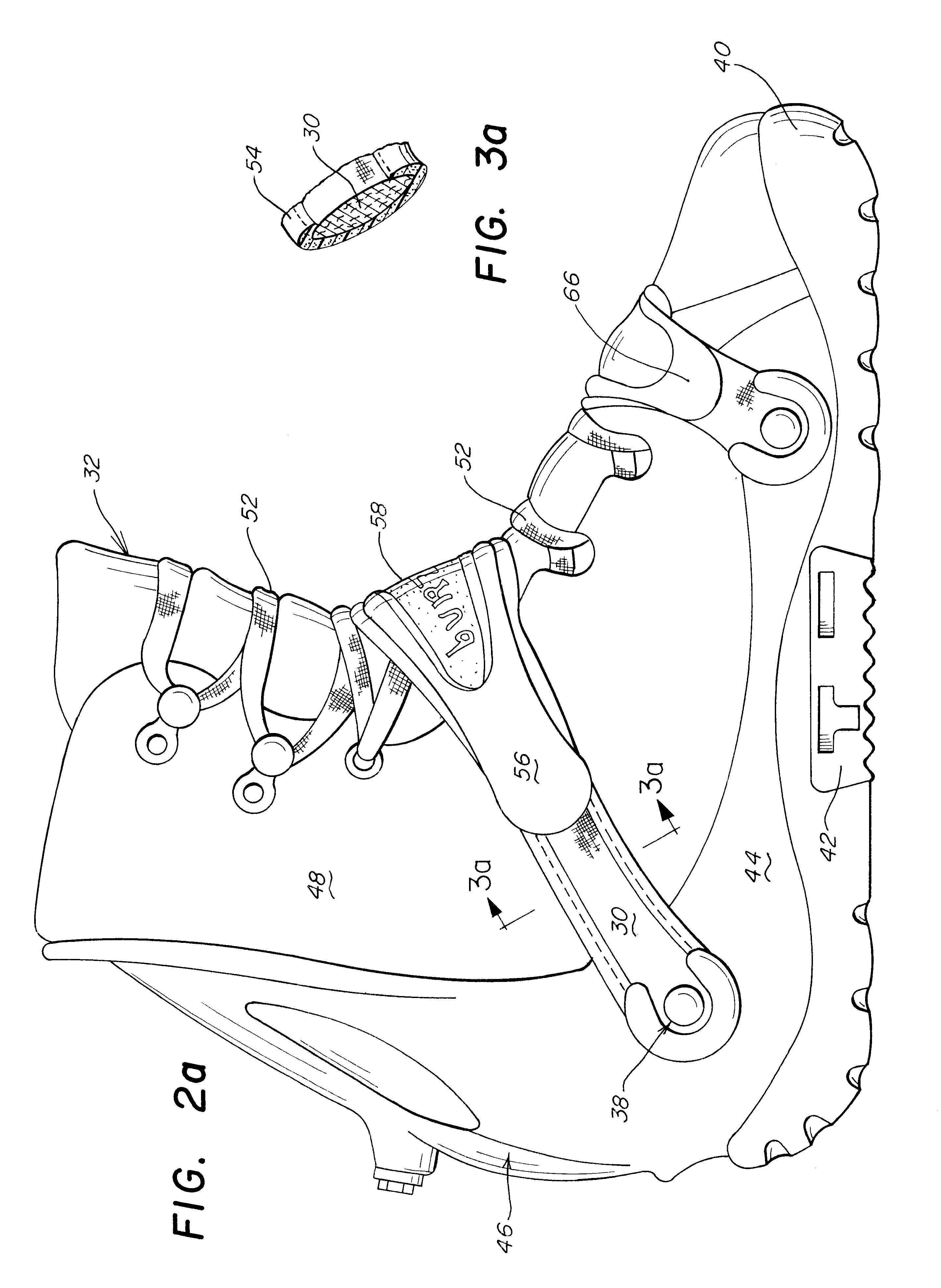

Snowboard boot and binding strap

One aspect of the invention is a removable strap for a snowboard boot to preventing the rider's foot from lifting in the boot. The ankle strap enables a soft boot to be used with both a strap-less step-in binding system, and a strap binding system. Another aspect is a snowboard binding including a strap adapted to releasably secure the snowboard boot and constructed and arranged to avoid creation of a pressure point at an instep bone of the rider. A further aspect is an apparatus comprising a snowboard boot and a strap attached thereto. The strap is arranged to prevent the rider's heel from lifting in the snowboard boot, and is constructed and arranged to avoid creation of a pressure point at an instep bone of the rider.

Owner:BURTON USA

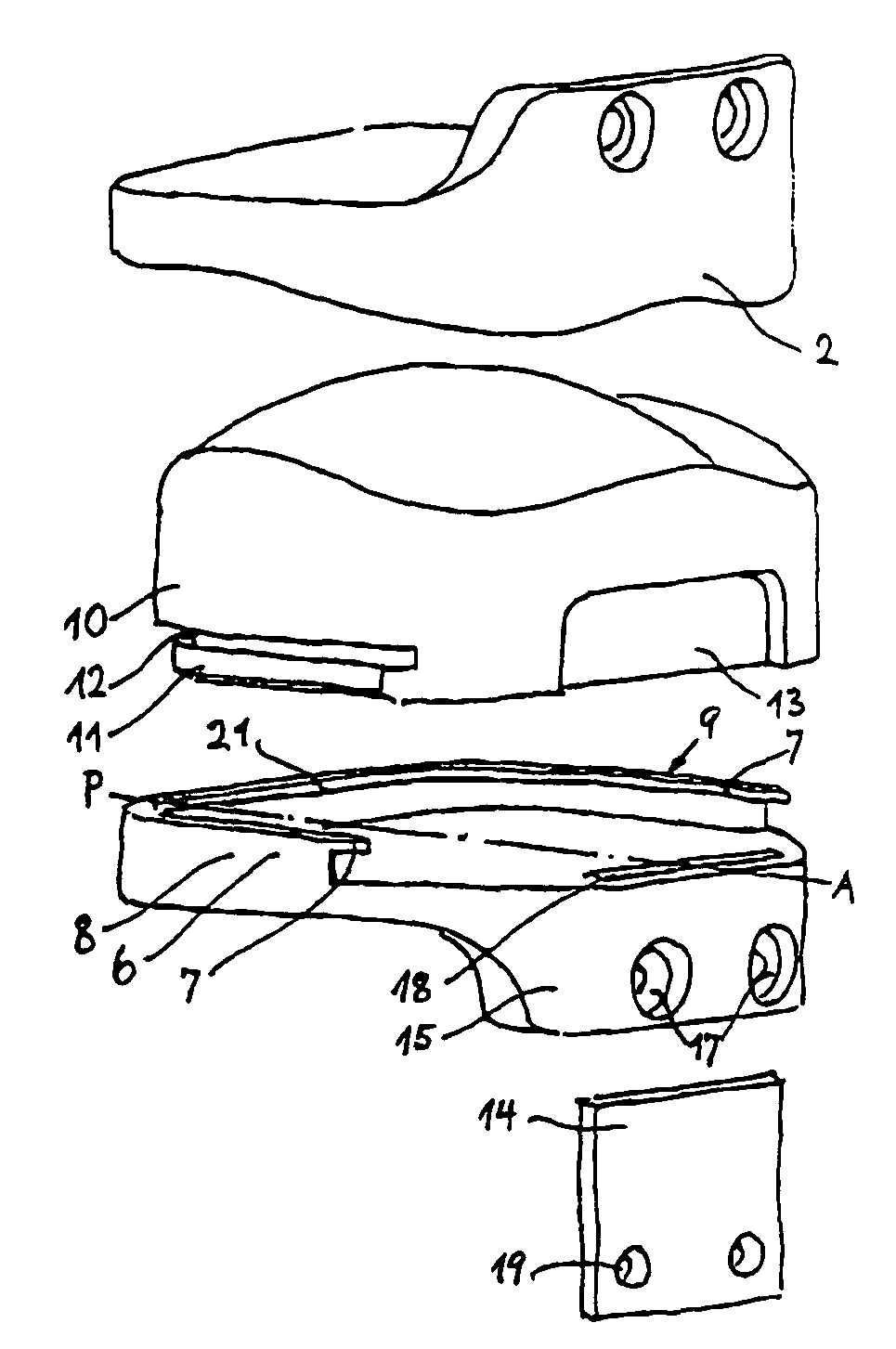

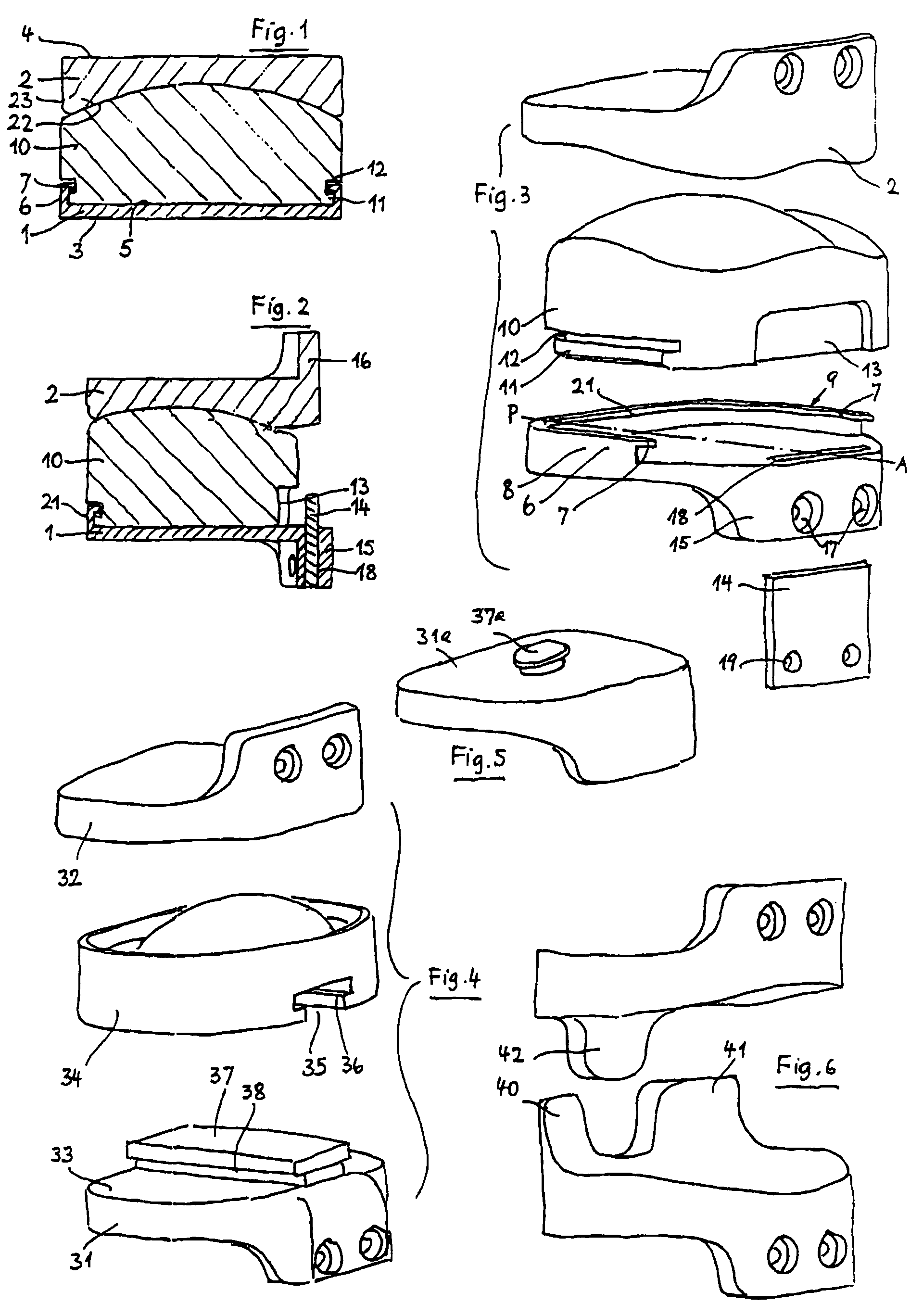

Knee prosthesis with a rotational plate

InactiveUS20060015185A1Avoid liftingShort heightJoint implantsKnee jointsPhysical medicine and rehabilitationKnee Joint

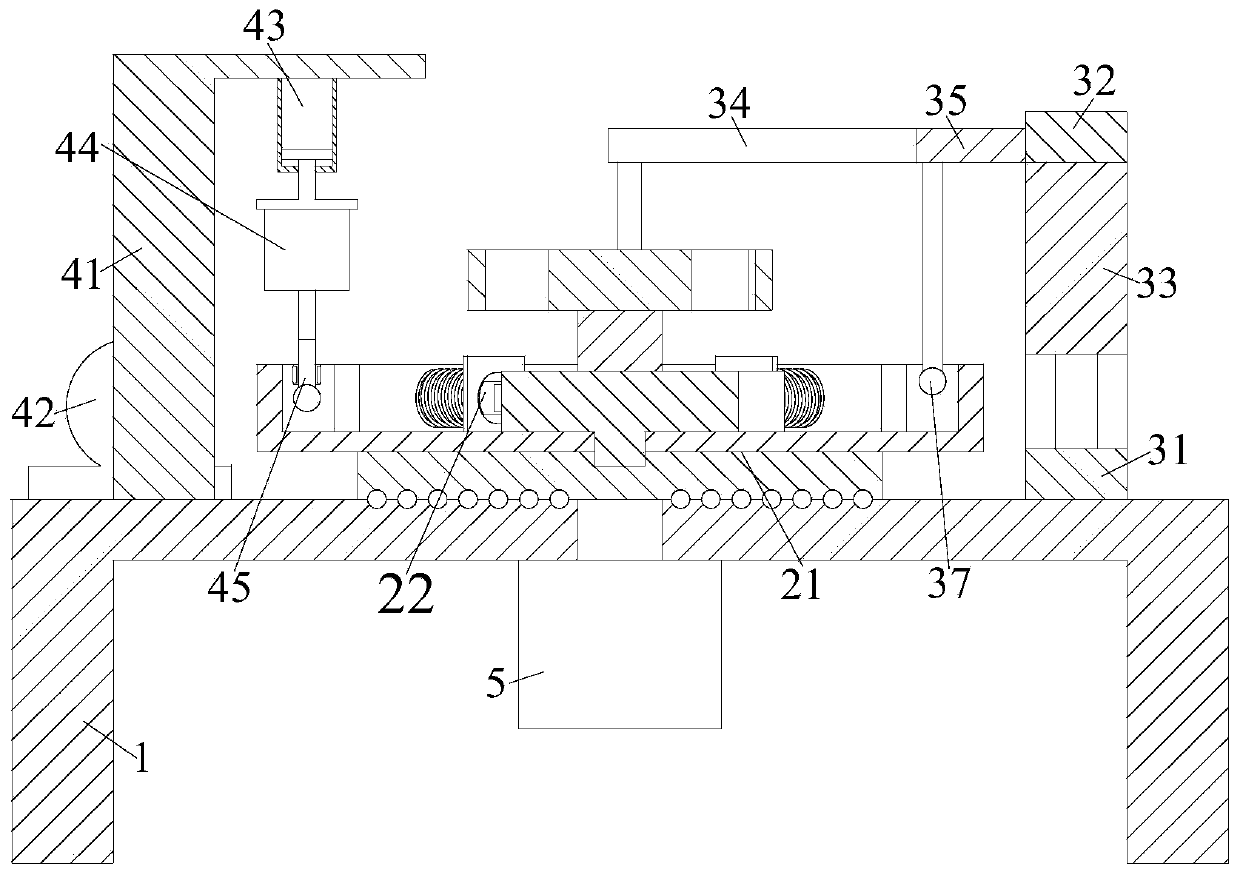

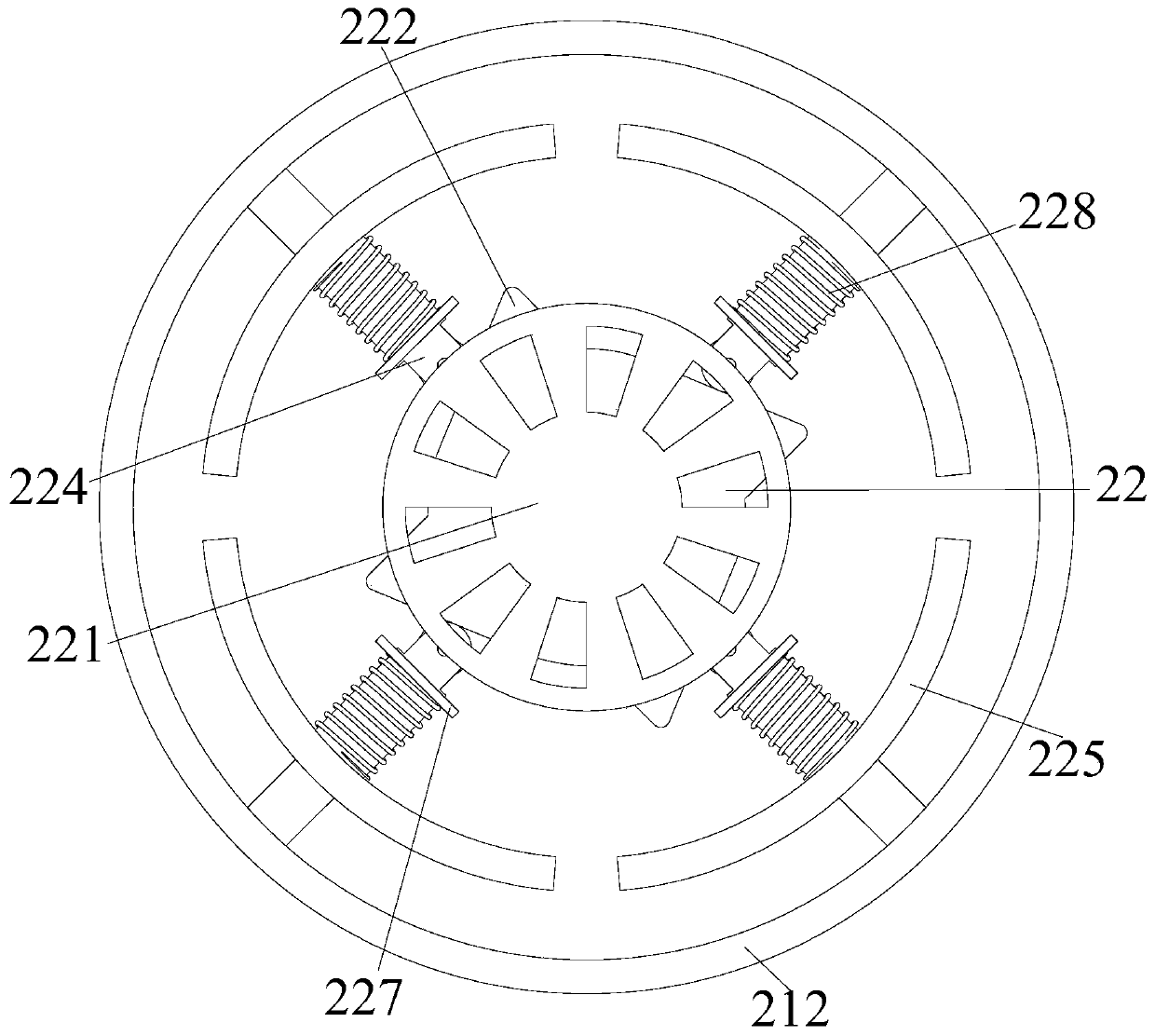

The knee prosthesis with rotary plate comprises a metal base (2) and a tibia plate (3) which are equipped with guide means (22, 22′, 22″, 26, 29, 5, 6, 5′, 9, 50, 51, 52, 13, 15, 18; 34, 34′, 34″, 35, 37, 7, 8, 10, 12, 53, 54, 55, 10′, 17) defining a center of rotation (C, C′) which may be offset from that of the tibia bone axis (YY′), so as to allow the tibia plate (3) to slide in rotation over the said base, the said guide means being positioned a certain distance away from the center of rotation (C, C′).

Owner:CORIN

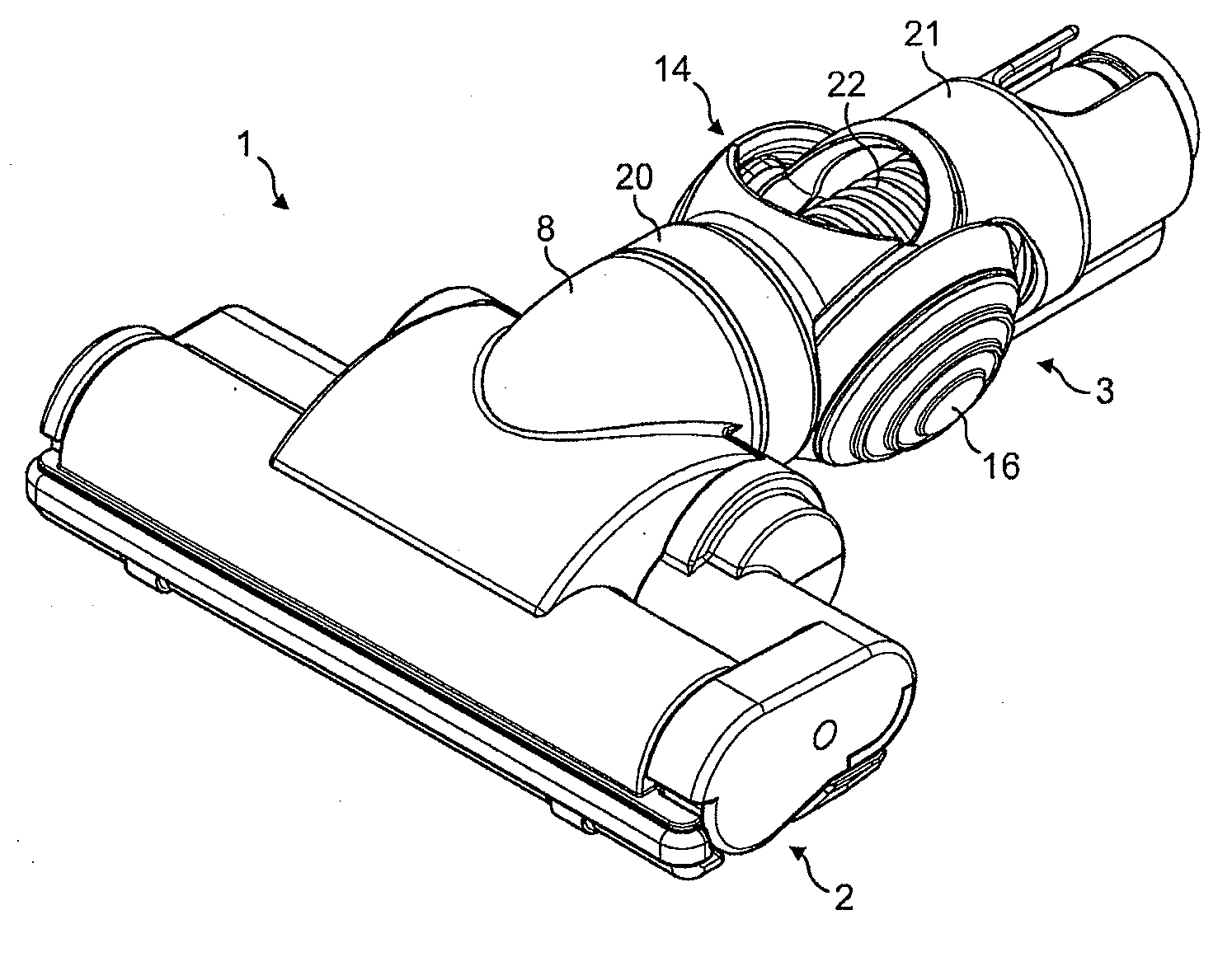

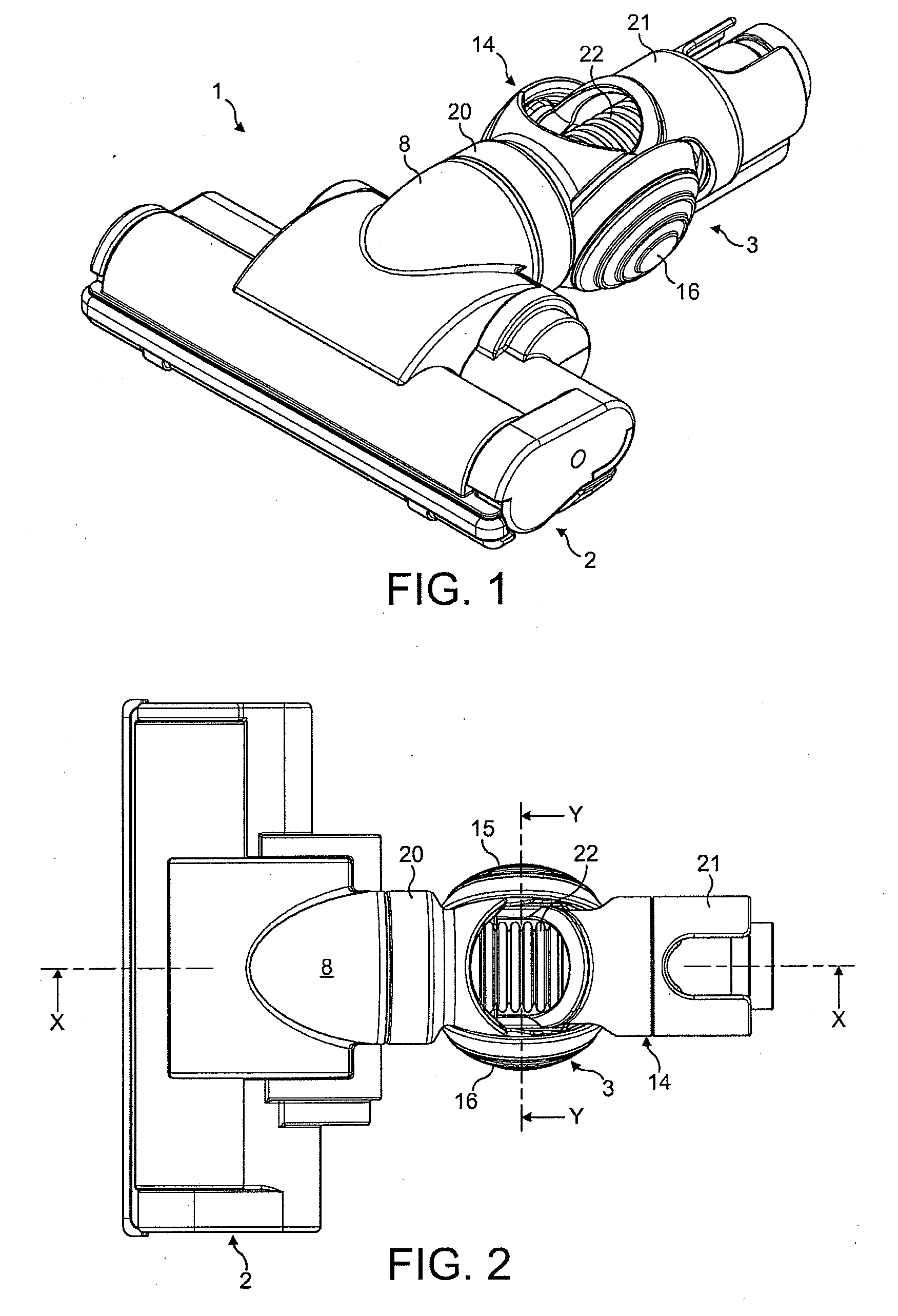

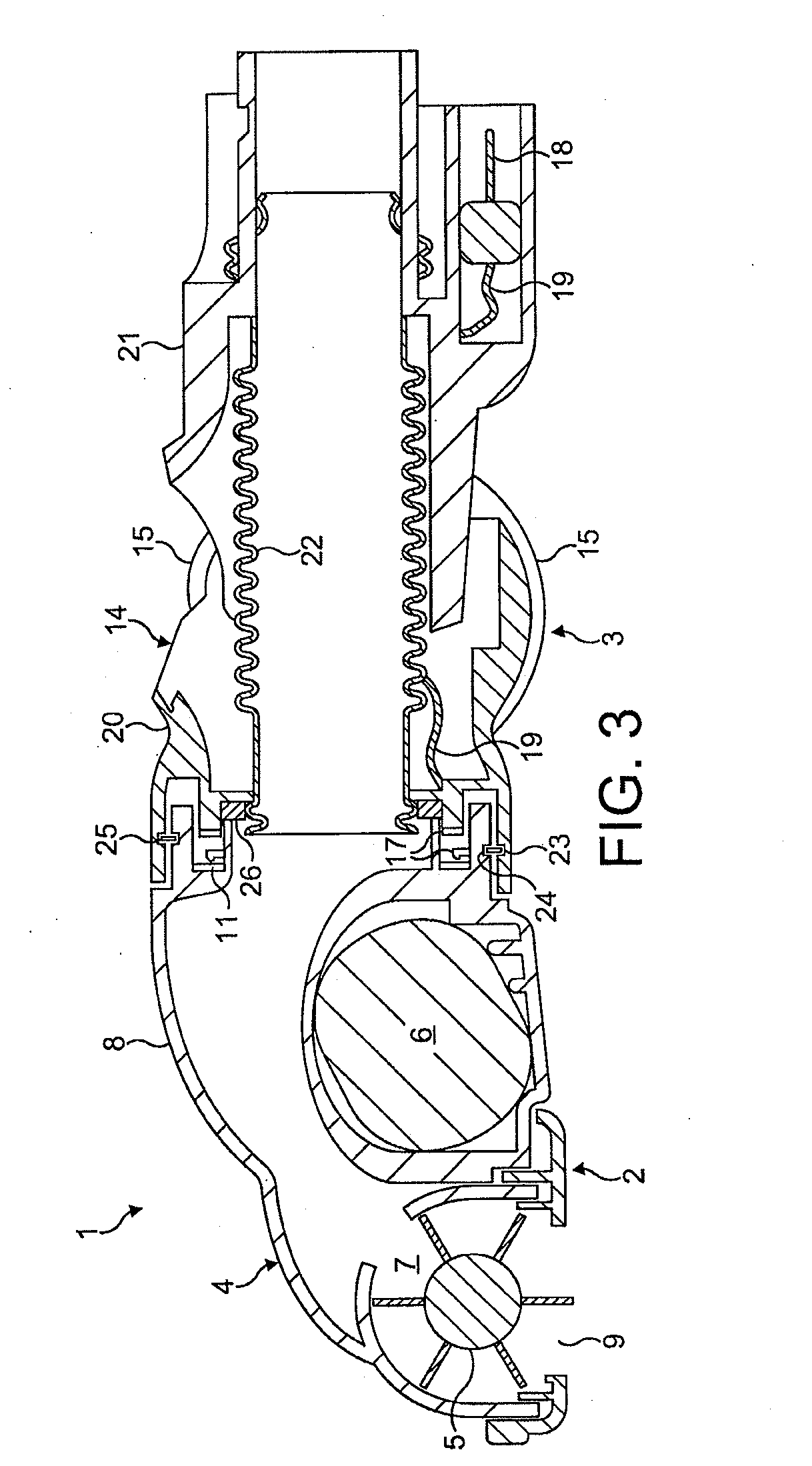

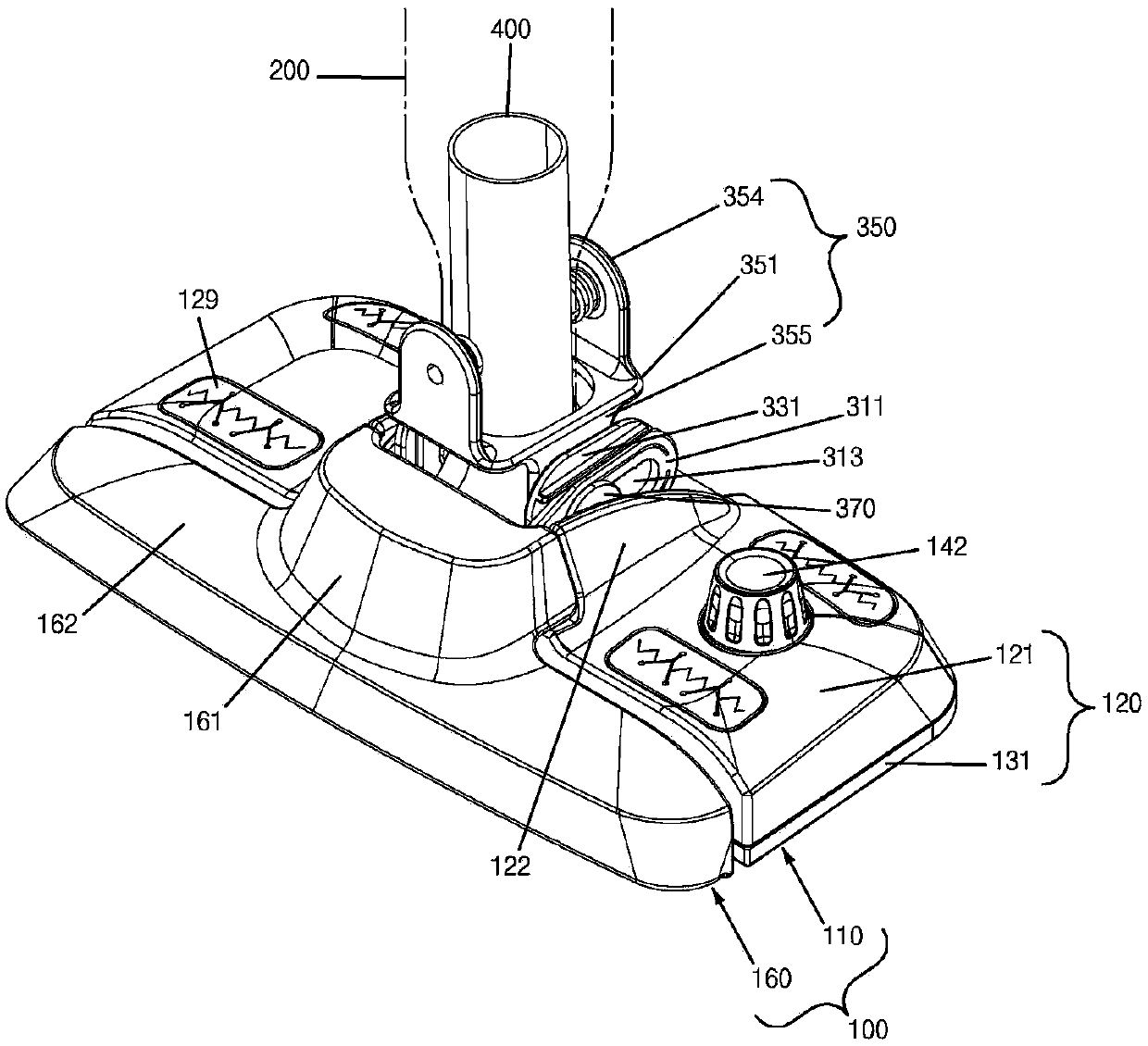

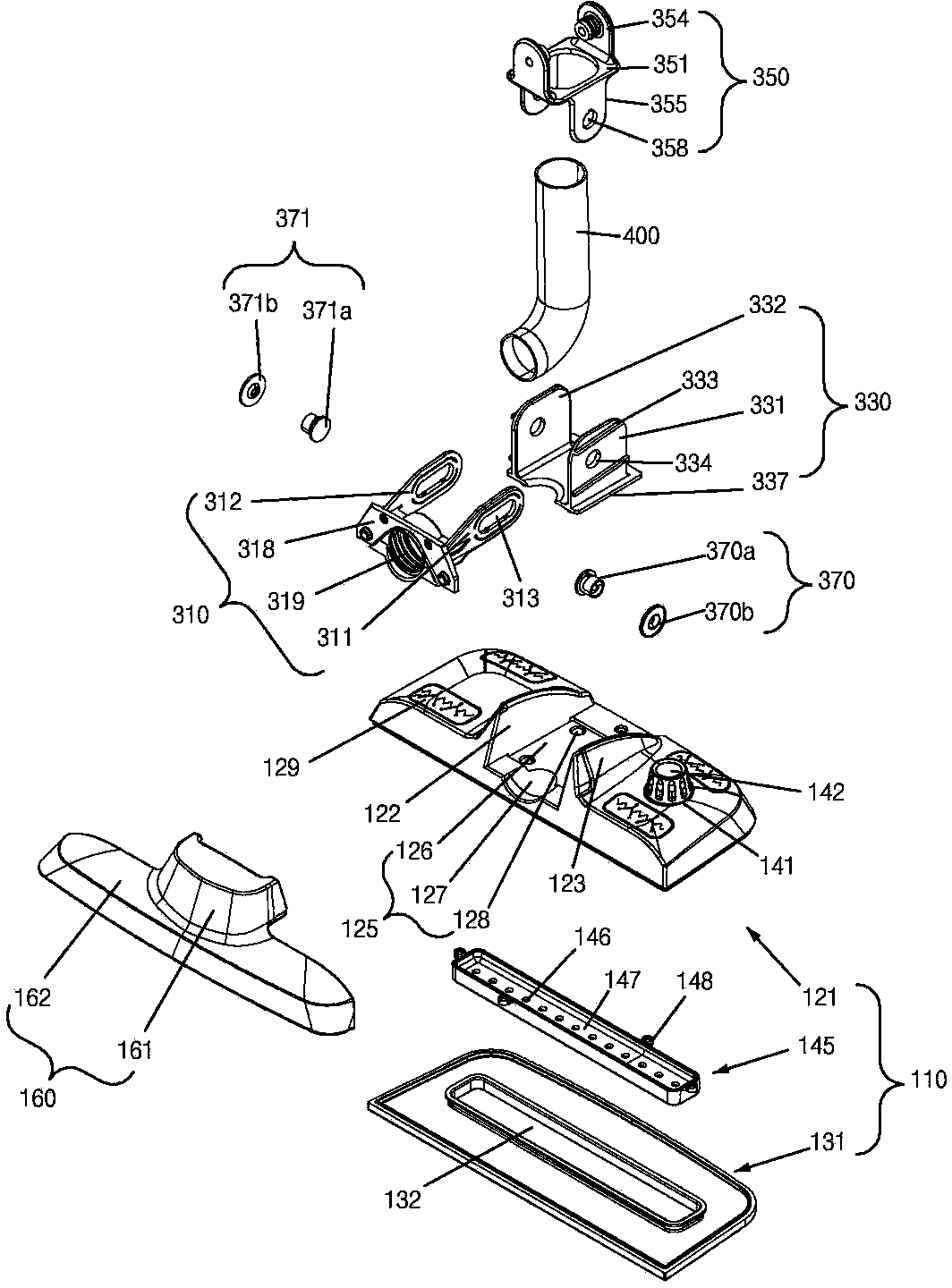

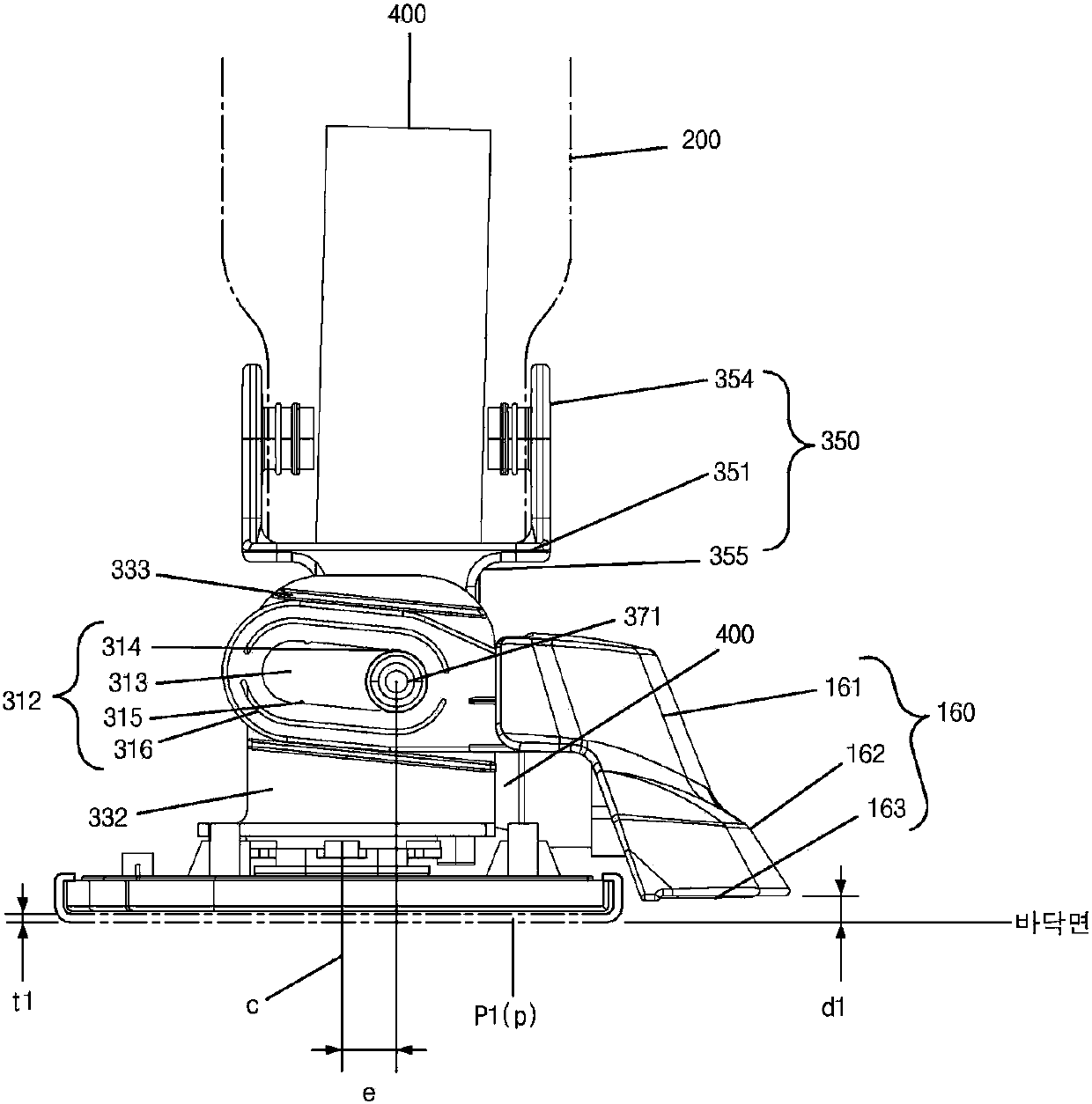

Floor tool for a cleaning appliance

ActiveUS20100154150A1Easy steeringMore compact floor toolBowling gamesCarpet cleanersEngineeringMechanical engineering

Owner:DYSON TECH LTD

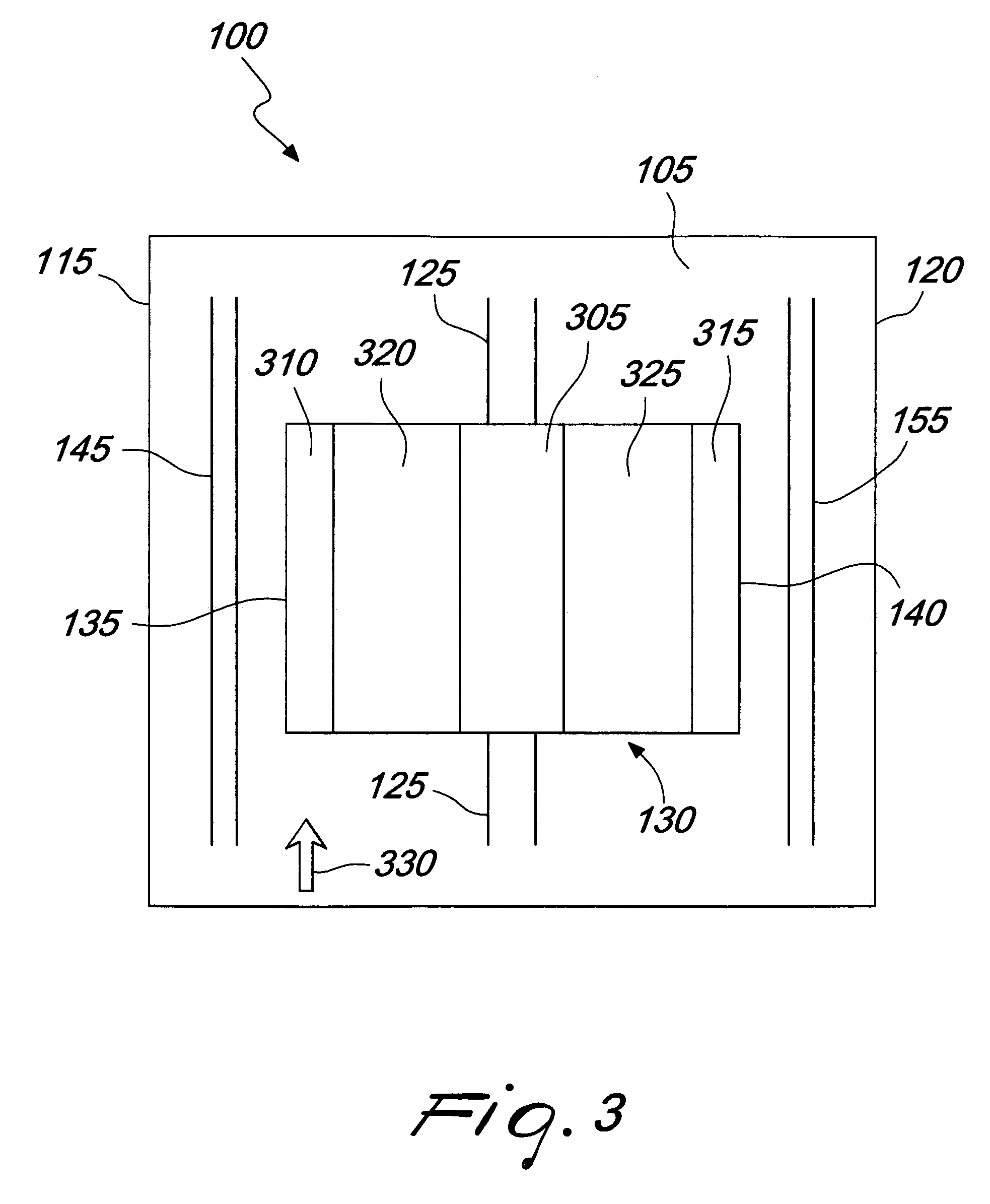

Intervertebral prosthesis system, in particular for the cervical spine

InactiveUS20060190082A1Great freedomAvoid liftingJoint implantsSpinal implantsBiomedical engineeringProsthetic graft

An intervertebral prosthesis system, in particular for the cervical spine, includes at least two types of prothesis. The type of prothesis includes a first cover plate that is configured to be connected to a first vertebral body, a second cover plate that is configured to be connected to a second vertebral body, and a prothesis core which is held by a seat on the first cover plate and forms an articulation with the second cover plate. The core of the first type of prosthesis is movable in the anterior-posterior direction relative to the first cover plate. Mobility can also be provided in the lateral direction and rotational direction. The second type of prosthesis of the system may be the same as the first type of prosthesis or may be different, but in all examples of the second type of prosthesis the core is not movable relative to either cover plate.

Owner:CERVITECH INC

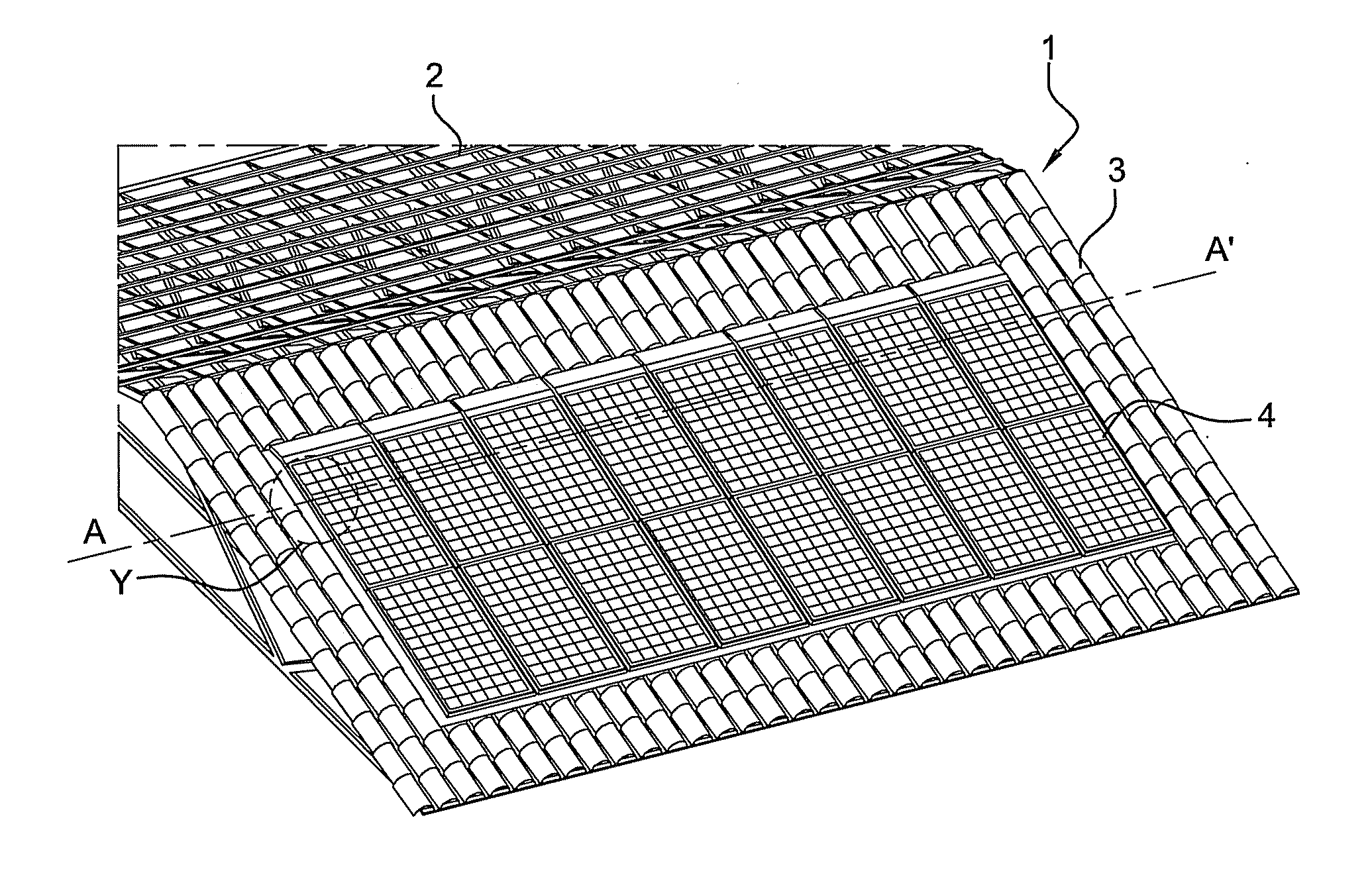

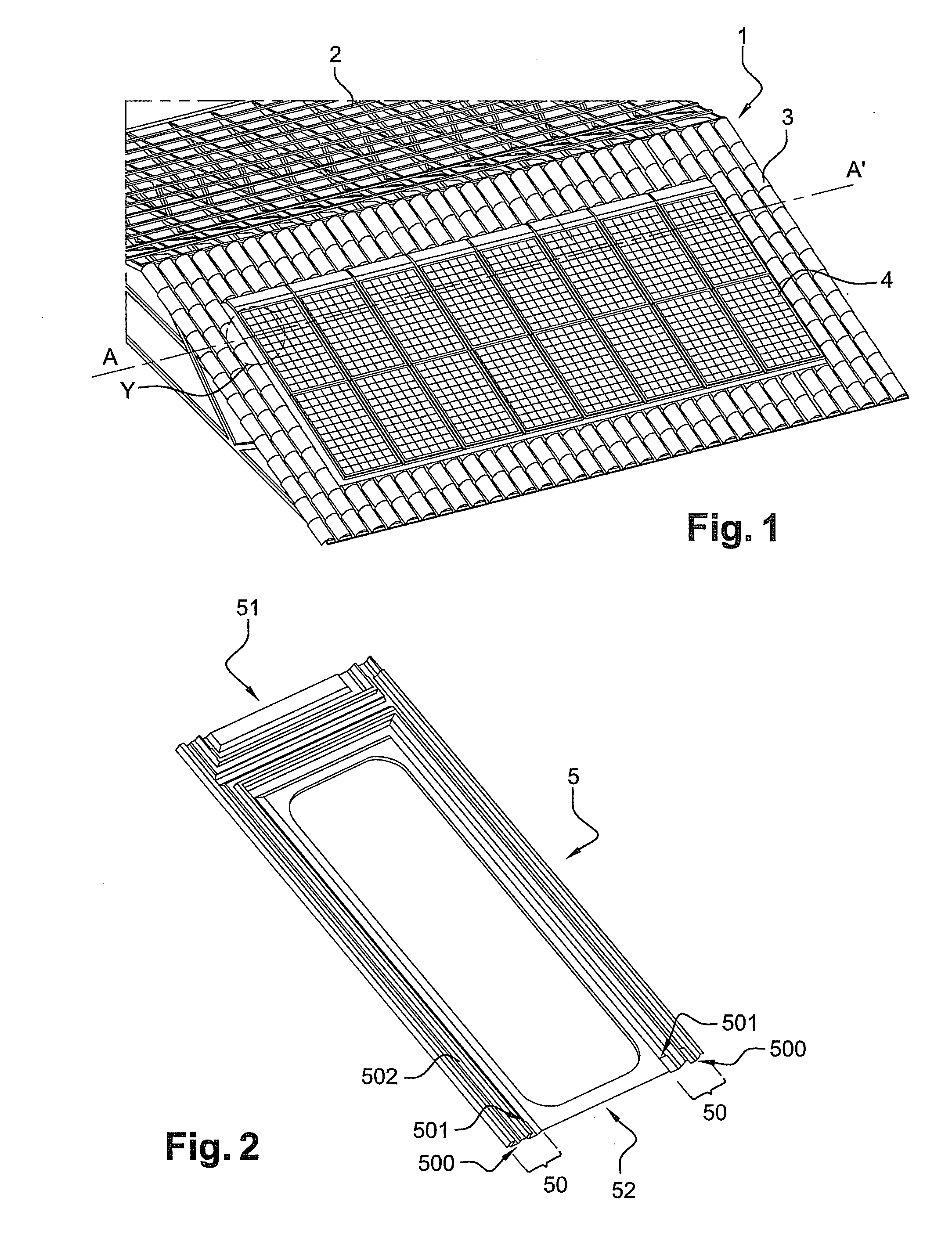

Structure for rigidly connecting solar panels to a fixture

InactiveUS20110302859A1Reduce water penetrationImprove sealingPhotovoltaic supportsSolar heating energyRoof pitchLinear element

A device for integrating solar panels on a fixture, in particular a roofing framework, that includes a plurality of frames intended to accommodate the solar panels, added to the fixture, said frames being defined by a peripheral edge fitted with linear elements that project relative to the plane in which the frames are set; tightening means for holding said panels on the frames; and means for securing the frames to the fixture. The frames are openwork and cover or partially overlap each other on the edges which define them, laterally on the one hand and in the direction of the roof pitch on the other hand, the projecting linear elements with which they are fitted cooperating with each other to form a barrier seal.

Owner:INSTITUT DE RECH FONDAMENTALE & TECH SOLAIRES - IRFTS

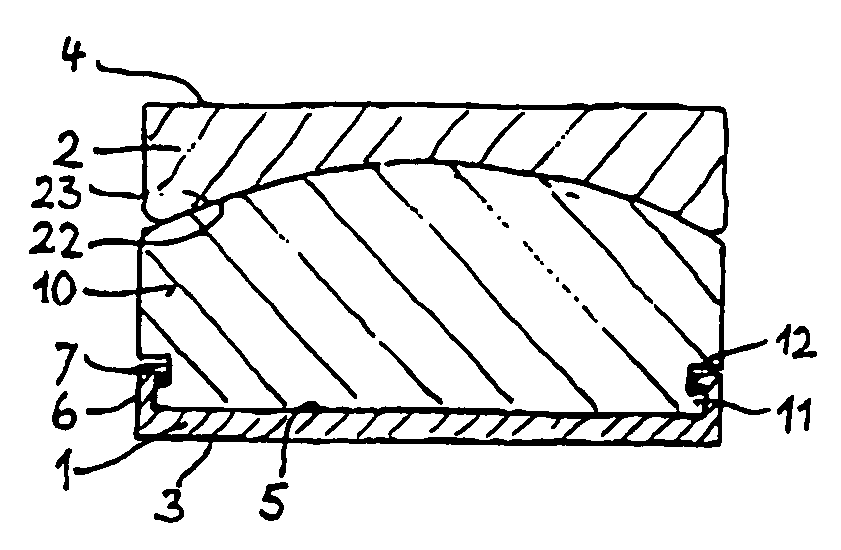

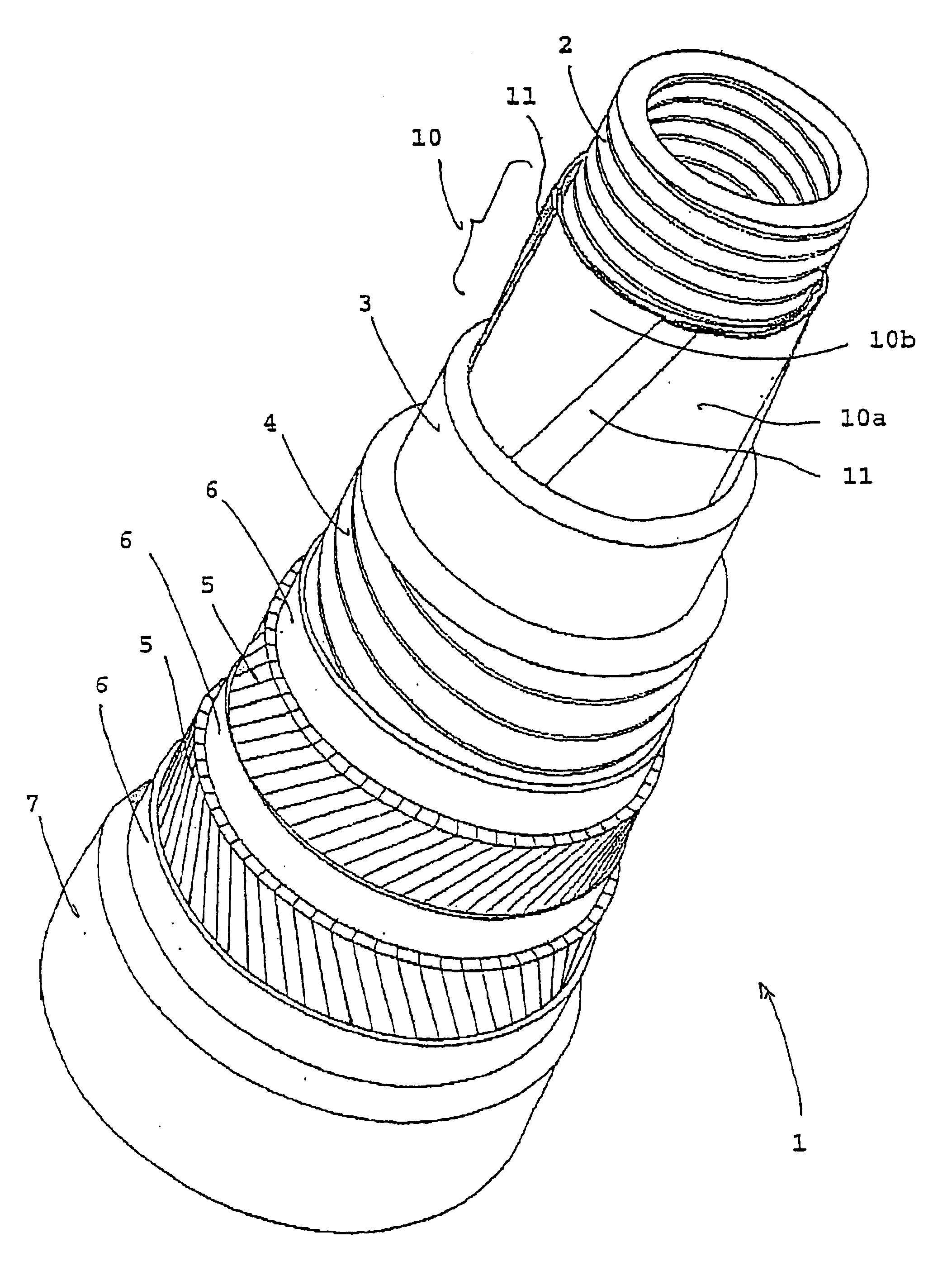

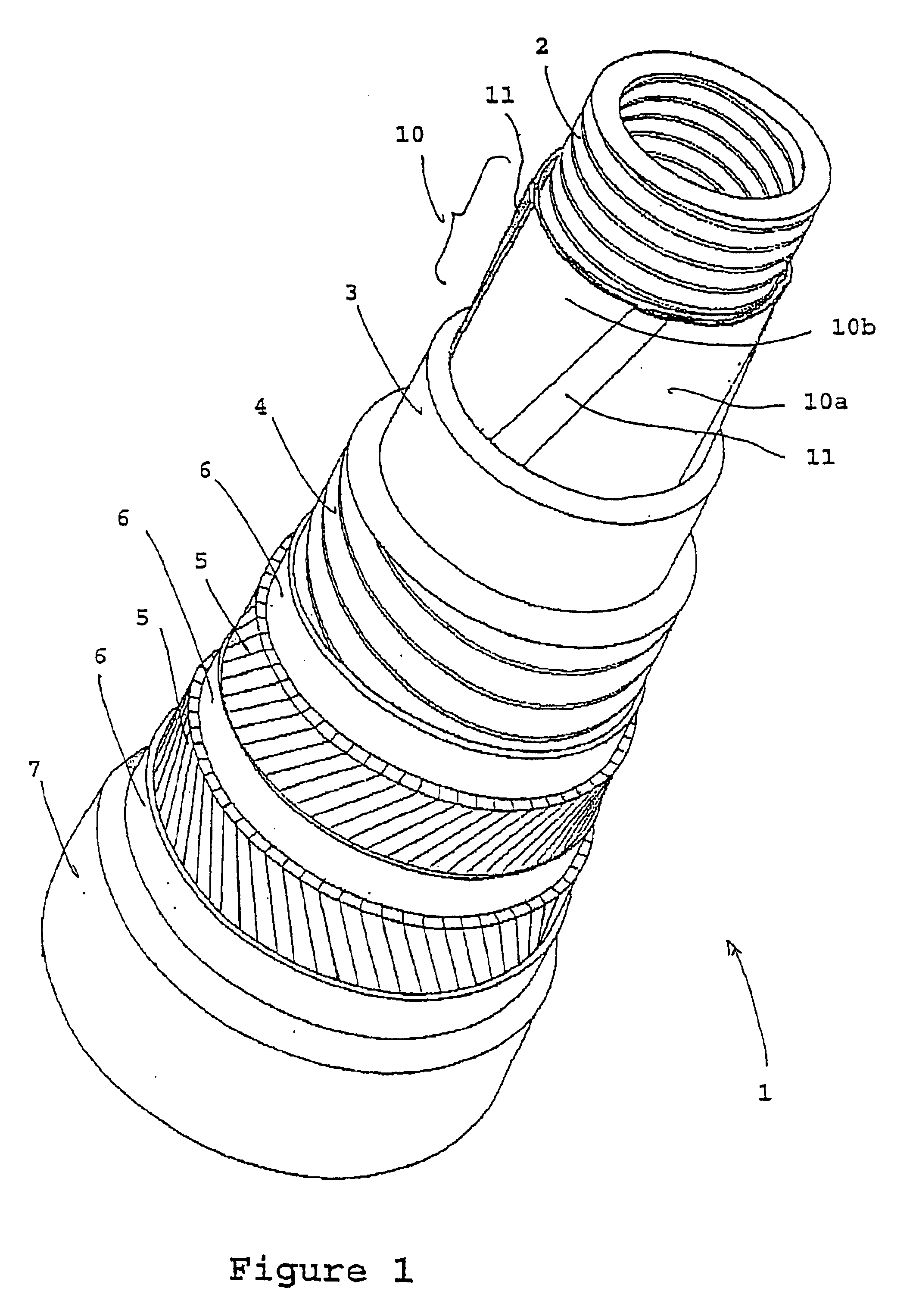

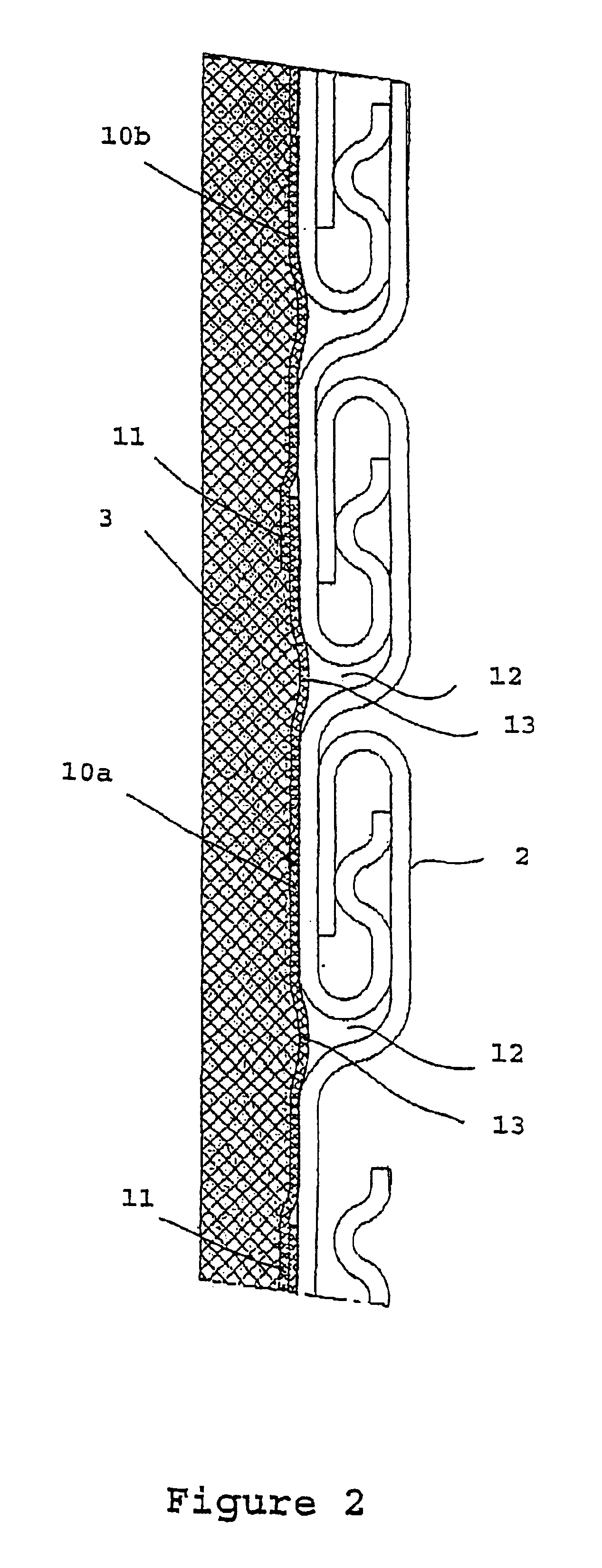

Flexible duct with shrinkage-proof film

The invention concerns a flexible duct (1) comprising from inside outwards a carcass (2) produced by a short-pitched metallic helical winding forming butt gaps (12), an overlapping layer (10) acting as a heat shield consisting of helically wound plastic strips (10a, 10b), a sealed inner pressure sheath (3), extruded in plastic on said overlapping layer (10), at least an armouring web (5) and at least an outer sealing sheath (7). The invention is characterised in that the overlapping strips (10a, 10b) are wound at a winding angle less than 35°.

Owner:TECH FRANCE SA

Container for welding wire

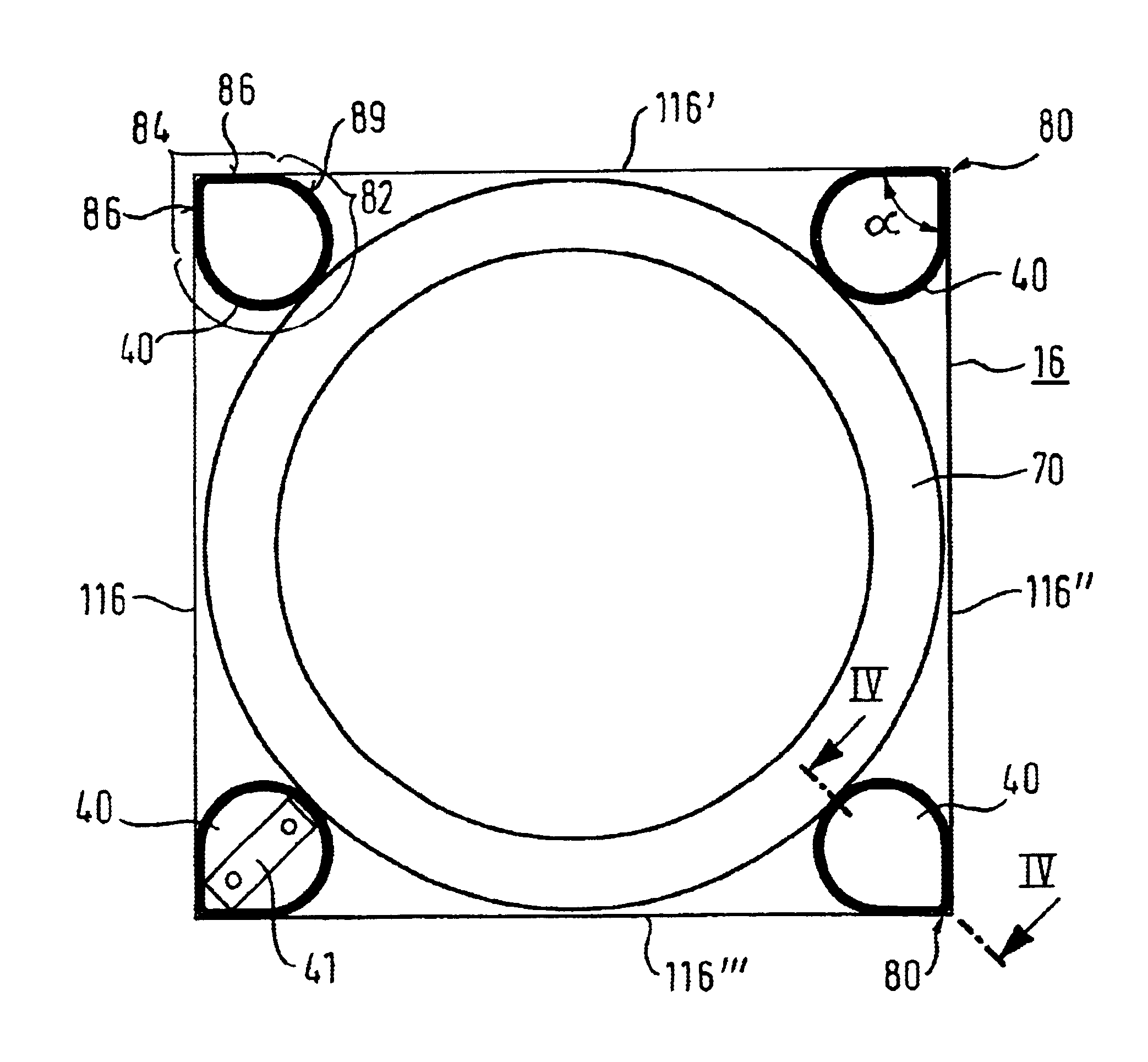

InactiveUS6938767B2Avoid deformationEasily descendContainers for annular articlesFilament handlingEngineeringWelding

A container for welding wire comprises a box-like body having a bottom and a side wall, the side wall having a polygonal cross section with corners, and stabilizing elements arranged at at least some of the corners. The stabilizing elements extend upwardly from the bottom and have an outer shell portion comprising a corner portion facing the adjacent side wall and an inner portion facing an interior of the container for housing welding wire. The corner portion has a shape adapted to the shape of the adjacent corner. The inner portion defines a continuous inner wall.

Owner:SIDERGAS

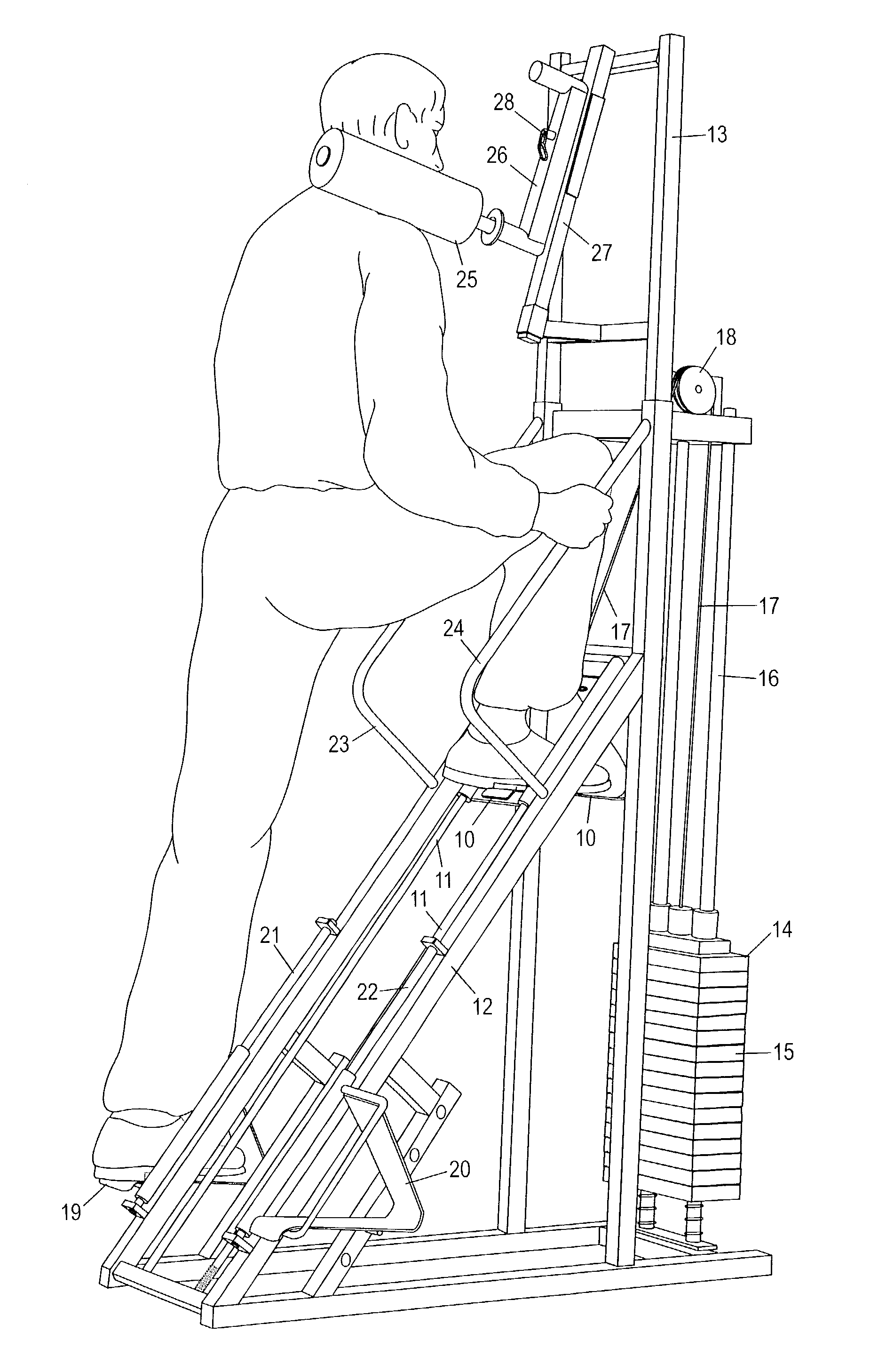

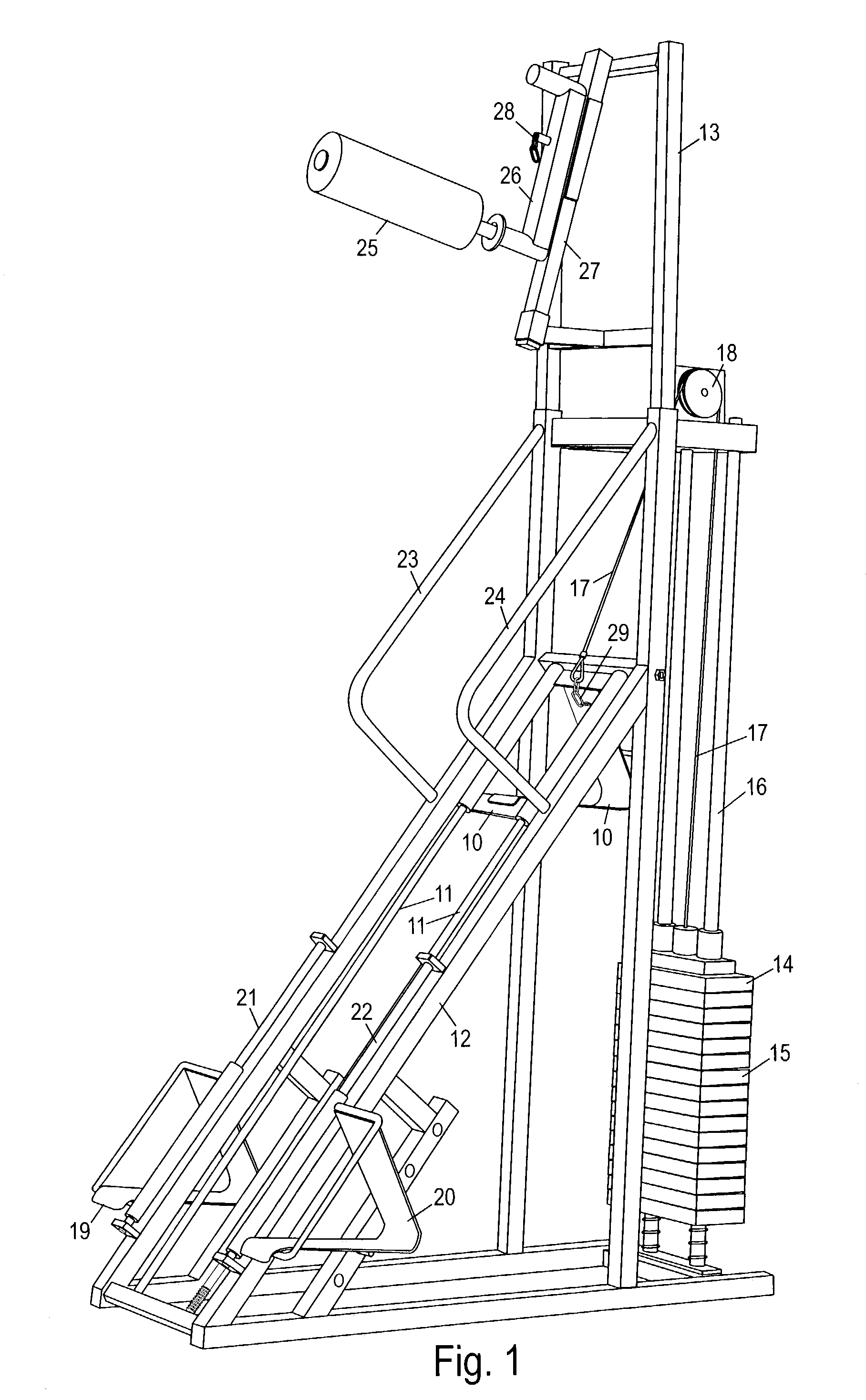

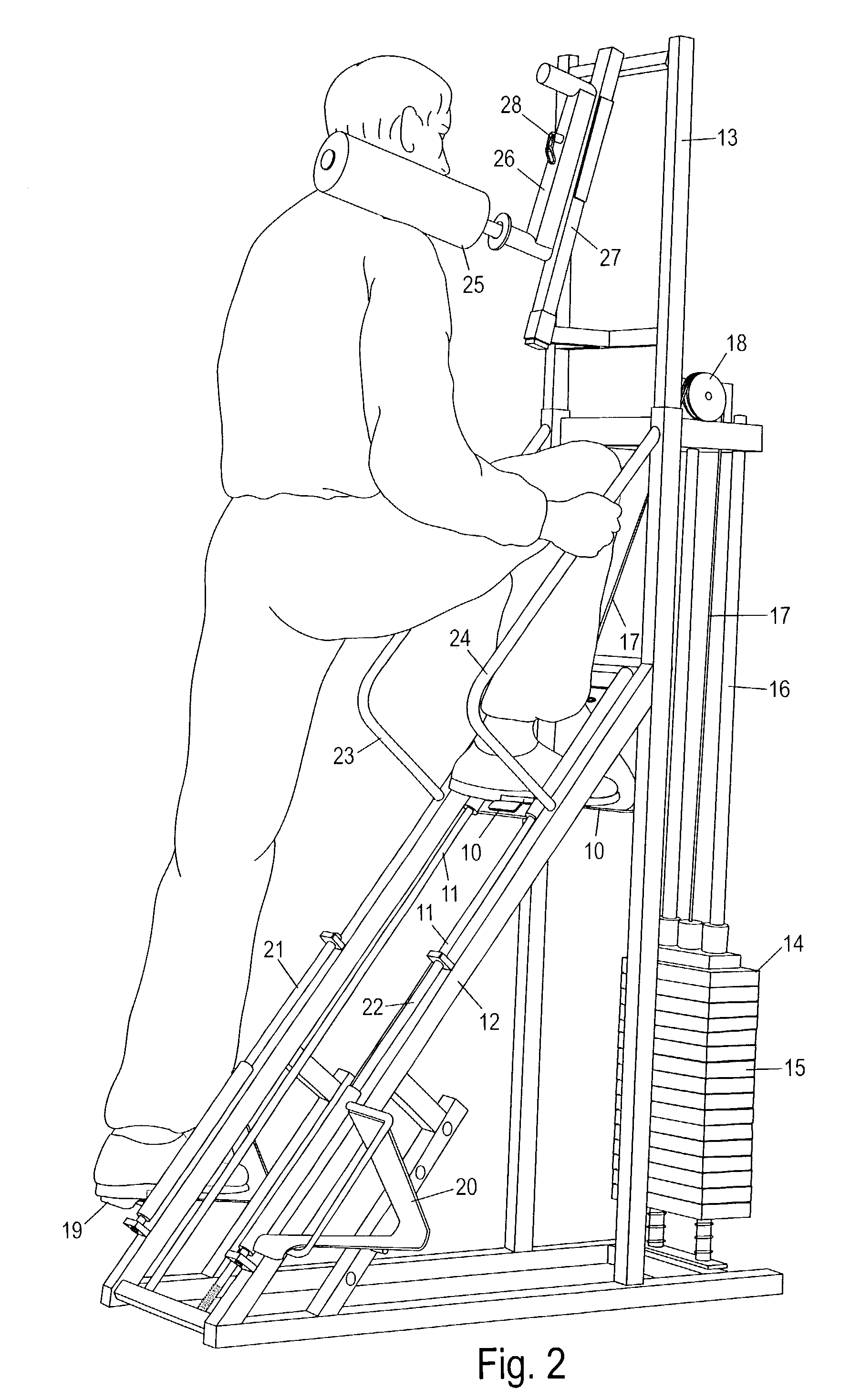

Standing single leg press exercise machine

A standing single leg press exercise machine is comprised of a single movable step arranged to move up and down along an inclined path for exercising only one leg at a time. A resistance mechanism is connected to the movable step for providing resistance to movement. Two stationary steps are positioned on either side of the bottom position of the movable step. Hand rails are also positioned on either side of movable step. A shoulder pad is positioned above the movable step. A method for using the leg press is comprised of standing on one of the stationary steps with a stationary leg, and repeatedly operating the movable step up and down with an active leg. The active leg is exercised until it is tired, and the legs are switched to exercise the previously stationary leg while the previously active leg is rested.

Owner:ADAMS FREDERICK R

Knee prosthesis with a rotational plate

InactiveUS7951204B2Avoid liftingShort heightJoint implantsKnee jointsTibiaPhysical medicine and rehabilitation

The knee prosthesis with rotary plate comprises a metal base (2) and a tibia plate (3) which are equipped with guide means (22, 22′, 22″, 26, 29, 5, 6, 5′, 9, 50, 51, 52, 13, 15, 18; 34, 34′, 34″, 35, 37, 7, 8, 10, 12, 53, 54, 55, 10′, 17) defining a center of rotation (C,C′) which may be offset from that of the tibia bone axis (YY′), so as to allow the tibia plate (3) to slide in rotation over the said base, the said guide means being positioned a certain distance away from the center of rotation (C, C′).

Owner:CORIN

Intervertebral prosthesis system, in particular for the cervical spine

InactiveUS7862614B2Great freedomUnified configurationJoint implantsSpinal implantsMedicineProsthesis

An intervertebral prosthesis system, in particular for the cervical spine, includes at least two types of prostheses. The type of prosthesis includes a first cover plate that is configured to be connected to a first vertebral body, a second cover plate that is configured to be connected to a second vertebral body, and a prosthesis core which is held by a seat on the first cover plate and forms an articulation with the second cover plate. The core of the first type of prosthesis is movable in the anterior-posterior direction relative to the first cover plate. Mobility can also be provided in the lateral direction and rotational direction. The second type of prosthesis of the system may be the same as the first type of prosthesis or may be different, but in all examples of the second type of prosthesis the core is not movable relative to either cover plate.

Owner:CERVITECH INC

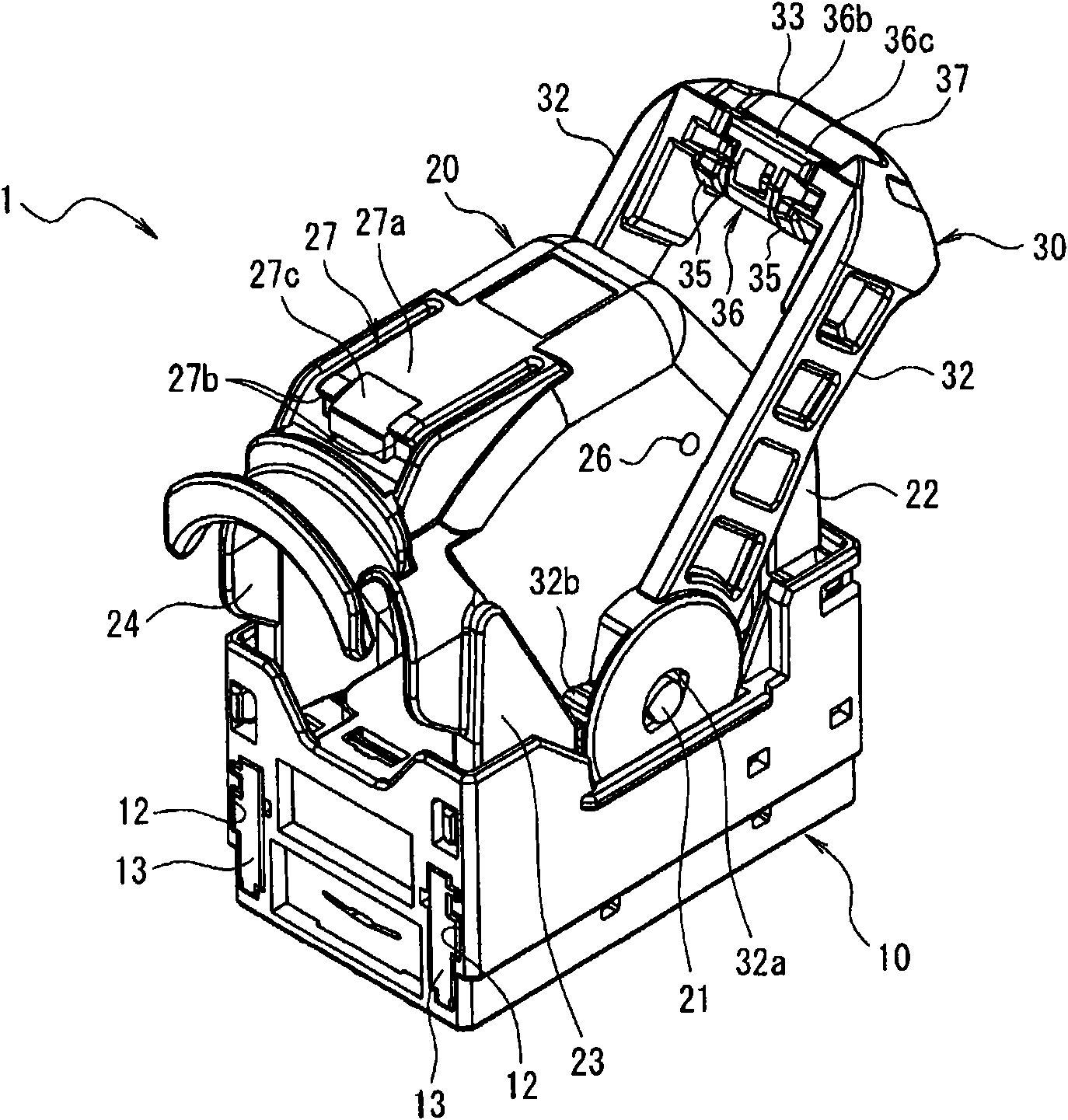

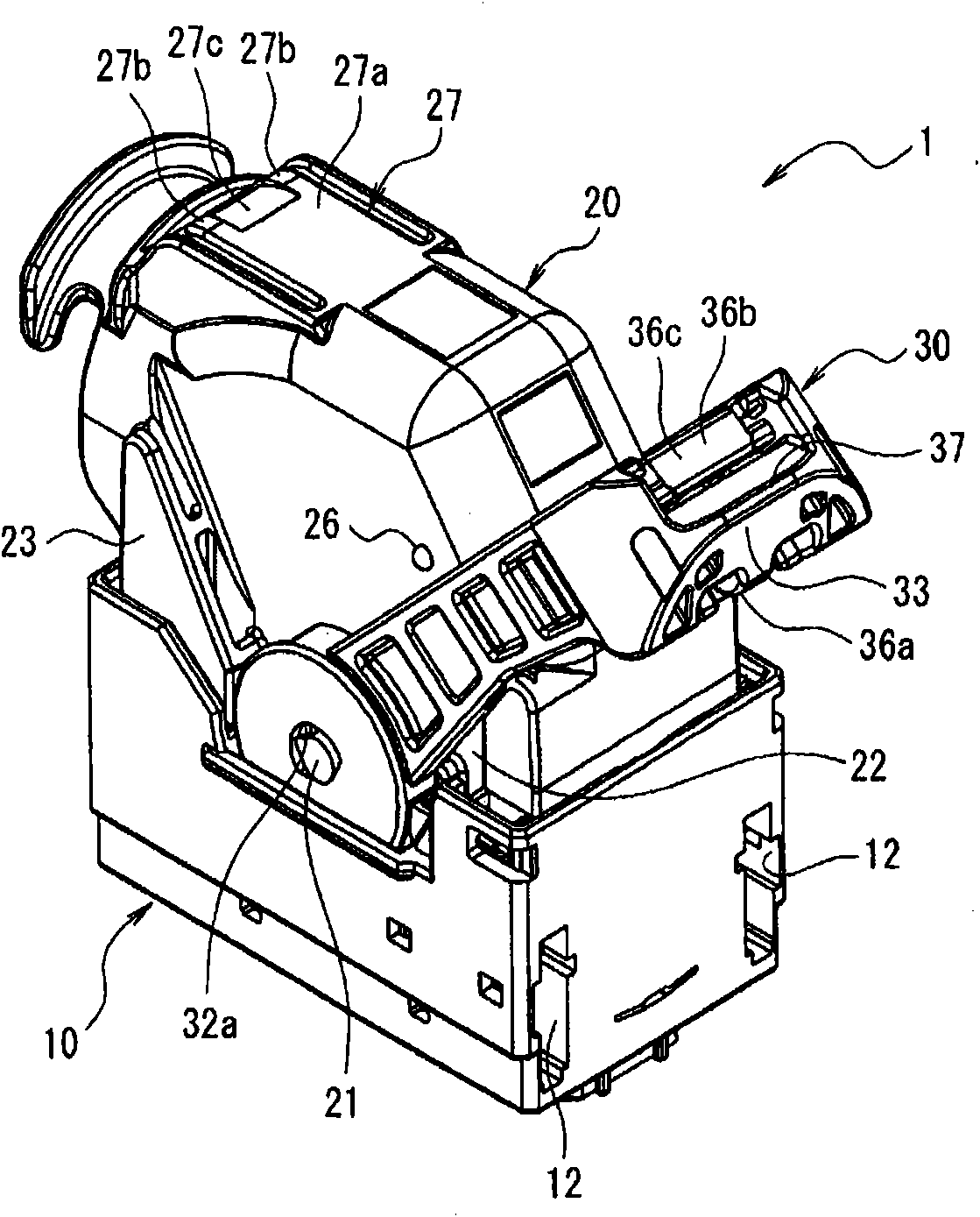

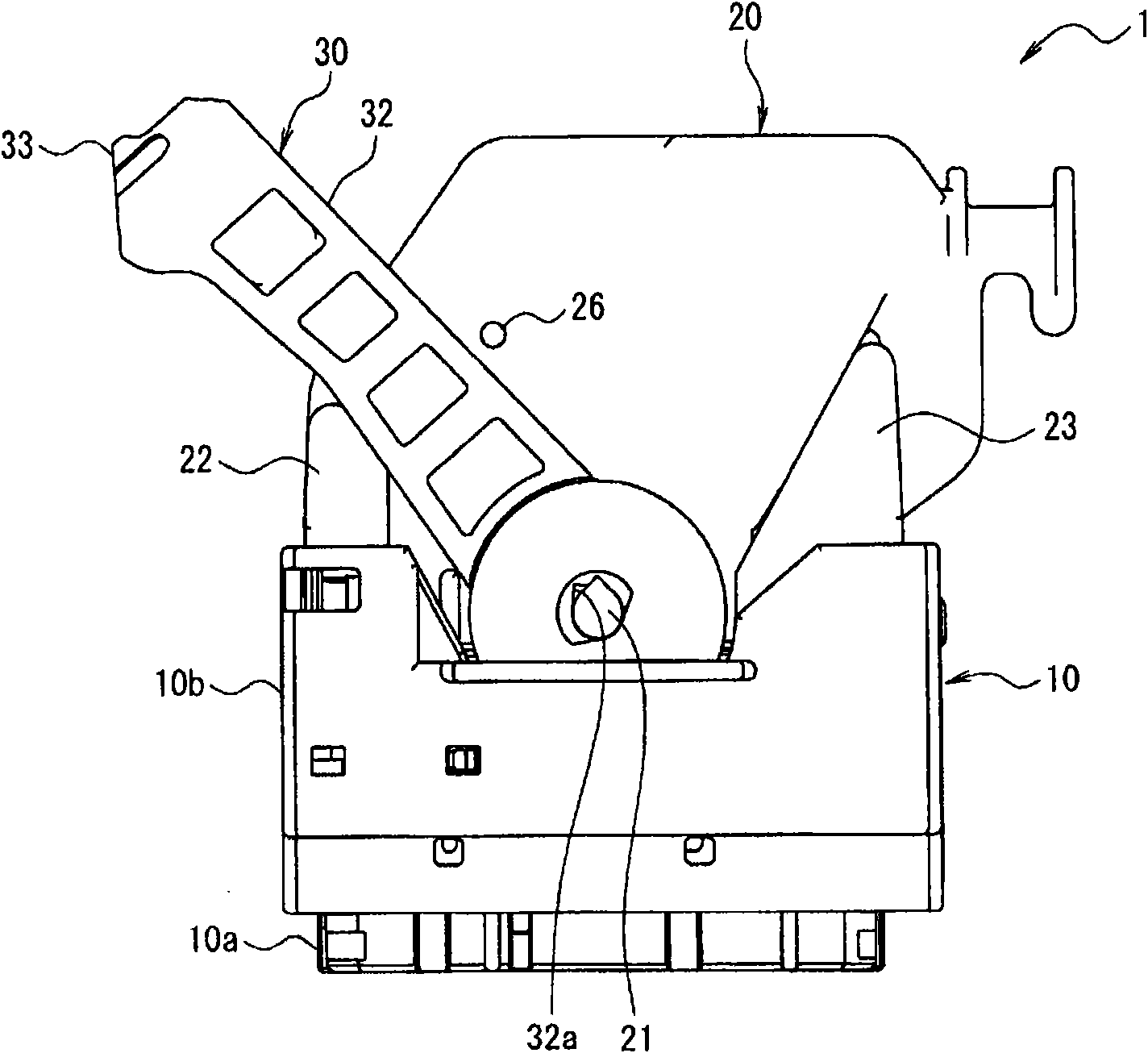

Vacuum cleaner

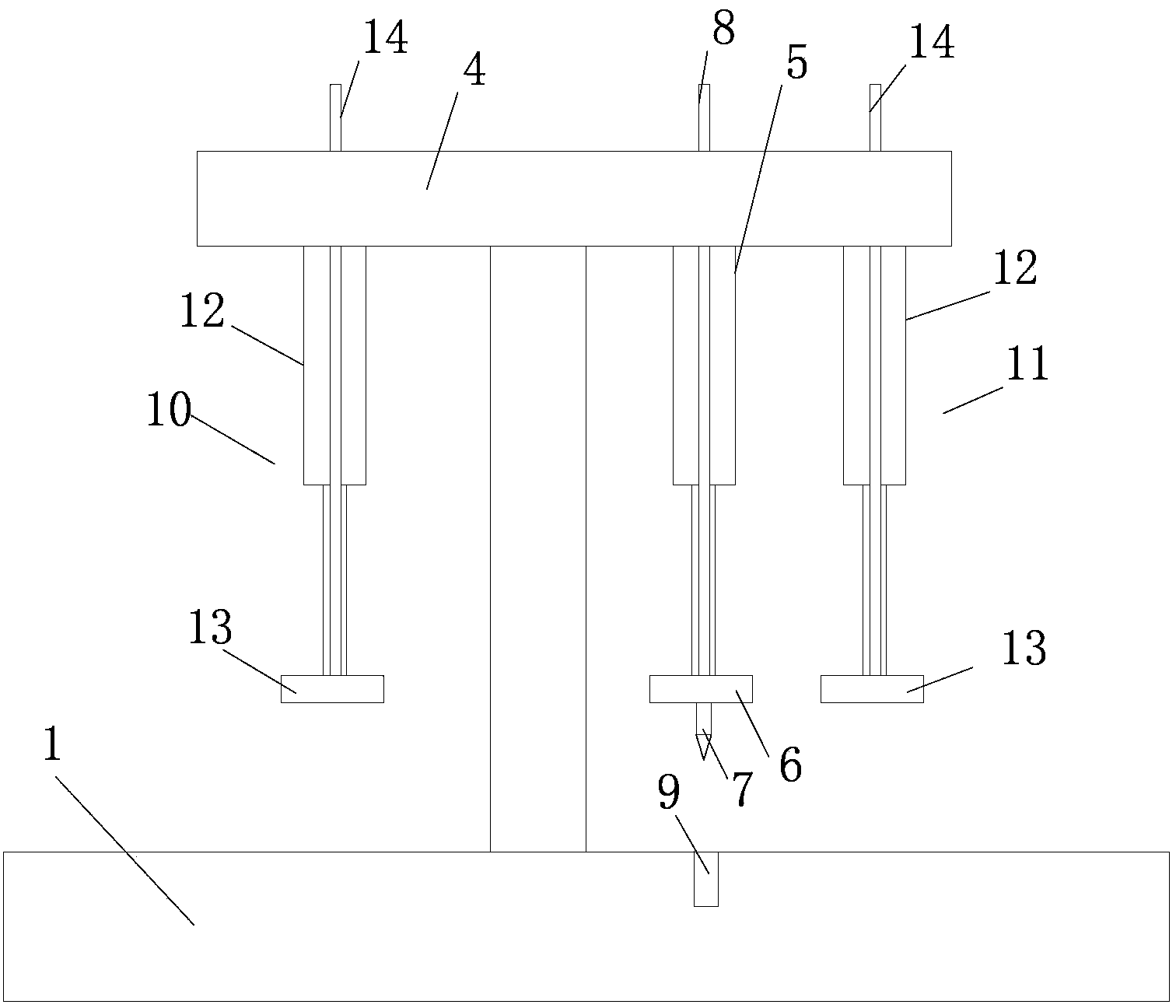

InactiveCN103356140APrevent liftingImprove work efficiencyCarpet cleanersFloor cleanersPhysicsSprayer

The invention relates to a suction head assembly used for a vacuum cleaner in which a cleaning pad is disposed on a front end of a removable mophead and a sprayer-head nozzle can slide back and forth. The suction head assembly comprises a mophead, the sprayer-head nozzle which is slidably disposed on the front end of the mophead, and a front-and-back sliding component which makes the sprayer-head nozzle slide back and forth on the mophead. The sprayer-head nozzle of the suction head assembly can move back and forth on the mophead, so that the cleaning pad can be taken out or inserted simply.

Owner:SUZHOU HAAN TECH +1

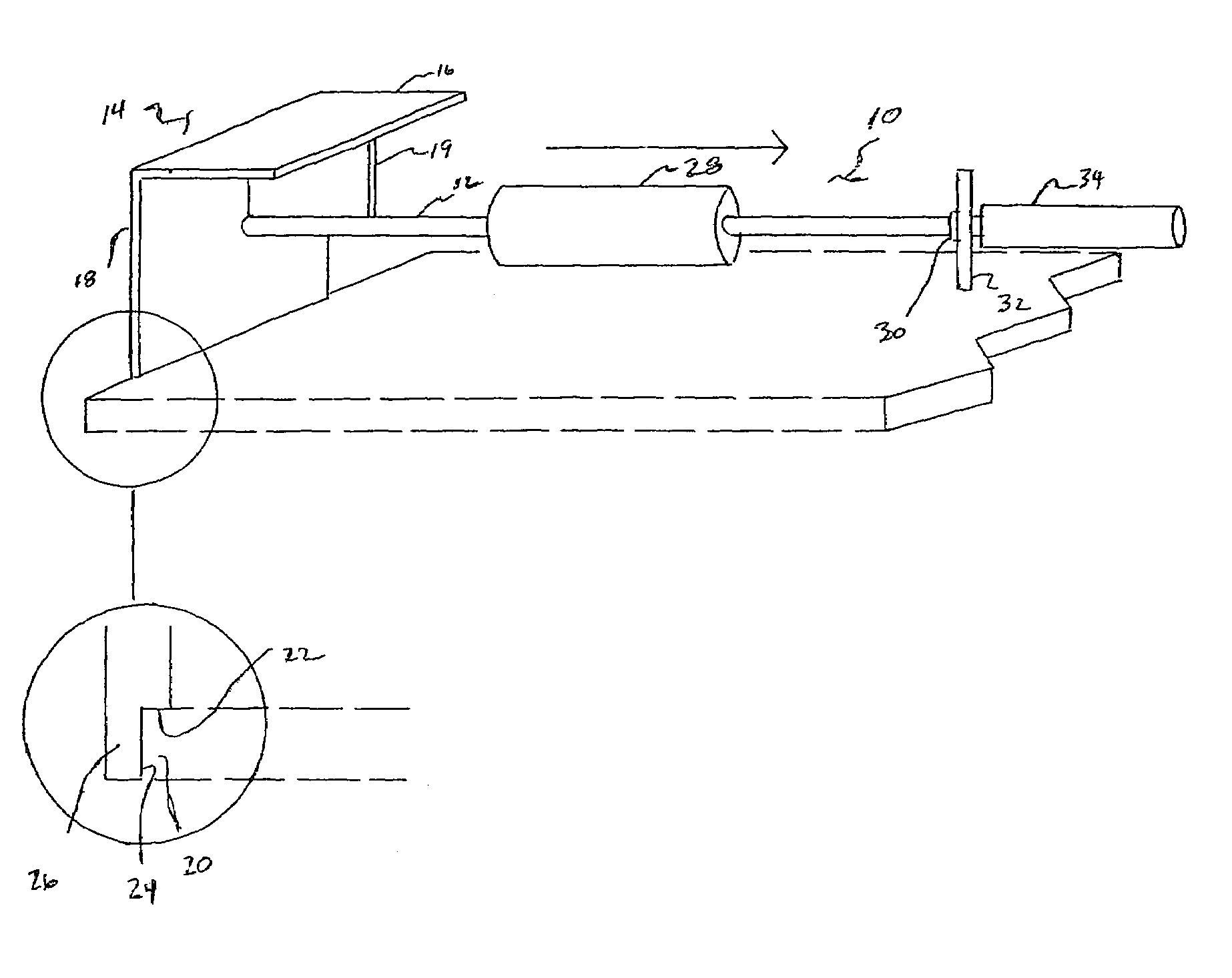

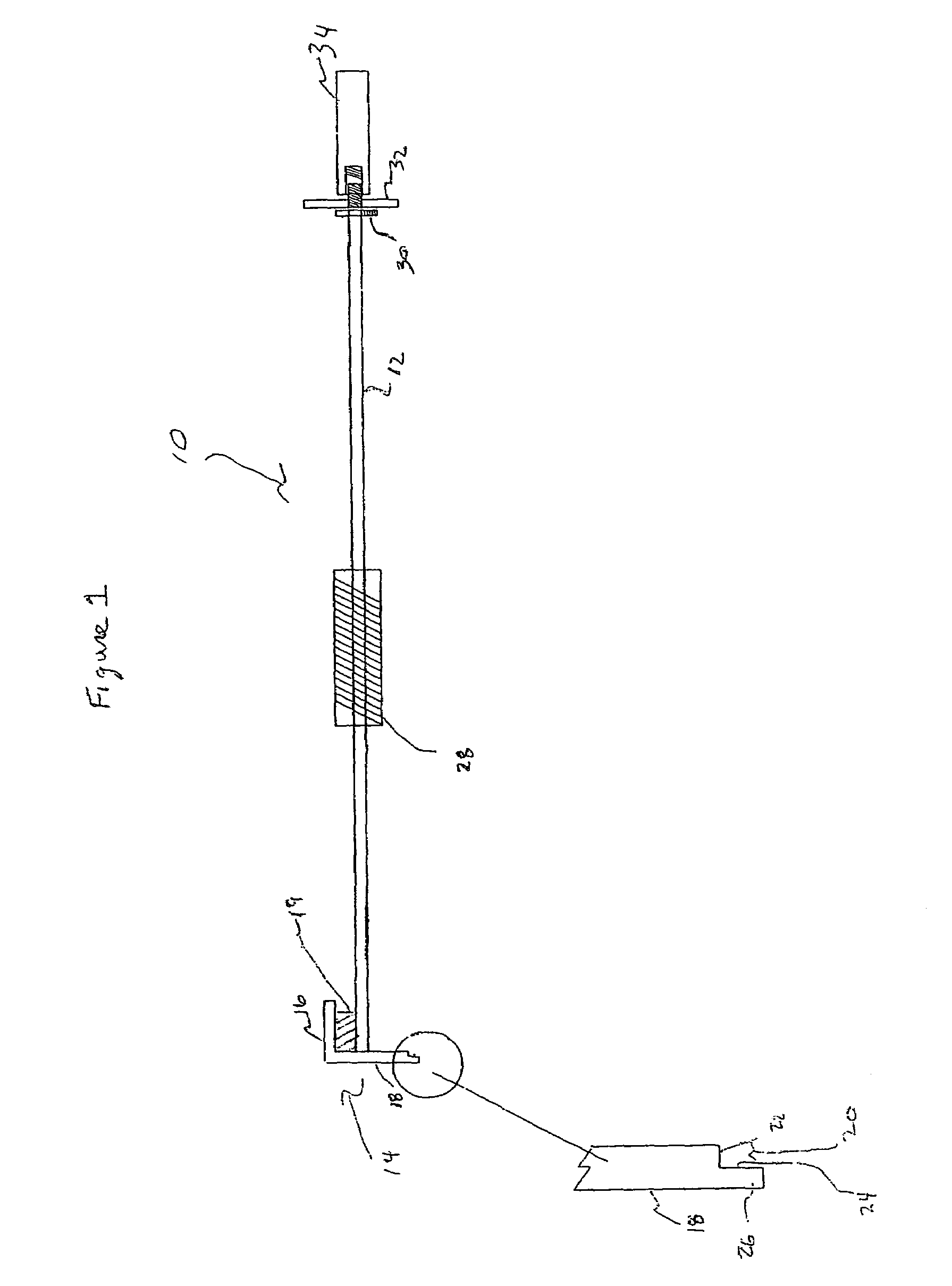

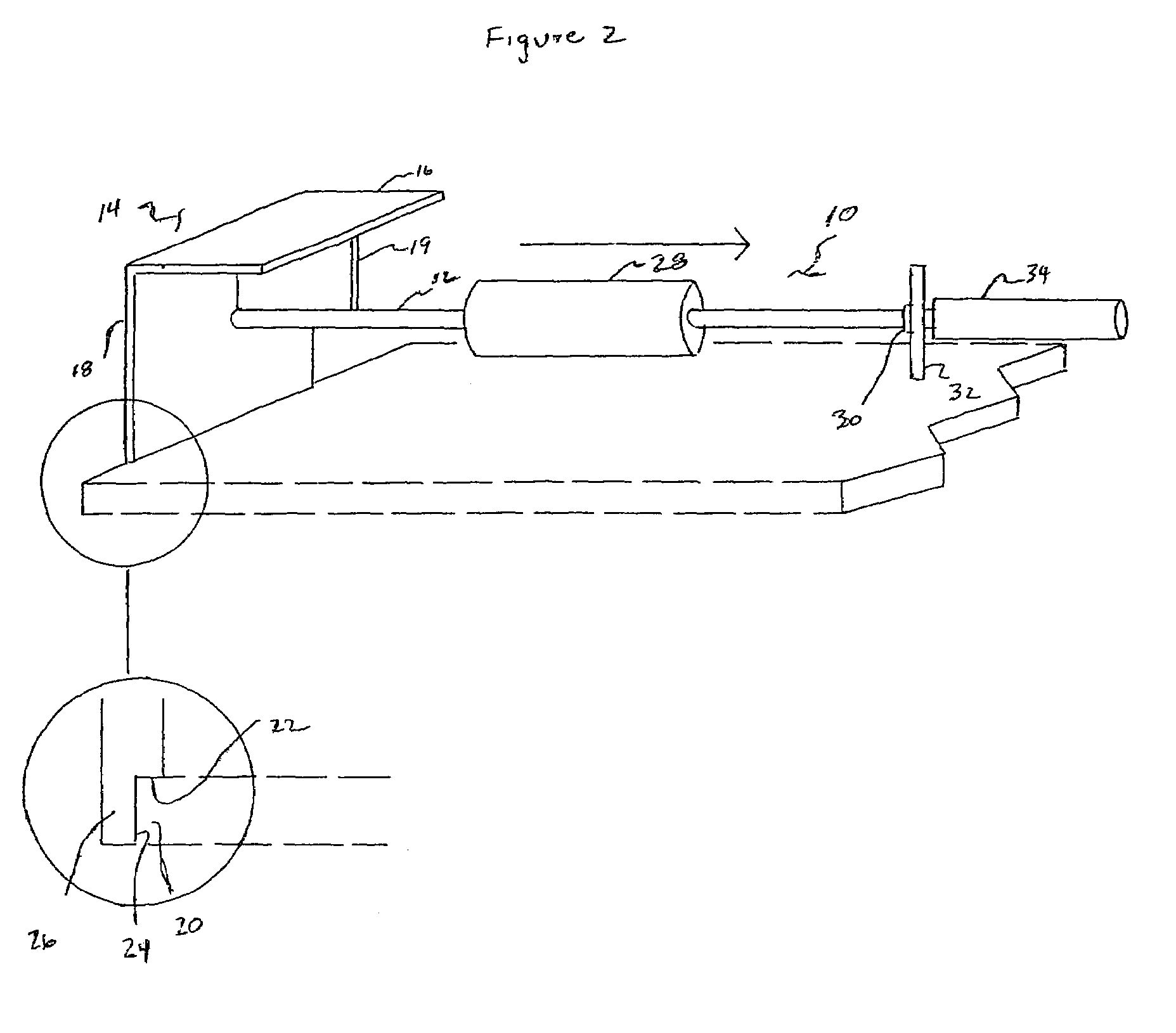

Method and apparatus for laying floors

ActiveUS7398628B2Avoid liftingThe equipment is easy to operateLifting devicesRoof toolsHorizontal forceEngineering

A tool and method for abutting an individual floor panel which is near an obstruction, such as a wall, to the assembled floor. The tool and method provide a rod having a flanged member at one end. The flanged member has a notch in its vertical flange which contacts the floorboard to be abutted, requiring a minimal amount of space between the obstruction and floorboard to be set. A sliding weight mounted on a rod can then be slid toward an impact surface resulting in a horizontal force being applied to the individual floorboard thereby abutting or setting that floorboard with respect to the assembled floor. An especially useful application for the device and method is in the installation of a tongue-in-groove laminate floor in which the individual floorboards have a tongue and groove connection on their ends.

Owner:VAN HORNE JR JEFFERSON

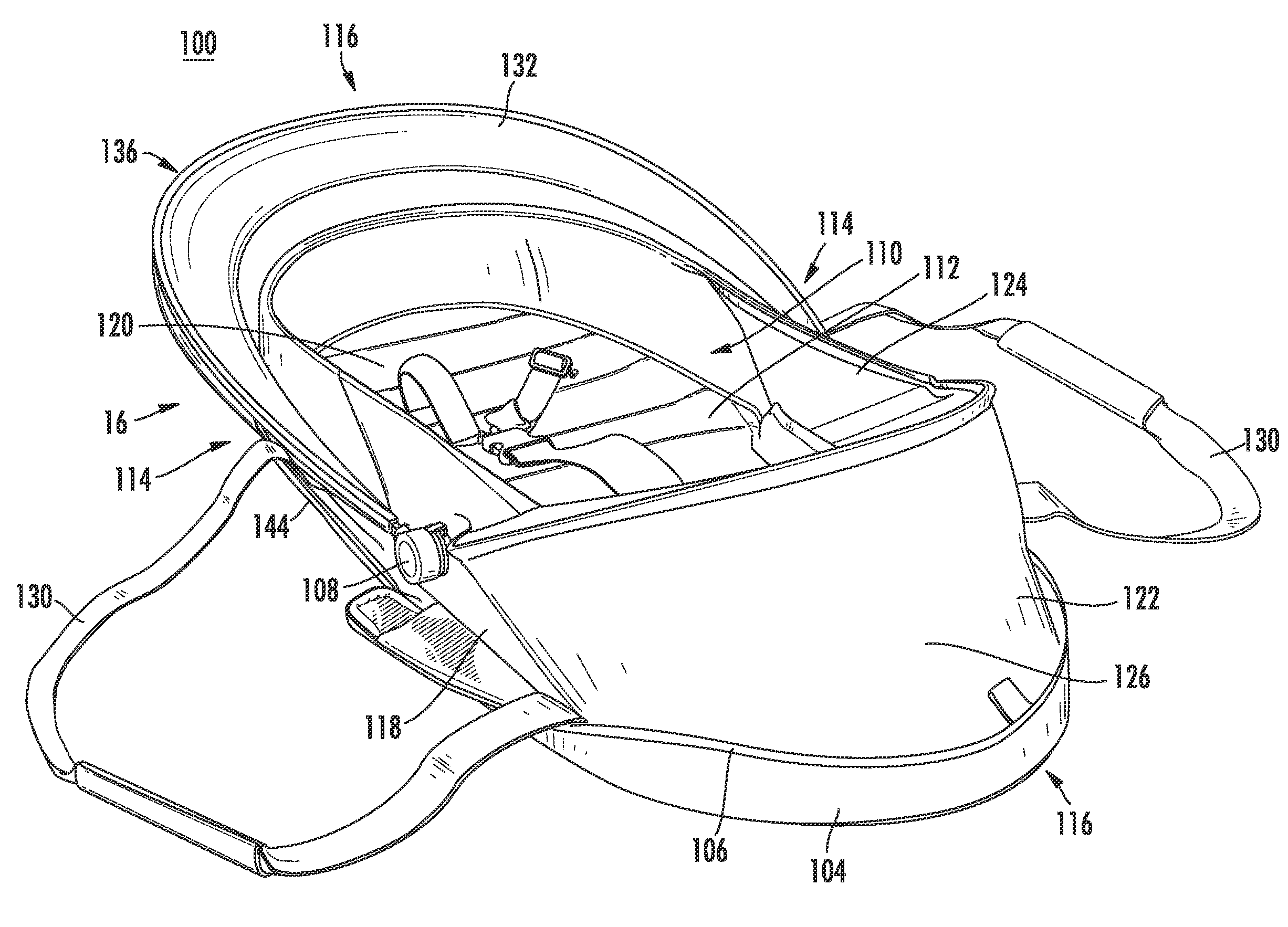

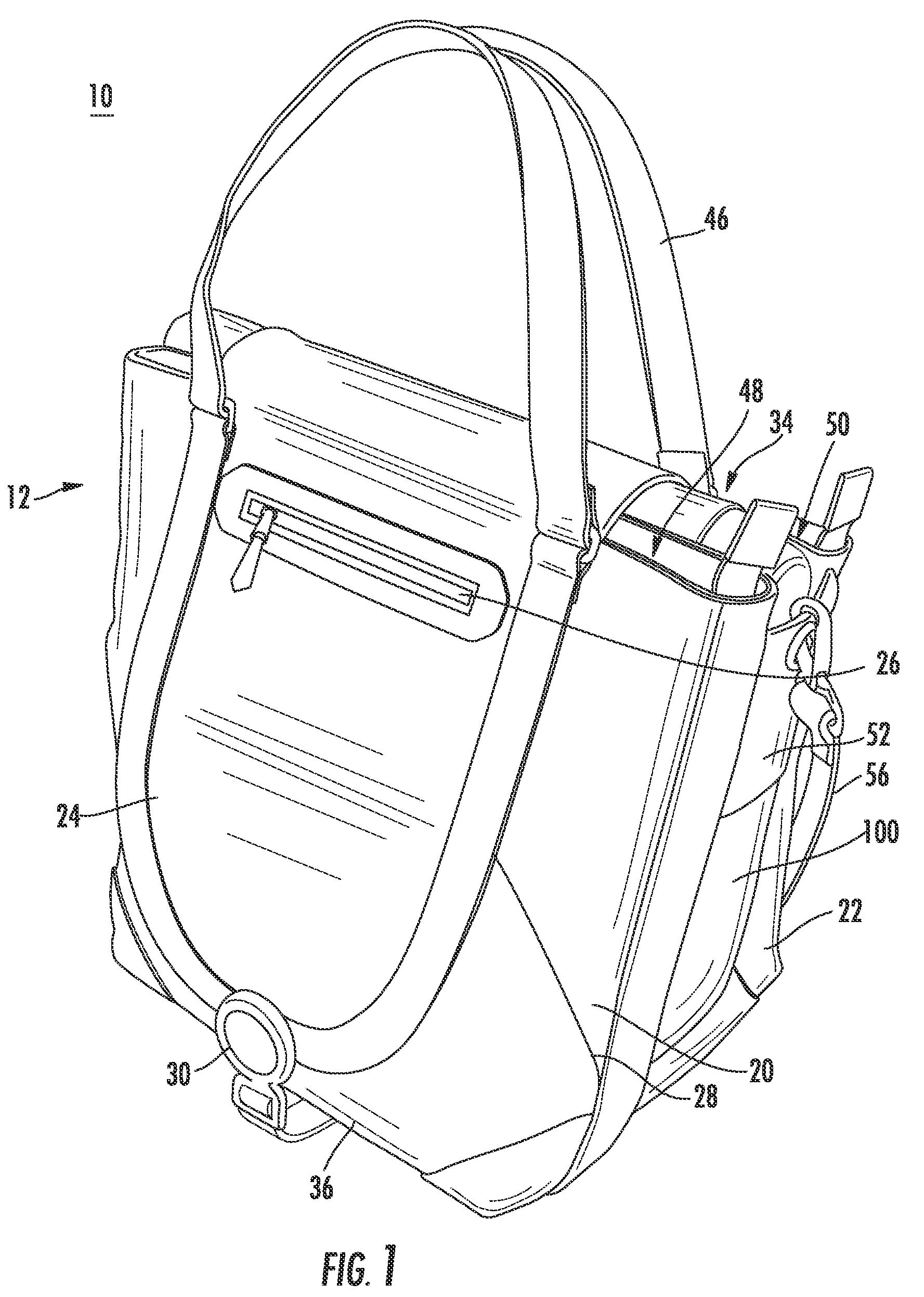

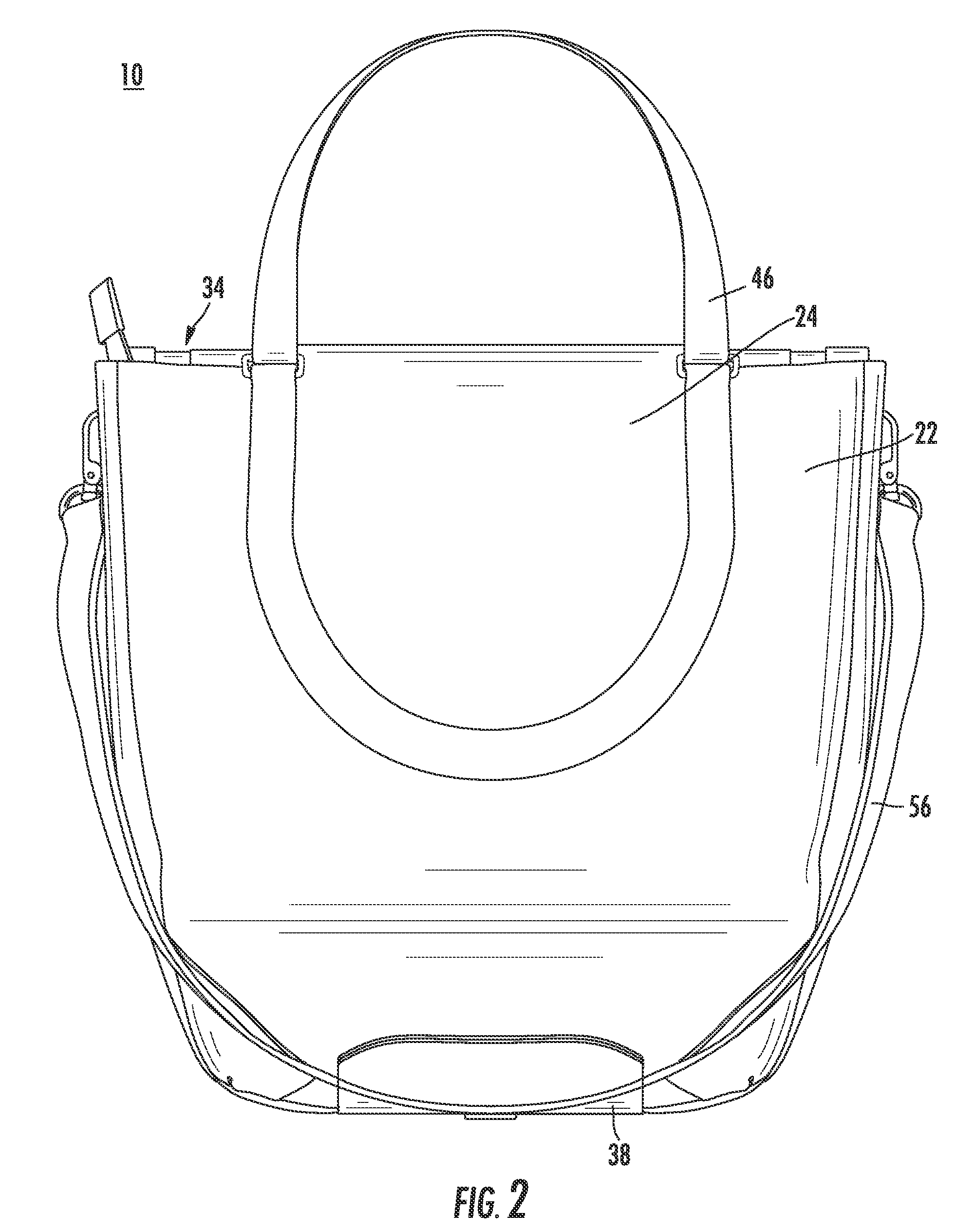

Baby care assembly

A baby care assembly includes a baby carrier positionable between an open, use configuration, wherein a baby may be placed in the carrier, and a closed, folded configuration; and a baby bag configured and dimensioned to receive and retain the baby carrier when the baby carrier is in the closed, folded configuration.

Owner:SNUGGLE NEST

Flexible display device

PendingCN111508372AExtended service lifeAvoid enteringDigital data processing detailsHermetically-sealed casingsFlexible displayMechanical engineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

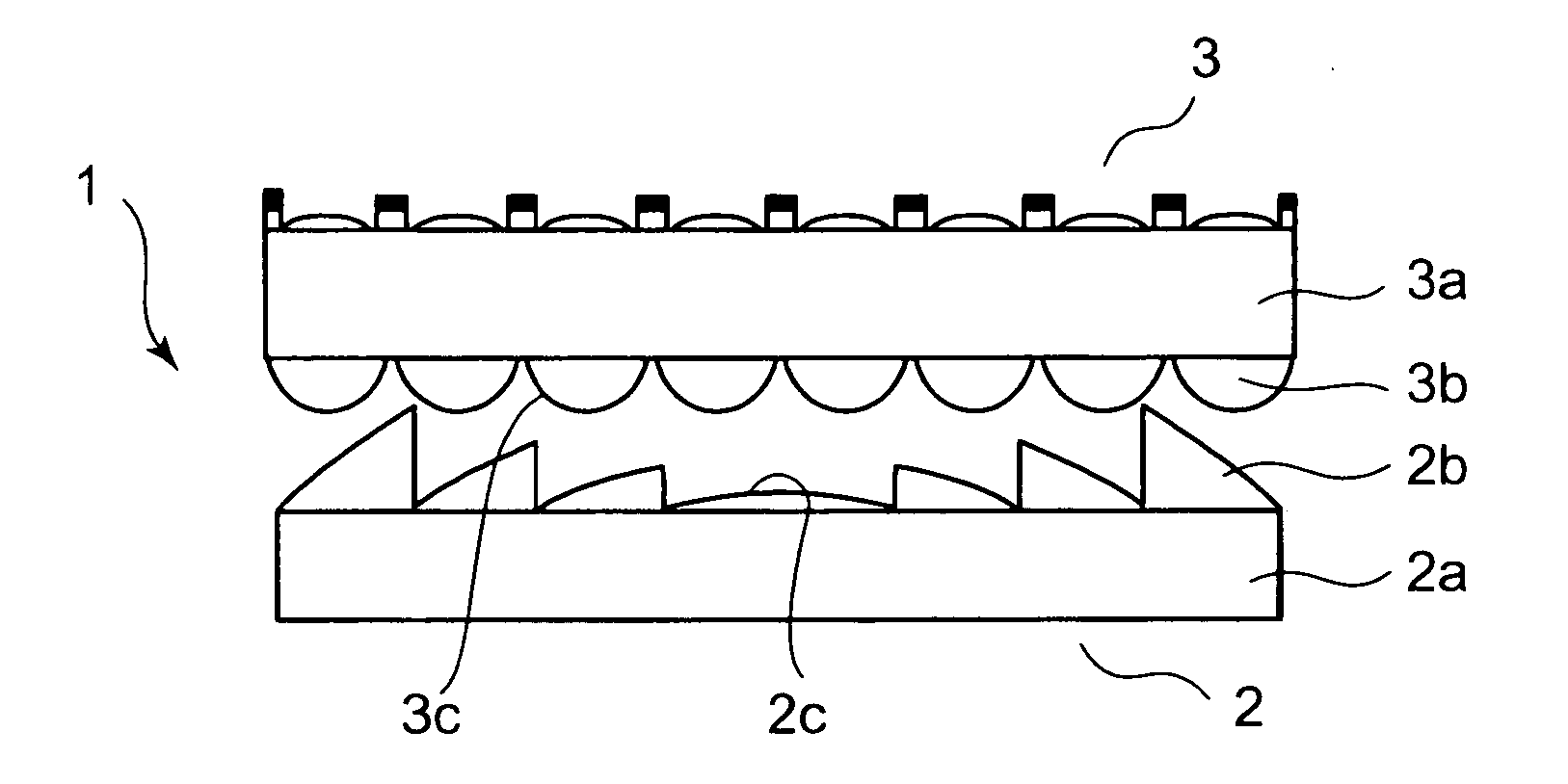

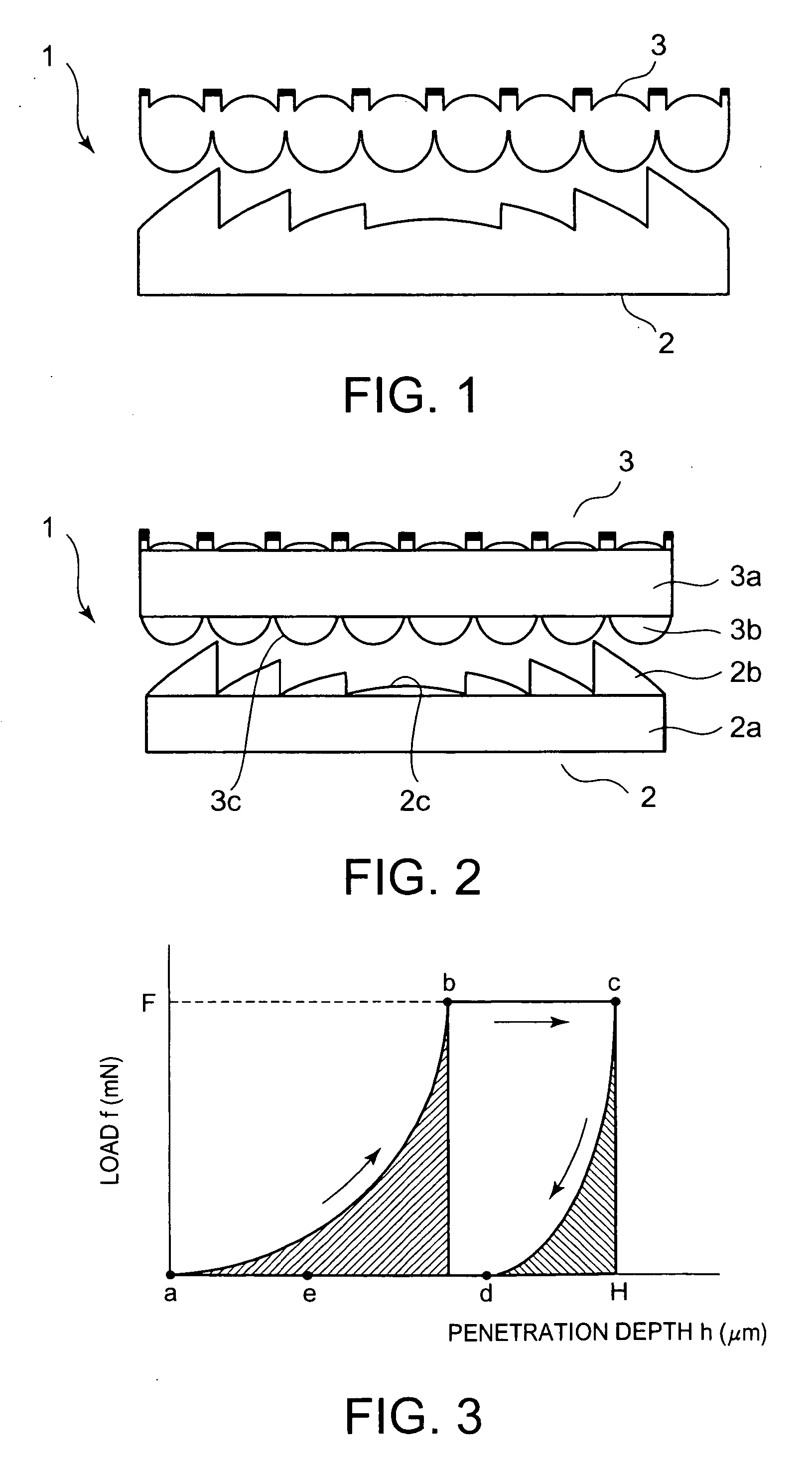

Lens sheet for screen

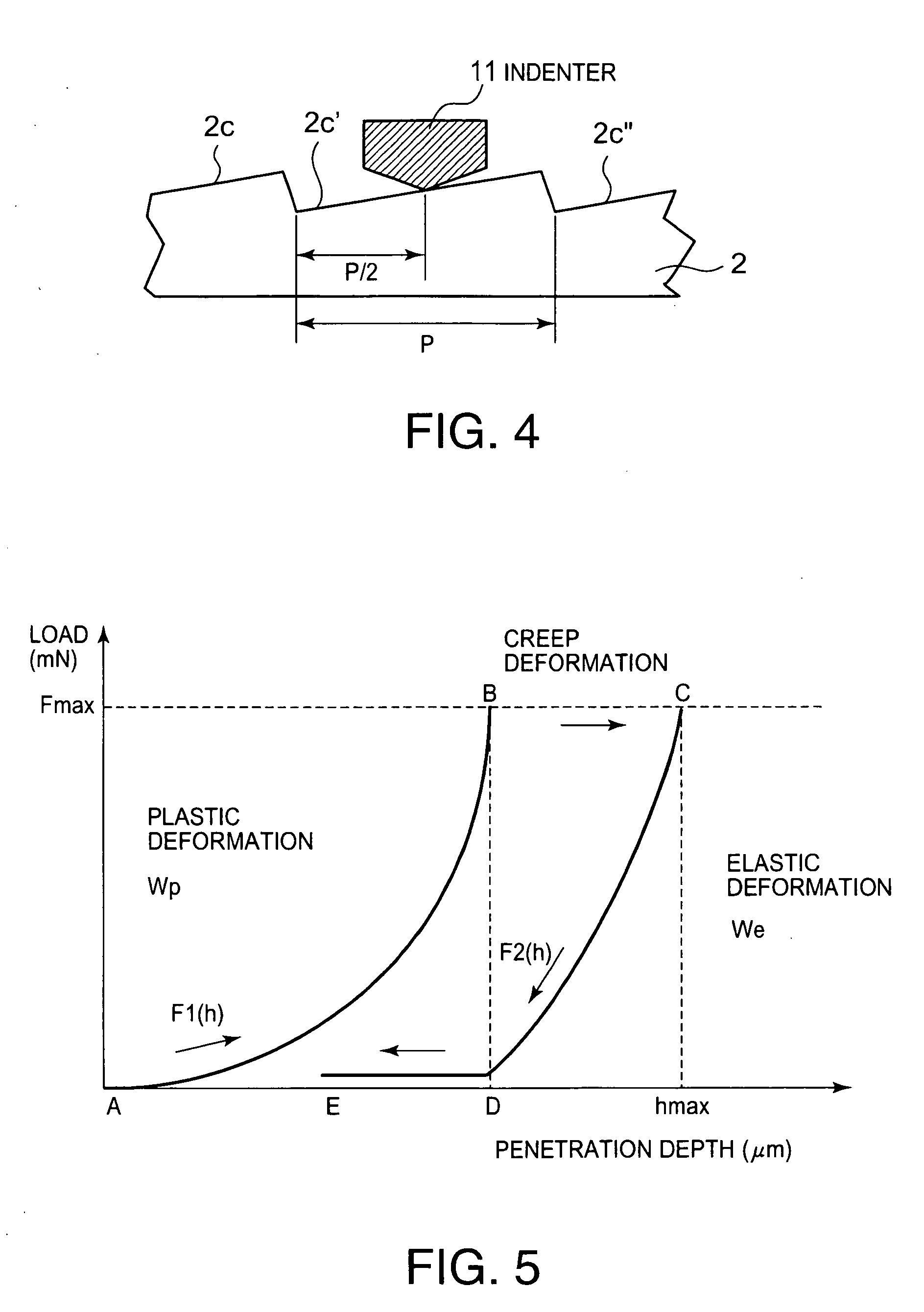

ActiveUS20060187545A1Trend downImprove dimensional stabilitySynthetic resin layered productsProjectorsHardnessPhysics

There are provided a lens sheet for a screen, which is highly stable by virtue of a reduced tendency toward warping, lifting and the like of the lens caused by external humidity and, at the same time, has a suppressed tendency toward friction between lenses during transport as a screen, and a resin composition for constituting the lens sheet. The lens sheet is used in combination with other lens sheet and comprises one or at least two layers. When the layer in contact with the above other lens is formed of a thermoplastic resin, the universal hardness of the thermoplastic resin composition is brought to a range of 31.0 to 42.0 N / mm2.

Owner:DAI NIPPON PRINTING CO LTD

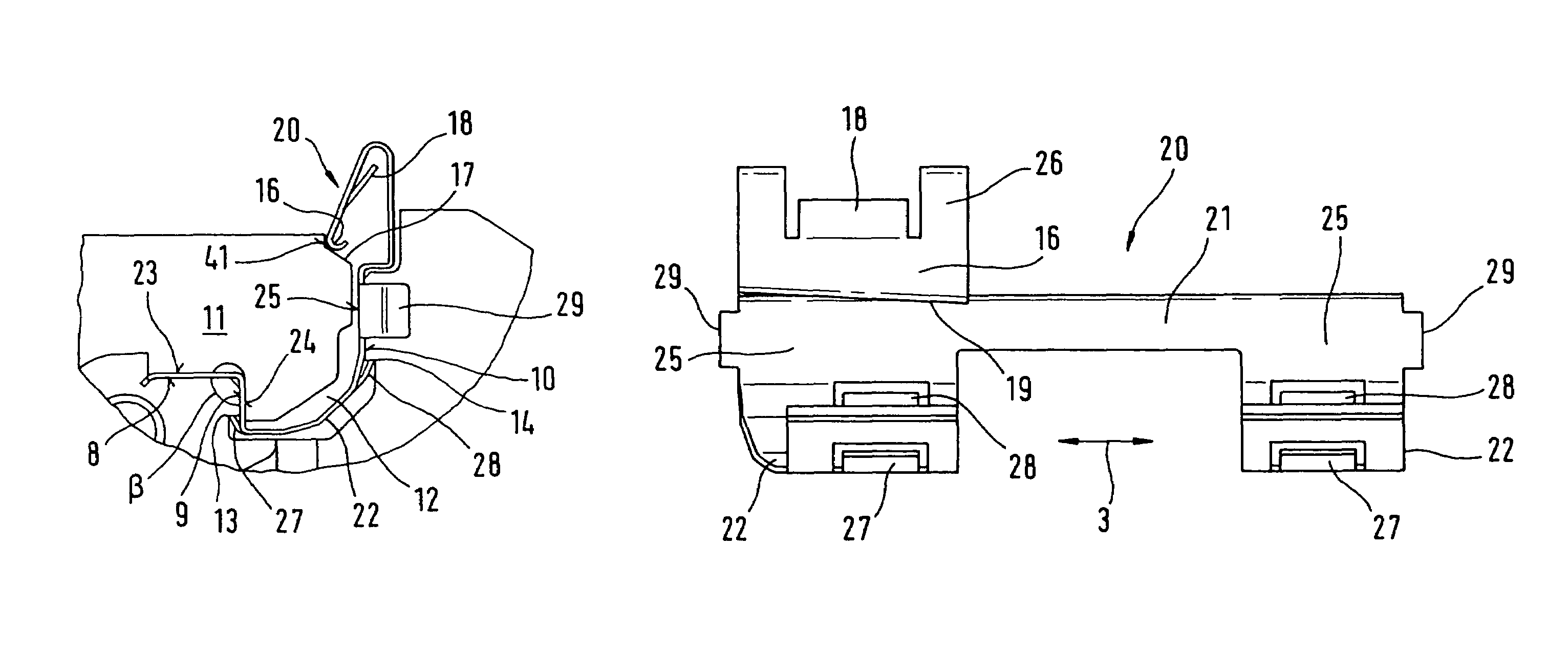

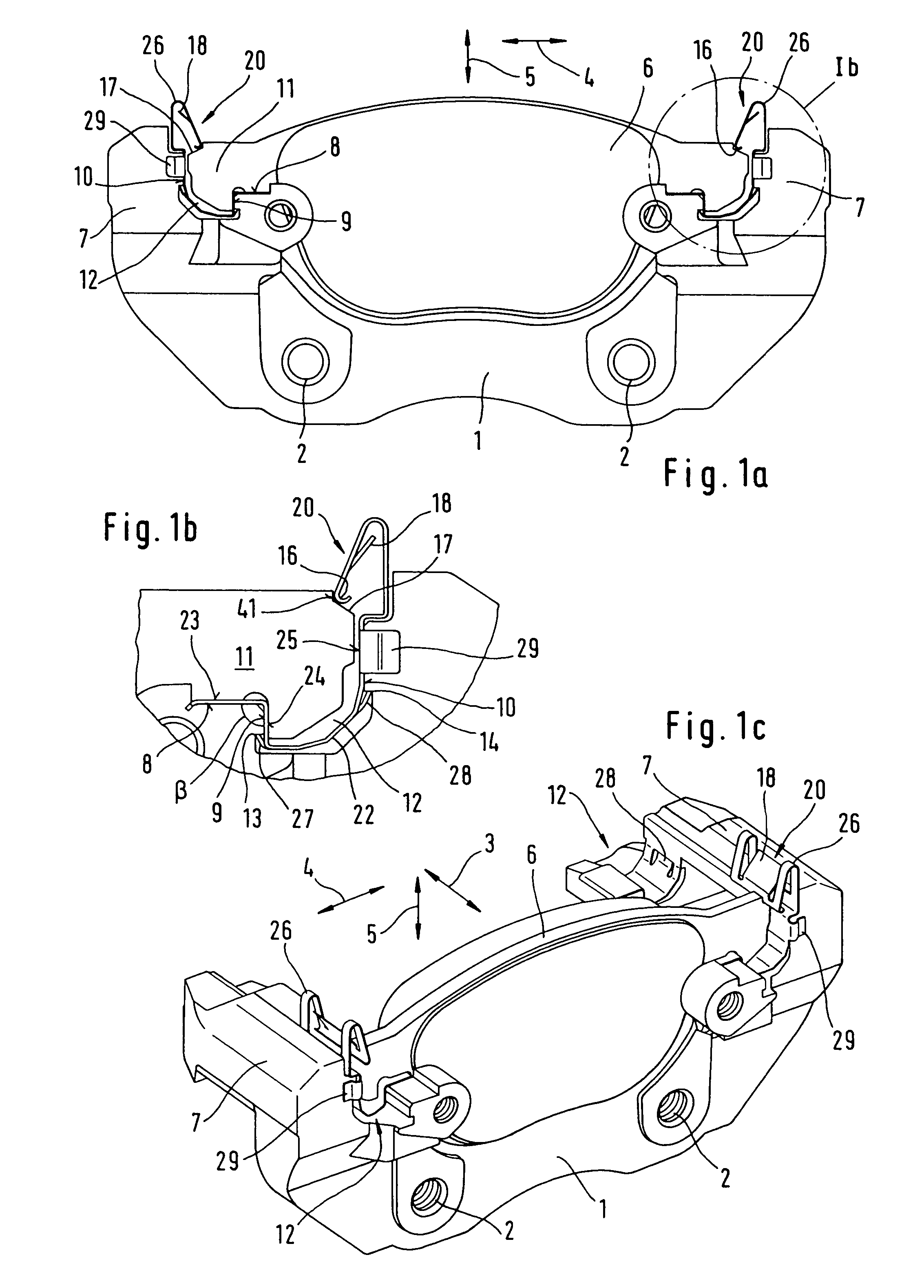

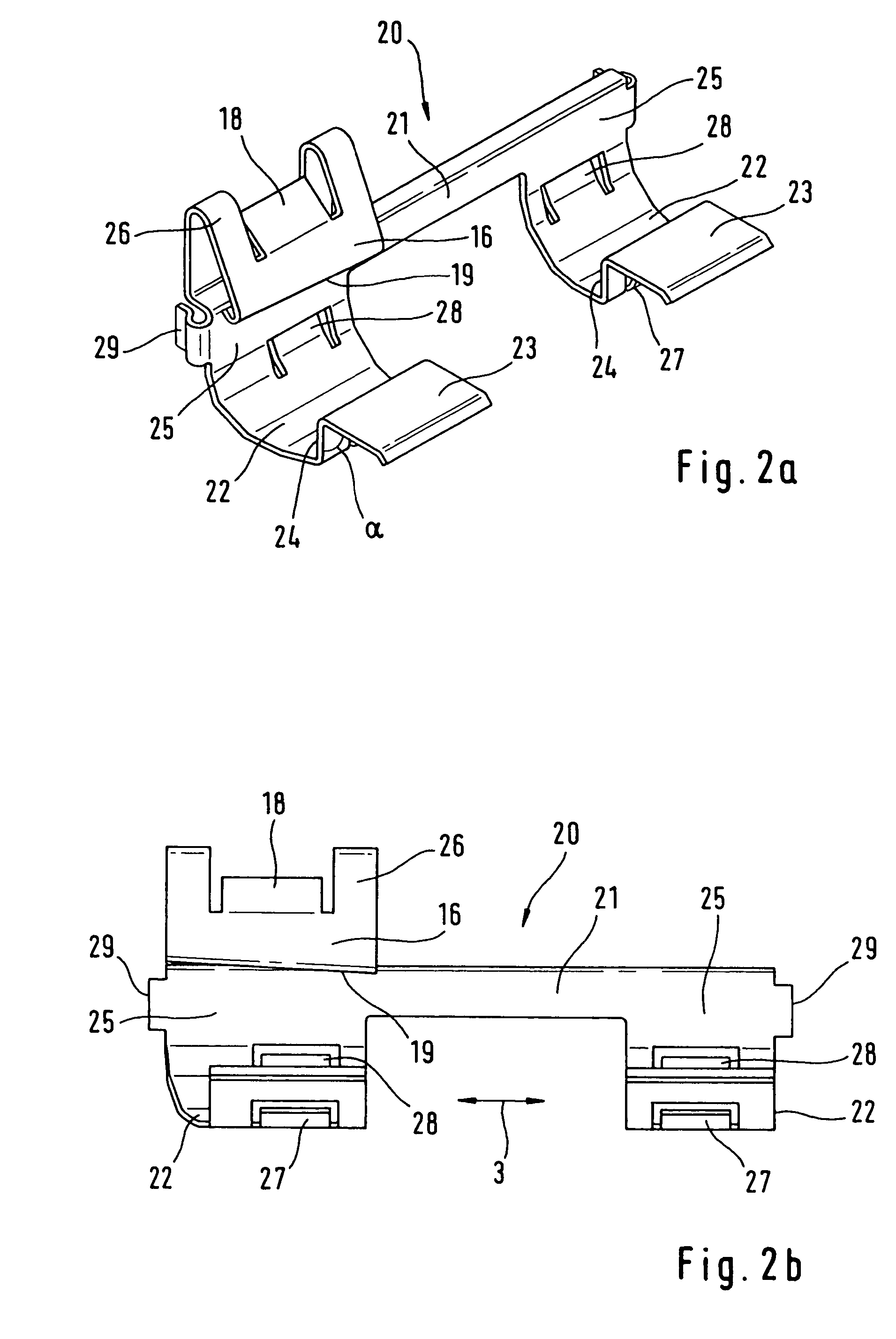

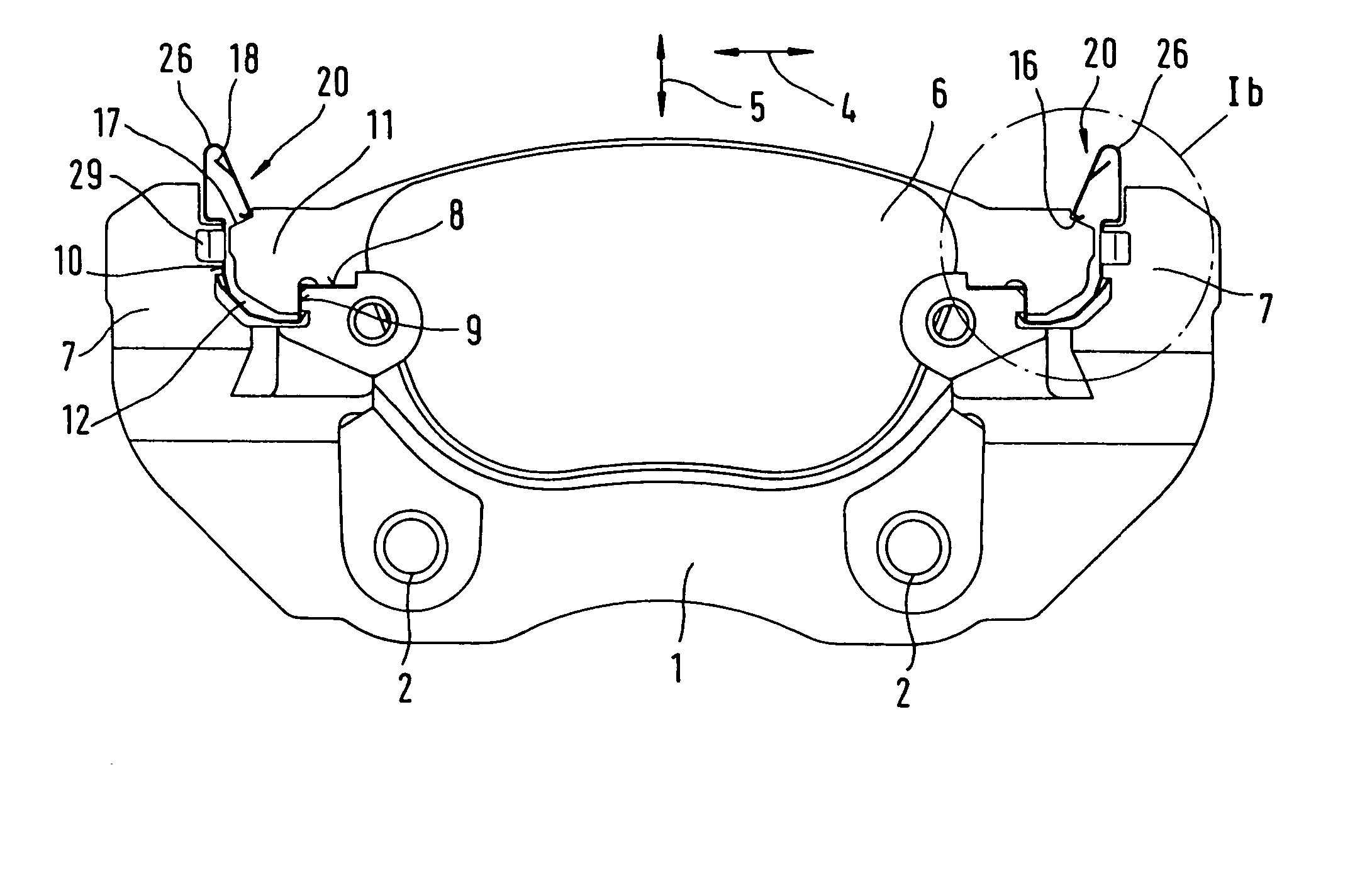

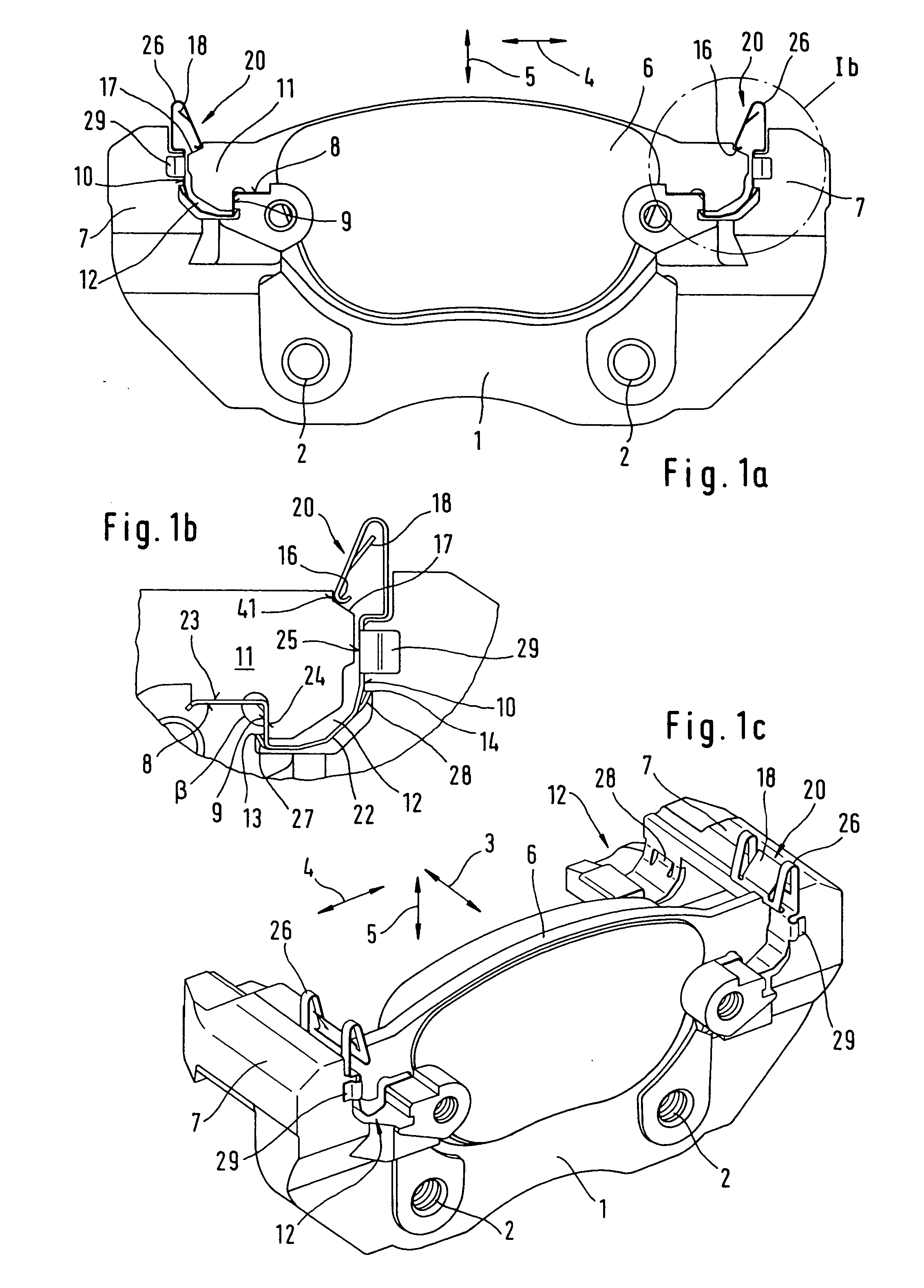

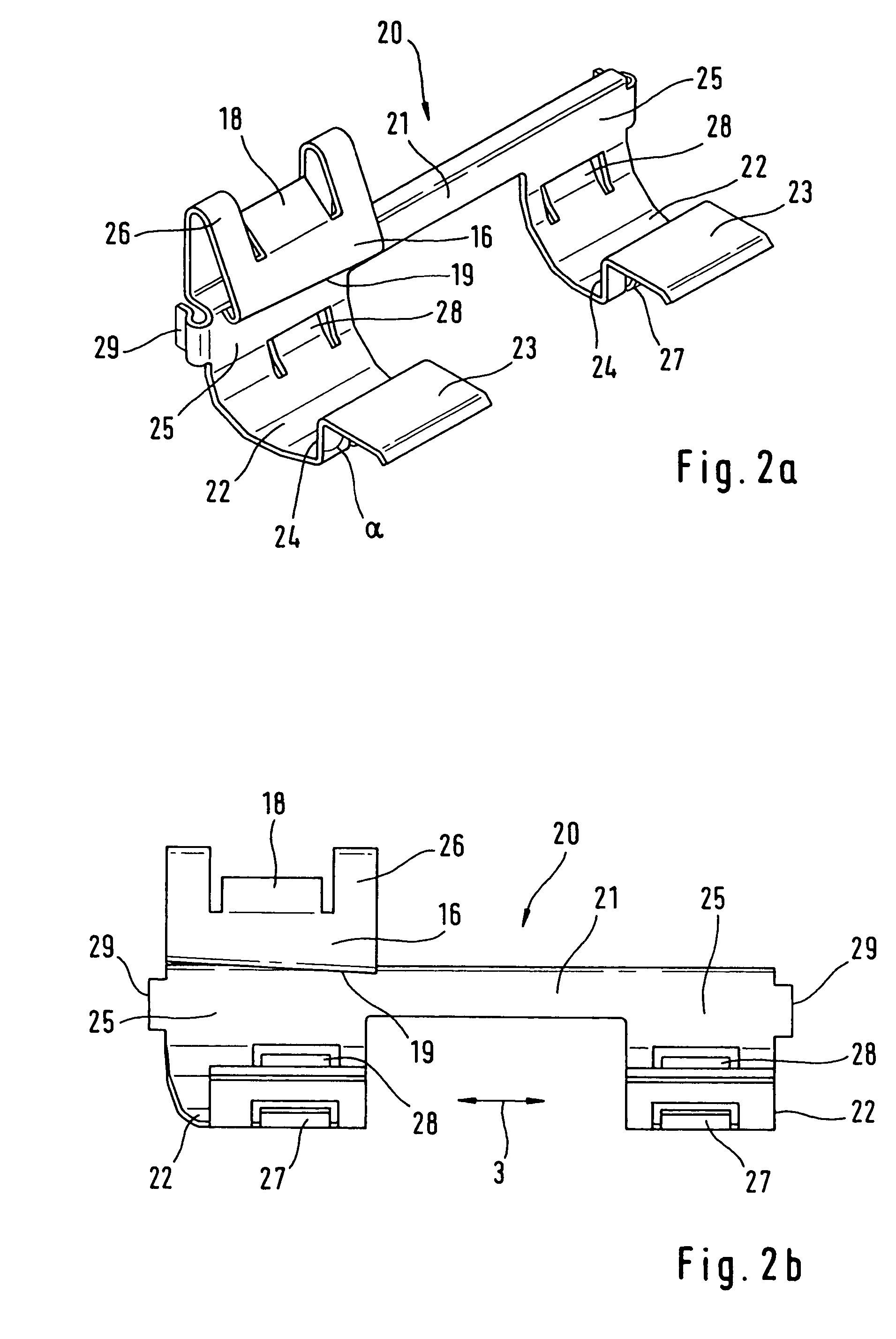

Brake holder for a floating-caliper disk brake with a brake pad guide spring

InactiveUS7513340B2Easy to installEasy to attachAxially engaging brakesBrake actuating mechanismsCalipersBrake pad

The present invention relates to a brake holder of a floating-caliper disc brake for motor vehicles at which brake pads arranged on either side of an associated brake disc are displaceably mounted. To ensure ease of displaceability a brake pad guide spring is provided that extends between the brake holder and the brake pads. For ease of mountability of both the brake pads and the brake pad guide spring, it is arranged for that the brake pad guide spring is mountable on the brake holder in a generally radial direction and is locked at the brake holder in both radial and axial directions by means of at least one fixing clamp, and at least one spring arm is designed at the brake pad guide spring and fixes at least one brake pad under spring bias in position on the brake holder in a clearance-free manner. These provisions not only improve the mountability of a brake of this type but also the rattle-free resilient arrangement of the brake pads.

Owner:CONTINENTAL TEVES AG & CO OHG

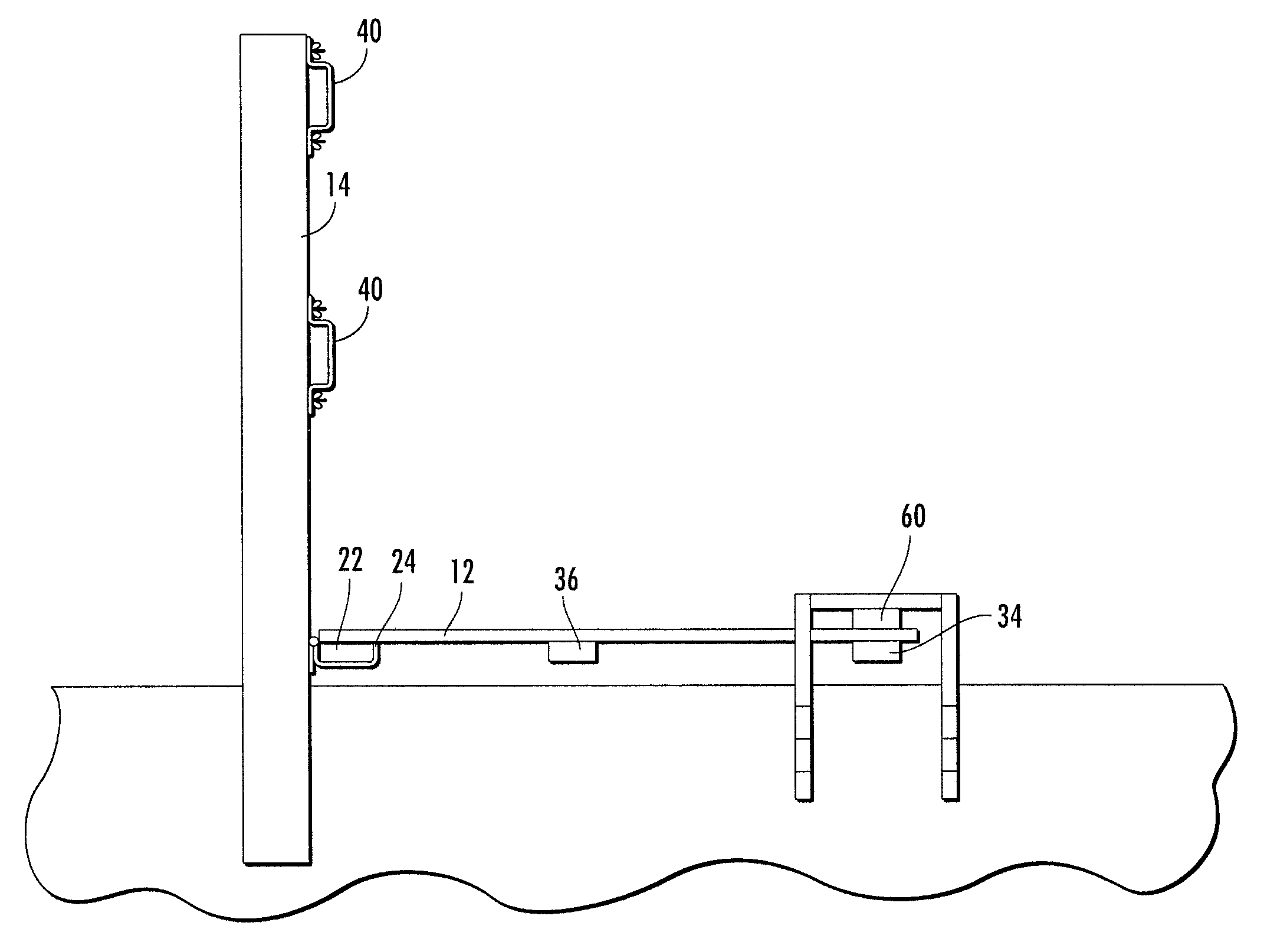

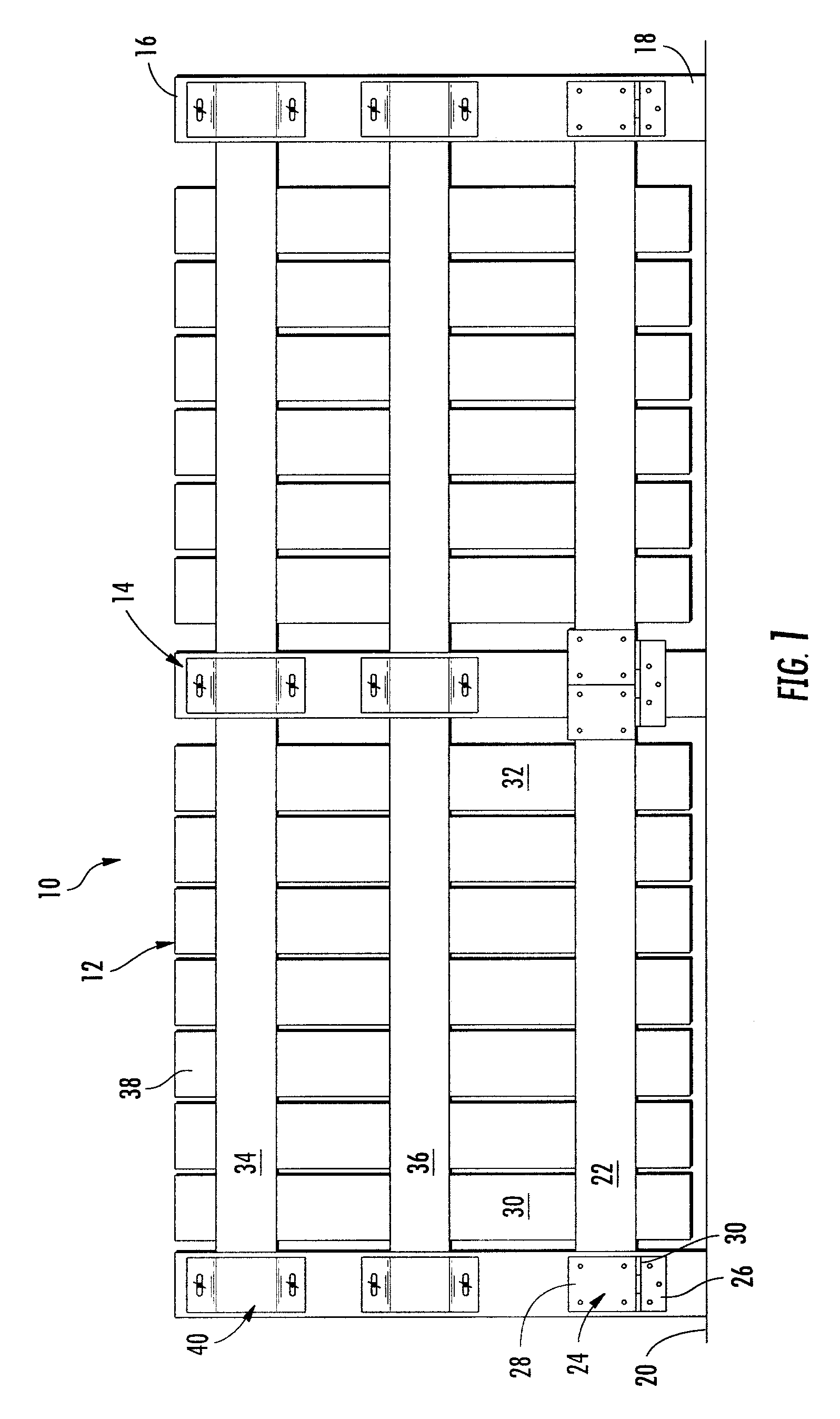

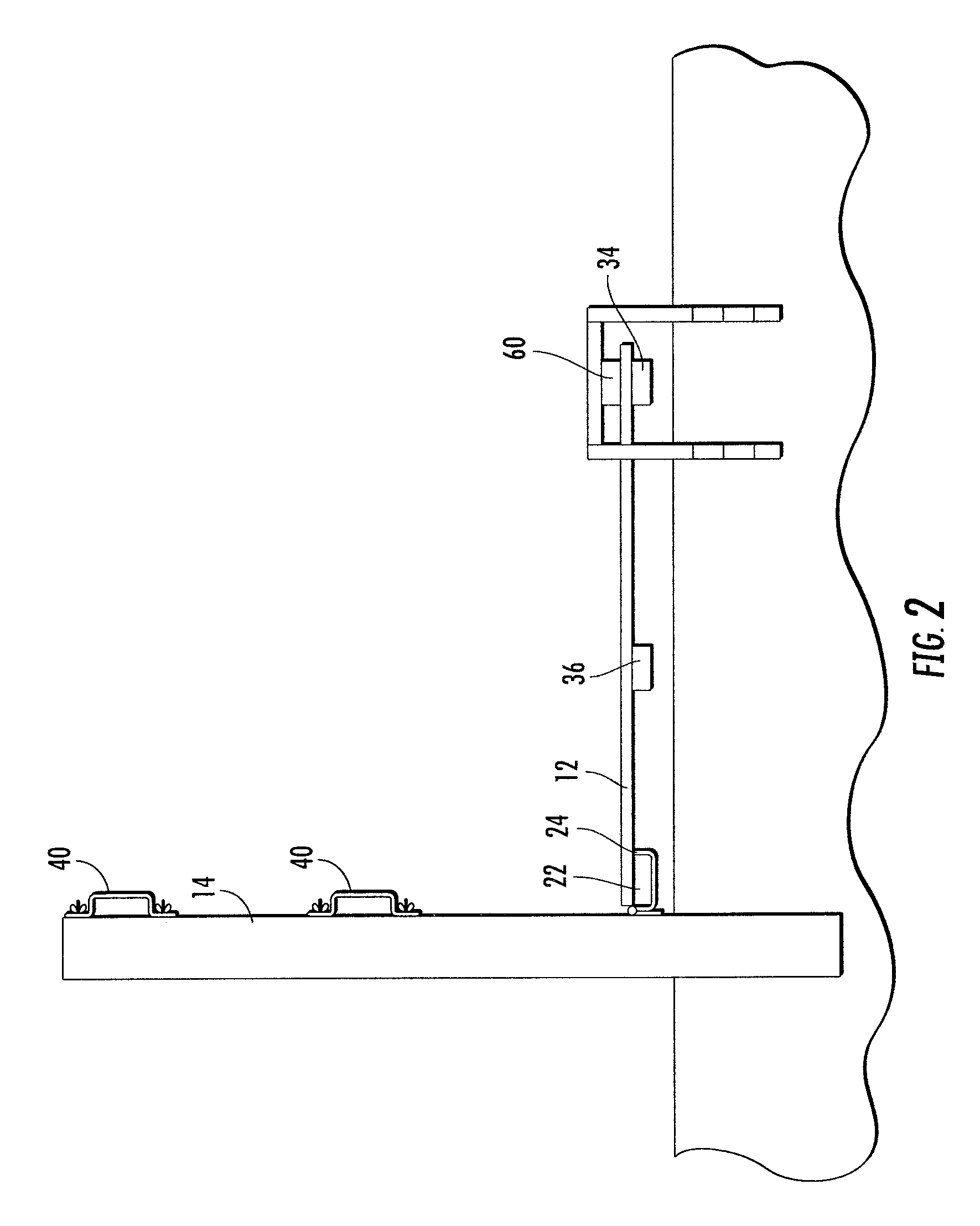

High wind fence system

InactiveUS7523921B2Reducing and eliminating damageAvoid liftingFencingHorizontal orientationVia fence

The present invention provides a fence system for homes, buildings and the like. The fence system according to the instant invention includes panels constructed and arranged to be pivoted between a vertical orientation and a horizontal orientation. When connected to permanently mounted posts in a vertical orientation, the fence panels may be utilized for privacy and / or security. Pivoting the panels to horizontal position during storms, such as hurricanes, reduces or eliminates the damage caused to the fence by high winds and / or wind-borne debris.

Owner:GARRITY ROBERT M

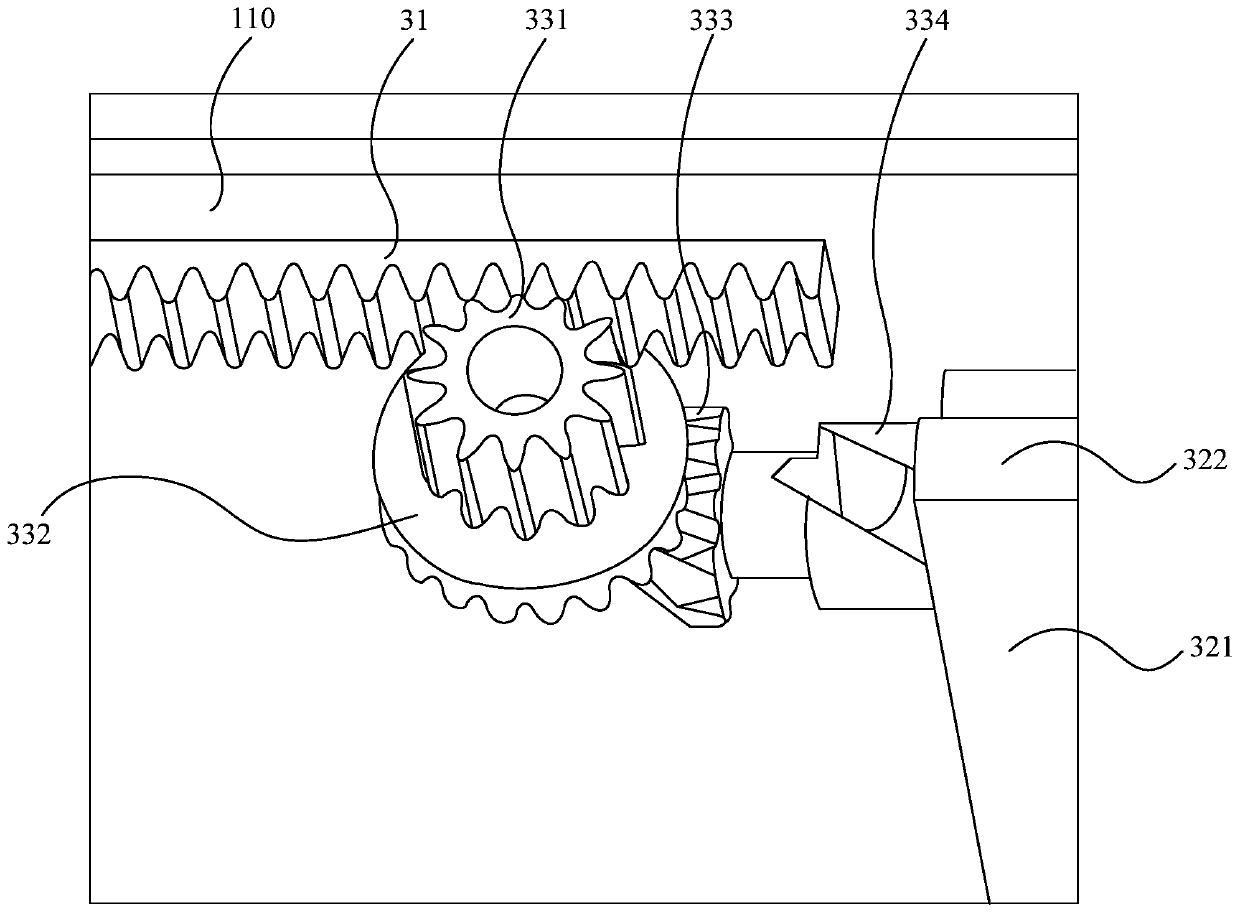

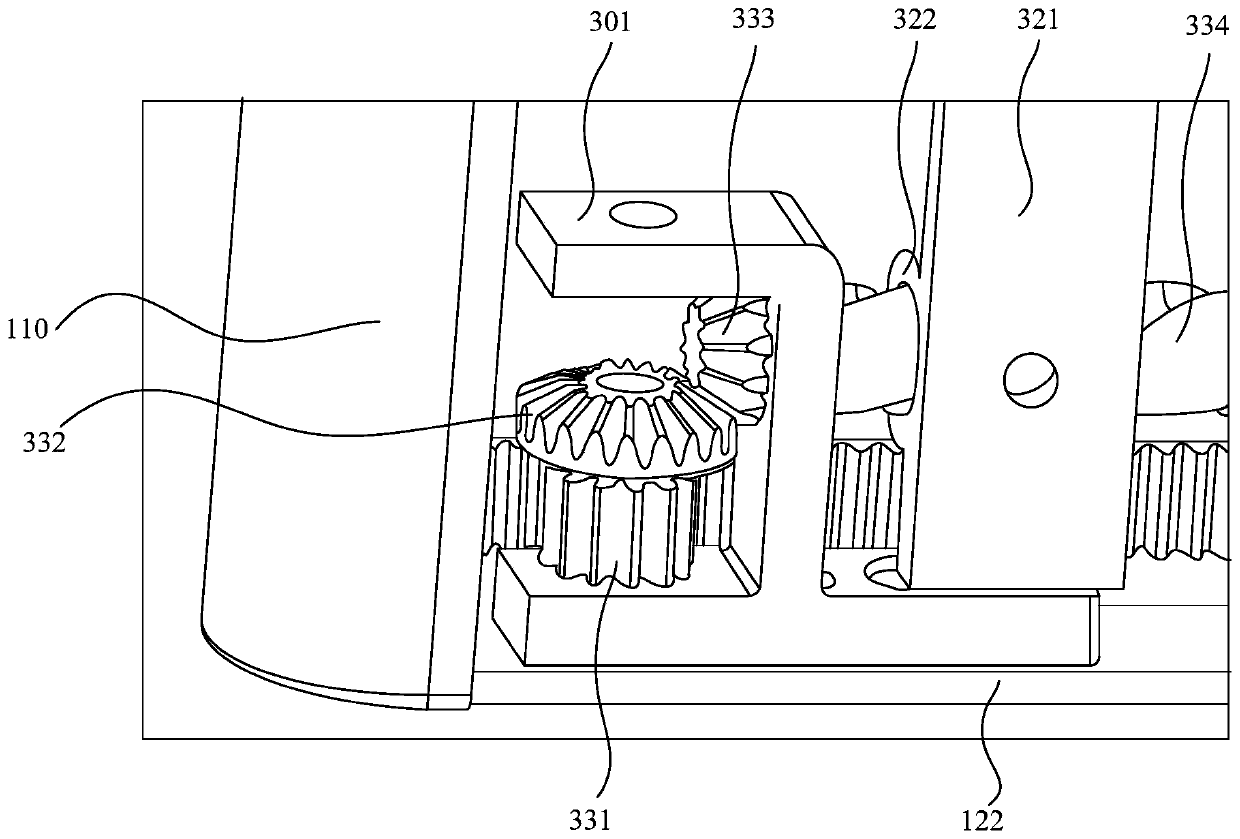

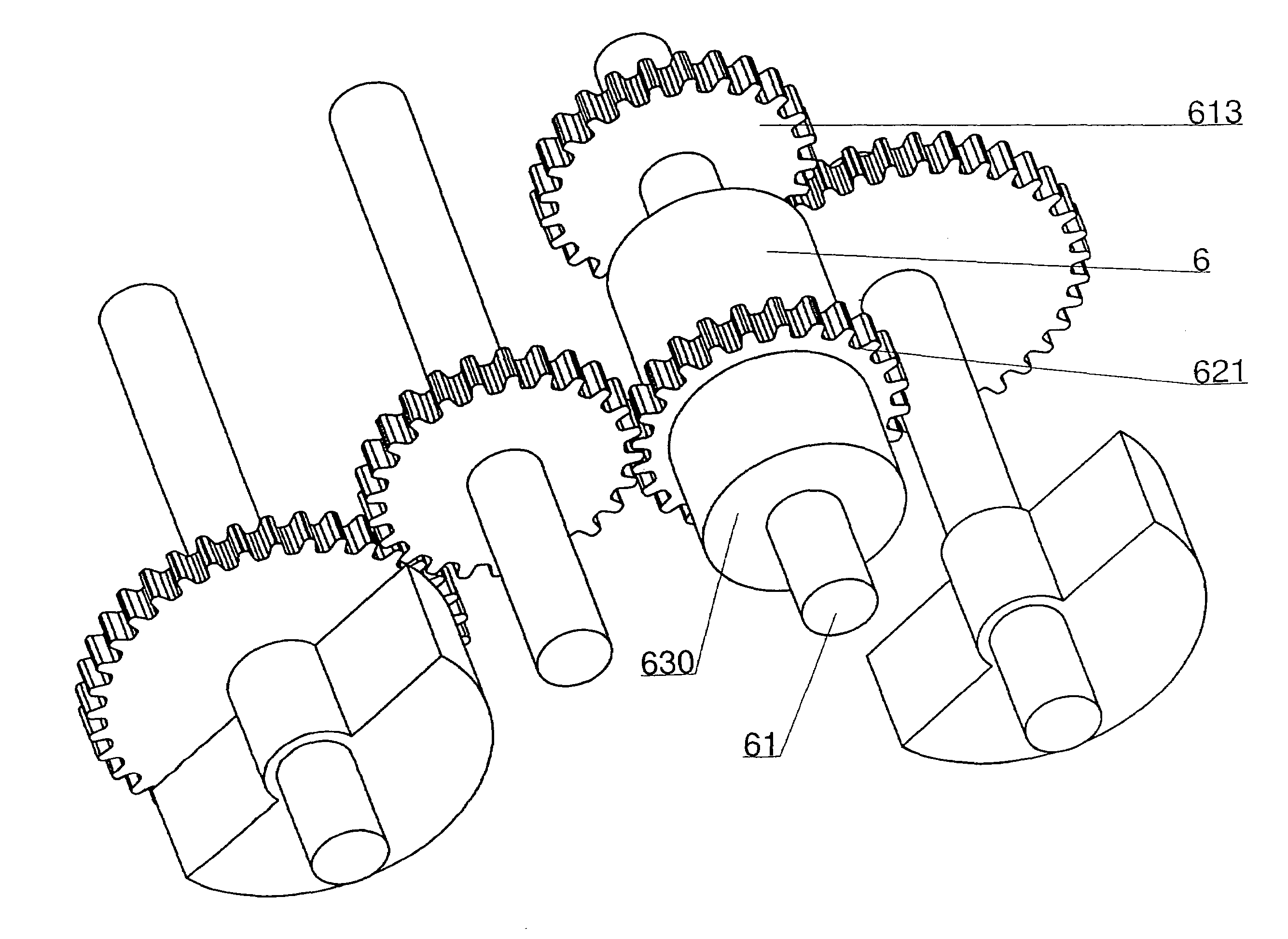

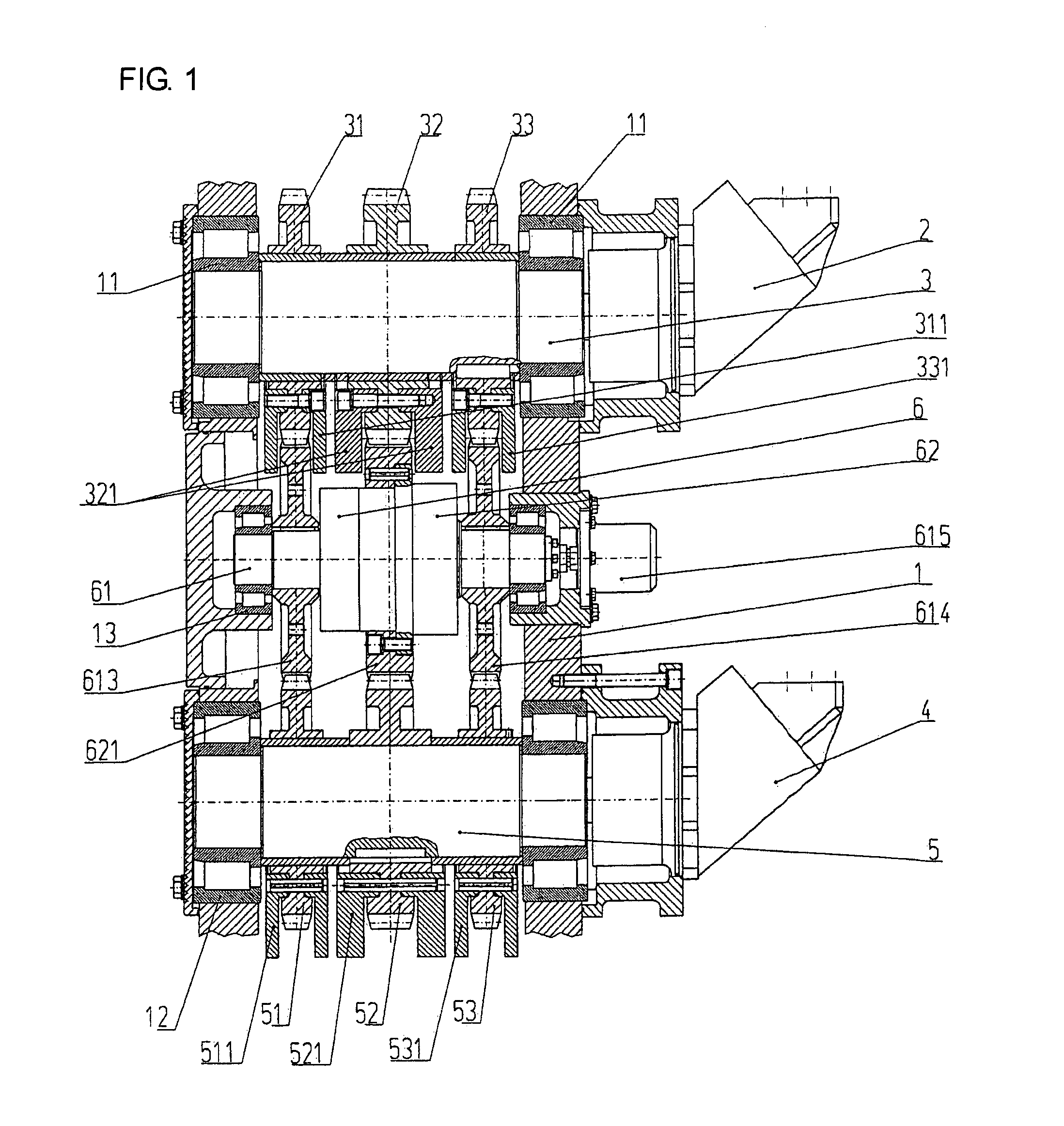

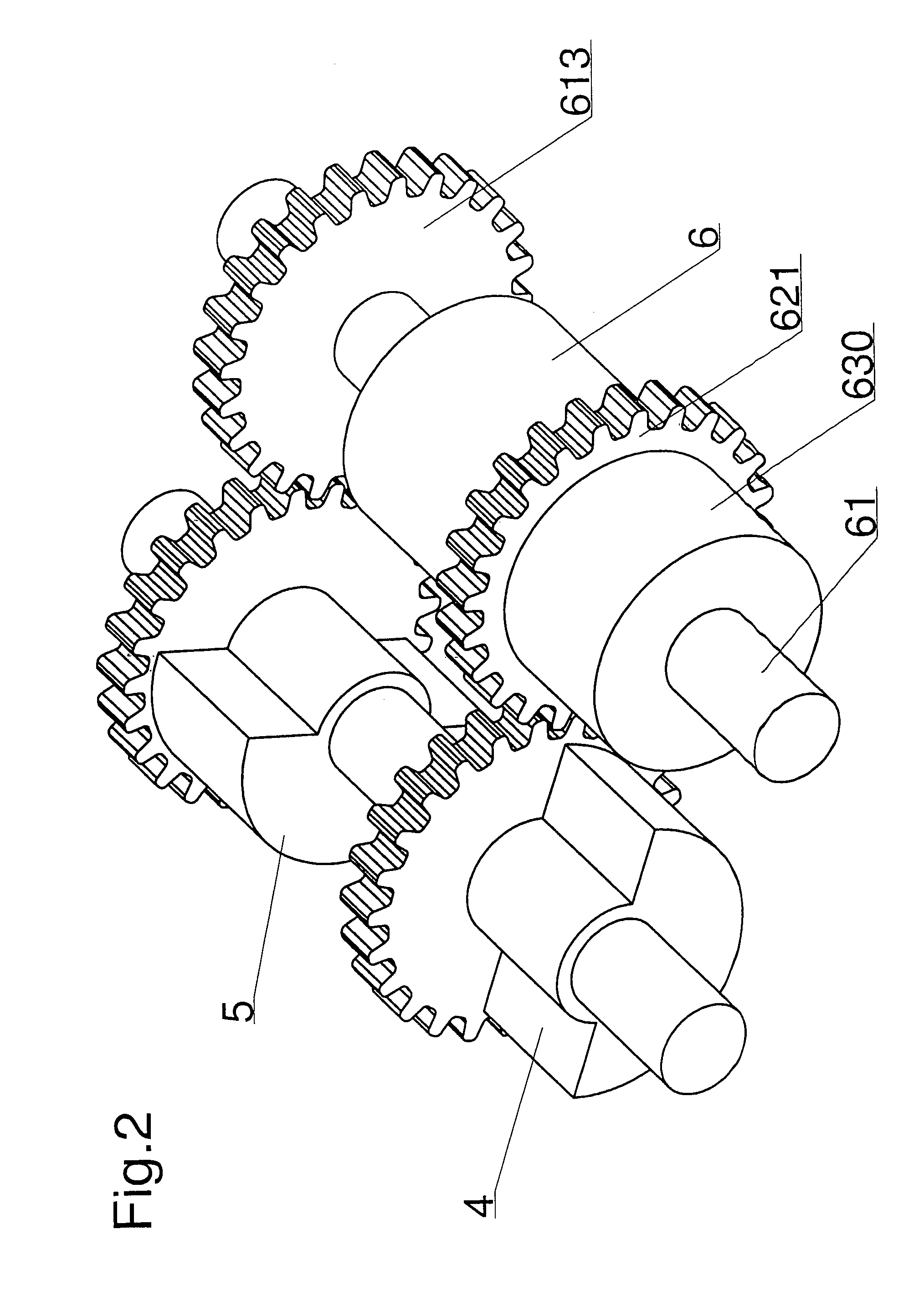

Vibration exciter

InactiveUS7598640B2Effective vibrationCompact structureGearingMechanical vibrations separationEngineeringVibration exciter

A vibration exciter has at least two axles disposed parallel to one another, as well as at least two imbalance masses, which are attached to one or more of the axles. The relative rotary position of the imbalance masses can be adjusted relative to one another by a rotary oscillating motor having a rotor shaft and a stator housing. The rotor shaft is an integral part of one of the axles, and the rotary position of the stator housing relative to the rotor shaft can be changed. The stator housing can be locked to the rotor shaft. The oscillating motor has a rotor shaft and a stator housing, between which working chambers are formed. The stator housing can rotate about the rotor shaft and can be locked relative to the rotor shaft.

Owner:ABI +1

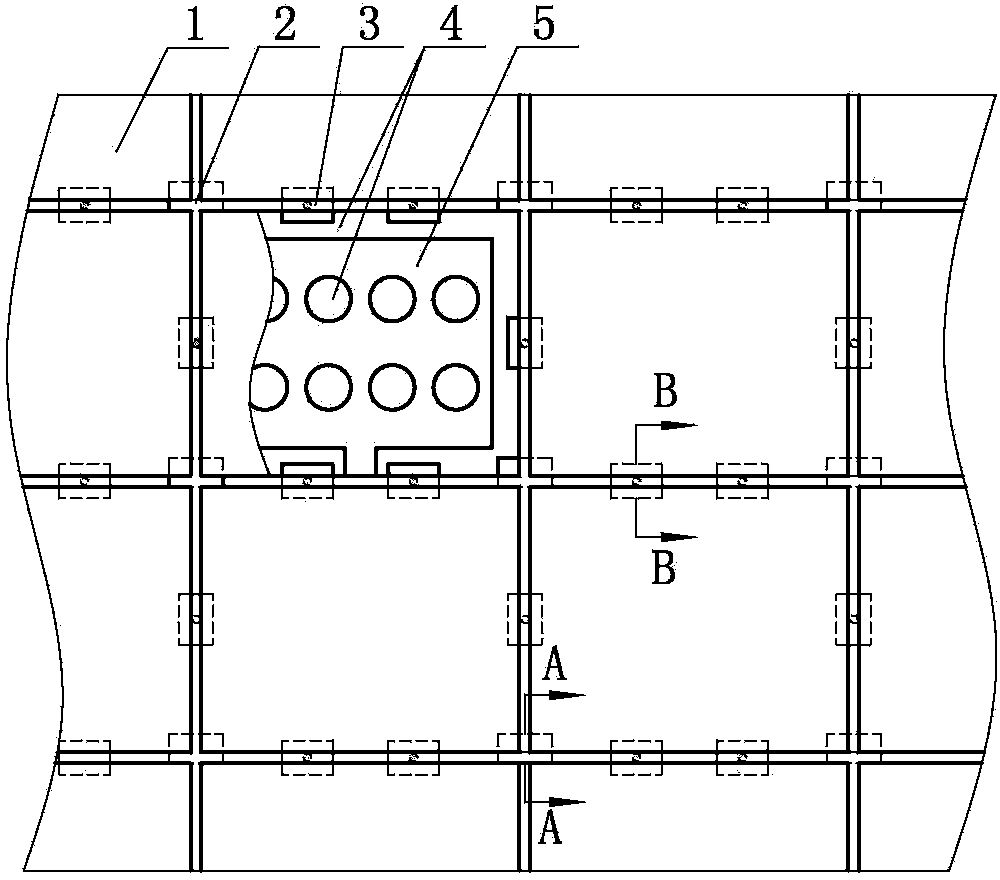

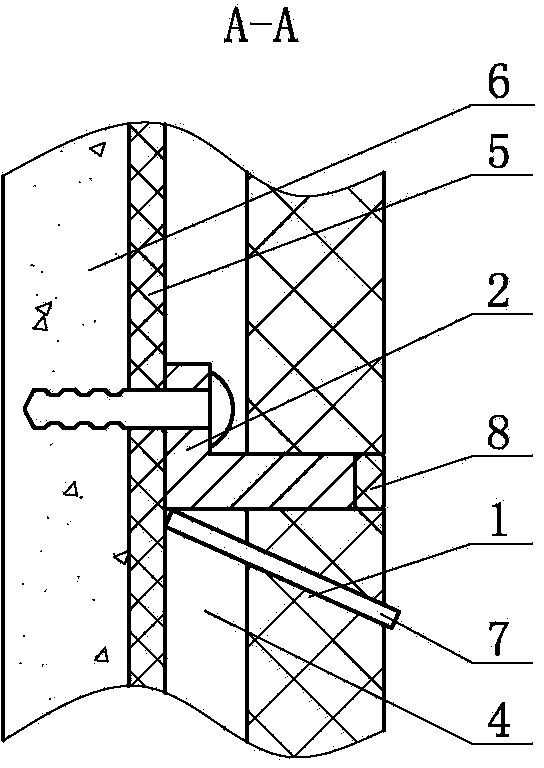

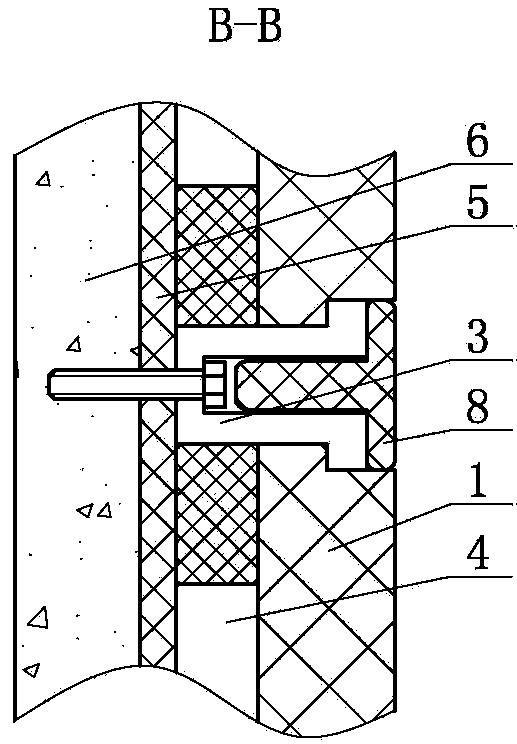

Inorganic thermal insulation decorative sheet and installation method thereof

ActiveCN103938822AImprove stabilityStrong firmnessCovering/liningsPolymer adhesiveThermal insulation

An inorganic thermal insulation decorative sheet comprises a leveling layer on the wall face of a basic wall. L-type brackets are anchored to the wall face of the basic wall. The brackets are composed of horizontal boards and vertical boards. The vertical boards of the brackets are anchored to the basic wall. Inorganic thermal insulation decorative sheet bodies adhere to the leveling layer. The lower portions of the sheet bodies are matched with the horizontal boards of the brackets. Multiple U-type clamping pieces are arranged between the adjacent sheet bodies and matched with the side edges of the sheet bodies. The U-type clamping pieces are anchored to the basic wall. Gaps between the adjacent sheet bodies are filled with sealant provided with venting plugs. One end of each venting plug is located in a gap between the leveling layer and the corresponding sheet body and an opening of the other end of each venting plug faces downwards and is communicated with the atmosphere. An installation method comprises the steps of treatment of the basic wall face, construction of wall face stay wires, cutting, machining of the inorganic thermal insulation decorative sheet bodies, installation of the brackets, preparation of polymer adhesive mortar, adhesion of the inorganic thermal insulation decorative sheet bodies, installation of the U-type clamping pieces, treatment of board seams and installation of the venting plugs.

Owner:SHANDONG LUTAI BUILDING MATERIAL SCI & TECH GRP CO LTD

Brake holder for a floating-caliper disk brake with a brake pad guide spring

InactiveUS20060070828A1Easy to installEasy to attachAxially engaging brakesSlack adjustersEngineeringCalipers

The present invention relates to a brake holder of a floating-caliper disc brake for motor vehicles at which brake pads arranged on either side of an associated brake disc are displaceably mounted. To ensure ease of displaceability a brake pad guide spring is provided that extends between the brake holder and the brake pads. For ease of mountability of both the brake pads and the brake pad guide spring, it is arranged for that the brake pad guide spring is mountable on the brake holder in a generally radial direction and is locked at the brake holder in both radial and axial directions by means of at least one fixing clamp, and at least one spring arm is designed at the brake pad guide spring and fixes at least one brake pad under spring bias in position on the brake holder in a clearance-free manner. These provisions not only improve the mountability of a brake of this type but also the rattle-free resilient arrangement of the brake pads.

Owner:CONTINENTAL TEVES AG & CO OHG

Lever-type connector

ActiveCN102017319ALock releaseImprove disengagementCoupling device detailsEngineeringMechanical engineering

Owner:TYCO ELECTRONICS JAPAN GK

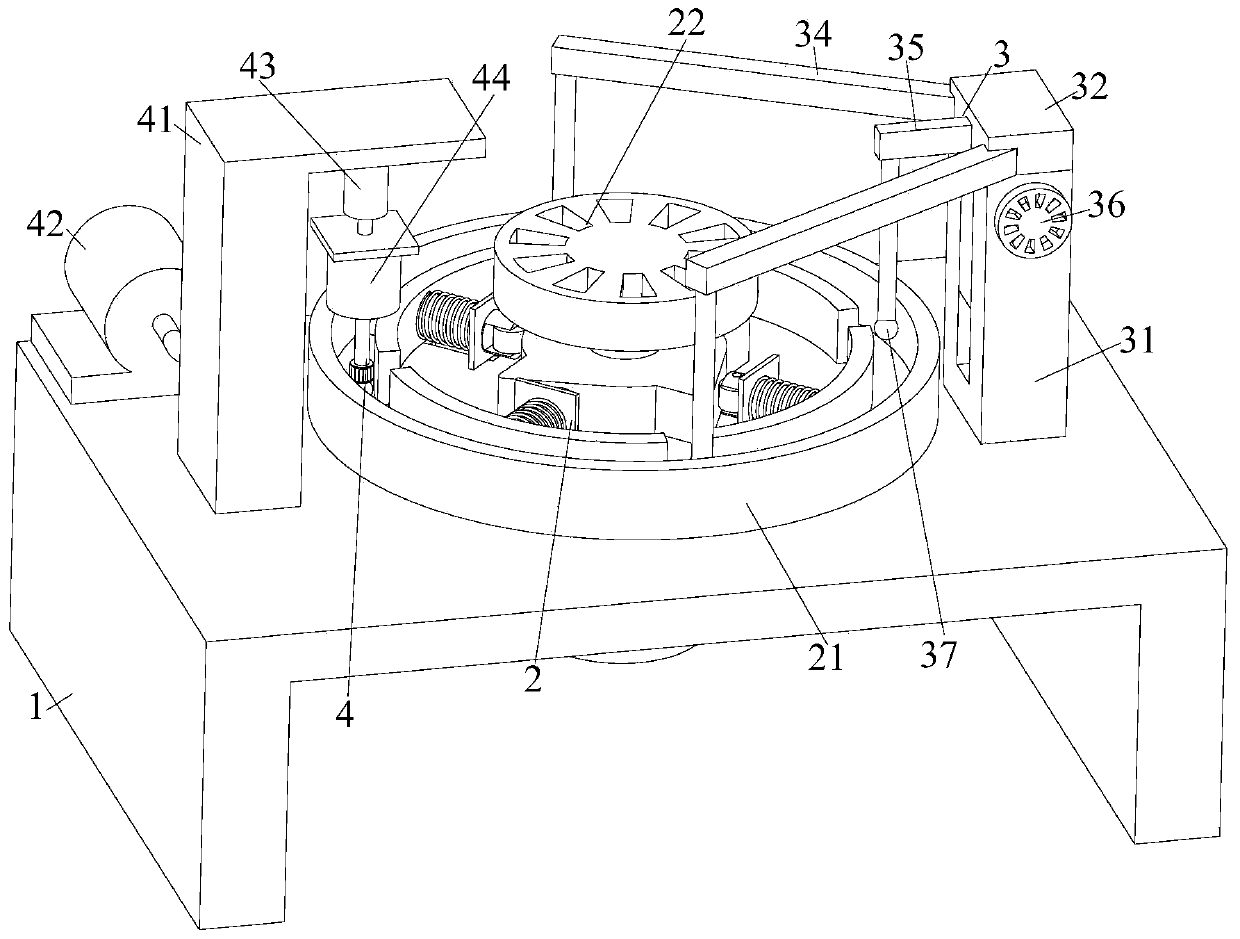

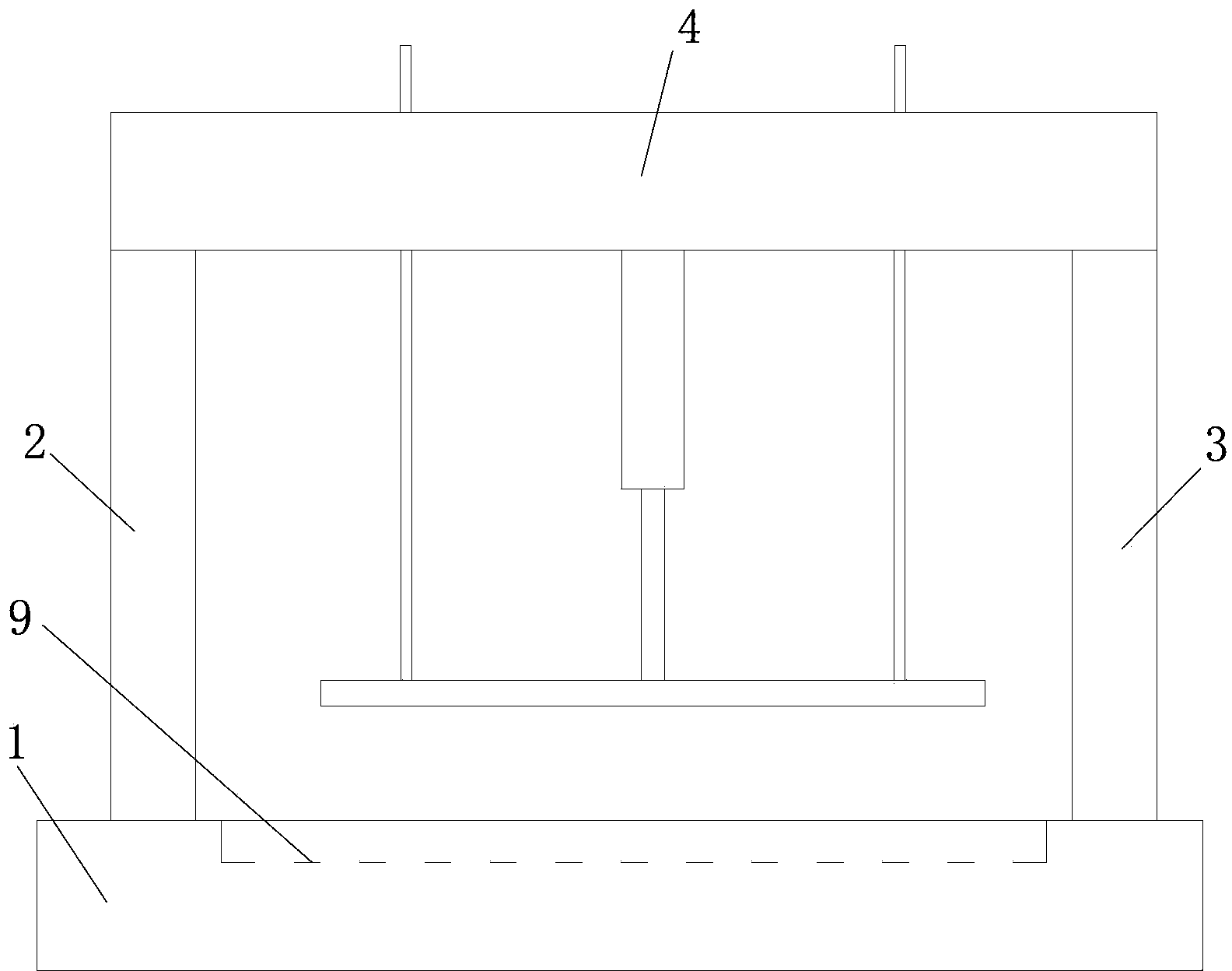

Finish machining machine for manufacturing rubber sealing part and finish machining method

ActiveCN110814926AImprove sealingAvoid offsetEdge grinding machinesGrinding drivesRubber materialElectric machine

The invention relates to a finish machining machine for manufacturing a rubber sealing part and a finish machining method. The machine comprises a workbench, a fixing device, a pressing device, a grinding device and a rotating motor, wherein the fixing device is arranged in the middle part of the upper end of the workbench in a sliding fit mode, the pressing device is arranged on the right side ofthe fixing device, the pressing device is welded on the right side of the upper end of the workbench, the left end of the fixing device is provided with the grinding device, the grinding device is welded on the left side of the upper end of the workbench, the lower end of the workbench is provided with the rotating motor, and the output end of the rotating motor is provided with the fixing devicein a welded mode. According to the finish machining machine for manufacturing the rubber sealing part and the finish machining method, the problems that rubber burrs are difficult to remove after existing rubber sealing part machining equipment performs die pressing, and when the burrs are manually removed, too much or too little rubber material may be removed when the burrs are manually removed,the precision of the rubber sealing part is difficult to control, and thus the sealing performance of a rubber sealing ring is poor are solved.

Owner:永康市易贝科技有限公司

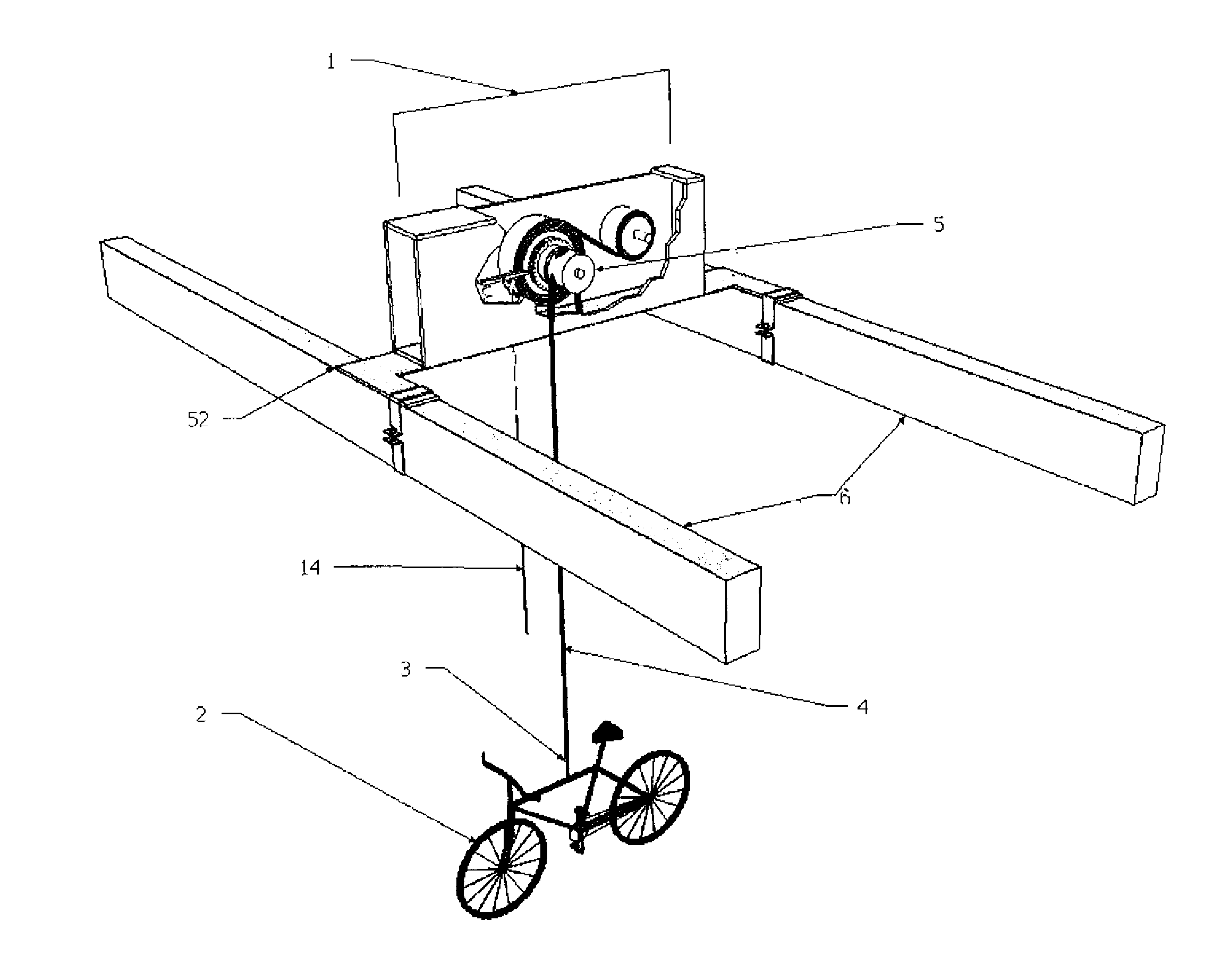

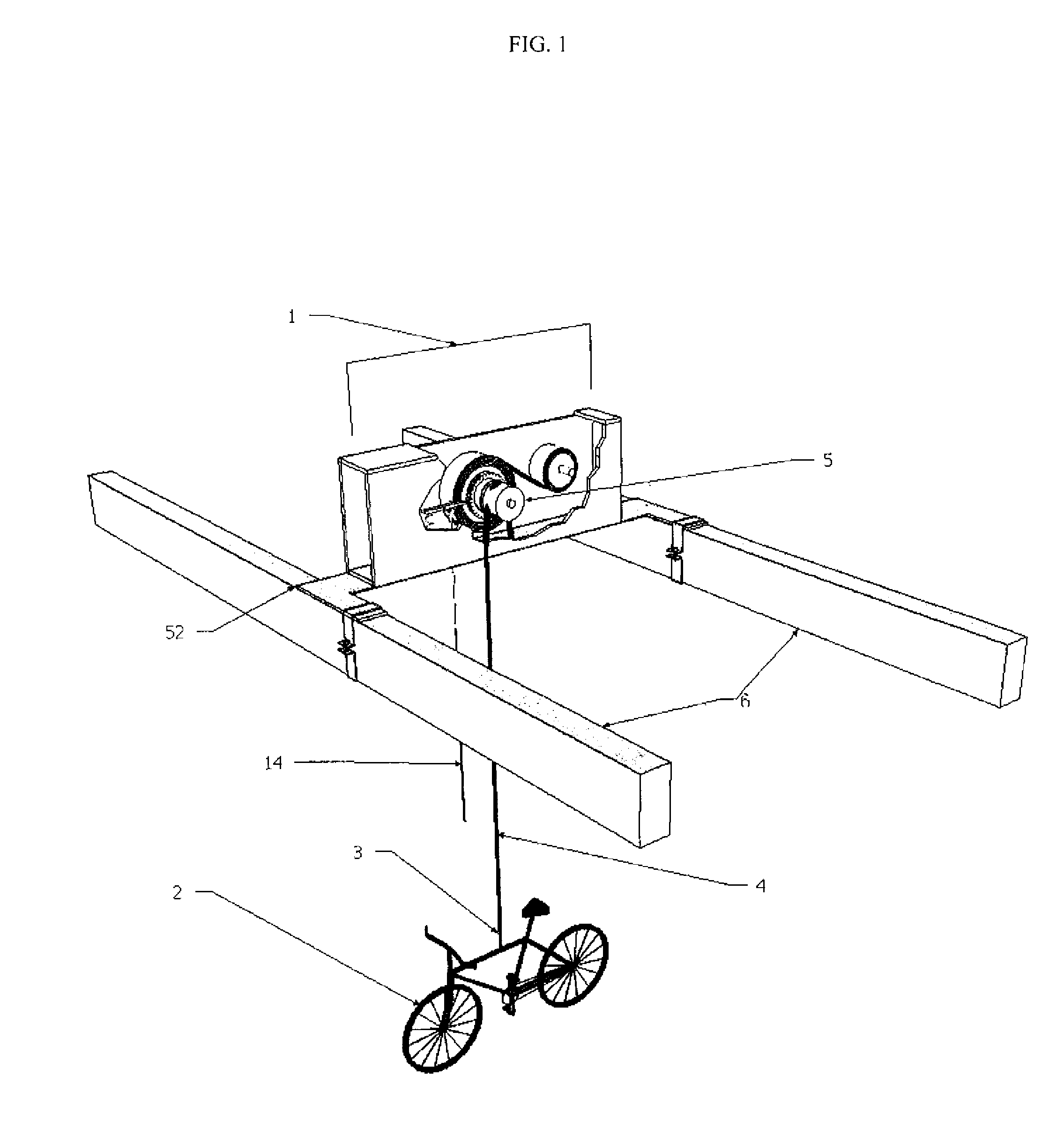

Overhead Storage Device

InactiveUS20120068133A1Prevent accidental releaseAvoid liftingCycle standsWinding mechanismsLocking mechanismEngineering

An overhead storage device having a lifting range. A constant torque spring is attached to a power pulley and is adapted to apply an approximately constant torque to the power pulley. A cable is partially wound around the power pulley and has an attachment mechanism at one end of the cable. A locking mechanism is adapted to permit the attachment mechanism and an attached load to be lowered and locked at any desired position within the range of the device. The approximately constant torque applied by the constant torque spring continuously causes the cable, unless restrained, to be further wound on the pulley.

Owner:OZARSKI ROBERT

Systems and methods for guiding conveyance elements

InactiveUS7121400B2Avoid liftingImprove efficiencyMechanical conveyorsManufacturing lineLinear distance

Systems and methods for controlling the planarity of a conveyance element with respect to a guide while the conveyance element is in motion. This control is achieved by coupling a guide to a conveyance element where the conveyance element is held in a level position by a magnetic force. The attractive force specifically holds the edges of the conveyance element in place, so that they do not lift up or separate from the guide as the guide, by way of a chain coupling the guide to the conveyance element, carries the conveyance element through a defined path over a linear distance or around a corner in, for example, a manufacturing line environment.

Owner:HABASIT AG

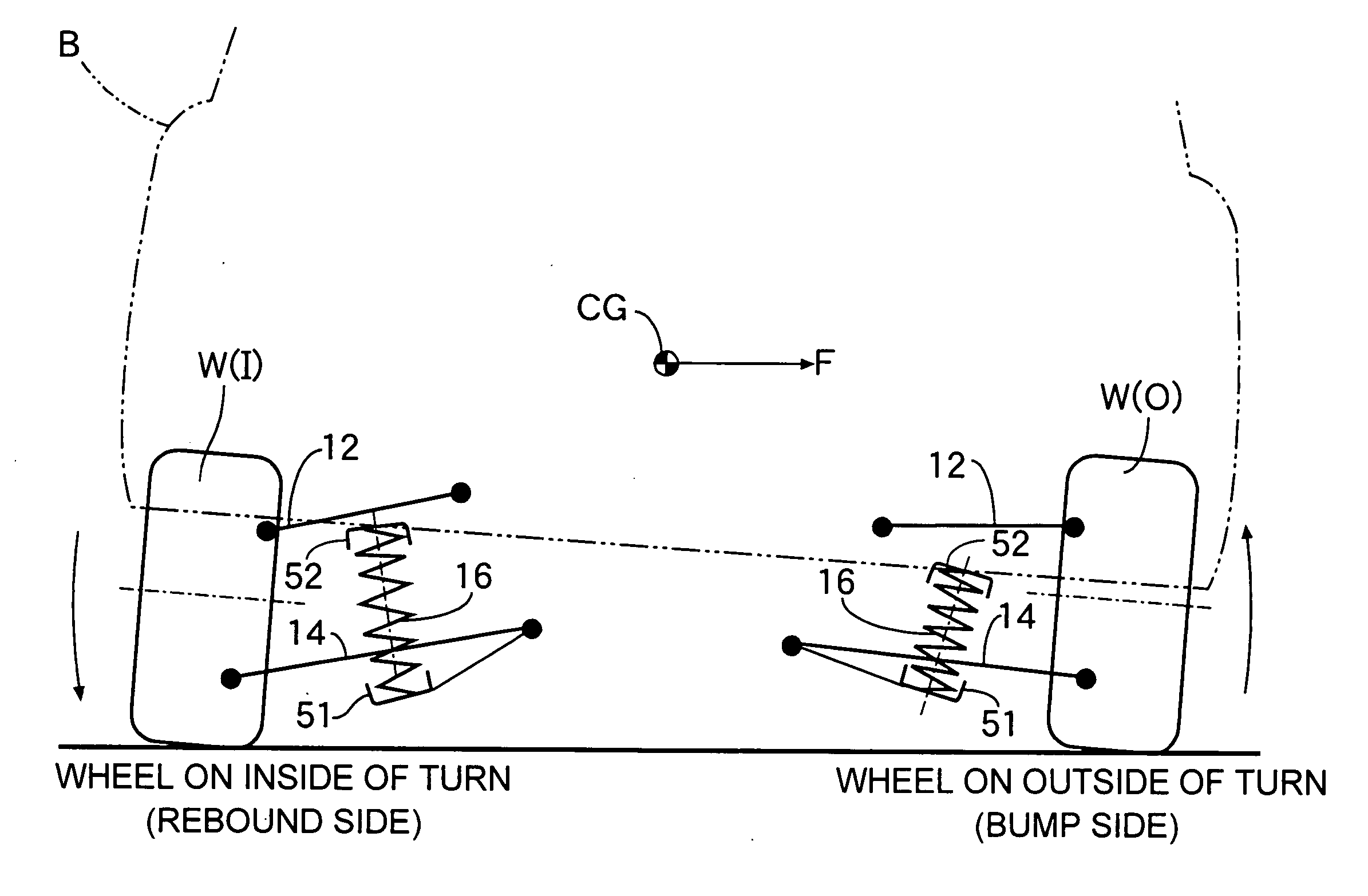

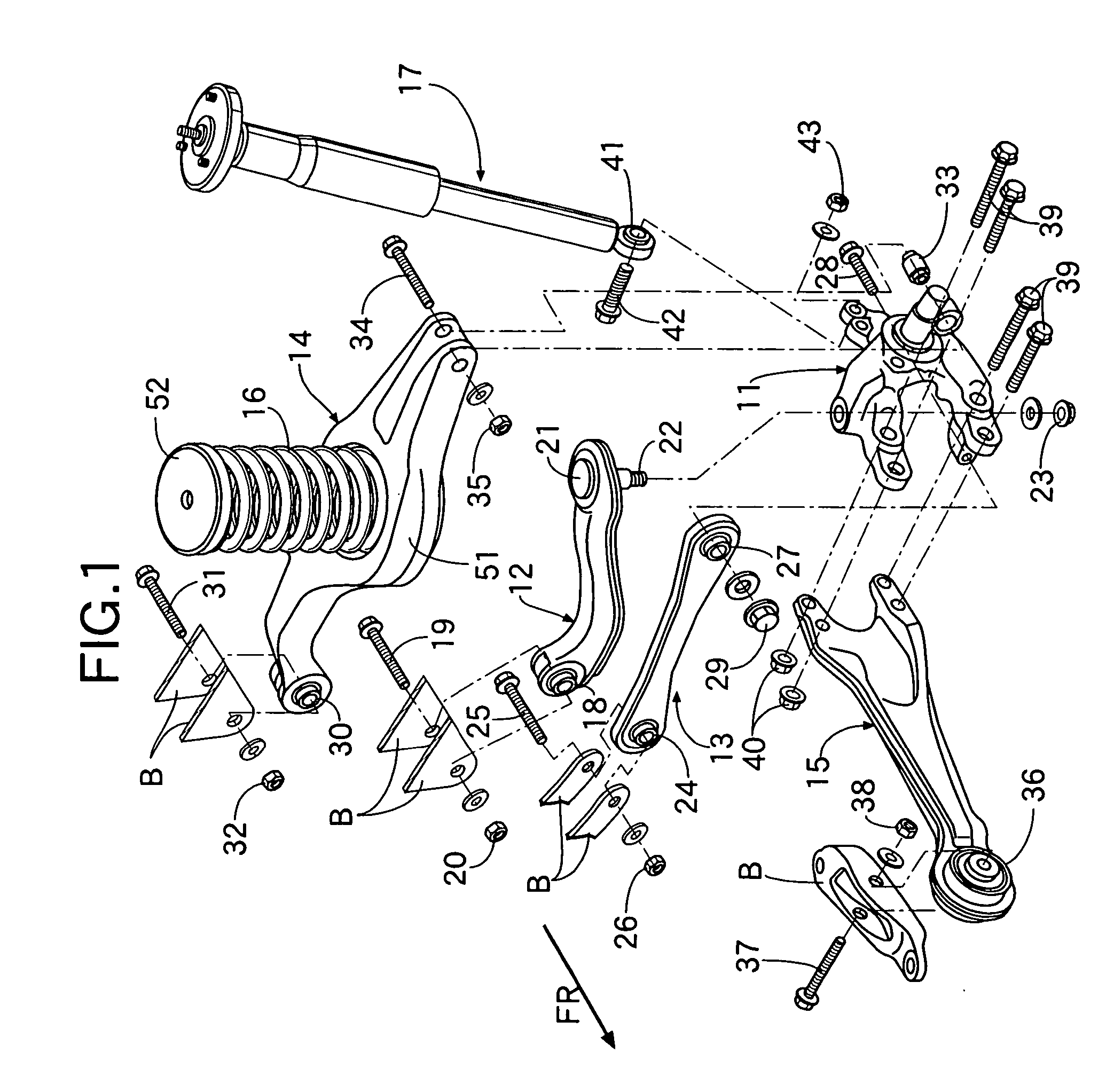

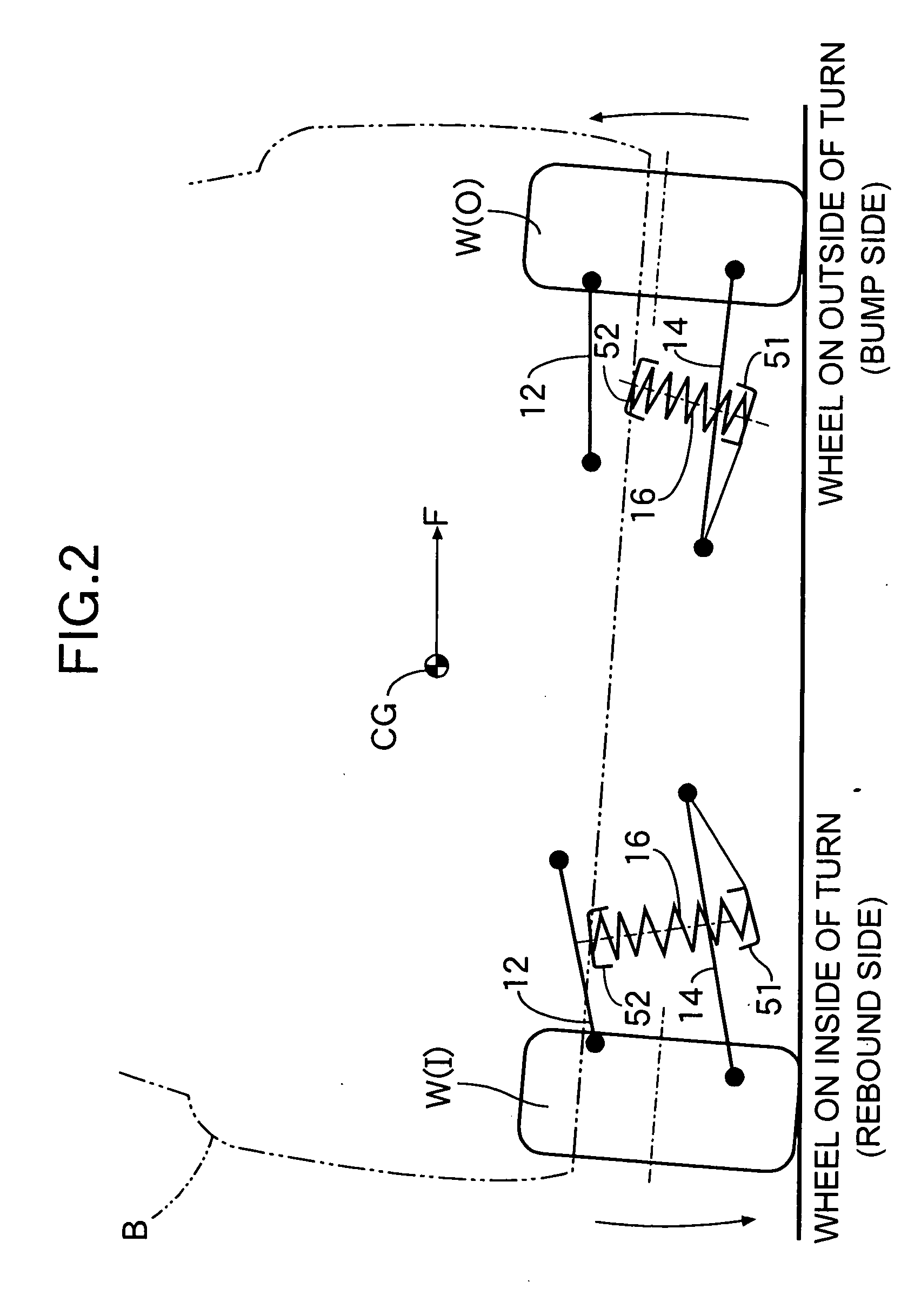

Suspension device for motor vehicle

InactiveUS20060220338A1Avoid performance degradationAvoid bendingResilient suspensionsPivoted suspension armsCoil springEngineering

A vehicular suspension system is provided in which the lower end of a coil spring (16) is positioned lower than a support part (30) where a suspension arm (14) is supported on a vehicle body, the lower end of the coil spring (16) is positioned on the laterally inner side of the vehicle body relative to the upper end of the coil spring (16), and when a wheel (W) rebounds and the coil spring (16) is elongated, the lower end of the coil spring (16) can therefore move along its axis. As a result, the coil spring (16) can be prevented from bending at a time of rebound, the spring constant thus increases, and the lower end of the coil spring (16) is pressed strongly against a spring seat (51) and thus prevented from lifting, thereby preventing any degradation in the turning performance. This can prevent the lower end of the coil spring of the vehicular suspension system from lifting from the spring seat when the coil spring is elongated, thus preventing any degradation in the turning performance.

Owner:HONDA MOTOR CO LTD

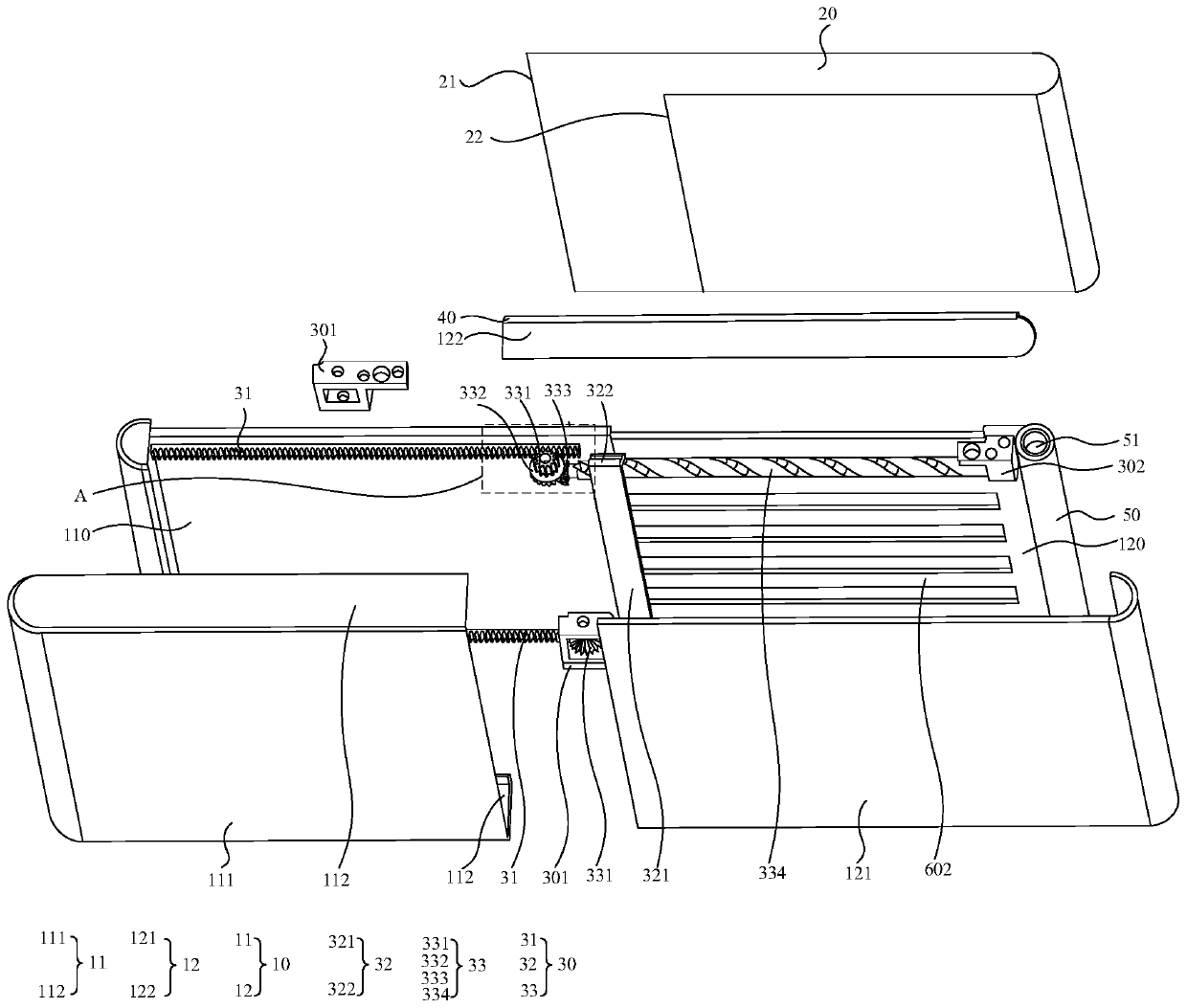

Cloth cutting device

The invention relates to a cloth cutting device capable of automatically cutting cloth. The cloth cutting device comprises a base, a first support, a second support and a third support, wherein the first support and the second support are vertically arranged on the upper end face of the base, and the third support is arranged at the upper ends of the first support and the second support. A cutting cylinder is arranged on the third support, a telescopic end of the cutting cylinder is connected with a blade holder, a cutting blade and a guide post are arranged on the blade holder, one end of the guide post is connected with the blade holder, the other end of the guide post penetrates the third support and guides lifting of the blade holder, a pressing mechanism is further arranged on the third support, lifts up and down and is used for pressing cloth, and a cutting notch matched with the cutting blade is formed in the base. When the cloth is cut, the cutting cylinder drives the blade holder and the cutting blade on the blade holder to descend, the cutting blade is matched with the cutting notch to cut the cloth, the pressing mechanism descends to press the cloth in the cutting process, so that the cloth is effectively prevented from turning upwards in the cutting process, and cutting precision of the cloth is ensured.

Owner:常州市嘉翔纺织印染有限公司

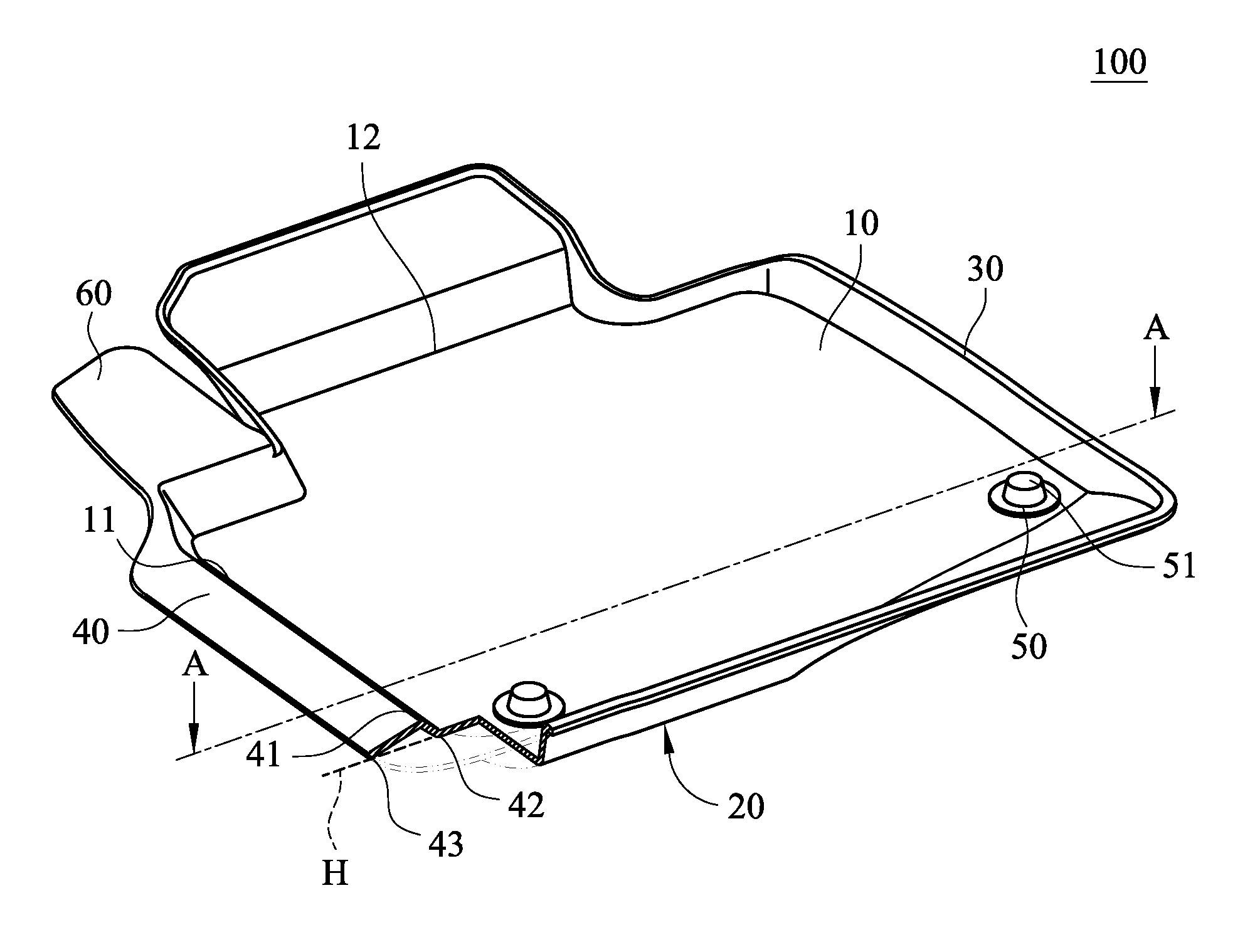

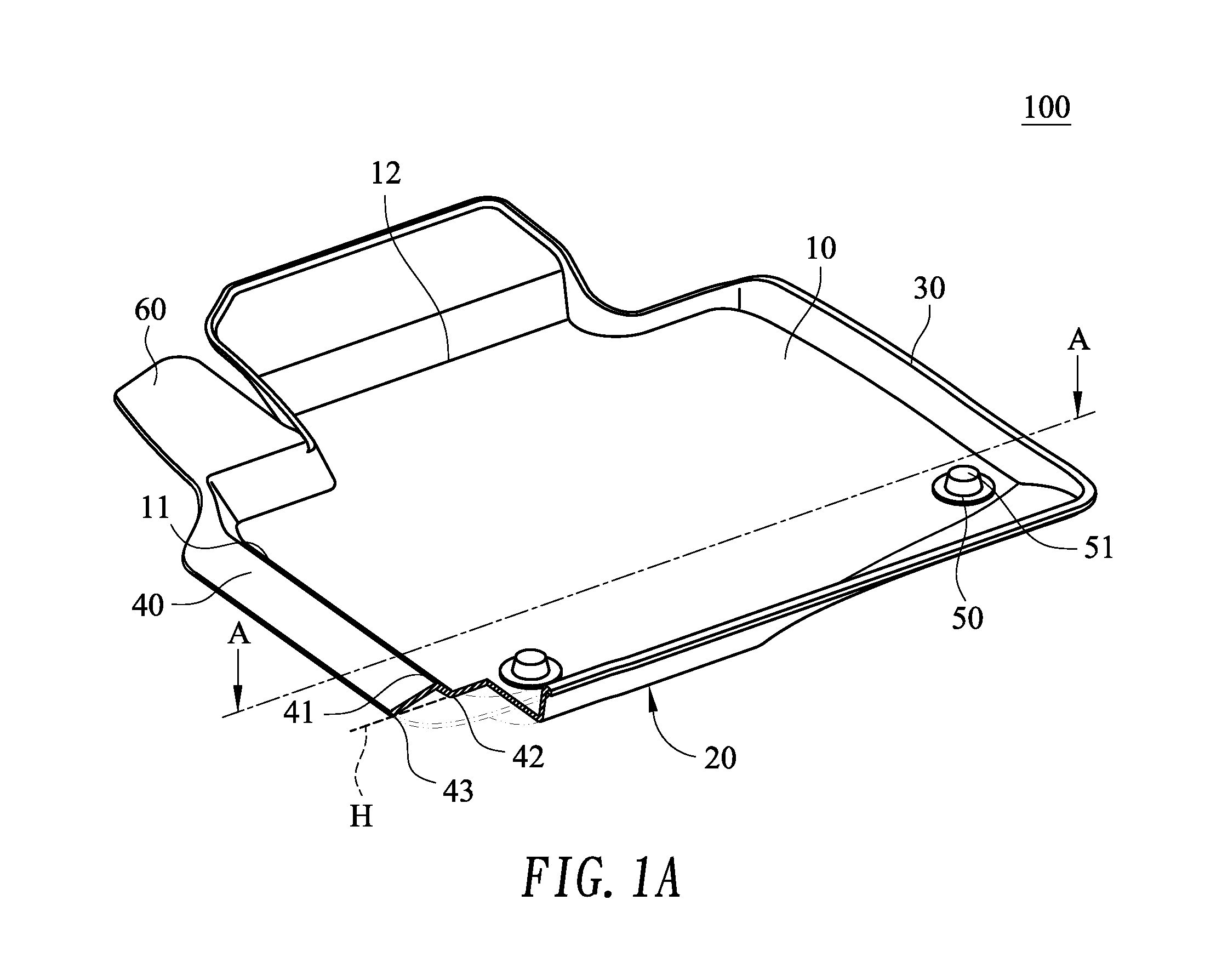

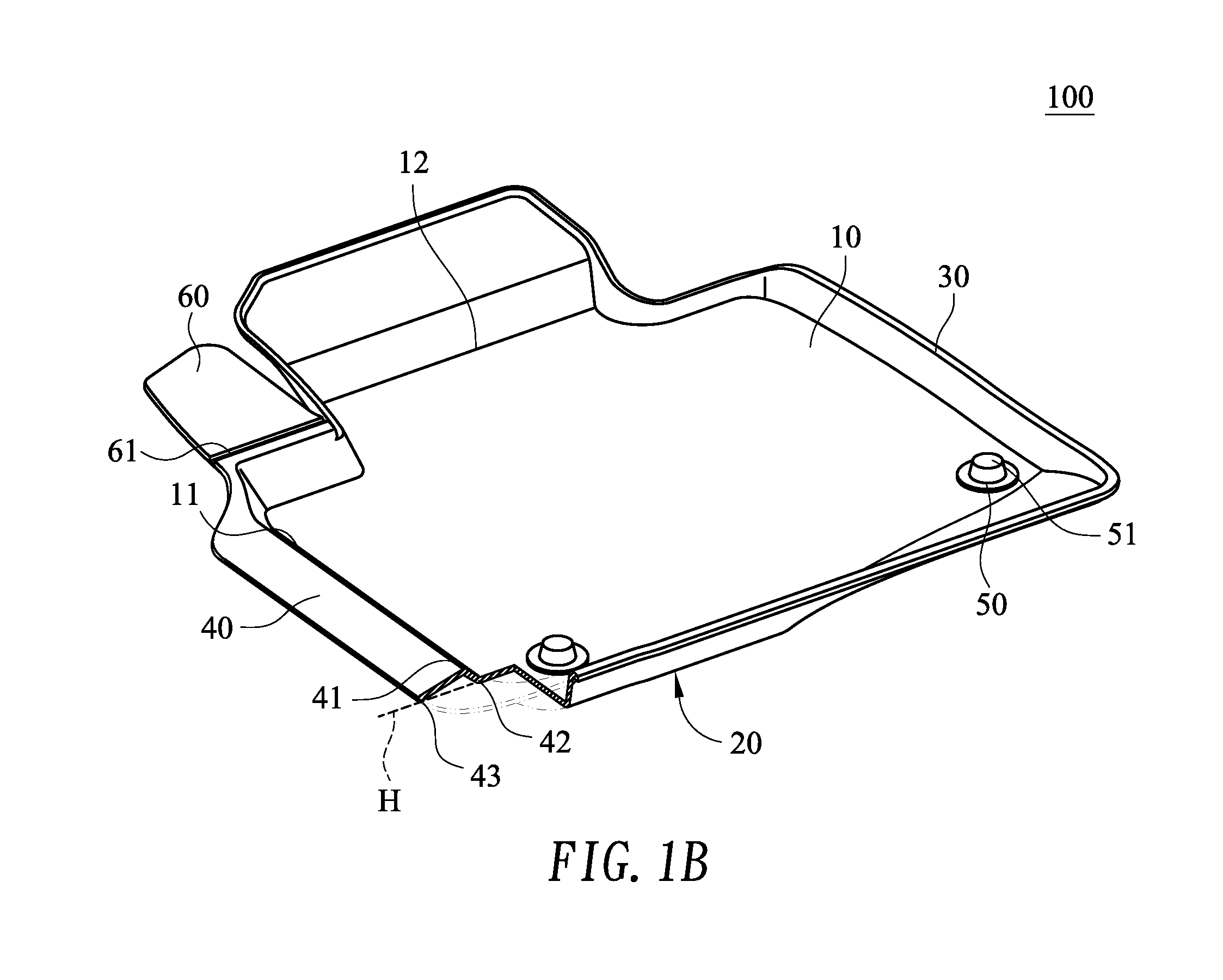

Automotive floor mat structure

ActiveUS8967697B1Reduce chanceAvoid liftingVehicle arrangementsSuperstructure subunitsPlateauForeign body

The present invention discloses automotive floor mat structures. The automotive floor mat structure comprises a containing plate, a bottom surface, a raised edge, a guarding edge, at least one plateau bump and a foot resting pedal. The cross-section of the guarding edge is an inverse-V shape, and one side of the inverse-V is longer than the other side. With the implementation of the present invention, the snow, water, mud, rocks, or foreign bodies carried into the chamber of the automotive can be greatly reduced, the resisting force by the foot resting pedal can prevent the automotive floor mat from being set off by foot accidently, and the plateau bump further prevents snow, water, mud, rocks, or foreign bodies on the containing plate from falling into the car chamber.

Owner:FORMOSA SAINT JOSE

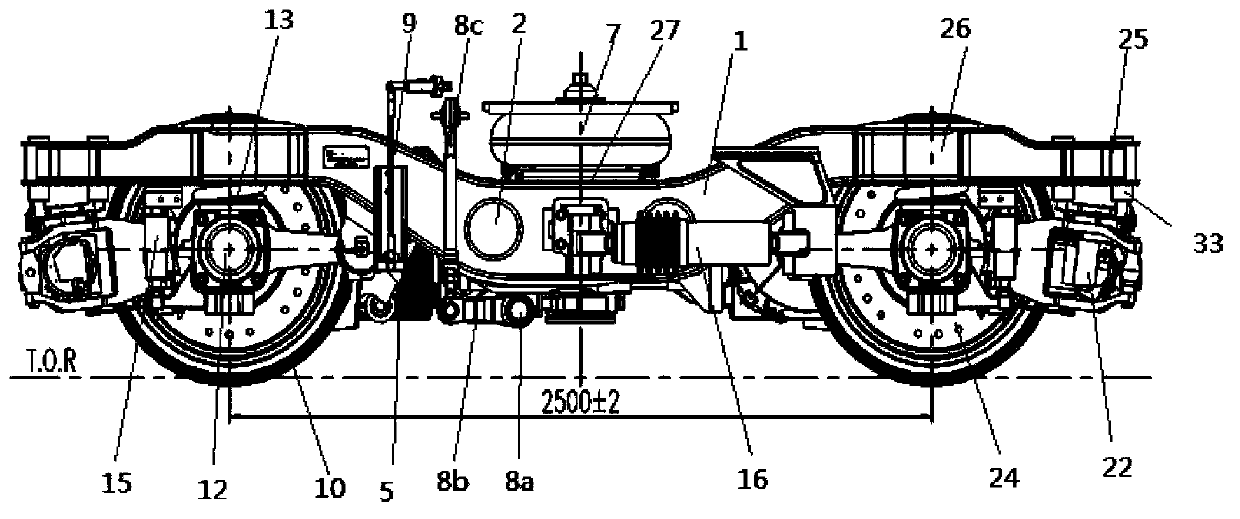

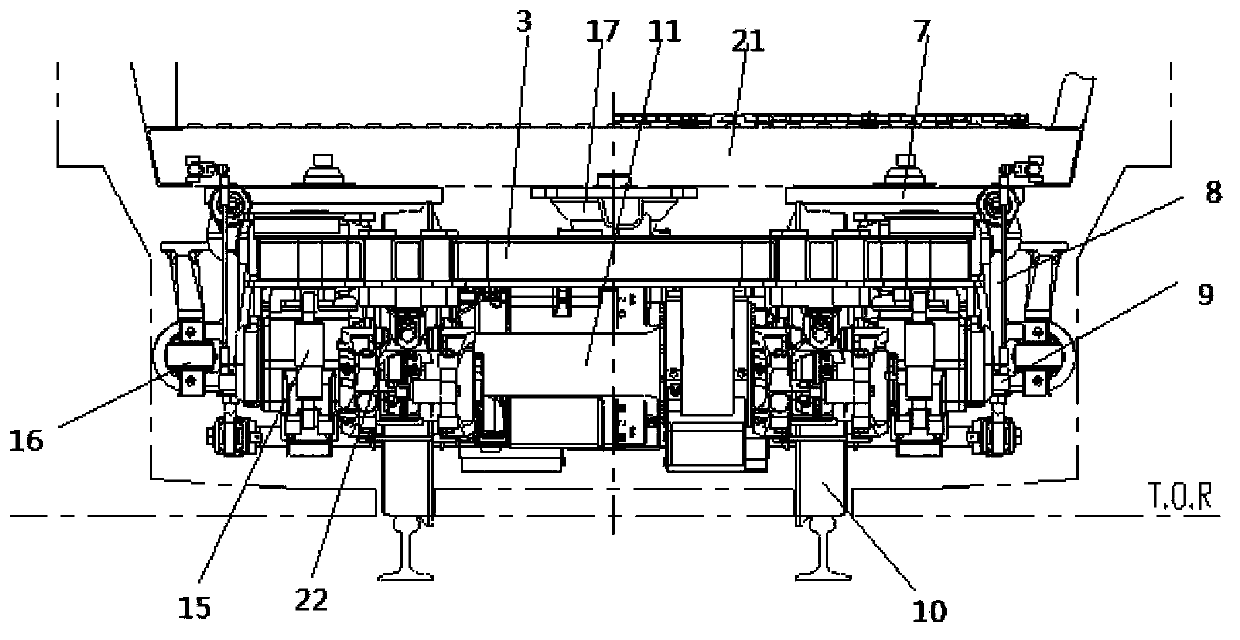

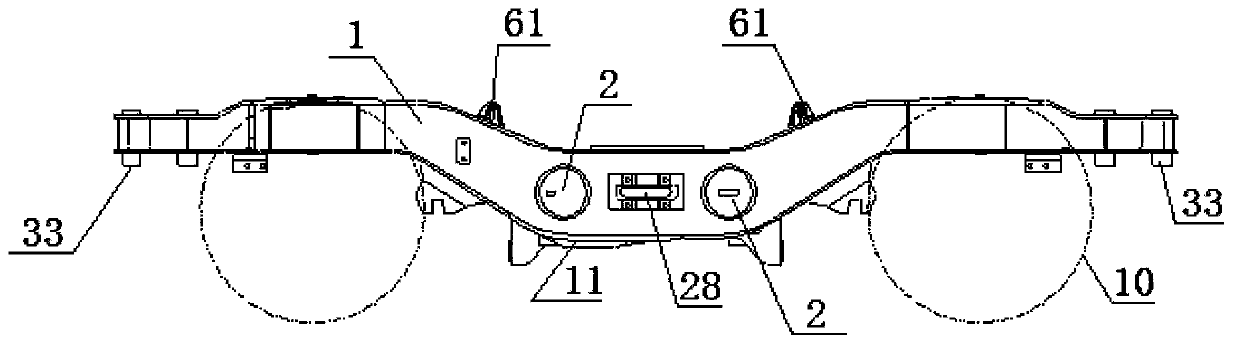

Narrow-gauge train bogie

The invention relates to a narrow-gauge train bogie which comprises a framework. Two wheel sets, a traction device, two traction motors, two gearboxes, a primary suspension device, a secondary suspension device and a foundation brake device are arranged on the framework. The primary suspension device is composed of a steel spring and a rocker arm type axle box, the rocker arm type axle box is connected with the framework through the steel spring, each wheel set comprises a wheel axle and wheels fixed to the two ends of the wheel axle, the wheel axles are connected with the rocker arm type axle box, the secondary suspension device comprises an air spring, a side rolling resisting torsion bar and a height control valve, the air spring, the side rolling resisting torsion bar and the height control valve are arranged on the framework, and the foundation brake device is a wheel-mounted disc brake device. The components are optimized and are combined in a matched mode, performance parameters are optimized, and therefore the performance of the bogie is greatly improved. As is proved by the experiment, according to the narrow-gauge train bogie, the operating speed of a train can be 160km / h on a narrow gauge of 1076mm, and the narrow-gauge train bogie has good stability, comfort and safety performance.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com