Patents

Literature

7257 results about "Bogie" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bogie (/ˈboʊɡi/ BOH-ghee) (in some senses called a truck in North American English) is a chassis or framework that carries a wheelset, attached to a vehicle—a modular subassembly of wheels and axles. Bogies take various forms in various modes of transport. A bogie may remain normally attached (as on many railroad cars and semi-trailers) or be quickly detachable (as the dolly in a road train or in railway bogie exchange); it may contain a suspension within it (as most rail and trucking bogies do), or be solid and in turn be suspended (as most bogies of tracked vehicles are); it may be mounted on a swivel, as traditionally on a railway carriage or locomotive, additionally jointed and sprung (as in the landing gear of an airliner), or held in place by other means (centreless bogies).

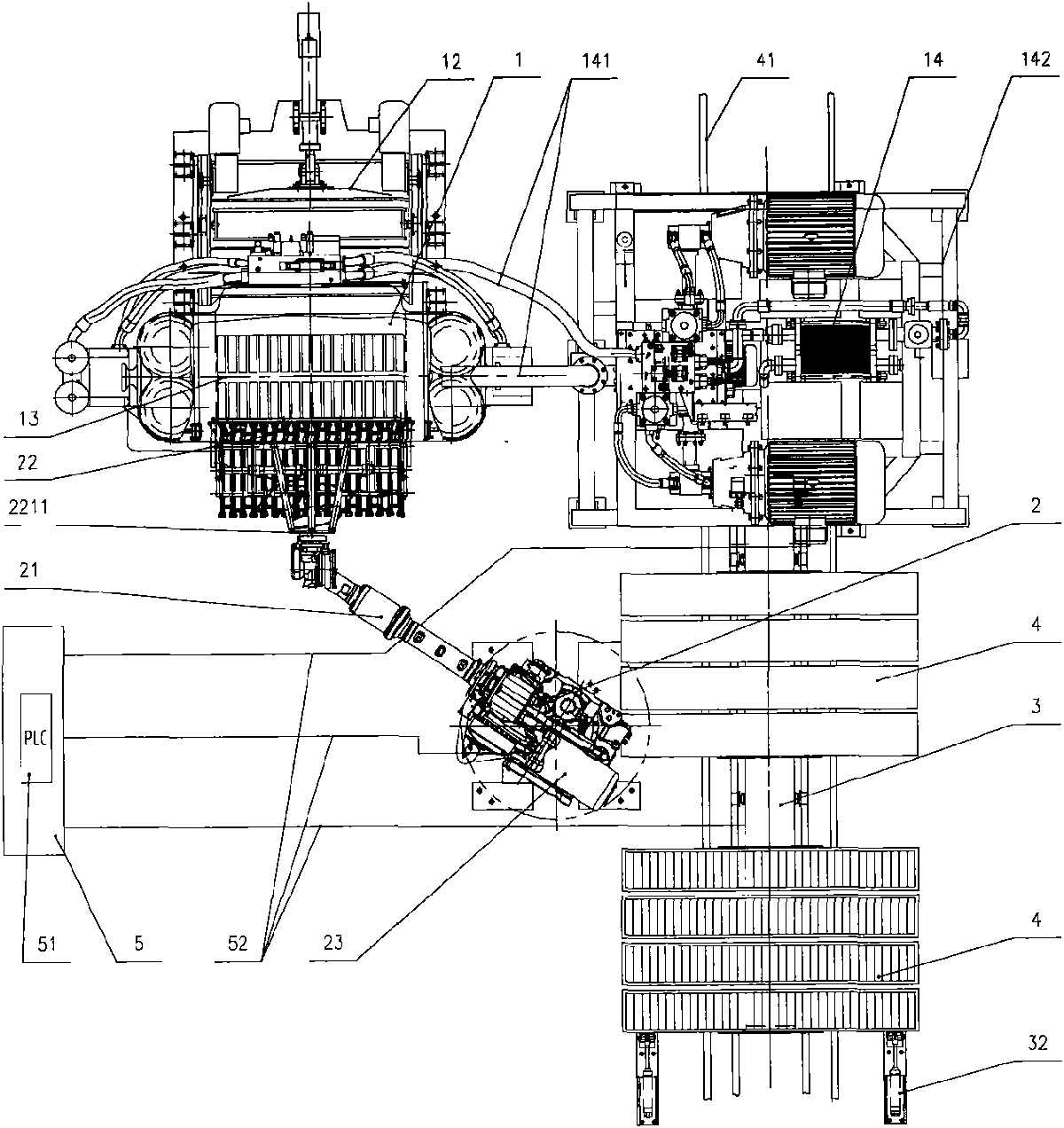

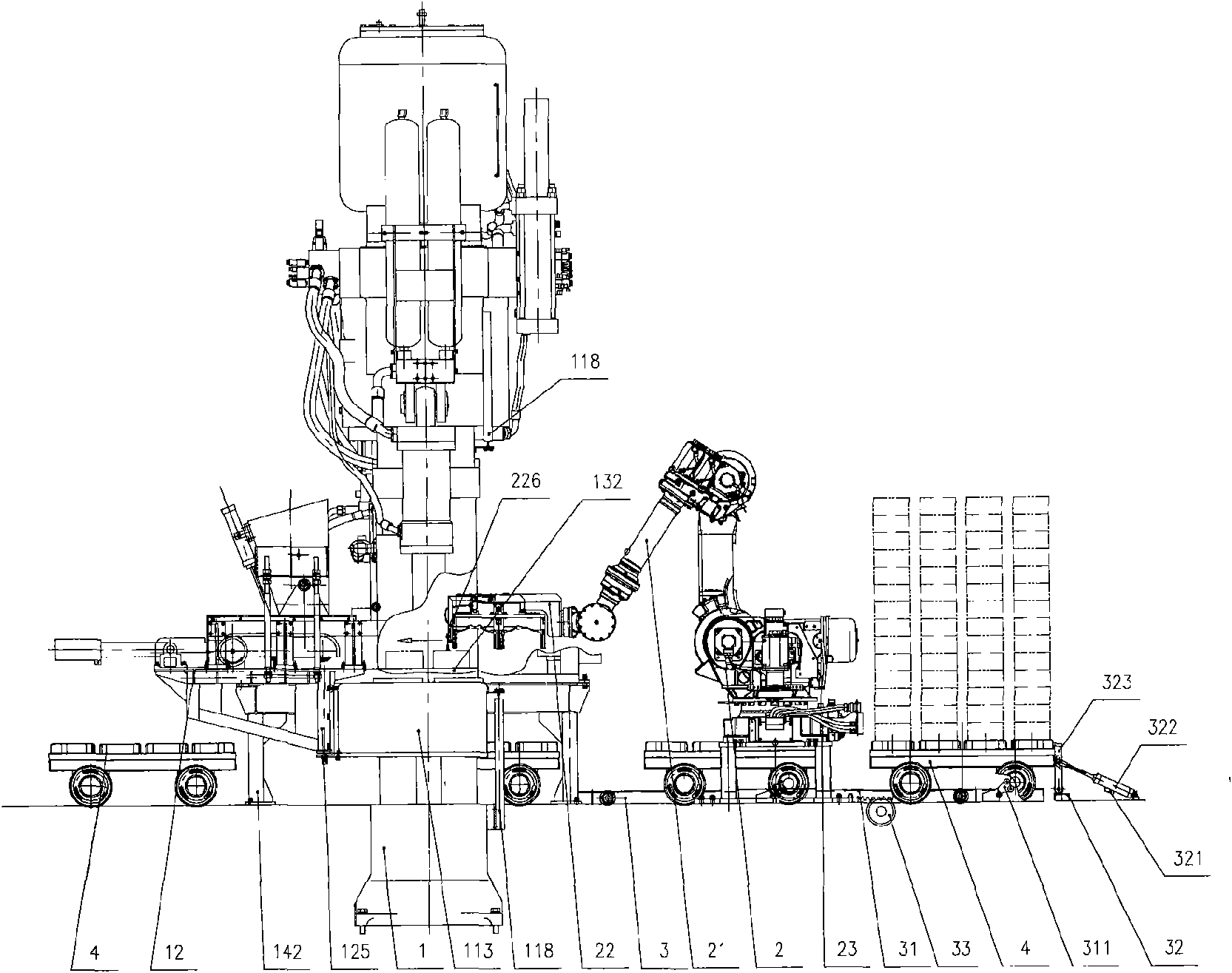

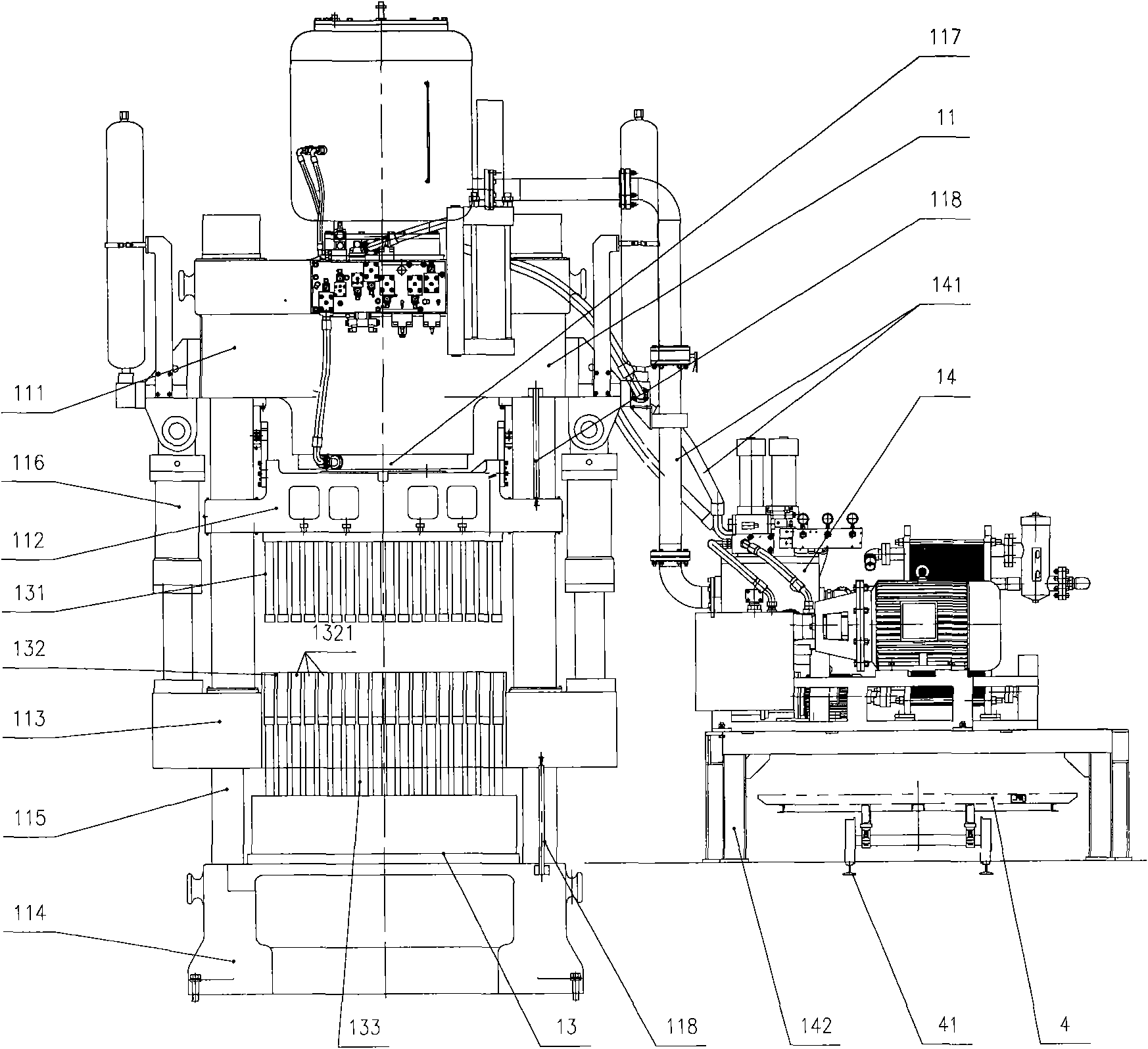

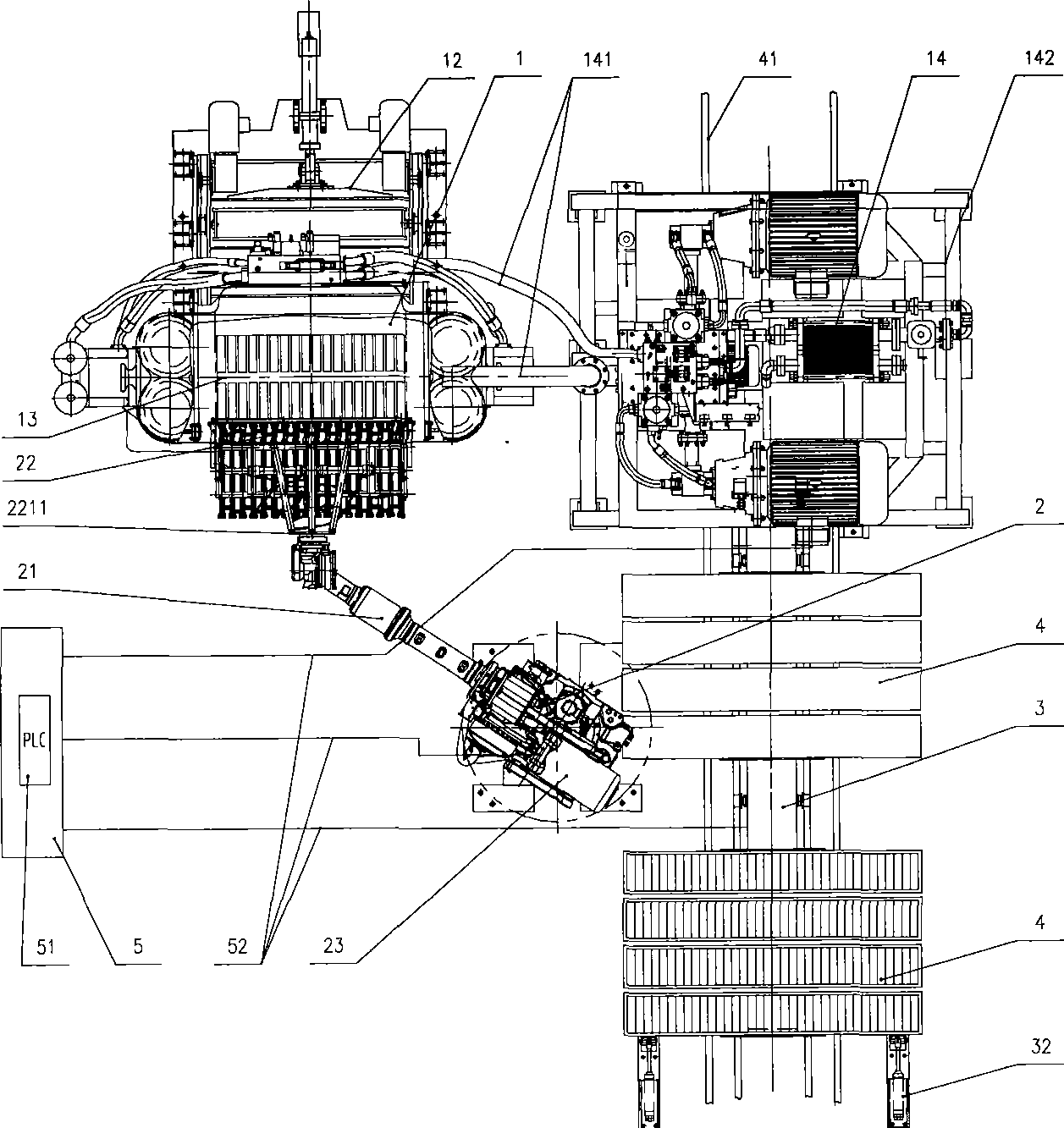

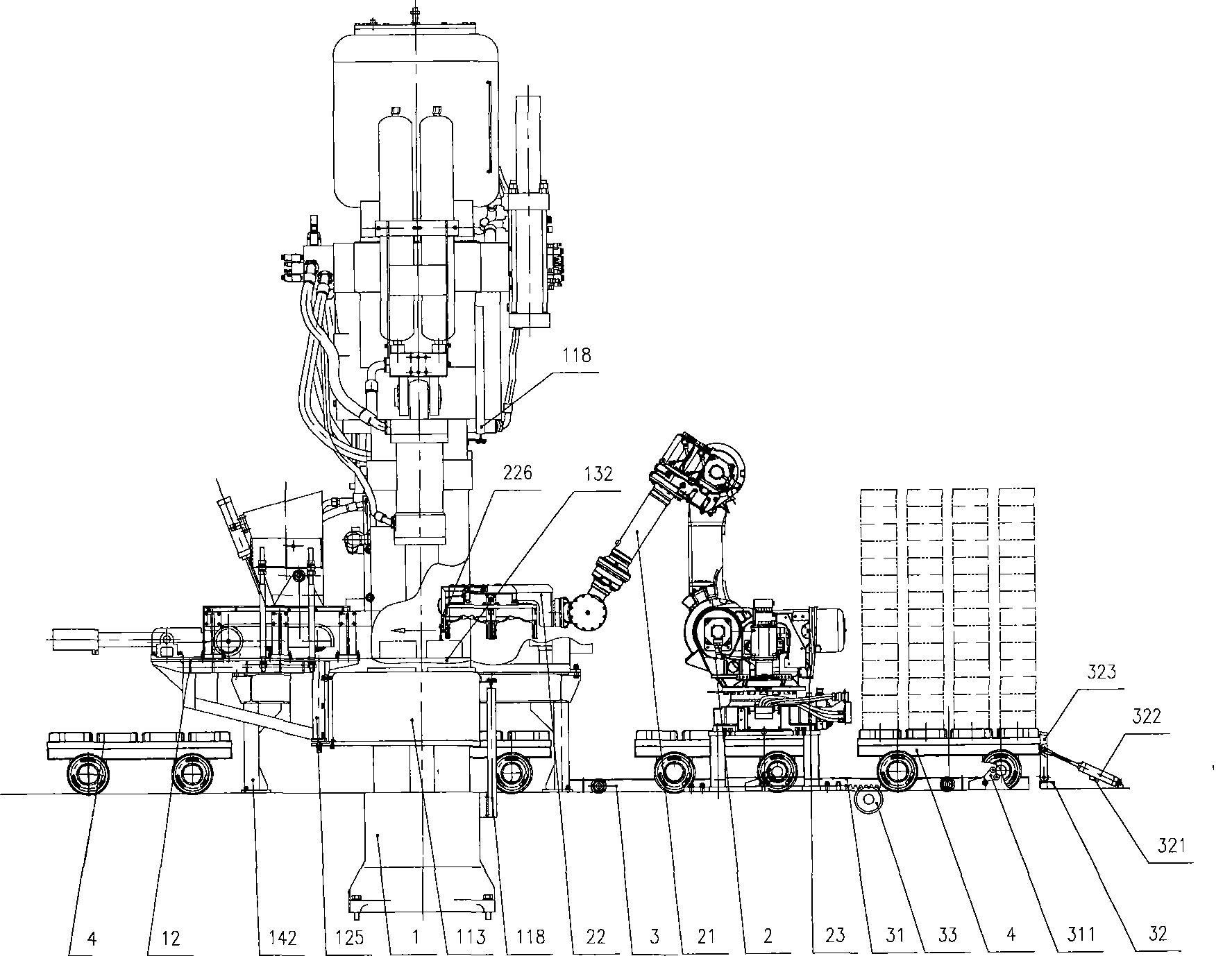

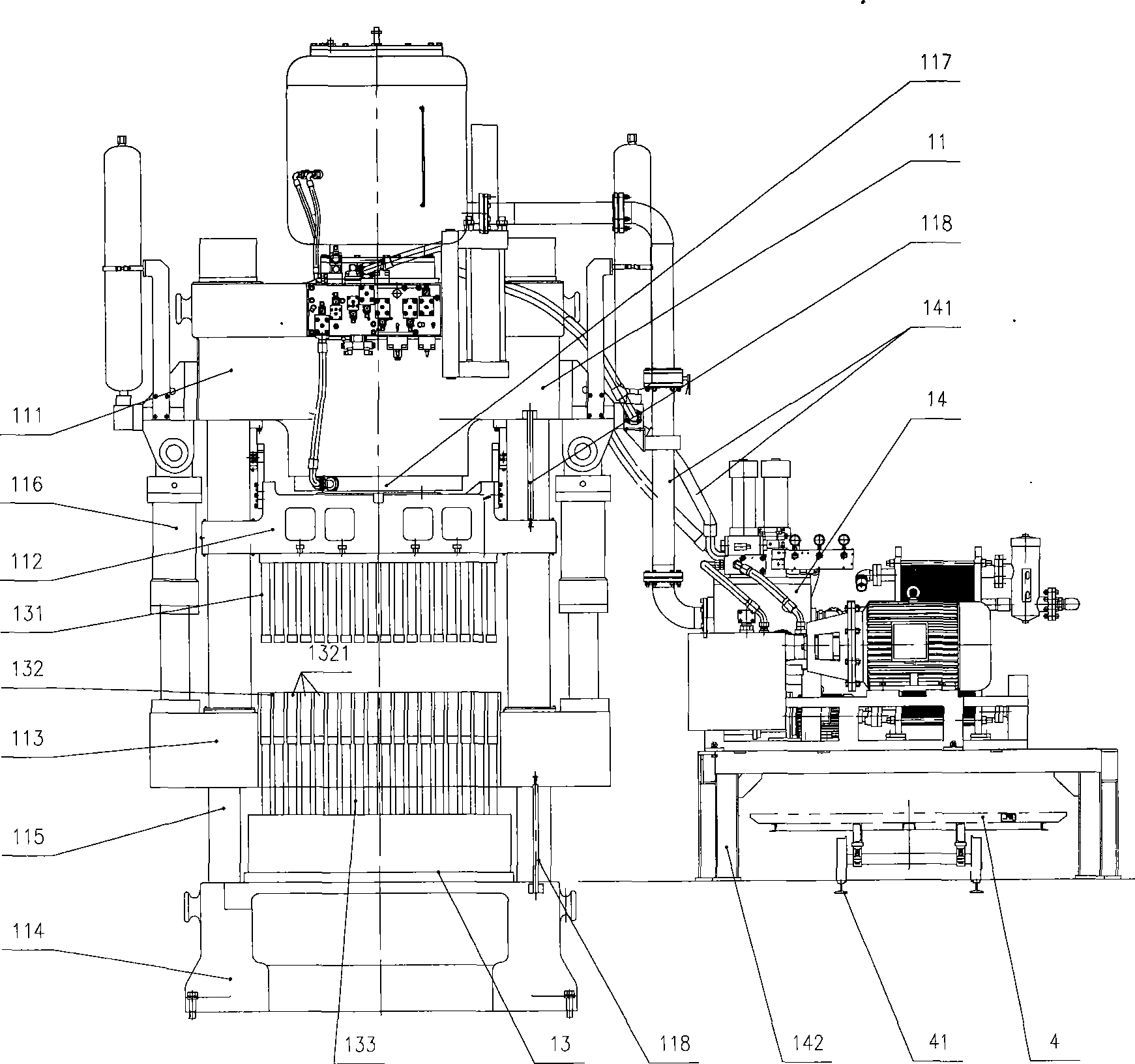

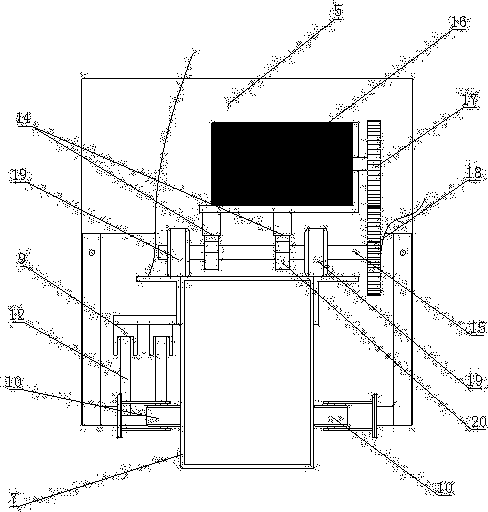

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

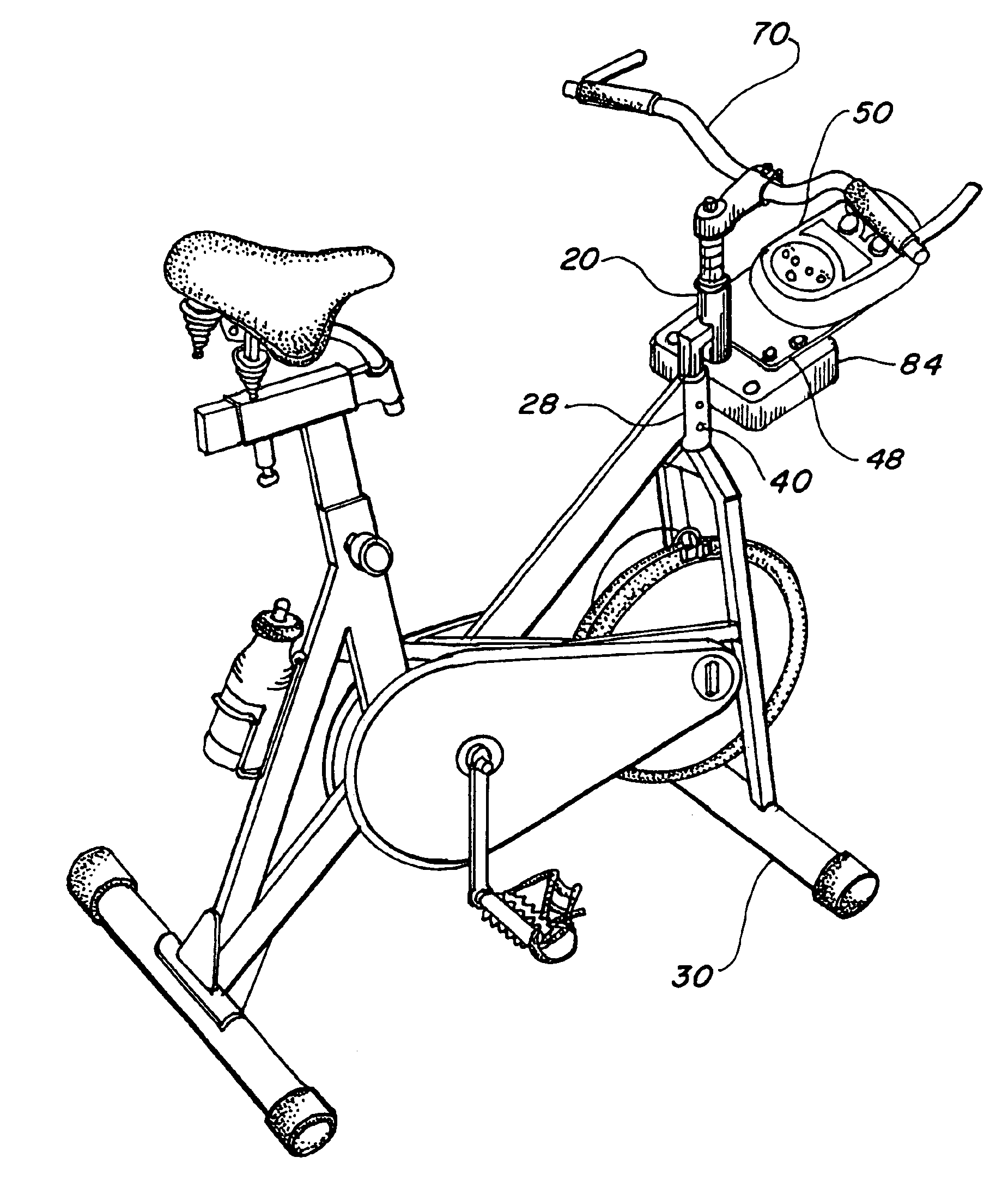

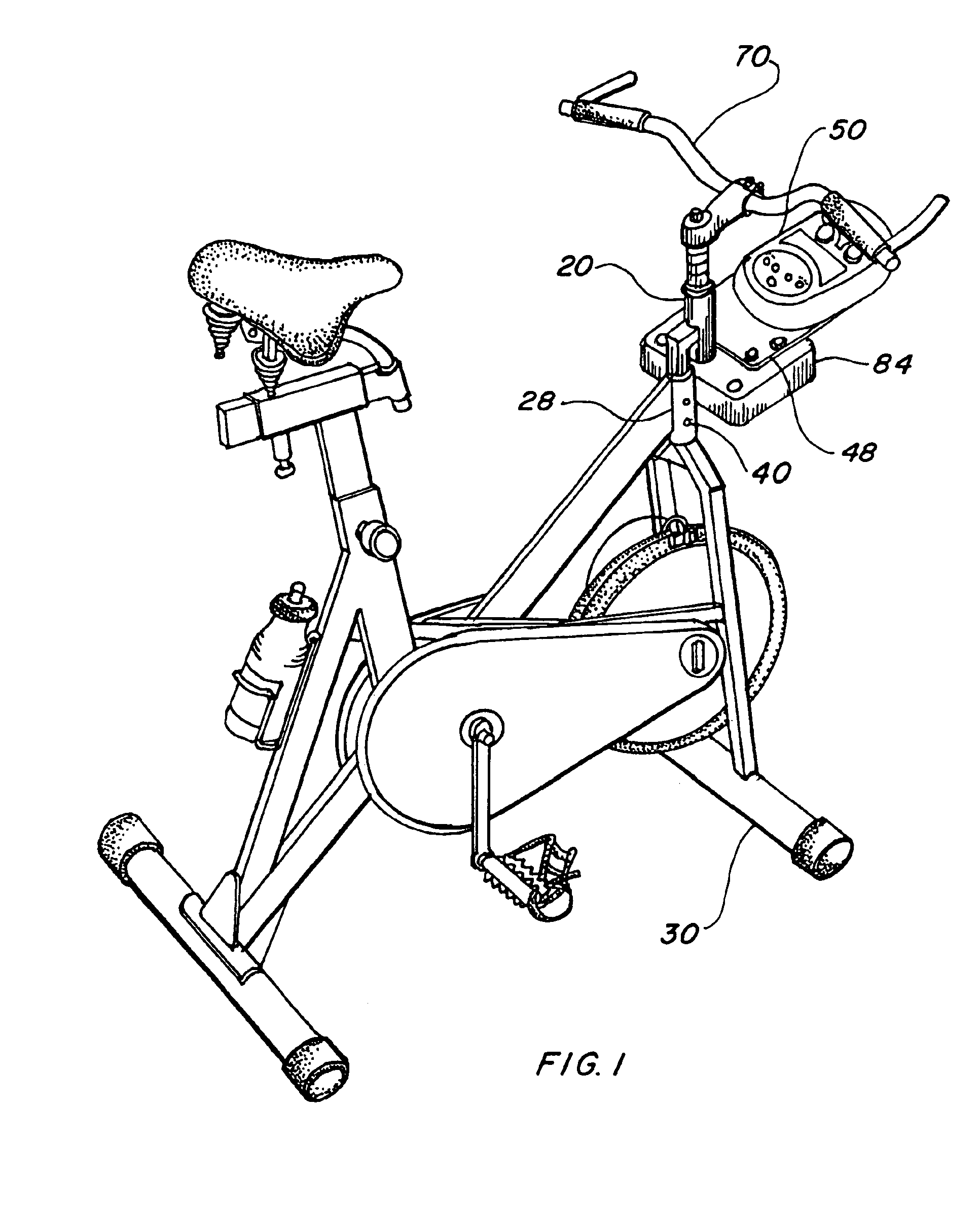

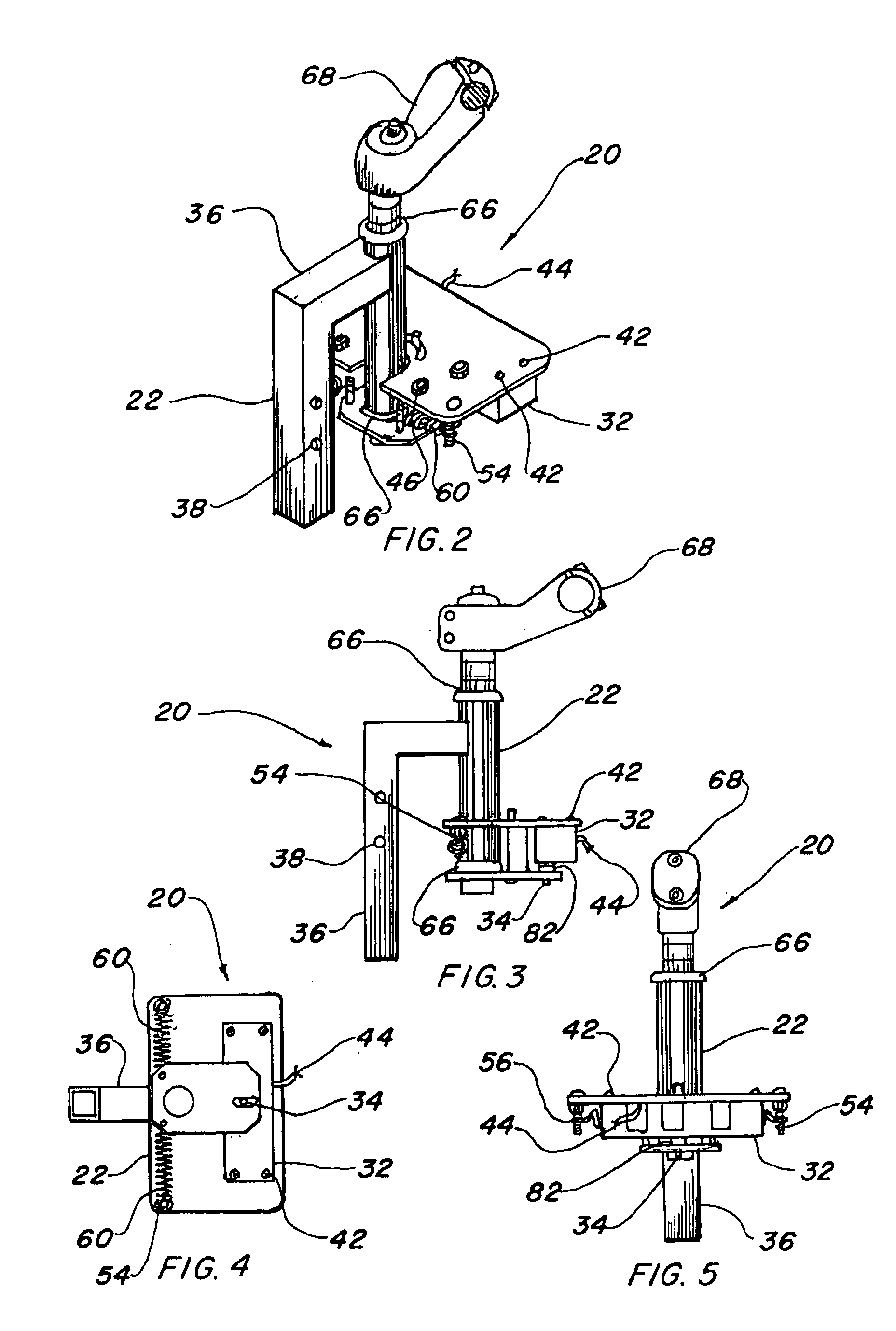

Exercise bicycle virtual reality steering apparatus

InactiveUS6918860B1Prevent movementImproves felting resistanceVideo gamesSpecial data processing applicationsElectricityBogie

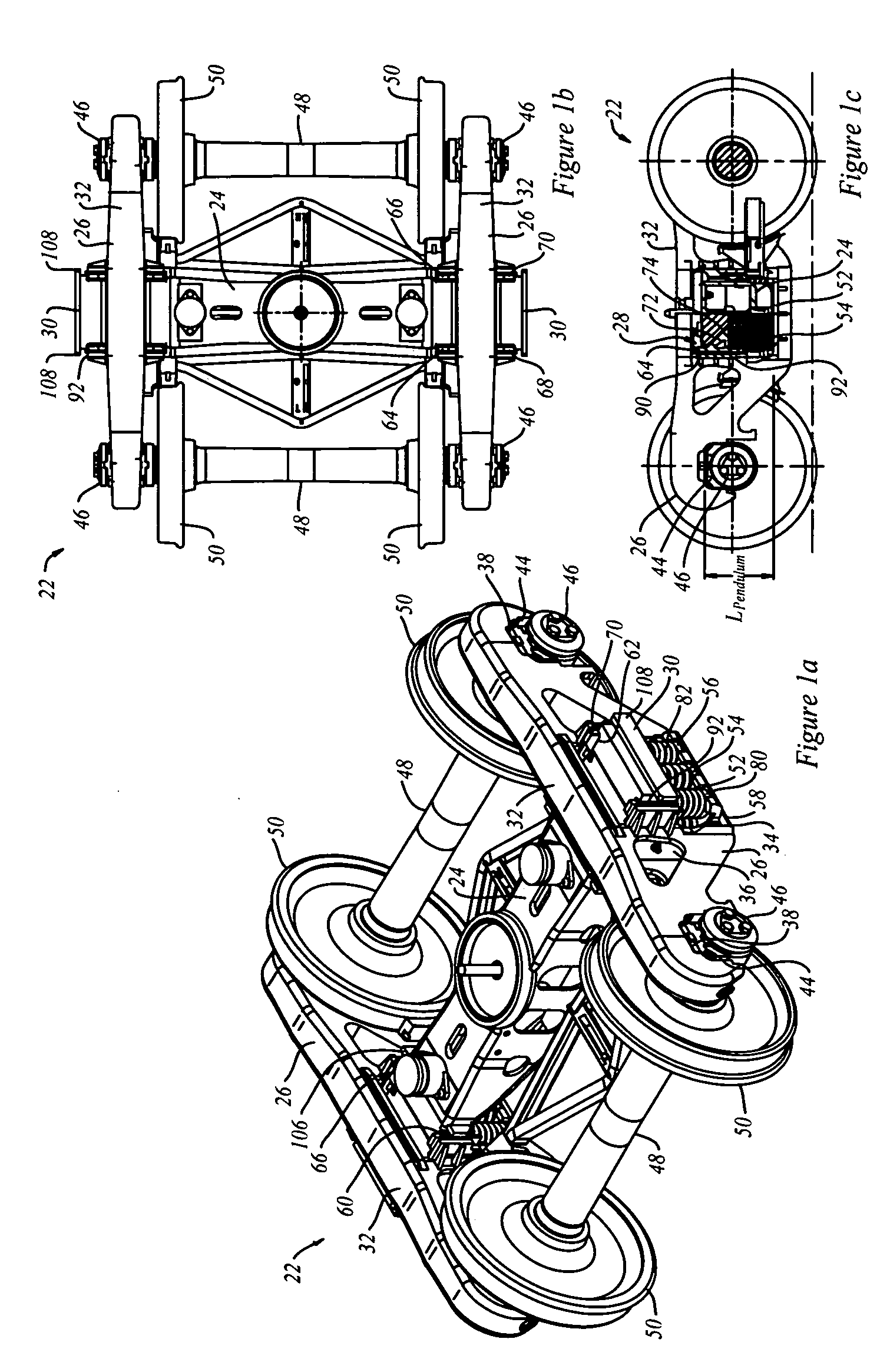

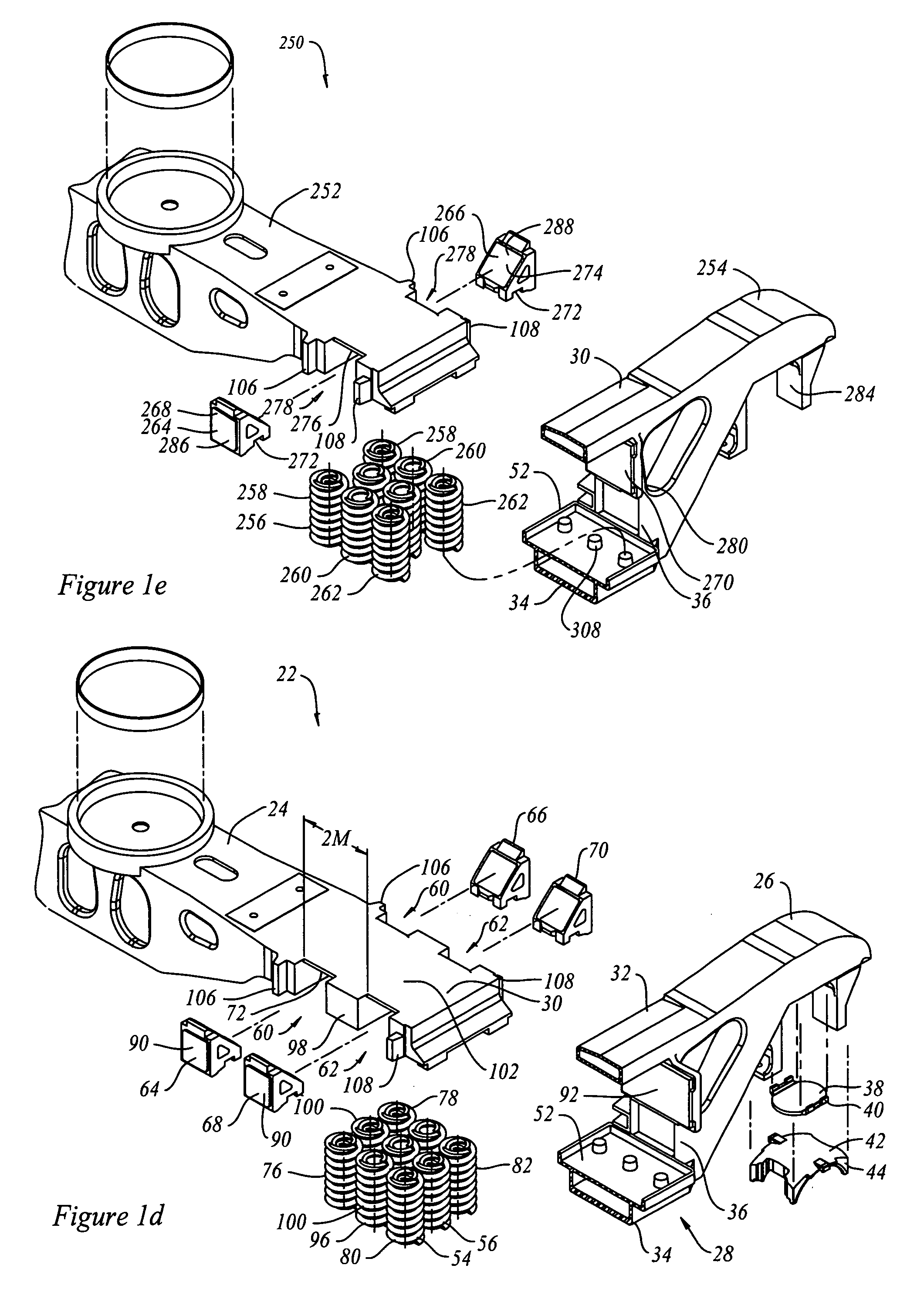

A steering apparatus for altering steering direction of an exercise bicycle utilizing an interactive computer or television video game simulation which consists of a steering mechanism primary frame (22) that includes a steering tube (24) and a steering plate (26). The steering tube is disposed within an exercise bicycle frame head. A steer frame (58) is rotatably mounted within the primary frame and utilizes a pair of springs (60) that are suspended between the primary frame and the steer frame. Changing steering direction by rotation of the handlebar (70) attached to the steer frame creates progressively linear resistance to the handlebar movement. The steer frame returns to a centered position when unrestrained, duplicating the feel and impression of riding a bicycle. A potentiometer (32) interfaces with the rotating steer frame providing variable electrical resistance relative to the directional movement of the steer frame to the primary frame. An electrical signal is transmitted from an interactive computer or television video game to the potentiometer which interprets the actual steering position of the exercise bicycle.

Owner:HUDSON FITNESS

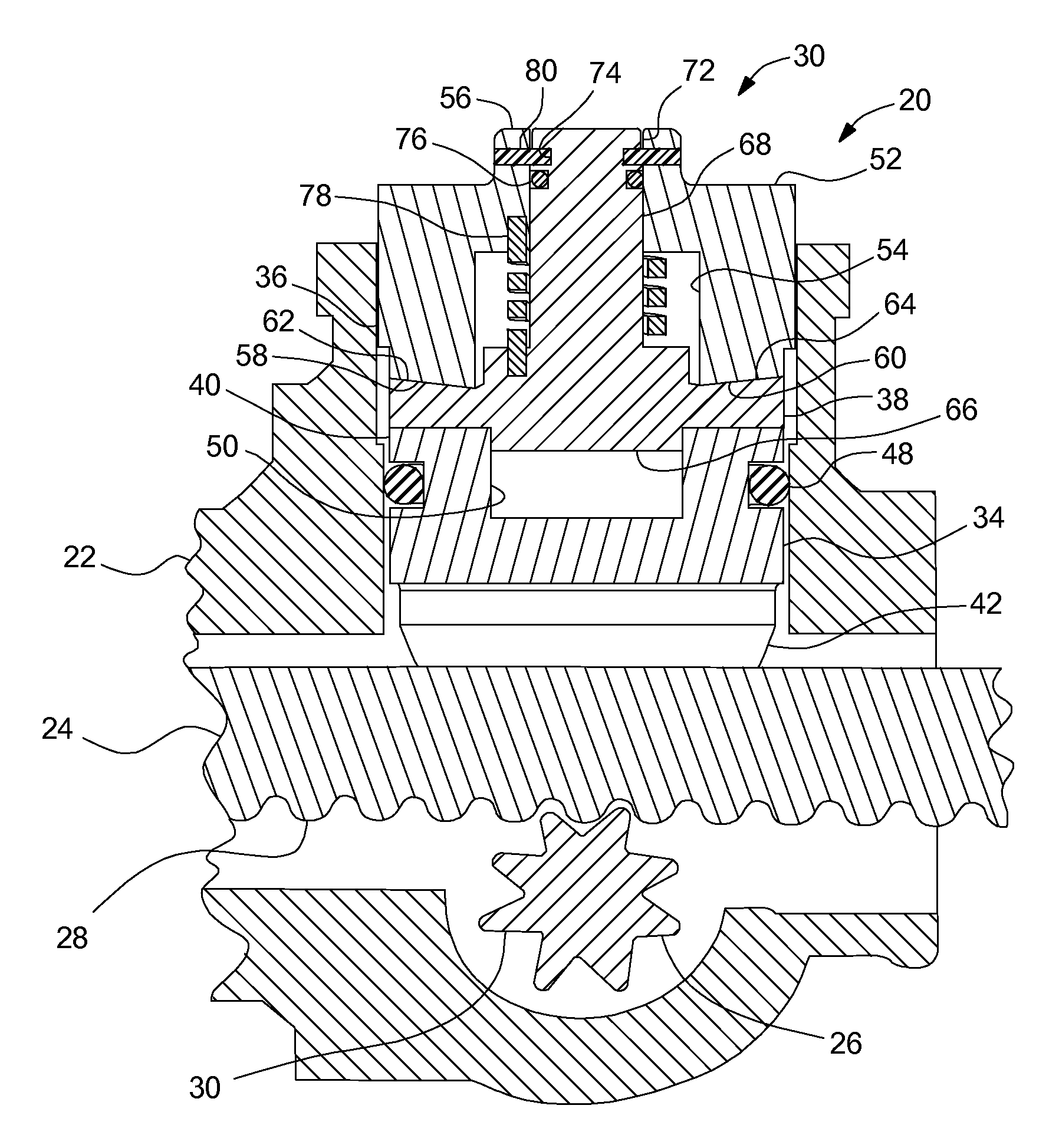

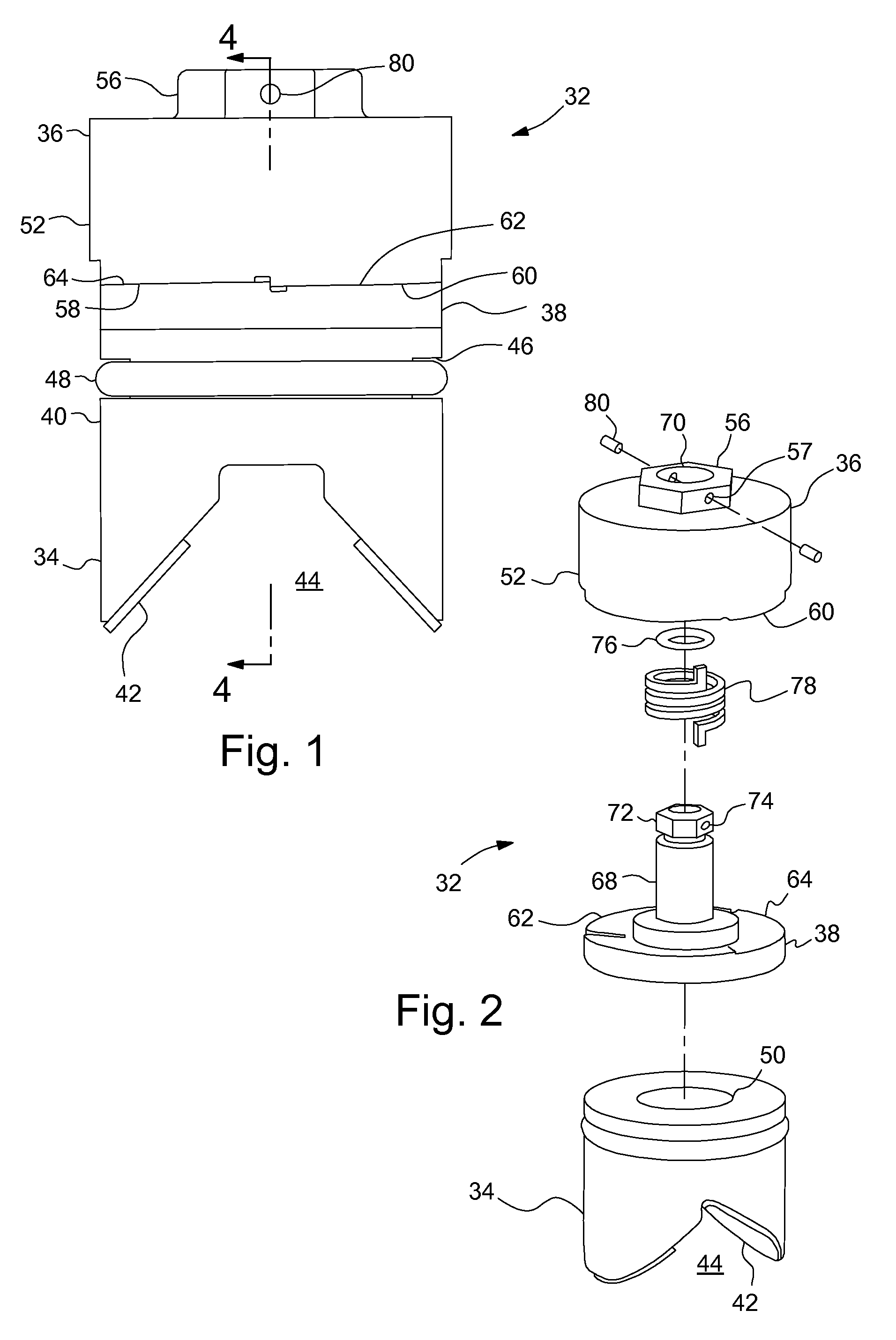

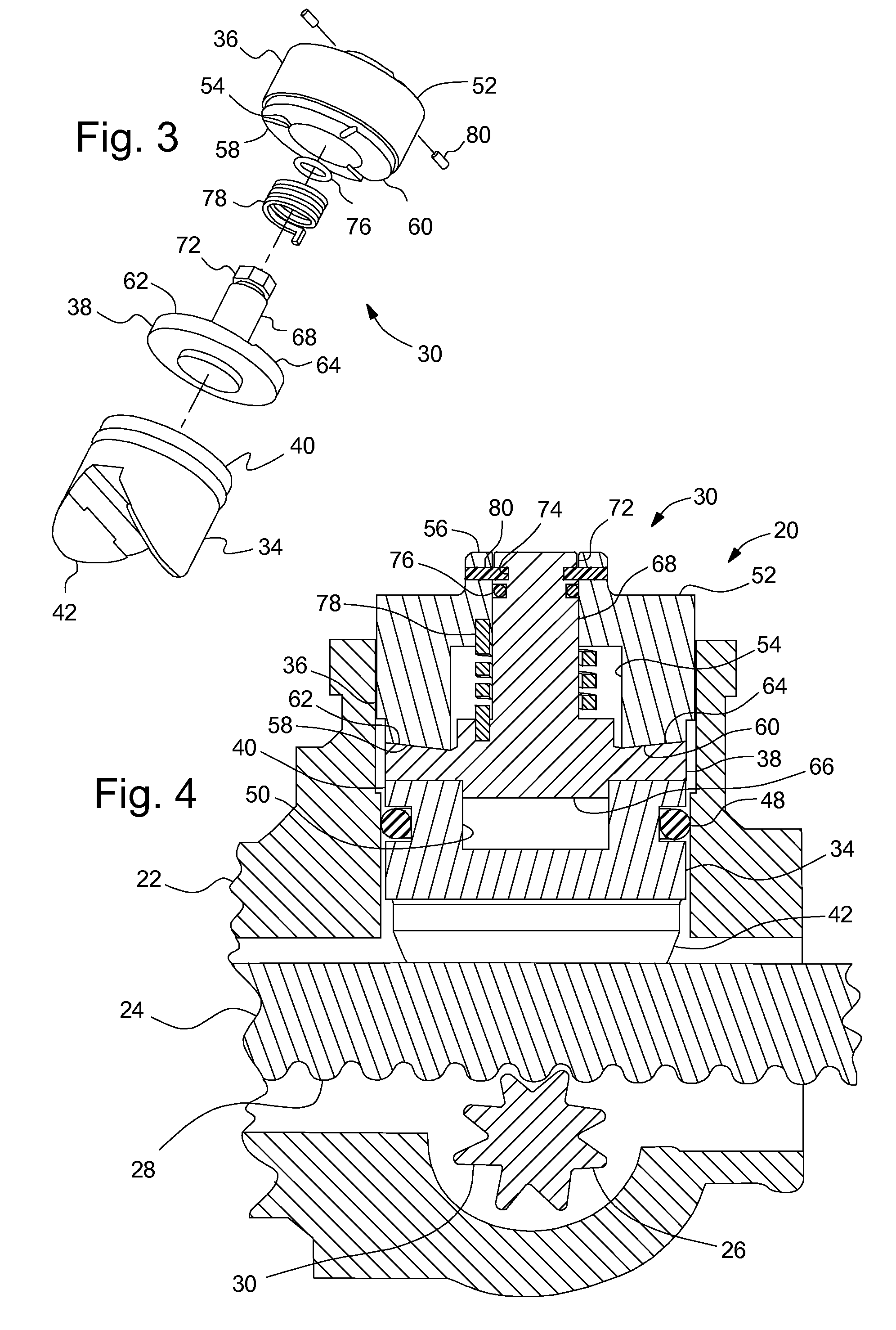

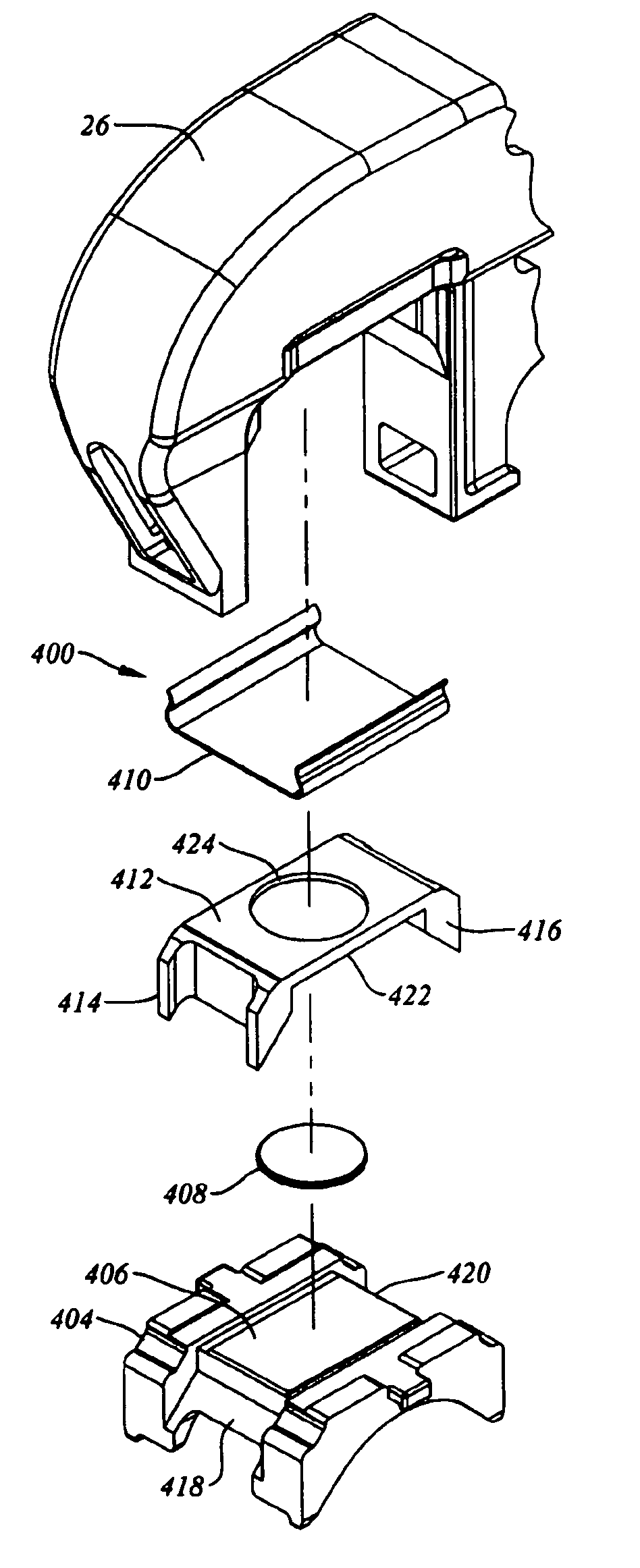

Steering rack wear compensator

ActiveUS7487984B1Reduction and elimination of rattleReduce eliminateToothed gearingsPortable liftingBogieEngineering

A wear compensator for use in a vehicle rack and pinion steering assembly and a method of biasing a rack against a pinion shaft gear in a rack and pinion steering assembly are disclosed. The wear compensator may include a rack follower, an adjuster plug, a wear cam and a torsion spring. The rack follower slides on the rack. The adjuster plug is retained by the steering gear housing and includes a plug cam surface. The wear cam includes a wear cam surface operatively engaging the plug cam surface, is mounted between the rack follower and the adjuster plug, and can rotate relative to the adjuster plug. The torsion spring connects between the adjuster plug and the wear cam in order to rotatably bias the wear cam relative to the adjuster plug.

Owner:GM GLOBAL TECH OPERATIONS LLC

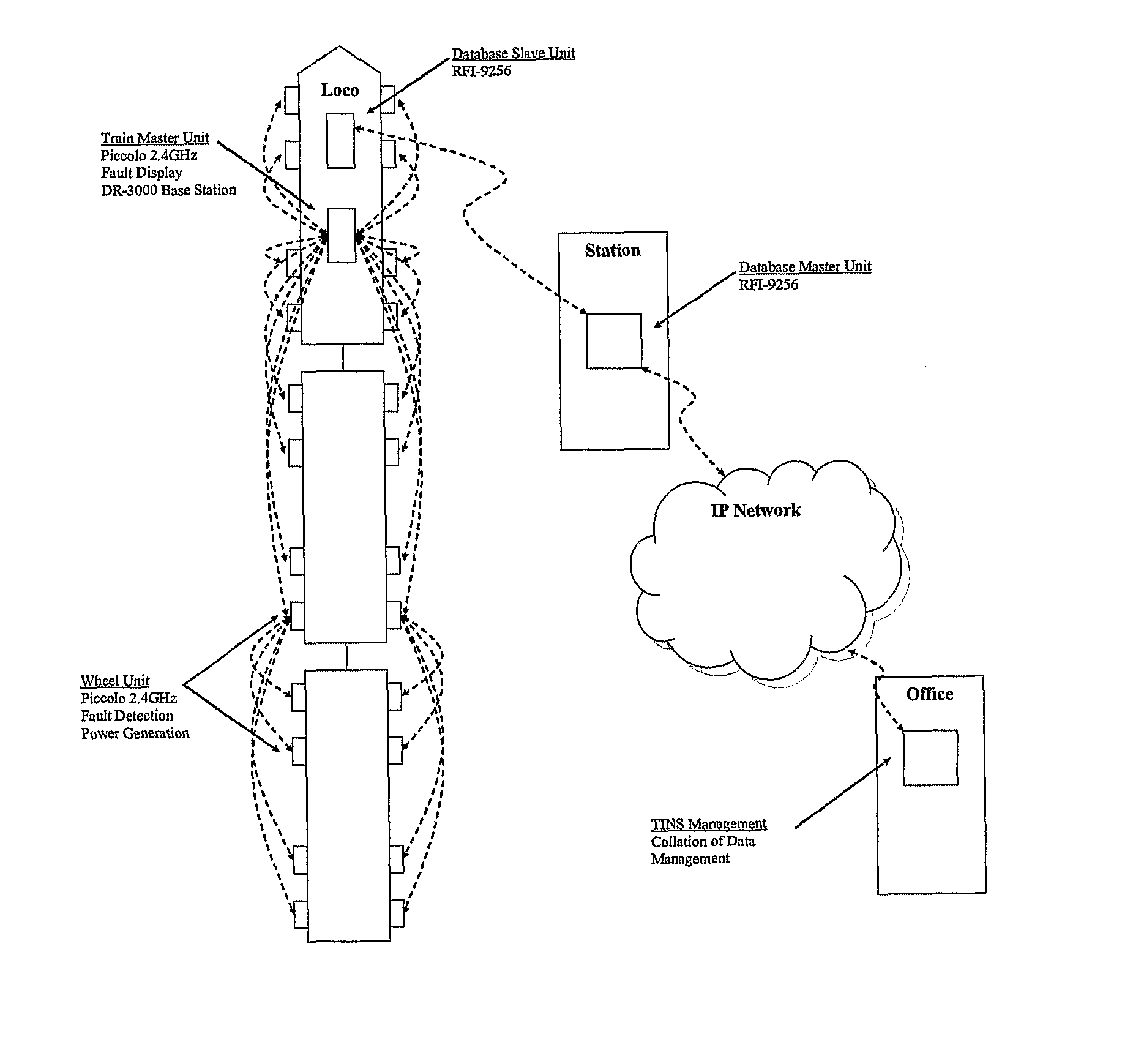

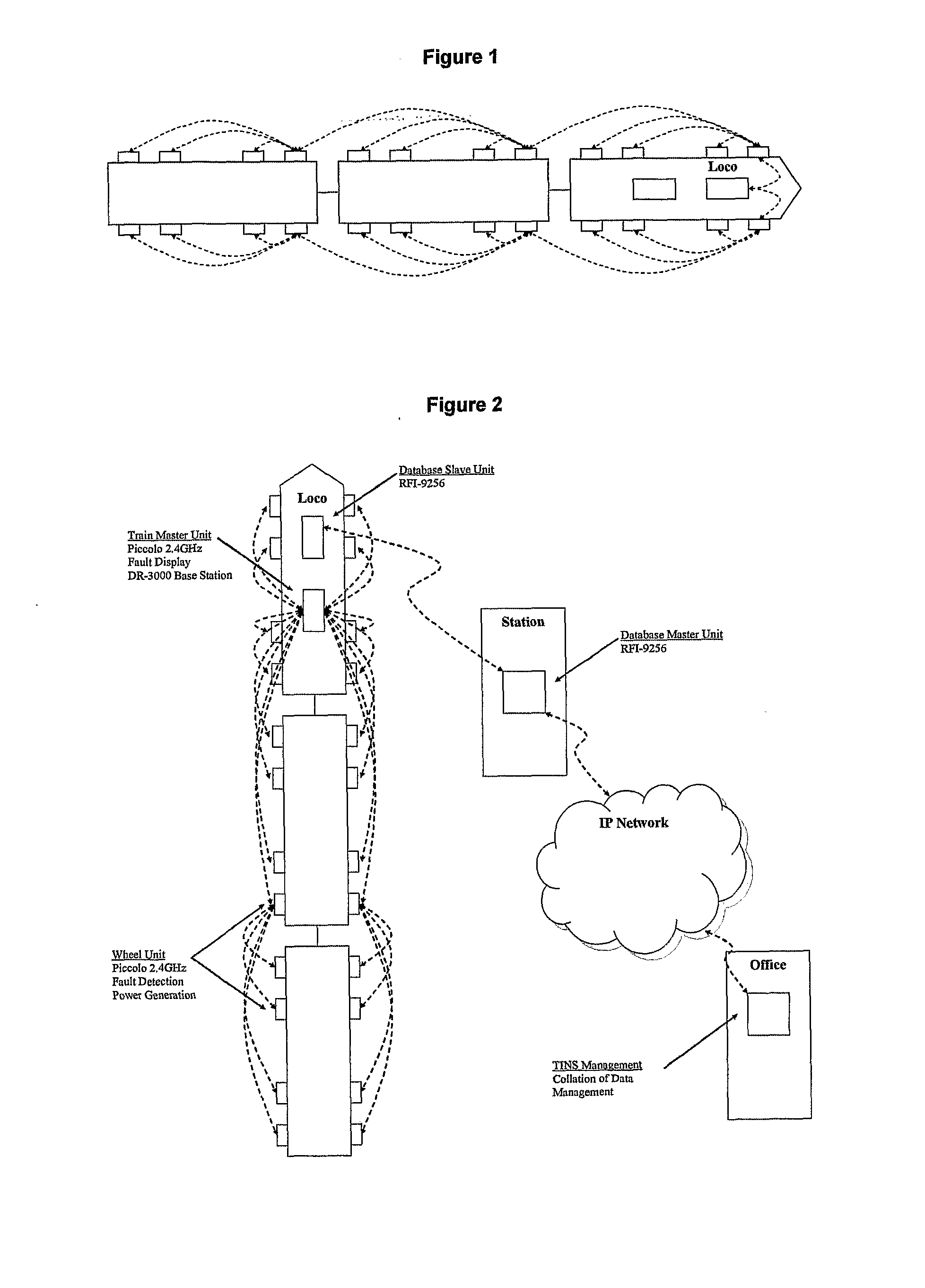

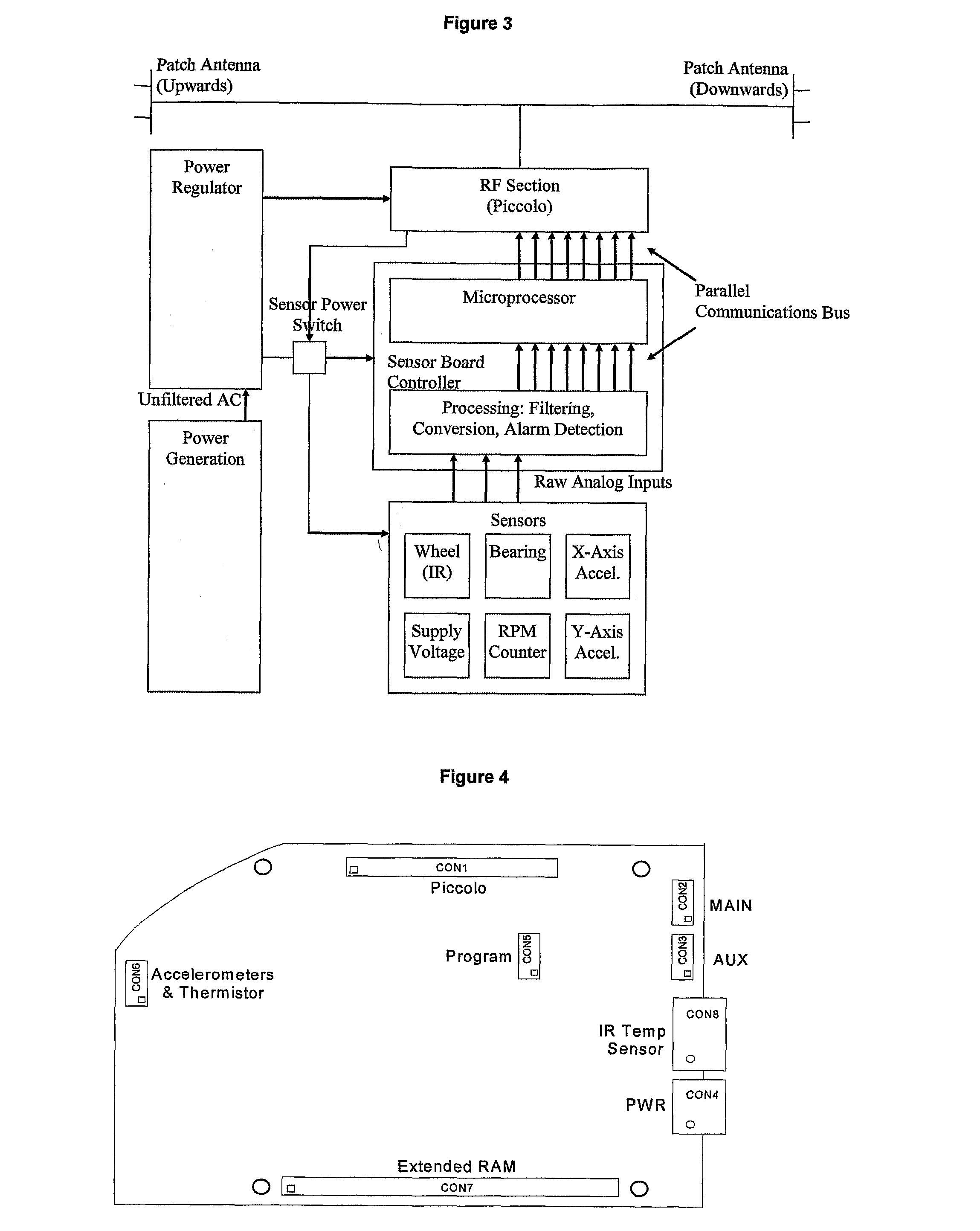

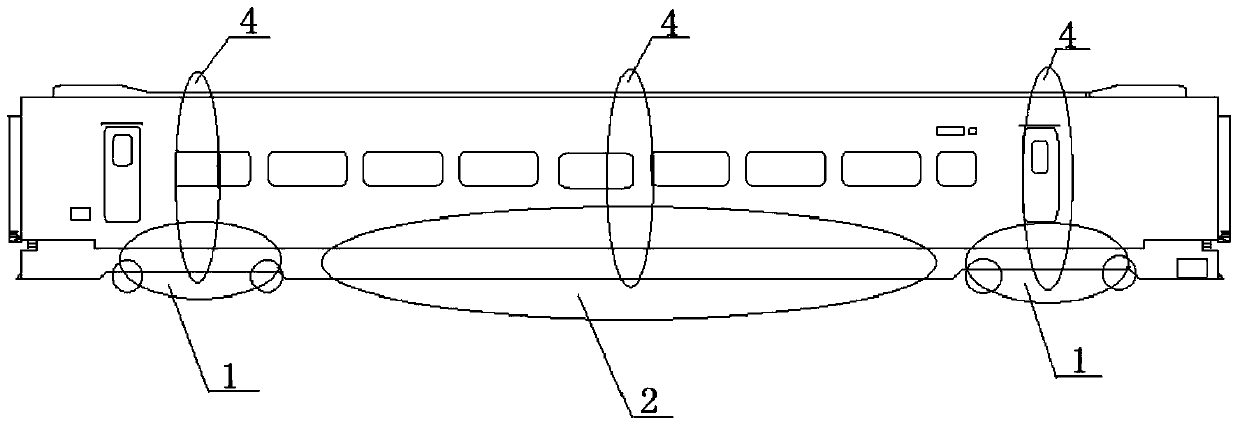

Train Integrity Network System

A train integrity network system comprises bogie units which monitor critical parameters relating to the condition of bogie components and the rail track they are travelling on, an onboard server which controls the bogie units and a wireless network which enables communication between the server and the bogie units. Each bogie unit is powered by an electrical generator which utilises the rotation of the bogie wheels and has a processor which compares the critical parameters against defined standards in order to issue alerts to the train driver. The wireless network utilises master / slave base band role switching, has store-and-forward nodes which convey quasi real time data to the server and utilises frequency hopping modes.

Owner:STI GLOBAL LTD

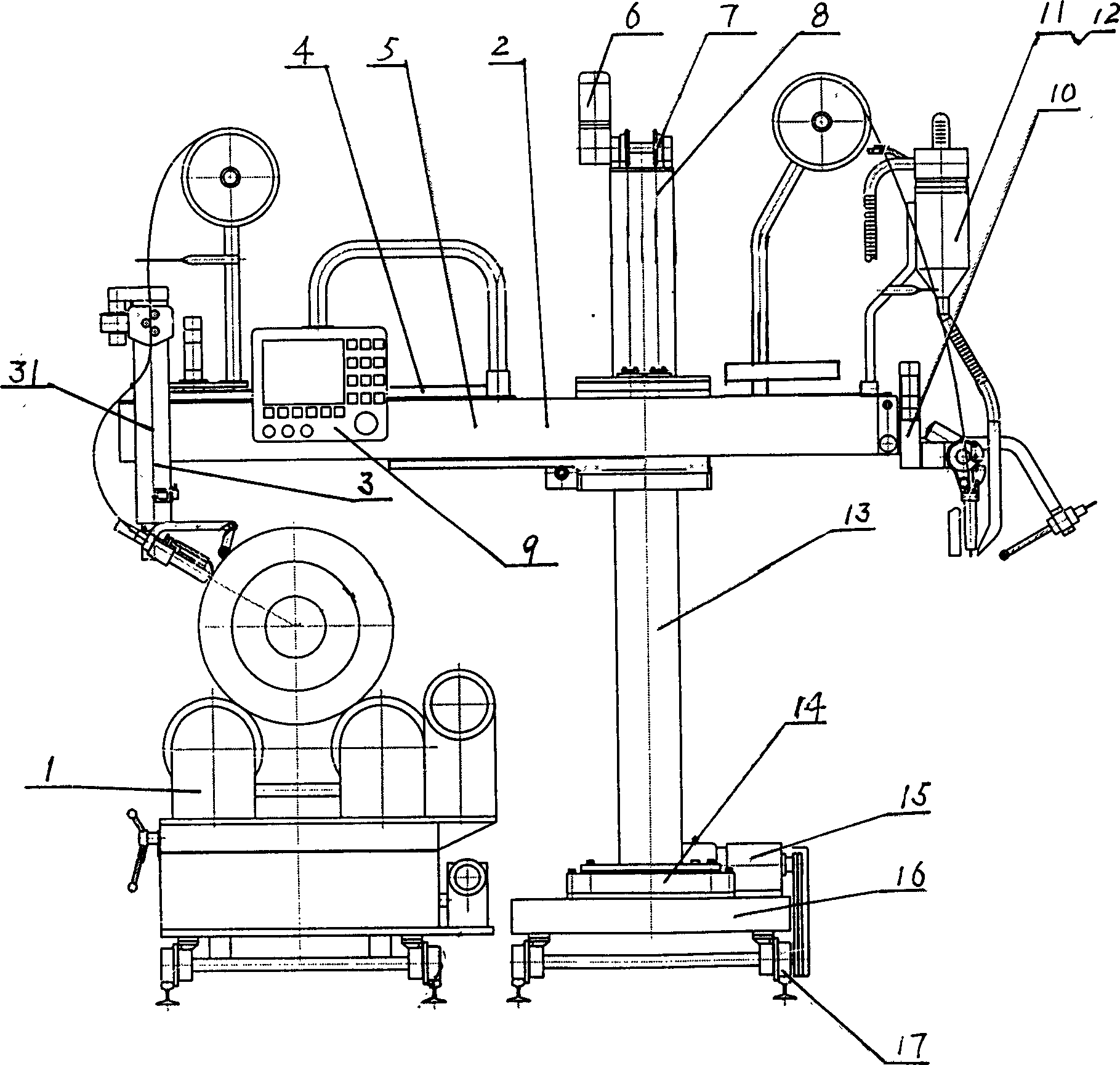

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN1714978AAutomatically calculate relative coordinate origin positionEnsure shapeArc welding apparatusBogieEngineering

The automatic argon arc welding and narrow gas submerged arc welding process for circular pipe header seam features the first horizontal and vertical welding with immobile workpiece and using automatic cold welding TIG wire until completing over one third of circle; the subsequent welding in the other two thirds of circle with automatically rotating welding roller frame; and the performing in the identical site of the annular seam assembling and the welding. The welding apparatus for the said technological process consists of roller device and welding frame bogie, and the welding frame bogie on some tracks parallel to roller frame tracks is movable. The present invention has the advantages of automatic operation, raised welding quality, etc.

Owner:SHANGHAI BOILER WORKS

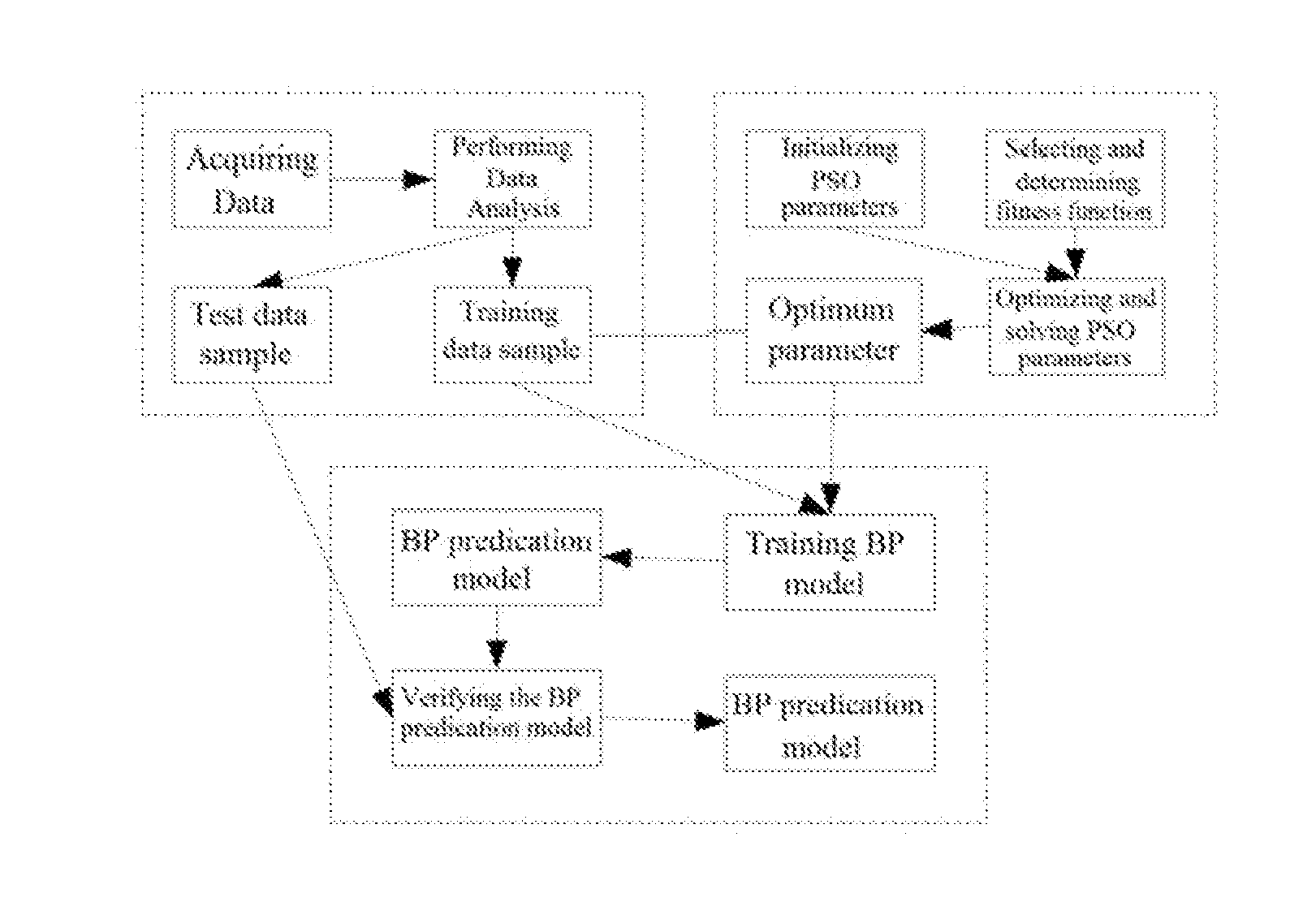

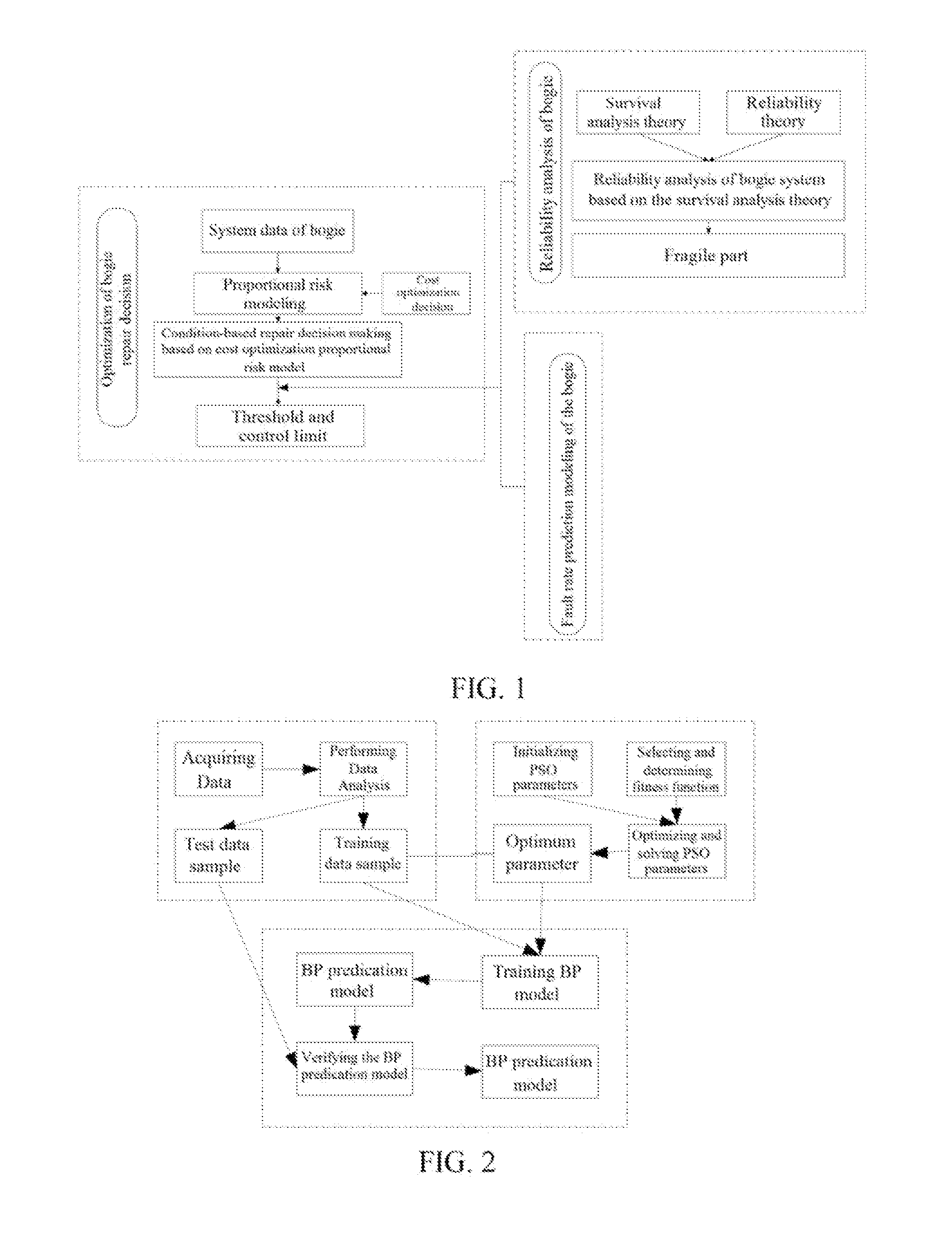

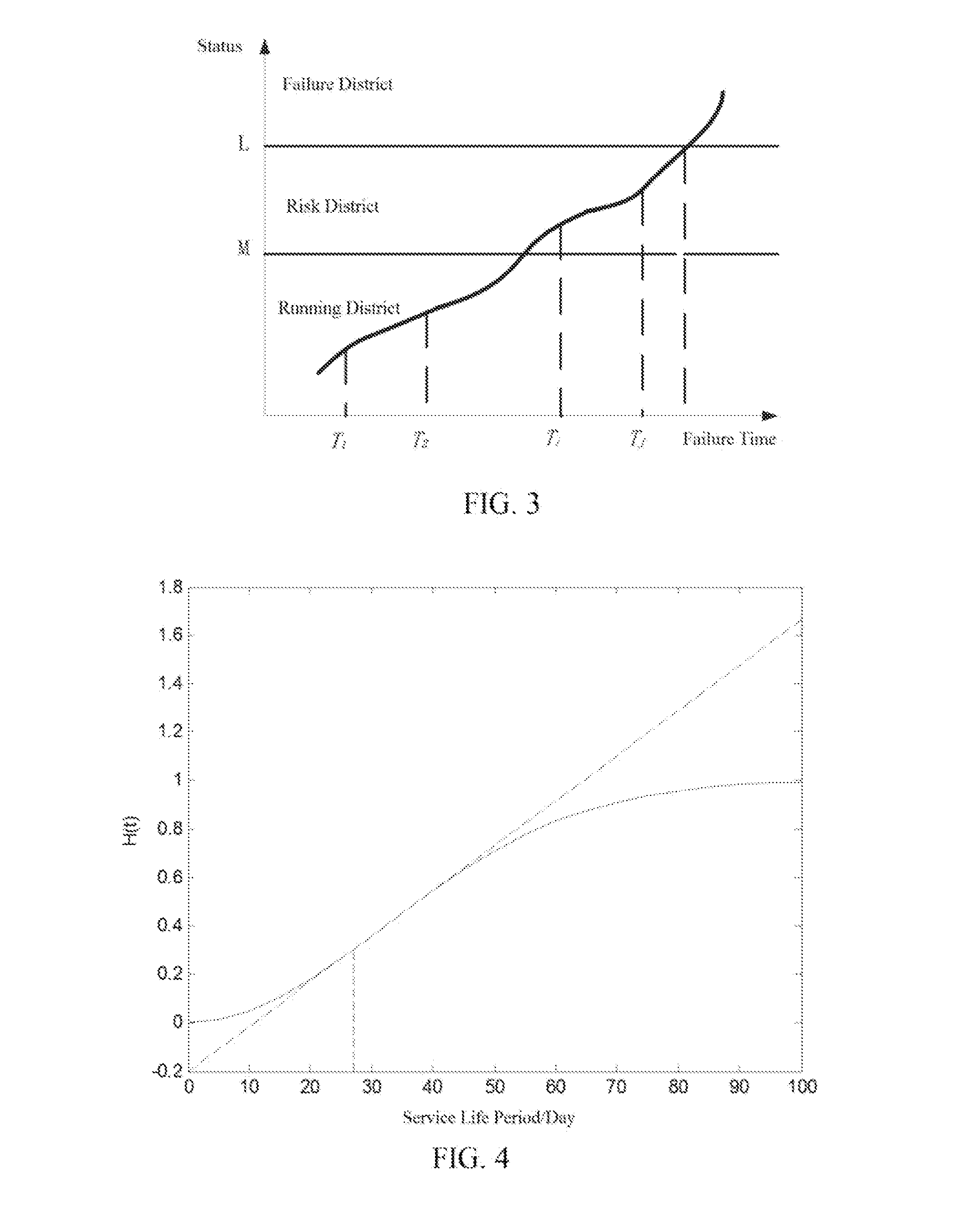

Fault Prediction and Condition-based Repair Method of Urban Rail Train Bogie

ActiveUS20160282229A1Failure rateAvoid waste of repair costArtificial lifeRailway vehicle testingFailure rateBogie

The present invention provides a fault prediction and condition-based repair method of an urban rail train bogie. An optimum service life distribution model of a framework, a spring device, a connecting device, a wheel set and axle box, a driving mechanism, and a basic brake device of a bogie is determined by adopting a method based on survival analysis; a reliability characteristic function of each subsystem is obtained; then, a failure rate of each subsystem of the bogie is calculated by adopting a neural network model optimized by an evolutionary algorithm; and finally, proportional risk modelling is conducted by taking the failure rate and safe operation days of each subsystem of the bogie as concomitant variables; and on the basis of cost optimization, thresholds and control limits for condition-based repair of a bogie system are obtained.

Owner:BEIJING JIAOTONG UNIV

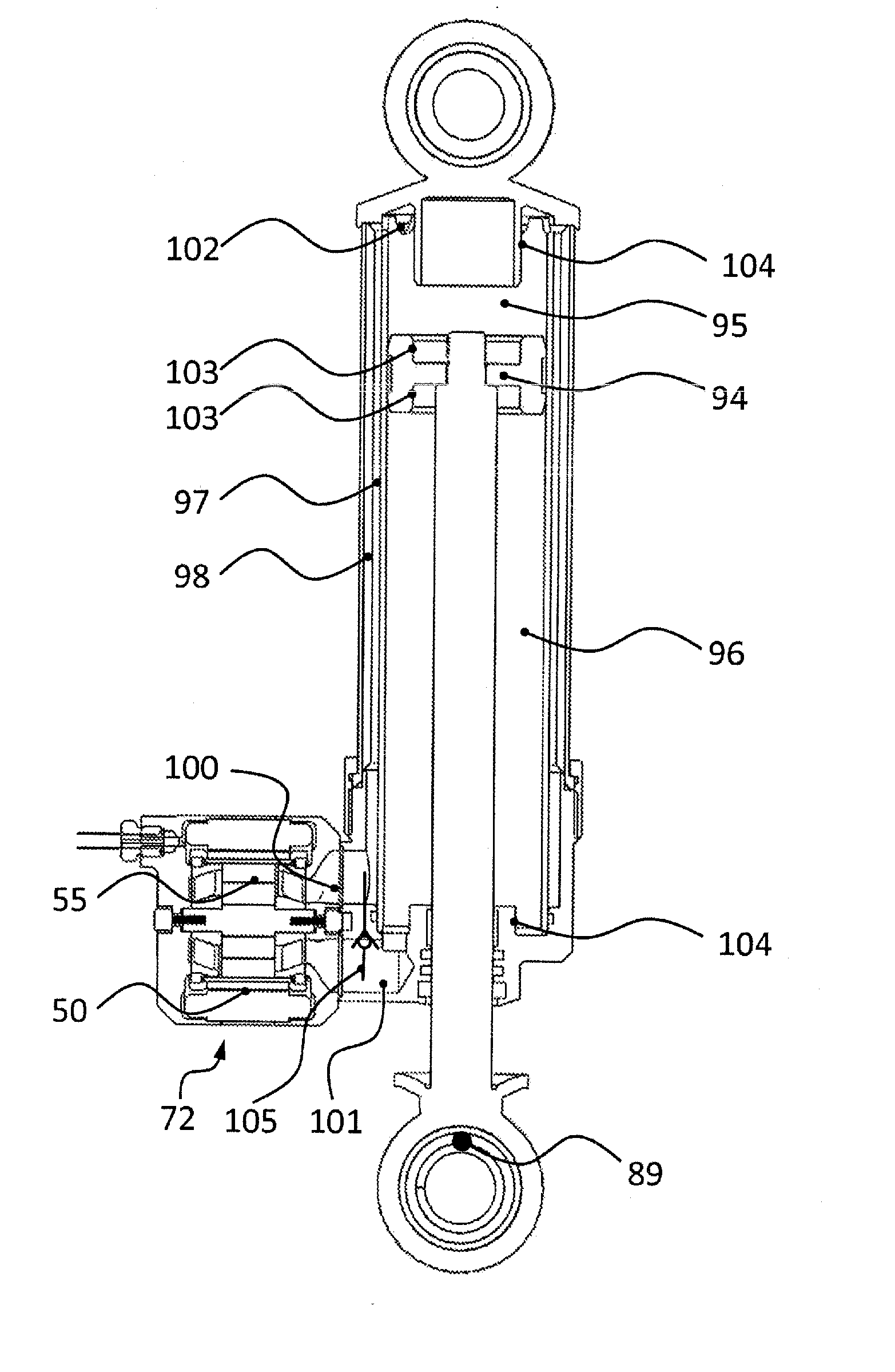

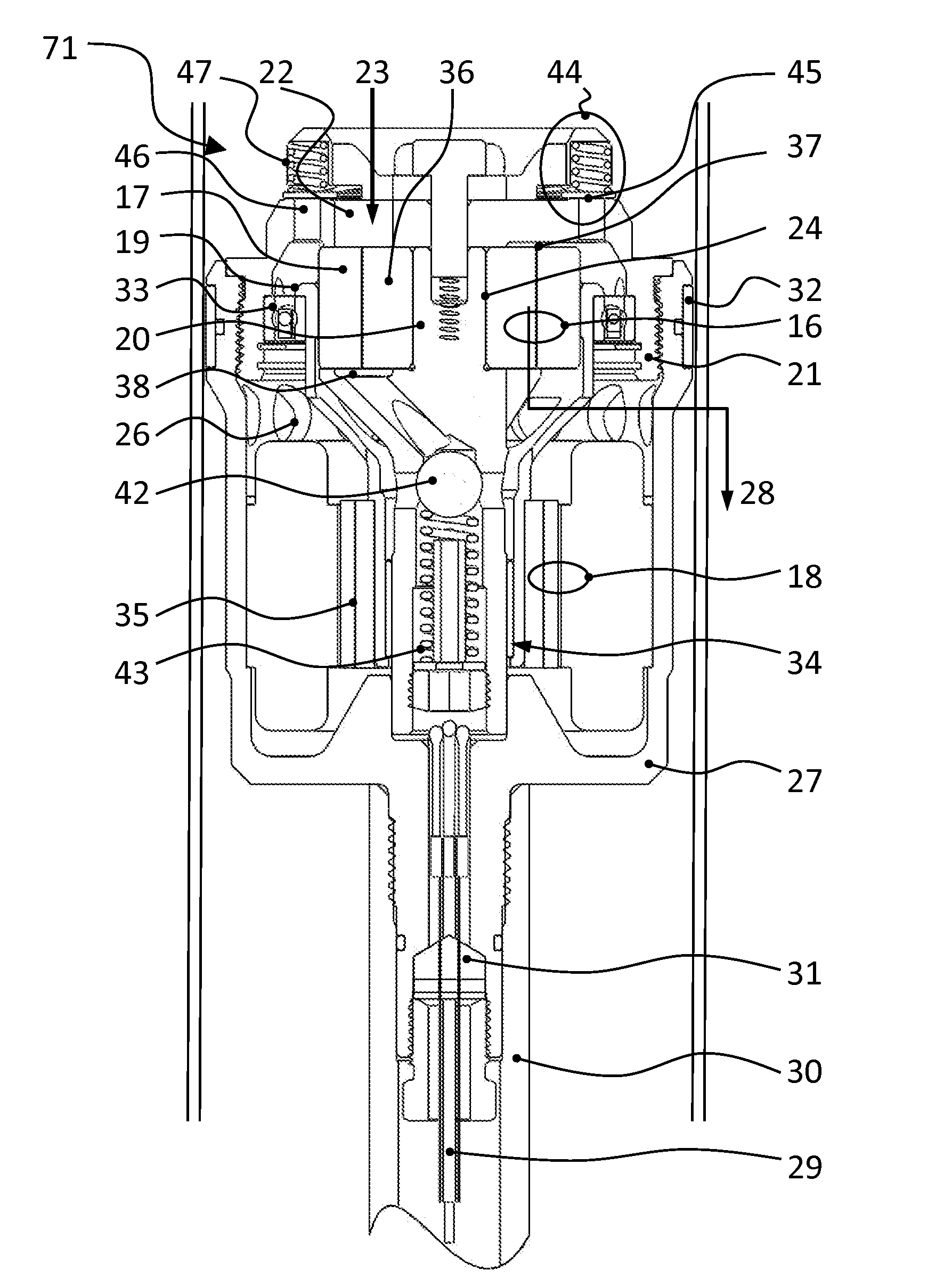

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of to the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

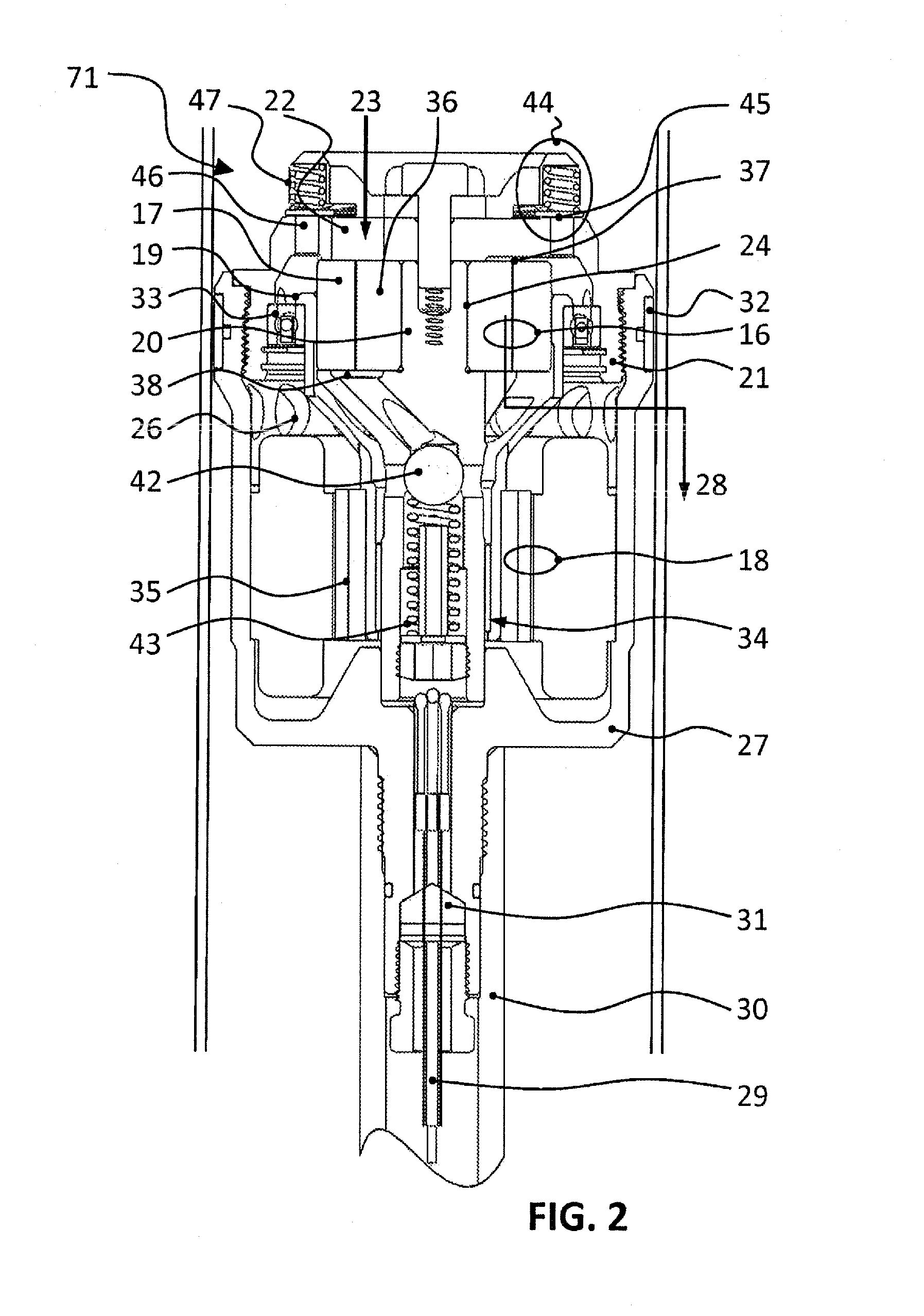

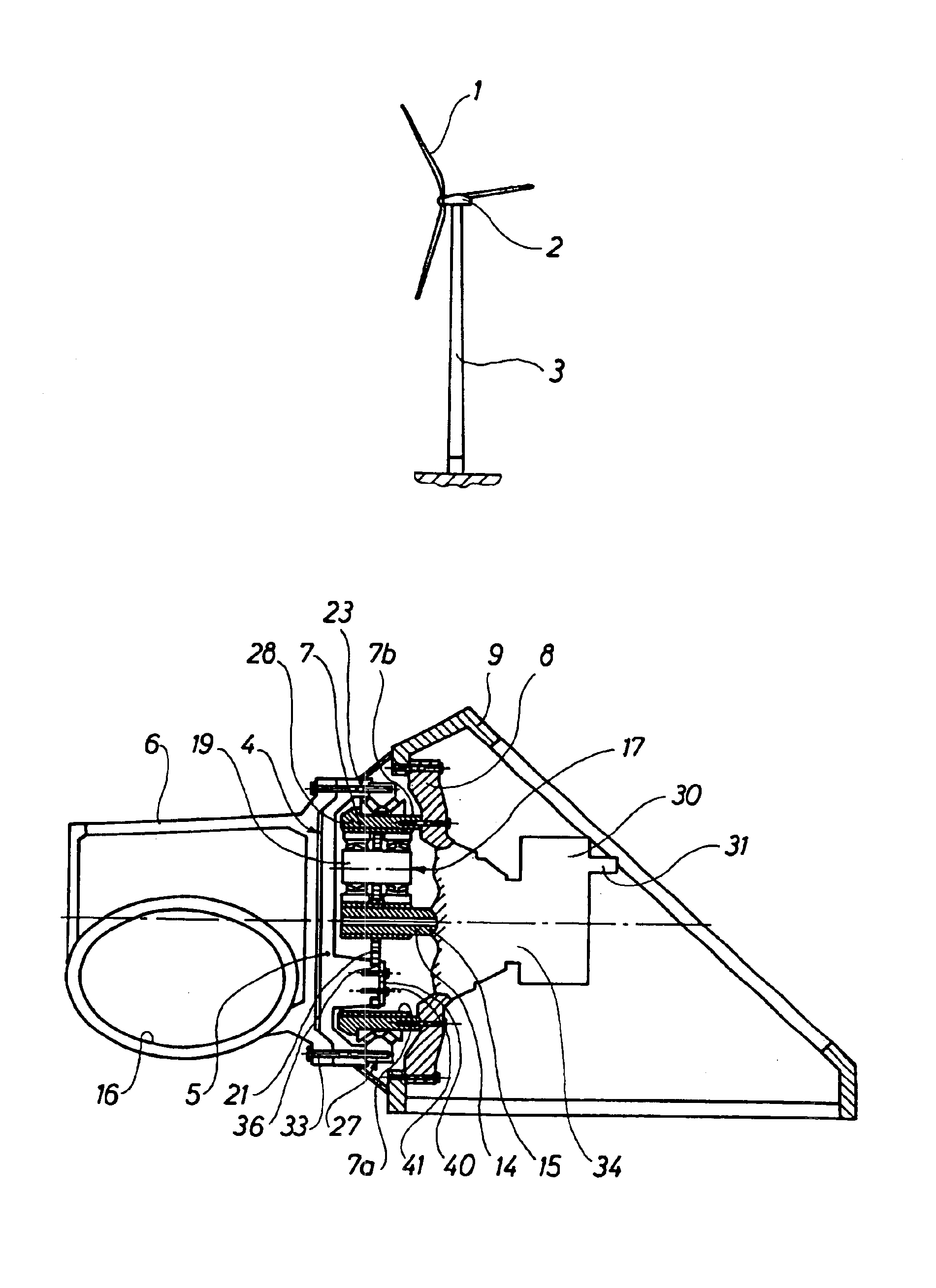

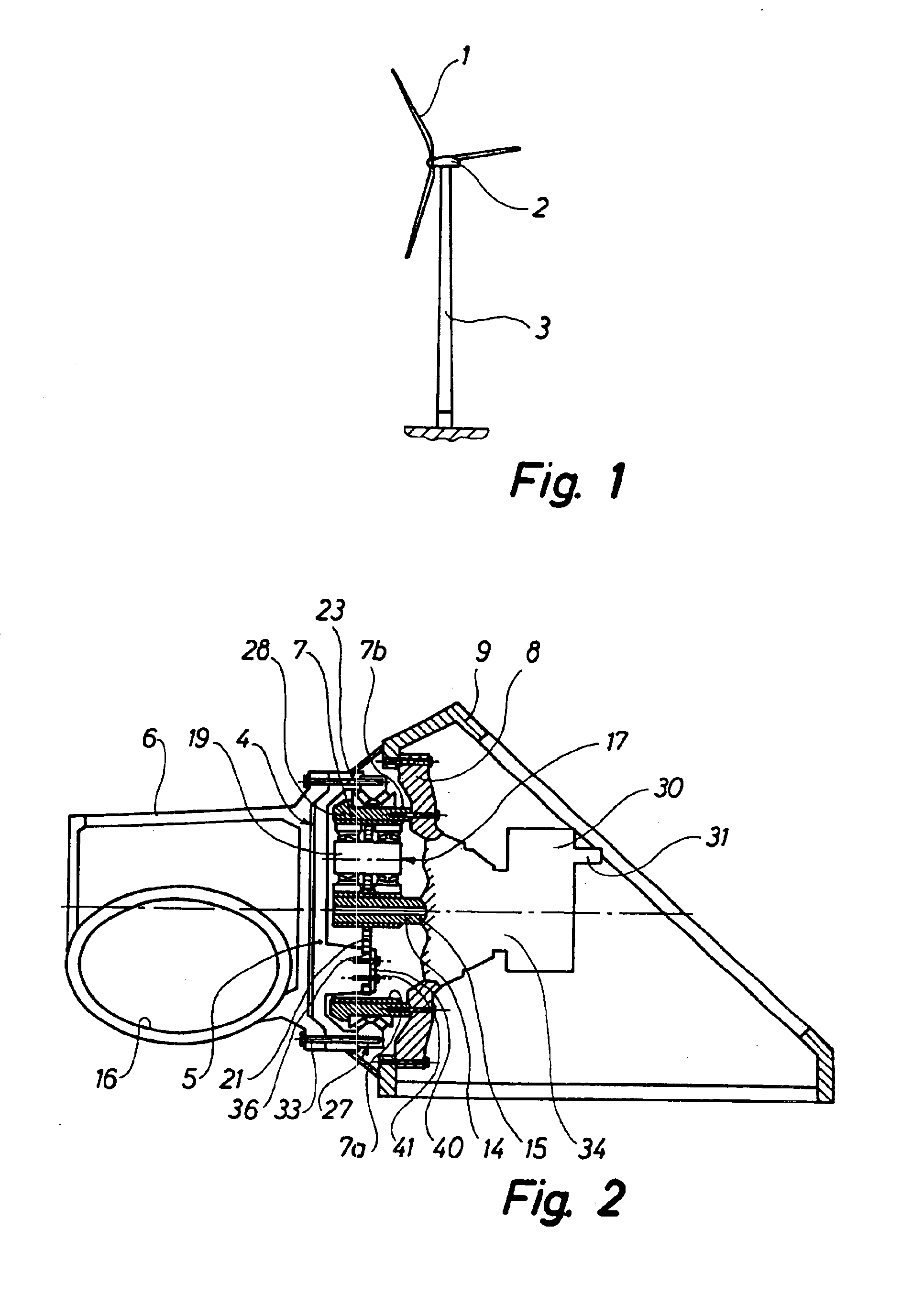

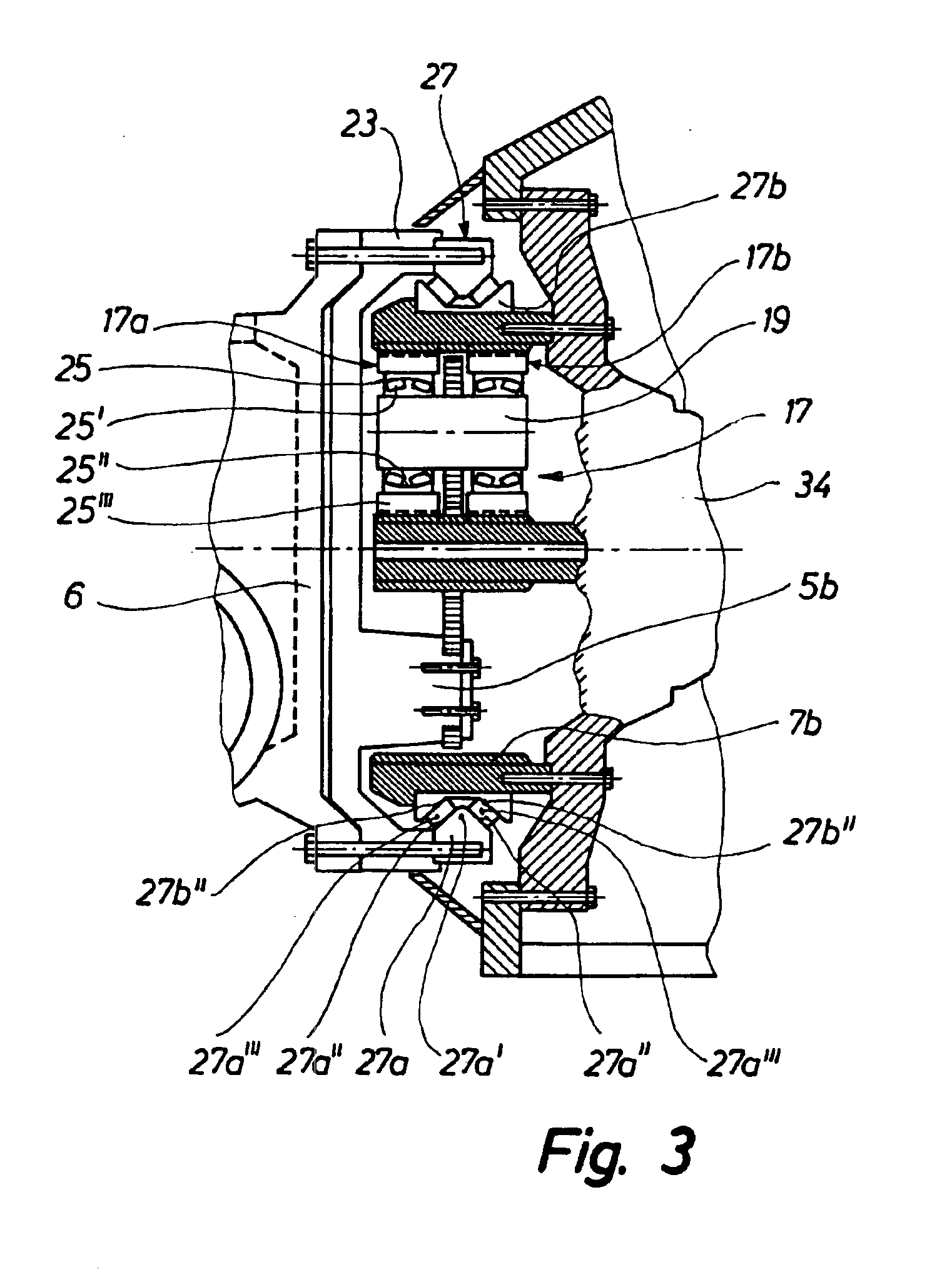

Wind turbine comprising a planetary gear

A wind turbine with a rotor, a nacelle and a tower. The nacelle comprises a planetary gear (4) with a planetary holder (5), on which the hub (6) of the rotor is rigidly secured, and which can be connected to the shaft of an electric generator. The planetary gear (4) comprises a ring gear (7) fixedly mounted on an engine frame (9) in the nacelle or on the member (8) rigidly connected to said frame. The planetary wheels (17a, 17b) of the planetary gear can run around a centrally arranged sun wheel (14) while engaging the latter. The sun wheel is optionally connected to a parallel gear (30). The planetary holder (5) is rotatably mounted in the ring gear (7) by means of at least two sets (17) of planetary twin wheels (17a, 17b). Each set of planetary twin wheels is mounted on a bogie shaft (19) on the planetary holder. Through an axially rearward collar (23) projecting beyond the ring gear, the planetary holder (5) is also rotatably arranged on the curved outer side (7b) of the ring gear (7) by means of an outer radial-axial-roller bearing (27). As a result, a wind turbine is obtained which is suited for generating very strong power and which is very compact and ensures a very advantageous transfer of the power at each planetary wheel.

Owner:HANSEN TRANSMISSIONS INT NV

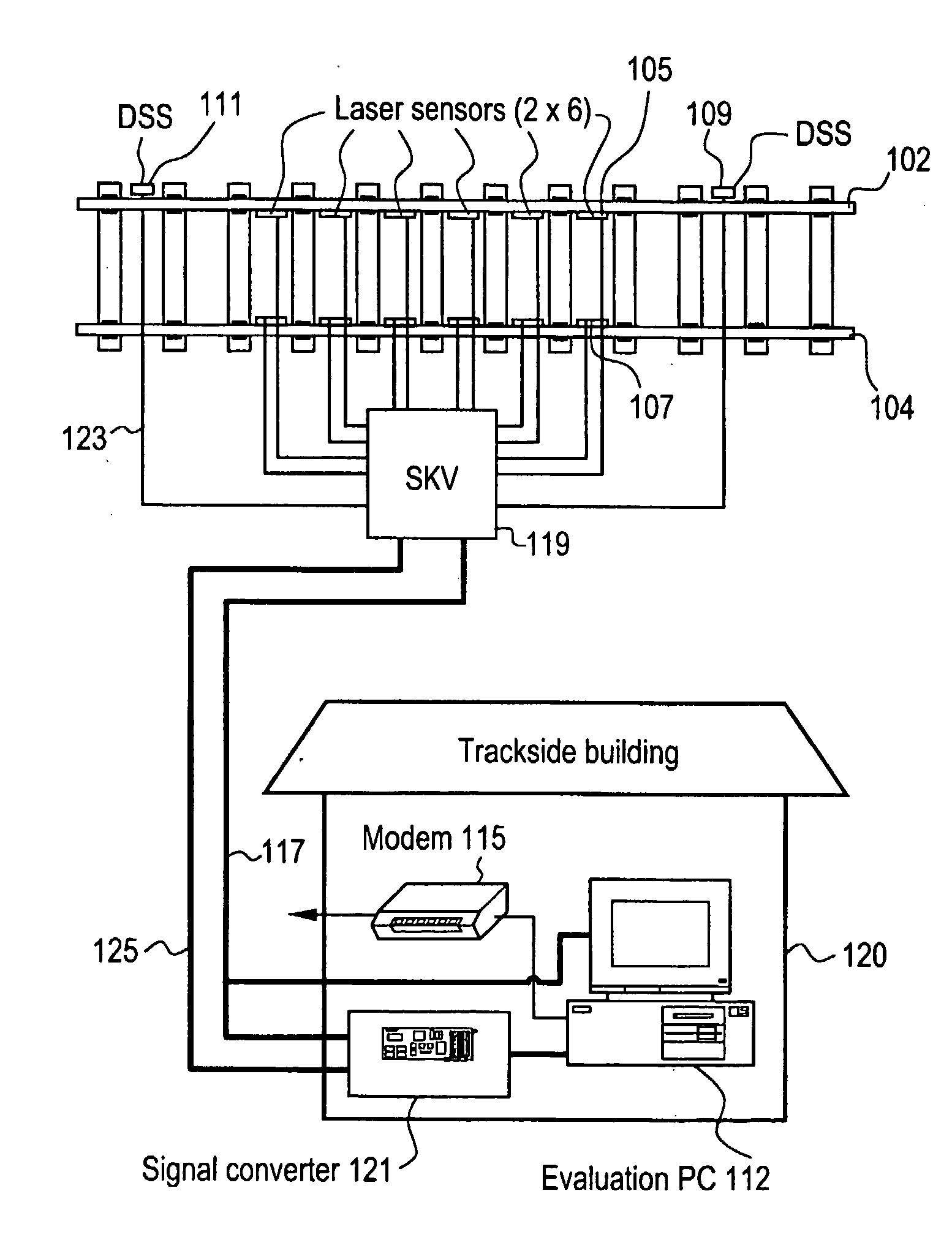

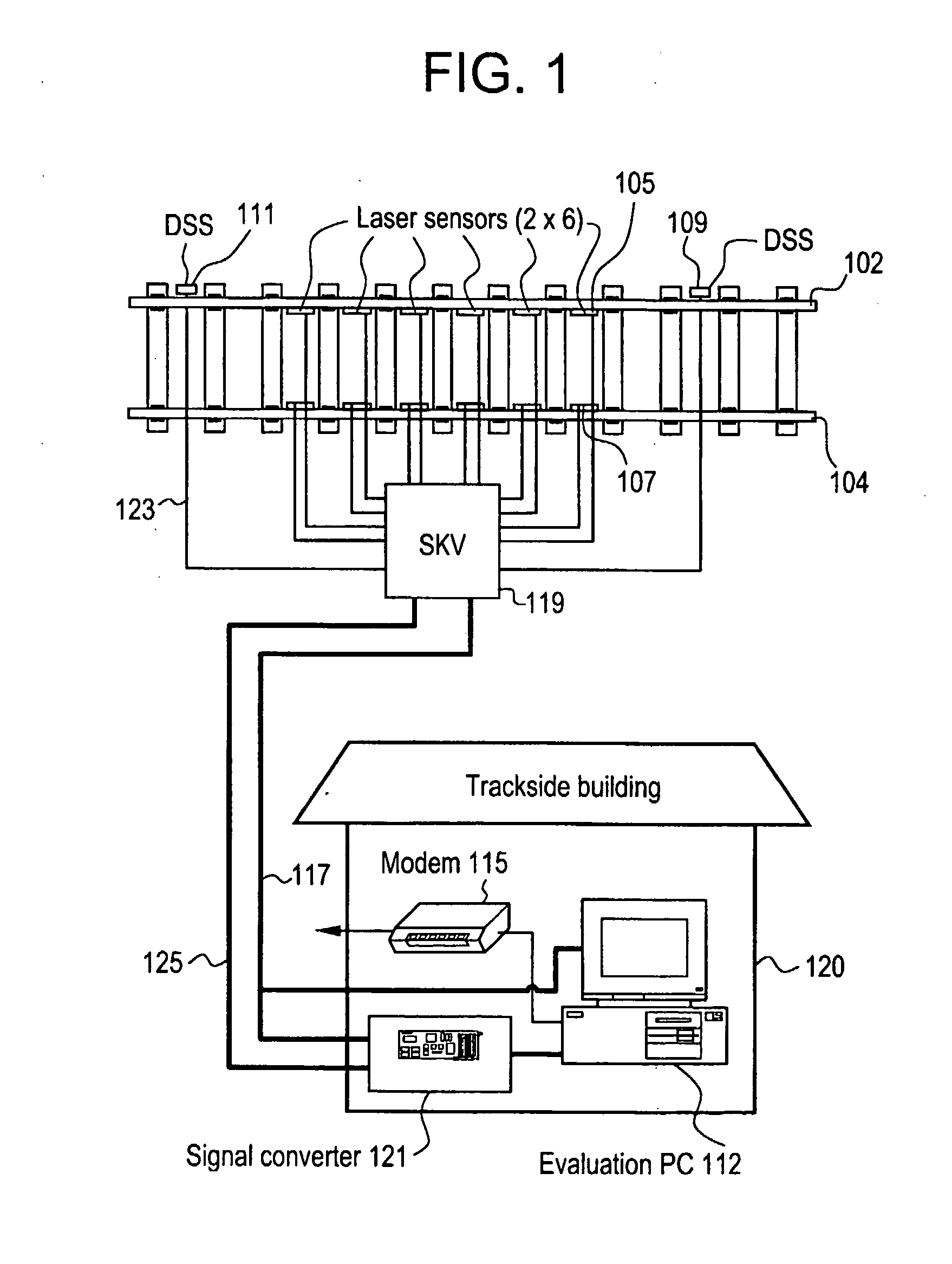

Rail Sensing Apparatus Method

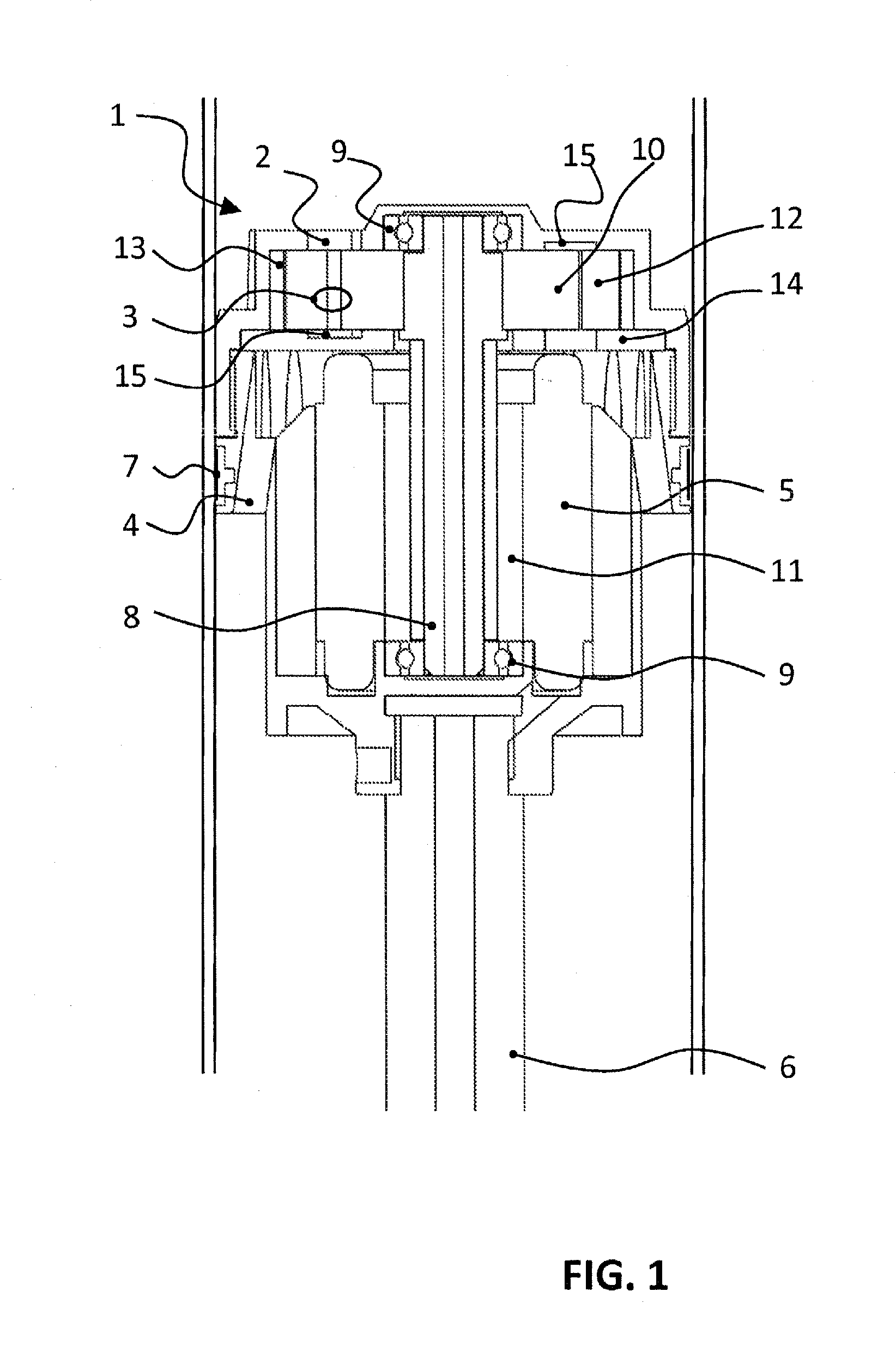

ActiveUS20080304065A1Measure directlyMaterial analysis by optical meansUsing optical meansBogieLaser sensor

A rail sensing and analysis system utilizes a laser sensor 105, 107 to detect displacement of a rail 102, 104 resulting from loads imposed by a passing rail vehicle. Vertical and / or lateral displacements / loads may be sensed. Signatures in the resulting signals are indicative of useful information about the rail vehicle; such as wheel condition, bearing condition, truck condition, degree of bogie hunting, total load, load distribution, etc. The ratio of Lateral over Vertical force (L / V) may be used as an evaluation criterion.

Owner:PROGRESS RAIL SERVICES

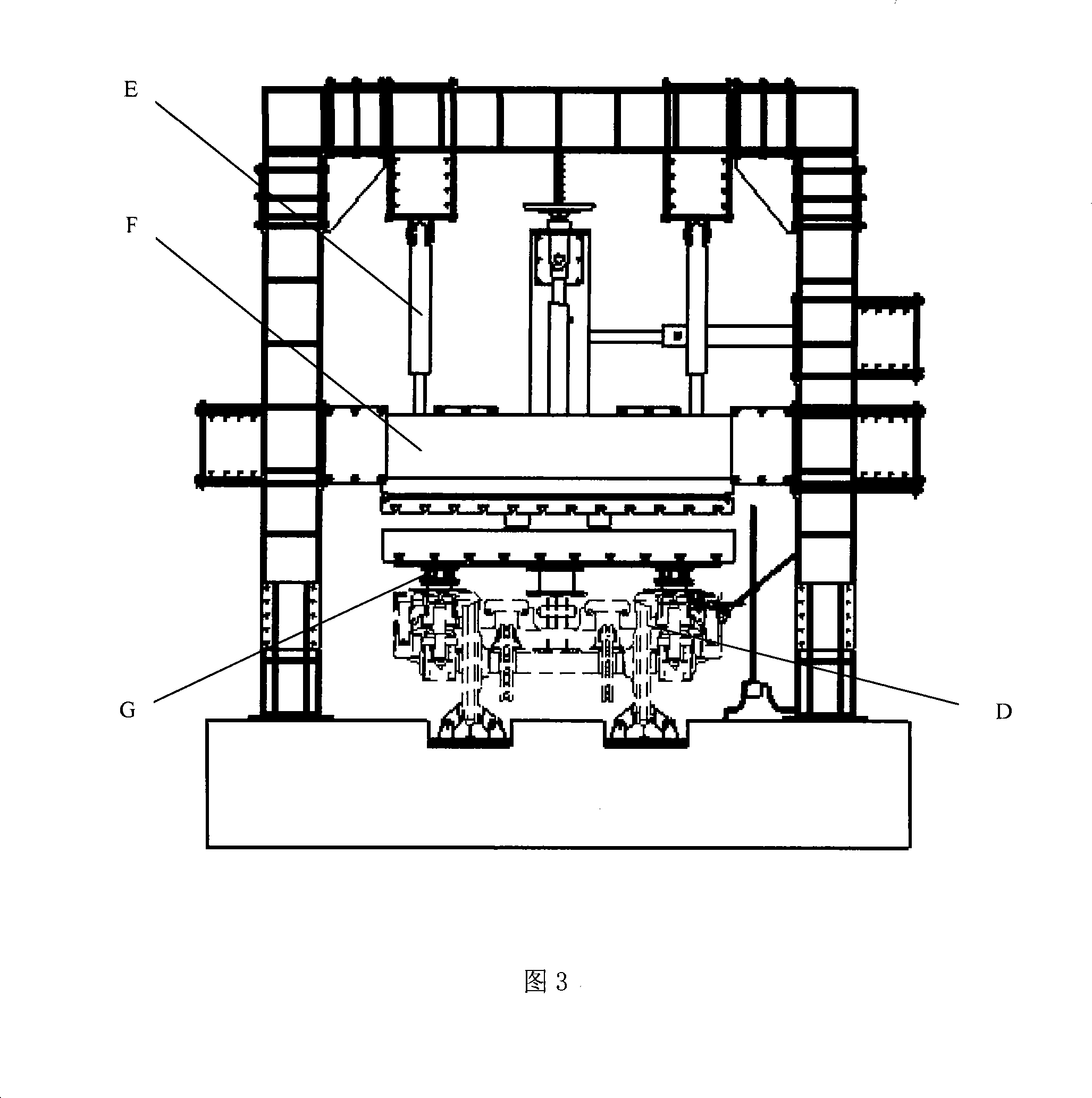

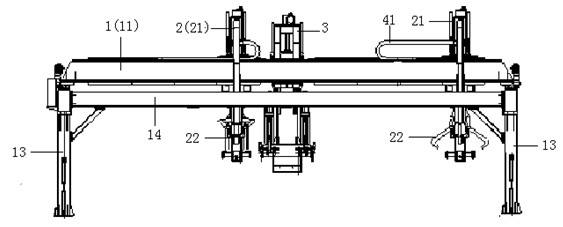

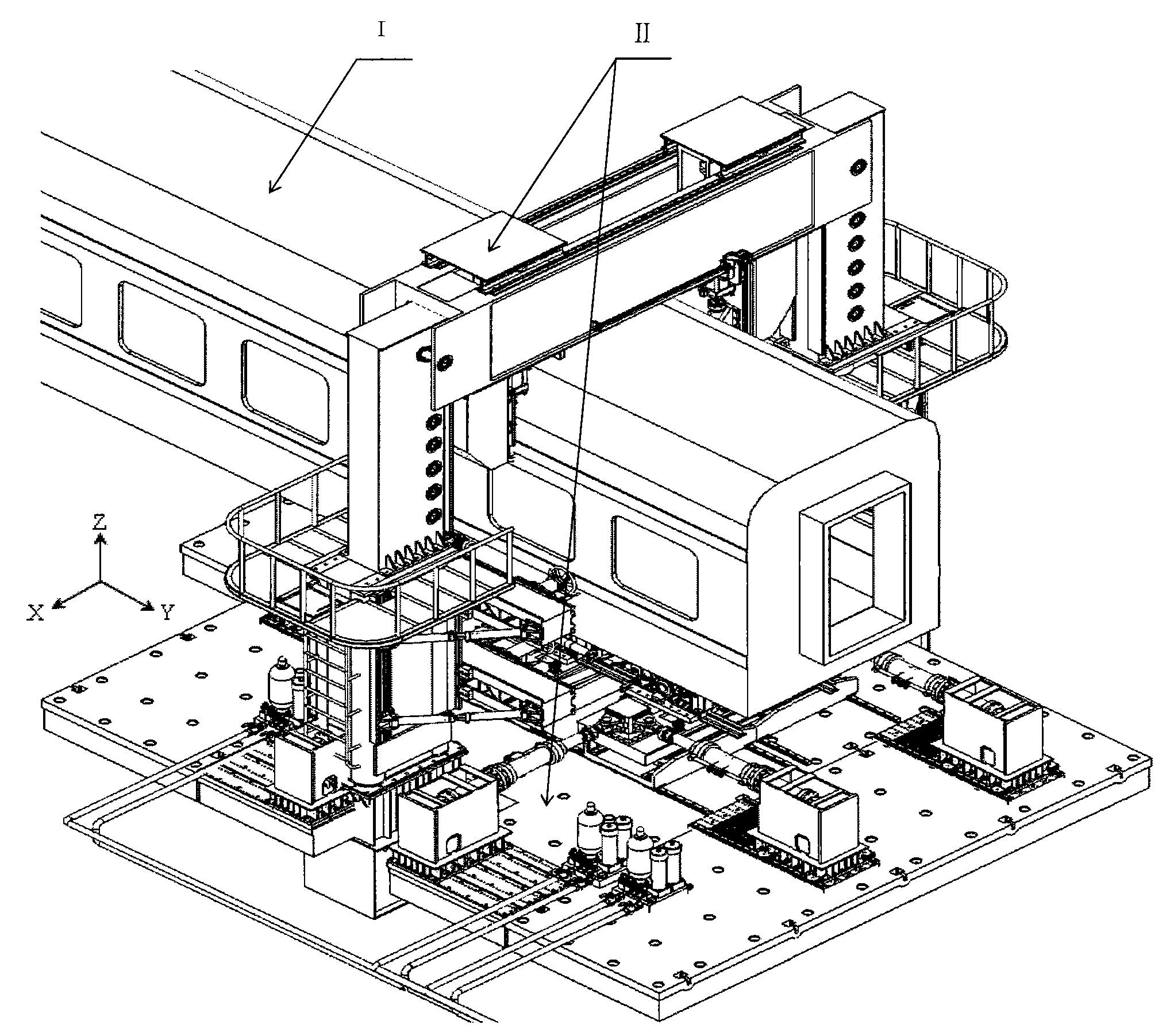

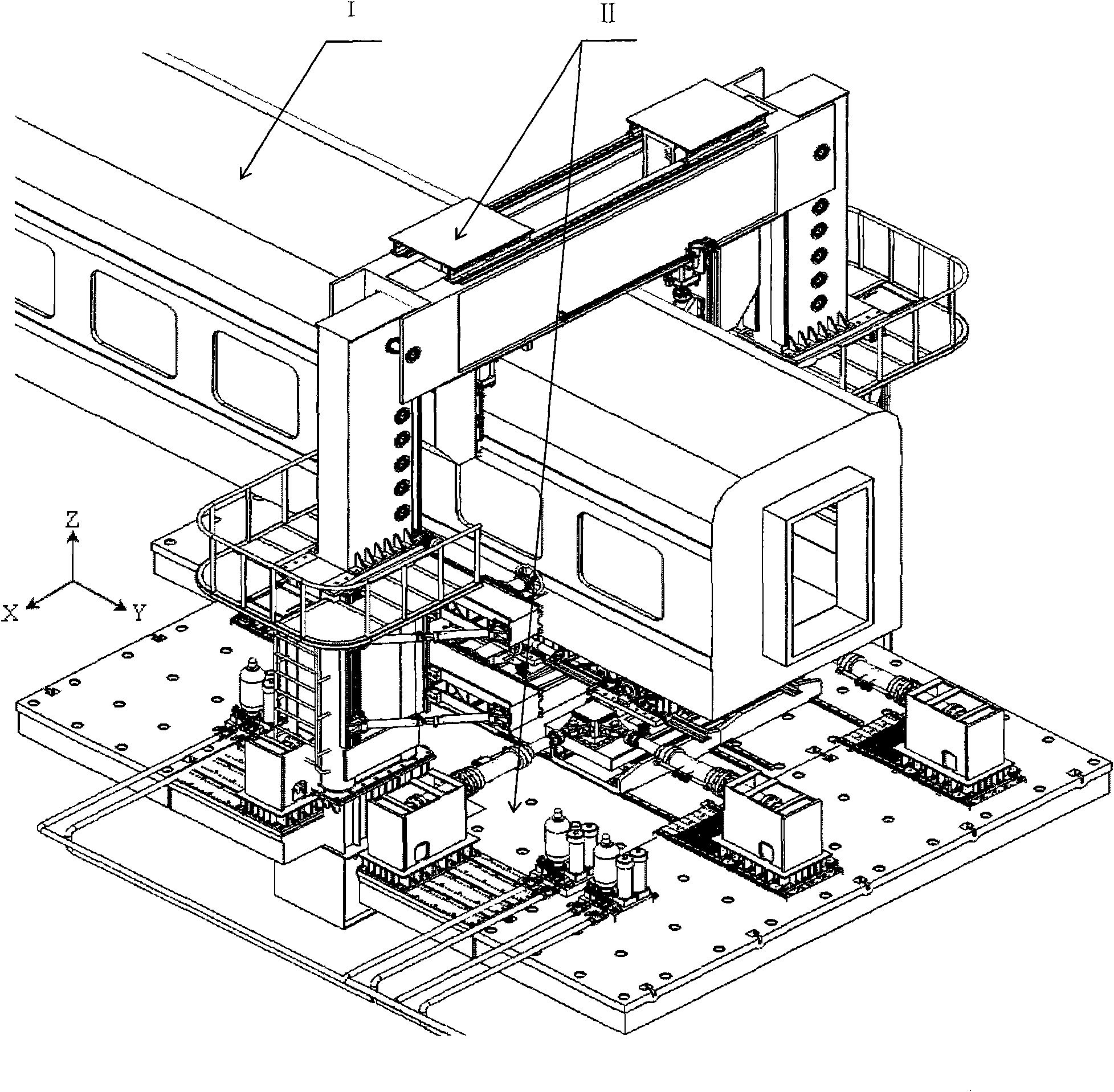

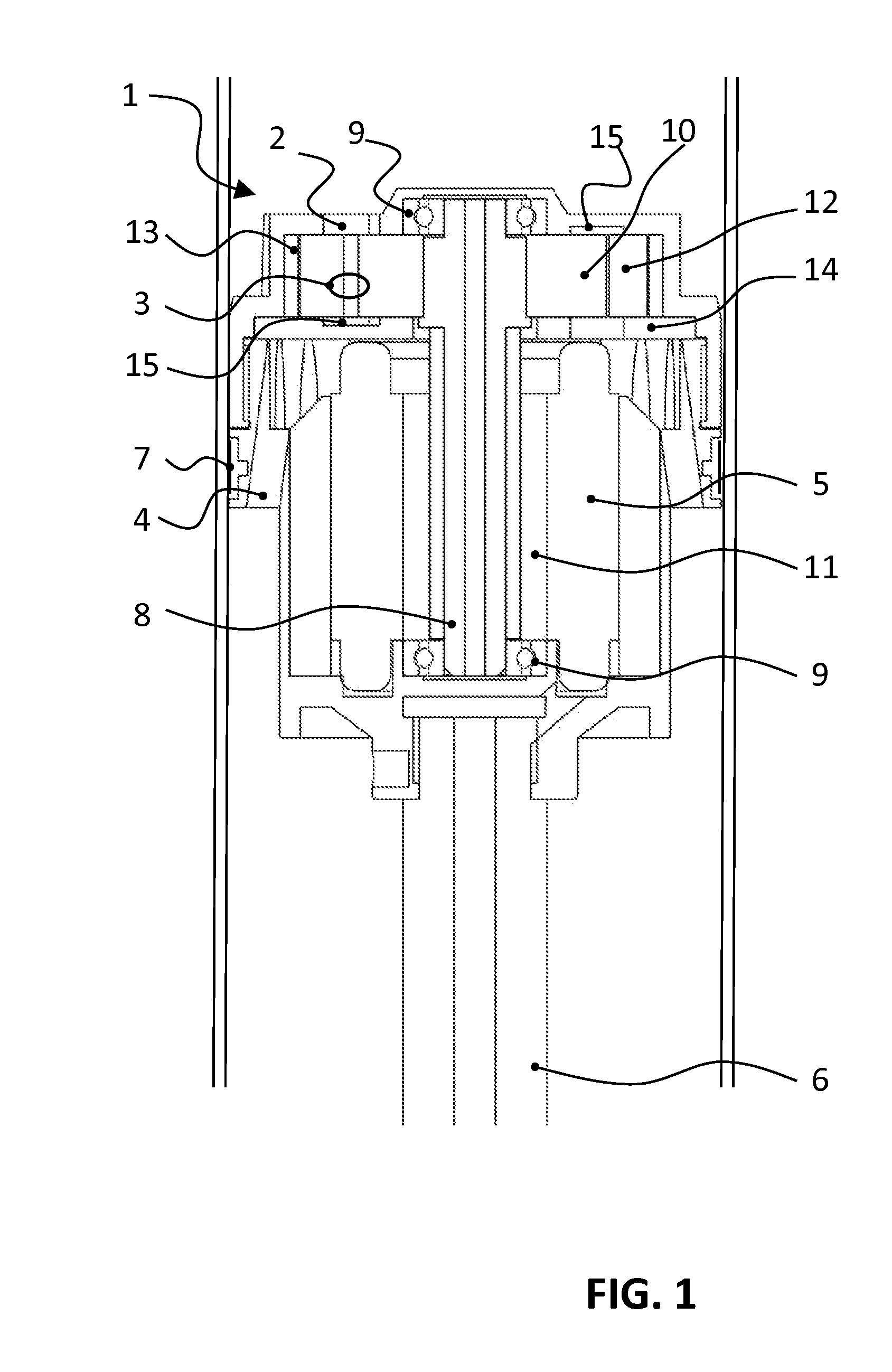

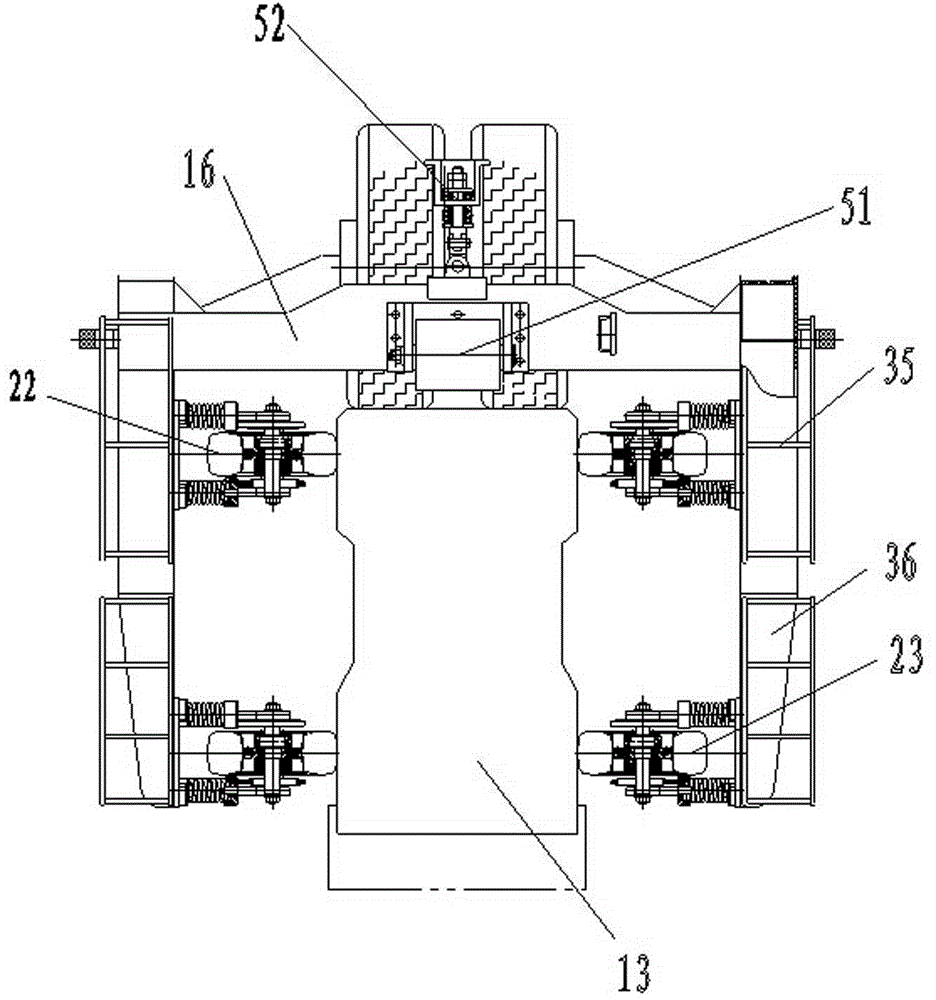

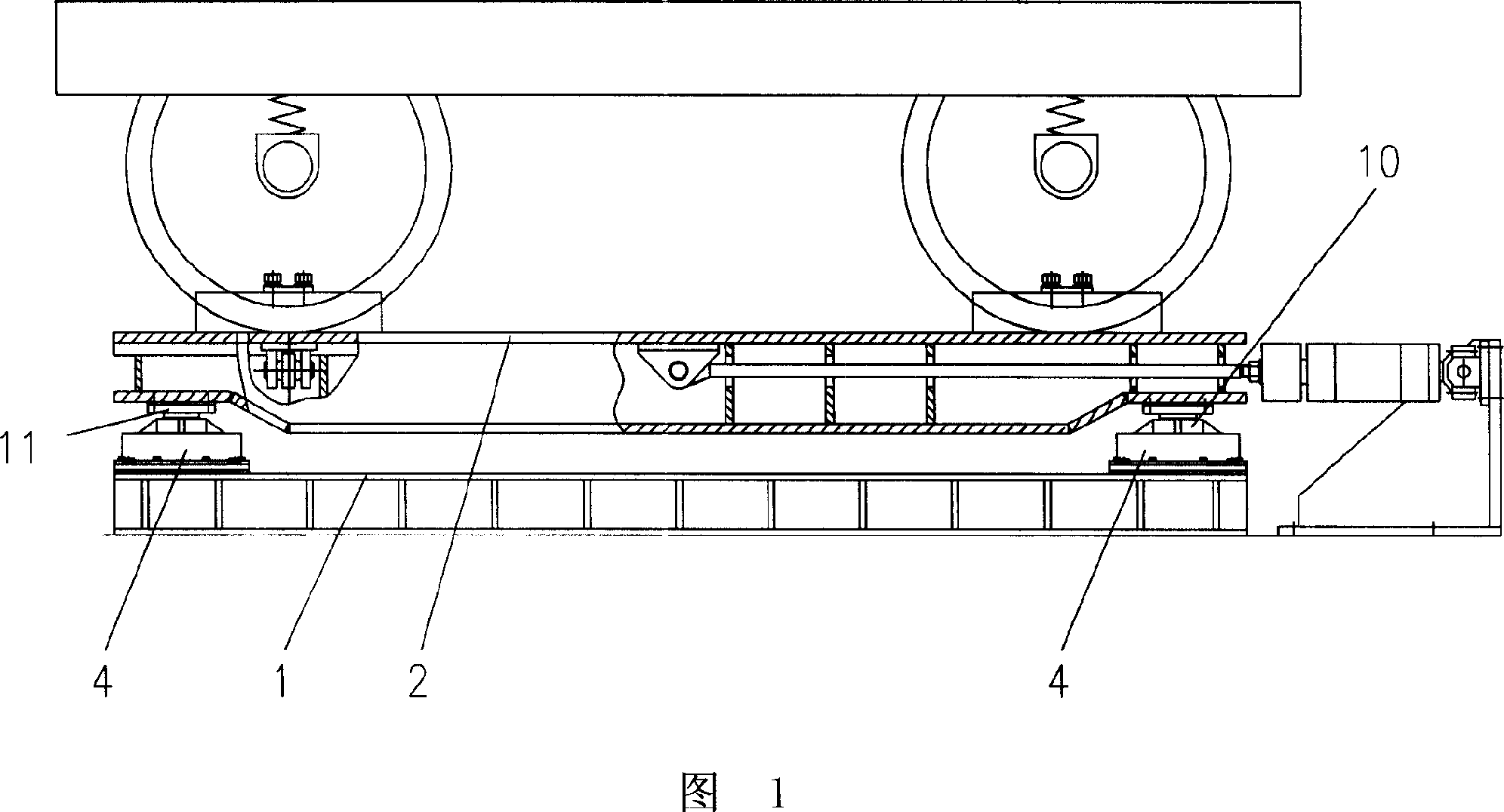

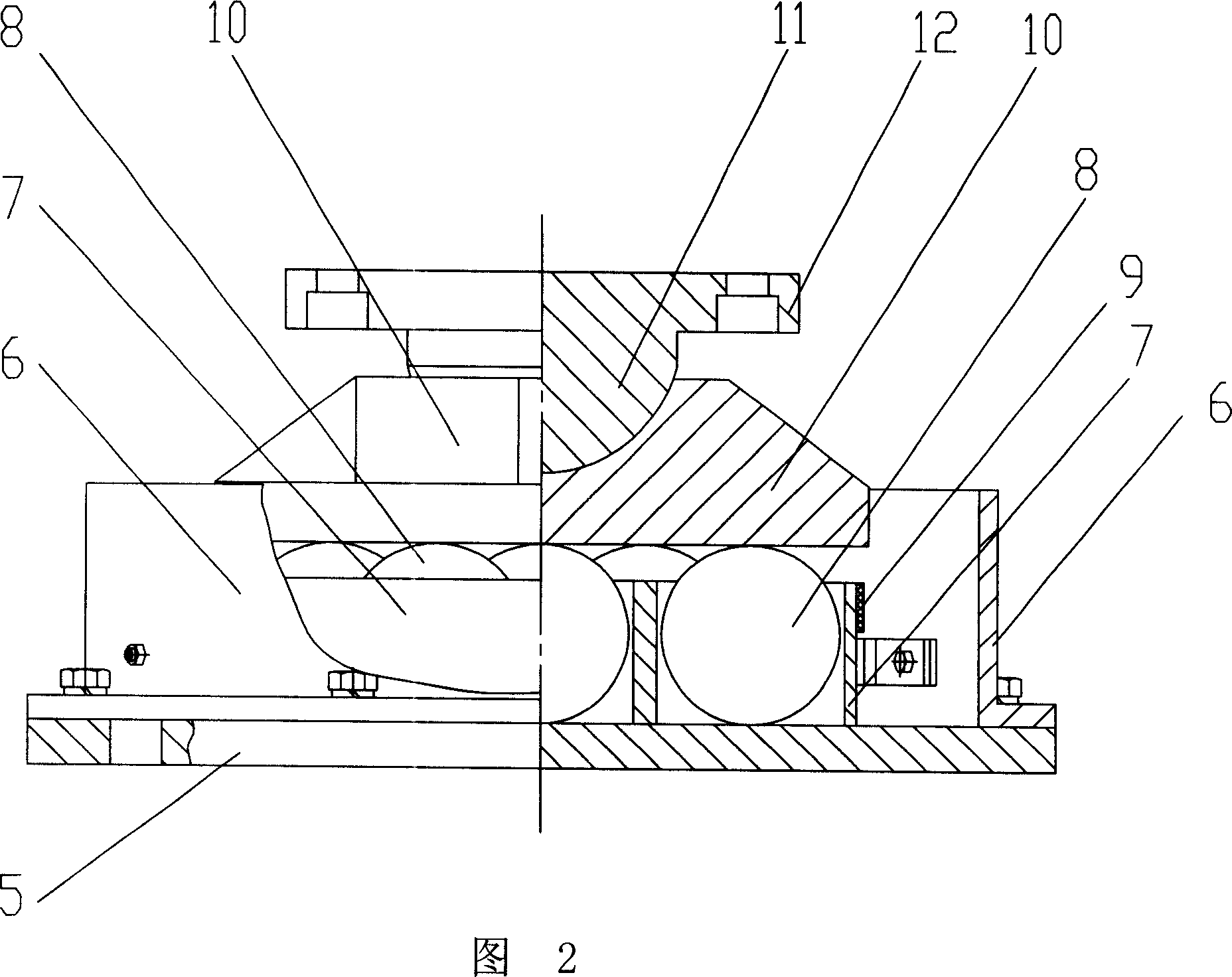

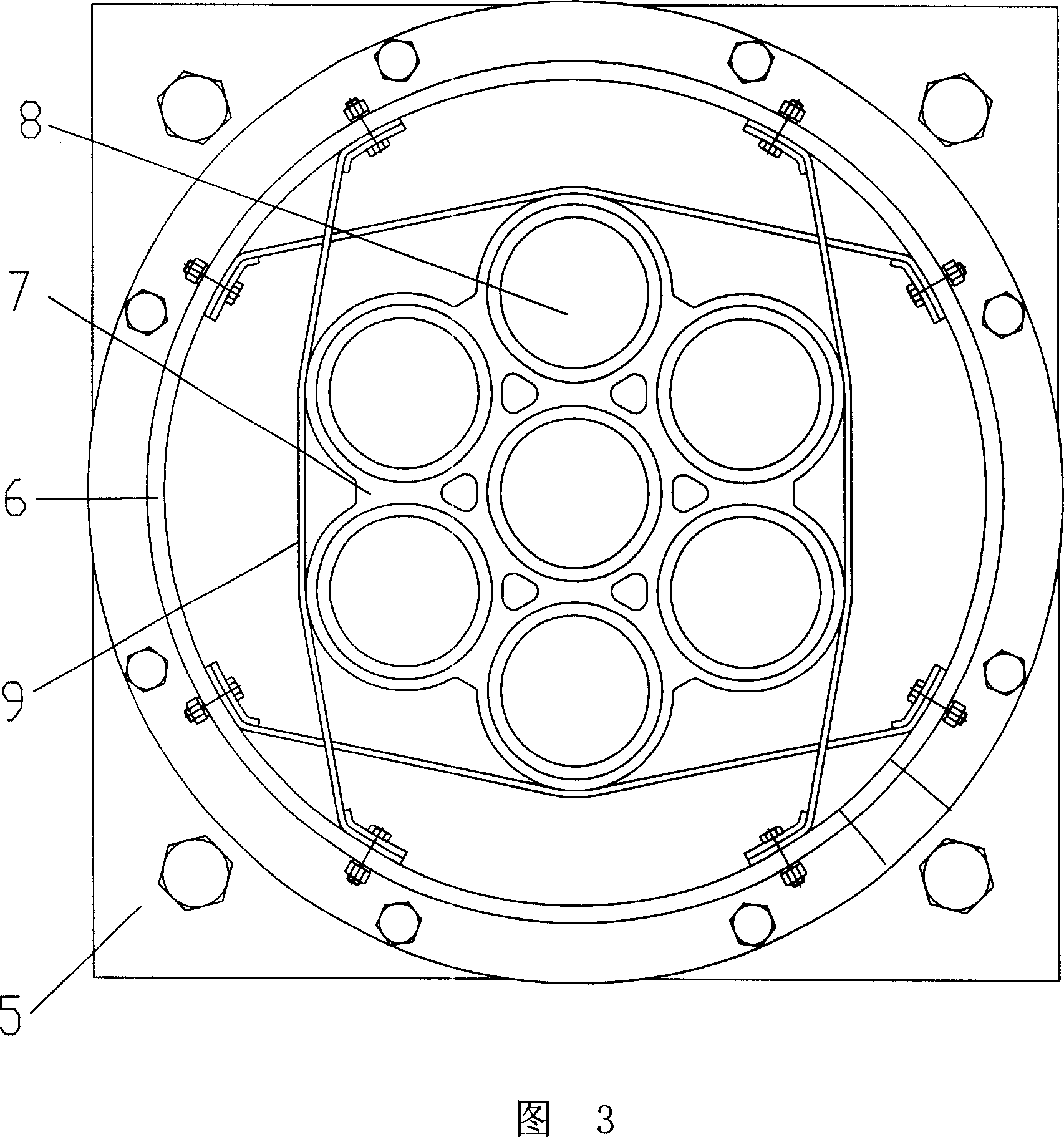

Four-column type rail vehicle bogie rigidity detection system

A rigidity detection system of four-column bogie of railway vehicles relates to railway vehicle performance detection equipment, which is designed for detecting the key kinetic parameters of bogie of railway vehicles under various motion states. The system comprises a mechanical system, a hydraulic system, a test system and a control system, wherein the mechanical system includes a gantry system (A) in frame structure composed of a crossbeam (1) and a vertical pillar (2), a five-degree-of-freedom force application system (F) composed of a simulated vehicle load pressure plate (5), a simulated vehicle load pressure column (4) and a simulated vehicle gravity center height adjusting mechanism (3), and a wheel pair positioning and clamping system (B) for clamping and positioning a rotation frame; the hydraulic system (E) includes a cylinder with vertical, longitudinal and transverse effects on the rotation frame; the test system includes a three-dimensional force detection system (G) and a rotation frame displacement detection system (C); and the control system is mainly composed of a hydraulic control system, an electric control system and a computer system.

Owner:JILIN UNIV

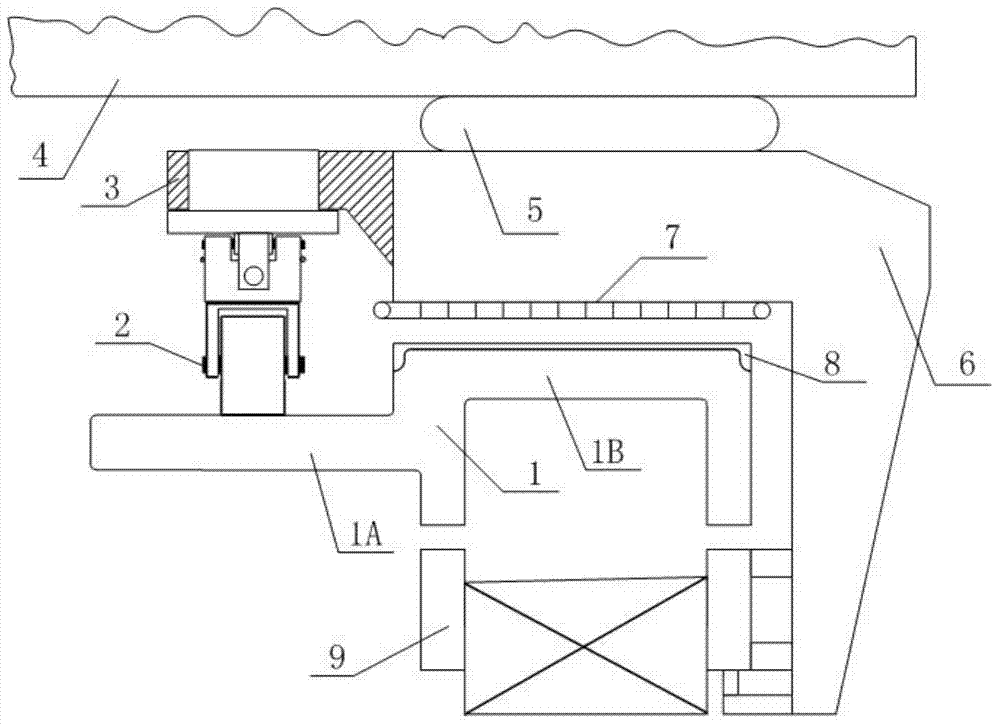

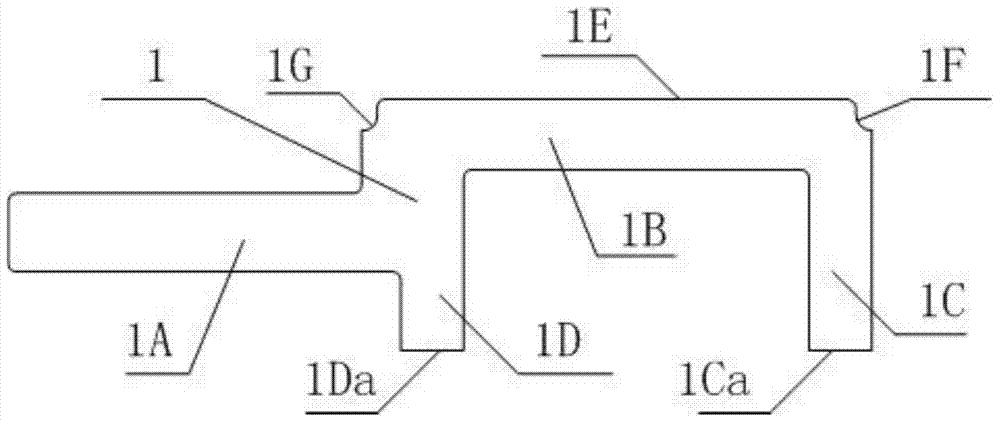

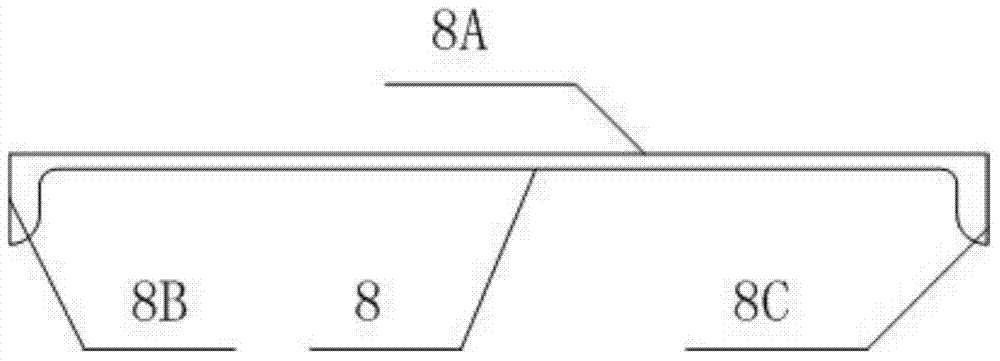

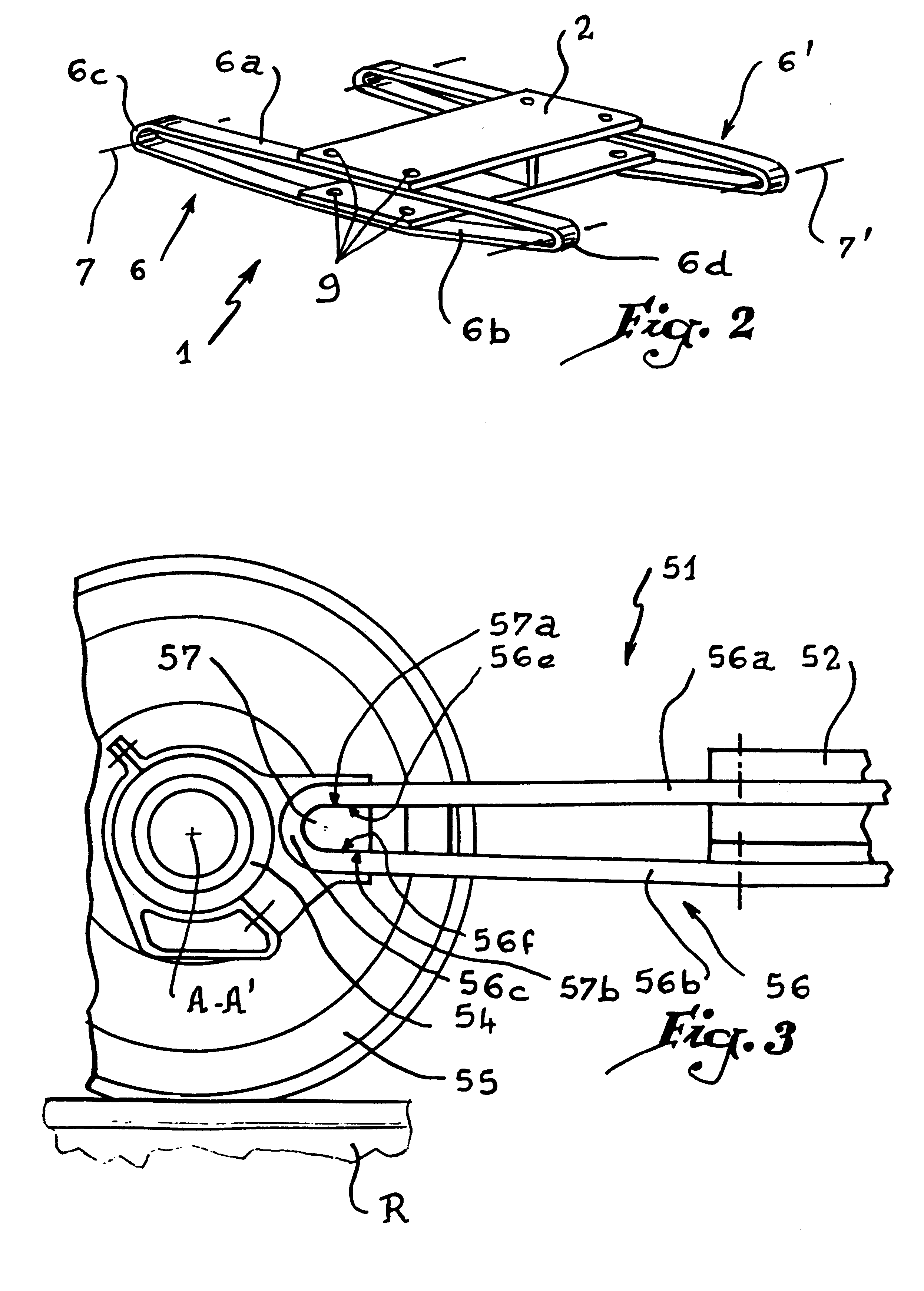

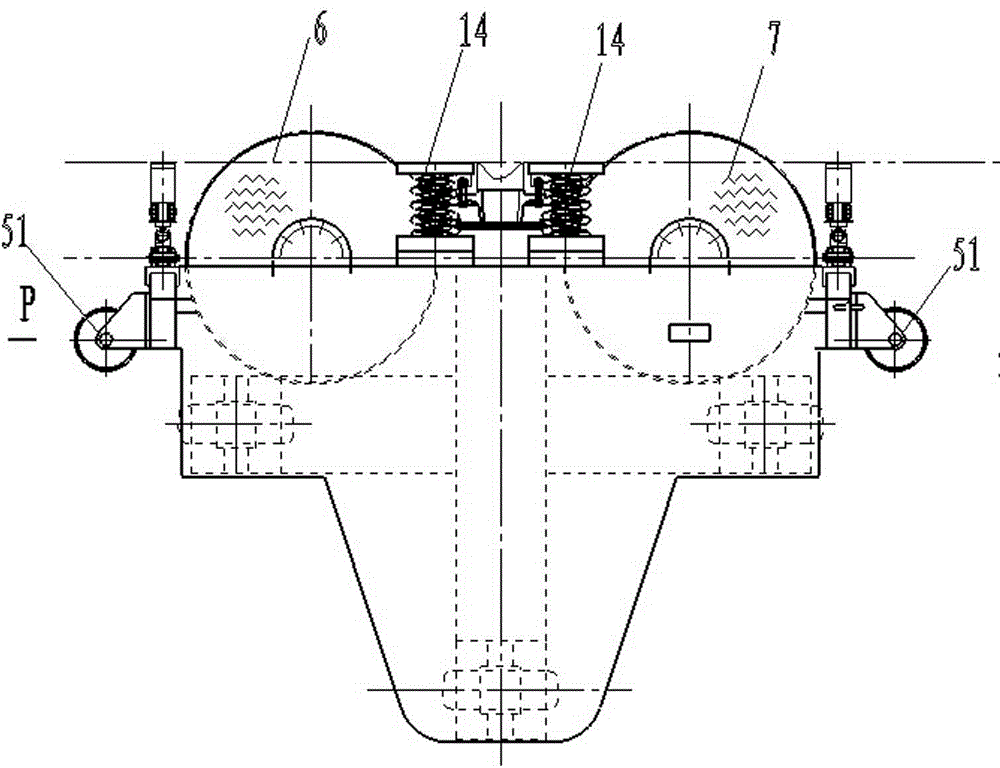

U-shaped rail double-safety running and levitation driving energy-saving mechanism

InactiveCN103612635AIncrease productivityImprove the level of precision controlRailway tracksSliding/levitation railway systemsLevitationAir spring

The invention belongs to the field of rail traffic and relates to a U-shaped rail double-safety running and levitation driving energy-saving mechanism which is suitable for low-medium-speed maglev train double-safety running and levitation driving energy saving. The mechanism is composed of a U-shaped rail 1, a self-locking hydraulic traveling wheel mechanism 2, a connecting frame 3, a train body 4, an air spring 5, a bogie arm 6, a spindle 7, an aluminum sensing plate 8 and levitation magnets 9. By designing a U-shaped rail structure, production efficiency of the U-shaped rail is improved, roller consumption in hot rolling production is reduced, and production cost is lowered. By combining the U-shaped rail structure with the self-locking hydraulic traveling wheel mechanism, a maglev train is enabled to have a magnetic levitation and rubber wheel double-safety running mechanism, levitation-starting energy consumption of the maglev train is reduced remarkably, traction levitation energy consumption is reduced by 10-15%, and energy-saving effect is obvious. Running safety and accident emergency response capability are improved remarkably, and when a full-levitation system is in a failure, driven by a linear motor, a rubber wheel supporting train still can safely get to a target station.

Owner:莱芜美澳冶金科技有限公司

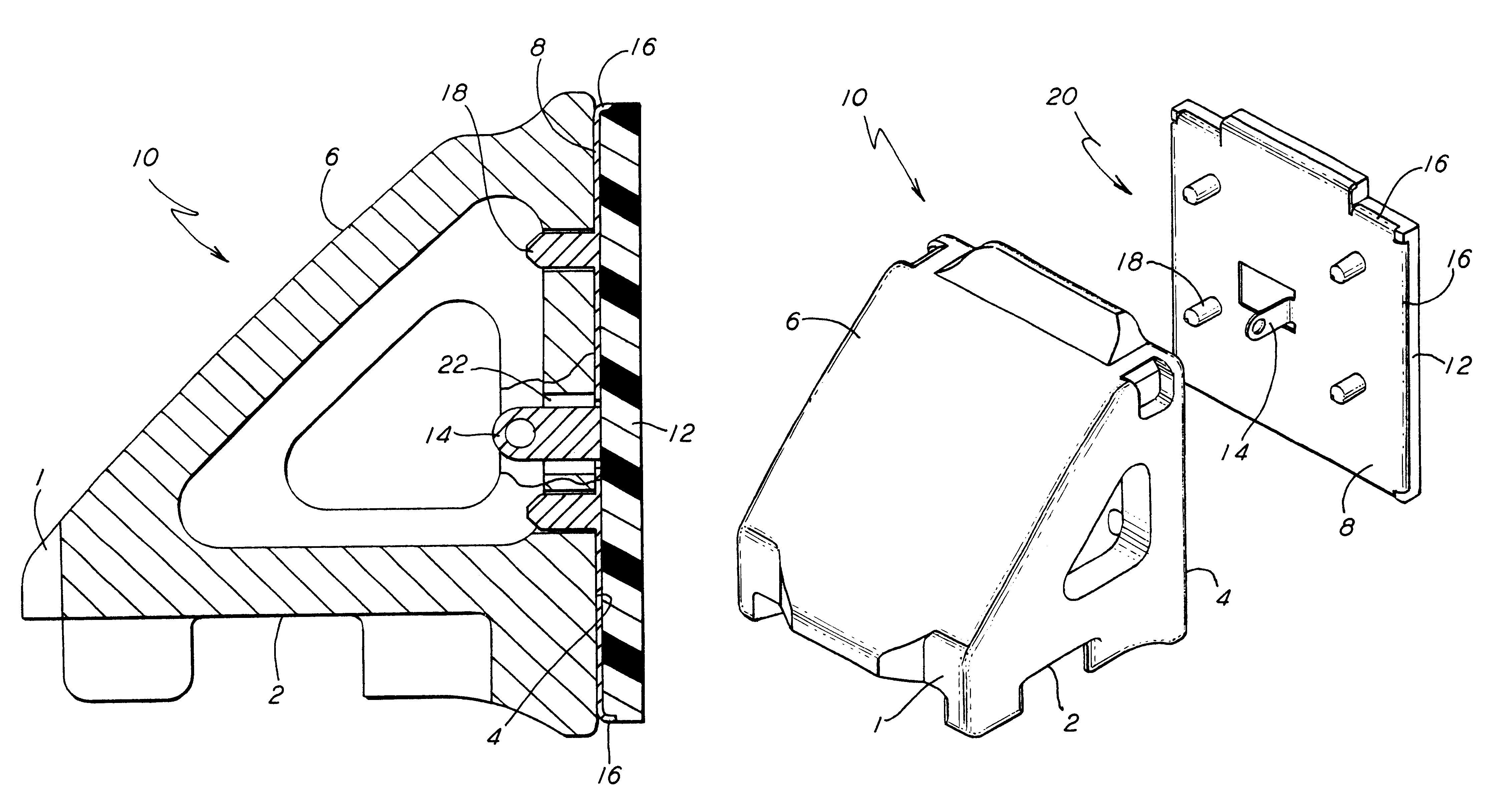

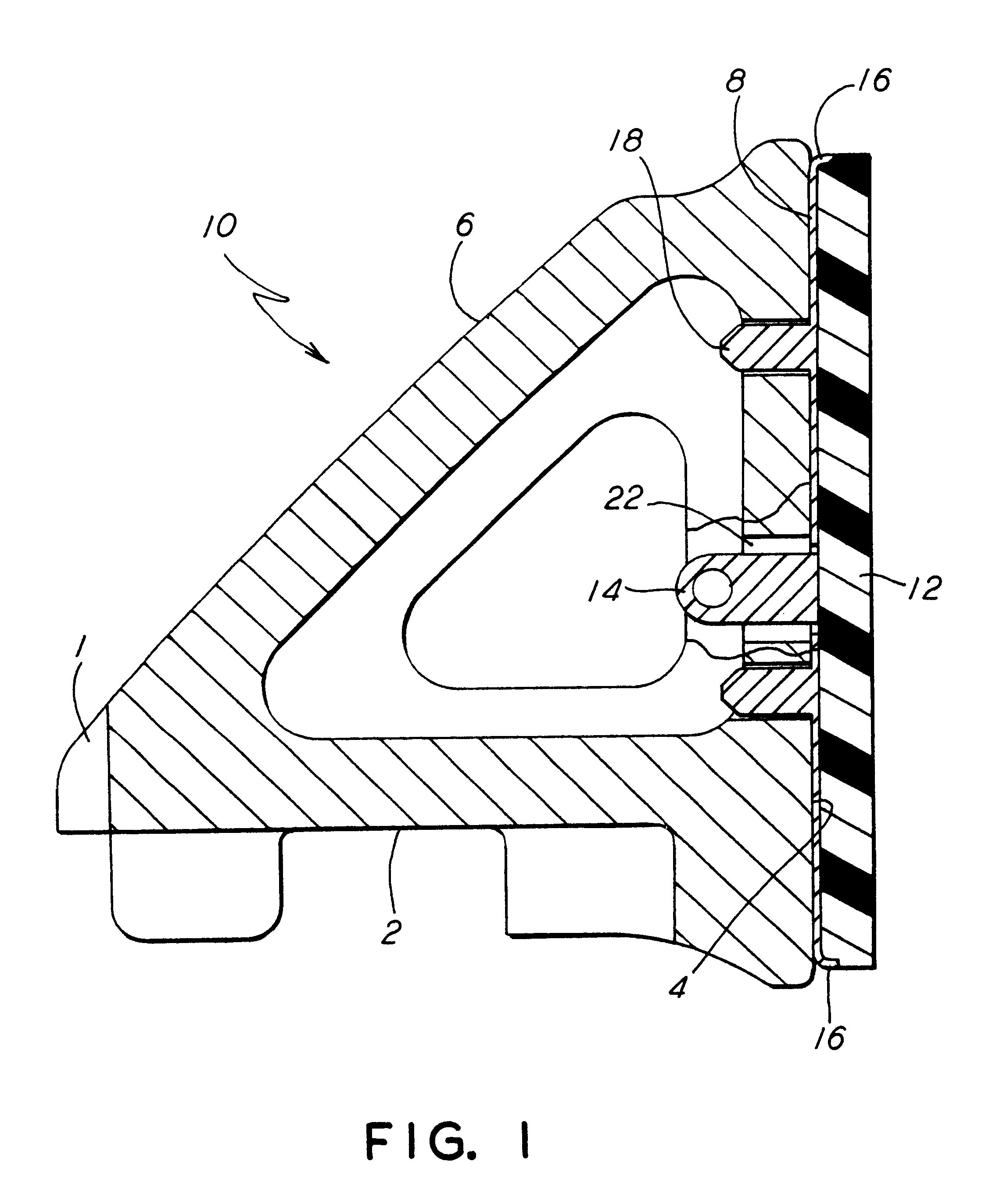

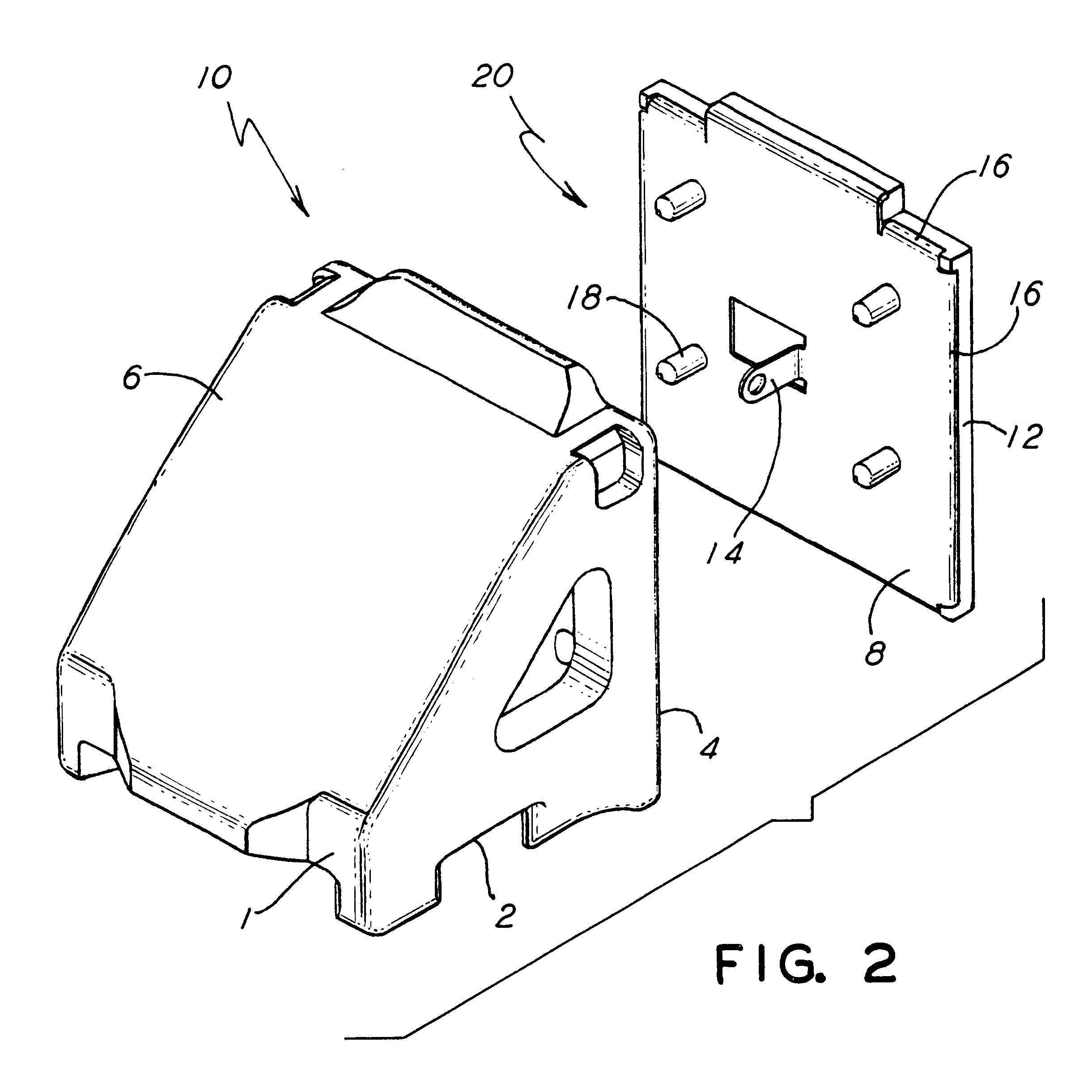

Friction wedge liner with backing plate

InactiveUS6701850B2Eliminate needReduce maintenanceBogiesBogie-underframe connectionsEngineeringTruck

Owner:RFPC HLDG CORP

Rail road car truck and fittings therefor

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

Railway vehicle bogie and process for manufacturing a side member of such a bogie

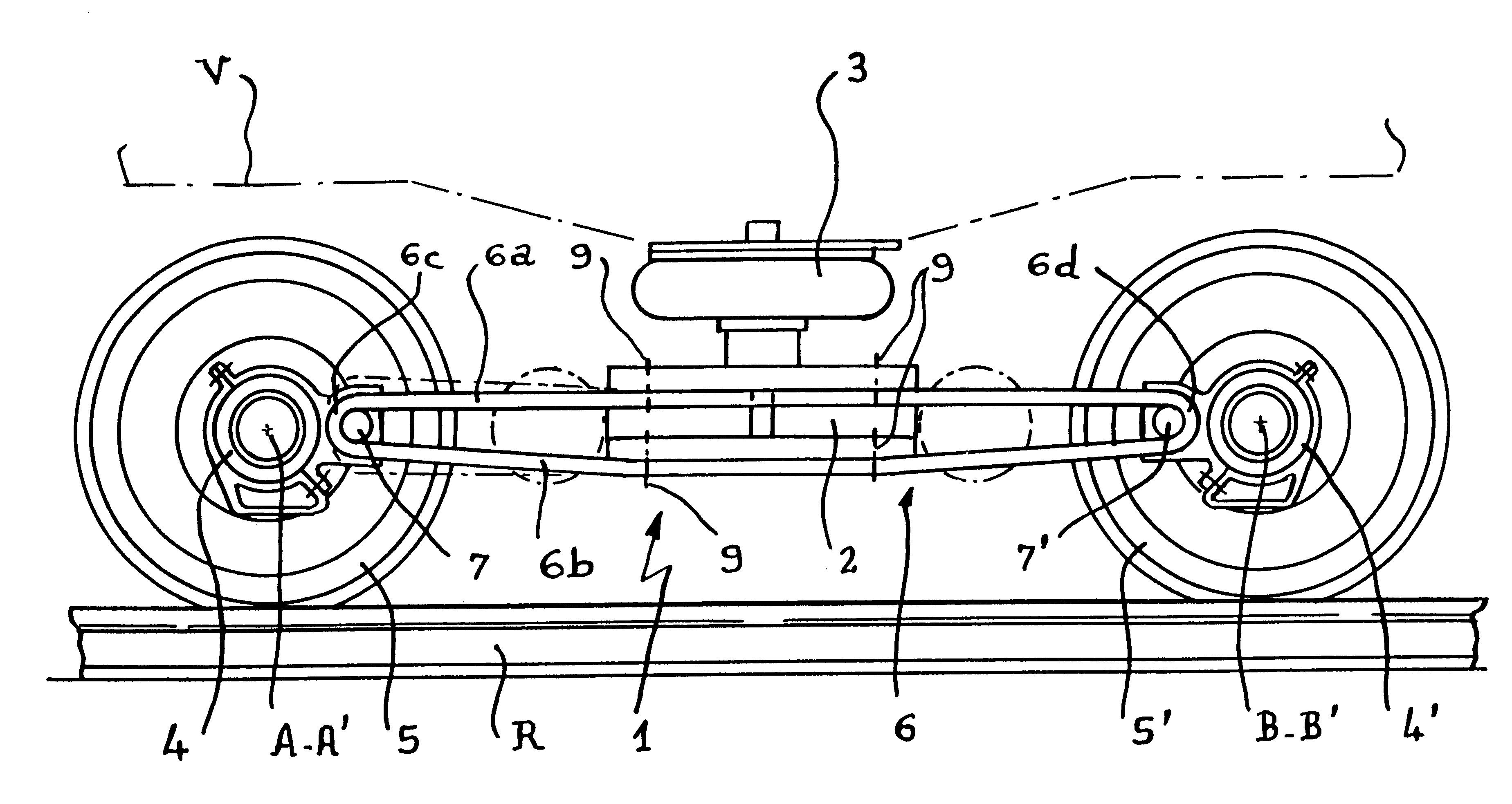

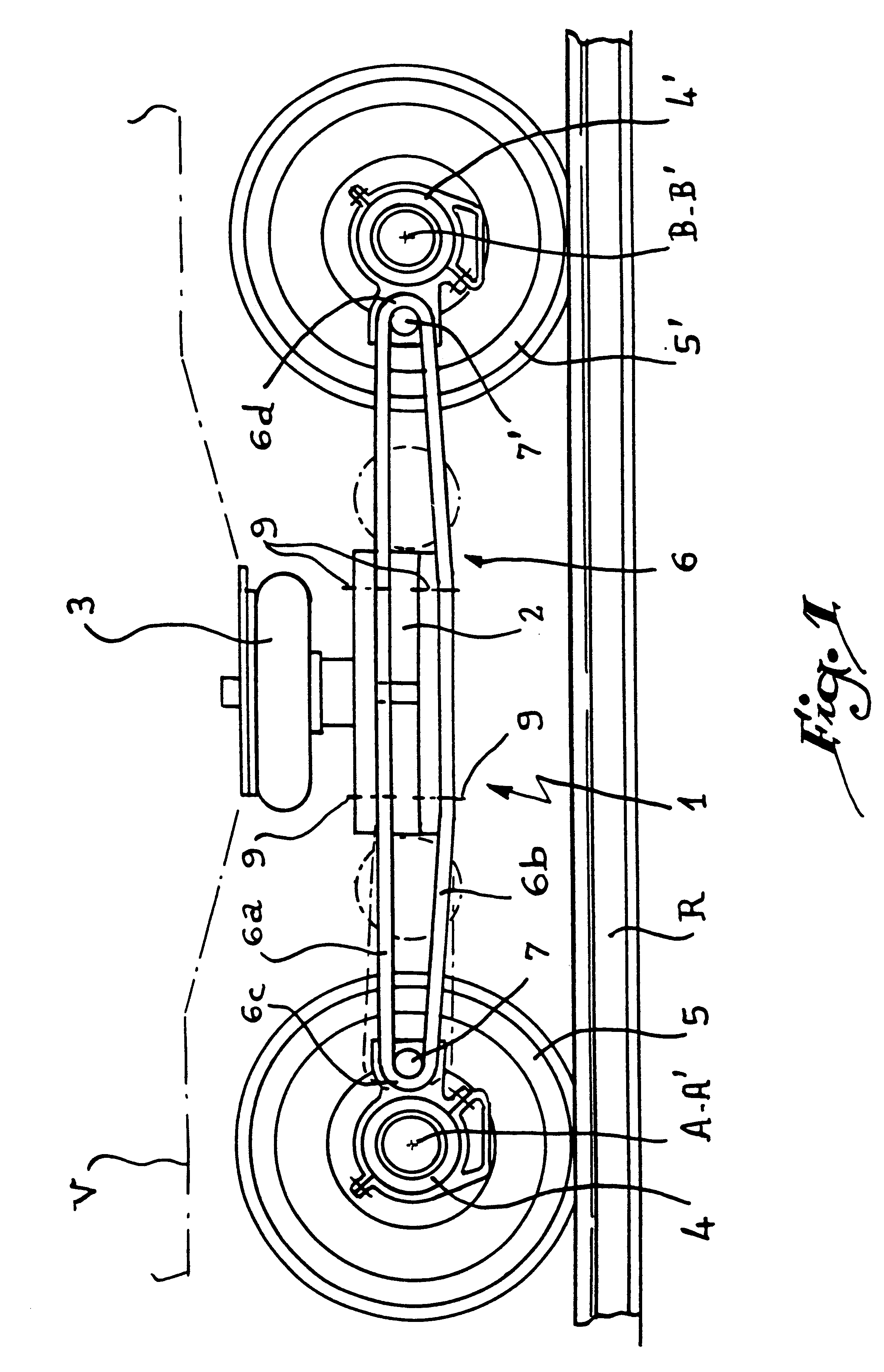

A railway vehicle bogie, including at least two axles, at least one side member being provided to connect the axles to a central part of the bogie. The side member is formed by an elastic blade shaped as a vertically oriented continuous flattened loop which may be made of composite material or of metal. A process for manufacturing a side member of composite material consists in winding a continuous lap of reinforcing fibers over at least one turn around two studs so as to form a loop, and polymerizing a resin-based matrix around the fibers.

Owner:ALSTOM TRANSPORT TECH SAS

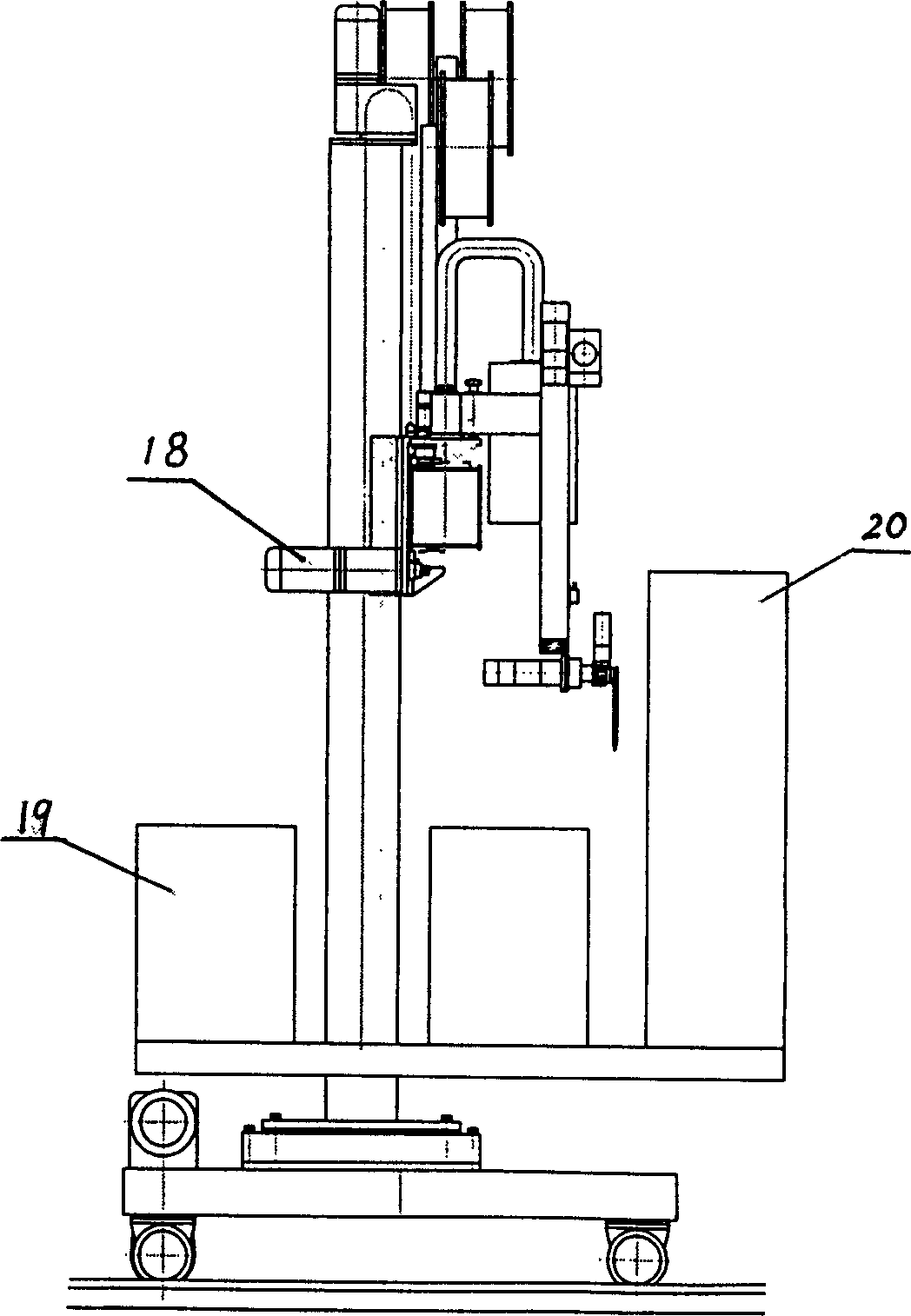

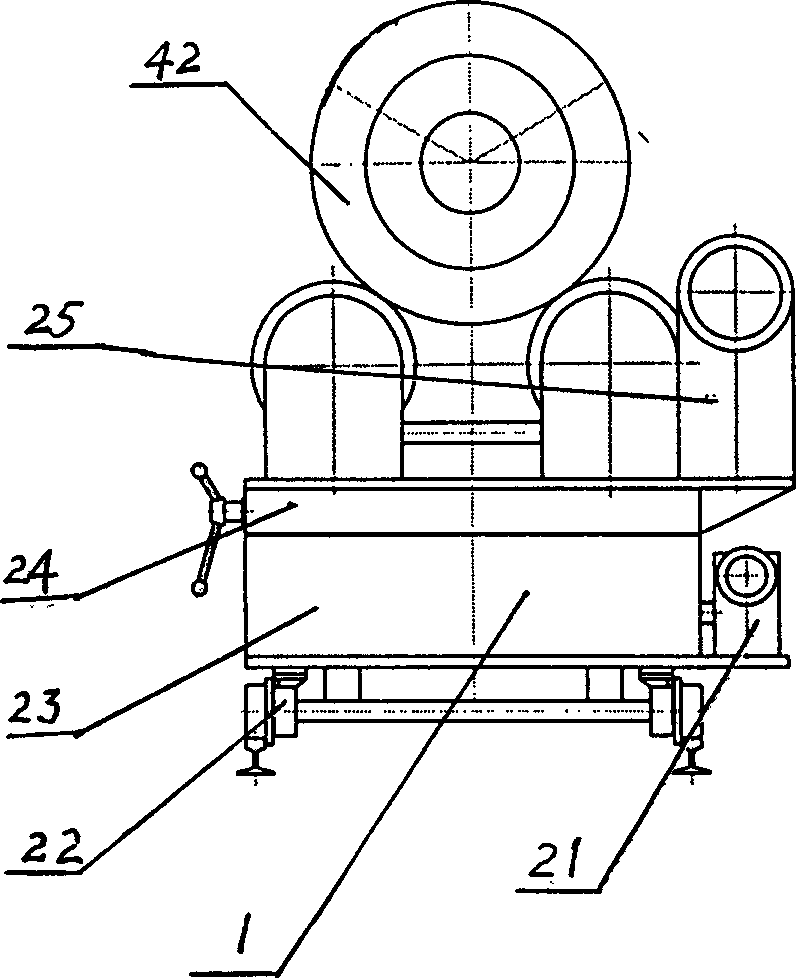

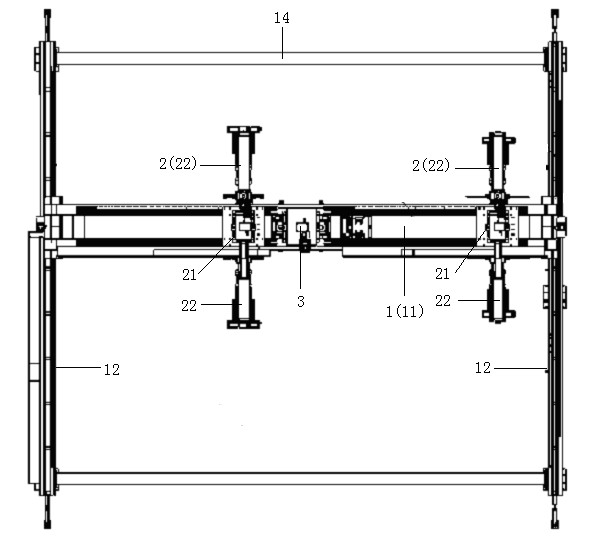

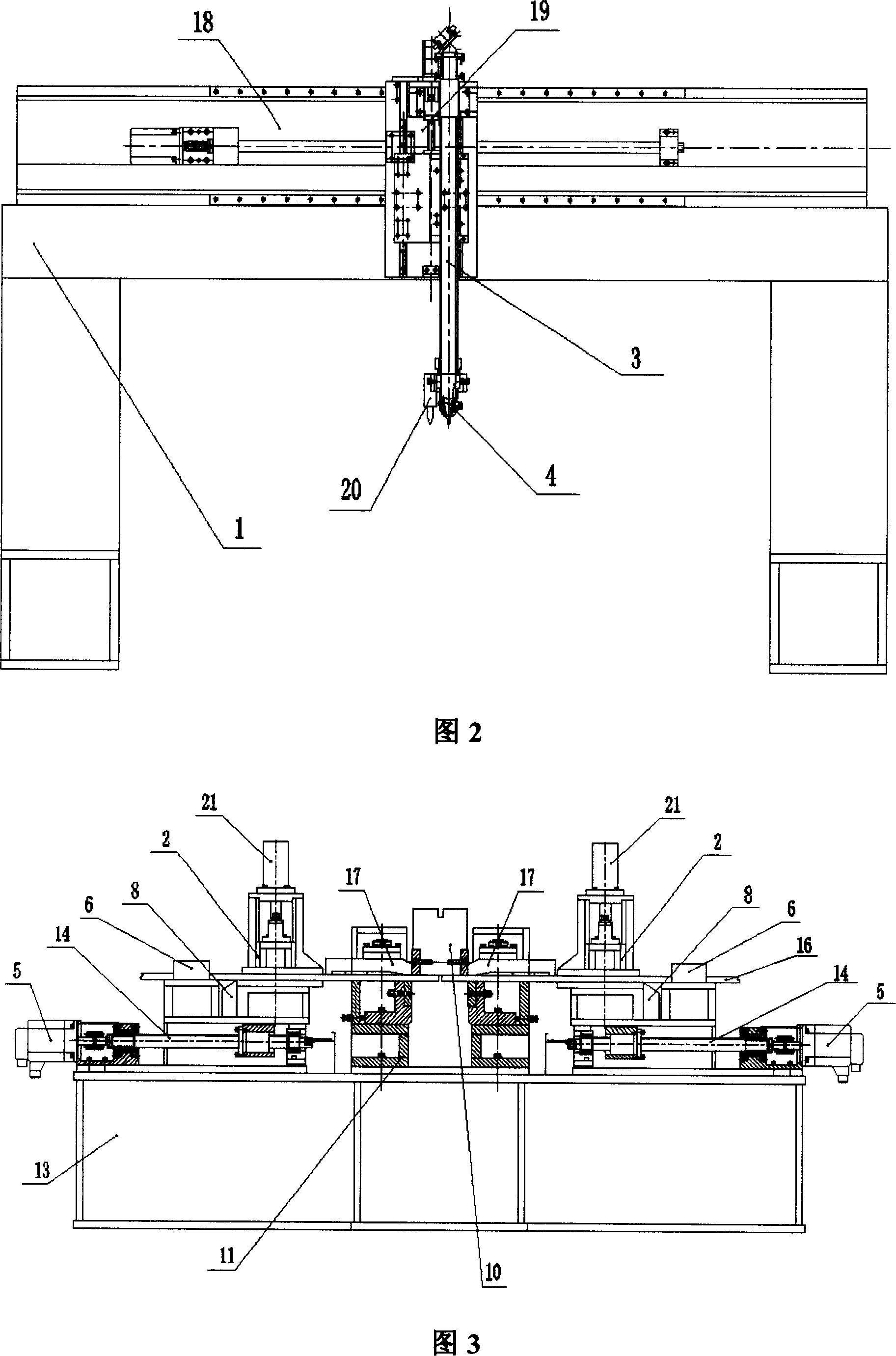

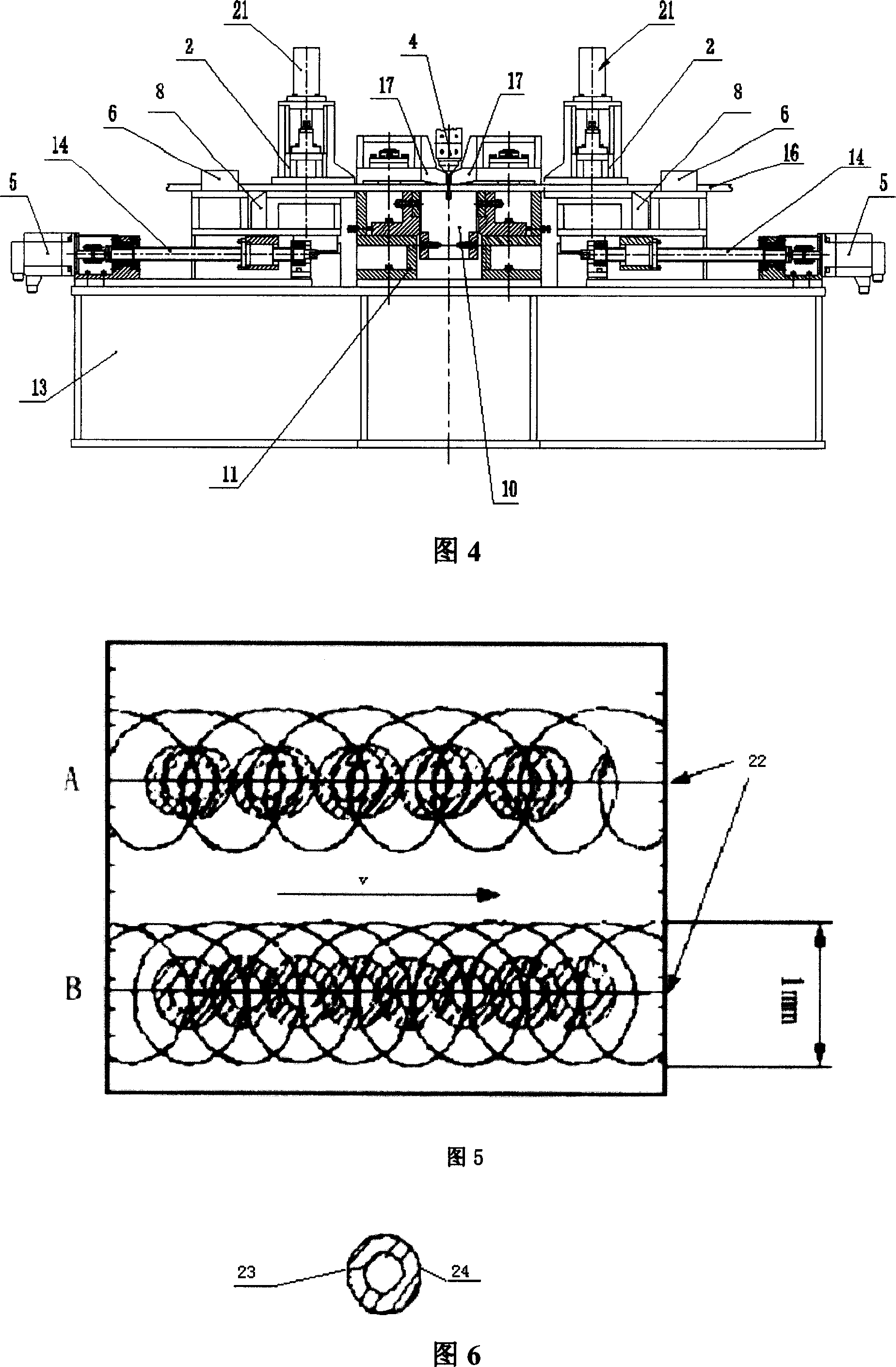

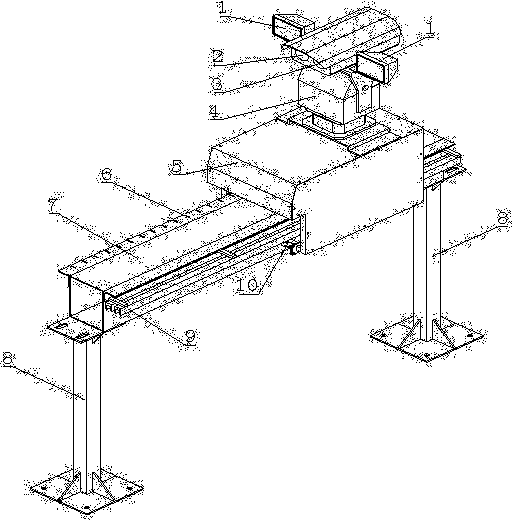

Special portal-type bolster frame assembly manipulator for truck bogie production line

ActiveCN102430906AEliminate potential safety hazardsImprove assembly qualityProgramme-controlled manipulatorMetal working apparatusBogieProduction line

The invention provides a special portal-type bolster frame assembly manipulator for a truck bogie production line, which is mainly composed of a frame, two side frame manipulators, a swing bolster manipulator and an electric control unit, wherein the side frame manipulators, swing bolster manipulator and electric control unit are installed on the frame; the frame is mainly composed of a cross beam, a support beam, a vertical support and a traveling beam which are connected with each other; the two side frame manipulators are installed on the cross beam, and each side frame manipulator is composed of a side frame transverse operating / vertical lifting unit and a side frame grabbing / clamping / turning unit; and the swing bolster manipulator is installed on the cross beam and positioned betweenthe two side frame manipulator. The invention provides an indispensable important apparatus of the key position bolster frame assembly for a truck bogie production line; the side frame manipulators can operate leftward and rightward or forward and backward to grab and lift the side frames transported by the transport vehicle, and smoothly align and assemble the side frame with the swing bolster grabbed by the swing bolster manipulator, and thus, the degree of mechanization and automation is high; and the invention has the advantages of labor saving, time saving and high assembly quality, and eliminates the potential safety hazard in the craning process.

Owner:江苏中创机械装备制造有限公司

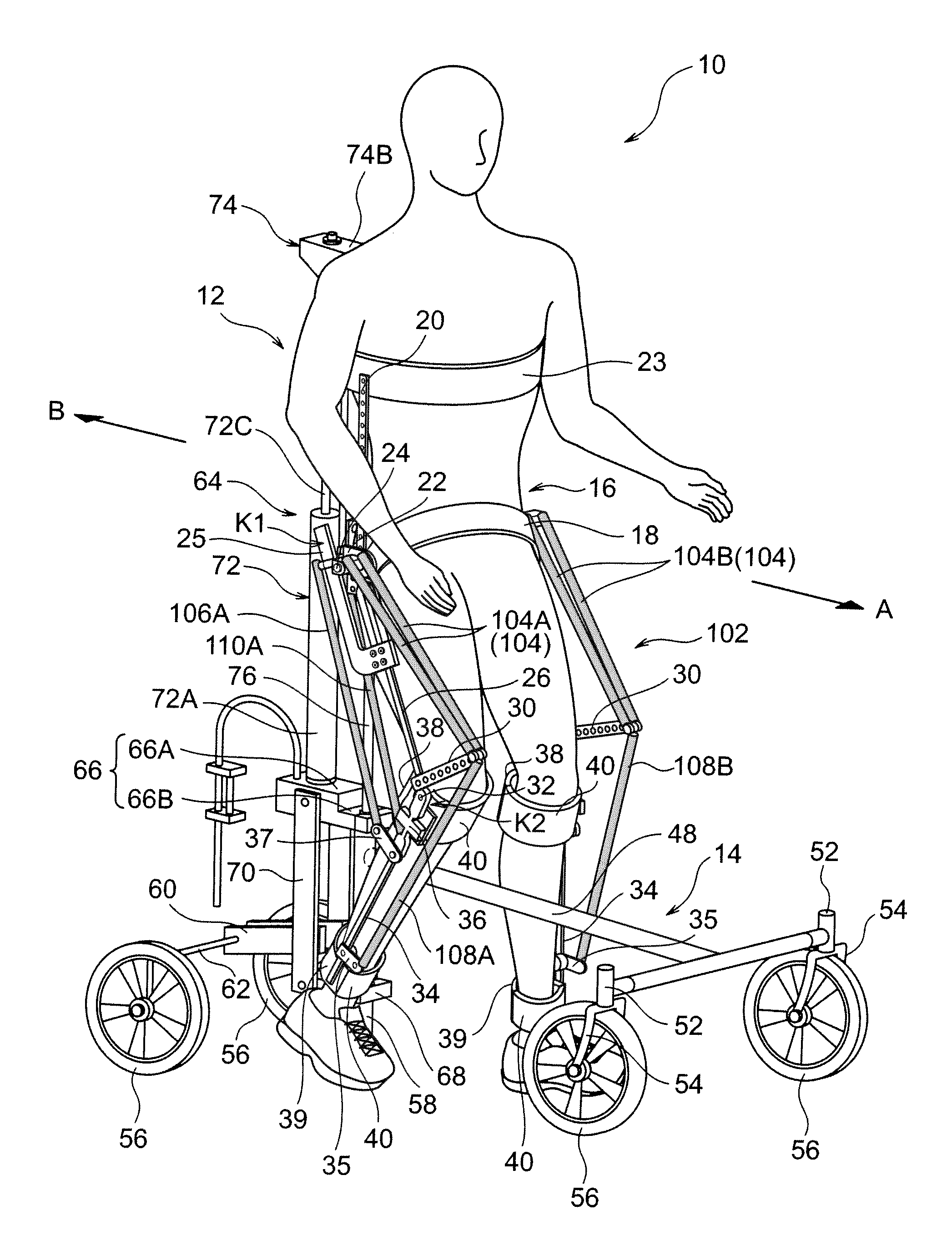

Walking auxiliary equipment

InactiveUS20100270771A1Problem still existProgramme-controlled manipulatorChain/belt transmissionBogieEngineering

Walking auxiliary equipment 10 includes a walking unit 12 and a bogie 14. The walking unit 12 has a lumber frame 16 put onto the lumber region of a user, a below-knee frame 34 put onto the leg of a user, an above-knee frame 26 for coupling the lumber frame 16 to the below-knee frame 34, through a first joint K1 and a second joint K2, and an assistance force imparting device 102. The assistance force imparting device 102 includes a first actuator 104 for generating assistance force to flex the first joint K1, a second actuator 106 for generating assistance force to flex the second joint K2, a third actuator 108 for generating assistance force to extend the second joint K2, and a fourth actuator 110 for generating assistance force to extend the first joint K1.

Owner:TOKYO UNIVERSITY OF SCIENCE

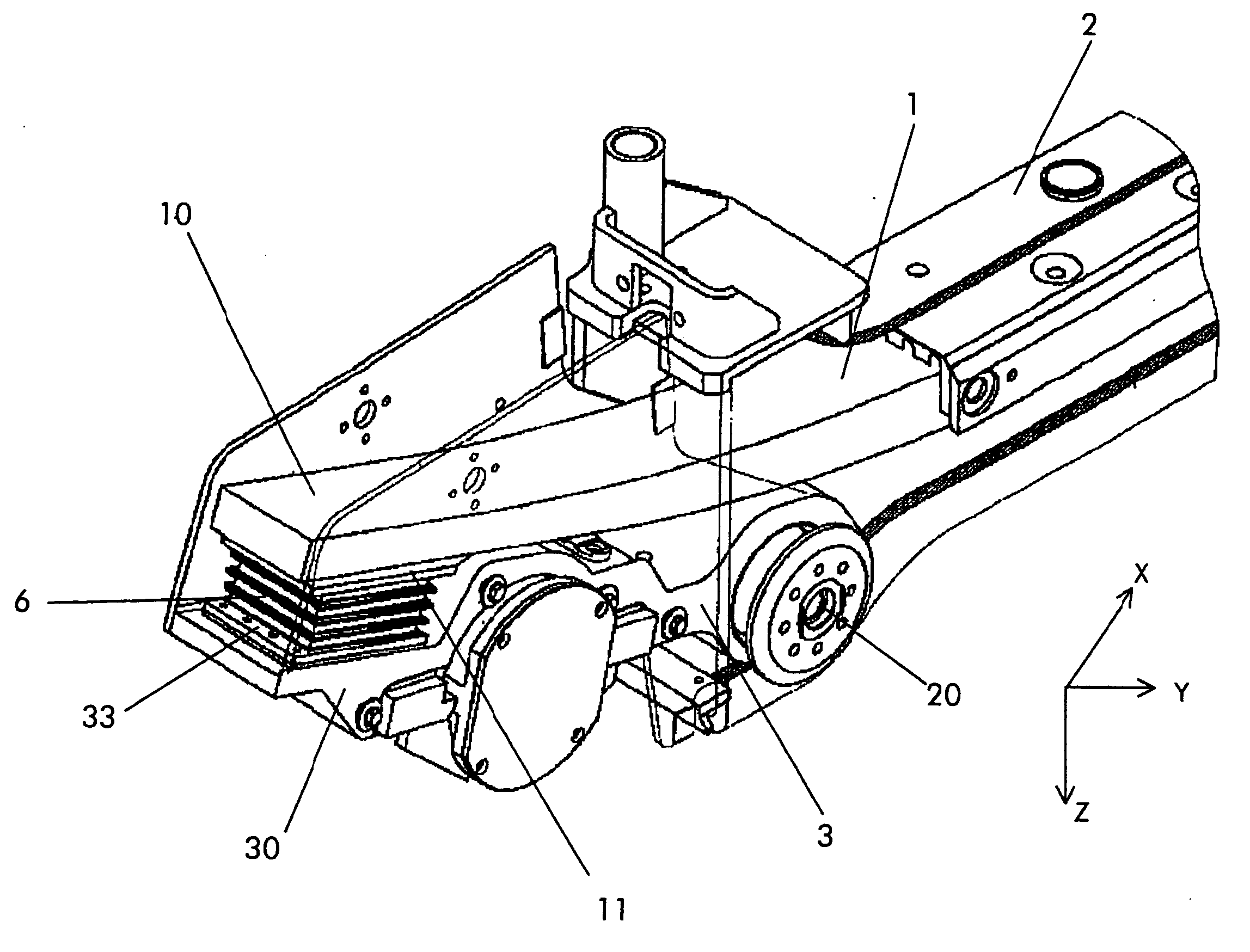

Plate-bending online laser welding technology and its equipment

InactiveCN101100030AReduce assembly requirementsSimple structureShearing machinesOther manufacturing equipments/toolsBogieEngineering

The present invention is plate bending and laser welding process and apparatus. The technological process includes cutting with one upper shearing machine and one lower shearing machine, lowering the upper shearing machine, raising the leveling plates on two sides and pushing with bogies on two sides for matching two cut edges of the workpiece, closing two leveling plates to clamp the workpiece on the upper shearing machine, and welding with the laser head to form weld seam. The apparatus includes one shearing system comprising two shearing machines, one workpiece fixture, tracked bogies and one driving mechanism; and one welding laser set comprising one laser guide unit, one laser head, and one X and Y axis assembly. The present invention has simple technological process, compact apparatus structure and low cost, and is suitable for plate bending and welding production.

Owner:HUAZHONG UNIV OF SCI & TECH

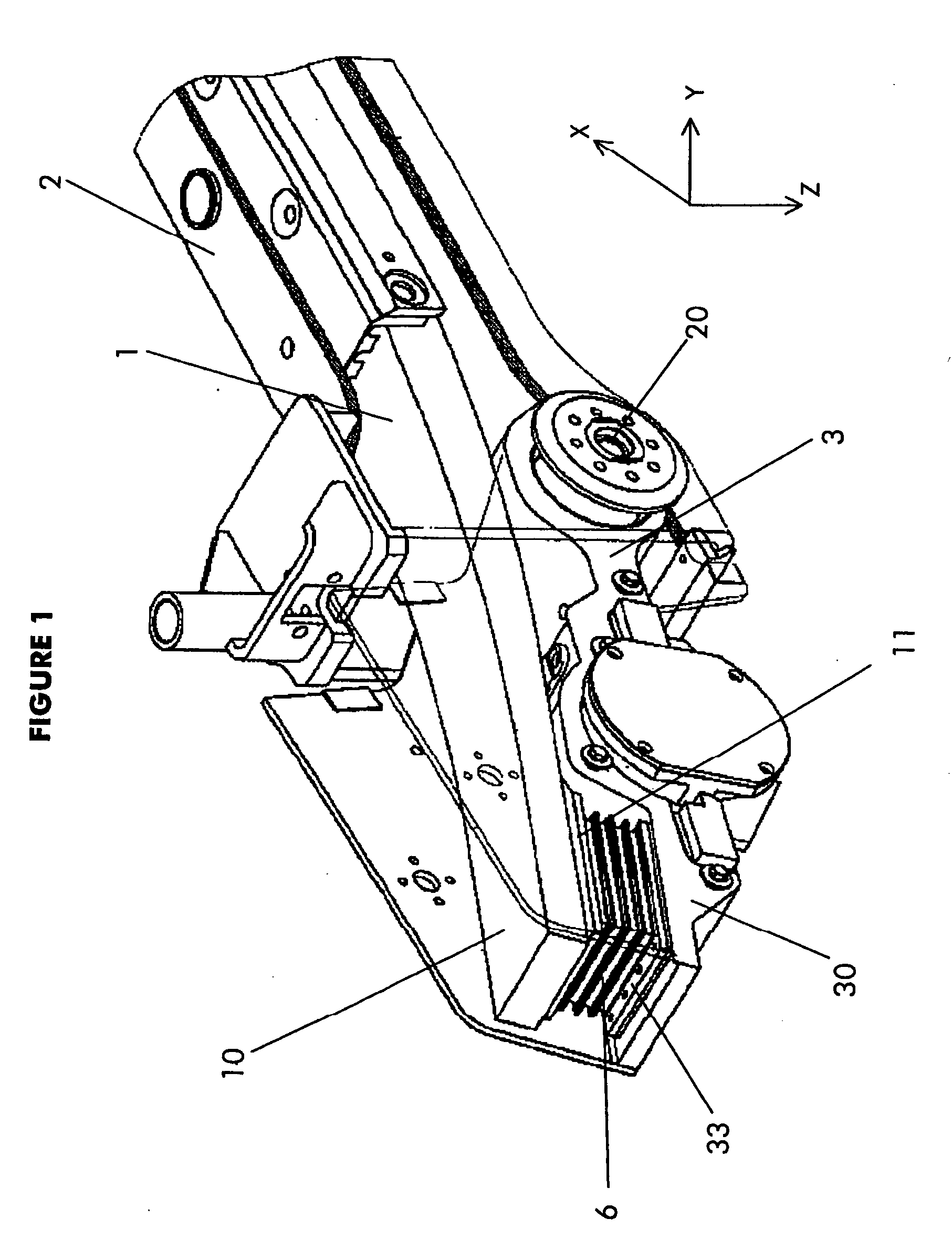

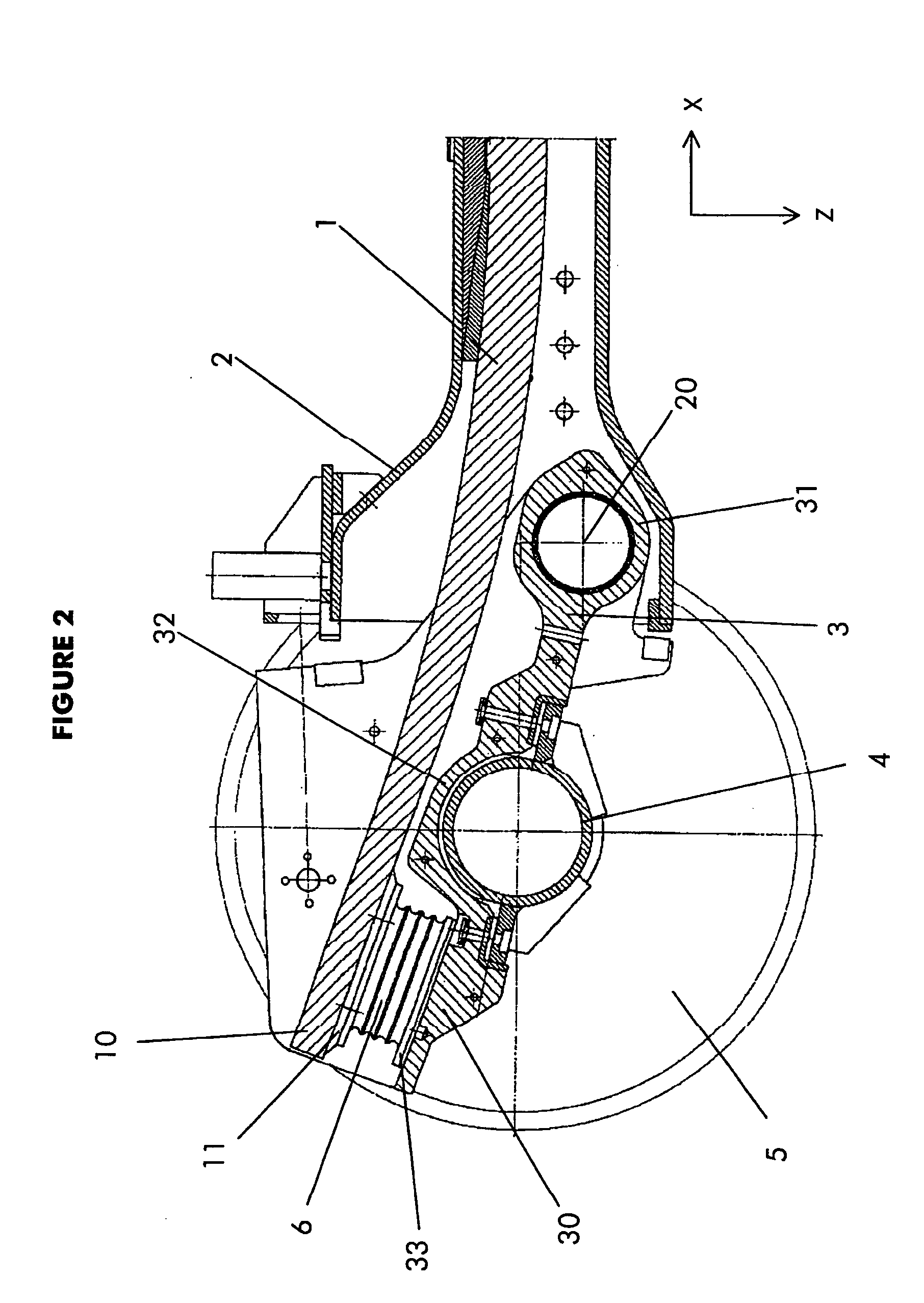

Flexible connection device between a bogey side beam and an axle-box

ActiveUS20050116436A1Reduce noise transmissionStop solid noiseUnderstructuresRailway transportRelative displacementEngineering

The flexible connection device of the invention is disposed between a flexible side beam of a bogey frame and an arm of an axle-box, and wherein the stiffness of the connection is greater in the vertical direction (Z) than in the two horizontal directions (X, Y). This enables the side beam to be decoupled from the axle-box, thereby reducing the stresses at the interfaces between these parts when the bogey frame moves transversely and vertically relative to the axles. This also presents the advantage of allowing relative displacements between the side beam and the axle-box.

Owner:ALSTOM TRANSPORT TECH SAS

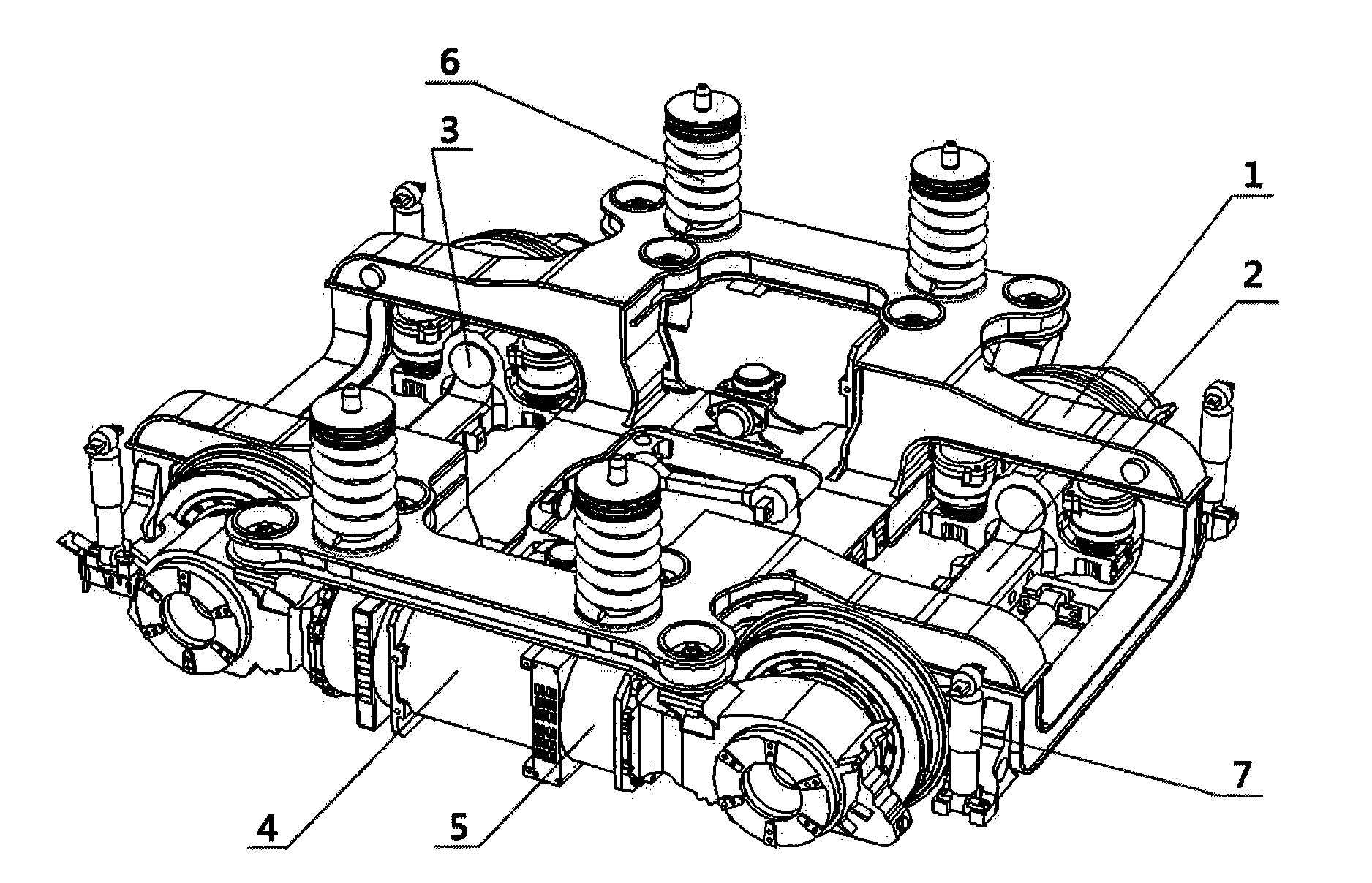

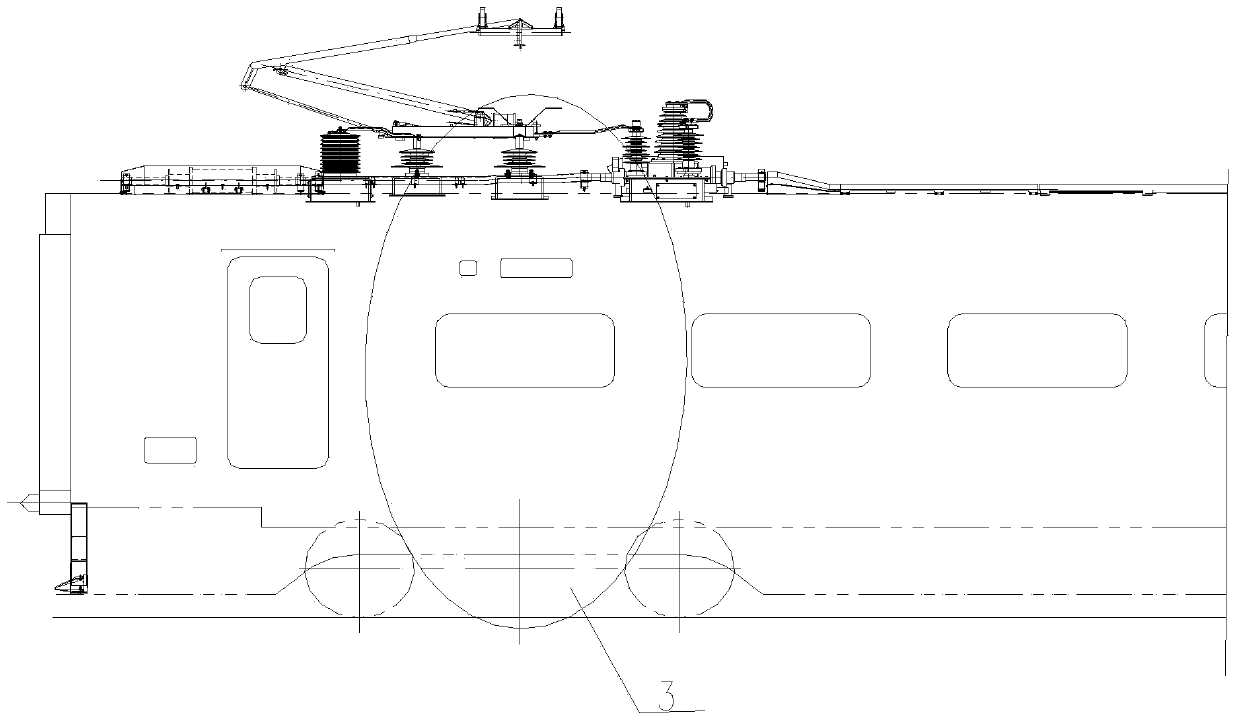

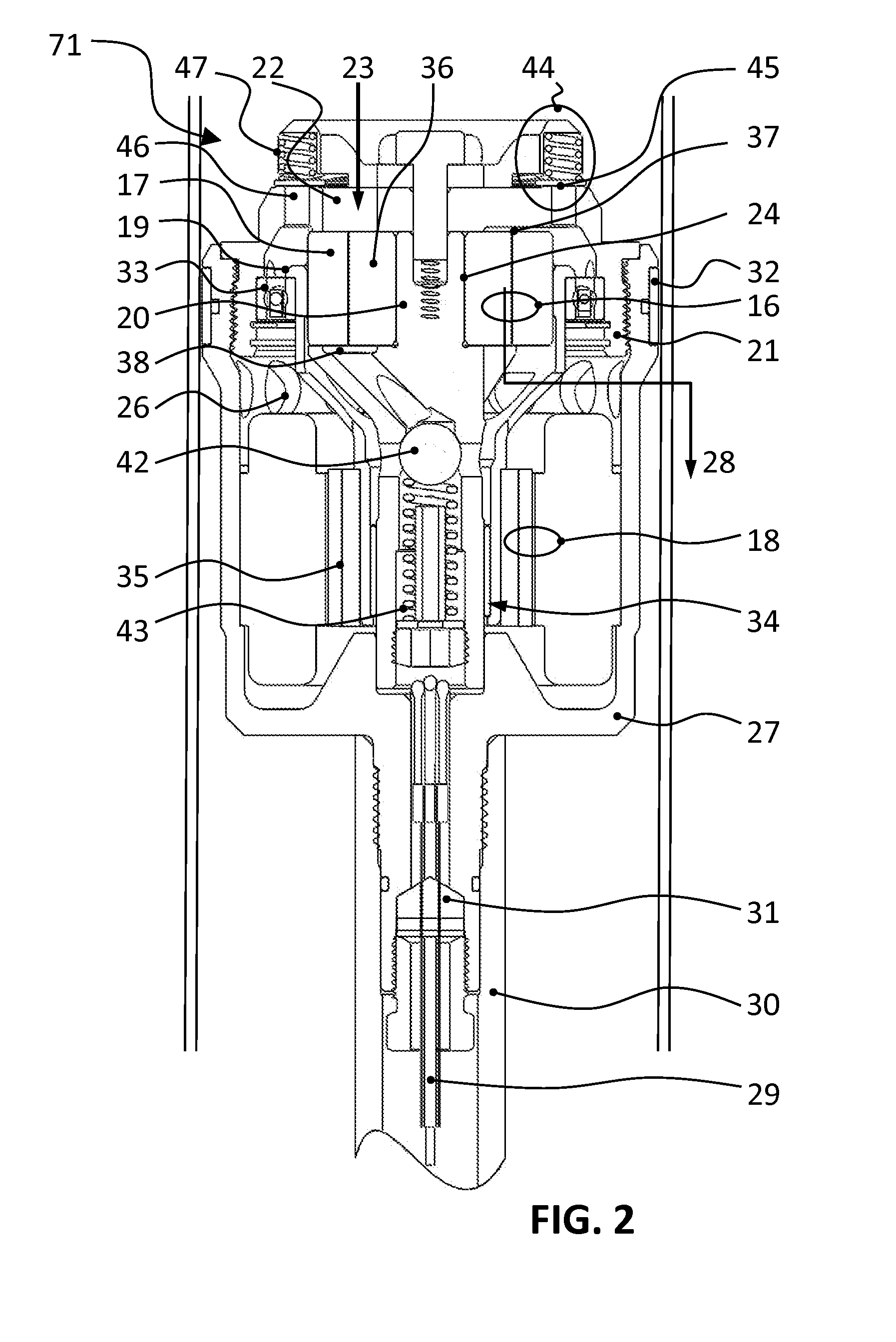

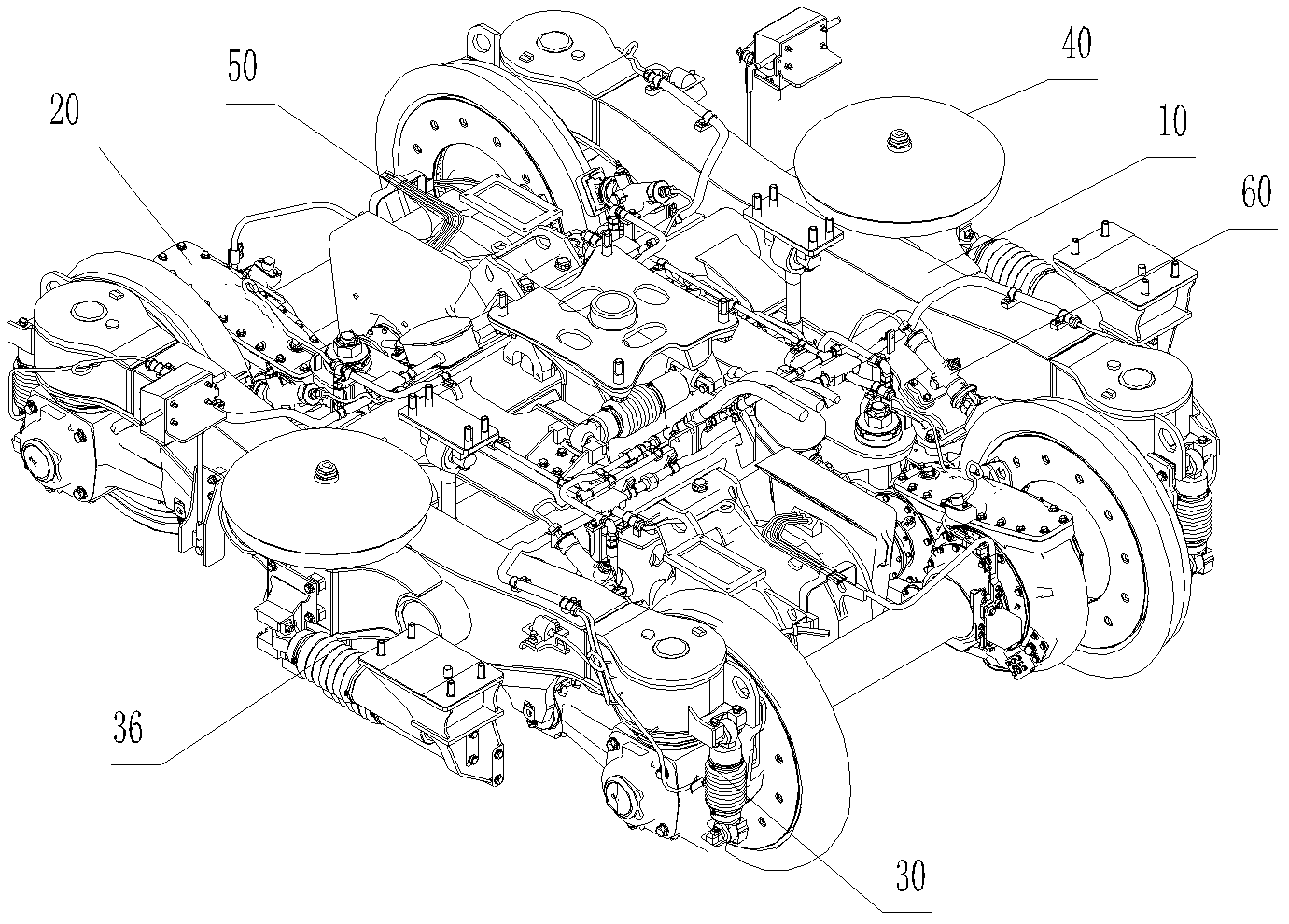

Power bogie with independent wheels for 100 percent low-floor light rail vehicles

The invention discloses a power bogie with independent wheels for 100 percent low-floor light rail vehicles. The power bogie with the independent wheels comprises a framework, an axle mechanism, primary springs, secondary springs, secondary vertical and transverse dampers, a double-pull rod traction mechanism, the longitudinal driving mechanism of an elastically frame-suspended motor and a hydraulic brake unit, wherein the side beams of the framework are cantilevers which protrude outward; two short shafts are supported by bearing units and connected with elastic wheels respectively; an axle consists of the two short shafts; two wheels on the same side of the bogie are fixed on a motor-driven shaft; a motor is coupled with two gear boxes; a brake system is integrated with a traction motor; the four secondary vertical dampers are arranged at the four corners of the framework; the secondary transverse dampers are arranged at the two ends of the framework; and a parallel double-pull rod traction system is arranged on the inner side of the framework. The requirement of 100 percent low floor on vehicle bodies is really realized by the high-strength welded framework, the independent wheel axle mechanism, the primary springs and the secondary springs which are rationally structured, the optimal secondary vertical and transverse dampers, the parallel double-pull rod traction device with internal traction, the longitudinal drive of the elastically frame-suspended motor, and the hydraulic brake unit which is integrated with the traction motor.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

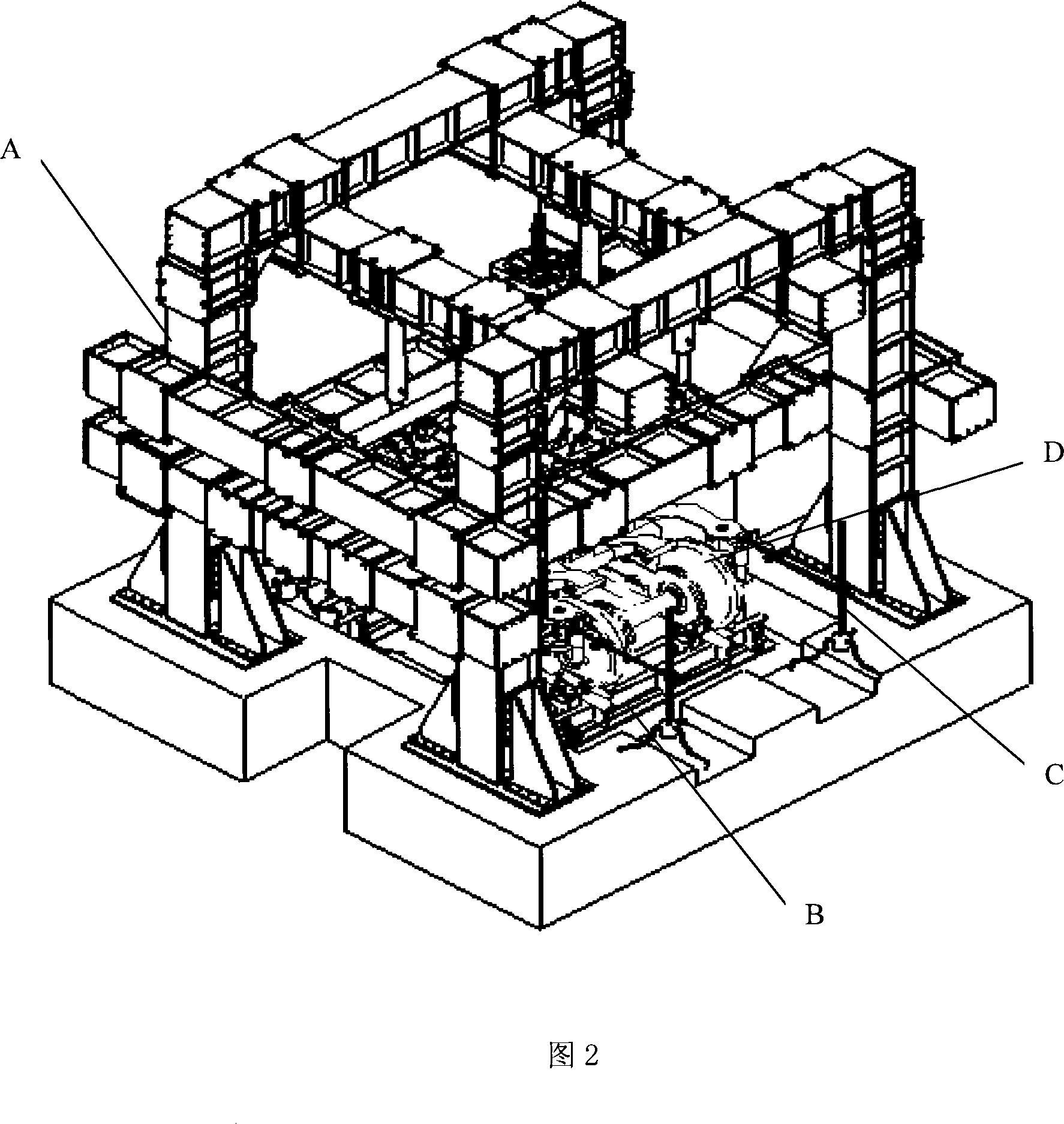

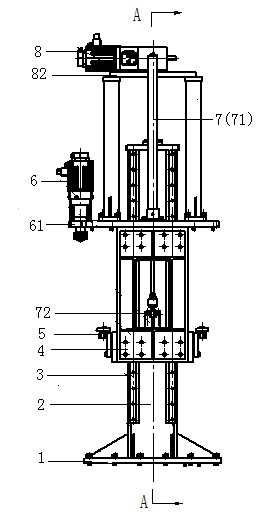

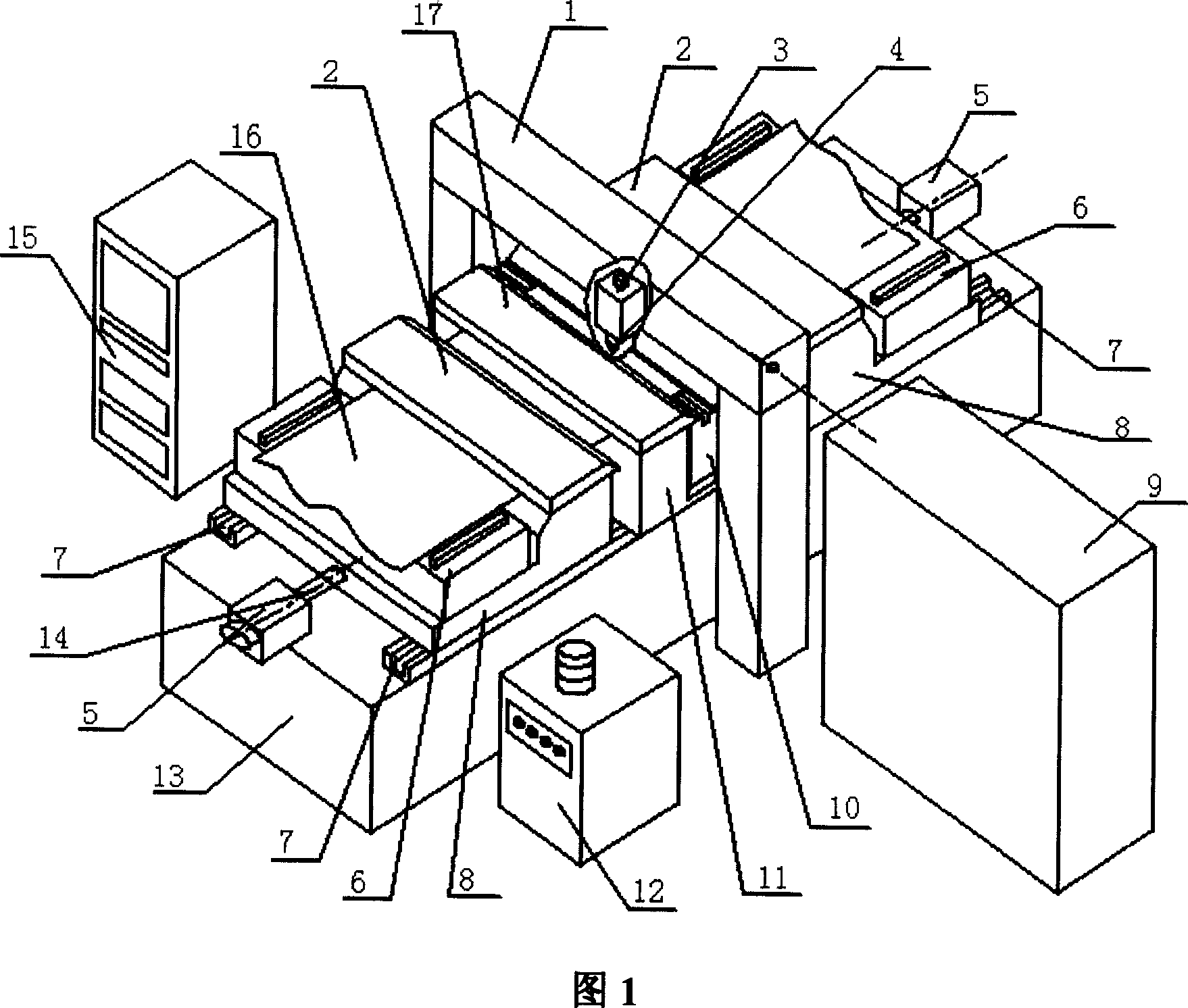

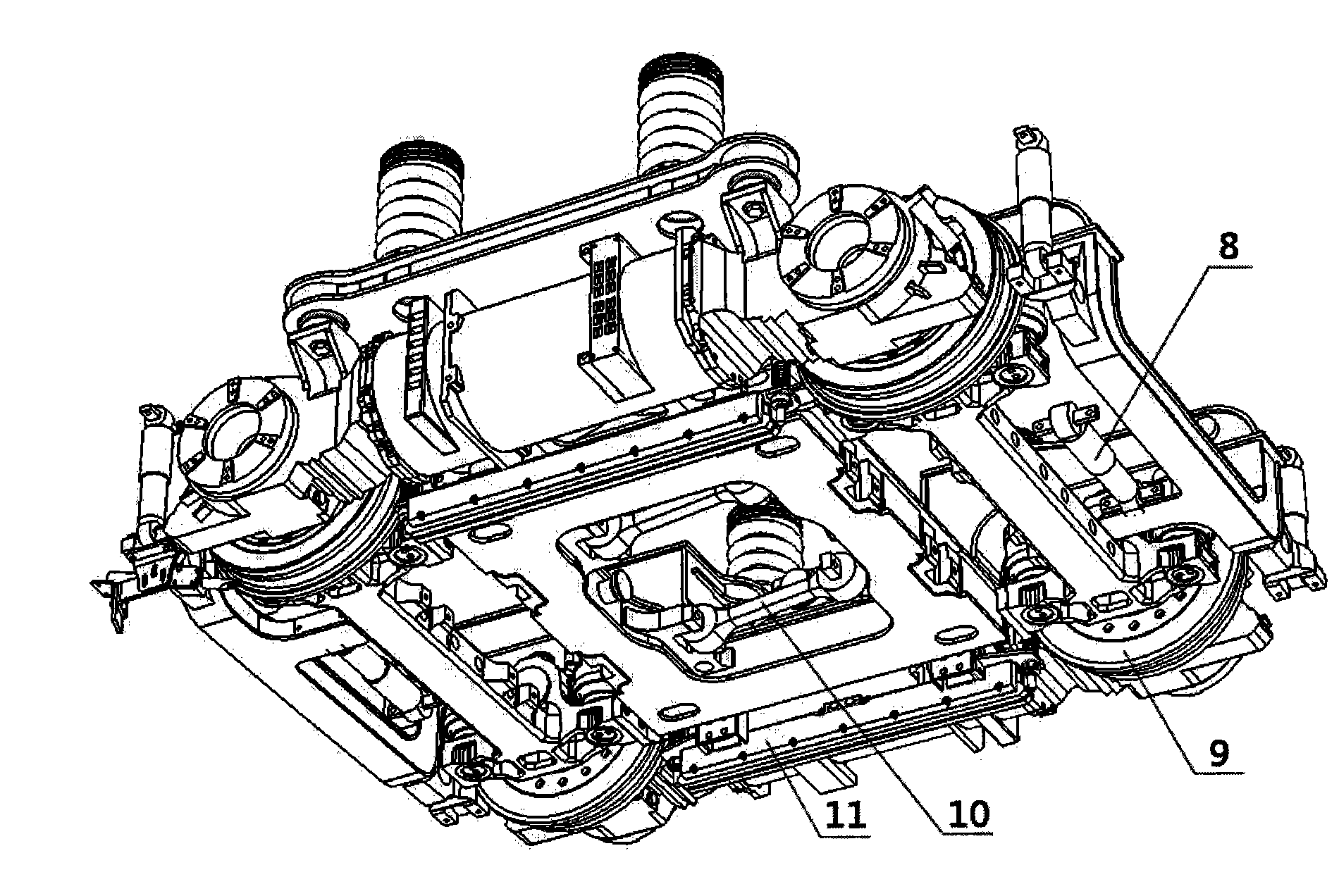

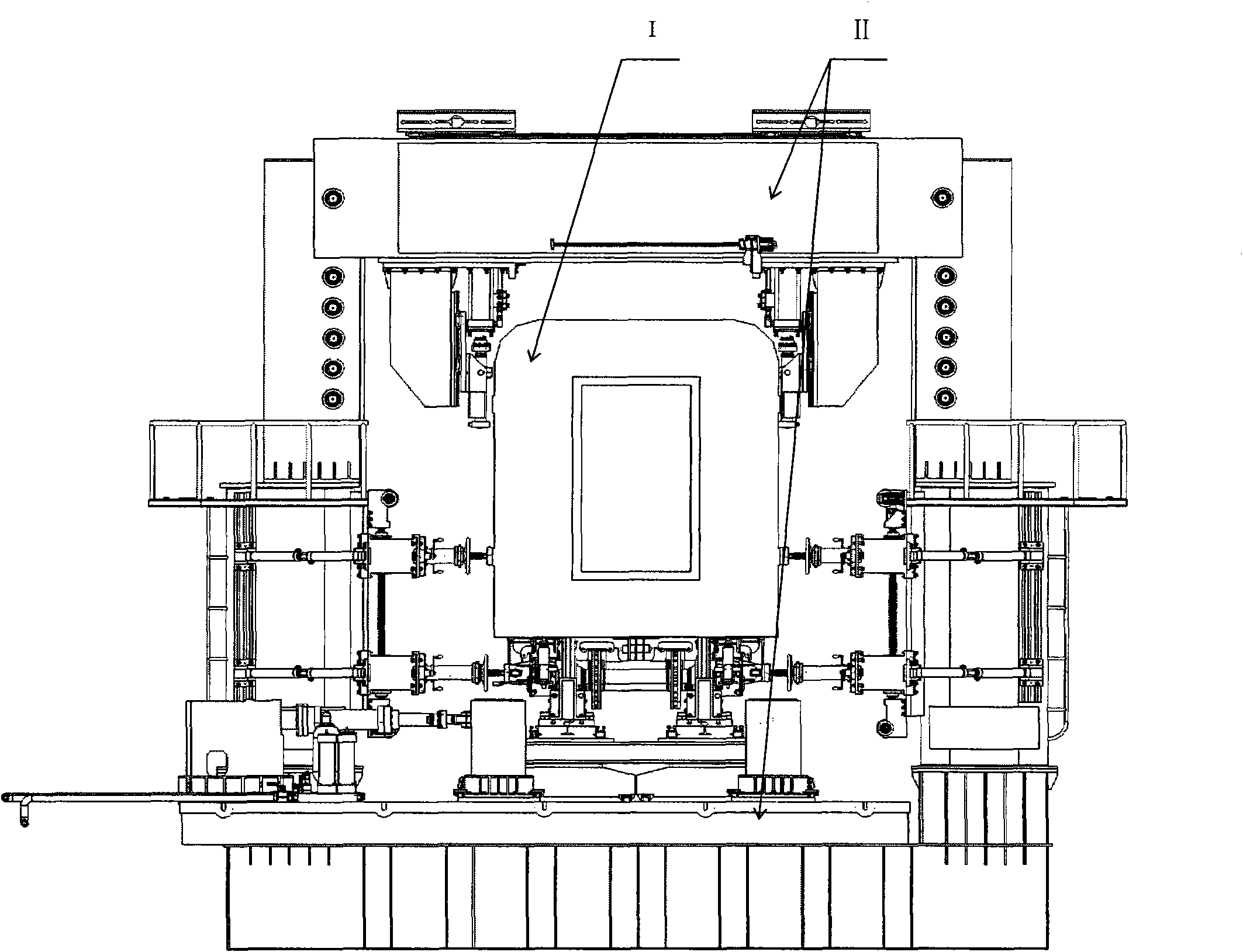

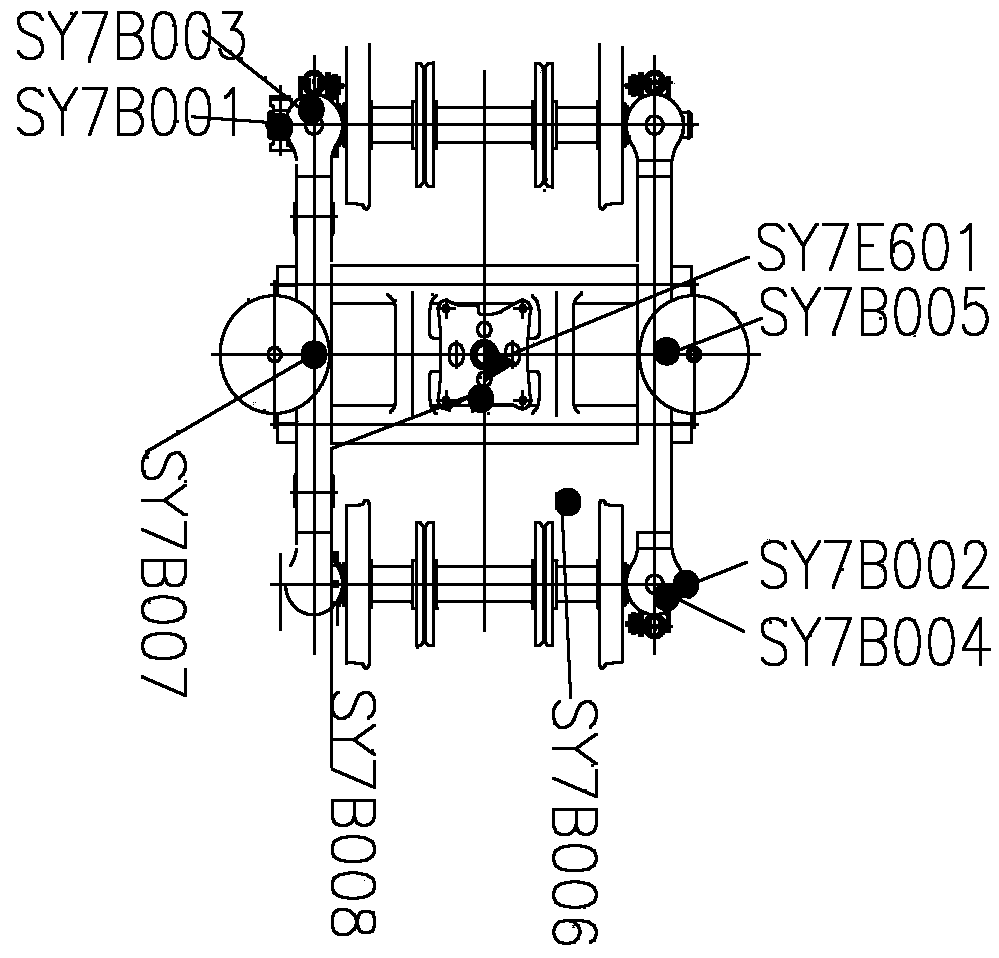

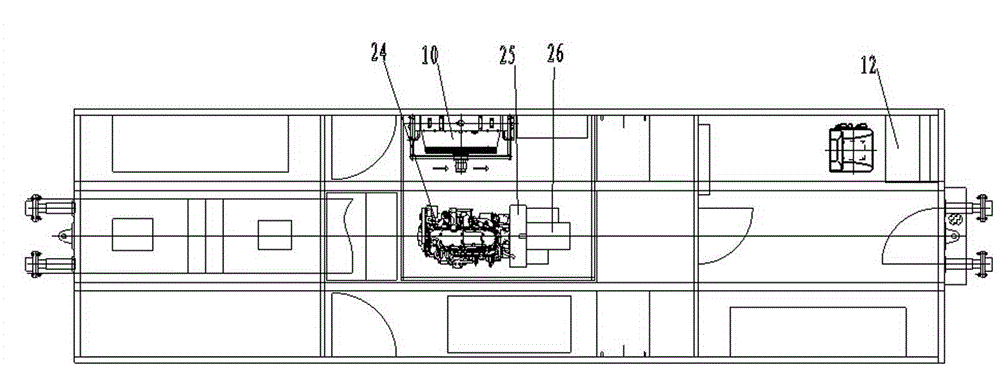

Integrated dynamic testboard of parameter of bogie of railway car

InactiveCN101813550ASolve the single functionProgrammatic highWork measurementRailway vehicle testingBogieEngineering

The invention relates to detection equipment of a kinetic parameter of a railway car, in particular to an integrated dynamic testboard of a parameter of a bogie of a railway car, which comprises a multi-freedom degree dynamic loading platform (A) and a lift type loading gantry (B), wherein the multi-freedom degree dynamic loading platform (A) mainly comprises a combined type cast steel reference platform (a), a peripheral hydraulic unit (b), a truss longitudinal limit device (c) and a multi-freedom degree sliding table loading device (d); the lift type loading gantry (B) mainly comprises a lift type gantry side beam assembly (e), a lift type gantry cross beam (f), a vertical loading assembly (g) and a lift type gantry sill beam (h). The testboard can carry out dynamic test on the rigidity parameter of a bogie under two states of carload completion and independence by regulating the truss longitudinal limit device (c), the lift type gantry cross beam (f) and the vertical loading assembly (g) without disassembly, and thereby, the goal of integrated multi-function test is achieved.

Owner:JILIN UNIV

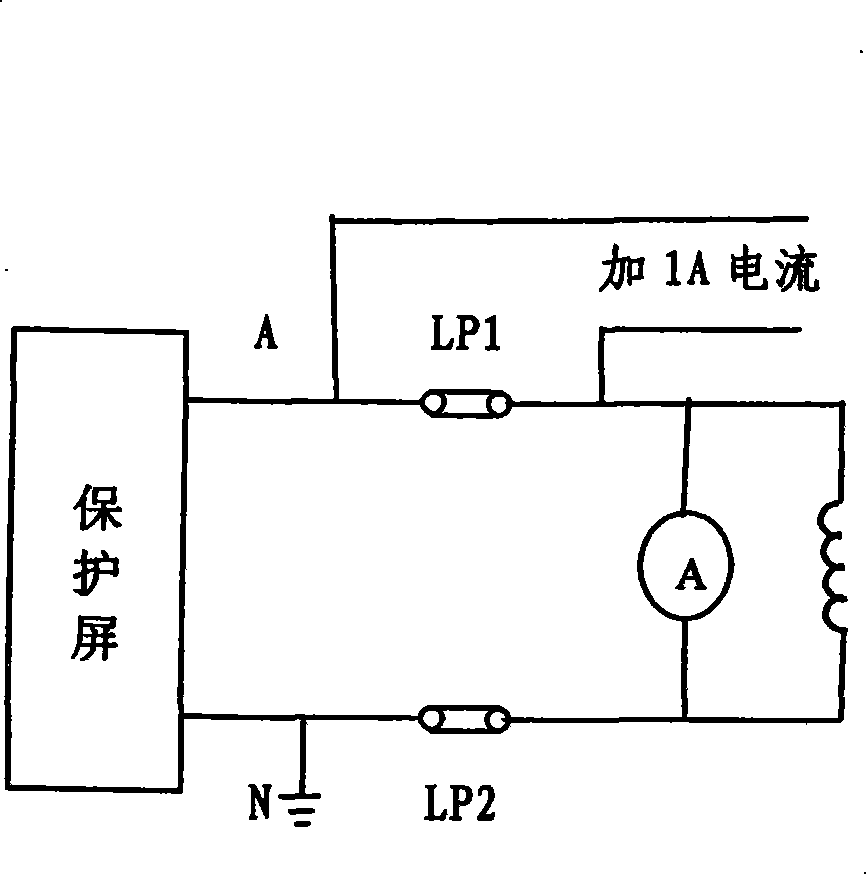

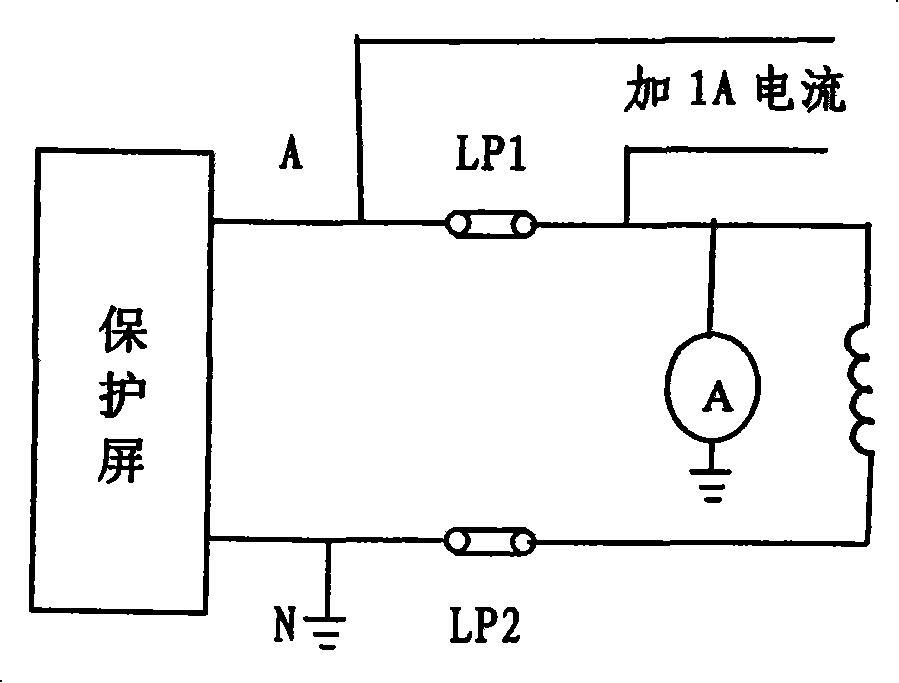

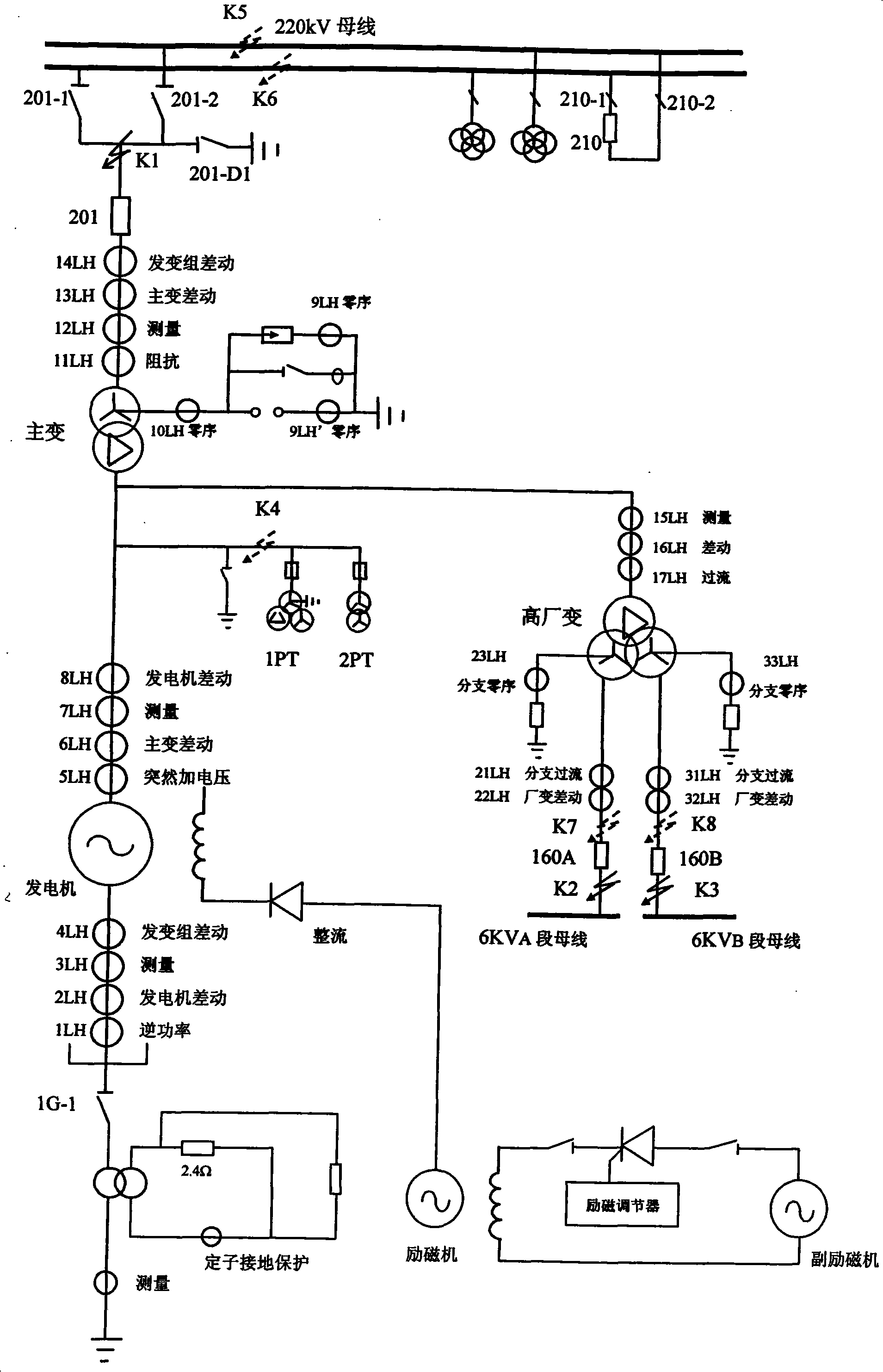

Method for testing electric secondary AC loop

ActiveCN101251569AGuaranteed correctnessCorrect circuitEmergency protective circuit arrangementsFault locationBogieLow voltage

The invention relates to an electric secondary AC circuit detection method which comprises the following steps: before a power plant machine set is started, a low-voltage short-circuit point or a short-circuit bogie is input; three-phase 380 V voltage is added at the high-voltage side of a booster station to form a circuit by means of the impedance of a transformer and a generator; current amplitude and phase are measured through a current detecting apparatus to check polarity and transformation ratio in advance; all current protective directions such as generator differential motion are measured. When a neutral point is not connected, a short-circuit point is made at a high plant transformer low-voltage side, and the three-phase 380 V voltage is added at the neutral point of the generator, thereby realizing overall checkup of a generator AC circuit; then, the three-phase 380 V voltage is converted into one-phase voltage or two-phase voltage to carry out overall checkup of a zero sequence circuit. The detection method can check all CT and PT circuits of a generation-transformer group before power transmission; moreover, all protection directions of the generation-transformer group are checked in advance, thereby saving time and fuel oil along with economical efficiency, environmental protection and safety. The electric secondary AC circuit detection method can check secondary circuits such as the transformer and the bus differential protection of a transformer substation.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

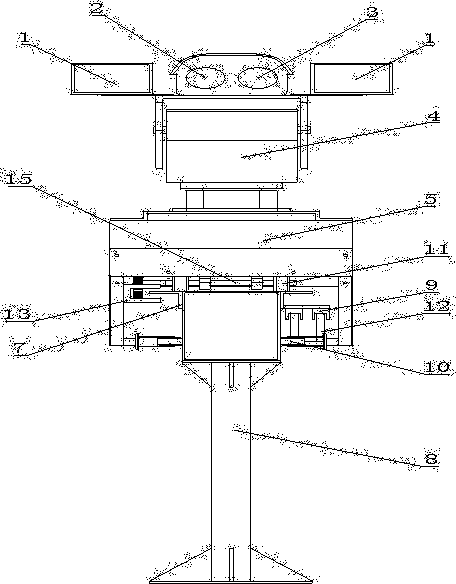

Infrared temperature measurement track inspection robot

ActiveCN104020768AWalk accuratelyPrecise positioningPosition/course control in two dimensionsBogieElectricity

The invention belongs to the field of industrial robots, and particularly relates to an infrared temperature measurement track inspection robot. The infrared temperature measurement track inspection robot comprises a robot control system. The robot control system comprises a cradle head, a robot control cabinet, a track, a slide wire, a current collector, an infrared photoelectric sensor and a bogie. The robot control cabinet is installed on the upper surface of a longitudinal girder of the bogie. The cradle head is installed on the upper surface of the robot control cabinet. The track is of a T shape, wherein an infrared detection scale is arranged on the upper surface of the protruding side. The bogie is operated on the track. The slide wire connected with an external power source is arranged on one side face of the track. One end of the current collector slides on the slide wire and the other end of the current collector is electrically connected with the robot control cabinet. The infrared photoelectric sensor is of a U shape and is installed on an upright inside a side baffle of the robot control cabinet and transversely suspended above the track with the infrared detection scale. According to the infrared temperature measurement track inspection robot, control over accurate walking, localization and the like on the arranged track can be achieved, infrared temperature measurement and inspection are conducted, and the inspection quality is improved.

Owner:广西电网有限责任公司崇左供电局 +1

Noise source identifying and testing method for high speed train

ActiveCN103630232ARealize sound source controlImplement path controlSubsonic/sonic/ultrasonic wave measurementBogieSound sources

The invention relates to a noise source identifying and testing method for high speed train. The method comprising the following steps: partitioning noise sources into a steering frame wheel track noise testing area, an equipment noise testing area, a pantograph noise testing area and a pneumatic noise testing area; distributing testing points respectively according to the transmission paths of air sound and structure sound in each area; acquiring testing point data; analyzing through sound and vibration transmission paths; separating the air sound from the structure sound; calculating the contribution of each noise source to interior noise. According to the noise source identifying and testing method, sound sources and vibration sources causing interior noise of the high speed train can be identified, the contribution of each noise source and each vibration source to the interior noise is determined, sound source control and path control of the interior noise are realized fundamentally, and a scientific basis is laid for the vibration and noise reduction structural design of the high speed train.

Owner:CRRC QINGDAO SIFANG CO LTD

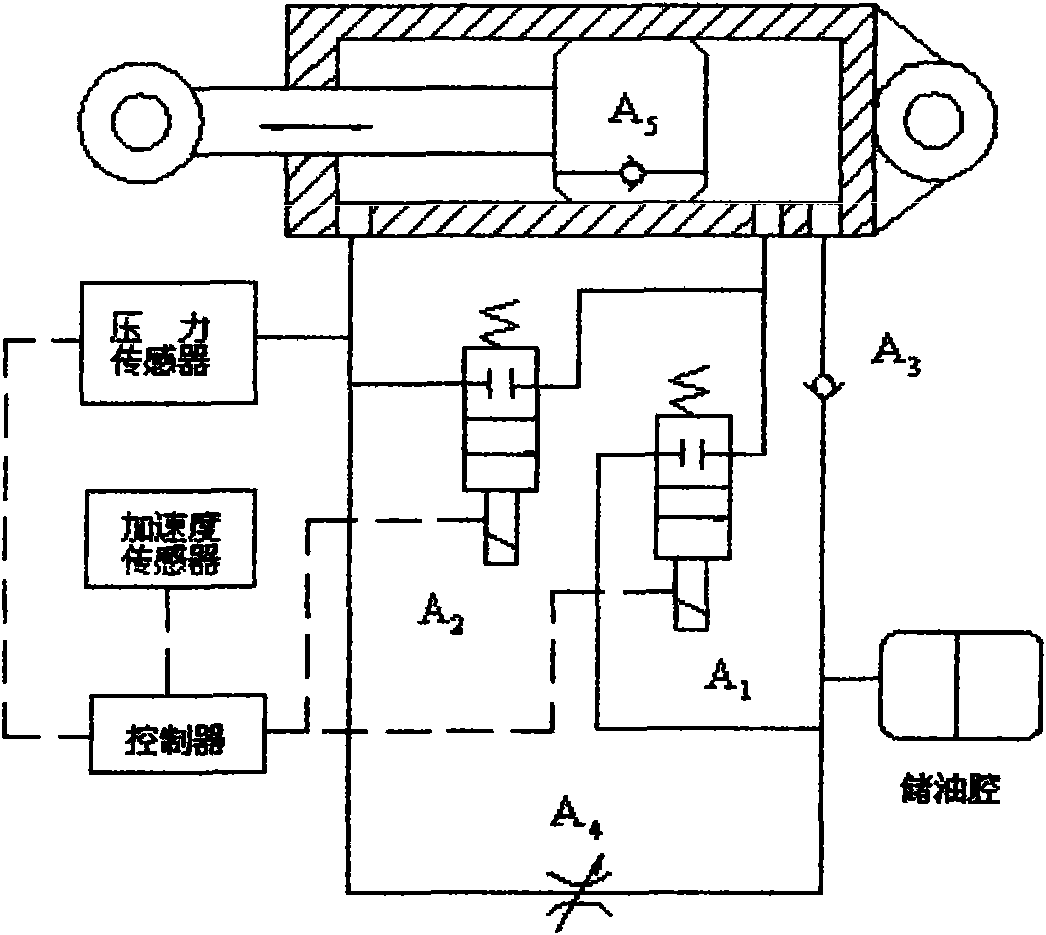

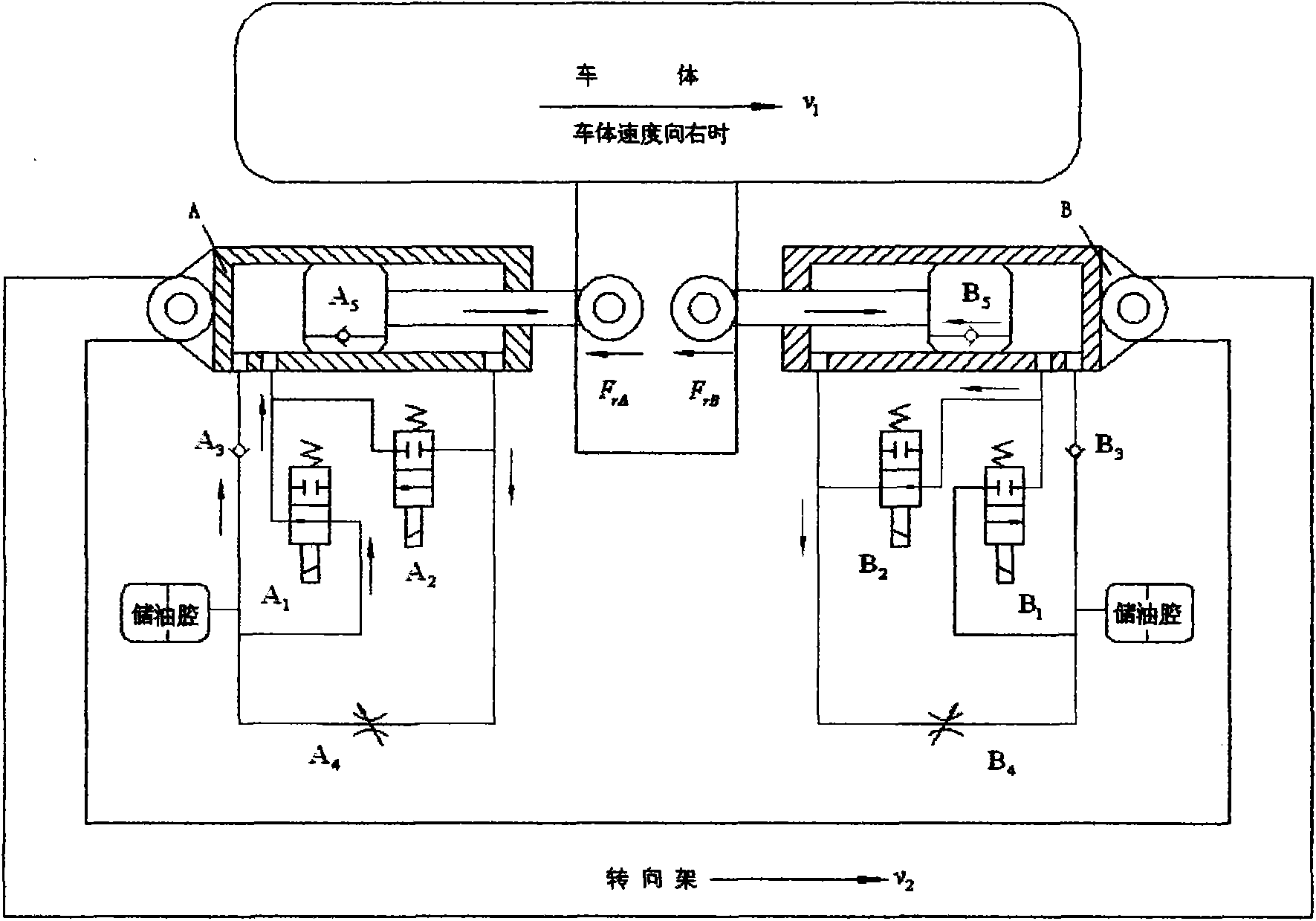

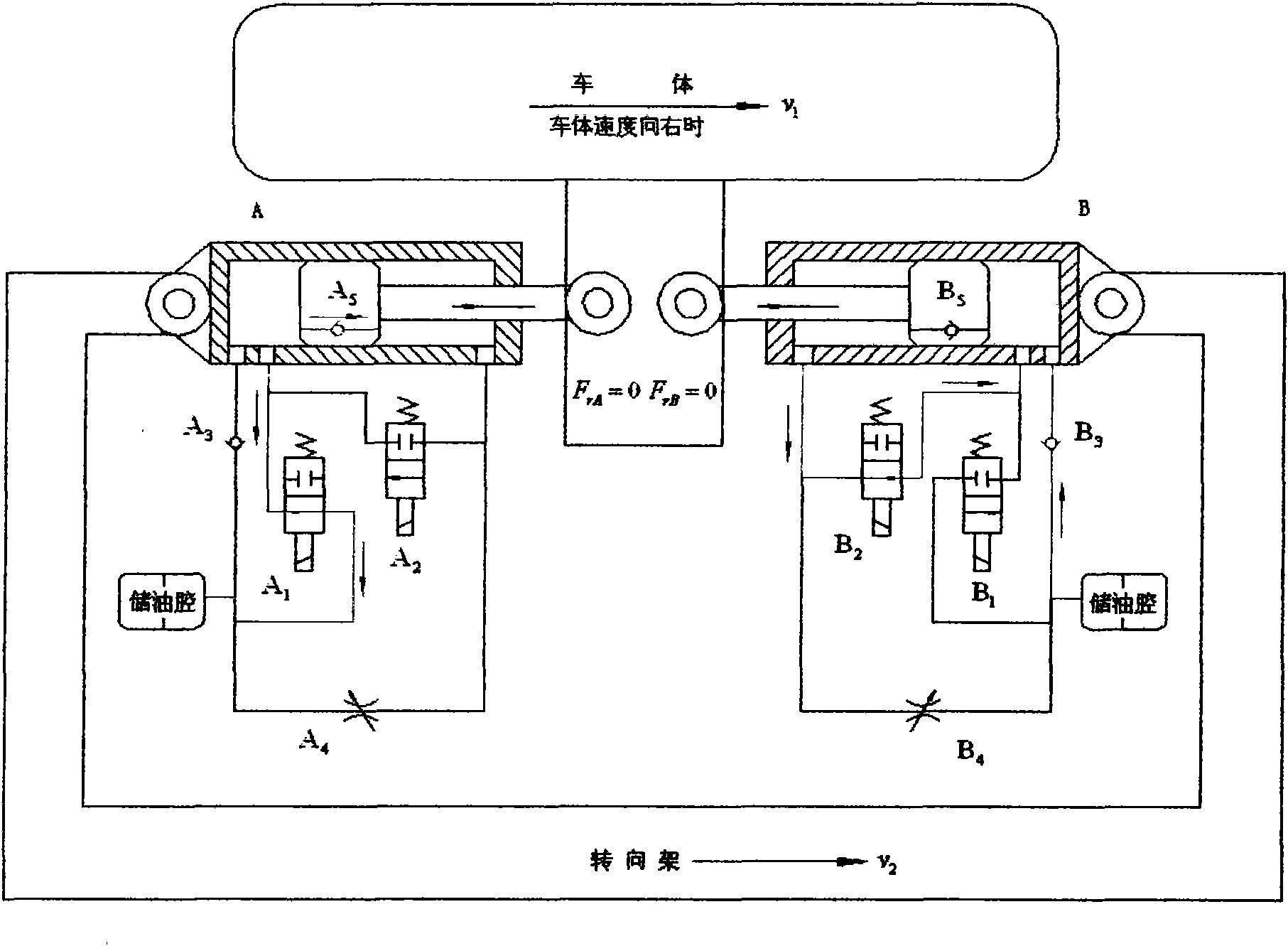

Switch type semi-active suspension system

ActiveCN102069813AReduce damping forceSmall pressure lossResilient suspensionsBogiesBogieSemi active

The invention relates to a switch type semi-active suspension system, which comprises four sets of switch type semi-active vibration absorbers, two acceleration sensors and a detection control system, wherein each two sets of the switch type semi-active vibration absorbers are arranged diagonally and act between a car body and a bogie; each set of switch type semi-active vibration absorbers respectively comprise a vibration absorber body A, high-speed switch valves A1 and A2, an adjustable damper valve A4 and a pressure sensor, wherein the high-speed switch valve A1 is used for communicating a rodless cavity with an oil storage cavity of the vibration absorber body; a check valve A3 is arranged between the oil storage cavity and the rodless cavity; the high-speed switch valve A2 is used for communicating the rodless cavity with a rod cavity; the adjustable damper valve A4 is arranged between the rod cavity and the oil storage cavity; and the pressure sensor is used for detecting the pressure of an oil way led out of the rod cavity of the vibration absorber body; and output signals of the acceleration sensor and the pressure sensor are transmitted to a controller after being processed, and the high-speed switch valves A1 and A2 are controlled by the controller to act.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

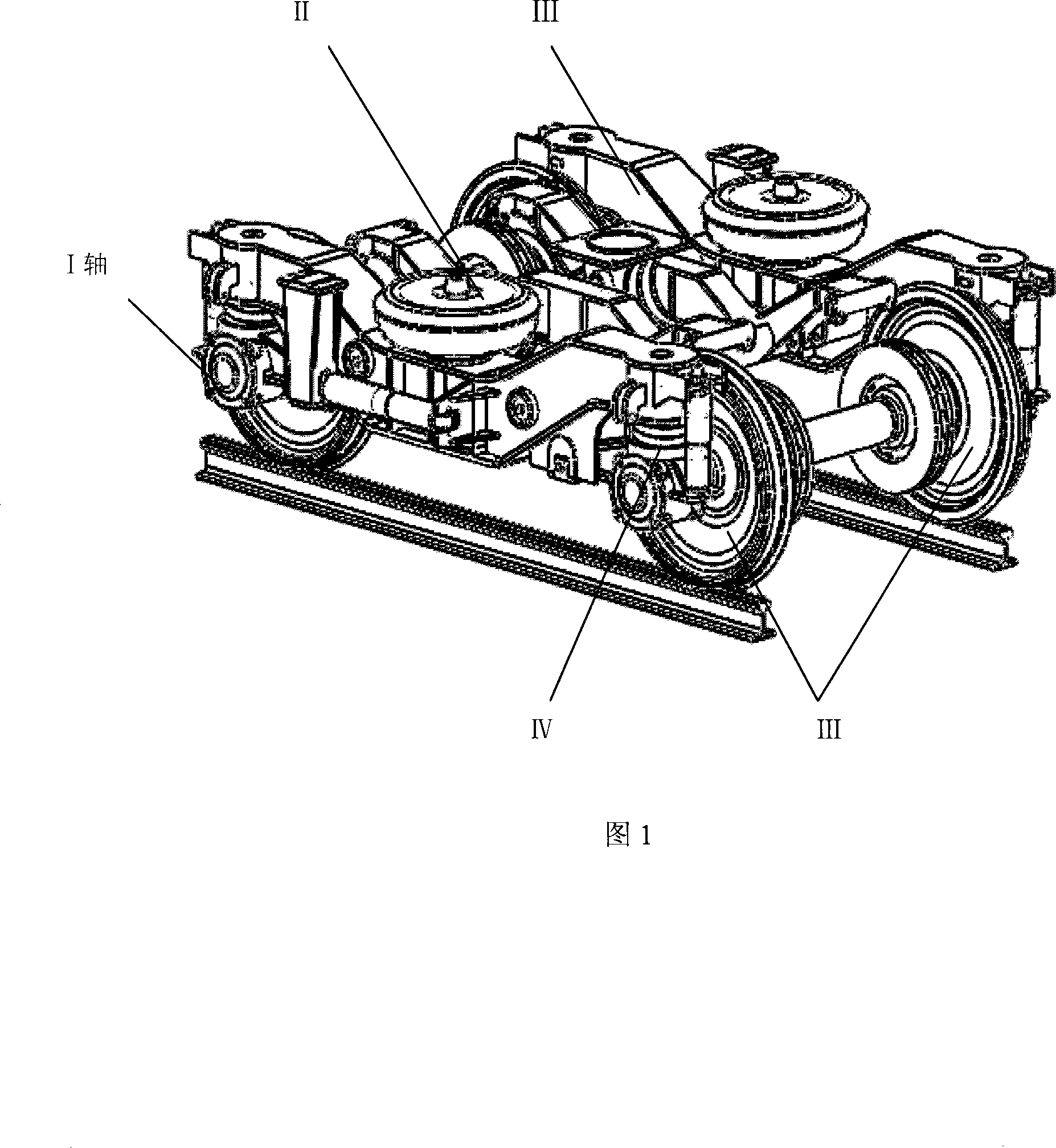

Straddle type single-track operating vehicle with four-wheel-pair structure

The invention relates to an urban railway operating vehicle and particularly relates to a straddle type single-track operating vehicle with a four-wheel-pair structure. The problems of heavy carriage, complex driving mode, low driving efficiency, heavy bogie, and the like, of the present operating vehicle are solved. The straddle type single-track operating vehicle comprises a carriage, a front bogie, a rear bogie, an I position wheel pair, an II position wheel pair, an III position wheel pair and an IV position wheel pair, wherein each bogie comprises a frame, a vehicle body supporting device and a dragging device; the whole frame has an II-shaped all-steel welded plate type box structure and comprises a lateral beam, an end beam, a central beam and a longitudinal beam; a motor bracket is fixed between the upper part of the lateral beam and the longitudinal beam; the I position wheel pair and the II position wheel pair are mounted on the motor bracket of the rear bogie; the III position wheel pair and the IV position wheel pair are mounted on the motor bracket of the front bogie; a guide wheel assembly is mounted in the middle of the lateral beam; a stable wheel assembly is mounted on the lower part of the lateral beam. The line demand on a single rail PC beam is reasonably met; the safety factor is high; the traction performance is excellent; the structure is simple; the repairing is easy; the vehicle running is stable; the braking performance is excellent.

Owner:太原中车时代轨道工程机械有限公司

Rail vehicle truck parameter measuring table

InactiveCN1975365ASimple structureGuaranteed accuracyWork measurementMaterial strength using tensile/compressive forcesBogieSteel ball

This invention disclosed a testing plate used for car bogie. The base of the plate connects to the measuring platform via a fulcrum bearing; the fulcrum bearing can be described like this: a bearing plate was fixed to the base, a spacing ring was placed on the bearing plate, a steel ball holding frame was set in the spacing ring, steel ball was placed in the cavity of holding frame and the upper side of the ball was connected to the platform.

Owner:SOUTHWEST JIAOTONG UNIV

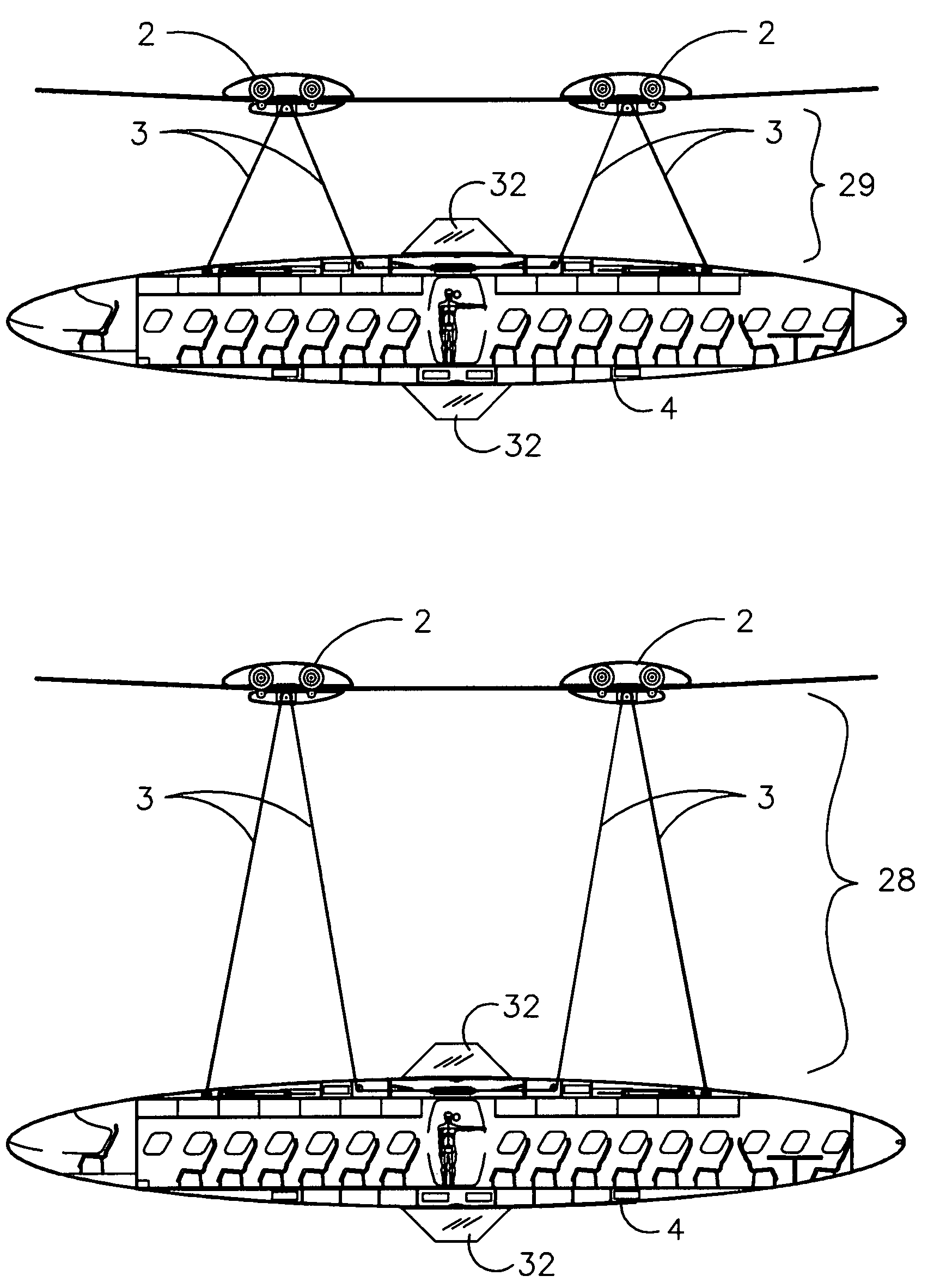

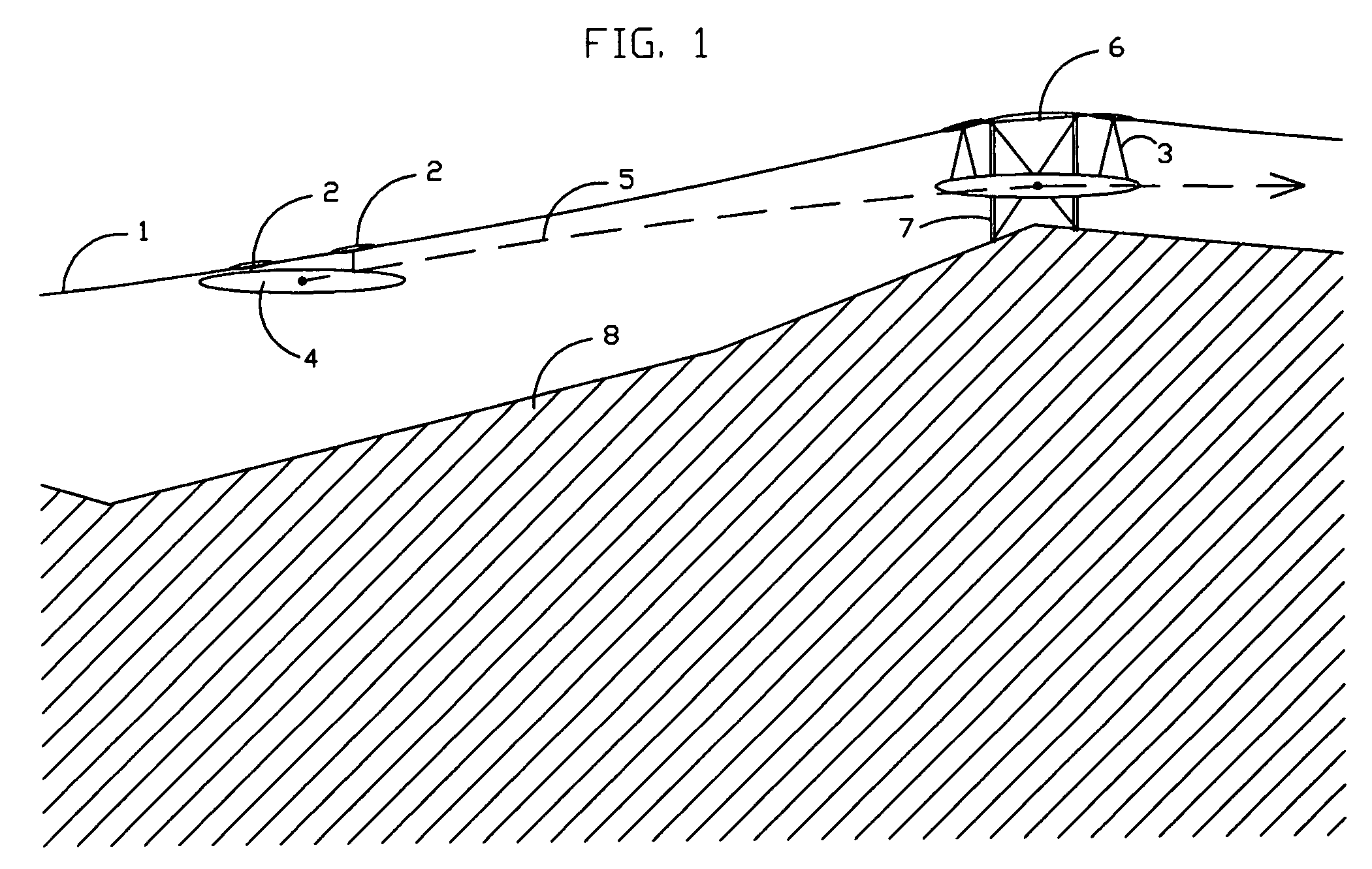

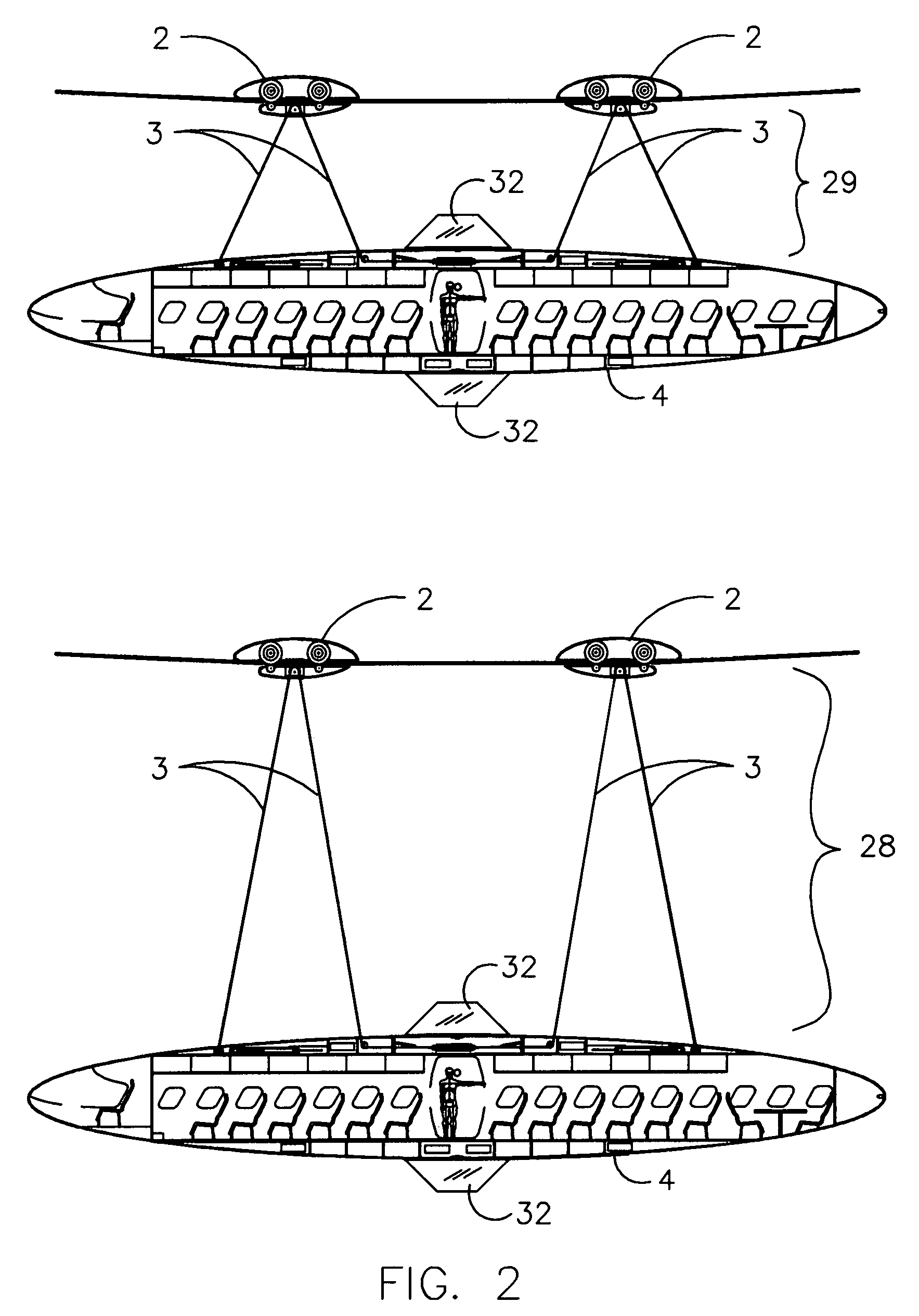

Cable suspended, self leveling tram with self-propelled tractor bogie

A cableway with suspended tram and remote bogie is disclosed. This includes a self-contained motor, traction and support sheaves with provision for adjusting the height of the tram below said cable for limiting vertical acceleration caused by travel along the cantenary curve of the cableway.

Owner:MORRIS RICHARD DAVID

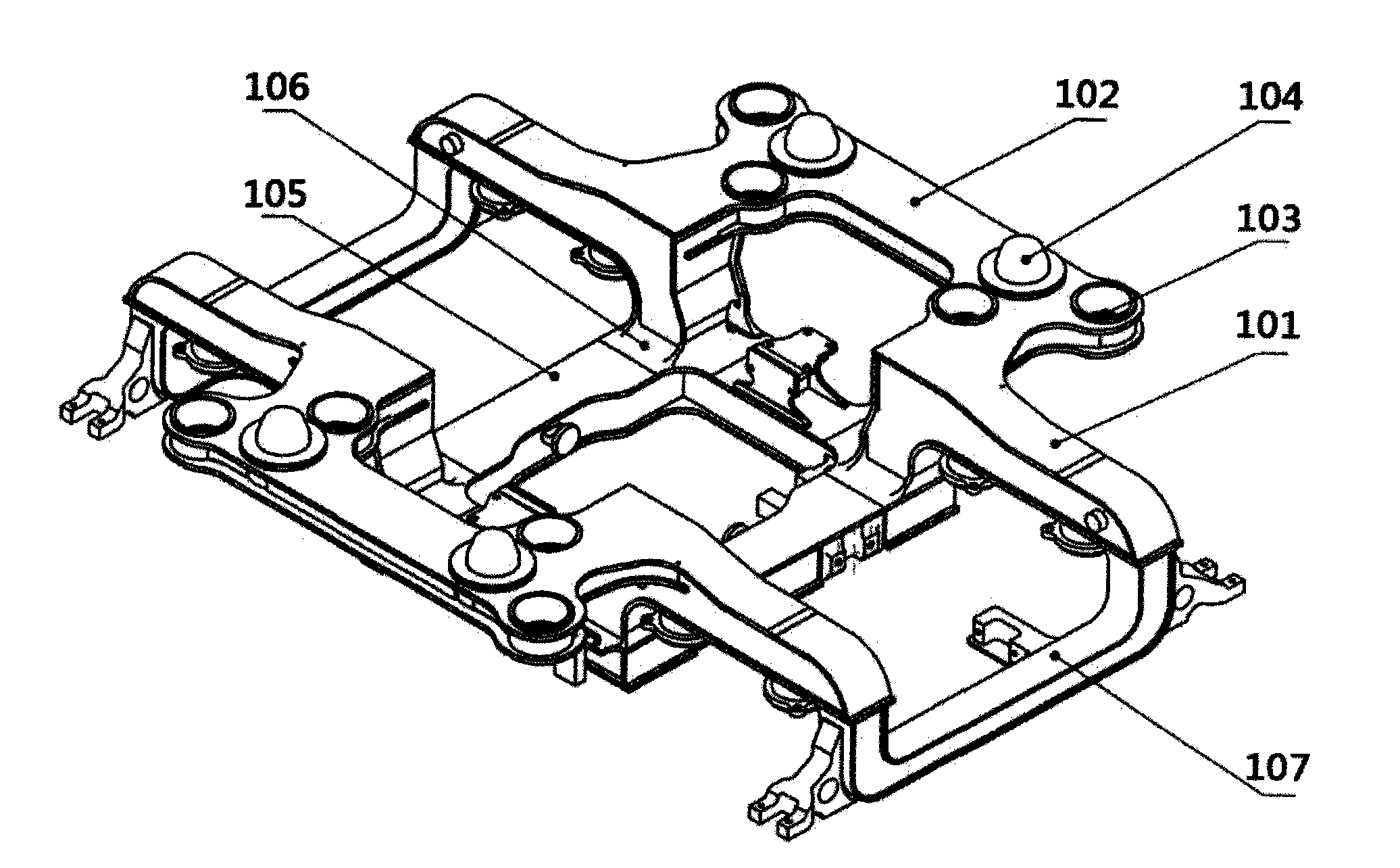

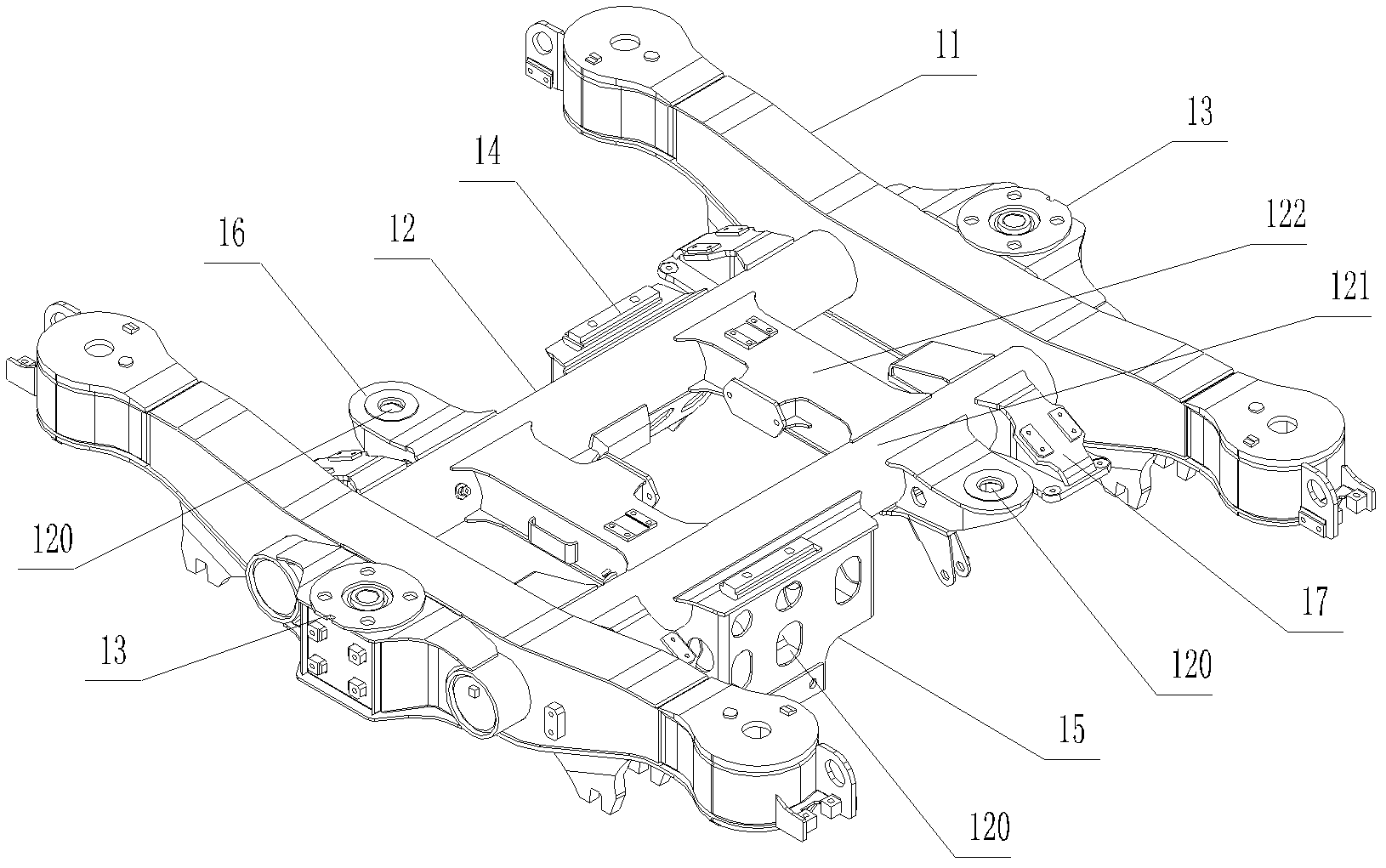

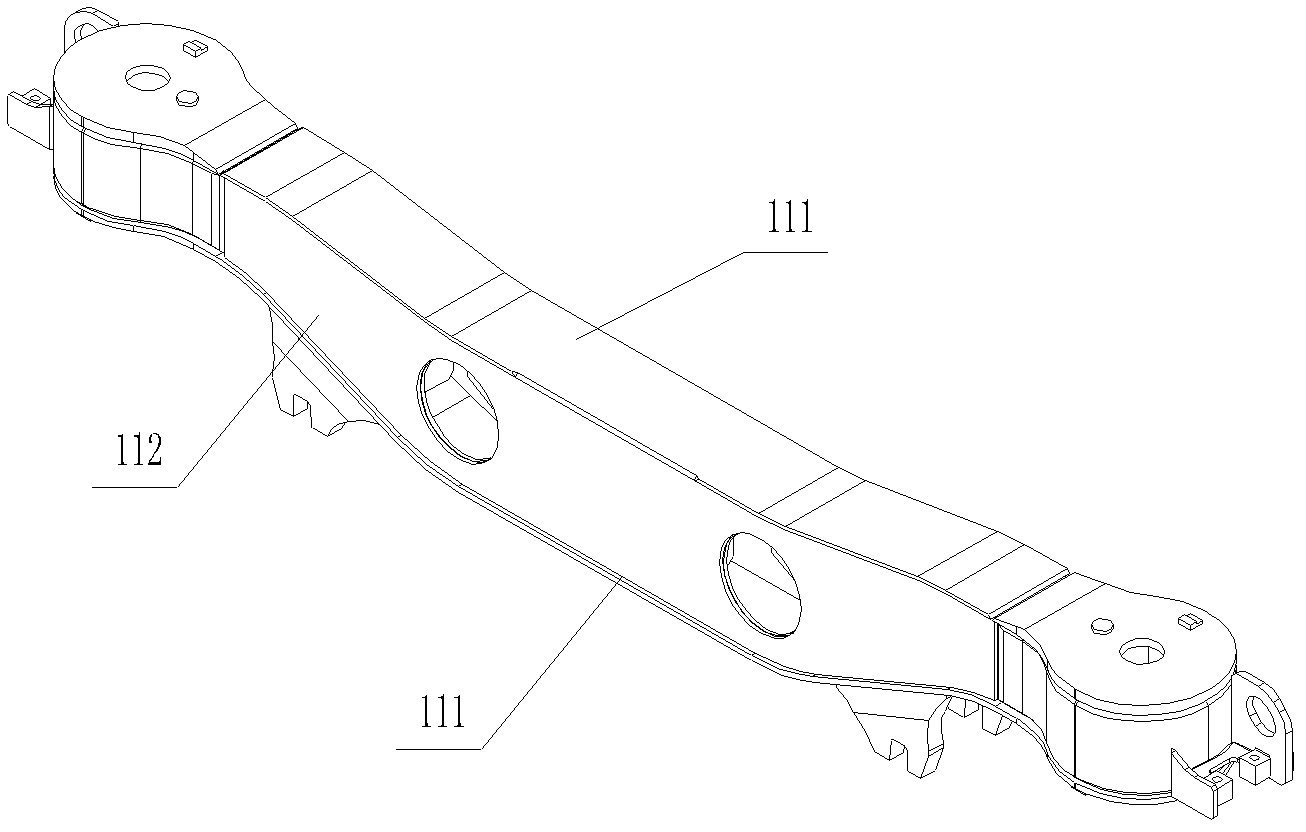

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com