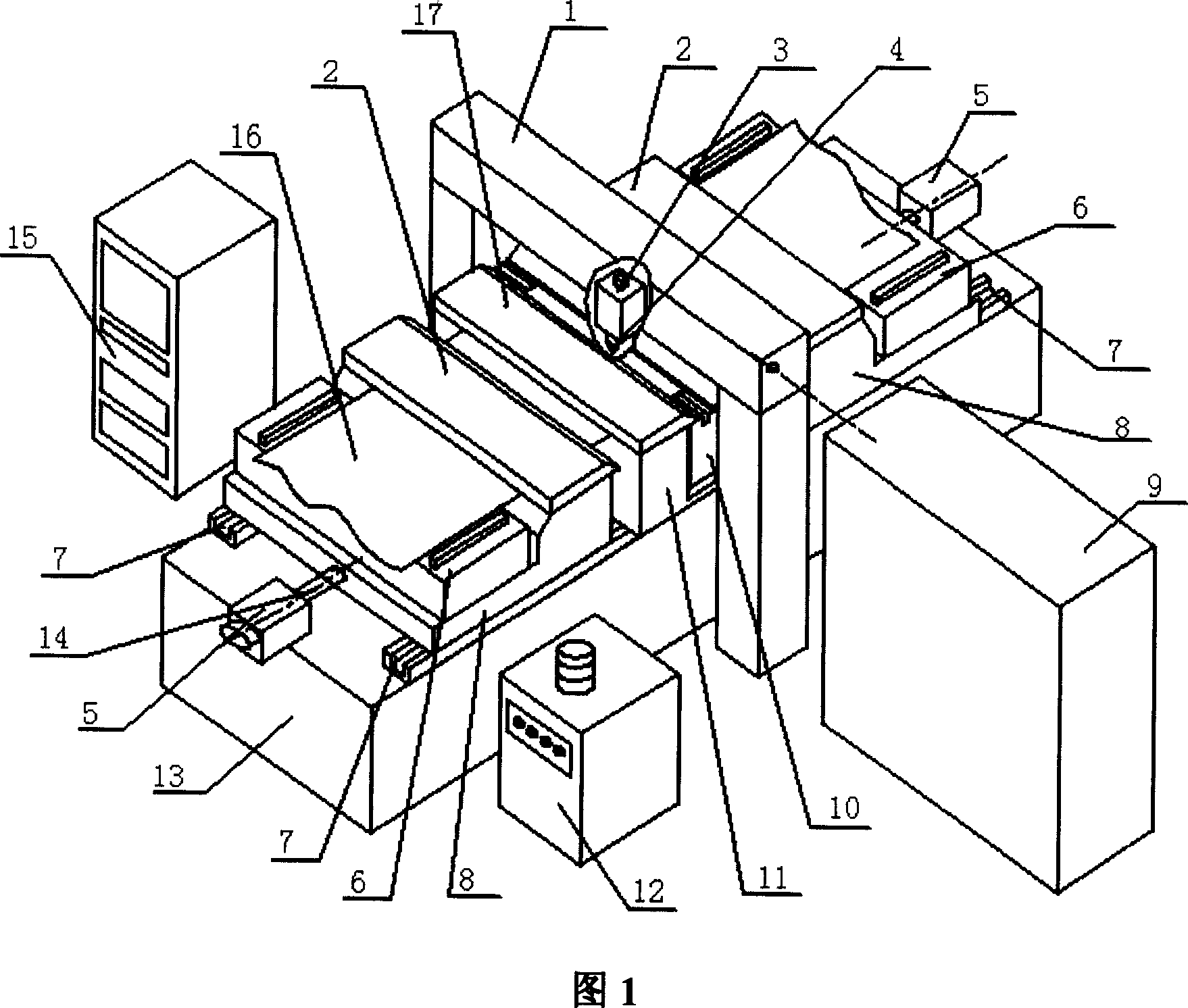

Plate-bending online laser welding technology and its equipment

A technology of laser welding and plate rolling, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of expensive equipment, expensive equipment, complex technology of high-precision double-edged shears, etc., and achieve low cost, The effect of compact equipment structure and reduced requirements for cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

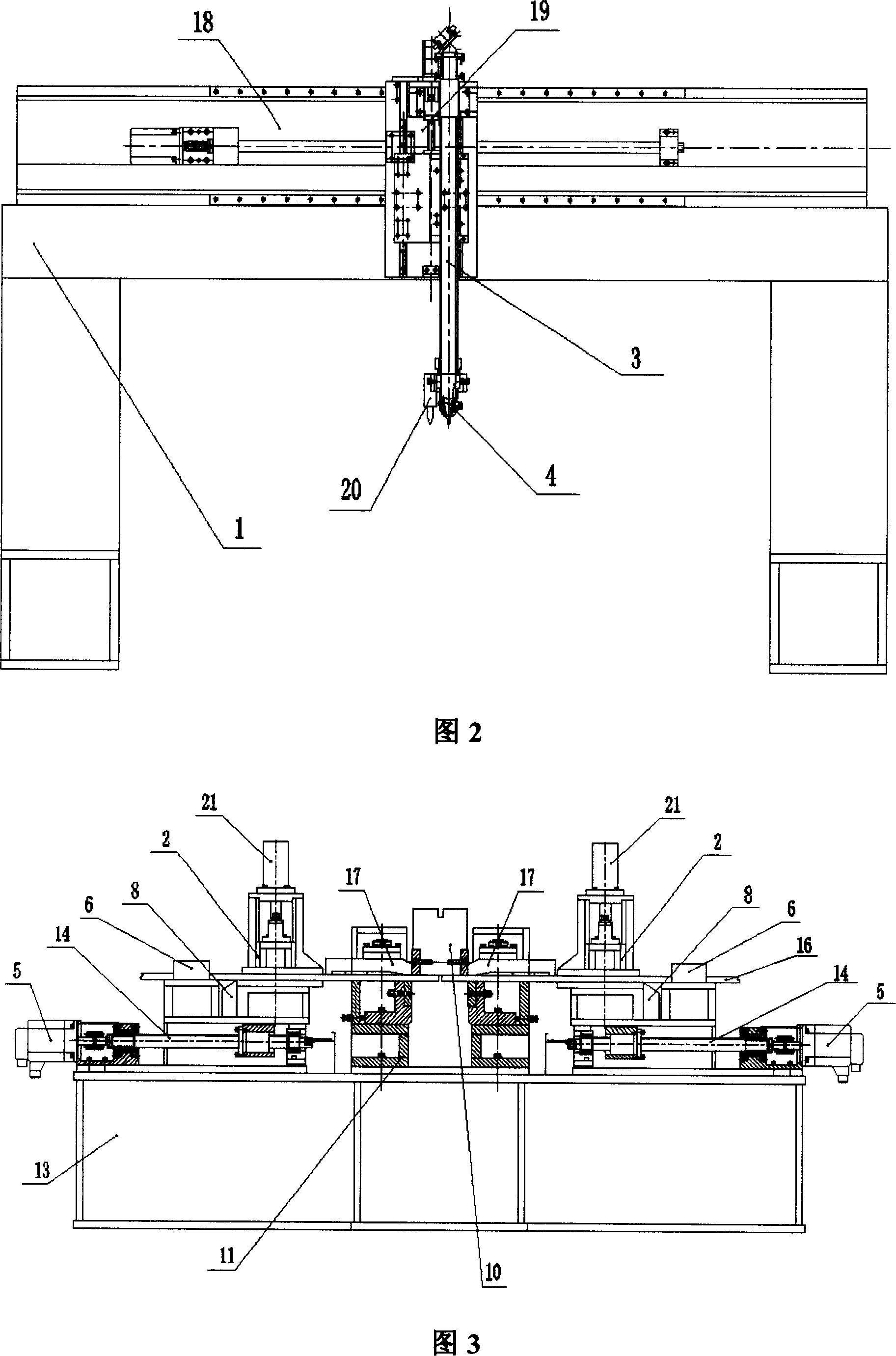

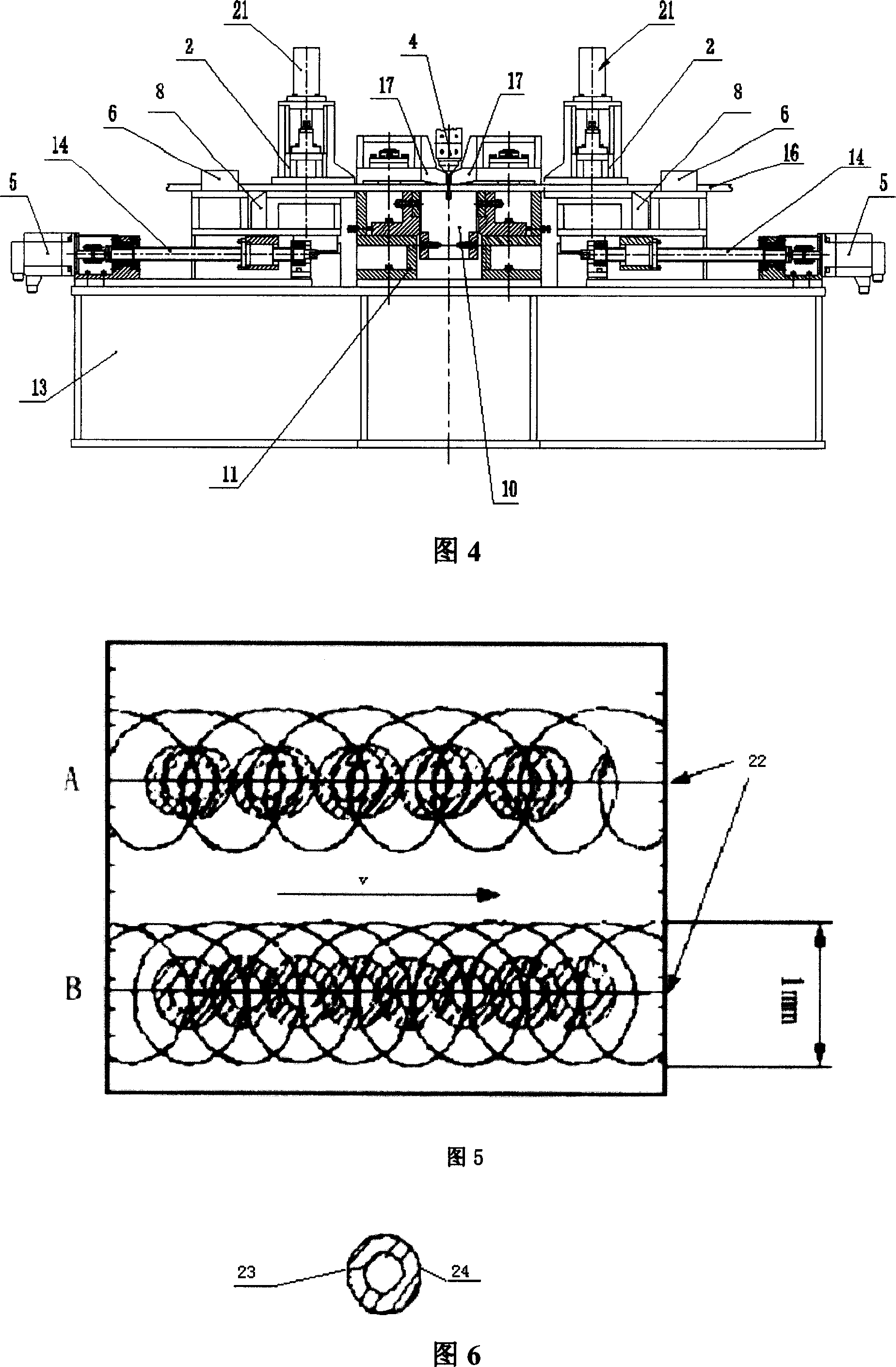

[0018] The present invention provides an on-line laser welding process for coiled plates. The basic laser welding process steps are as follows: (1) Return the system to its original position. (2) In the production process, the head and tail of the steel strip are introduced into the front and rear feeding mechanism of the laser welding equipment, and the front and rear feeding heads are pinched and pressed by the pressure plate to press the steel belt. , and centered by the centering mechanism, the front and rear leveling platens press the steel belt to ensure that the steel belt is flat when shearing. (3) The upper shearing machine punches the head and tail of the steel strip coil, and sinks directly into the lower shearing machine after punching, so that the back of the shear body is horizontally aligned with the steel strip. (4) The front and rear leveling pressure plates are loosened and fed to the middle, the front and rear pinch pressure plates are sent to the centering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com