Patents

Literature

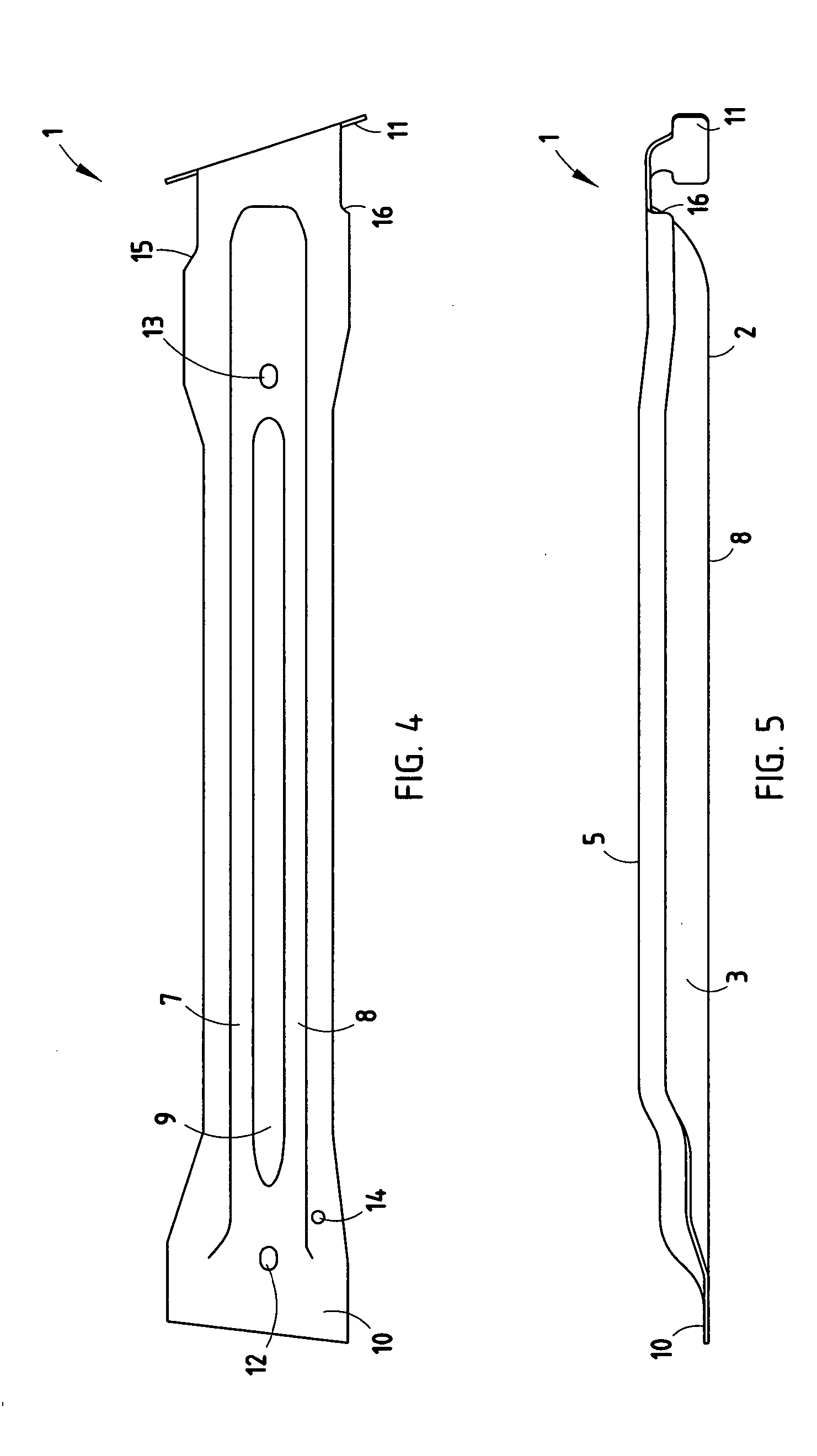

7796 results about "Steel belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steels belts are used in many industries such as food, chemical, wood processing, and transportation.

Conveyor system

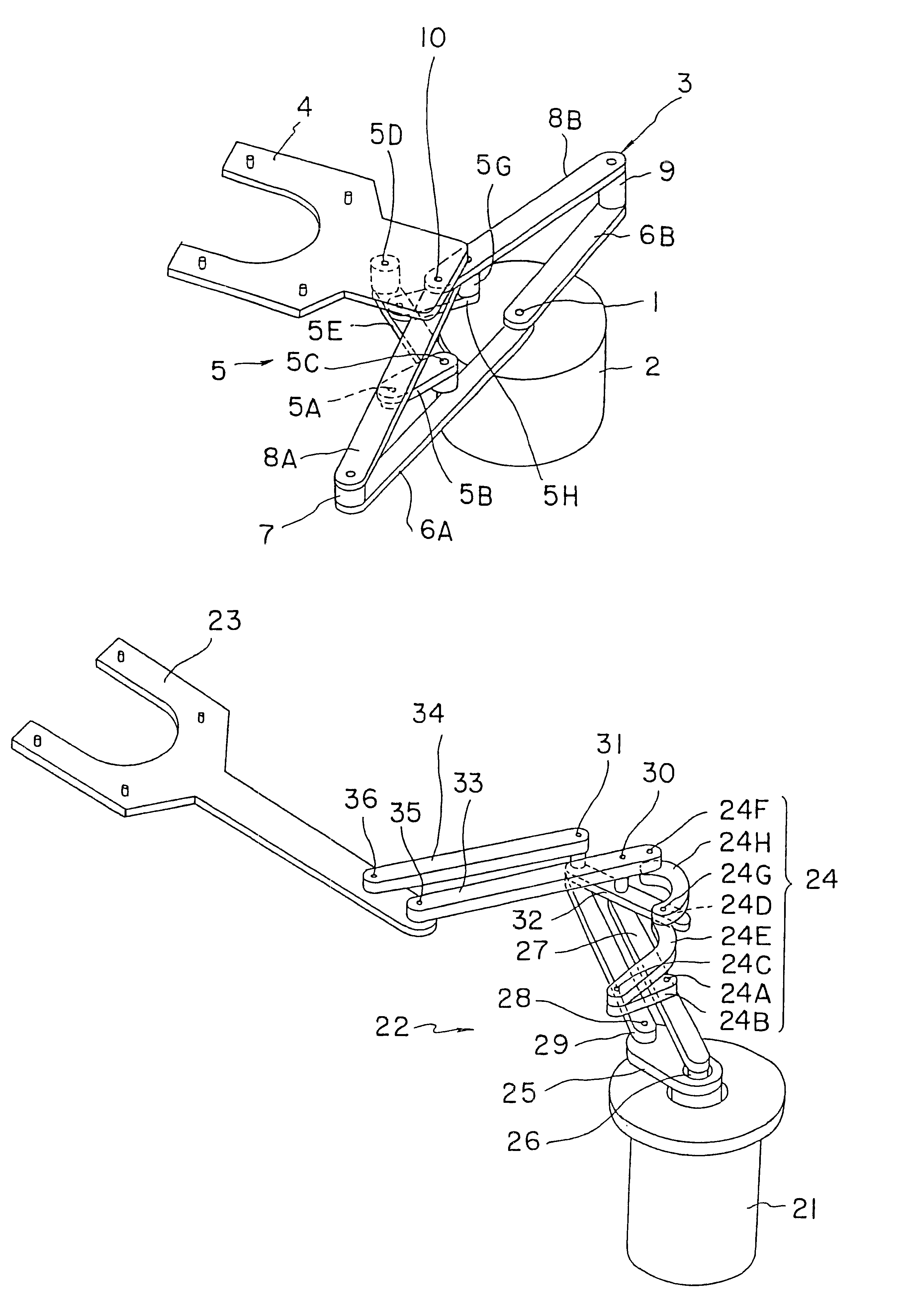

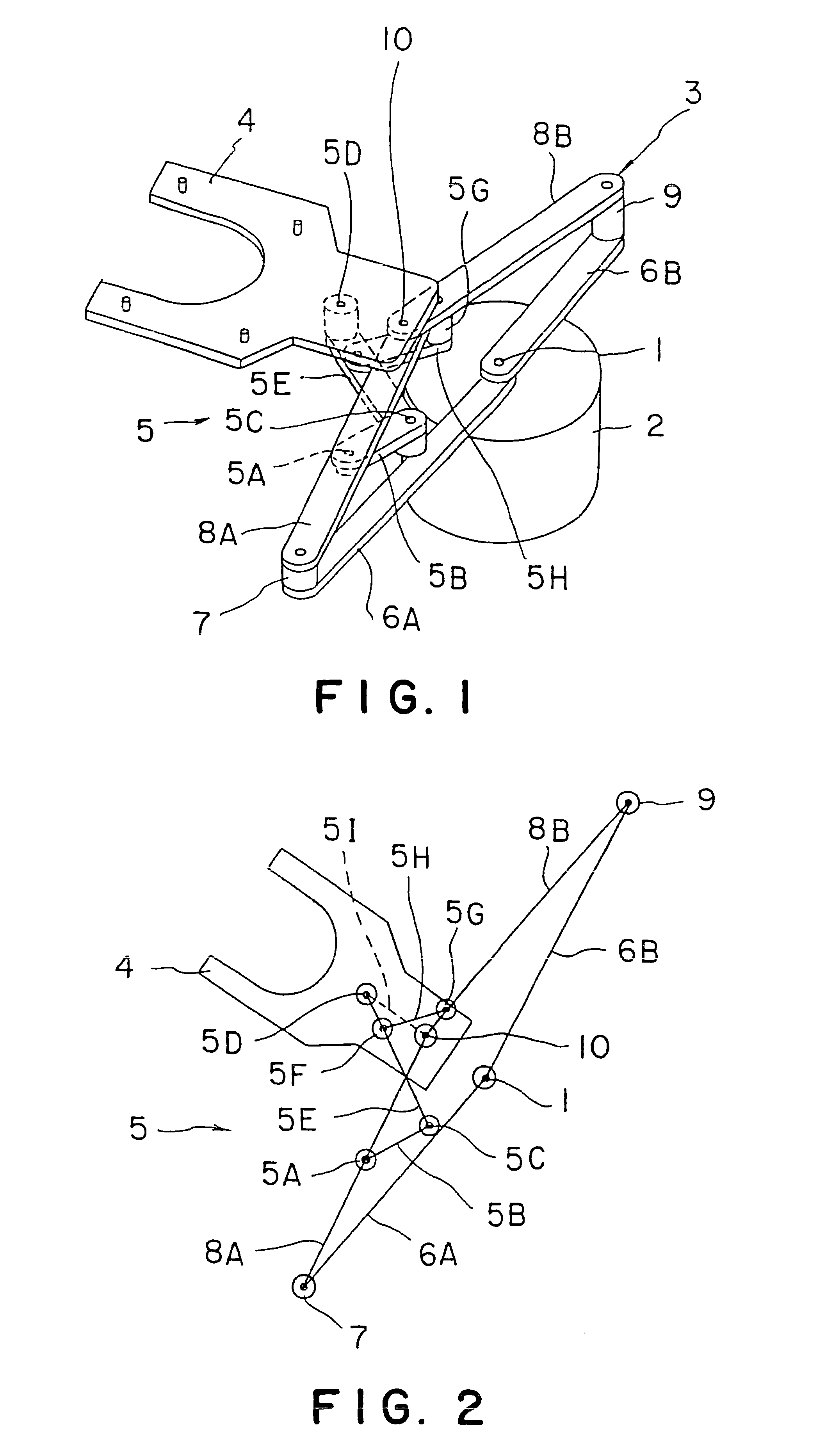

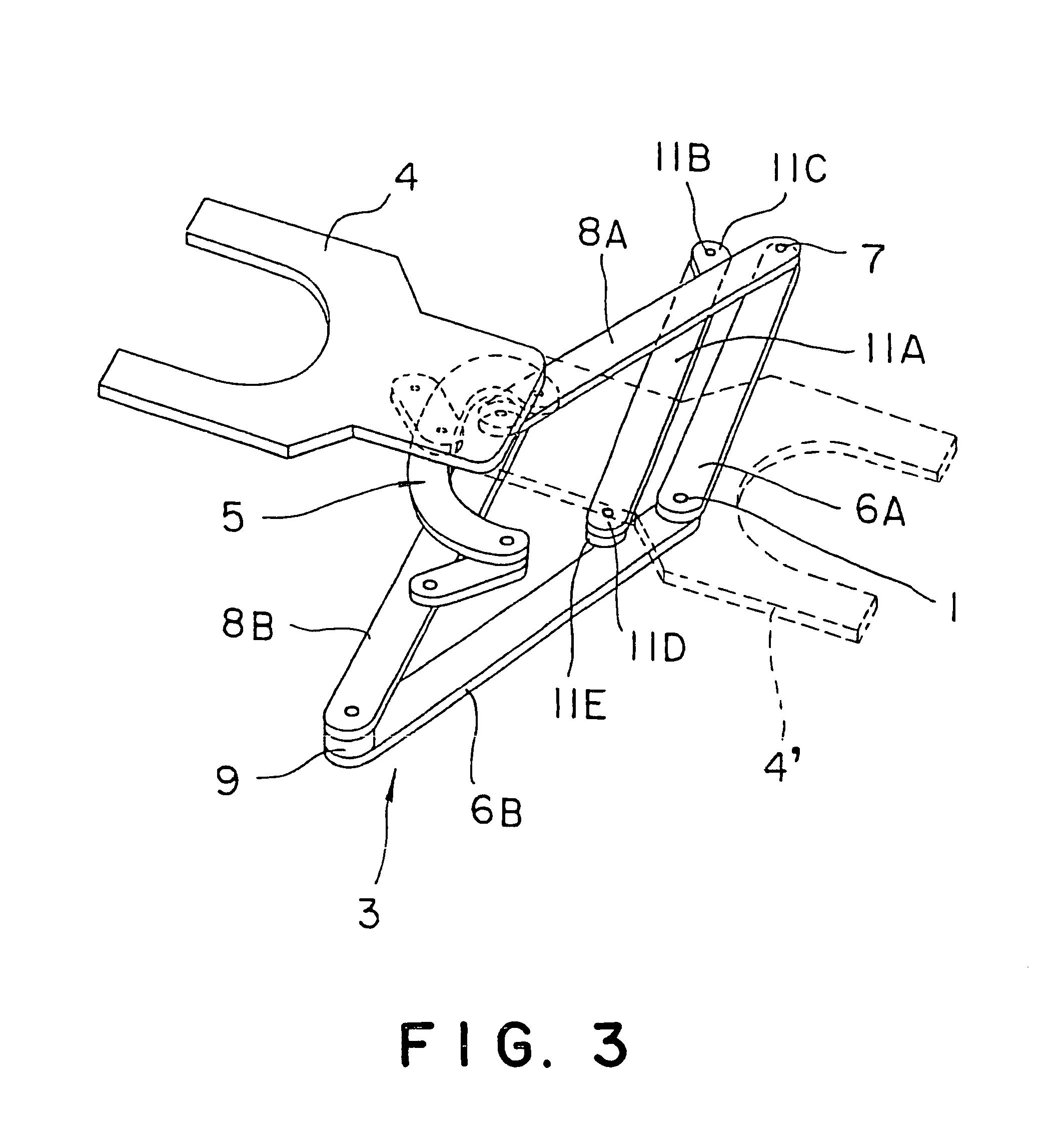

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

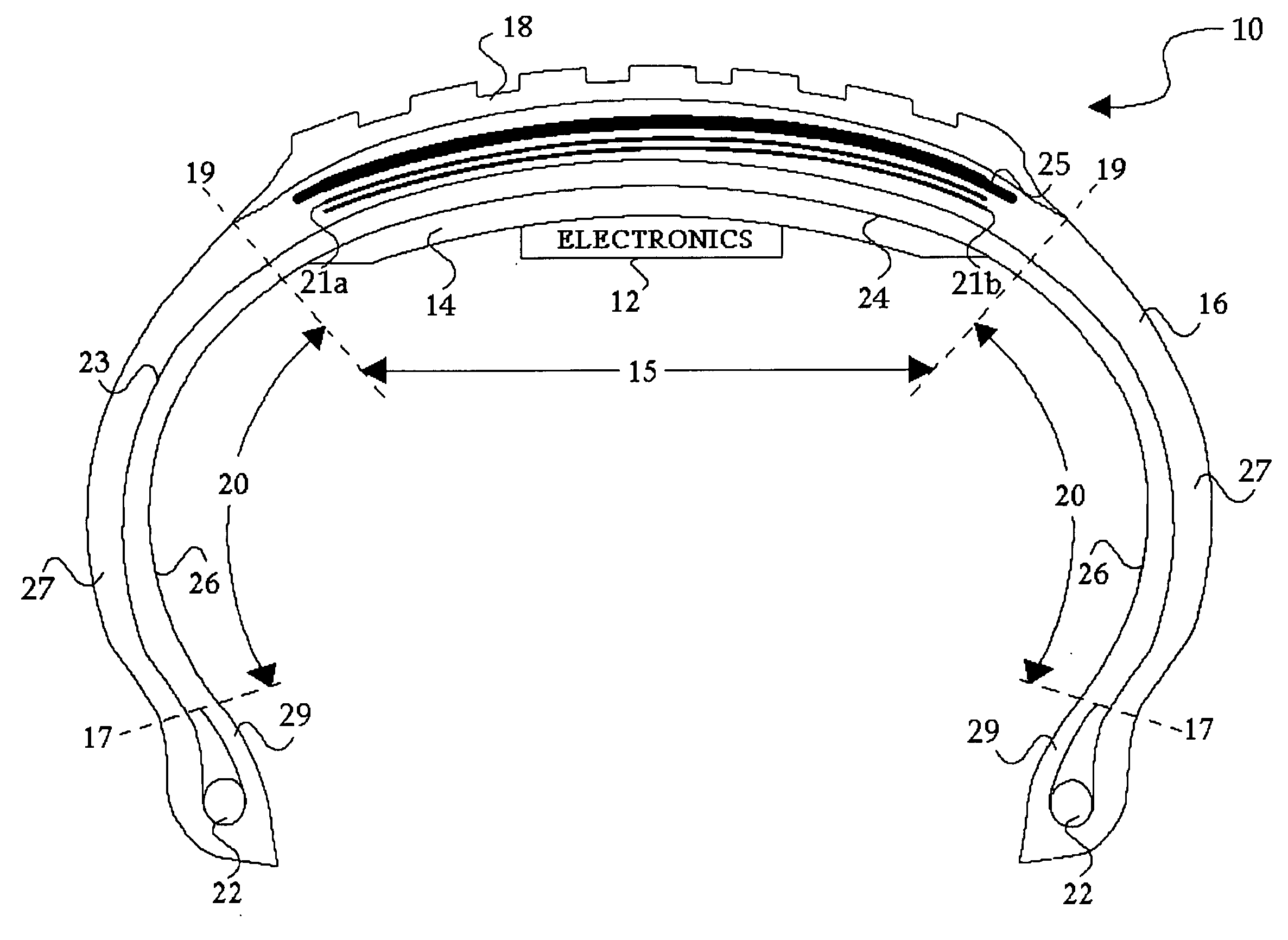

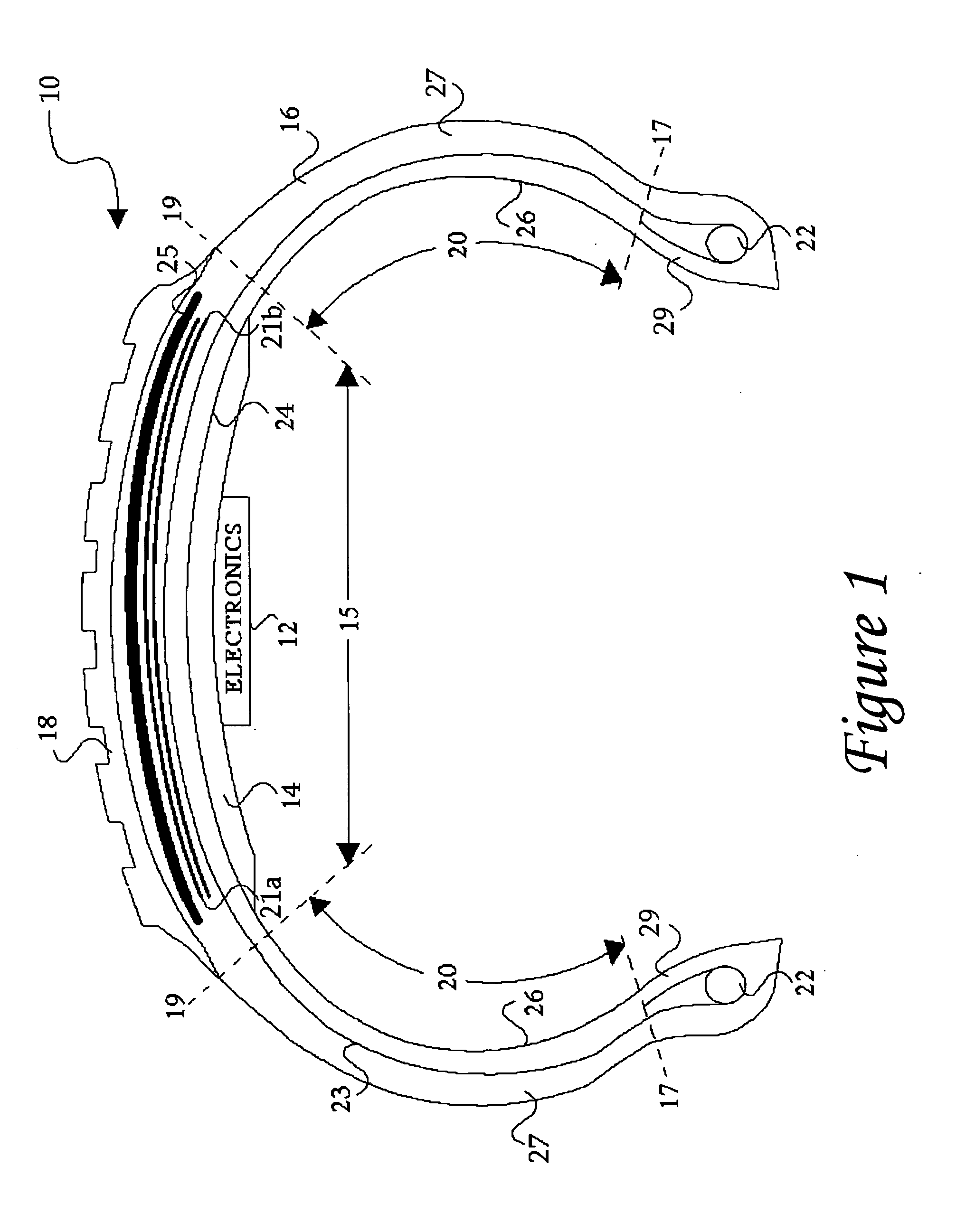

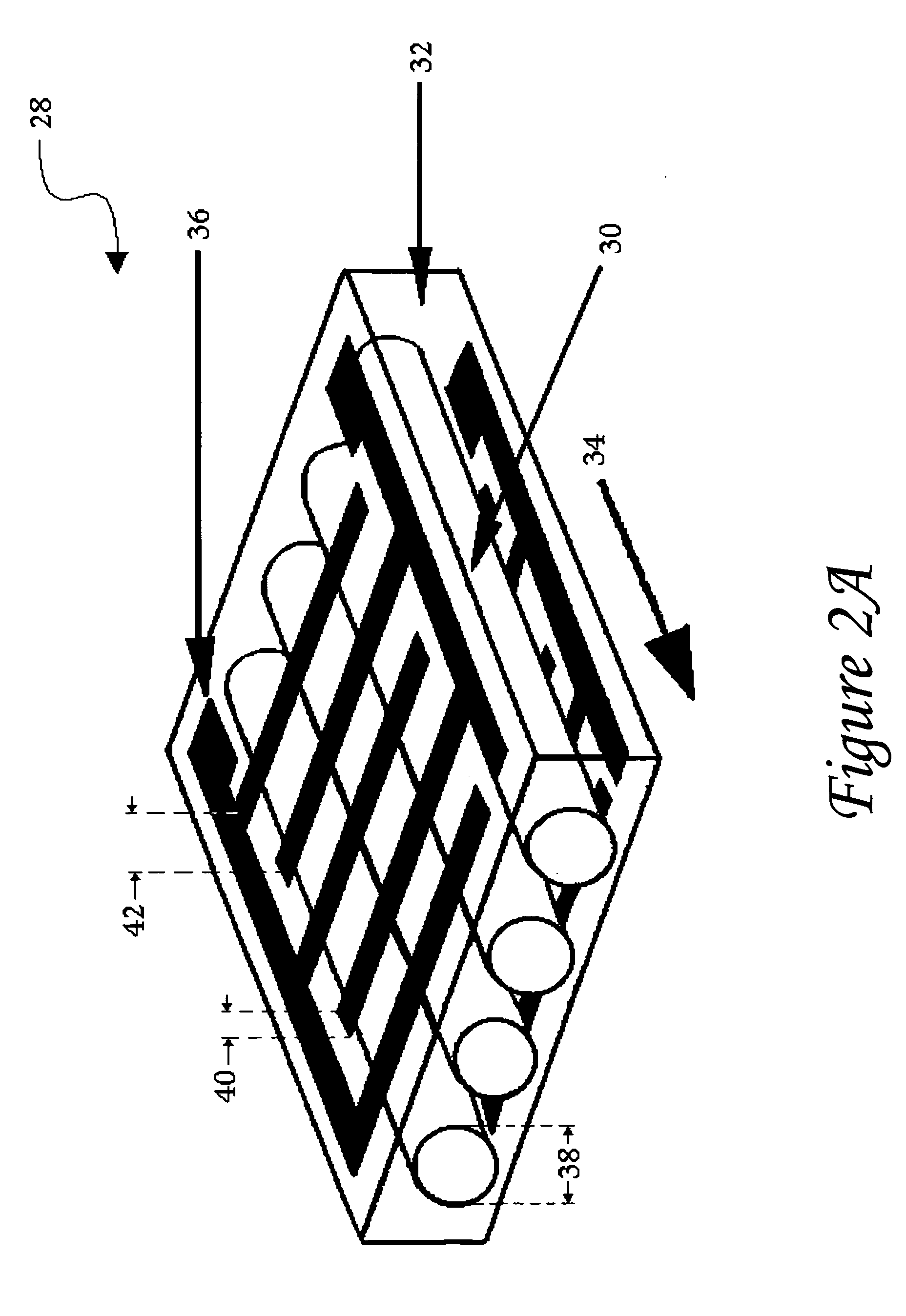

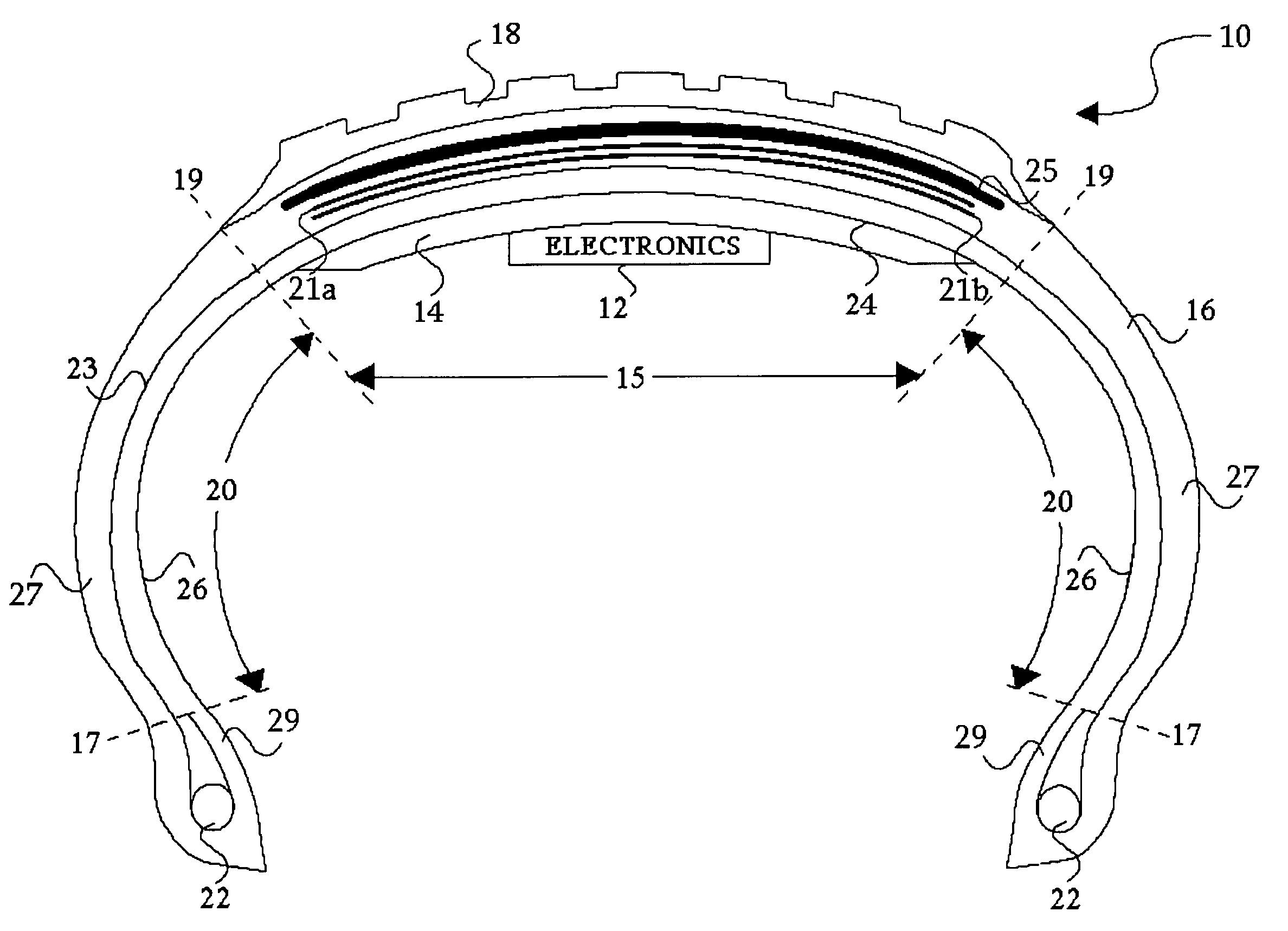

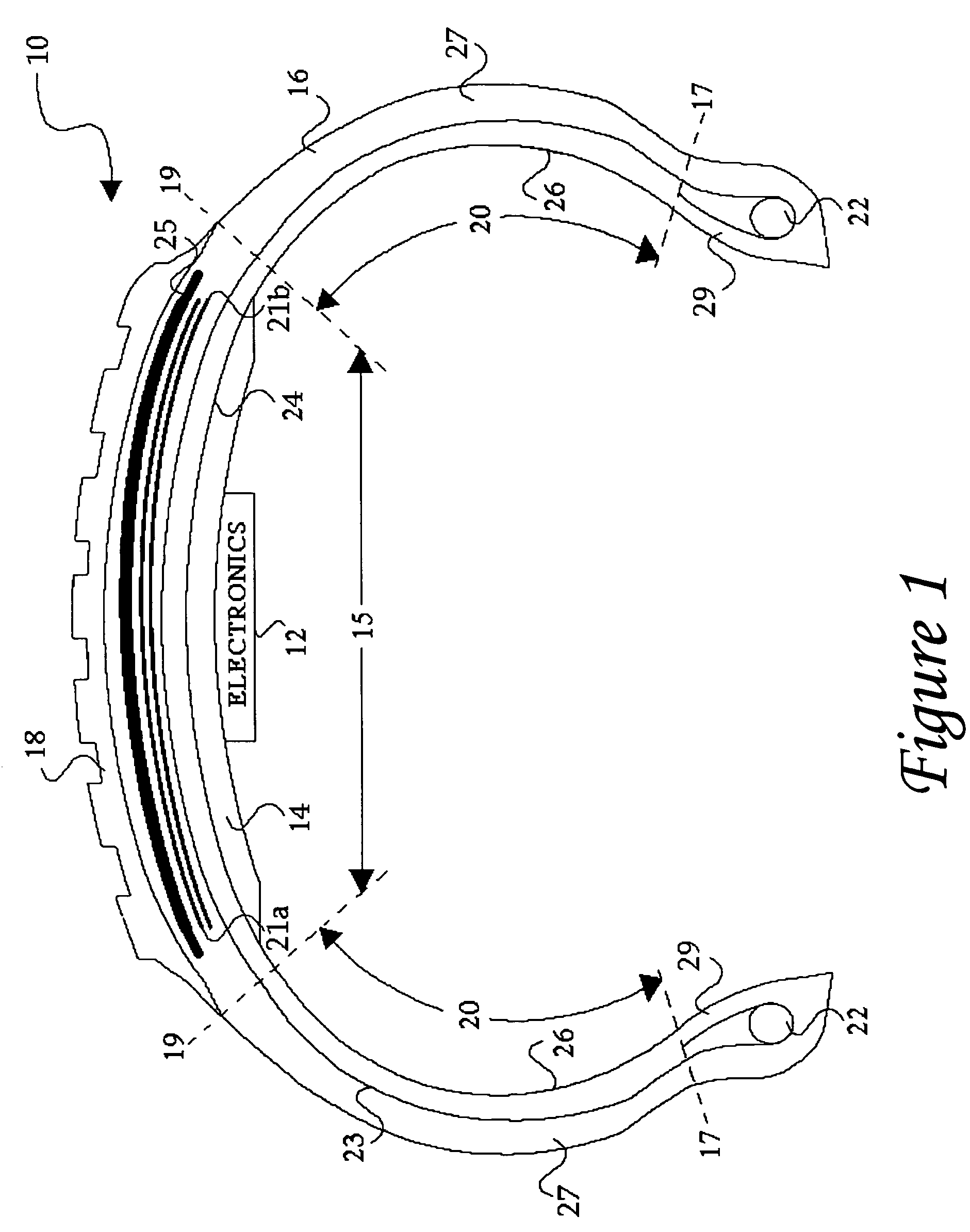

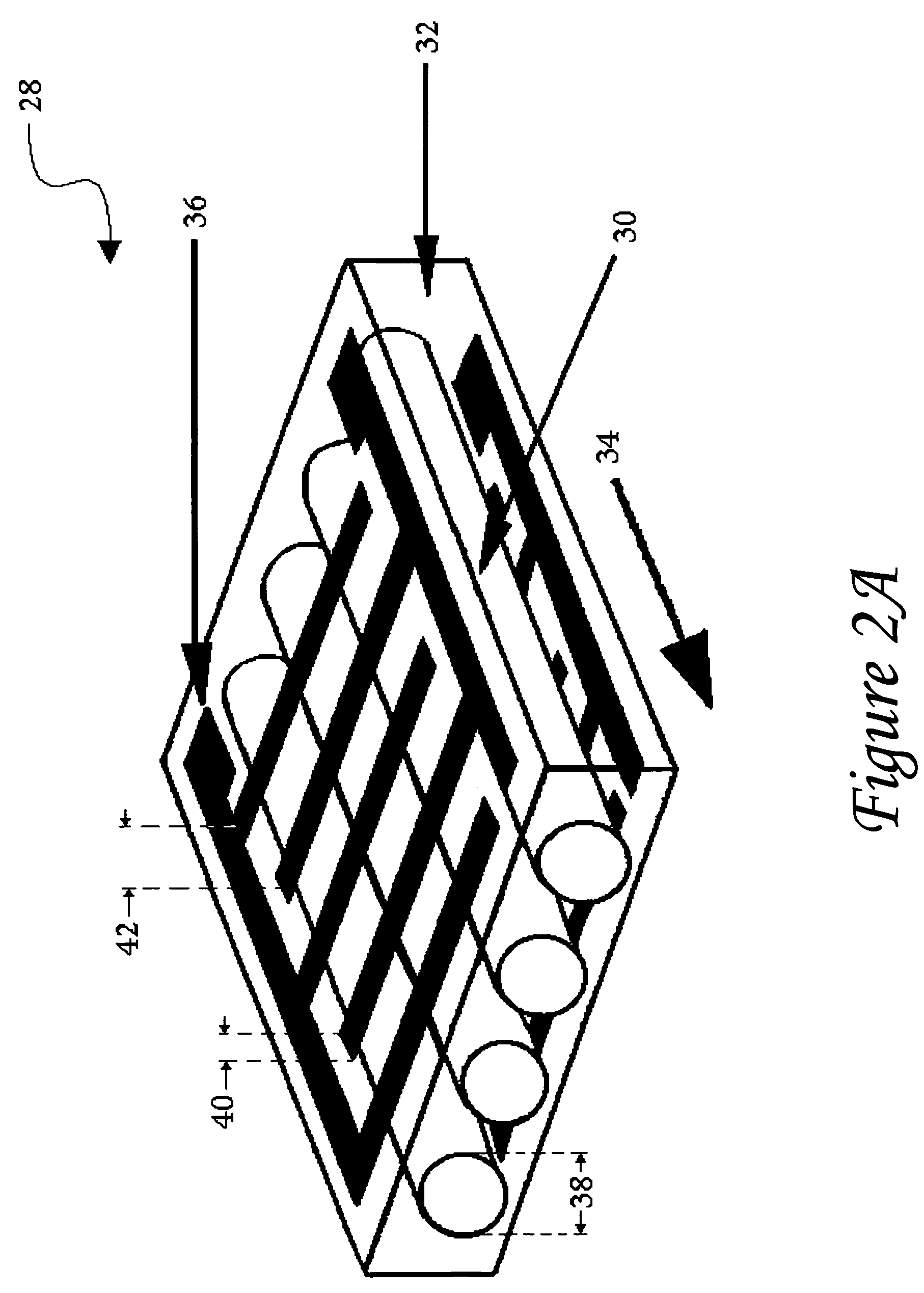

System and method for generating electric power from a rotating tire's mechanical energy

InactiveUS20050110277A1Reduce amountFunction increaseAuxillary drivesPiezoelectric/electrostriction/magnetostriction machinesElectricityMechanical energy

A tire assembly with integrated power generation features includes one or more piezoelectric devices configured to generate electric charge therein upon being subjected to mechanical strains associated with flexure of tire or wheel components. The piezoelectric device may be incorporated in a variety of tire structures and in many different locations. In pneumatic tire structures, the piezoelectric device and related electronics may be embedded in crown or sidewall locations among such selected components as the exterior tread portion, first and second steel belts of a belt package, carcass, cap ply portion, inner liner, zone base, etc. The piezoelectric device with optional rubber casing may also be attached to such locations as the inner liner and tire exterior. Piezoelectric devices may also be integrated with a tire and safety support combination that is configured to operate in an extended mobility mode when the tire structure loses air pressure. Piezoelectric devices may alternatively be integrated with a non-pneumatic structurally supported tire such as one including a reinforced annular band, a plurality of web spokes extending transversely across and radially inward from the annular band, a mounting band at the inner end of the web spokes and a tread portion disposed on the annular band.

Owner:MICHELIN RECH & TECH SA

Oil country tubular goods excellent in collapse characteristics after expansion and method of production thereof

InactiveUS20050217768A1Excellent in collapse characteristicSmall rate of dropFurnace typesHeat treatment furnacesMethods of productionSteel belt

The present invention provides a method of production of oil country tubular goods having a small drop in collapse pressure after expansion and having a collapse pressure recovering by low temperature ageing at about 100° C. and oil country tubular goods obtained by this method of production. This method of production comprises hot rolling a steel slab having amounts of addition of C, Mn, P, S, Nb, Ti, Al, and N in specific ranges and having a balance of iron and unavoidable impurities and shaping the steel strip coiled at a temperature of not more than 300° C. as it is into a tube. Alternatively, it comprises heating steel pipe having amounts of addition of C, Mn, P, S, Nb, Ti, Al, and N in specific ranges and having a balance of iron and unavoidable impurities to a temperature of the Ac3 [° C.] to 1150° C., then cooling it in a range of 400 to 800° C. at a rate of 5 to 50° C. / second.

Owner:NIPPON STEEL CORP

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

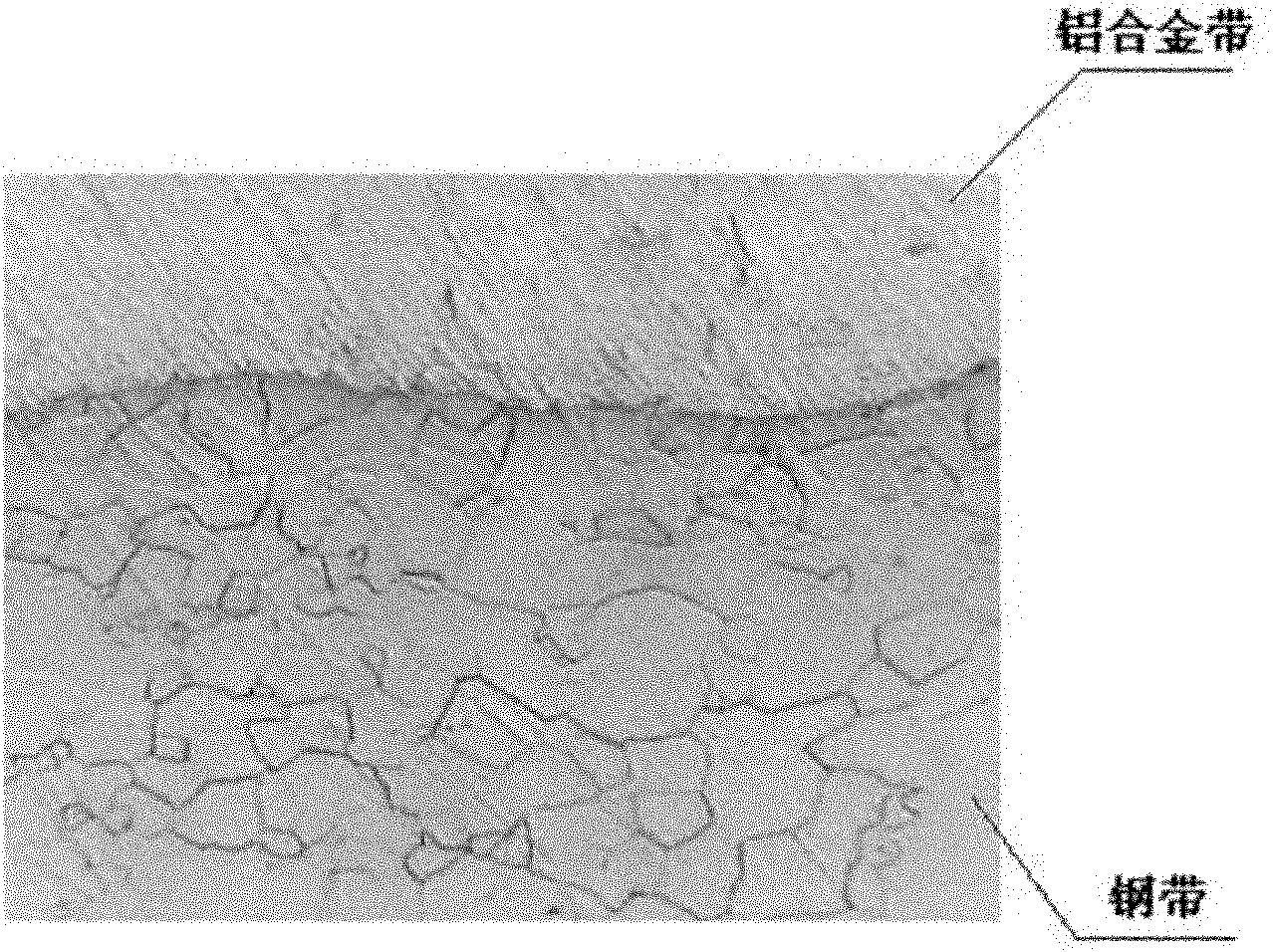

Aluminium-clad steel strip for coolers and preparation method thereof as well as steel strip and aluminium alloy strip used thereby

InactiveCN102019727AGuaranteed bonding strengthImprove mechanical propertiesLaminationLamination apparatusAluminum compositesSteel belt

The invention relates to an aluminium-clad steel strip and a preparation method thereof as well as a steel strip and an aluminium alloy strip used thereby, in particular to an aluminium-clad steel strip for coolers and a preparation method thereof as well as a steel strip and an aluminium alloy strip used thereby. The invention solves the problems of pinholes, composite layer inclusions, generation of brittle iron aluminium metallic compounds and failure to adapt to brazing technology in the industrially produced steel-aluminium composite material at present. The aluminium-clad steel strip for coolers is prepared by cladding a steel strip and an aluminium alloy strip. The preparation method comprises the following steps: 1. pretreating the surfaces of the steel strip and the aluminium alloy strip; 2. sandwich-rolling; and 3. recrystallization annealing. In the steel strip, the content of C is less than 0.01%, the content of Si is less than 0.01%, the content of Mn is 0.20-0.30%, and the content of Alt is less than 0.005%. In the aluminium alloy strip, the content of Si is 0.70-0.90%, and the content of Fe is 0.30-0.45%. The invention is applicable to the field of brazing coolers.

Owner:HARBIN SONGRUN METAL PRODS

System and method for generating electric power from a rotating tire's mechanical energy

InactiveUS7429801B2Reduce amountFacilitates great functionalityAuxillary drivesPiezoelectric/electrostriction/magnetostriction machinesElectricityElectric power system

A tire assembly with integrated power generation features includes one or more piezoelectric devices configured to generate electric charge therein upon being subjected to mechanical strains associated with flexure of tire or wheel components. The piezoelectric device may be incorporated in a variety of tire structures and in many different locations. In pneumatic tire structures, the piezoelectric device and related electronics may be embedded in crown or sidewall locations among such selected components as the exterior tread portion, first and second steel belts of a belt package, carcass, cap ply portion, inner liner, zone base, etc. The piezoelectric device with optional rubber casing may also be attached to such locations as the inner liner and tire exterior. Piezoelectric devices may also be integrated with a tire and safety support combination that is configured to operate in an extended mobility mode when the tire structure loses air pressure. Piezoelectric devices may alternatively be integrated with a non-pneumatic structurally supported tire such as one including a reinforced annular band, a plurality of web spokes extending transversely across and radially inward from the annular band, a mounting band at the inner end of the web spokes and a tread portion disposed on the annular band.

Owner:MICHELIN RECH & TECH SA

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

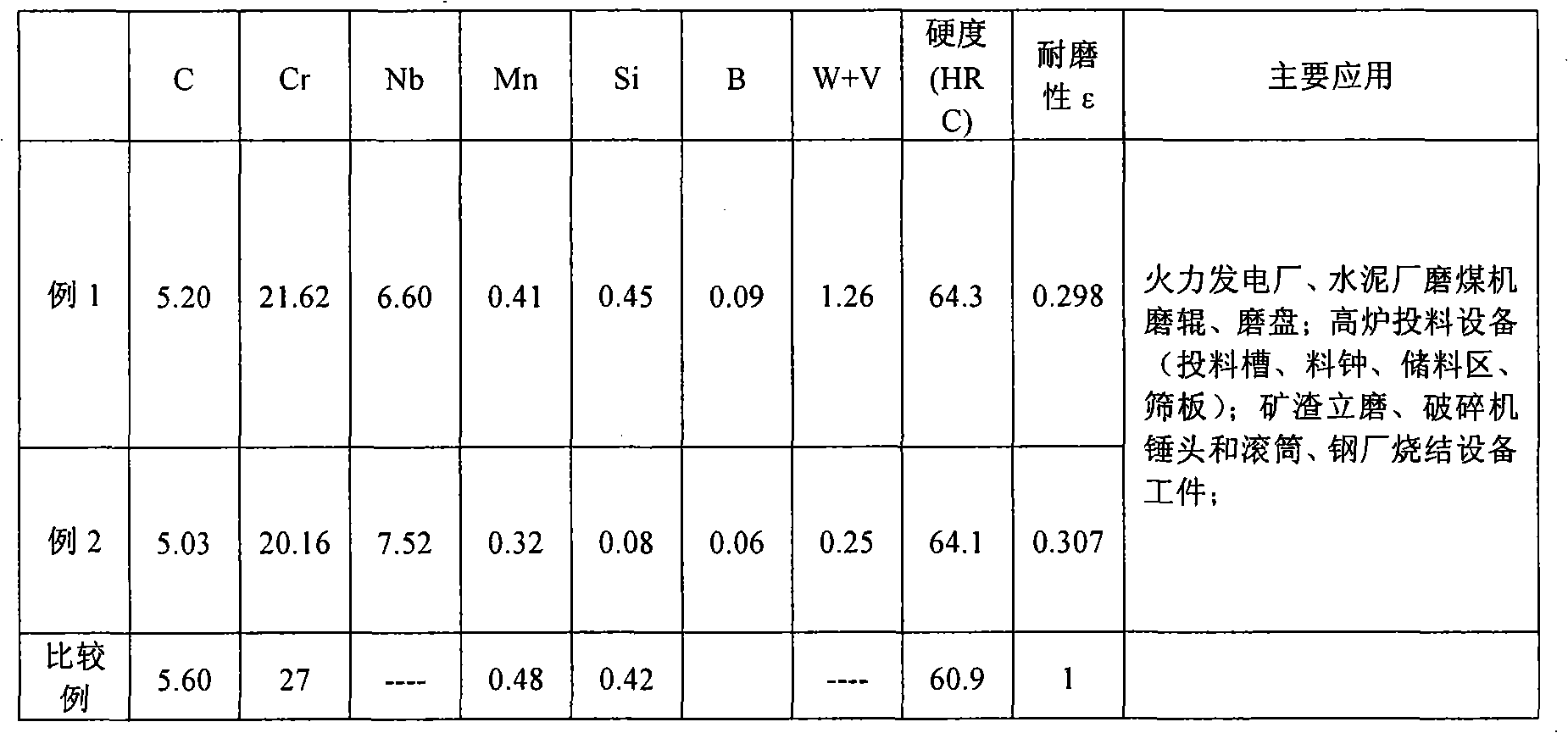

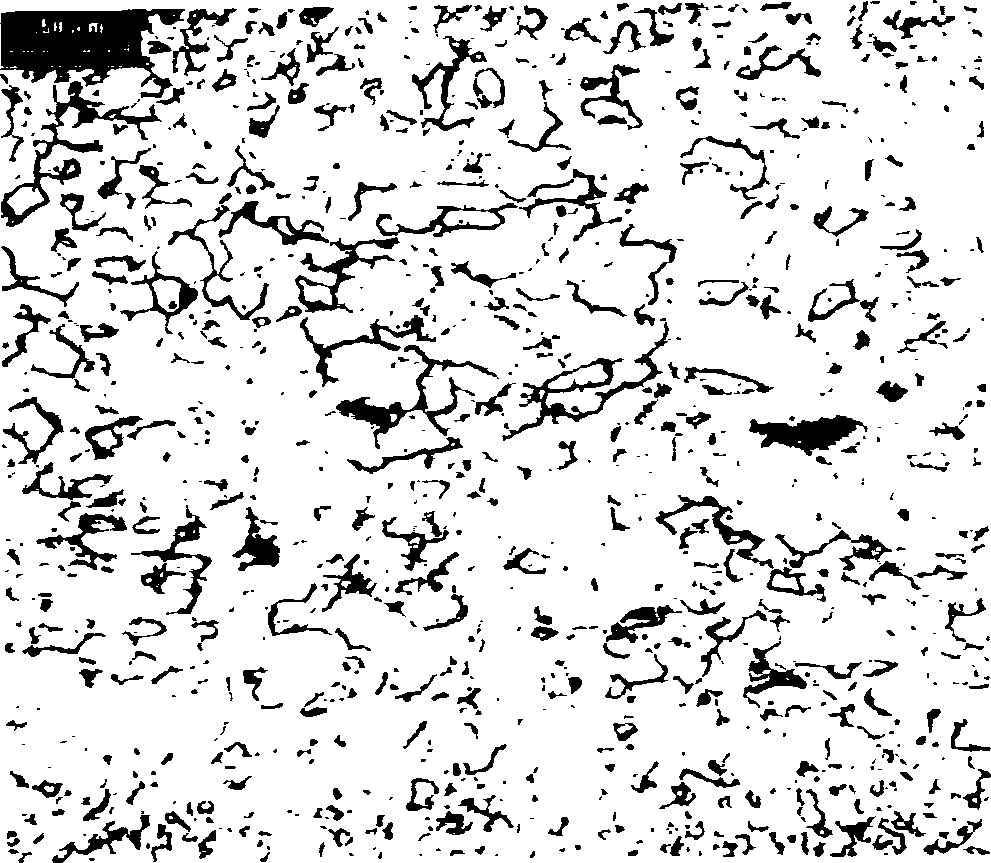

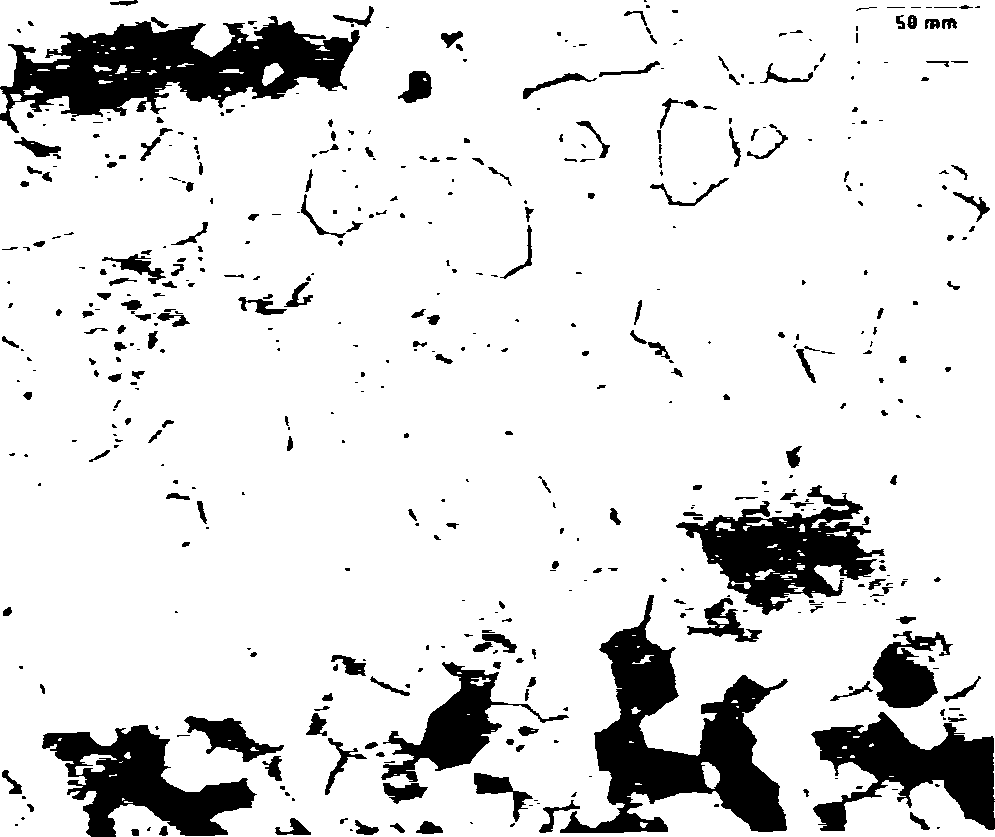

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

High magnetic induction and high grad non-orientation electrical steel and its making process

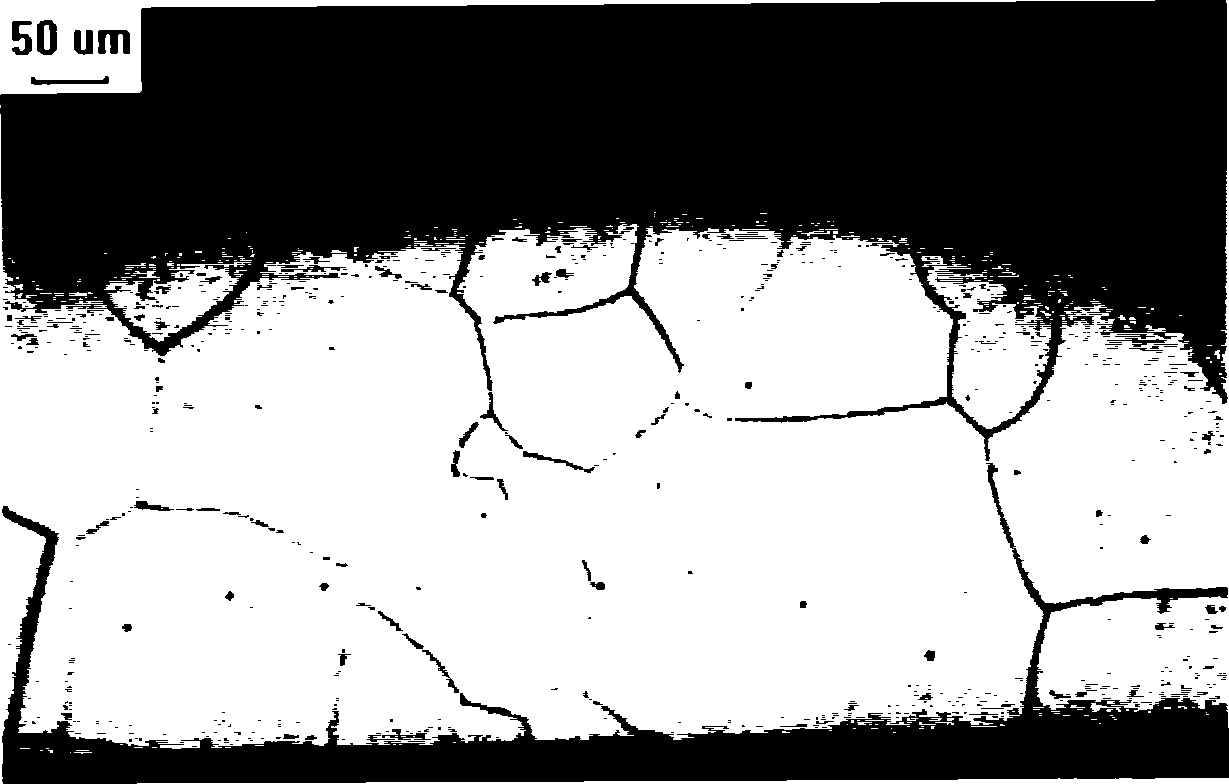

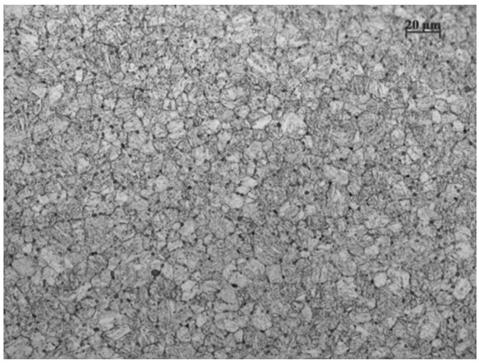

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

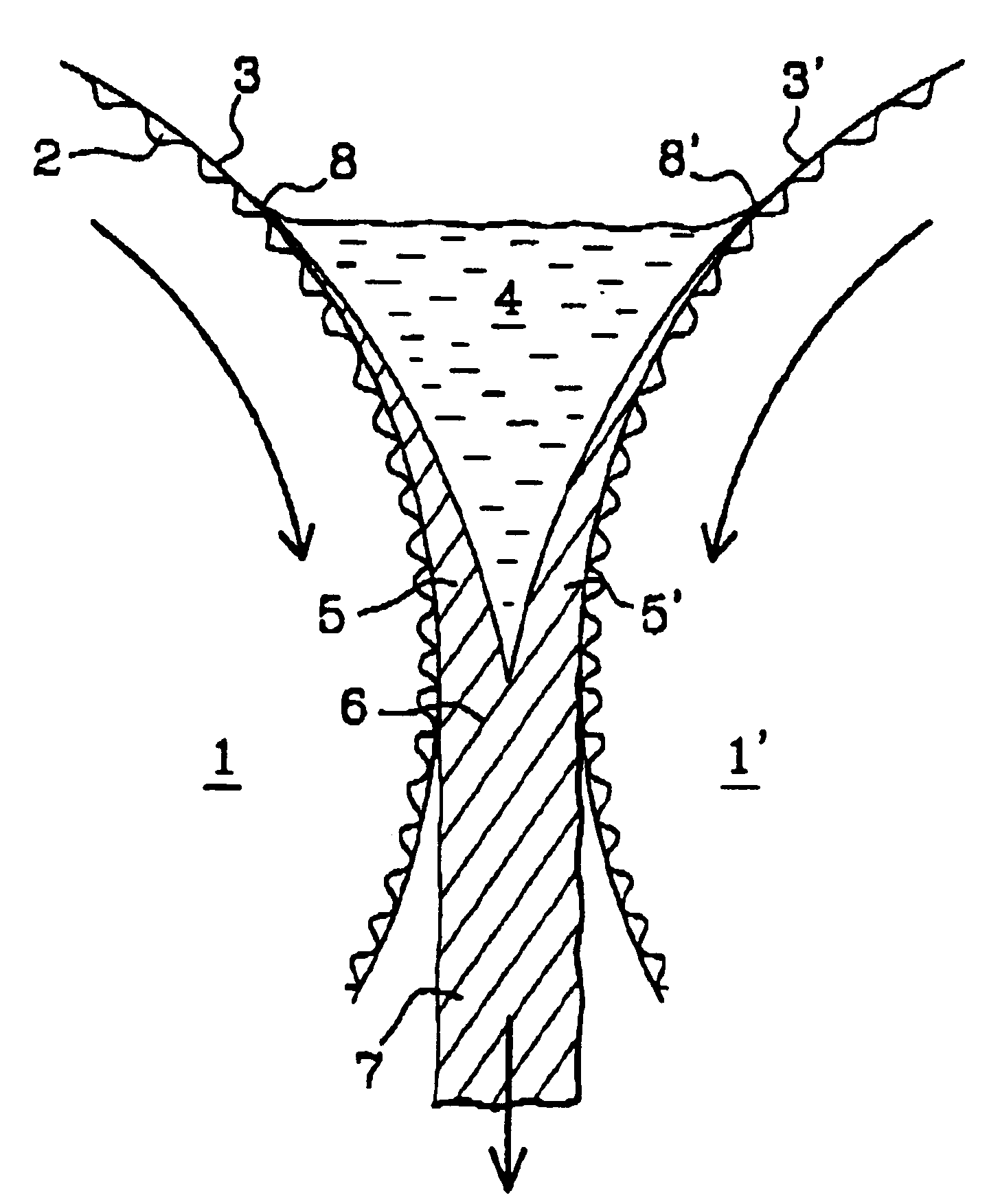

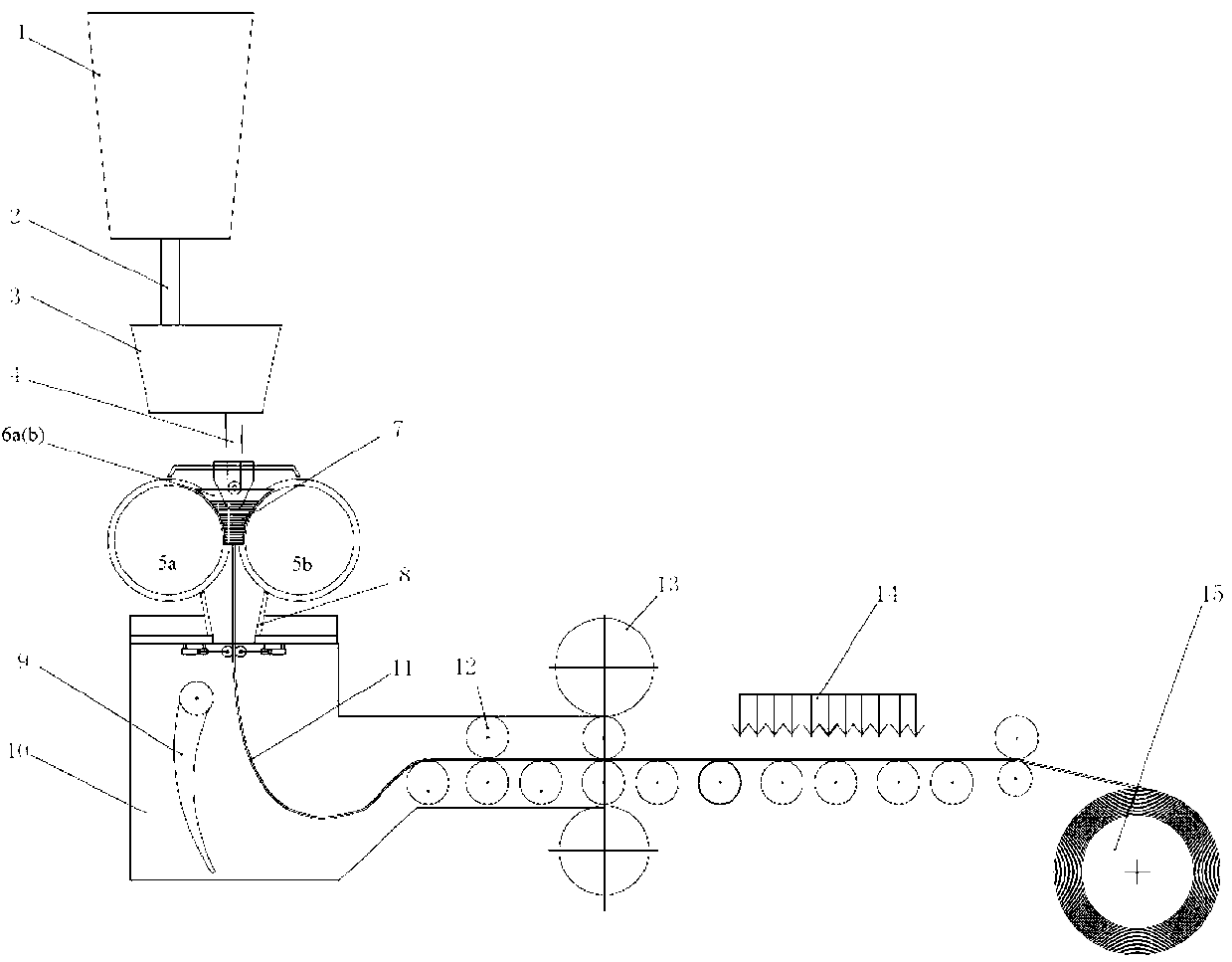

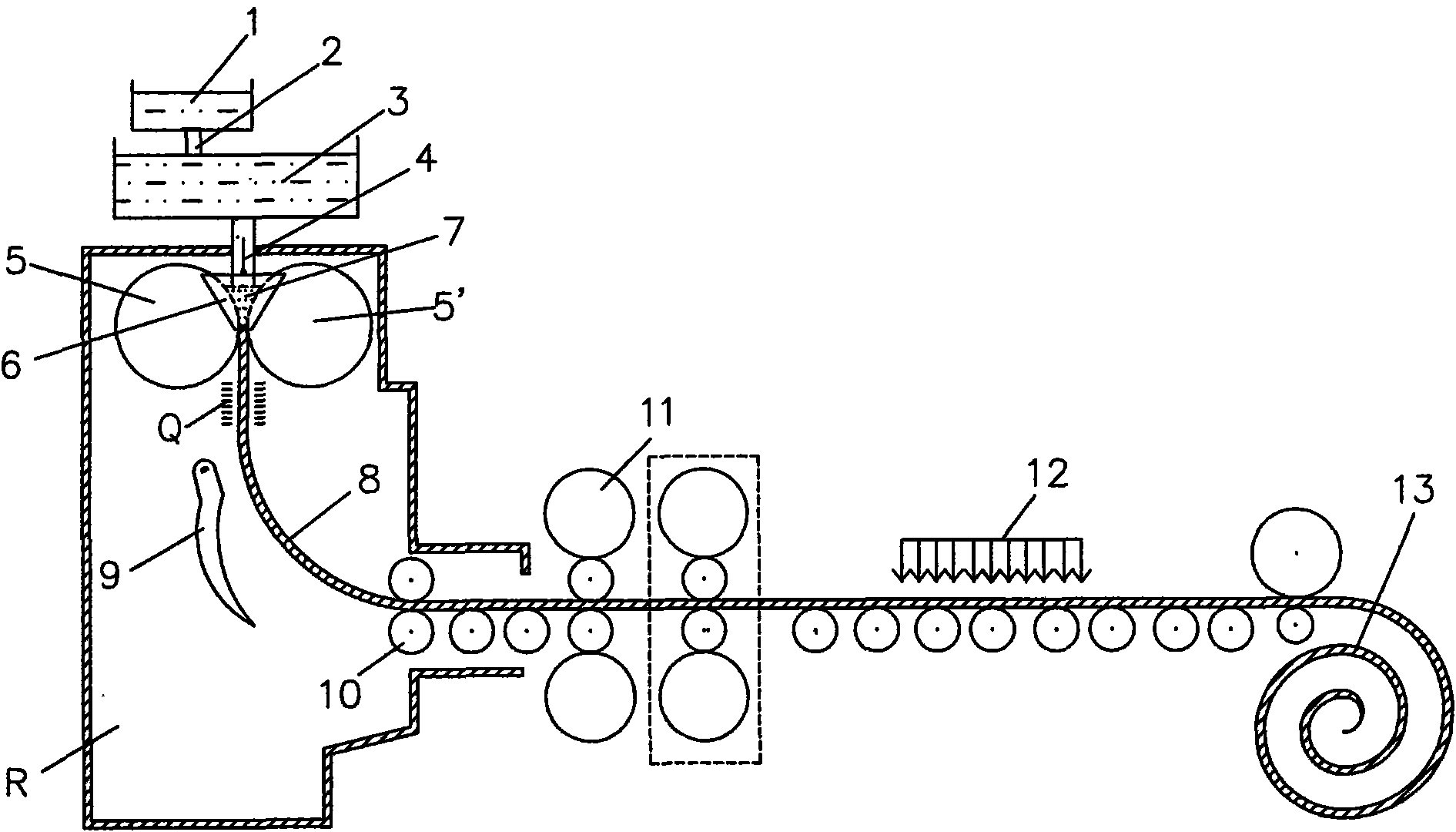

Process for manufacturing carbon-steel strip by twin-roll continuous casting, product produced and apparatus

A process for manufacturing carbon-steel strip having a thickness of less than or equal to 10 mm directly from liquid steel, by casting said liquid steel between the lateral surfaces, made of copper or copper alloy, of two internally cooled rotating horizontal rolls.

Owner:SOLLAC (SA)

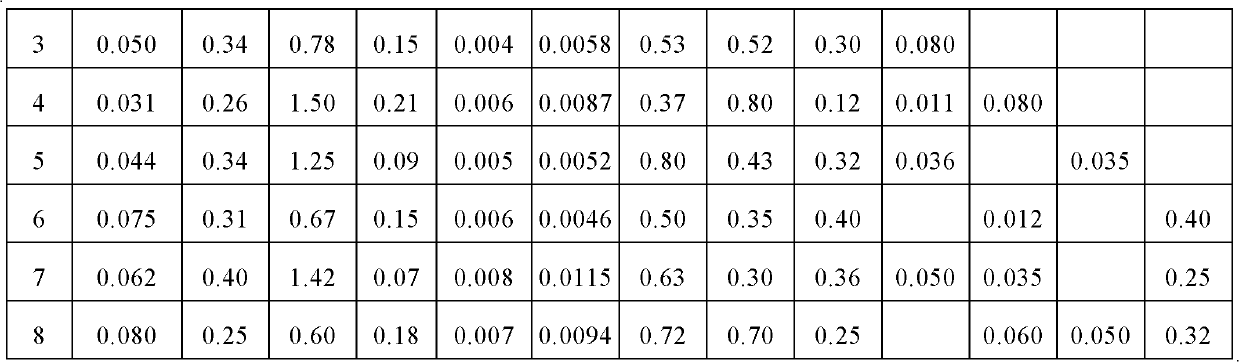

Stainless-steel band special apparatus for steel-aluminum composite contact rail

InactiveCN101028685AImprove performanceQuality improvementMetal-working feeding devicesOther manufacturing equipments/toolsButt weldingControl theory

Owner:南京赛彤铁路电气化有限公司

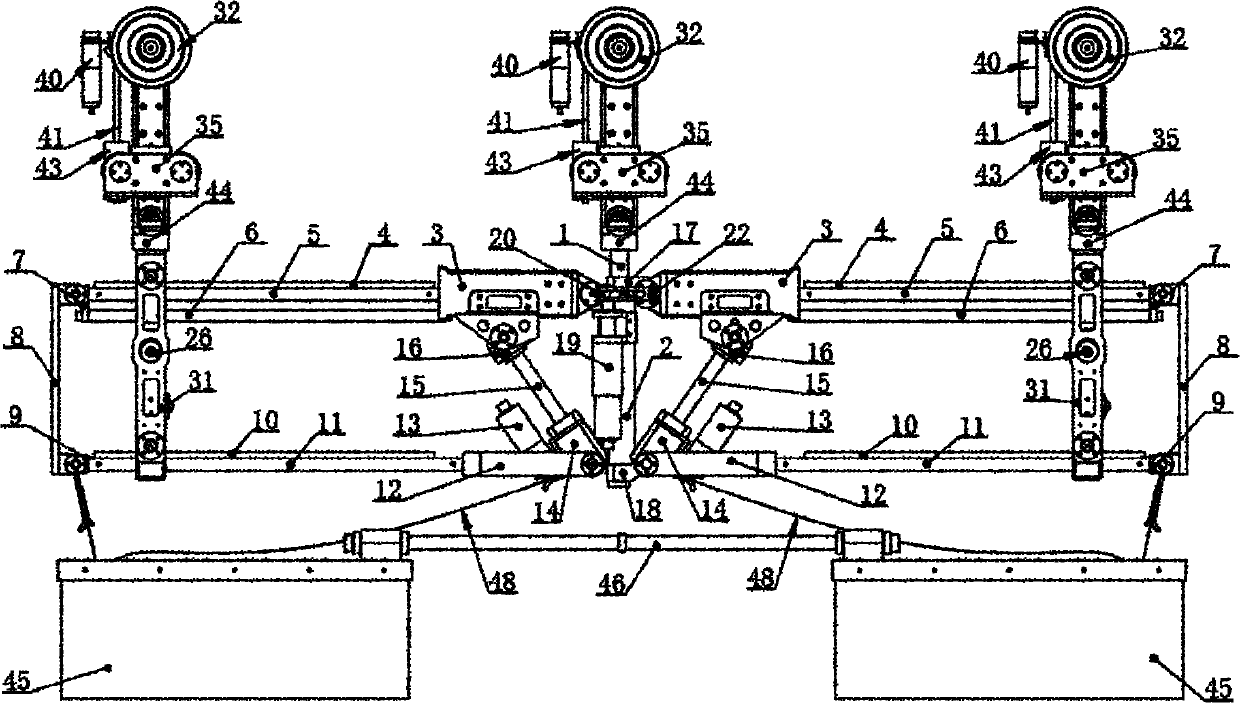

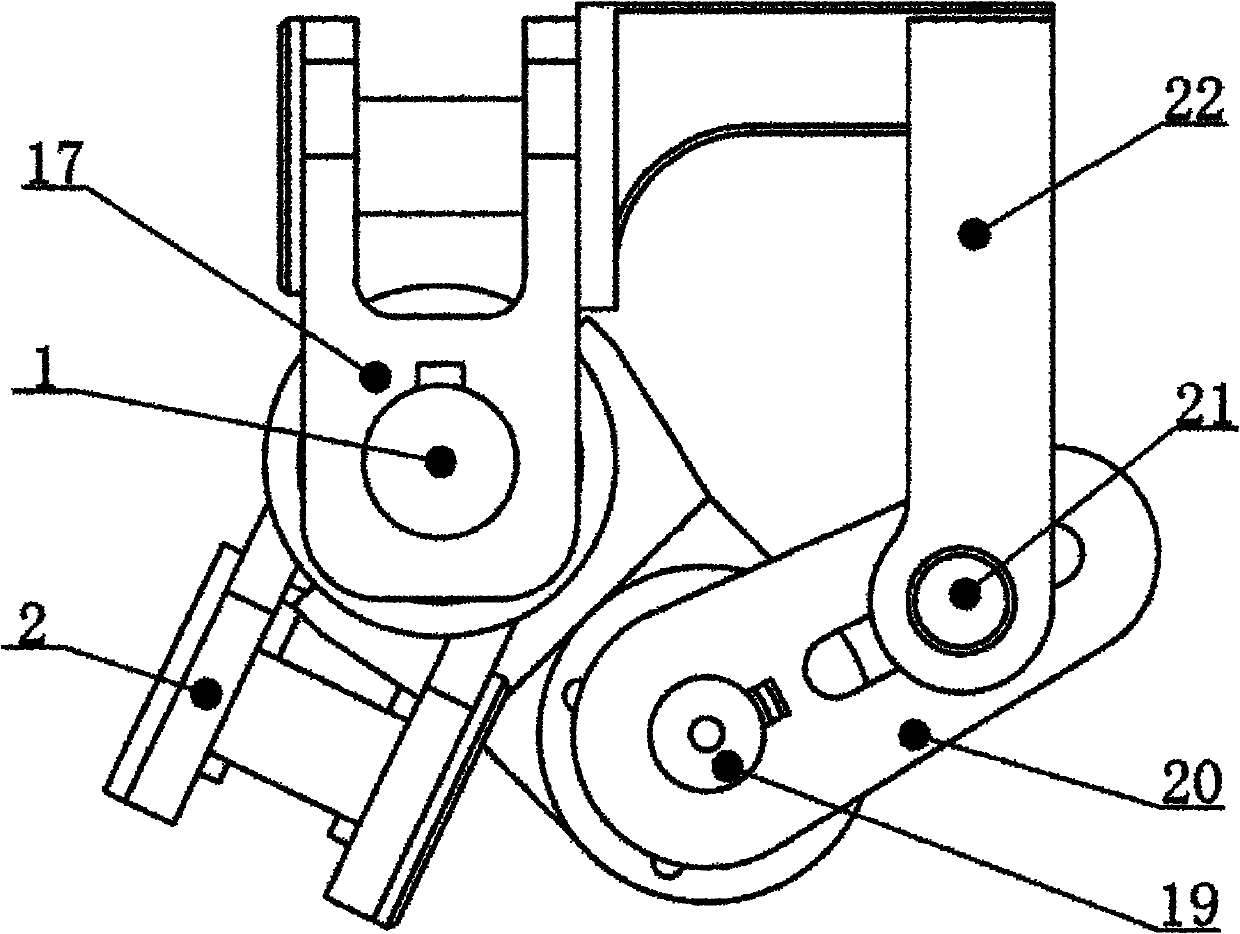

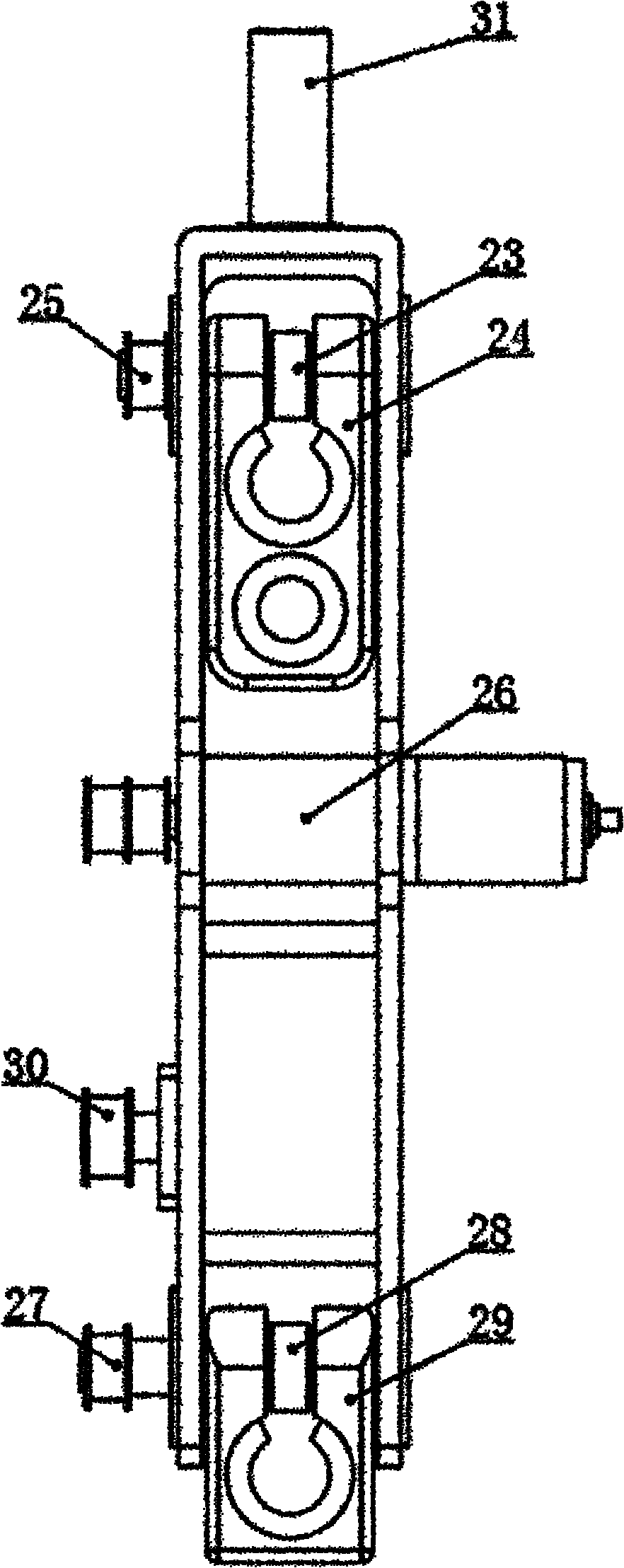

Suspended line walking robot

The invention discloses a suspended line walking robot which comprises a walking part and a suspending cabin, wherein the walking part consists of two trunks and three driving wheel claws; the two trunks form double parallelogram structures; the three driving wheel claws are guaranteed to face toward the same direction; five motors on the trunks drive the trunks to longitudinally swing, transversely swing and stretch to ensure that each obstacle detouring driving wheel can realize three-freedom-degree translational upper and lower lines; each driving wheel claw comprises a driving wheel and a clamping device, and the motors drive the driving wheels to ensure that the robot moves on the line; each clamping device comprising a motor, a ball screw pair, a spring, a clamping wheel, and the like guarantees that enough friction force is maintained between the driving wheels and the lines; the suspending cabin and the walking part are connected through two steel belts; and two motors on the suspending cabin adjust own gravity center position relative to the trunks through a steel belt so as to guarantee the flexibility of the mechanism while crossing an obstacle. The invention guarantees that the line walking robot can cross various line obstacles including corner line towers, can climb a diagonal tensile line larger than 60 degrees, has high safety factor and can replace man power to realize autonomous line walking.

Owner:XI AN JIAOTONG UNIV

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

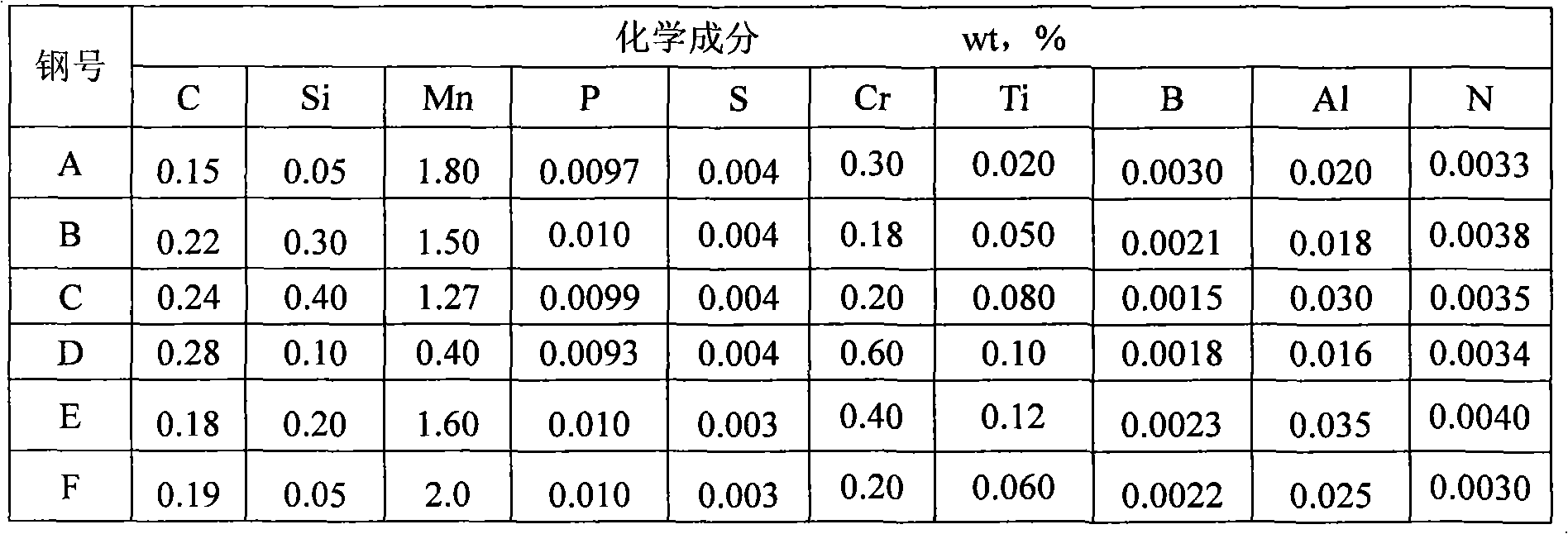

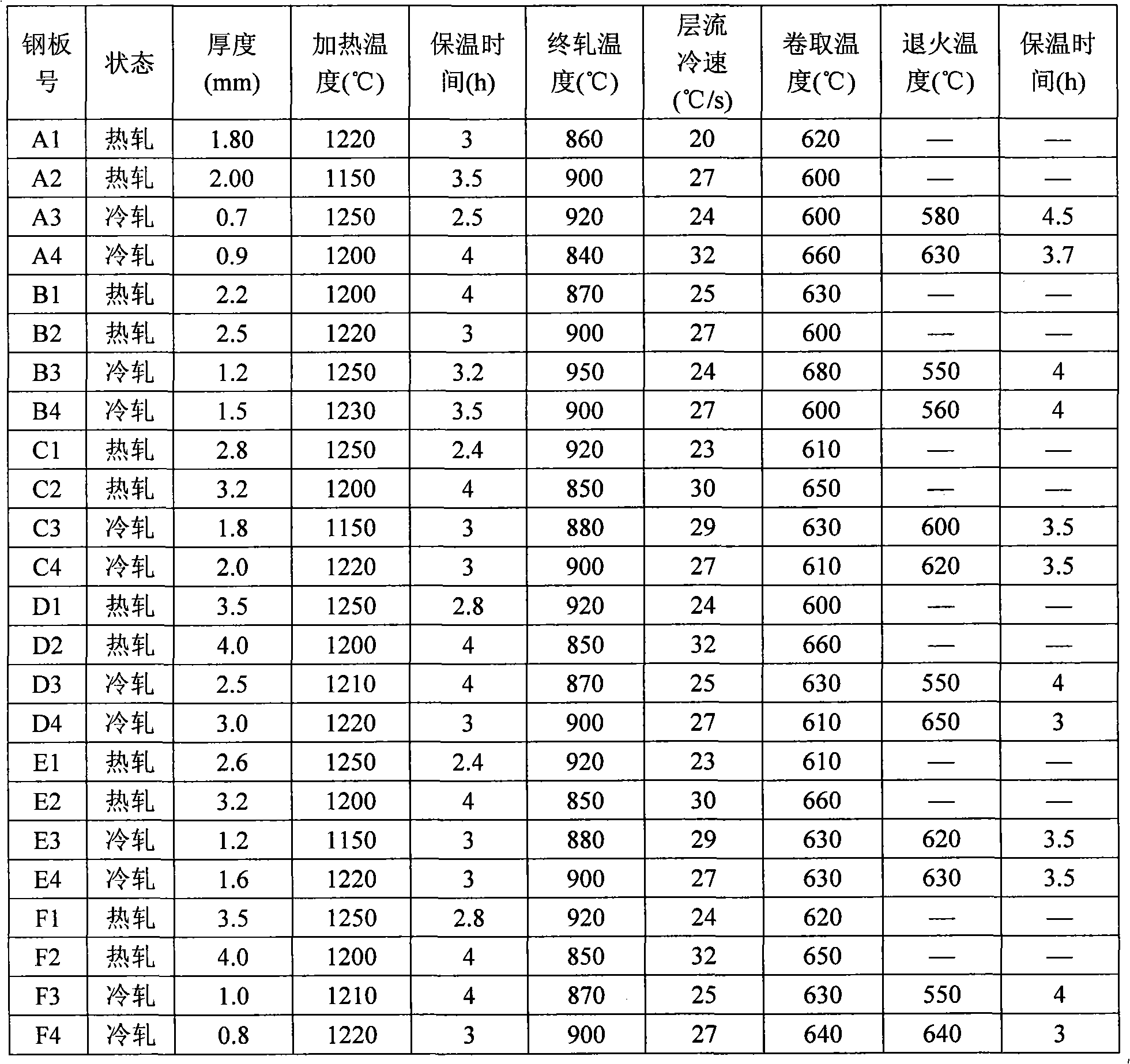

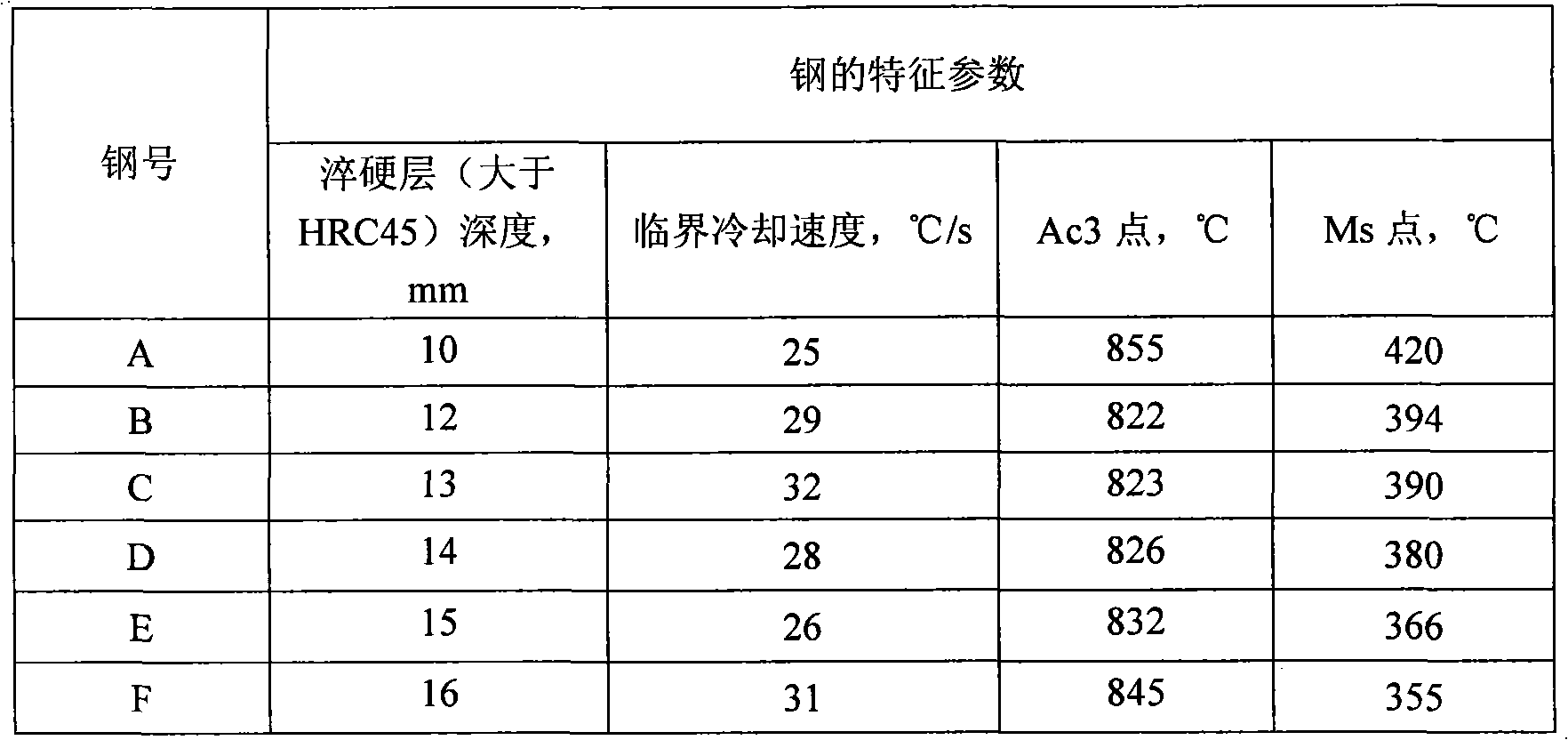

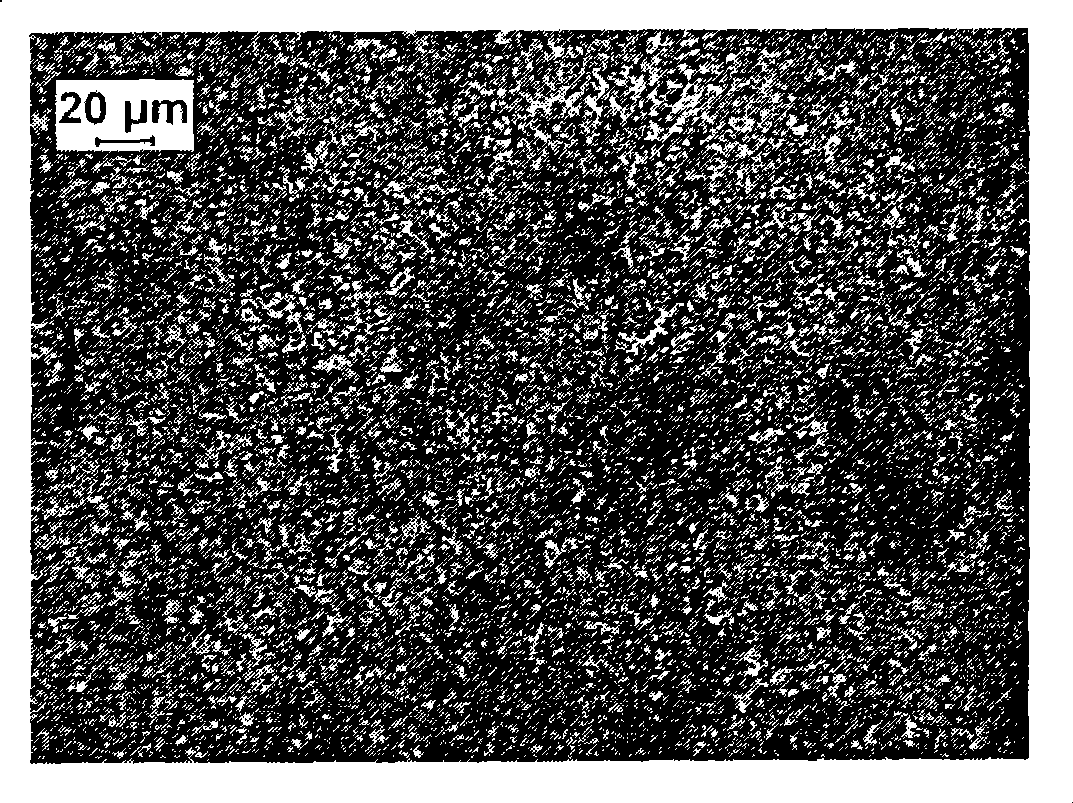

Steel plate for stamping and quenching and manufacturing method thereof

The invention discloses a steel plate for stamping and quenching and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.28 percent of C, less than 0.40 percent of Si, 0.4 to 2.0 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, 0.016 to 0.040 percent of Al, 0.15 to 0.8 percent of Cr, 0.015 to 0.12 percent of Ti, 0.001 to 0.005 percent of B, less than or equal to 0.005 percent of N, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps of: heating a blank to 1,150 to 1,250 DEG C, preserving heat for 2.5 to 4 hours and performing rough rolling, and then performing finish rolling under multichannel pressure and at the final rolling temperature of between 830 and 950 DEG C, performing laminar cooling, and cooling to the rolling temperature at the cooling speed of more than 10 DEG C / s and the rolling temperature of between 600 and 680 DEG C. The cold-rolled steel plate is obtained by the following steps of: performing cold rolling on a hot rolled steel strip, annealing through a pure hydrogen gas cover furnace, and oiling and packaging. The annealing temperature is 550 to 650 DEG C and the heat preserving time is 3 to 5 hours. The steel has a simple component design and high hardenability. The depth of a hardening layer of more than HRC45 is 10 to 16mm. The steel plate consists of ferrite and pearlite. After thermal stamping and quenching, an all-martensite structure can be obtained. The tensile strength is above 1,300N / mm<2>.

Owner:ANGANG STEEL CO LTD

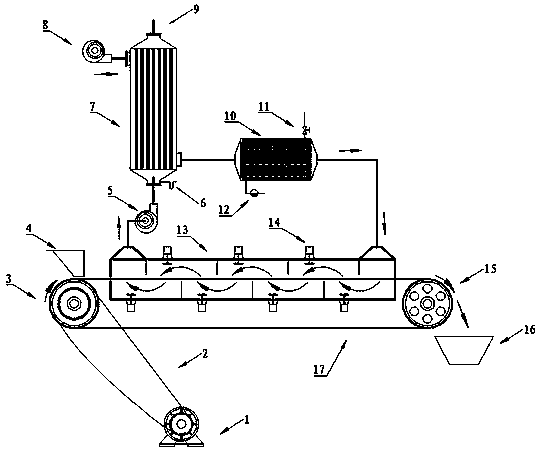

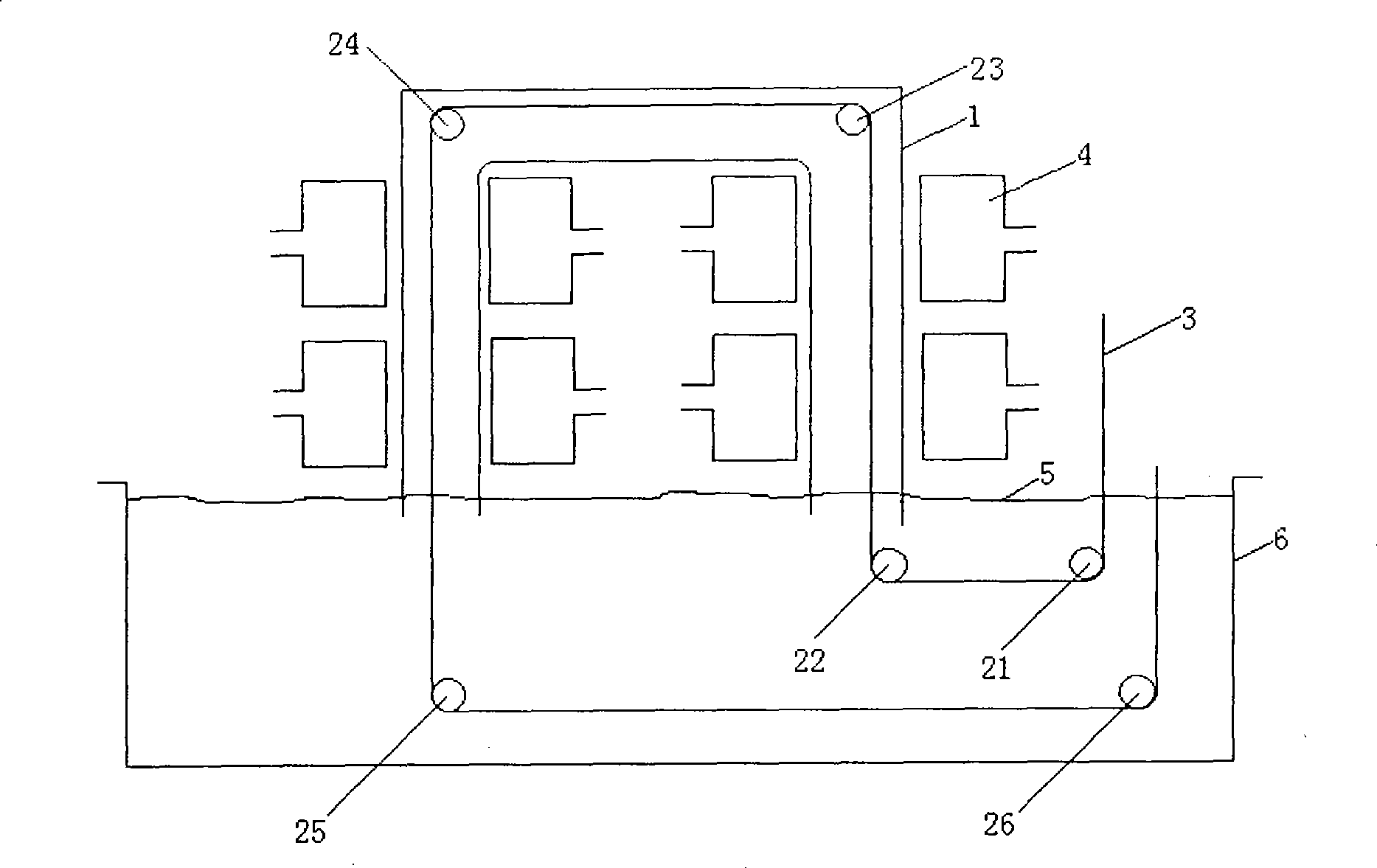

Penetrating type reverse-flow drying device

InactiveCN103471373AStrong penetrating powerLow running costDrying gas arrangementsDrying machines with progressive movementsTransport systemPulp and paper industry

The invention discloses a penetrating type reverse-flow drying device. The penetrating type reverse-flow drying device comprises a heat exchanger, an air heater, a driving drum, a driven drum, a sieve plate type conveying steel belt and a dryer body, wherein an air blower is connected with one side of the upper end of the heat exchanger, the air heater is connected with one side of the lower end of the heat exchanger, the driving drum is connected with a double-stage cycloidal-pin wheel speed reducer through a transmission chain, a material conveying system is formed by the driving drum and the driven drum through the sieve plate type conveying steel belt, a feeding hopper is arranged at one end of the material conveying system, a discharging hopper is arranged at the other end of the material conveying system, the sieve plate type conveying steel belt penetrates through the dryer body, the dryer body is of a sealed structure, a plurality of axial fans are reasonably distributed on the top face and the bottom face of the dryer body, one side of the dryer body is connected with an outlet of the air heater, the other side of the dryer body is connected with an suction fan, and an air outlet of the suction fan is connected with an inlet pipe arranged at the bottom of the heat exchanger. The penetrating type reverse-flow drying device is simple in structure and good in practicability, can achieve rapid and efficient drying of materials, is low in energy consumption and has broad prospects.

Owner:东莞市胜源纸品有限公司

Heat treatment method of steel belt for packages and steel belt for packages

ActiveCN101363078AGuaranteed plasticityExtend the time of austemperingFurnace typesProcess efficiency improvementTowerWater cooling

The invention relates to a heat treatment method of a steel strip for packaging, comprising the following steps: a) the steel trip is heated to the austenitizing temperature; b) isothermal quenching is carried out in molten lead; c) the lead is scraped off in a carbon tower; and d) the strip is cooled by water. The heat treatment method is characterized in that the temperature range of the isothermal quenching in the step b) is 355-365 DEG C and the isothermal quenching time is 21-28s. The invention further discloses a steel strip for packaging obtained by the heat treatment method. The components of the steel strip (by weight percentages) are as follows: 0.29-0.35% of C, 0.15-0.35% of Si, 1.20-1.55% of Mn, not more than 0.030% of P, not more than 0.030% of S and Fe. The heat treatment method solves the problems that tensile strength of the existing steel strips for packaging can not exceed 1250MPa, the elongation after fracture is less than 6%, and the two-phase region quenching profile of a sheet is poor.

Owner:上海宝钢新材料技术有限公司

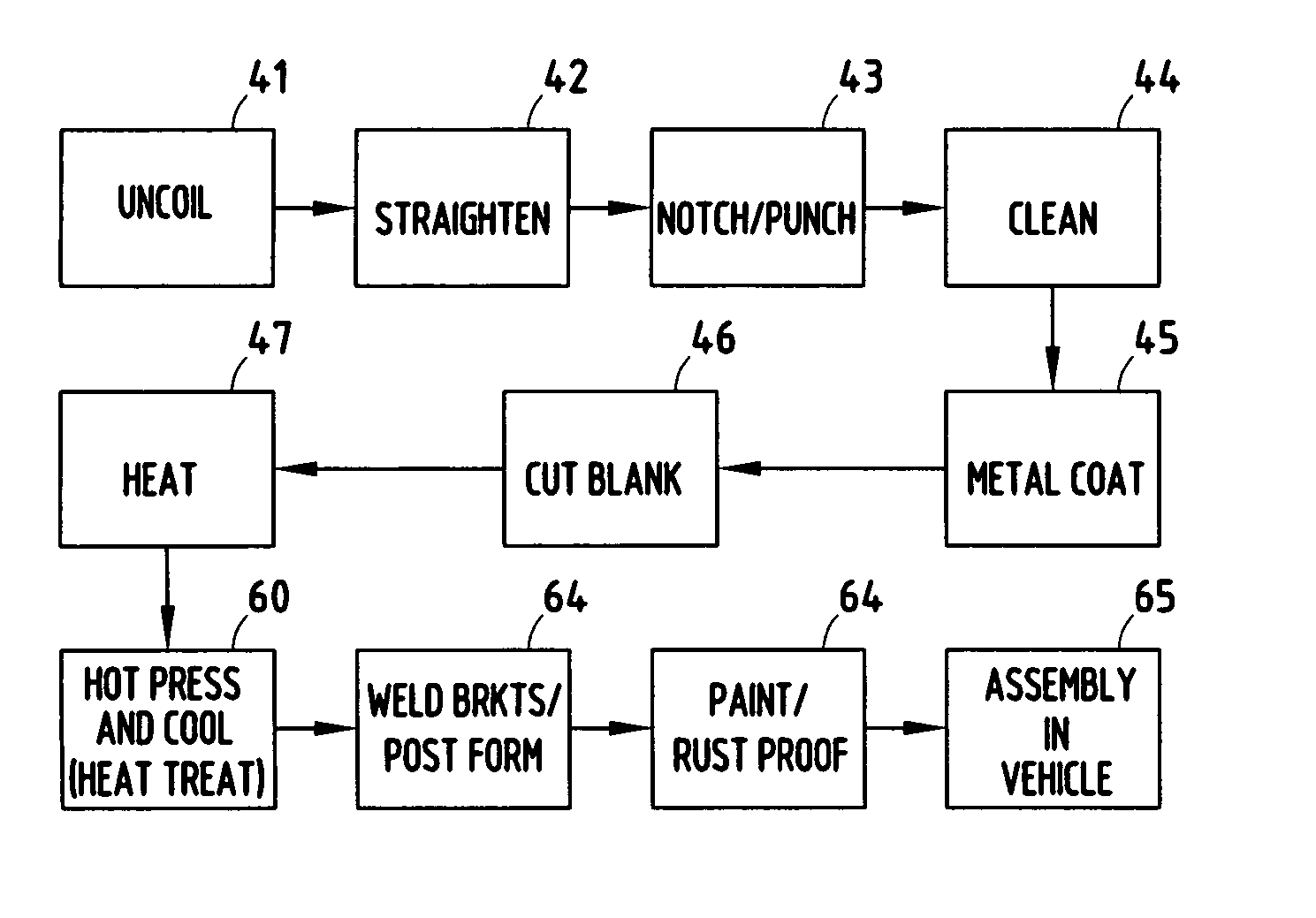

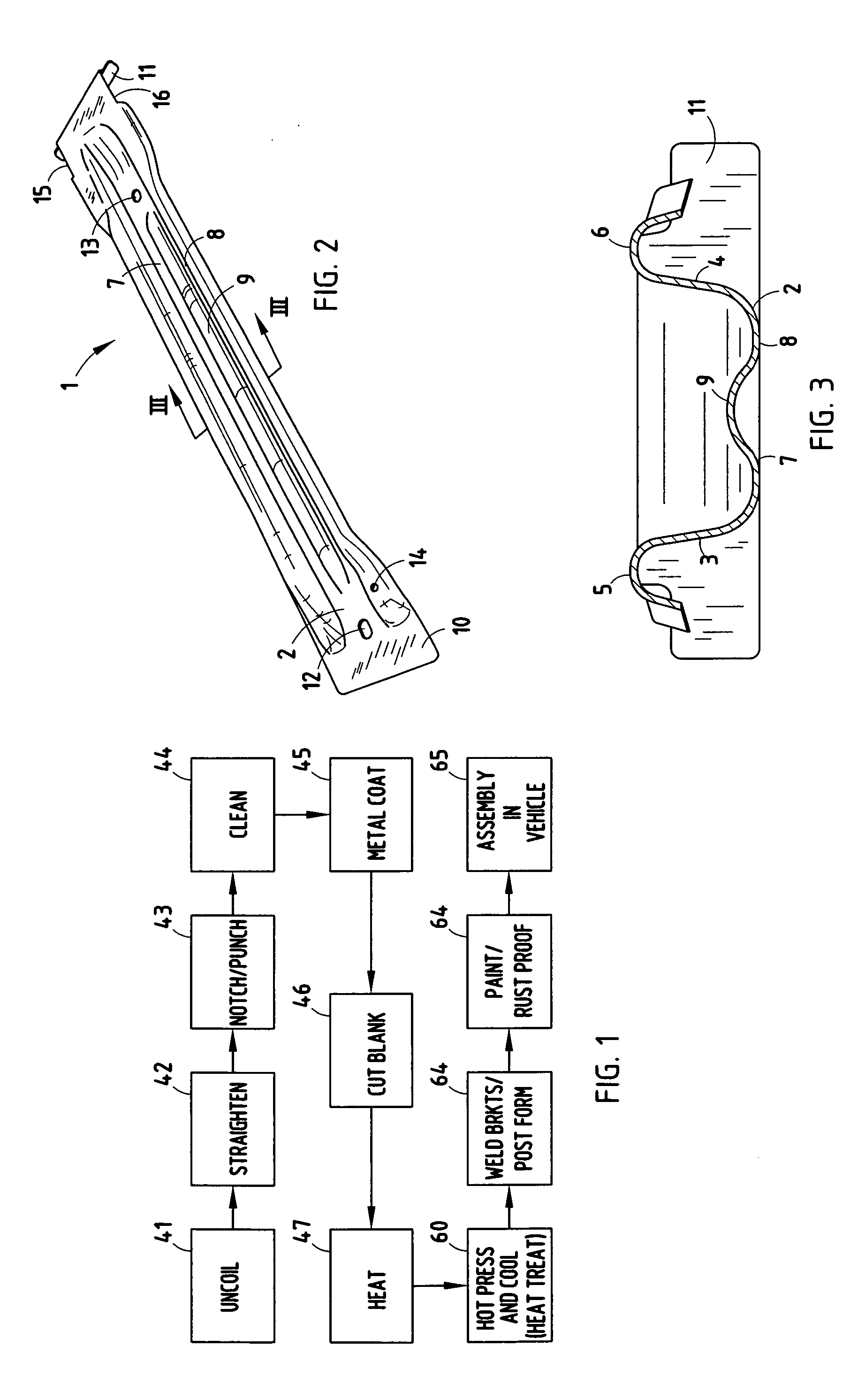

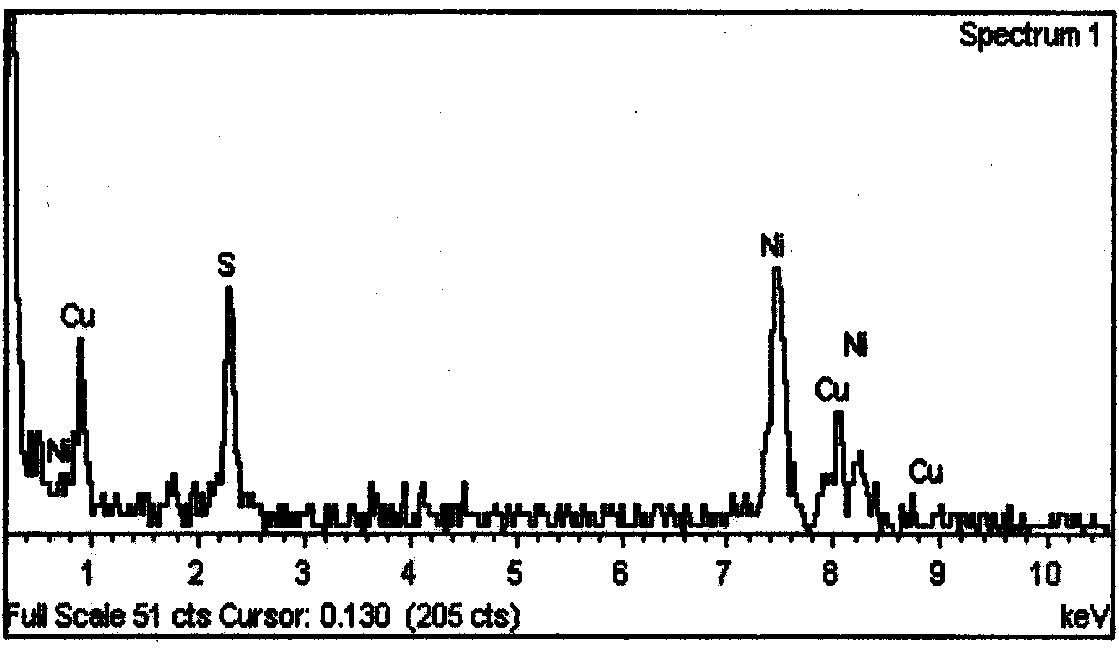

Method for making structural automotive components and the like

InactiveUS20060130940A1Reduce scaleReduced decarburizationVacuum evaporation coatingSurface reaction electrolytic coatingHigh intensityPhase change

A method for making structural automotive components and the like provides a strip of high strength steel having a selected thickness. A predetermined thickness of a metal coating, such as nickel, is applied to the opposite faces of the steel strip. The coated steel strip is cut to form a blank. The blank is heated in a generally open atmosphere to a temperature in the range of 800° C. to 1000° C. within less than ten minutes, thereby diffusing at least a portion of the metal coating a predetermined distance into the faces of the steel strip portion of the blank to alleviate scale formation, and simultaneously raise the temperature of the blank for hot forming the same. The heated blank is hot formed in a pressing tool, and cooled therein to heat treat the formed component through microstructure phase change, without substantial scale formation, such that the component need not be descaled prior to post-form processing and / or assembly in a vehicle.

Owner:BENTELER AUTOMOTIVE CORP

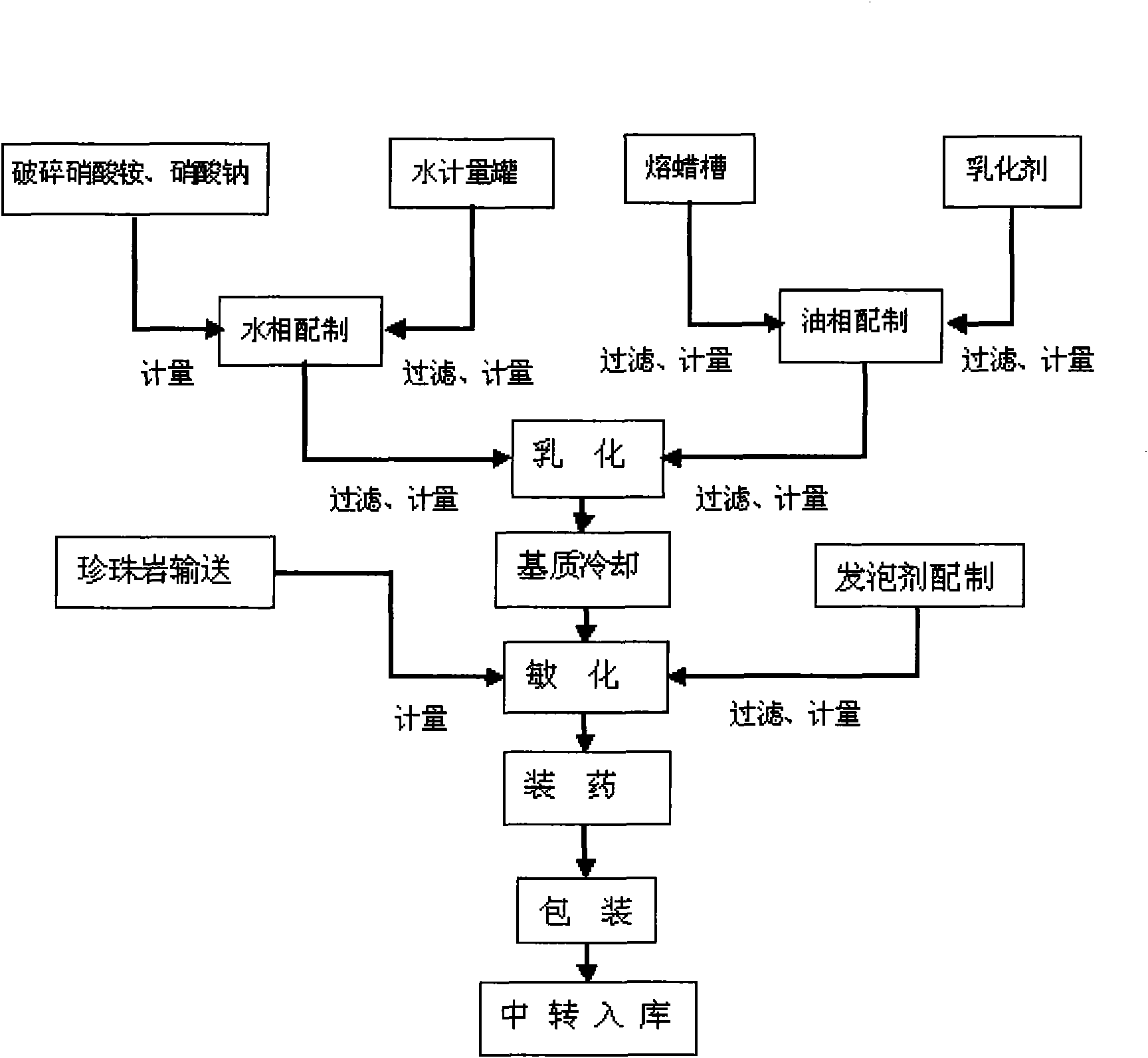

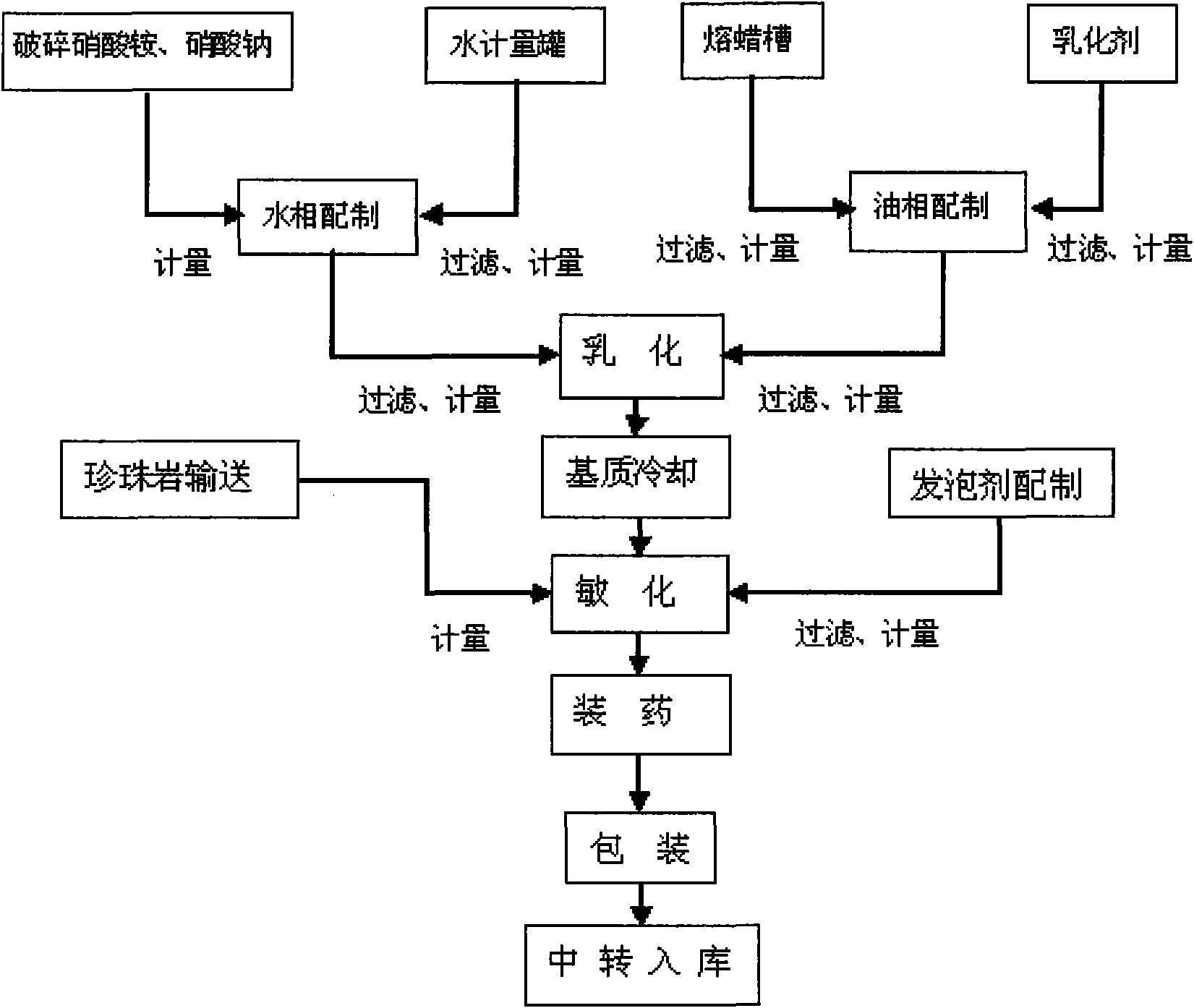

Production method of emulsified explosive

The invention discloses a production method of an emulsified explosive, which comprises the following steps that: water phase and oil phase are prepared, and then water phase solution is added into oil phase solution to be emulsified by an emulsifier to prepare a latex matrix, and simultaneously a cooling steel strip controls the temperature of the latex matrix to be 90 to 105DEG C; and the matrix is cooled, the cooled latex matrix is added into a sensitizing machine, and then one or two of perlite and chemical blowing agent is added in for sensitization; and then the explosive is charged, and finally the loaded explosive is packaged to prepare the emulsified explosive. The production method of the emulsified explosive has the advantages of reducing the production cost, having no waste explosive, waste material, waste gas, waste water and dust in production, realizing the free switching of a plurality of sensitization methods, such as physical sensitization, chemical sensitization and physical and chemical composite sensitization, so as to meet the needs of different consumers; perlite is adopted for physical sensitization, and can improve the explosion performance and the storage performance; and the production method of the emulsified explosive can adapt to the requirements of small-diameter explosive charging and full-automatic packaging automatic calandria.

Owner:宜兴市阳生化工有限公司

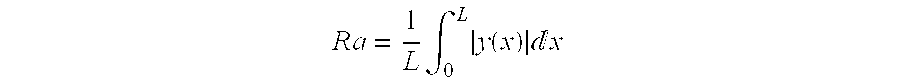

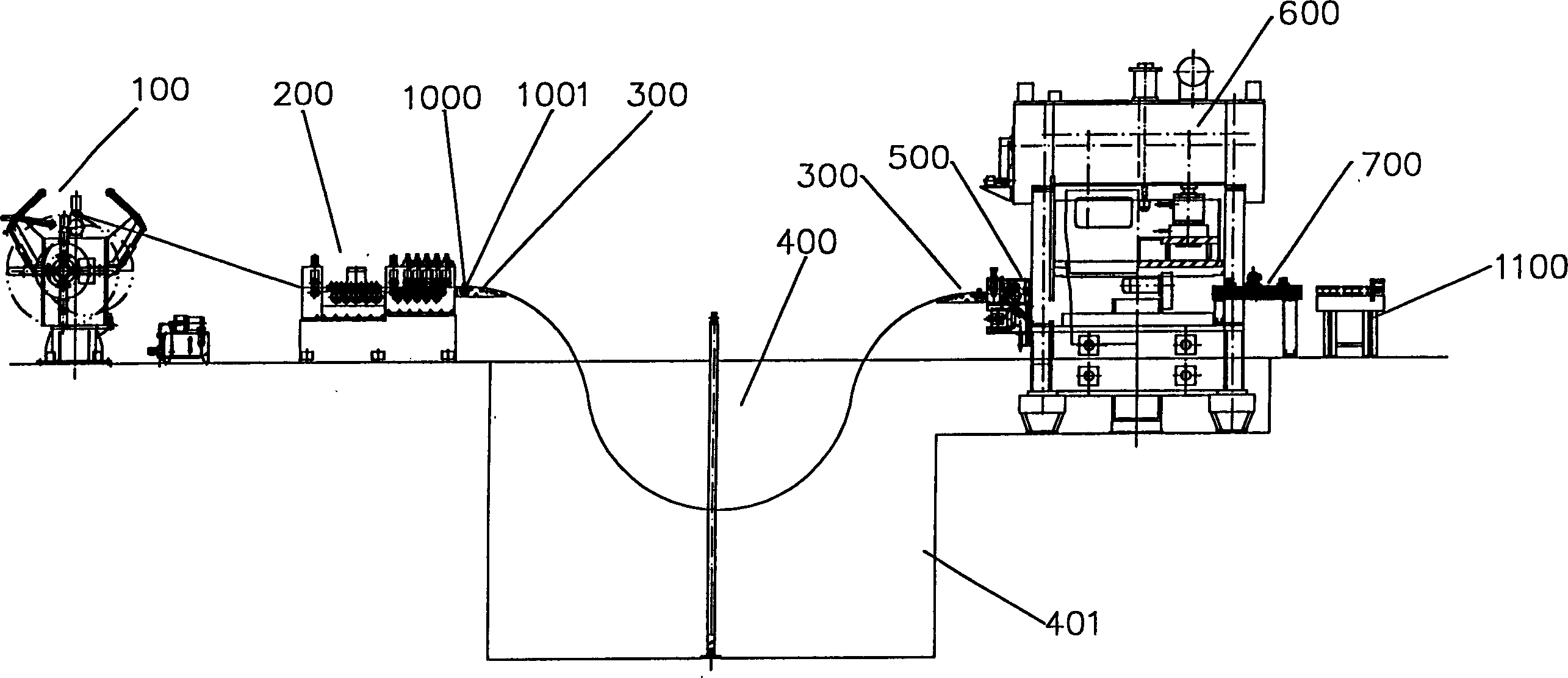

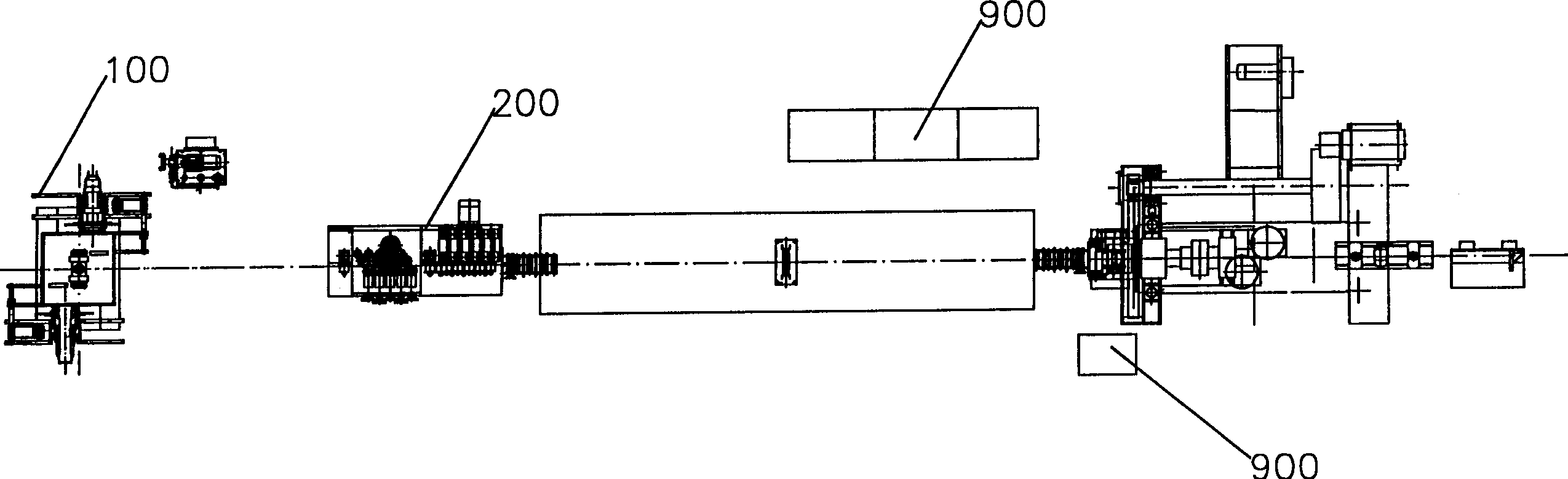

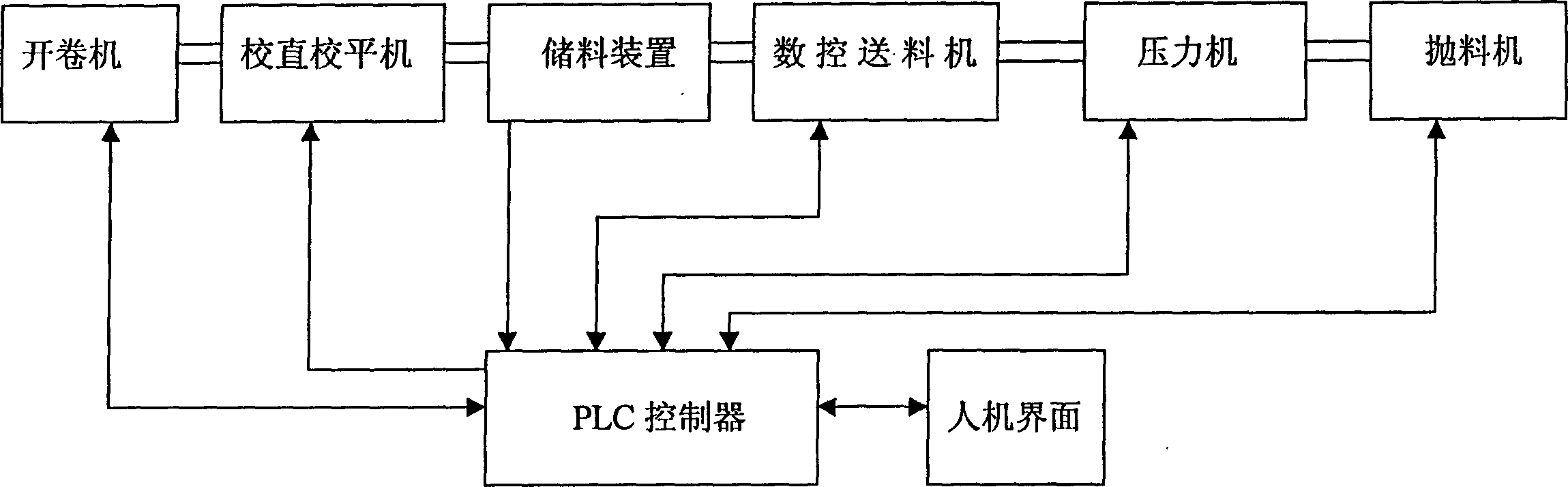

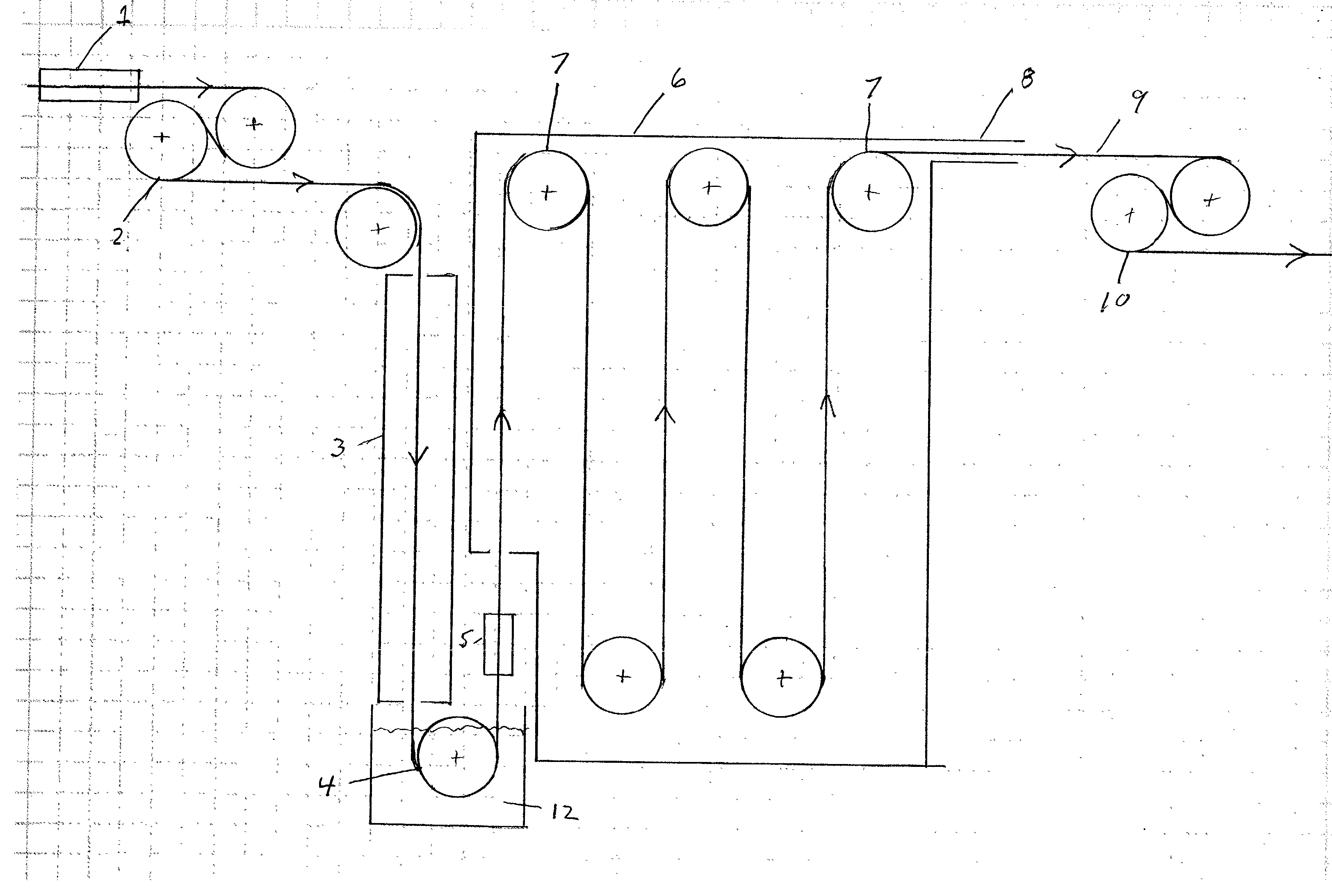

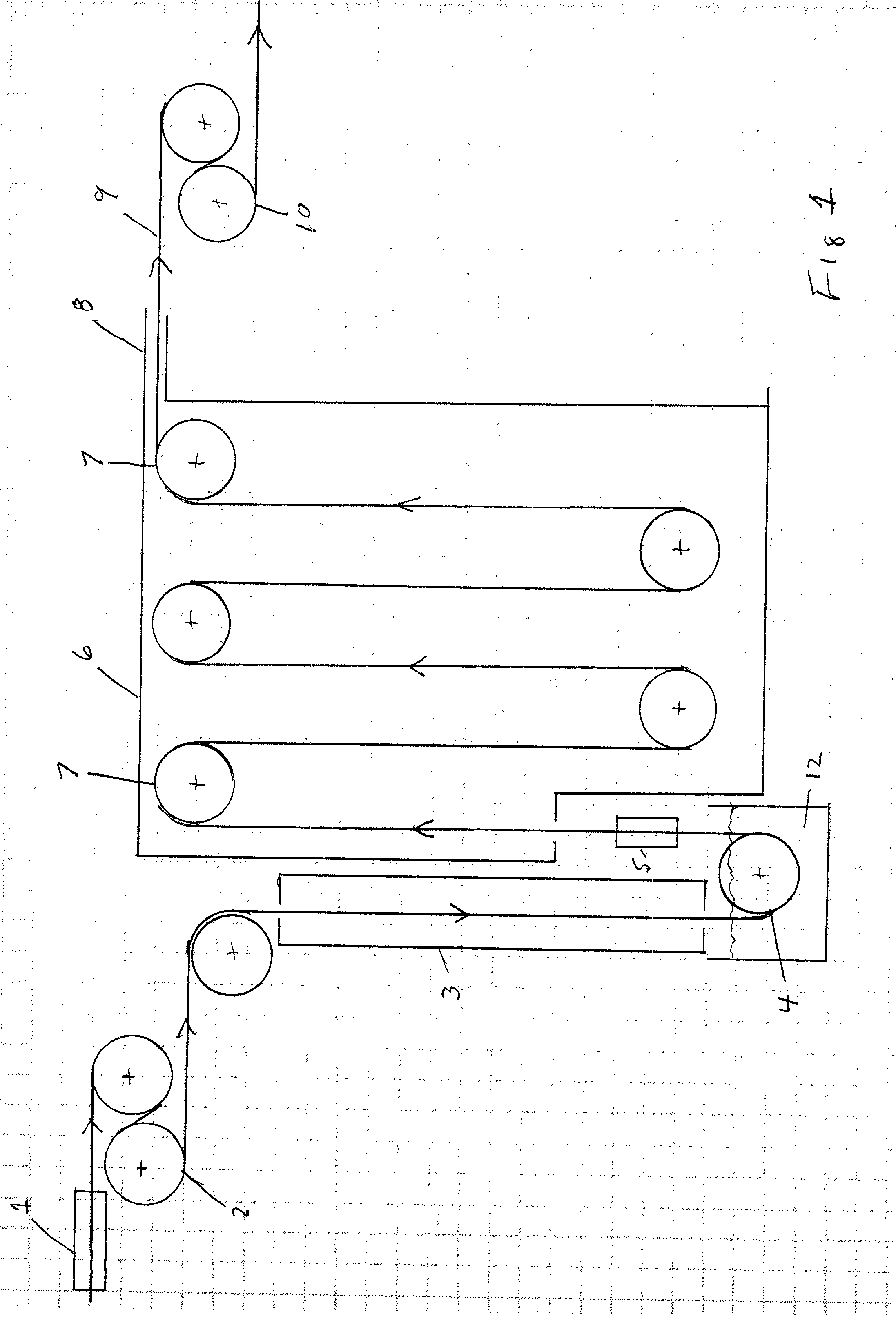

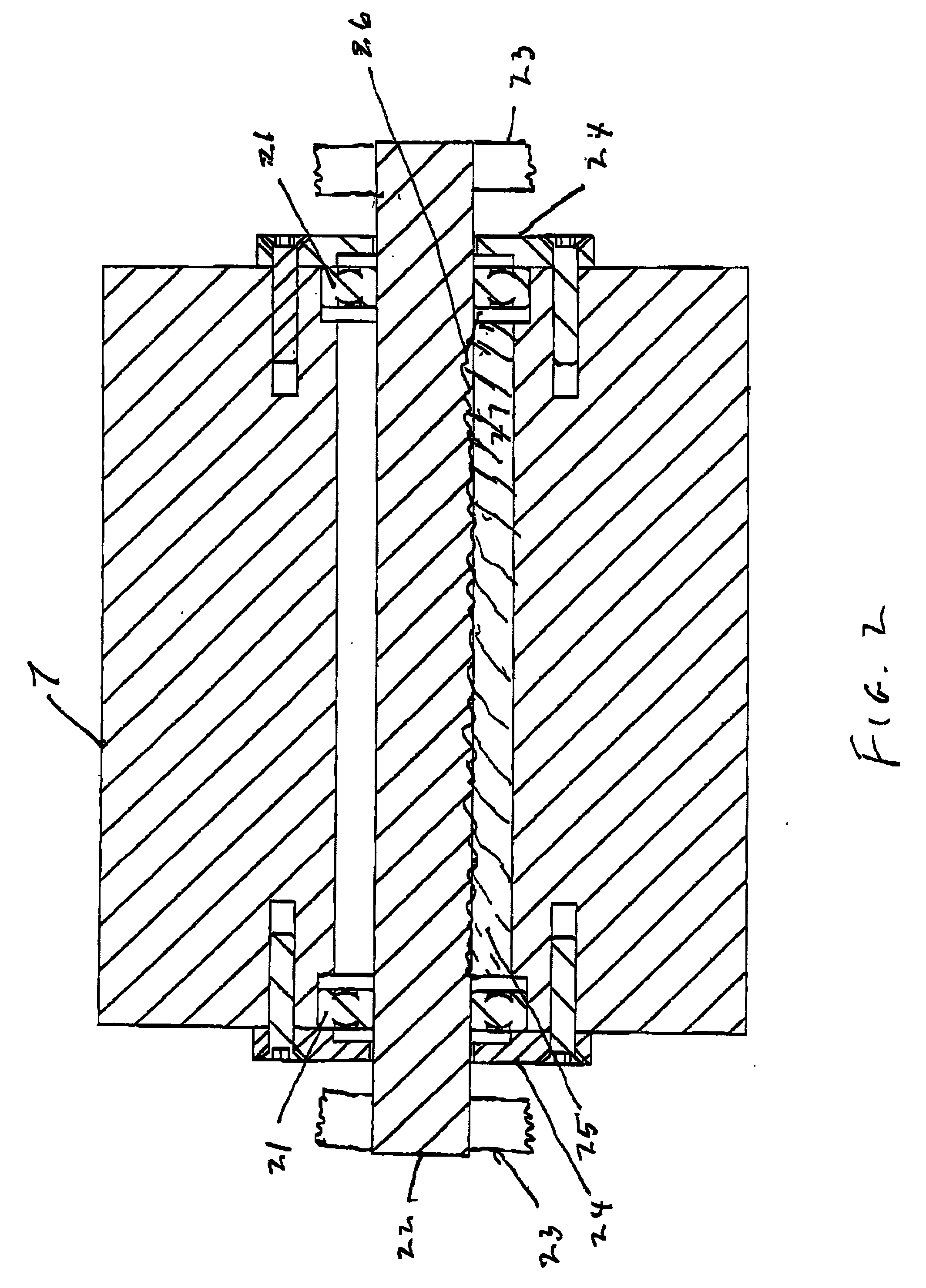

Continuous steel belt punching production line

InactiveCN1416974AImprove machining accuracyIncrease productivityMetal-working feeding devicesShaping safety devicesProduction linePunching

The continuous steel belt punching production line incldues steel belt unwinding machine, straightening machine, material storage in the back of the straightening machine, numerically controlled feeding mechanism connected to the material storage, pressing machine, material thrower, laser ranger, two regulating trays in the tail and the feeding end of the numerically controlled feeding mechanism separately and electric controller unit. By means of the PLC program controller in the electric controller unit, the production line can punch continuously and automatically in high production efficiency and high product precision.

Owner:BEI JING NEW BUILDING MATERIALGRP

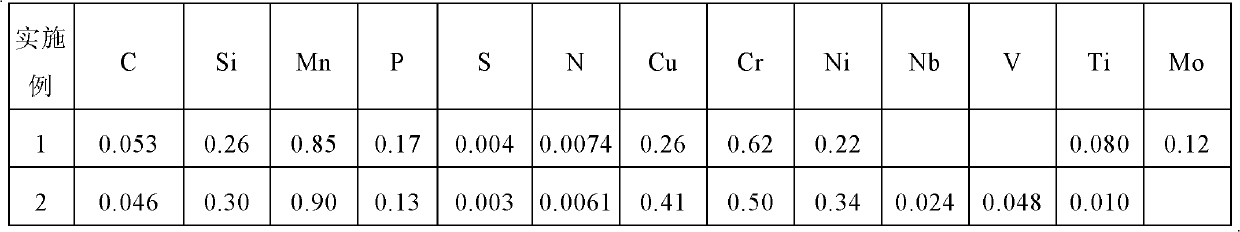

Method for manufacturing 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting

ActiveCN103305770AHigh strengthHigh elongationFurnace typesMetal rolling arrangementsReduction rateChemical composition

The invention provides a method for manufacturing a 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting. The method comprises the following steps of: 1) smelting, wherein molten steel comprises the following chemical components: 0.03-0.08% of C, not more than 0.4% of Si, 0.6-1.5% of Mn, 0.07-0.22% of P, not more than 0.01% of S, not more than 0.012% of N, 0.25-0.8% of Cu, 0.3-0.8% of Cr, 0.12-0.4% of Ni, at least one of microalloy elements including 0.01-0.08% of Nb, 0.01-0.08% of V, 0.01-0.08% of Ti and 0.1-0.4% of Mo, and the balance of Fe and inevitable impurities; 2) strip continuous casting: directly casting a cast strip with thickness of 1-5mm; 3) strip cooling, wherein the cooling rate is more than 20 DEG C / s; 4) online hot rolling of the cast strip, wherein the hot rolling temperature is 1050-1250 DEG C, the reduction rate is 20-50% and the deformation rate is more than 20s<-1>; online austenite recrystallization happens after hot rolling; and the hot-rolled strip is 0.5-3.0mm in thickness; and 5) cooling and coiling, wherein the cooling rate is 10-80 DEG C / s, and the coiling temperature is 570-720 DEG C. The microstructure of the obtained steel strip is mainly formed by fine polygonal ferrite and pearlite.

Owner:BAOSHAN IRON & STEEL CO LTD

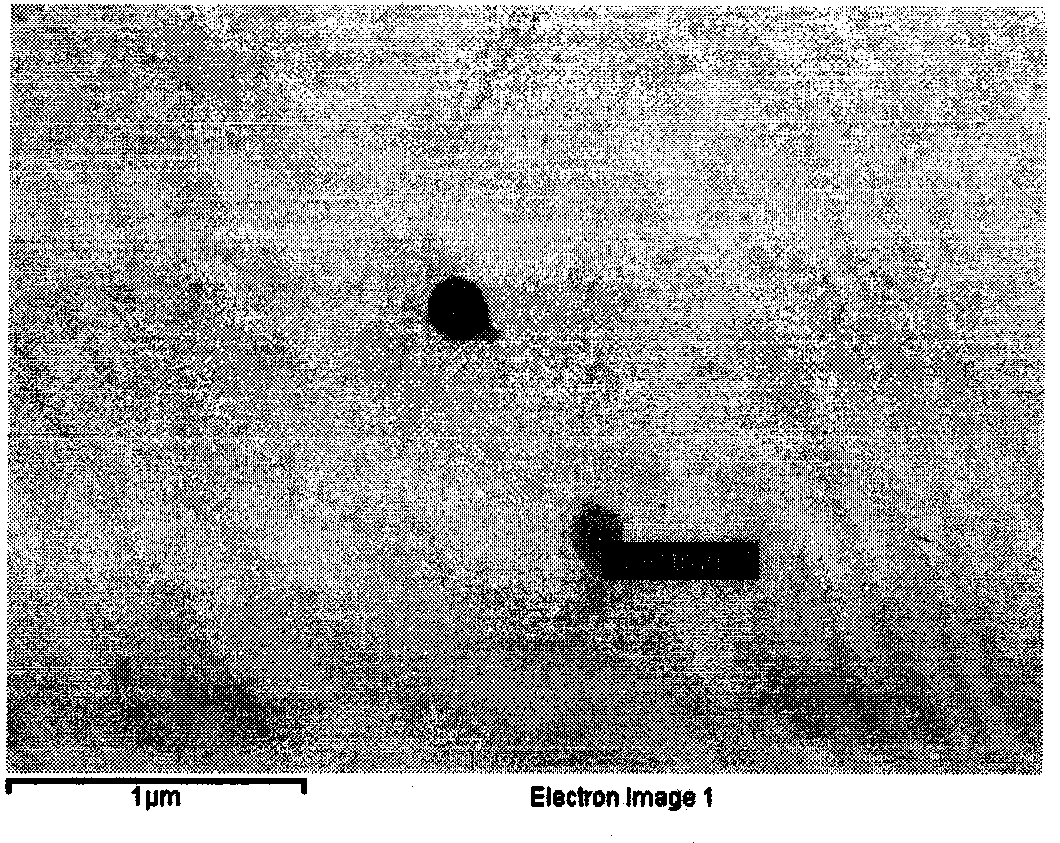

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894AReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

The invention relates to high-strength weather resisting steel with Cu2-xS dispersed precipitates, which comprises the following chemical components in percentage by weight: 0.04-0.08% of C, 0.20-0.40% of Si, 0.4-1.0% of Mn, 0.03-0.12% of P, not more than 0.2% of S, 0.01-0.06% of Al, 0.20-0.80% of Cu, 0.40-0.6% of Cr, 0.12-0.40% of Ni, 0.001-0.006% of Ca and the balance of Fe and inevitable impurities. The welding cold crack sensitivity coefficient Pcm is not more than 0.18%. A manufacturing method comprises the following steps of: acceleratedly cooling both sides of a cast belt formed by continuous casting by using a gas and adopting a thin belt continuous casting production technology, wherein the cooling rate is 150-200 DEG C / s; performing the entire double-roller continuous casting process in a closed chamber filled with protective atmosphere; and arranging one to two stands for online hot rolling, wherein the thickness of a finished steel belt reaches 0.6-2 mm. The desulfurization procedure in steel making process can be omitted, and the steel making cost is reduced. The segregation of copper elements is inhibited, meanwhile, a large quantity of dispersed Cu2-xS precipitates can be formed to achieve the effect of dispersion strengthening.

Owner:BAOSHAN IRON & STEEL CO LTD

Zinc-plated hot-formed steel plate or steel strip with excellent cold bending performance and manufacturing method thereof

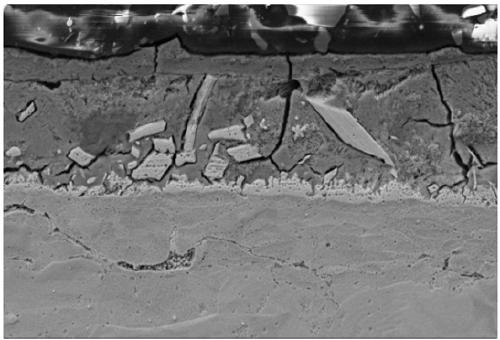

InactiveCN109371325AGood cold bending performanceHot-dipping/immersion processesSheet steelAustenite grain

The invention discloses a zinc-plated hot-formed steel plate or steel strip with excellent cold bending performance and a manufacturing method thereof. The zinc-plated hot-formed steel plate or steelstrip comprises a base plate with a surface decarburization layer thickness of 20 [mu]m or below and a zinc coating with an adhesion amount of 10-100 g / m<2> on the base plate. The constituent weight percentage of the base plate is C: 0.1-0.8%, Si: 0.05-2.0%, Mn: 0.5-3.0%, P: <=0.1%, S: <=0.05%, Al: <=0.1%, N: <=0.01%, and the balance Fe and unavoidable impurities. The average size of original austenite grains of the base plate is 15 [mu]m or below. The hot-formed steel plate or steel strip has a continuous and complete coating, no cracks extending to the base plate and excellent cold bending performance on the basis of meeting the conditions that the tensile strength of the base plate after hot-forming is 1500 MPa and the elongation after breaking is 5%.

Owner:BAOSHAN IRON & STEEL CO LTD

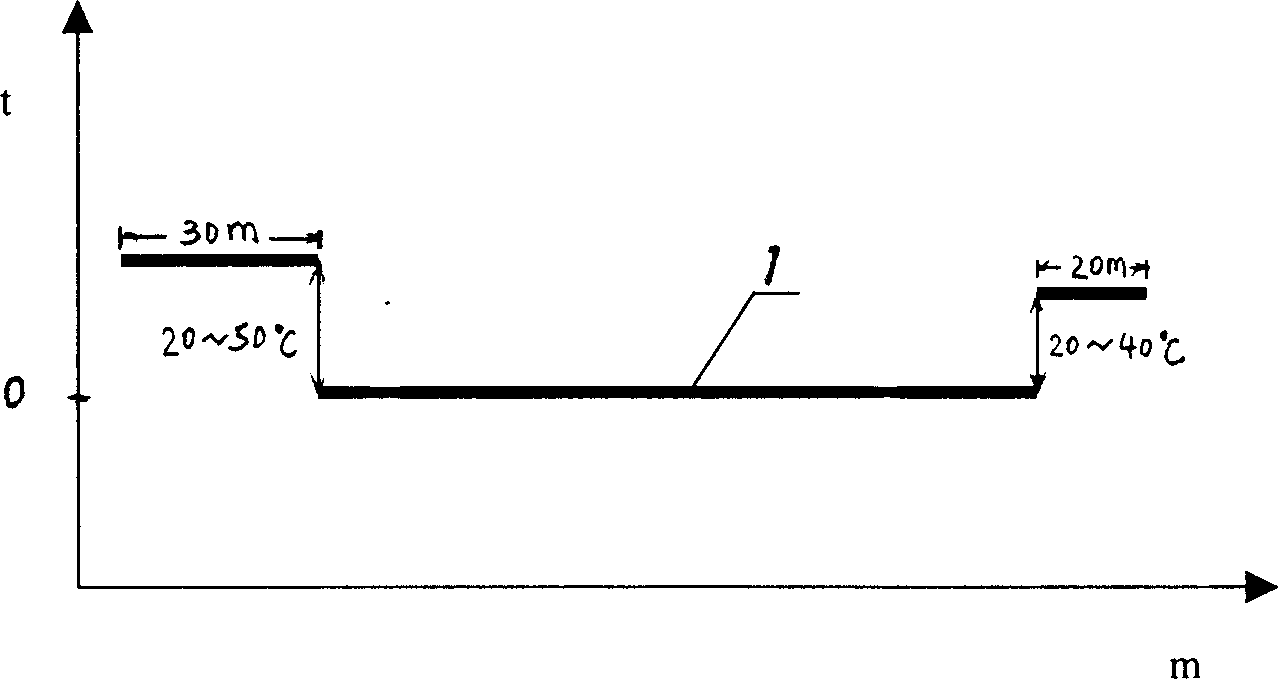

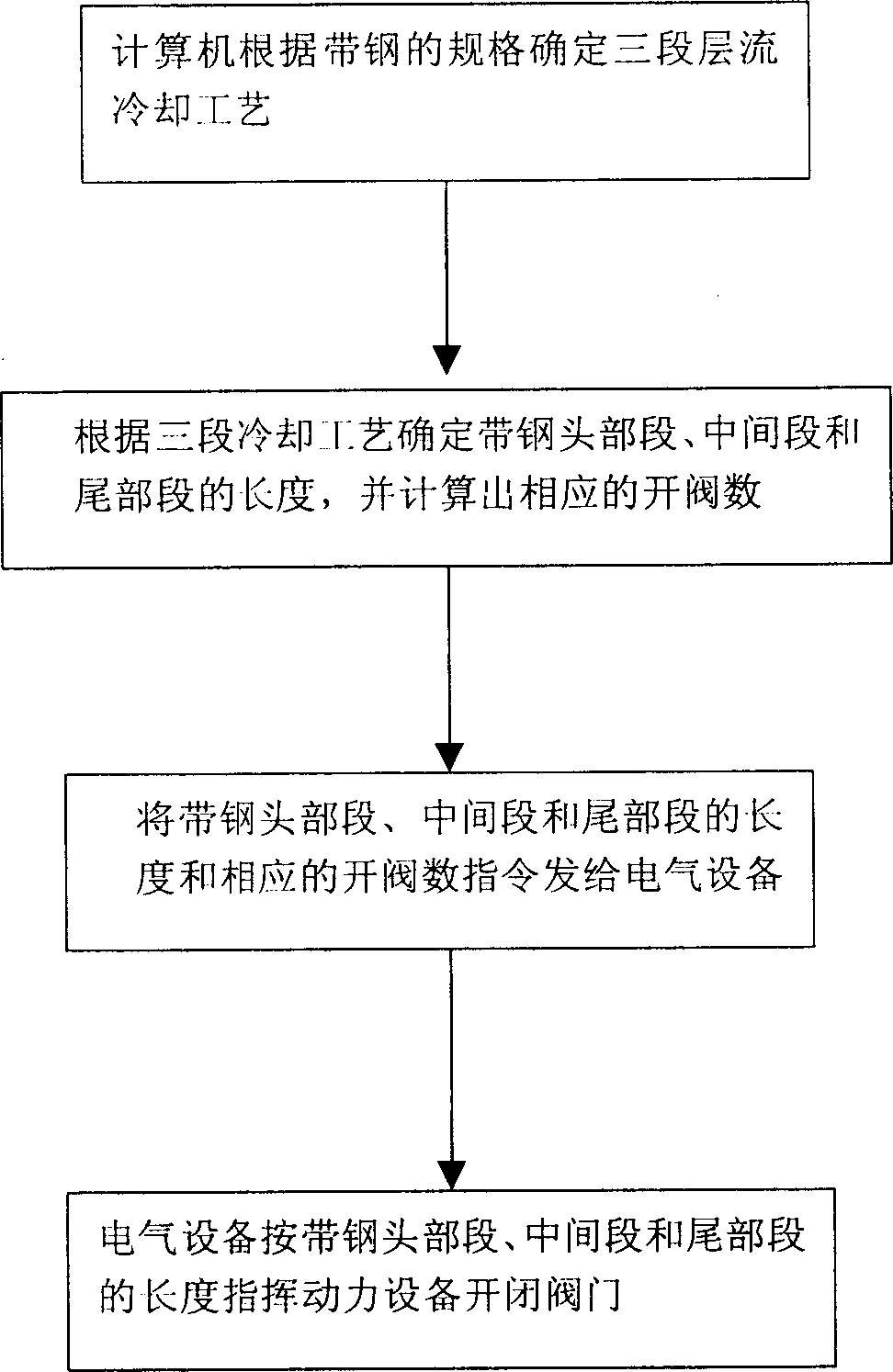

Three section laminar flow cooling technology for hot rolling band steel

InactiveCN1483528AImprove performance uniformitySolve productivityTemperature control deviceWork treatment devicesEngineeringStrip steel

The present invention provides a three-section cooling process by laminar flow for hot-rolled steel strip. Said process adopts the computer laminar flow cooling control, and is characterized by that the steel strip can be divided into three sections for cooling, first section is head portion section whose length is 30 m, second section is intermediate section of the steel strip, and third section is the tail portion section whose length is 20 m, and the cooling temperatures of said three sections are respectively controlled in that its intermediate section temp. is equal to the objective coiling temp., its head portion section temp. is 20-50 deg.C higher than that of objective coiling section, and its tail portion section temp. is 20-40 deg.C higher than objective coiling temp. Said invention can improve the performance uniformity of steel strip.

Owner:ANGANG STEEL CO LTD

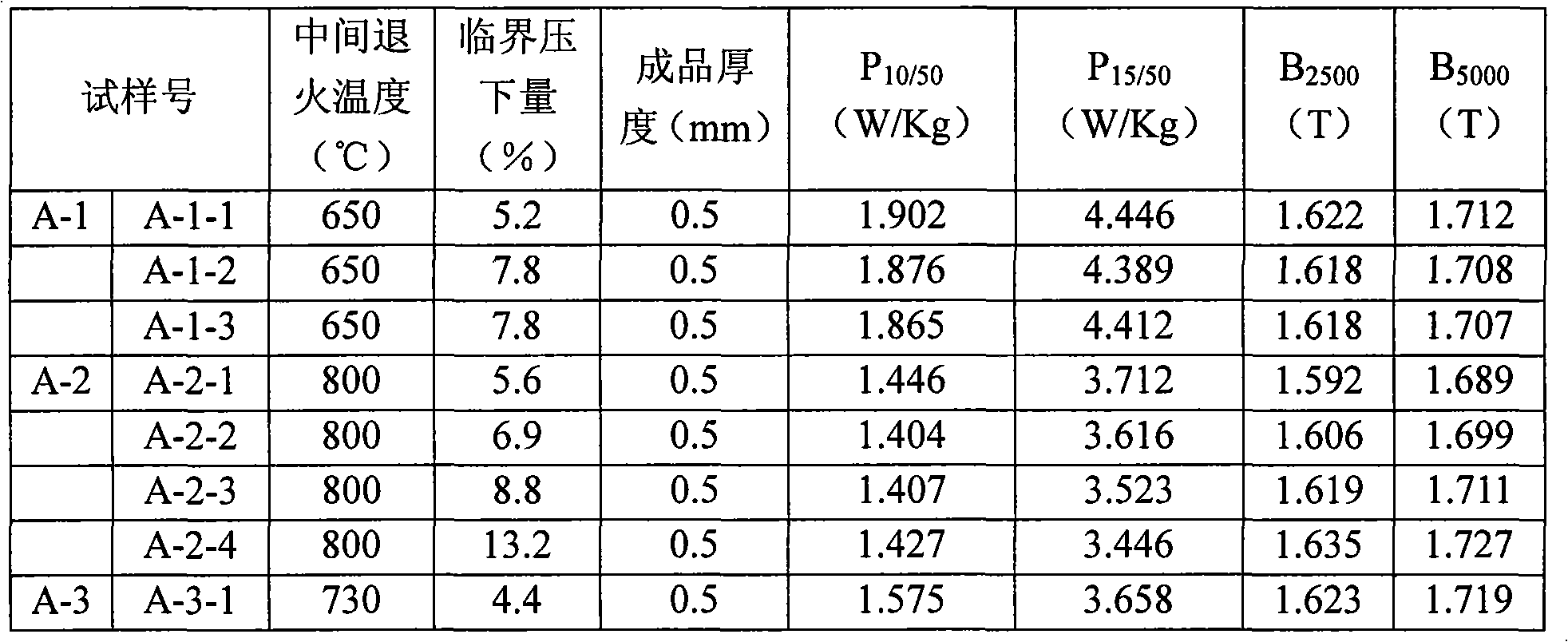

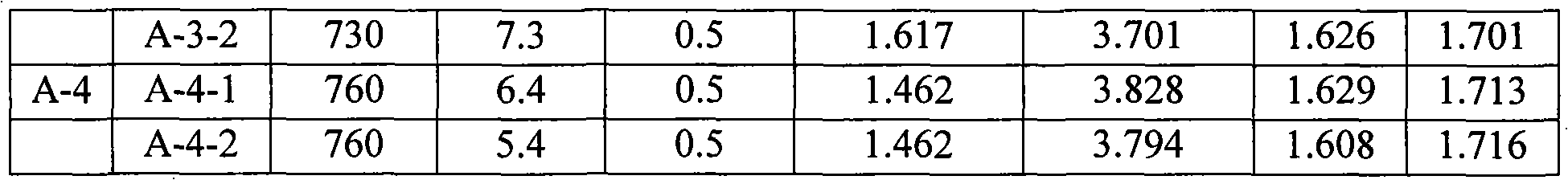

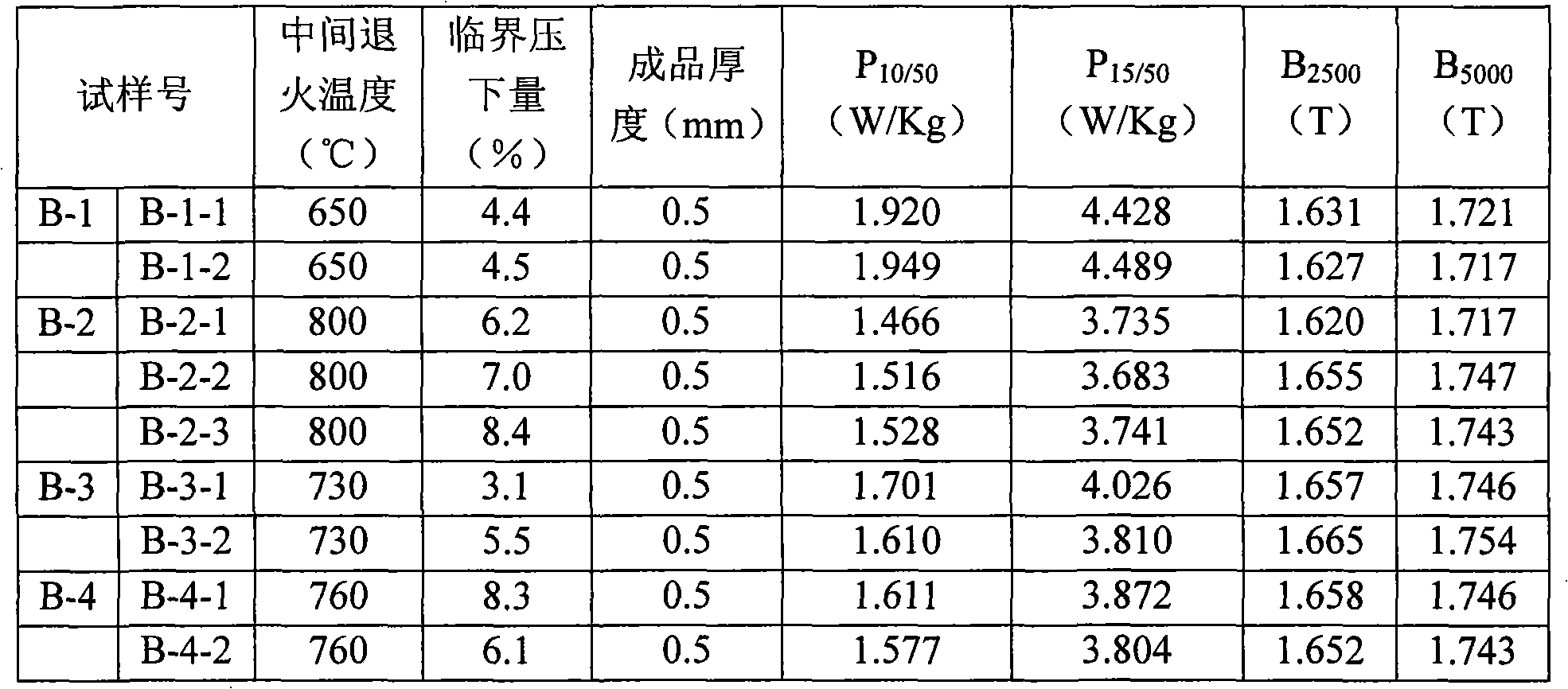

Preparation method of low carbon low silicon no-aluminum half-technique non oriented electrical steel

ActiveCN101306434AStrong magnetismLow costTemperature control deviceMetal rolling arrangementsRare-earth elementChemical composition

A method for preparing low-carbon low-silicon non-aluminum semi-process non-oriented electrical steel belongs to the technology field of the electrical steel with good magnetic performance. The preparation method includes the processing steps of meeting the requirements for the casting blank, such as the chemical components comprise less than or equal to 0.005% of C, 0.1%-1.0% of Si, less than or equal to 0.35% of Mn, less than or equal to 0.08% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, less than or equal to 0.015% of O, inevitable impurities and Fe in balancing amount, according to the composition design for the hot rolling raw material; hot-charging and hot-rolling of the casting blank; acid-cleaning and cold-rolling of the steel plate after the hot-rolling; intermediate-annealing of the steel strip; cold-rolling of the critical deformation; relieving stress and annealing by users; and obtaining the semi-process non-oriented electrical steel with good magnetic performance. The method has the advantage that the final product has good magnetic performance: P15 / 50 is equal to 3.45-5.05 W / Kg, and B5000 is equal to 1.69-1.76 T. The casting blank contains no alloying elements such as Al, Sn, Sb, Cu, Cr, Ni, B, rare earth elements, etc., thus considerably reducing the production cost. The larger critical rolling reduction is adopted, the annealing technique is optimized, and the prepared finished products have better magnetic performance.

Owner:SHOUGANG CORPORATION

Industrial vapour generator for the deposition of an alloy coating onto a metal strip

ActiveUS20110000431A1Improve evennessEasy to superviseLiquid surface applicatorsVacuum evaporation coatingMetal stripsMetal coating

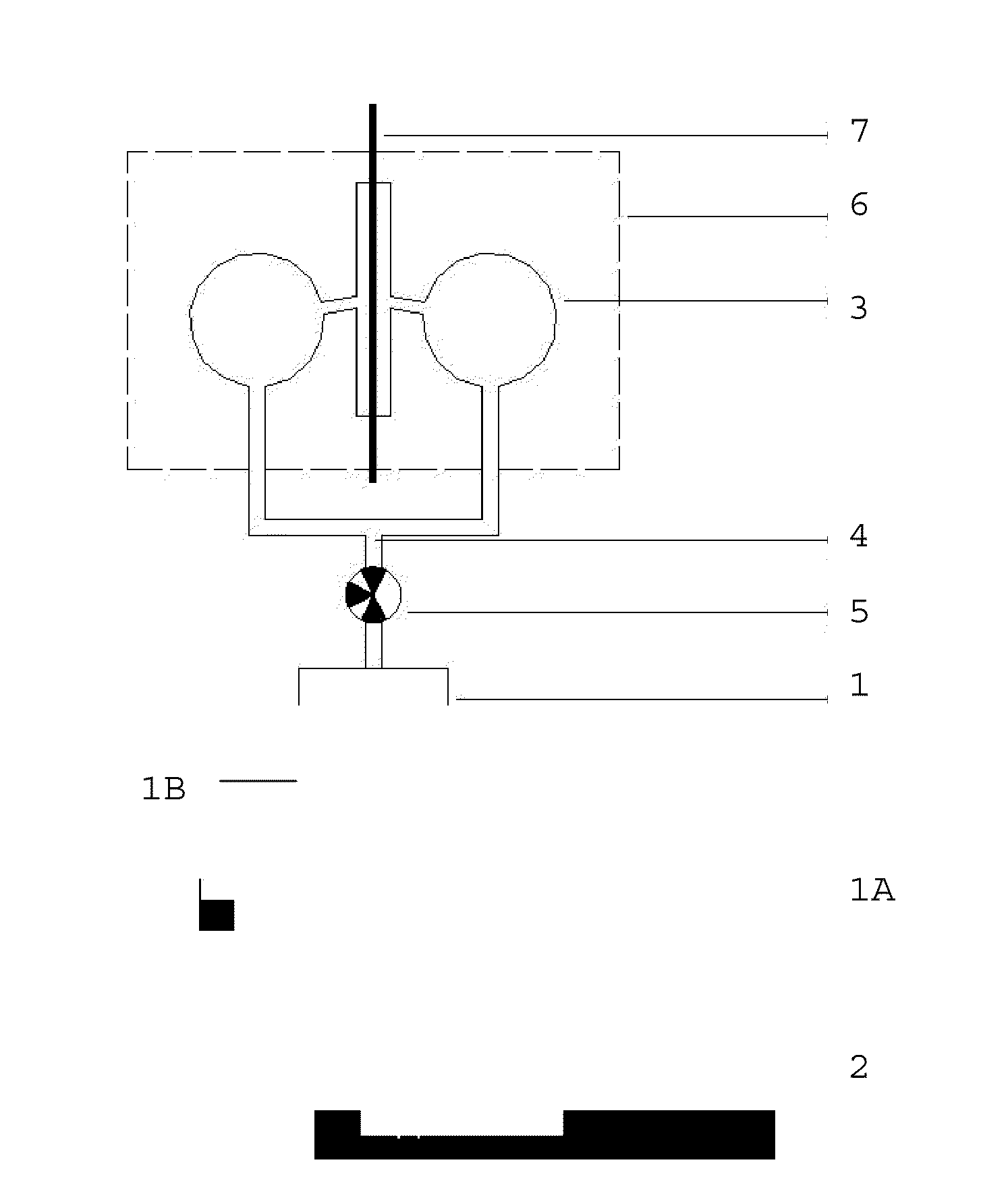

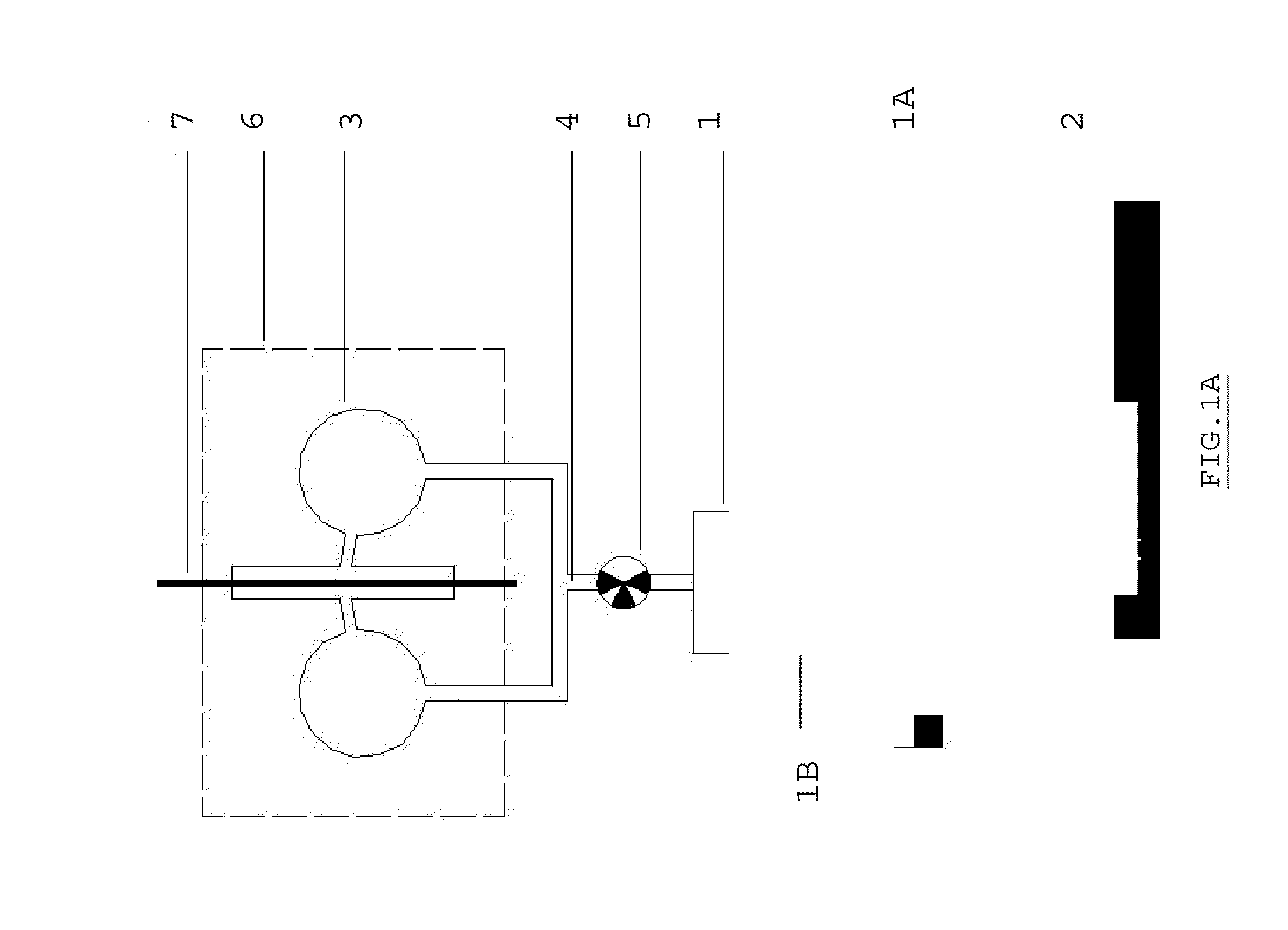

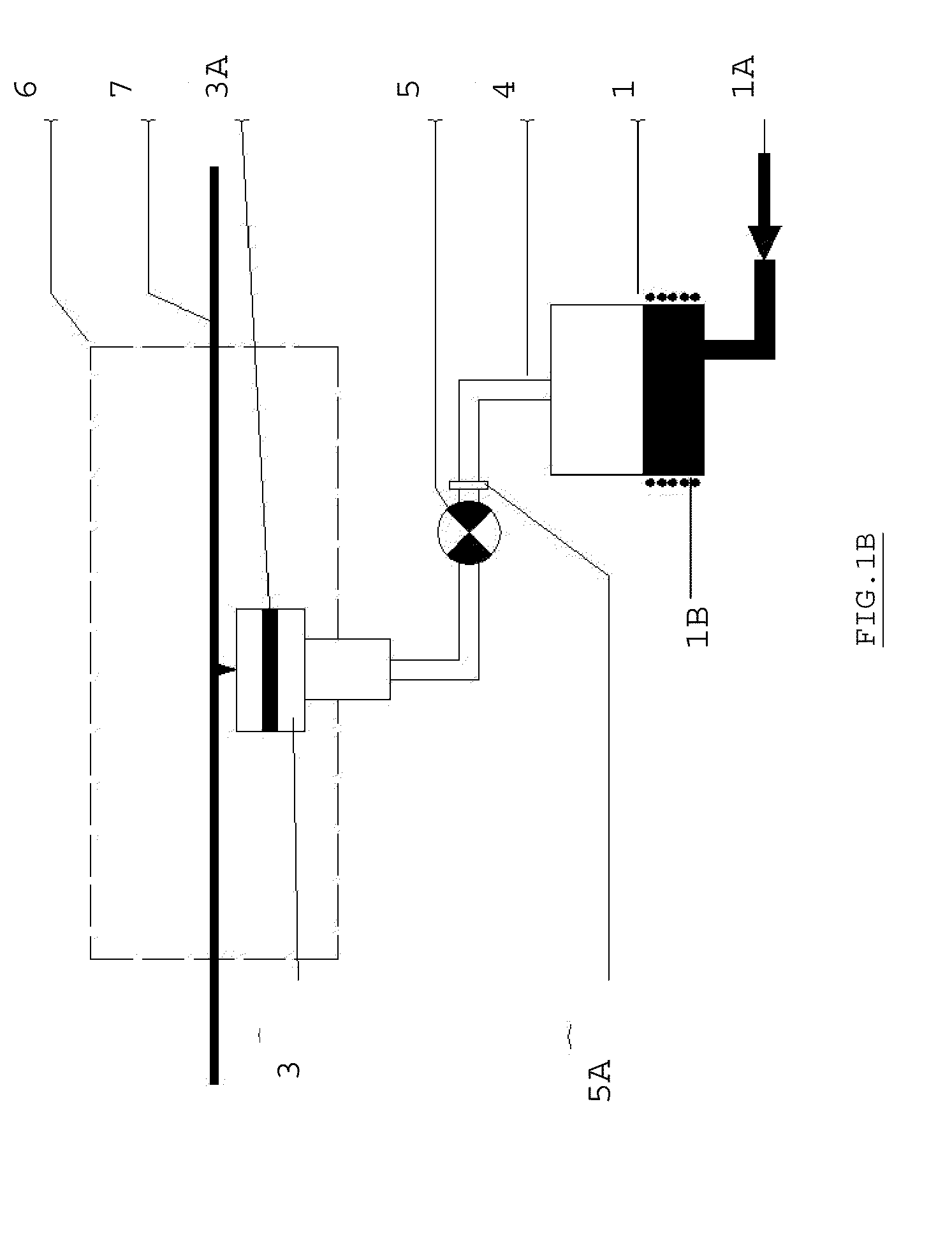

The invention relates to a vapour generator for the deposition of a metal coating onto a substrate (7), preferably a steel strip, that comprises a vacuum chamber (6) in the form of a housing including a vapour deposition head or ejector (3) in tight communication via a supply duct (4) with at least one crucible (1) containing the coating metal in a liquid form and located outside the vacuum chamber (6), characterised in that the ejector (3) includes a longitudinal slot for the vapour outlet acting as a sonic throat and extending on the entire width of the substrate (7), a filtration medium or a charge loss member (3A) made of a sintered material being provided in the ejector immediately before said slot on the vapour path in order to equalise the flow speed of the vapour exiting the ejector (3) through the sonic throat.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Superfast heat treatment method of high-speed steel

The invention relates to a superfast heat treatment method of high-speed steel. The problems that high-strength steel is low in heat treatment efficiency, wastes energy and pollutes the environment are solved. According to the method, a heating device is adopted to heat the high-strength steel to the peak temperature Tp from the room temperature within 30 s, heat preservation is carried out for 5to 10 s, a cooling device is used for cooling the high-strength steel to the room temperature within 5 to 10 s, and the whole process is finished within 60 s; the high-strength steel is a steel wire or steel strip with the carton content ranging from 0.16 to 0.55% and the diameter or thickness being 5 mm or below; Tp exceeds the austenite transformation temperature Ac3 by more than 50 DEG C, Tp isequal to 1000 to 1200 DEG C, the maximum heating speed exceeds 400 DEG C / s, the maximum cooling speed exceeds 3000 DEG C / s, and 50cm / min continuous work is achieved. The method is novel and unique, scientific and reasonable, easy to operate, convenient to use, high in work efficiency, energy-saving, environment-friendly and capable of being widely applied to heat treatment strengthening of thin-specification steel strips and small-specification wire rods, and the method is creation of the high-strength steel heat treatment.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method and apparatus for bainite blades

InactiveUS20020100522A1Maximize propertyMaximize straightnessRotary intaglio printing pressFurnace typesPad printingFerritic matrix

The present invention includes bainitic steel doctor blades, bainitic steel coating blades, bainitic steel creping blades and bainitic steel rule die knives used in gravure printing, flexographic printing, paper making, die cutting of materials including paper, plastic, foam, leather, etc. Other uses include printing processes such as pad printing and electrostatic printing. The invention also includes an improved method for producing bainitic steel strip. The present invention is accomplished by using bainitic steel components that exhibit superior straightness and wear properties and are bendable around small radii. The process of the present invention comprises the steps of annealing a carbon steel resulting in a microstructure of the steel having a dispersion of carbides in a ferritic matrix; cold rolling the annealed steel; cleaning the cold rolled steel to remove oil and dirt; bridle braking the cleaned steel to increase strip tension; austenitizing the steel; submersing the austenitized steel into a quenchant; removing excess quenchant; and isothermally transforming the austenitized steel into bainite. The present process of the invention also includes the use of turn rolls that are housed in an assembly containing salt and / or tin.

Owner:BENTON GRAPHICS

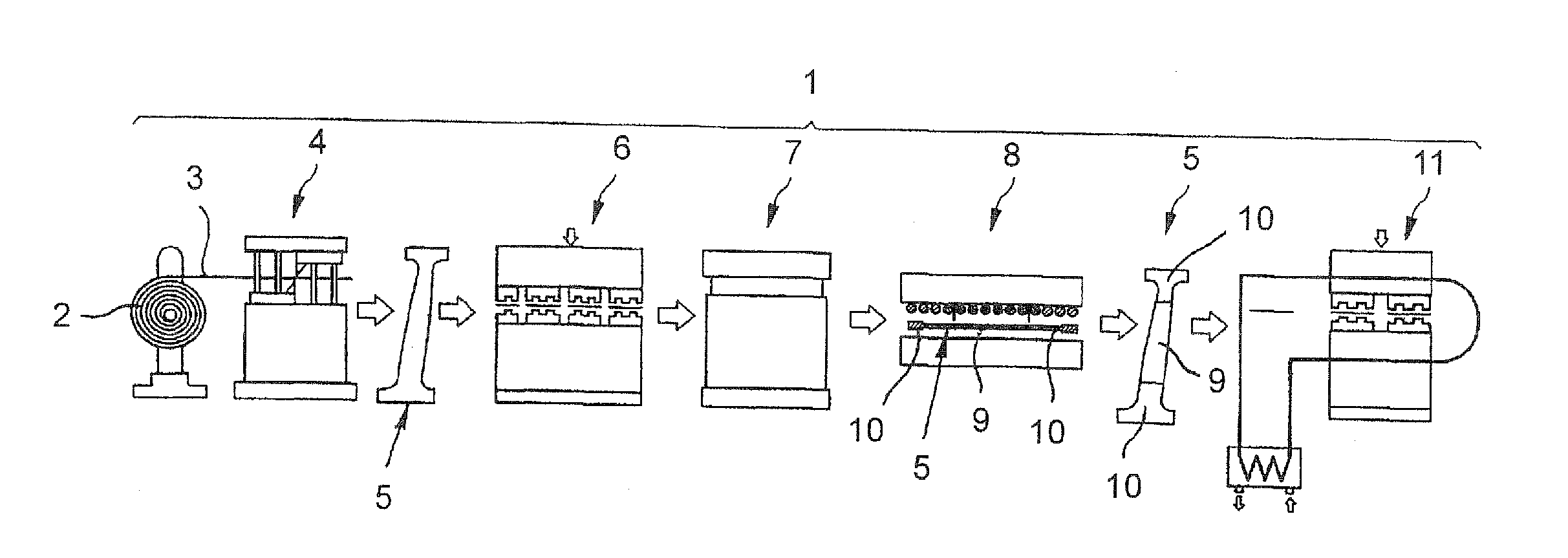

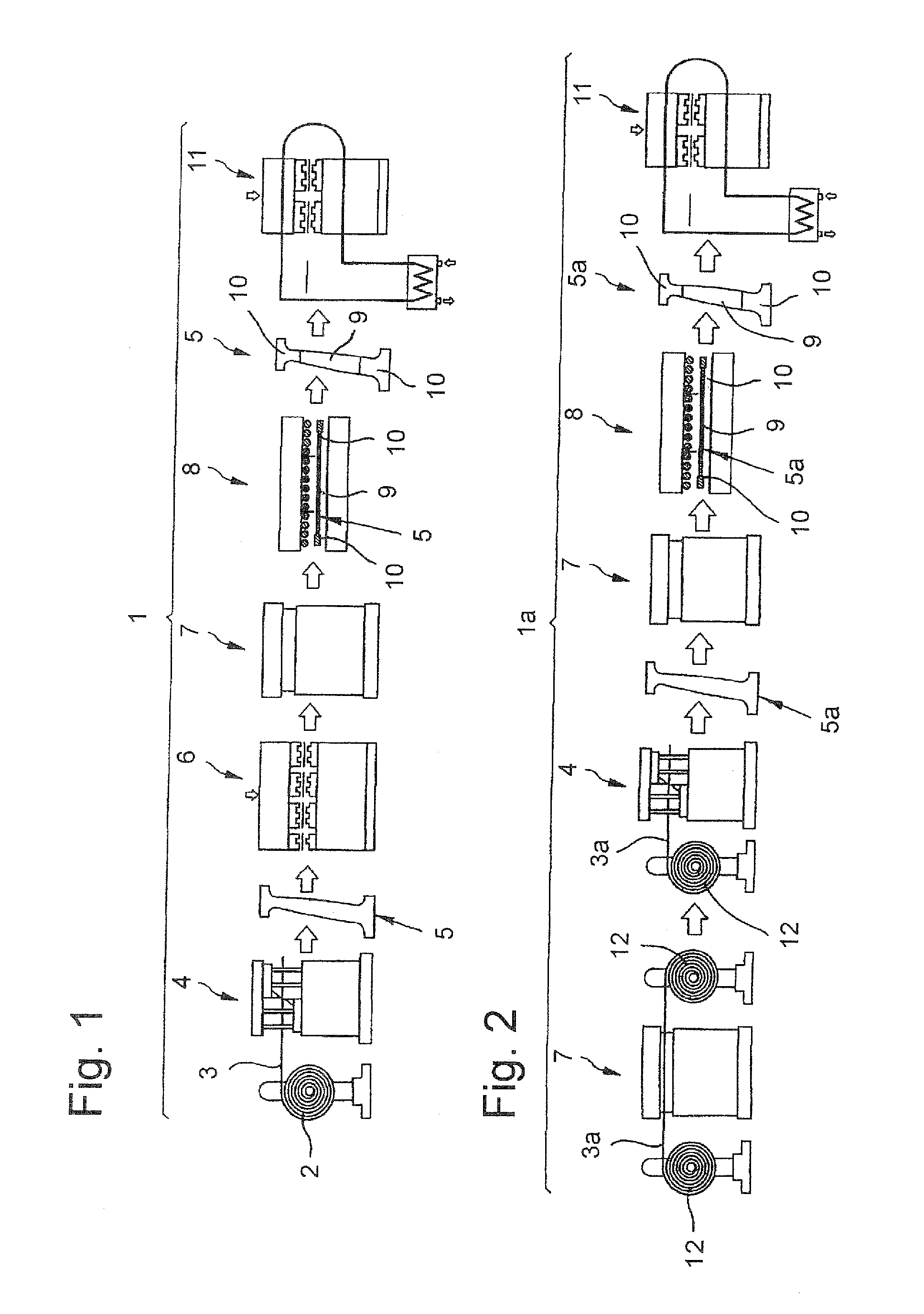

Method and apparatus for hot forming and hardening a blank

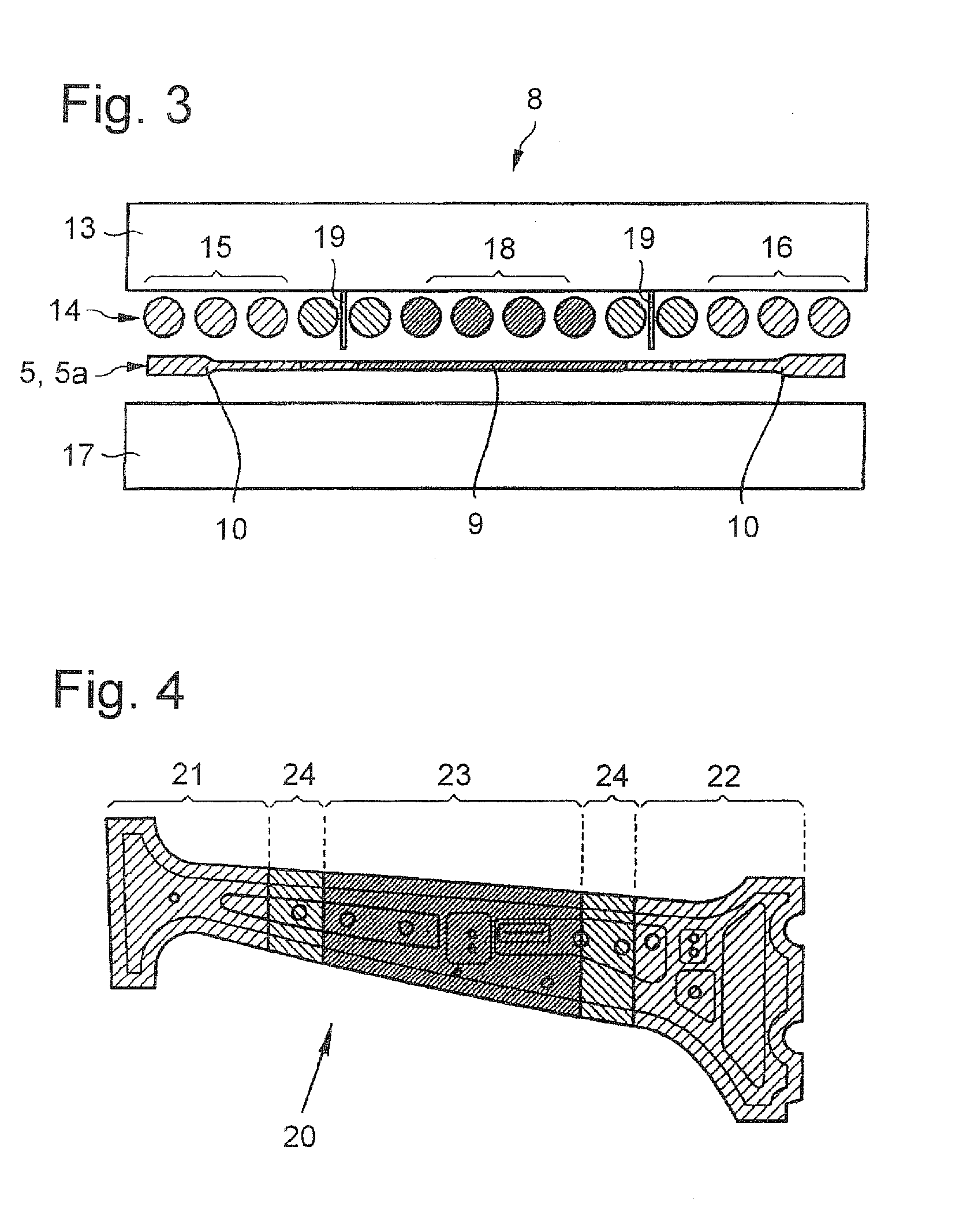

InactiveUS20120006089A1Better withstandInhibition formationShaping toolsFurnace typesSteel beltDuctility

A blank cut from a strip of hardenable hot-formed steel is heated in a furnace to a temperature which is smaller than an Ac3 transformation point in an iron carbon diagram. A first region of the blank is then heated in a conductive heating station to a temperature above the Ac3 transformation point and subsequently hardened in a hot forming and hardening tool to produce a steel part with at least two microstructured regions of different ductility.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Method for producing hot rolled steel strip for automotive frame

The invention discloses a method for producing a hot rolled steel band used for an automotive frame, comprising the following steps: the pretreated liquid iron is smelt conventionally in a top and bottom combined-blowing revolving furnace, argon is blown at the bottom of the furnace in the whole process, the contents of carbon, phosphorus, silicon and manganese at the terminal of the liquid iron are controlled; the liquid iron discharged from the furnace is refined by an LF furnace, argon is blown to the liquid iron and is stirred and decarbolized at the same time of blowing the argon at the bottom of the LF furnace in the whole process, the liquid iron is subjected to microalloying by adding vanadium, titanium, niobium alloy or niobium and titanium alloy, the content of the microalloy in the liquid iron is controlled to between 0.15 and 0.20 percent, the refined liquid iron is continuously cast into a casting blank through a CSP sheet billet conticaster, the casting blank is soaked in a roller-hearth type soaking furnace and is rolled initially through a vertical miller as well as is sent to a finishing mill set to be rolled, the rolling force of each stander and the finishing temperature of the steel band are controlled, and the hot rolled steel band is cooled through a laminar flow and is cut by a pair of flying shears as well as is wound into a steel coil through a recoiling machine. The produced steel band in 510 L and 590 L or 610 L used for the automotive frame has excellent comprehensive mechanical property, and technique processing and welding performances, can be taken as the automotive frames of a light truck, a medium truck and a heavy truck as well as an agricultural automobile and has remarkable benefits.

Owner:湖南华菱涟源钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com