Patents

Literature

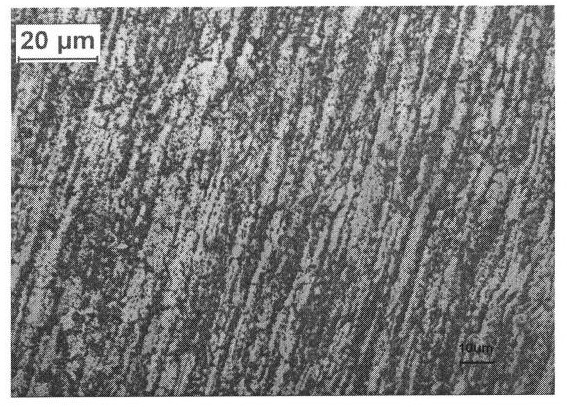

383results about How to "Guaranteed plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

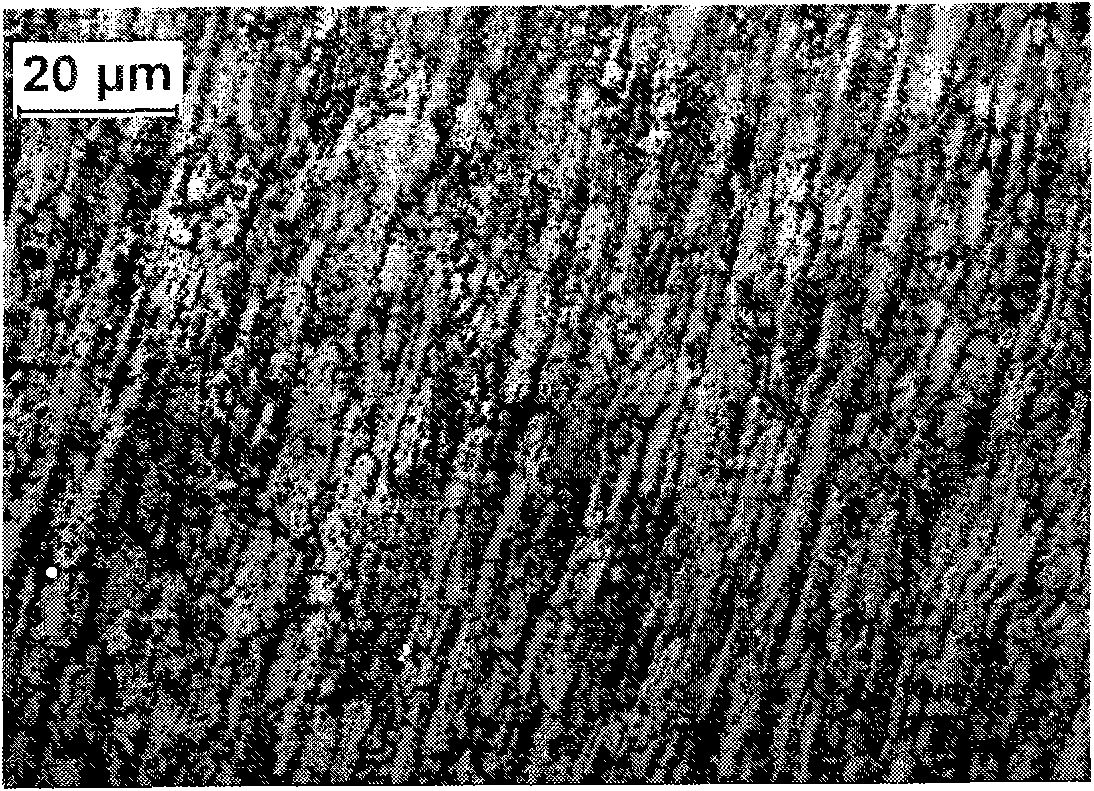

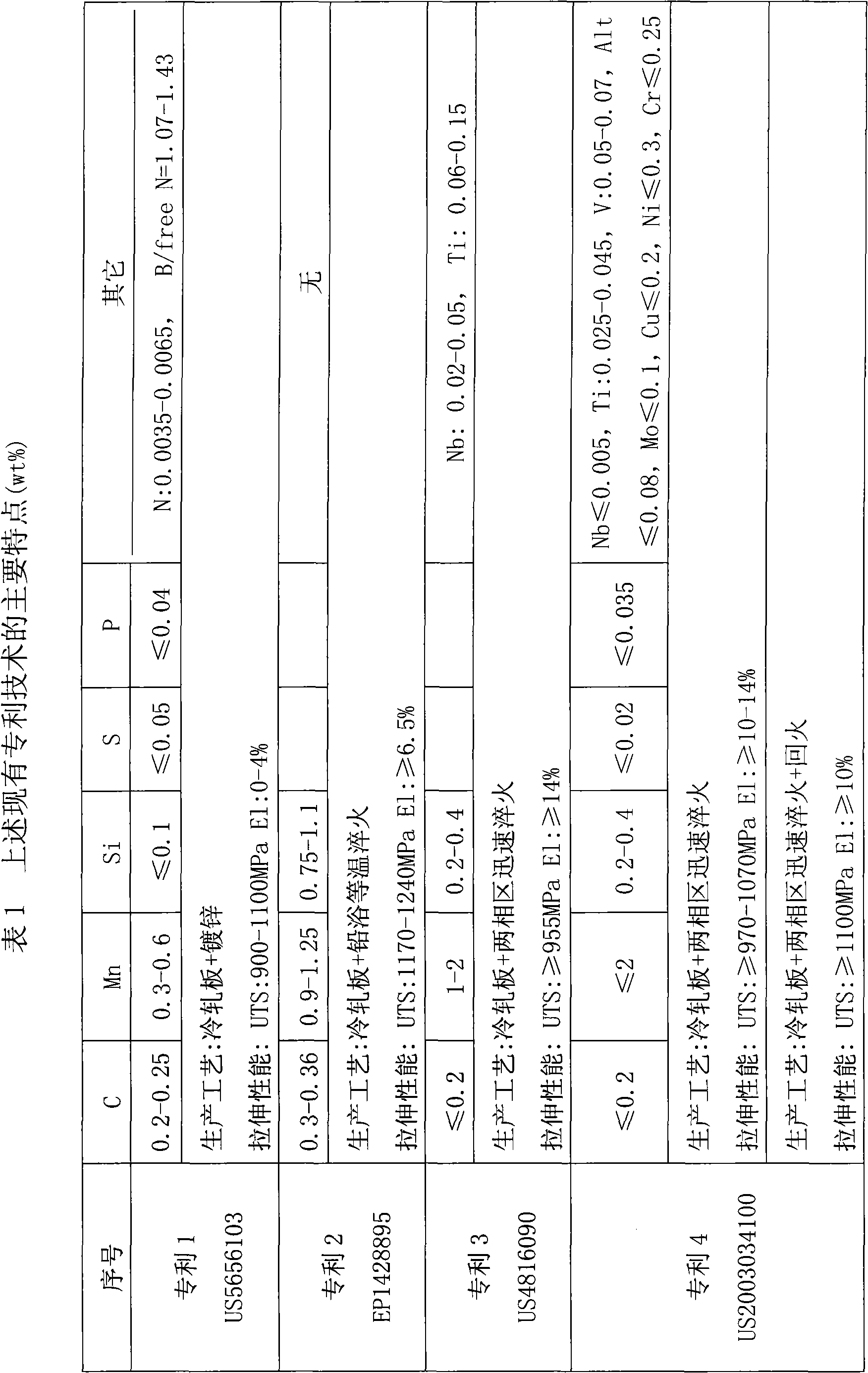

The invention discloses high strength strapping steel with tensile strength over 1,100 MPa and a manufacturing method thereof. The high strength strapping steel comprises the following components in percentage by weight: 0.25 to 0.35 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steel smelting process, hot rolling process, cold rolling process and ferrite-austenite two-phase region quick quenching and annealing heat treatment process for smelting pure steel while controlling the state of impurities. The method can realize the excellent combination of strength and plasticity, realizes the clean production of the high-strength strapping steel which has a tensile strength over 1,100MPa and an elongation over 10 percent, and has the advantages of easy-to-implement production operation, high production efficiency, low production cost, light environmental pollution. Thus, the method has a good application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

Al-Mg-Sc series solder wire

ActiveCN1954959AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaChemical compositionManganese

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Method for preparing seamless titanium alloy tube for aircraft engine

The invention discloses a method for preparing a seamless titanium alloy tube for an aircraft engine. The seamless titanium alloy tube for the aircraft engine which meets corresponding requirements is manufactured by improving the technological plasticity of the titanium alloy tube material. The method comprises the following steps of: firstly, smelting a spongy cast ingot to introduce interstitial elements as little as possible; secondly, cogging and forging heated cast ingot at large deformation and repeatedly upsetting and stretching the cast ingot to ensure that as-cast coarse grains are completely crushed and thinned, thermally processing formed tube billet under vacuum to eliminate residual stress produced during tube billet extrusion so as to improve the plasticity of the tube billet; thirdly, cogging and rolling the tube billet at large deformation and further thinning the grains; and finally, annealing at a low temperature after cold rolling of intermediate rolling and finished product rolling to effectively control the coarsening of the grains. Therefore, full recrystallization can be ensured by prolonging the heating time, and mechanical property and processing property required by material consumption of the aircraft engine can be met under the condition that the tube structure is fully recrystallized.

Owner:WESTERN TITANIUM TECH

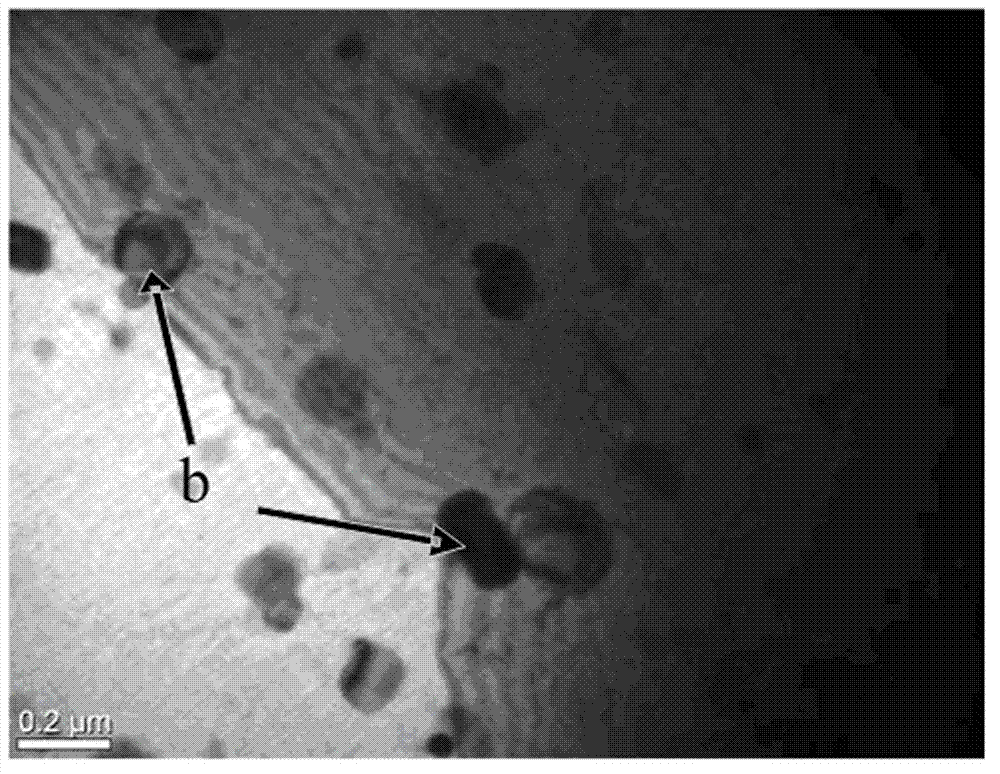

Oxide-dispersion-strengthening ferrite/martensitic steel and preparing method

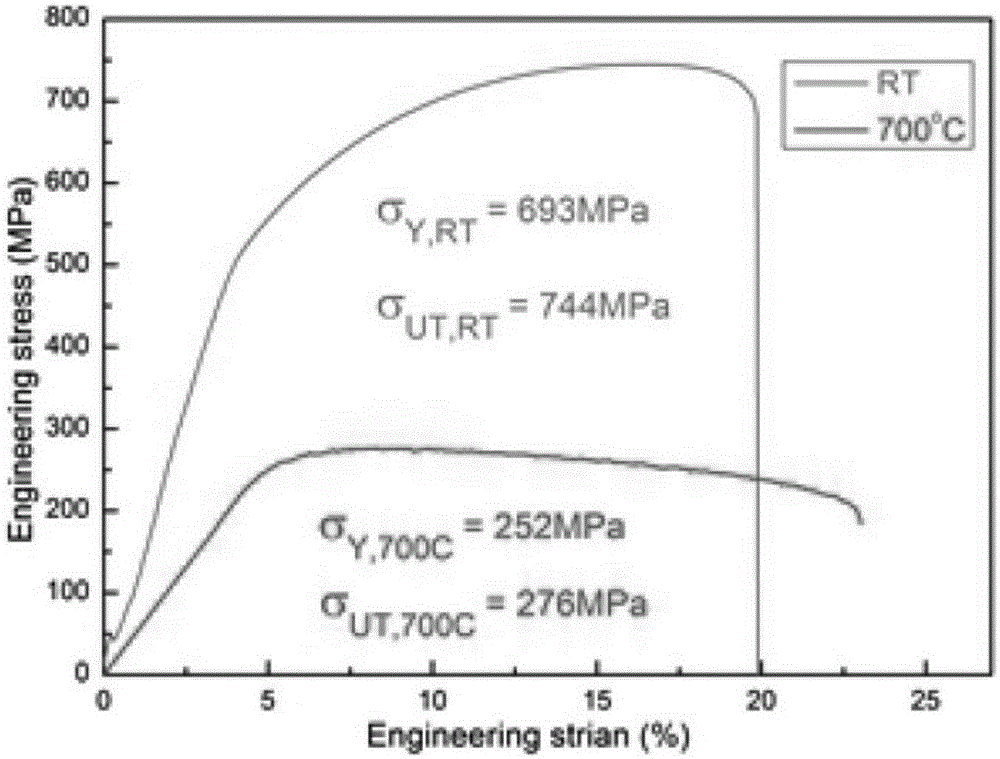

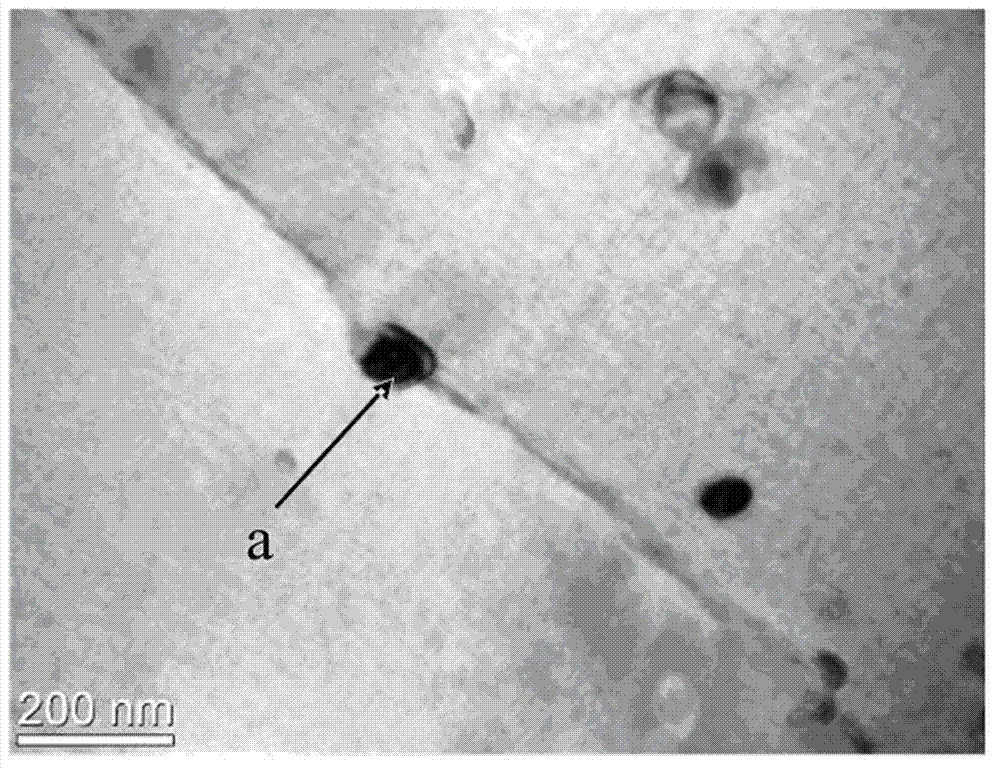

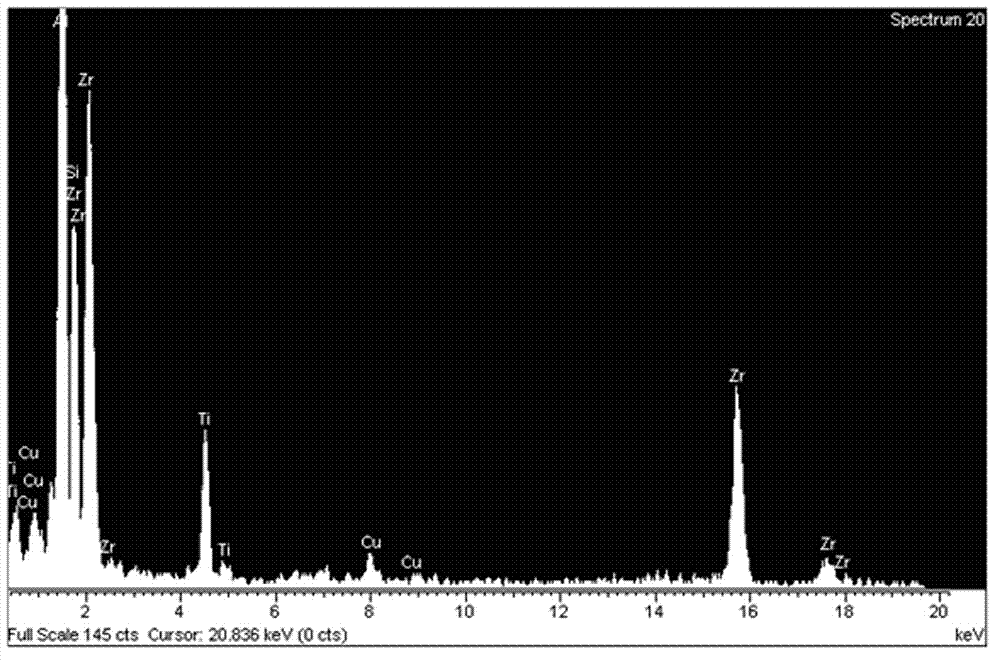

The invention relates to oxide-dispersion-strengthening ferrite / martensitic steel with the excellent high-temperature strength and the good oxidation resistance and a preparing method of the oxide-dispersion-strengthening ferrite / martensitic steel. The oxide-dispersion-strengthening ferrite / martensitic steel comprises 8% to 10% of Cr, 0.5% to 2% of W, 1.5% to 5.5% of Al, 0.1% to 0.4% of V, 0.1% to 0.5% of Mn, 0% to 1.0% of Zr, 0% to 1.0% of Hf and 0.25% to 0.5% of Y2O3. The content of C and the content of N are controlled to be lower than 0.1%, and at least one kind of the Hf and the Zr is contained; the oxygen content of atomized powder is controlled to be lower than 0.05 wt.%, the atomized powder with the particle size ranging from 50 meshes to 200 meshes is selected to be mechanically alloyed with Al powder, Zr powder, Hf powder and Y2O3 powder, and the size of obtained powder ranges from 90 micrometers to 200 micrometers; silicate glass is used for wrapping, compressing and molding, the pressure is started to be boosted to 120 MPa to 180 MPa at the temperature of 850 DEG C, a two-stage sintering manner in which the temperature ranging from 850 DEG C to 950 DEG C is kept for 1 hour and the temperature ranging from 1050 DEG C to 1150 DEG C is kept for 1 hour is adopted, the tensile strength of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 250 MPa to 320 MPa, and the ductility of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 18% to 32%; and the oxidation performance of the dispersion-strengthening steel is also greatly improved on the premise that the high-temperature strength and the high-temperature plasticity are guaranteed, and after 100-h oxidation is carried out at the temperature of 850 DEG C, the oxidation weight increase only ranges from 0.0327 mg / cm<3> to 0.098 mg / cm<3>.

Owner:UNIV OF SCI & TECH BEIJING

Abrasion-resistant rubber and plastic composite material

The invention relates to a composite material, in particular to a rubber and plastic composite material which is specially used for the components of shoe materials, sports goods, leather and the like. The composite material is mainly prepared by mixing a colloidal particle raw material, a bulking agent, a coupling agent, metal oxides, a lubricating agent, a foaming agent and a bridging agent according to a certain ratio, wherein the colloidal particle raw material is prepared by mixing EVA (Ethylene Vinyl Acetate), POE (Polyolefin Elastomer) and ethylene propylene rubber. The composite material provided by the invention improves the compatibility and associativity of each component material by adding the ethylene propylene rubber and the coupling agent into the formula so as to enhance the strength and abrasion resistance of the rubber and plastic blended material, thus the obtained rubber and plastic composite material maintains the plasticity of the EVA material and has the advantages of flexibility, elasticity, skid resistance and excellent abrasion resistance of a rubber material.

Owner:JINJIANG CHENGCHANG SHOES

Ultrahigh strength 6000 series aluminium alloy and preparation method thereof

Ultrahigh strength 6000 series aluminium alloy and a preparation method thereof belong to the technical field of metallurgy. The ultrahigh strength 6000 series aluminium alloy comprises the following components by weight: 0.9-1.4% of Si, 1.4-1.8% of Mg, 0.9-1.3% of Cu, 0.05-0.25% of Cr, 0.05-0.25% of Zr, 0.3-0.7% of Fe, no more than 0.04% of Ti, the balance of Al and impurities, has tensile strength of 500-520 MPa, yield strength of 465-503 MPa and elongation percentage no less than 10%. The preparation method is as below: (1) preparing raw materials; (2) melting and uniformly stirring the raw materials and heating to 745-755 DEG C; (3) carrying out degassing treatment, allowing standing and removing scum; (4) carrying out semi continuous casting to obtain ingot casting; (5) carrying out homogenization treatment; (6) insulating at 400-500 DEG C for 1-2 h, and then carrying out hot extrusion deformation, mold stripping and on-line water passing to obtain a extruded bar; and (7) carrying out solid solution treatment, water quenching and artificial aging treatment in order, carrying out air cooling to room temperature to obtain an ultrahigh strength 6000 series aluminium alloy bar. According to the invention, trace elements of Zr, Cr and a proper amount of Fe are added to the aluminium alloy to gain excellent strength and toughness performance, maintain the characteristics of easy formability, good welding performance and corrosion resistance; and the ultrahigh strength 6000 series aluminium alloy is suitable for production of high-strength lightweight structural members with complex sections.

Owner:NORTHEASTERN UNIV

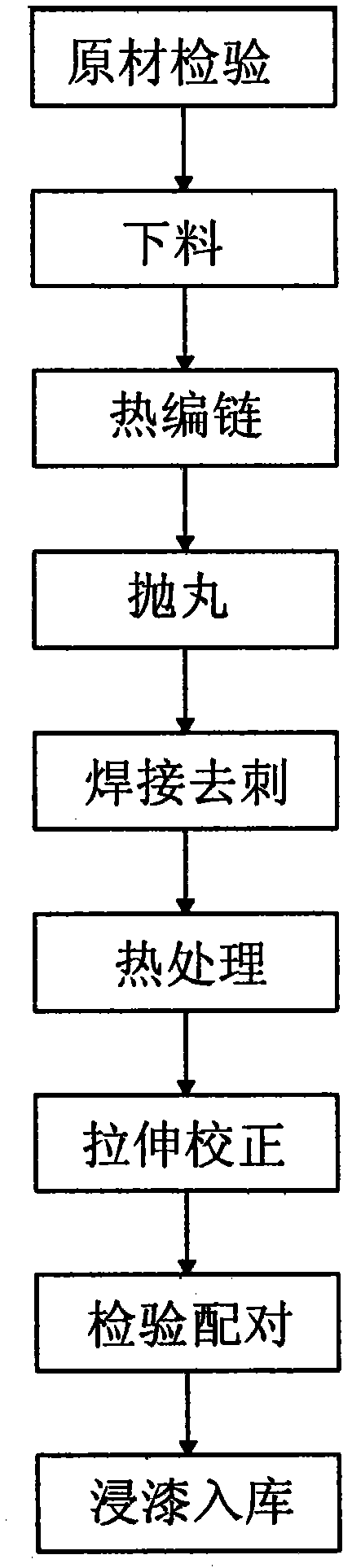

Method for producing round-link chain

The invention discloses a method for producing a round-link chain, which comprises the following steps: A1) raw material selecting: adopting high-quality alloy steel 23MnNiMoCr54; A2) baiting, wherein baiting demands are as follows: being capable of standing, being free from burr and chamfer, and keeping a length error of a bar stock being plus / minus 0.5mm; A3) hotly chaining: bending the bar stock into a chain in a given size under the action of hydraulic power of a chaining machine; A4) ball blast: removing an oxide skin from the surface, preparing for the next process and ensuring the welding quality; A5) welding and removing the burs; A6) heat treatment; A7) stretching and calibrating: once stretching under a stretching load being 80% of a fracture load; and A8) checking, pairing, painting and placing the chain into a storage. By using the method, the efficiency of producing the round-link chain is increased and the cost is lowered. The fracture load, a coefficient of elongation under a test load, a fracture elongation coefficient and a fatigue life of the round-link chain all meet the national standard.

Owner:SHANDONG LIANGDA FASING ROUND LINK CHAINS

Ceramic particle reinforced aluminum-based gradient composite material and preparation method thereof and jetting precipitation device for preparing material

The invention belongs to the field of aluminum-based composite material and preparation technology thereof and in particular discloses a ceramic particle reinforced aluminum-based gradient composite material, a preparation method thereof and a device used by the method. The composite material uses aluminum alloy as a matrix; the volume fractions of ceramic particles serving as a reinforcement material in the surface layer and the bottom layer are between 30 and 40 percent and between 0 and 5 percent respectively; the ceramic particles perform continuous gradient variation from the surface layer to the bottom layer; and the preparation method comprises the following steps: introducing the ceramic reinforced particles to a high-pressure airflow channel by a discharge amount regulation device to form a solid phase flow and a gas phase flow; atomizing molten aluminum alloy liquid, mixing the molten aluminum alloy liquid and the ceramic particles of the solid phase flow and the gas phase flow, and precipitating the mixture on a deposition matrix to prepare a deposition billet; and controlling the discharge amount regulation device and output air pressure through a programmable logic controller according to the height information of the deposition billet to obtain the ceramic particle reinforced aluminum-based gradient composite material. The preparation method of the invention has convenient operation and high automation degree; and the prepared composite material has the advantages of light weight, high wear resistance and anticorrosion of the surface and the like.

Owner:HUNAN UNIV

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

Steel-aluminum compound hot rolled steel with tensile strength of 340MPa and production method thereof

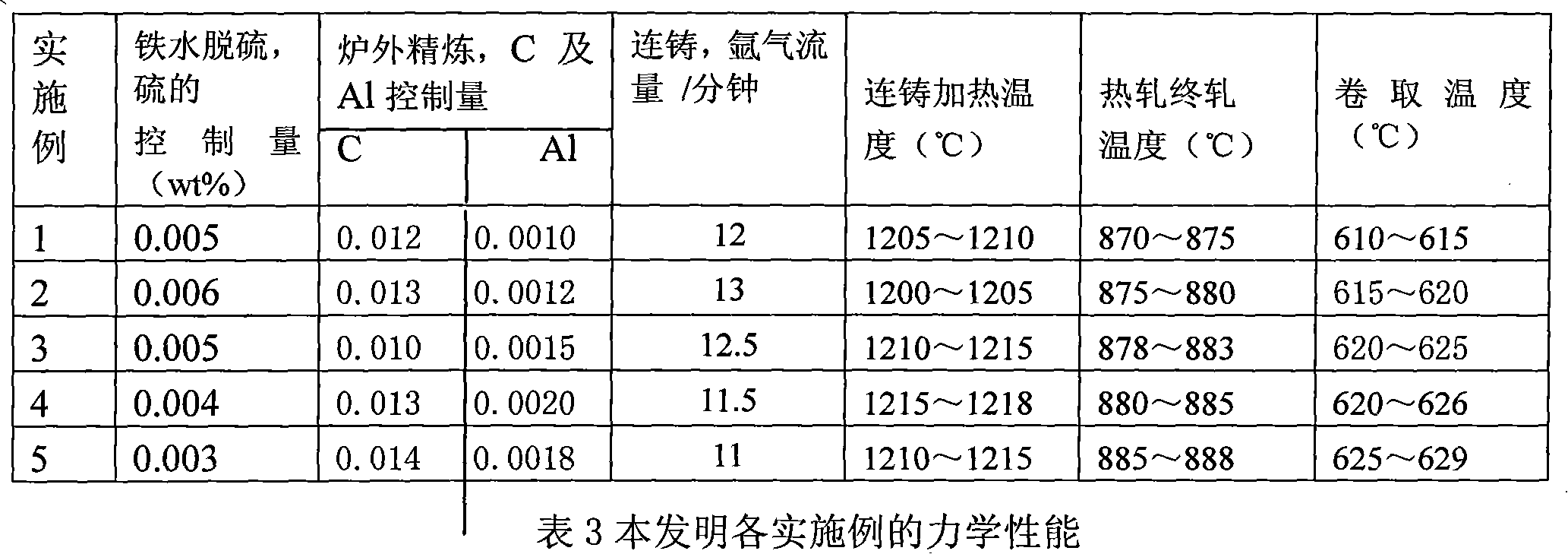

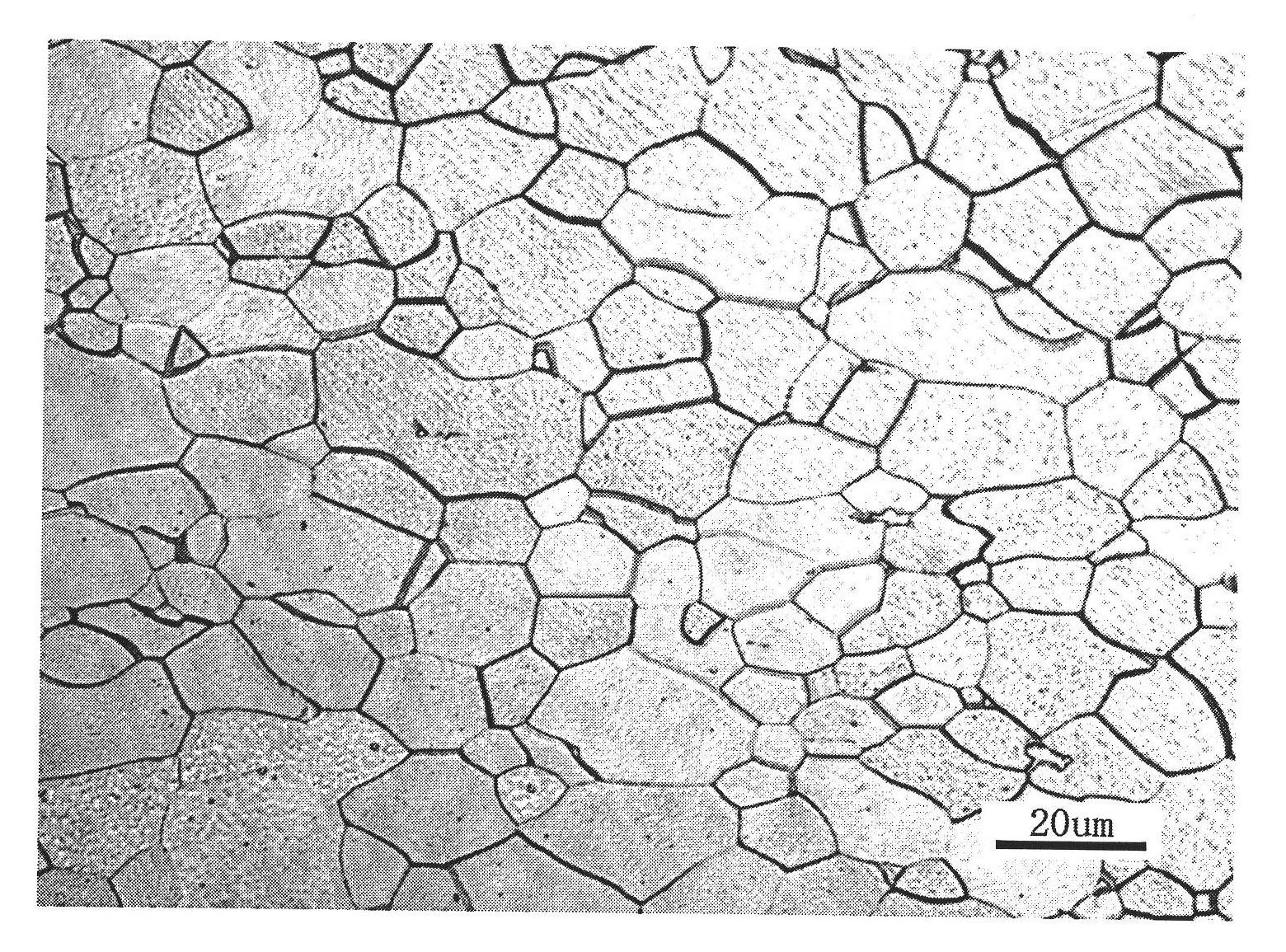

The invention relates to steel for parts with high requirements on thermal conductivity, such as radiators and the like used by power plants of 0.3 million kilowatts and above. The steel comprises the following components by weight percentage: 0.010-0.014% of C, less than 0.018% of Si, 0.30-0.35% of Mn, 0.001-0.002% of Al, not more than 0.02% of P, less than 0.06% of S and not more than 0.003% of O. The steps are as follows: carrying out desulfurization on molten iron; refining outside a furnace; carrying out continuous casting, and adopting a covering agent with 0.5% of C and argon for protecting pouring; heating a continuous casting slab to 1200-1218 DEG C; carrying out hot rolling, and controlling the final rolling temperature to be 870-888 DEG C; and coiling and controlling the temperature to be 610-629 DEG C. The steel can ensure the plasticity of the radiators used by the power plants of 0.3 million kilowatts and above; a compound layer does not form Fe-Al brittle phase and has good compound performance; and the steel can lead the rigidity of the radiator to be high and ensure the stability of the shape and the size of the processed heat exchanger.

Owner:武汉钢铁有限公司

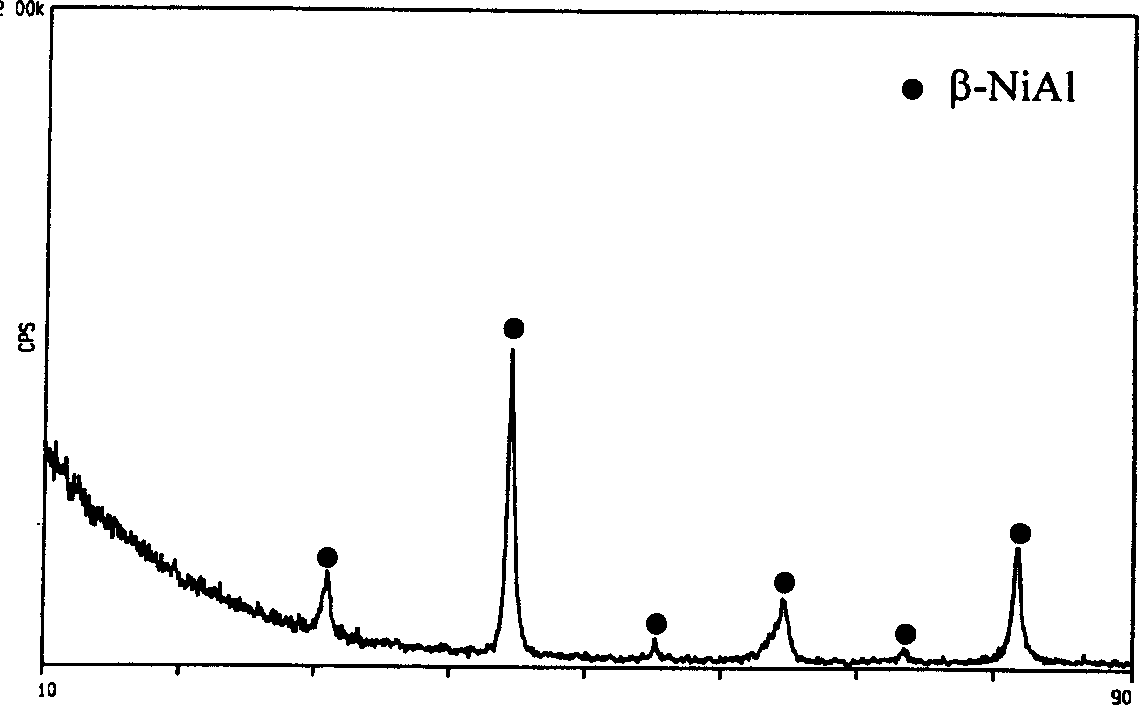

Laser synthesis preparation method of intermetallic compound and granule reinforced composite material

InactiveCN1546694AThe ingredients are designed to be simpleReduce manufacturing costHigh power lasersChemical compound

The invention relates to a laser synthesis preparation method of intermetallic compound and granule reinforced composite material which includes, using the powder stock containing the same elements with the intermetallic compound to be prepared, adding additionally elements during the process of sedimentation and mixing, forming local molten pool on the base material surface through high power laser irradiation, feeding the mixed powder into molten pool, stacking up to obtain large area coating, block material or formed parts, adjusting powder components or laser technique to obtain intermetallic compound or particle reinforcement intermetallic composite material with dissimilar compositions, structure and property.

Owner:TSINGHUA UNIV

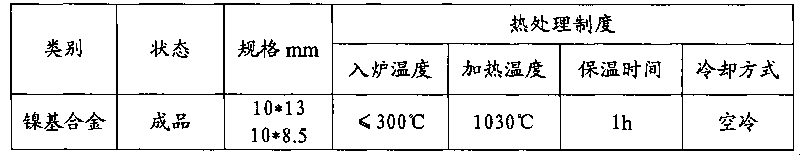

Nickel-based alloy of nuclear power steam generator

The invention relates to a nickel-based alloy of a nuclear power steam generator. The invention can maintain or increase the alloy performance while reducing the alloy cost. The specific scheme of the invention is as follows: 1. a defined amount of rare earth elements are added in steel to have purification and metamorphism functions of deoxidizing, desulfurizing, changing the shape of inclusion and the like, have microalloy function in the alloy and finally increase the oxidation resistance, high temperature strength and plasticity, fatigue life, corrosion resistance, crack resistance and the like of the steel; 2. in view of the production cost, the content of the precious element nickel is needed to be as low as the lower limit under the premise of ensuring the processability and ensuring that the alloy can form the desired metallographic structure; 3. the content of chromium element is increased properly so as to increase the high temperature oxidation resistance and corrosion resistance of alloy; 4. the content of silicon element is adjusted so as to increase the tensile strength and corrosion resistance of alloy while the plasticity of alloy is ensured; and 5. the content of carbon is controlled and titanium element is added at the same time so as to further increase the oxidation resistance and corrosion resistance of steel.

Owner:江苏龙鑫特殊钢实业总公司

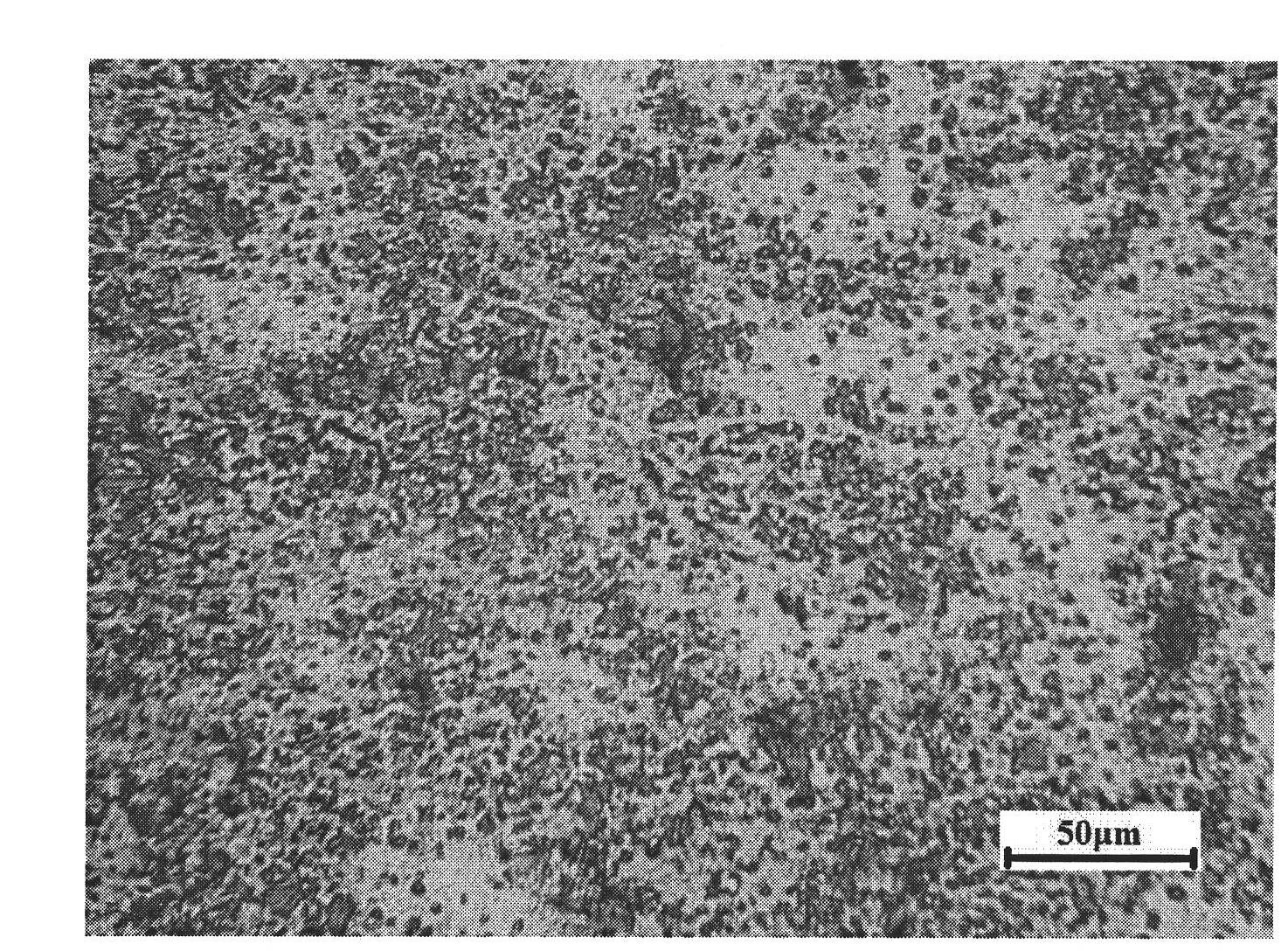

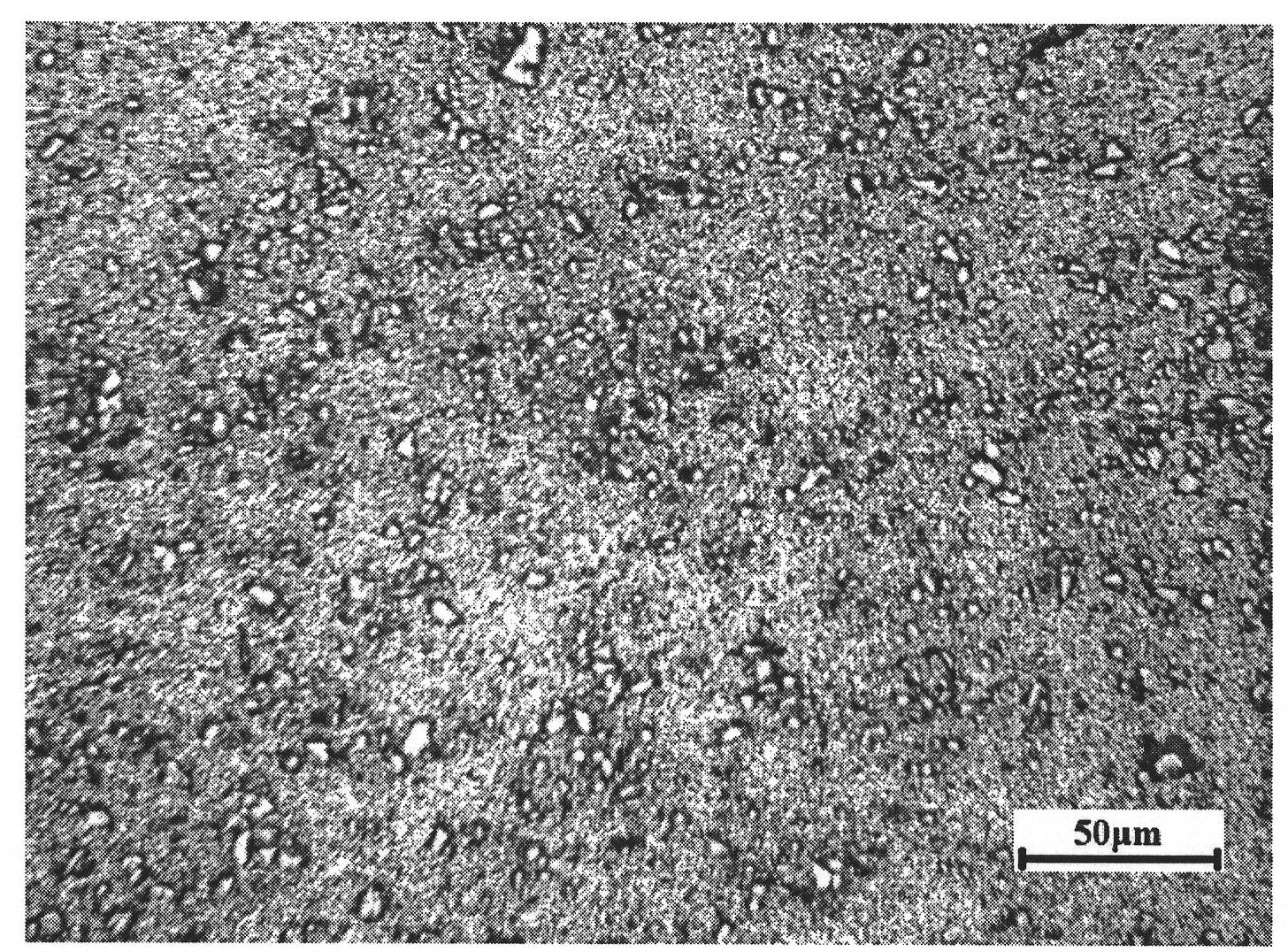

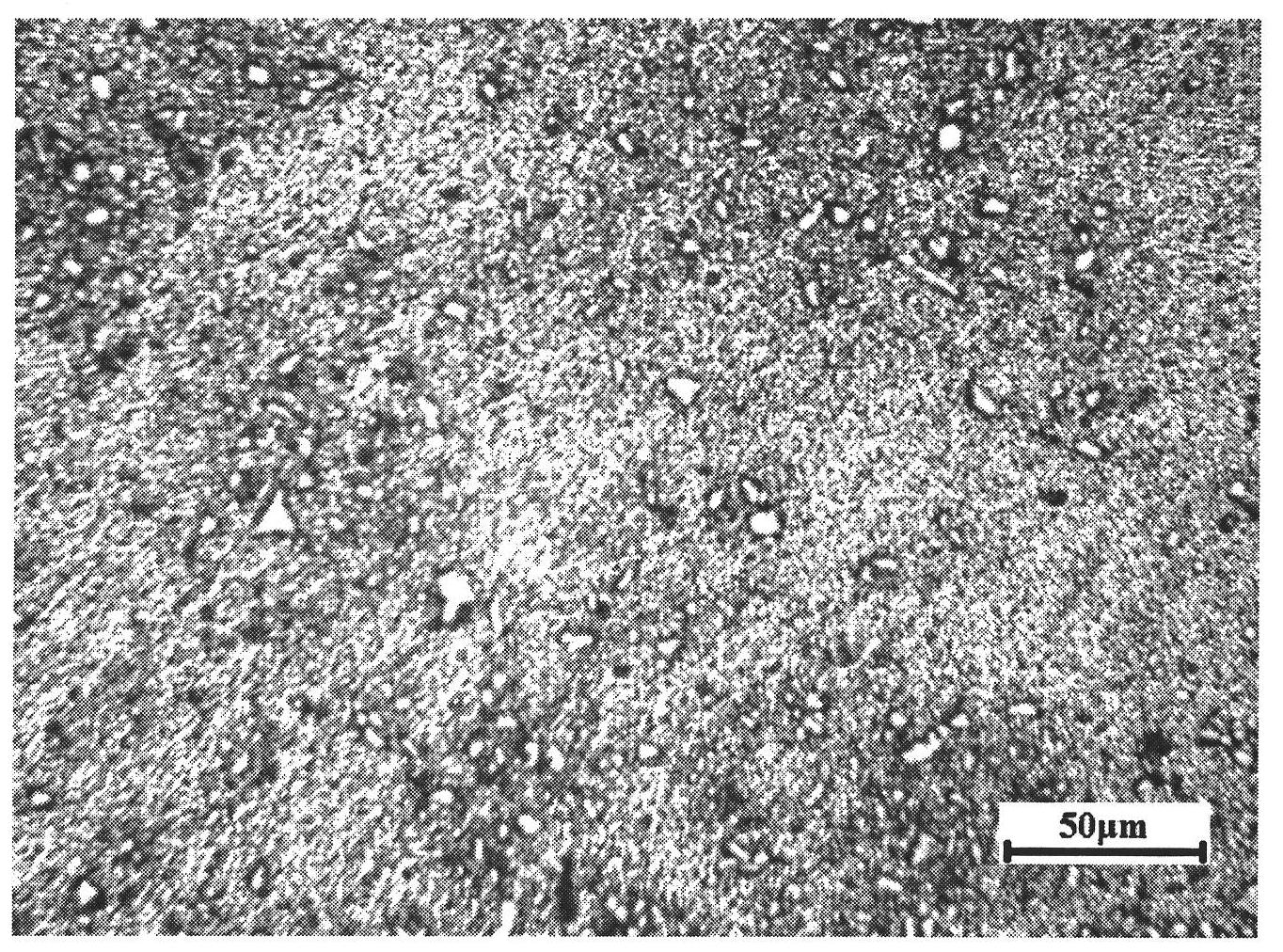

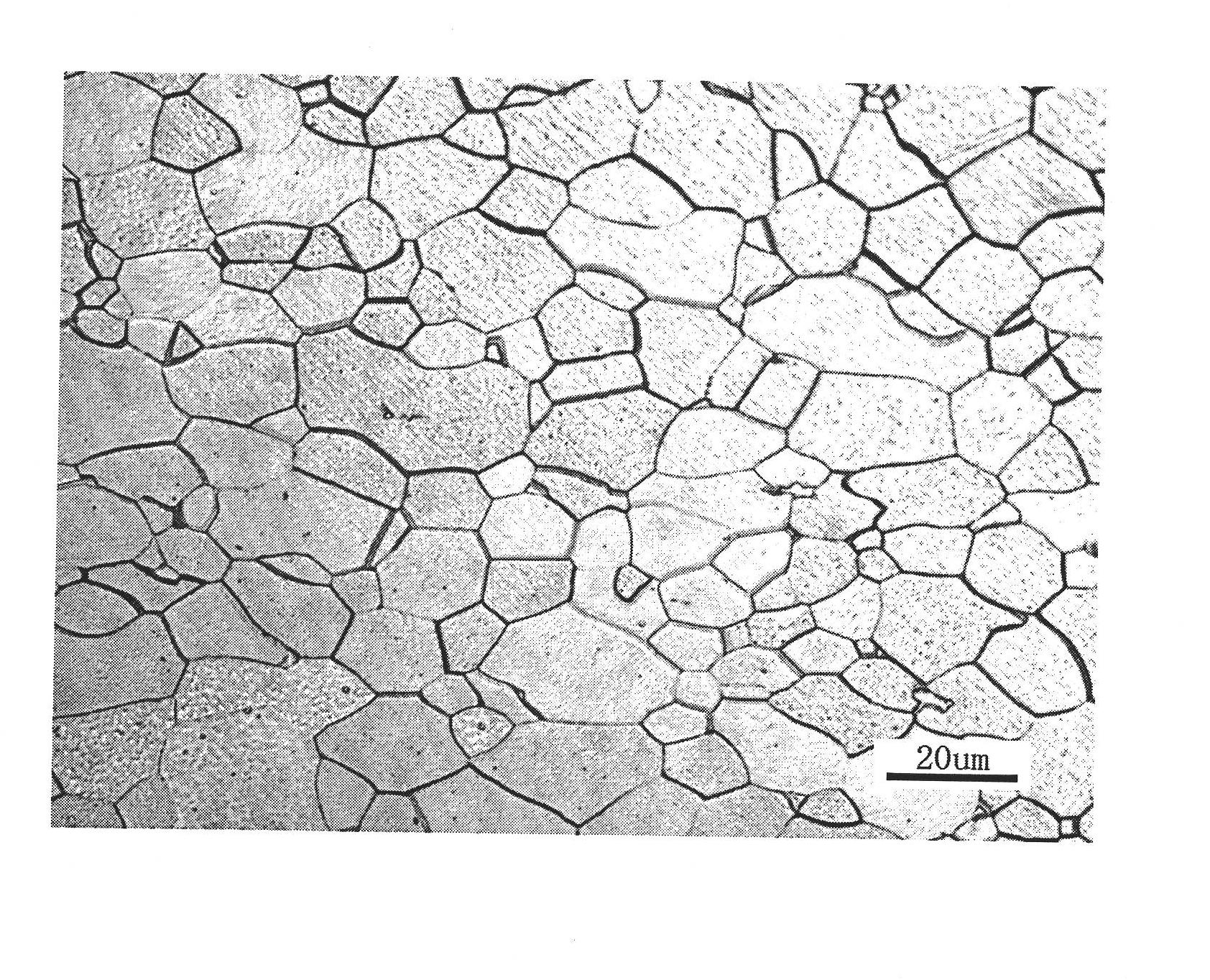

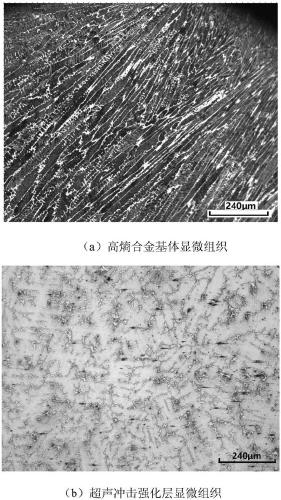

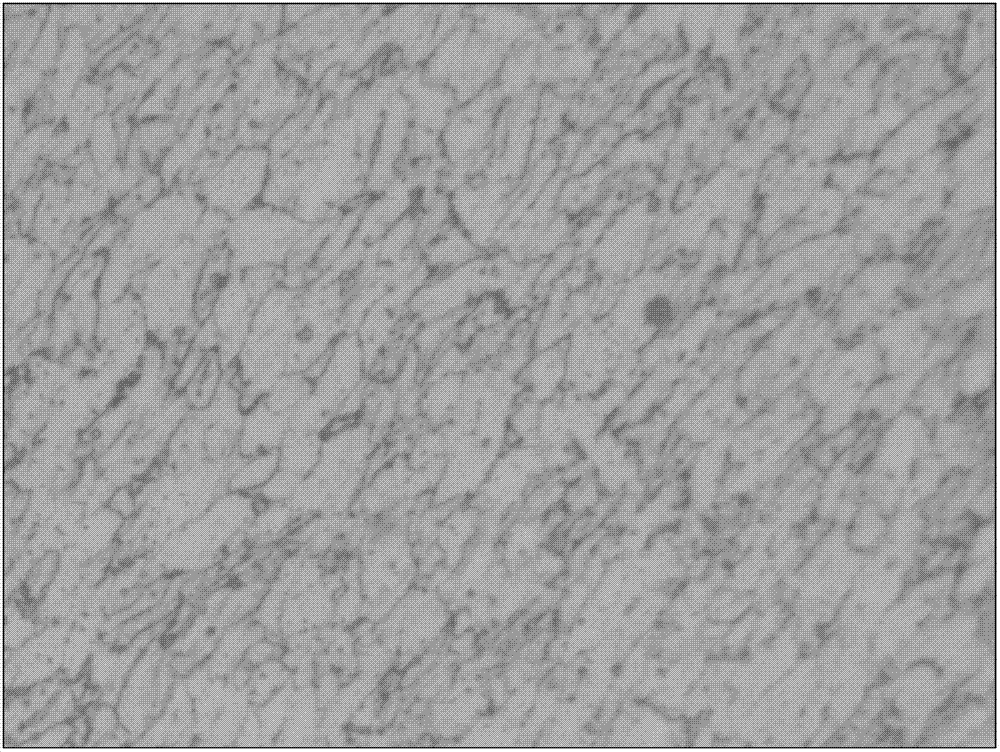

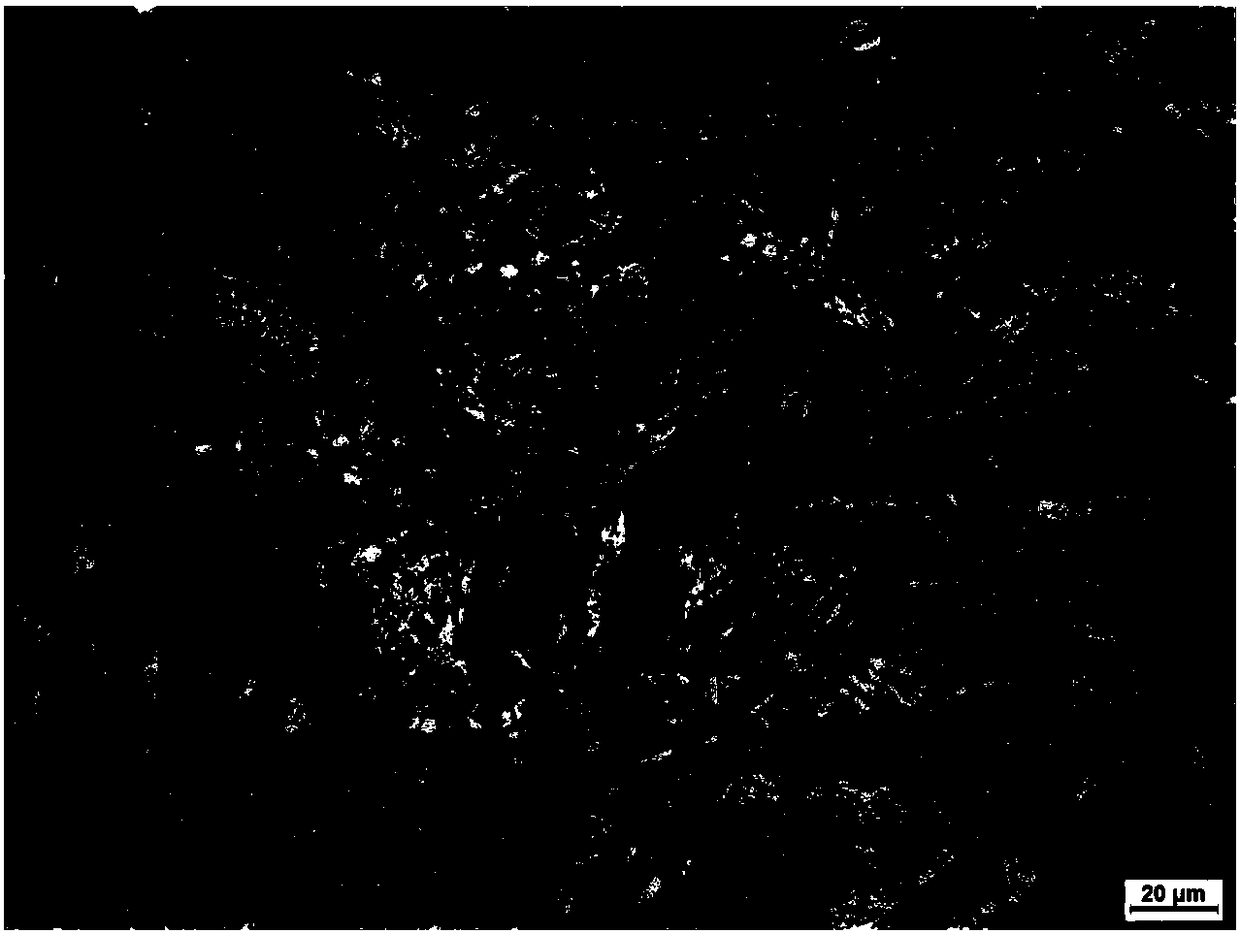

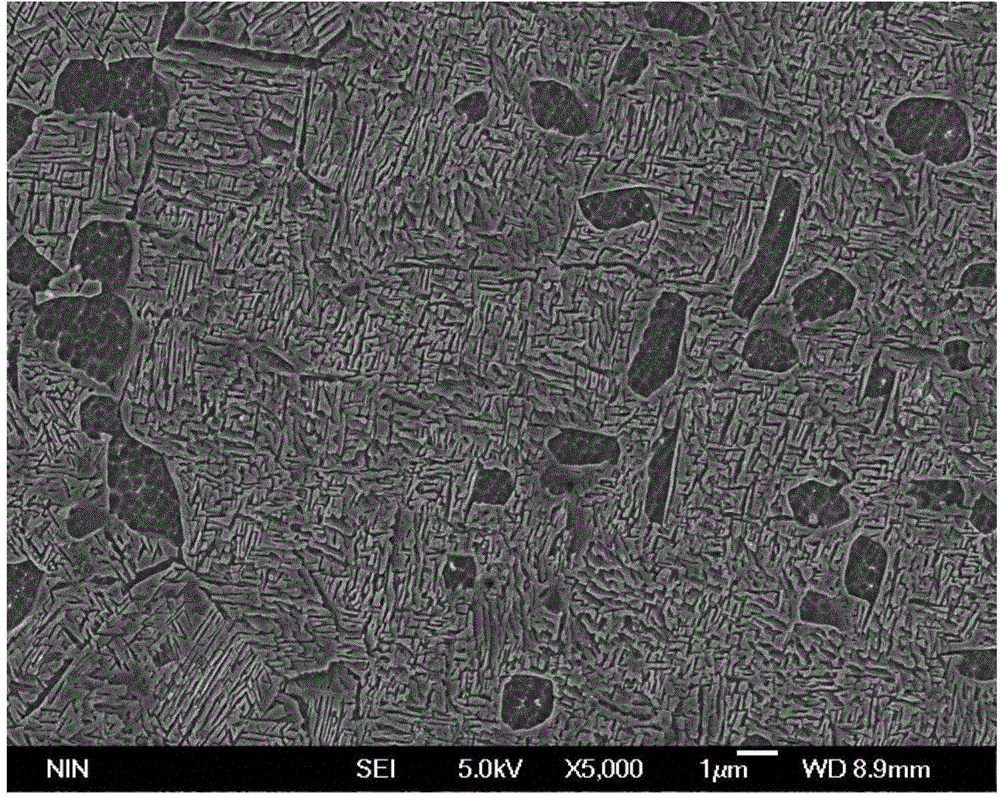

Method for improving surface performance of single-phase high-entropy alloy

The invention discloses a method for improving surface performance of a single-phase high-entropy alloy, and belongs to the technical field of high-entropy alloy surface strengthening. The single-phase high-entropy alloy is an Al<x>CrCoFeMnNi alloy, wherein x represents the mole number, and is equal to 0-0.5; after the single-phase high-entropy alloy is subjected to solution treatment and surfacepretreatment, the surface of the high-entropy alloy is strengthened through ultrasonic impact equipment; and the high-entropy alloy is of a single-phase face-centered cubic structure, a certain depthof plastic deformation layer is formed on the surface of the high-entropy alloy after ultrasonic impact, grains are obviously refined, a gradient structure is formed from the surface to the core, andhardness and abrasion resistance are significantly improved. According to the method, a fine structure and a large number of microscopic defects can be obtained on the surface of the high-entropy alloy while the chemical composition of the surface of the high-entropy alloy is ensured to be unchanged and the toughness of the core is ensured, thus the hardness of the surface of the high-entropy alloy is increased by 1.8-2.5 times, the abrasion resistance is increased by 1.3-2.5 times, the method is simple, easy to operate, safe, reliable, small in energy consumption, economical and practical.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Steel strip for LED bracket and manufacturing method thereof

The invention provides a steel strip for an LED bracket and a manufacturing method thereof. The steel strip comprises the following chemical compositions by mass percent: 0.03%<=C<=0.07%, 0.01%<=Si<=0.03%, 0.2%<=Mn<=0.3%, 0%<P<0.02%, 0%<S<0.02%, 0.01%<=Al<=0.035% and the balance of Fe, as well as a trace of inevitable impurities. Repeated tests and trials show that the LED steel strip completely satisfies the quality requirements on the strength, the rigidity and the extensibility, which ensure that the LED bracket is free from cracks after being punched and bent for 6 times, and at present, the LED steel strip gains popularity of customers; and as the LED new material cold-rolled strip has a very wide development prospect, the popularization and application values are extremely high and the prospect is very wide.

Owner:浙江龙盛薄板有限公司

Degradable zinc alloy material, and preparation method and application thereof

InactiveCN105648272AOptimal effect of diffusion enhancementEvenly heatedSurgeryBiocompatibility TestingZinc alloys

The invention relates to a degradable zinc alloy material which comprises the following components in percent by mass: 0.5-3 percent of magnesium, 0.1-1 percent of calcium, and the balance of zinc. The invention further relates to a preparation method of the degradable zinc alloy material. The preparation method comprises the following steps: mixing and smelting the raw materials of magnesium, calcium and zinc for 5-15 min at the temperature of 550-700 DEG C to prepare an ingot; extruding the ingot to obtain a bar, and conducting the thermal treatment on the bar for 1-3 h at the temperature of 300-400 DEG C; and placing the bar in air for cooling, and conducting the cold-drawing to obtain a wire. The degradable zinc alloy material is applied to medical implantable instruments, especially nose bridge brackets. The zinc alloy material is high in mechanical property, machining property and biocompatibility and appropriate in biodegradation rate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Plastic stabilizer for wet-mixed mortar

InactiveCN104556812AImprove performanceShorten the setting timeWater soluble polysaccharidesProcess engineering

The invention discloses a plastic stabilizer for wet-mixed mortar. The plastic stabilizer comprises the following components in parts by weight: 0.1-5 parts of a water retention agent, 0.1-5 parts of an air entraining agent, 0.1-1 part of a defoaming agent, 0.01-1 part of water soluble polysaccharide, 1-10 parts of a special effect retarder, 1-10 parts of a water reducing agent and 68-98 parts of water. The plastic stabilizer for the wet-mixed mortar, provided by the invention, is liquid, is beneficial for automatic feeding and metering, and overcomes the defects that most mortar additives on the market are solid powder products and cannot realize automatic metering. Meanwhile, the water retention rate of the plastic stabilizer for the wet-mixed mortar, provided by the invention, can reach 98%, so that the setting time of the mortar can be deferred to 10-72 hours.

Owner:JIANGSU ZHONGKAI NEW MATERIALS

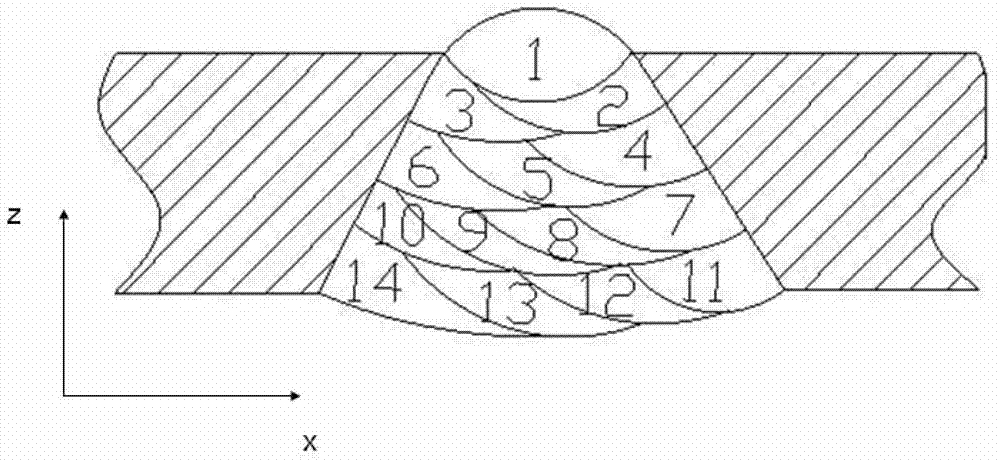

Manual arc welding bottoming layer Z-shaped arc extinction method and application thereof in Q460 high-strength steel horizontally-fixed steel pipe butt welding

ActiveCN102922085AFusion wellNo accumulationArc welding apparatusTubular articlesShielded metal arc weldingButt welding

The invention discloses a manual arc welding bottoming layer Z-shaped arc extinction method and application of the manual arc welding bottoming layer Z-shaped arc extinction method in Q460 high-strength steel horizontally-fixed steel pipe butt welding. An arcing point is located at a position of a root part of a groove 2 to 3mm close to a truncated edge, an electric arc is lightly led to an oblique rear part of a fusing tank along the groove after being struck and then transversely swung to the other side of the groove after a pause, act extinction is carried out towards the oblique rear part of an arcing point after fusing of the groove at the side is good through observation, and a running track of an end of a welding rod is Z-shaped. As the fusing tank can be well observed in a welding process, welding defects of a bottoming layer can be reduced and technical support is provided to ensure welding quality of the bottoming layer of a butt joint. With the adoption of the arc extinction method, shaping of the root part of a welding seam can be effectively controlled and a good welding seam structure can be obtained.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

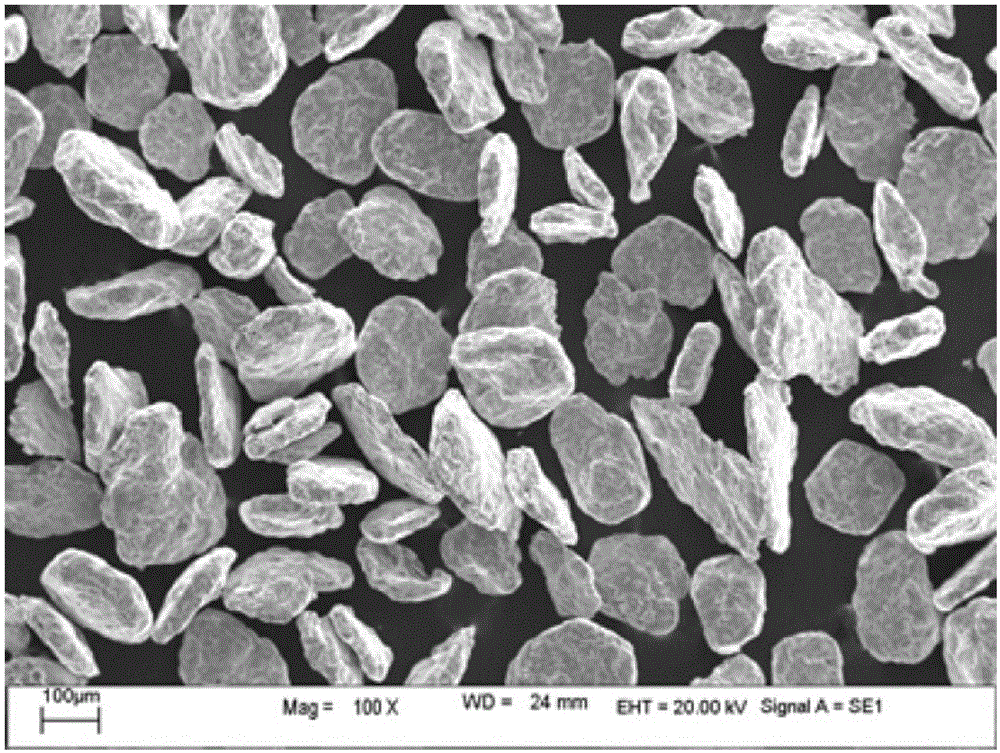

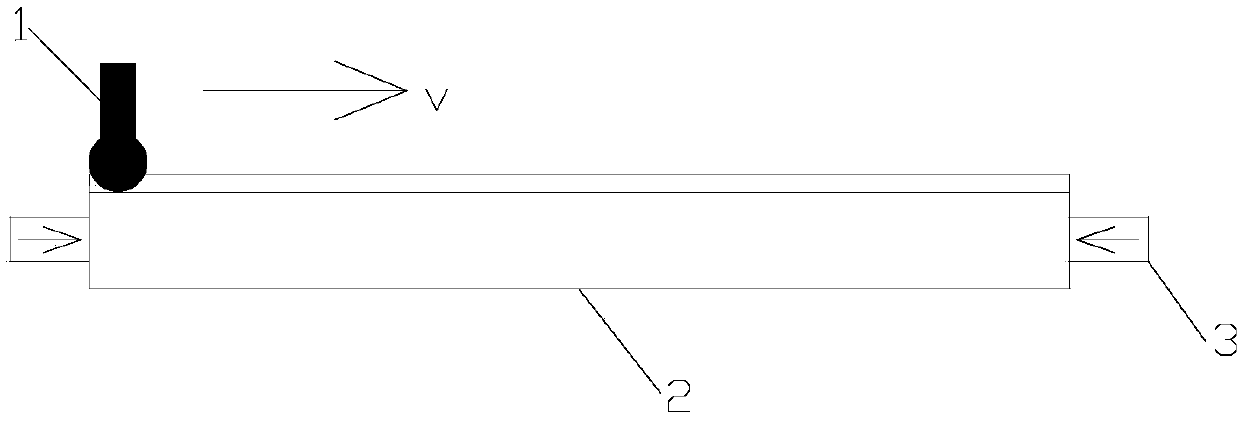

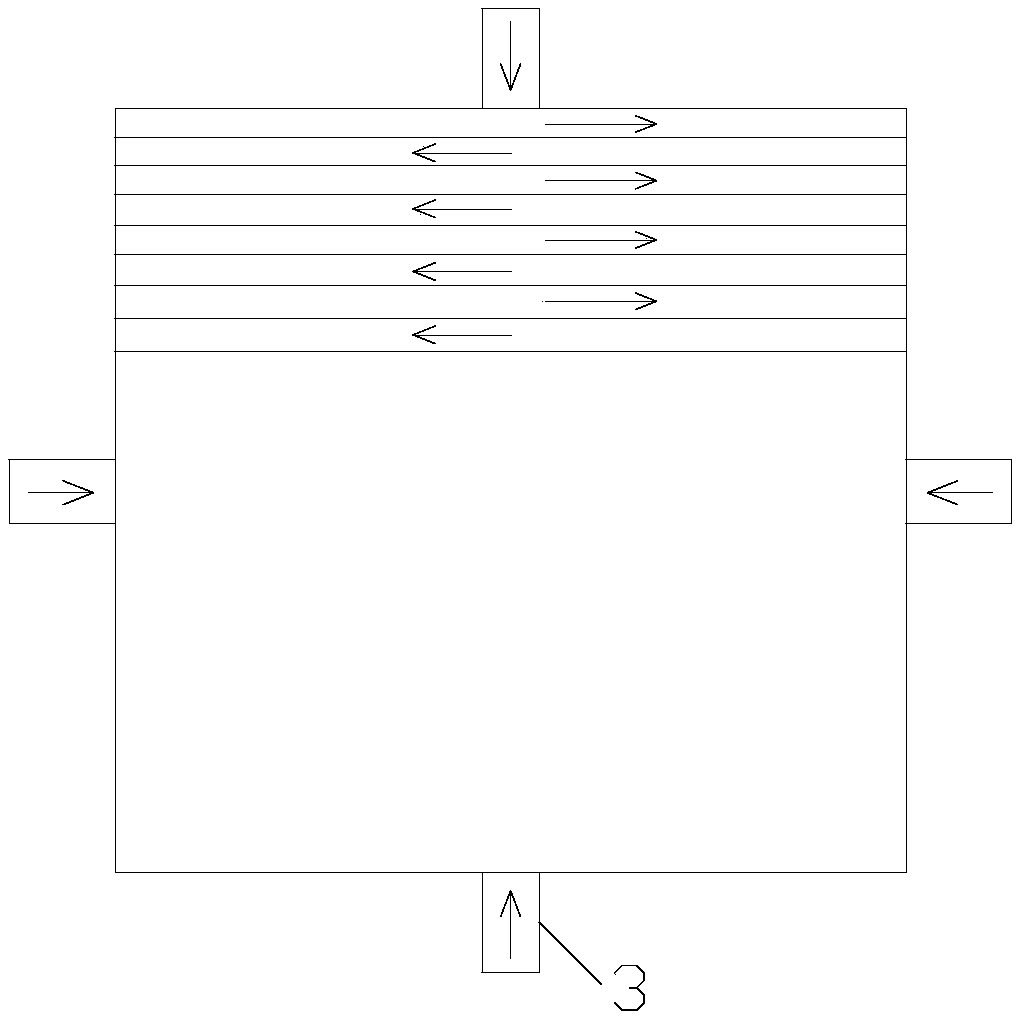

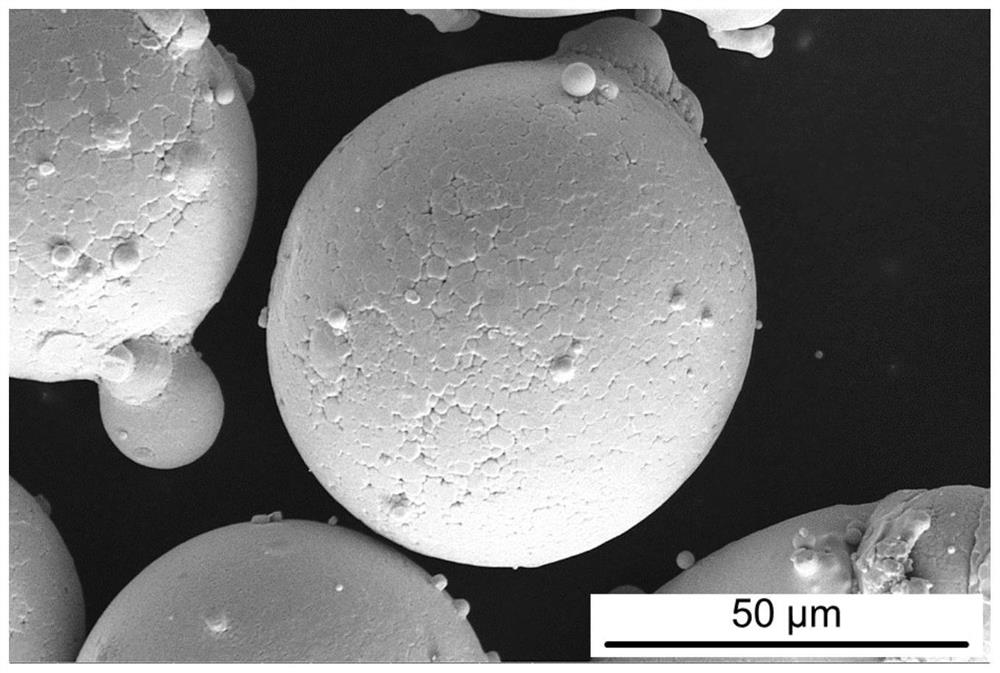

Method for improving formability of high-strength aluminum alloy powder for 3D printing

InactiveCN111360257AHigh strengthLow costAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingLaser scanning

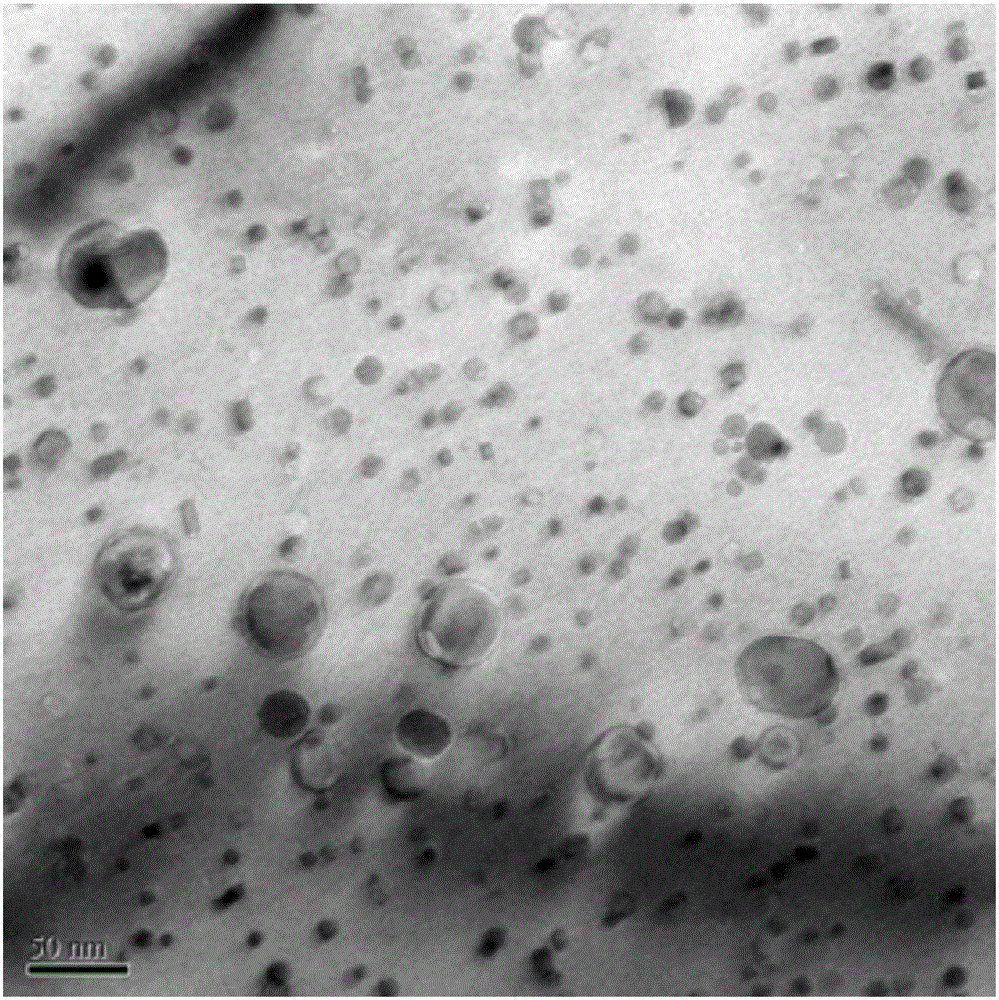

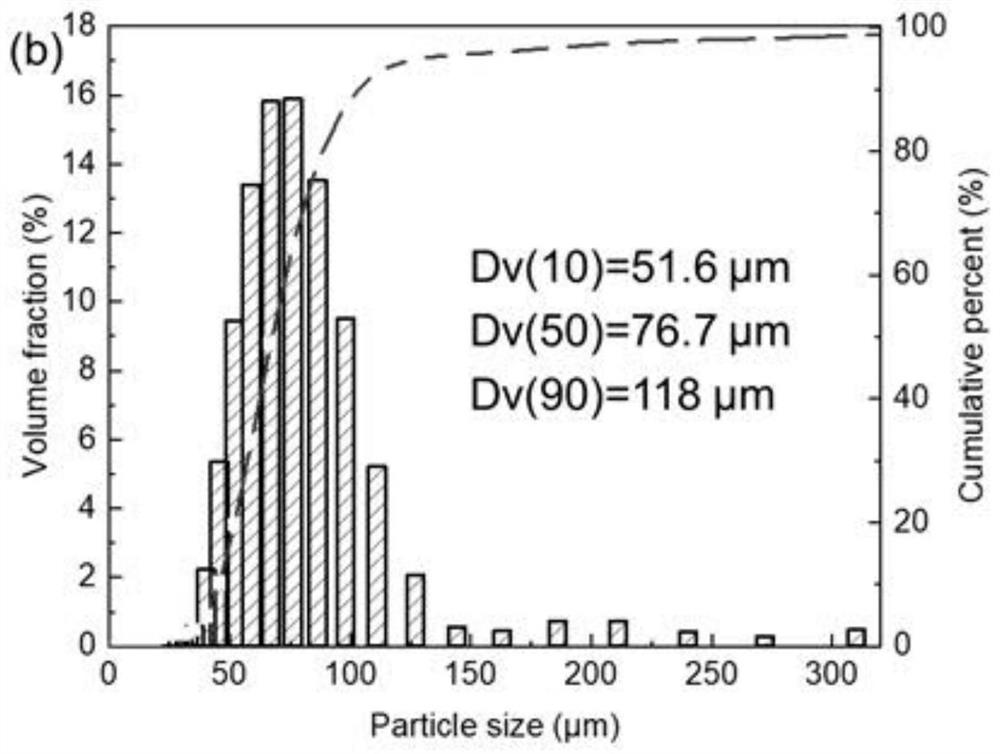

The invention discloses a method for improving formability of high-strength aluminum alloy powder for 3D printing. The method comprises the following steps that the Al-Mg-Sc-series high-strength aluminum alloy powder is prepared by using a gas atomization method in a selective laser melting forming device, wherein alloy comprises the following components of, in percentage by mass, 3%-6% of Mg, 0.1%-2% of Sc, 0.1%-0.8% of Zr, 0.2%-1% of Mn, and the balance Al. By optimizing the forming process, that is, adjusting the sintering strategy, the single-layer sintering energy density is reduced, andthe sheet layer thickness is increased to 0.04-0.07 mm; and by adopting a layer-by-layer independent sintering mode, that is, performing two-time laser scanning on single-layer alloy powder, and through second laser scanning, the alloy surface solidified after first laser scanning can be remelted, so that the non-penetration phenomenon caused by single scanning is avoided, holes and cracks in a formed part are effectively reduced, the forming rate of a workpiece is improved, and finally, the high-strength aluminum alloy workpiece with excellent comprehensive performance is obtained.

Owner:COMAC +1

Copper-containing low-carbon high-strength high-ductility steel for ocean platform and preparation method thereof

InactiveCN108179351AImprove low temperature toughnessReduce carbon contentChemical compositionIn process control

The invention belongs to the technical field of metallurgy and particularly relates to copper-containing low-carbon high-strength high-ductility steel for an ocean platform and a preparation method thereof. The copper-containing low-carbon high-strength high-ductility steel for oceanographic engineering consists of the following chemical components in percentage by weight: 0.06-0.11% of C, 0.15-0.35% of Si, 0.95-1.3% of Mn, 0.4-0.6% of Mo, 2.3-2.8% of Ni, 0.5-1.0% of Cr, 1.0-2.0% of Cu, less than and equal to 0.05% of Nb, less than and equal to 0.08% of V, greater than and equal to 0.02% of Al, less than and equal to 0.025% of P, less than and equal to 0.010% of S and the balance of Fe, wherein yield strength is 785-820 MPa, tensile strength is 870-925 MPa, and low-temperature impact powerat (-)40 DEG C is 140-220 MPa. The preparation method comprises the following steps of: roughly milling and finely milling forged steel billets in an austenite re-crystallization region and an austenite a non-recrystallization region to obtain a hot-rolled steel plate; and performing QLT two-step critical thermal treatment on air-cooled steel, wherein a quenching temperature is 850 DEG C, a critical annealing temperature is 680 DEG C, a critical tempering temperature is 620 DEG C and heat-preservation time is 60 minutes. The copper-containing low-carbon high-strength high-ductility steel is reasonable in component design, and is simple and easy in process control; and the obtained steel has ultrahigh strength and good low-temperature toughness.

Owner:NORTHEASTERN UNIV

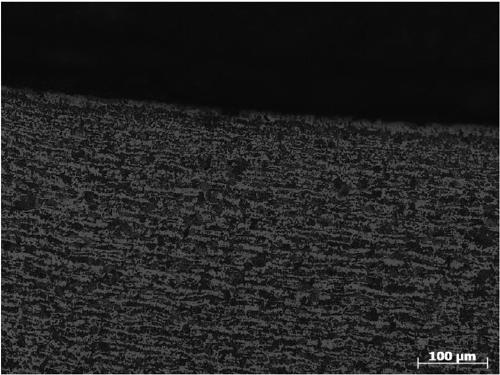

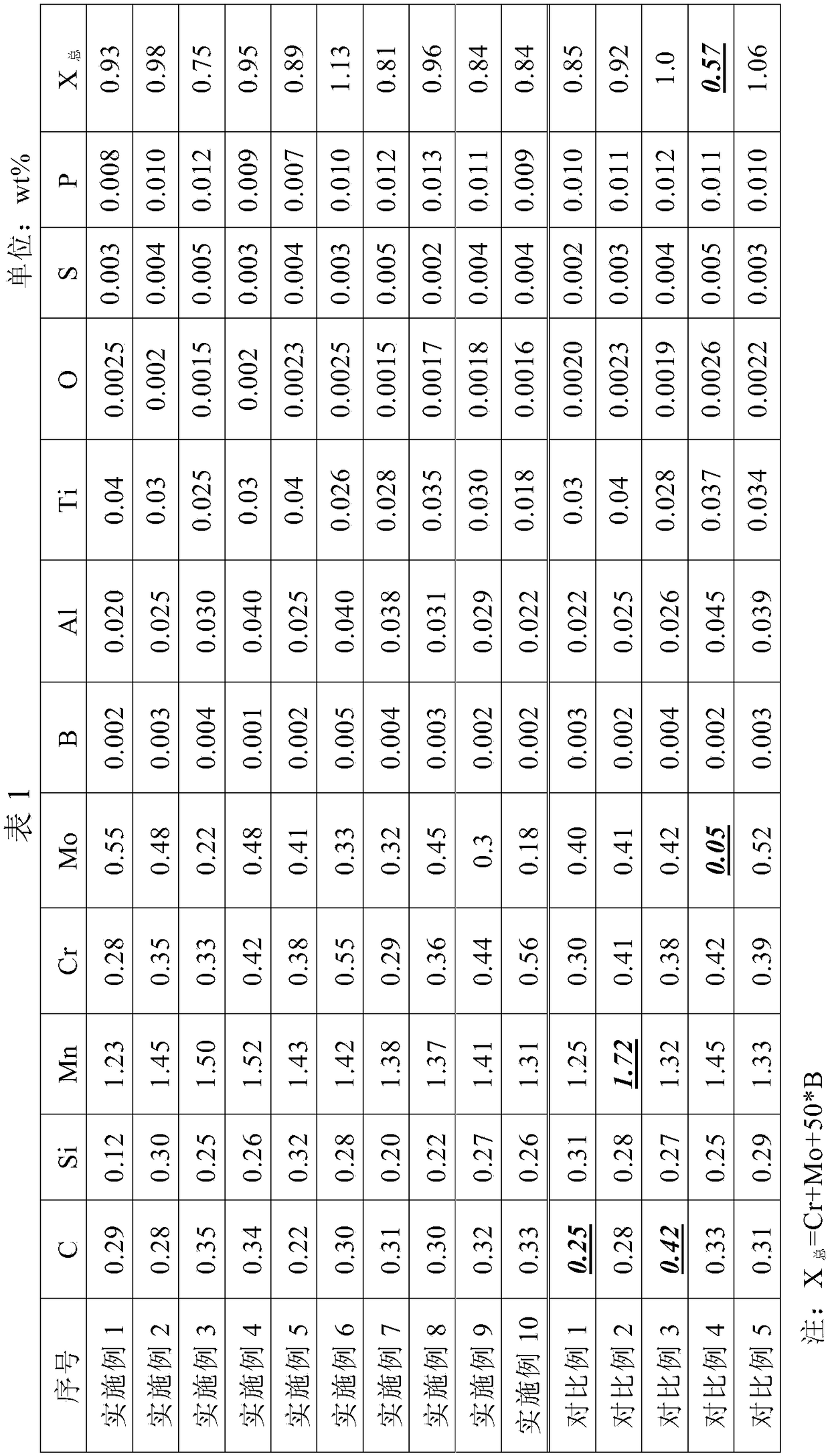

Steel tube used for hollow stabilizer bar of automobile and manufacturing method of steel tube

The invention discloses a steel tube used for a hollow stabilizer bar of an automobile and a manufacturing method of the steel tube. The steel tube is prepared from the following chemical components in mass percent: 0.28 to 0.40 percent of C, 0.05 to 0.35 percent of Si, 1.05 to 1.60 percent of Mn, 0.1 to 0.6 percent of Mo, 0.001 to 0.006 percent of B, 0.015 to 0.060 percent of Al, 0.1 to 0.8 percent of Cr, 0.003 to 0.06 percent of Ti, not greater than 0.006 percent of S, not greater than 0.015 percent of P, not greater than 0.003 percent of O and the balance Fe and other inevitable impurities,wherein Mo+50B+Cr is not less than 0.7 percent but is not greater than 1.3 percent. The steel tube disclosed by the invention is high in strength and plasticity, has high torsion fatigue resistance under a relatively high stress level, and can meet the using requirement of the stabilizer bar under a high-stress condition; and the specific performance indexes are shown as follows: as-quenched tensile strength is not less than 1700 MPa, as-quenched yield strength is not less than 1300 MPa, as-quenched ductility is not less than 12 percent, inner surface decarburization depth and outer surface decarburization depth are both 0, and under the condition of 550 MPa, the number of times of torsion fatigue is greater than 1200000.

Owner:BAOSHAN IRON & STEEL CO LTD

Modified graphene enhanced aluminum-based composite material and preparation method thereof

InactiveCN107299257AGood comprehensive mechanical propertiesIncreased strength and hardnessAluminum matrix compositesCarbide silicon

The invention discloses a modified graphene enhanced aluminum-based composite material and a preparation method thereof. The modified graphene enhanced aluminum-based composite material comprises the following components in percentage by weight: 0.01 to 0.3 percent of modified graphene, 0.3 to 2.4 percent of copper, 0.2 to 1.3 percent of carbon, 1.2 to 4.6 percent of iron, 0.8 to 1.9 percent of silicon carbide, 0.1 to 1.5 percent of lanthanum oxide, 1.9 to 4.5 percent of a surfactant and the balance of aluminum. The modified graphene enhanced aluminum-based composite material provided by the invention has high comprehensive mechanical property, and the strength and the hardness are improved; the composite material maintains the original plasticity of the aluminum-based composite material; by using the method, the wettability of the graphene and a metal melt is guaranteed, compact structure and good interfacial bonding force of the composite material are guaranteed, and the graphene is distributed into the aluminum base uniformly in a sheet shape.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

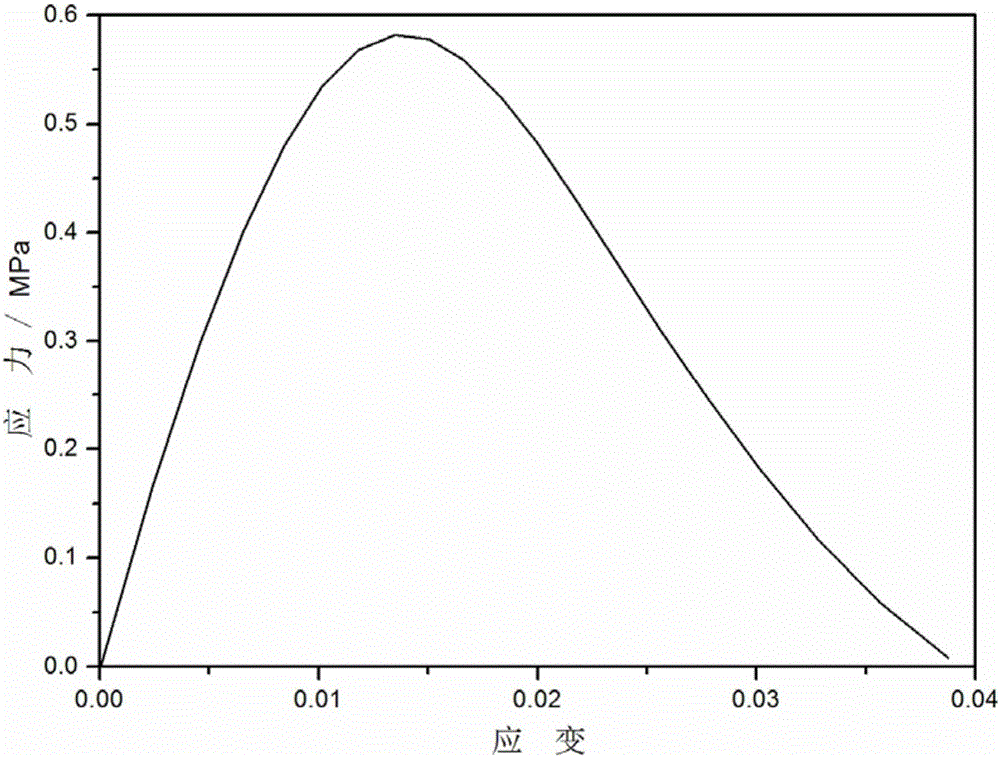

Fluid-solid coupling simulation material for coal series pressure-bearing fault activation water inrush similarity test and preparation method

ActiveCN105784945AGuaranteed plasticityGuaranteed StrengthPreparing sample for investigationGypsumCoal

The invention relates to a fluid-solid coupling simulation material for a coal series pressure-bearing fault activation water inrush similarity test. The fluid-solid coupling simulation material for the coal series pressure-bearing fault activation water inrush similarity test consists of three parts, i.e., a coal seam, a fault and surrounding rock; the coal seam consists of coal powder, talcum powder, gypsum, Vaseline, silicon oil and mixing water, the fault consists of coarse sand, talcum powder, gypsum, kaolin, Vaseline, silicon oil, soybeans and mixing water, and the surrounding rock consist of fine sand, talcum powder, gypsum, kaolin, cement, Vaseline, silicon oil and mixing water, wherein the gypsum, the cement and the Vaseline are used as cementing agents, the properties that the soybeans are expanded while absorbing water and the kaolin is granulated while meeting with water are combined, the fault surrounding rock similar material is guaranteed to have certain plasticity and strength and not to be softened and collapsed when meeting with water, simultaneously the purposes of producing a fracture with displacement when the fault similar material meets with water, reducing the strength, gradually increasing the permeability, causing seepage washing and slow collapse to form a water inrush passage are realized, and the difference between fluid-solid coupling properties of the fault and the surrounding rock in the same similarity test is inversed to enable test results to be more compliant with the reality.

Owner:ANHUI UNIV OF SCI & TECH

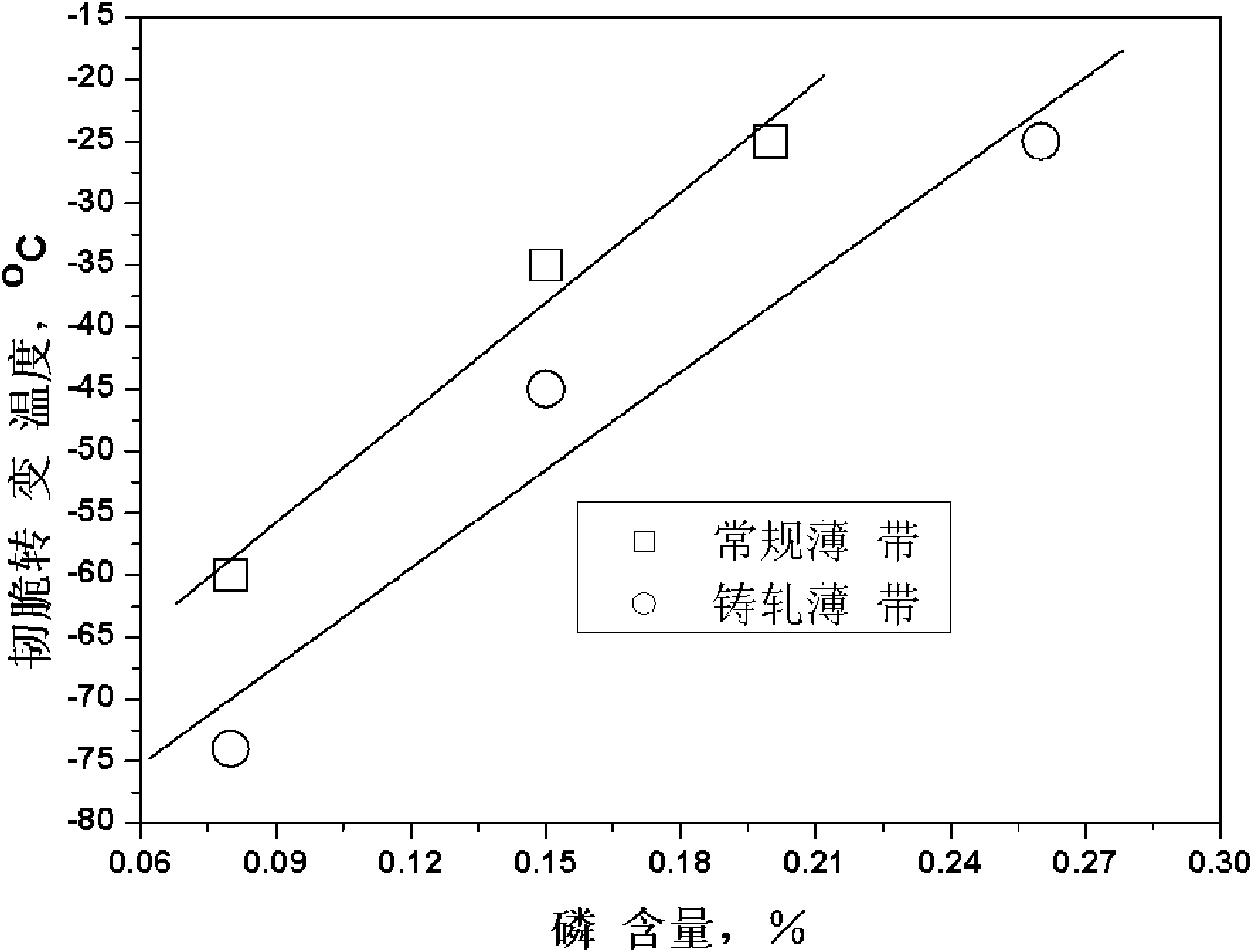

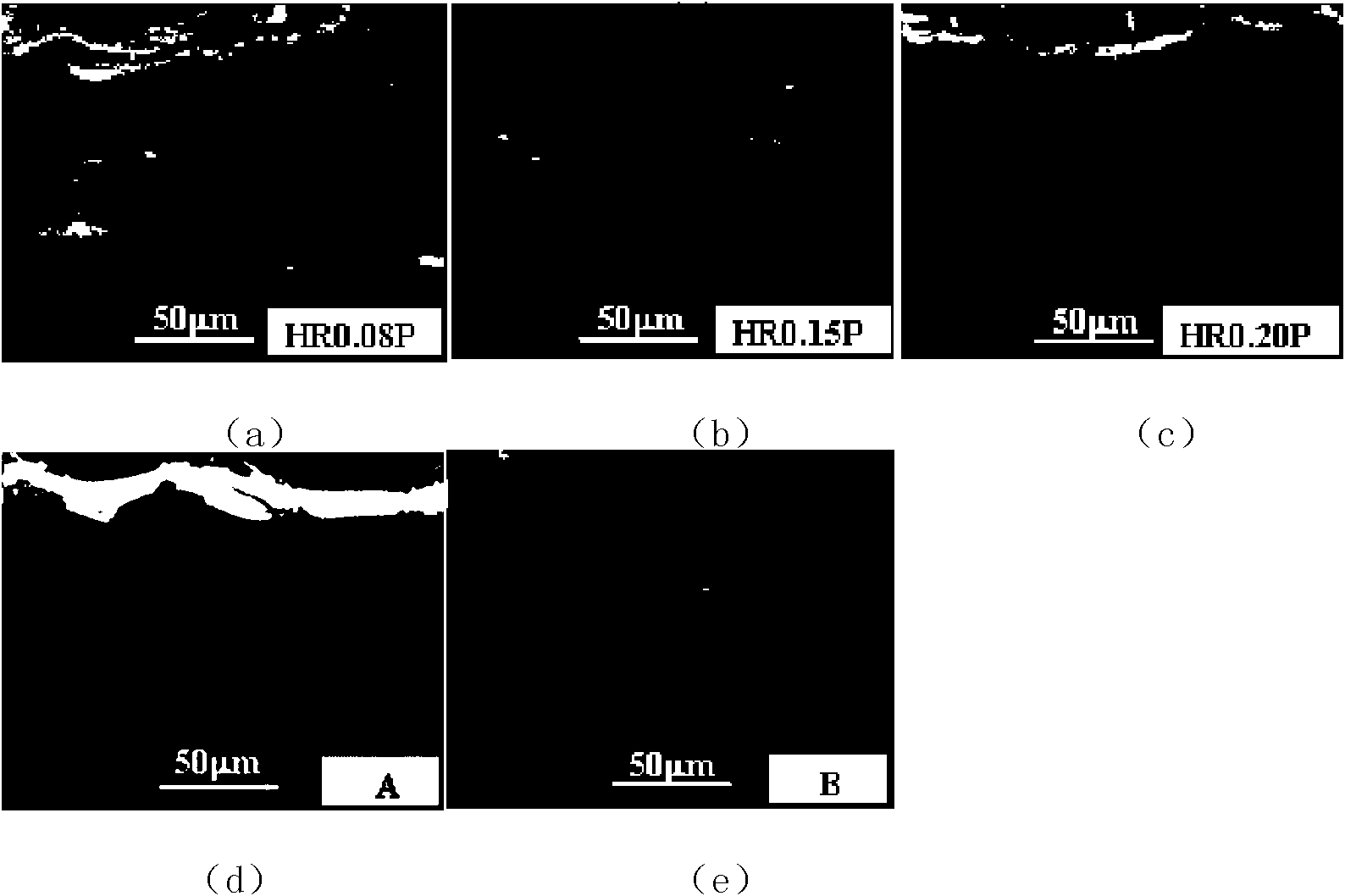

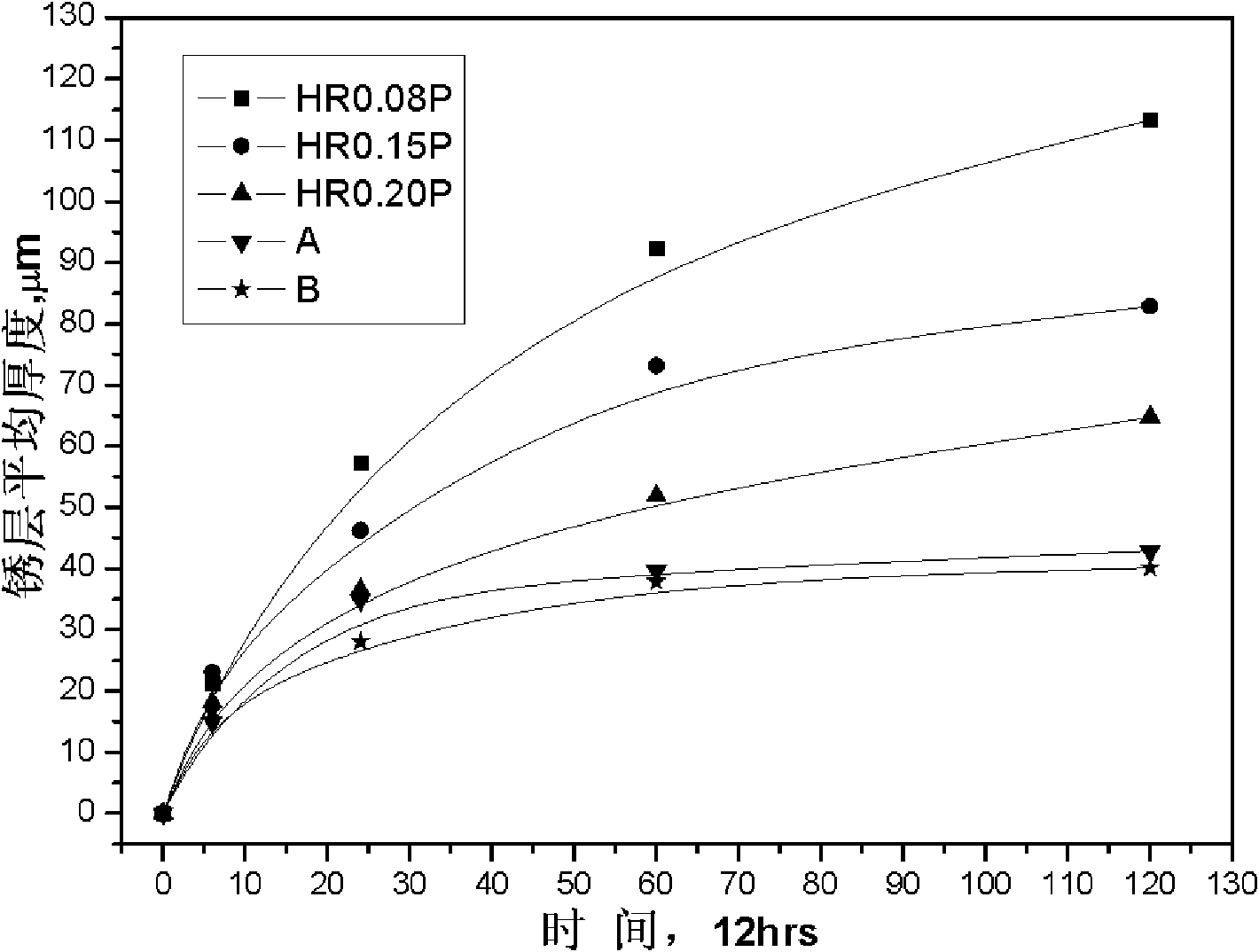

High-phosphorous weather-proof steel cast-rolling thin strip with negative phosphorous segregation on surface and preparation method thereof

The invention relates to a high-phosphorous weather-proof steel cast-rolling thin strip with negative phosphorous segregation on the surface and a preparation method thereof. The chemical components of the thin strip in terms of percentage by mass are as follows: 0.061-0.099% of C, 0.15-0.75% of SiO, 0.20-0.49% of Mn, 0.07-0.30% of P, 0.02% or less of S, 0.25-0.50% of Cu, 0.30-1.25% of Cr, 0.12-0.65% of NiO, and Fe as remainder. The preparation method of the thin strip comprises the following steps of: melting, refining, casting and rolling the refining liquid steel by a double-roller thin strip casting and rolling device, and controlling the cast-on temperature at 1540-1600 DEG C and the casting and rolling speed at 12-60m / min, and presetting the roll-gap as 1-4mm; obtaining the cast-rolling strip with negative phosphorous segregation on the surface, with a thickness of 1-5mm; and then cold-rolling and annealing. The negative phosphorous segregation on the surface guarantees the strength and the plasticity of the thin strip and also greatly improves the anti-corrosion performance of the thin strip; the ductile-to-brittle transition temperature of the high-phosphorous weather-proofsteel cast-rolling thin strip with negative phosphorous segregation on the surface is about 10 DEG C lower than that of the products produced by common processes, and the tenacity of steel is improved.

Owner:NORTHEASTERN UNIV

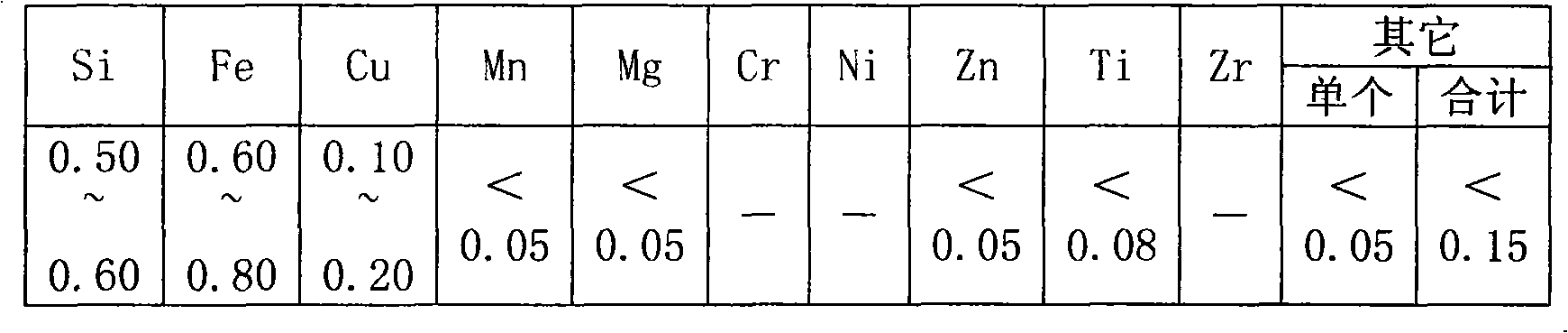

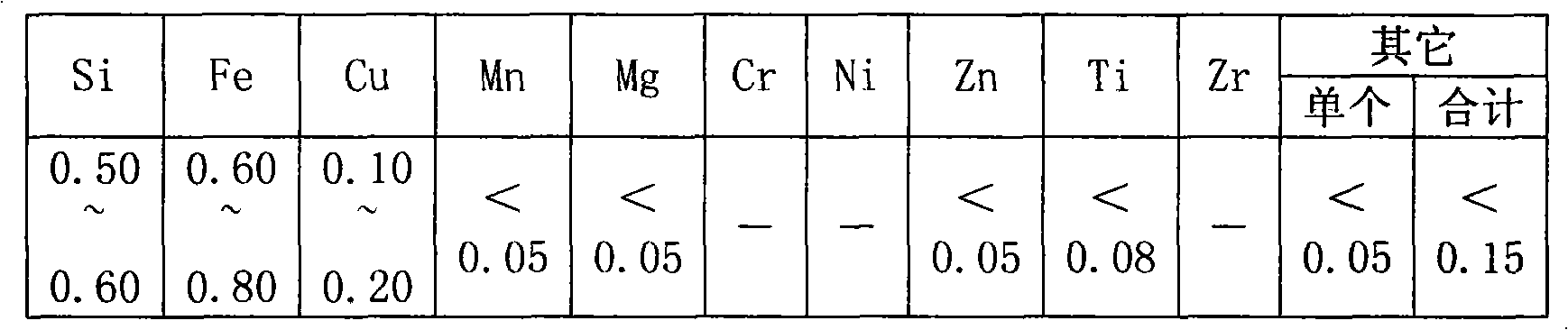

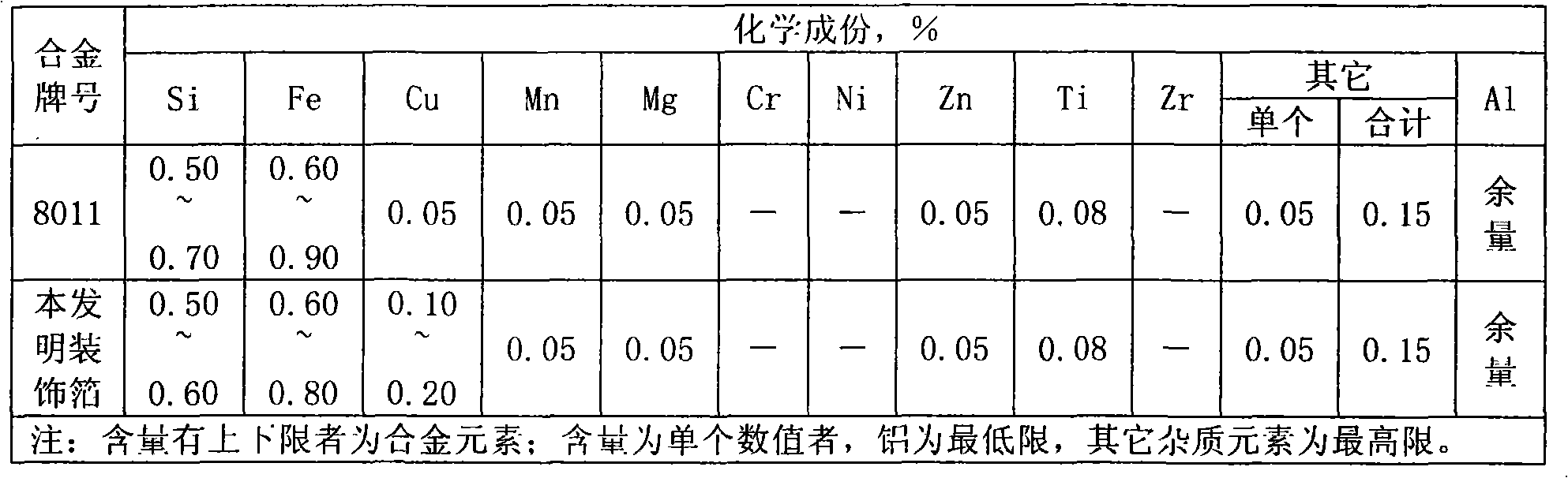

0.022 mm temperature-tolerance decoration foil and preparation method thereof

The invention relates to a 0.002 mm temperature-tolerance decoration foil and a preparation method thereof. The decoration foil is characterized by being made by adding 0.10-0.20 percent by weight of Cu element on the basis of 8011 alloy. The preparation method comprises the following process procedures: cold-rolling a cast-rolling plate into 0.44-0.85 mm from 6.0-10.0 mm, adopting an H22 status for interannealing, cold-rolling to 0.28-0.60 mm, foil-rolling to reach a finished thickness of 0.022 mm, and slitting, wherein the H22 status annealing process comprises the following steps: adopting a burner-gas temperature controlling way for annealing, namely, charging below 100 DEG C, heating 1.5 hours till the temperature reaches 350-450 DEG C, and preserving the temperature for 5-15 hours; cooling for 0.5 hour till the temperature reaches 320-380 DEG C, preserving the temperature for 5-15 hours, cooling for 1.5 hours till the temperature reaches 200 DEG C, and discharging; and achieving the total processing ratio being more than 95 percent after interannealing. The invention has good temperature tolerance and stable quality.

Owner:新疆天展新材料科技有限公司

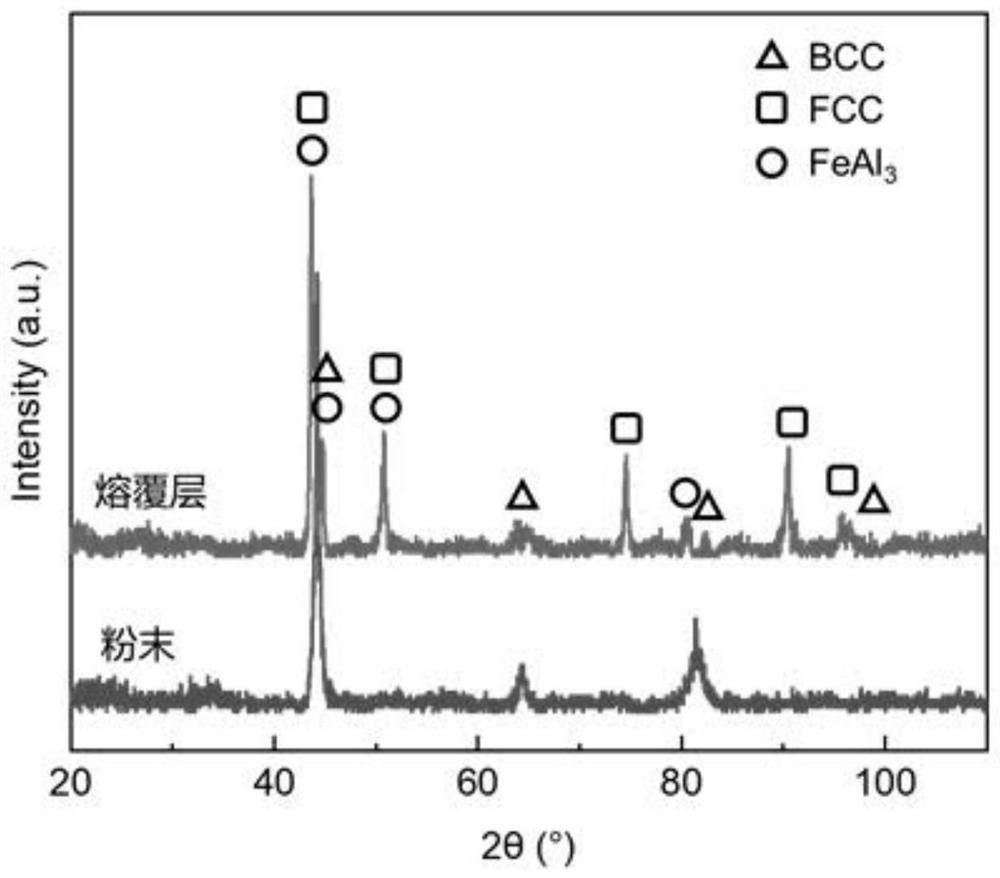

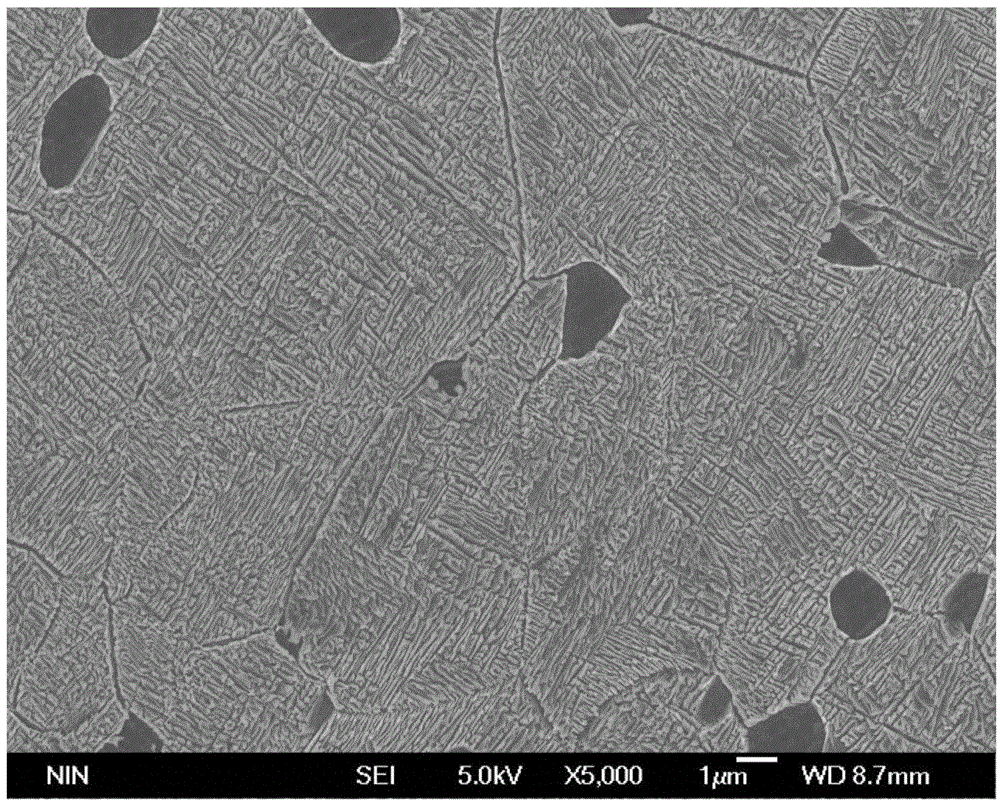

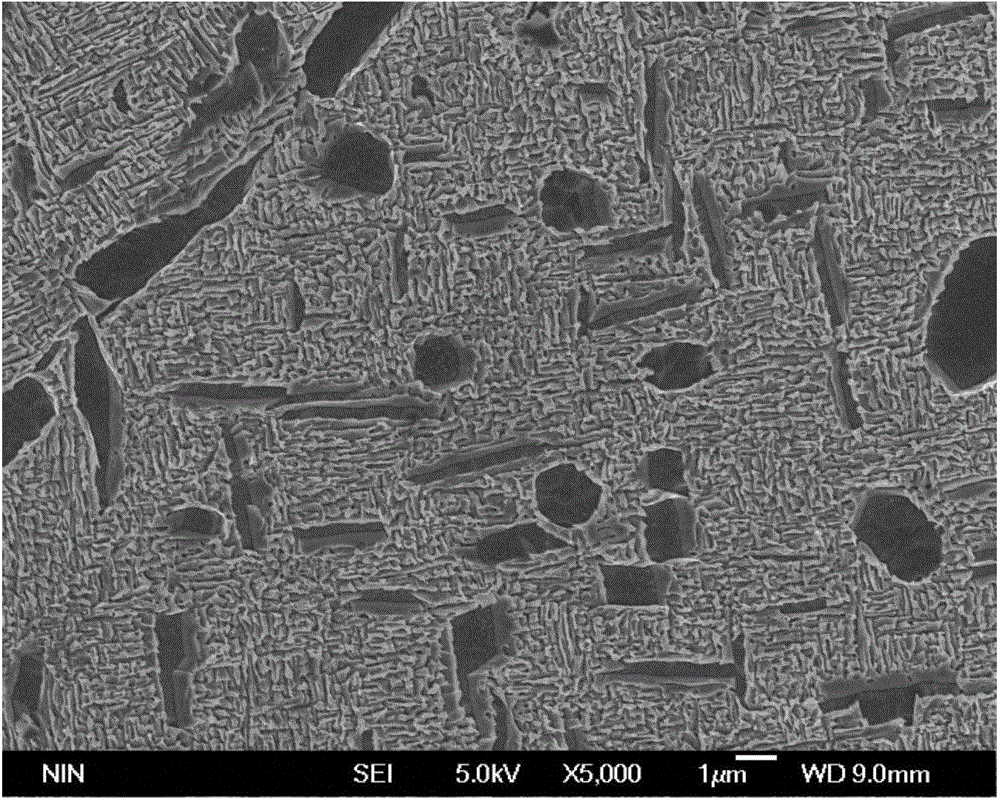

High-entropy alloy, preparation method and laser cladding method

ActiveCN113913667AImprove high temperature resistanceAccelerated corrosionAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysOil drilling

The invention discloses a high-entropy alloy, a preparation method and a laser cladding method, and relates to the technical field of high-performance metal powder materials. The high-entropy alloy material is prepared from the following chemical components in percentage by atom: 15%-25% of Fe, 15%-25% of Co, 15%-25% of Ni, 15%-25% of Cr, 5%-15% of Al and 5%-15% of Ti. The high-hardness wear-resistant high-entropy alloy material is a high-hardness wear-resistant high-entropy alloy material suitable for surface laser cladding of precise molds, maritime work parts, oil drilling well rods and the like; a corresponding high-strength, high-hardness and wear-resistant high-entropy alloy coating is prepared from the powder prepared from alloy components by adopting a laser cladding technology, and the hardness and wear resistance of the high-entropy alloy coating have excellent effects; and in addition, the material has good weldability and is a special nickel-based high-entropy alloy material suitable for laser additive manufacturing.

Owner:GUANGDONG INST OF NEW MATERIALS

Super-high strength and high-plasticity titanium alloy

ActiveCN104862529AGood heat treatment strengthening effectImprove plasticityRoom temperatureStable element

The invention discloses a super-high strength and high-plasticity titanium alloy, which is prepared from the following components in percentage by weight: 4%-6% of Al, 8%-11% of Mo, 2%-6% of V, 2%-5% of Cr, and the balance of Ti and inevitable impurities, wherein the tensile strength Rm of the super-high strength and high-plasticity titanium alloy at a room temperature is greater than or equal to 1500MPa; and the ductility A is greater than or equal to 10%. The titanium alloy disclosed by the invention contains a beta isomorphous stable element Mo with relatively high mass percent; the diffusion speed of the element Mo in the titanium alloy is slow, so that the size of a precipitated phase in the titanium alloy is small, and the titanium alloy has a relatively good heat treatment strengthening effect; an alpha phase can be dissolved and strengthened by the element V; meanwhile, the c / a ratio of the alpha phase is reduced; slippage of the alpha phase is facilitated; and the titanium alloy has relatively low creep resistance and good plasticity.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

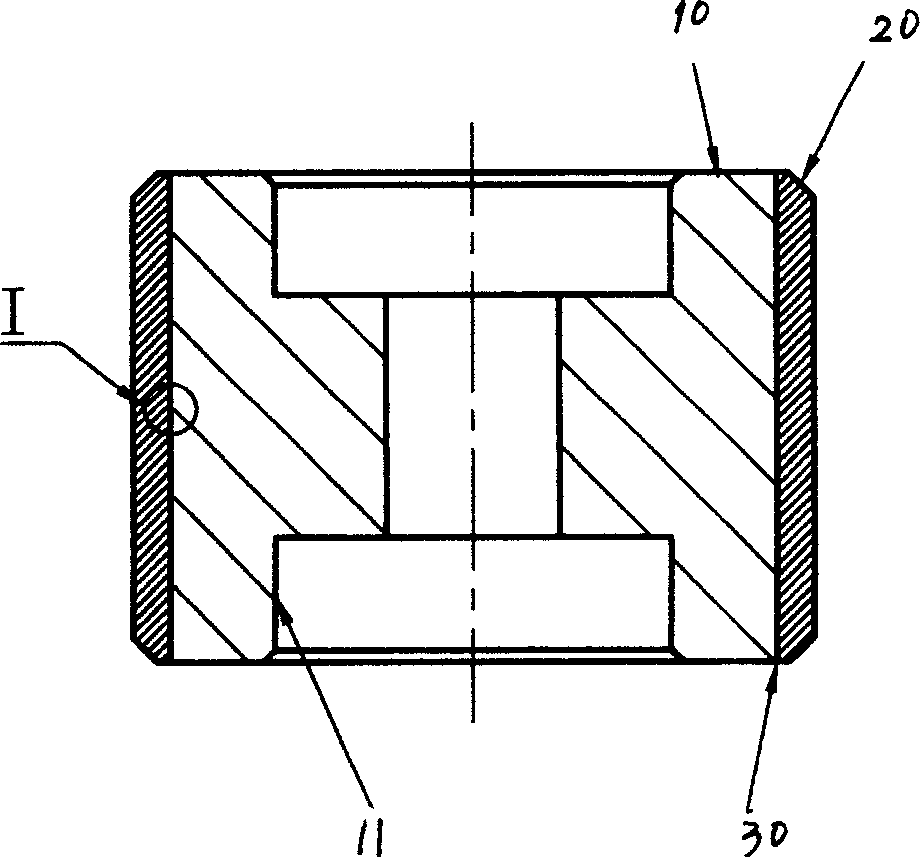

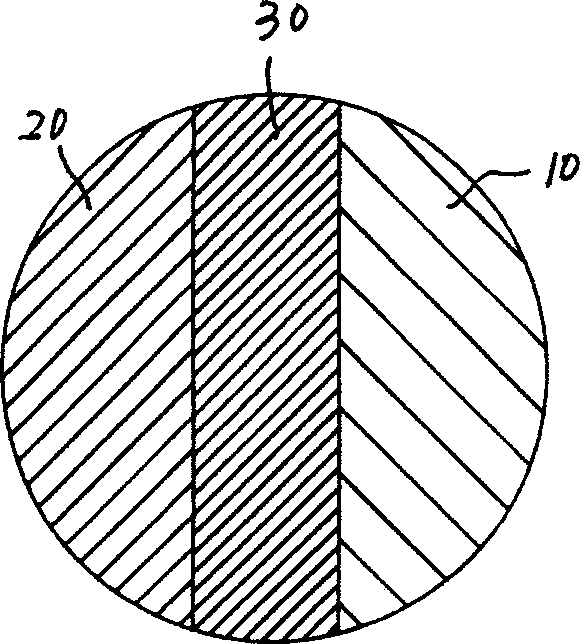

Composite Roll Collar

InactiveCN1736626ALow costGuaranteed StrengthGuiding/positioning/aligning arrangementsHardnessUltimate tensile strength

The invention relates to a composite guide roller and the method for preparation, the roller base being prepared with plain carbon steel, the roller surface of the roller base being coated with a heat-stable and antiwear hard surfacing; the processing employing the vacuum sintering method, the base being prepared with simple carbon steel and the surface treated with hard material, which can save the cost of material and is convenient for mechanical manufacture, and it imposes the high hardness, the perfect abradability, and corrosion prevention onto the surface of the guide roller, besides keeping the original intensity and drawability of the base material.

Owner:合肥市泰通冶金科技有限公司

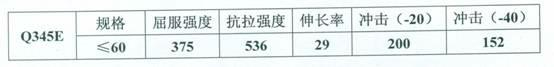

Low-alloy Q345E medium plate and production process thereof

InactiveCN102041442AGuaranteed matching of strength and plasticityLow heating temperatureTemperature control deviceProcess efficiency improvementAlloy elementSteel plates

The invention discloses a low-alloy Q345E medium plate produced without adding micro-alloy element and a production process thereof. The low-alloy Q345E medium plate comprises the following chemical components in percentage by weight: 0.13-0.19% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.015-0.050% of Als, and the balance of Fe and residual elements. The process disclosed by the invention comprises the following steps: KR (knotted reactor) hot metal pretreatment of high-quality hot metal, processing with a top-bottom combined blowing converter, LF ((ladle furnace) refining, casting blank stack cooling, processing with a heating furnace, rolling, ACC (accelerated cooling) laminar flow cooling, processing with a hot straightener, stack cooling, finishing, external inspection, flaw detection and storage. The invention has the beneficial effects that: compared with the traditional Q345E, precious alloys such as Nb, Ti and the like are not added without changing the carbon equivalent, all performance indexes of Q345E are guaranteed, and the production cost is remarkably reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

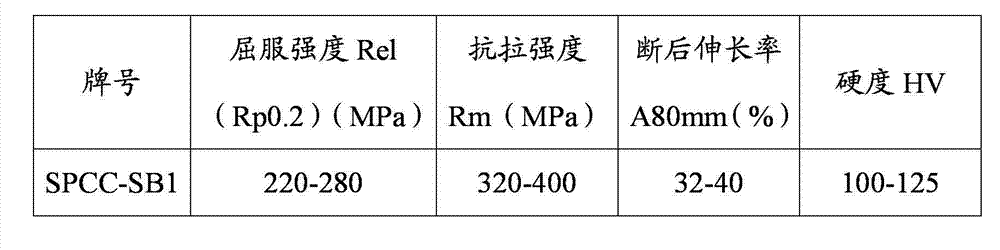

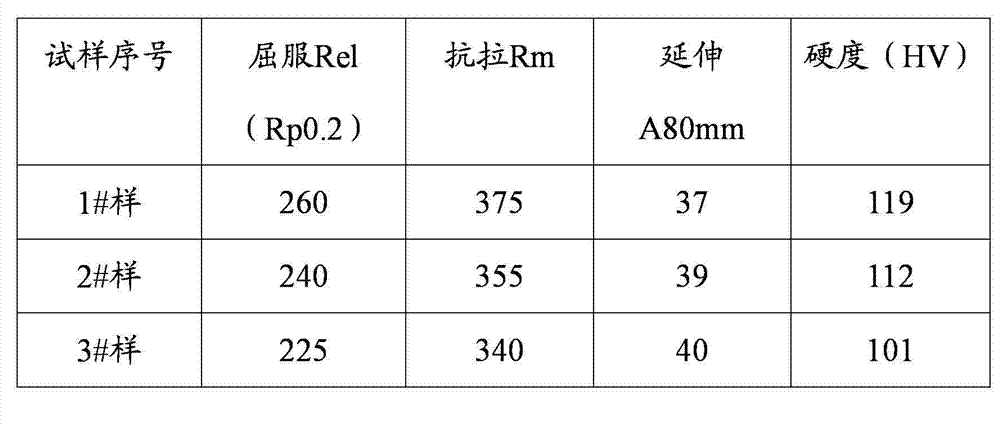

Steel strip for household electric appliance panel and production method thereof

ActiveCN103194670AGuaranteed plasticityGuaranteed thickness accuracyFurnace typesHeat treatment furnacesChemical compositionHardness

The invention provides a steel strip for deep drawing of a household electric appliance panel film. The steel strip comprises the following chemical components by mass percent: 0.01 percent<=C<=0.03 percent; zero percent<Si<=0.02 percent; 0.1 percent<=Mn<=0.25 percent; zero percent<P<=0.02 percent; zero percent<S<=0.025 percent; 0.02 percent<=Al<=0.05 percent; and the balance of Fe. The high-hardness steel strip for a household electric appliance panel totally meets the quality requirements for strength, hardness and elongation of refrigerator panel steel based on many tests and trial use, is popular among clients, and has popularization application value and broad prospect as the cold rolled strips for household appliances have a very broad development prospect.

Owner:浙江龙盛薄板有限公司

Abrasion-resistant and corrosion-resistant molybdenum alloy and preparation method thereof

ActiveCN107245621AThe group ratio is reasonableRaise the recrystallization temperatureAlloyUltimate tensile strength

The invention relates to an abrasion-resistant and corrosion-resistant molybdenum alloy and a preparation method thereof. The abrasion-resistant and corrosion-resistant molybdenum alloy comprises the following components by volume percent: 0.2% to 10% of ZrO2 and 0.05% to 1% of Y2O3, and the balance being molybdenum. According to the abrasion-resistant and corrosion-resistant molybdenum alloy provided by the invention, ZrO2 is adopted as dispersed phases and is added into the molybdenum alloy, Y2O3 is added to stabilize tetragonal phases ZrO2 in the molybdenum alloy, crystal transition of ZrO2 under the high temperature is prevented, and plasticity and toughness are guaranteed; and the components in the alloy are reasonable in proportion and cooperate to act, recrystallization temperature of the molybdenum alloy is increased, grain-boundary strength of the molybdenum alloy is improved while processing performance is improved, and high-temperature creep resistance, abrasion resistance and corrosion resistance of the molybdenum alloy are strengthened.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com